Patents

Literature

265 results about "Original equipment manufacturer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An original equipment manufacturer (OEM) is a company that produces parts and equipment that may be marketed by another manufacturer. The largest OEM company in the world by both scale and revenue is Foxconn, a Taiwanese electronics company, which manufactures parts and equipment for companies including Apple, Dell, Google, Huawei and Nintendo.

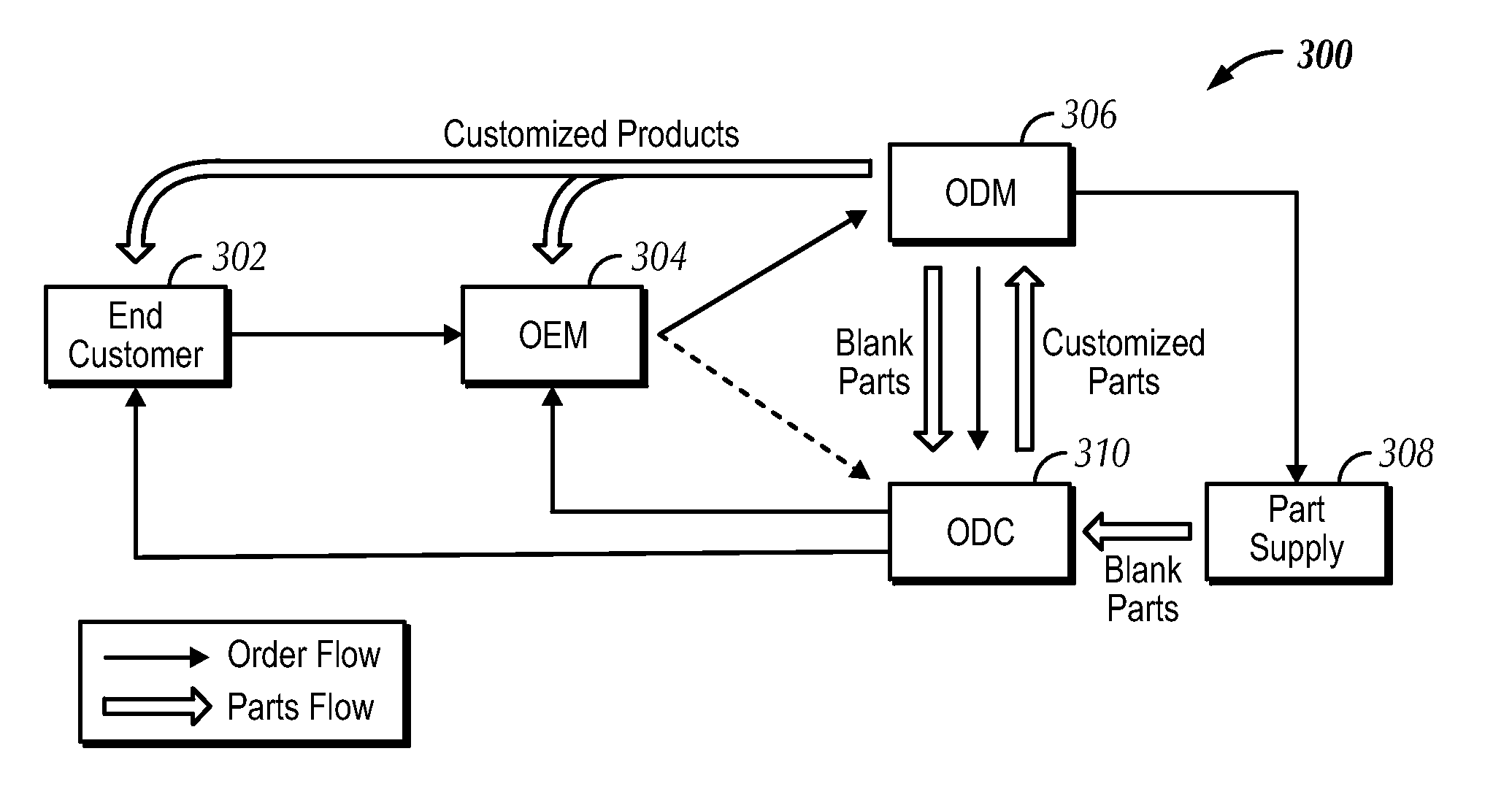

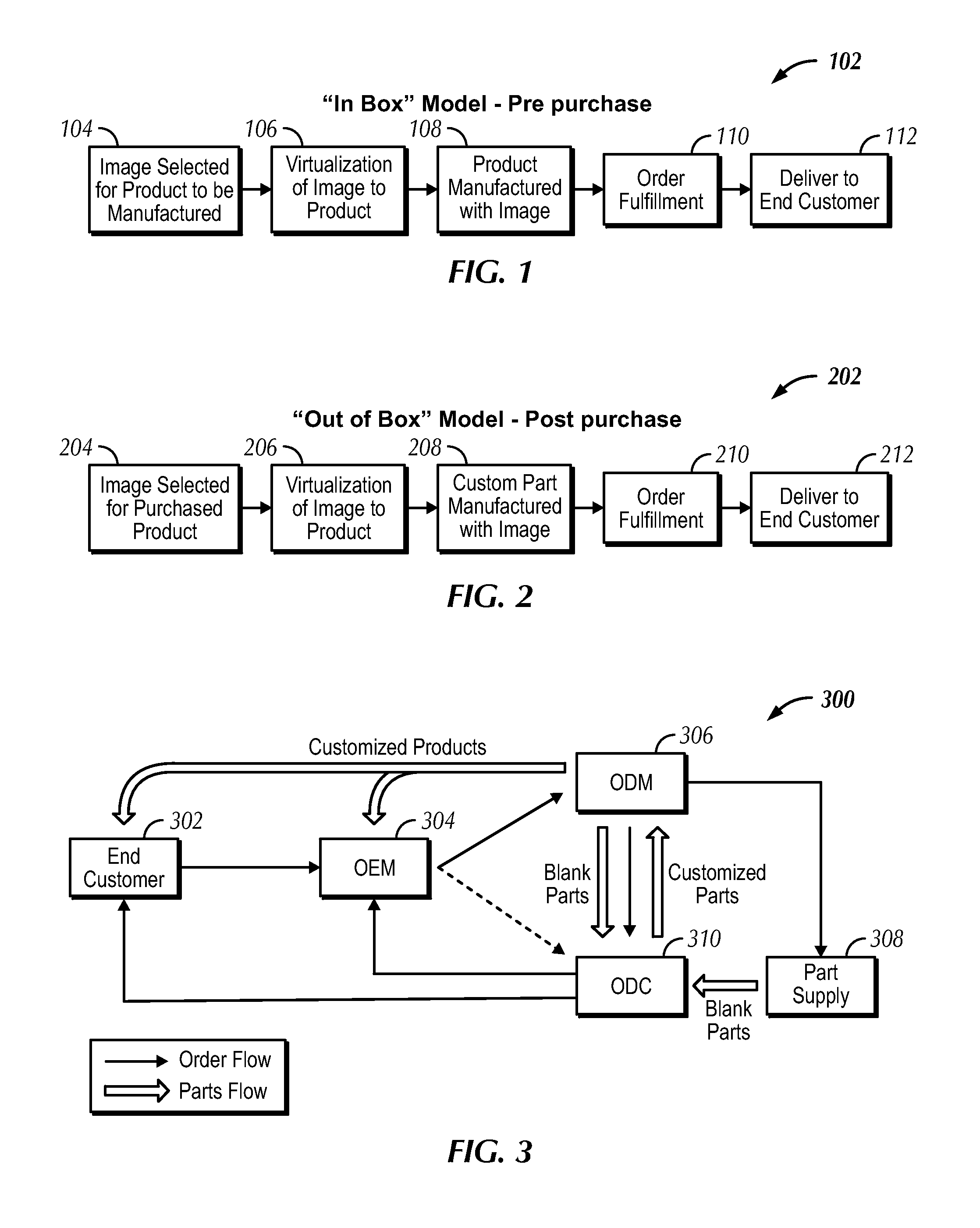

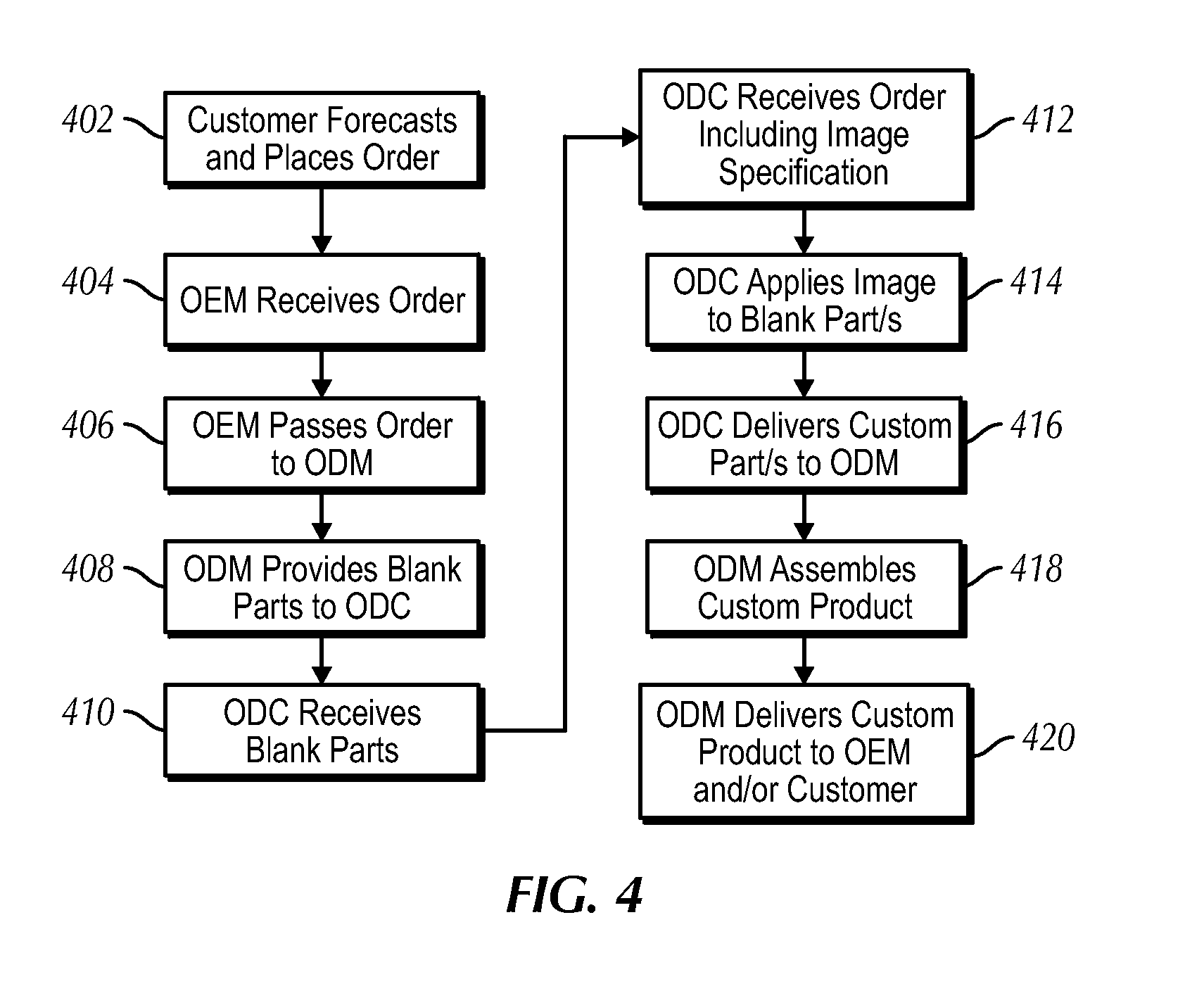

Systems and methods of on demand manufacturing of customized products

Systems and methods are described herein relating to managing an on-demand manufacturing supply chain personalization process. In some embodiments, the management system and method is described in order to manufacturing customized products according to image and customization data with images applied to parts using a post mold image application process. In other embodiments, customized products are defined by electronic orders that specify product manufacturing data including imagery to be applied to the products. In other embodiments, manufacturing methods are described in which an original equipment manufacturer (OEM) or an original design manufacturer (ODM) leverages use of an on demand customizing entity in the manufacturing supply chain. In other embodiments, customized products are described in which imagery spans across multiple components of the products. In other embodiments, re-usable tracking devices and scheduling processes based on filtered options are additionally described. Some embodiments combine one of more of these mentioned embodiments.

Owner:SKINIT

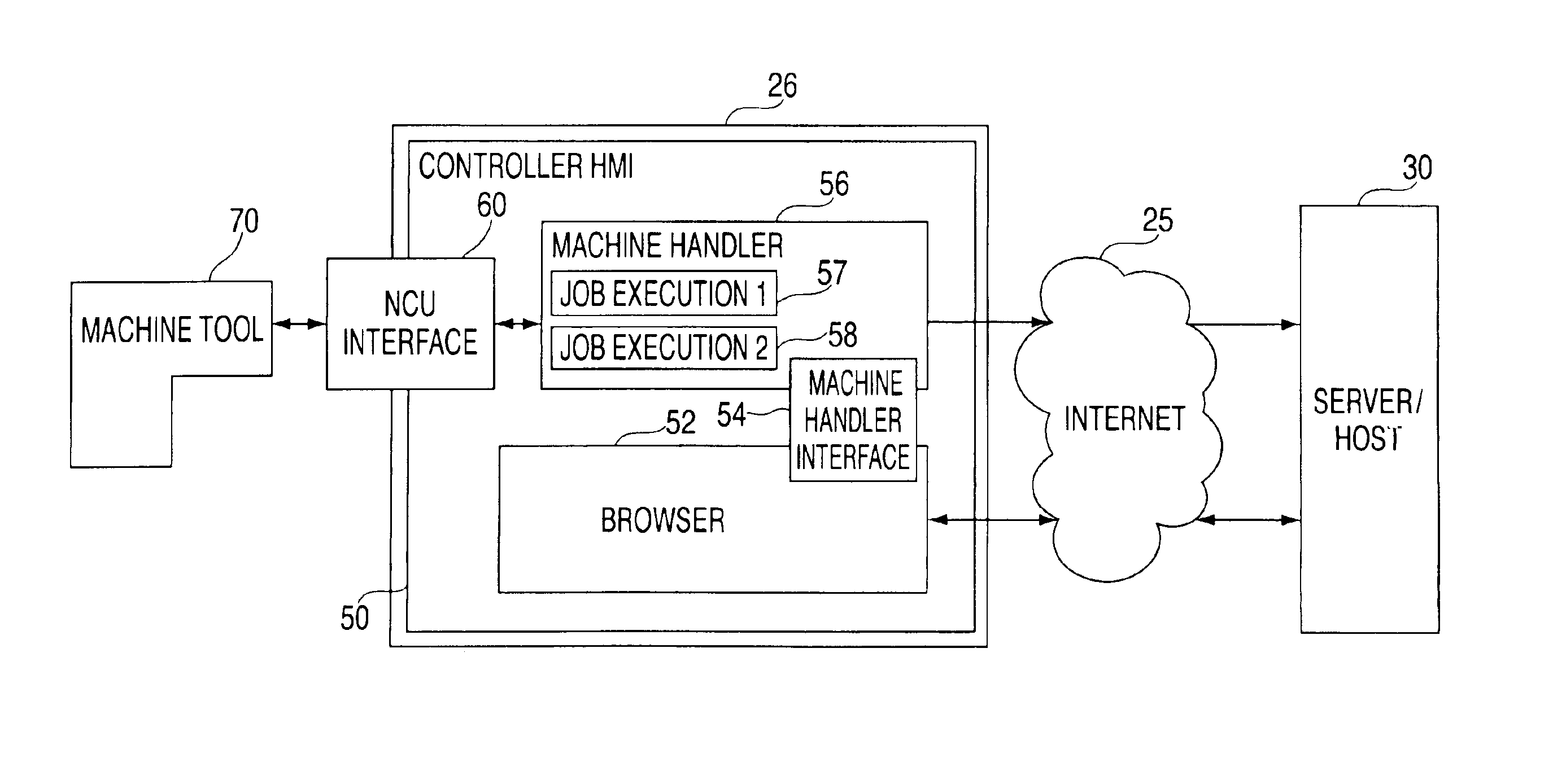

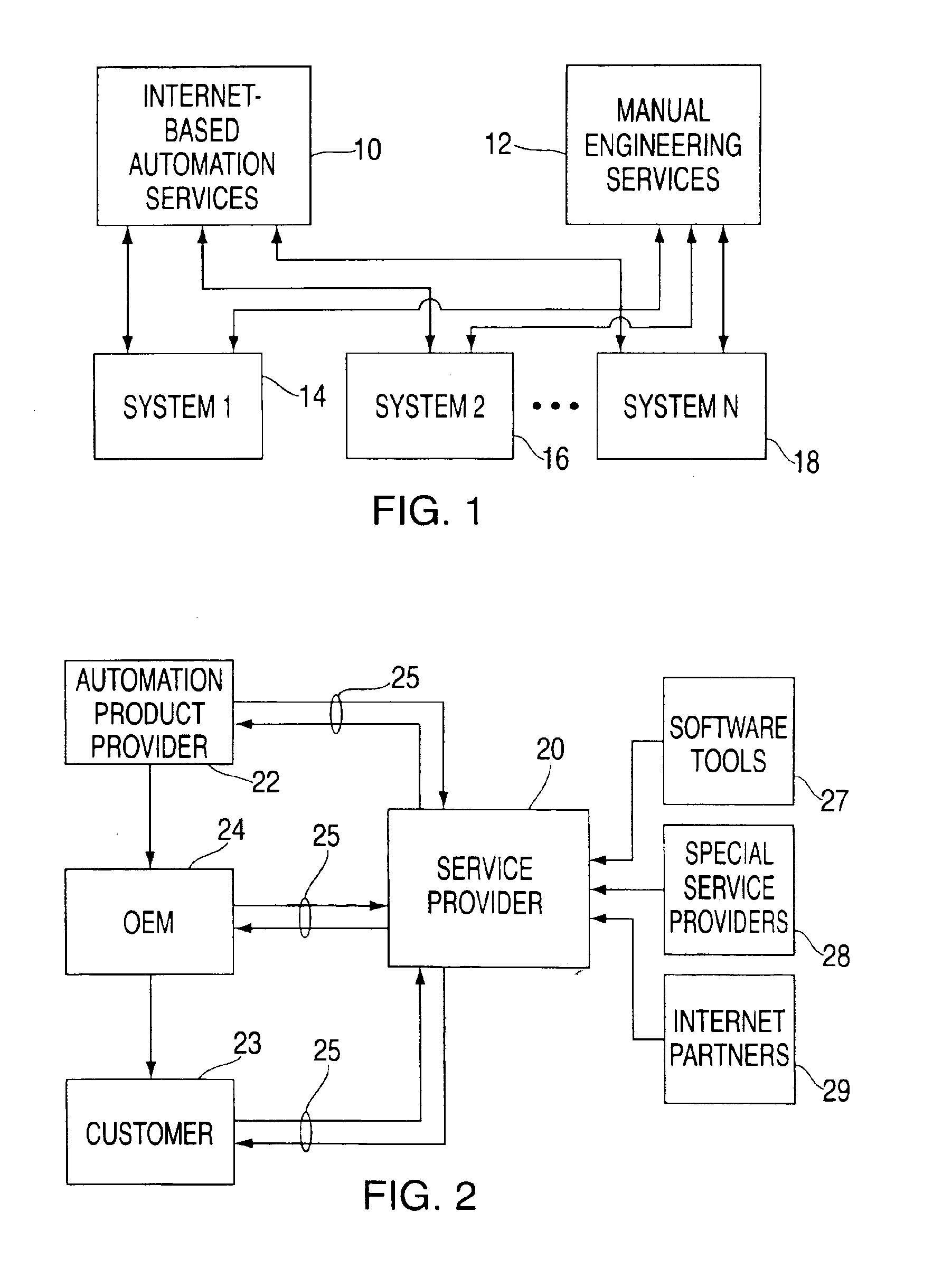

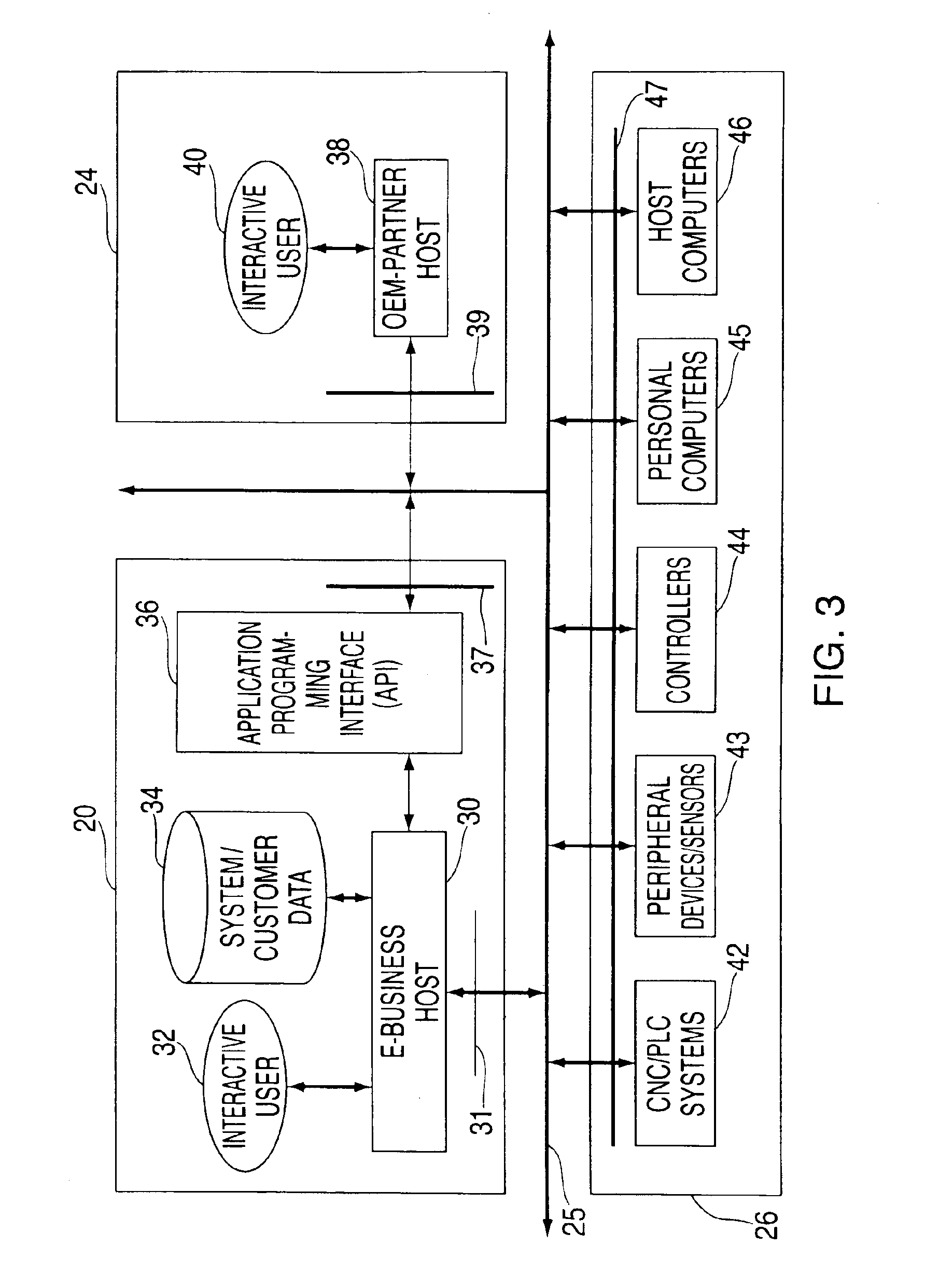

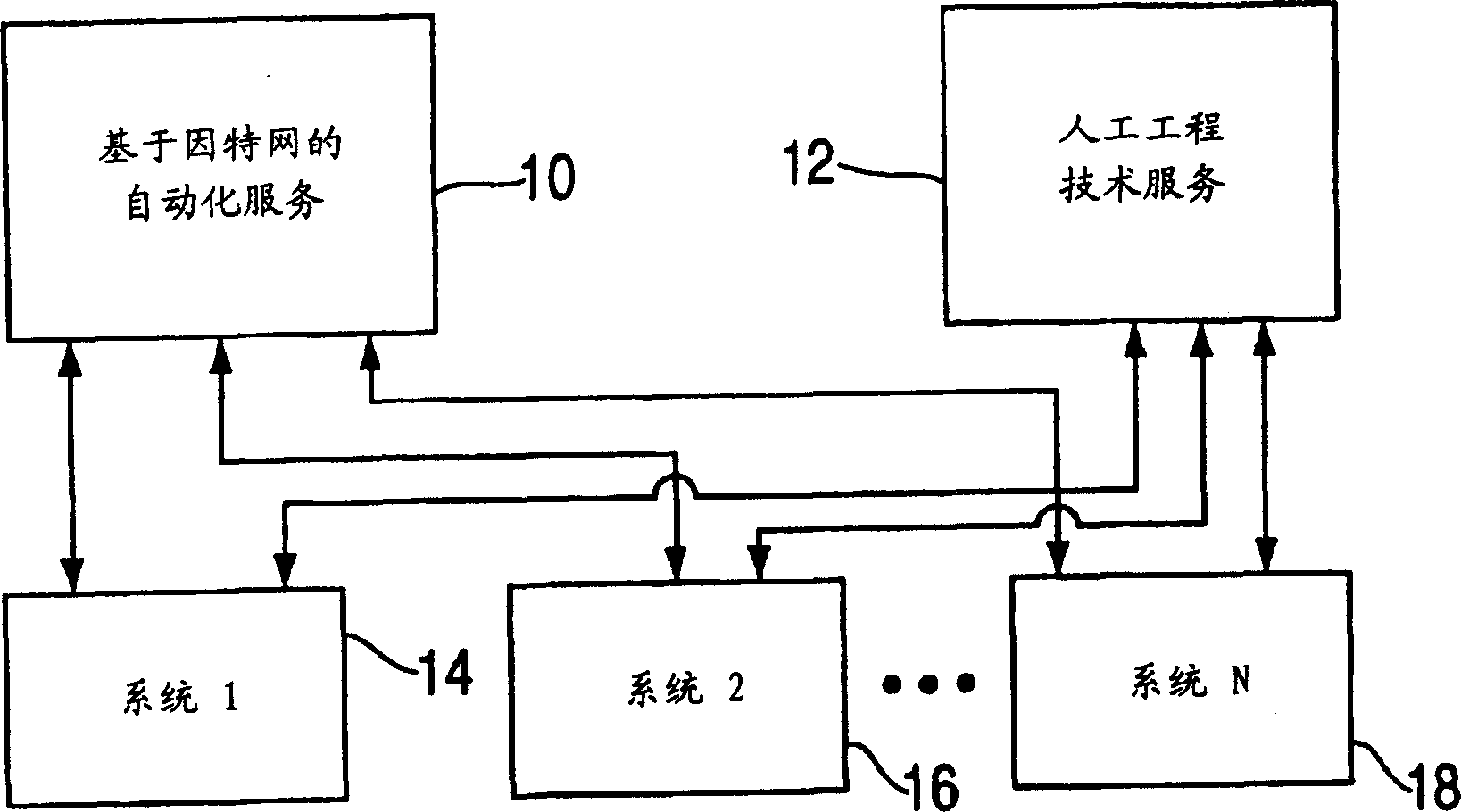

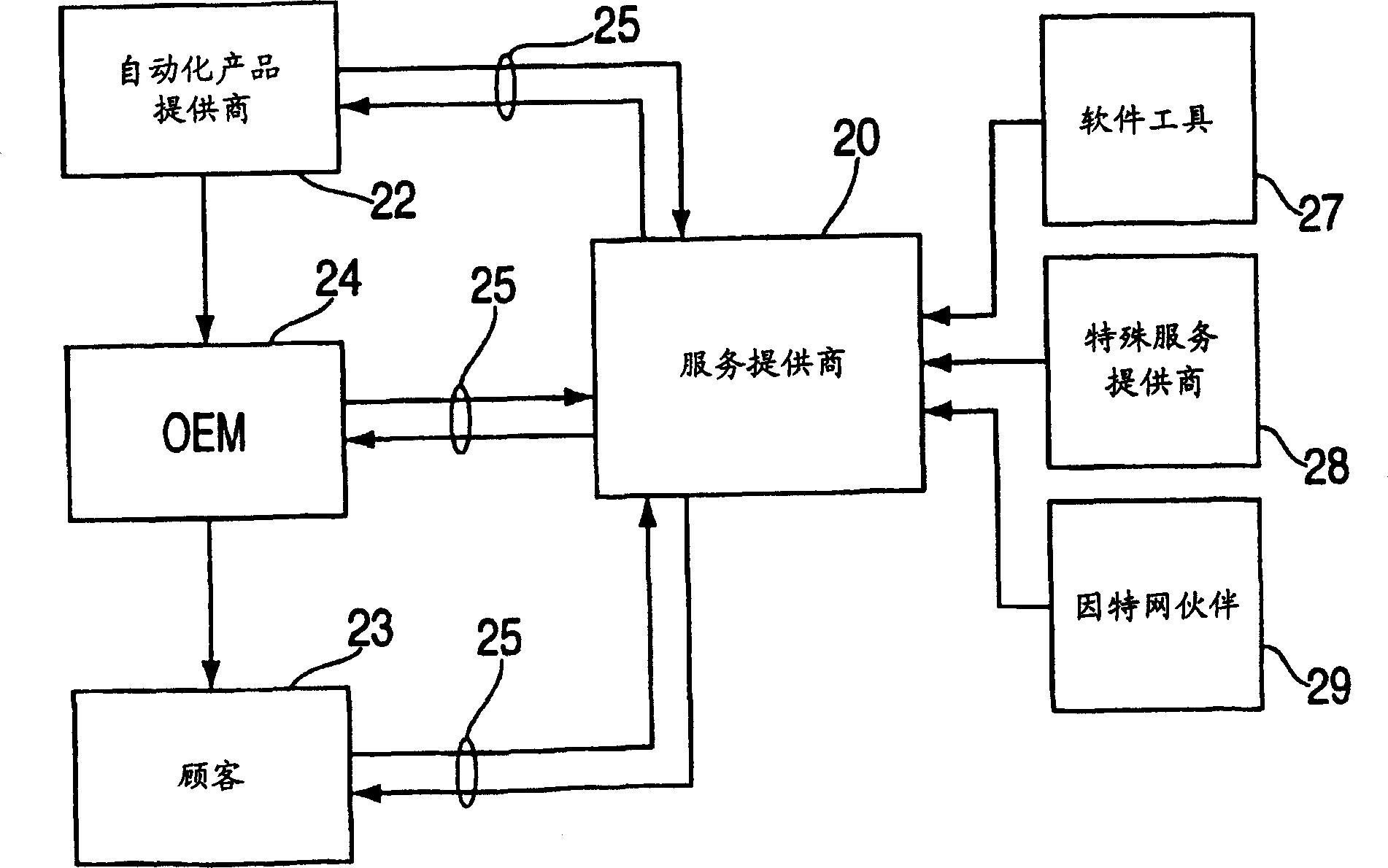

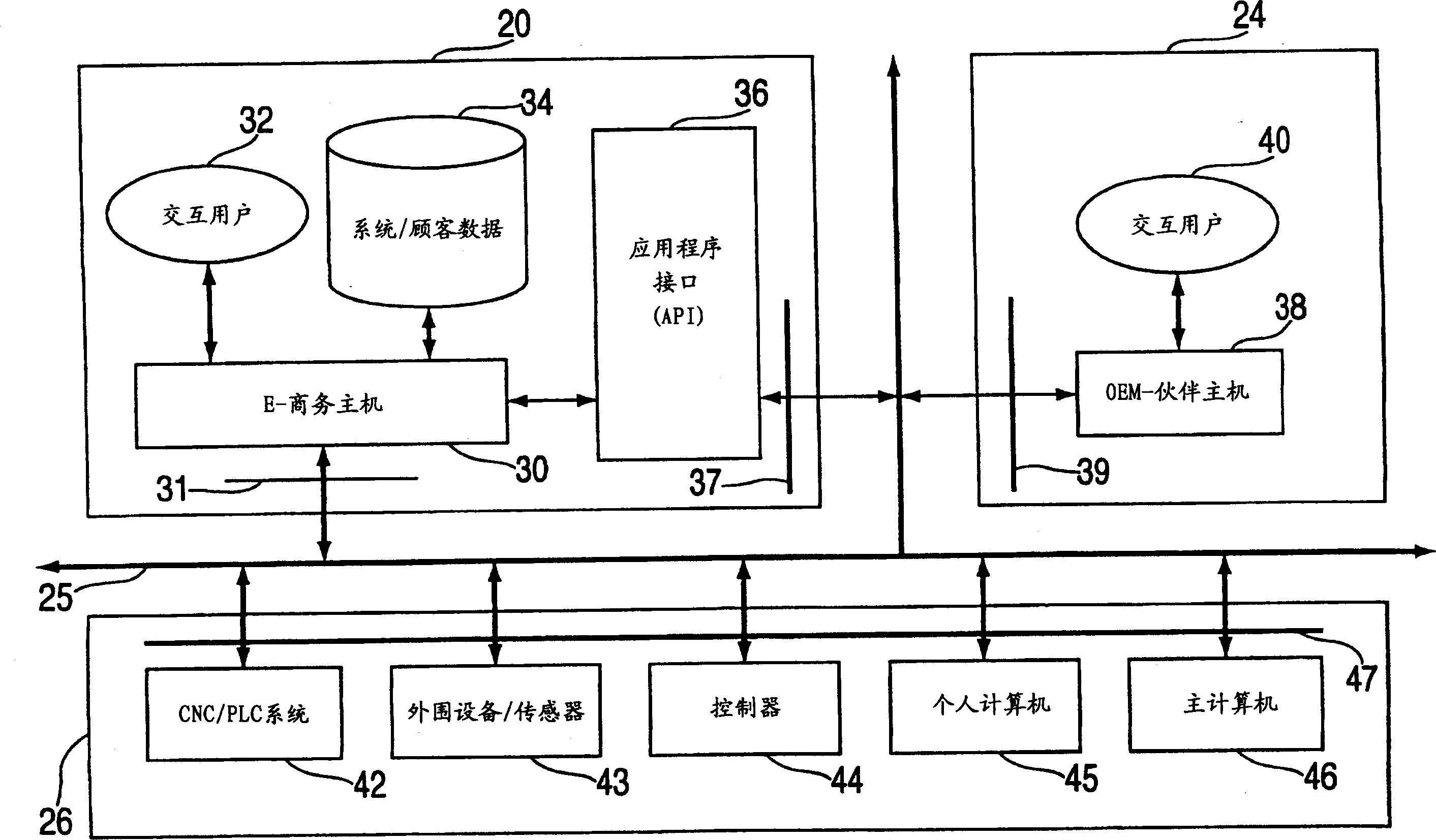

Database system and method for industrial automation services

InactiveUS6975913B2Improve data securityProvide informationComputer controlSimulator controlReal-time dataOriginal equipment manufacturer

A host system generates and manages databases incorporating data gathered from a plurality of client automation systems, such as CNC machine tools. The data may include real-time data, and is captured from the client systems under supervision of software downloaded over a network from the host system to the client systems. The captured data is transmitted over the network to the host, which creates the databases. The databases preferably include a commercial database comprising data associated with customer owners or operators of the client automation system, as well as a technical database, comprising captured data, administrative and other data, organized by customer and client system. Captured data is preferably associated with the date of capture, providing for the creation of a historical database for given client equipment. With customer authorization, others, such as original equipment manufacturers, may access the captured data, for which they may be charged a fee.

Owner:SIEMENS AG

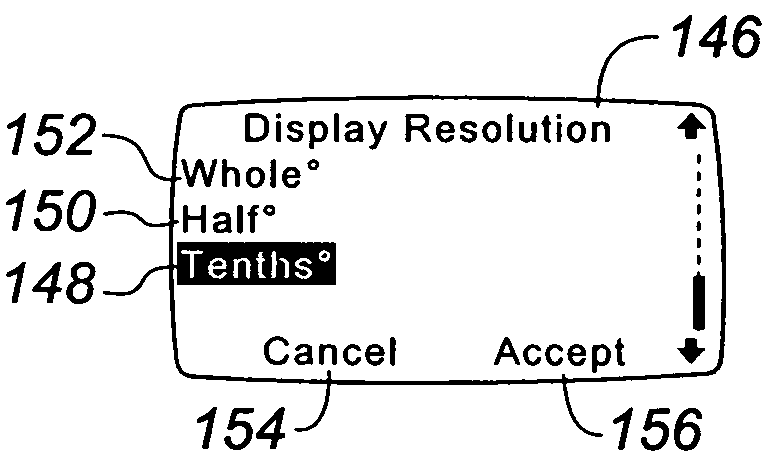

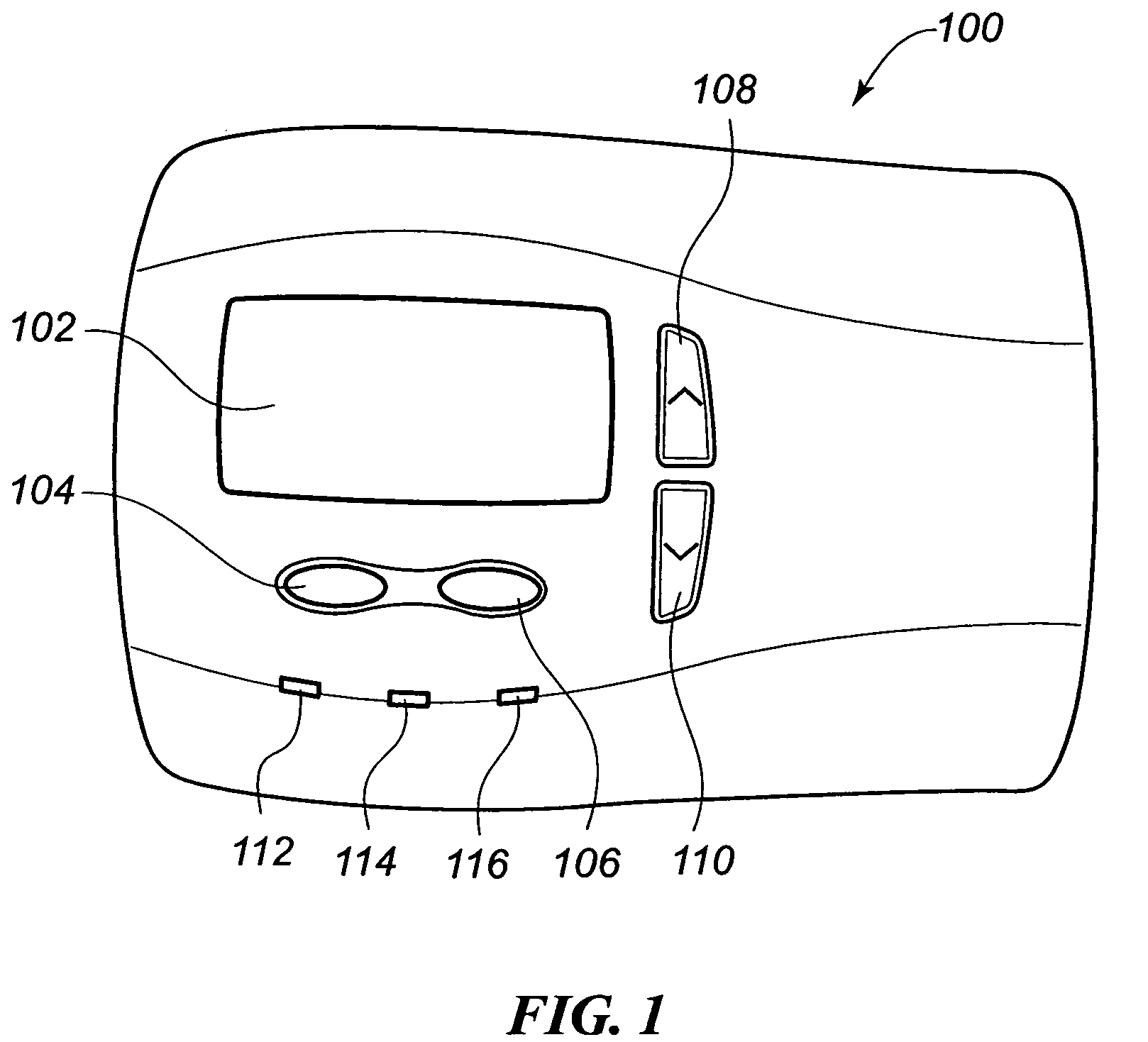

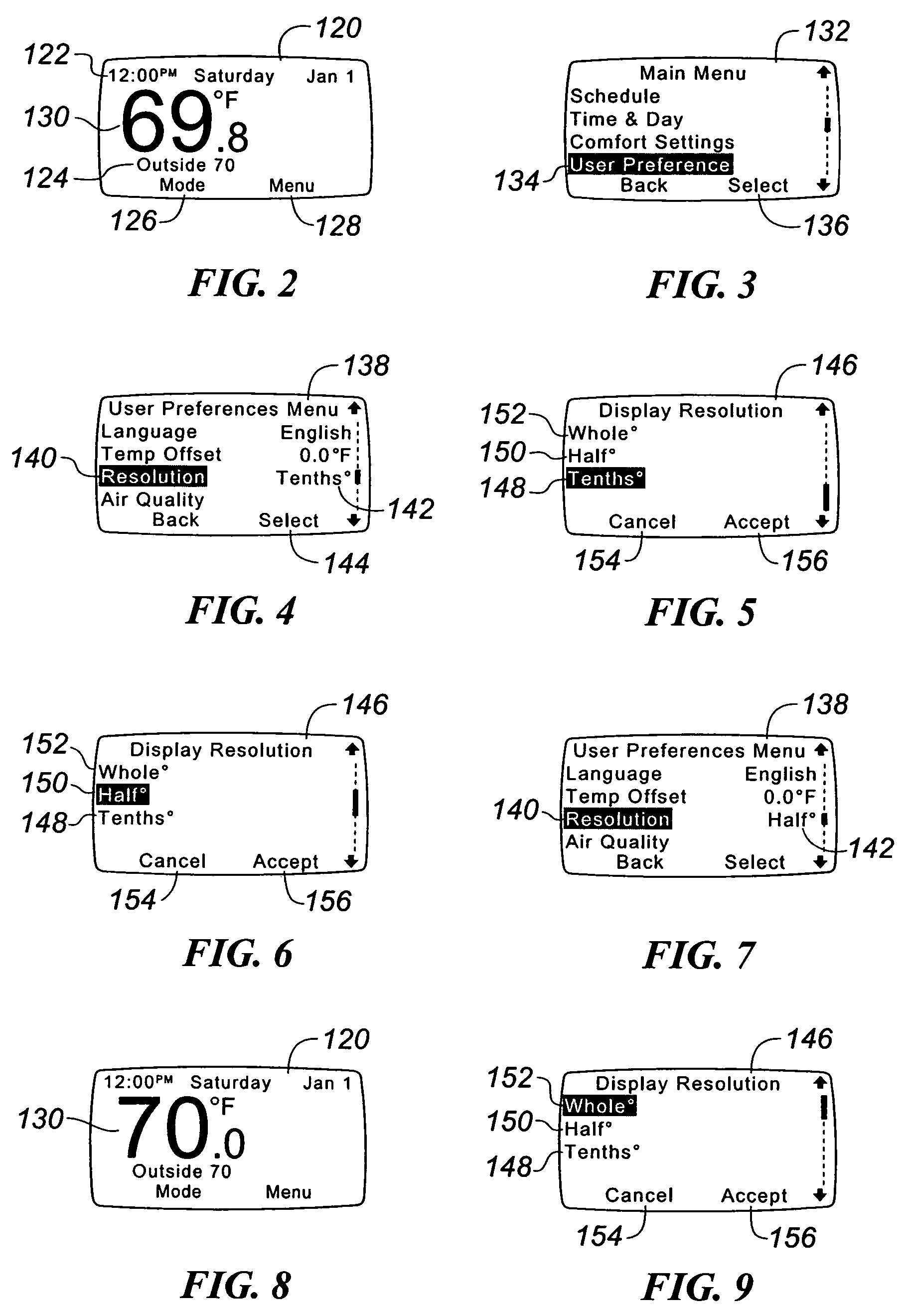

Adjustable display resolution for thermostat

ActiveUS7624931B2Process controlMechanical apparatusTemperatue controlImage resolutionOriginal equipment manufacturer

A visual display system for use with a digital thermostat is provided. The visual display system provides an adjustable display resolution for the temperature readout provided thereon. This adjustable display resolution may be changed as desired by a user via a resolution adjustment menu. The display resolution may be adjusted to display the temperature information in tenths of degrees, half degrees, whole degrees, etc. as desired by a user. Such a display system accommodates different display resolution requirements of different original equipment manufacturer (OEM) customers who may desire different displayed resolutions without having to manufacture and stock different models.

