Patents

Literature

61 results about "Crumple zone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Crumple zones, crush zones, or crash zones, are a structural safety feature used in vehicles, mainly in automobiles, to increase the time over which a change in velocity (and consequently, momentum) occurs from the impact during a collision by controlled deformation; in recent years also incorporated into trains and railcars. Crumple zones are designed to increase the time over which the total force from the change in momentum is applied to an occupant, as the average force applied to the occupants is inversely related to the time over which it is applied.

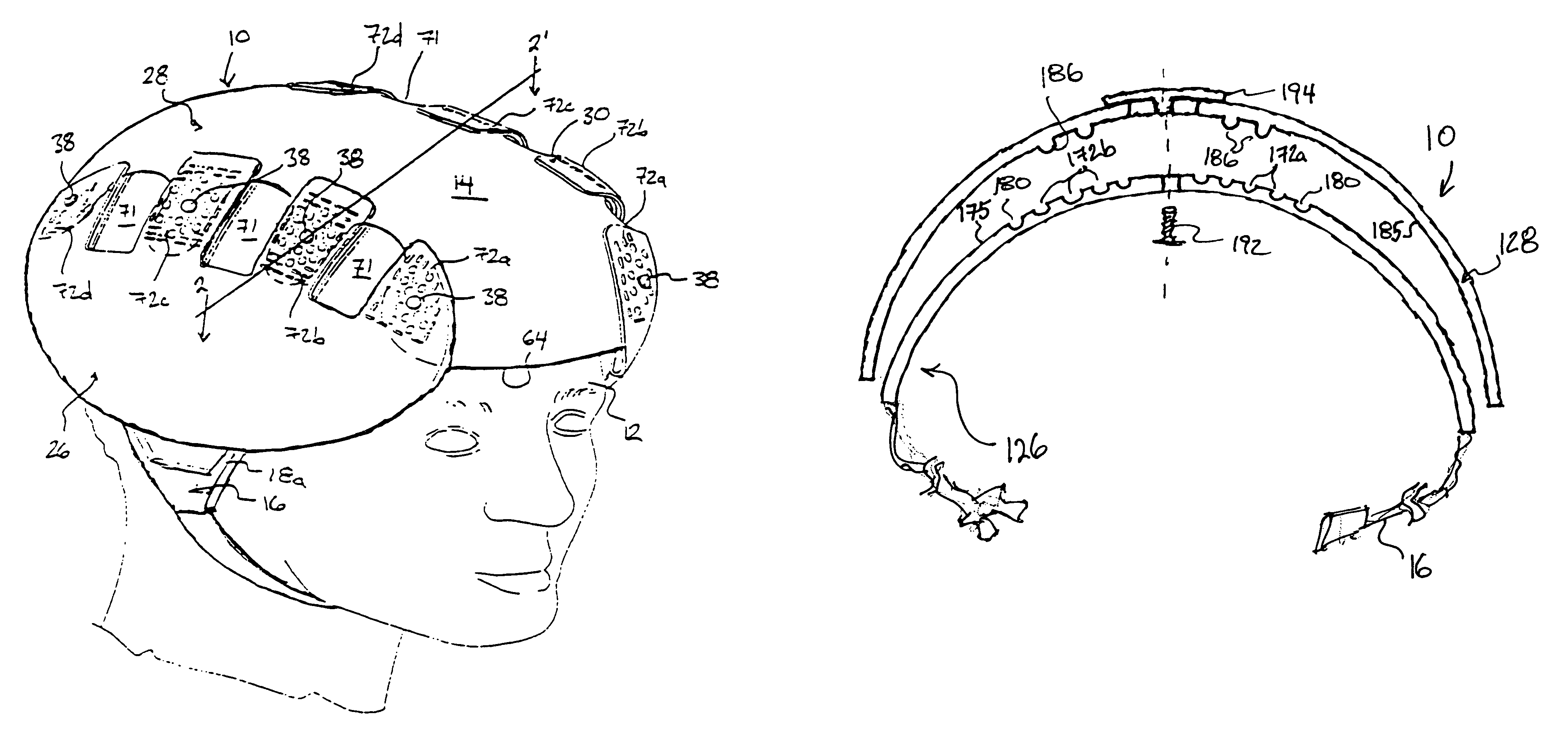

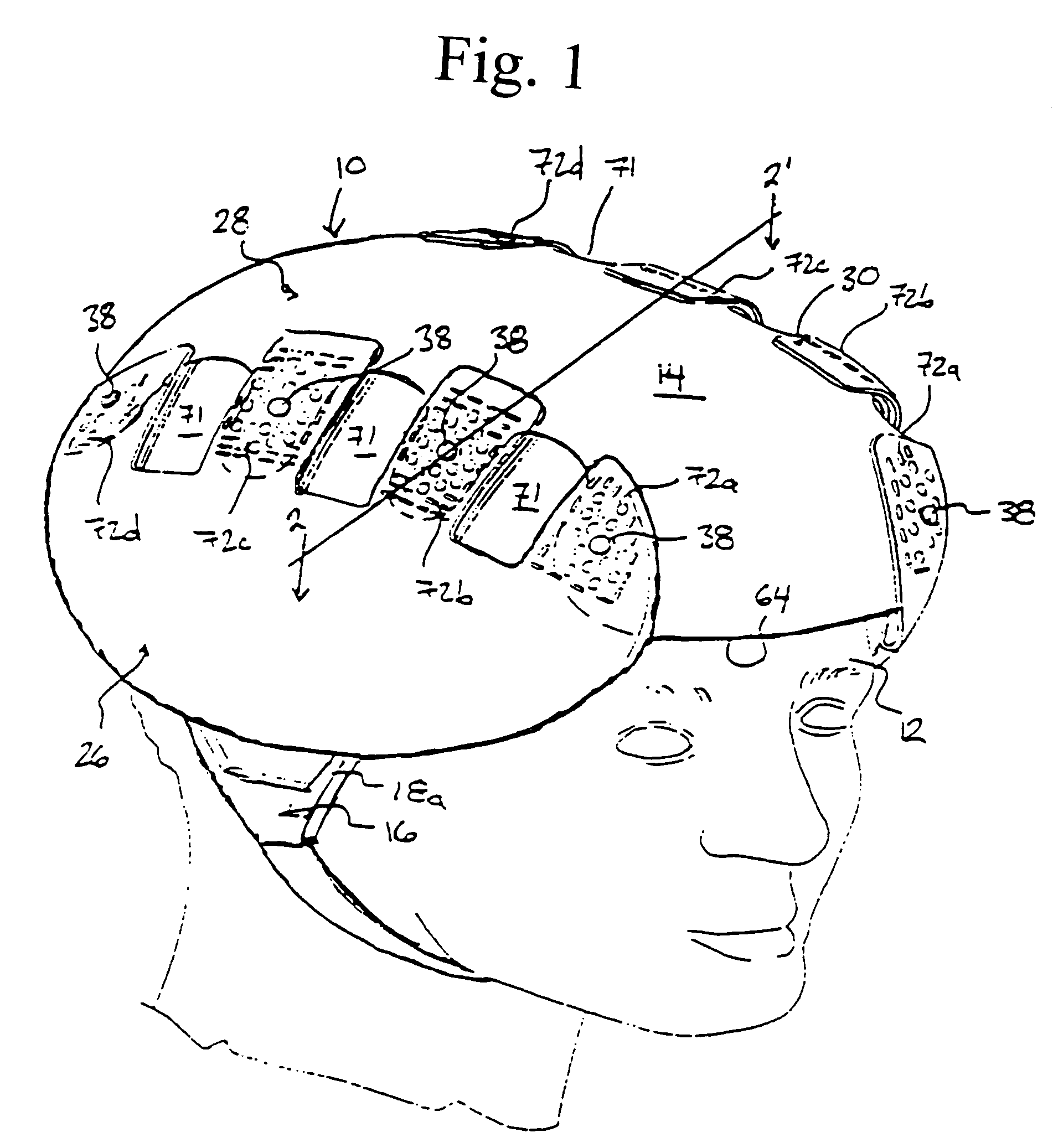

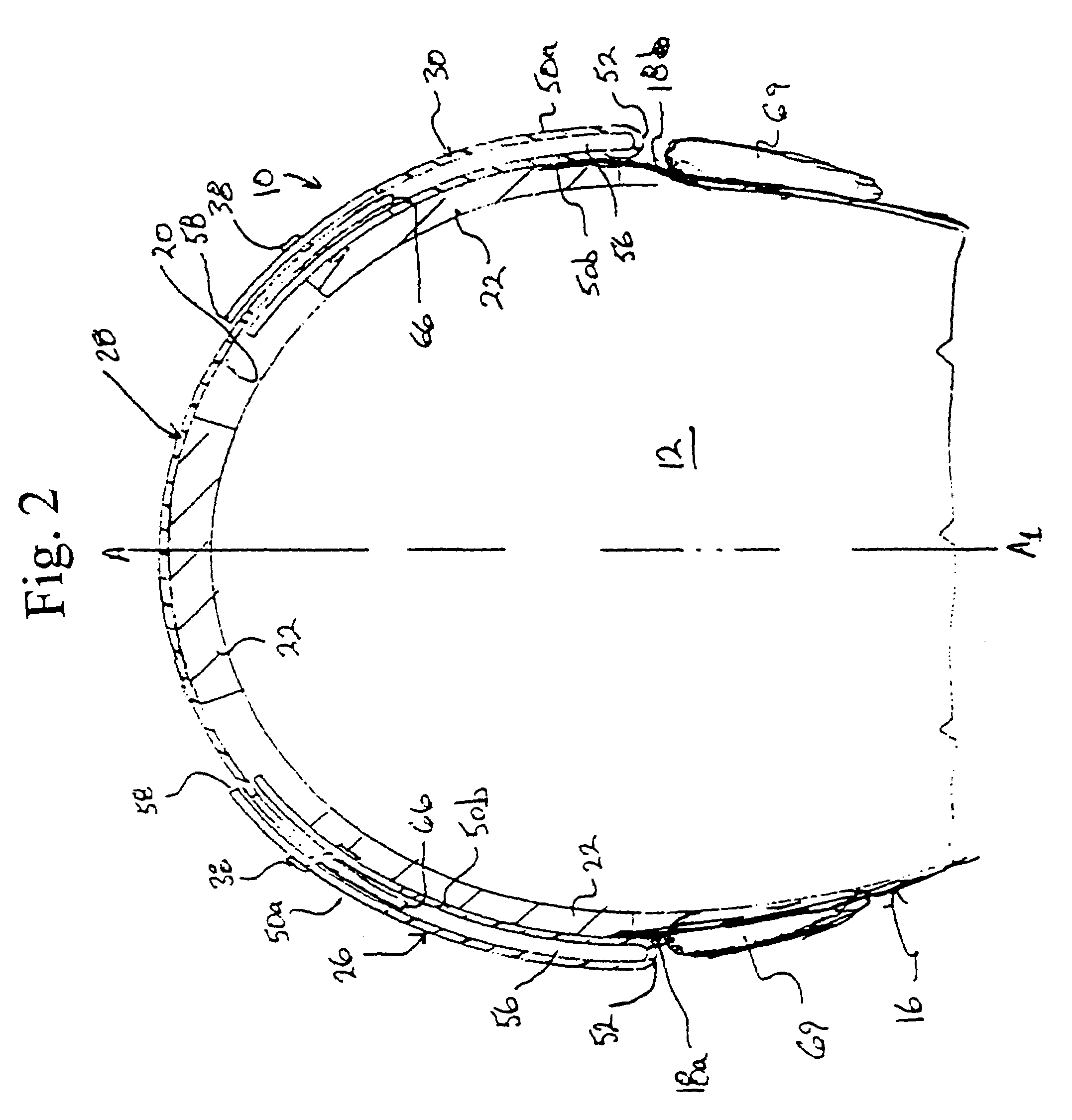

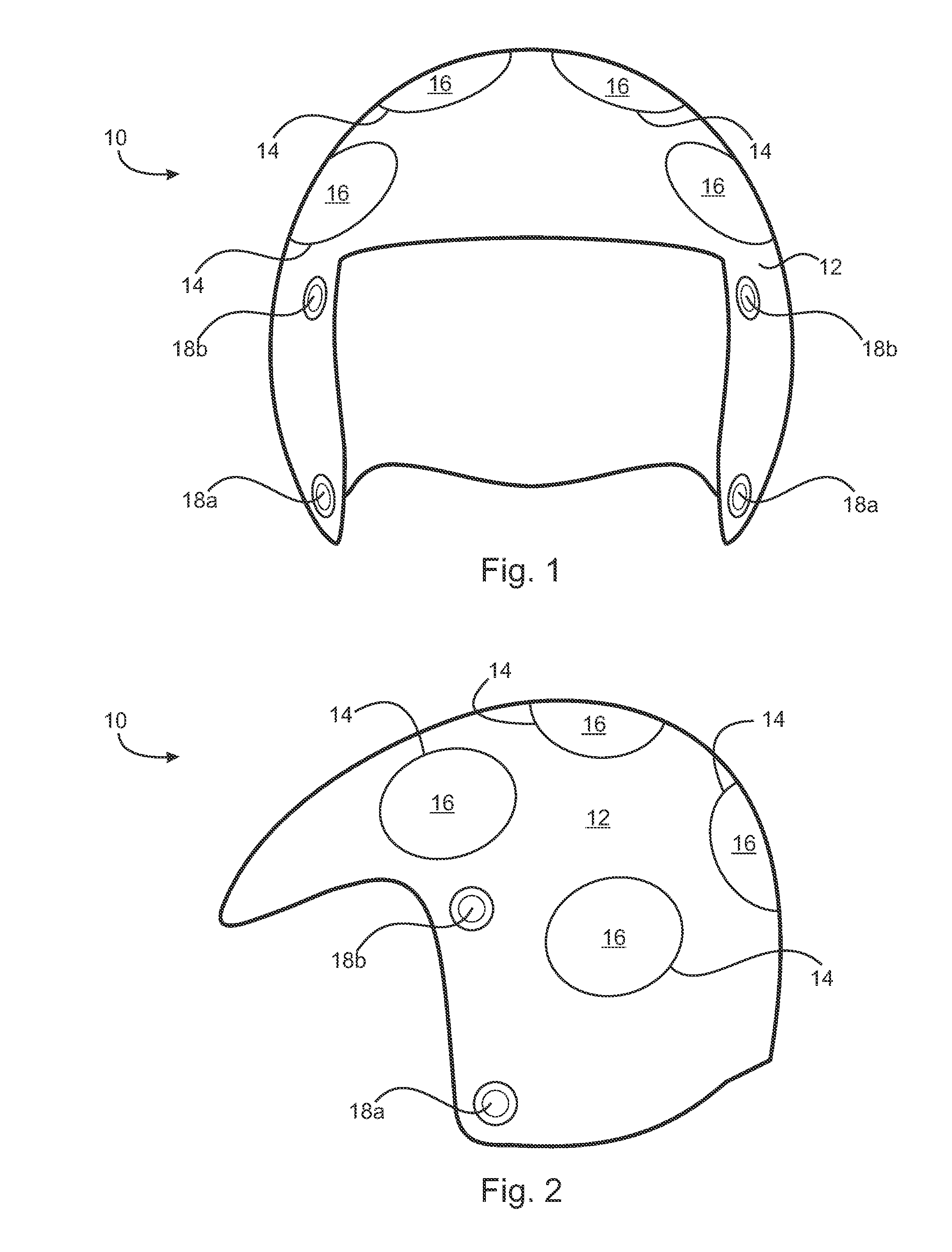

Protective head covering having impact absorbing crumple zone

InactiveUS6996856B2Closer in weight and sizeMinimizing resultant disproportionHatsSport apparatusMostly TrueEngineering

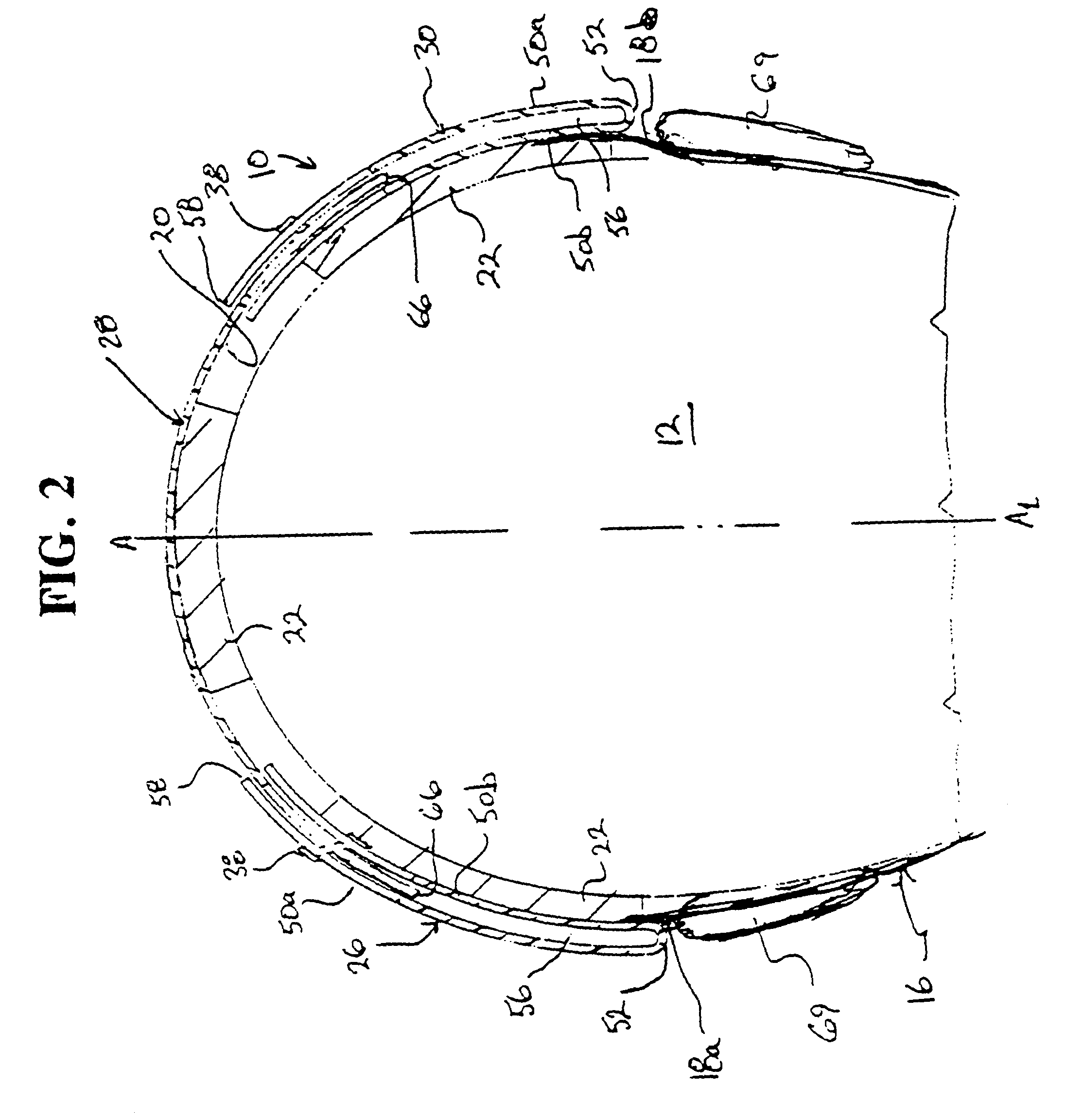

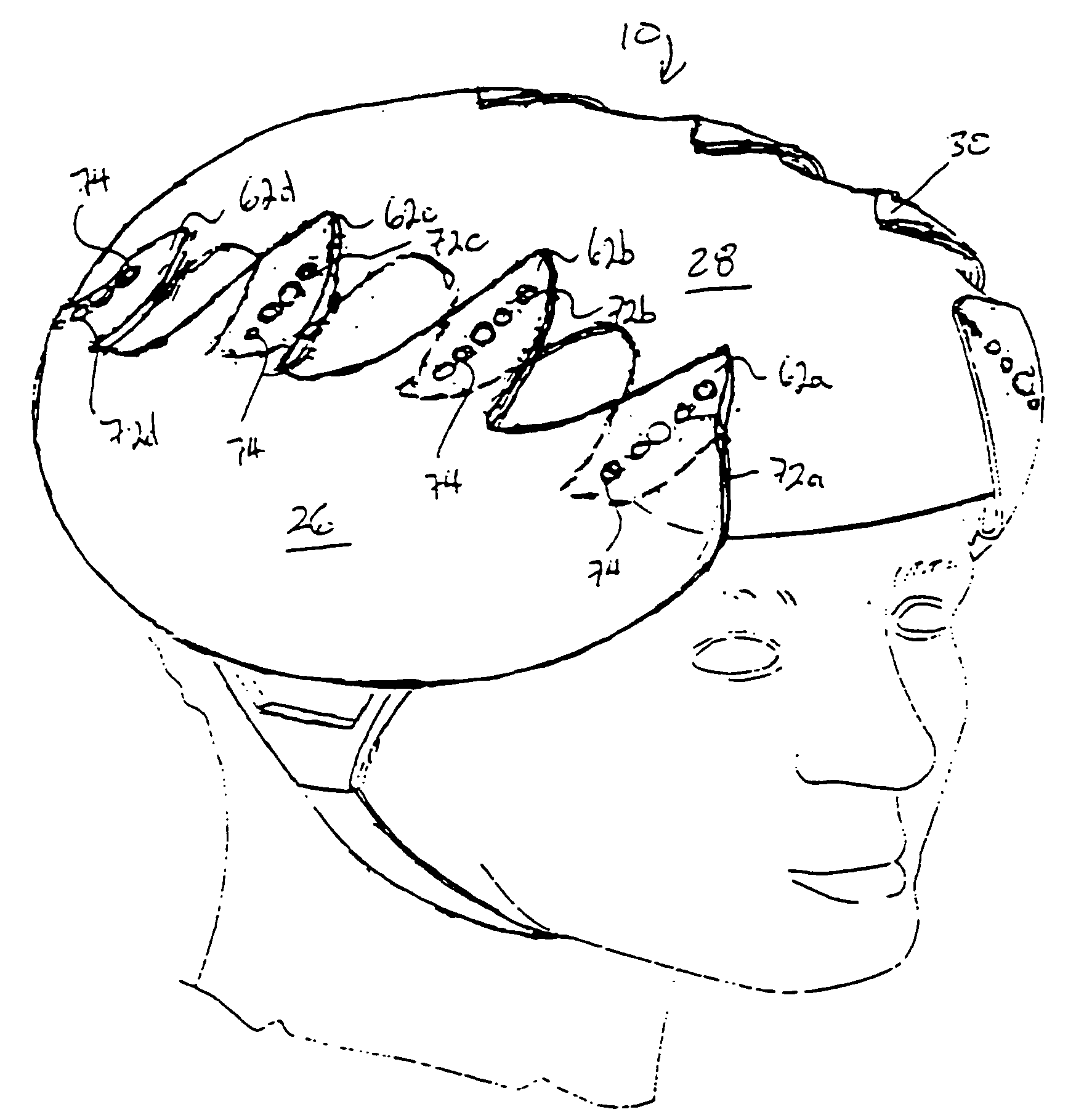

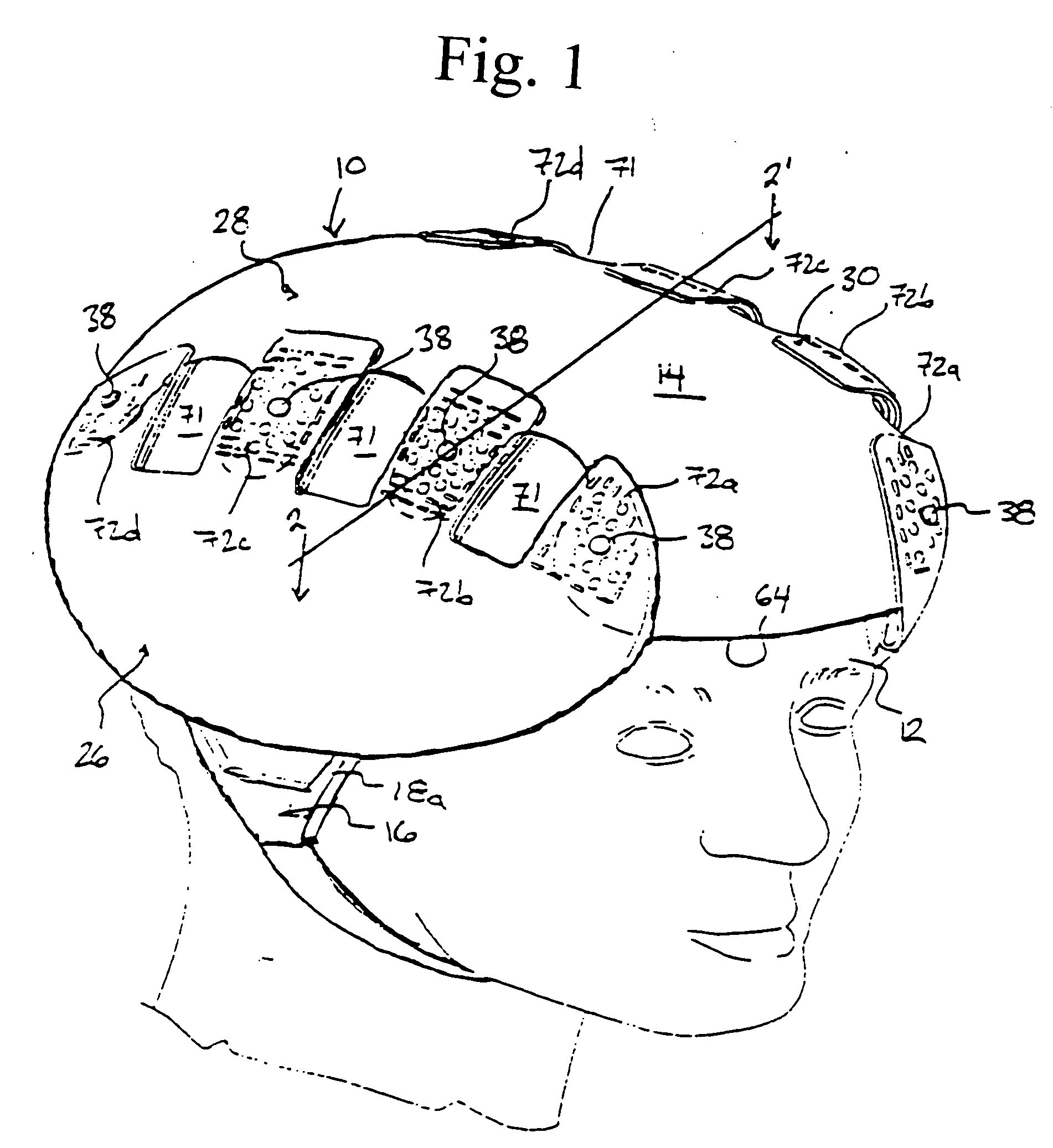

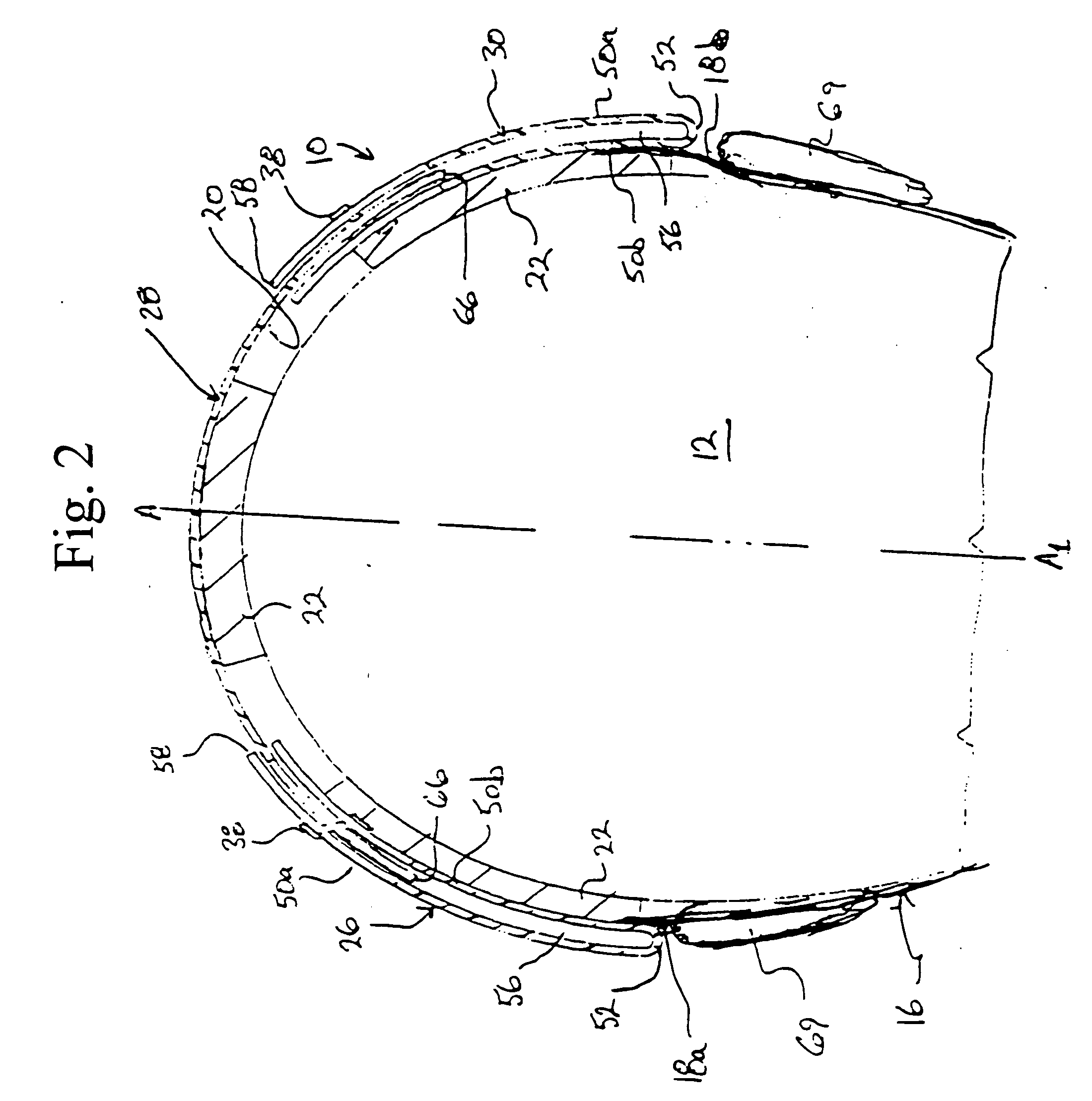

A helmet construction for protecting a user's head, and the brain within the cranium from impact forces, includes a shell contoured to the shape of the user's head, with cushioning along at least part of the shell interior and a chinstrap. The shell consists of three (or more) discrete panels that are physically and firmly coupled together providing rigid protection under most circumstances, but upon impact the panels move relative to one another, but not relative to the user's head, thereby permitting impact forces to be dissipated and / or redirected away from the cranium and brain within. Upon impact to the helmet, there are sequential stages of movement of the panels relative to each other, these movements initially being recoverable, but with sufficient vector forces the helmet undergoes structural changes in a pre-determined fashion, so that the recoverable and permanent movements cumulatively provide a protective ‘crumple zone’ or ‘shear zone’. The first two stages of protection arise from the design of the fasteners that have the ability to invaginate and collapse within themselves, and their design having a 45 degree angle, which will allow movement of a region of connected panels to translate along the fastener shaft. Both of these movements will be recoverable and provide a ‘functional crumple zone’. The final stage of protection arises from the braking function of the pins, as they are forced from one aperture through to the next, the direction and extent of which is determined by the impact force and direction. This final level of panel movement and protection is not recoverable and thus provides a ‘structural crumple zone’. Finally the fastener size and thickness, together with the thickness of webbing and distance between apertures, functions to provide varying degrees of resistance to impact forces, thus making the helmet design suitable for activities with different levels of impact speed and risk potential.

