Patents

Literature

37779 results about "Workbench" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A workbench is a sturdy table at which manual work is done. They range from simple flat surfaces to very complex designs that may be considered tools in themselves. Workbenches vary in size from tiny jewellers benches to the huge benches used by staircase makers. Almost all workbenches are rectangular in shape, often using the surface, corners and edges as flat/square and dimension standards. Design is as varied as the type of work for which the benches are used but most share these attributes...

PLM-supportive CAD-CAM tool for interoperative electrical & mechanical design for hardware electrical systems

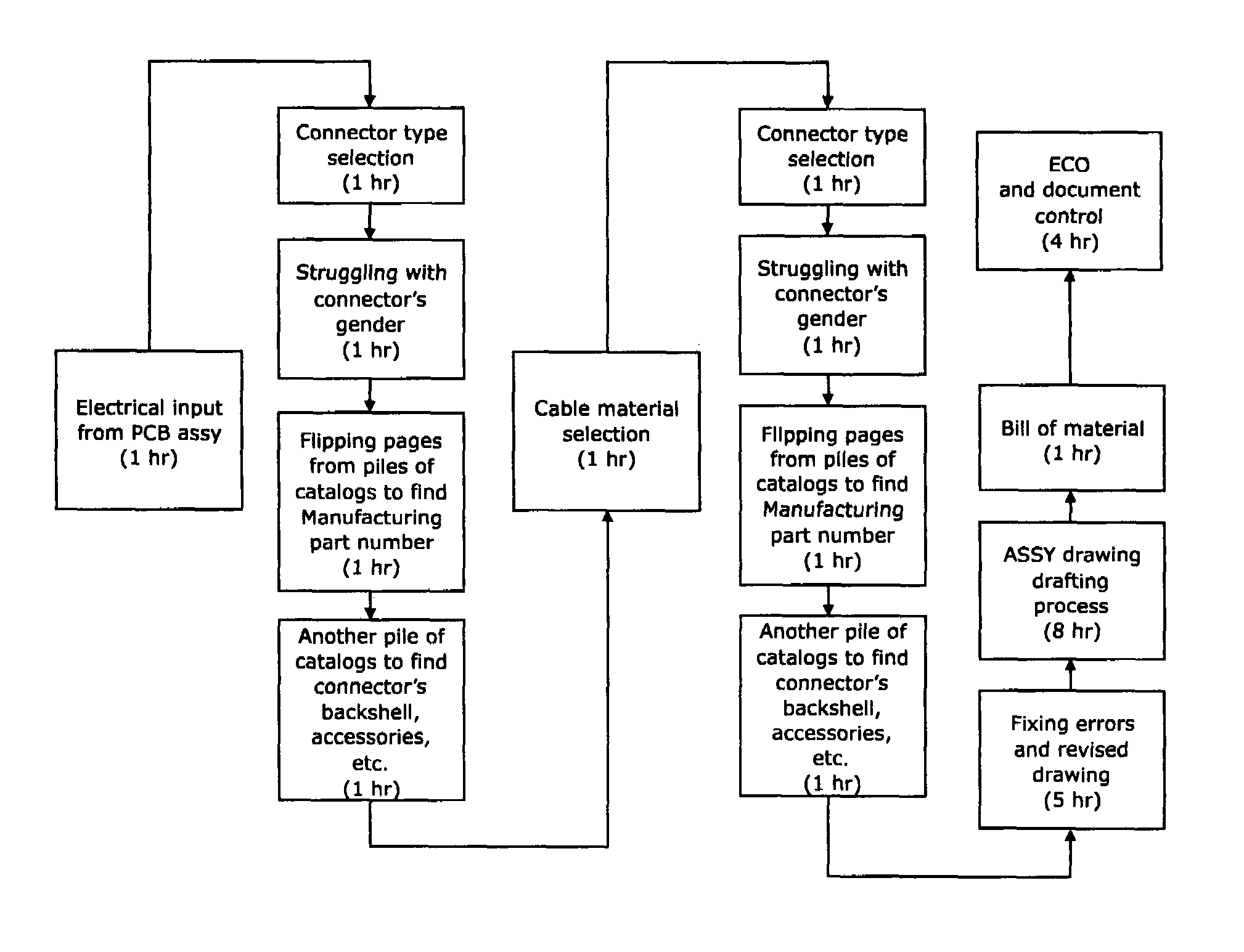

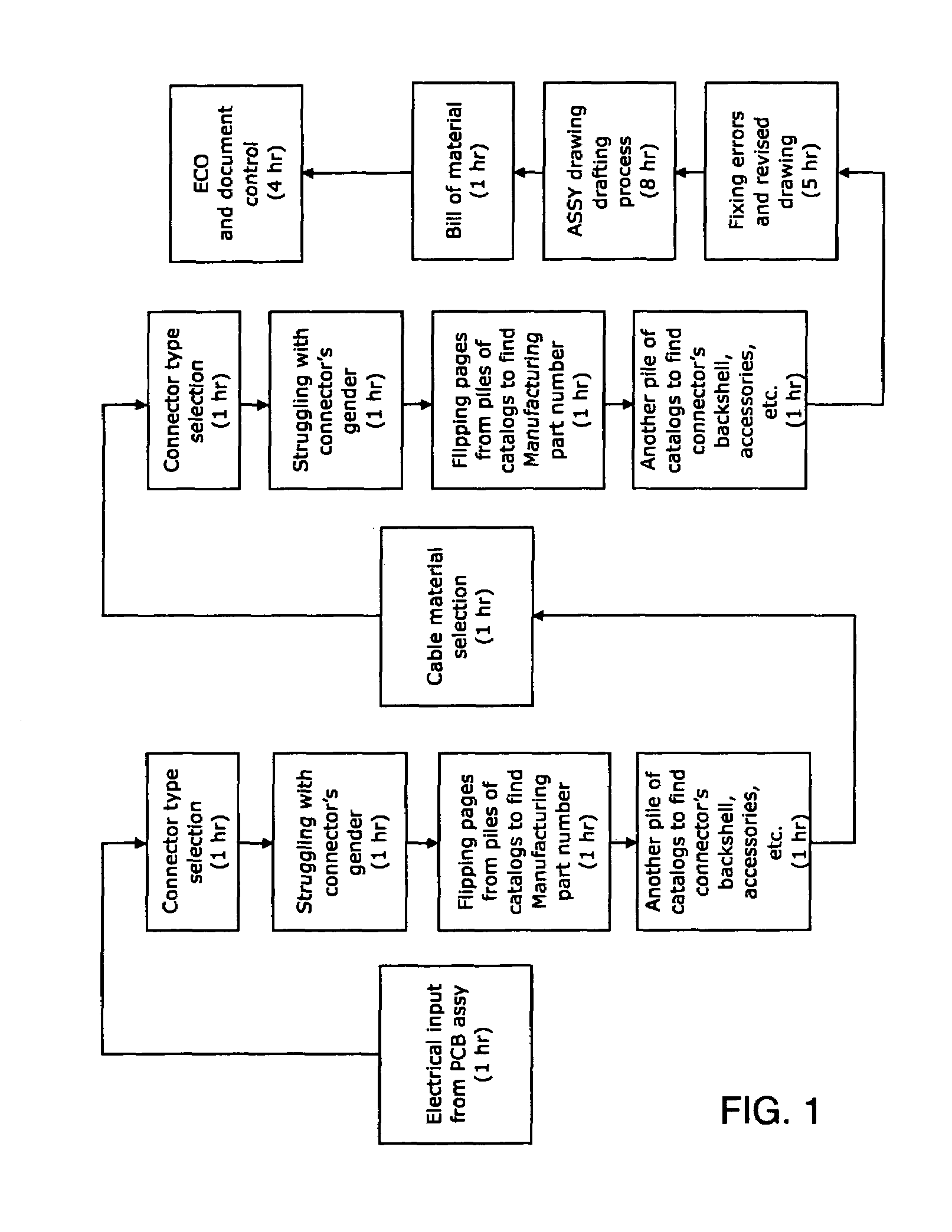

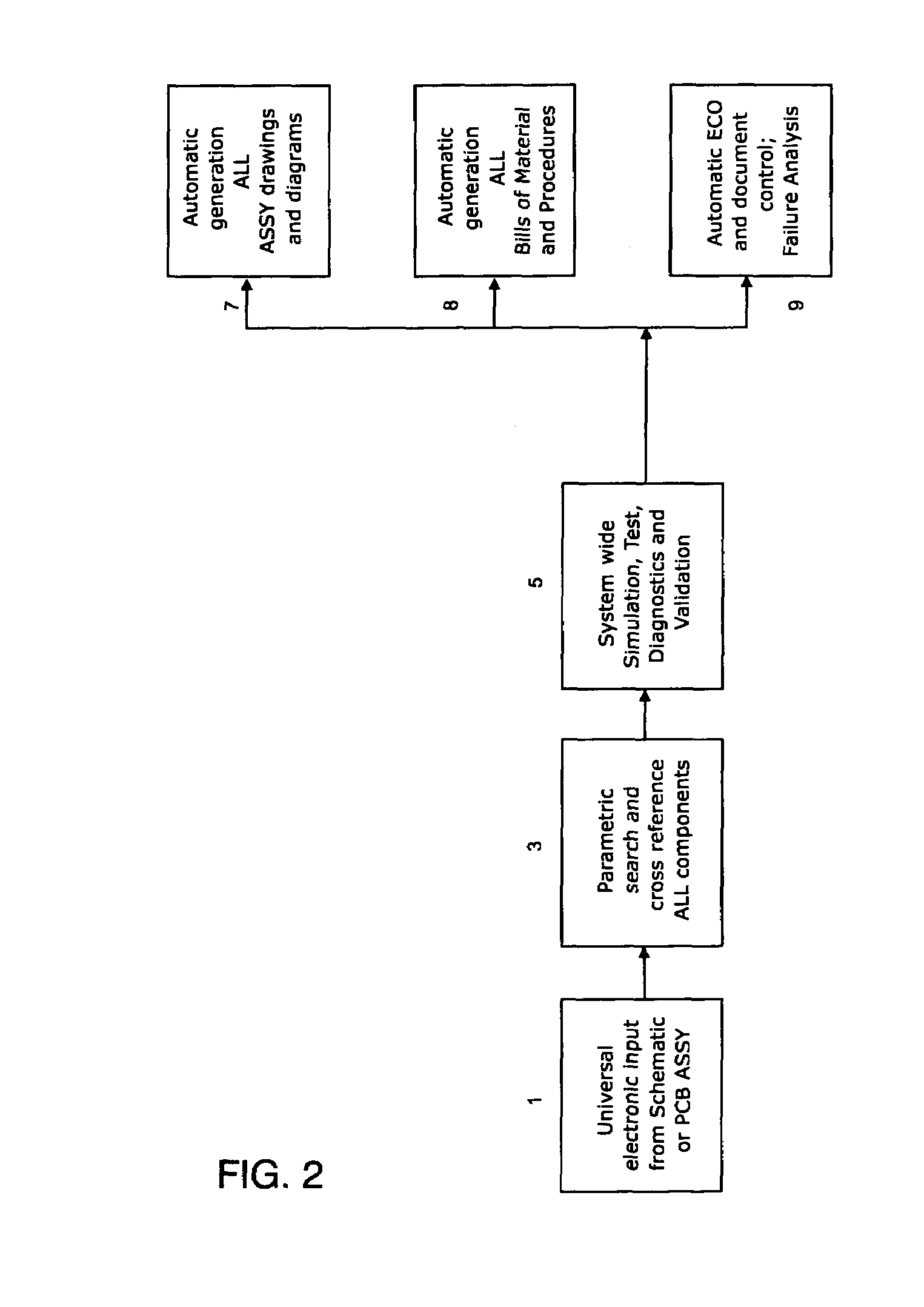

InactiveUS20050080502A1Reduce frictionCAD network environmentComputer programmed simultaneously with data introductionTask completionBill of materials

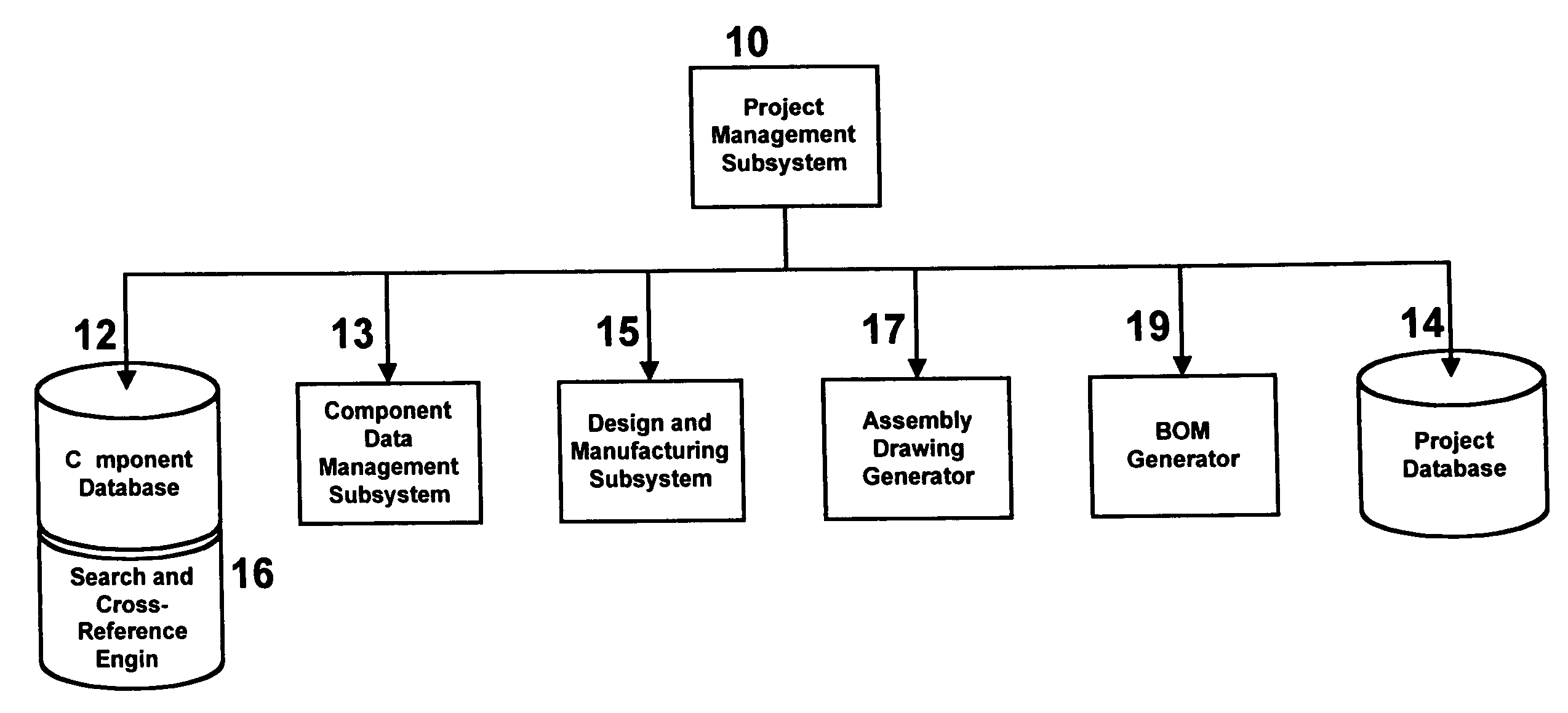

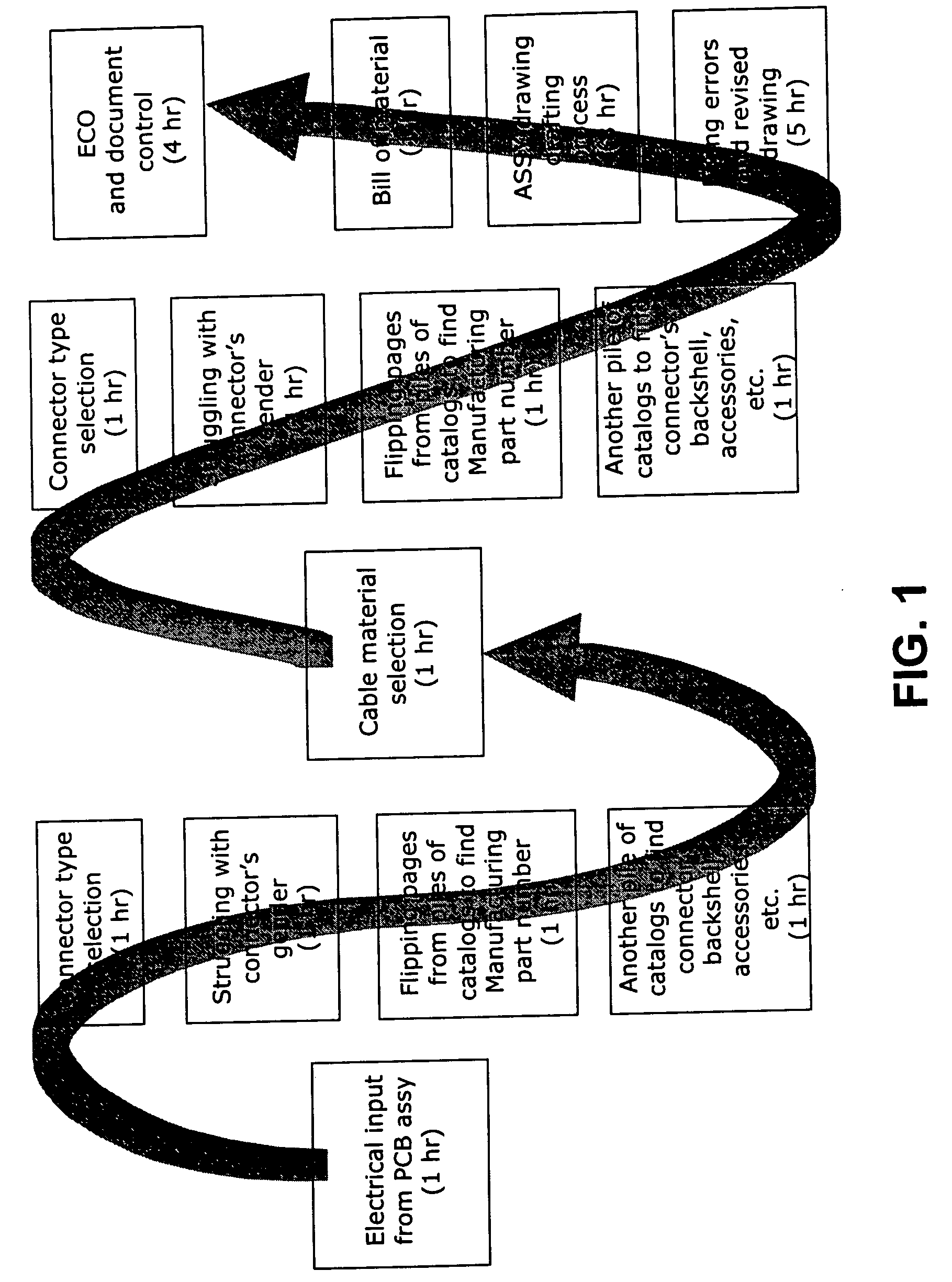

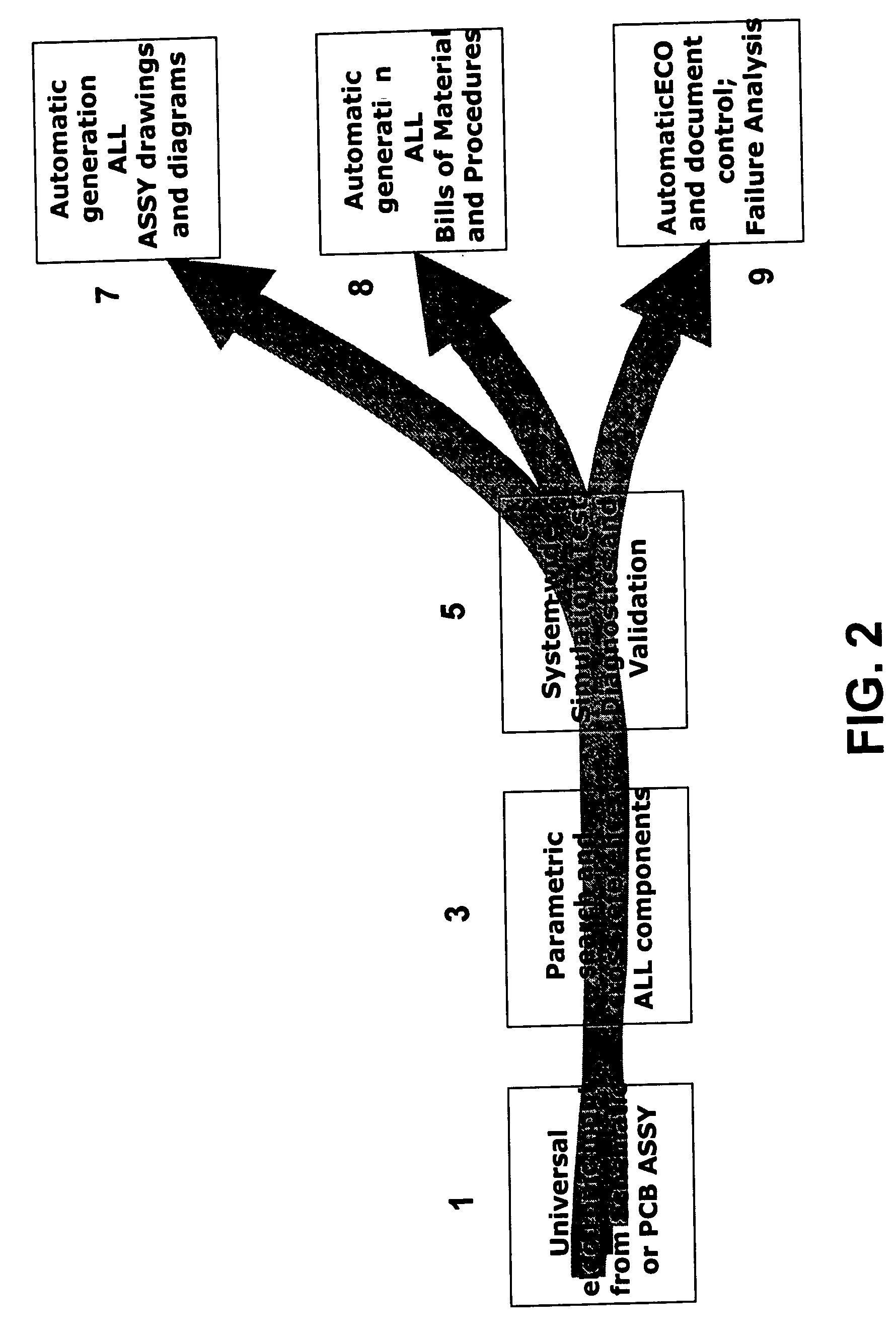

This invention is a tool for computer-aided design, computer-aided manufacturing forming a Project Management System, comprising: (1) a Component Database; (2) a Component Data Management System; (3) a Design and Manufacturing System; (4) an Assembly Drawing Generator; (5) a Bill of Materials Generator; and, (7) a Project Database. The Project Manager tracks the process and actions, recording and supervising version and change order compliance and task completion, from the start through verification of a production-ready finished version. Each project uses a master workbench. On it design specifications are entered for each subassembly element and connector. Then the user consults the Component Database using a Search and Cross Reference engine for components meeting those design specifications, until a constraint-satisfying design is completed. The tool generates a Bill of Materials, Assembly Drawings, and process records for the project in process.

Owner:CHERNYAK ALEX H +3

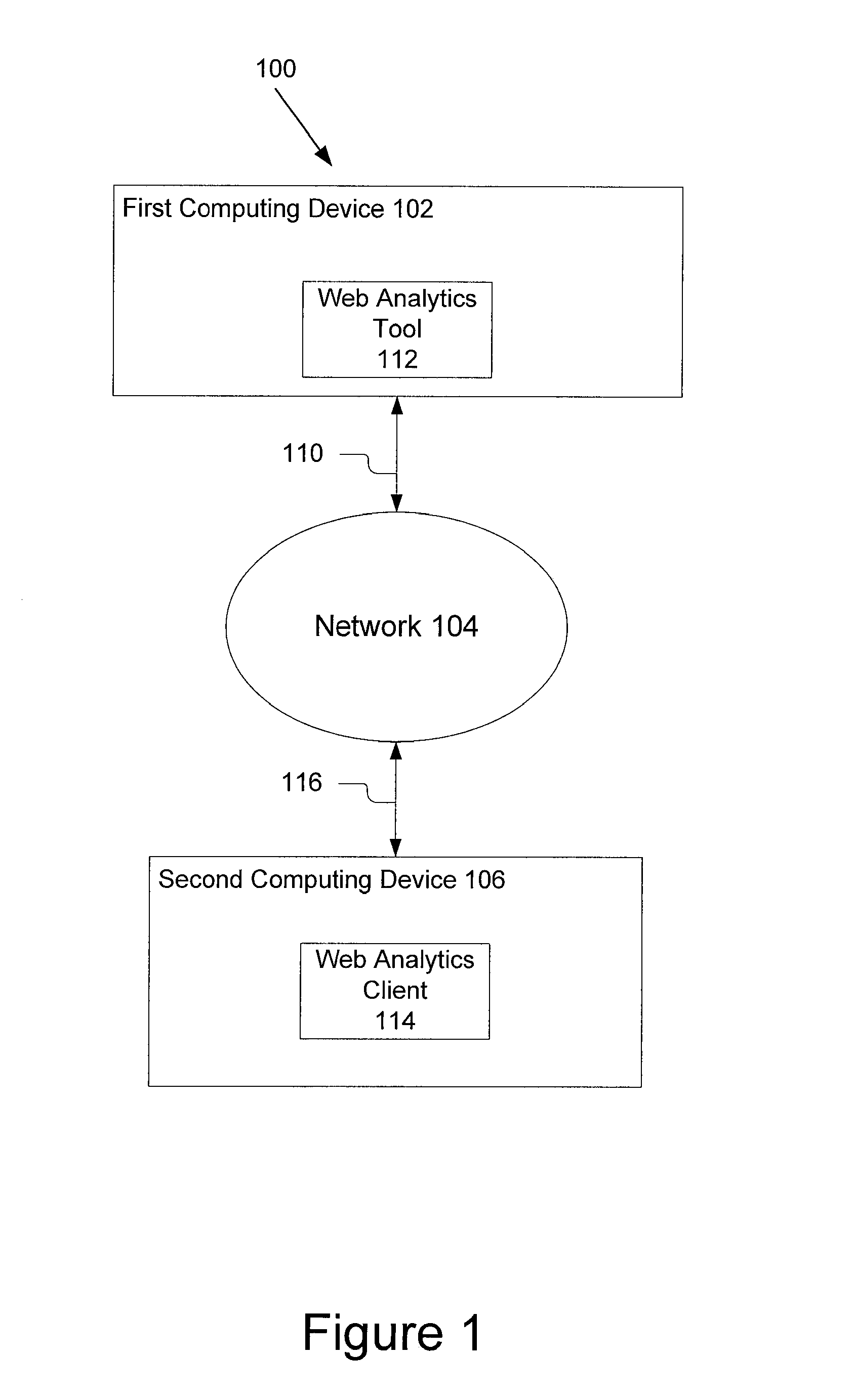

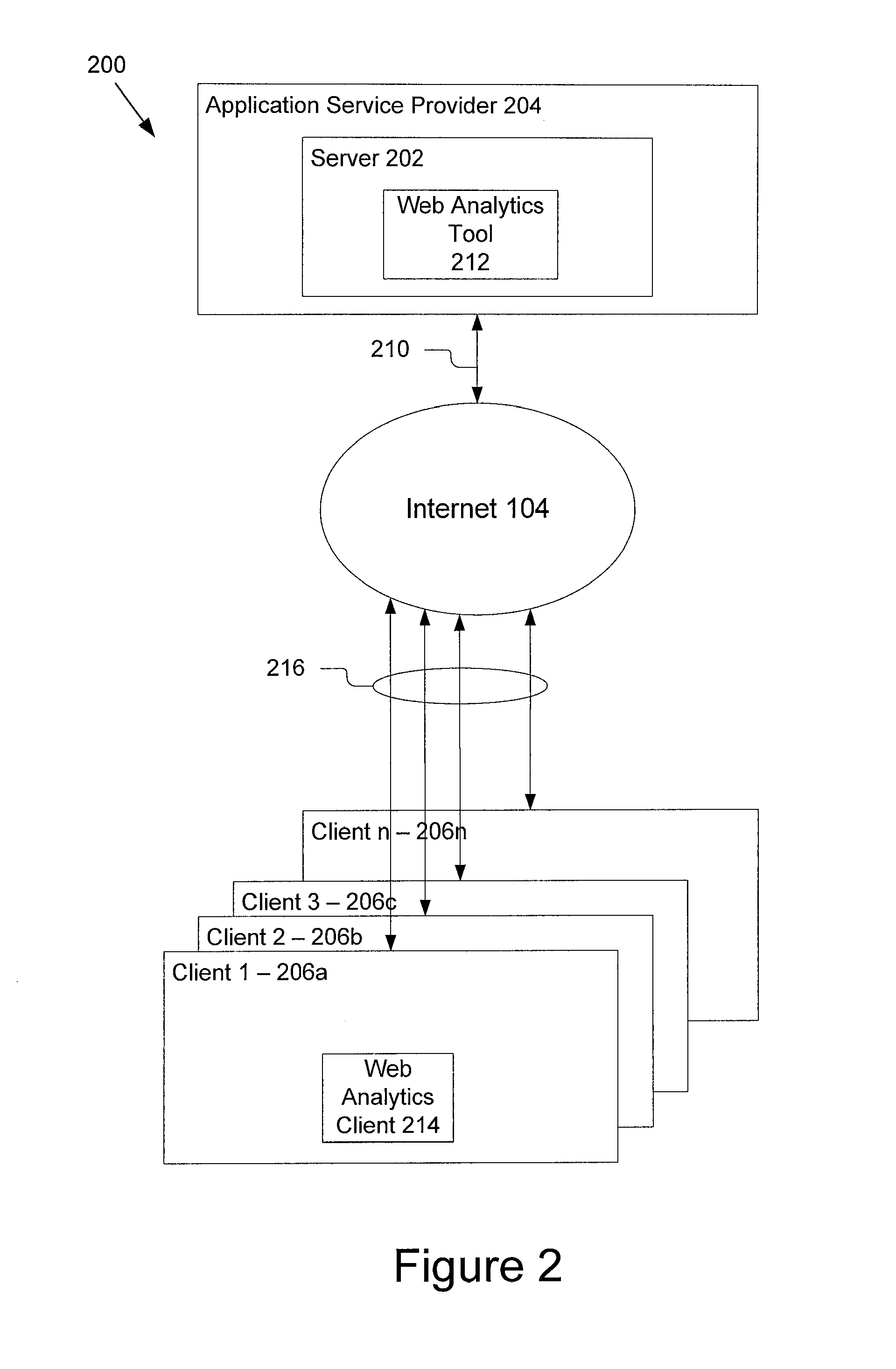

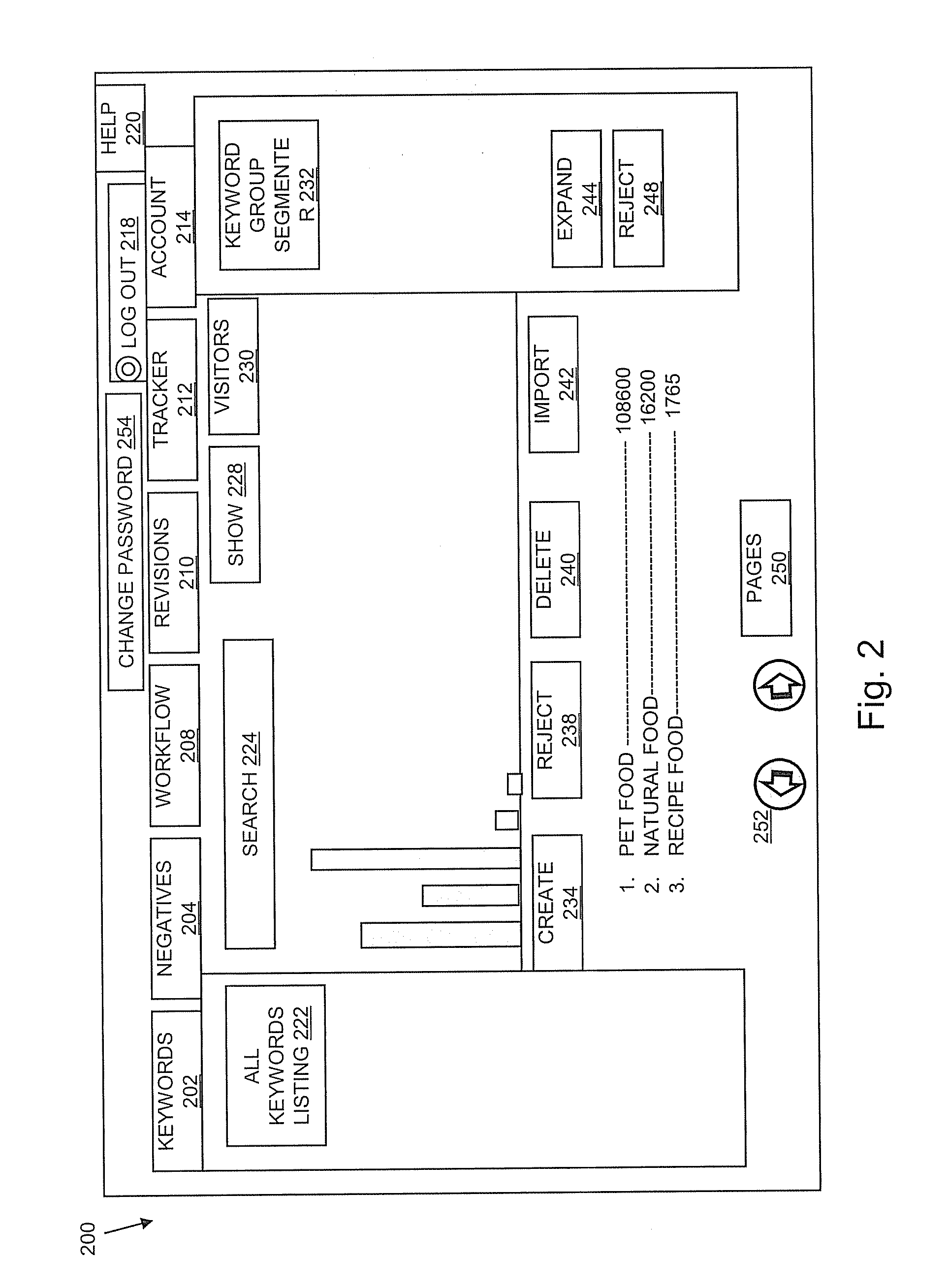

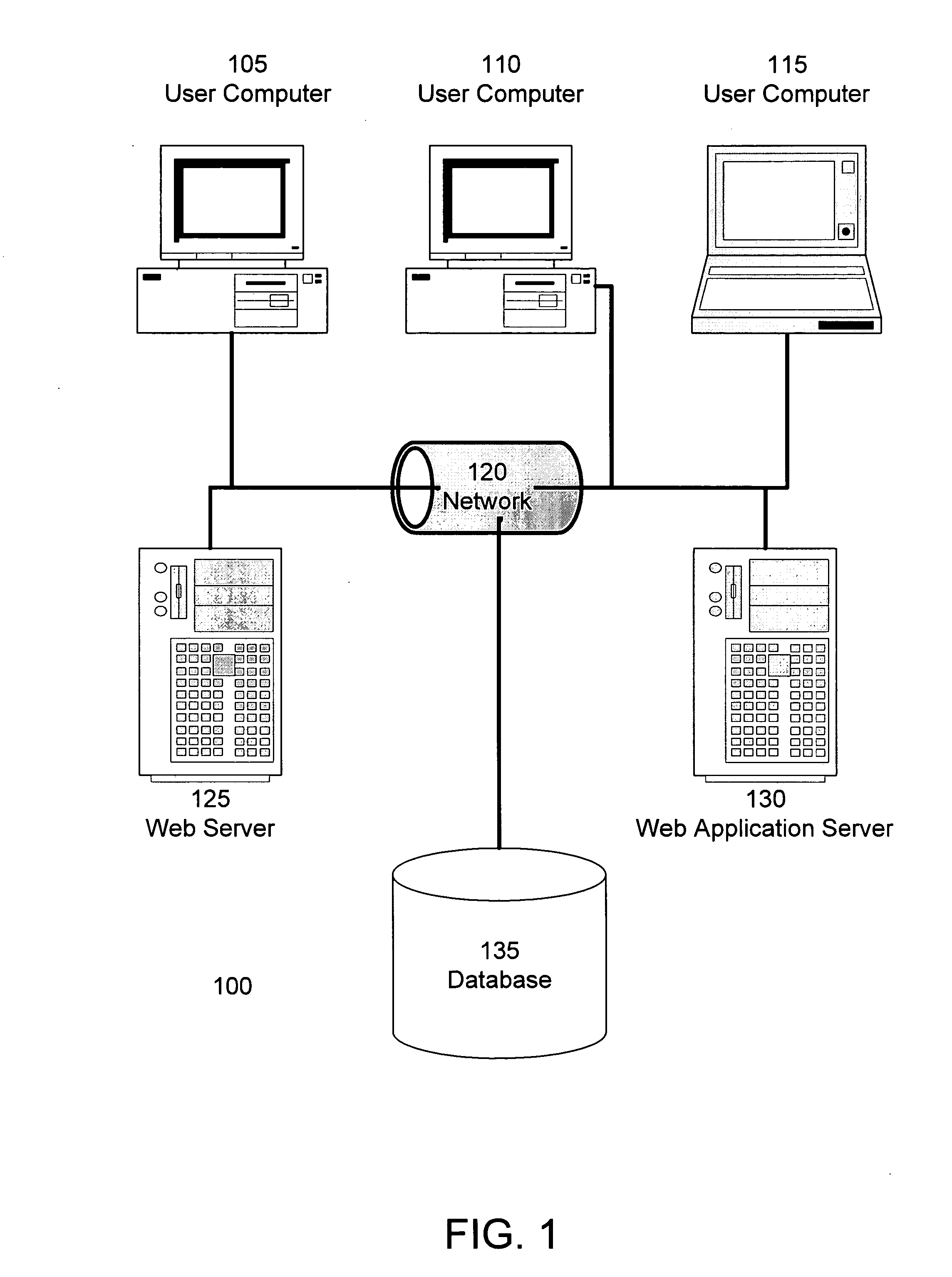

Asp for web analytics including a real-time segmentation workbench

ActiveUS20070011304A1Function increaseReal-time accessDigital computer detailsMarketingService provisionWeb analytics

