Patents

Literature

660 results about "It design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

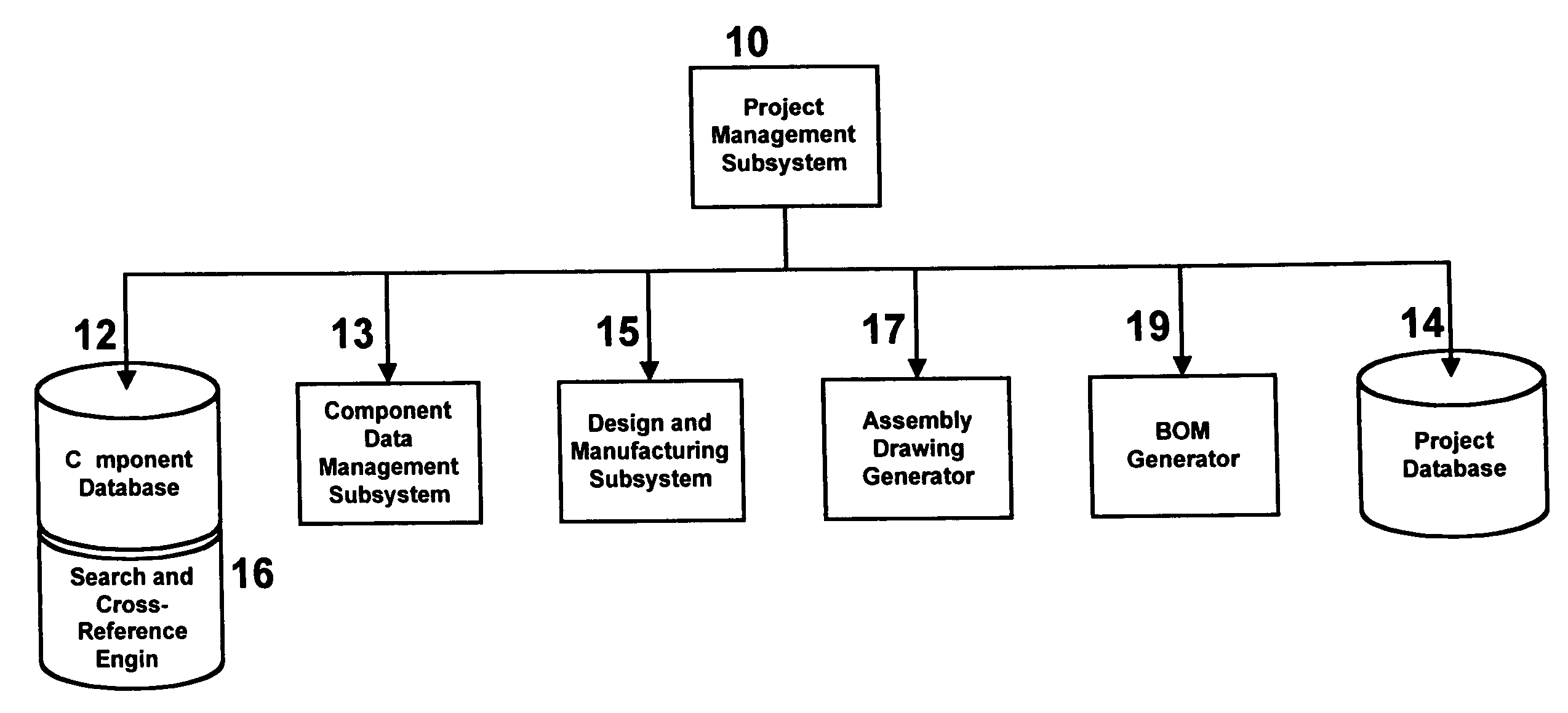

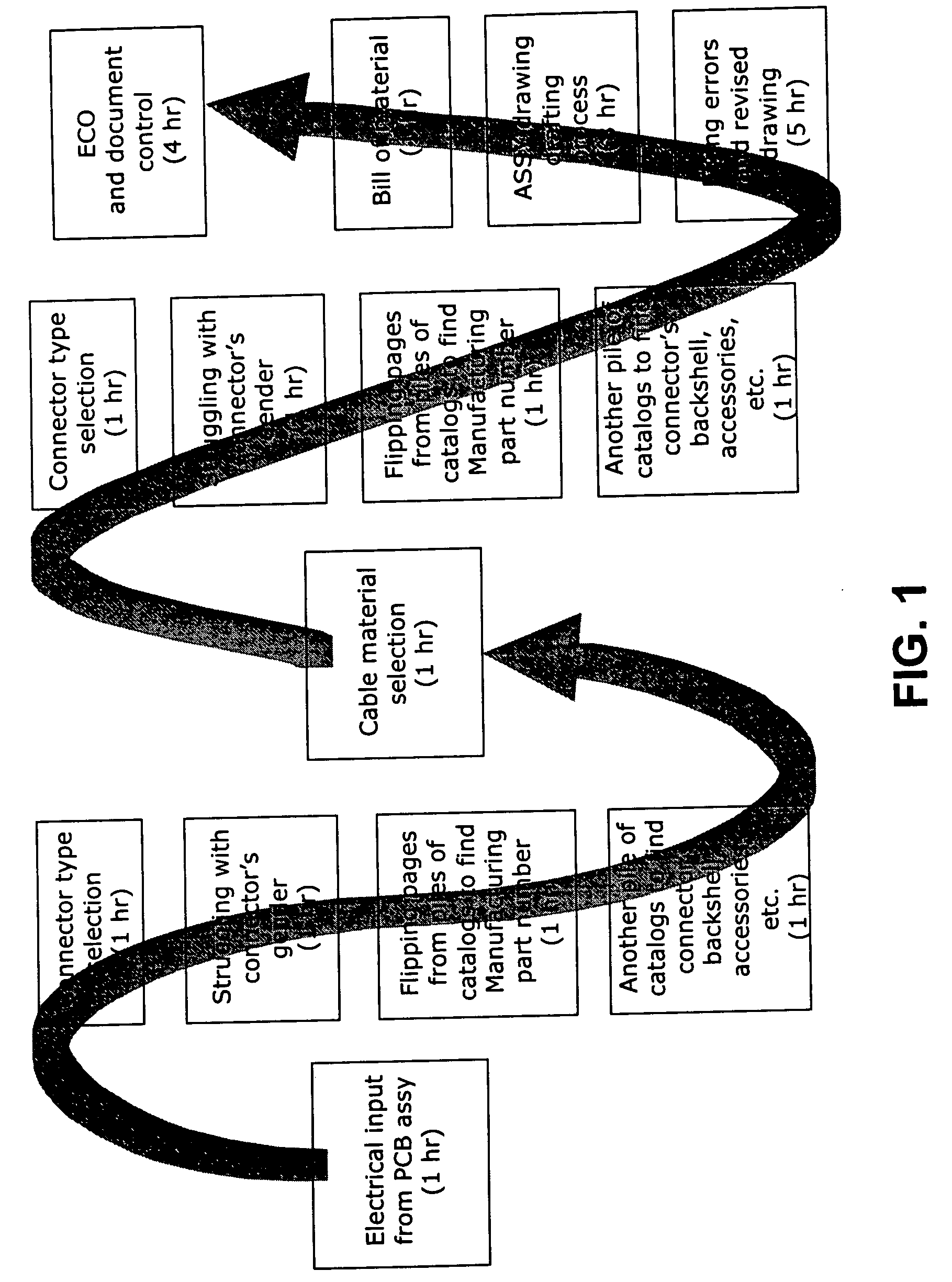

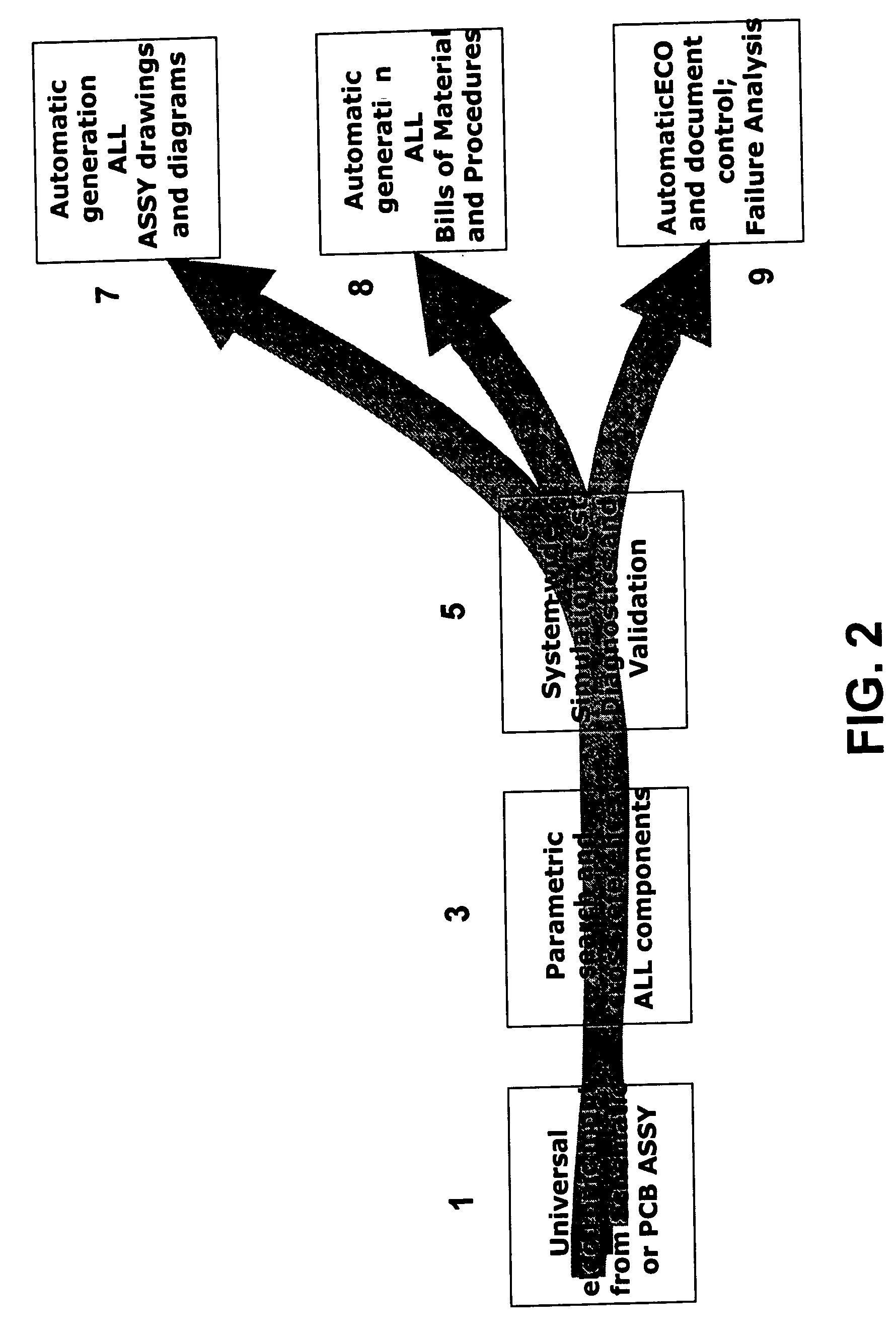

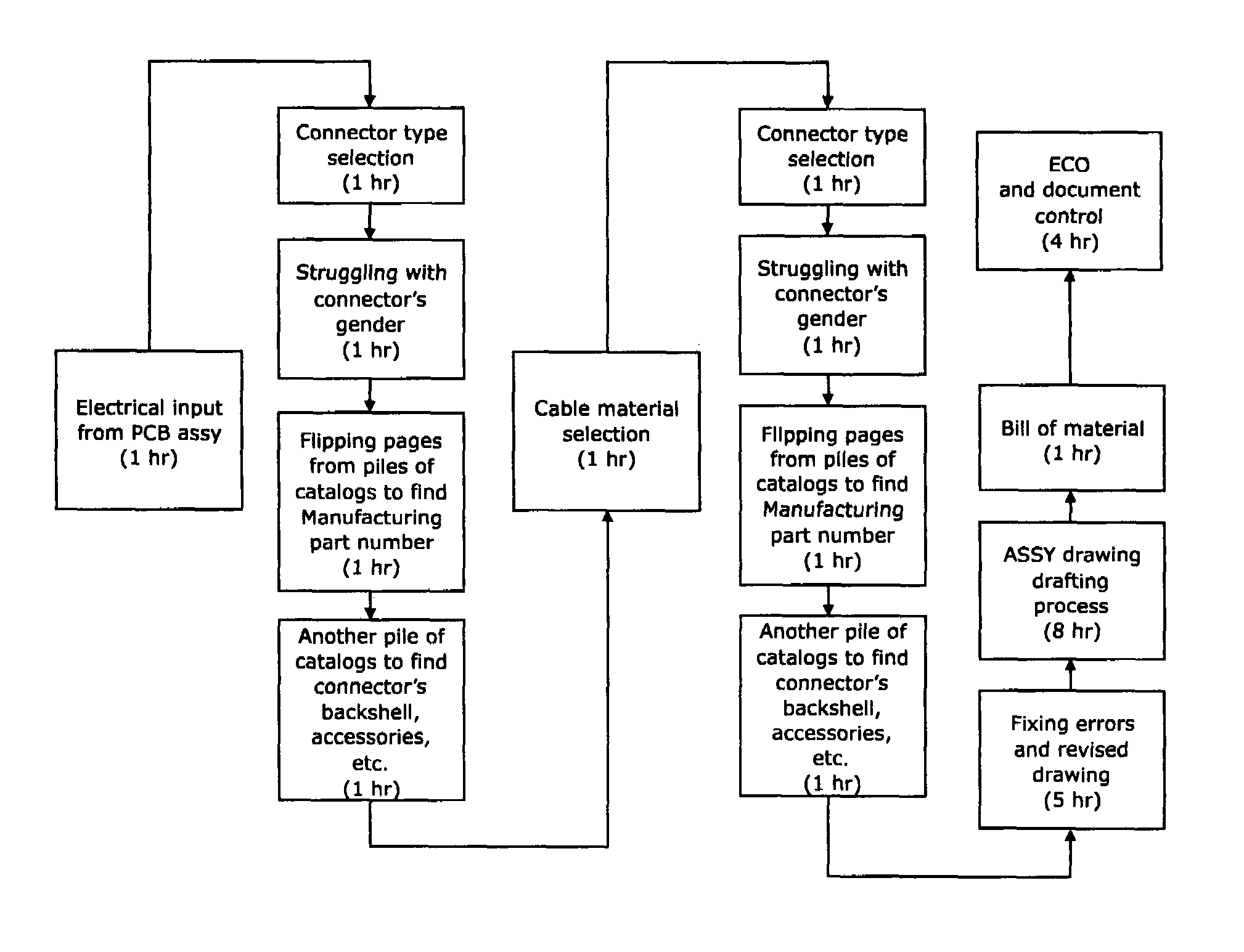

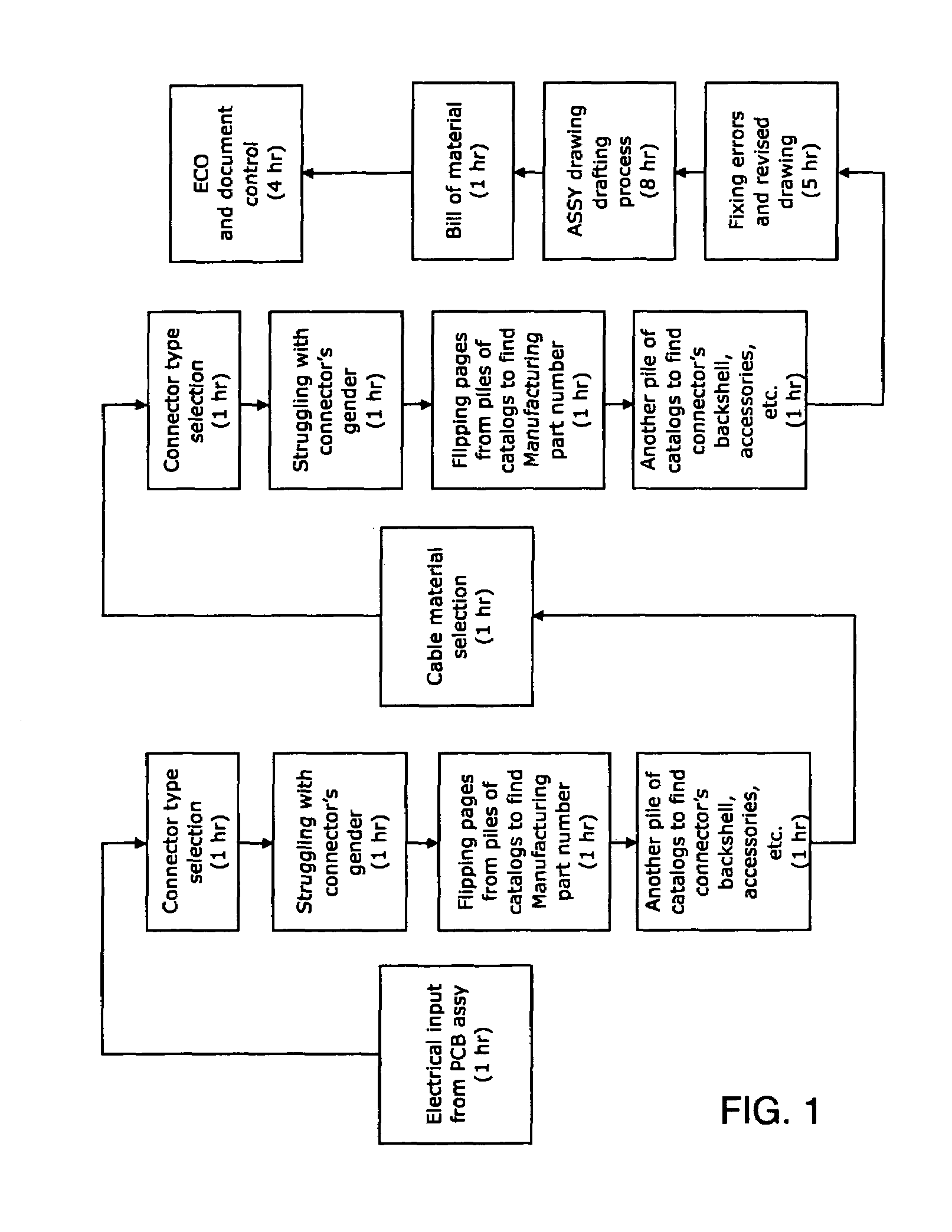

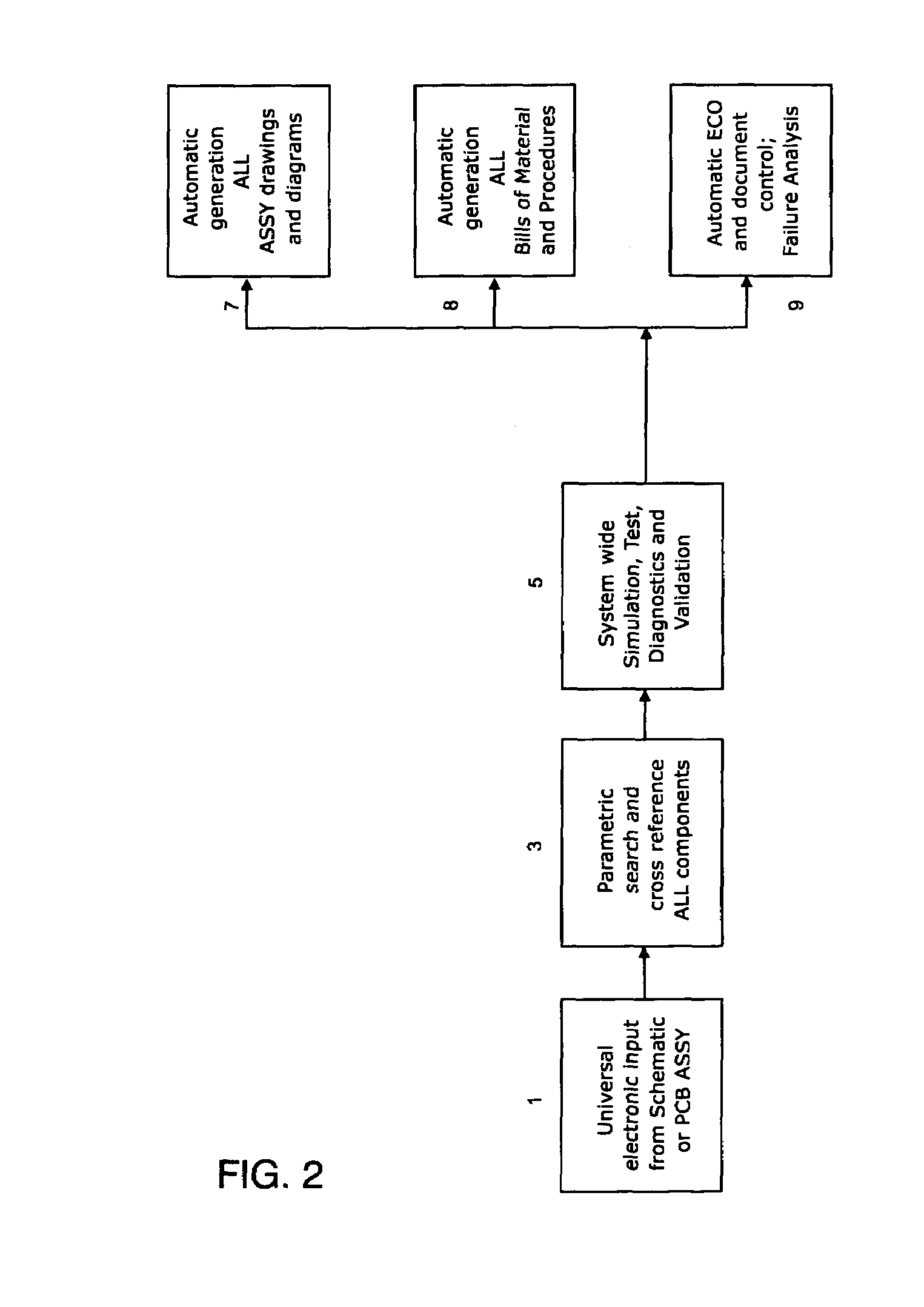

PLM-supportive CAD-CAM tool for interoperative electrical & mechanical design for hardware electrical systems

InactiveUS20050080502A1Reduce frictionCAD network environmentComputer programmed simultaneously with data introductionTask completionBill of materials

This invention is a tool for computer-aided design, computer-aided manufacturing forming a Project Management System, comprising: (1) a Component Database; (2) a Component Data Management System; (3) a Design and Manufacturing System; (4) an Assembly Drawing Generator; (5) a Bill of Materials Generator; and, (7) a Project Database. The Project Manager tracks the process and actions, recording and supervising version and change order compliance and task completion, from the start through verification of a production-ready finished version. Each project uses a master workbench. On it design specifications are entered for each subassembly element and connector. Then the user consults the Component Database using a Search and Cross Reference engine for components meeting those design specifications, until a constraint-satisfying design is completed. The tool generates a Bill of Materials, Assembly Drawings, and process records for the project in process.

Owner:CHERNYAK ALEX H +3

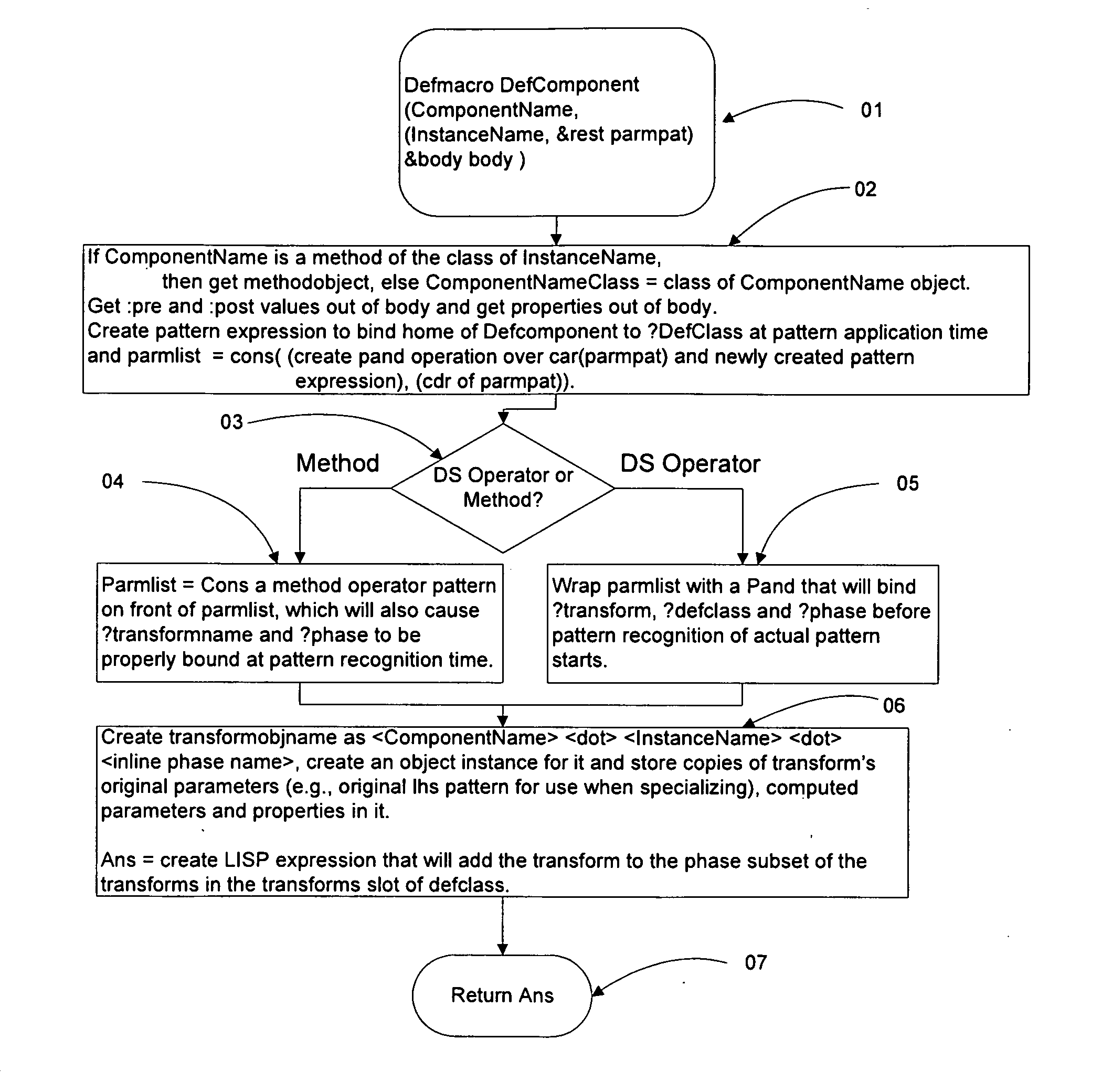

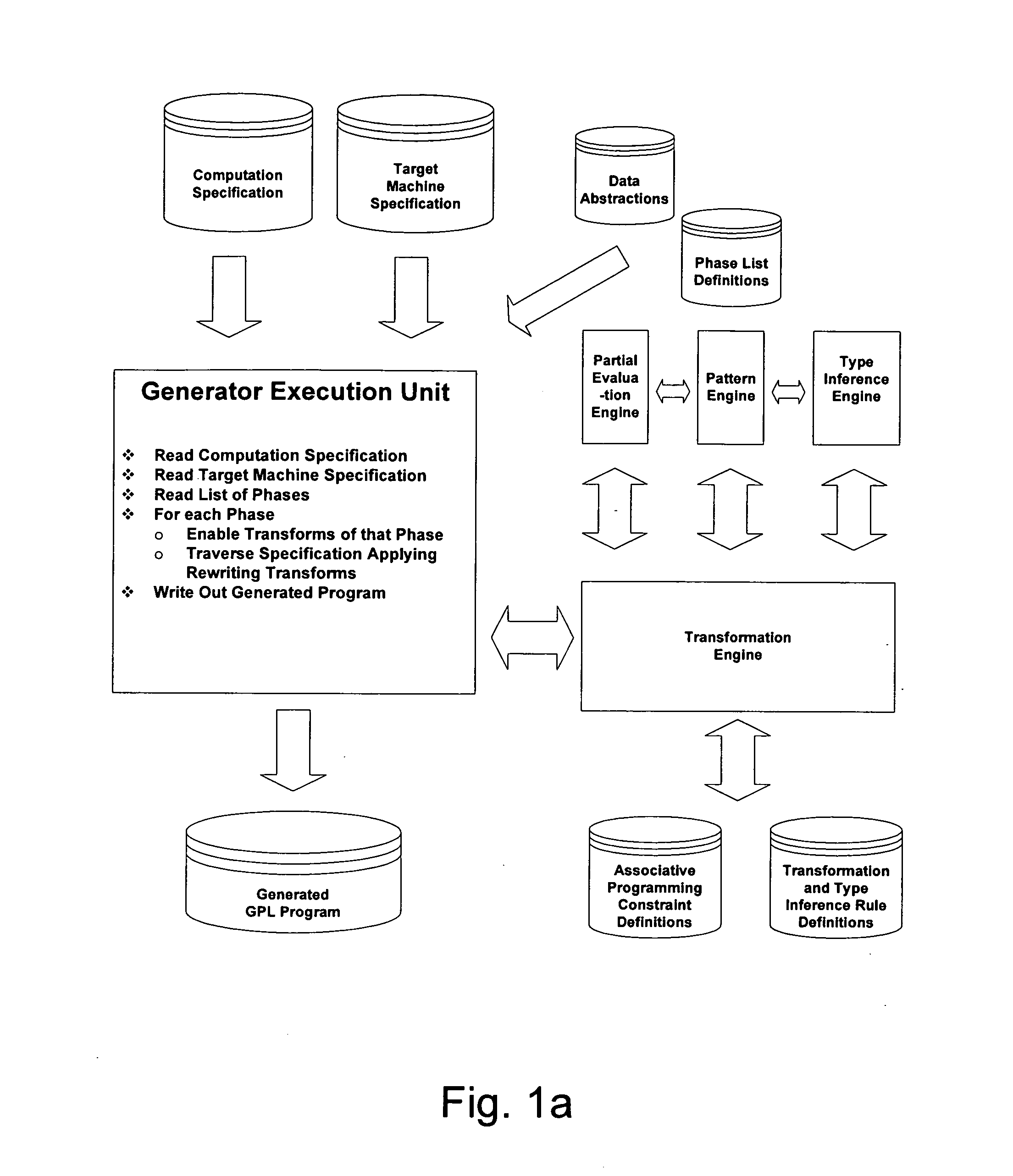

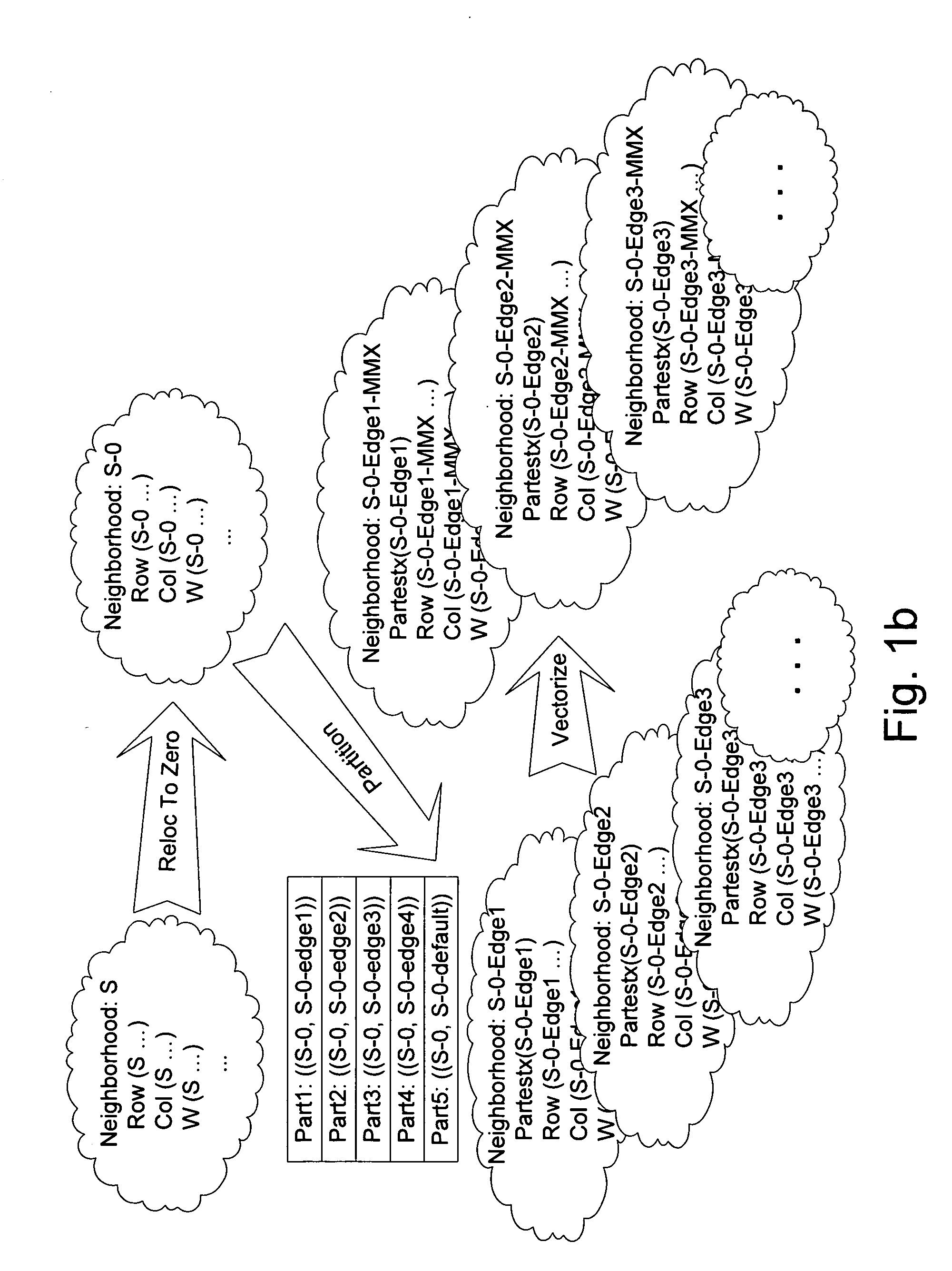

Automated Partitioning of a Computation for Parallel or Other High Capability Architecture

ActiveUS20100199257A1Program code adaptionSpecific program execution arrangementsProblem domainComputer science

A method and a system for transformation-based program generation using two separate specifications as input: An implementation neutral specification of the desired computation and a specification of the execution platform. The generated implementation incorporates execution platform opportunities such as parallelism. Operationally, the invention has two broad stages. First, it designs the abstract implementation in the problem domain in terms of an Intermediate Language (IL) that is unfettered by programming language restrictions and requirements. Concurrently, the design is evolved by specializing the IL to encapsulate a plurality of desired design features in the implementation such as partitioning for multicore and / or instruction level parallelism. Concurrently, constraints that stand in for implied implementation structures are added to the design and coordinated with other constraints. Second, the IL is refined into implementation code. With this invention, porting an implementation neutral computation to an arbitrary architecture can be automated.

Owner:BIGGERSTAFF TED J

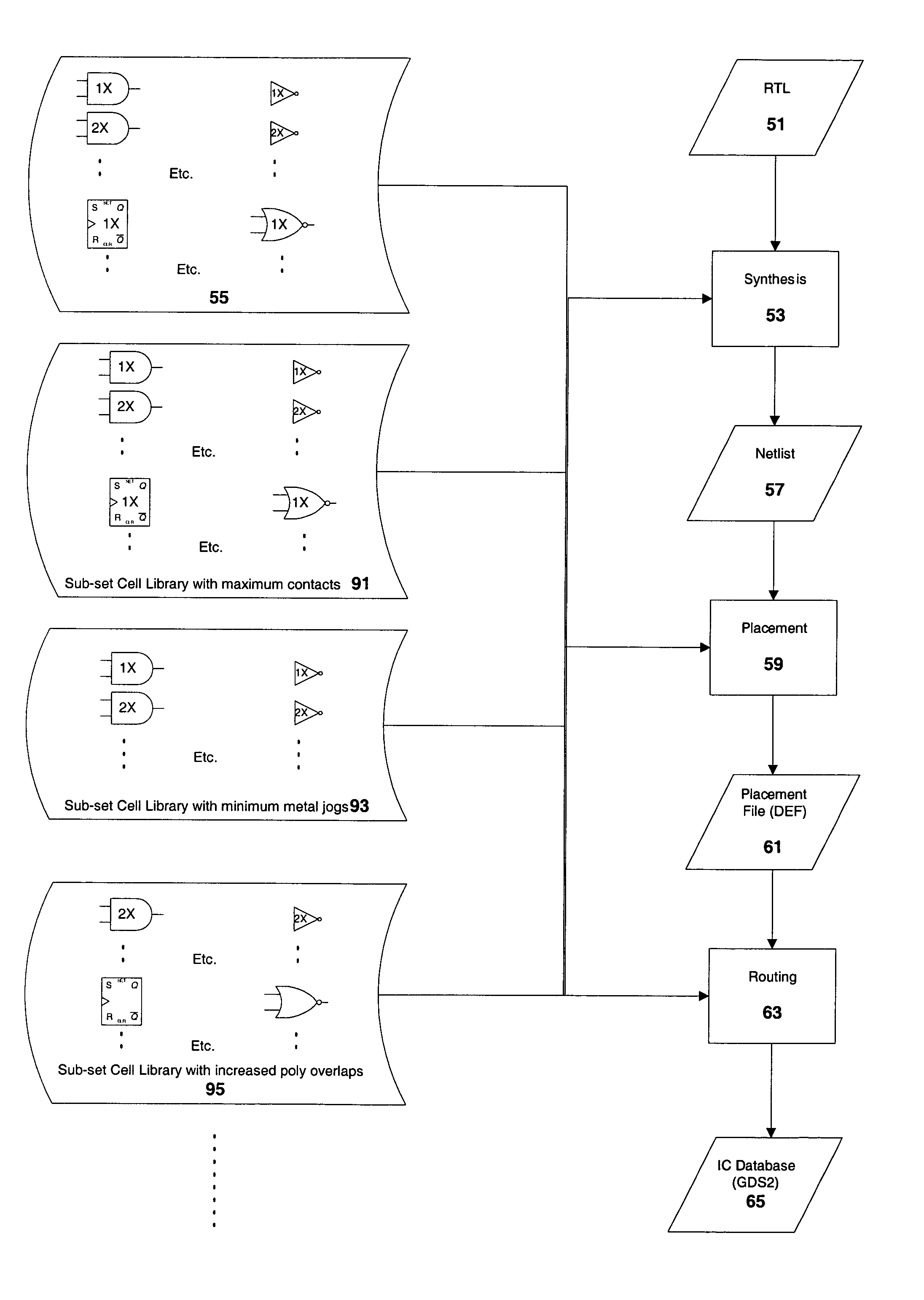

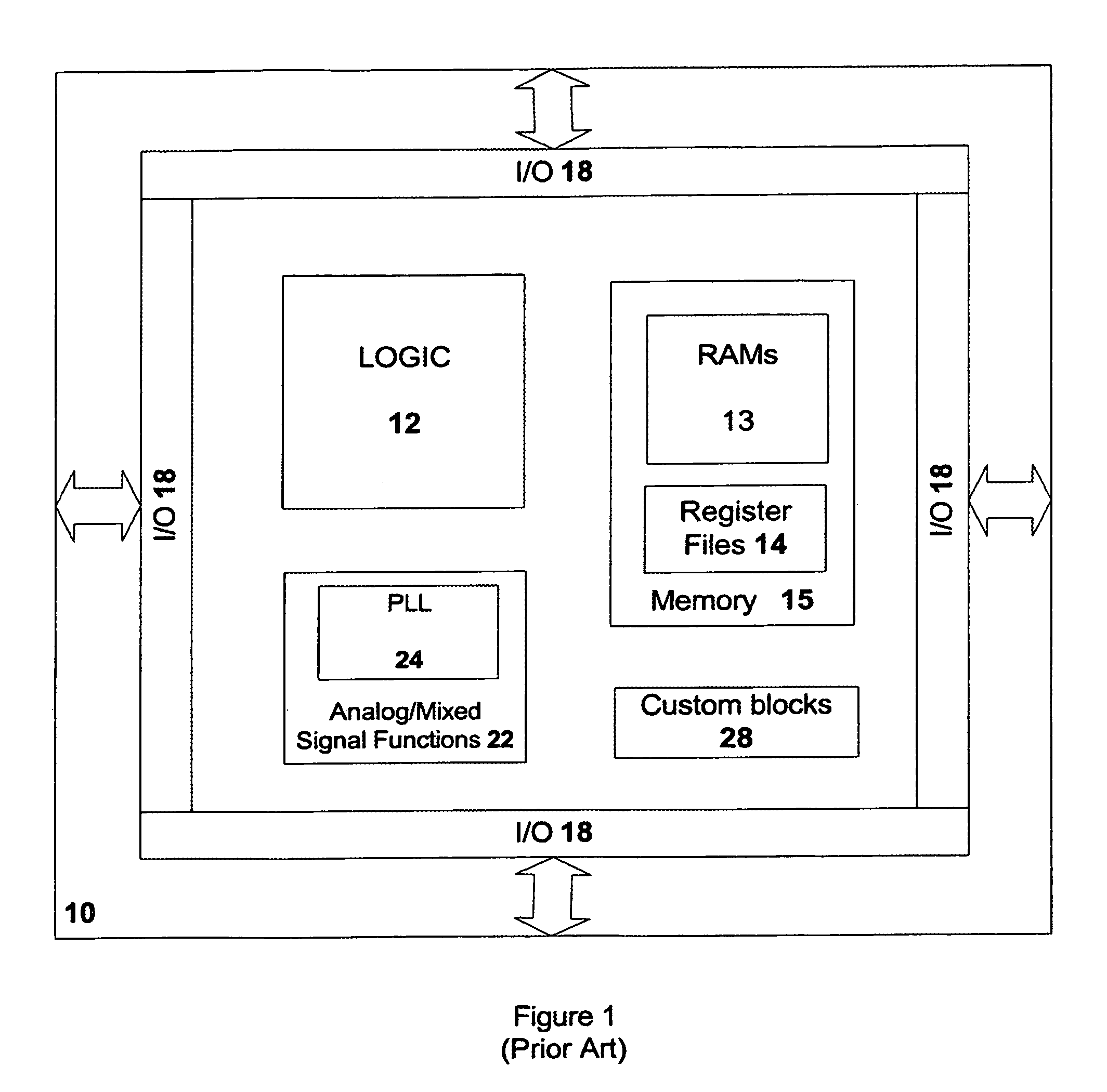

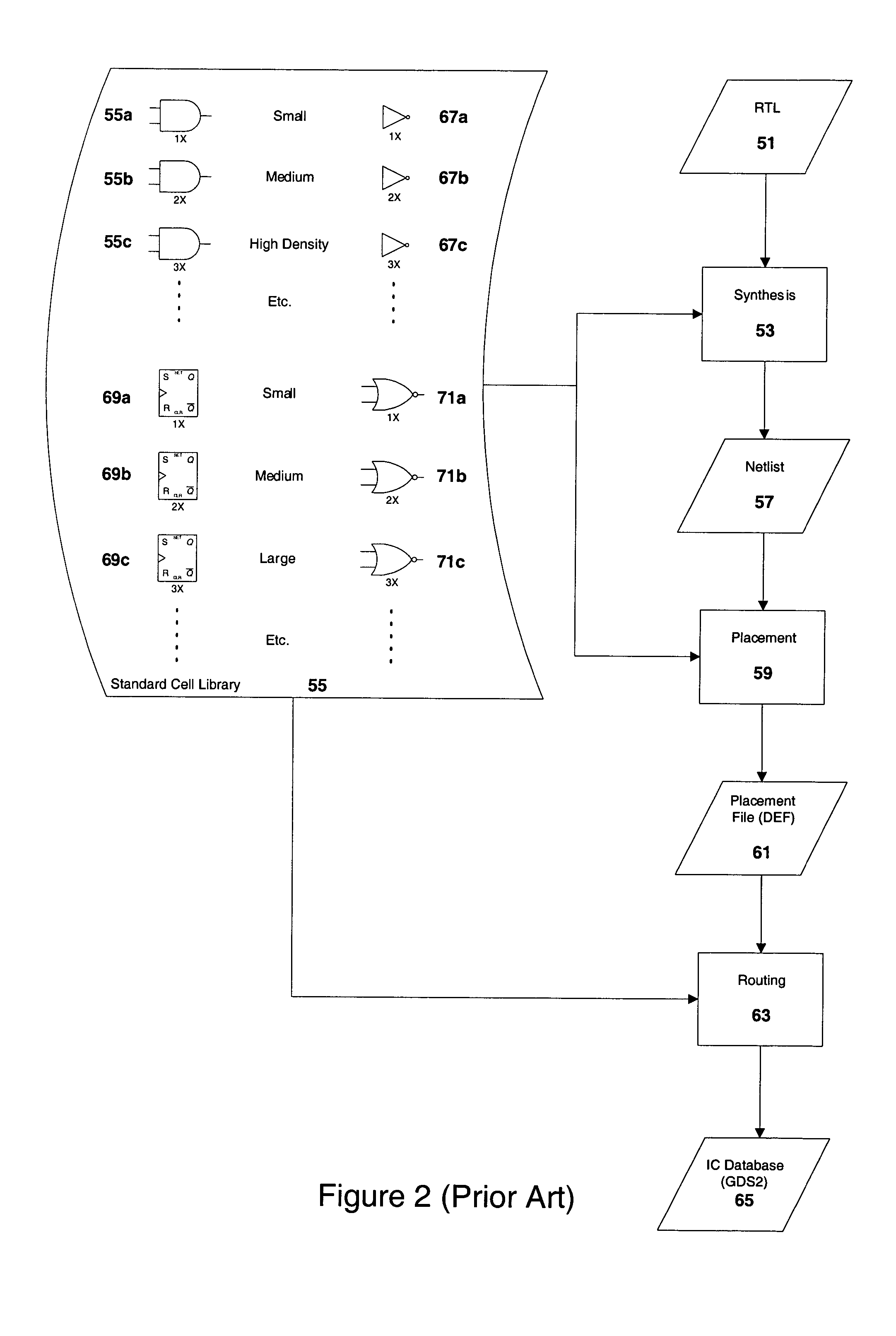

Yield maximization in the manufacture of integrated circuits

InactiveUS6957402B2Increase productionHigh yieldSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingComputer-aidedEngineering

A method and apparatus for improving the manufacturability of Integrated Circuits (ICs) formed on semiconductor dies is described. A plurality of different designs for some or all of the standard cells are made available to the circuit designer. Each different design may address a different problem associated with different manufacturing processes or a different design related yield limiter. Each of the design variants is characterized indicating its relative ease of manufacture, or it's yield sensitivity to certain IC design factors. The designer, typically with assistance from computer aided tools, can then select the standard cell variant for each of the cell used in the IC design that best addresses his or her design constraints. In other embodiments, variant versions of I / O cells and memory cells could also be created and made available to the designer in a similar fashion.