Owner:PUCHALSKI TECHN

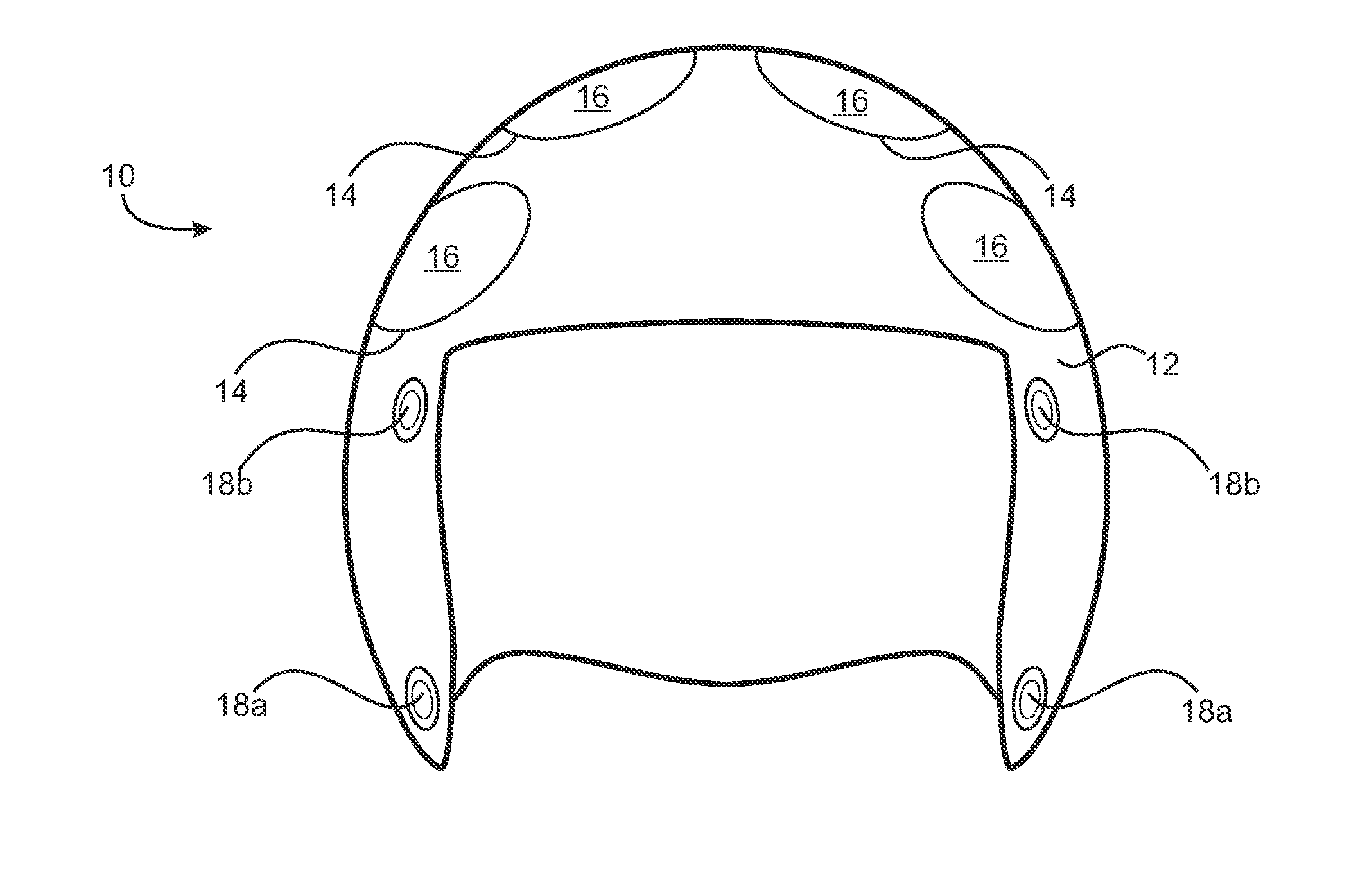

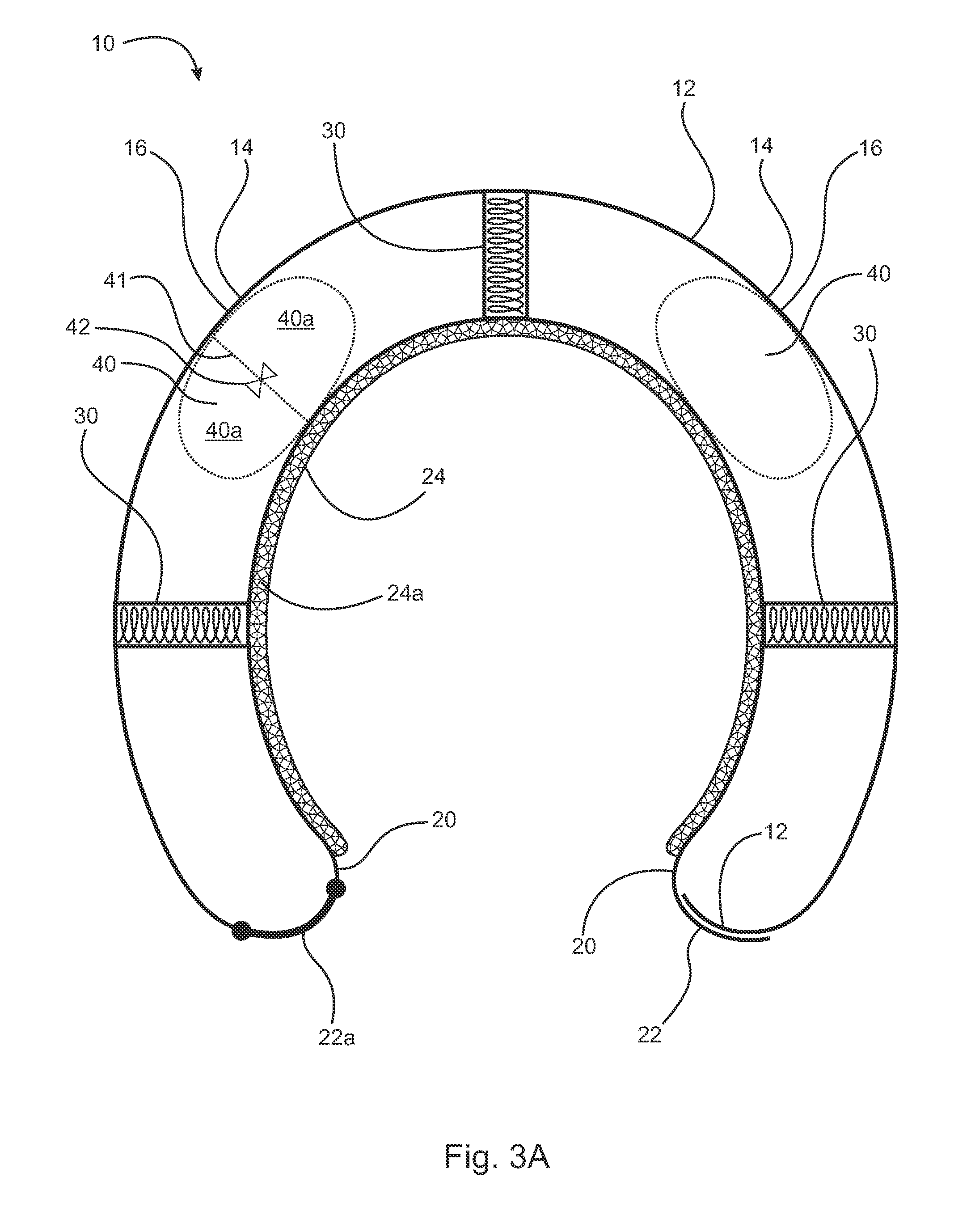

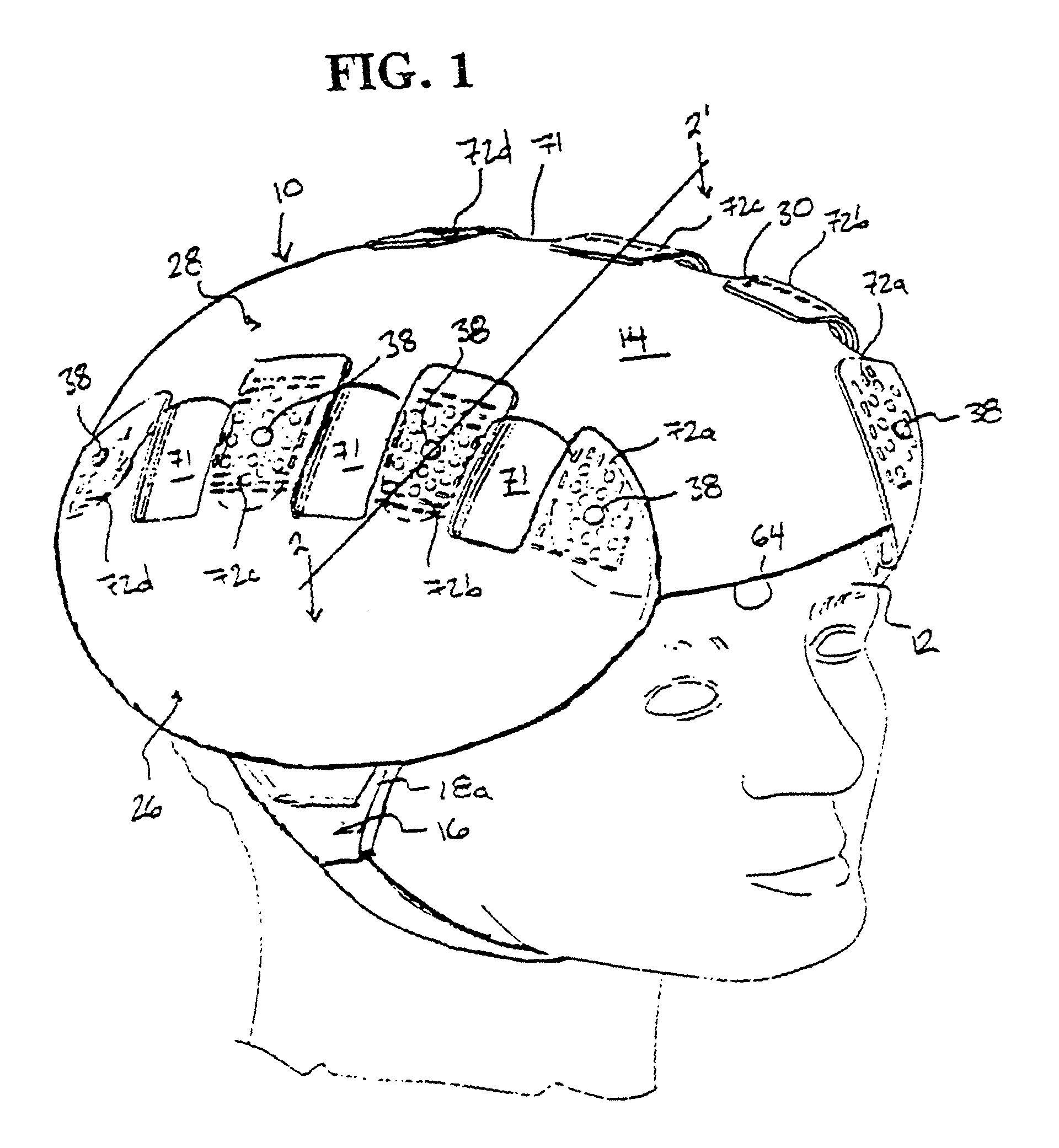

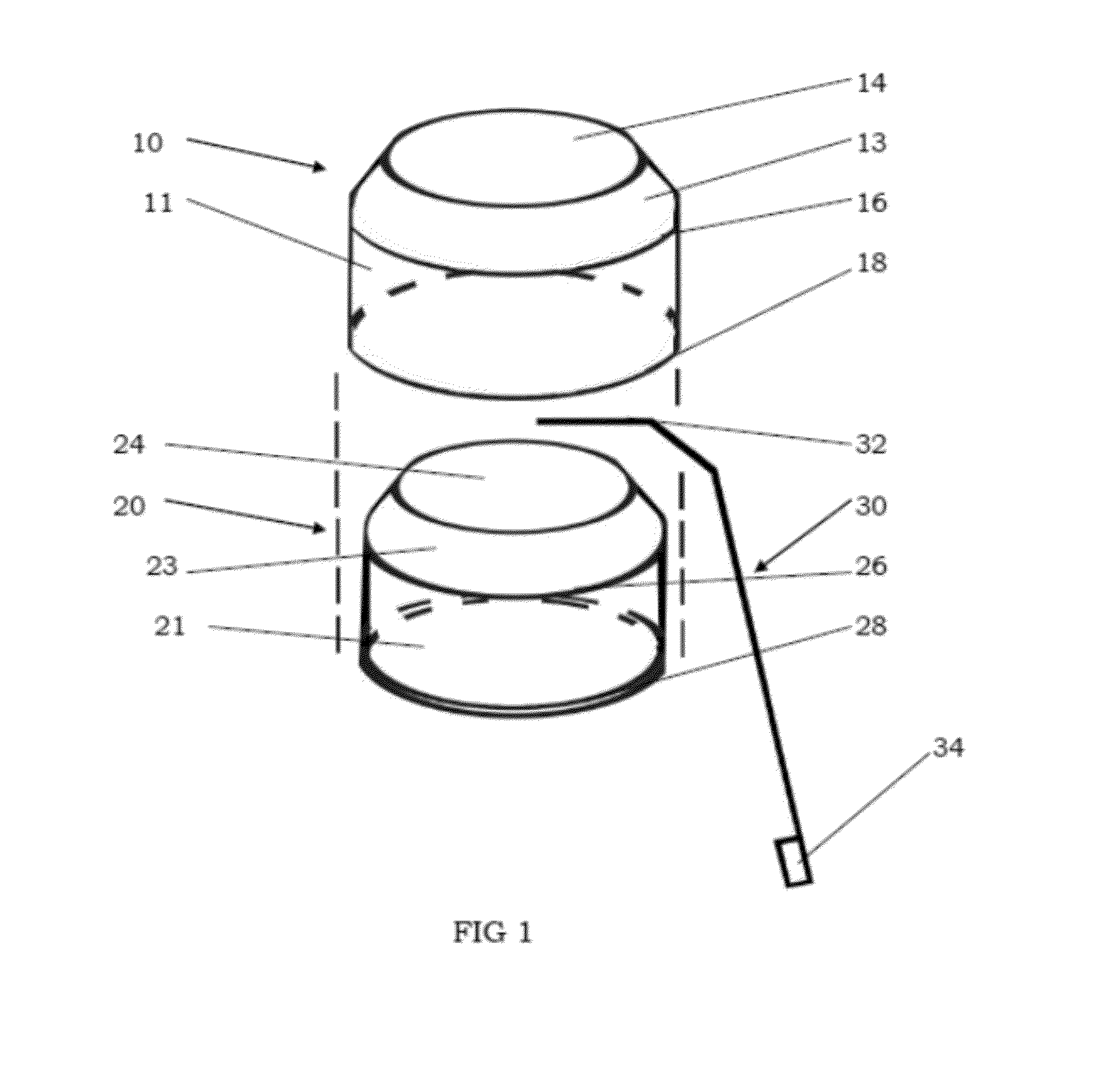

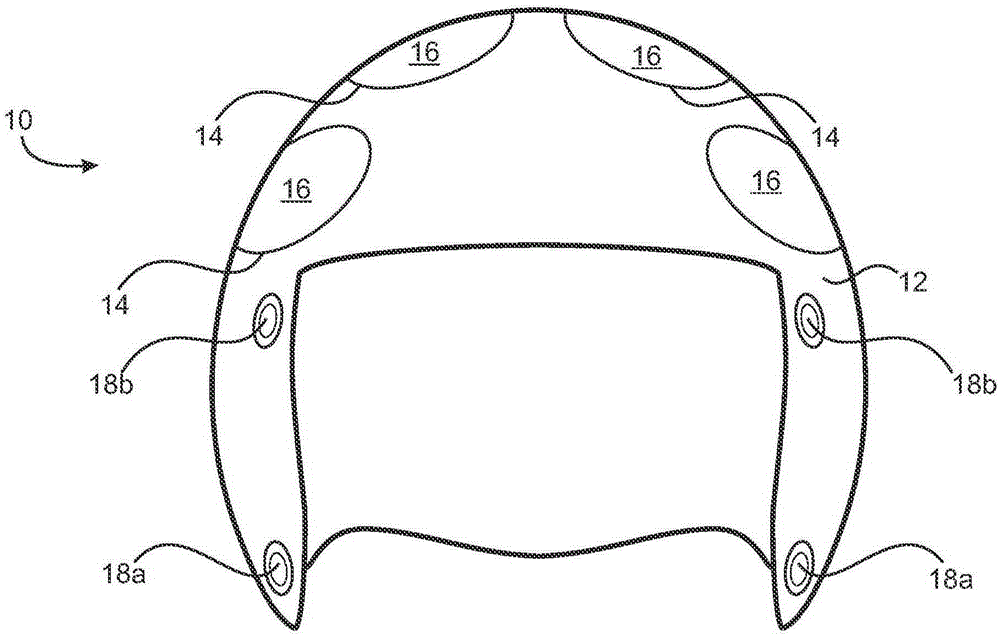

Helmet with multiple protective zones

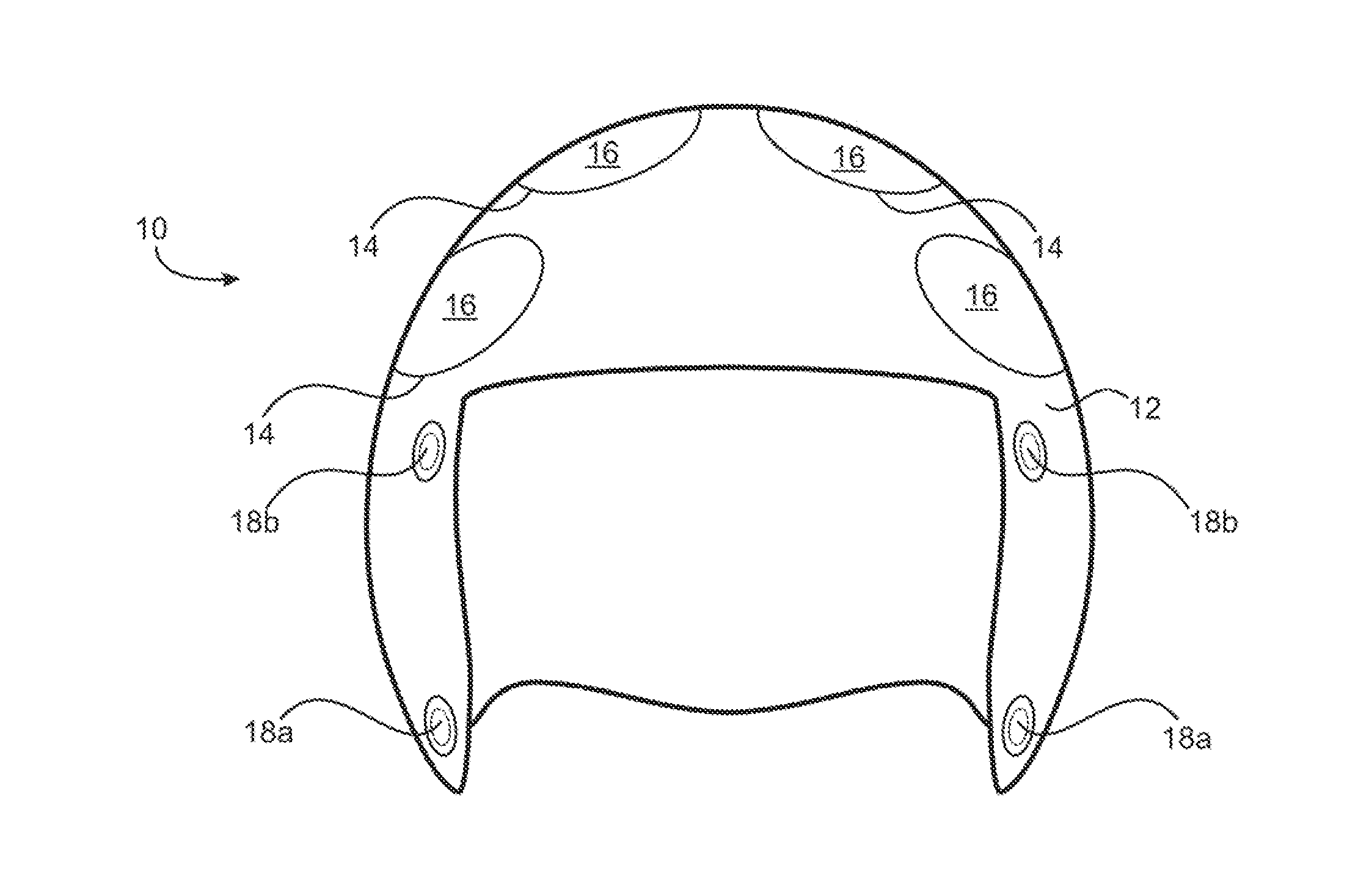

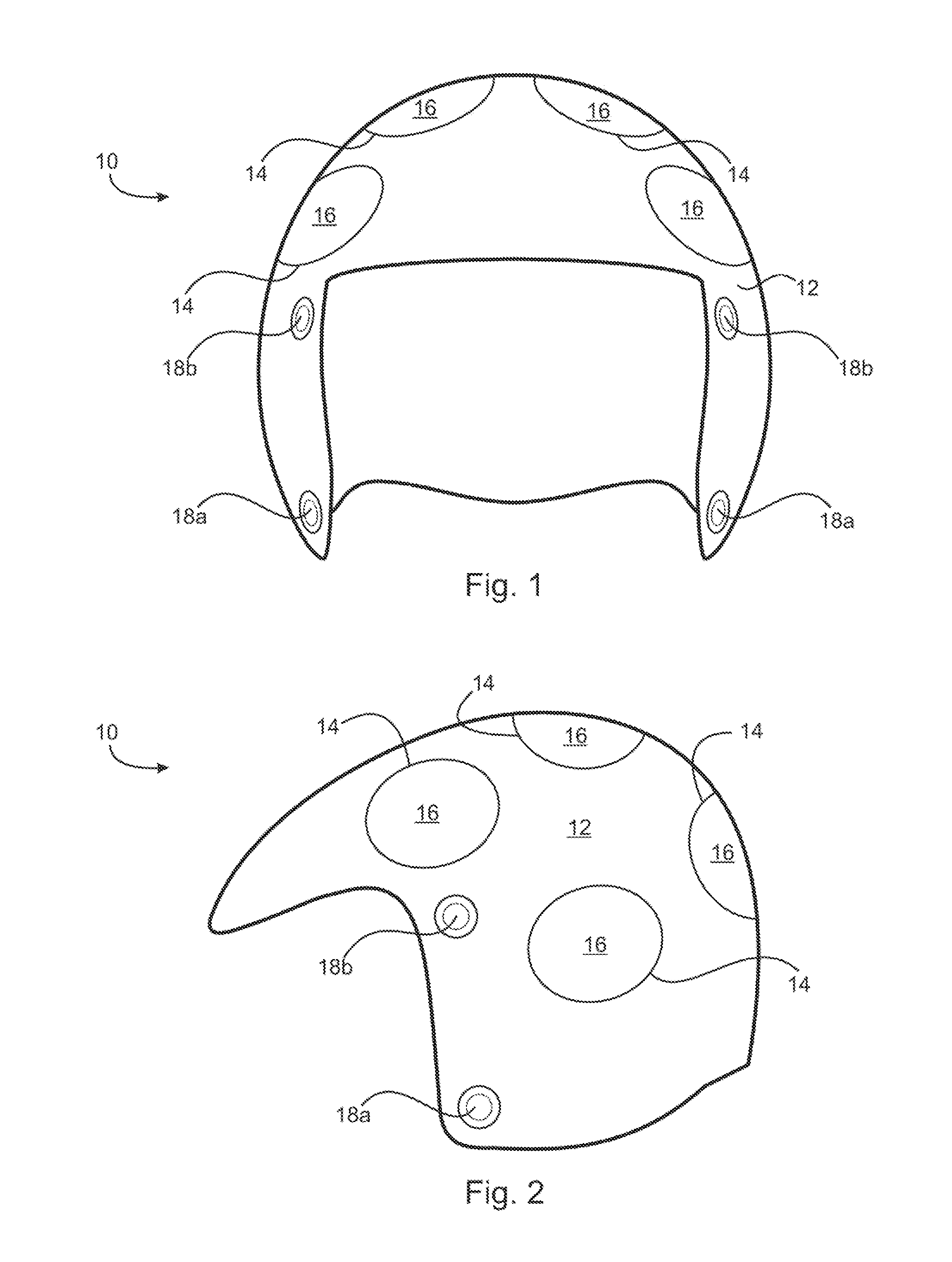

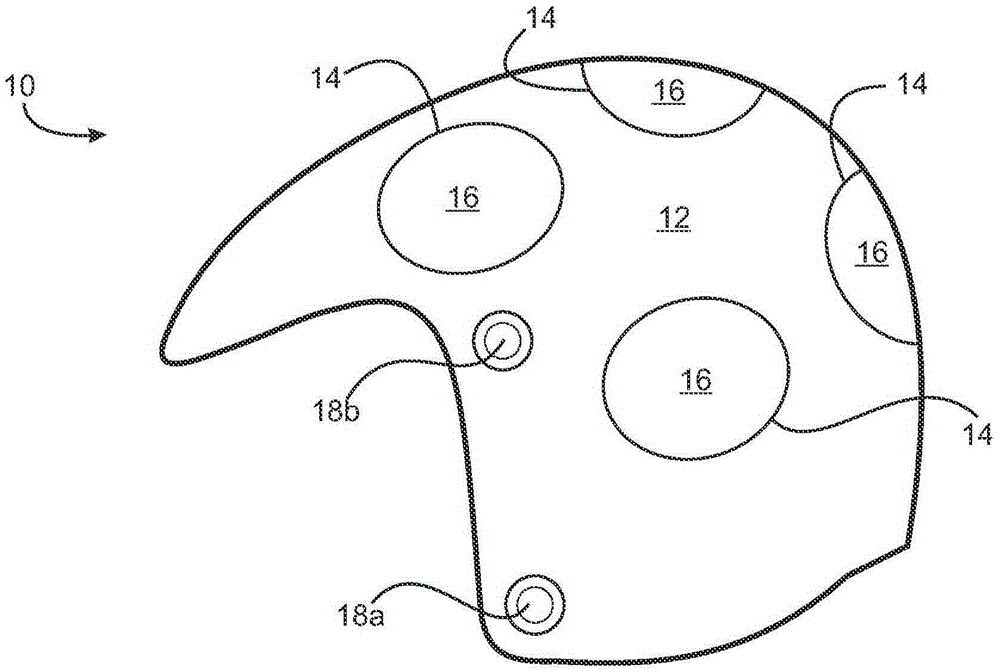

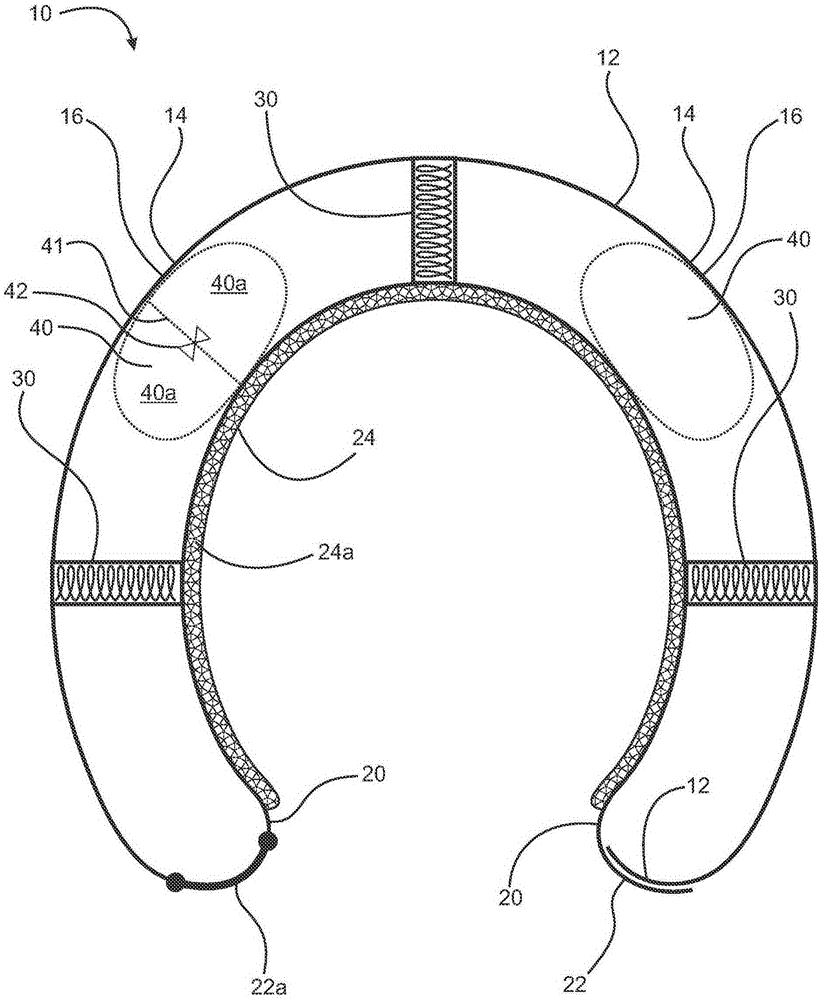

The present invention is a protective helmet having multiple zones of protection suitable for use in construction work, athletic endeavors, and similar activities. The helmet includes a hard outer protective that is suspended over a hard anchor zone by elastic cords extending between an elastomeric zone between the outer and inner zones. Fluid filed bladders are positioned in the elastomeric zone and bulge through one or more of a plurality of apertures located in the outer zone. In one embodiment, an additional crumple zone is present. The structure enables the helmet to divert linear and rotational forces away from the user's braincase.

Owner:SUDDABY LOUBERT S

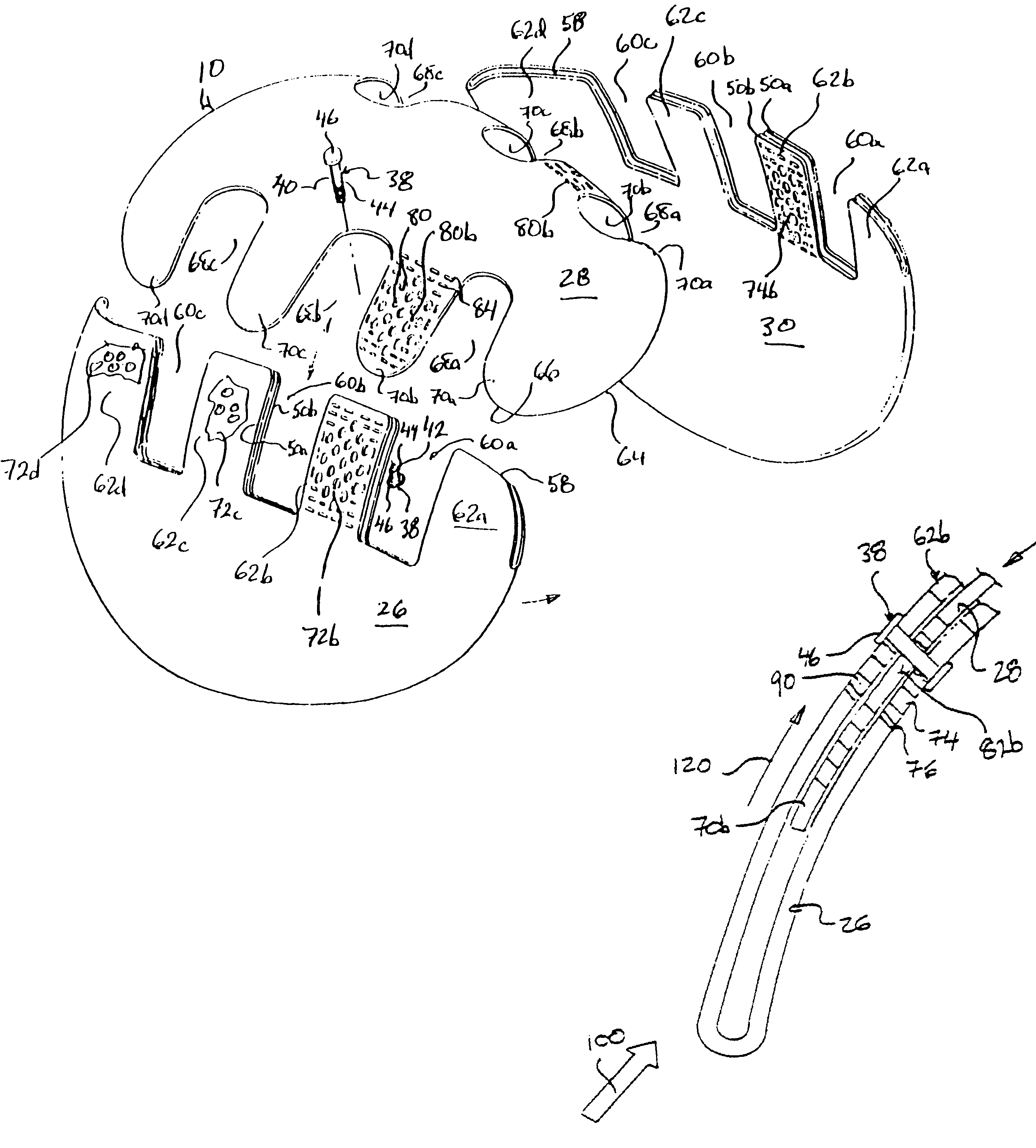

Protective head covering having impact absorbing crumple or shear zone

A helmet construction for protecting a user's head, and the brain within the cranium from impact forces, includes a shell contoured to the shape of the user's head, with cushioning along at least part of the shell interior and a chinstrap. The shell consists of three (or more) discrete panels that are physically and firmly coupled together providing rigid protection under most circumstances, but upon impact the panels move relative to one another, but not relative to the user's head, thereby permitting impact forces to be dissipated and / or redirected away from the cranium and brain within. Upon impact to the helmet, there are sequential stages of movement of the panels relative to each other, these movements initially being recoverable, but with sufficient vector forces the helmet undergoes structural changes in a pre-determined fashion, so that the recoverable and permanent movements cumulatively provide a protective ‘crumple zone’ or ‘shear zone’. The first two stages of protection arise from the design of the fasteners that have the ability to invaginate and collapse within themselves, and their design having a 45 degree angle, which will allow movement of a region of connected panels to translate along the fastener shaft. Both of these movements will be recoverable and provide a ‘functional crumple zone’. The final stage of protection arises from the braking function of the pins, as they are forced from one aperture through to the next, the direction and extent of which is determined by the impact force and direction. This final level of panel movement and protection is not recoverable and thus provides a ‘structural crumple zone’. Finally the fastener size and thickness, together with the thickness of webbing and distance between apertures, functions to provide varying degrees of resistance to impact forces, thus making the helmet design suitable for activities with different levels of impact speed and risk potential.

Owner:PUCHALSKI TECHN

Helmet with multiple protective zones

The present invention is a protective helmet having multiple zones of protection suitable for use in construction work, athletic endeavors, and similar activities. The helmet includes a hard outer protective that is suspended over a hard anchor zone by elastic cords extending between an elastomeric zone between the outer and inner zones. Fluid filed bladders are positioned in the elastomeric zone and bulge through one or more of a plurality of apertures located in the outer zone. In one embodiment, an additional crumple zone is present. The structure enables the helmet to divert linear and rotational forces away from the user's braincase.

Owner:SUDDABY LOUBERT S

Protective head covering having impact absorbing crumple zone

InactiveUS20050257312A1Closer in weight and sizeMinimizing resultant disproportionHatsSport apparatusMostly TrueEngineering

A helmet construction for protecting a user's head, and the brain within the cranium from impact forces, includes a shell contoured to the shape of the user's head, with cushioning along at least part of the shell interior and a chinstrap. The shell consists of three (or more) discrete panels that are physically and firmly coupled together providing rigid protection under most circumstances, but upon impact the panels move relative to one another, but not relative to the user's head, thereby permitting impact forces to be dissipated and / or redirected away from the cranium and brain within. Upon impact to the helmet, there are sequential stages of movement of the panels relative to each other, these movements initially being recoverable, but with sufficient vector forces the helmet undergoes structural changes in a pre-determined fashion, so that the recoverable and permanent movements cumulatively provide a protective ‘crumple zone’ or ‘shear zone’. The first two stages of protection arise from the design of the fasteners that have the ability to invaginate and collapse within themselves, and their design having a 45 degree angle, which will allow movement of a region of connected panels to translate along the fastener shaft. Both of these movements will be recoverable and provide a ‘functional crumple zone’. The final stage of protection arises from the braking function of the pins, as they are forced from one aperture through to the next, the direction and extent of which is determined by the impact force and direction. This final level of panel movement and protection is not recoverable and thus provides a ‘structural crumple zone’. Finally the fastener size and thickness, together with the thickness of webbing and distance between apertures, functions to provide varying degrees of resistance to impact forces, thus making the helmet design suitable for activities with different levels of impact speed and risk potential.