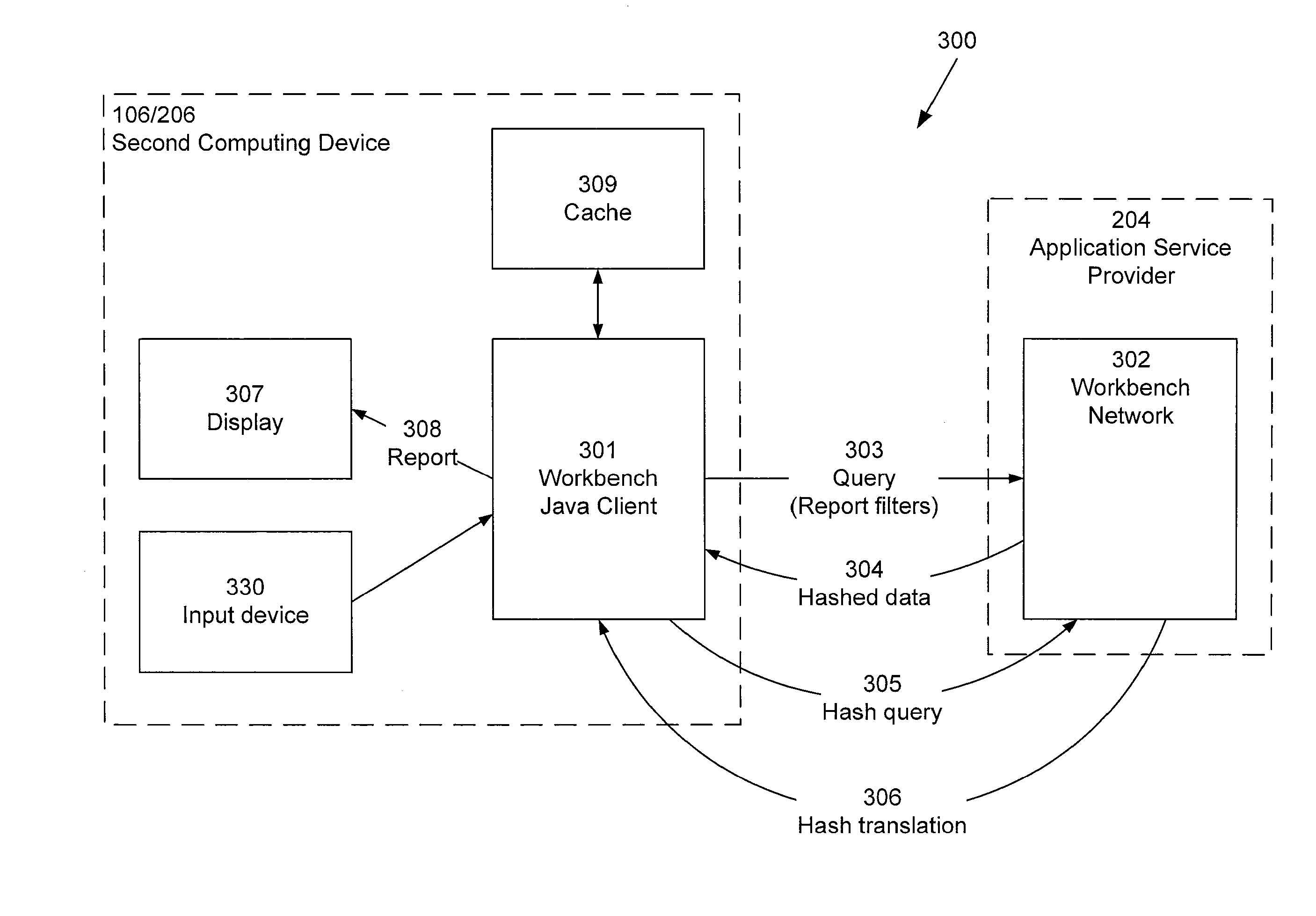

An application service provider system for retrieving and displaying web analytic data, or segmentation workbench, comprises a server and several client computing devices. The server includes a web analytics tool. Each of the clients preferably includes a web analytics client for communication with the server. The application service provider system is architecture allows web analytics service to be provided to users with an application service provider where the web traffic information for different users can be segregated and share a single server while communicating with different clients of different user companies. The present invention also includes a number of methods for retrieving and presenting web analytics data

Owner:ADOBE INC

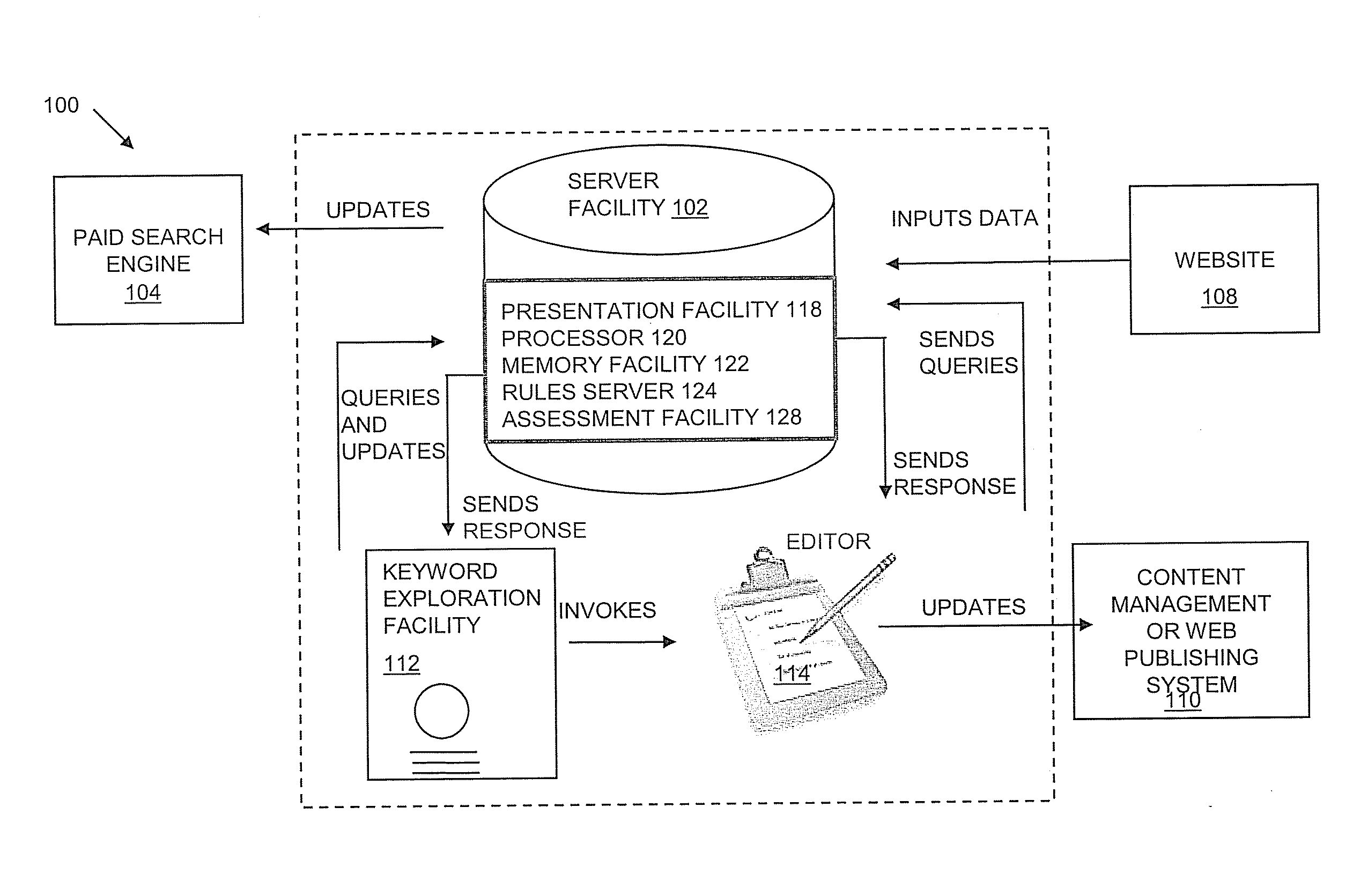

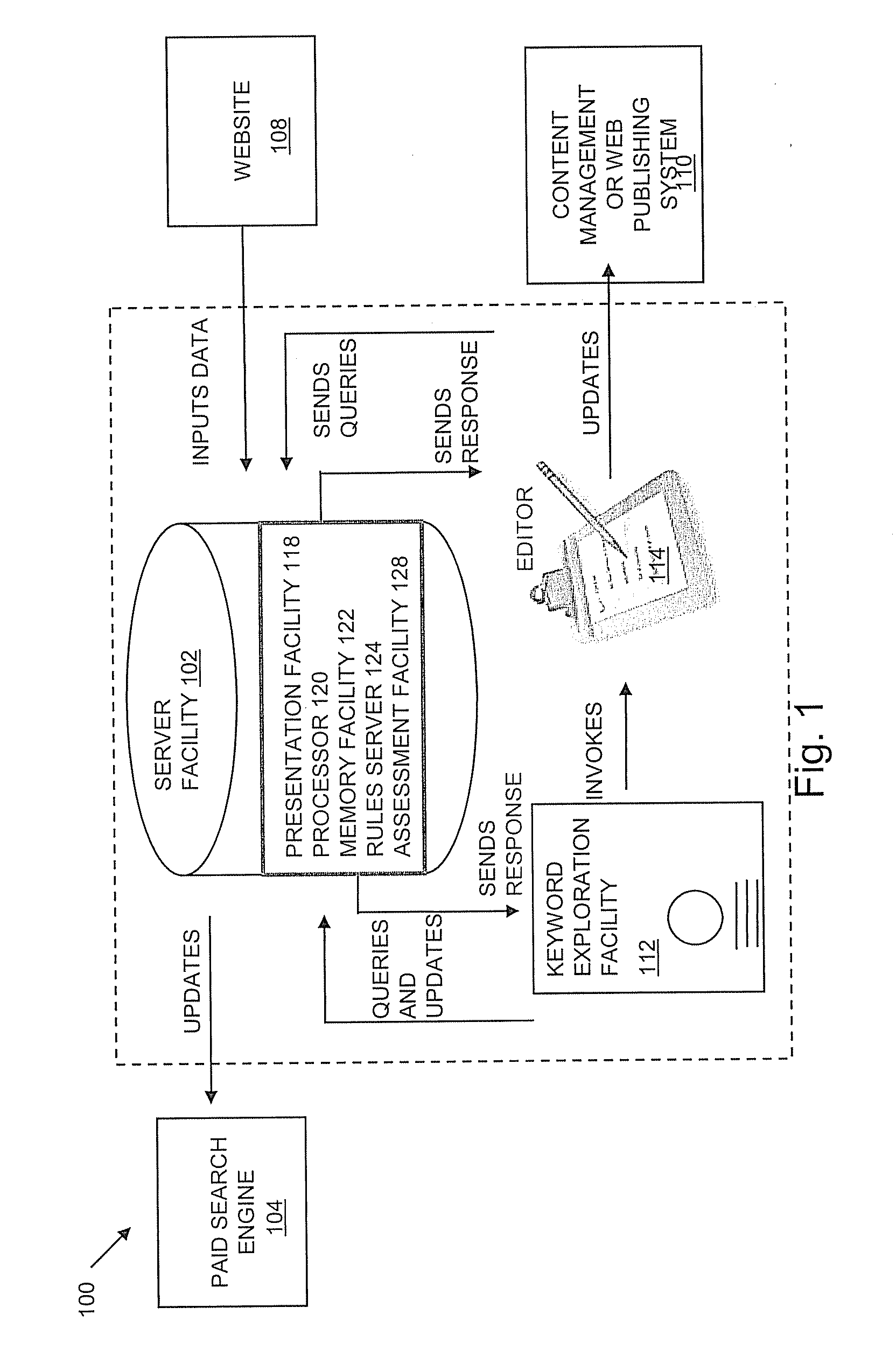

Integrated web analytics and actionable workbench tools for search engine optimization and marketing

InactiveUS20090292677A1High quality scoreEasy to identifyWebsite content managementSpecial data processing applicationsWeb analyticsApplication software

Methods and systems disclosed herein relate to a private keyword database and method of generating the database, such as compilation, manipulation, segmentation, analysis, and leveraging, to enable search engine optimization and marketing tools. The private keyword database may include search marketing data, such as keywords, a character string, a phrase, a slogan, an idiom, a string of characters of alpha-numeric codes, and the like, which may be aggregated from any number of public and proprietary data sources. Related user interfaces, applications, and computer program products are disclosed.

Owner:WORDSTREAM

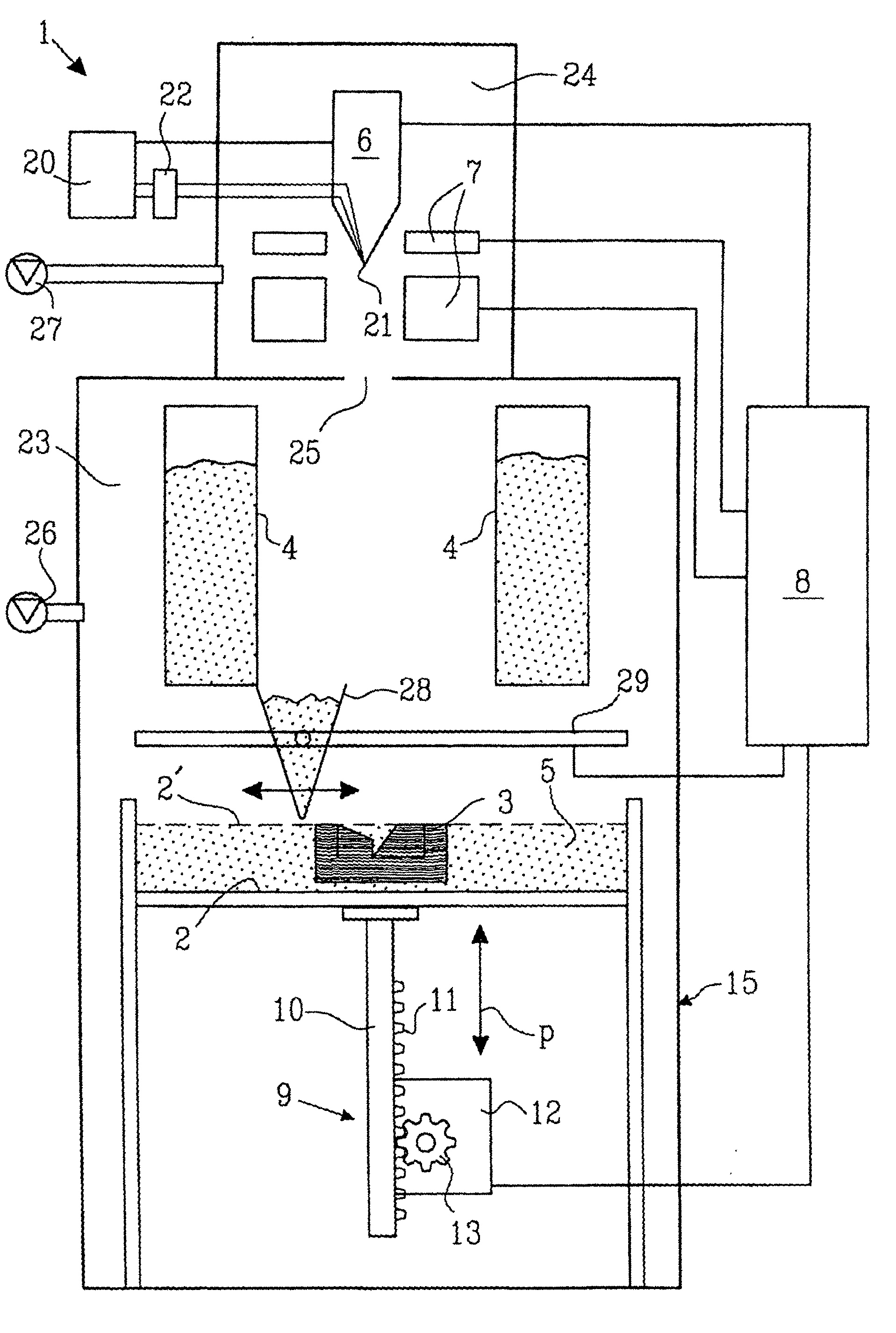

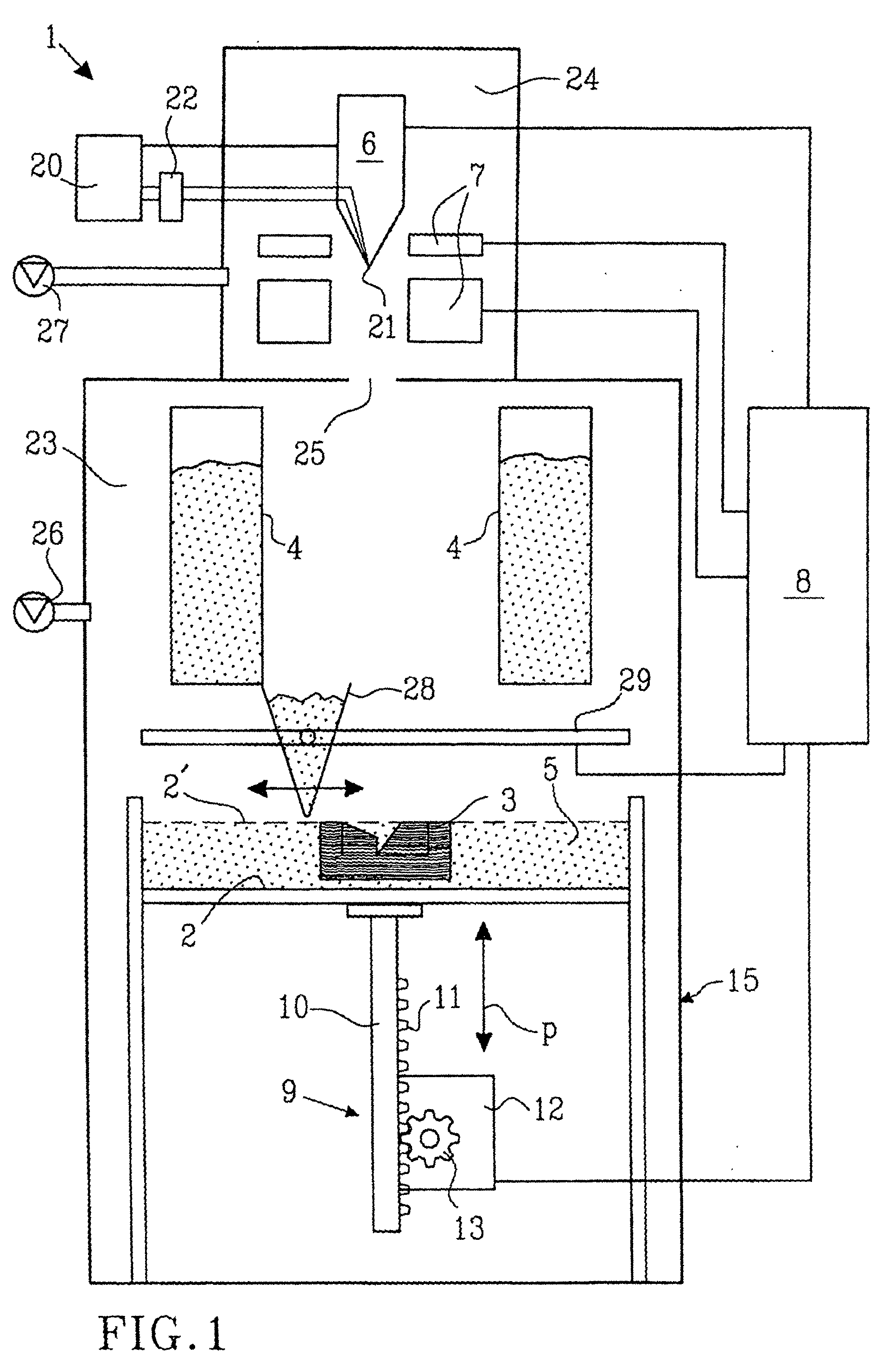

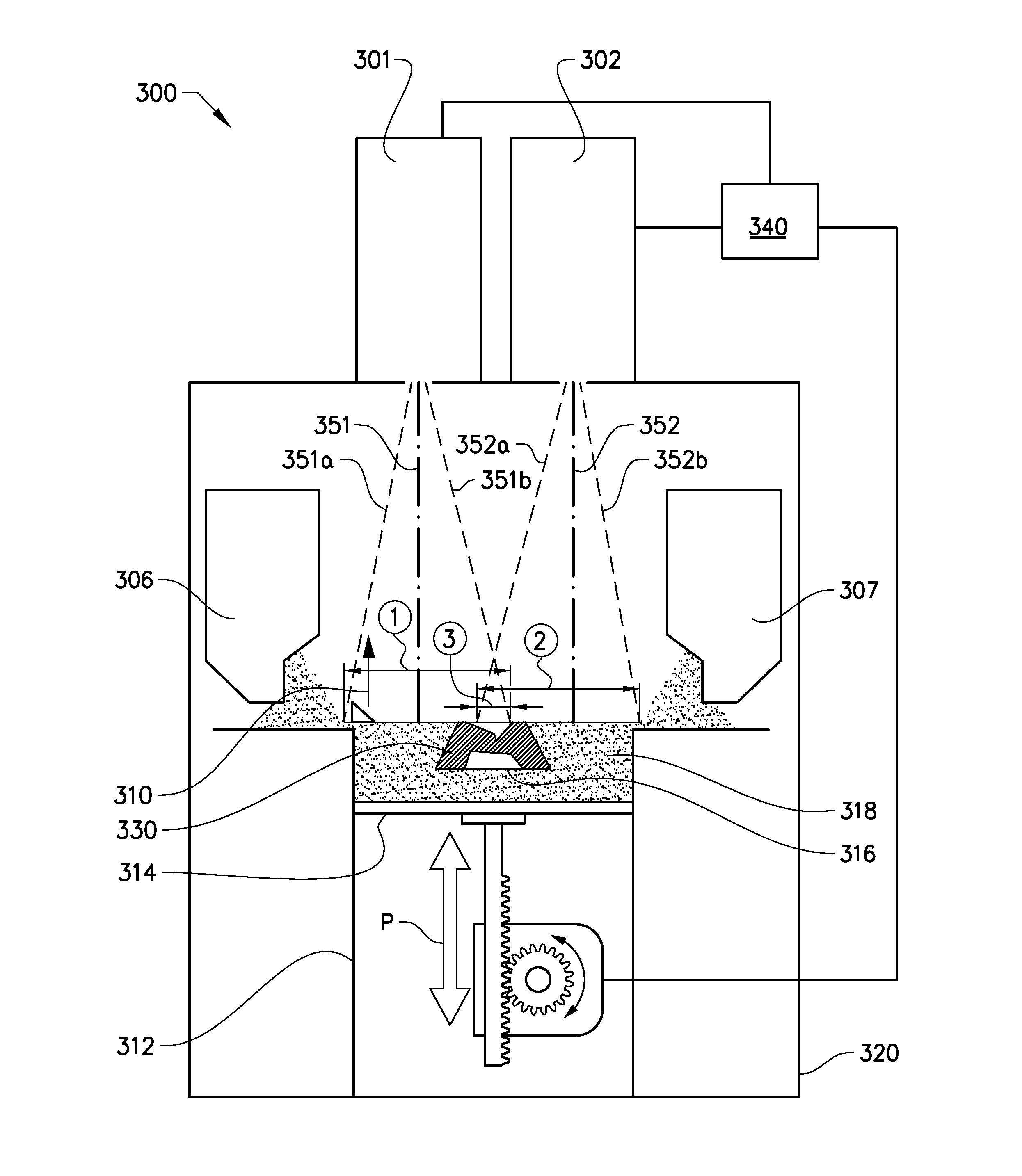

Device and arrangement for producing a three-dimensional object

InactiveUS20040026807A1Reduced form requirementsSmall sizeConfectioneryWood working apparatusThin layerRunning time

A device for manufacturing a three-dimensional product, which device comprises a work table on which said three-dimensional product is to be built, a powder dispenser which is arranged to lay down a thin layer of powder on the work table for the formation of a powder bed, a ray gun for giving off energy to the powder whereby fusion of the powder takes place, members for controlling of the beam released by the ray gun across said powder bed for the formation of a cross section of said three-dimensional product through fusion of parts of said powder bed, and a controlling computer in which information about successive cross sections of the three-dimensional product is stored, which cross sections build the three-dimensional product, the controlling computer intended to control said members for guiding the ray gun across the powder bed according to a running schedule forming a cross section of said three-dimensional body, whereby said three-dimensional product is formed by successive fusion of successively formed cross sections from powder layers successively laid down by the powder dispenser.

Owner:ARCAM AB

PLM-supportive CAD-CAM tool for interoperative electrical and mechanical design for hardware electrical systems

InactiveUS7103434B2Reduce frictionCAD network environmentComputer programmed simultaneously with data introductionTask completionBill of materials

Owner:CHERNYAK ALEX H +3

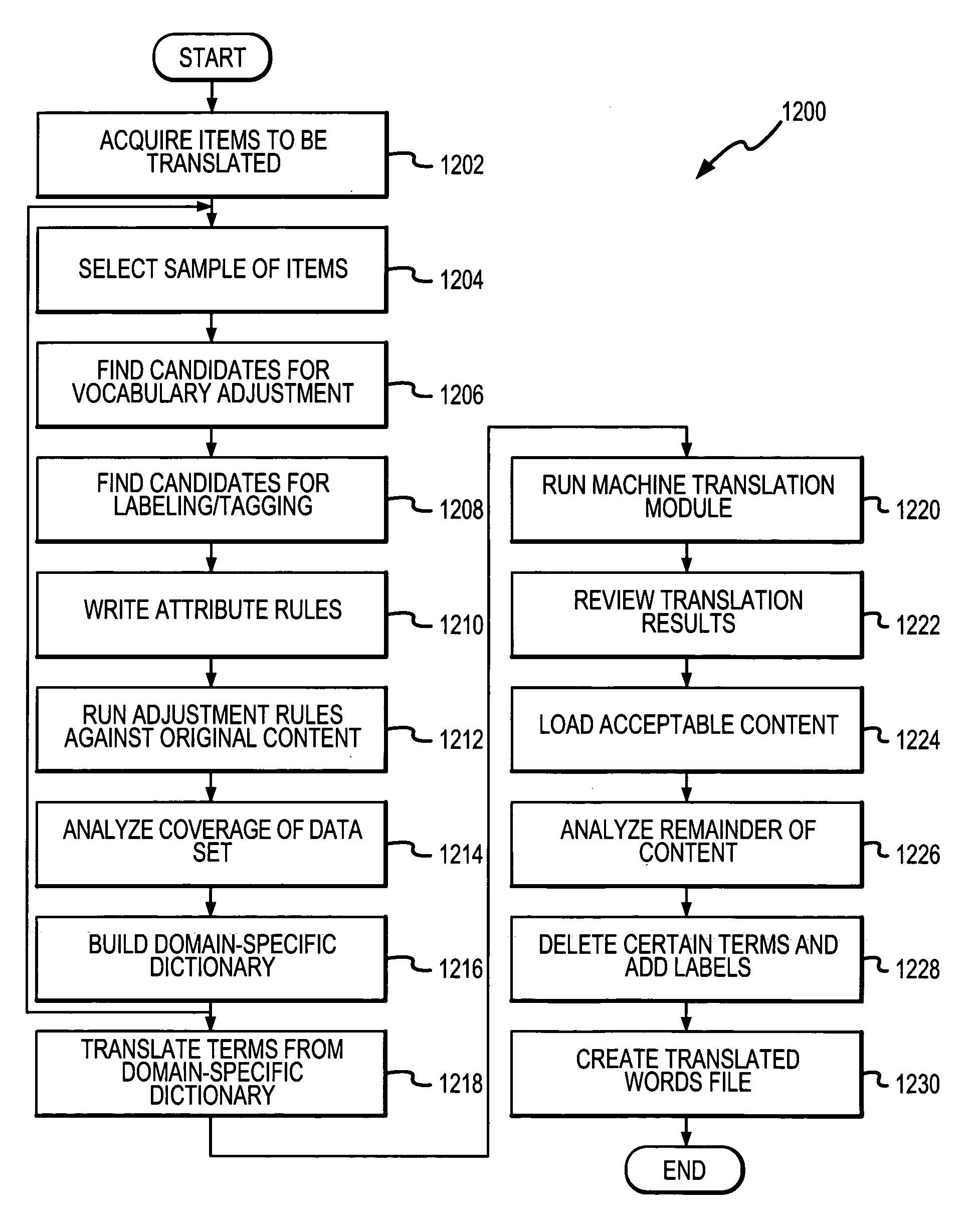

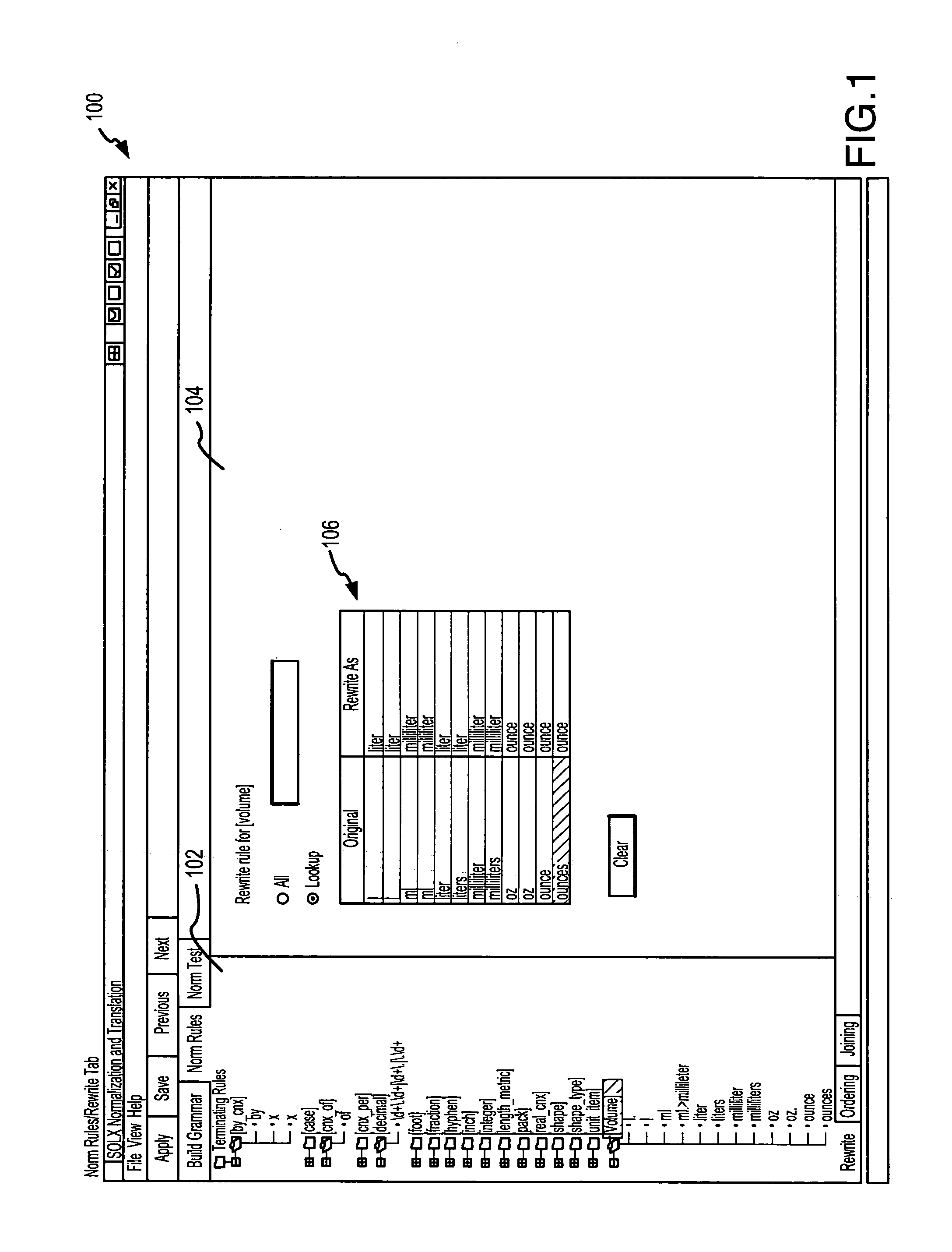

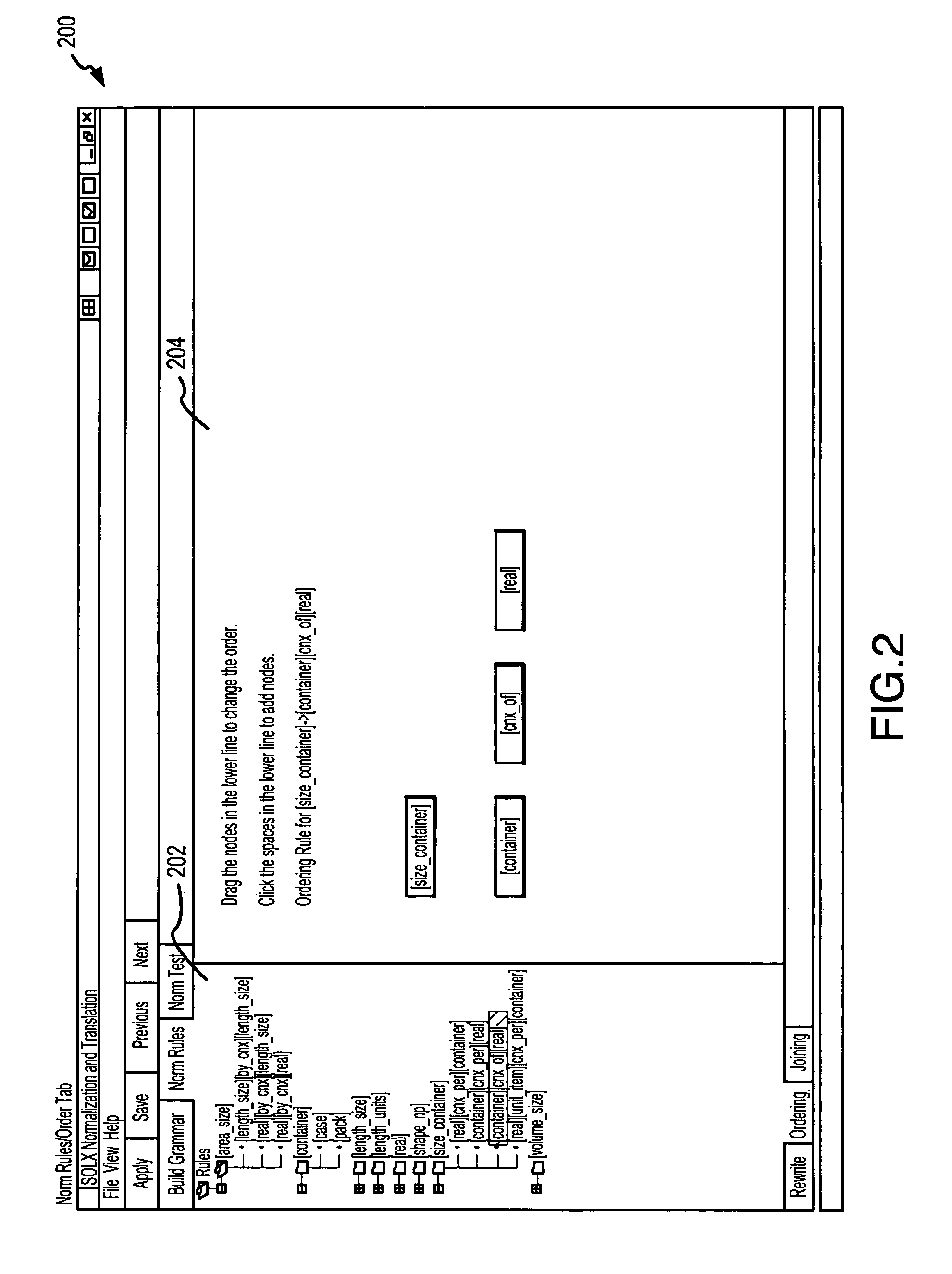

Method and apparatus for normalizing and converting structured content

InactiveUS6986104B2Meet growth needsHigh degreeNatural language translationSemantic analysisStructured contentTime transformation

A method and apparatus are disclosed for transforming information from one semantic environment to another. In one implementation, a SOLx system includes a Normalization / Translation NorTran Workbench and a SOLx server. The NorTran Workbench is used to develop a knowledge base based on information from a source system, to normalize legacy content according to various rules, and to develop a database of translated content. During run time, the SOLx server receives transmissions from the source system, normalizes the transmitted content, accesses the database of translated content and otherwise translates the normalized content, and reconstructs the transmission to provide substantially real-time transformation of electronic messages.

