Patents

Literature

3464 results about "Order form" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

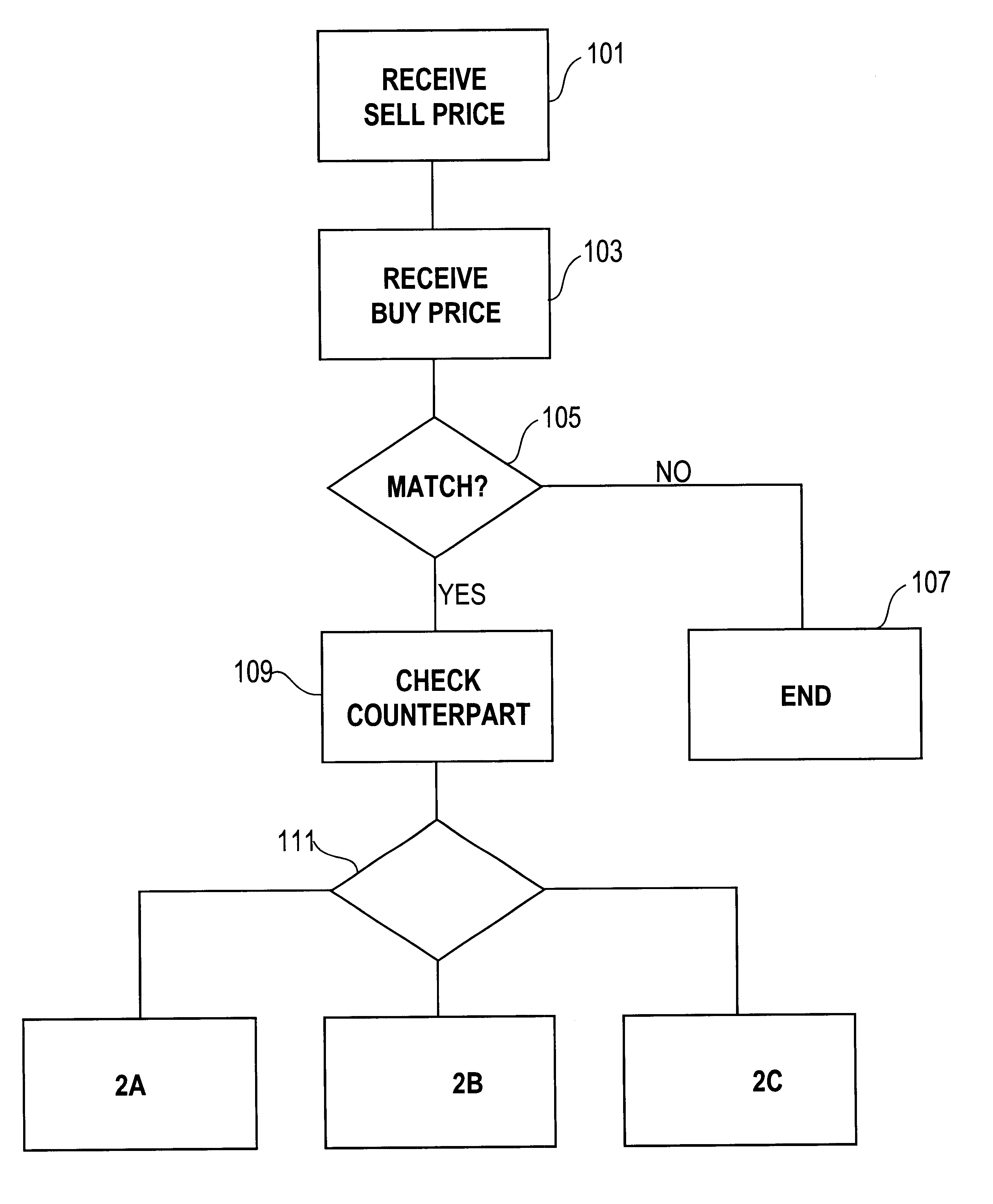

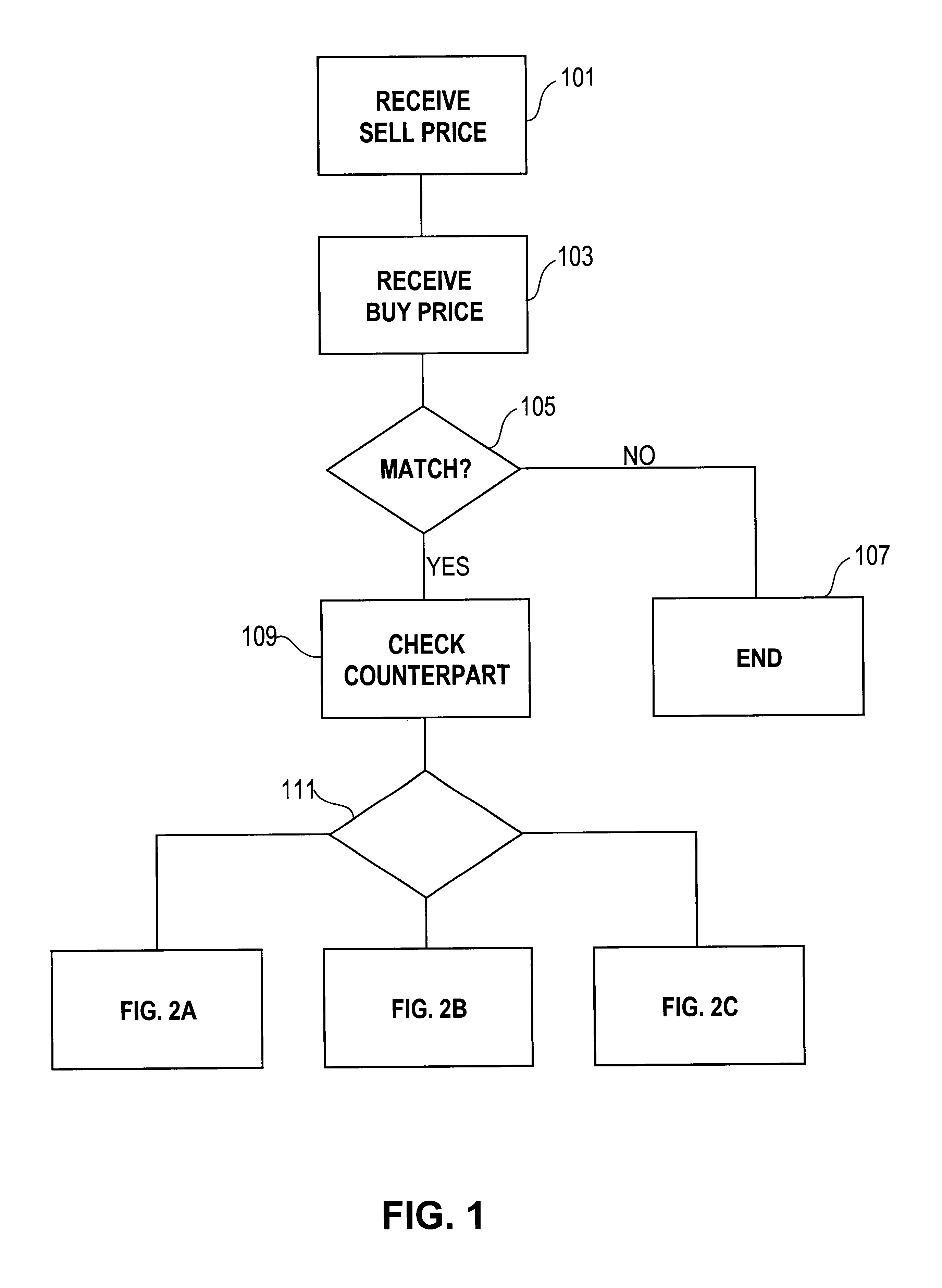

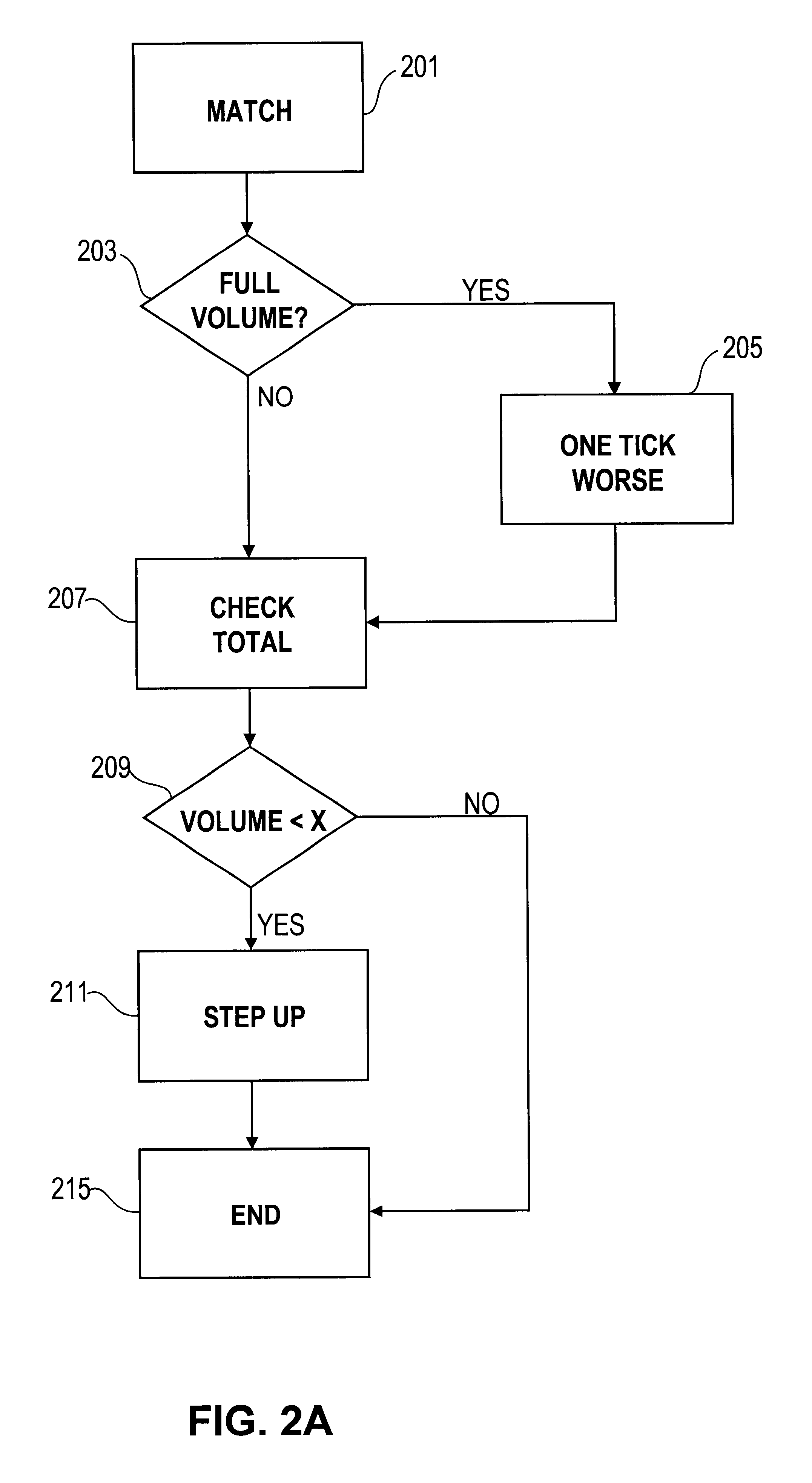

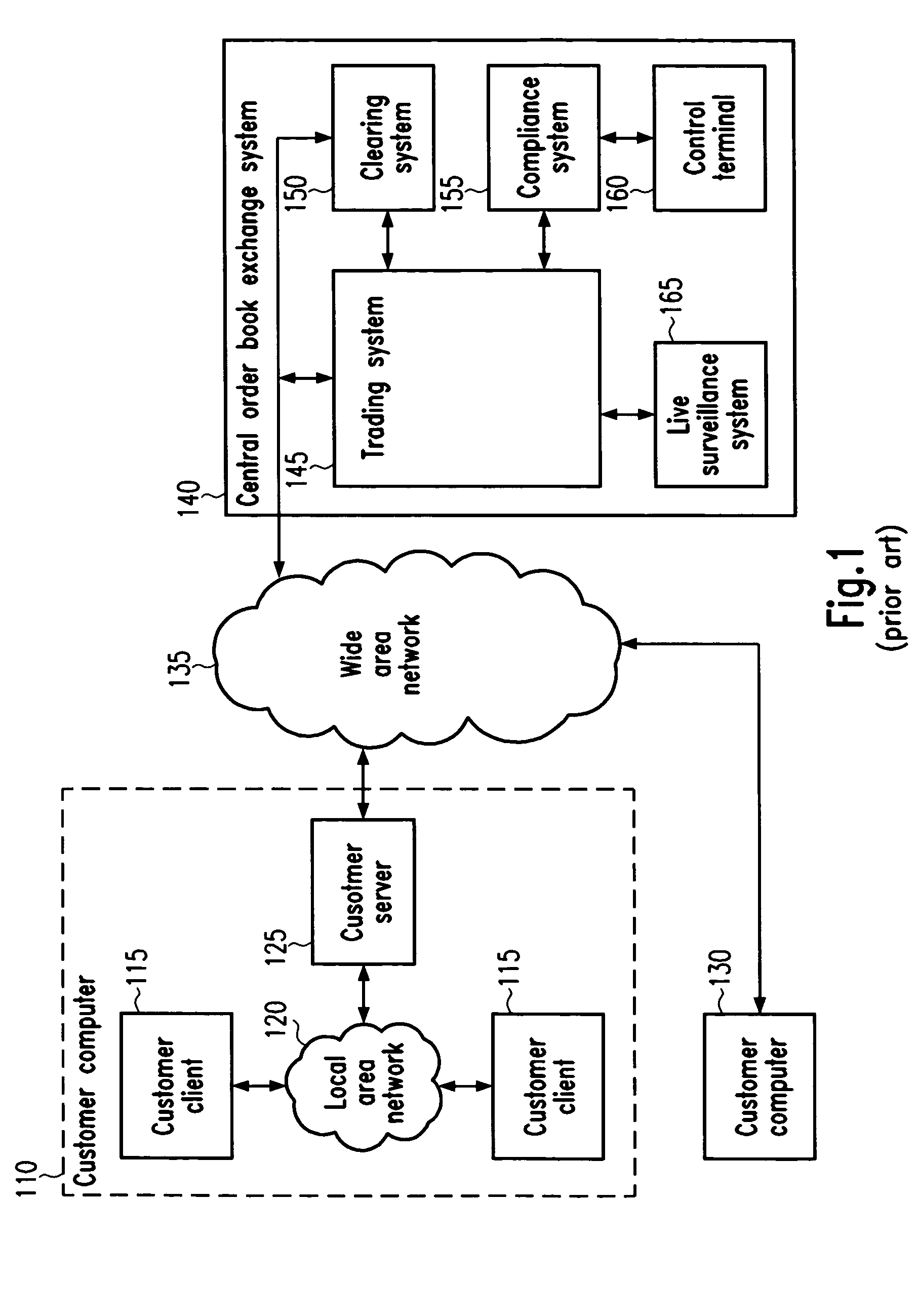

Automated exchange for matching bids between a party and a counterparty based on a relationship between the counterparty and the exchange

InactiveUS6405180B2Tight spreadReduced volume (risk)Special service provision for substationFinanceOrder formCourse of action

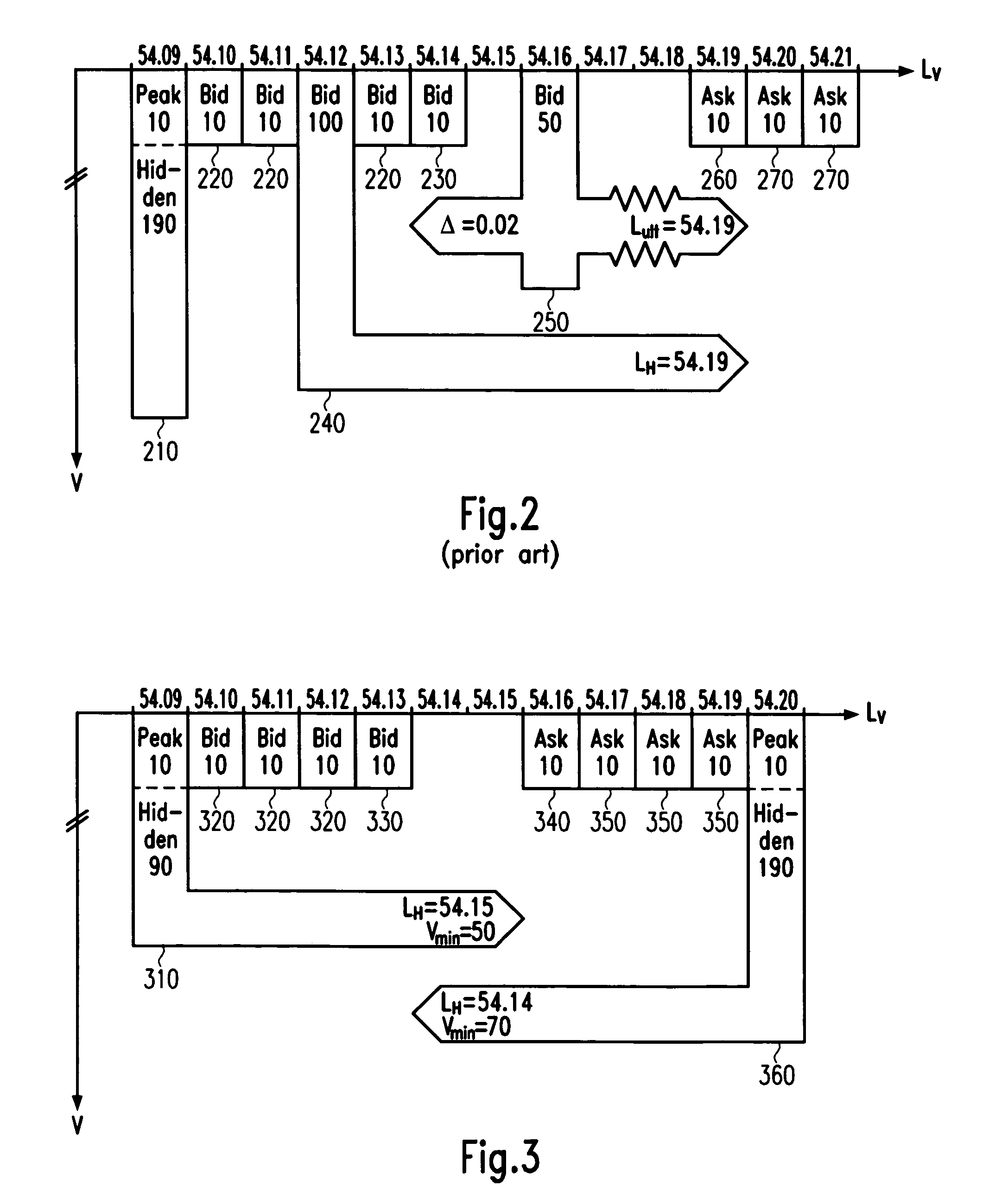

In an automated exchange system means are provided by means of which a market maker can enter a course of action in advance, so that the volume in the orderbook is continuously updated, and where the updating is performed differently with respect to different counter parts. Also, quotes that may result in a trade between Market Makers are hidden for some time before being matched, thus giving the Market Makers a chance to back off. The system employs a function that supports that Market Makers through pre-defined parameters will have new orders generated by the system and that a market maker can act differently with respect to different counterparts. The parameters specify if a Market Maker should add extra volume on an existing price or generate a new order at a worse price. In order to make it possible for market makers to have a very tight spread without forcing them to take larger risks, additional logic is used when matching orders. The algorithm used for this purpose protects the market makers in certain situations and gives market makers the possibility to have a tight spread without taking a large risk. The algorithm also supports that the market makers can take the risk to quote large volumes.

Owner:ISE LLC

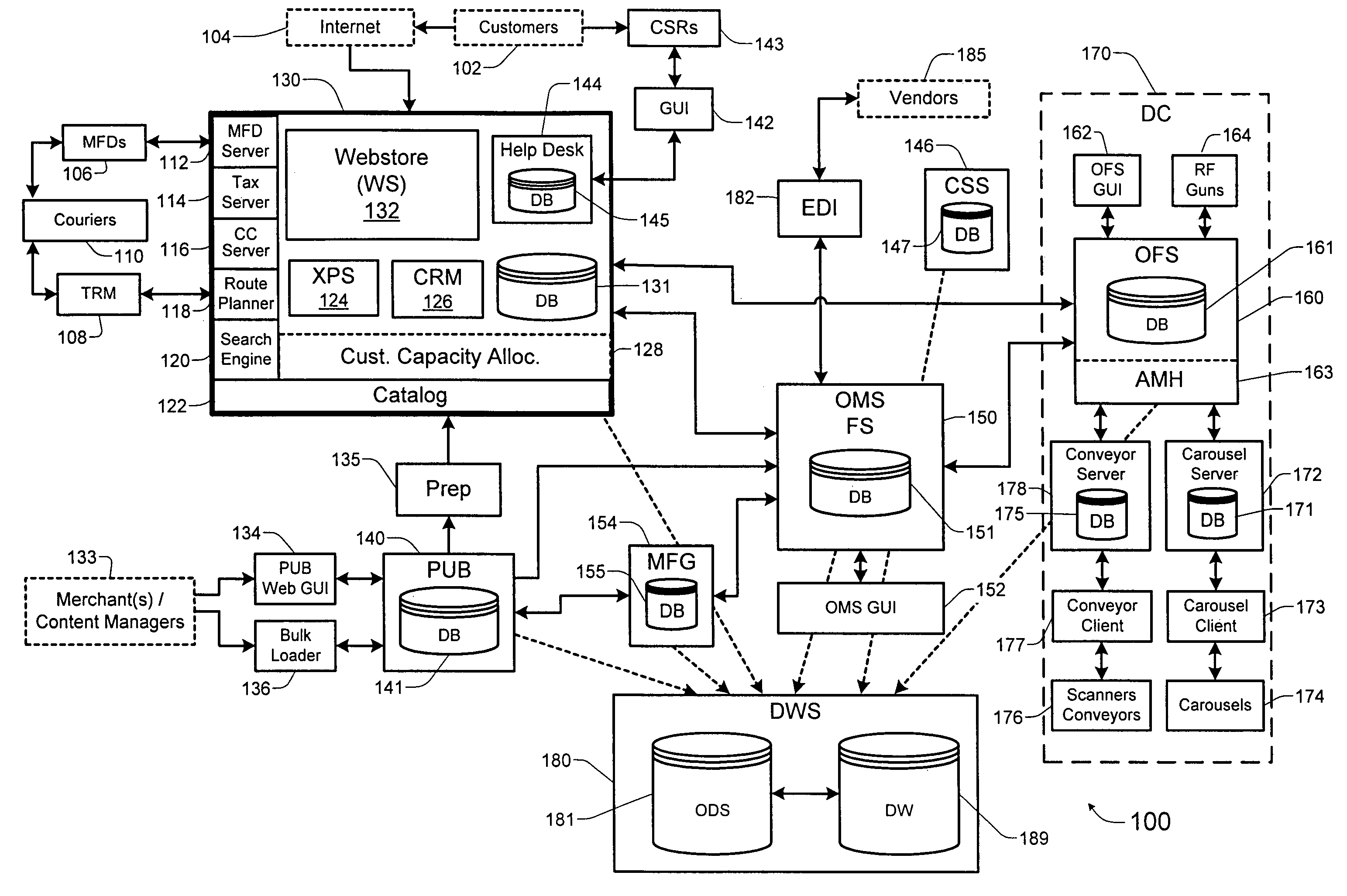

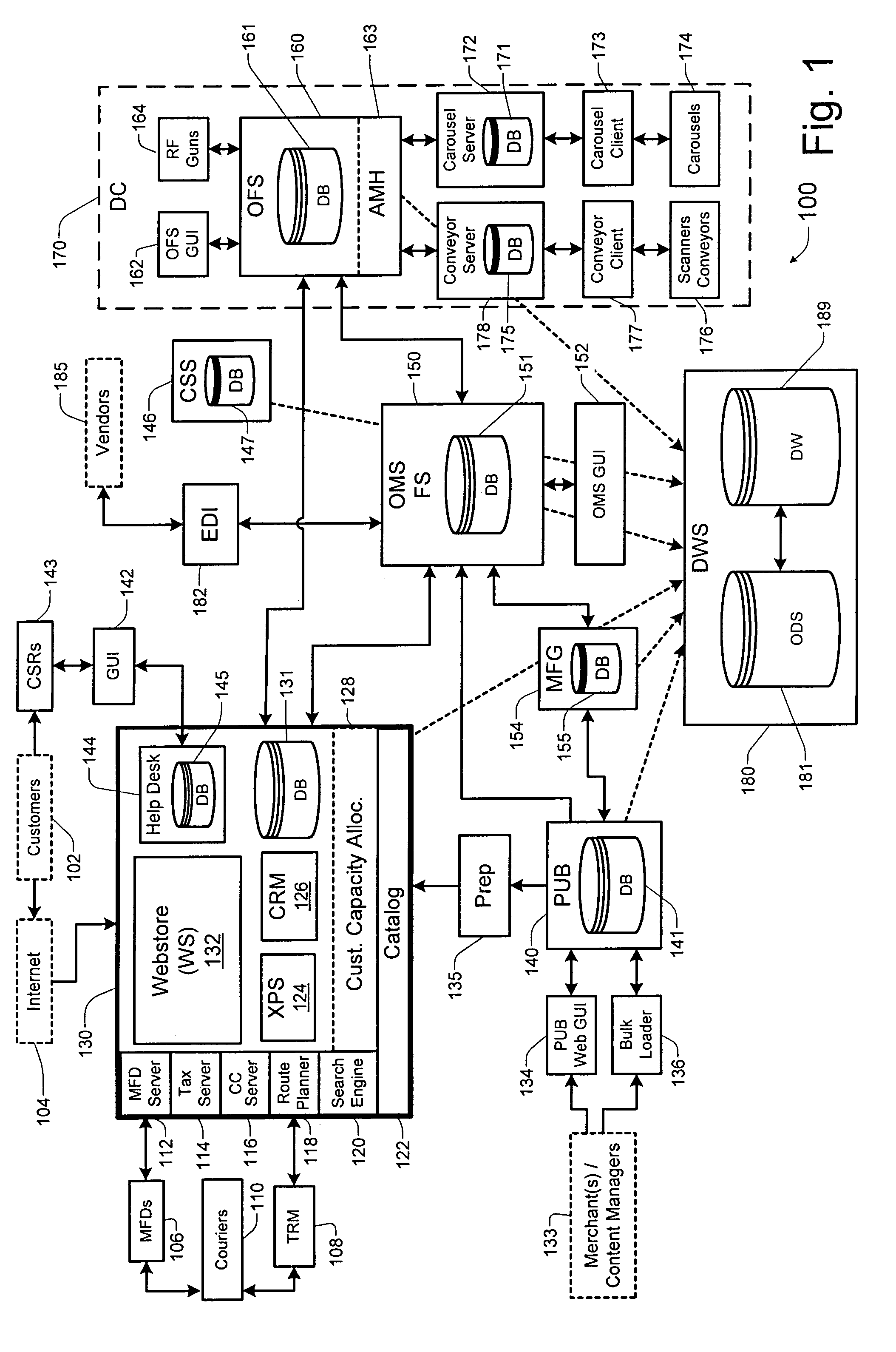

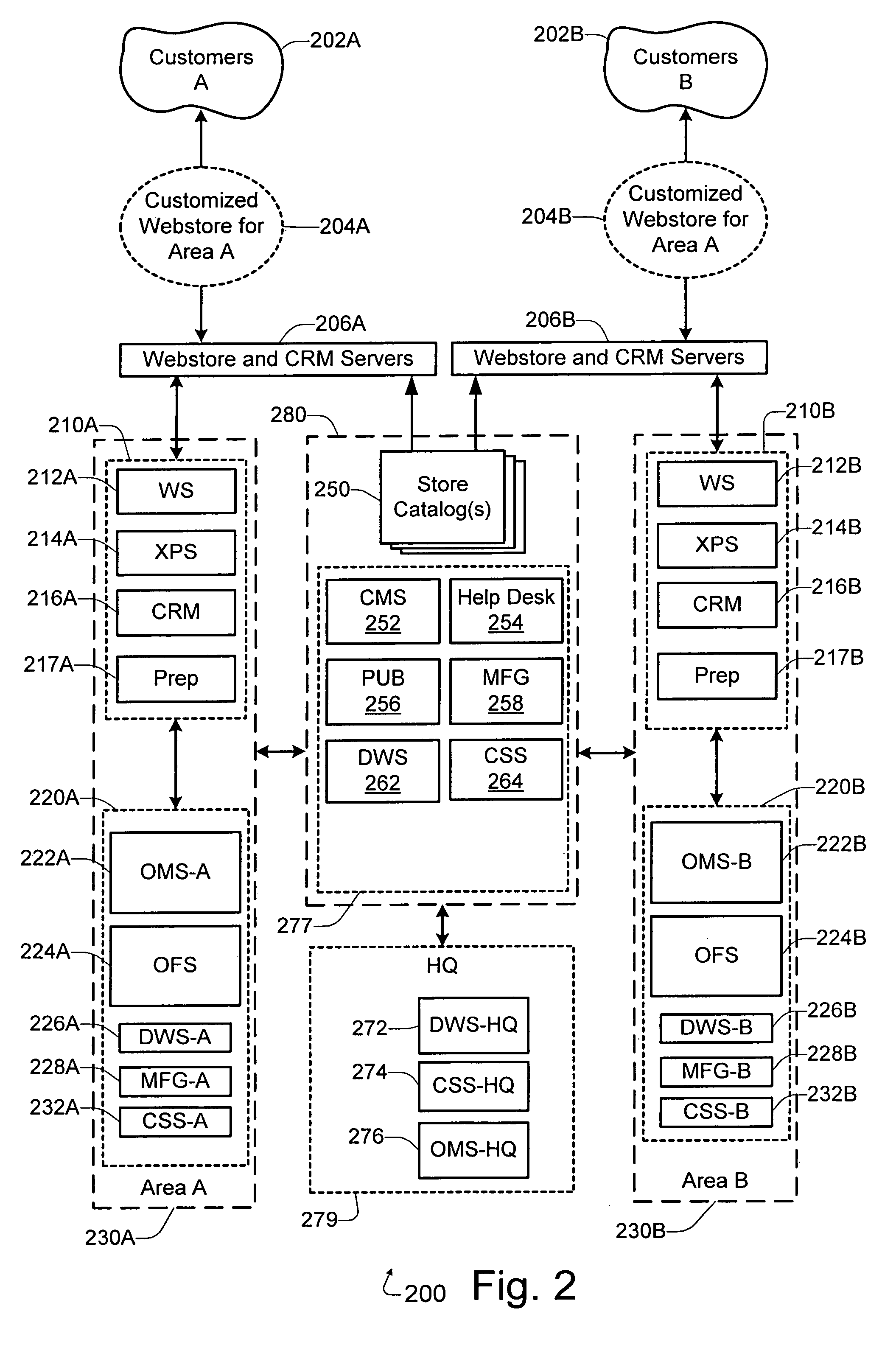

Integrated system for ordering, fulfillment, and delivery of consumer products using a data network

A technique for effecting electronic commerce using a data network is described. The data network includes a plurality of subsystems which, together, form an integrated system for receiving customer orders for selected items via a data network, fulfilling the customer orders, and delivering the ordered products to the customers. Moreover, according to a specific embodiment, the integrated nature of the system architecture of the present invention allows the on-line merchant to provide a guarantee to the customer that the ordered items will be available to be delivered to the customer at the specified delivery date, time, and location.

