Patents

Literature

1074 results about "Product inspection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Product inspection is the process of checking goods for compliance with your specifications and requirements. Generally conducted at the factory manufacturing your product, the product inspection process primarily focuses on checking the appearance, construction and basic function of a product.

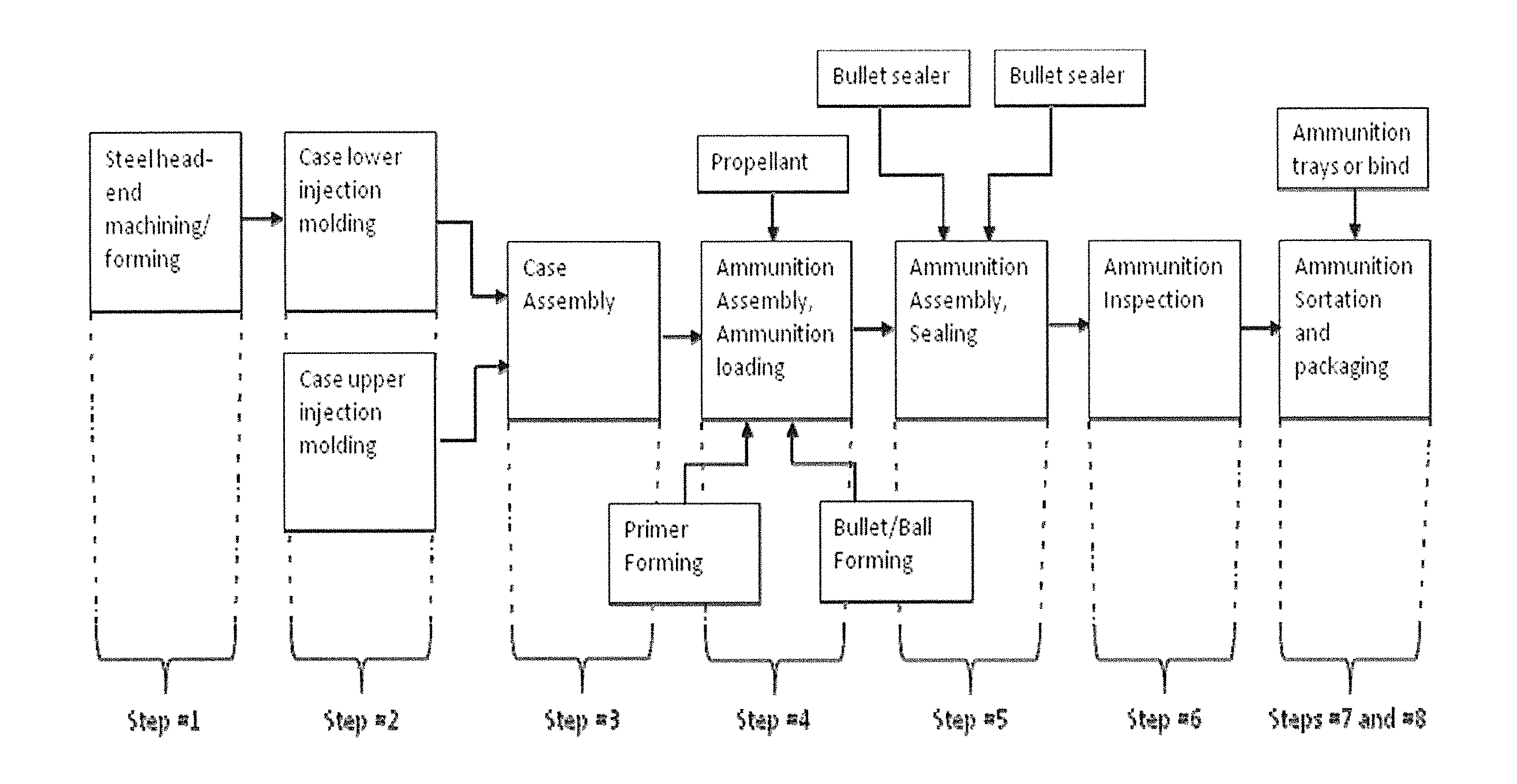

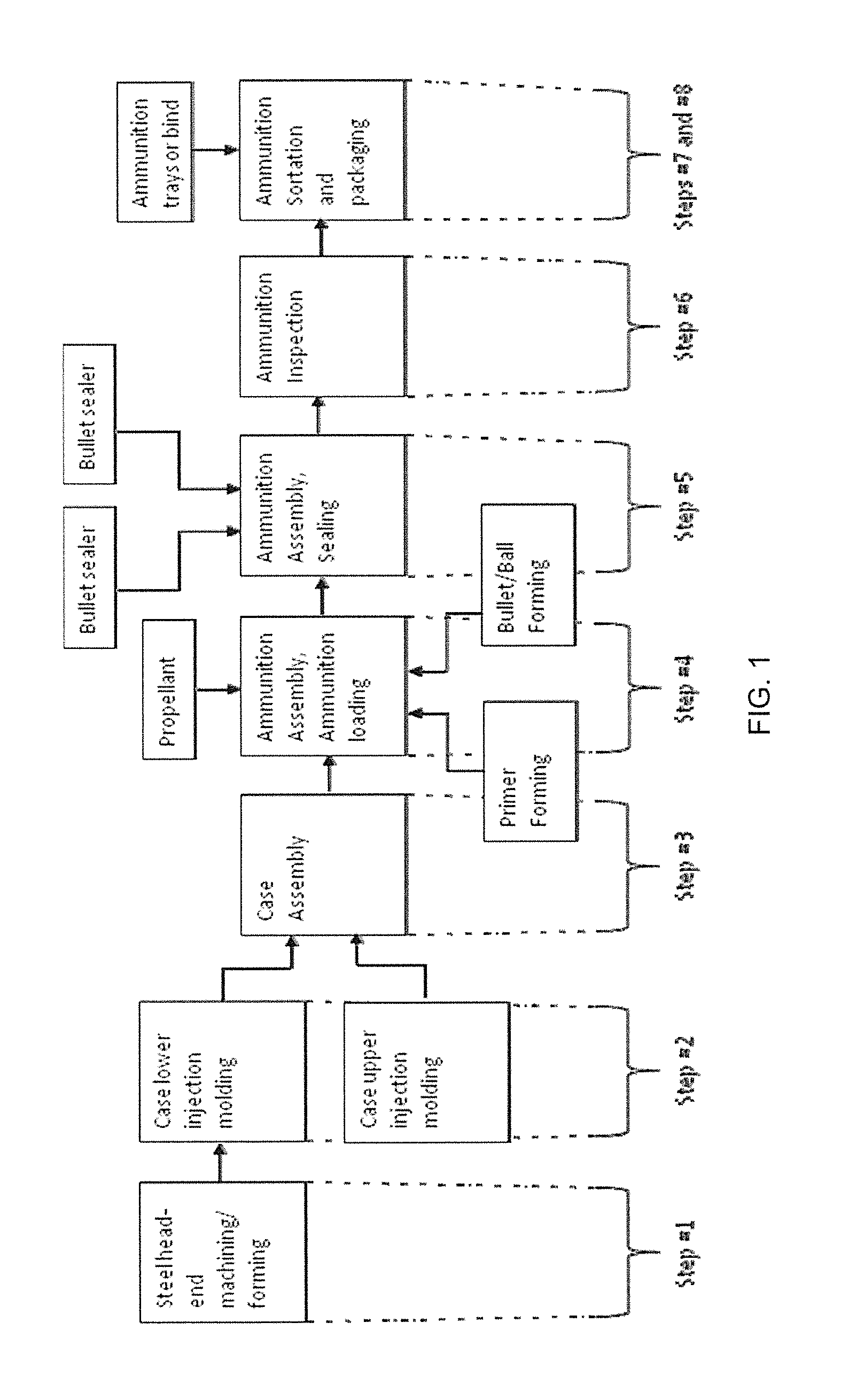

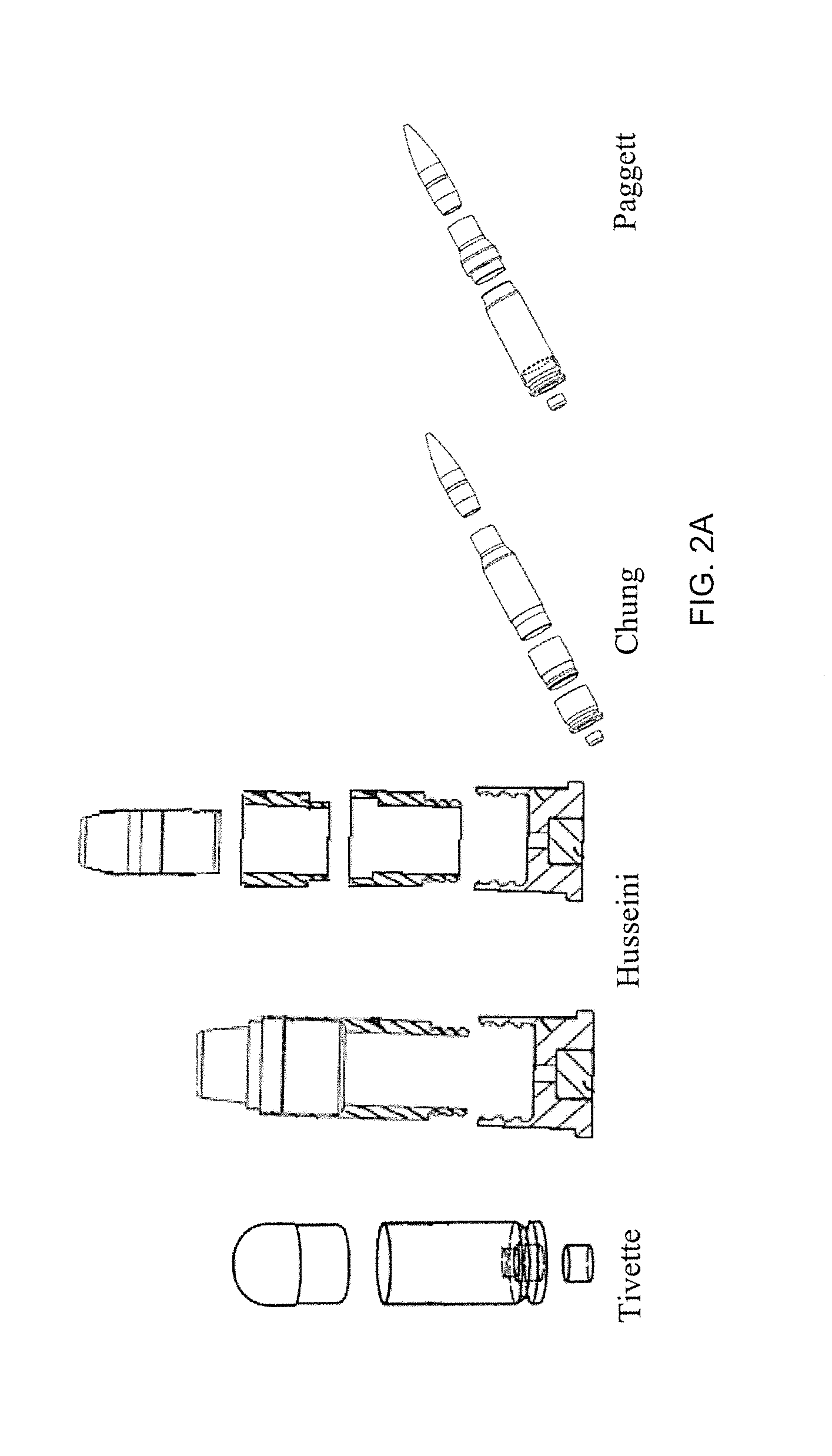

Integrated polymer and metal case ammunition manufacturing system and method

A fully automated, integrated, end-to-end synchronized and compact manufacturing system produces polymer or metal case ammunition. Manufacturing stations support case assembly, sealing (gluing / welding), final product inspection, cartridge packaging or binning, and loading. Station modularity facilitates rapid changeover to accommodate ammunition of differing calibers. Sensors and apparatus may be provided to place a manufacturing cell in a wait state until all components or materials are received in a preferred orientation for proper assembly. The system may join and use multipart cases, each including a lower portion with a head end attached thereto and at least one upper portion having a necked-down transition to the open top end. Elevator feeders, vibratory bowl feeders, and robotic pick-and-place feeders may be used to deliver components for assembly.