Owner:ARM INC

PLM-supportive CAD-CAM tool for interoperative electrical and mechanical design for hardware electrical systems

InactiveUS7103434B2Reduce frictionCAD network environmentComputer programmed simultaneously with data introductionTask completionBill of materials

Owner:CHERNYAK ALEX H +3

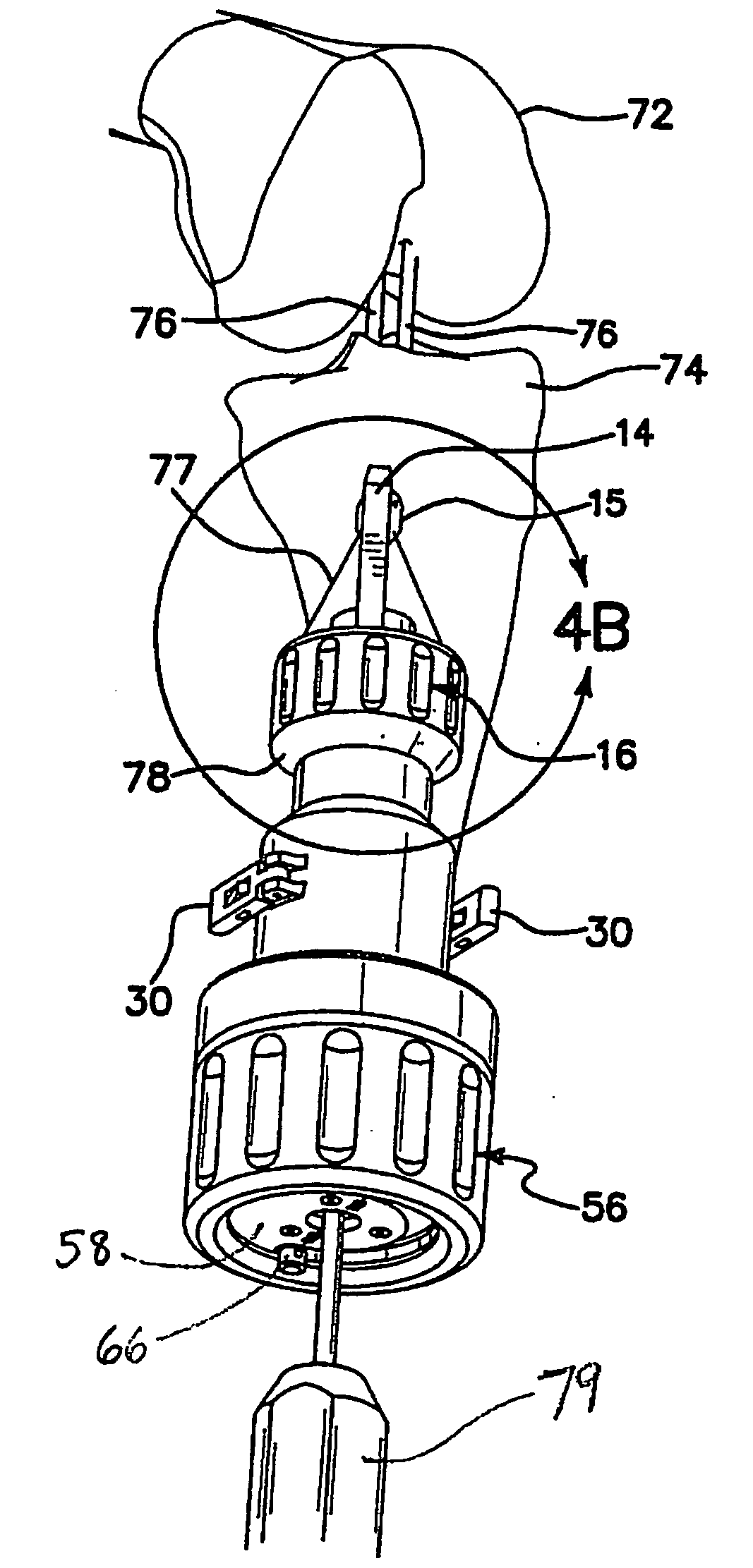

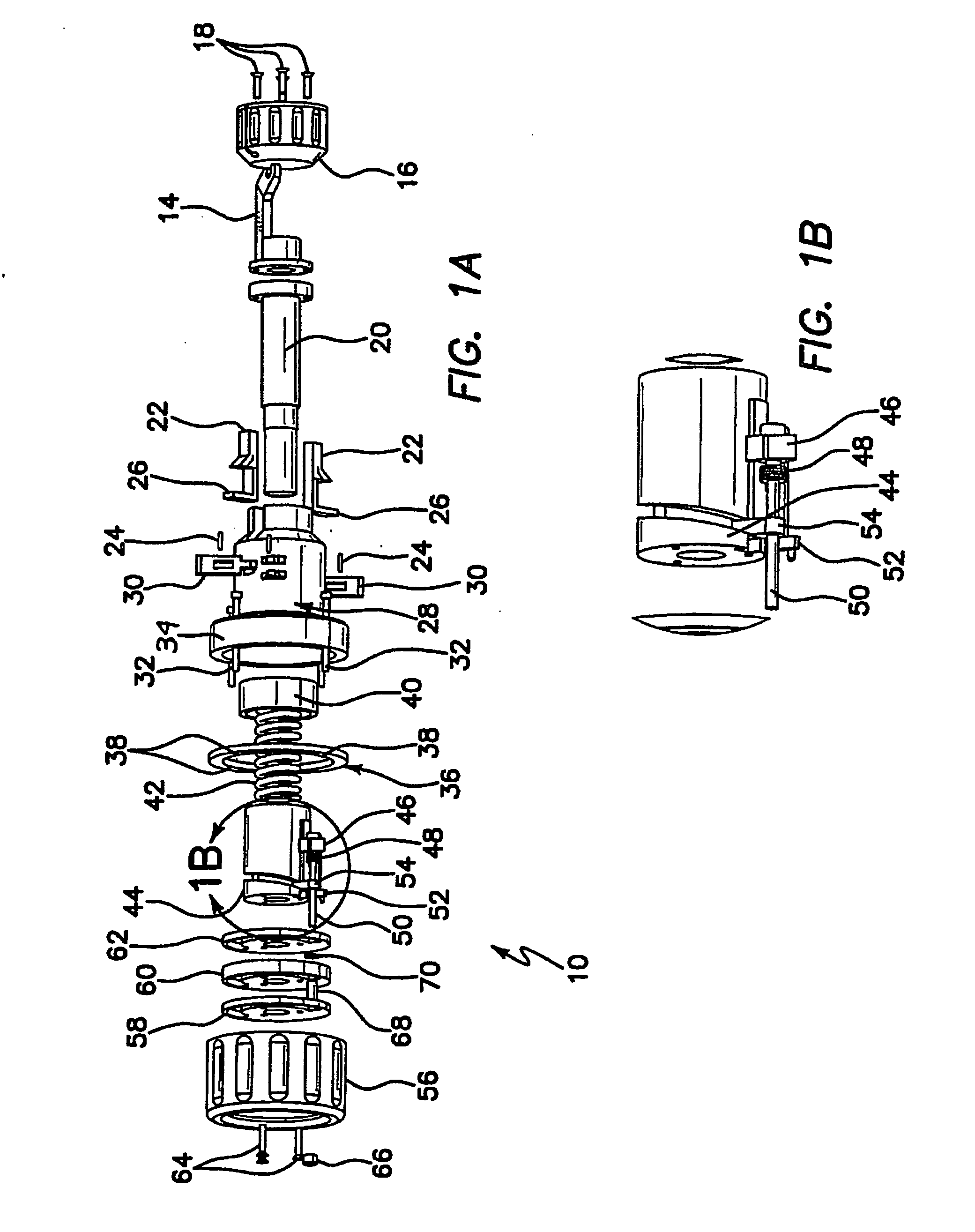

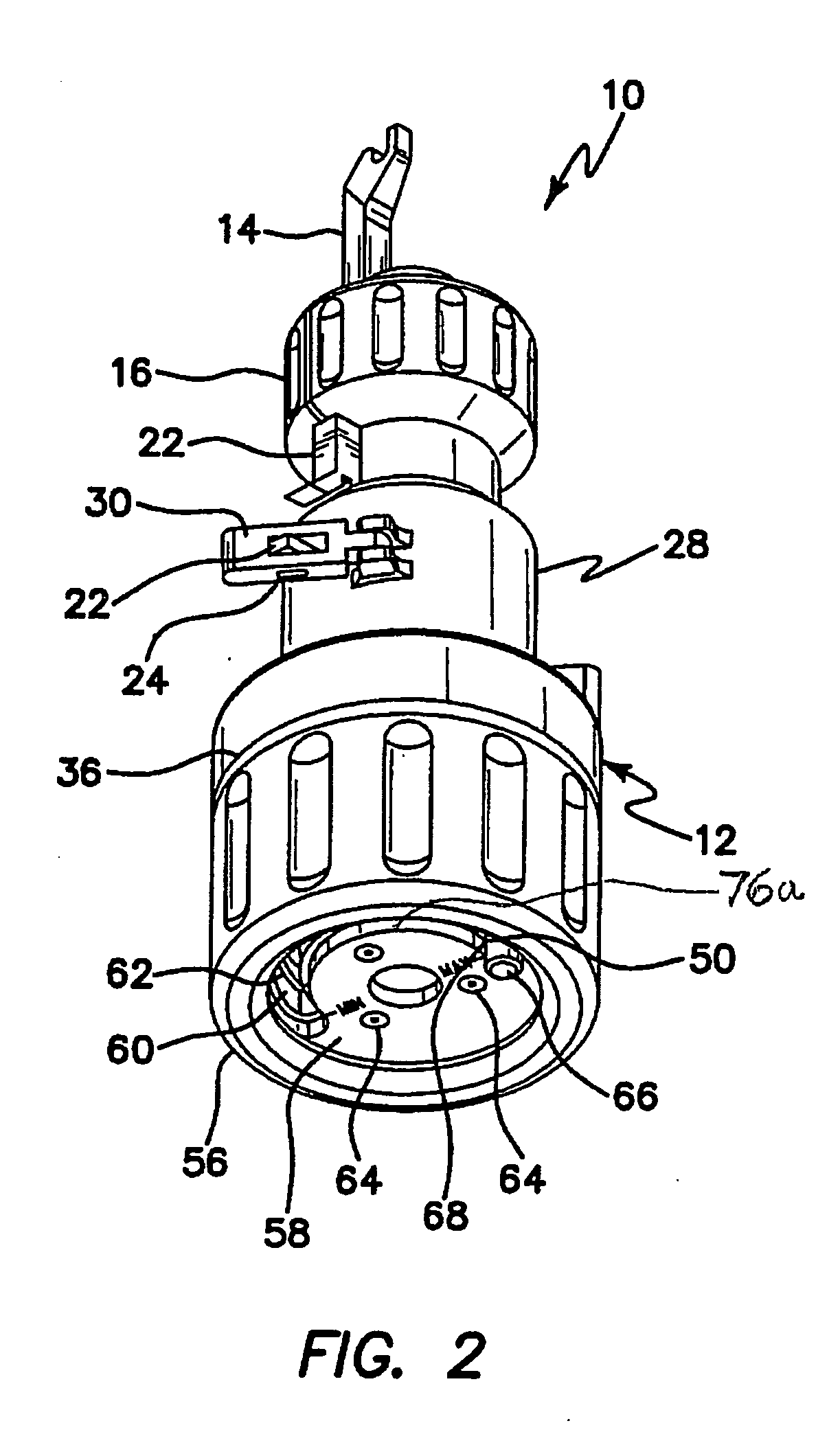

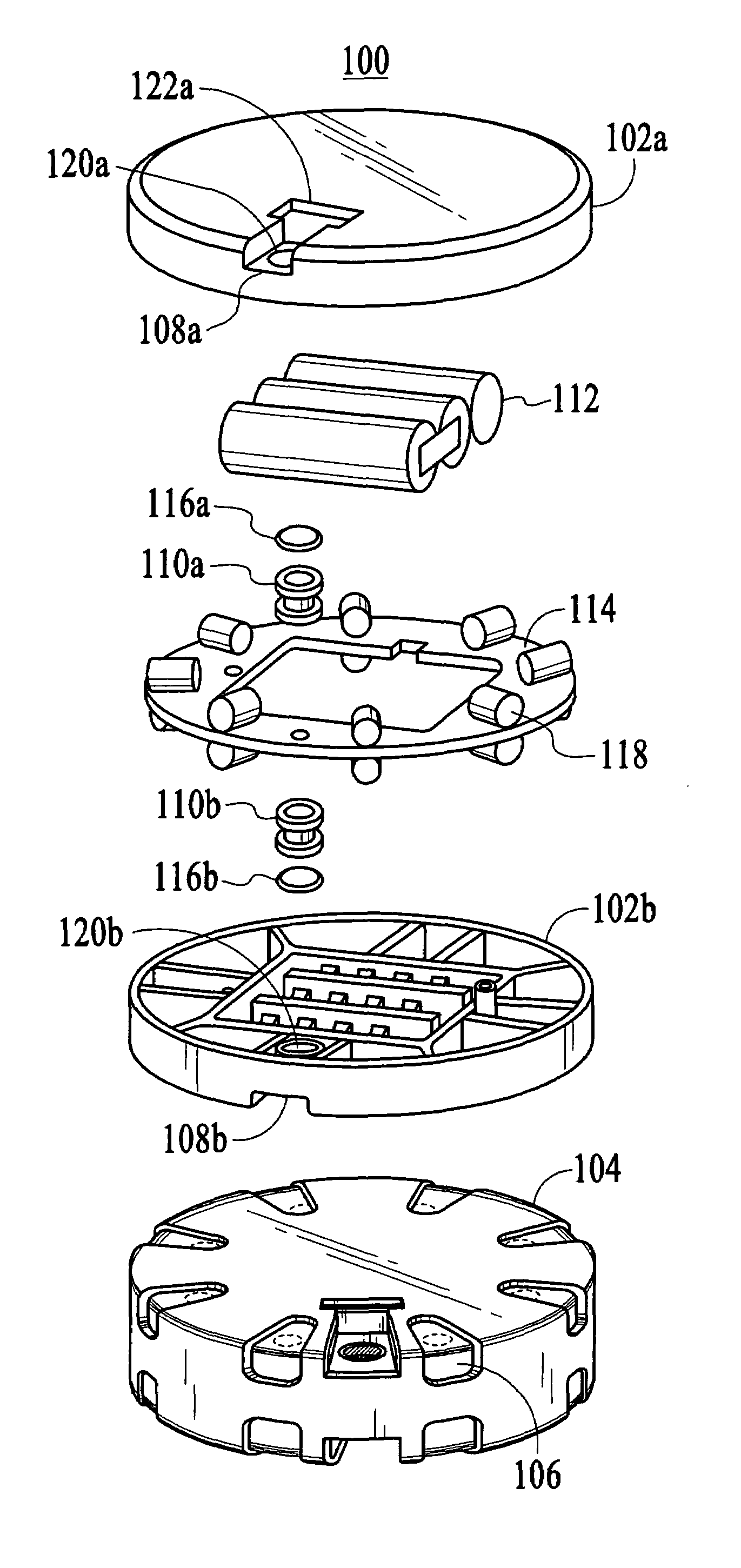

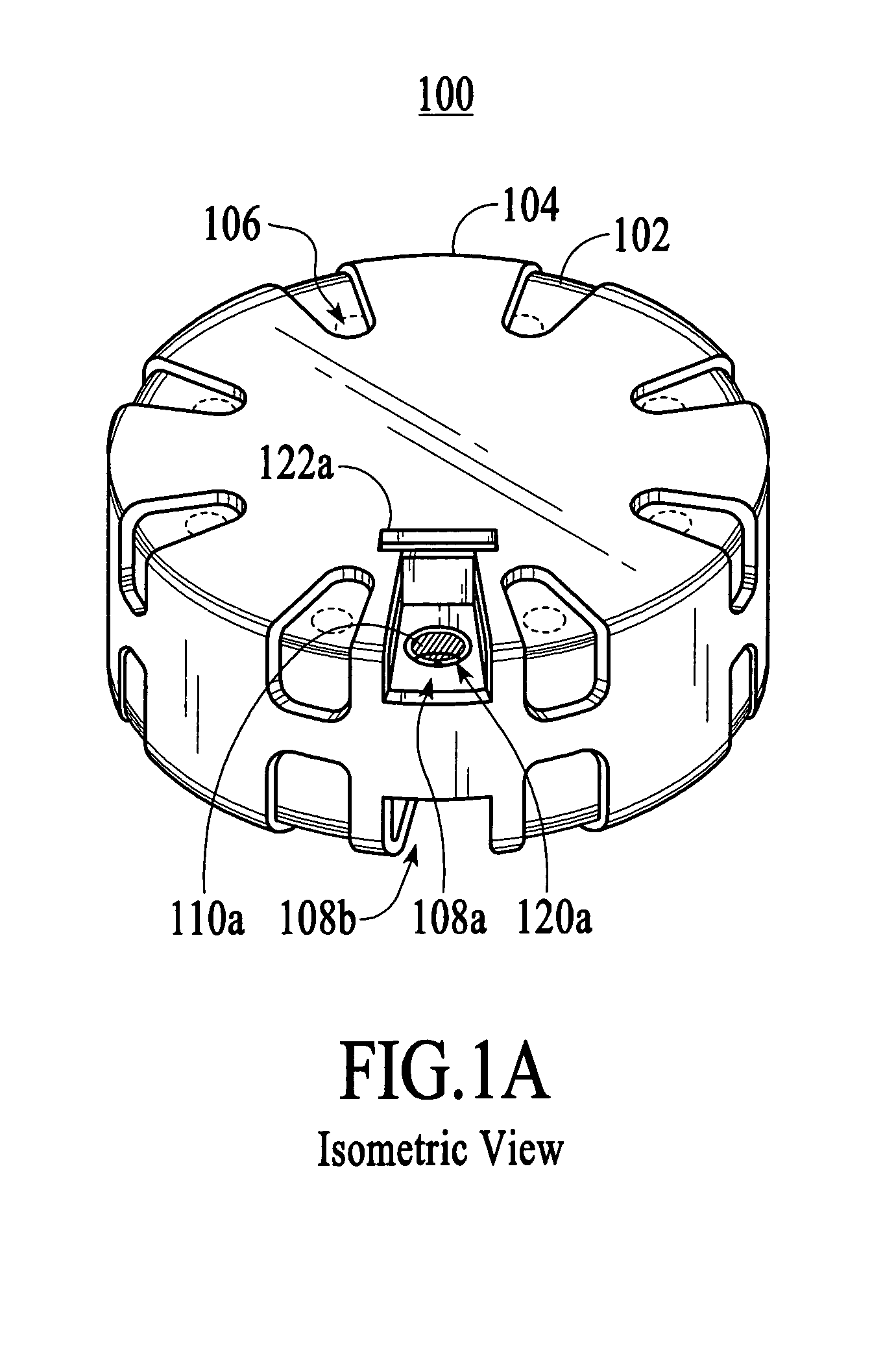

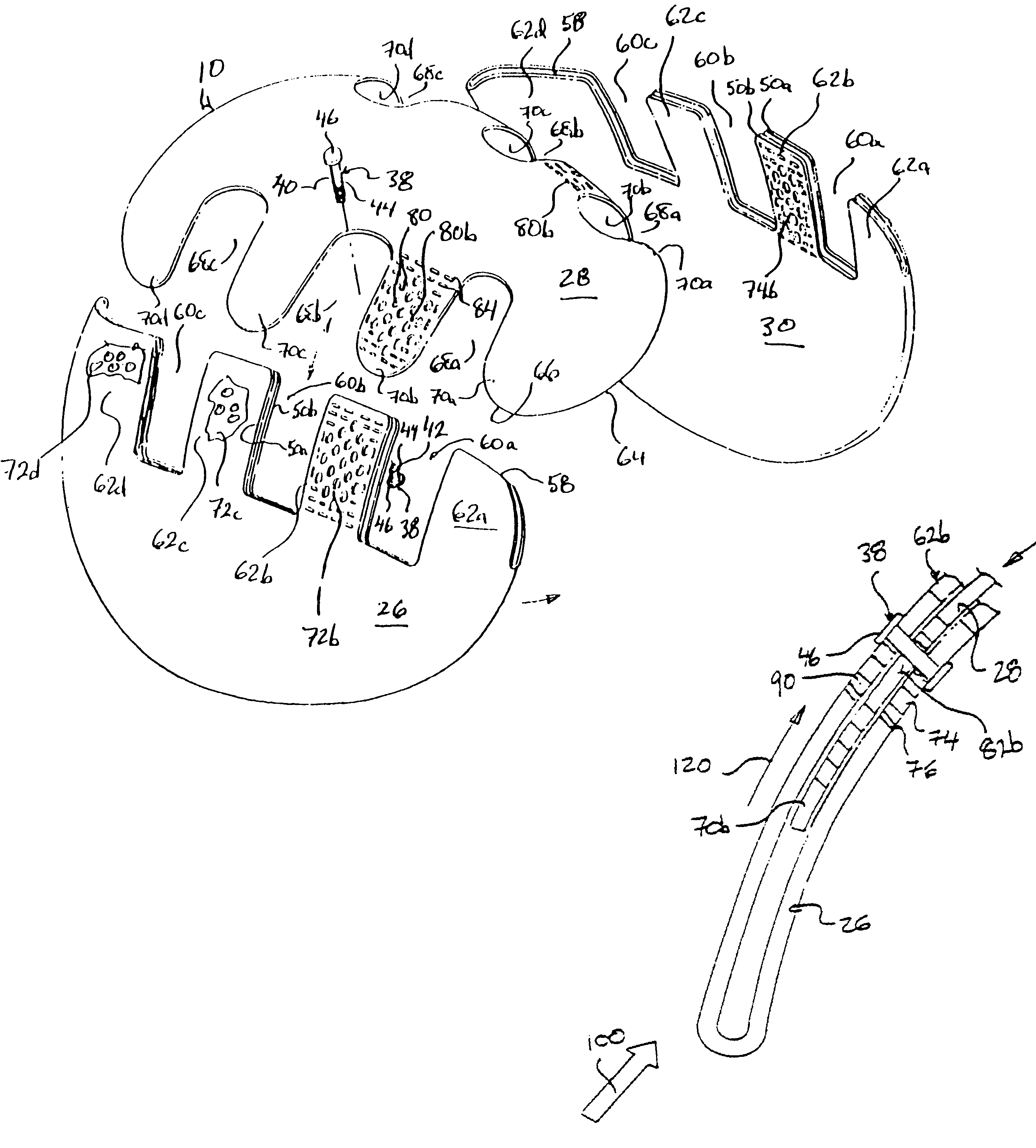

Suture management and tensioning devices and methods for soft tissue reconstruction or bone-to-bone fixation

ActiveUS20080154260A1Convenient introductionSimplifying retention of sutureSuture equipmentsDiagnosticsBone fixationSoft tissue reconstruction