Owner:RANCO OF DELAWARE +1

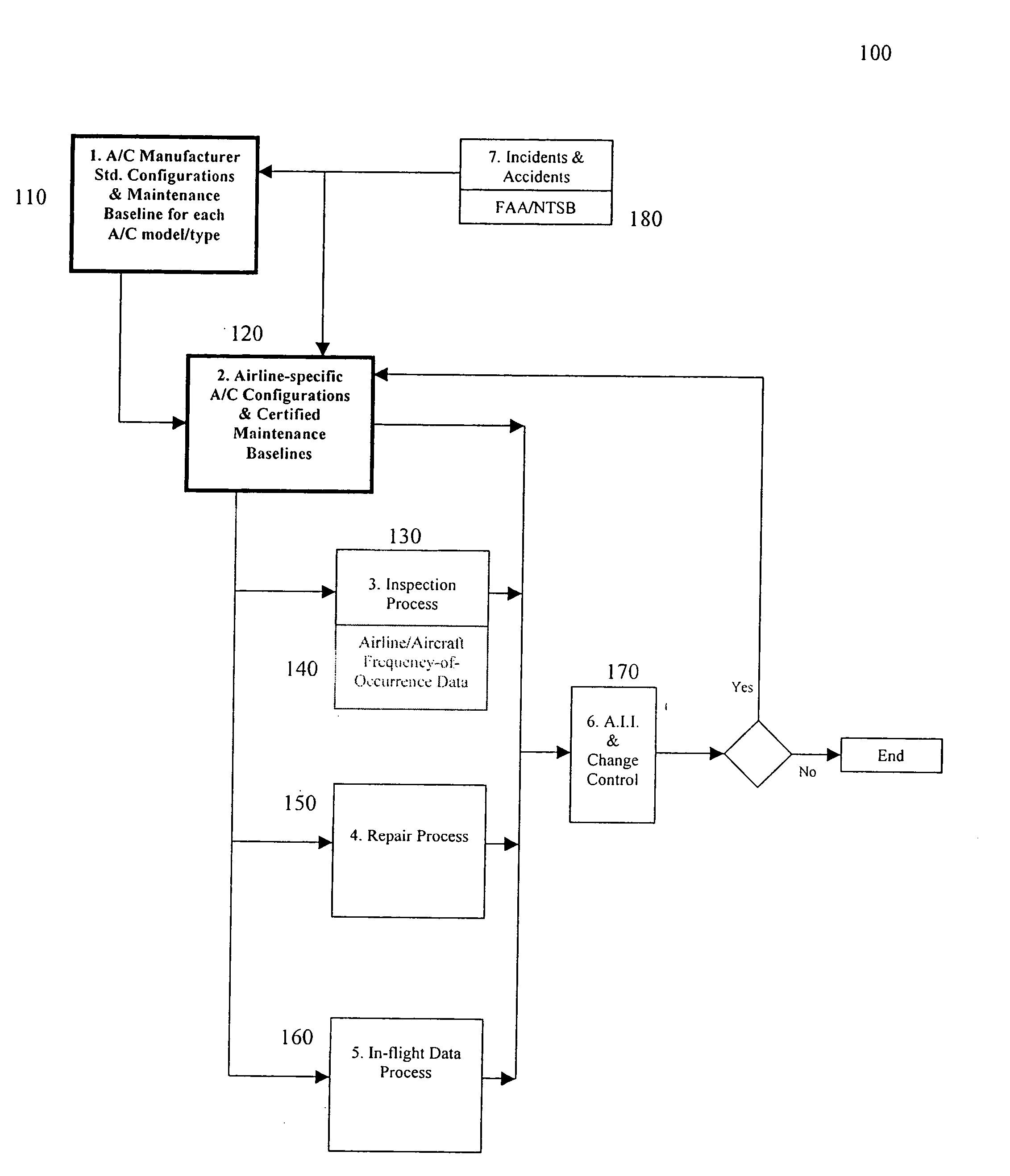

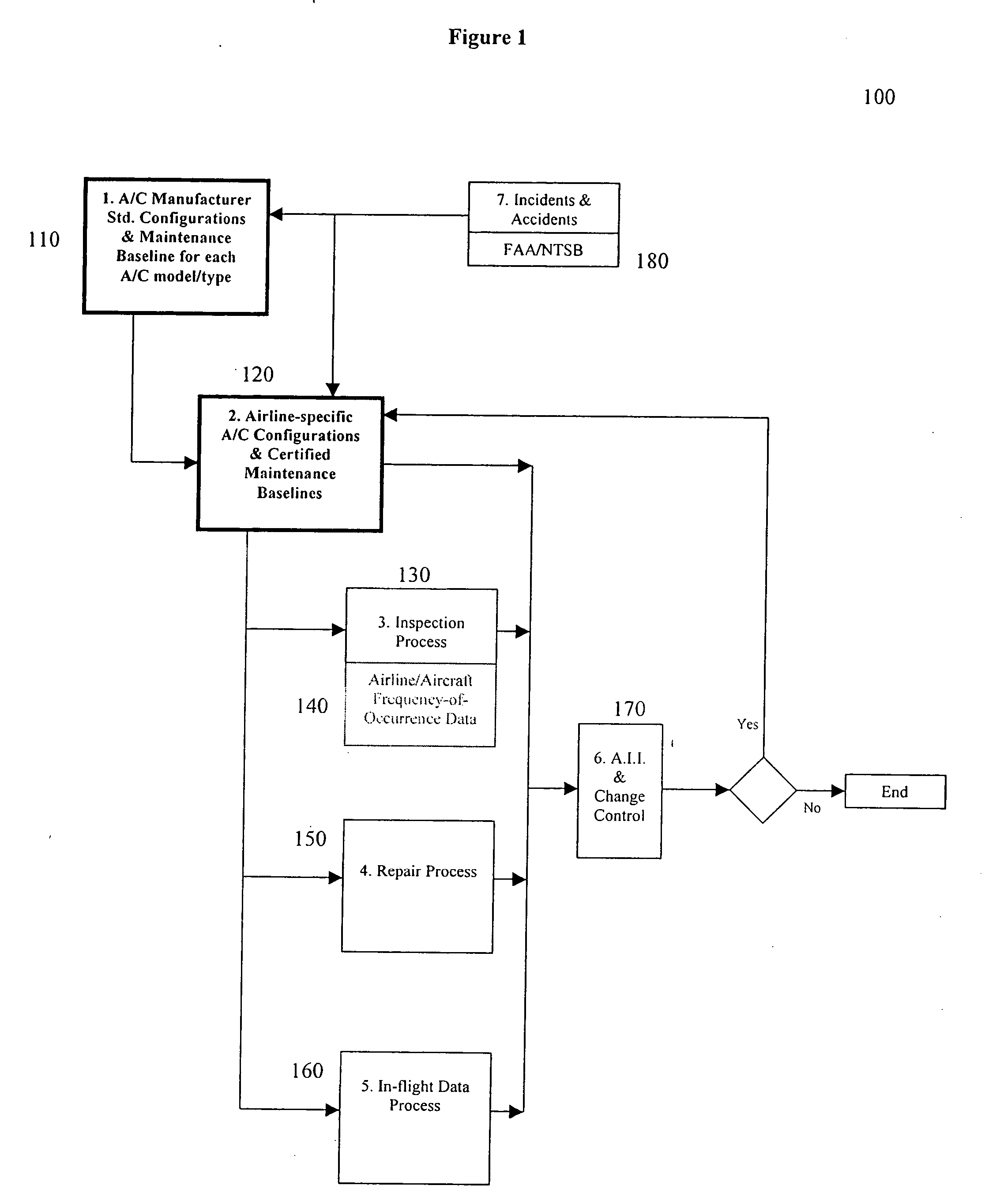

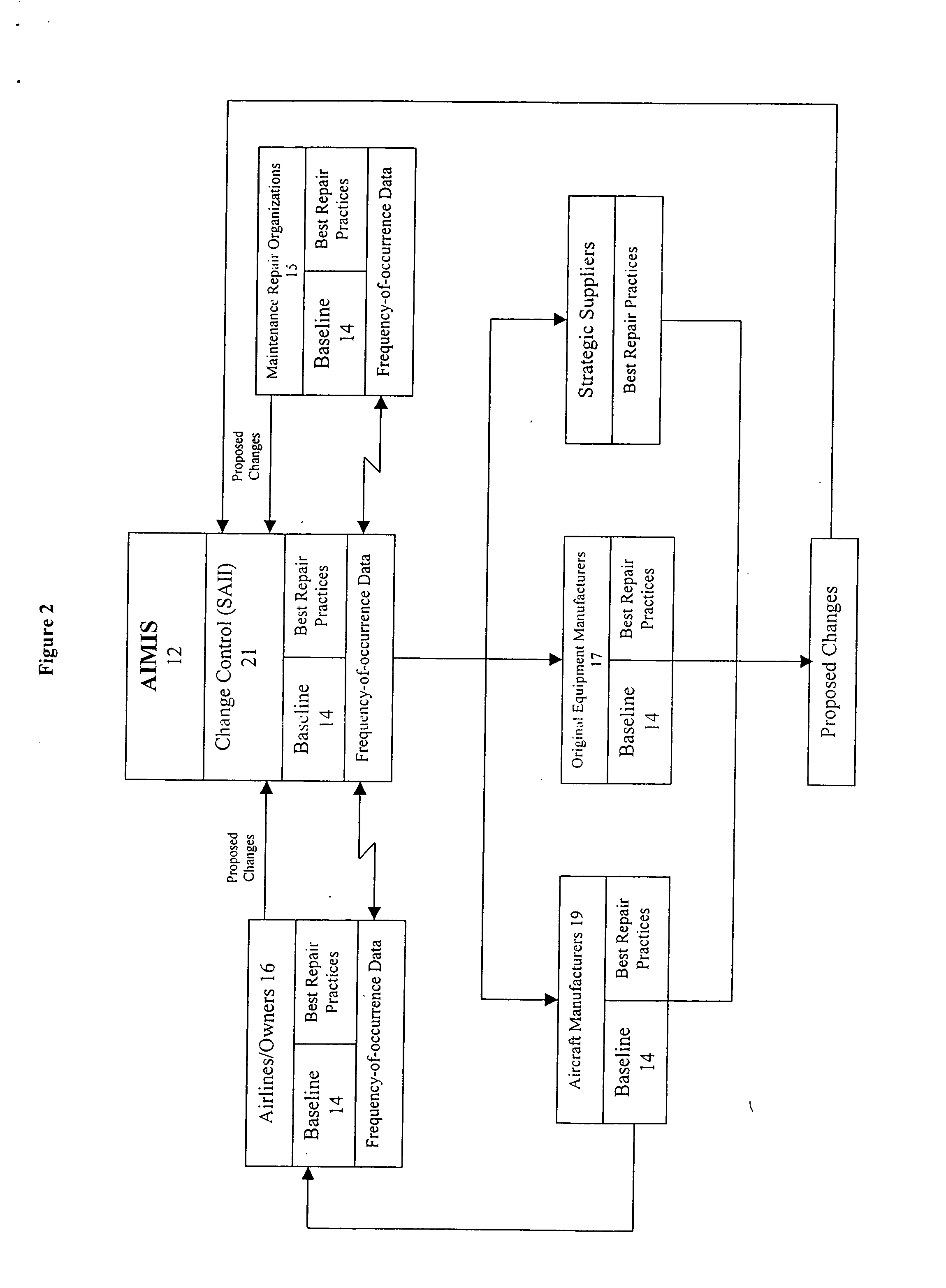

System and method for coordinating product inspection, repair and product maintenance

InactiveUS20050065842A1Economic impactEconomic securityTechnology managementResourcesProduct inspectionOriginal equipment manufacturer

A system and method for coordinating product inspection, repair and product maintenance features a proactive, data-driven process where industry-wide maintenance baselines, problems, frequency-of-occurrence data and best-in-class repair processes are identified in a central, secure, structured database environment and thereby where the safety and operational and economic impact of a problem can be evaluated and acted upon. Using industry-wide data provided by users, the present system and method will link repair and inspection finds (non-routines), reason codes and severity data related to potential safety, reliability, cycle time and cost implications with the root cause analysis and certified best inspection / repair / preventative process instructions, materials, tools and / or equipment. This information, combined with a maintenance provider's, manufacturer's and OEM's information, will greatly improve safety, reliability, cycle time and budget performance on repair, maintenance and inspection of equipment utilizing the present system and method.

Owner:THE SUMMERS GRP

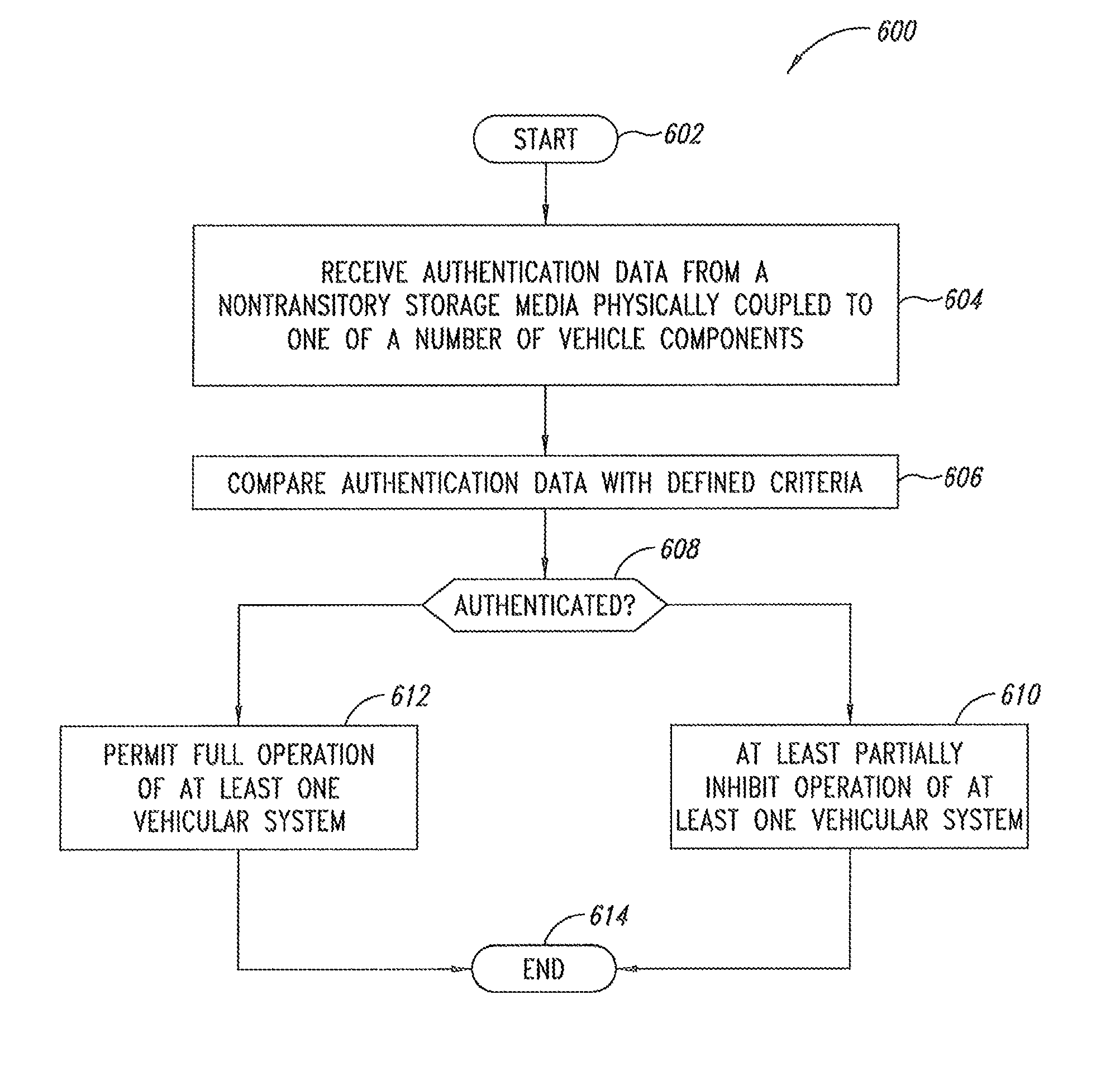

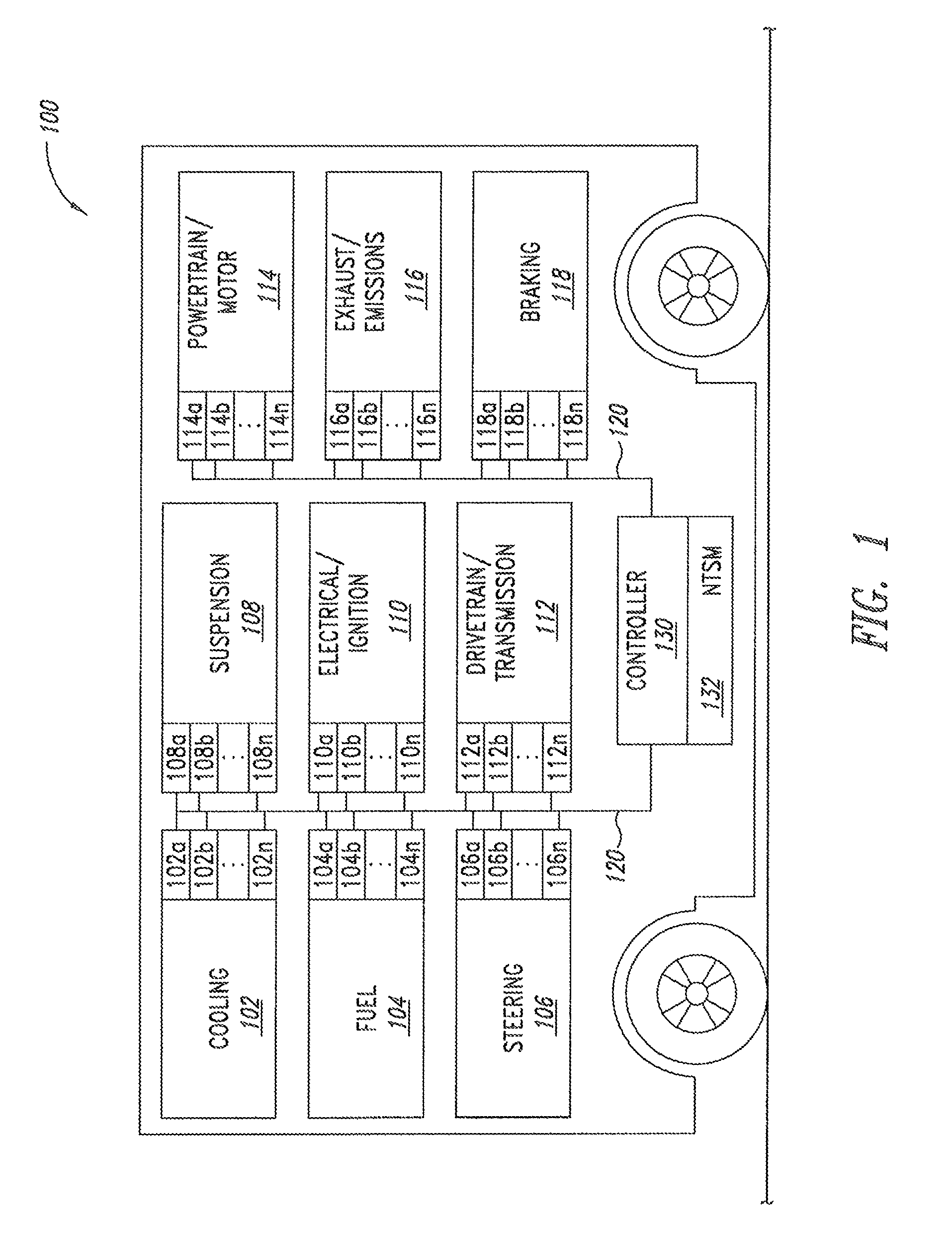

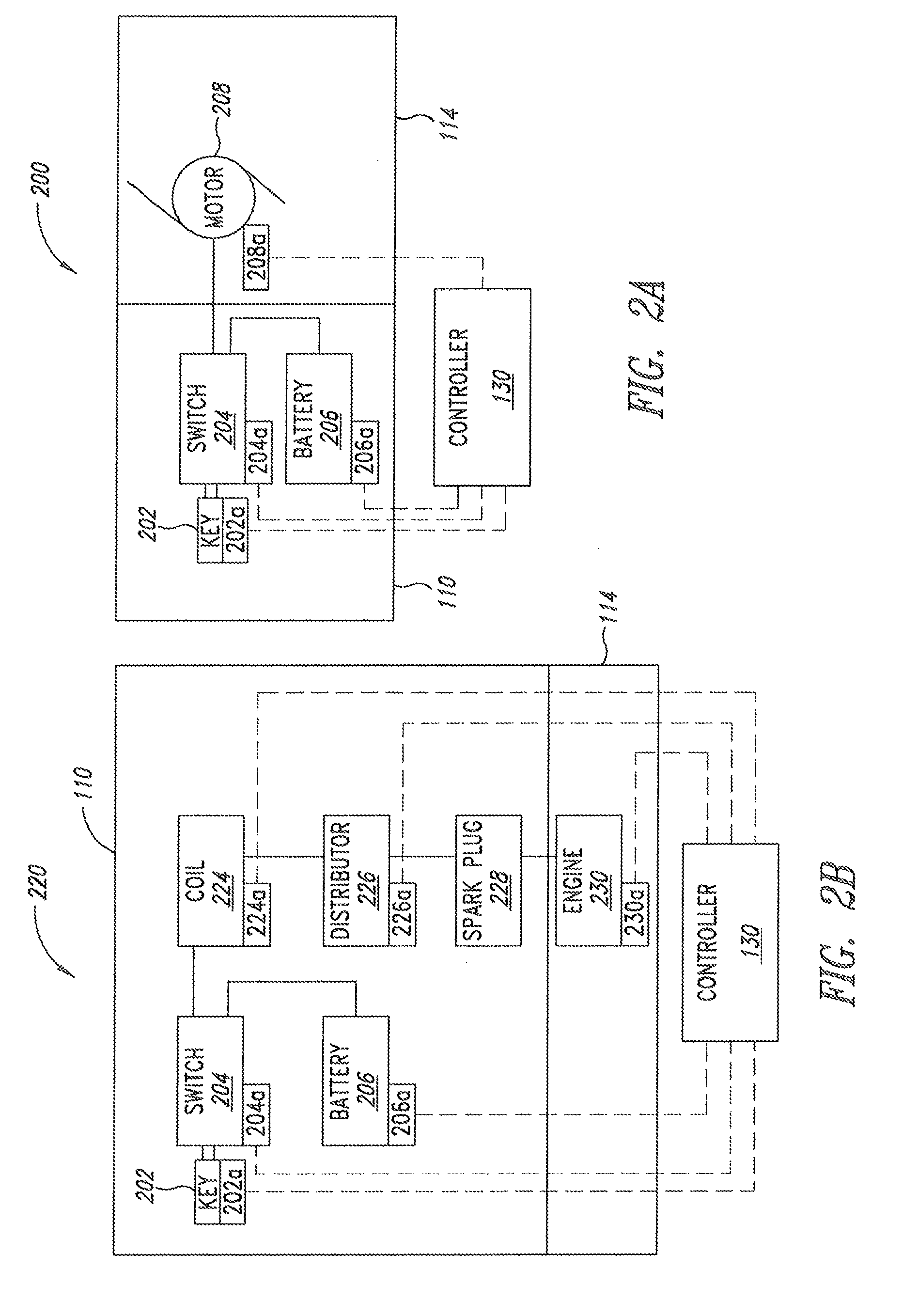

Apparatus, system, and method for authentication of vehicular components

ActiveUS8798852B1Reduce sizing costsEasy to storeVehicle testingRegistering/indicating working of vehiclesControl systemOriginal equipment manufacturer

Manufacturers and original equipment manufacturers provide vehicles that include various components and systems that operate to provide safe, environmentally conscious transportation compliant with local, state, and federal requirements. Each of the components or systems may include a nontransitory storage media containing data indicative of an authentication code specific to the respective component or system. Authentication data may be communicated from each of the nontransitory storage media on a vehicle to a control system where the authentication data is compared to one or more defined criteria. If the one or more criteria confirm the validity of the authentication data supplied by the components or systems, full operation of one or more vehicular systems is permitted. If the one or more criteria fail to confirm the validity of the authentication data supplied by the components or systems, the operation of at least one vehicular system is at least partially inhibited.

Owner:GOGORO

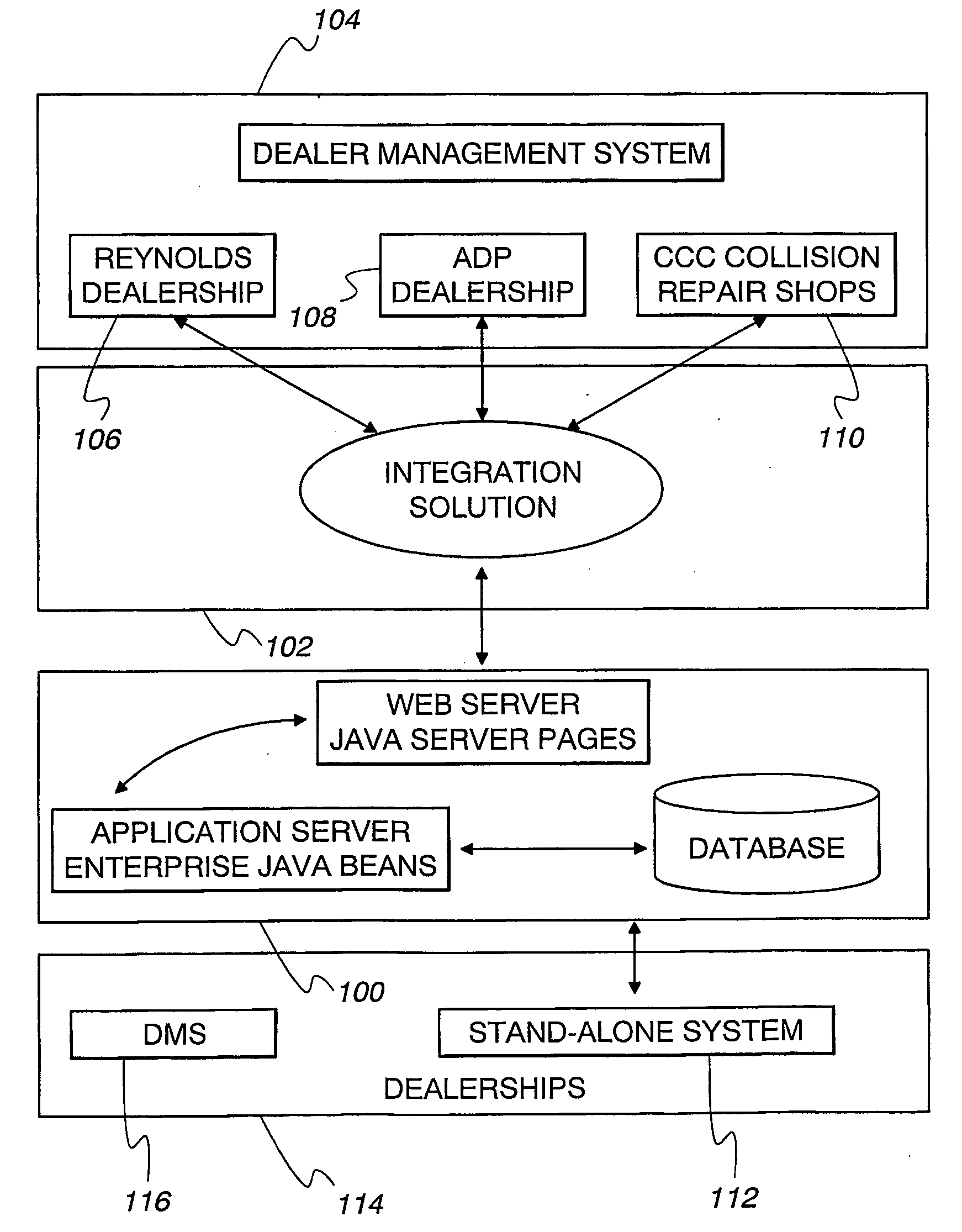

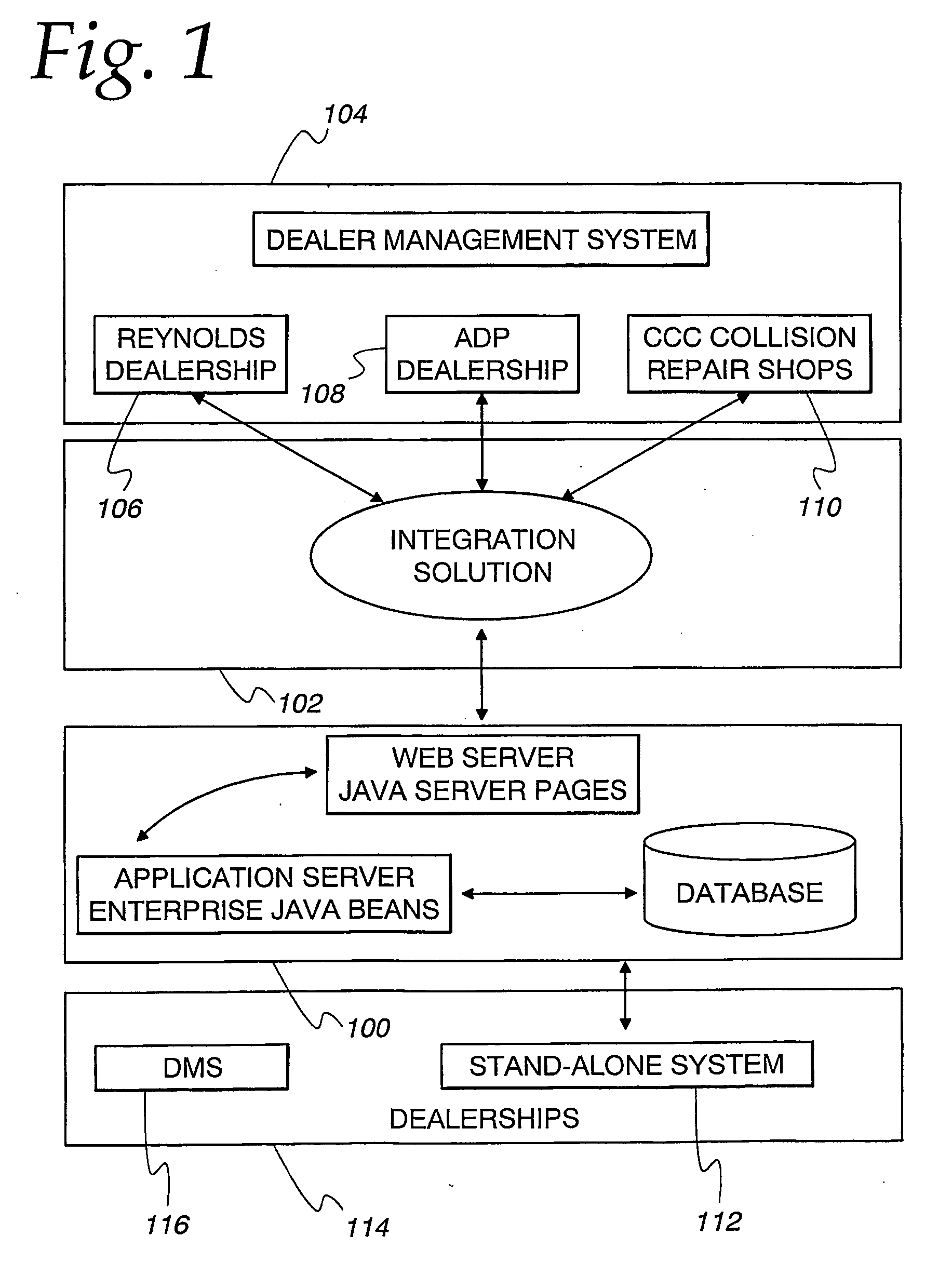

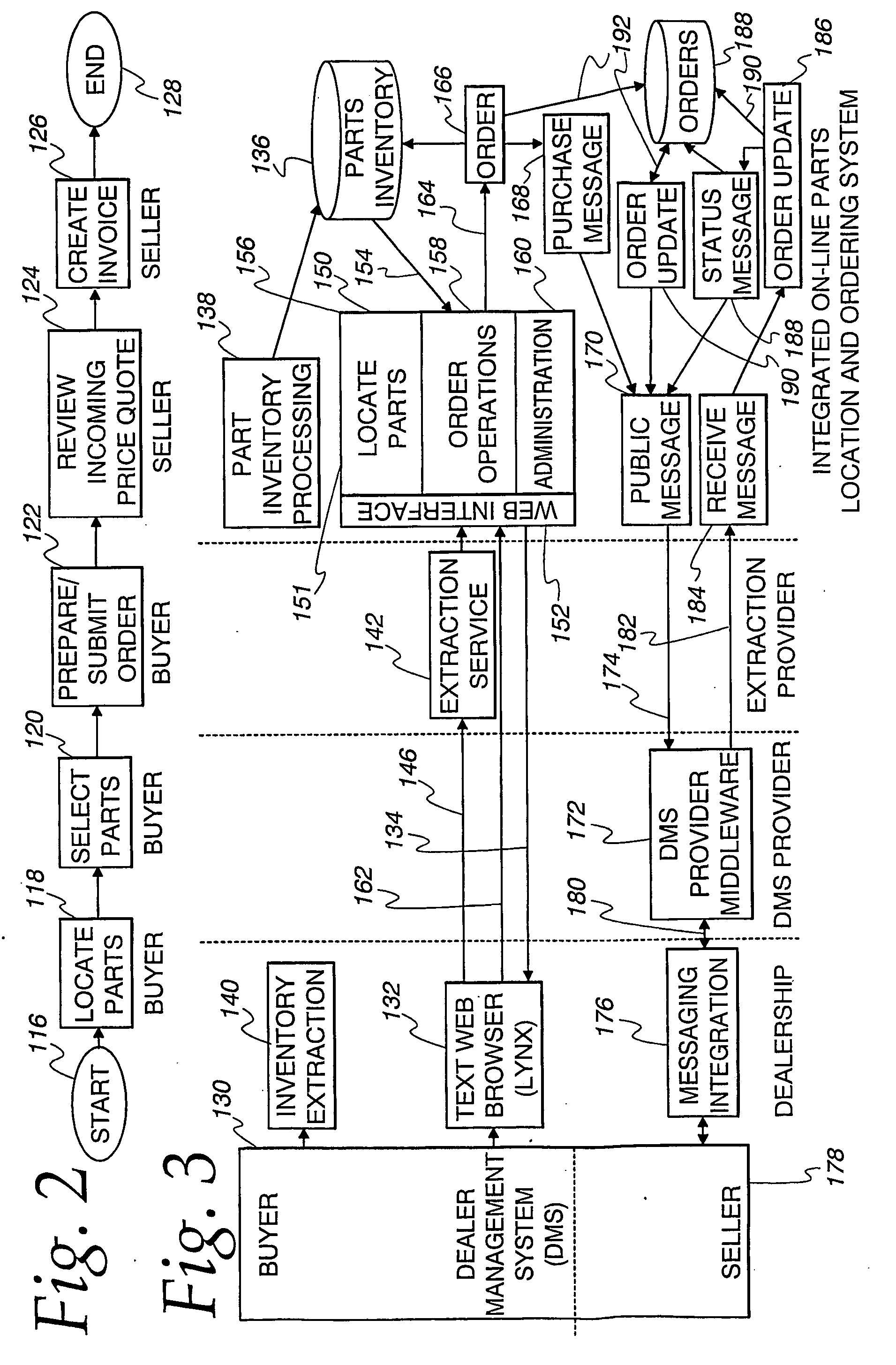

On-line parts location and transaction system

InactiveUS20050187834A1Easily and quickly locateBuying/selling/leasing transactionsLogisticsRepair shopPrivate communication

An integrated parts location and transaction system for original equipment manufacturer (OEM), non-OEM as well as aftermarket automobile parts is adapted to be integrated with business management computer system (BMS) software, currently used by automobile dealerships (210) as well as repair shops. All participating parts suppliers, including dealerships (210), and repair shops are networked together, for example, over a combination of public and private communication networks to enable participating parts suppliers and potential buyers (for example, dealers and repair shops) to easily and quickly locate as well as buy and sell parts from each other.