Owner:JUNE RAY

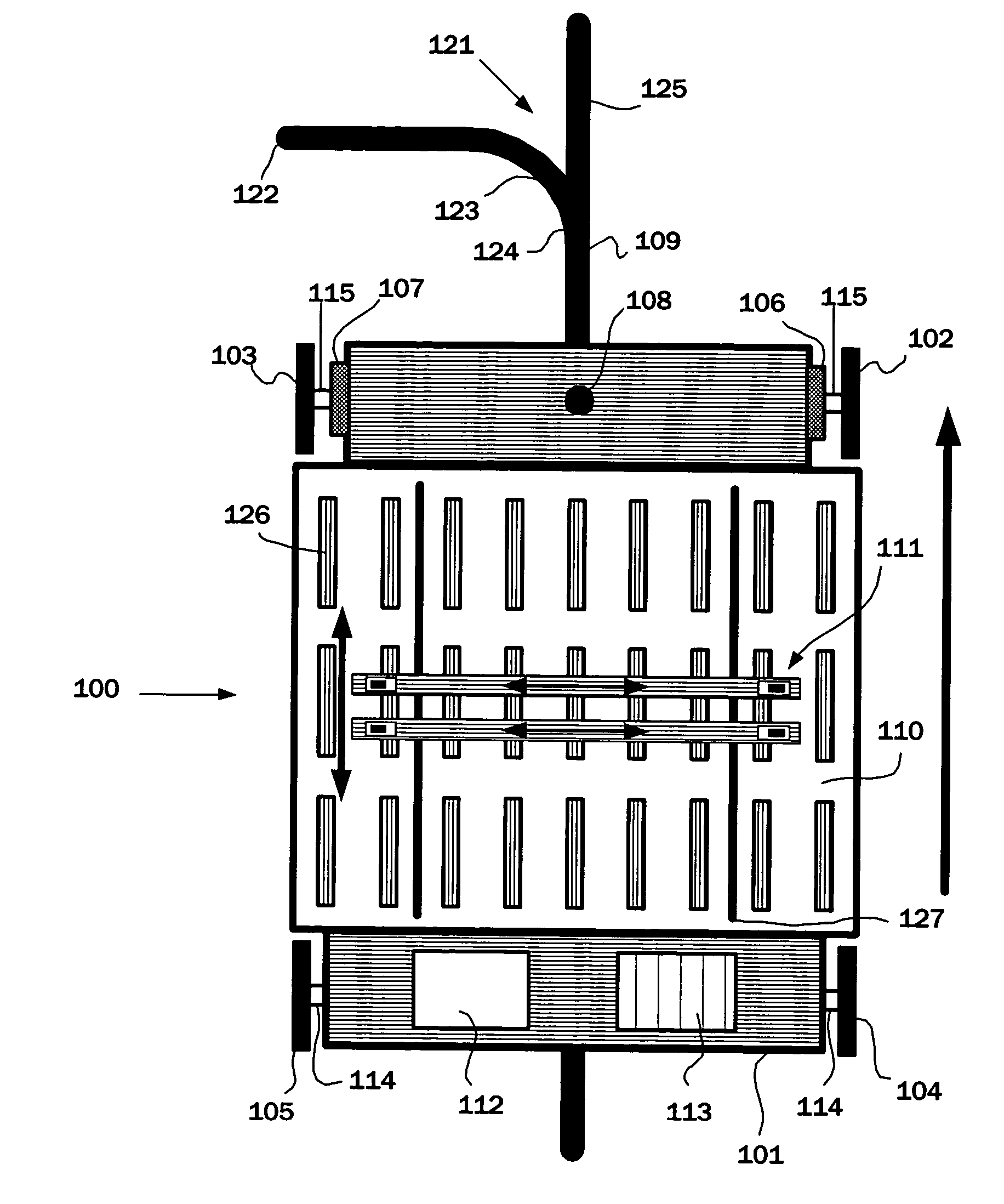

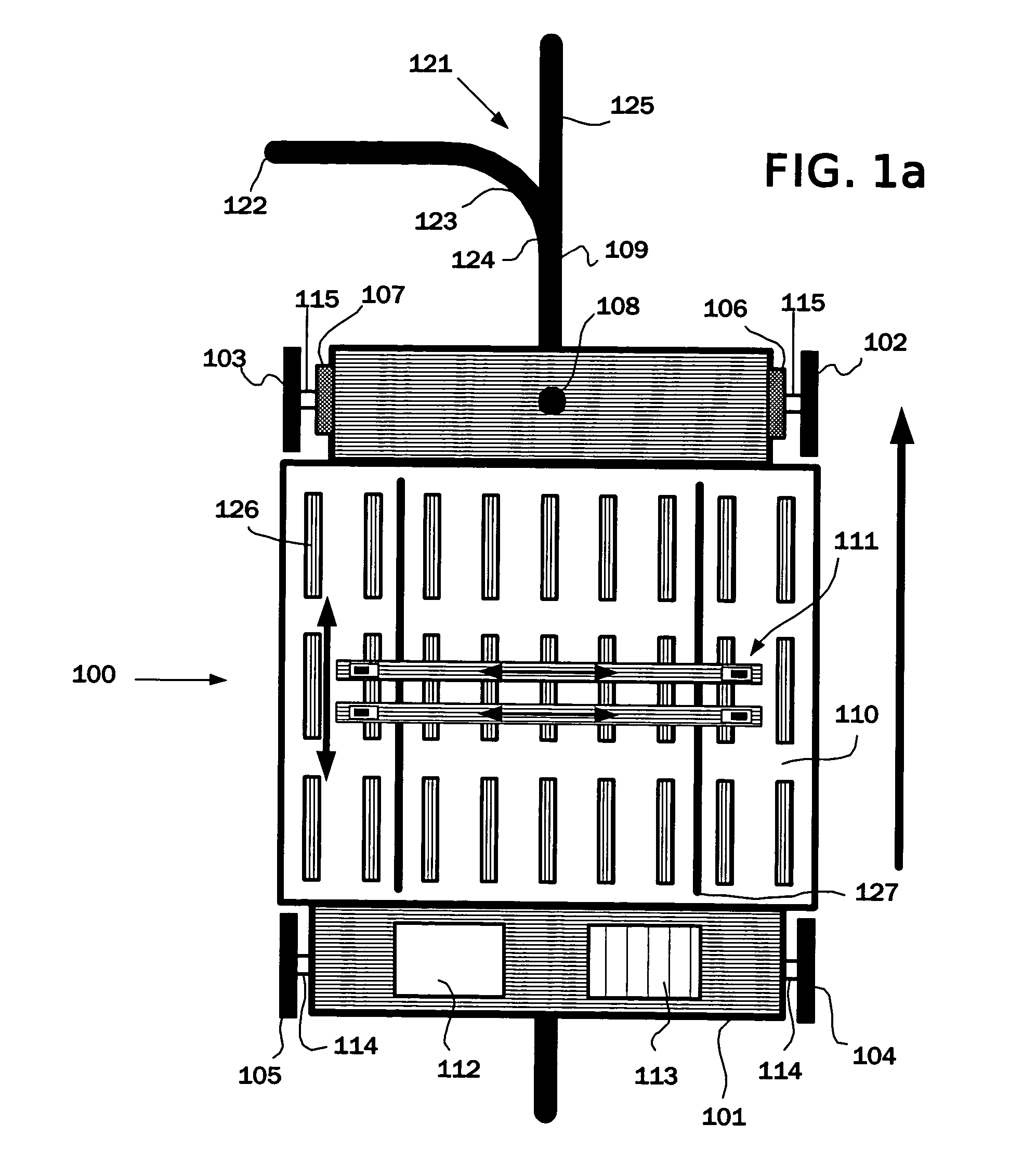

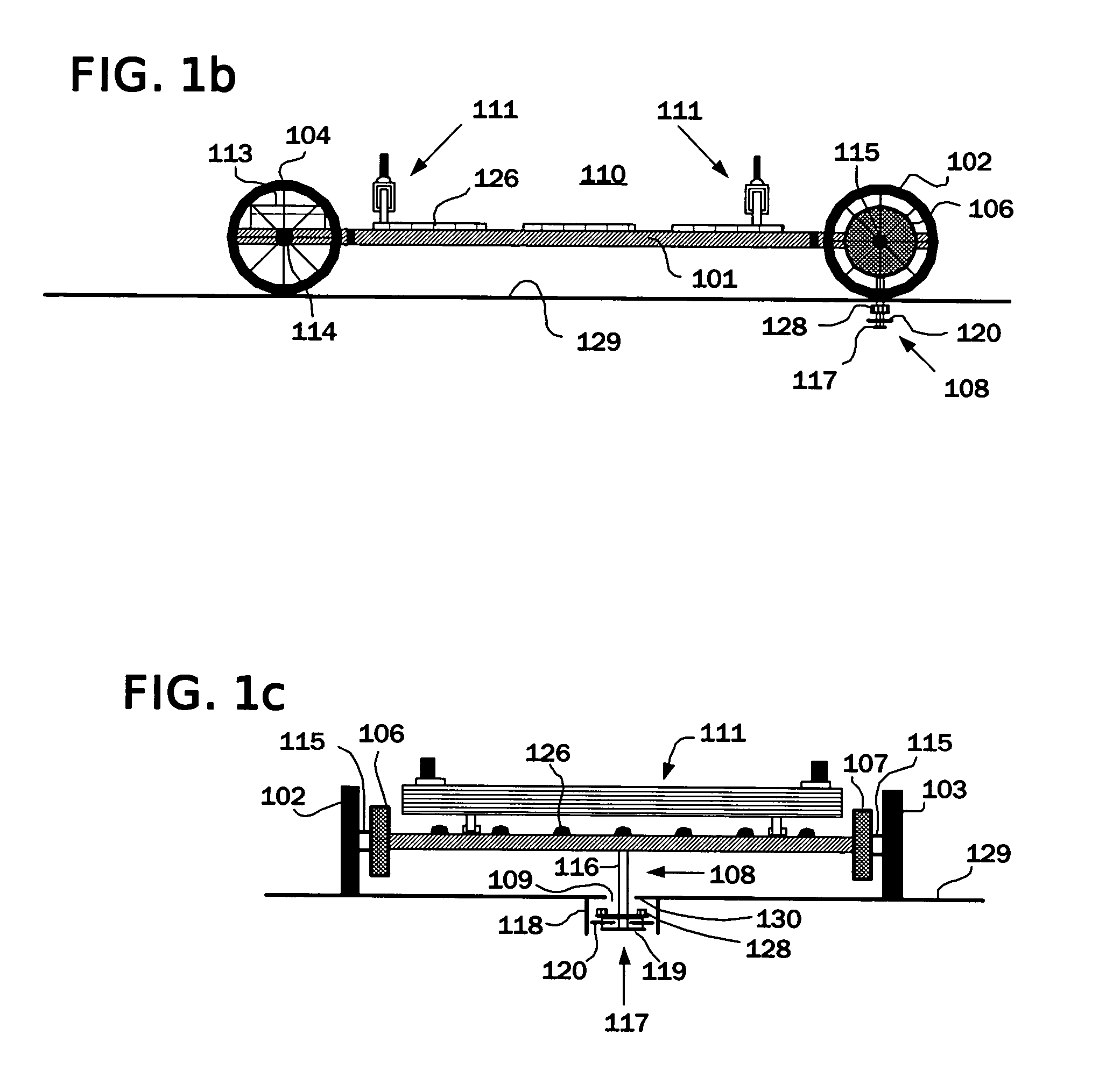

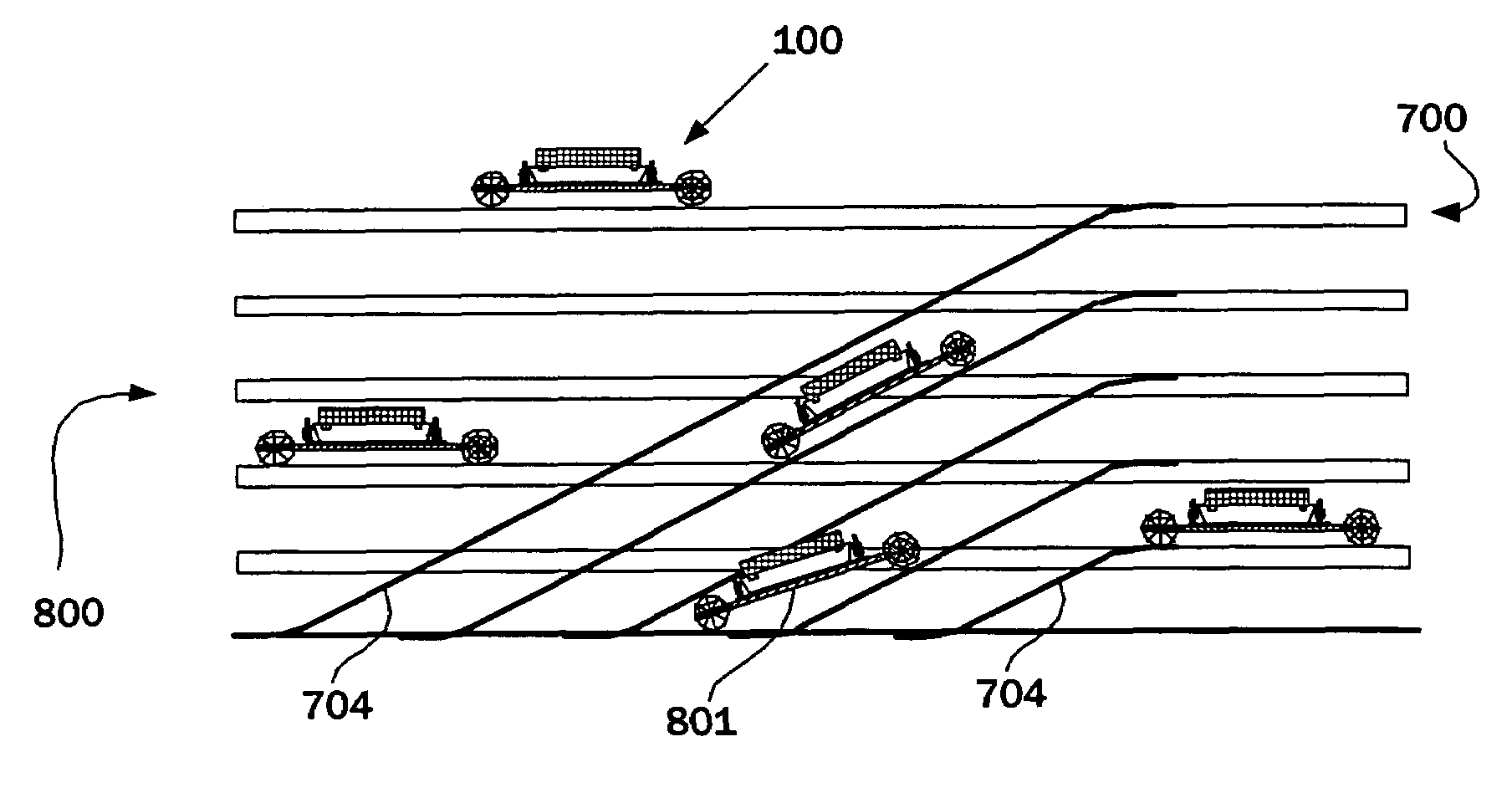

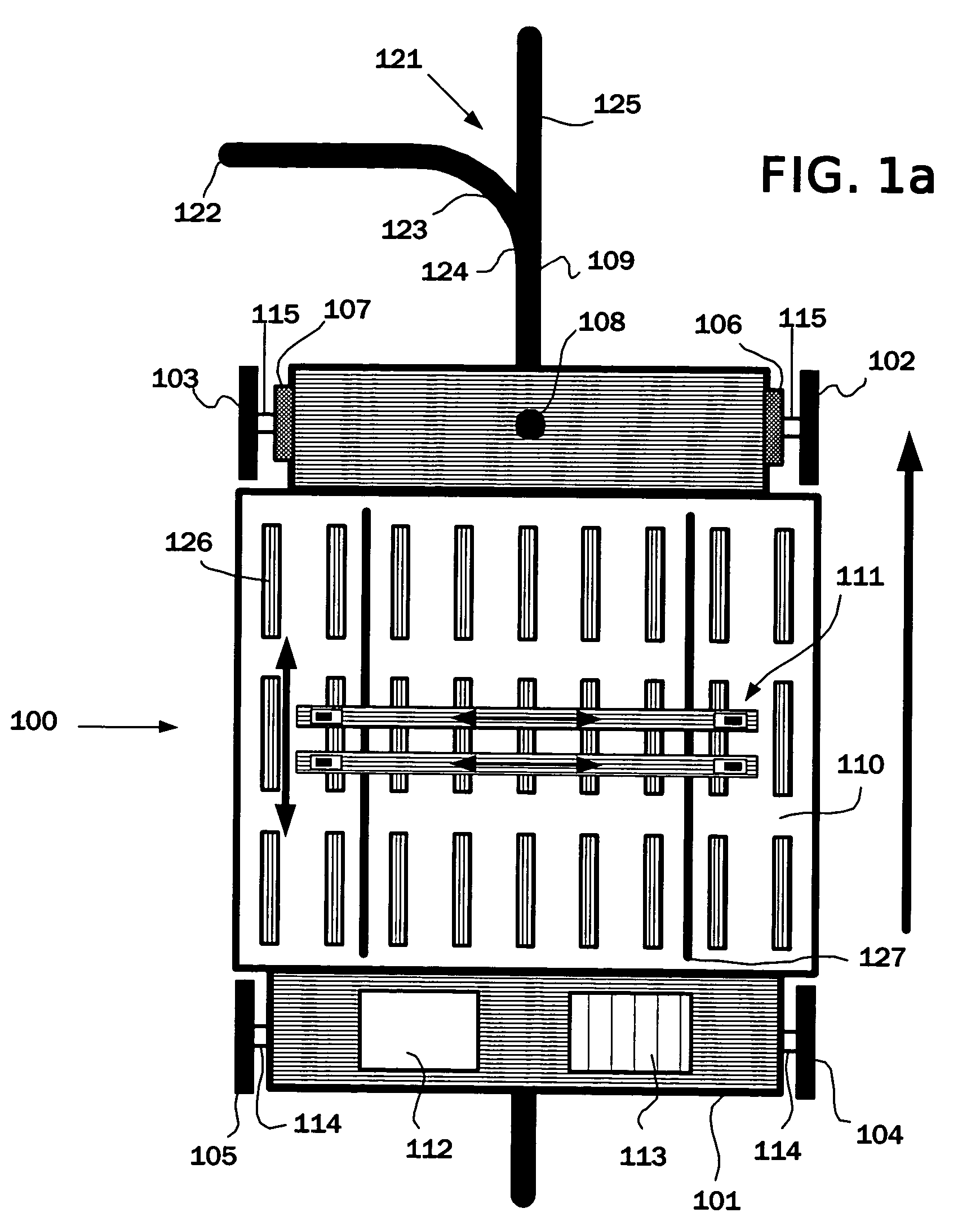

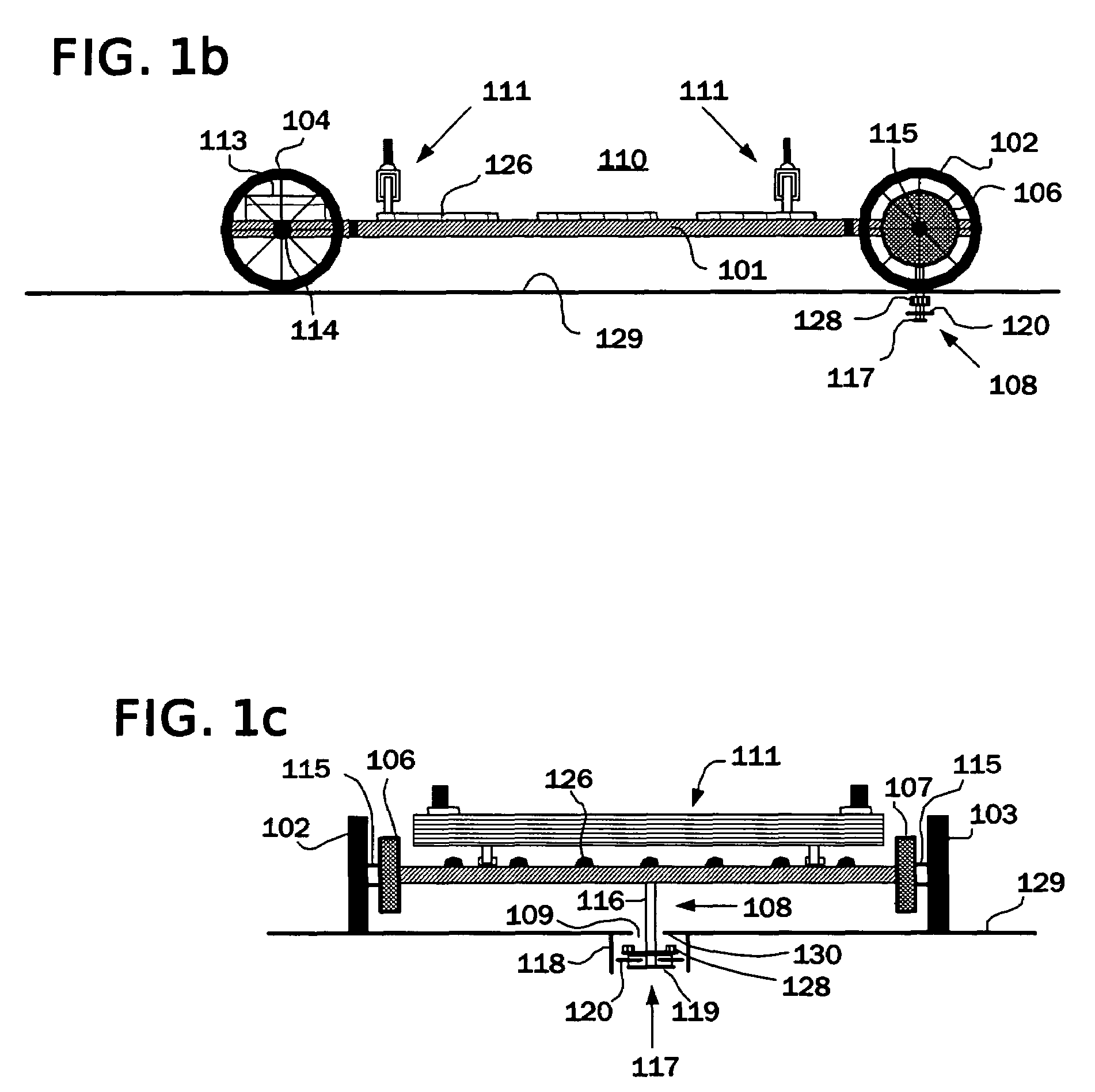

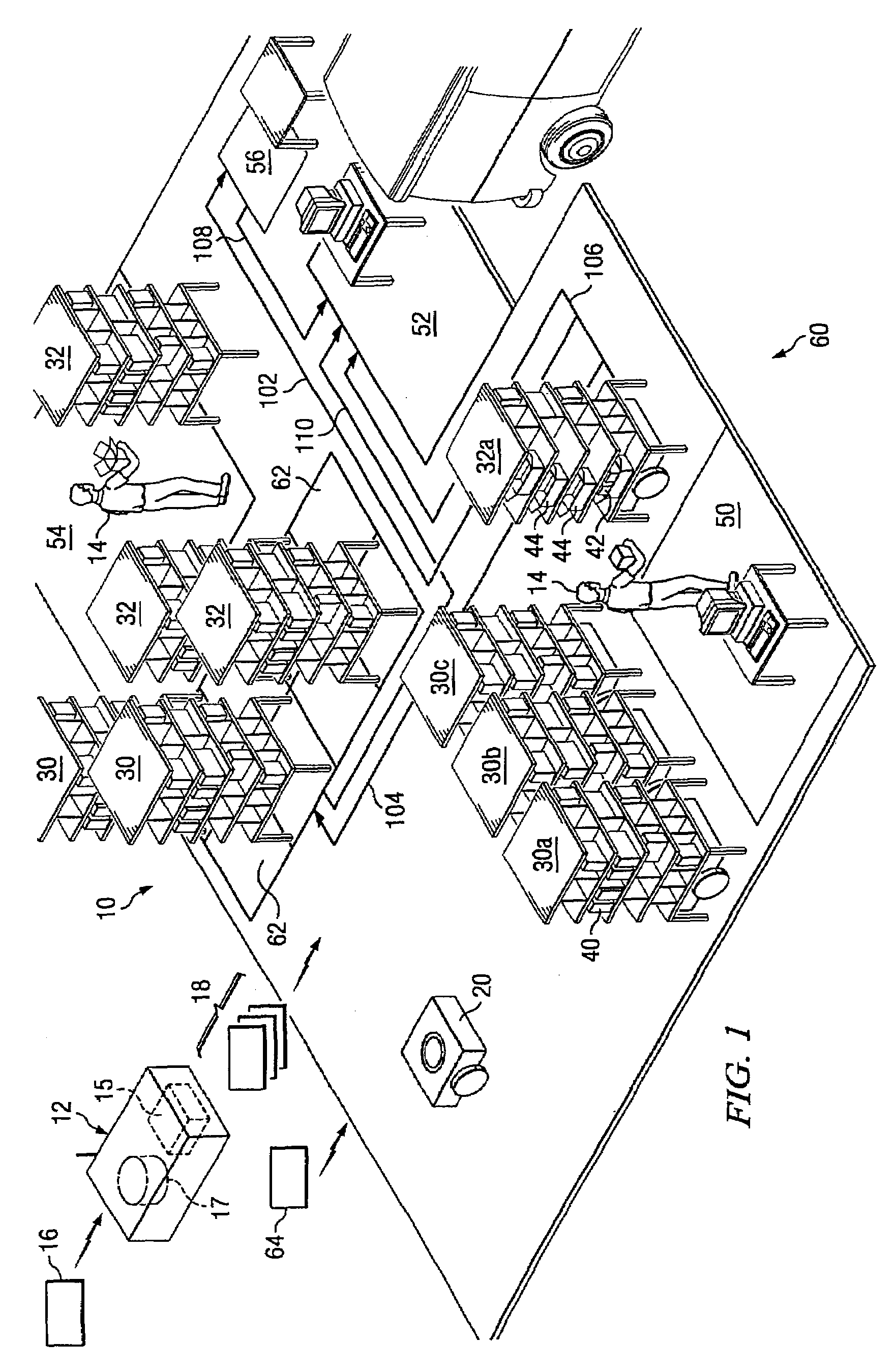

Materials-handling system using autonomous transfer and transport vehicles

Methods and apparatus for selecting and combining items in an outbound container through the use of autonomous vehicles, each of which includes means for automatically loading and unloading a payload, to perform both transfer and transport functions in moving containers of items within a workspace via a network of roadways. Under computer control, said autonomous vehicles transfer and transport case containers of item units between incoming receiving stations, intermediate storage locations, and outgoing order-assembly stations where entire containers or individual item units are combined in the outbound container.

Owner:SYMBOTIC LLC

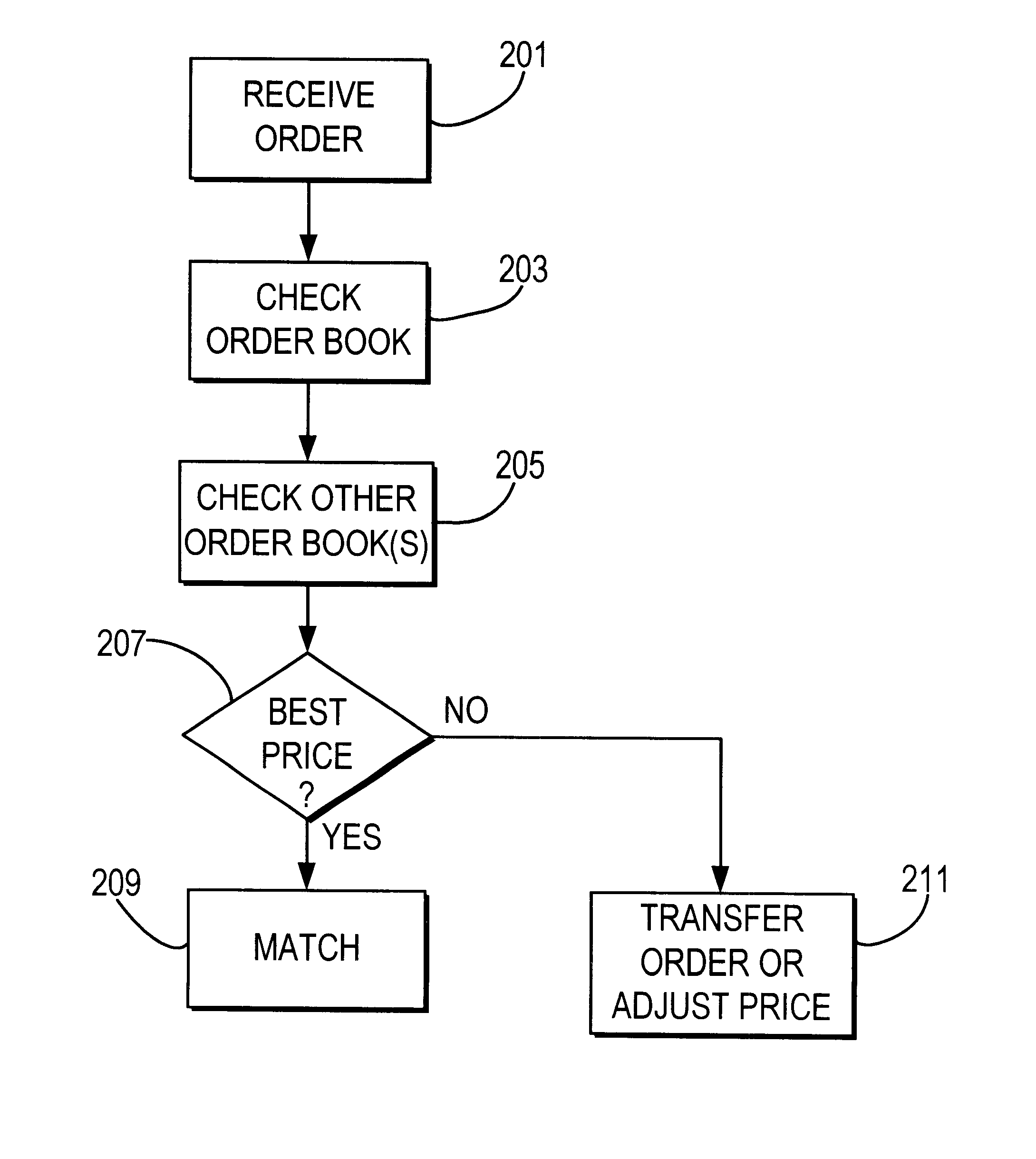

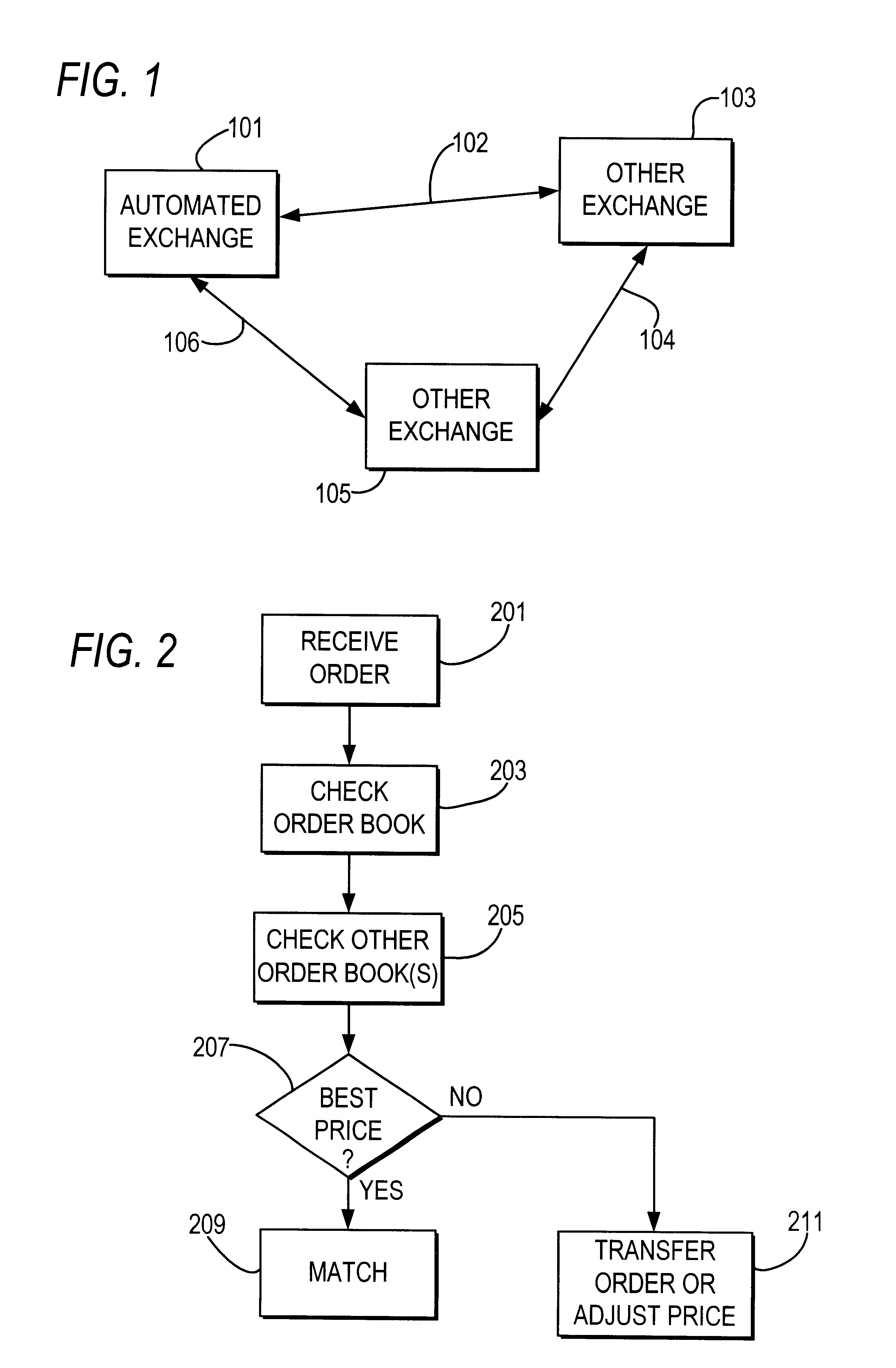

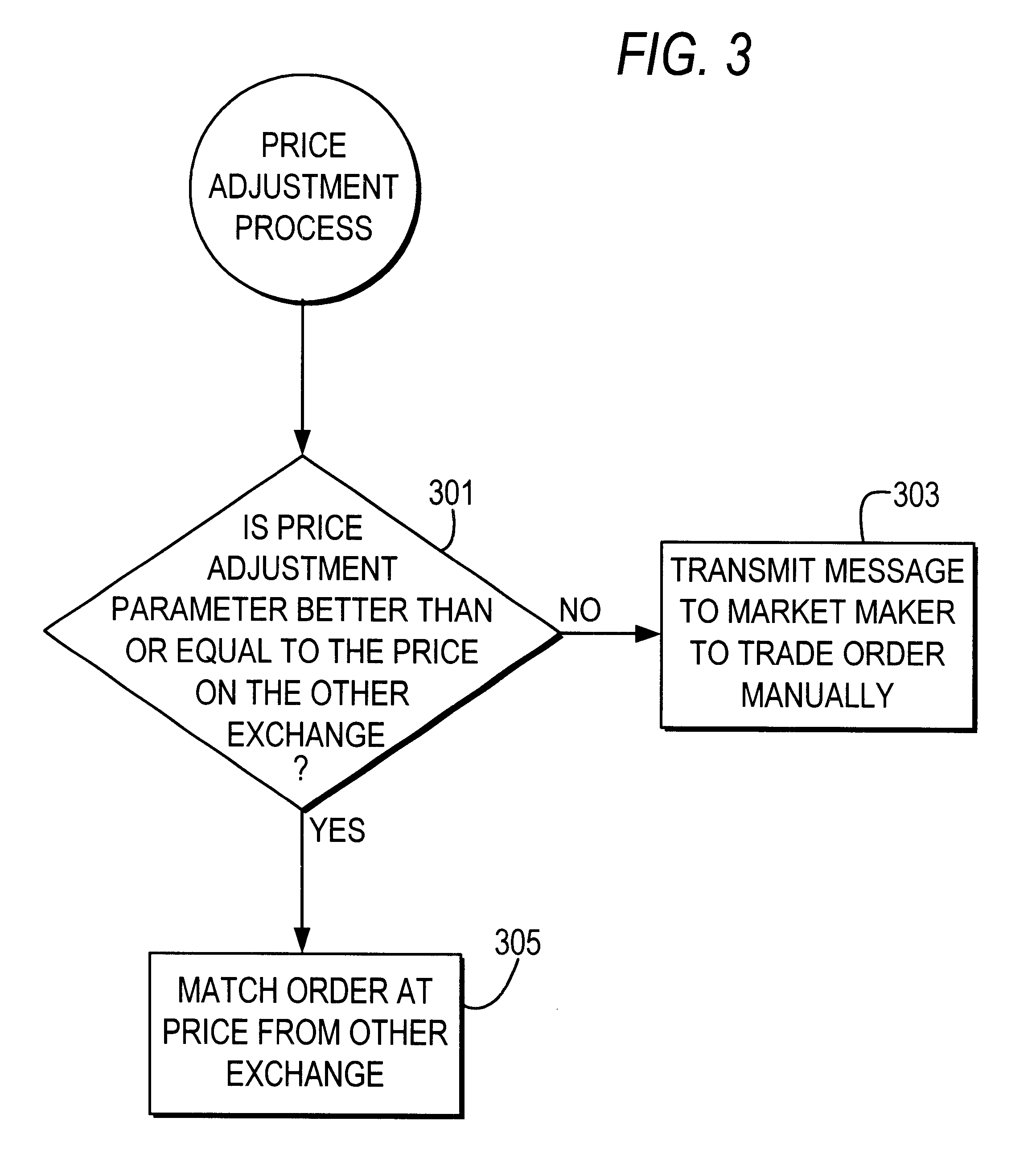

Method and apparatus for setting a price for a security on an automated exchange based on a comparison of prices on other exchanges

In an automated exchange system a method and a device which automatically checks the corresponding price in other exchange's order books is provided the exchange only allows a match if a better price cannot be found elsewhere. In a preferred embodiment the order is automatically transferred to the exchange having the better price if this is the case, and the order is further processed at that exchange the method and device provides means so that investors will not have to worry about getting a better price elsewhere, when entering bids into an automated exchange.

Owner:ISE LLC

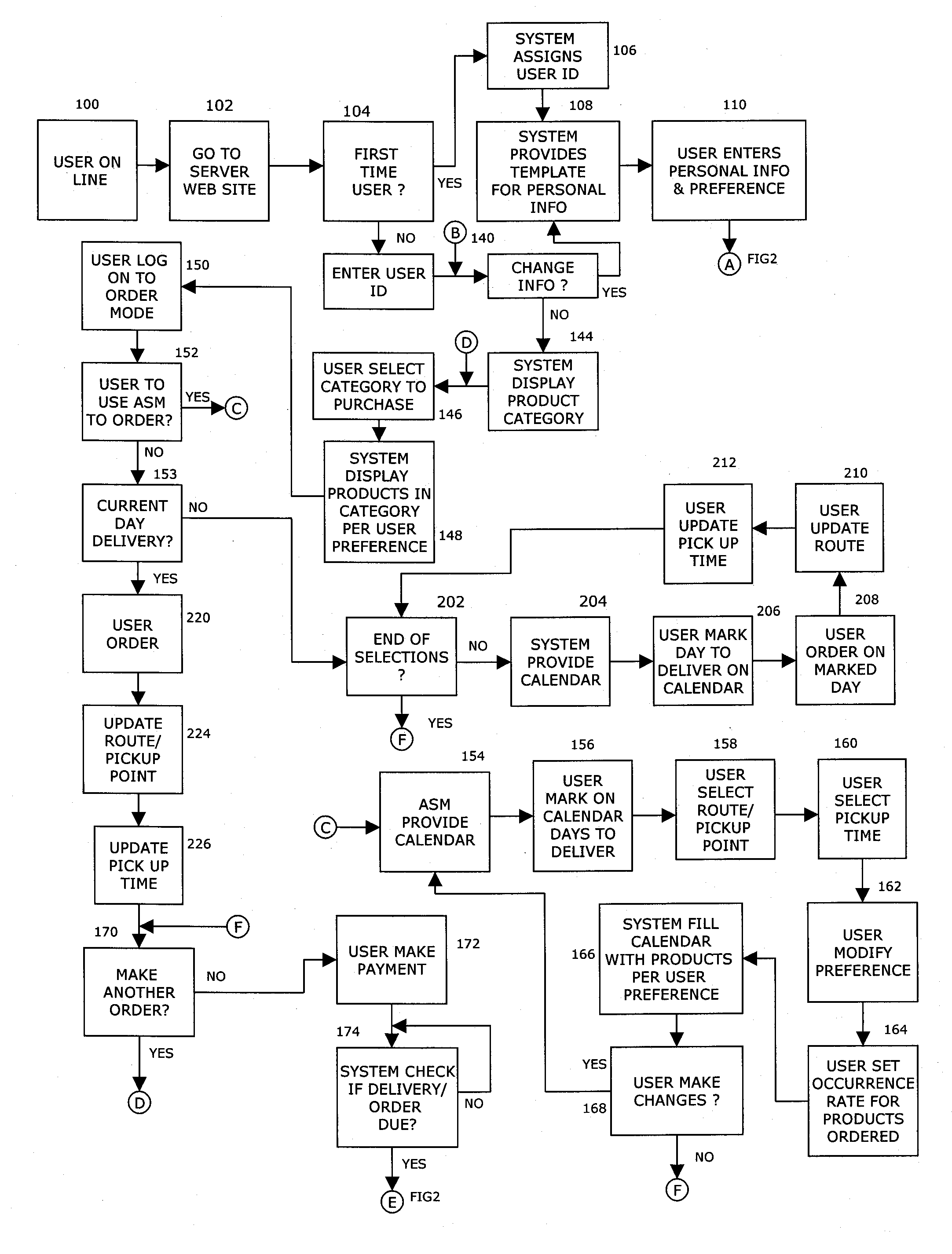

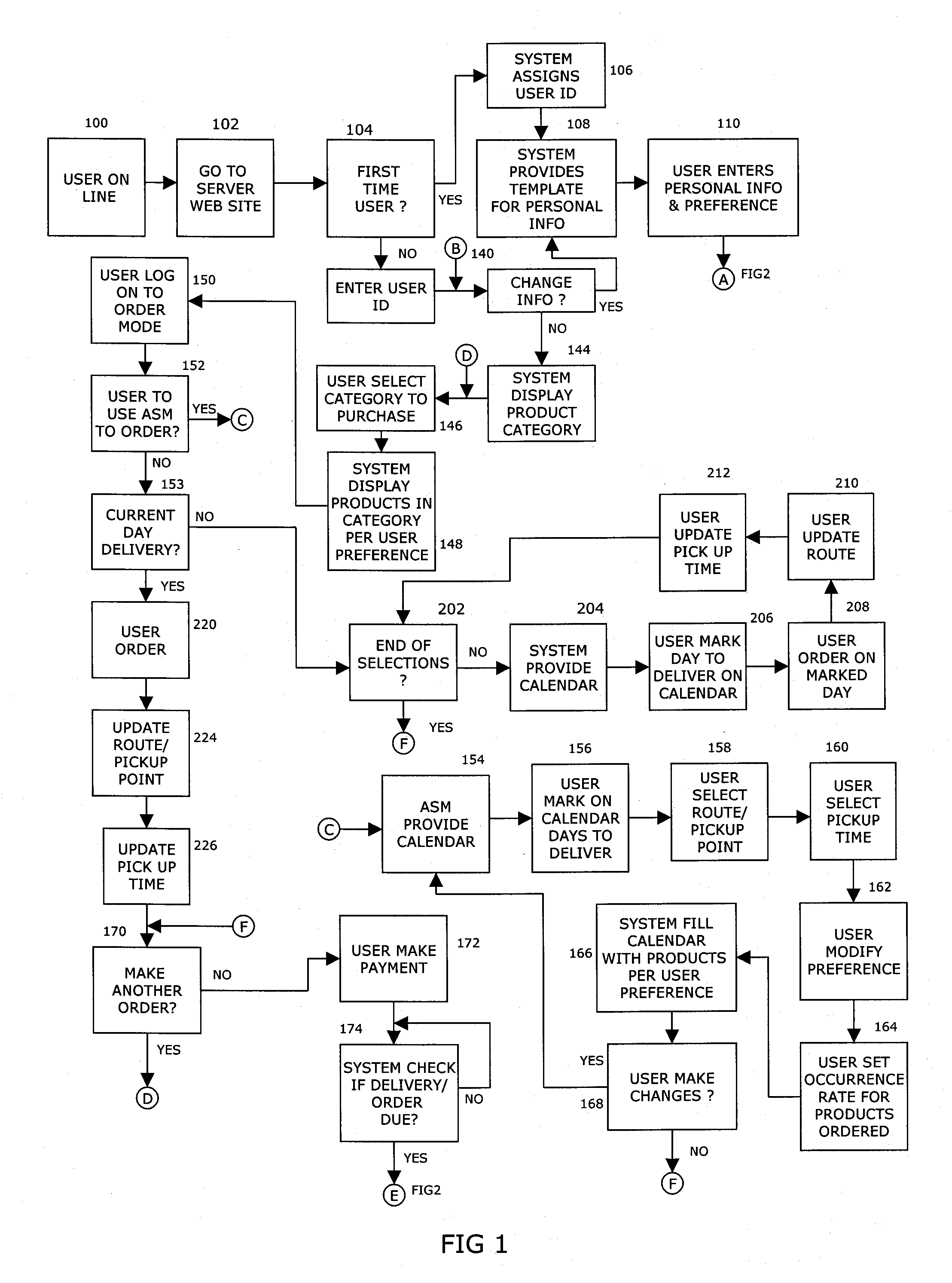

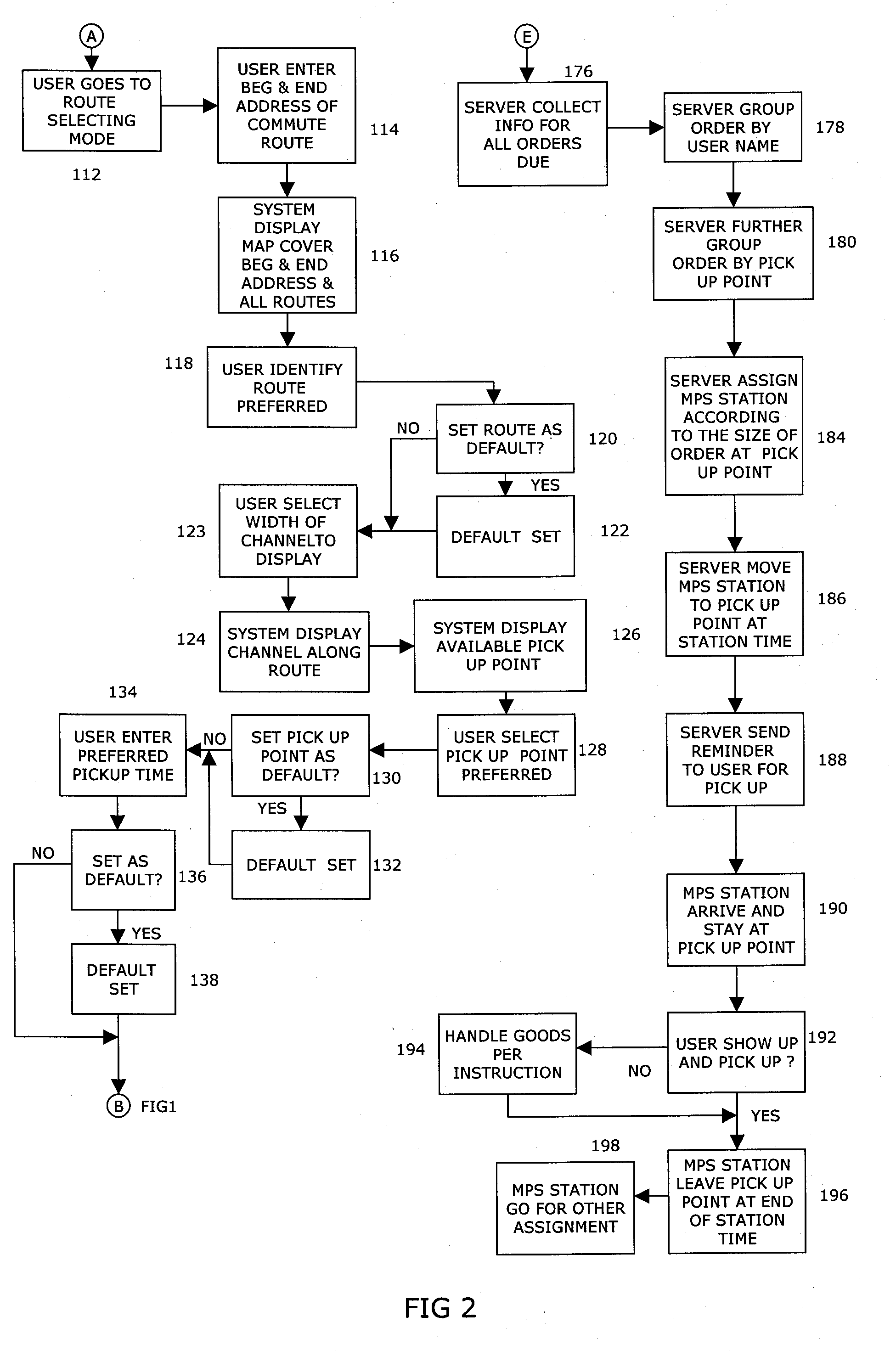

Method and apparatus for efficient meal delivery

InactiveUS20070150375A1Improves conventional meal delivery processSimple processBuying/selling/leasing transactionsLogisticsTemperature controlWeb site

A method and system for accepting order and scheduling delivery of meals to buyers. A Mobile Pickup Station (MPS) server is placed within a computer network and lists a number of participating restaurants on its web site. A buyer logs onto the MPS web site to order food from a participating restaurant. The server passes the order to the participating restaurant for production. An optimal pickup location is selected and the order is picked up from the participating restaurant and is delivered to the pickup location for pickup. A temperature-controlled truck enclosing the buyer order is dispatched to the pickup location. The truck is then stationed at the pickup location for a determined period of time waiting for buyers to pick up their orders.

Owner:YANG PING

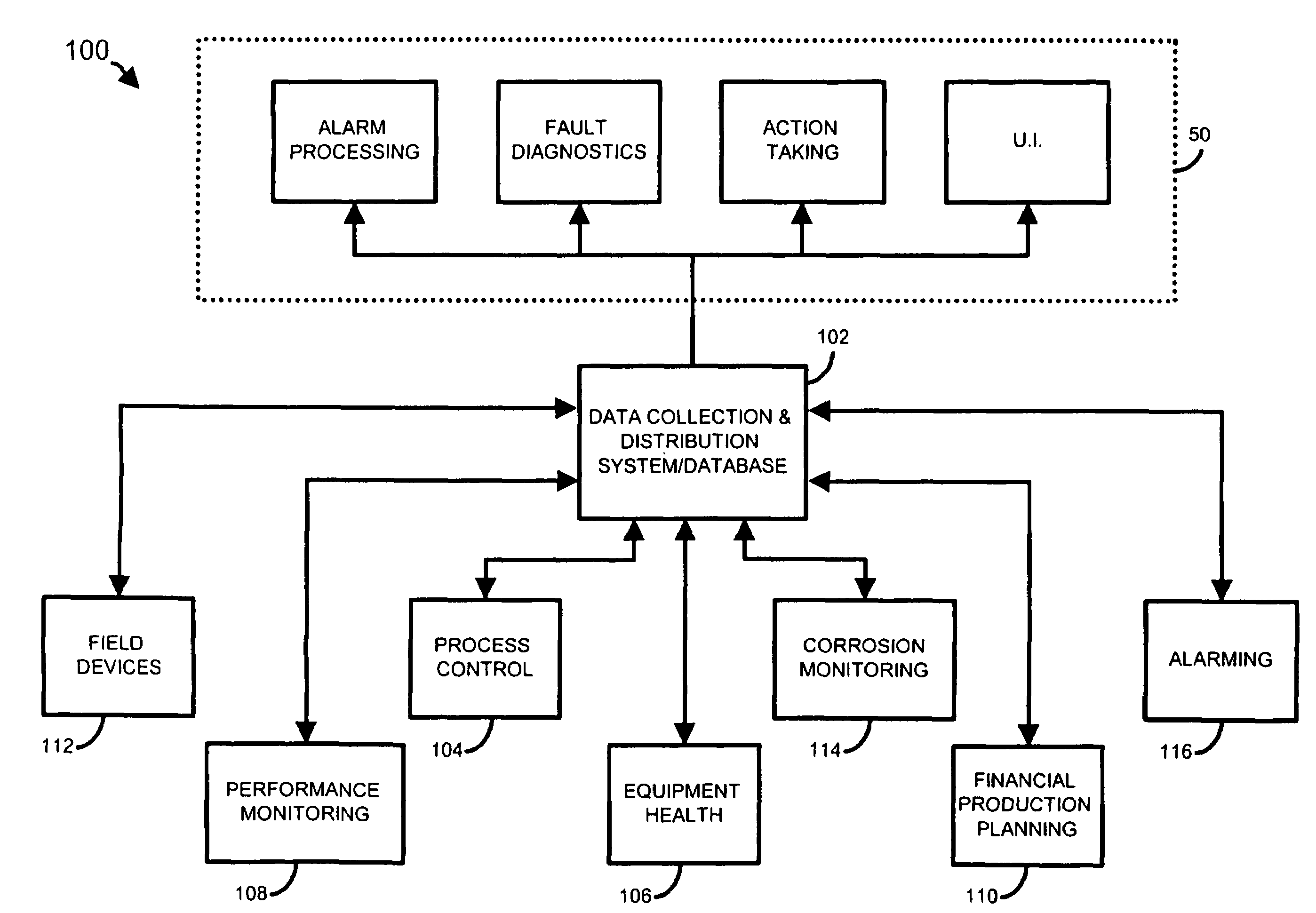

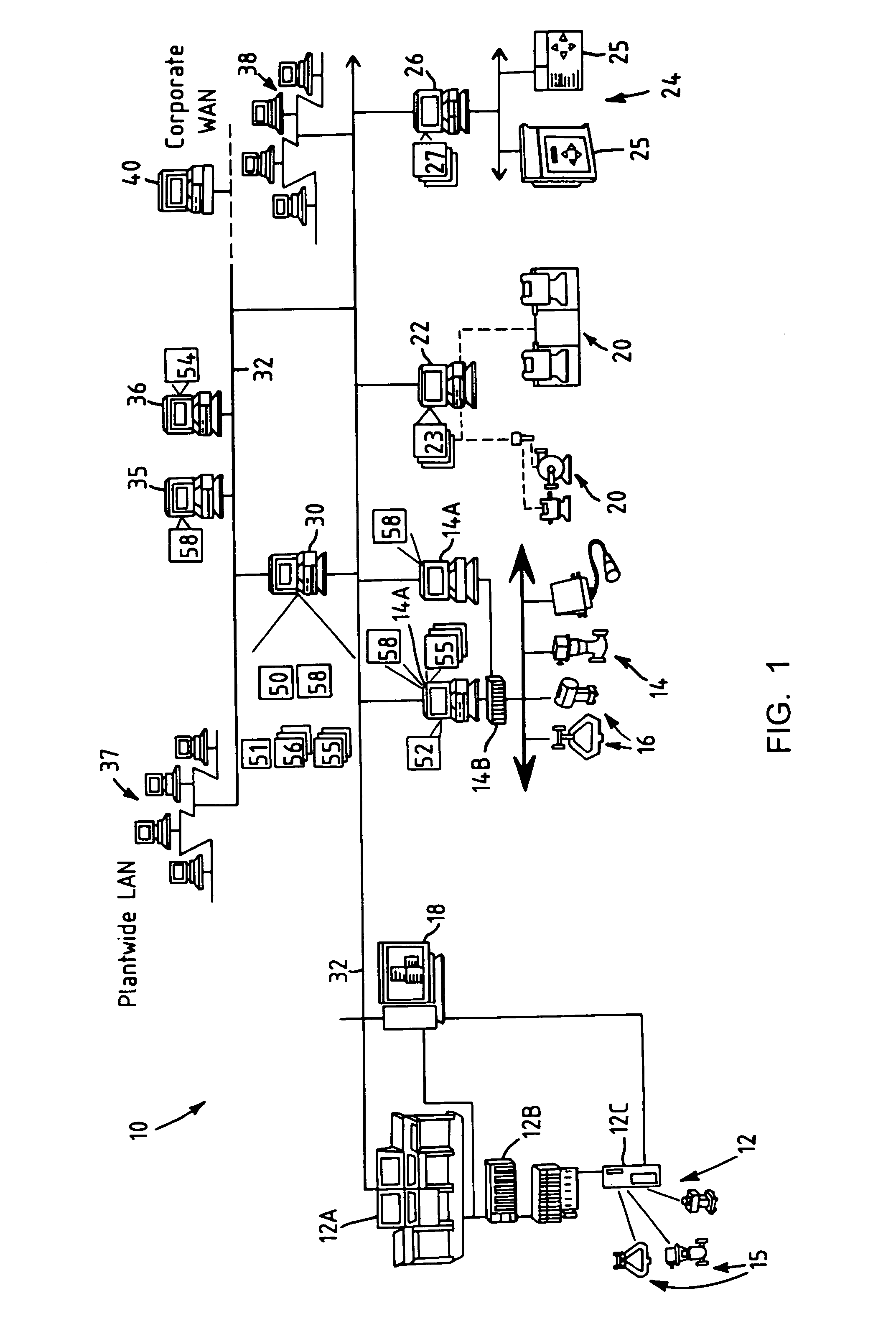

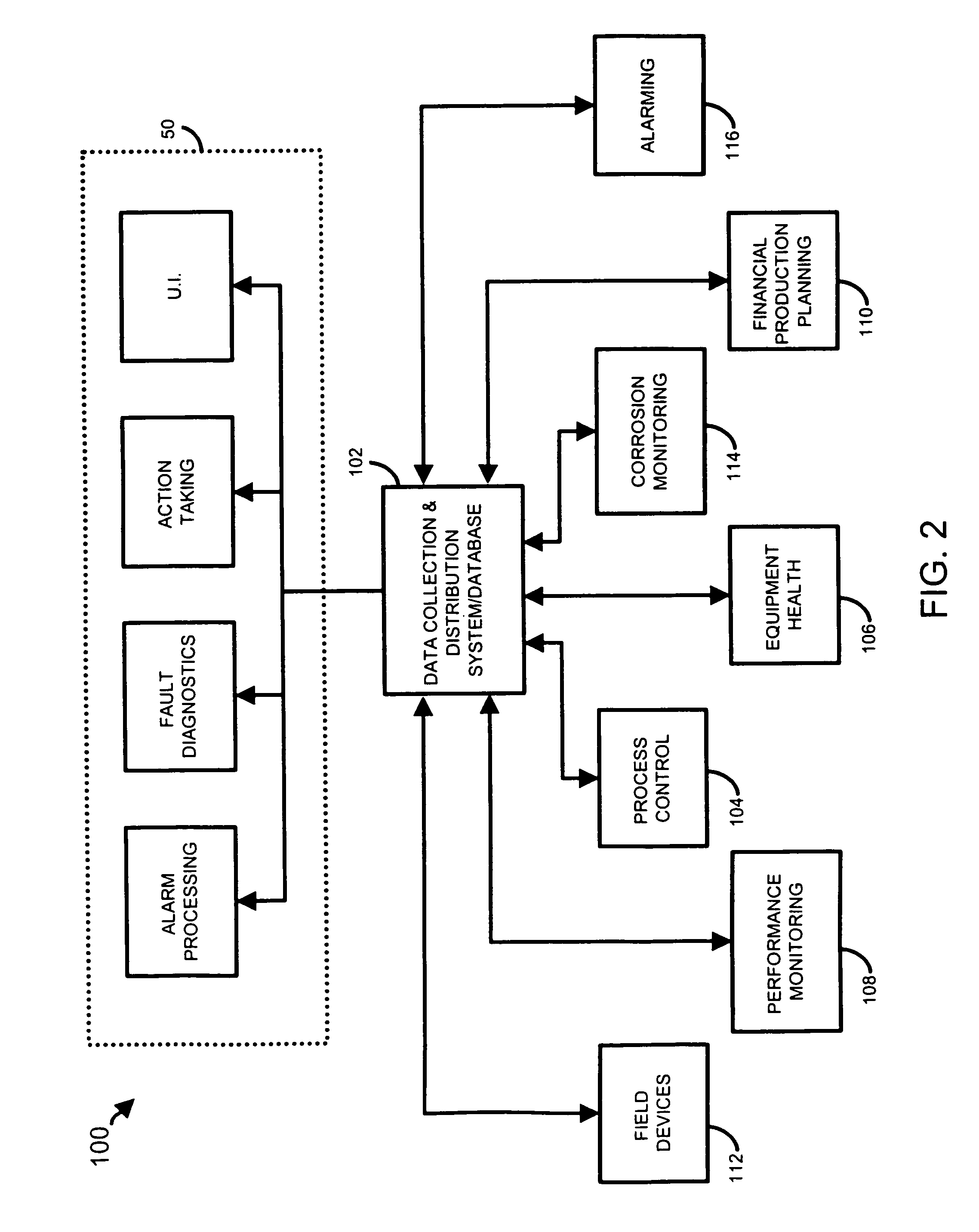

Method and apparatus for performing a function in a plant using process performance monitoring with process equipment monitoring and control

InactiveUS7206646B2Easy to operateBetter stateSafety arrangmentsCatalytic crackingProcess equipmentOptimal control

A process control system uses a data collection and distribution system and an asset utilization suite to collect data or information pertaining to the assets of a process plant from various sources or functional areas of the plant including, for example, the process control functional areas, the maintenance functional areas and the process performance monitoring functional areas. This data and information is manipulated in a coordinated manner by the data collection and distribution system and is redistributed to other applications where this it is used to perform overall better or more optimal control, maintenance and business activities. Information or data may be collected by maintenance functions pertaining to the health, variability, performance or utilization of a device, loop, unit, area, etc. and this information may then be sent to and displayed to a process operator or maintenance person to inform that person of a current or future problem. A user interface is provided that enables users to access and manipulate the expert engine to optimize plant operation or cause optimization of plant operation, to get information about the operation of the plant, etc. Furthermore, applications, such as work order generation applications may automatically generate work orders, parts or supplies orders, etc. based on events occurring within the plant.