Owner:CAYENNE MEDICAL INC

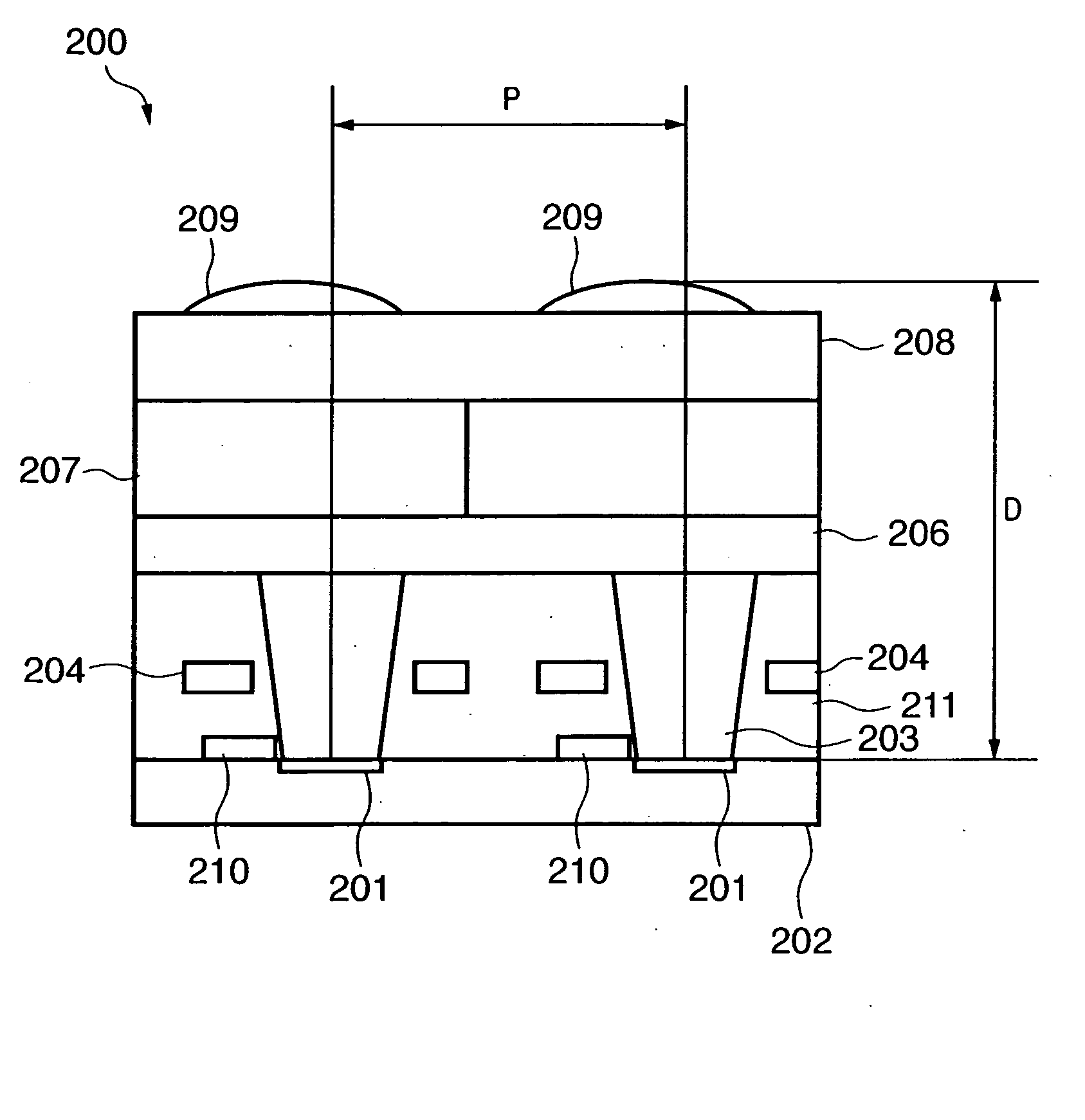

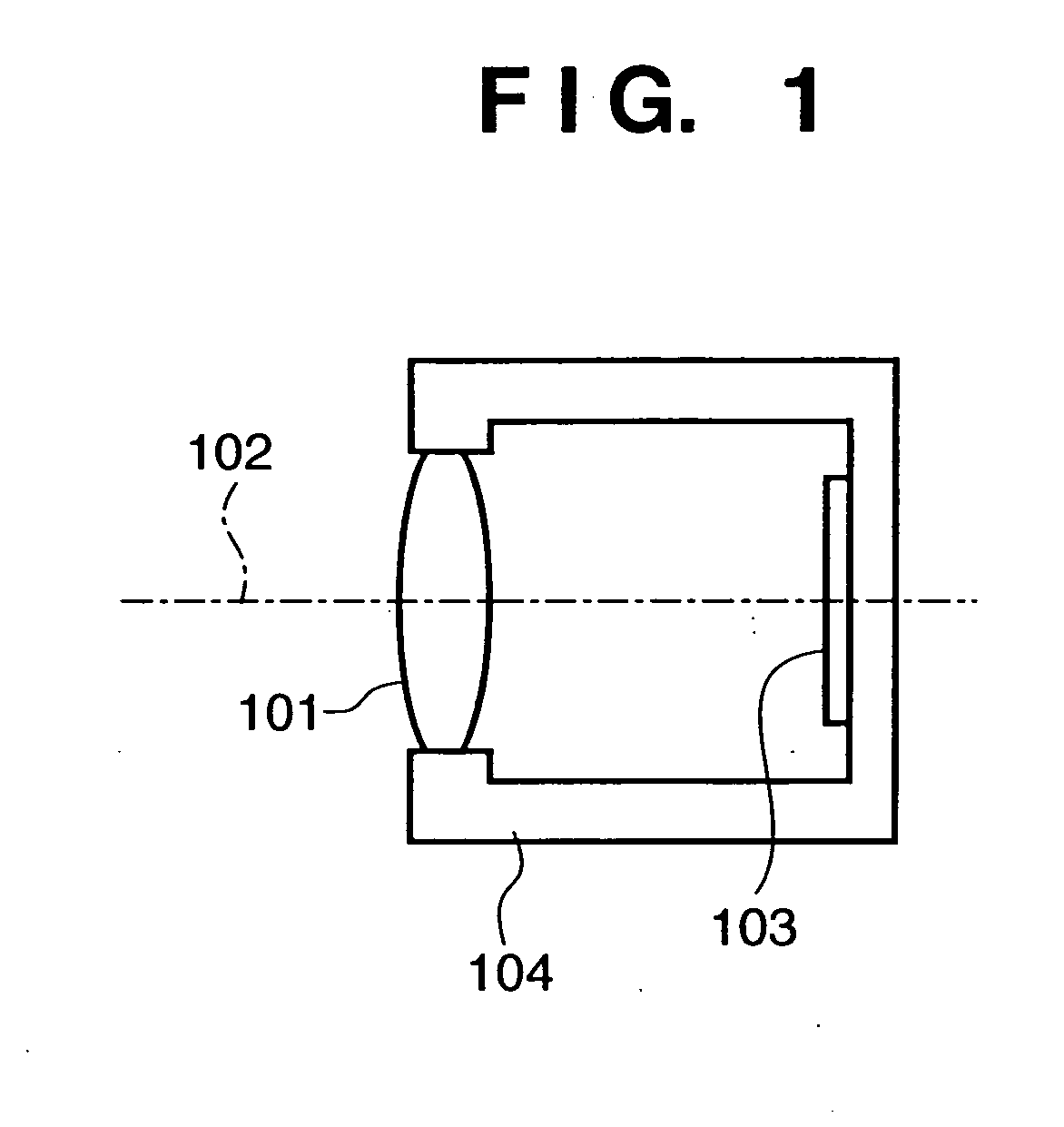

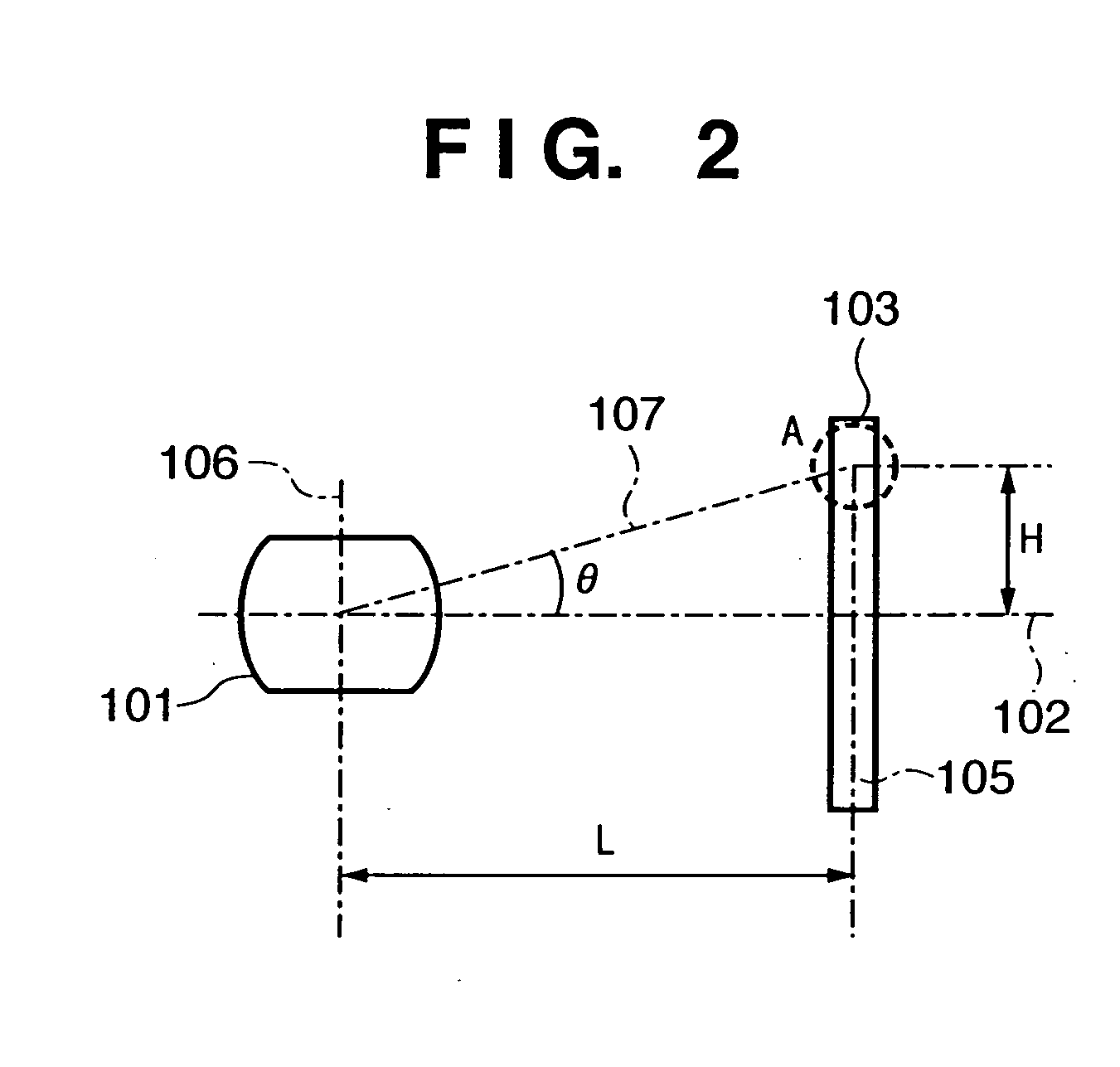

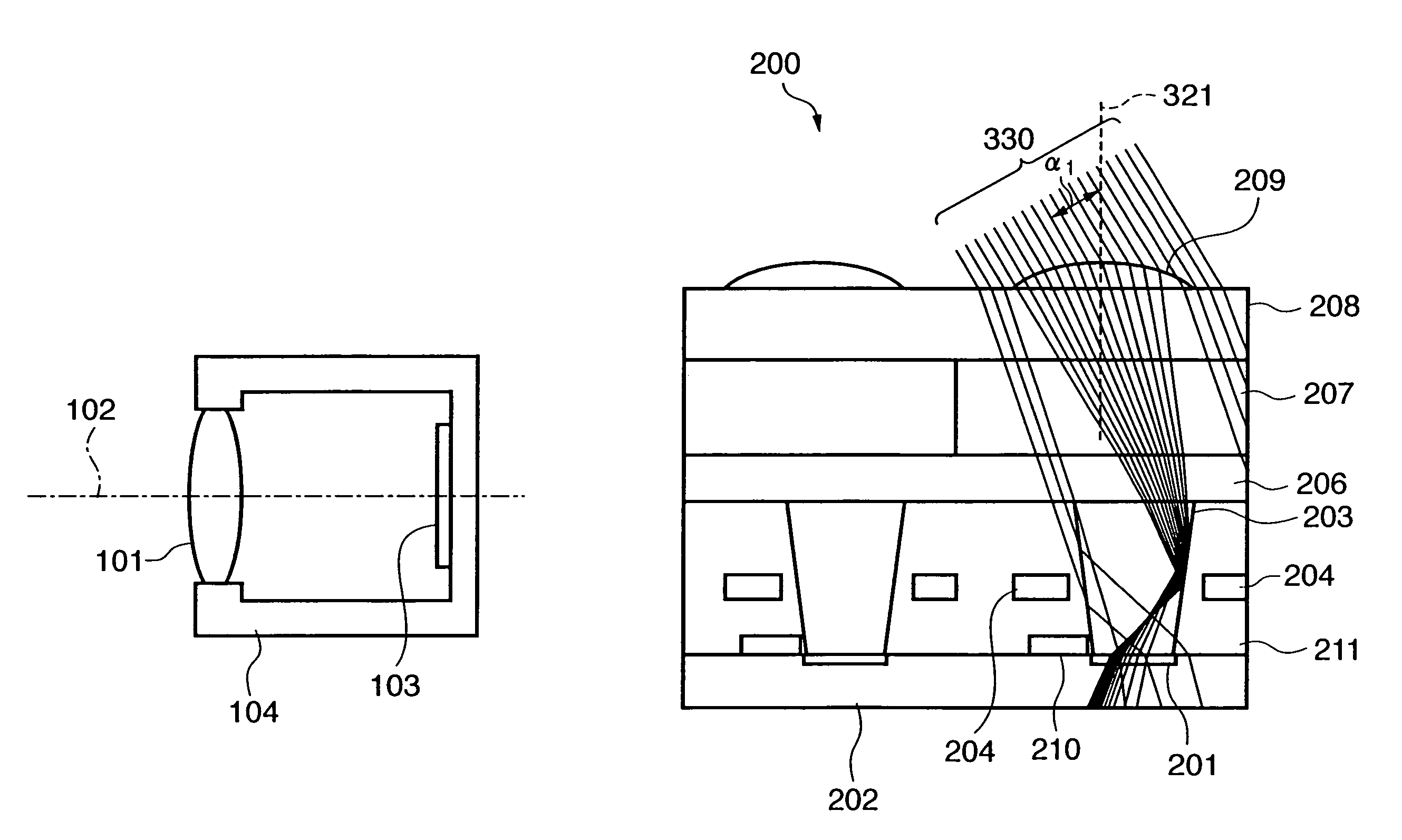

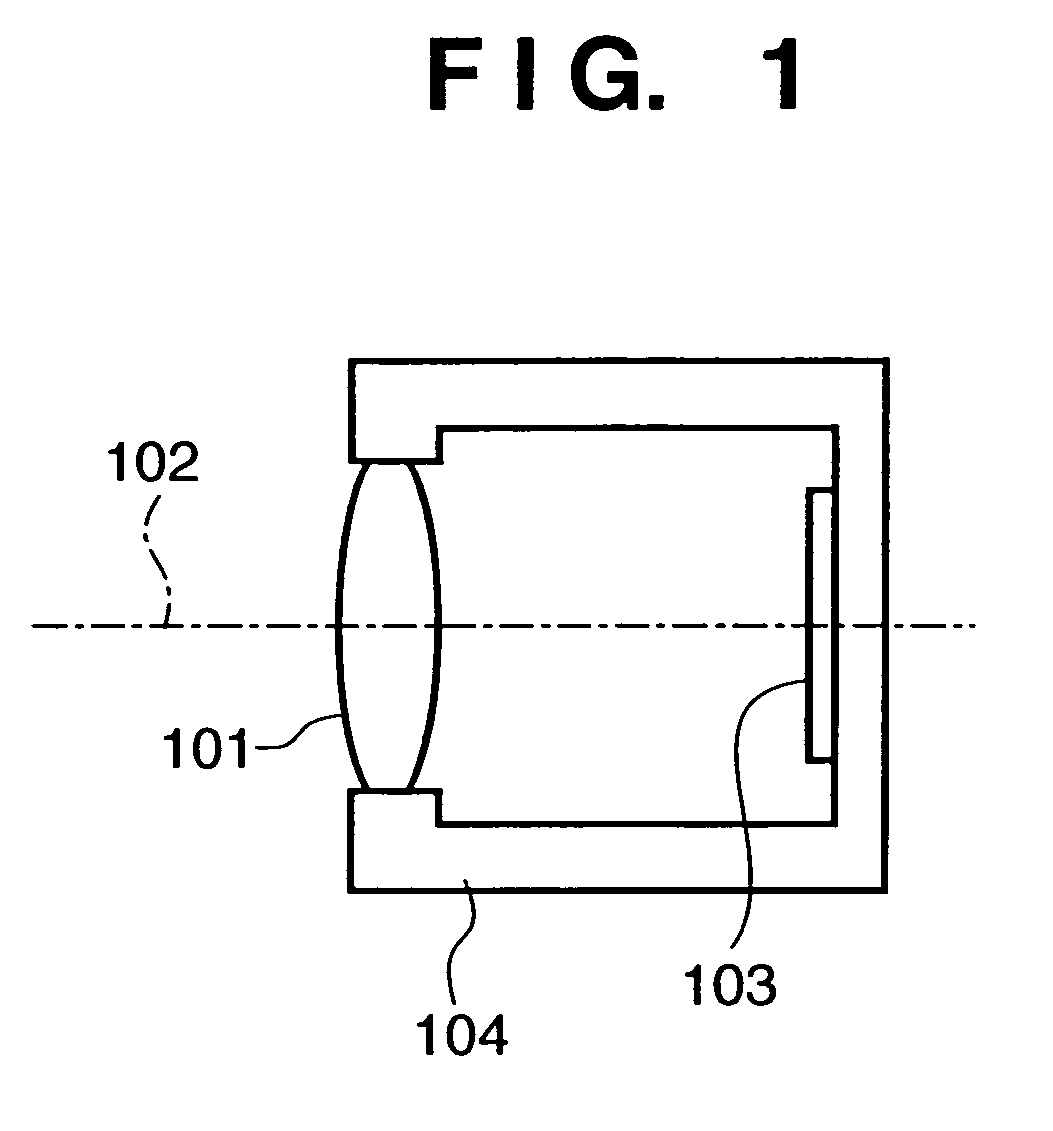

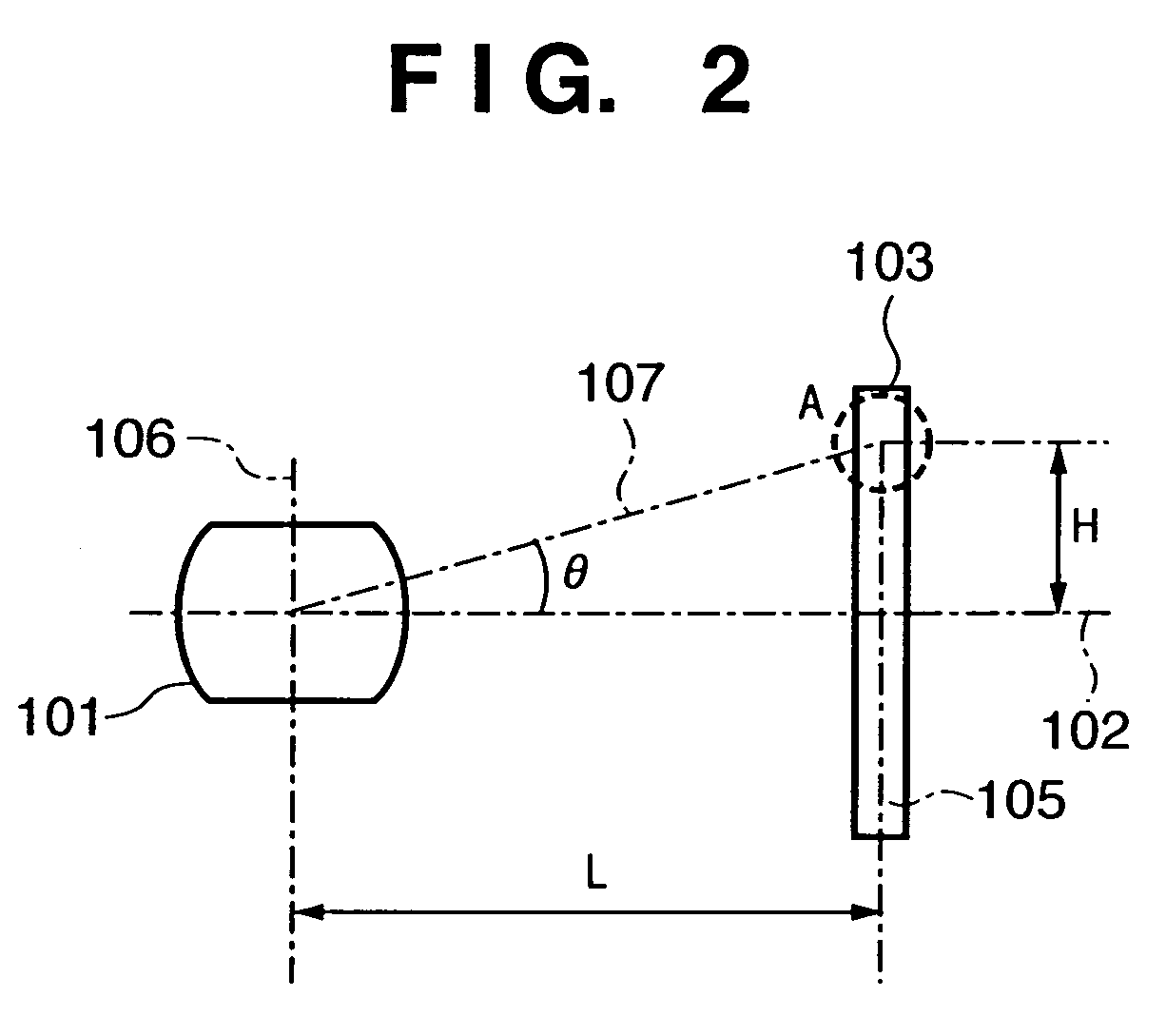

Solid-state image sensing element and its design support method, and image sensing device

ActiveUS20050236553A1Increase freedomImprove light collection efficiencyTelevision system detailsSolid-state devicesExit pupilLight guide

A solid-state image sensing element has a photoelectric conversion element which converts incoming light into an electrical signal in accordance with an amount of the light, a microlens which is arranged on an incident surface, a light guide which is arranged between the photoelectric conversion element and the microlens, and an insulating interlayer which is arranged around the light guide. The solid-state image sensing element located at a distance (H) satisfies: H·DL·P<a·NHNL for 0<a<1where L is the distance from an exit pupil of an image sensing optical system of an image sensing device, which mounts an image sensor formed by two-dimensionally arranging a plurality of the solid-state image sensing elements, H is the distance from a center of the image sensor to a position of the solid-state image sensing element on the image sensor, D is the height from the photoelectric conversion element to an apex of the microlens, P is the spacing between the plurality of solid-state image sensing elements, NH is the refractive index of the light guide, and NL is the refractive index of the insulating interlayer.

Owner:CANON KK

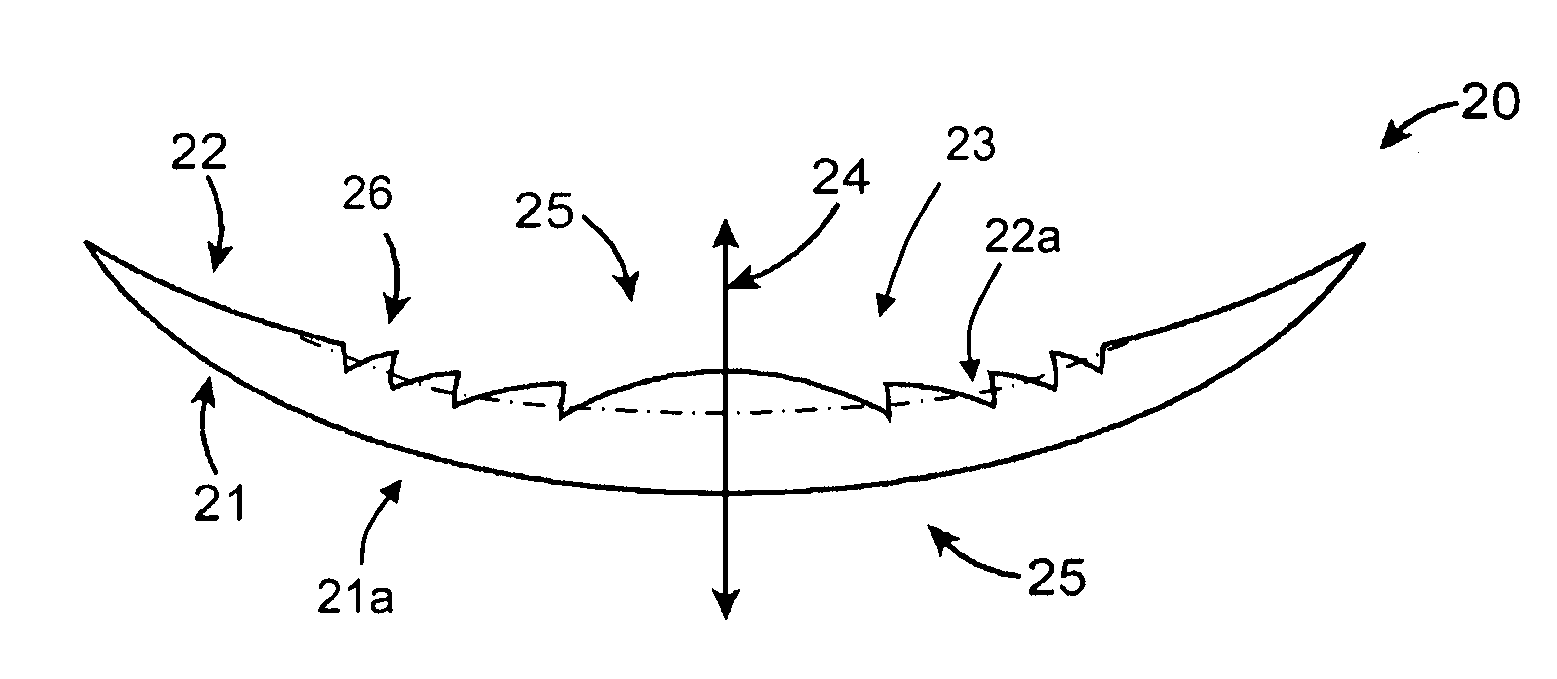

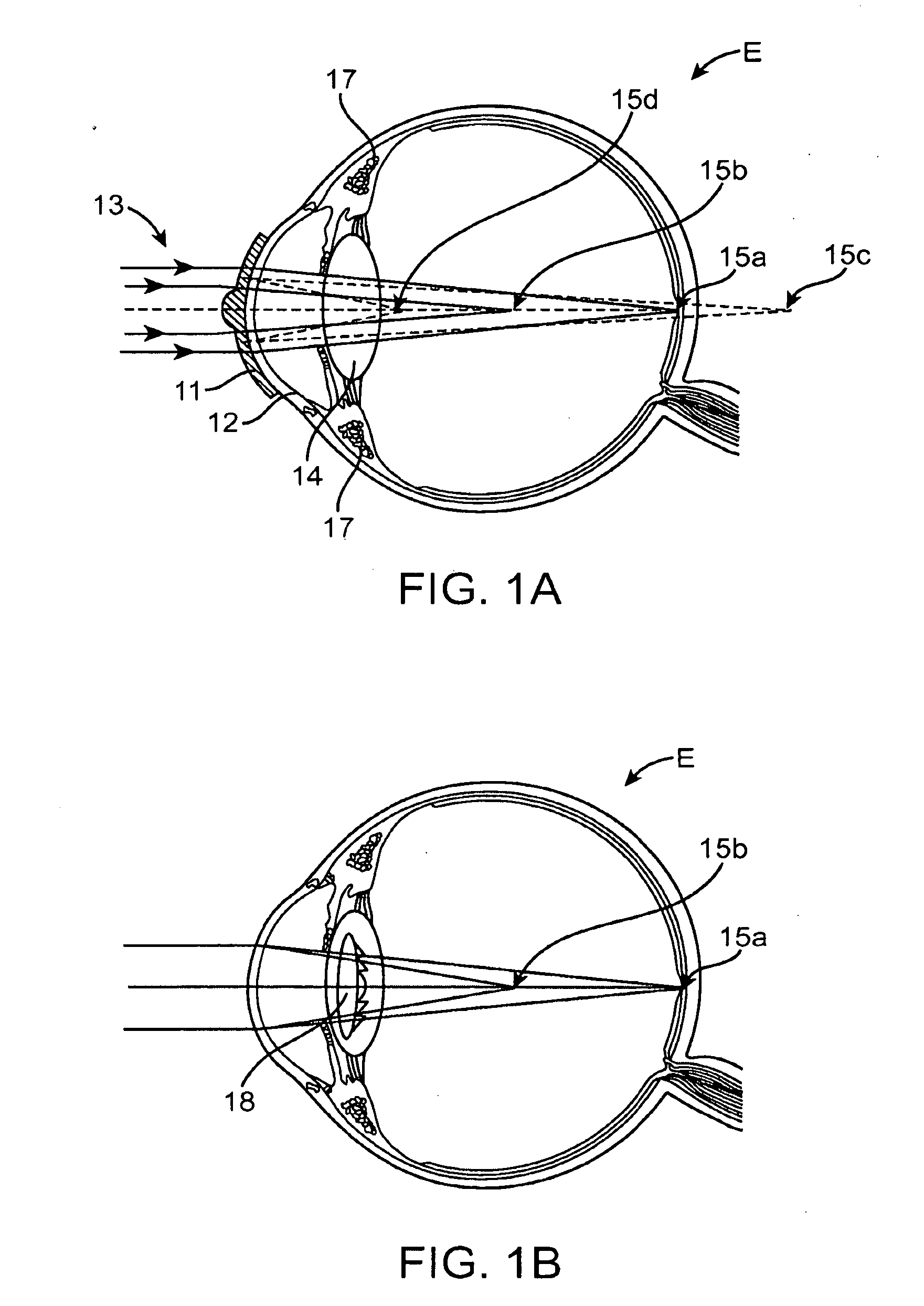

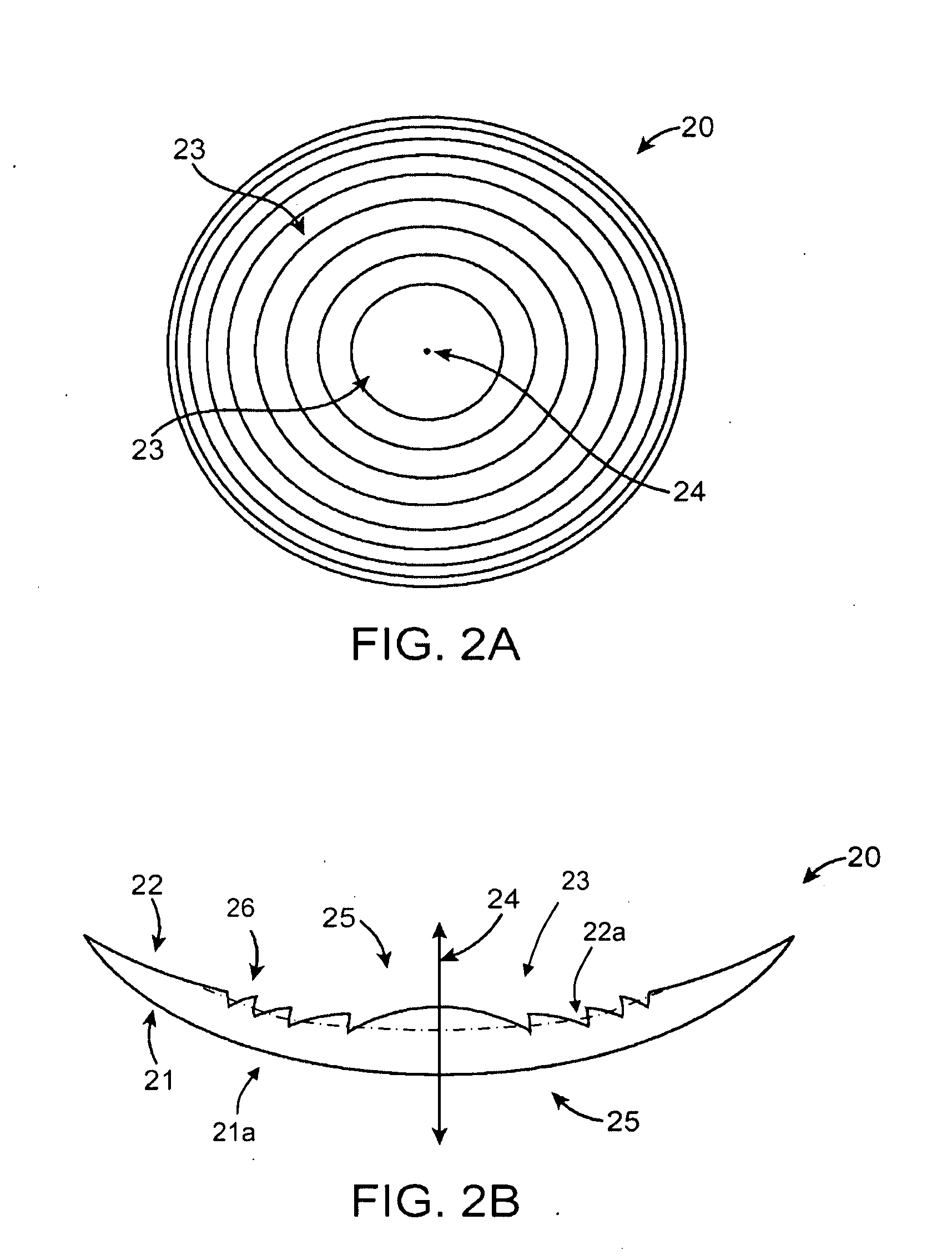

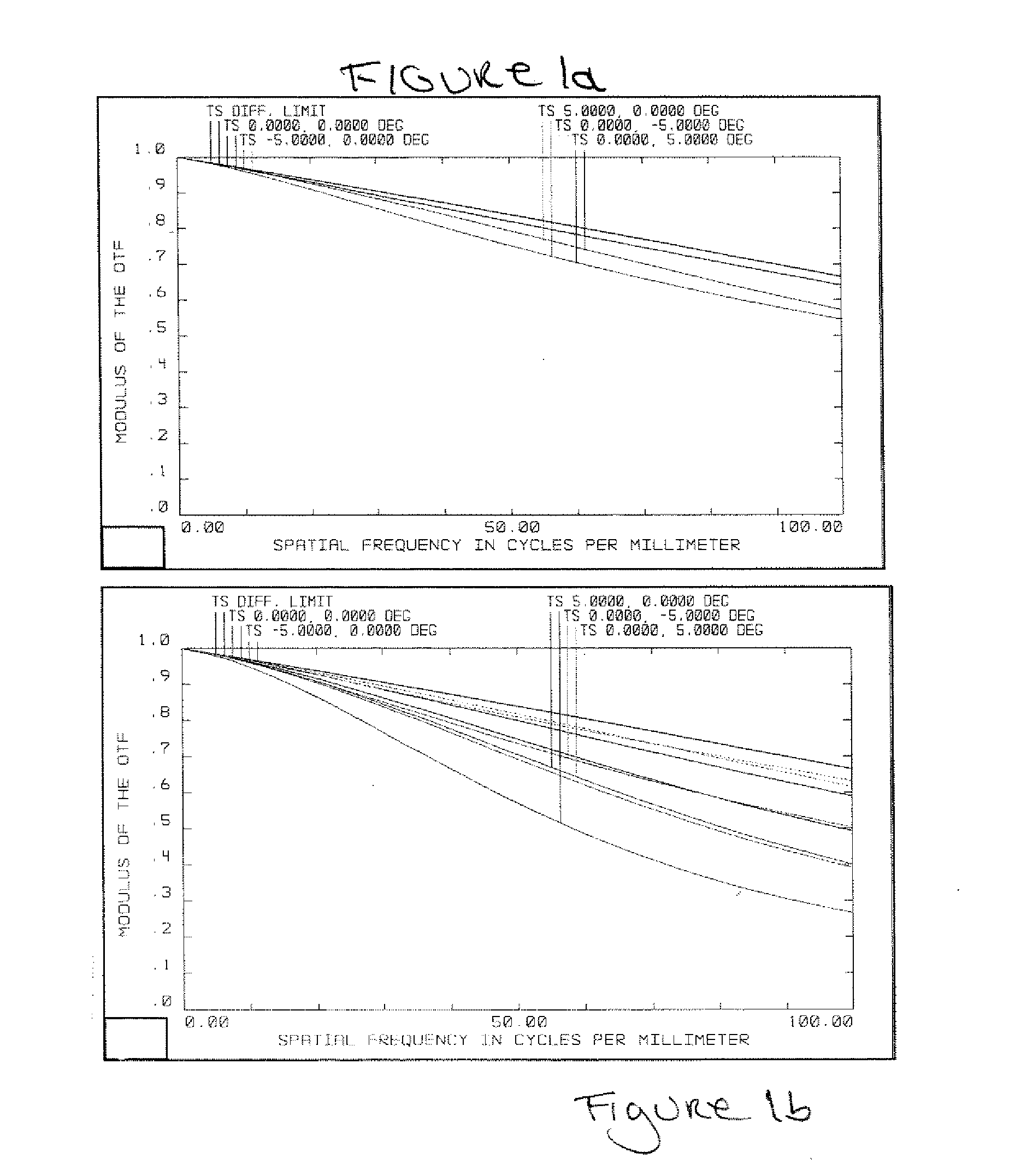

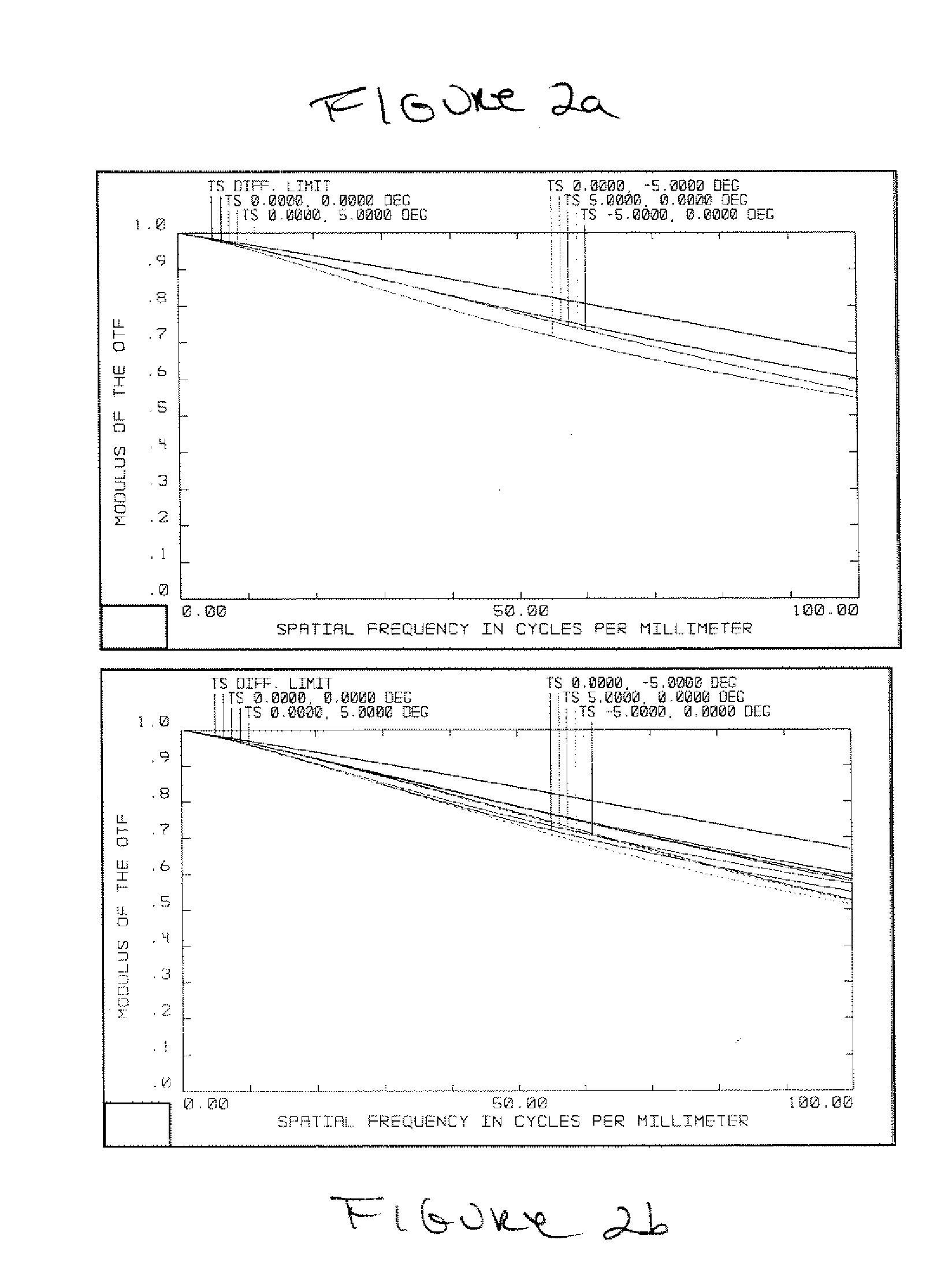

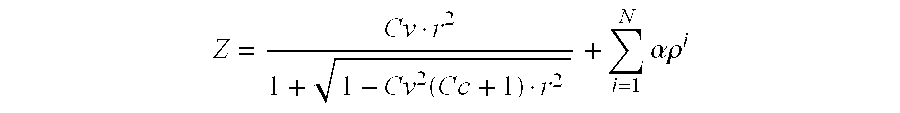

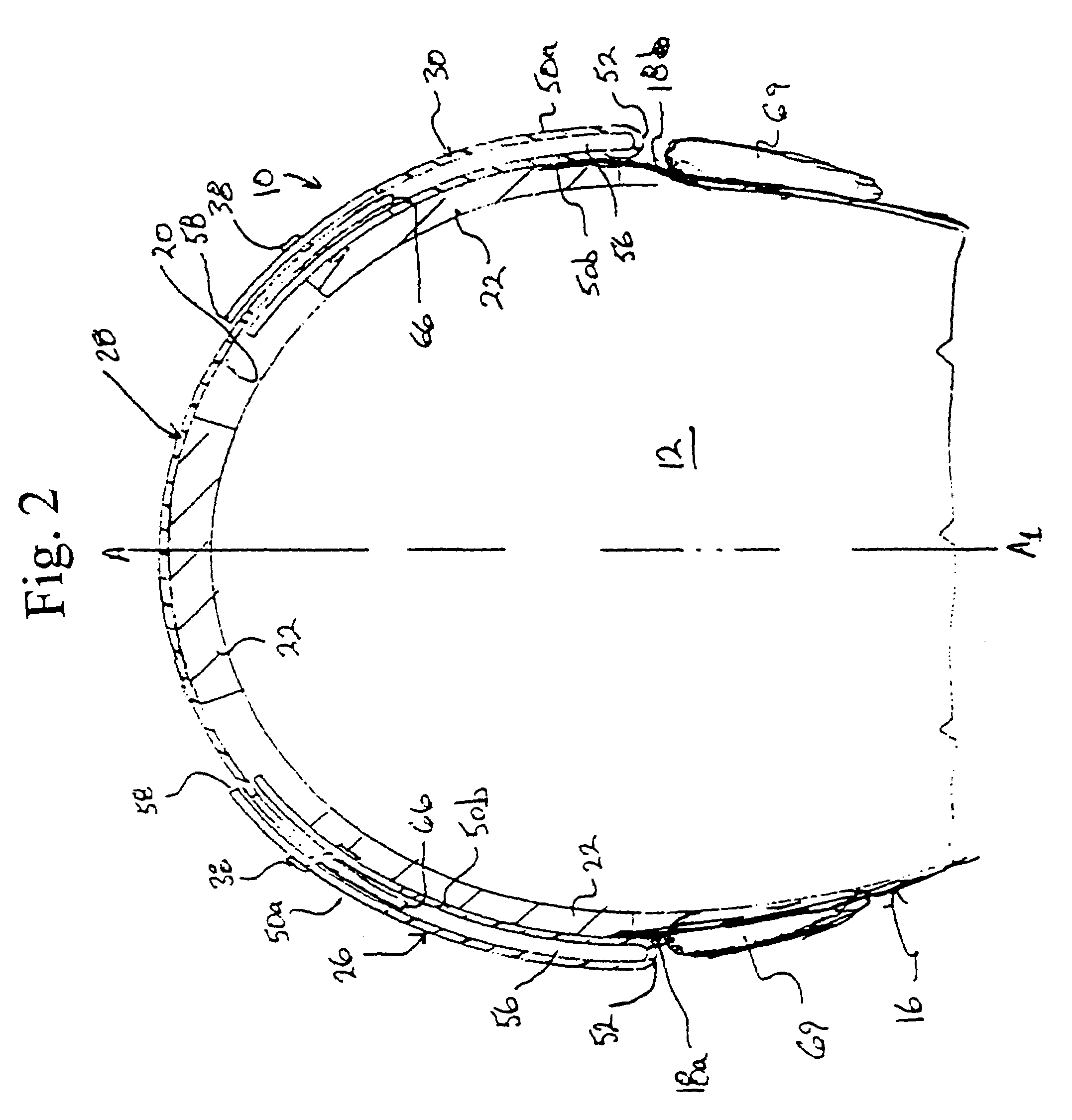

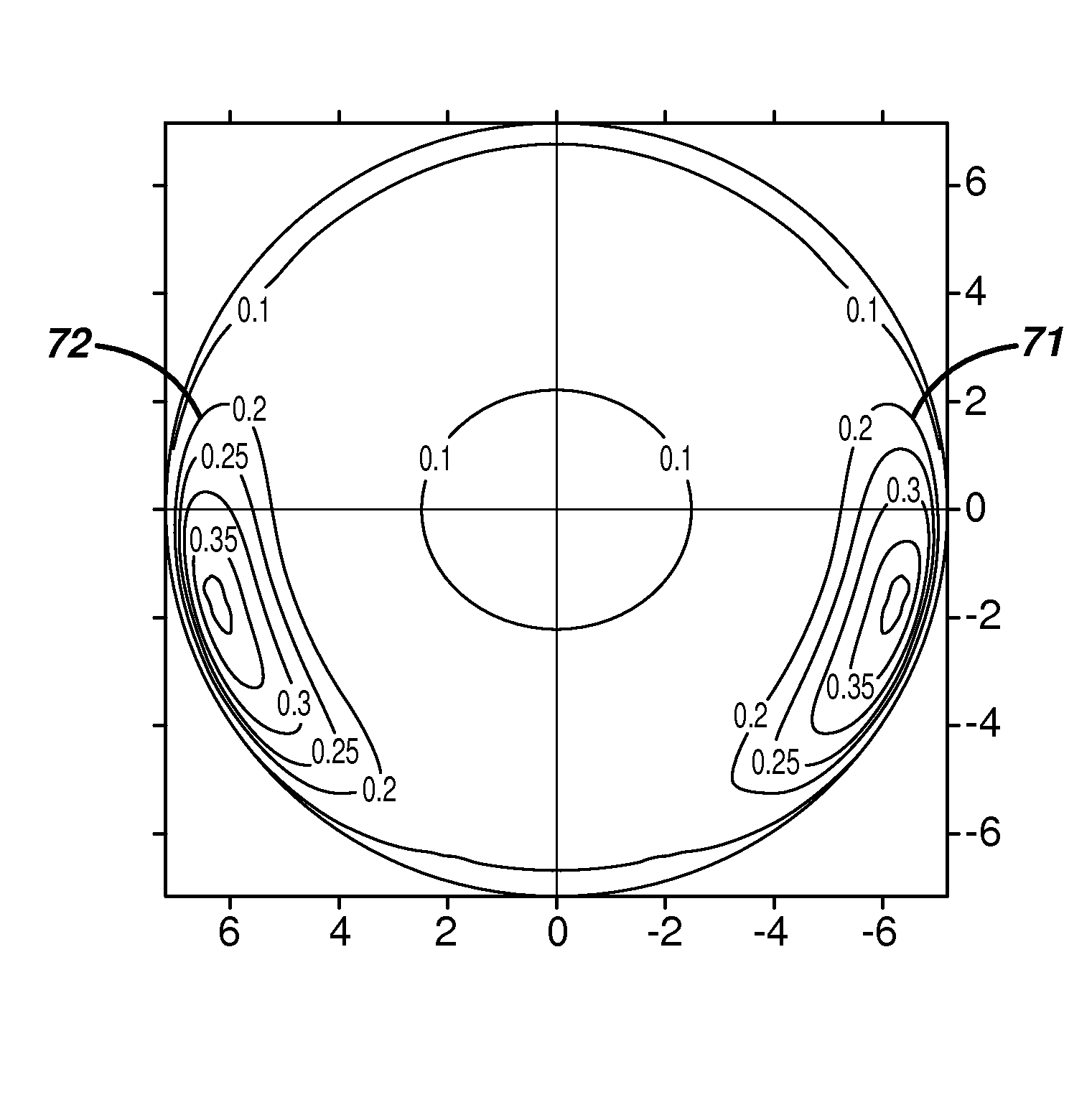

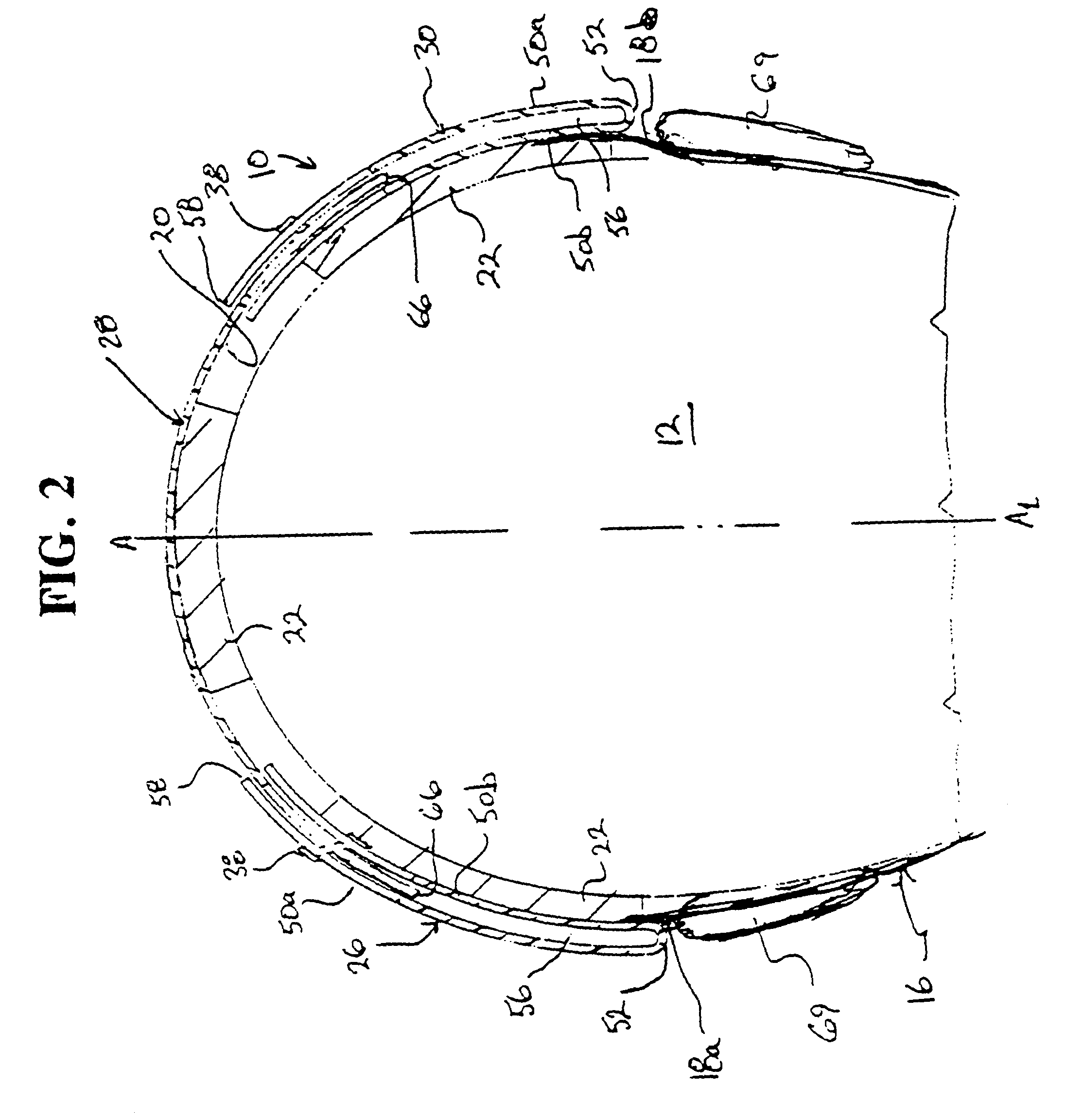

Diffractive lens exhibiting enhanced optical performance

ActiveUS20090268155A1Reduce light scatterOptimize light energy distributionSpectales/gogglesDiffraction gratingsLight energyDiffractive lens

The present invention provides improved ophthalmic lenses and methods for their design and use. Monofocal and multifocal diffractive ophthalmic lenses having reduced light scatter, improved light energy distribution properties, and / or other improvements in optical performance are provided. These properties are provided, at least in part, by the diffractive profiles of the invention, often having subtlety shaped echelettes with appropriately curving profiles. Smooth diffractive profiles may be used reduce light scatter. Diffractive profiles may be configured to limit the light energy in certain selected orders, thereby improving viewing quality and mitigating unwanted effects such as dysphotopsia. Diffractive profiles of may additionally or alternatively vary the light energy distributed between individual echelettes, providing additional advantages in various viewing situations.