Owner:ORACLE INT CORP

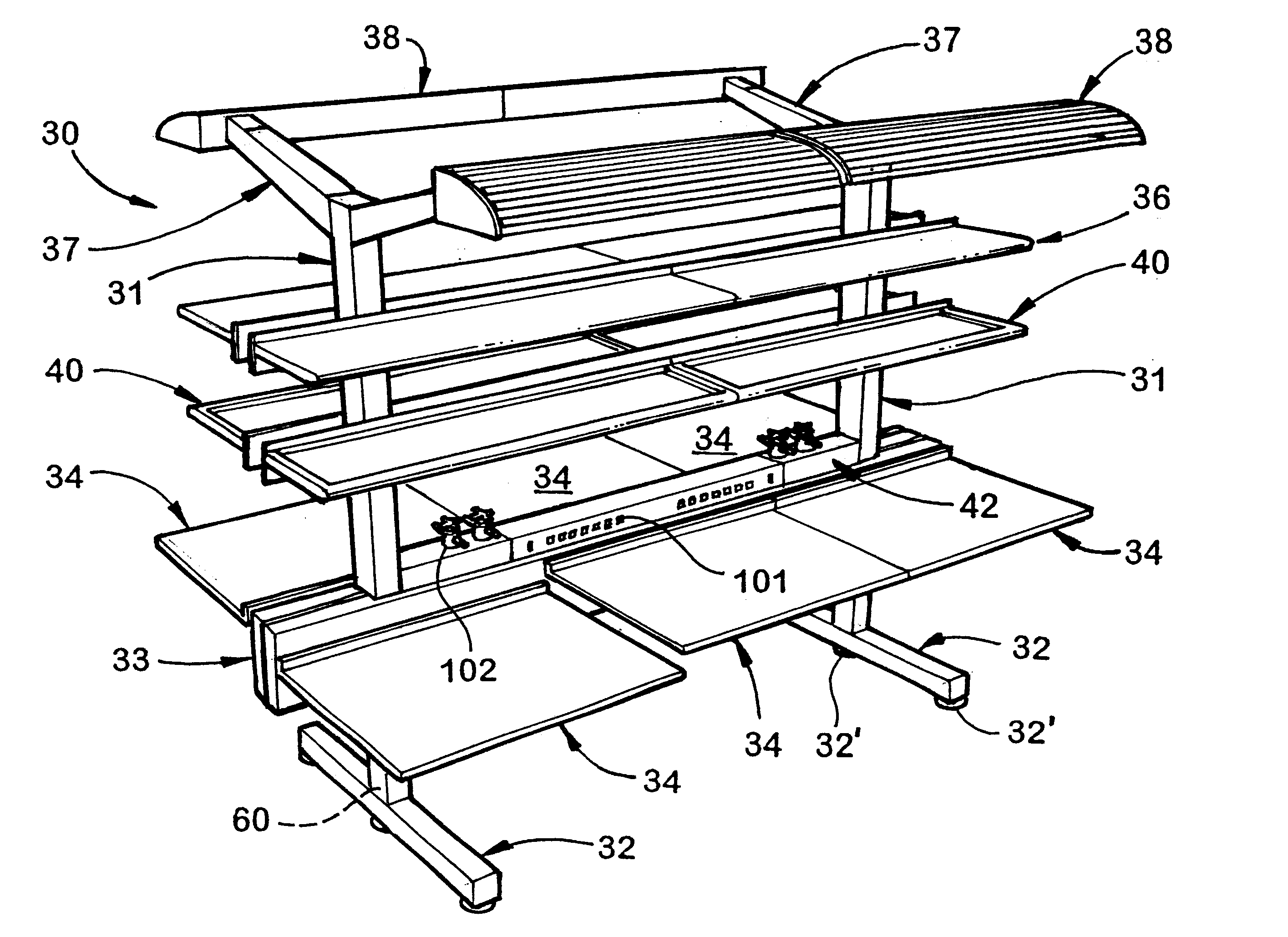

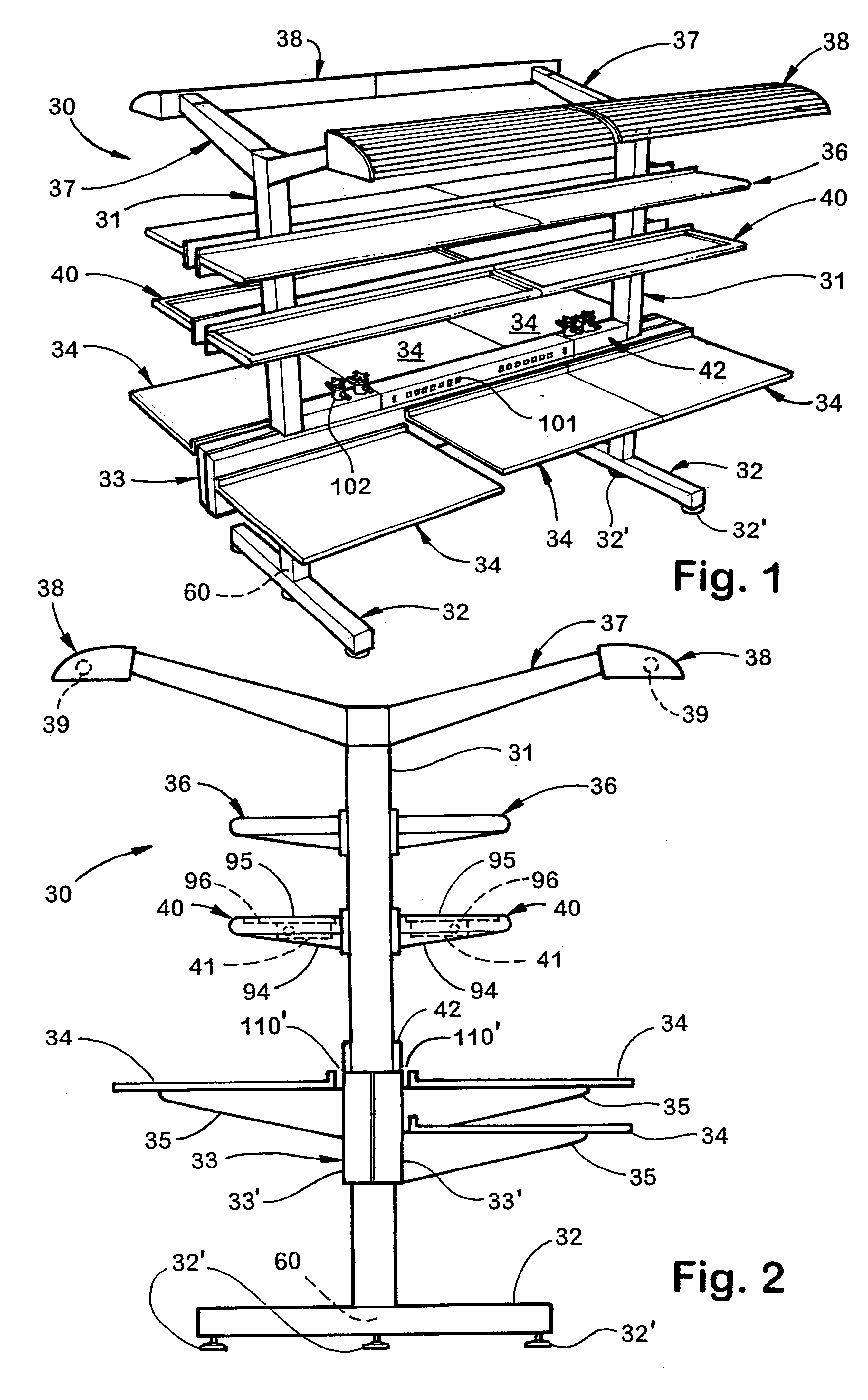

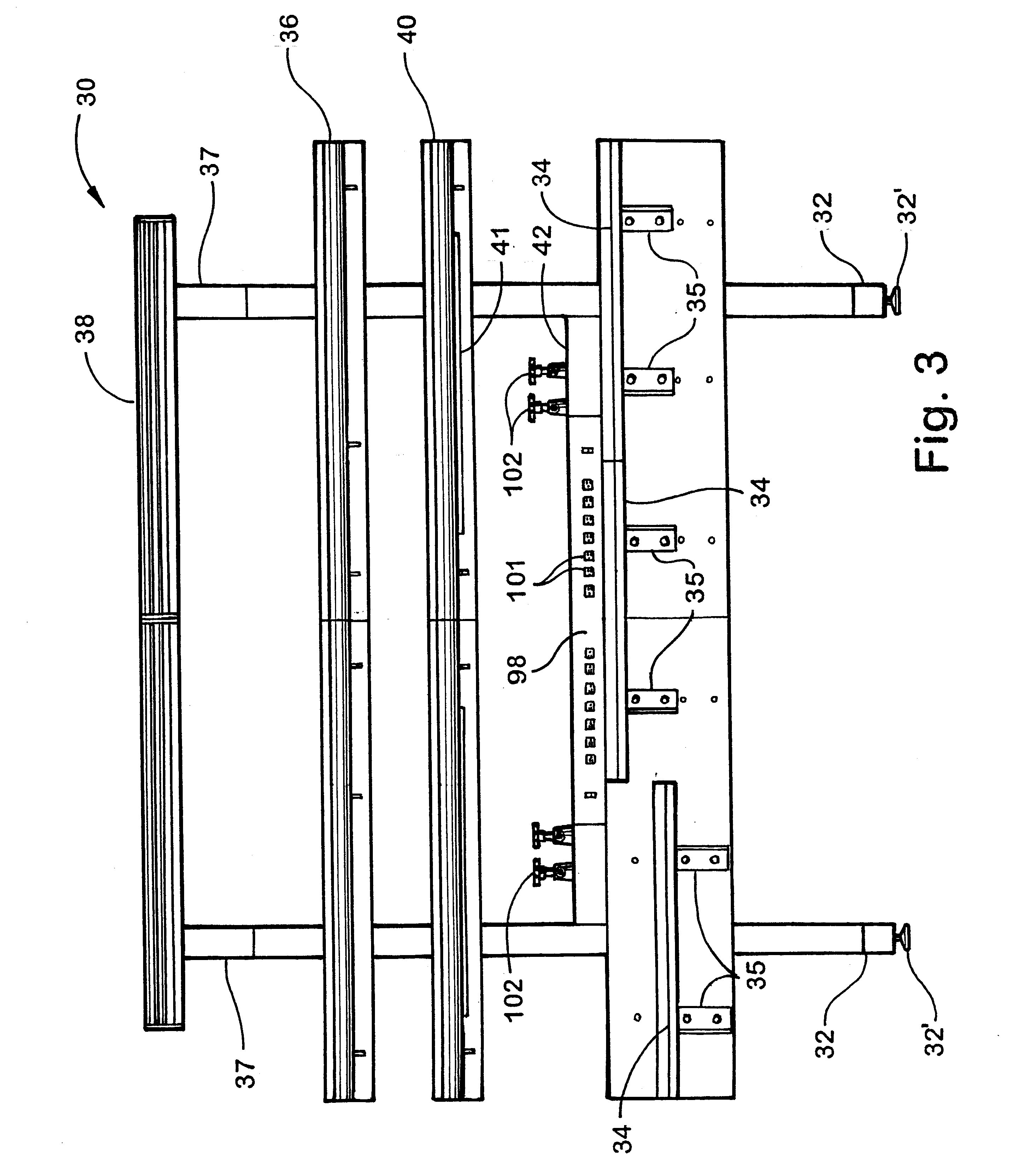

Laboratory furniture unit

A furniture unit is provided specially adapted for use in laboratories. The furniture unit includes a pair of spaced-apart uprights and vibration-dampening legs extending from the uprights for stably supporting the furniture unit on a floor surface. A belt-high structural beam comprising two opposing C-shaped beams is fixedly attached to the uprights to rigidly interconnect the uprights in a spaced relationship. A plurality of worksurfaces is provided, each having a pair of cantilever brackets configured to rigidly connect to a side of the belt-high structural beam and to extend laterally therefrom. The plurality of worksurfaces is separately adjustably supported on the belt-high structural beam for vertical height adjustment, with at least one of the cantilever brackets engaging the belt-high structural beam at a location between the uprights. Shelves are attached between the uprights above the plurality of worksurfaces. Optionally, an accessory panel is mounted between the front and rear shelves for visual shielding and / or for function use, such as a marker board. A Y-shaped lighting support includes a bayonet that telescopingly engages a top of the uprights. A lamp housing structure spans between the lighting supports in a location where a lamp in each lamp housing structure is generally above a front edge of the worksurfaces. A utility distribution beam is mounted between the uprights above the structural beam for communicating utilities, including piped utilities and cabled utilities, to accessible locations along a rear edge of the worksurfaces. The legs include gussets that telescope into the uprights to provide a stable bottom joint.

Owner:STEELCASE INC

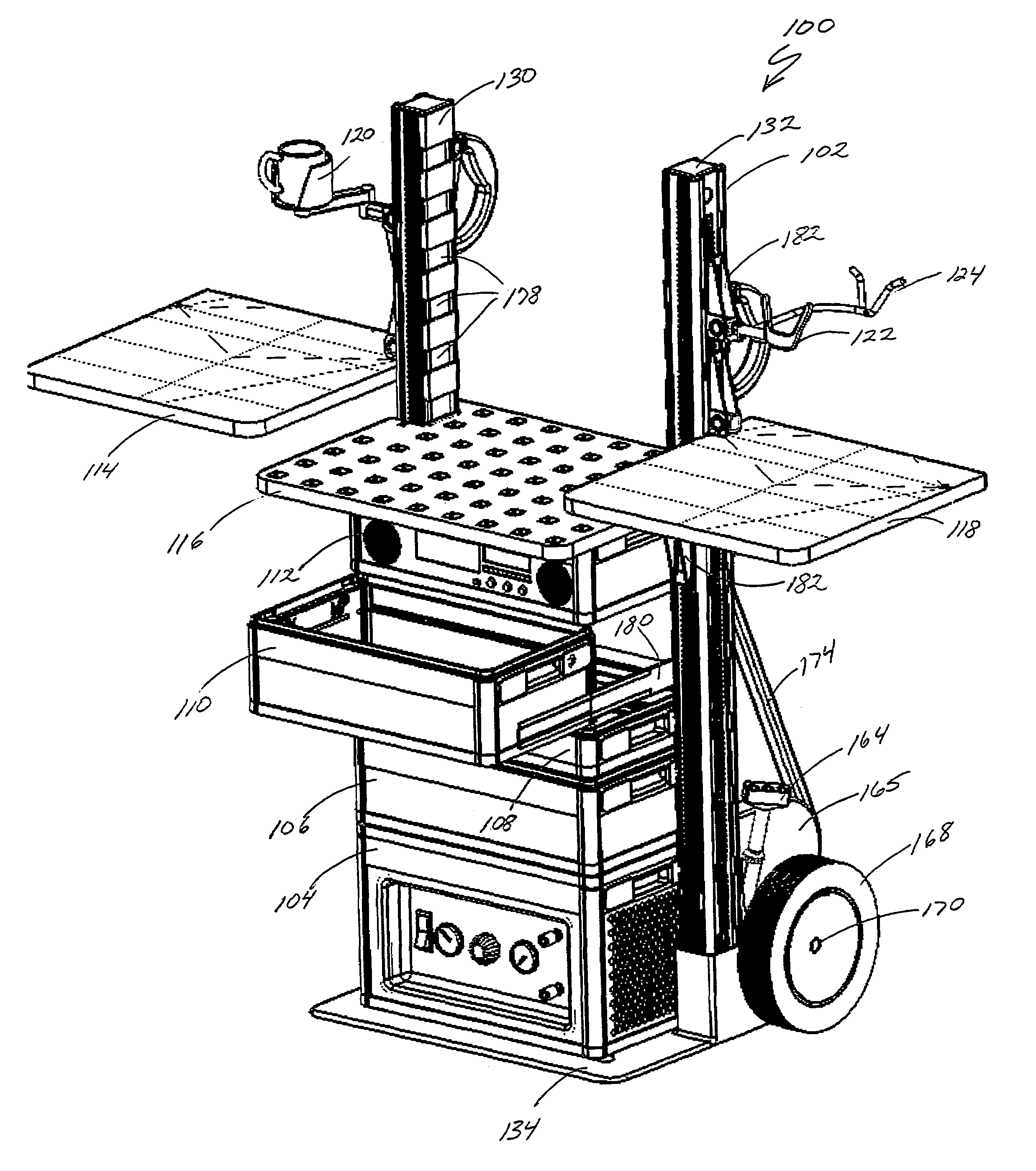

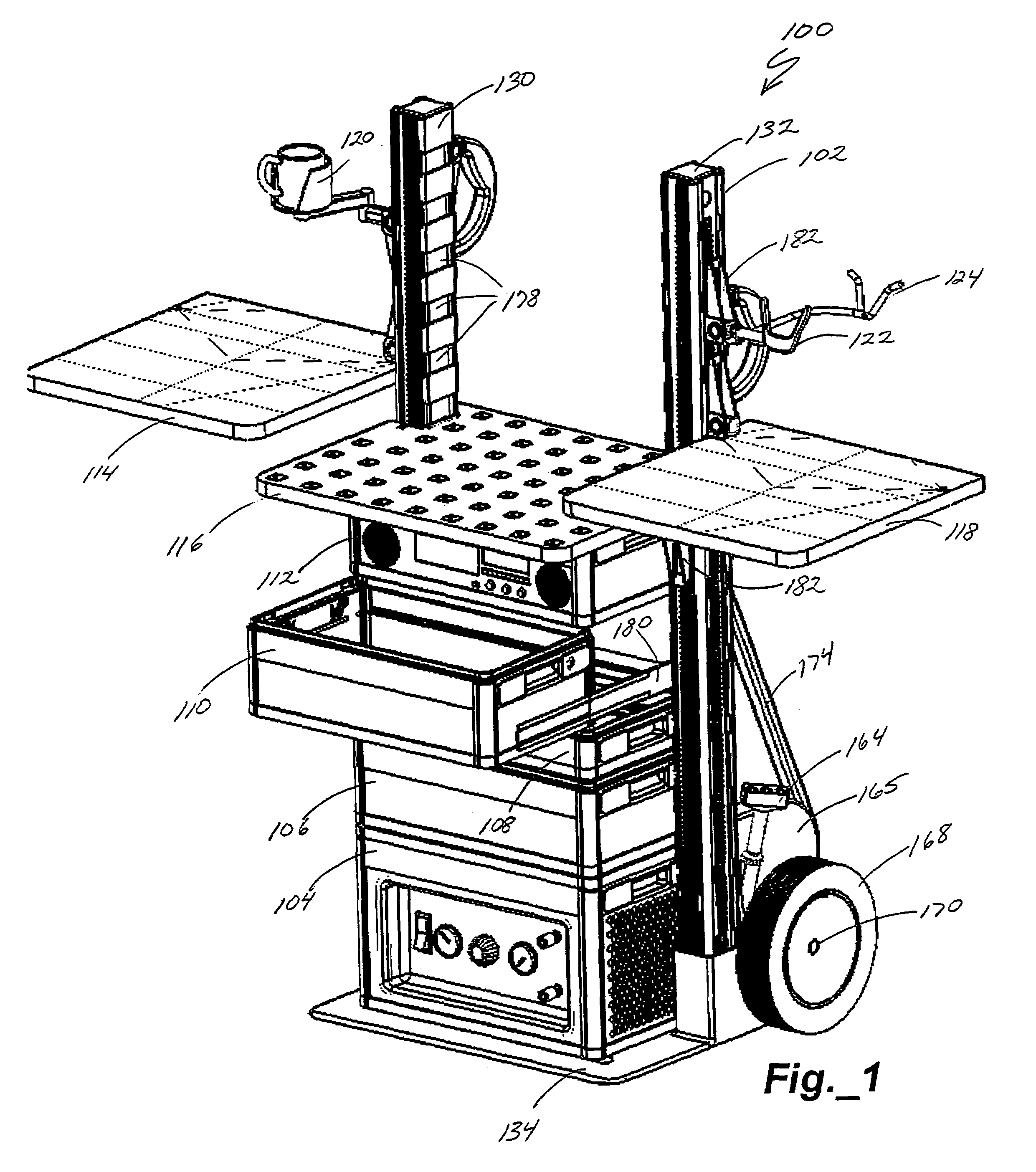

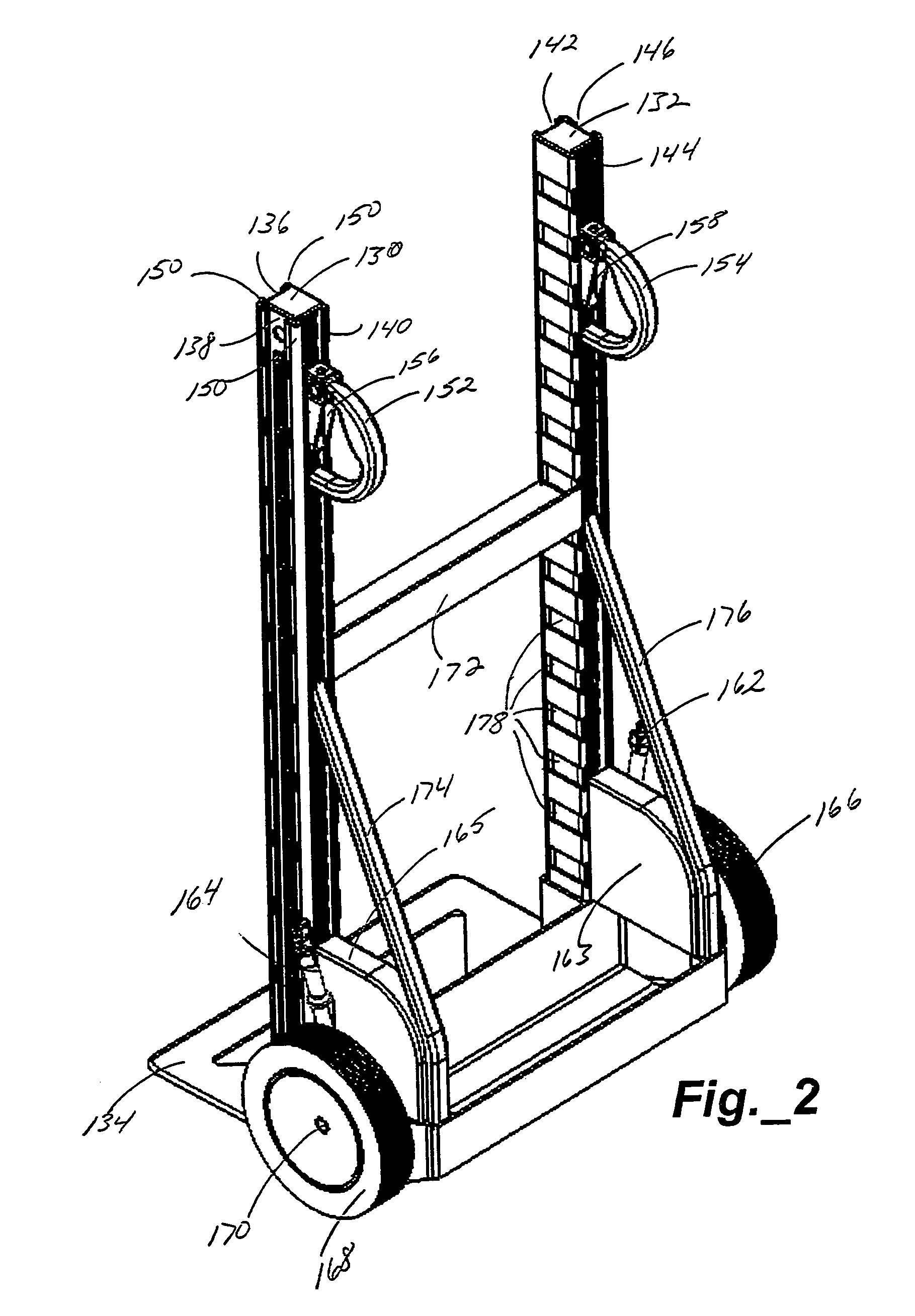

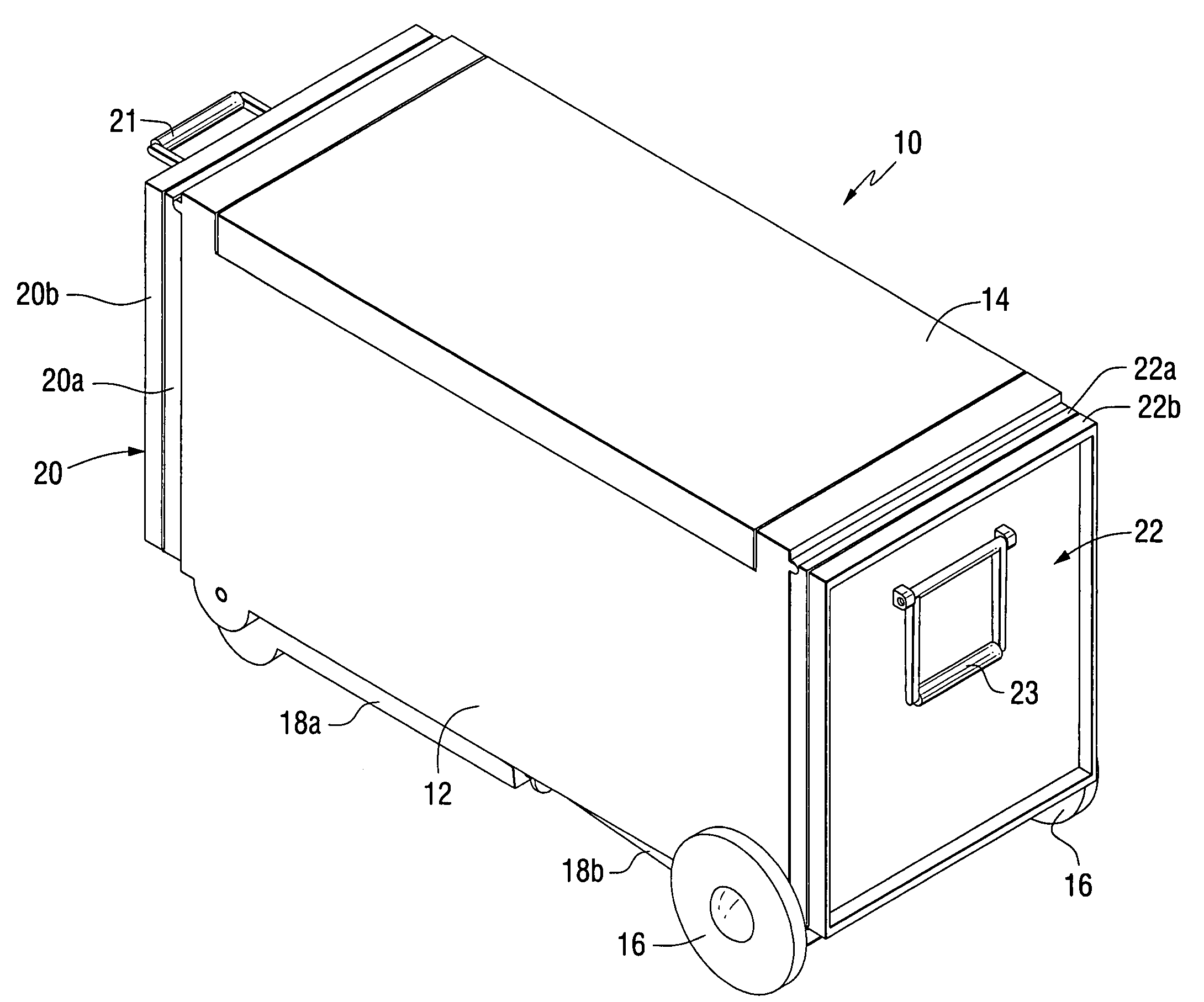

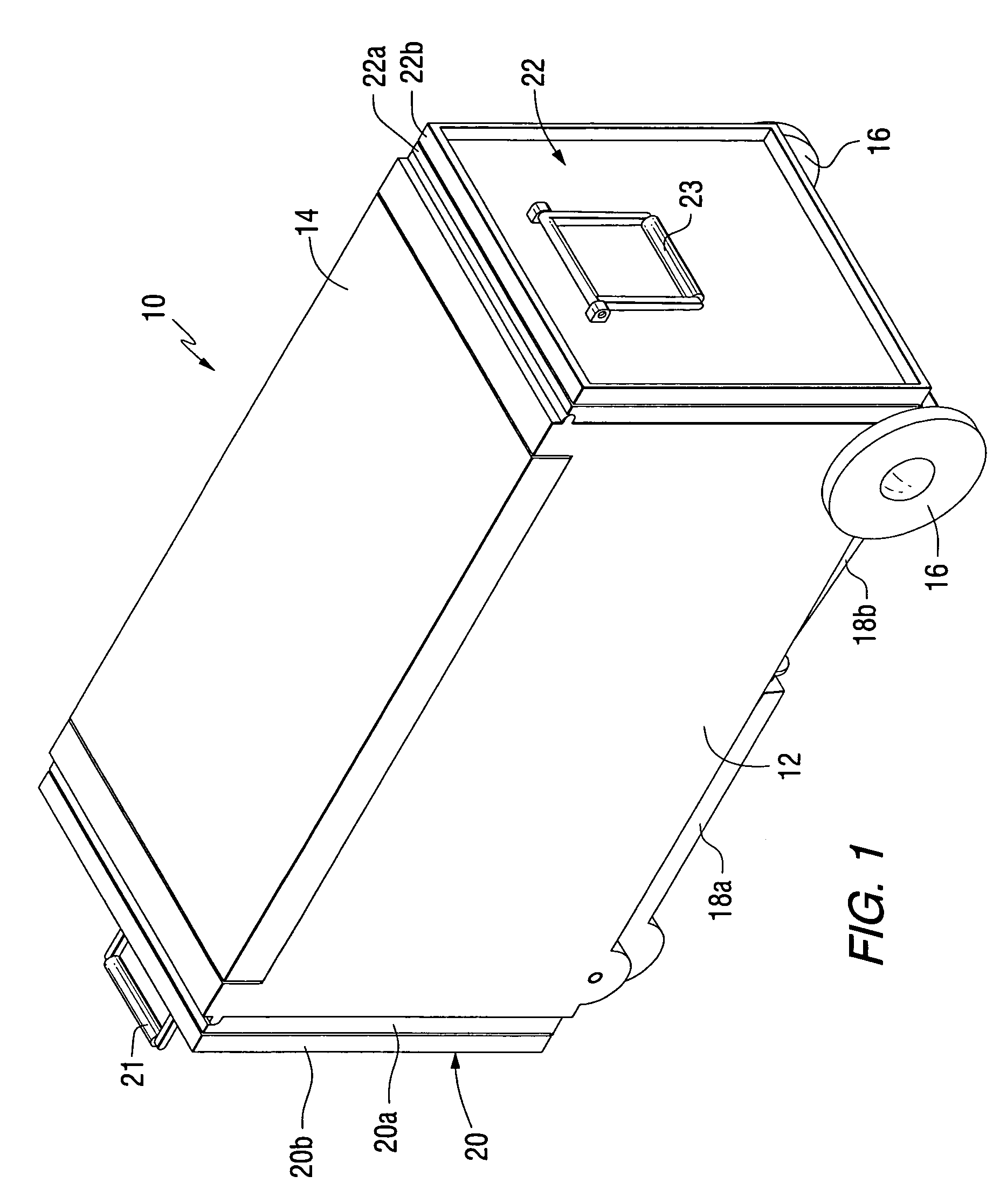

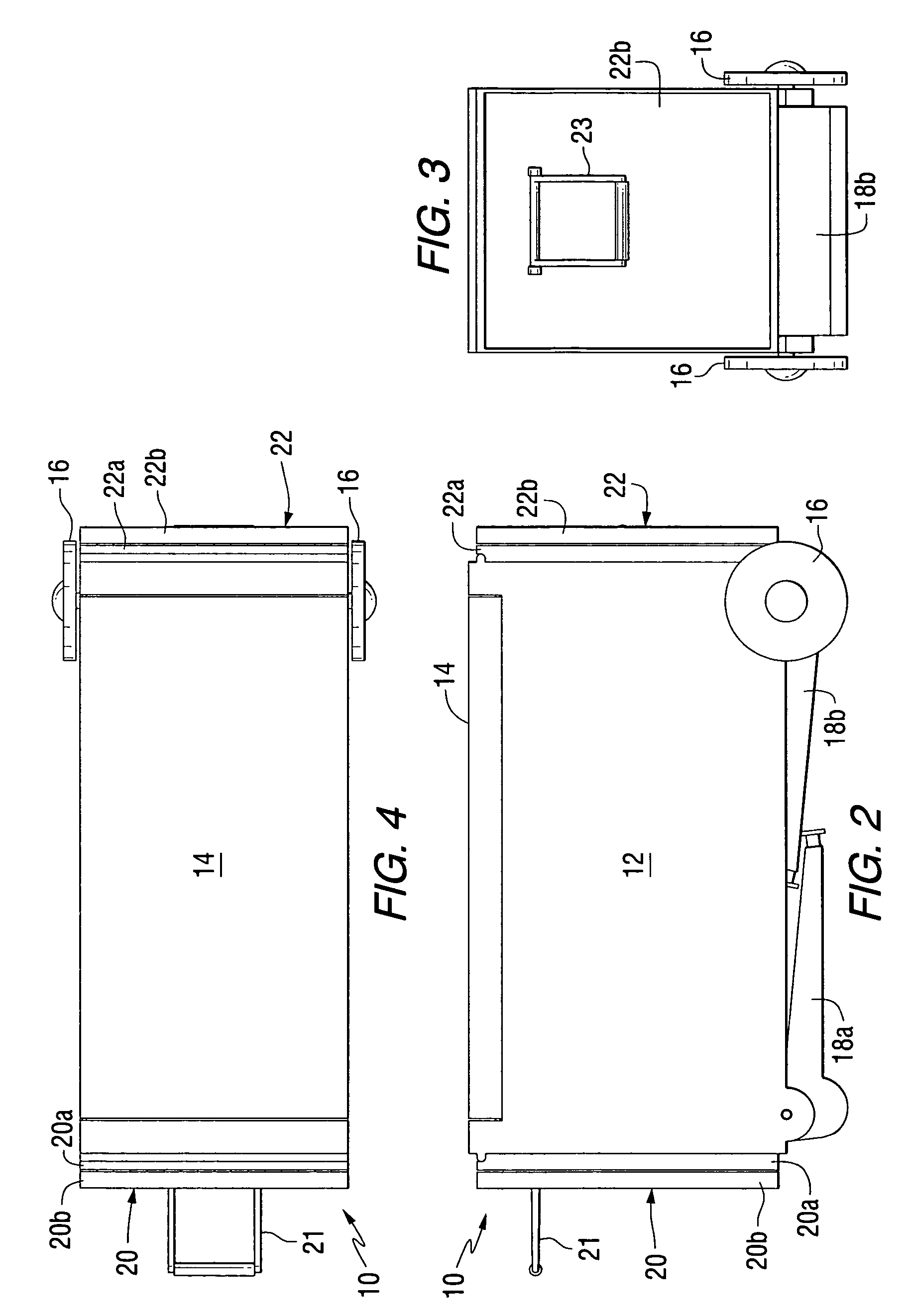

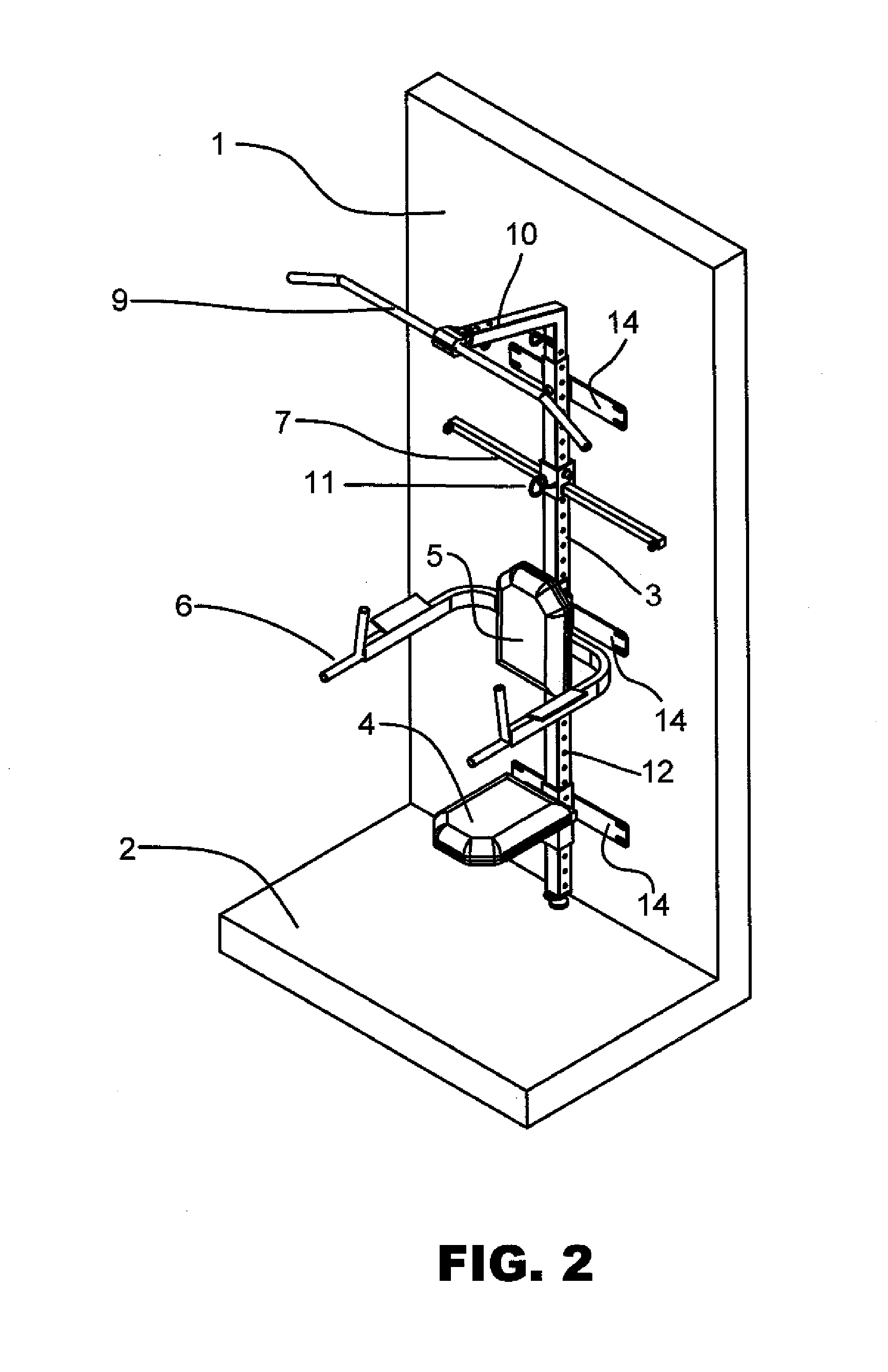

Tool and task box storage, transport, and workbench system

InactiveUS7367571B1Easy to liftCarriage/perambulator with single axisWork benchesMachine toolWorkbench

A machine tool stand and / or workbench, electrical outlet panel, light supply, and modular task box system, combined into an integrated system that includes a support structure having a support base on wheels and side rails disposed on the surface of the support base. The side rails include structure for attaching tool holders, work pieces holders, work surfaces, and the like.

