Automatic spraying machine for steel pipe

An automatic spraying and pipe technology, applied in spray booths, spraying devices, etc., can solve the problems of inability to spray steel pipes, high labor intensity, and unsprayed steel pipes, so as to improve rust prevention ability, improve production efficiency, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

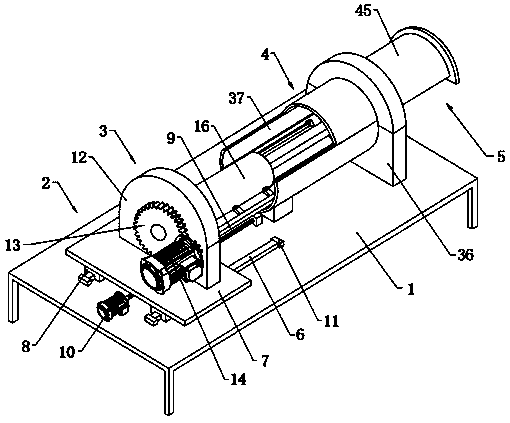

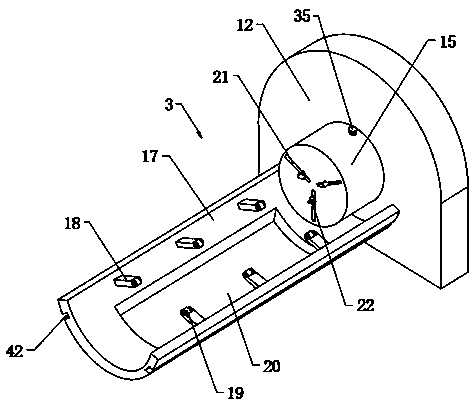

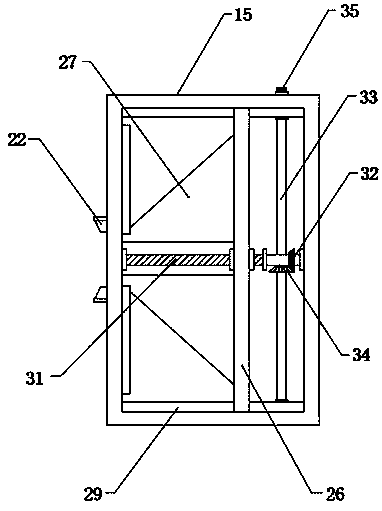

[0025] Embodiment: a kind of automatic spraying machine for steel pipe, constitutes as figure 1 As shown, it includes a workbench 1, and the two ends of the top of the workbench 1 are respectively equipped with a conveying mechanism 2 and an in-pipe spraying mechanism 4. The conveying mechanism 2 transports the steel pipe 16 horizontally to facilitate feeding. The rotating mechanism 3 clamps and rotates the steel pipe 16 to facilitate uniform spraying of the steel pipe 16. An outer spraying mechanism 5 is arranged above the inner spraying mechanism 4, and the inner spraying mechanism 4 and the outer spraying mechanism 5 can spray the steel pipe 16 respectively. The inner and outer walls are sprayed, the clamping and rotating mechanism 3 clamps the steel pipe 16, and the clamping and rotating mechanism 3 is connected with the spraying mechanism 4 in the pipe. The conveying mechanism 2 includes a first slide rail 6 fixed on the top of the workbench, a bearing plate 7 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com