Owner:CYBERNET SYST

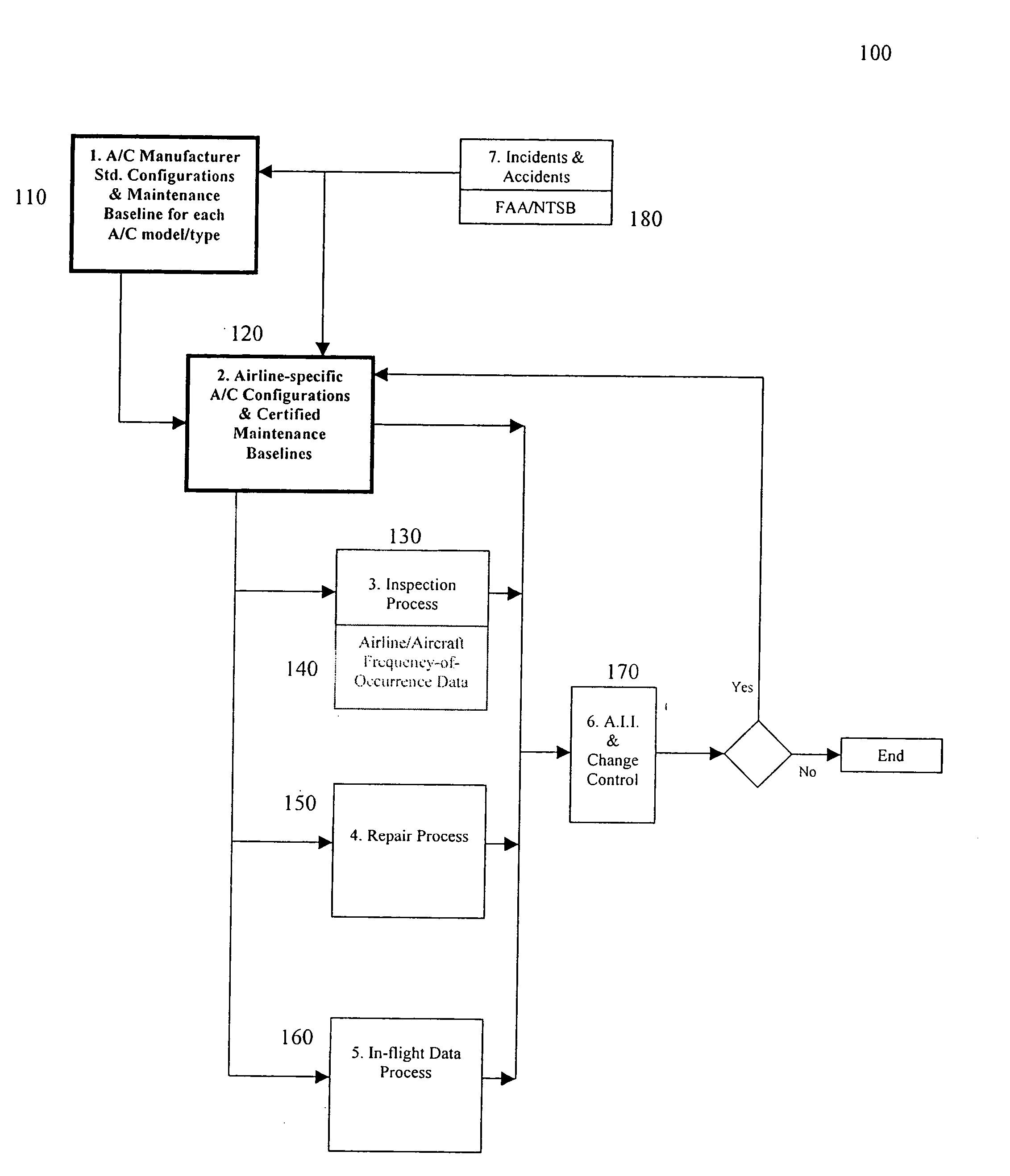

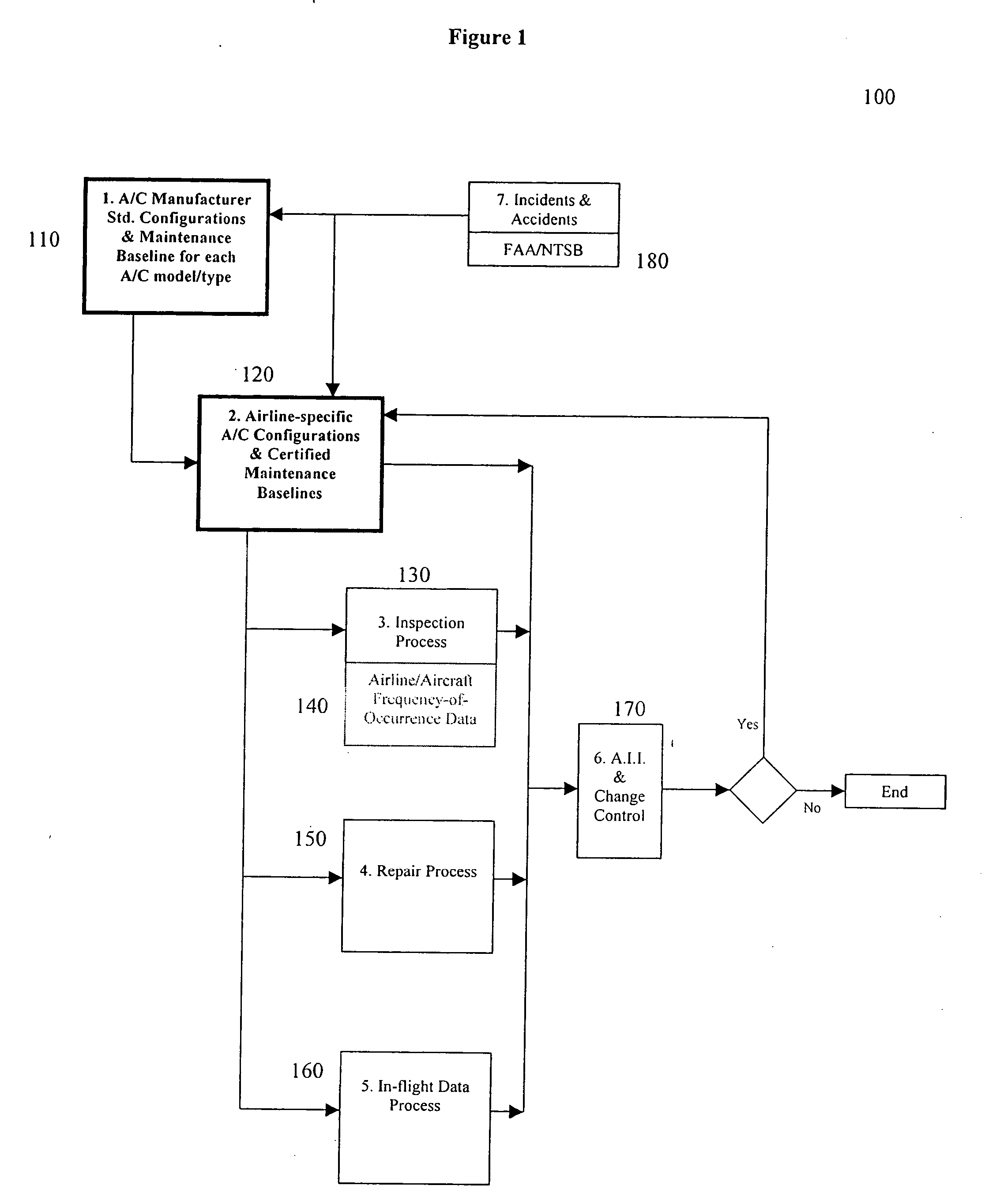

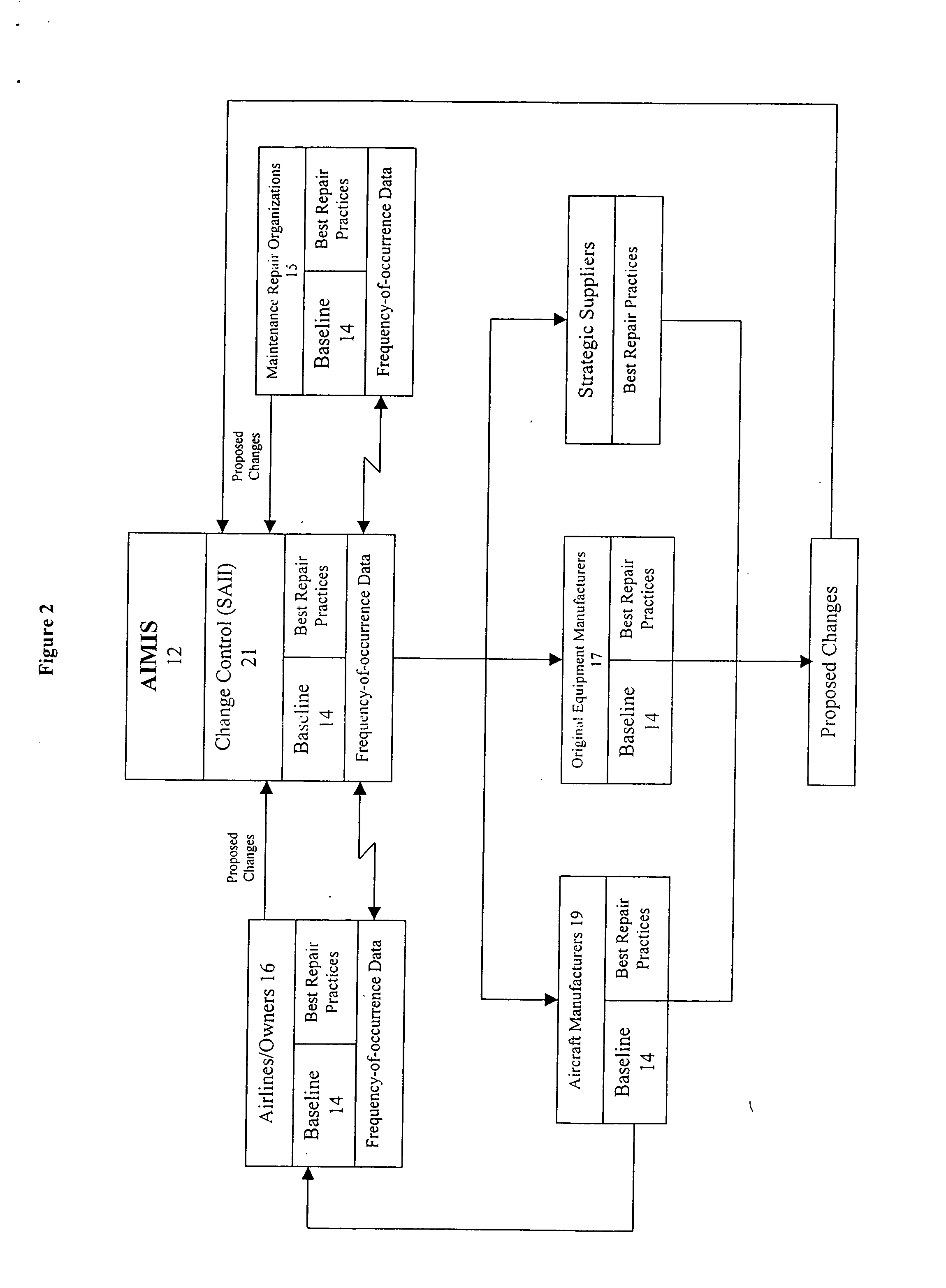

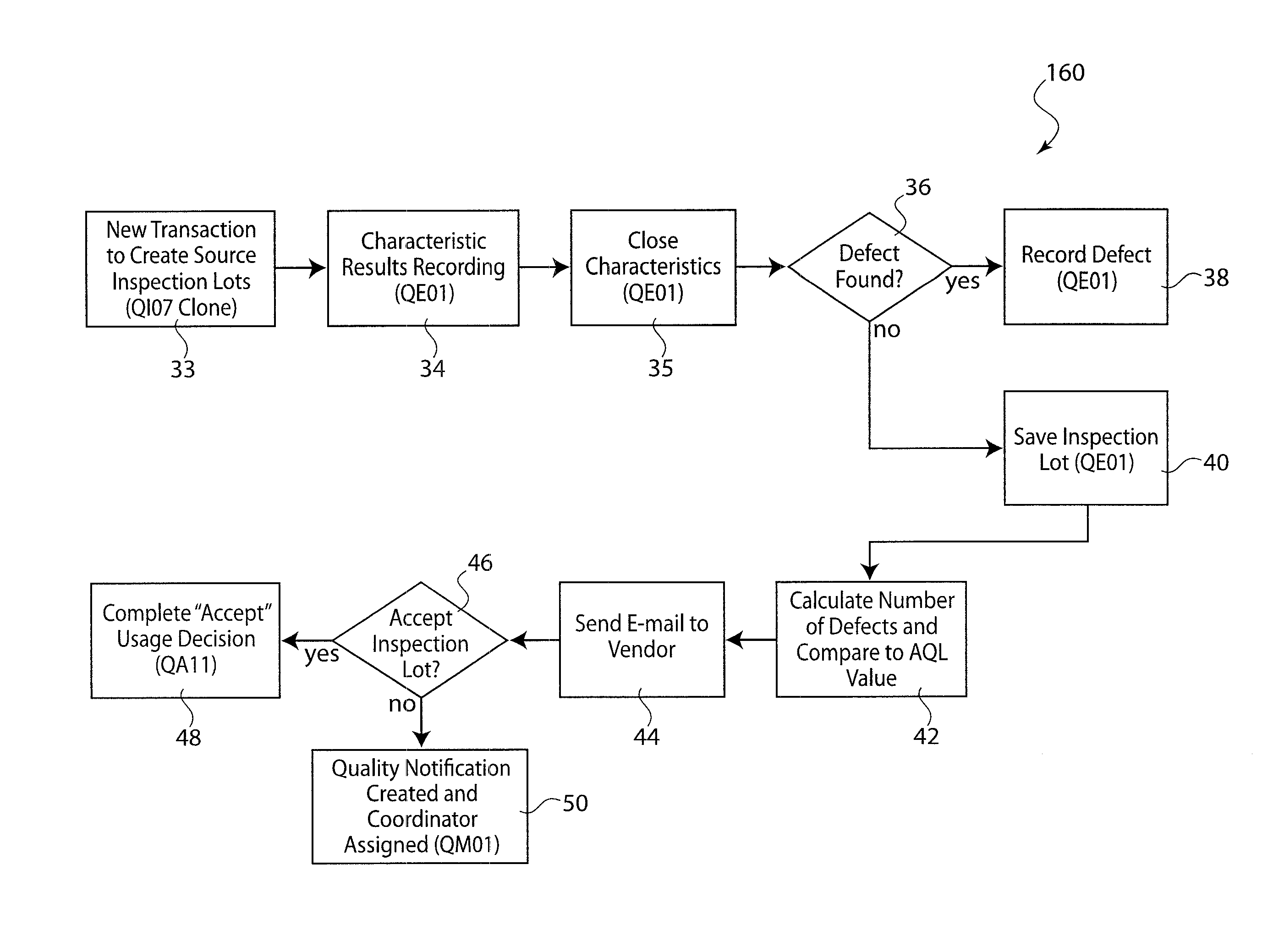

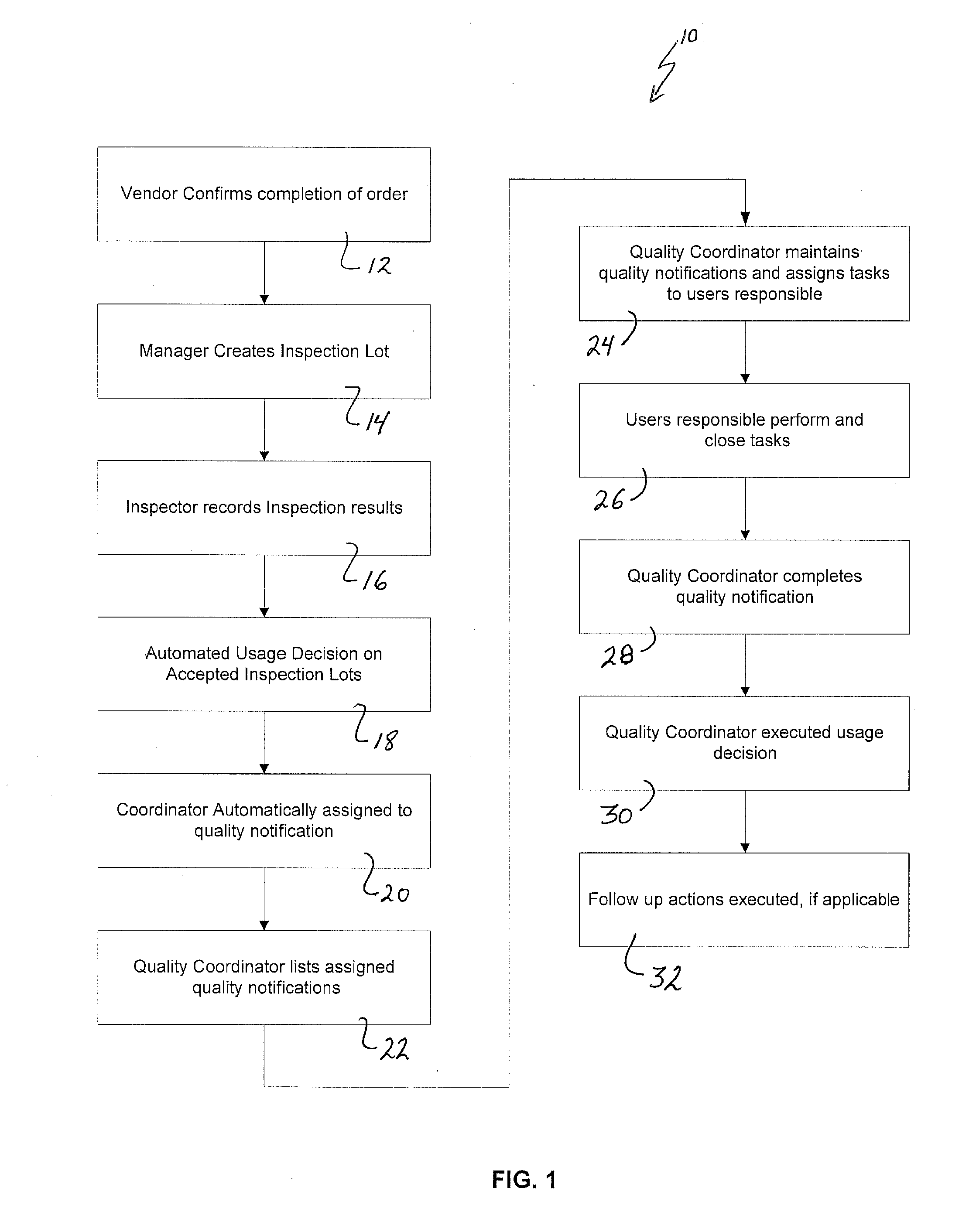

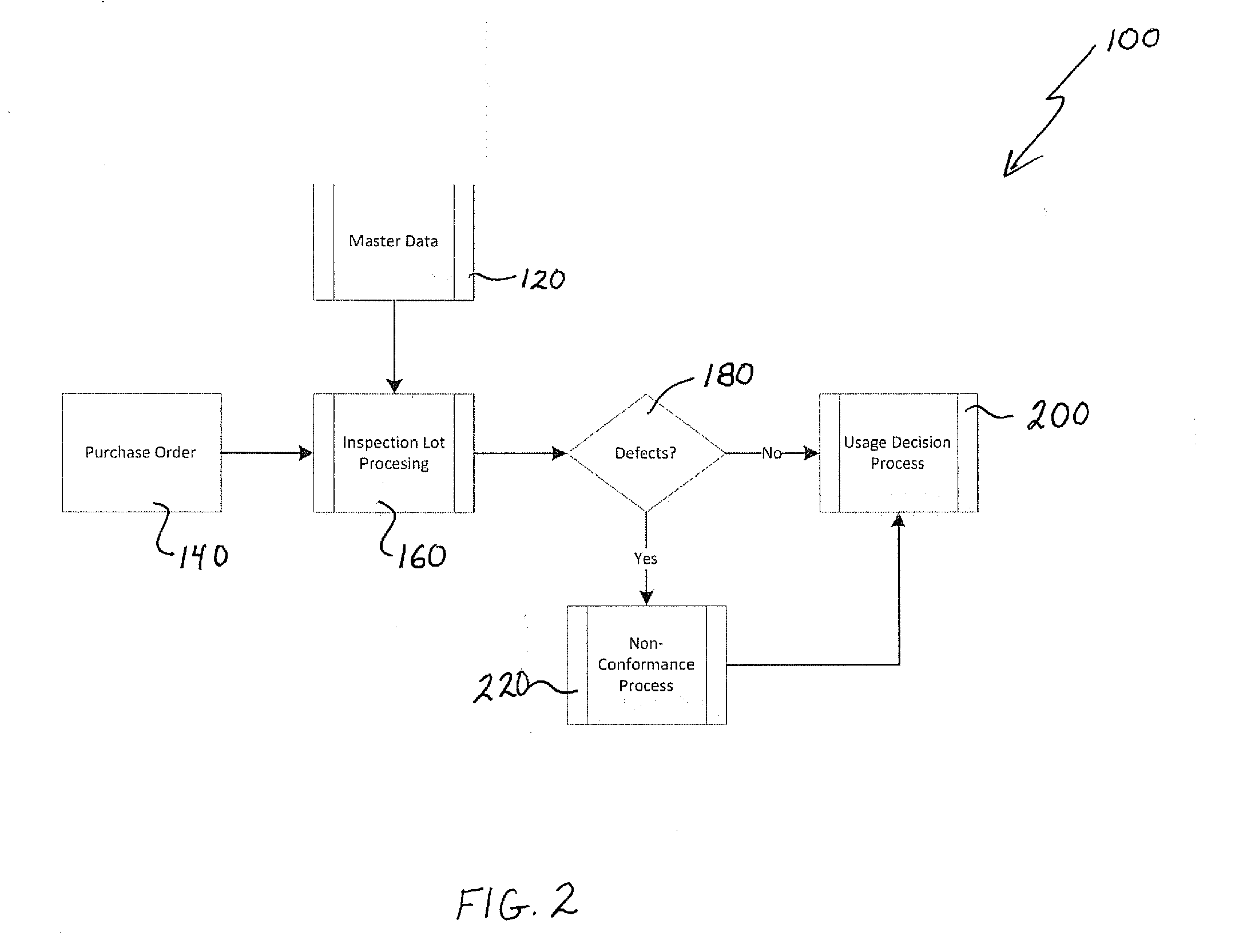

System and method for coordinating product inspection, repair and product maintenance

InactiveUS20050065842A1Economic impactEconomic securityTechnology managementResourcesProduct inspectionOriginal equipment manufacturer

A system and method for coordinating product inspection, repair and product maintenance features a proactive, data-driven process where industry-wide maintenance baselines, problems, frequency-of-occurrence data and best-in-class repair processes are identified in a central, secure, structured database environment and thereby where the safety and operational and economic impact of a problem can be evaluated and acted upon. Using industry-wide data provided by users, the present system and method will link repair and inspection finds (non-routines), reason codes and severity data related to potential safety, reliability, cycle time and cost implications with the root cause analysis and certified best inspection / repair / preventative process instructions, materials, tools and / or equipment. This information, combined with a maintenance provider's, manufacturer's and OEM's information, will greatly improve safety, reliability, cycle time and budget performance on repair, maintenance and inspection of equipment utilizing the present system and method.

Owner:THE SUMMERS GRP

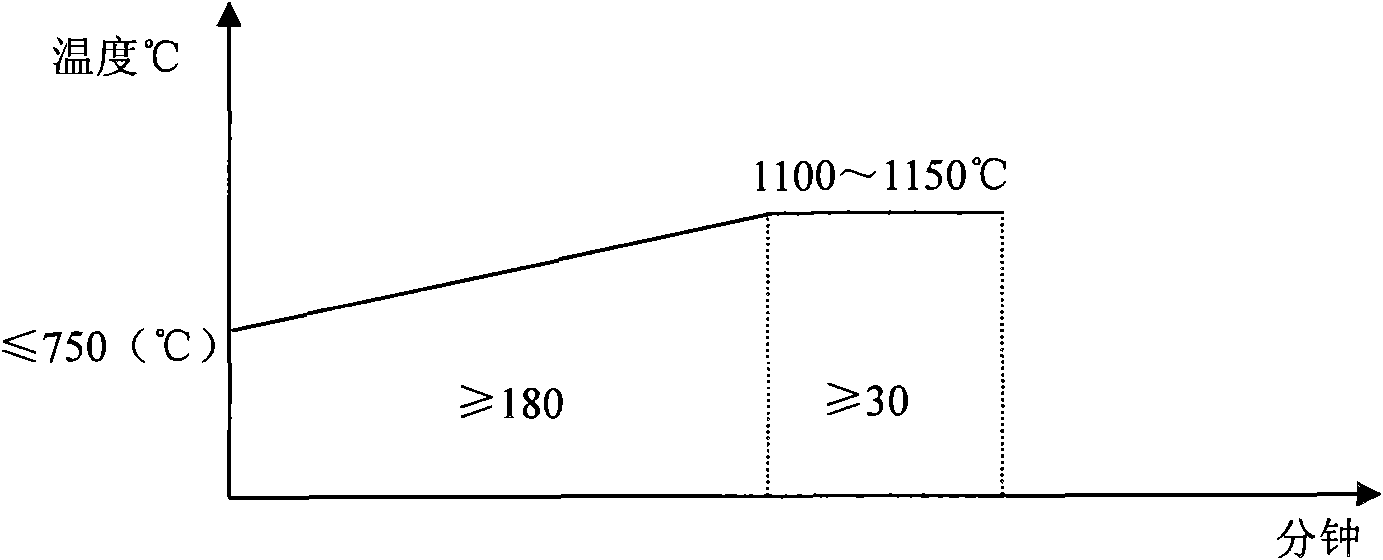

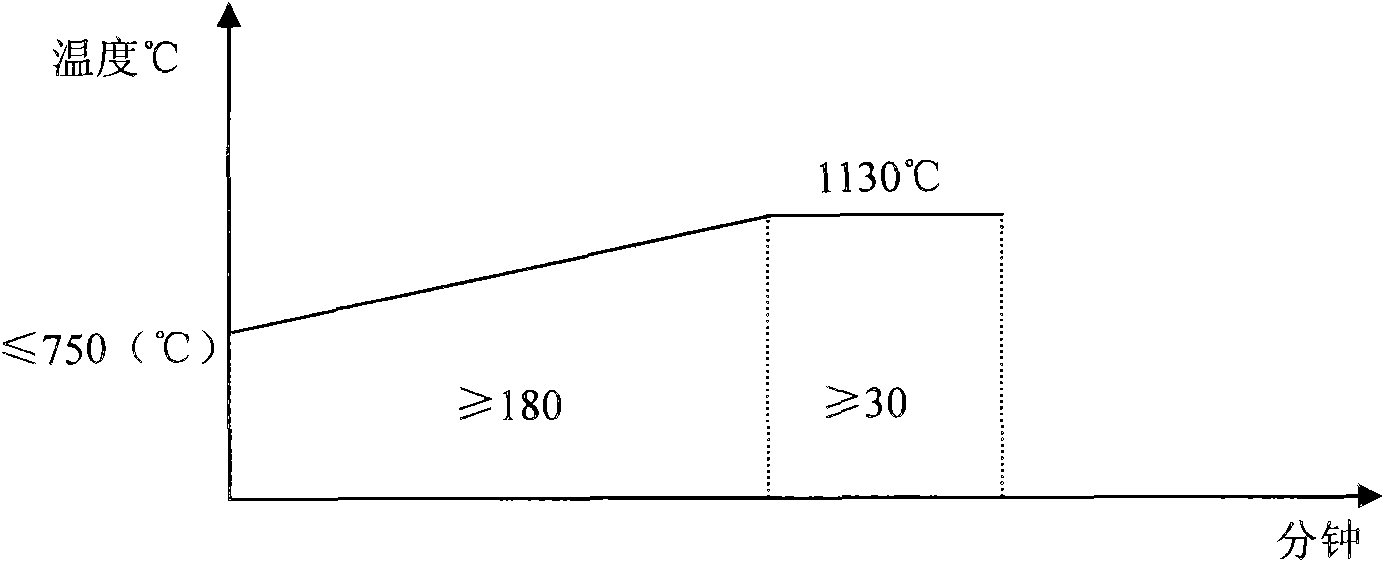

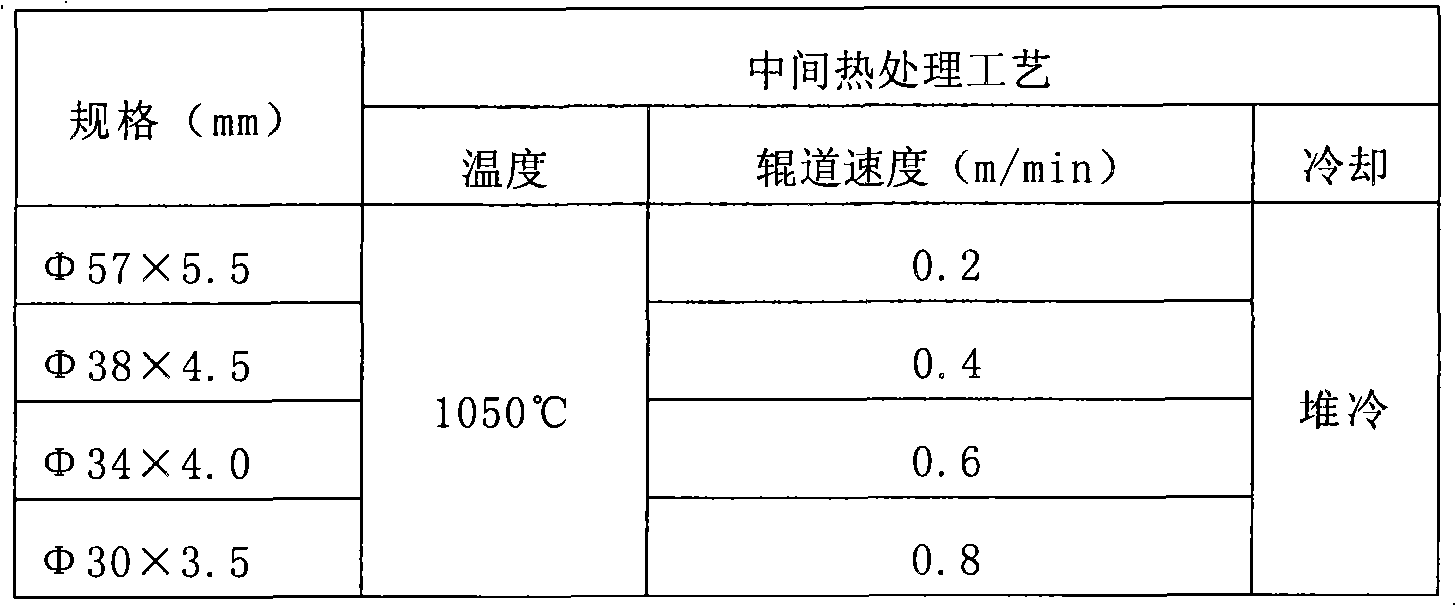

Method for preparing seamless steel tubes made of martensite precipitation hardening stainless steel