Owner:STAINBROOK & STAINBROOK

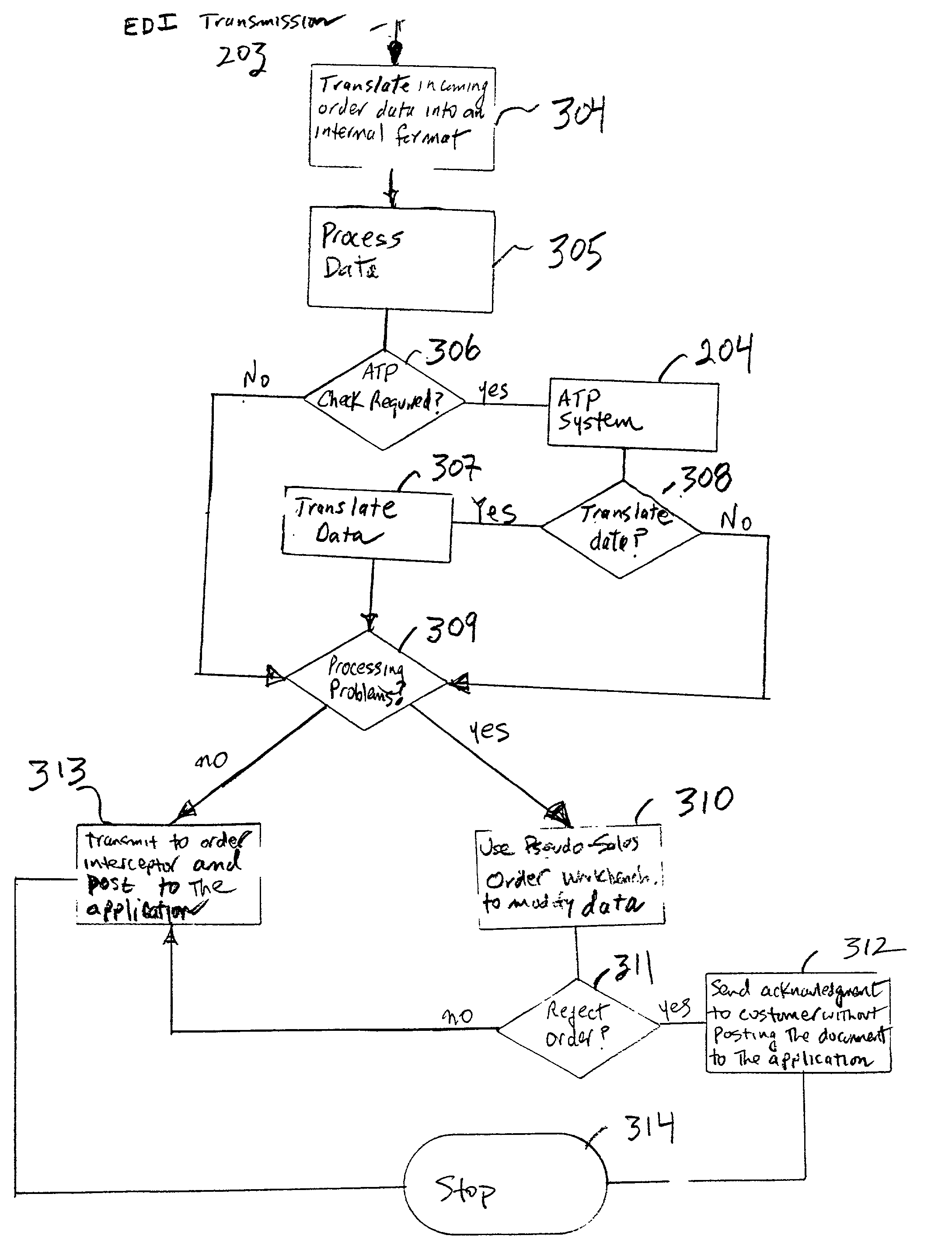

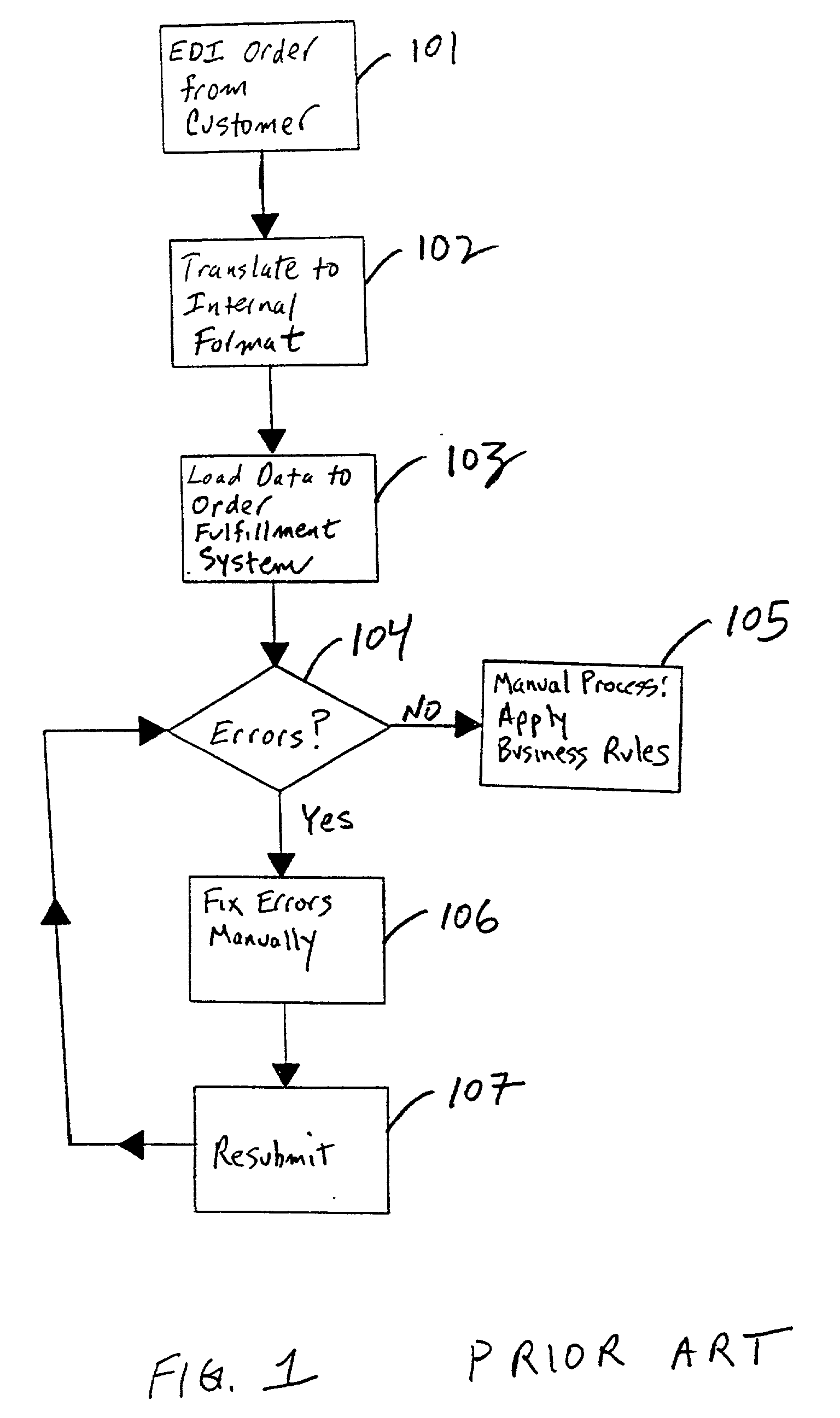

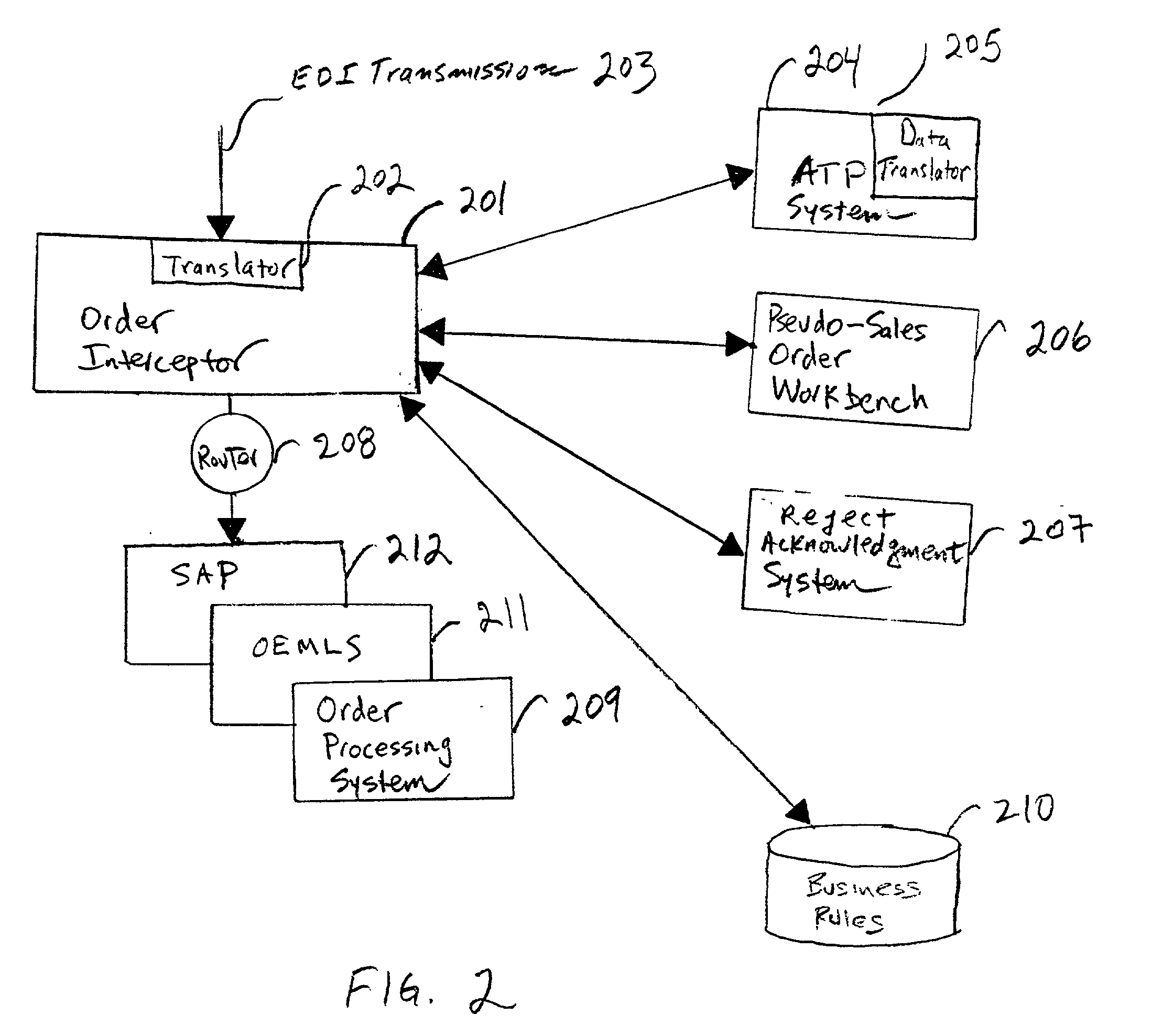

Pre-processor for inbound sales order requests with link to a third party available to promise (ATP) system

InactiveUS20020013731A1Hand manipulated computer devicesAnimal feeding devicesOrder fulfillmentDocumentation procedure

A method and apparatus for pre-processing electronic data requests within the EDI subsystem layer and within the order fulfillment application system. An order interceptor, third-party Available To Promise (ATP) interface, pseudo-sales order workbench, and the reject acknowledgment system processes are provided within the order fulfillment application system to accomplish the pre-processing. The order interceptor performs an asynchronous availability check before a sales order is posted. The result of the ATP check is stored in an ESO, and is applied during the posting process with unique user exits. The result of the ATP check is also used to determine key information about the sales order, such as the sales organization, and division and distribution channels. The pre-processor uses business rules to determine if the ESO should be split into multiple documents for requests satisfied across multiple sales areas. The Workbench provides a customer purchase order view of the ESO that looks, feels and behaves like actual order entry screens. The Workbench also displays messages generated from the pre-processor describing why the ESO was held for review. After the condition is corrected the Workbench re-executes the ESO pre-processor. This continues until all messages are corrected or marked reviewed. The supplier can decide to either accept the request, reject the request or accept individual line items.

Owner:IBM CORP

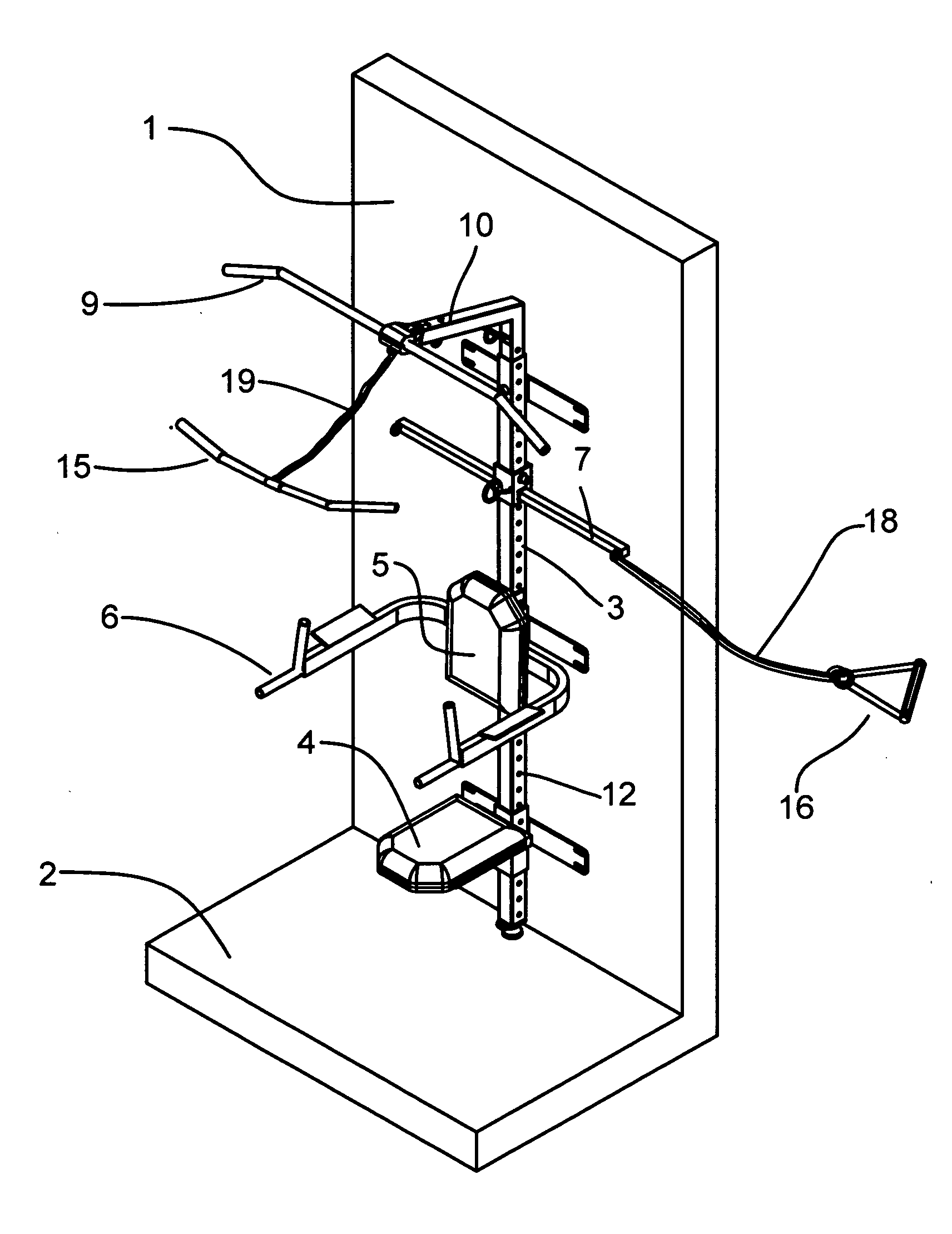

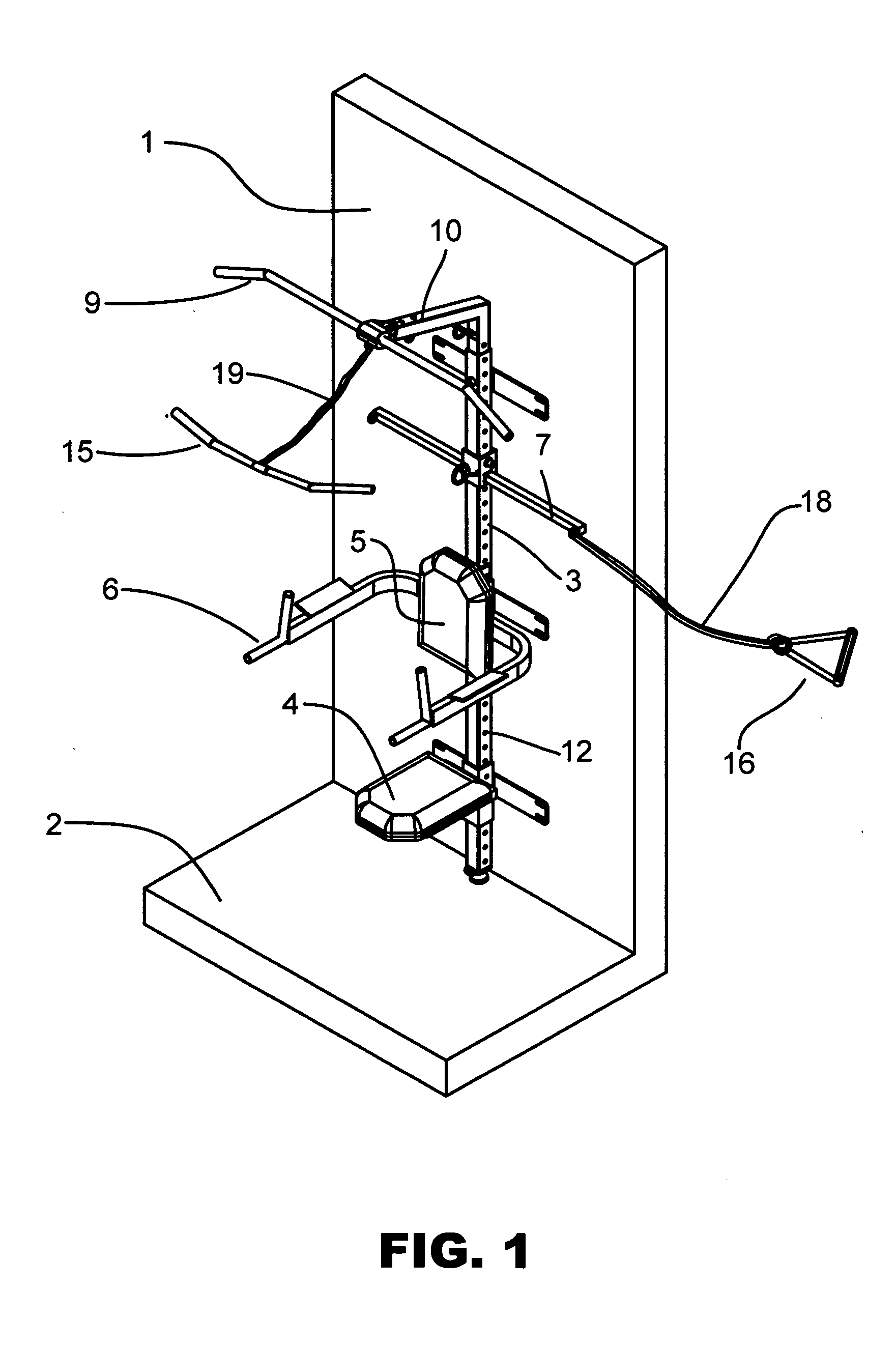

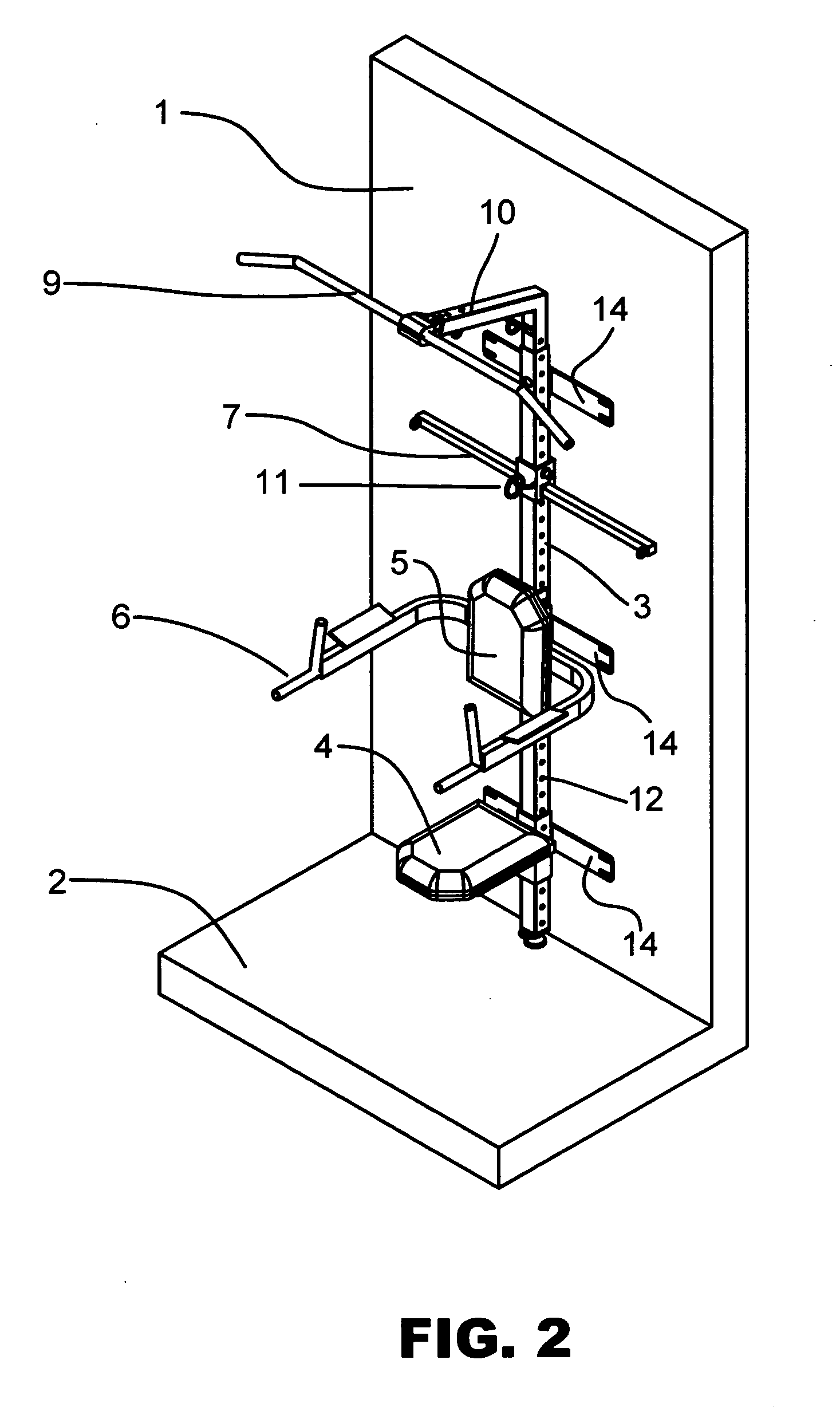

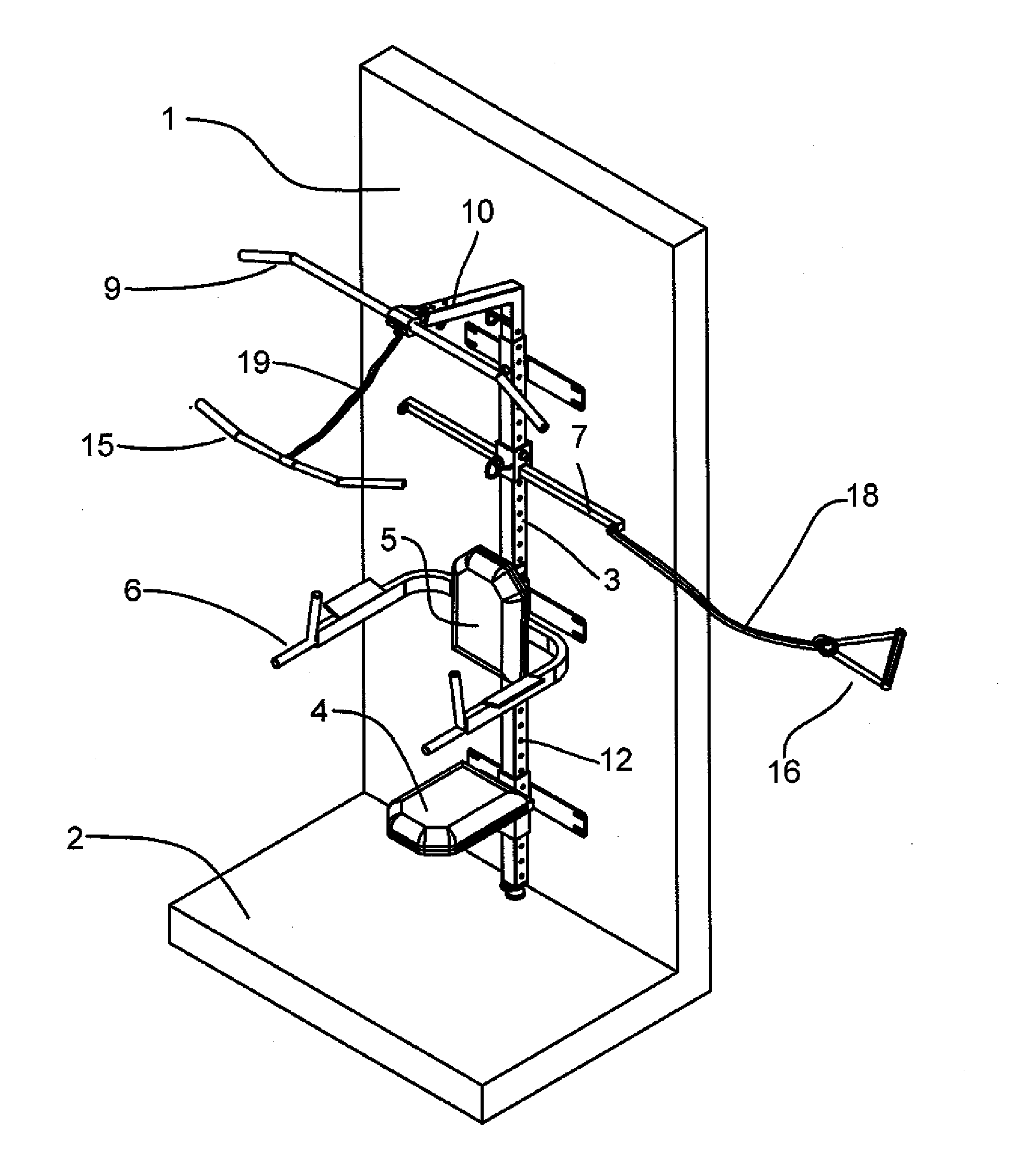

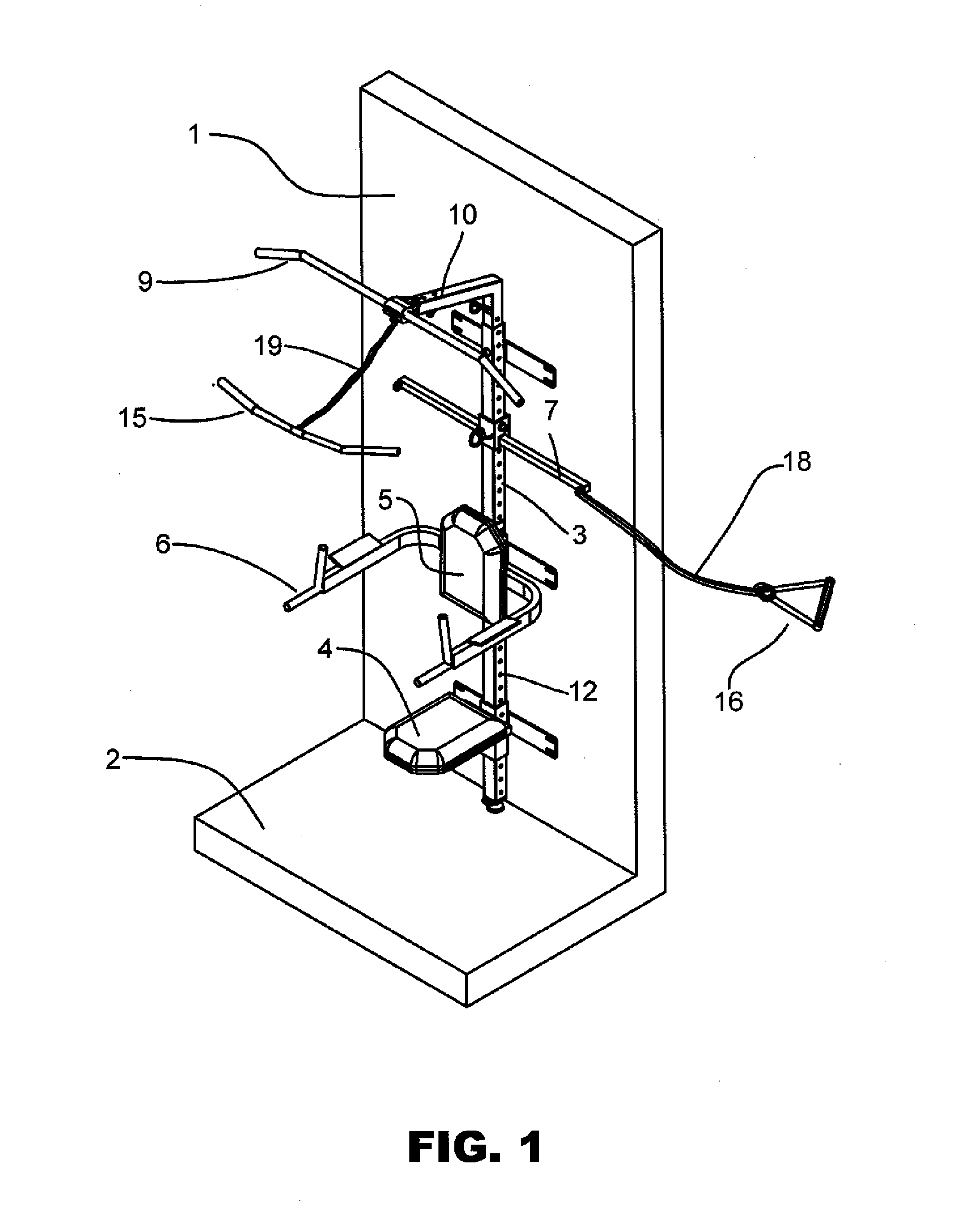

Wall-mounted home fitness training equipment

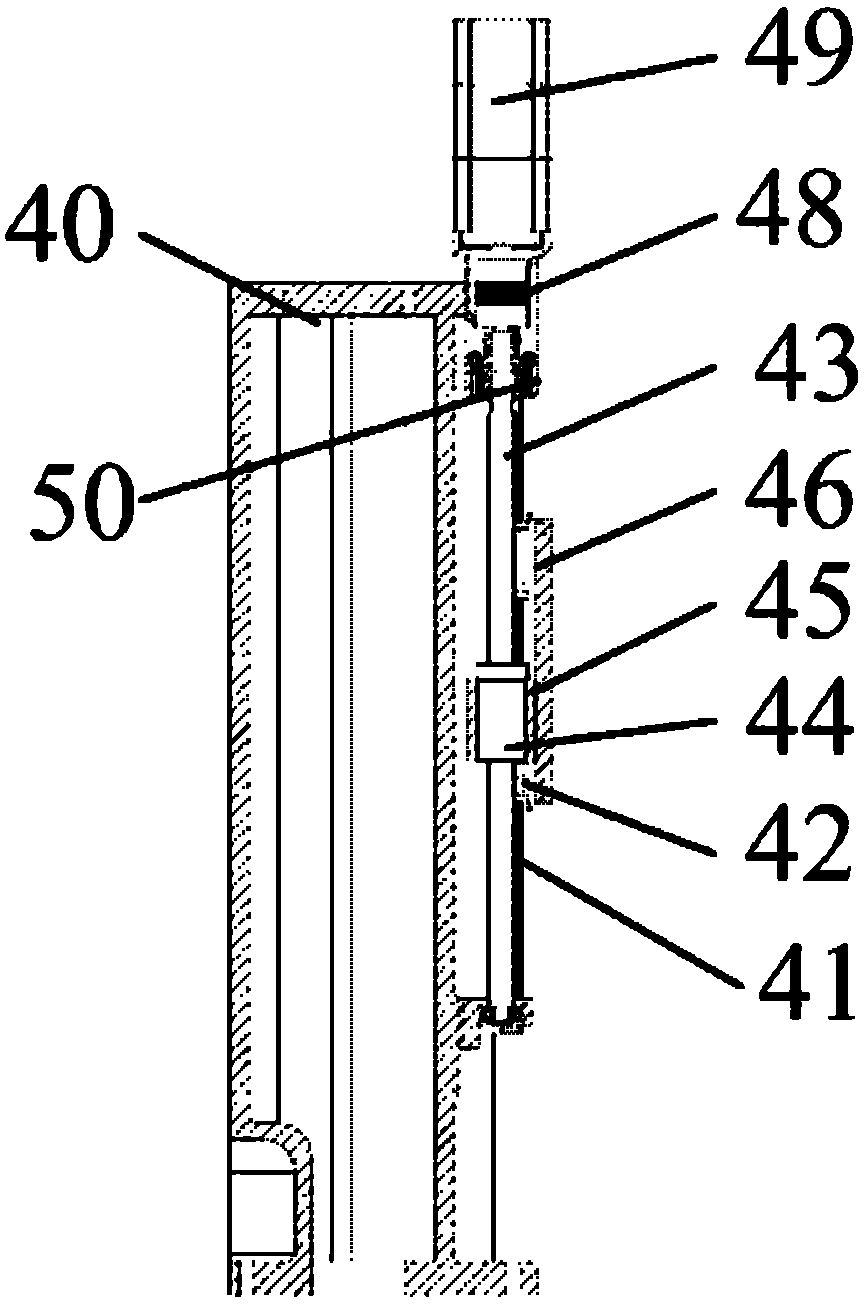

InactiveUS20100048368A1Easy to adjustIncrease the number ofStiltsHorizontal barsPull forceEngineering

An overall fitness trainer and can be a wall mounted unit that can utilize clip resistance bands as well as other techniques. These bands generally clip on the unit and onto different handles, bars and attachments to perform exercises. The unit can have a removable / adjustable pull up bar, dip bar and seat. It also includes a spring loaded, pull pin carriage that moves freely up and down a vertical spine. This allows for easy adjustment of the carriage and allows the user to attach the bands at multiple angles, widths and levels. This in turn increases the number of exercises the user can perform on the unit. The unit also typically has an o ring that attaches through the arm of the pull up attachment as well as a ½ O-ring at the bottom of the unit again increasing the number of exercises the user can perform. The unit can be attached to the wall with lag bolts into two or more studs. Some embodiments of the invention have an adjustable swivel foot that takes the stress off of the lag bolts and also adds to the overall load capacity of the unit. The apparatus typically has an optional telescoping central vertical spine that splits in two pieces to make the unit easier to ship. The central vertical spine allows attachments to be added and removed using spring loaded pins or plunger pins. Various embodiments of the invention can have an oscillating and telescopic bench, a dip bar, a seat, a knee stabilizer and a foot rest. All of these accessories can be attached and removed to the central spine adding to the versatility and scope of exercises that can be performed.

