Patents

Literature

97 results about "Change order" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In project management, a change order also referred to as a contract change note refers to the changes in the scope of work agreed to by the owner, contractor, and architect or engineer. A change order is work that is added to or deleted from the original scope of work of a contract, however, depending on the magnitude of the change, it may or may not alter the original contract amount and/or completion date. A change order may force a new project to handle significant changes to the current project.

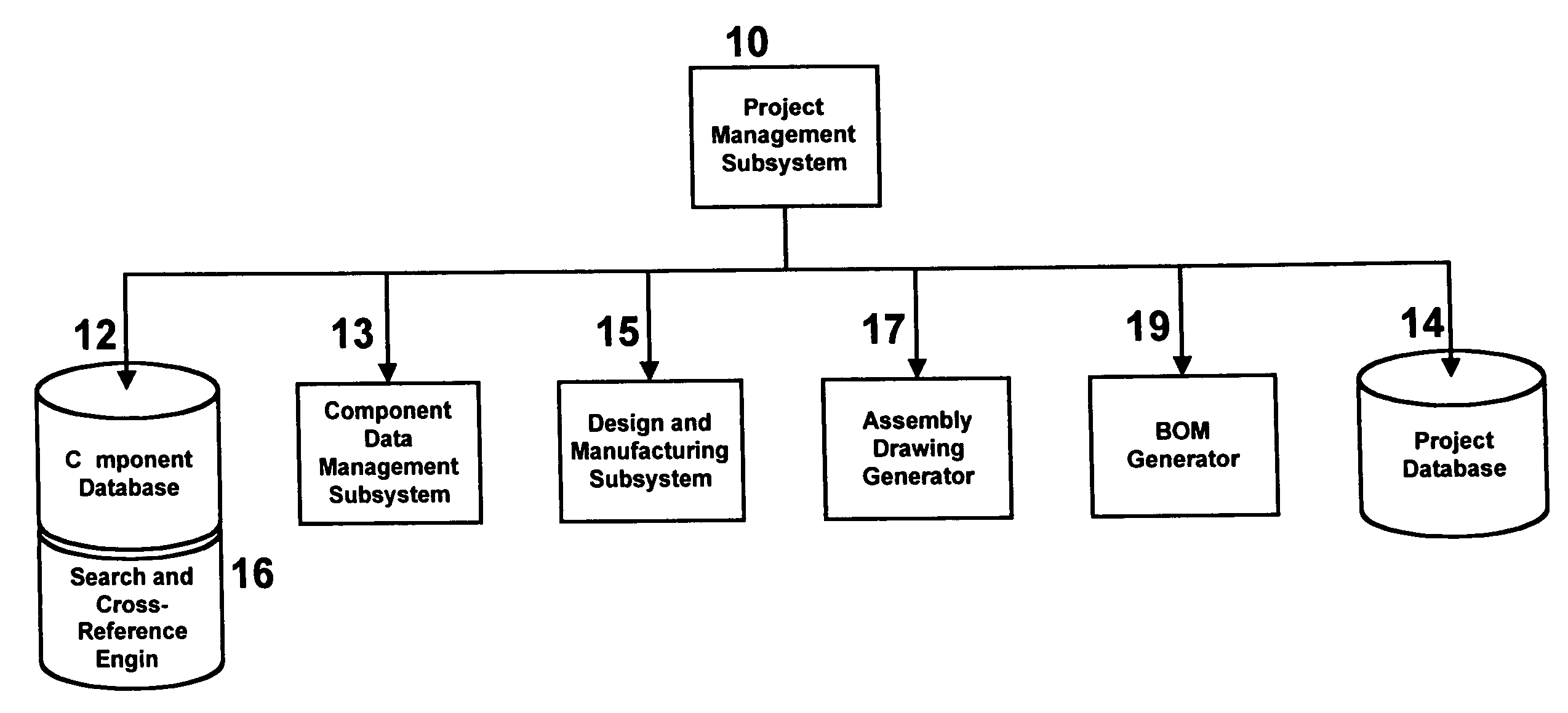

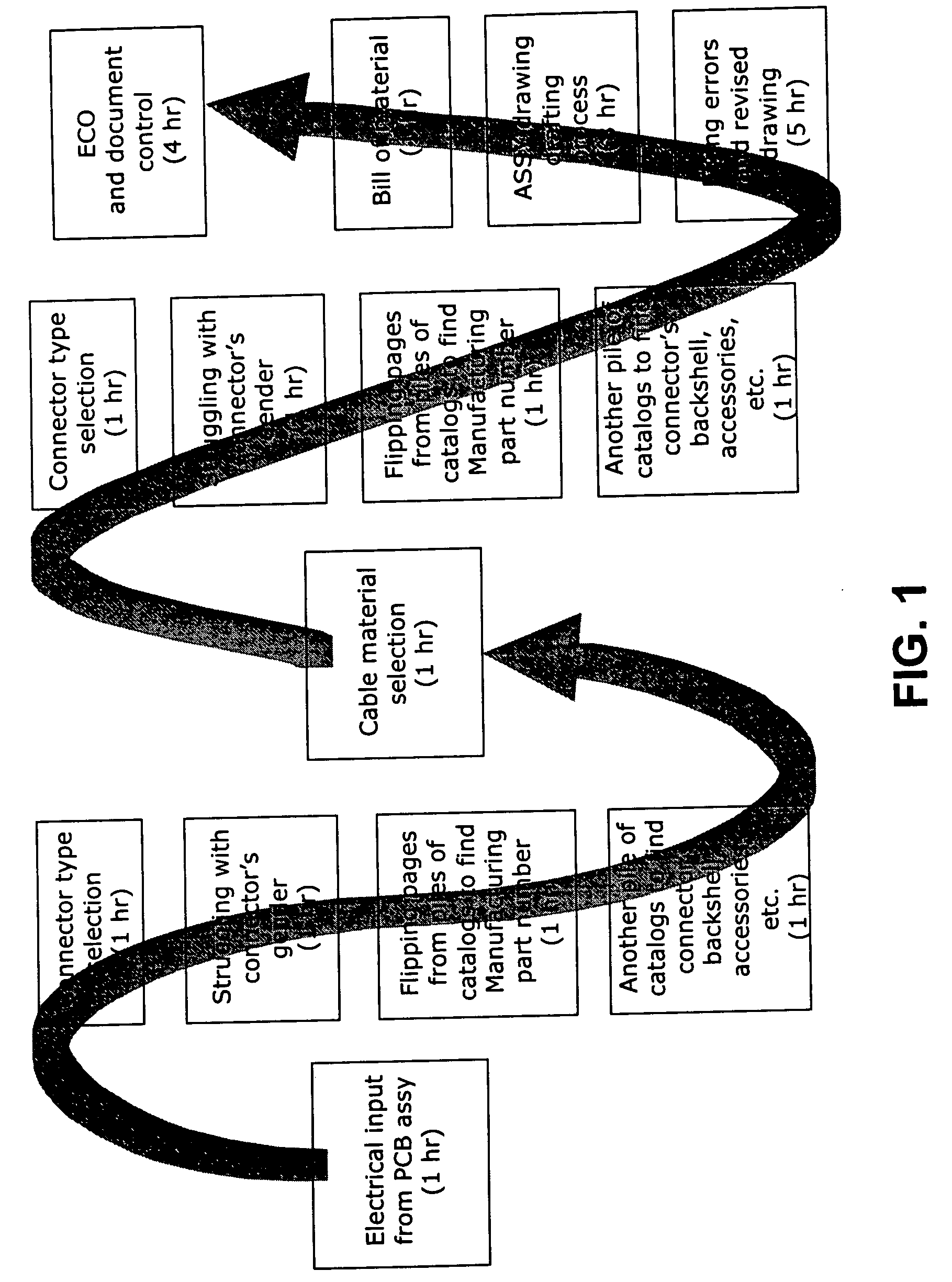

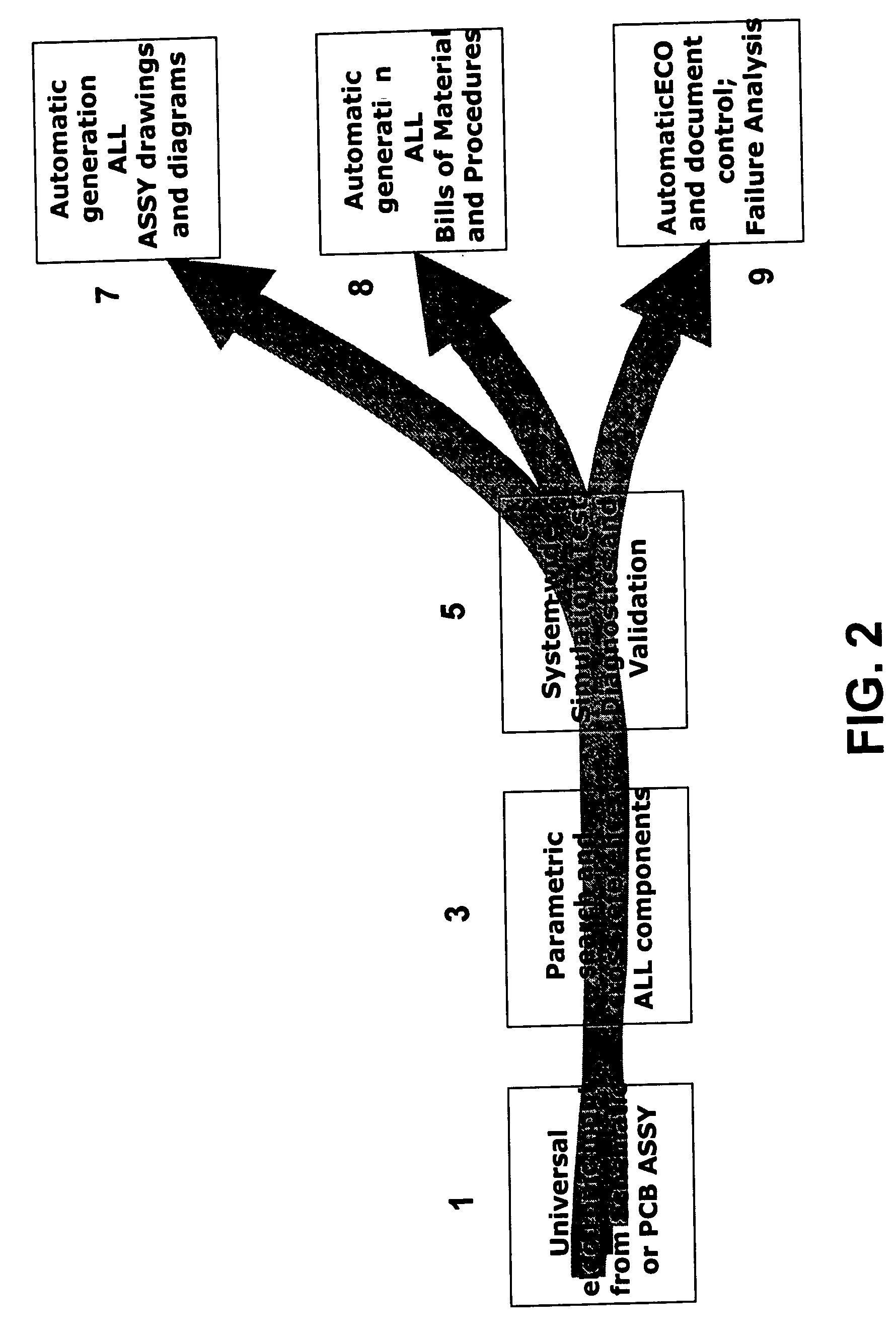

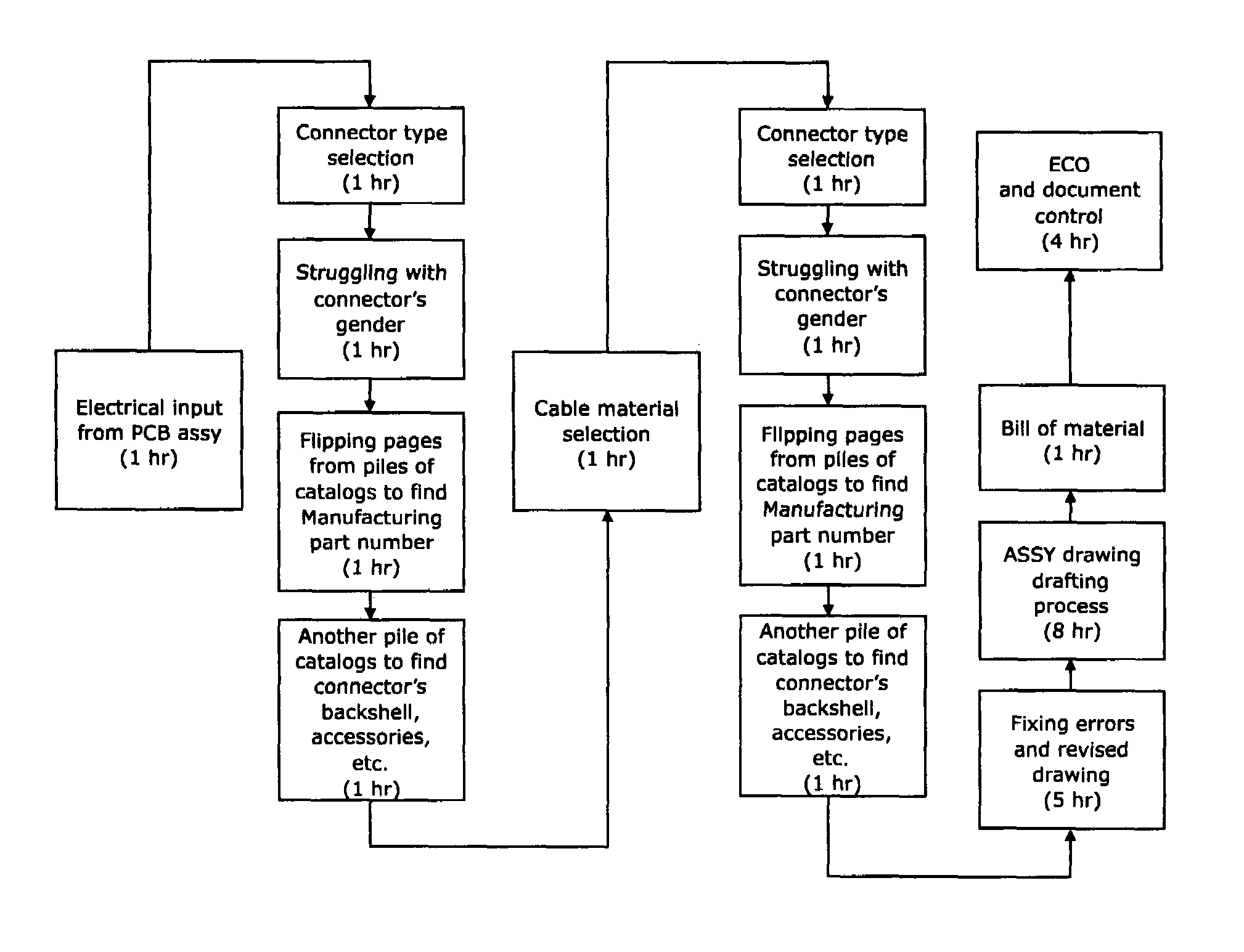

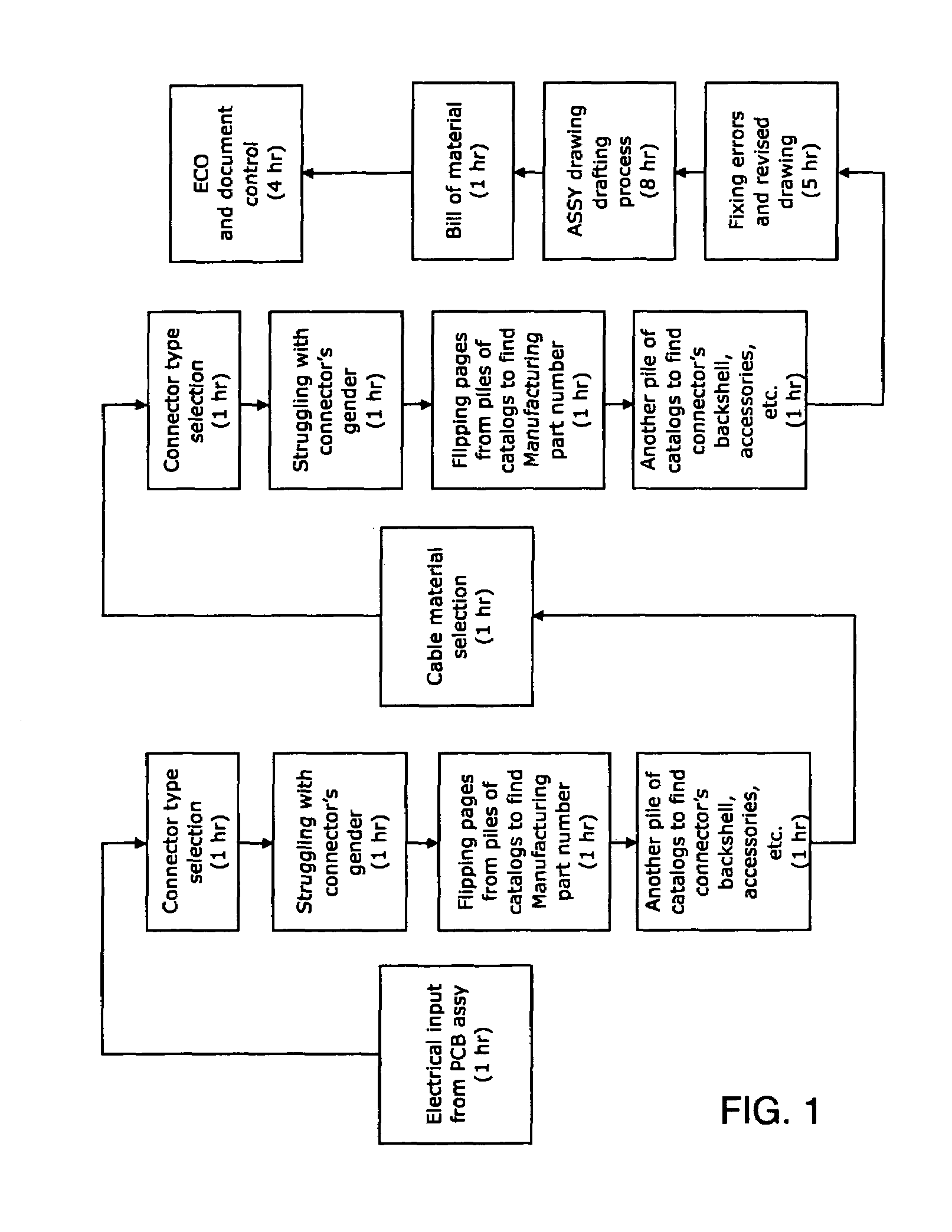

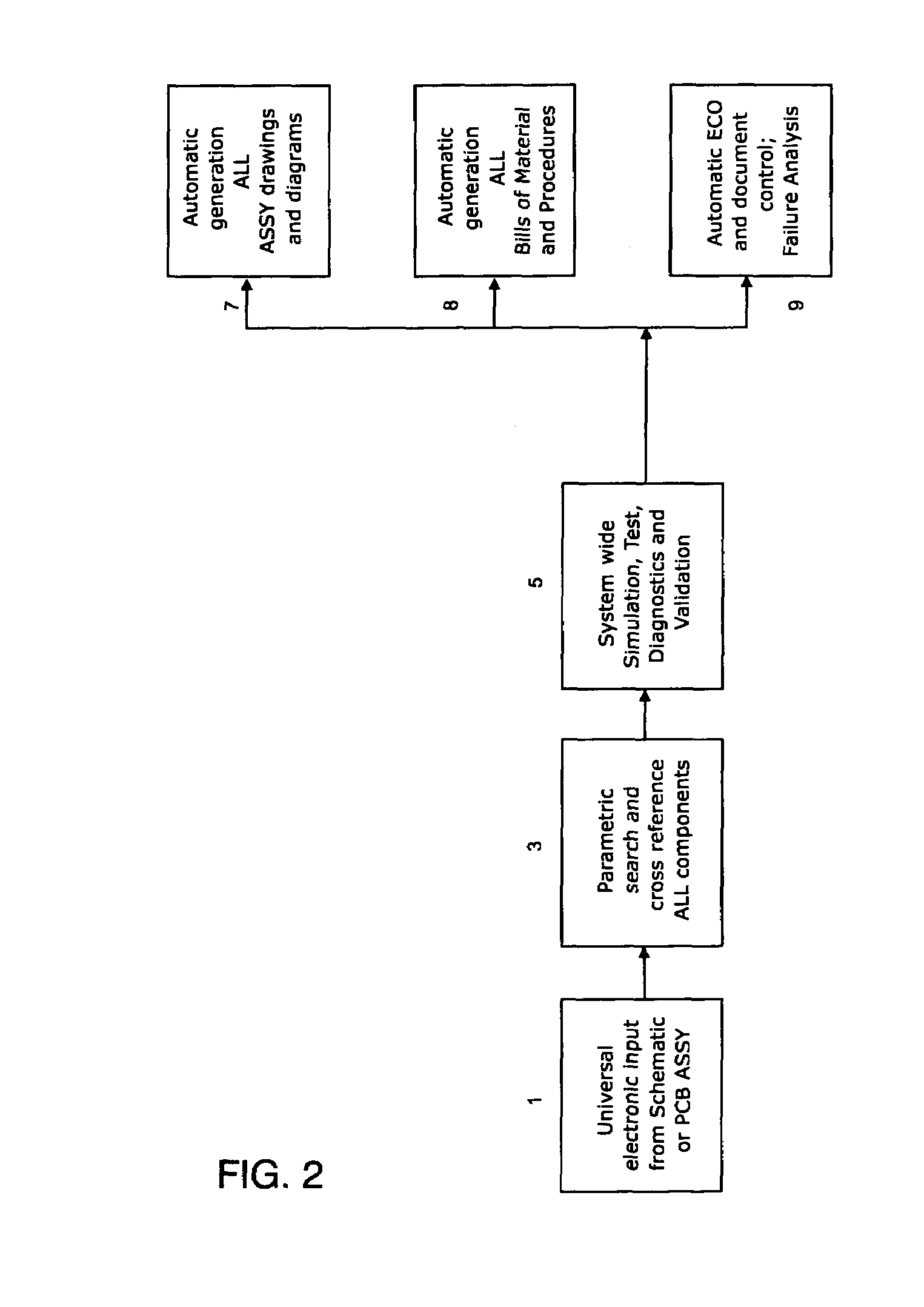

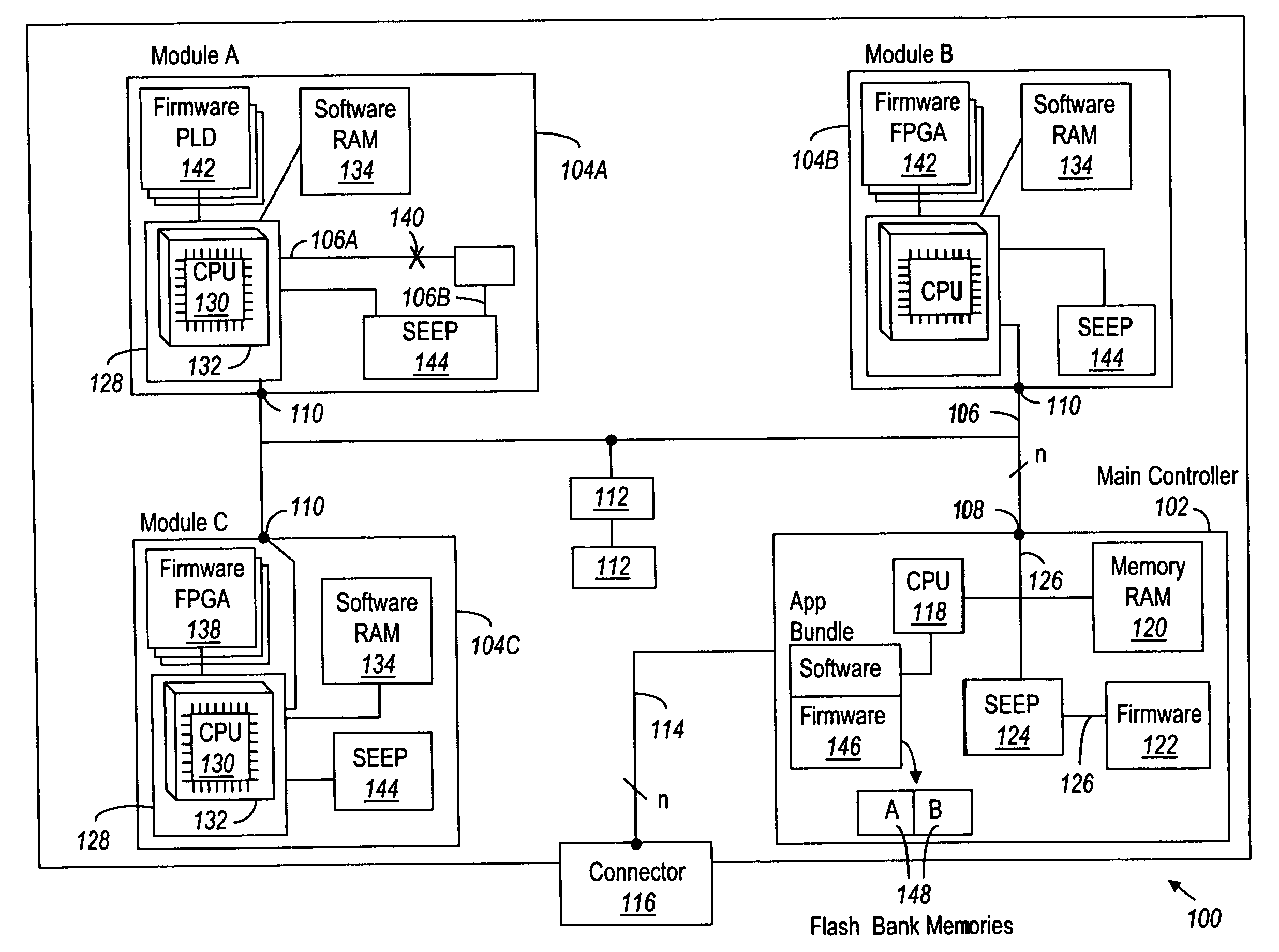

PLM-supportive CAD-CAM tool for interoperative electrical & mechanical design for hardware electrical systems

InactiveUS20050080502A1Reduce frictionCAD network environmentComputer programmed simultaneously with data introductionTask completionBill of materials

This invention is a tool for computer-aided design, computer-aided manufacturing forming a Project Management System, comprising: (1) a Component Database; (2) a Component Data Management System; (3) a Design and Manufacturing System; (4) an Assembly Drawing Generator; (5) a Bill of Materials Generator; and, (7) a Project Database. The Project Manager tracks the process and actions, recording and supervising version and change order compliance and task completion, from the start through verification of a production-ready finished version. Each project uses a master workbench. On it design specifications are entered for each subassembly element and connector. Then the user consults the Component Database using a Search and Cross Reference engine for components meeting those design specifications, until a constraint-satisfying design is completed. The tool generates a Bill of Materials, Assembly Drawings, and process records for the project in process.

Owner:CHERNYAK ALEX H +3

PLM-supportive CAD-CAM tool for interoperative electrical and mechanical design for hardware electrical systems

InactiveUS7103434B2Reduce frictionCAD network environmentComputer programmed simultaneously with data introductionTask completionBill of materials

Owner:CHERNYAK ALEX H +3

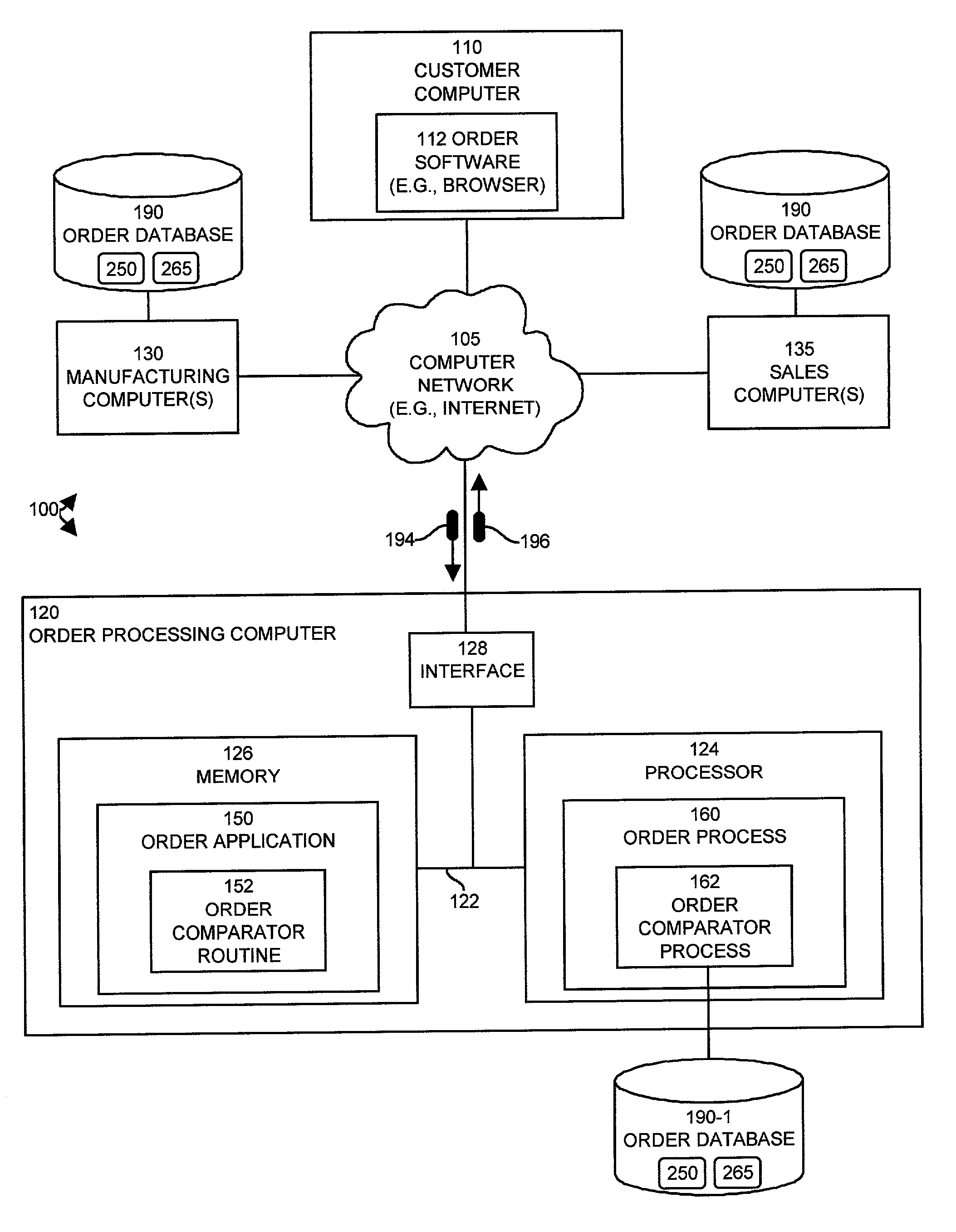

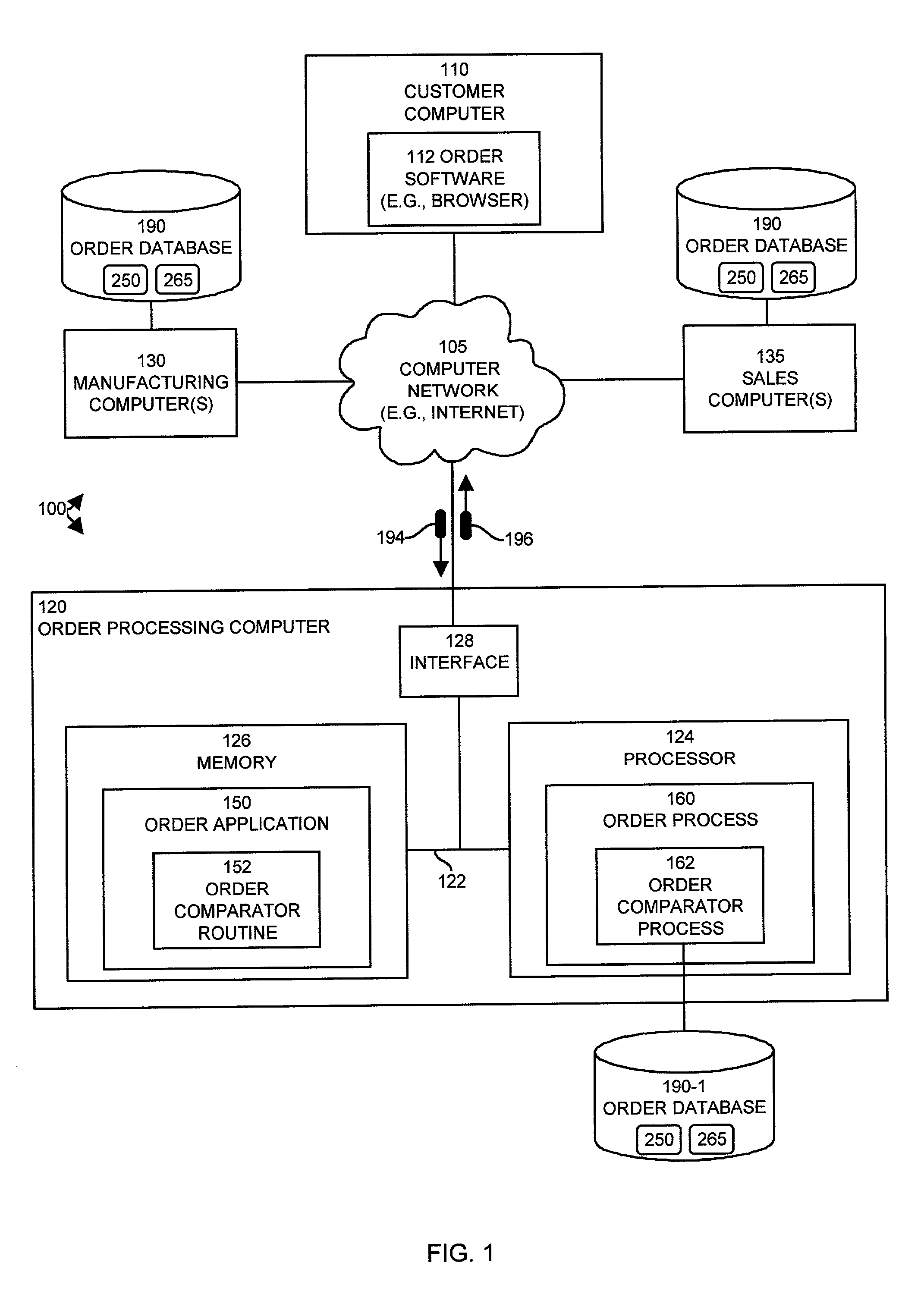

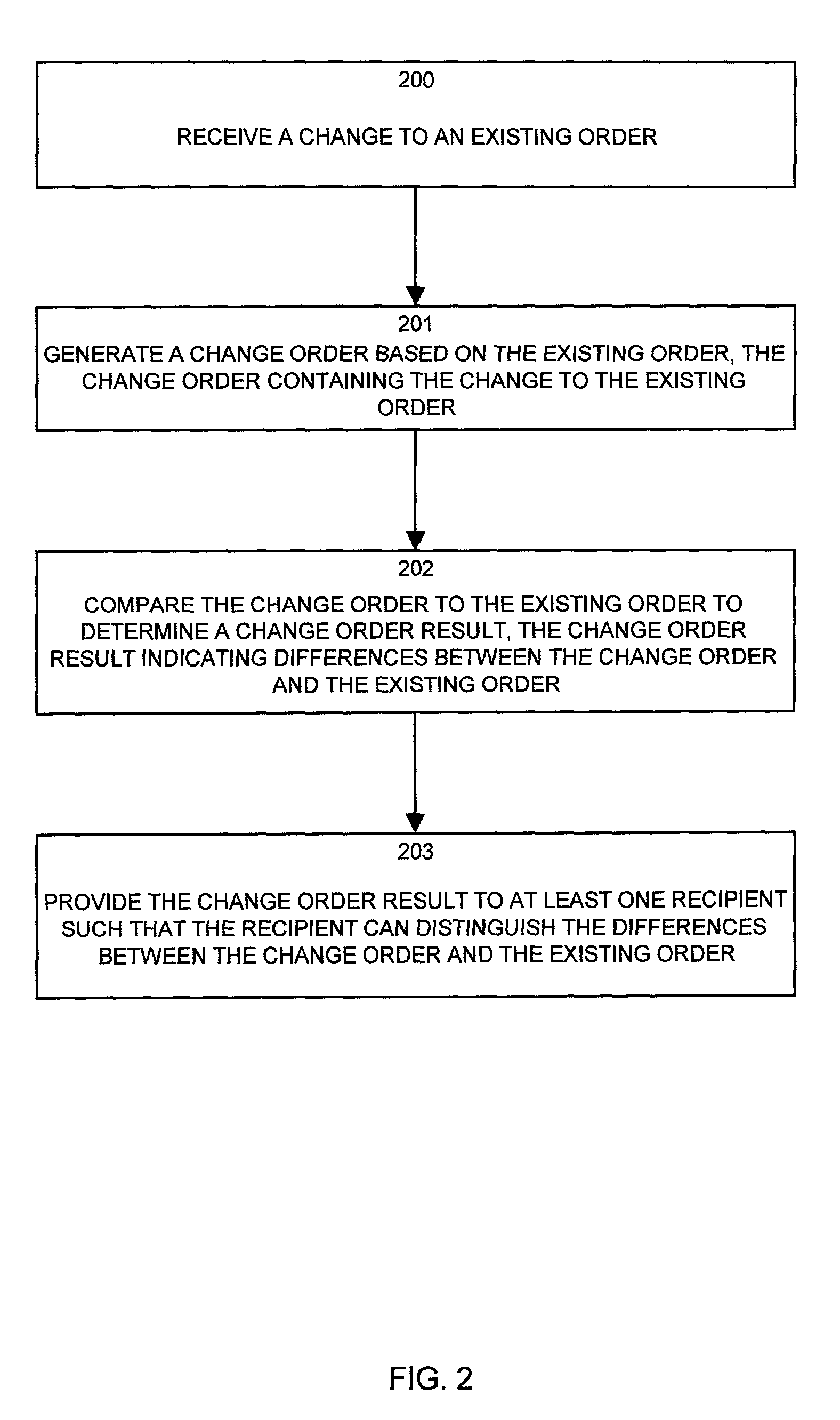

Methods and system for processing changes to existing purchase orders in an object-oriented order processing system

In an order processing system, mechanisms and techniques receive a change to an existing order in the order processing system and generate a change order based on the existing order. The change order includes the change to the existing order. The system can then compare the change order to the existing order to generate change order result that indicates differences between a change order in the existing order. The system then provides the change order result to at least one recipient such that the recipient may distinguish the differences between a change order in the existing order. Since a change to an existing order can result in changes other than those specifically specified in the received change, the system of the invention allows a person making the change to be presented with the change order results that convey all of the changes that result to the existing order.