Owner:CHOICEPARTS

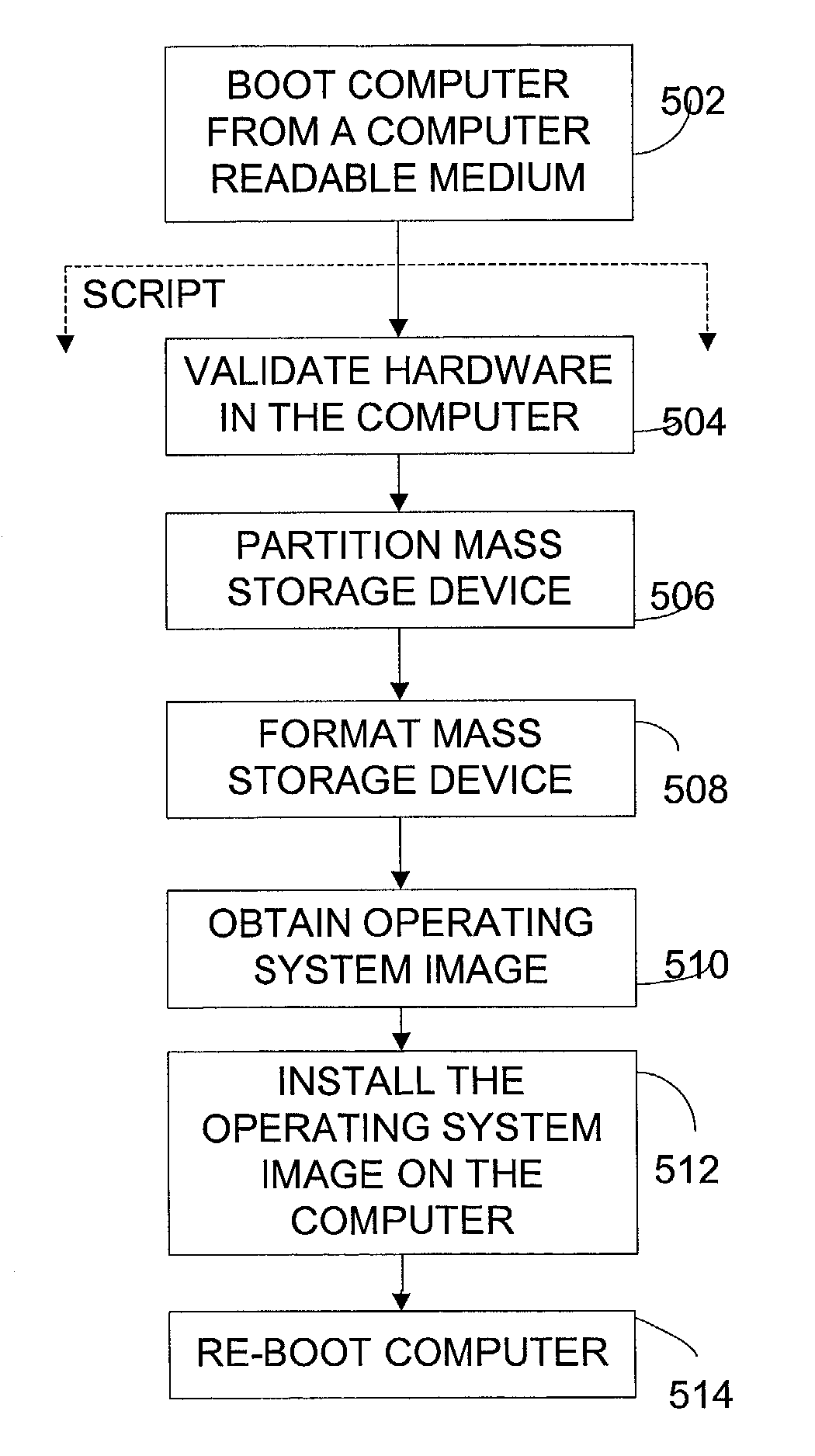

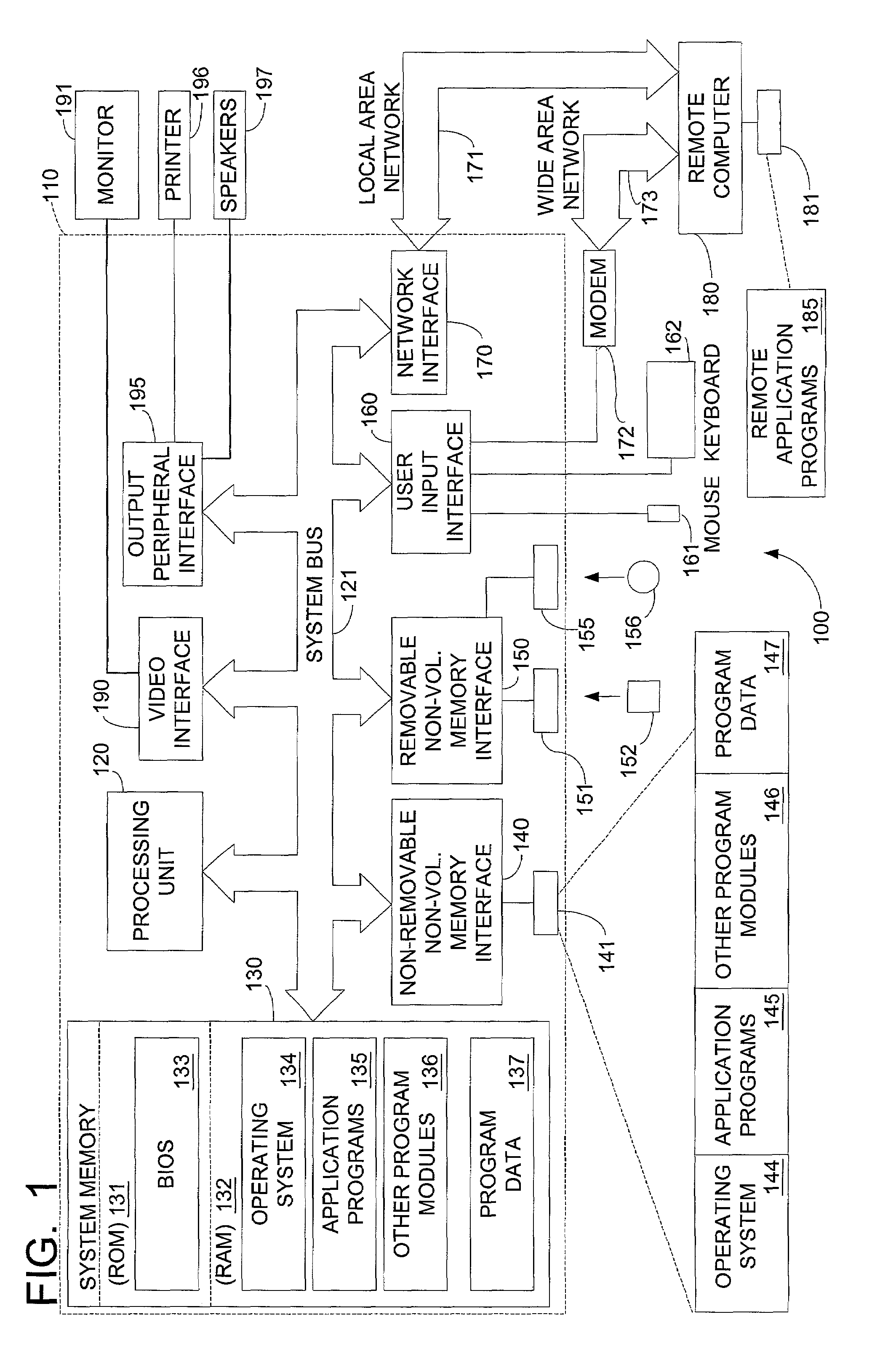

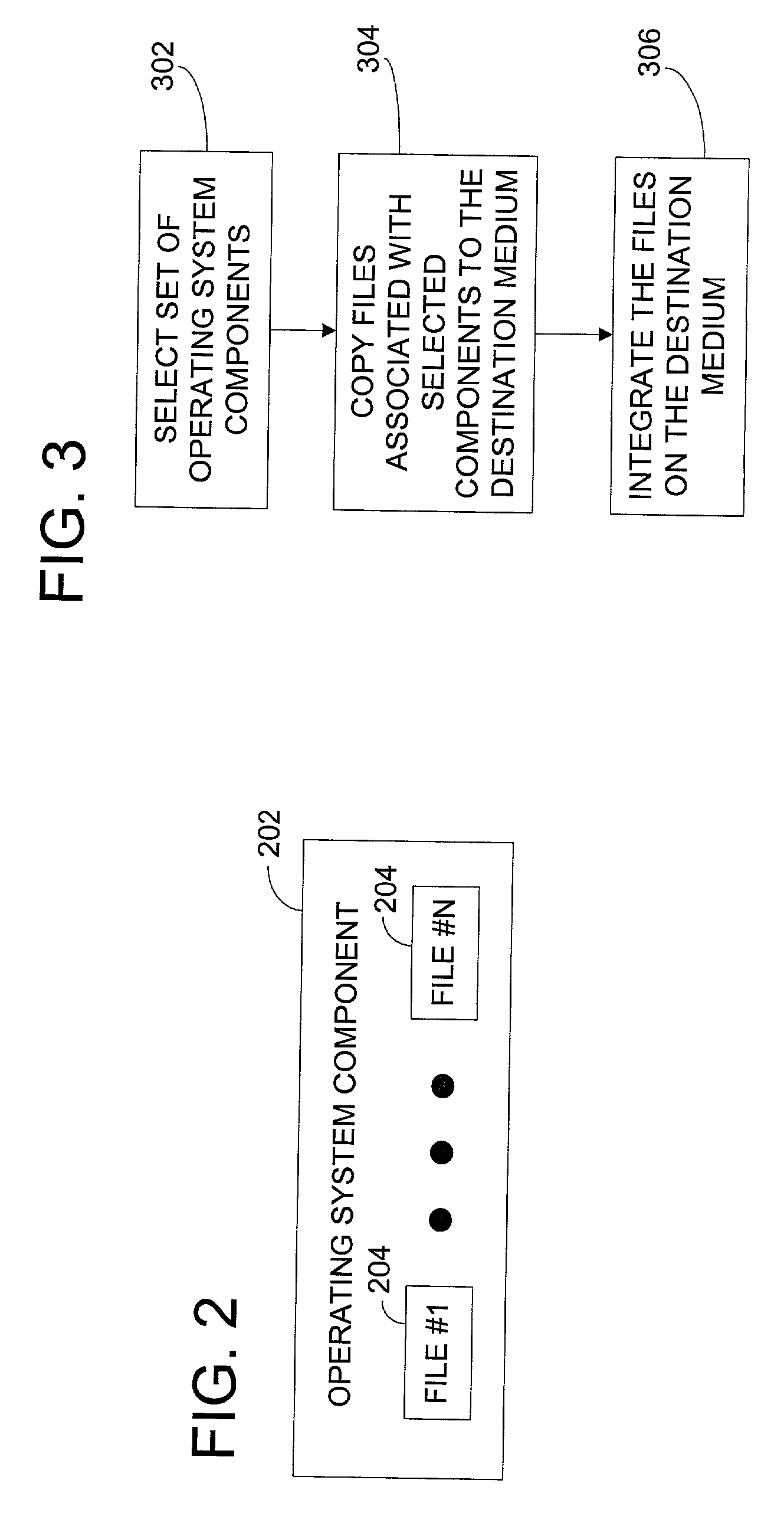

Method and system for creating and employing an operating system having selected functionality

InactiveUS6993642B2Digital computer detailsProgram loading/initiatingOperational systemOriginal equipment manufacturer

A system and method of creating and employing an operating system (OS) image having selected functionality. A user, such as an original equipment manufacturer (OEM) of personal computers (PCs) or an information technology professional, selects a set of OS components from a plurality of OS components available in an installation OS image. The selected set of OS components is installed as the OS image on a computer readable medium such as a CD-ROM. The OS image includes a script for interacting with the OS image to perform functions desired by a user, such as booting a destination computer and installing a reference OS image or recovering the destination computer from a failed installation of the reference OS image.

Owner:MICROSOFT TECH LICENSING LLC

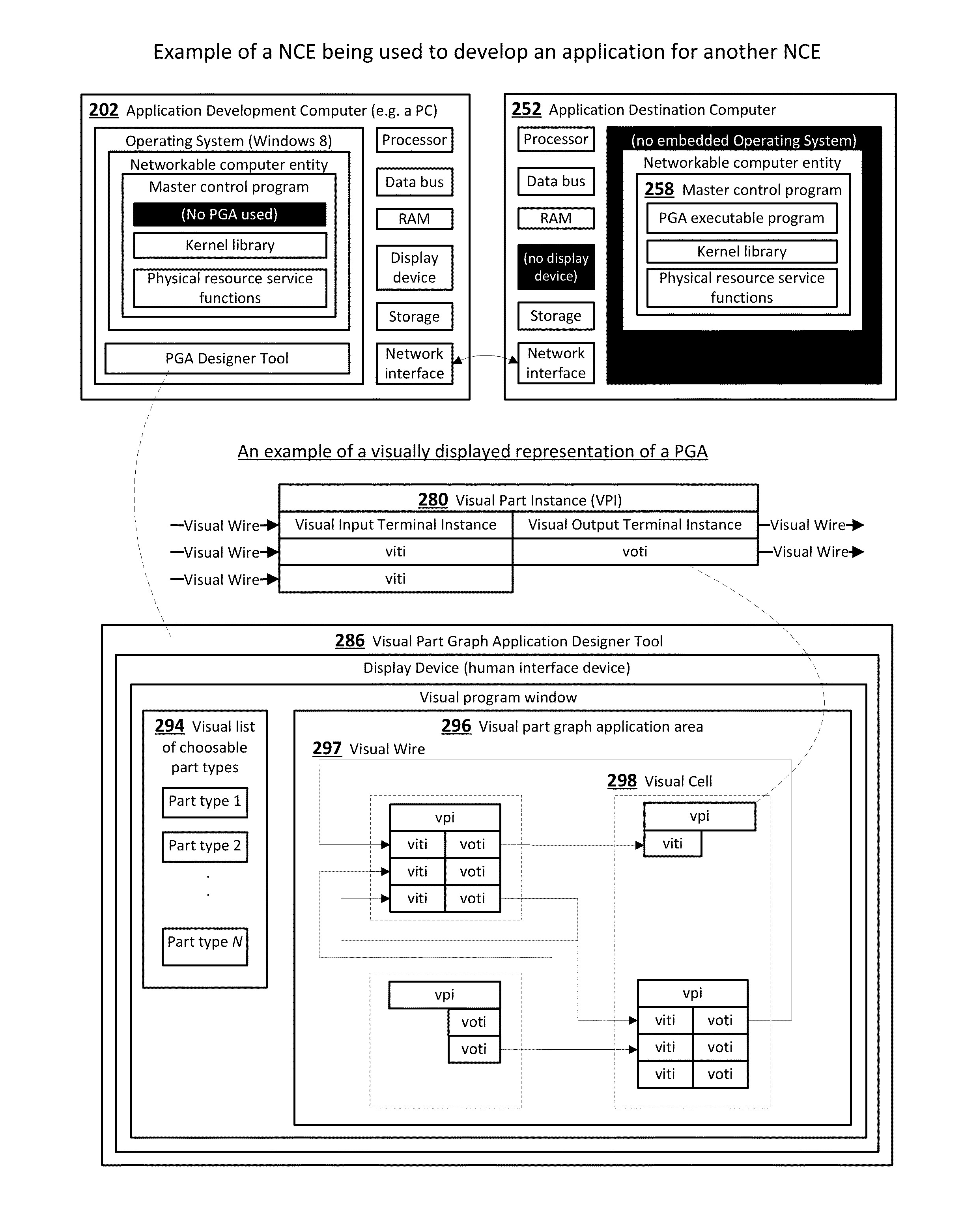

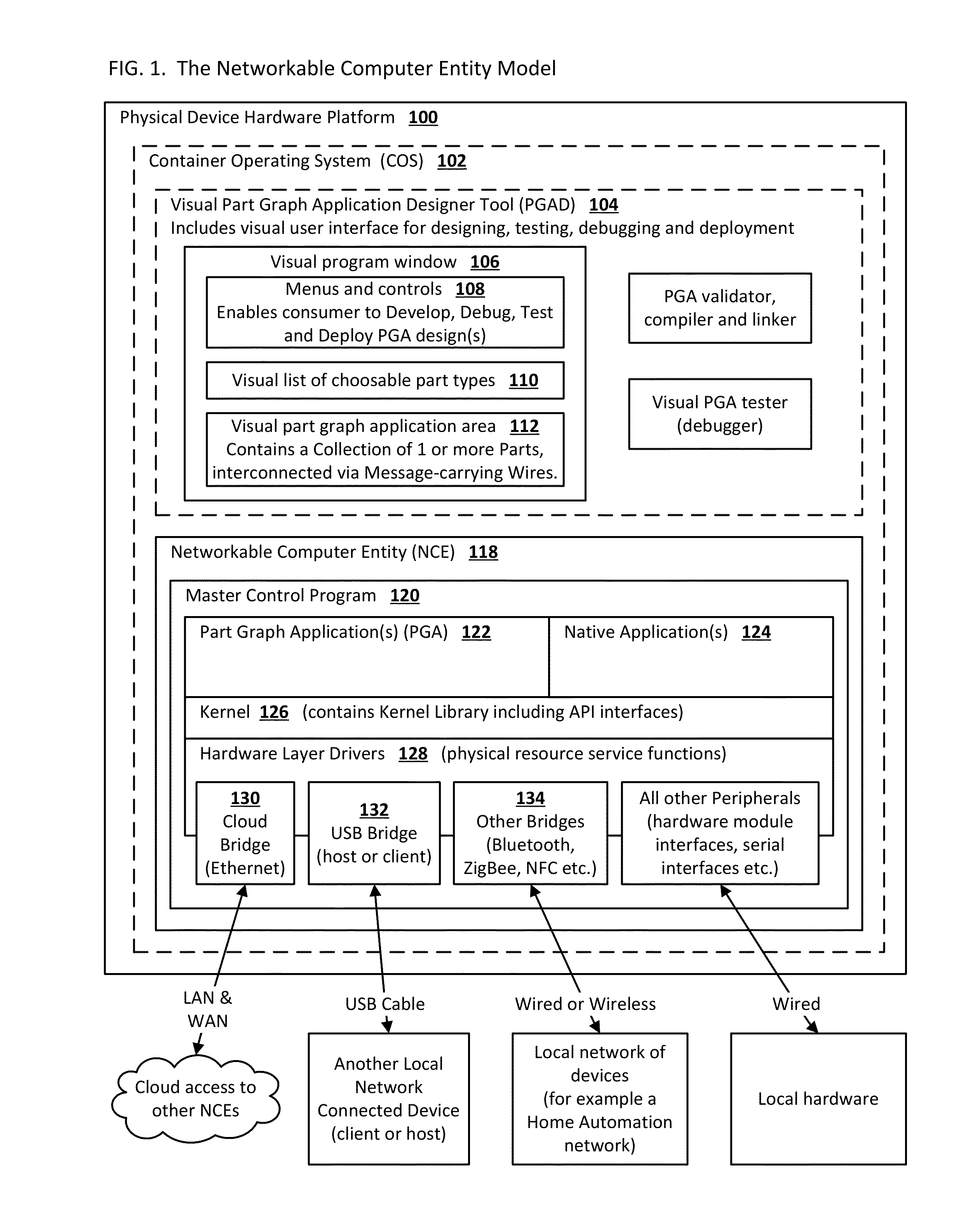

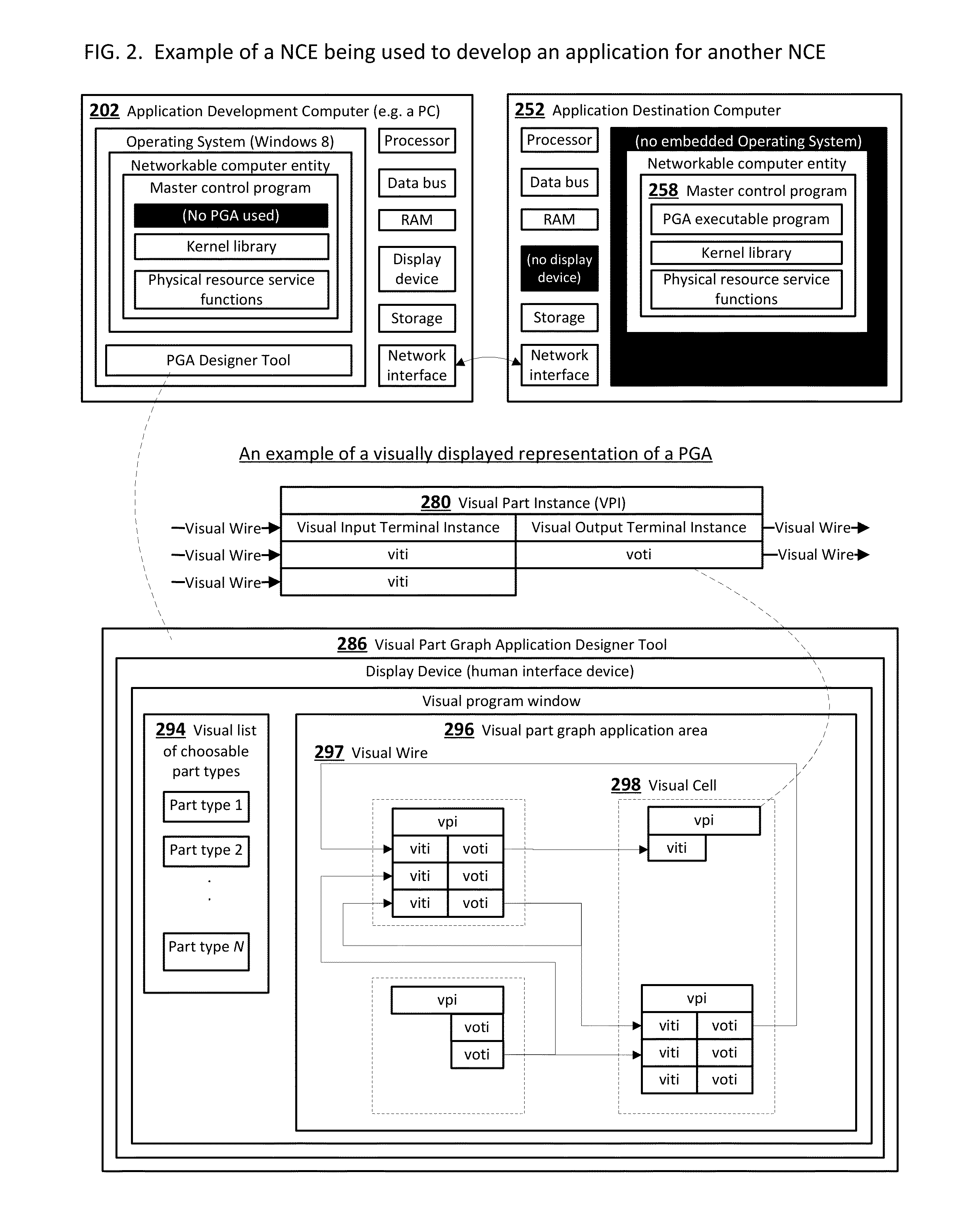

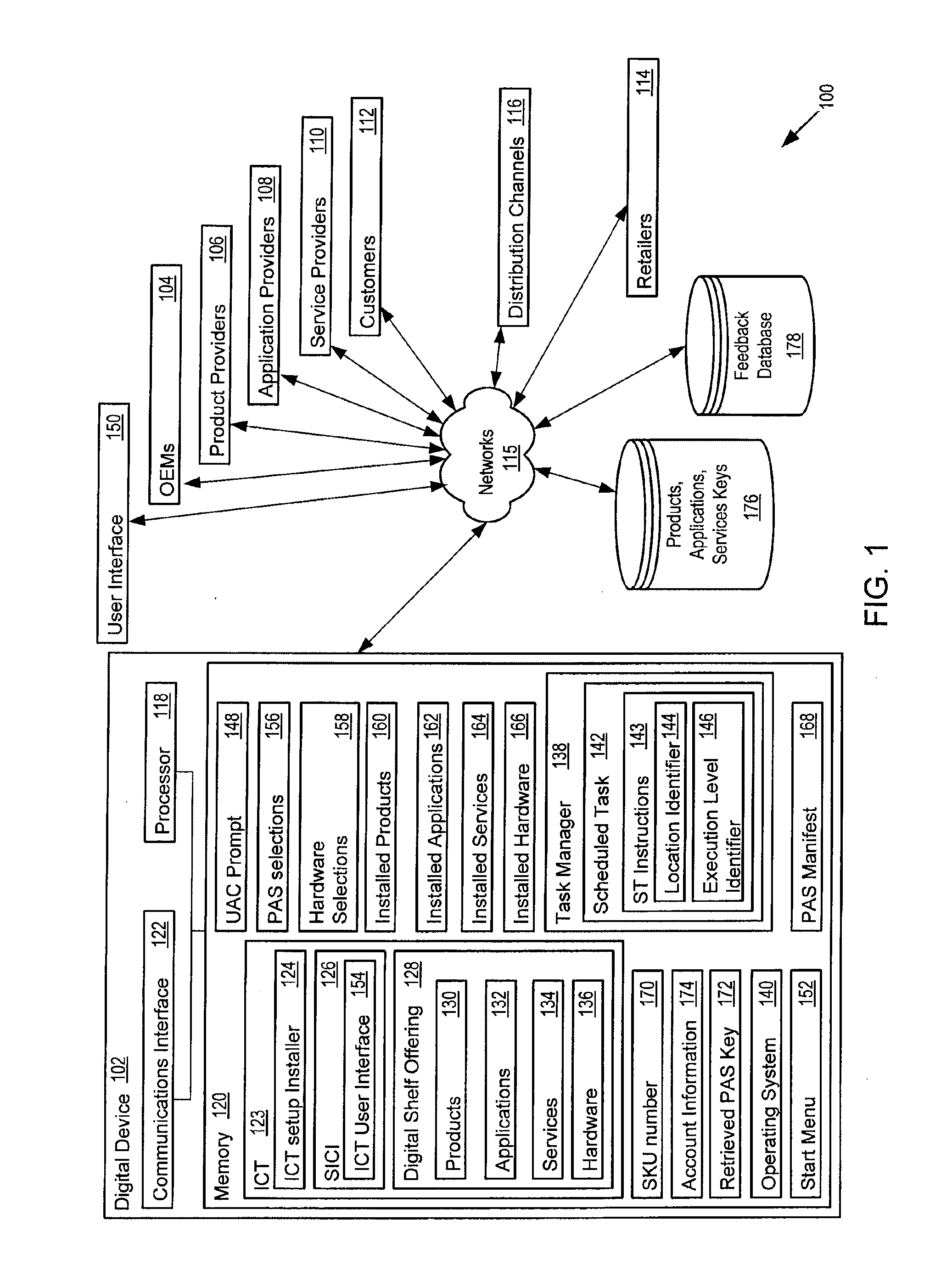

System and methods for end-users to graphically program and manage computers and devices

InactiveUS20140359558A1Reduce needReduce testingSoftware designVisual/graphical programmingInformation processingGraphics

A system that enables end-users who are not skilled in the art of traditional computer programming to intuitively program, configure and manage computers and devices and / or systems that contain many computers and devices. End-users connect graphical parts using graphical wires using a graphical user interface. The timing of the messages that are carried in the wires that connect the parts is deterministic, consistent and intuitive to the end-user. Parts and their user-configurable features are typically designed, fully tested and certified by the original equipment manufacturer or independent software vendor. This invention relates to ubiquitous computing, a model of human-computer interaction in which information processing has been thoroughly integrated into everyday objects and activities associated with those objects.

Owner:CHAMBERLAIN MARK SPENCER

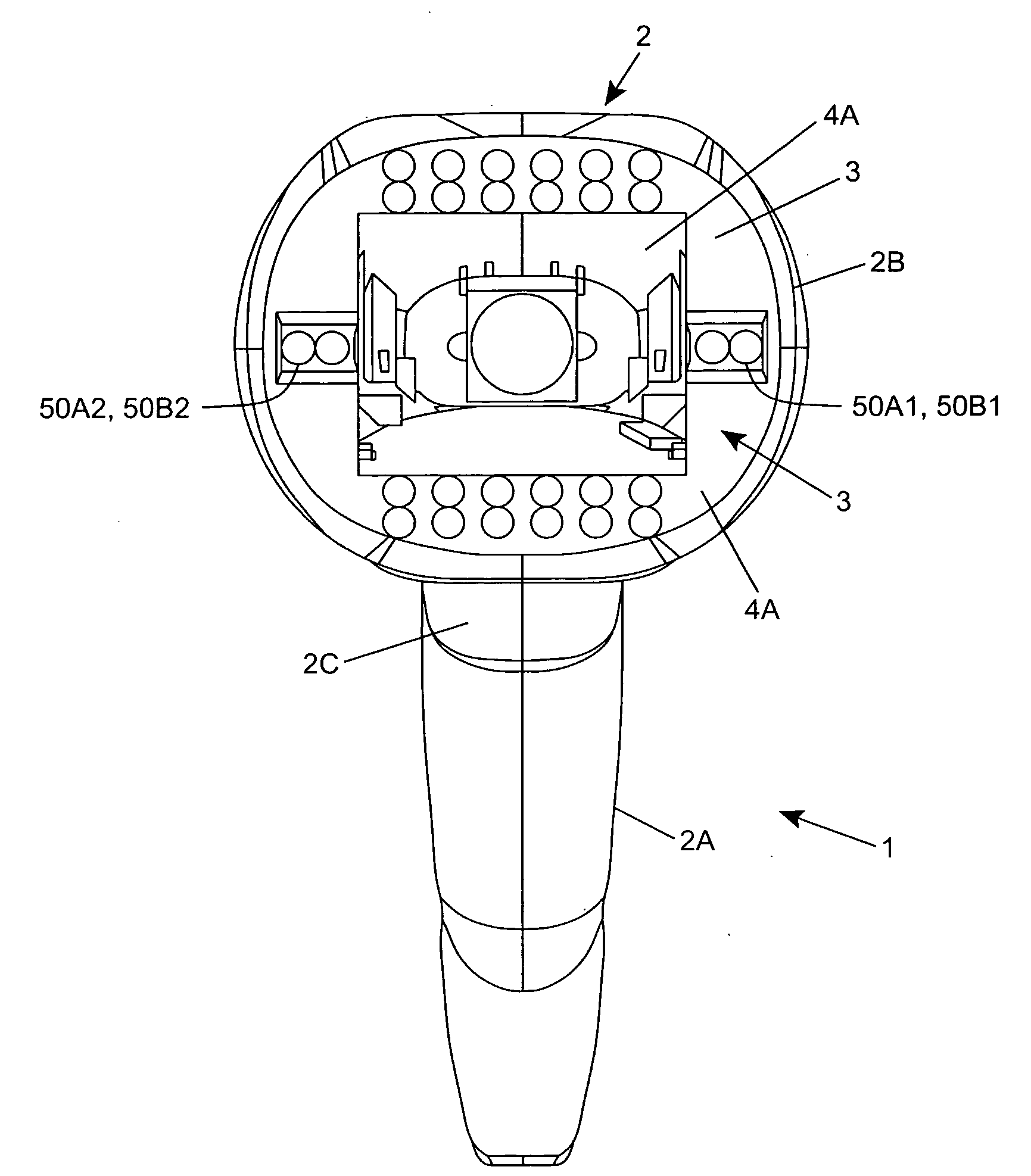

Brush holder assemblies including brush holders with handles

ActiveUS7365470B1Safer and easy on-line brush replacementAdverse effect of vibrationRotary current collectorSupports/enclosures/casingsOriginal equipment manufacturerEngineering