Owner:DONOFRIO DARREN

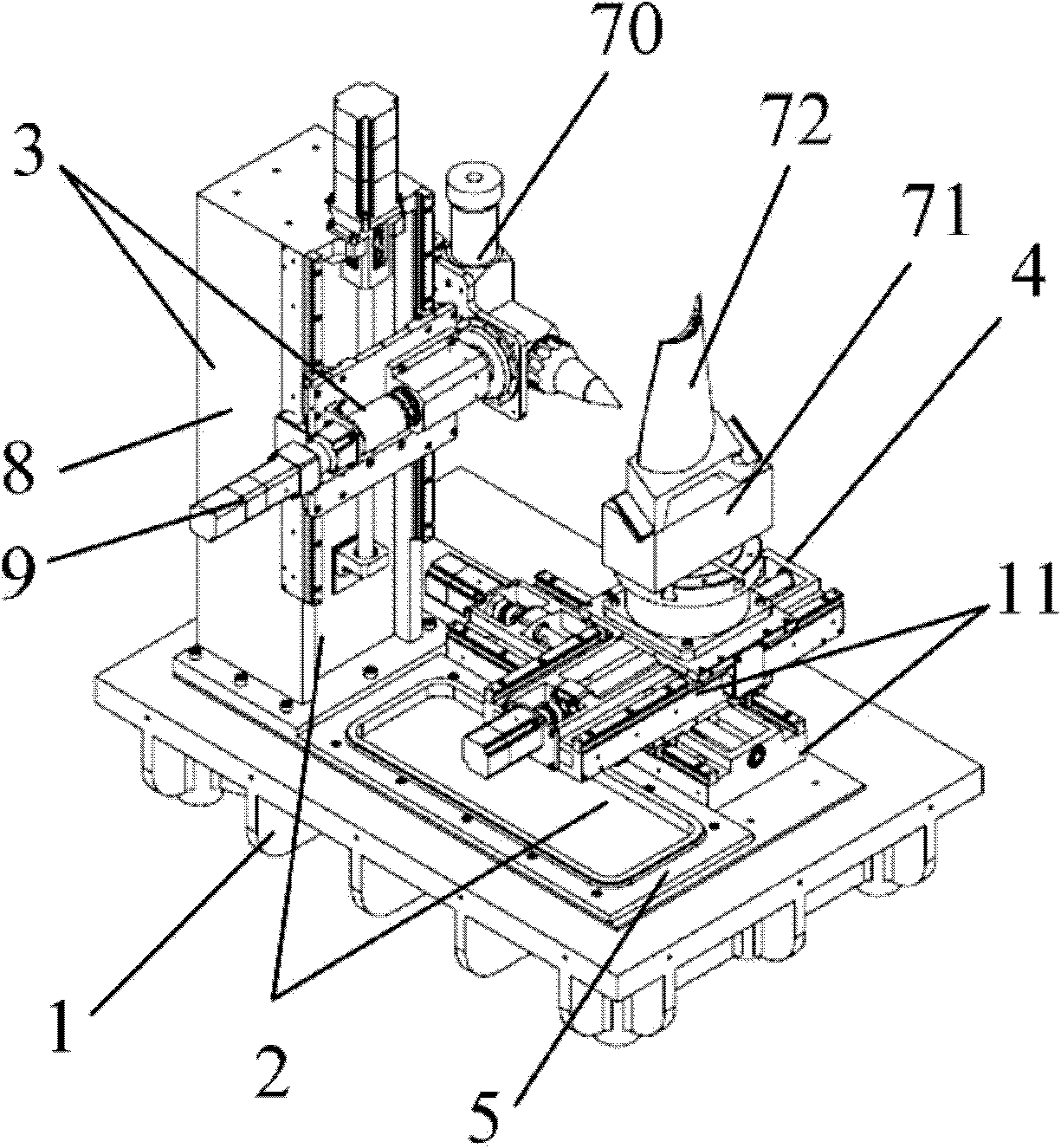

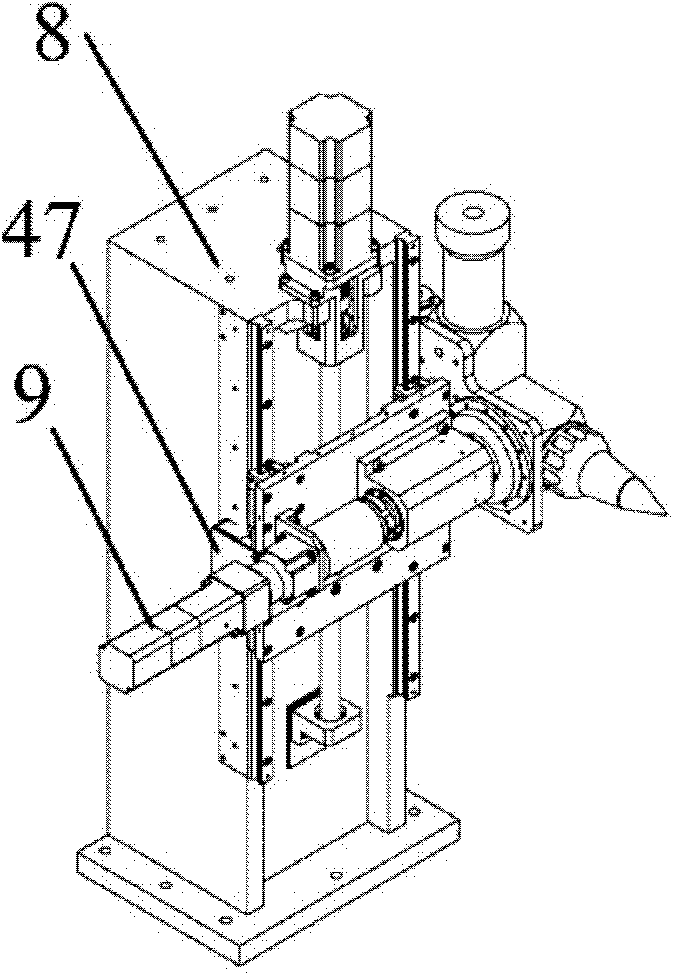

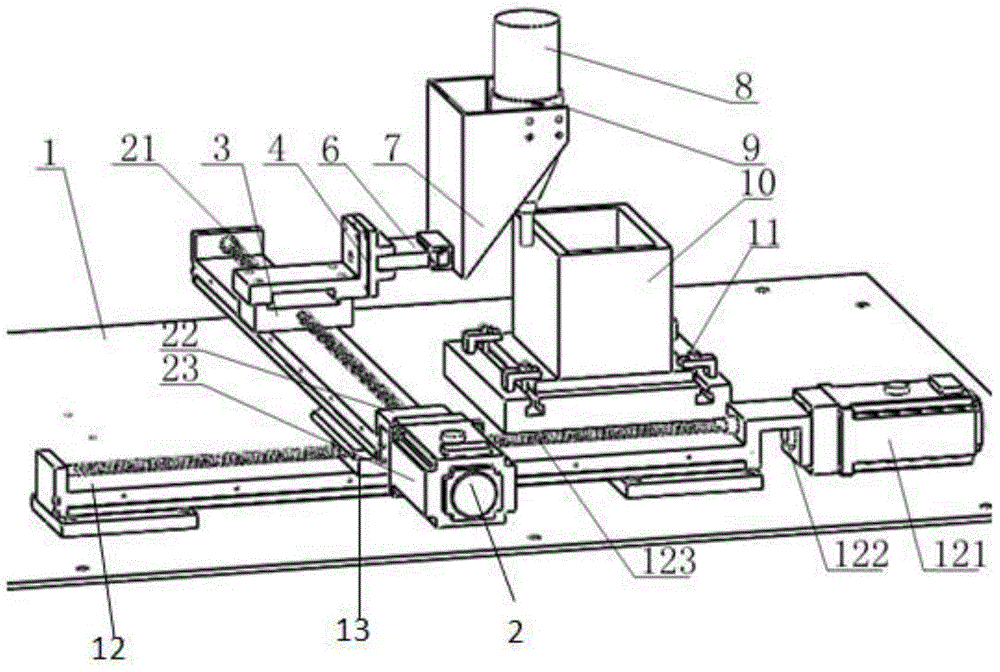

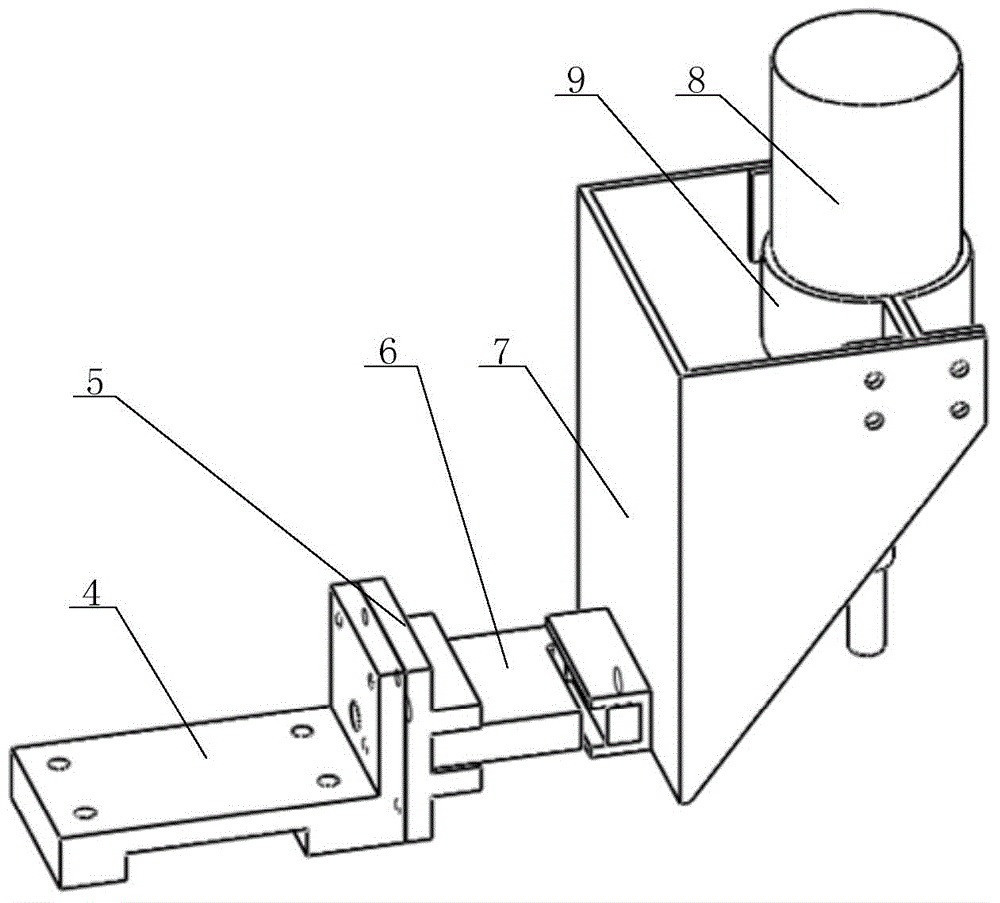

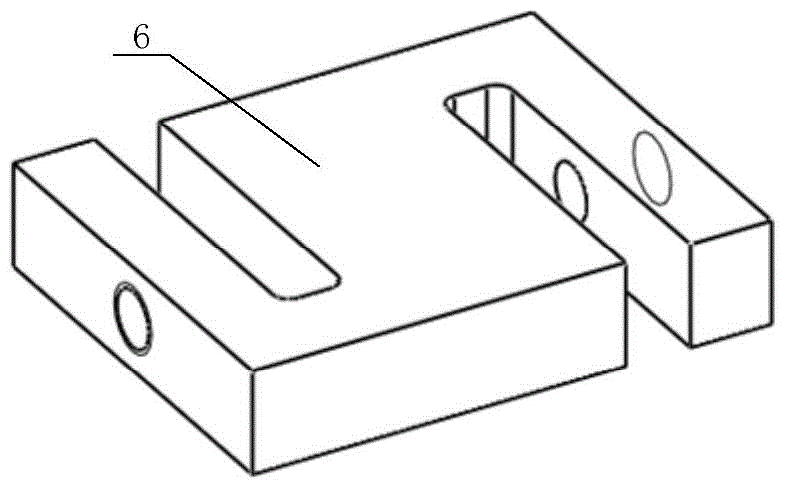

Five-axis linkage laser processing machine

InactiveCN102000911ASimple designEasy to processLarge fixed membersLaser beam welding apparatusLaser processingTorque motor

The invention discloses a five-axis linkage laser processing machine which comprises a base (1) and a machine body (2), wherein the machine body (2) comprises an upright column module (3) and a platform module (4) which are installed on the base (1), the upright column module (3) comprises a Z-axis submodule (8) and an A-axis rotary motion module (9), the Z-axis submodule (8) is provided with a Z-axis slide carriage (46) which moves in the vertical direction, the slide carriage is provided with the A-axis rotary motion module (9), a laser head (70) is installed at the end of an A axis and rotates along with the A axis, the platform module (4) consists of an XY workbench (11) and a C-axis rotary motion module (10) installed on the workbench, a C axis is driven by a torque motor (52) and is provided with a rotary workbench (53), and a workpiece is vertically installed on the rotary workbench through a special clamp. The invention has the advantages of novel structure layout, compact size and high processing accuracy and can also greatly enhance the processing efficiency.

Owner:XI AN JIAOTONG UNIV

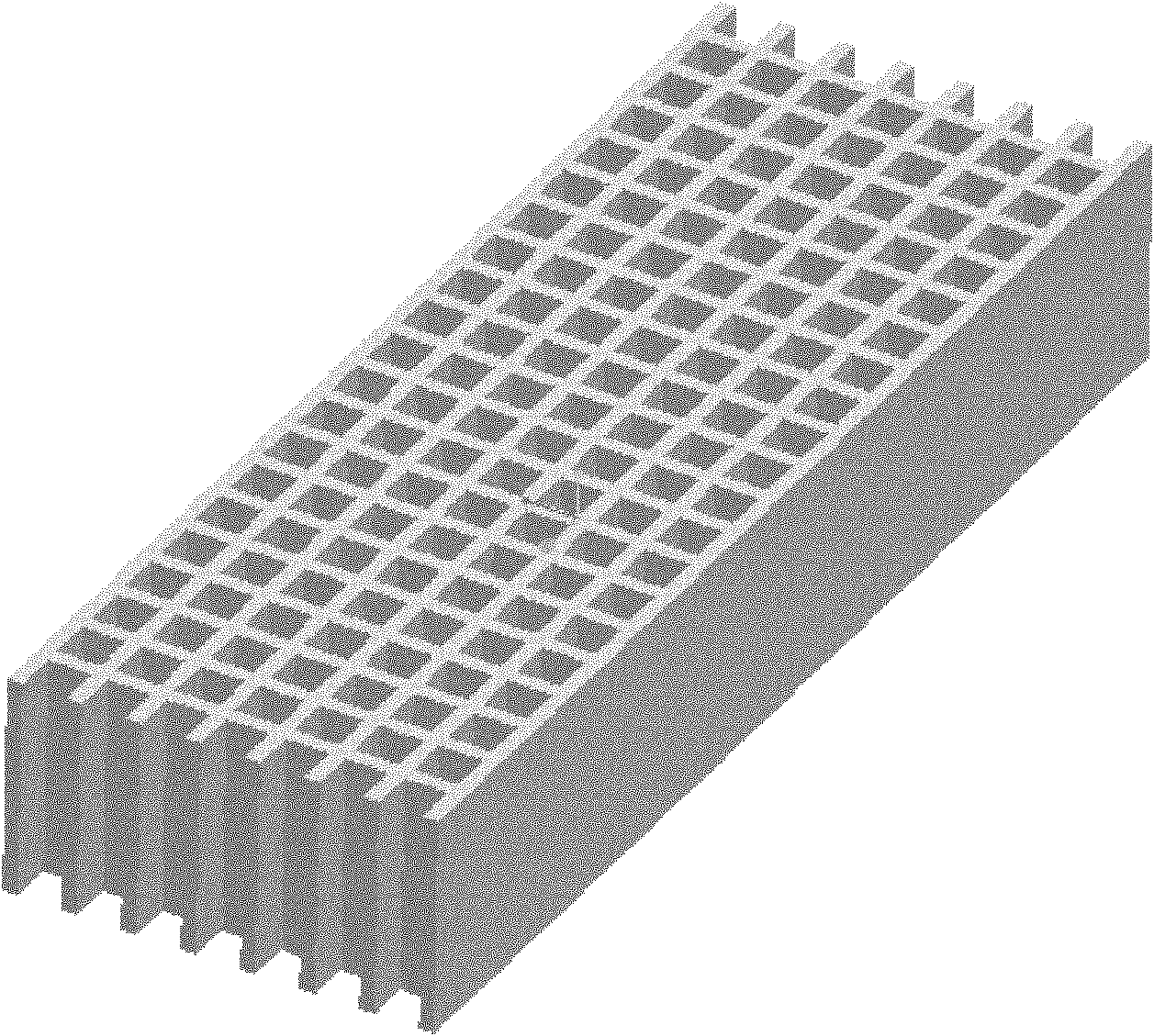

Lightweight plastic furniture

InactiveUS6058854AImprove structural propertiesEasy to carryFoldable tablesStowable tablesEngineeringHigh intensity

A lightweight, high-strength support platform for use in furniture construction, which has superior structural integrity and can be used, by way of example, in portable folding tables, in work tables and in modular furniture of the character typically used in modern office complexes. The support platform embodies a novel structural reinforcement core, and exhibits superior strength characteristics. In one form of the invention, the support platform is used in the construction of a lightweight, readily portable folding table which includes two pair of legs that are pivotally connected to the platform for pivotal movement between an extended operational position and a retracted storage and transport position.

Owner:VIRCO MFG

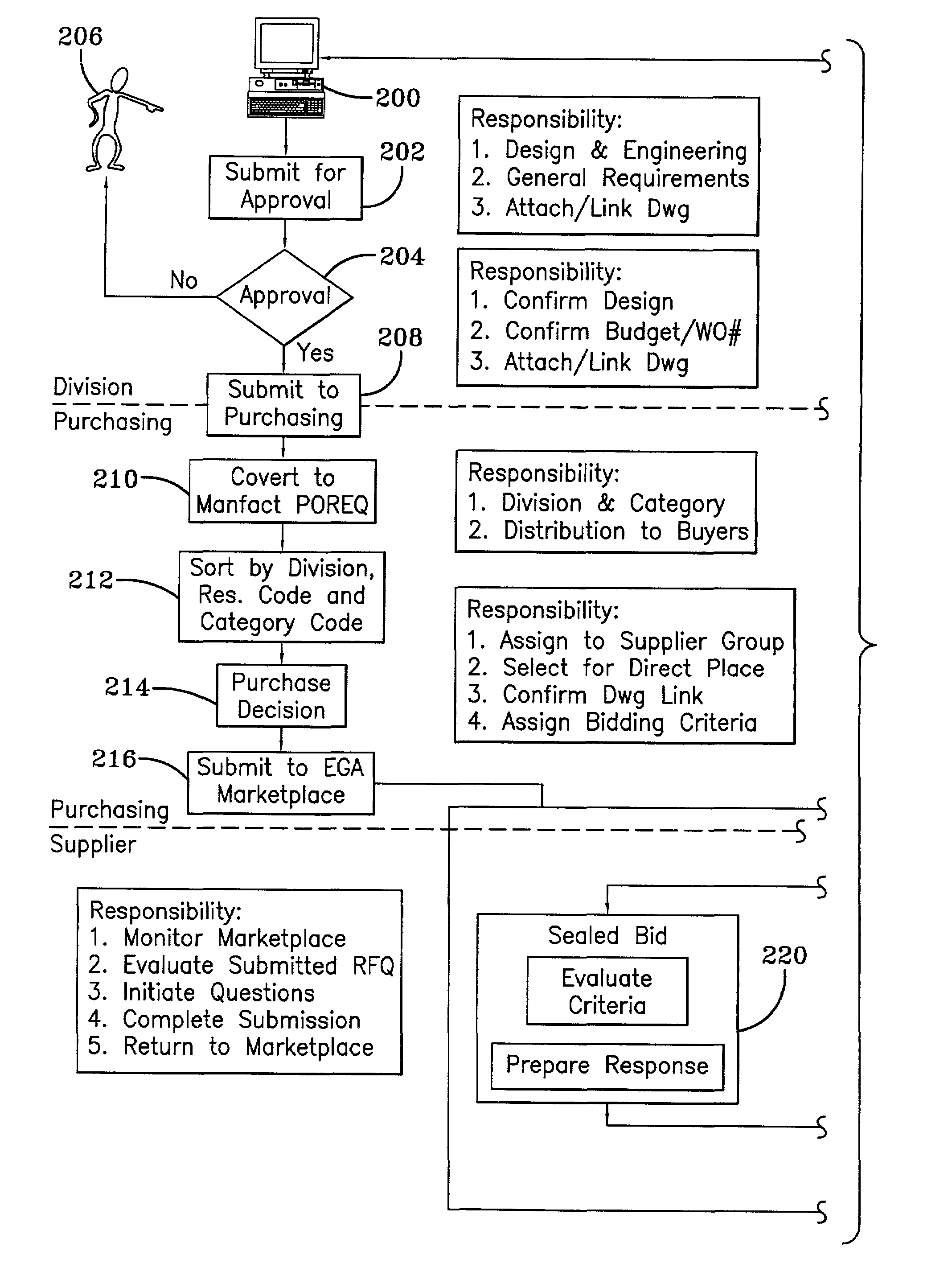

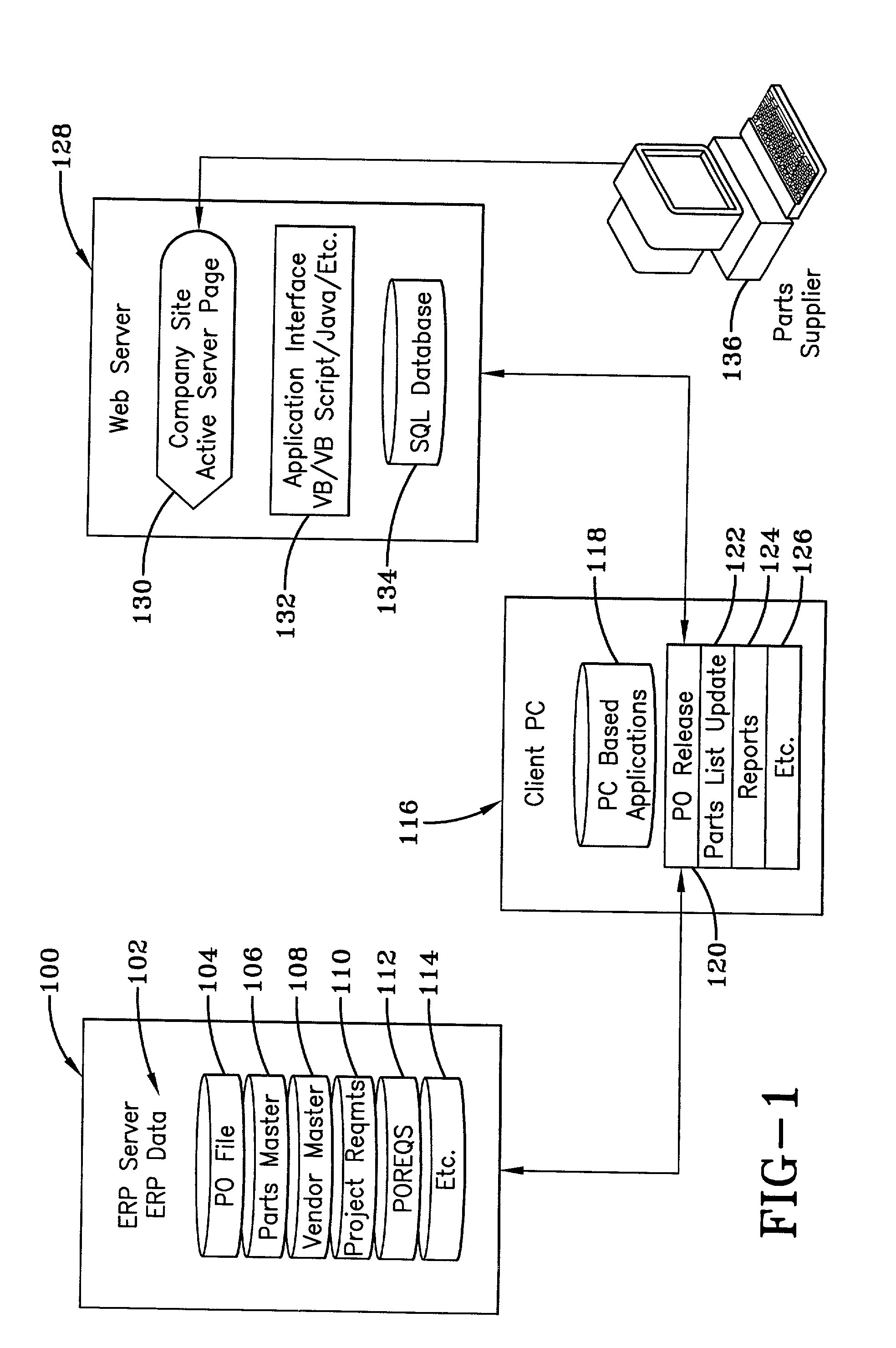

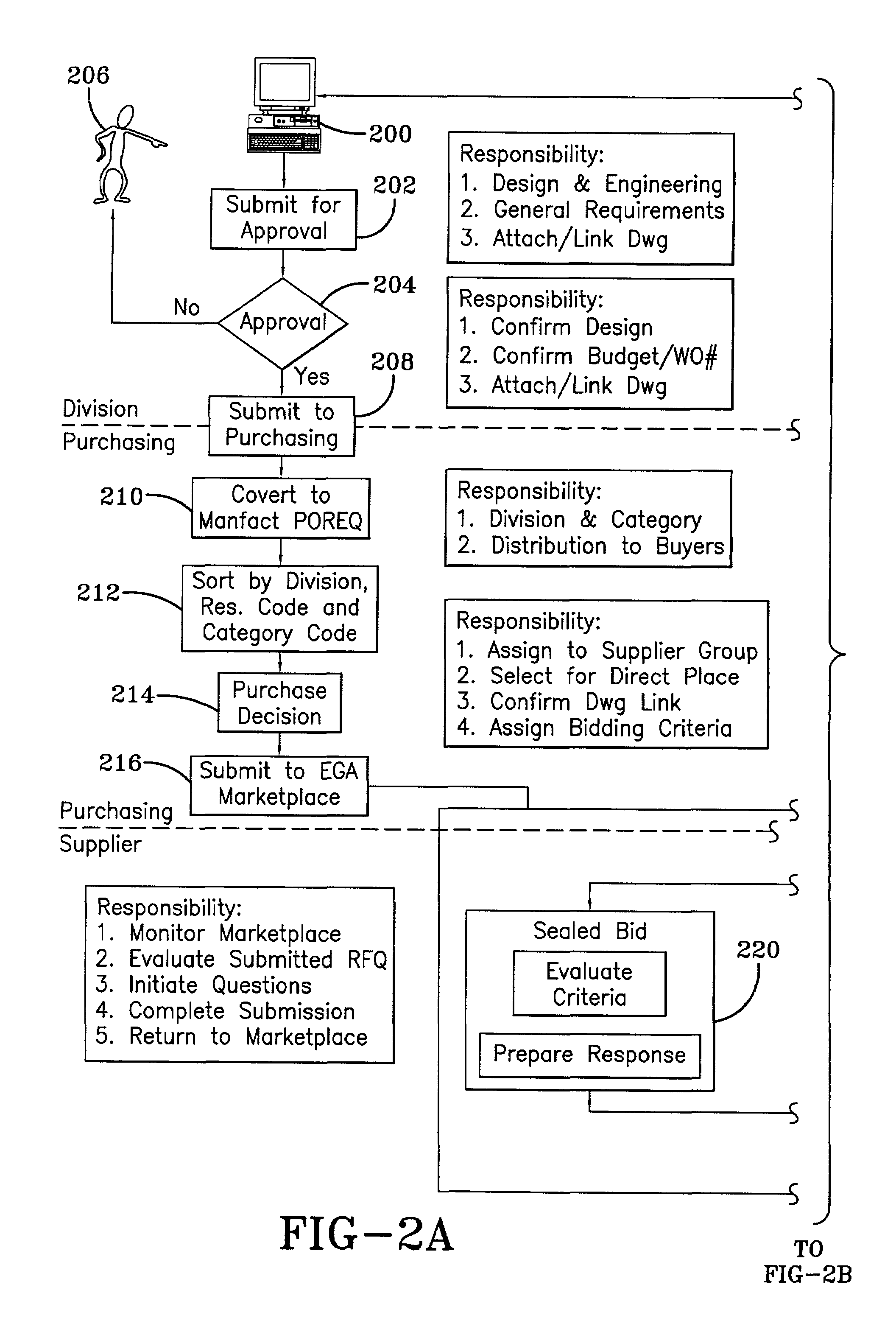

System and method for procurement of products

InactiveUS7499871B1Easy to manageEasy to operatePayment architectureResourcesOrder formEnterprise resource planning

A system and method for procurement of engineered-to-order products that facilitates the workflow management for buyers is disclosed. The present invention comprises a buyer's workbench (BWB) that operates in conjunction with a web-based marketplace application for suppliers and an enterprise resource planning system (ERP) that links together a company's operations. The BWB facilitates the workflow management for buyers by allowing them to review purchasing requirements and to obtain an optimal procurement strategy. Supplier performance data is tracked through the ERP system and is a factor in determining the total cost of buying products from a particular supplier. The web-based marketplace application for suppliers comprises an interface that allows suppliers to review and collect information about opportunities to fulfill orders for engineered-to-order products. They may review information regarding current and past purchase order activity with the company, current quality and delivery information on their own companies and their peers.

Owner:HONDA MOTOR CO LTD

Portable cooler and table

InactiveUS7451709B2Easy to transportSmall sizeTravelling sacksLighting and heating apparatusEngineeringRefrigeration

A portable cooler and table assembly that may be easily transported in a single, self-contained unit is disclosed. The assembly may be converted for use as a table for a variety of recreational activities, e.g., dining, drinking, games such as ping pong, beer pong, table hockey, card games, board games, preparation for sporting events and meals. The table and cooler may be permanently attached to each other, or alternatively, the cooler may be detachable from the table. The table may fold or collapse to assist in converting the assembly from a compact, lightweight transportable unit into a fully extended and operable table and cooler. The table surface may contain surface features such as grooves, indentations, nets, game pieces, etc. The cooler may comprise any container that is capable of containing ice or some other refrigeration or heating system, e.g., a conventional 54 quart beverage cooler. Alternatively, the cooler may be replaced with a storage container or other storage device. The assembly may also contain various wheels, legs and handles to assist in mobility and conversion.

Owner:SWARTFAGER BRIAN ALLEN +3

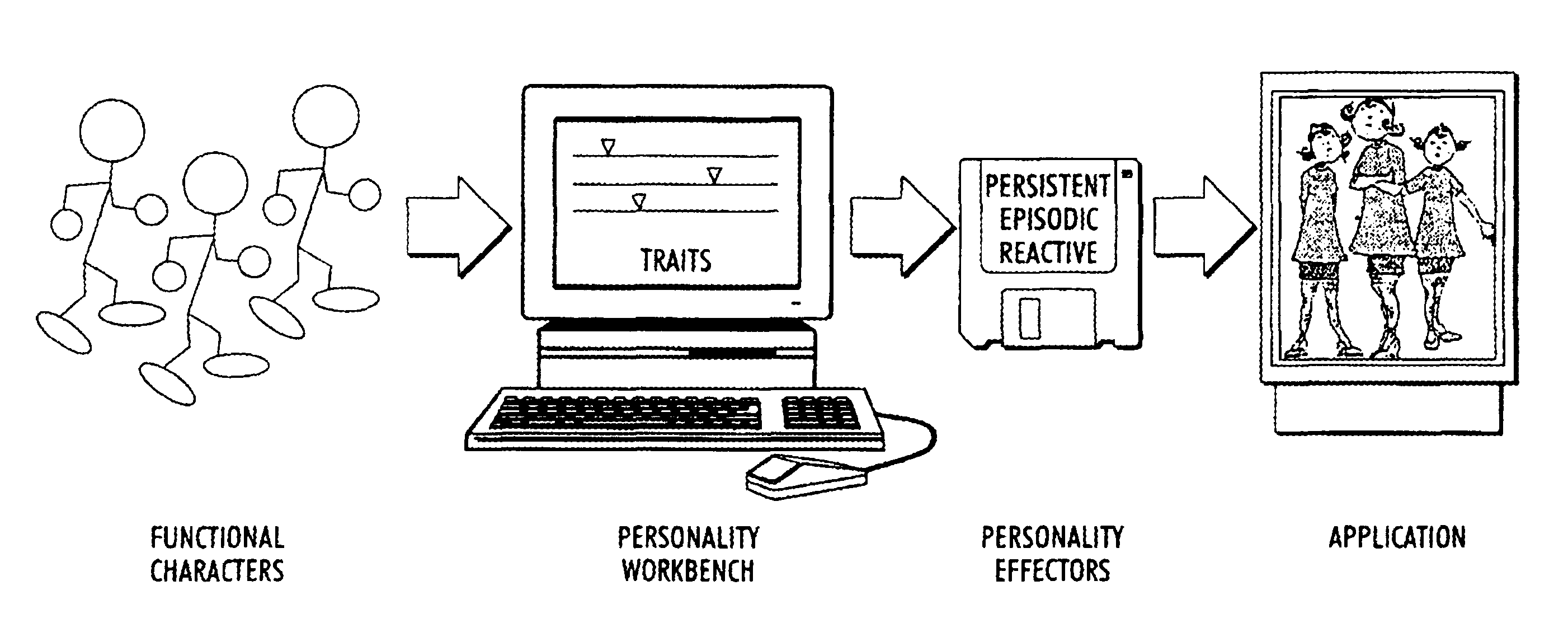

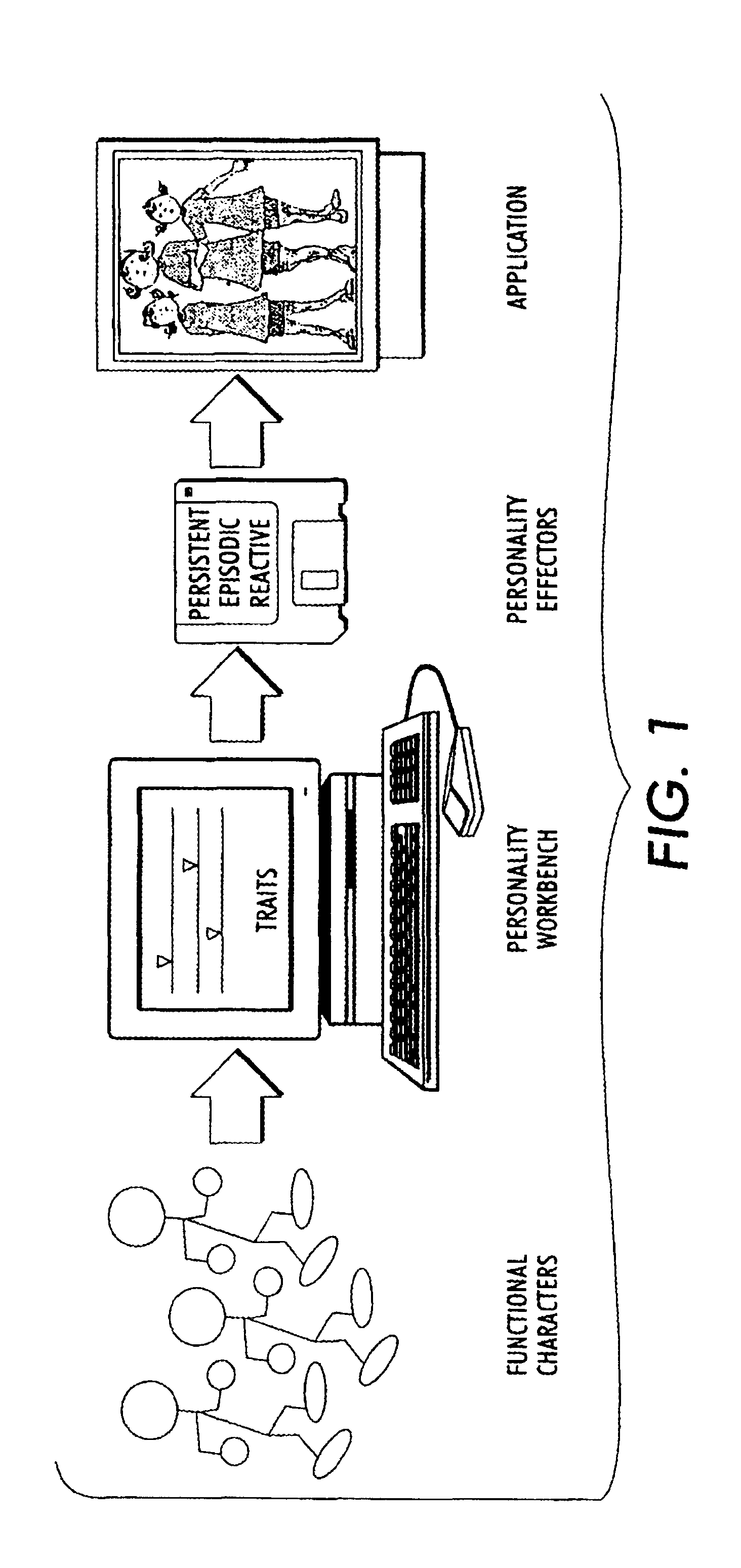

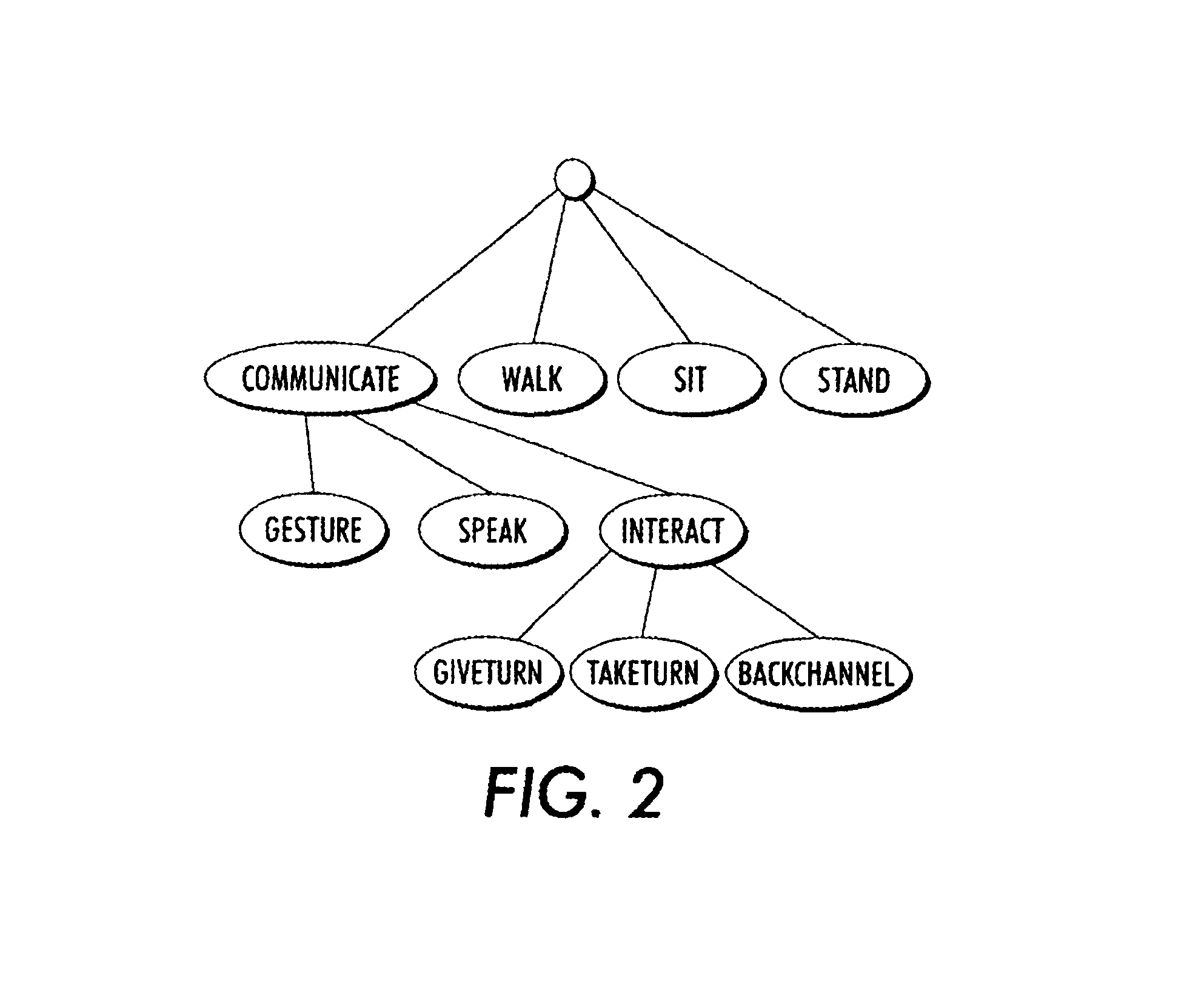

System for designing and rendering personalities for autonomous synthetic characters

InactiveUS7061493B1Accept fastEasy to synthesizeAnimationSpecial data processing applicationsBiological activationHuman–computer interaction

Personality traits displayed on a workbench are grouped into a character profile that is utilized in determining the personality and / or specific actions of a synthetic character. The personality traits are selectable by an operator from graduated dials. The personality traits may also be displayed in the form of selectable attributes or trait indicative behaviors that, when selected, are mapped into predetermined amounts of each trait in the character profile. The character profile is utilized to compute activation levels for primary behaviors, which are selected to influence or direct behavior of the synthetic character. Secondary behaviors are also selected, but discarded if conflicting with the selected primary behaviors. When behaviors are selected, the corresponding behaviors are translated into classes of ‘personality effectors’ that modulate the synthetic character's behavioral expression to reflect the desired set of traits.