Owner:PUCHALSKI TECHN

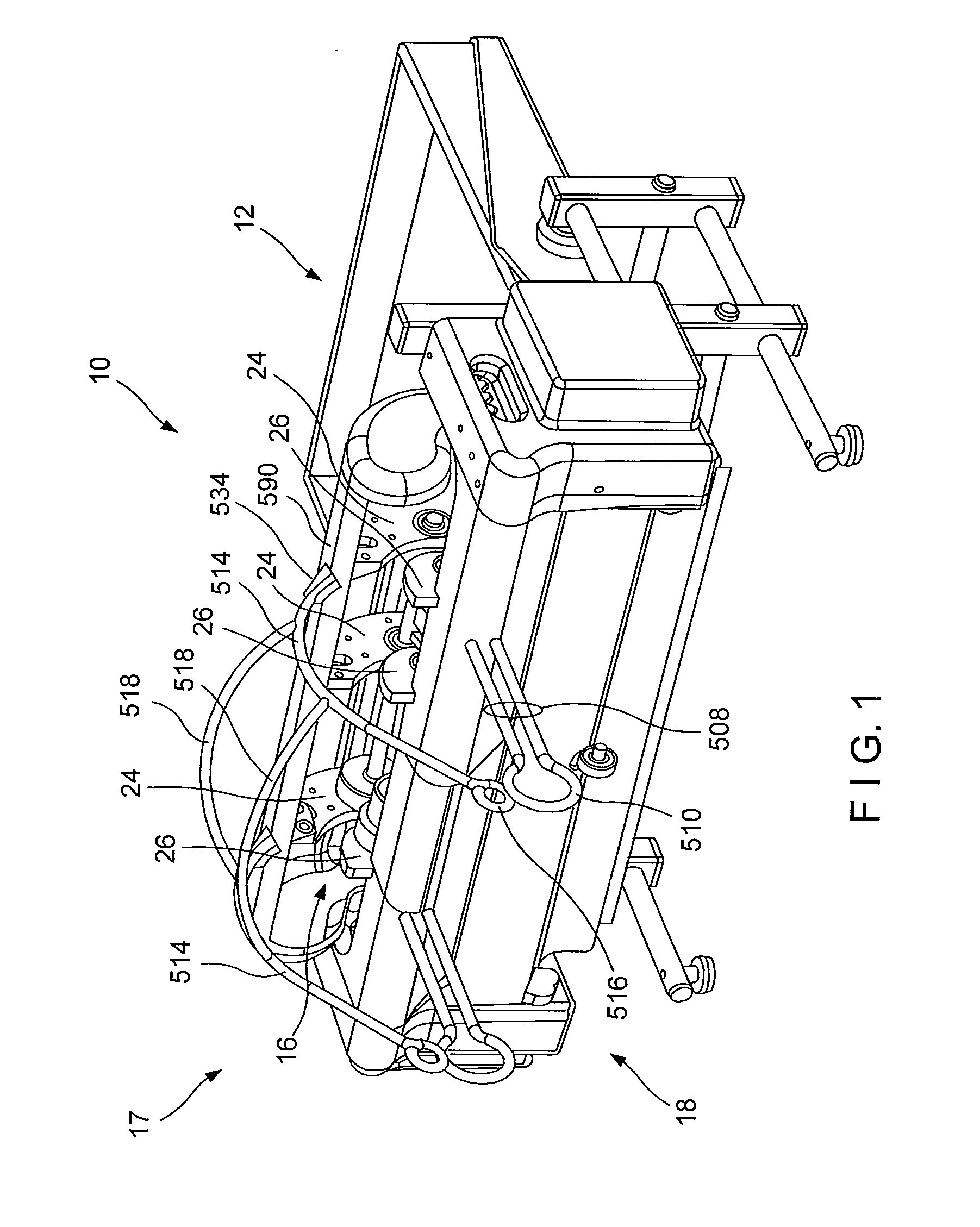

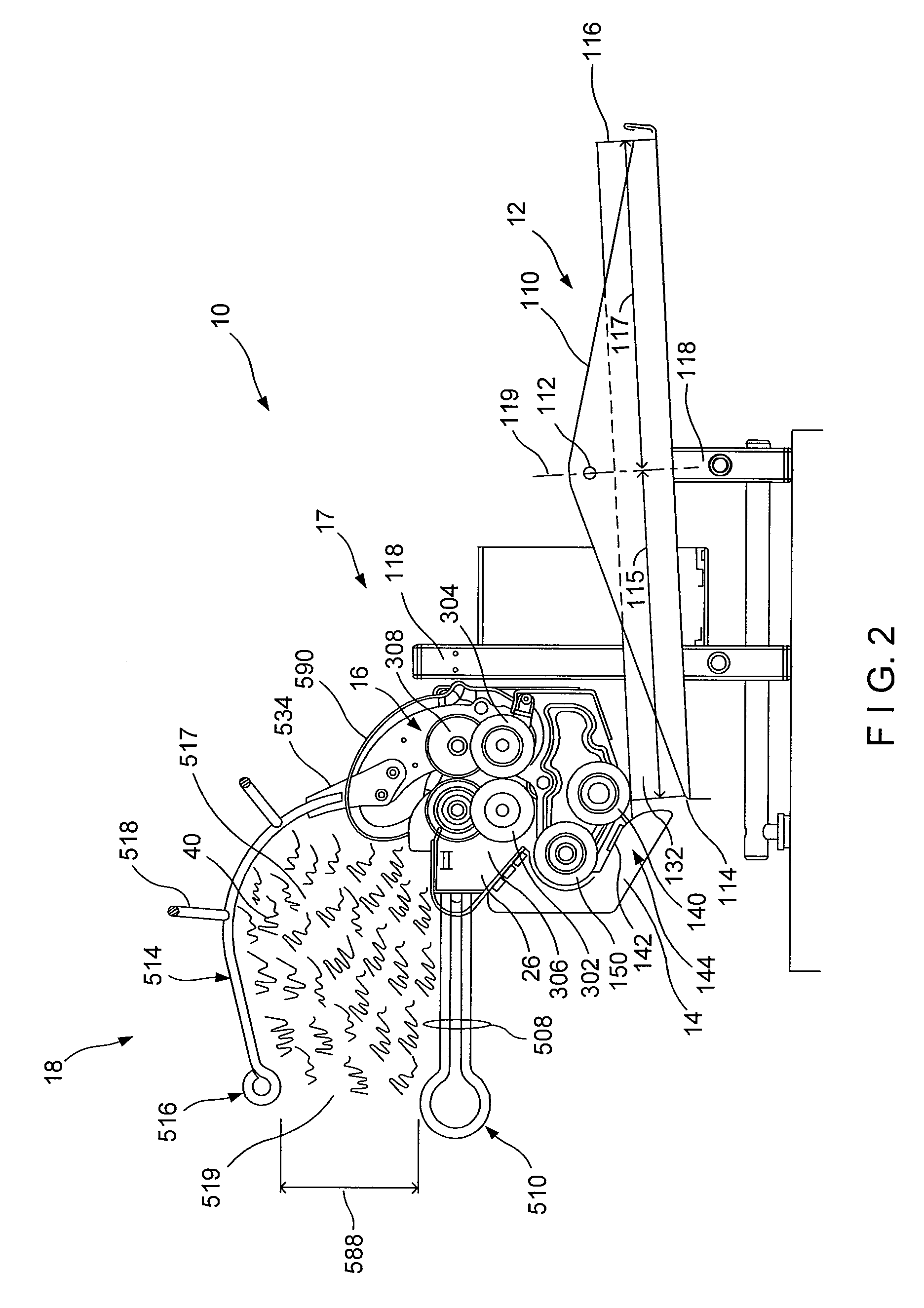

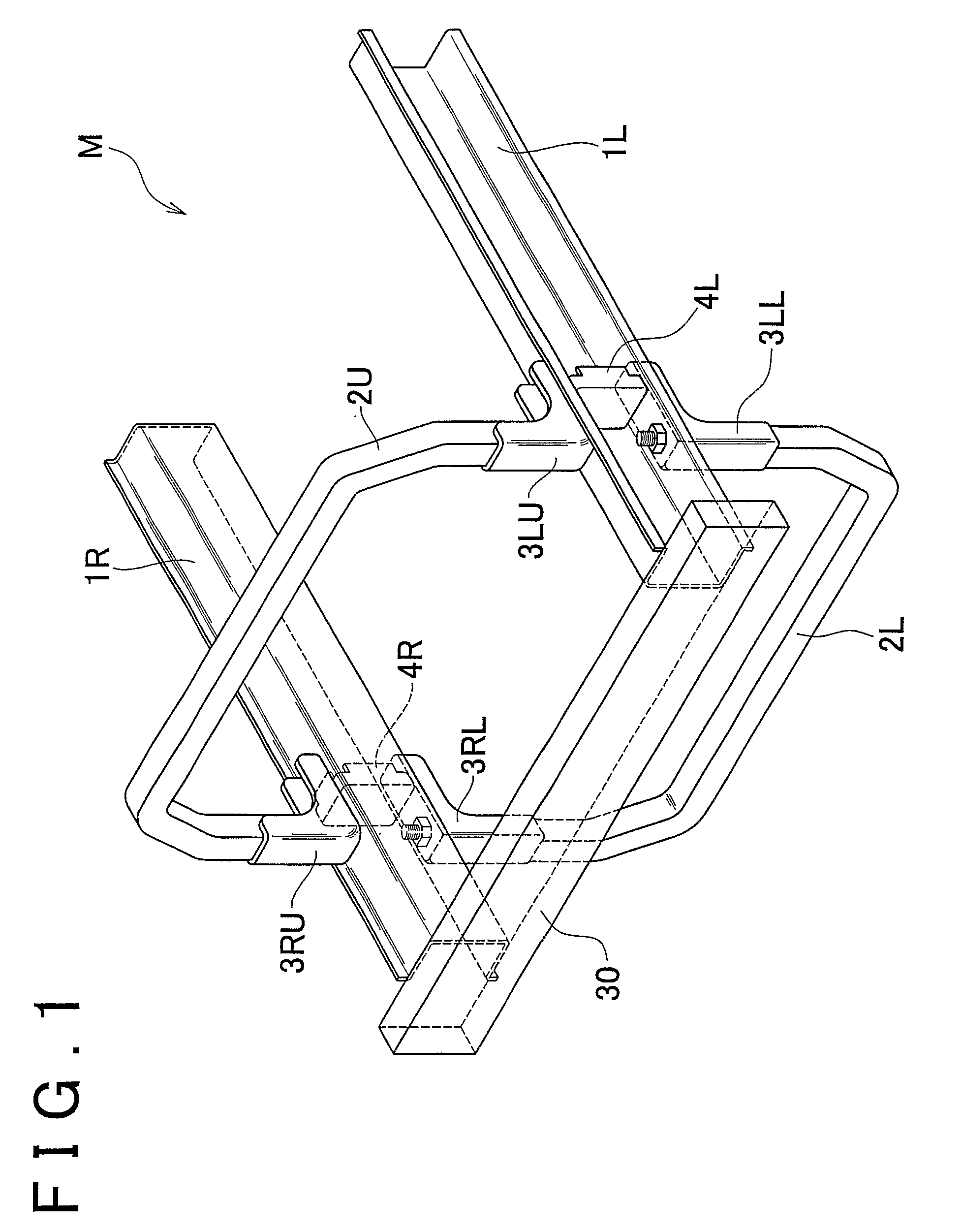

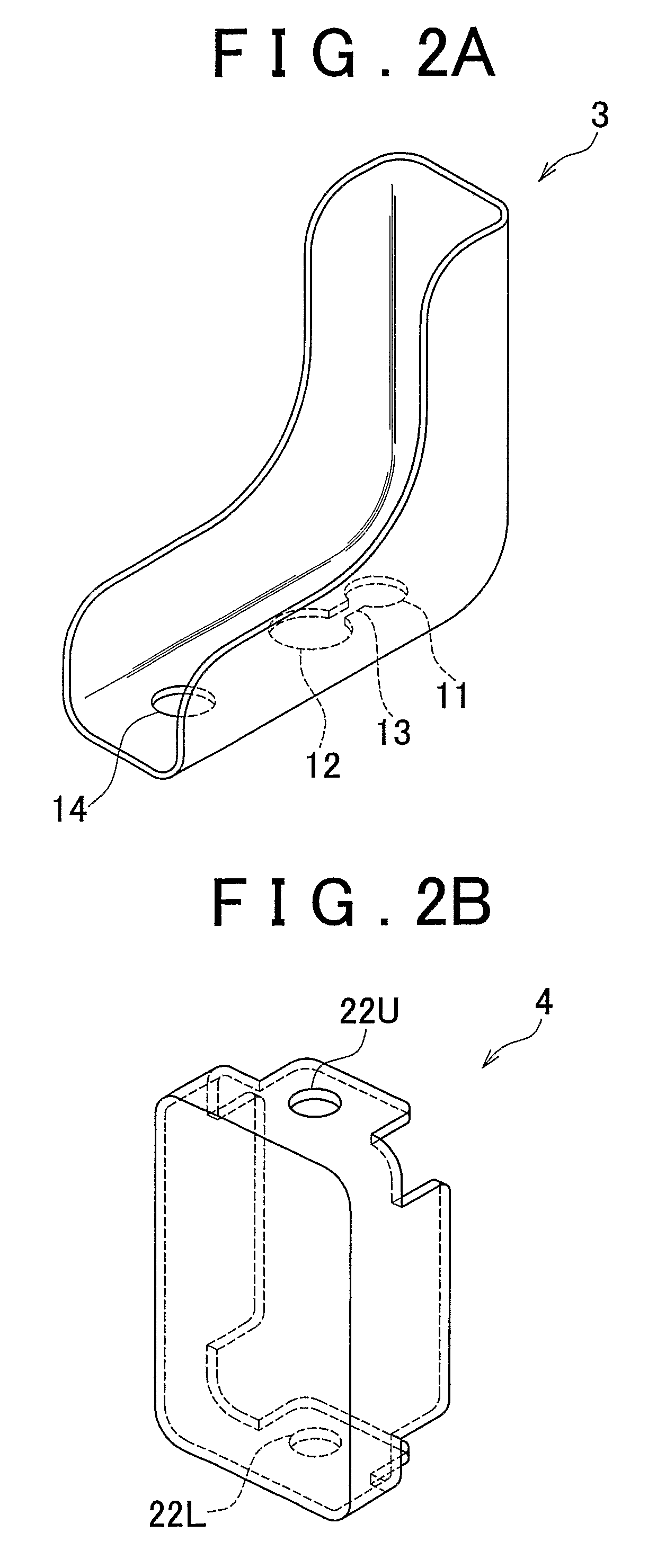

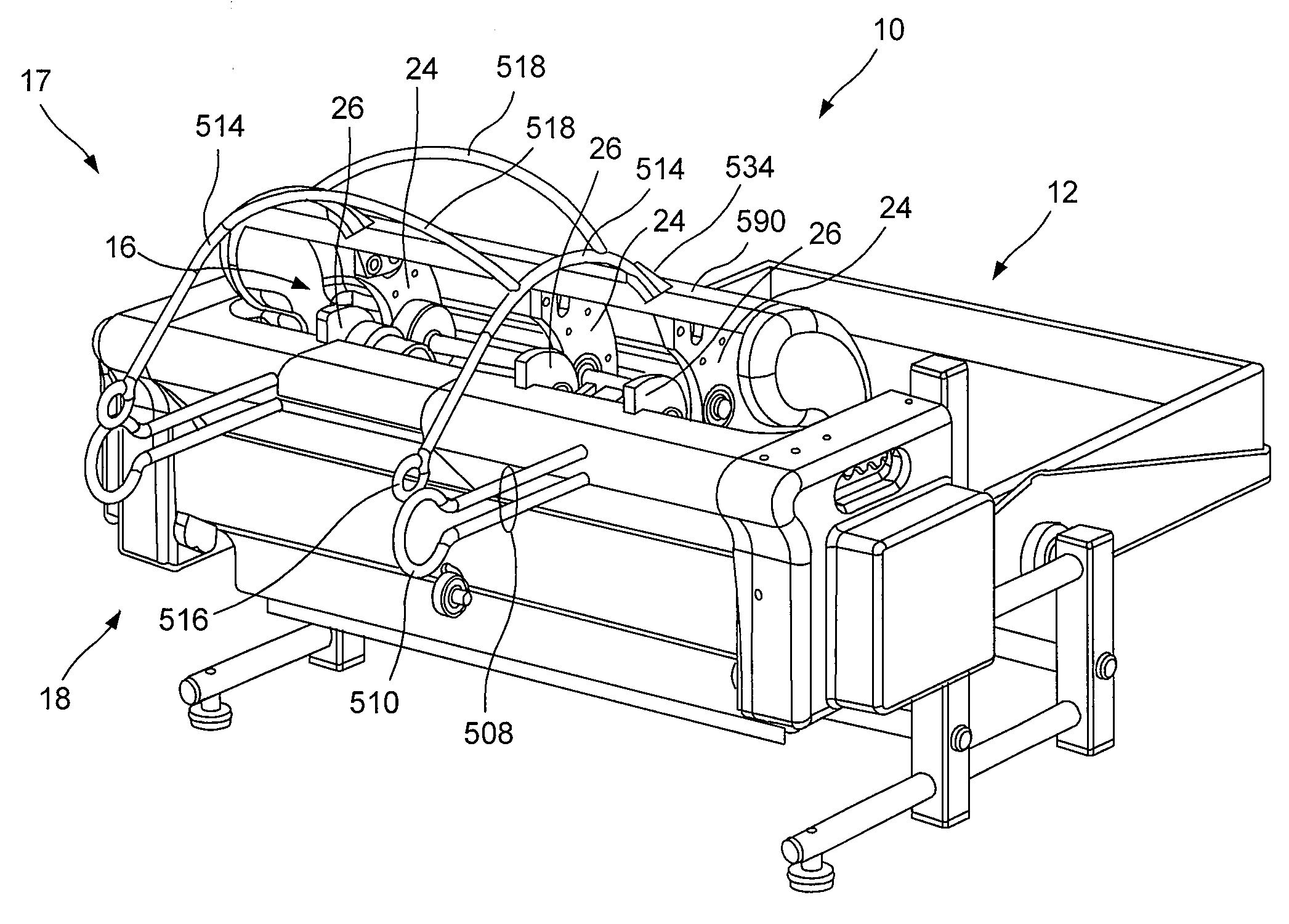

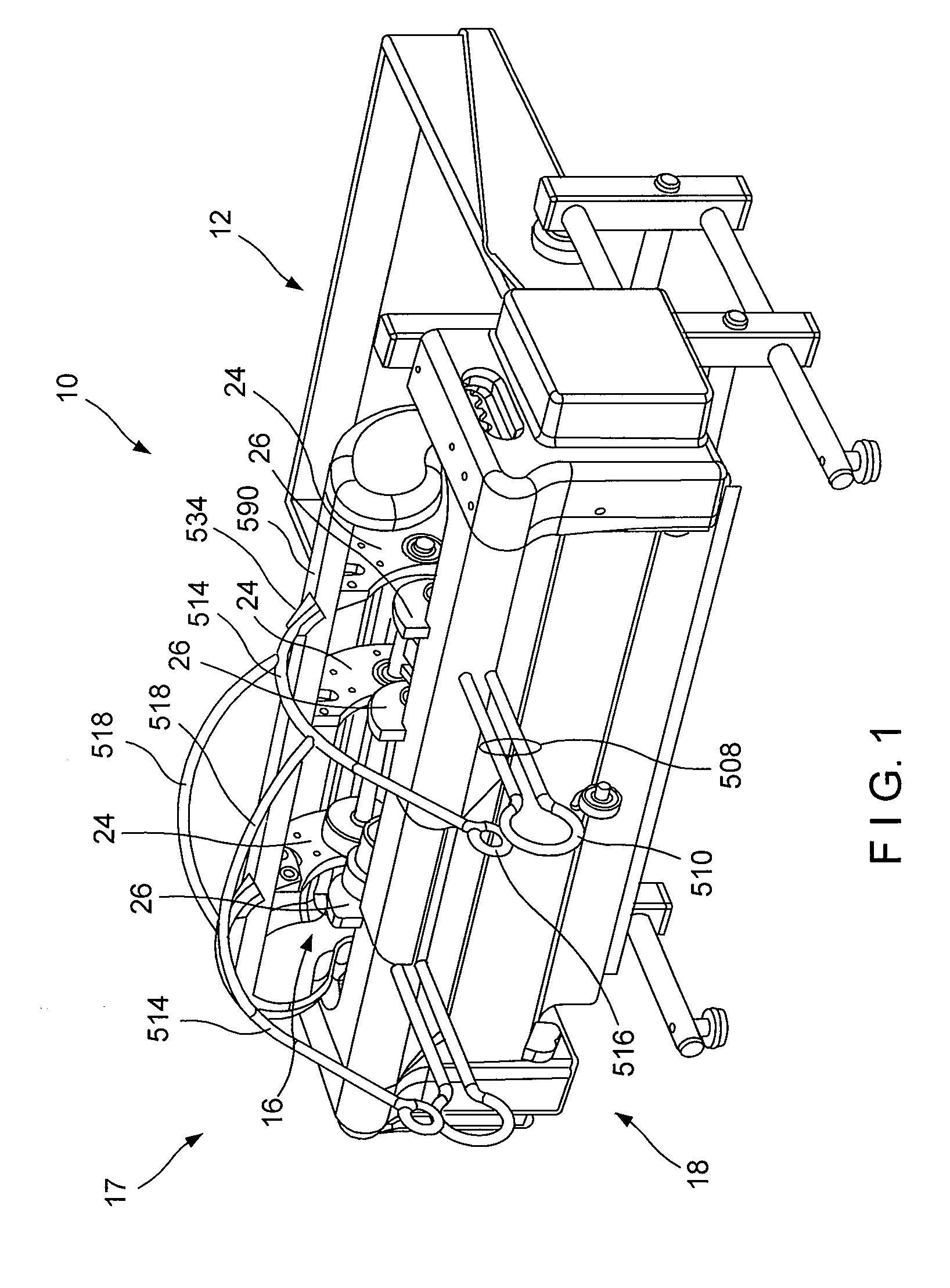

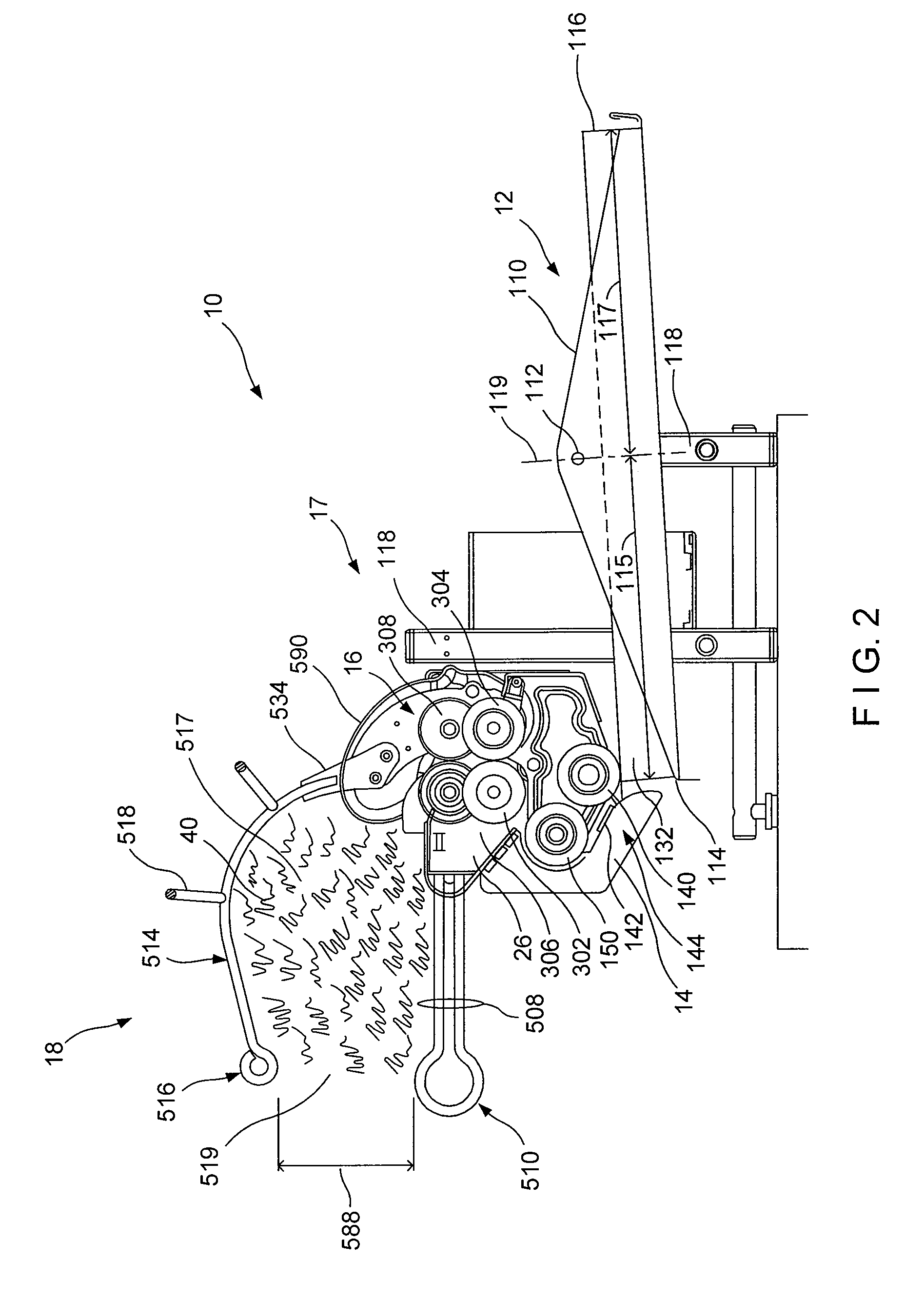

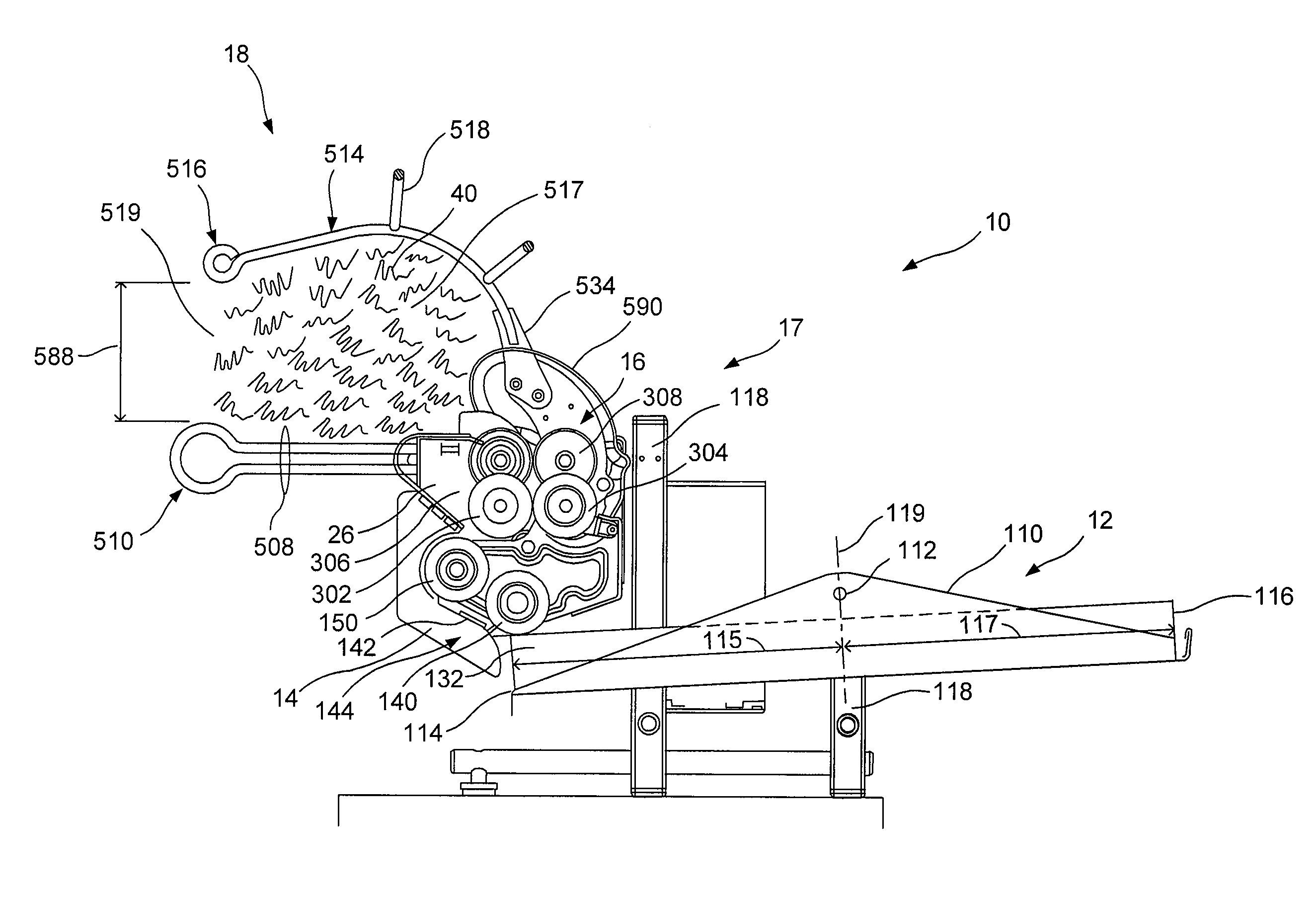

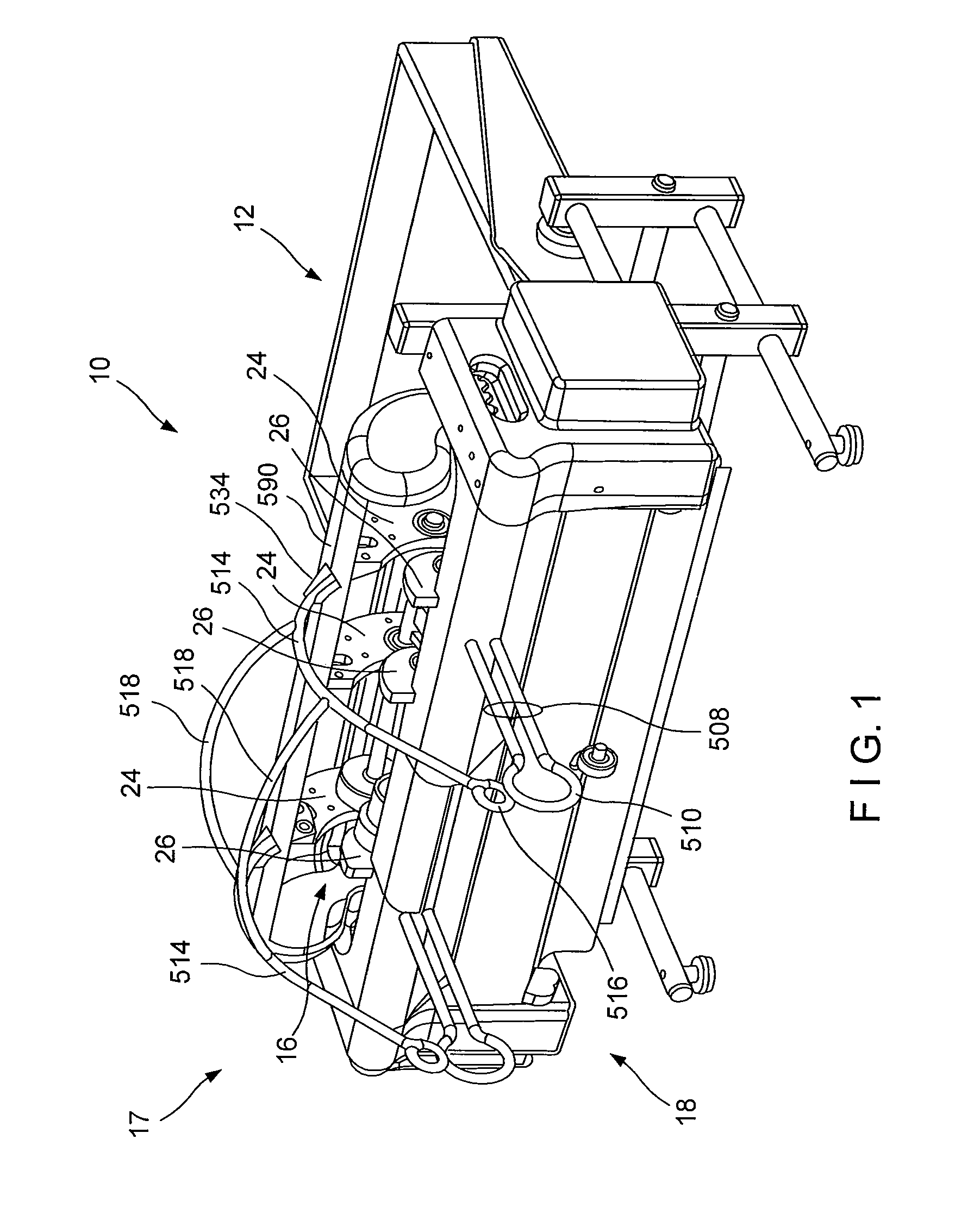

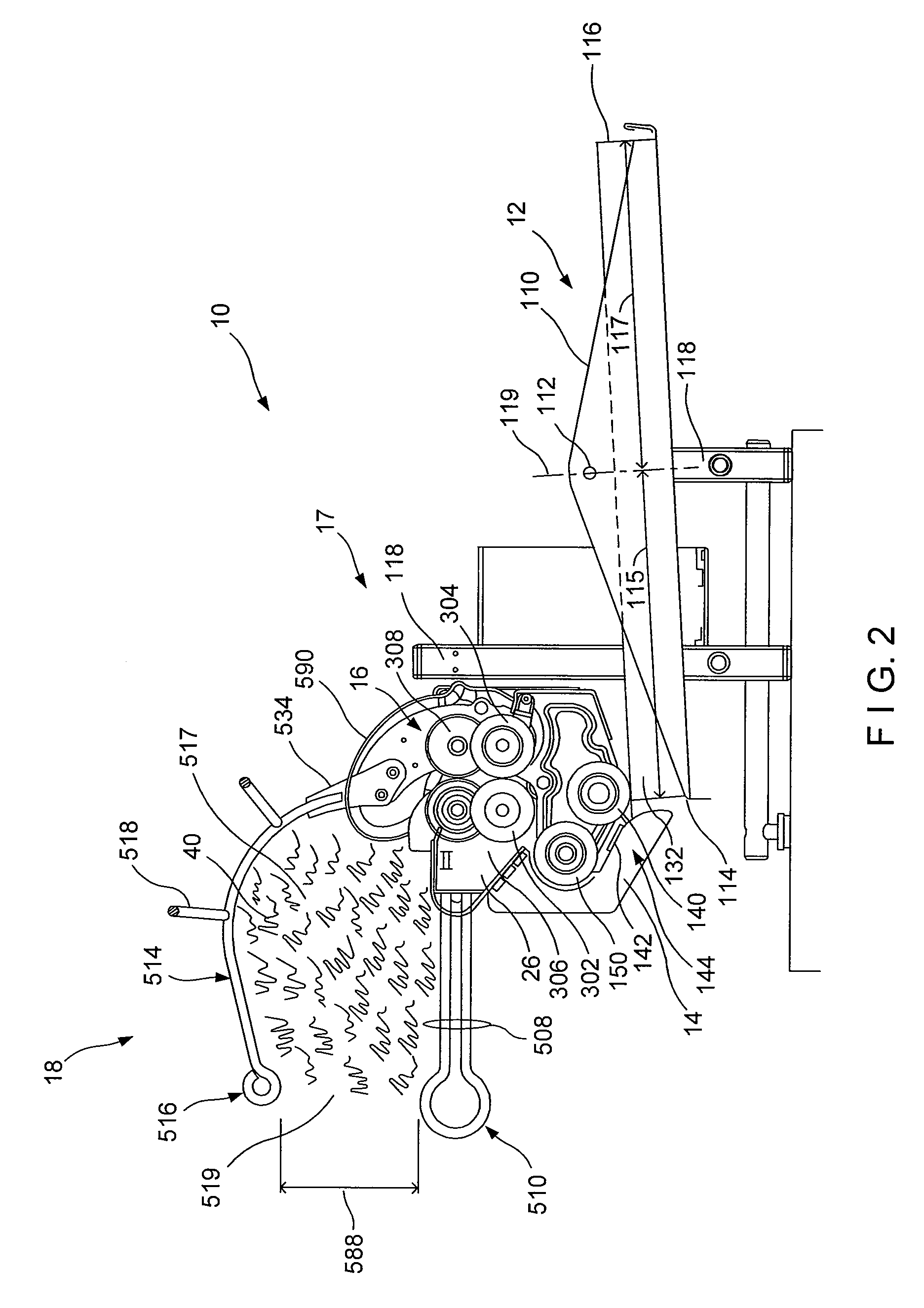

Crumpling mechanism for creating dunnage

A dunnage crumpling apparatus is provided having first and second entry-side crumpling members and first and second exit-side crumpling members. The first and second entry-side crumpling members define an entry therebetween. The first and second exit-side crumpling members define an exit therebetween that is disposed along the longitudinal path downstream of the entry. A crumpling zone being defined between the entry and exit. The first entry-side crumpling member is configured for moving at an first rate and is associated with the second entry-side crumpling member for moving sheet material through the entry in a first direction along a longitudinal path at an entry rate. The first exit-side crumpling member is configured for moving at an second rate and is associated with the second exit-side crumpling member for moving the sheet material through the exit in the first direction along the path at a exit rate that is slower than the entry rate to crumple the sheet material for producing dunnage. The entry and exit-side crumpling members are displaced laterally along the path with respect to each other to cause shearing of the sheet within the crumpling zone.

Owner:PREGIS INNOVATIVE PACKAGING

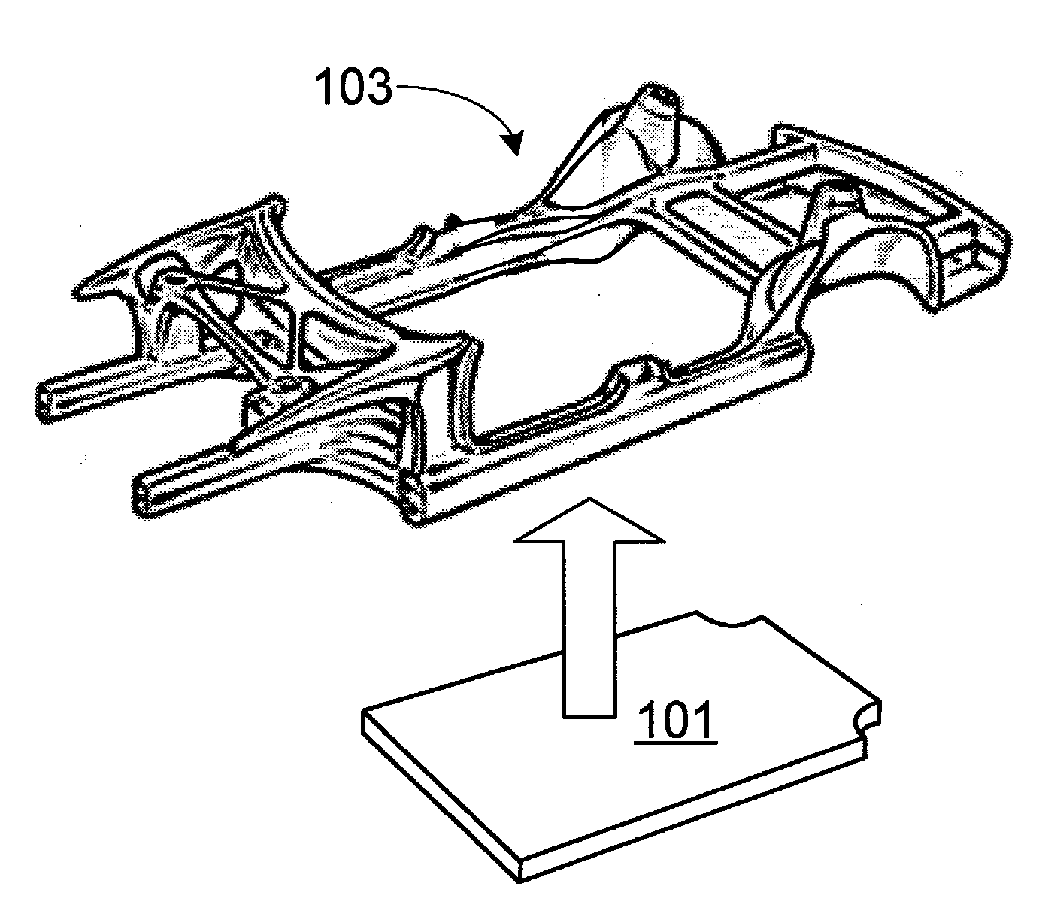

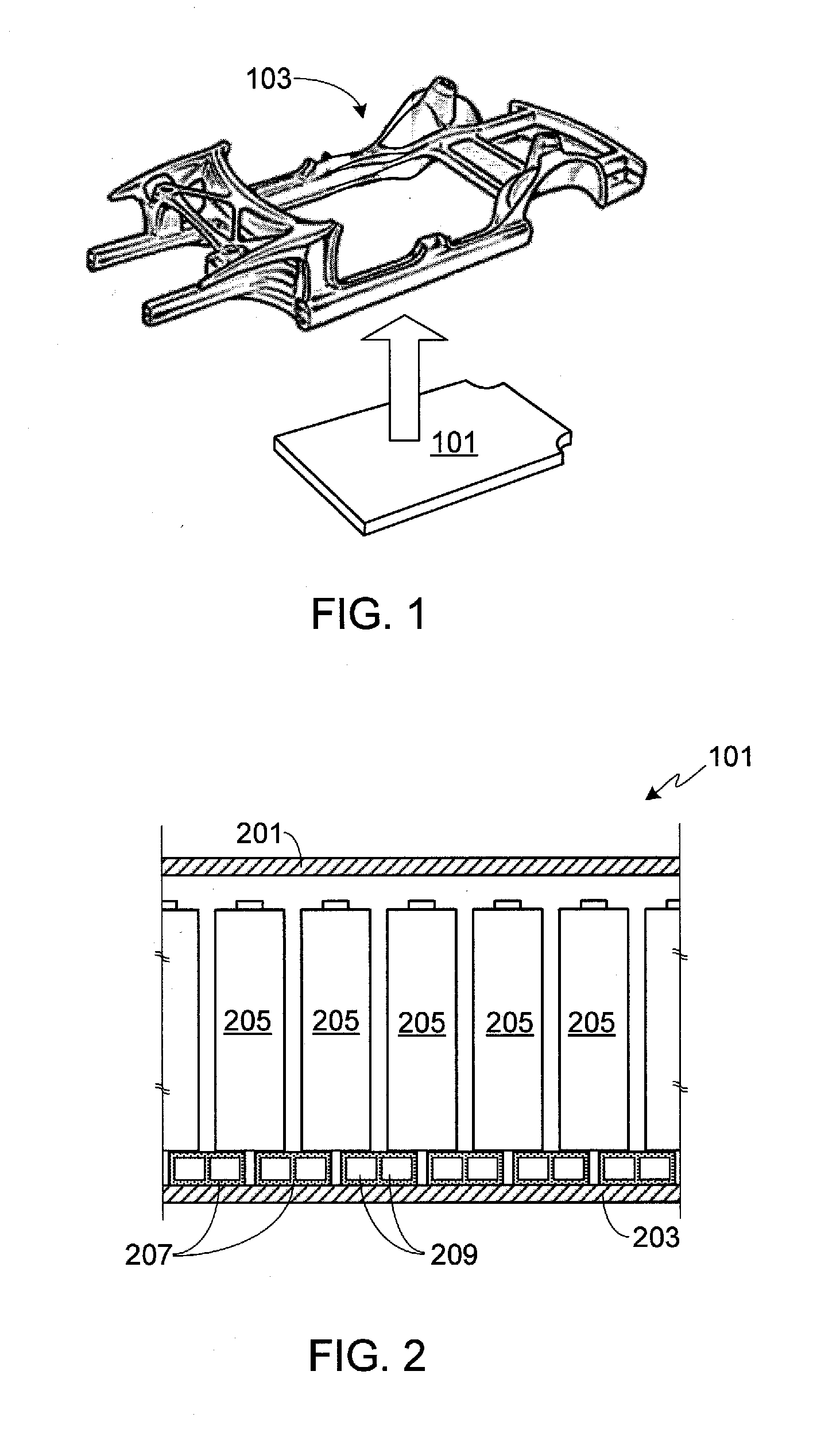

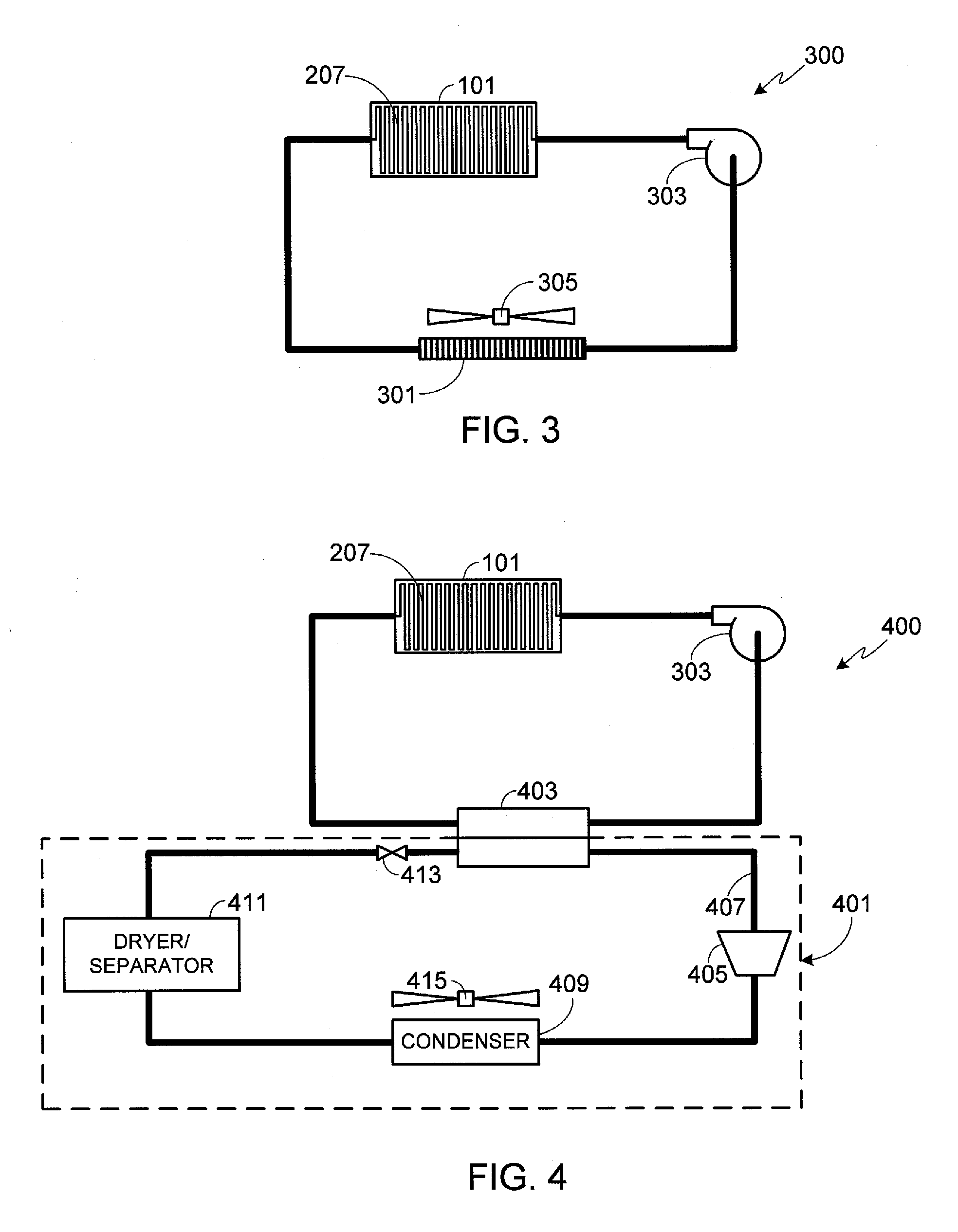

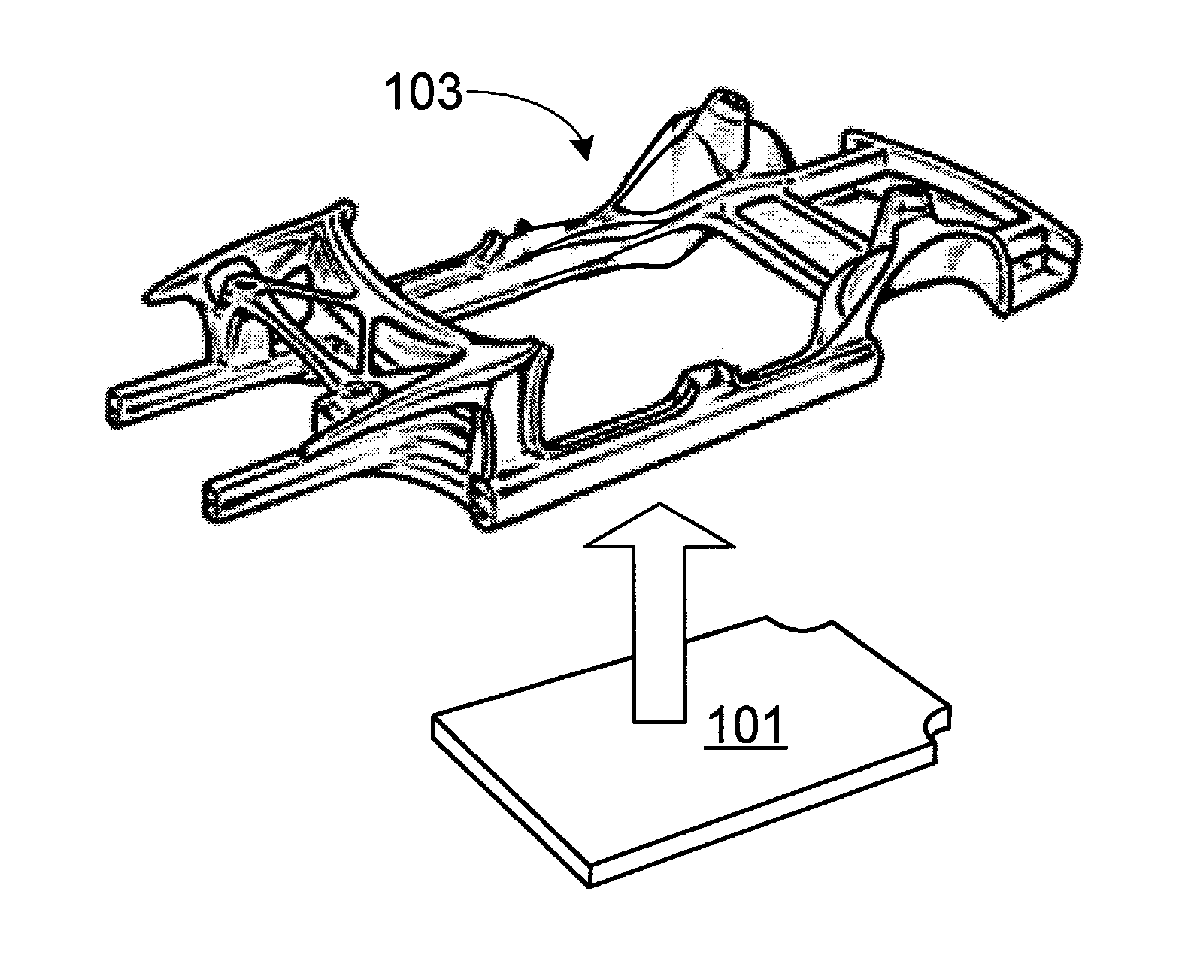

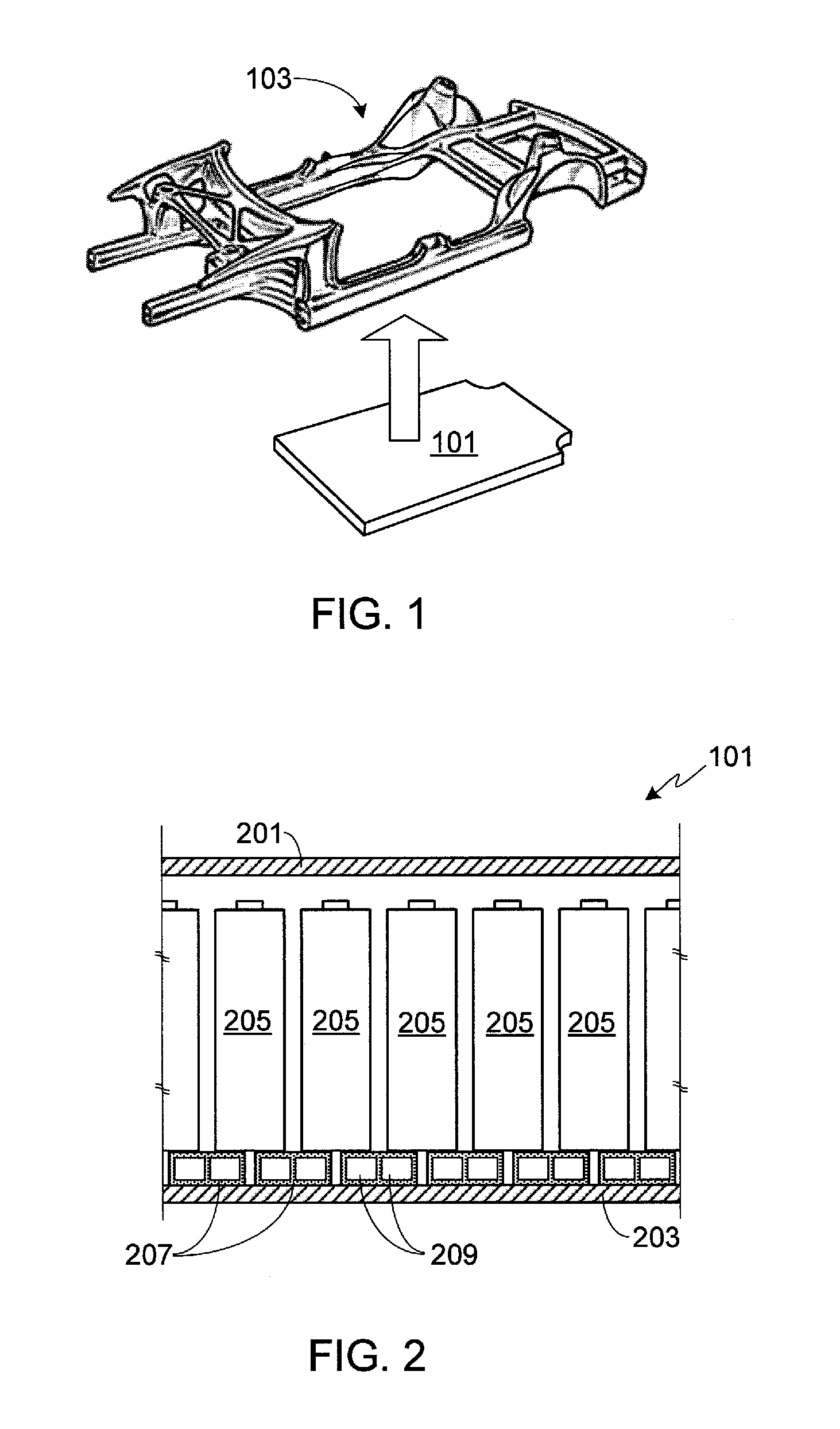

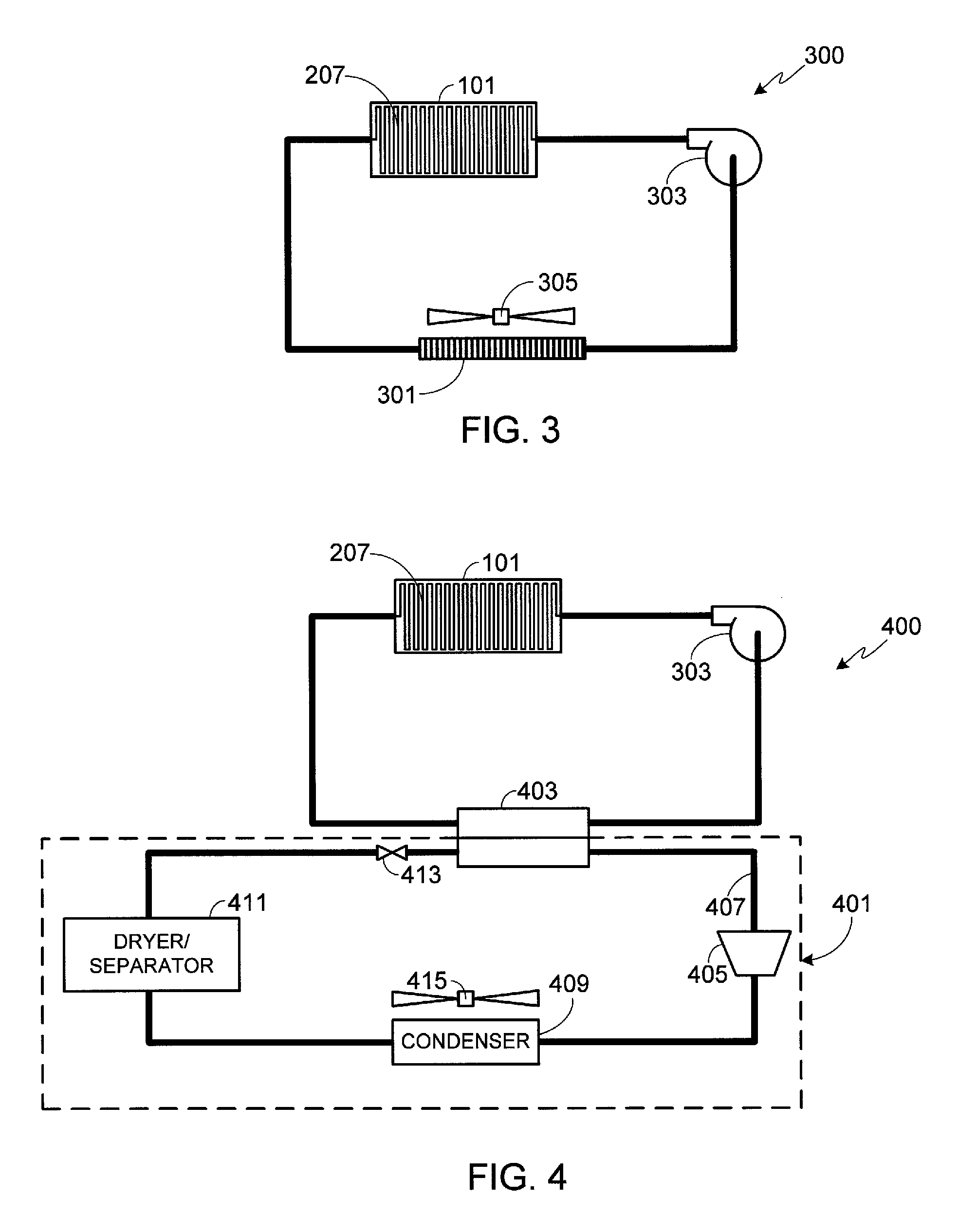

Electric Vehicle Undercarriage Crumple Zone

ActiveUS20150135939A1Improve protectionArmoured vehiclesElectric propulsion mountingCompressible materialRoad debris

A battery pack protection system is provided for use with an electric vehicle in which the battery pack is mounted under the car. The system utilizes a plurality of deformable cooling conduits located between the lower surface of the batteries within the battery pack and the lower battery pack enclosure panel. The cooling conduits are configured to deform and absorb impact energy when an object, such as road debris, strikes the lower surface of the lower battery pack enclosure panel. Further protection may be achieved by positioning a ballistic shield, alone or with a layer of compressible material, under the bottom surface of the battery pack.