InactiveCN101612700AAvoid Surface Quality IssuesReduce lossFurnace typesMetal rolling arrangementsSolution treatmentProduct inspection

The invention discloses a method for preparing seamless steel tubes made of martensite precipitation hardening stainless steel, which comprises the following steps of billets, peeling, blanking, heating, hot punching, cooling, finishing, acid cleaning, lubricating, degreasing, heat treatment, straightening, tube cutting, acid cleaning, inspection, and packaging and warehousing. Compared with the prior art, the method has the following advantages that: pierced billets after hot punching are cooled in a pile so as to reduce working procedures and cost; the intermediate heat treatment adopts solution treatment, has short time and high efficiency, and improves surface quality; the tubes all adopt cold rolling process to improve yield; and vacuum aging treatment is adopted to improve the comprehensive mechanical property, the finished product inspection qualified rate reach 95 percent, and the yield from the billets to the finished products reach 51.31 percent.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

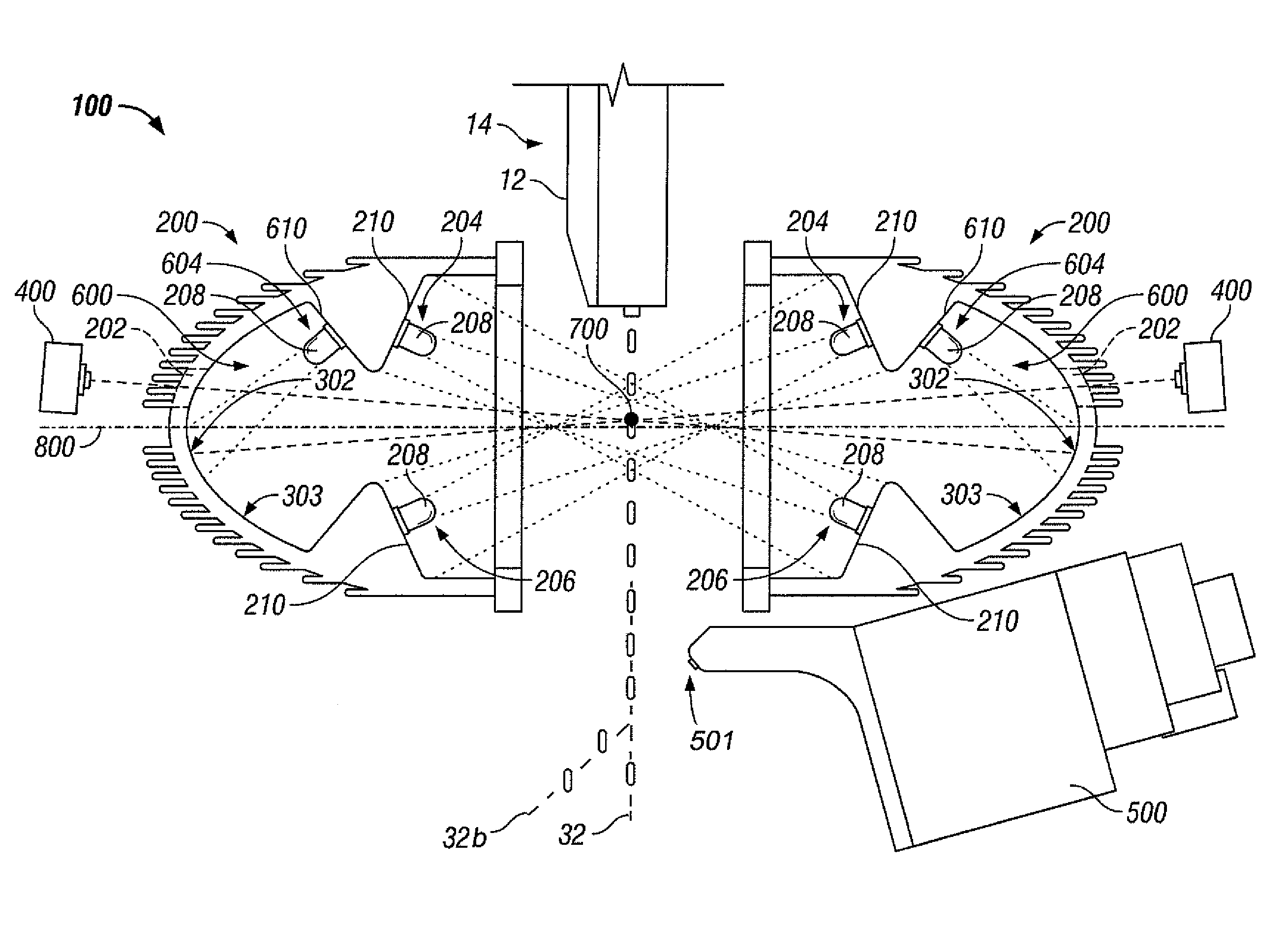

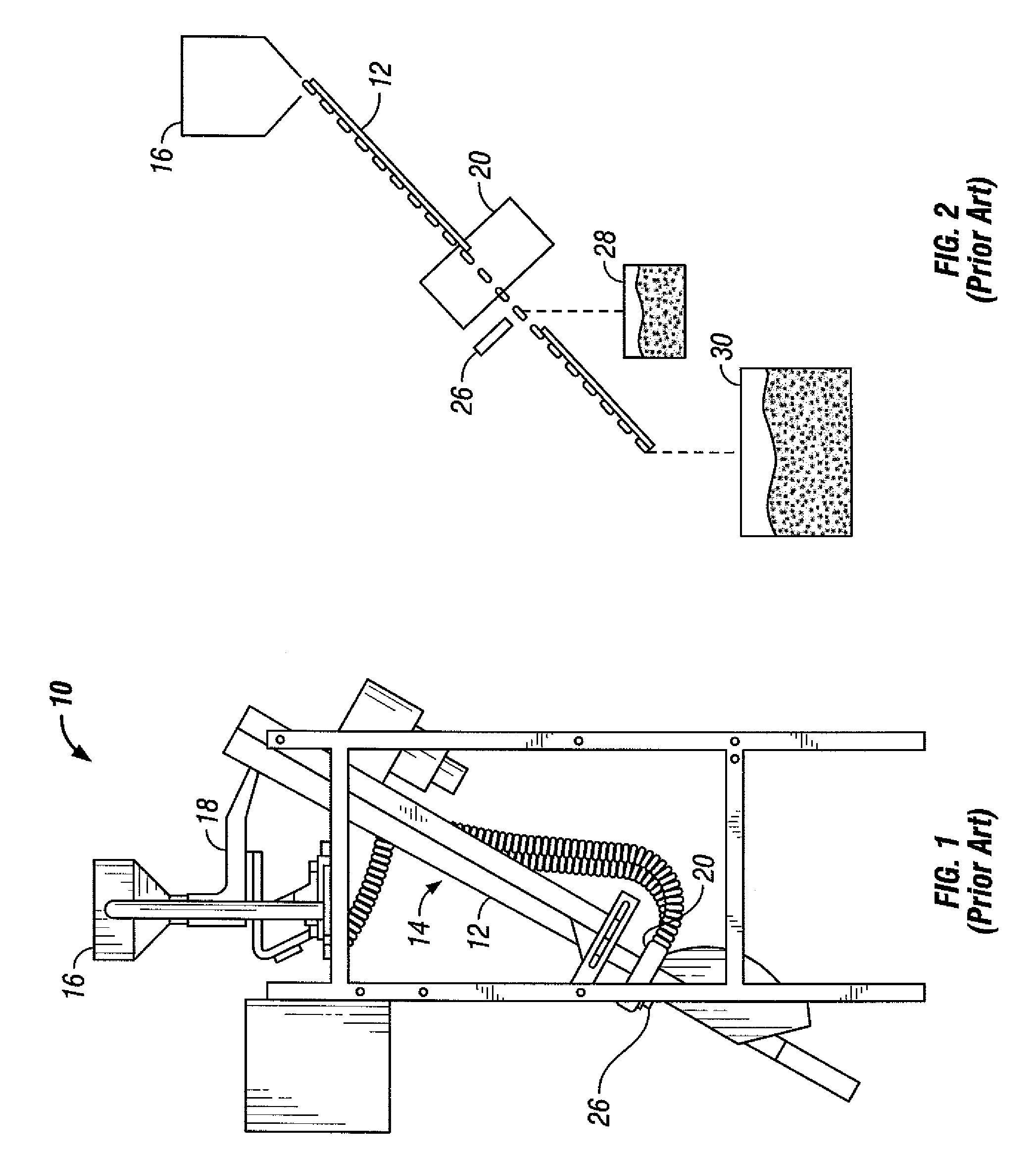

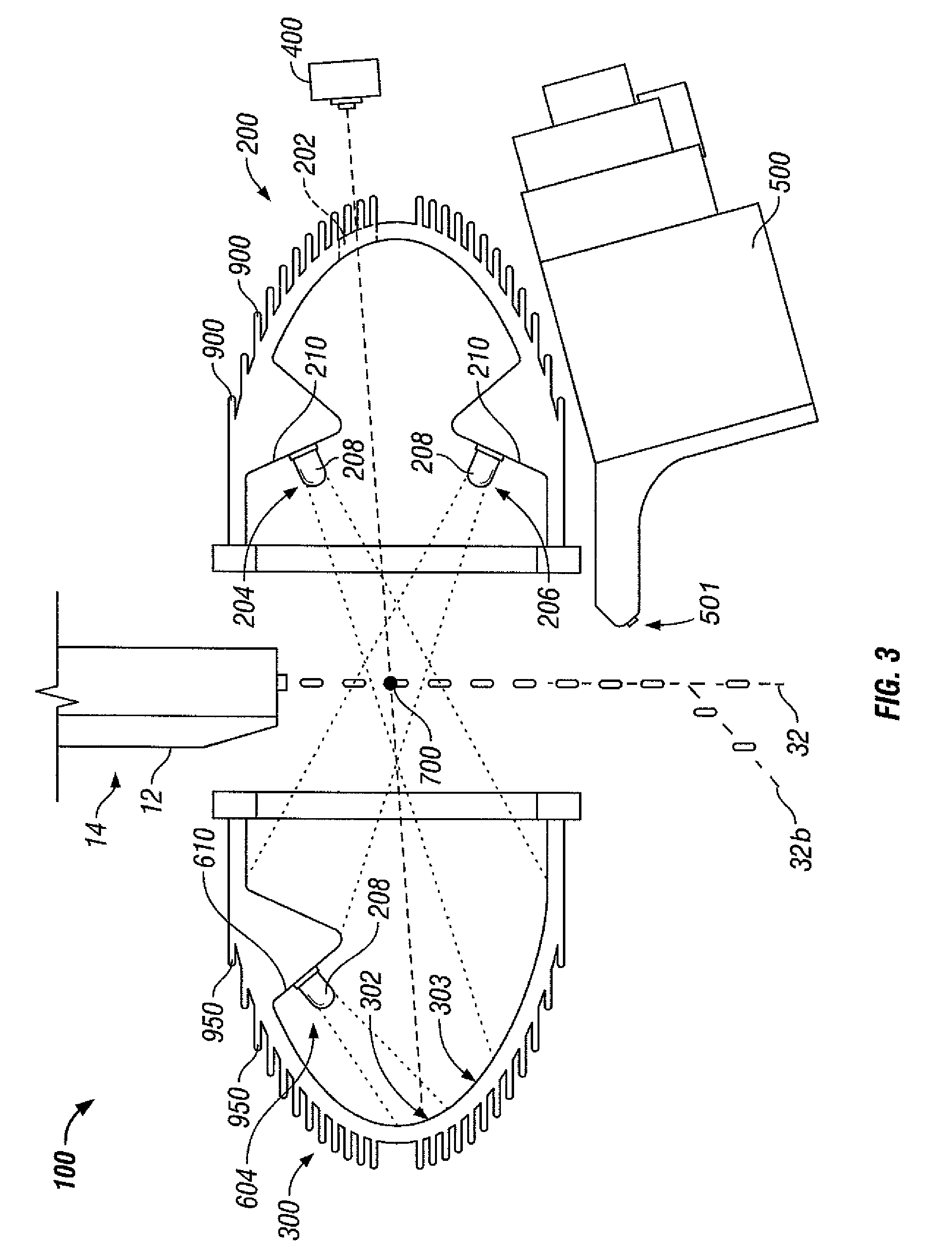

Illumination device for product examination

ActiveUS7339660B1Increase chromatic aberrationDifferent wavelengths and intensities for characteristic selection is eliminatedRadiation pyrometryInvestigating moving fluids/granular solidsProduct inspectionLength wave

An illumination device for use with a product inspection machine inspecting products according to at least one characteristic. The invention also pertains to an illumination device for use in sorting machines that optically sort or separate nonstandard fungible objects from standard objects as they pass a viewing station by viewing such objects illuminated by at least one wavelength. The invention includes a plurality of arrays of semiconductor light sources impinging on passing product and at least one array of semiconductor light sources of wavelength and intensity equal to the plurality of arrays impinging on a background surface for detection and comparison.

Owner:SATAKE USA INC

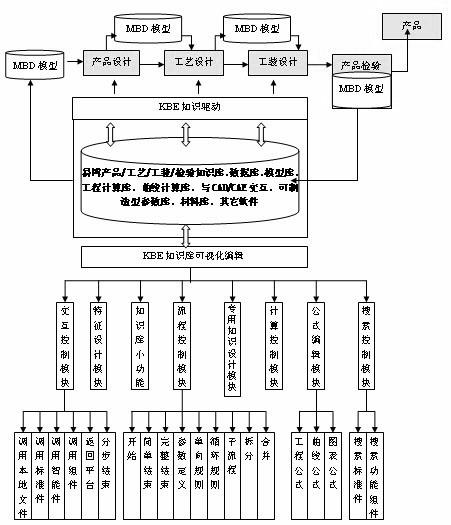

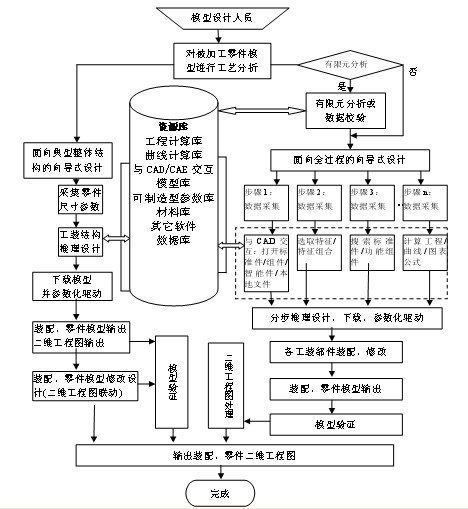

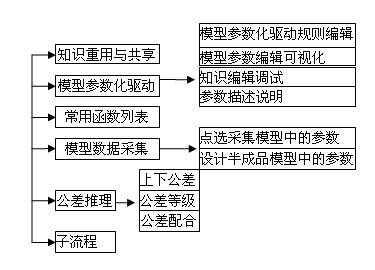

Full three-dimensional digital knowledge base system and application method of knowledge base

ActiveCN102324072AImprove general performanceDo not disclose design experienceData processing applicationsSpecial data processing applicationsData acquisitionDigitization

The invention discloses a full three-dimensional digital knowledge base system and an application method of a knowledge base. The knowledge base system comprises a flow control module, a specific knowledge design module, an interaction control module, an equation editing module, a search control module, a computing control module and a knowledge base small functional module and is an independent knowledge driving system capable of being hung on different CAD (Computer-Aided Design). The application method of the knowledge base can be applied to various fields such as products, processes, tool design, product inspection and the like in the mechanism manufacture industry. A designer expresses knowledge such as purposes, industry design specifications, standard manuals, design experience, computational formulas and the like through an open programming-free visual knowledge editing function and stores the knowledge into the knowledge base, a database and a model base for reusing; and wizard design is realized through parameter passing, data acquisition and interaction and platform interaction. The system has the advantages of strong generality, convenience and rapidness, no leakage of enterprise core technology experience knowledge and the like and provides means for technical innovation and knowledge and experience accumulation.