Owner:XEROX CORP

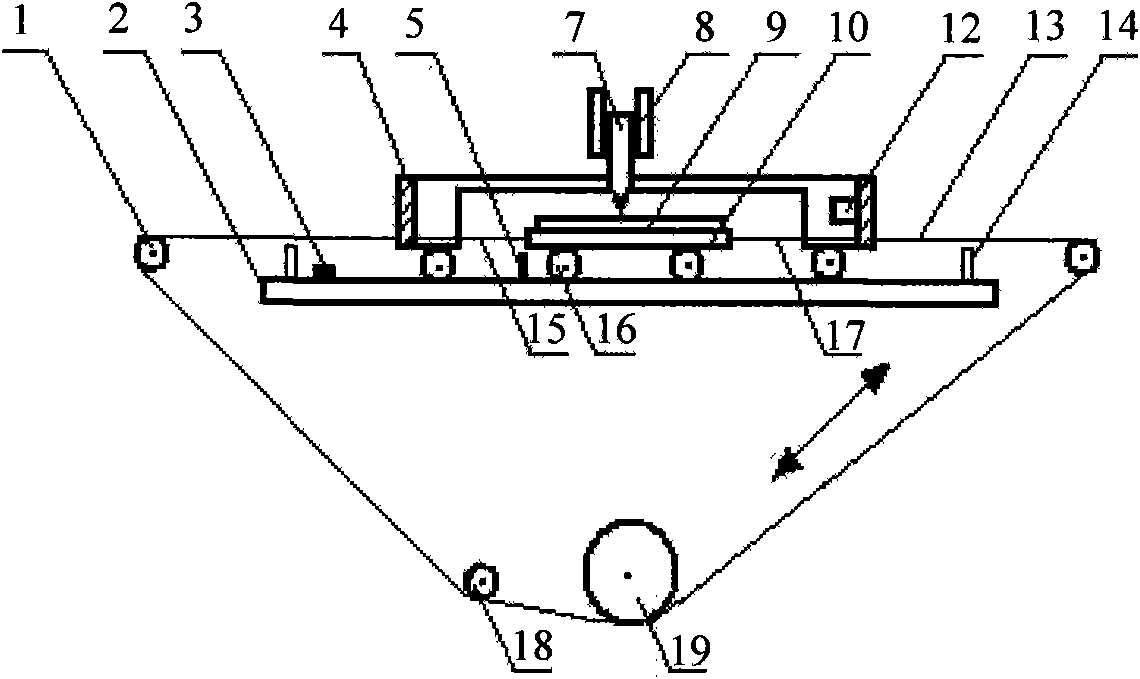

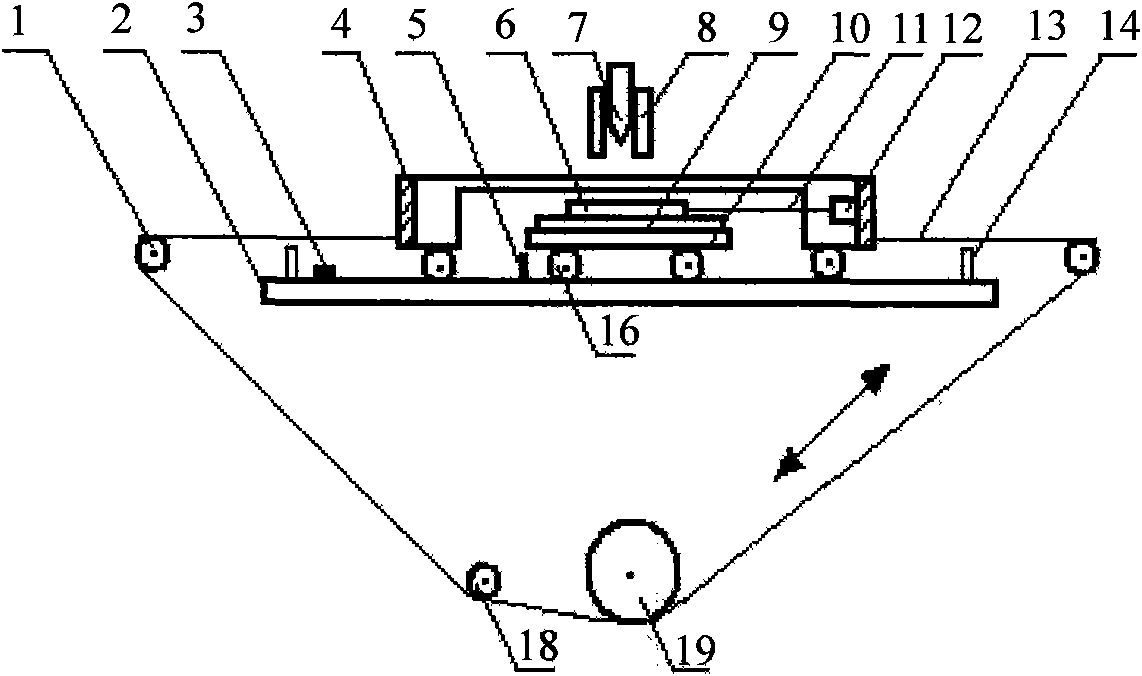

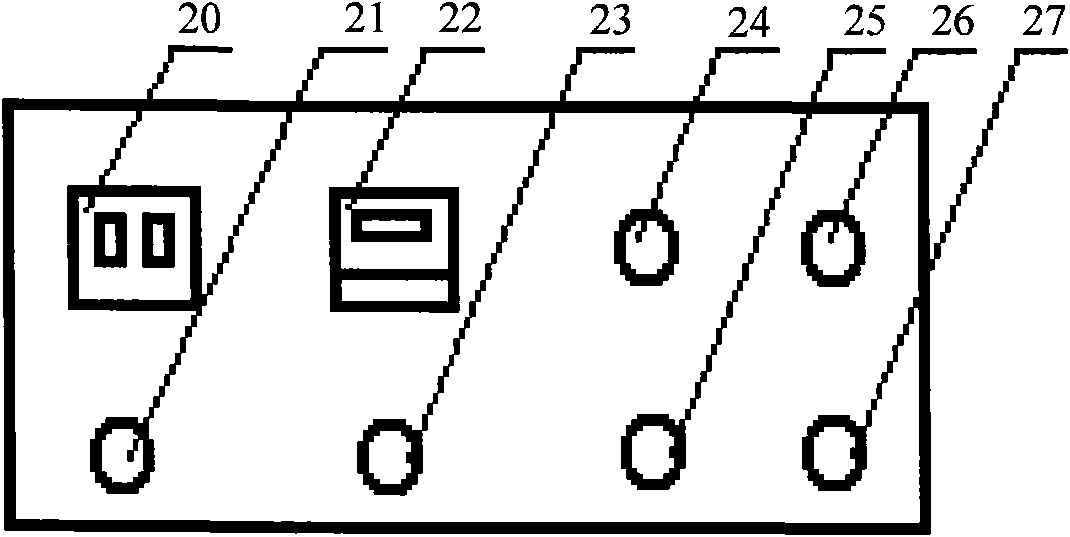

Device and method for testing linear reciprocating sliding friction and abrasion

InactiveCN101556238AAdjustable sliding speedAdjustable loadUsing mechanical meansMaterial weighingPositive pressurePeak value

The invention discloses a device and a method for testing linear reciprocating sliding friction and abrasion; the device consists of a transducer, a workbench, a sample table, a dragging frame, a force sensor, a changeover switch, a counter, a locking device, a guideway, a baffle, a cable wire, a reducer, a peak value stabilizer, a control part and an auxiliary component; the equipment can automatically complete the abrasion test of an arranged period and can manually complete the test to friction coefficient. The testing method comprises the following steps of: leading the friction block and the sample to reciprocate to slide horizontally with constant pressure, obtaining an abrasion weight loss rate after abrading, keeping a certain positive pressure and leading the sliding block to move from stillness to uniform movement, thus obtaining the maximum static friction coefficient and the sliding friction coefficient. The device and the method can realize uniformly linear and reciprocating relative sliding abrasion in long unidirectional journey, test the maximum static friction coefficient between two bodies and the maximum static friction coefficient, the speed, the load and the adjustable journey with other materials, and can be widely applied to the detection of various samples of different materials and different structural forms.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

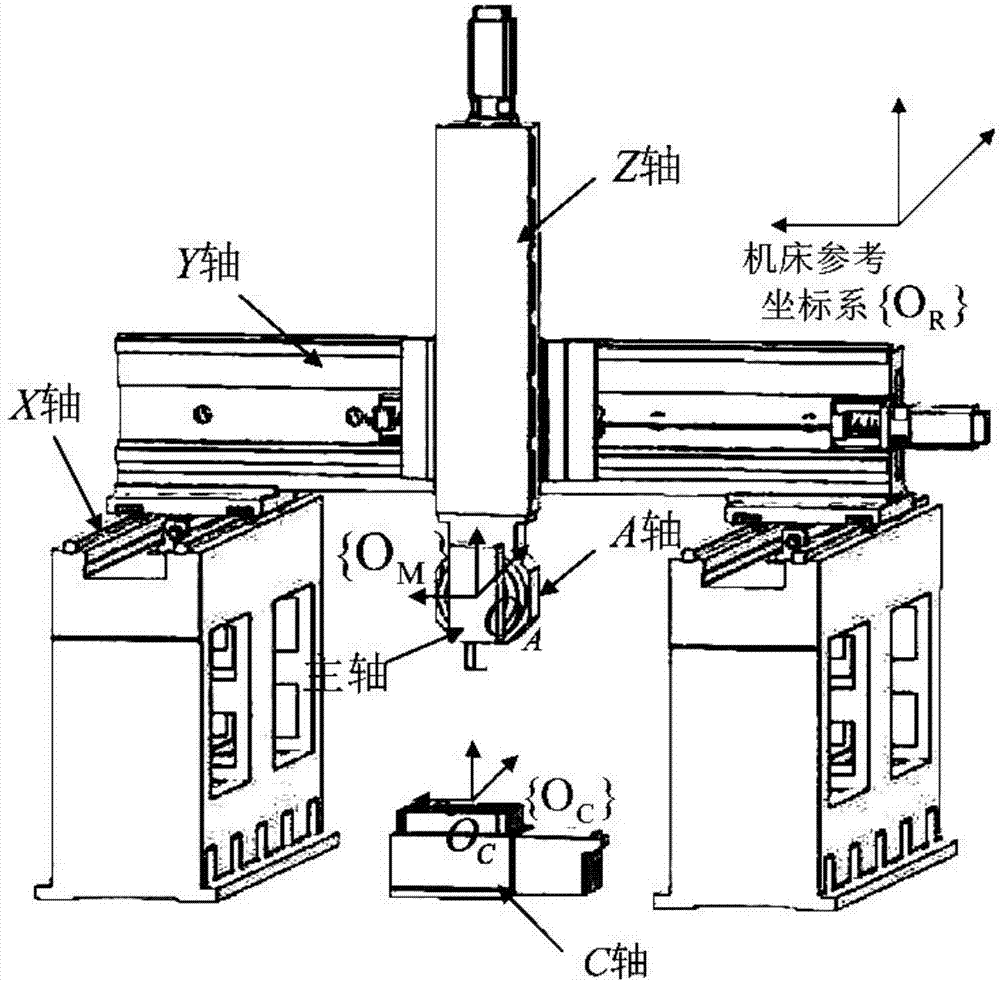

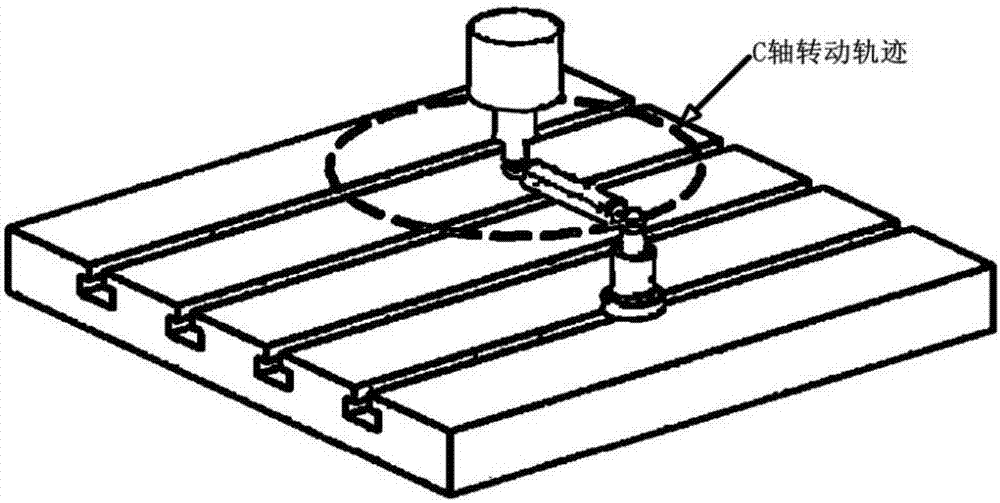

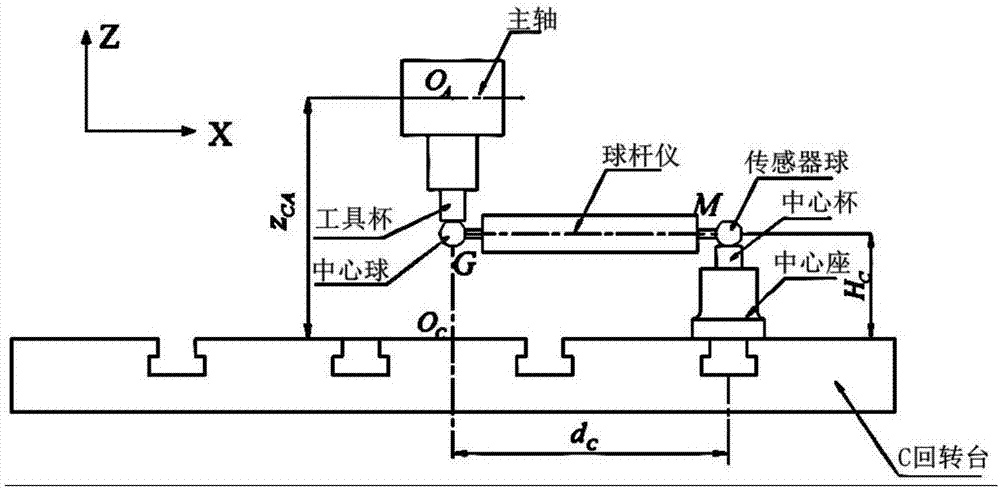

CFXYZA type five-axis numerical control machine tool rotation axis geometrical error calculation, compensation and verification method thereof

The invention discloses a CFXYZA type machine tool rotation axis geometrical error calculation, compensation and verification method thereof. When the rotation axis of a CFXYZA type five-axis numerical control machine tool rotates, a ball bar is installed between the spindle end and a workbench to establish the relative position point coordinates and attitude vectors between the centers of spheres of two measurement balls of the ball bar, and then the position point error and the attitude vector error are compensated through the corrected numerical control codes. The concrete process is that firstly the rotation angle of the A-axis and the C-axis is corrected to compensate the attitude vector error, then the moving axis is adjusted to compensate the position point error, and finally the circular trajectories in the motion process before and after compensation are measured by using the ball bar so that the error compensation effect is evaluated by comparing the roundness deviation of the error trajectories between the actually measured circular trajectories and the geometrical circle. The code correction operation involved in the error compensation and verification process is discussed in a detailed way so as to be quite suitable for rapid compensation and verification of the machine tool rotation axis geometrical error.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

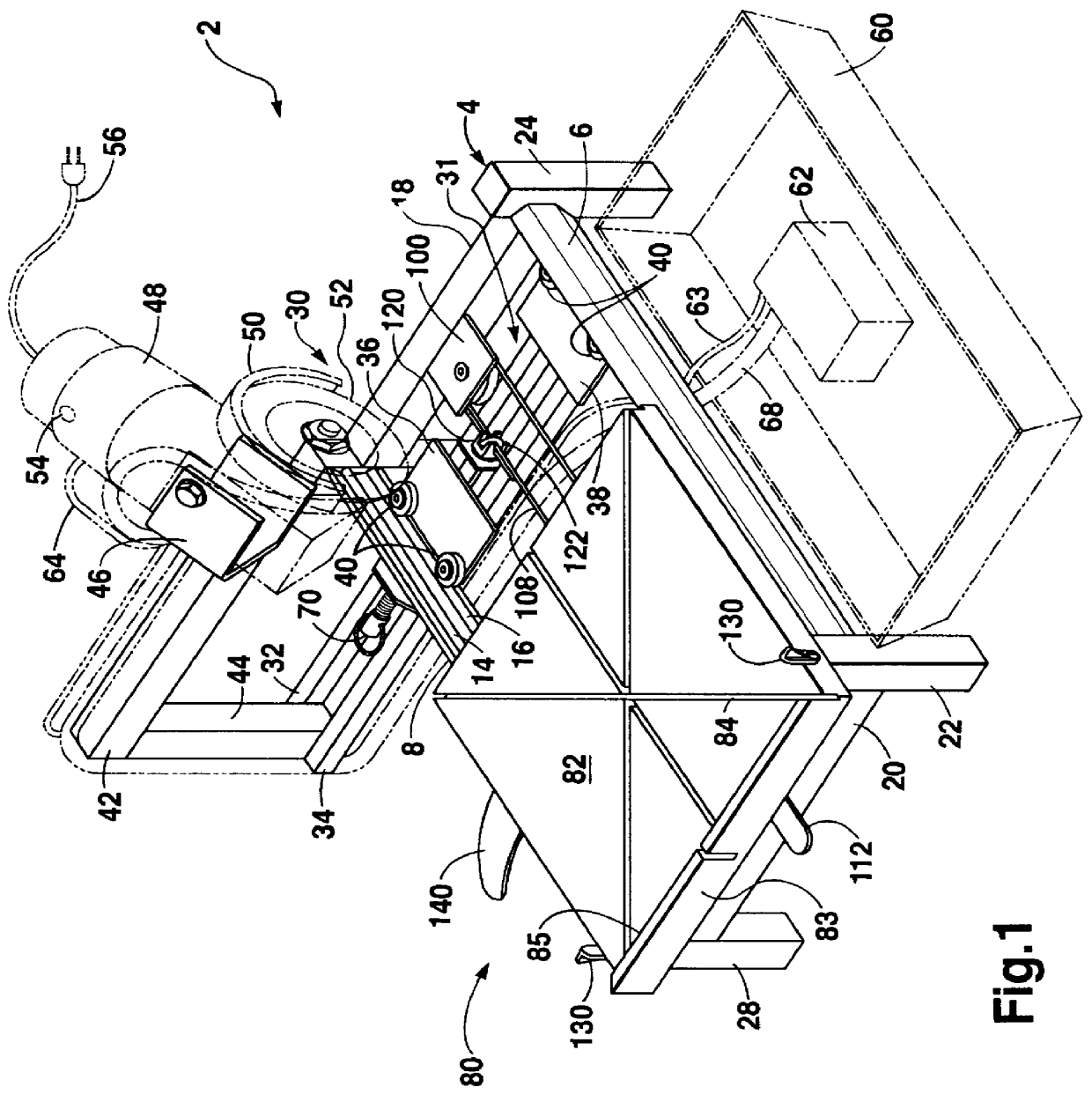

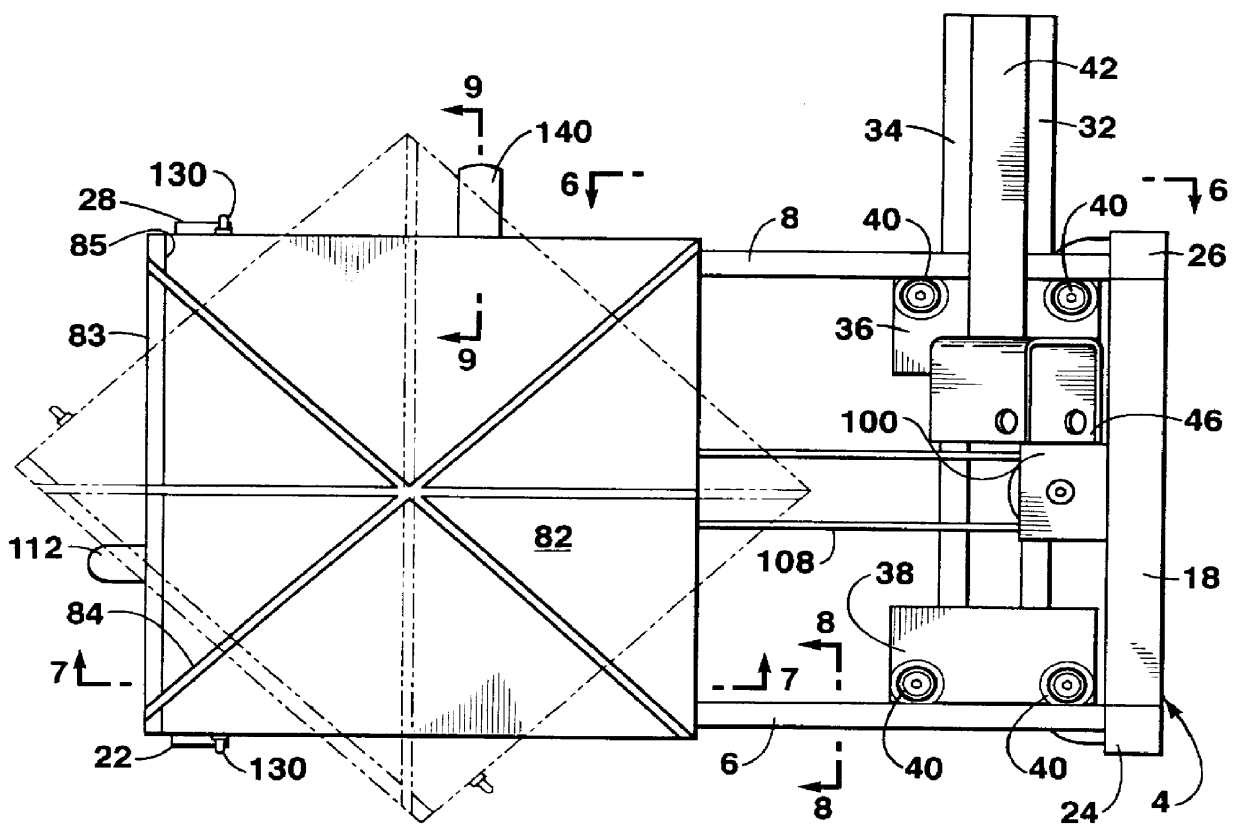

Saw having movable table and saw blade

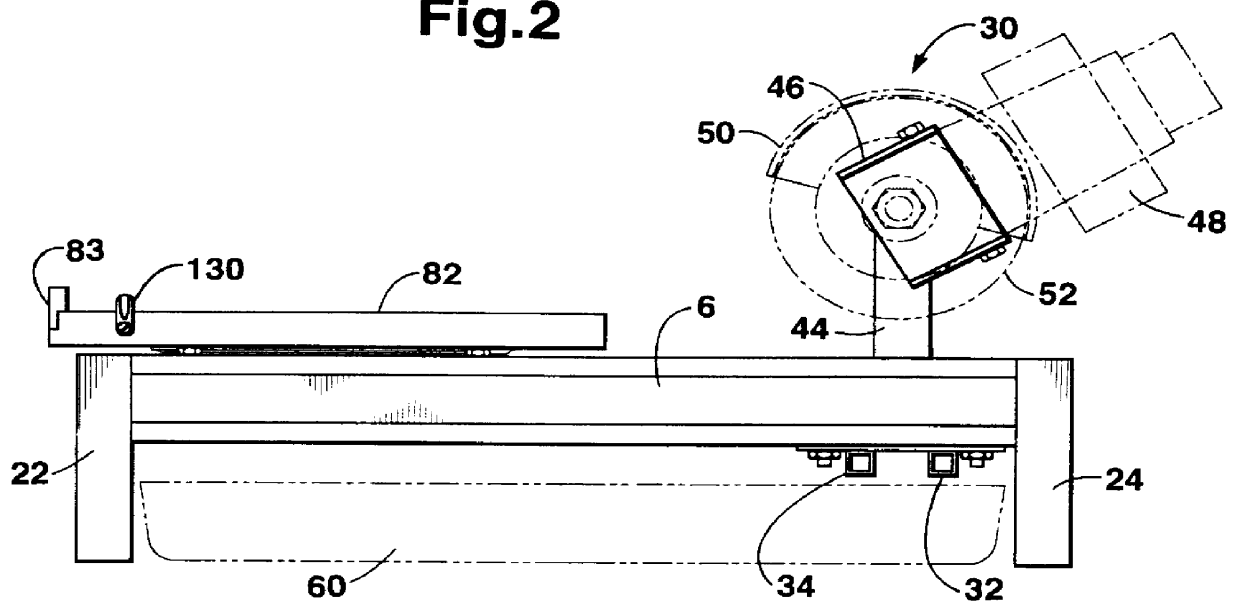

InactiveUS6119676ANot up much spaceEasy to carryGrinding machine componentsWorking accessoriesWorkbenchEngineering

A compact tile saw which is especially adaptable for cutting of large-sized tiles wherein the table supporting the tile is movable towards the cutting saw, while at the same time the cutting saw is positionable in one of two positions of either being stationary or in moving in unison towards the table supporting the tile to be cut.

Owner:GREENLAND DARRELL

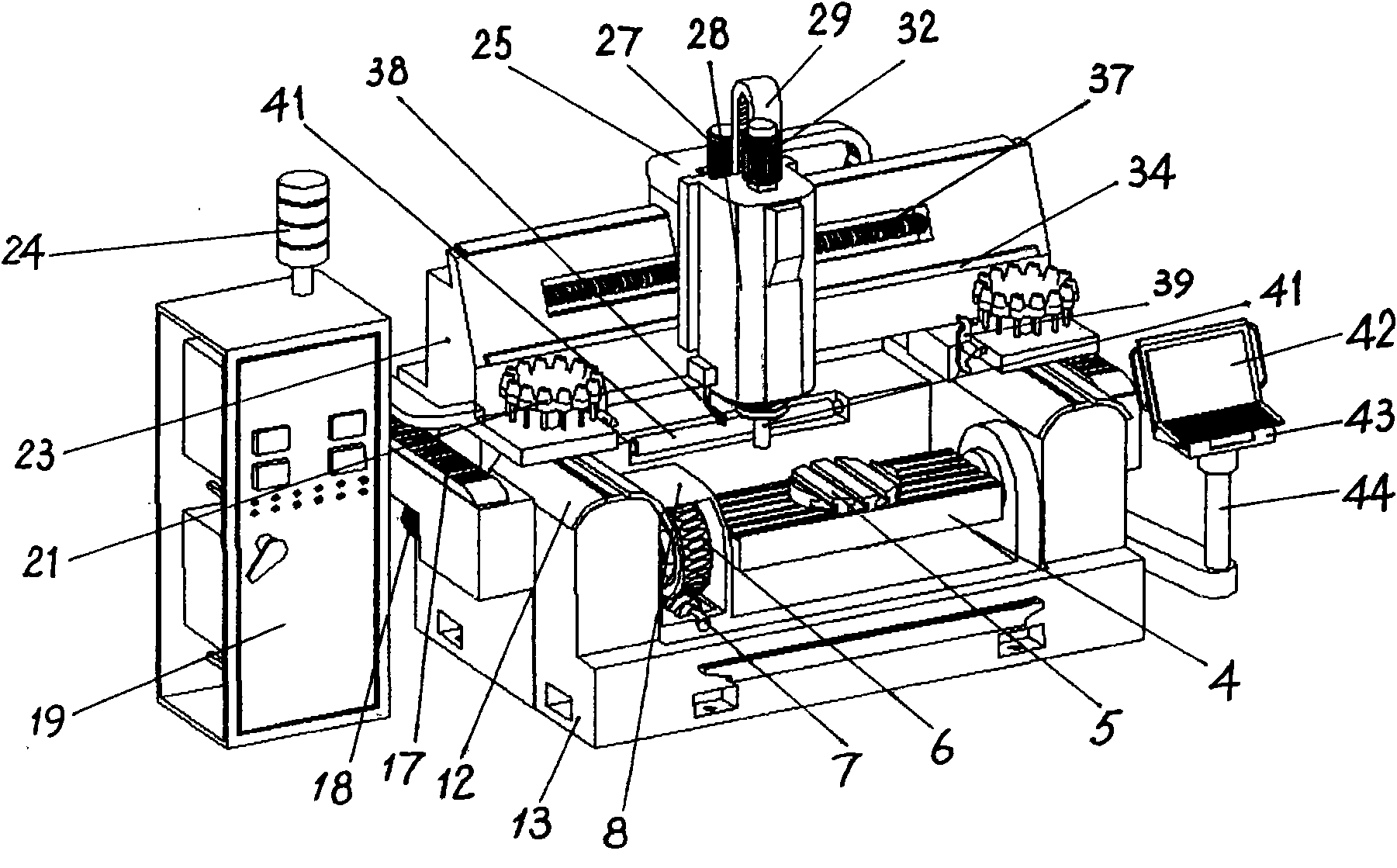

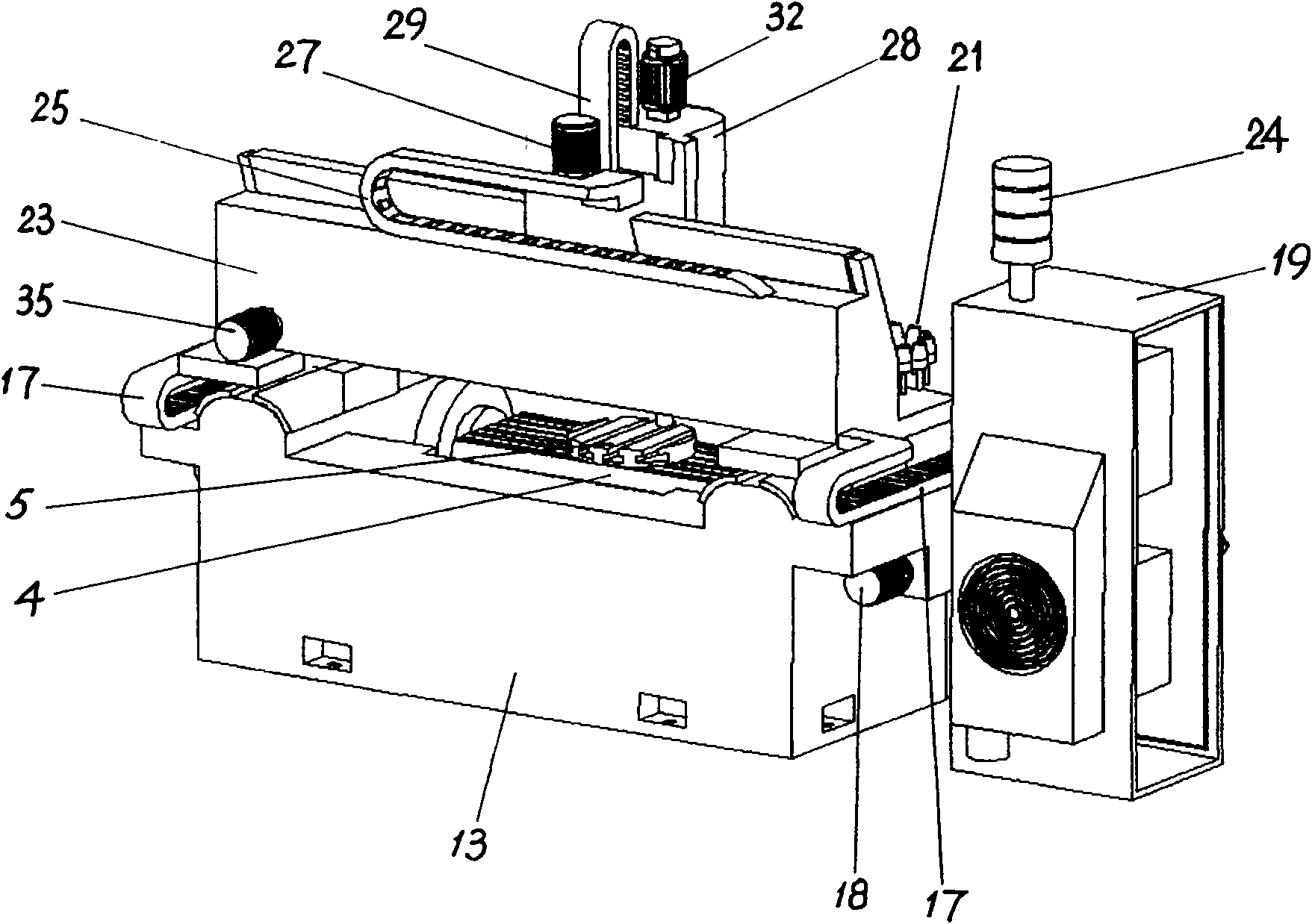

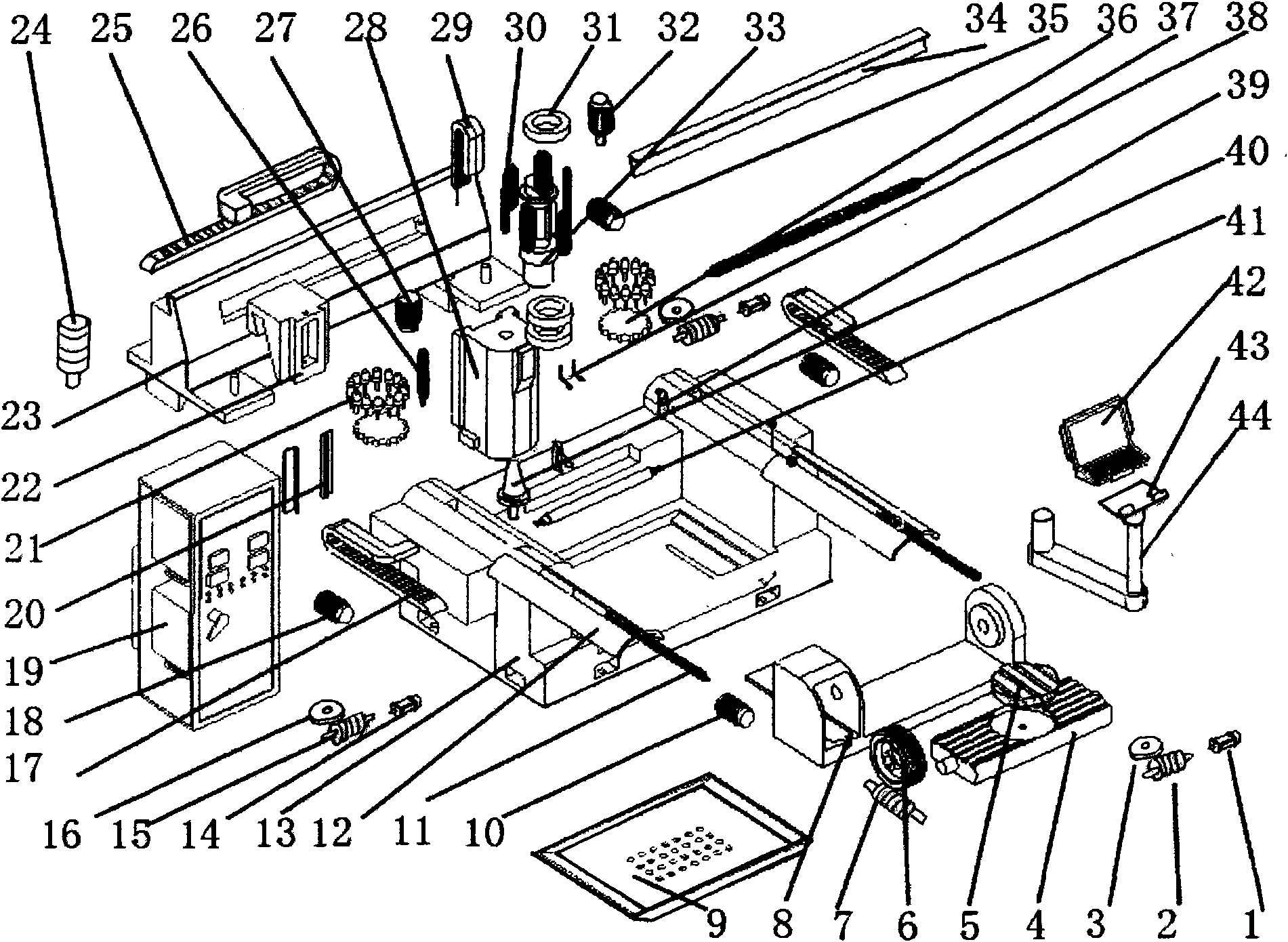

Vertical five axle interlocked gantry digital control milling machining center

ActiveCN101870063AReduce the number of clampingReduce machining errorsOther manufacturing equipments/toolsMilling cutterEngineering

The invention provides a vertical five axle interlocked gantry digital control milling machining center, comprising a planer body, a portal frame, a rotary workbench stand, an electrical appliance control cabinet, a cutter, a main spindle box, an operation panel, a rotary workbench, X, Y and Z shaft driving screws and rotary tool changers, wherein the rotary workbench is formed by a large rotary workbench and a small rotary workbench which respectively rotate around an A shaft and a B shaft; the portal frame is arranged on the planer boxy and can move back and forth via the X shaft driving screws arranged at the two sides of the planer body, a Y-Z shaft connection block moves left and right via the Y shaft driving screw in the portal frame, and a main spindle in the main spindle box moves up and down via the Z shaft driving screw on the Y-Z connection block so as to form five axle interlocking; and the rotary tool changers arranged at the two sides of the portal frame are internally provided with 32 grinding cutters and milling cutters, and tool changing is realized by a tool changing manipulator. The invention has the positive effects of realizing multiply functions of one machine, and can process as many as five interfaces by primary clamping, thus reducing clamping times, saving labor, time and space, and having convenient equipment maintenance.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