Owner:ATIEVA USA INC

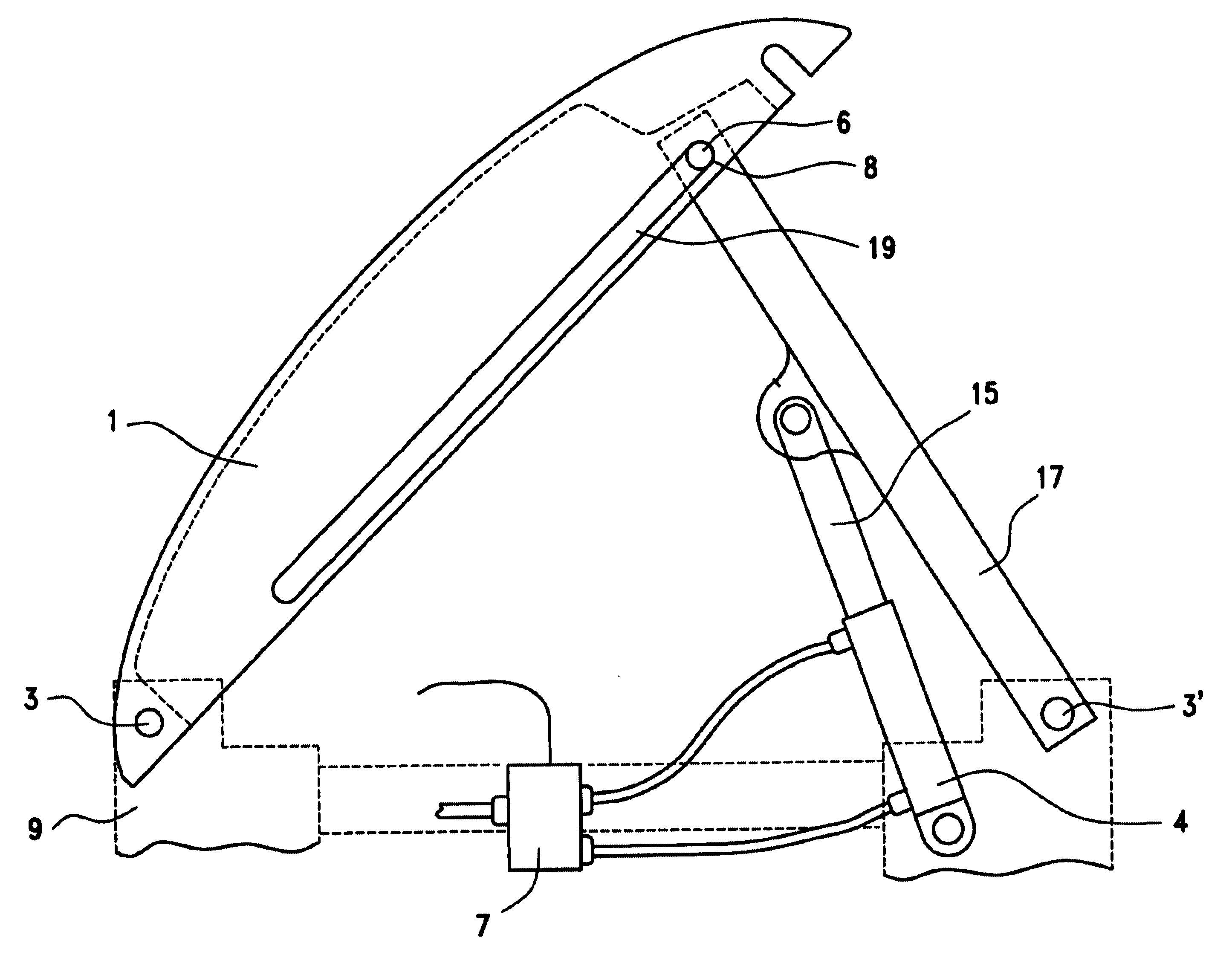

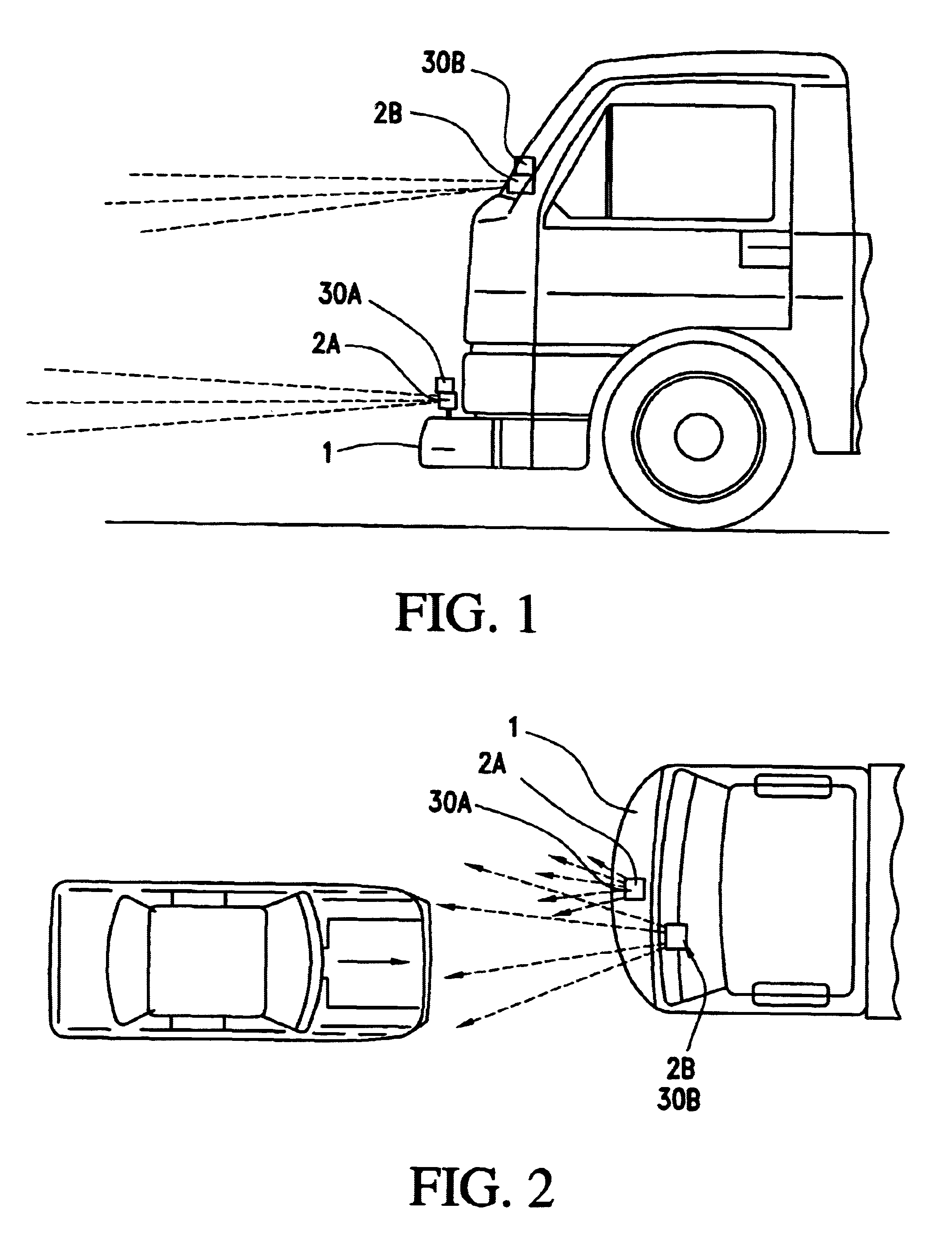

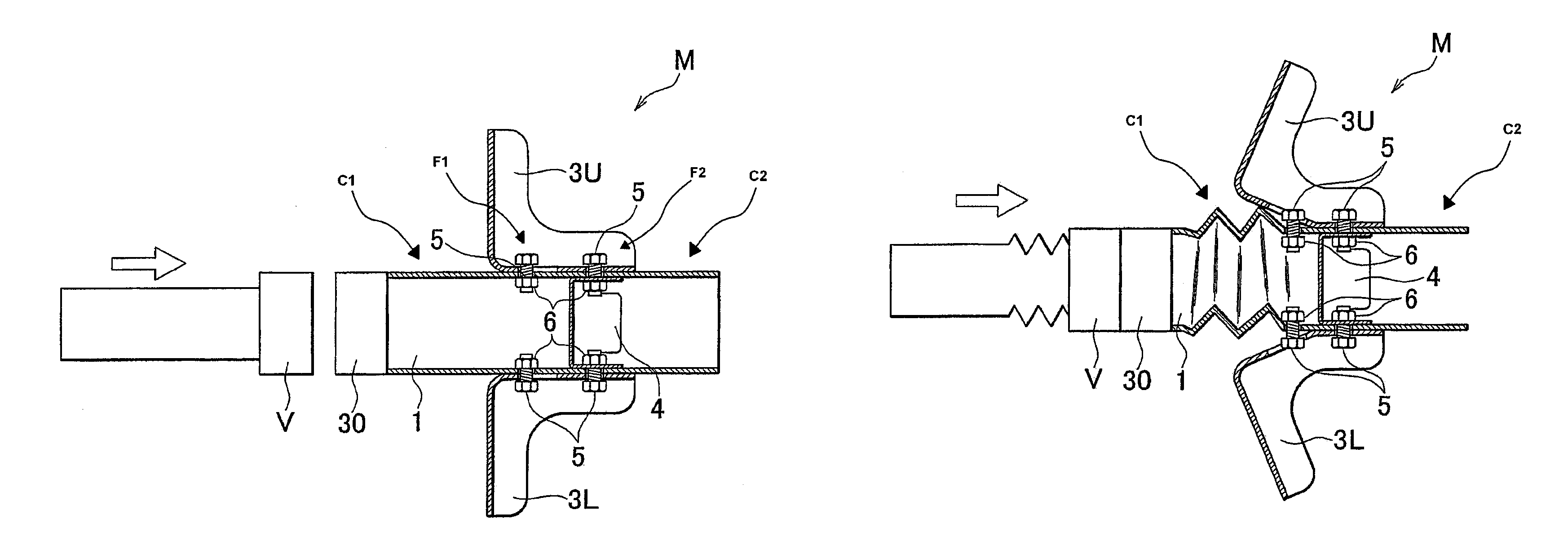

Collision safety device for vehicles

InactiveUS6623054B1Belt control systemsPedestrian/occupant safety arrangementMobile vehicleAutomatic braking

Device for motor vehicles designed to prevent traffic accidents or to reduce their injurious consequences. The extent of injuries in traffic accidents can be reduced significantly by employing the vehicle bumper (1) as a crumple (deformation) zone. A sensor (2) is used to record this distance from and speed relative to an obstacle in the direction of travel. When a collision is unavoidable, one end of the bumper (1) is projected outward by a propellant charge (13) so that, together with a strut (17, 22, 24), if forms a crumple zone ahead of the vehicle. The device can also be provided with a system to warn of dangerous traffic situations, and to brake the vehicle automatically or reduce its speed if the risk of a collision exists. In the case of trucks and buses, the bumper (1) may be deployed by means of a pneumatic cylinder (4) and valve (7), which are controlled by the vehicle's ordinary speedometer. The bumper remains depolyed above a certain threshold speed.

Owner:PALMQUIST EVERT

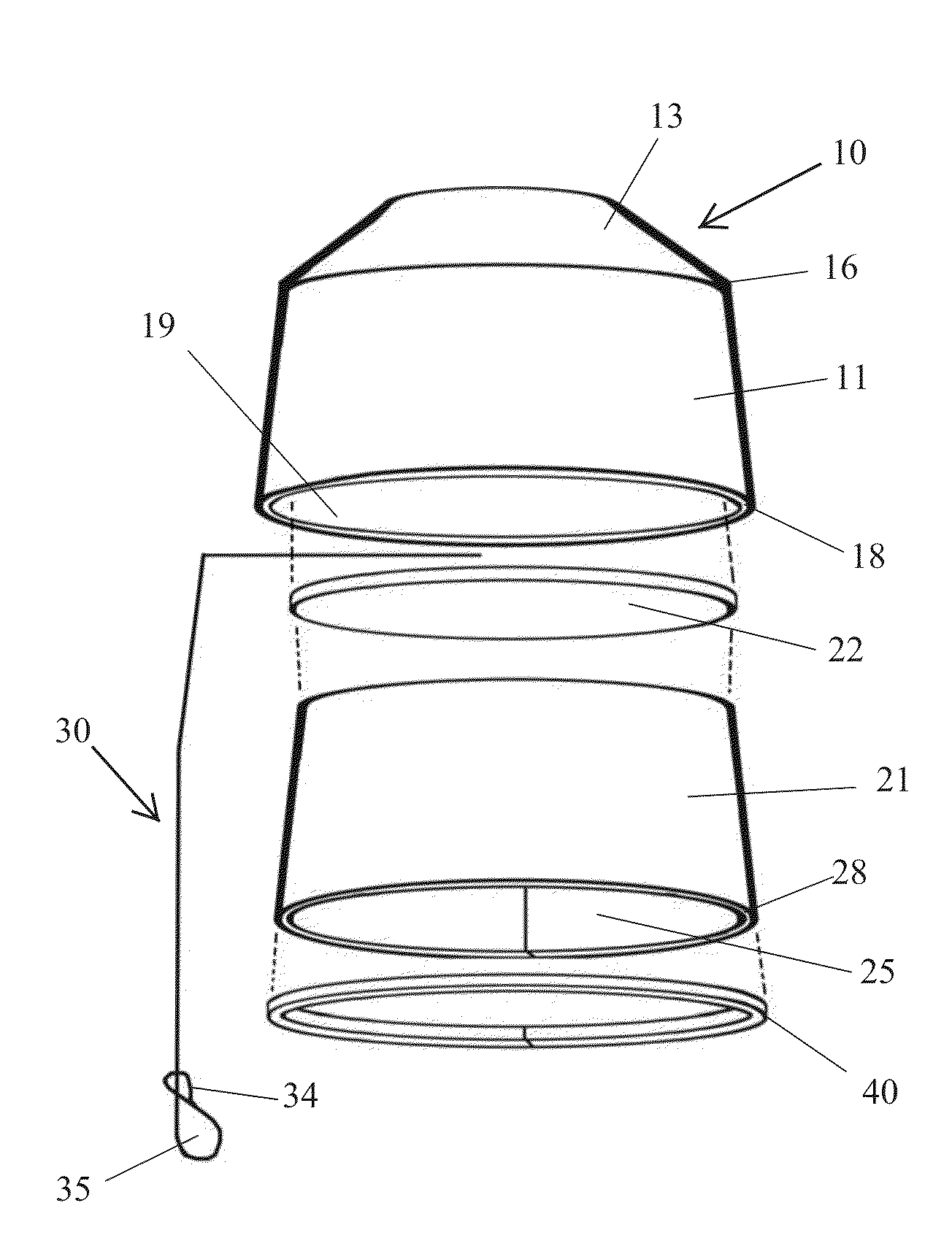

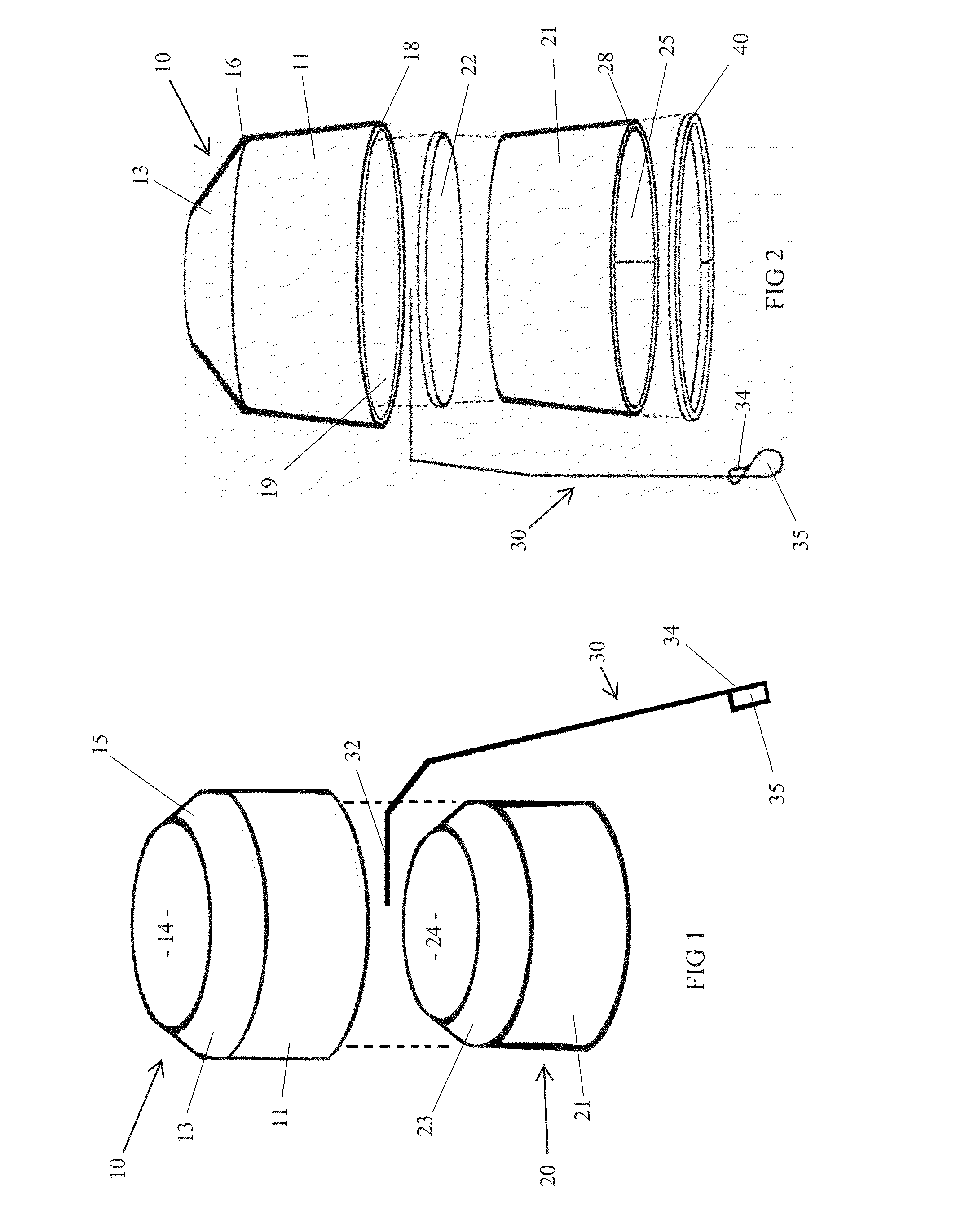

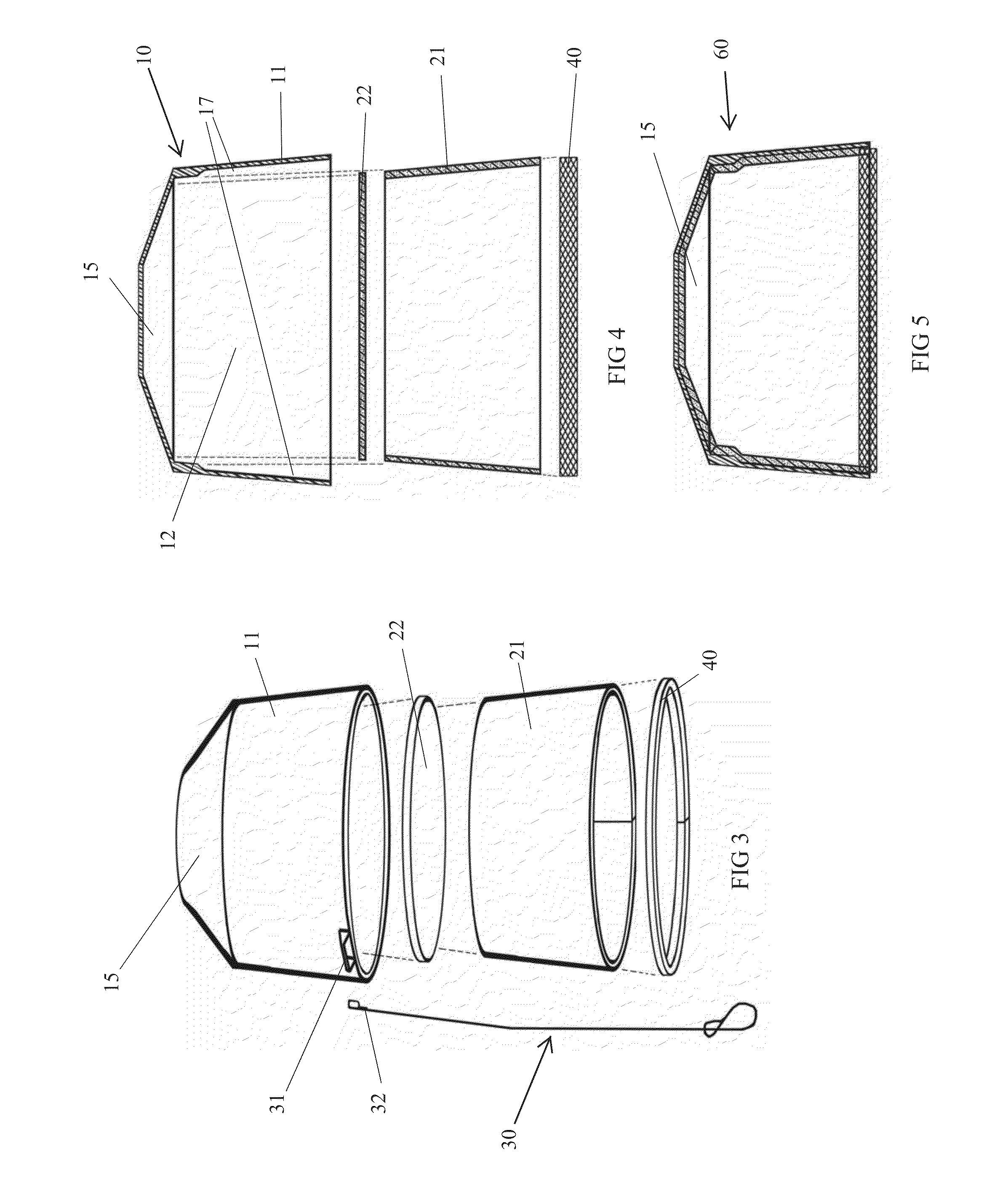

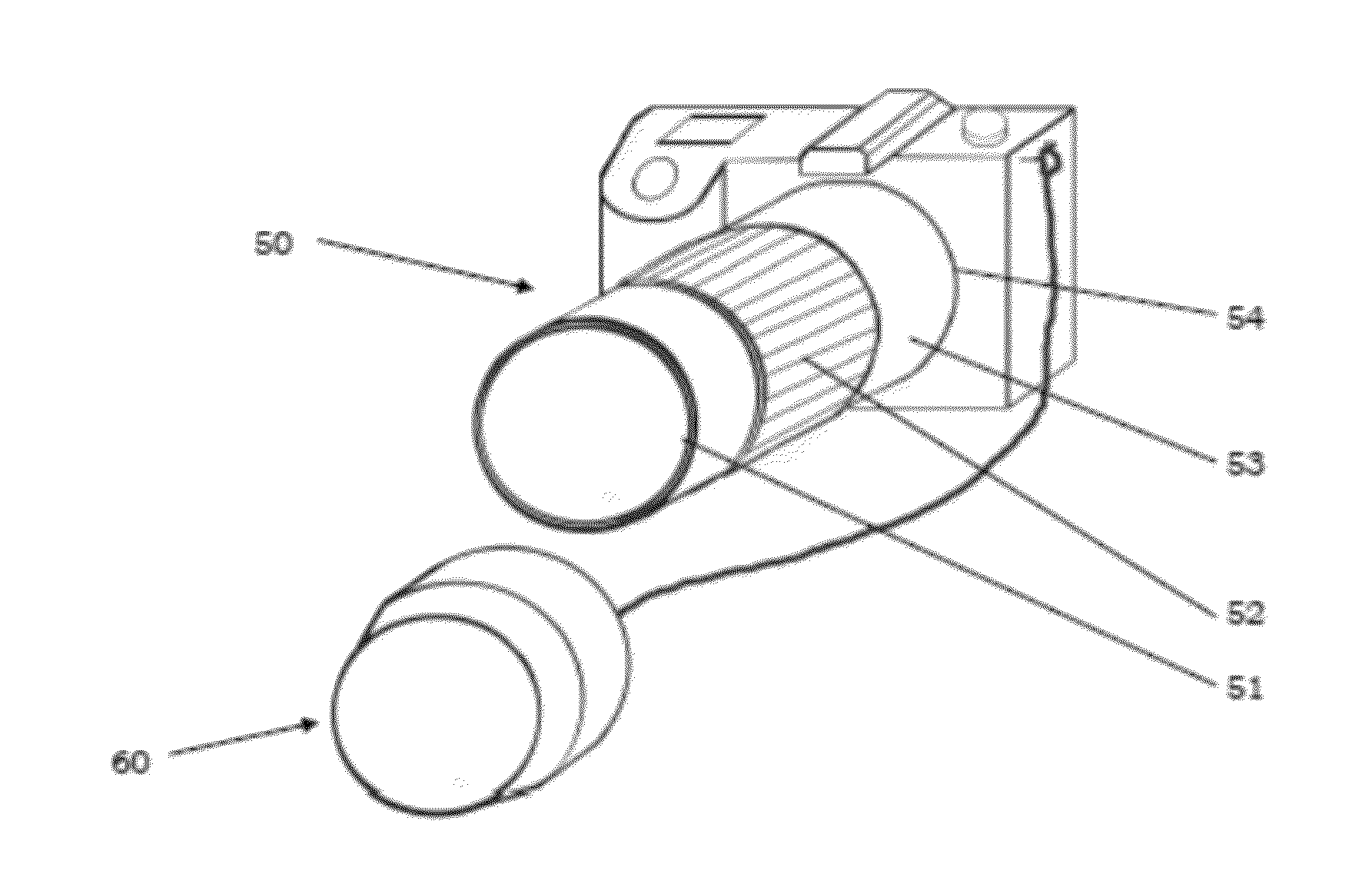

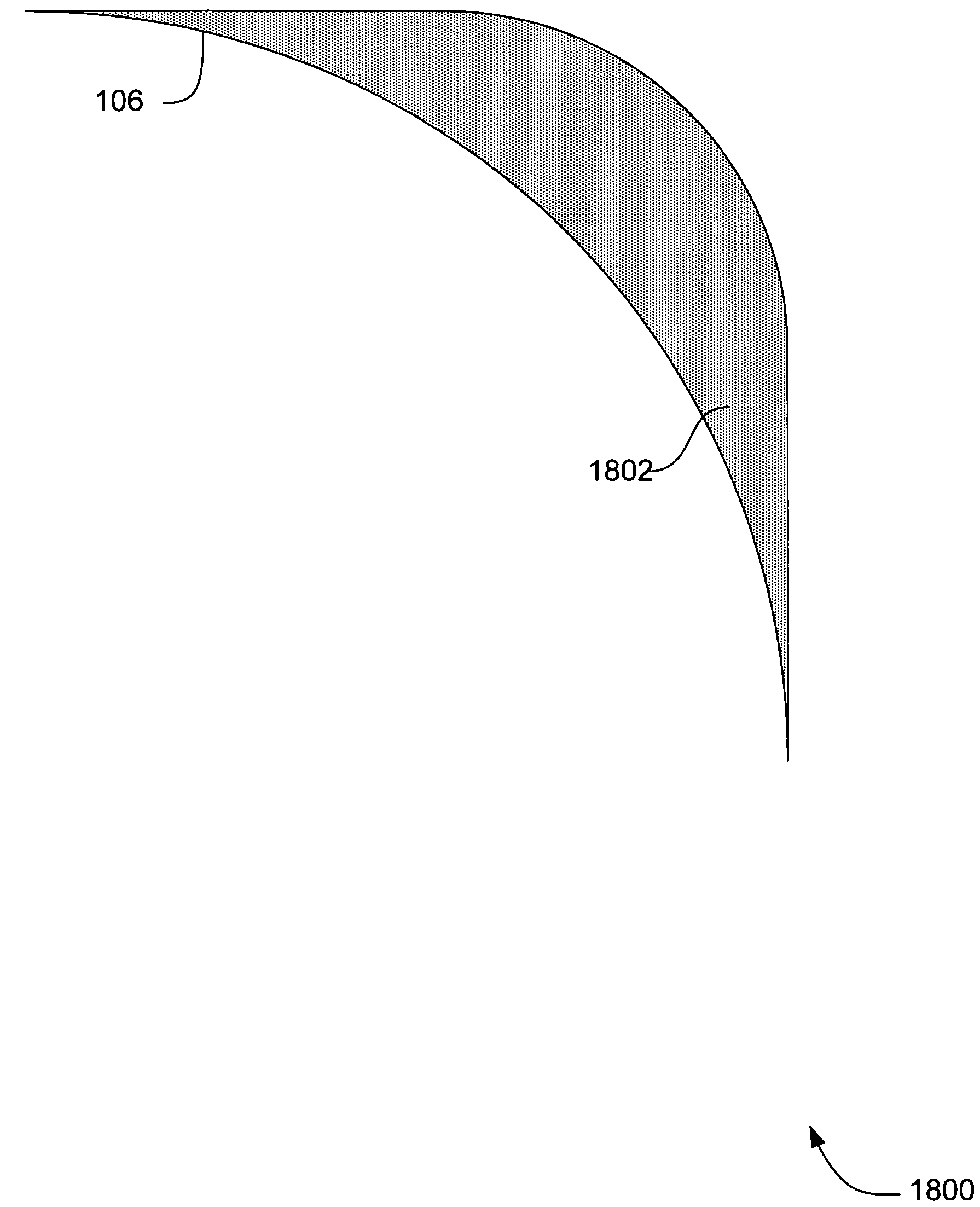

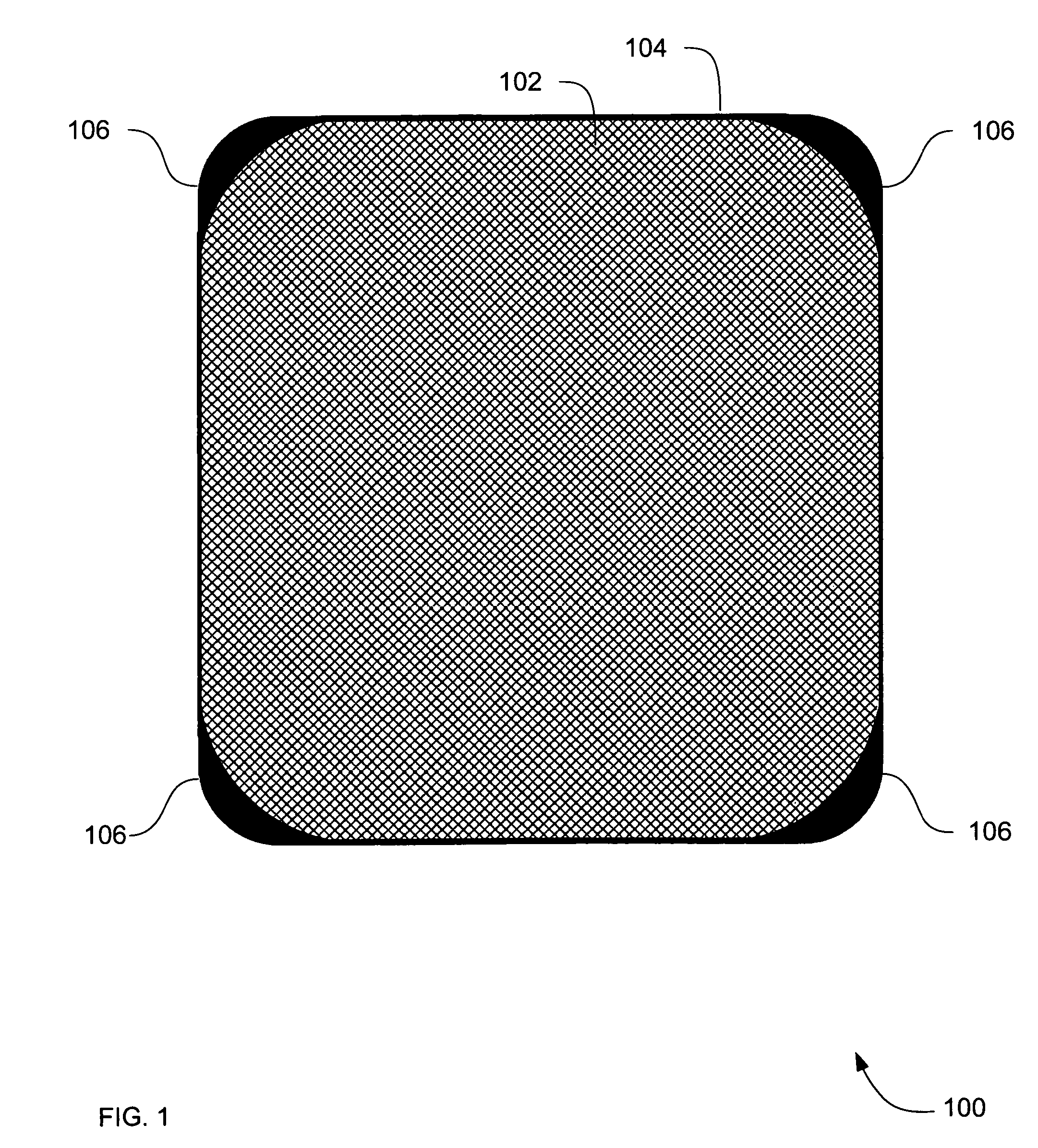

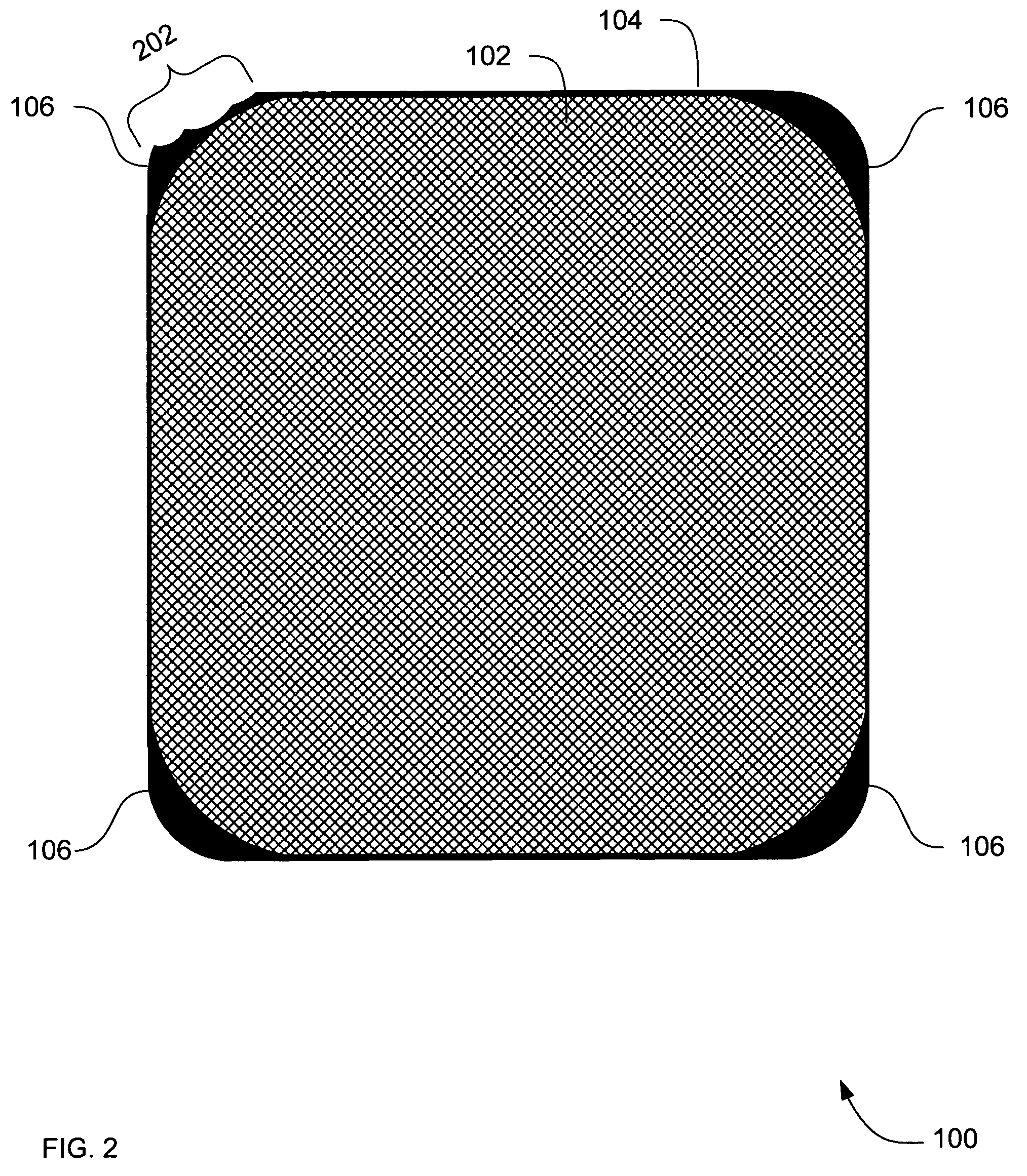

Protective Lens Cover

InactiveUS20130129338A1Prevent slippageAvoid separationCamera filtersTelescopesCamera lensConical forms

A padded protective frusto-conical shaped cup covering sized to slip over a camera lens is disclosed. The covering is designed to fit on either the front portion of the lens or the rear lens mount. The protective covering has beveled side walls which allow it to fit easily on a variety of different lenses. The protective covering is made from two separate layers of material, an outer cup made from a firm yet flexible material, and the inner liner made from a soft pliable material. In one embodiment the outer cup includes a circumferential retaining ring on the inside of the cup to help secure the cup onto a lens. The soft inner liner allows the covering to easily adhere to the camera lens, and also provides impact protection. The outer cup provides additional impact protection. The outer cup also includes a domed top portion which provides a crumple zone or impact bumper. In one embodiment the outer cup has an opening in the domed top, and in one embodiment thereof there is a clear optical grade lens or filer lens inserted or incorporated into the opening, which allows the camera user to take a photograph without removing the protective lens.

