Patents

Literature

322 results about "Conical forms" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Conical(adj) having the form of, or resembling, a geometrical cone; round and tapering to a point, or gradually lessening in circumference; as, a conic or conical figure; a conical vessel. Conical(adj) of or pertaining to a cone; as, conic sections.

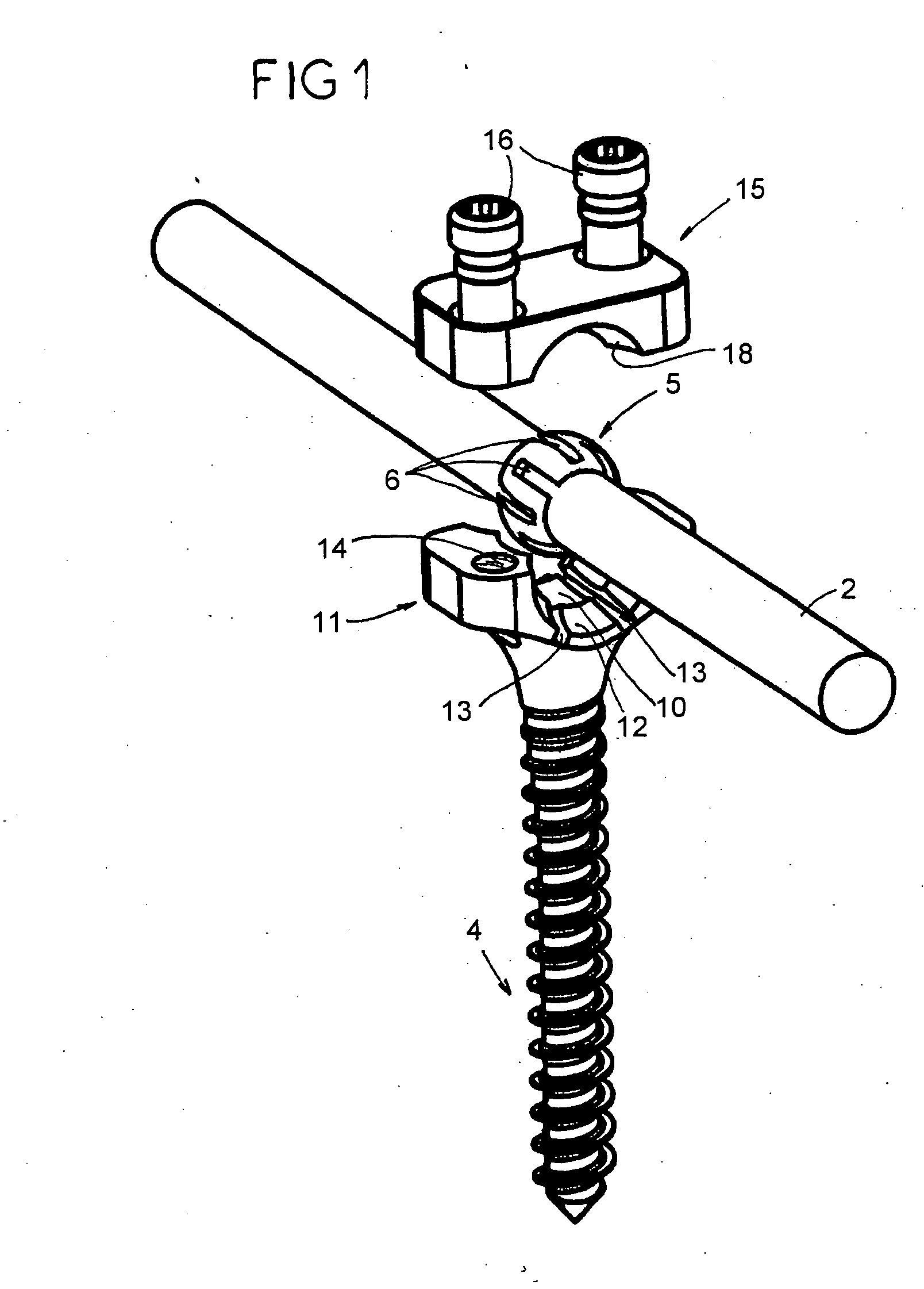

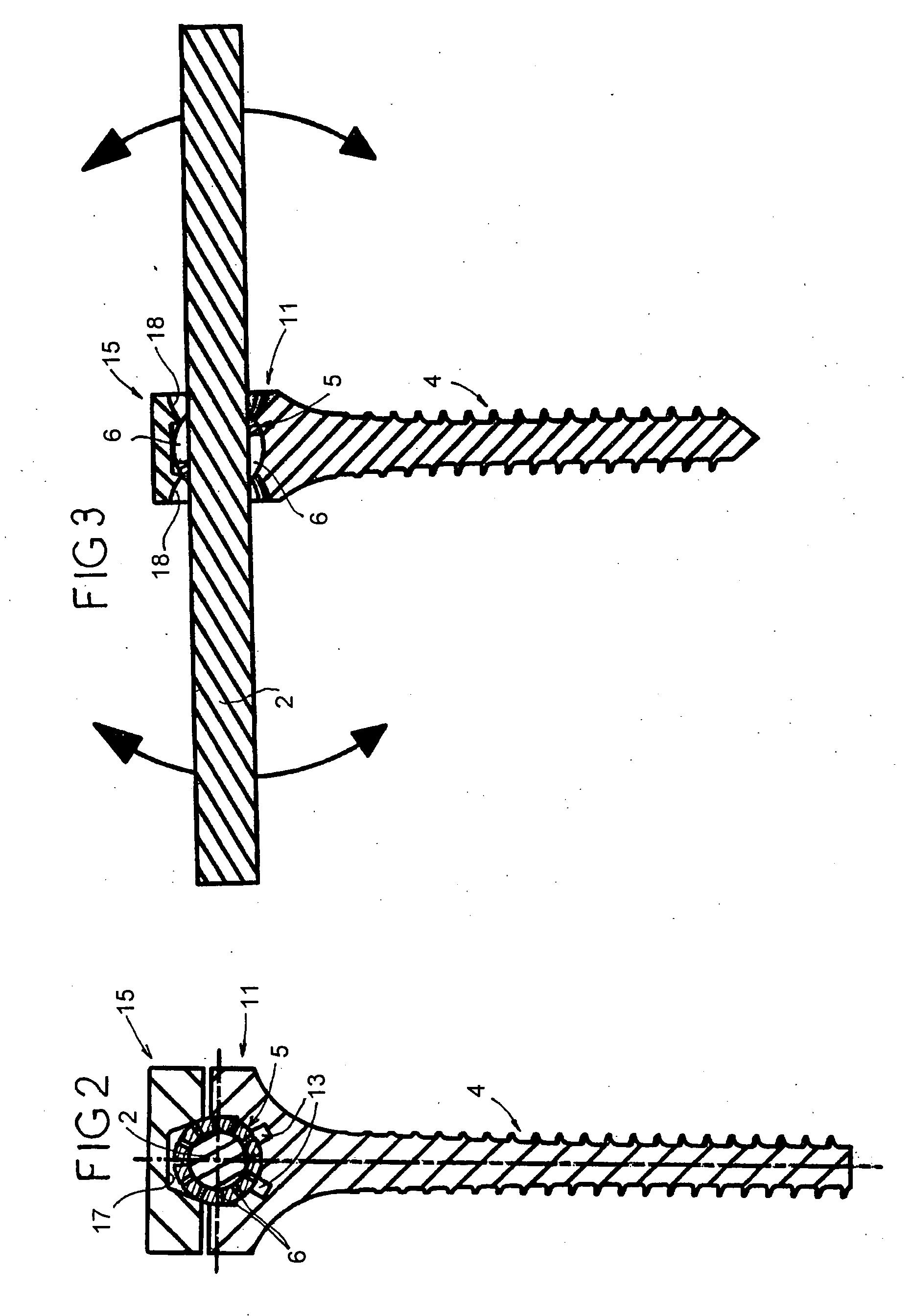

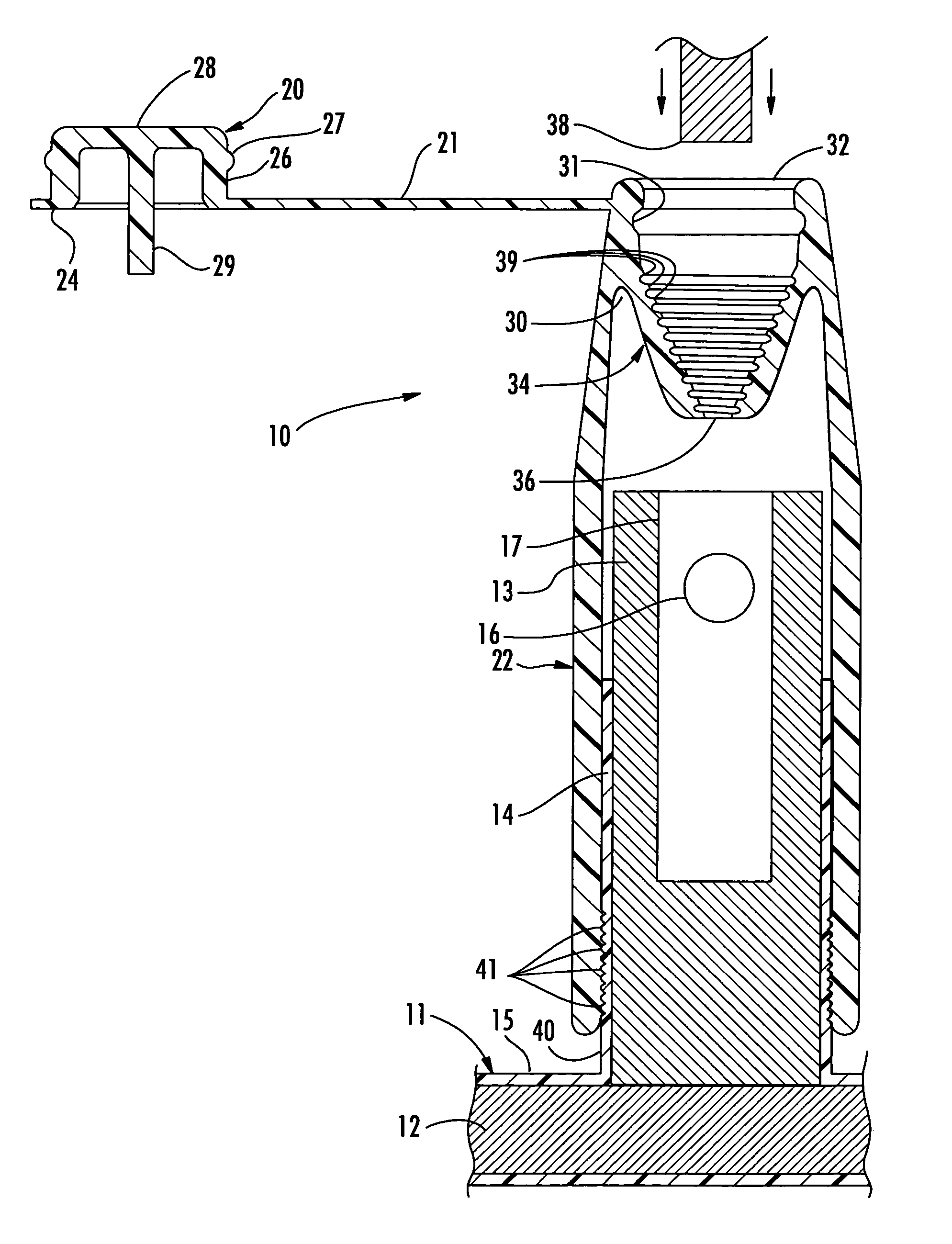

Surgical screw system and related methods

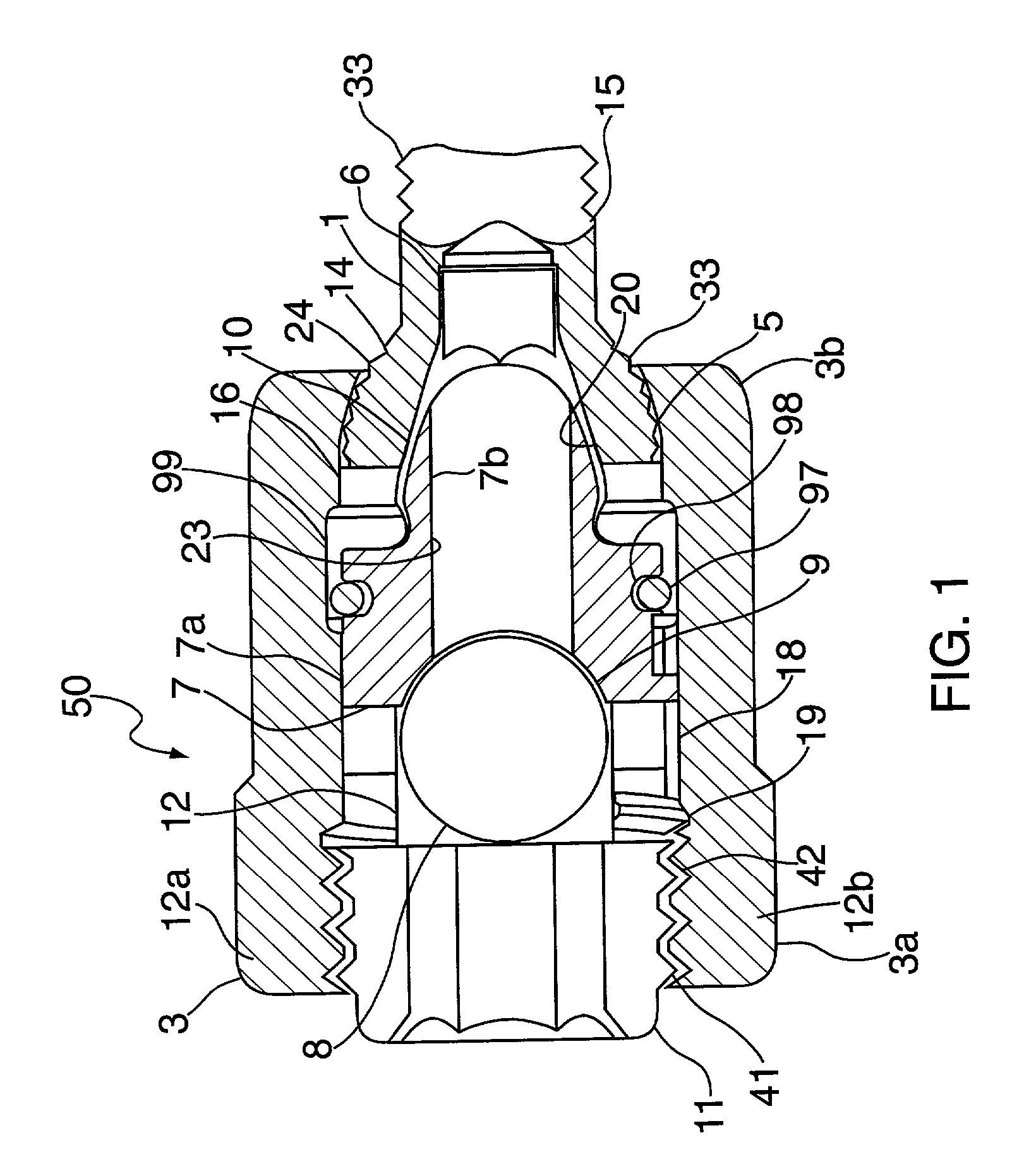

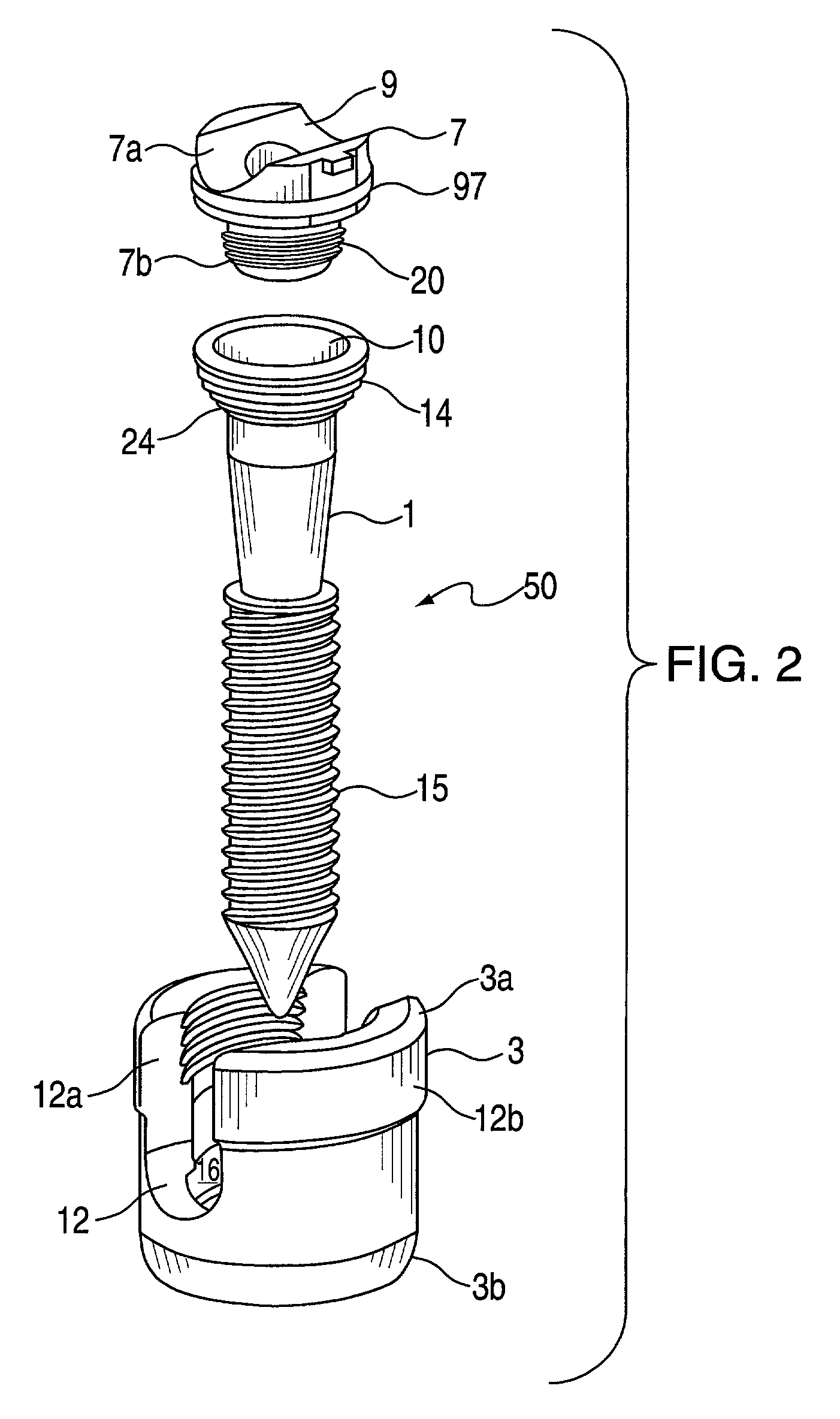

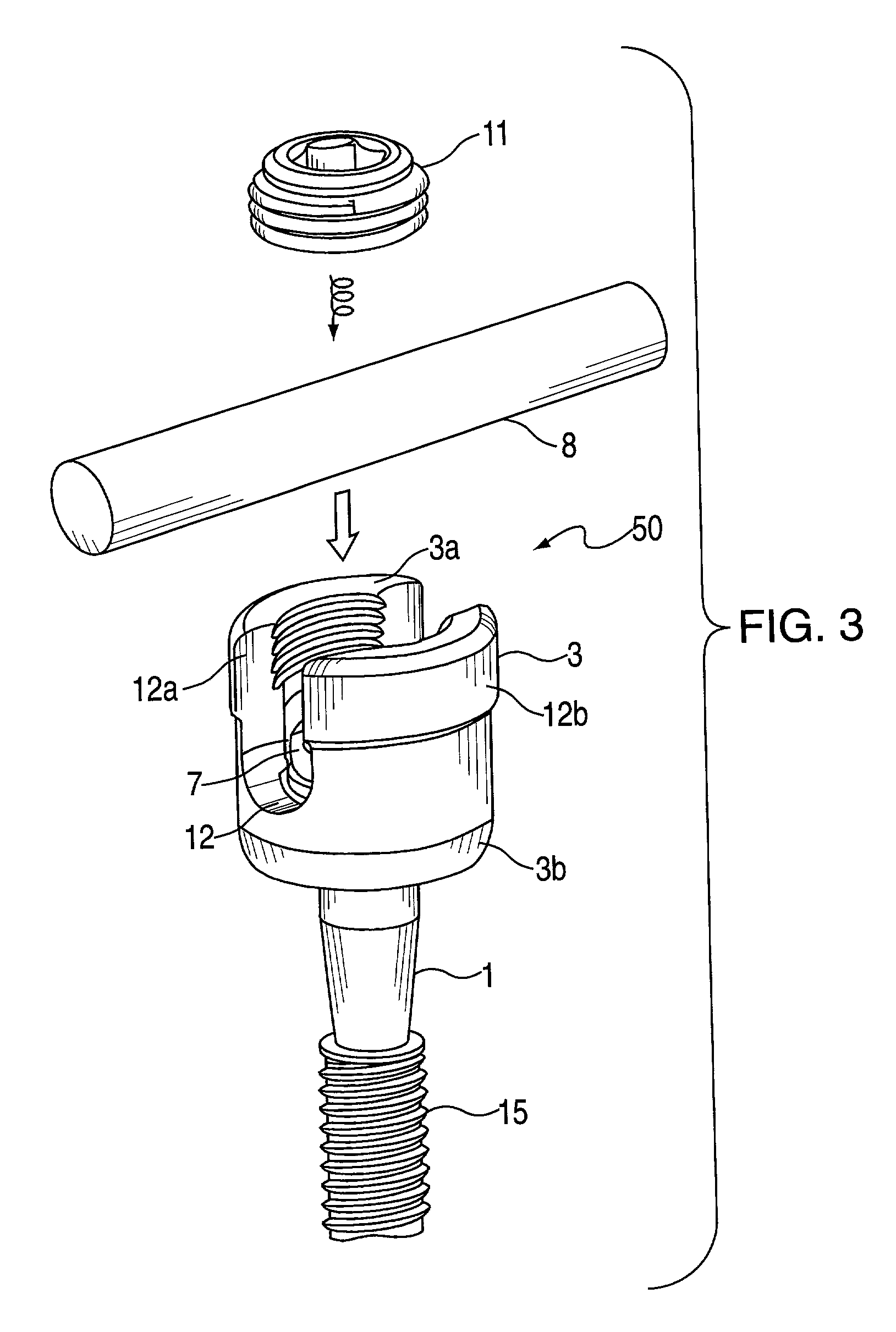

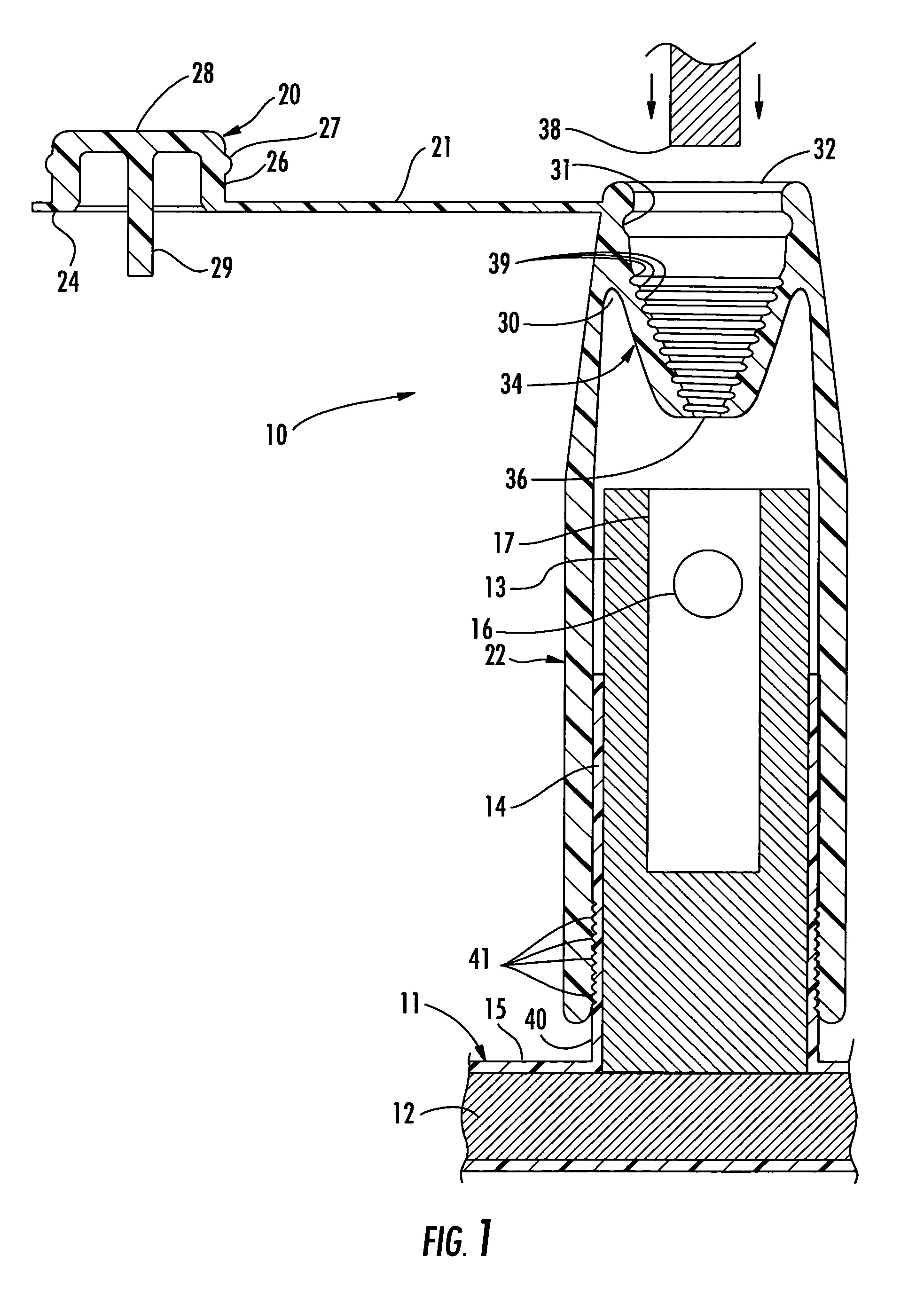

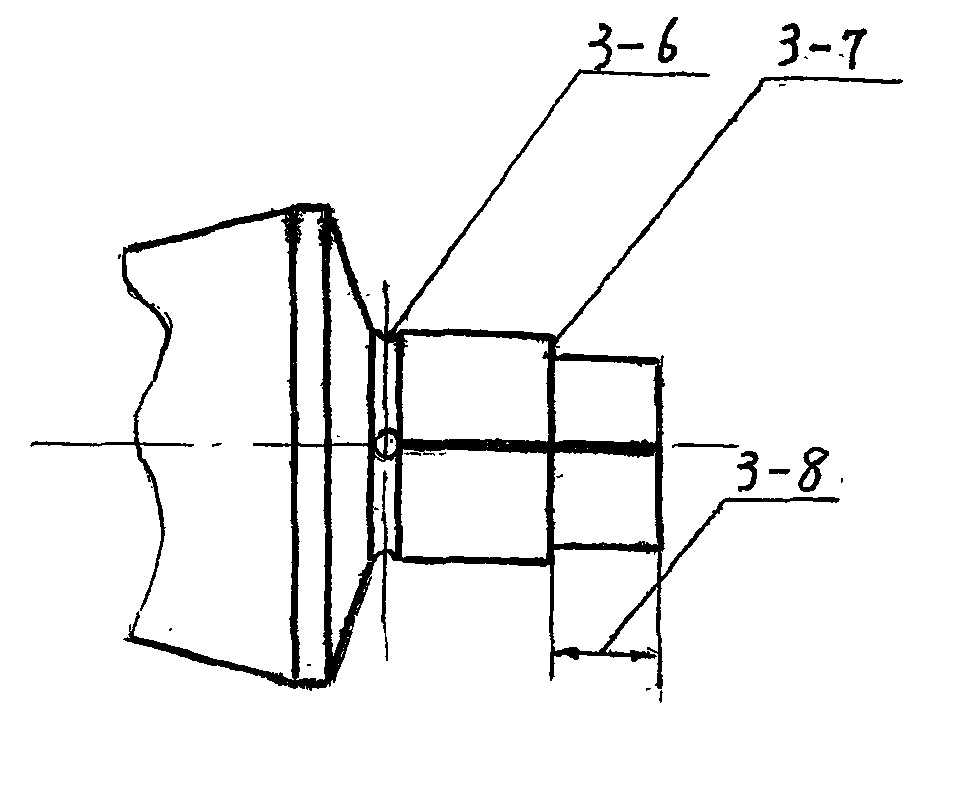

A surgical screw system for use with implantation rods includes a screw member, a receiver member, a pressure cap and a locking device. The screw member has a shaft and a head with a spherical undersurface and a conical tapered recess. The receiver member has an upper and lower portion, a u-shaped rod receiving channel and an axial bore. The u-shaped channel has two lateral legs at the upper portion and forms an opening leading to the axial bore. The axial bore near the lower portion includes an inwardly conical tapered surface which has a diameter larger than the shaft of the screw member but smaller than the head of the screw member. The conical surface forms a support upon which the spherical undersurface of the head of the screw member rests when the screw member is guided through the bore of the lower portion of the receiver member. The pressure cap is positioned within the axial bore and situated upon the head of the screw member. The locking device is designed for securing the rod within the u-shaped channel of the receiver member by applying a tightening torque upon the rod when positioned within the opening and the bore near the upper portion of the receiver member.

Owner:BLACKSTONE MEDICAL

Vertebral arthrodesis device

Owner:PARADIGM SPINE LLC

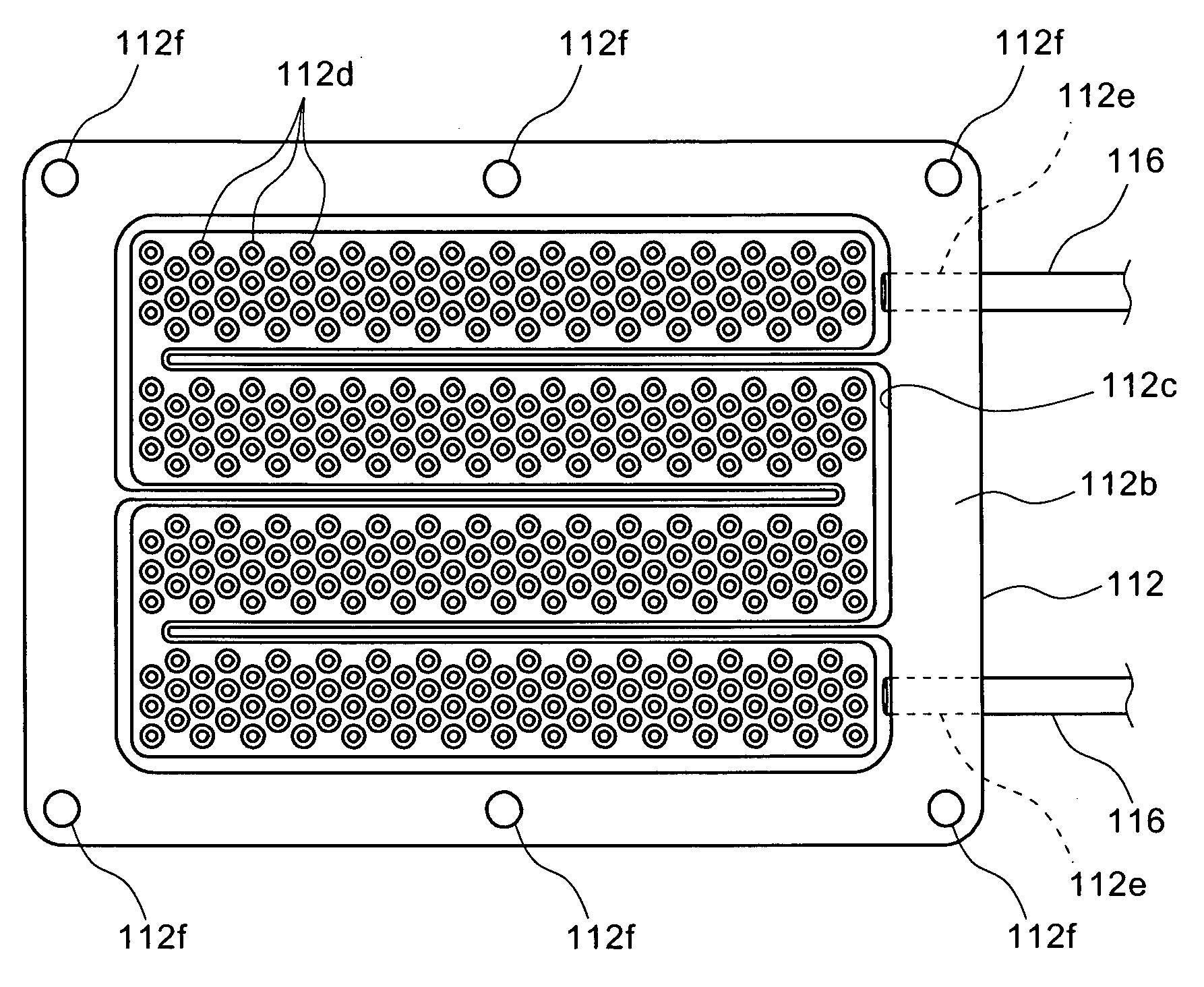

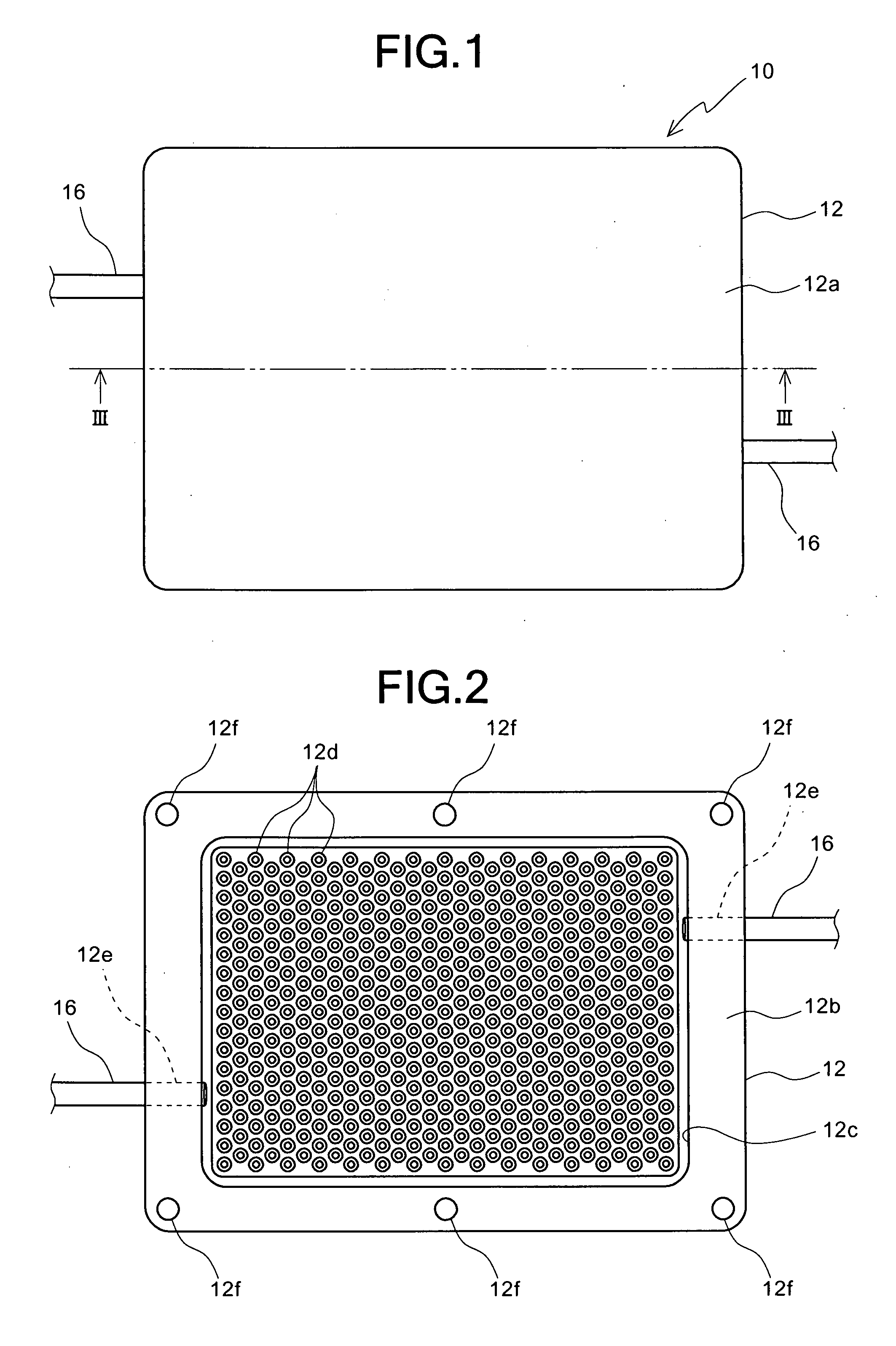

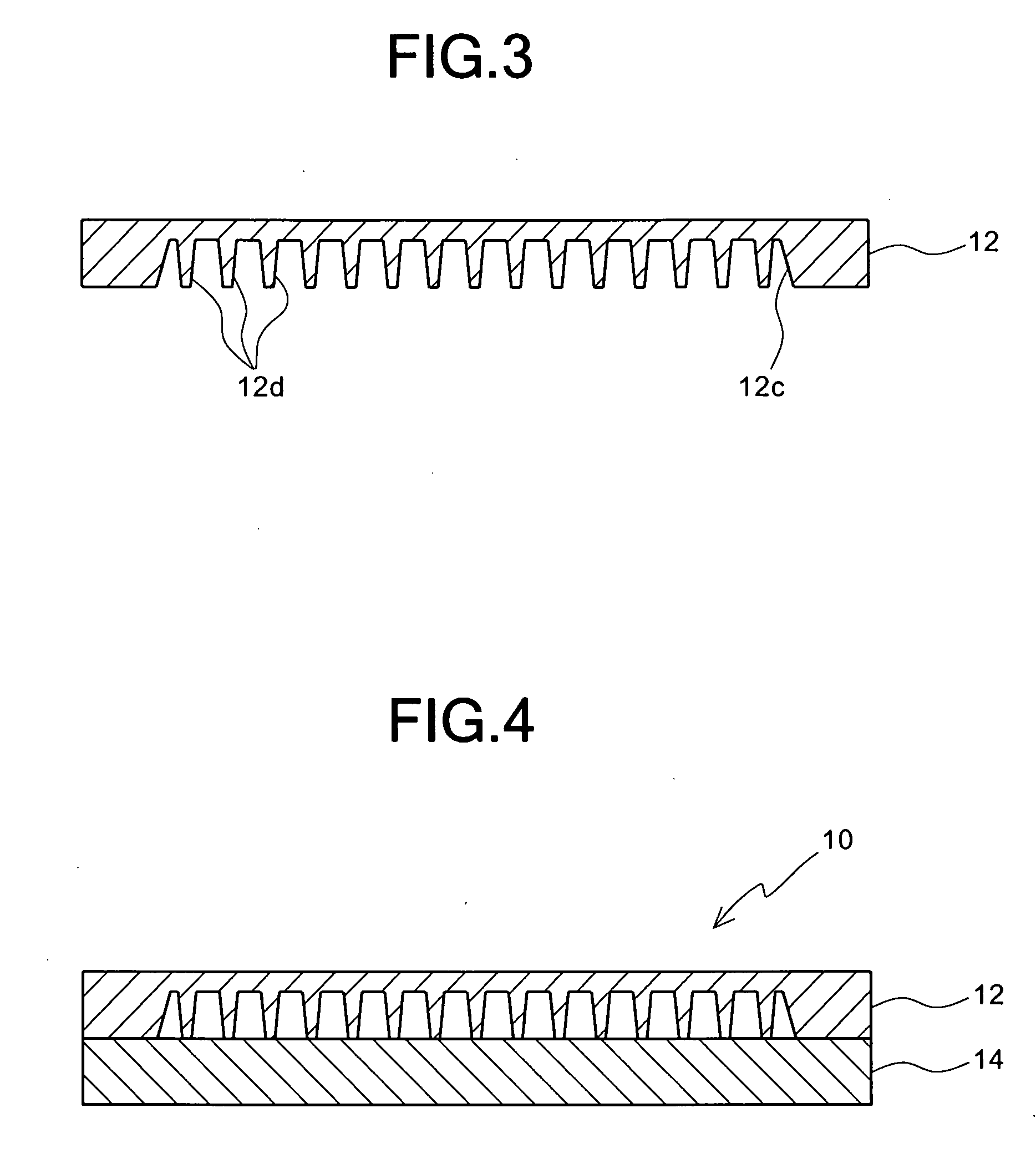

Heat radiator

InactiveUS20070227697A1Increase cooling powerSimple structureSemiconductor/solid-state device detailsSolid-state devicesConical formsHeat spreader

A heat radiator 10 includes: a first member 12 which has a recessed portion 12c in one side thereof and which has a large number of substantially circular truncated conical protruding portions 12d formed on the bottom face of the recessed portion 12c; and a second member which is fixed to the first member 12 on the side of the recessed portion 12c for defining an internal cavity and which contacts the tip end face of each of the large number of protruding portions 12d of the first member 12, wherein the first member 12 has a pair of through holes 12e for supplying a coolant into the internal cavity and for discharging the coolant from the internal cavity.