Owner:CISCO TECH INC

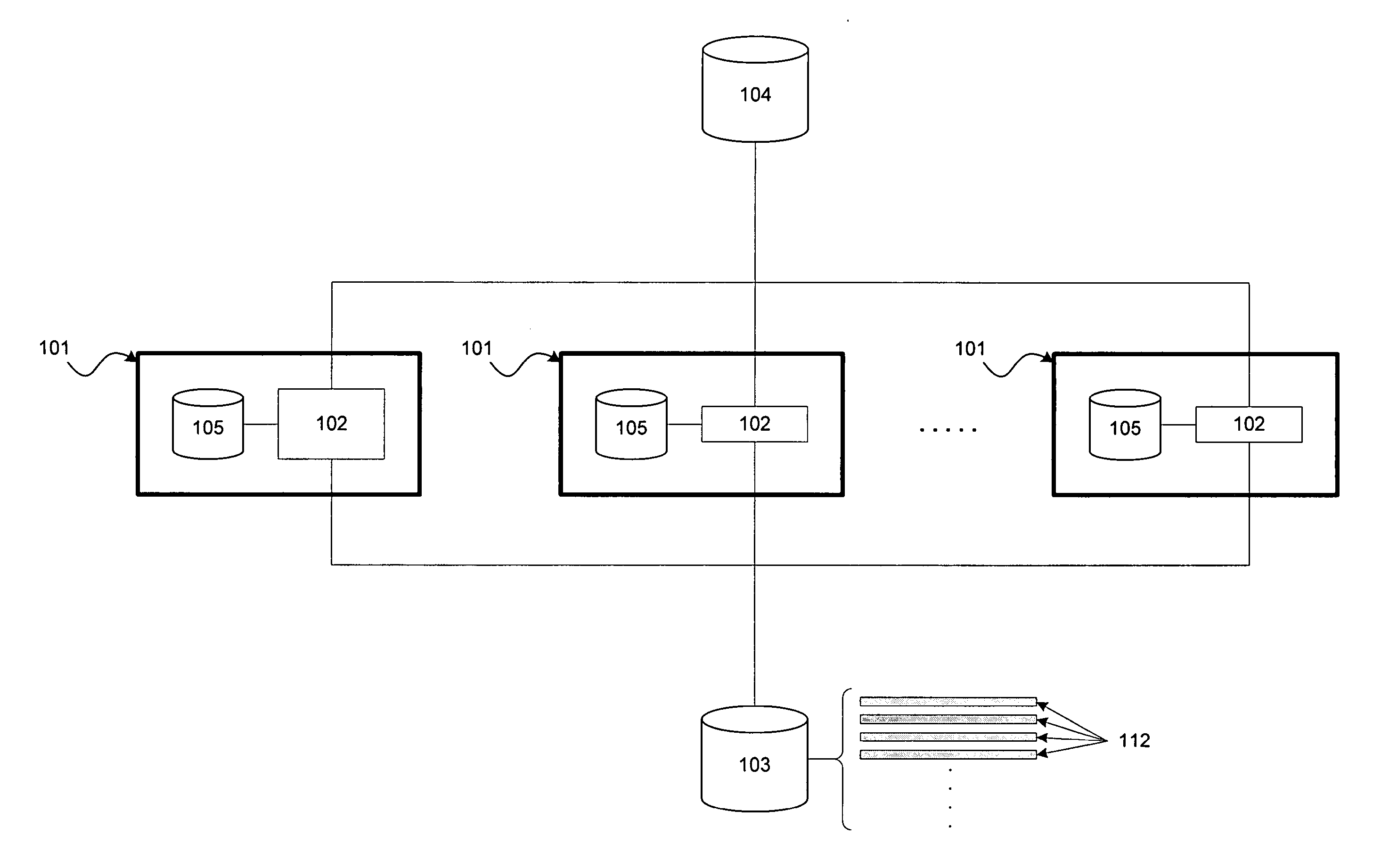

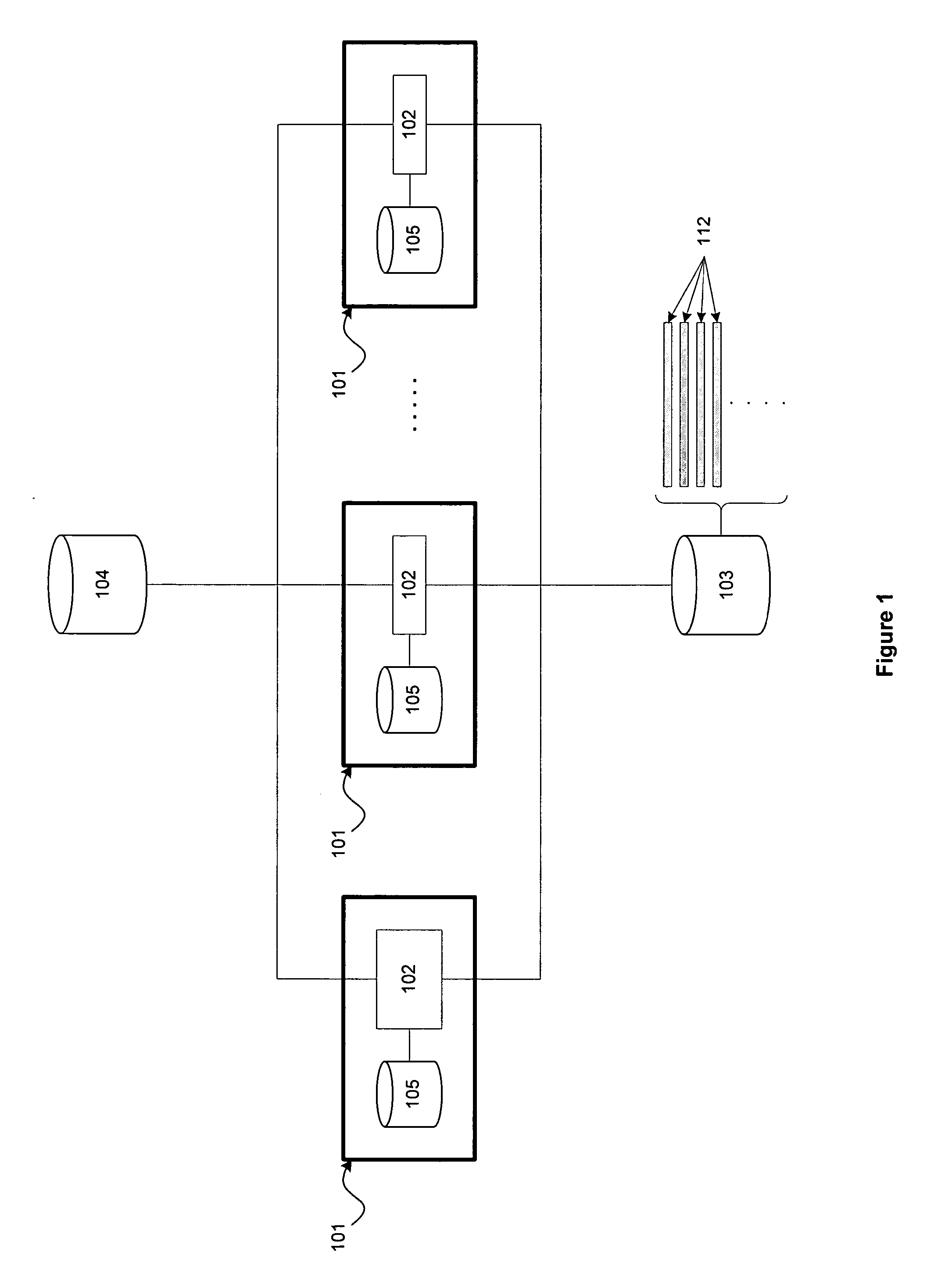

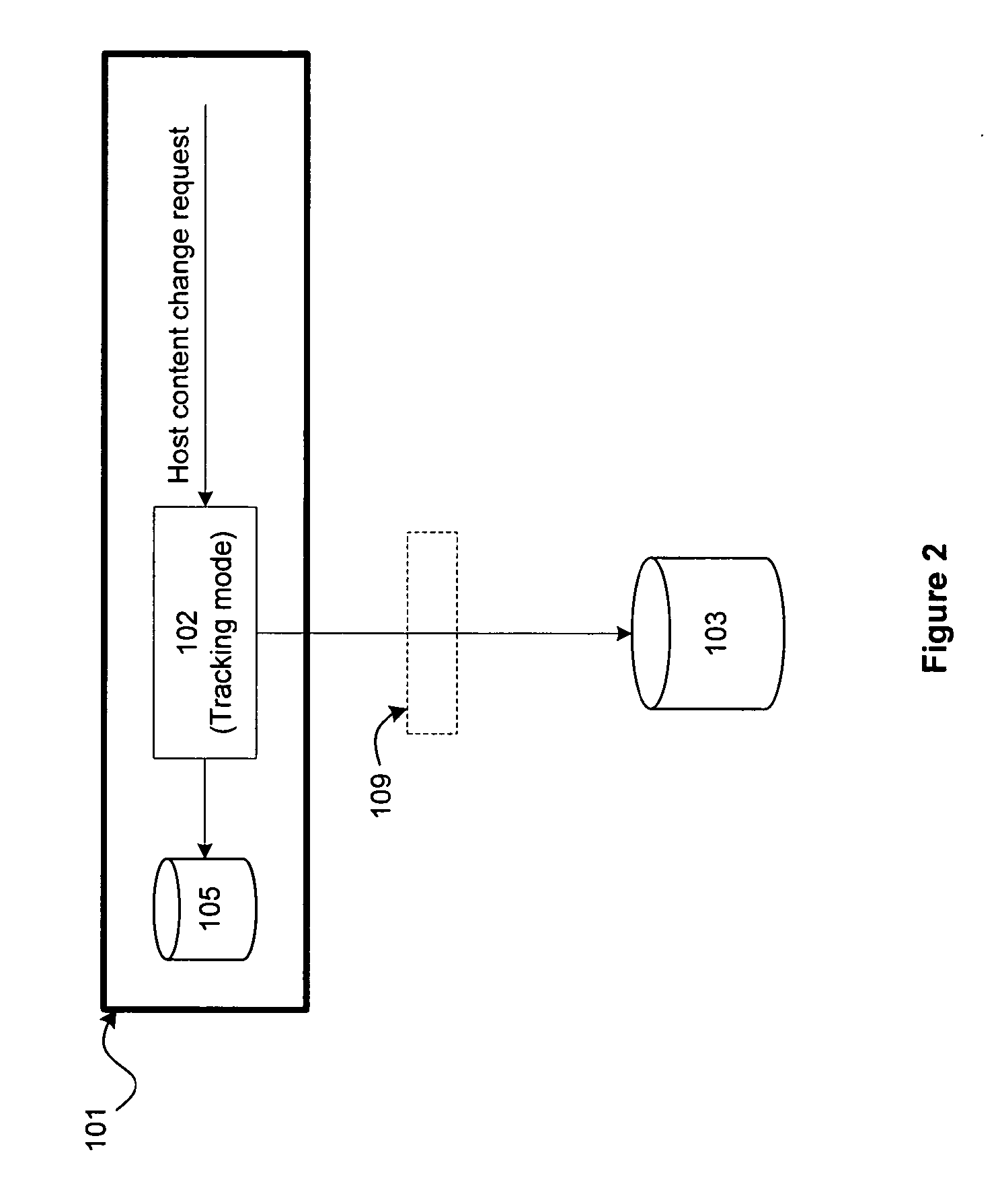

Enforcing alignment of approved changes and deployed changes in the software change life-cycle

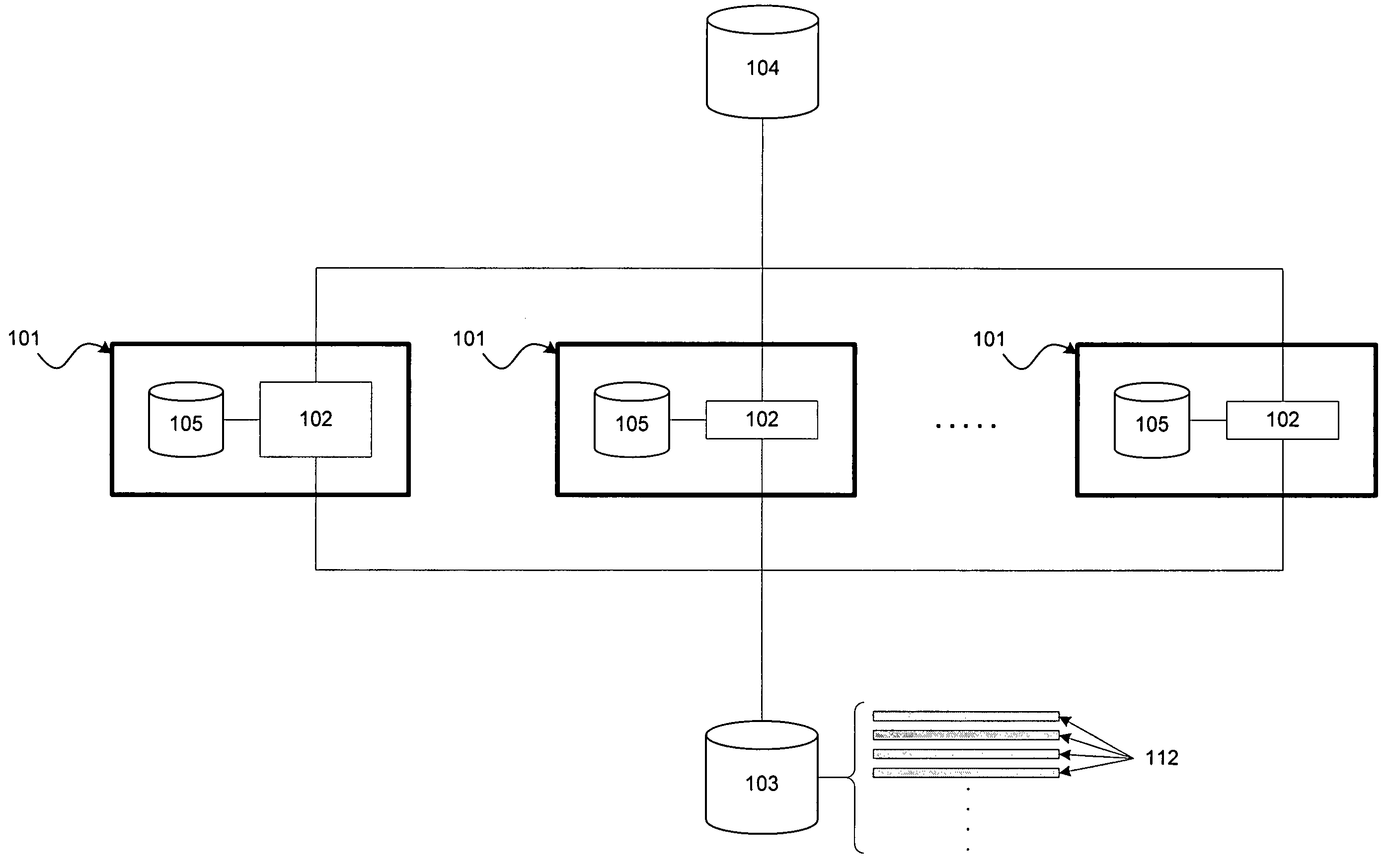

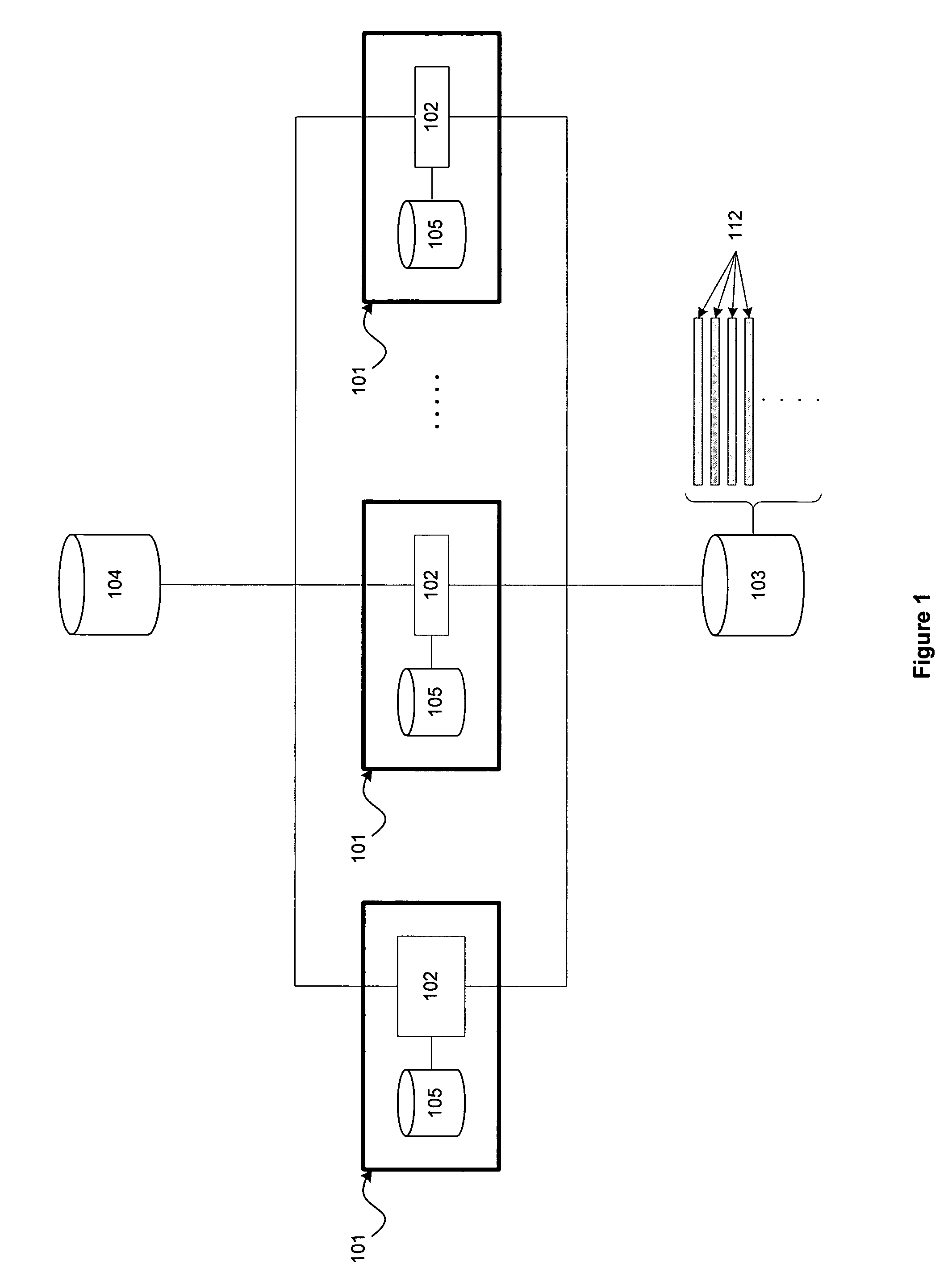

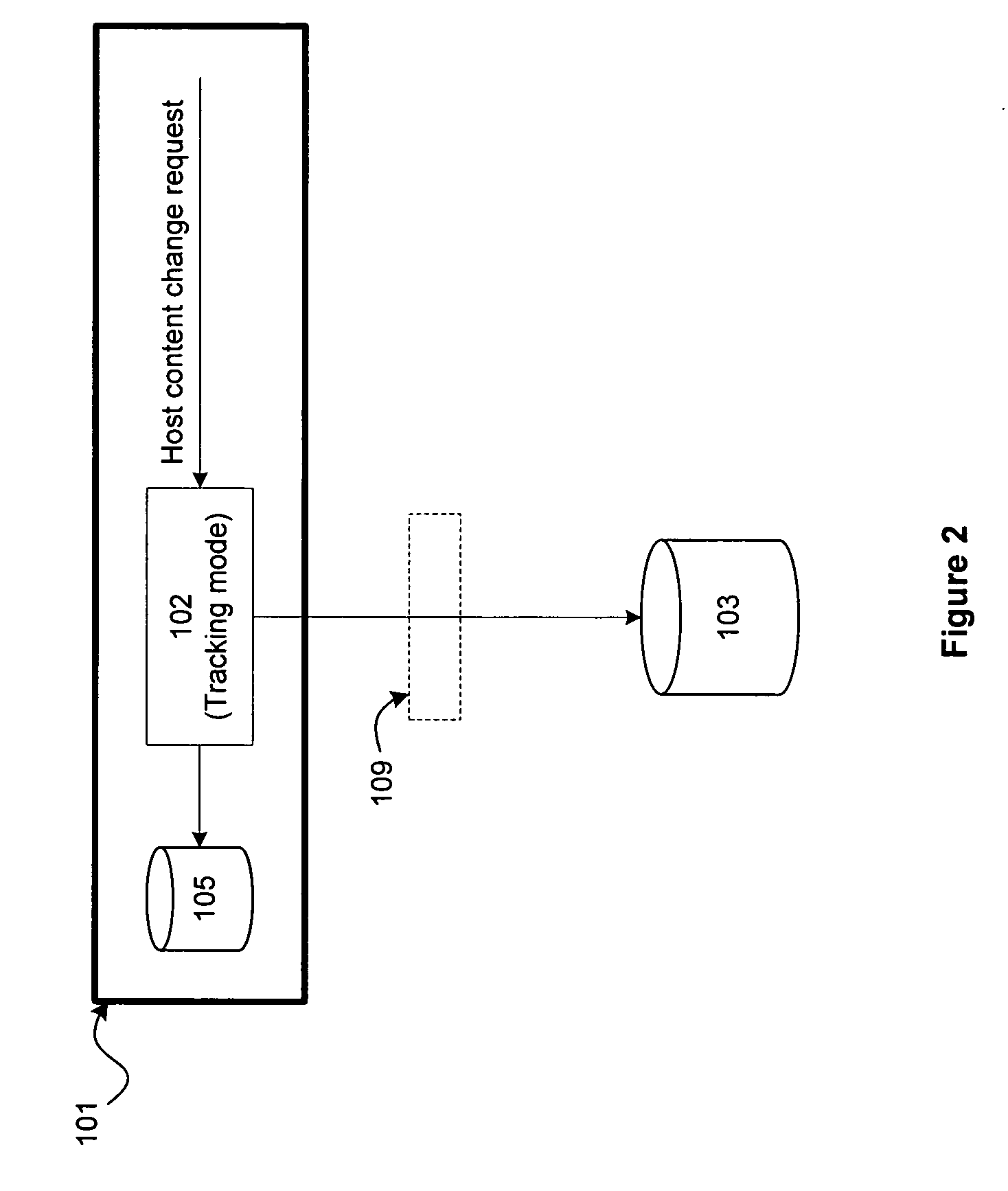

On a host, host content change requests are intercepted in real-time. In a tracking mode, the change requests are logged and allowed to take effect on the host. In an enforcement mode, the change requests are logged and additionally compared against authorized change policies and a determination is made whether to allow the change to take effect or to block the changes, thereby enforcing the authorized change policies on the host. Tracking and enforcement can be done in real-time. In either mode and at any time, the logged changes can be reconciled against a set of approved change orders in order to identify classes of changes, including changes that were deployed but not approved and changes that were approved but not deployed.

Owner:MCAFEE LLC

Enforcing alignment of approved changes and deployed changes in the software change life-cycle

InactiveUS7757269B1Digital data processing detailsUser identity/authority verificationComputer scienceChange request

On a host, host content change requests are intercepted in real-time. In a tracking mode, the change requests are logged and allowed to take effect on the host. In an enforcement mode, the change requests are logged and additionally compared against authorized change policies and a determination is made whether to allow the change to take effect or to block the changes, thereby enforcing the authorized change policies on the host. Tracking and enforcement can be done in real-time. In either mode and at any time, the logged changes can be reconciled against a set of approved change orders in order to identify classes of changes, including changes that were deployed but not approved and changes that were approved but not deployed.

Owner:MCAFEE LLC

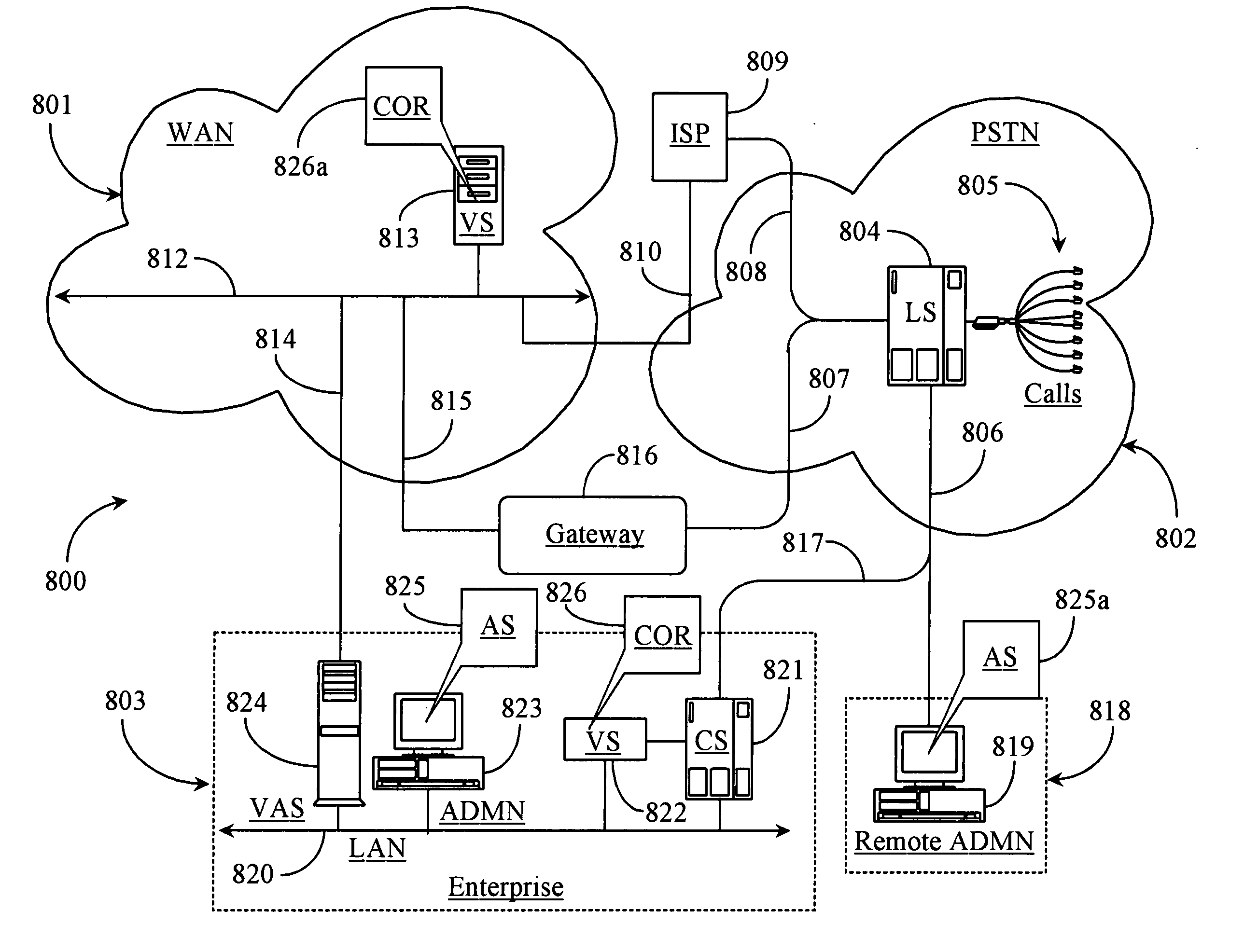

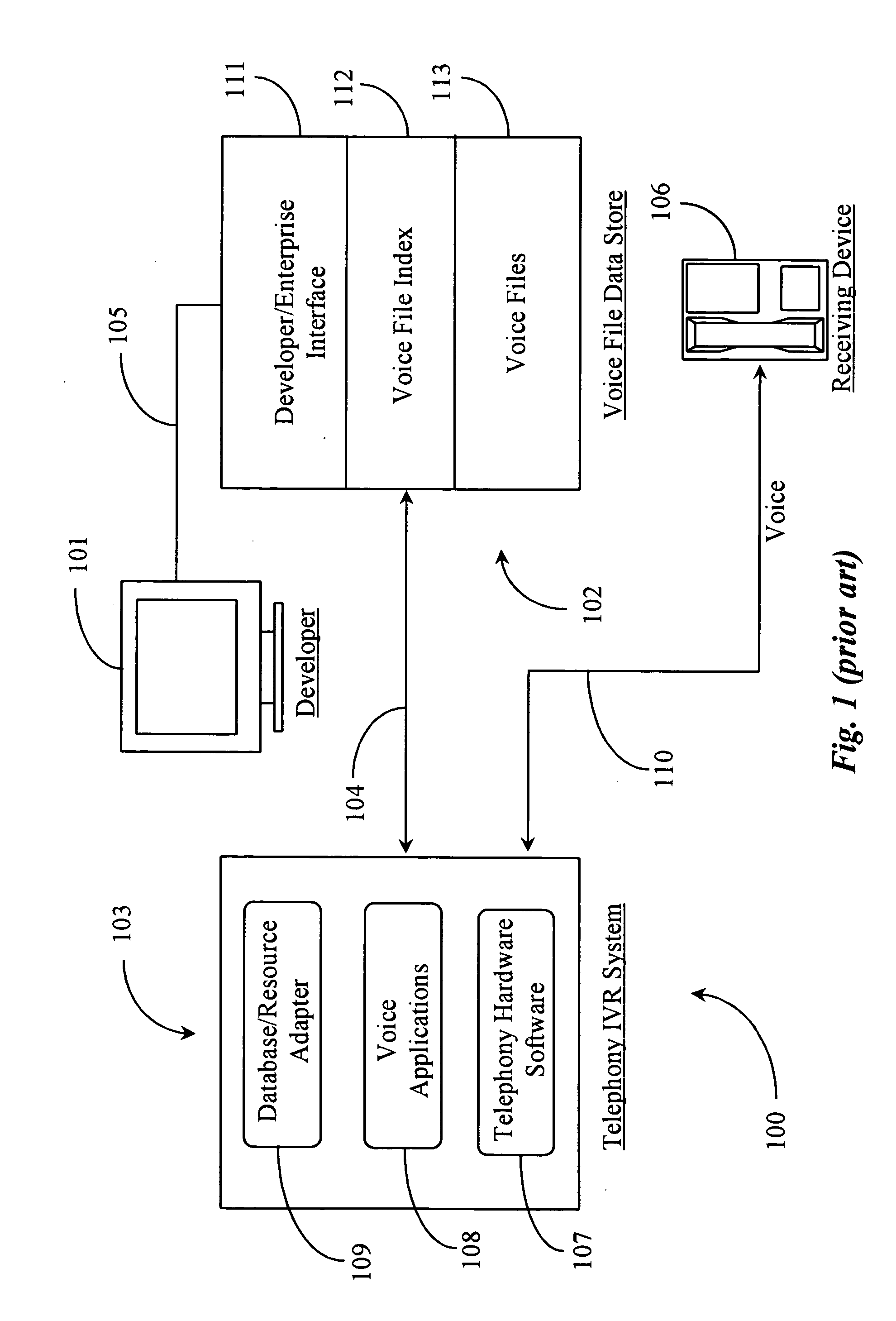

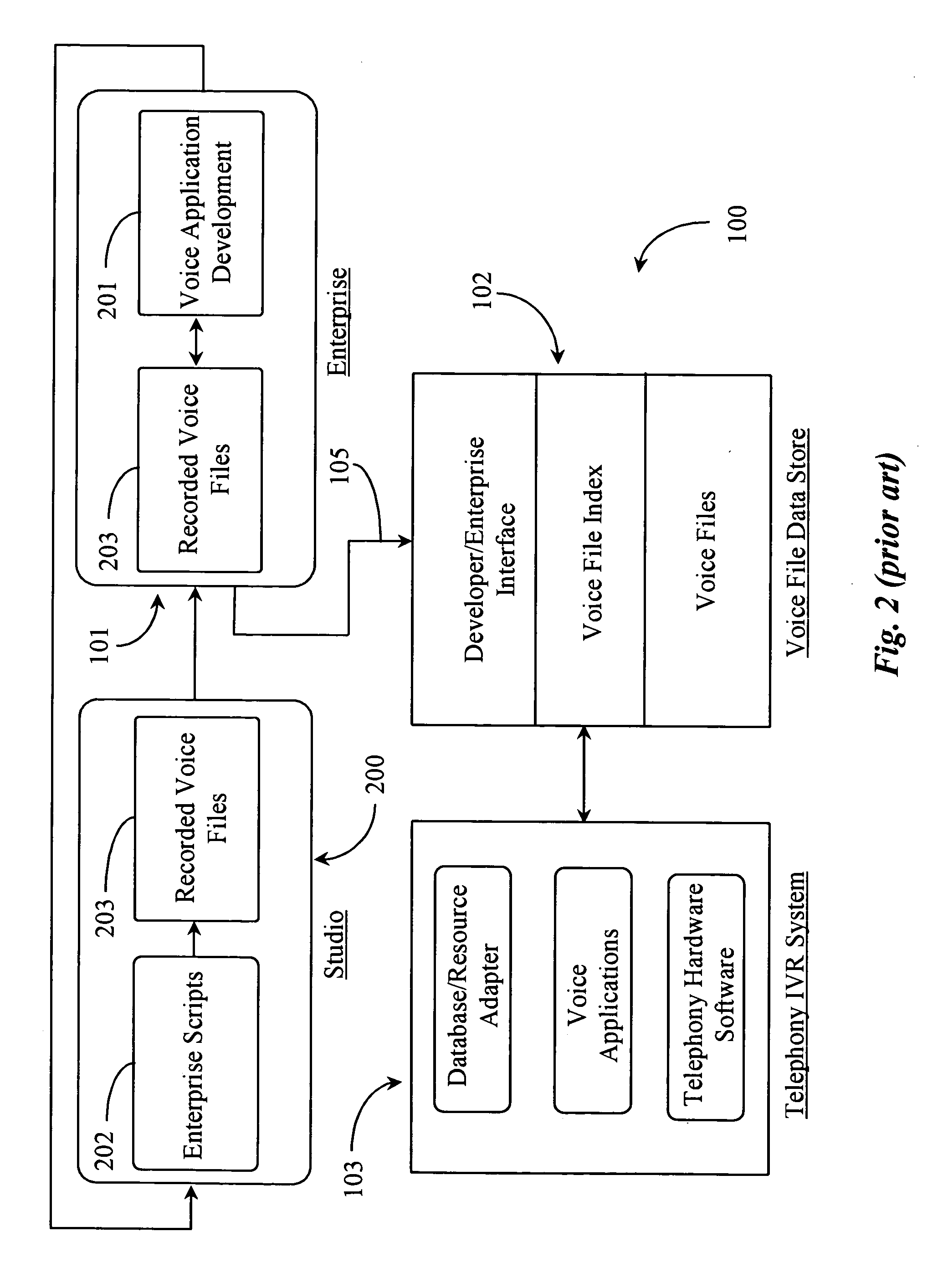

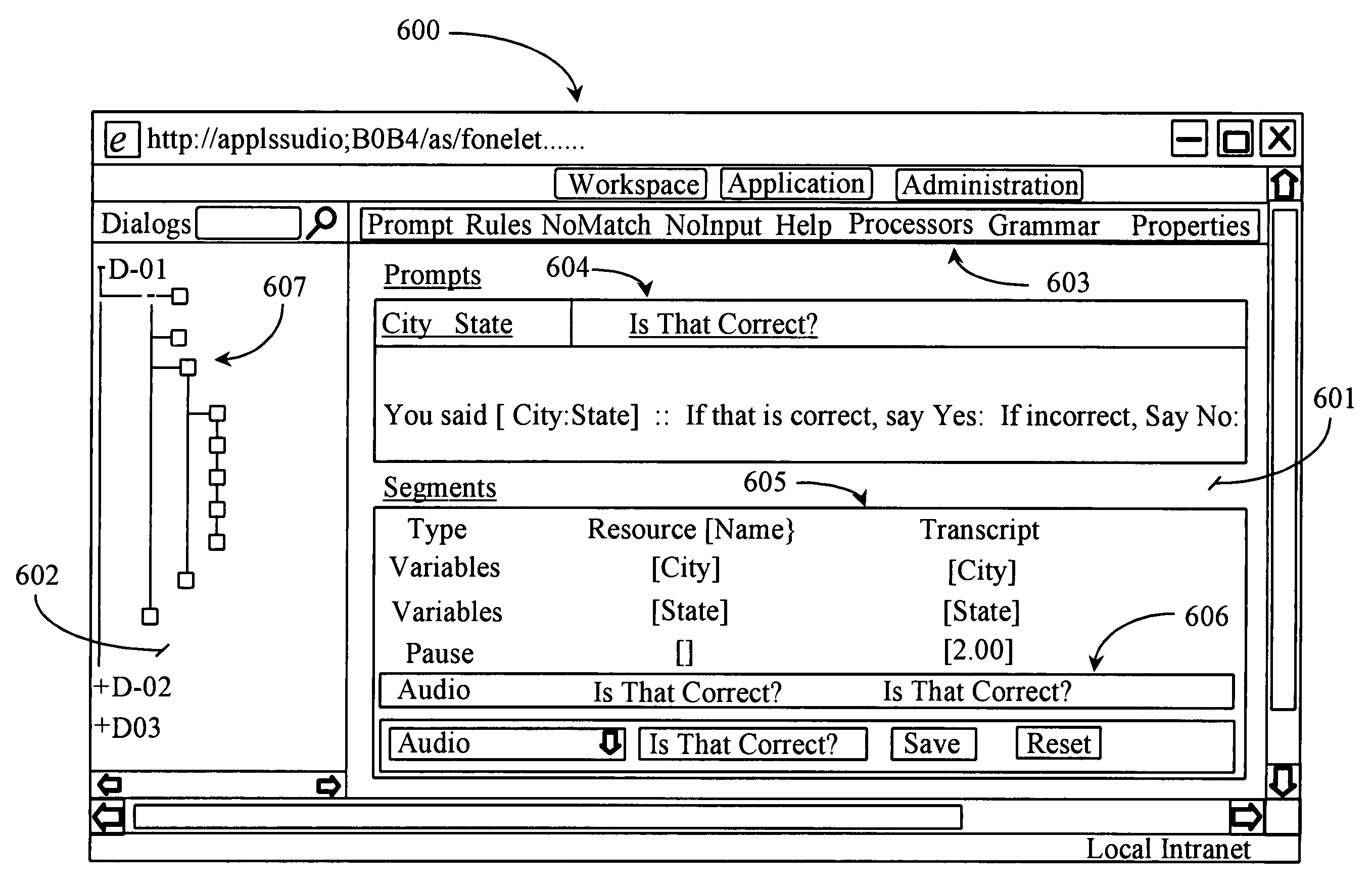

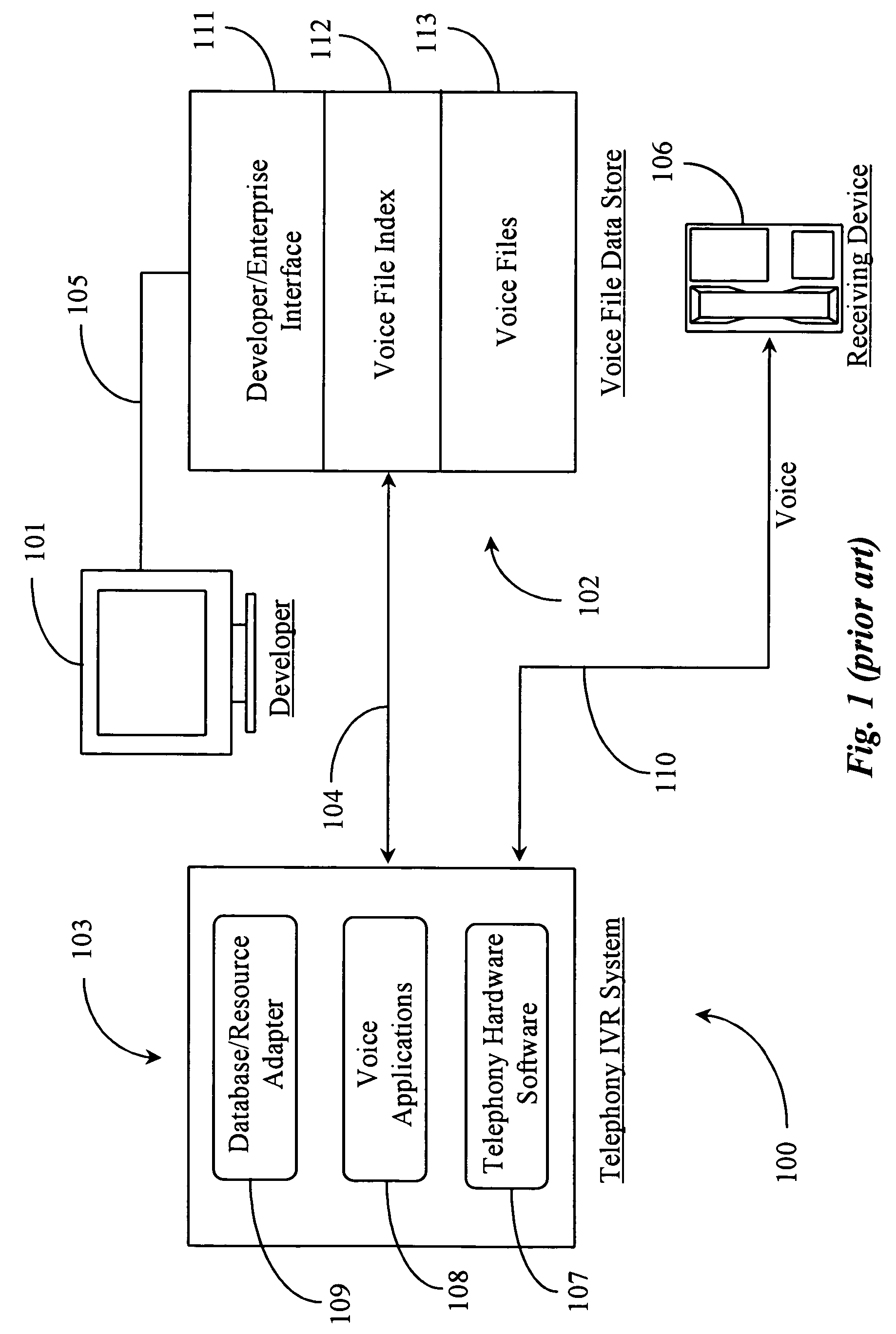

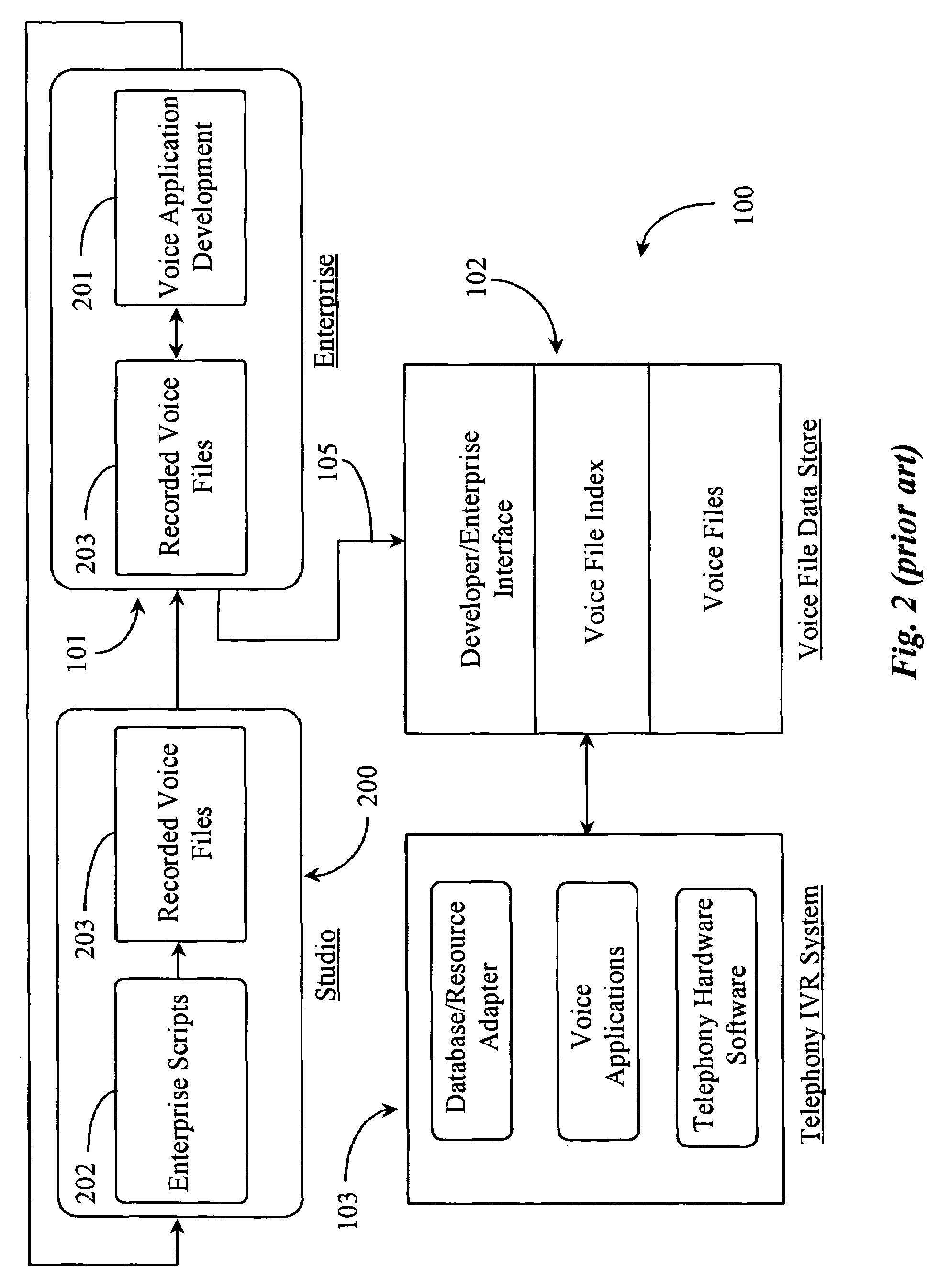

Method for creating and deploying system changes in a voice application system

ActiveUS20050135338A1Special service for subscribersAutomatic call-answering/message-recording/conversation-recordingSpeech applicationsSoftware

A system for configuring and implementing changes to a voice application system has a first software component and host node for configuring one or more changes; a second software component and host node for receiving and implementing the configured change or changes; and a data network connecting the host nodes. In a preferred embodiment, a pre-configured change-order resulting from the first software component and host node is deployed after pre-configuration, deployment and execution thereof requiring only one action.