Owner:AMO GRONINGEN

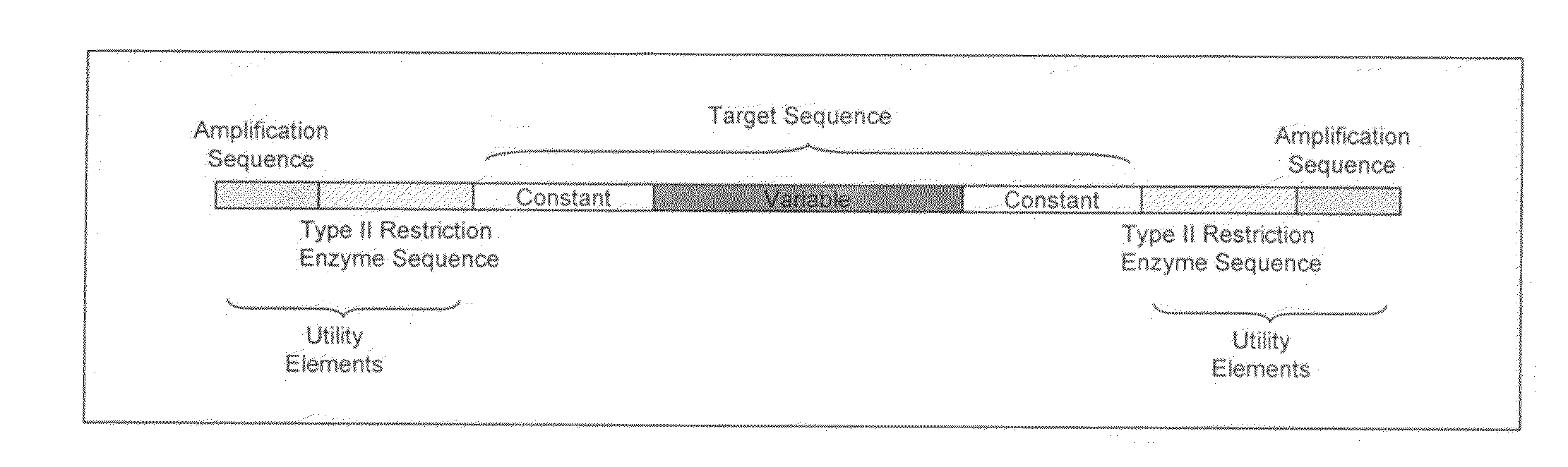

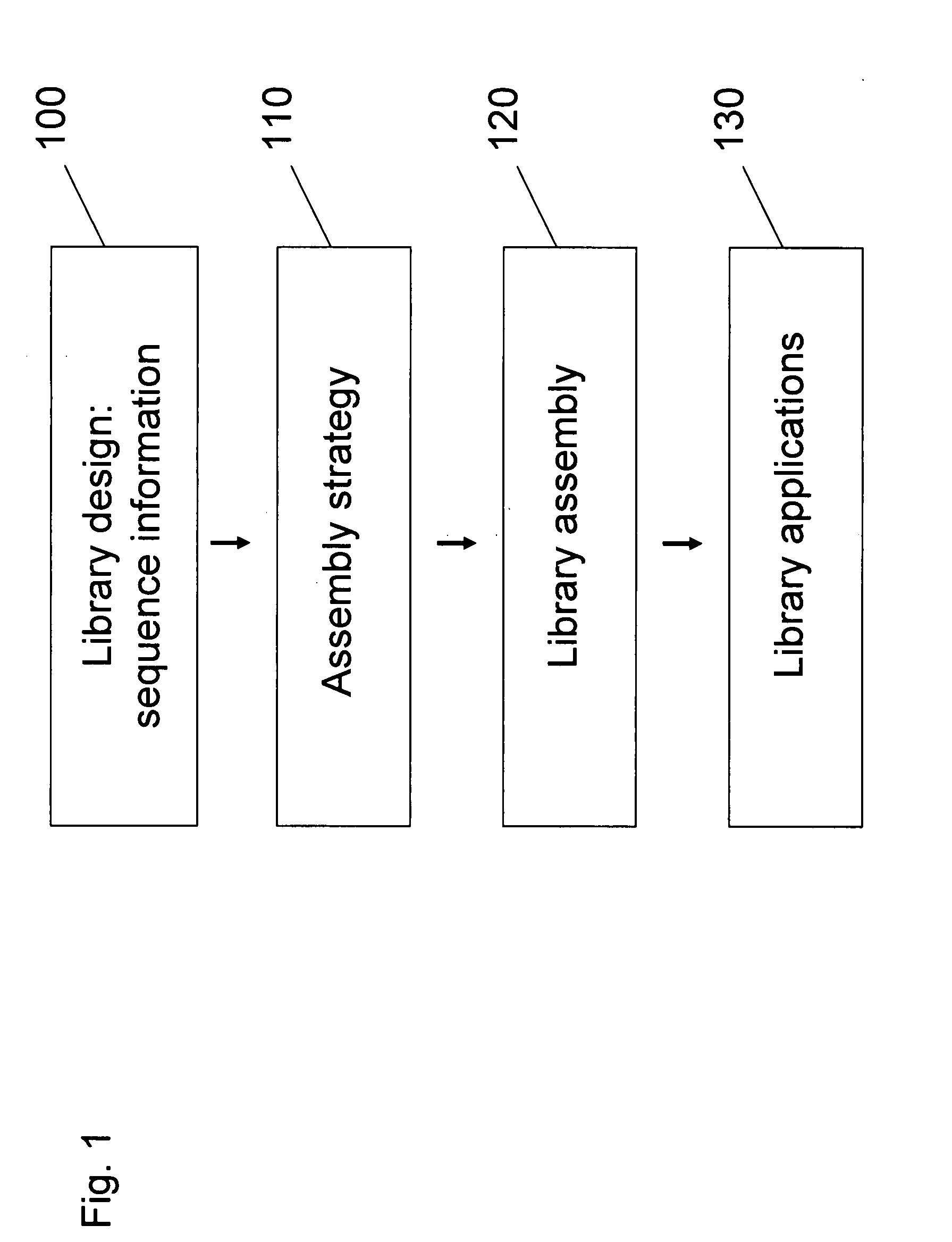

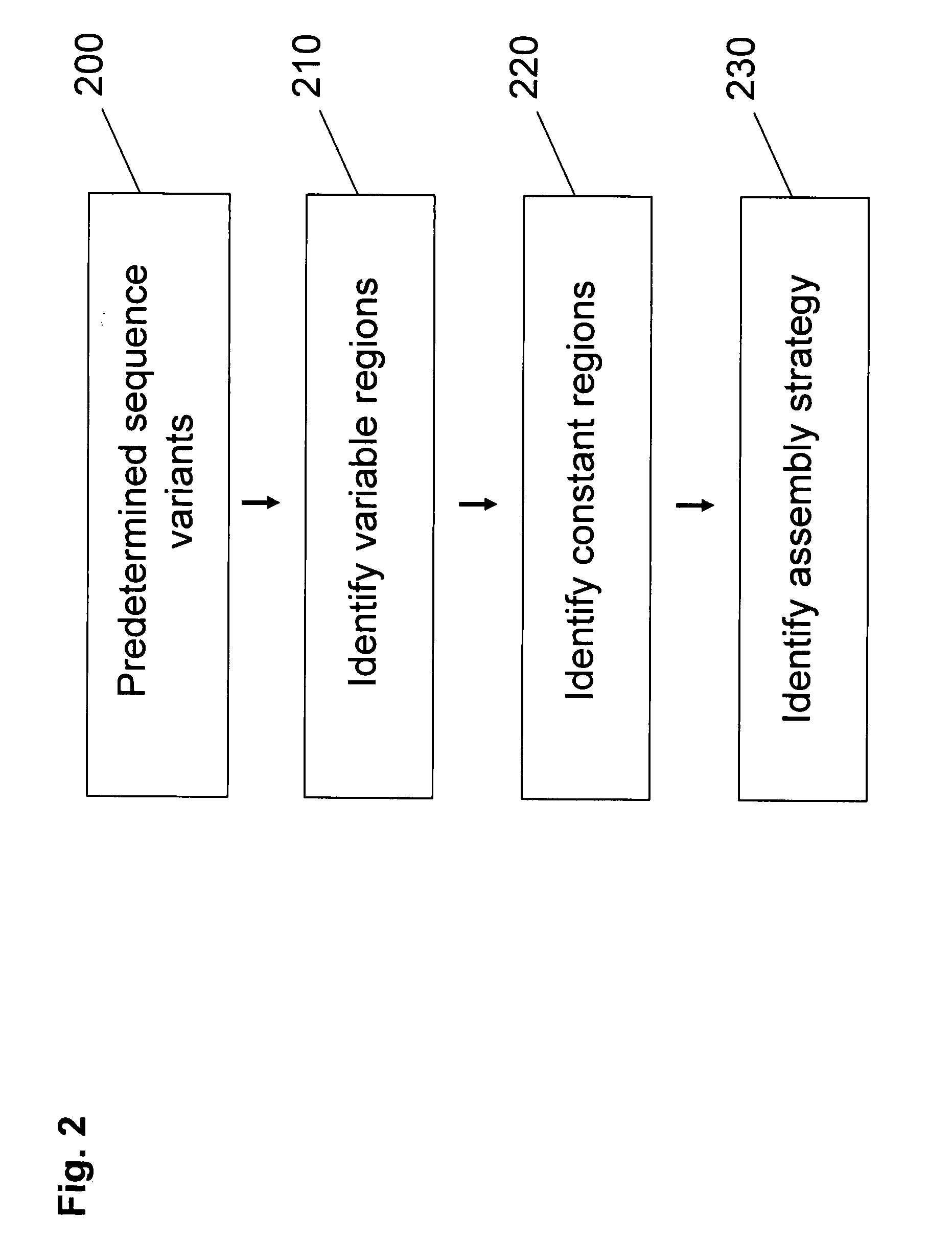

Libraries and their design and assembly

InactiveUS20080287320A1Reduce solubilityImproving immunogenicityVector-based foreign material introductionLibrary creationRandom mutationHigh density

Aspects of the invention relate to the design and synthesis of nucleic acid libraries containing non-random mutations or variants. Aspects of the invention provide methods for assembling libraries containing high densities of predetermined variant sequences. Certain embodiments relate to the design and synthesis of nucleic acid libraries that express a predetermined polypeptide from a library of nucleic acids having silent sequence variants. Certain embodiments relate to the design and synthesis of nucleic acid libraries that express predetermined RNA variants that encode the same polypeptide sequence.

Owner:CODON DEVICES

Solid-state image sensing element and its design support method, and image sensing device

ActiveUS7119319B2Increase freedomHigh light collecting efficiencyTelevision system detailsSolid-state devicesExit pupilLight guide

A solid-state image sensing element has a photoelectric conversion element which converts incoming light into an electrical signal in accordance with an amount of the light, a microlens which is arranged on an incident surface, a light guide which is arranged between the photoelectric conversion element and the microlens, and an insulating interlayer which is arranged around the light guide. The solid-state image sensing element located at a distance (H) satisfies:H·DL·P<a·NHNLfor0<a<1where L is the distance from an exit pupil of an image sensing optical system of an image sensing device, which mounts an image sensor formed by two-dimensionally arranging a plurality of the solid-state image sensing elements, H is the distance from a center of the image sensor to a position of the solid-state image sensing element on the image sensor, D is the height from the photoelectric conversion element to an apex of the microlens, P is the spacing between the plurality of solid-state image sensing elements, NH is the refractive index of the light guide, and NL is the refractive index of the insulating interlayer.

Owner:CANON KK

Ruggedized illuminating, marking, or signaling device and system

ActiveUS7088222B1Easy to deployEasy to usePoint-like light sourceRoad vehicles traffic controlUnderwaterEffect light

An illumination device, including: a shell with a plurality of sides, where the device can be positioned upon a surface or attached or suspended at any of the plurality of sides; and at least one light-emitting device within the shell, where when the device is positioned upon a surface or attached or suspended at any of the plurality of sides of the shell, light from the at least one light-emitting device emits through each of the plurality of sides of the shell. The device is thus easy to deploy and use. Its design is compatible with outsourced manufacturing, allowing for cost savings. The device can be reused many times. The device can also emit light for many hours longer and has ruggedness that far exceeds conventional devices. The device can also be used where conventional devices and other lighting devices cannot, including underwater.

Owner:POWERFLARE CORP

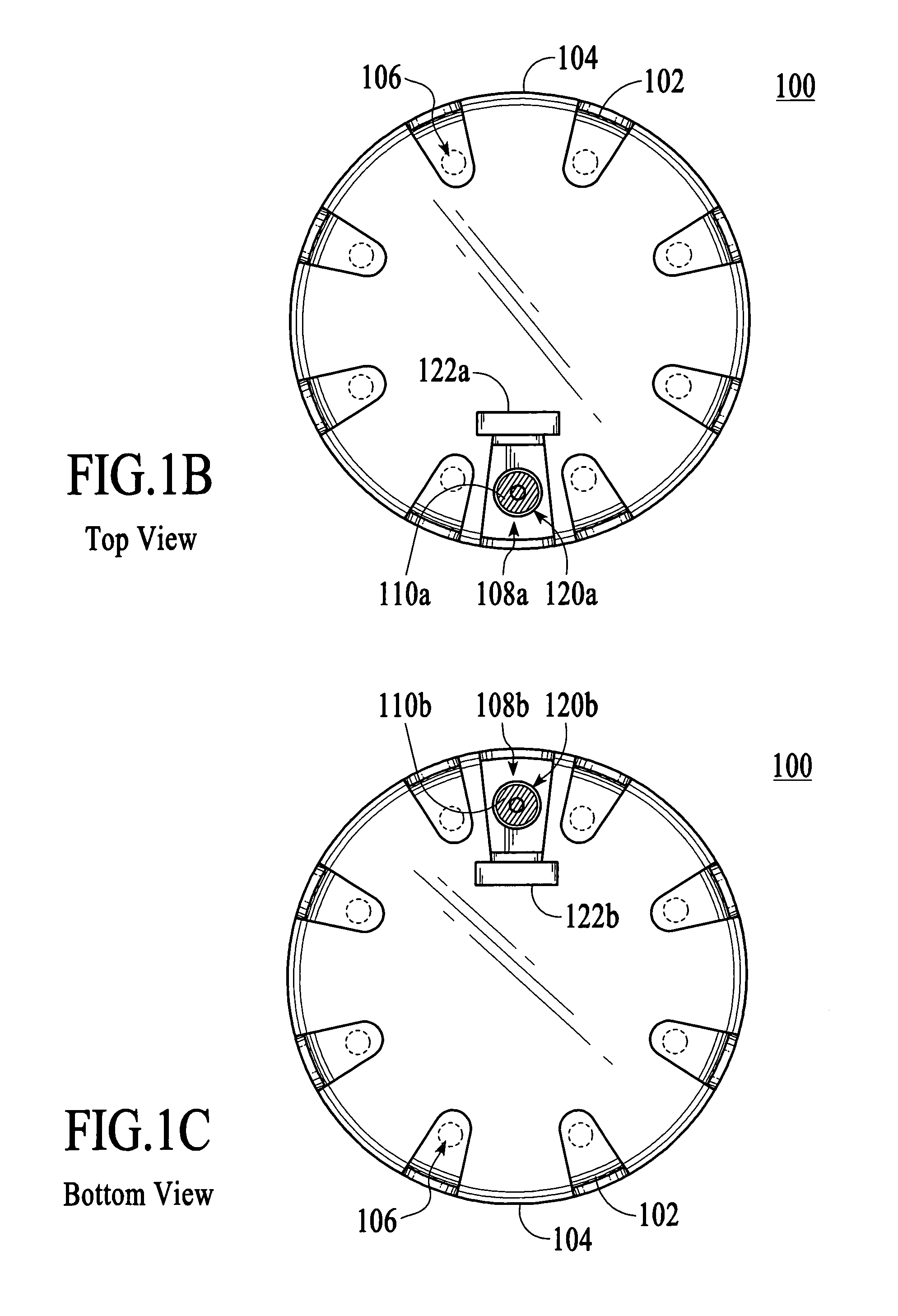

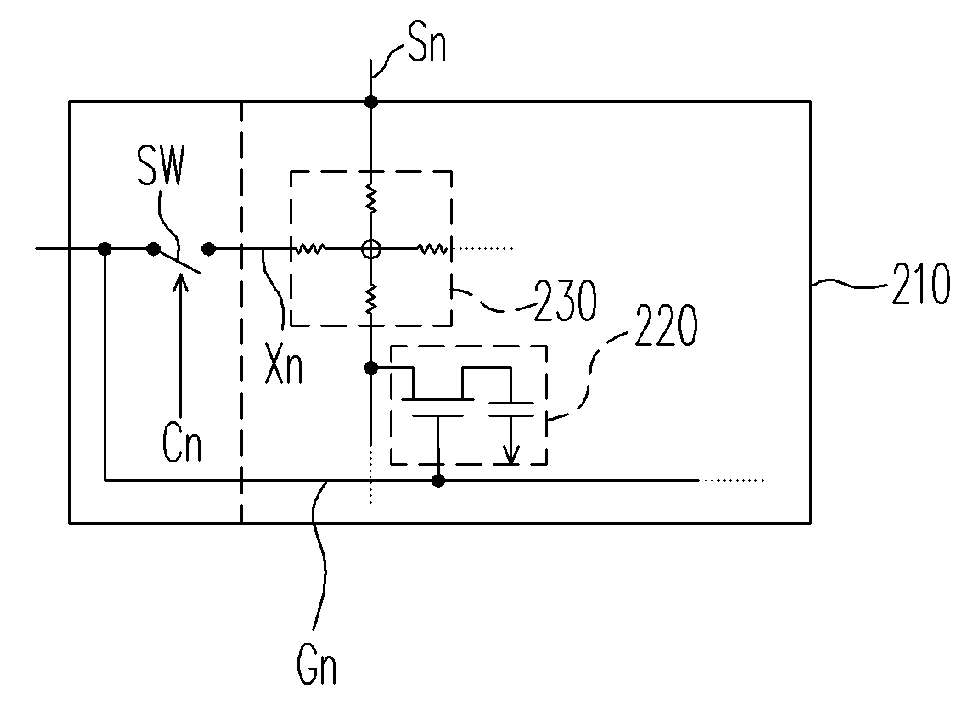

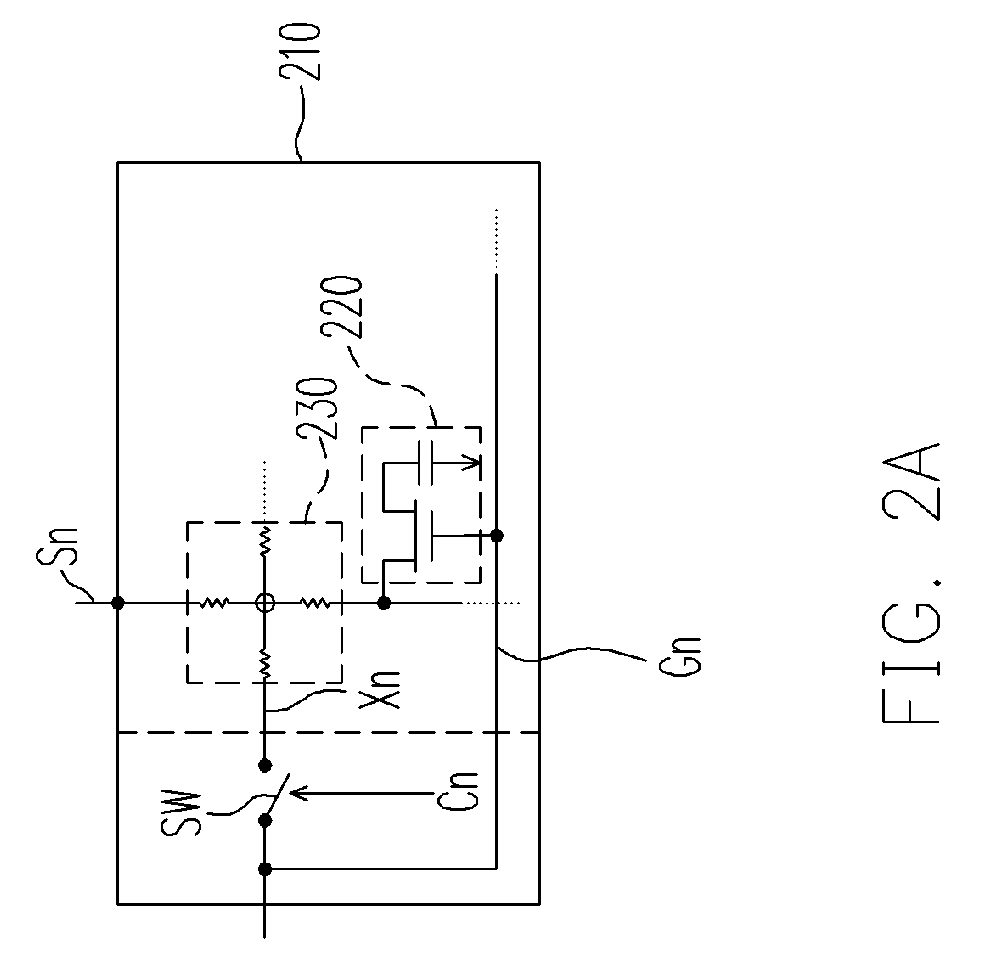

Touch screen liquid crystal display device and system driving method therefor

InactiveUS20060244736A1Reducing pluralityCathode-ray tube indicatorsInput/output processes for data processingLiquid-crystal displayImage resolution

A touch screen liquid crystal display (LCD) device is provided. In its design, a LCD panel and an input panel are integrated, to prevent damages or impurity contamination in the manufacturing and assembly process of the LCD, further to spare the additional analog-to digital converter and control circuit. With the driving method of the present invention, the touch screen LCD device with integrated display and input function doesn't affect the original LCD display function. Moreover, the simple on / off driving mode also enhances the resolution requirement of the touch screen LCD.

Owner:NOVATEK MICROELECTRONICS CORP

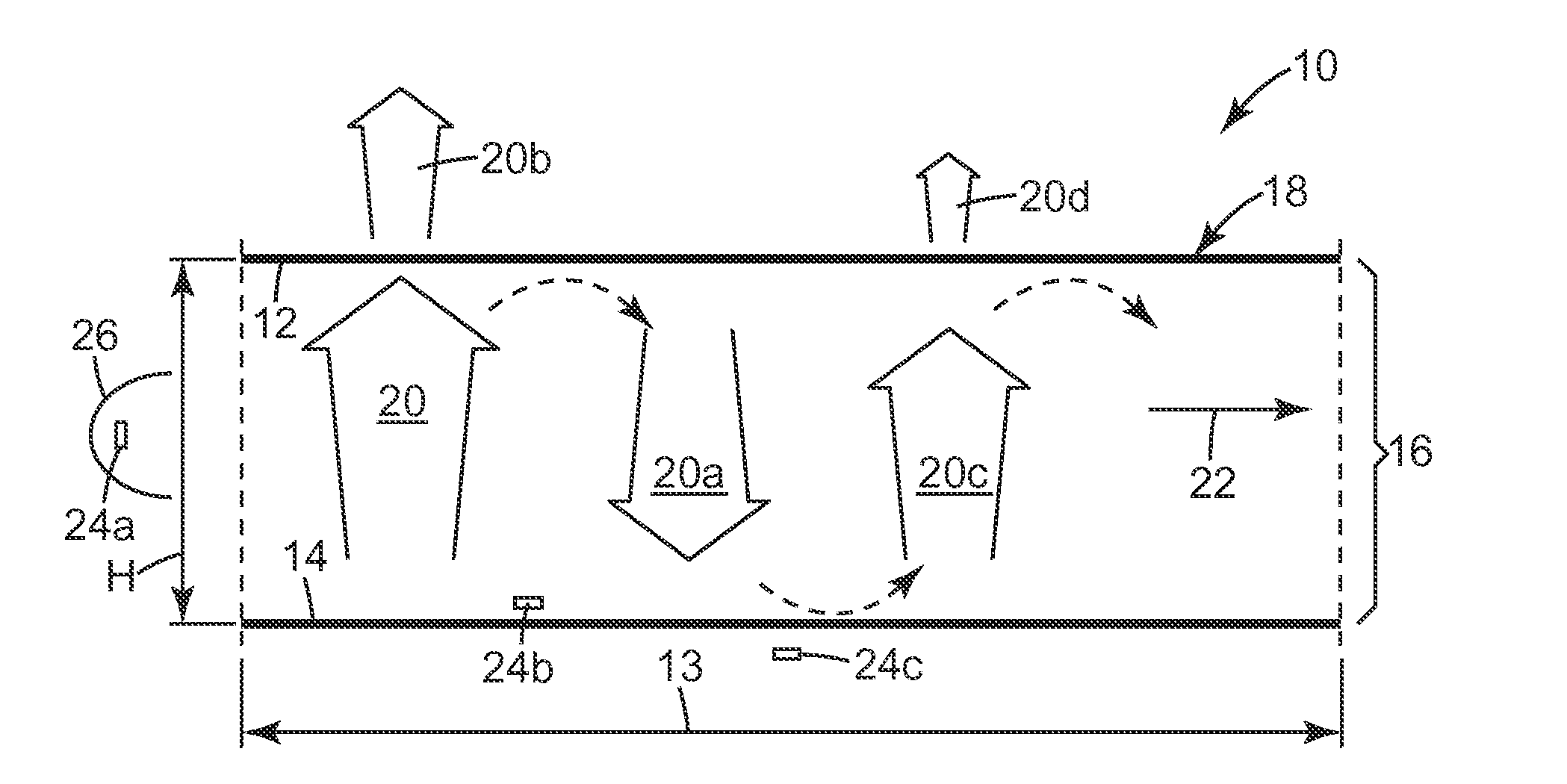

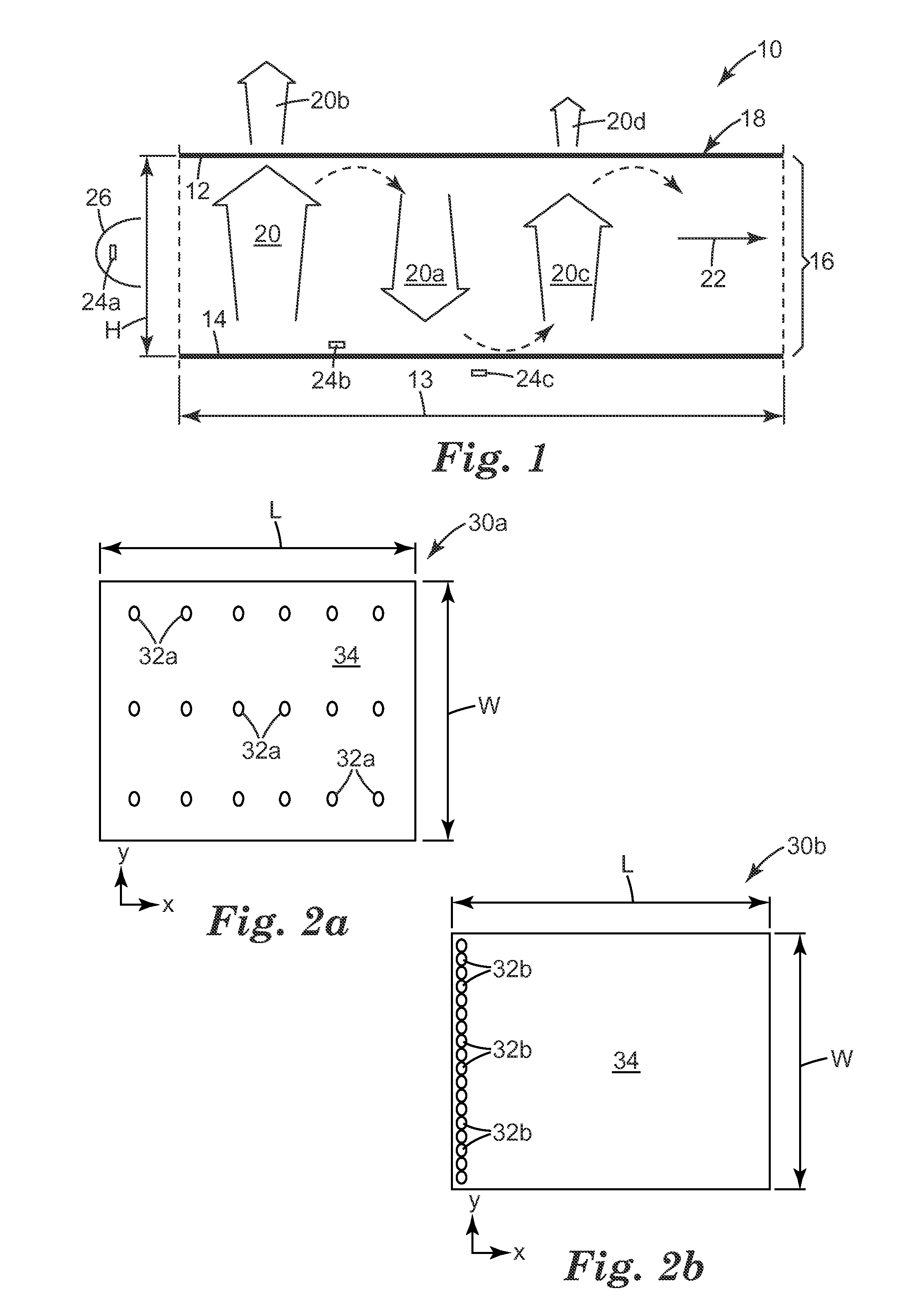

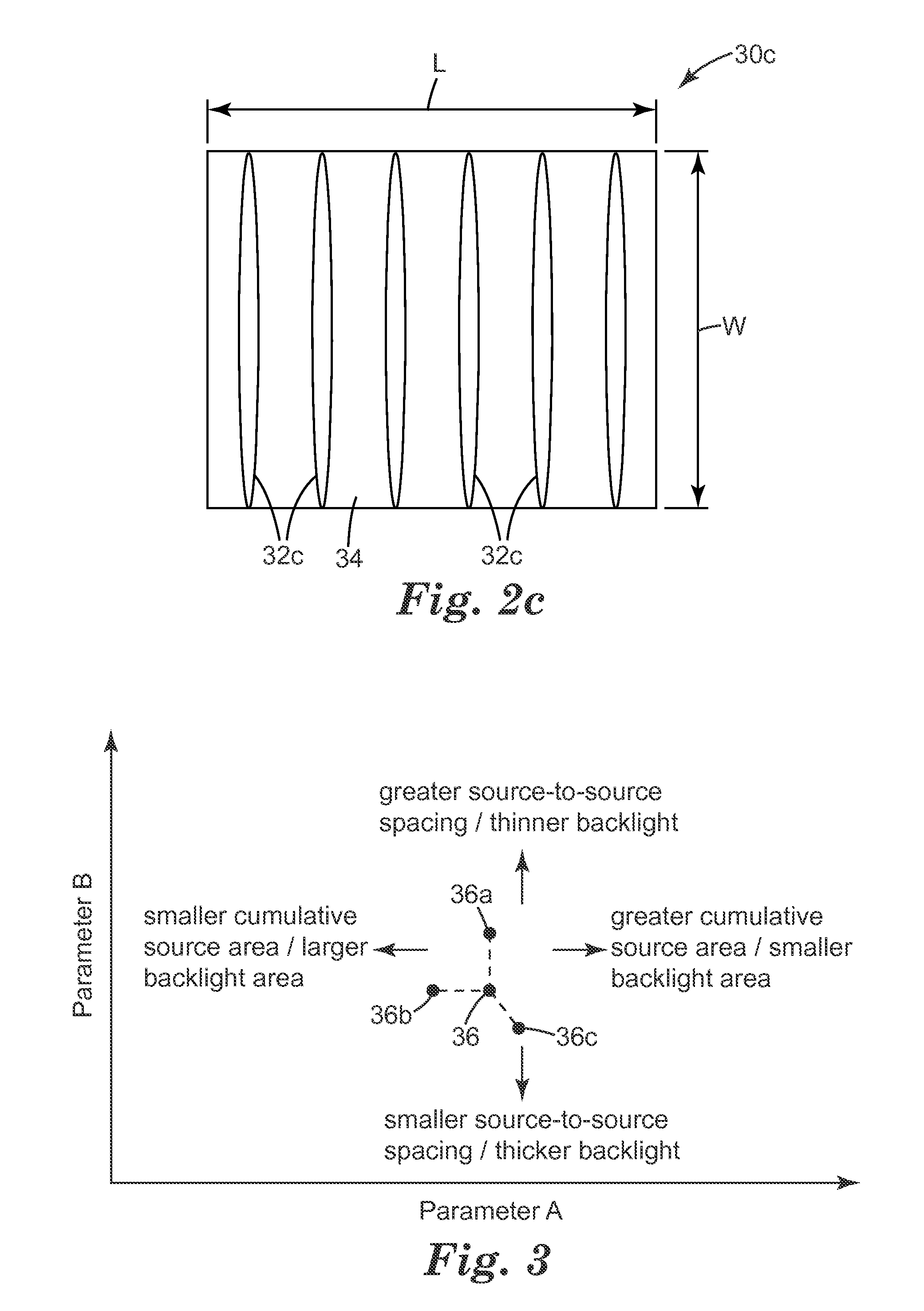

Thin hollow backlights with beneficial design characteristics

InactiveUS20100156953A1Reduce the total massLosses associated with the light sources are kept to minimal levelsCathode-ray tube indicatorsHollow light guidesBack reflectorLight guide

A backlight unit (10) has a hollow cavity (16) instead of employing a light guide. One or more light sources (24a-c), such as LEDs, are arranged to emit light into the cavity, which is formed by a front (12) and a back reflector (14). The backlight is typically of the edge-lit type. The backlight can have a large area, is thin and consists of fewer components than conventional devices. Its design permits light recycling. The unit emits light of a predefined polarisation and can be arranged to have desired horizontal / vertical viewing angle properties. Light is uniformly distributed within the guide and the light output (20b, 2Od) is substantially collimated. Such backlights occupy a specific region in a parameter space defined by two parameters: first, the ratio of the output emission area to the total source emission area should lie in the range 0.0001 to 0.1; and second, the ratio of the SEP to the height of the cavity (H) should be in the range 3 to 10, where the SEP is an average plan view source separation, a special measure of the average spacing of light sources in the plane of the unit. There is also a discussion on the required number of light sources N, their arrangement near the periphery of the cavity, as well as the shape and size of the output emission area. A required minimum brightness uniformity (VESA) value to be maintained, when a subset of Madjacent sources is switched off (where M is at least 0.1 N or M>2 or both), is also disclosed. The backlight can be used for a display or for general lighting purposes.

Owner:3M INNOVATIVE PROPERTIES CO

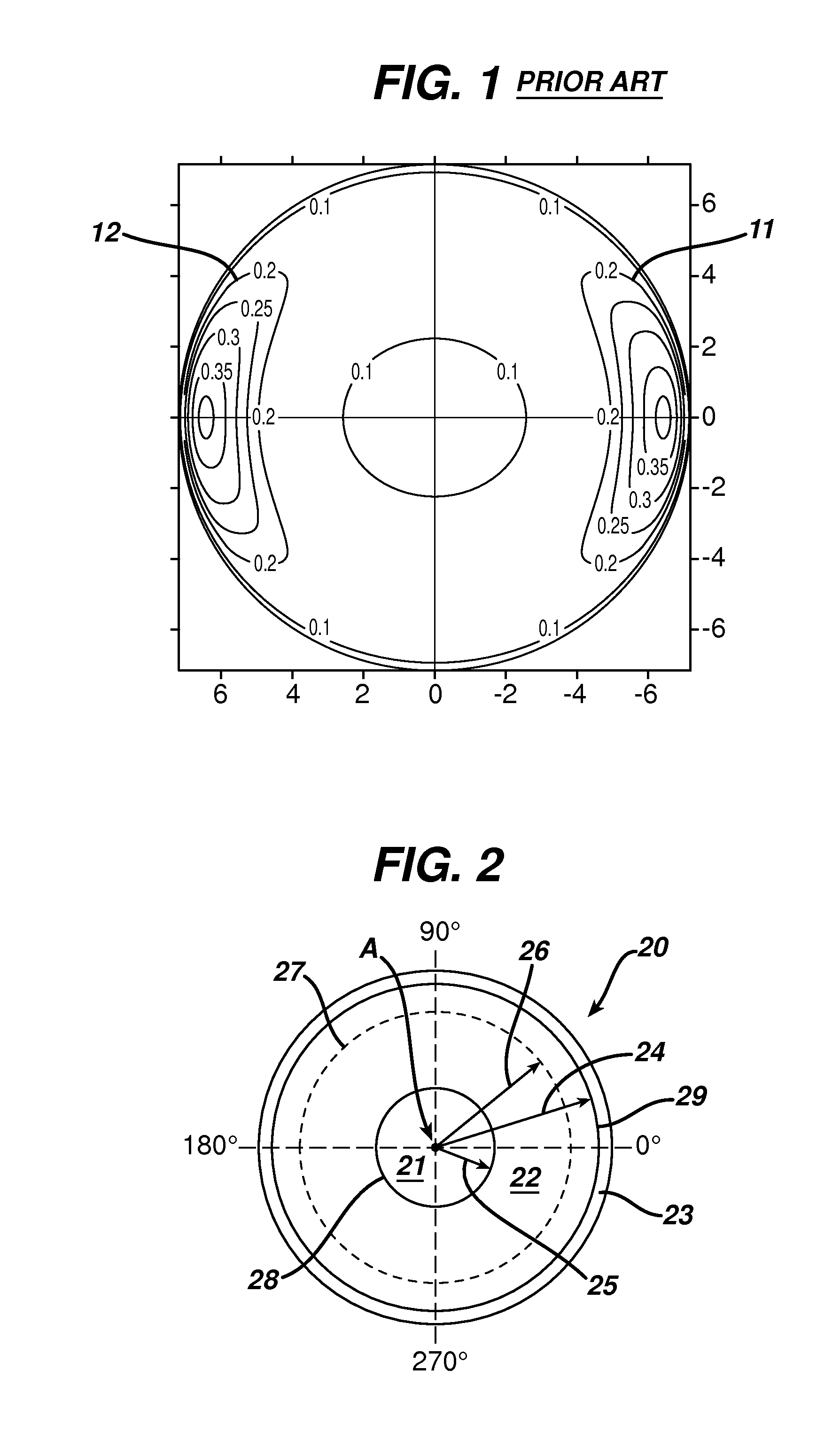

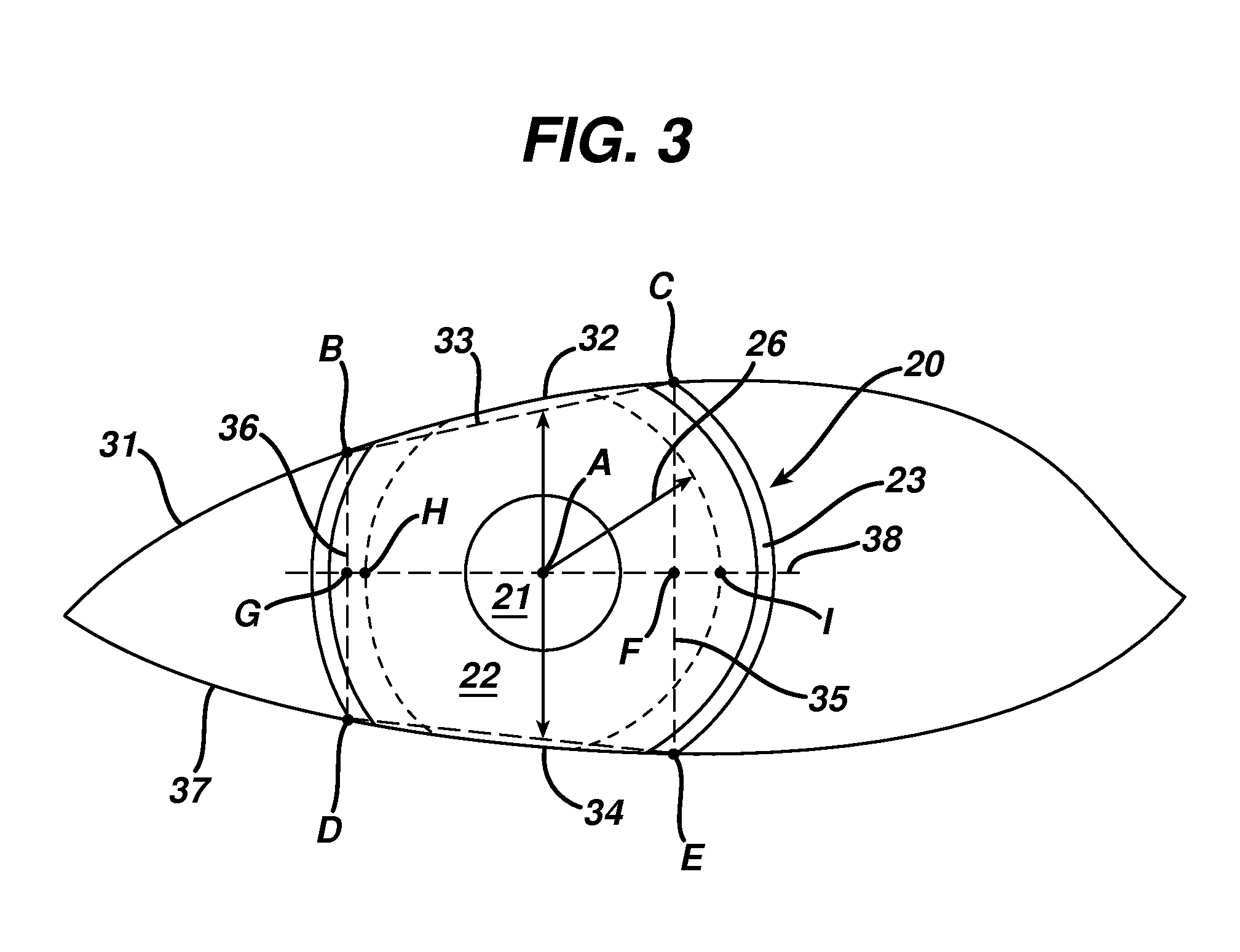

Contact lenses and methods for their design

The invention provides methods for designing contact lenses in which method the lens flexure is taken into account. The method of the invention is insensitive to the lens' back surface design and does not require complex back surface designs. Additionally, the lens design can be optimized virtually, eliminating the need for iterative design-test on-eye-re-design cycles.