Owner:DOWA METALTECH CO LTD

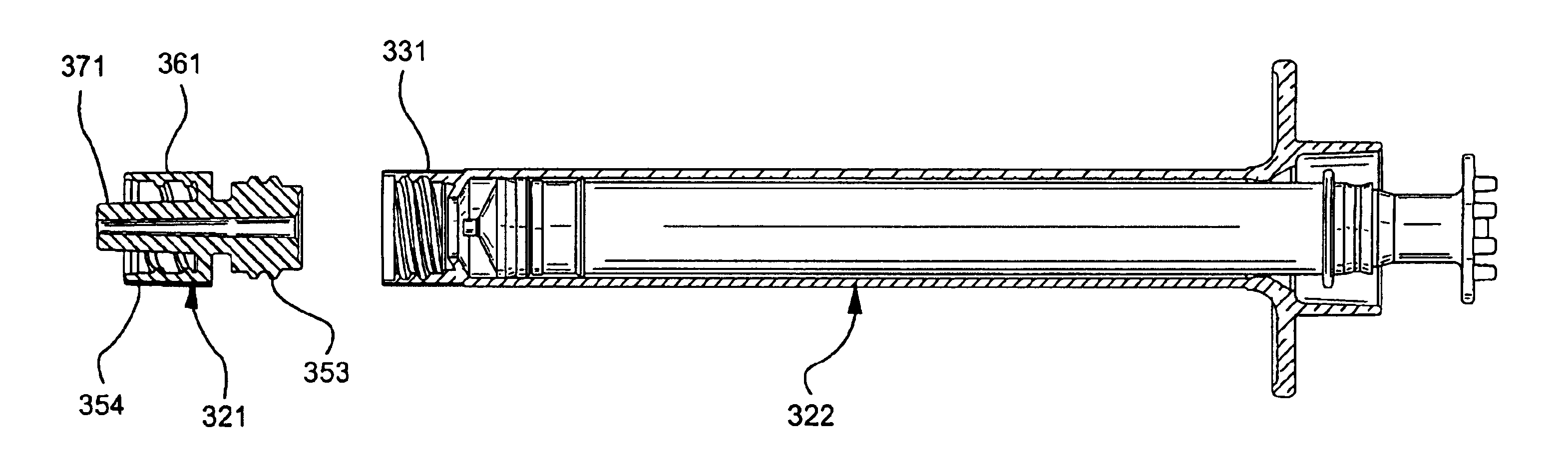

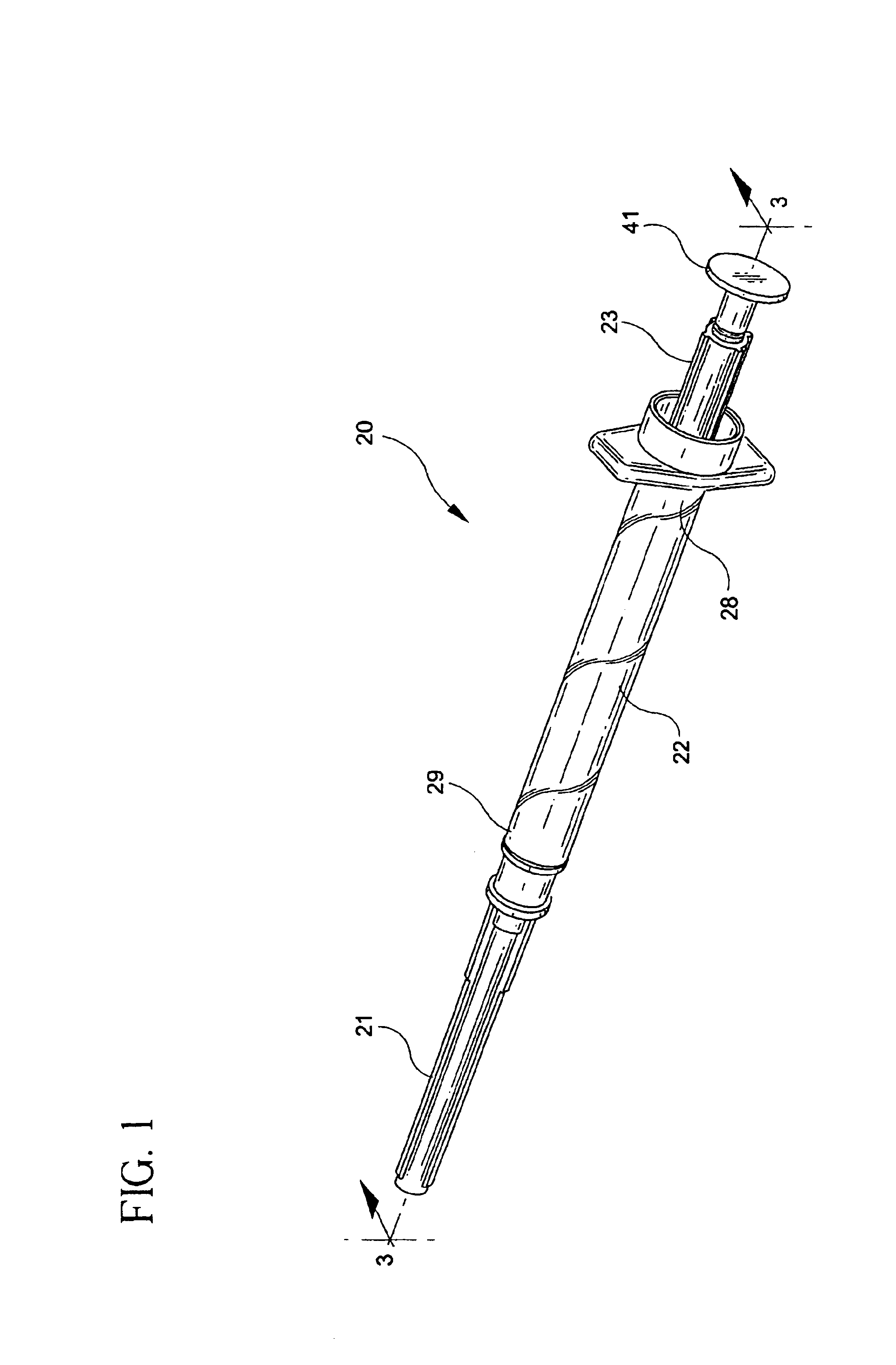

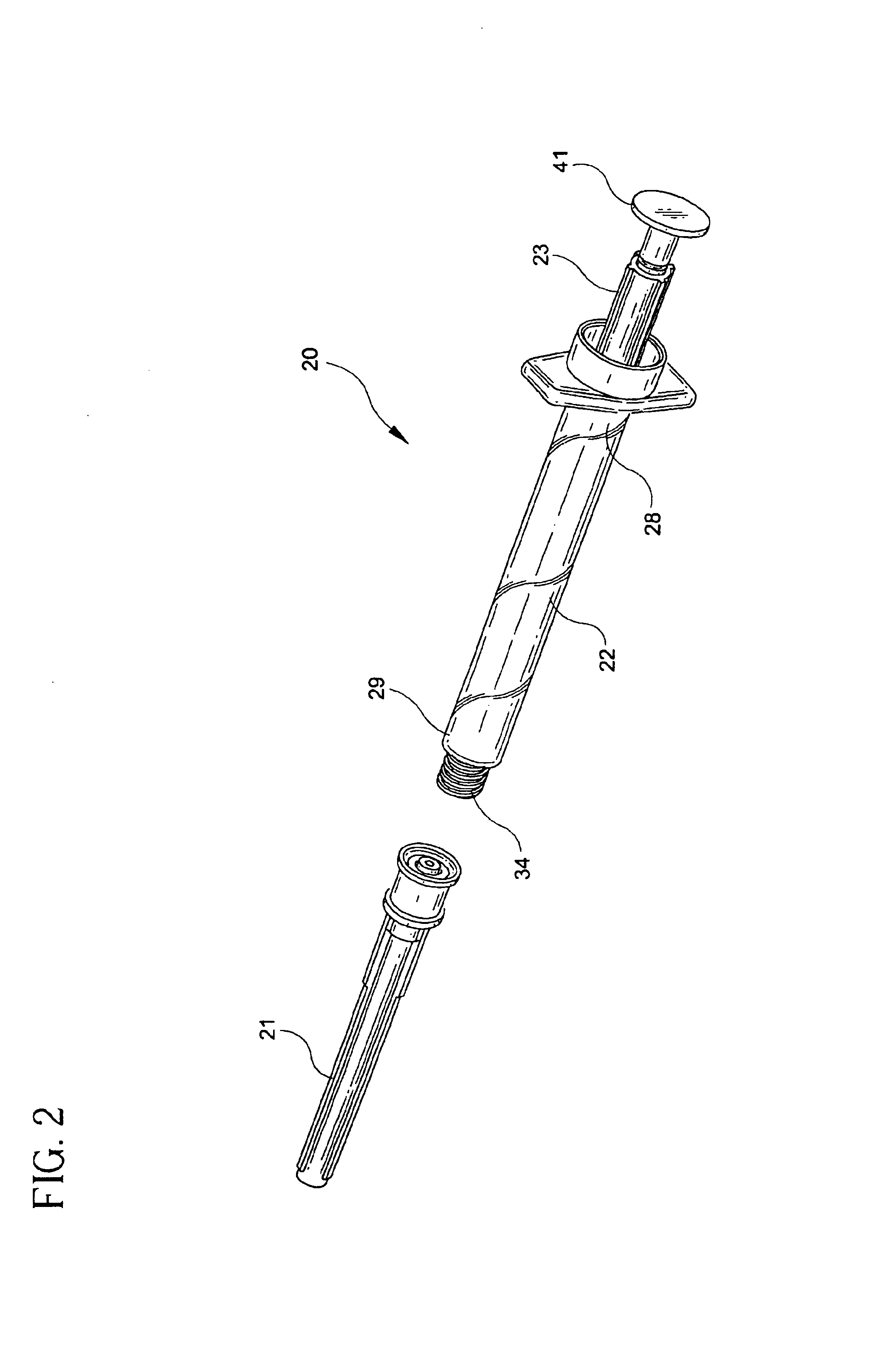

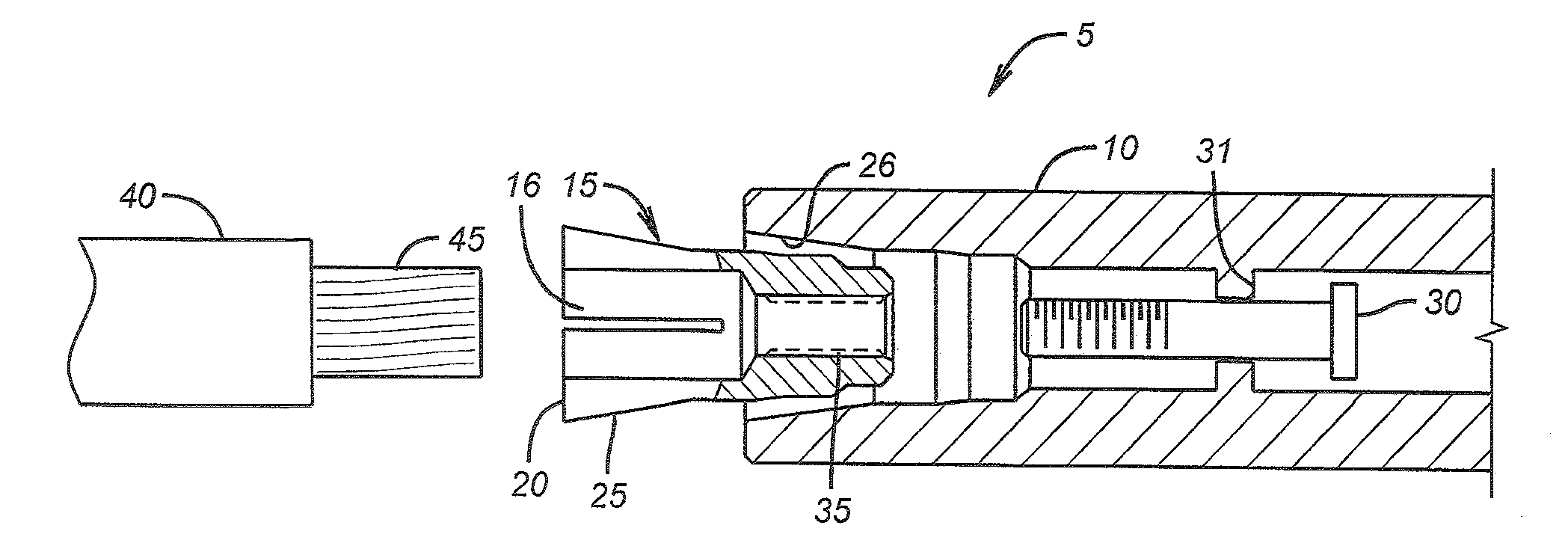

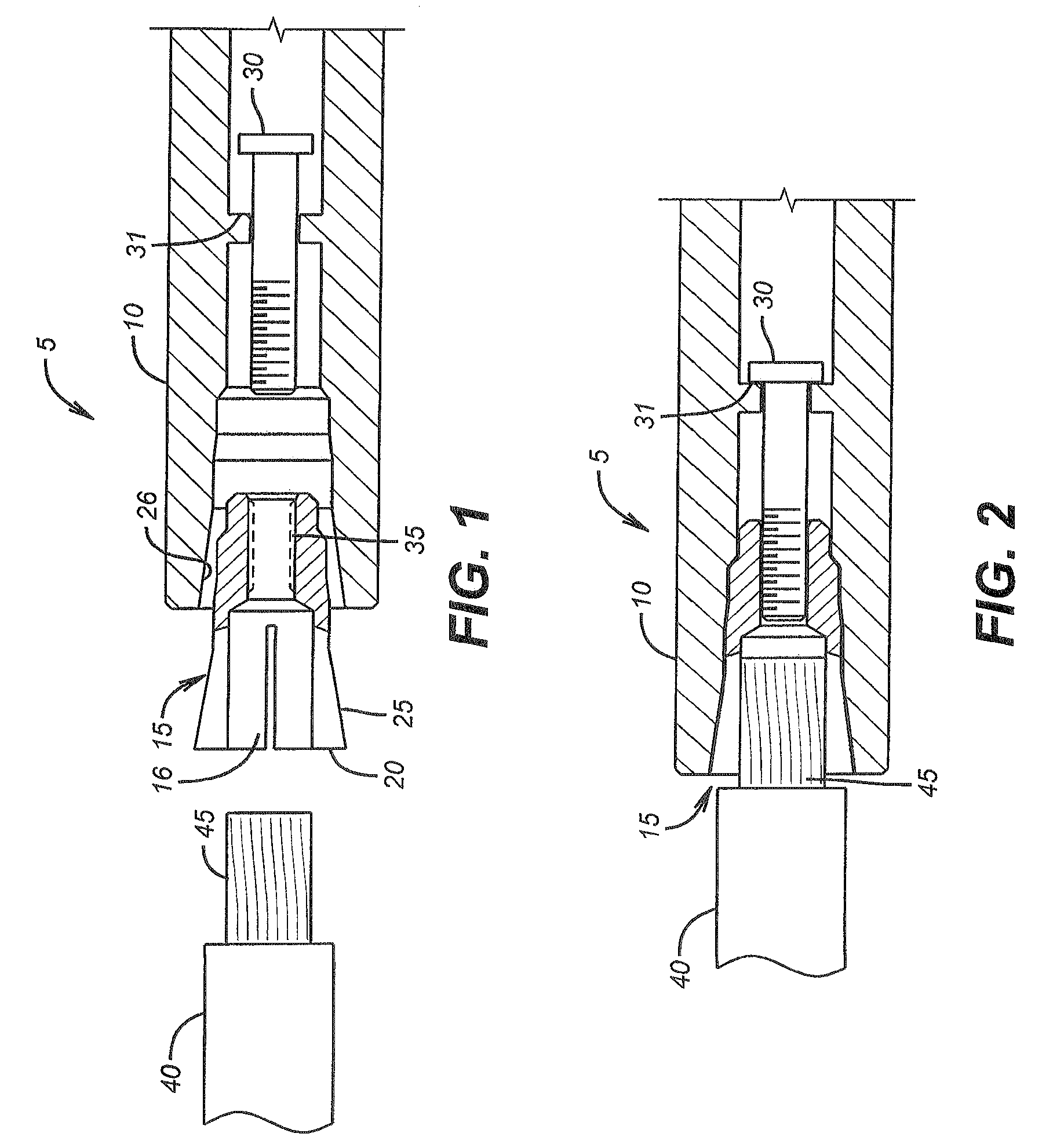

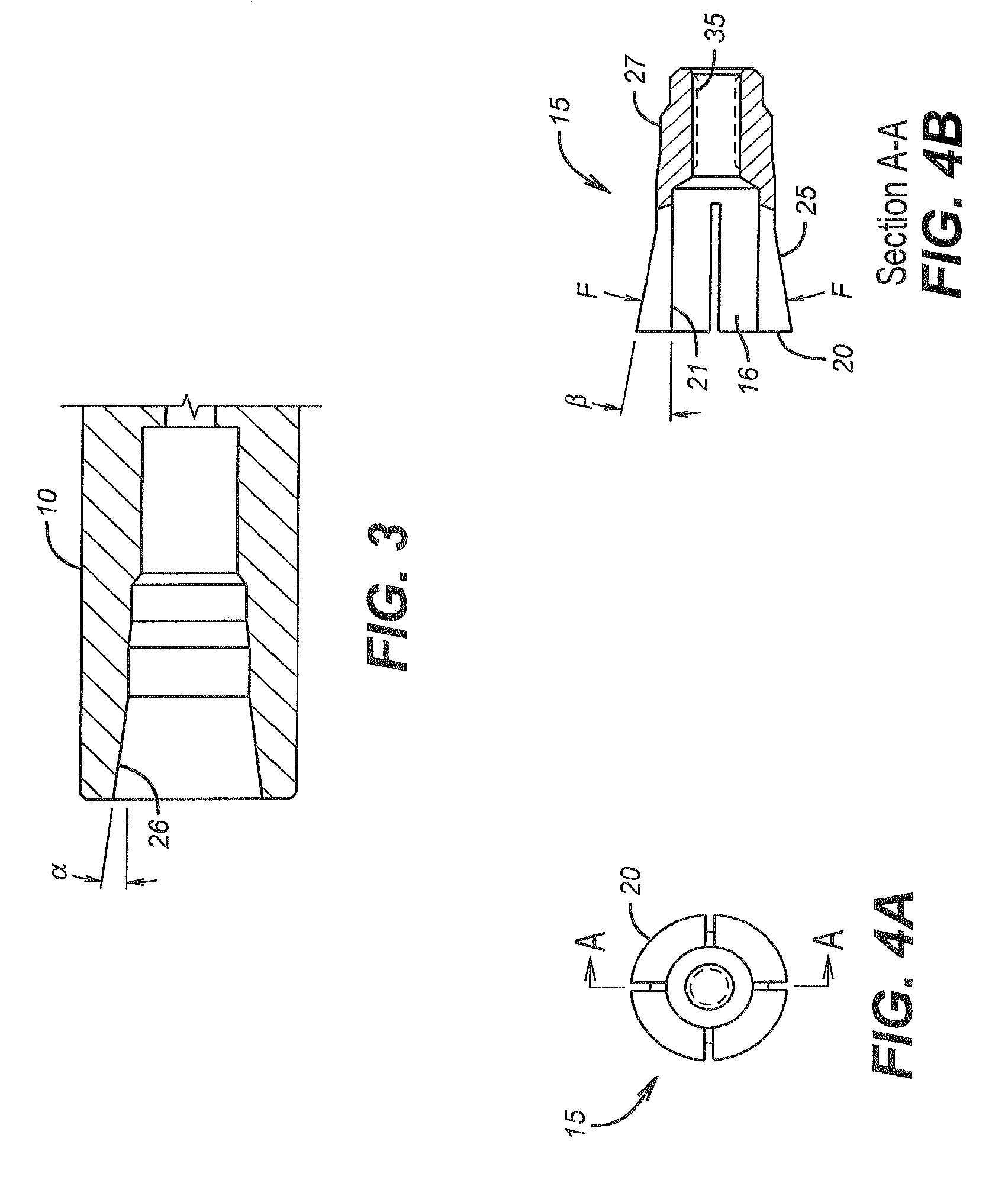

Attachment for a medical device

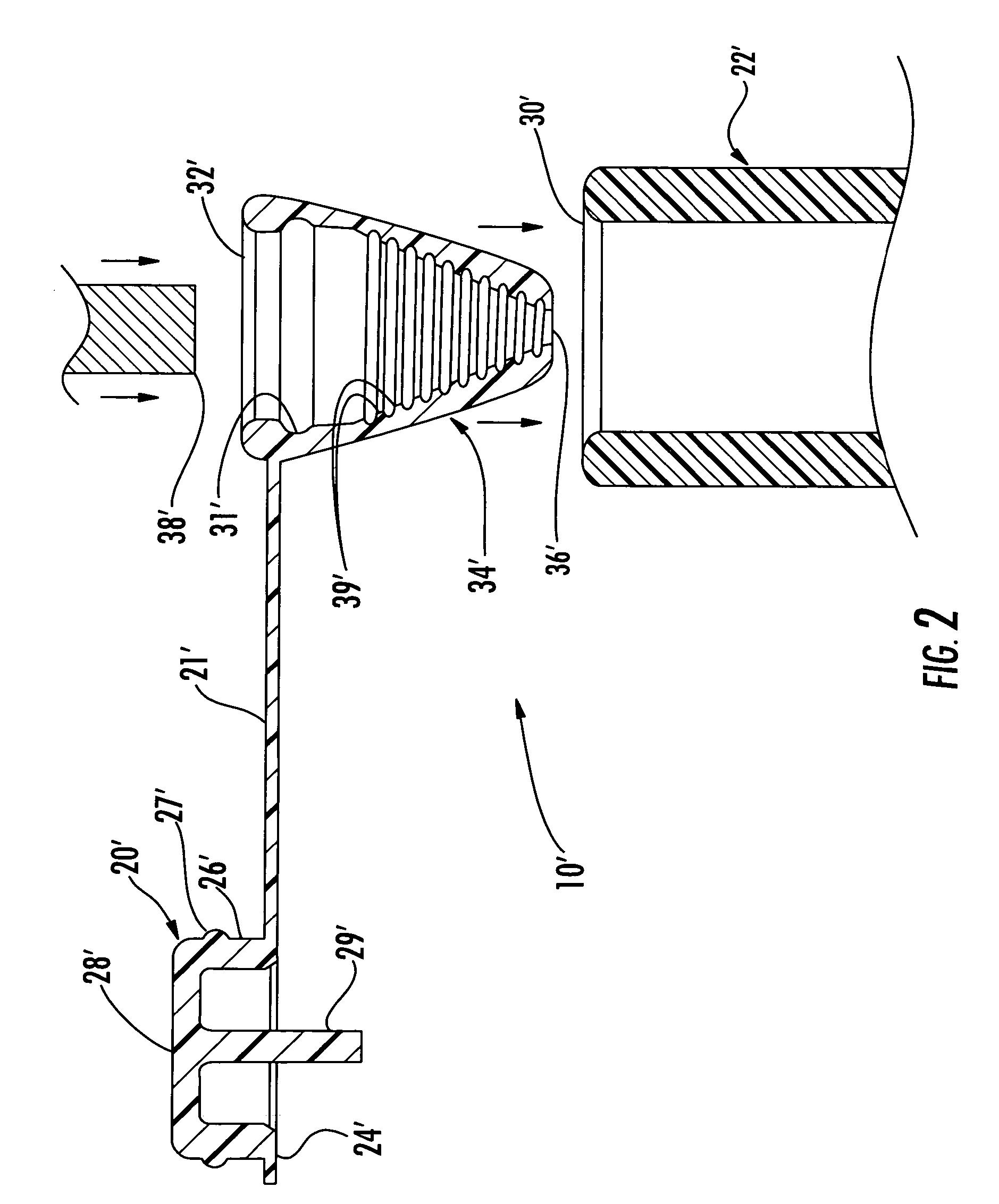

A fluid transfer adapter for use with a syringe barrel having a collar with adapter engaging structure and a distally-facing frusto-conically shaped surface is disclosed. The adapter includes a hub having a proximally-facing frusto-conically shaped surface for mating with the frusto-conically shaped surface on the barrel, structure for threadably engaging the hub to the collar of the barrel so that the frusto-conically shaped surface of the hub contacts the frusto-conically shaped surface of the barrel to prevent liquid flow between the surfaces and a fluid transfer having a passageway therethrough, connected to the distal end of the hub so that the lumen is in fluid communication with a conduit in the hub. The passageway includes a frusto-conically shaped edge that aligns with the frusto-conically shaped edge of the barrel, when the adapter is connected to the barrel, thereby reducing waste space.

Owner:BECTON DICKINSON & CO

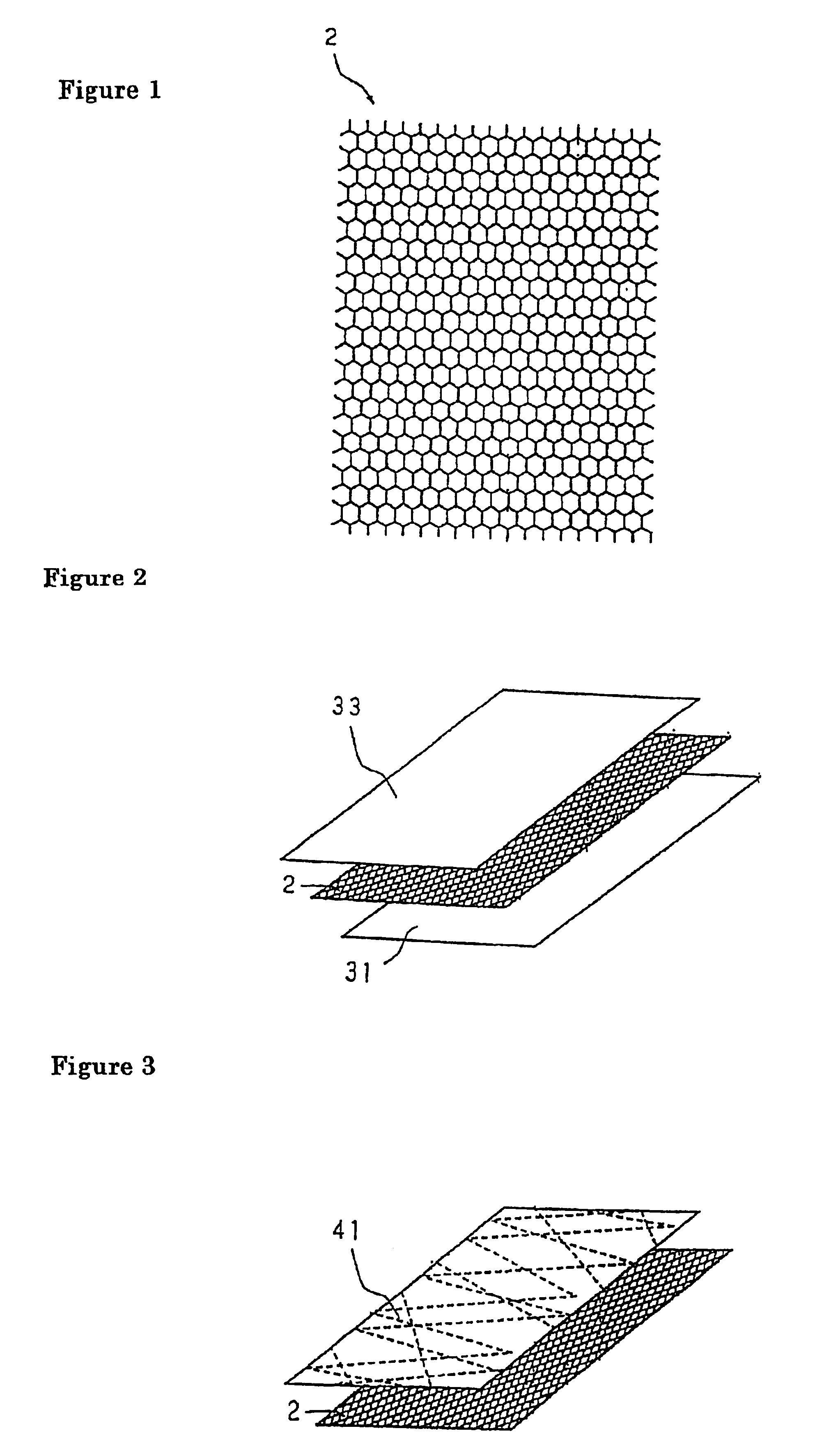

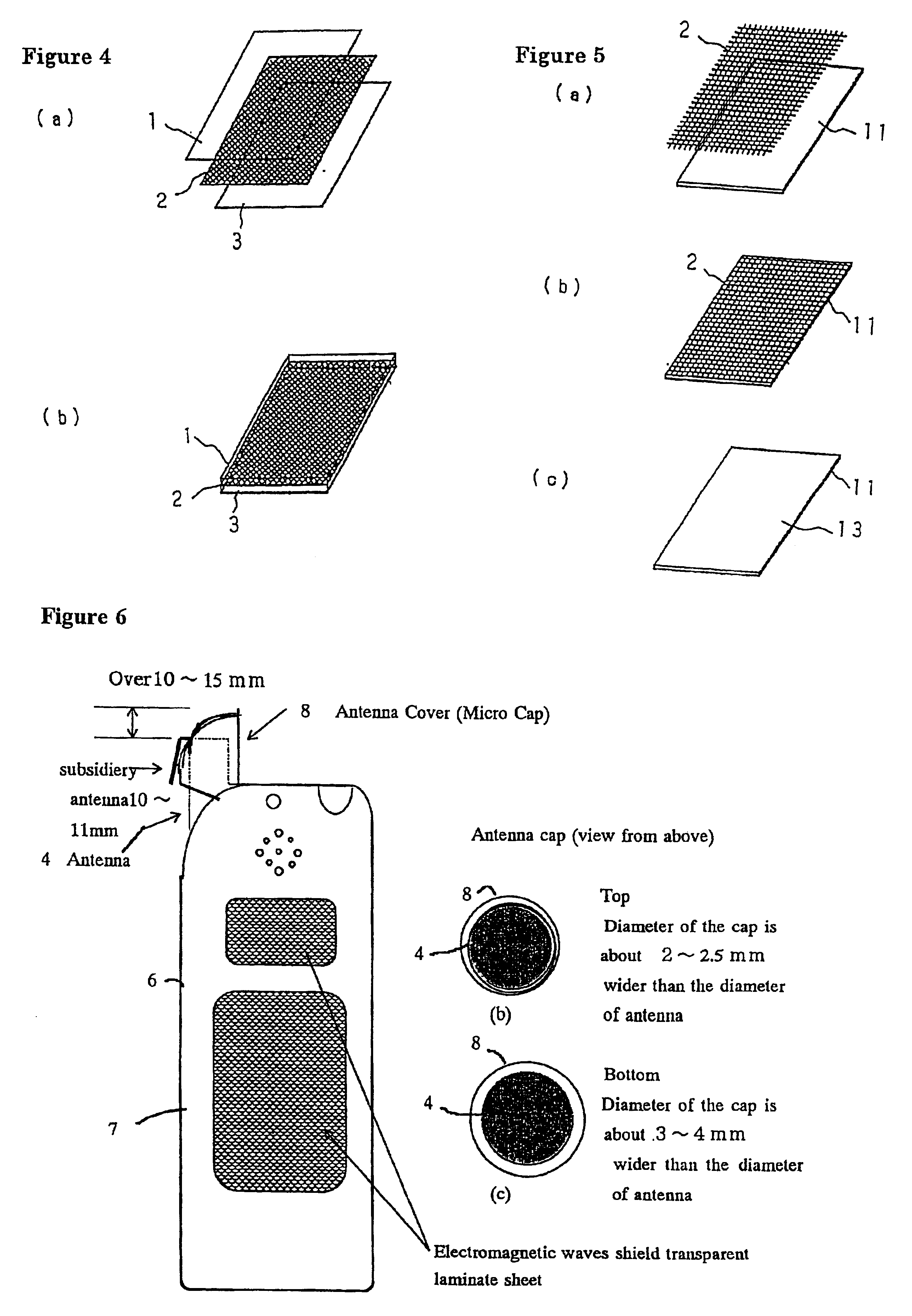

Electromagnetic wave blocking material and electromagnetic wave blocking case

InactiveUS6855883B1Improve shielding effectReduce total usageShielding materialsAntenna supports/mountingsFiberElectricity

This invention provides the electromagnetic waves shield material that has a sufficient effect of shielding the electromagnetic waves by making the electric conductive fibers into mesh. And this invention also provides the electromagnetic waves shield mobile phone case that avoids a harmful effect on the human body without reducing the function of communication of the mobile phone used the said electromagnetic waves shield material.The fibers with electric conductivity are woven into mesh by a general knitting machine like a machine for tricot. The cost is low even used for the wide area to shield the electromagnetic waves because the consumption of the fibers needed is less. The coarseness of the net is maintained the same by controlling the movement of the length and breadth each other.To avoid the radiation to the head direction, the electromagnetic waves shield material is used for the front and upper sides of the mobile phone case which are the direction to the head when the mobile phone is in use. The regular material without electromagnetic waves shield effect is used for the both sides of the mobile phone case.The antenna cap with electromagnetic shield structure is attached to the said upper side of the electromagnetic wave shield case. The electricity with high frequency is conducted between the above antenna cap and the upper side of the electromagnetic wave shield case. The said antenna cap is a conic tube cut it's head obliquely. The opening part is made to face in the opposite side of the head when it is attached to the antenna. A metallic pin is attached to the outside of the antenna cap. This metallic pin conducts high frequent electricity with the wire antenna at the mobile phone body when it is attached. It functions as an additional antenna to the wire antenna at the mobile phone body.