Owner:FISHER-ROSEMOUNT SYST INC

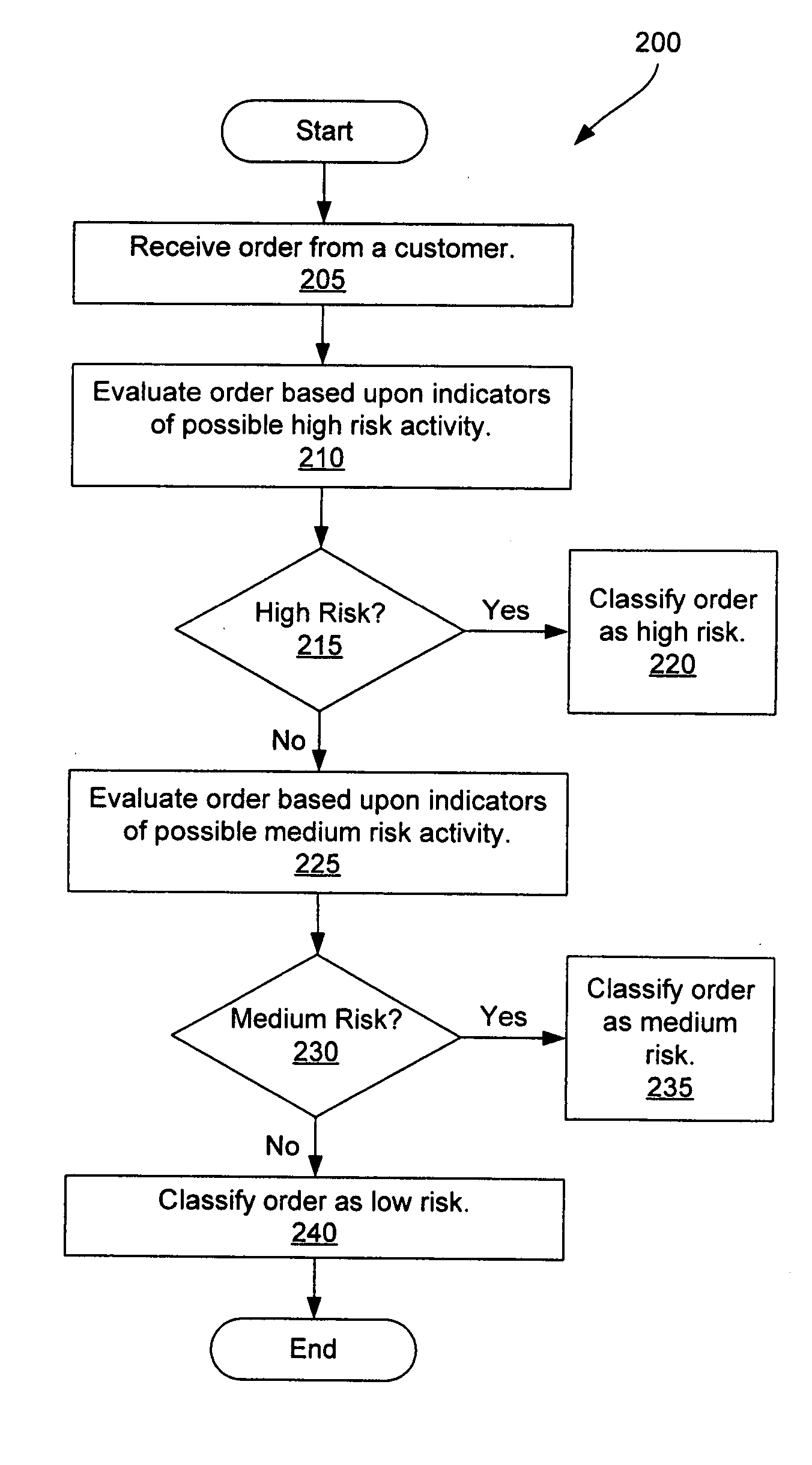

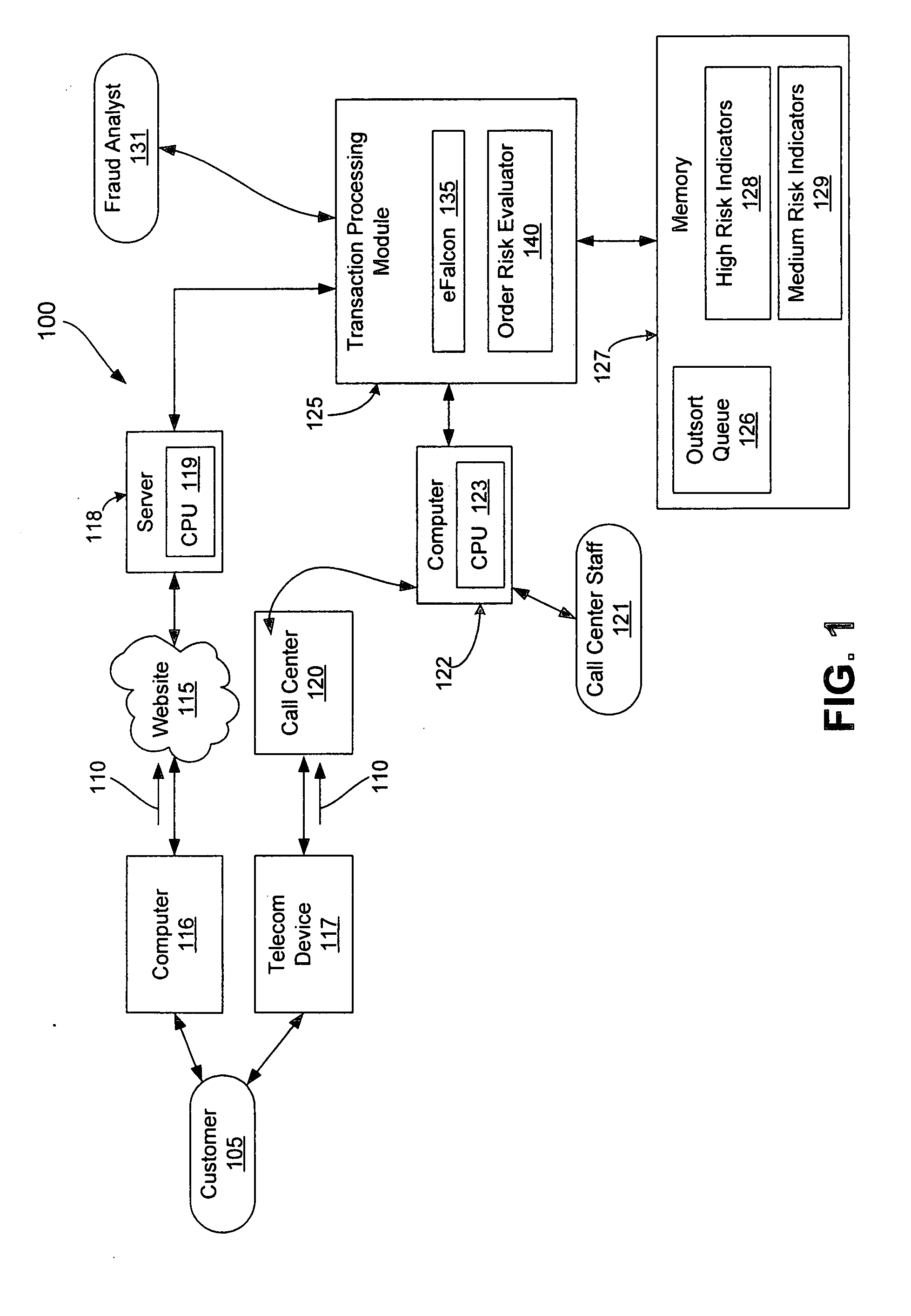

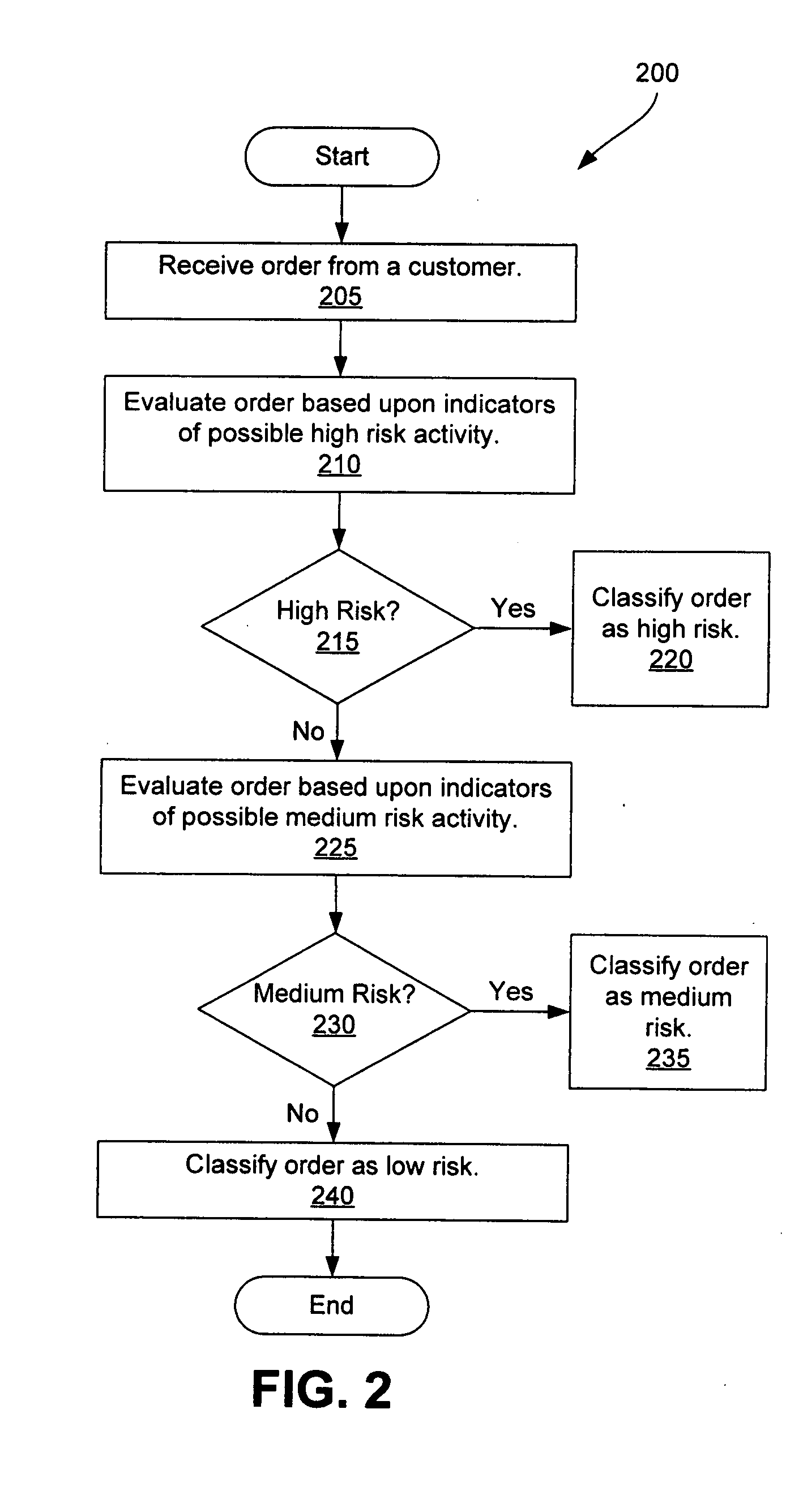

Order risk determination

InactiveUS20050108178A1Readily apparentPayment architectureBuying/selling/leasing transactionsMedium RiskLower risk

In one embodiment, the invention provides a method of determining a risk for fraud for an order, including: receiving an order from a customer; evaluating an order based upon indicators of possible high risk activities; if the order is not classified as a high risk order, then evaluating the order based upon indicators of possible medium risk activities; and if the order is not classified as a medium risk activity, then classifying the order as a low risk order.

Owner:HEWLETT PACKARD CO

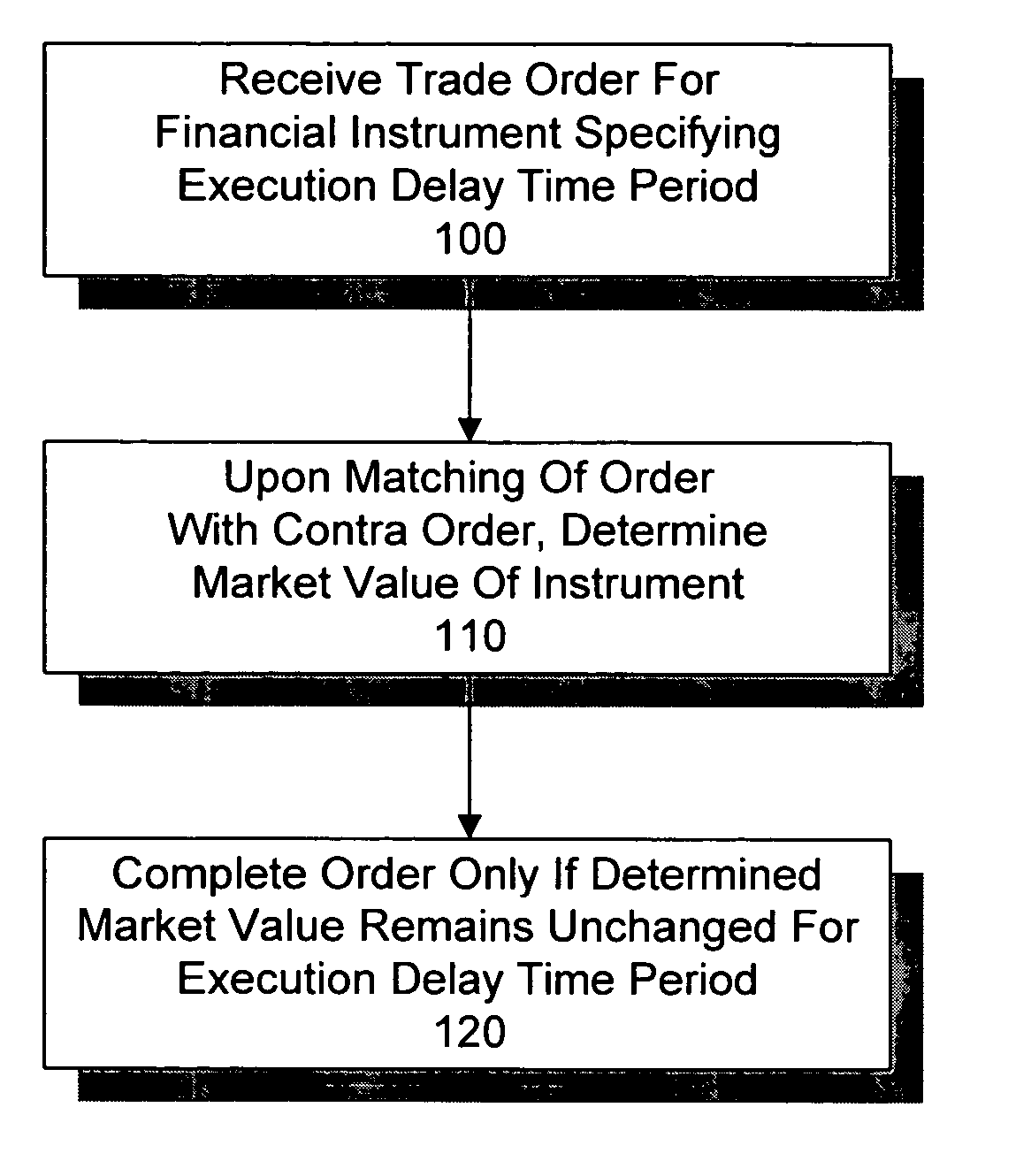

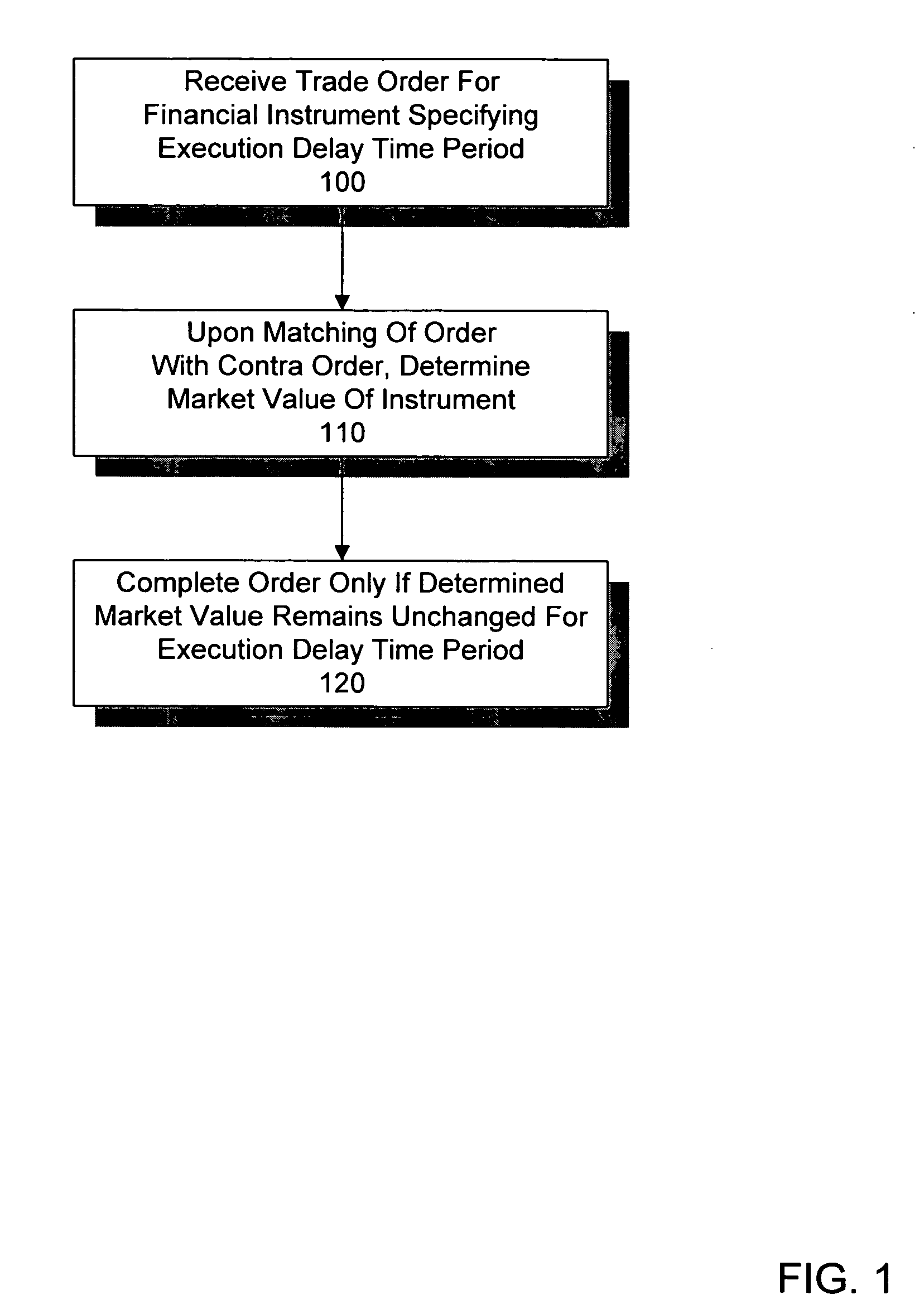

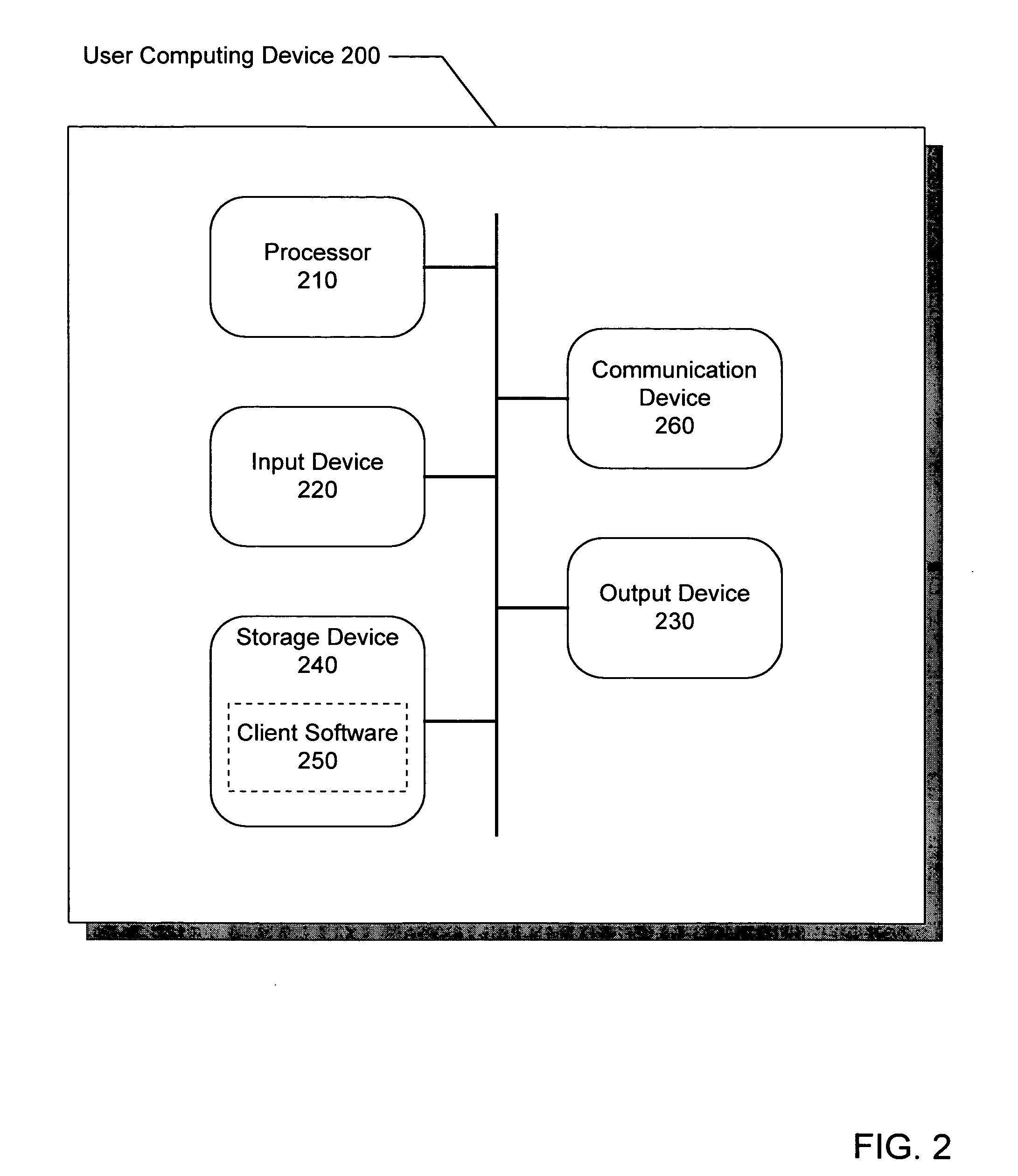

System and method for execution delayed trading

InactiveUS20050075963A1Low costImprove liquidityFinanceSpecial data processing applicationsTemporal informationOrder form

Owner:DEEP LIQUIDITY

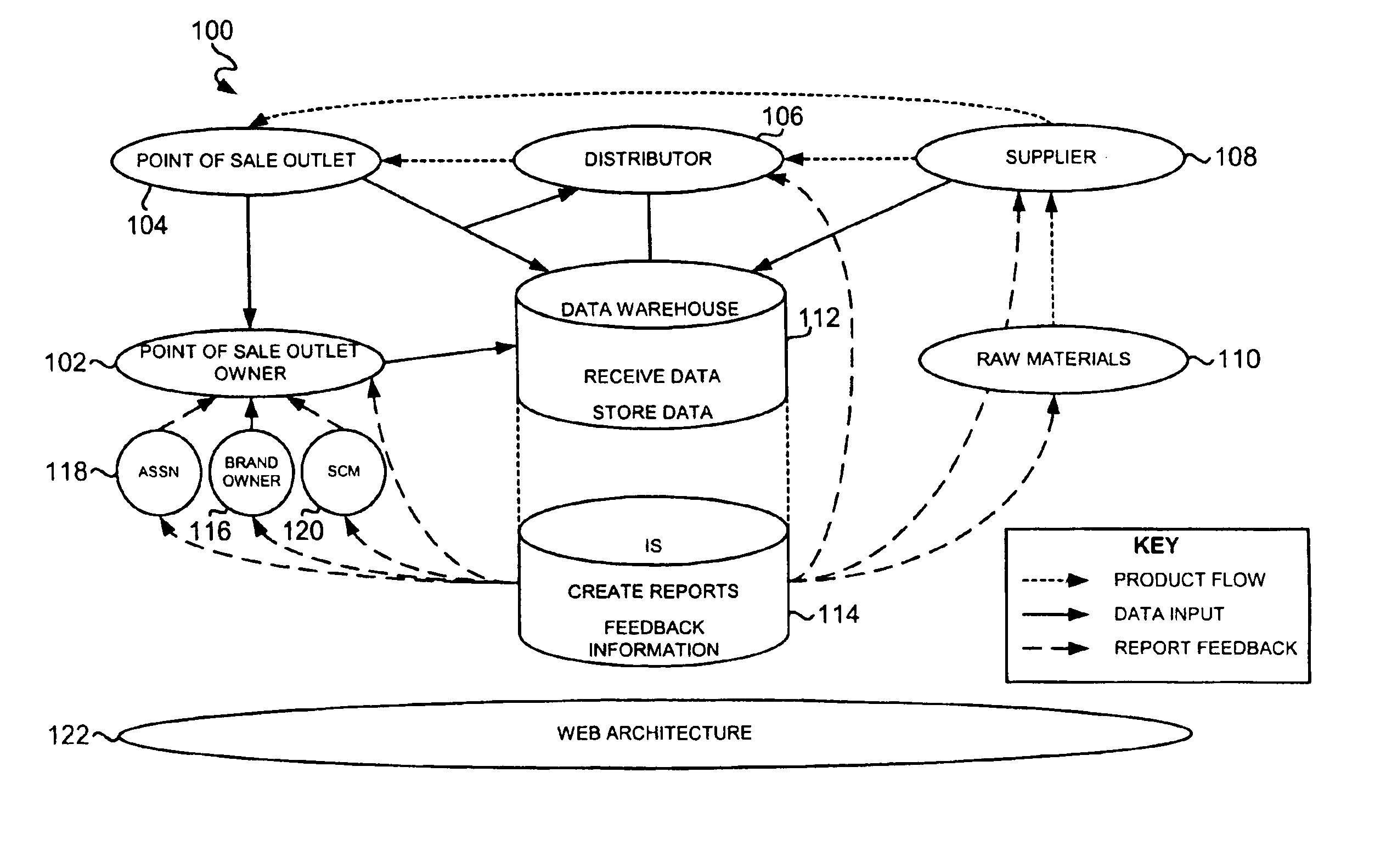

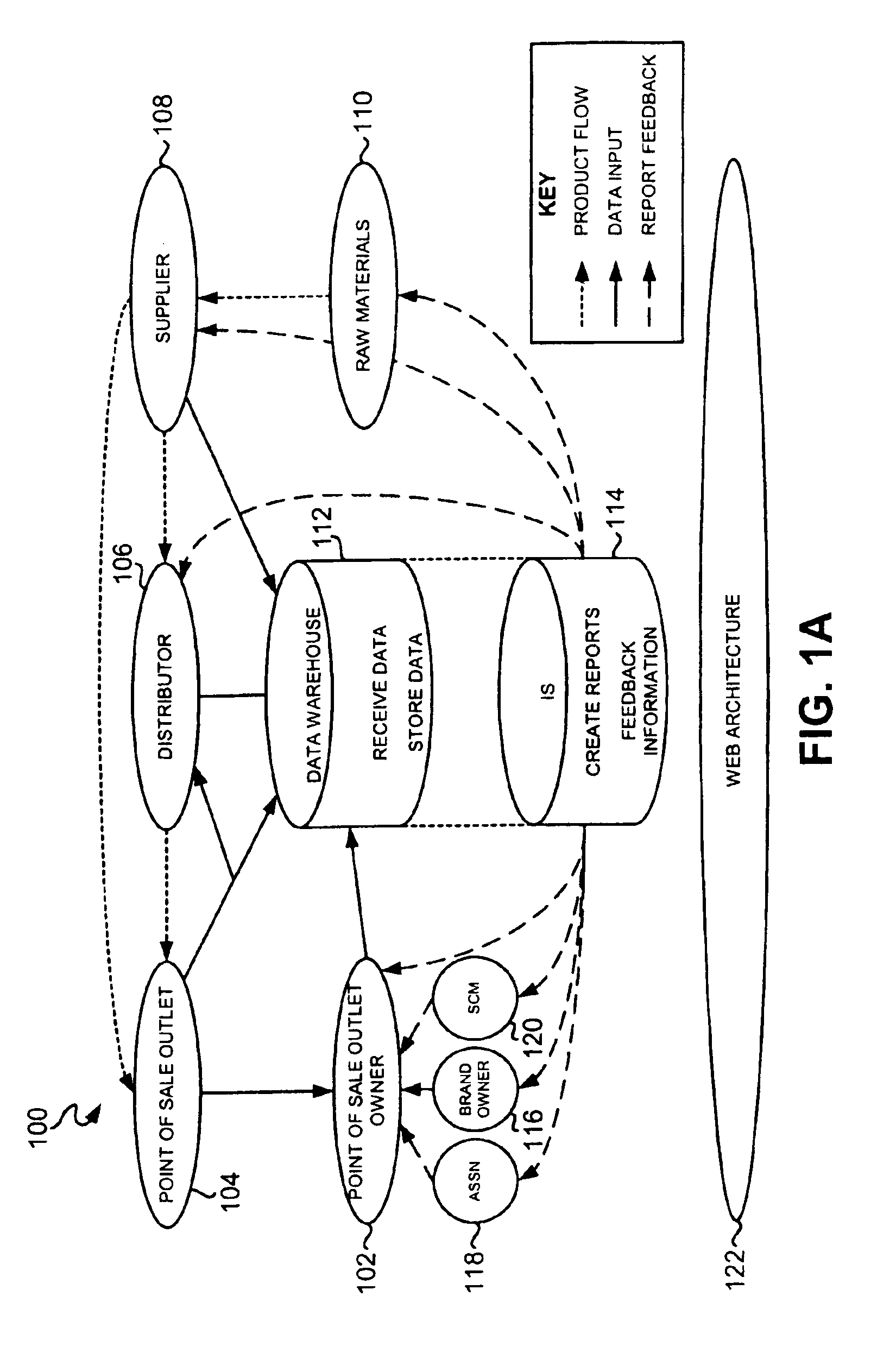

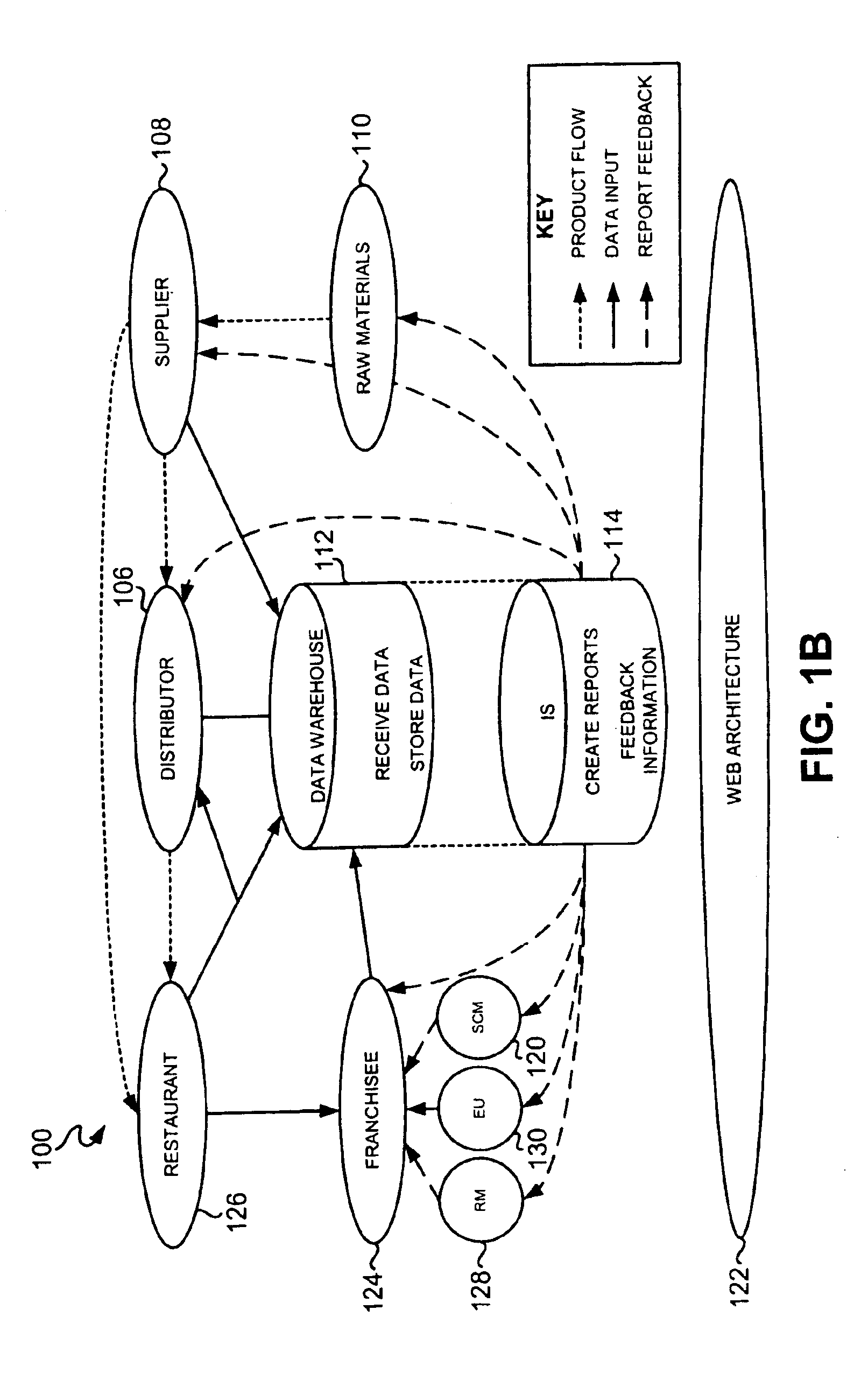

System, method and computer program product for order confirmation in a supply chain management framework

InactiveUS6954736B2Hand manipulated computer devicesBuying/selling/leasing transactionsOrder formDistributor

A system, method and computer program product are disclosed for order confirmation in a supply chain management framework. A network is utilized to collect from a plurality of stores of a supply chain data relating to the sale of goods by the stores. Access is allowed to the data utilizing a network-based interface. Electronic order forms are generated based on the data for ordering goods from a plurality of distributors of the supply chain. These electronic order forms request a confirmation of the receipt of the electronic order forms. A determination is made as to whether the confirmation of the receipt of the electronic order forms is received from the distributors. If it is determined that the confirmation of the receipt of the electronic order forms was not from the distributors, then an alert is generated.