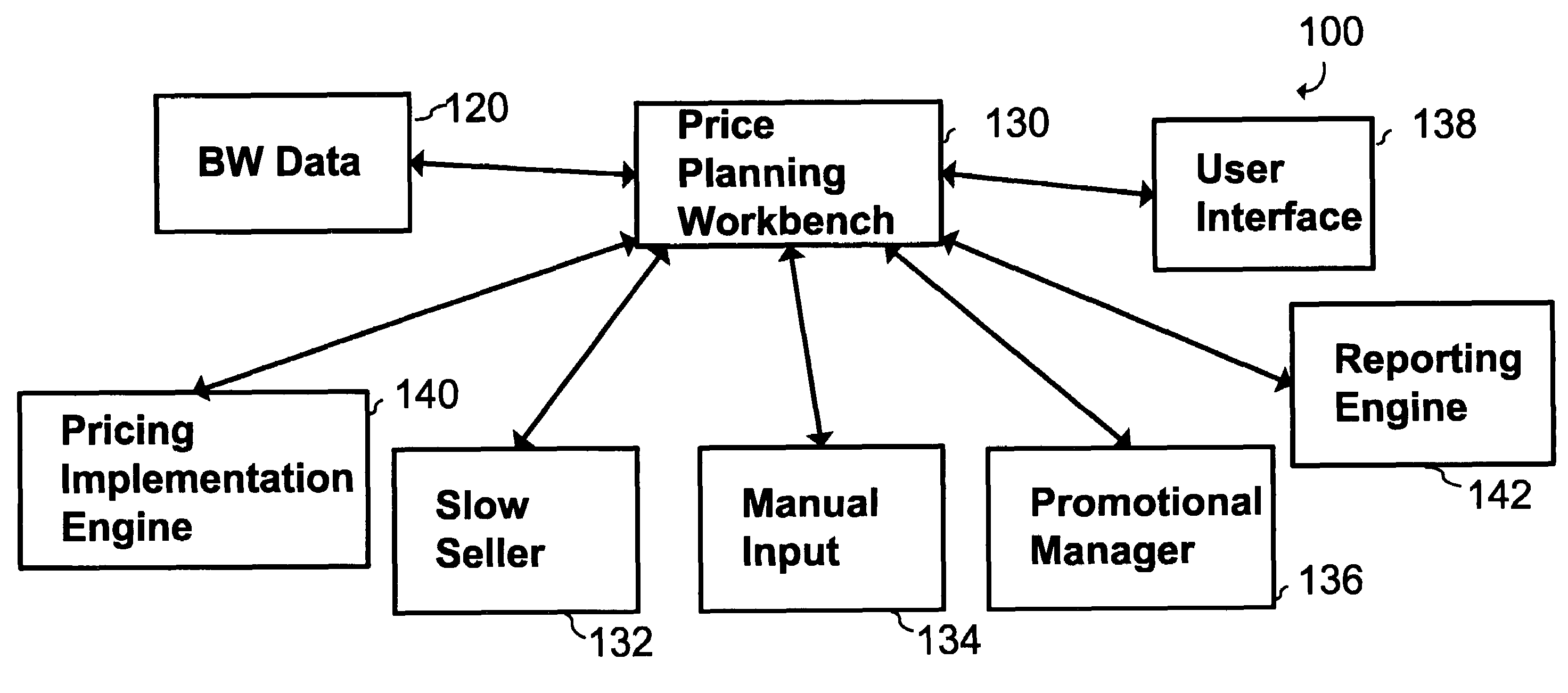

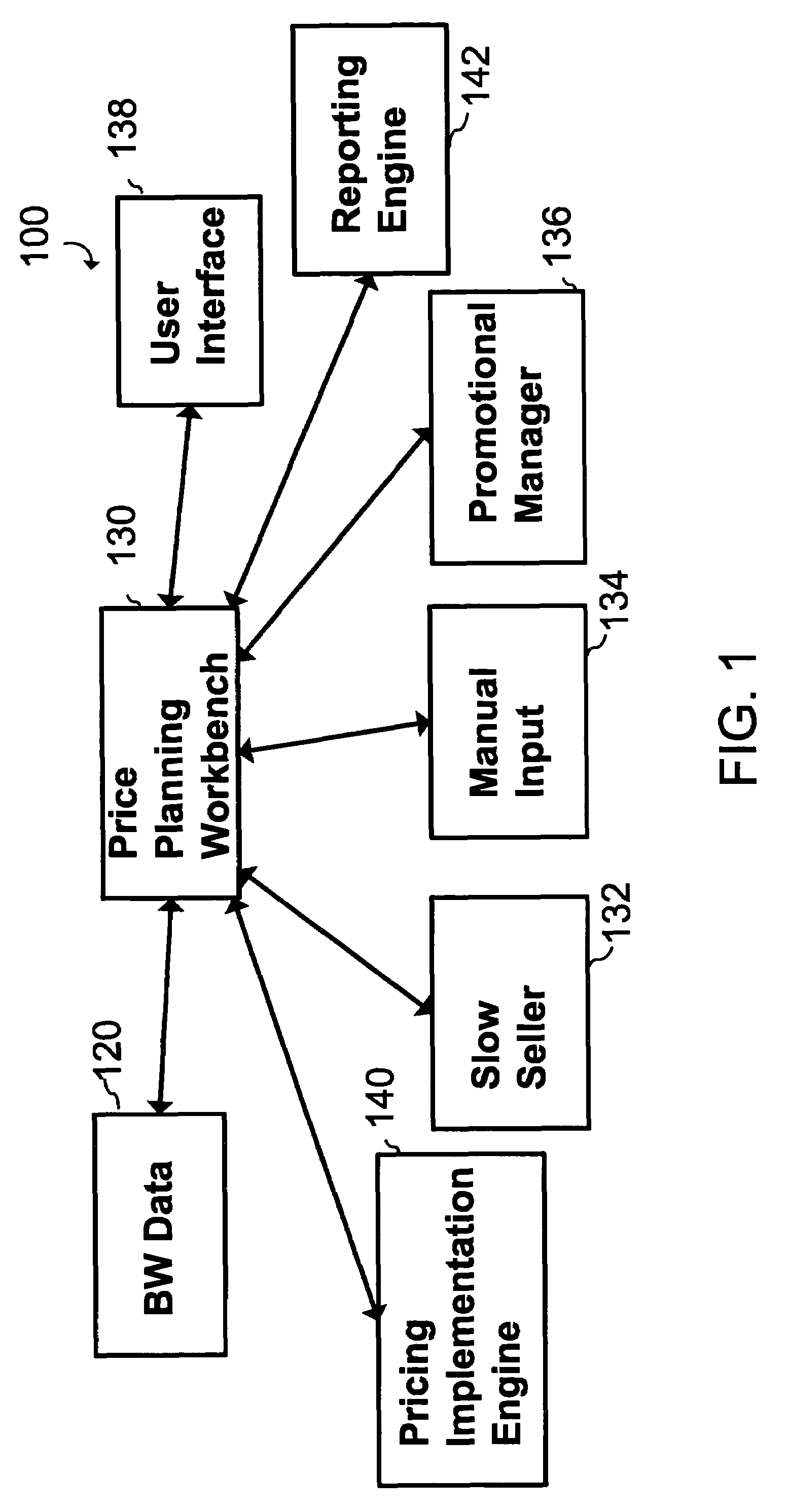

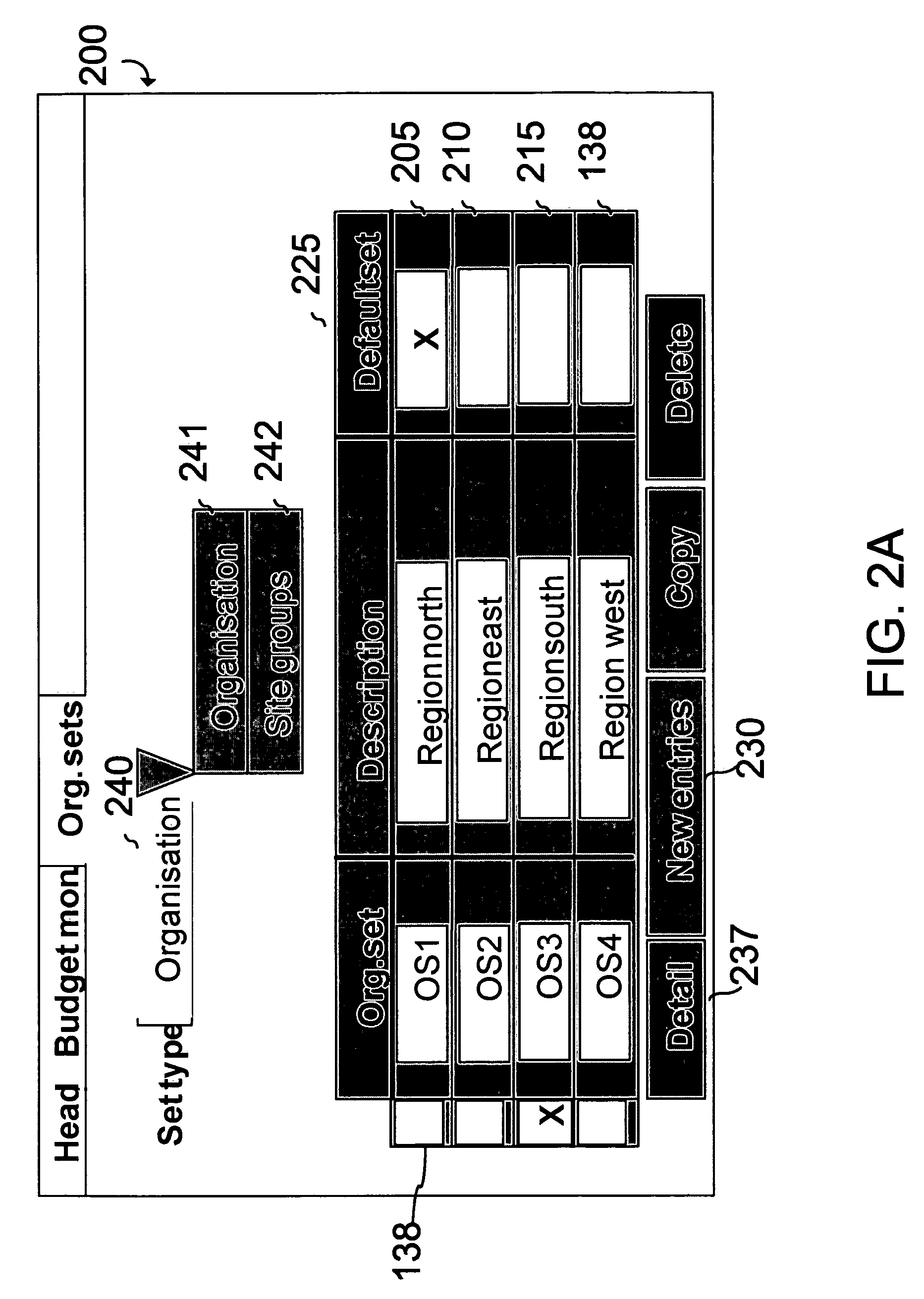

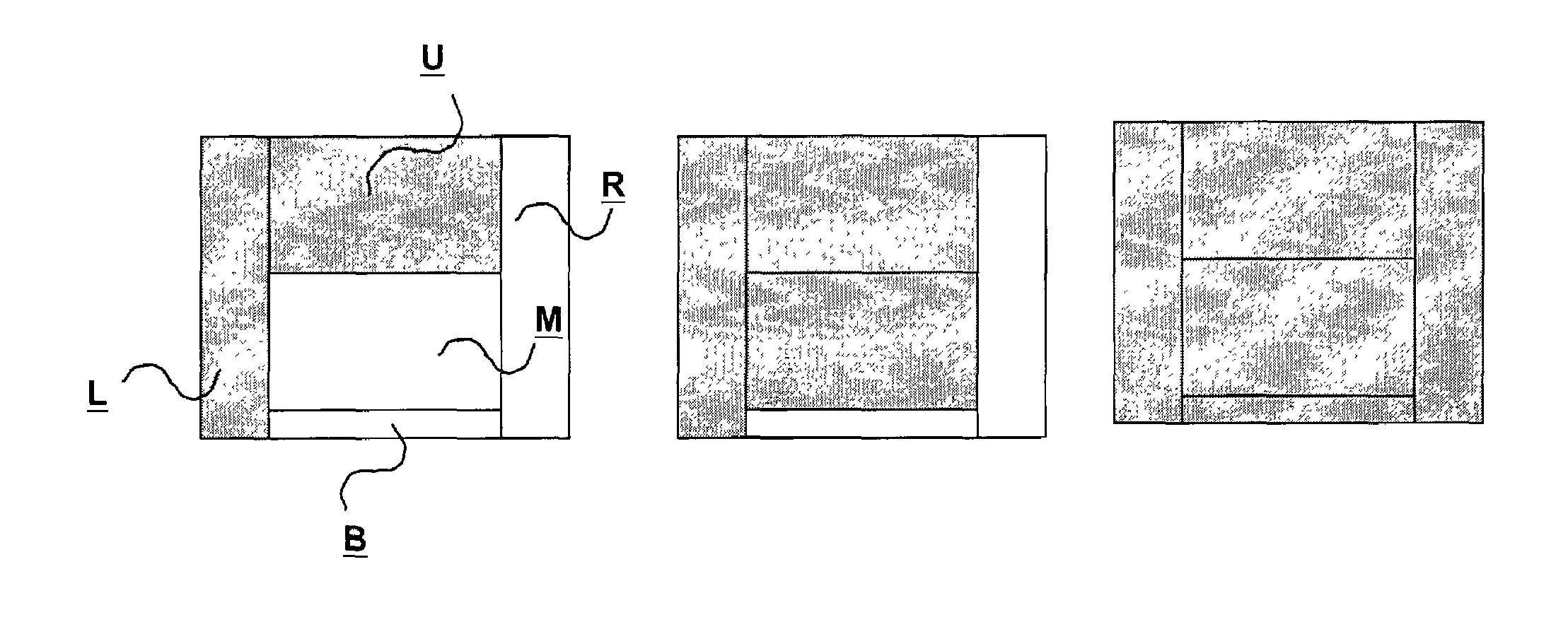

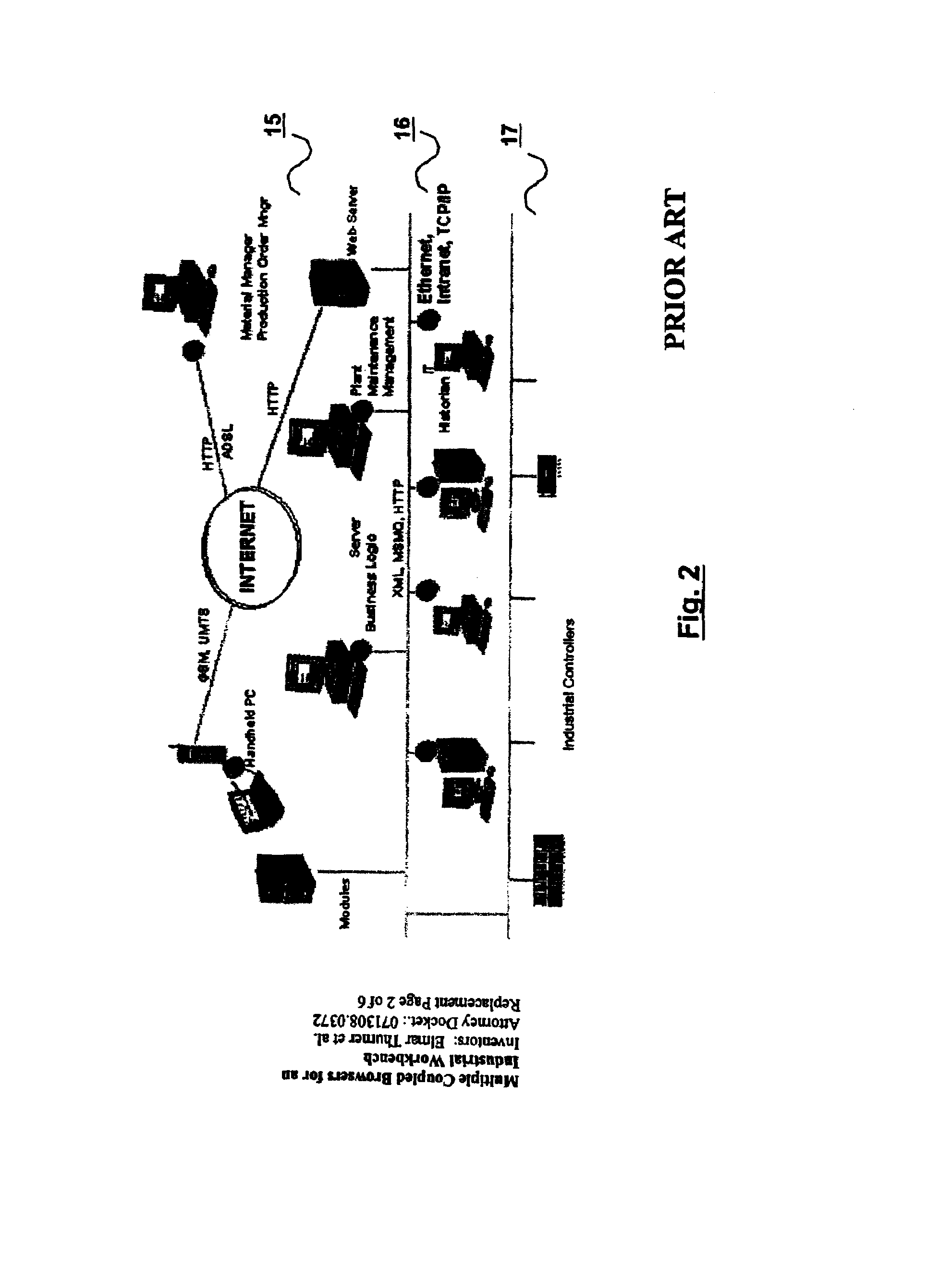

Multiple coupled browsers for an industrial workbench

Multiple Views of an Industrial Plant are graphically displayed and viewed. A graphical user interface displays the views in corresponding panes or windows of the graphical user interface. The views, being graphical representations of systems of the Industrial Plant, are coupled by a coupler according to a predetermined relationship between the underlying systems of the Industrial Plant represented by the coupled views. The coupler automatically refocuses the panes to display different views of the Industrial Plant based on a selection of an object in any of the panes or on a manual refocus of one view and on the predetermined relationship for coupling the views. The Coupled views represent different domains of the Industrial Plant or Industrial Network e.g. real-time monitoring and operation, configuration, debugging, maintenance, scheduling, asset management, documentation, training, simulation, physical construction, material flow monitoring, programming, interconnecting function blocks, performance analysis. The analysis may be provided at different points in time (now, past, predicted future) and with a different spatial focus (parts, whole). Coupling different views greatly reduces handling effort for building and operating Industrial Plants.

Owner:SIEMENS AG

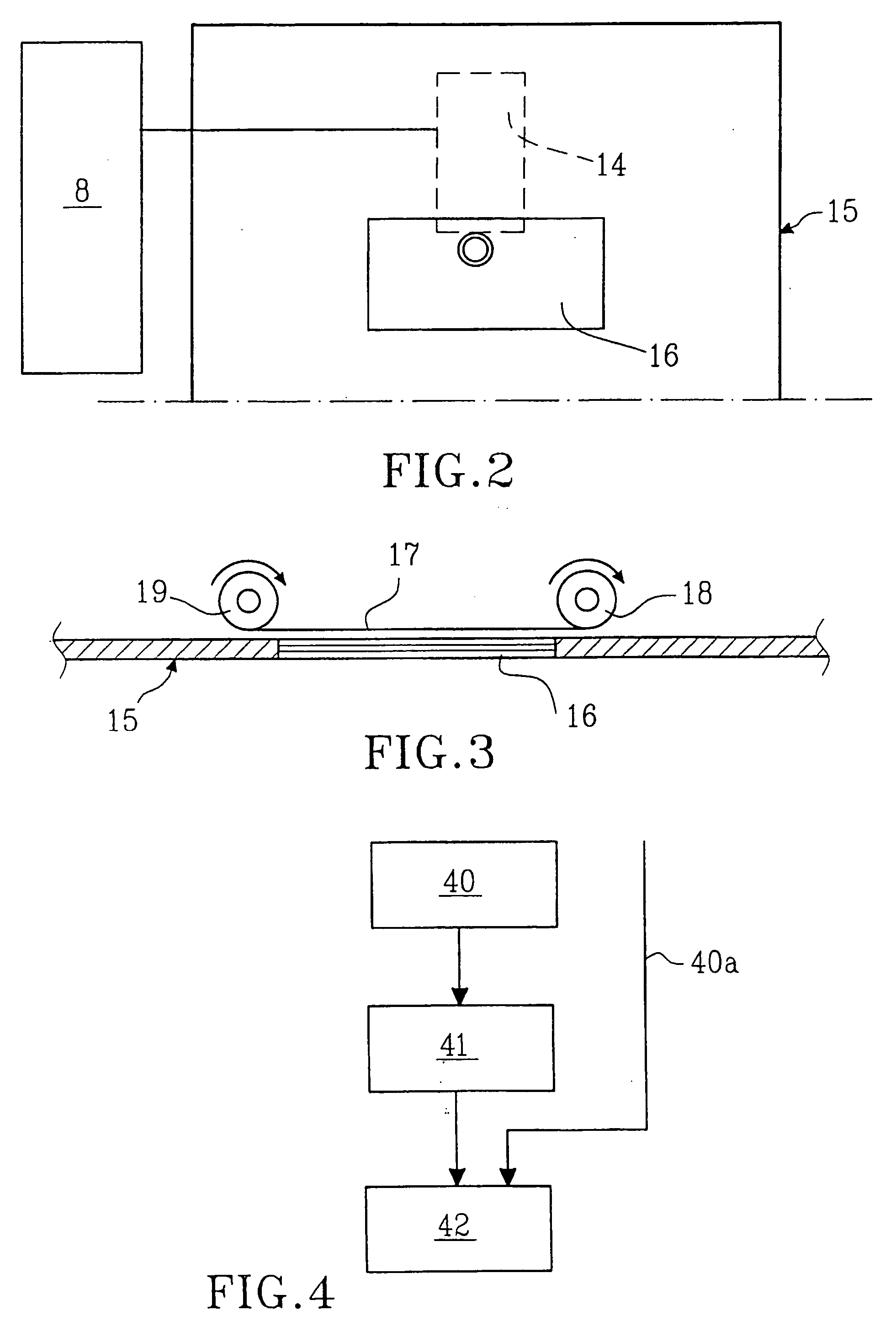

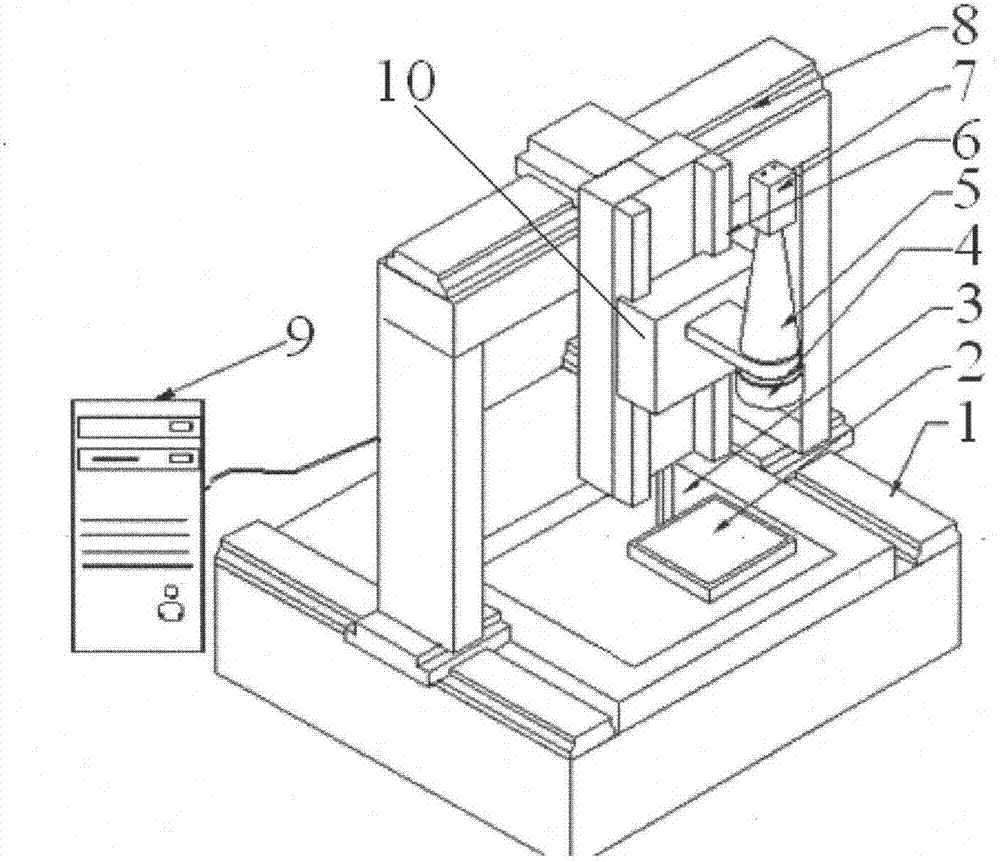

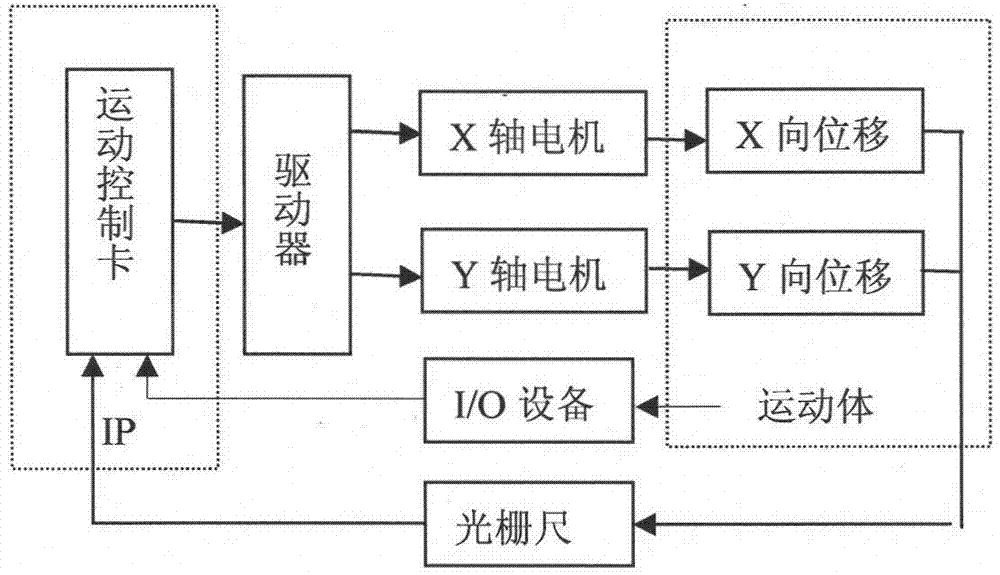

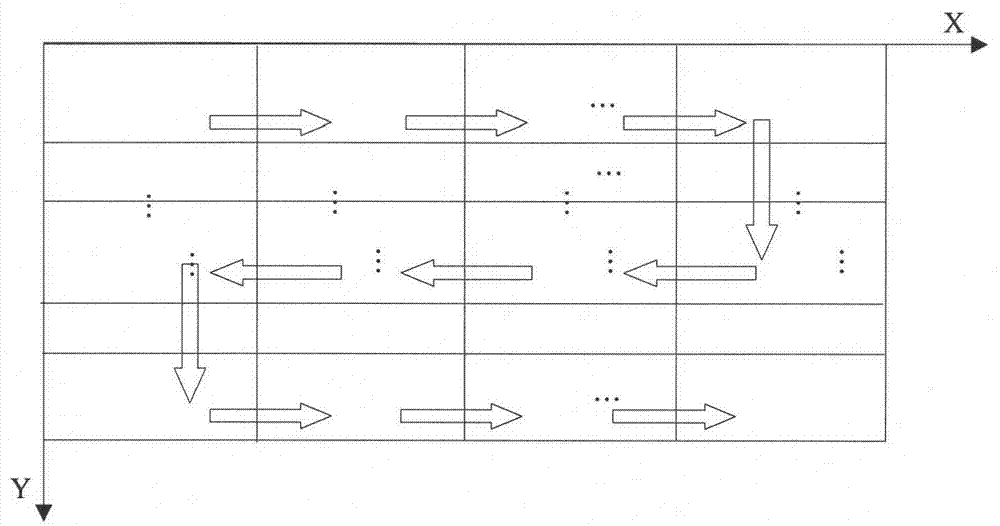

System and method for numerical control (NC) workbench error self correction based on machine vision

InactiveCN103197599AHigh positioning accuracyImprove efficiencyNumerical controlNumerical controlAlgorithm

The invention provides a system for numerical control (NC) workbench error self correction based on machine vision. The system comprises an X-Y-Z-coordinate motion workbench, an image collecting system is arranged on a motion body of the X-Y-Z-coordinate motion workbench, a calibration plate is arranged on an objective table of the X-Y-Z-coordinate motion workbench, and an industrial computer is connected with the image collecting system. The invention further provides a method for NC workbench error self correction based on the machine vision. The method comprises the following steps: controlling the motion body and a high-resolution industrial camera to move, and collecting sequential images; obtaining a current absolute coordinate according to the imaging data of the motion body at different positions, comparing with a movement directive the encoder feedback value of a servo motor, and obtaining positioning error compensation values; and continuously conducting positioning detecting at different positions, and enabling the positioning error compensation values of all positions to be stored into a databank. According to the system and the method for NC workbench error self correction based on the machine vision, the defects of the prior art are overcome, self calibration and compensation can be conducted to the X-Y positioning error of the whole workbench, and positioning accuracy is markedly improved.

Owner:DONGHUA UNIV

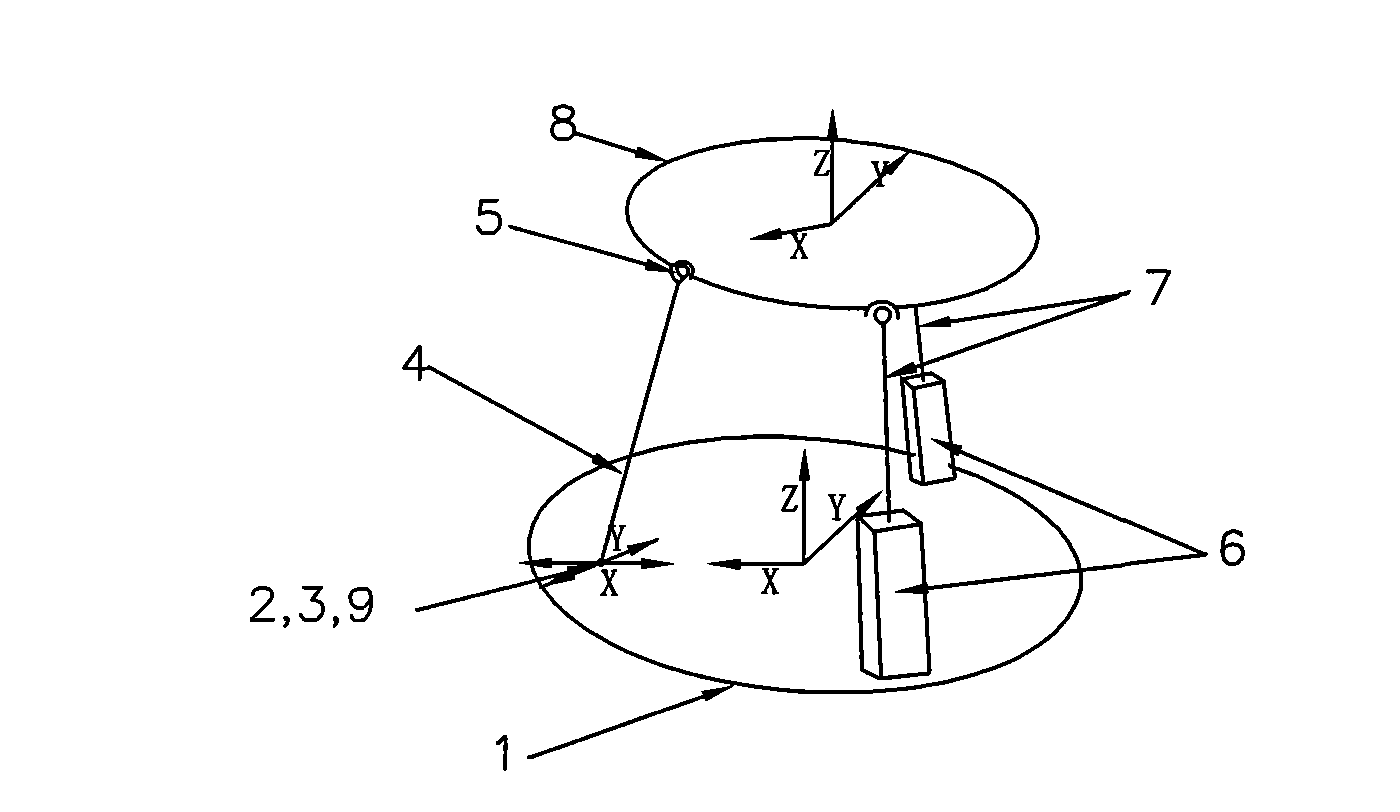

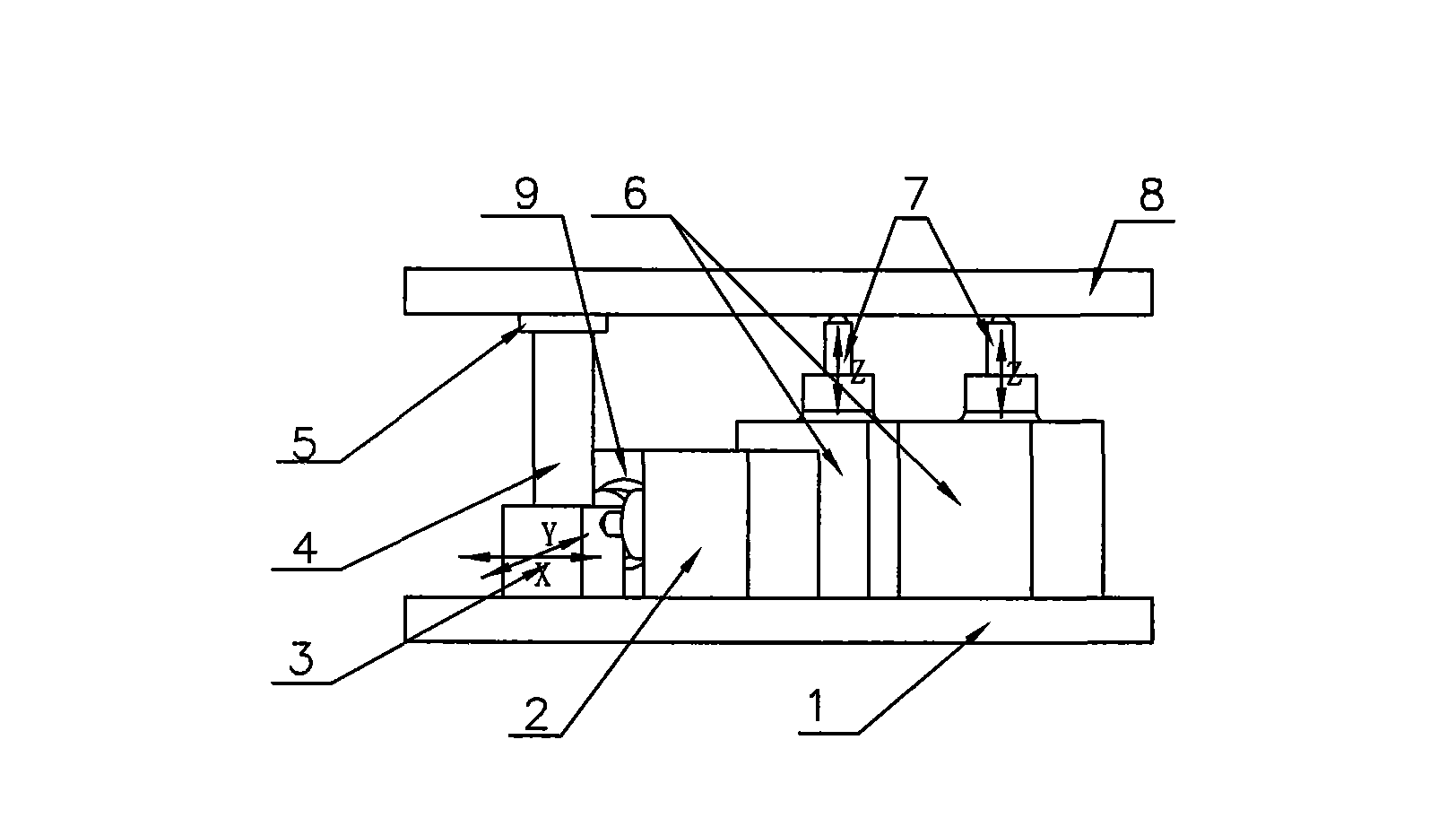

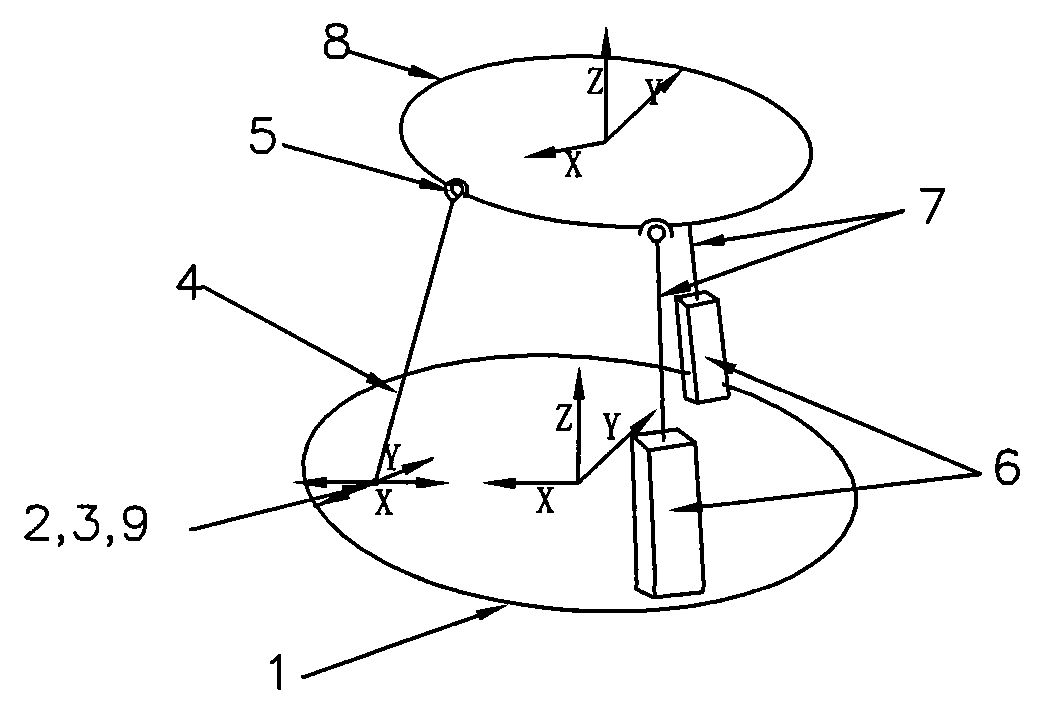

Roundness/cylindricality measurement workbench capable of automatically regulating center and inclination

InactiveCN102102986AImprove adjustment efficiencyRealize the function of automatic centering and tiltingMeasurement devicesEngineeringLinear motor

The invention relates to a roundness / cylindricality measurement workbench capable of automatically regulating center and inclination, which comprises a pedestal fixedly connected with a power shaft, an operating platform for placing a measured workpiece, three support frames, a sensor for measuring the eccentricity of the measured workpiece, and a control computer for receiving an output signal of the sensor and regulating the space position of the operating platform. The output signal of the sensor is transmitted to the control computer; the support frames comprise two telescopic support frames and a fixed support frame, the upper ends of the telescopic support frames are in spherical contact with the operating platform, the lower parts of the telescopic support frames are connected with a Z-axis linear motor, the Z-axis linear motor is fixed on the pedestal, the upper end of the fixed support frame is connected with the operating platform through a Hooke hinge assembly, and the lower part of the fixed support frame is connected with a sliding block assembly; the sliding block assembly is connected with an X-axis linear motor and a Y-axis linear motor respectively; and the X-axis linear motor and the Y-axis linear motor are fixed on the pedestal. The workbench has high regulating efficiency.