Owner:JOHNSON & JOHNSON VISION CARE INC

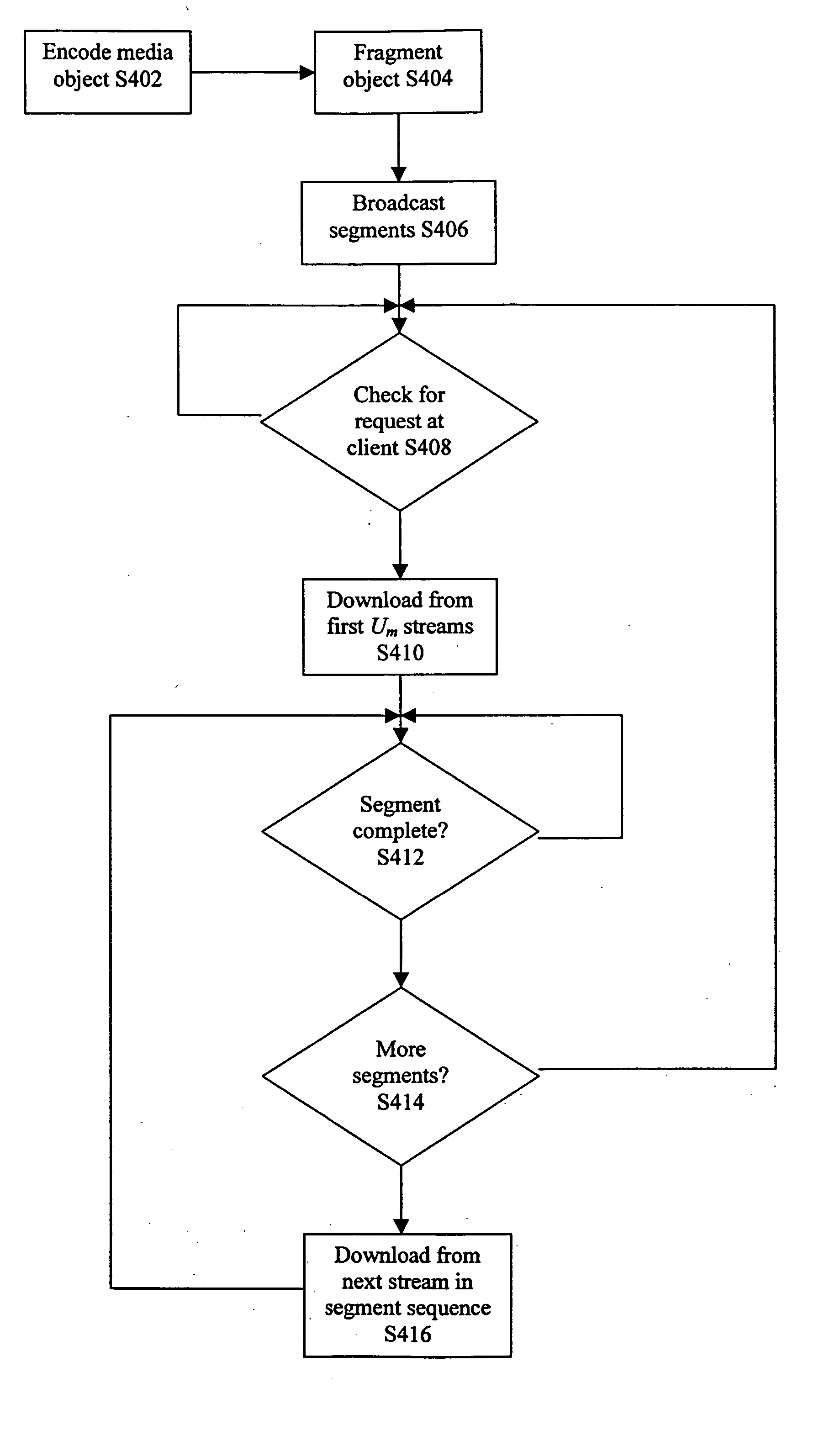

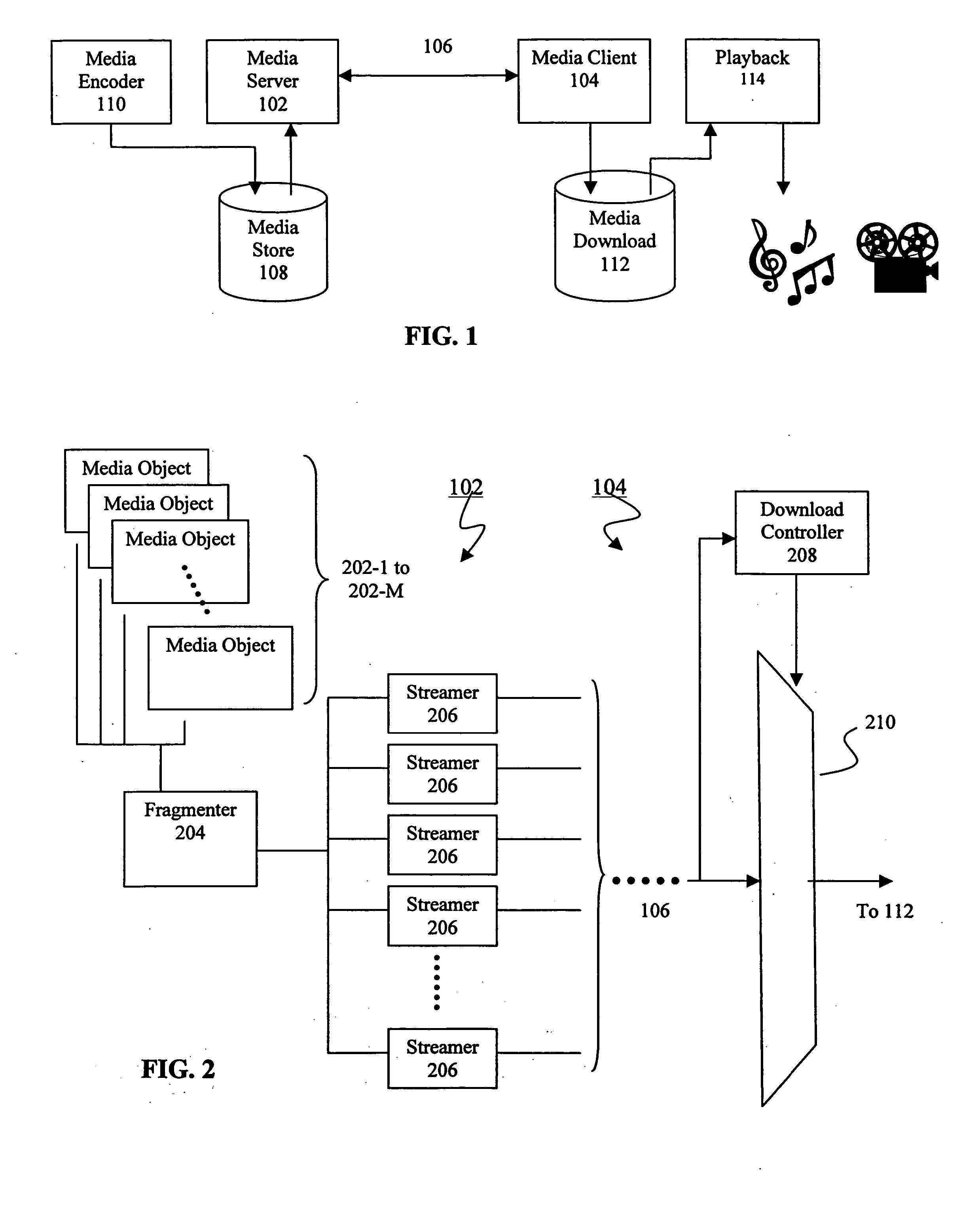

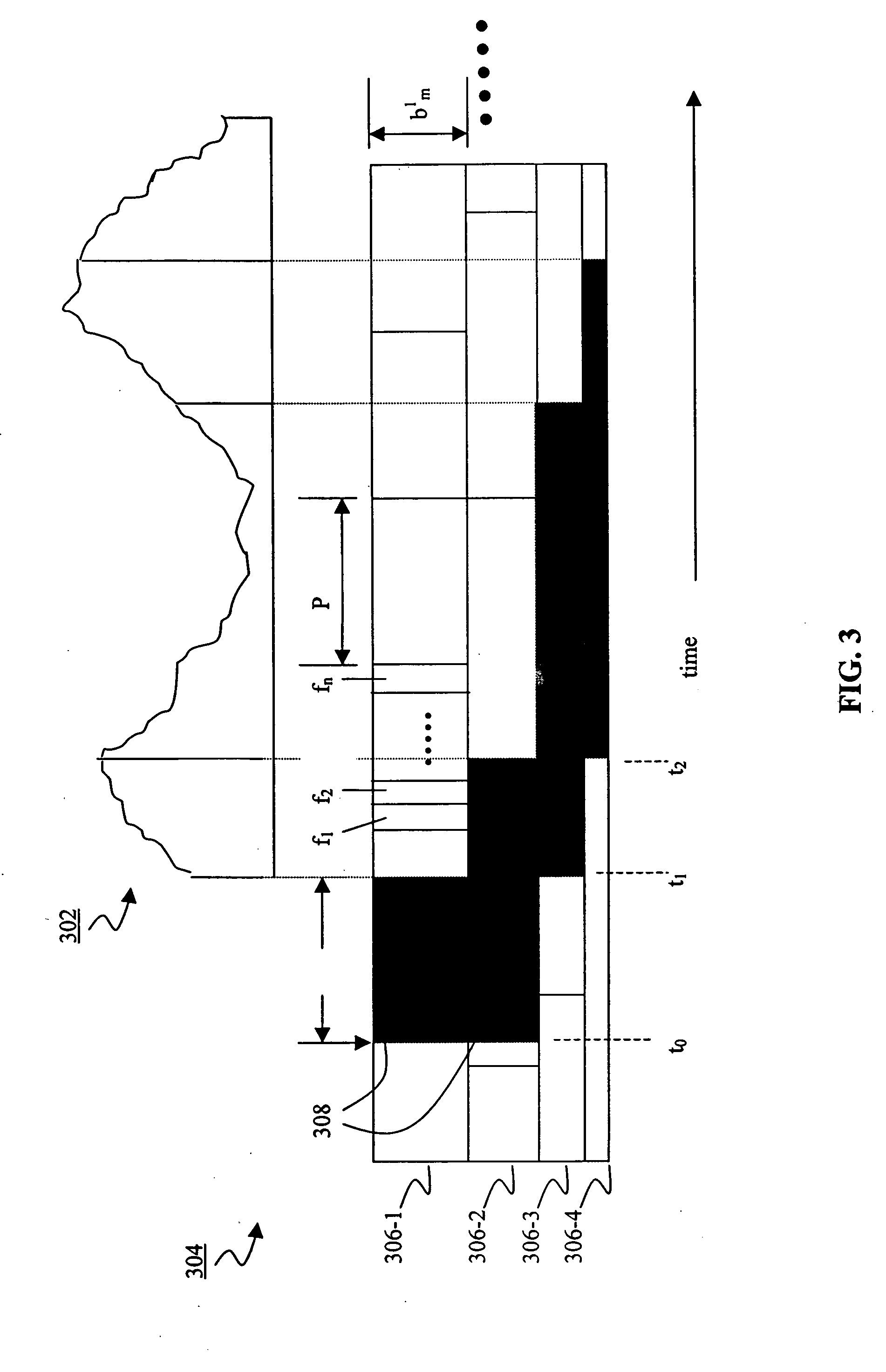

Method and apparatus for broadcasting media objects with guaranteed quality of service

InactiveUS20050033856A1Multiple digital computer combinationsTwo-way working systemsQuality of serviceStreaming data

A method and apparatus for broadcasting media objects for such bandwidth-intensive applications as Media on Demand (MoD) or Video on Demand (VoD) employ a novel StairCase Broadcast (SCB) scheme. A media server in accordance with one example of the invention includes a fragmenter that fragments media objects into multiple segments, with each segment provided to a corresponding streamer. Each streamer periodically and continuously streams data associated with its corresponding media segment on a connection between the server and a media client. A download controller in the media client selectively causes the proper streams to be received for downloading from the server in accordance with the fragmentation of the selected media object and the number of streams that the client can simultaneously receive for downloading. A selector is operable to cause data from each successive segment to be downloaded from the corresponding stream immediately regardless of the position in the period associated with the successive segment. By its design, the method and apparatus of the present invention allow for lossless broadcast of media contents with de-coupled per-media-object server and client bandwidth design considerations.

Owner:RPX CLEARINGHOUSE

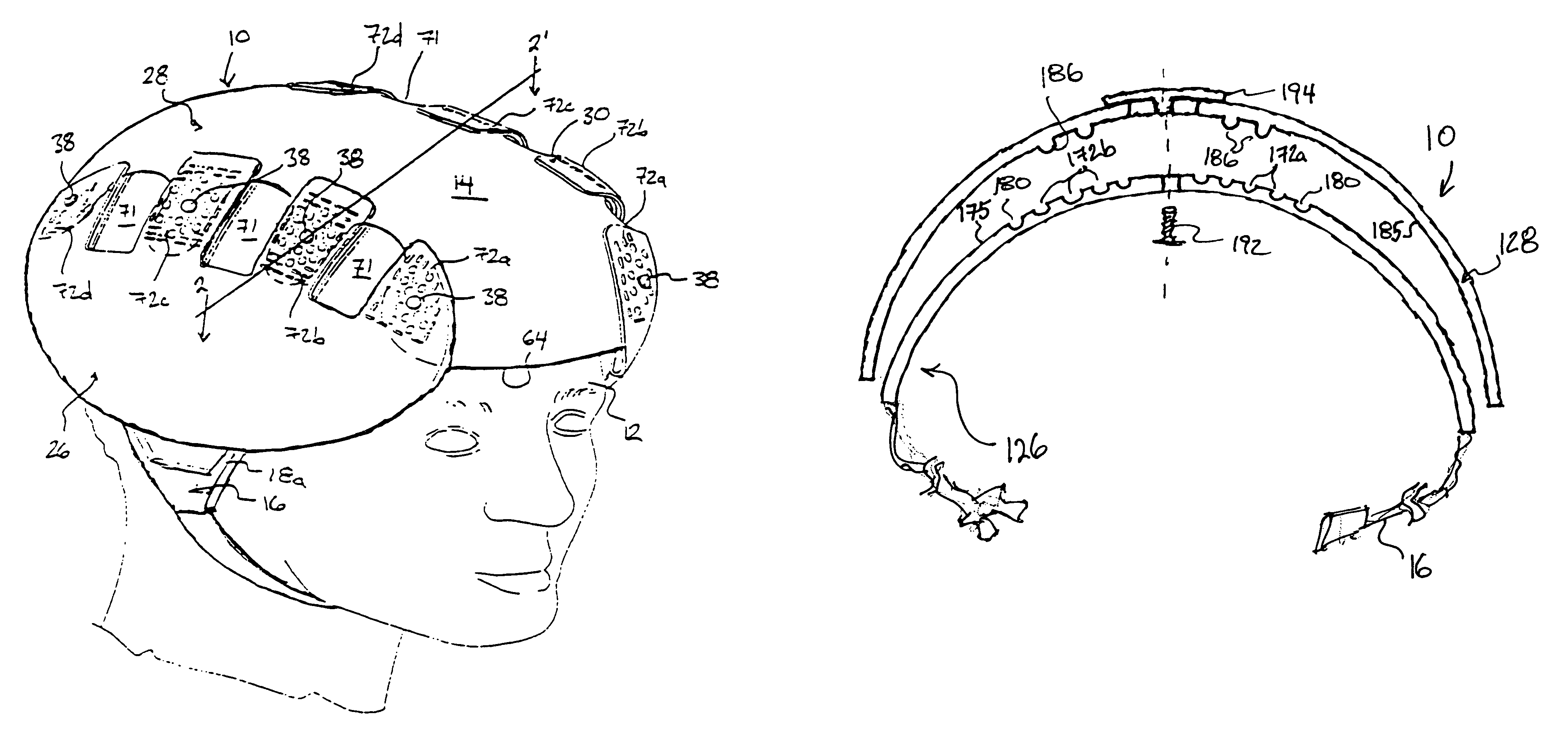

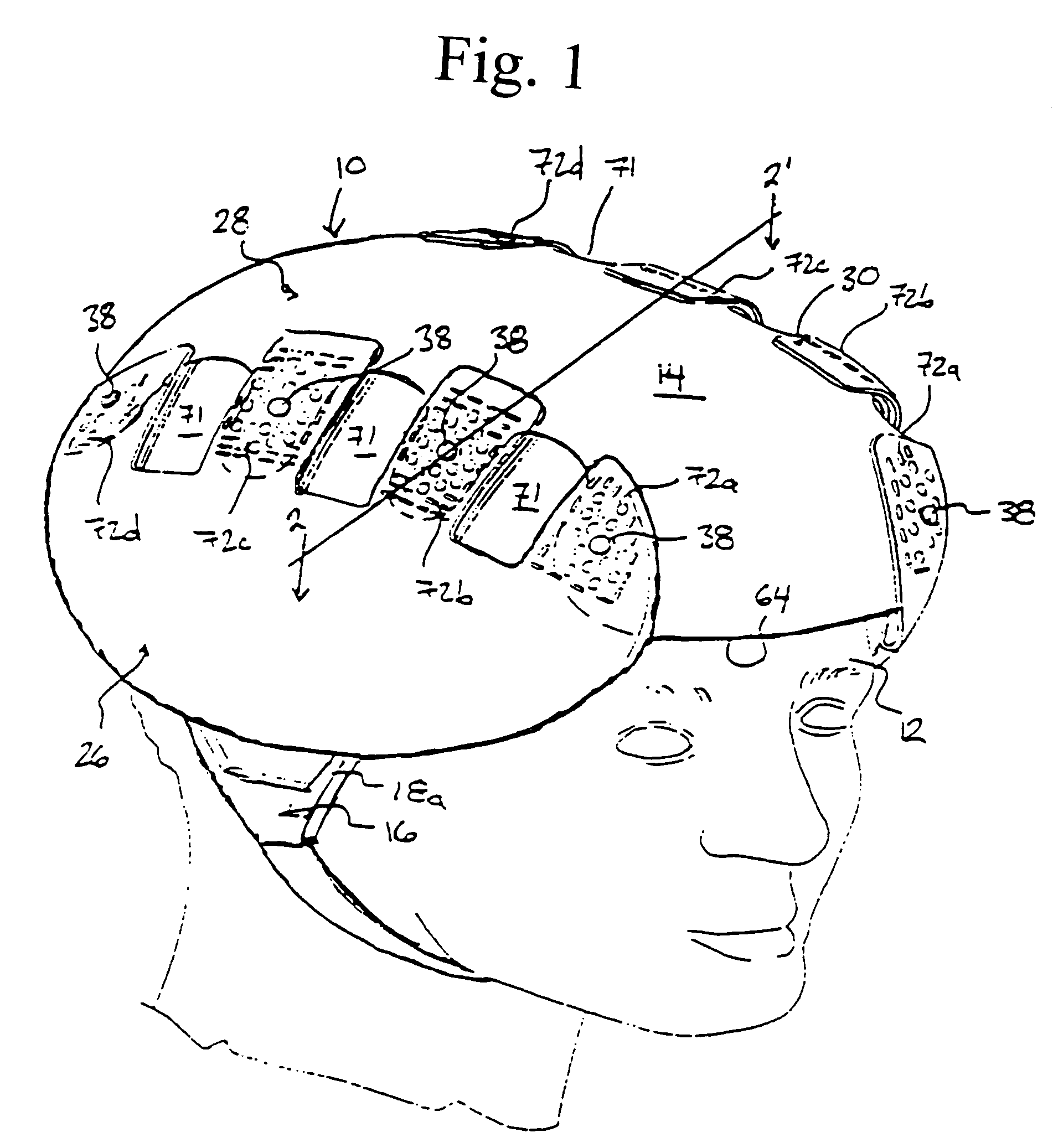

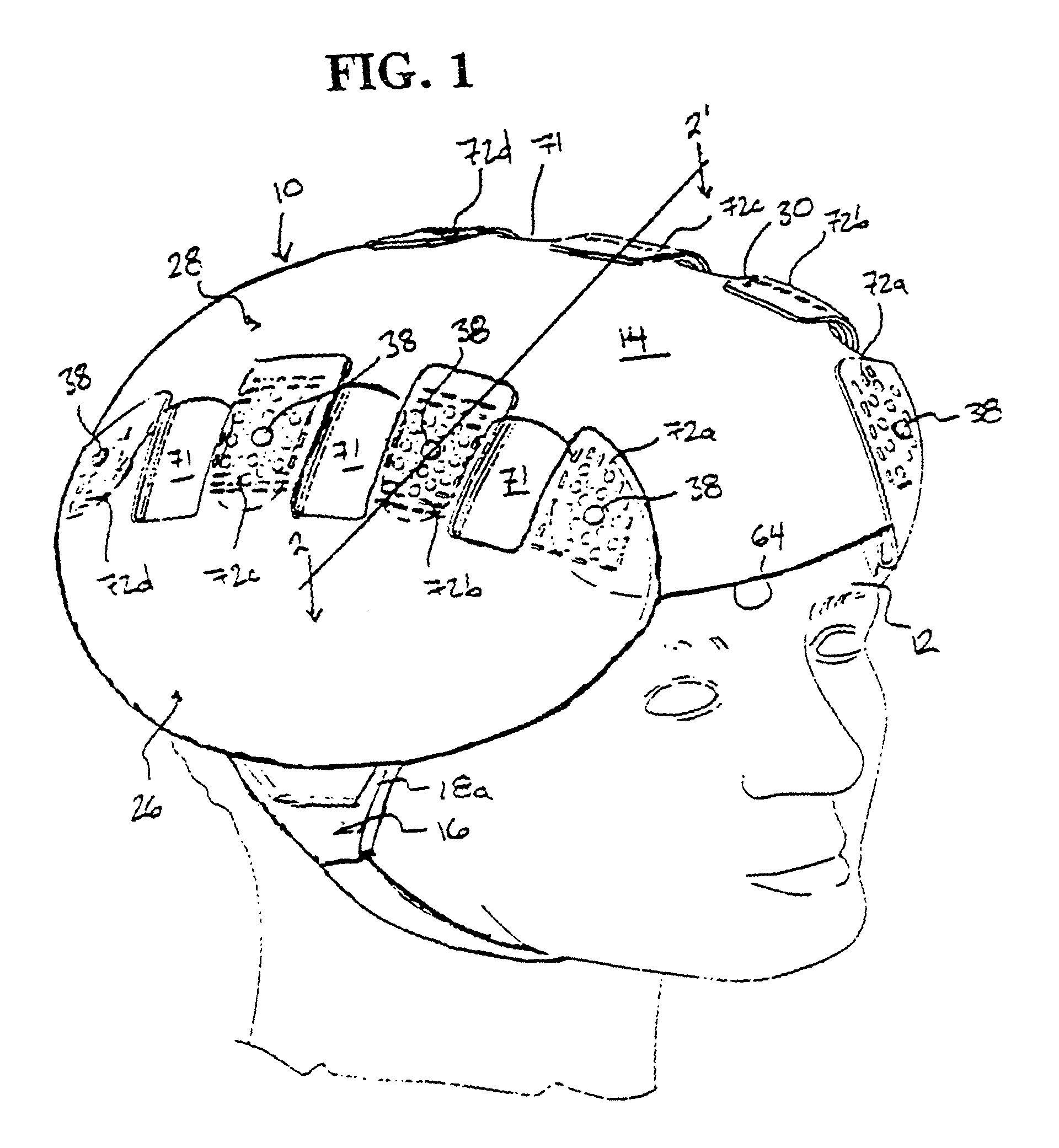

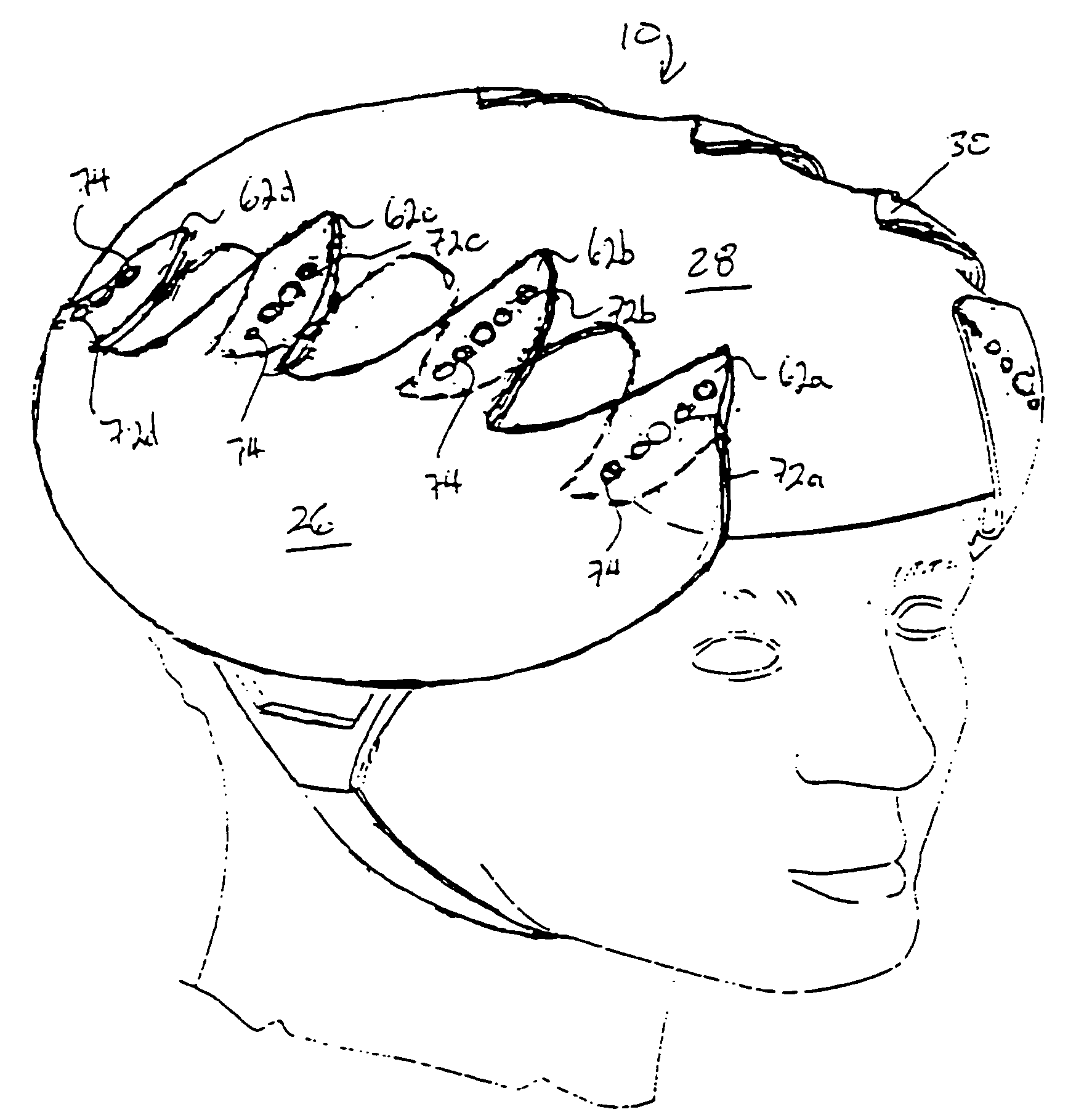

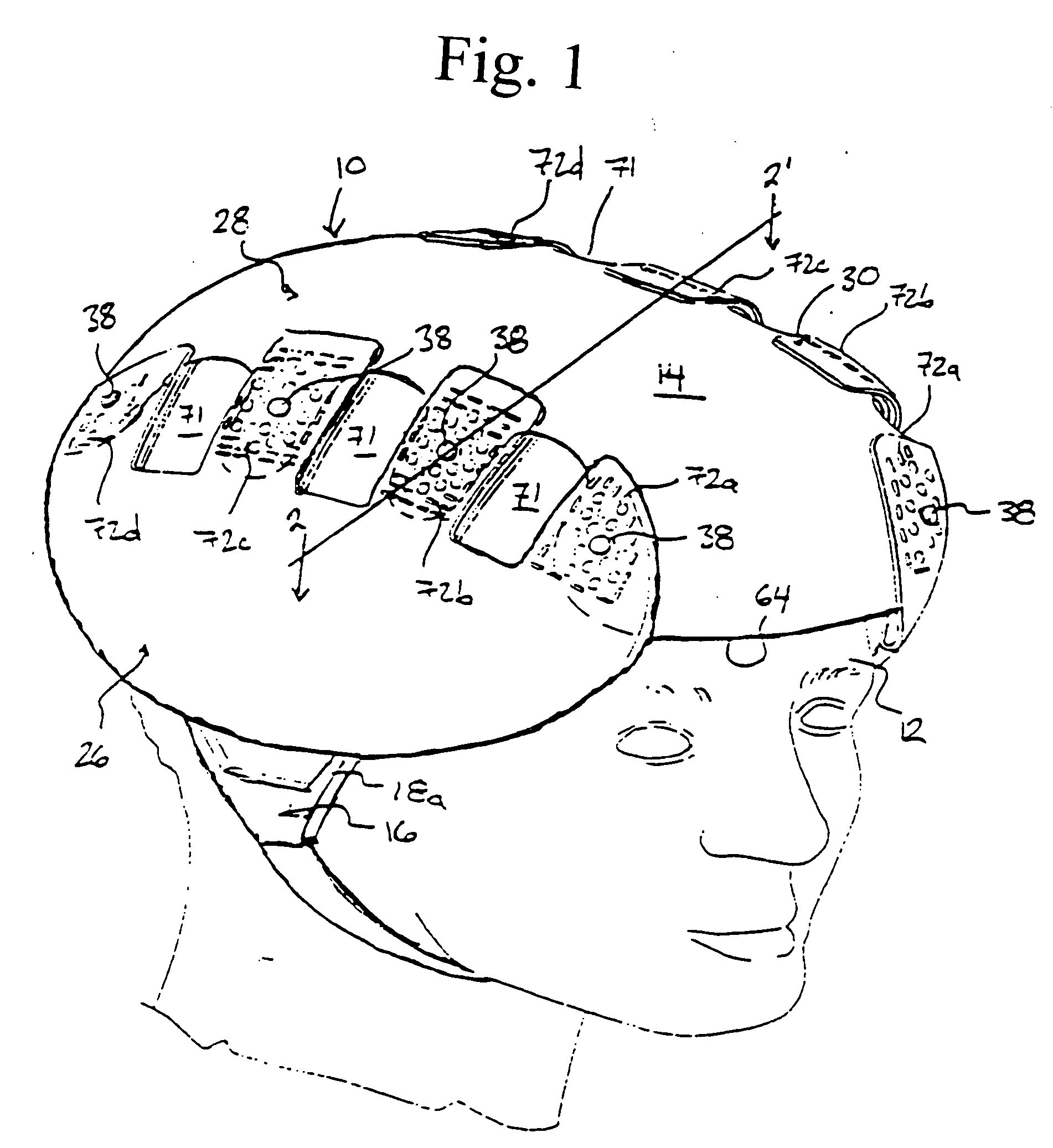

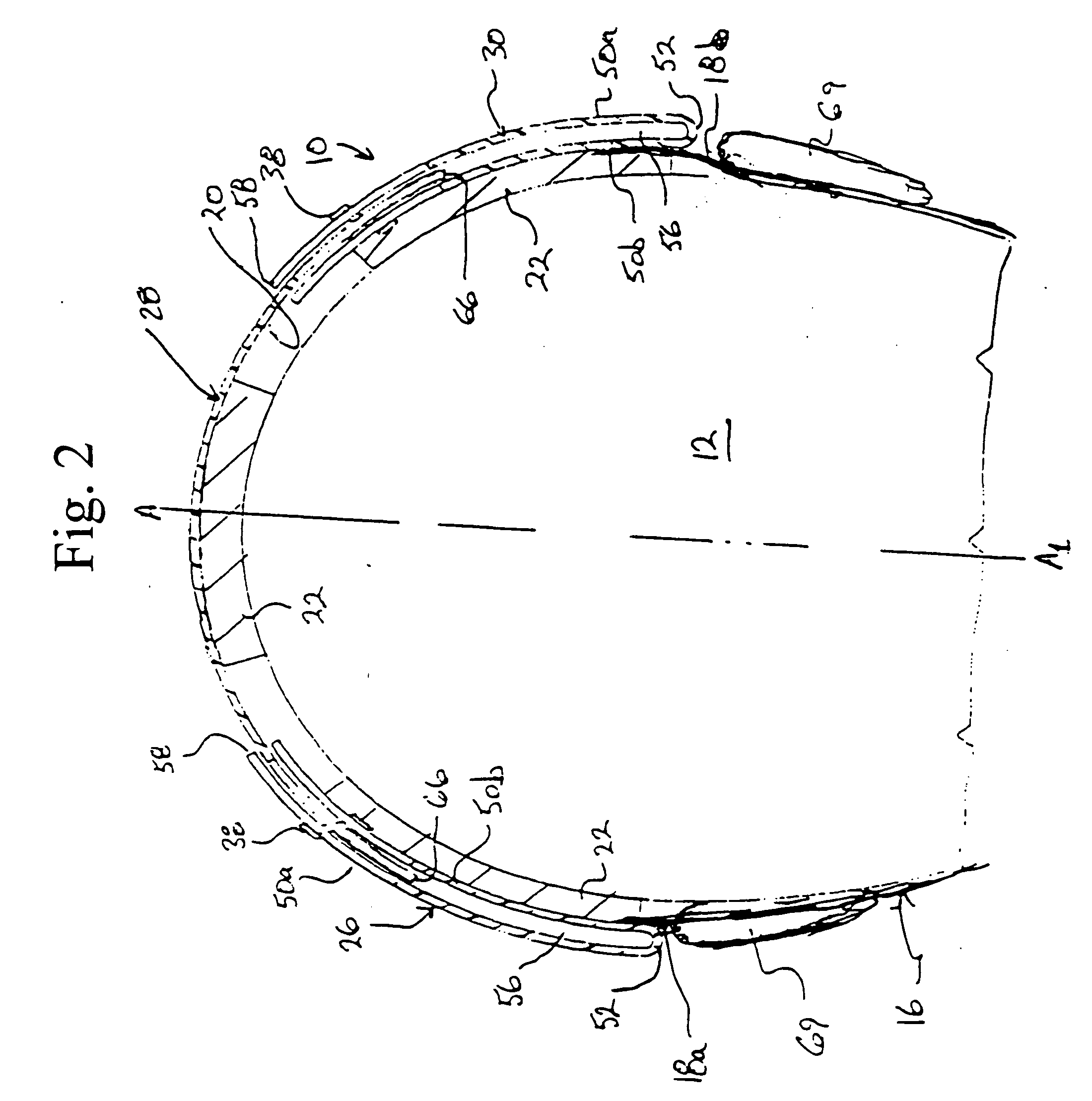

Protective head covering having impact absorbing crumple zone

InactiveUS6996856B2Closer in weight and sizeMinimizing resultant disproportionHatsSport apparatusMostly TrueEngineering

A helmet construction for protecting a user's head, and the brain within the cranium from impact forces, includes a shell contoured to the shape of the user's head, with cushioning along at least part of the shell interior and a chinstrap. The shell consists of three (or more) discrete panels that are physically and firmly coupled together providing rigid protection under most circumstances, but upon impact the panels move relative to one another, but not relative to the user's head, thereby permitting impact forces to be dissipated and / or redirected away from the cranium and brain within. Upon impact to the helmet, there are sequential stages of movement of the panels relative to each other, these movements initially being recoverable, but with sufficient vector forces the helmet undergoes structural changes in a pre-determined fashion, so that the recoverable and permanent movements cumulatively provide a protective ‘crumple zone’ or ‘shear zone’. The first two stages of protection arise from the design of the fasteners that have the ability to invaginate and collapse within themselves, and their design having a 45 degree angle, which will allow movement of a region of connected panels to translate along the fastener shaft. Both of these movements will be recoverable and provide a ‘functional crumple zone’. The final stage of protection arises from the braking function of the pins, as they are forced from one aperture through to the next, the direction and extent of which is determined by the impact force and direction. This final level of panel movement and protection is not recoverable and thus provides a ‘structural crumple zone’. Finally the fastener size and thickness, together with the thickness of webbing and distance between apertures, functions to provide varying degrees of resistance to impact forces, thus making the helmet design suitable for activities with different levels of impact speed and risk potential.

Owner:PUCHALSKI TECHN

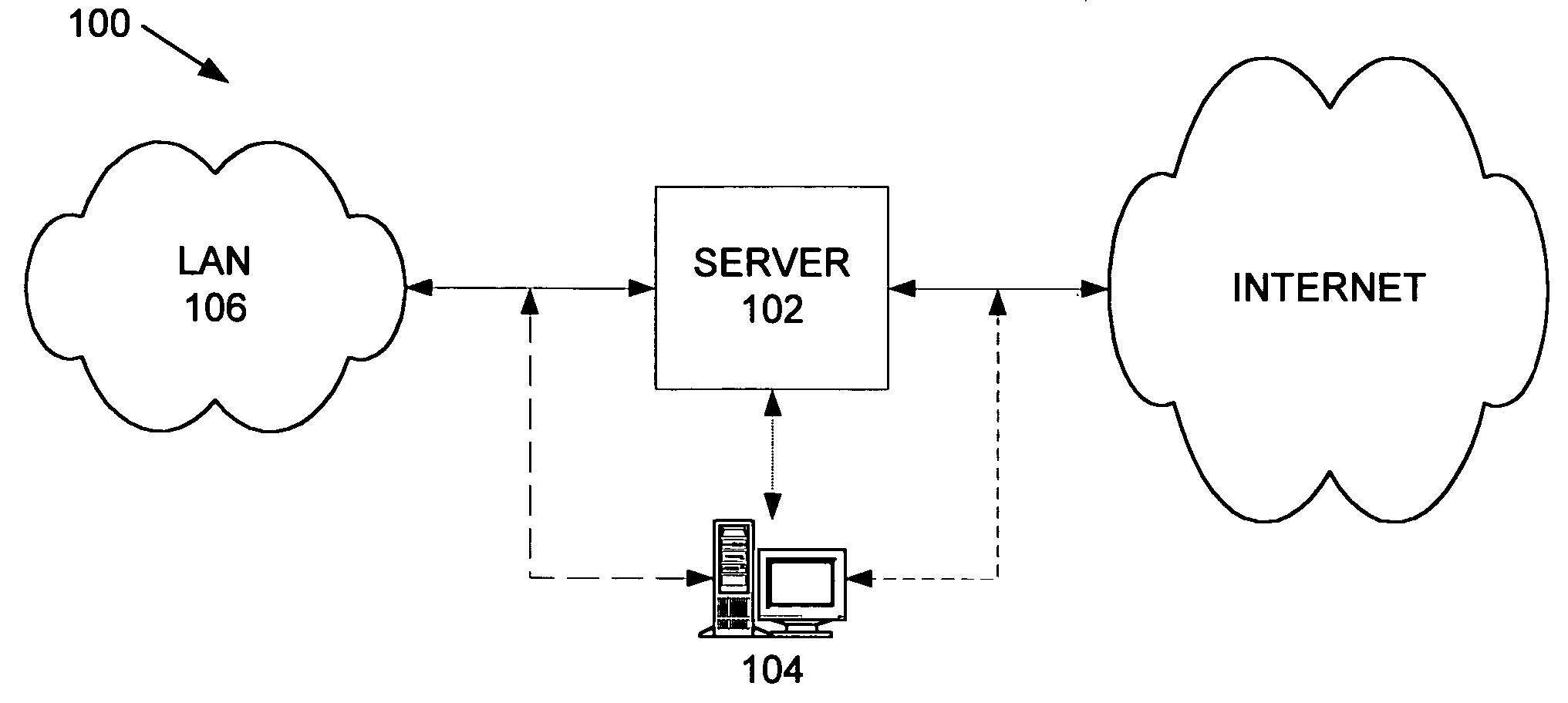

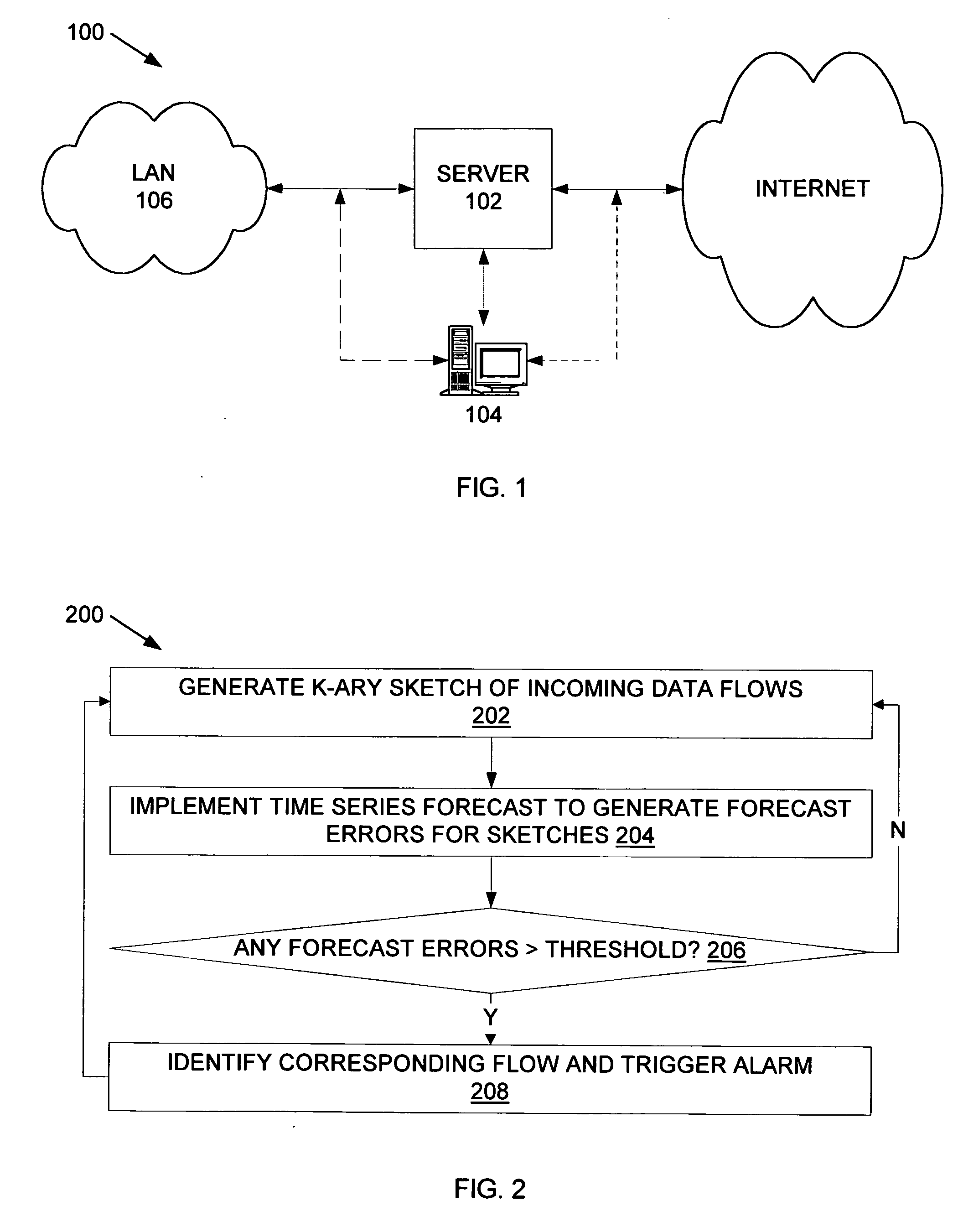

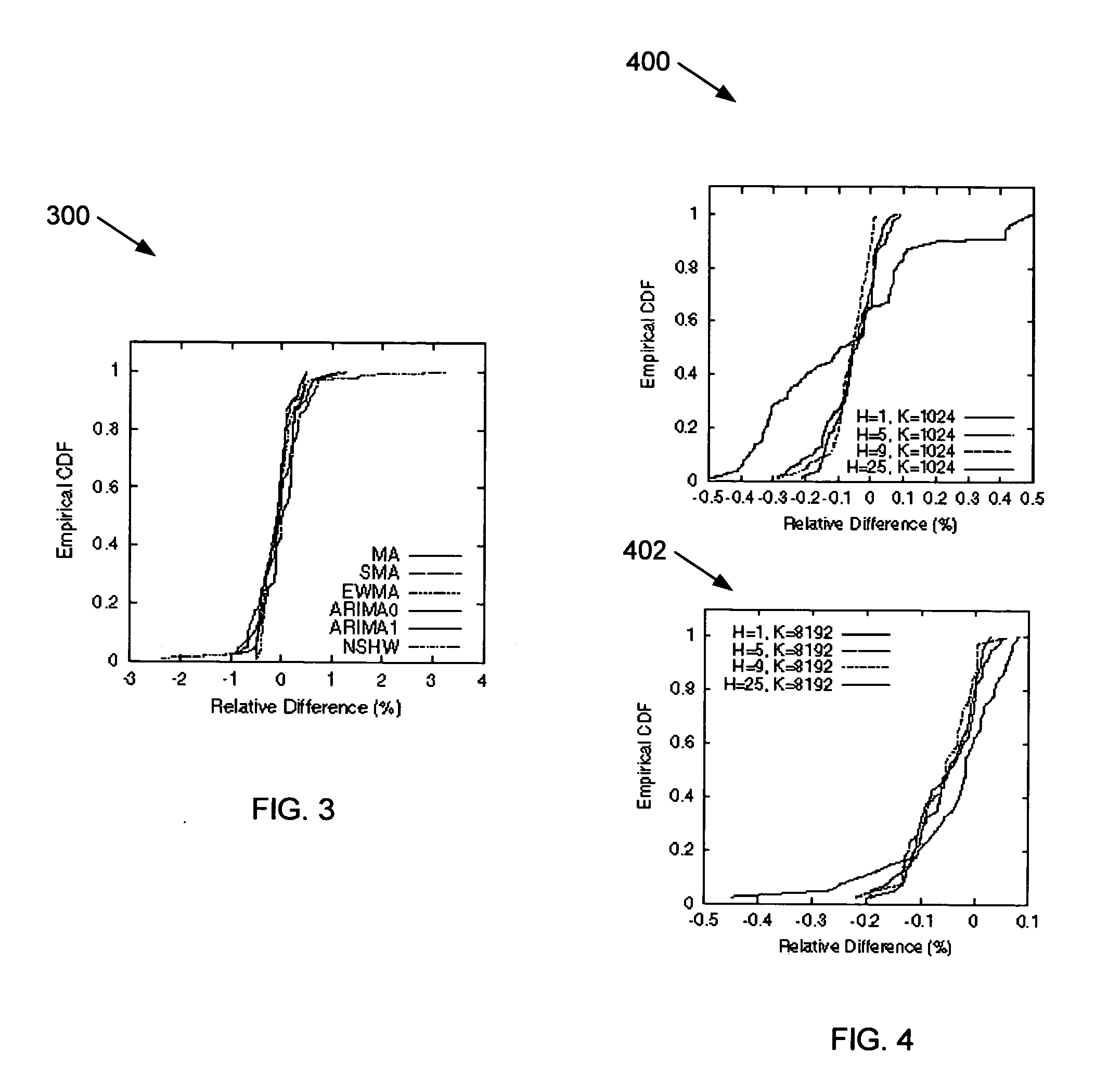

Method and apparatus for sketch-based detection of changes in network traffic

InactiveUS20050039086A1Easy to useImprove accuracyError preventionTransmission systemsData streamInternet traffic

A sketch-based change detection technique is introduced for anomaly detection and other applications that can benefit from having a quick and efficient change detection mechanism. The technique is capable of detecting significant changes in massive data streams with a large number of network time series. As part of the technique, we designed a variant of the sketch data structure, called k-ary sketch, uses a constant, small amount of memory, and has constant per-record update and reconstruction cost. A variety of time series forecast models are implemented on top of such summaries and detect significant changes by looking for flows with large forecast errors. Heuristics for automatically configuring the forecast model parameters are presented. Real Internet traffic data is used to demonstrate that the sketch-based change detection method is highly accurate when compared with per-flow analysis, and can be implemented at low computation and memory costs. The results validate using the technique as a building block for network anomaly detection and traffic measurement in large computer networks.