Owner:KAZU INVESTMENT

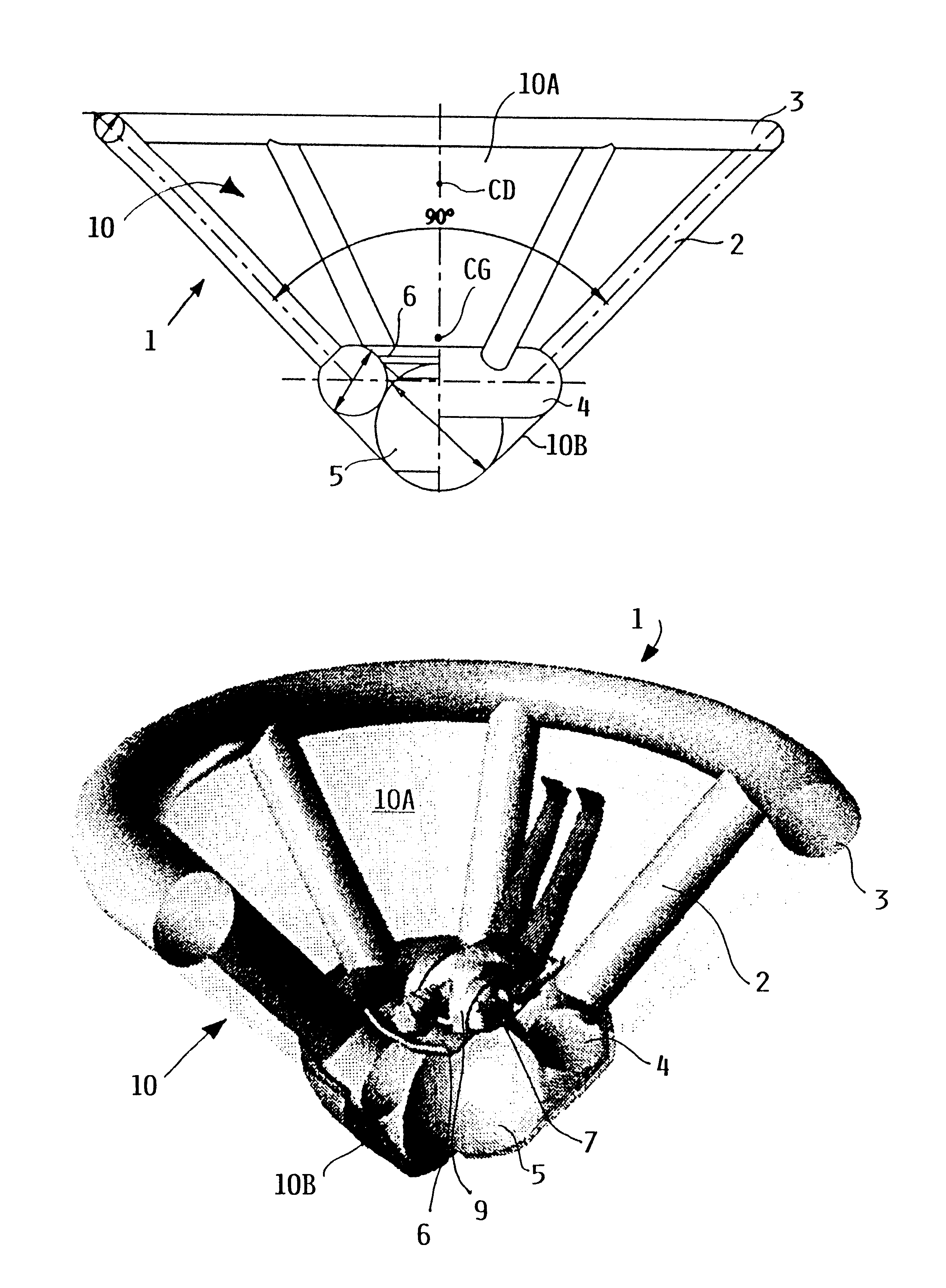

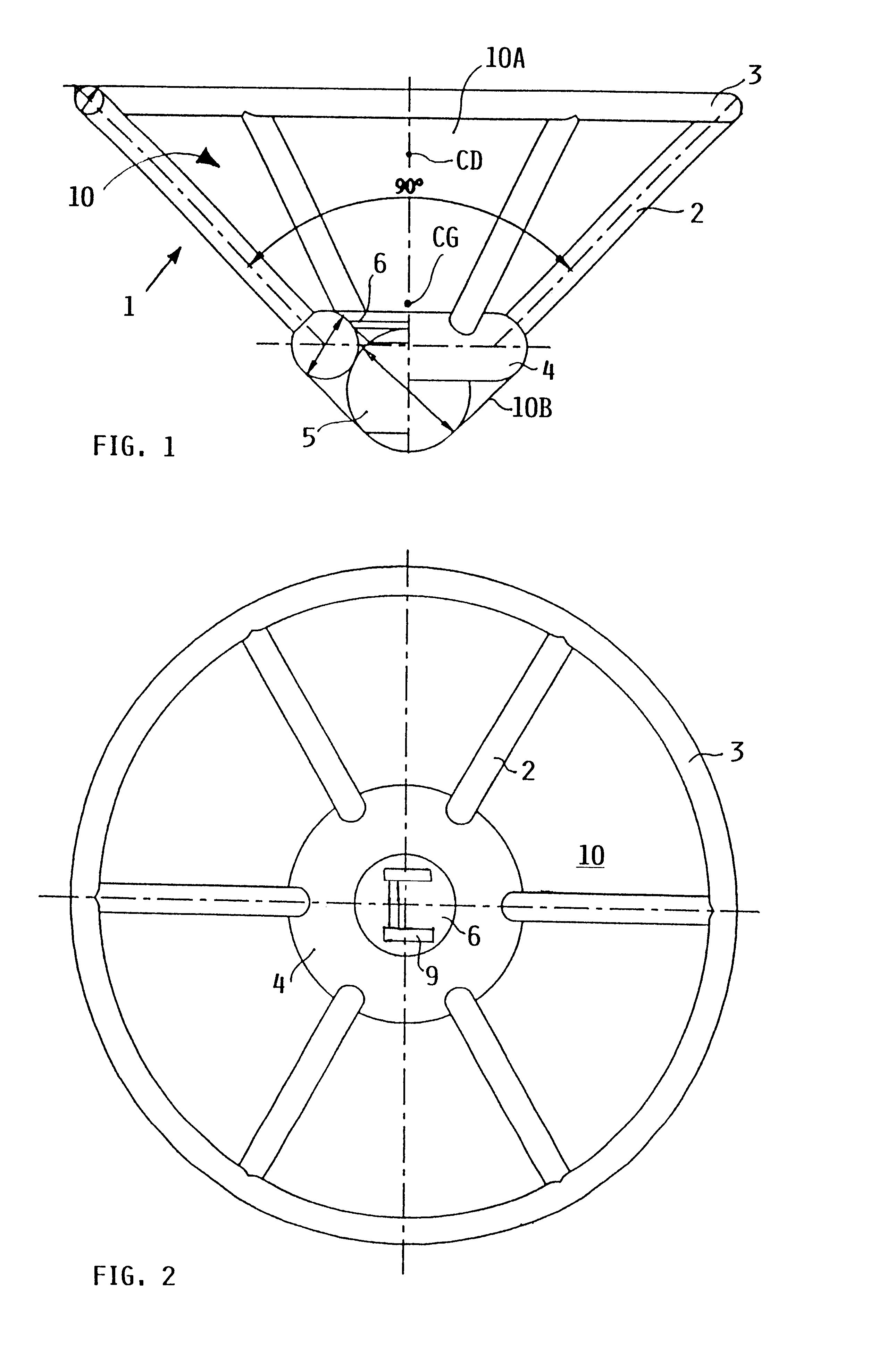

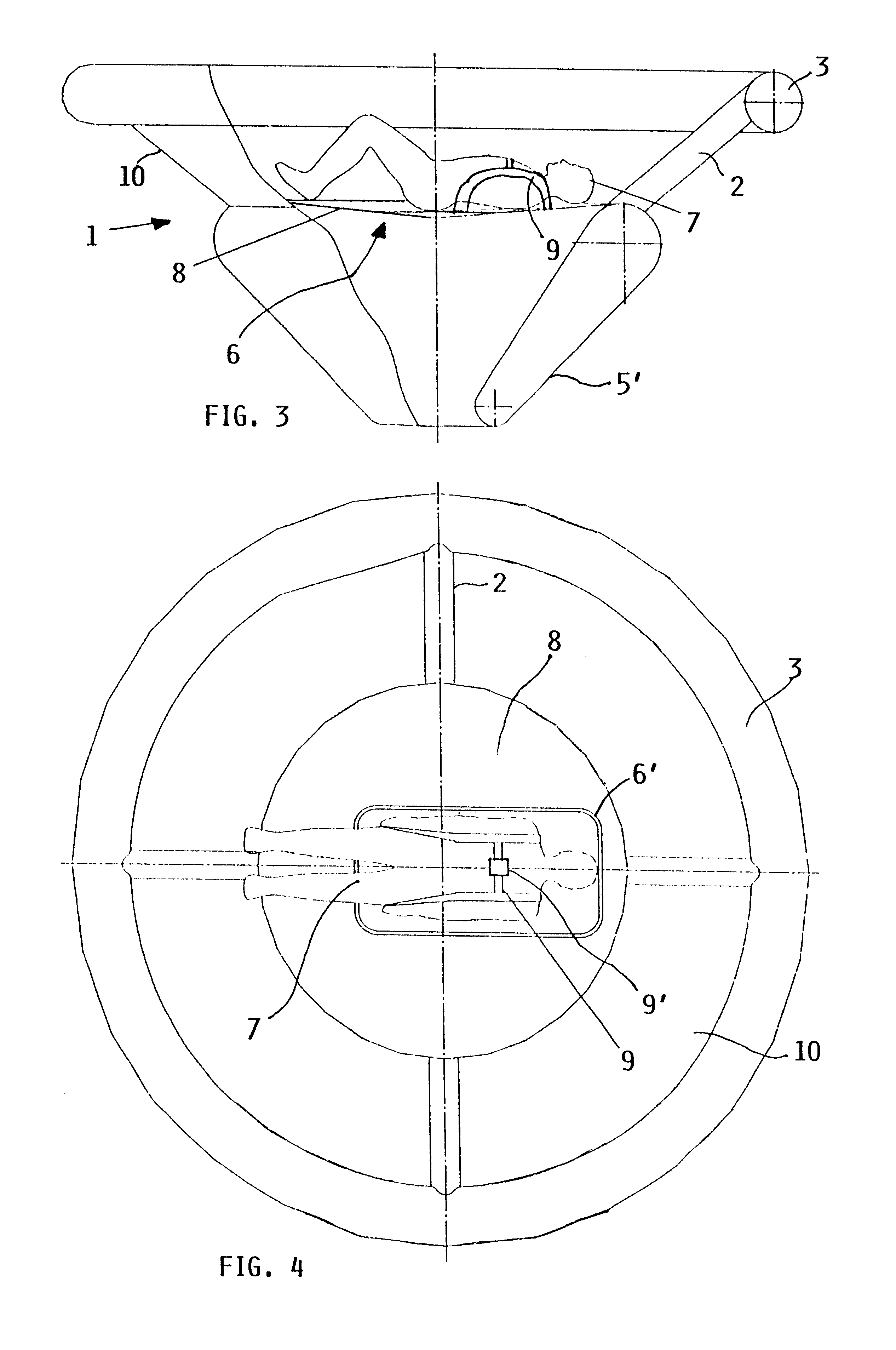

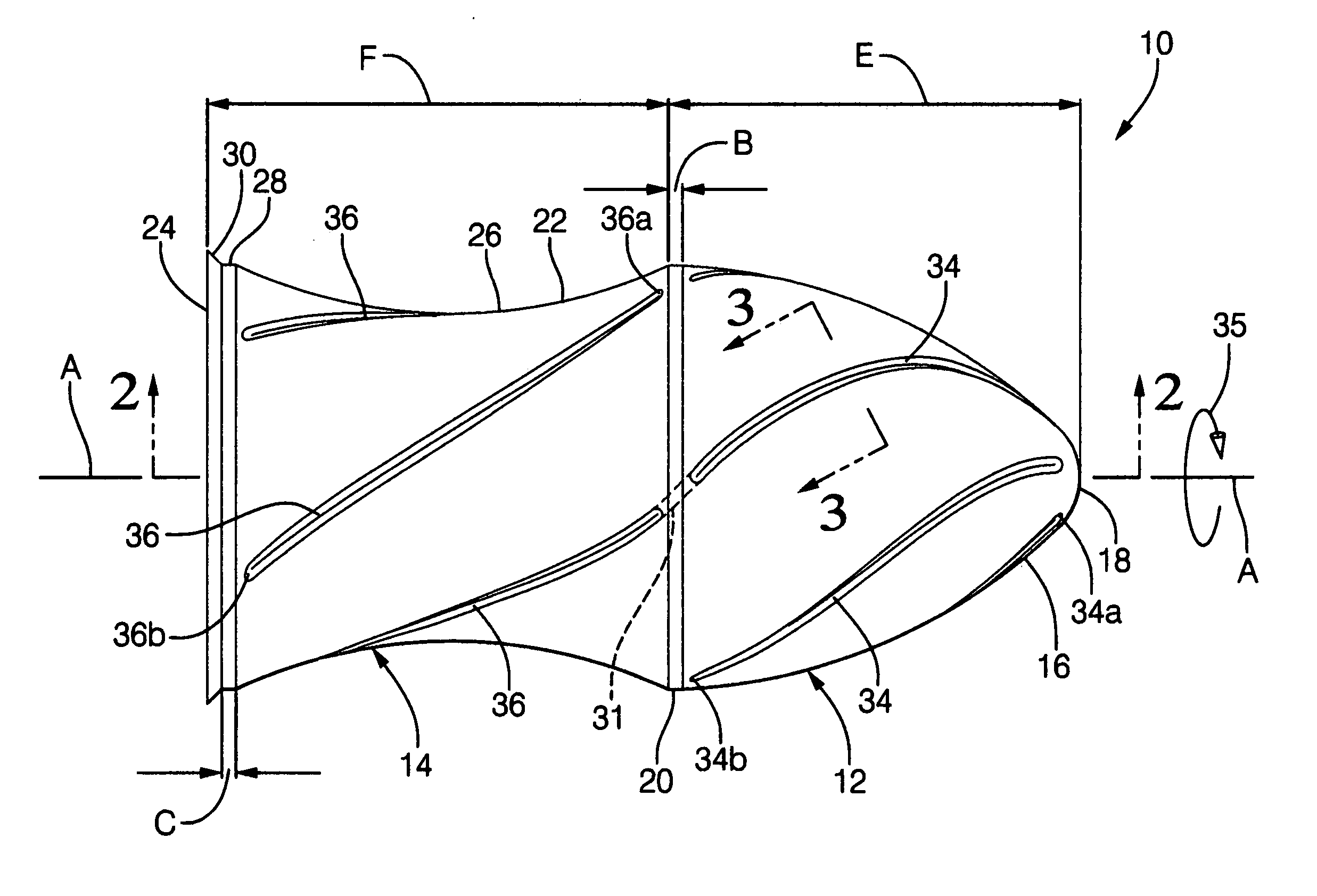

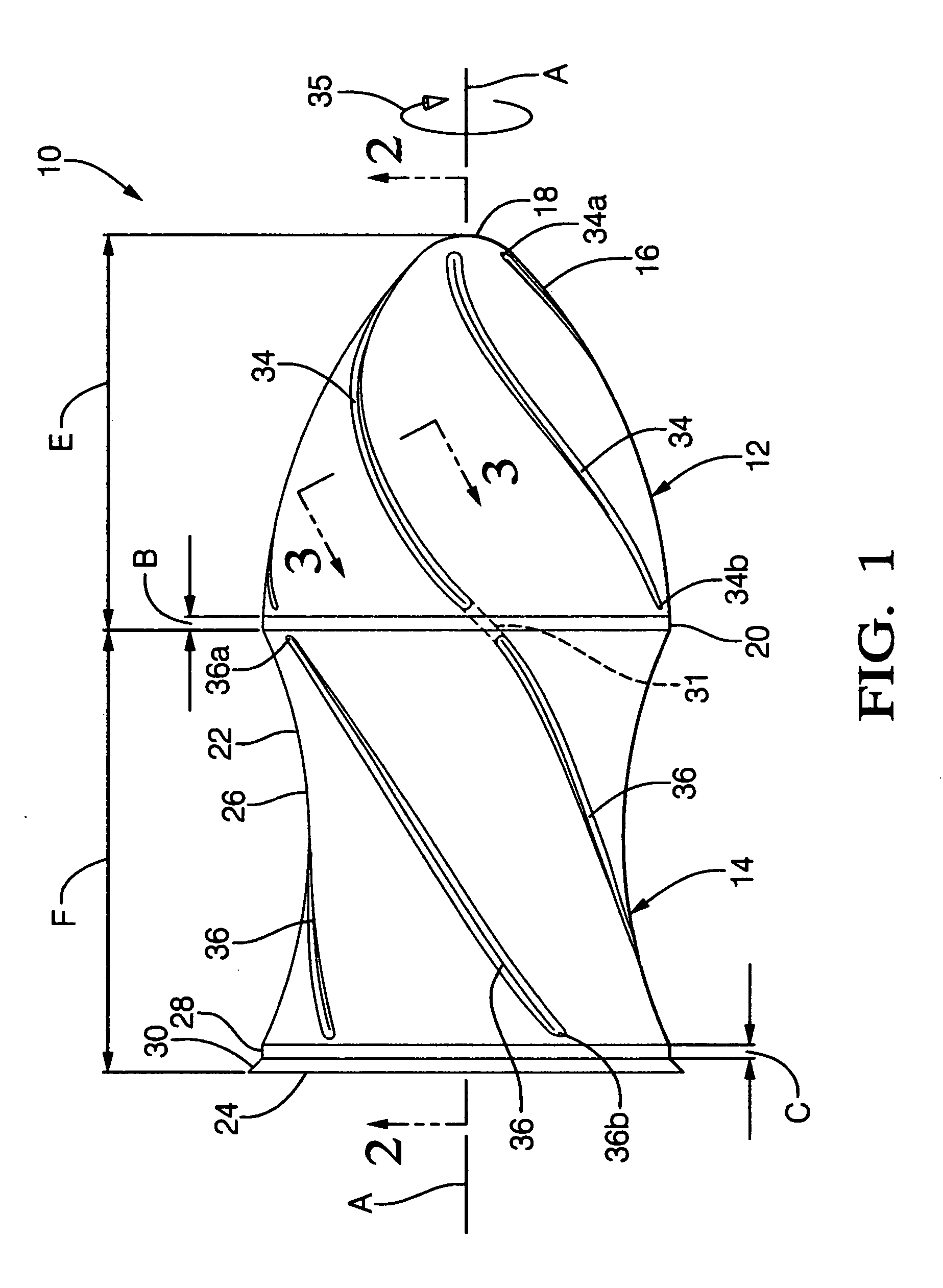

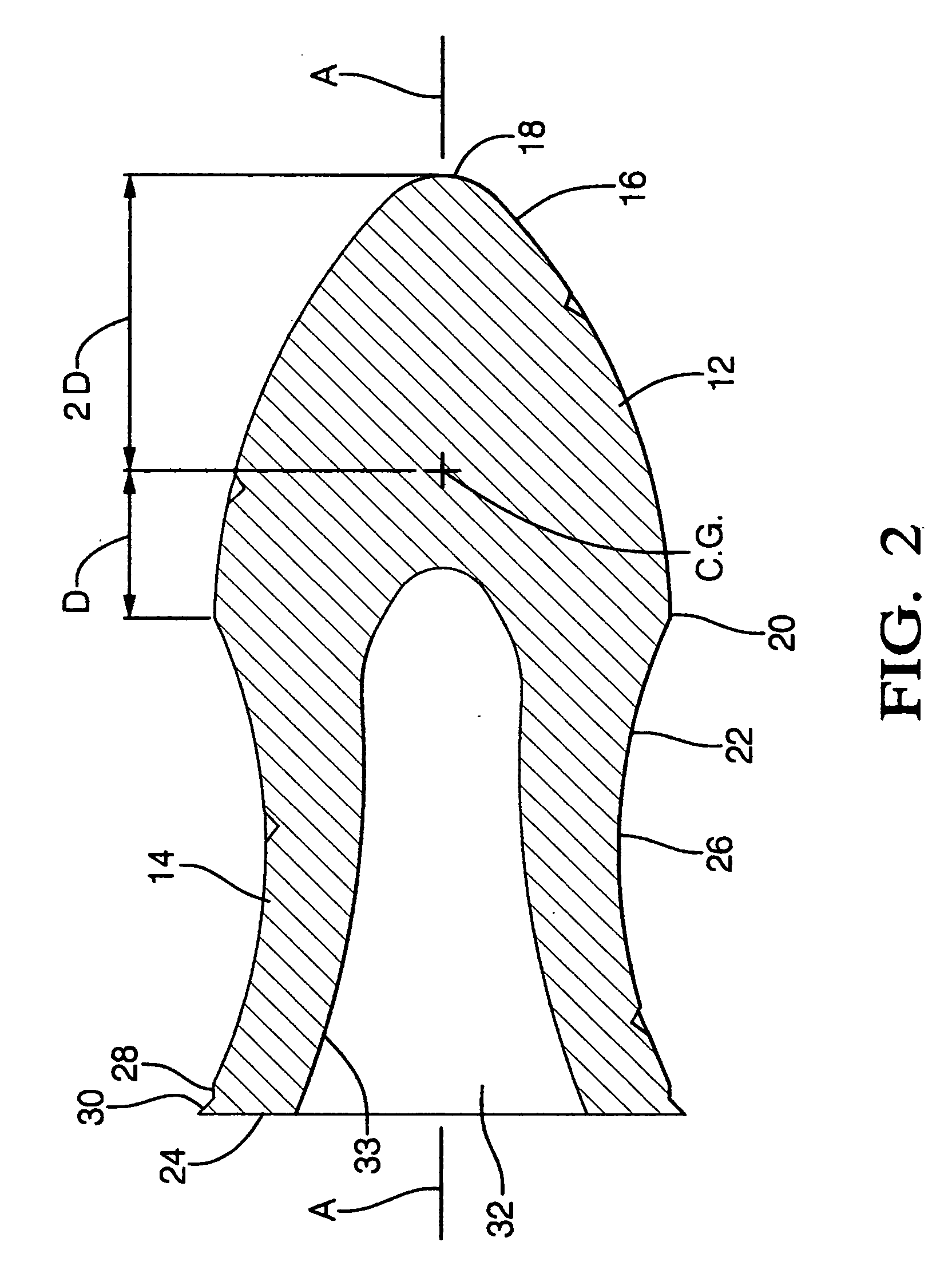

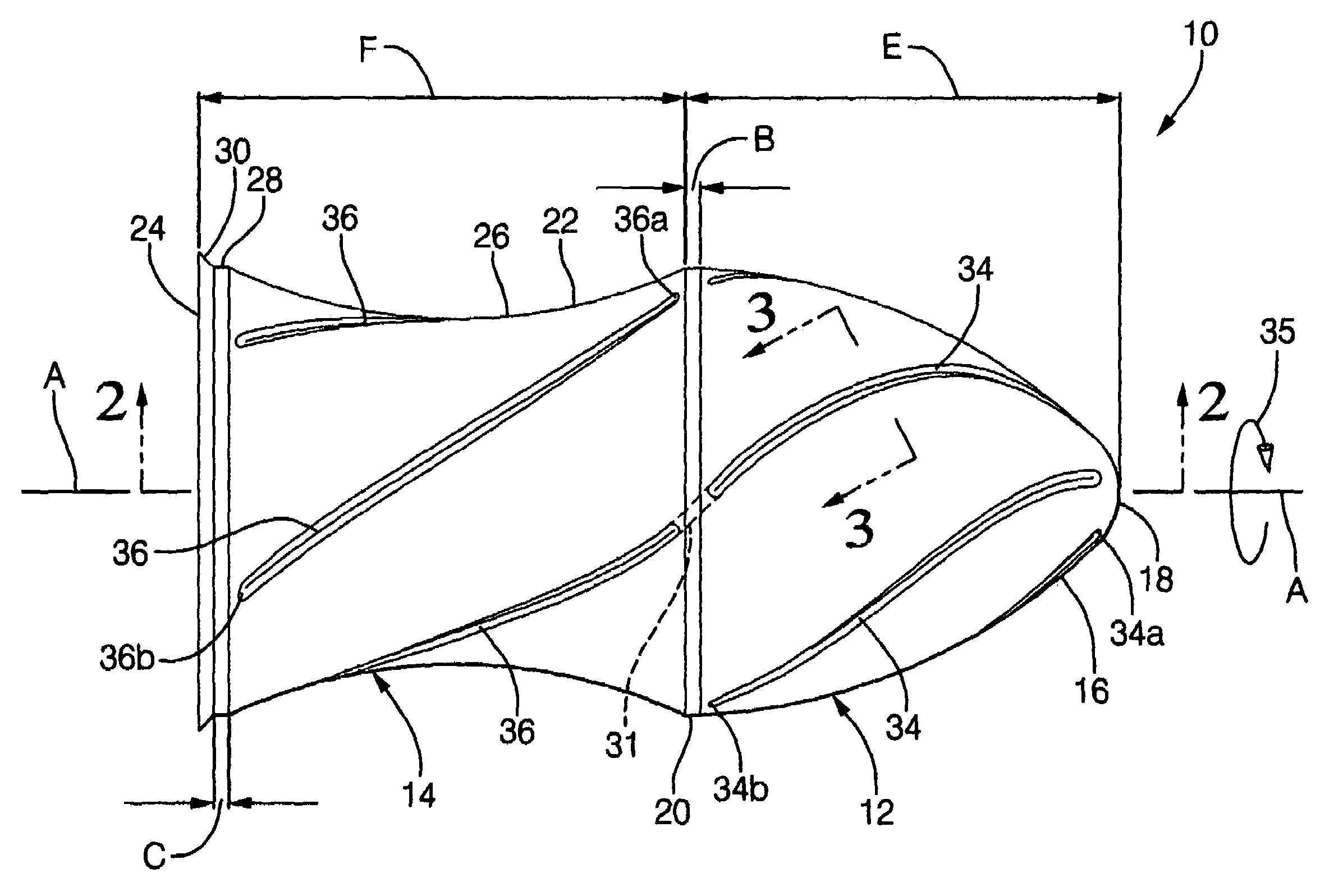

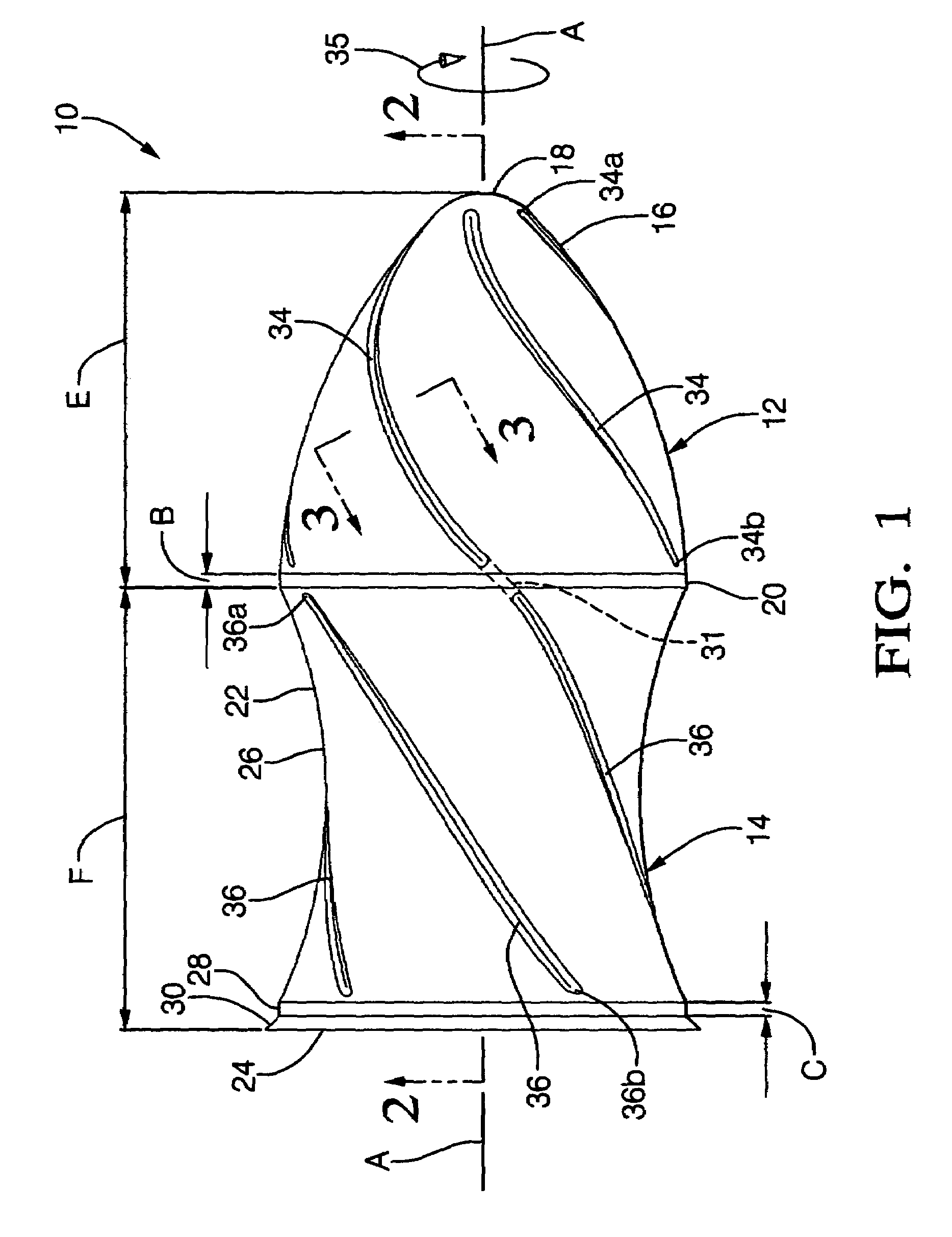

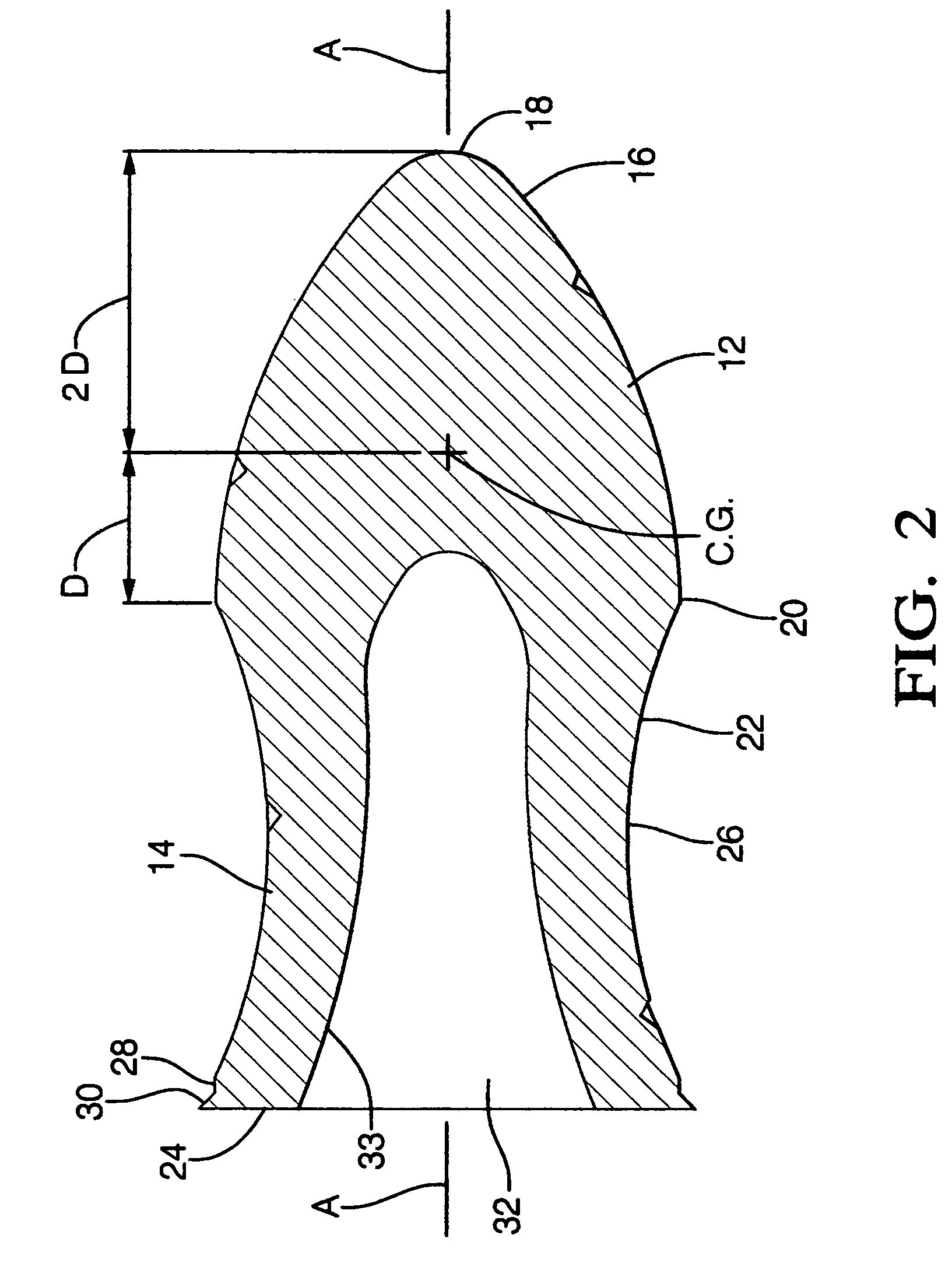

Inflatable flying body for the rescue descent of a person

InactiveUS6607166B1Slow its descentDistribute over timeAircraft ejection meansCosmonautic partsConical formsNose

A person can safely descend from a burning high-rise building or the like using an inflatable flying body that has a hollow conical form in an inflated deployed condition, but is deflated and folded into a backpack form in a stowed condition. The flying body includes an upper stabilizing ring, a lower nose structure with a pneumatic damping body, spoke struts extending conically therebetween, a cover skin covering the abovementioned inflatable components to form the conical outer surface and provide aerodynamic braking drag, and gas generators to inflate the inflatable components. A person straps on the apparatus in the stowed backpack form and pulls a handle to actuate the gas generators for inflating the apparatus, whereby the expanding apparatus ejects the person from the building and then orients itself in a nose-down attitude during the descent. The pneumatic damping body damps and dissipates the landing impact energy.

Owner:AIRBUS DEFENCE & SPACE

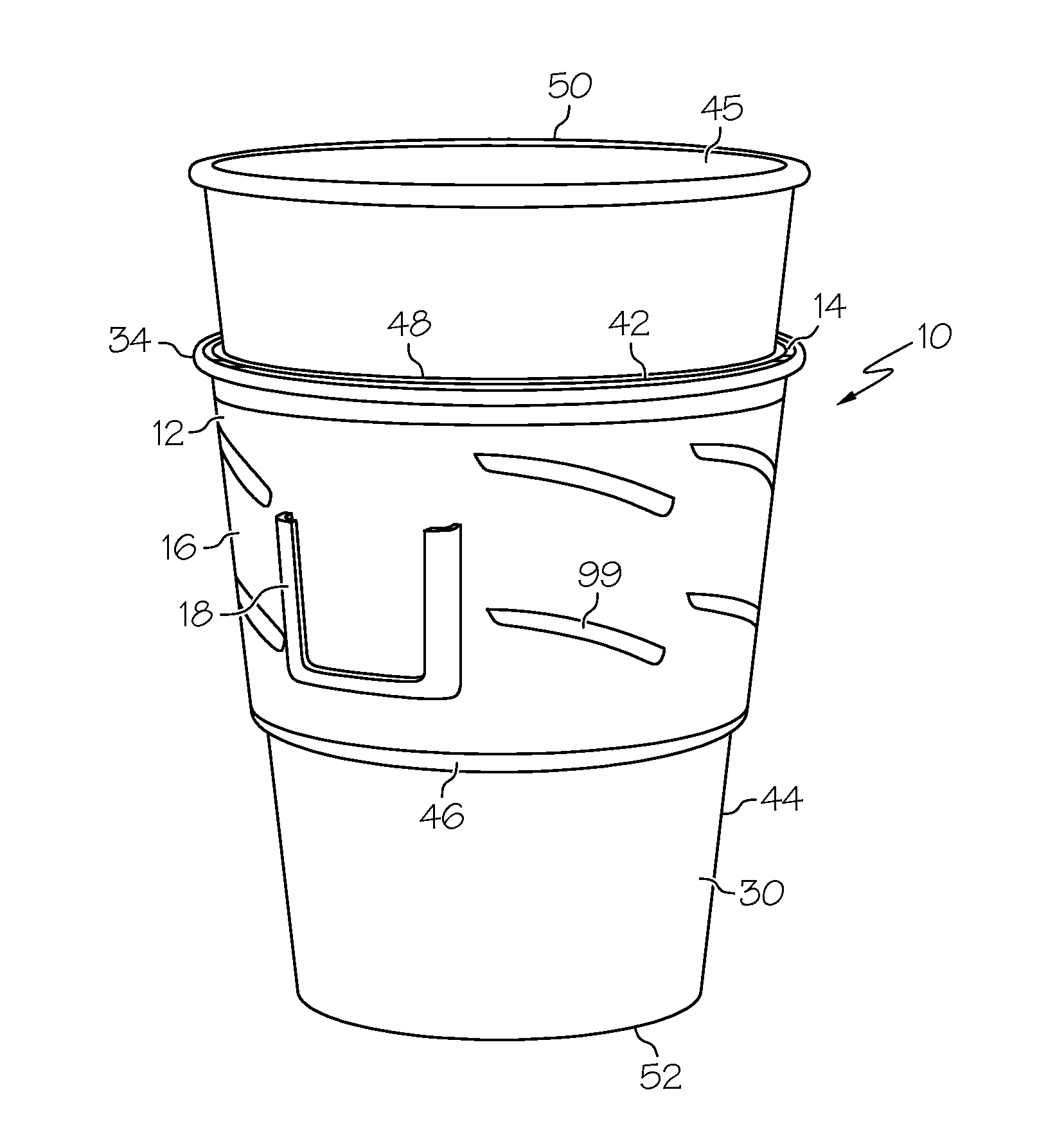

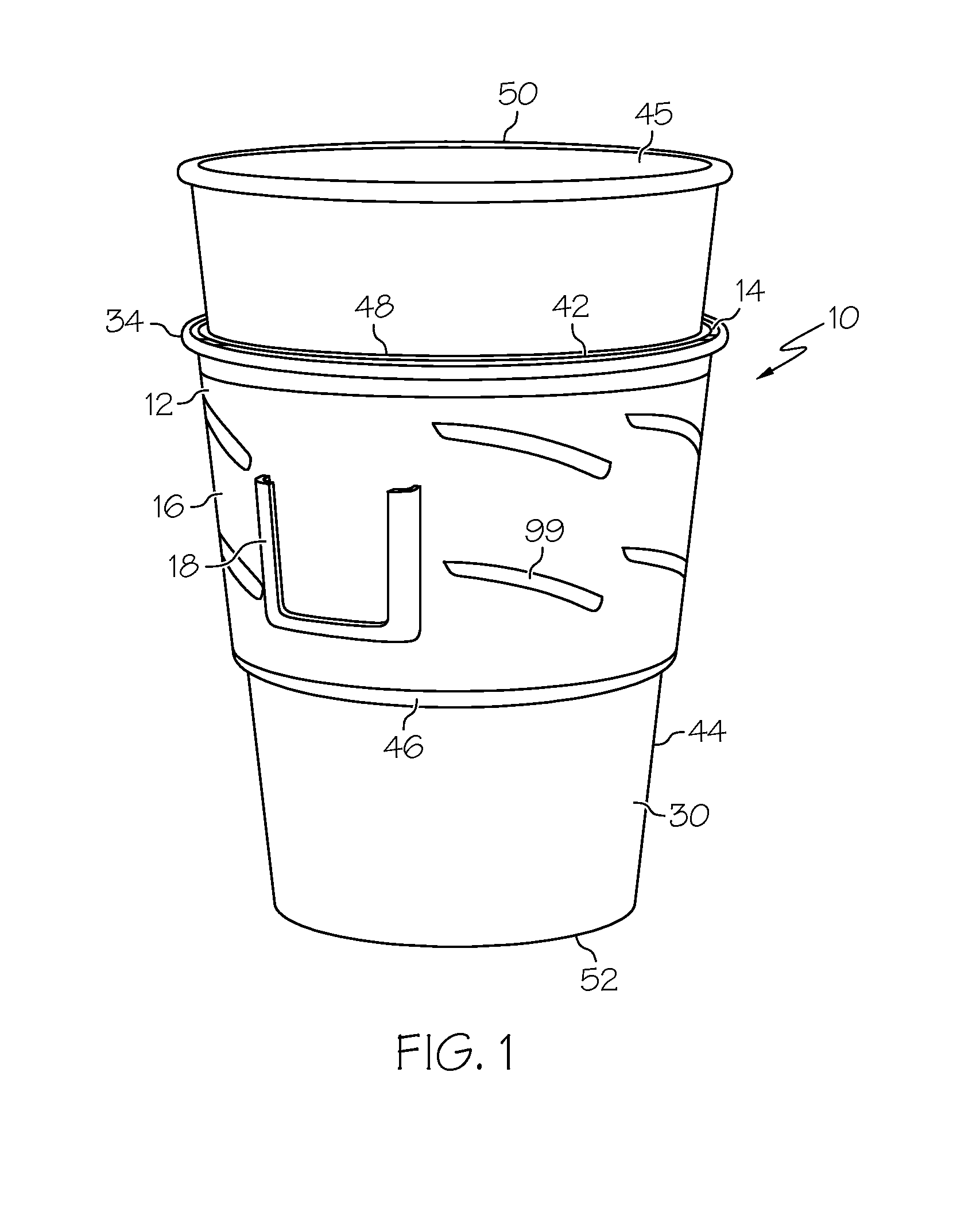

Reusable sleeve cover

Owner:GRAUEL JAMES ALBERT +1

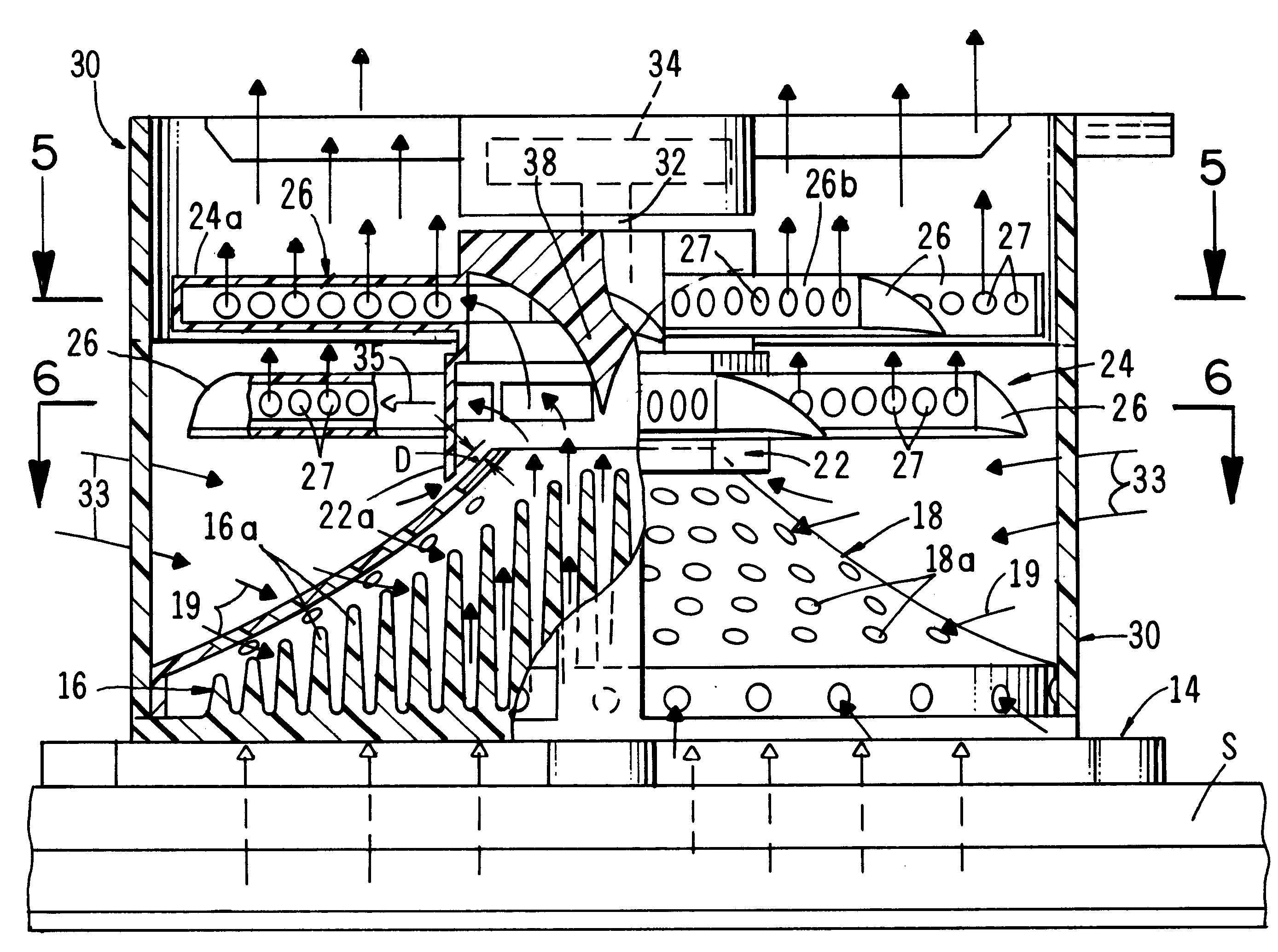

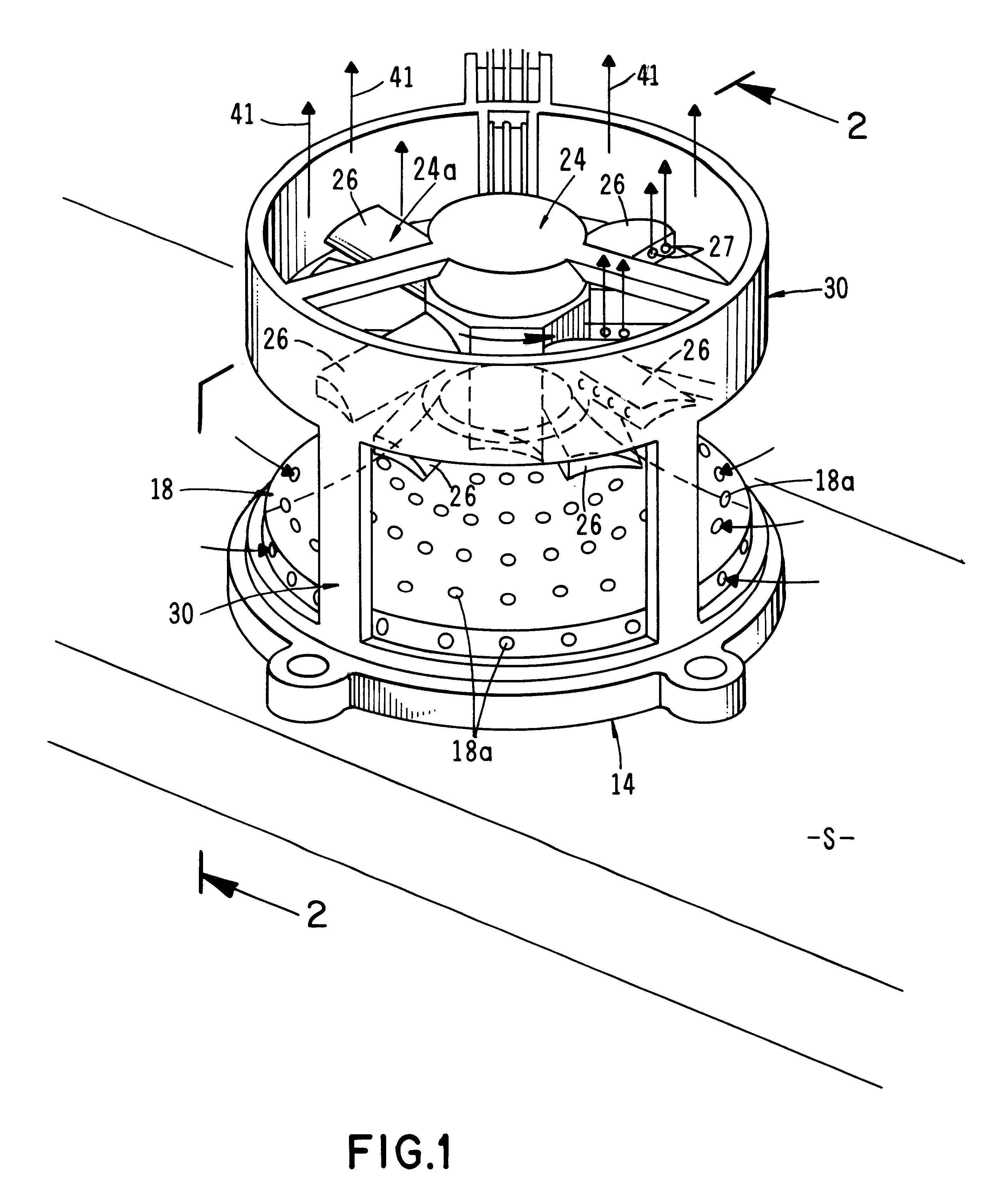

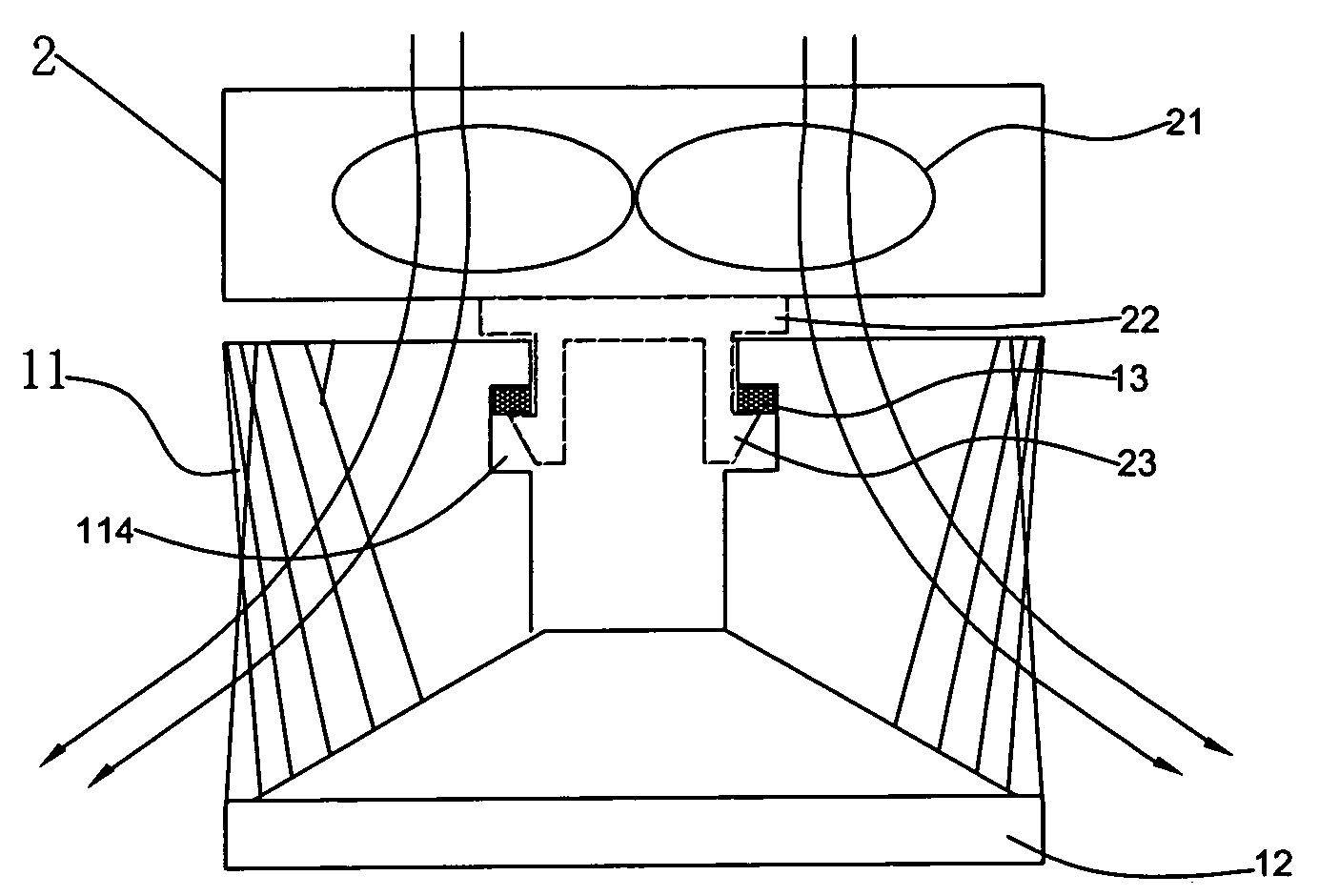

Apparatus for cooling a heat producing member

InactiveUS6219242B1Digital data processing detailsSemiconductor/solid-state device detailsLeading edgeConical forms

A heat extraction and cooling system which can be attached to the central processing unit (CPU) of a computer for exchanging heat through an enclosure which houses a ducted fan. The apparatus includes a dual section rotary blade system that is driving by a conventional direct current motor. The apparatus also includes a heat conducting base that is placed in thermal engagement with the CPU. Attached to the base is a uniquely configured heat dissipating member which includes a plurality of upstanding heat dispensing fins, a generally conically shaped shroud and is provided with a plurality of apertures for drawing the flow of cooling air through the shroud and past the fins of the heat dissipating member. The dual section rotary blade system pulls air inwardly through the apertured shroud, past the heat dissipating fins and into the hub portion of the rotary blade system. The heat air is then forced into the interior of the uniquely configured, hollow blades which are attached to the hub portion. Each of the blades is provided with a leading edge portion and trailing edge portion having a plurality of small apertures formed therein. As the blades rotate, a negative pressure is formed proximate the trailing edge of each blade and the heated gases are expelled through the small apertures. This provides a jet thrust action to the rotating assembly and causes the heated gases expelled from the hollow blades to expand rapidly thereby producing an additional cooling effect.