Owner:WABTEC HLDG CORP

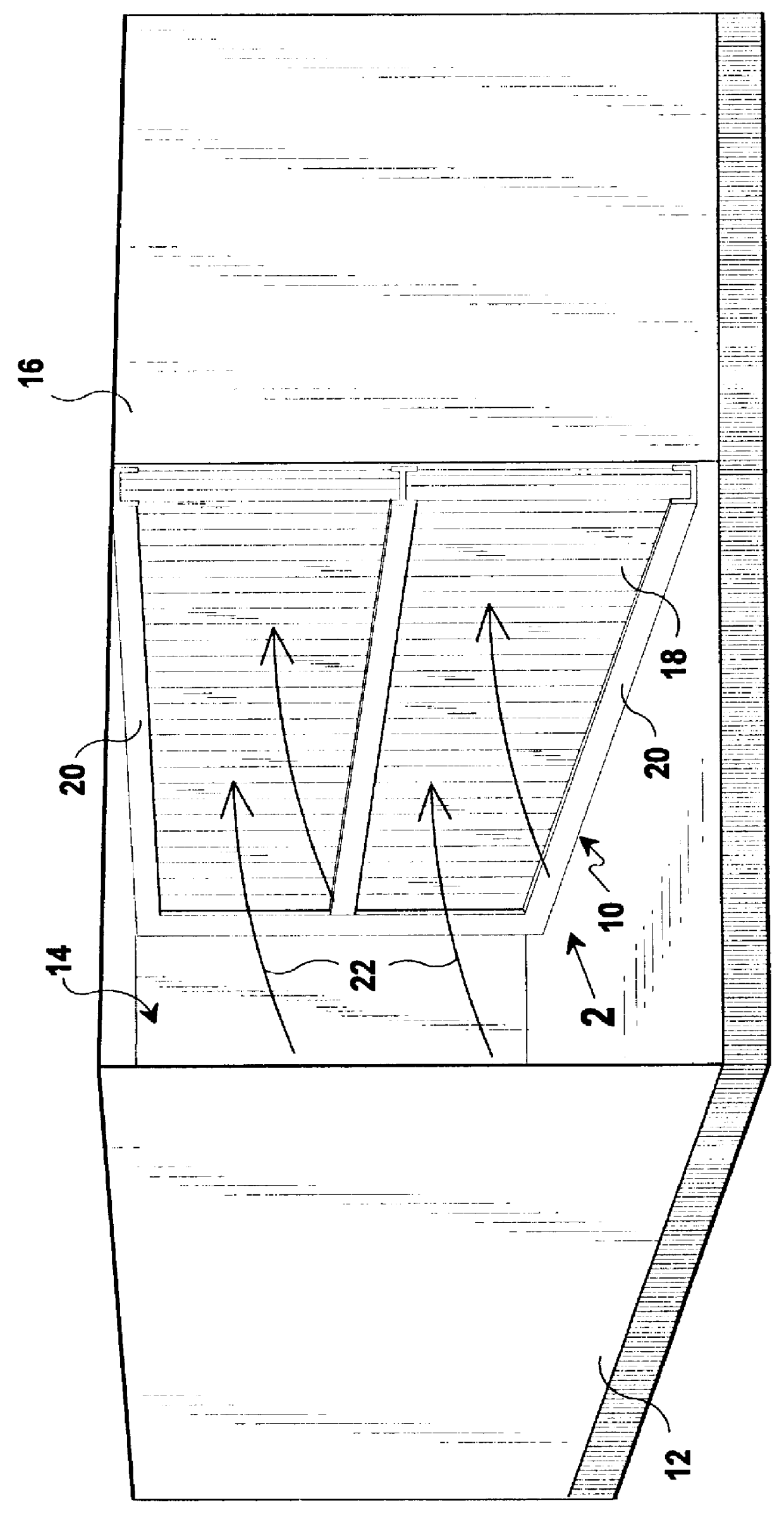

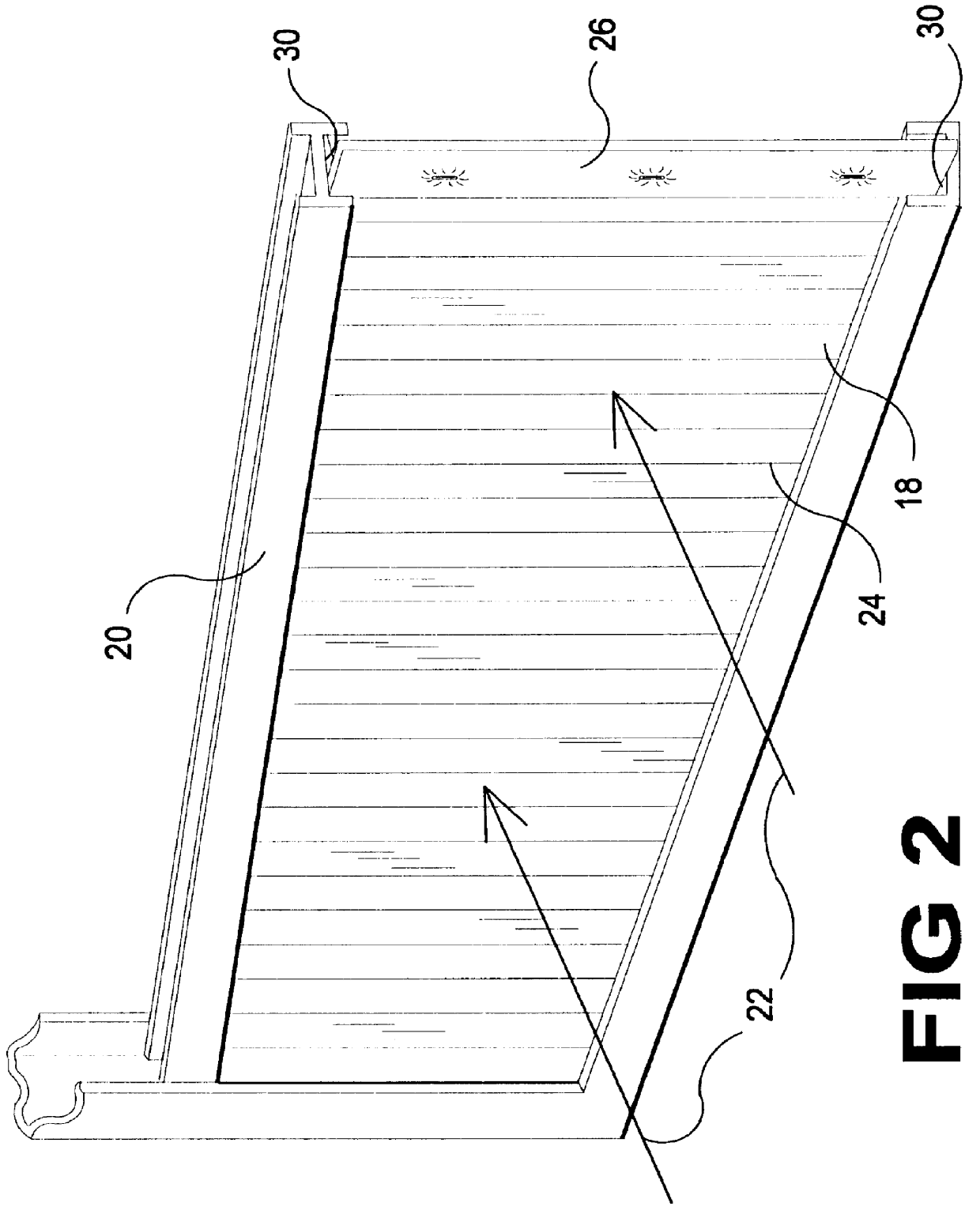

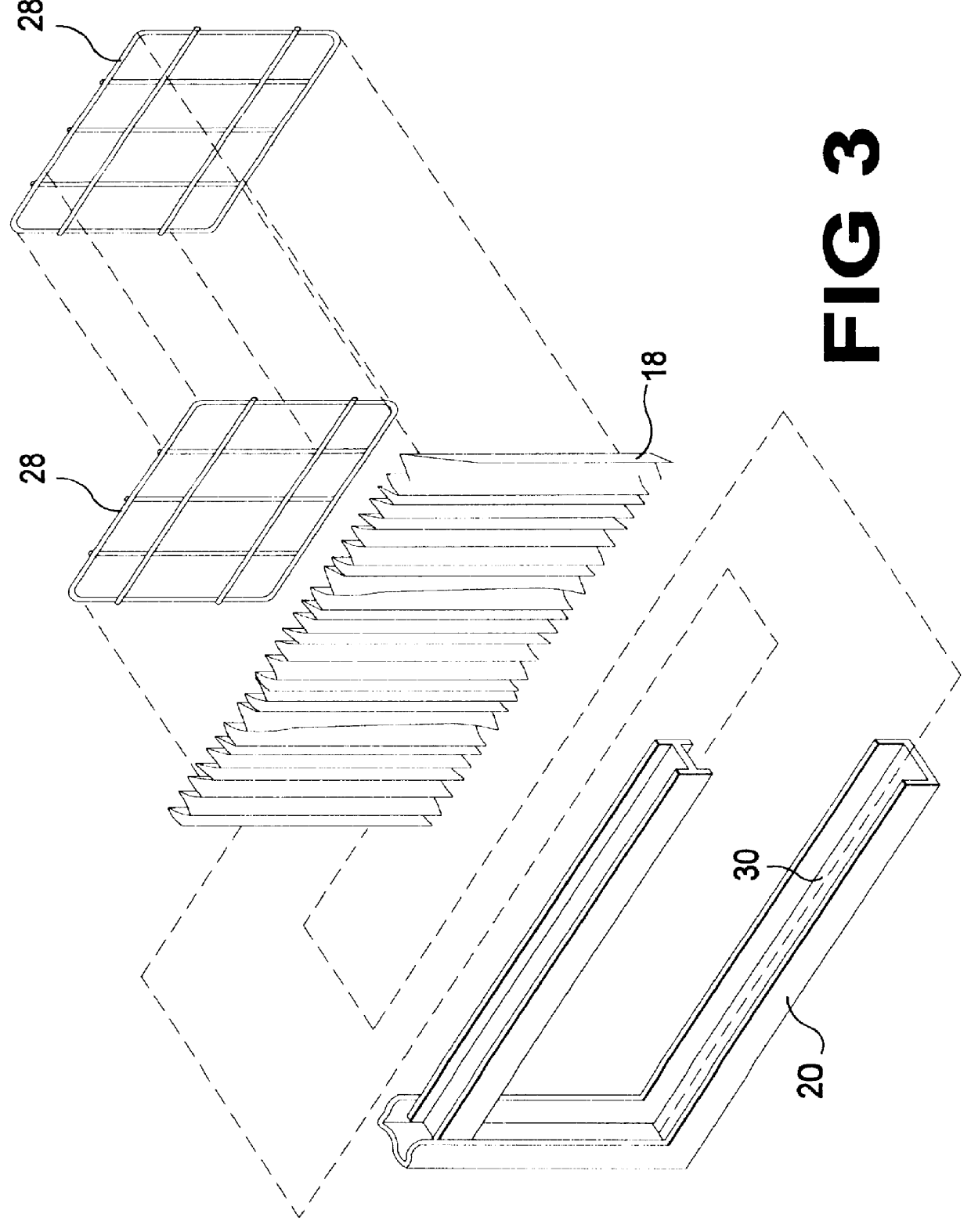

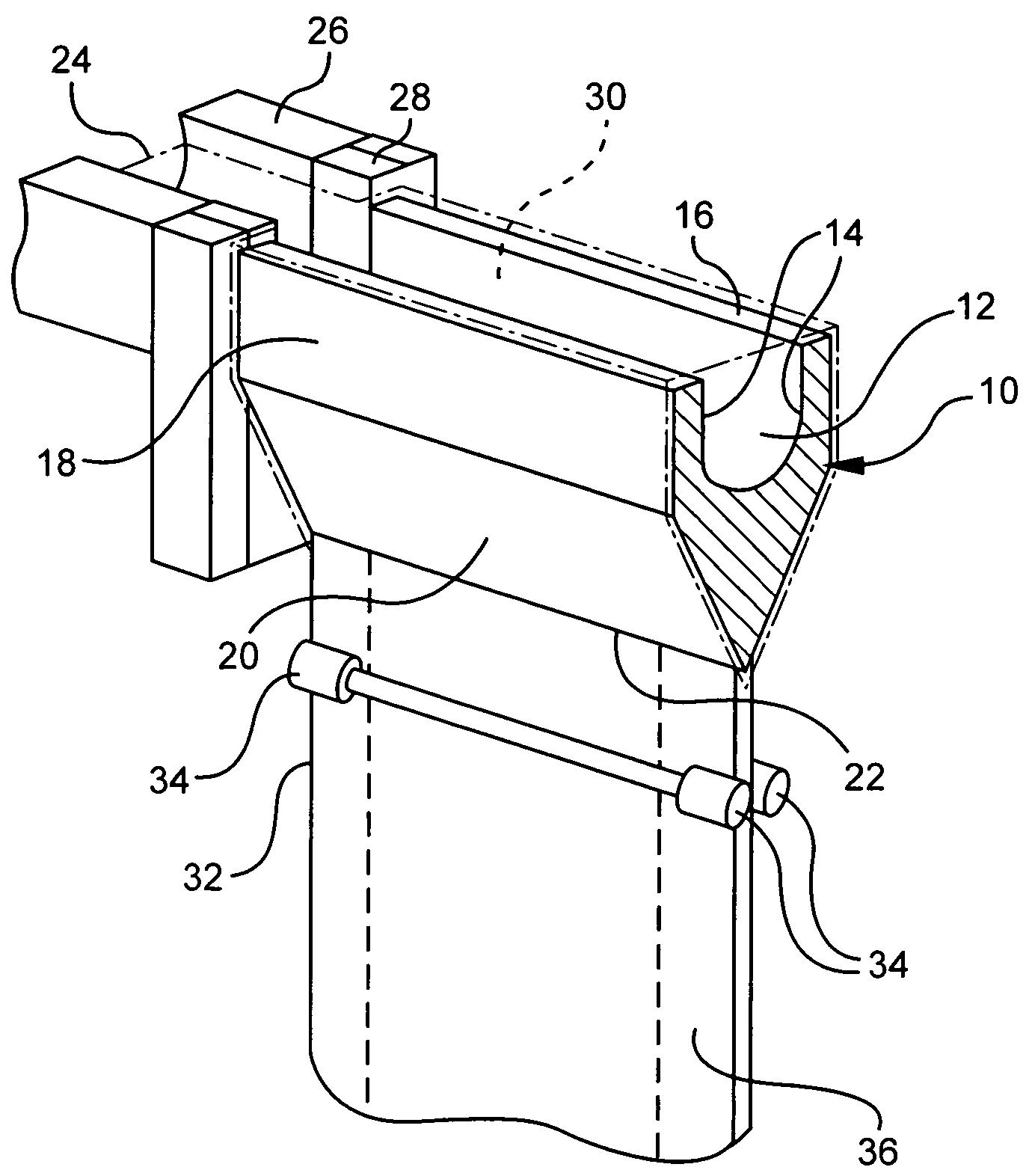

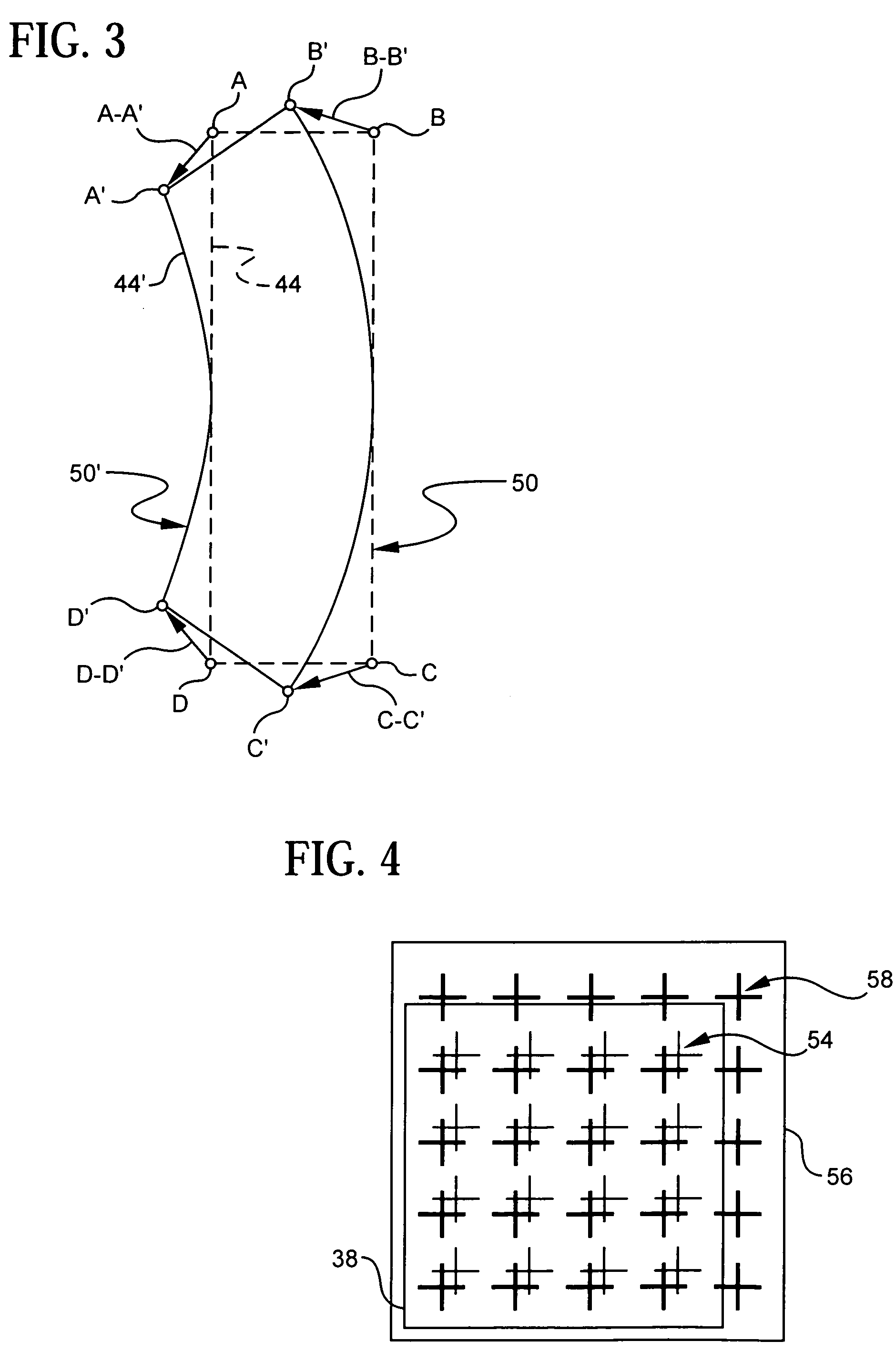

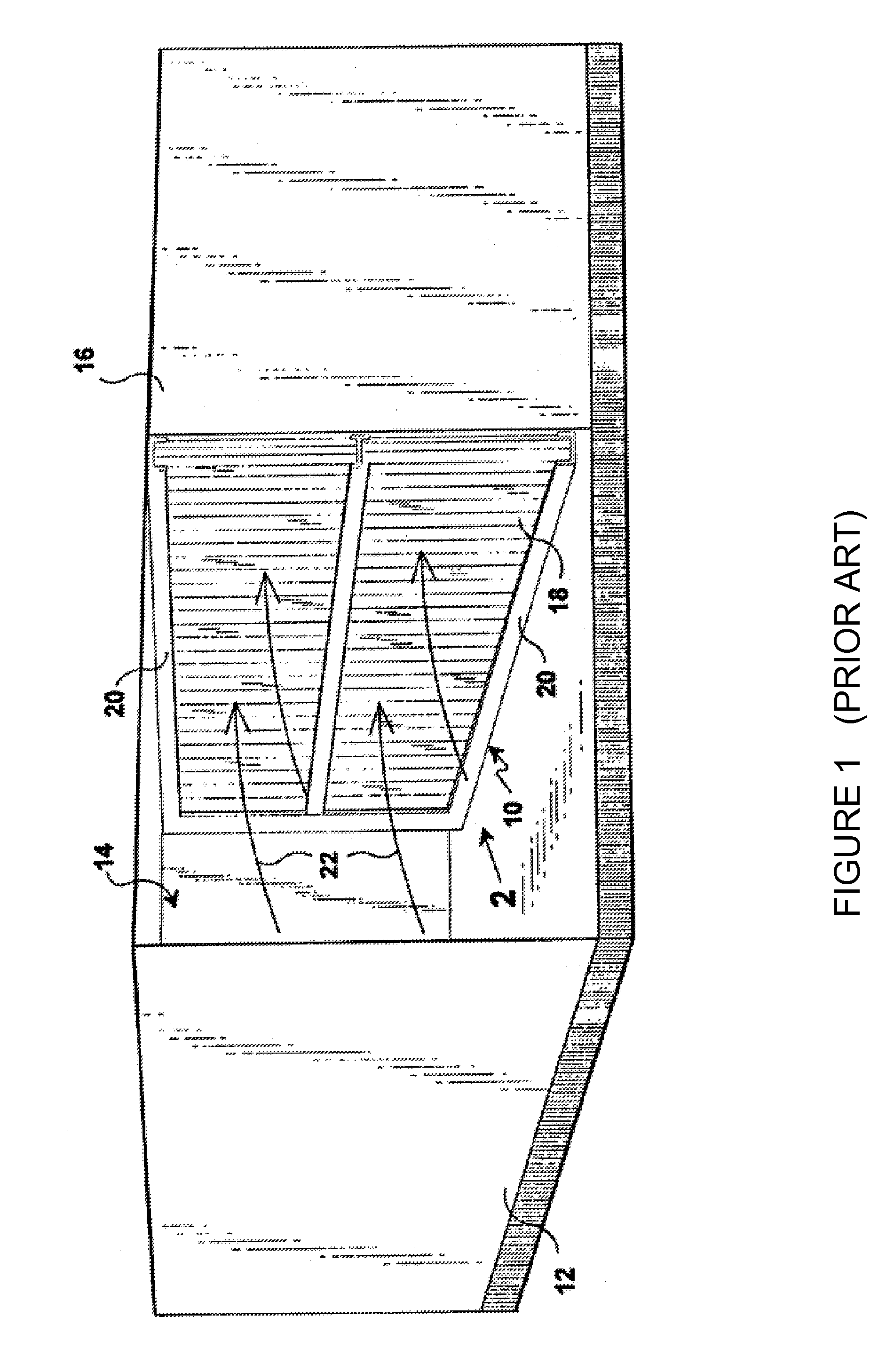

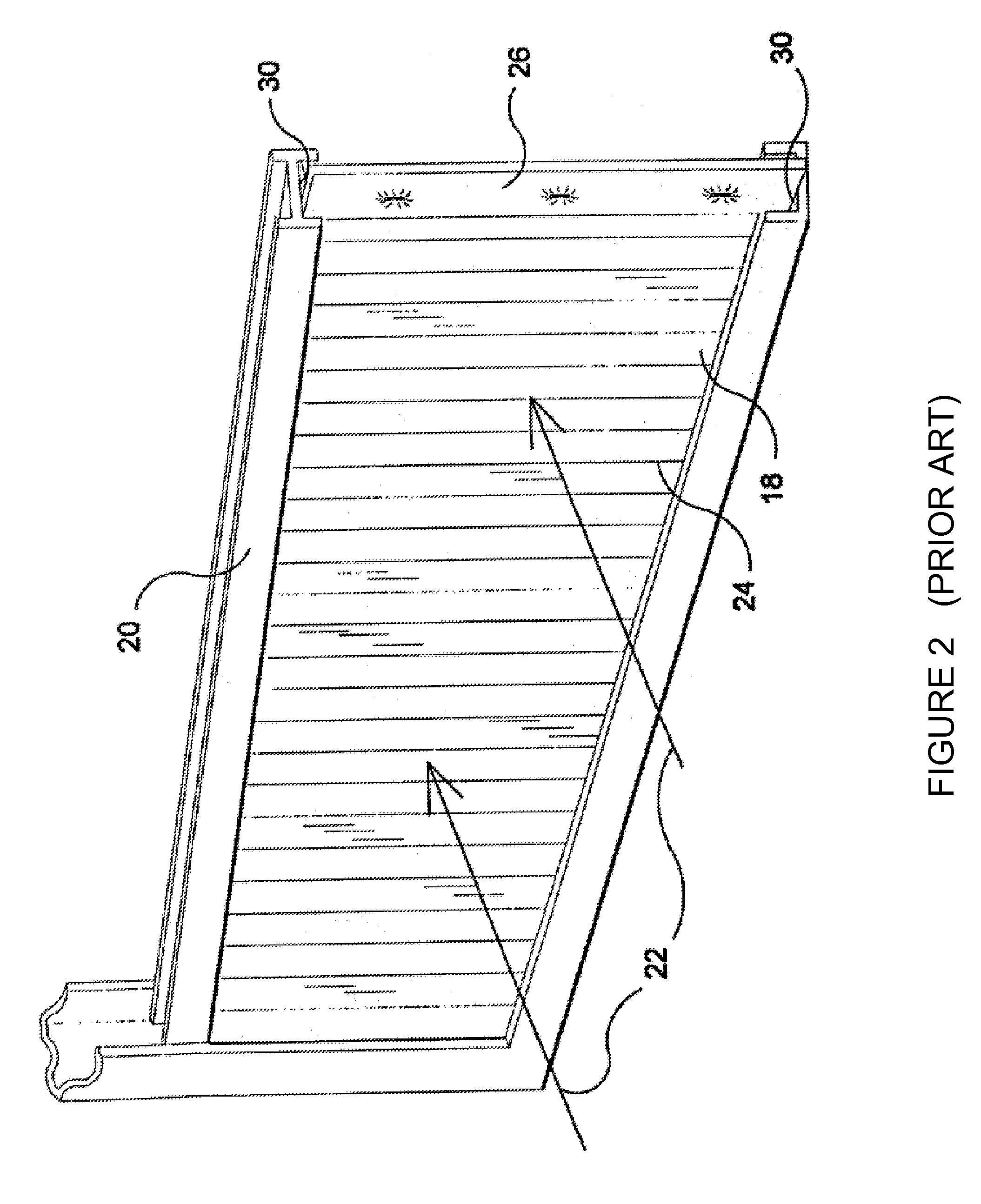

Size adjustable filter element

InactiveUS6152980AImprove mechanical efficiencyImprove thermodynamic efficiencyCombination devicesGas treatmentEpoxyWire rod

The present invention 10 discloses an air filter element 18 that is partially fabricated on site wherein one or more wire frames 28 are fastened to one another using a high tensile strength adhesive tape 34 to form a structure substantially conforming to the dimensions of the original equipment manufacturers' filter housings 20. The filter media 18 is attached to the rigid wire frame 28 by selectively drawing pleats 24 around a portion of a wire member 28 and securing the pleats to each other by means of epoxy coated staples 36 thereby securing the filter media 18 to the wire frame 28. Whereupon the on-site partially fabricated filter element 18 can be inserted into the channels 30 of the appropriate original equipment manufacturers filter housing 20 wherein the skirt 38 of the on-site fabricated filter element will fill and conform to the filter housing channel 30 providing an air-seal thus forcing all airflow through the air filter 18.

Owner:BONDED FILTER

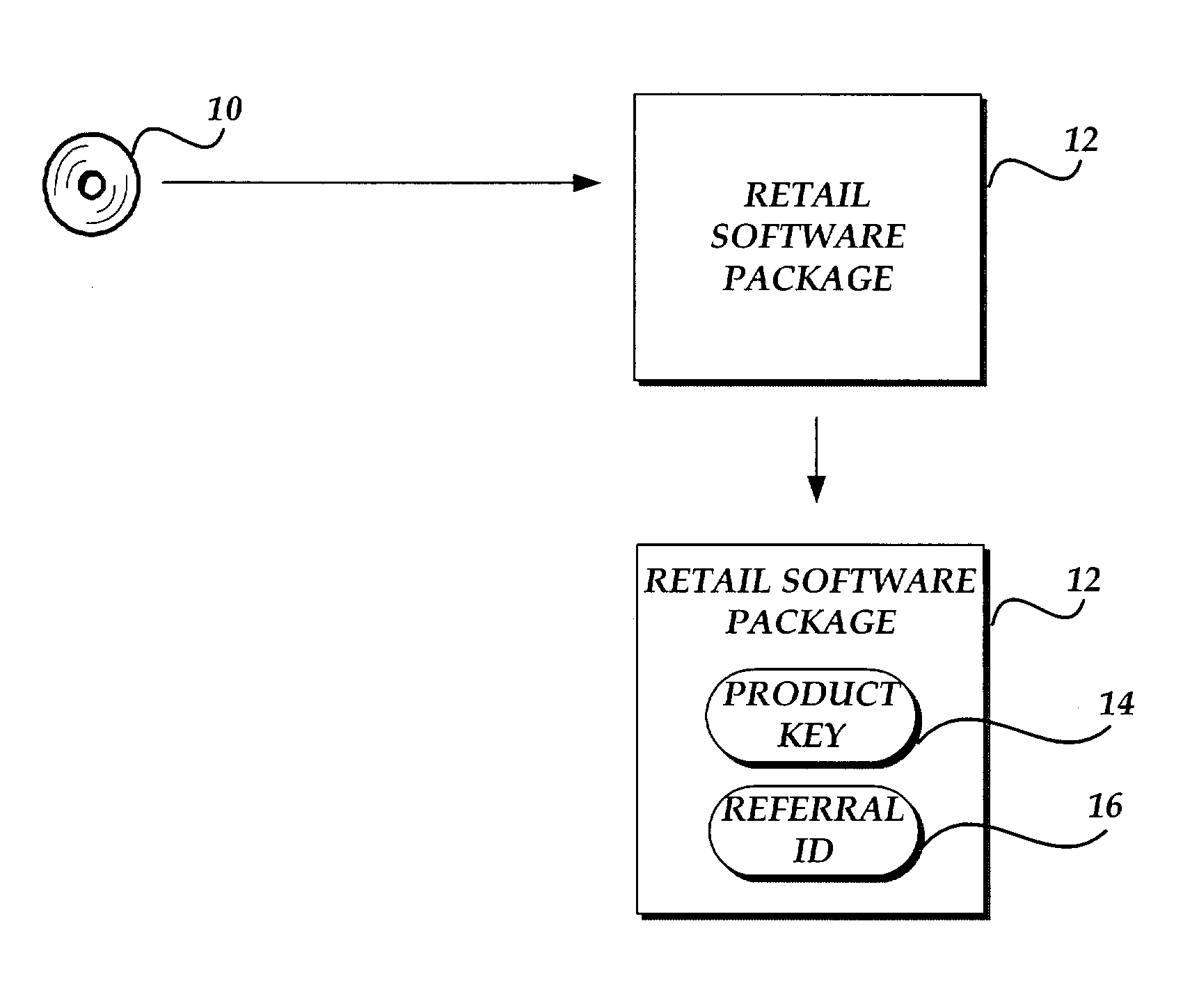

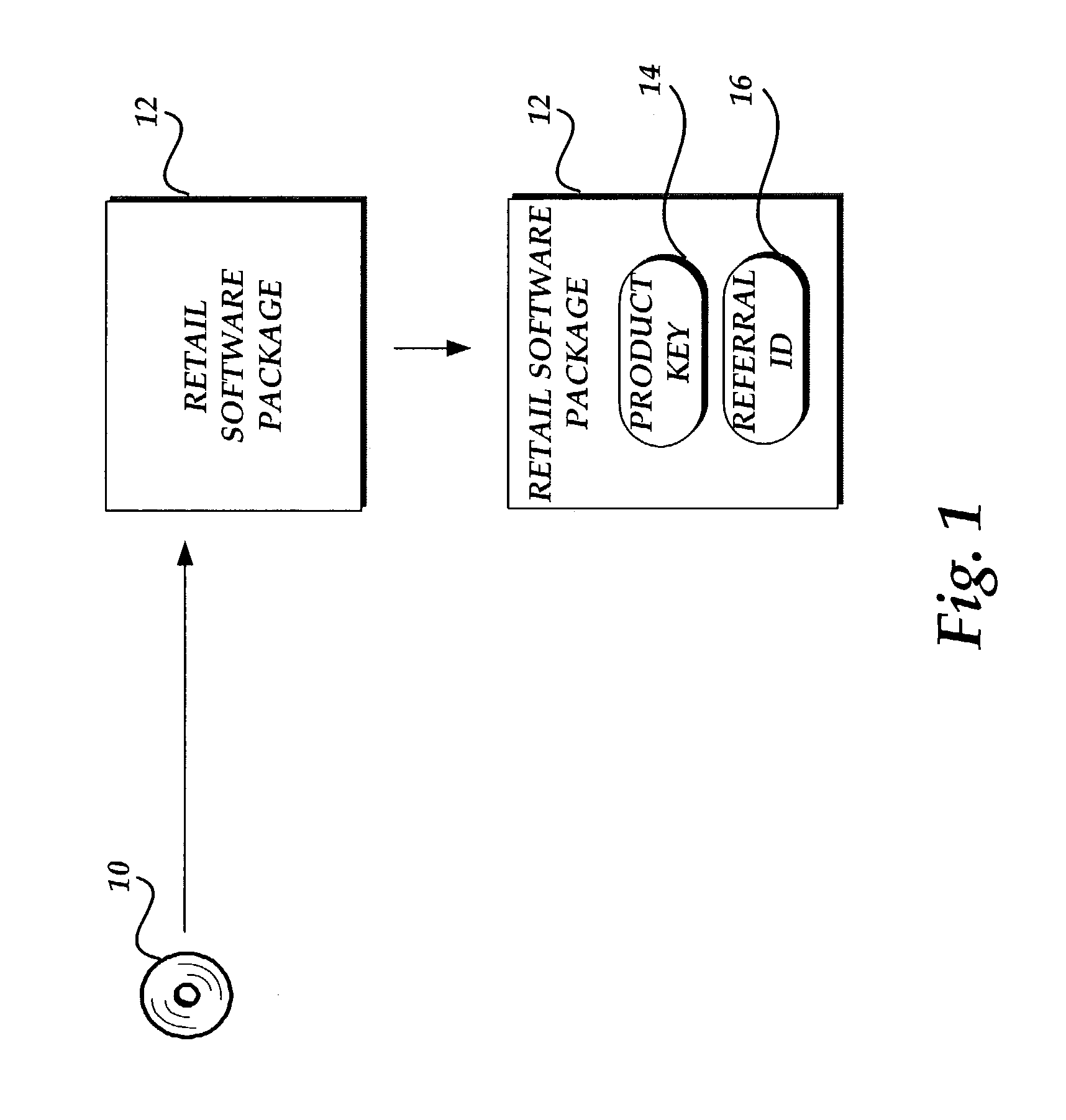

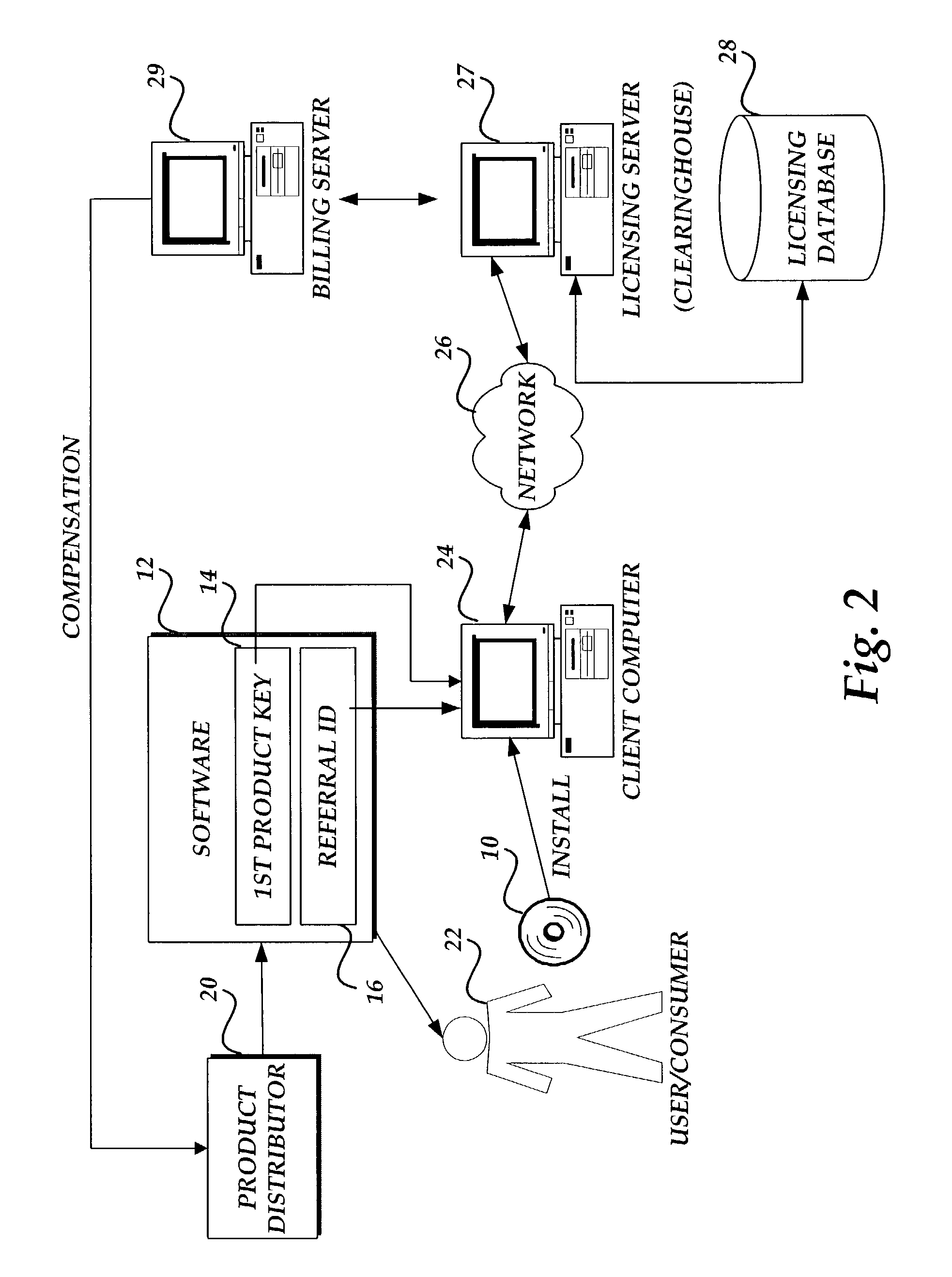

Method, system, apparatus, and computer-readable medium for tracking referrals and product sell-through

InactiveUS7702536B1Satisfies needImprove reliabilityComputer security arrangementsMarketingOriginal equipment manufacturerBiological activation

A method is provided for using referral data to track software product sell-through and compensate software product distributors. A referral identifier (ID), that identifies a product distributor, is associated with a product. The referral ID may be placed on or within the product container, or in the original equipment manufacturer (OEM) case, directly written to the registry or other storage of a new computer. During product activation, the referral ID is sent, along with other referral data, to a server computer where it is stored. Once the server computer determines that a purchase related to the product has occurred, the server retrieves the referral data to identify the referring product distributor, the product involved, the date the product was activated, the date the related purchase was activated, and other related parameters. The referral data may then be audited and used to determine compensation for the identified product distributor.

Owner:MICROSOFT TECH LICENSING LLC

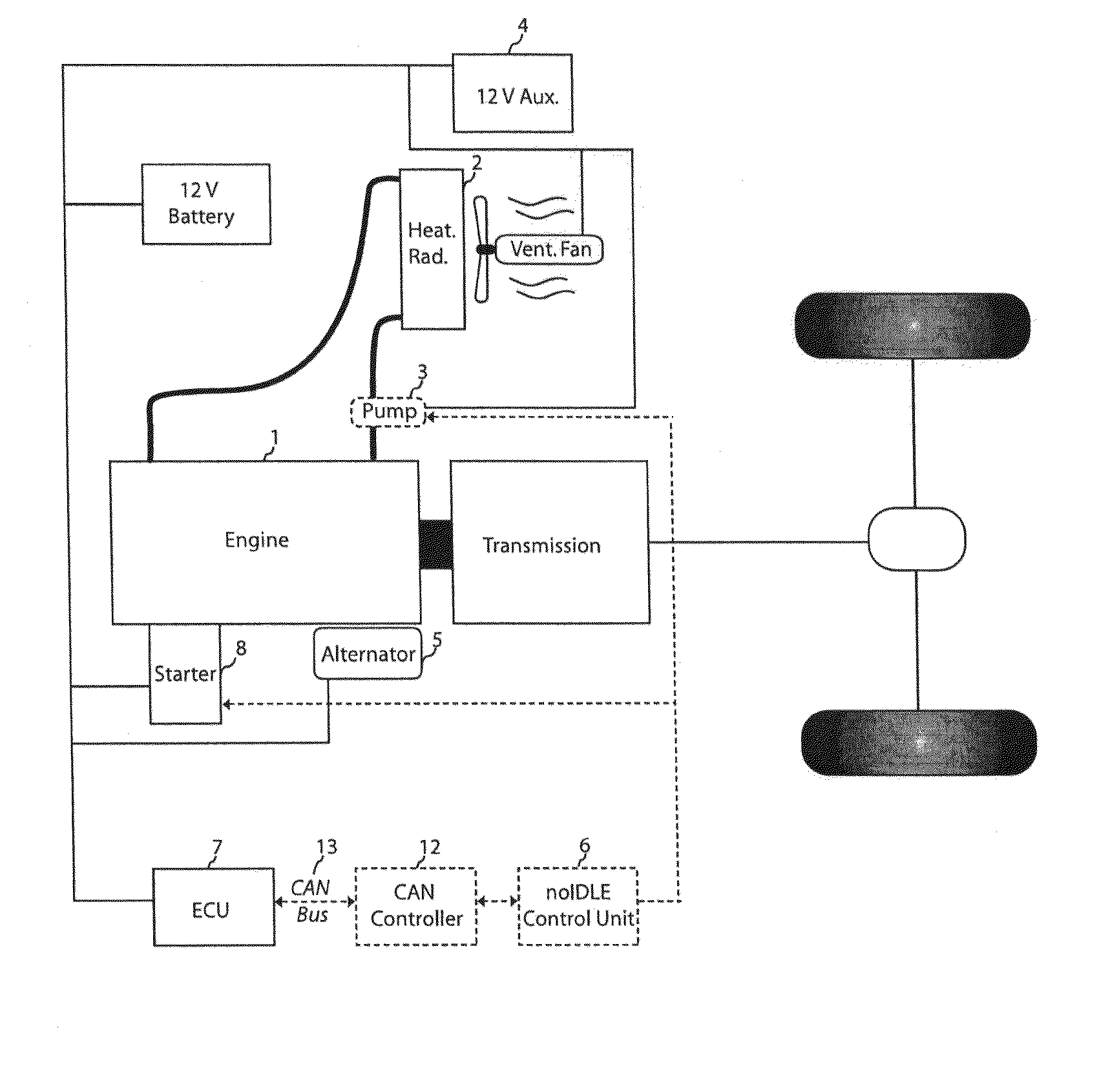

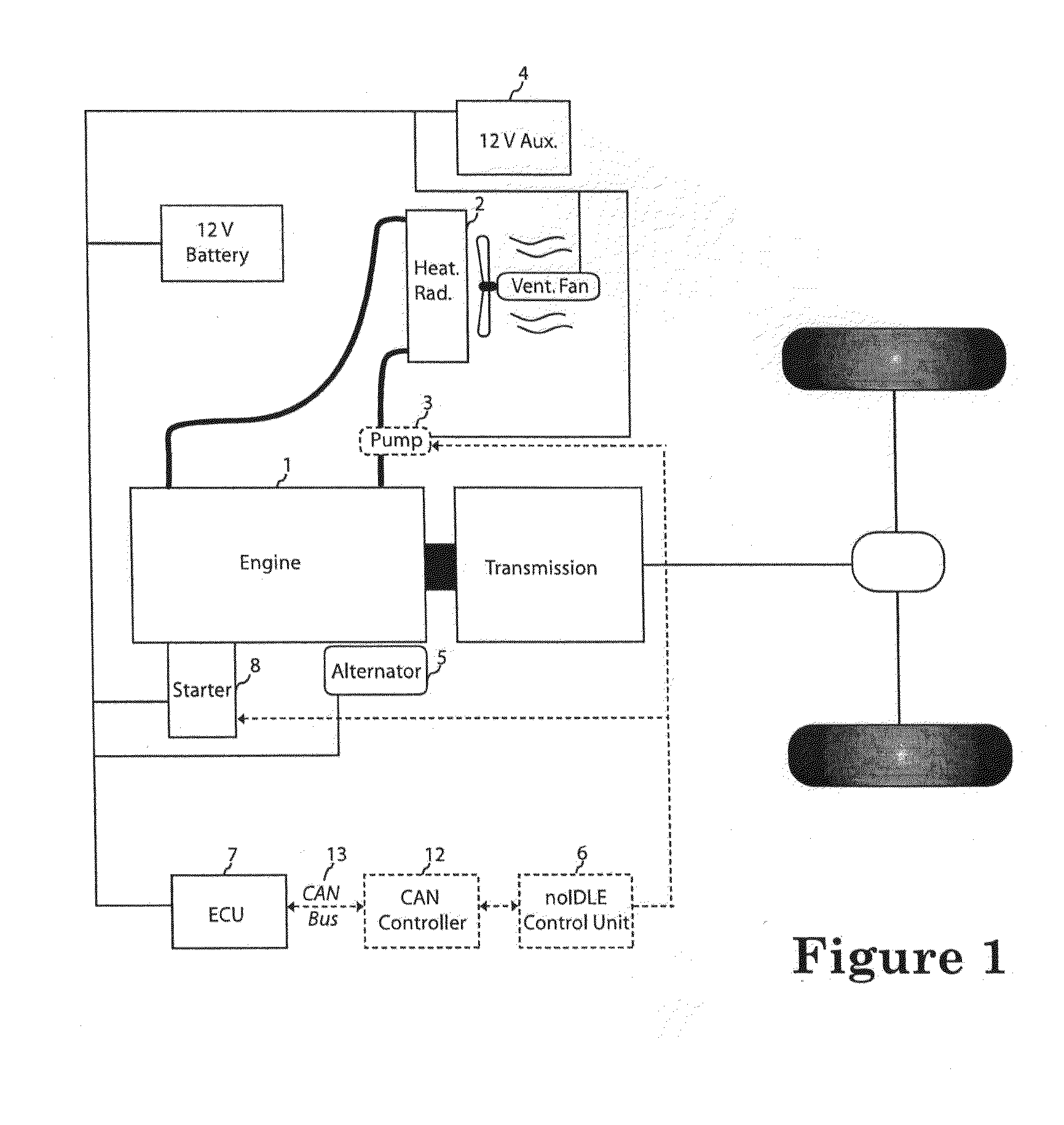

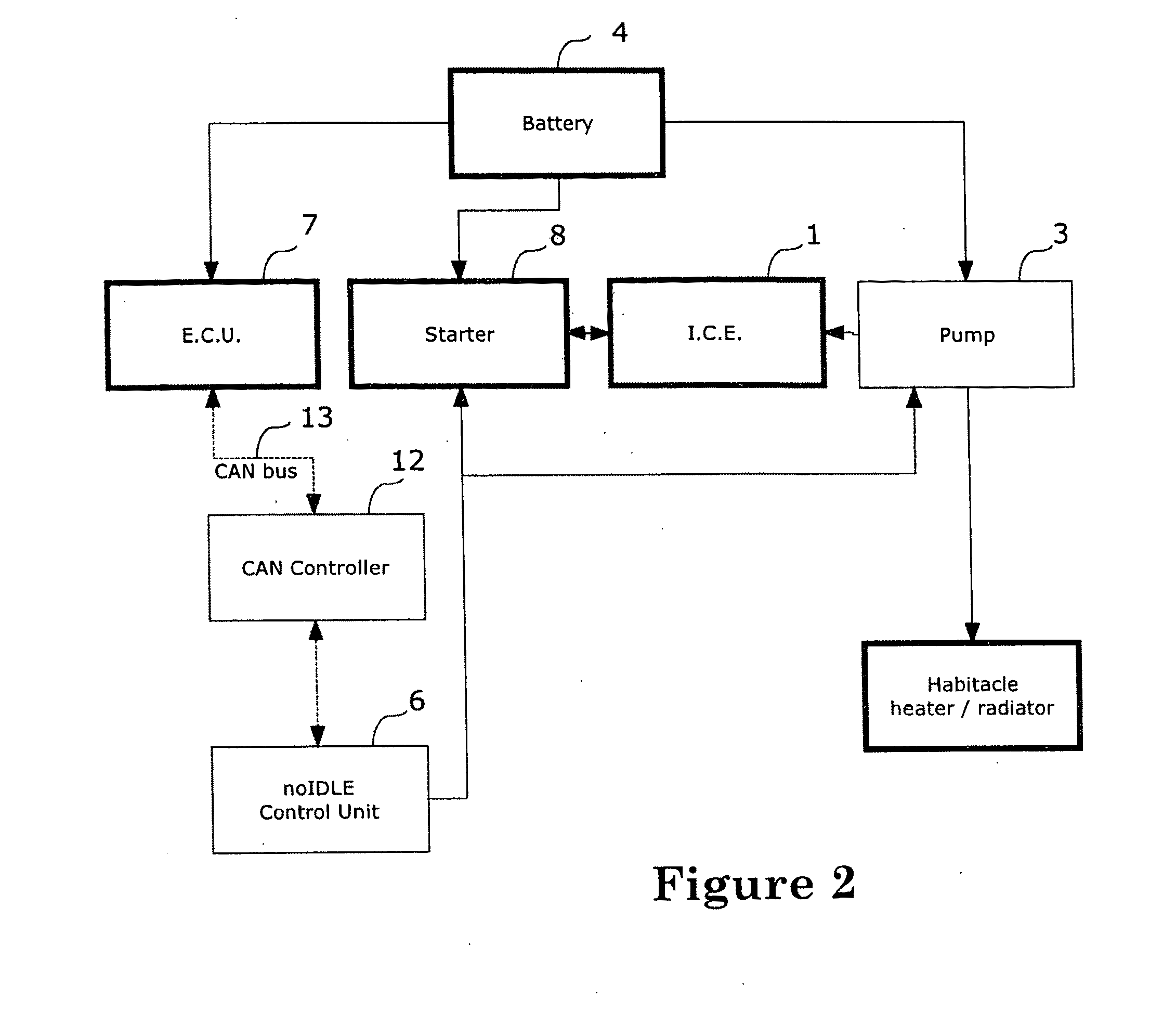

System, device and method for automatically stopping and starting engines of motor vehicles

InactiveUS20100131152A1Deep dischargeSufficient powerAnalogue computers for vehiclesAir-treating devicesInternal combustion engineNormal conditions

Systems, control methods and related apparatus for engine idling reduction, to decrease operating cost and pollution related to the use of an automotive vehicle, while increasing its autonomy. Integrated are an automatic start-stop device, an increased onboard energy capacity, an electric pump that circulates engine coolant to the heater radiator to extract engine thermal inertia for cabin heating and an engine electric cooling system. The system is designed to reduce fuel consumption and air pollution while maintaining auxiliary systems in function and the cabin temperature at an acceptable level when the engine is stopped. This system may be integrated aboard internal combustion engine vehicles that have important idling periods in normal conditions. Such systems can either be implemented as retrofit kits or during a vehicle's manufacturing, directly by the original equipment manufacturer (OEM).

Owner:CASTONGUAY SYLVAIN +1

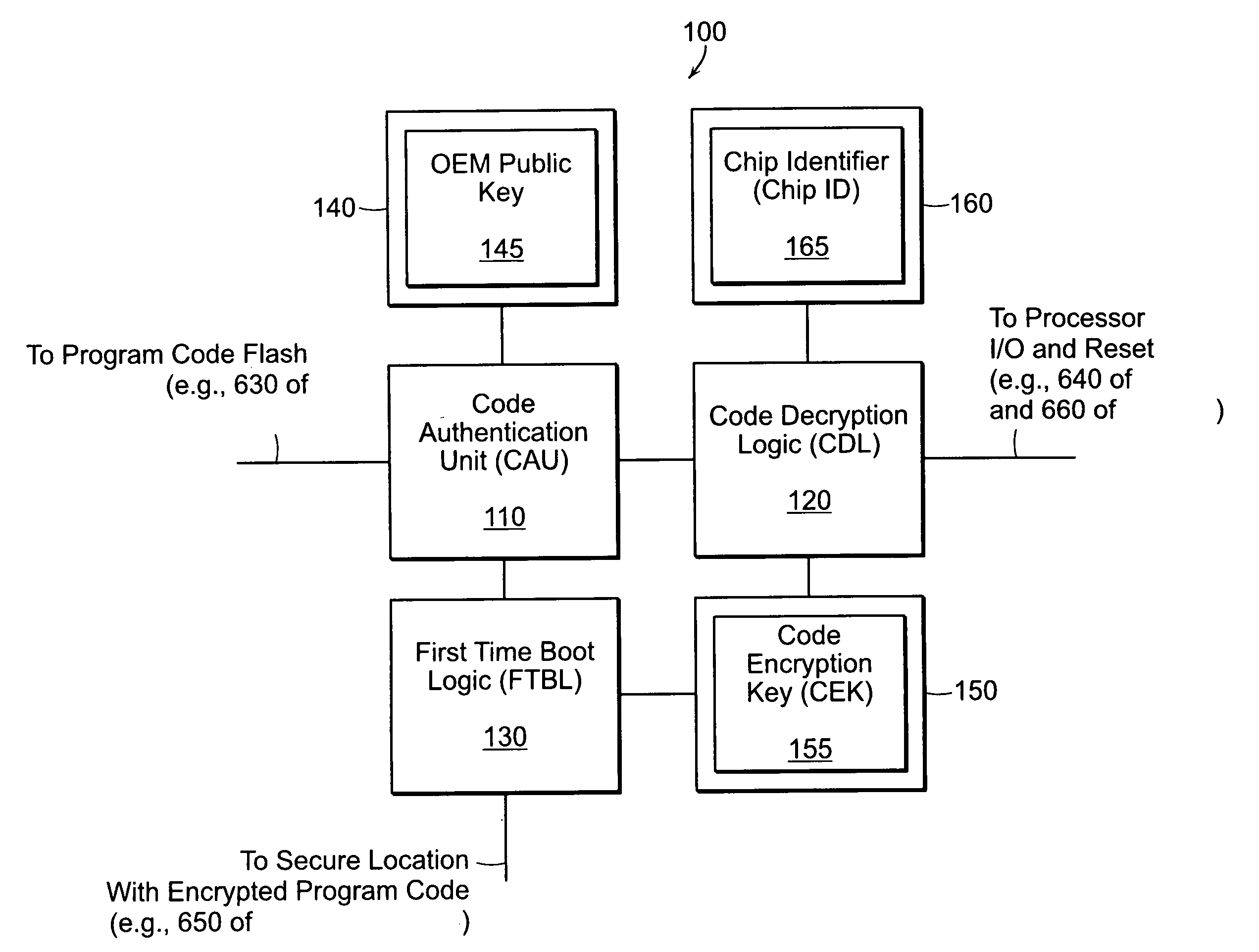

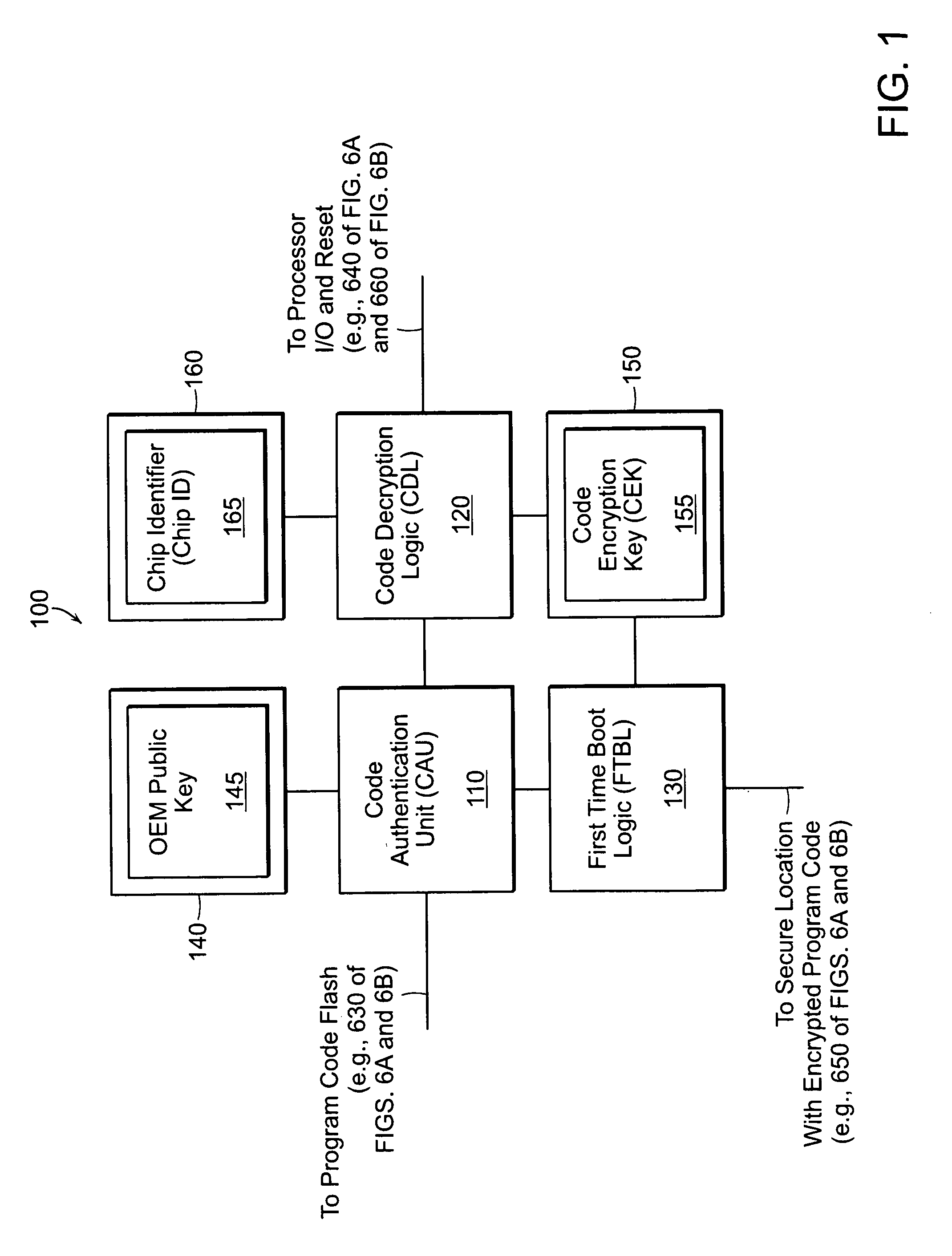

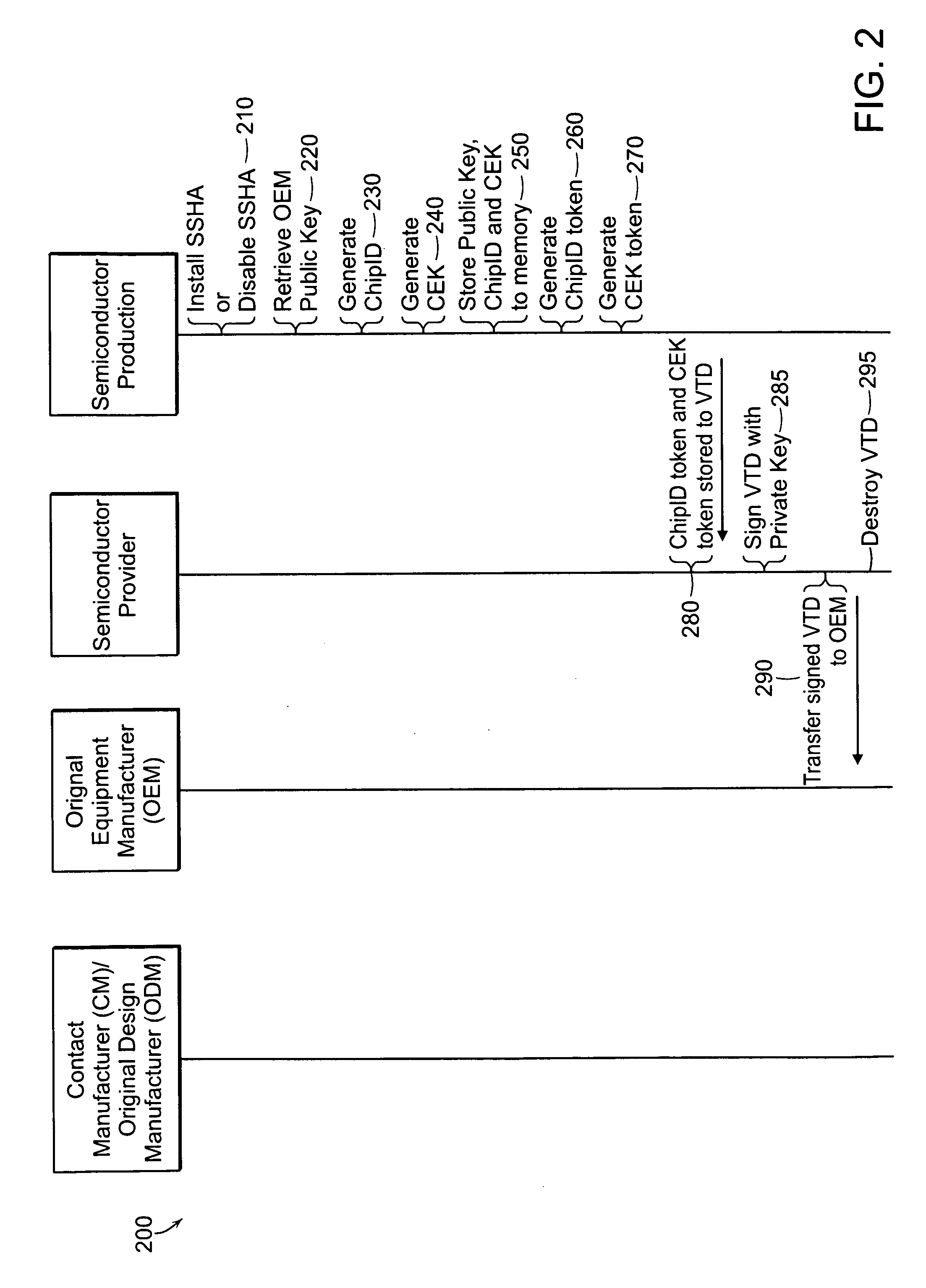

Secure software and hardware association technique

ActiveUS20090217054A1Encryption apparatus with shift registers/memoriesUnauthorized memory use protectionComputer hardwareOriginal equipment manufacturer

In an embodiment, authenticated hardware and authenticated software are cryptographically binded using symmetric and asymmetric cryptography. Cryptographically binding the hardware and software ensures that original equipment manufacturer (OEM) hardware will only run OEM software. Cryptographically binding the hardware and software protects the OEM binary code so it will only run on the OEM hardware and cannot be replicated or altered to operate on unauthorized hardware. This cryptographic binding technique is referred to herein as secure software and hardware association (SSHA).