Owner:RESTAURANT SERVICES

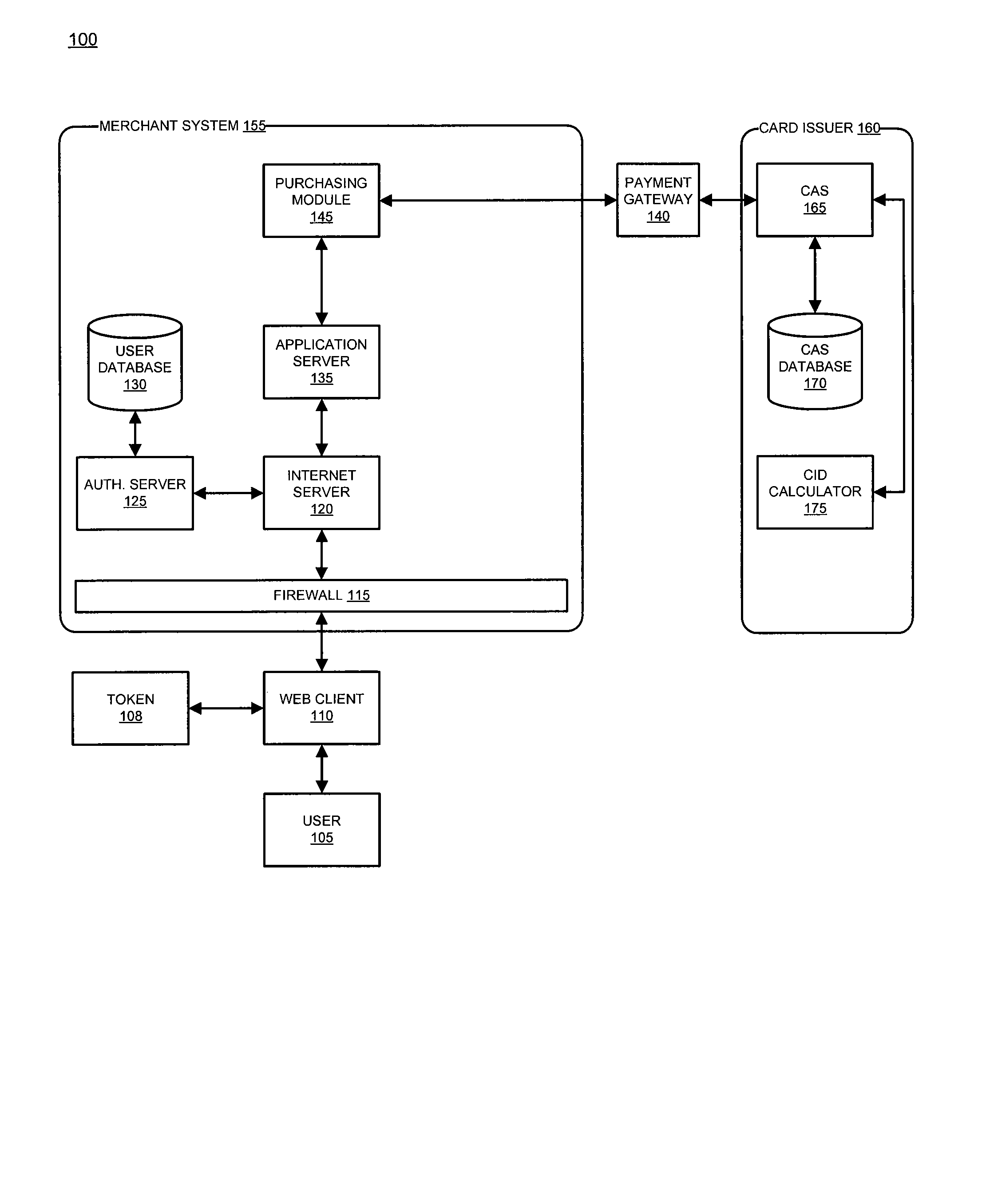

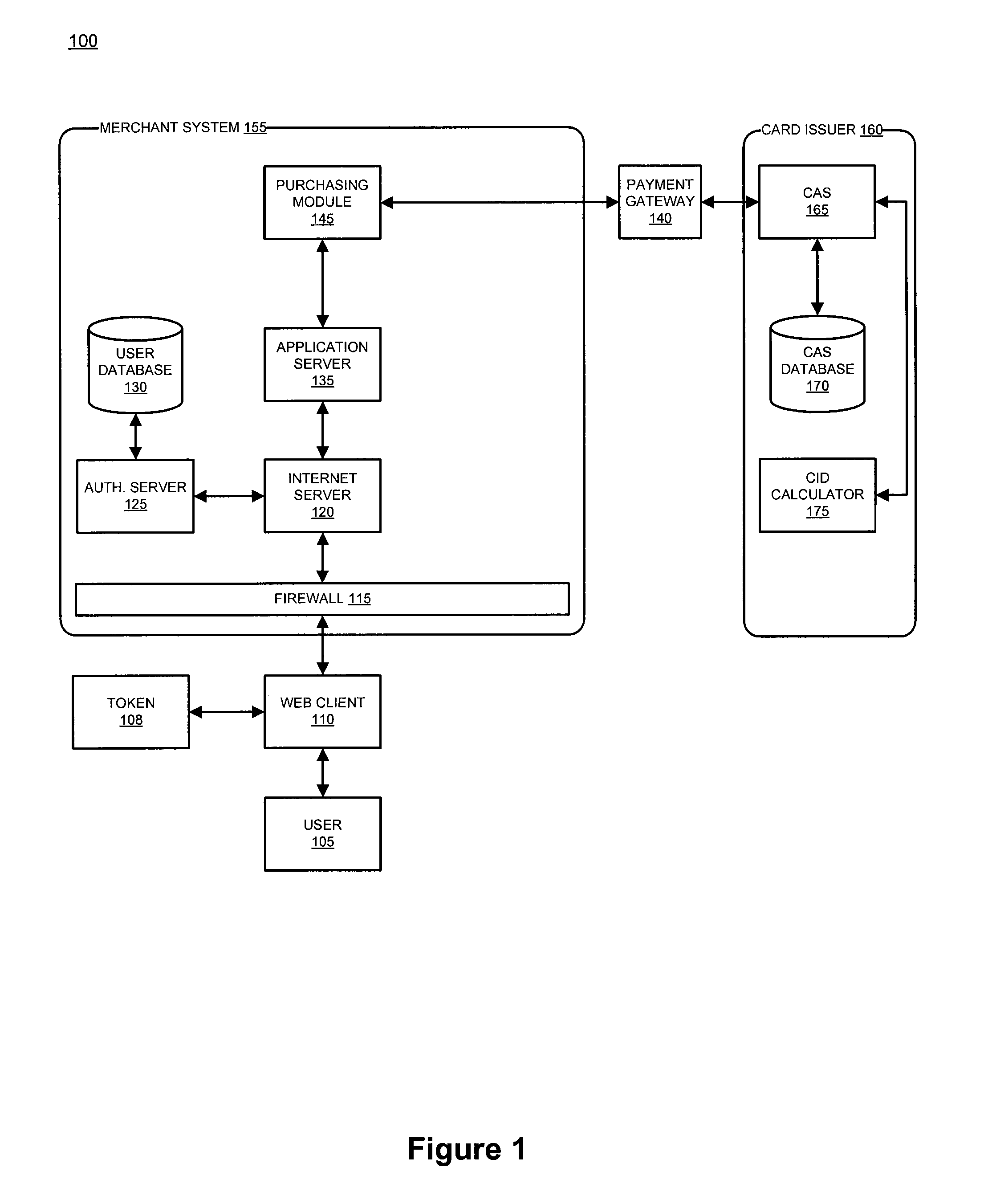

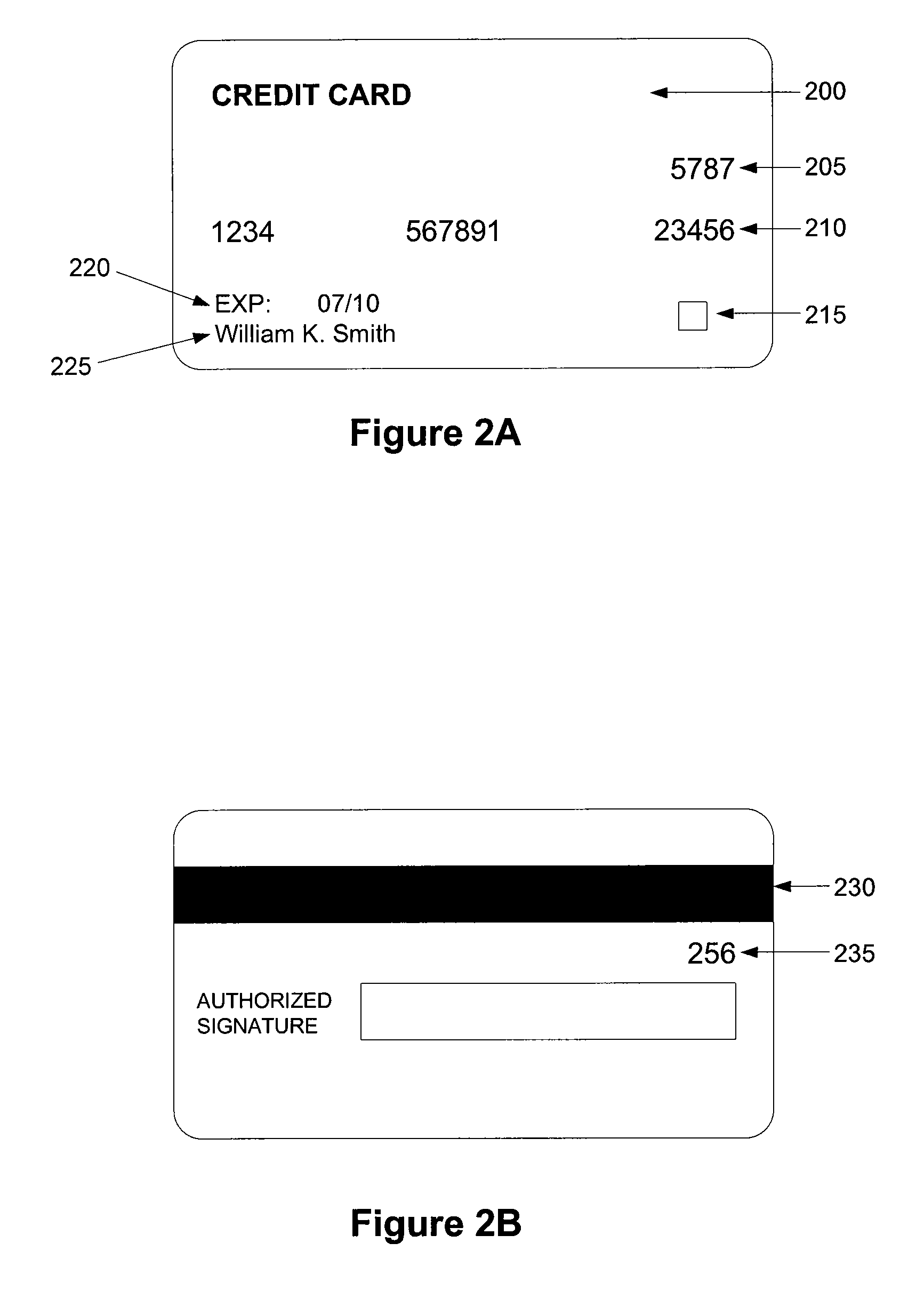

System and method for facilitating a financial transaction with a dynamically generated identifier

Owner:LIBERTY PEAK VENTURES LLC

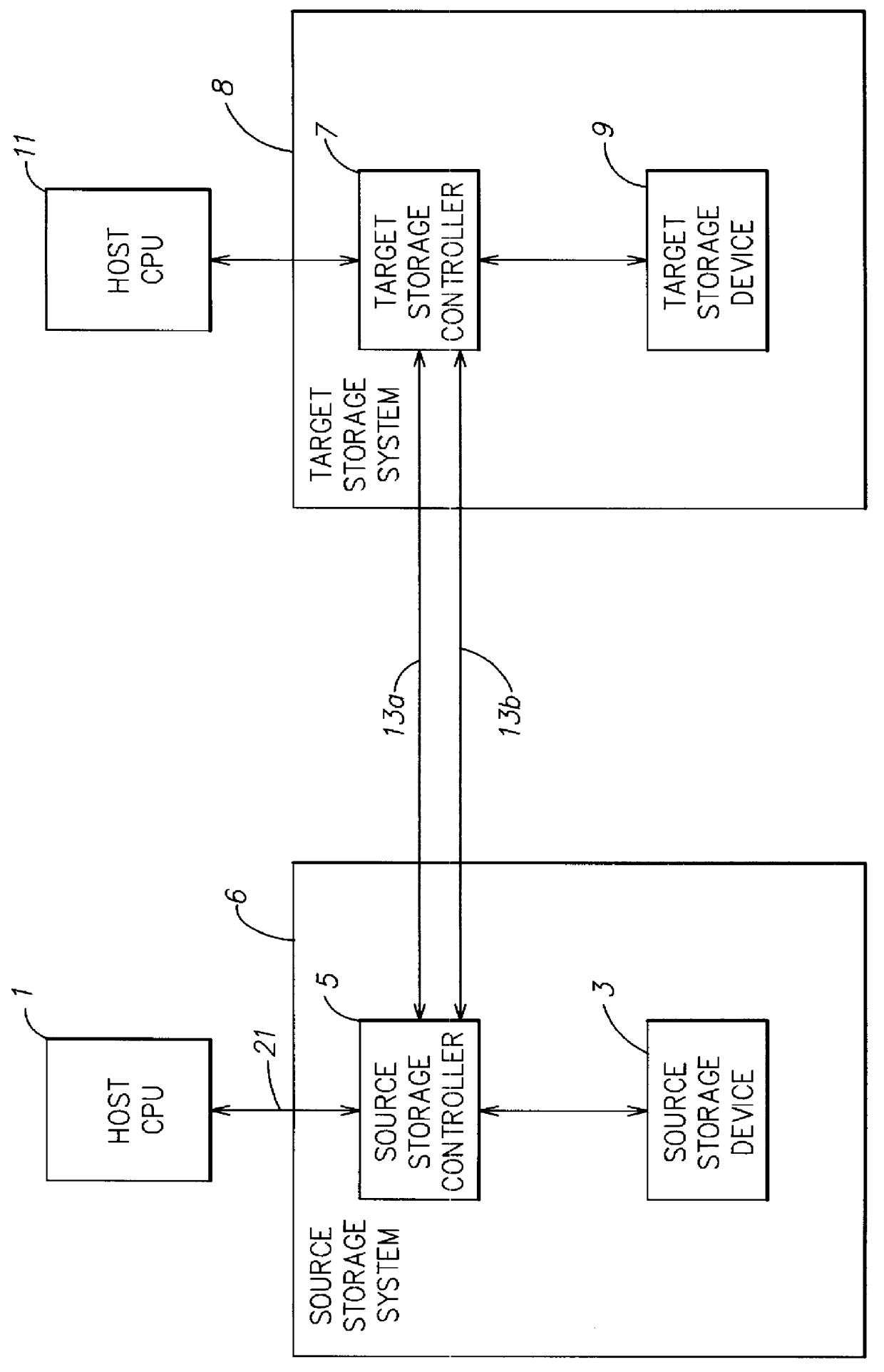

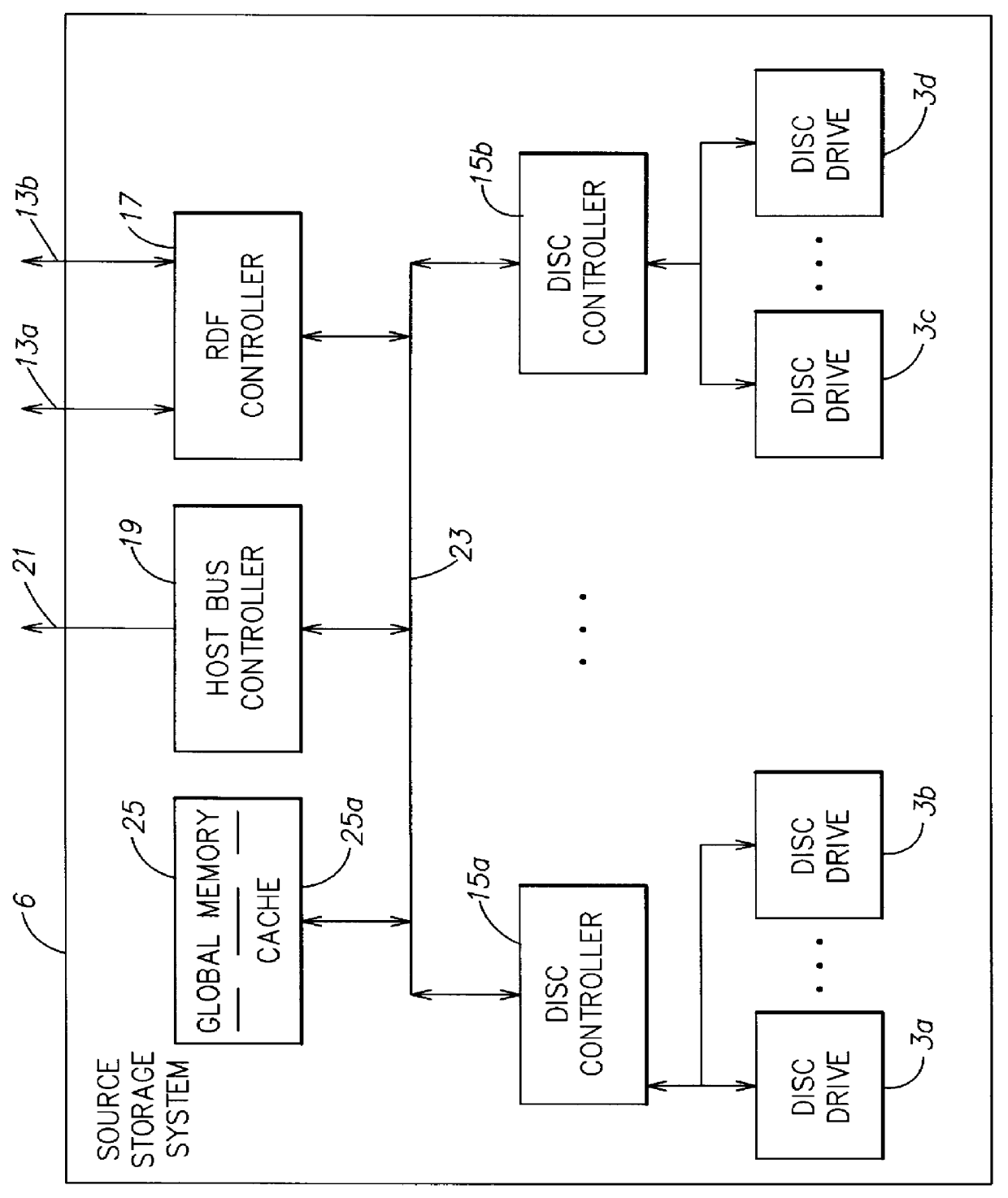

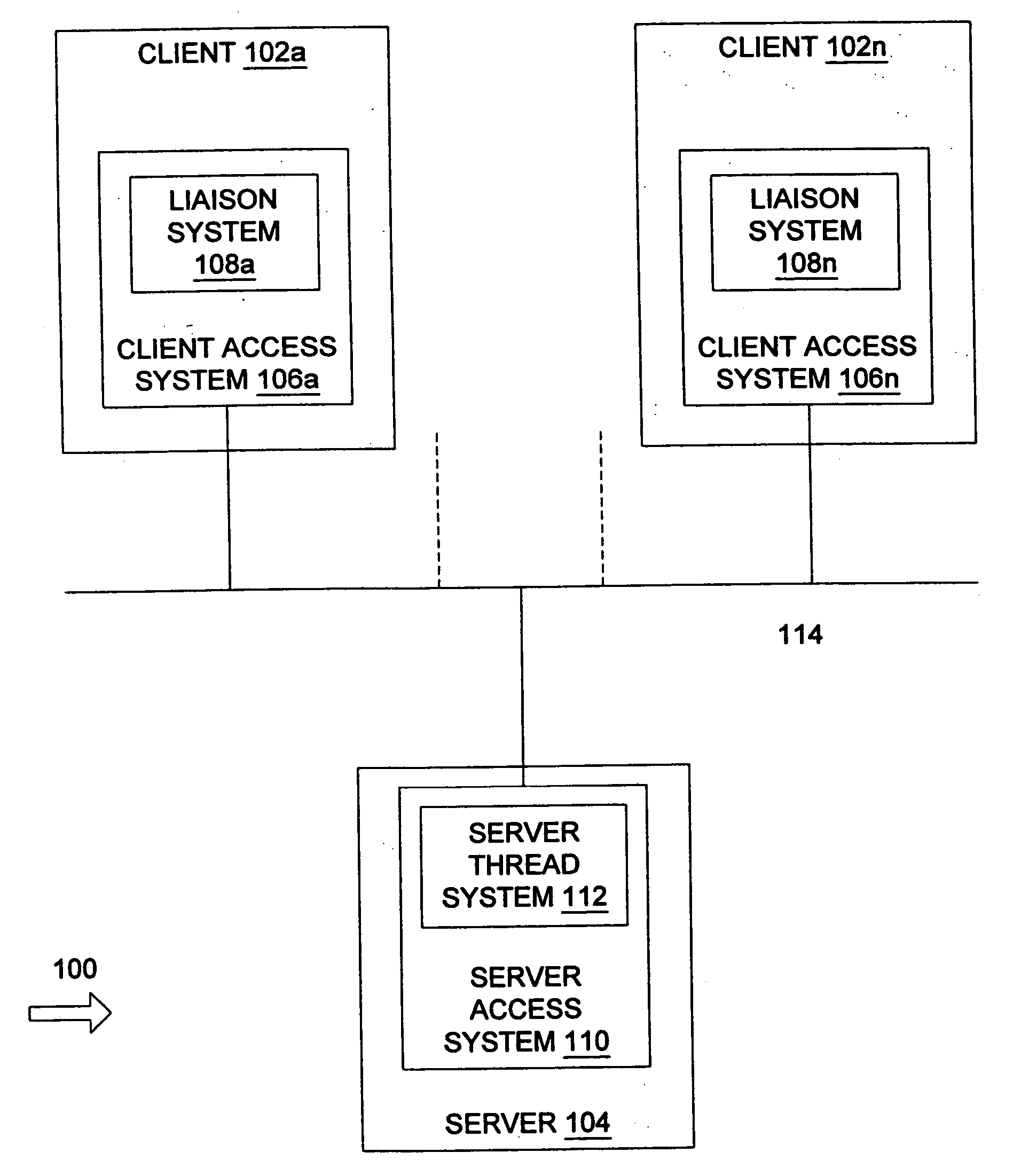

Method and apparatus for asynchronously updating a mirror of a source device

InactiveUS6157991AInput/output to record carriersMemory loss protectionComputer hardwareTelecommunications link

In a computer system including a CPU, a first storage system coupled to the CPU, a second storage system, and a communication link coupling the second storage system to the first storage system, a method and apparatus for asynchronously mirroring, to the second storage system, a plurality of units of data written by the CPU to the first storage system. In one aspect of the invention, the CPU writes units of data to the first storage system in a first order, and the units of data are asynchronously transmitted over the communication link from the first storage system to the second storage system in a second order that is different than the first order. In another aspect, the units of data are committed in the second storage system in an order that is independent of the order in which the units of data are received at the second storage system. In a further aspect of the invention, a packet of information is transmitted over the communication link to the target storage system to specify a commitment order in which the units of data should be committed in the target storage system. In another aspect of the invention, a single copy of each of the units of data is written into the first storage device, without buffering a copy to support asynchronous mirroring. In a further aspect, the storage locations in the first storage system are organized into a plurality of consistency sets, and the units of data are asynchronously transmitted over the communication link so that each consistency set has a representation in the second storage system that is consistent with a valid representation of the consistency set in the first storage system at some point in time.

Owner:EMC IP HLDG CO LLC

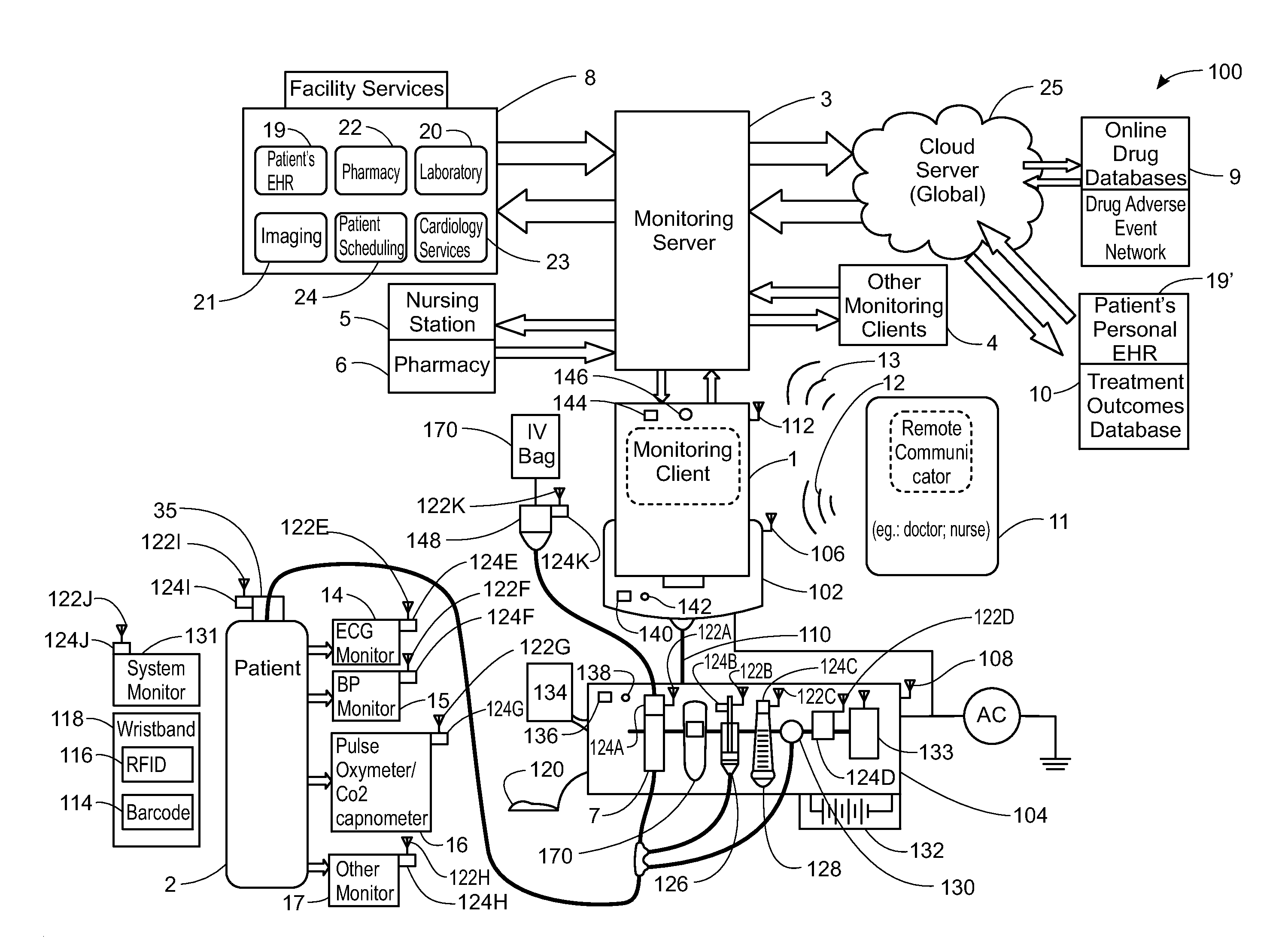

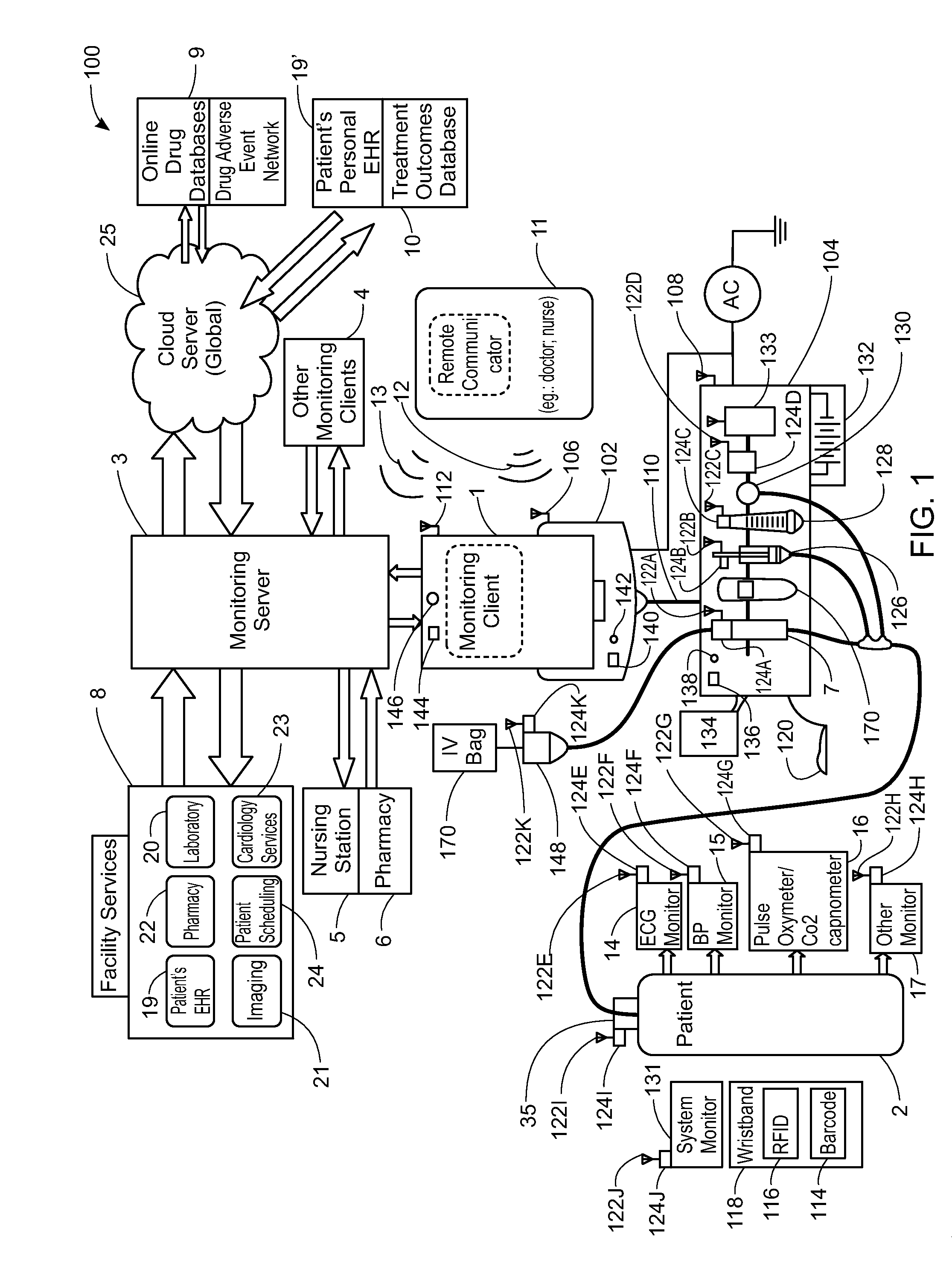

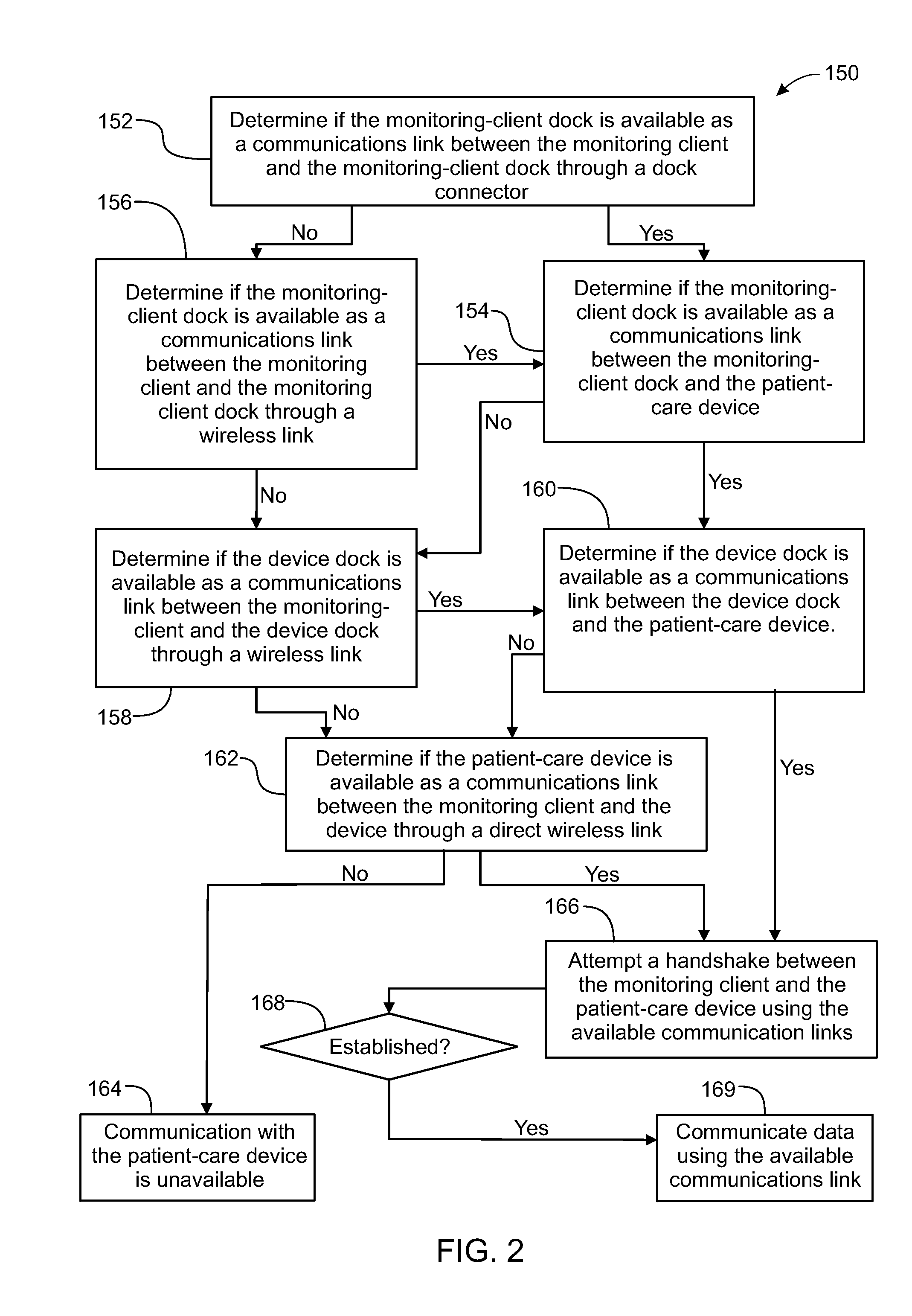

System, Method, and Apparatus for Electroinic Patient Care

ActiveUS20130297330A1Quantity minimizationMechanical/radiation/invasive therapiesDrug and medicationsOrder formMonitoring system

An electronic patient monitoring system includes first and second modules. The first module is configured to receive and store information pertaining to a patient, said information including data related to a first parameter of the patient measured by a device connected to the patient, and data related to a second parameter of the patient received from a first database containing information about the patient. The second module is configured to receive a medication order from a user via a user interface associated with the second module, said second module being further configured to transmit said treatment order to the first module.

Owner:DEKA PROD LLP

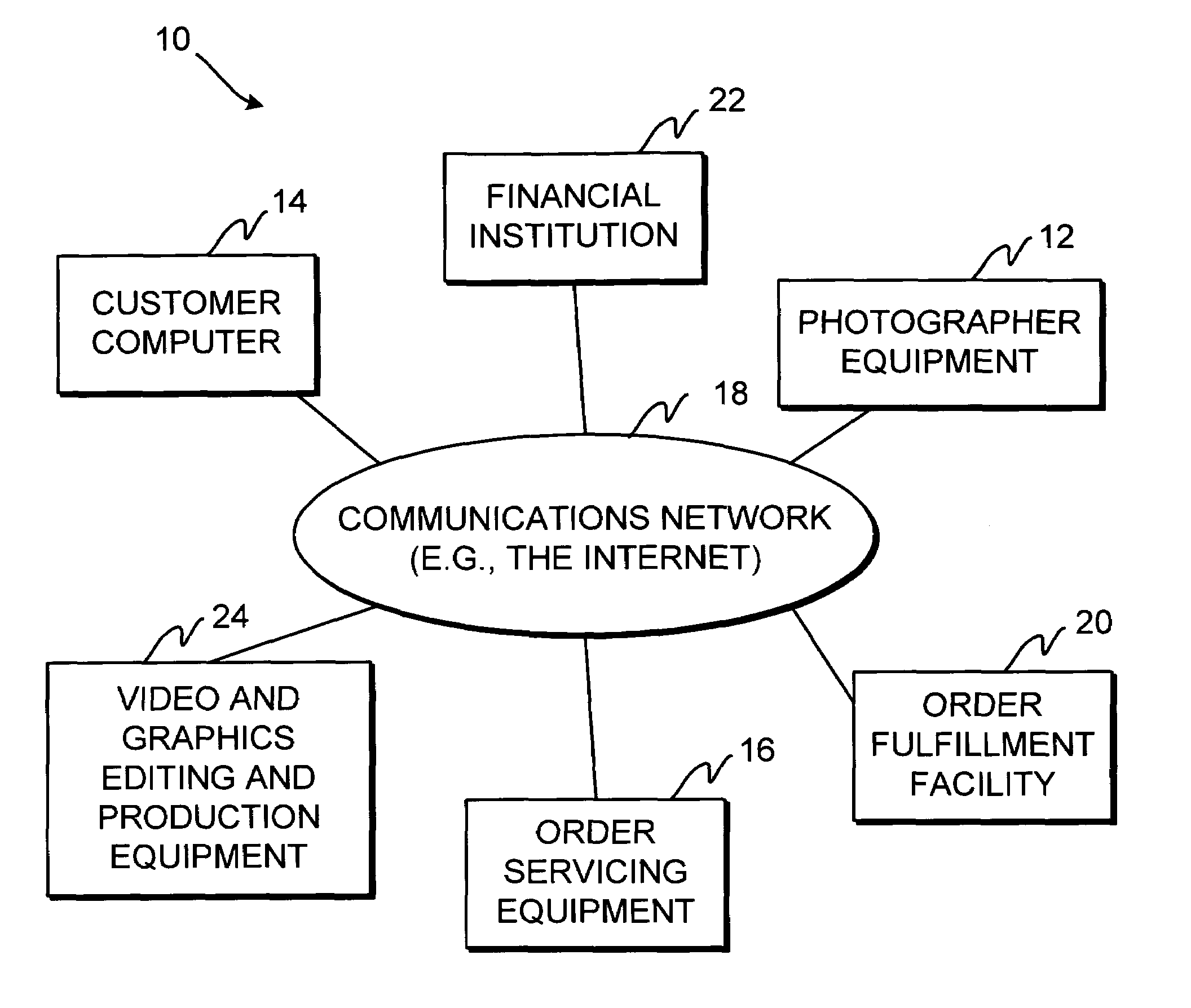

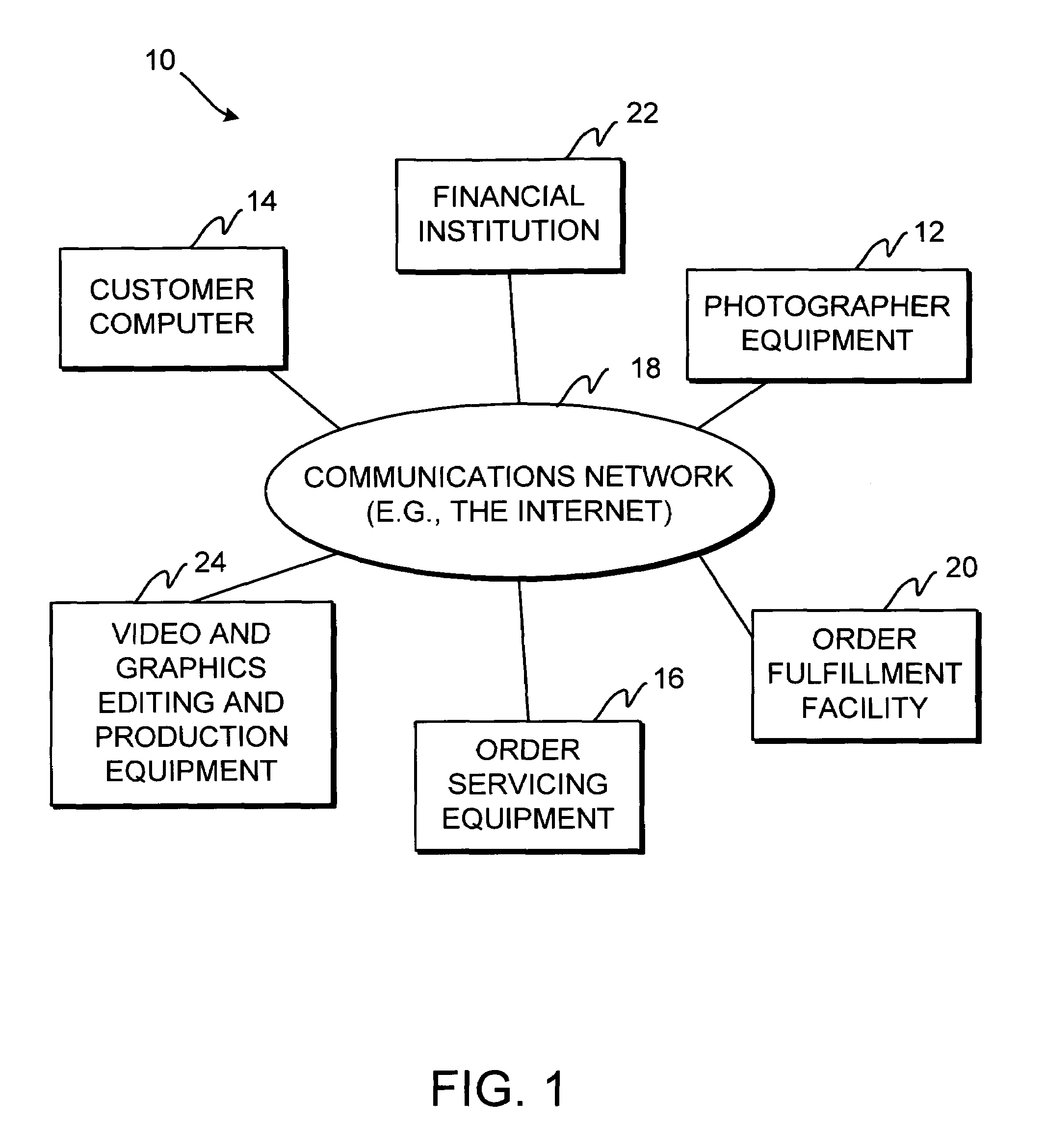

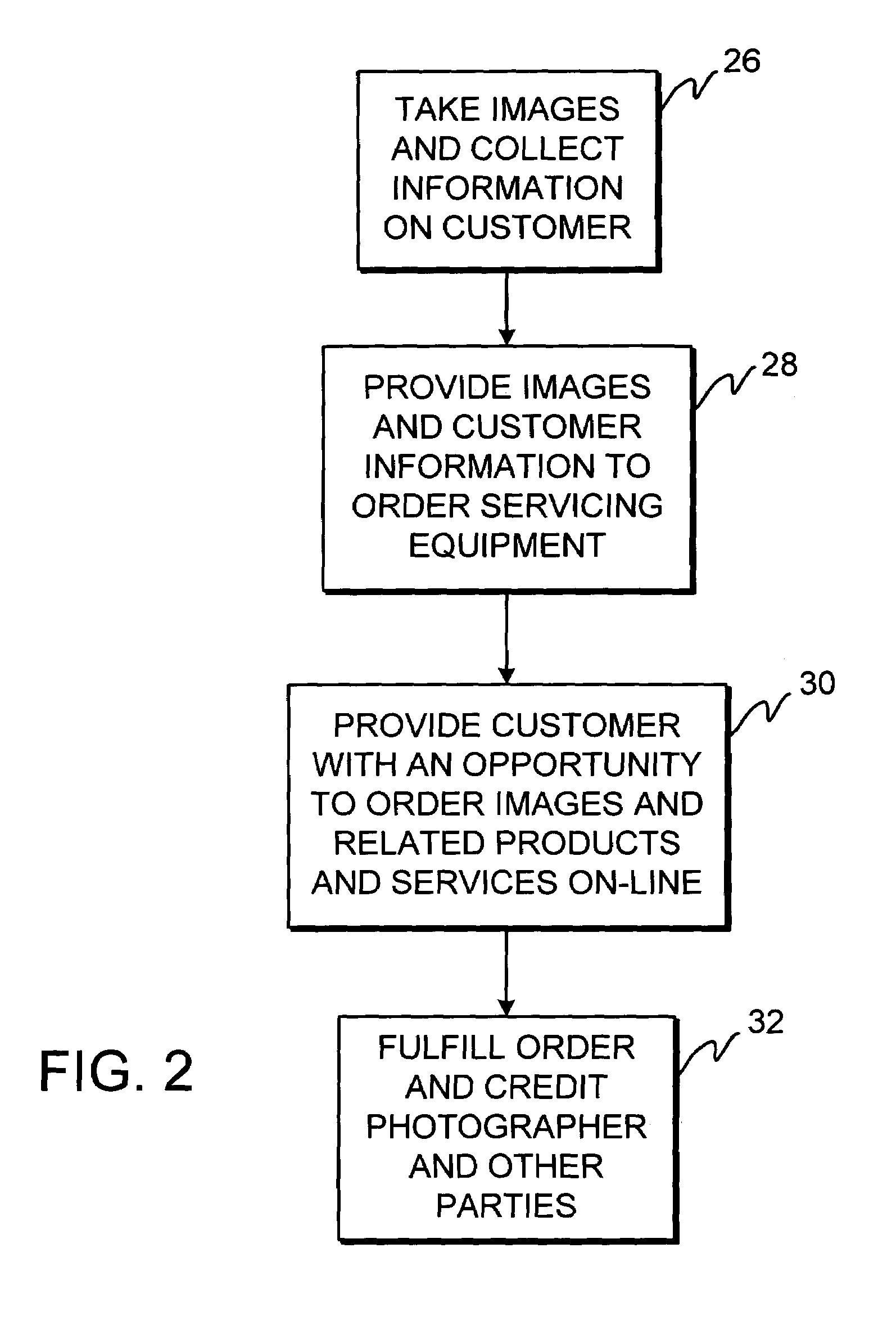

Online digital image-based product ordering system

InactiveUS7343320B1Image changeProcessingVisual presentationServicing equipmentComputer graphics (images)

A system is provided that allows a photographer to take images for a customer and provide those images to order servicing equipment with which the images are placed on-line for the customer to view. The customer may place orders for the images and products and services related to the images. The order servicing equipment may credit the photographer when the customer orders images, products, or services. Images may be manipulated before images, products, or services are ordered. Images may be taken using film-based cameras or digital image acquisition equipment. Image presentation options may be selected. Content may be appended to the images. Web sites and digital albums may be created using the images. The photographer may check the status of assignments that have been submitted to the order servicing equipment and may check on account status. Different rights levels may be established for different parties. Loyalty rewards may be awarded for frequent use of the system.