Owner:MARTINEZ RAUL

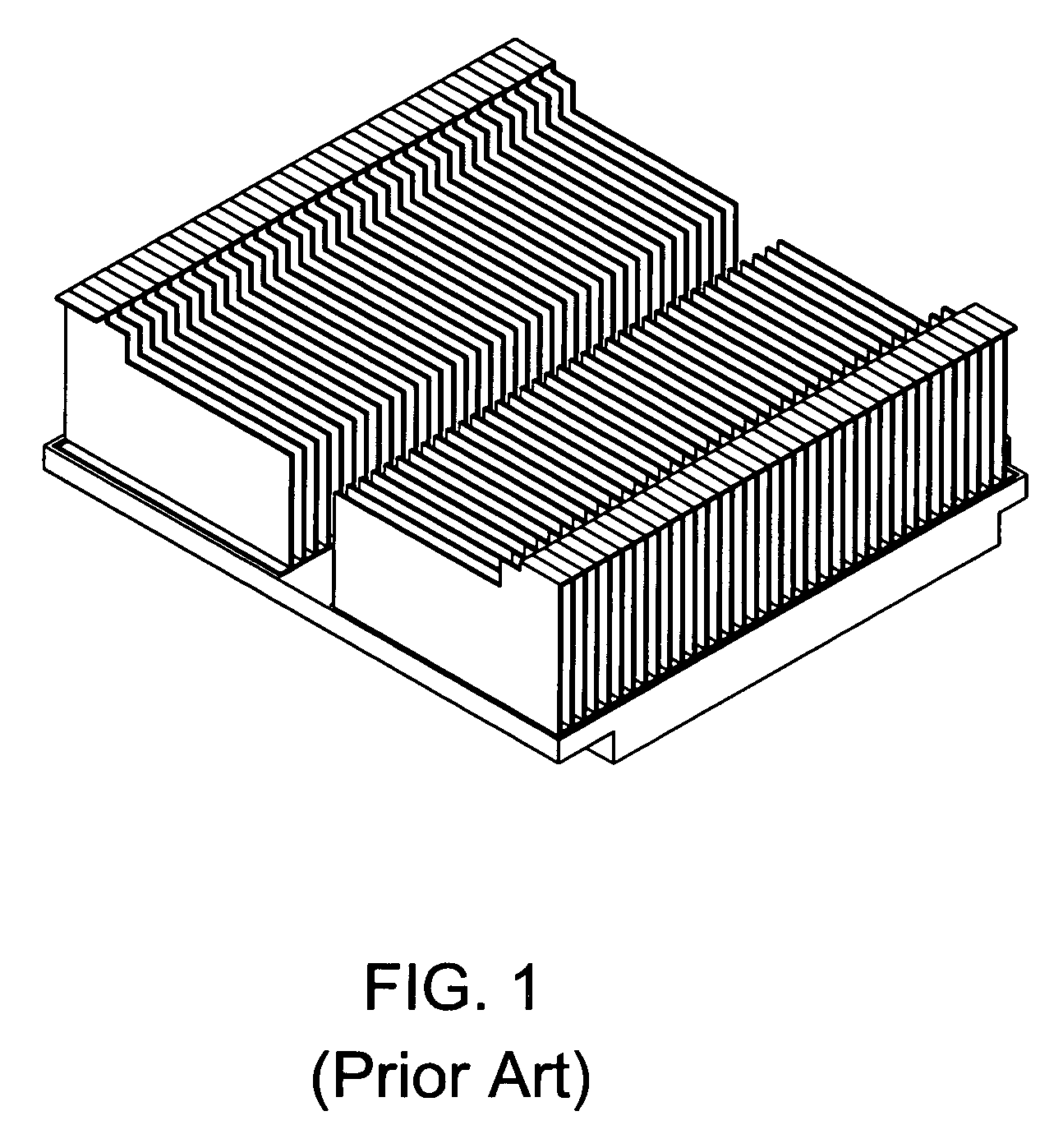

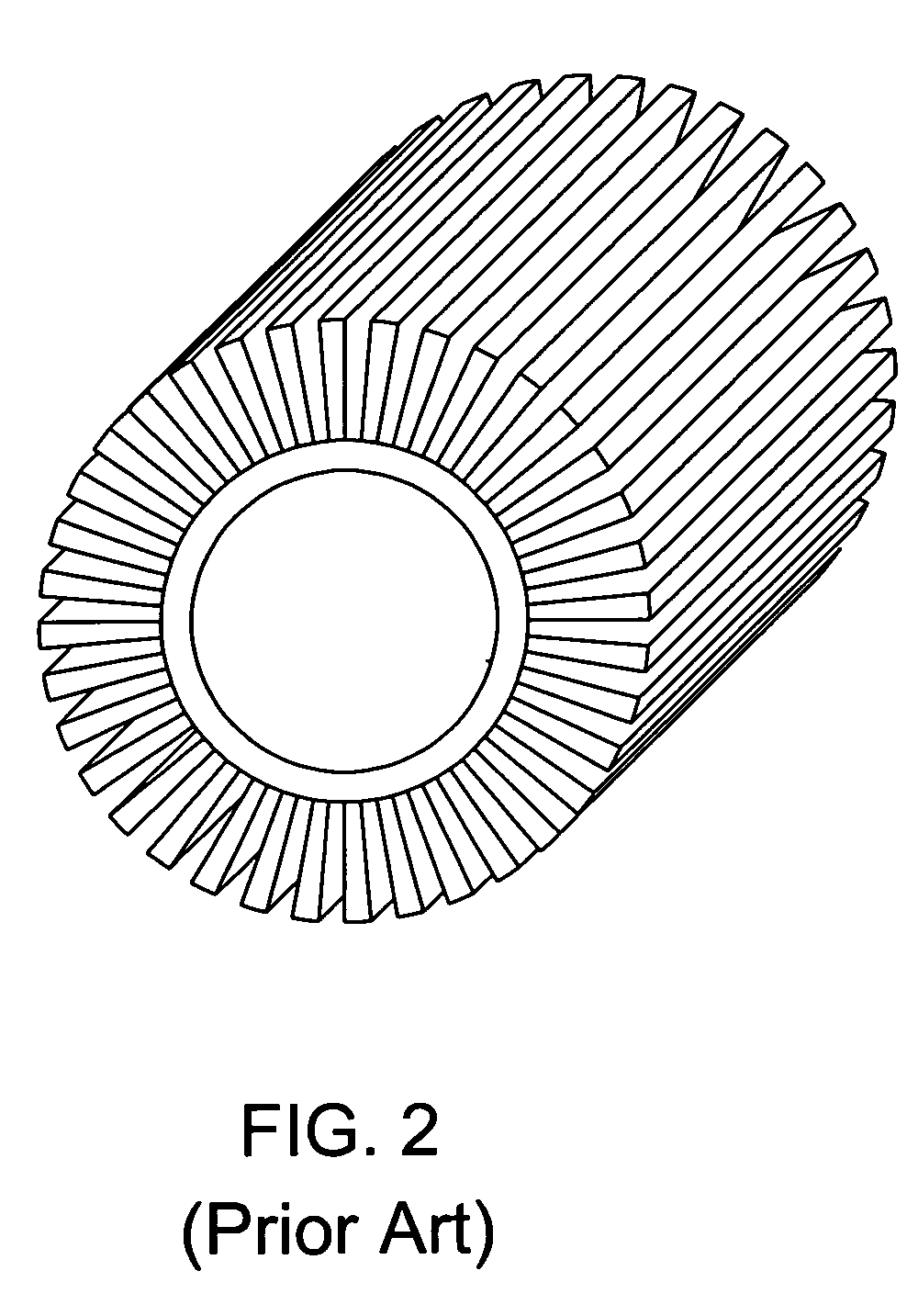

Circular heat sink assembly

InactiveUS7063130B2Simple structureImprove cooling effectSemiconductor/solid-state device detailsLighting heating/cooling arrangementsConical formsEngineering

The present invention discloses a circular heat sink to improve a traditional extruded aluminum heat sink or a traditional compressed aluminum heat sink by adopting a plurality of streamlined curved heat dissipating fins and a conical base to constitute the circular heat sink. The shape of the heat dissipating fin is designed to have a streamlined curved surface; and the circular heat sink assembly comprises a plurality of fan-shaped heat dissipating fins stacked and encircled into a circular shape and the curvature of the bottom of the heat dissipating fin can be designed according to the conical shape of the conical base, and a latch structure for the heat dissipating fin is adopted. If the plurality of the heat dissipating fins with a streamlined curved surface is stacked into a circular shape, then a plurality of folded flanges along the sides of the plurality of heat dissipating fins are latched and encircled to form a circular ring, and the fan-shaped folded flanges at the bottom of the heat dissipating fins also are stacked and encircled to form a circular ring and then connected to a conical base to form a circular heat sink having a plurality of streamlined heat dissipating fins with a curved surface.

Owner:HUANG CHU TSAI

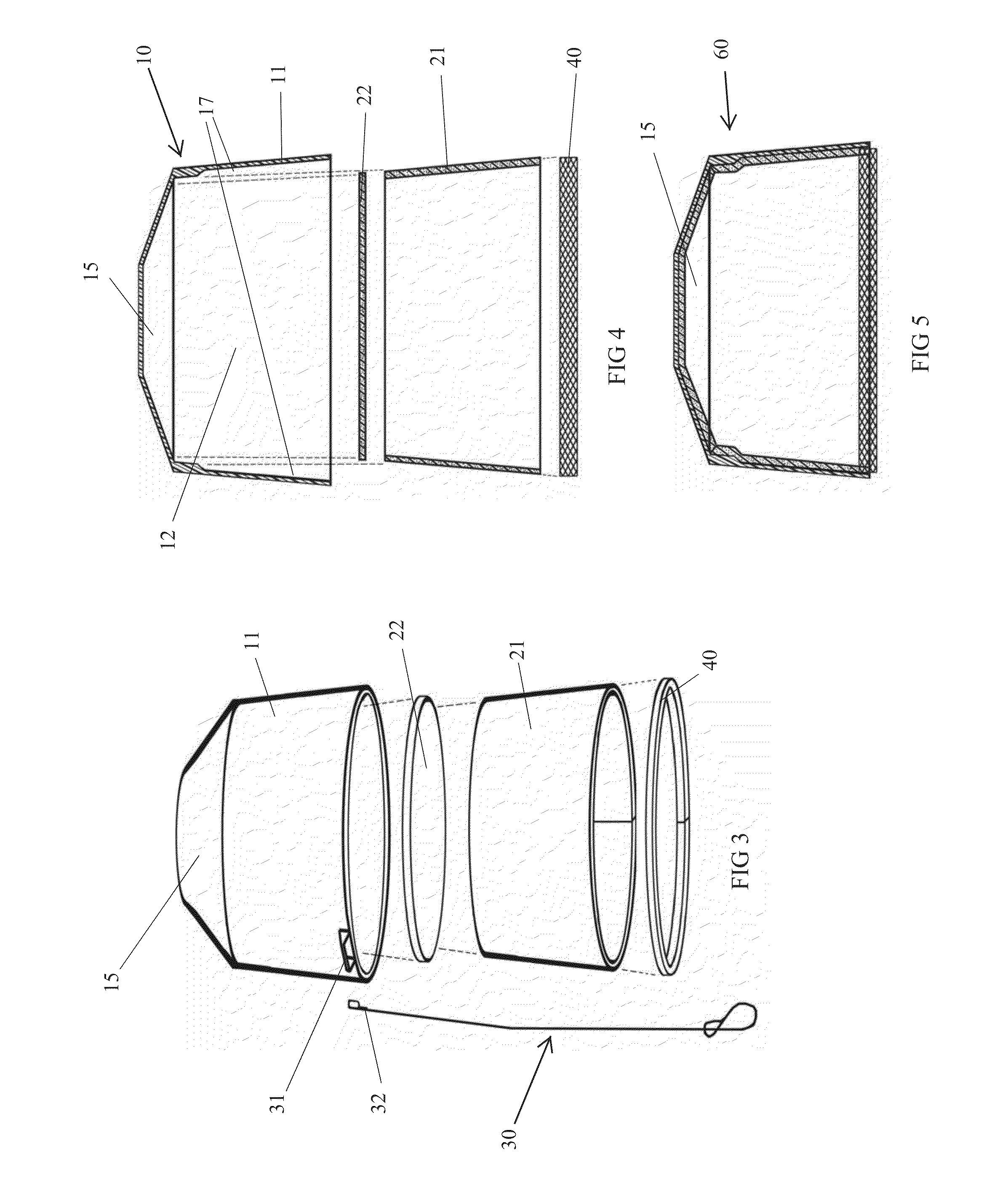

Reusable insulating and sealing structure including tethered cap and associated methods

InactiveUS20060286862A1Reduce the overall diameterSecuring/insulating coupling contact membersCouplings bases/casesEngineeringConical forms

A reusable insulating and sealing structure may include an insulating tube and a frusto-conical seal having an enlarged diameter open distal end carried by an open distal end of the insulating tube and having a reduced diameter open proximal end extending into the insulating tube. The reduced diameter open proximal end may be resiliently deformable to accommodate a range of sizes of cable ends therethrough. The reusable insulating and sealing structure may also include a removable seal closure cap for removable positioning in the enlarged diameter open distal end of the frusto-conical seal, and an integrally molded tether connecting the removable seal closure cap to the frusto-conical seal adjacent the enlarged diameter open distal end thereof. The closure cap and tether permit the insulating and sealing structure to be sealed when a cable is not extending therethrough and thus permit the insulating and sealing structure to be reused.

Owner:HOMAC MFC CO +1

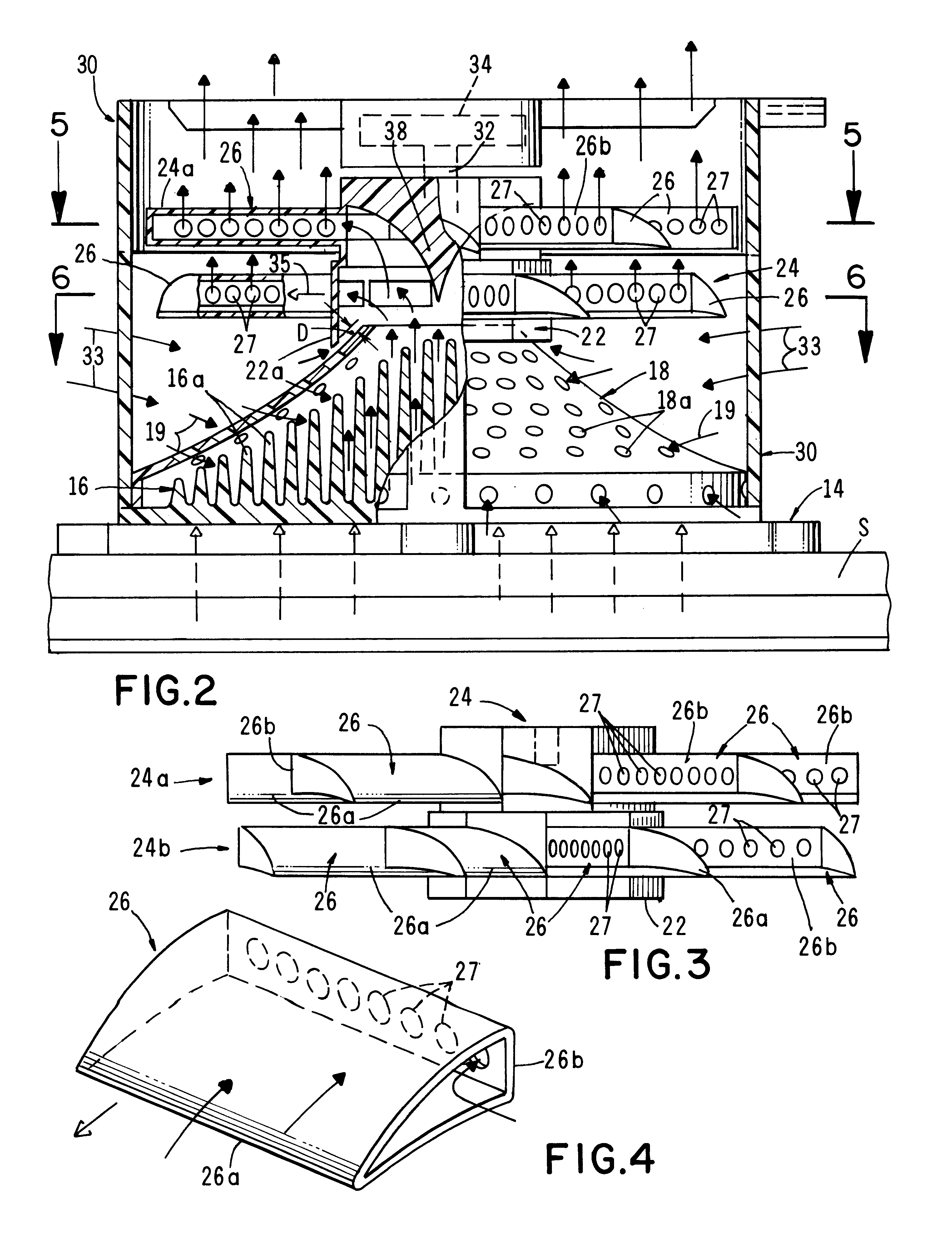

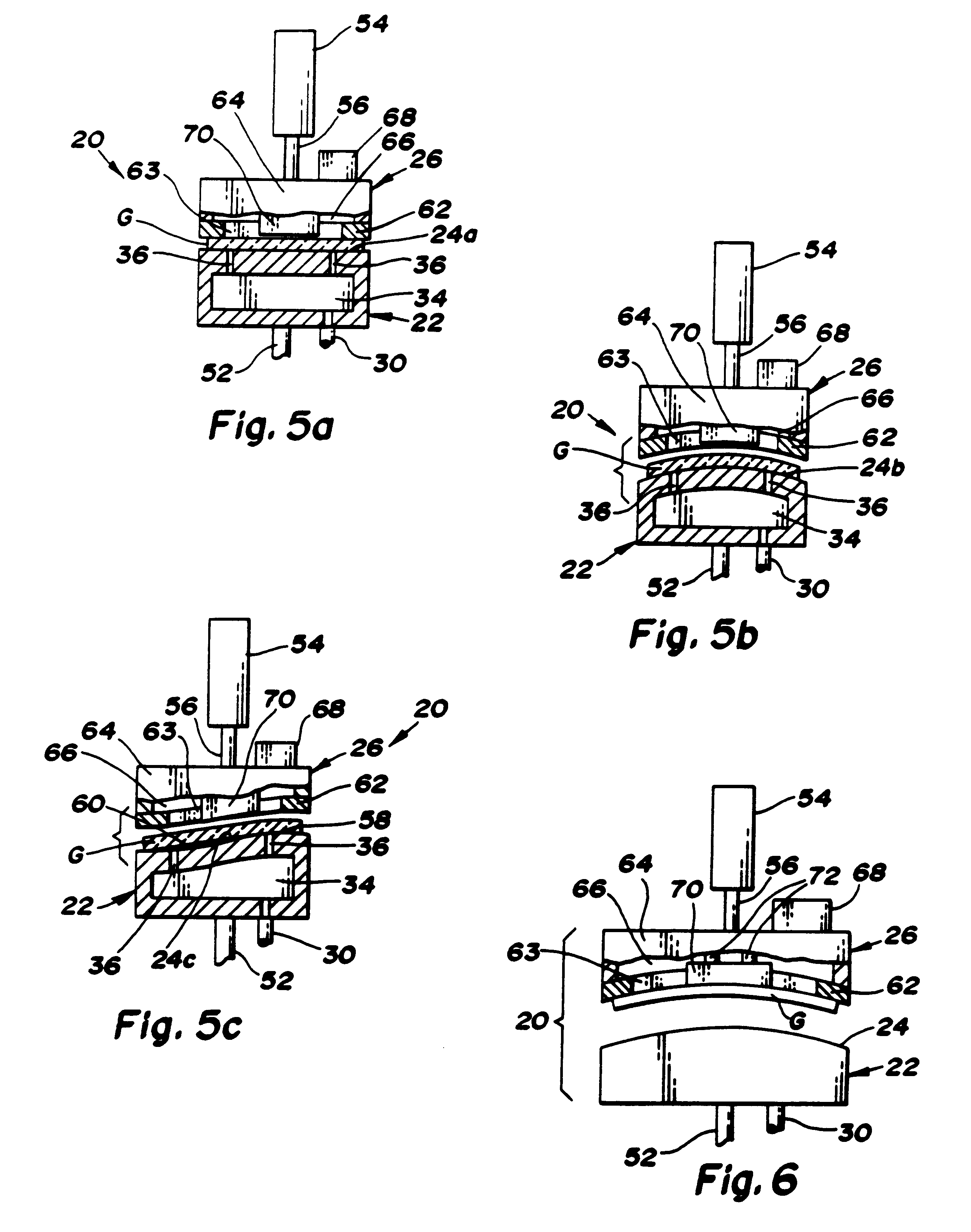

Apparatus for vacuum impulse forming of heated glass sheets

InactiveUS6227008B1Reduced optical distortionIncrease vacuumGripping headsGlass reforming apparatusGlass sheetMaterials science

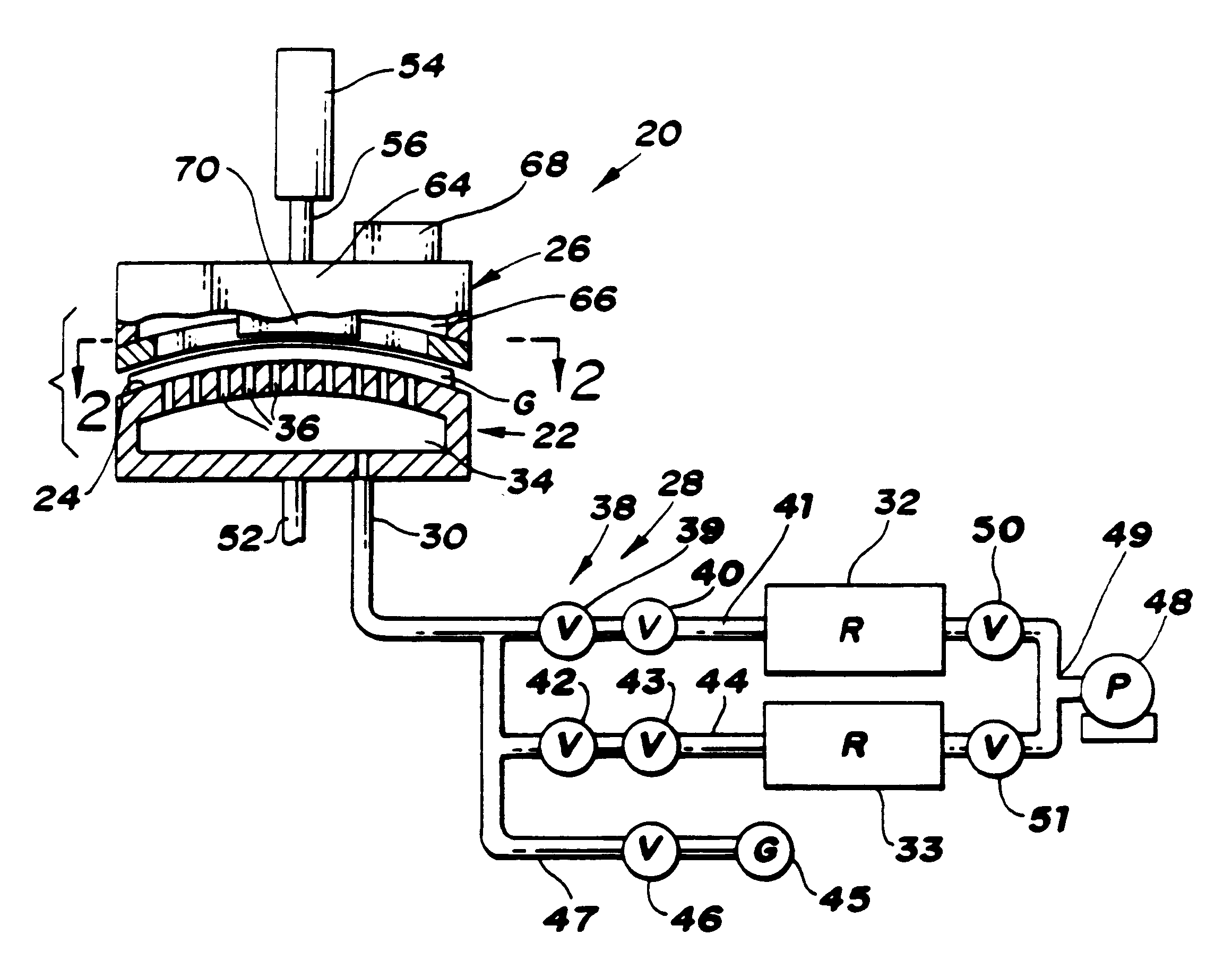

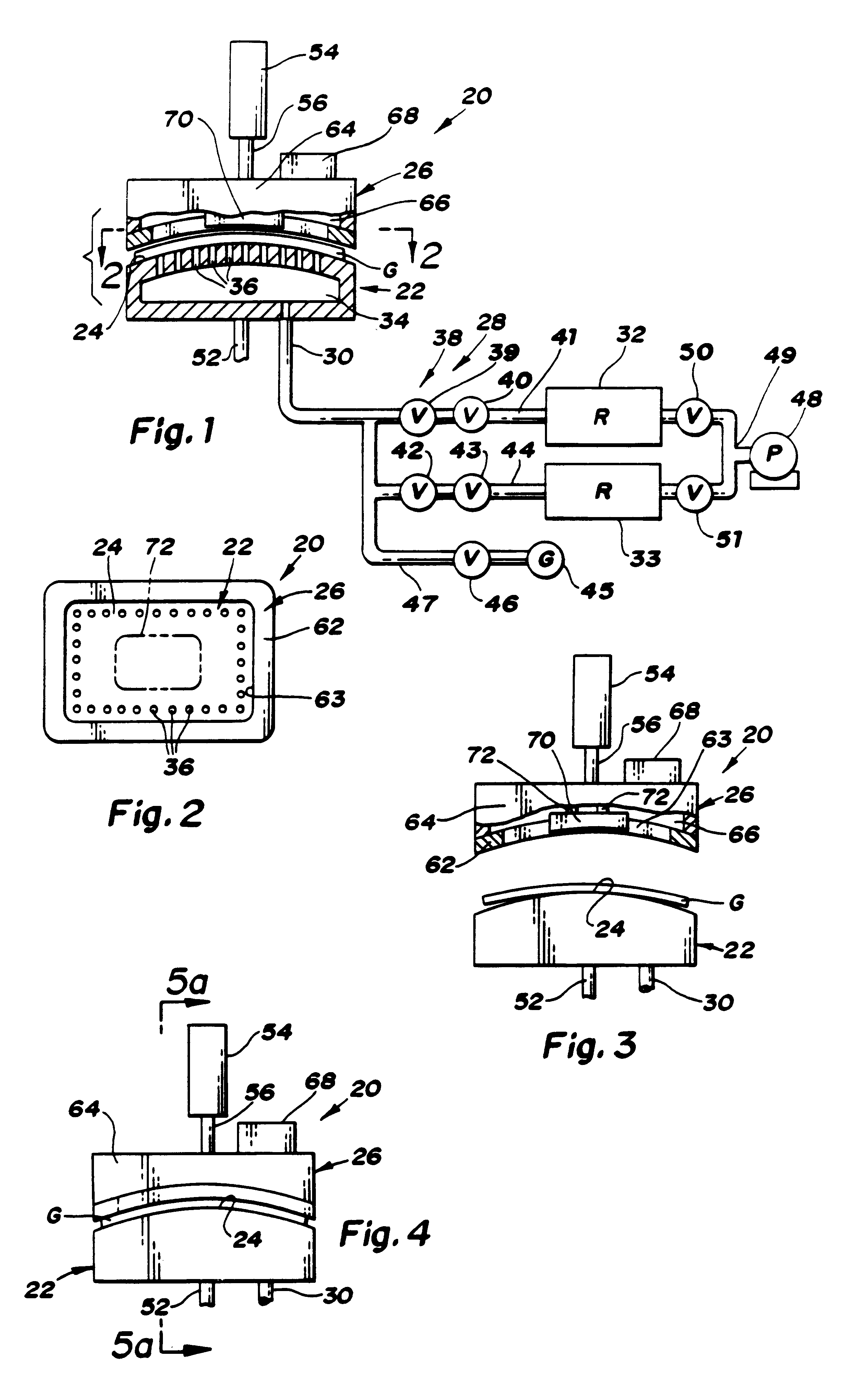

Apparatus (20,120) for forming a heated glass sheet G is disclosed as including a vacuum mold (22,22a,122,122a) having a full surface (24,24a,124,124a) against which a peripheral mold (26,26a,126,126a) presses the glass sheet periphery and with which at least one vacuum reservoir (32,33) is communicated within the interior of the sealed glass sheet periphery to form the glass sheet to the shape of the vacuum mold surface. Valving (38) of a vacuum system (28) is preferably operable to provide the vacuum impulse in two stages with an initial limited extent of vacuum and a subsequent greater extent of vacuum by communication first with one vacuum reservoir (32) and subsequently with another vacuum reservoir (33). Different embodiments of the vacuum mold have the vacuum mold surface facing upwardly and downwardly with convex and concave shapes. Glass sheet shapes including straight line elements such as cylindrical and conical bends as well as shapes including curvatures in transverse directions and inverse curvatures can be effectively provided by this vacuum impulse forming.

Owner:GLASSTECH

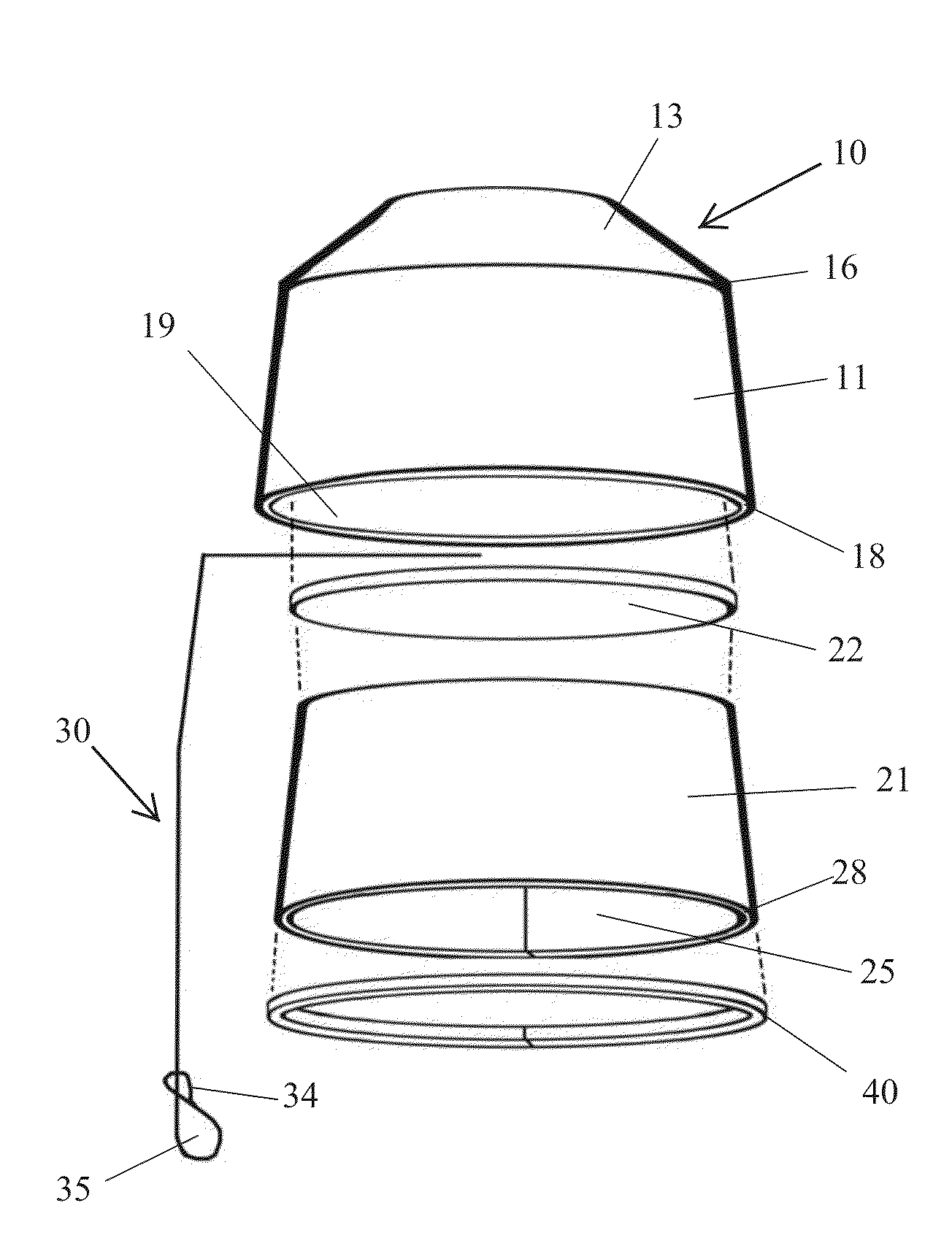

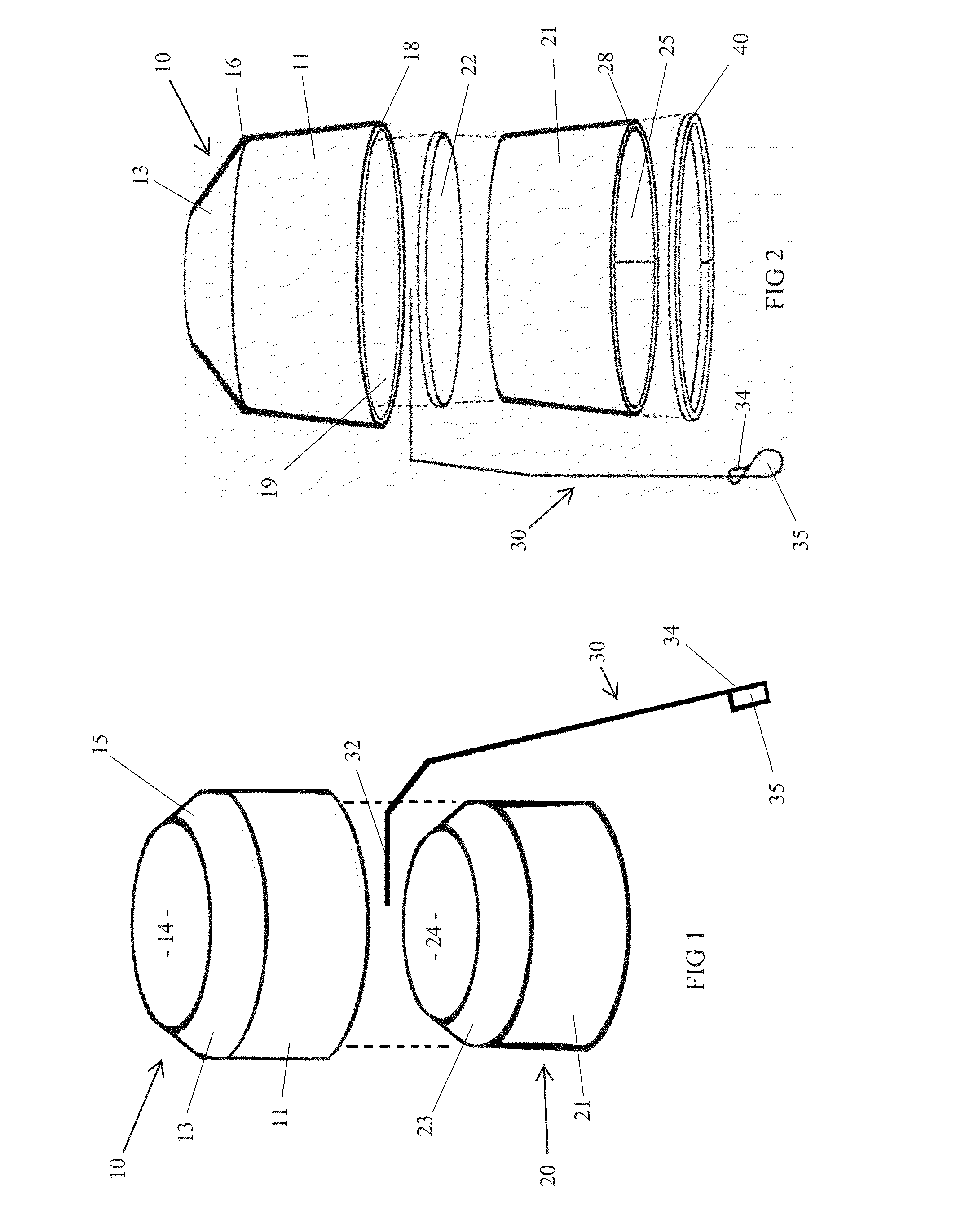

Protective Lens Cover

InactiveUS20130129338A1Prevent slippageAvoid separationCamera filtersTelescopesCamera lensConical forms

A padded protective frusto-conical shaped cup covering sized to slip over a camera lens is disclosed. The covering is designed to fit on either the front portion of the lens or the rear lens mount. The protective covering has beveled side walls which allow it to fit easily on a variety of different lenses. The protective covering is made from two separate layers of material, an outer cup made from a firm yet flexible material, and the inner liner made from a soft pliable material. In one embodiment the outer cup includes a circumferential retaining ring on the inside of the cup to help secure the cup onto a lens. The soft inner liner allows the covering to easily adhere to the camera lens, and also provides impact protection. The outer cup provides additional impact protection. The outer cup also includes a domed top portion which provides a crumple zone or impact bumper. In one embodiment the outer cup has an opening in the domed top, and in one embodiment thereof there is a clear optical grade lens or filer lens inserted or incorporated into the opening, which allows the camera user to take a photograph without removing the protective lens.

Owner:DOWELL MICHAEL

Aerodynamic air gun projectile

InactiveUS20070074637A1Reduce turbulent airflowGood laminar flowAmmunition projectilesHollow inflatable ballsInterference fitConical forms

A projectile for an air arm is integrally formed from a single piece of dense malleable material formed as a body of revolution about a longitudinal axis having a head portion dimensioned for free sliding in the bore of an air arm and a skirt-like portion of frusto-conical form. The rearward end of the skirt portion is dimensioned to be in slight interference fit with the bore and the forward end is joined with the head portion to define a reduced diameter waist. The frustum is shell-walled, having a central recess opening to the rear and extending forwardly into the head portion. The head portion has a parabolically shaped outer surface which transitions smoothly into a hyperbolically shaped outer skirt surface for aerodynamic efficiency. Vanes are formed on the head portion to enhance in-flight spiraling rotation.