Owner:HTC CORP

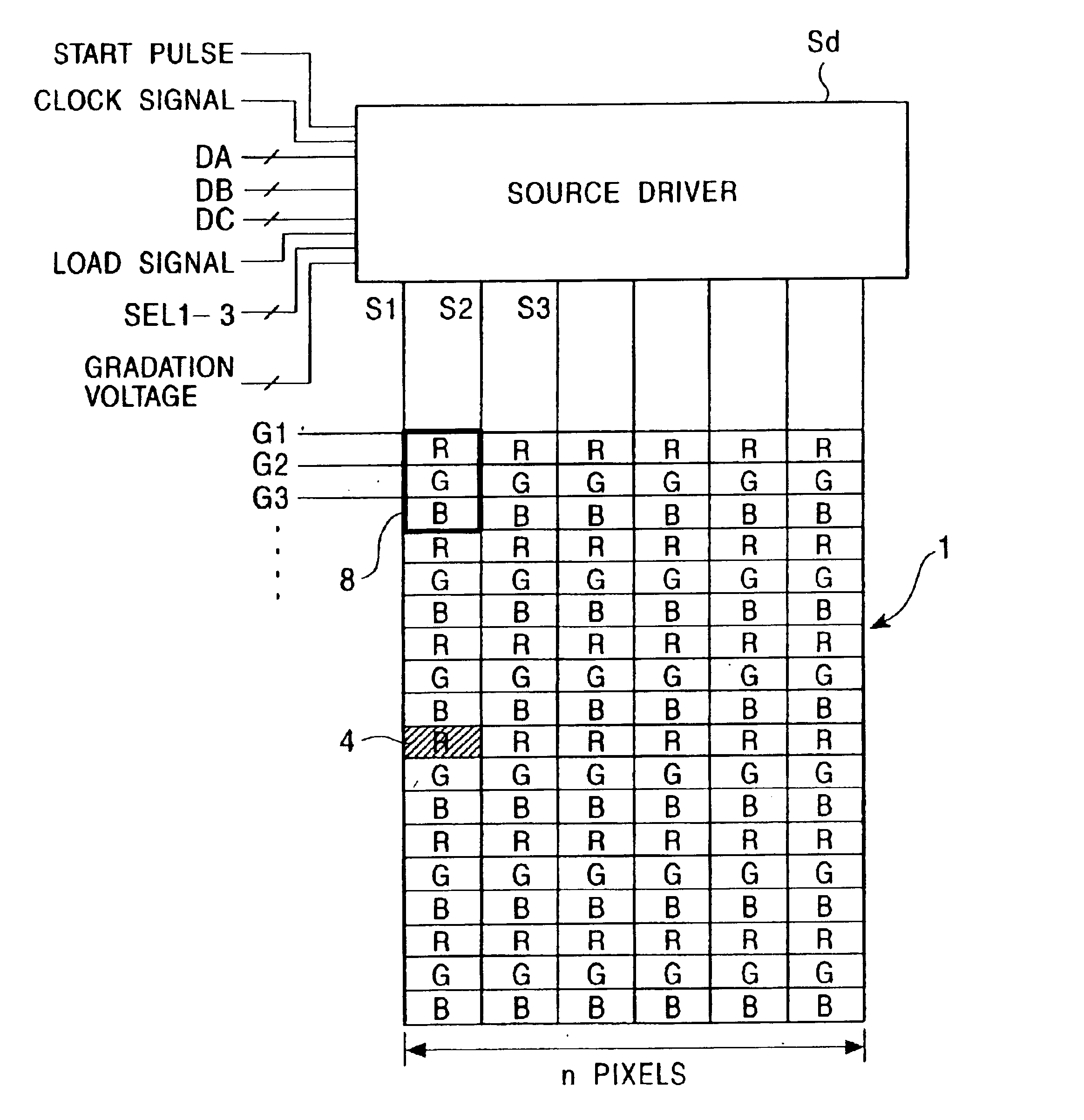

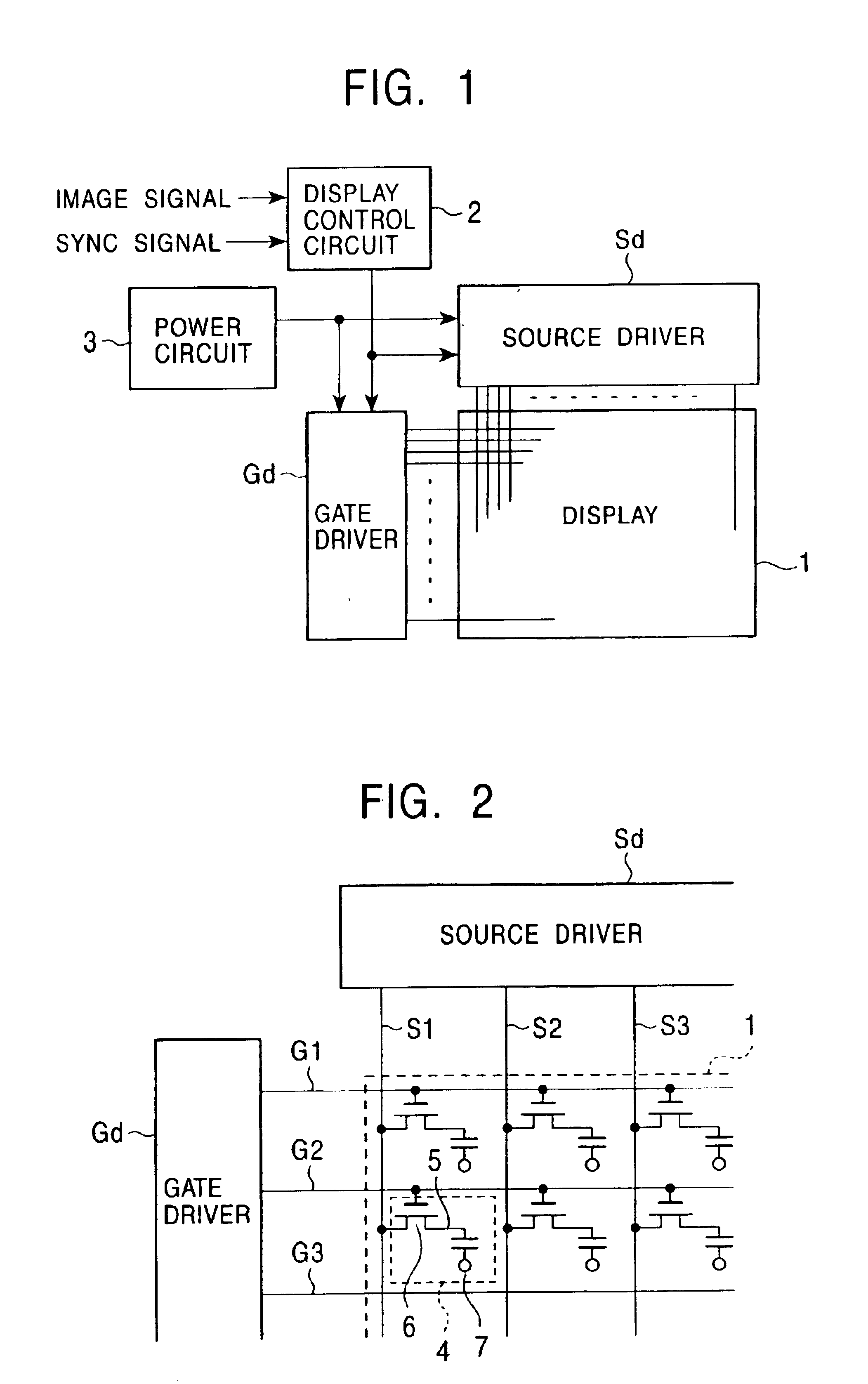

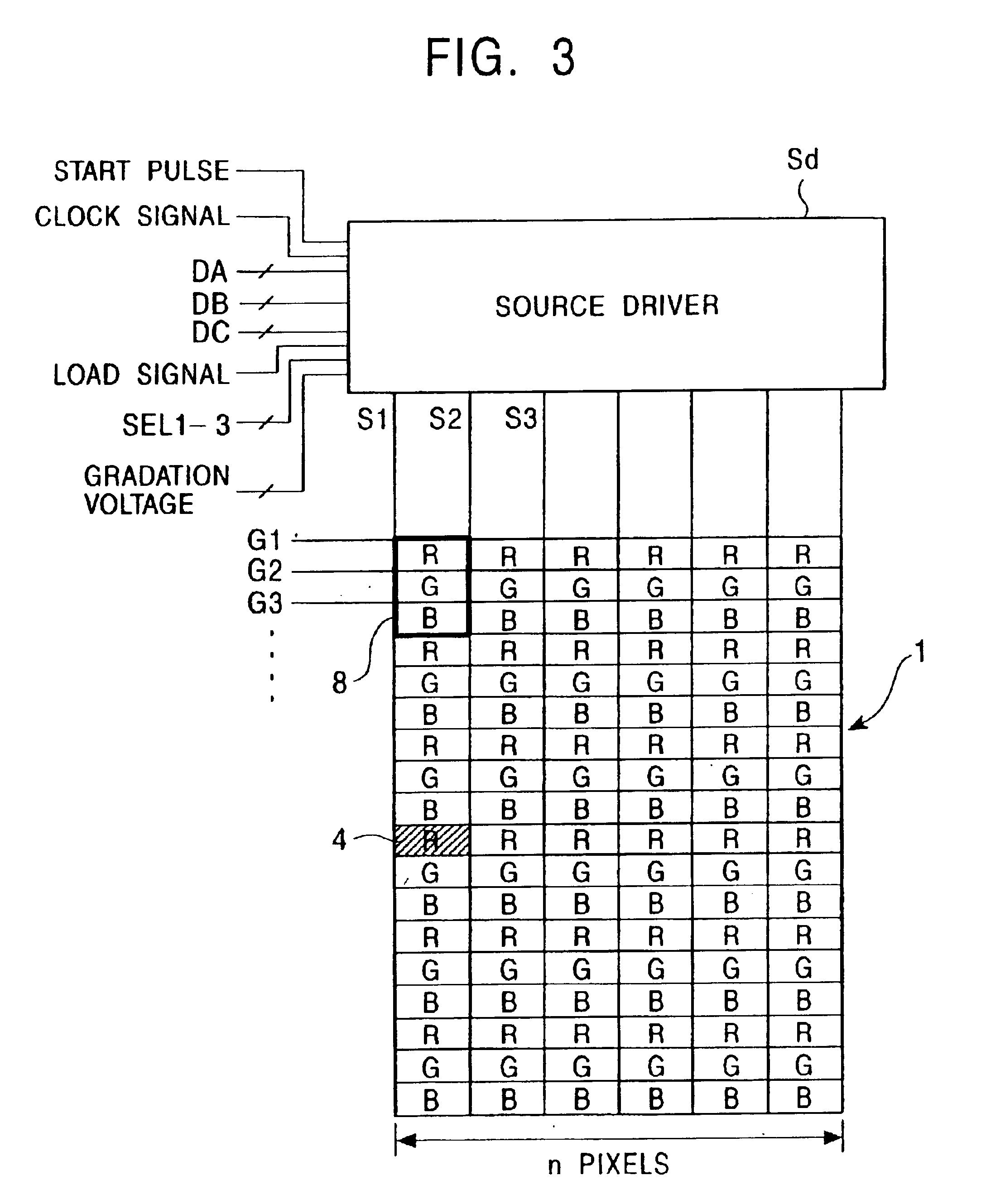

Image-signal driving circuit eliminating the need to change order of inputting image data to source driver

InactiveUS6922189B2Low costReduce power consumptionCathode-ray tube indicatorsPicture reproducersData transformationProcessor register

An image-signal driving circuit inputs serial sequences of image data DA, DB, and DC for key or primary colors, converts the image data into parallel data for displaying one line on a display, and supplies the parallel data to the display. The image-signal driving circuit comprises a register that inputs sequences of image data for the number of primary colors, stores the image data in order, and outputs the image data as parallel data; a latch that latches the sequences of image data for the number of primary colors output from the register as the parallel data; and a selector that selects one sequence of image data from the sequences of image data for the number of primary colors latched by the latch in predetermined order, and supplies the image data to the display.

Owner:ONANOVICH GROUP

Method for creating and deploying system changes in a voice application system

ActiveUS7206391B2Special service for subscribersAutomatic call-answering/message-recording/conversation-recordingSpeech applicationsSoftware

A system for configuring and implementing changes to a voice application system has a first software component and host node for configuring one or more changes; a second software component and host node for receiving and implementing the configured change or changes; and a data network connecting the host nodes. In a preferred embodiment, a pre-configured change-order resulting from the first software component and host node is deployed after pre-configuration, deployment and execution thereof requiring only one action.

Owner:HTC CORP

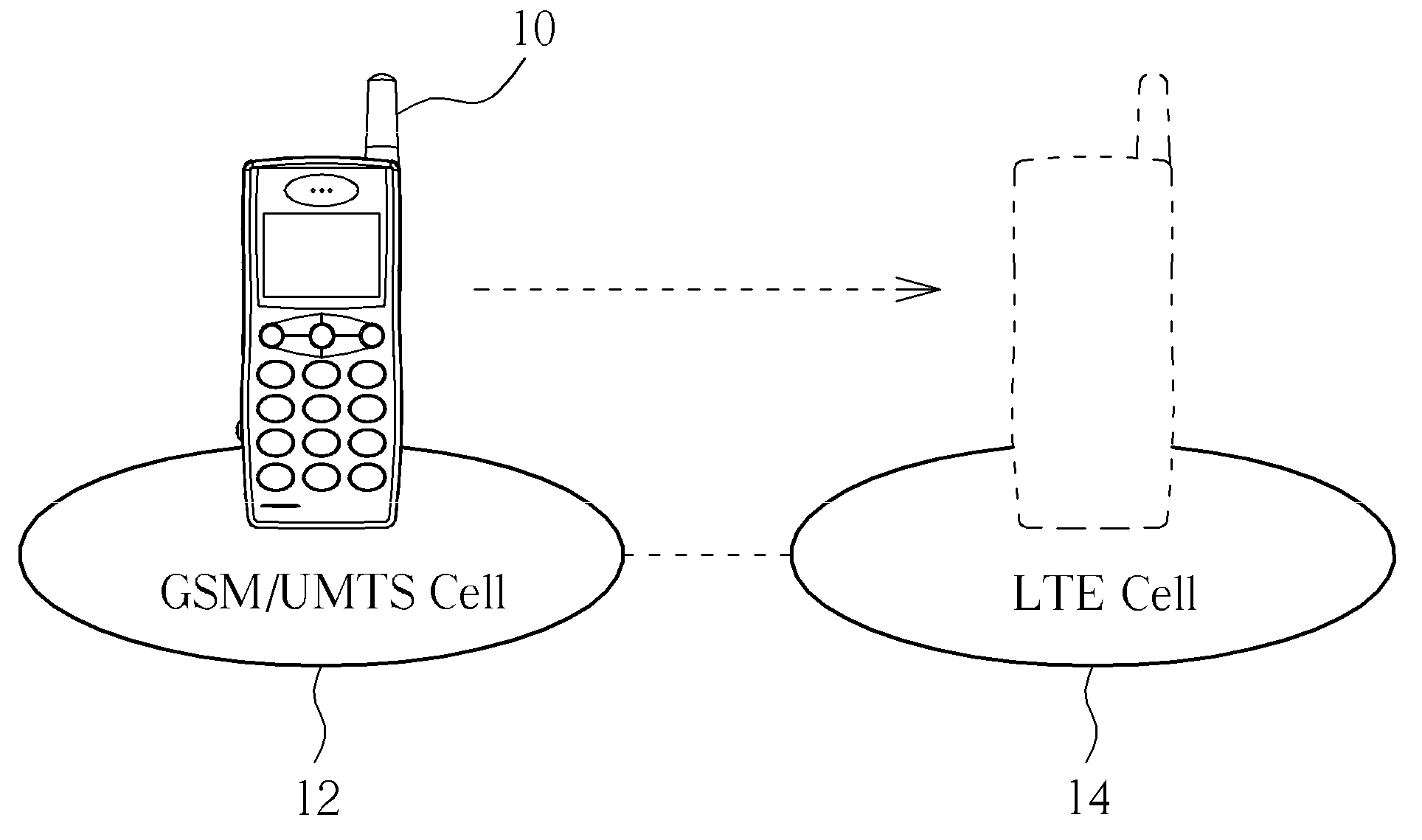

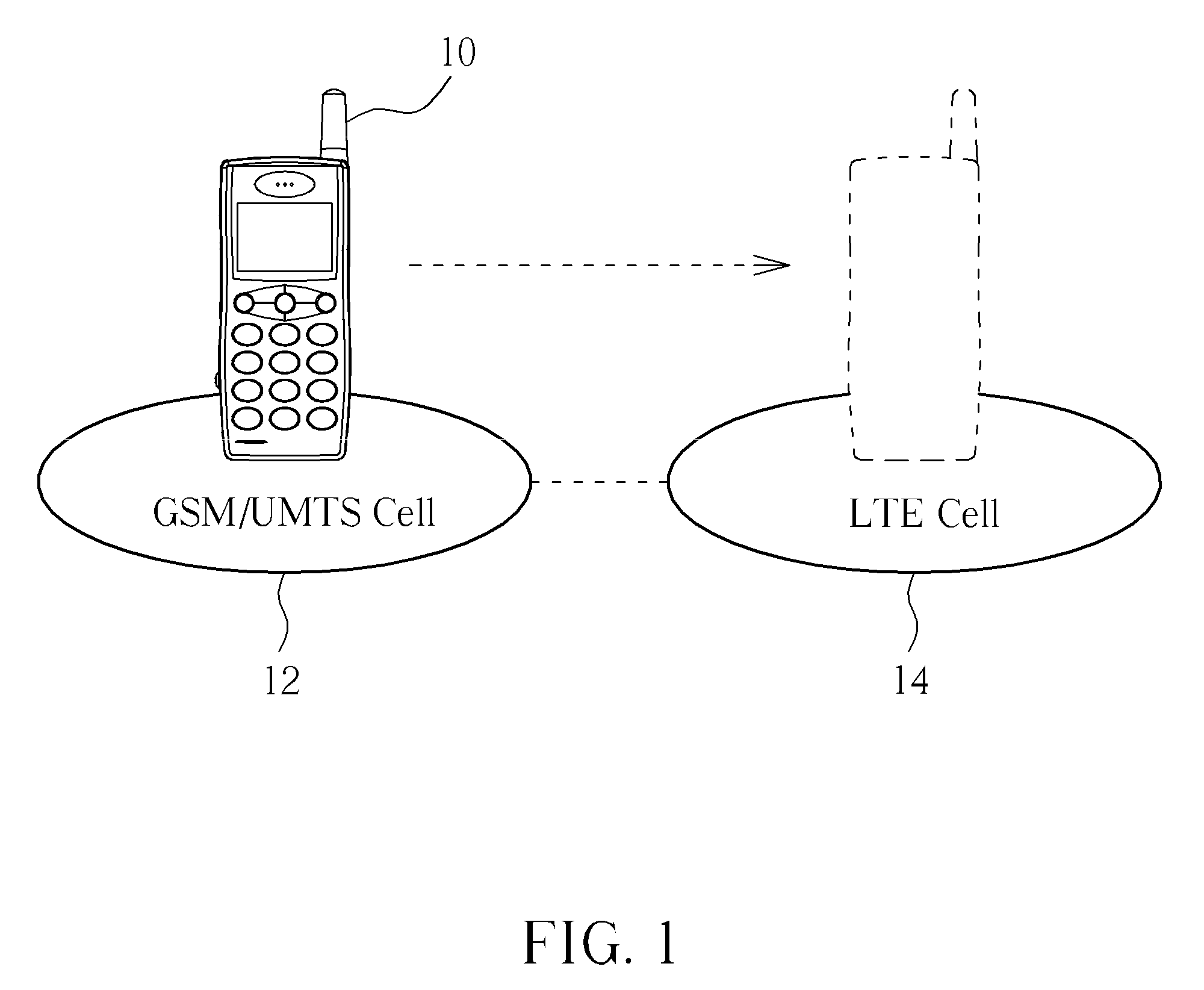

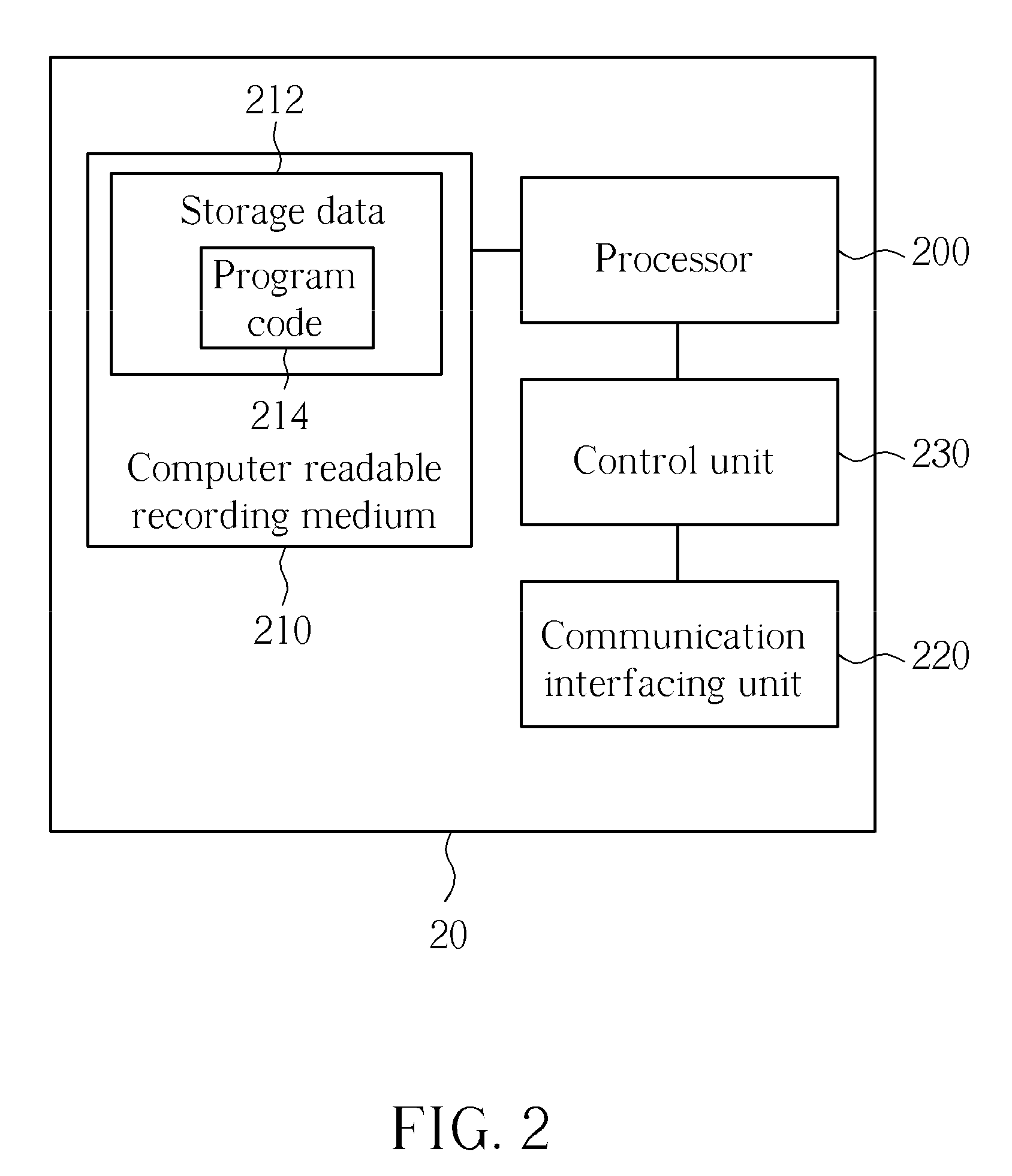

Method of Handling Cell Change and Related Apparatus

A communication device of handling cell change for a mobile device includes performing a cell change order procedure from a source cell of a first radio access technology to a target cell of a second radio access technology, establishing a returning condition corresponding to access barring of the target cell, and determining that the cell change order procedure is failed when the returning condition is conformed.

Owner:HTC CORP

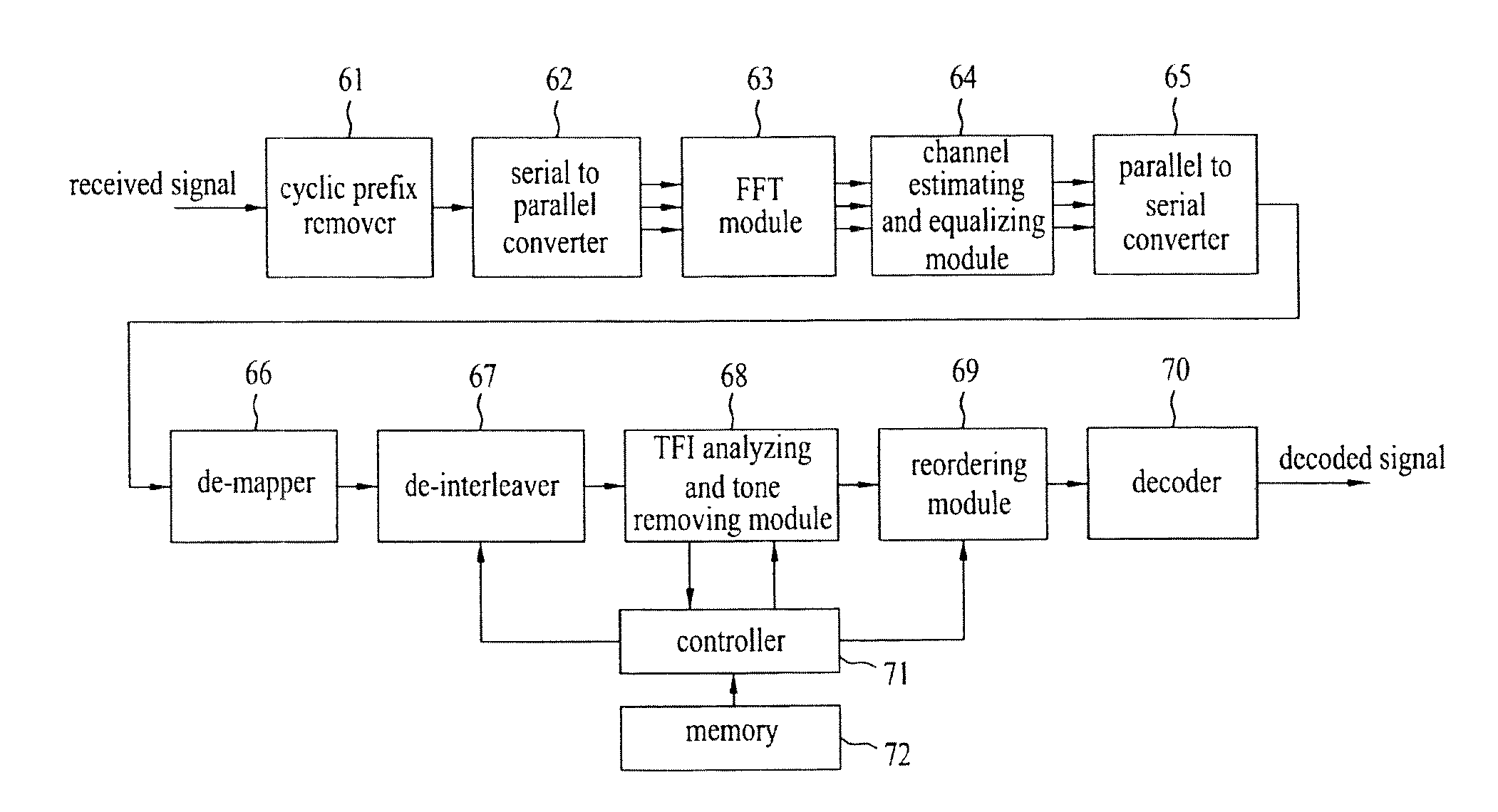

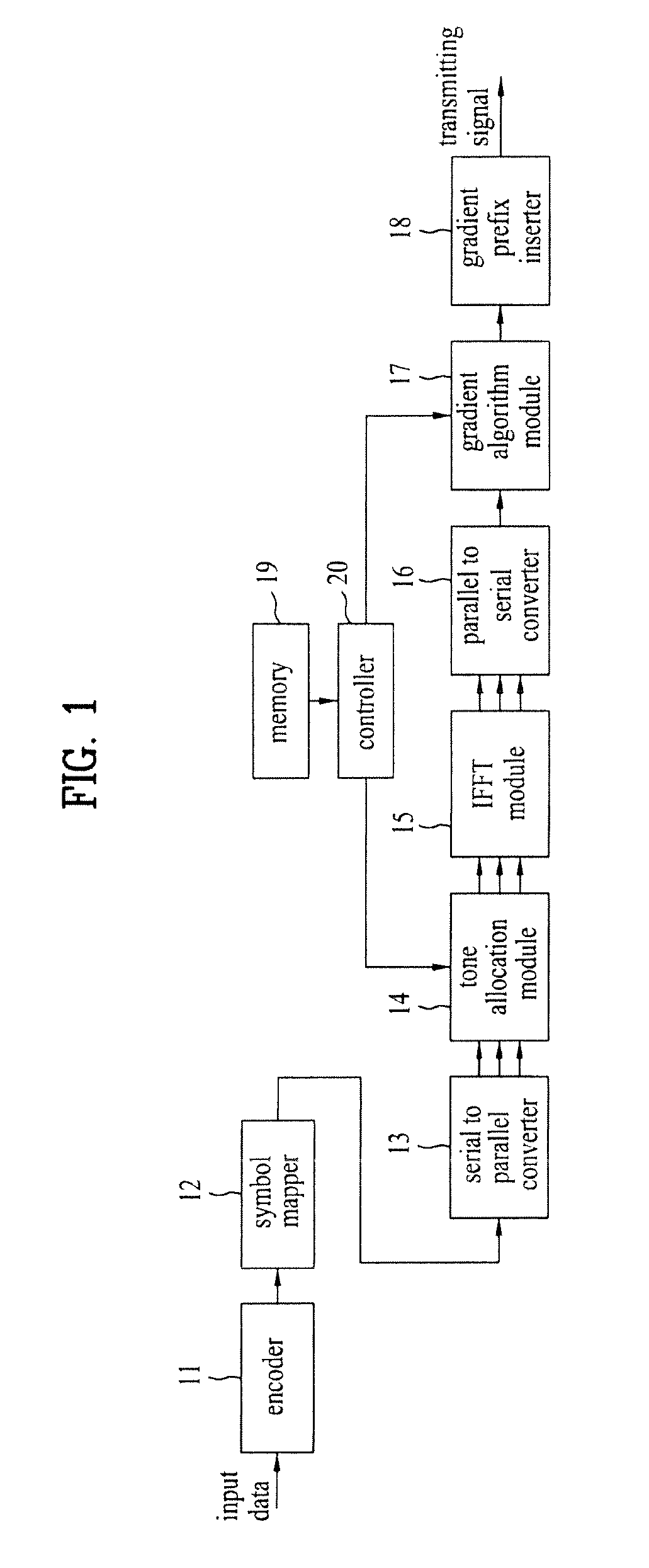

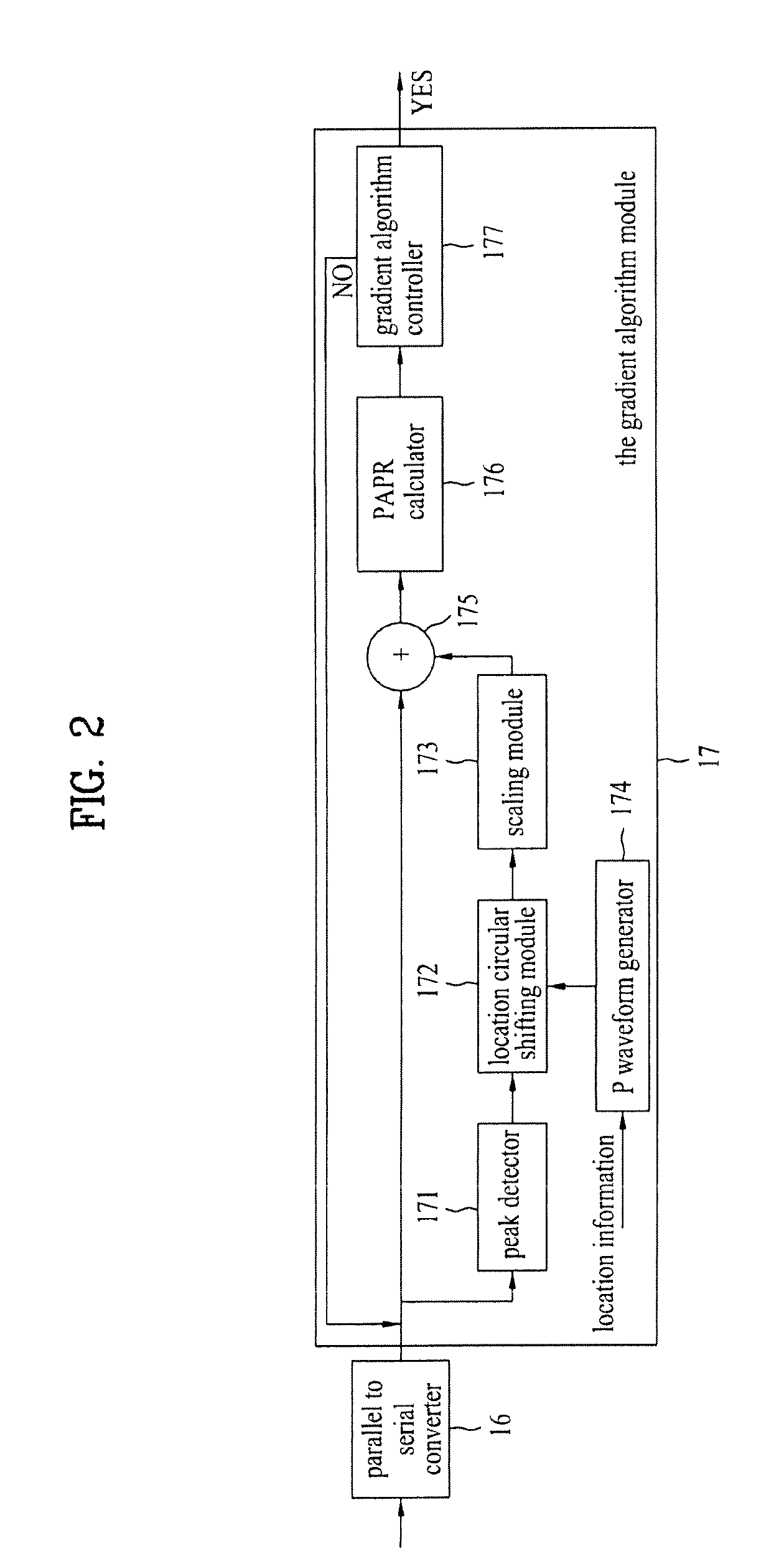

Transmitting apparatus and method using tone reservation in OFDM system

The present invention relates to an apparatus and a method for transmitting orthogonal frequency division multiplexing (OFDM) signals using a tone reservation scheme. Preferably, the present invention comprises an inserter to add a transmit format indicator (TFI) to an encoded packet, the TFI including a tone reservation rate for a peak to average power ratio (PAPR) control; a reordering module to change order of bits included in the encoded packet by discriminating information bits and parity bits of the encoded packet; a zero replacement module to replace a portion of the parity bits with at least one bit set for a PAPR control;’ a transmitter to transmit the replaced output using a plurality of orthogonal sub-carriers; and a controller to control the tone reservation rate based on status of received signals.