Owner:AT&T INTPROP I L P +1

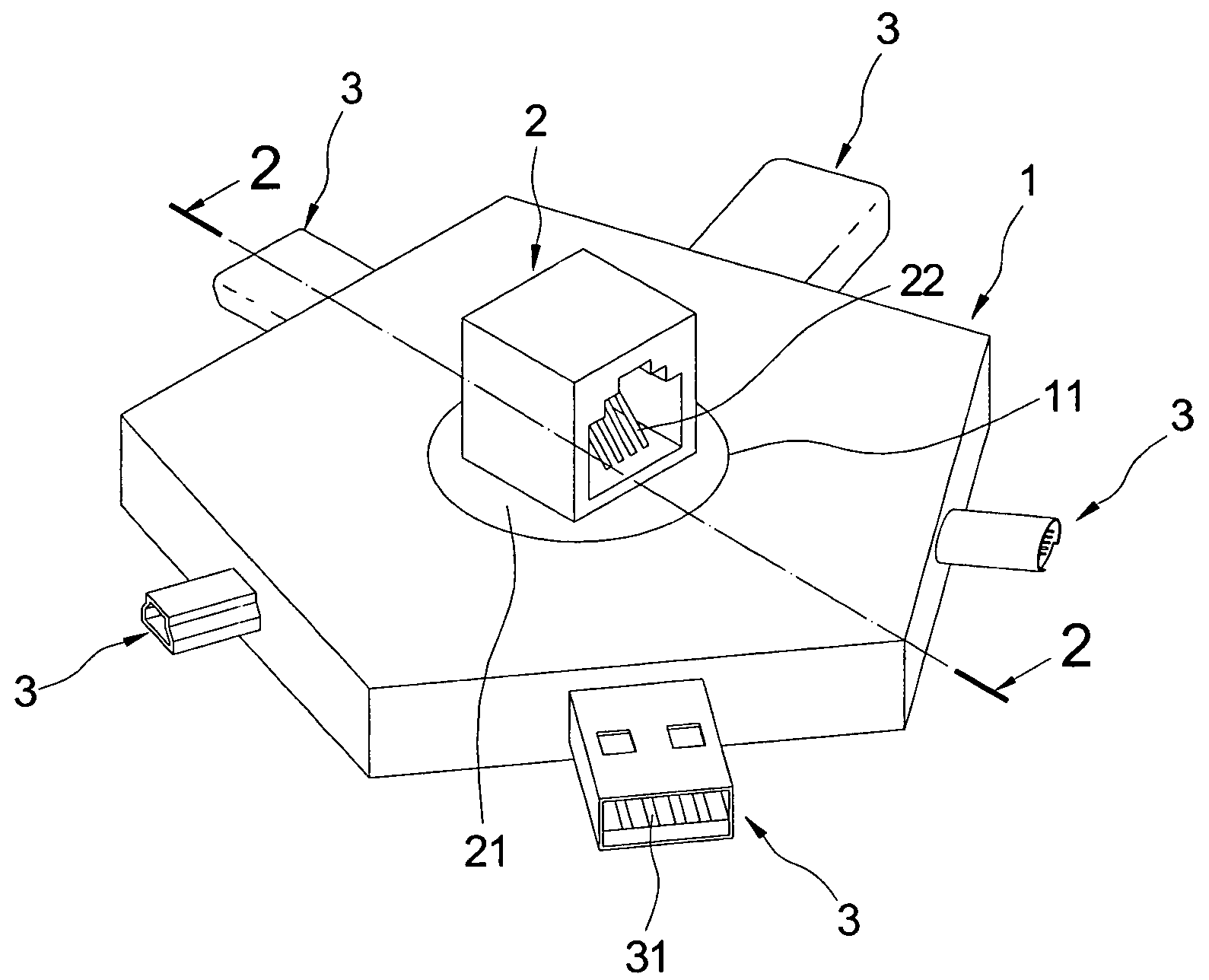

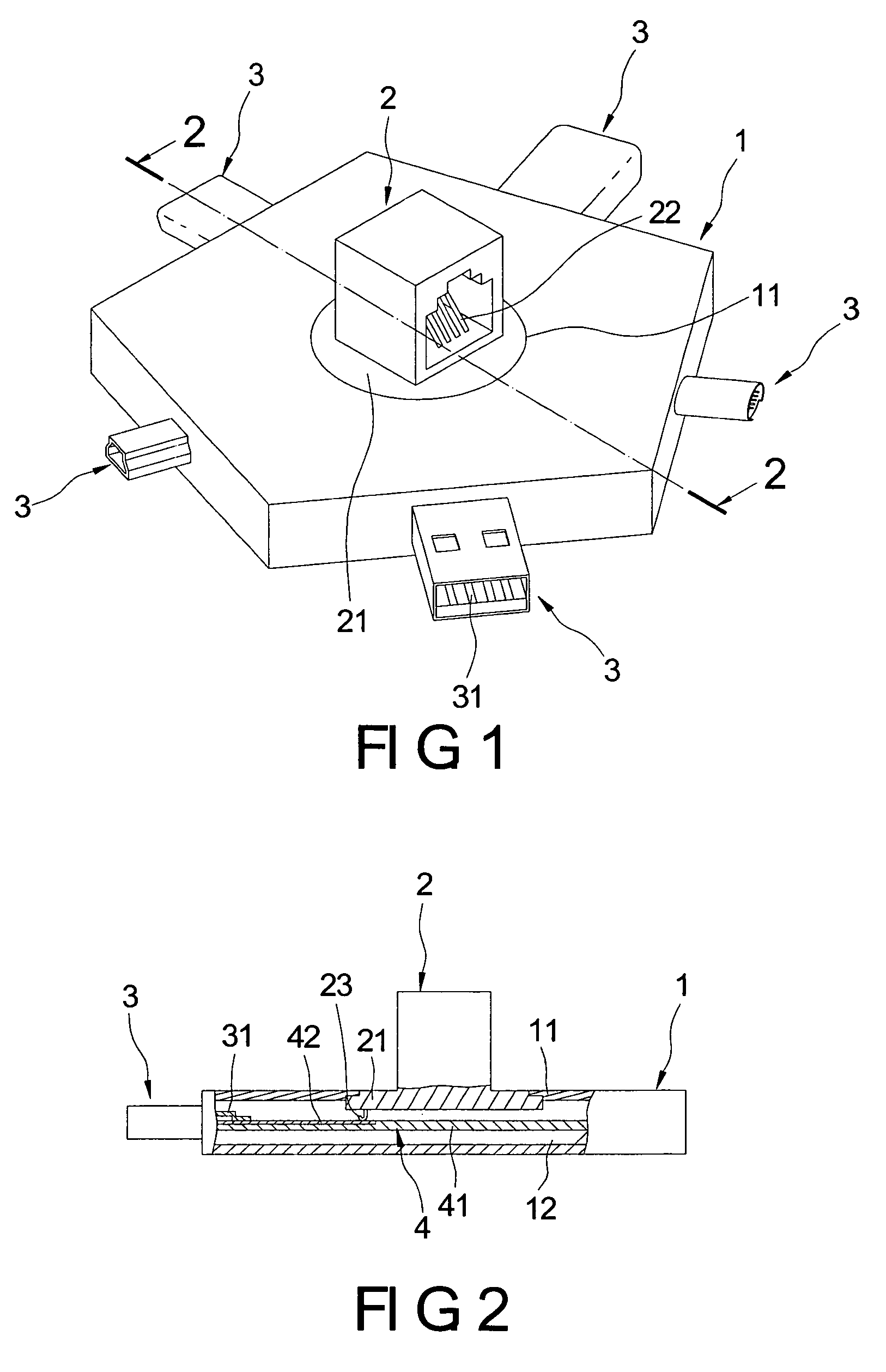

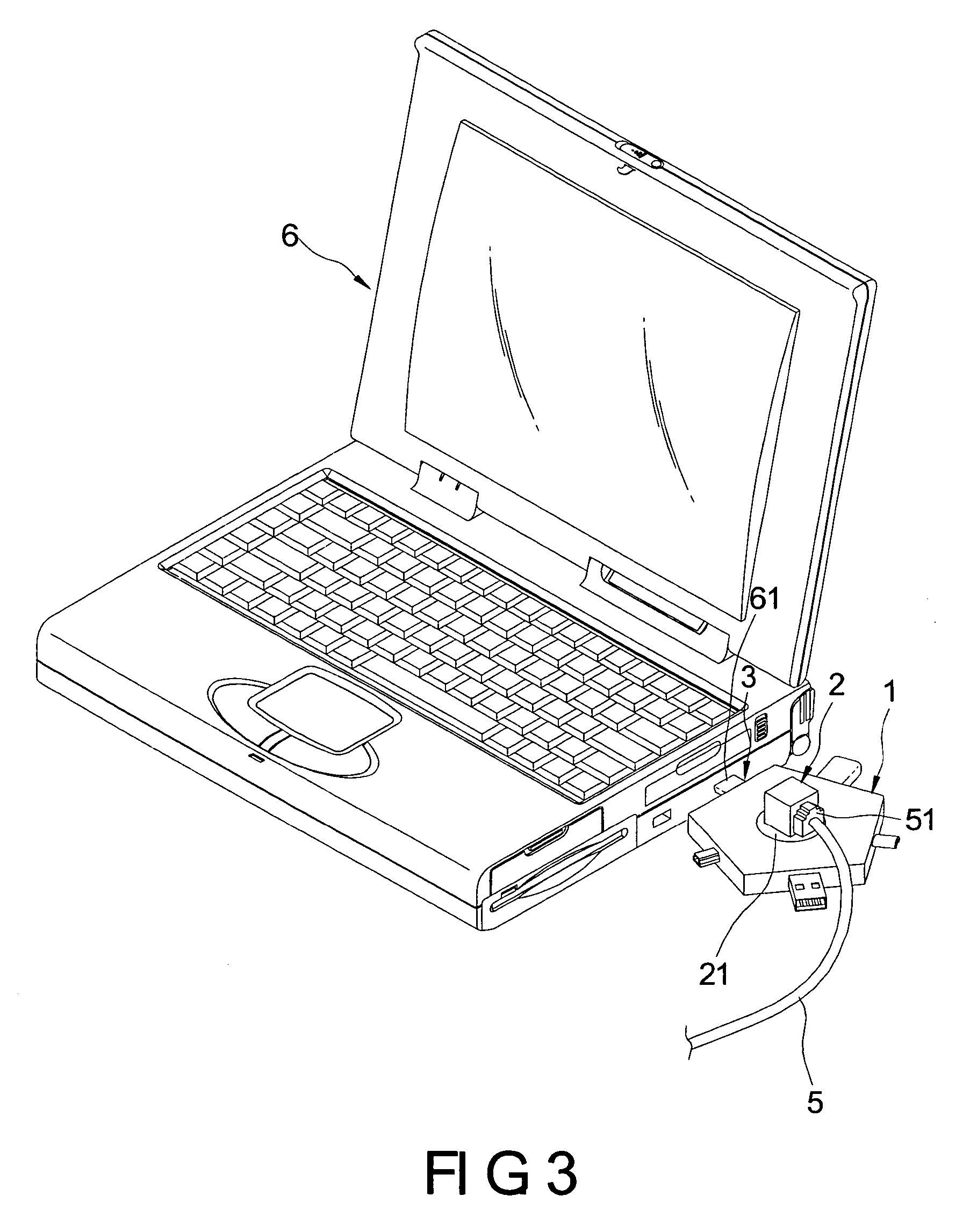

Rotatable adapter device with multiple connectors

InactiveUS7066767B2Avoid obstructionFirmly connectedEngagement/disengagement of coupling partsRotary current collectorElectrical connectorSignal lines

A rotatable adapter device with multiple connectors includes a main body, a first electrical connector, a plurality of second electrical connectors and a conducting unit. The first electrical connector is disposed rotatably on the main body, the plurality of second electrical connectors are disposed fixedly on the main body and the conducting unit is electrically connected to the first electrical connector and at least one of the second electrical connectors. Therefore, it has a transforming function and is more convenient for a user. Moreover, its design avoids the signal lines becoming intertwined with each other when they are inserted into the adapter.

Owner:LIAO SHENG HSIN

Rotationally Stabilized Contact Lenses and Methods for their Design

The invention provides dual stabilization zones that interact with an individual's eyelids so that at least the upper eyelid strikes both stabilization zones of a lens at the same time. The stabilized lenses of the invention maintain their on-eye orientation better as compared to conventionally stabilized lenses.

Owner:JOHNSON & JOHNSON VISION CARE INC

Protective head covering having impact absorbing crumple or shear zone

A helmet construction for protecting a user's head, and the brain within the cranium from impact forces, includes a shell contoured to the shape of the user's head, with cushioning along at least part of the shell interior and a chinstrap. The shell consists of three (or more) discrete panels that are physically and firmly coupled together providing rigid protection under most circumstances, but upon impact the panels move relative to one another, but not relative to the user's head, thereby permitting impact forces to be dissipated and / or redirected away from the cranium and brain within. Upon impact to the helmet, there are sequential stages of movement of the panels relative to each other, these movements initially being recoverable, but with sufficient vector forces the helmet undergoes structural changes in a pre-determined fashion, so that the recoverable and permanent movements cumulatively provide a protective ‘crumple zone’ or ‘shear zone’. The first two stages of protection arise from the design of the fasteners that have the ability to invaginate and collapse within themselves, and their design having a 45 degree angle, which will allow movement of a region of connected panels to translate along the fastener shaft. Both of these movements will be recoverable and provide a ‘functional crumple zone’. The final stage of protection arises from the braking function of the pins, as they are forced from one aperture through to the next, the direction and extent of which is determined by the impact force and direction. This final level of panel movement and protection is not recoverable and thus provides a ‘structural crumple zone’. Finally the fastener size and thickness, together with the thickness of webbing and distance between apertures, functions to provide varying degrees of resistance to impact forces, thus making the helmet design suitable for activities with different levels of impact speed and risk potential.

Owner:PUCHALSKI TECHN

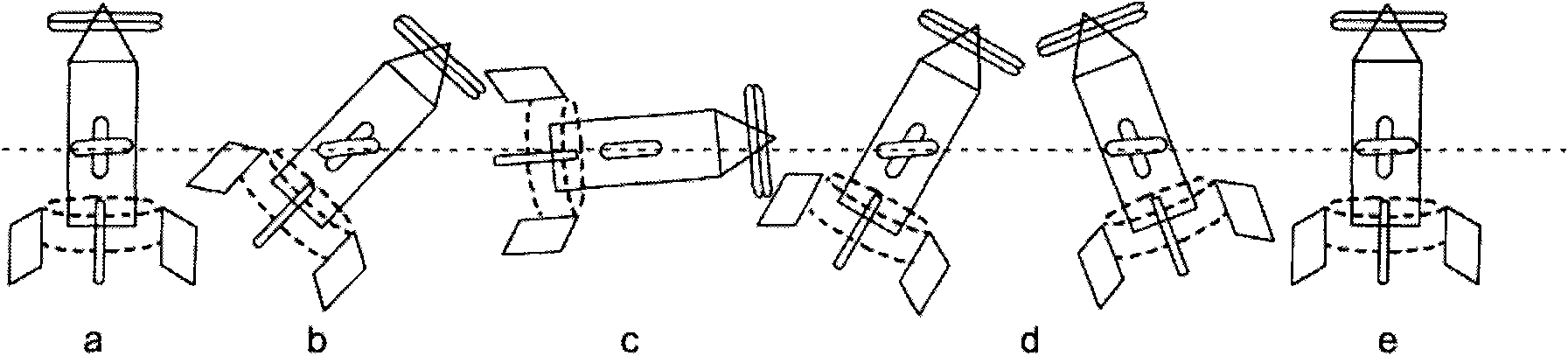

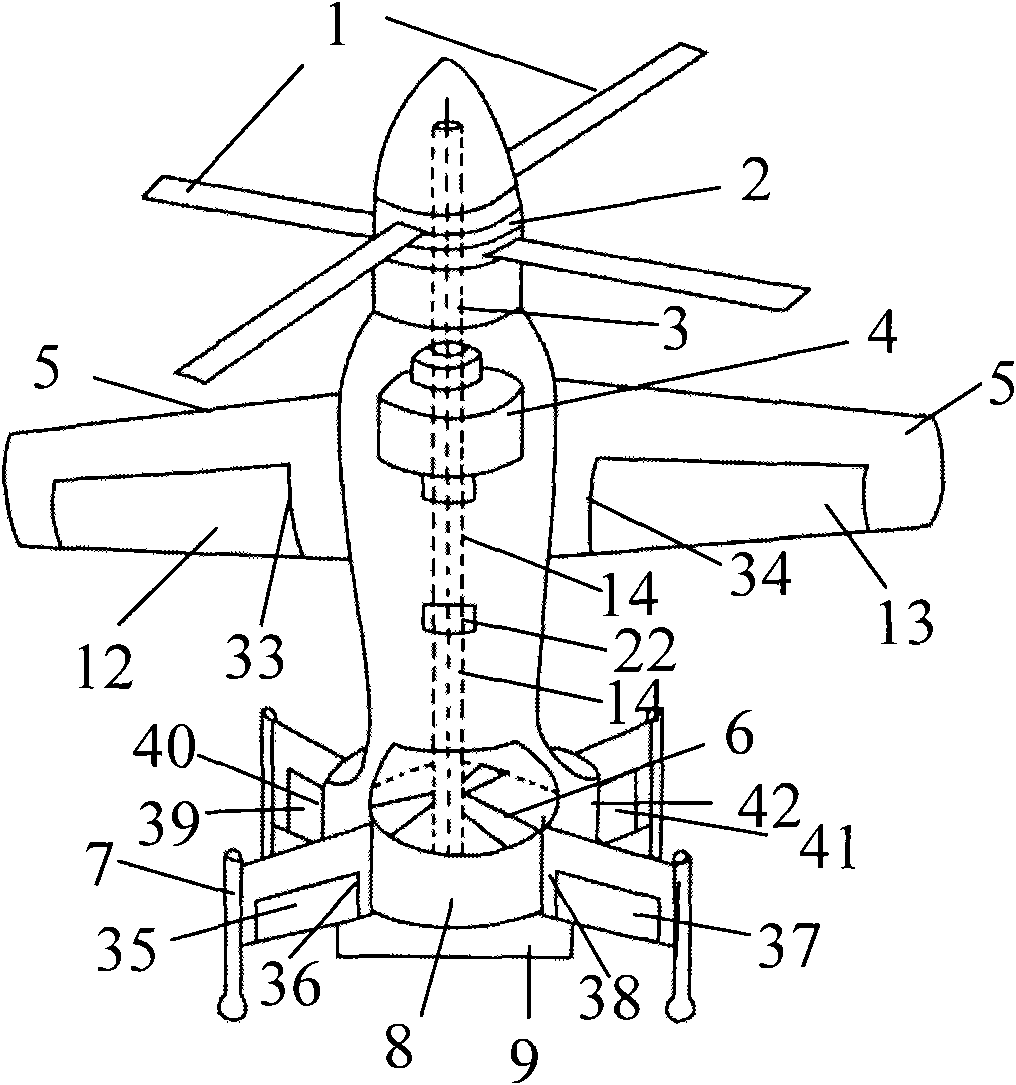

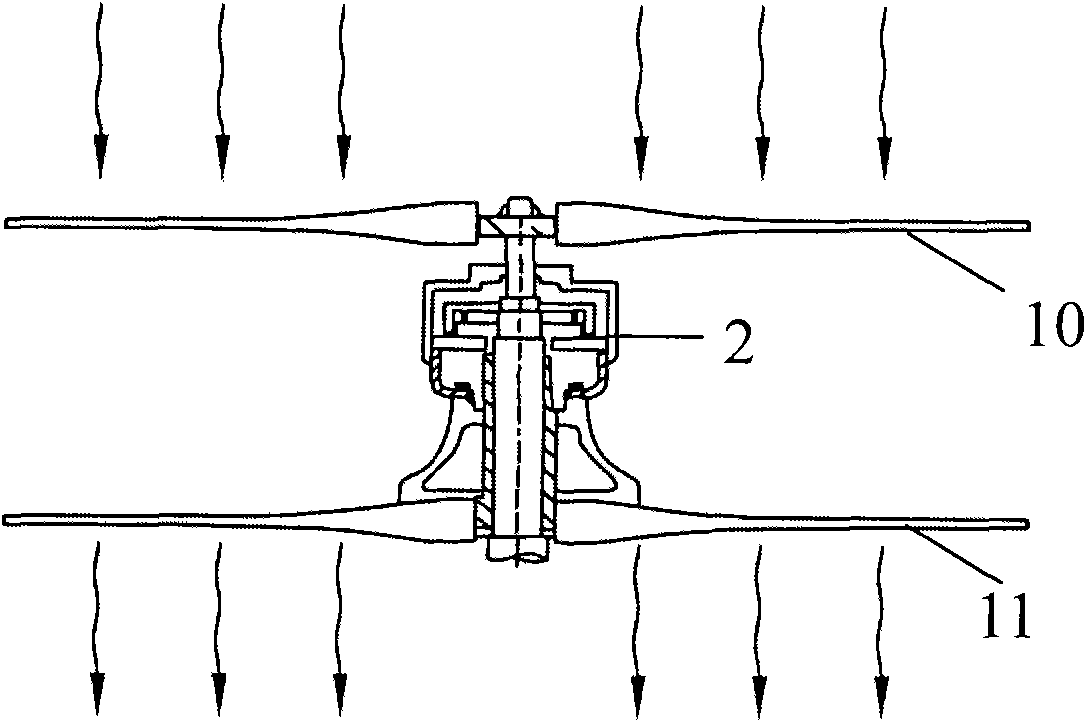

A composite rotating fixed-wing aircraft and its design method

InactiveCN101549754APrevent rolloverPrevent sideslipVehicle position/course/altitude controlGround installationsStarter generatorMotor drive

The composite rotating fixed-wing aircraft consists of the coaxial counter-paddle, reverse gear, engine output shaft, engine with a starter-generator, wings, tail blades, landing device, culvert, steering gear, fairing, fuselage, motor, motor drive shaft, wing control unit of small angle of attack, aileron rudder surface, and tailplane rudder surface. Co-axial counter-blade is located in the upper part of the aircraft, which connects with the engine output shaft; the reverse gear is installed between the co-axial counter-propellers; the motor connects with motor drive shaft powered by the starter-generator of the engine; the wings are located on both sides of aircraft and connect with the fuselage; the tail blades are located at the aircraft tail, which are installed behinde motor drive shaft; the landing device is located under the lower part of the fuselage and fixed with it; the culvert connects with the landing device; the fairing is installed in the culvert and connects with the steering gear; the wing control unit of small angle of attack is installed on the wing. The aircraft design method has six steps with strict scientific idea; this invention has a wide range of practical value and application prospect.

Owner:BEIHANG UNIV

Protective head covering having impact absorbing crumple zone

InactiveUS20050257312A1Closer in weight and sizeMinimizing resultant disproportionHatsSport apparatusMostly TrueEngineering

A helmet construction for protecting a user's head, and the brain within the cranium from impact forces, includes a shell contoured to the shape of the user's head, with cushioning along at least part of the shell interior and a chinstrap. The shell consists of three (or more) discrete panels that are physically and firmly coupled together providing rigid protection under most circumstances, but upon impact the panels move relative to one another, but not relative to the user's head, thereby permitting impact forces to be dissipated and / or redirected away from the cranium and brain within. Upon impact to the helmet, there are sequential stages of movement of the panels relative to each other, these movements initially being recoverable, but with sufficient vector forces the helmet undergoes structural changes in a pre-determined fashion, so that the recoverable and permanent movements cumulatively provide a protective ‘crumple zone’ or ‘shear zone’. The first two stages of protection arise from the design of the fasteners that have the ability to invaginate and collapse within themselves, and their design having a 45 degree angle, which will allow movement of a region of connected panels to translate along the fastener shaft. Both of these movements will be recoverable and provide a ‘functional crumple zone’. The final stage of protection arises from the braking function of the pins, as they are forced from one aperture through to the next, the direction and extent of which is determined by the impact force and direction. This final level of panel movement and protection is not recoverable and thus provides a ‘structural crumple zone’. Finally the fastener size and thickness, together with the thickness of webbing and distance between apertures, functions to provide varying degrees of resistance to impact forces, thus making the helmet design suitable for activities with different levels of impact speed and risk potential.

Owner:PUCHALSKI TECHN

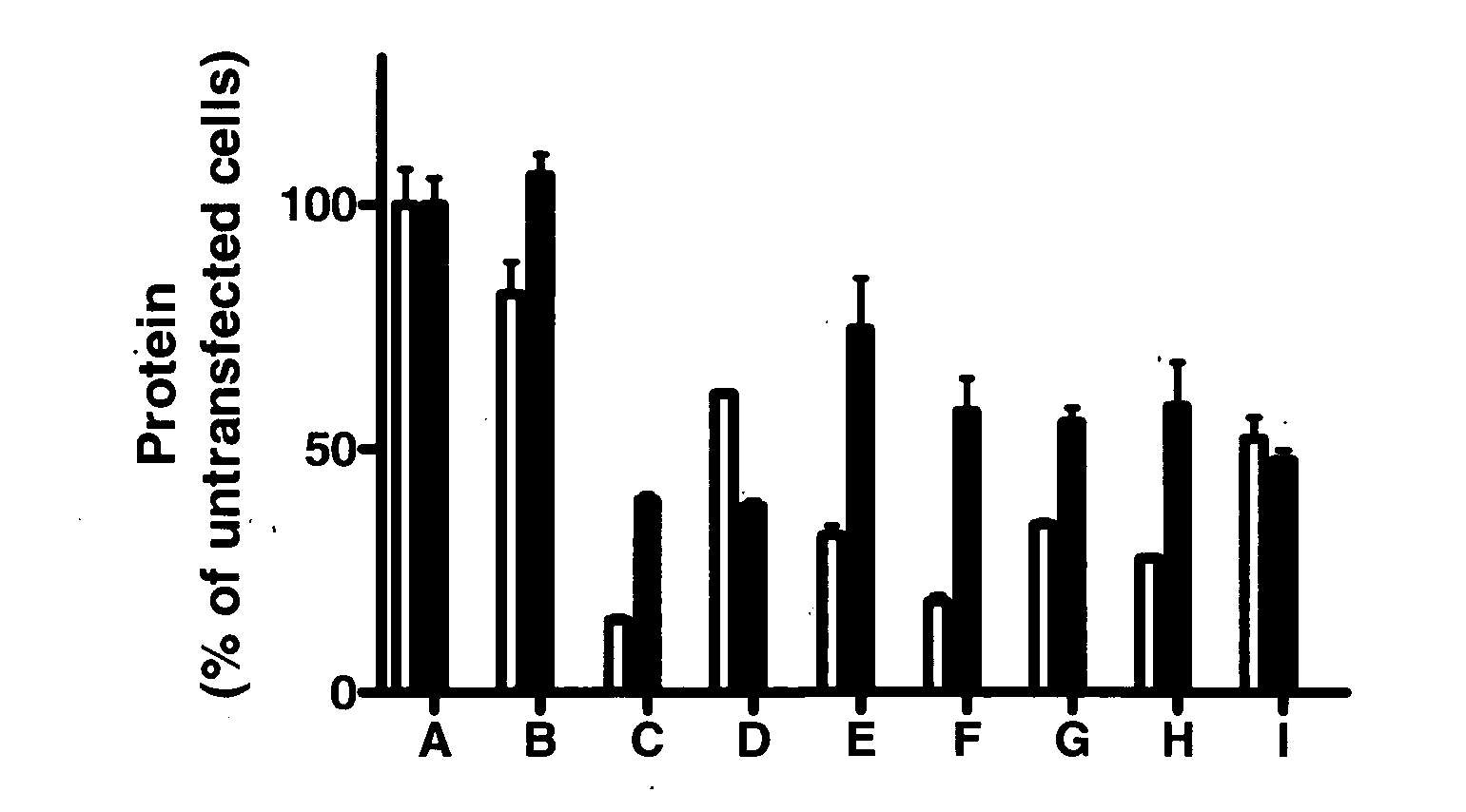

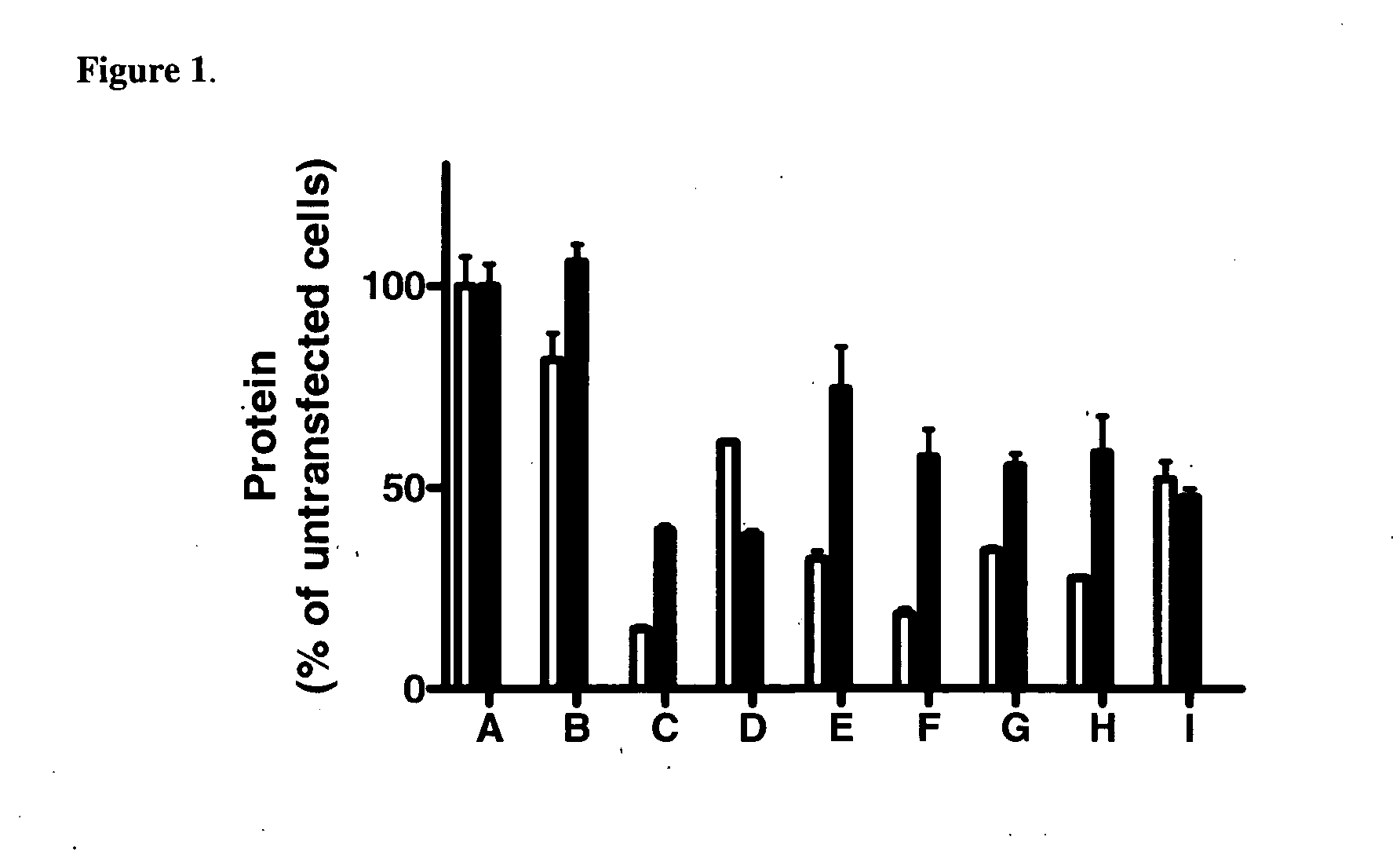

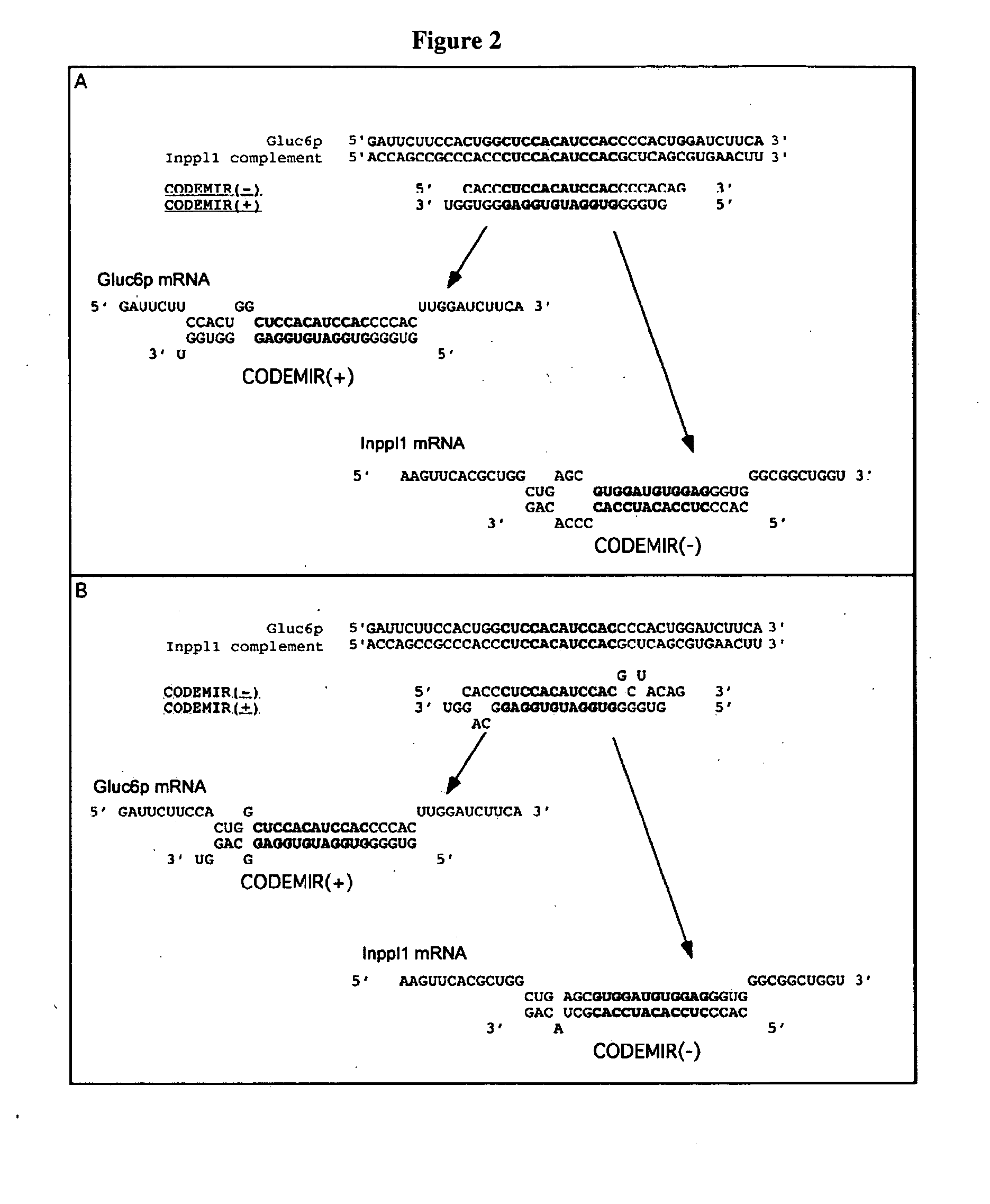

Multitargeting interfering RNAs having two active strands and methods for their design and use

InactiveUS20070269815A1Increase and decrease modulationReduced responseOrganic active ingredientsActivity regulationBioinformaticsRNA molecule

Interfering RNA molecules are now designed and produced with specificity for multiple binding sequences present in distinct genetic contexts in one or more pre-selected target RNA molecules and are used to modulate expression of the target sequences. The multitargeting interfering RNA molecules have two strands that target multiple target sites on one or more pre-selected RNA molecules. Such a multitargeting interfering RNA approach provides a powerful tool for gene regulation.