Owner:西安易博软件有限责任公司

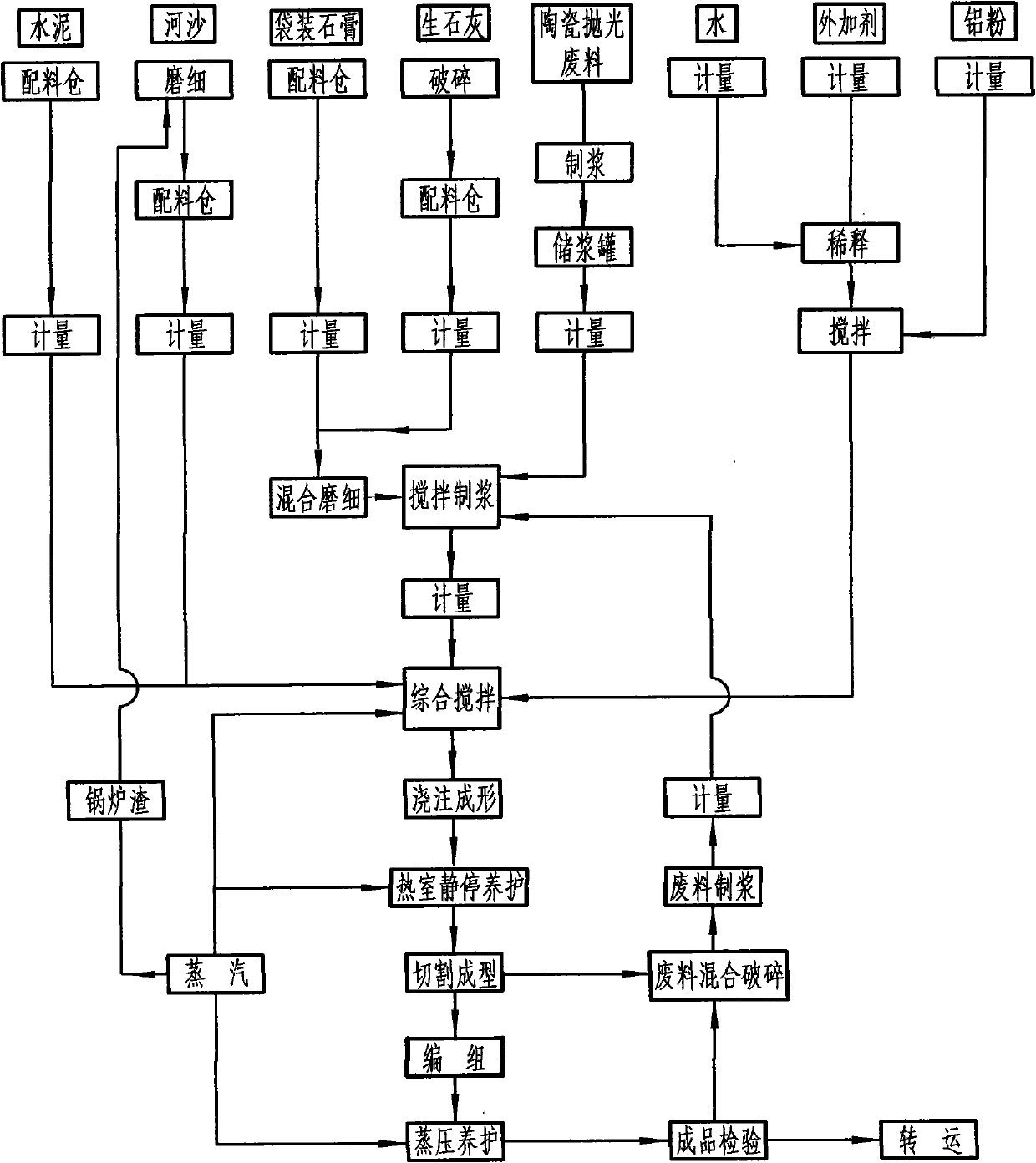

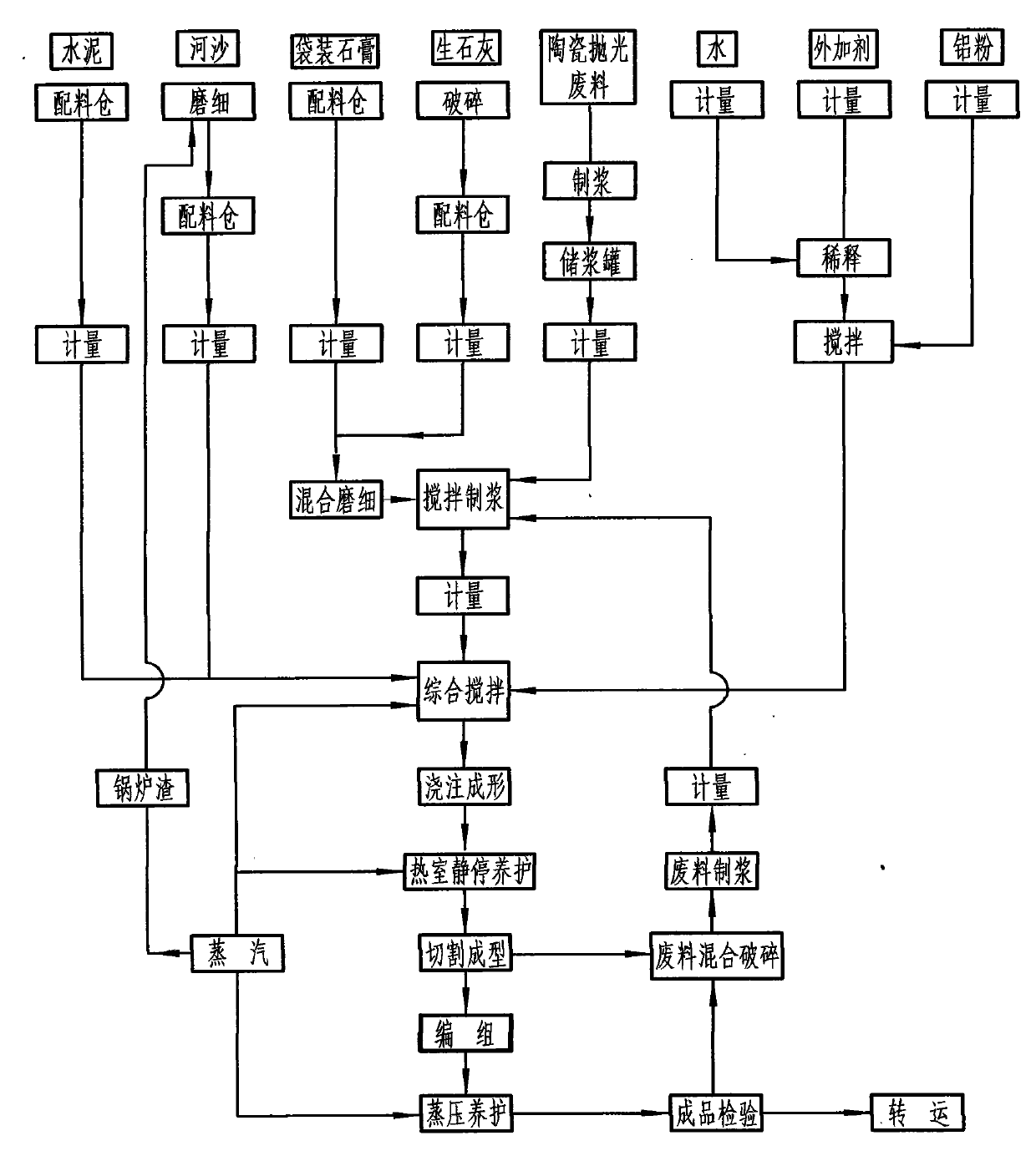

Autoclaved aerated concrete building block and preparation method thereof

The invention discloses an autoclaved aerated concrete building block, which is prepared by adding water into 50 to 55 weight parts of ceramic polishing waste, 10 to 15 weight parts of fine sand, 20 to 24 weight parts of calcined lime, 10 to 20 weight parts of cement, 0.05 to 0.09 weight part of aluminum powder and 3 to 5 weight parts of gypsum. The invention also discloses a preparation method for the autoclaved aerated concrete building block, which comprises the production processes of raw material fetching, slurry preparation, proportioning and pouring, standing and curing in a hot chamber, blank cutting, grouping, autoclaved maintenance, finished product inspection, recycle of waste liquid, waste slag and waste products and the like. The obtained autoclaved aerated concrete building block has the characteristics of high forming speed, light weight, high strength, heat insulation, sound insulation, good fireproof performance, low elasticity, seismic resistance, convenient construction and the like. The preparation method realizes utilization of the ceramic polishing waste, reduces the discharge of wastes of the ceramic industry, and is favorable for protection of ecological environment.

Owner:周石镭 +3

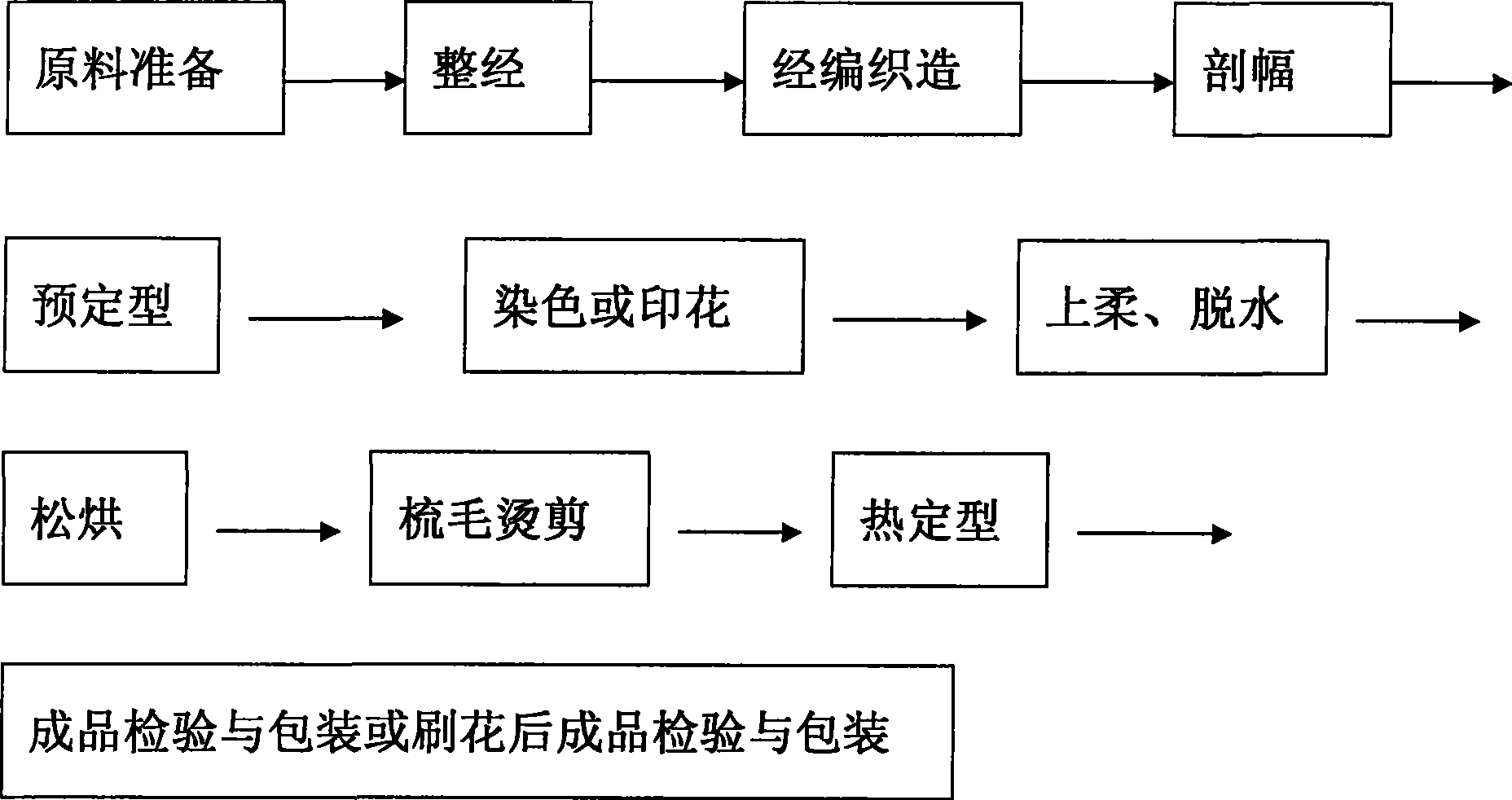

Processing method for full-cleansing woollen plush face fabric

InactiveCN101429703AHigh structural densitySoft feelWarp knittingHeating/cooling textile fabricsProduct inspectionPolyester

The invention relates to a processing method for a polyester plush fabric, which comprises the following processing steps: preparing raw materials; warping; warp knitting and weaving; slitting; pre-setting; dyeing or printing; lustring and dehydrating; baking; combing, scalding and shearing; heat shaping; and product inspection and packing, or product inspection and packing after pattern brushing, wherein the setting temperature for the pre-setting is between 190 and 230 DEG C; and in the pre-setting process, the tension of grey cloth is controlled, and the progression speed of controlling the grey cloth is 35 to 45 meters per minute, and the rotating speed of a blower is 1, 750 to 1, 900 revolutions per minute. The processing method has the advantages that the height of plush is increased to 5 to 30 millimeters, the plush is long and inflexible, and the plush surface is smooth and subtle, and the plush is soft and has good hand feel; the plush is straighter and can comb floating plush at the bottom; at the same time, resetting resulted from difference of fabric width and style caused by high-temperature ironing and cutting is reduced; by adopting warp knitting and weaving, a bottom tissue structure has high density and a bottom fabric tissue has good stability; and the step of pattern brushing makes patterns flexible and the fabrics extend from single toy fabrics to clothing fabrics.

Owner:CHANGSHU YATAIYA TEXTILE ADORN

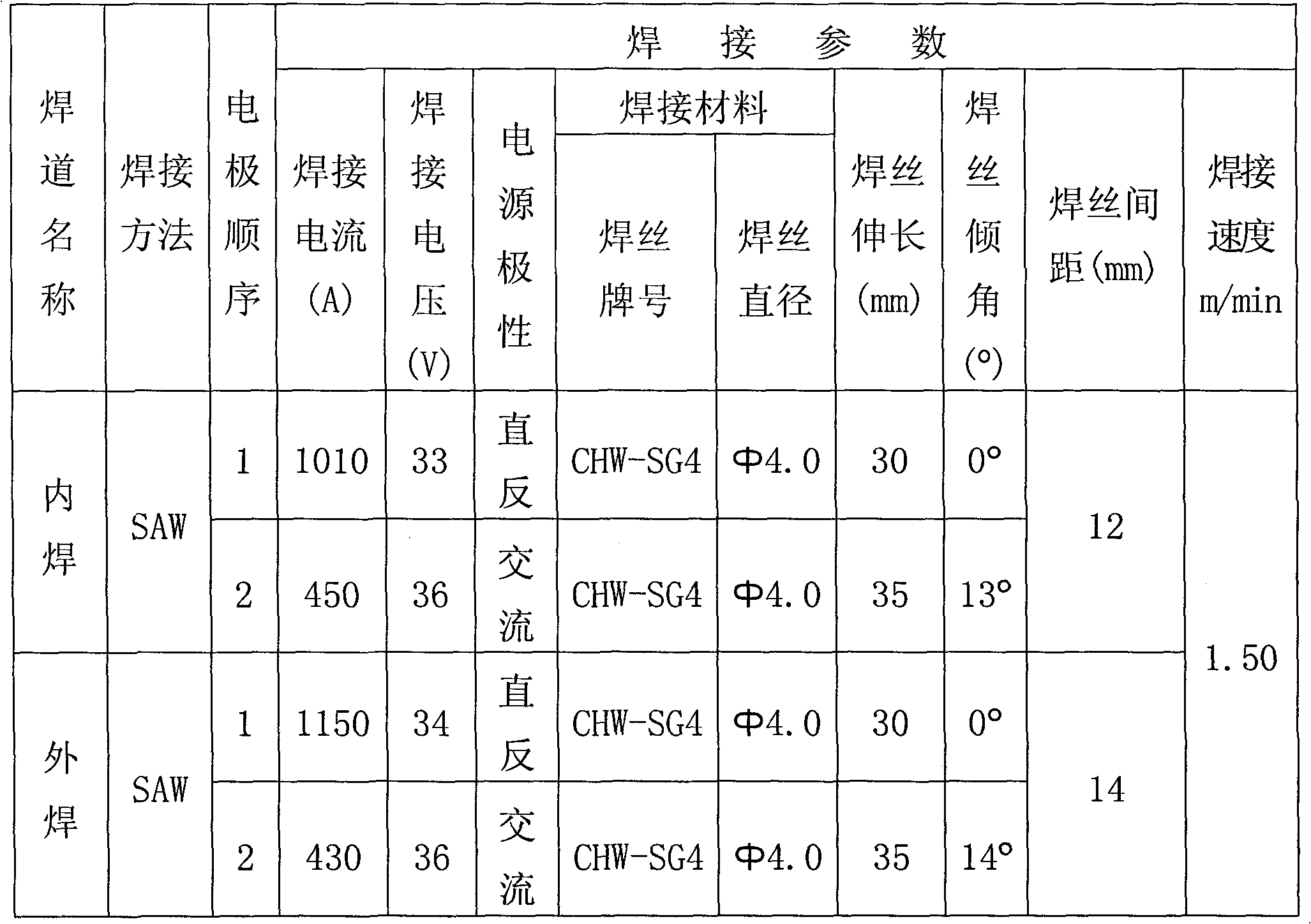

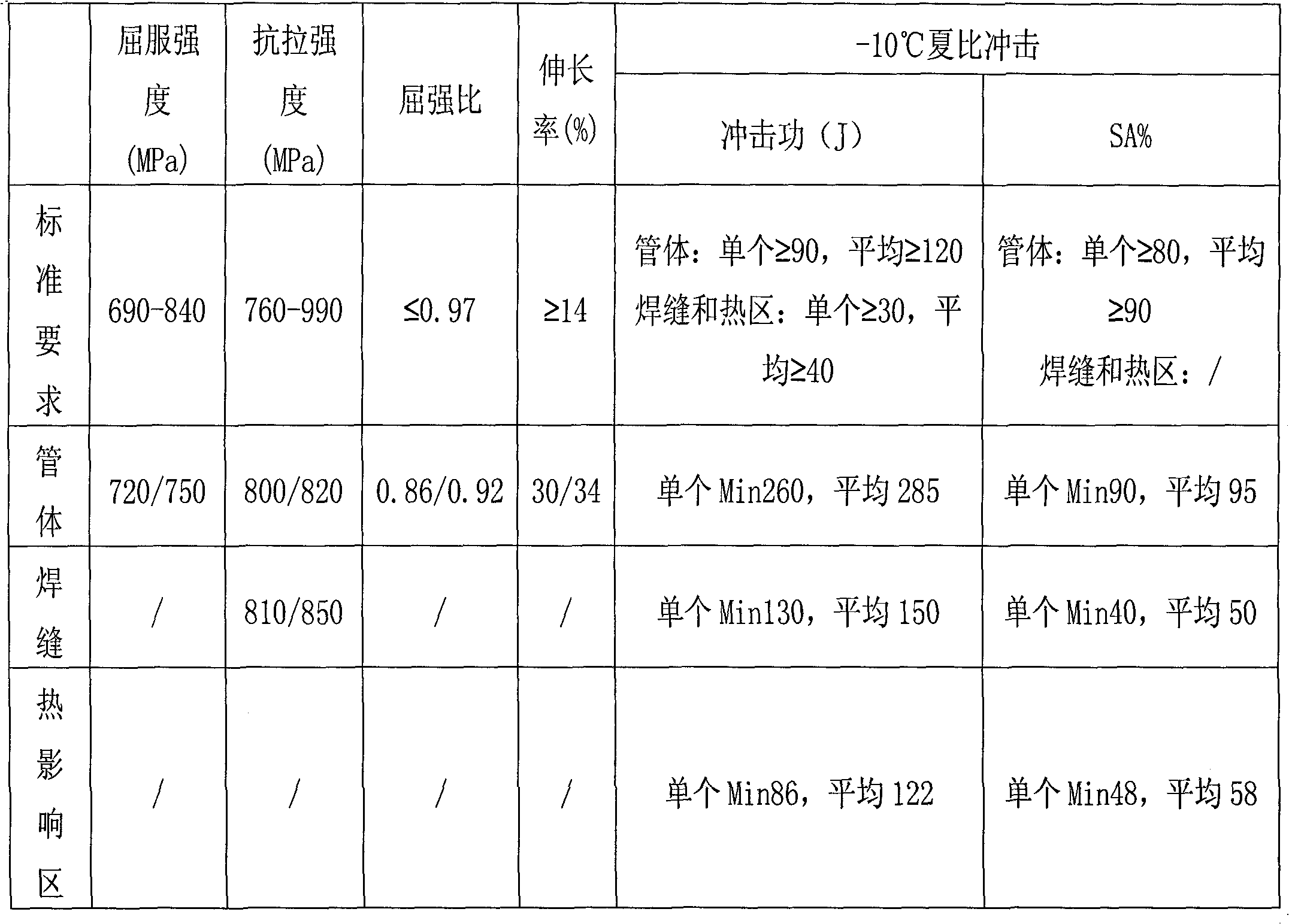

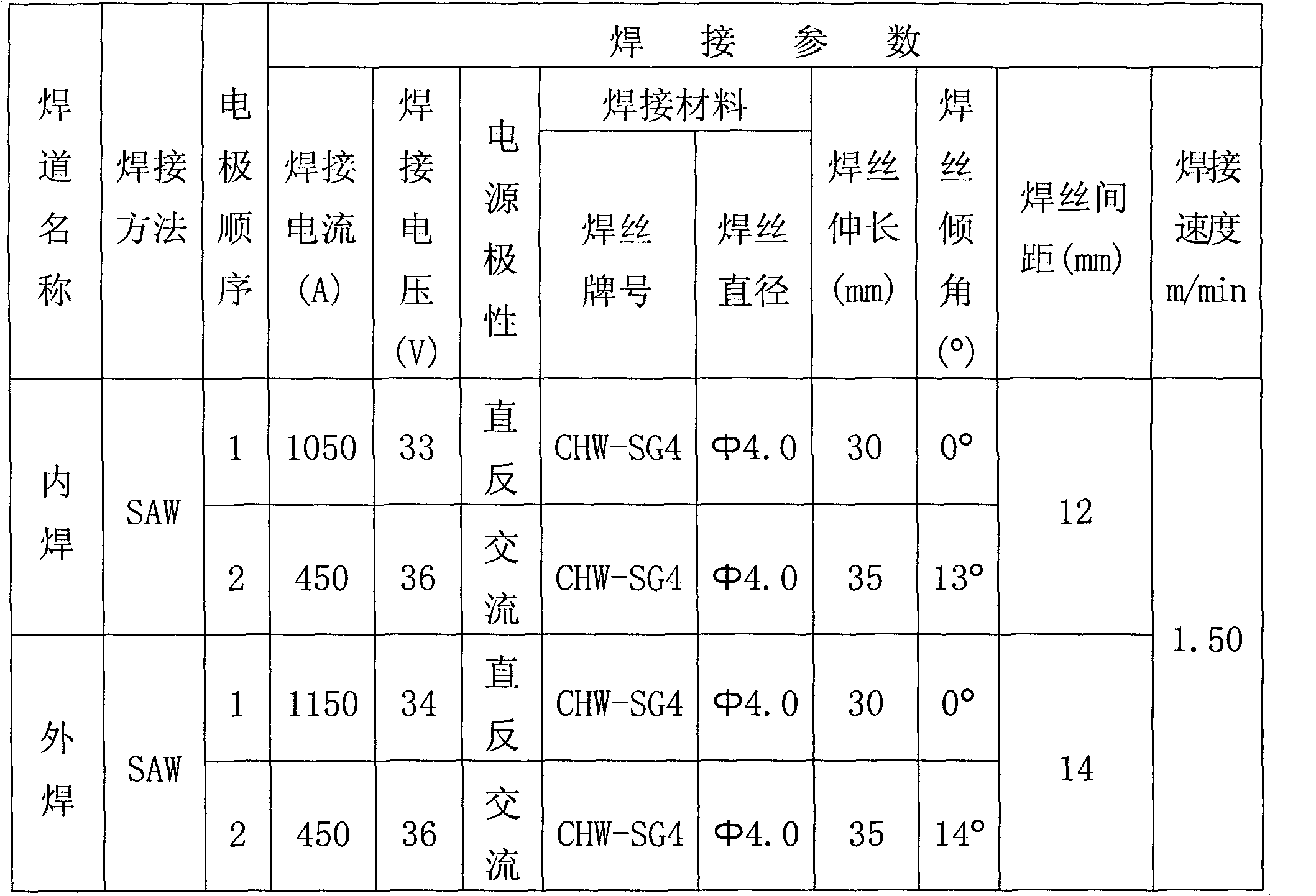

Method for manufacturing high-strength X100 steel grade spiral seam submerged arc welded pipe