Owner:LG ELECTRONICS INC

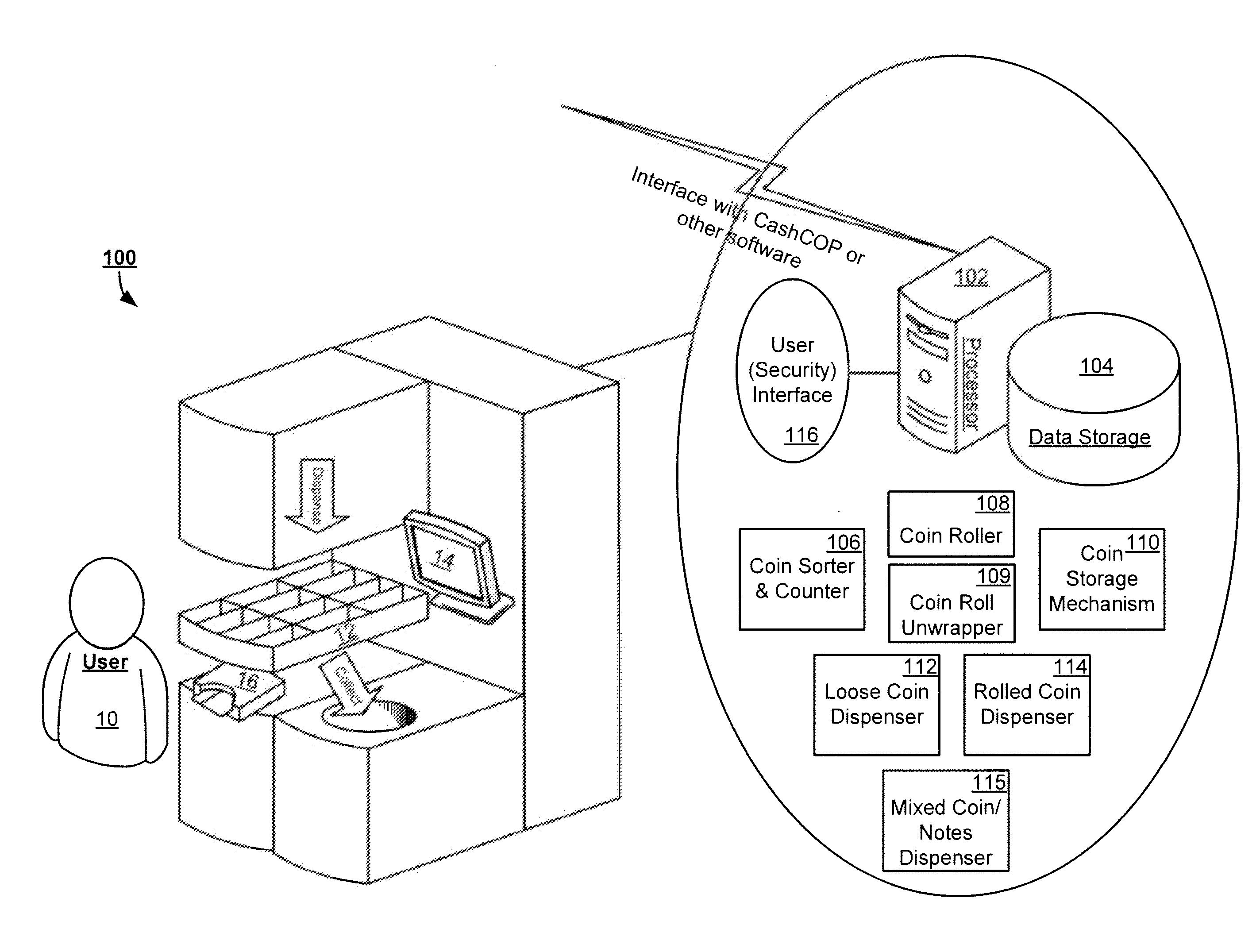

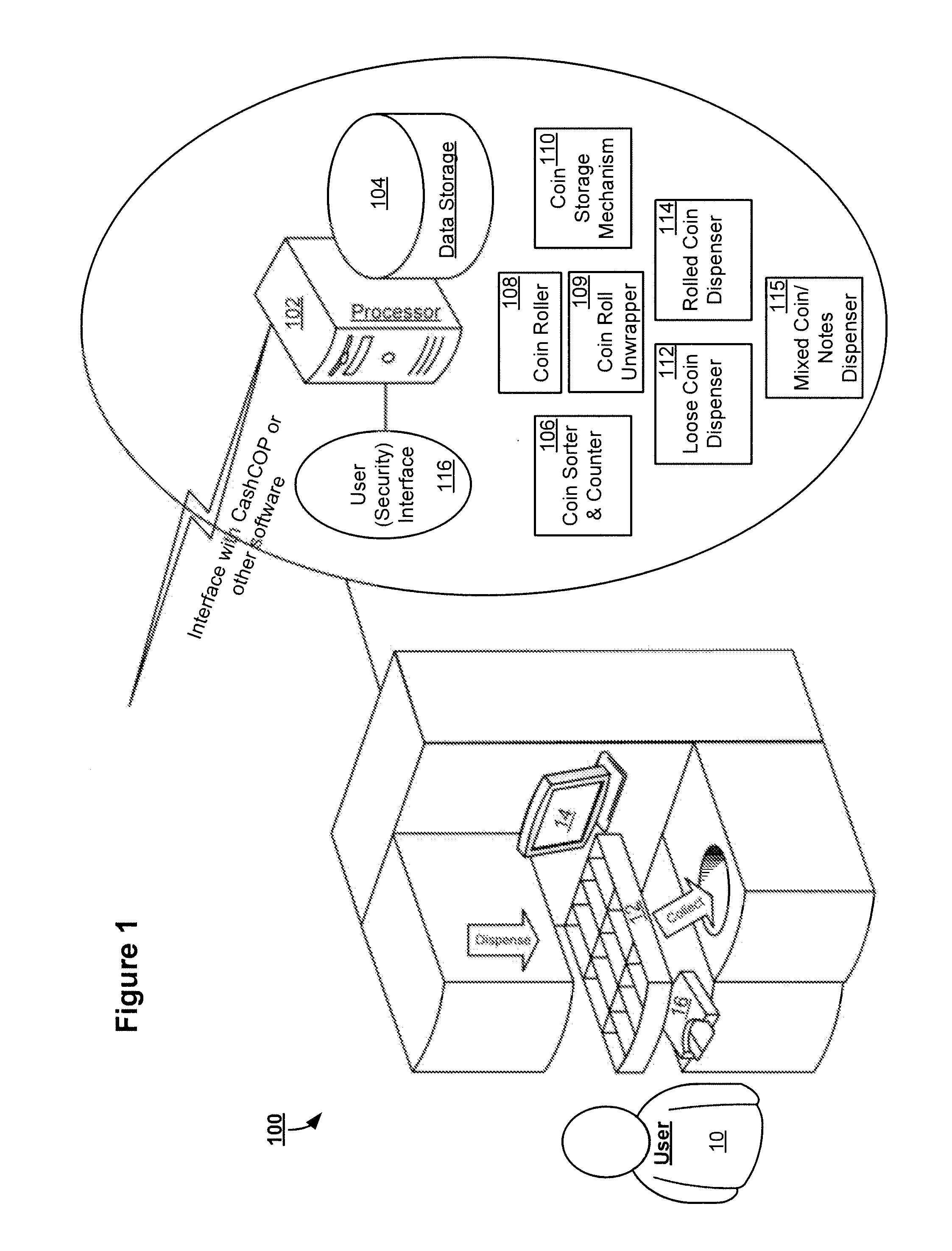

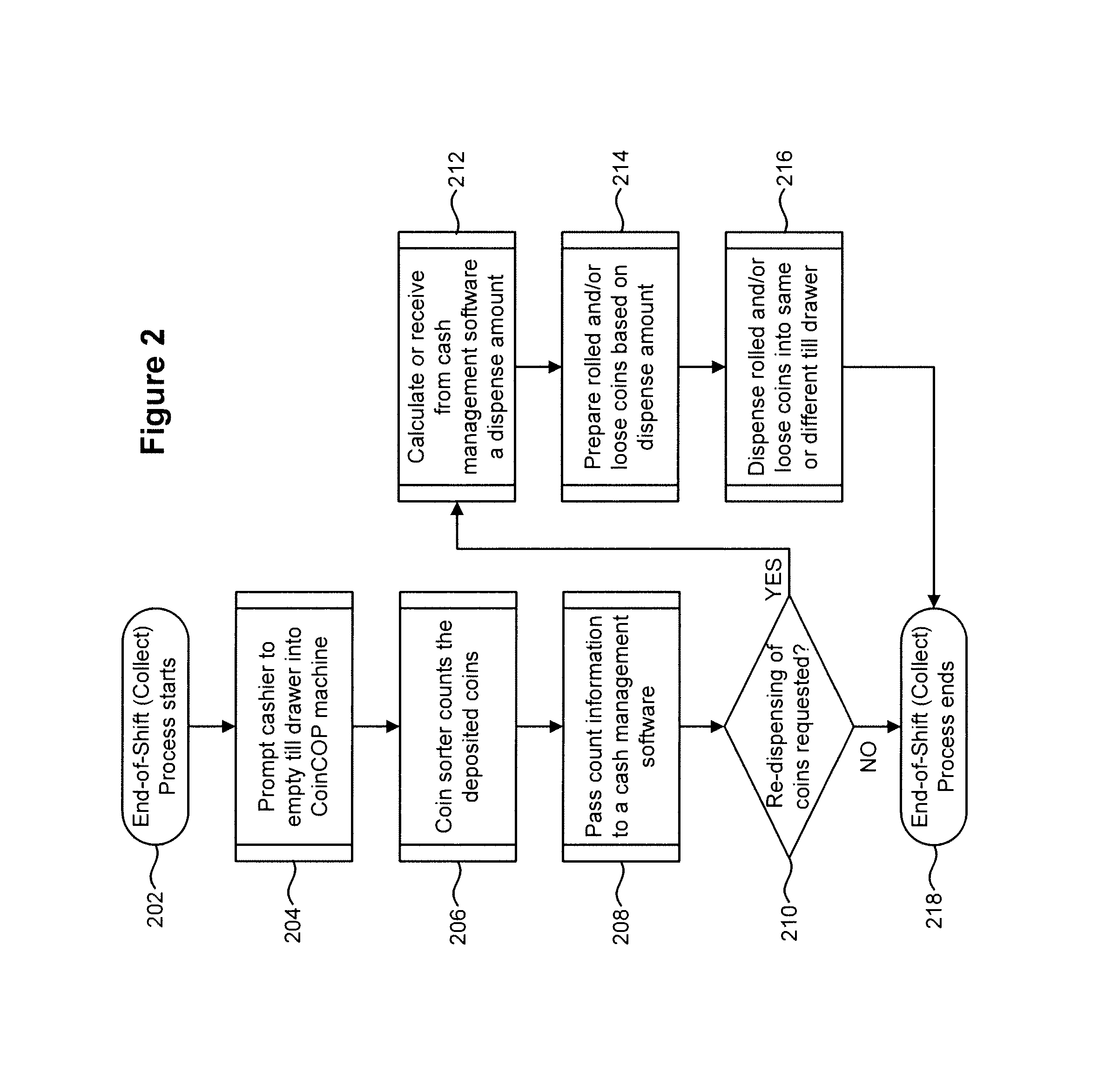

Methods and apparatus for managing cash items

Methods and apparatus for managing cash items are disclosed. For example, a predetermined or calculated amount / composition of rolled coins may be dispensed based on a count of loose coins, or a mixture of rolled and / or loose coins may be dispensed based on a command from a cash management software program or module. Coins from an end of day deposit may be utilized to calculate a dispense requirement for start-of-day till preparation. A self-service device such as a kiosk, self-checkout lane, or payment island may be configured to also perform cash management tasks and / or to transmit an output to a back office and / or bank to receive provisional credit. Change orders, bank deposits, and / or other cash service tasks may be automated in various aspects including, for instance, scheduling, preparation of cash items (e.g., with predetermined or optimized amount / composition), central management of business rules, and reconciliation of fulfillment with invoices or SLAs.

Owner:MCCORMICK IAN

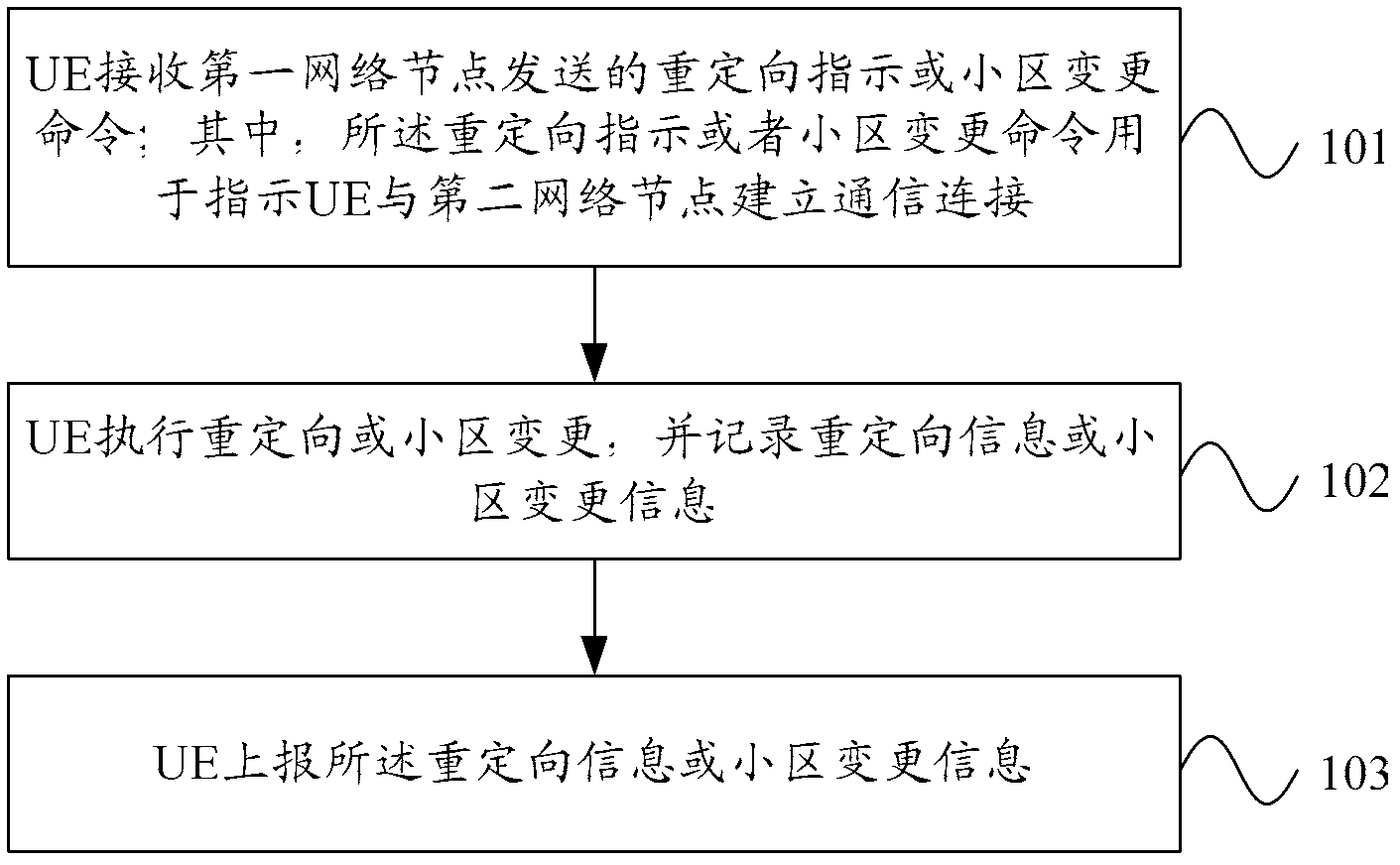

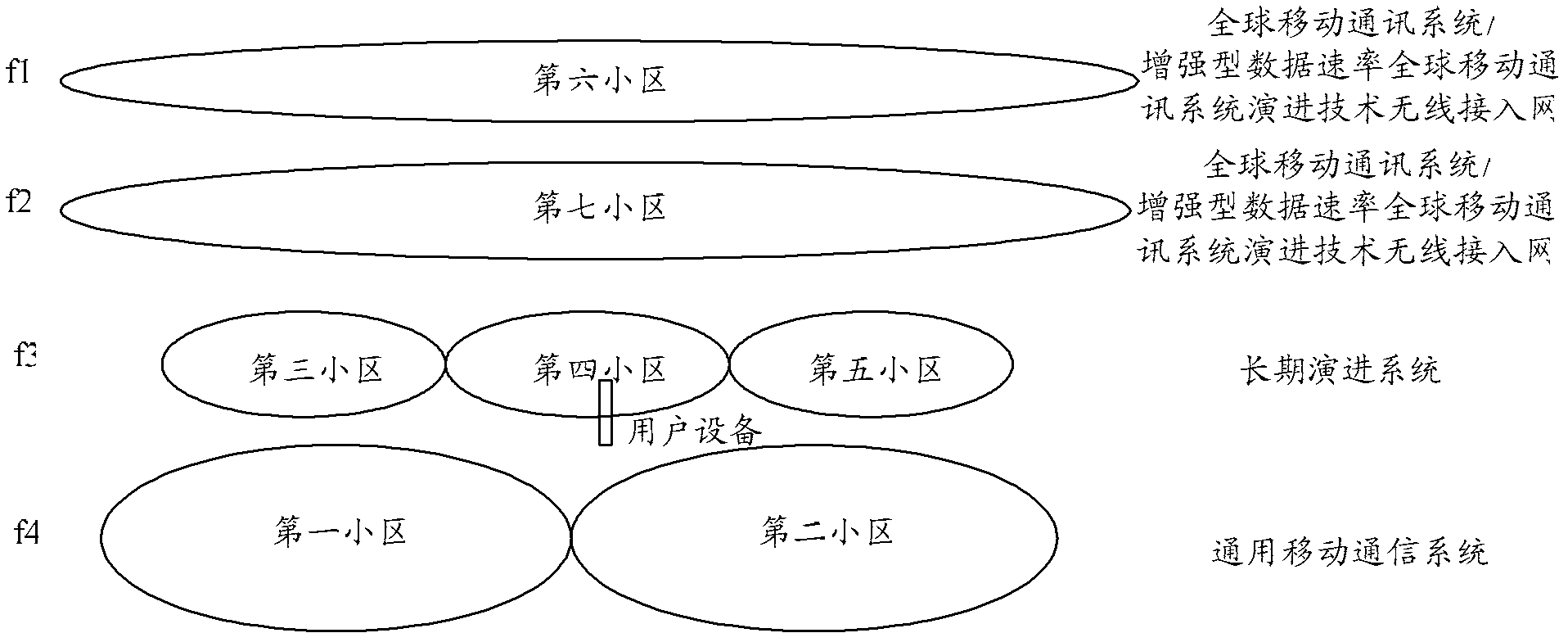

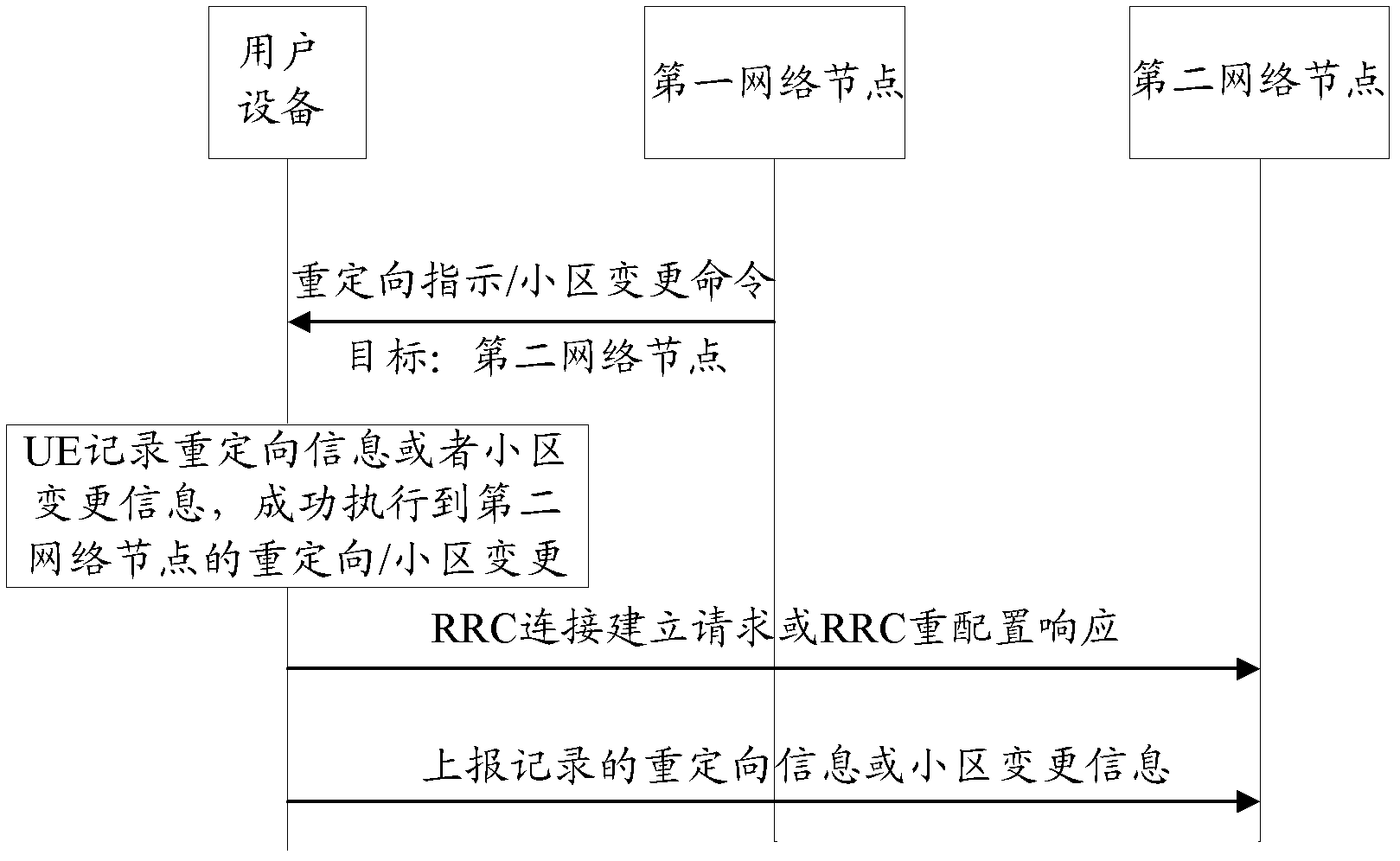

Information recording method, information acquisition method, equipment and system

The invention provides an information recording method, an information acquisition method, equipment and a system. The information recording method comprises the steps that UE receives redirect instructions or cell change orders sent by a first network node, wherein the redirect instructions or the cell change orders are used for indicating the UE and a second network node to build communicating connection; the UE executes the redirect instructions or the cell change orders and records redirect information or cell change information; the UE reports the redirect information or the cell change information. According to the information recording method, the information acquisition method, the equipment and the system, the fact that the redirect information and CCO information are recorded under the condition of redirection or CCO is achieved.

Owner:HUAWEI TECH CO LTD

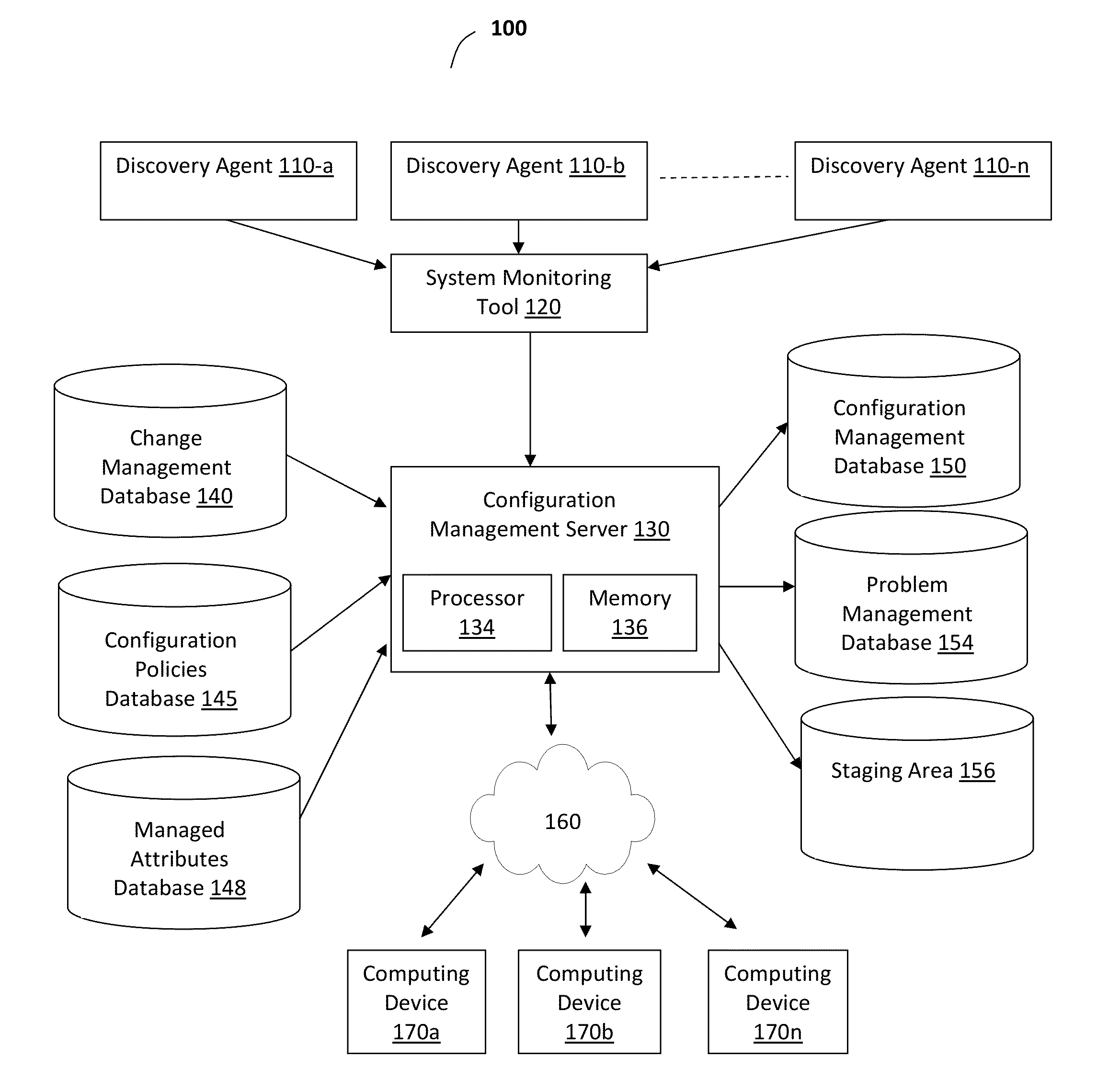

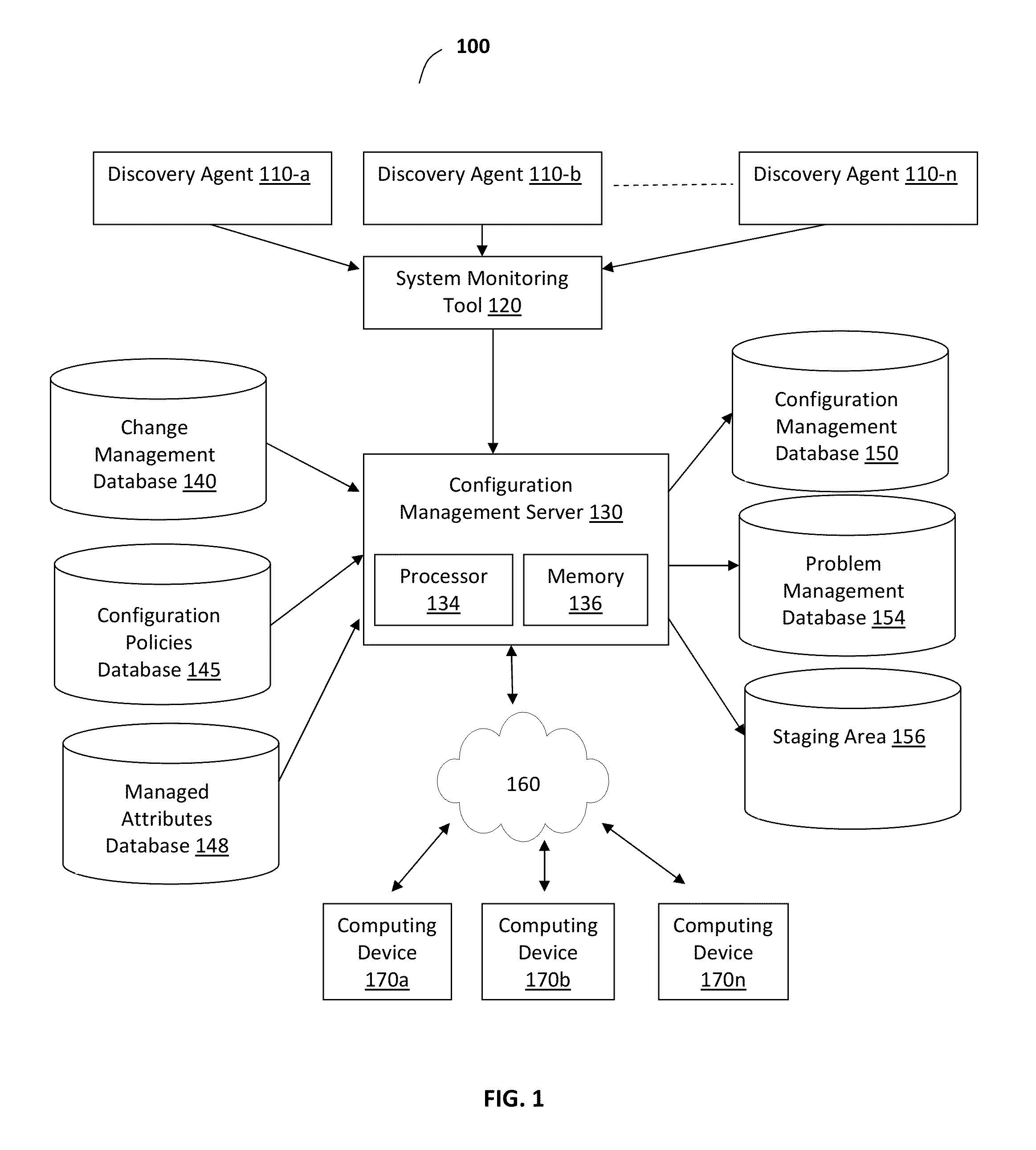

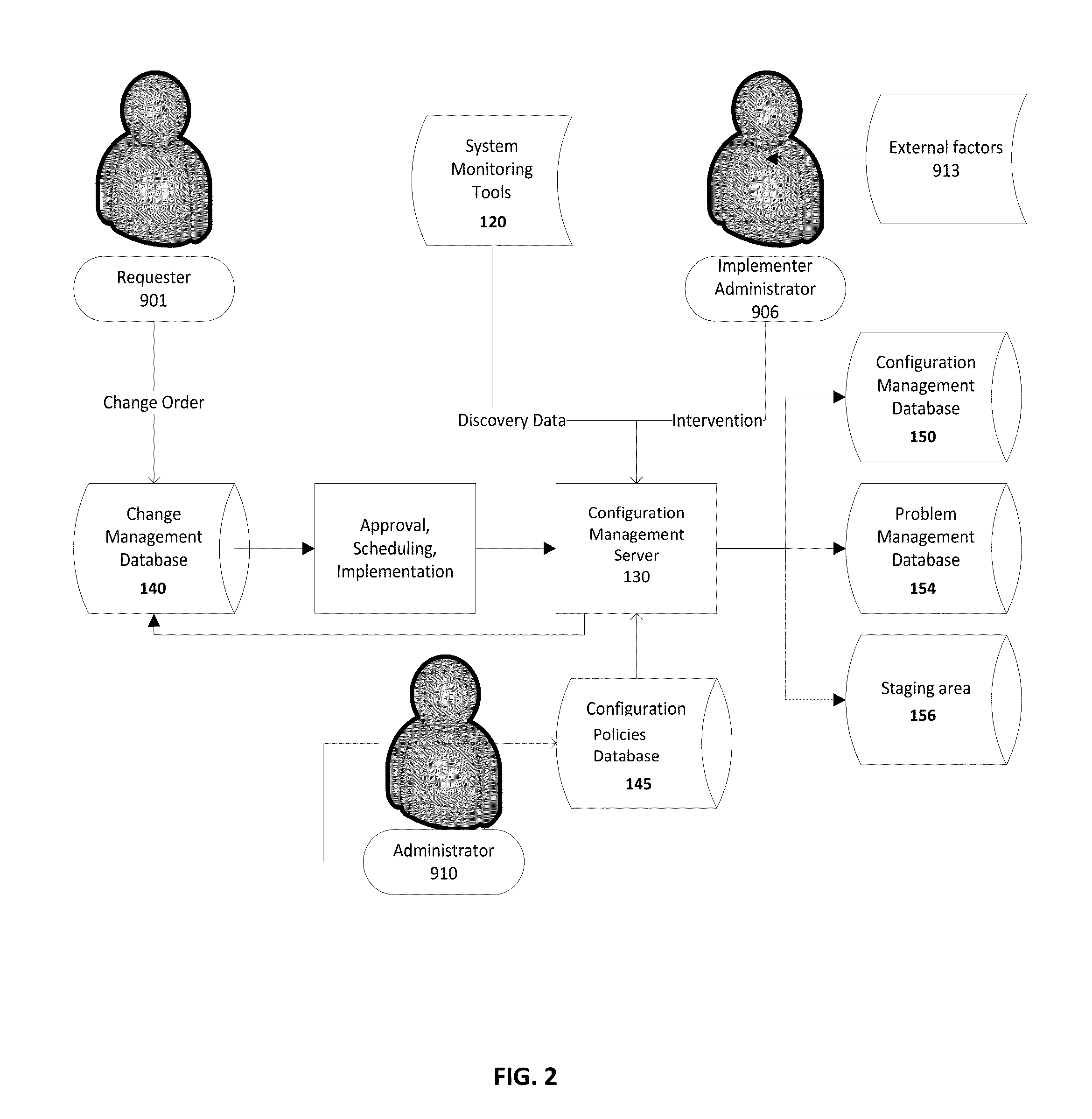

System and method for verifying configuration item changes

A system and method is provided for managing verification of configuration item changes. Discovered configuration data associated with a configuration item may be received. A determination may be made regarding whether a change order for the configuration item exists. A determination may be made regarding whether the change order is in a “verification in progress” state. When the change order is in the “verification in progress” state, alignment of the discovered configuration data with the change order may be determined and a verification policy may be determined based on the determined alignment.

Owner:CA TECH INC

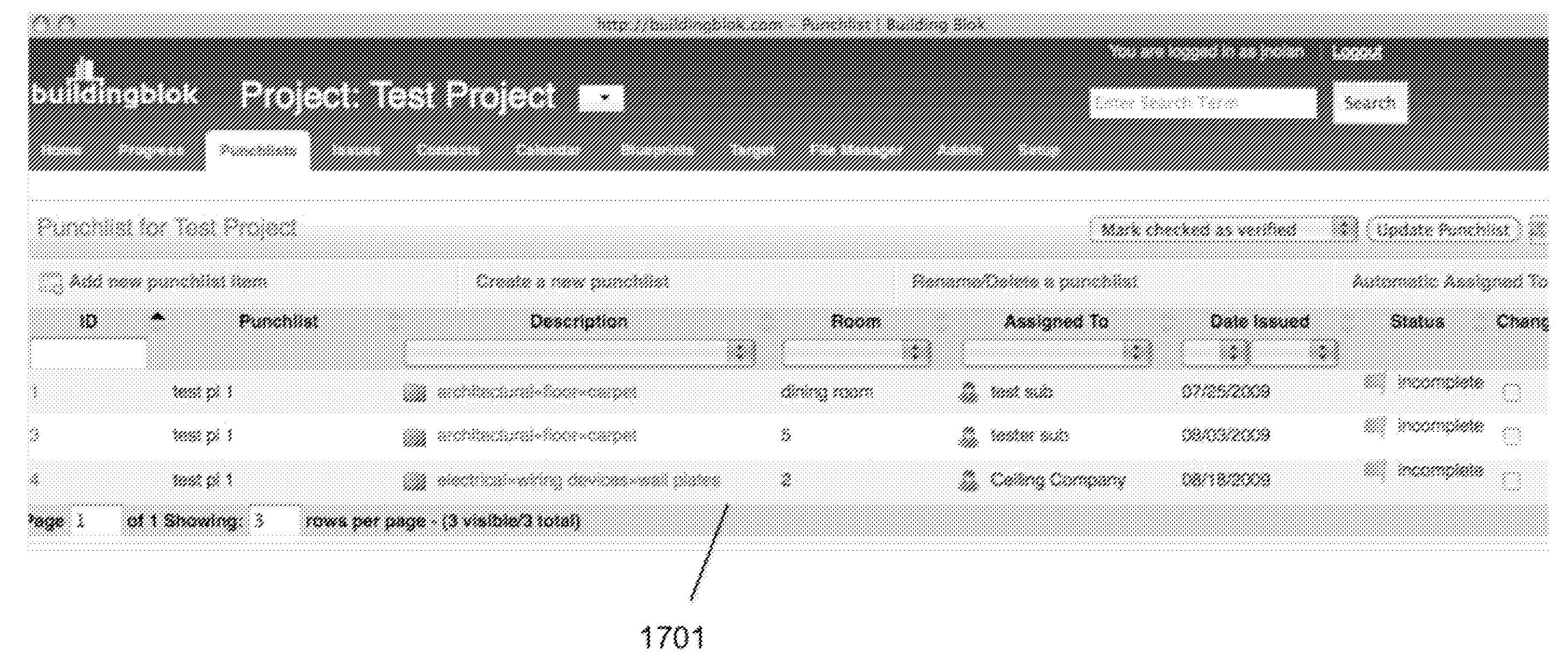

System And Method For Coordinating Building And Construction Activities

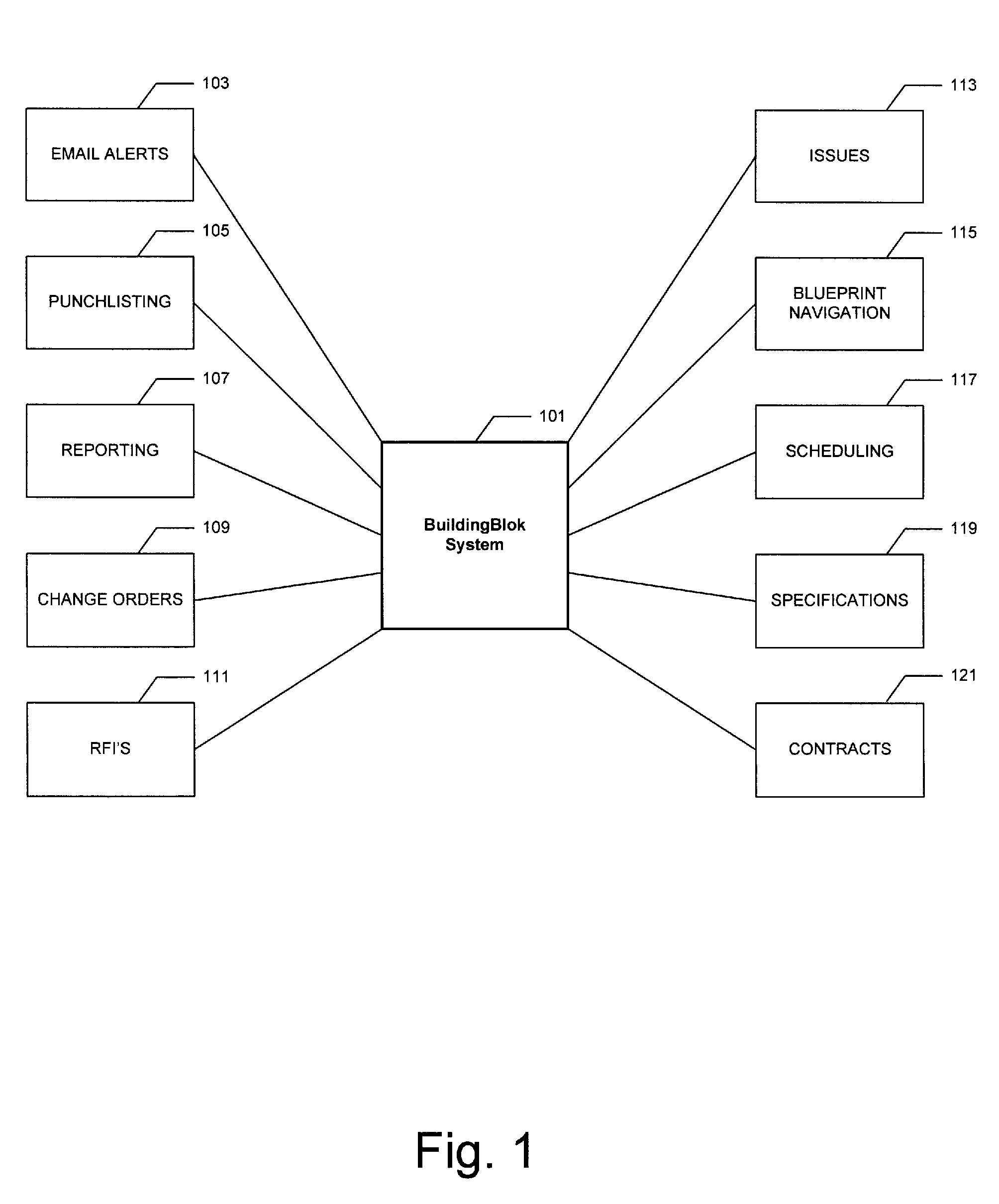

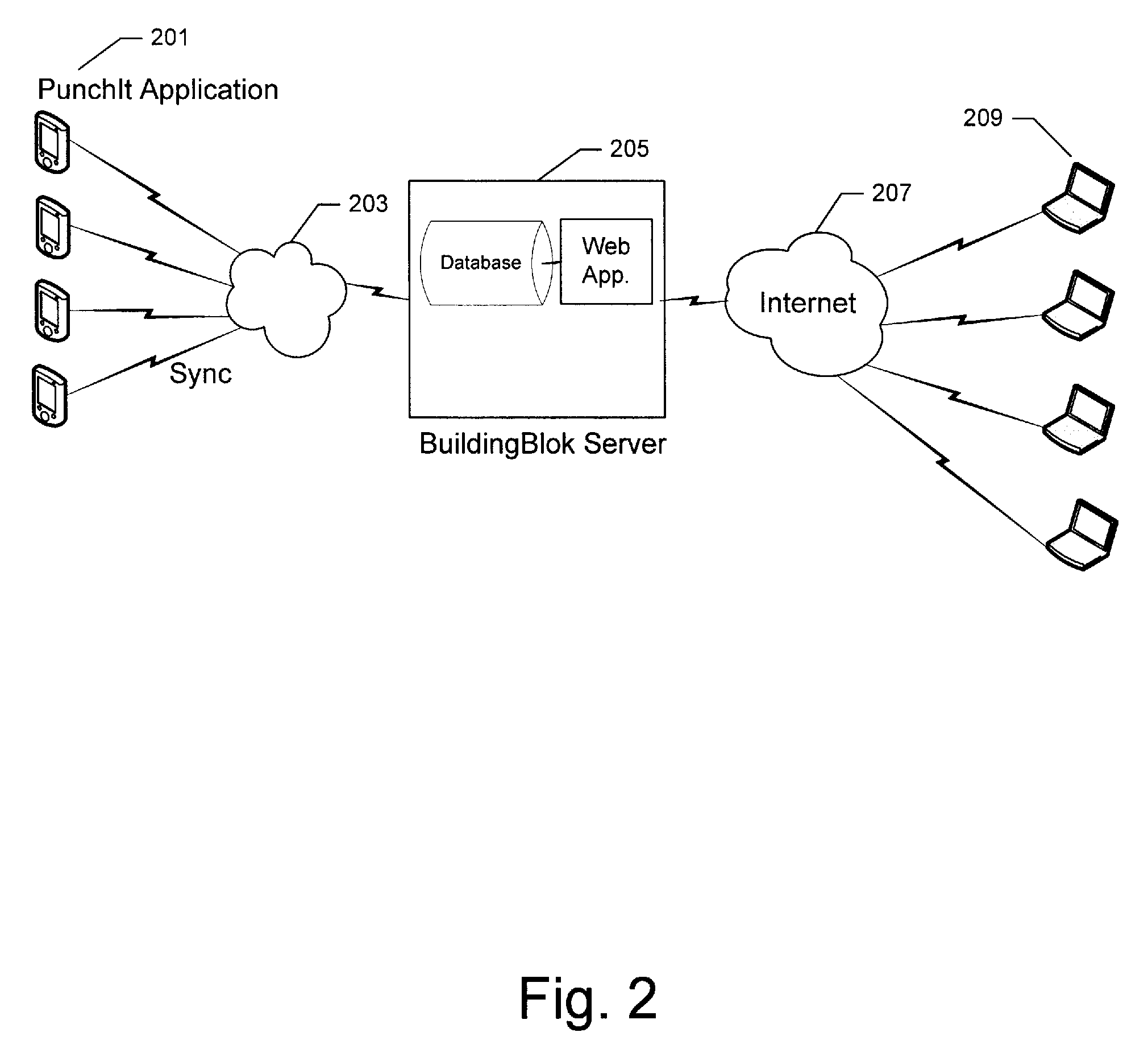

InactiveUS20100174656A1Multiple digital computer combinationsOffice automationThe InternetHand held devices

A computer based system and method for coordinating building and construction activities that allows electronic punchlists to be created, updated, and managed remotely using a handheld device or a computer with access to the internet. The system and method allows for complete control in the field. The electronic punchlists may also be mapped to electronic blueprints for ease of navigation through multiple punchlists and tasks. Additional information such as digital media, change orders, issues, scheduling, specifications, contracts, and requests for information may also be mapped to the electronic punchlists. The punchlist data may also be used to generate reports.