Owner:DOWELL MICHAEL

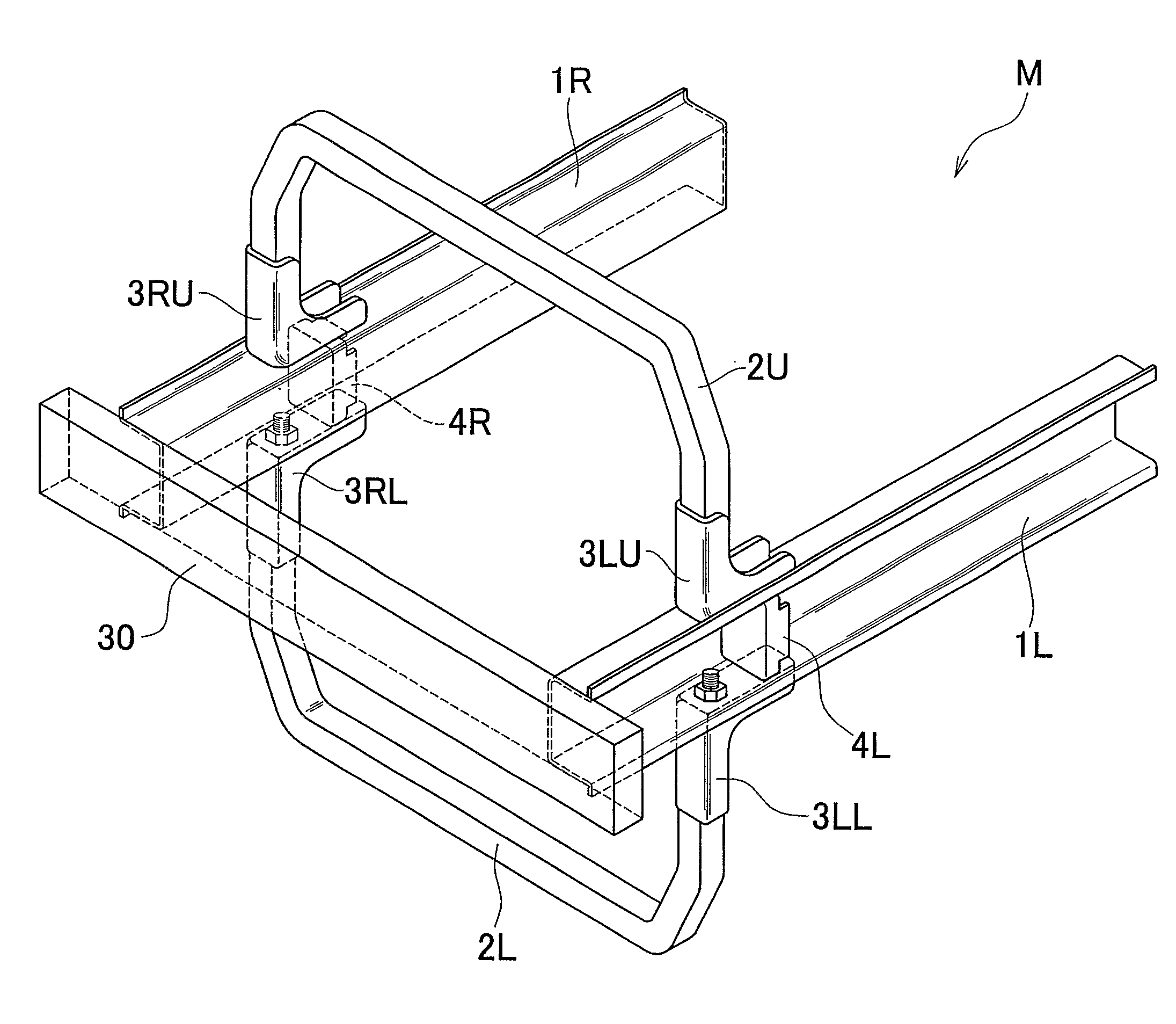

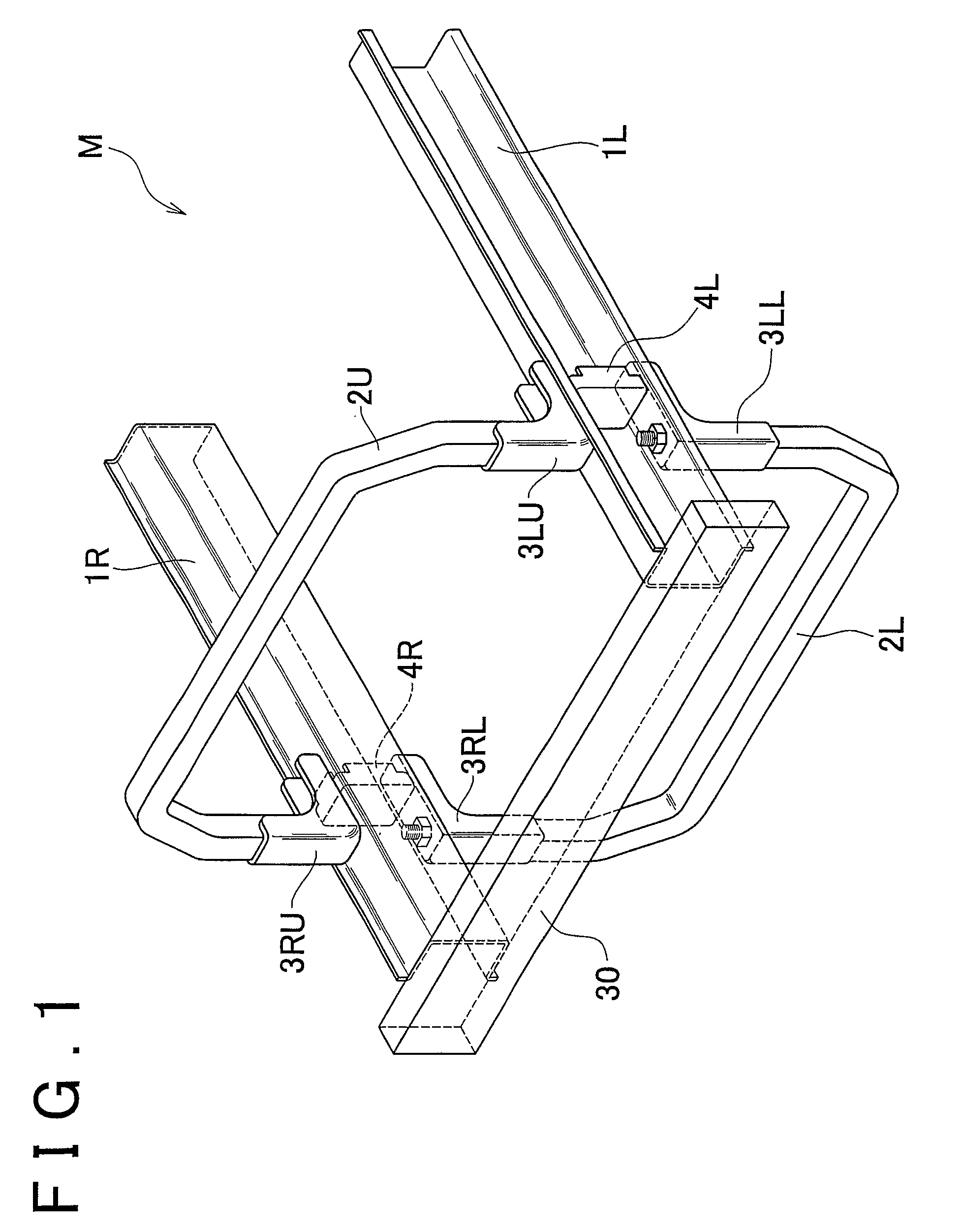

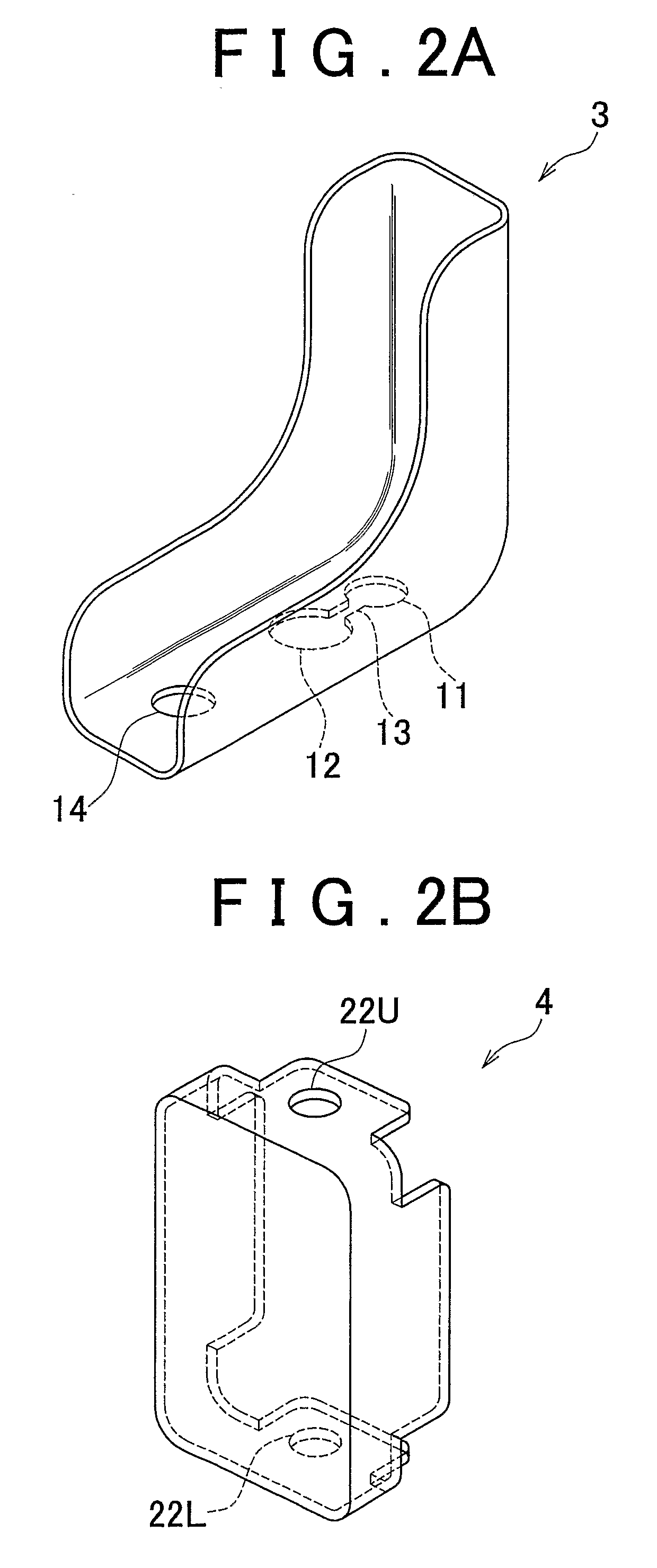

Vehicle end portion structure

InactiveUS7992926B2Guaranteed normal transmissionImprove impact absorption performanceVehicle seatsUnderstructuresCrumple zoneMechanical engineering

A front end portion of a side member functions as a crumple zone during a collision with another vehicle or the like. A radiator support is attached via a bracket to this crumple zone. When another vehicle or the like collides with the side member, the radiator support separates from the side member. When another vehicle or the like collides with the radiator support, external force applied in the rear direction to the radiator support is transmitted to the side member.

Owner:TOYOTA JIDOSHA KK

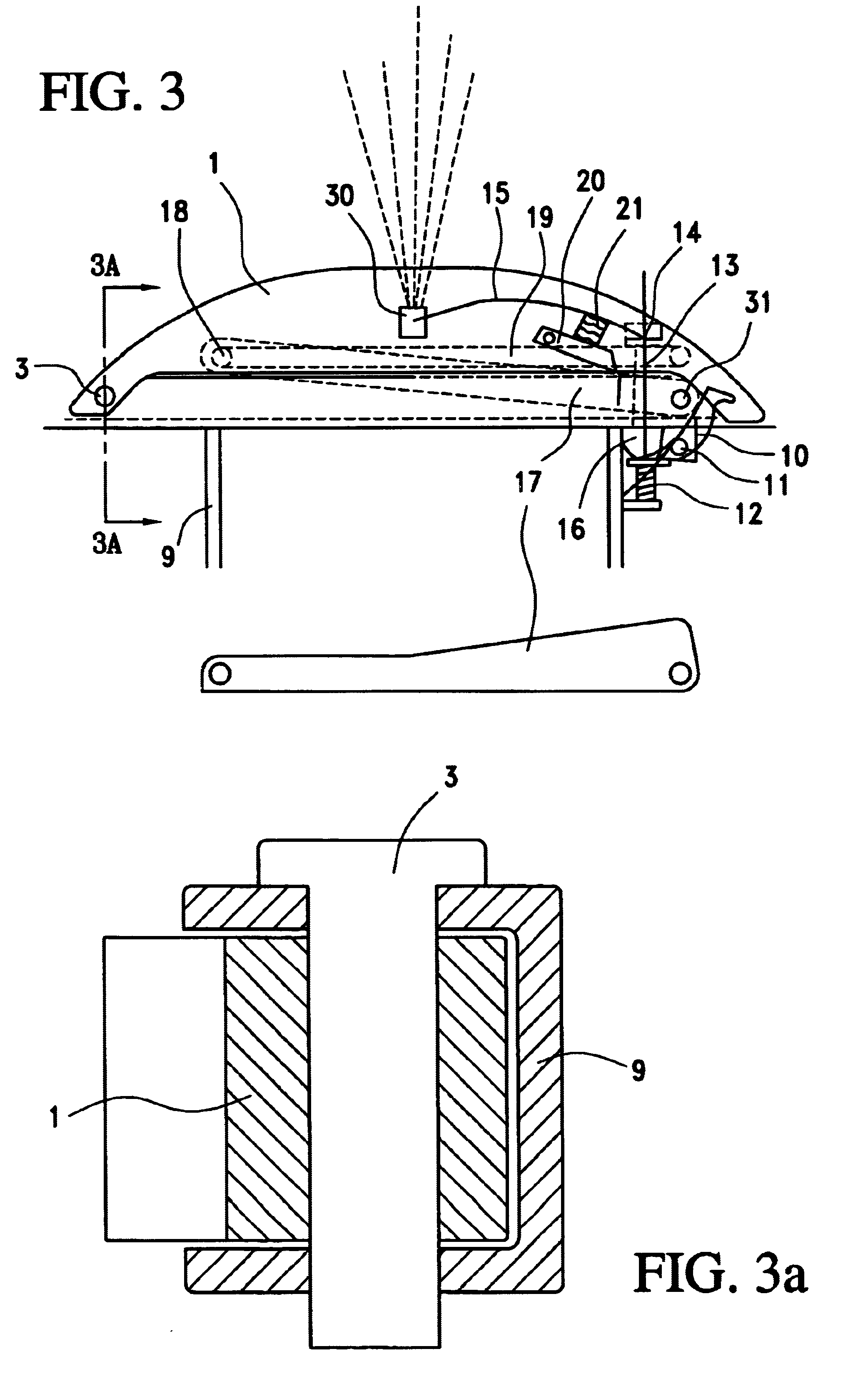

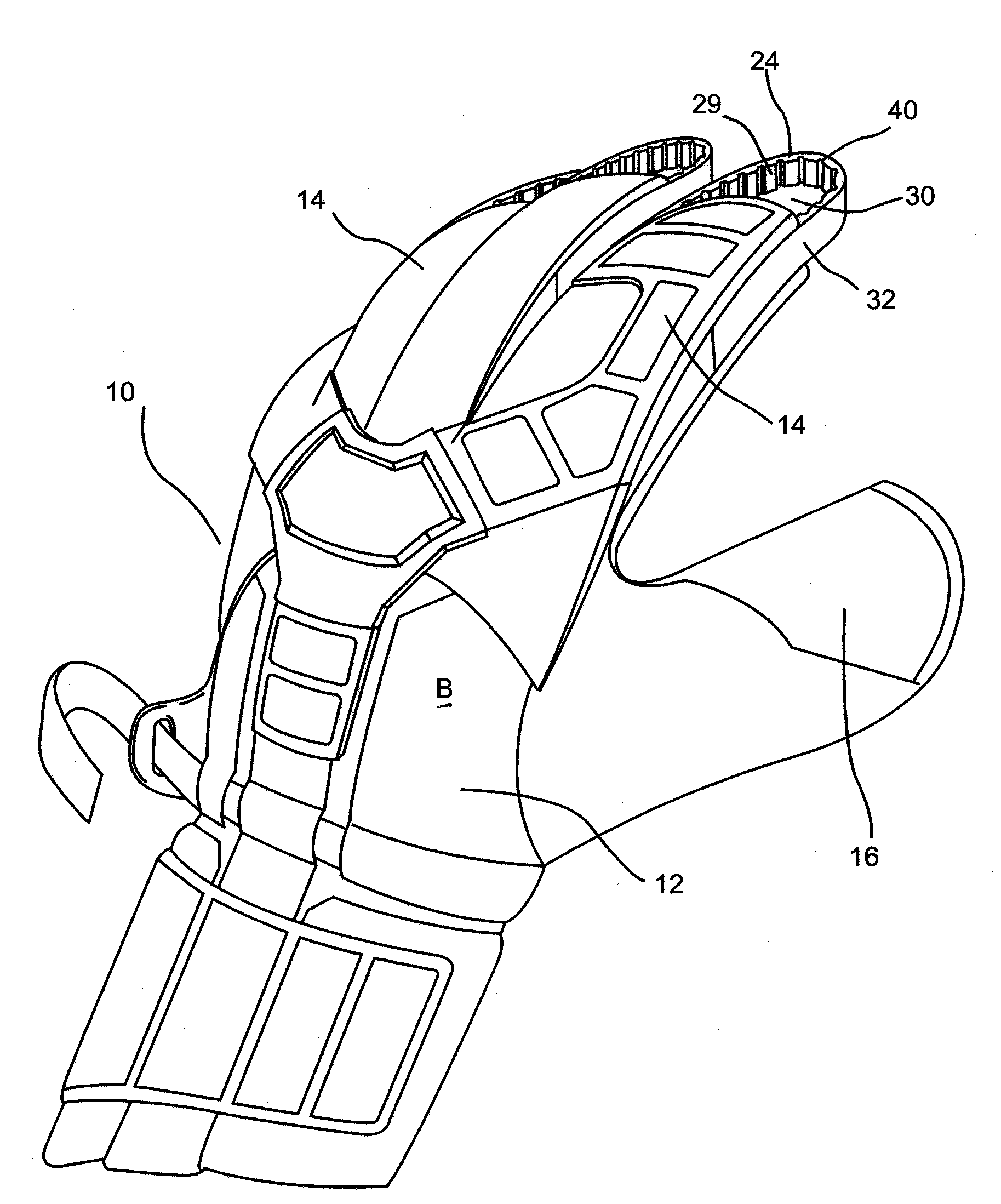

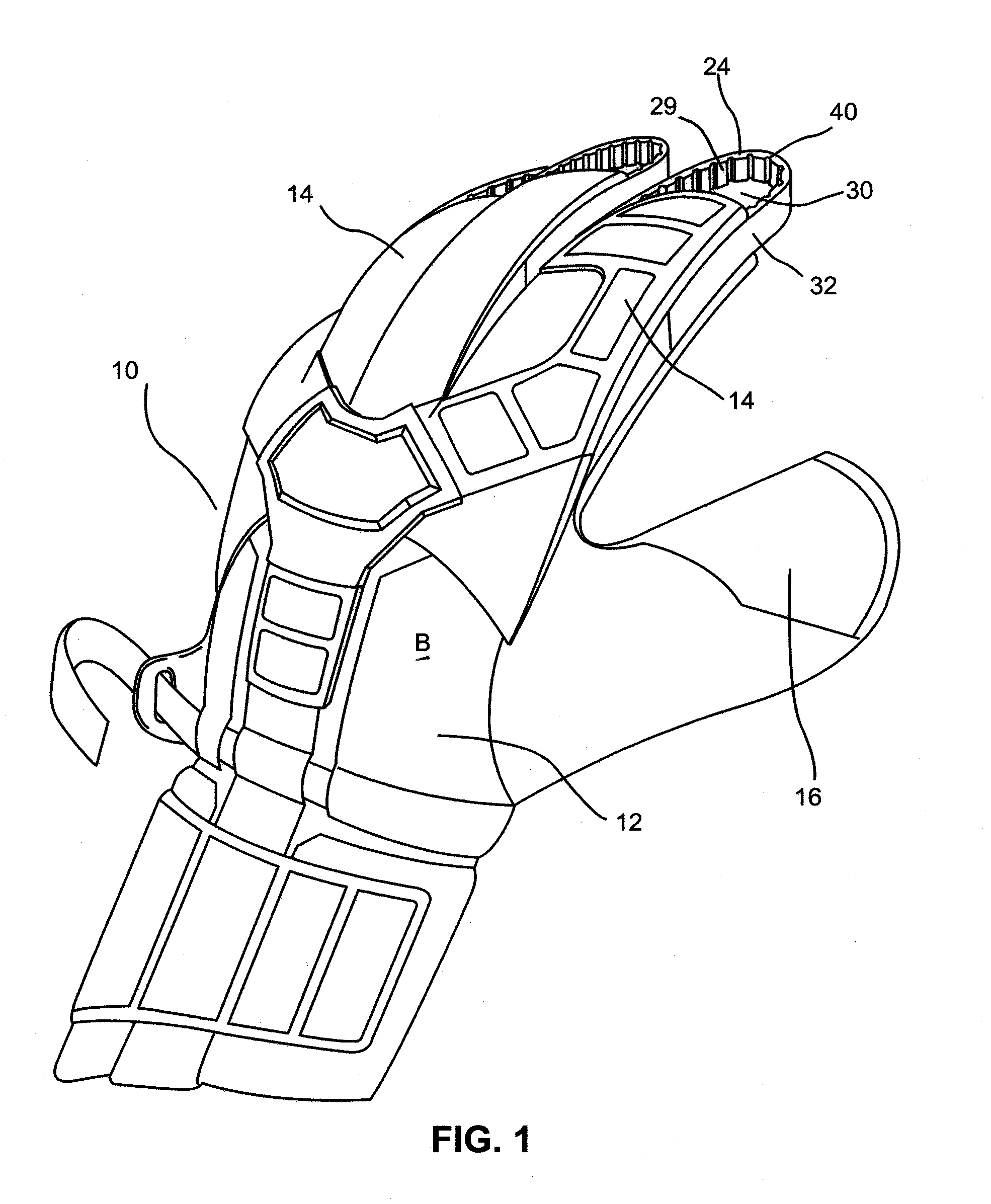

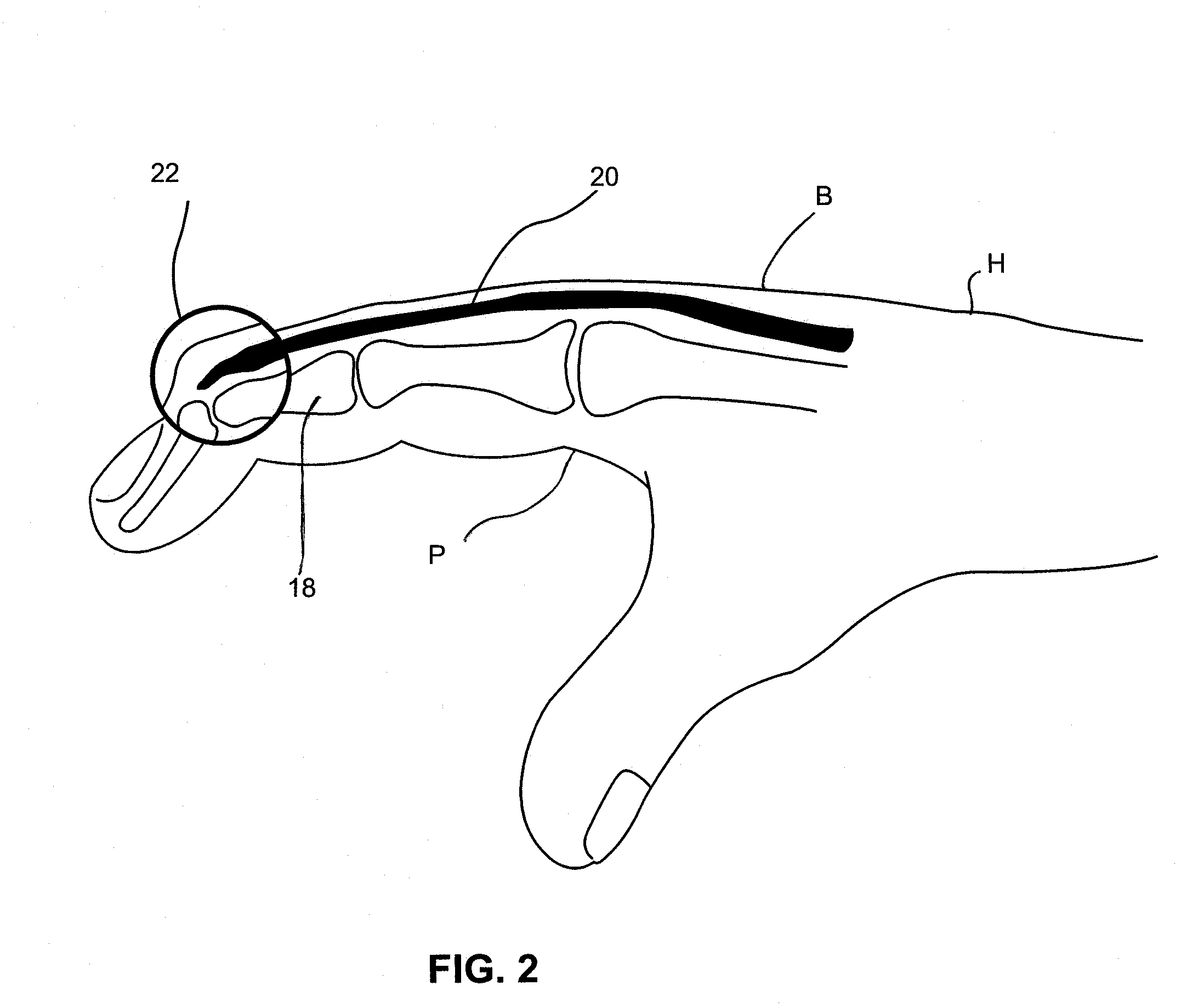

Goalkeeper's glove with protective fingertip extension

ActiveUS20080109935A1Enhanced protection against jamming injuryIncrease reachGlovesBall sportsCrumple zoneMechanical engineering

A goalkeeper's glove with a glove body portion and glove fingers attached to and in communication with the body portion for enveloping a wearer's hand includes an open arch extension with attachment legs on at least one glove finger to protect the finger from jamming injuries and to extend the reach of the wearer. The arch of the extension creates an air gap between the extension tip and the tip of the finger that acts as a crumple zone in absorbing and dissipating the energy of the impact away from the fingertip to prevent a jamming injury. The arch construction ensures that the energy from the impact will be directed along the attachment legs along the length of the finger instead of the fingertip.

Owner:NIKE INC

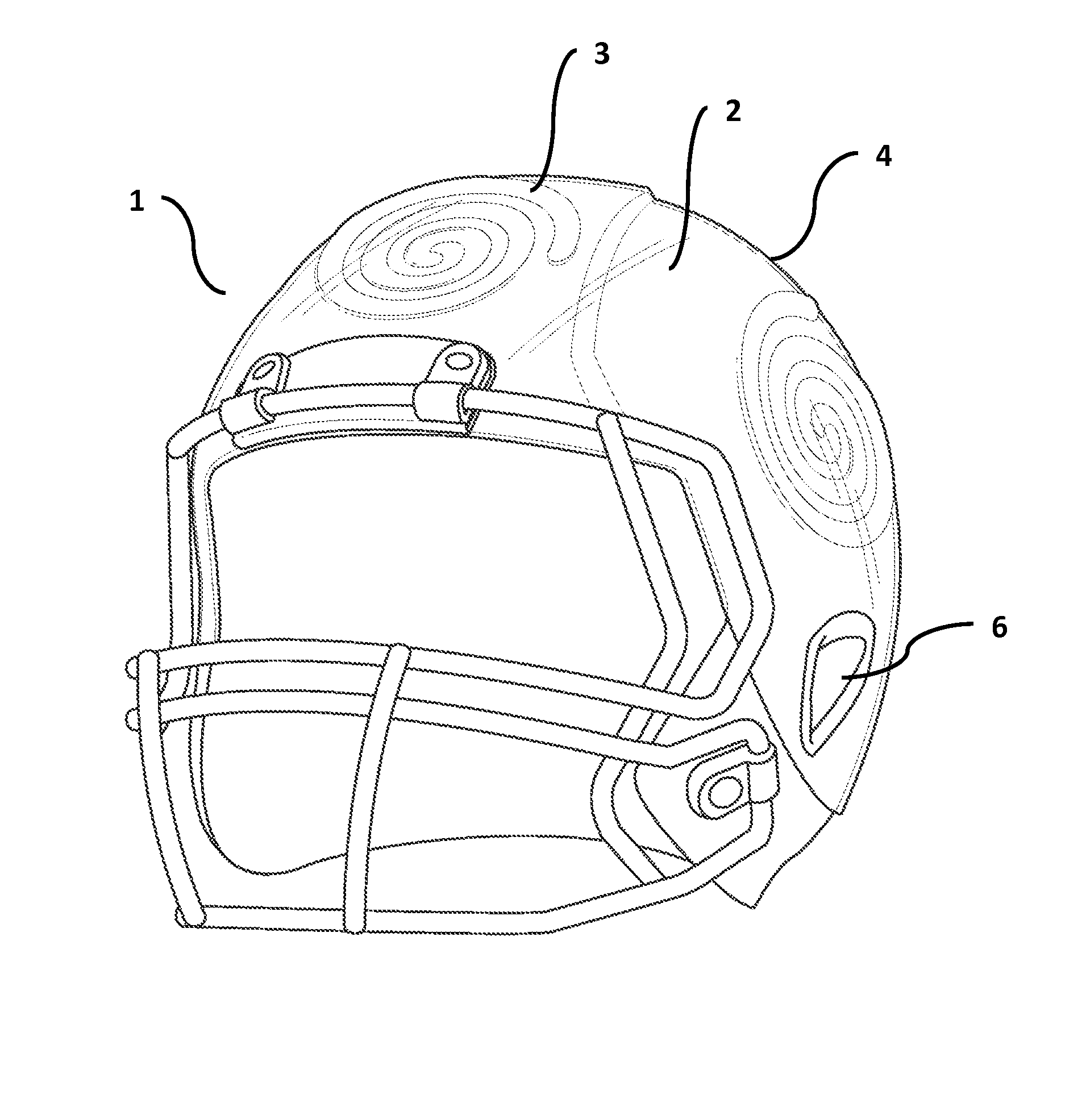

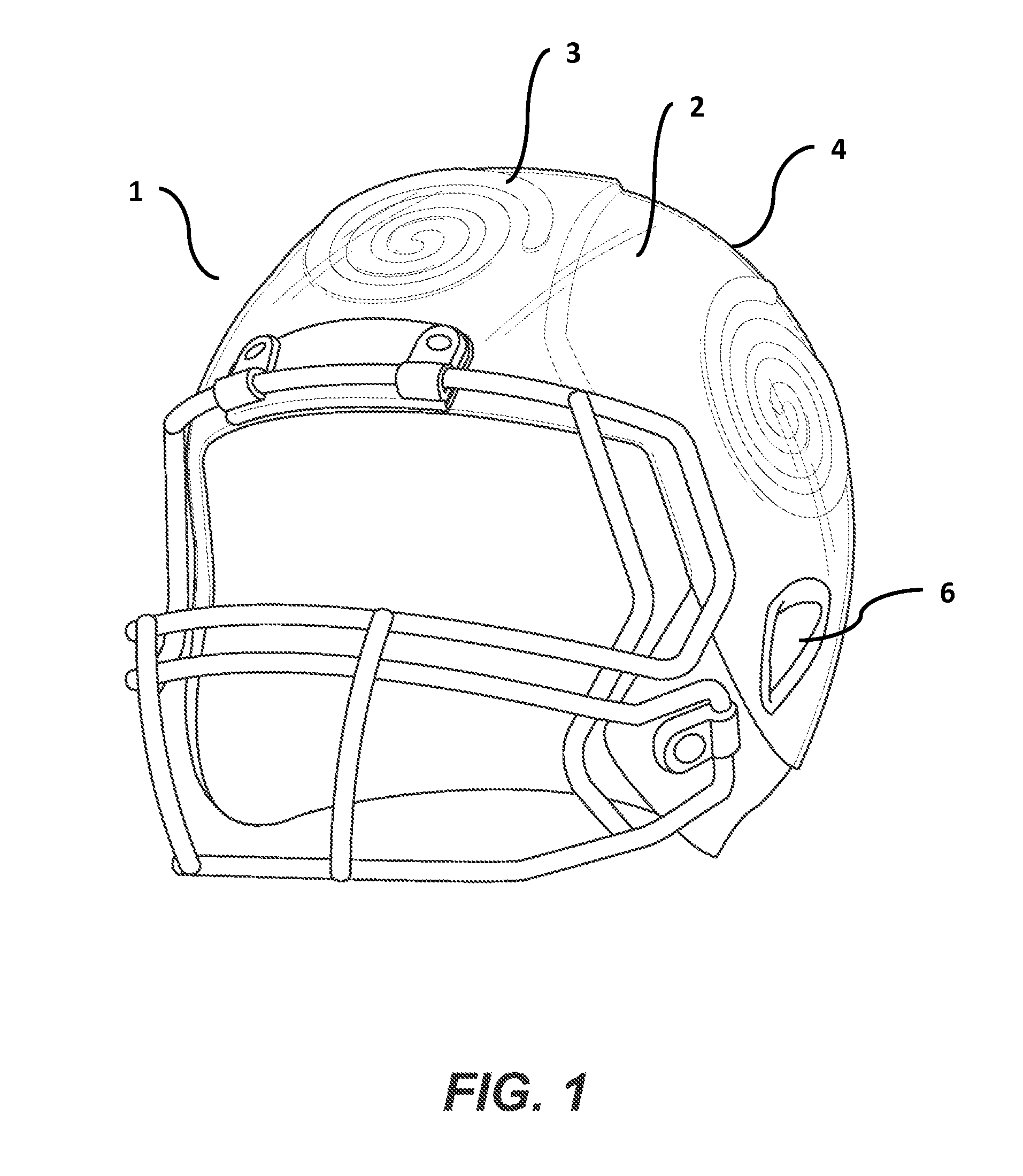

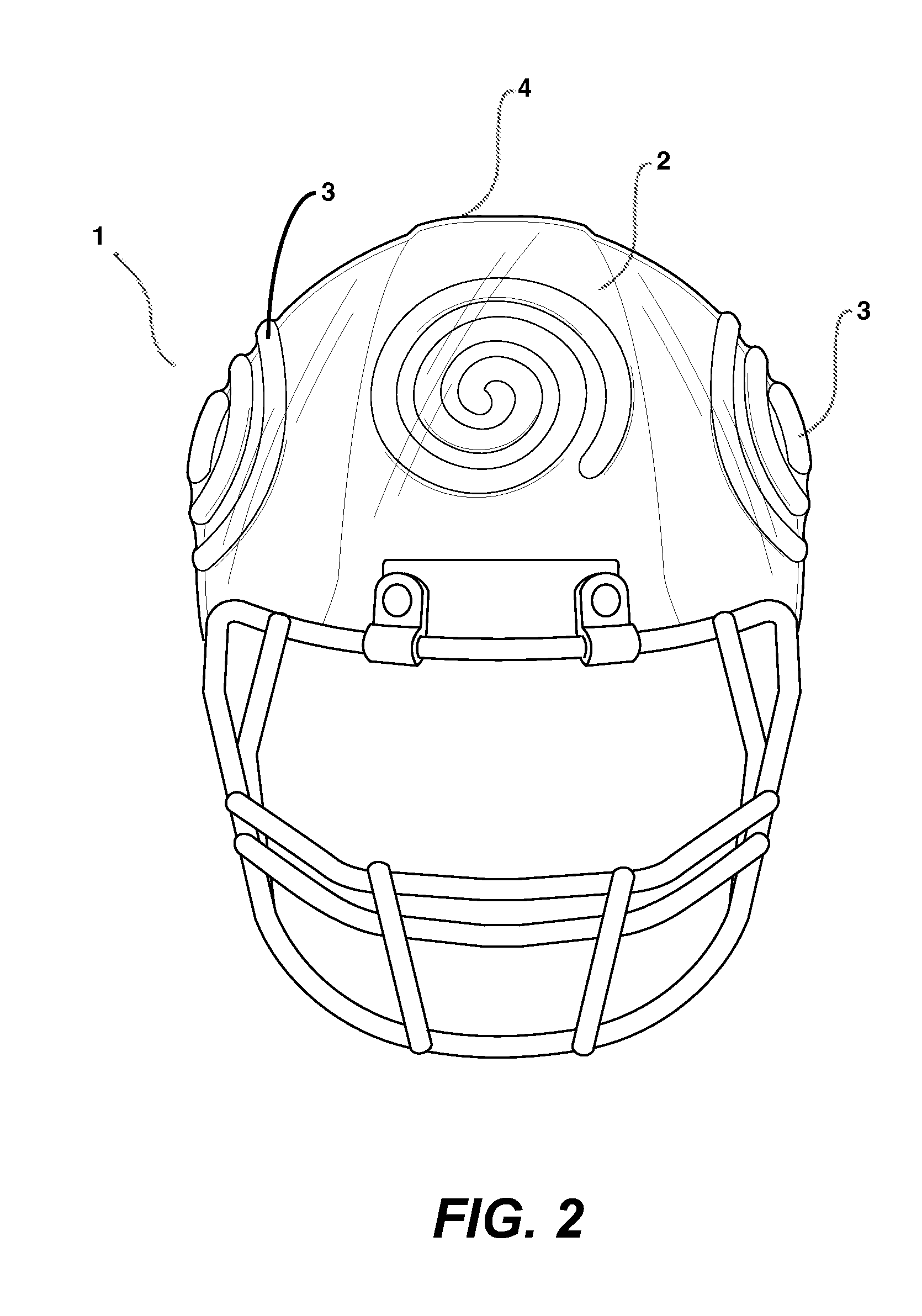

Helmet for reducing concussive forces during collision

InactiveUS9119431B2Reduction in peak acceleration to the brainHelmetsHelmet coversInjury causeThin layer

An improved design for a helmet to reduce injuries caused by helmet-to-helmet collisions. The helmet has a thin layer of padding added onto the hard shell of the helmet. The padding may be textured to add “crumple zones.” A thin, rugged, low-friction exterior cover is affixed to the padding. In one embodiment of the helmet, the cover is separated slightly from the padding to provide air space. The air space, combined with the textured padding, provides a substantial reduction in peak acceleration resulting from a helmet-to-helmet collision.

Owner:BAIN JULIANA

Electric vehicle undercarriage crumple zone

A battery pack protection system is provided for use with an electric vehicle in which the battery pack is mounted under the car. The system utilizes a plurality of deformable cooling conduits located between the lower surface of the batteries within the battery pack and the lower battery pack enclosure panel. The cooling conduits are configured to deform and absorb impact energy when an object, such as road debris, strikes the lower surface of the lower battery pack enclosure panel. Further protection may be achieved by positioning a ballistic shield, alone or with a layer of compressible material, under the bottom surface of the battery pack.