Owner:JOHNSON & JOHNSON RES PTY LTD

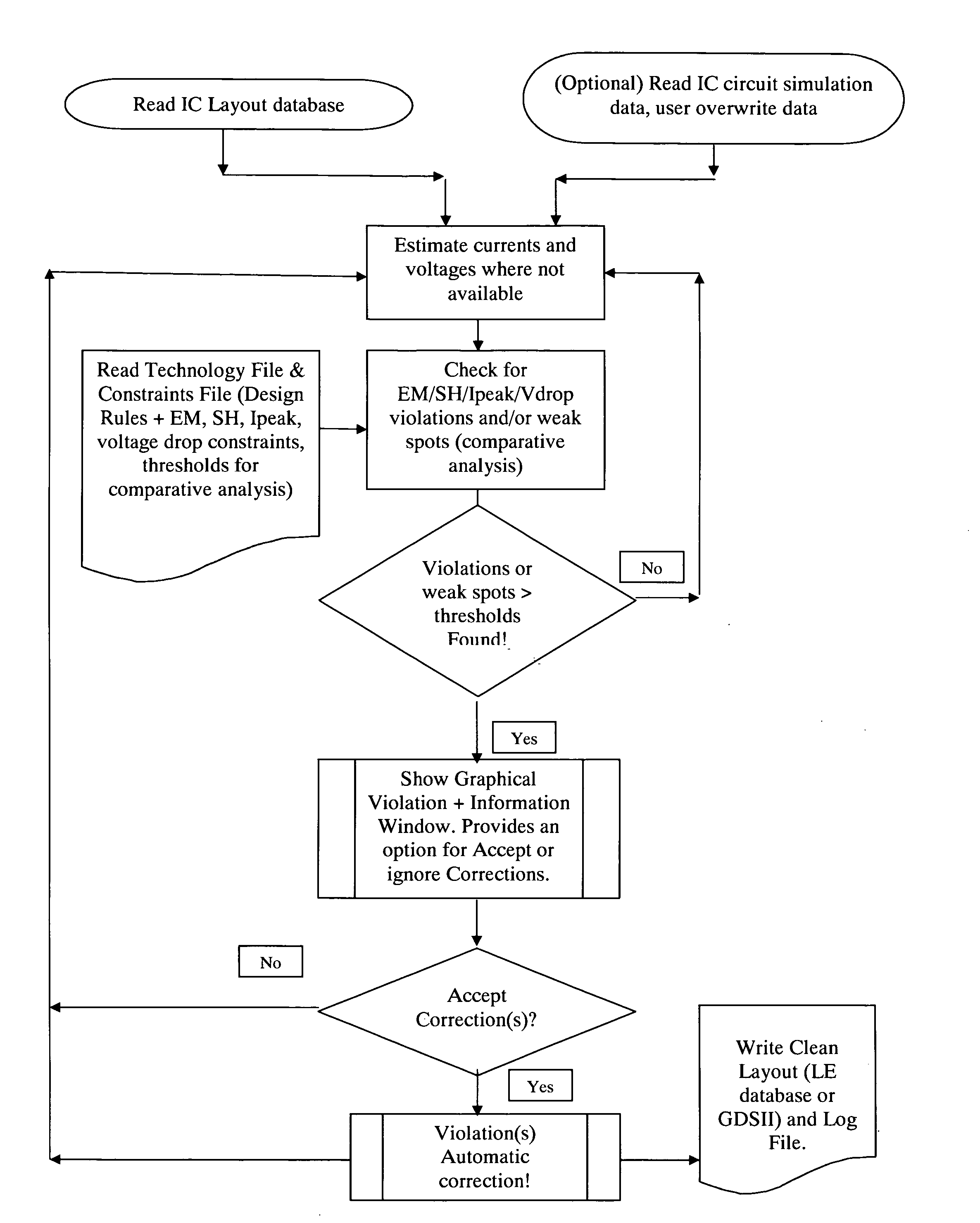

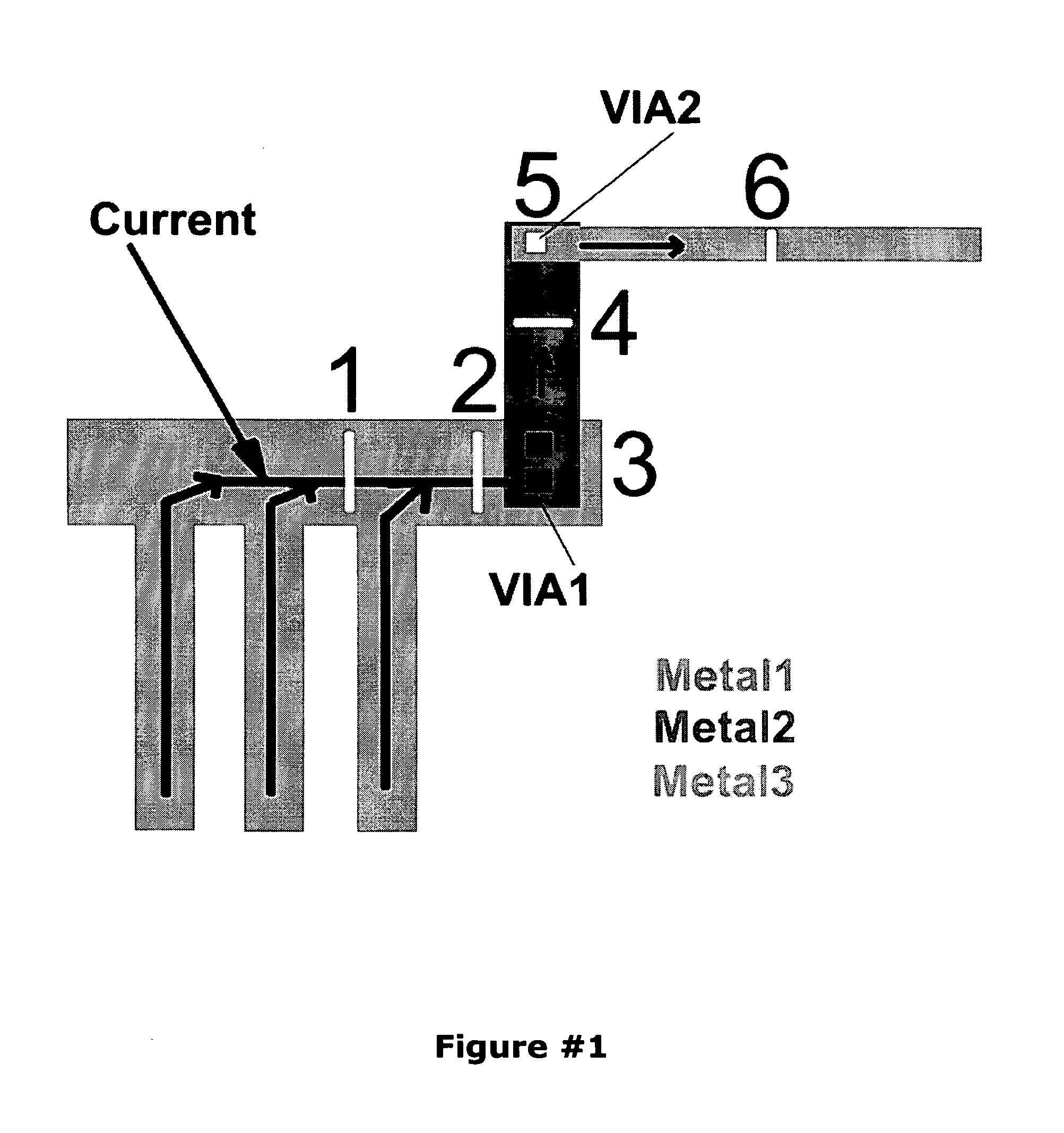

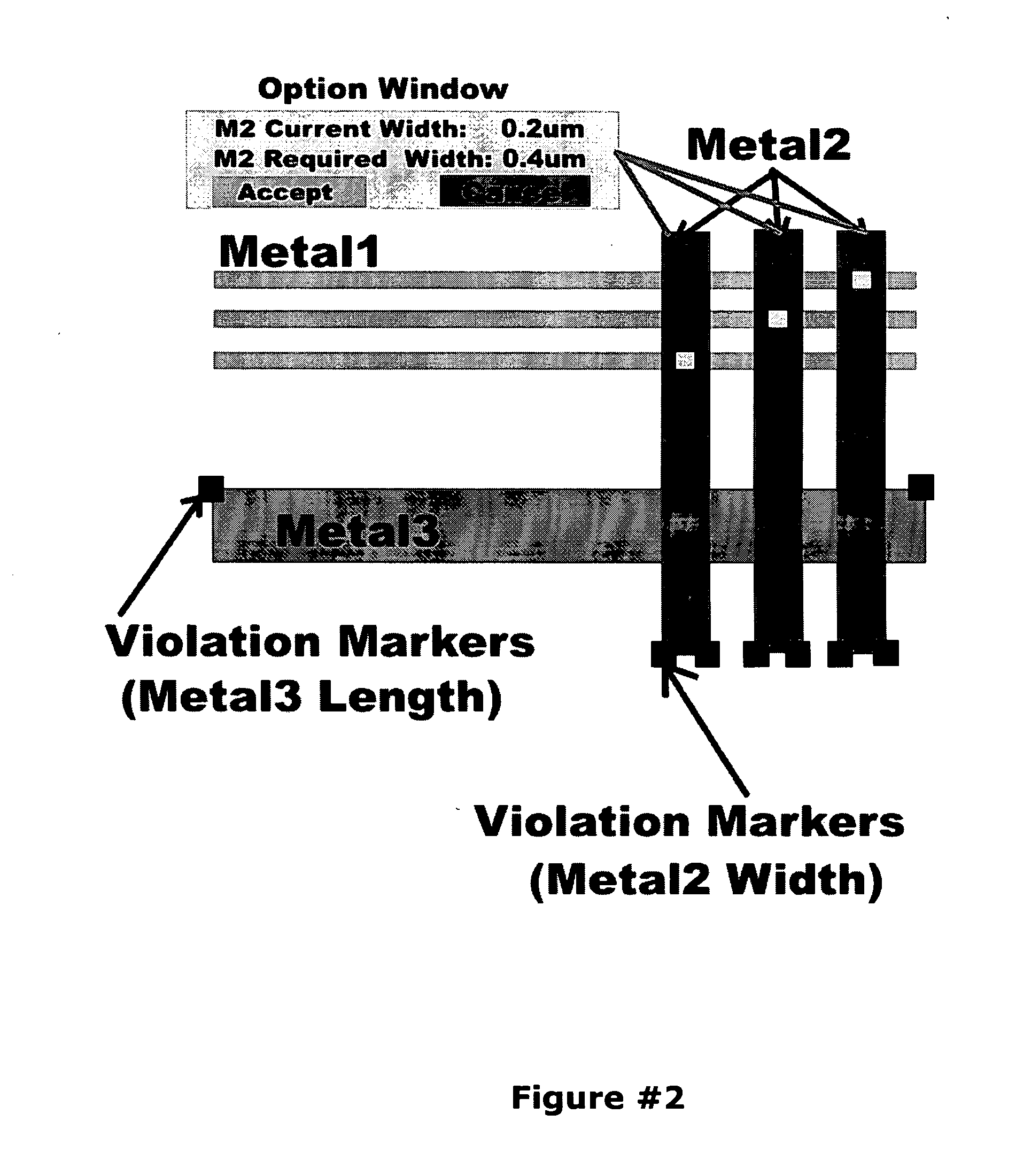

System and method for finding electromigration, self heat and voltage drop violations of an integrated circuit when its design and electrical characterization are incomplete

InactiveUS20090031264A1Eliminating and of reduced eliminatedShorten design timeComputer aided designSoftware simulation/interpretation/emulationElectricityVoltage drop

A system and method for finding electromigration (EM), self heat (SH) and voltage drop / droop violations of an integrated circuit, when its design and electrical characterization are not complete, are disclosed. The method includes analyzing polygons for average, root-mean-square (RMS) and Ipeak current densities and voltages of a mask layout block and obtaining one or more electromigration, self heat and / or voltage drop / droop rules associated with the polygon from a technology and an external constraints file. The system reads the available design simulation data to calculate the average, RMS and Ipeak current densities and voltages, and estimates the current densities and voltages when no data available. The method also includes topological analysis of the mask layout and analysis of the electrical circuit elements of the design. The method finds the polygons where the current densities are higher than electromigration and self heat rules as taken from technology or external constraints file. The method also finds the polygons where the current densities are higher than in other polygons, by the defined threshold. The method also finds the nodes where the voltage drop / droop is larger than the rule. The method also finds the polygons where the voltage drop / droop is larger than in other polygons by the defined threshold. The method and system work on GDSII, GDSIII format files and on industry standards layout editors' database.

Owner:MICROLOGIC DESIGN AUTOMATION

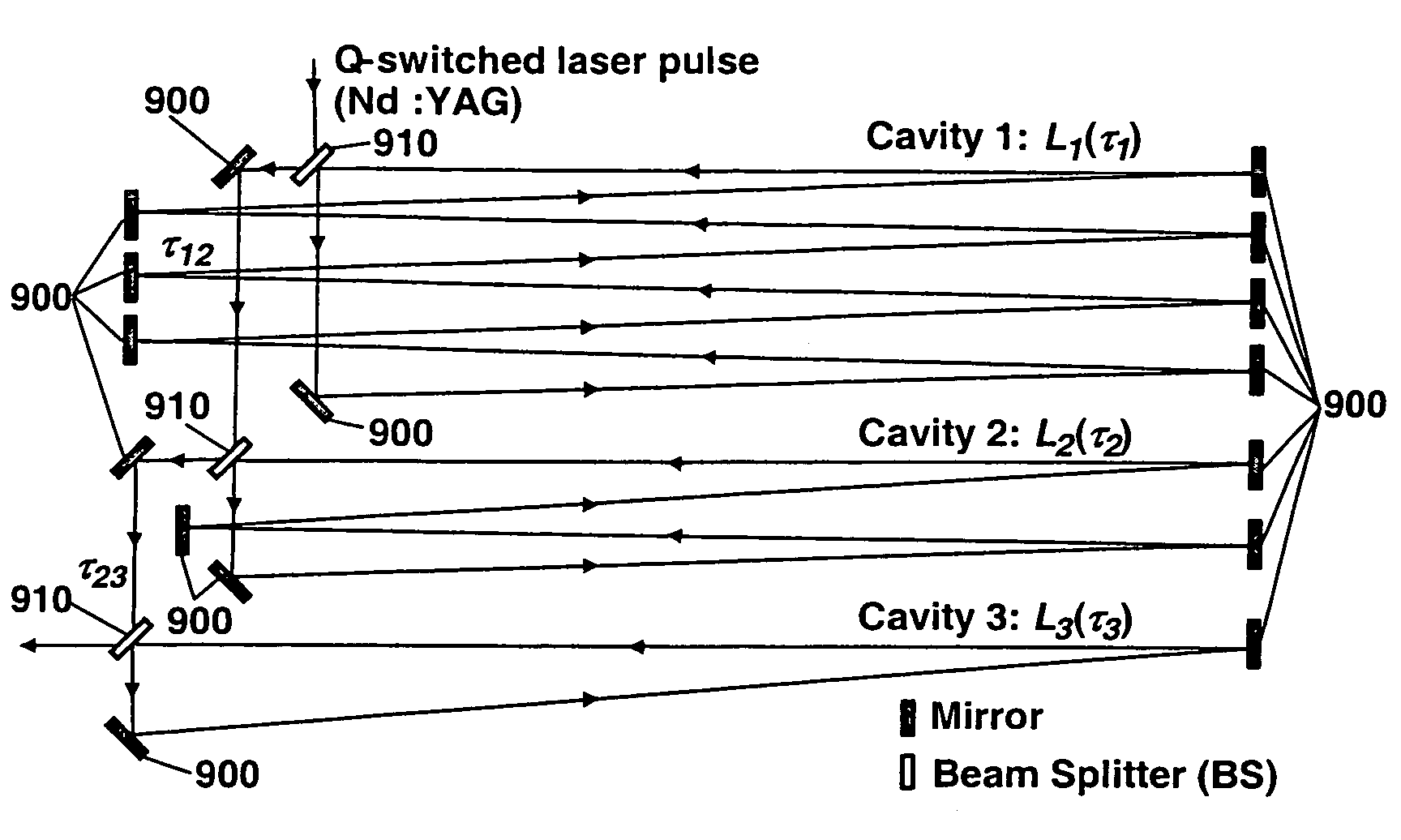

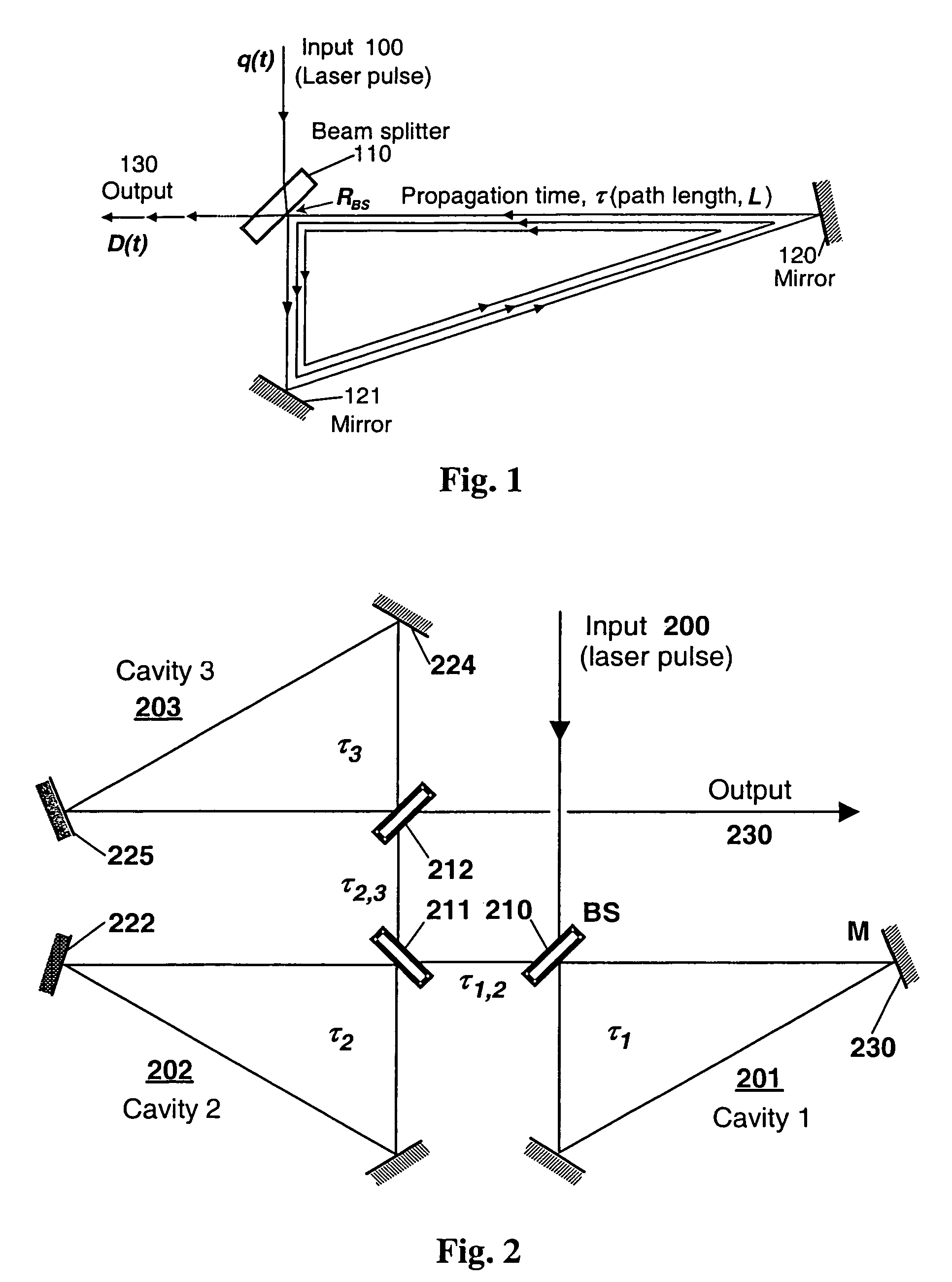

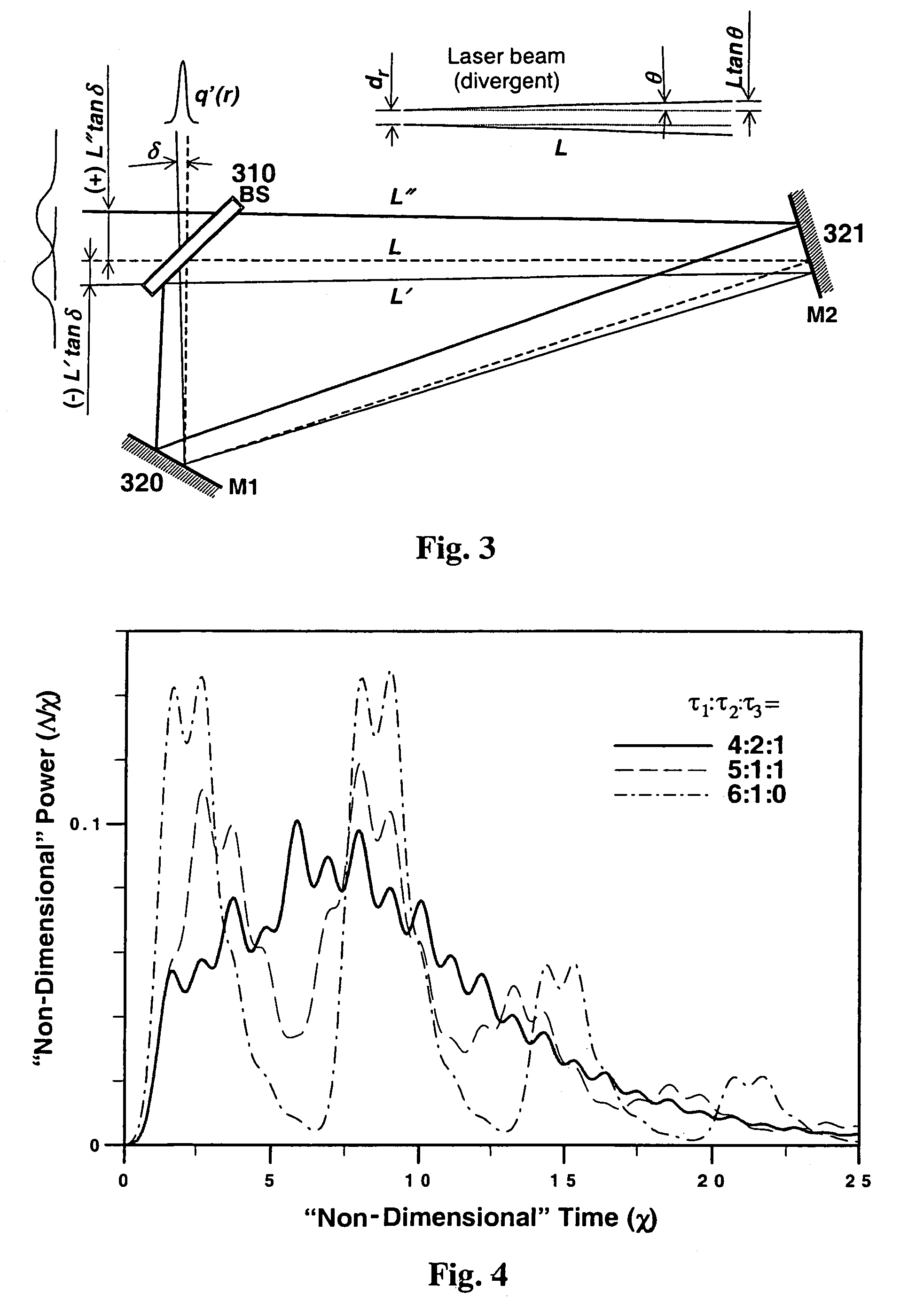

Temporal laser pulse manipulation using multiple optical ring-cavities

An optical pulse stretcher and a mathematical algorithm for the detailed calculation of its design and performance is disclosed. The optical pulse stretcher has a plurality of optical cavities, having multiple optical reflectors such that an optical path length in each of the optical cavities is different. The optical pulse stretcher also has a plurality of beam splitters, each of which intercepts a portion of an input optical beam and diverts the portion into one of the plurality of optical cavities. The input optical beam is stretched and a power of an output beam is reduced after passing through the optical pulse stretcher and the placement of the plurality of optical cavities and beam splitters is optimized through a model that takes into account optical beam divergence and alignment in the pluralities of the optical cavities. The optical pulse stretcher system can also function as a high-repetition-rate (MHz) laser pulse generator, making it suitable for use as a stroboscopic light source for high speed ballistic projectile imaging studies, or it can be used for high speed flow diagnostics using a laser light sheet with digital particle imaging velocimetry. The optical pulse stretcher system can also be implemented using fiber optic components to realize a rugged and compact optical system that is alignment free and easy to use.

Owner:NASA

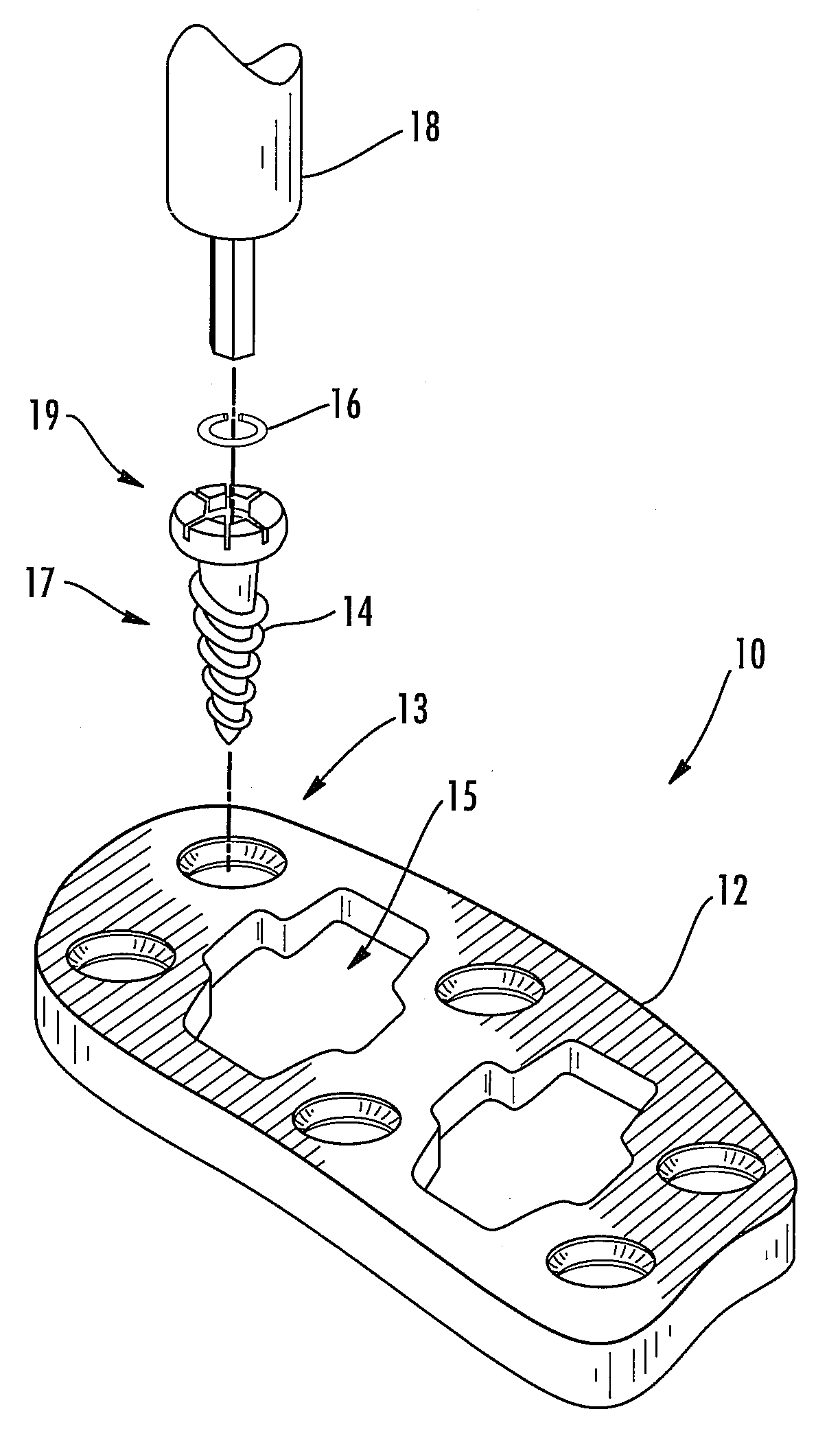

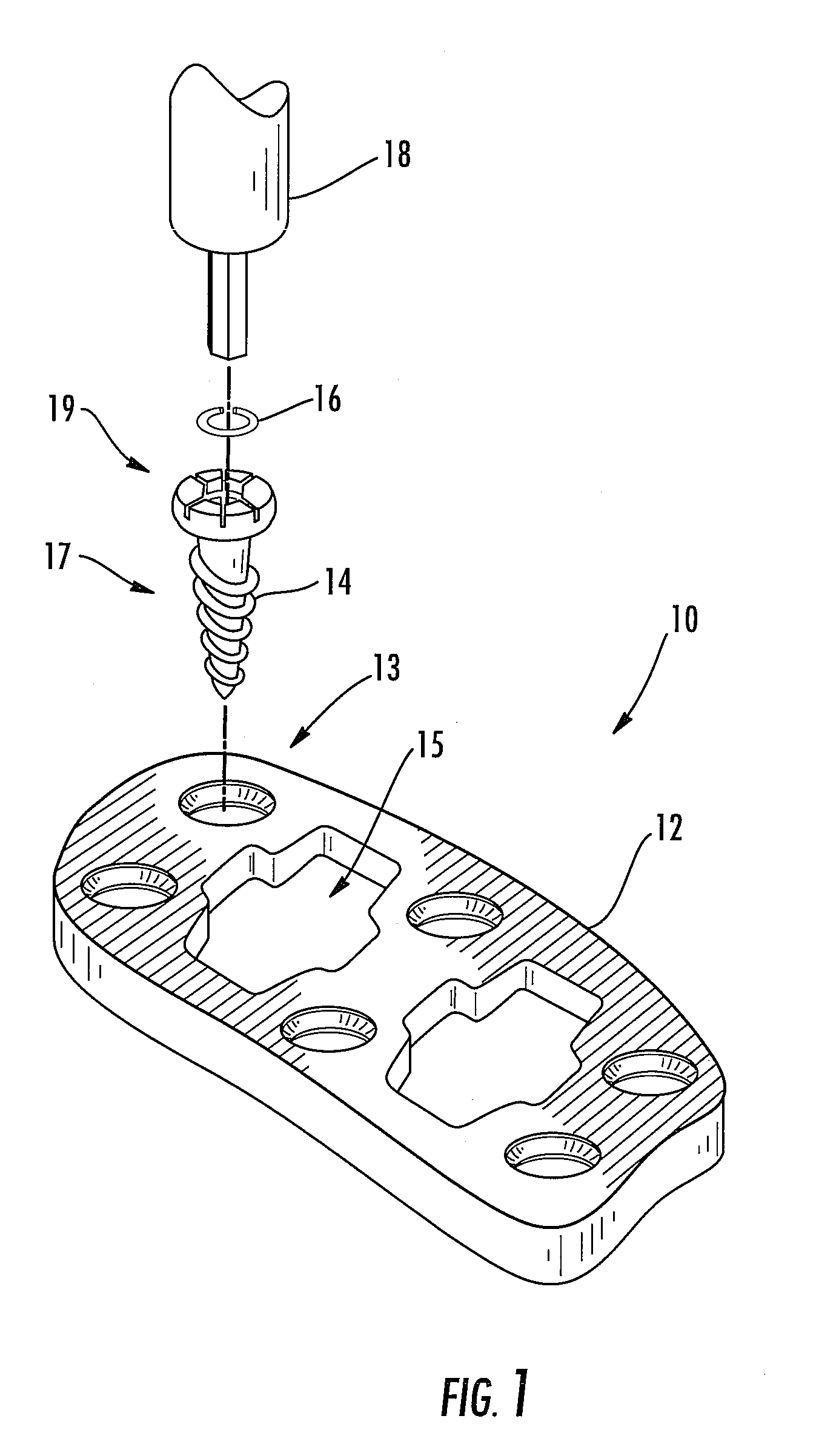

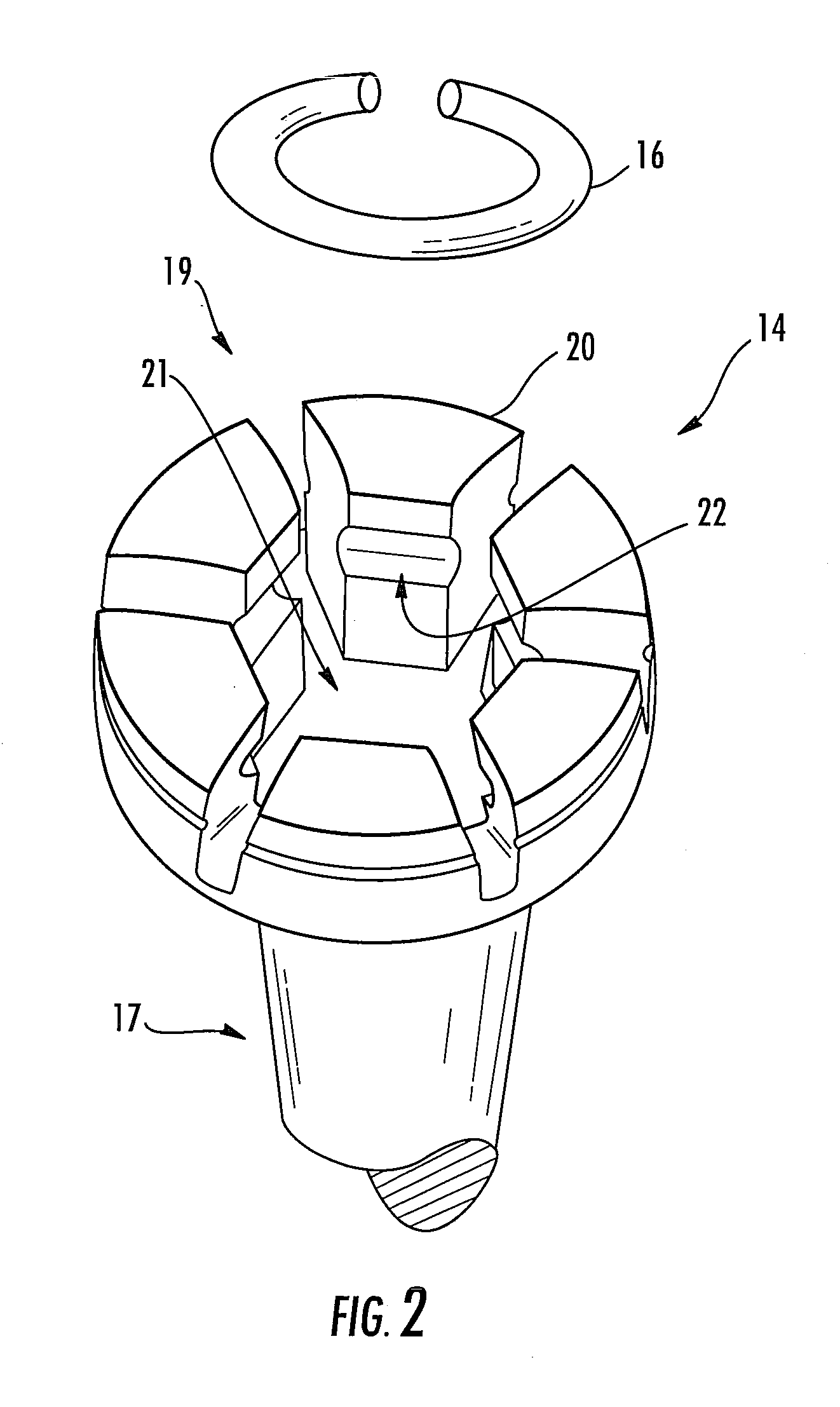

Cervical plate locking mechanism and associated surgical method

InactiveUS20080288001A1Elegant designEfficient executionInternal osteosythesisFastenersLocking mechanismEngineering

The cervical plate locking mechanism of the present invention is elegant in its design and effective in its performance, and utilizes a plate with holes that each incorporate a locking lip structure and locking screws that each incorporate a head portion having petal structures that are outwardly biased prior to insertion via an internally-disposed c-ring or the like. Advantageously, the lead-in torque of each of the locking screws is less than the lead-out torque of each of the locking screws. Thus, reverse threading or backing out is prevented. Alternatively, the cervical plate locking mechanism of the present invention utilizes a locking plate having petal structures that are inwardly biased prior to insertion of the head portion of the locking screws via an externally-disposed c-ring or the like.