Owner:PONTIERI JAMES M

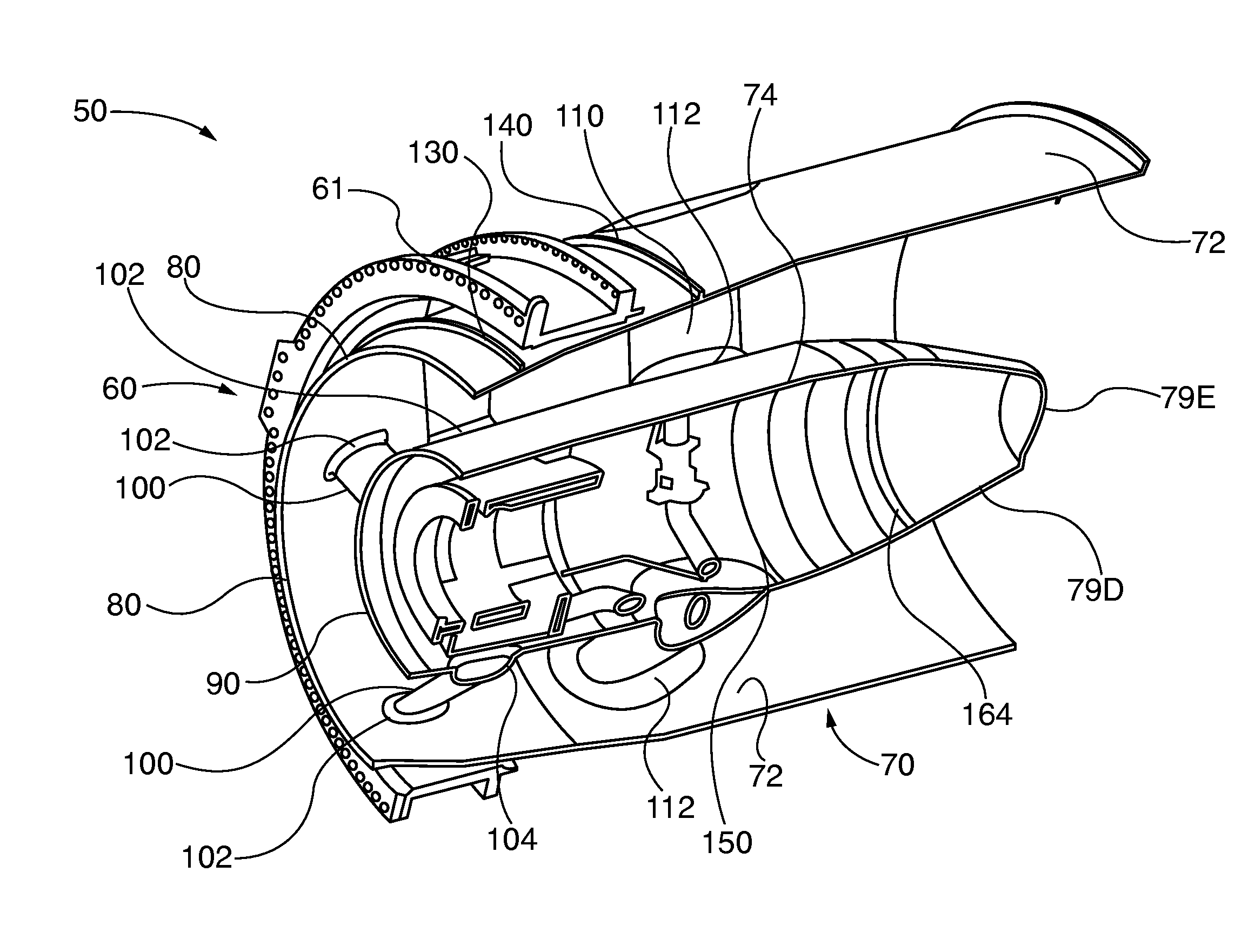

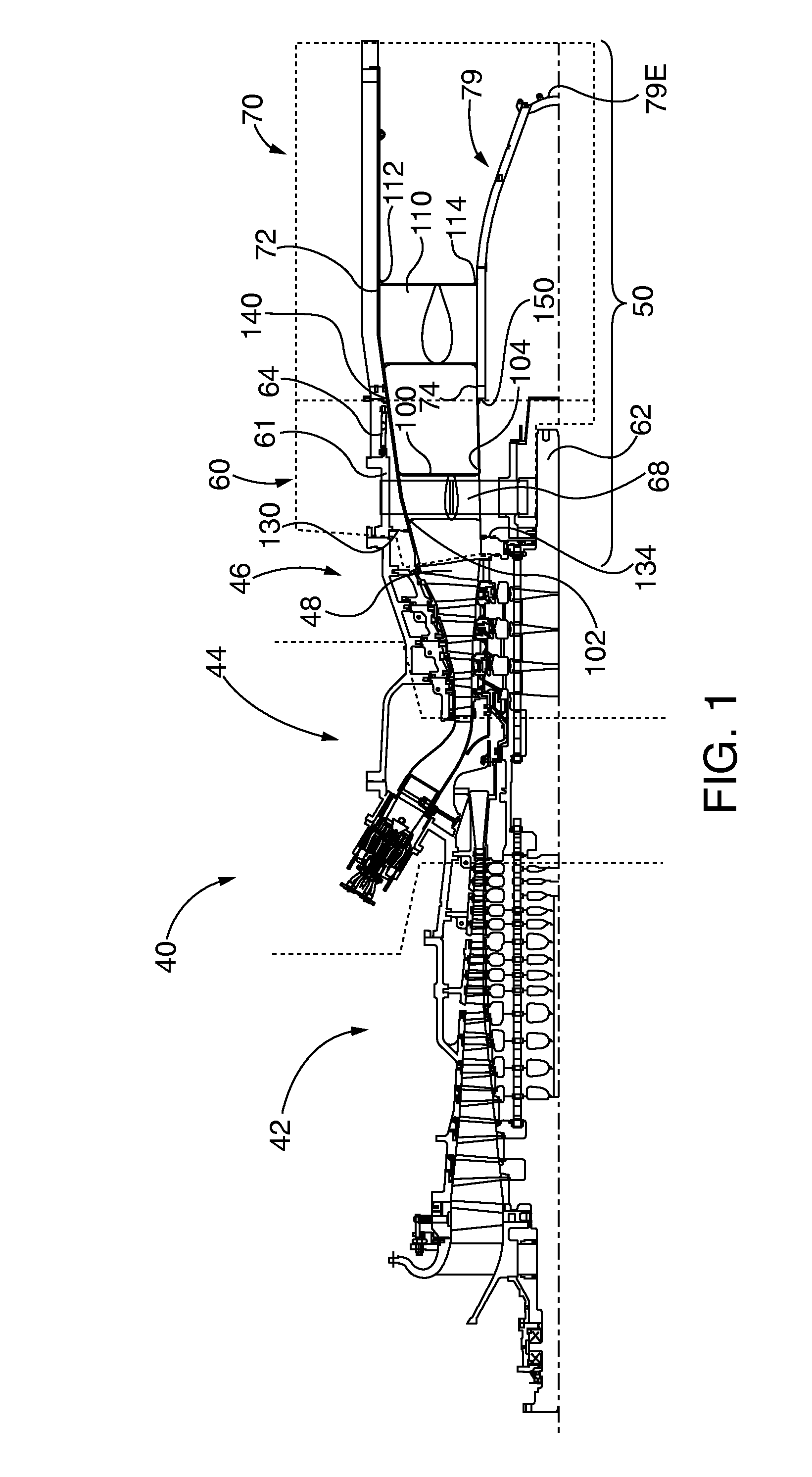

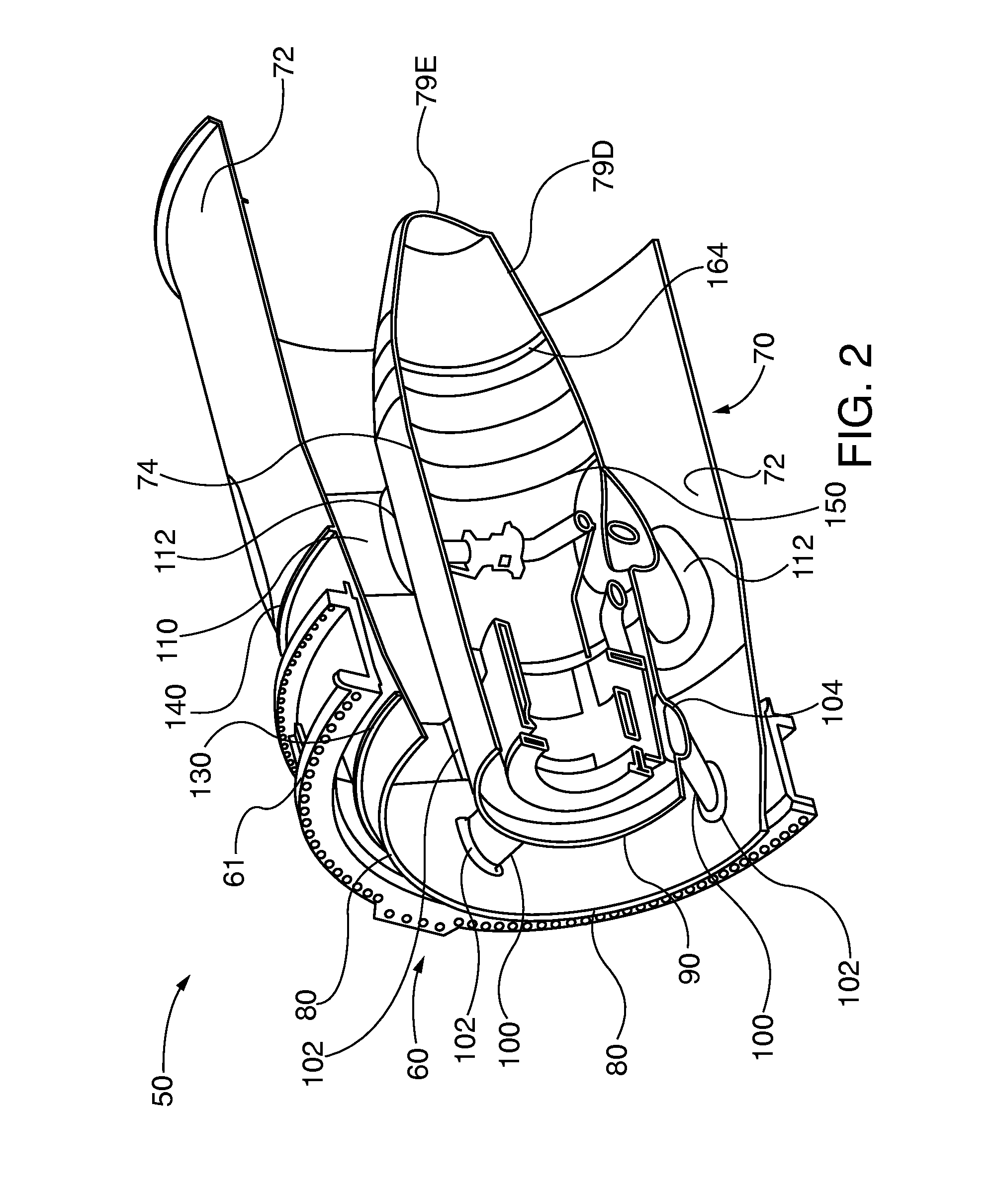

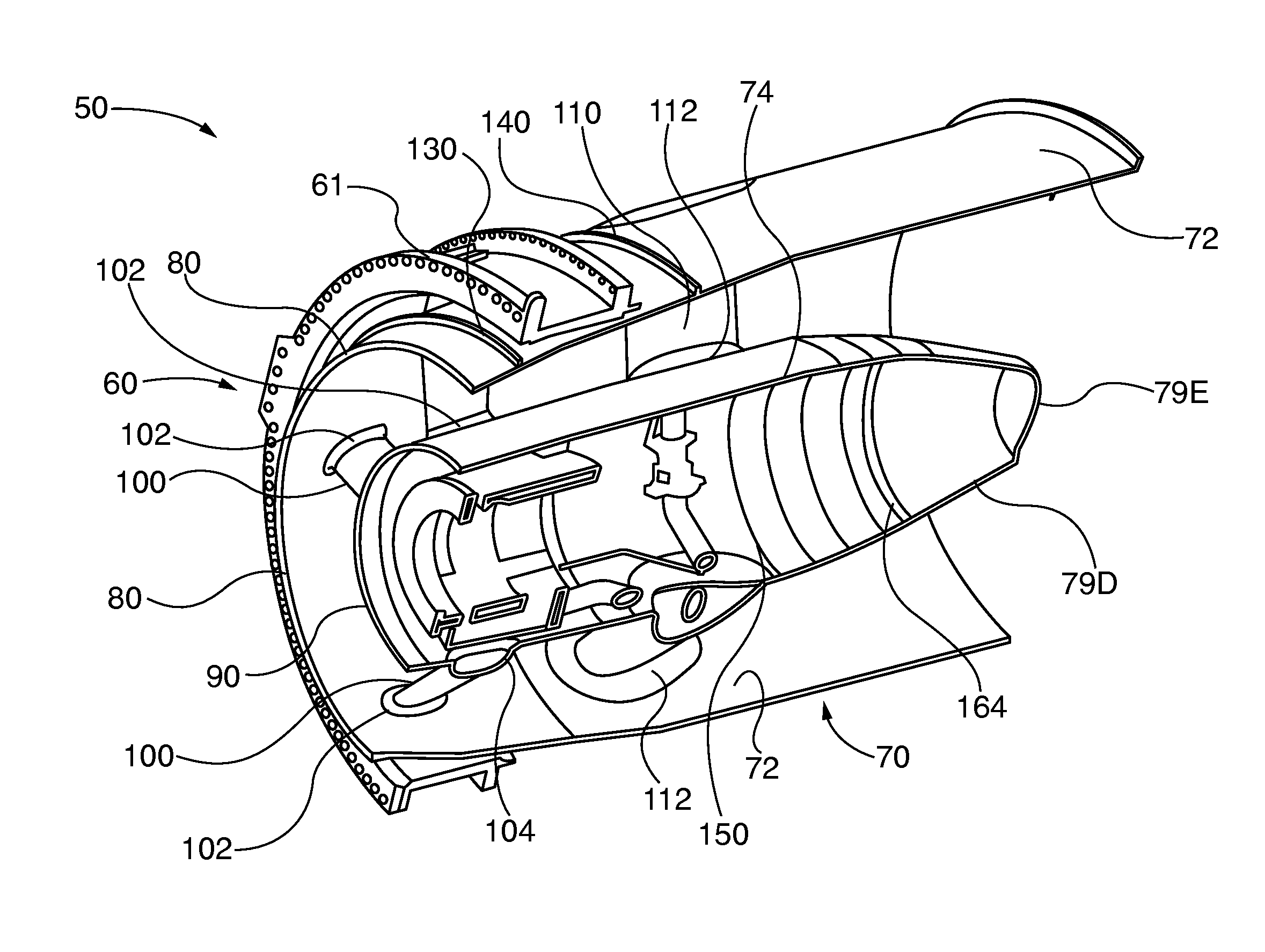

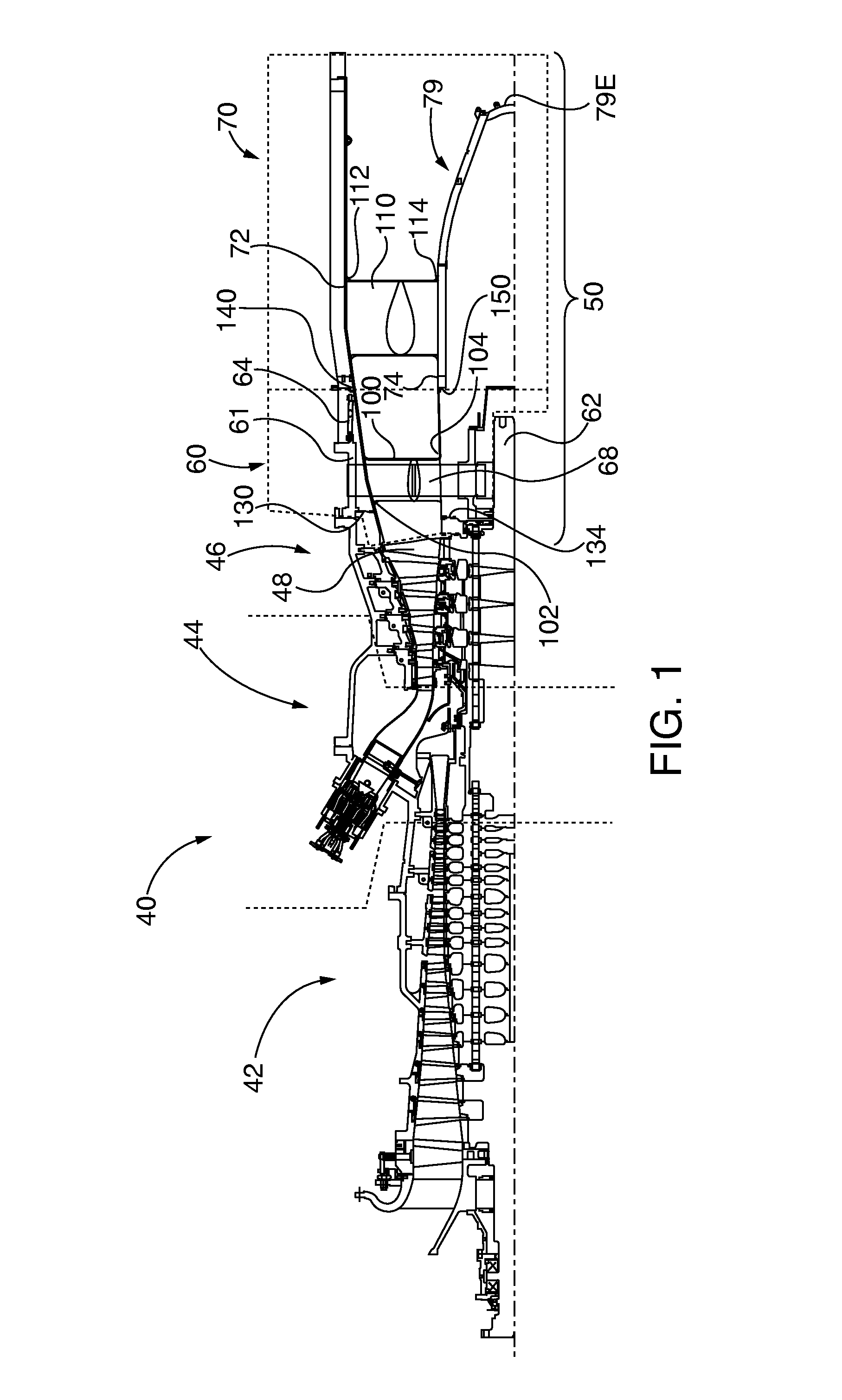

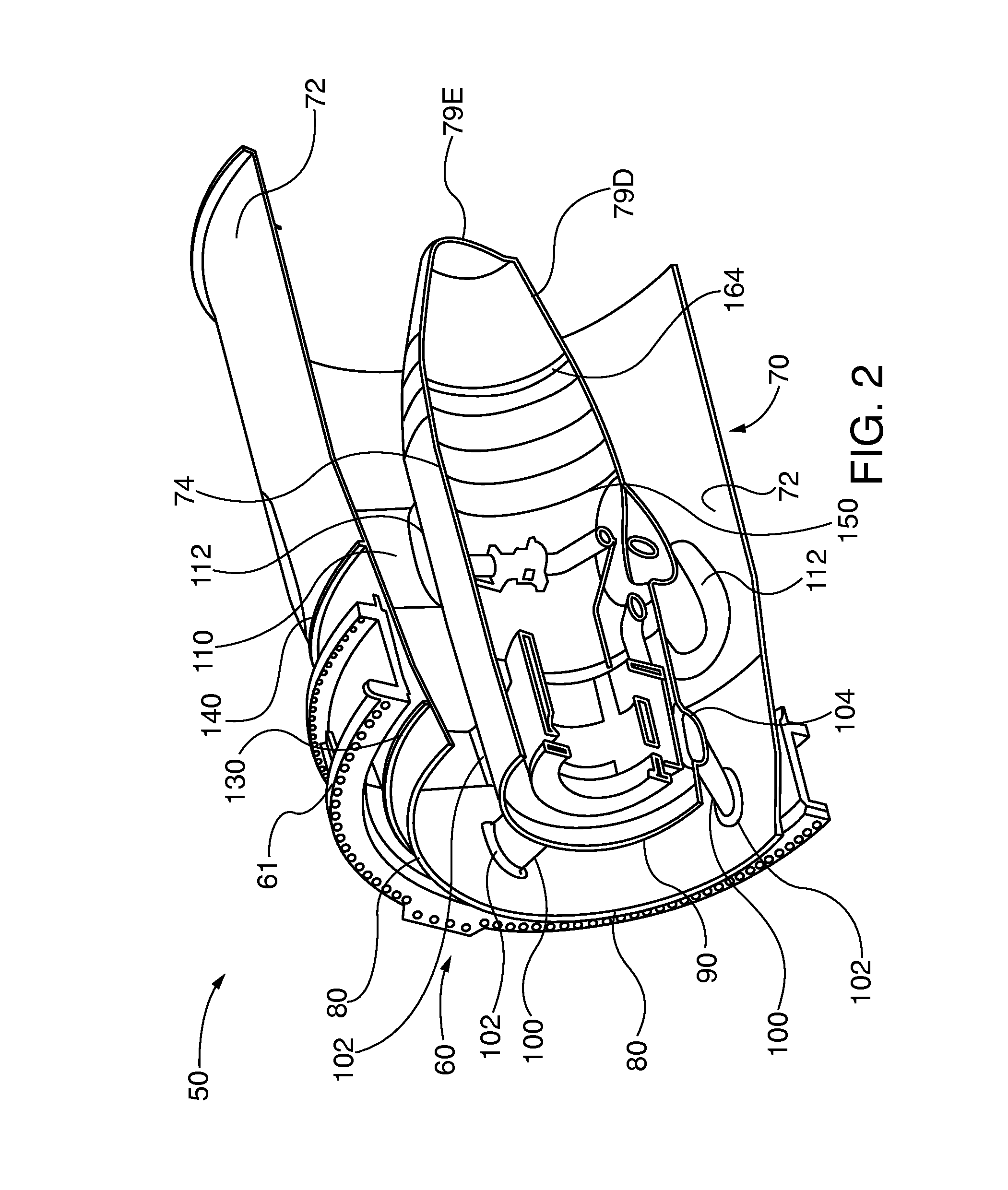

Modular industrial gas turbine exhaust system

ActiveUS20150143816A1Improved aerodynamicsImproves Structural IntegrityEngine manufactureGas turbine plantsConical intersectionThermal expansion

An integrated single-piece exhaust system (SPEX) with modular construction that facilitates design changes for enhanced aerodynamics, structural integrity or serviceability. The SPEX defines splined or curved exhaust path surfaces, such as a series of cylindrical and frusto-conical sections that mimic curves. The constructed sections may include: (i) a tail cone assembly fabricated from conical sections that taper downstream to a reduced diameter; or (ii) an area-ruled cross section axially aligned with one or more rows of turbine struts; or both features. Modular inner and outer diameter inlet lips enhance transitional flow between the last row blades and the SPEX, as well as enhance structural integrity. Modular strut collars have large radius profiles between the SPEX annular inner diameter and outer diameter flow surfaces, for enhanced airflow and constant thickness walls for uniform heat transfer and thermal expansion. Scalloped mounting flanges enhance structural integrity and longevity.

Owner:SIEMENS ENERGY INC

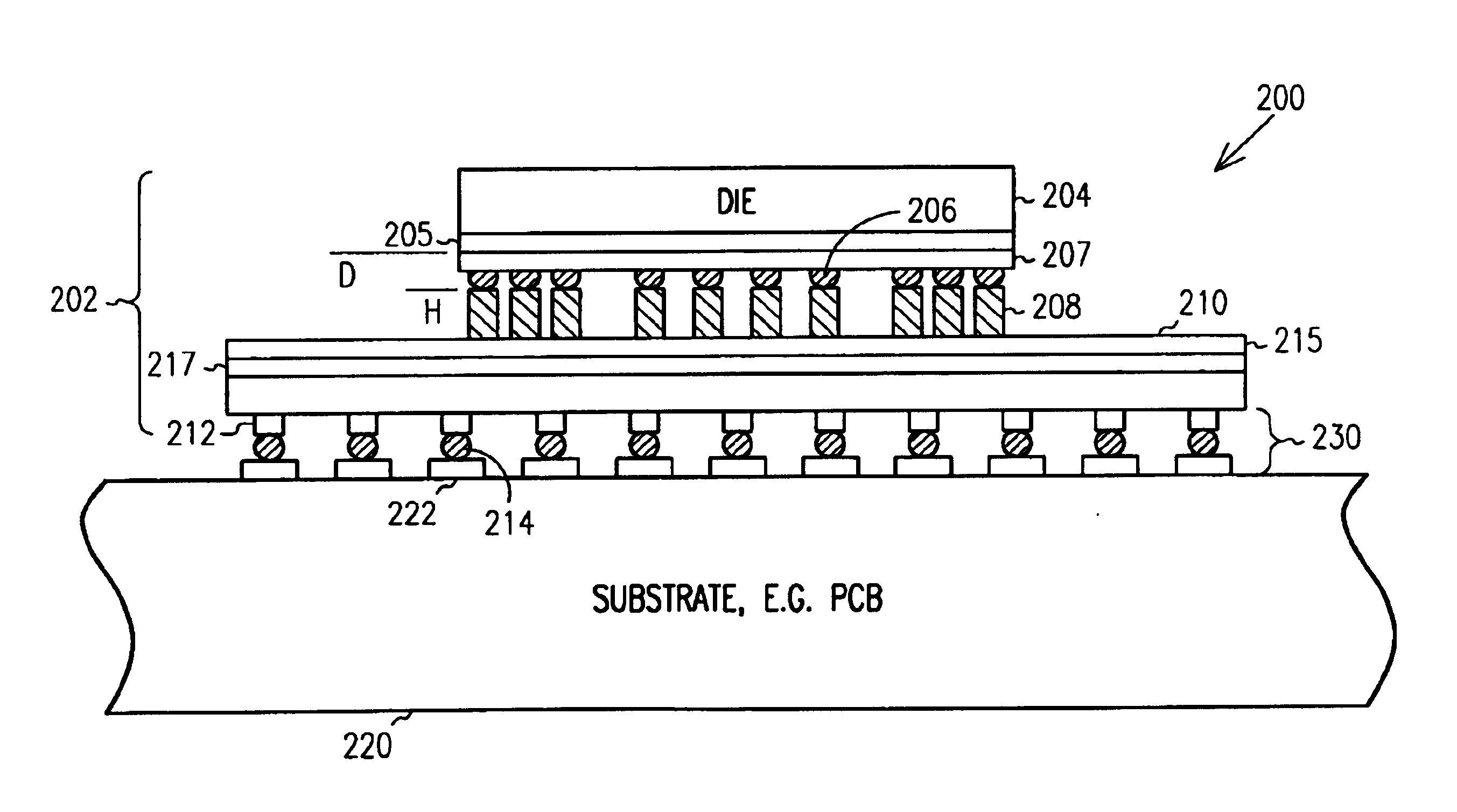

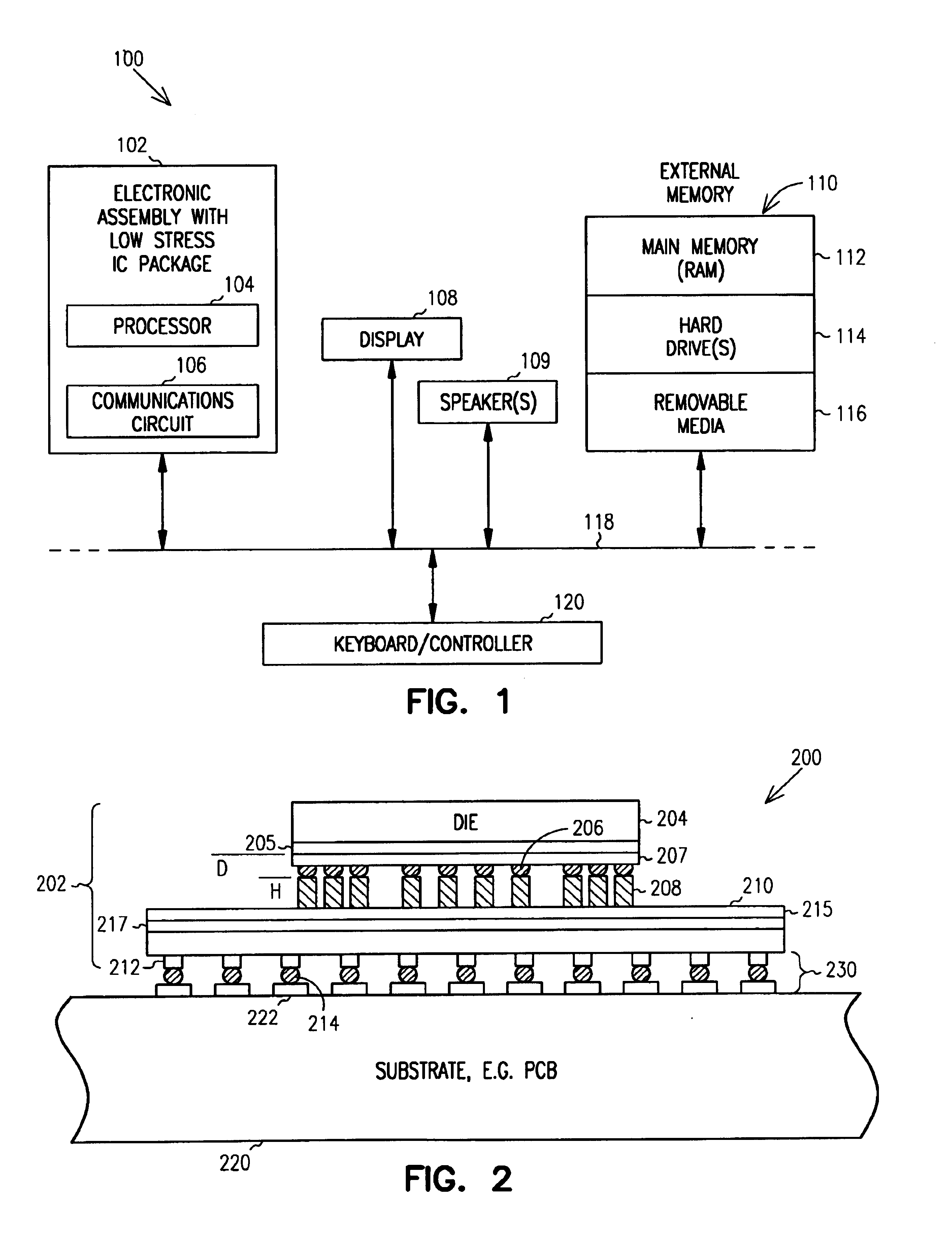

Integrated circuit packages with reduced stress on die and associated substrates, assemblies, and systems

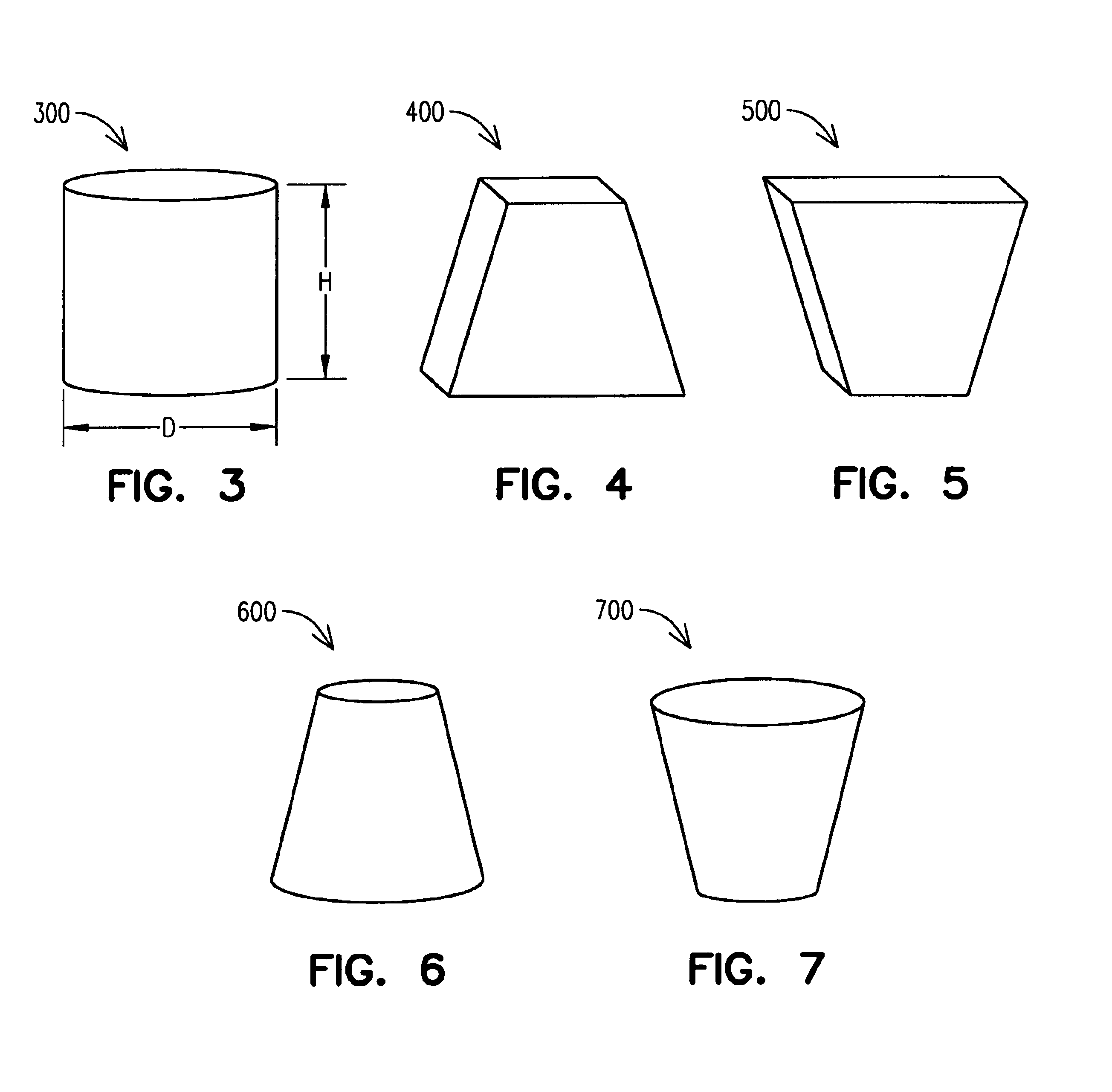

InactiveUS6989586B2Printed circuit assemblingFinal product manufactureElectronic systemsConical forms

Mechanical stresses are reduced between an electronic component having relatively low fracture toughness and a substrate having relatively greater fracture toughness. In an embodiment, the component may be a die having mounting contacts formed of a low yield strength material, such as solder. A package substrate has columnar lands formed of a relatively higher yield strength material, such as copper, having a relatively higher melting point than the component contacts and having a relatively high current-carrying capacity. The component contacts may be hemispherical in shape. The lands may be substantially cylinders, truncated cones or pyramids, inverted truncated cones or pyramids, or other columnar shapes. Methods of fabrication, as well as application of the package to an electronic assembly and to an electronic system, are also described.

Owner:INTEL CORP

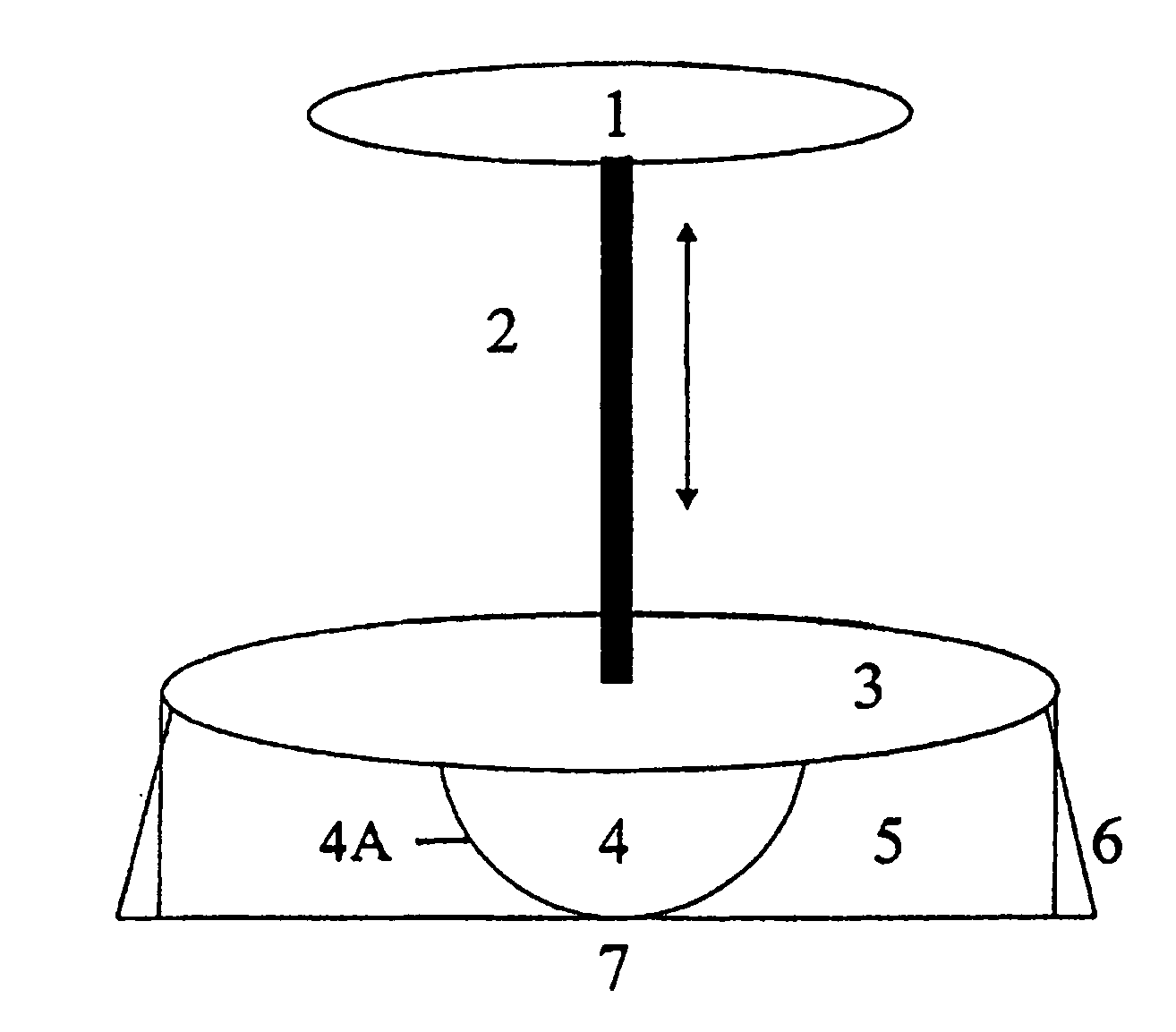

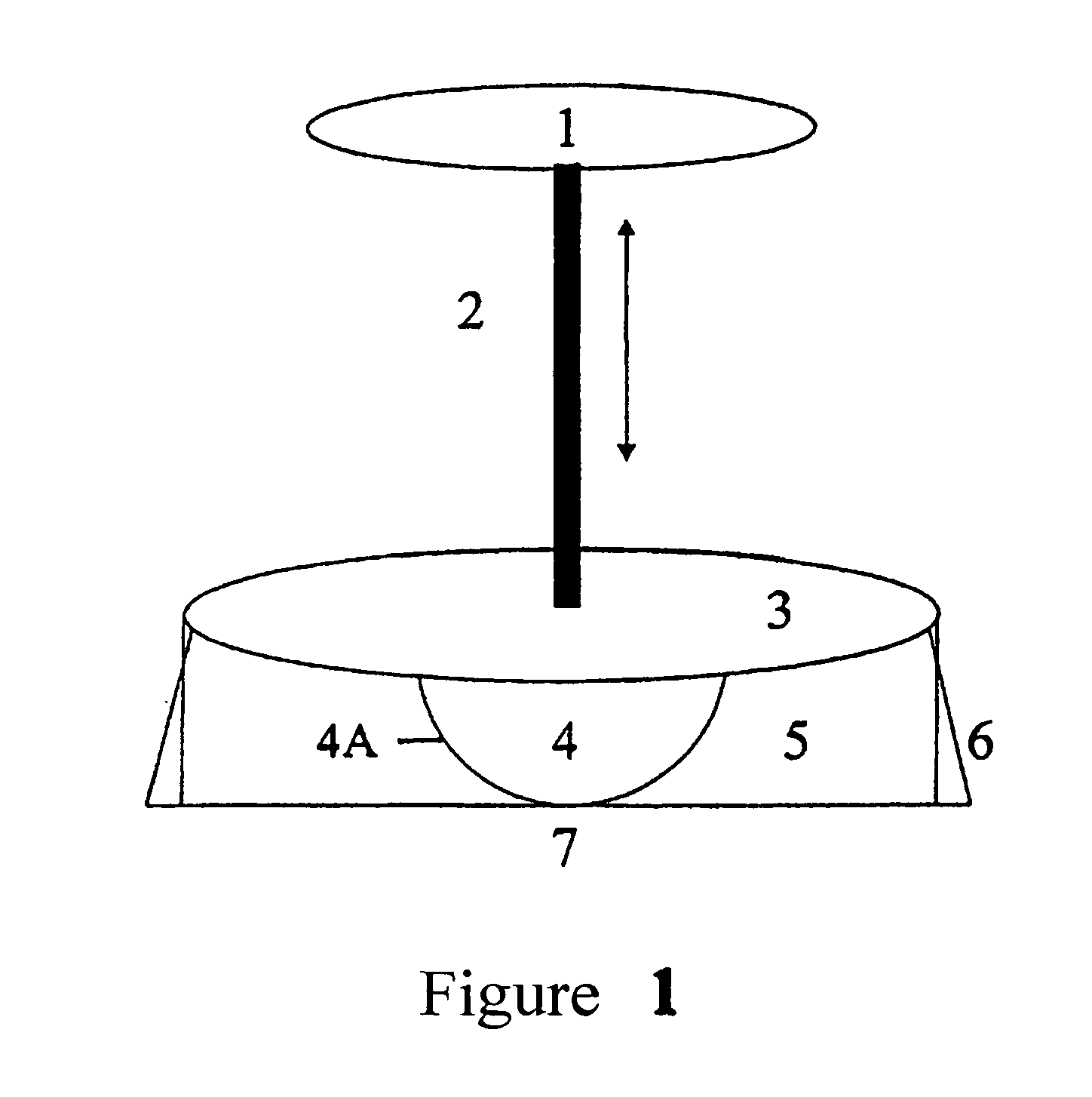

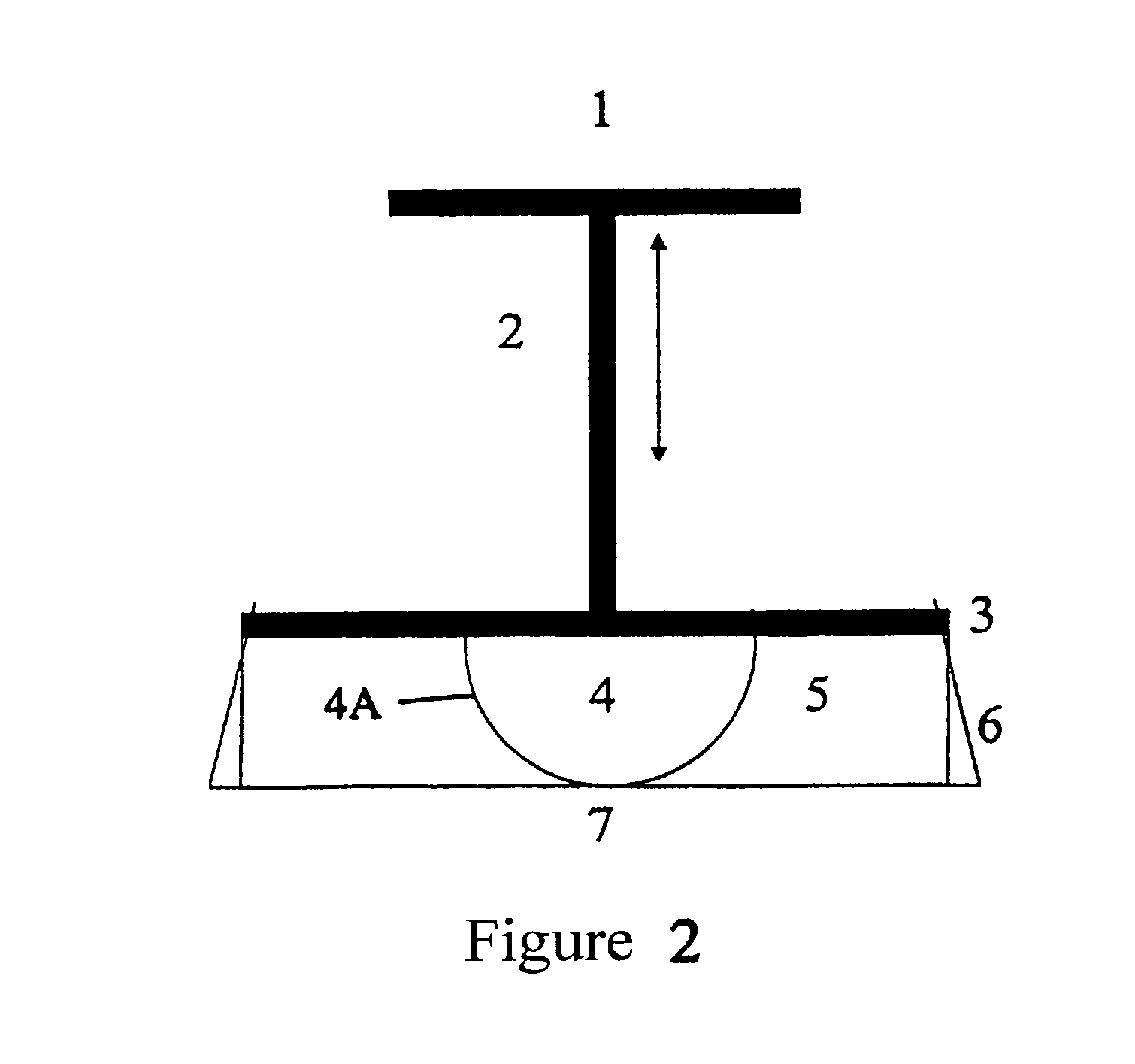

Training apparatus/chair

A device is provided for exercising the muscles of the back, which includes a chair seat and a rod fastened to a feet plate. The feet plate is coupled to a tilting member which is surrounded by a damping member. The damping member can rest on a bottom plate which is fastened by a fastening member. A cloth which surrounds the damping member and is fastened to the feet plate can replace the bottom plate and the fastening member. It is further an advantage that the rod is telescopic. The tilting member can have a circular cross section and a downwardly conical form. The damping member which surrounds the tilting member is of a flexible material and may be fastened to the feet plate by the fastening means member which can assist in dampening the movement of the tilting member.