Owner:MARVELL ASIA PTE LTD

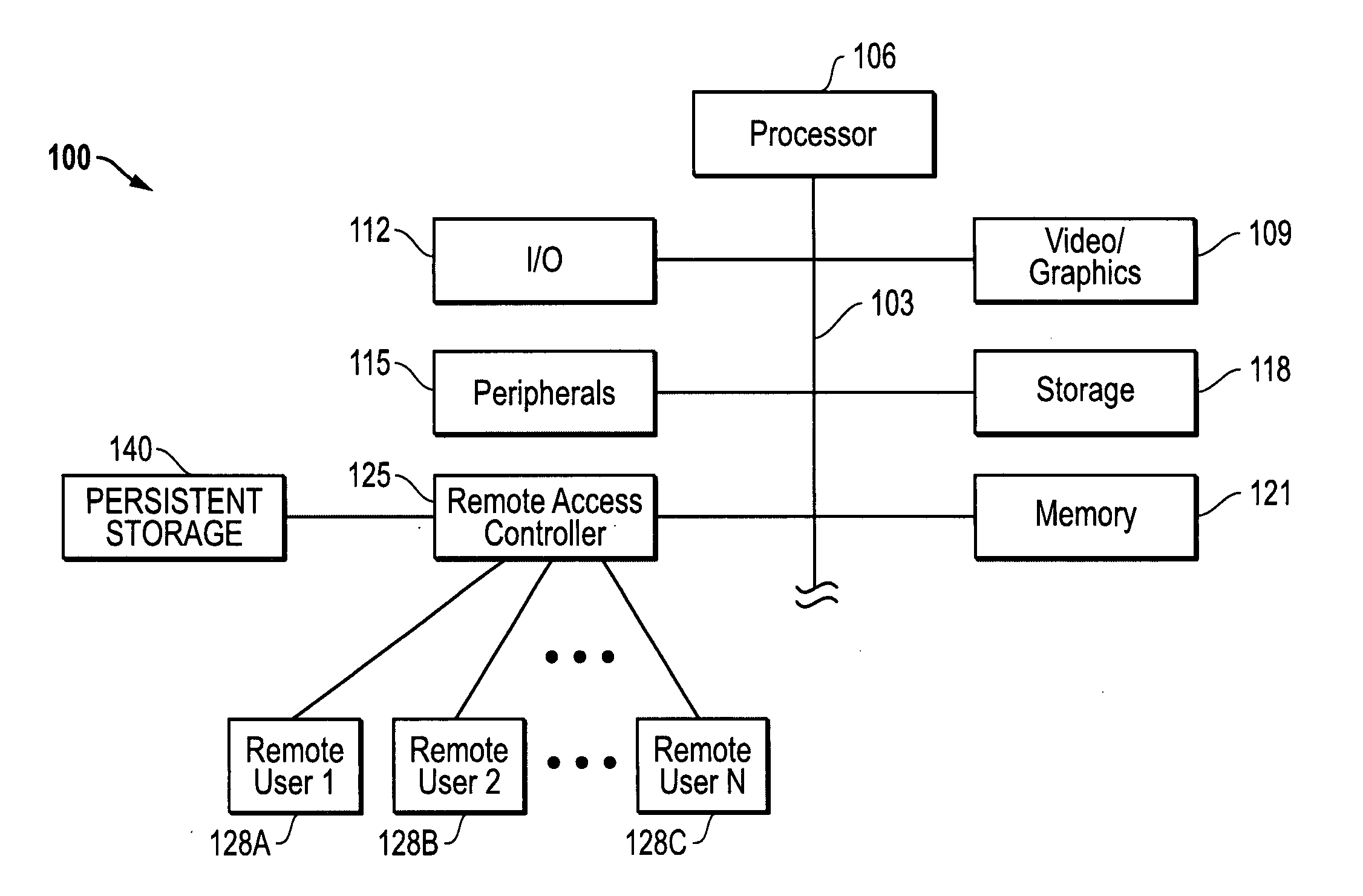

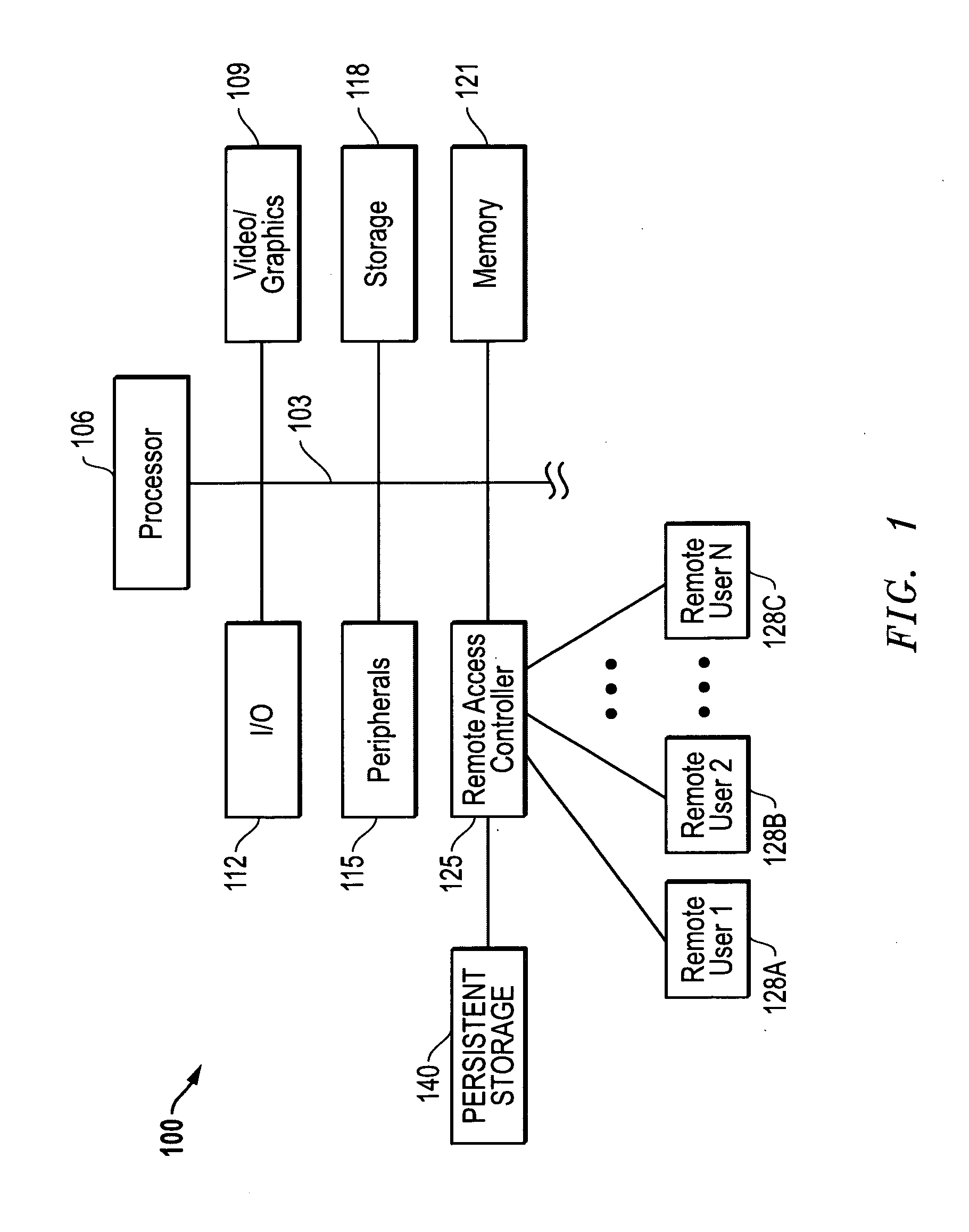

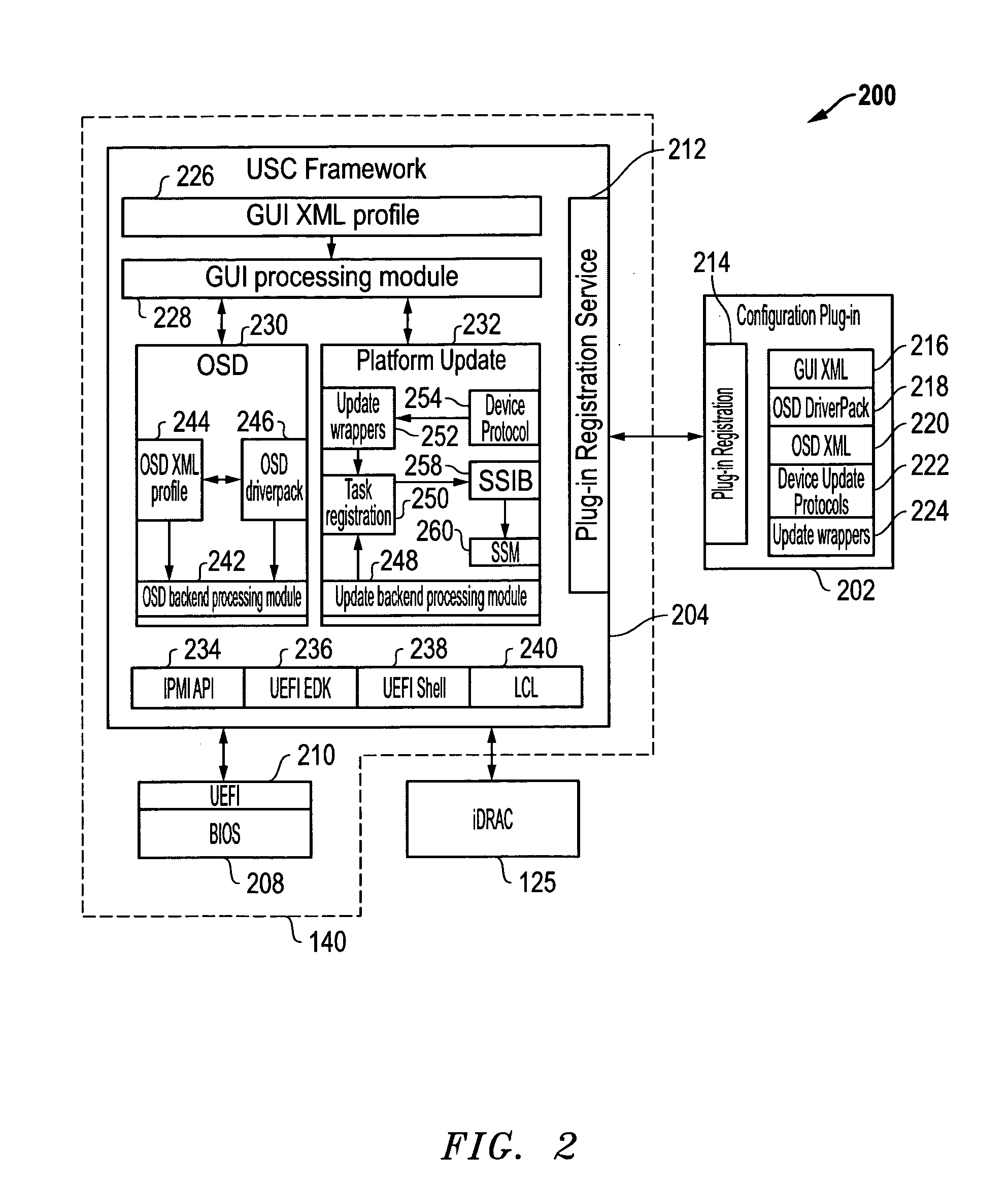

Systems and methods for extension of server management functions

ActiveUS20110078293A1Improve usabilityEasy to customizeDigital computer detailsTransmissionThird partySystems management

Systems and methods that may be implemented to provide a plug-in architecture framework to allow extension of server management functionalities in a unified extension firmware interface (“UEFI”) environment using available remote access controller memory space. The disclosed systems and methods may be implemented to provide a hardware and software interface to allow use of a plug-in framework in the embedded system management that may be run under the BIOS firmware and the UEFI environment. The disclosed systems and methods may also be implemented to provide a server management architecture that may be modified and enhanced over time, and / or that may also be employed to extend availability of the server management framework to third parties, as well as to extend support to original equipment manufacturer (“OEM”) servers.

Owner:DELL PROD LP

Method of minimizing distortion in a sheet of glass

InactiveUS7685840B2Reduce distortion problemsMinimize distortionLayered productsGlass drawing apparatusIn planeOriginal equipment manufacturer

A method of minimizing distortion in a glass sheet manufacturing process wherein the stress in a parent sheet of glass is measured along each edge of the sheet. The stress data is then used to develop a distortion predictor for predicting the in-plane distortion which sub-sheets of the parent sheet are likely to exhibit when the parent sheet is cut into pre-determined sizes. The in-plane distortion may be predicted based on criteria established by the glass manufacturer, or supplied by an original equipment manufacturer (OEM).

Owner:CORNING INC

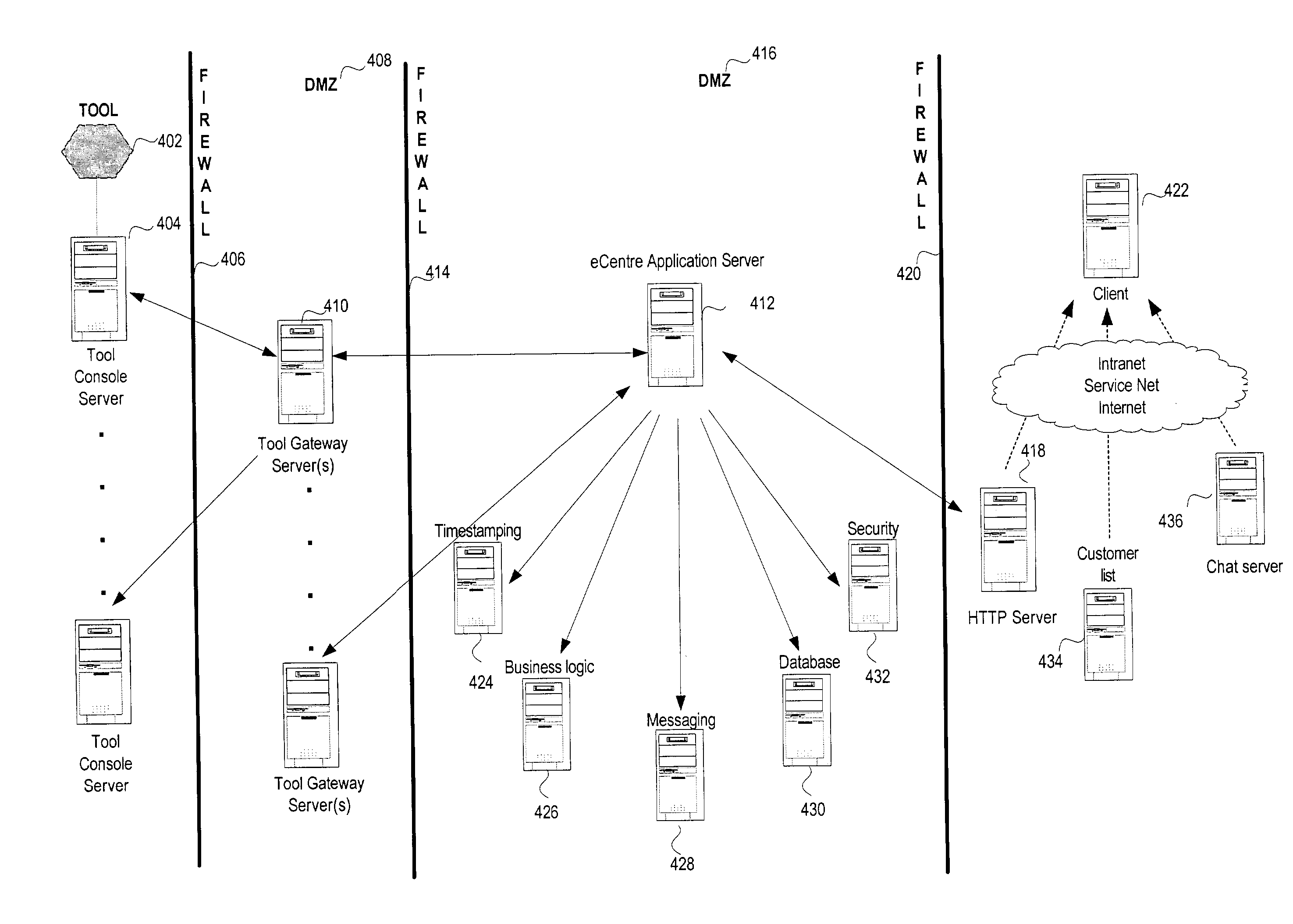

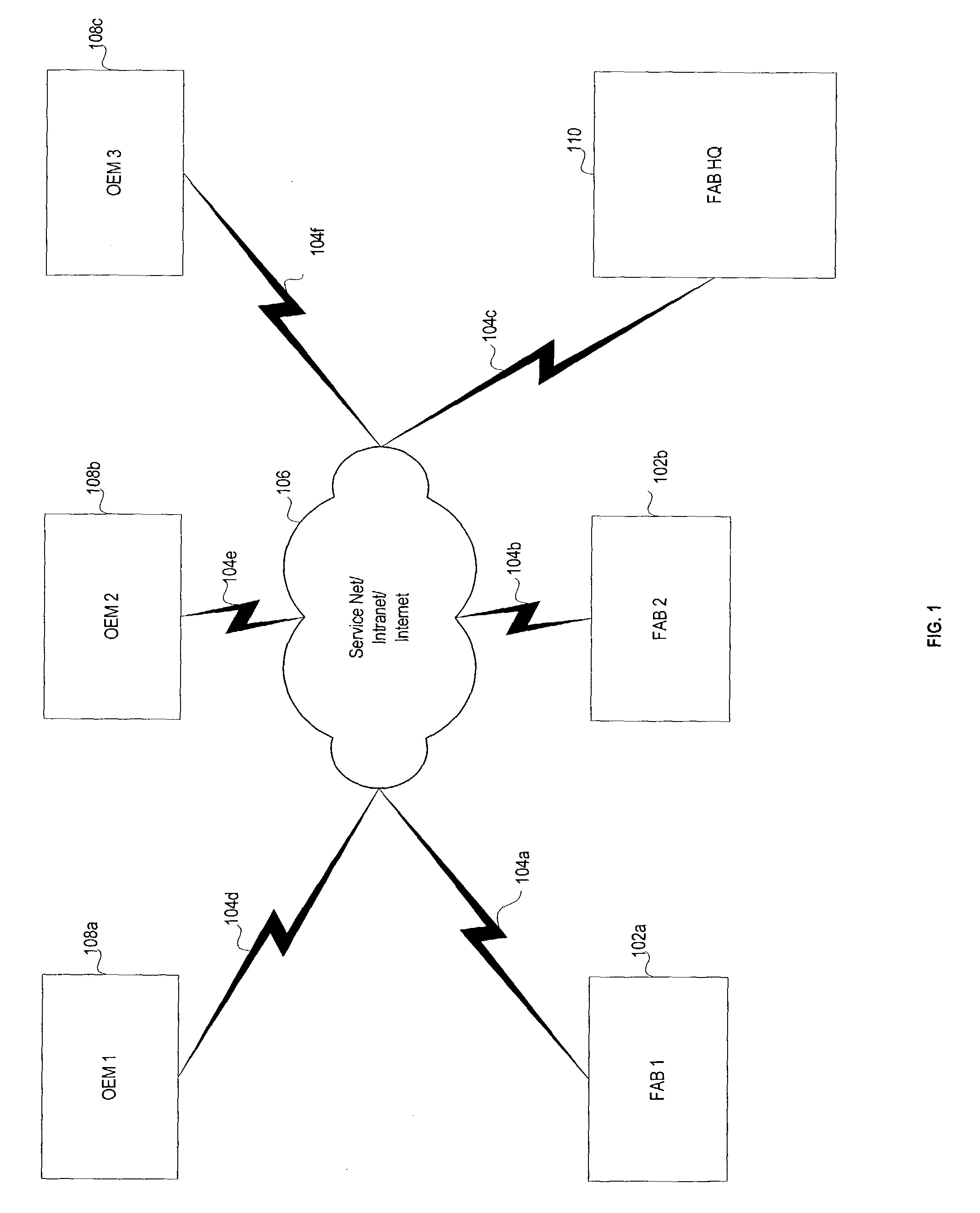

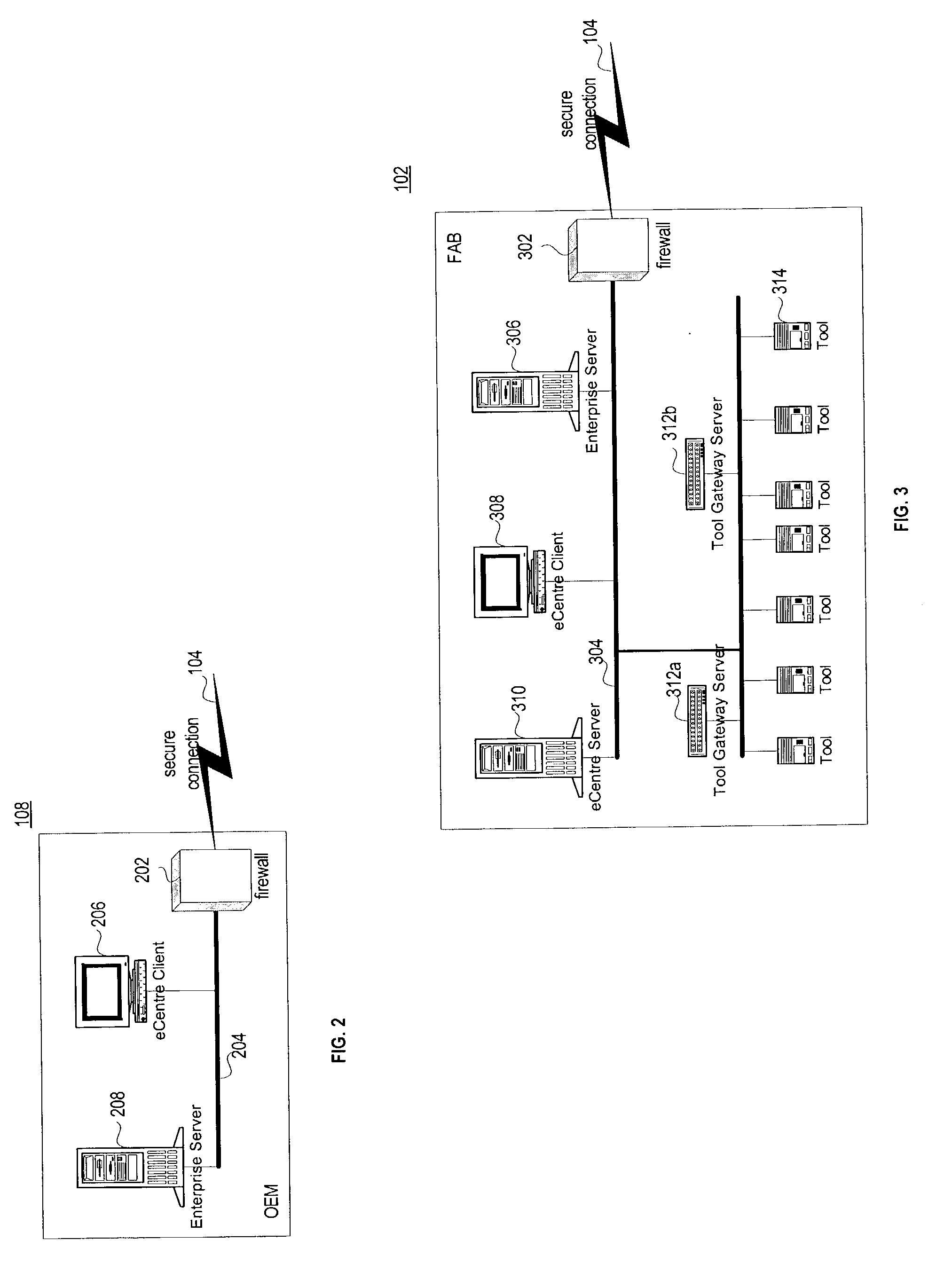

Diagnostic system and method for integrated remote tool access, data collection, and control

InactiveUS20030220768A1Detecting faulty hardware by remote testDigital computer detailsOriginal equipment manufacturerDiagnostic system

A remote diagnostics system is presented comprising: a first internal network in a fabricator (FAB), the FAB having at least one automated manufacturing tool, a tool controller, and internal secure storage means; a second internal network in an original equipment manufacturer (OEM), the OEM having internal secure storage means; an external network; a first secure shared network coupling the first internal network to the external network; a second secure shared network coupling the second internal network to the external network; and a secure channel which propagates data from the tool at the FAB to the OEM for e-diagnostics; wherein the tool generates data proprietary to at least one of the FAB and the OEM.