Owner:NOLAN JUSTIN HUMPHREY

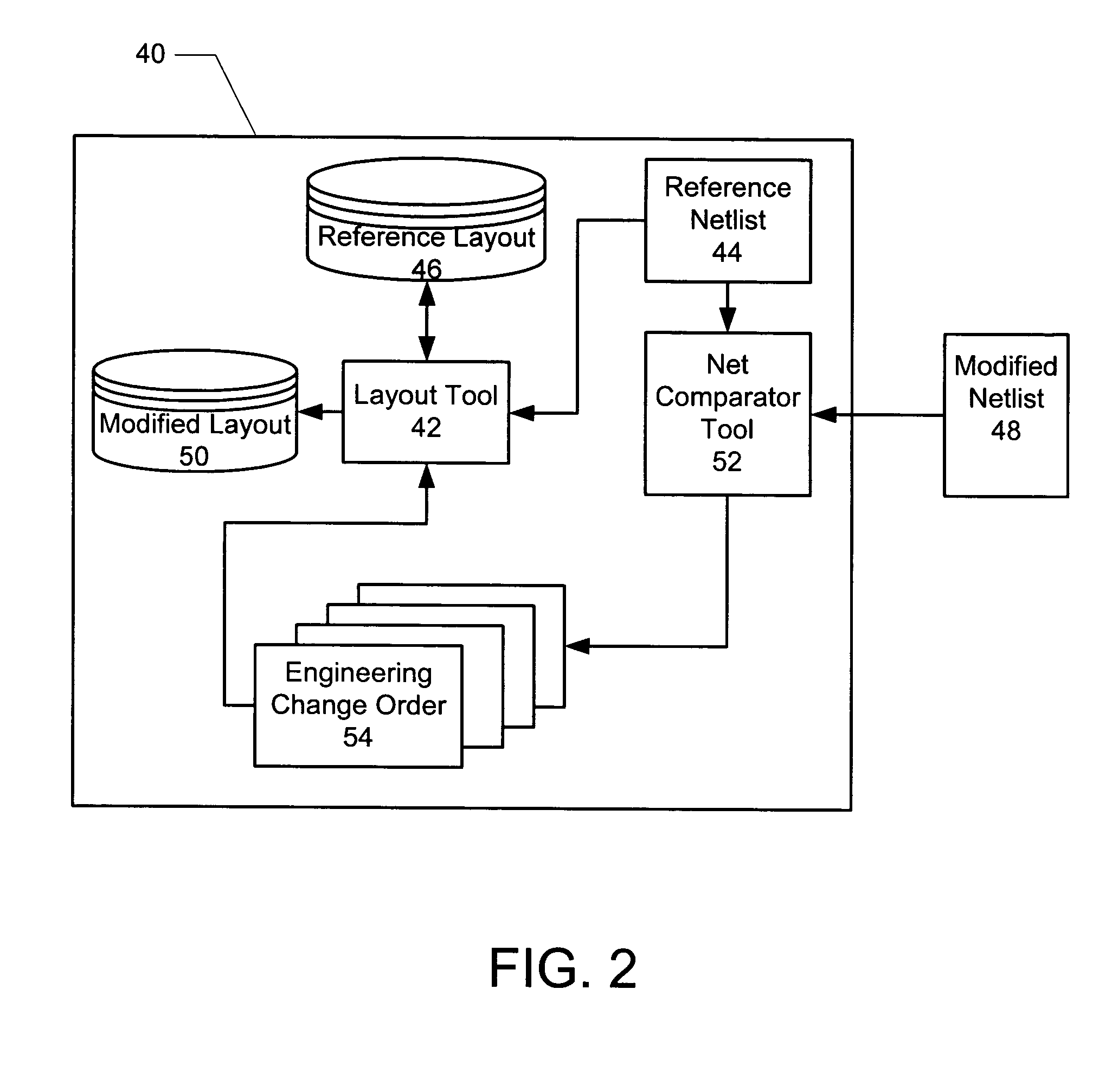

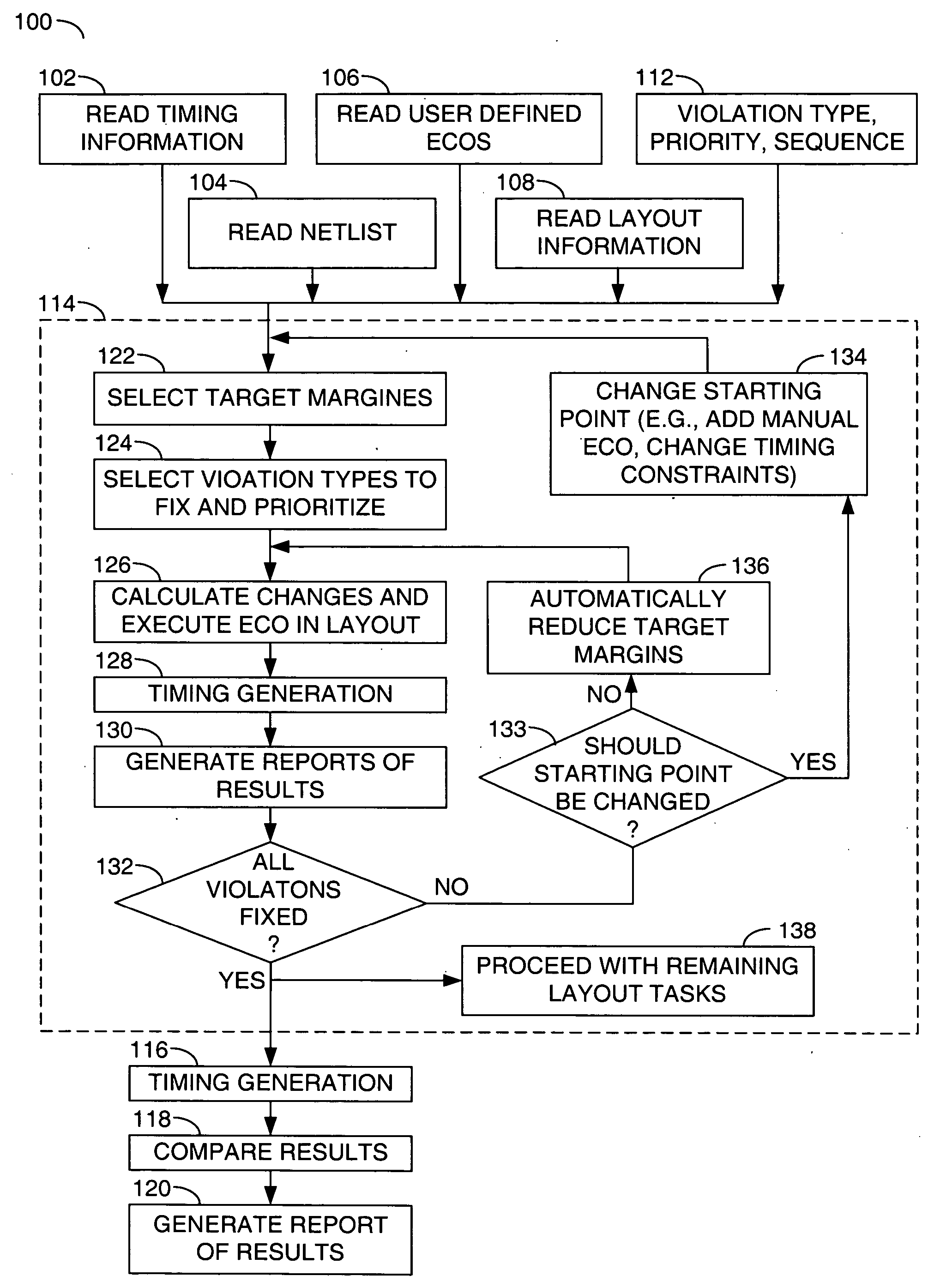

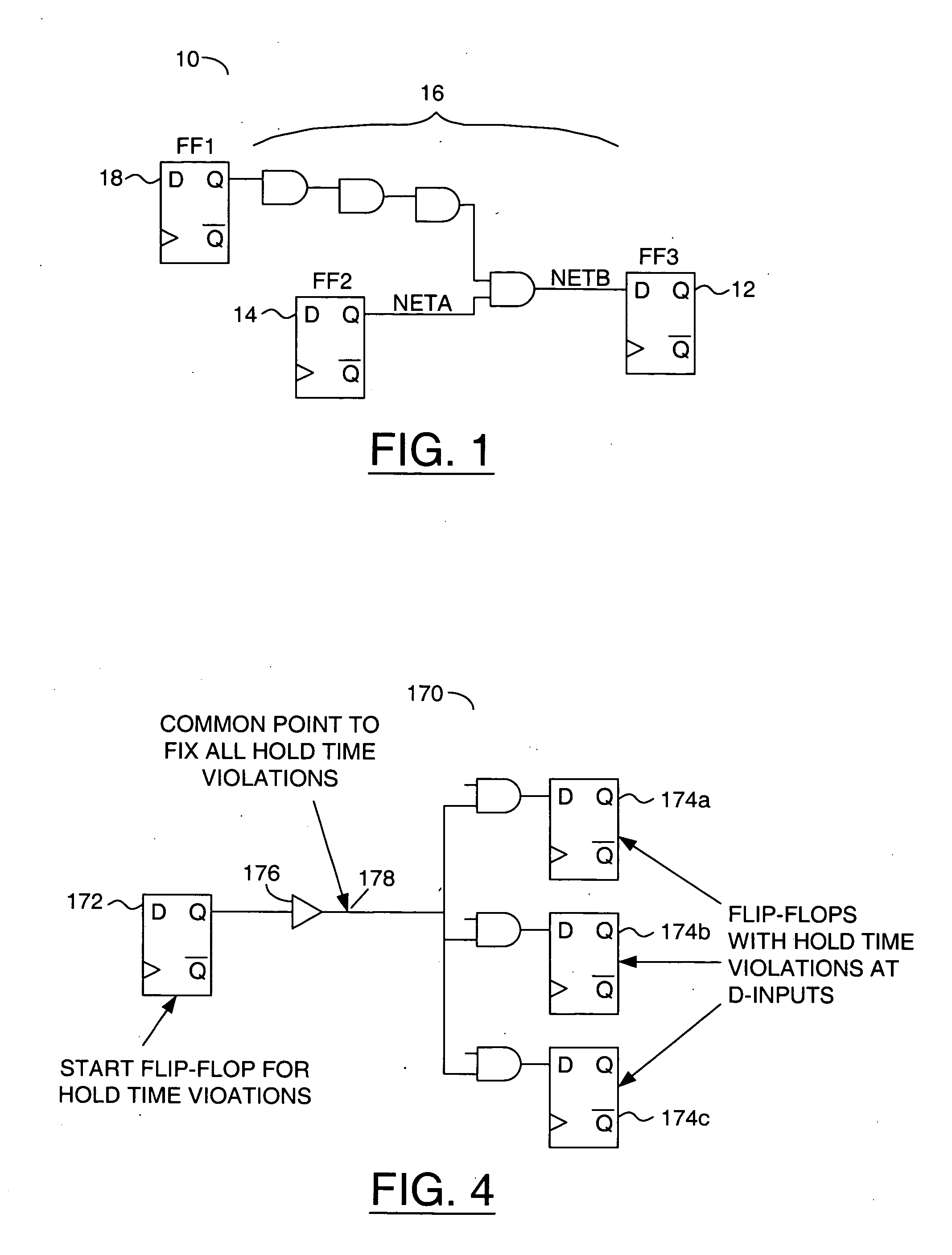

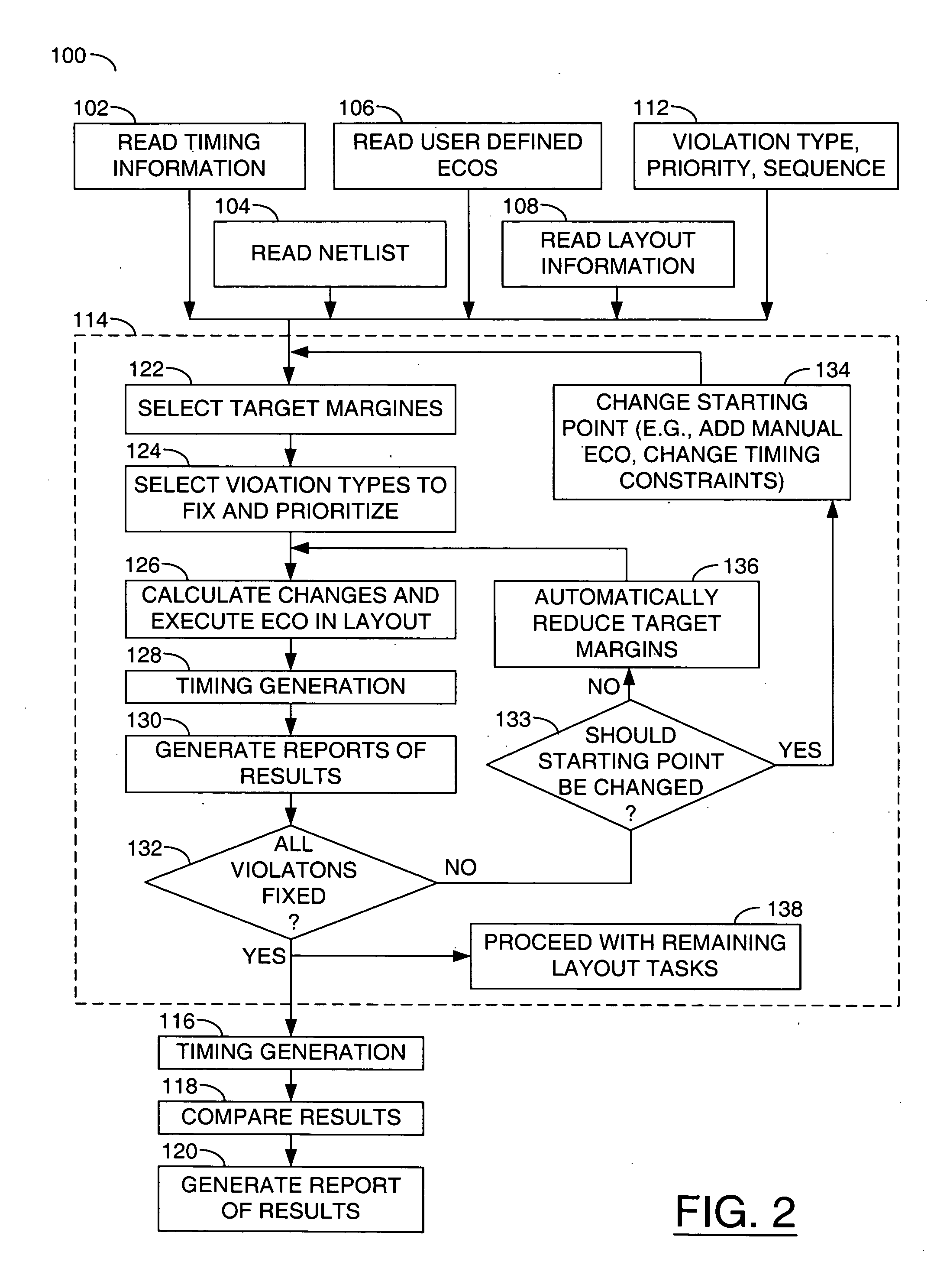

Comparison of two hierarchical netlist to generate change orders for updating an integrated circuit layout

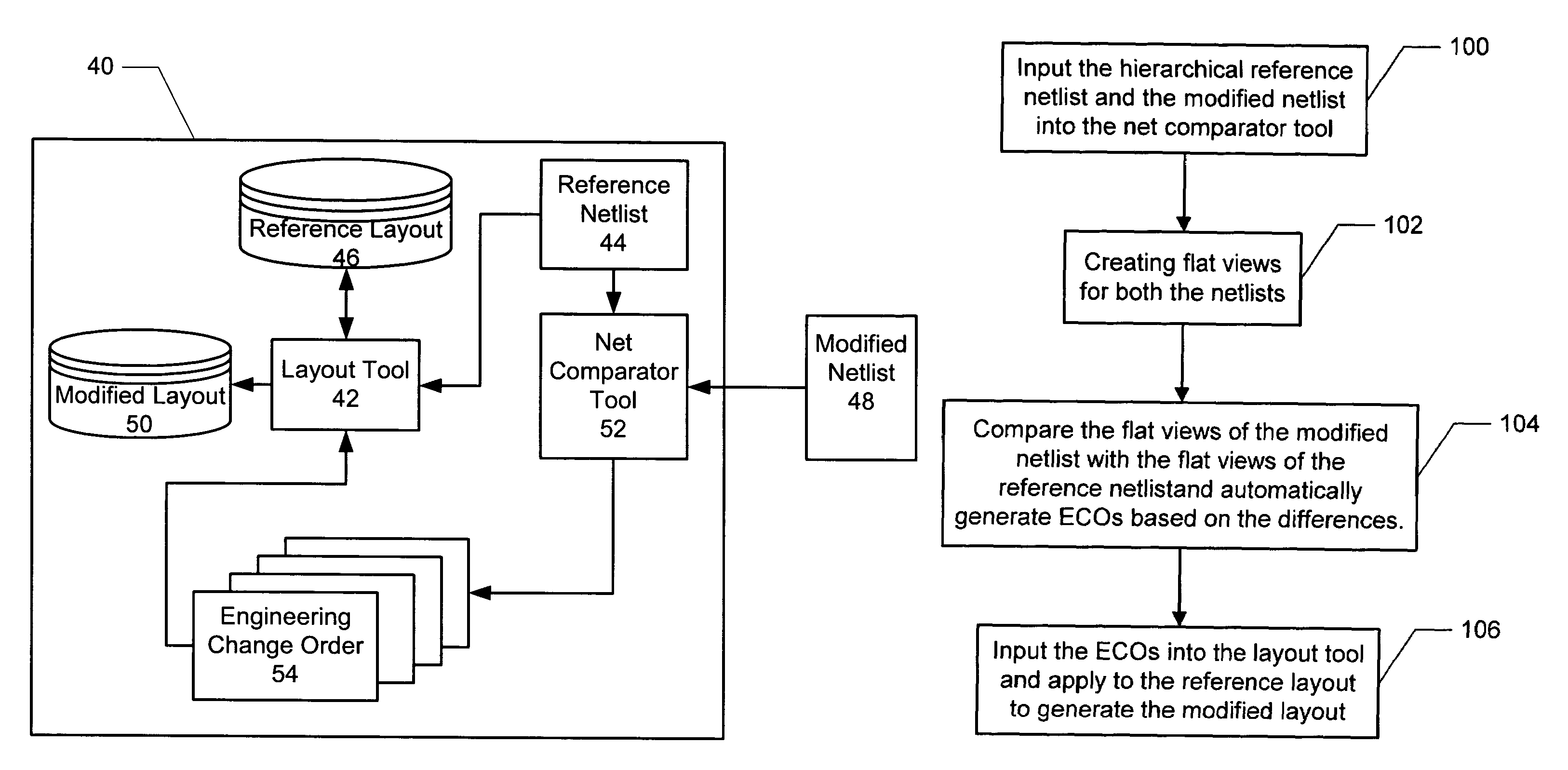

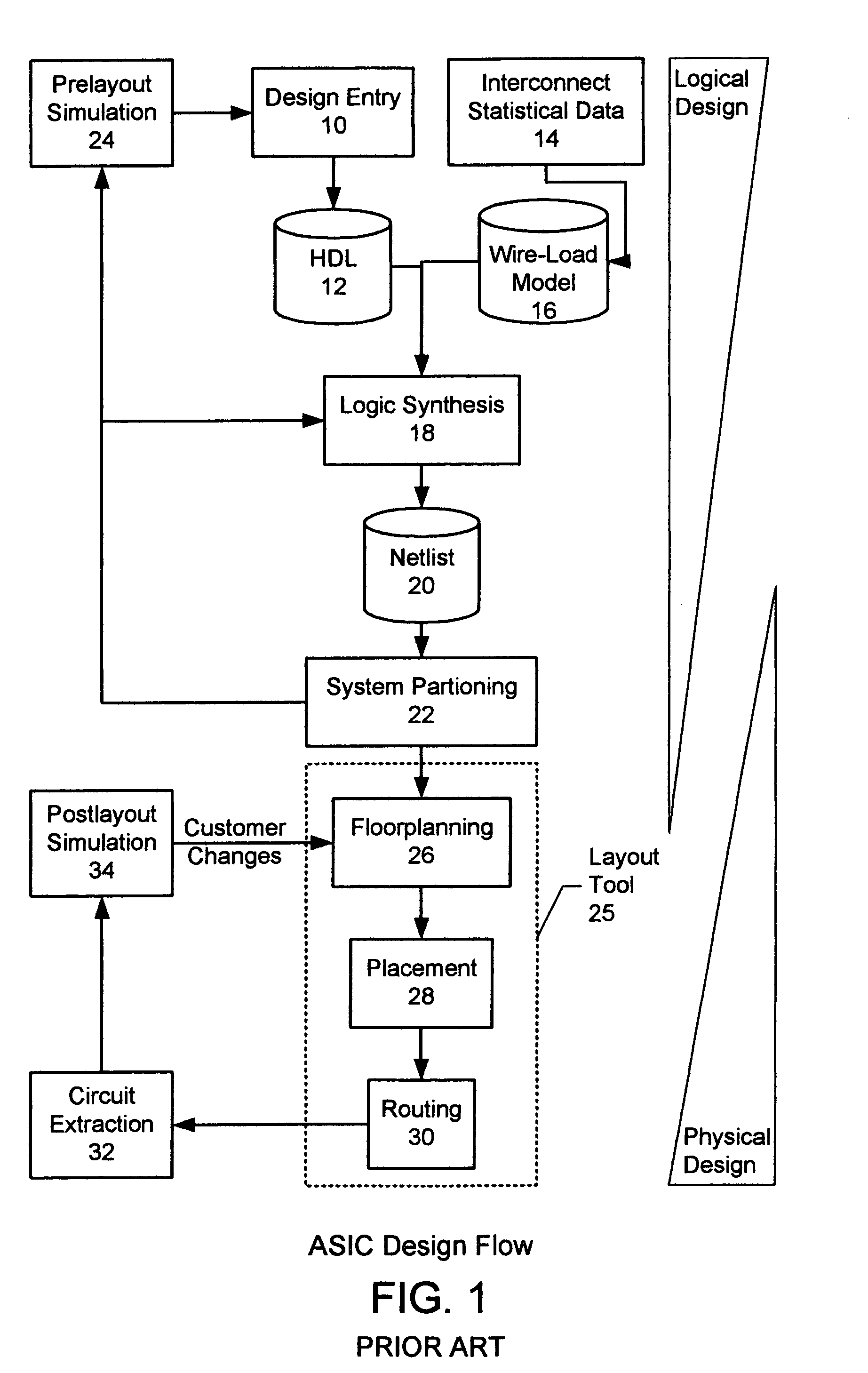

ActiveUS7111269B2Eliminate needSure easyComputer programmed simultaneously with data introductionCAD circuit designTheoretical computer scienceLayout

A method and system for optimizing a netlist change order flow is disclosed, wherein a design layout created by a layout tool using a reference netlist is to be changed by a modified version of the netlist, and wherein both netlists are hierarchical comprising. Aspects of the present invention include comparing the modified netlist with the original netlist outside of the layout tool, and automatically generating at least one change order based on differences found between the two netlists. After the change order is generated, the change order is then applied to the design layout to generate a modified design layout.

Owner:BELL SEMICON LLC

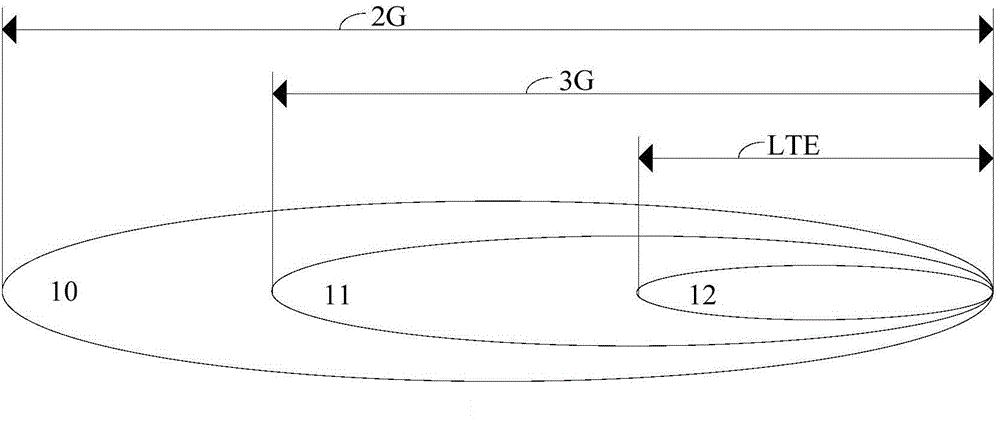

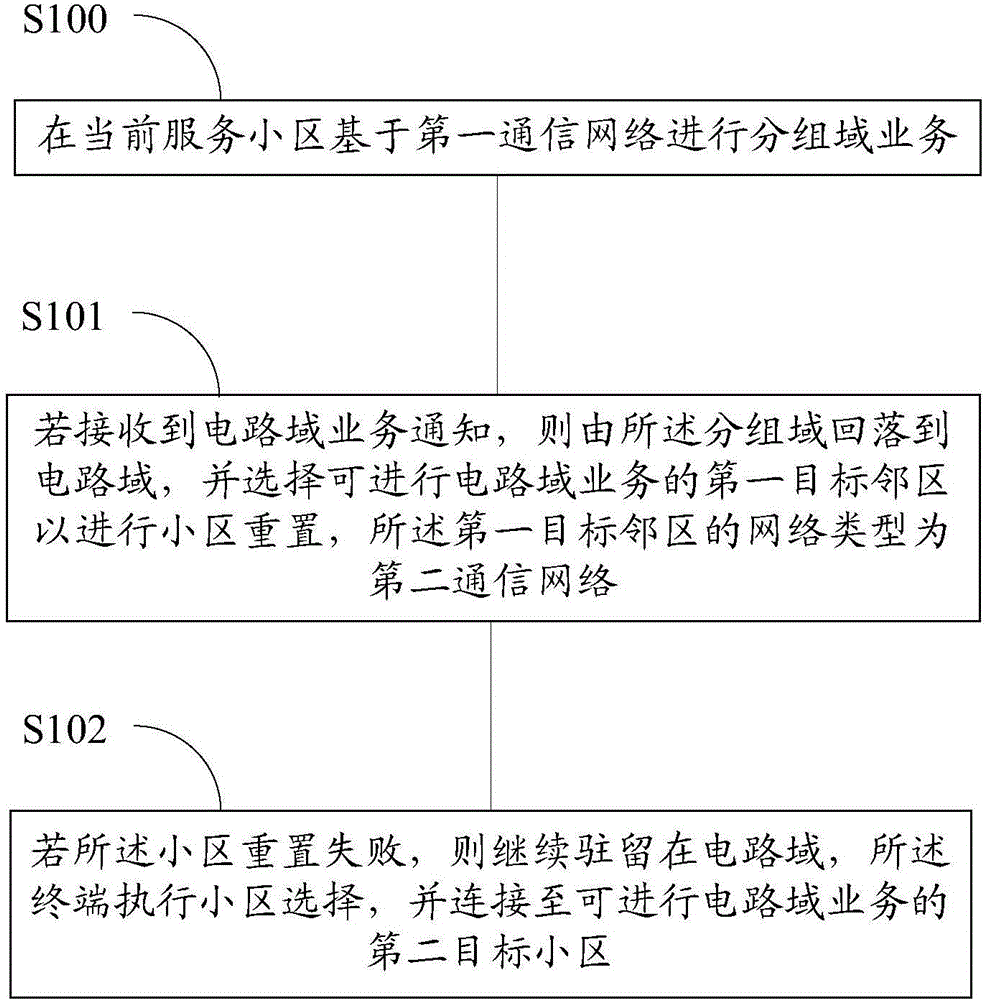

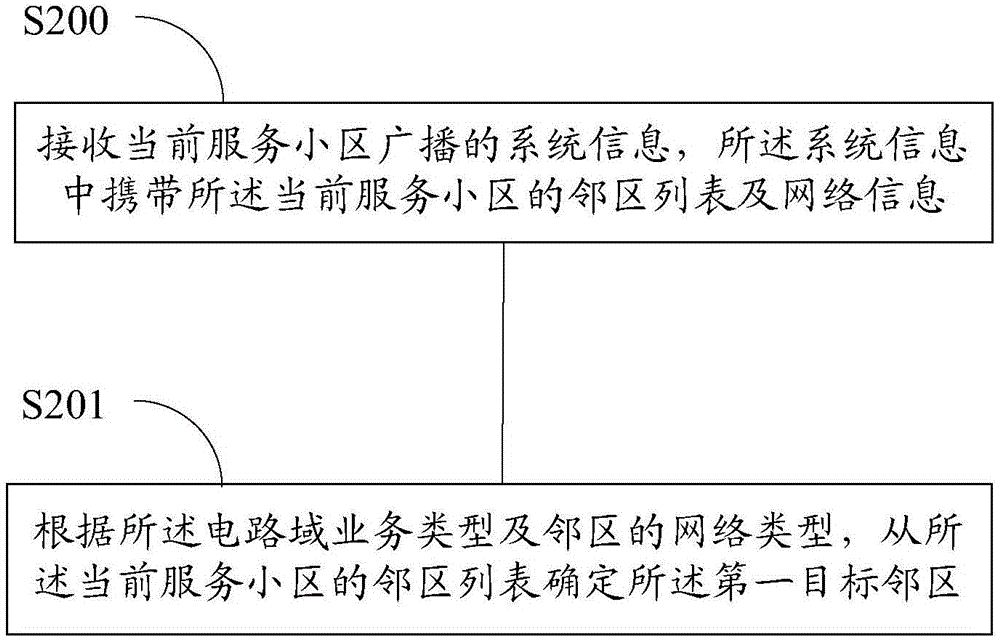

Cell change order method based on circuit switched domain fall back (CSFB)

ActiveCN105451276ALower latencyImprove experienceWireless communicationCommunication qualityCell selection

The invention relates to a cell change order method based on circuit switched domain fall back (CSFB). The method comprises the following steps: carrying out packet domain service in a current service cell based on a first communication network; if receiving notification of circuit switched domain service, falling back from a packet domain to a circuit switched domain, and selecting a first target adjacent region capable of carrying out the circuit switched domain service to carry out cell change order, the network type of the first target adjacent region being a second communication network; and if the cell change order fails, residing in the circuit switched domain continuously, a terminal carrying out cell selection and connecting to a second target cell capable of carrying out circuit switched domain service. The method can improve conversation establishment success rate, and thus communication quality is improved.

Owner:SPREADTRUM COMM (SHANGHAI) CO LTD

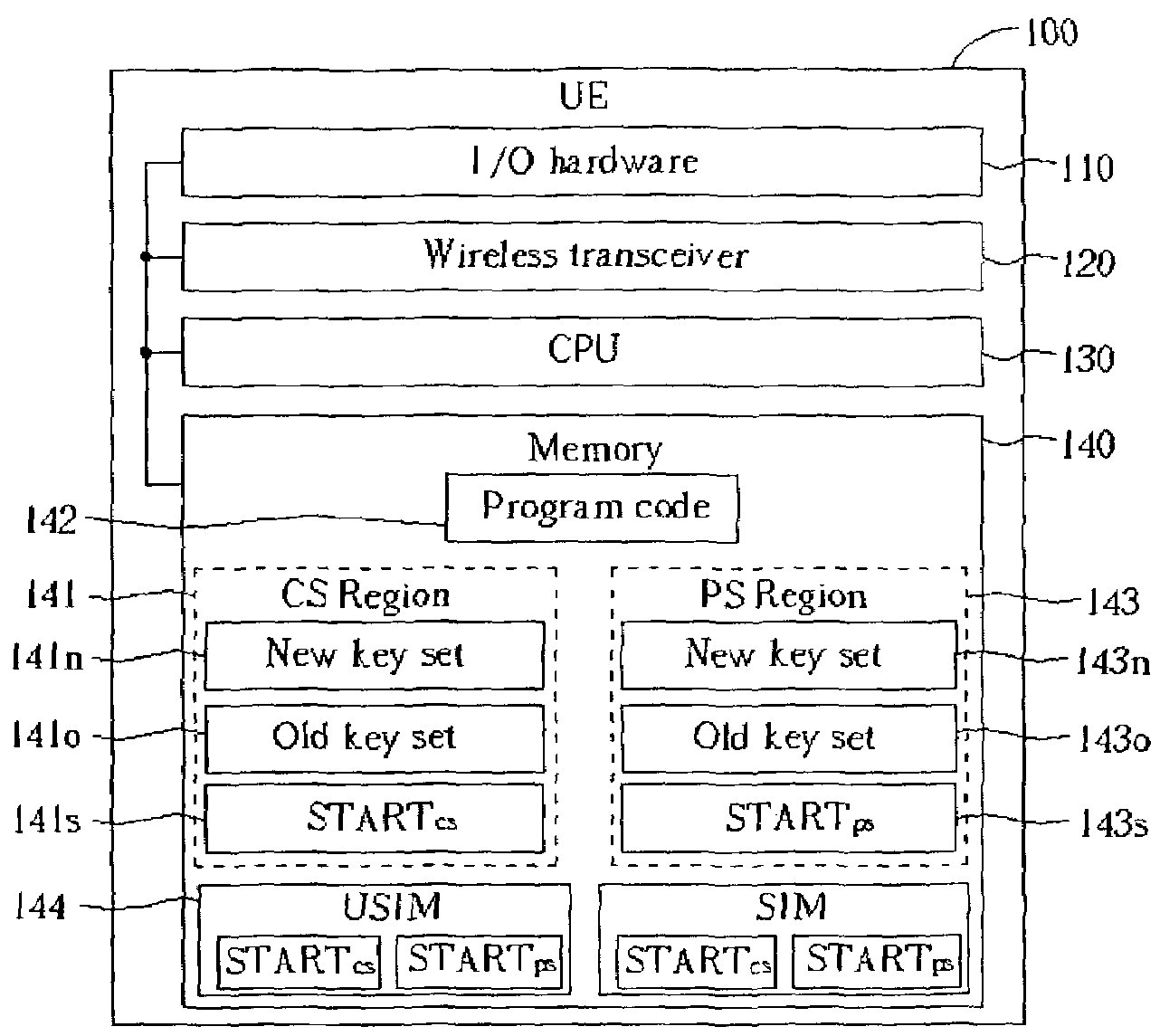

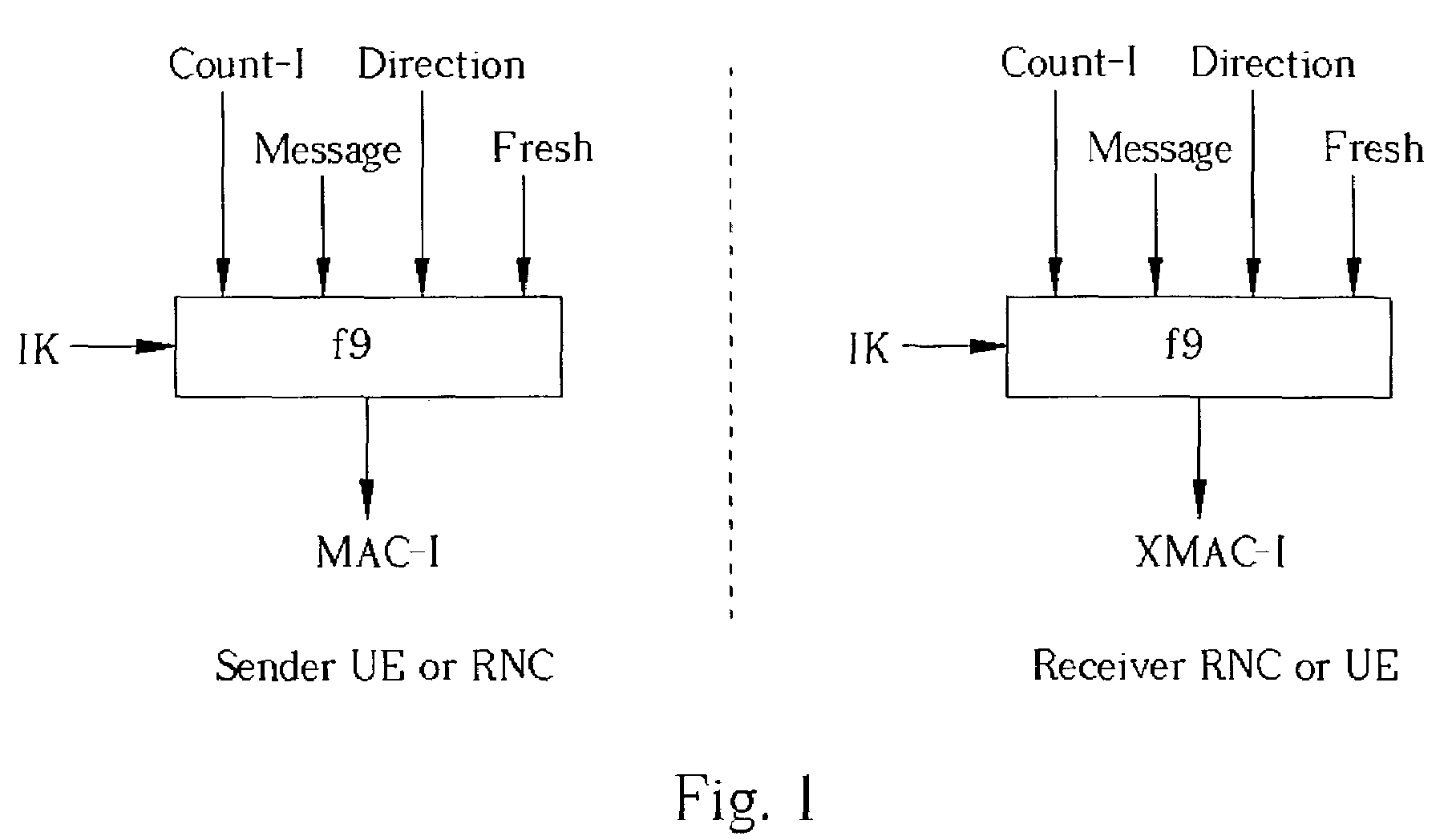

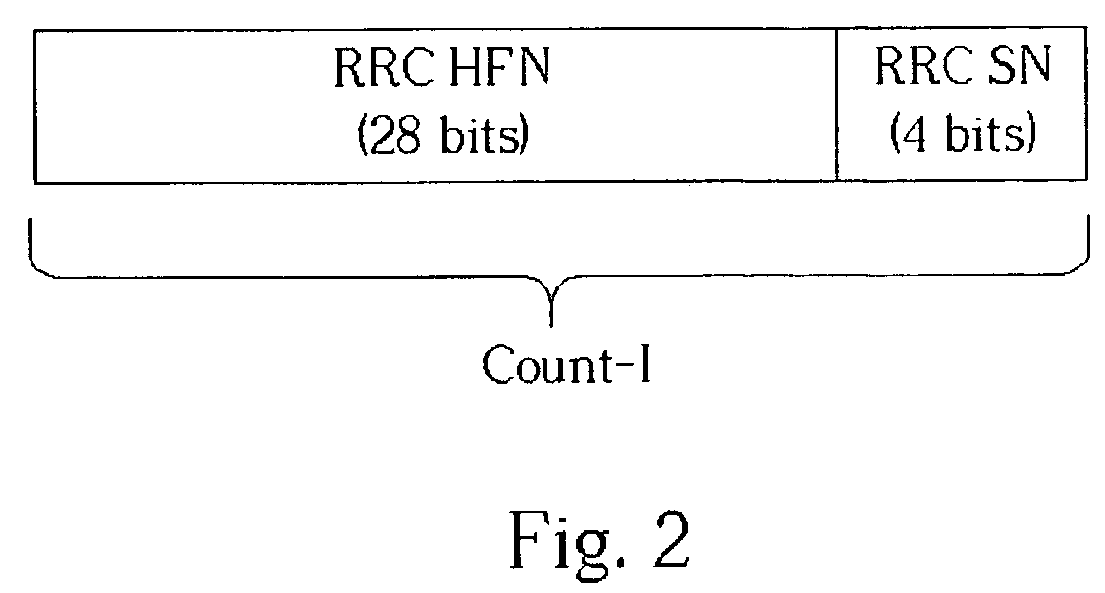

Method for storing a security start value in a wireless communications system

ActiveUS7233671B2Prevent unnecessary deletionIncrease valueUnauthorised/fraudulent call preventionEavesdropping prevention circuitsCommunications systemHandover

A wireless device first successfully completes an Inter-RAT procedure, which is either an Inter-RAT handover, Inter-RAT cell reselection or Inter-RAT cell change order from UTRAN procedure. The wireless device then determines if a USIM is present. If the USIM is present, the wireless device determines if a new security key set was received and unused for ciphering and integrity functions during a current RRC connection. If a new key set was present and unused, the wireless device stores a value of zero into the USIM as a security START value for the CN domain associated with the RRC connection.