Owner:ATIEVA USA INC

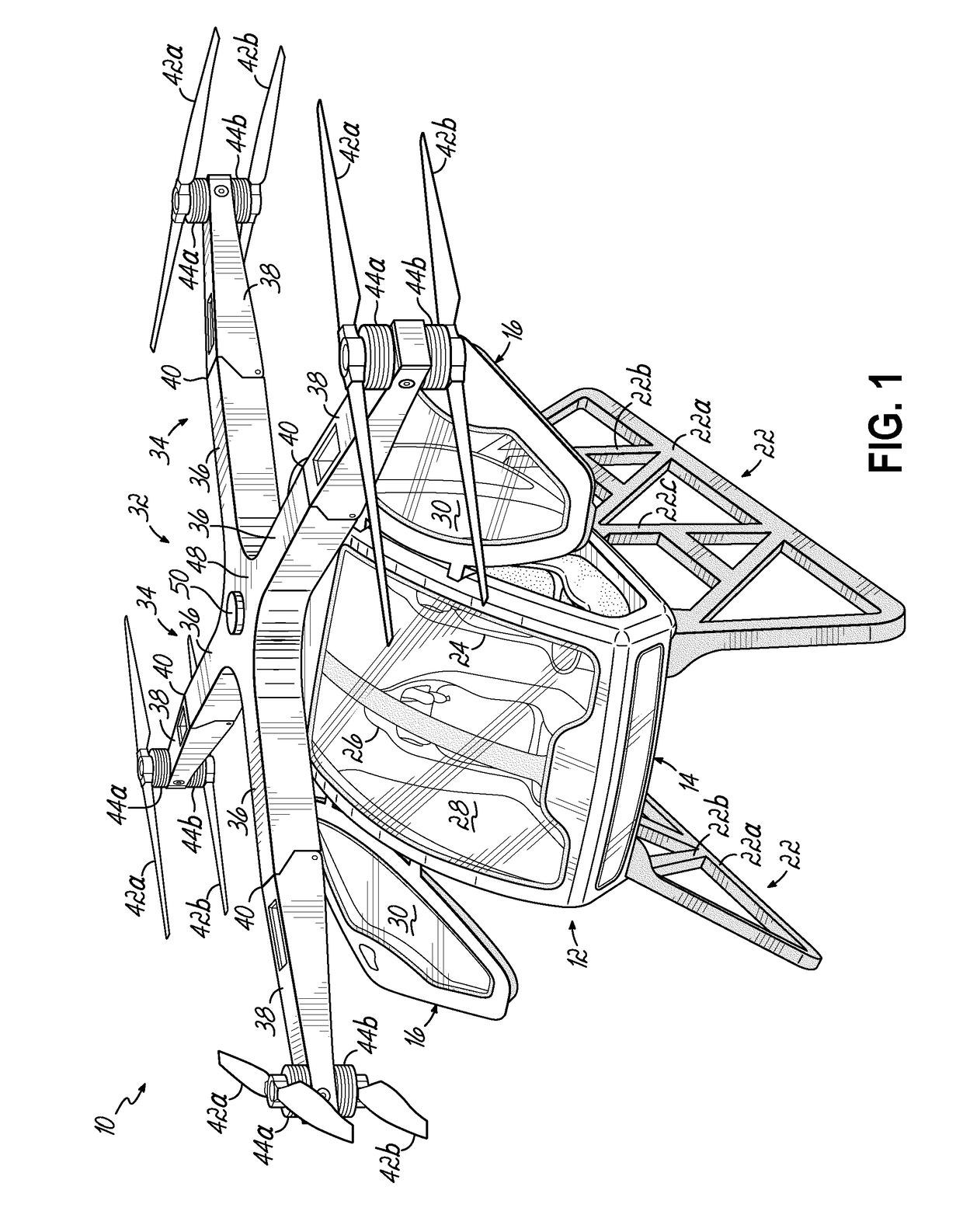

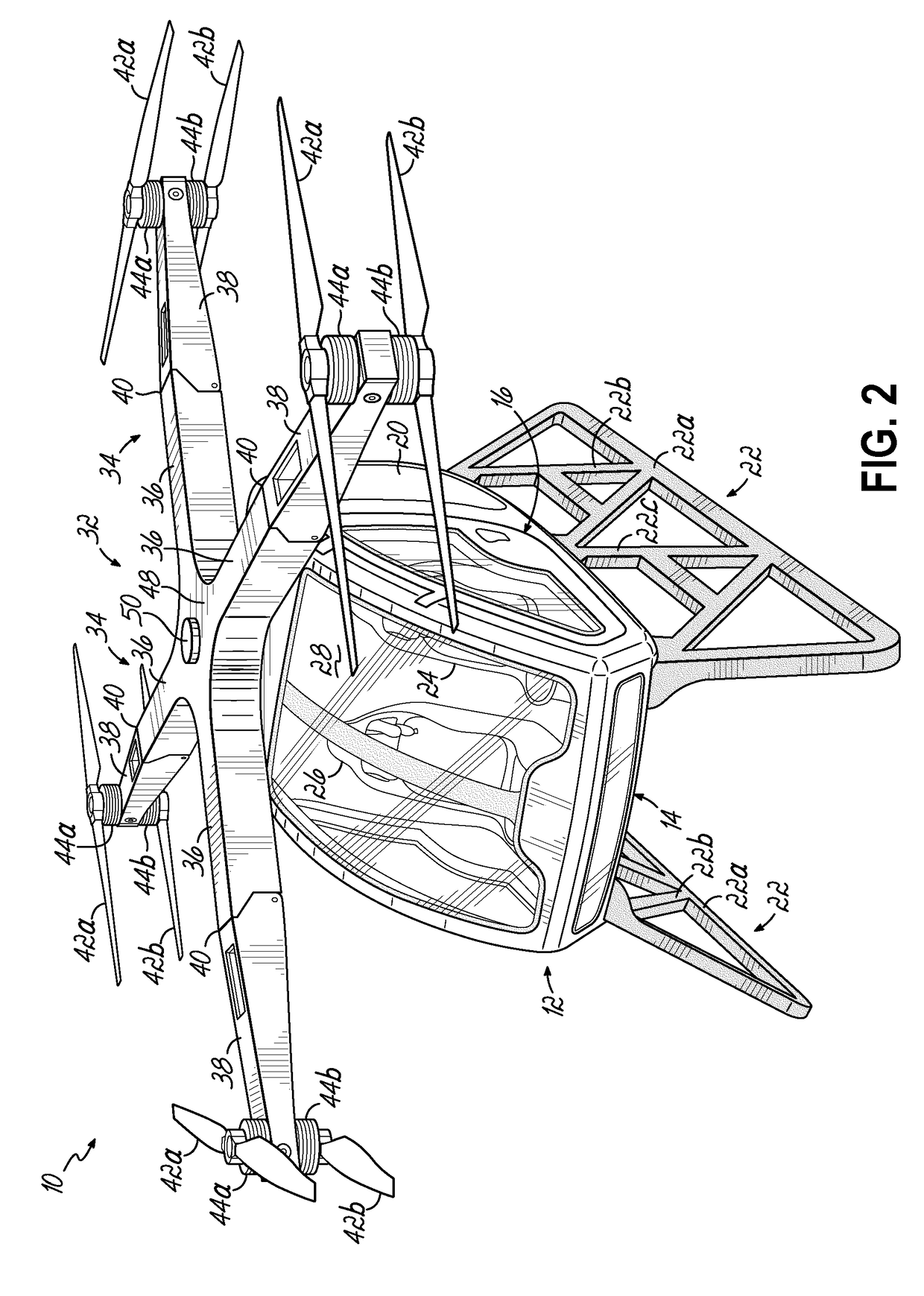

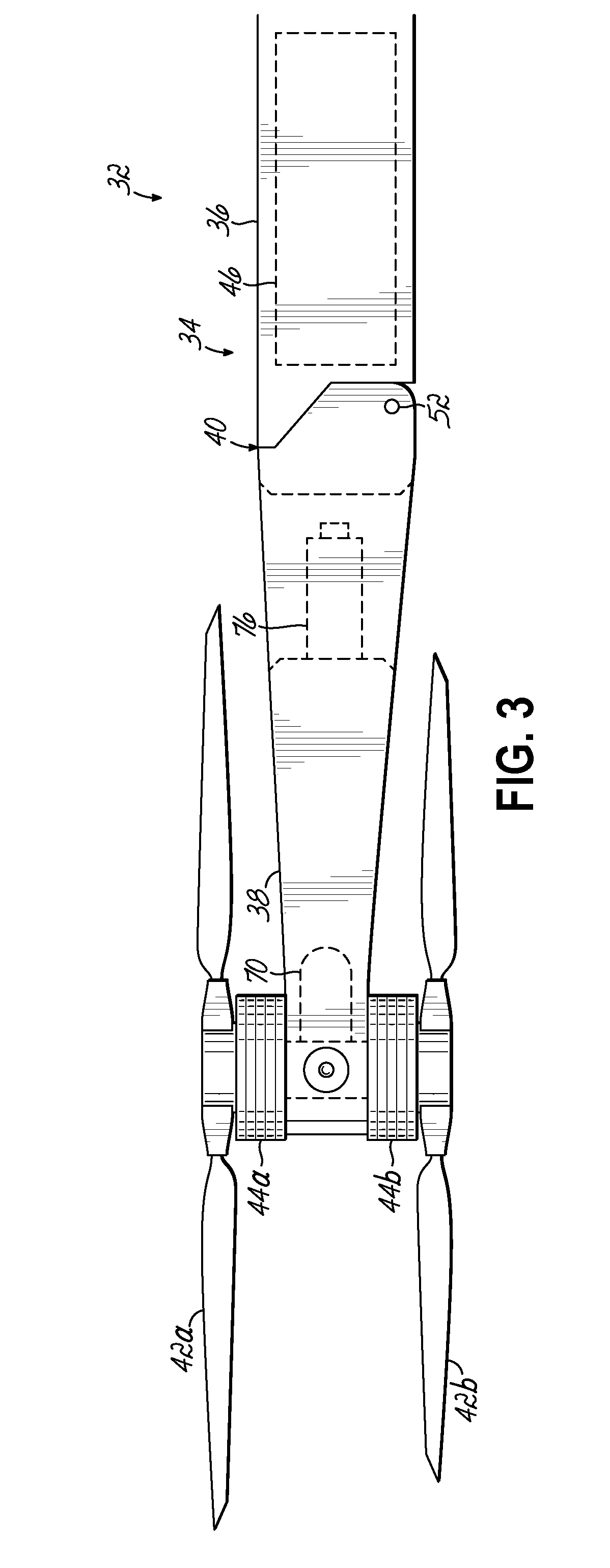

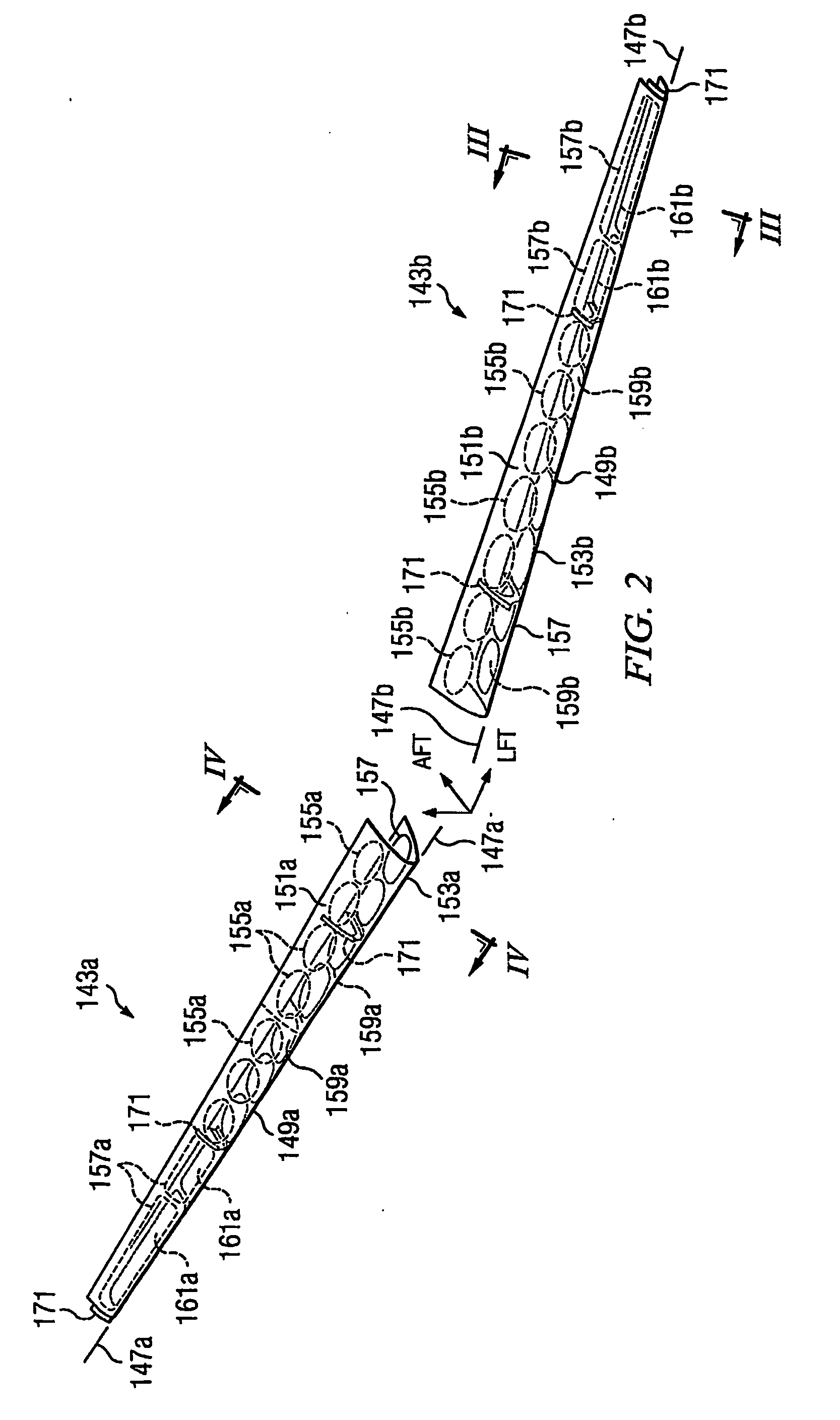

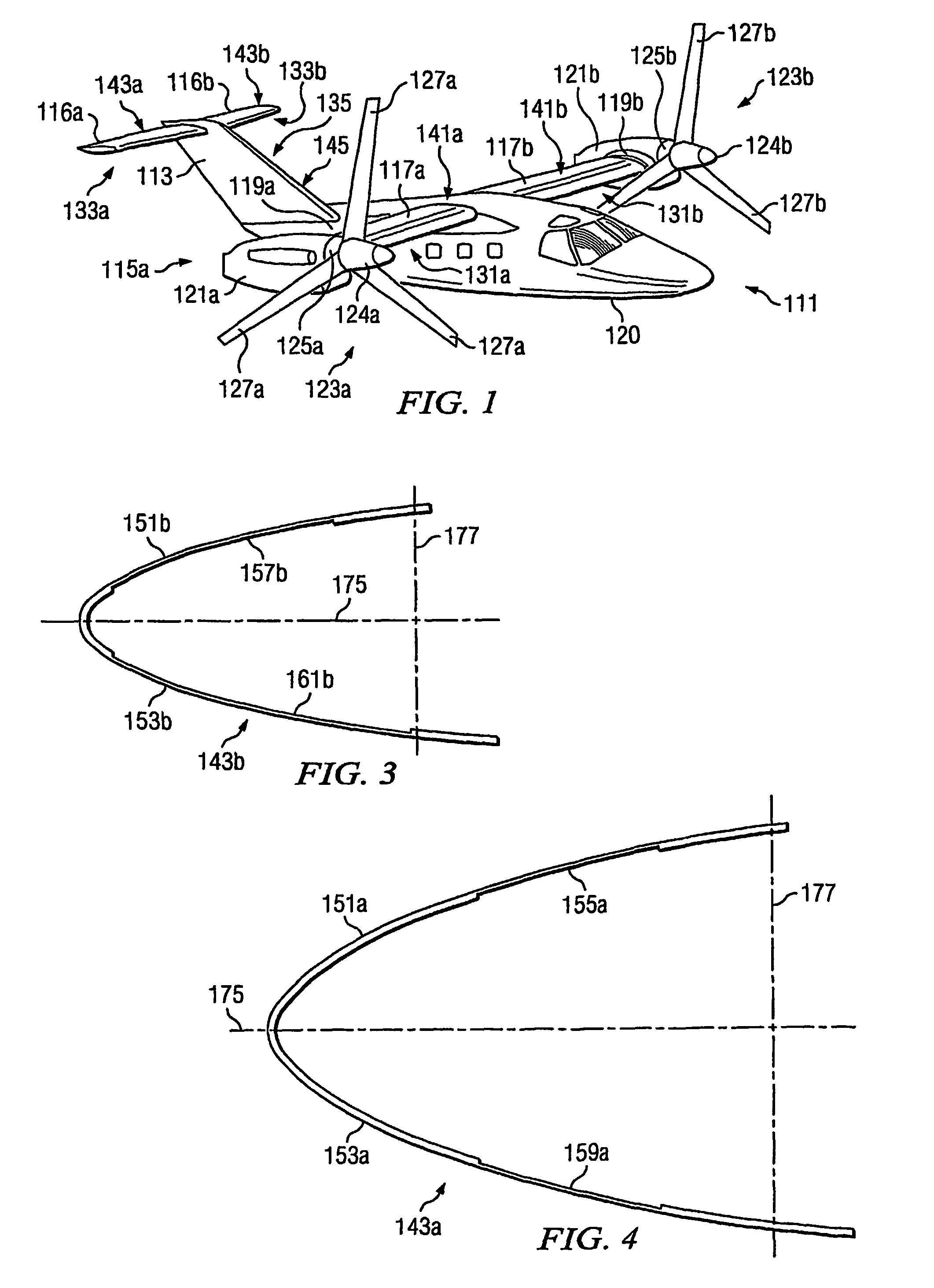

Auxiliary power system for rotorcraft with folding propeller arms and crumple zone loading gear

ActiveUS20180346136A1Safely bring downFuselage framesElectric power distributionGear wheelEngineering

A vertical take-off and loading (VTOL) rotary aircraft or helicopter has eight propellers in a quad propeller arm configuration where each propeller arm has two counter-rotating propellers. Folding propeller arms are designed to allow storage in a single car sized garage. Each propeller may be powered by a three-phase alternating current motor. The main power plant for the aircraft is a gas combustion engine that generates electricity. If the gas engine fails, a battery backup system will safely bring the aircraft down for a controlled landing. The direct current bus is redundant in that even with a gas combustion engine failure the direct current bus battery pack will safely bring down the aircraft. Various embodiments of this invention may also include a landing gear crumple zone designed to soften a hard landing.

Owner:MOOG INC

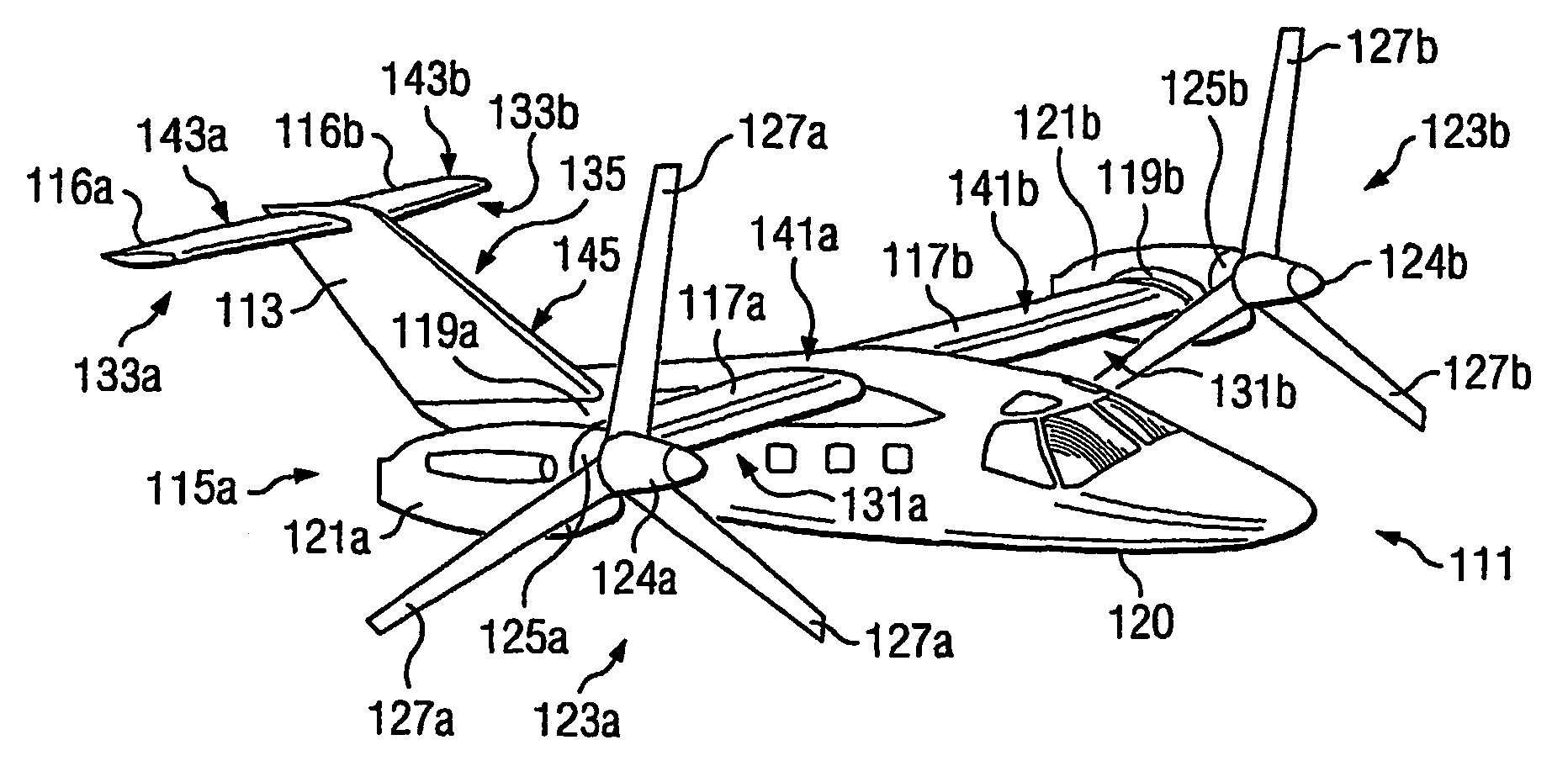

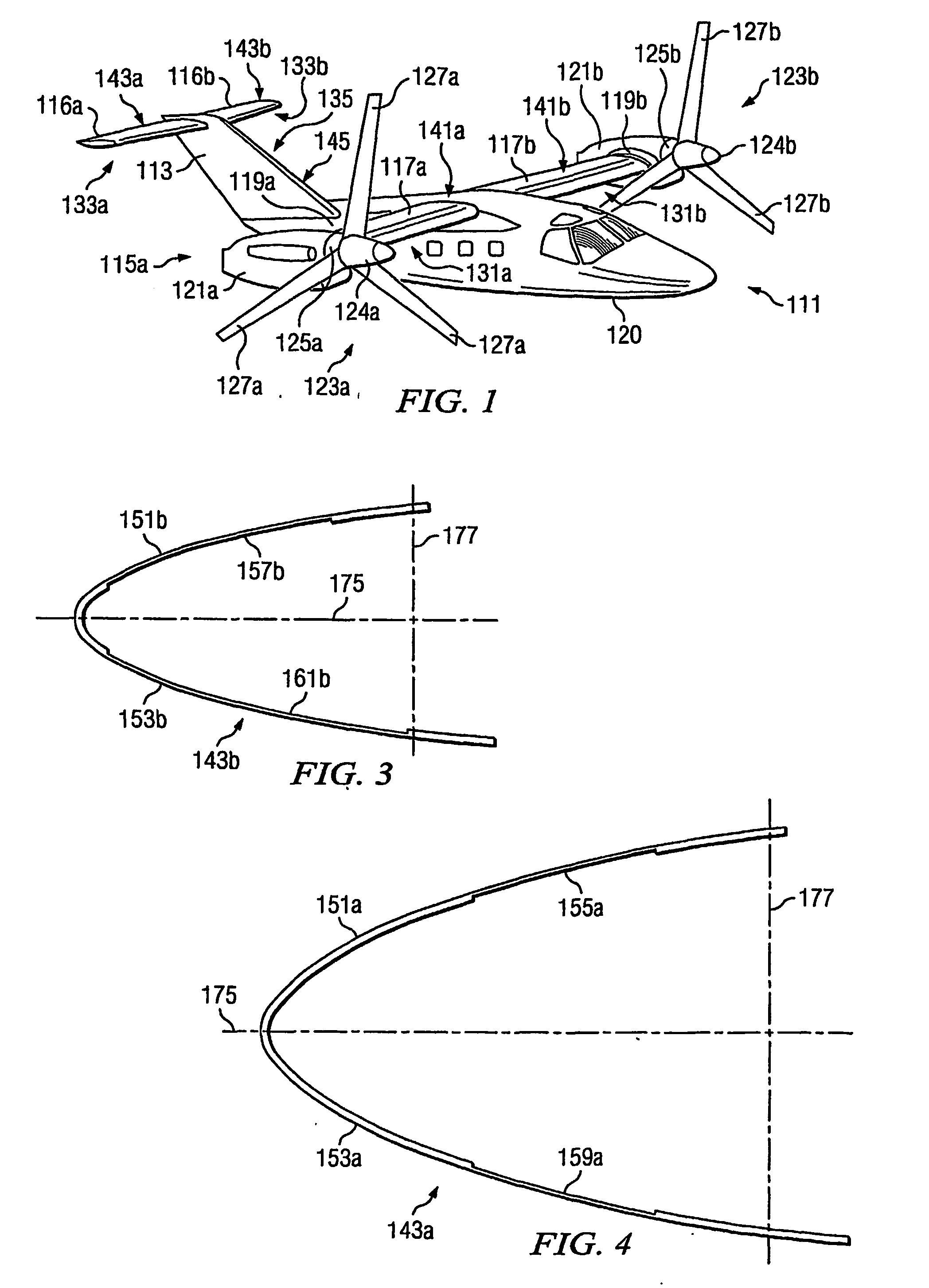

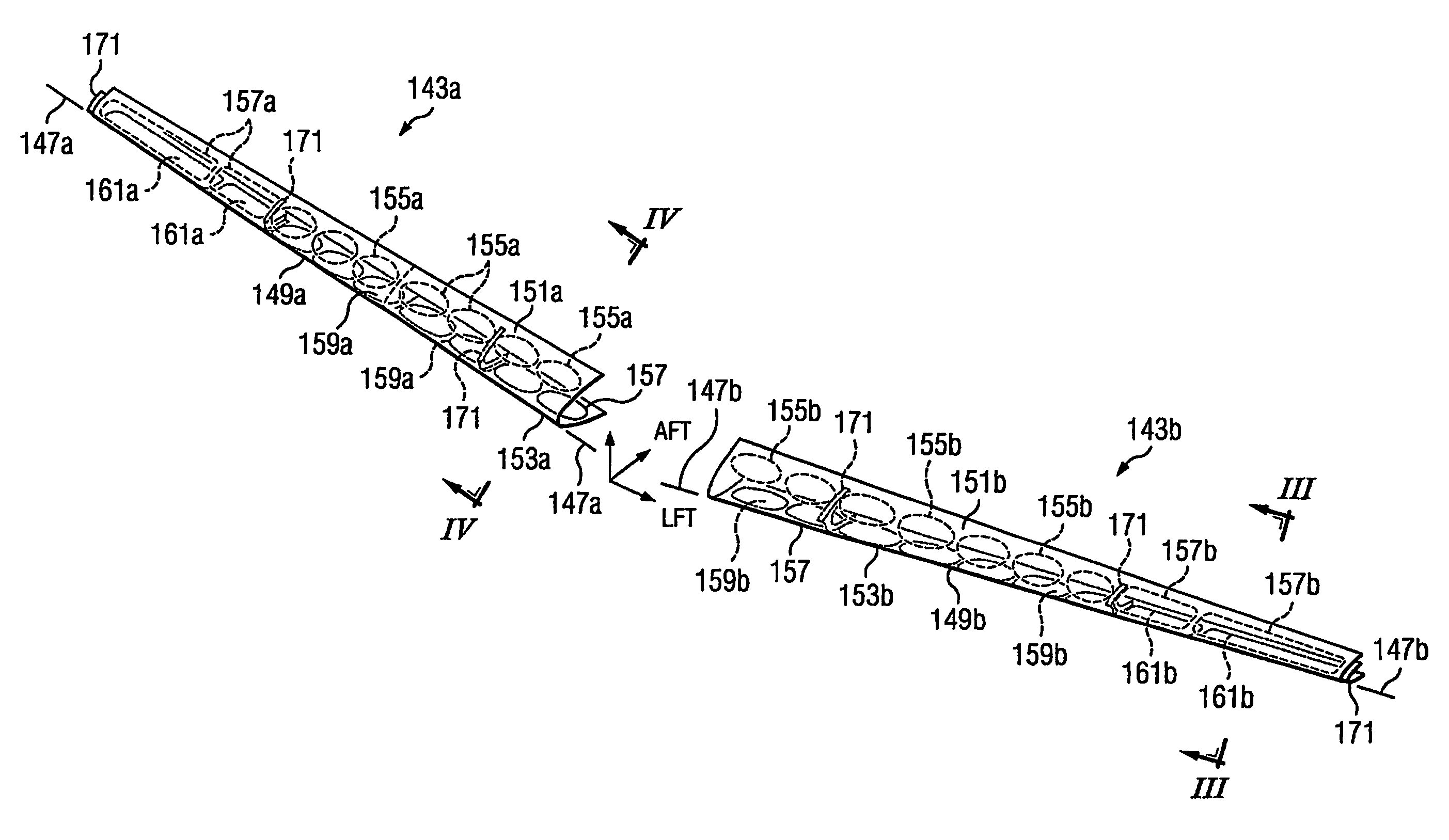

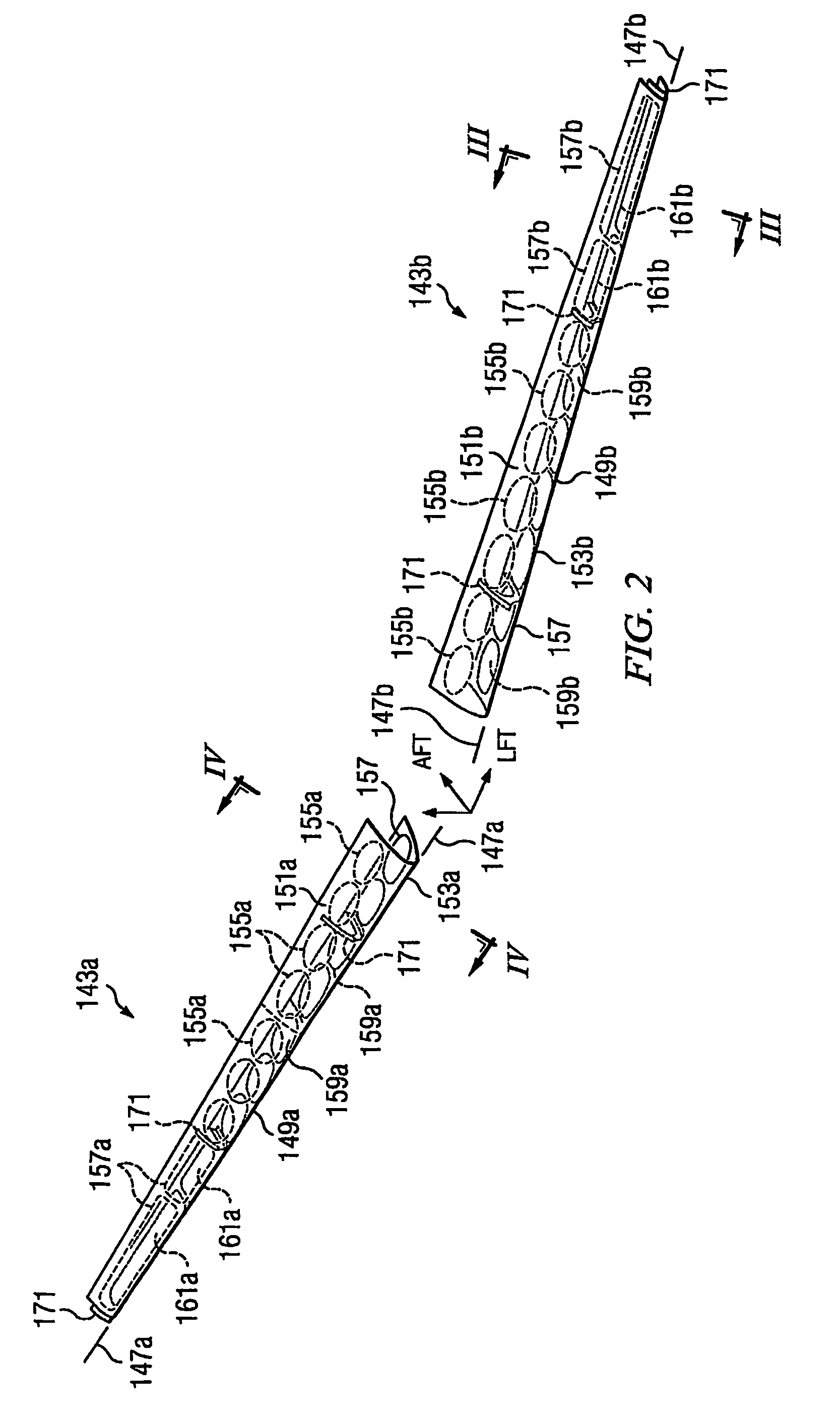

Protective skin for aircraft

ActiveUS20070138340A1Minimize damageIncrease stiffnessAircraft stabilisationMilitary adjustmentLeading edgeEngineering

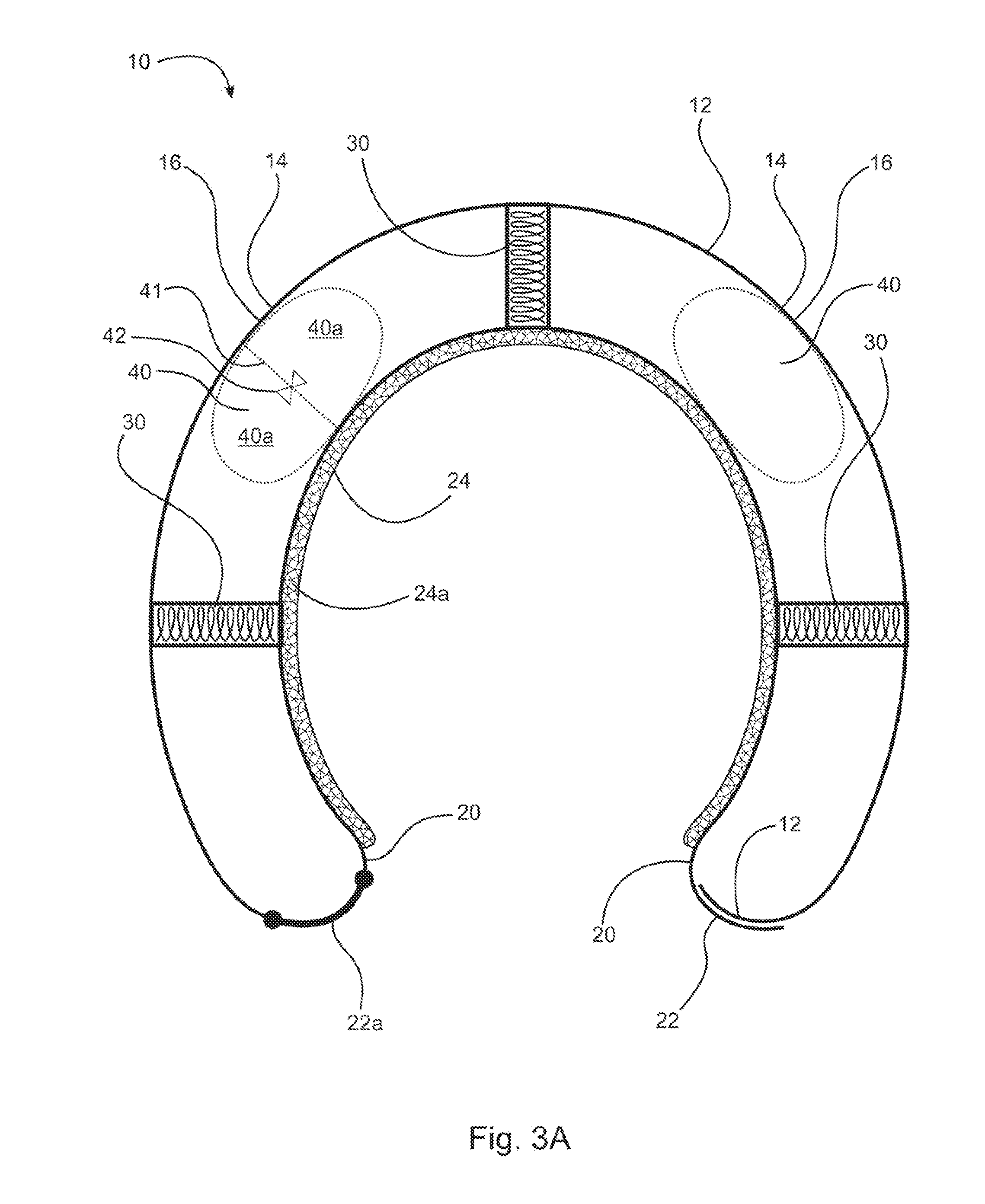

A protective skin (143a, 143b) for an aircraft is disclosed. The protective skin (143a, 143b) forms the leading edges of wing members, horizontal stabilizers, and vertical fins. A portion of the skin material (143a, 143b) is removed in a selected pattern (155a, 157a, 159a, 161a, 155b, 157b, 159b, 161b) from the interior surface of the skin (143a, 143b). In the preferred embodiment, the interior surface of the skin is chemically etched and / or mechanically milled in oval and rectangular patterns so as to create crumple zones (155a, 157a, 159a, 161a, 155b, 157b, 159b, 161b) and generate progressive failure of the metal. This allows the leading edge to absorb the impact energy from a collision with a bird or other object, and prevent the bird or other object from penetrating through the leading edge into the substructure.

Owner:AGUSTA SPA +1

Protective skin for aircraft

ActiveUS7931233B2Minimize damageIncrease stiffnessAircraft stabilisationMilitary adjustmentLeading edgeEngineering

A protective skin (143a, 143b) for an aircraft is disclosed. The protective skin (143a, 143b) forms the leading edges of wing members, horizontal stabilizers, and vertical fins. A portion of the skin material (143a, 143b) is removed in a selected pattern (155a, 157a, 159a, 161a, 155b, 157b, 159b, 161b) from the interior surface of the skin (143a, 143b). In the preferred embodiment, the interior surface of the skin is chemically etched and / or mechanically milled in oval and rectangular patterns so as to create crumple zones (155a, 157a, 159a, 161a, 155b, 157b, 159b, 161b) and generate progressive failure of the metal. This allows the leading edge to absorb the impact energy from a collision with a bird or other object, and prevent the bird or other object from penetrating through the leading edge into the substructure.

Owner:AGUSTA SPA +1

Protective cup lens cover

InactiveUS8292523B2Without potentially damaging the delicate components of the camera lens or the finish of the lens barrelImprove protectionTelescopesCamera filtersCamera lensProtective cup

A padded protective cup shaped covering sized to slip over a camera lens is disclosed. The covering is designed to fit on either the front portion of the lens or the lens mount. The protective covering has beveled side walls which allow it to fit easily on a variety of different lenses. The protective covering is made from two separate layers of material, an outer cup made from a firm yet flexible material, and the inner liner made from a soft pliable material. The soft inner liner allows the covering to easily adhere to the camera lens, and also provides impact protection. The outer cup provides additional impact protection. The outer cup also includes a domed top portion which provides a crumple zone or impact bumper. In one embodiment the outer cup has a clear optical grade lens or filer lens inserted or incorporated therein, which allows the camera user to take a photograph without removing the protective lens.

Owner:DELUXGEAR

Vehicle end portion structure

ActiveUS20090315311A1Improve impact absorption performanceGuaranteed normal transmissionSteering linkagesUnderstructuresEngineeringCrumple zone

A front end portion of a side member functions as a crumple zone during a collision with another vehicle or the like. A radiator support is attached via a bracket to this crumple zone. When another vehicle or the like collides with the side member, the radiator support separates from the side member. When another vehicle or the like collides with the radiator support, external force applied in the rear direction to the radiator support is transmitted to the side member.