Owner:西安威而信精密仪器有限公司

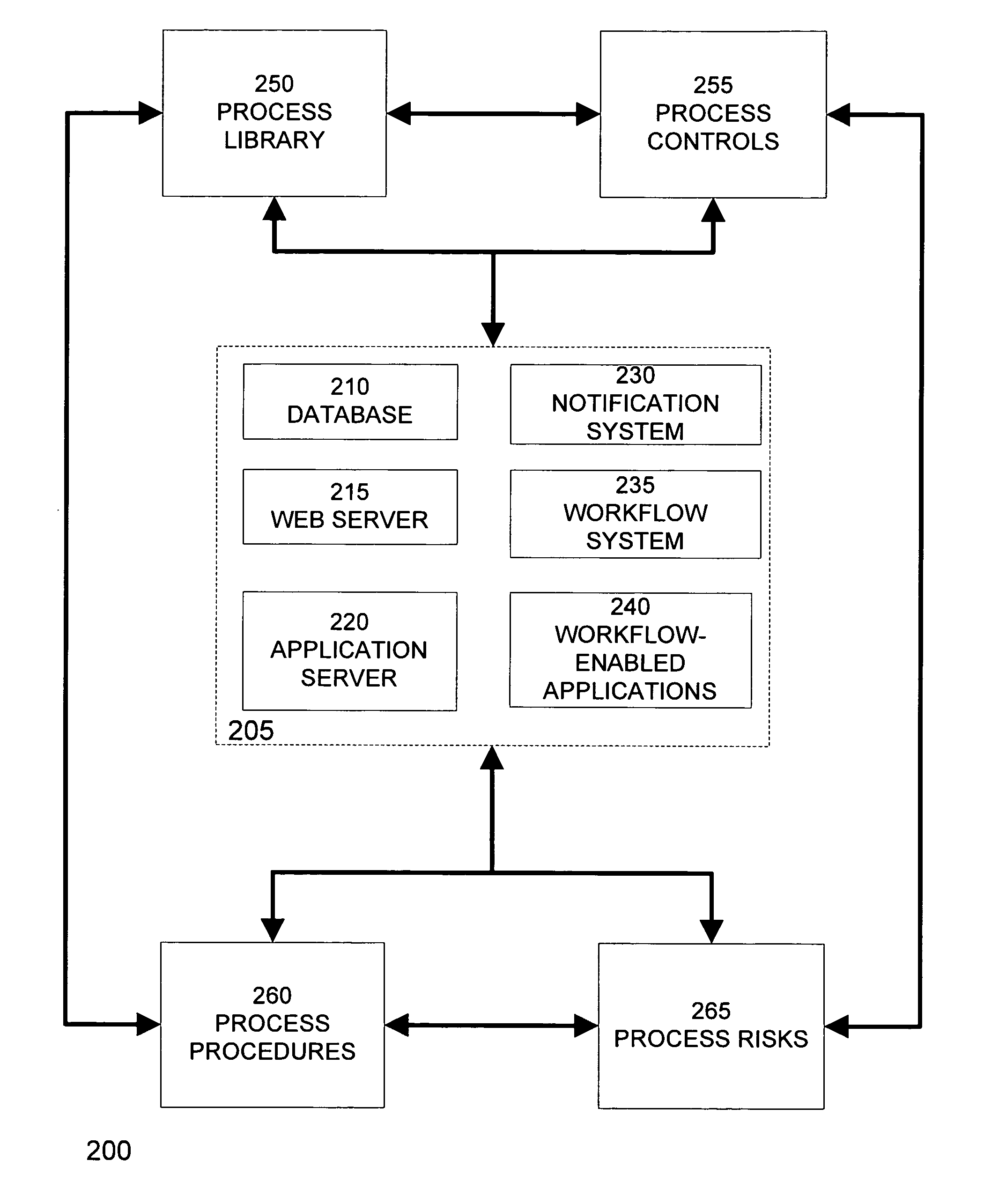

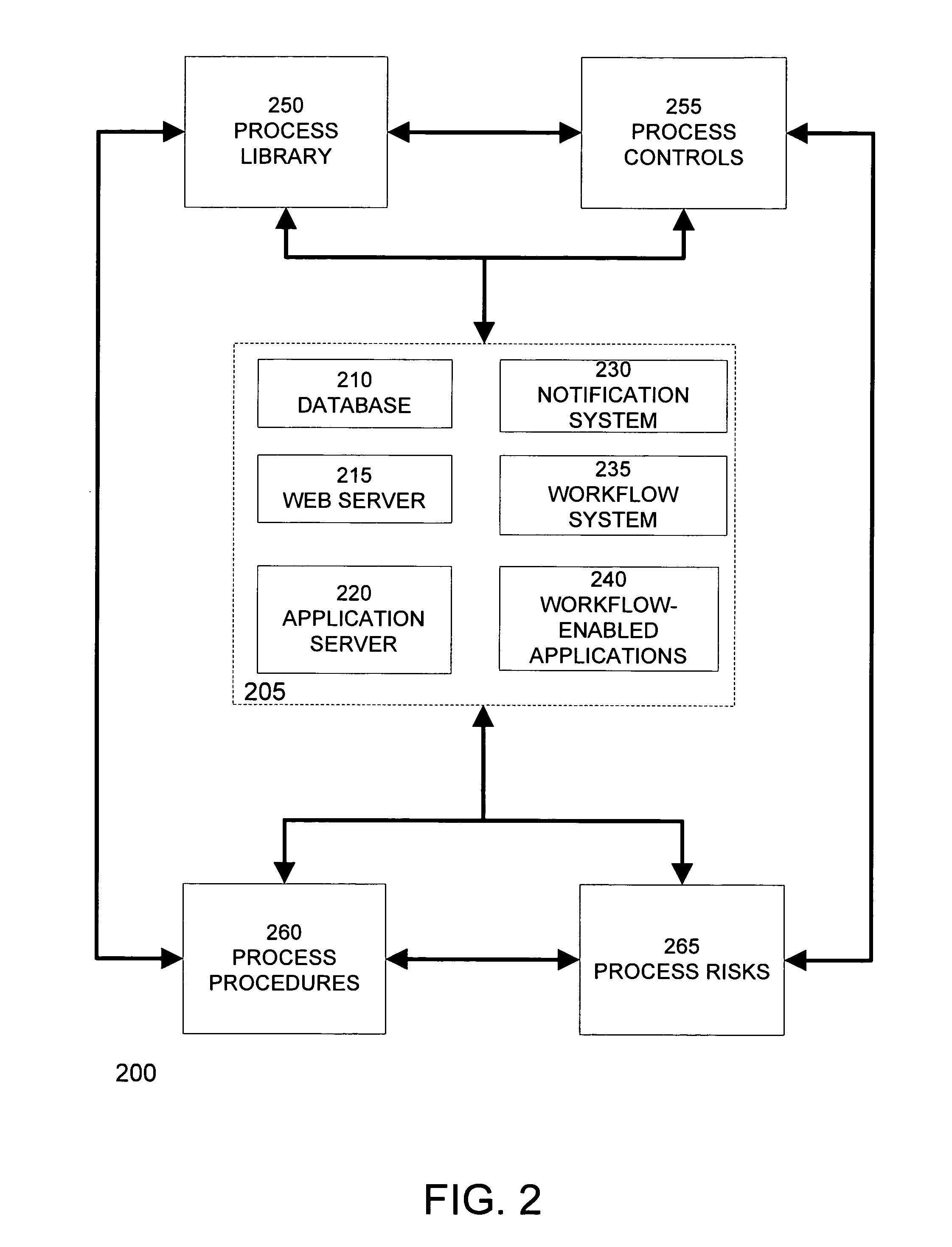

Compliance workbench

An audit system formally communicates the results of an audit to company officers. The audit system allows company officers to review the audit information in detail to identify specific risks, their associated financial controls, and the potentially impacted financial accounts. The audit system displays a summary of audit results identifying specific financial items, risks, business processes, and organizations that fail to meet audit requirements. The audit system can also summarize audit results by their associated financial items, enabling company officers to see the potential impact of audit results on specific financial items. Similarly, the audit system can summarize audit results by their associated organizations, enabling company officers to see the source of audit shortcomings. If a company officer decides to certify the audit results, the audit system documents the company officers' approval. The audit system can receive an electronic signature to record the company officer's certification of audit results.

Owner:ORACLE INT CORP

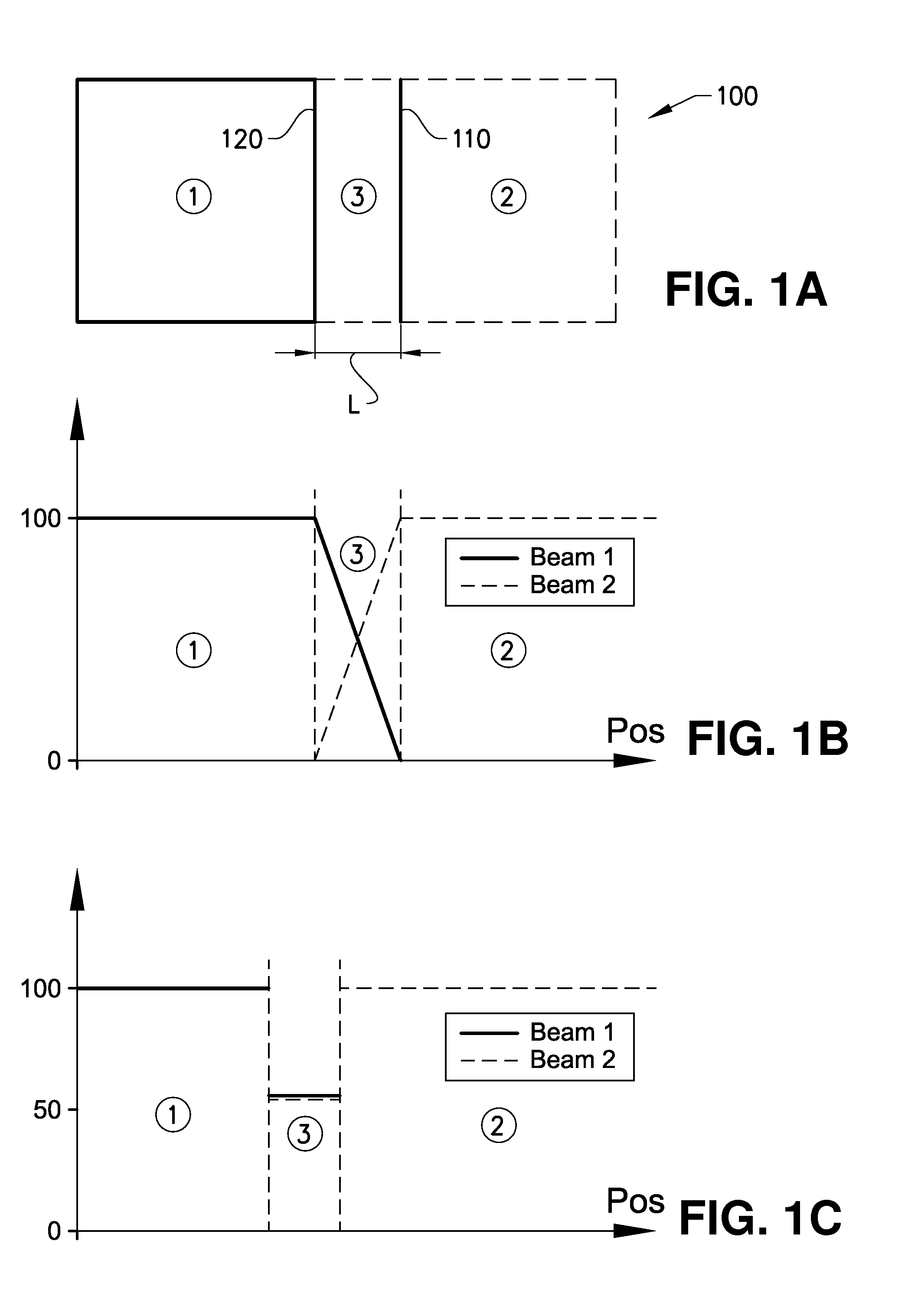

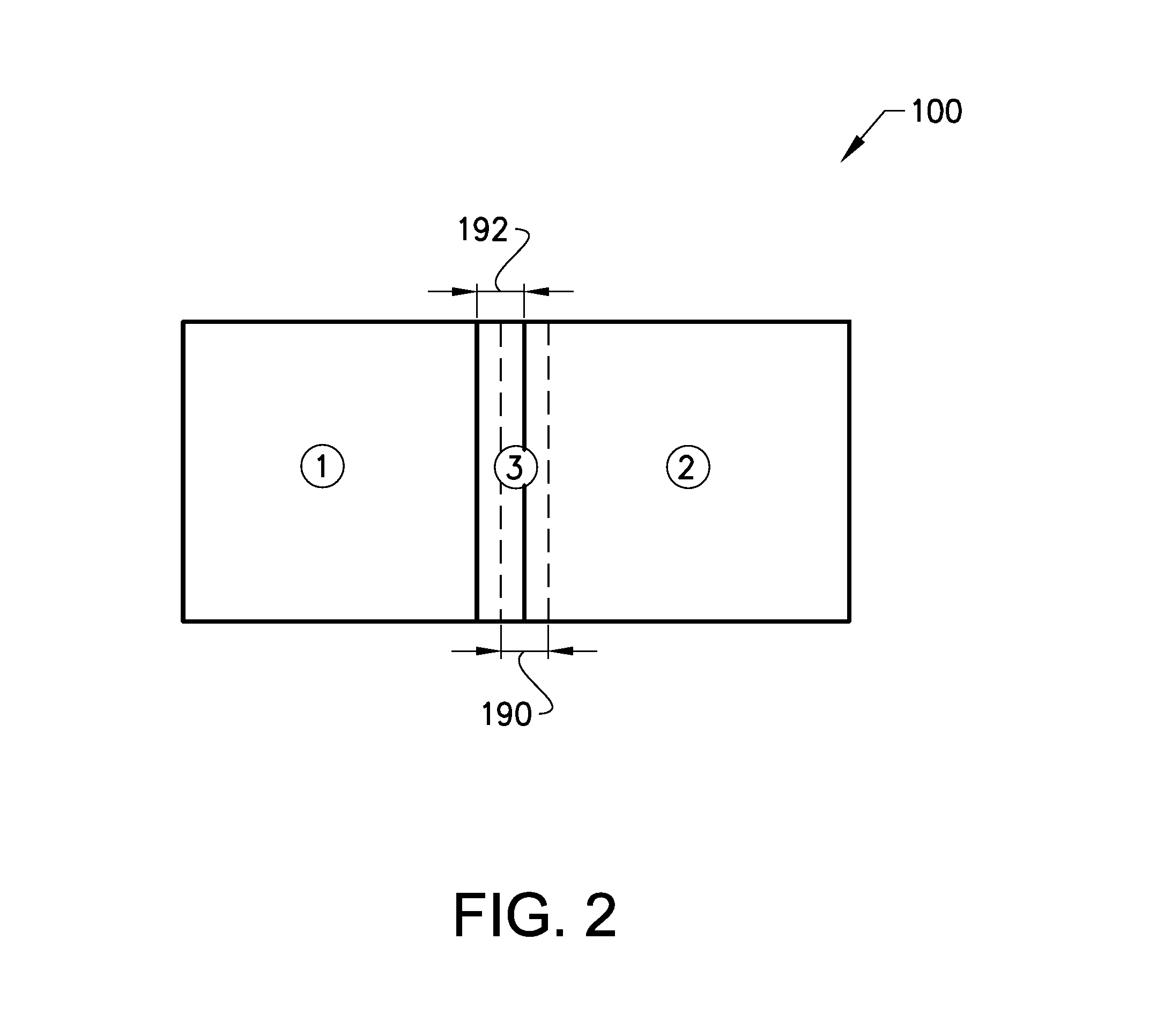

Method and apparatus for additive manufacturing

ActiveUS9415443B2Large build volumeSacrificing qualityAdditive manufacturing apparatusIncreasing energy efficiencyPowder bedBeam source

A method for forming a three-dimensional article through successive fusion of parts of a powder bed, which parts corresponds to successive cross sections of the three-dimensional article, said method comprising the steps of: providing a model of said three dimensional article, providing a first powder layer on a work table, directing a first energy beam from a first energy beam source over said work table causing said first powder layer to fuse in first selected locations according to said model to form a first cross section of said three-dimensional article, directing a second energy beam from a second energy beam source over said work table causing said first powder layer to fuse in second selected locations according to said model to form the first cross section of said three-dimensional article, wherein said first and second locations of said first powder layer are at least partially overlapping each other.

Owner:ARCAM AB

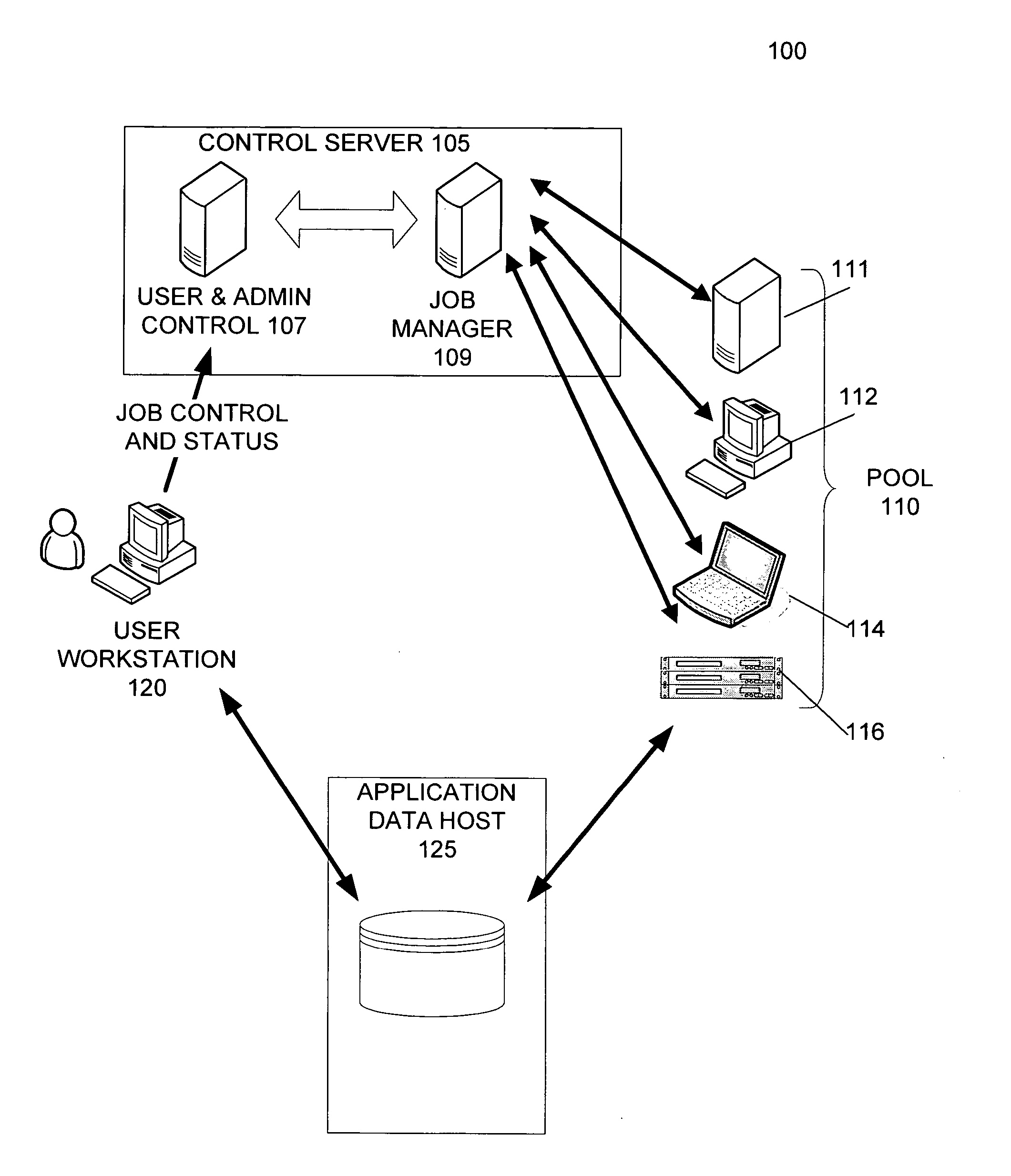

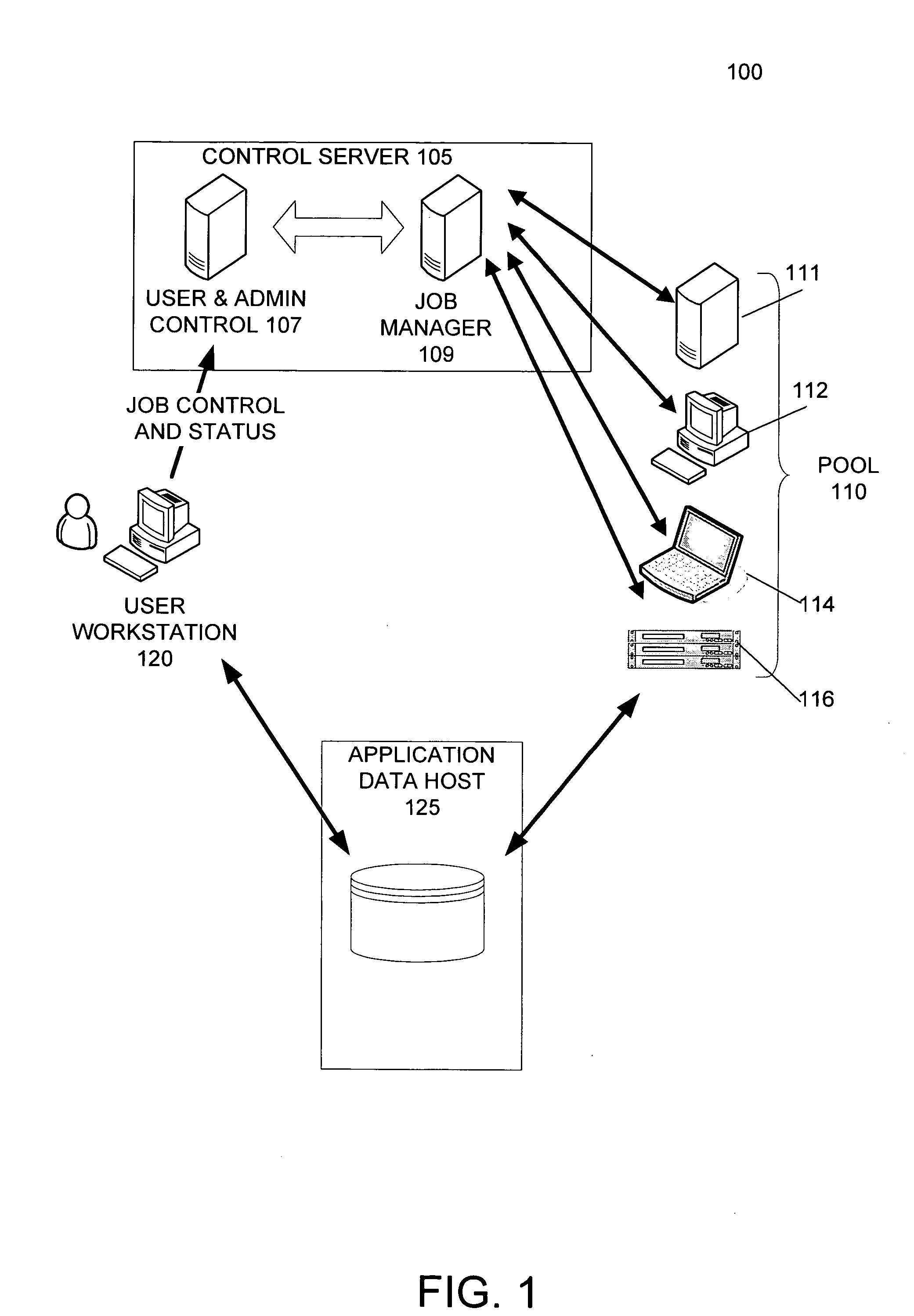

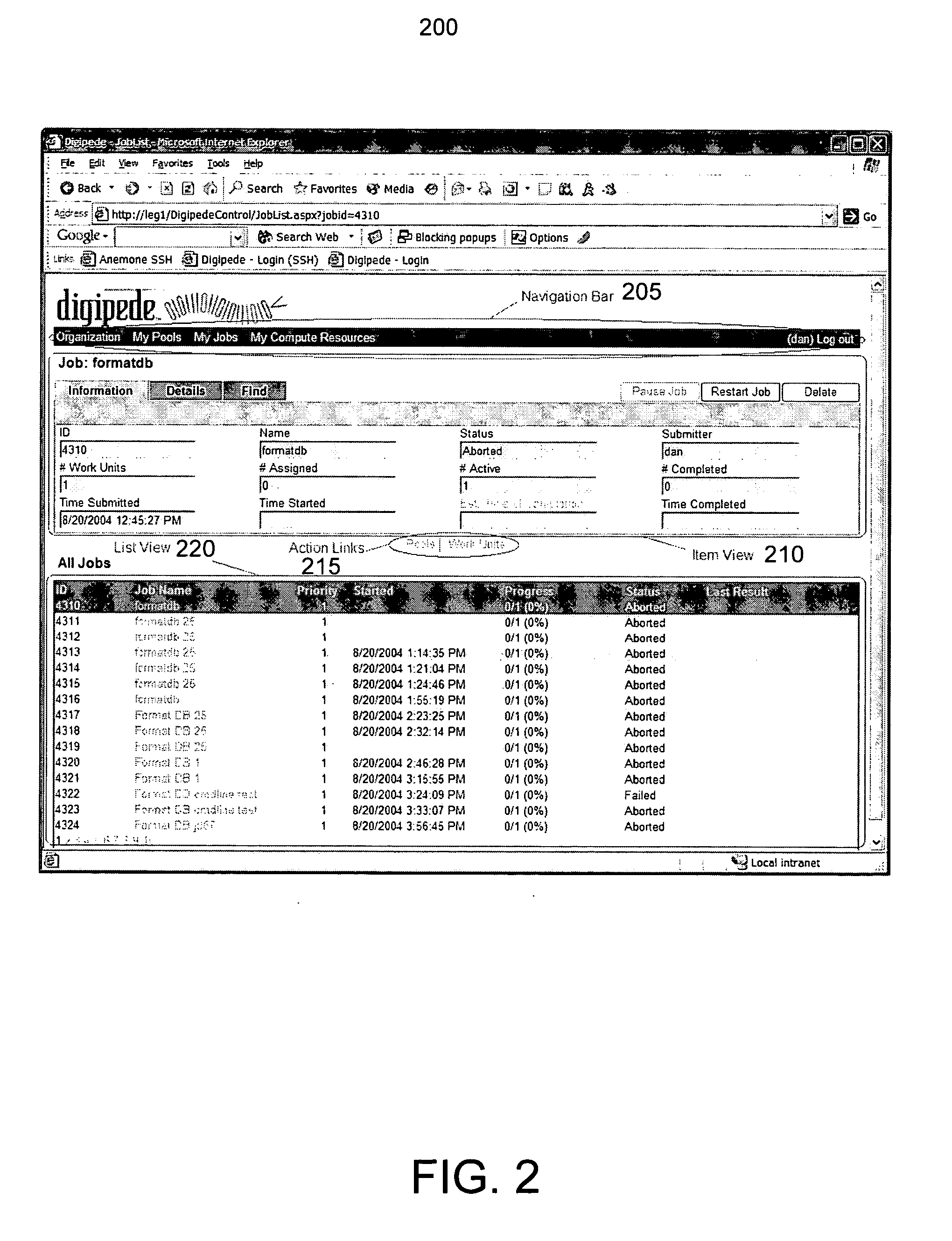

Distributed system interface

InactiveUS20060075407A1Multiprogramming arrangementsRequirement analysisJob descriptionError processing

A distributed processing system delegates the allocation and control of computing tasks to intelligent agent applications running on computing resources. This provides flexible control, efficient allocation, scalability, and simple adaptation of applications to the distributed processing system. The distributed processing system includes an agent, a server, application programming interfaces, and a workbench application. The workbench application includes a user-interface enabling the description, submission, monitoring, and control of distributed computing jobs. The workbench application includes a wizard or a guided step-by-step interface that allows users to specify the distributed computing job, including applications, application parameters, input and output data, computing resource requirements, job priority, error handling, and other job aspects. The wizard interface generates a job template, which can be reused for additional similar jobs, and a job description. An inspector interface allows users direct access to the job template and job description if needed.

Owner:DIGIPEDE TECH LLC

Wall-Mounted Home Fitness Training Equipment

An overall fitness trainer and can be a wall mounted unit that can utilize clip resistance bands as well as other techniques. These bands generally clip on the unit and onto different handles, bars and attachments to perform exercises. The unit can have a removable / adjustable pull up bar, dip bar and seat. It also includes a spring loaded, pull pin carriage that moves freely up and down a vertical spine. This allows for easy adjustment of the carriage and allows the user to attach the bands at multiple angles, widths and levels. This in turn increases the number of exercises the user can perform on the unit. The unit can be attached to the wall with lag bolts into two or more studs. Various embodiments of the invention can have an oscillating and telescopic bench, a dip bar, a seat, a knee stabilizer and a foot rest. All of these accessories can be attached and removed to the central spine adding to the versatility and scope of exercises that can be performed. Accessories can also include a baseball bat handle, baseball, medicine ball, boxing gloves, football, squat belt, golf club handle, hockey stick handle, lacrosse stick handle and any other handle of any other sport unit.

Owner:VERSAFLEXX

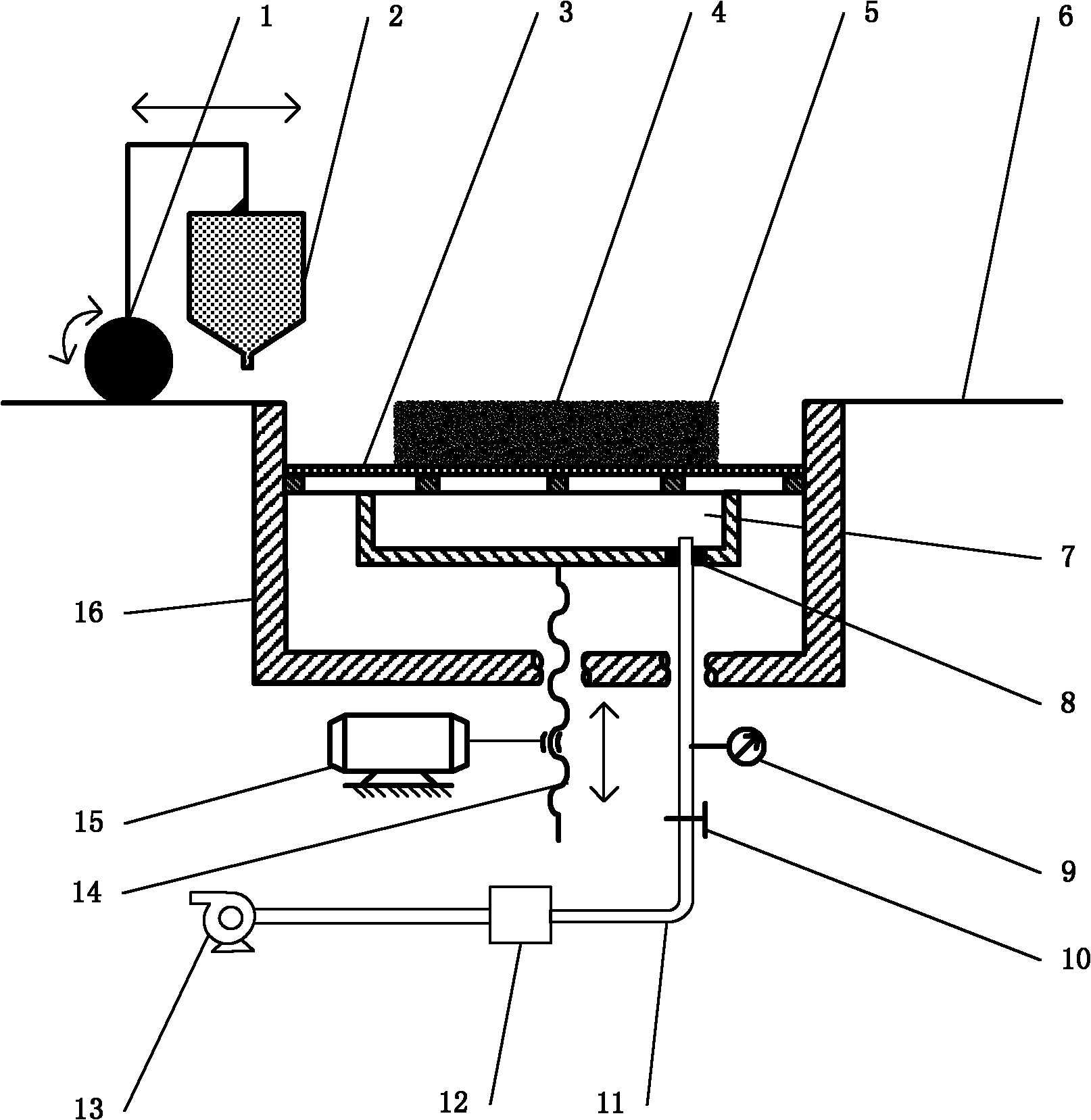

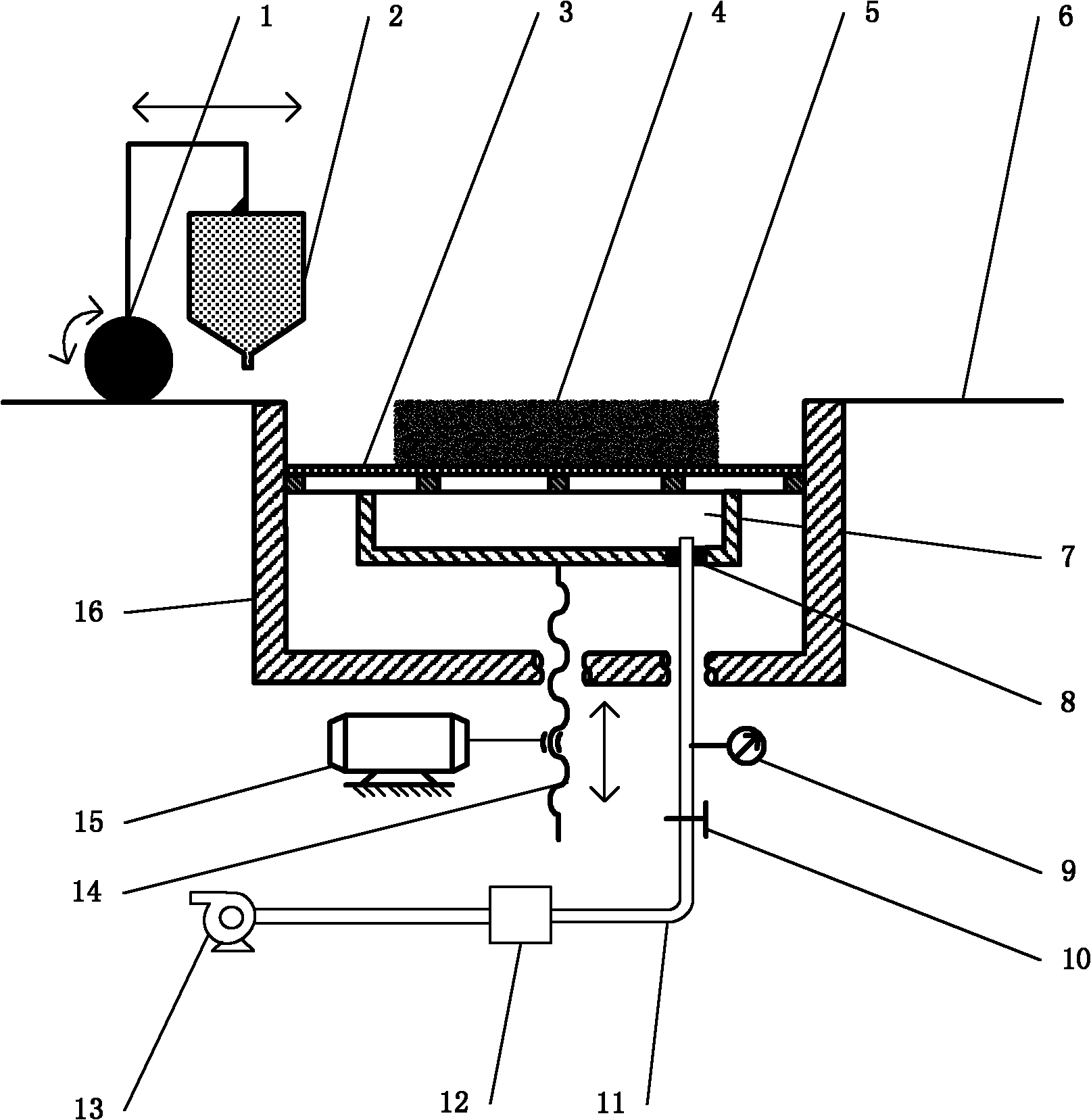

Negative pressure-based device and method for manufacturing porous textures by laser sintering and quick molding

InactiveCN102029389AFast molding speedGuaranteed porosityIncreasing energy efficiencySelective laser sinteringReciprocating motion

The invention relates to a negative pressure-based device and a negative pressure-based method for manufacturing porous textures by laser sintering and quick molding. The device comprises an X-Y workbench, wherein a pair of guide rails is arranged on the workbench, and the guide rails have a powder spreading roller and a power spreading groove which can move reciprocally along the guide rails; the X-Y workbench is provided with a molding tank, and a molding workbench capable of moving vertically is arranged in the molding tank; the molding workbench consists of a screen with holes distributed densely and a carriage, and a negative pressure chamber is formed on the lower surface of the molding workbench; the bottom end of the negative pressure chamber is connected with a screw and a servo motor in turn; an absorption tube is communicated with the negative pressure chamber through an opening; and the other end of the absorption tube is connected with a filter and a vacuum pump in turn. In the invention, based on a negative pressure absorption principle, powder which is not sintered on each layer is removed and recycled through an absorption tube; and through layer-by-layer absorption, the powder which is not sintered and solidified is cleaned completely, while the sintered and solidified powder is continuously stacked and overlaid to form parts, so that the manufacturing of the porous texture with an aperture of less than 1mm is realized through selective laser sintering and quick molding.

Owner:NANJING HONNY 3 DIMENSIONAL TECH

Constant pressure automatic grinding device and method based on fuzzy adaptive force control

InactiveCN104858782AReal-time control of grinding normal forceImprove versatilityGrinding feed controlSpeed/accelaration controlContact forceEngineering

The invention discloses a constant pressure automatic grinding method based on fuzzy adaptive force control. The grinding method comprises the following steps: detecting the contact force of a grinding head and a workpiece in a real-time manner to feed back force signals; changing an analog voltage value output by a controller according to a preset control algorithm, thereby controlling the output torque of an x-axis servomotor to control the contact force. The invention further provides a grinding device for realizing the grinding method. The grinding device comprises an industrial control main engine, a workbench, motion mechanisms, one-dimensional sensing equipment, a position sensor for acquiring the position coordinate of the workpiece, grinding equipment and workpiece clamping equipment. The grinding device can be used for detecting the normal grinding force in a grinding process based on an intelligent force control technology, and feeding back detection results; through the processing of the controller, driving signals are generated for continuous adjustment of the output torque of a driver, so that the normal grinding force can be controlled in a real-time manner and the constant pressure grinding can be realized.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com