ActiveCN101797600ATo achieve effective detectionFully automatedArc welding apparatusMilling equipment detailsProduct inspectionX-ray

The invention discloses a method for manufacturing a high-strength X100 steel grade spiral seam submerged arc welded pipe. The method comprises the following steps: uncoiling, flattening, edge milling, pre-springing, molding, inside welding, outside welding, pipe end belling, base metal layering ultrasonic examination, weld seam X ray inspection, hydrostatic test, weld seam ultrasonic inspection, pipe end chamfering and finished product inspection. In the technical steps of the preparation method, double edge milling process, pre-springing process and pipe end belling process are added so as to successfully solve the technical problems that the high-strength X100 steel grade spiral seam submerged arc welded pipe has poor molding stability, the welding joint performance cannot meet technical requirement and the like.

Owner:NORTH CHINA GASOLINEEUM STEEL PIPE +3

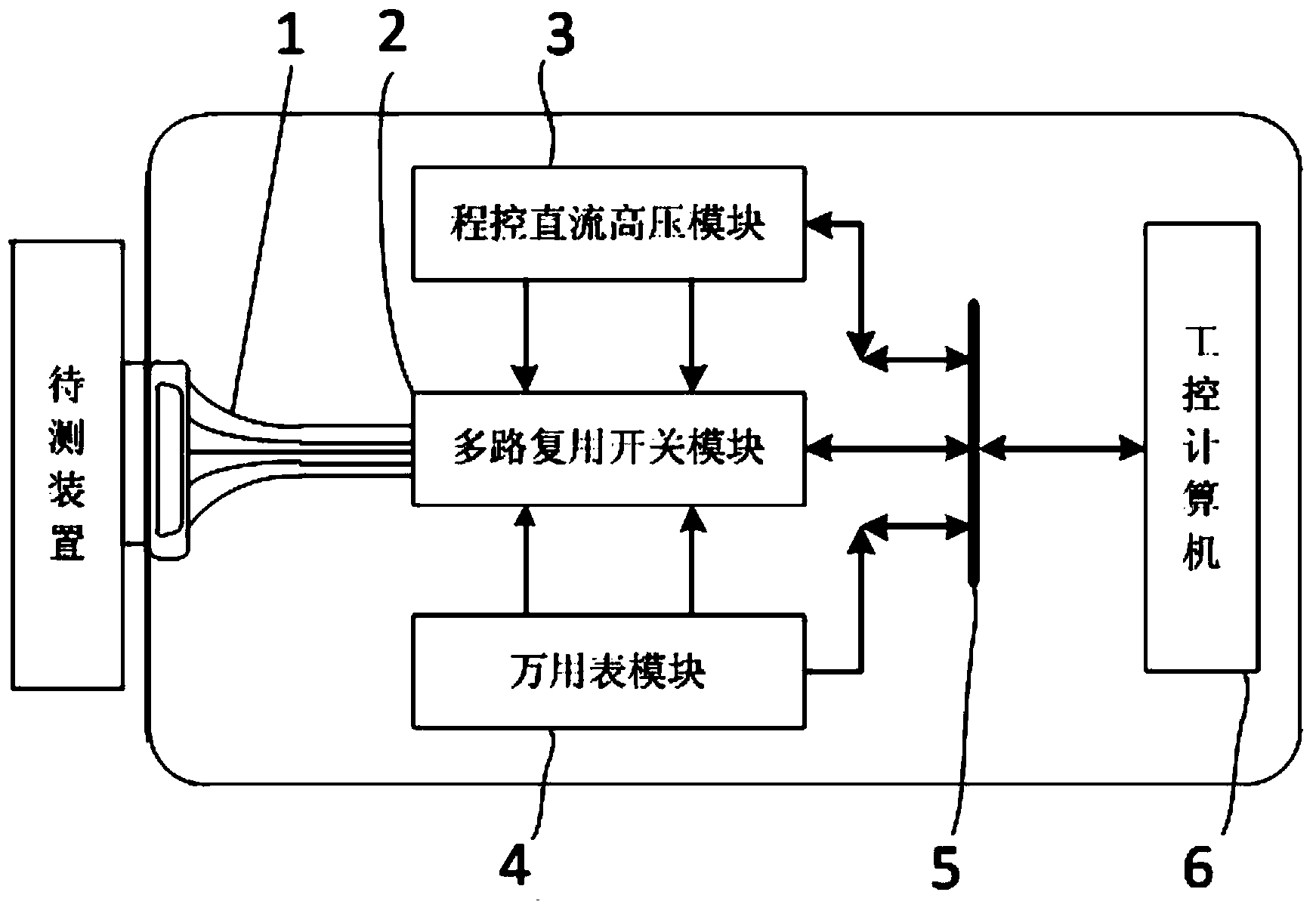

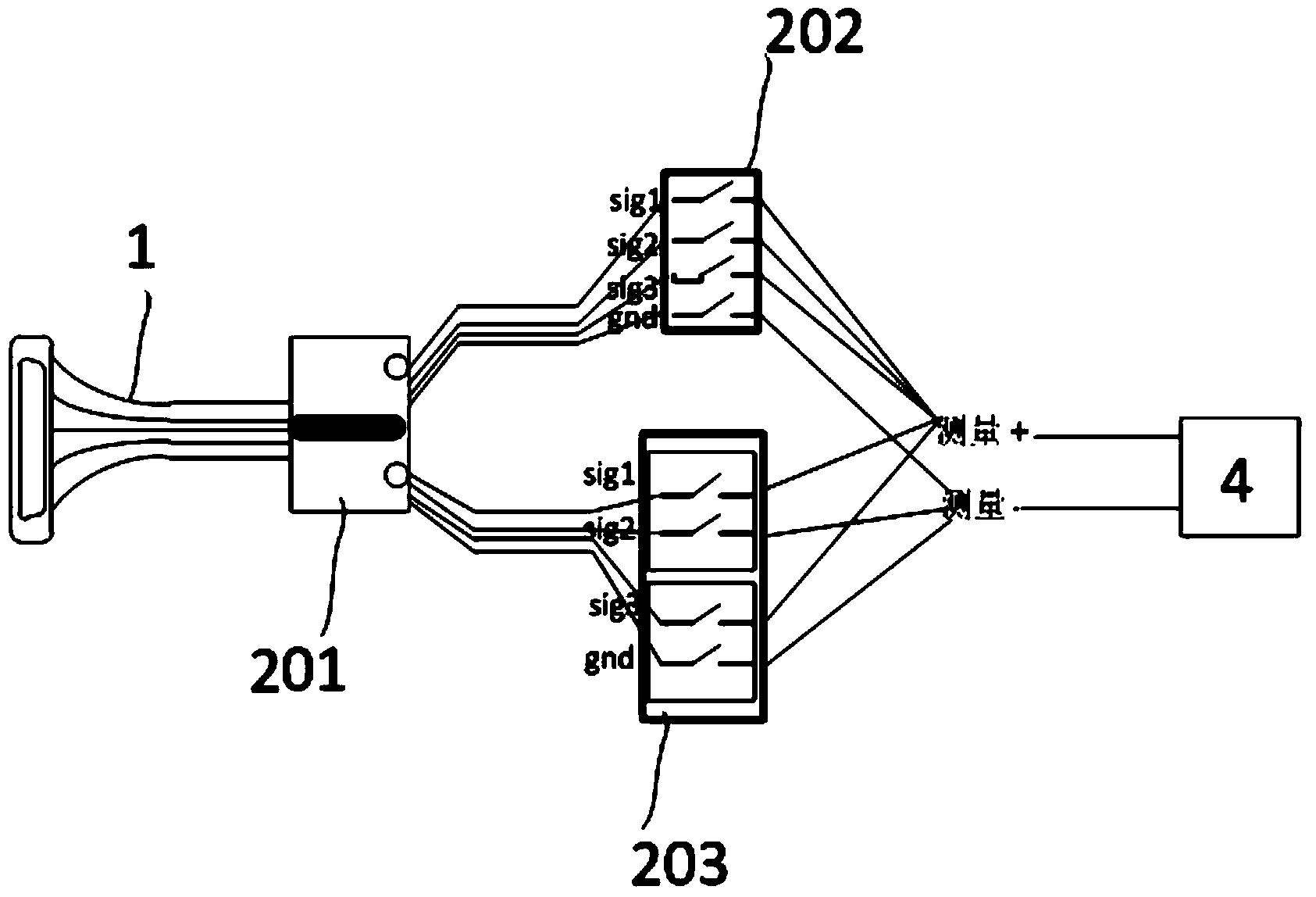

Automatic insulation resistance and characteristic resistance tester

ActiveCN103675458AWork reliablyImprove reliabilityResistance/reactance/impedenceMultiplexingProduct inspection

The invention discloses an automatic insulation resistance and characteristic resistance tester which comprises a testing cable, a multiplexing switch module, a universal meter module, a CPCI bus and an industrial personal computer. The multiplexing switch module is connected with an electrical node interface of a device to be tested through the testing cable and can control an internal relay switch through programs to enable input channels to be automatically disconnected and connected with an output channel, the universal meter module automatically measure a resistance value of an electrical node of the device to be tested through the multiplexing switch module and outputs a measurement result to the CPCI bus, the industrial personal computer reads data from the CPCI bus and performs processing and displaying. The automatic insulation resistance and characteristic resistance tester can automatically test insulation resistance and characteristic resistance of the electrical node of the device to be tested, the problems including complicated connection in the traditional product checkout process and errors, time waste and the like caused by manual operation are solved, and the tester has the advantages of being high in reliability and accuracy and saving the time.

Owner:BEIJING AEROSPACE TIMES OPTICAL ELECTRONICS TECH

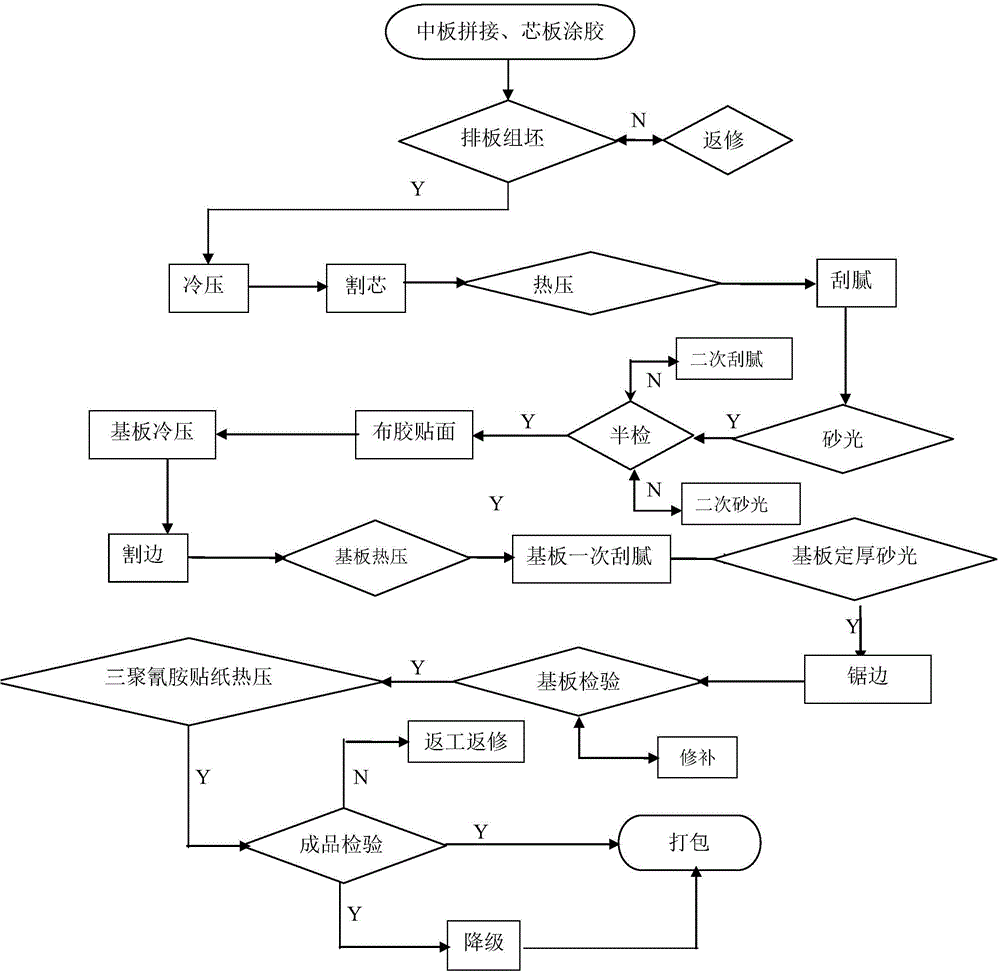

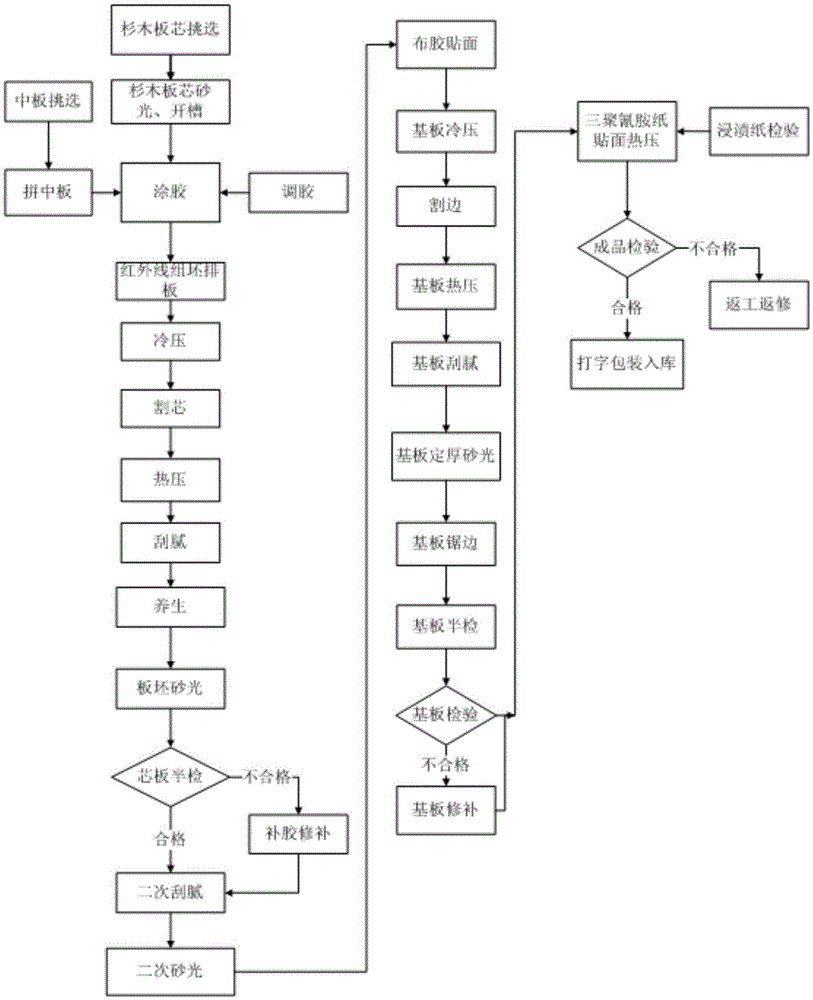

Production technology for melamine ecological plate

ActiveCN104526789ASimple and reasonable colorFlat surfaceOther plywood/veneer working apparatusWood veneer joiningProduct inspectionHeat resistance

The invention relates to a production technology for a melamine ecological plate. The production technology specifically comprises the following steps of (1) middle plate splicing; (2) core plate glue coating; (3) plate arrangement and blank forming; (4) cold pressing; (5) core cutting; (6) hot pressing; (7) putty applying; (8) sanding; (9) semi-inspection; (10) secondary putty applying; (11) secondary sanding; (12) glue coating and face attaching; (13) base plate cold pressing; (14) edge cutting; (15) base plate hot rolling; (16) first-time base plate putty applying; (17) base plate fixed-thickness sanding; (18) edge sawing; (19) base plate inspection; (20) repair; (21) melamine paper attaching and hot pressing; (22) finished product inspection and packaging. Compared with the prior art, melamine impregnated paper is directly pressed and attached to the surface of a base plate, the technology is simple and reasonable, various patterns can be imitated on the melamine ecological plate processed through the technology, the melamine ecological plate is bright in color, smooth in surface, wide in application range, high in hardness, resistant to abrasion, good in heat resistance, capable of resisting the corrosion of common solvents, economical and environmentally friendly.