Owner:TOYOTA JIDOSHA KK

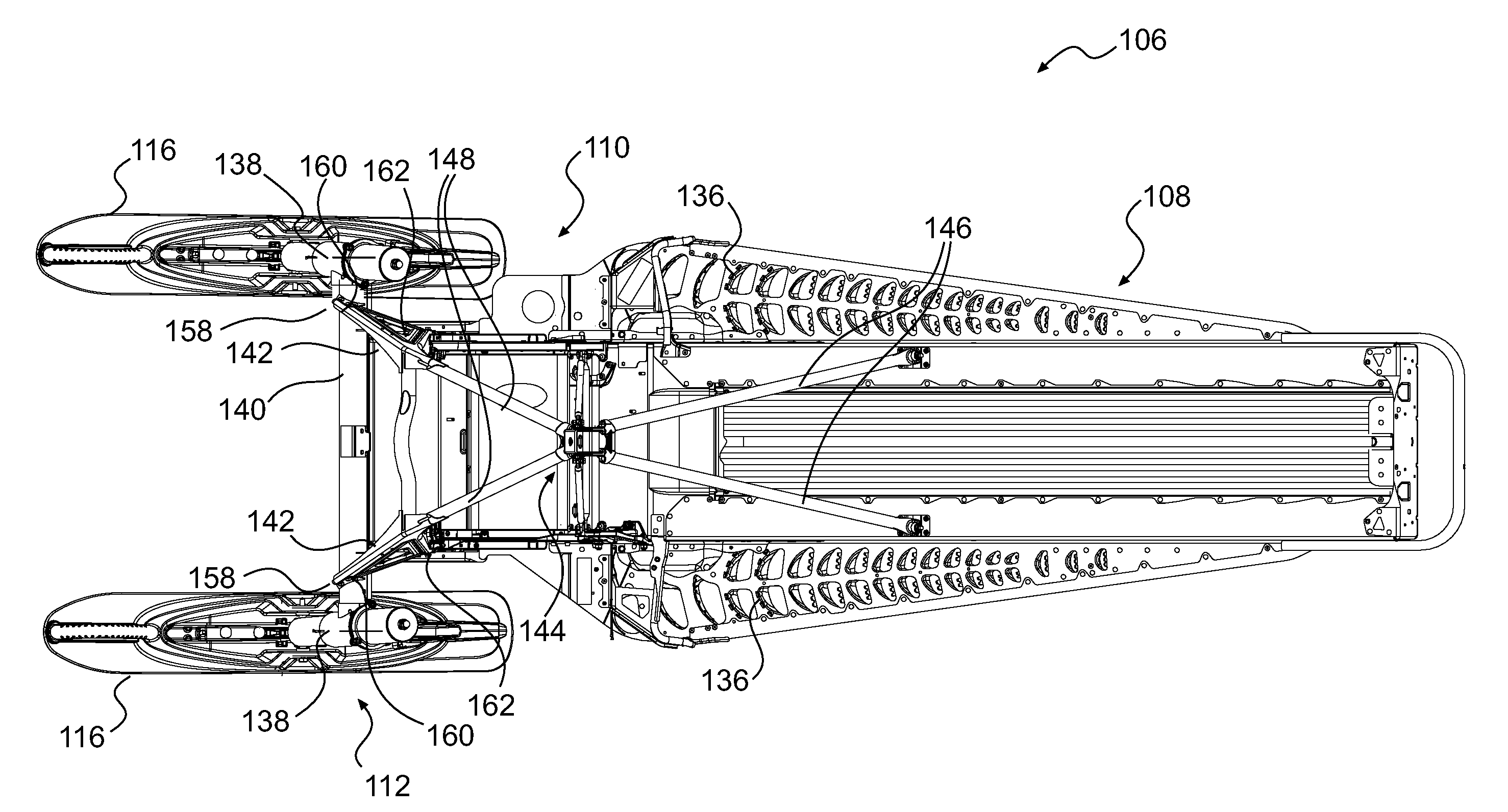

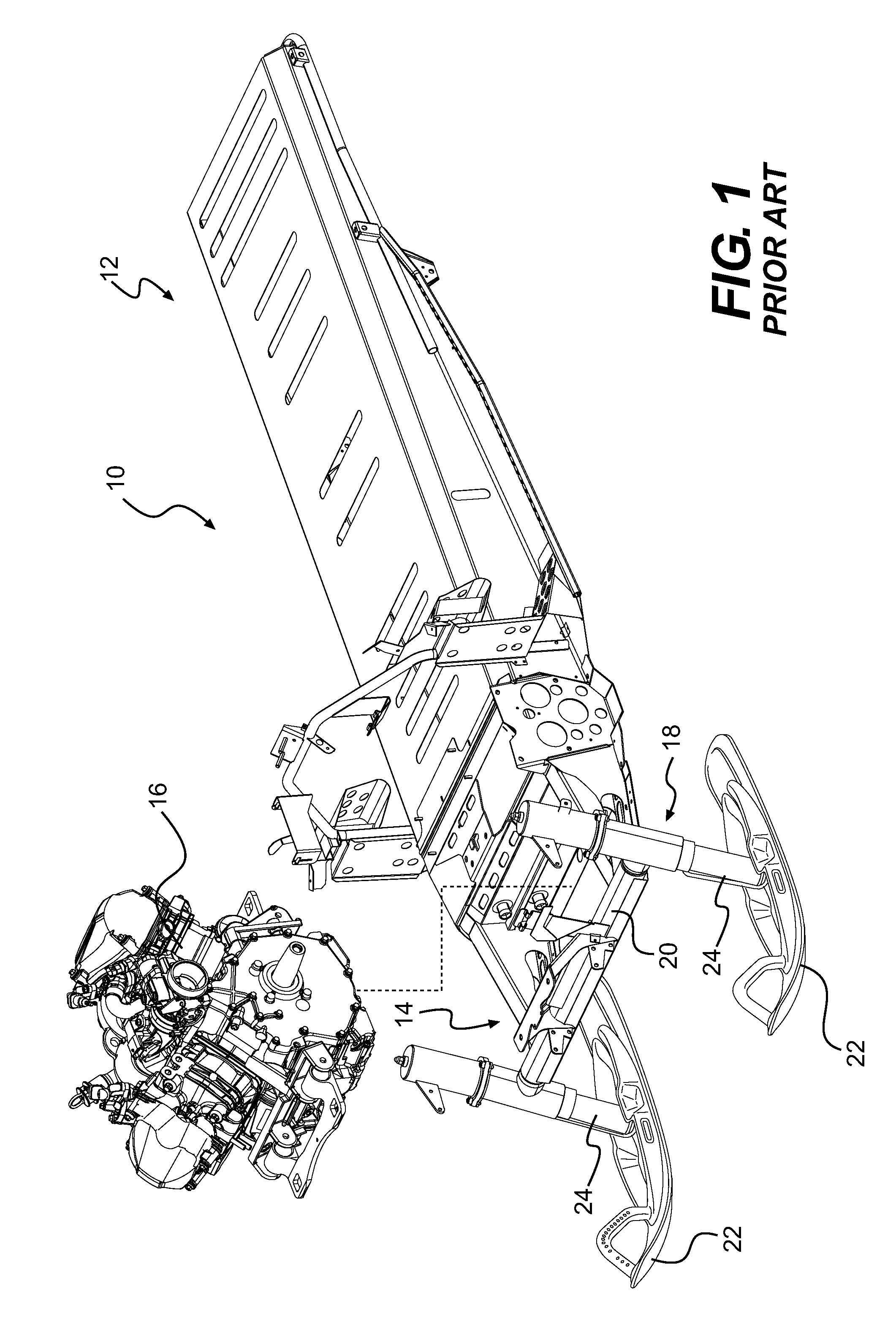

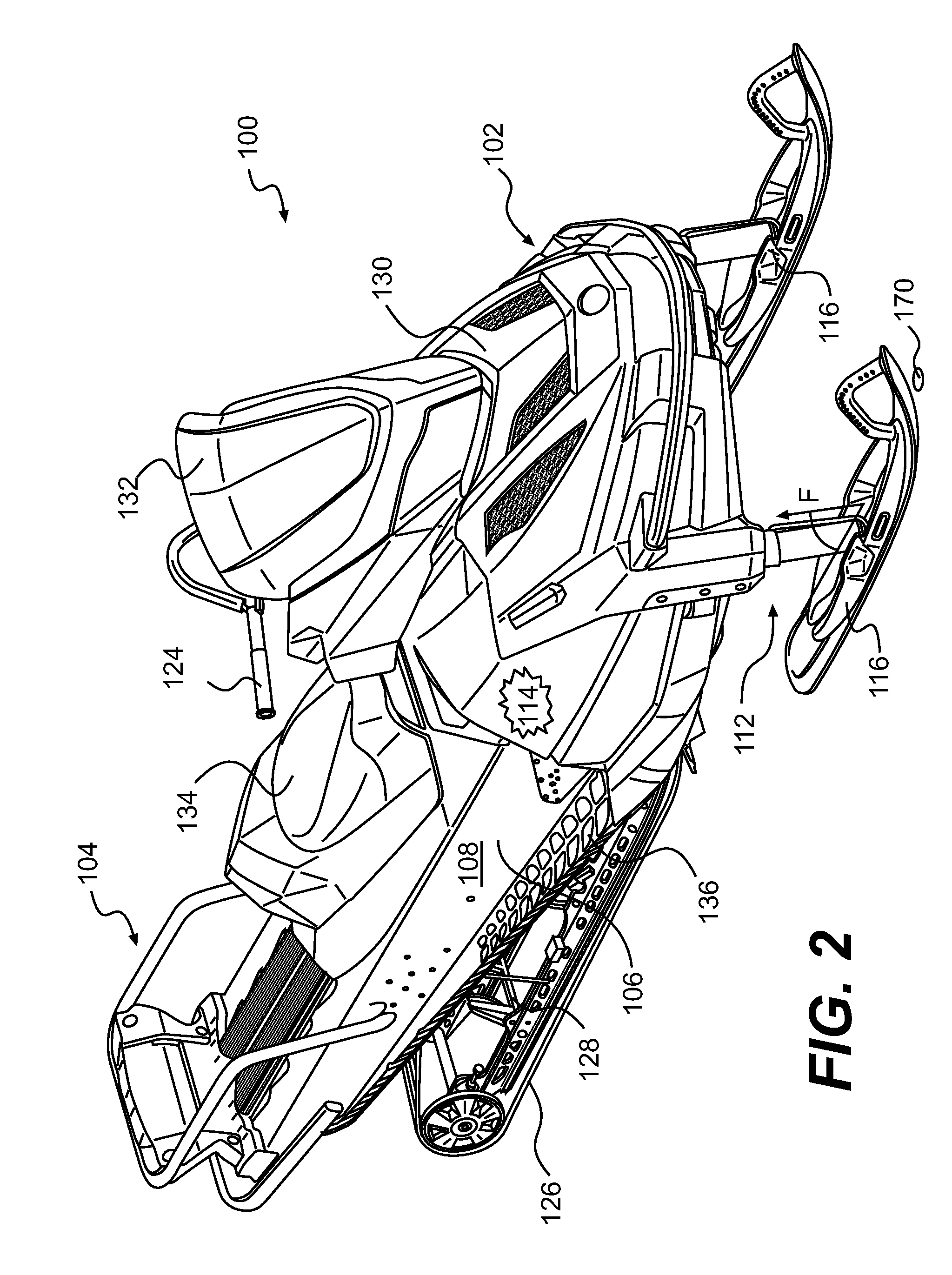

Snowmobile Frame

A snowmobile frame (106) is described, with a tunnel (108) having an inverted U-shape. An engine cradle (110) is attached to a forward portion of the tunnel. A suspension assembly (112) is disposed forwardly of the engine cradle. At least one support member (142) supports the suspension assembly on the engine cradle. The at least one support member forms a crumple zone between the suspension assembly and the engine cradle. The at least one support member resists plastic deformation in response to the first predetermined force exerted on the suspension assembly. The at least one support member undergoes plastic deformation in response to a second predetermined force being exerted on the suspension assembly. The second predetermined force is greater in magnitude than the first predetermined force. The tunnel resists plastic deformation in response to the second predetermined force.

Owner:BOMBARDIER RECREATIONAL PROD INC

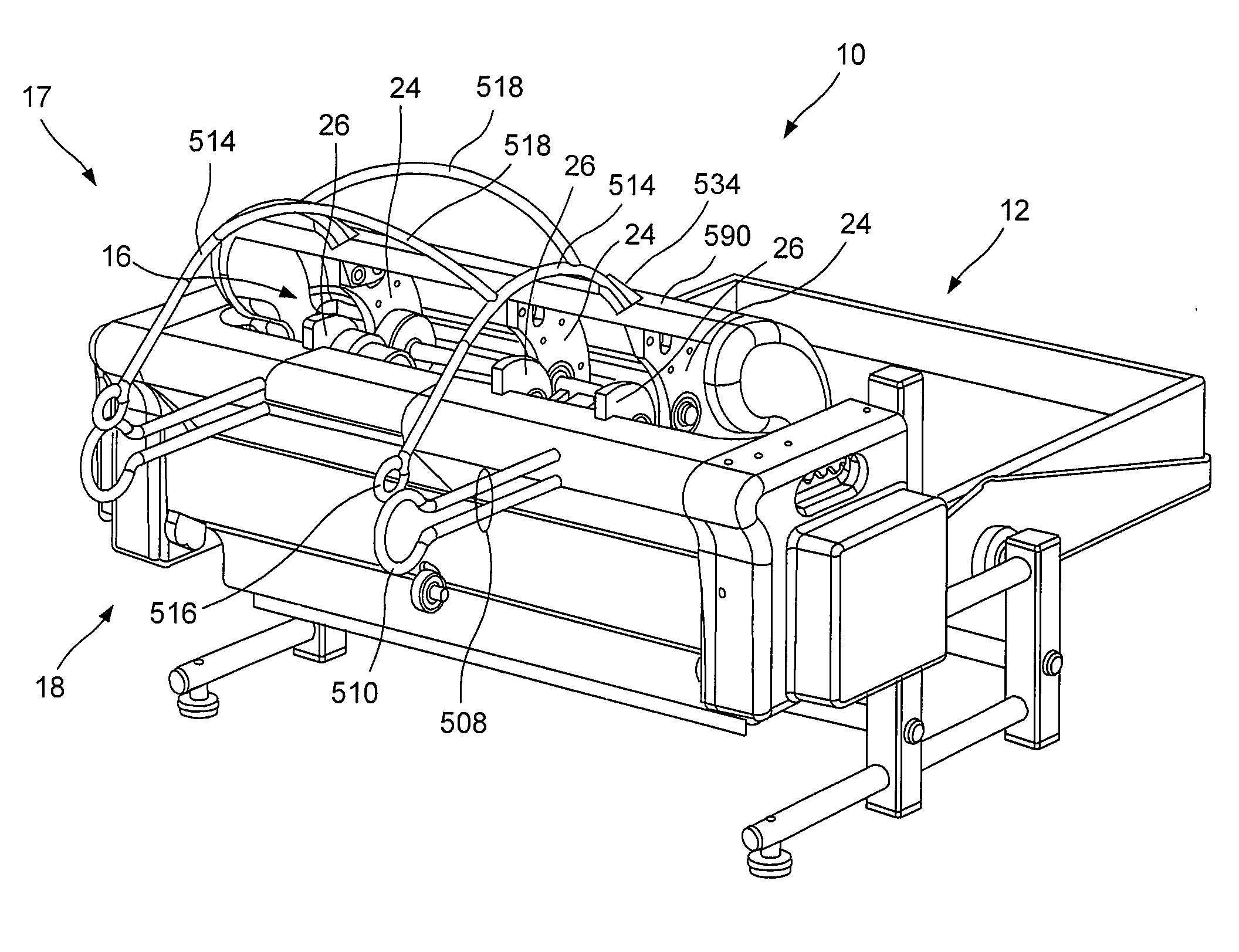

Crumpling mechanism for creating dunnage

A dunnage crumpling apparatus is provided having first and second entry-side crumpling members and first and second exit-side crumpling members. The first and second entry-side crumpling members define an entry therebetween. The first and second exit-side crumpling members define an exit therebetween that is disposed along the longitudinal path downstream of the entry. A crumpling zone being defined between the entry and exit. The first entry-side crumpling member is configured for moving at an first rate and is associated with the second entry-side crumpling member for moving sheet material through the entry in a first direction along a longitudinal path at an entry rate. The first exit-side crumpling member is configured for moving at an second rate and is associated with the second exit-side crumpling member for moving the sheet material through the exit in the first direction along the path at a exit rate that is slower than the entry rate to crumple the sheet material for producing dunnage. The entry and exit-side crumpling members are displaced laterally along the path with respect to each other to cause shearing of the sheet within the crumpling zone.

Owner:PREGIS INNOVATIVE PACKAGING

Systems, methods, and apparatus for a kinetic energy absorbing device

InactiveUS7566877B2Improves reliability and longevityImprove the level ofSolid-state devicesMaterial analysis by optical meansEngineeringSystems approaches

Systems, methods and apparatus are provided through which an impact absorbing material is affixed to a transportable device to protect the transportable device from impact with another object. In some embodiments, the impact absorbing material is a crumple zone material that has plastic deformation characteristics.

Owner:GENERAL ELECTRIC CO

Helmet with multiple protective zones

The present invention is a protective helmet having multiple zones of protection suitable for use in construction work, athletic endeavors, and similar activities. The helmet includes a hard outer protective that is suspended over a hard anchor zone by elastic cords extending between an elastomeric zone between the outer and inner zones. Fluid filed bladders are positioned in the elastomeric zone and bulge through one or more of a plurality of apertures located in the outer zone. In one embodiment, an additional crumple zone is present. The structure enables the helmet to divert linear and rotational forces away from the user's braincase.

Owner:劳伯特·S·萨德达比

Crumpling mechanism for creating dunnage

A dunnage crumpling apparatus is provided having first and second entry-side crumpling members and first and second exit-side crumpling members. The first and second entry-side crumpling members define an entry therebetween. The first and second exit-side crumpling members define an exit therebetween that is disposed along the longitudinal path downstream of the entry. A crumpling zone being defined between the entry and exit. The first entry-side crumpling member is configured for moving at an first rate and is associated with the second entry-side crumpling member for moving sheet material through the entry in a first direction along a longitudinal path at an entry rate. The first exit-side crumpling member is configured for moving at an second rate and is associated with the second exit-side crumpling member for moving the sheet material through the exit in the first direction along the path at a exit rate that is slower than the entry rate to crumple the sheet material for producing dunnage. The entry and exit-side crumpling members are displaced laterally along the path with respect to each other to cause shearing of the sheet within the crumpling zone.

Owner:PREGIS INNOVATIVE PACKAGING

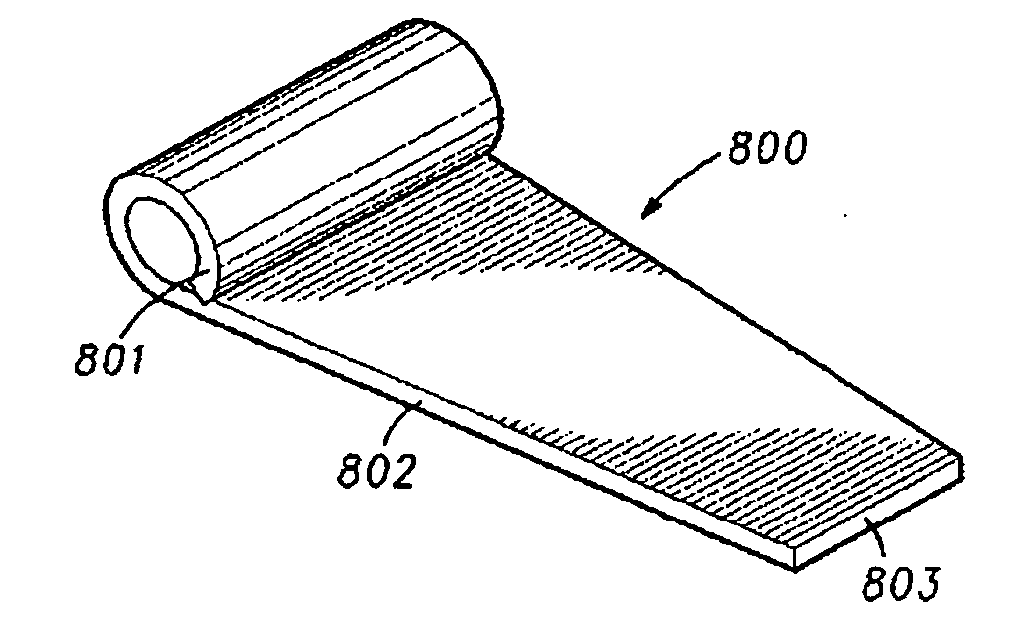

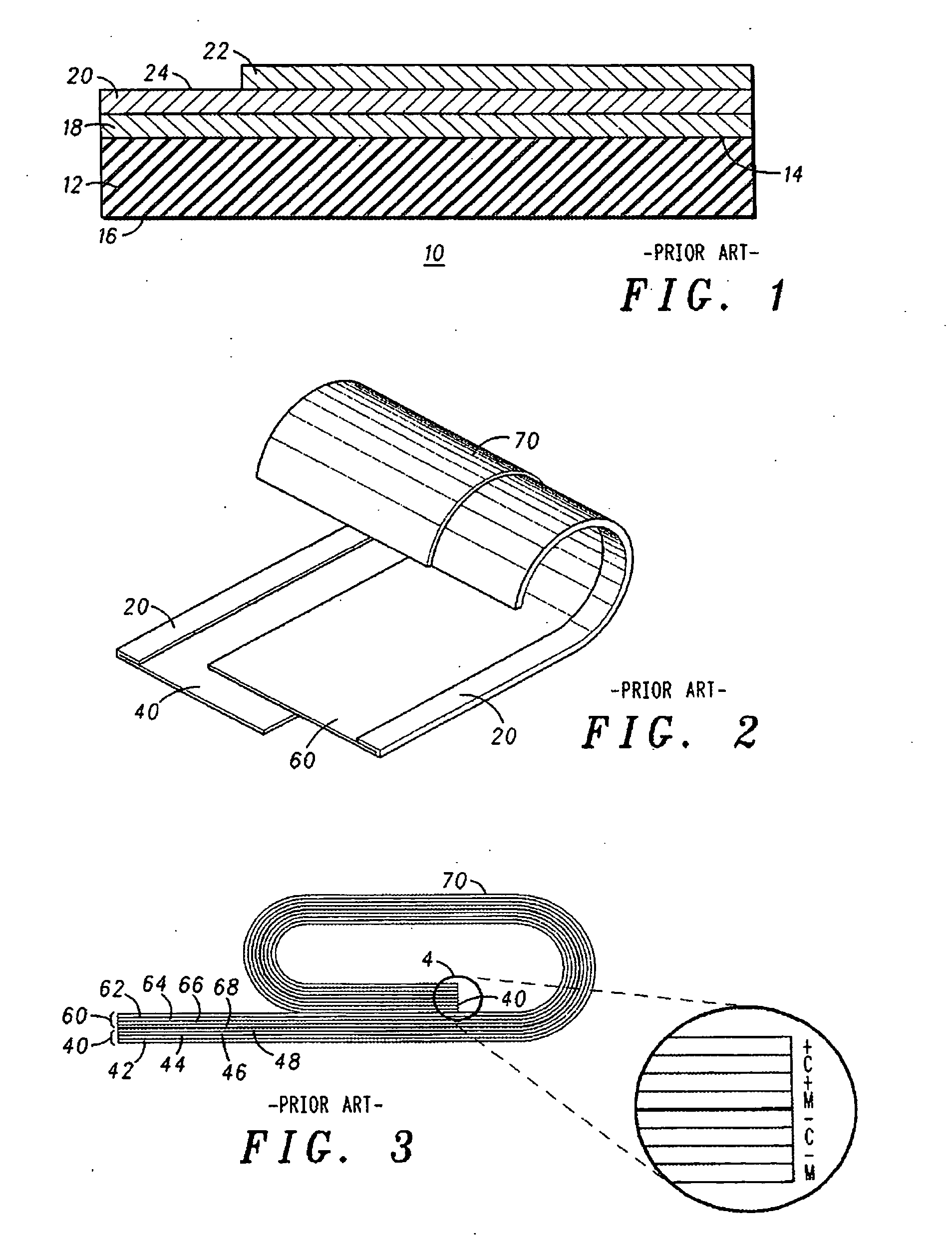

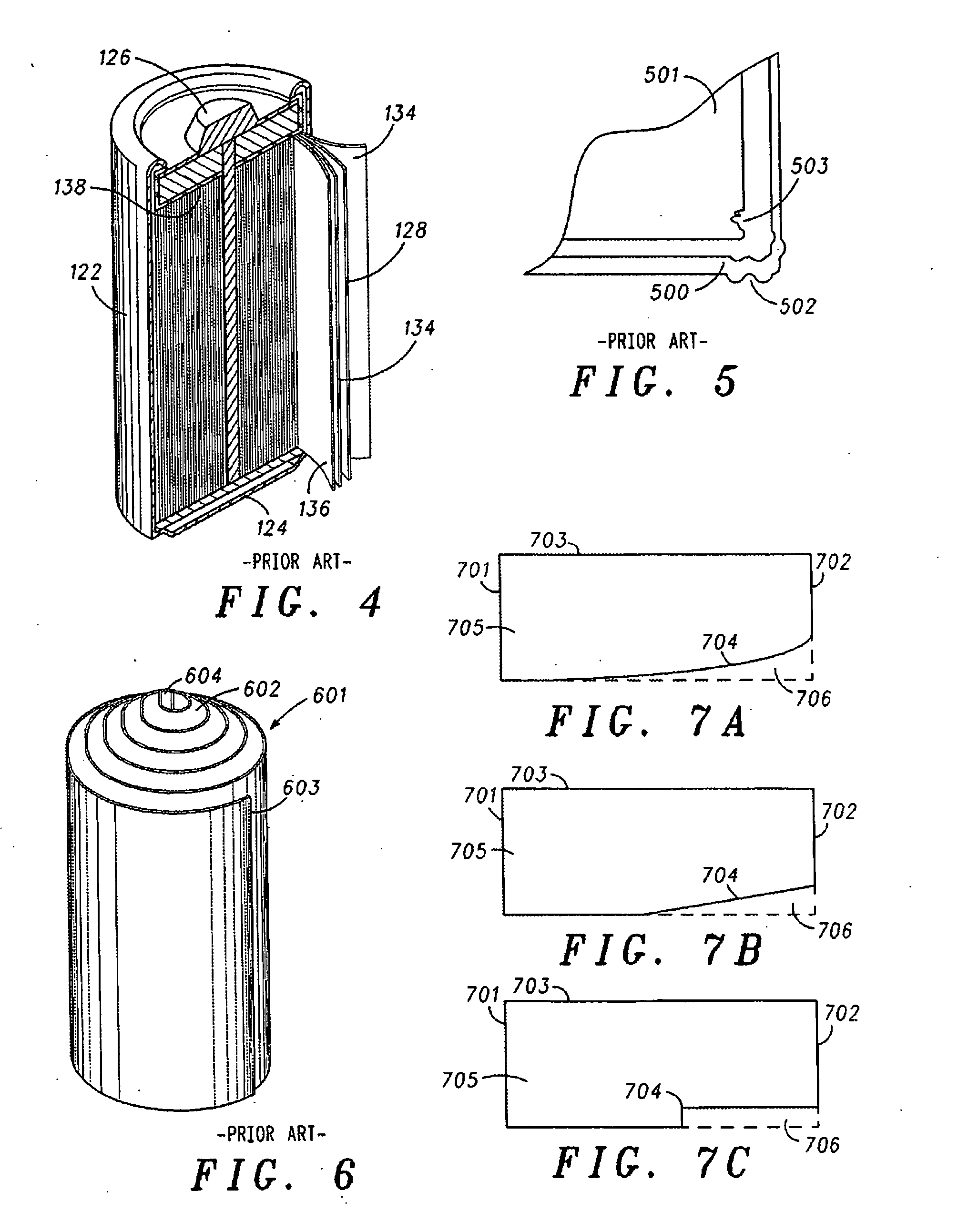

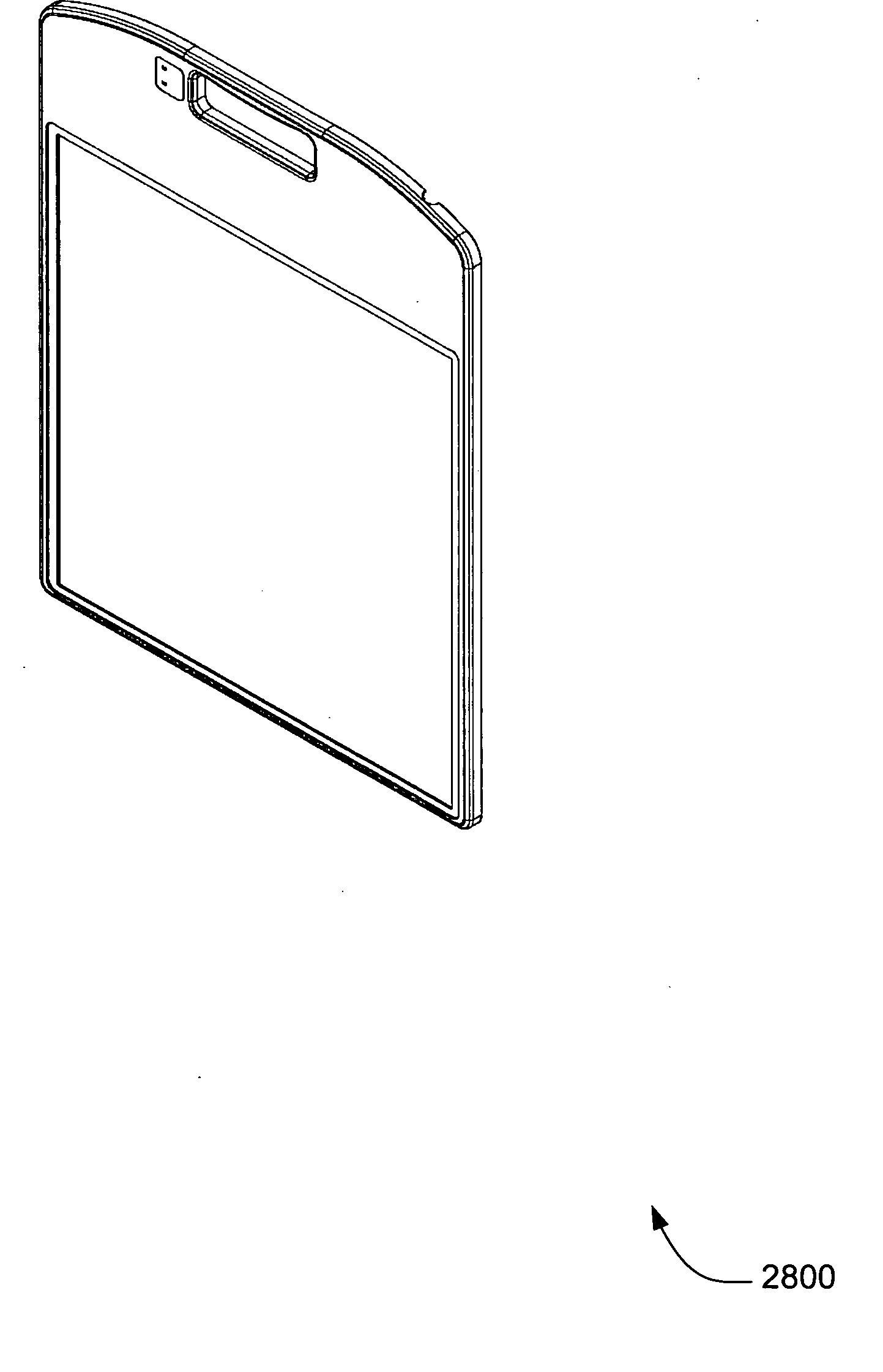

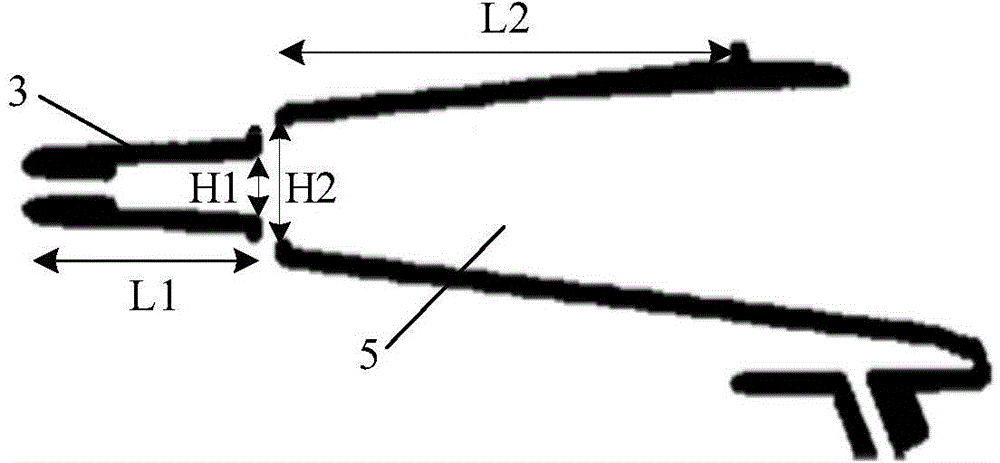

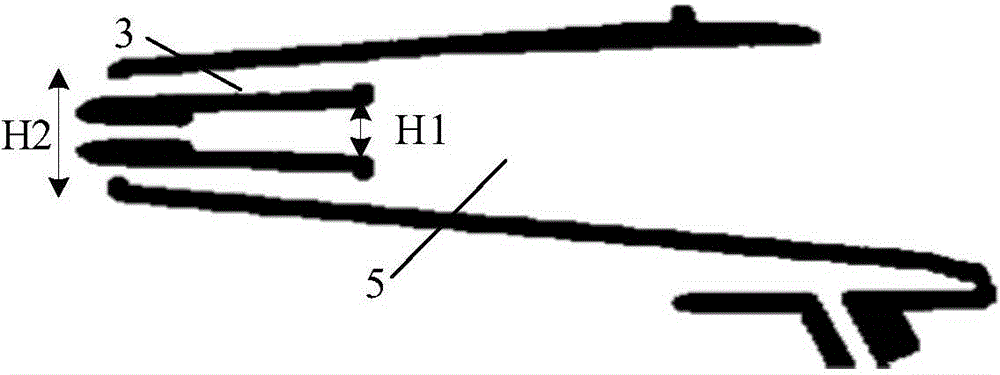

Impact resistant electrochemical cell with tapered electrode and crumple zone

InactiveUS20060127762A1Cell seperators/membranes/diaphragms/spacersFinal product manufactureRechargeable cellCrumple zone

This invention includes a tapered electrode assembly for providing a crumple zone in a rechargeable cell. The taper, which may be curvilinear, angular or piecewise linear, allows a void to exist between the corner of the metal can and the electrode assembly. This “crumple zone” prevents any external damage to the can from damaging the internal electrode assembly. The invention facilitates passage of common OEM drop testing without compromising cell performance or energy storage capacity. The invention increases the reliability of the cell by allowing the cell to resist external impacts.

Owner:MOTOROLA INC

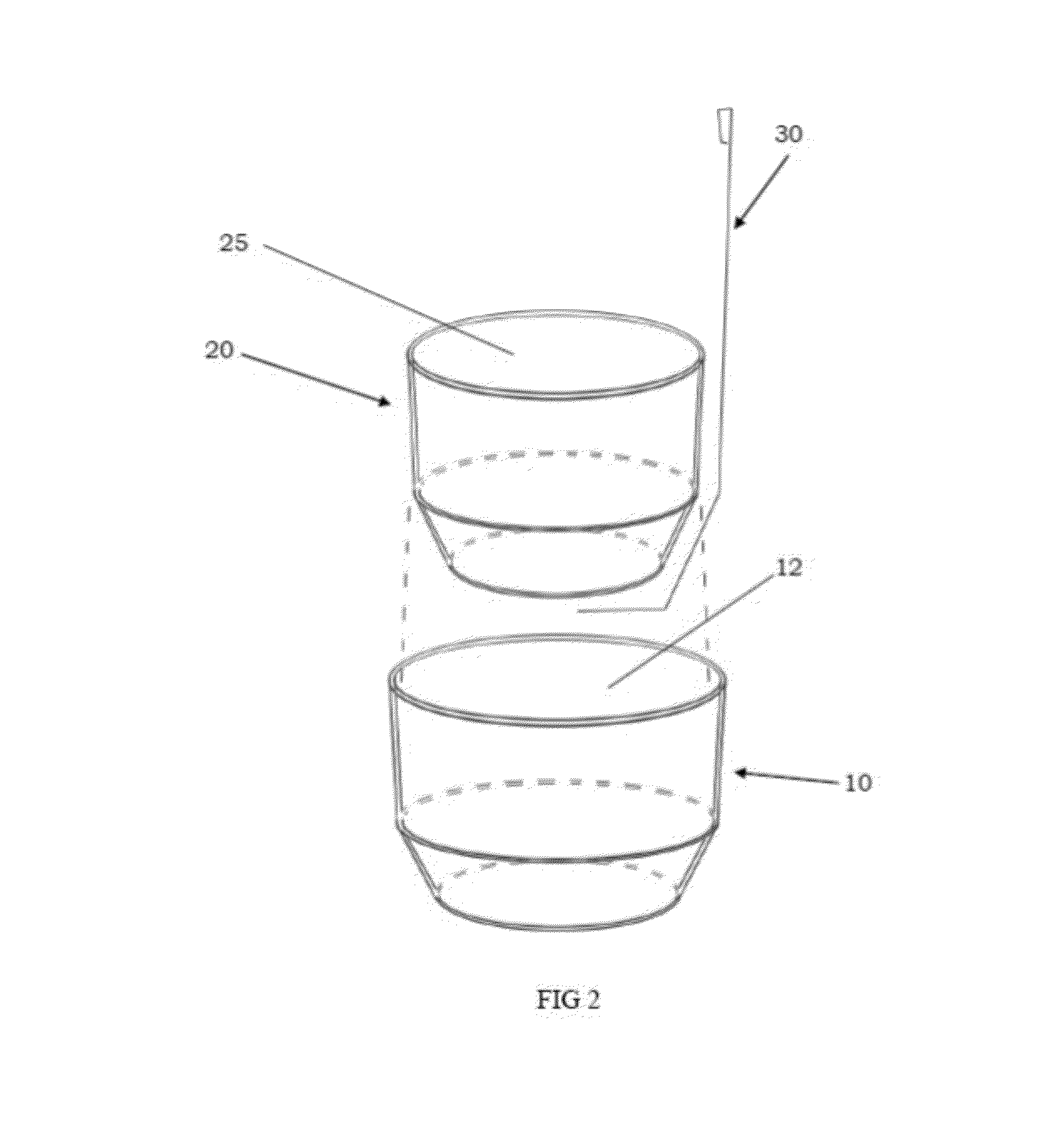

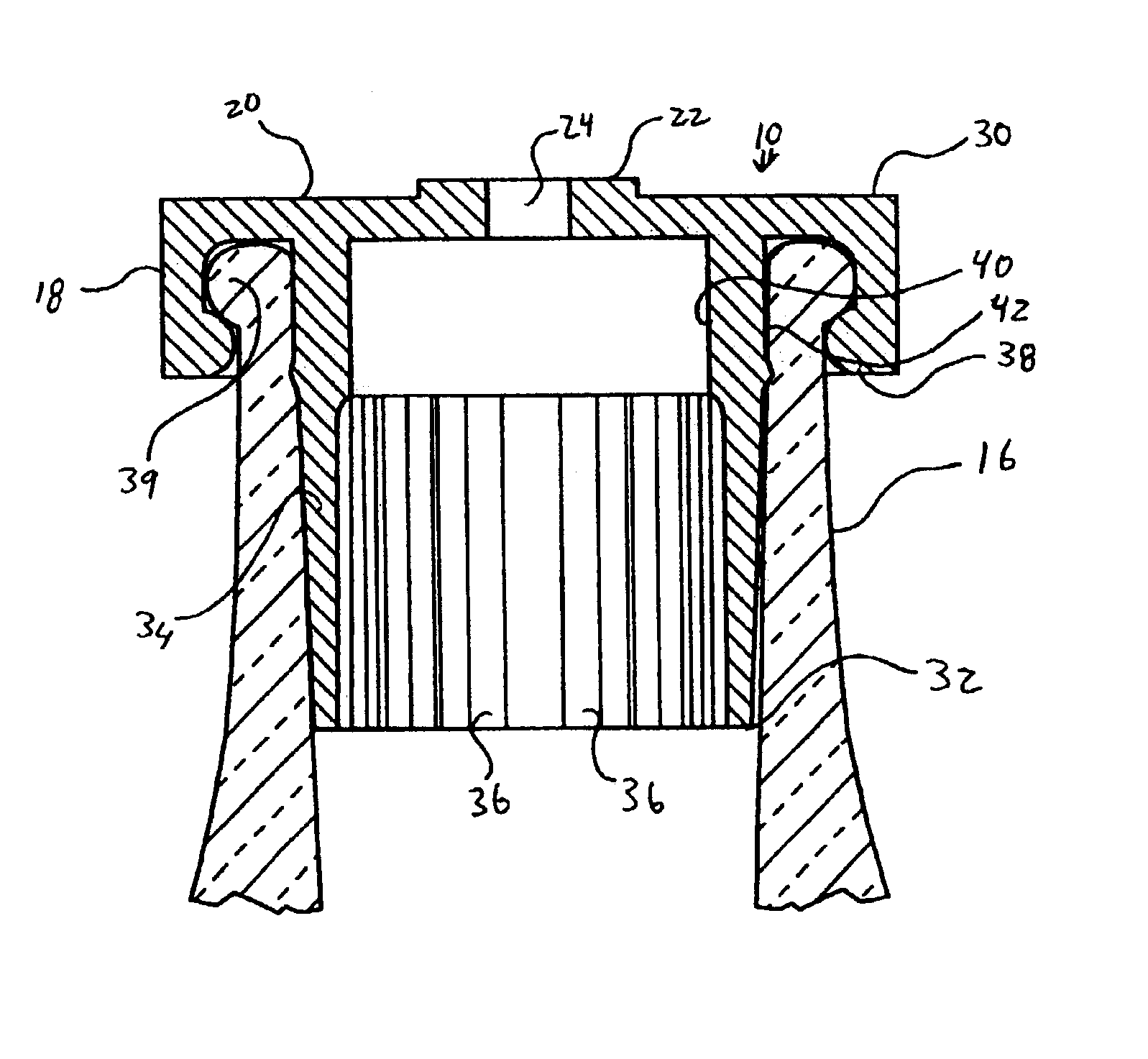

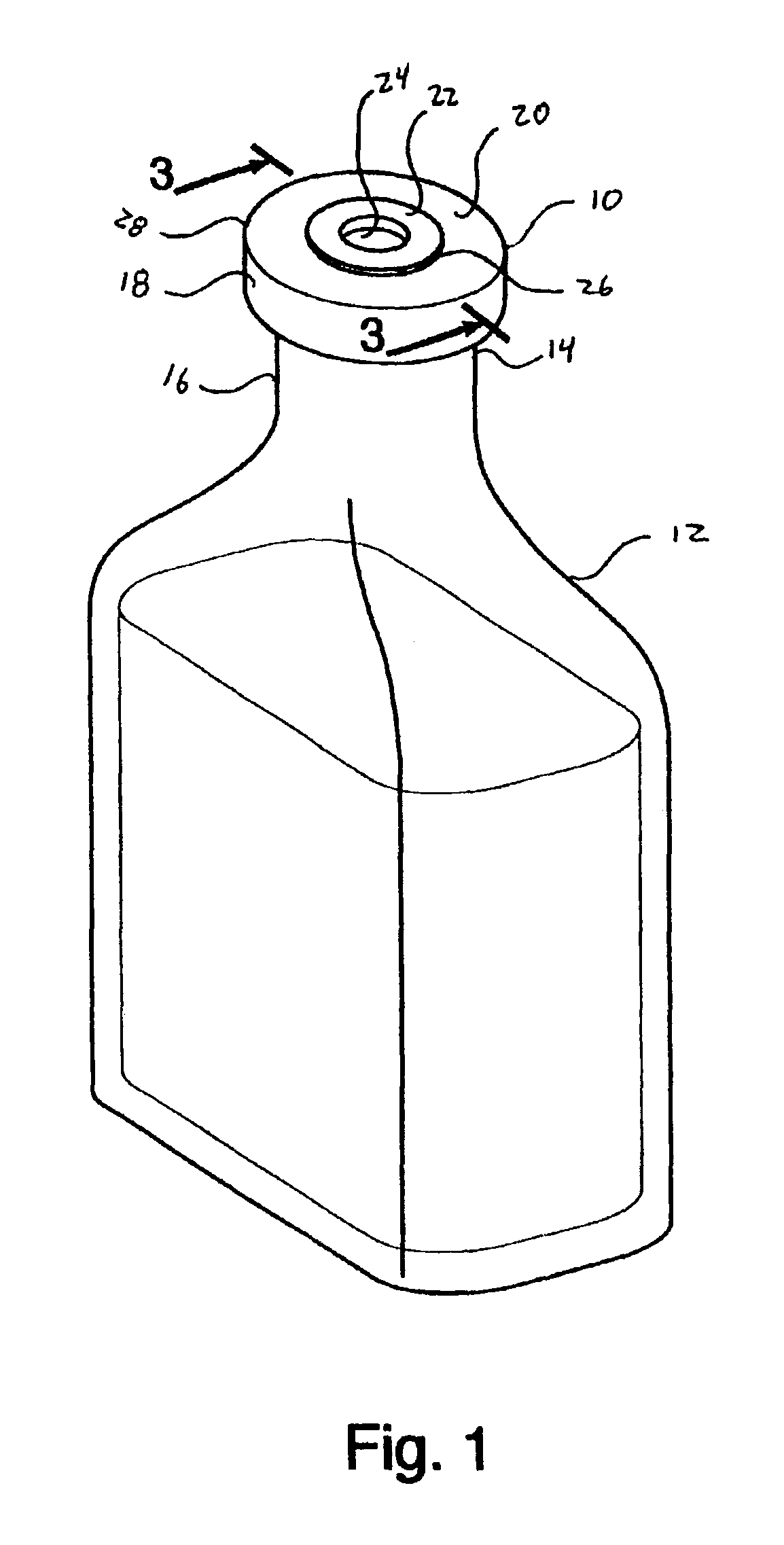

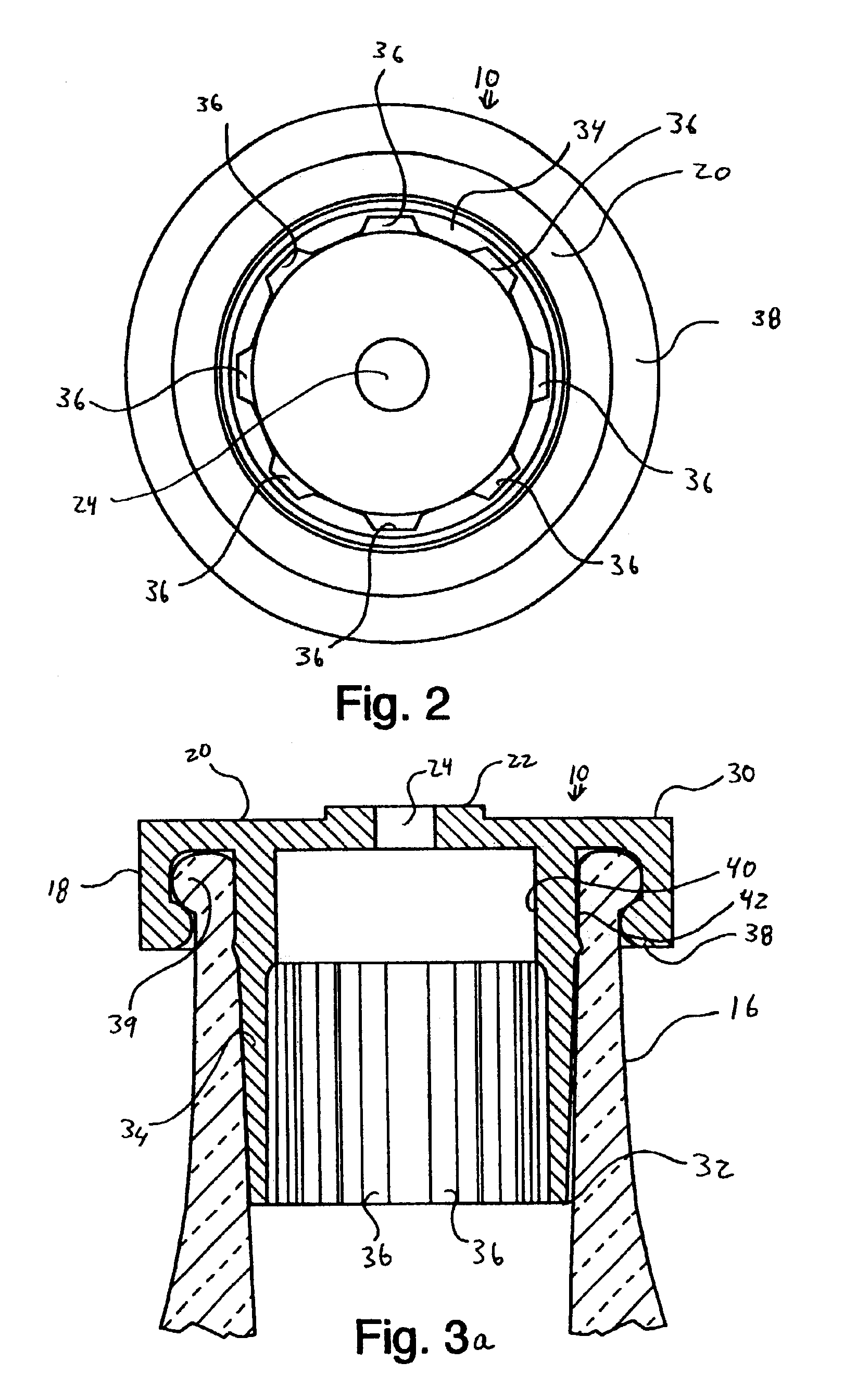

Orifice reducer for container neck

An orifice reducer with crumple zones well suited for use with an extrusion blow molded bottle having an uneven surface finish. The device includes a circumferential wall having a number of vertically extending reduced thickness regions, preferably spaced symmetrically about the circumferential wall. The reduced thickness regions deform upon insertion of the orifice reducer into the neck of a bottle to account for irregularity of the surface finish of the bottle. This allows the orifice reducer to be more easily inserted into standard extrusion blow molded bottles.