Owner:INNOVATIVE SONIC

Engineering change order scenario manager

InactiveUS20060026546A1Reduce in quantityComputer programmed simultaneously with data introductionComputer aided designEngineering change orderCircuit design

A method and apparatus for managing a plurality of change orders for a circuit design is disclosed. The method generally includes the steps of (A) receiving the change orders generated manually by a user, (B) analyzing the circuit design with all of the change orders implemented and (C) generating a report suitable for the user to understand based on a result of the analyzing.

Owner:BELL SEMICON LLC

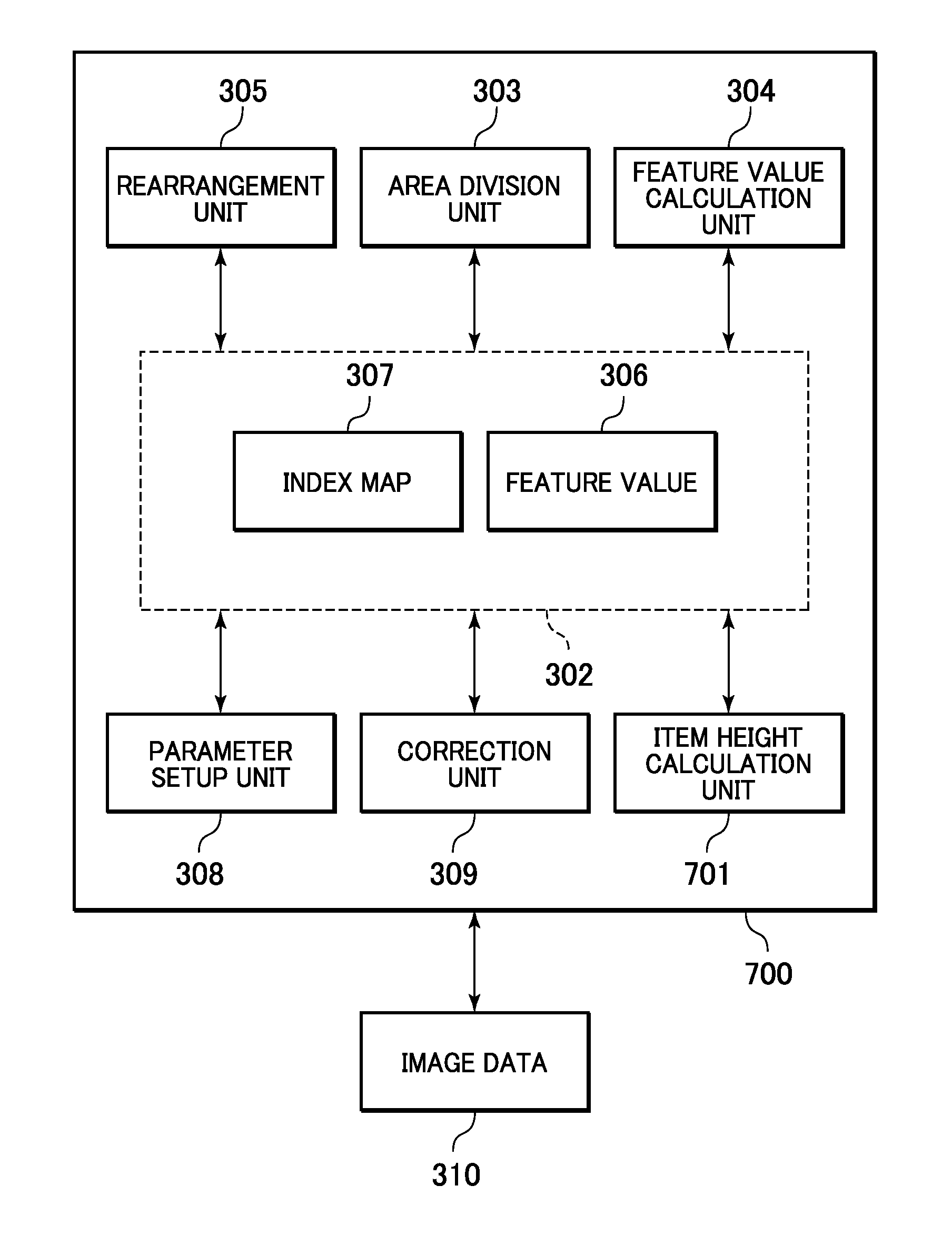

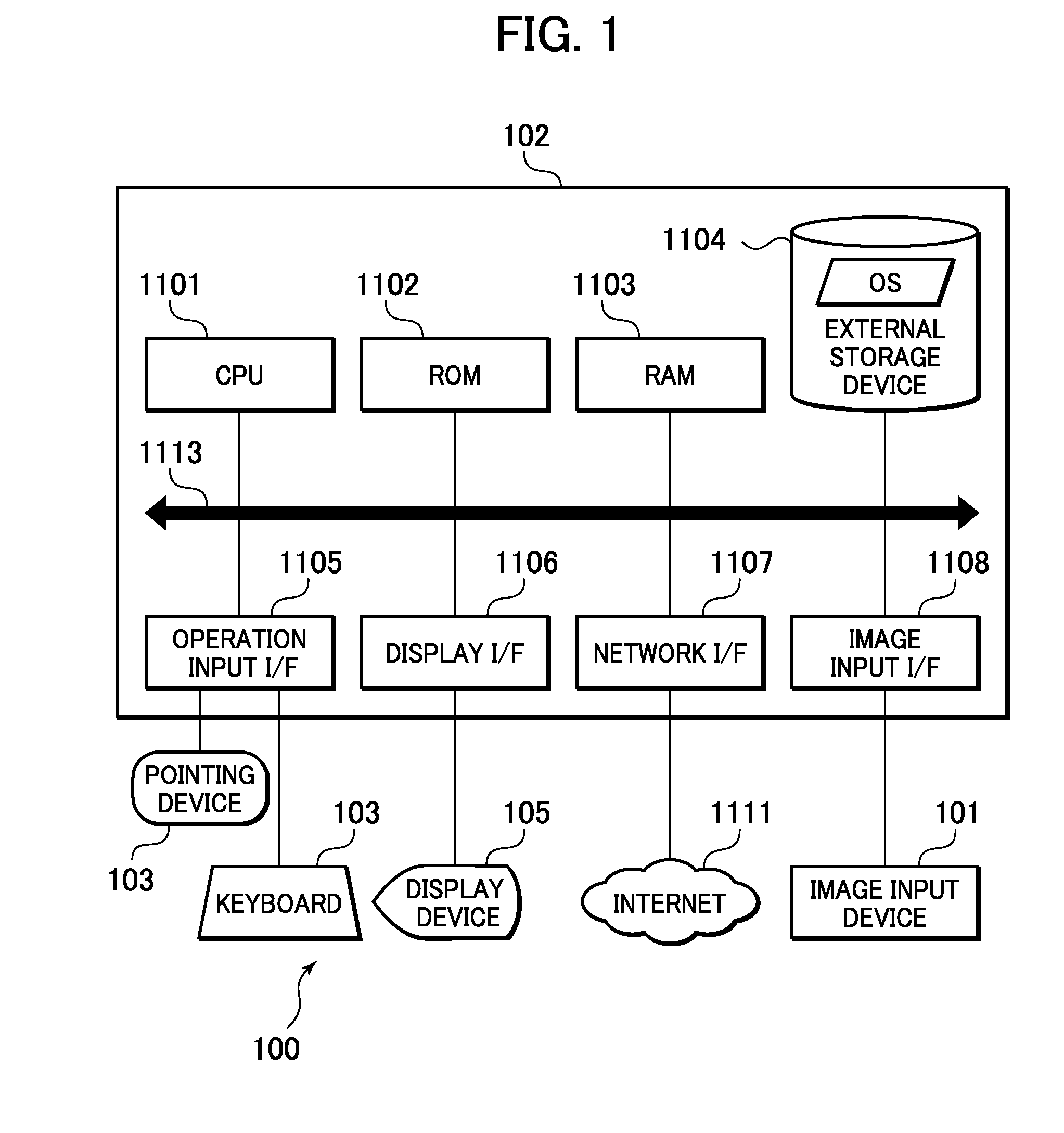

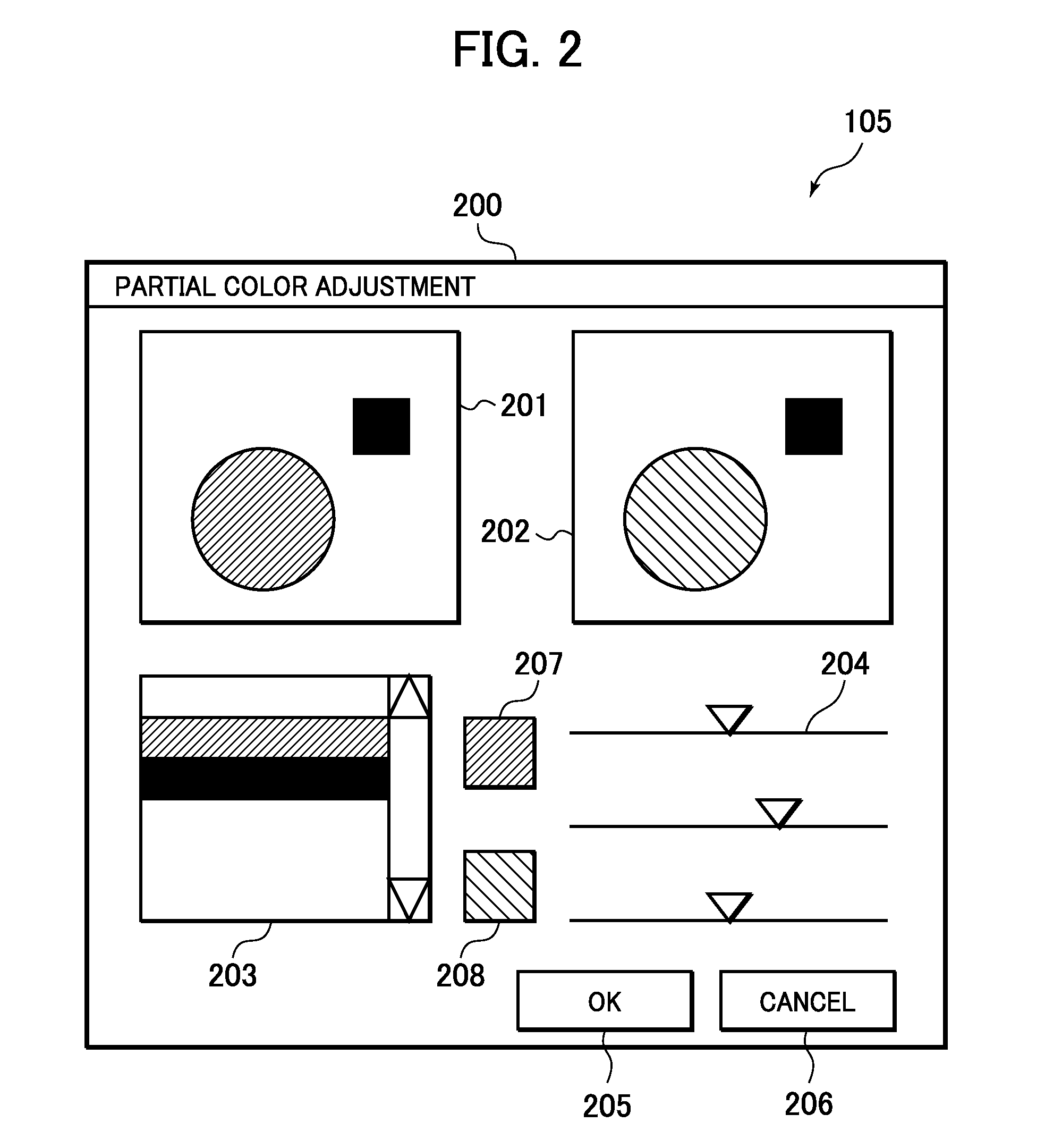

Image processing apparatus for displaying colors included in a color image and an image processing method, and a storage medium therefor

InactiveUS20070030501A1Easy to identifyTelevision system detailsDigitally marking record carriersColor imageImaging processing

The present invention enables a user to easily identify individual colors included in a color image. Specifically, a color image is divided into two or more areas based on colors, and based on the feature values for the individual areas obtained by division, the order of the colors is changed. Then, the colors of the individual areas are displayed in accordance with the changed order.

Owner:CANON KK

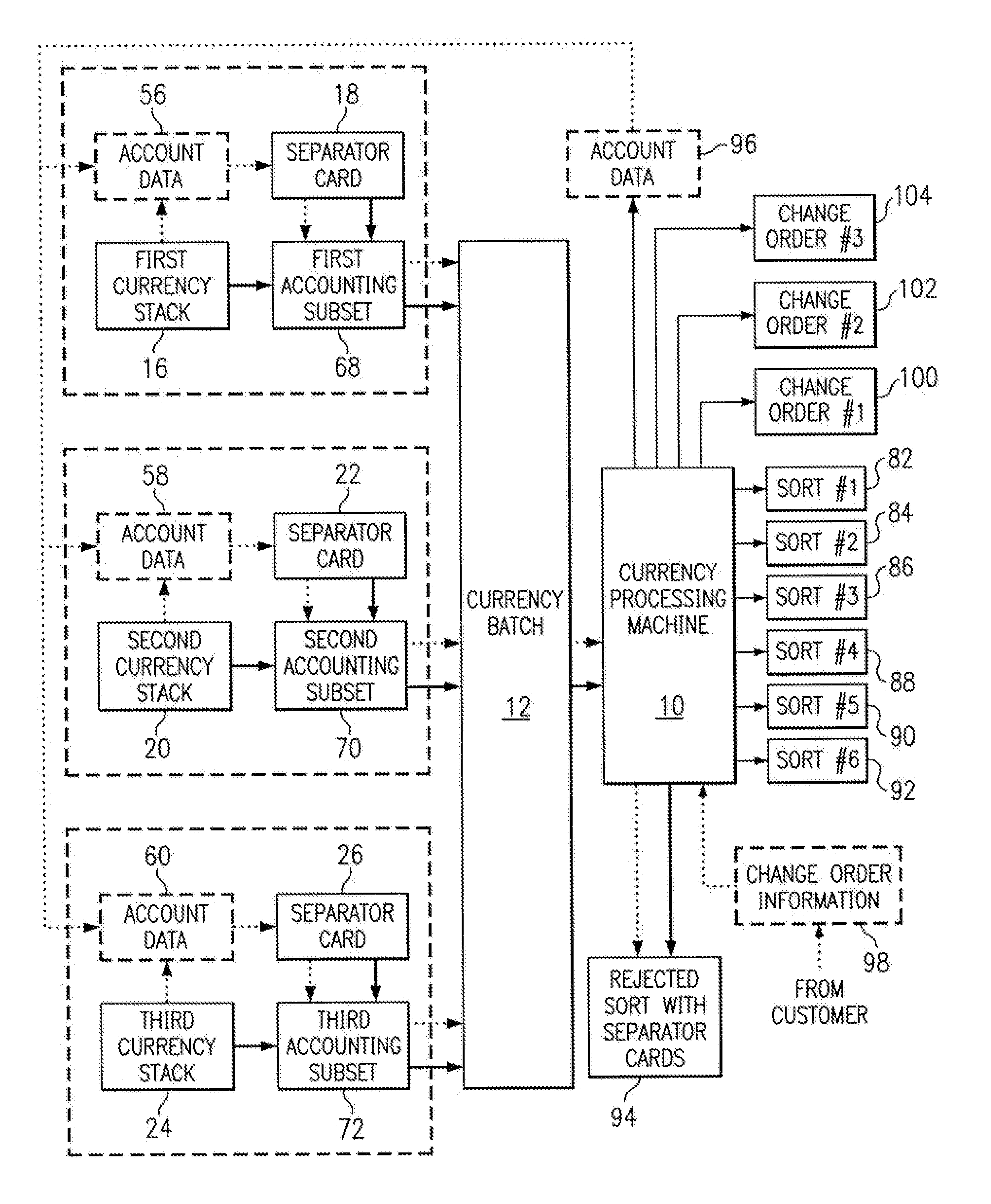

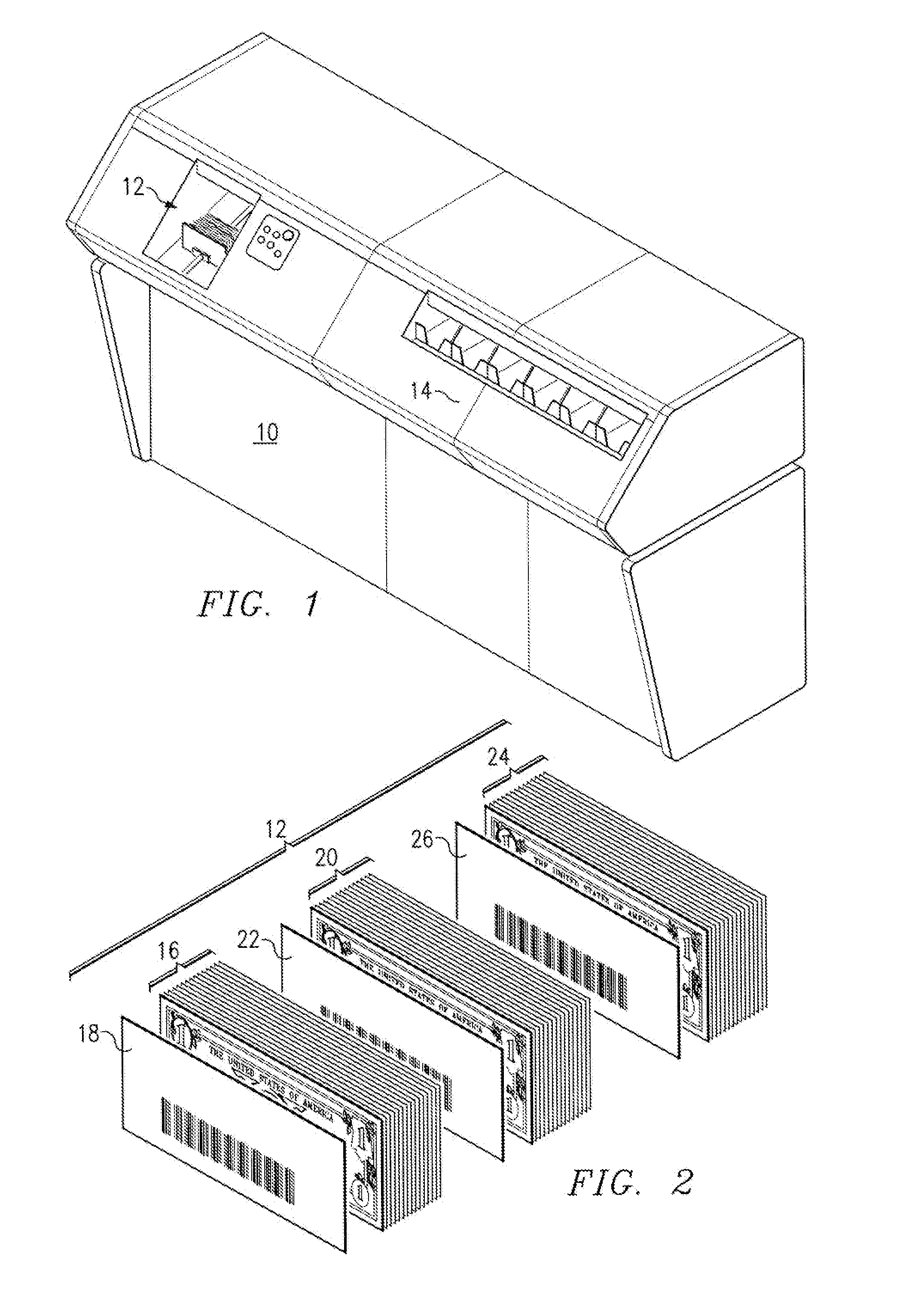

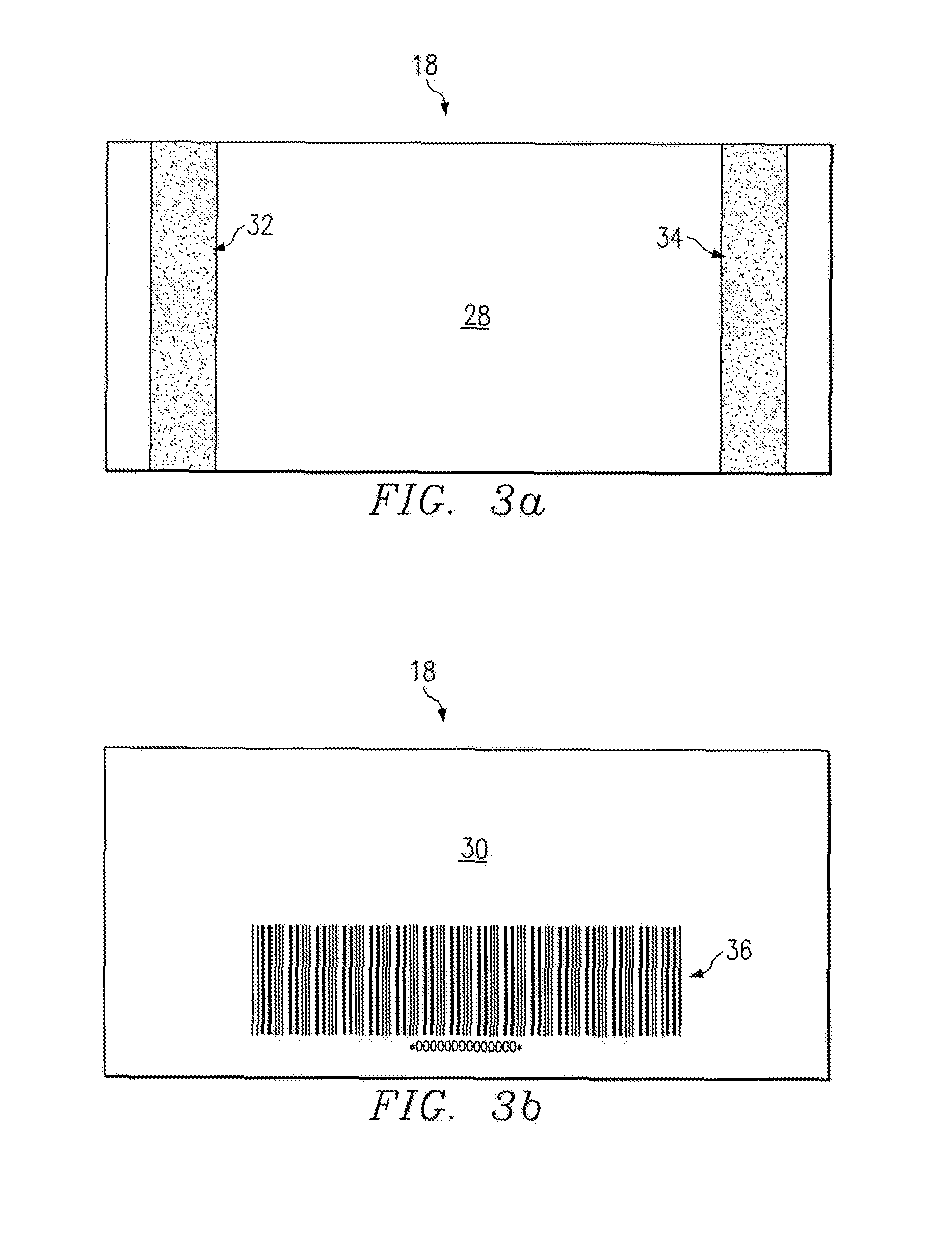

Continuous change order processing

InactiveUS7422117B2Digital data processing detailsCoin/currency accepting devicesData processing systemCollection system

A currency processing machine and method, system, and computer program product for filling change orders is provided. In one embodiment, the currency processing machine includes a document input which receives a stack of documents and feeds single documents from the stack of documents into the document processing machine. The currency processing machine also includes an information collection system collects identifying information about the documents, sorting bins for receiving the documents, a sorter; and a data processing system. The data processing system receives information regarding the quantity of each of several denominations needed by a customer for a change order and dynamically dedicates at least one of the sorting bins for use for filling the change order. The data processing system instructs the sorter to deliver specified quantities of notes of specified denominations to the sorting bins designated for use for filling the change order.

Owner:DE LA RUE NORTH AMERICA

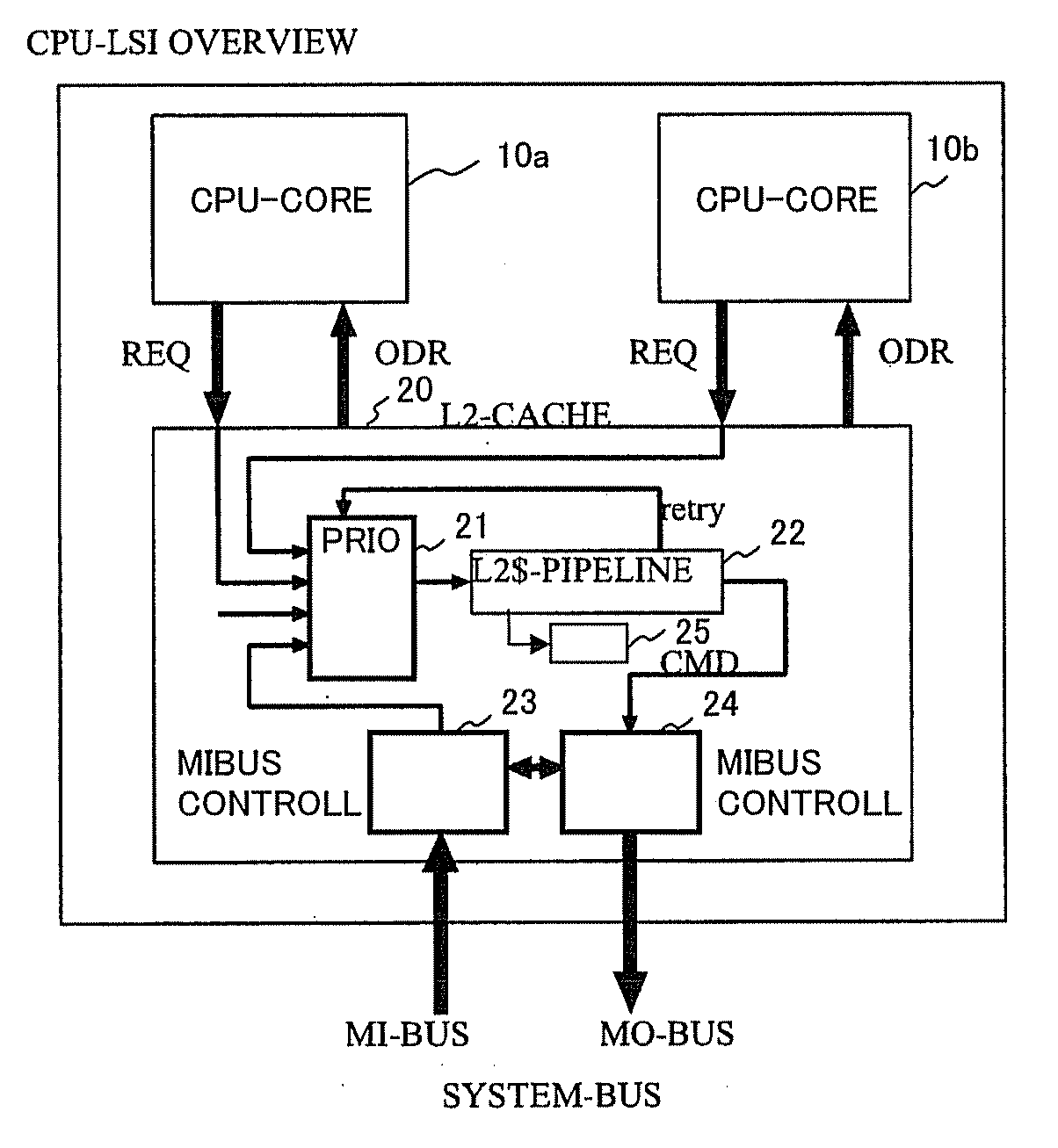

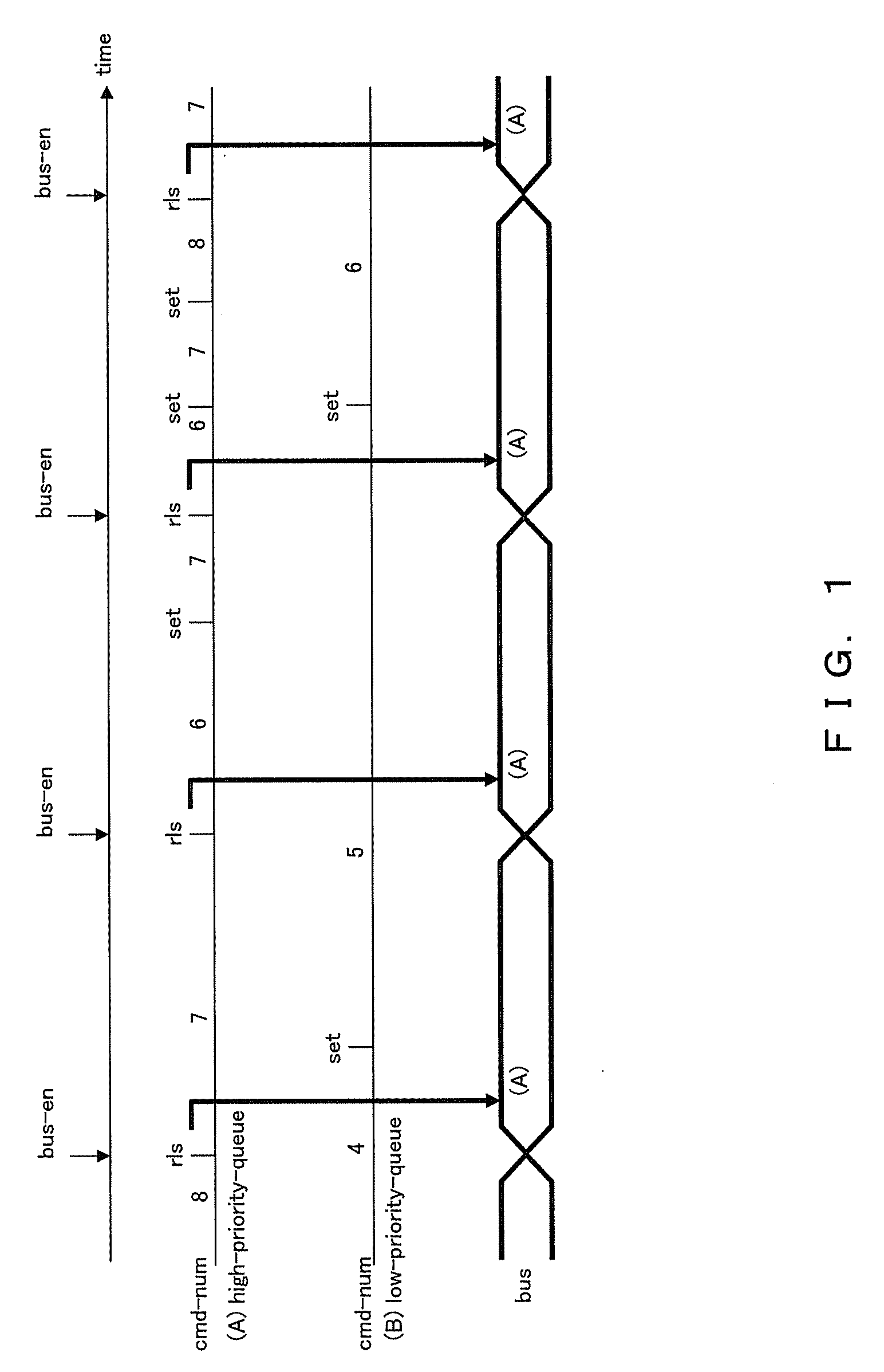

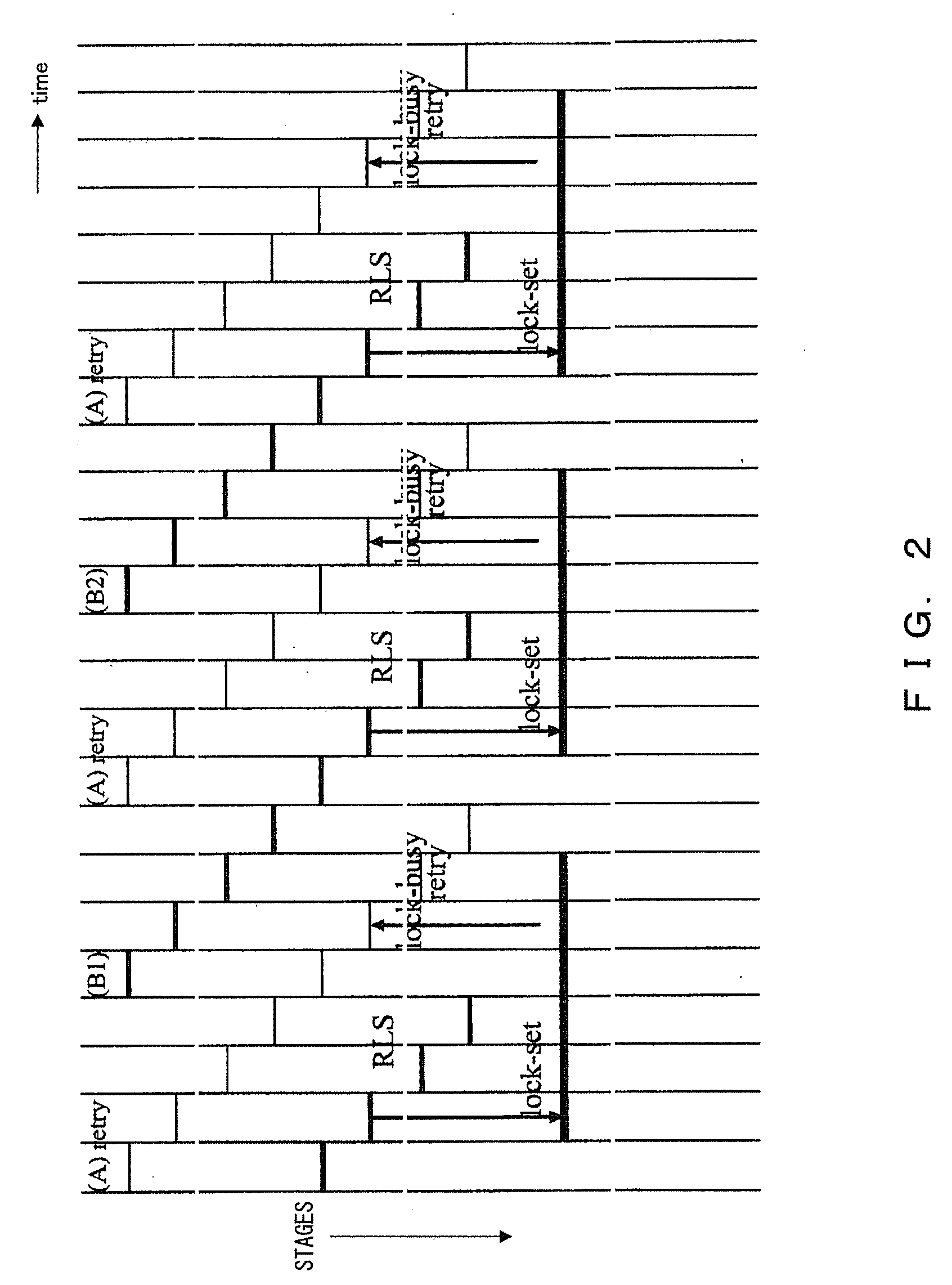

Command selection method and its apparatus, command throw method and its apparatus

InactiveUS20090064153A1Raise the possibilityReduce selection requirementsDigital computer detailsMultiprogramming arrangementsComputer scienceReal-time computing

When selecting one command within a processor from a plurality of command queues vested with order of priority, the order of priority assigned to the plurality of command queues is dynamically changed so as to select a command, on a priority basis, from a command queue vested with a higher priority from among the plurality of command queues in accordance with the post-change order of priority.