Owner:ILS TECH INC

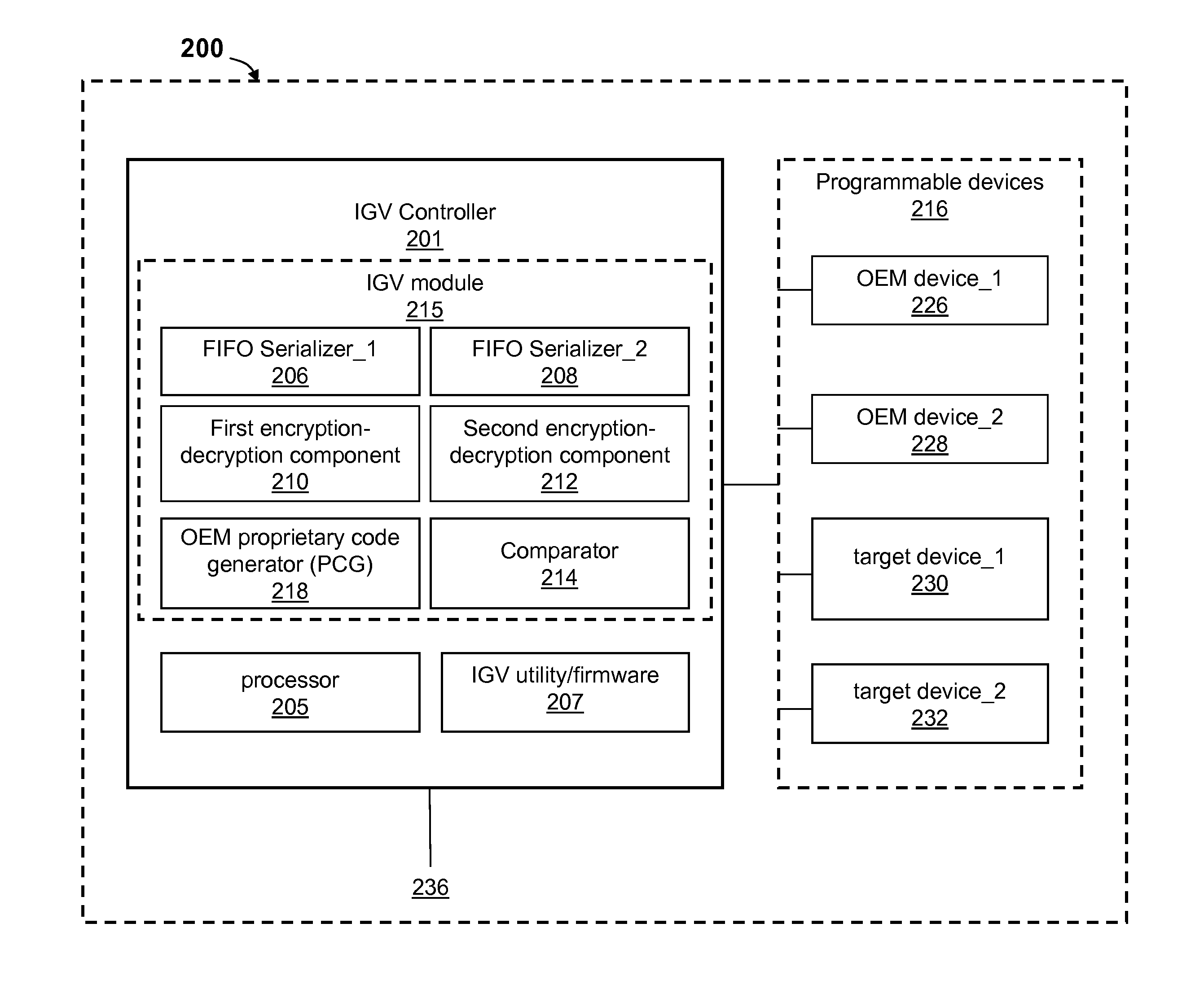

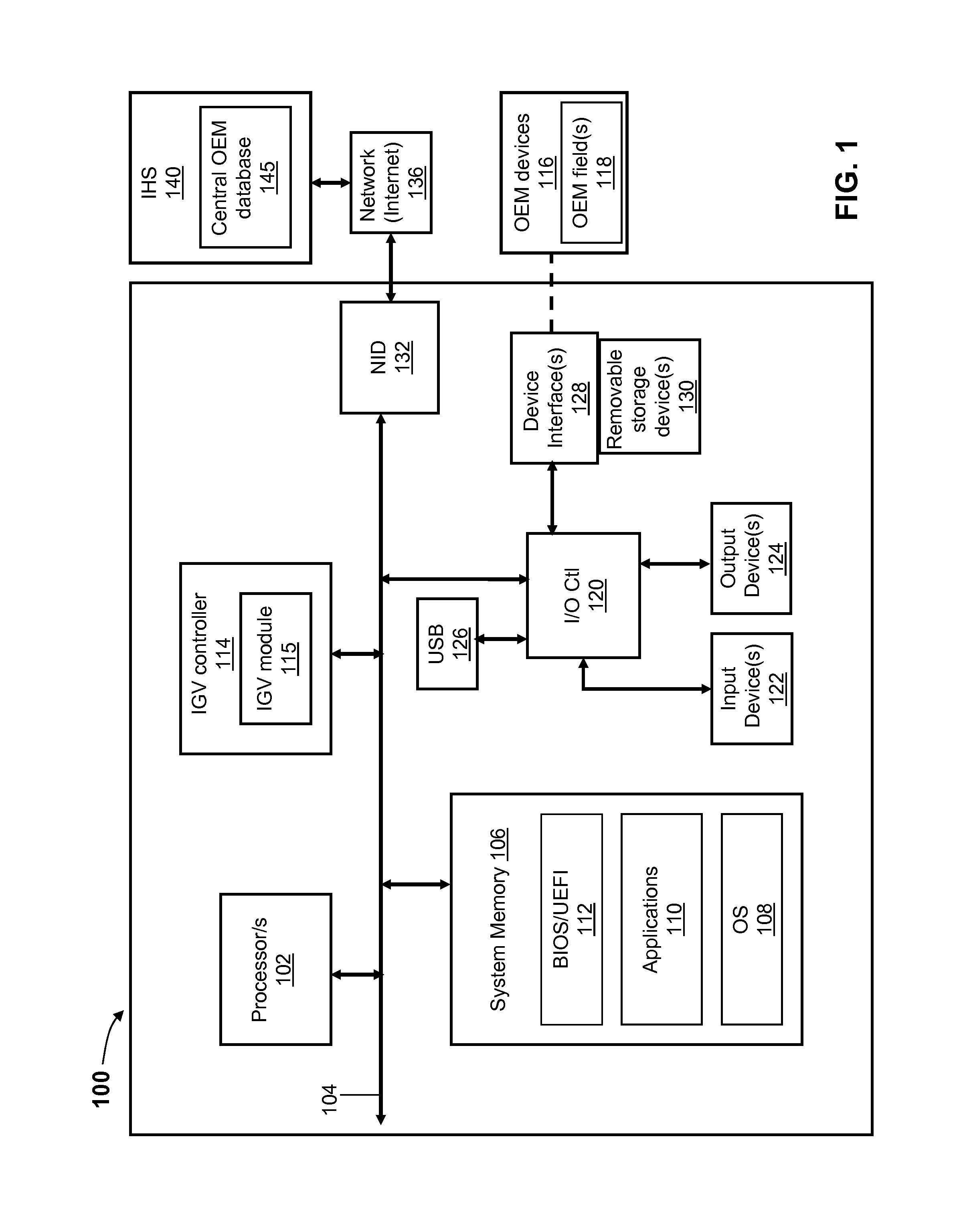

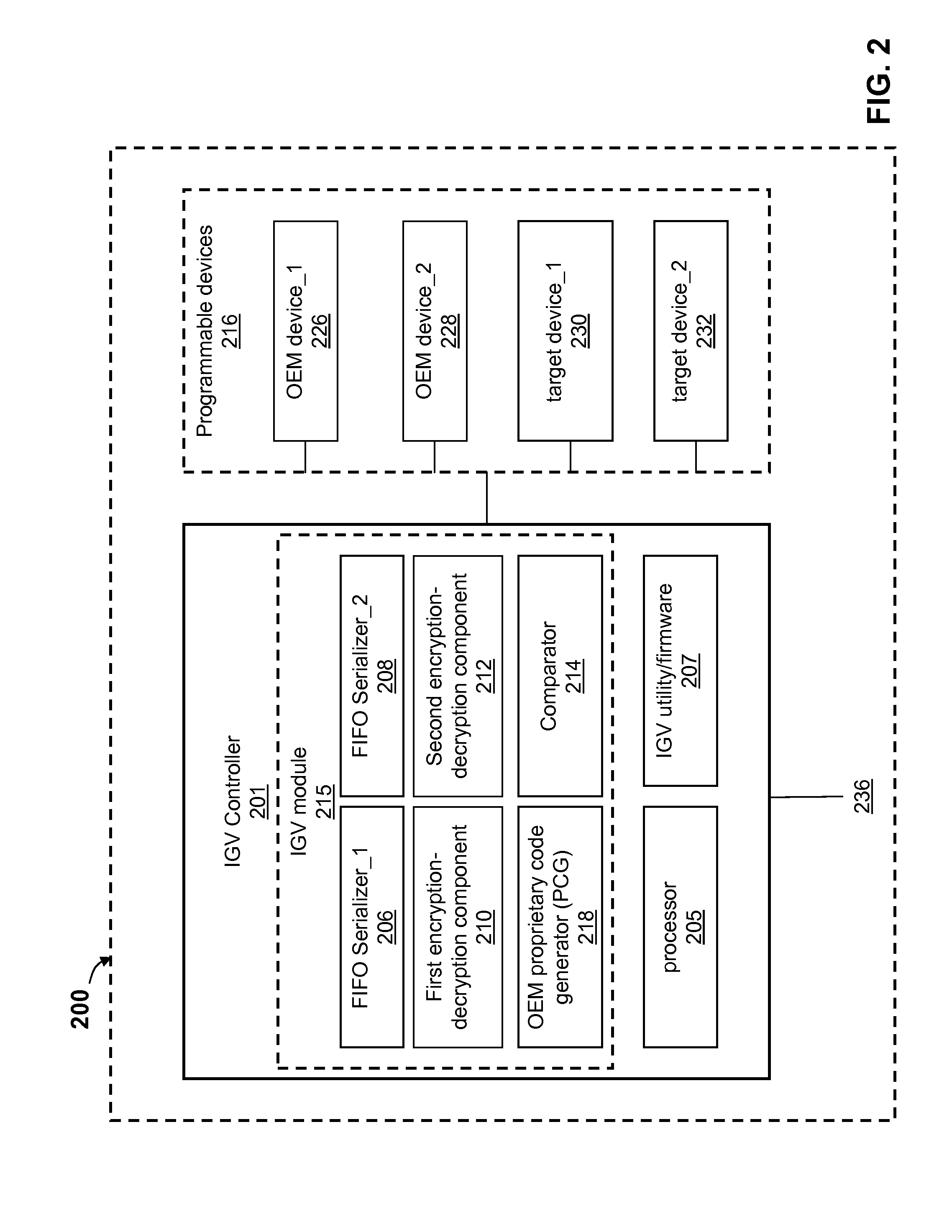

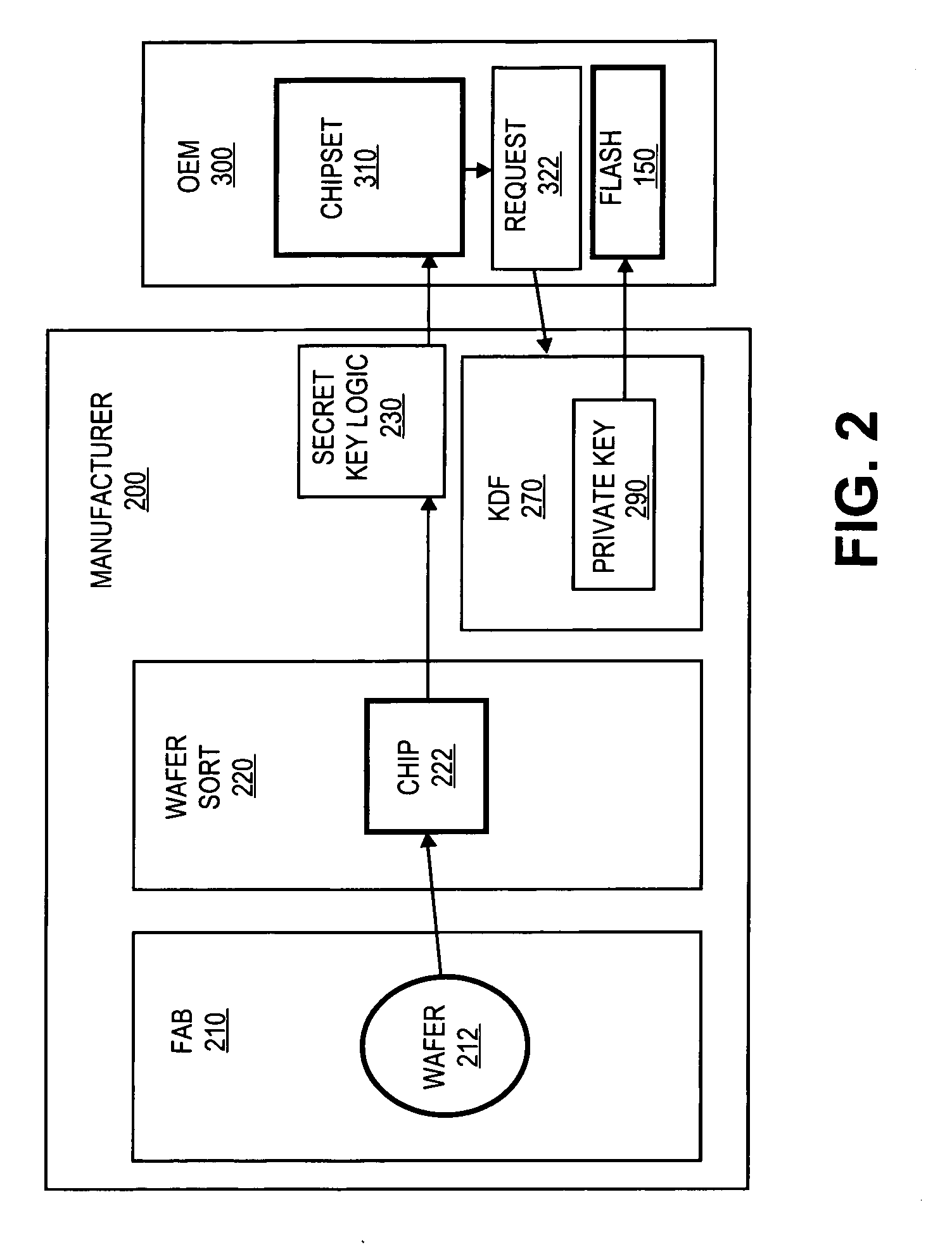

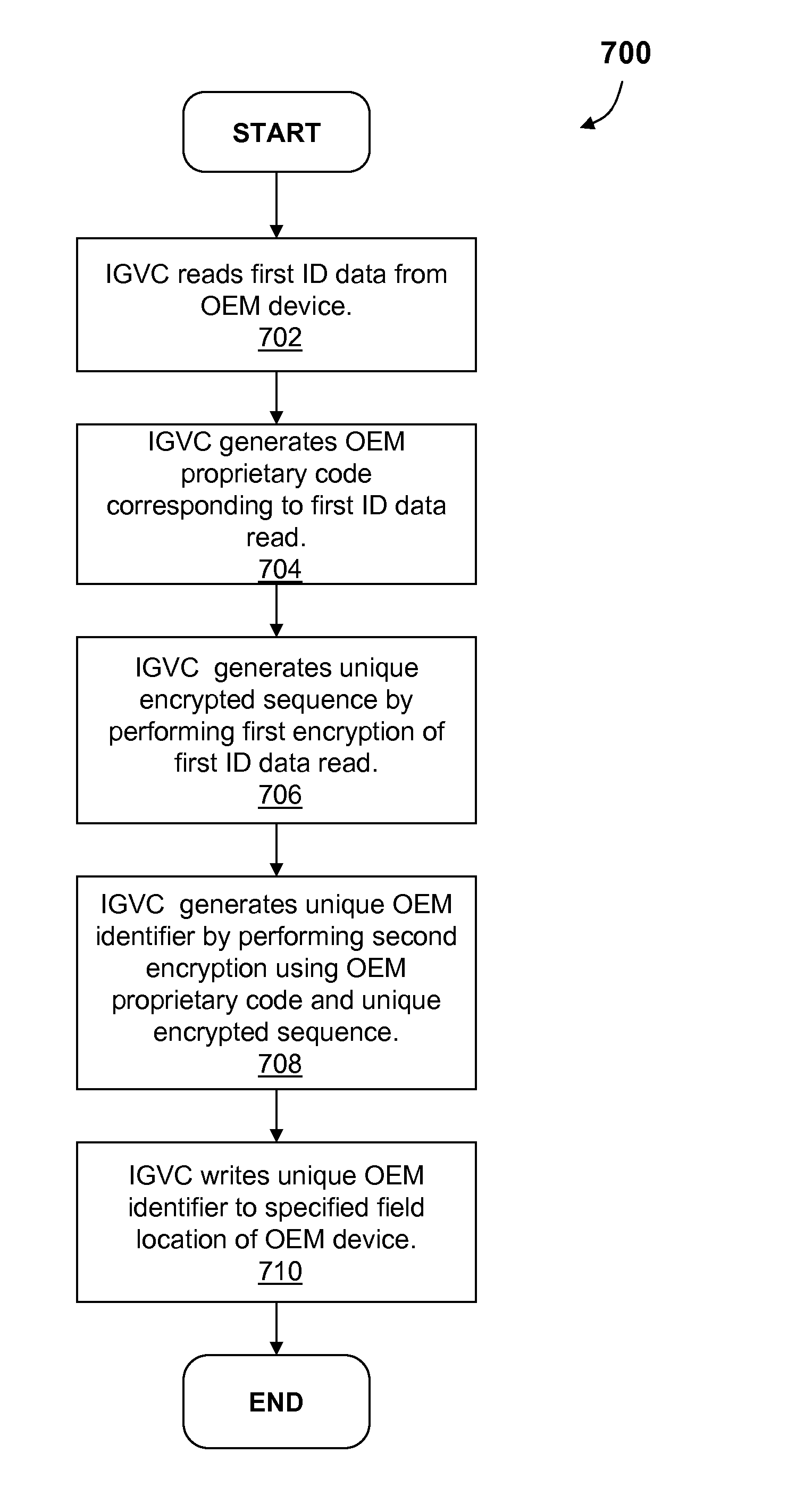

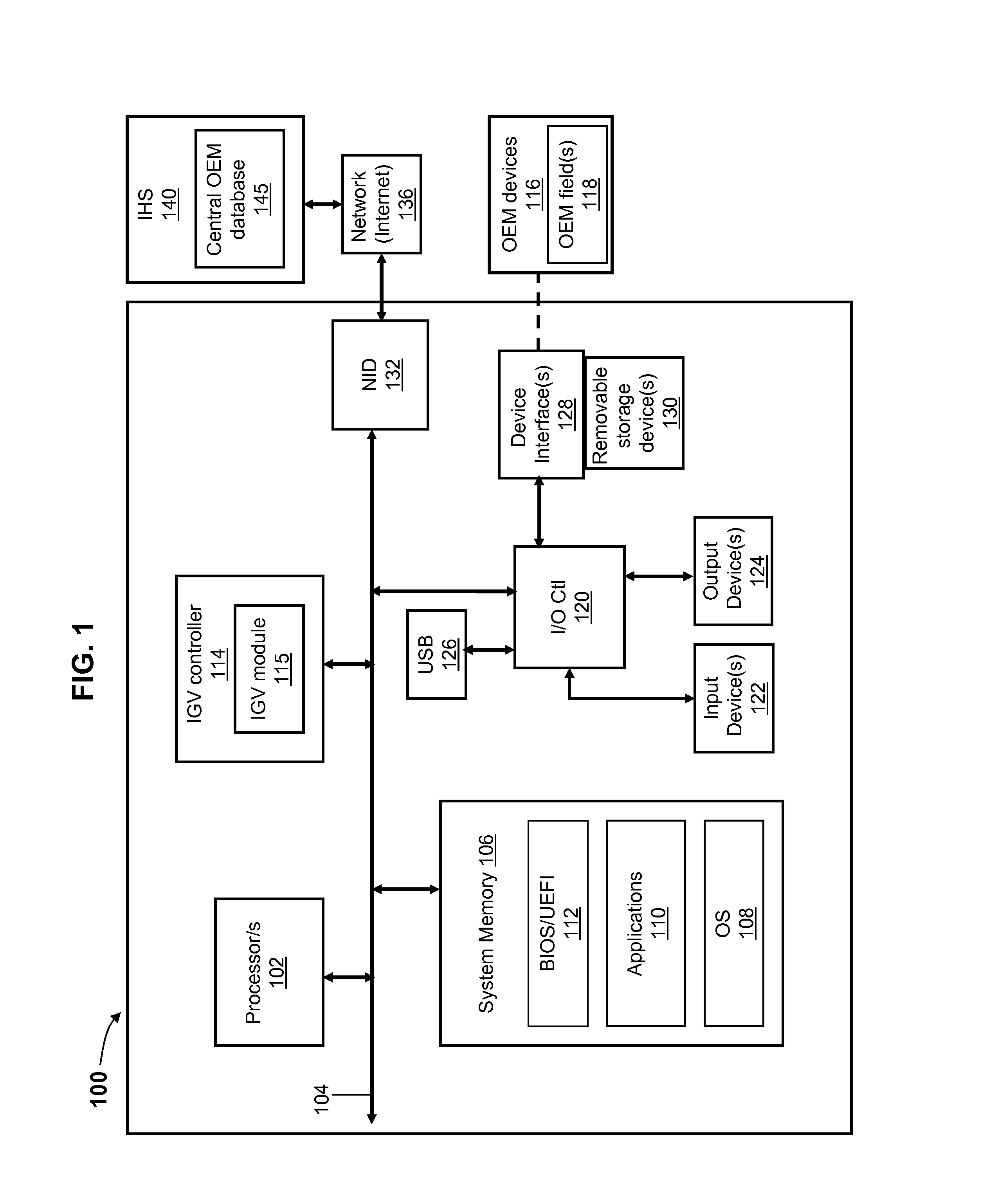

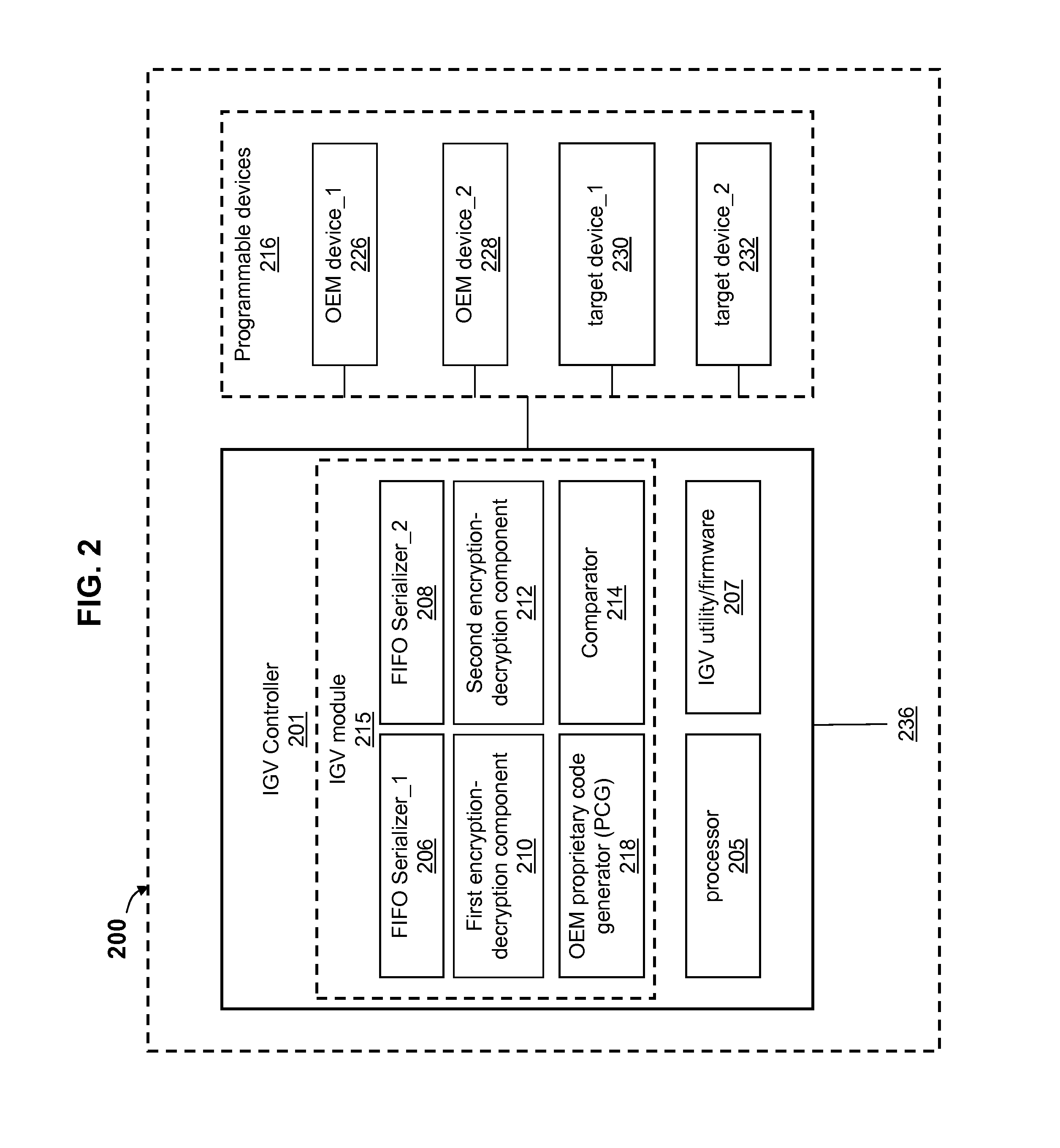

Secure Original Equipment Manufacturer (OEM) Identifier for OEM Devices

ActiveUS20140359303A1Unauthorized memory use protectionHardware monitoringOriginal equipment manufacturerUnique identifier

An authorized information handling system (IHS) generates unique identifier codes for an OEM (programmable) device designed as a component for an IHS. An identifier generation and validation (IGV) controller in the authorized IHS generates a unique encrypted sequence by encrypting identification (ID) data read from the OEM device. The IGV controller generates a unique OEM identifier code by further encrypting the encrypted sequence using a first OEM proprietary code. The IGV controller writes the first identifier code to a pre-specified storage location of the OEM device. According to one embodiment, the IGV controller generates the unique OEM identifier code using a second reversible encryption-decryption component that comprises an Exclusive-OR (XOR) scrambler engine and generates the unique encrypted sequence using a first reversible encryption-decryption component that comprises an LFSR based scrambler, which utilizes polynomial coefficients that are securely generated and maintained.

Owner:DELL PROD LP

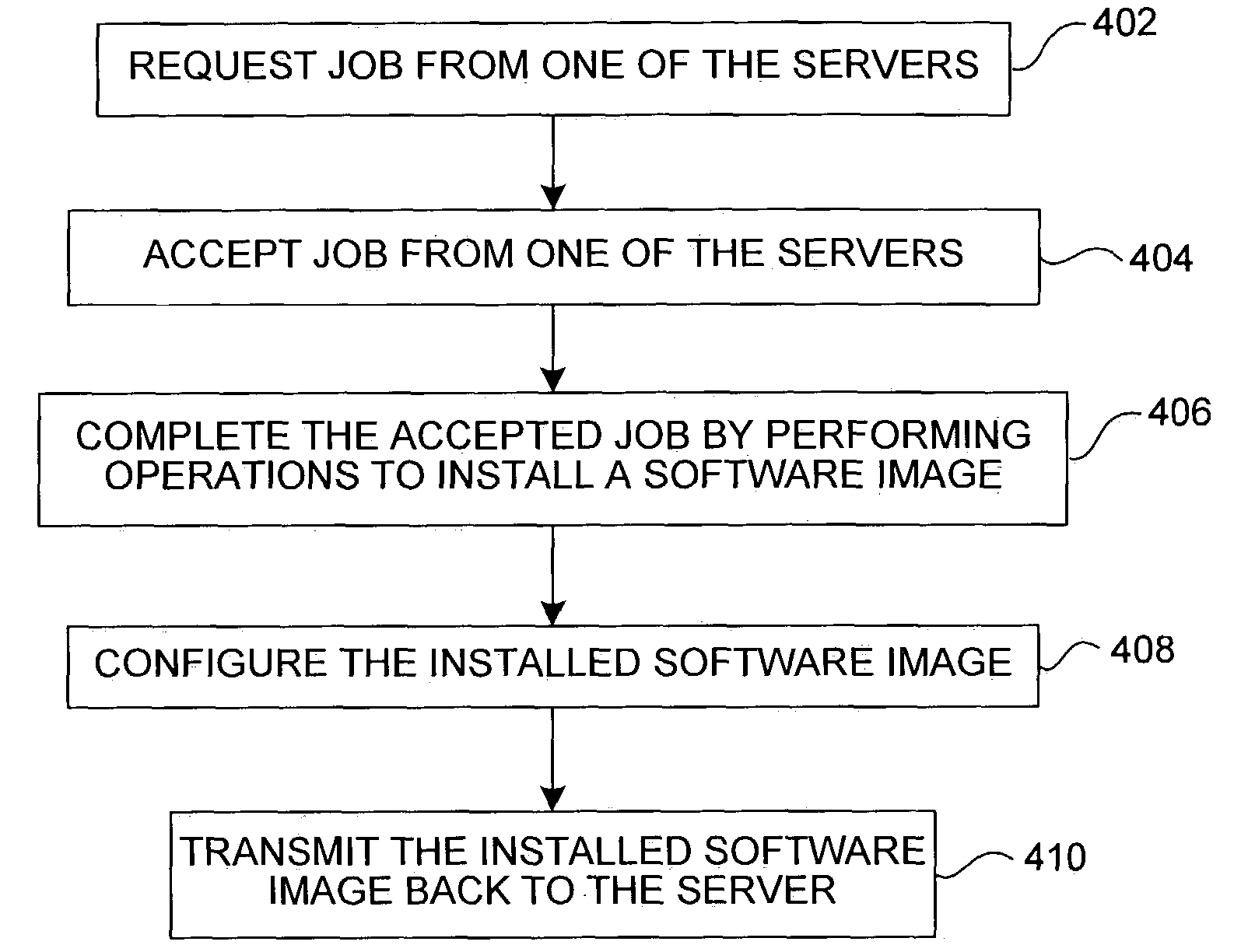

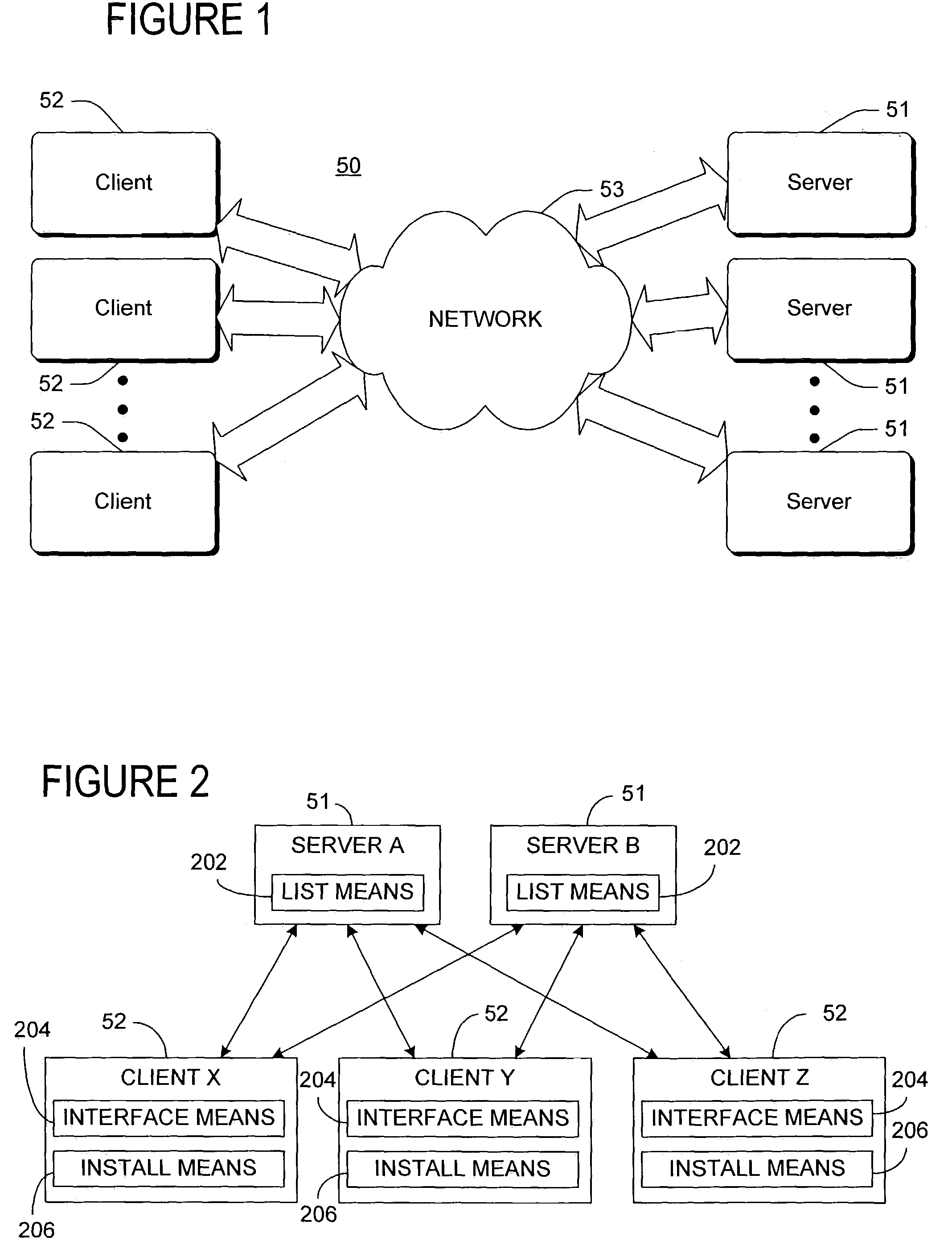

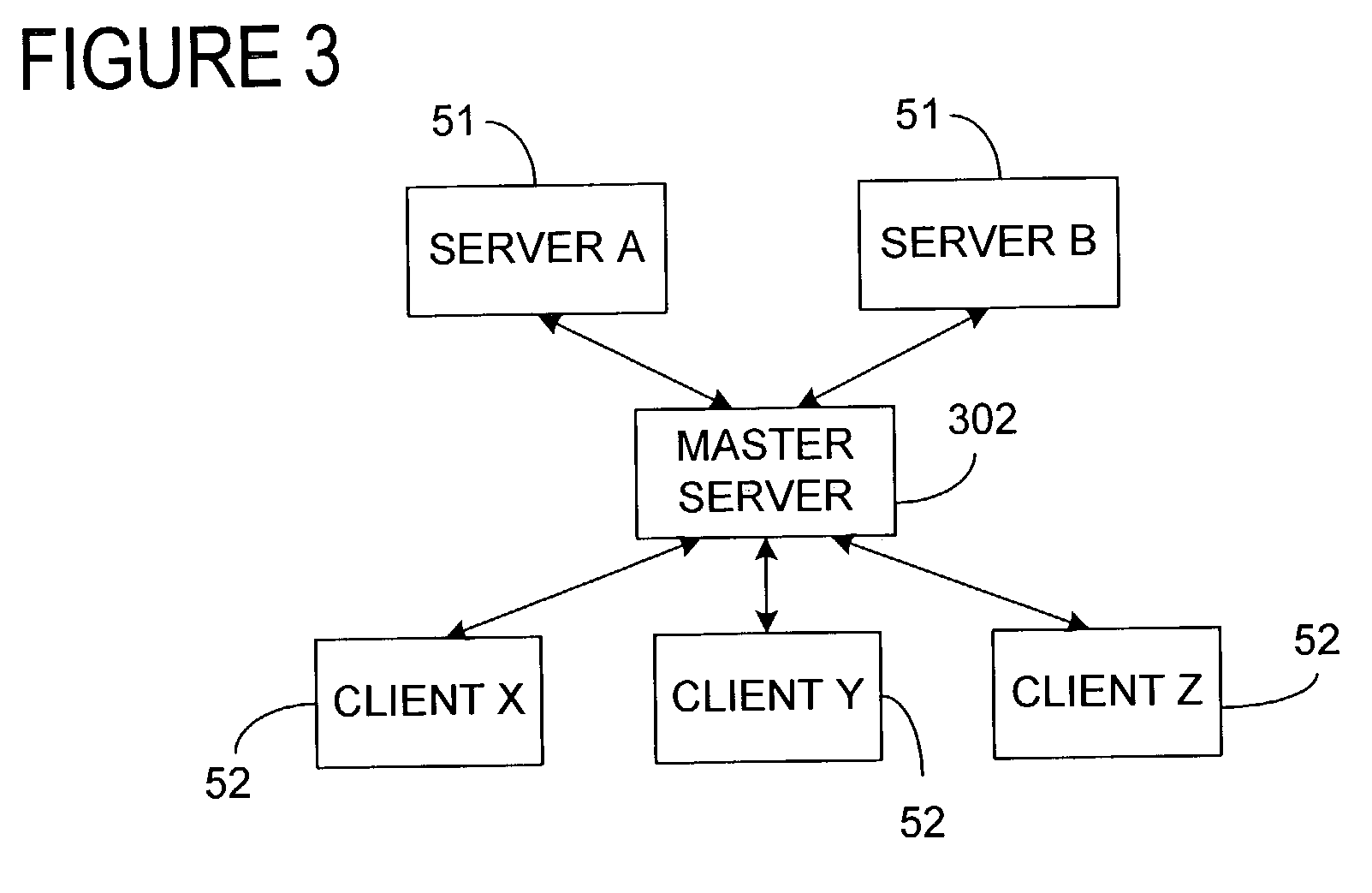

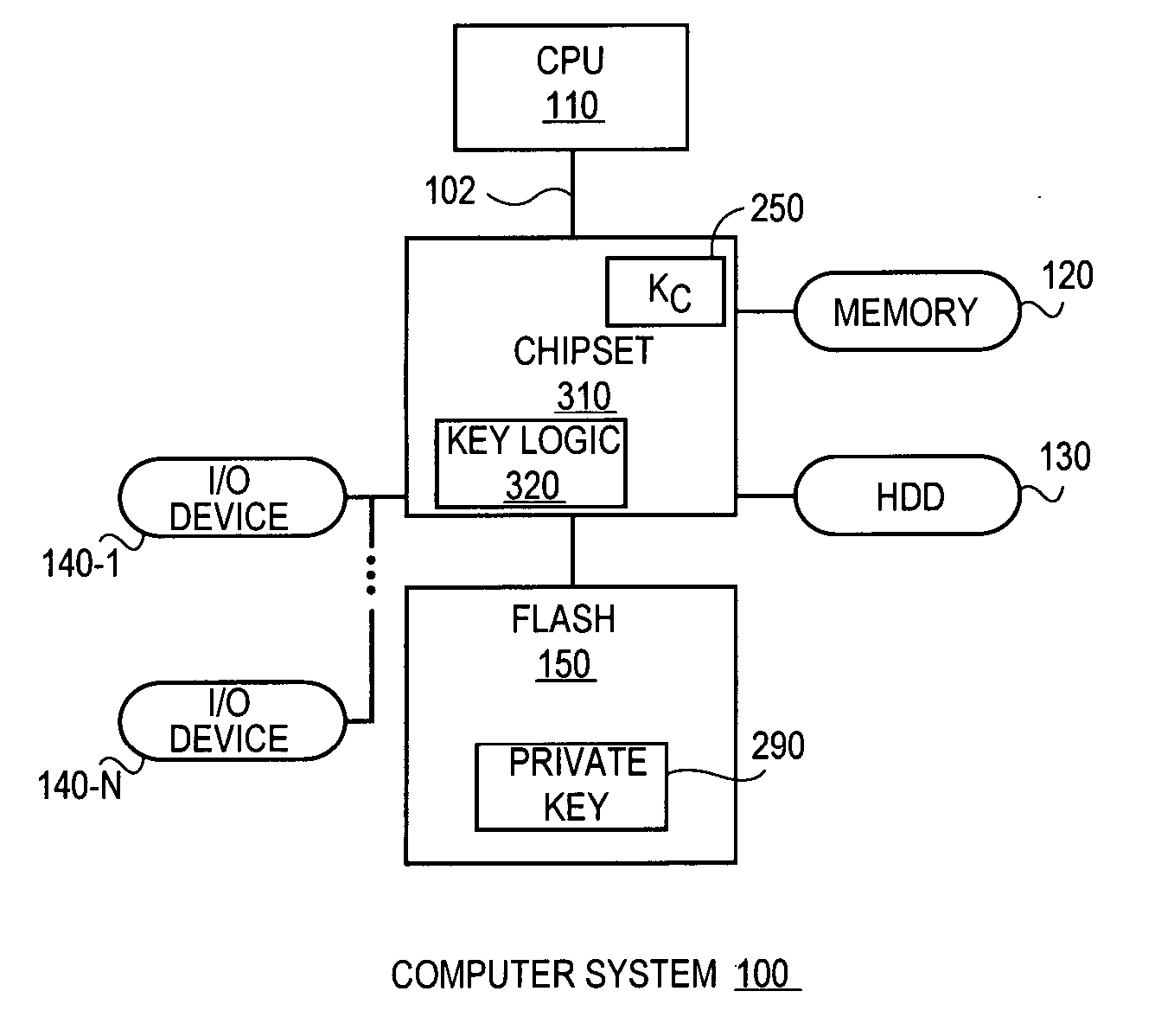

Software image creation in a distributed build environment

ActiveUS7281247B2Reduce in quantityEasily modify and create and imageResource allocationVersion controlResource consumptionOriginal equipment manufacturer

Distributing software image creation and configuration among a plurality of client computers. Server computers define jobs related to software image creation. Each of the client computers communicates with the servers to identify, accept, and complete jobs. The server and client computers maintain data structures indicating job availability and status. In the distributed build environment, original equipment manufacturers (OEMs) and system builders may easily modify, create, and image software in the factory to dramatically reduce resource consumption and time.

Owner:MICROSOFT TECH LICENSING LLC

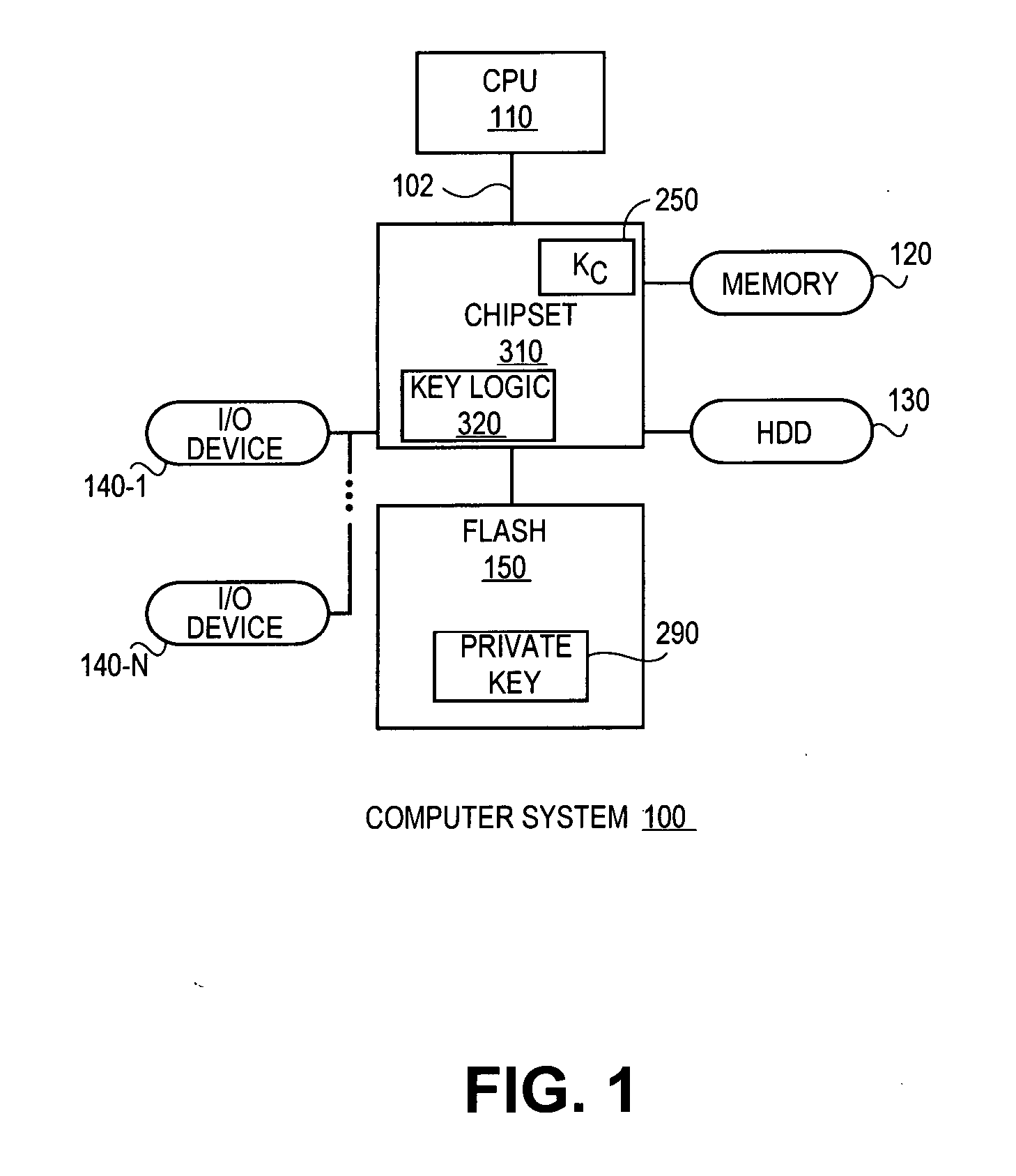

Apparatus and method for distributing private keys to an entity with minimal secret, unique information

InactiveUS20050180572A1Key distribution for secure communicationDigital computer detailsOriginal equipment manufacturerKey distribution

In some embodiments, a method and apparatus for distributing private keys to an entity with minimal secret, unique information are described. In one embodiment, the method includes the storage of a chip secret key within a manufactured chip. Once the chip secret key is stored or programmed within the chip, the chip is sent to a system original equipment manufacturer (OEM) in order to integrate the chip within a system or device. Subsequently, a private key is generated for the chip by a key distribution facility (KDF) according to a key request received from the system OEM. In one embodiment, the KDF is the chip manufacturer. Other embodiments are described and claims.

Owner:INTEL CORP

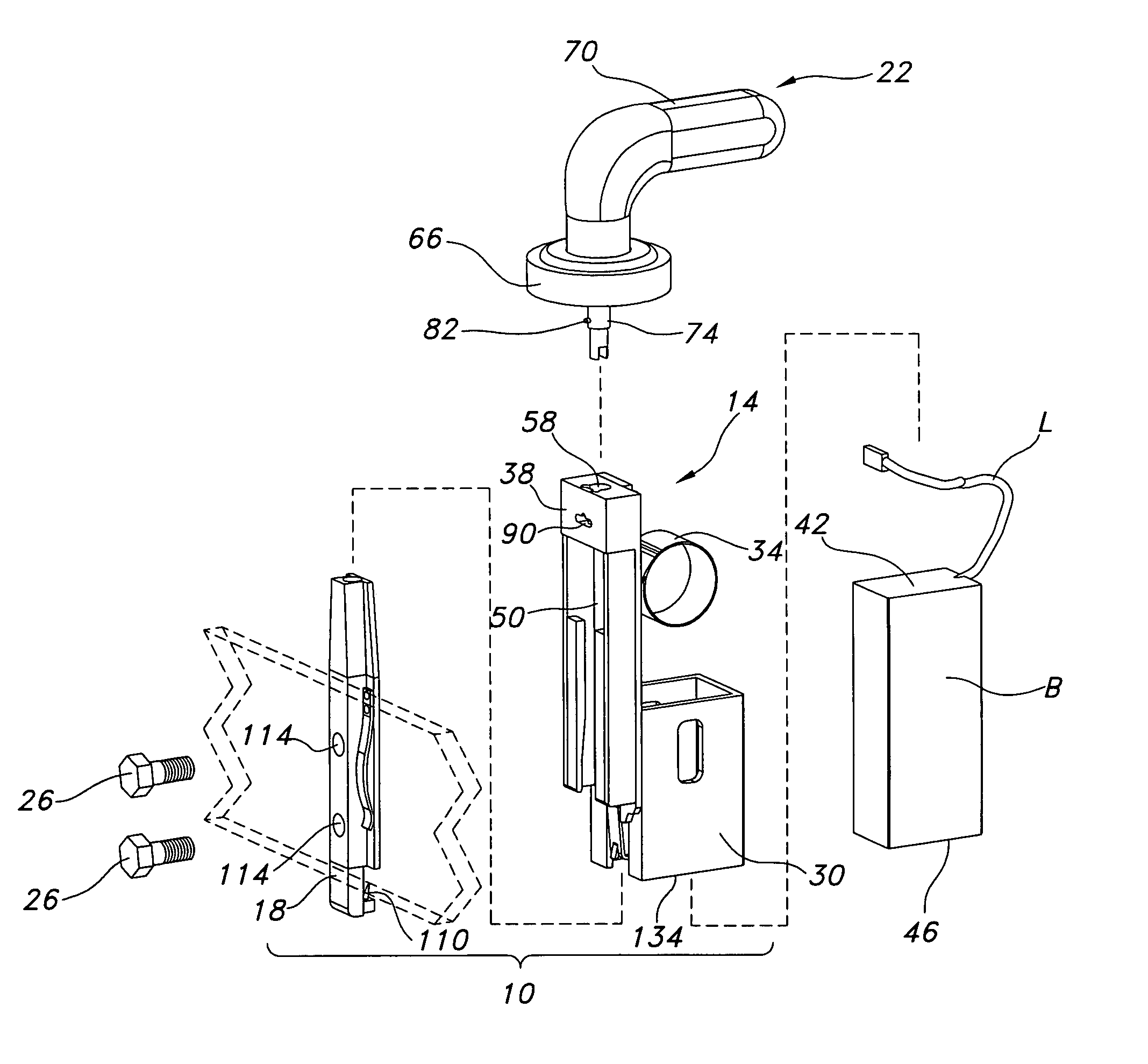

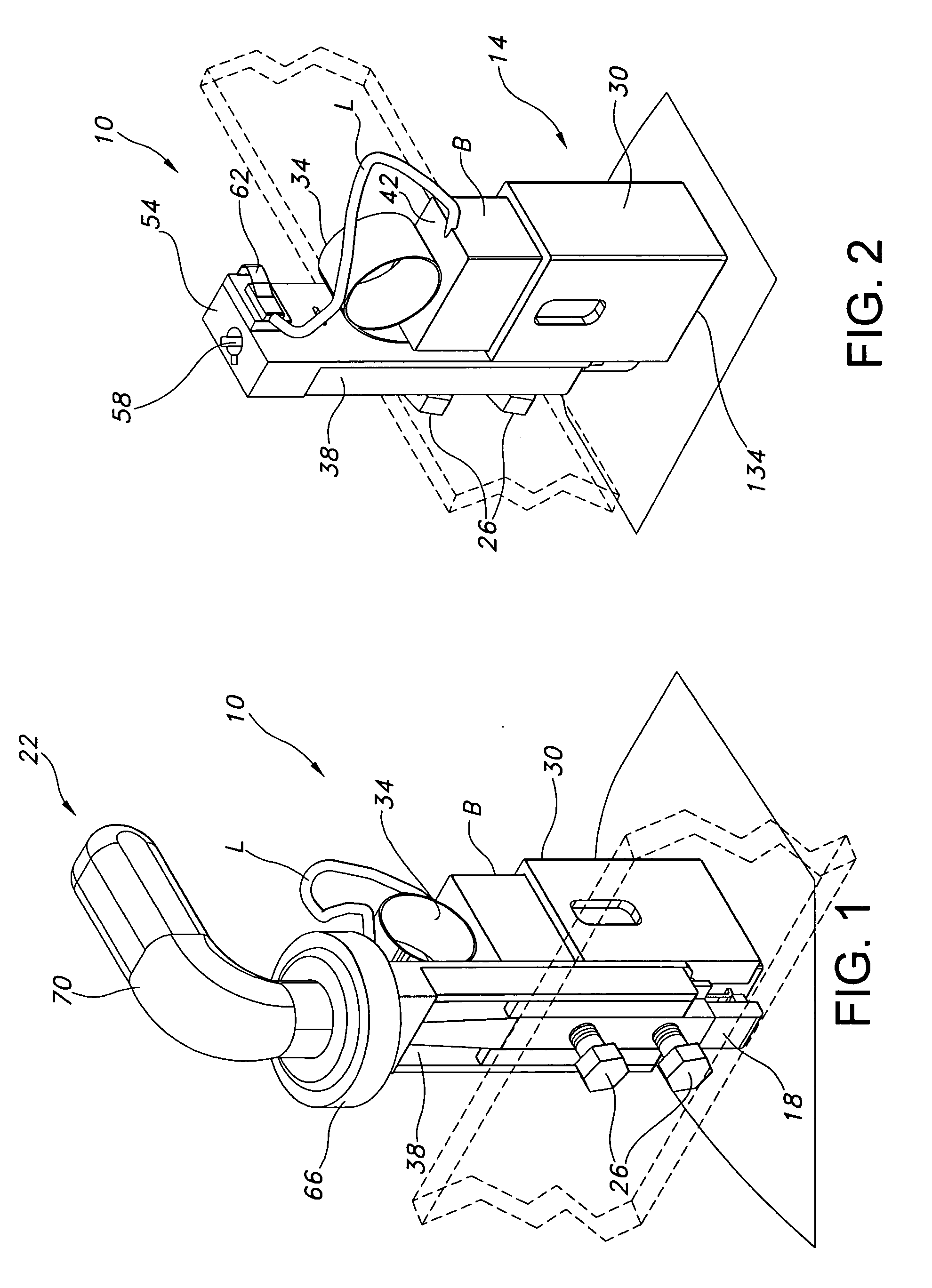

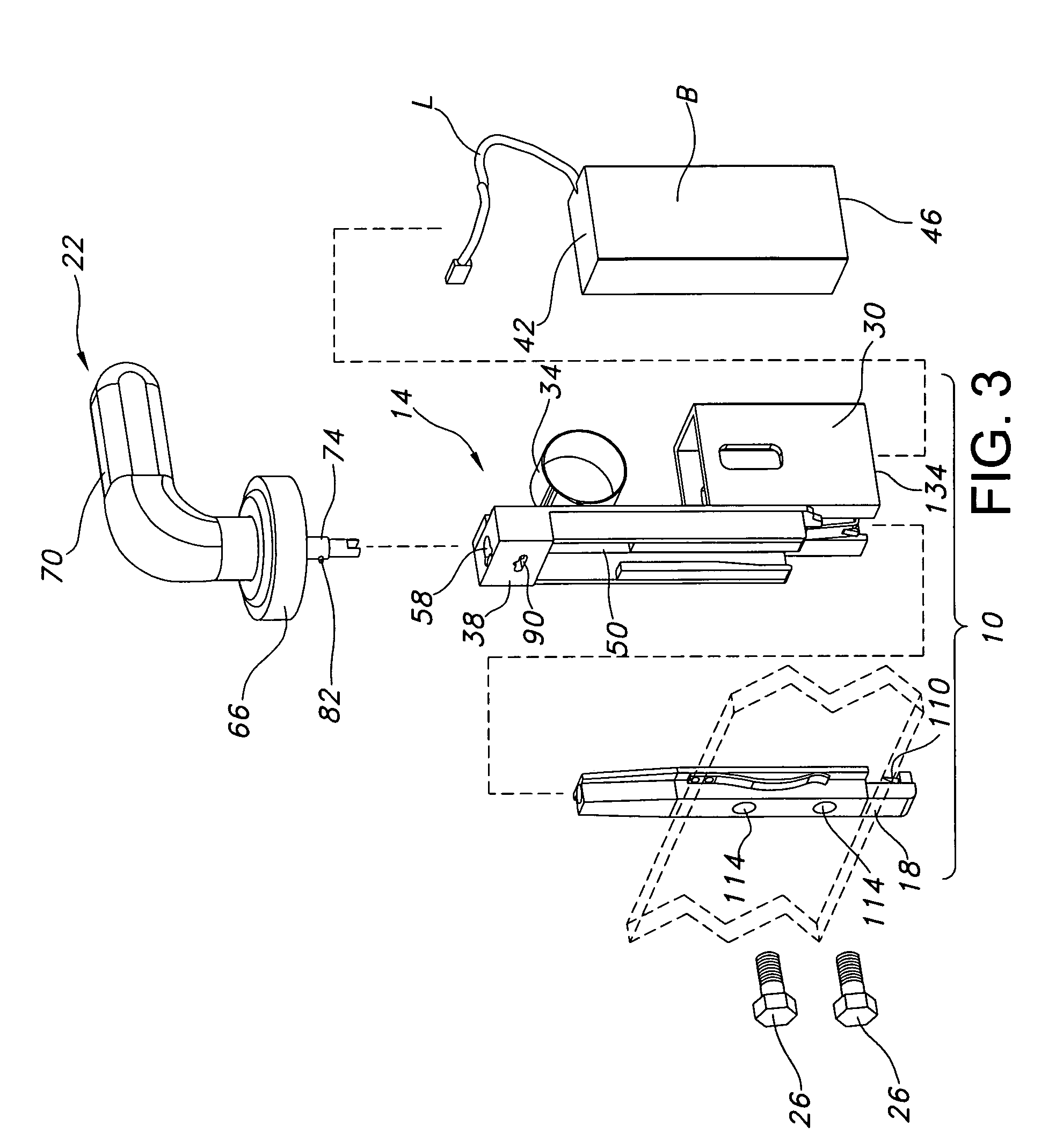

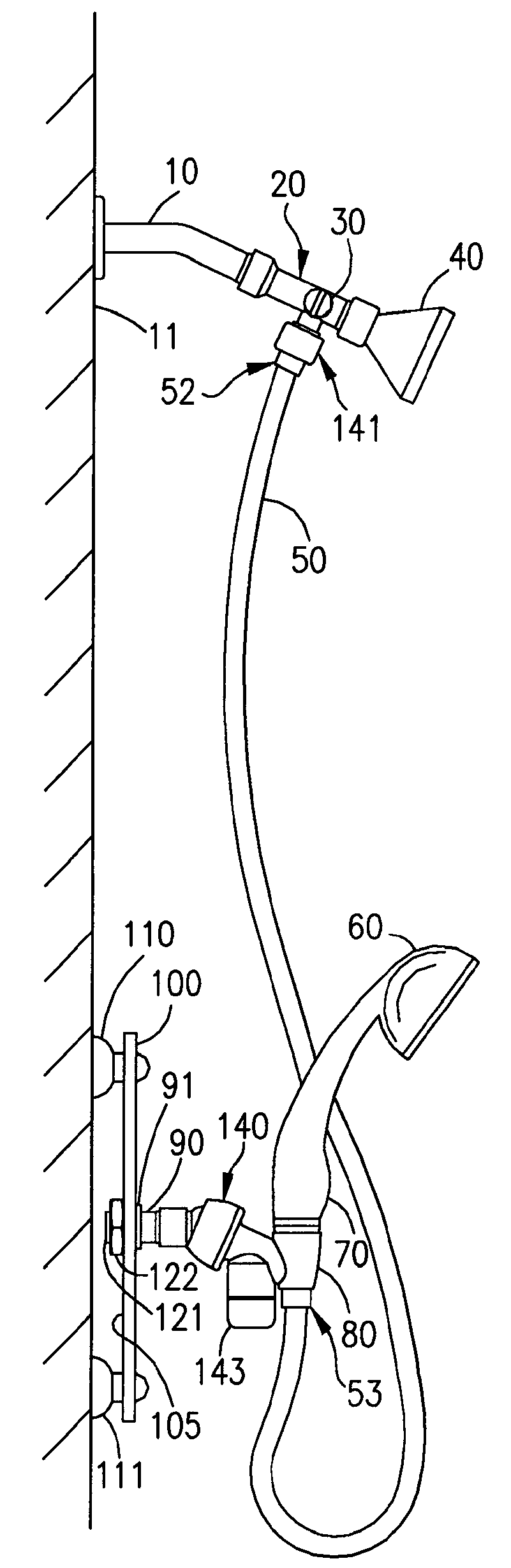

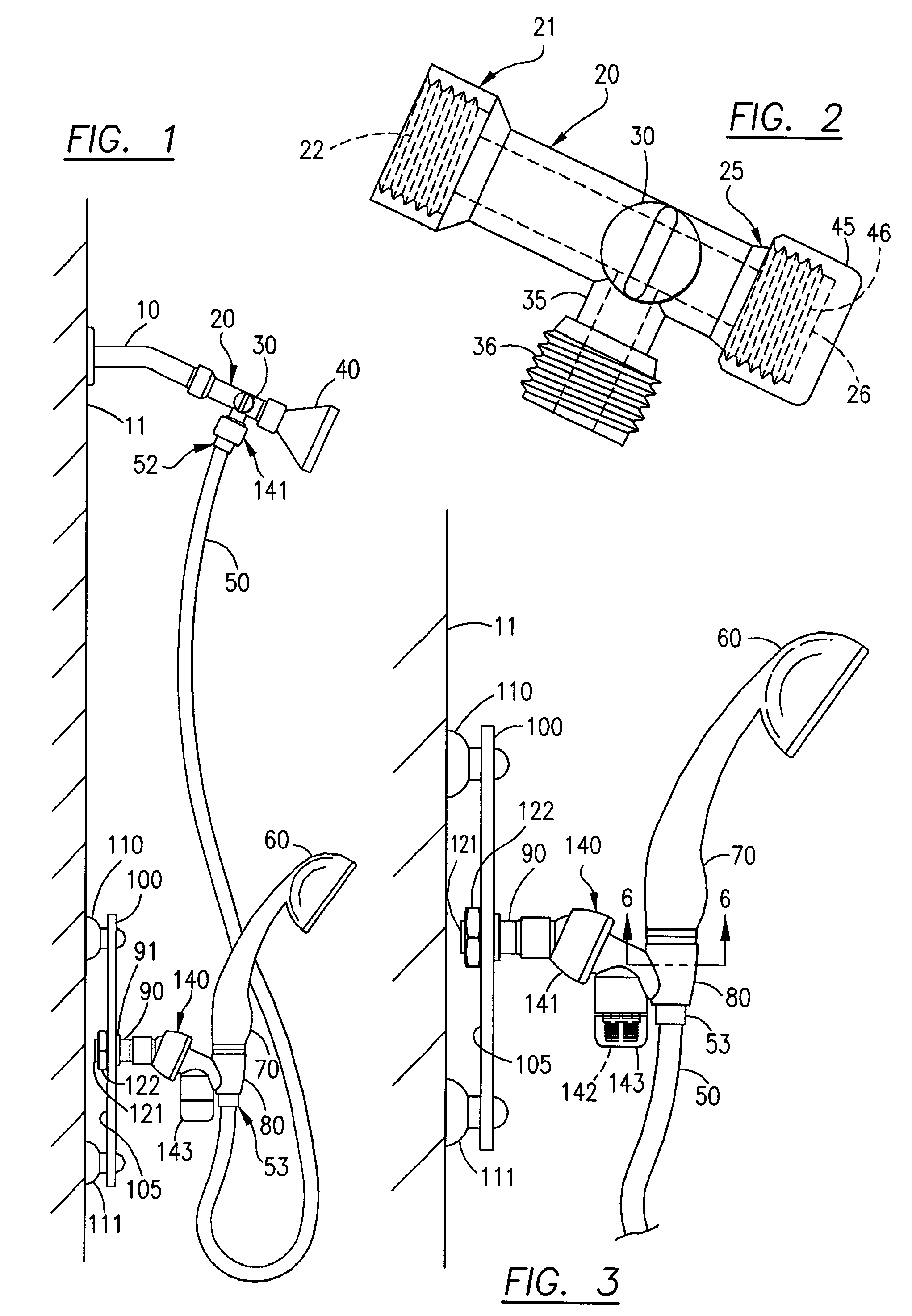

Showerhead Holder

InactiveUS20060272086A1Easy to useOvercome disadvantagesBathsDouchesOriginal equipment manufacturerElectrical and Electronics engineering

The present invention is a showerhead holder for use with an original equipment manufacturer's showerhead connector and cradle to hold the handle of the removable showerhead in a desired position selected by the user.