Owner:LG ELECTRONICS INC

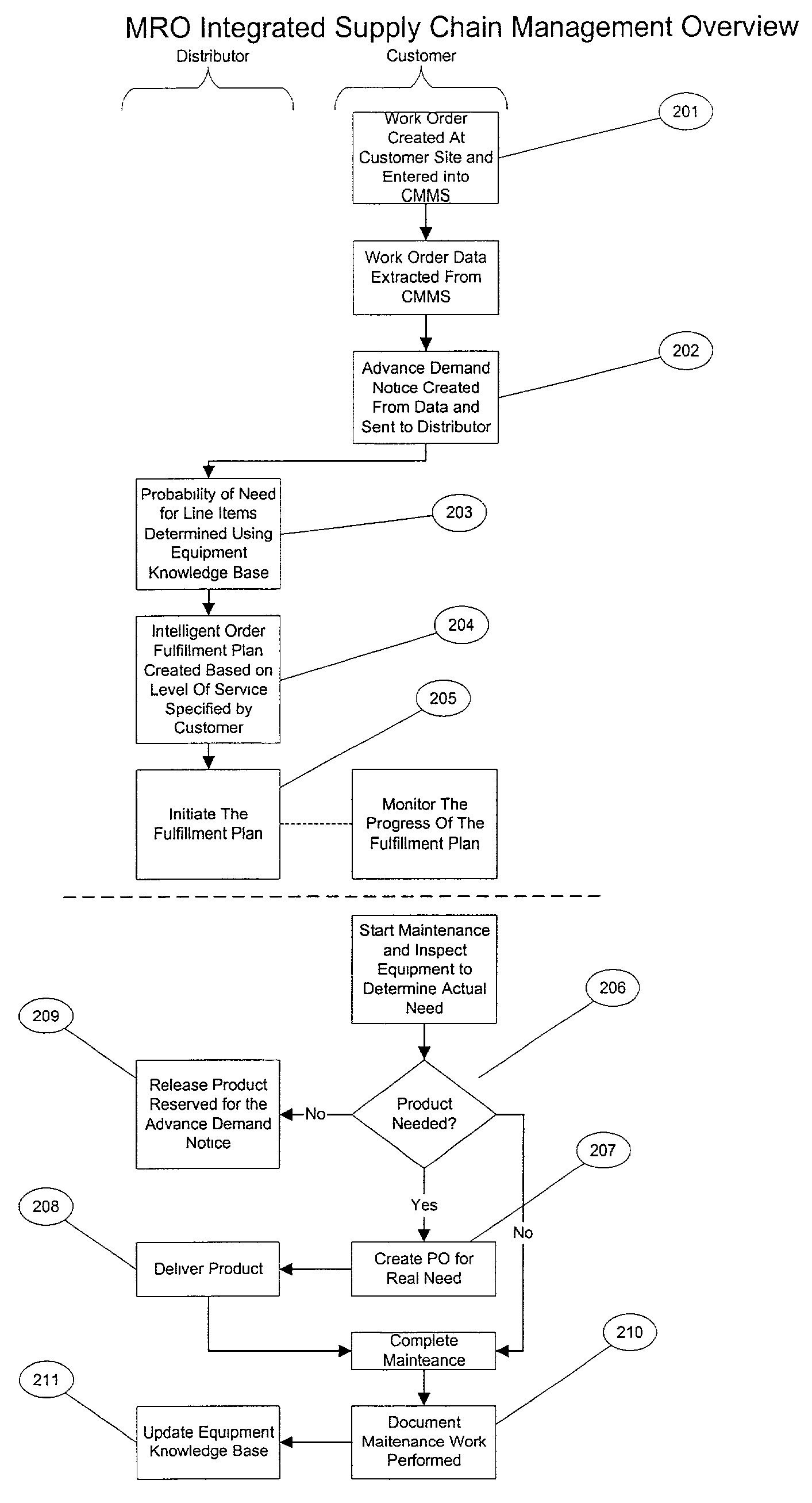

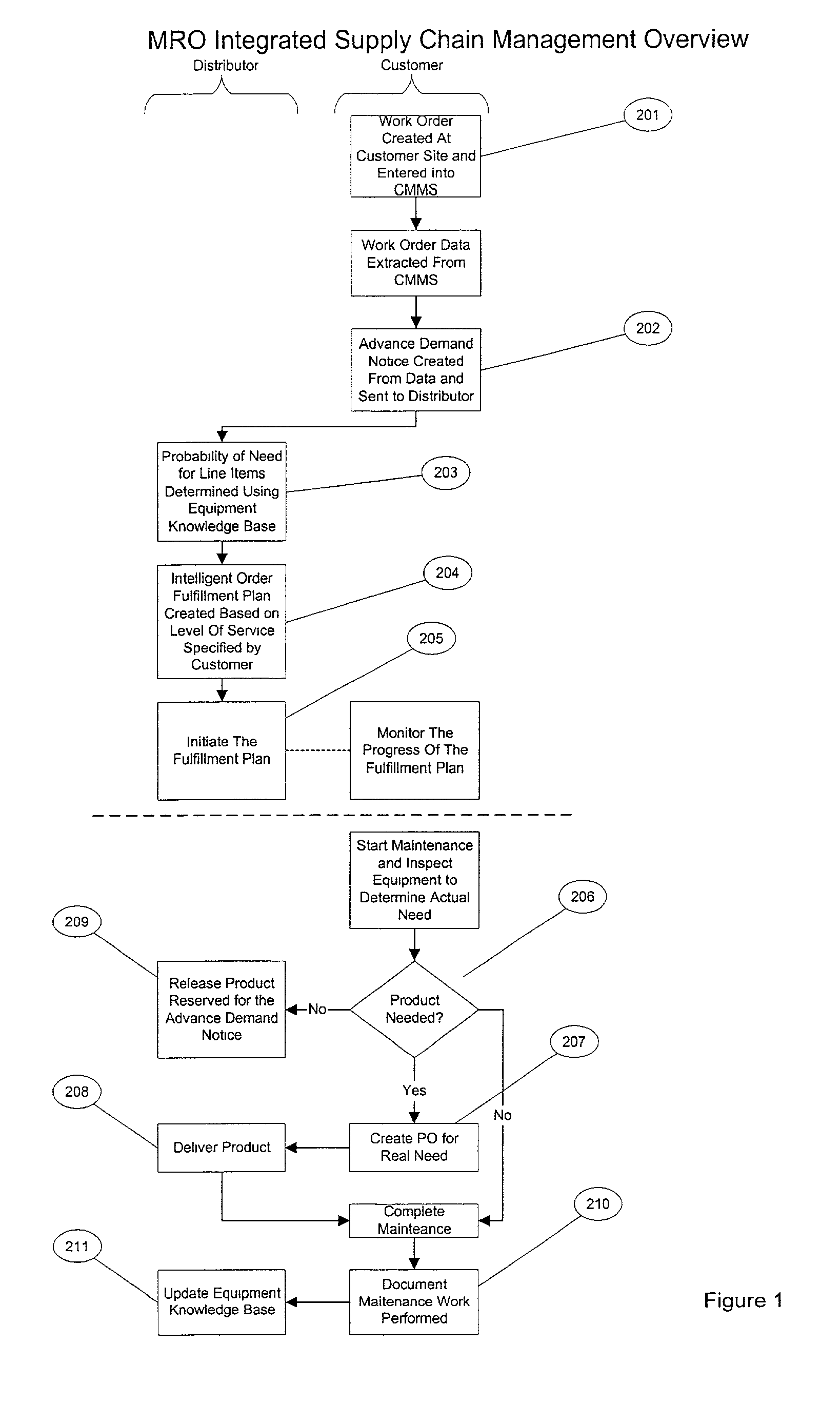

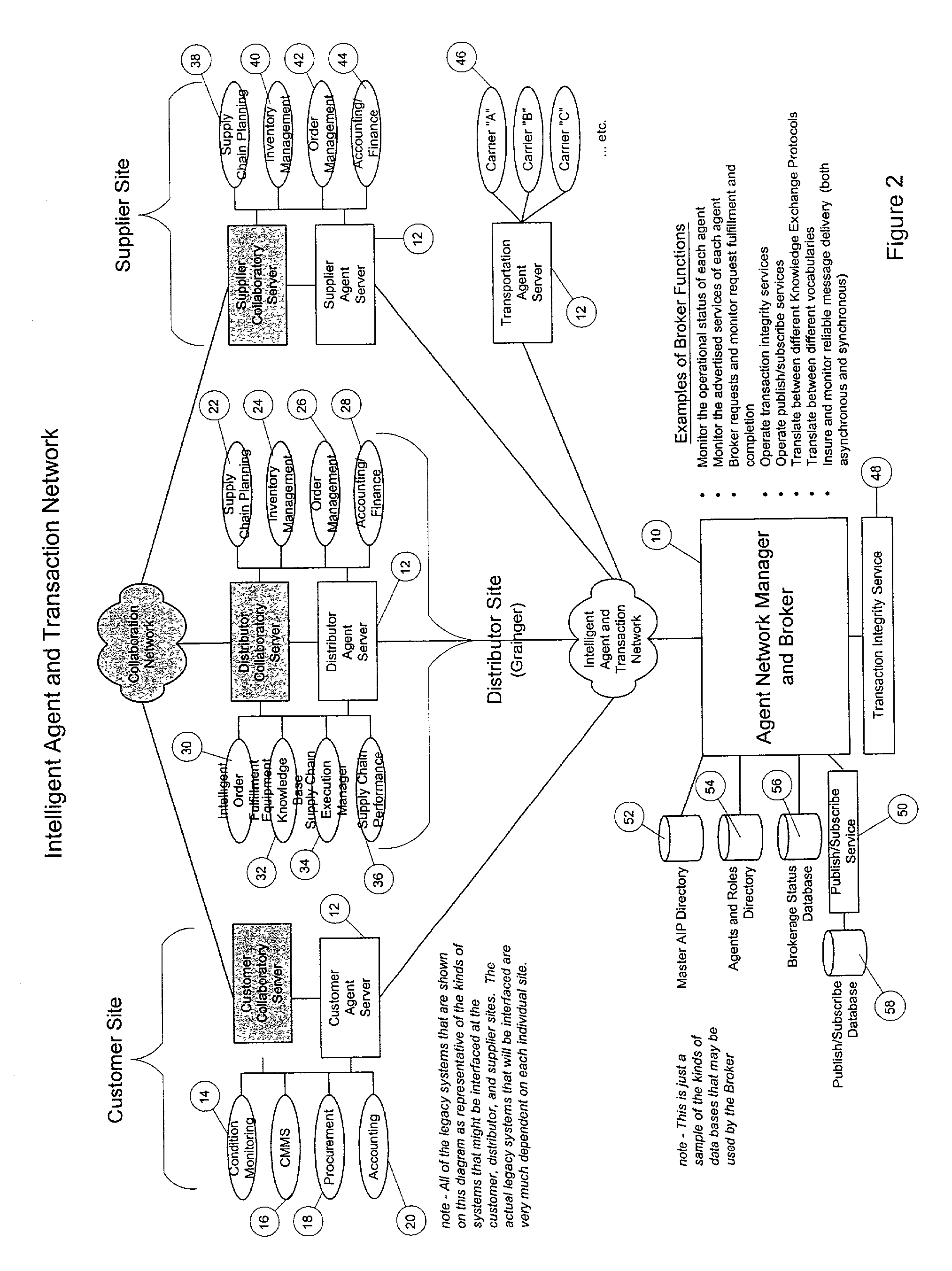

Method for fulfilling an order in an integrated supply chain management system

A method for fulfilling an order in a supply chain. The method is performed by extracting from a customer system information pertaining to the work order that specifies a piece of equipment to be repaired and items expected to be used during the repair procedure, determining, using an equipment knowledge base, a probability that each of the items will be needed to effect the repair procedure, and using the determined probability to stage the items within the supply chain whereby the items are made ready for use in the repair procedure. Further steps can include extracting from the customer system information pertaining to a completion of the repair procedure and using the information pertaining to the completion of the repair procedure to populate the equipment knowledge base for use in future probability of need calculations.

Owner:W W GRAINGER

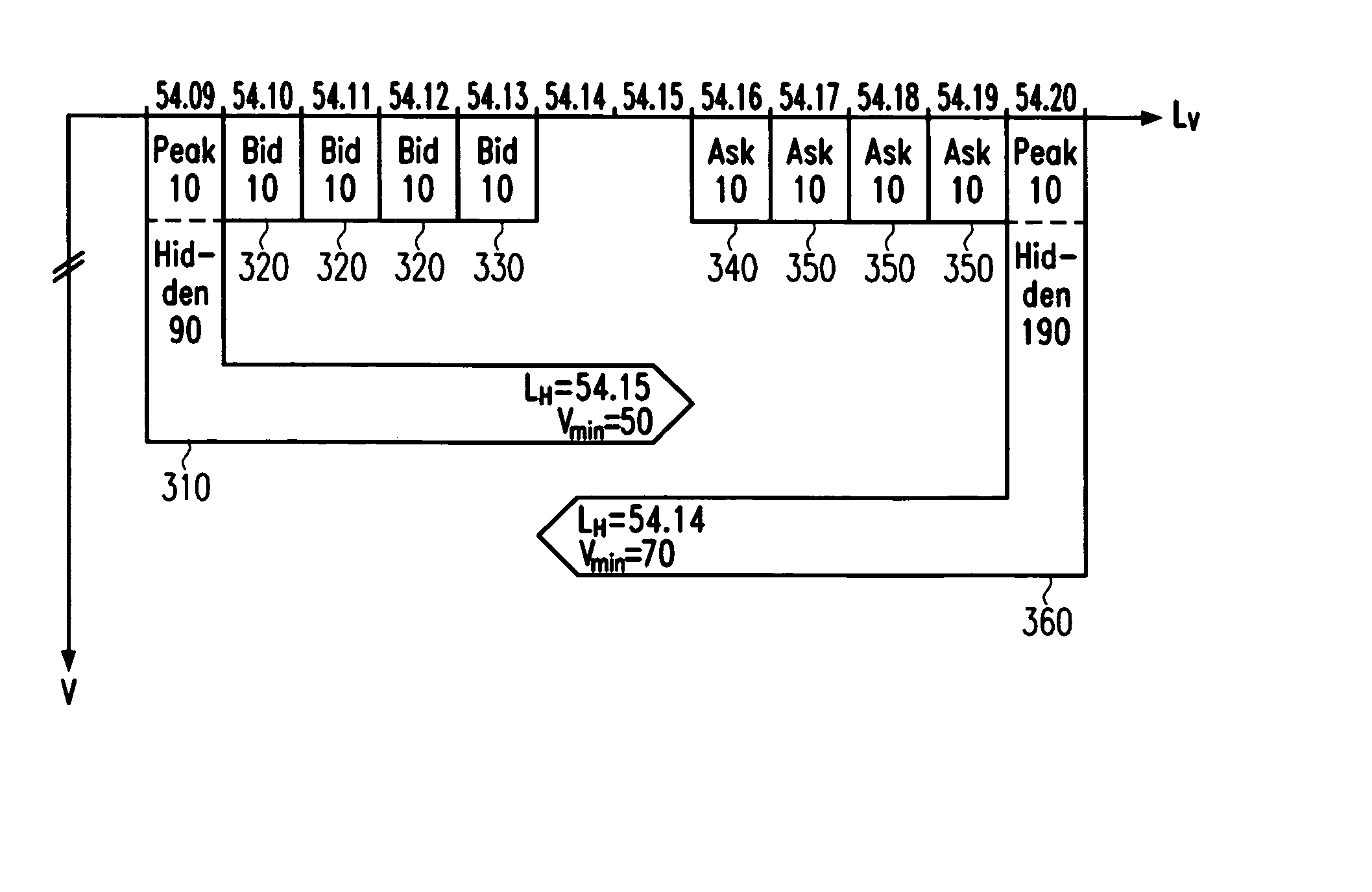

Integrated order matching system combining visible and hidden parameters

The invention provides back-end functionality for order processing in electronic order book trading. A sell / buy order is received comprising a lower / upper limit and a conditional lower / upper limit defining a conditional selling / buying price range for executing the sell / buy order under certain selling / buying conditions. A buy / sell order is received comprising an upper / lower limit, visible buy / sell volume parameter and hidden buy / sell volume parameter specifying a first part disclosed to all customers and a second part not disclosed to all customers, respectively, of the buy / sell order volume. It is determined whether the selling / buying conditions are fulfilled, including determining whether the sum of the first and second part of the buy / sell order is superior or equal to a threshold volume. The sell / buy order and the buy / sell order are executed against each other if at least the selling / buying conditions are fulfilled. Embodiments allow rapidly executing large trading interests with minimized market impact and opportunity costs.

Owner:DEUT BORSE

Materials-handling system using autonomous transfer and transport vehicles

Methods and apparatus for selecting and combining items in an outbound container through the use of autonomous vehicles, each of which includes means for automatically loading and unloading a payload, to perform both transfer and transport functions in moving containers of items within a workspace via a network of roadways. Under computer control, said autonomous vehicles transfer and transport case containers of item units between incoming receiving stations, intermediate storage locations, and outgoing order-assembly stations where entire containers or individual item units are combined in the outbound container.

Owner:SYMBOTIC LLC

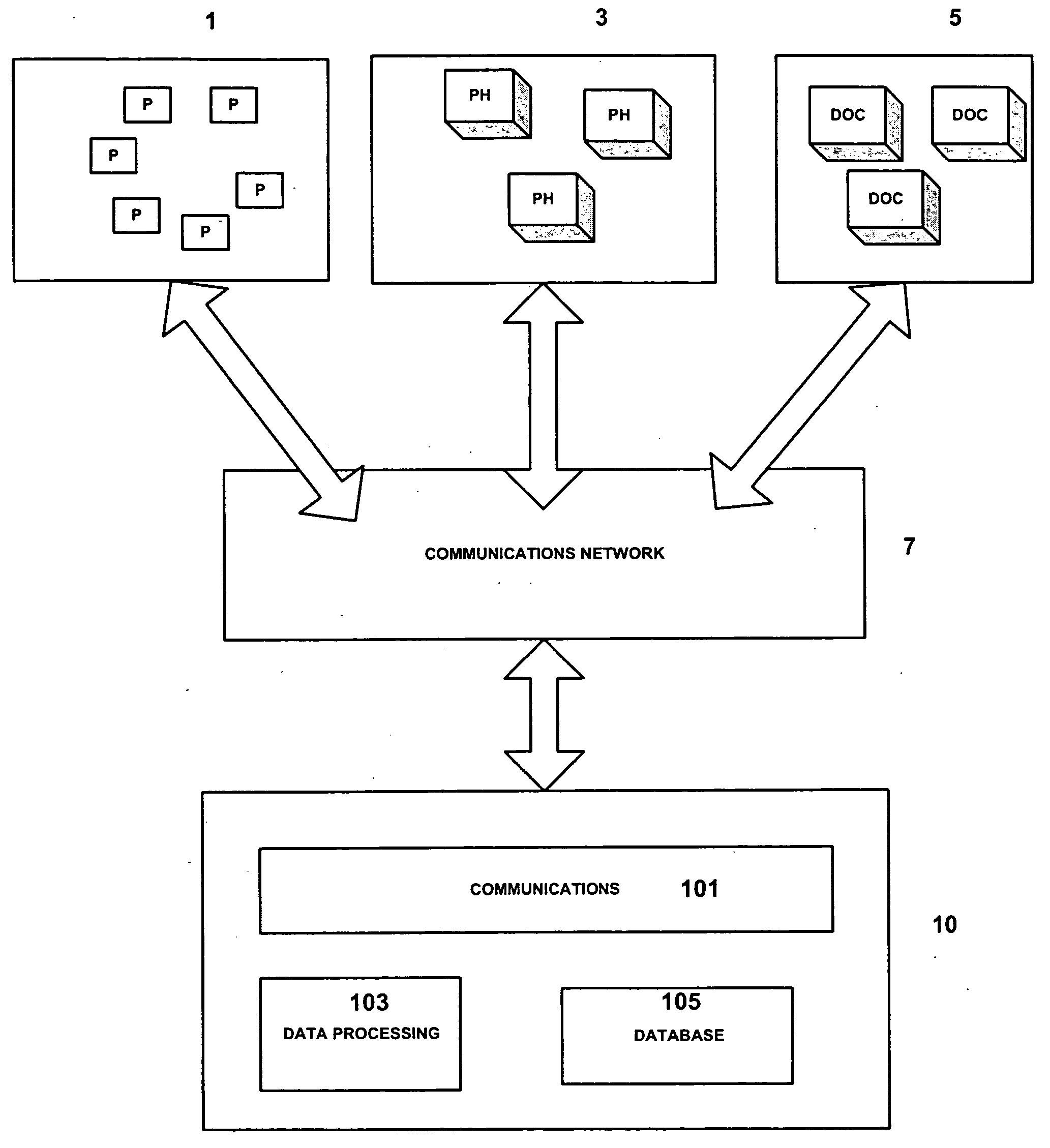

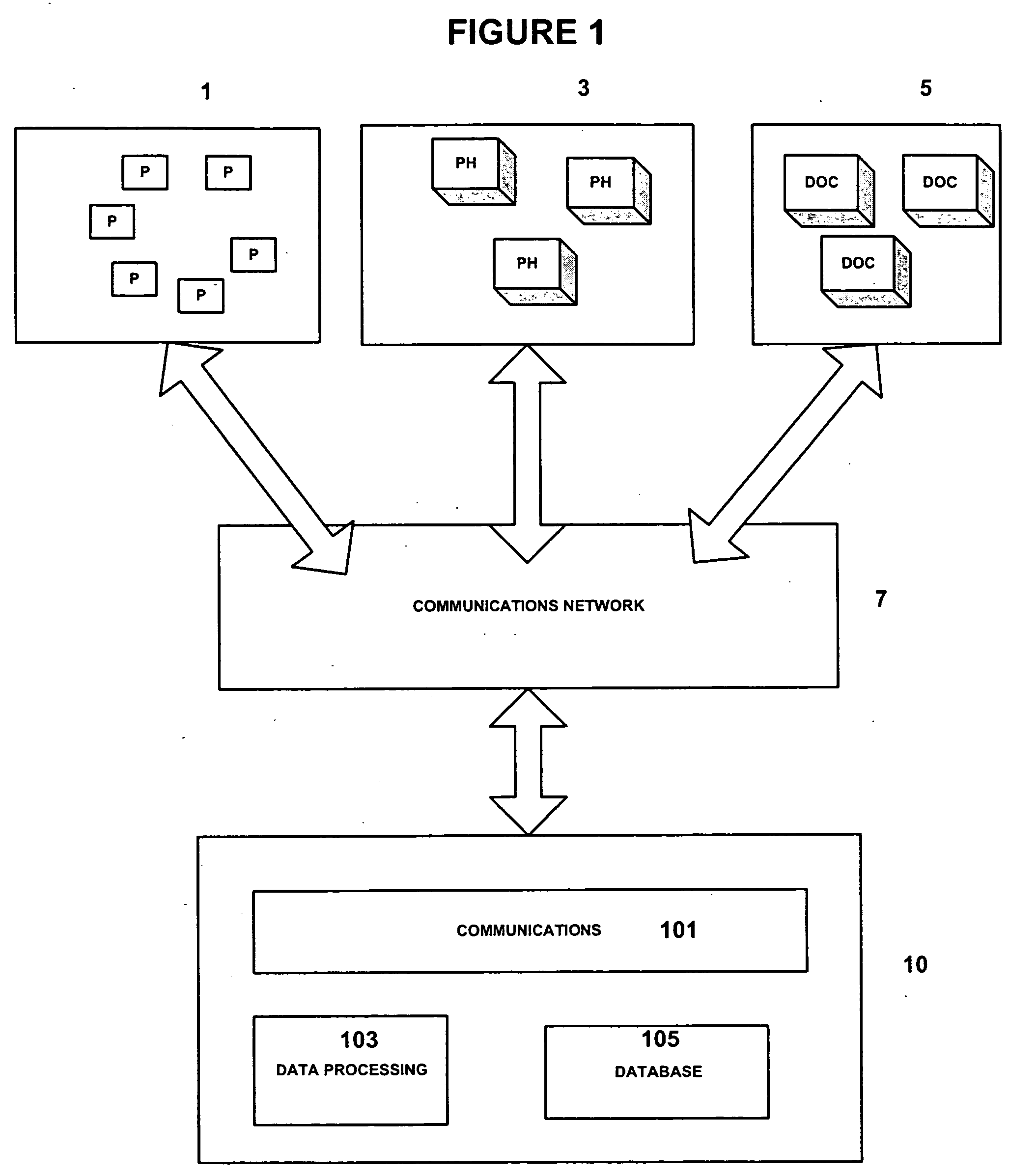

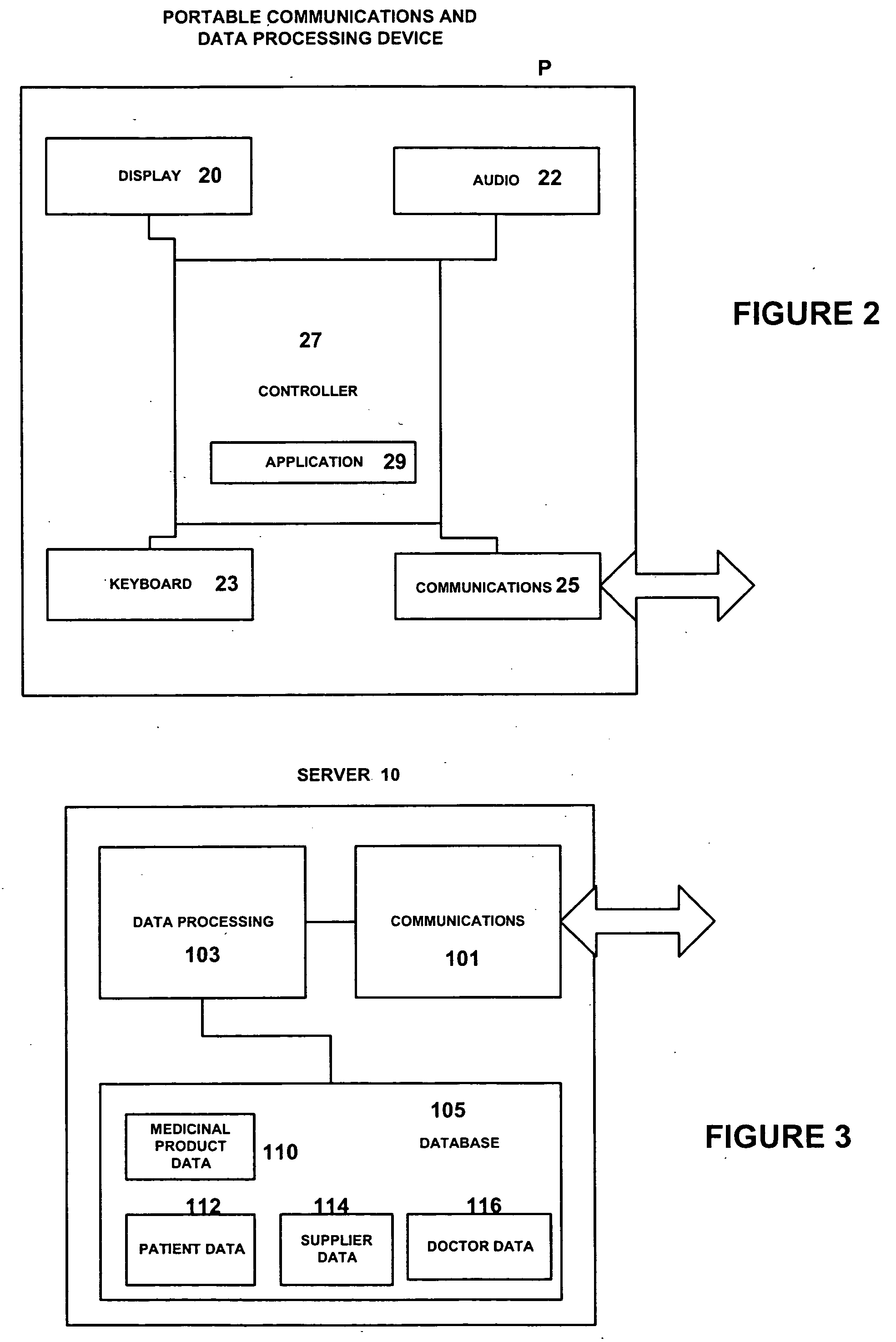

Medicinal product order processing system

InactiveUS20060136266A1Improve monitoring qualityProcess is repeatedDrug and medicationsPatient personal data managementRepeated prescriptionRegimen

A repeat prescription ordering system for allowing patients requiring resupply of medication or medical products to access a server using a portable communications and data processing device such as a smart phone or personal digital assistant. The server supplies to the patient a list of medication and medical products which they are authorized to order. The patient can select the products required, and the order is logged by the server and allocated to a supplier for completion of the order. The server maintains an estimate of the amount of medication or medical product held by the patient, this being based on the prescribed dosage regimen and information entered by the patient on their usage and, optionally, on checks on their own health. The patient may be alerted when the estimate indicates that their supplies are running low. The estimate is allowed to go below zero, this implying a possible departure from the prescribed medication regimen.

Owner:E SAN LTD

System and method for enterprise resource management

InactiveUS20050125251A1Facilitate enterprise resource managementEfficient managementResourcesSpecial data processing applicationsResource Management SystemControl data

A system for enterprise resource management is provided. The system includes a purchase order helper system that receives purchase order entry data and generates purchase order data. The system also includes a sales order helper system that receives sales order entry data and generating sales order data. An inventory control helper system connected to the purchase order system and the sales order system generates inventory control data based upon the sales order data and the purchase order data. A general ledger helper system coupled to the purchase order helper system, the sales order helper system, and the inventory control helper system generates general ledger data based upon the sales order data, purchase order data, and the inventory control data.

Owner:BERGER KENNETH A +2

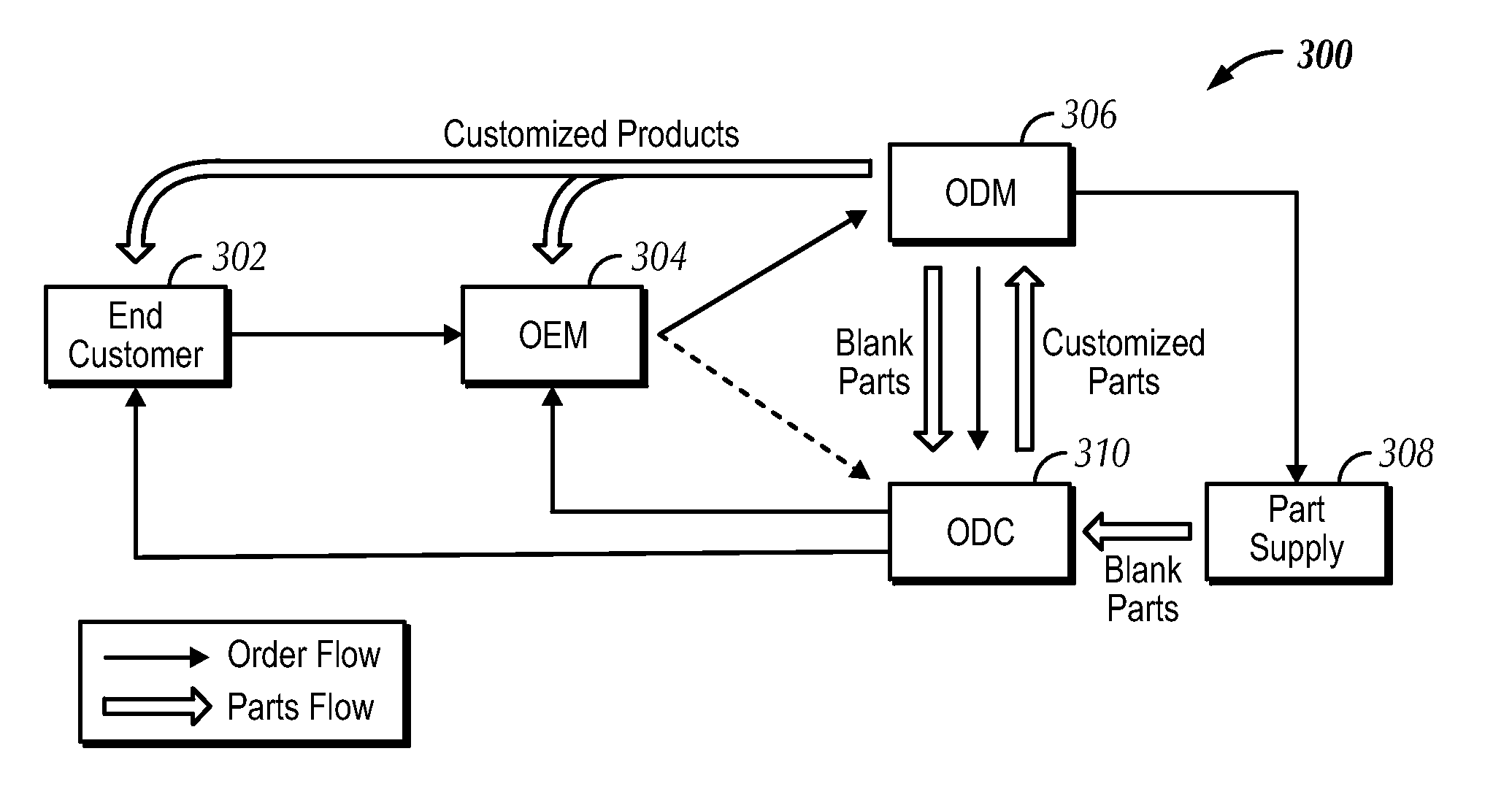

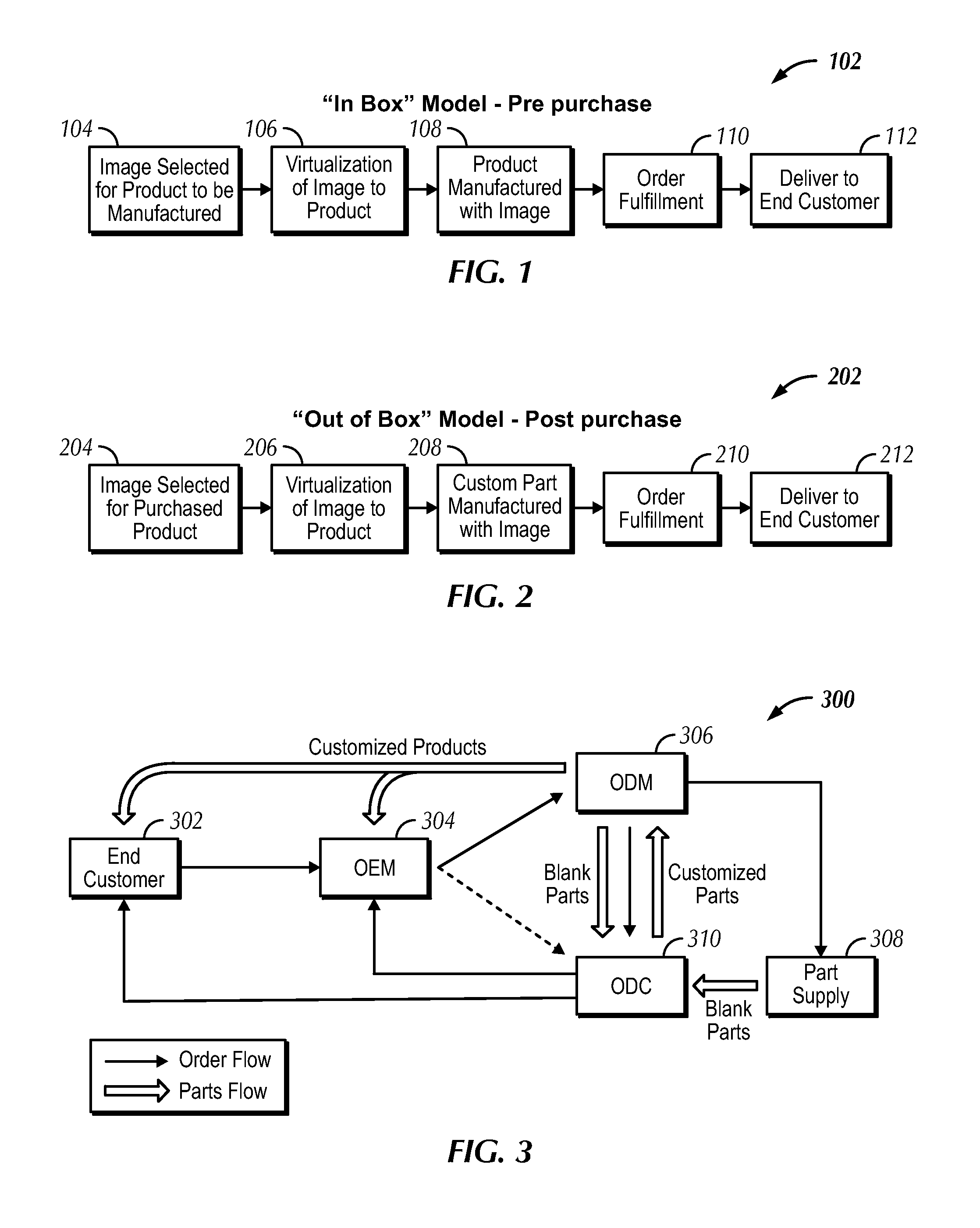

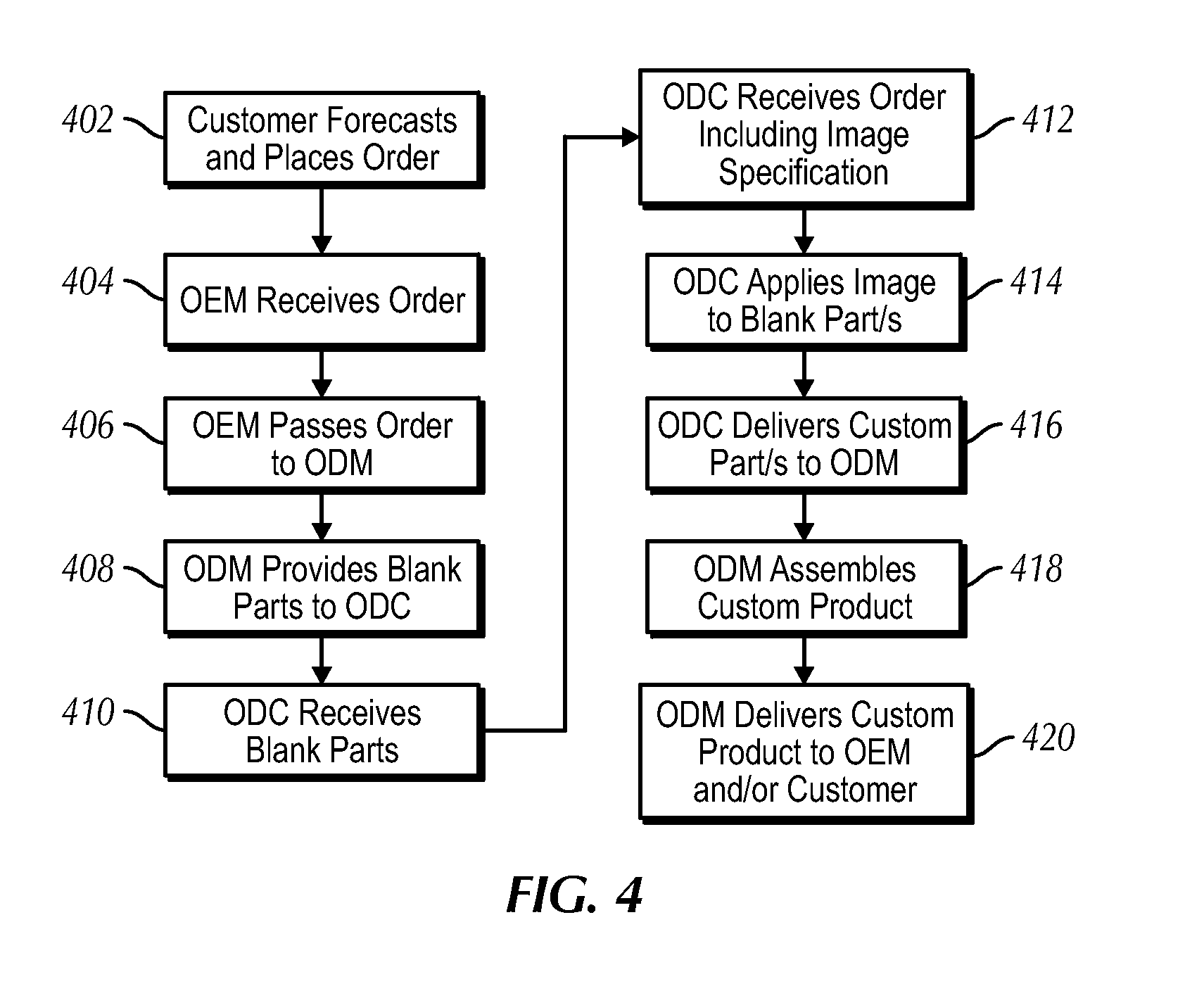

Systems and methods of on demand manufacturing of customized products

Systems and methods are described herein relating to managing an on-demand manufacturing supply chain personalization process. In some embodiments, the management system and method is described in order to manufacturing customized products according to image and customization data with images applied to parts using a post mold image application process. In other embodiments, customized products are defined by electronic orders that specify product manufacturing data including imagery to be applied to the products. In other embodiments, manufacturing methods are described in which an original equipment manufacturer (OEM) or an original design manufacturer (ODM) leverages use of an on demand customizing entity in the manufacturing supply chain. In other embodiments, customized products are described in which imagery spans across multiple components of the products. In other embodiments, re-usable tracking devices and scheduling processes based on filtered options are additionally described. Some embodiments combine one of more of these mentioned embodiments.