Owner:FUJITSU LTD

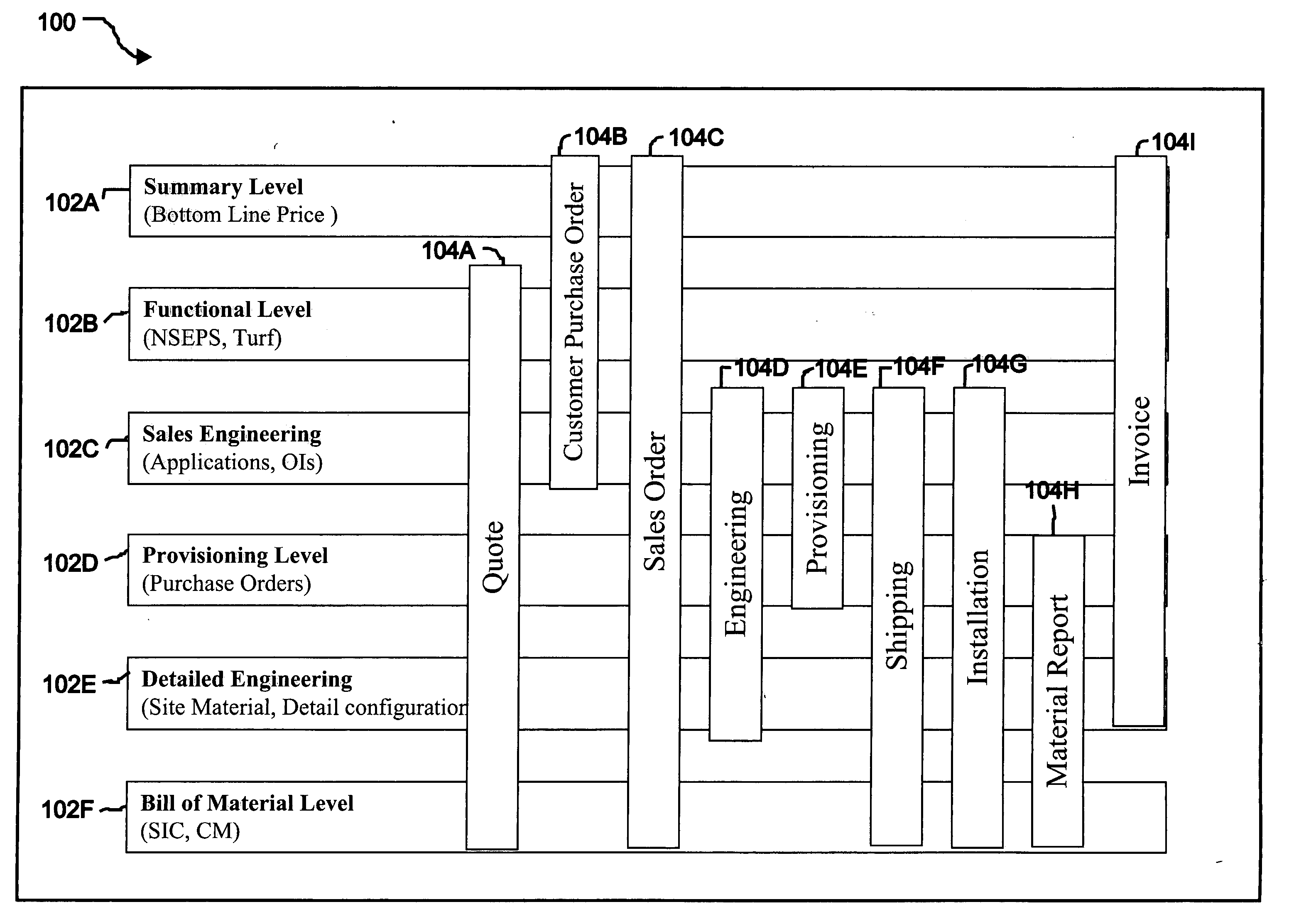

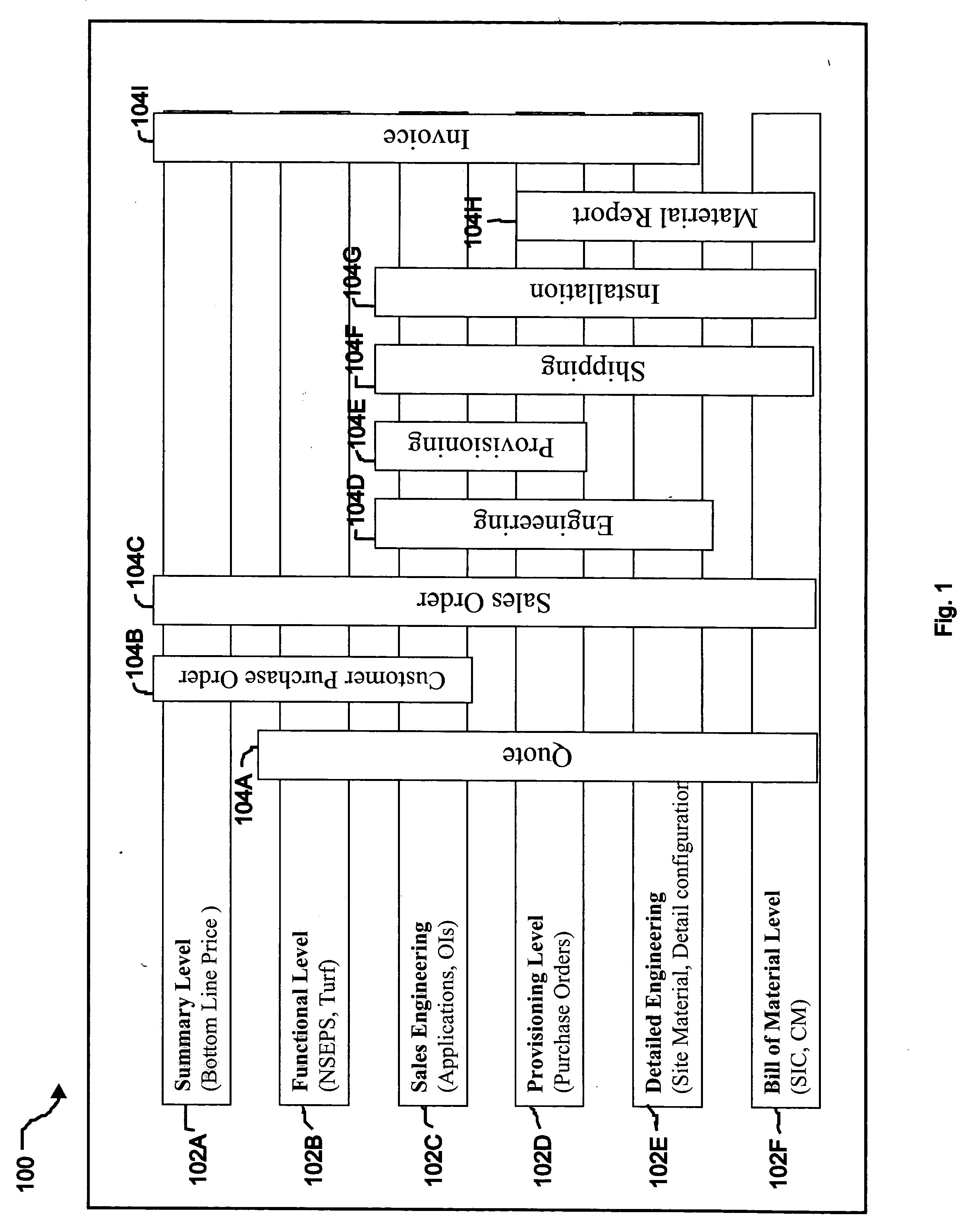

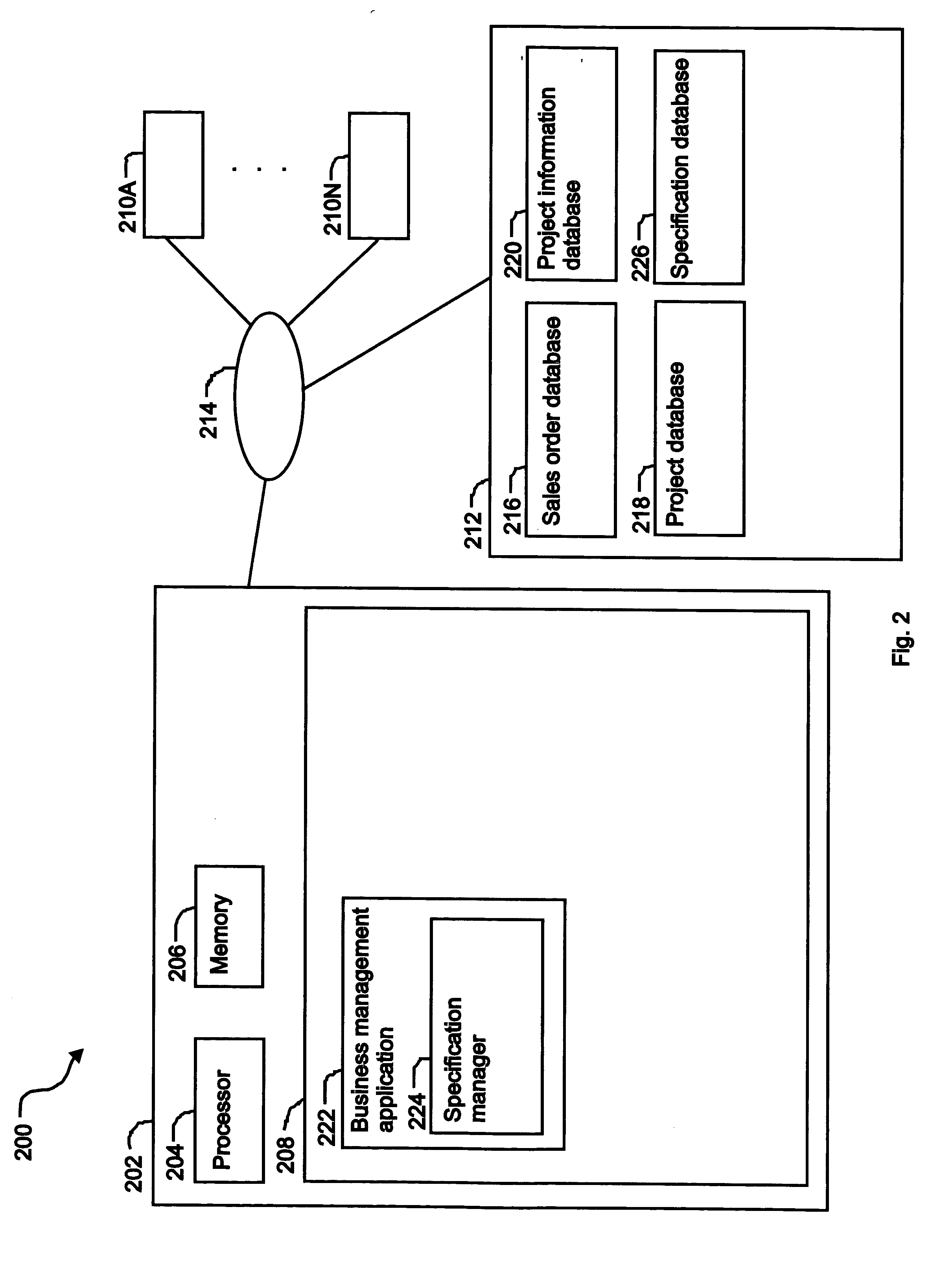

Methods and apparatus for transaction and project management

InactiveUS20050240458A1Low costRevenue easilyResourcesSpecial data processing applicationsLevel of detailBusiness management

Systems and techniques for project management and reporting. A specification manager suitably operates in the context of a business management system. The specification manager collects project information useful for constructing a high level overview of a project and creates a project model describing high level functional elements of the project. The specification manager receives detailed information about the project, suitably by periodically querying a database that is continually updated with project information as the project proceeds. The specification manager organizes the information. The information is organized around high level functional elements. The specification manager may report on and manage the project at a more general or a more specific level of detail. The specification manager supports project changes by maintaining links between change orders and the project model, so progress on a change order is automatically tracked and its impact on cost and revenue easily seen.

Owner:LUCENT TECH INC

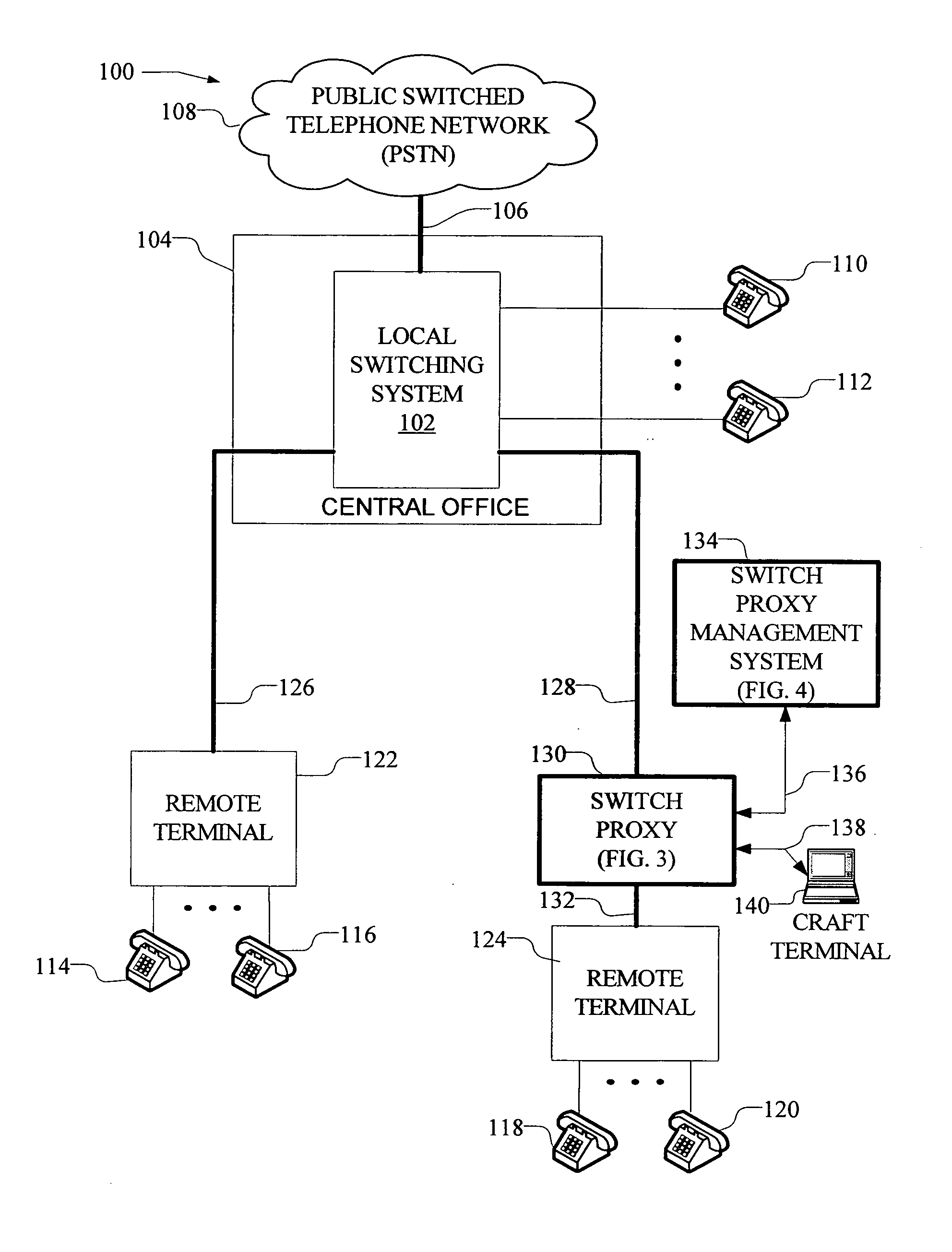

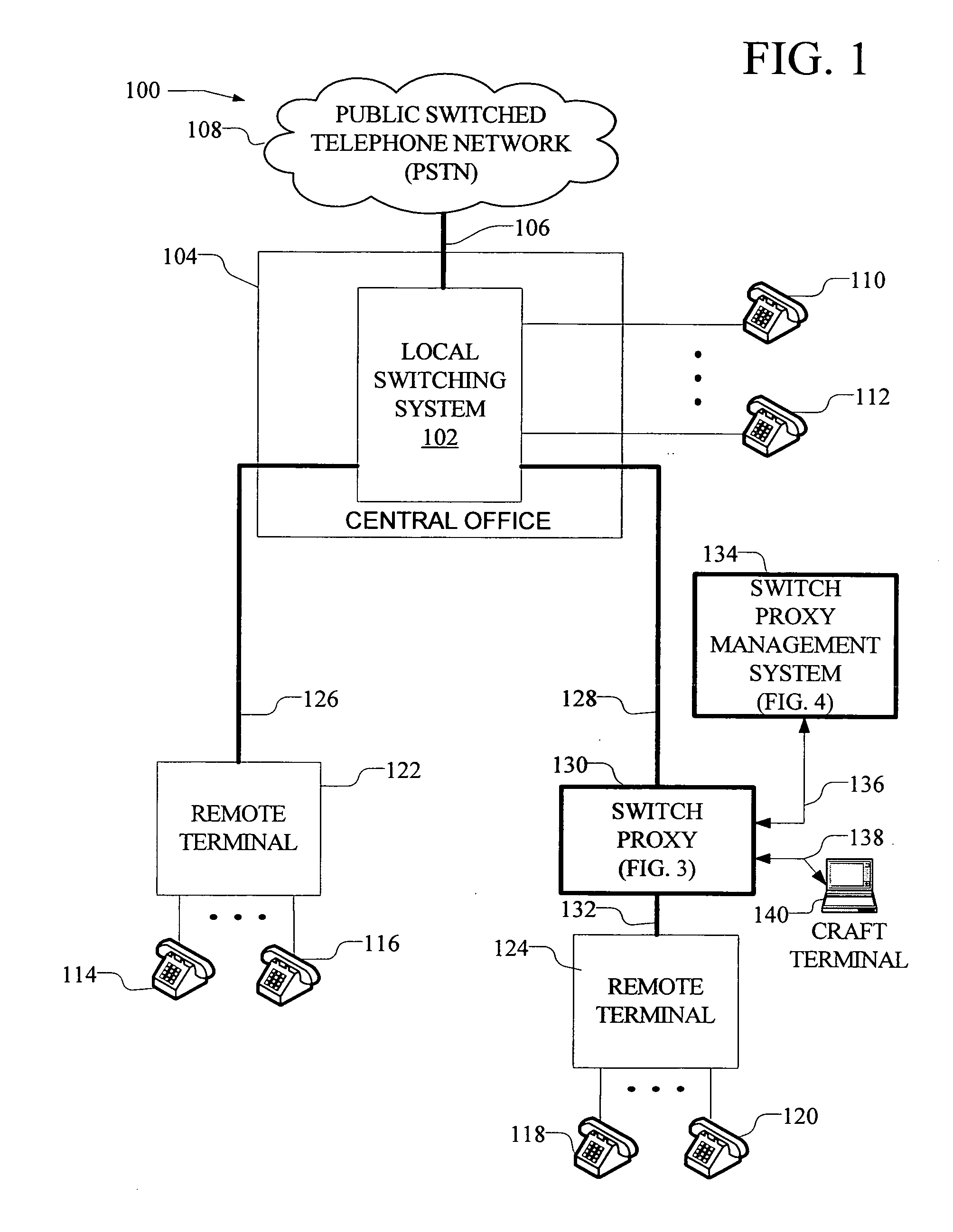

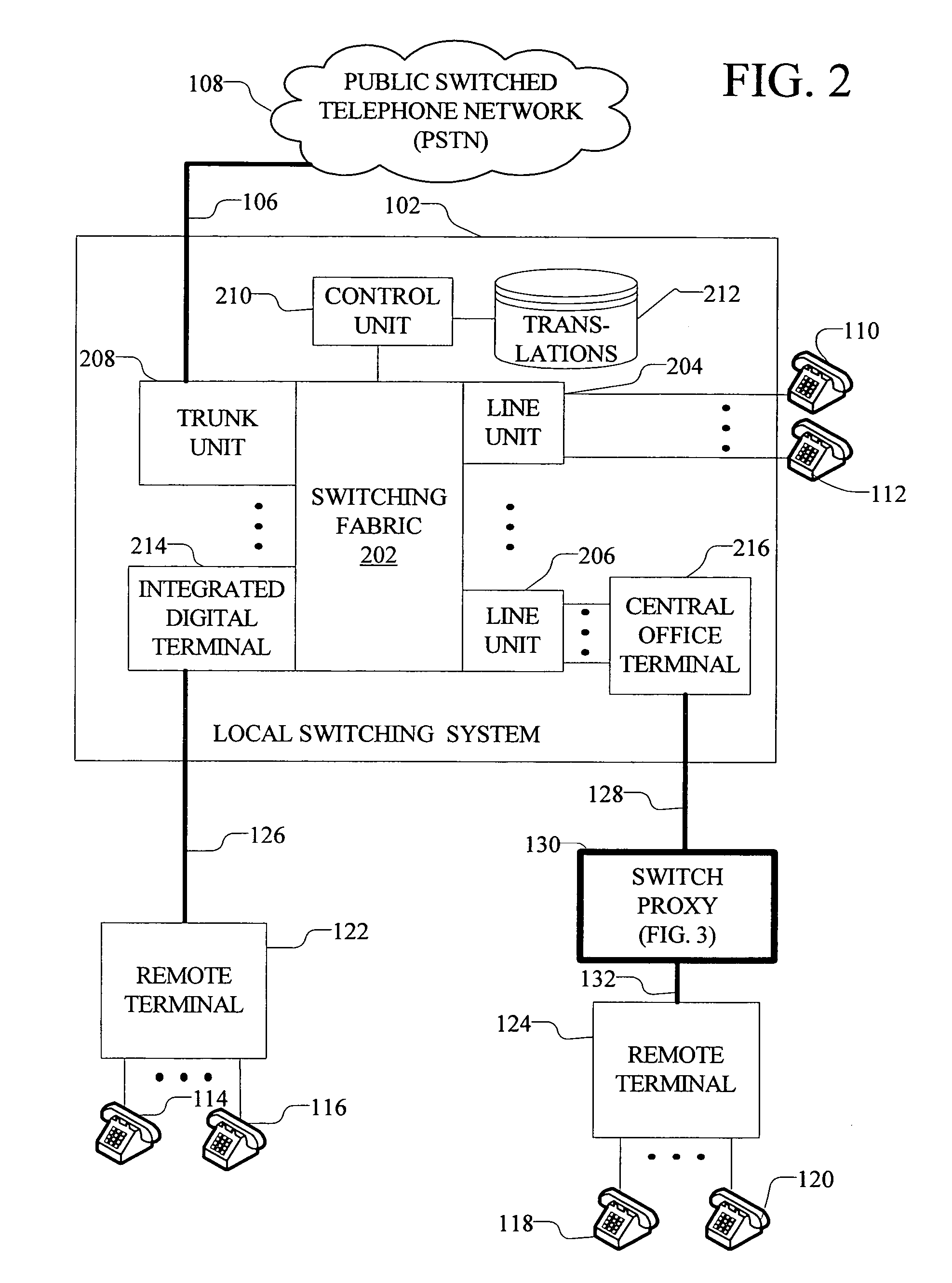

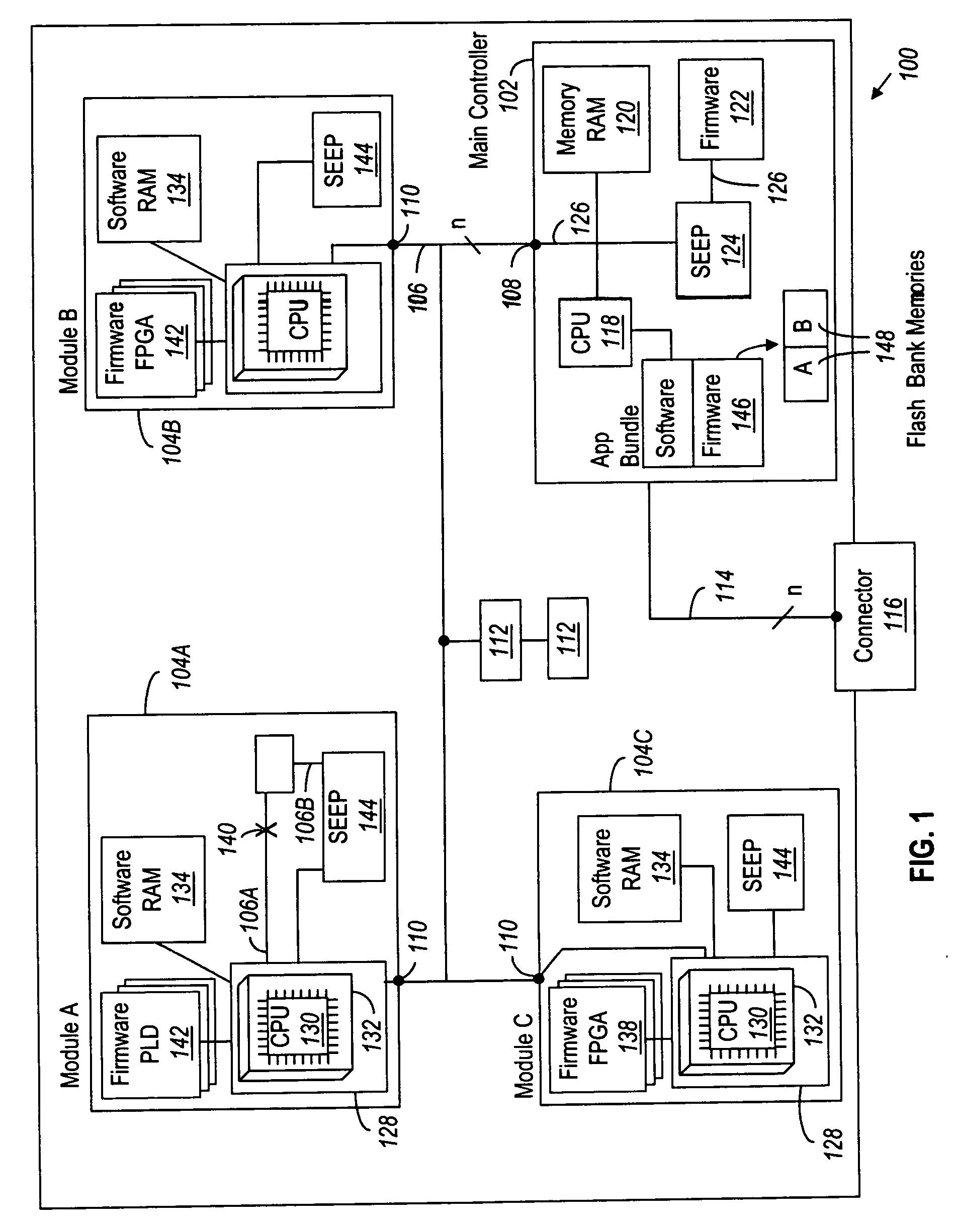

Switch proxy for providing emergency stand-alone service in remote access systems

A switch proxy comprising a controller, a translations database and a switching fabric are connected to a trunk group between a remote terminal and its controlling local switching system. The switch proxy monitors control and alarm signals to and from the switching system on the trunk. In the event of loss of control signals from the host switching system, the switch proxy intercepts requests for service, etc. from a calling telephone connected to the remote terminal and performs a look up in the translation database. If the call can be completed without the controlling switching system the call is looped back to the remote terminal. The translation database is maintained by a switch proxy management system that receives change orders from the local exchange carrier. The switch proxy management system forwards relevant changes to the switch proxy's translation database in the field.

Owner:AZTEK ENG +1

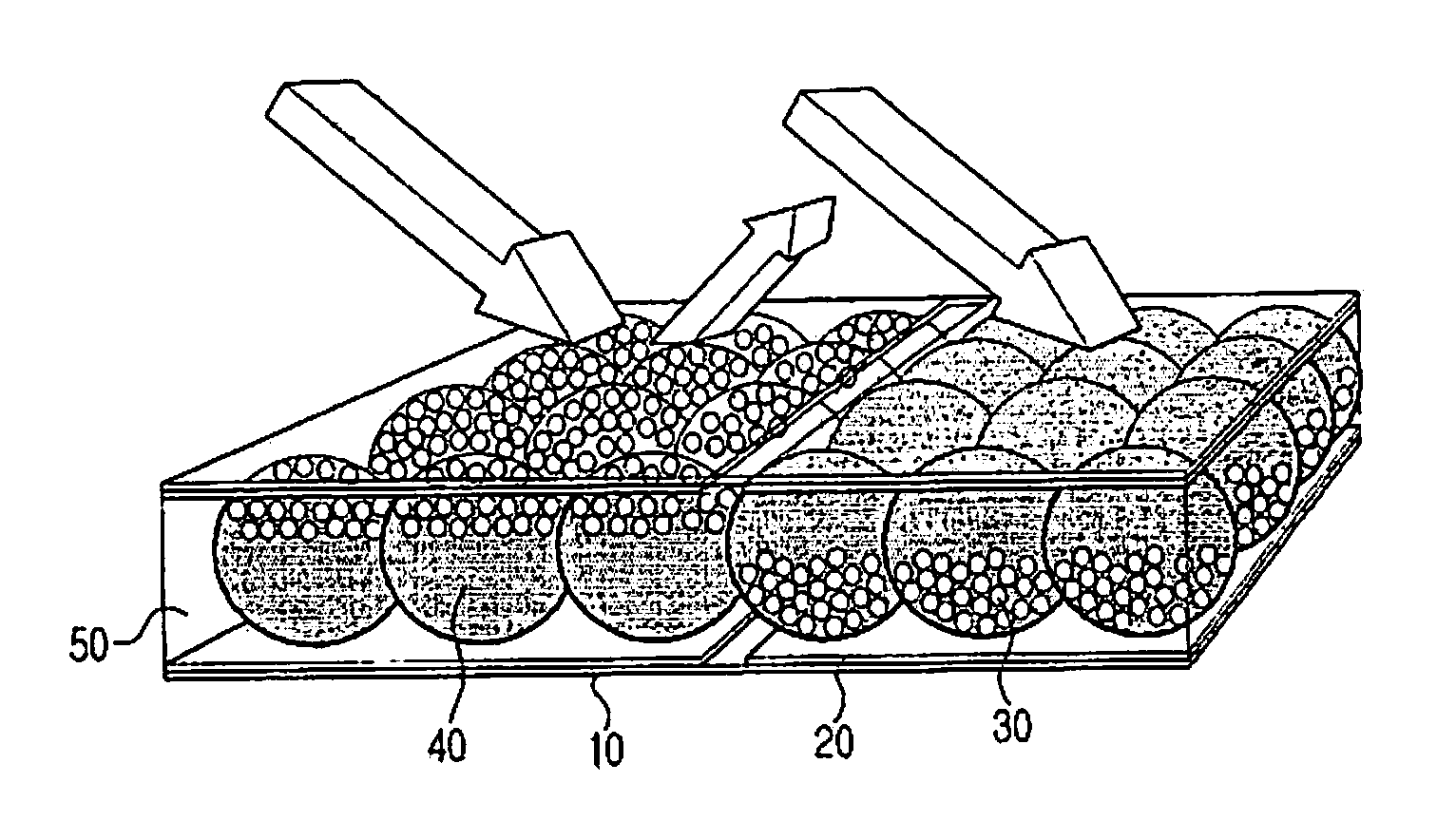

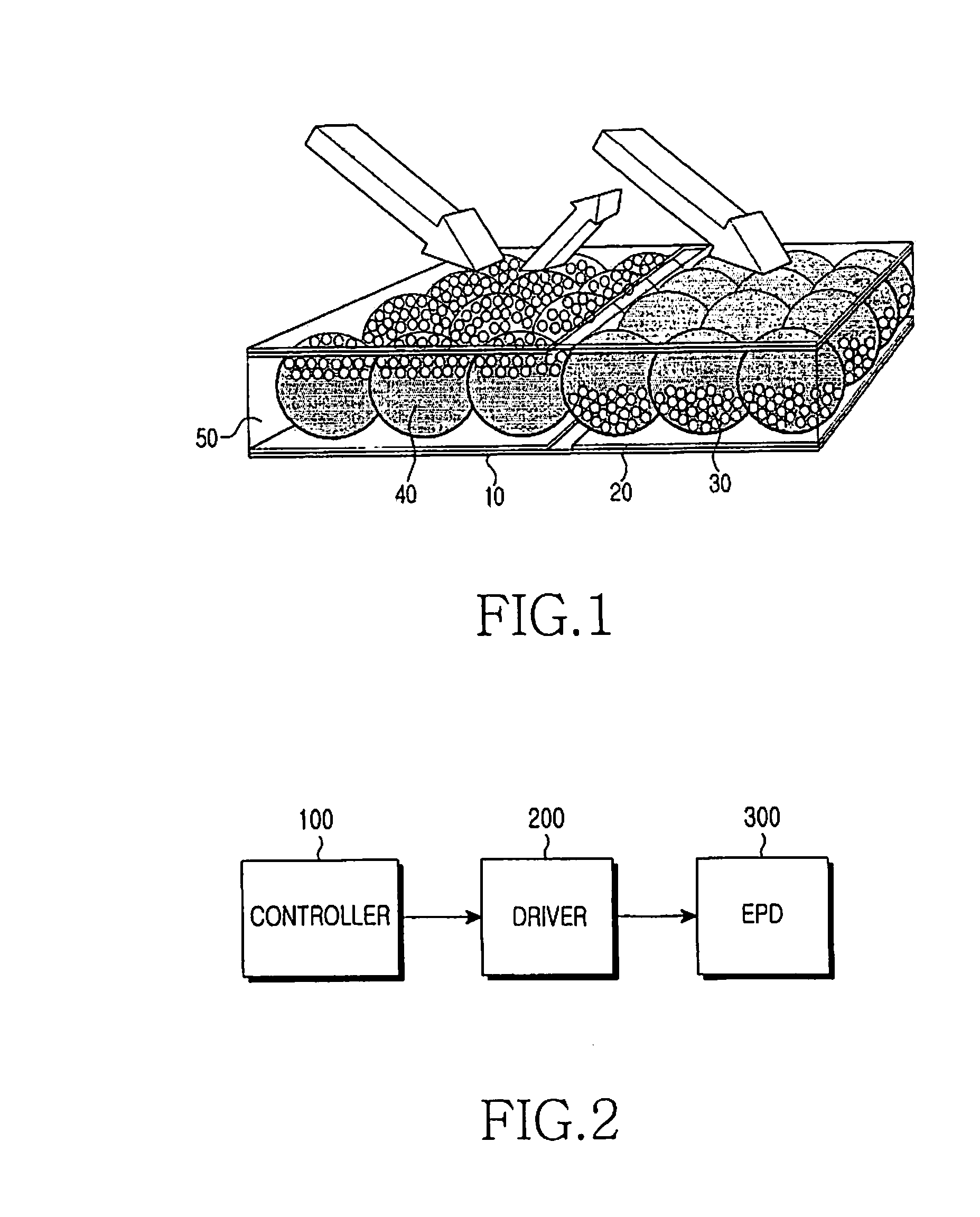

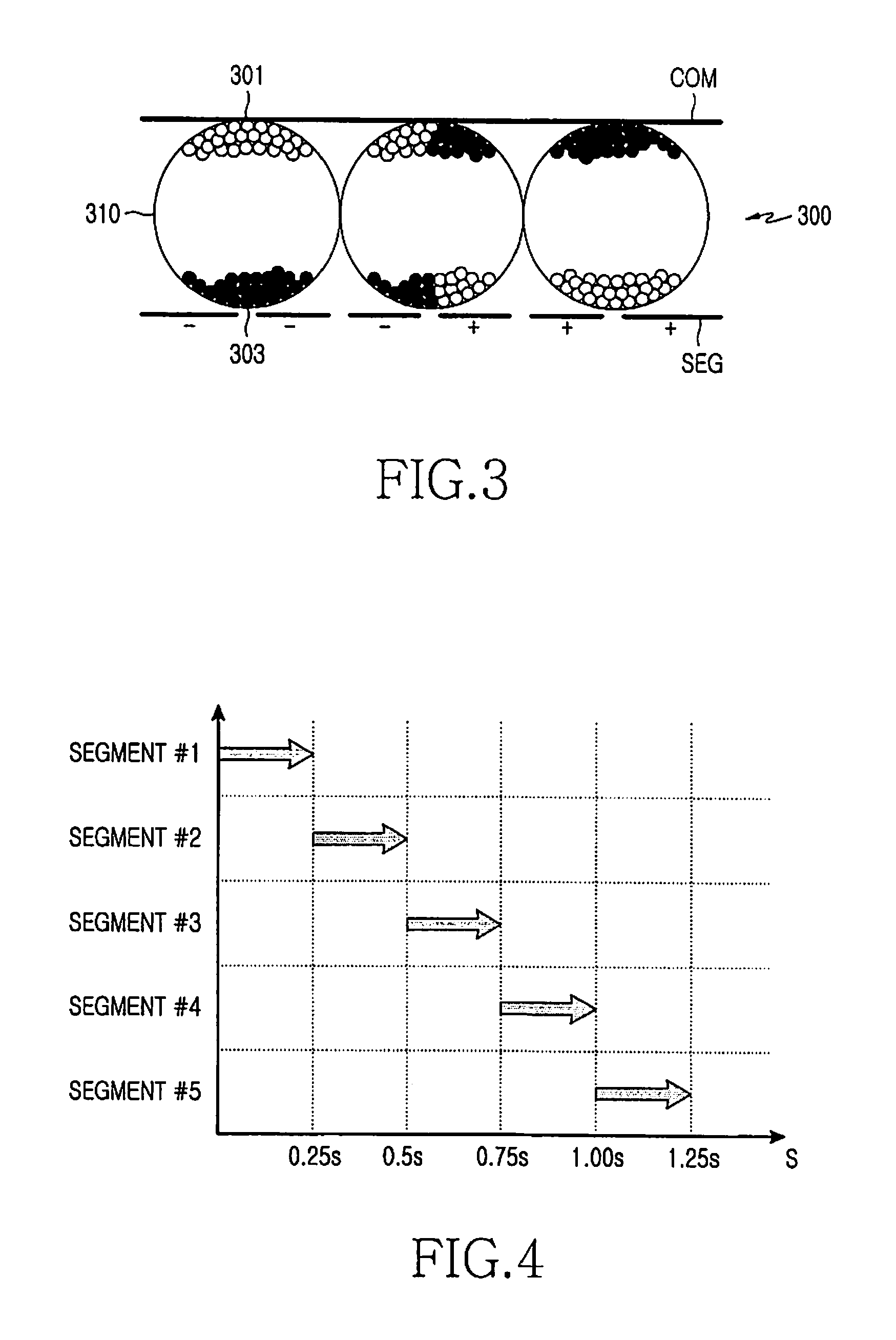

Method and apparatus for driving epd

A method and apparatus for driving an ElectroPhoretic Display (EPD) are provided, in which upon sensing a request for displaying data in a gradual graphic representation scheme, a plurality of segments for displaying the data are determined, a display changing order of the segments is determined, an inter-segment time interval is calculated, driving voltage pulses are applied to a first segment according to the display changing order, and driving voltage pulses are applied to each of the other segments at the inter-segment time interval after driving voltage pulses are applied to a previous segment according to the display changing order.

Owner:SAMSUNG ELECTRONICS CO LTD

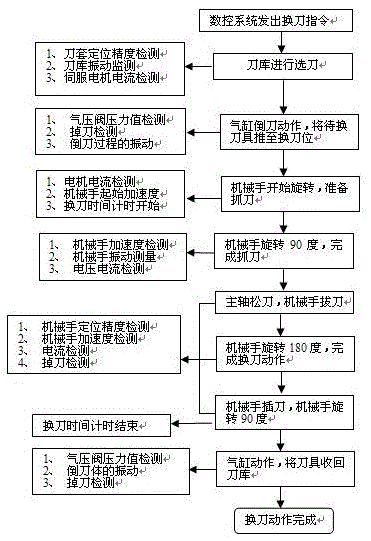

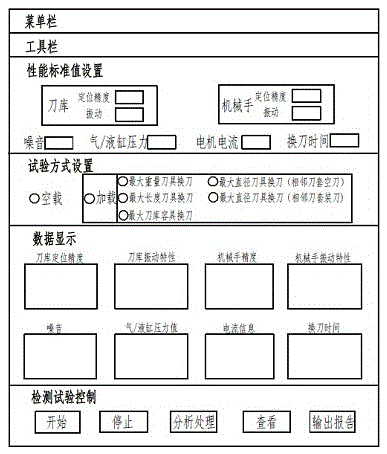

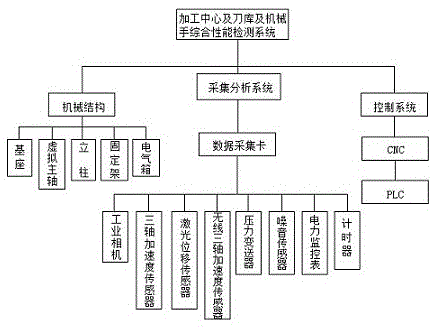

Tool magazine and manipulator comprehensive performance detection method and platform

InactiveCN105643365ADetection performanceAdjustable positionMeasurement/indication equipmentsHuman–machine interfaceEngineering

The invention belongs to the technical field of numerical control machine tools, and particularly relates to a tool magazine and manipulator comprehensive performance detection method and platform. The tool magazine and manipulator comprehensive performance detection method comprises the steps that 1, a numerical control system is controlled to issue a tool change order through a human-computer interface, and a tool magazine starts to select tools; 2, the position precision of tool magazine movement is measured; 3, a pressure value of a cylinder in the tool chamfering process is measured; 4, a manipulator starts to rotate, and a wireless acceleration sensor starts to collect data; 5, noise of the manipulator is detected; 6, the position precision and whether tool falling exists or not are detected; 7, the vibration condition of the manipulator is detected; 8, when the manipulator is in place, whether tool falling exists or not is detected, and the position precision of the manipulator is detected through a laser displacement sensor; 9, the manipulator rotates by 90 degrees and returns to the normal position. Compared with the prior art, the tool magazine and manipulator comprehensive performance detection method and platform have the advantages of being easy to operate, high in practicability, high in precision and the like.