Owner:ACCESS BUSINESS GRP INT LLC

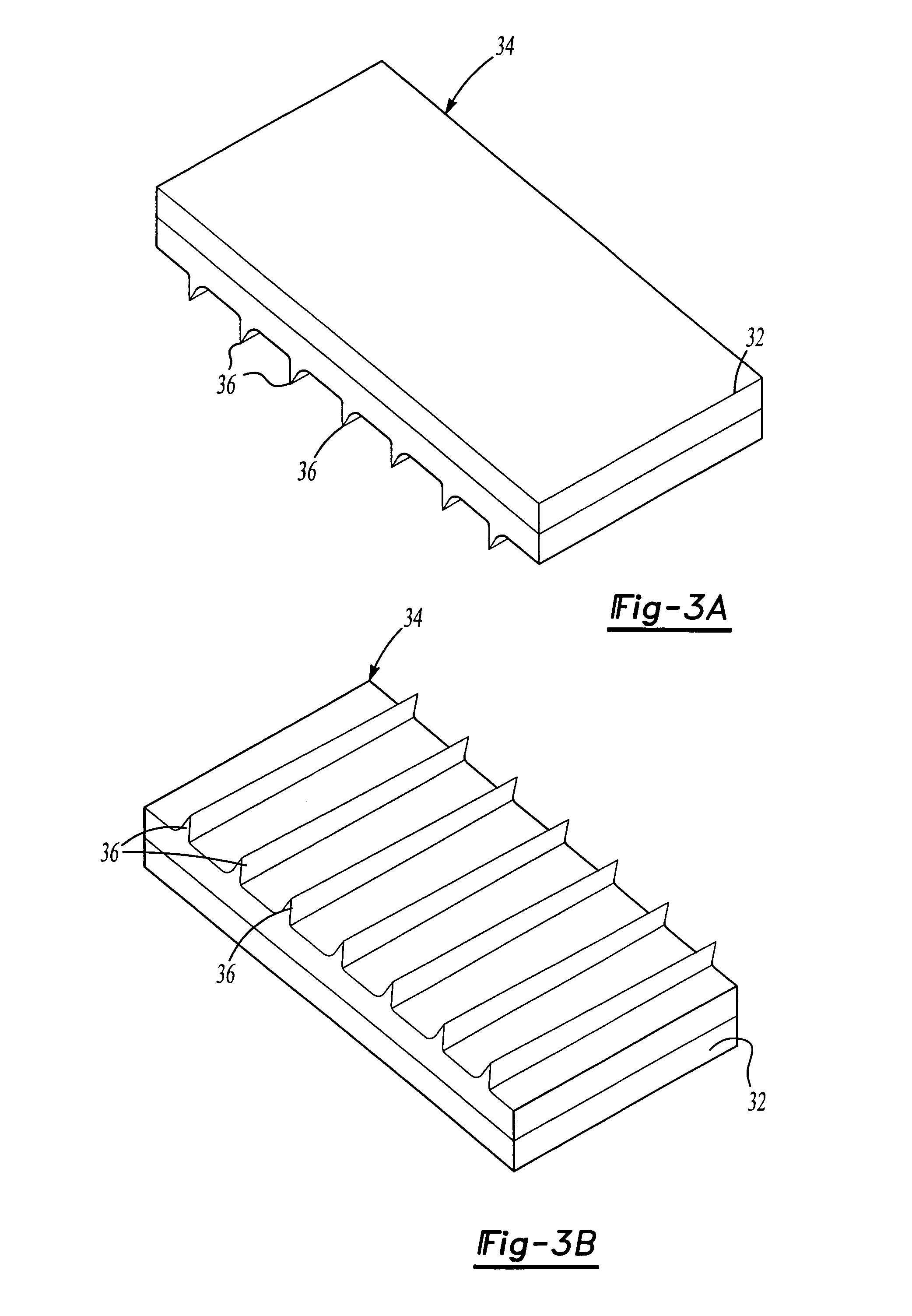

Crumple zone for body panels

InactiveUS7052077B1Less-harmful to pedestrianLess-expensive to produceUnderstructuresSuperstructure connectionsThermoplasticCOLORED MATERIAL

The body panels of the present invention are designed to crumple in a predisposed manner upon impact. The body panels are preferably made from a polymeric material. Further, the body panels can include a sheet of colored material attached to the polymeric material so that no painting of the panel is necessary. Preferably, the colored material is on an exterior surface of the panel. The colored material could be made from a thermoplastic with molded in color. The preferred embodiment of the present invention includes a polymeric material reinforced with spaced reinforcing fibers. An alternative embodiment of the body panel includes a sheet of polymeric material that is reinforced with spaced mechanical ribs that are preferably molded into the sheet of material. Another alternative embodiment of the body panel includes alternating sections of high density polymeric foam and low density polymeric foam. Yet another alternative embodiment of the body panel includes a sheet of foam material, preferably polymeric, that is reinforced with spaced metal inserts. The metal inserts are preferably notched to yield in a predetermined manner.

Owner:MERITOR LIGHT VEHICLE SYST UK

Systems, methods, and apparatus for a kinetic energy absorbing device

InactiveUS20060169906A1Improves reliability and longevityImprove the level ofSolid-state devicesMaterial analysis by optical meansEngineeringSystems approaches

Systems, methods and apparatus are provided through which an impact absorbing material is affixed to a transportable device to protect the transportable device from impact with another object. In some embodiments, the impact absorbing material is a crumple zone material that has plastic deformation characteristics.

Owner:GENERAL ELECTRIC CO

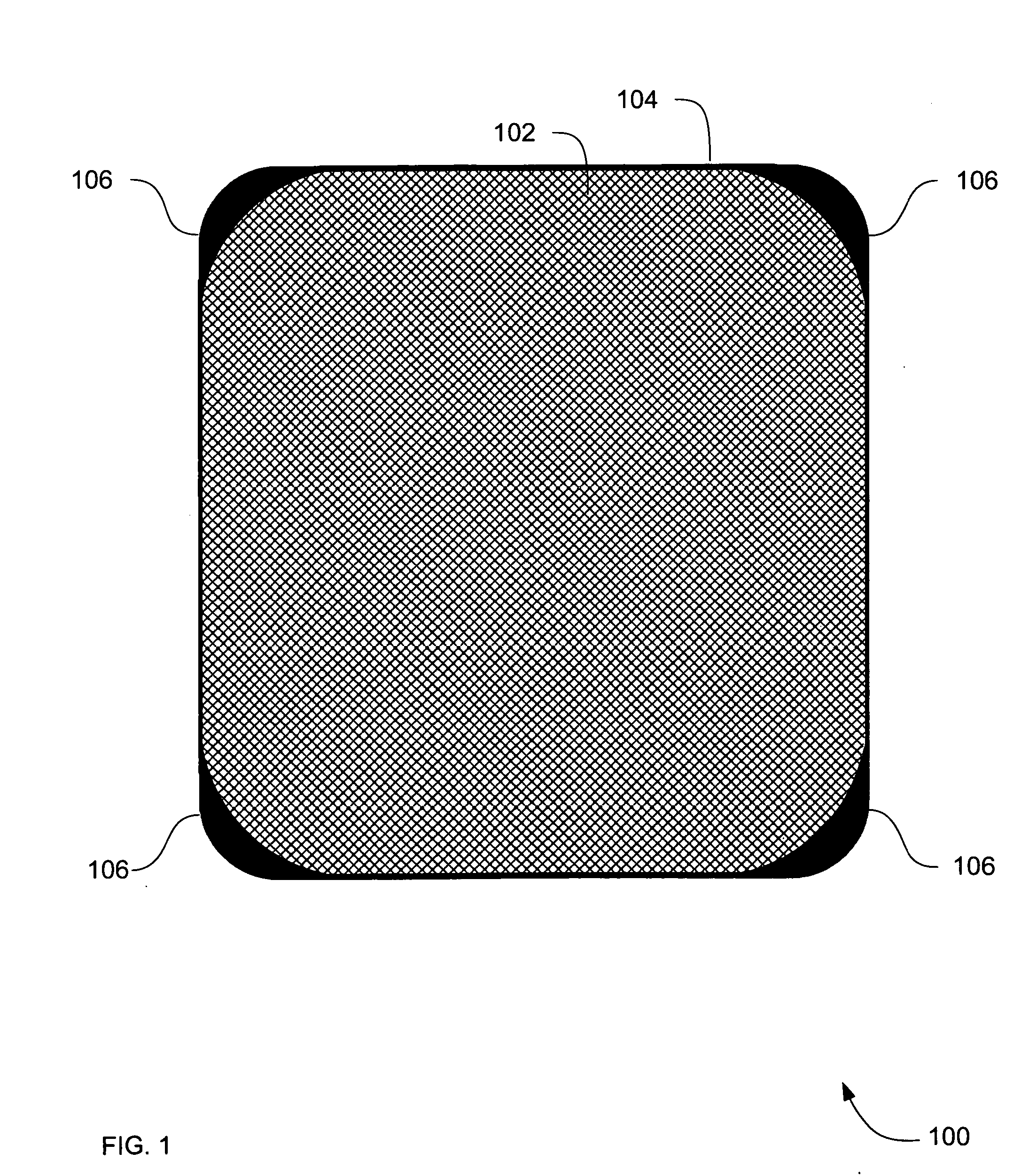

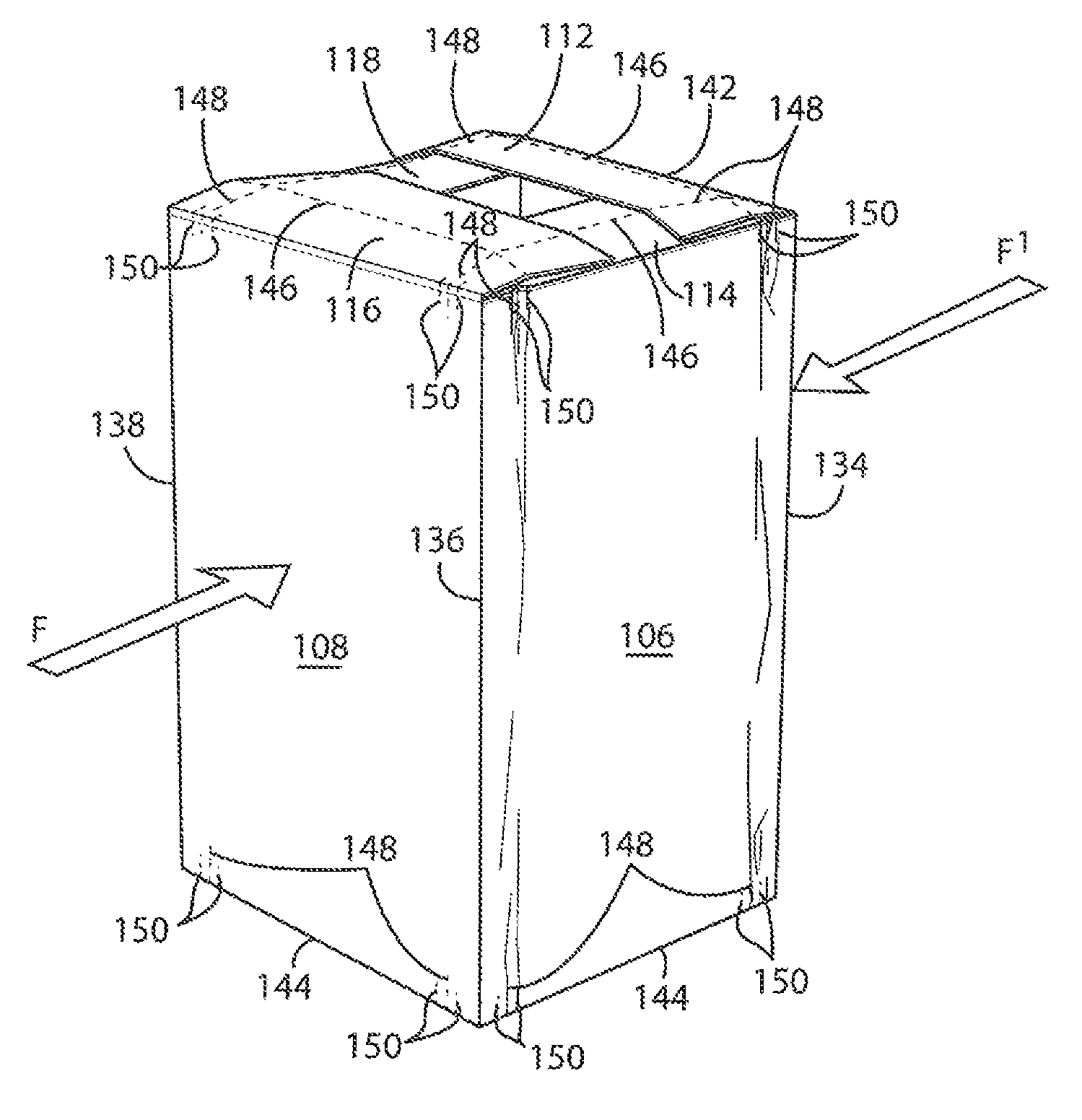

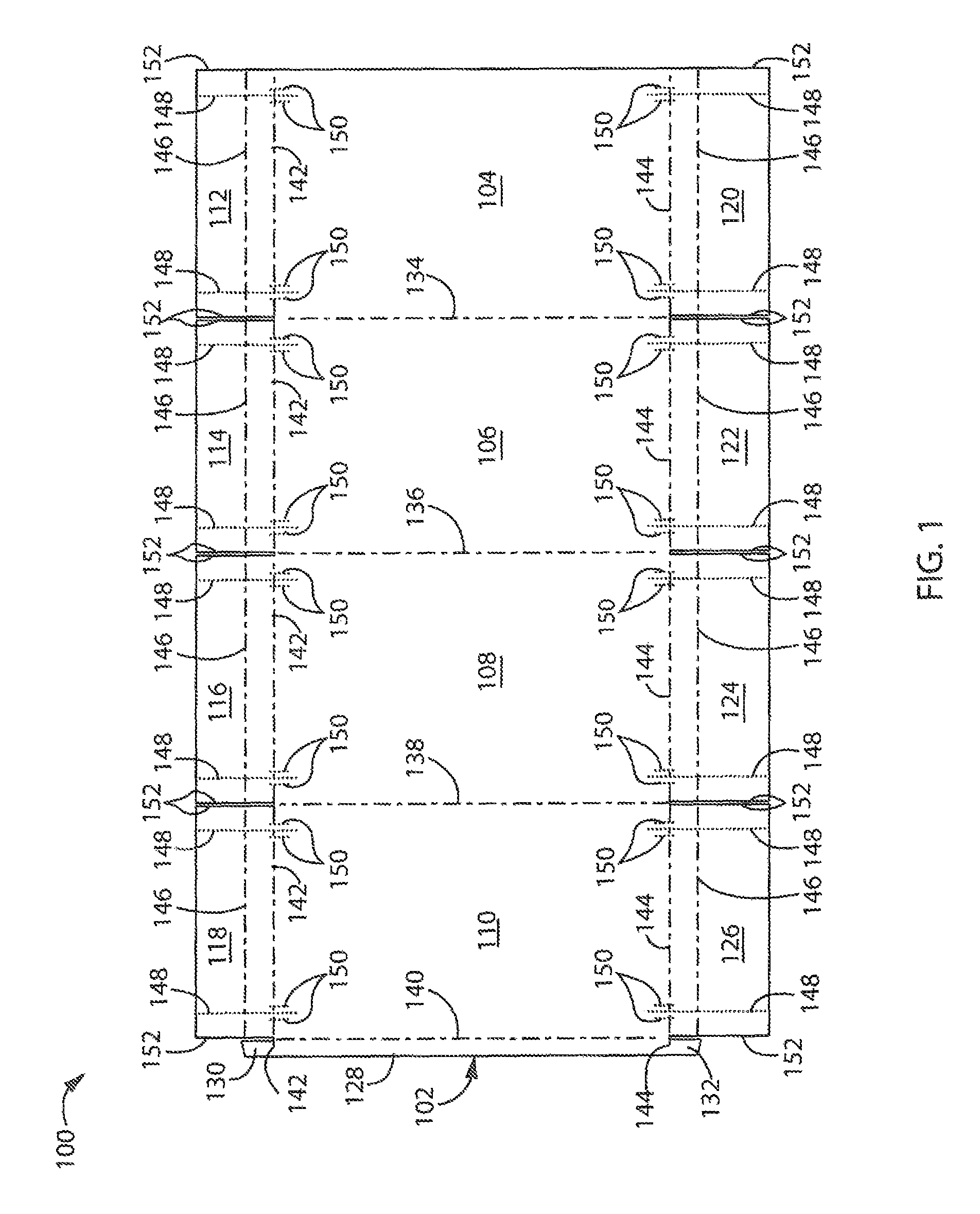

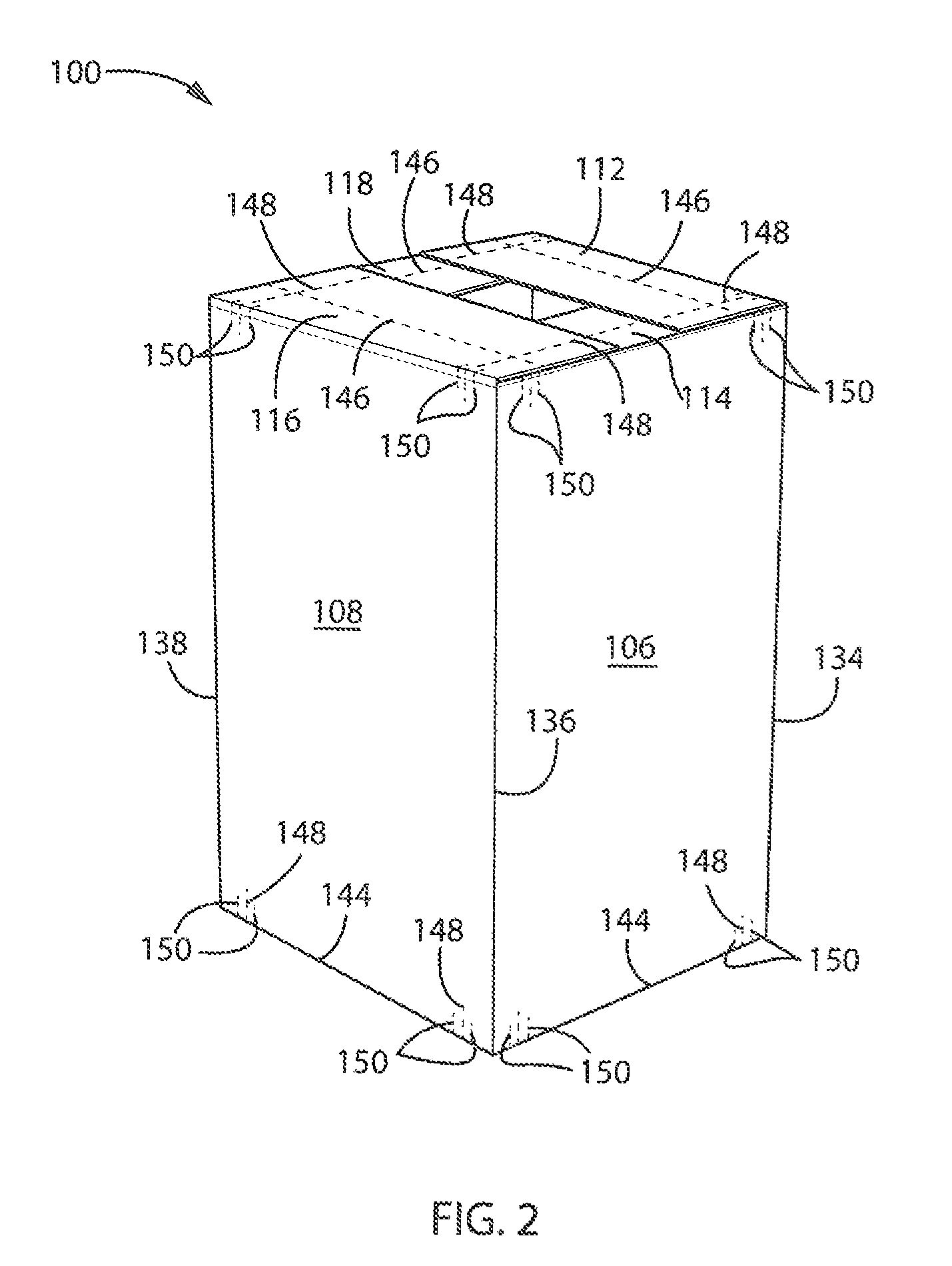

Carton with corner crumple zones

ActiveUS9573722B1Minimizes deformation of surfaceDeformation MinimizationPackaging vehiclesContainers for machinesCartonCrumple zone

A shipping carton having a force receiving area located adjacent opposing edges of the carton's top and bottom edges. The force receiving area is configured to deform in the presence of an external force and distribute that force through the force receiving area while minimizing the transfer of force directly to the appliance and minimizing damage to the surface panels of the shipping carton.

Owner:GREEN BEI PACKAGING INC

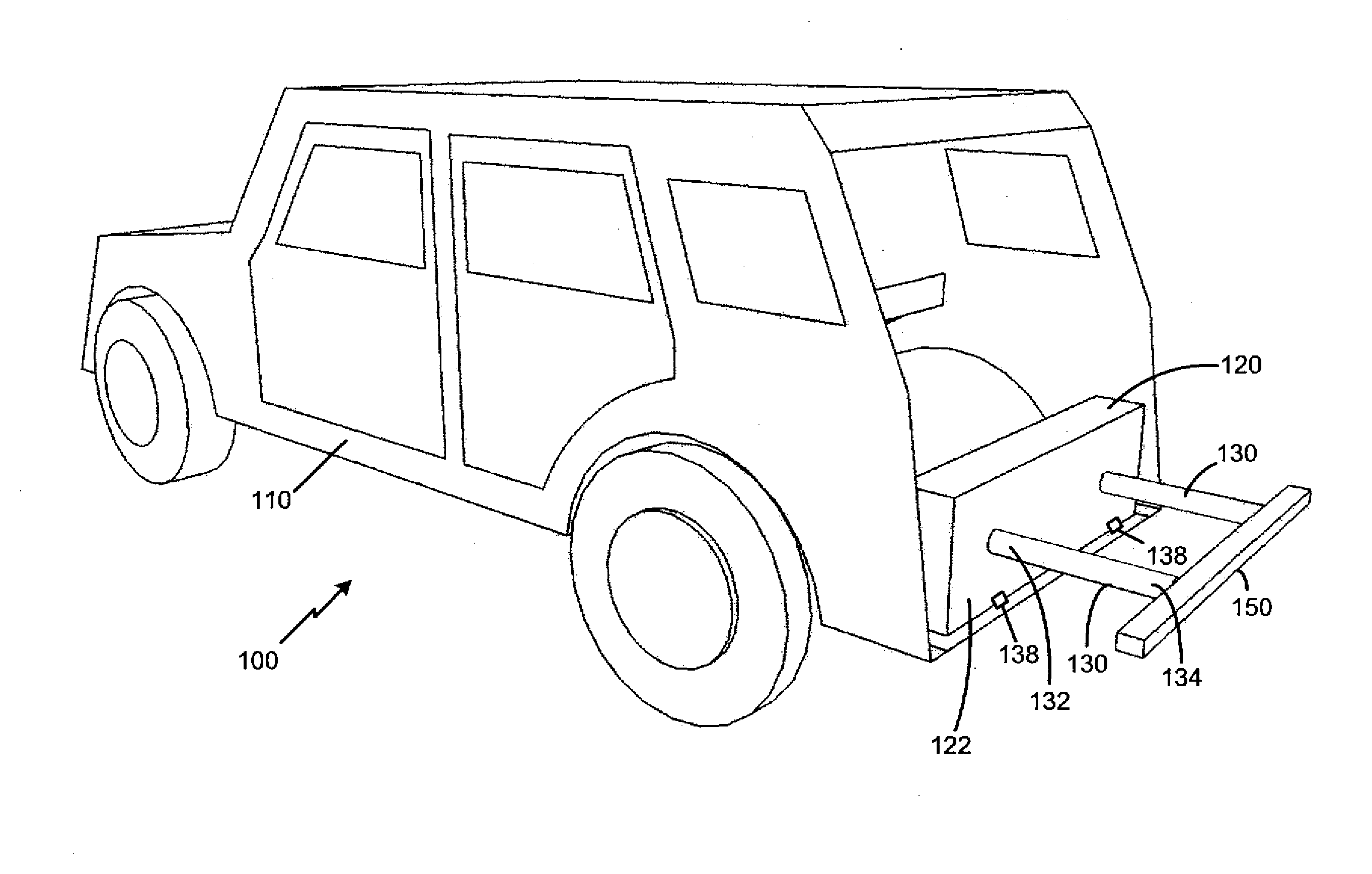

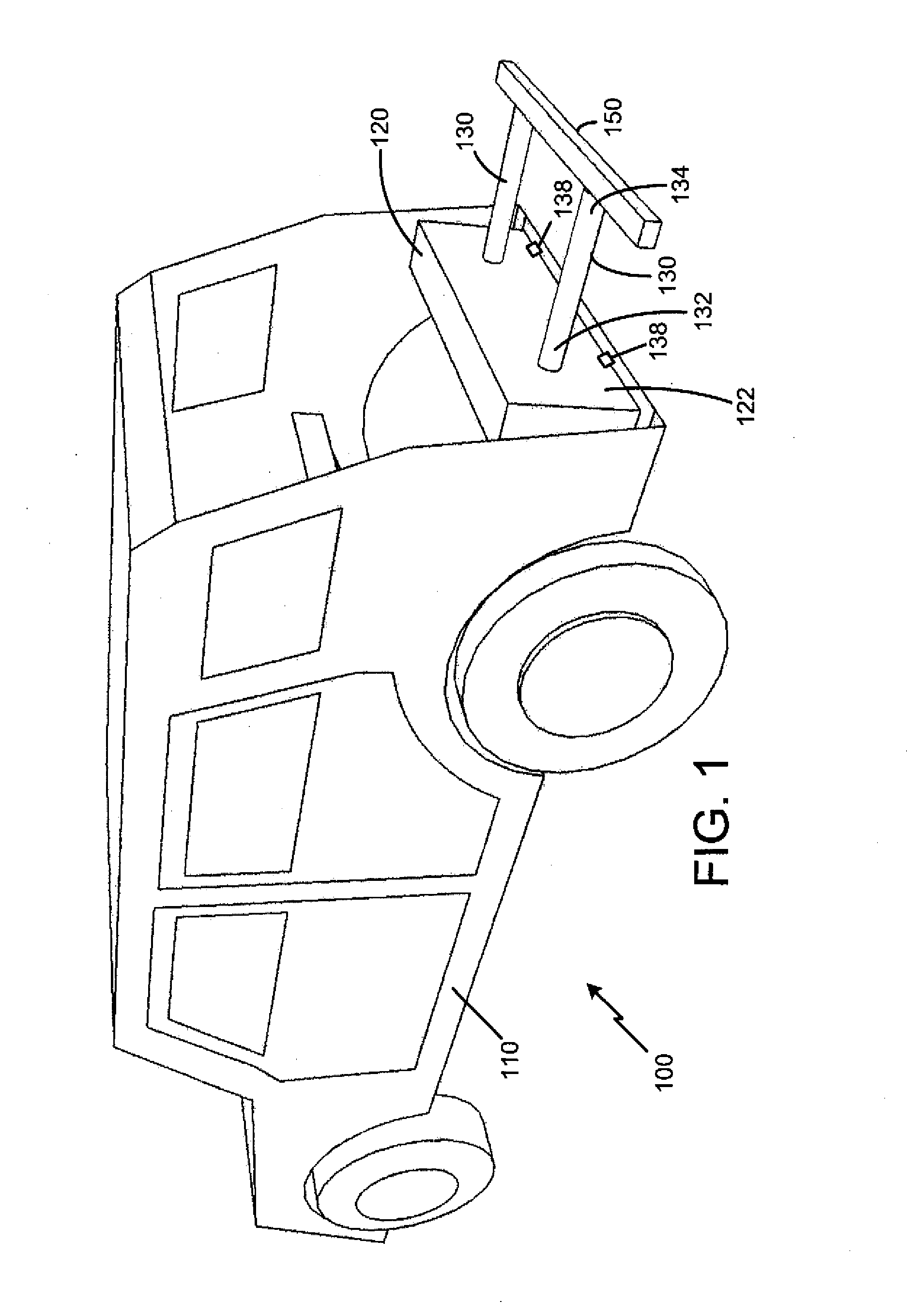

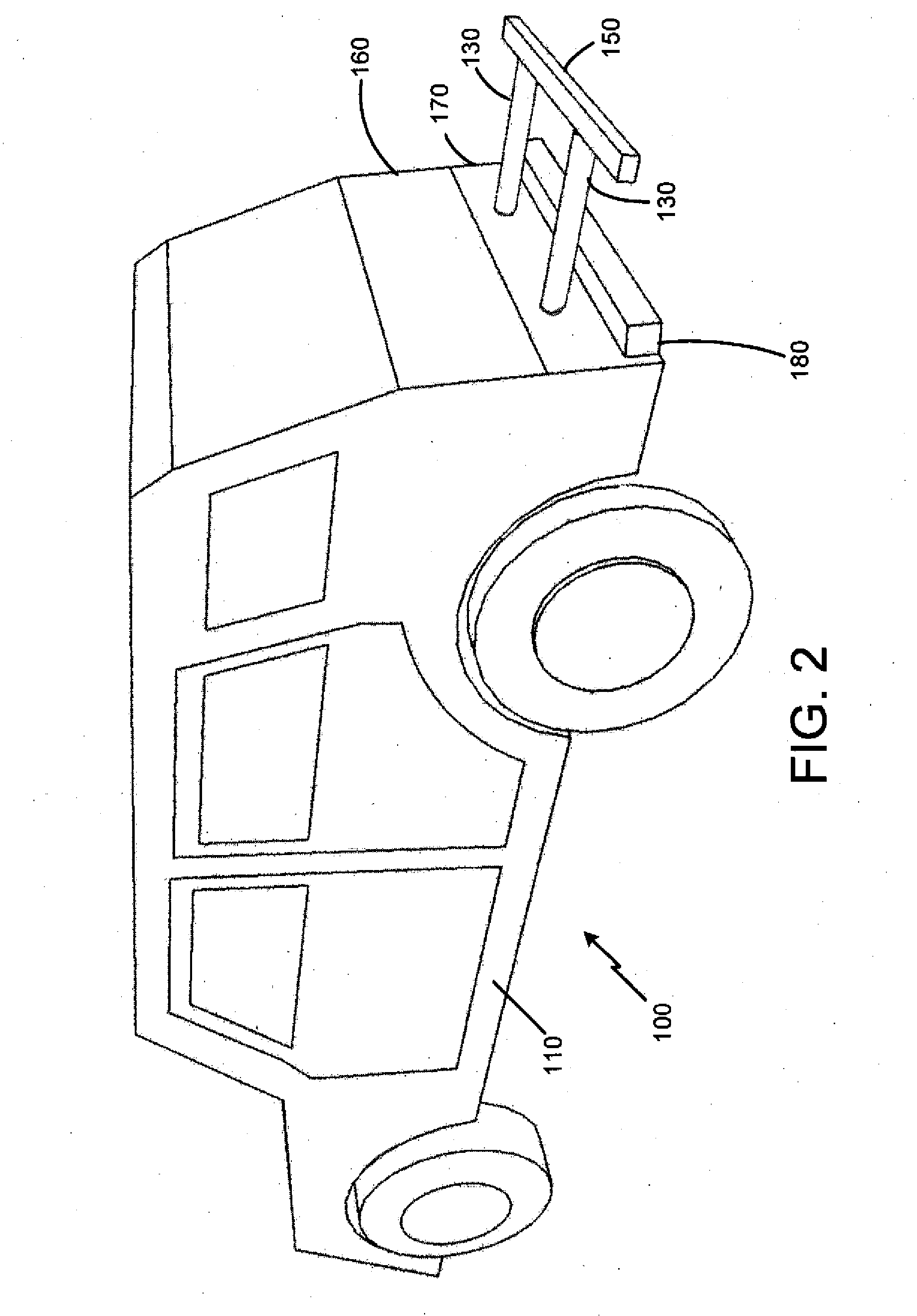

Method and Apparatus for an Attachable and Removable Crumple Zone

A system for absorbing impact energy includes a container formed with a plurality of faces, wherein the container is attached to a vehicle. An energy-absorbing material is substantially contained within the container. At least one elongated member having a proximate end and a distal end is included, wherein the proximate end is proximate to a first face of the container. A long axis of the at least one elongated member may intersect the first face. A bumper may be connected to the distal end of the at least one elongated member.

Owner:SHOAP STEPHEN D

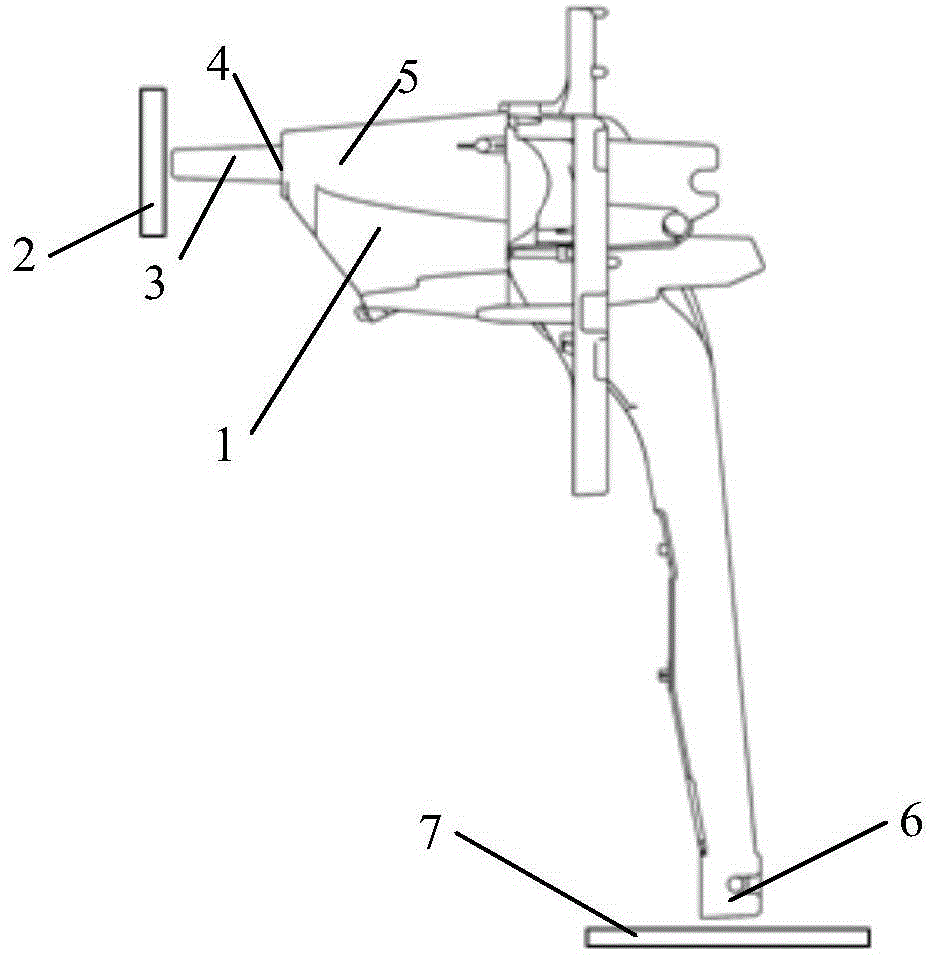

Car instrument panel crossbeam

The invention relates to a car instrument panel crossbeam. The car instrument panel crossbeam is connected with a front-wall zone of a car body. A structure connected to the front-wall zone of the car body comprises a crumple zone, a breaking zone and a maintaining zone; the crumple zone is connected with the car-body front-wall zone and is suitable for receiving an impact force transferred by virtue of the car-body front-wall zone; the breaking zone is respectively connected with the crumple zone and the maintaining zone and suitable for being broken when the crumple zone receives the impact force transferred via the car-body front-wall zone; the end surface of the end, connected with the breaking zone, of the maintaining zone is larger than that of the end, connected with the breaking zone, of the crumple zone; the maintaining zone is suitable for containing the crumple zone when the breaking zone is broken. By virtue of the car instrument panel crossbeam, the safety performance of a car can be improved.

Owner:SAIC MOTOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com