Owner:BACKUP

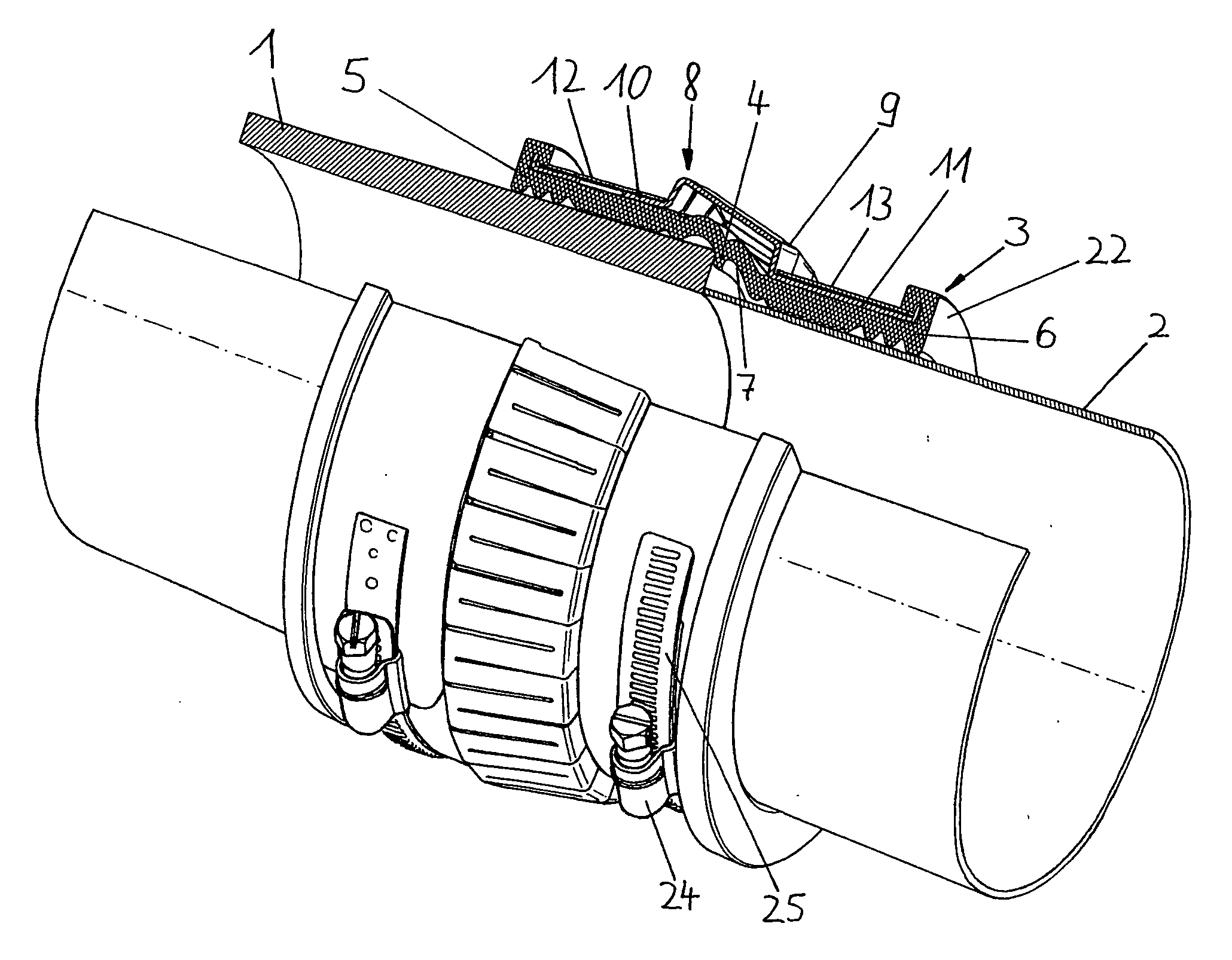

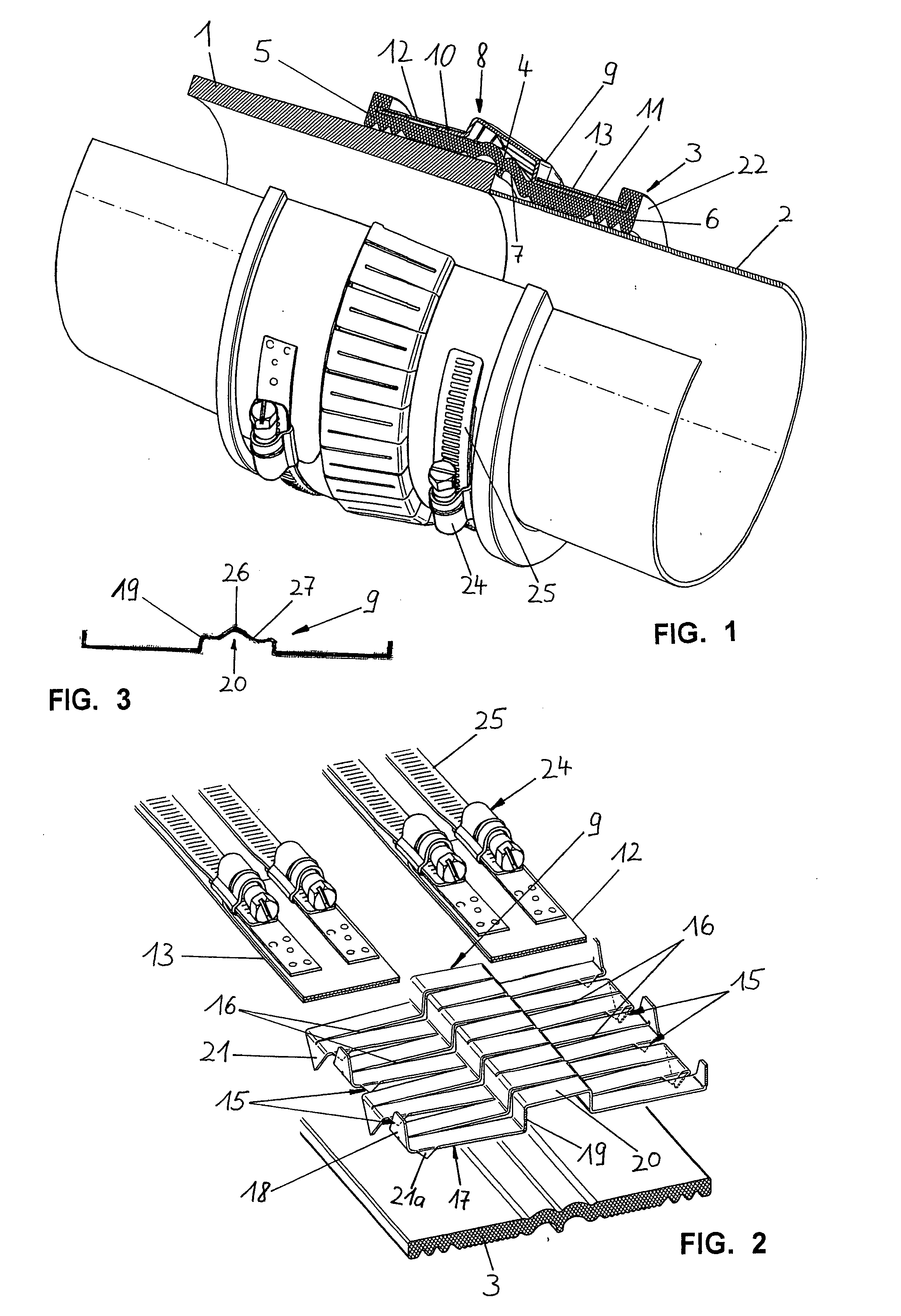

Device for connecting two pipes with different external diameters

ActiveUS20090160183A1Improve sealingBetter sealing arrangementSleeve/socket jointsPipe elementsButt jointConical forms

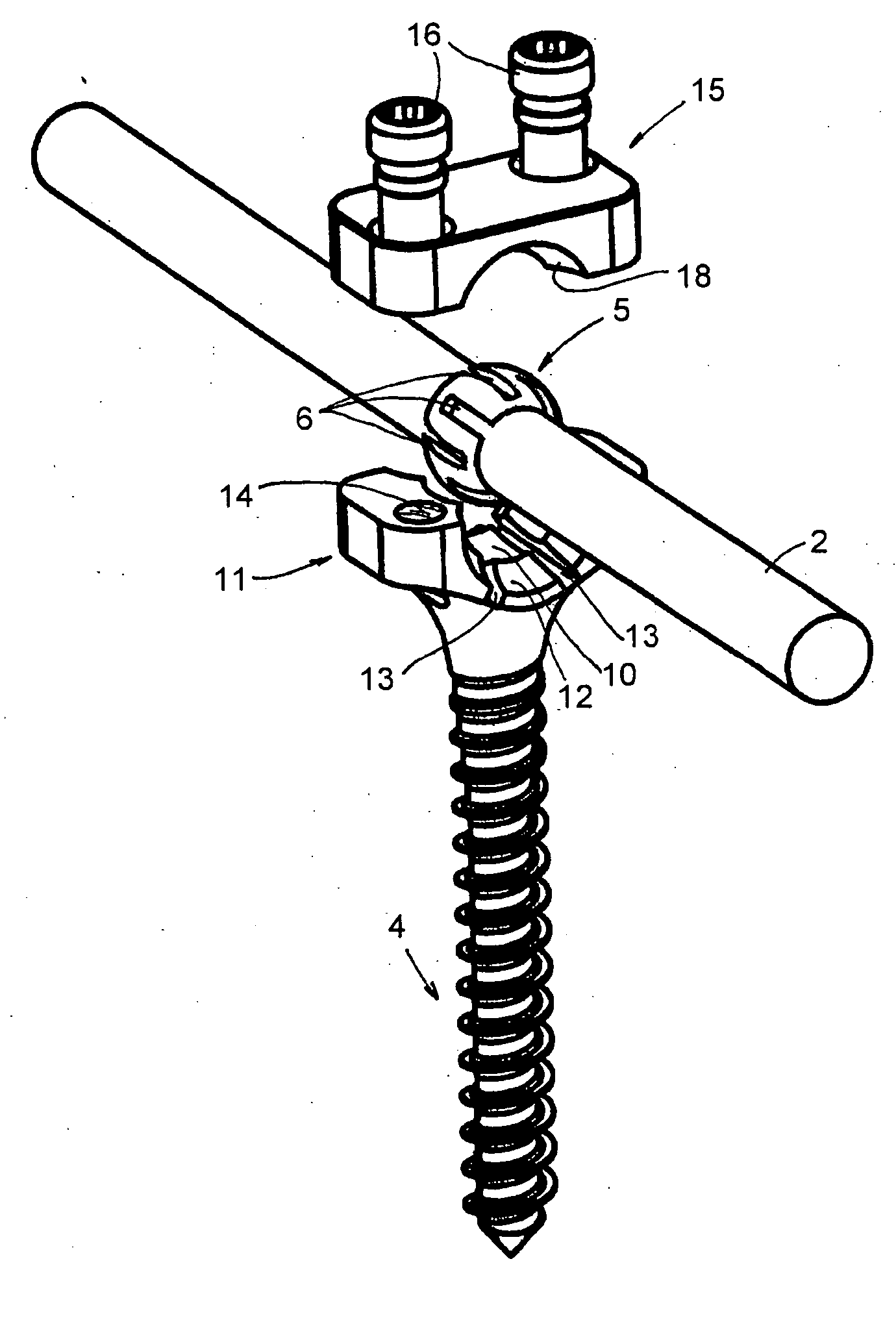

For a device for connecting two pipes (1, 2) with different external diameters using a sleeve arrangement which bridges the butt joint between the ends of the pipe (1, 2) facing each other and contains at least a fixing sleeve (8, 8a) which can take up the clips (12, 13) for the two pipes (1, 2) and if necessary a sealing sleeve (3) which is surrounded by the fixing sleeve (8, 8a), high economy and safety can be achieved by the fact that each sleeve of the sleeve arrangement has cylindrical contact sections (5, 6; 10, 11) which can be adjusted to the different external diameters of the two pipes (1, 2) and are connected by a central section (7, 9) which can take a conical form to suit the diameter difference wherein the contact sections (5, 6) of the sleeve next to the external circumference of the two pipes (1, 2) can be brought into direct contact with the two pipes (1, 2) and the contact sections (10, 11) of the fixing sleeve (8, 8a) contain encircling mounting channels assigned to the clips (12, 13) and wherein the fixing sleeve (8) takes the form of a closed encircling ring which is suitable for three-dimensional deformation.

Owner:FELBER WINFRIED

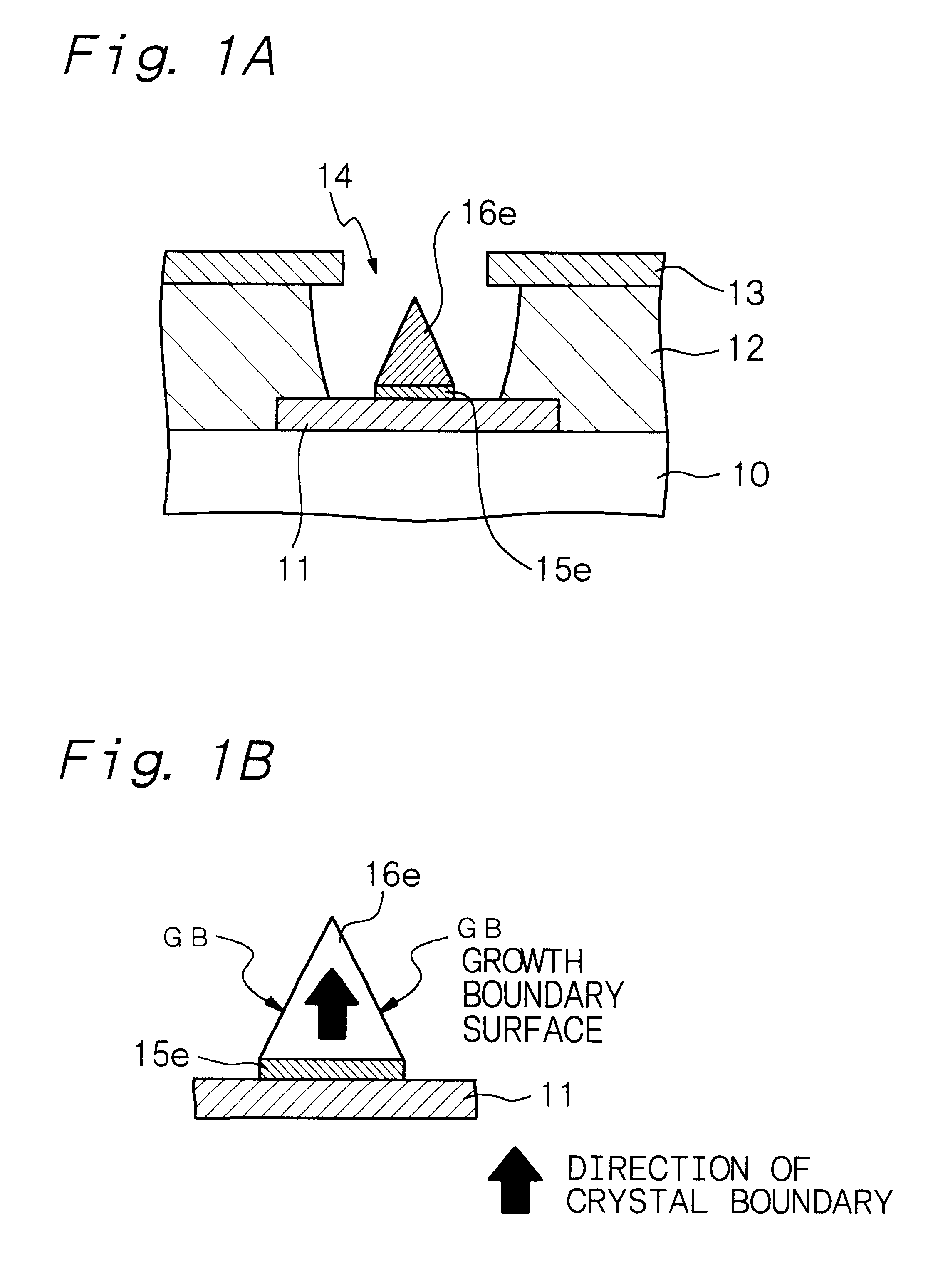

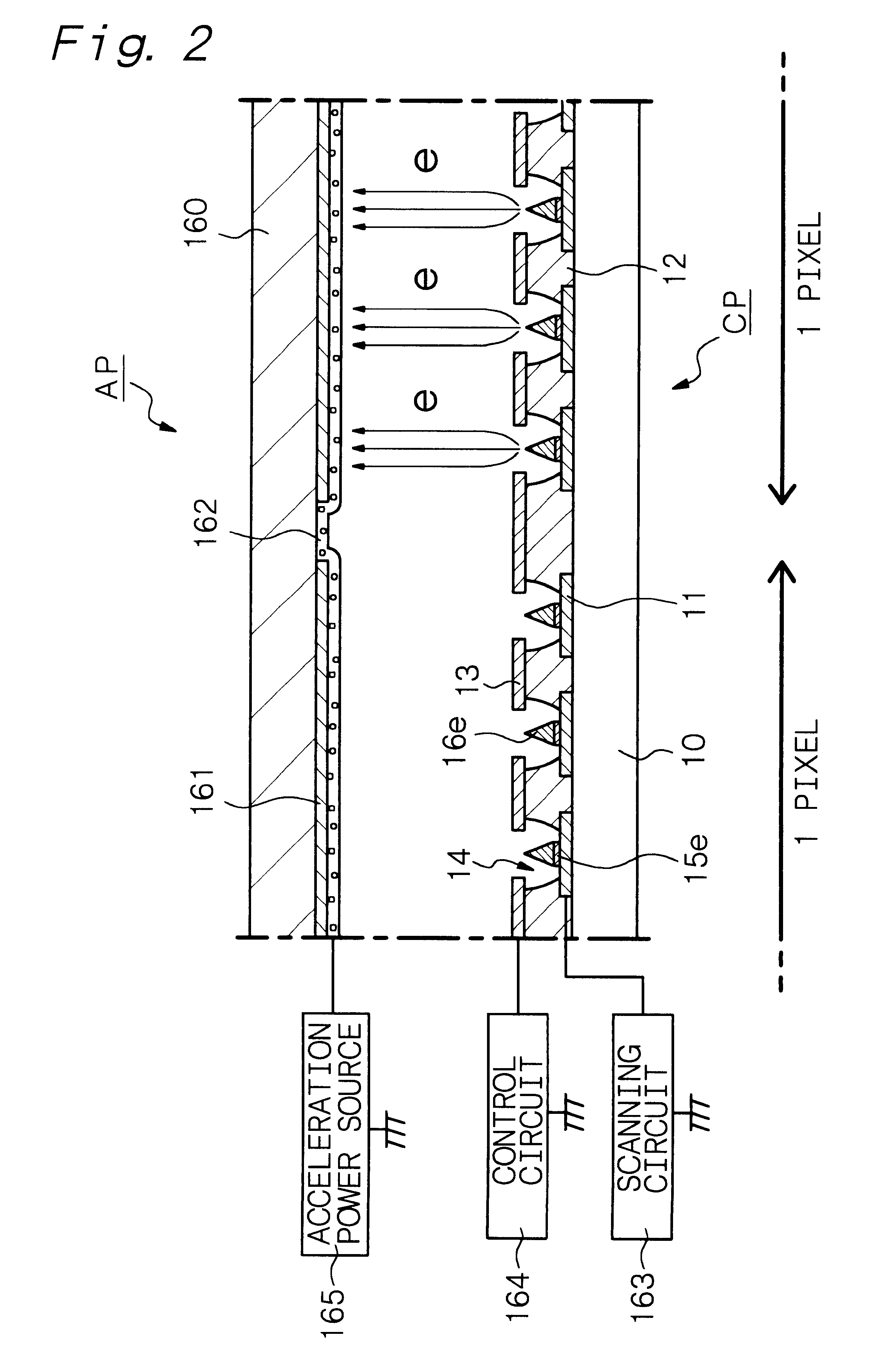

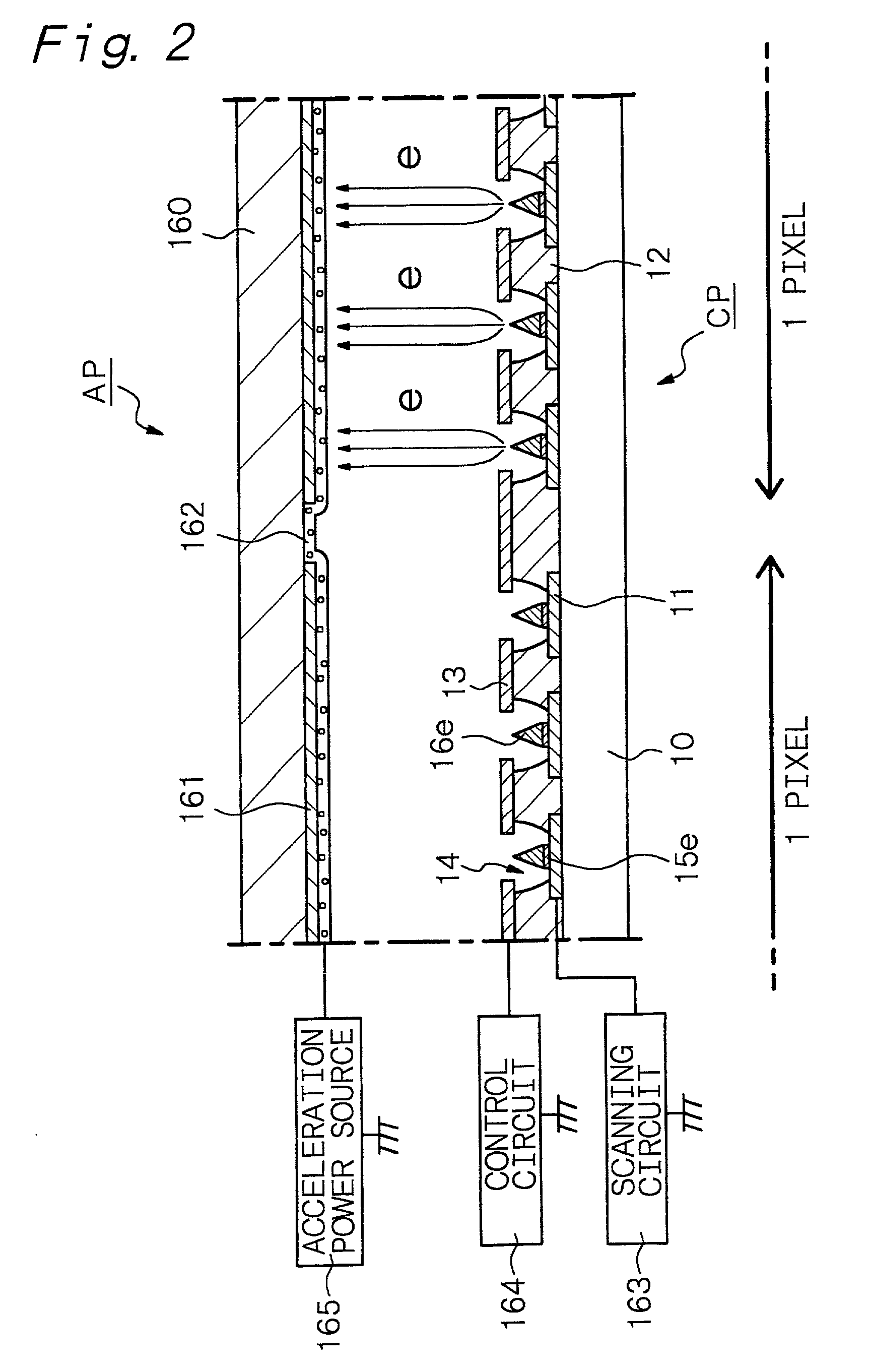

Cold cathode field emission device and display

InactiveUS6465941B1Uniform and excellent electron emitting characteristicGood step coverageDischarge tube luminescnet screensLamp detailsField emission deviceConical forms

Owner:SONY CORP

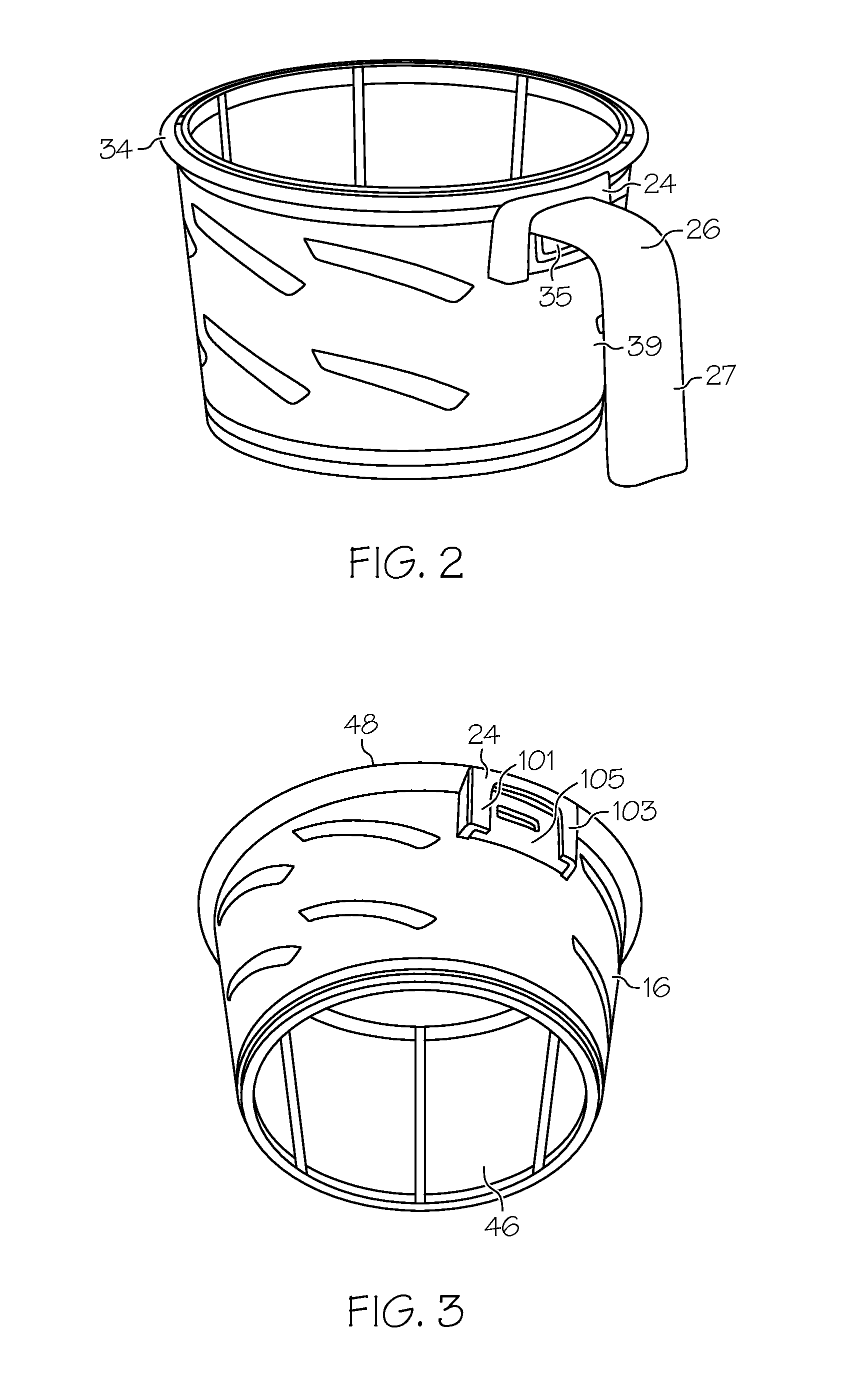

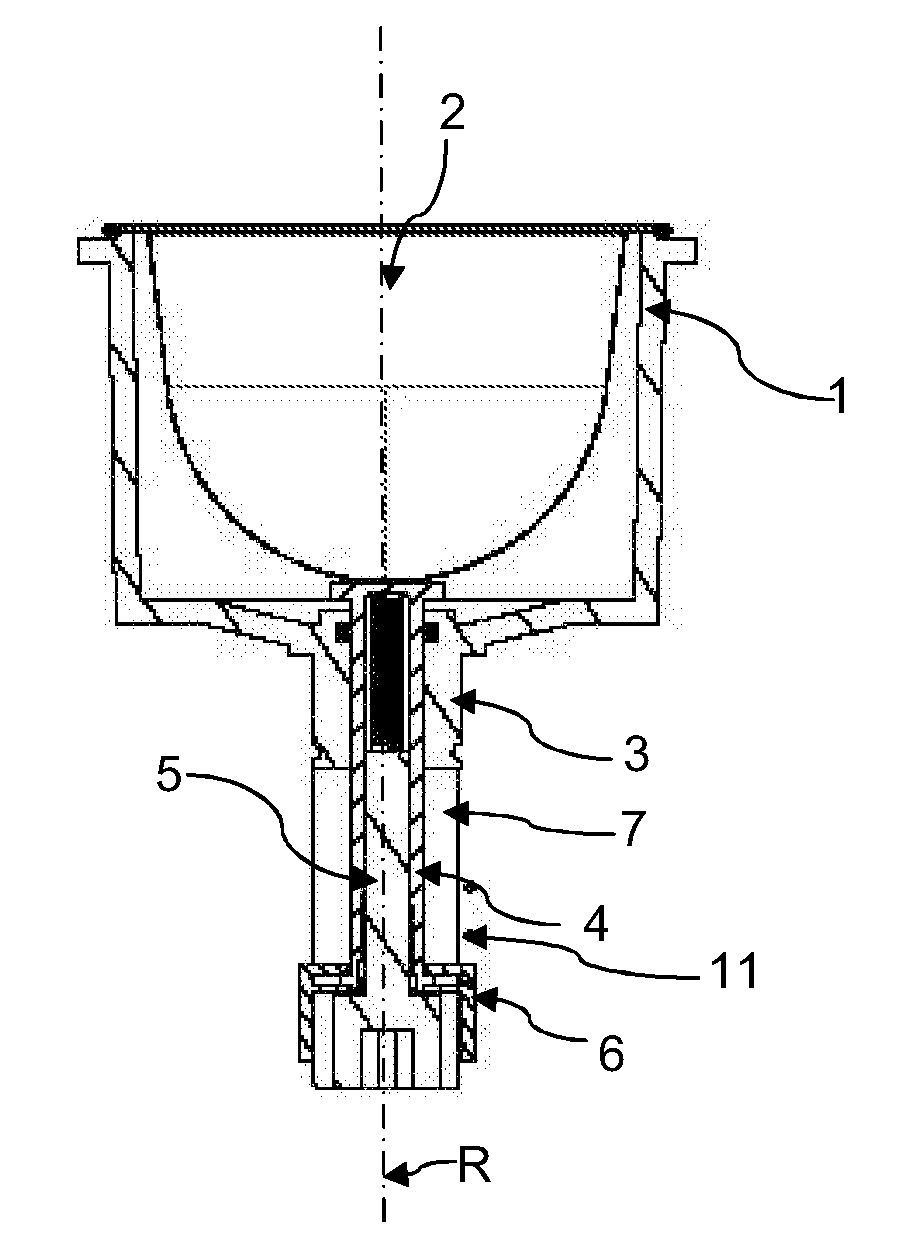

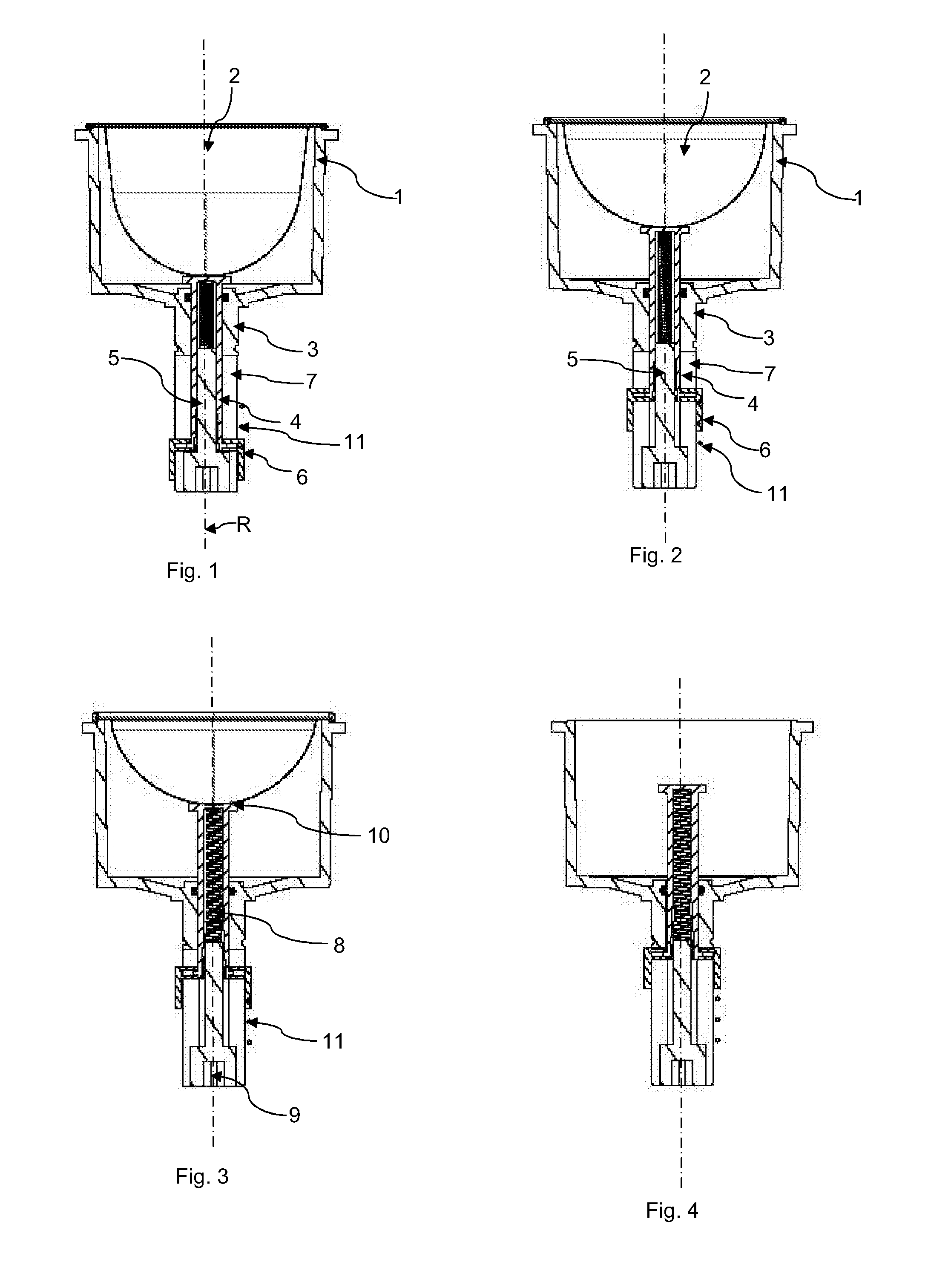

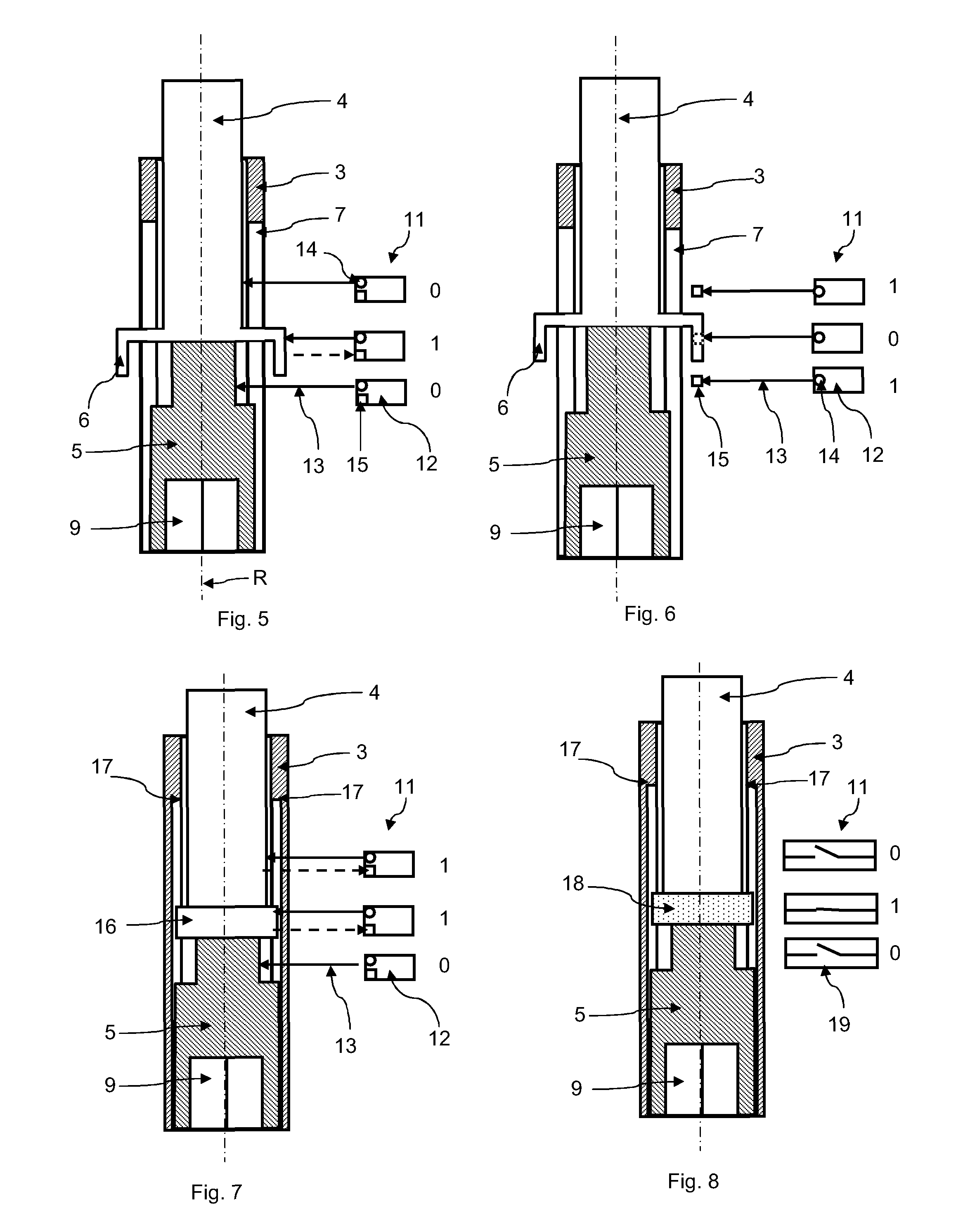

Device for sensing a capsule in a beverage production apparatus

ActiveUS20130114089A1Reliable controlReduce riskMagnetic measurementsUsing electrical meansConical formsAdditive ingredient

The invention aims to provide a device sensing a capsule (2) inserted in a receptacle (1) in machine and physical parameters of liquid supplied by a beverage production apparatus flowing through the capsule in function of the type of capsule. The capsule containing beverage ingredient is inserted in a cylindrical or conical wide mouthed receptacle having an upper opening for inserting the capsule and a lower bottom closing the receptacle. The receptacle rotates around an axis of a hollow shaft (3) attached at the center and perpendicularly to the external face of the bottom of the receptacle, said shaft forming a hole at the center of the inner face of the bottom of the receptacle. The device comprises a rod sliding in the shaft and passing through the hole of the inner face of the bottom of the receptacle, said rod (4) being provided with a spring maintaining an end of the rod lifted inside the receptacle in contact with the capsule, the other end being inside the shaft. The device further comprising means for measuring the position of the end of the rod in the shaft, in order to control, in function of the size of the capsule inserted in the receptacle, rotation speed of the receptacle, discharge and physical parameters of liquid supplied by the beverage production apparatus flowing through the capsule.

Owner:SOC DES PROD NESTLE SA

Aerodynamic air gun projectile

InactiveUS7222573B2Increase relative motionImprove stabilityAmmunition projectilesHollow inflatable ballsInterference fitConical forms

A projectile for an air arm is integrally formed from a single piece of dense malleable material formed as a body of revolution about a longitudinal axis having a head portion dimensioned for free sliding in the bore of an air arm and a skirt-like portion of frusto-conical form. The rearward end of the skirt portion is dimensioned to be in slight interference fit with the bore and the forward end is joined with the head portion to define a reduced diameter waist. The frustum is shell-walled, having a central recess opening to the rear and extending forwardly into the head portion. The head portion has a parabolically shaped outer surface which transitions smoothly into a hyperbolically shaped outer skirt surface for aerodynamic efficiency. Vanes are formed on the head portion to enhance in-flight spiraling rotation.

Owner:PONTIERI JAMES M

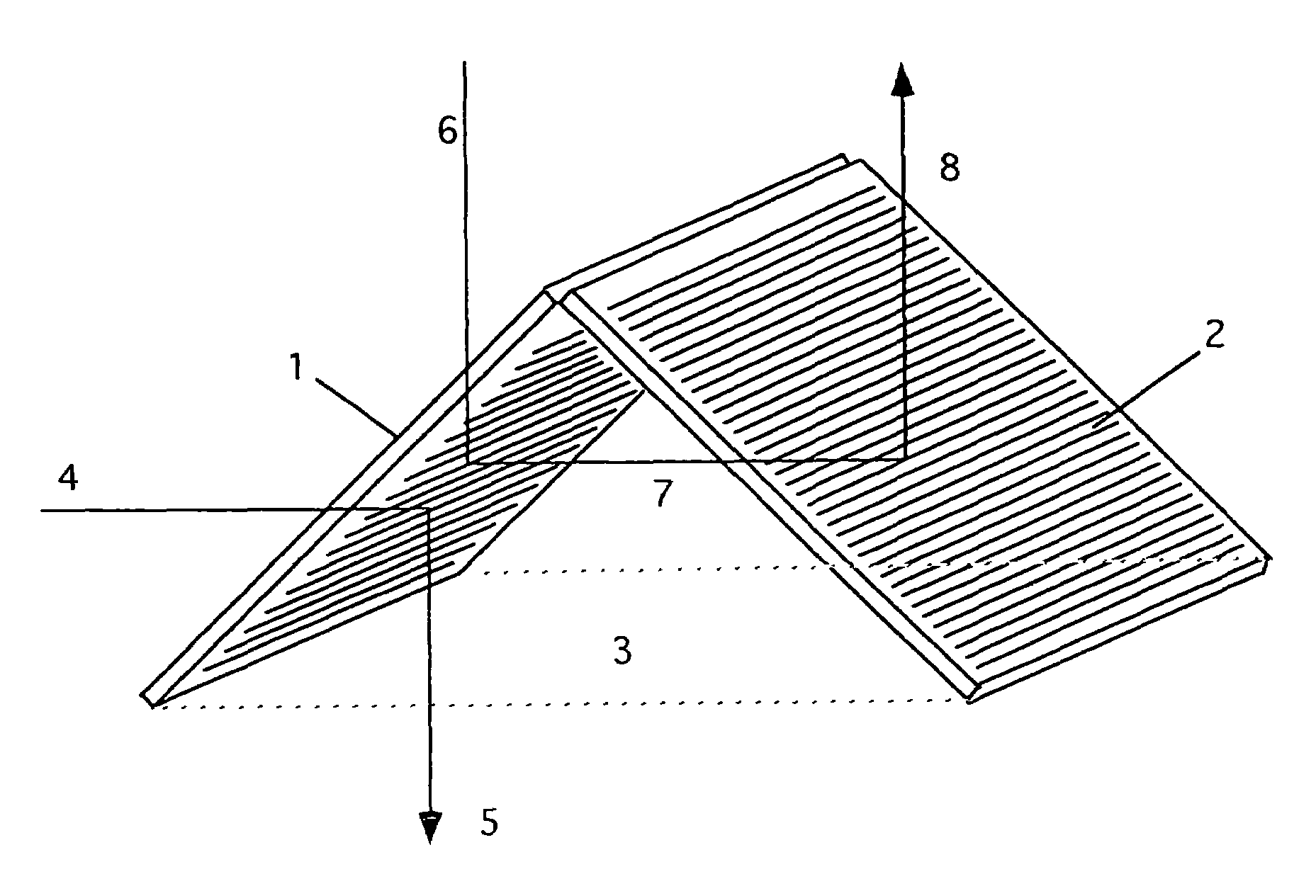

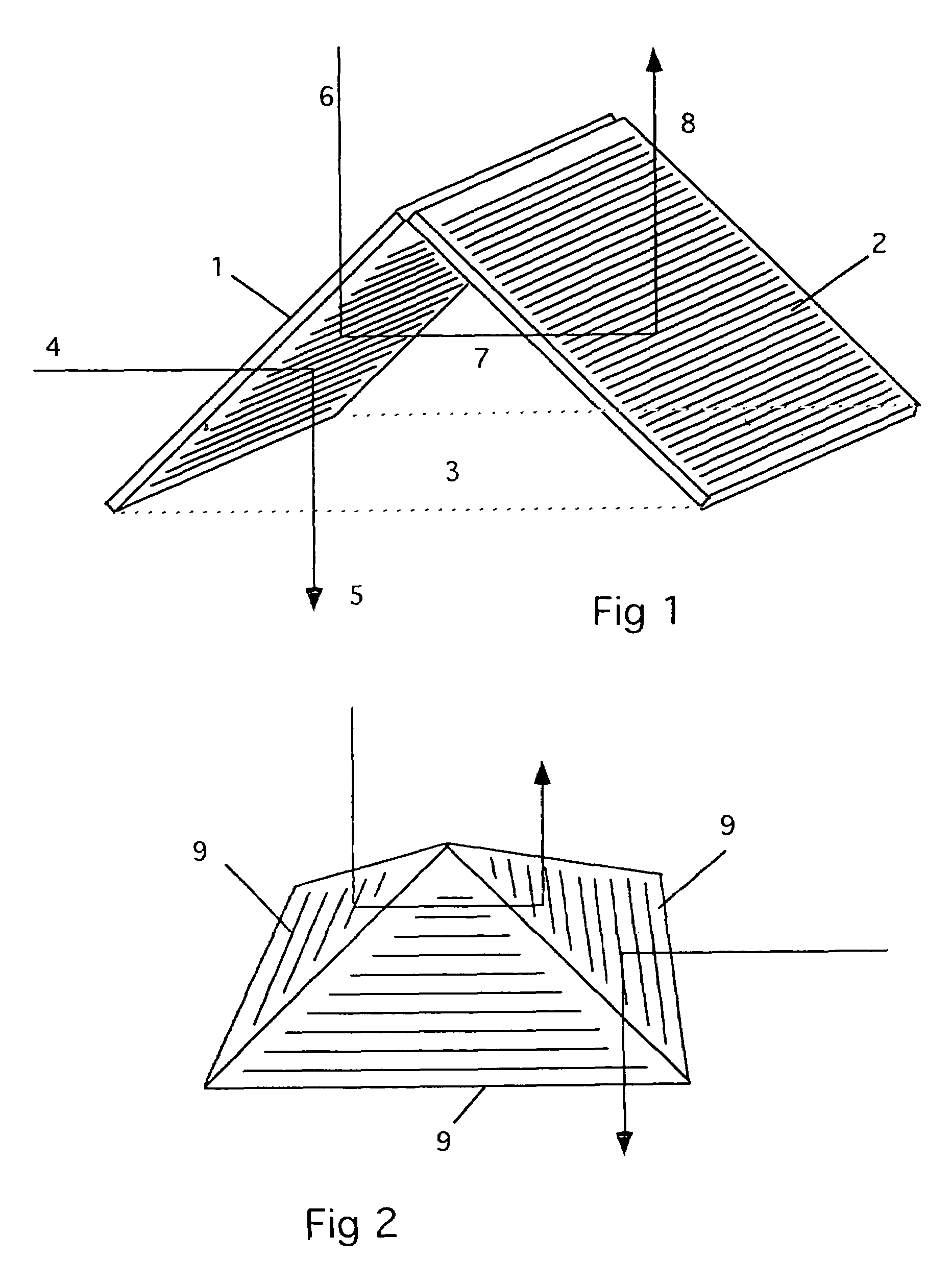

Methods for producing three dimensional, self-supporting, light redirecting roof lighting systems

A self-supporting roof lighting system that accepts low elevation light and rejects high elevation light may be produced by making arrays of parallel laser cuts through, or partly through, a flat sheet of transparent acrylic, cutting the segment containing the arrays from the sheet, positioning the segment over linear heating elements to soften the acrylic along the lines between adjoining laser cut arrays, folding the segment along the softened lines through the angle necessary to form a multi-faceted structure of saddle, pyramid or higher order form and allowing this structure to cool and solidify to produce a self-supporting angle-selective roof lighting system with an array of light redirecting laser cuts on each facet. The sequence of the method may be changed so that a saddle, pyramid or higher order structure is first formed by folding or moulding transparent acrylic and, subsequently, an array of parallel laser cuts is made in each facet of the structure to produce an angle-selective roof lighting system. A conical angle-selective roof lighting system may be produced by making concentric laser cuts through, or partly through, a disc of transparent acrylic with a segment cut out, softening the laser cut disc and moulding the disc into conical form.