Owner:SKINIT

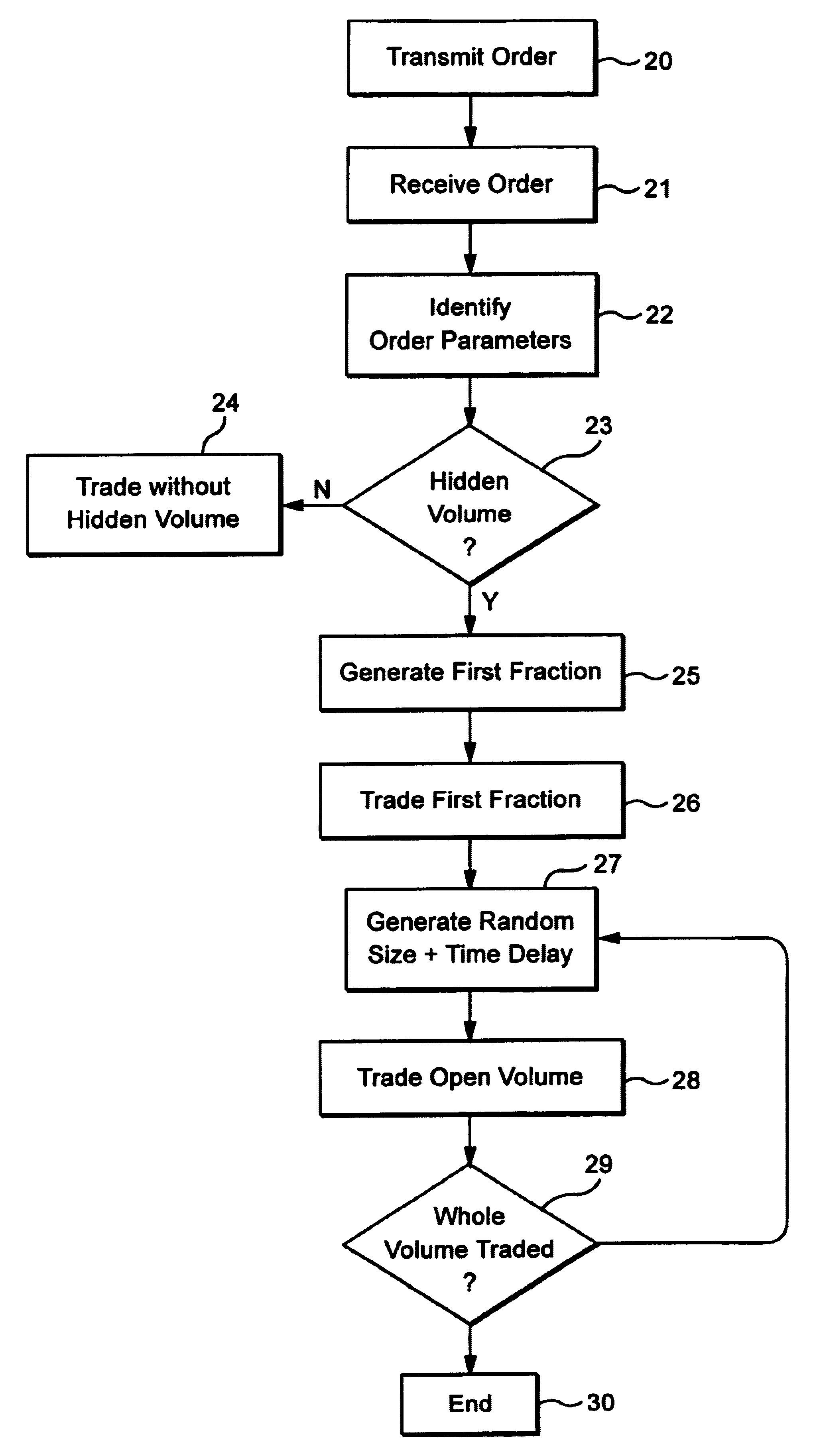

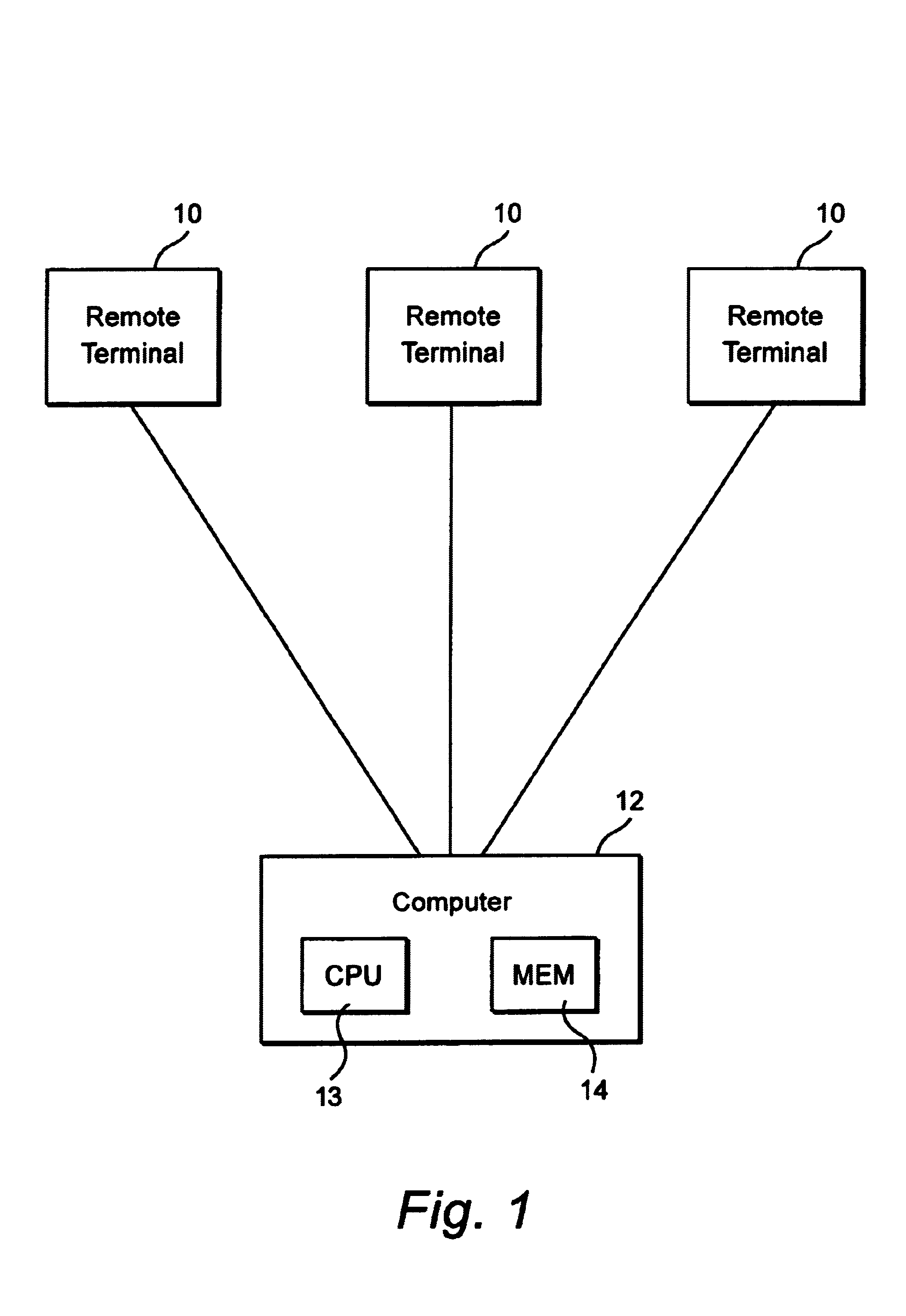

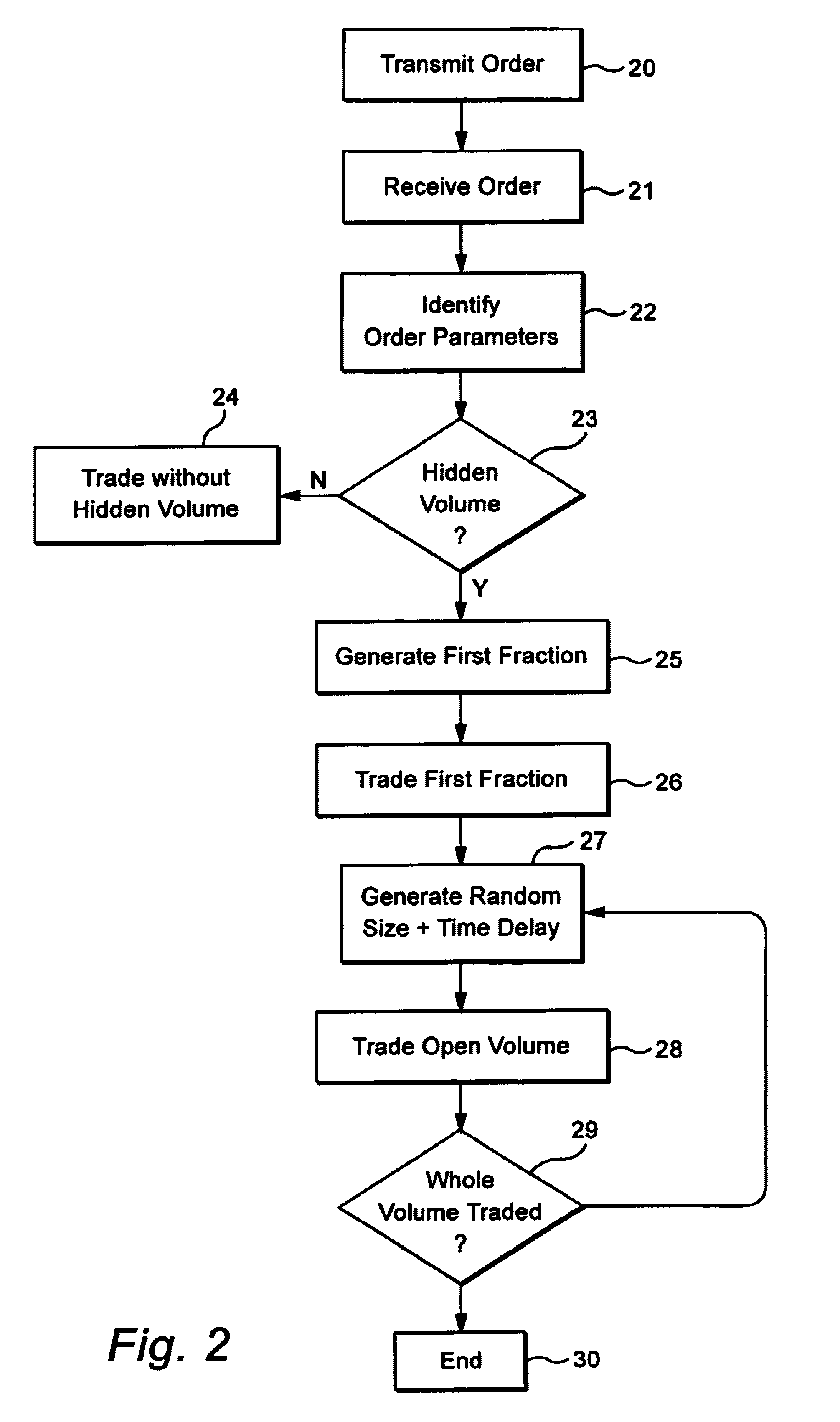

Automated exchange system for trading orders having a hidden volume

An automated exchange system for trading an order having a hidden volume. An order is received requesting a hidden volume trade. The automated exchange generates an open volume with a random / pseudo-random size and / or at a random / pseudo-random time based on one or more parameters associated with the order.

Owner:NASDAQ TECHNOLOGY AB

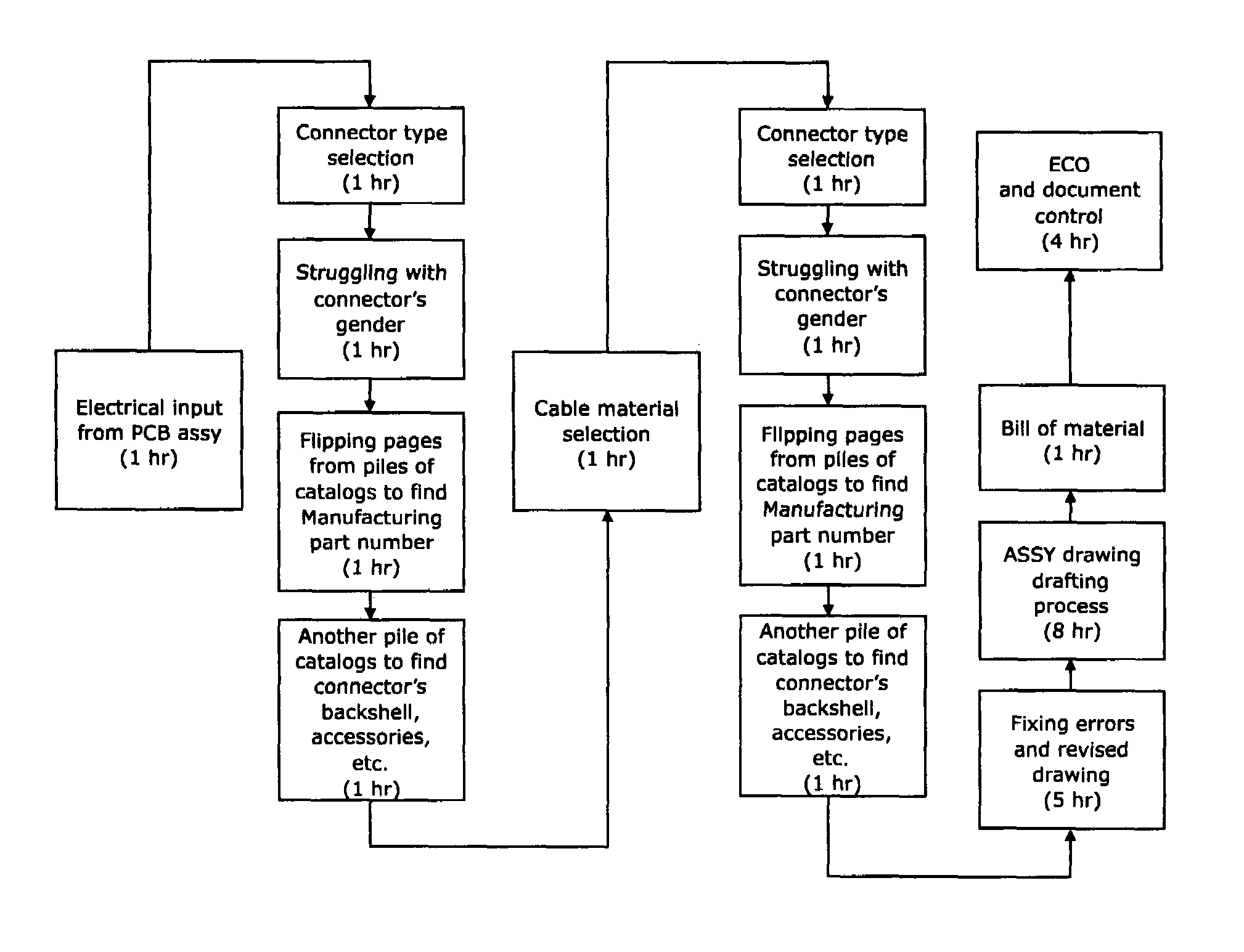

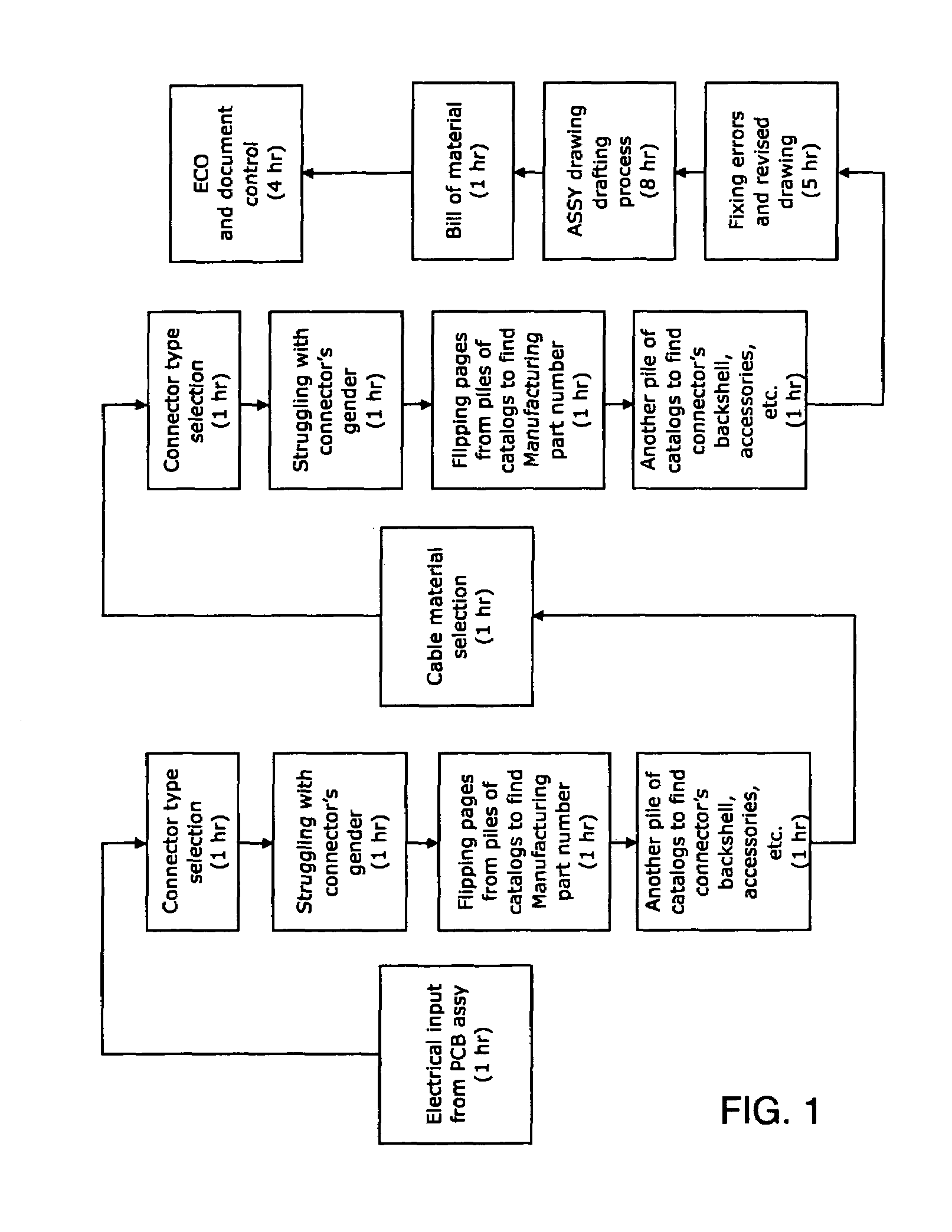

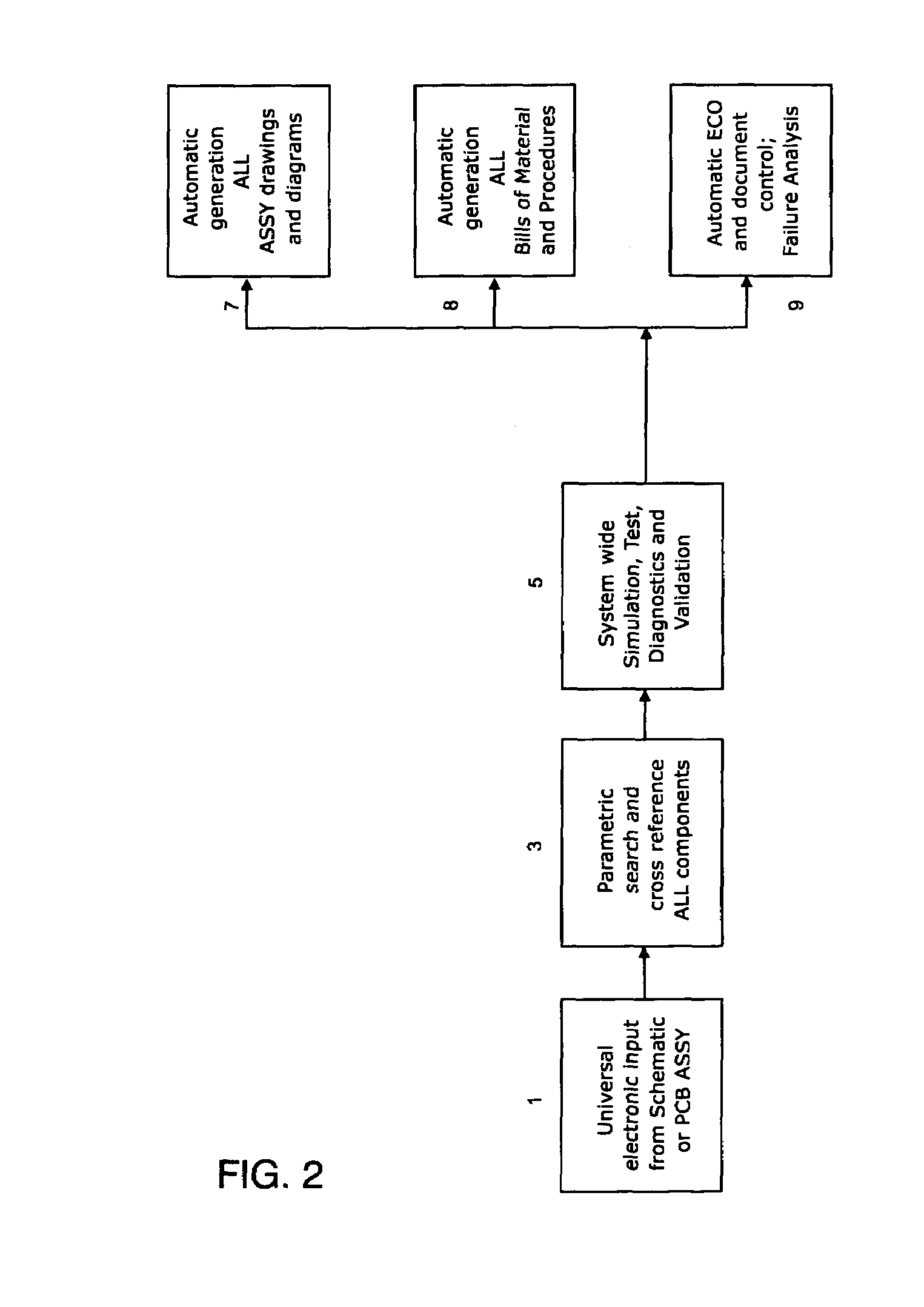

PLM-supportive CAD-CAM tool for interoperative electrical and mechanical design for hardware electrical systems

InactiveUS7103434B2Reduce frictionCAD network environmentComputer programmed simultaneously with data introductionTask completionBill of materials

Owner:CHERNYAK ALEX H +3

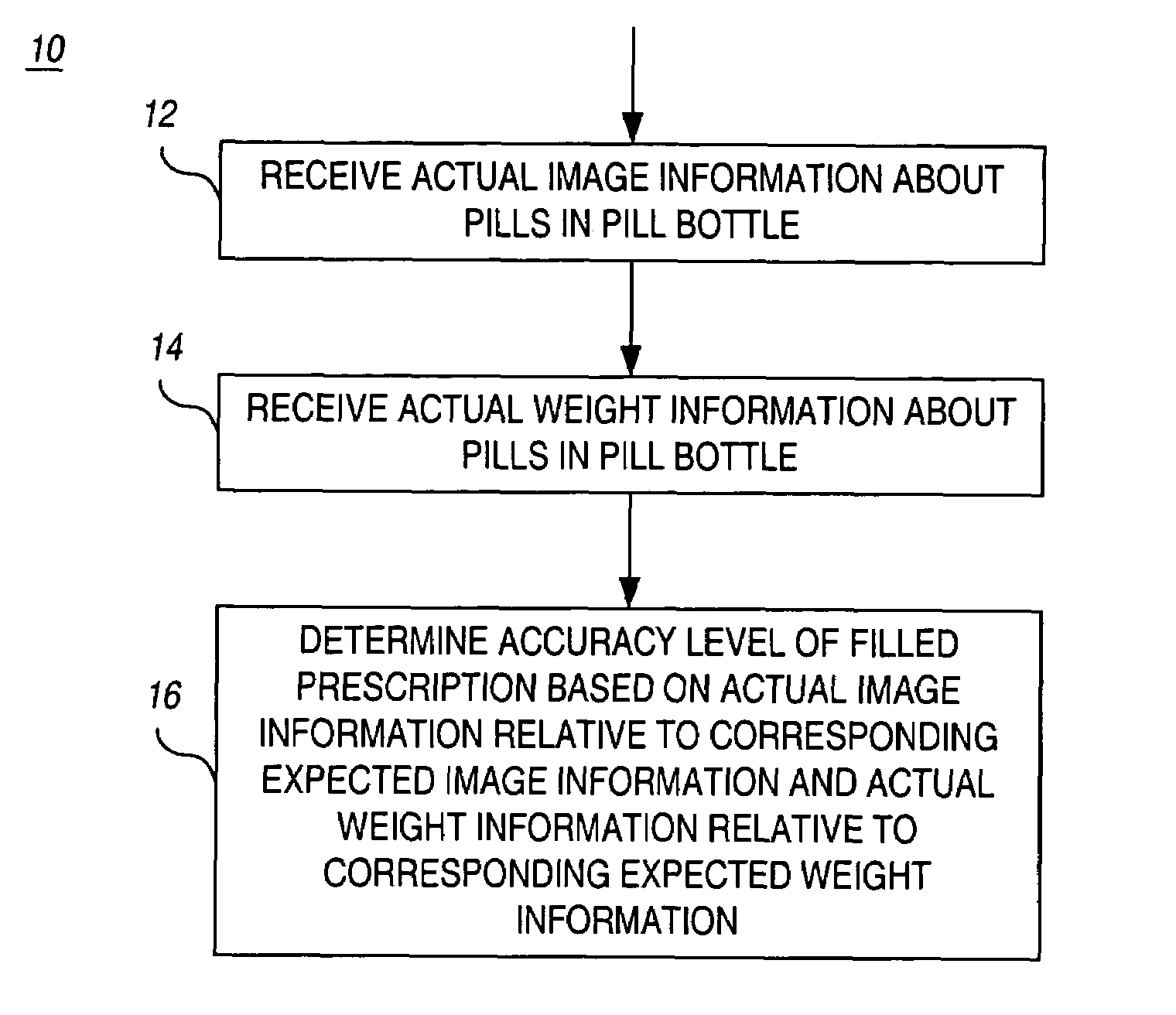

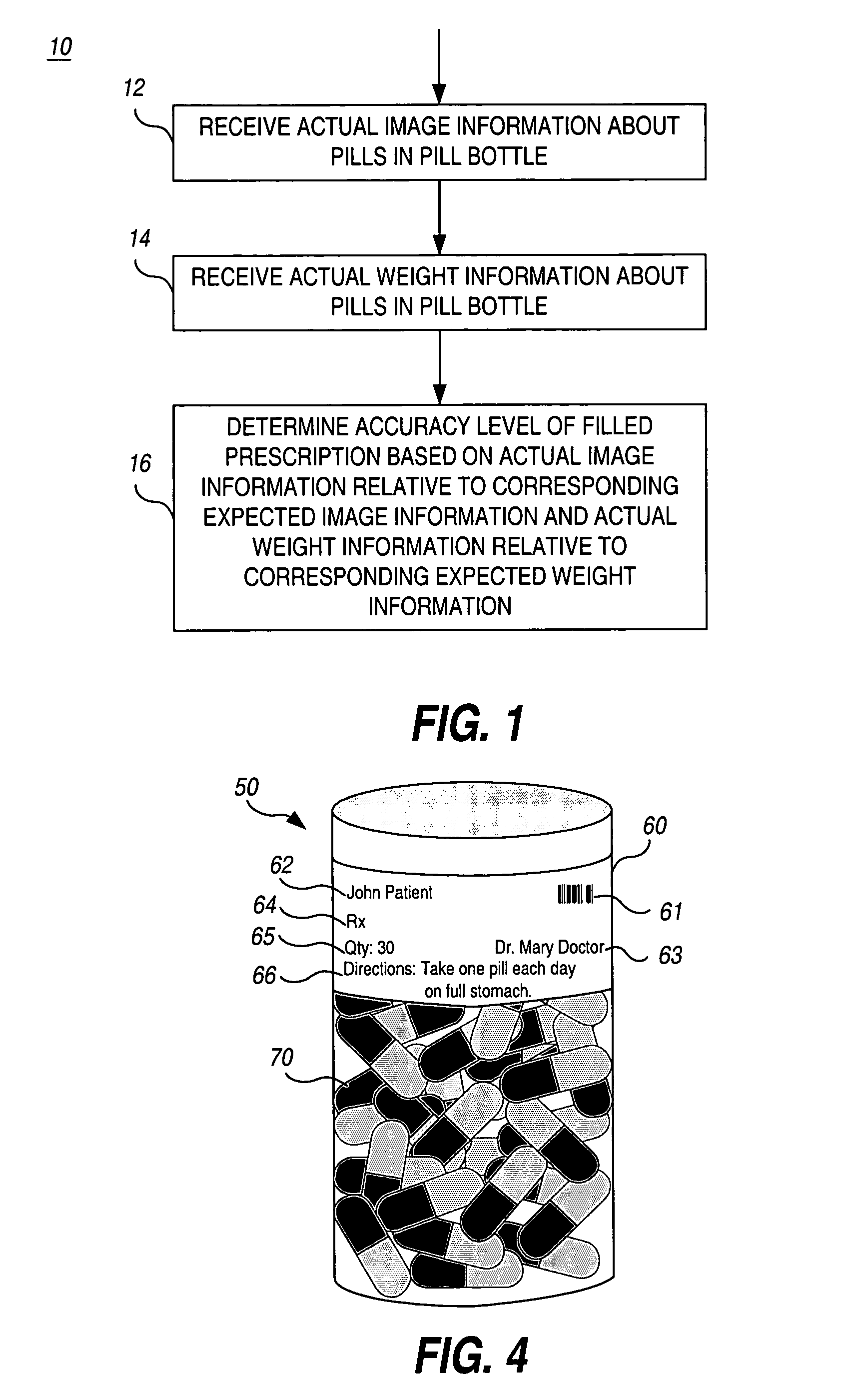

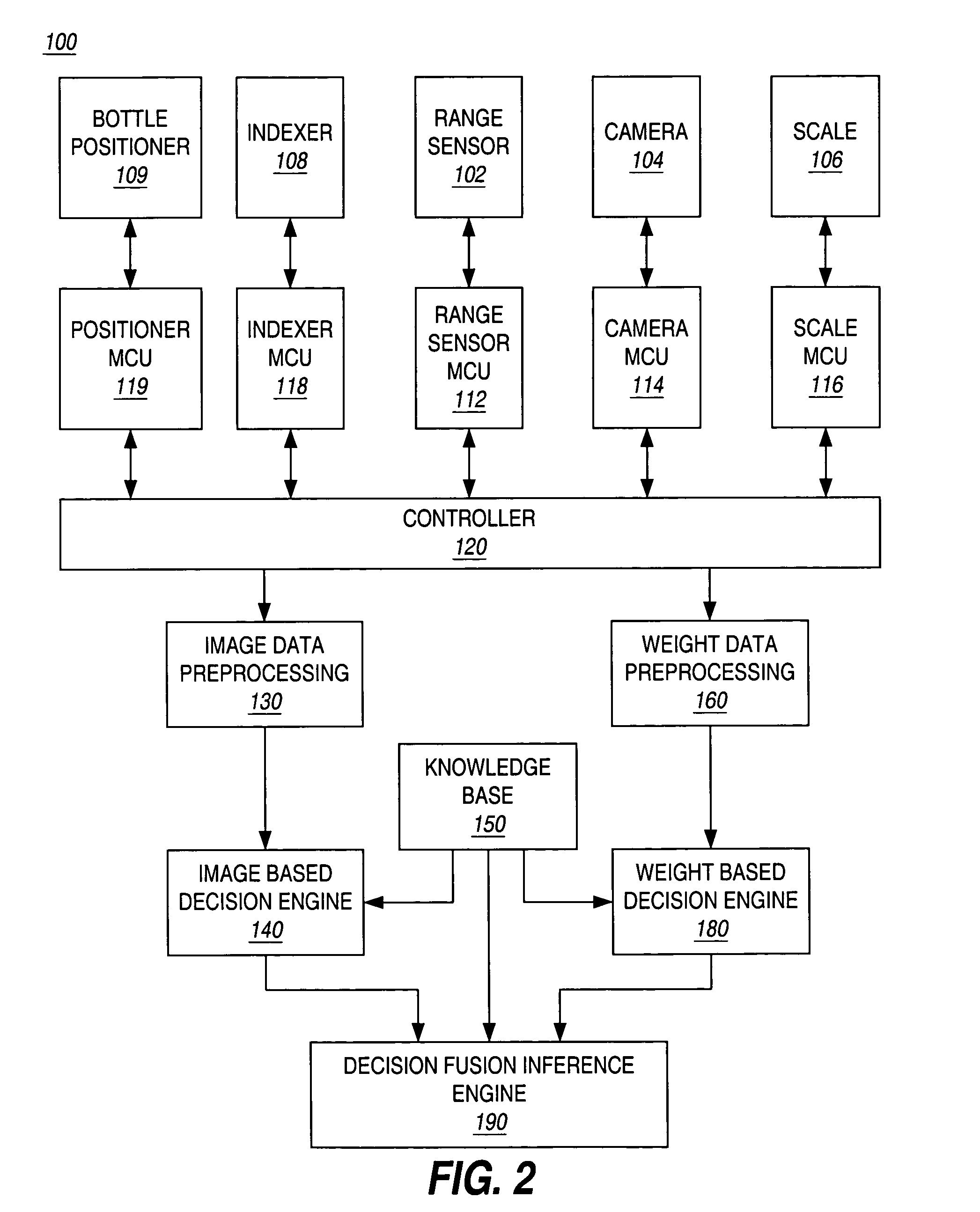

Apparatus and method for automatic prescription verification

InactiveUS7028723B1Eliminate unnecessary idle timeLiquid fillingDrug and medicationsThe InternetOrder form

An apparatus and method are used to perform the verification of a pharmaceutical prescription after it is filled but prior to shipment. Due to the high volume of mail / internet orders, the analysis is to be performed on the whole prescription, not on each individual pill of the prescription. The apparatus automatically gathers information about the pills contained in a pill bottle, including image and weight information, and incorporates a decision-making engine to decide whether the content of the pill bottle matches the prescription order.

Owner:ALOUANI ALI TAHOR +1

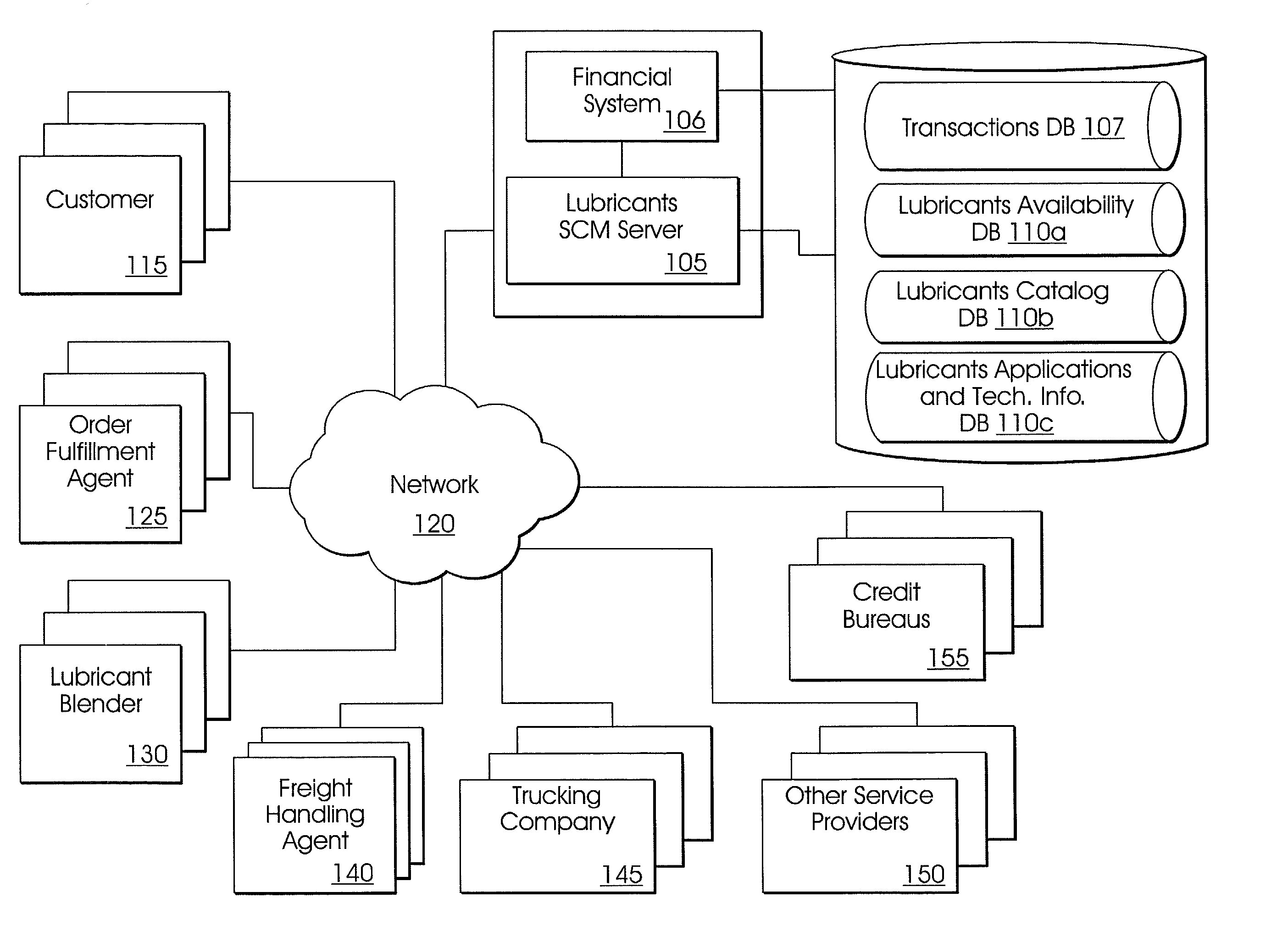

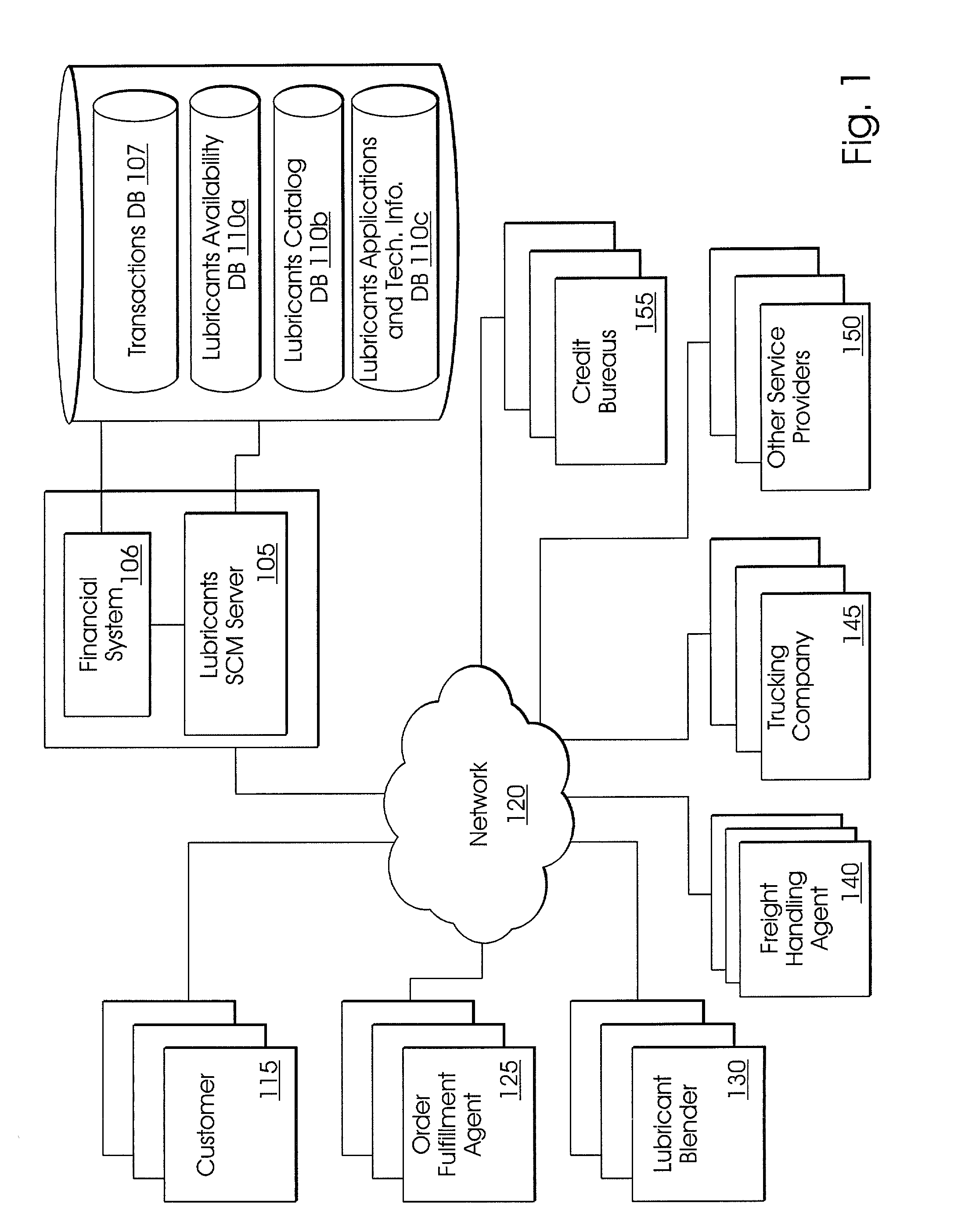

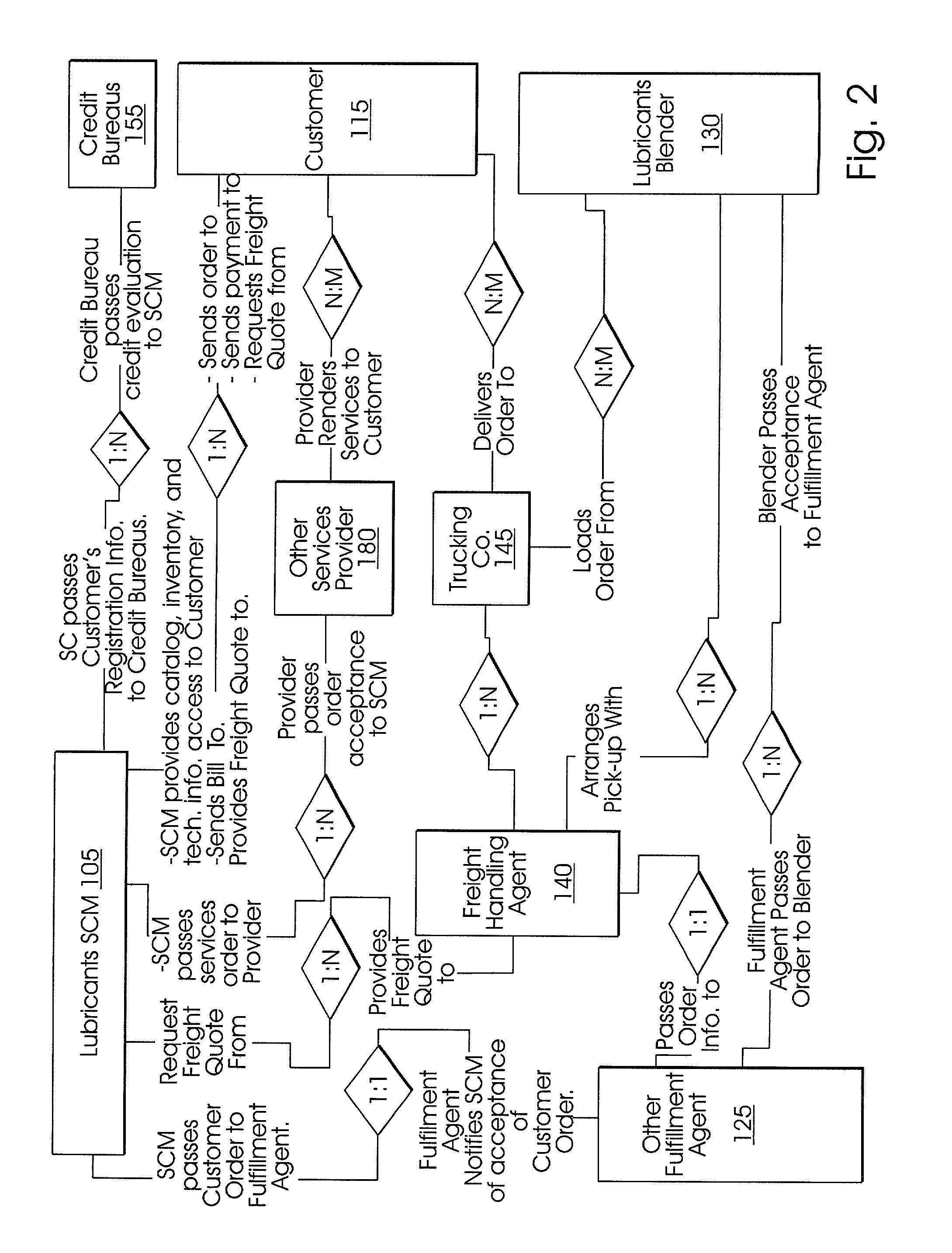

System and method for lubricants supply chain management

The invention includes a method of lubricants supply chain management including: storing in a web-accessible database a catalog of lubricants and prices-per-unit for same which prices-per-unit optionally decrease based on certain pre-determined cumulative volume purchases; upon receiving at a web server a request from a web-browser client, querying the database and serving the results of the query to the requesting web-browser client for display; serving an order form to the web-browser client which is configured to contain fields for order quantity and type for lubricants, delivery type preferences and delivery address entered in the web-browser client, and determining and displaying on the web-browser client a delivery price quote; receiving an order from the web-browser client for a specific type and quantity of lubricants and having a specific delivery type selected; electronically transmitting over a network the order to an order fulfillment agent; where the order fulfillment agent electronically transmits over a network the order to at least one lubricant blender; electronically transmitting over a network the order and the delivery information to a freight-handling agent; where the freight-handling agent inputs the information into a delivery optimization system which outputs a delivery schedule which includes the order, and electronically transmits over a network the order and the delivery information to at least one trucking company; and maintaining the status and all actions and communications for the order in a second web-accessible database.