Owner:ZHEJIANG SHENGHUA YUNFENG GREENEO

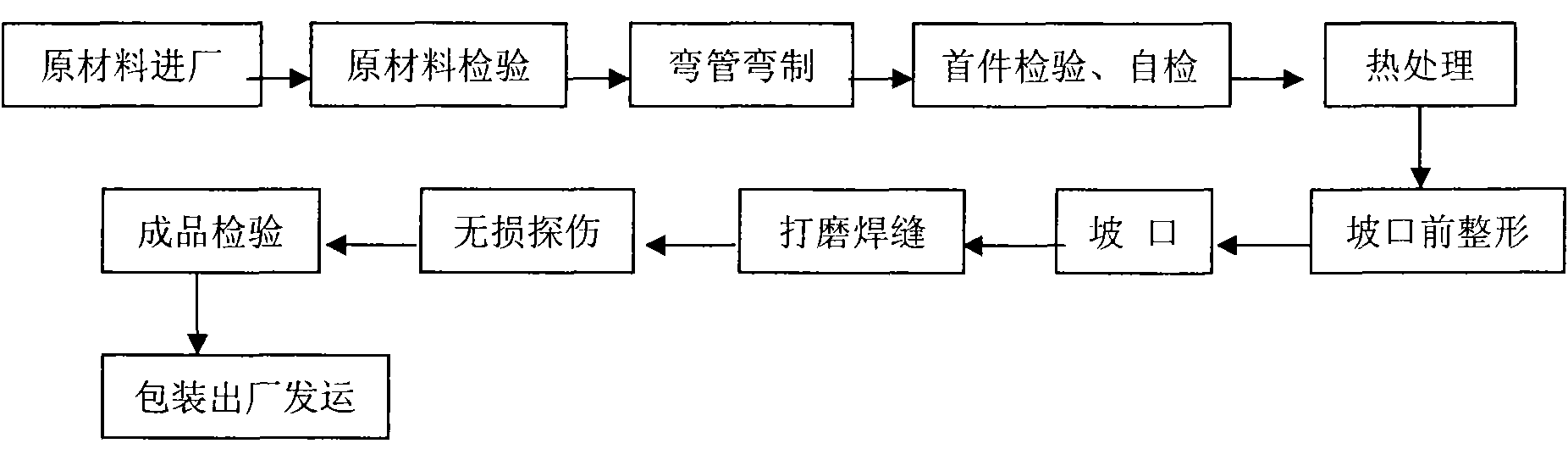

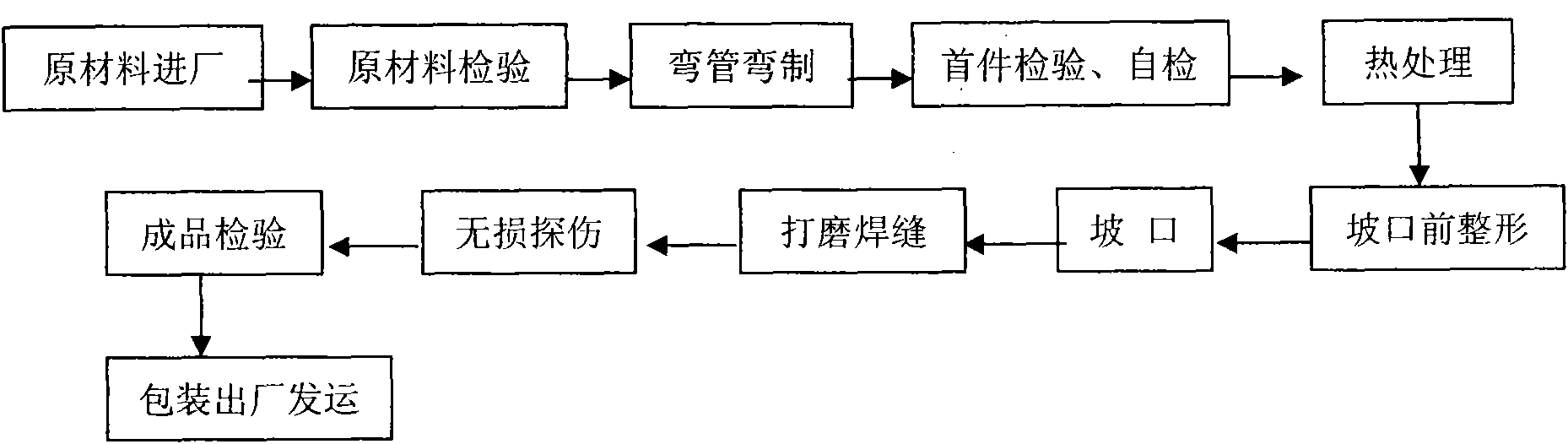

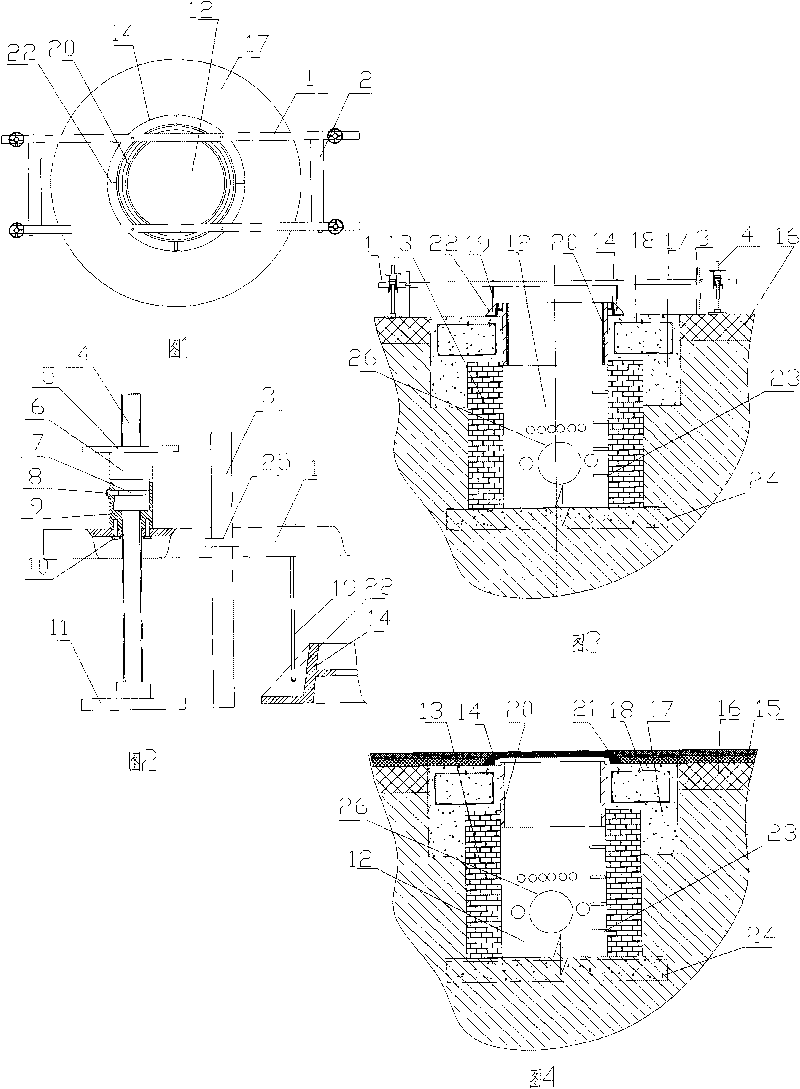

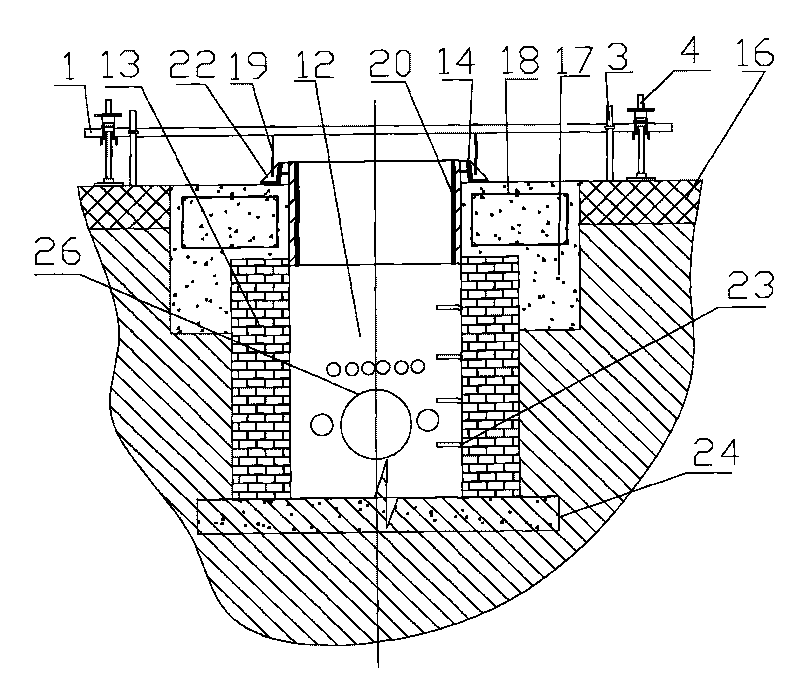

Method for producing hot-bending elbow

The invention discloses a method for producing a hot-bending elbow, and relates to the technical field of treatment of metal pipes and piping systems. The method comprises the following steps: purchasing raw materials, and storing; inspecting the raw materials; bending to obtain the elbow; carrying out first sample inspection and self-inspection; heat-treating; shaping before beveling; beveling; grinding welding seams; carrying out nondestructive inspection; carrying out product inspection; and packing, and sending the finished products out of the factory. From purchasing the raw materials to sending the finished products out of the factory, the invention specifies a complete and strict technological process. Thus, the invention has the advantages of safe production process, high speed, controllability and stable quality, and is a refined method for producing hot-bending elbows.

Owner:CHINA PETROLEUM PIPELINE BUREAU +1

Concrete integral pouring construction method and device for road inspection well

InactiveCN101718101APrevent slippingResistance to the effects of horizontal thrustArtificial islandsUnderwater structuresProduct inspectionReinforced concrete

The invention provides concrete integral pouring construction method and device for a road inspection well. The method comprises advance constructions and post constructions, wherein the advance constructions comprise the following steps of: measuring and paying off; excavating a wellhole; pouring a reinforced concrete foundation bottom and building a wellhole protection wall; connecting pipelines; building a well chamber; mounting a tread; backfilling well perimeters; reserving a branch pipe; building a close up section; mounting a cover plate; building the wellhole; covering and protecting; backfilling cement and stone dust to the well perimeters; and constructing a pavement basic layer. The post constructions comprise the following steps of: excavating the pavement basic layer covered on the wellhole to expose the wellhole, dismantling the cover plate and excavating a concrete foundation pit by using the wellhole as a center, wherein the radius of the excavated foundation pit two times larger than or equal to that of the wellhole; laying reinforcing steel bars in the foundation pit and supporting an inner mold in the wellhole; overhanging a well cover on the wellhole by a fixing bracket overhanging device; adjusting the altitude of the well cover; pouring concrete into the foundation pit and keeping the height of the concrete parallel to the bottom of the well cover; building the perimeters of the well cover into a cement slope by concrete; carrying out acceptance checks; paving a bituminous pavement on the perimeters of the well cover and keeping the bituminous pavement parallel to the well cover.

Owner:JINAN URBAN CONSTR GRP

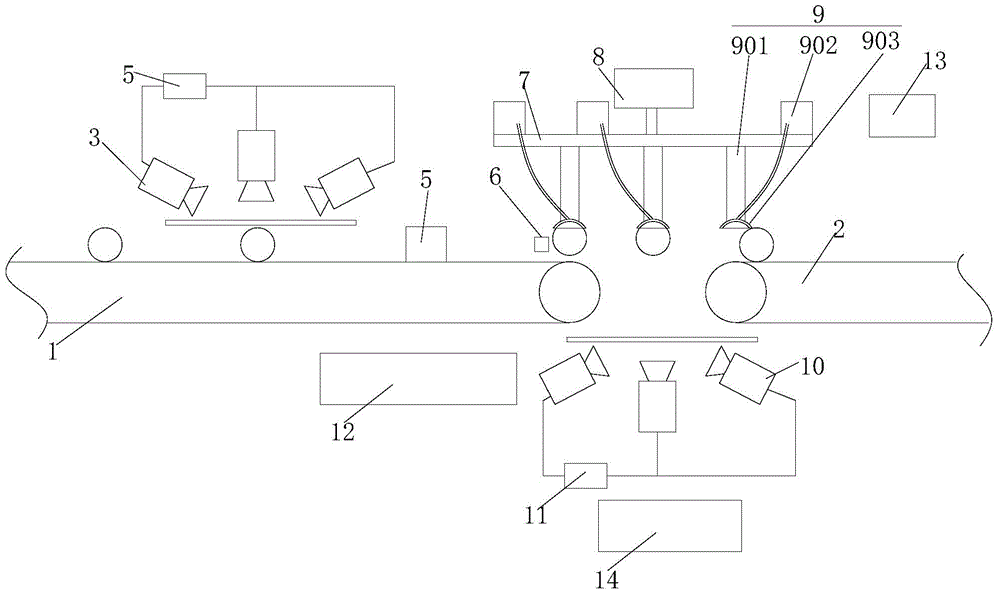

Vision inspection device for appearance defects of rollers

ActiveCN104889075ARealize visual inspectionHigh precisionOptically investigating flaws/contaminationSortingProduct inspectionVision inspection

The invention discloses a vision inspection device for appearance defects of rollers, and relates to the technical field of vision inspection devices. The device comprises a first conveying belt, a second conveying belt, a first image device, a first image processing system and a first inferior-quality product removing device and further comprises a rotating disc, a rotating disc driving device, roller sucking devices, a second image capturing device and a second image processing system. The first conveying belt conveys rollers to be inspected, the second conveying belt conveys qualified rollers, and the first image capturing device, the first image processing system and the first inferior-quality product removing device inspect the appearance defects of the upper sides of the rollers and remove unqualified inferior-quality products; and the rotating disc, the rotating disc driving device, the roller sucking devices, the second image capturing device and the second image processing system are used for inspecting the appearance defects of the lower sides of the rollers and remove the unqualified inferior-quality products. Vision inspection can be comprehensively carried out on the rollers in a no-dead-corner manner, and meanwhile, the unqualified inferior-quality products are removed; and automation and intelligence of the whole process are achieved, and precision and efficiency of roller inferior-quality product inspection can be improved.