Owner:EDMONDS IAN ROBERT

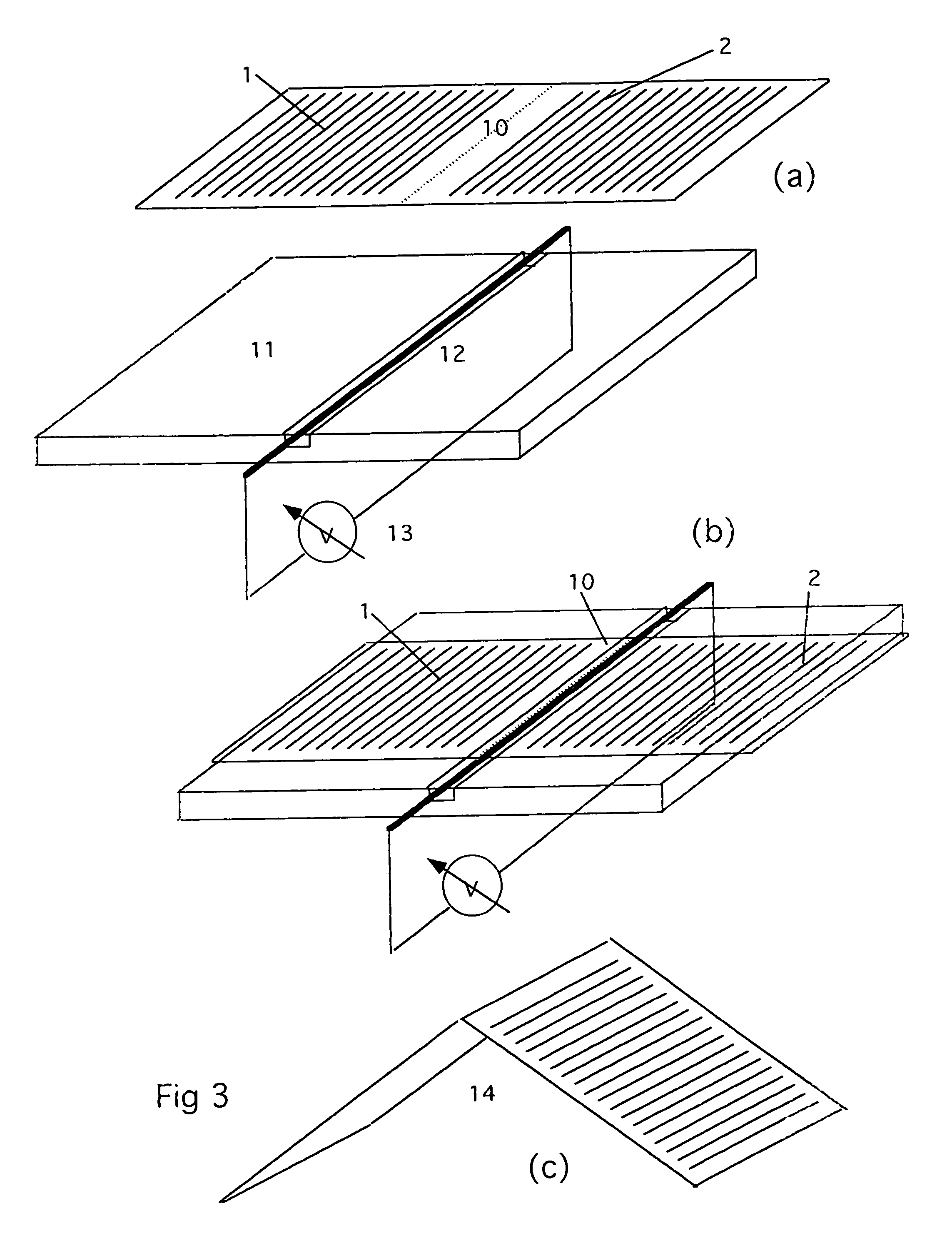

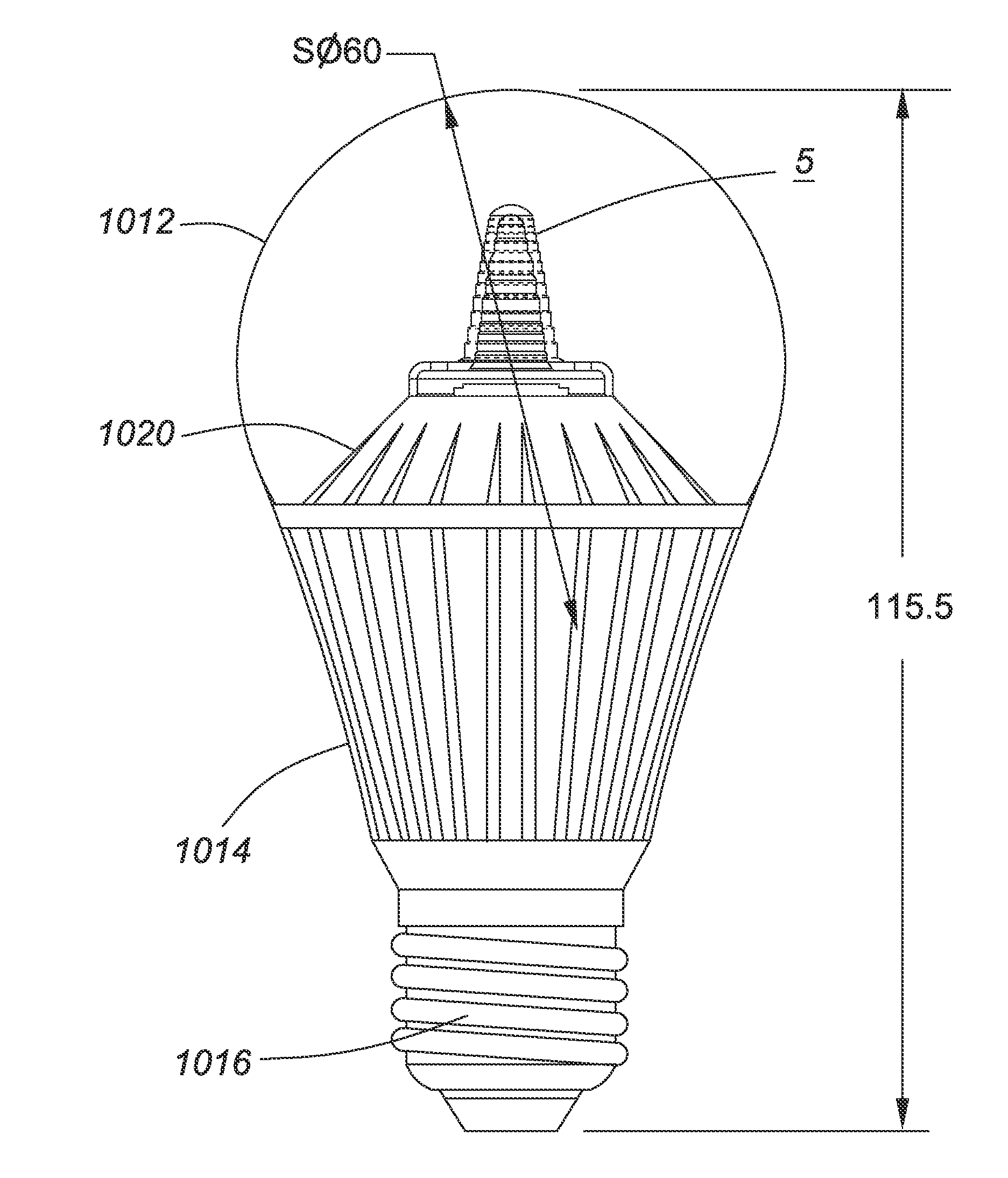

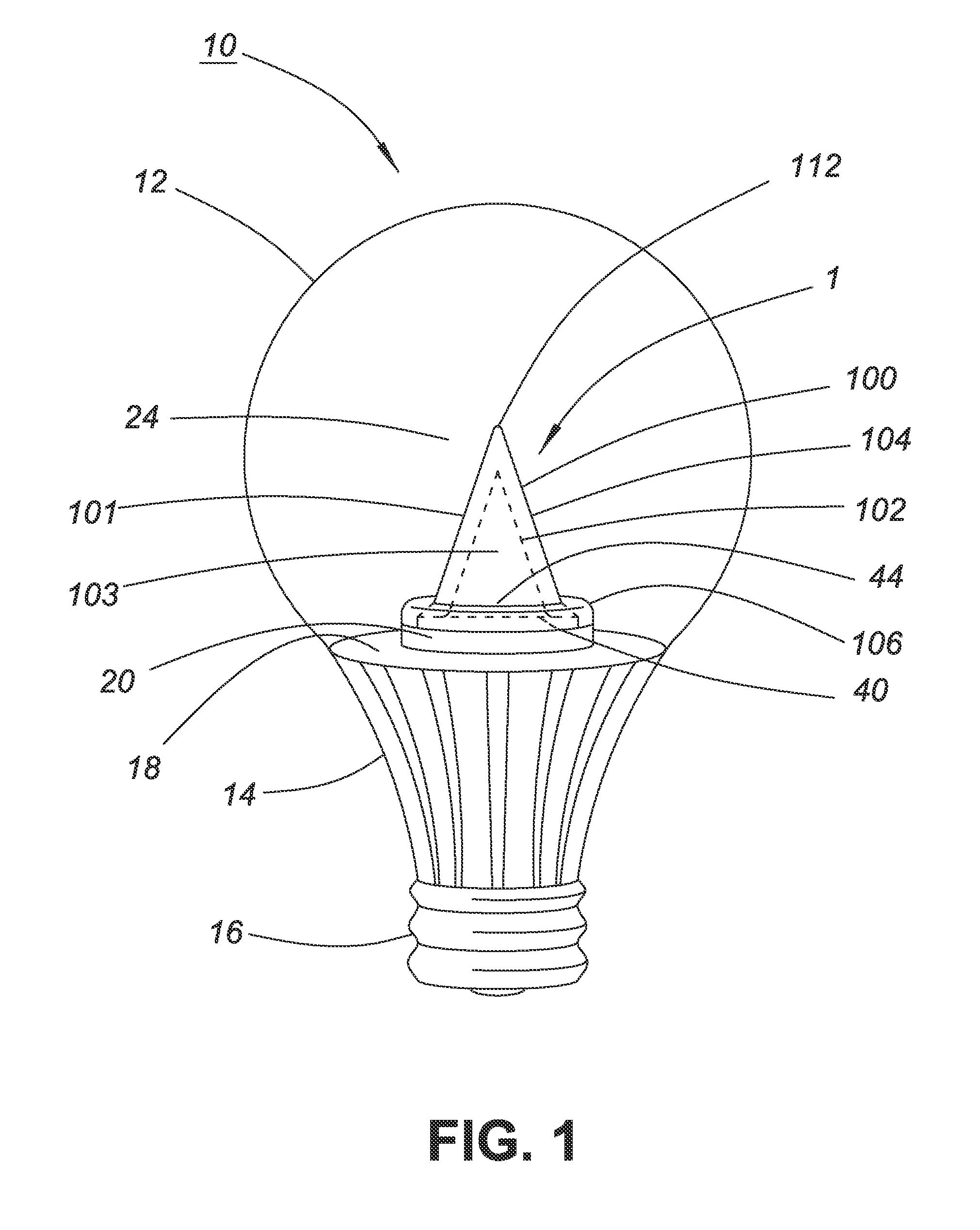

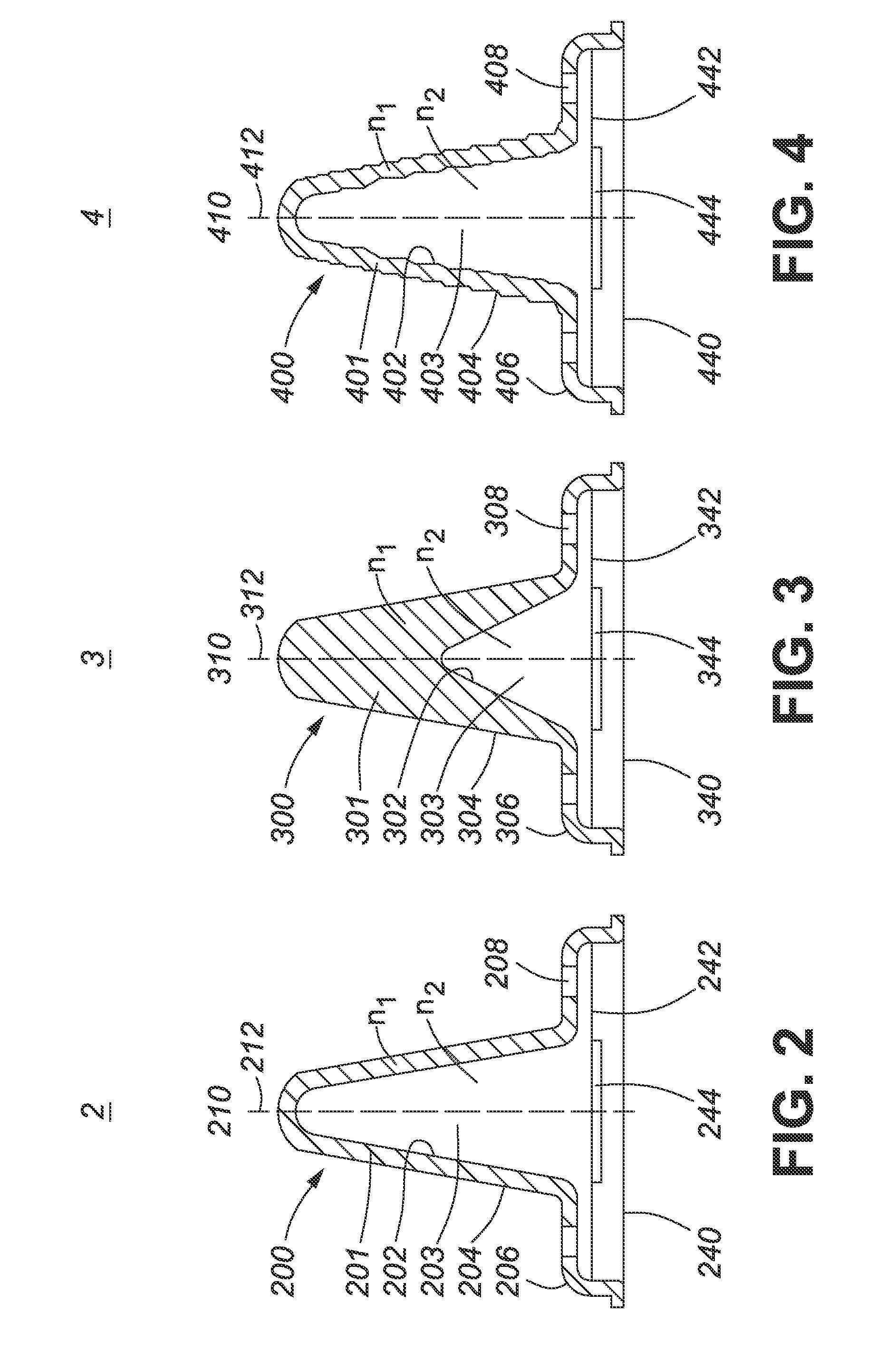

Optical device and system for solid-state lighting

ActiveUS20140268802A1Light weightEasy to shapeLighting heating/cooling arrangementsSemiconductor lamp usageGratingCircular cone

An optical device for transforming an input light distribution from an LED light source to provide an omni-directional output light distribution for solid-state lighting is disclosed. The optical device has a conical form, comprising first and second coaxial cones of different refractive index, defined by coaxial inner and outer cone surfaces, which converge from a cone base to a rounded tip at the apex. Preferably, each of the inner and outer cone surfaces comprises a plurality of conical facets defining a grating structure. The inner cone, i.e. air cavity, is directly coupled to an LED emitter area. Cone angles and spacings of conical facets, defining inner and outer gratings, are tailored to reshape a predetermined input light distribution. Apertures assist in heat dissipation. A lightweight, compact device with high transmission efficiency can be manufactured at low cost by one-step injection molding from an optical-grade polymer, such as PMMA.

Owner:1947796 ONTARIO INC

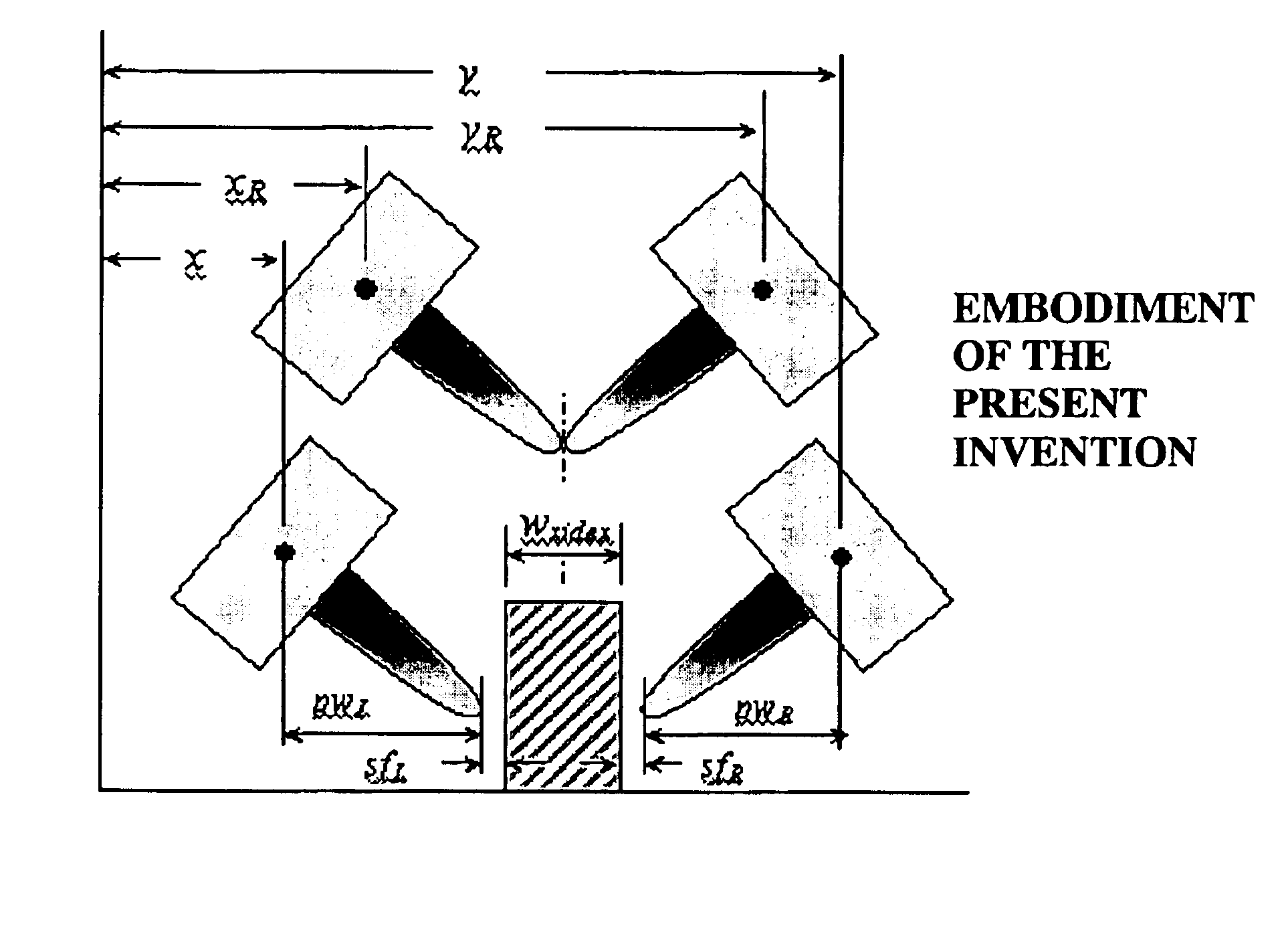

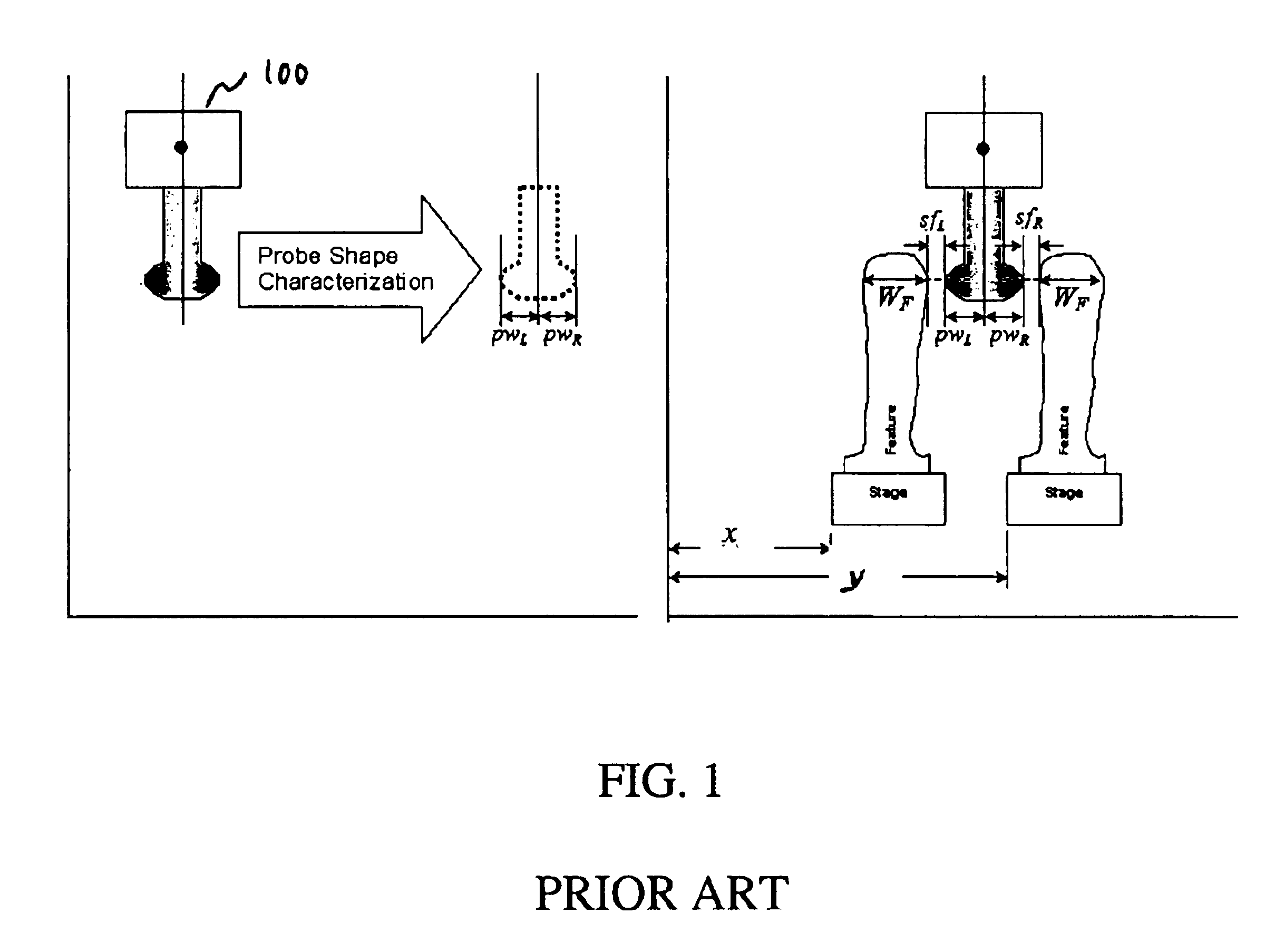

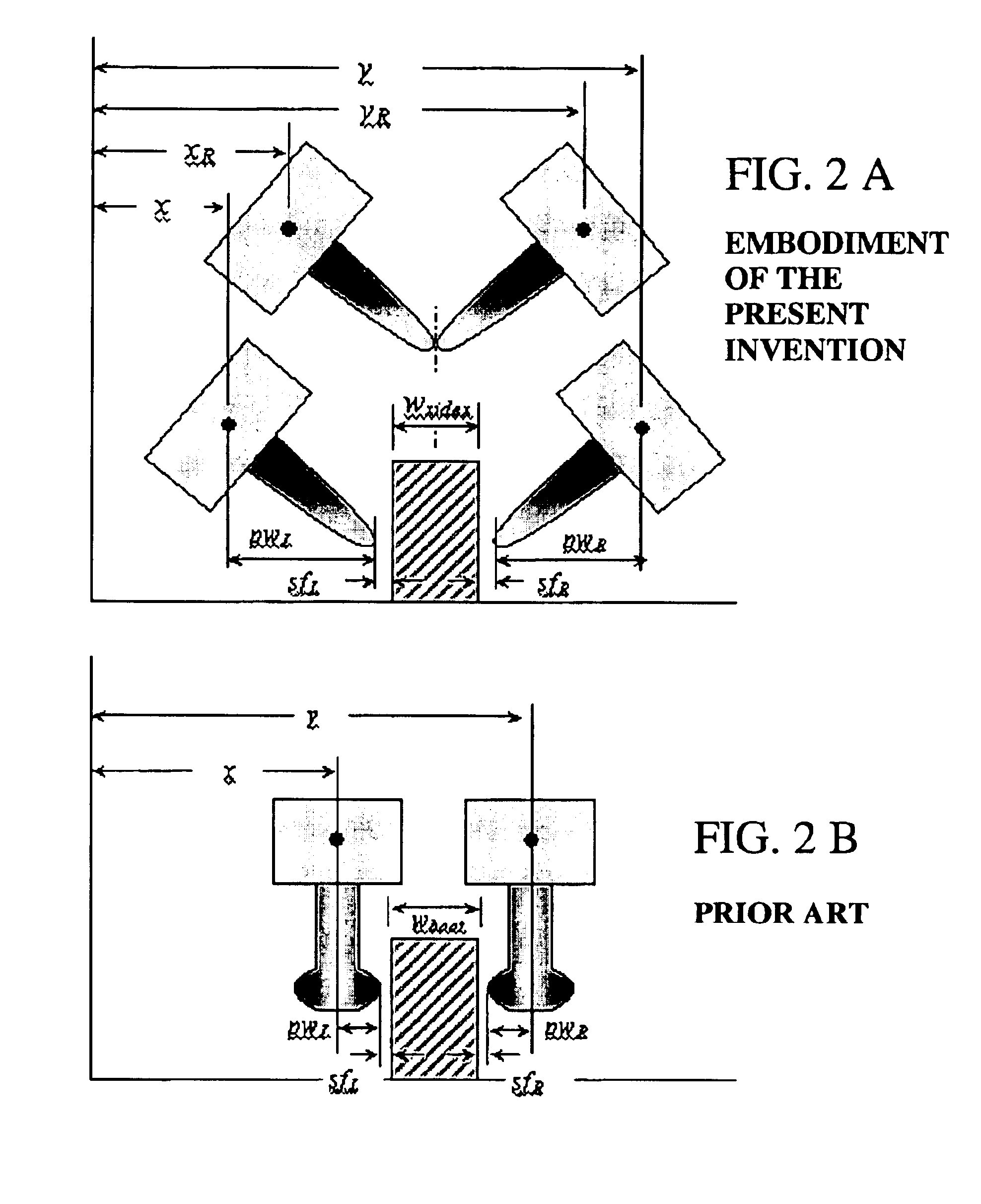

Caliper method, system, and apparatus

A caliper atomic force microscope (AFM) comprises two AFM probes (each comprised of an oscillator and an attached tip) that operate on a sample in a coordinated manner. The coordinated operation of the AFM probes may be spatially or temporally coordinated. The result of the coordinated operation may be an image of the sample or a dimensional measurement of an unknown sample. The probes of the caliper AFM may be tilted, or the tips may be tilted at a non-orthogonal angle with respect to the probes, so as to enable the tips to access vertical sample surfaces or to enable the tips to touch each other. The tip shapes may include conical, boot-shaped, cylindrical, or spherical and materials from which the tips are fabricated may include silicon or carbon nanotubes. The oscillators may be beveled to allow the tips to operate in close proximity or in contact without interference of the oscillators. The disclosure of the present invention is discussed in terms of an atomic force (van der Waalls) interaction. Other interaction forces are contemplated, such as electrostatic force, magnetic force, and tunneling current. The caliper AFM may be calibrated with the help of a sample with known dimensions or by touching the probe tips. The tip-to-tip calibration enables absolute measurements without the need for a reference artifact, and it enables in-line calibration that may be performed during the measurement process.

Owner:XIDEX CORP

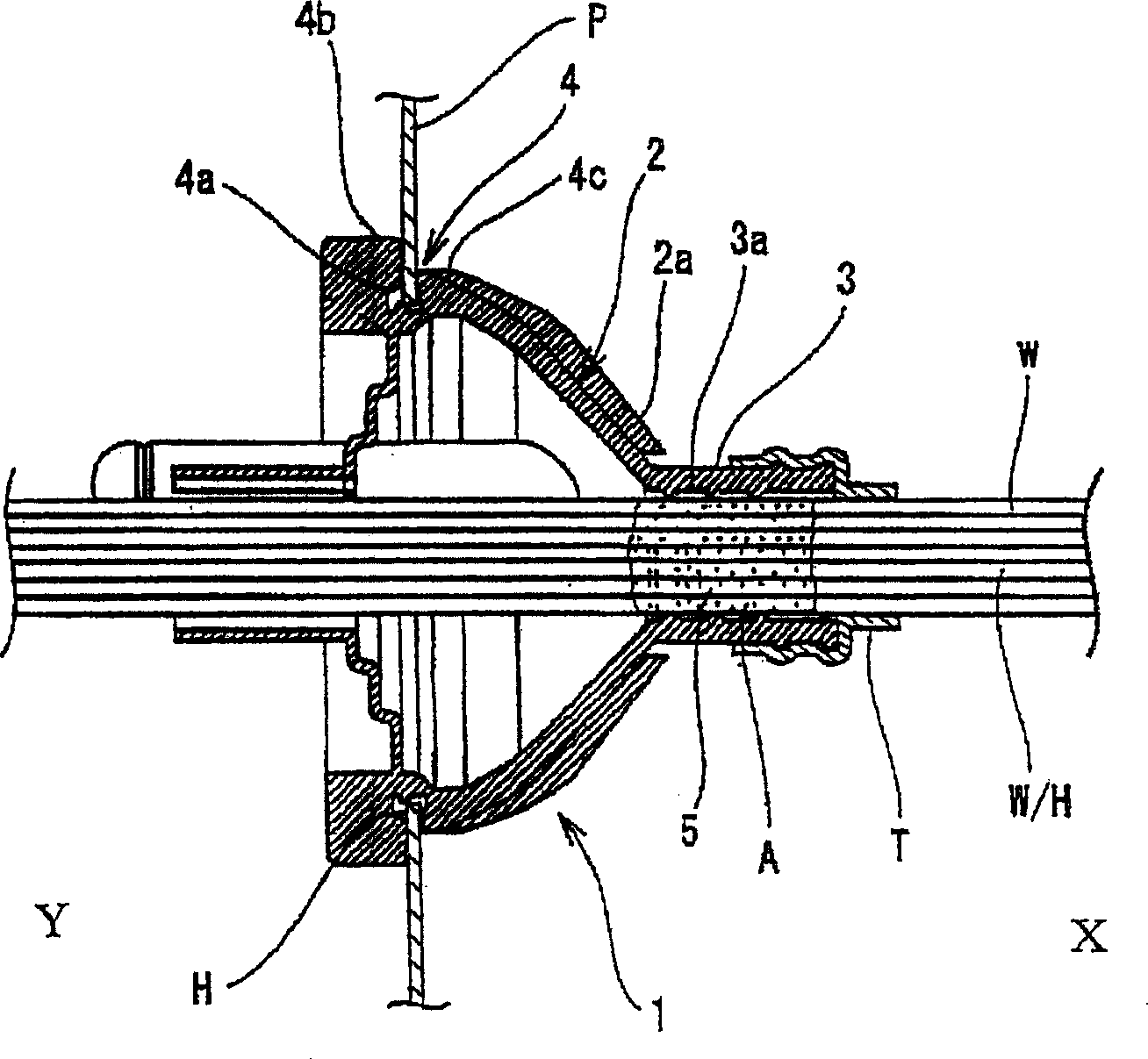

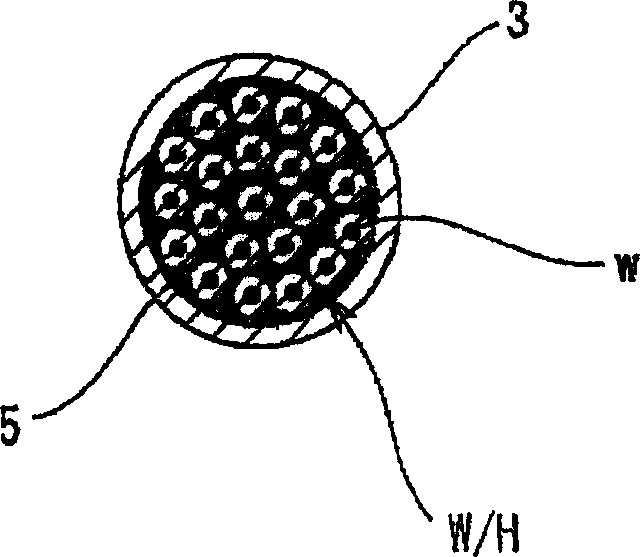

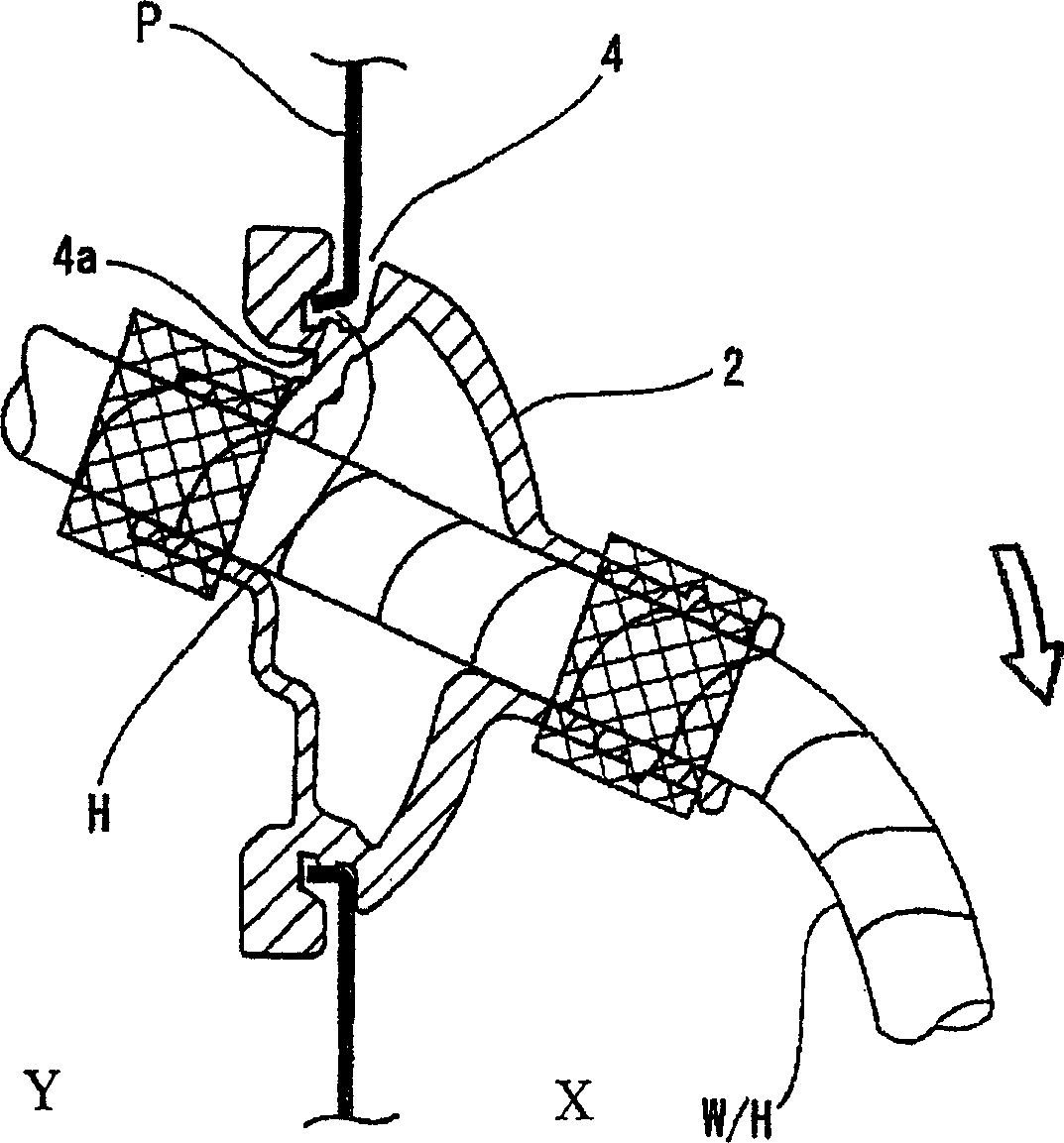

Protective ring for bunch

The grommet (10) with axis Z comprises a funnel-shaped portion (12) having a flared end, a narrowed end and a conical wall. The grommet (10) further comprises a tubular portion (11) extending outwardly from a circular joint section (25) formed at the narrowed end of the funnel-shaped portion (12). The funnel-shaped portion (12) comprises at least one means for improving the flexibility and space availability of the wire harness to be mounted, selected from the group consisting of an extended tubular portion (18) adapted to hold the water-trapping zone (A) of the wire harness, a structural configuration allowing the length along the axis Z of the funnel-shaped portion to be reduced and a plurality of funnel ribs having closely arranged first end sections (13a) that form a circular space (V) around the tubular portion (11).