Owner:QINGHAI NO 1 MACHINE TOOL

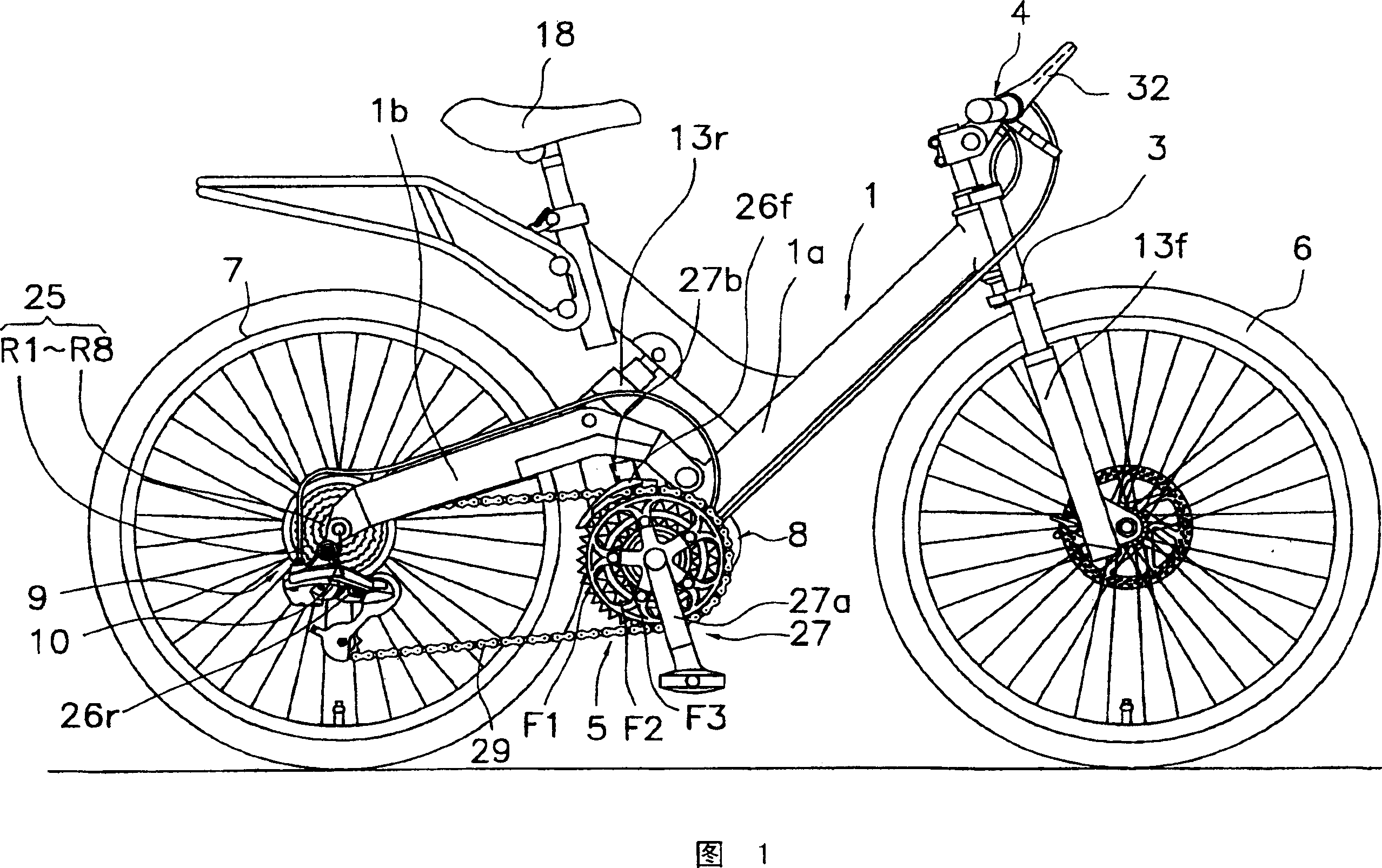

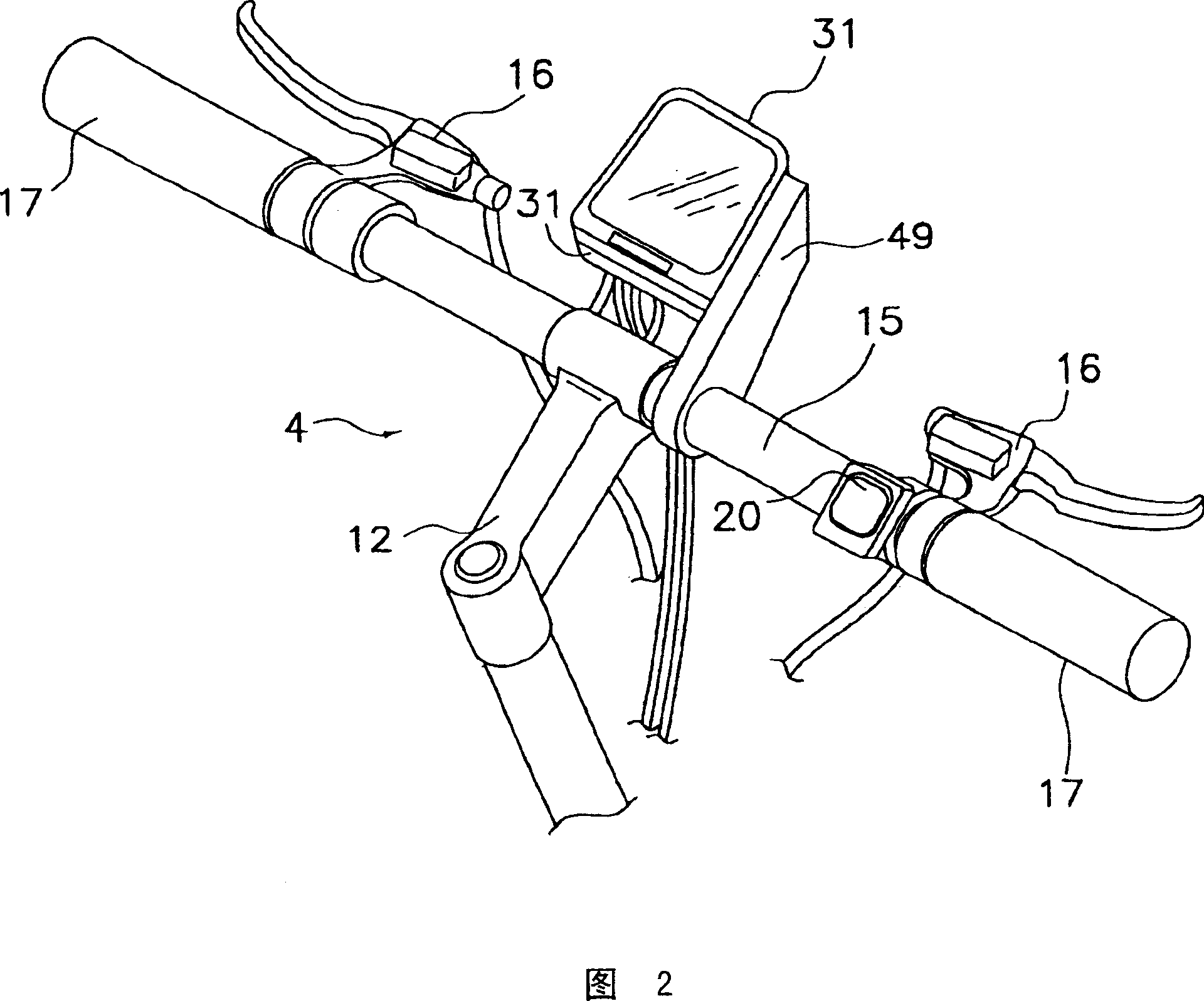

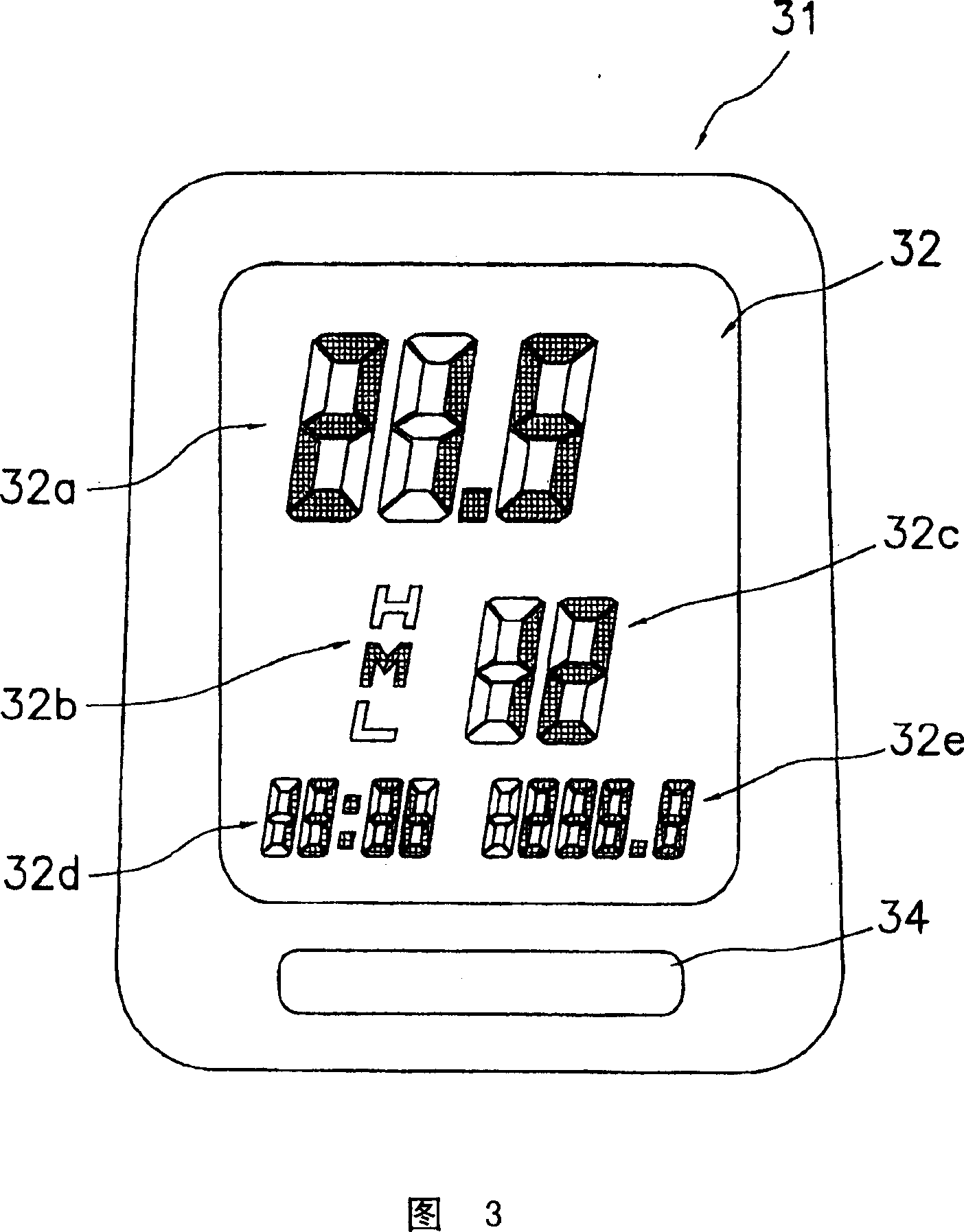

Bicycle shift control device that responds to a manually operated switch

InactiveCN101092158AChain/belt transmissionOptical signalElectrical and Electronics engineeringChange order

To provide a gear shift control device for a bicycle capable of easily performing gear shift operations according to rider's will even if he / she is a beginner. This gear shift control device 11 includes a gear shift switch 20, a speed detection section 36 and a gear shift control section 30. The gear shift switch is a switch for performing the output operation of a speed change order to a front derailleur 26f and a rear derailleur 26r having a plurality of gear shift stages. The speed detection section is a device for detecting the speed of a bicycle. The gear shift control section sets the front derailleur and the rear derailleur to the specified gear shift stage according to the detection result by the speed detection section when the speed change order is output by the operation of the gear shift switch.

Owner:SHIMANO INC

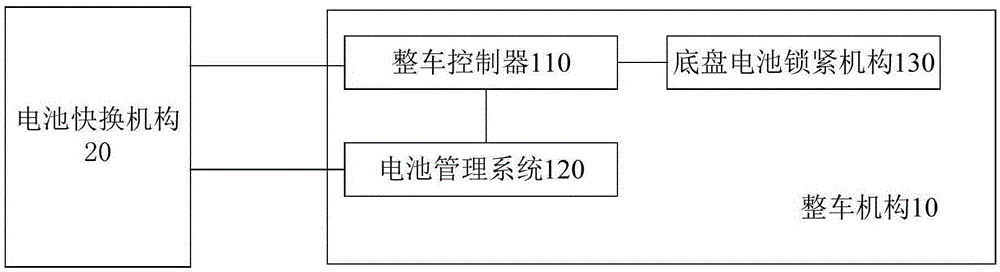

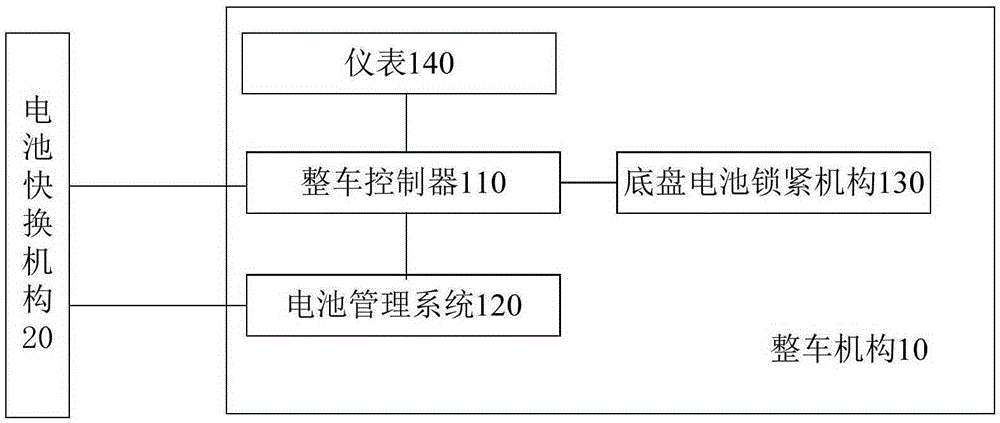

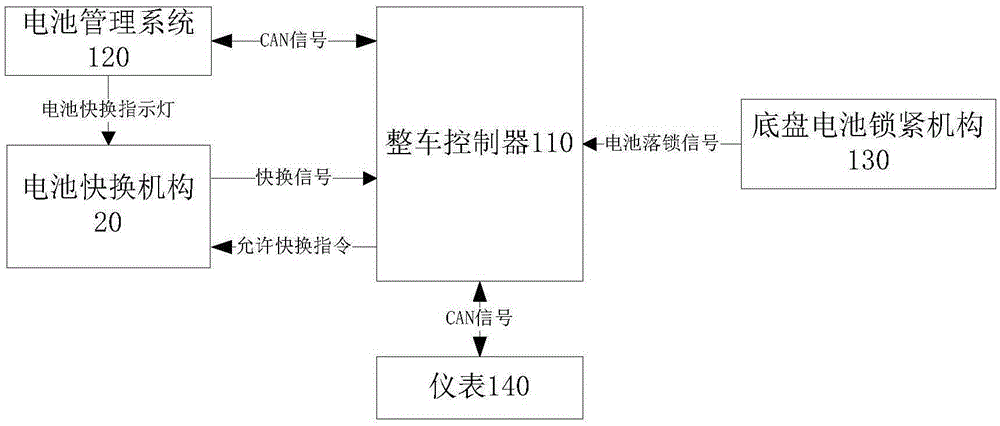

Power-change type electric vehicle power on/off control system and method

ActiveCN105235544ARealize monitoringImprove efficiencyVehicular energy storageElectric propulsionElectrical batteryLow voltage

The invention discloses a power-change type electric vehicle power on / off control system and method; the system comprises a vehicle mechanism and a vehicle control unit; the vehicle mechanism comprises the vehicle control unit, a battery management system, and a chassis batter locking mechanism; the vehicle control unit is used for detecting a battery locking signal sent by the chassis battery locking mechanism and a battery fast change signal sent by a battery fast change mechanism, controlling high / low voltage power on / off of the vehicle in a battery fast change process according to the battery locking signal and the battery fast change signal, and sending a permitted fast change order to the battery fast change mechanism; the battery fast change mechanism is used for replacing the cell pack in the battery manage system according to the permitted fast change order. The system and method can monitor the power change process of the vehicle; if the vehicle high voltage system is connected and electrified in the beginning of the power change process, the system and method can automatically disconnect the high voltage, thus improving efficiency and safety of the power change process.

Owner:BEIJING ELECTRIC VEHICLE

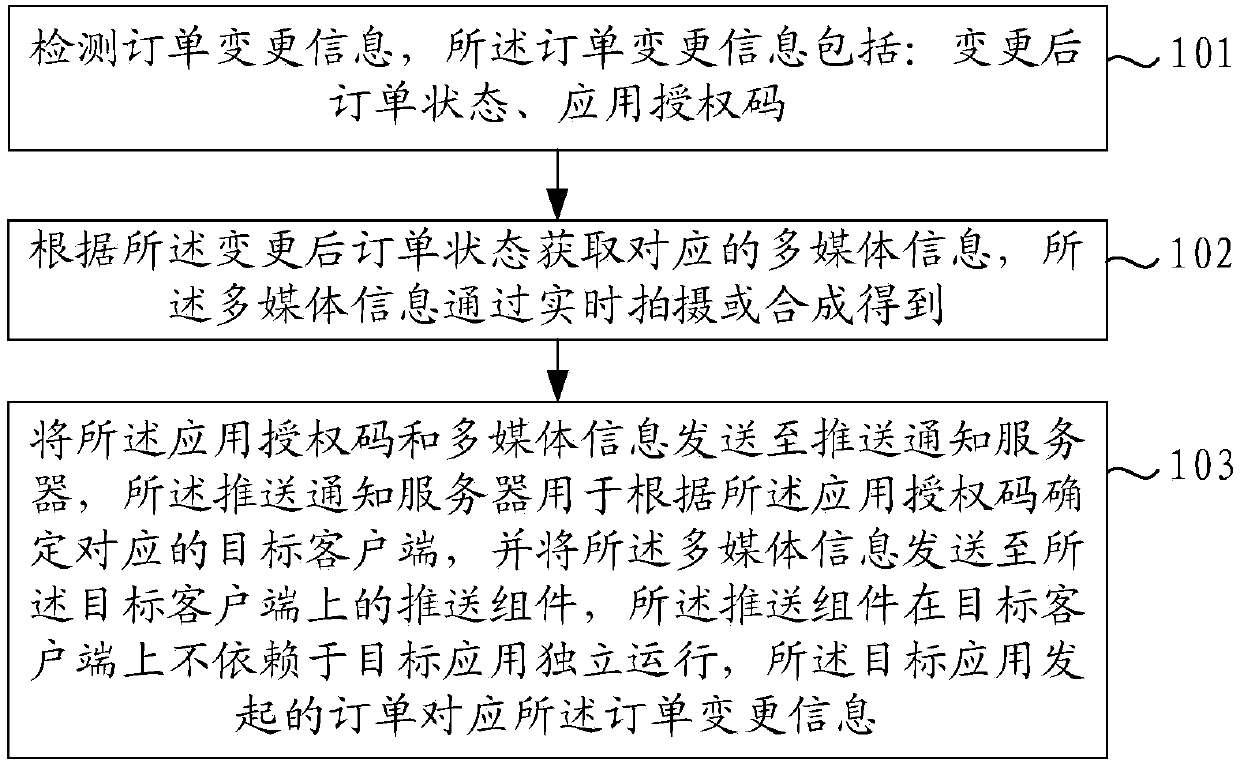

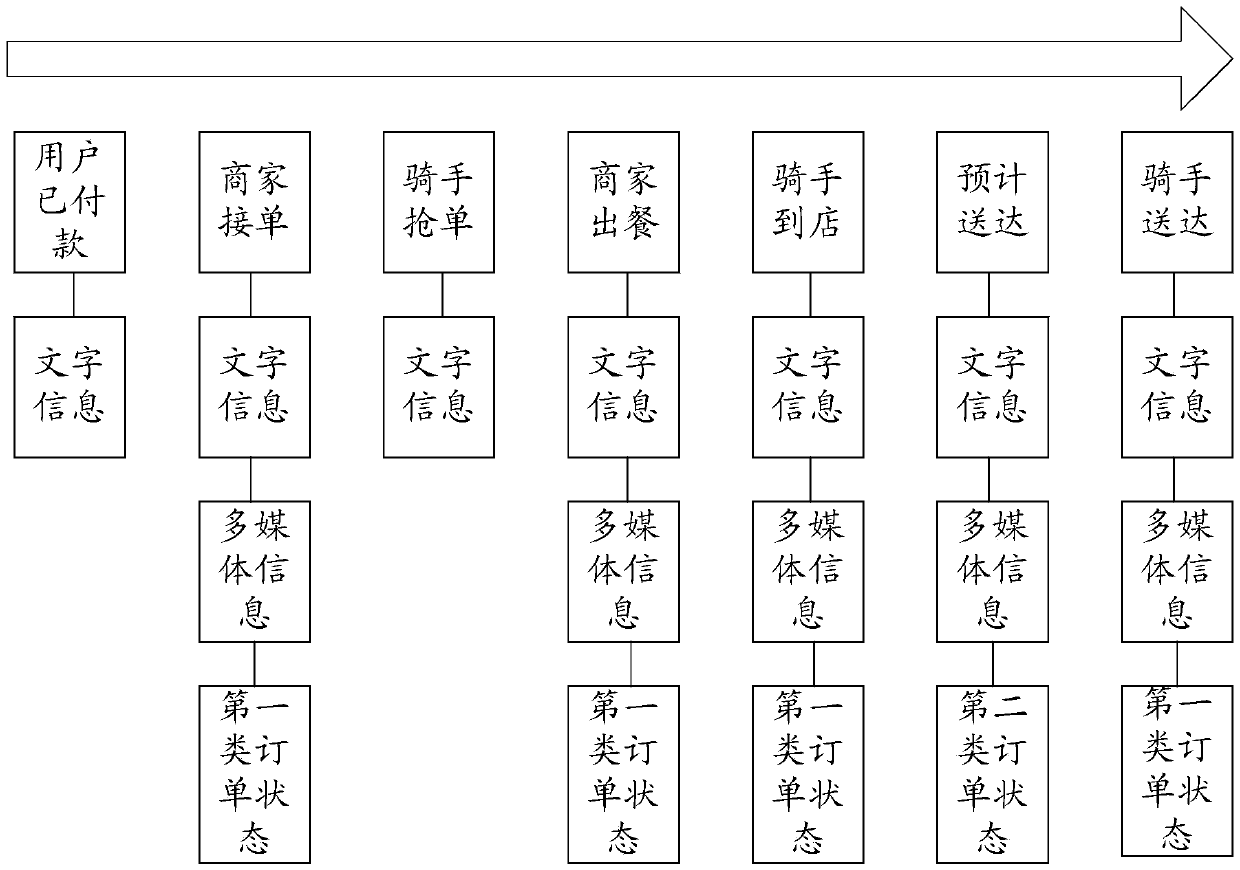

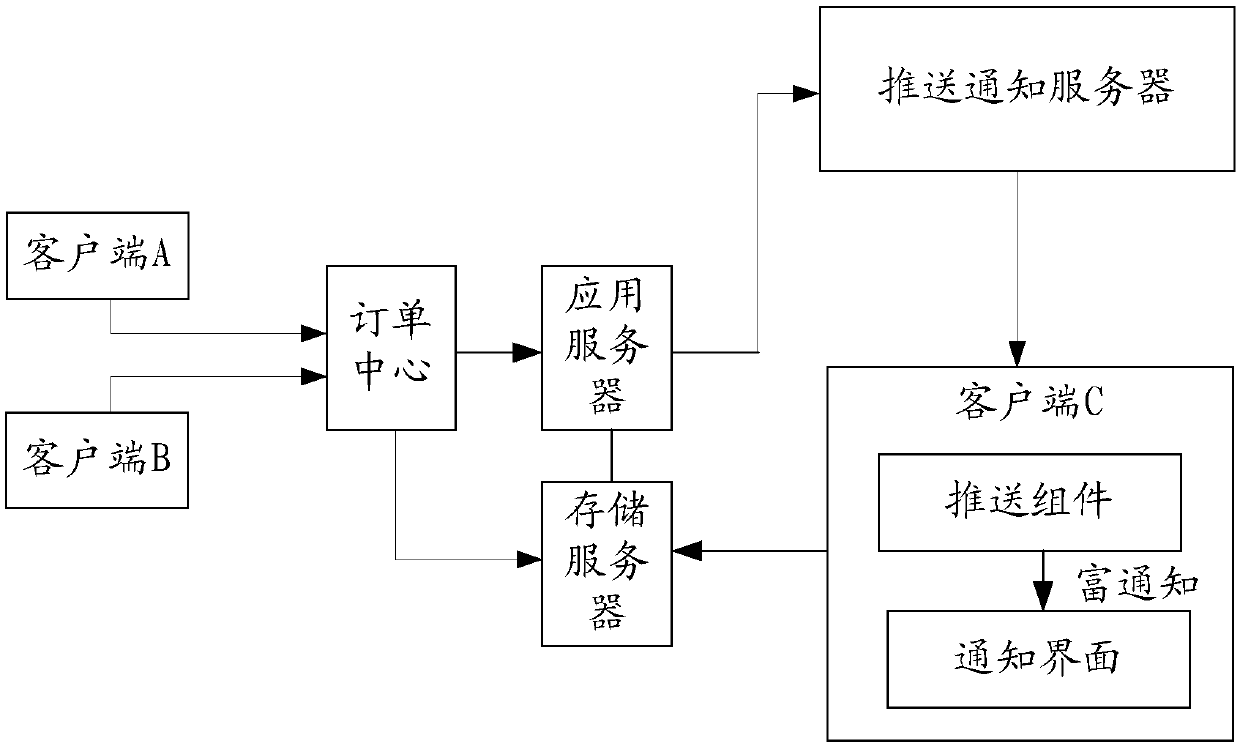

Order status push method and device, electronic equipment and readable storage medium

ActiveCN109688196AEnsuring rich expressionAvoid problems with high operational complexityTransmissionOrder statusAuthorization

The embodiments of the disclosure provide an order status push method and device, electronic equipment and a readable storage medium. The method comprises the following steps: detecting order change information, including: a changed order status and an application authorization code; acquiring real-time shot or synthesized multimedia information according to the changed order status; and sending the application authorization code and the multimedia information to a push notification server to determine a corresponding target client according to the application authorization code, and sending the multimedia information to a push component on the target client, wherein the push component runs independently of a target application on the target client, and an order initiated by the target application corresponds to the order change information. Change prompt information containing multimedia information and / or text information can be sent to the independently running push component to ensure rich expression while helping to avoid the problem of high operational complexity caused by online calls.

Owner:BEIJING SANKUAI ONLINE TECH CO LTD

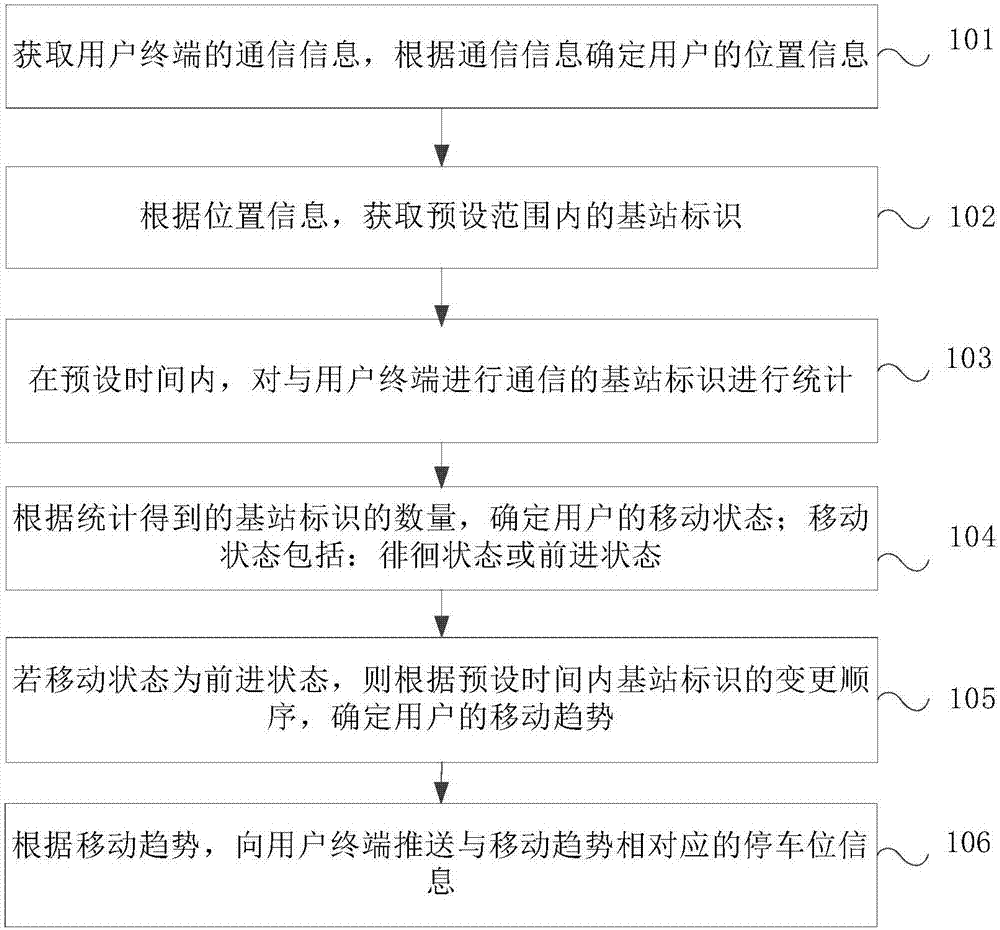

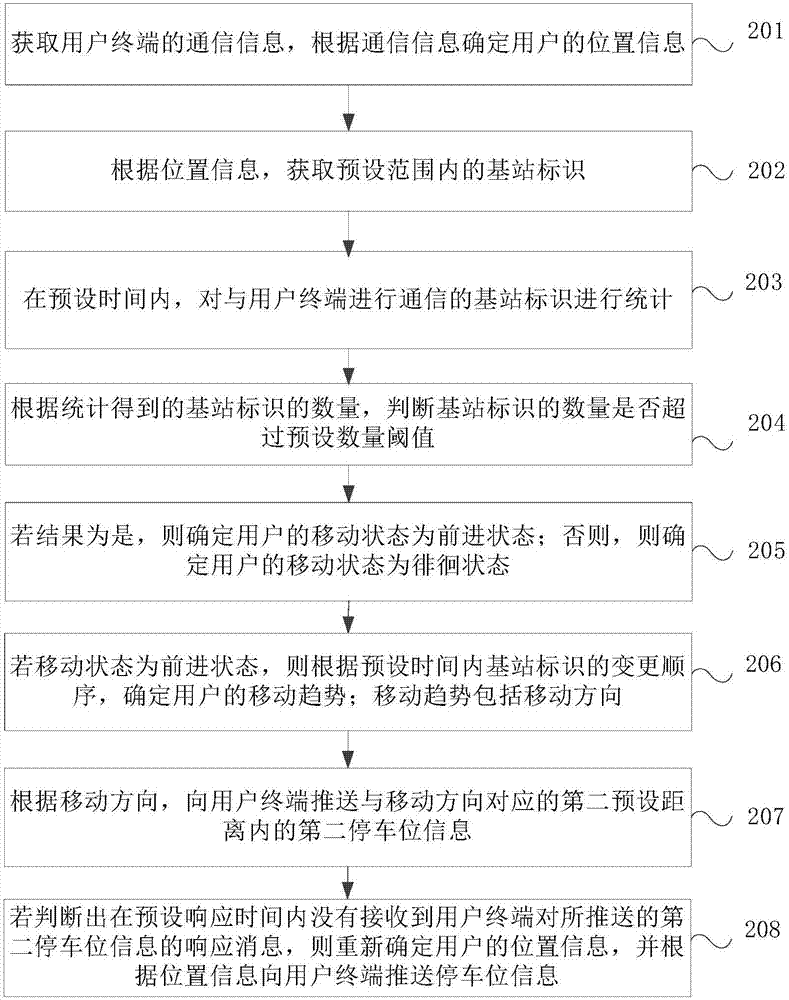

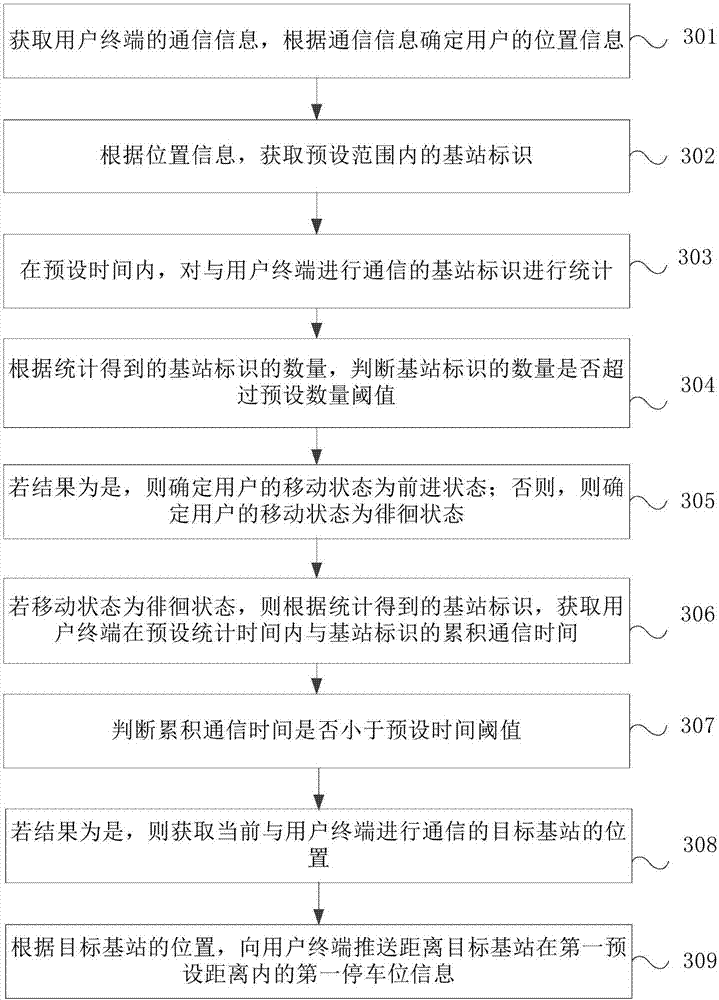

Method and device for pushing parking spaces

ActiveCN107274714AImprove parking efficiencyAvoid wasting timeIndication of parksing free spacesMessaging/mailboxes/announcementsParking areaParking space

The invention provides a method and a device for pushing parking spaces. The method includes the following steps: acquiring communication information of a user terminal, and determining location information of a user according to the communication information; acquiring base station identifiers in a preset range according to the location information; counting base station identifiers communicating with the user terminal within a preset time; determining the moving state of the user according to the number of the base station identifiers, wherein the moving state is a wandering state or an advancing state; if the user is an advancing state, determining the moving trend of the user according to the change order of the base station identifiers within the preset time; and pushing parking space information corresponding to the moving trend to the user terminal according to the moving trend. According to the invention, users can acquire parking space information of a parking lot in real time before arriving at the parking lot. Therefore, the parking efficiency of users is improved, waste of time and manpower cost is avoided, and traffic jam is avoided.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

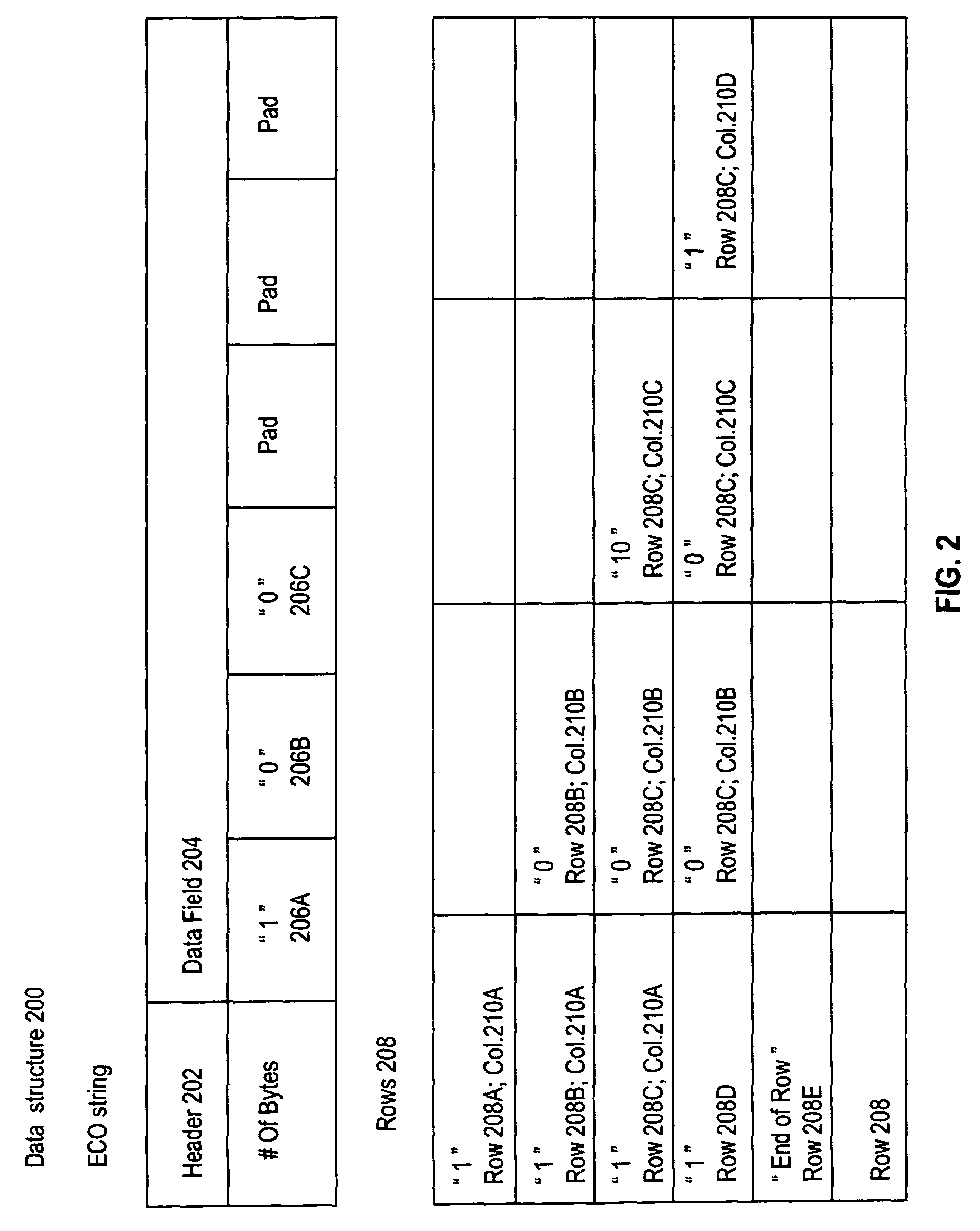

System and method for tracking engineering changes relating to a circuit card

InactiveUS20040186690A1Printed circuit aspectsDigital computer detailsHistory of engineeringComputer compatibility

The invention provides a system and a method of electronically tracking a history of engineering change orders (ECOs) associated with a manufactured device. The device has at least one electronic component thereon. The method comprises, generally, storing in an electronic storage device associated with the device, the history of ECOs and updating the history of ECOs when a new ECO is associated with the device to indicate whether the new ECO was implemented on the device. The system utilizes the method and has an electronic storage device associated with the device and a data element stored therein. The contents thereof indicate the history of ECOs for the device and allow modification thereto to indicate whether a new ECO was implemented thereon. An ECO history enables a determination to be made of compatibilities between hardware and software elements and between hardware and firmware elements.

Owner:ALCATEL LUCENT SAS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com