Owner:MESA ALLAN A

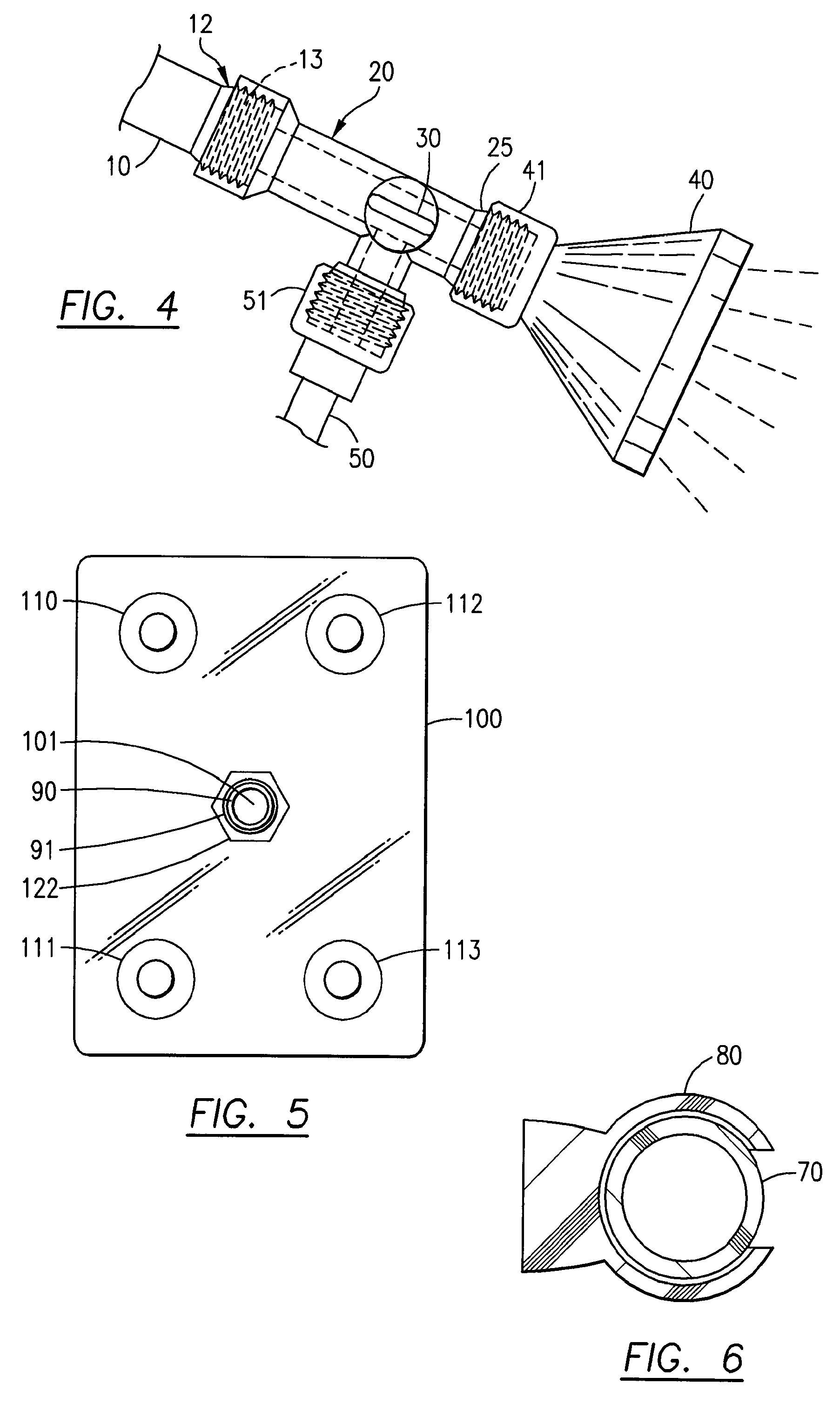

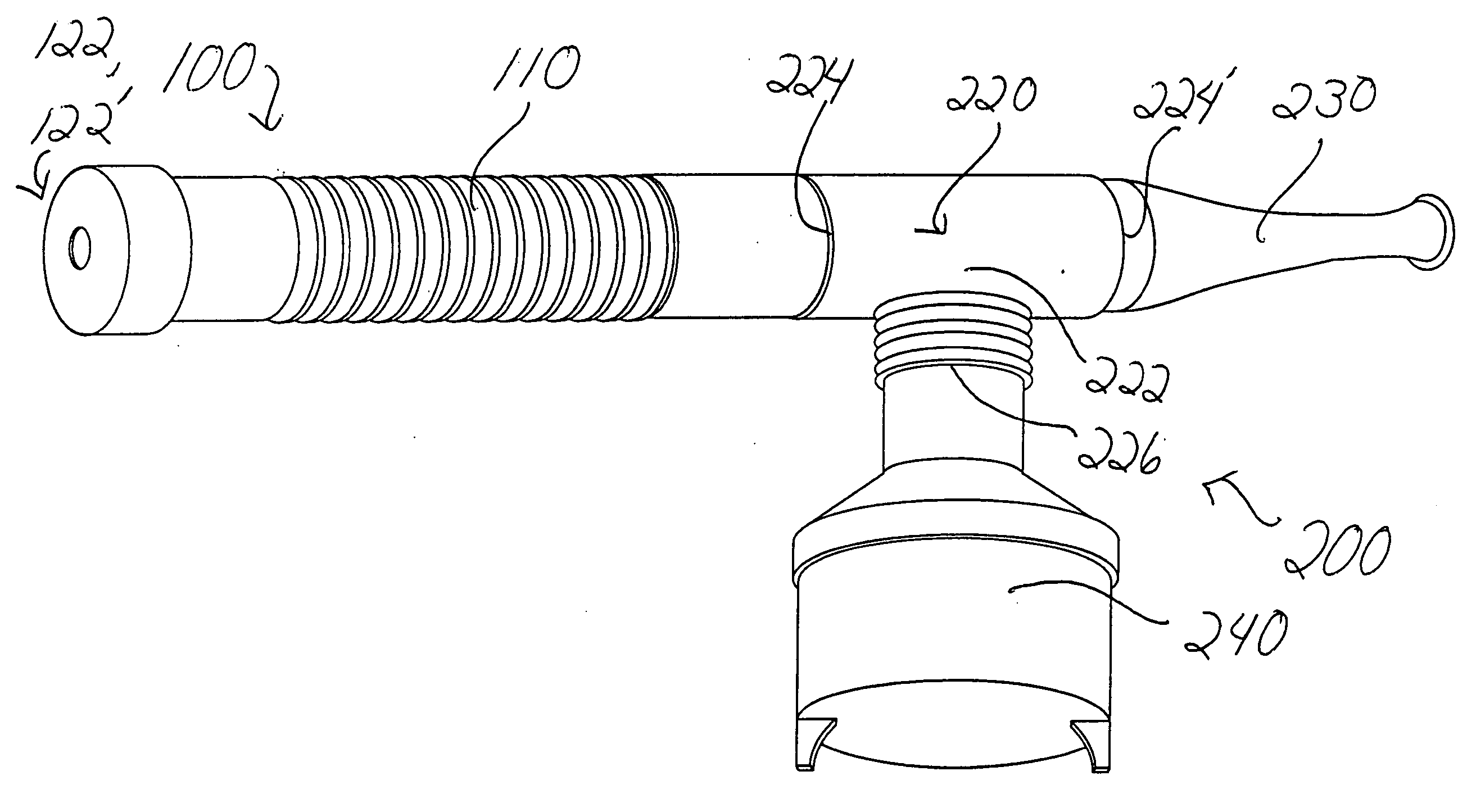

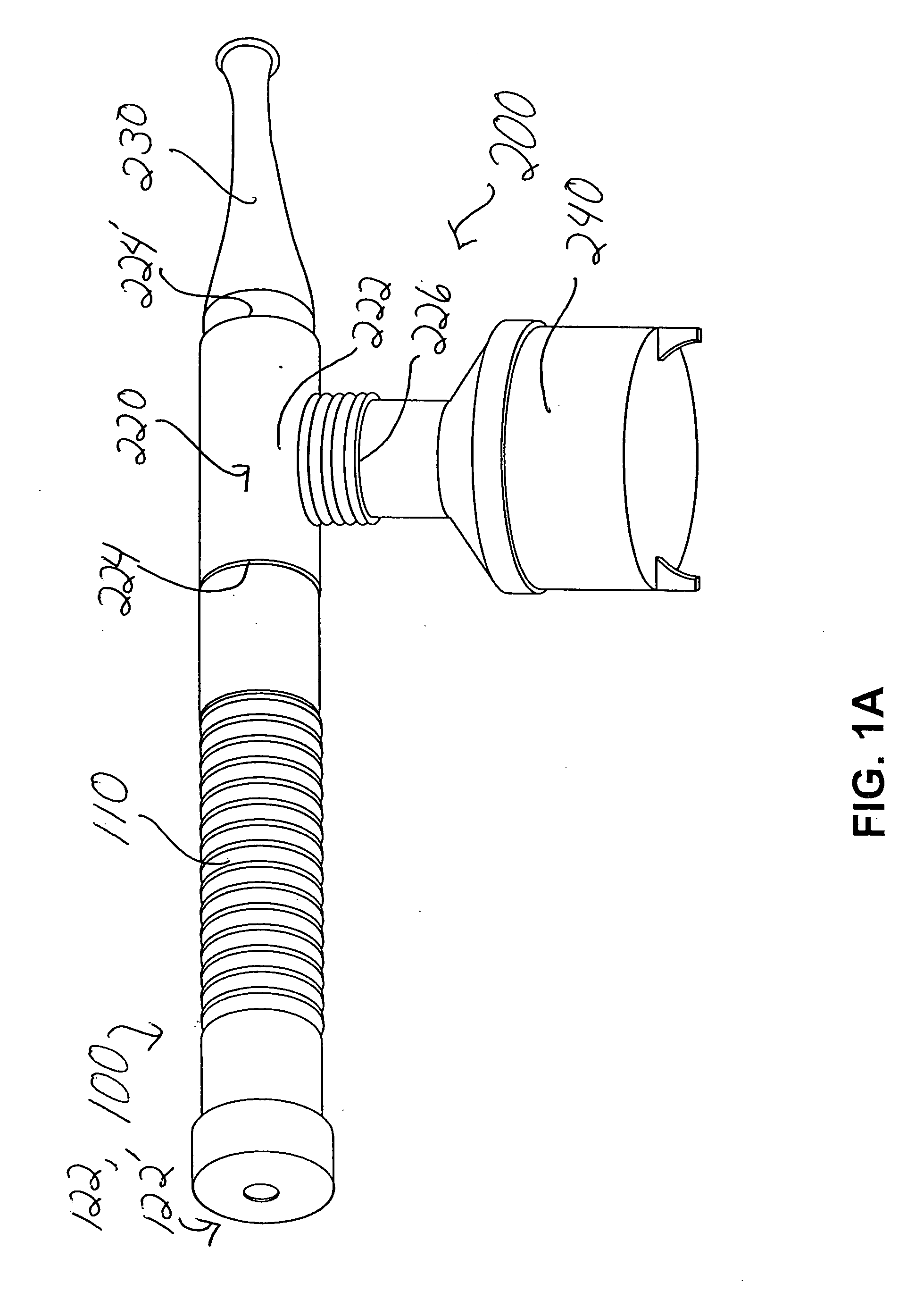

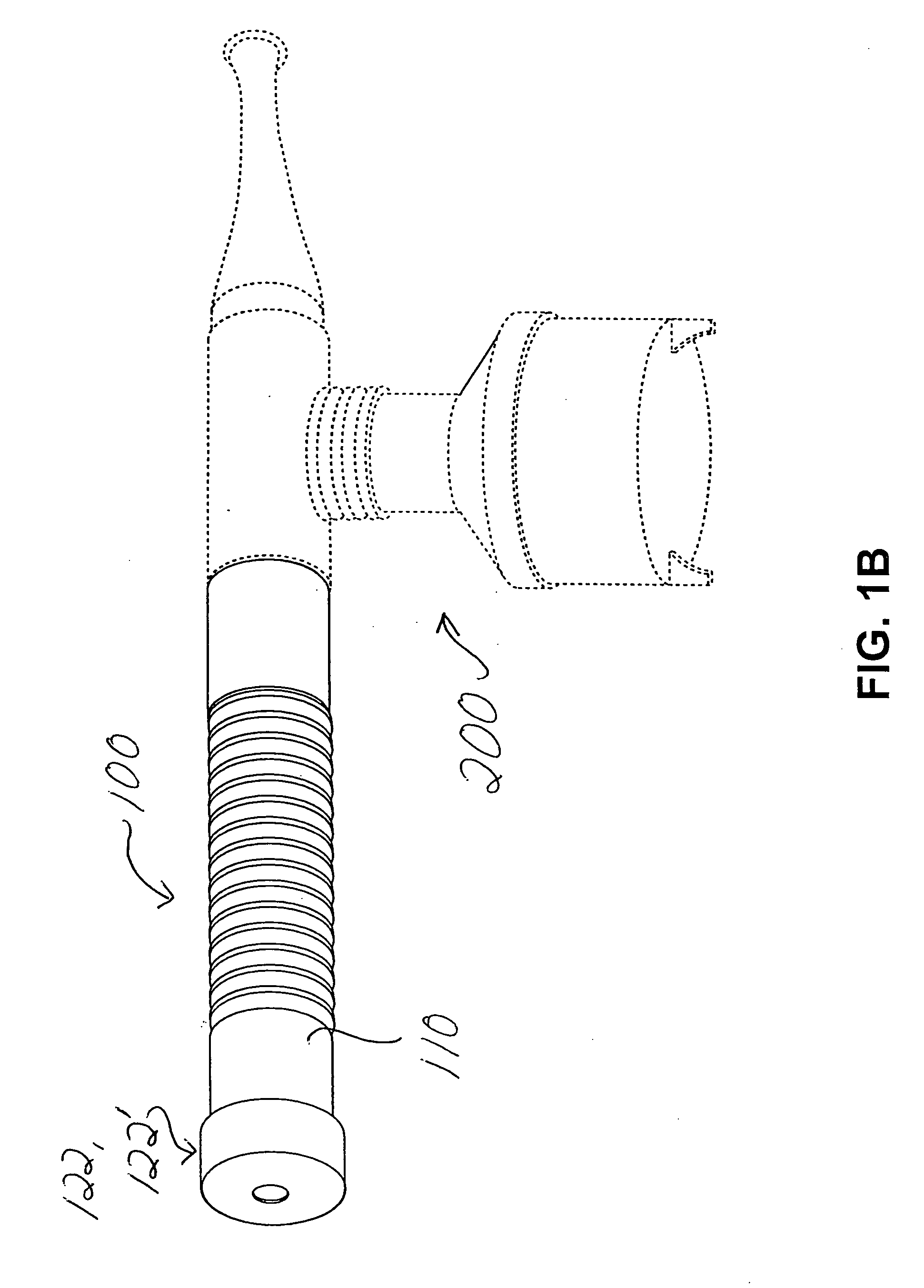

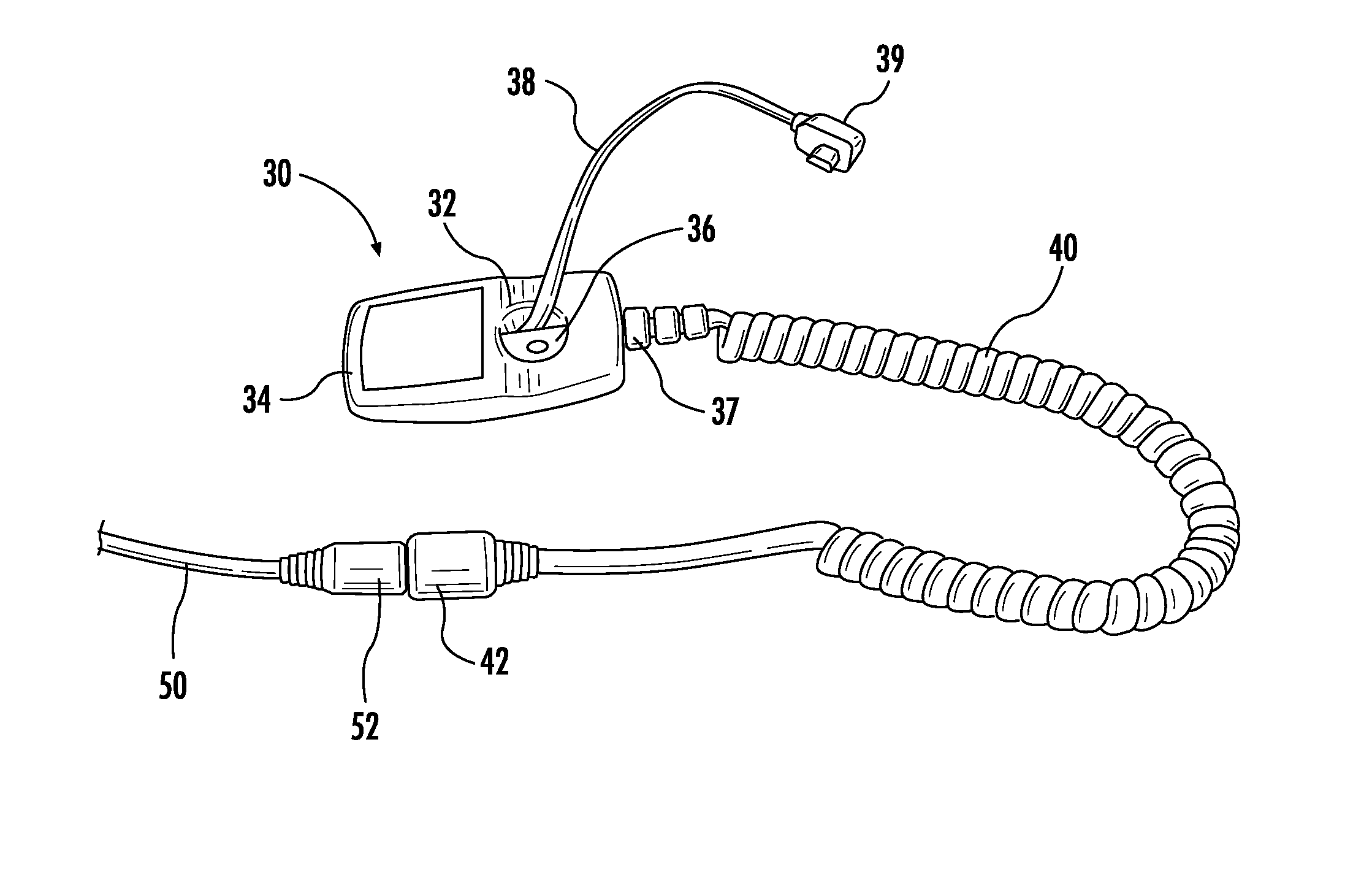

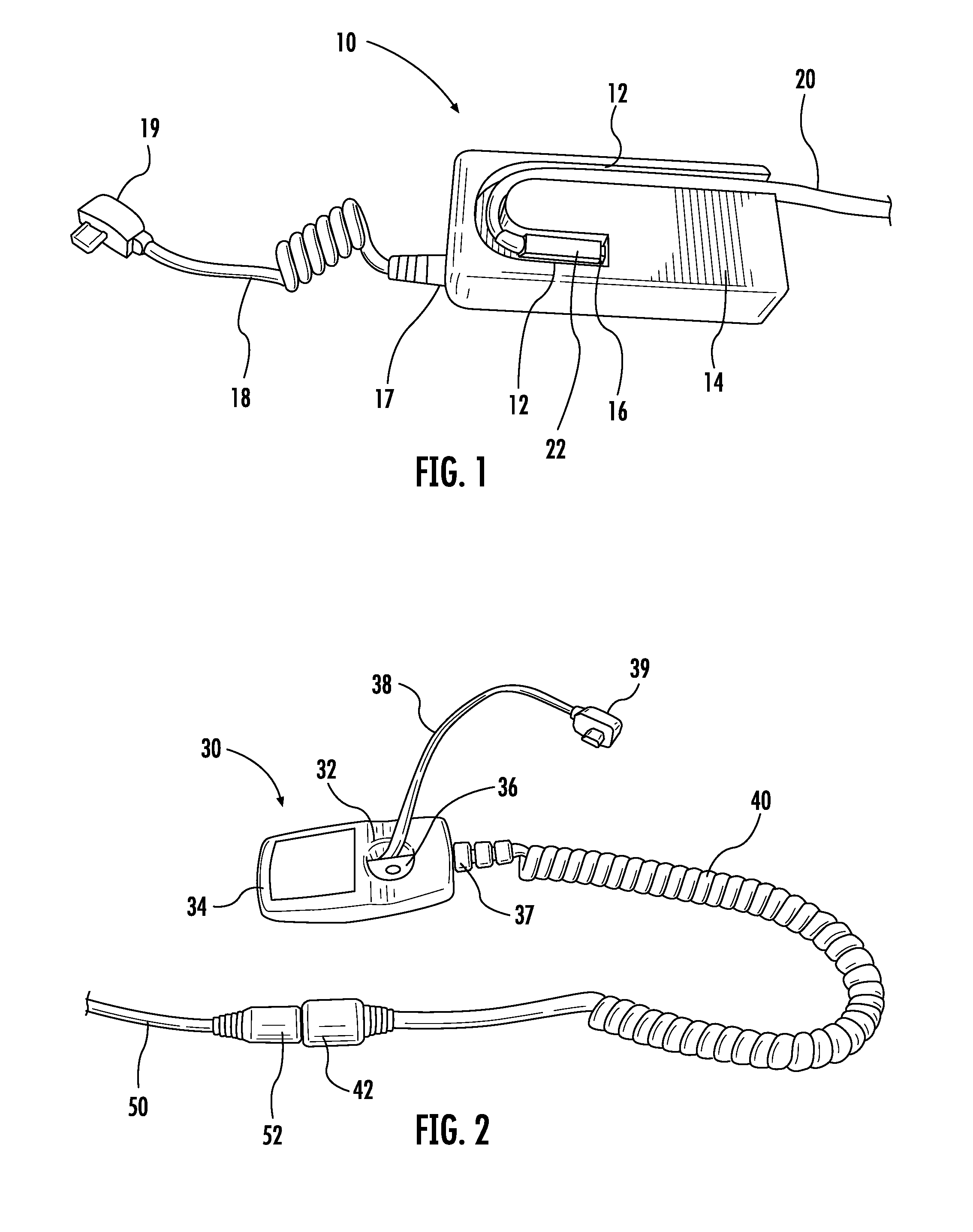

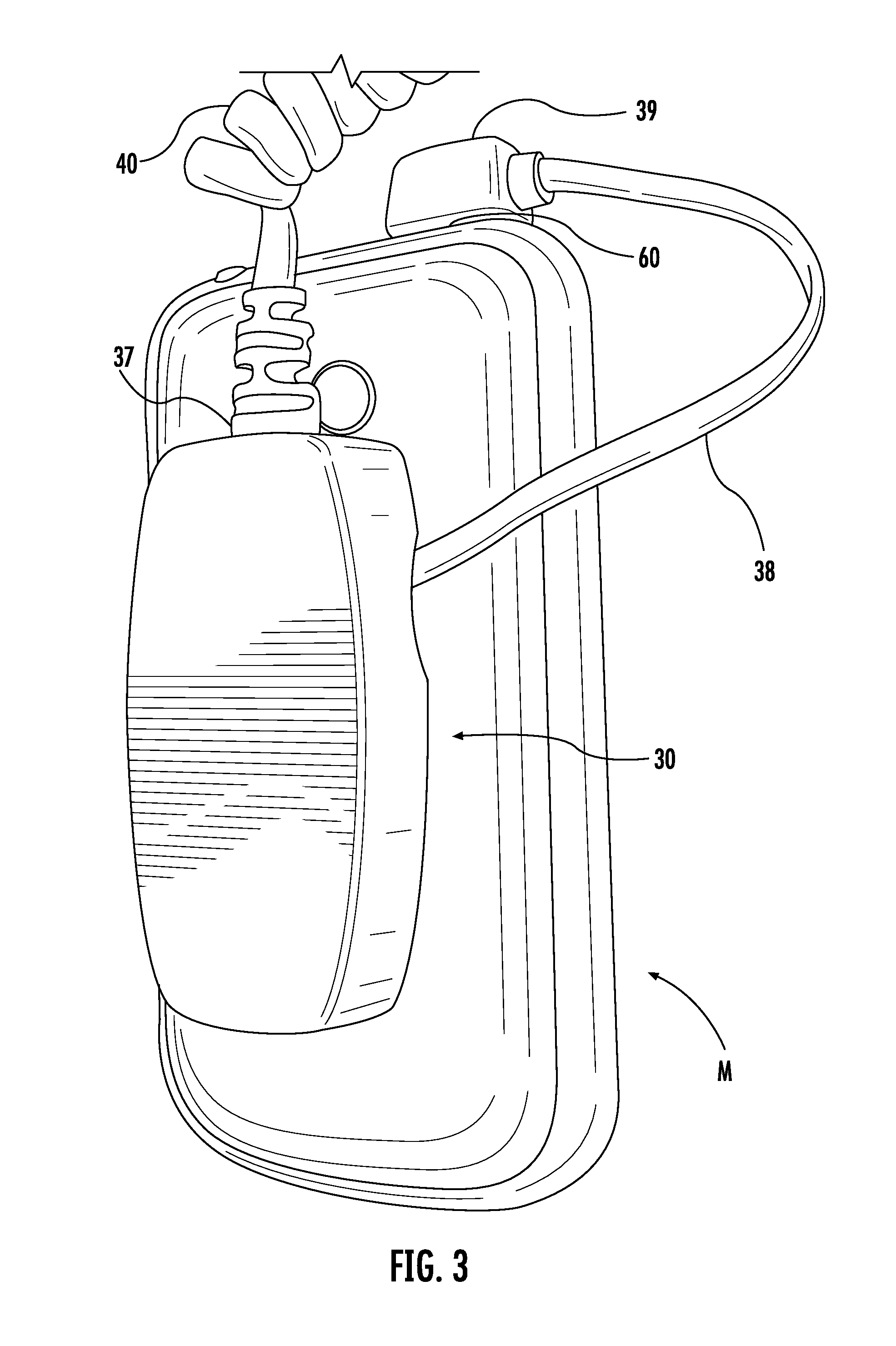

Accessory for nebulizer inhaler system

An accessory for an inhaler unit may be retrofit into a conventional nebulizer system having a manifold or an inlet air tube. The accessory includes a one-way air valve that closes except when air is being inhaled. The one-way valve closes to prevent exhaled air / gas from flowing through the manifold and inlet air tube and out to the surrounding atmosphere. Thus, exhaled air / gas does not flow out of the system and does not carry medicine with it, greatly reducing medicine waste. Because the preferred inhaler system does not include any exhale / exhaust valve or any other outlet for exhaled air / gas, the user may loosen his lips, for example, to exhale. The accessory may be provided simply as a single one-way valve retrofit into an existing air tube of a conventional nebulizer system, as an air tube-valve combination that may be attached to a nebulizer system manifold, or as original equipment manufacture (OEM) for a nebulizer system.

Owner:OVERLANDER ROBERT

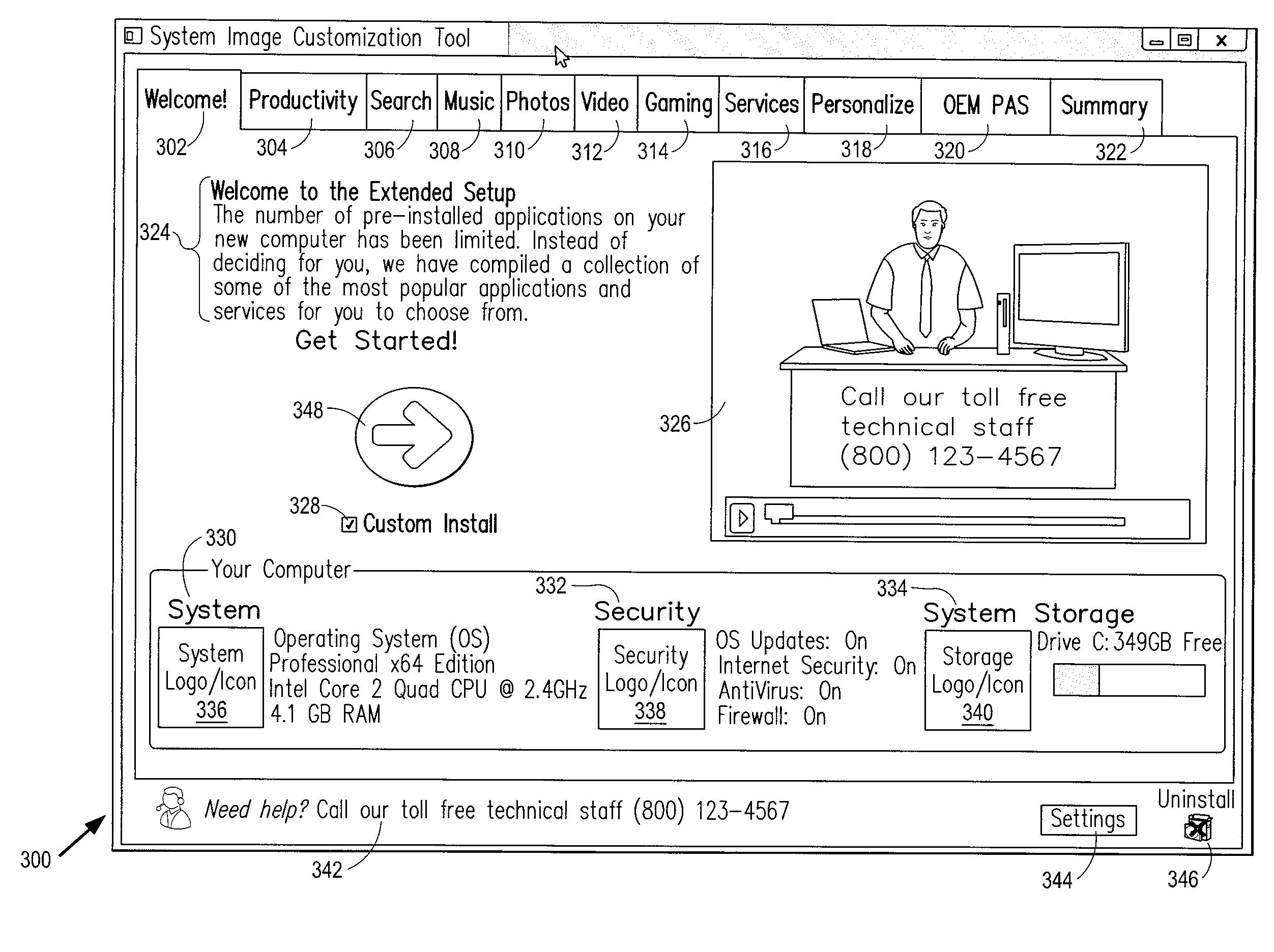

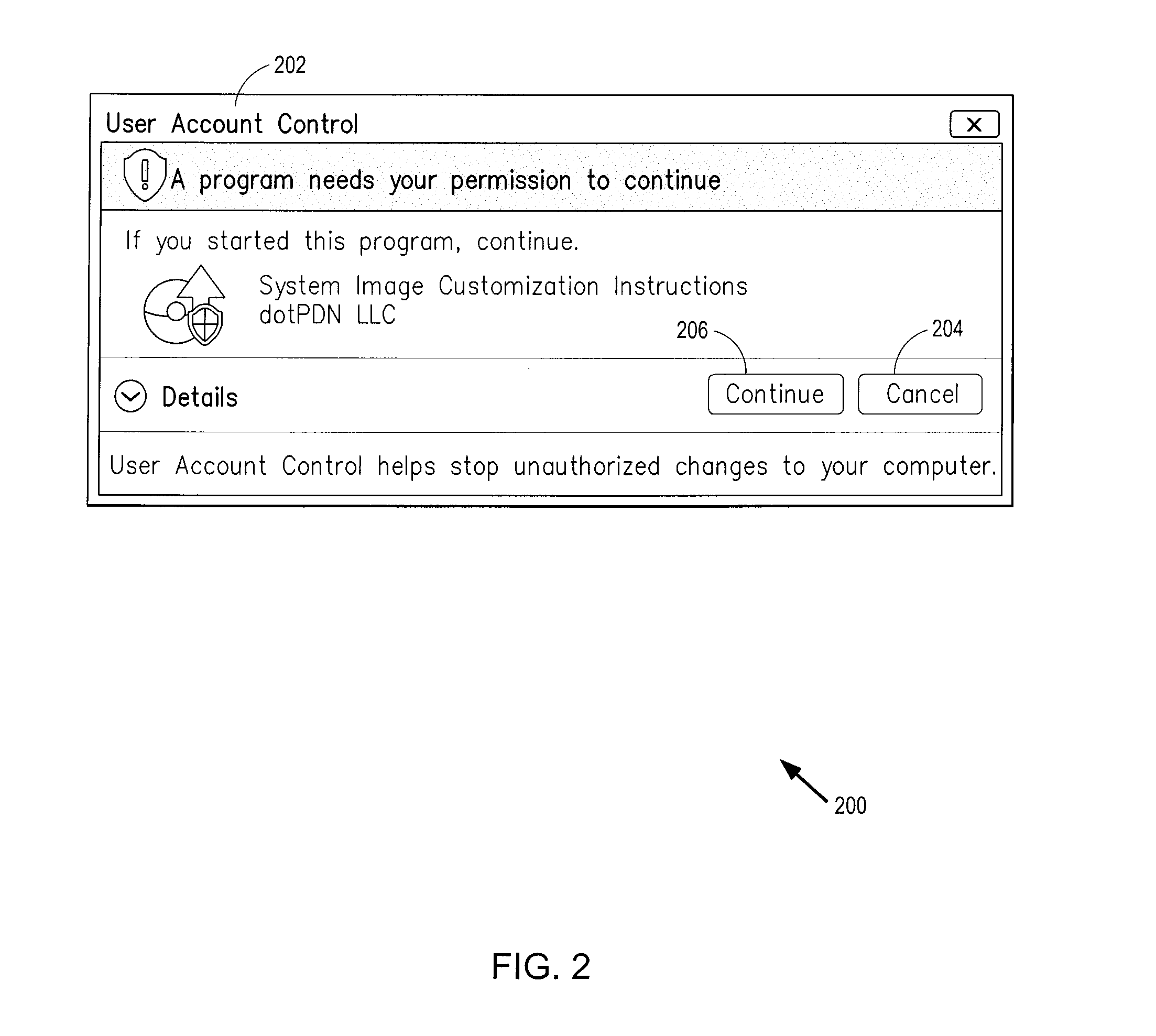

System image customization tool

ActiveUS20110016414A1Better meetingProgram loading/initiatingMemory systemsOriginal equipment manufacturerService provision

A system image customization tool provides an efficient and cost effective way to implement a highly customizable system image for a digital device. The system image customization tool controls application installation, device settings, and selection, delivery methods and licensing options for products, applications and services with minimal or no customer interaction from the customer's first out of box experience with the device and through the lifecycle use of the device. The system image customization tool provides retailers, original equipment manufacturers and products, applications and services providers a way to create new distribution channels and partnerships.