Owner:CHEVROU USA INC

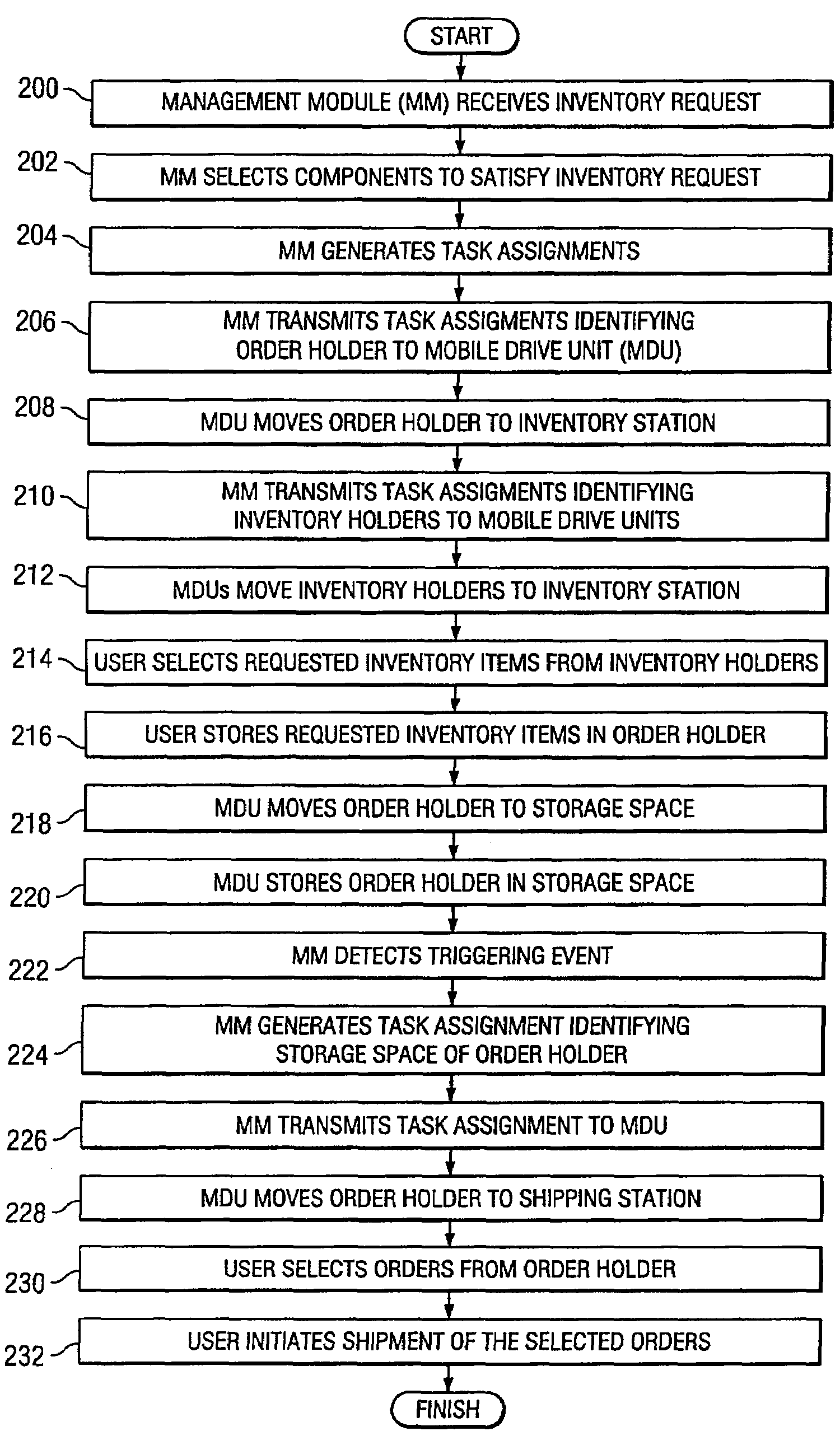

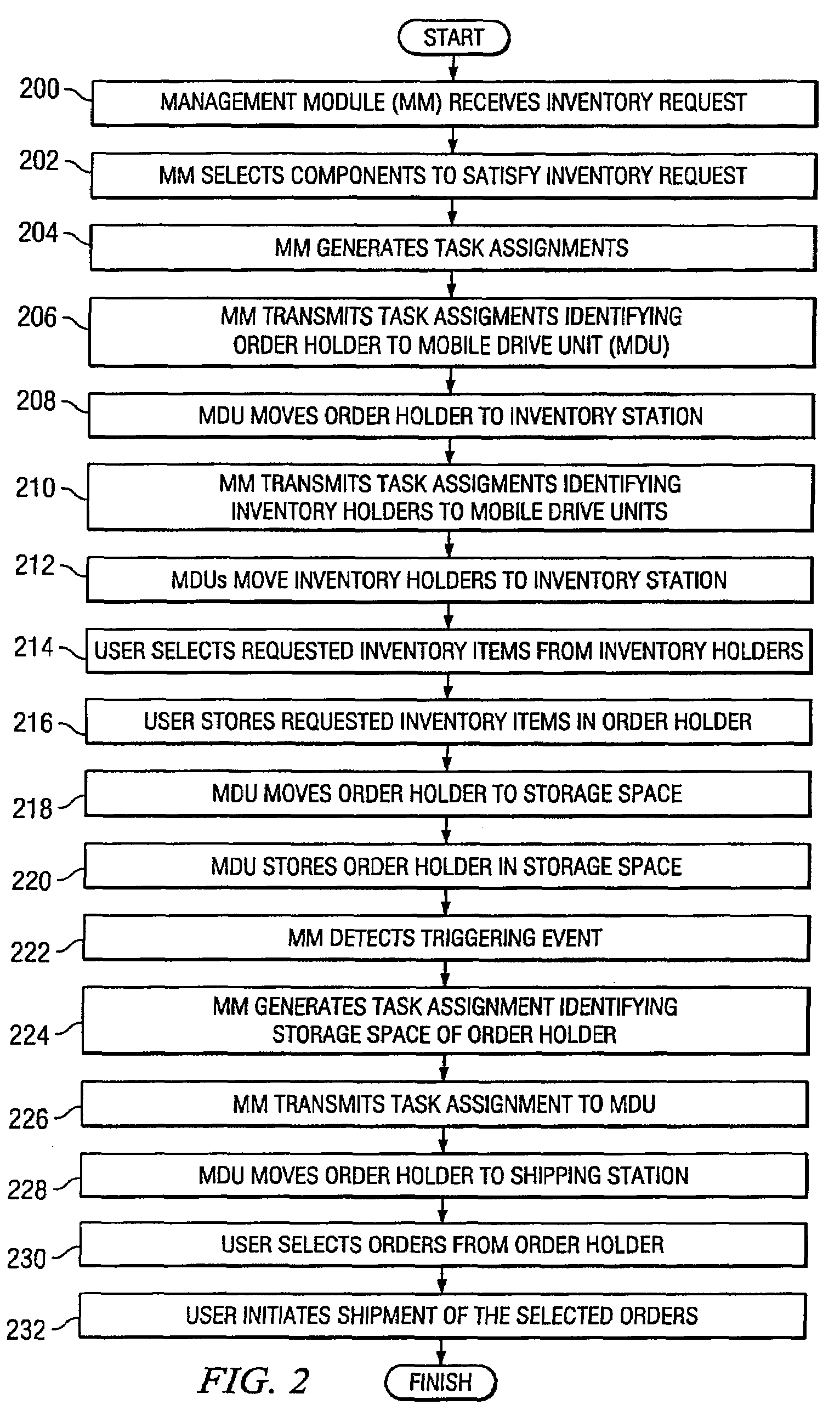

System and Method for Filling an Order

ActiveUS20080167884A1Faster order fulfillmentEasy to useAnimal feeding devicesLogisticsOrder formDatabase

Owner:AMAZON TECH INC

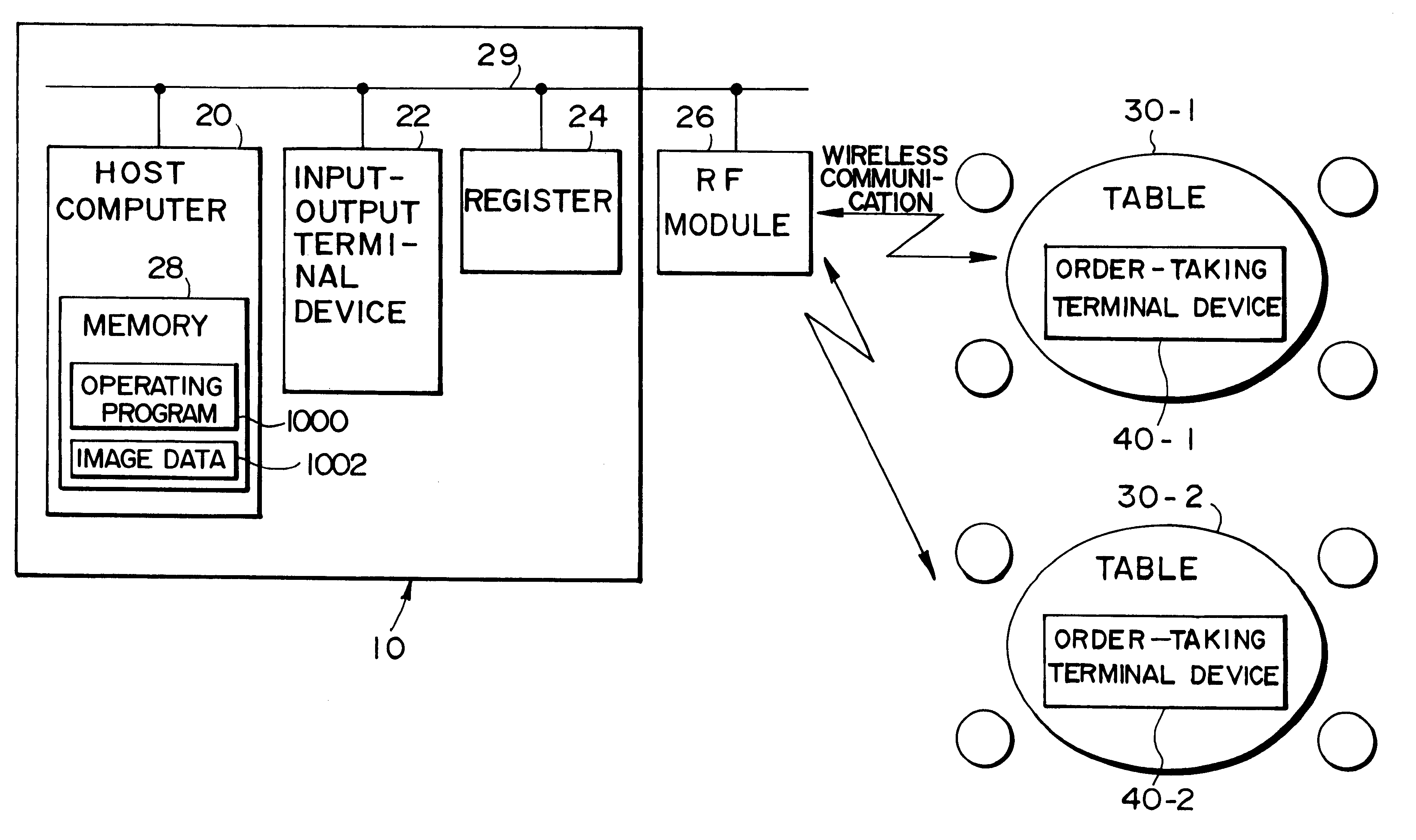

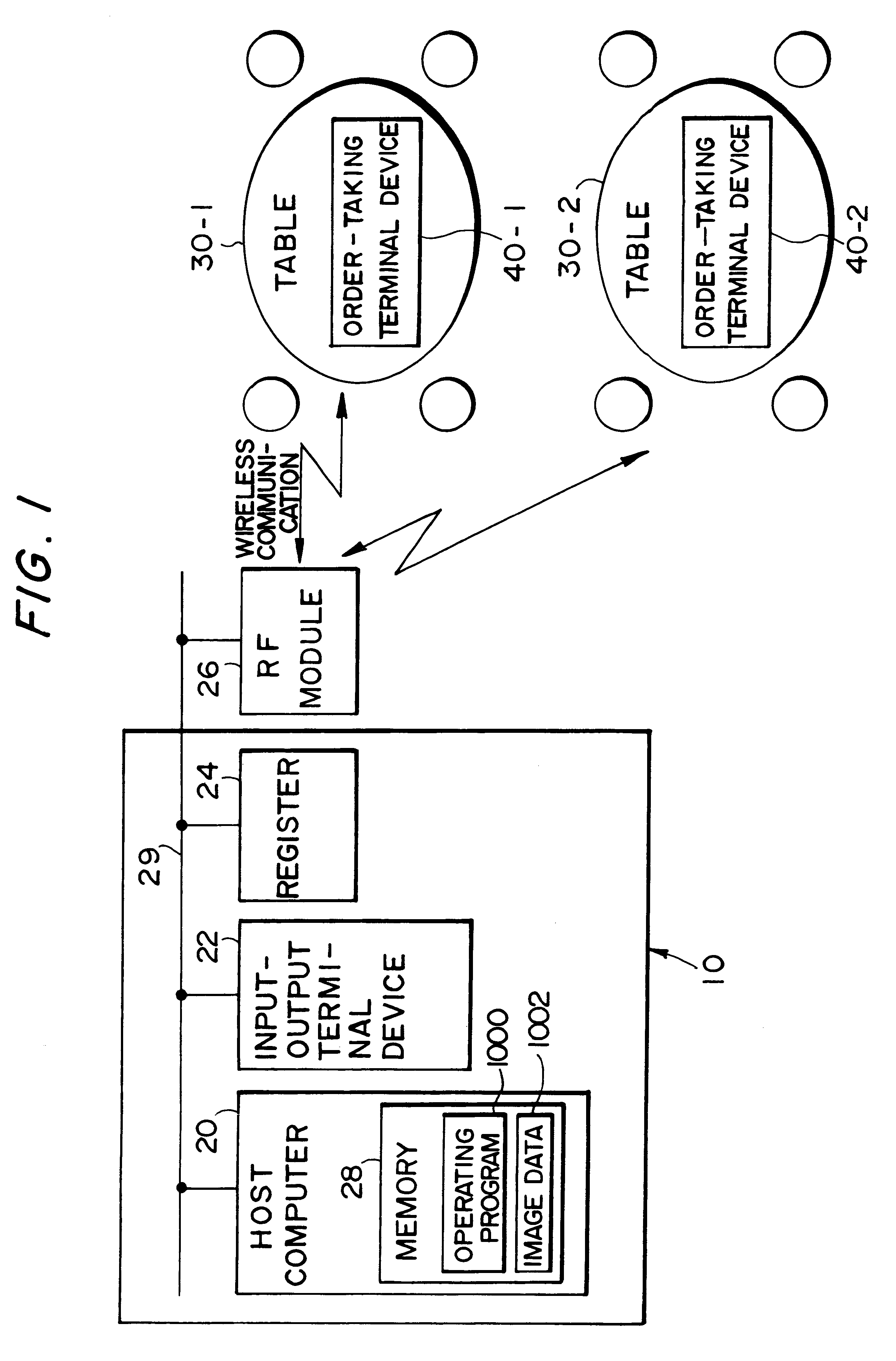

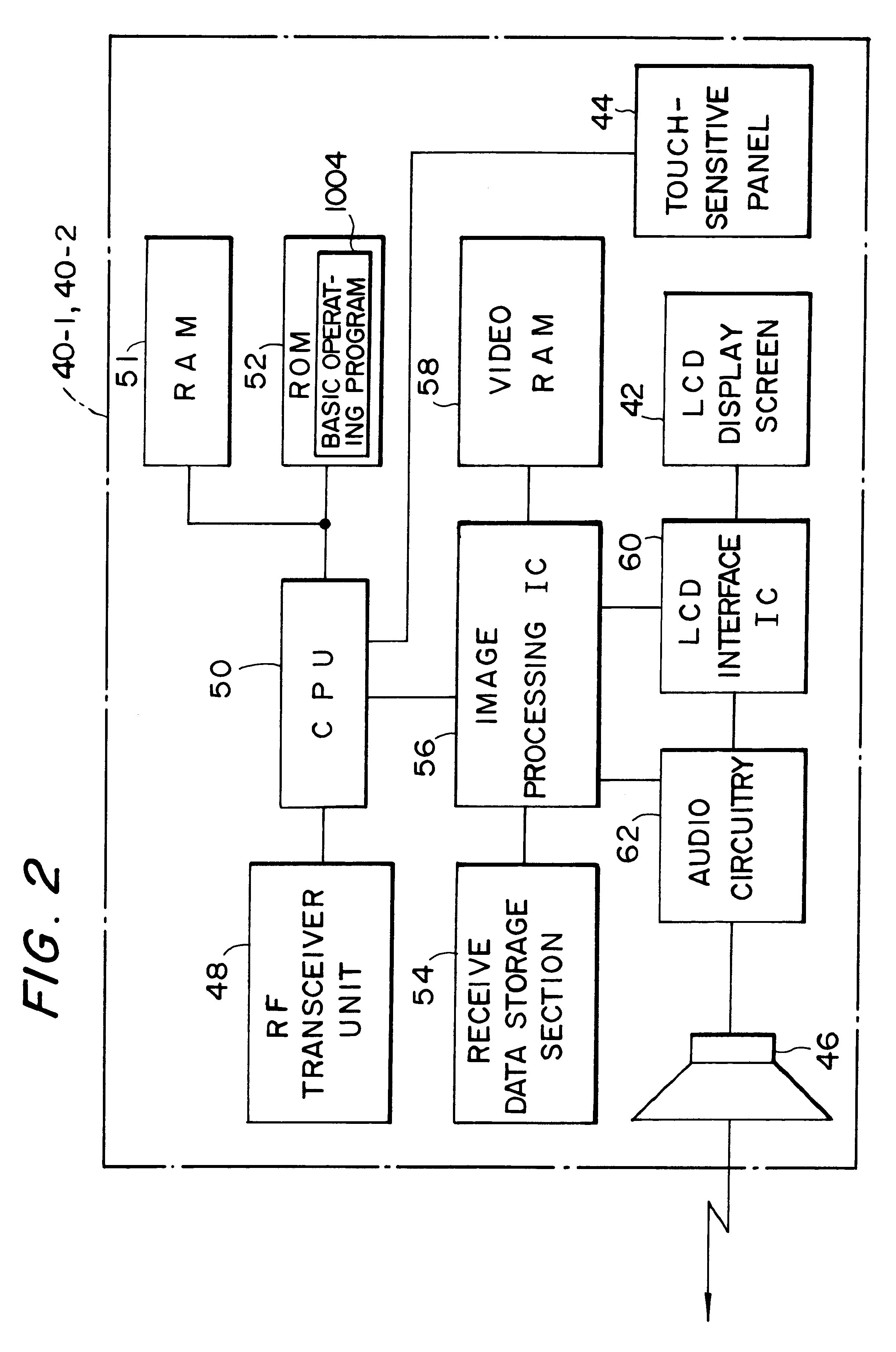

Order management system with automatic menu updating

InactiveUS6208976B1Easy to useEasy for users to understandAcutation objectsHand manipulated computer devicesOrder management systemTerminal equipment

An order management system enables a customer to use a terminal device to order food, but can respond rapidly to changes and additions to the menu. When this system starts up, it transmits an operating program and image data from main management equipment to each of a number of order-taking terminal devices. Each order-taking terminal device stores the thus received operating program and image data and displays a menu screen on a display screen on the basis of the thus stored operating program and image data.

Owner:SEIKO EPSON CORP

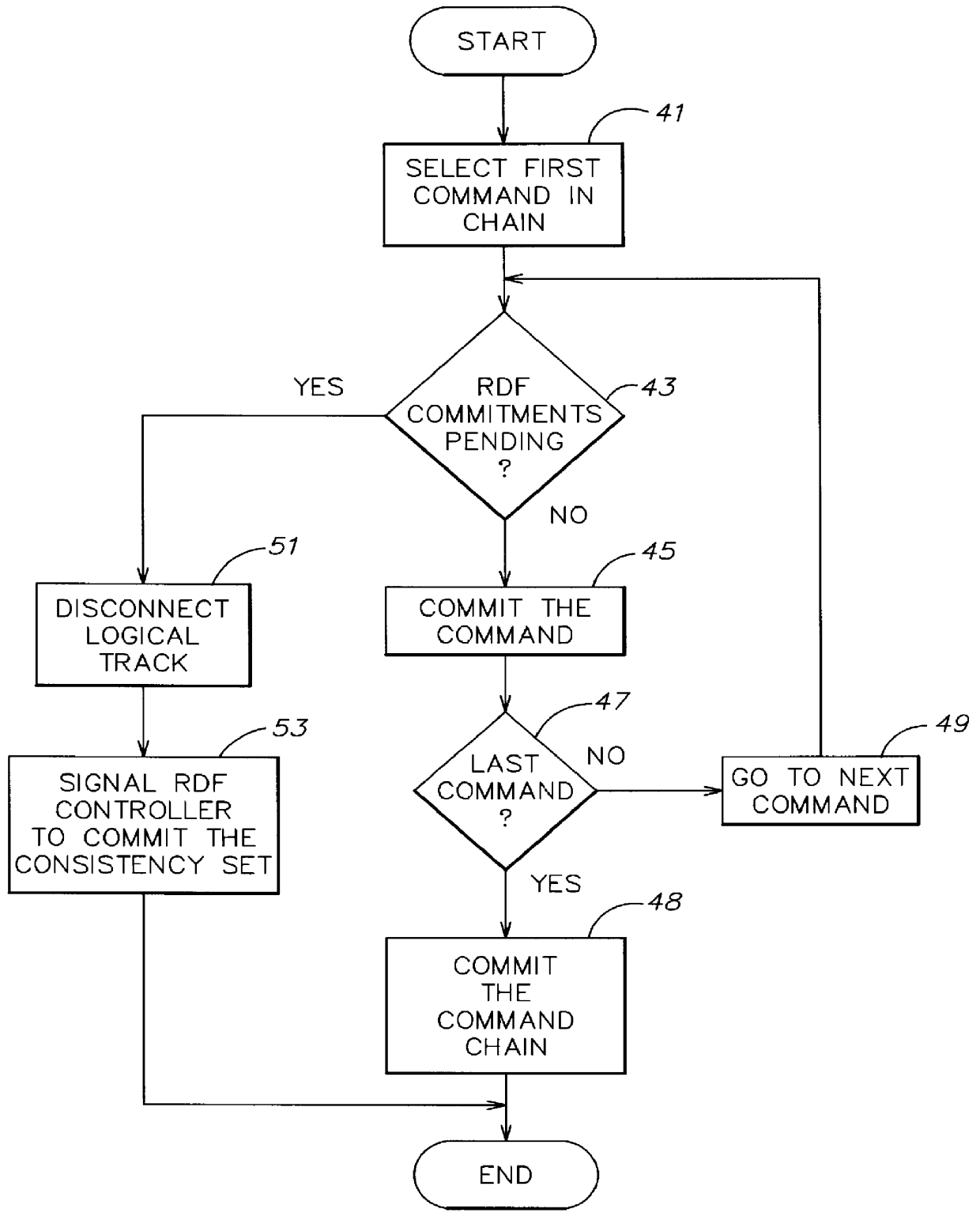

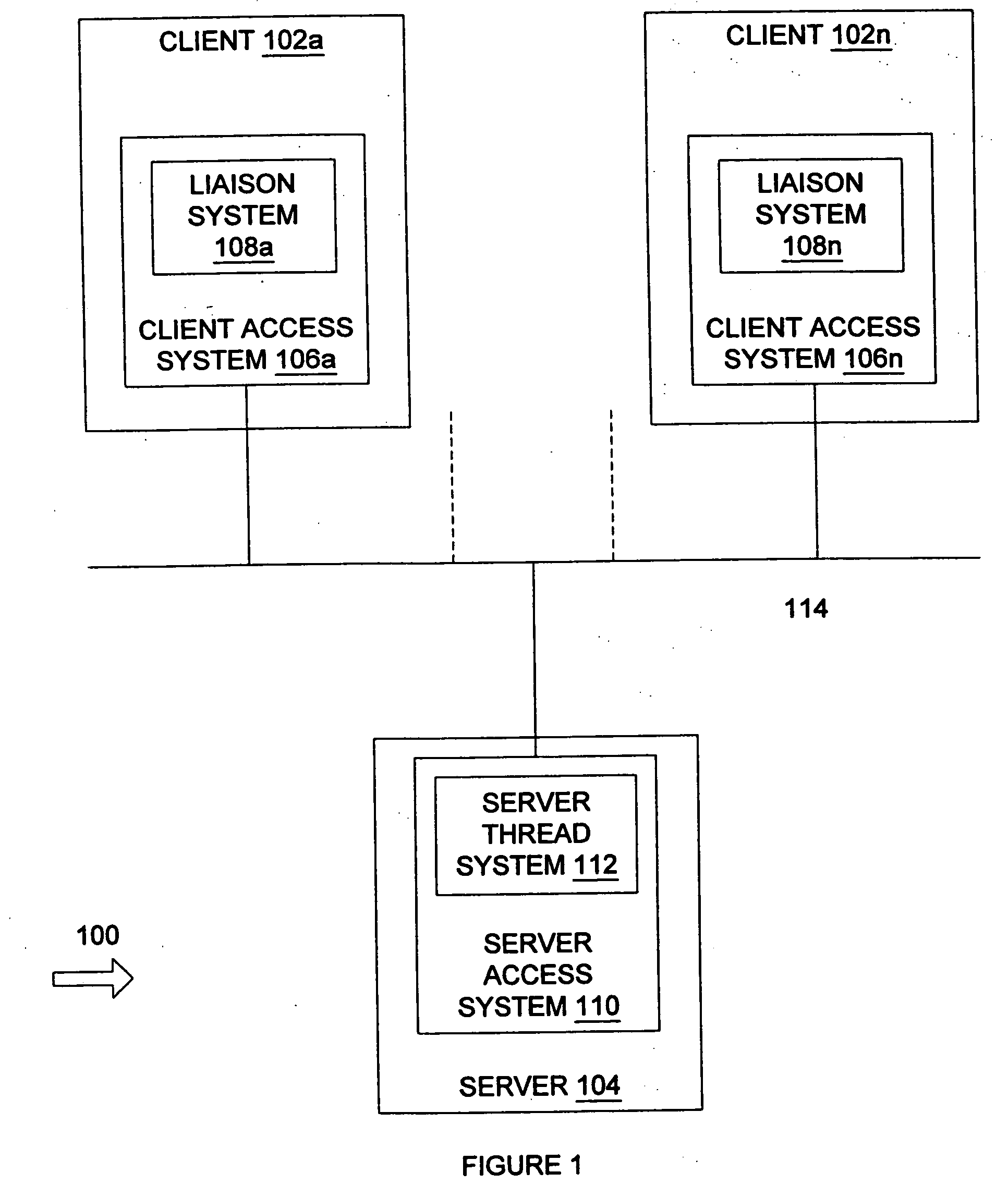

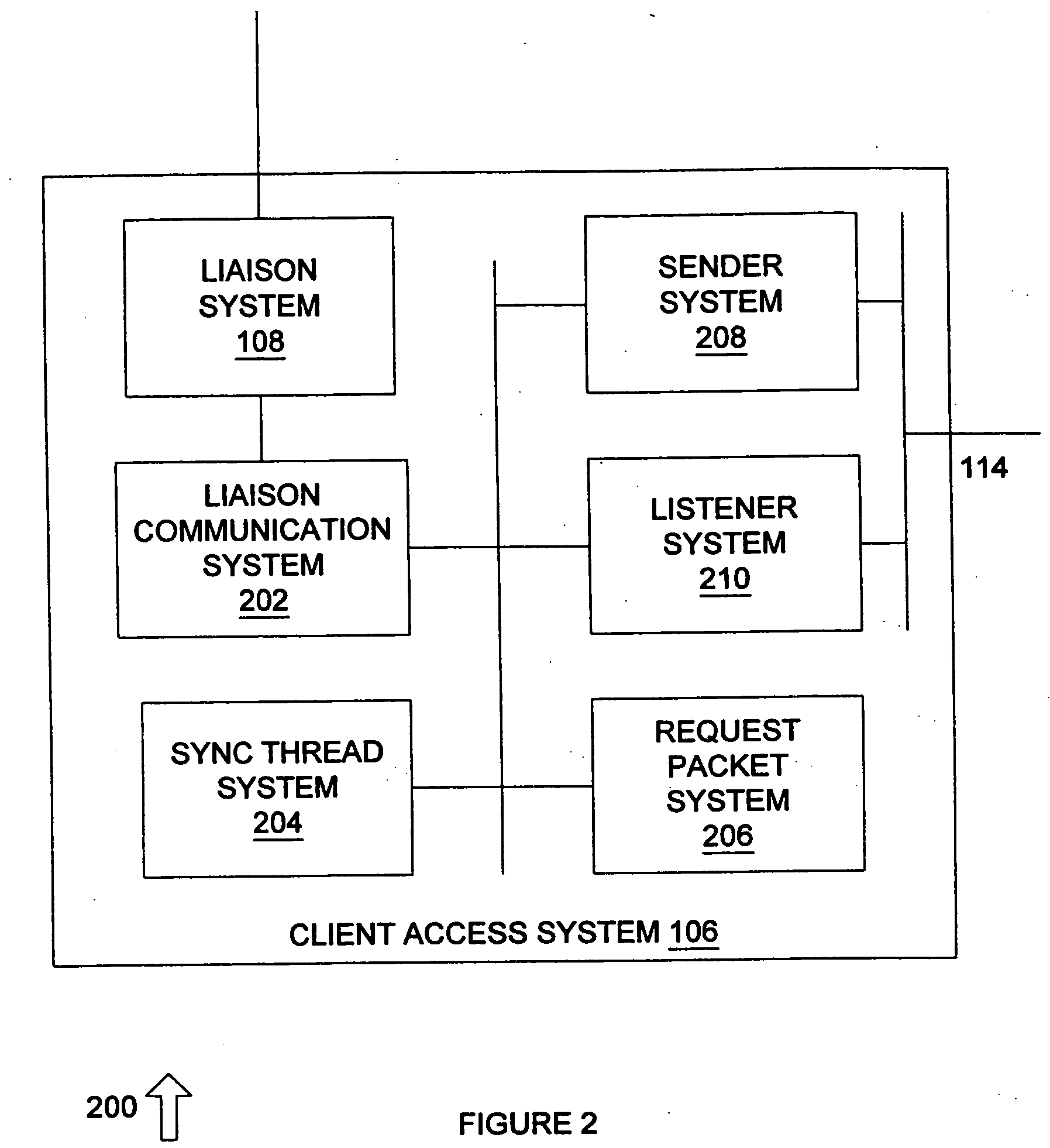

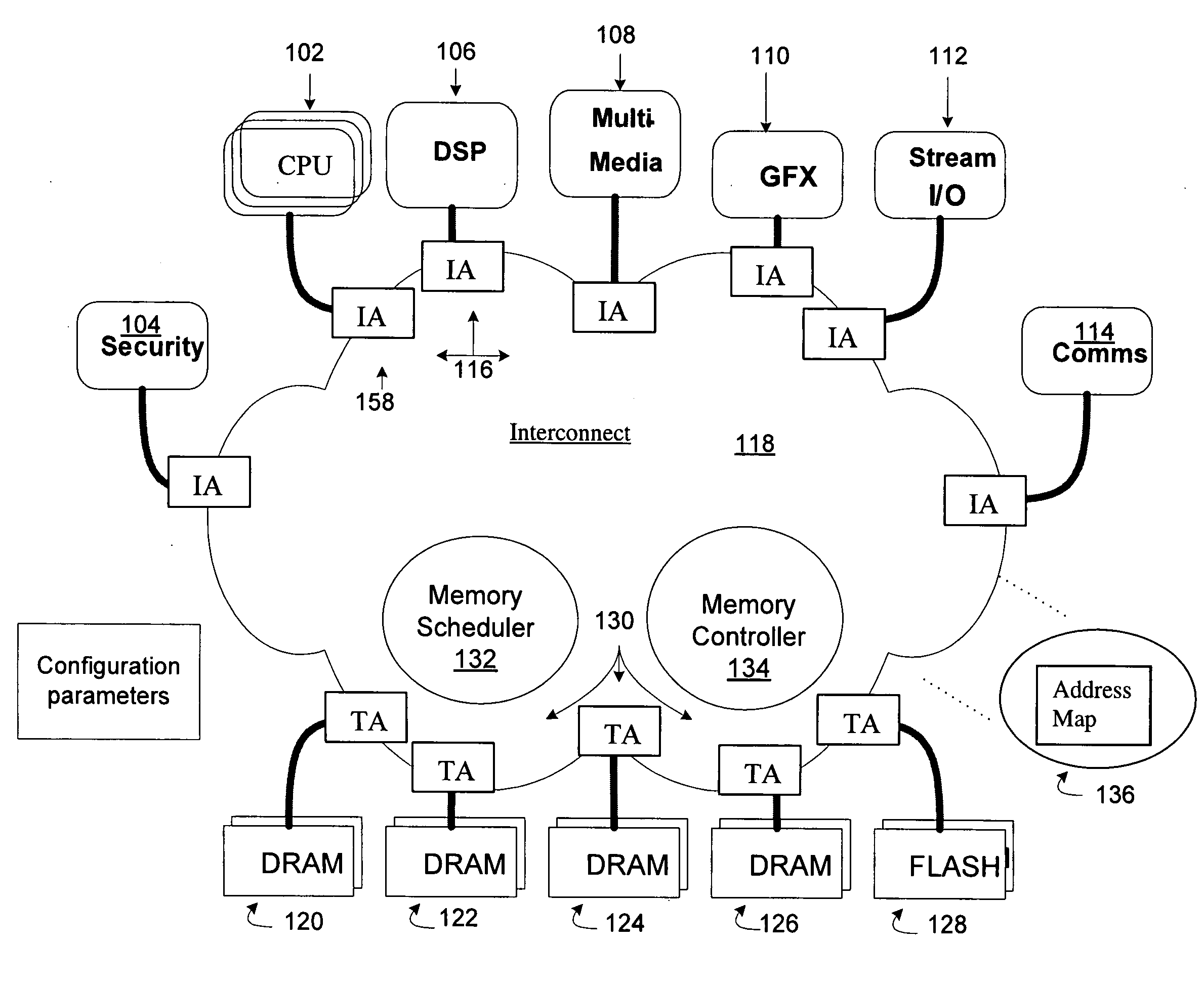

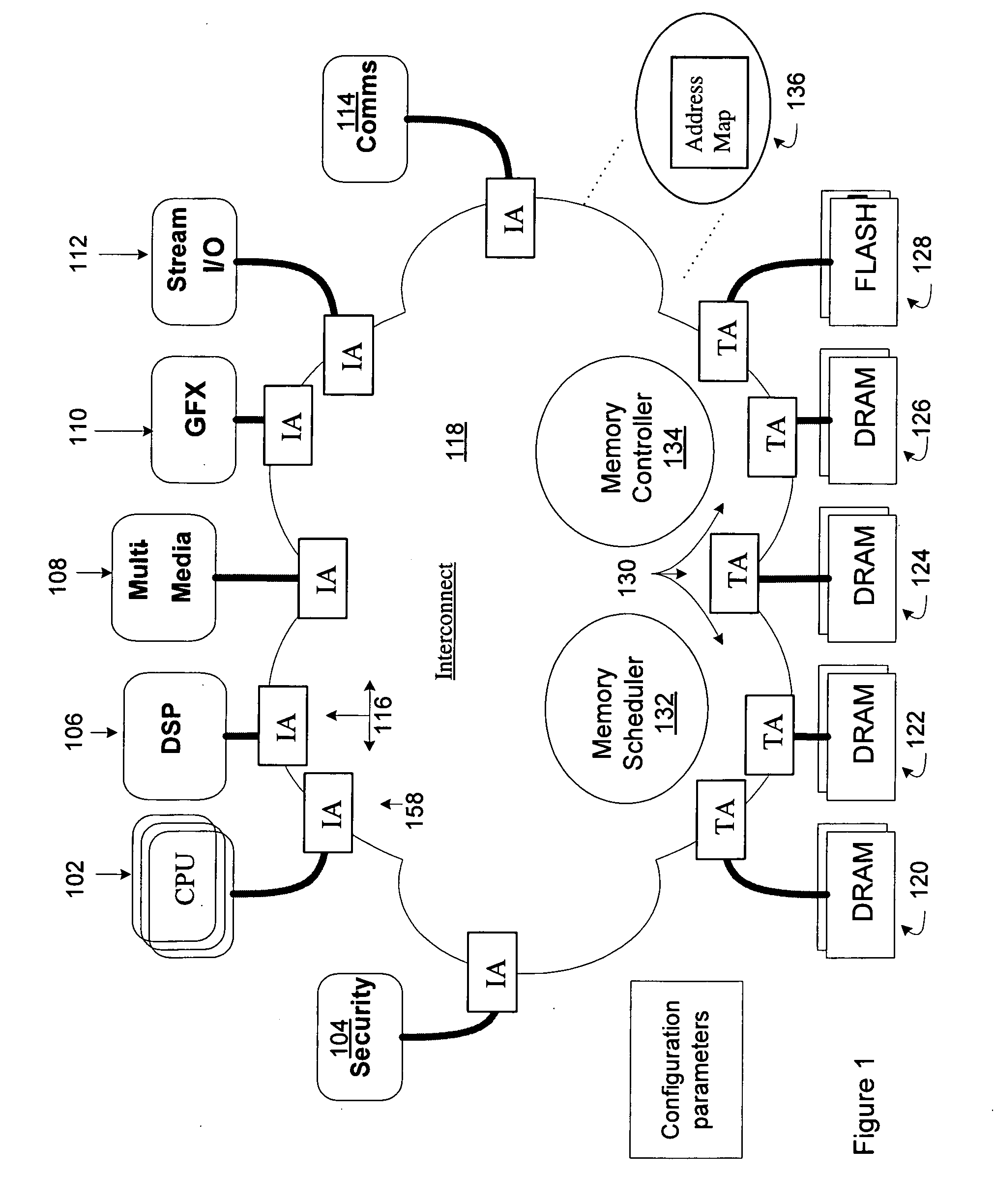

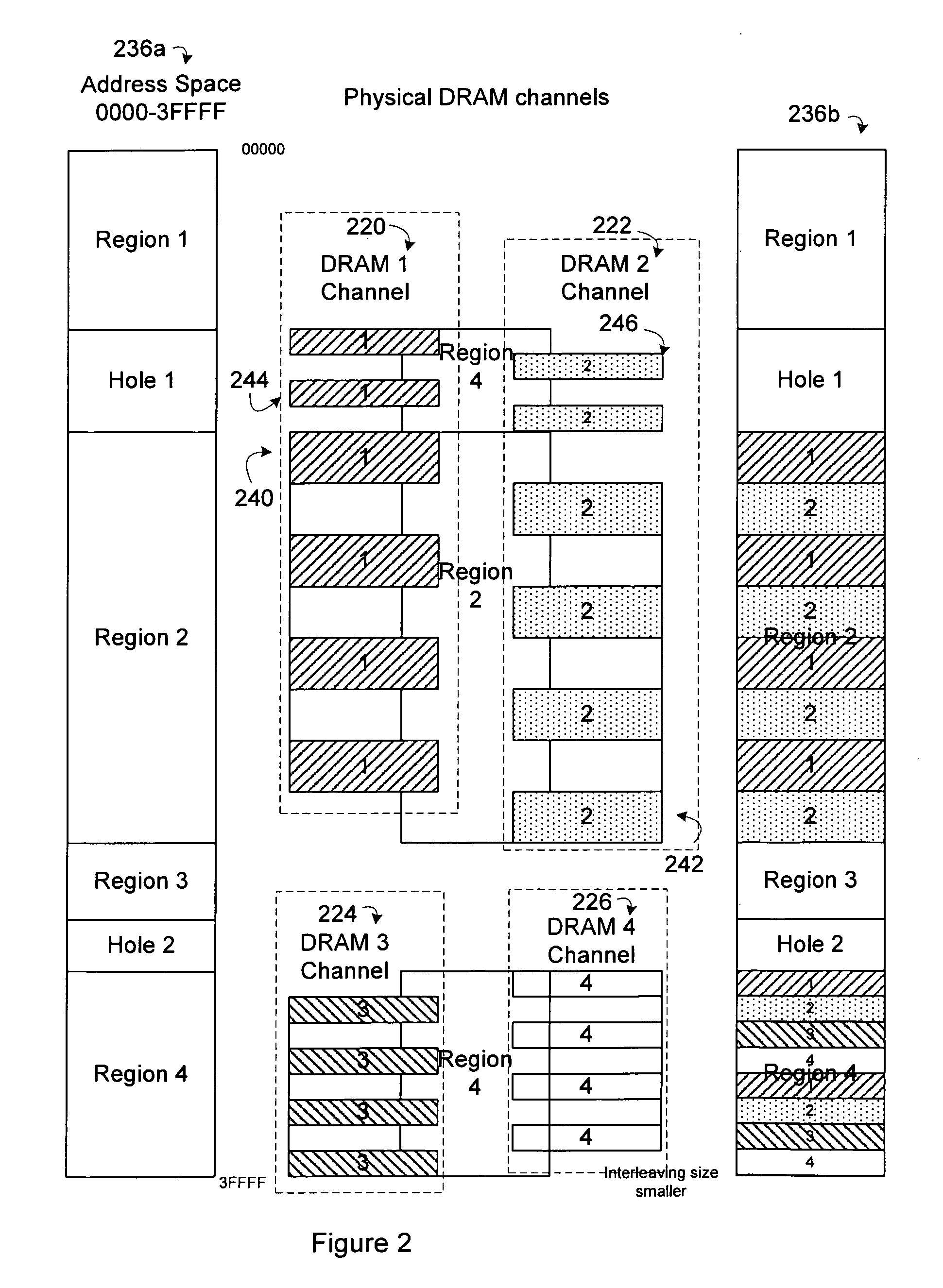

Various methods and apparatus to support outstanding requests to multiple targets while maintaining transaction ordering

ActiveUS20080320476A1Digital computer detailsMultiprogramming arrangementsIntellectual propertyOrder form

A method, apparatus, and system are described, which generally relate to an integrated circuit having an interconnect that implements internal controls. The interconnect in an integrated circuit communicates transactions between initiator Intellectual Property (IP) cores and target IP cores coupled to the interconnect. The interconnect implements logic configured to support multiple transactions issued from a first initiator IP core to the multiple target IP cores while maintaining an expected execution order within the transactions. The logic supports a second transaction to be issued from the first initiator IP core to a second target IP core before a first transaction issued from the same first initiator IP core to a first target IP core has completed while ensuring that the first transaction completes before the second transaction and while ensuring an expected execution order within the first transaction and second transaction are maintained. The logic does not include any reorder buffering.