Owner:临清市万达轴承有限公司

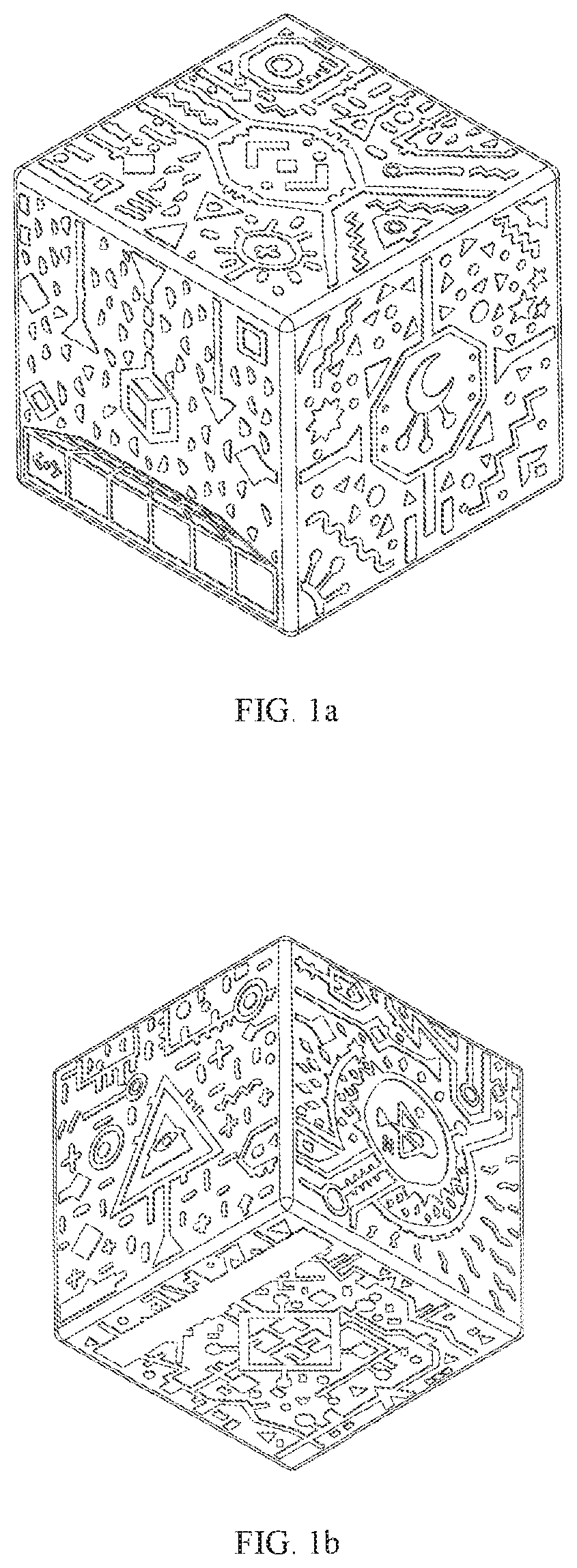

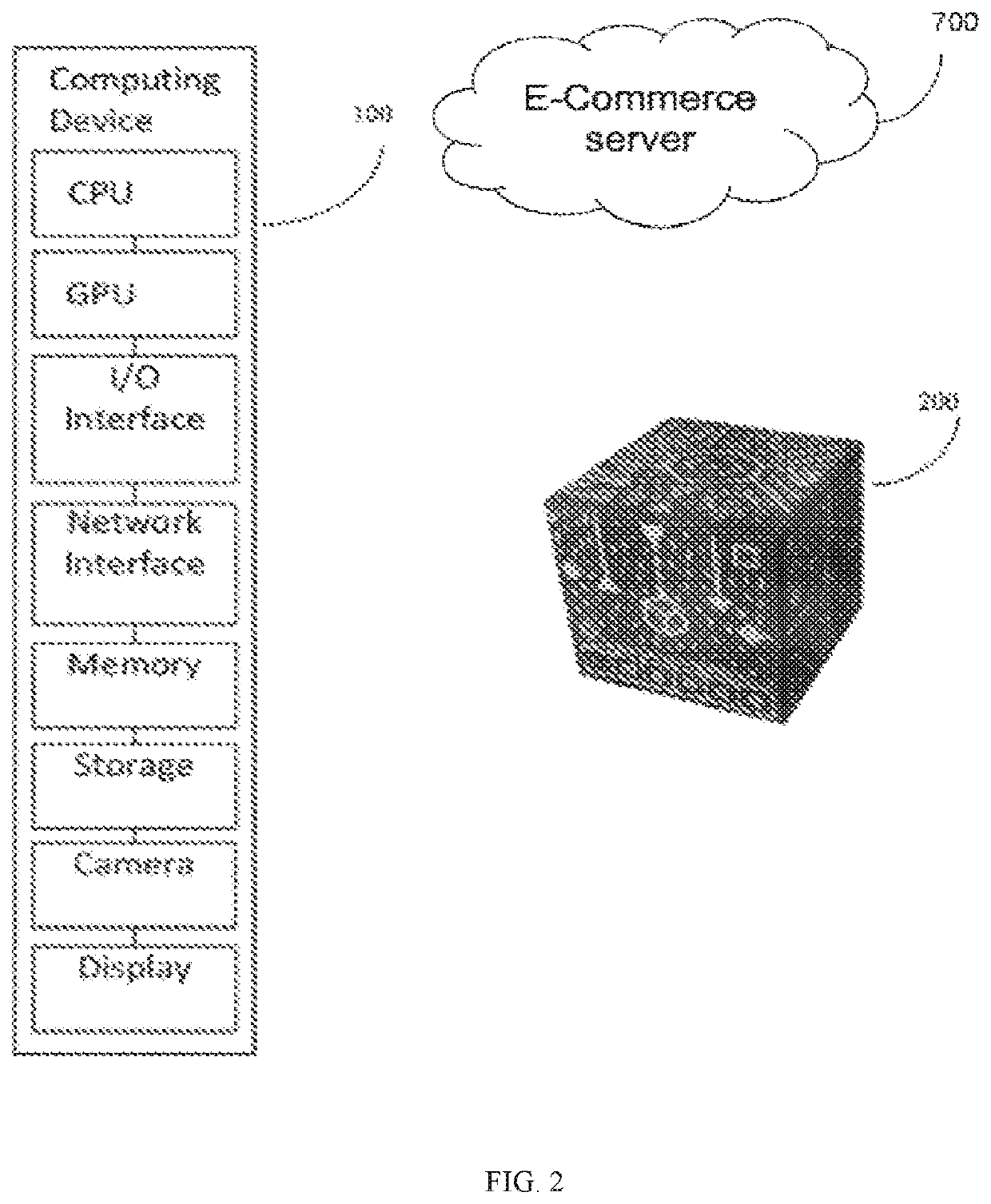

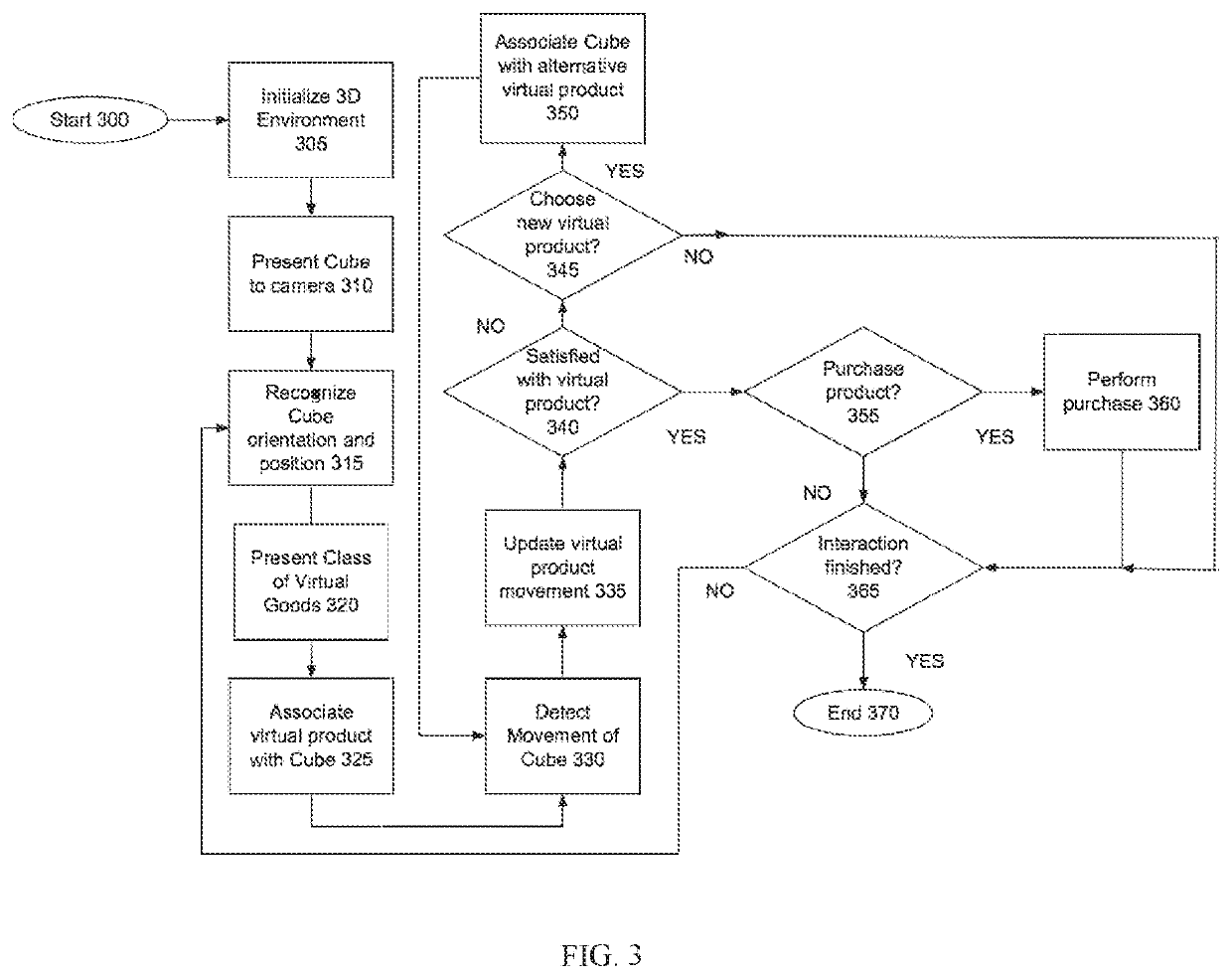

Virtual product inspection system using trackable three-dimensional object

InactiveUS20200020024A1Input/output for user-computer interactionBuying/selling/leasing transactionsProduct inspectionComputer graphics (images)

A system and method for viewing and inspecting a virtual item for purchase including a handheld trackable three-dimensional physical object for use with an augmented reality application providing a shopper with a life-sized, handheld virtual product allowing the shopper to interact with the virtual product in a natural way by manipulating the physical handheld item.

Owner:MERGE LABS

Manufacturing process of raw bamboo furniture

InactiveCN103659999AConsistent moisturePut an end to the hidden danger of mildewWood working apparatusProduct inspectionCarbonization

The invention discloses a manufacturing process of raw bamboo furniture. The manufacturing process includes the following steps: selecting bamboos, breaking though bamboo joints, conducting carbonization and stewing, straightening, polishing, conducting purification with water, wiping to be dry, conducting stoving at the low temperature, conducting molding machining, polishing and assembling, conducting semi-finished product detection, conducting ash removal on semi-finished products, coating the semi-finished products with sealing agents, polishing, priming for the first time, polishing, priming for the second time, polishing, conducting antique finishing, conducting coloring, embellishing colors, polishing, coating the products with finishing paints, conducting finished product inspection and conducting packaging and bank storage. According to the manufacturing process, raw bamboos serve as raw materials, the manufactured raw bamboo furniture is firm, durable, environmentally friendly and low in carbon, and has the industrial art performance and the naturality, and the manufacturing process is mainly used for manufacturing artware, the raw bamboo furniture and the like.

Owner:WUXUE XINGZHANG BAMBOO PROD CO LTD

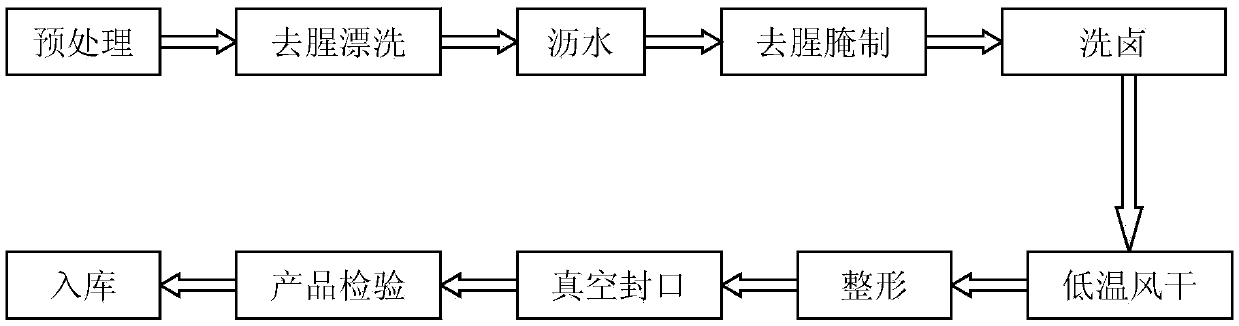

Method for producing de-fishy low-salt half-dry freshwater fish

InactiveCN105361001AReduce the degree of oxidationPreserve meat qualityFood dryingFood ingredient for microbe protectionProduct inspectionEvaporation

Owner:WUHAN RES INST OF FISHERIES SCI +1

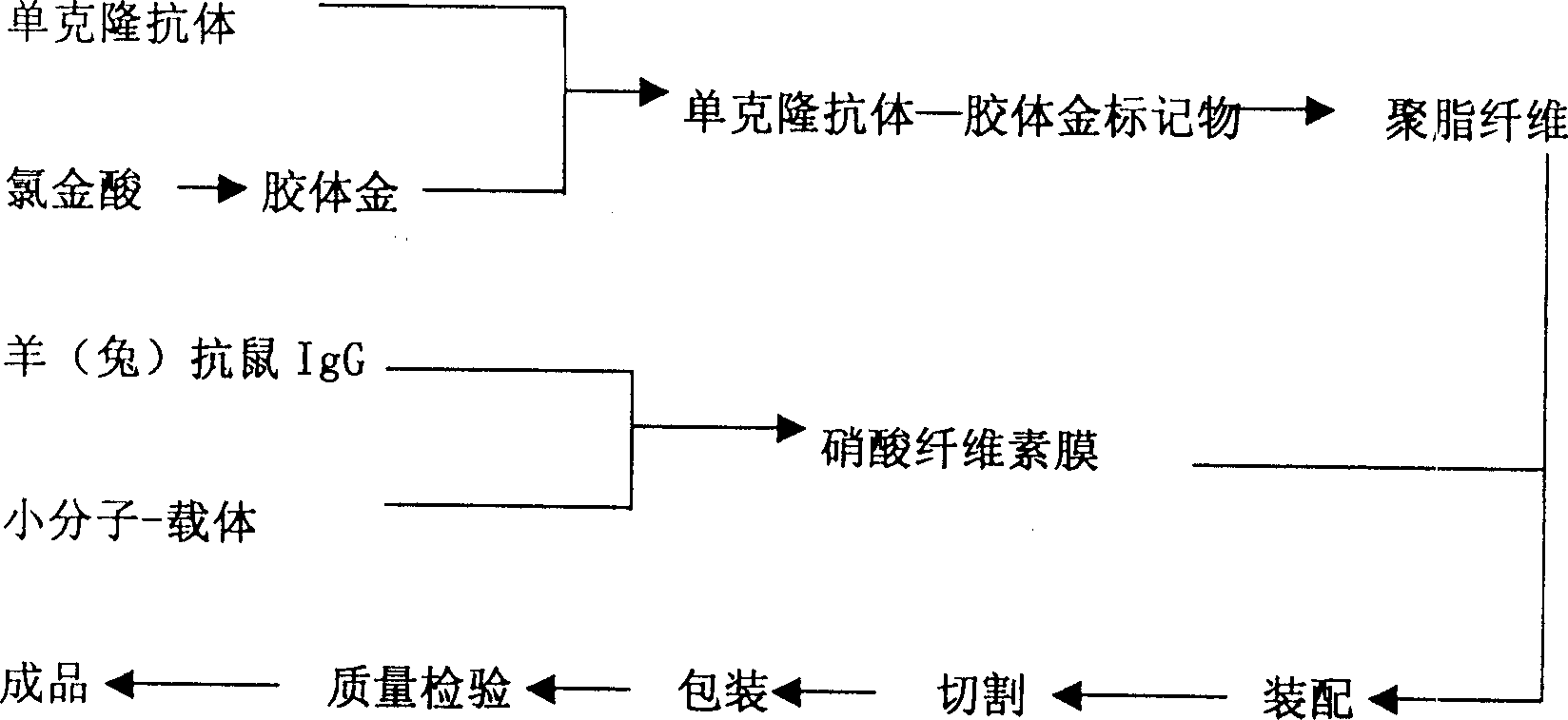

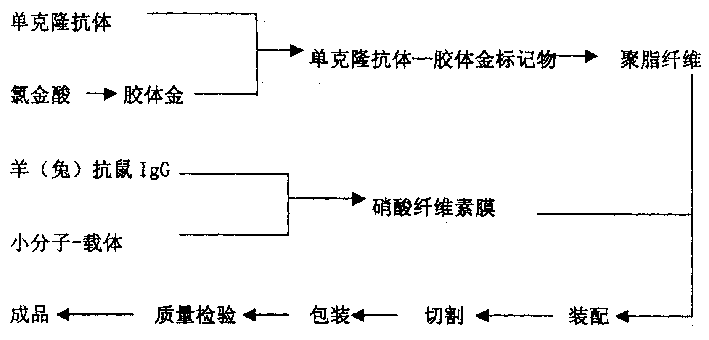

Use of colloidal gold immunological chromatography in detection of aquatic, agricutural and livestock products

InactiveCN1409113AStrong specificityIncreased sensitivityBiological testingProduct inspectionAquatic product

A colloidal gold immunity chromatograph to be used for the inspection of aquatic product, agricultural product and livestock product belongs to the technical field of biological medicine. The presentinvention with high sensitiivty and high specificity and be widely used in the departments of inspection and epidemic prevention to overcome the problems such as short of inspecting means and limitation by the conditions existed in the product inspection for the quatic, and livestock agricultural prdoucts.

Owner:张少恩

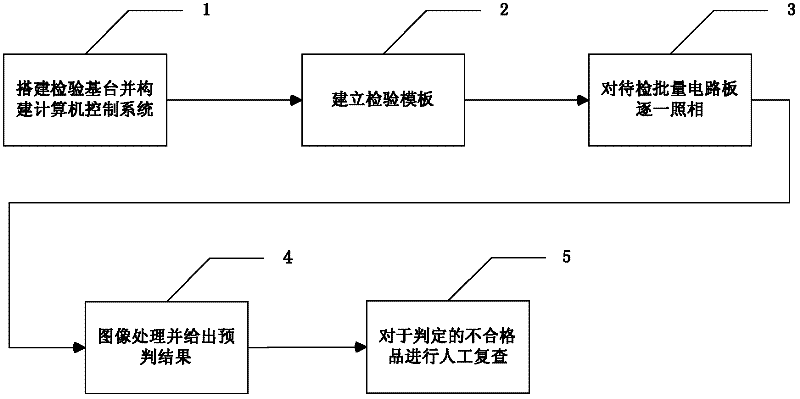

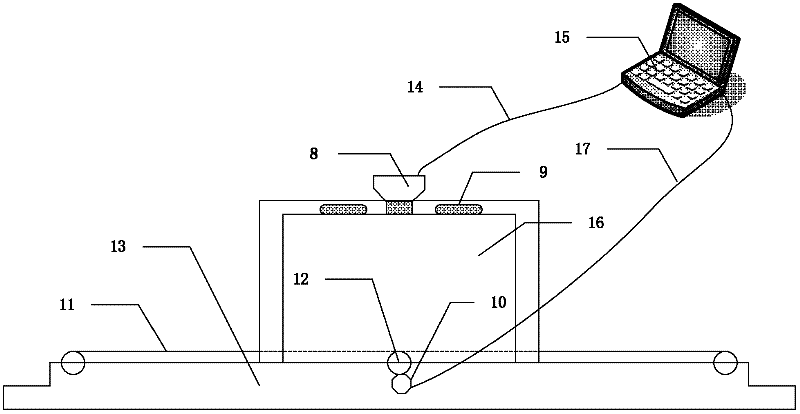

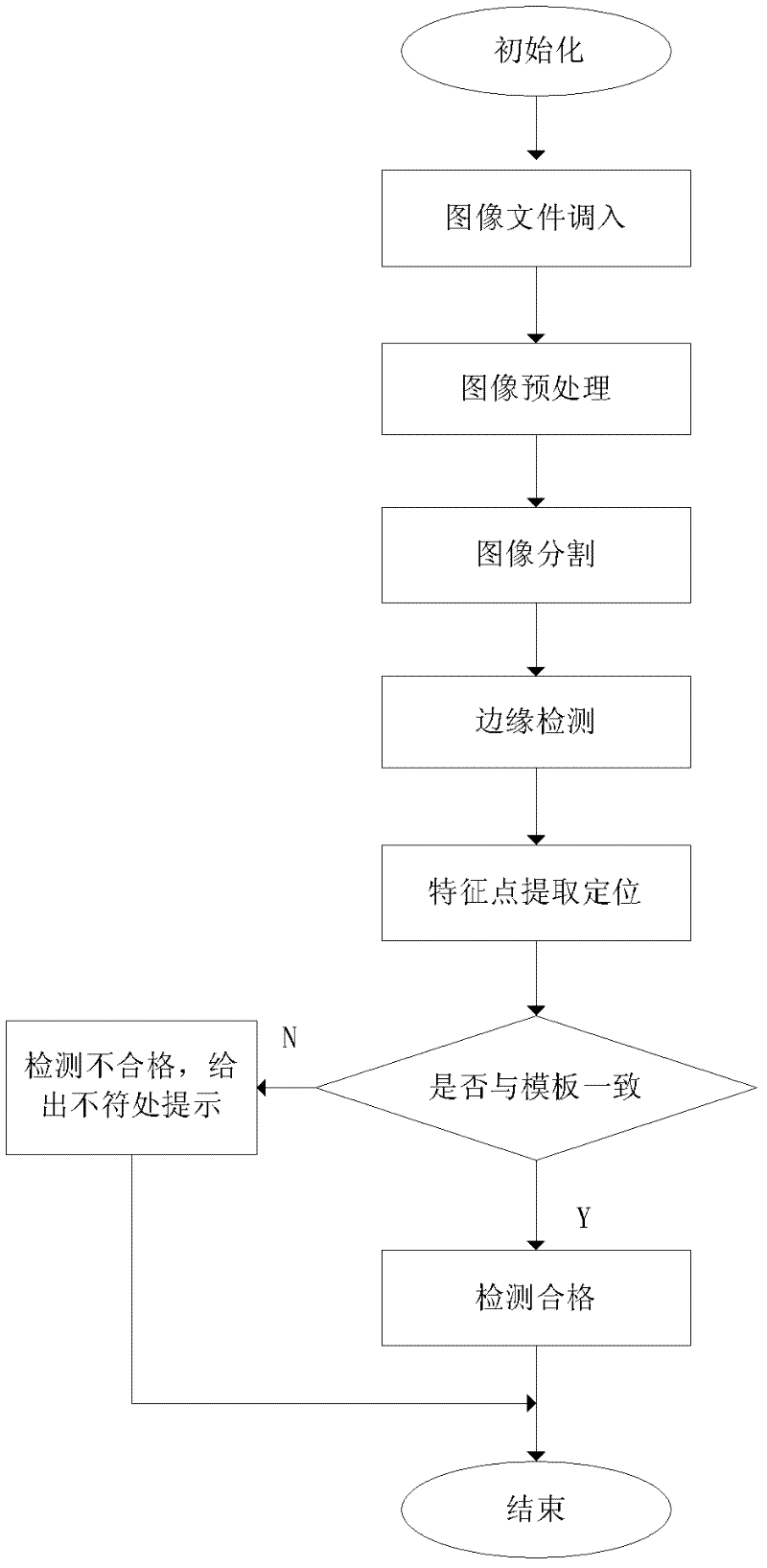

Inspection method for inspecting welding correctness of the device of device on circuit board in batch

InactiveCN102539441ASolve efficiency problemsSolve the problem that is prone to missed detectionOptically investigating flaws/contaminationComputer control systemProduct inspection

The invention provides an inspection method for inspecting the welding correctness of a device on a circuit board in batch, and belongs to the inspection method for inspecting the welding correctness of the device on the circuit board in batch, related in the technical field of photoelectric detection. The inspection method aims at solving the technical problem to provide the inspection method for inspecting the welding correctness of the device on the circuit board in batch. In order to solve the problems, the inspection method adopts the technical scheme that an inspection base platform is built, a computer control system is constructed, an inspection template is built, circuit board to be inspected in batch are subjected to photo taking and image processing one by one, in addition, pre-judging results are given out, and the manual re-checking is carried out on the judged unqualified products. The photo taking and image processing technology is utilized in the method. Compared with the manual inspection, the method has the advantages that the inspection accuracy is high, the inspection efficiency is high, the fast inspection of the circuit board in batch can be realized, the work intensity of inspectors is reduced, the inspection efficiency is improved, and the product inspection period is shortened.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