Owner:ACCENTURE GLOBAL SERVICES LTD

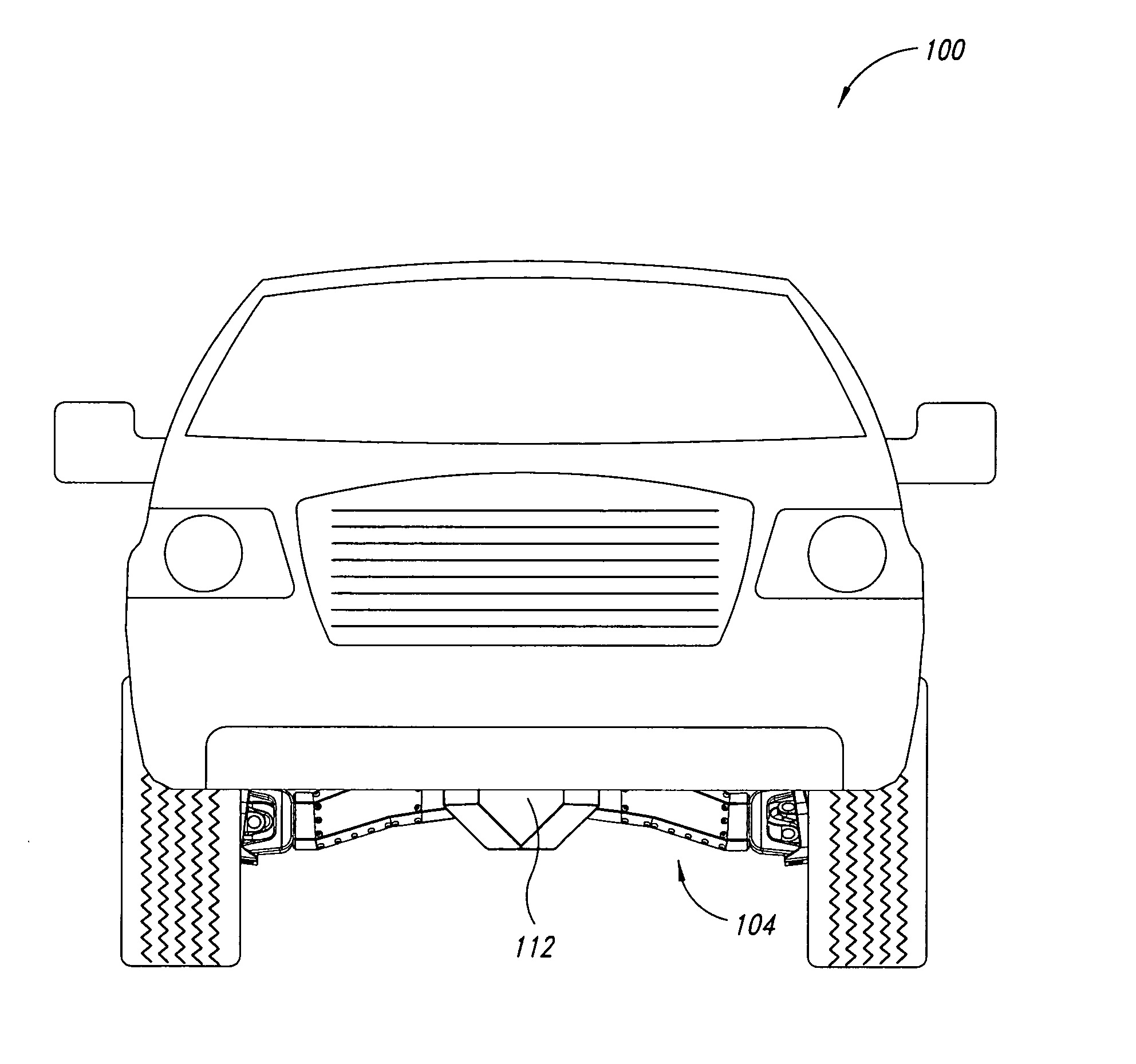

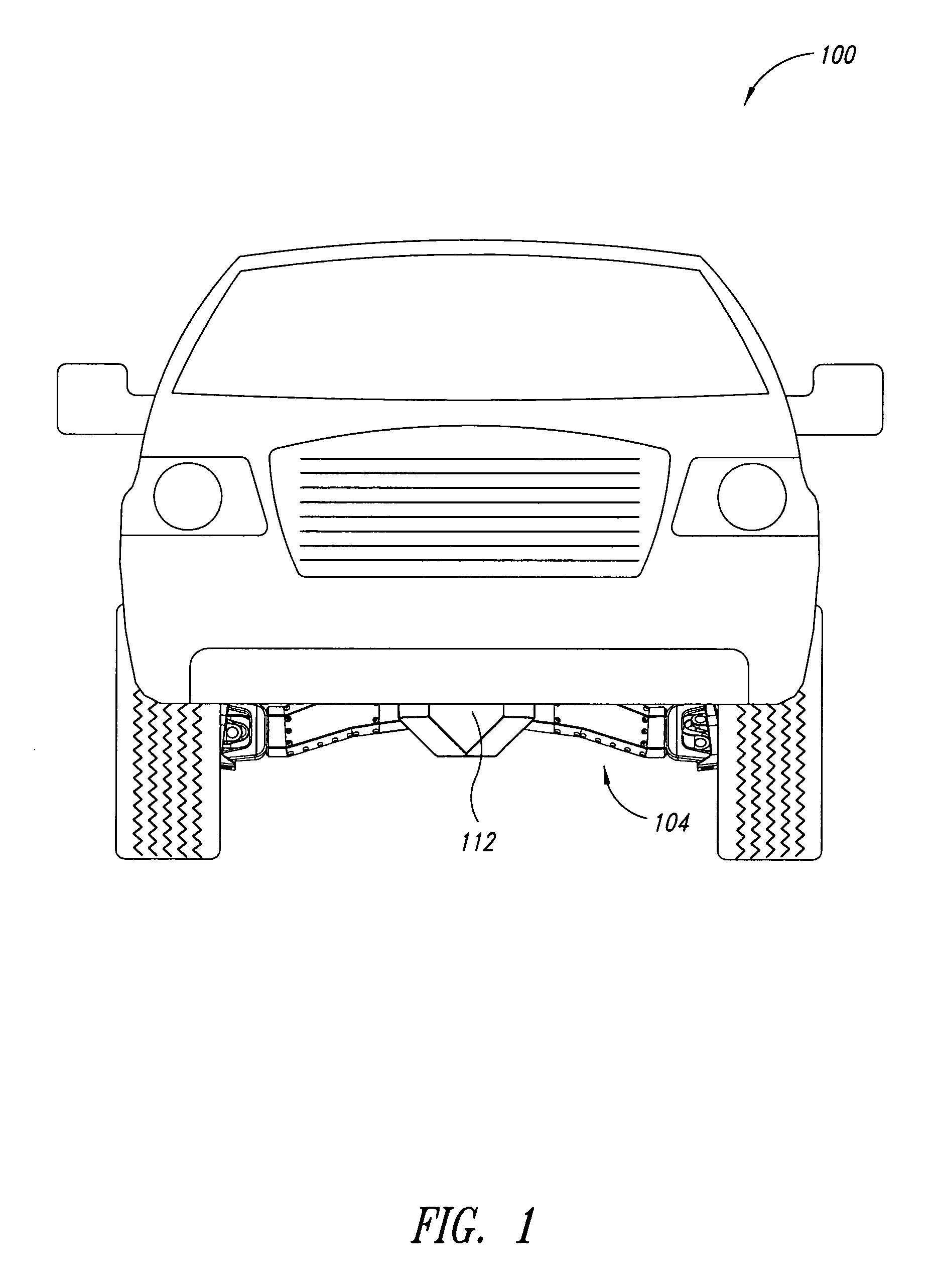

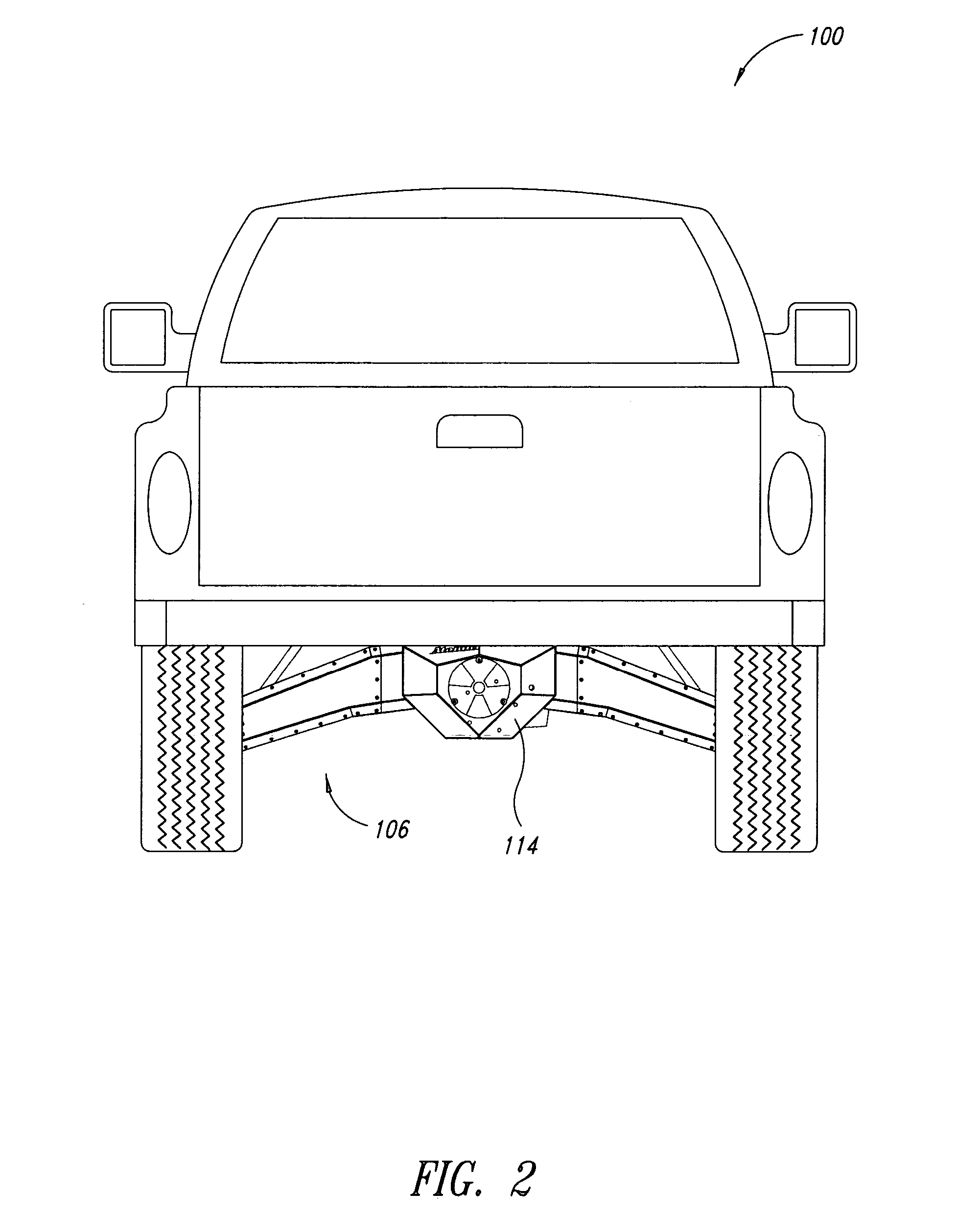

High clearance axle system

InactiveUS20070145816A1Increase ground clearanceLarge range of motionOff-road vehiclesPassengers carsTerrainOriginal equipment manufacturer

Apparatuses, systems, and methods for increasing ground clearance of vehicles are shown and described. High clearance axles can provide increased ground clearance so that the vehicle can travel over large obstacles. When a vehicle is driven over rough terrain, the axles can maintain proper alignment of the wheels mounted to the axle. The disclosed embodiments can be installed by either original equipment manufactures or aftermarket.

Owner:SYNERGY TECH & DESIGN

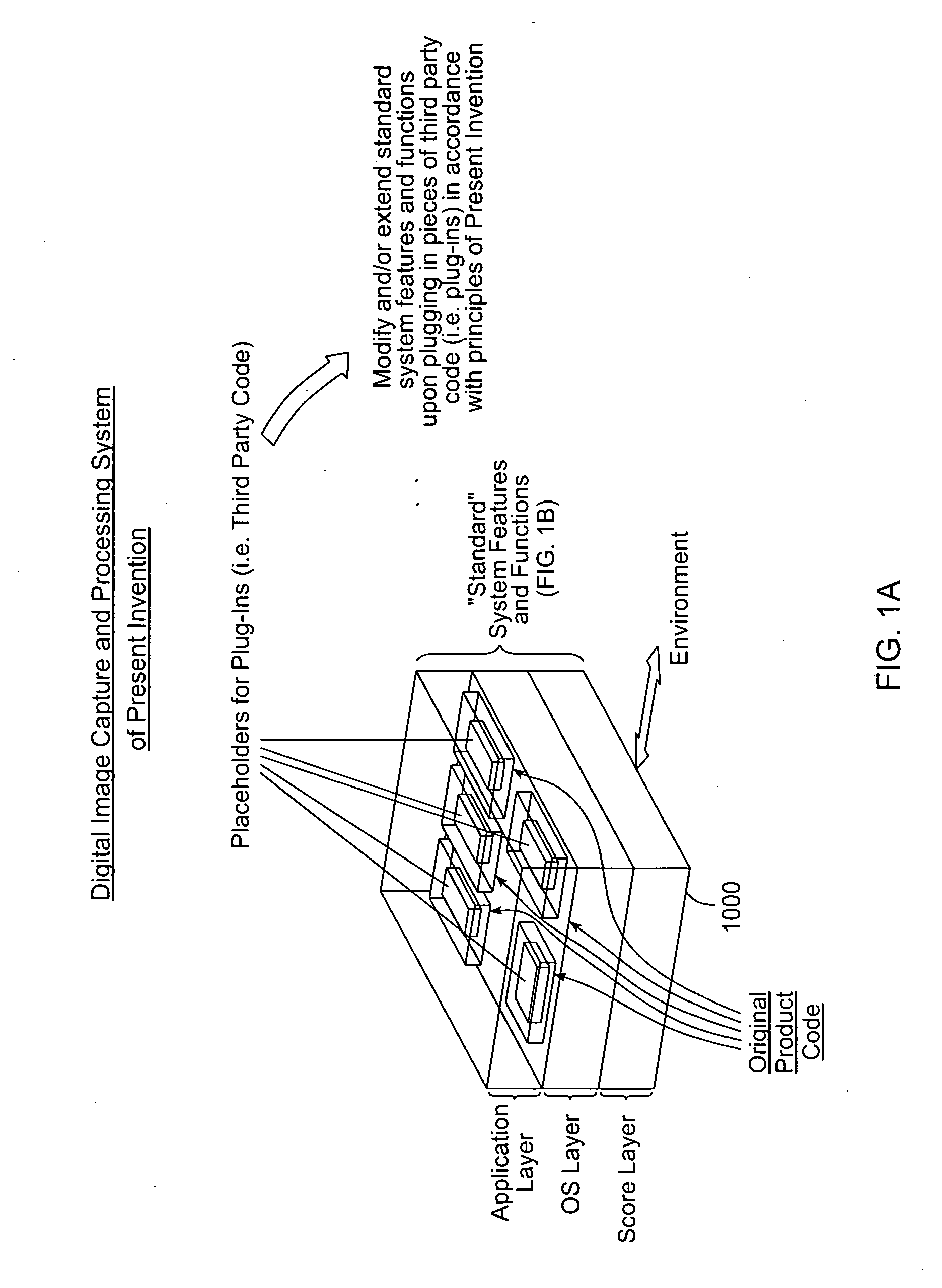

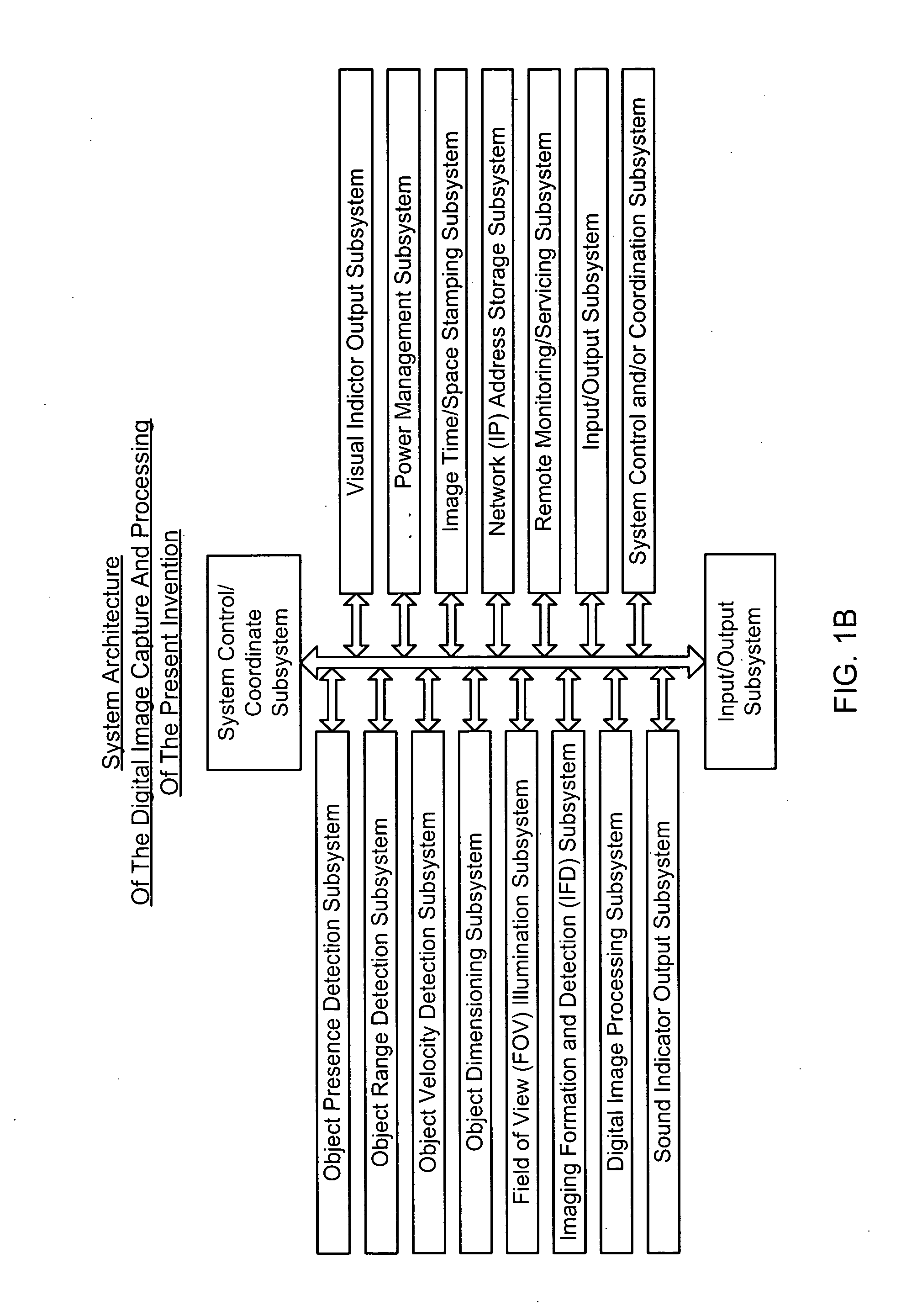

Method of modifying and/or extending the standard features and functions of a digital image capture and processing system

ActiveUS20080164317A1Character and pattern recognitionProgram controlThird partyOriginal equipment manufacturer

A method of modifying and / or extending the standard features and functions of a digital image capture and processing system. The method involves providing the system with a set of standard features and functions, and a computing platform which includes (i) memory for storing pieces of original product code written by the original designers of the system, and (ii) a microprocessor for running one or more applications by calling and executing pieces of the original product code in a particular sequence, so as support the set of standard features and functions which characterize a standard behavior of the system. The one or more pieces of original product code have a set of place holders into which third-party product code can be inserted or plugged by third parties, including value-added resellers (VARs), original equipment manufacturers (OEMs), and also end-users of the system. one or more pieces of third-party code are plugged into the set of place holders, so as operate to modify and / or extend the features and functions of the system, and thereby modify or extend the standard behavior of system into a custom behavior for the system.

Owner:METROLOGIC INSTR

Verifying OEM components within an information handling system using original equipment manufacturer (OEM) identifier

ActiveUS20140358792A1Computer security arrangementsCommerceOriginal equipment manufacturerHandling system

A method validates whether a component / device installed within an information handling system (IHS) is an OEM (original equipment manufacturer) programmed device, by: reading identification (ID) data and an identifier code from the target device; generating a unique encrypted sequence using the ID data; providing a unique validation check code based on the ID data; generating a component validation code corresponding to the target device via a decryption process involving the unique encrypted sequence; and comparing the component validation code to the validation check code. The method further includes: in response to the component validation code matching the validation check code, identifying the target device as an OEM programmed device with a valid identifier code stored as the identifier code; and enabling certain processes reserved for only verified OEM programmed devices. The decryption process reverses an encryption process utilized when generating the unique OEM identifier code of the target device.

Owner:DELL PROD LP

System structure and system for providing cervice to automatic system through network

Owner:SIEMENS AG

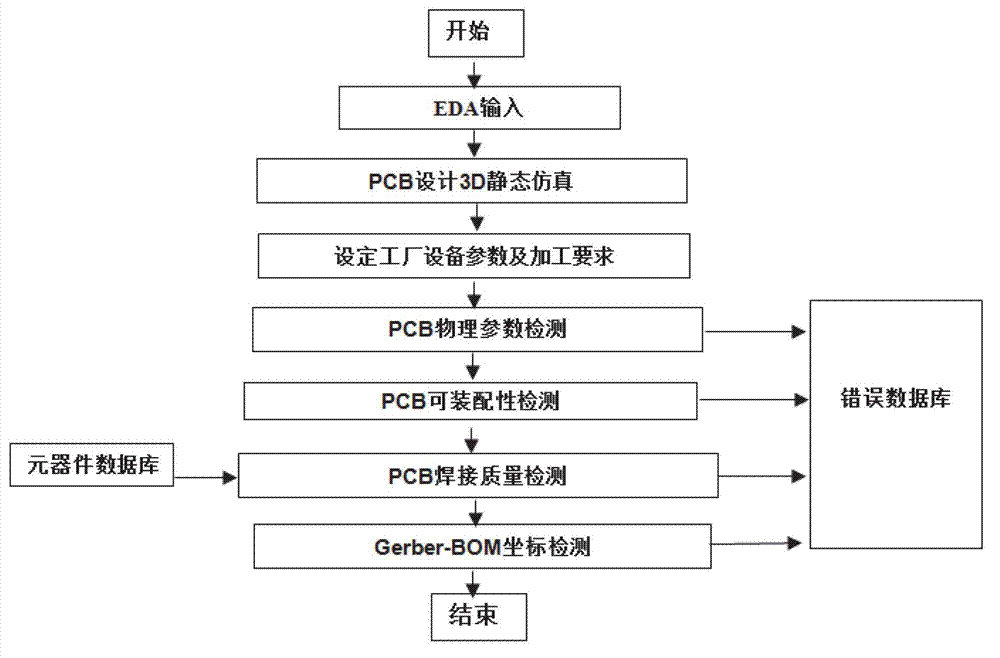

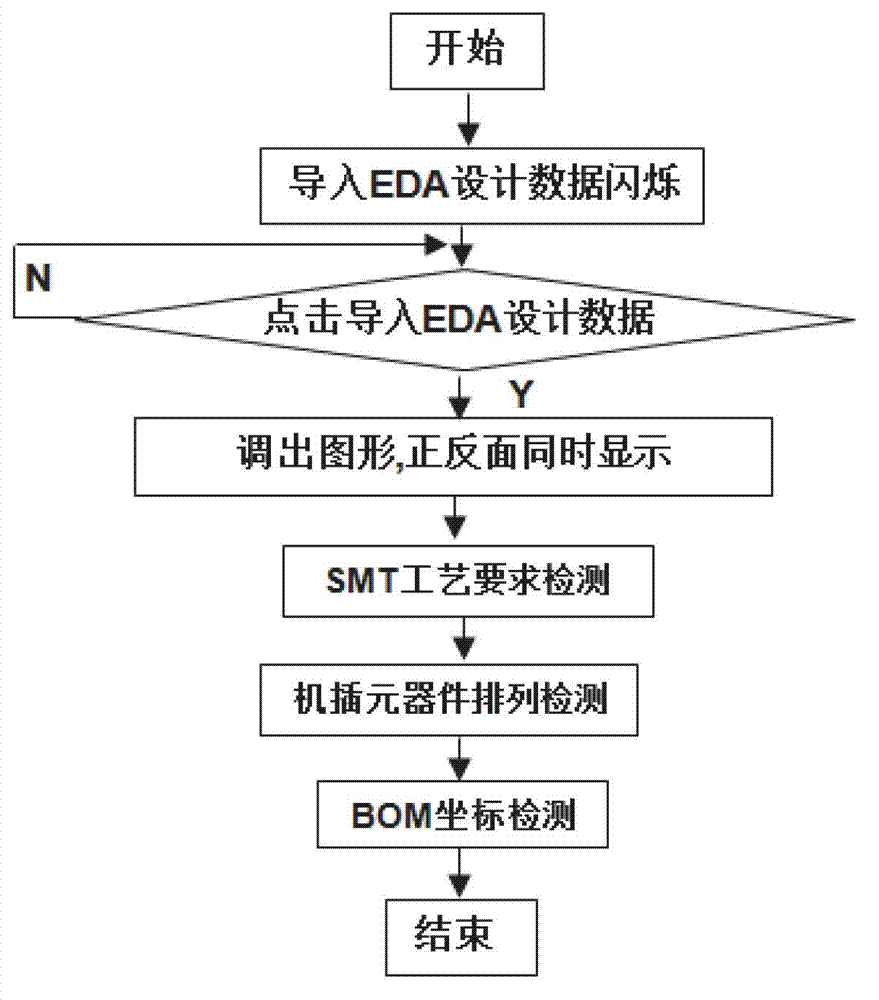

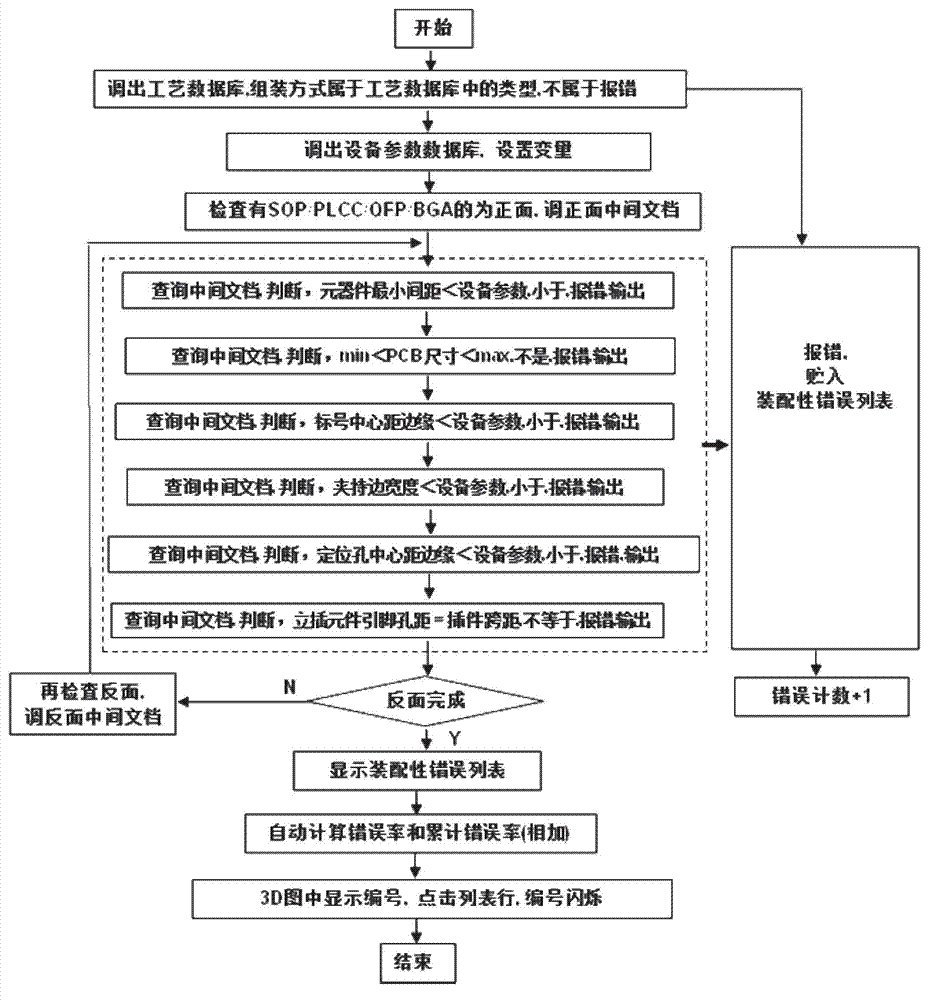

Visualization detection method of electronic product electronic design automation (EAD) design manufacturability

ActiveCN102930114AImprove efficiencyQuality improvementSpecial data processing applicationsInformation processingGraphics

The invention discloses a visualization detection method of electronic product electronic design automation (EDA) design manufacturability. Printed circuit board (PCB) three dimensional (3D) simulation of an EDA design document is conducted, PCBphysical parameter detection, PCB assembling ability, PCB welding quality detection and Gerber bill of material (BOM) coordinate detection are conducted in sequence, and specific error positions and types of former four steps of detection are displayed in visualization mode on a PCB 3D figure. On the basic of complete actual production experiences, the visualization detection method and a system of the EAD design manufacturability are developed according to international standard of information processing center (IPC), the PCB physical parameter detection, the PCB assembling ability, the PCB welding quality detection and the gerber BOM coordinate detection which are all designed by EDA are integrated, the various actual problems which are the contradictions of manufacture and design of PCB and are faced by enterprises are resolved, and efficiency and quality of electronic manufacture in particular to an original equipment manufacturer (OEM) are improved.

Owner:CHANGZHOU AUTOSMT INFORMATION TECH

Reduced cost merchandise display security device including merchandise power supply

InactiveUS20130307692A1Low costLess complicatedBurglar alarm by hand-portable articles removalConnectionsElectricityOriginal equipment manufacturer

A merchandise display security device for displaying and protecting an article of merchandise is provided. For example, the security device comprises an alarm unit and a first connector electrically coupled to the alarm unit and configured to releasably engage the article of merchandise. The security device further comprises a second connector electrically coupled to the alarm unit. The second connector is configured to releasably engage an original equipment manufacturer (OEM) power supply cable such that the alarm unit is disposed between a source of electric power and the article of merchandise, and the power supply cable is configured to provide power to both the alarm unit and the article of merchandise. The alarm unit is configured to at least one of activate an alarm in the event that the first connector is removed from the article of merchandise or the second connector is removed from the power supply cable.

Owner:INVUE SECURITY PROD INC

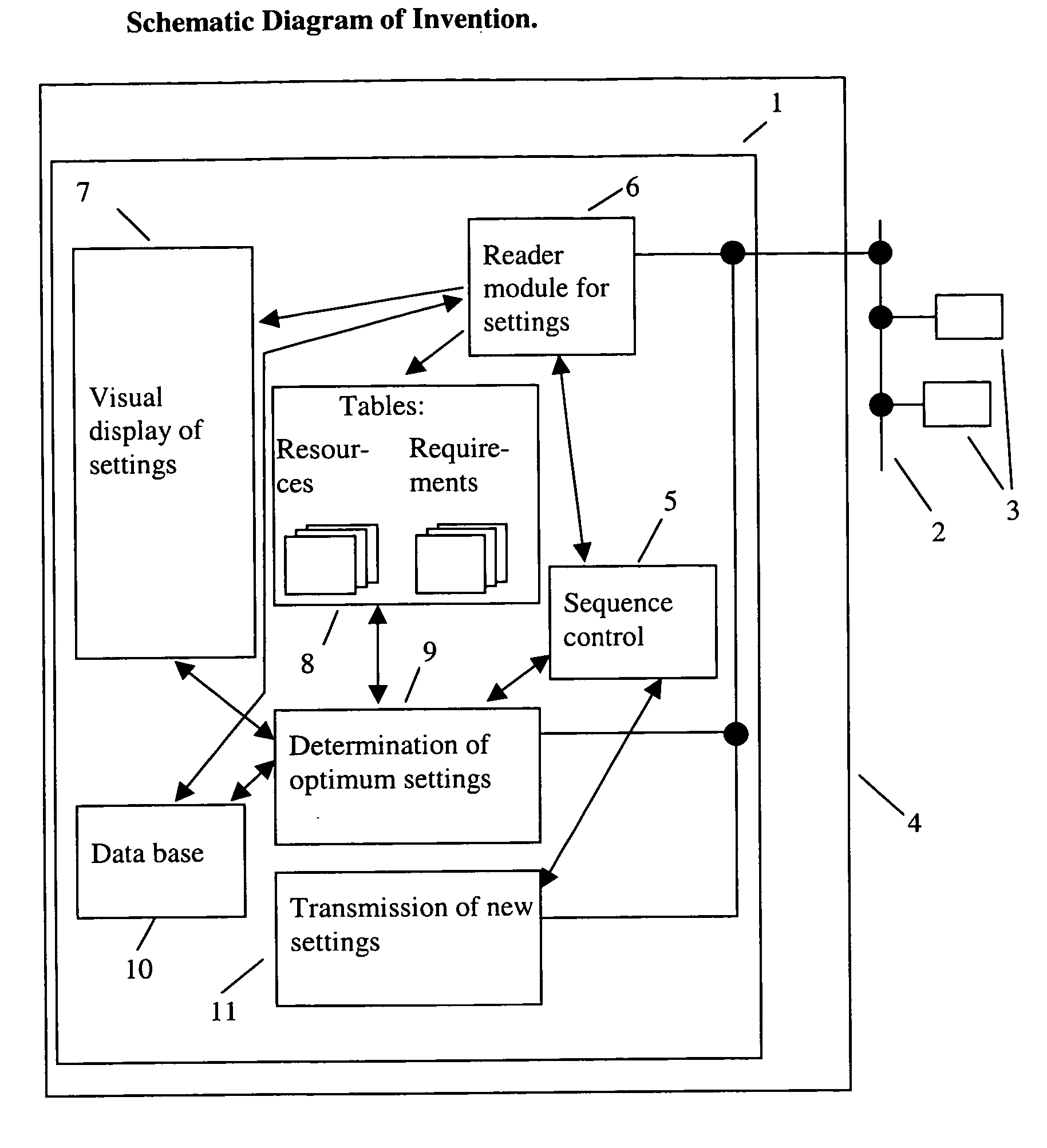

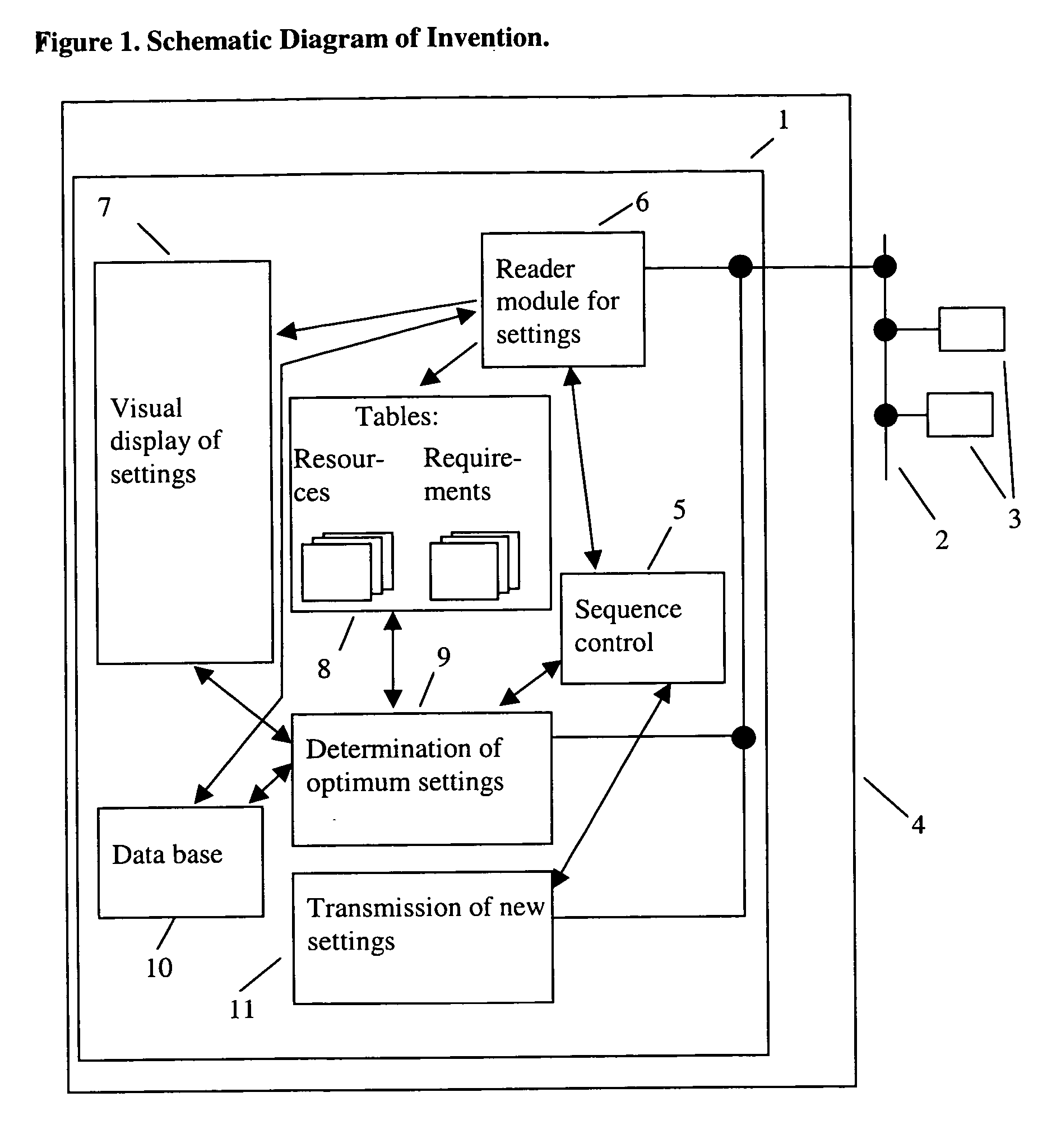

Method for configuration of devices in a computer network by a computer program

InactiveUS20060173979A1Impossible to detectDigital data processing detailsUnauthorized memory use protectionAuto-configurationOriginal equipment manufacturer

The Method provided is for the configuration of devices in a computer network by a computer program. The method renders fully automatic management of all devices in a LAN possible. Internet Service Providers and Original Equipment Manufacturers will be able to deliver products that configure themselves automatically. The invention regards a method to configure devices in a computer network which is executed by a computer program that makes the following steps: Query current settings of one or more devices in the network by using HTTP, FTP, Telnet or a comparable standard protocol. Determine optimum settings with the aid of a data base. Transfer of the previously determined optimum settings to configurable devices in the network. The new settings are being stored on the configurable devices in the network.

Owner:ROELLGEN BERND

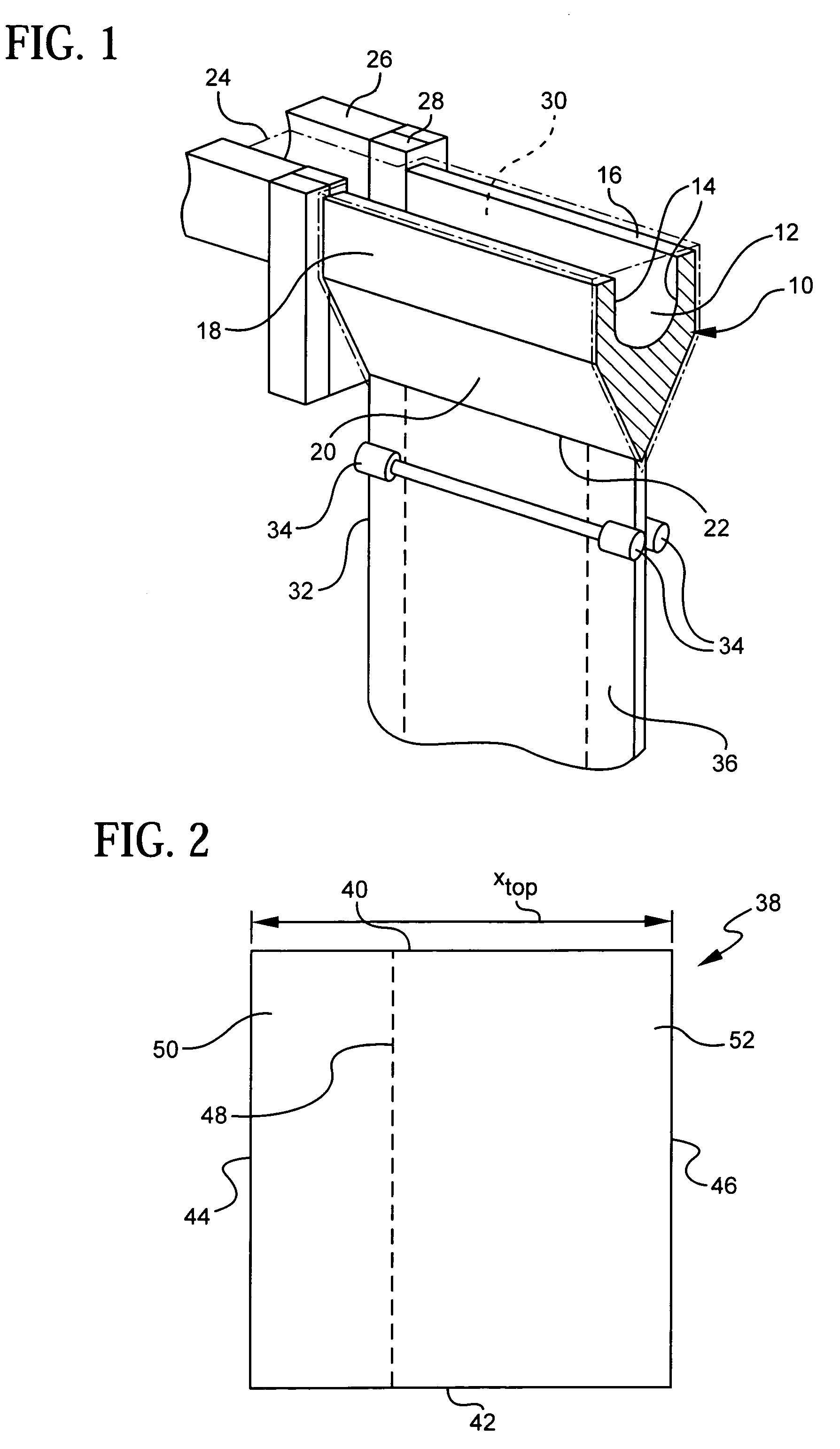

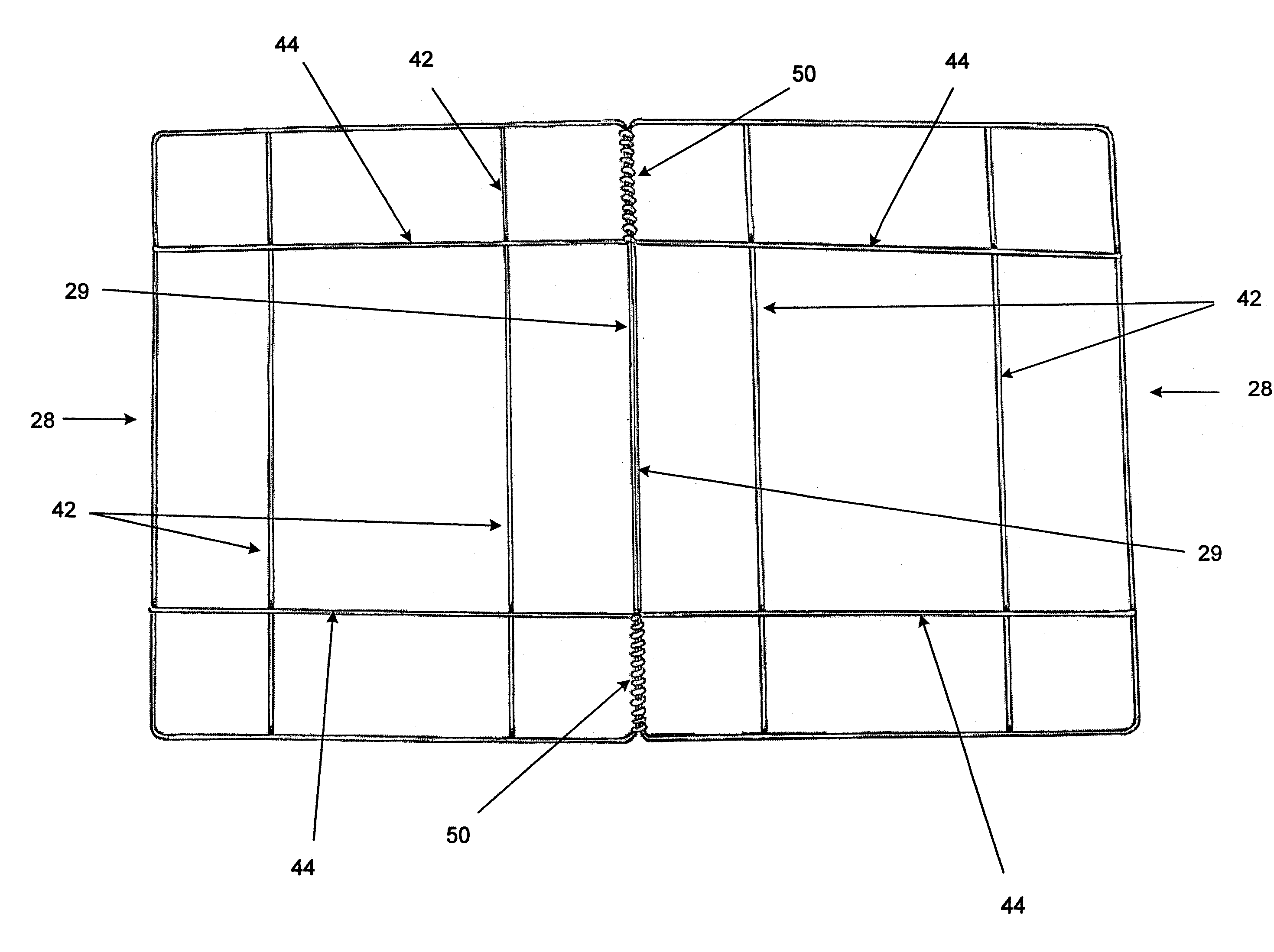

Flexible size adjustable filter element

ActiveUS7497888B2Overcomes shortcomingCombination devicesDispersed particle filtrationOriginal equipment manufacturerAir filter

An air filter element partially-fabricated on site wherein one or more wire frames are fastened to one another to form a structure substantially conforming to the dimensions of the original equipment manufacturer's filter housing. One or more of the wire frames are flexibly attached to each other end-to-end by flexible attachment means, allowing the assembled filter unit to be inserted into the filter housing one frame at a time, with the frame sections yet to be inserted folded or directed off to one side, thus bypassing space restrictions. Flexible attachment means may comprise spring connectors. Also disclosed is an end-cap affixed to or formed at one or both ends of the filter element. The end-caps may also contain printed material, such as text or pictures, which may include instructions for use, identifying labels or symbols, or the like.

Owner:BONDED FILTER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com