Owner:AMEDICA A DELAWARE

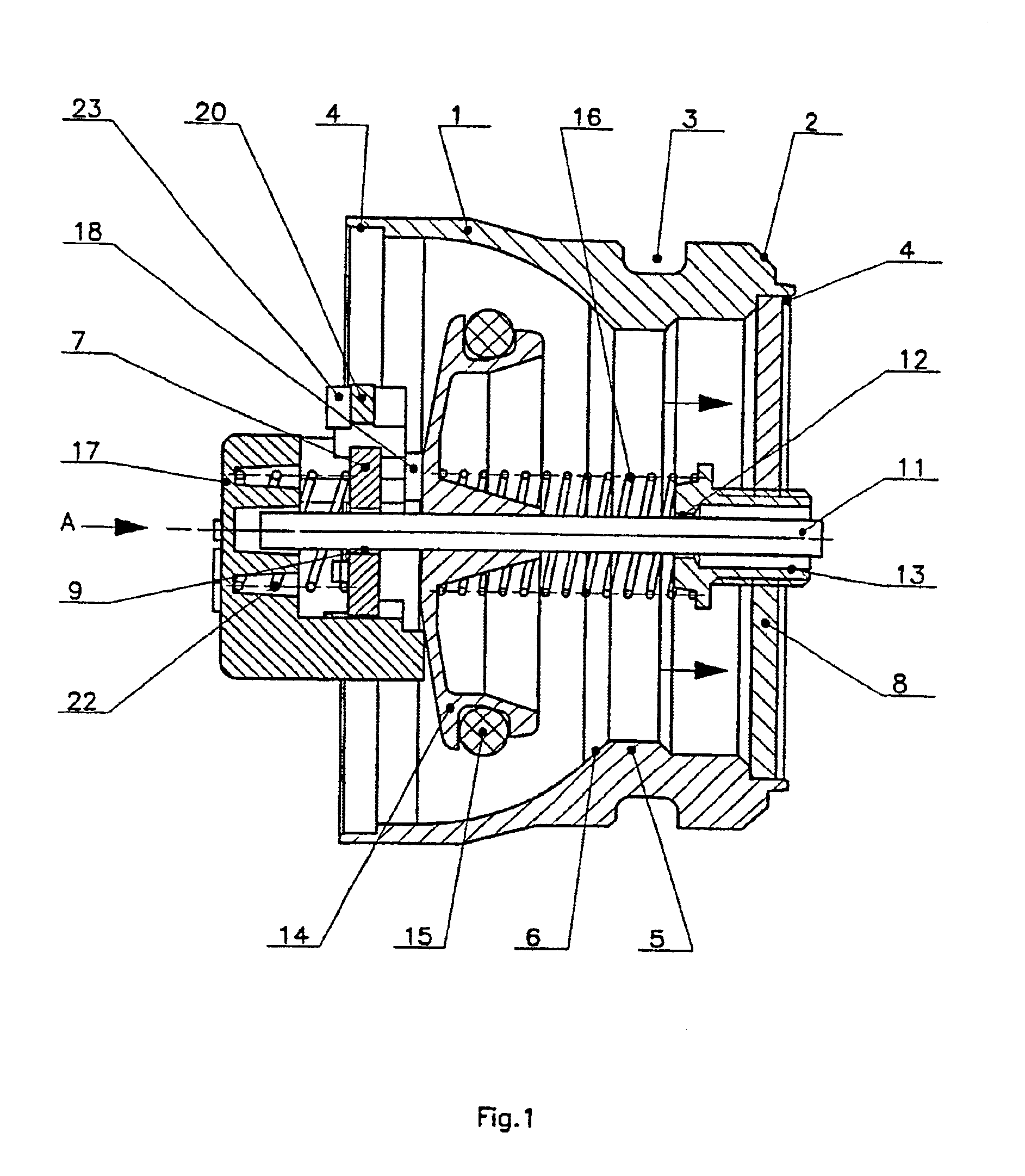

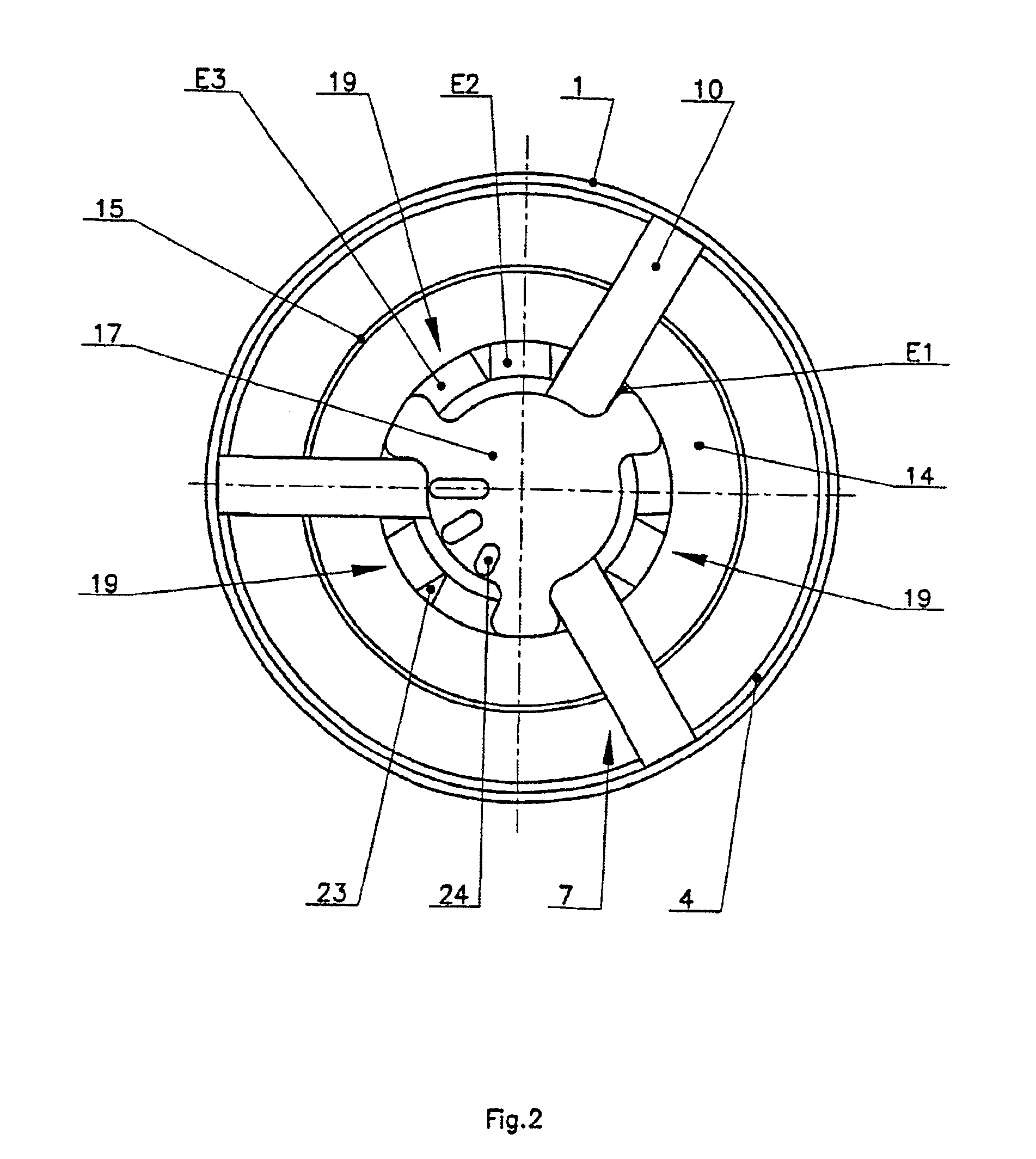

Gas flow monitoring device

Owner:MERTIK MAXITROL

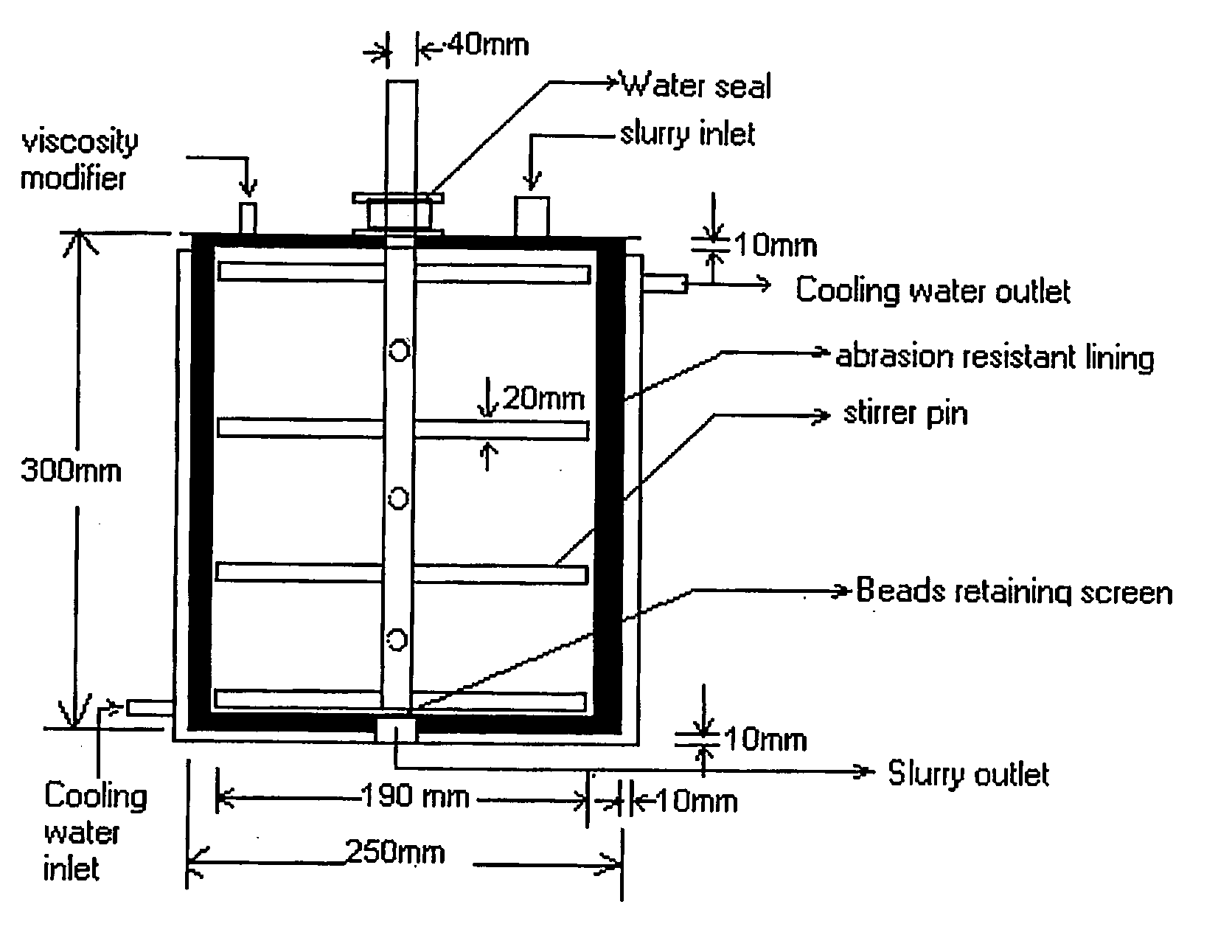

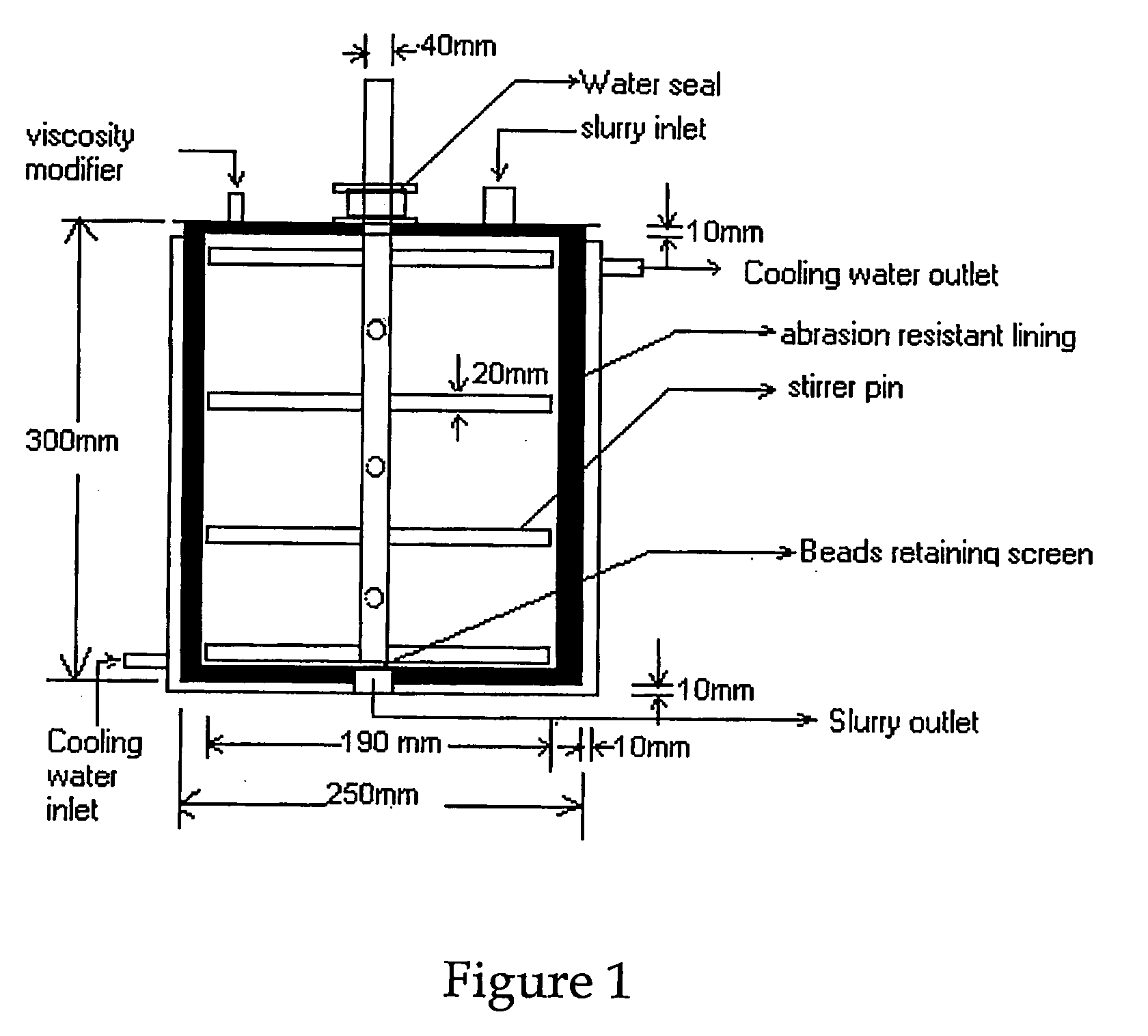

Method of producing nanoparticles and stirred media mill thereof

The field of invention is related to a method of producing nanoparticles of less than 100 nm using a stirred media mill and a novel stirred media mill for producing the nanoparticles. The dead zones present in the stirred media mill, are the main cause of long time grinding and wide size distribution of product and is rectified in our design by optimum design of stirrer which will transfer the energy to beads at all parts in the chamber homogeneously for efficient and fast. The invention also discloses the design and operating conditions for production of nanoparticle in stirred media mill.

Owner:ALAM HILAAL +1

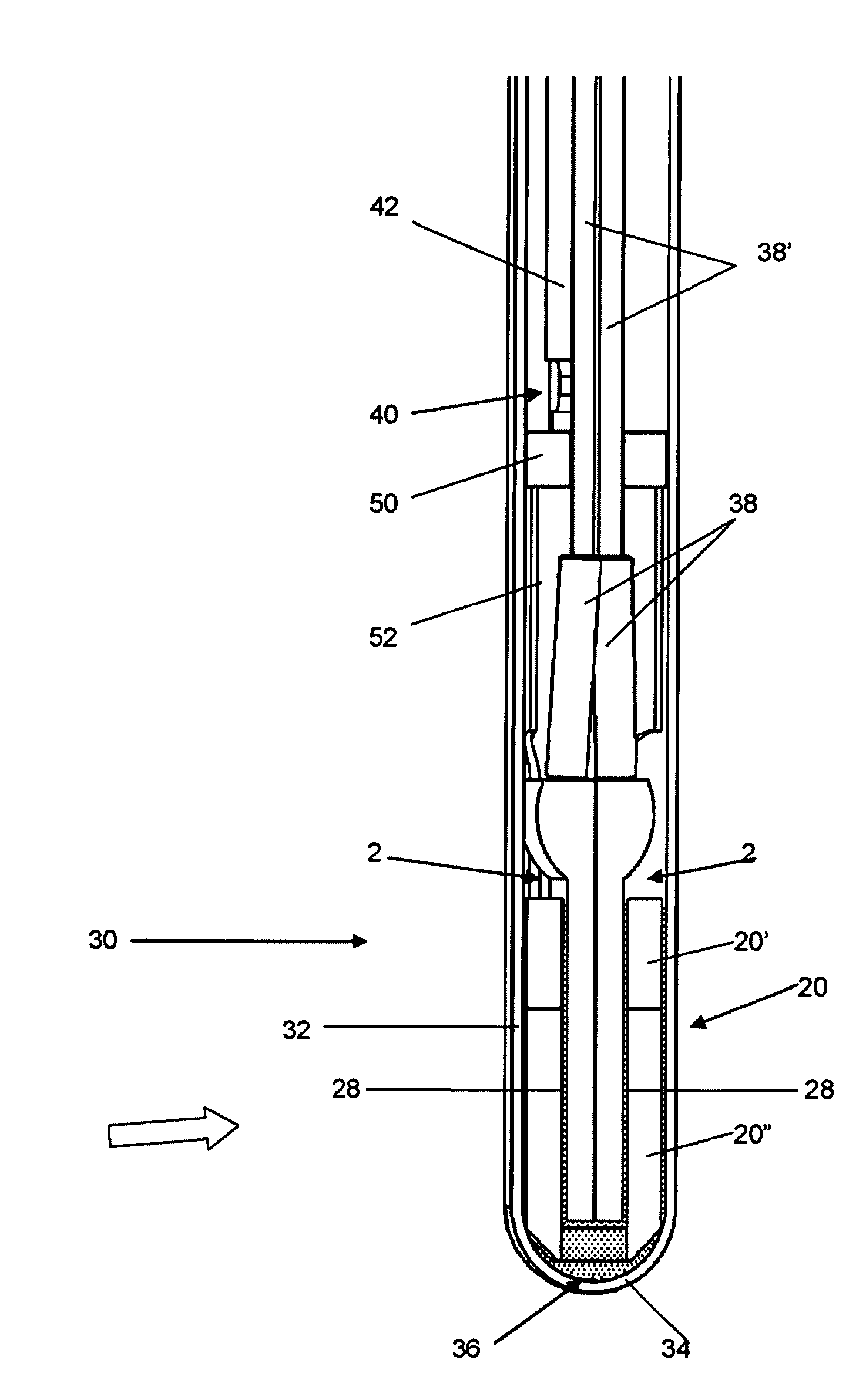

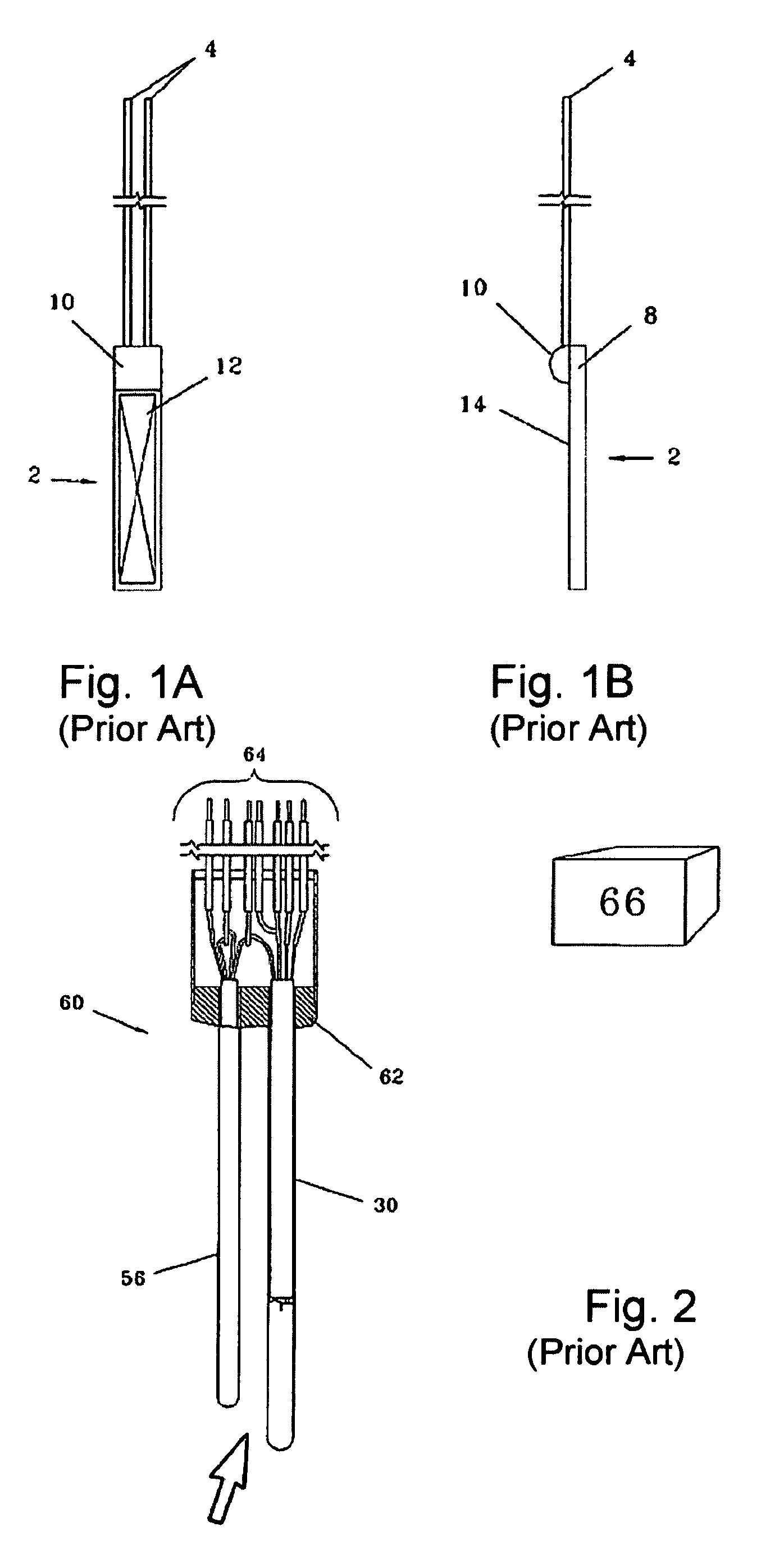

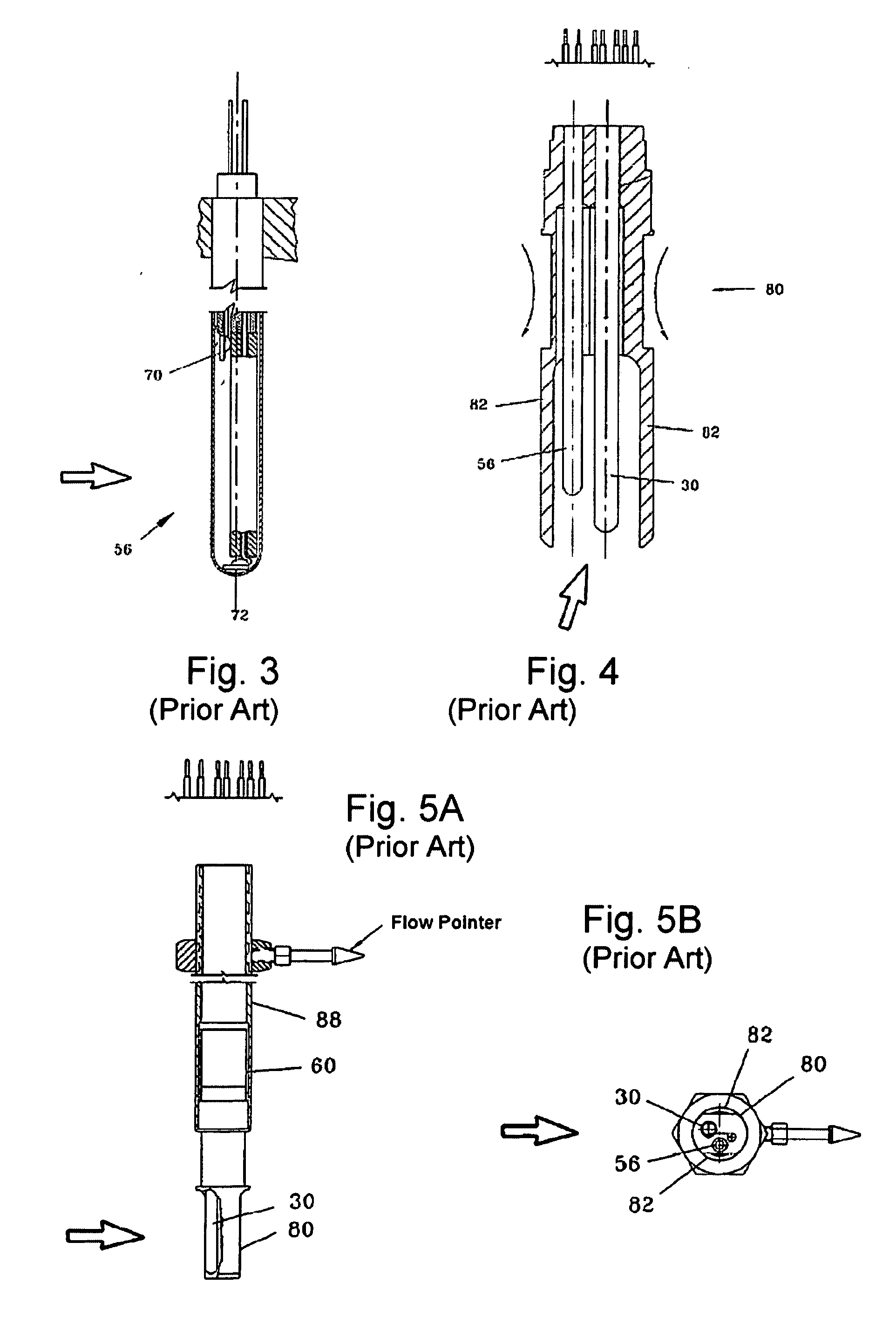

Mass flow meter with solder/braze-flow secured spacer

InactiveUS20090260431A1Reduce mistakesFew pointVolume/mass flow by thermal effectsFluid speed measurement using thermal variablesCopperWind speed

A thermal anemometer or mass flow meter typically having temperature and flow velocity sensor elements is provided in which a thin film temperature sensor is used in the heated sensor of the fluid velocity sensor element of the system. At least one thin-film RTD sensor is held within a spacer or interface member and the spacer, optionally, received within a housing. The thermal anemometer is preferably constructed to offer sufficient precision and accuracy in its design to be suitable for sensitive scientific and industrial applications. This goal is achieved while using cost effective parts by employing a construction approach in which the spacer and RTD sensor(s) is secured in place by solder, braze or another compound flowed into place while inserting the spacer and / or sensor(s).

Owner:SIERRA INSTR

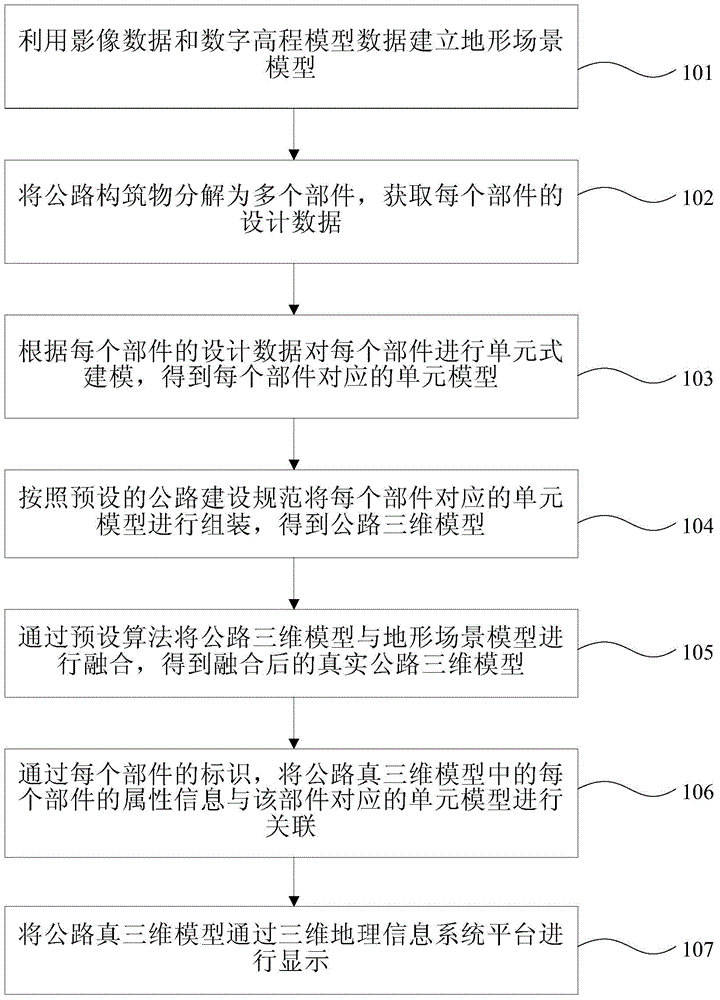

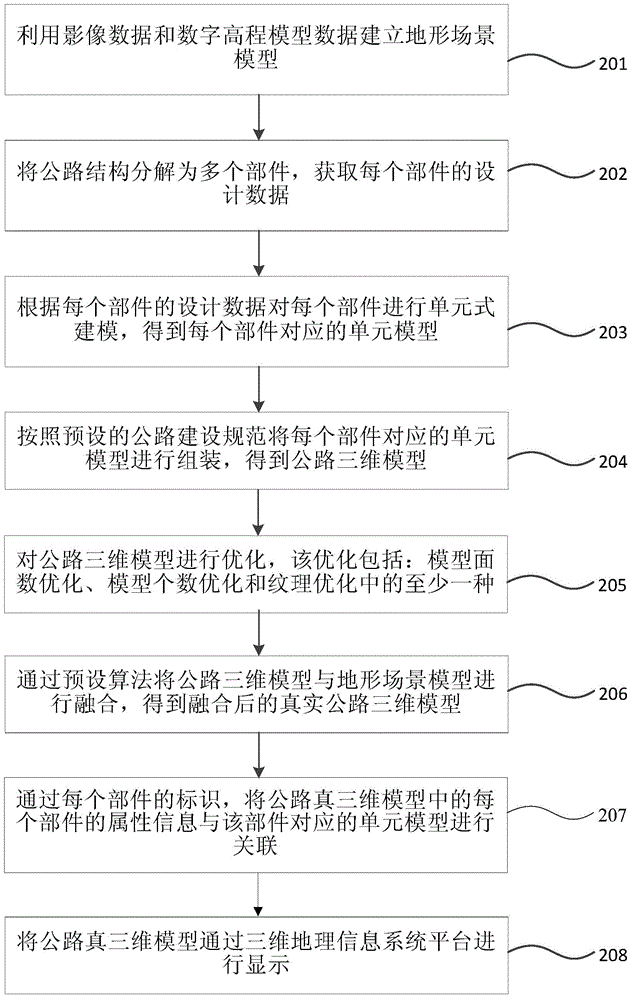

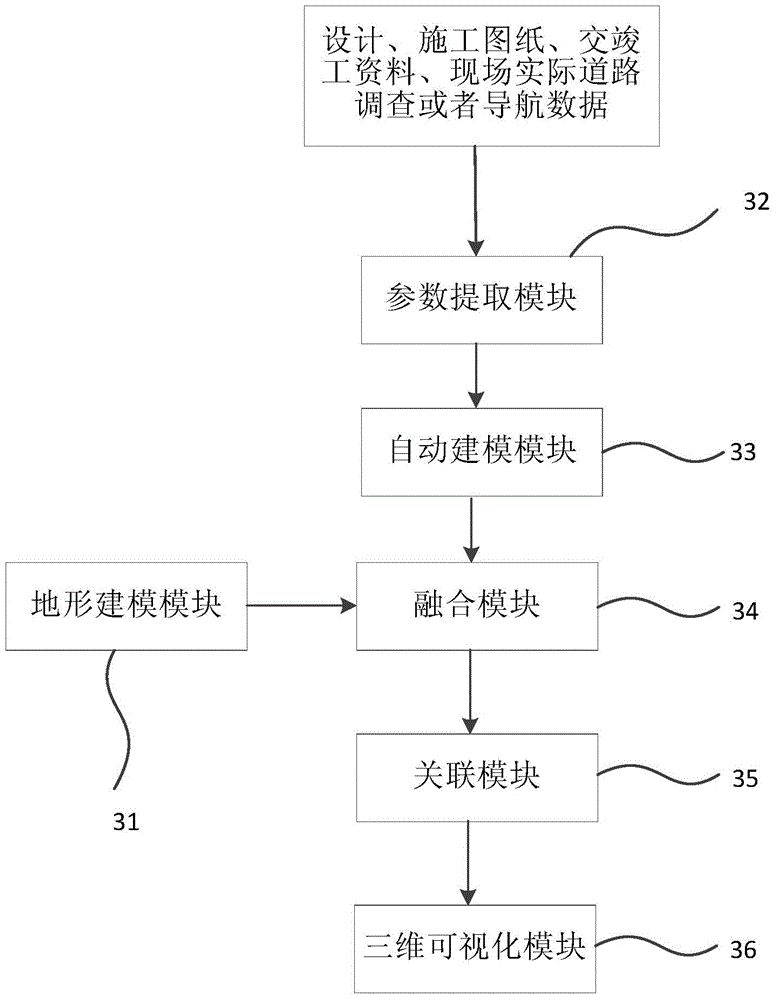

BIM-based (building information modeling based) road parametric auto-modeling method and system

ActiveCN105989198AImprove interoperabilityAutomatic modeling implementationImage data processingSpecial data processing applicationsSimulationLandform

Embodiments of the invention provide a BIM-based (building information modeling based) road parametric auto-modeling method and system. The method comprises: establishing a topographic scene model using image data and digital elevation model data; breaking a road structure into multiple parts, and acquiring design data of each part; subjecting each part to unitary modeling according to its design data to obtain a corresponding unitary model; assembling the unitary models corresponding to the parts according to preset road construction specifications to obtain a road three-dimensional model; merging the road three-dimensional model with the topographic scene model through a preset algorithm to obtain a merged road real three-dimensional model; correlating the unitary models in the road real three-dimensional model with attribute information, and displaying. The embodiments of the invention also provide a BIM-based road parametric auto-modeling system. The method and system enable automatic modeling of a road and improved modeling efficiency and provide realistic three-dimensional displaying.

Owner:中交宇科(北京)空间信息技术有限公司 +1

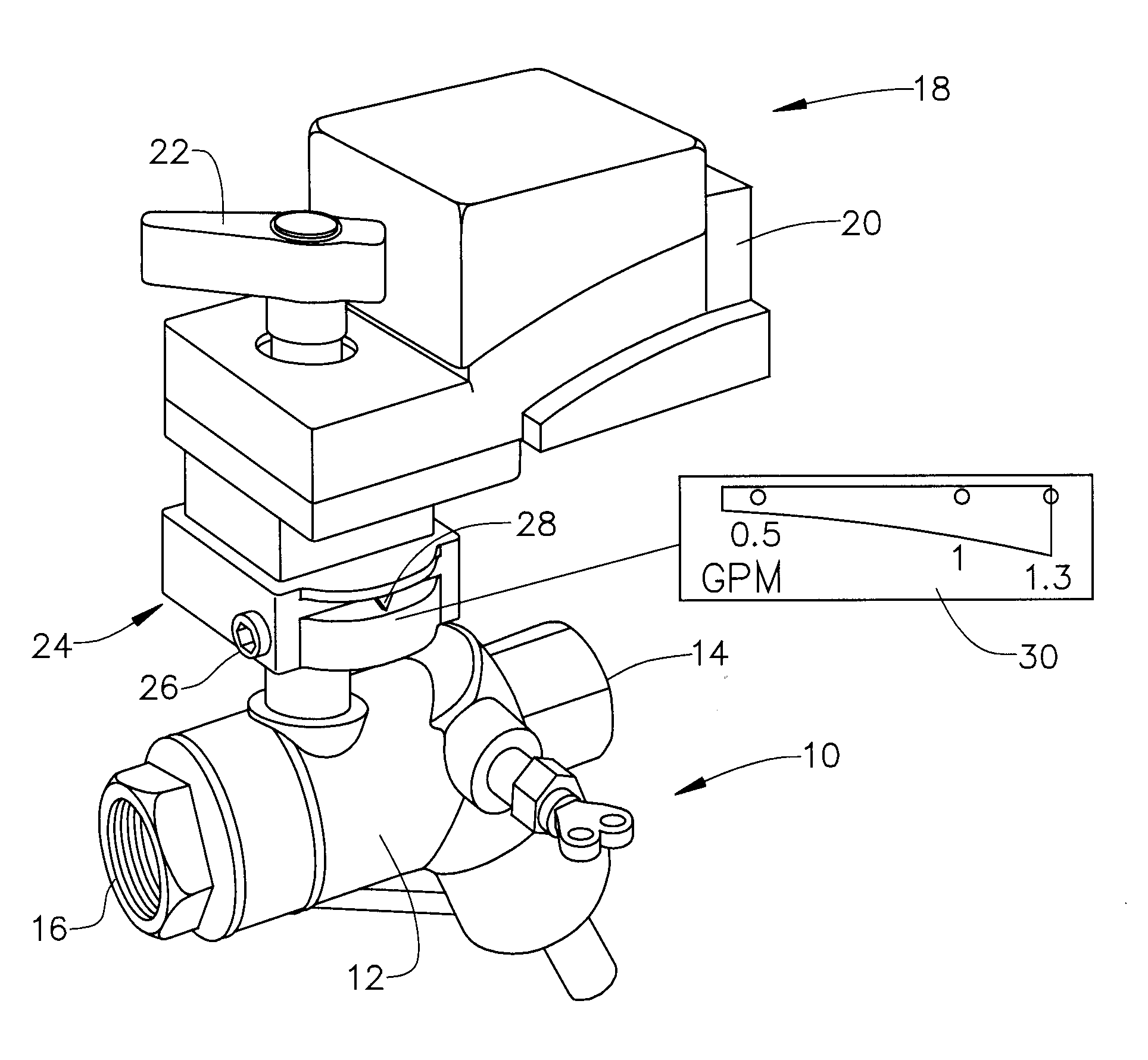

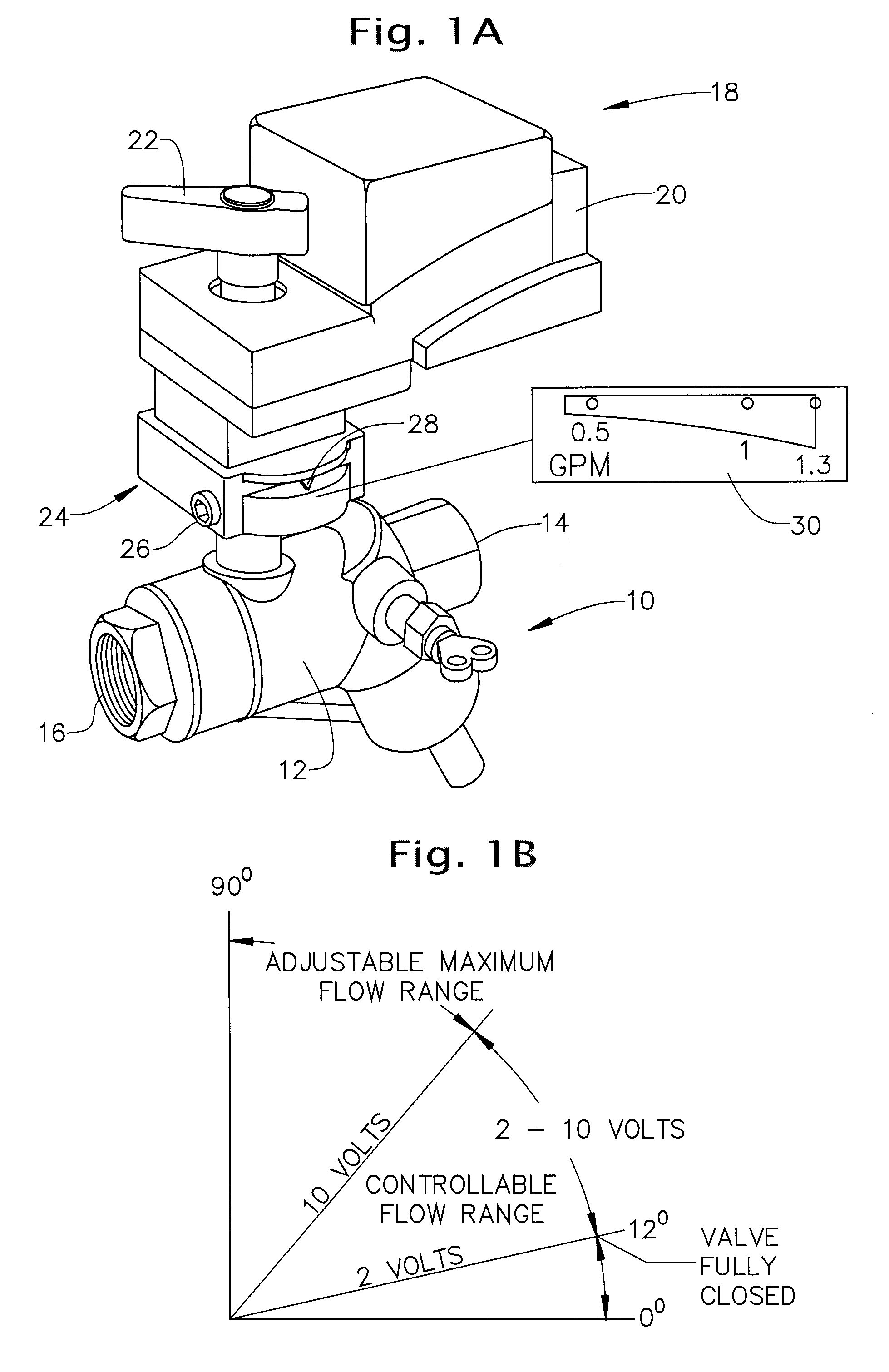

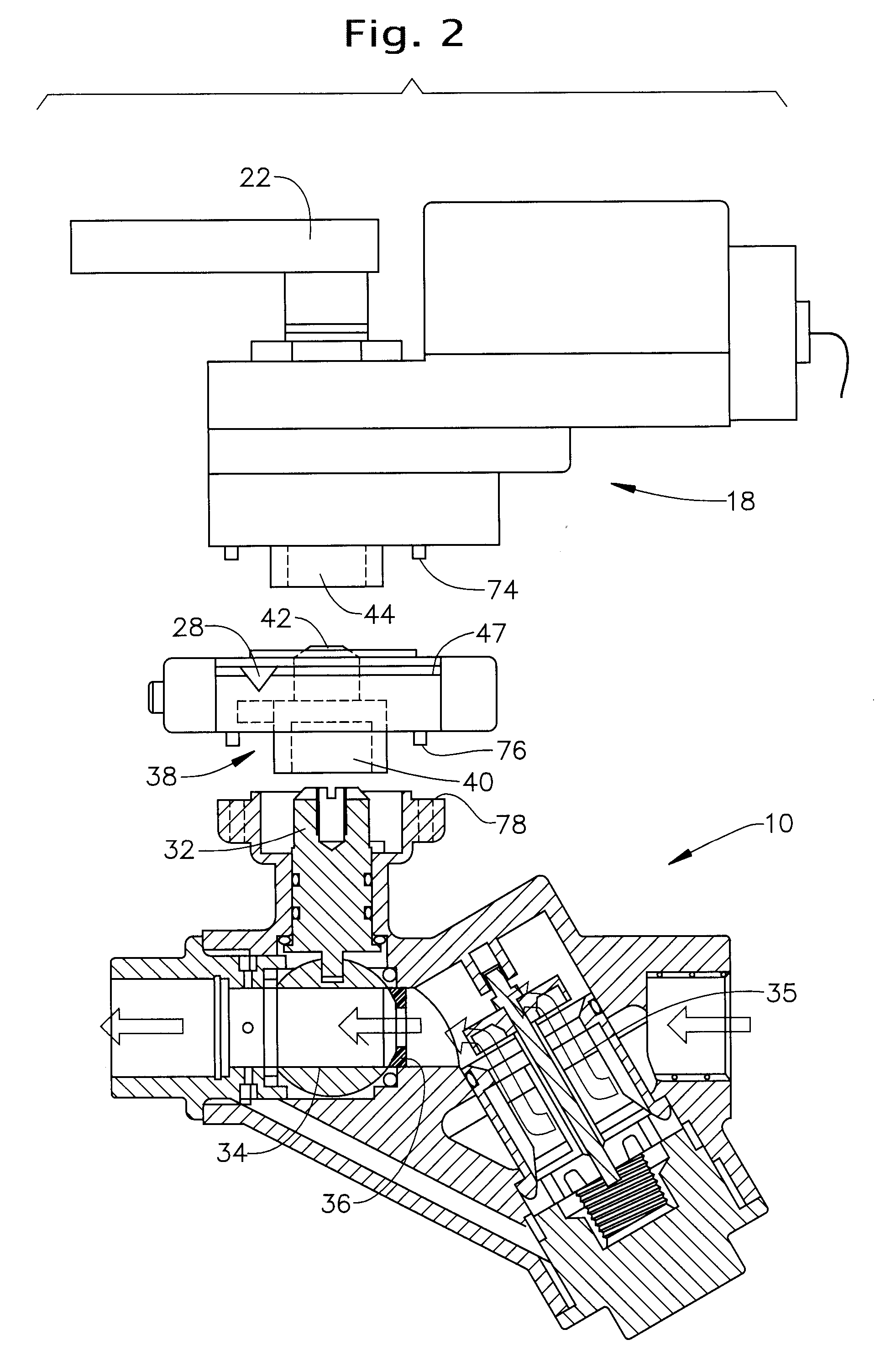

A field adjustable control valve assembly and field adjustment module

ActiveUS20070012367A1Plug valvesOperating means/releasing devices for valvesControl signalFloating point

A flow setting assembly is provided to permit field adjustment of an electronically actuated flow control valve, particularly a pressure independent characterized control valve (PICCV). In a preferred form, flow can be field adjusted by using a hex tool. Therefore, the maximum flow can be increased or decreased within the valve's adjustable flow range. As with all high close-off valves that employ a ball in their design, the ball passes well into the seat when rotated to the actuator's zero-degree position. Therefore, there is an amount of travel within the first degrees of ball rotation that passes back over this seat. The flow setting assembly eliminates this excess rotation (12°) resulting in a closed position that is offset to improve control resolution and system accuracy. This offset continues to allow the high close-off rating of 200 PSI. MFT actuators electronically adjust to and maintain the 2-10 Volt control signal at the reduced angle, as well as the 100 second running time and feedback signal. On floating point (−3) actuators, the running time is constant but dependent on the overall angle of rotation.

Owner:BELIMO HOLDING AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com