Owner:SUMITOMO WIRING SYST LTD

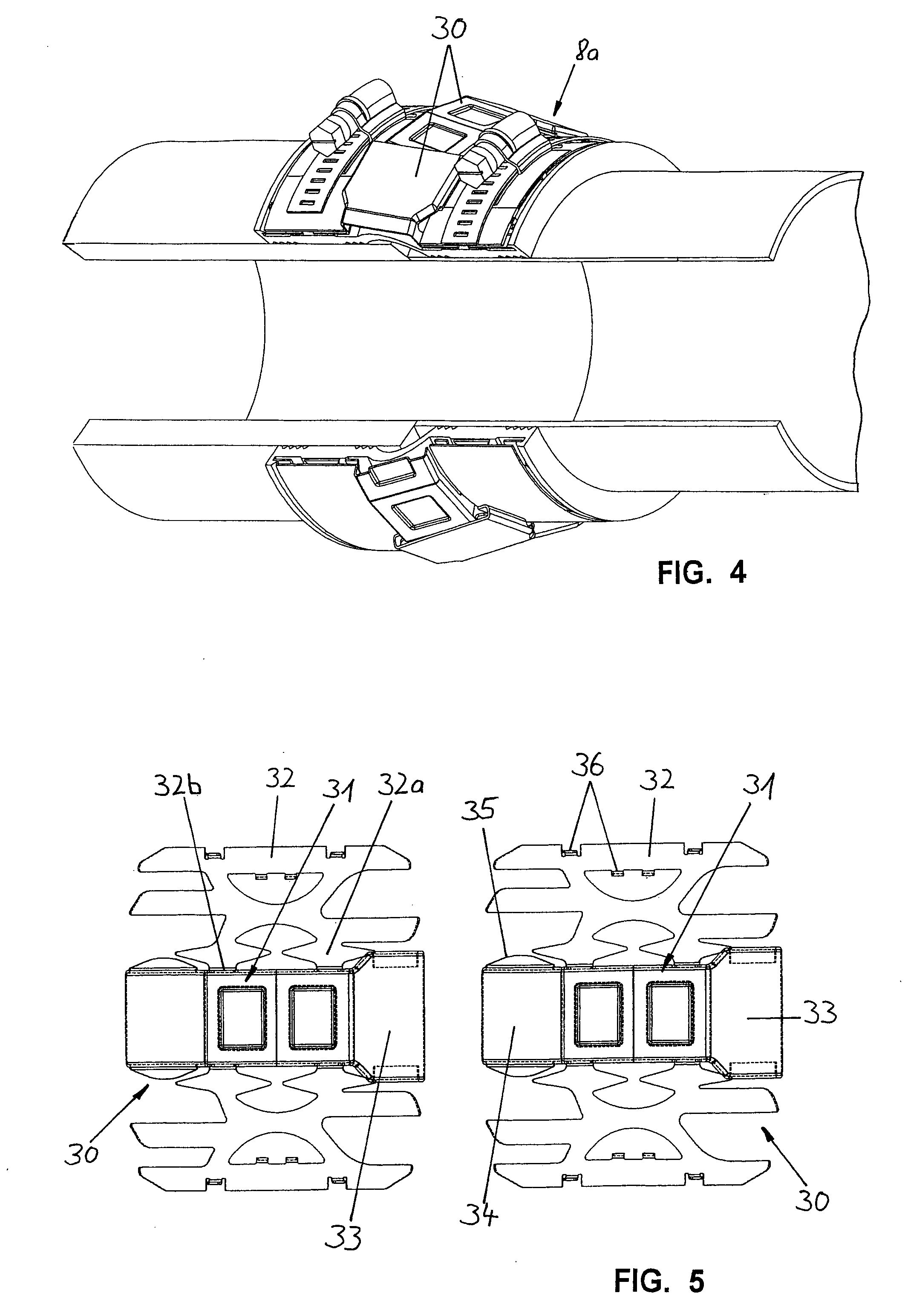

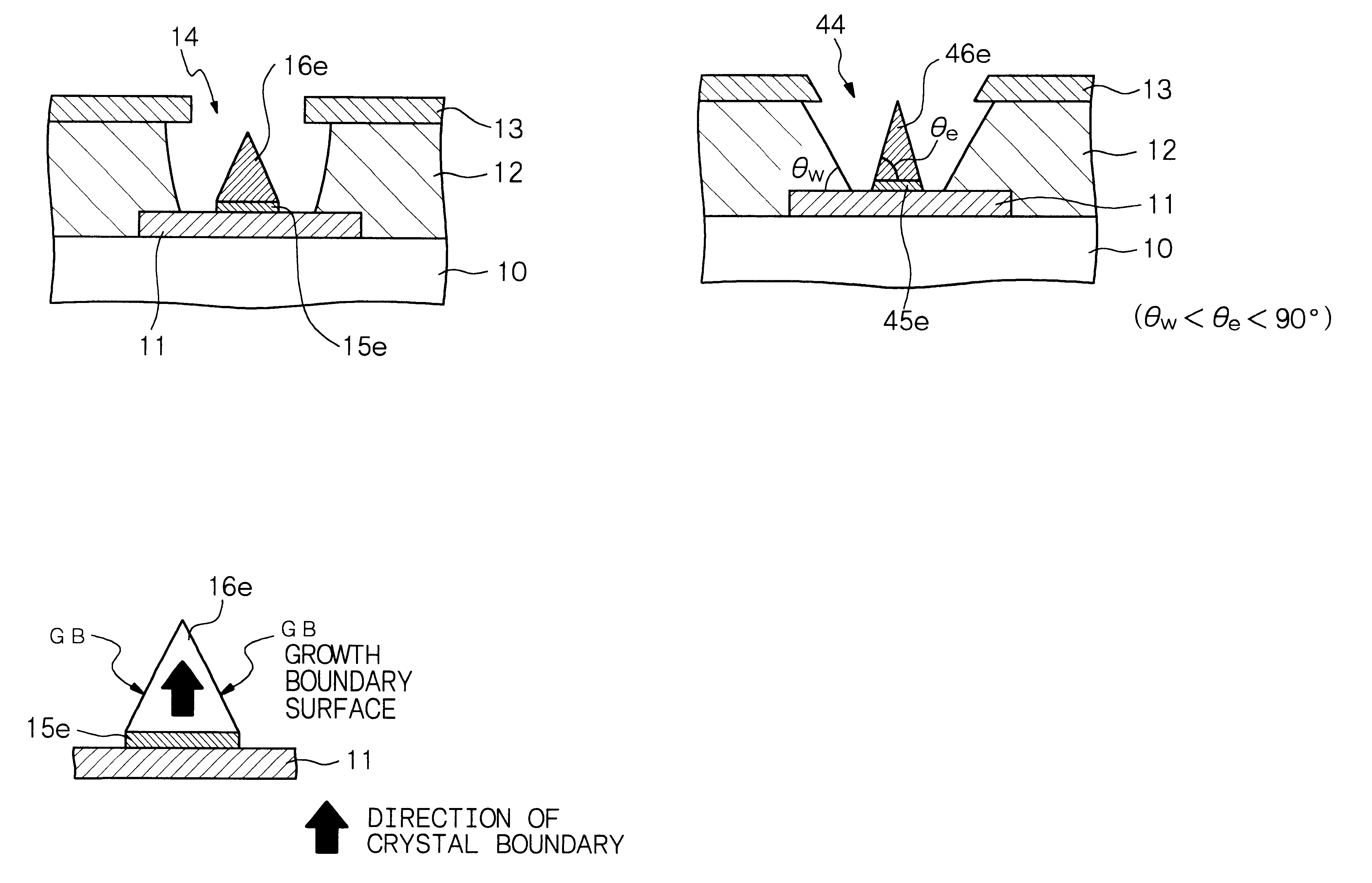

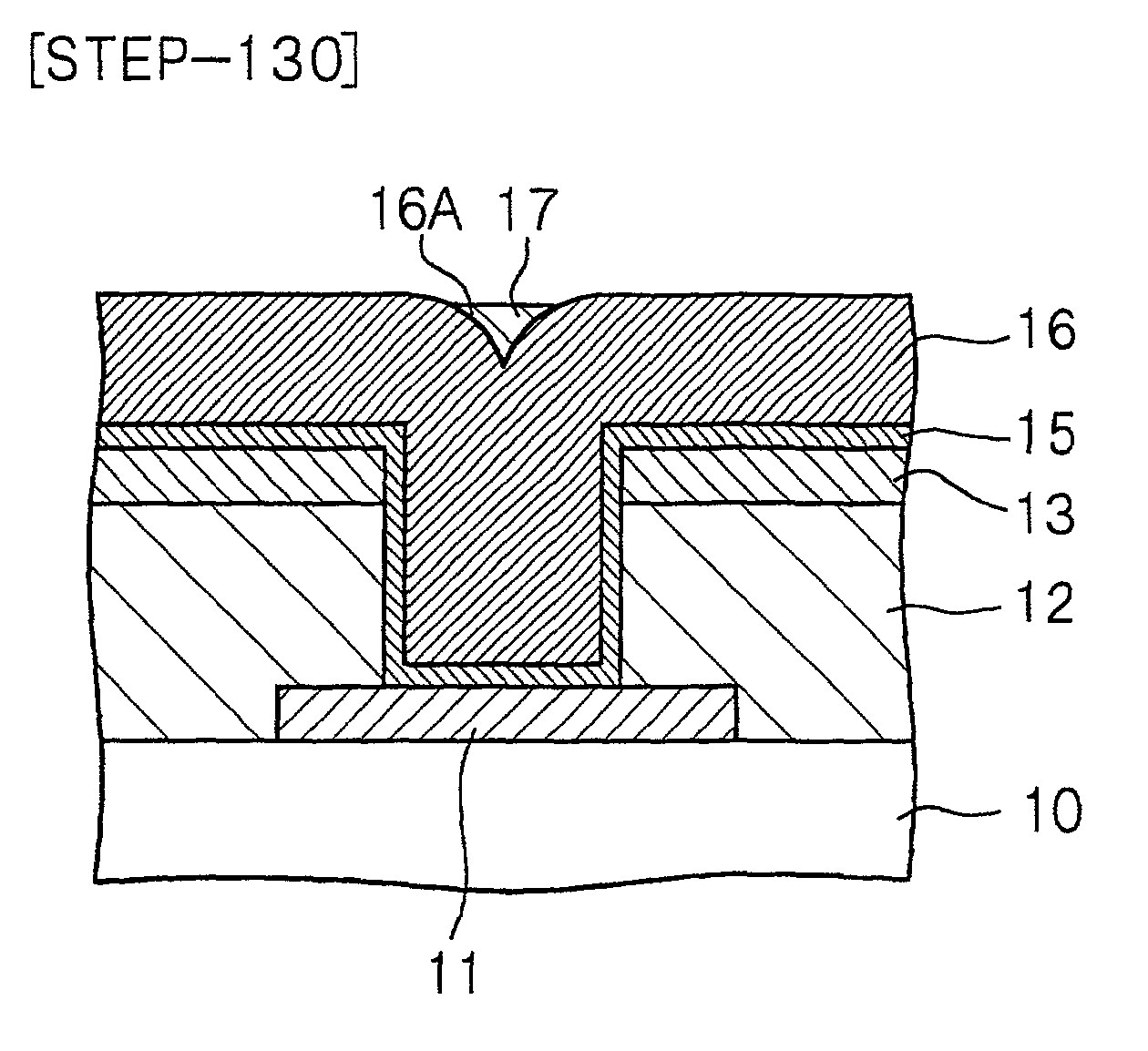

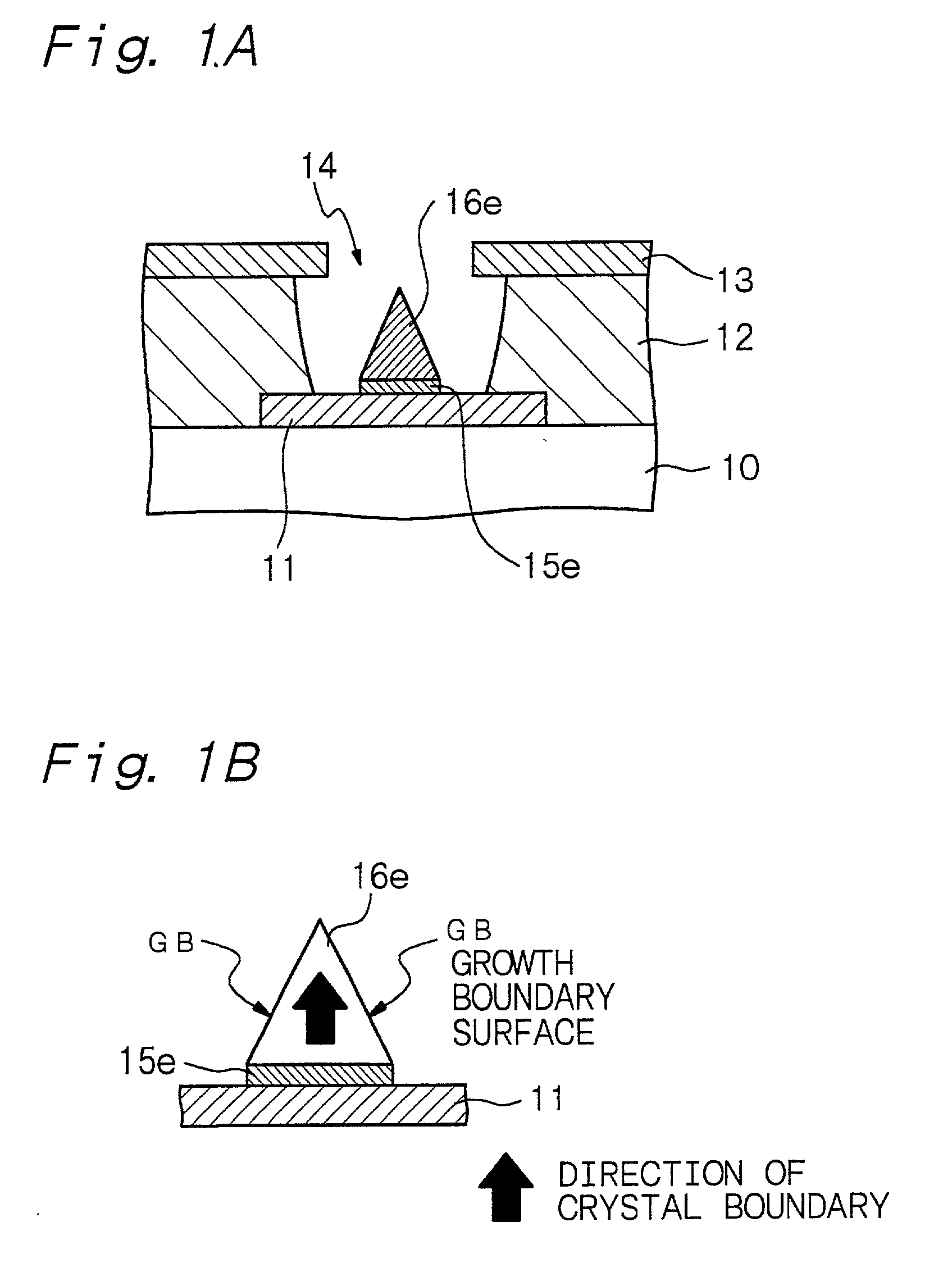

Cold cathode field emission device, process for the production thereof, and cold cathode field emission display

InactiveUS20020050776A1Uniform and excellent electron emitting characteristicThermionic cathodesVessels or leading-in conductors manufactureField emission deviceConical forms

A cold cathode field emission device comprising; (A) a cathode electrode formed on a support, (B) an insulating layer formed on the support and the cathode electrode, (C) a gate electrode formed on the insulating layer, (D) an opening portion which penetrates through the gate electrode and the insulating layer, and (E) an electron emitting portion which is positioned at a bottom portion of the opening portion and has a tip portion having a conical form and being composed of a crystalline conductive material, the tip portion of the electron emitting portion having a crystal boundary nearly perpendicular to the cathode electrode.

Owner:SONY CORP

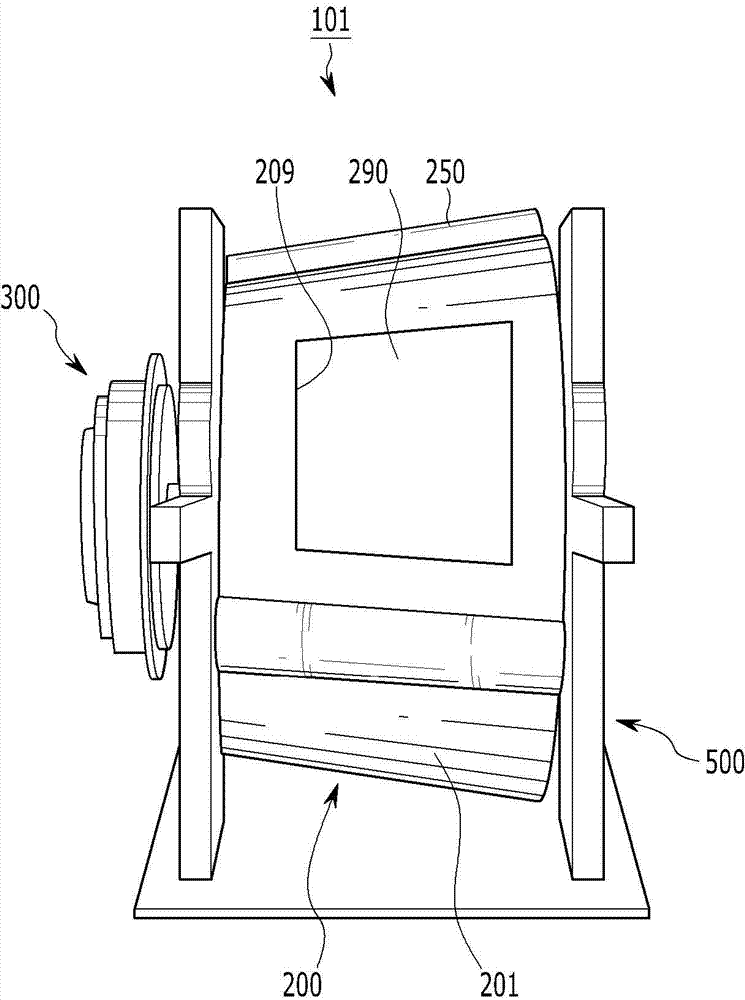

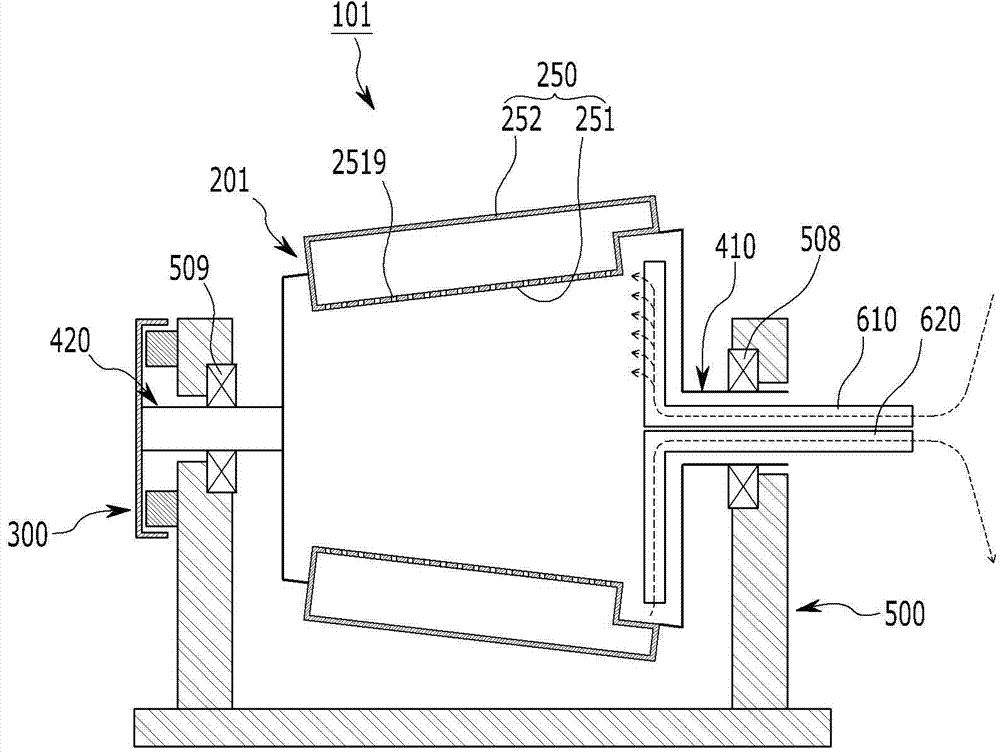

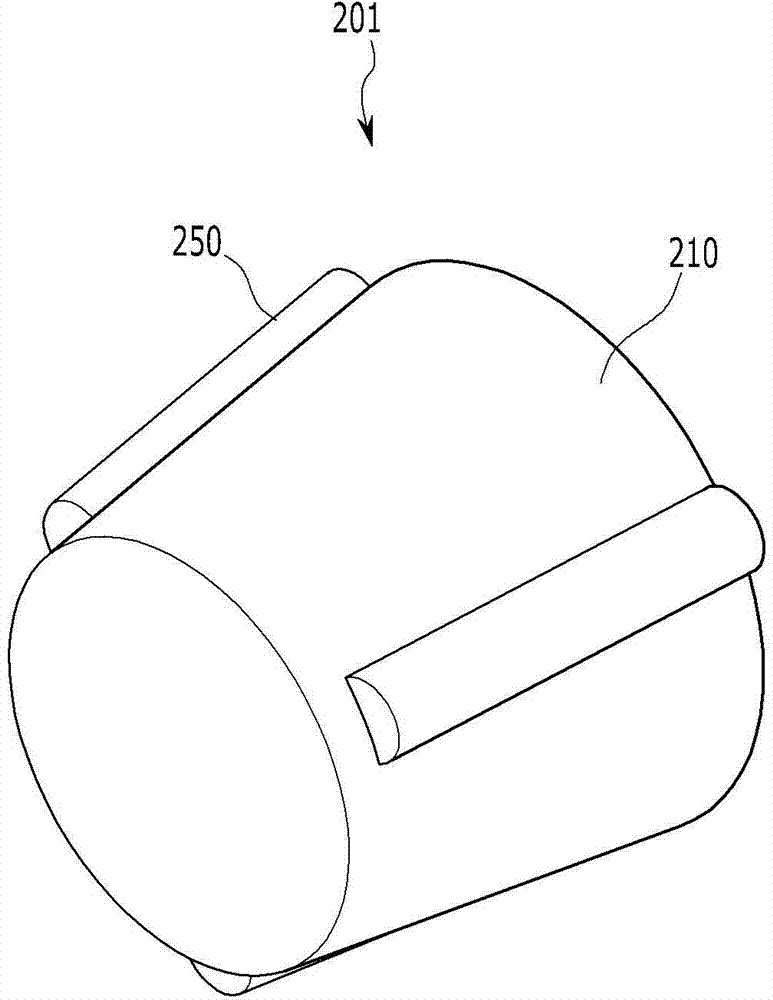

Washing machine

InactiveCN104727077AEasy to cleanPollution suppressionOther washing machinesWashing machine with receptaclesLaundryConical forms

The present disclosure relates to a washing machine. The washing machine (101) may include an integrated tub / drum (201, 202) that includes a drum main body (210) that has a cylindrical shape or a truncated conical shape, stores water, holds or accommodates laundry and water, and rotates, and a plurality of hollow lifters (250) that extend or protrude outward from a circumferential surface of the drum main body (210), and extend or protrude inward from the circumferential surface of the drum main body (210); a hollow rotary shaft (410) that is coupled to and / or that penetrates one end and / or surface of the drum main body (210); and a drain pipe (620) that is in the integrated tub / drum (201, 202) through the hollow rotary shaft (410), configured to discharge water from the drum main body (210) and that may be collected by the lifter (250).

Owner:DONGBU DAEWOO ELECTRONCIS CORP

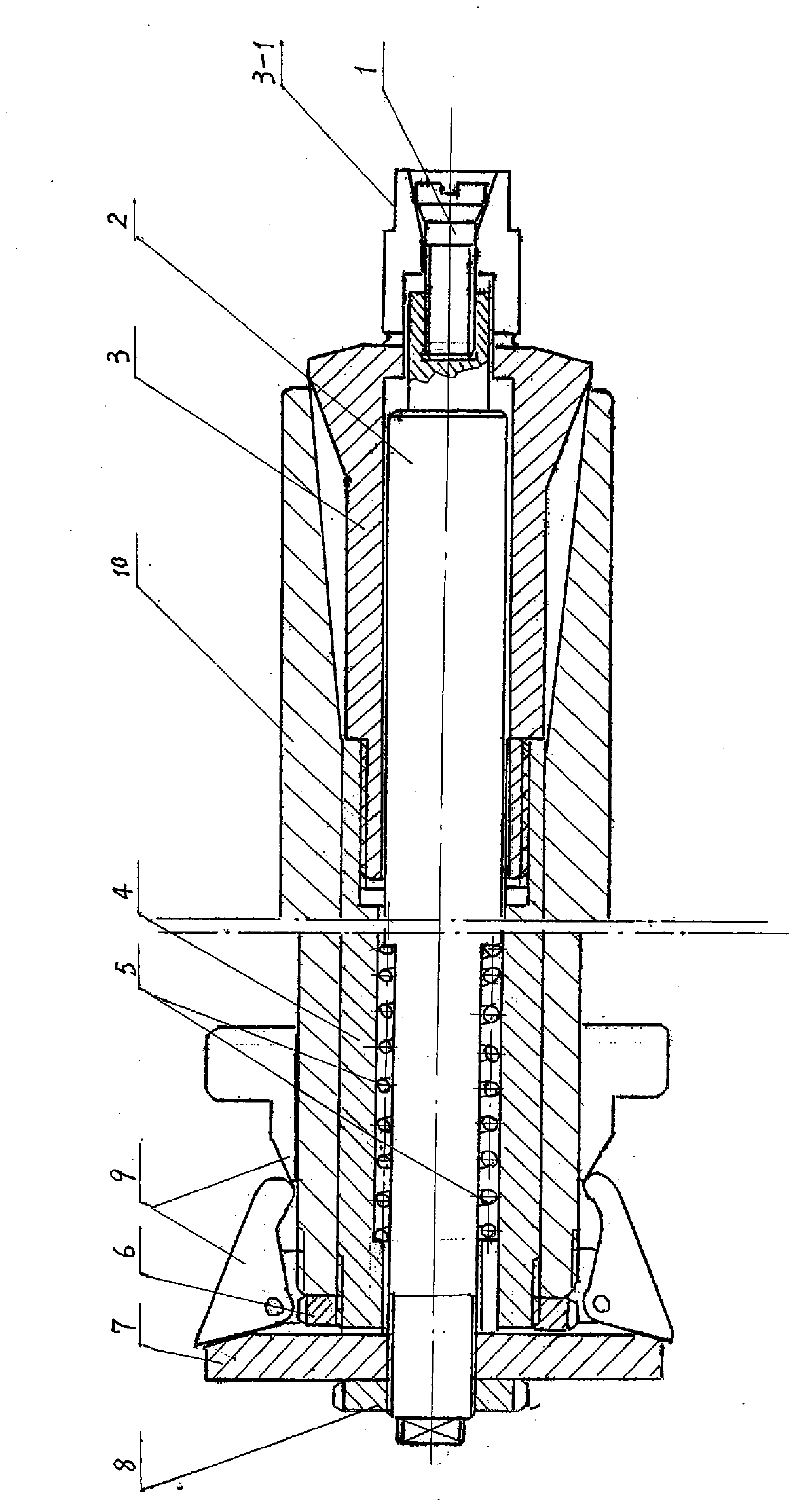

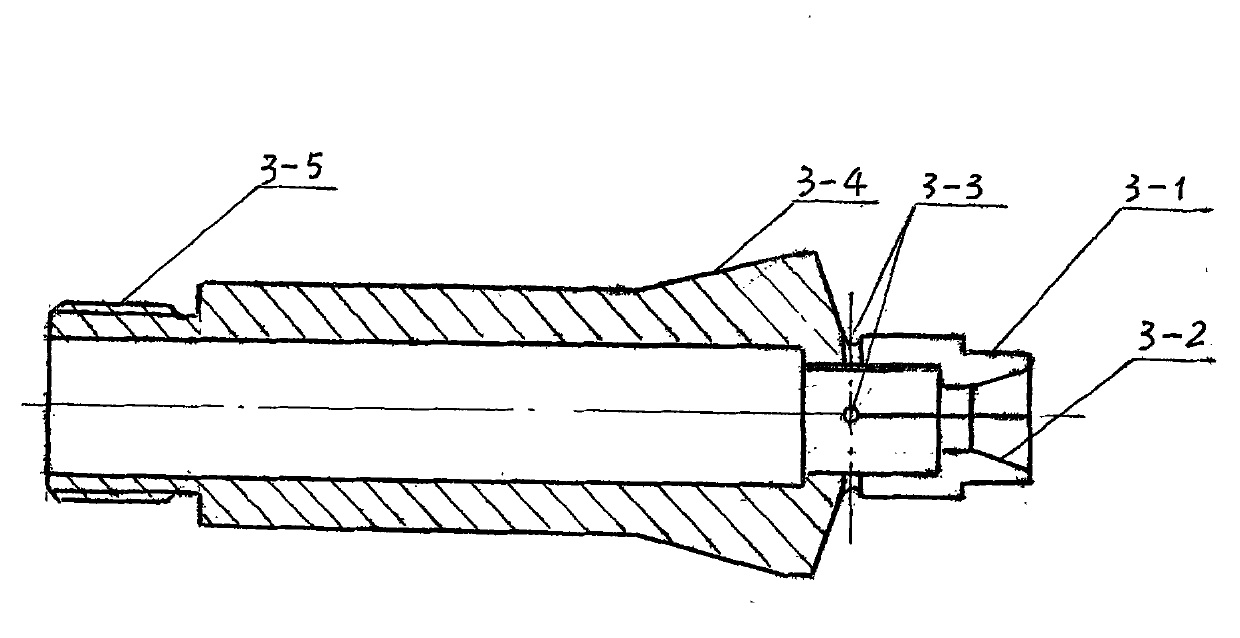

Expanding type clamp used on lathe and machining method thereof

The invention discloses an expanding type clamp used on a lathe and a machining method thereof. A workpiece is usually clamped from outside to inside when being machined on the lathe. However, for a short thin-wall workpiece which has a cone-shaped outer surface, does not have a cylindrical surface and has high requirements for machining accuracy and coaxiality, when machining of one end of the workpiece is finished and the other end needs to be machined, a universal clamp can not meet the requirements due to the fact that the universal clamp is low in clamping force and prone to deformation. The expanding type clamp used on the lathe and the machining method thereof are suitable for being used in the situation that machining of one end of a short thin-wall workpiece, with a small inner diameter and a cone-shaped or angular outer surface and having high requirements for machining accuracy and coaxiality and free of a cylindrical surface, is finished and the other end needs to be machined. A hole of the machined workpiece is sleeved on an expanding type clamping head first, and then the circumference of the clamp expands outwards evenly in a clamping process to stretch the inner diameter of the workpiece to be machined to carry out lathe work. The clamp is loosened after the machining is finished, the expanding type clamping head contracts elastically, and then the machined workpiece is taken down easily.

Owner:JIANGSU XINGHE VALVE +1

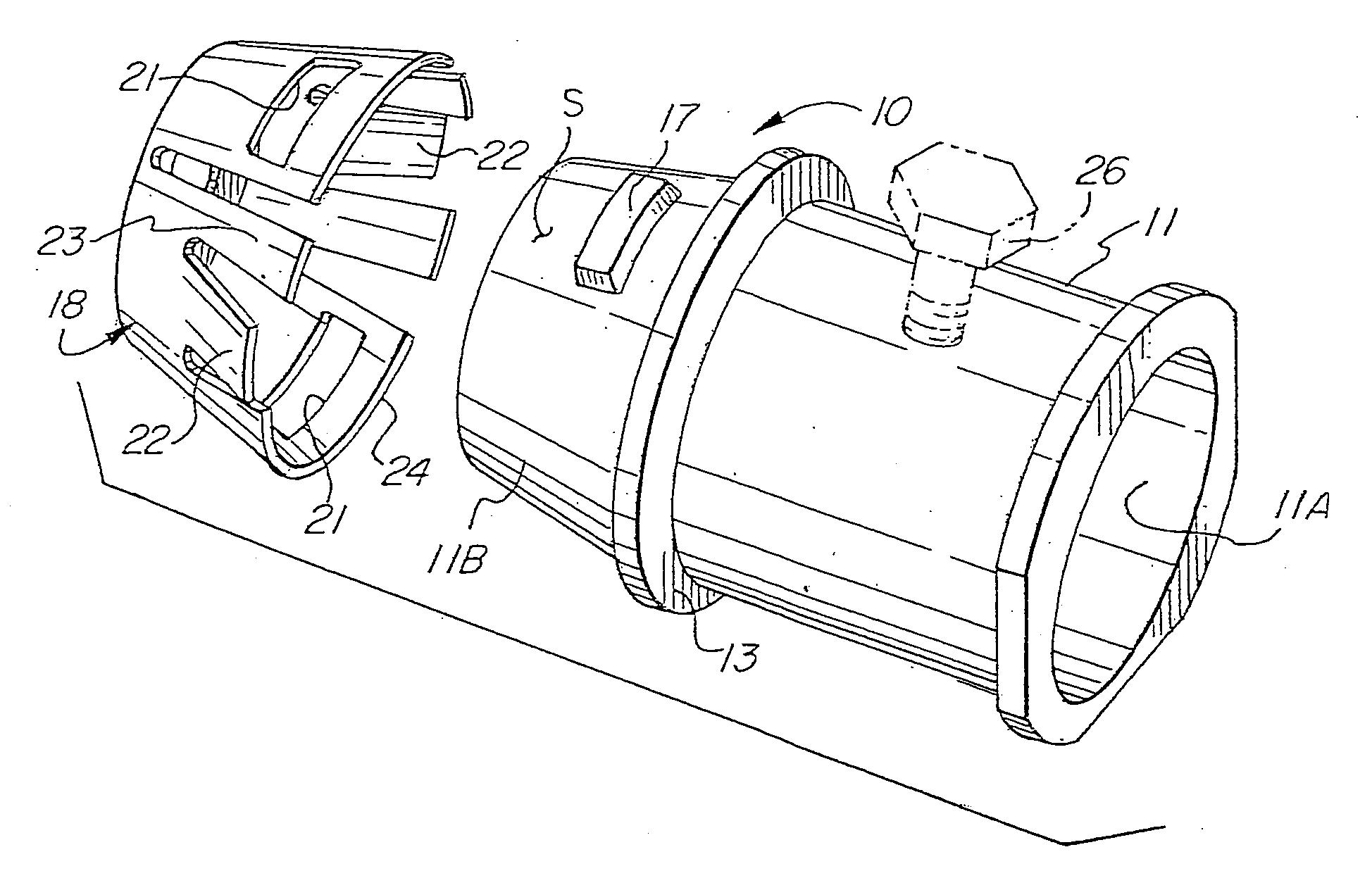

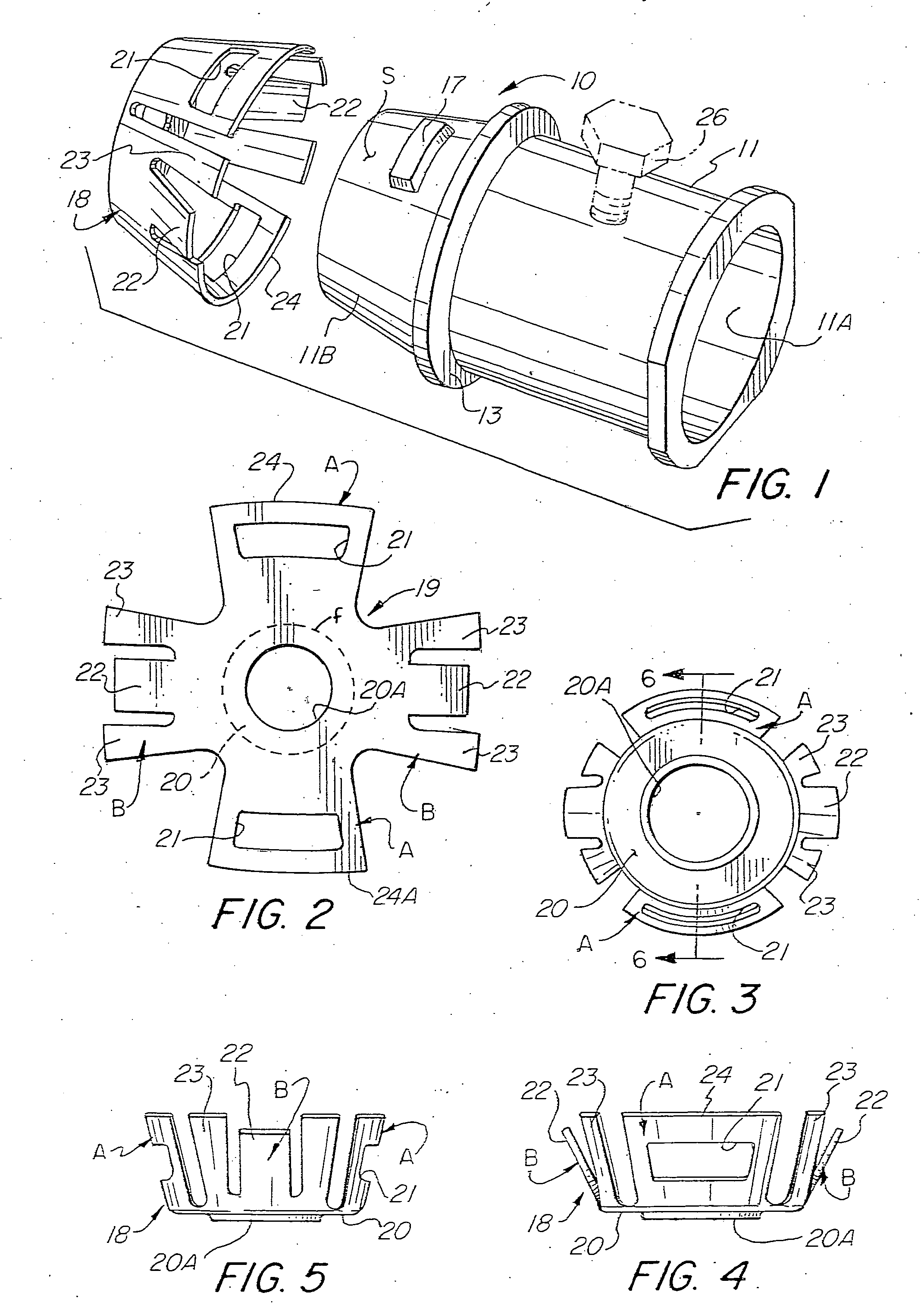

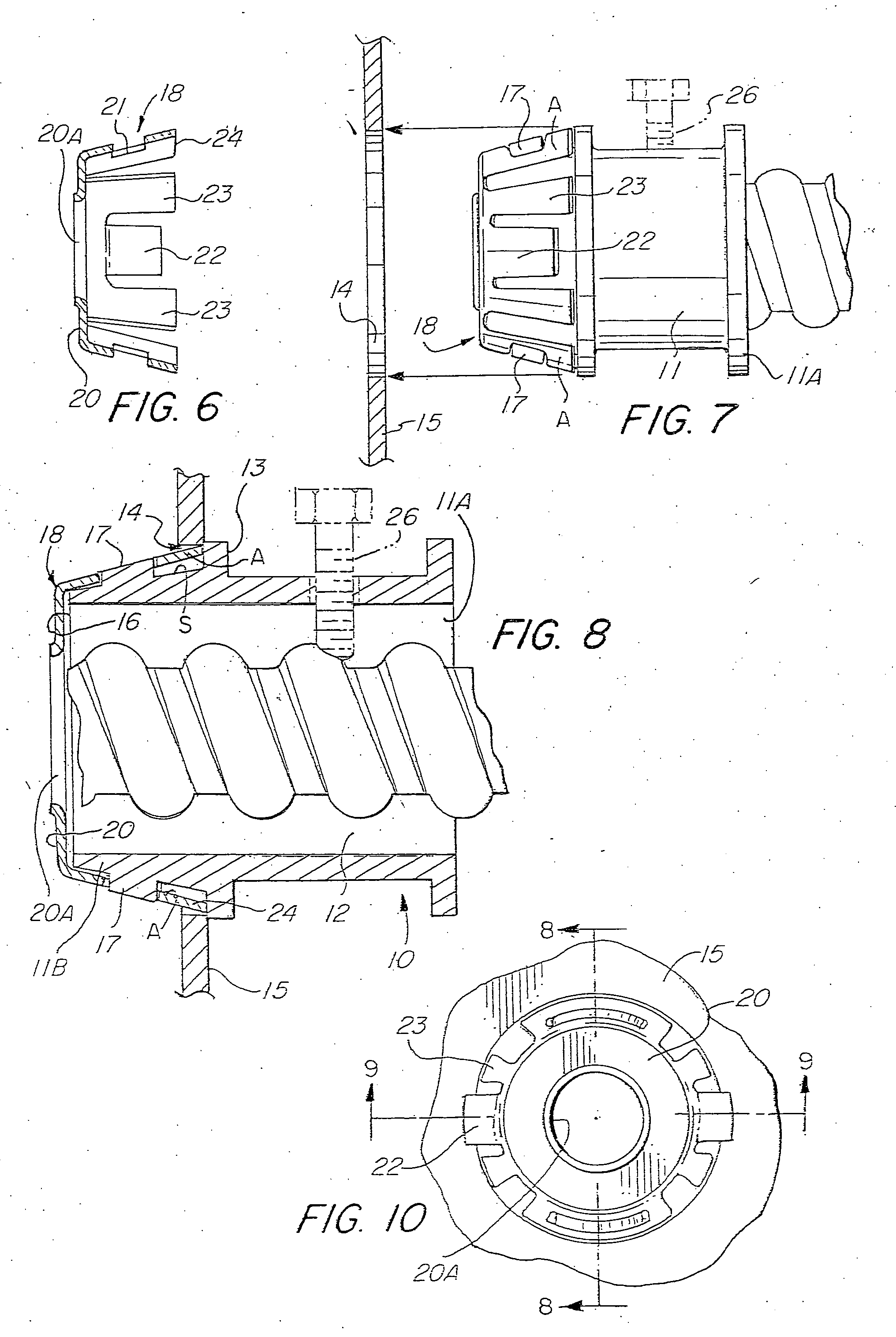

Apparatus and method for electrical and mechanical connection

ActiveUS20070287323A1Promote disseminationCoupling device detailsContact members penetrating/cutting insulation/cable strandsElectrical conductorConical forms

An apparatus for engaging an electrical conductor comprises a gripping contact having a plurality of fingers, where the plurality of fingers has a substantially conical outer surface. A contact receptacle has a substantially conical inner surface. A tension member urges the gripping contact toward the contact receptacle such that interaction between the substantially conical outer surface and the substantially conical inner surface forces the plurality of fingers to engagingly compress the electrical conductor placed between the fingers. A method of engaging an electrical conductor comprises inserting an electrical conductor between a plurality of fingers of a gripping contact, lo where the plurality of fingers has a substantially conical outer surface. The substantially conical outer surface of the gripping contact is urged to interact with a substantially conical inner surface of a contact receptacle such that the interaction forces the plurality of fingers to engage the electrical conductor.

Owner:POWER FEED THRU SYST & CONNECTORS

Snap fit electrical connector assembly with operating tool for facilitating the connection of a connector assembly to an electrical box

ActiveUS20060141827A1Simple structureEasy to assembleSubstation/switching arrangement detailsCoupling device engaging/disengagingConical formsEngineering

An electric connector assembly having a connector body defining an inlet end portion and an outlet end portion and having a frustro-conical retainer ring connected to the outlet end portion wherein the retainer ring is formed with locking and grounding tangs arranged to effect a snap-fit locking and grounding connection to a knockout hole of an electric box located in an existing wall and a tool arranged to engage slots formed in the retainer ring to facilitate the pulling of the connector assembly through the knockout hole of an electric box for seating and locking the electric connected thereto, and a method for securing the electrical connector assembly to an electric box installed in a finished wall.

Owner:BRIDGEPORT FITTINGS LLC

Industrial gas turbine exhaust system diffuser inlet lip

ActiveUS20150143810A1Improved aerodynamicsImproves Structural IntegrityEngine manufactureBlade accessoriesIndustrial gasConical forms

An integrated single-piece exhaust system (SPEX) with modular construction that facilitates design changes for enhanced aerodynamics, structural integrity or serviceability. The SPEX defines splined or curved exhaust path surfaces, such as a series of cylindrical and frusto-conical sections that mimic curves. The constructed sections may include: (i) a tail cone assembly fabricated from conical sections that taper downstream to a reduced diameter; or (ii) an area-ruled cross section axially aligned with one or more rows of turbine struts; or both features. Modular inner and outer diameter inlet lips enhance transitional flow between the last row blades and the SPEX, as well as enhance structural integrity. Modular strut collars have large radius profiles between the SPEX annular inner diameter and outer diameter flow surfaces, for enhanced airflow and constant thickness walls for uniform heat transfer and thermal expansion. Scalloped mounting flanges enhance structural integrity and longevity.

Owner:SIEMENS ENERGY INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com