Owner:META PLATFORMS TECH LLC

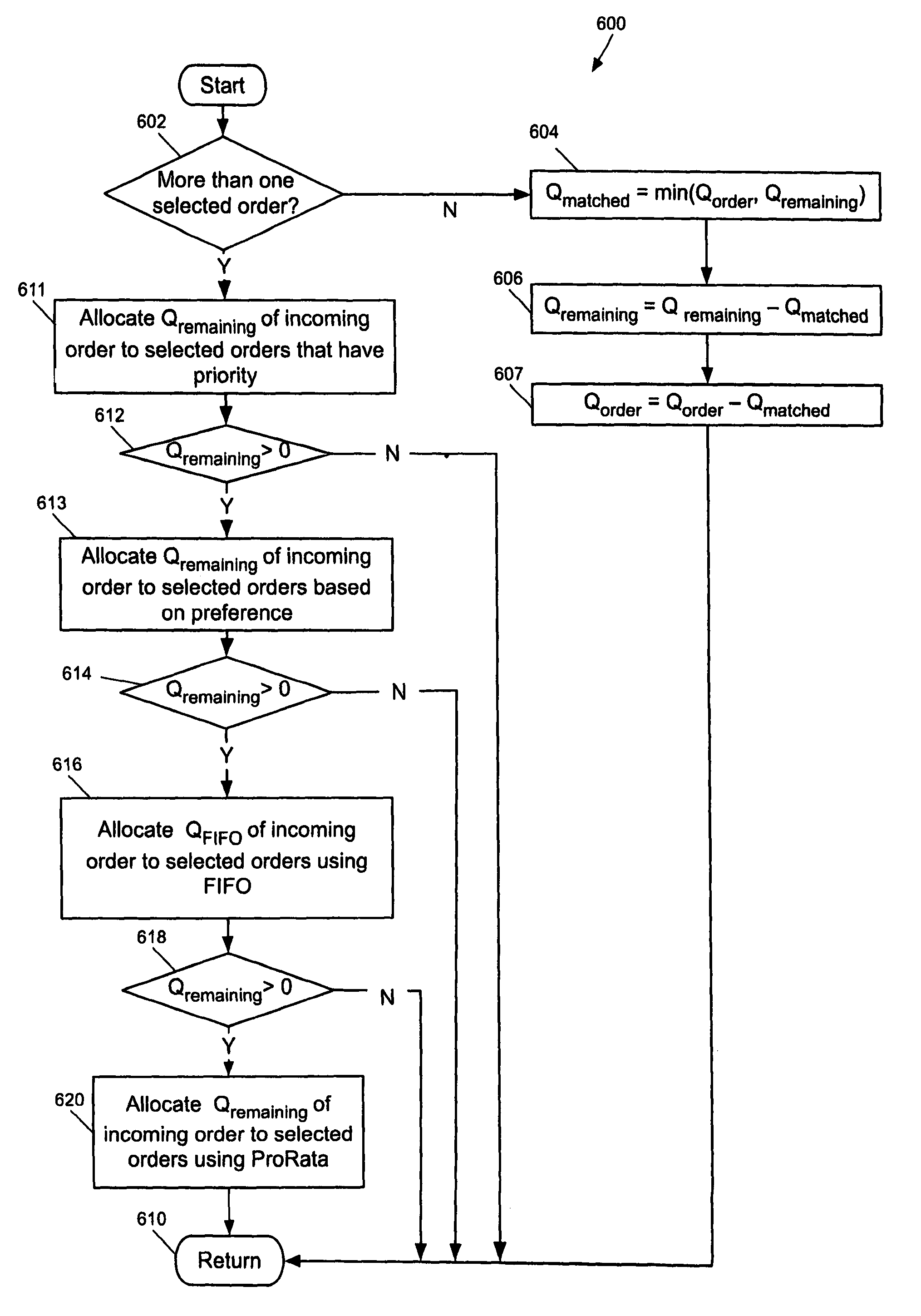

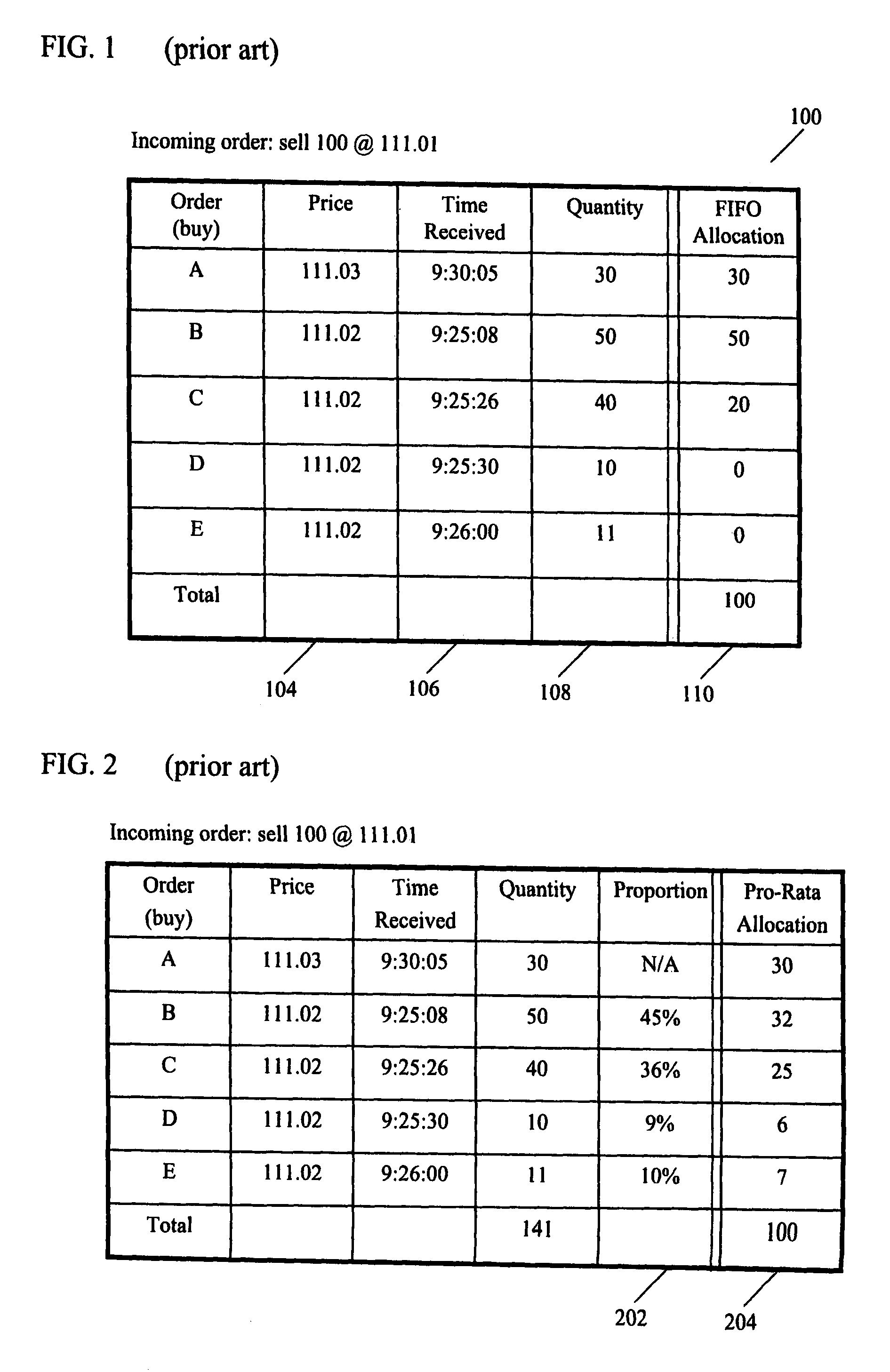

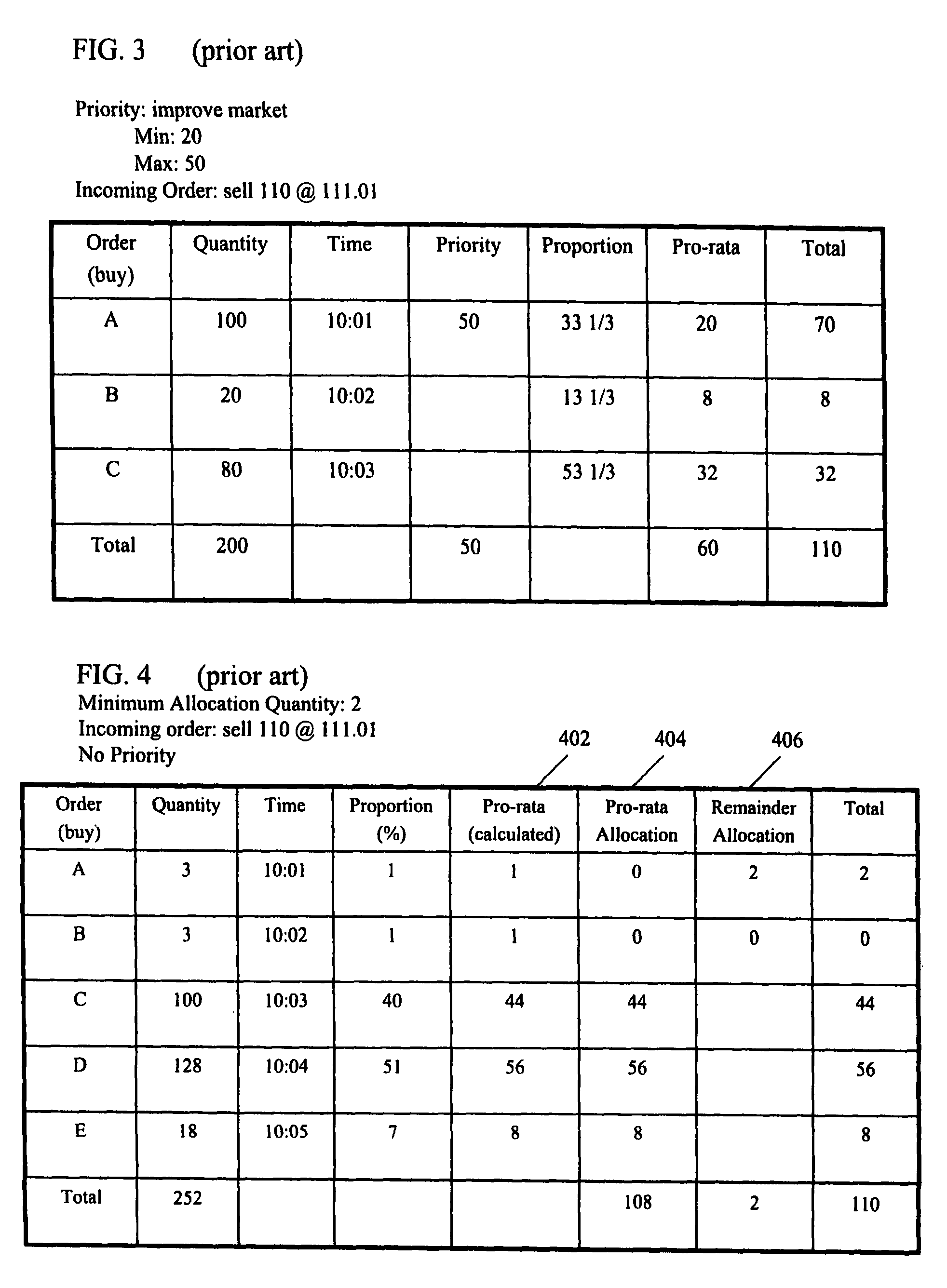

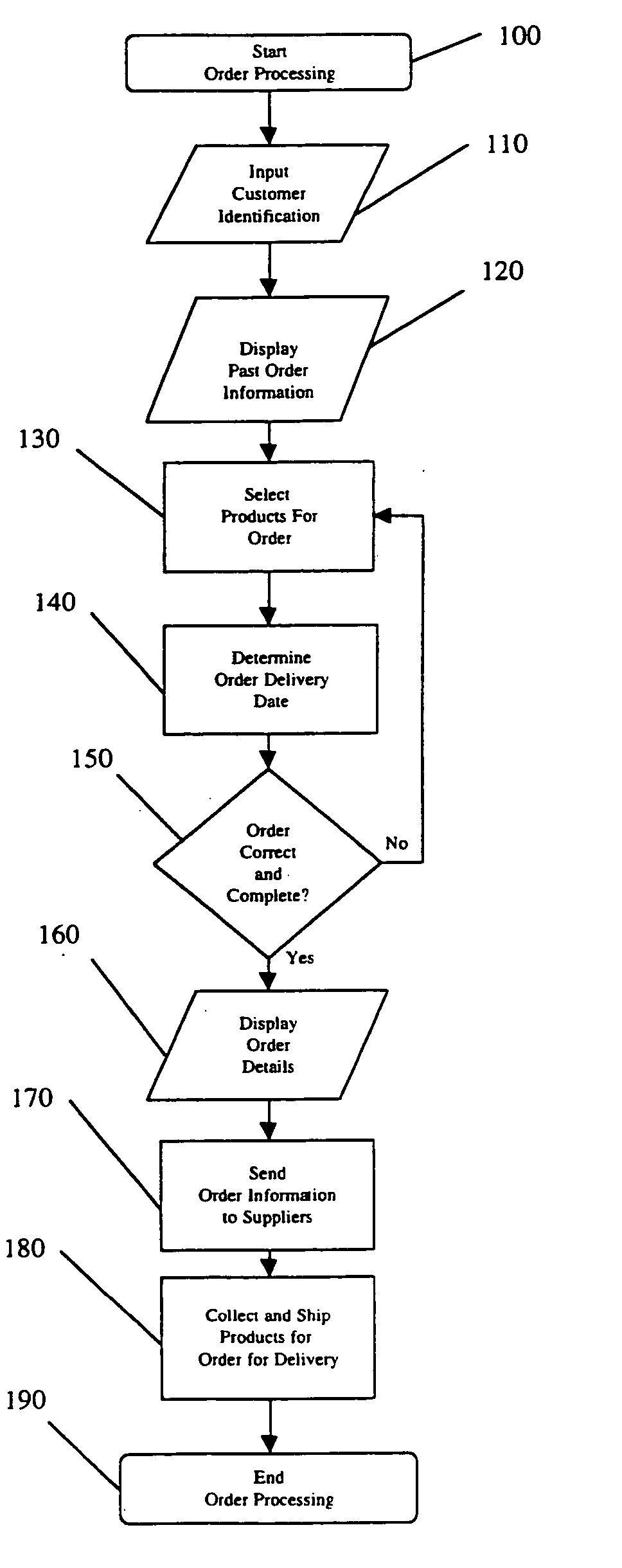

System and method of allocating an incoming order to standing orders

A method of allocating a quantity of an incoming order for a product develops a value that indicates a portion of the incoming order this is to be allocated using a FIFO algorithm and allocates a first portion of the incoming order to standing orders using the FIFO algorithm. The method further allocates a second portion of the incoming order to standing orders using a pro-rata algorithm, wherein the step of allocating the second portion leaves a remaining quantity of the incoming order. In addition, the method allocates the remaining portion to the standing orders using a FIFO algorithm.

Owner:BOARD OF TRADE OF THE CITY OF CHICAGO

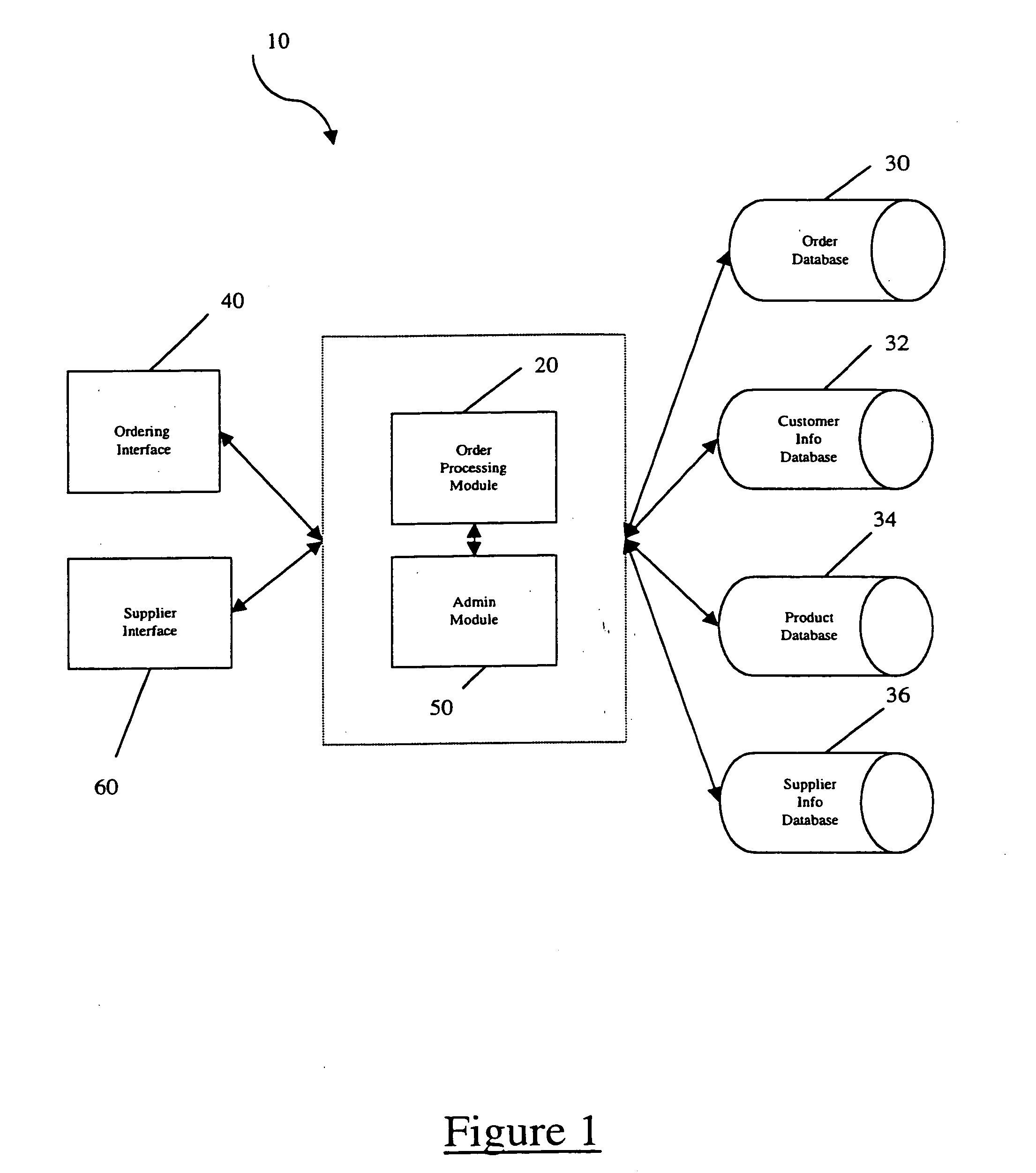

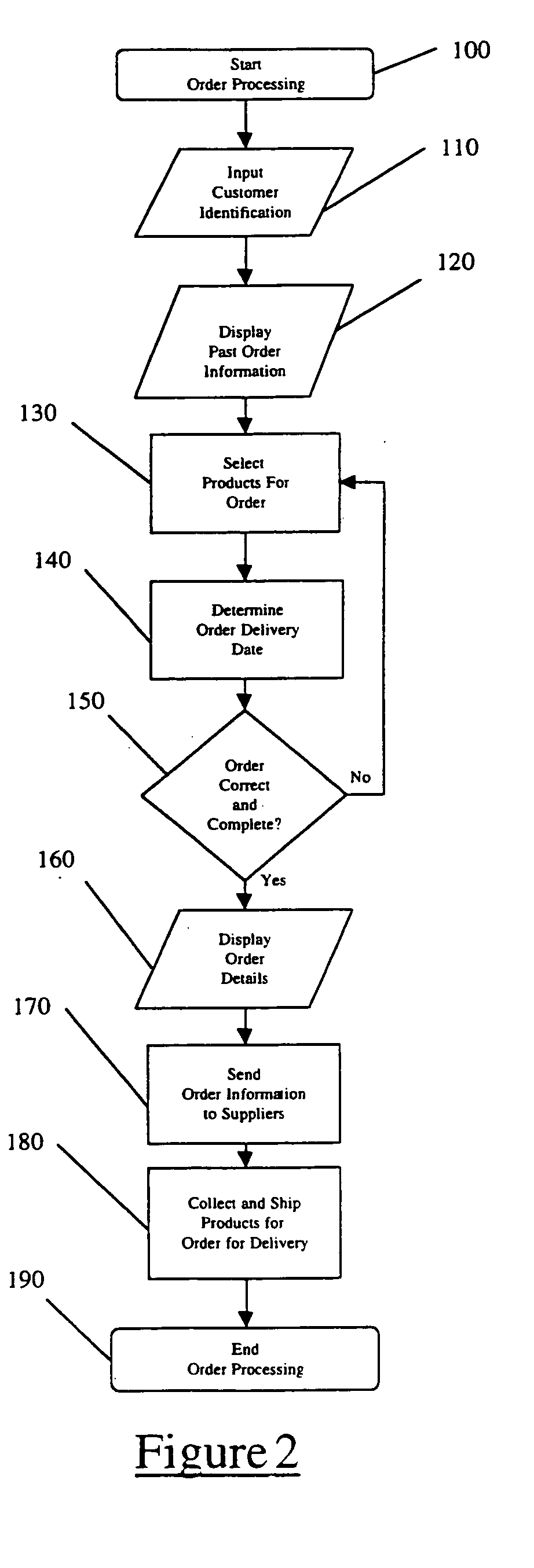

System and method for processing product orders

InactiveUS20050055283A1Buying/selling/leasing transactionsLogisticsRelevant informationProduct order

The present invention is a computer-based system and method for processing orders over the Internet. In one embodiment, the method of the present invention comprises the steps of identifying a customer placing a product order, displaying information relating to other orders associated with the customer, receiving details of a new product order from the customer, confirming details of the new product order from the customer, determining the date on which the products ordered is to be delivered to the customer, and sending order information to at least one supplier associated with the product order. Preferably, some or all of the steps of the method are performed in real-time.

Owner:ZAROVINSKY ADOLPH

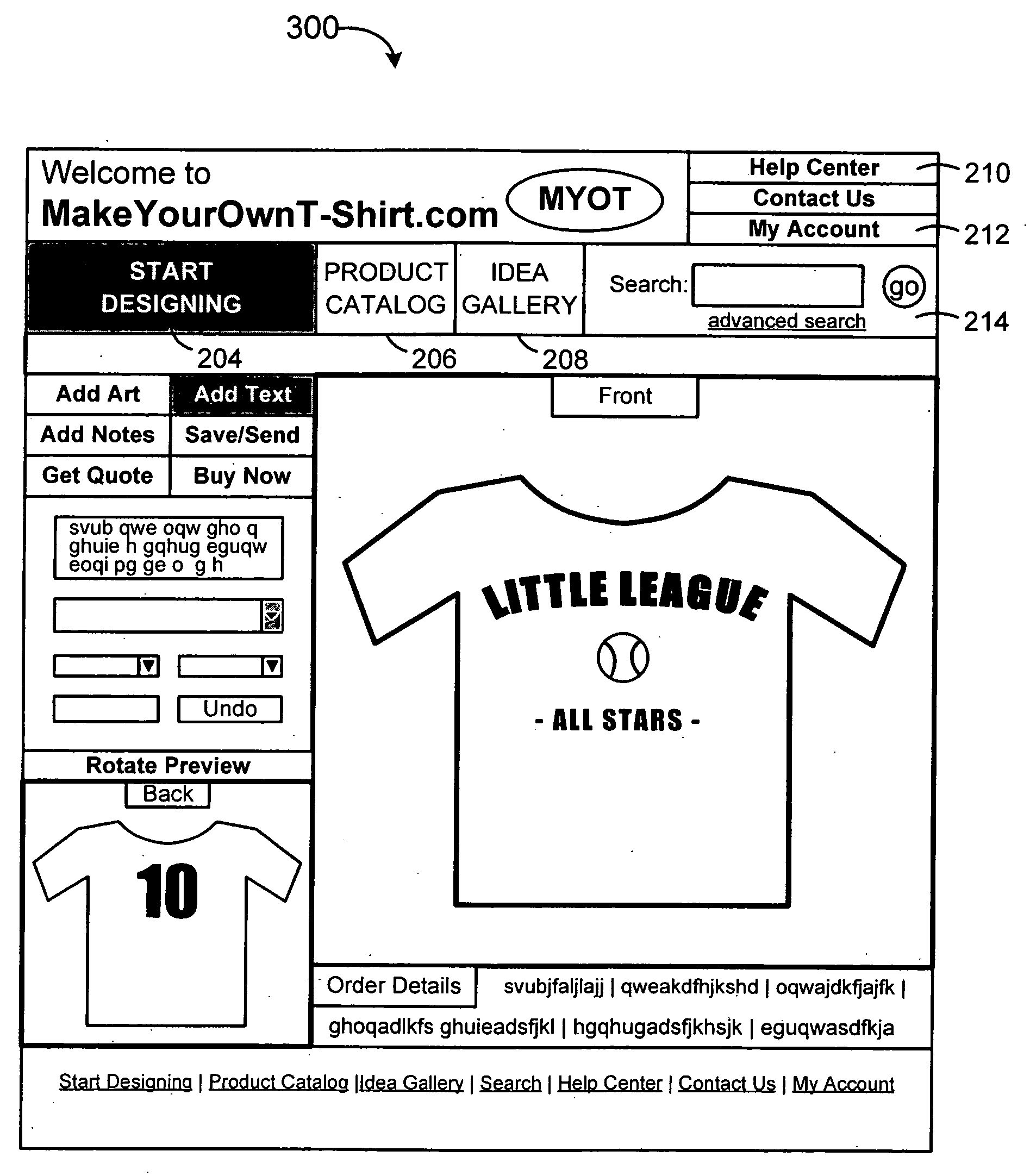

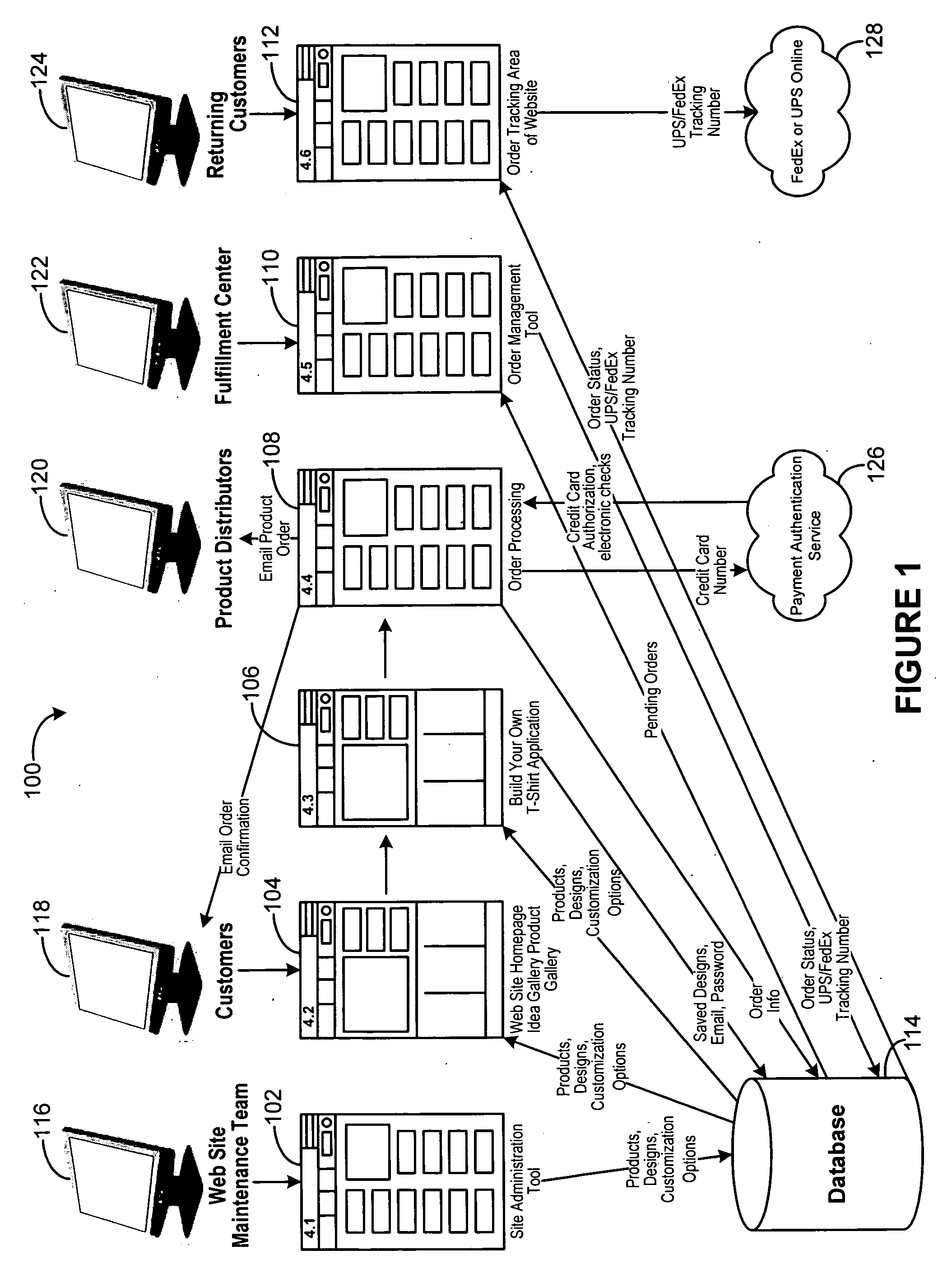

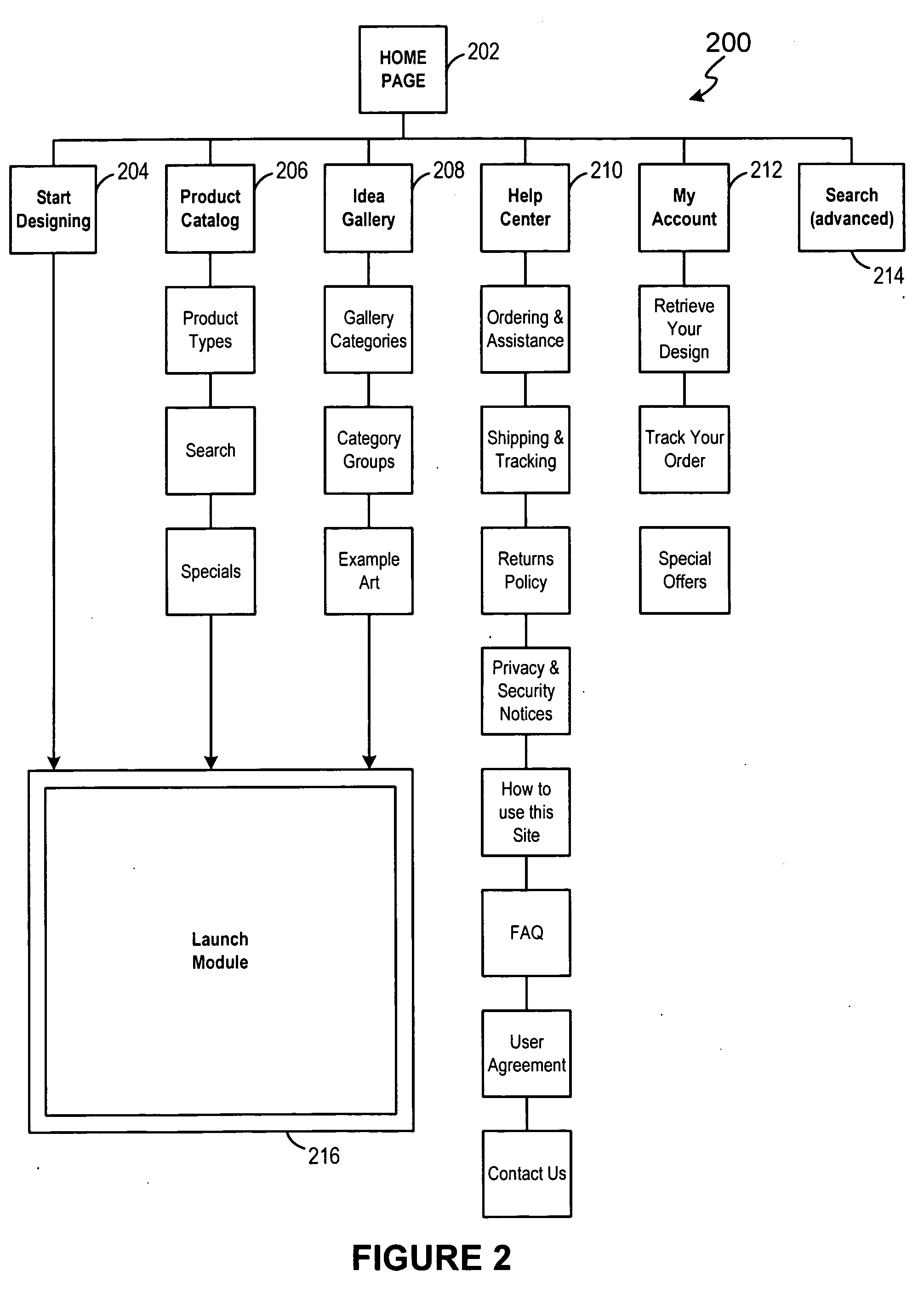

Method and system for customization of consumer products

InactiveUS20050177453A1Create displayBuying/selling/leasing transactionsSpecial data processing applicationsGraphicsManagement tool

A method and system for customization of consumer products, such as the creating, designing and / or selecting of artwork, graphic elements and / or designs for consumer products, are provided. An exemplary method and system can allow for a customer to select, design, save and / or purchase customized products more efficiently, and enable merchandizing and operations personnel to be able to more readily create, approve and publicly display products and related designs without possessing extensive technical capabilities. In accordance with an exemplary embodiment, a system for customization of consumer products can comprise a database configured with a plurality of modules, such as an administration tool module, a home or anchor website module, a customization module, an order processing module, an order management module, and / or an order tracking module. To facilitate a more efficient customization and design process, an exemplary system for customizing consumer products comprises an application configured to use the capabilities of a local computer of the consumer to provide substantially instantaneous design changes and modifications for evaluation by the customer.

Owner:HAVANA CLUB

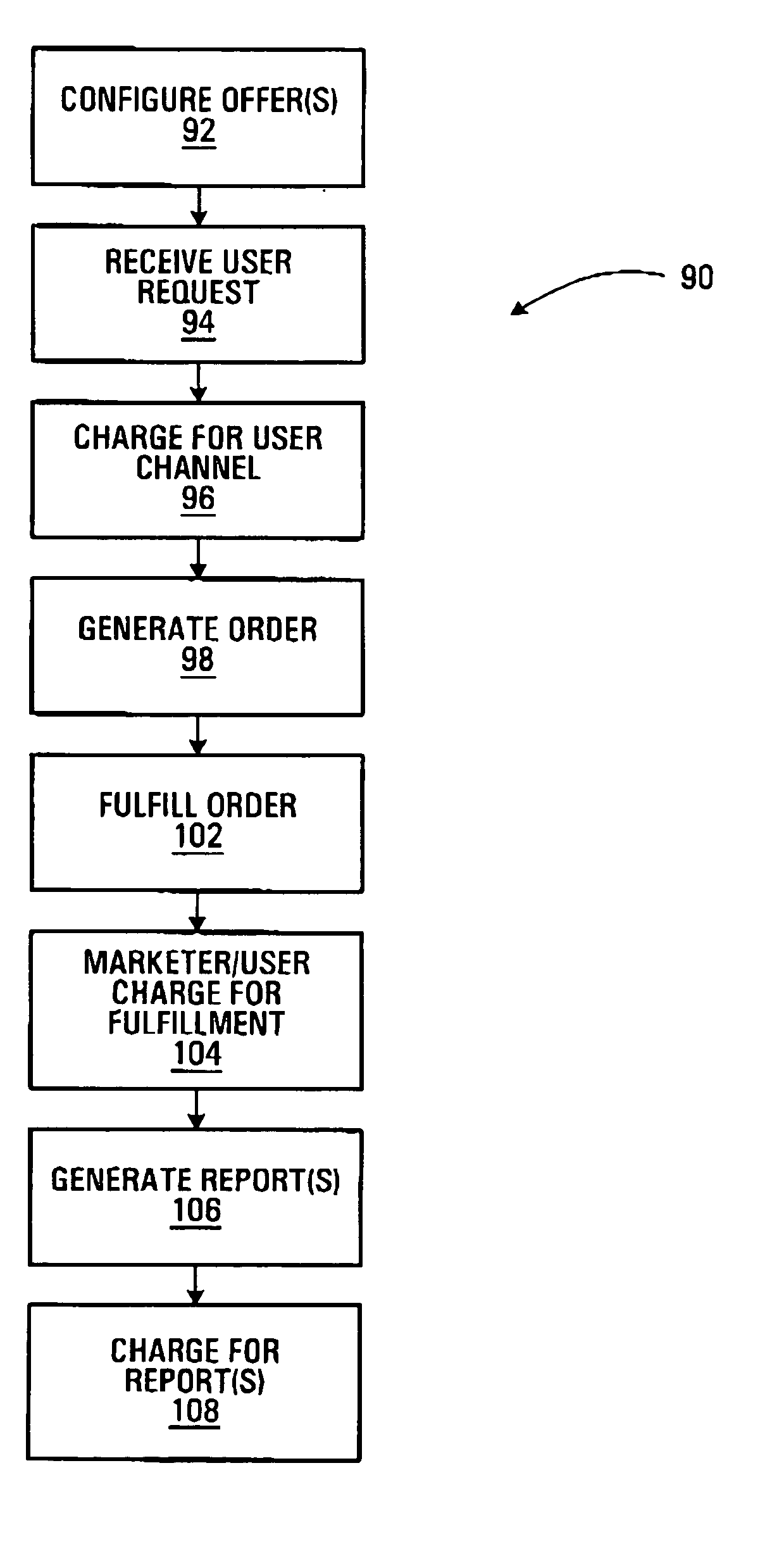

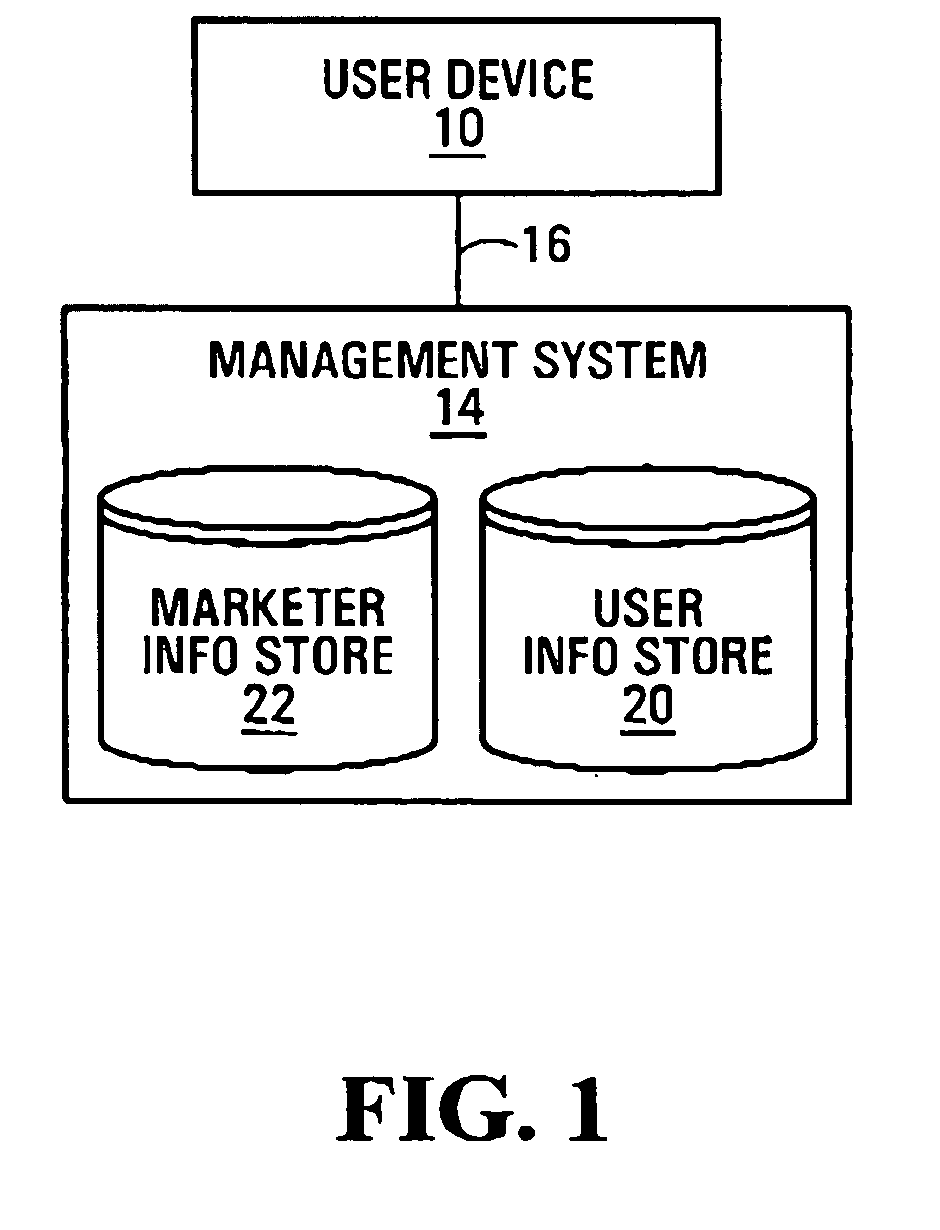

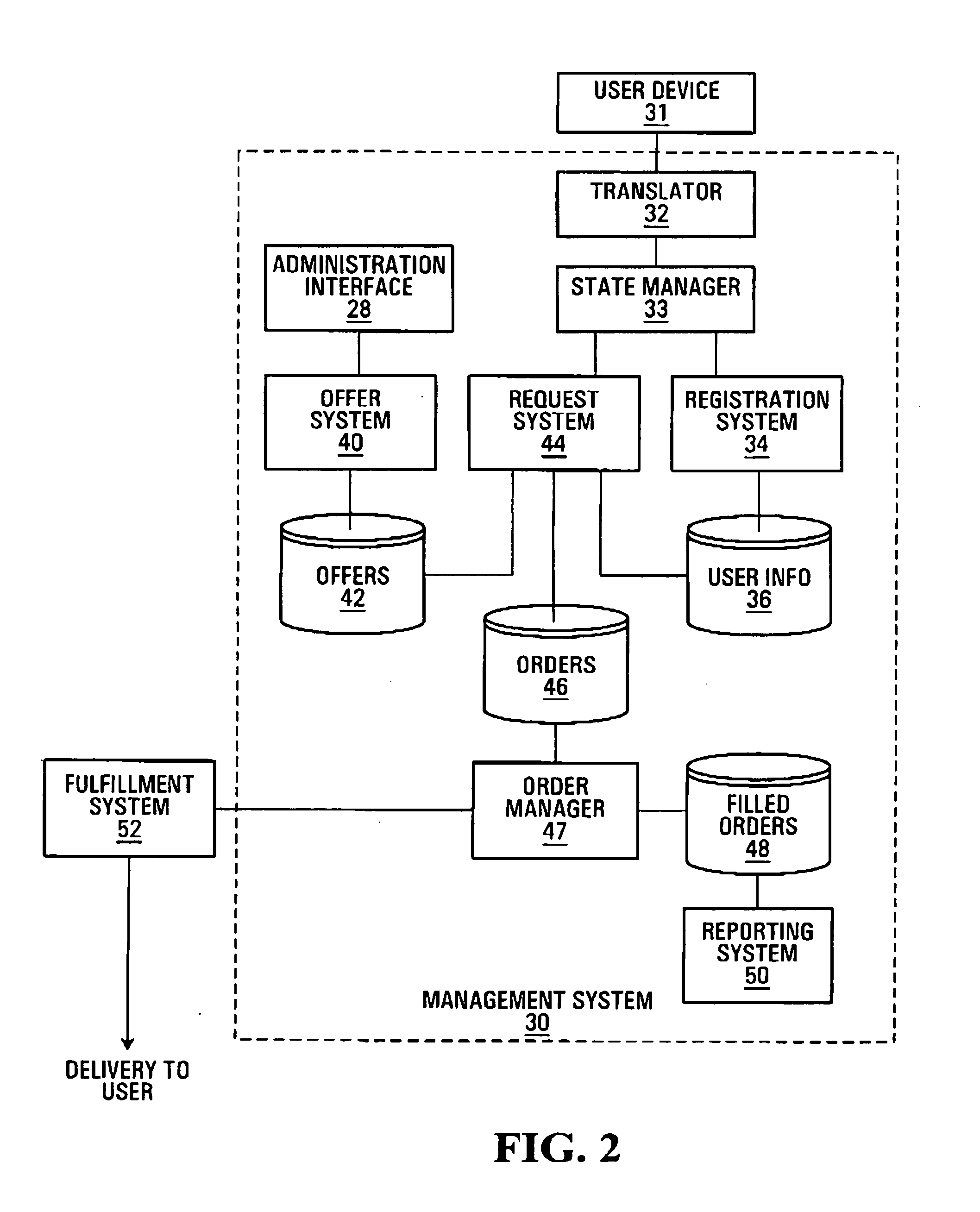

Systems and methods of managing marketing campaigns

InactiveUS20050125291A1Special service provision for substationUser identity/authority verificationService provisionOrder form

Systems and methods relating to management of marketing campaigns are provided. Requests from users are matched to stored offers relating to available marketing materials to generate an order for each request. Orders may be fulfilled by delivering the marketing materials to the user, for example. The matching of requests to offers may be based on information in the requests, user information associated with users from which the requests are received, offer rules associated with the stored offers, or any combination thereof. Some embodiments provide for user registration with a marketing campaign management system which exploits user information which is available from an external source, such as a service provider system which provides a service for which the user has previously registered or a system which provides a reverse lookup function.

Owner:CANADA POST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com