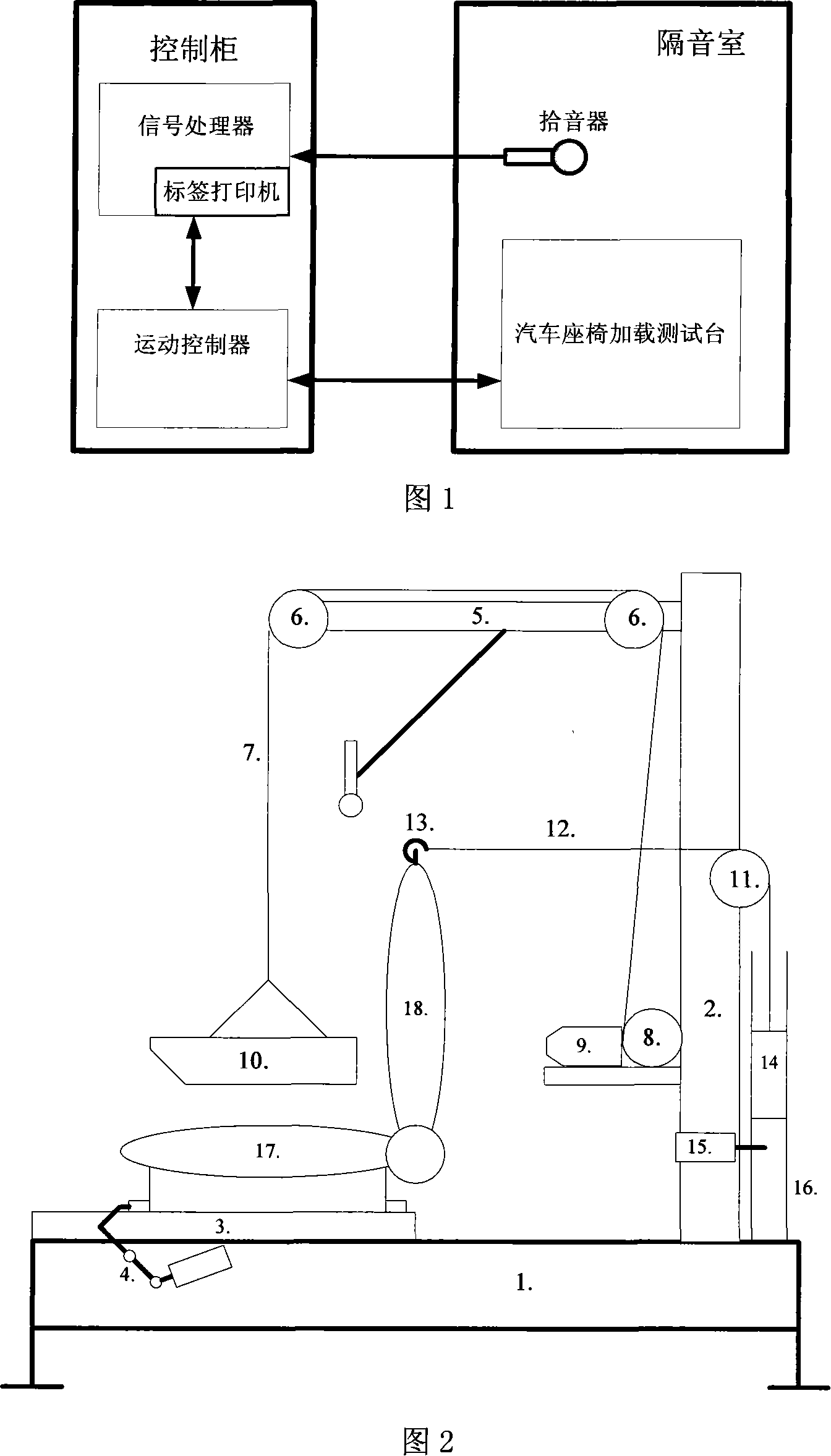

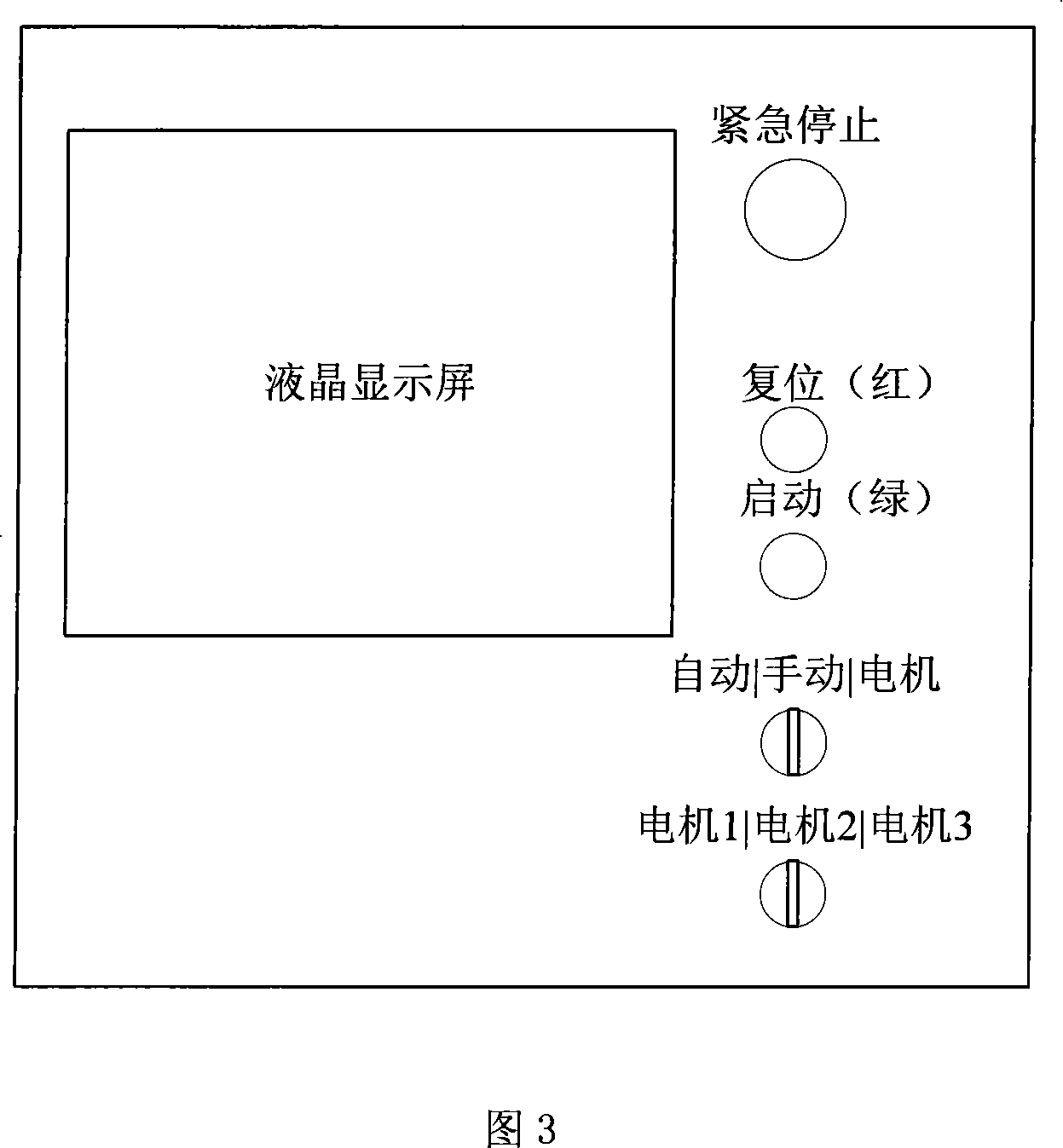

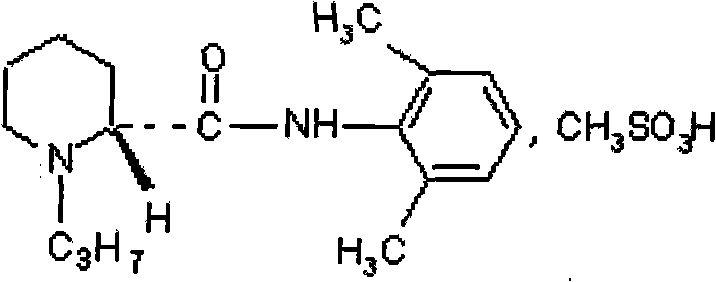

Automobile electric chair noise and motor current detection device

InactiveCN101149310AAccurate detectionHigh degree of automationVehicle testingSubsonic/sonic/ultrasonic wave measurementProduct inspectionElectric machine

A detection device for the noise and current of automobile electric seat includes the automobile seat loading test table, sport controller, sensor and signal processor. The automobile seat loading test table and sensors are set in the isolation booth; the sport controller and signal processor are set in the controlling ark out of the isolation booth. The system can fix the automobile seat automatically and load the simulating human load, controls each electric engine run and detect the noise and electric engine current to judge if it meets the request and print the product test table. The character of invention is high automatization, standardization and accuracy measurement. The whole detection process is finished automatically; the each test load is identical with the action journey and accord with the detection condition. It detects the current and noise precisely and remove the artificial subjective factors to meet the request of quality management.

Owner:SHANGHAI JIAO TONG UNIV

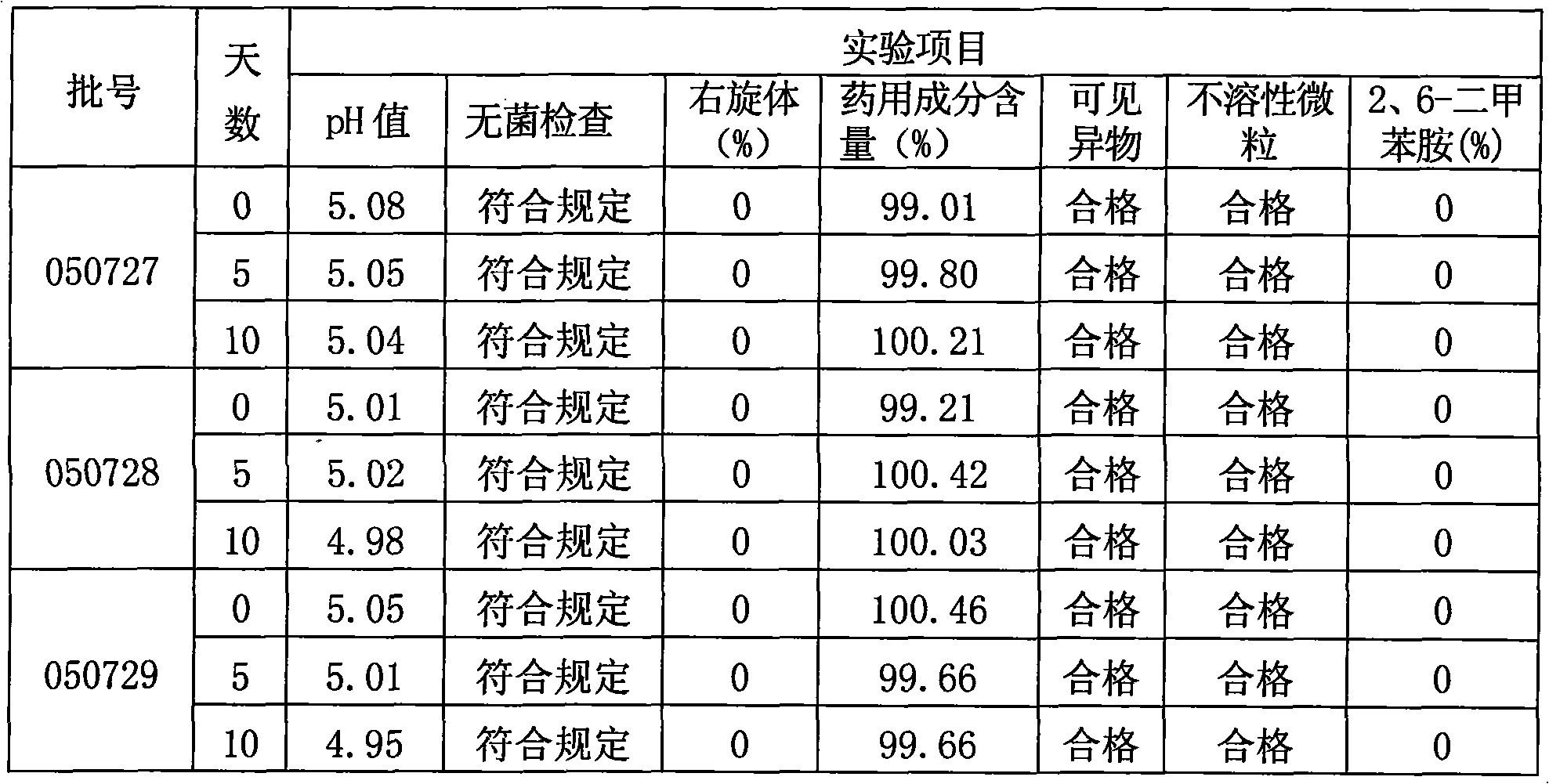

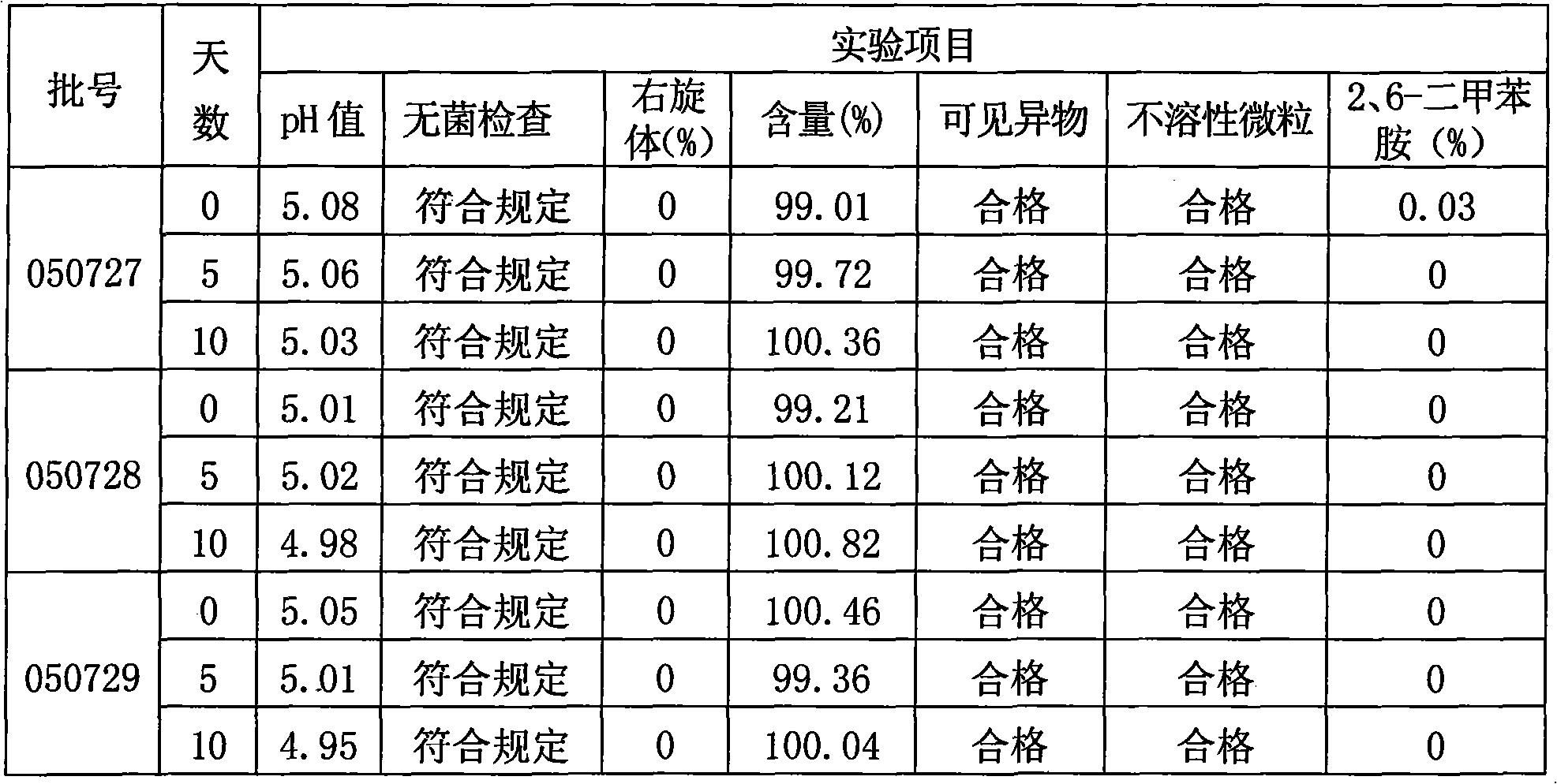

Preparation method of ropivacaine mesylate injection packed by soda-lime glass bottle

InactiveCN101658490AGuaranteed stabilityGood acid and alkali resistanceAmpoule syringesPharmaceutical delivery mechanismFiltrationAdditive ingredient

The invention relates to a preparation method of ropivacaine mesylate injection packed by a soda-lime glass bottle, which comprises the following processing steps of ingredient preparation, liquor preparation, soda-lime glass bottle and rubber plug cleaning, filling, capping, sterilization, lamp test, labeling, packing and finished product inspection. The injection is subject to a filtration sterilization processing step once and a flowing steam sterilization processing step once, wherein microorganisms larger than 0.22 microns in liquid medicine are removed by a filter method, microorganismssmaller than 0.22 microns are killed by flowing steam sterilization, and insoluble particles in the liquid medicine are removed during filtration sterilization simultaneously, thereby greatly reducingthe occurrence of phlebitis; and the invention is packed by the soda-lime glass bottle which has the advantages of heat resistance, acid and alkali resistance, large strength, and the like, thereby ensuring the stability of the medicine. Clinic comparison tests show that the ropivacaine mesylate injection packed by a soda-lime glass bottle has the advantages of quicker effect, long action time, reliable anesthetic effect, small toxicity to heart, separate blocking pf sensory and motor nerves, and the like, thereby being suitable for anesthesia in surgeries and postoperative analgesia.

Owner:陕西吉尾斯美业有限公司

TR cloth desizing refining and dispersed dyeing-bath dyeing production method

ActiveCN104213349ALittle power lossShade effect is smallSingeingDyeing processDisperse dyeProduct inspection

The invention provides a dyeing method, and particularly relates to a TR cloth desizing refining and dispersed dyeing-bath dyeing production method. The method is performed according to the following steps comprising sample cloth selection, blank cloth pre-shaping, white cloth singeing, compound auxiliary agent recipe design, preparation and dosage determining, dyeing recipe design, piece cloth jar dyeing, drying and shaping, color cloth singeing, water washing and drying, oiling and shaping, after finishing calendaring, after finishing decator steaming and finished product inspection. The TR cloth desizing refining and dispersed dyeing-bath dyeing production method has the advantages that the energy-saving and emission reduction effects are obvious, in addition, the hand feeling of fabrics after the production and the processing is soft, full color and luster can be realized, and the like. Various internal indexes such as the quality can meet requirements of different customers.

Owner:ZHEJIANG HANGMIN STOCK

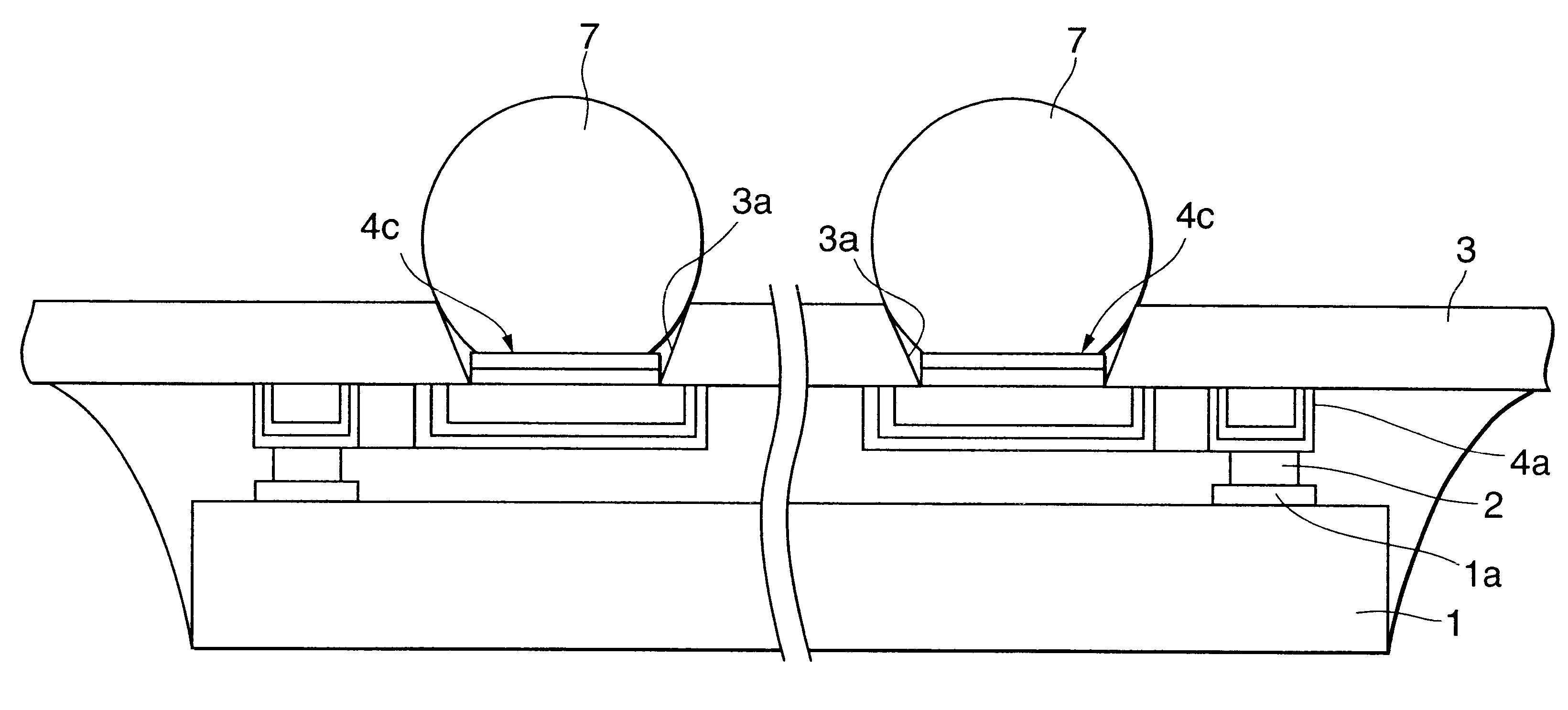

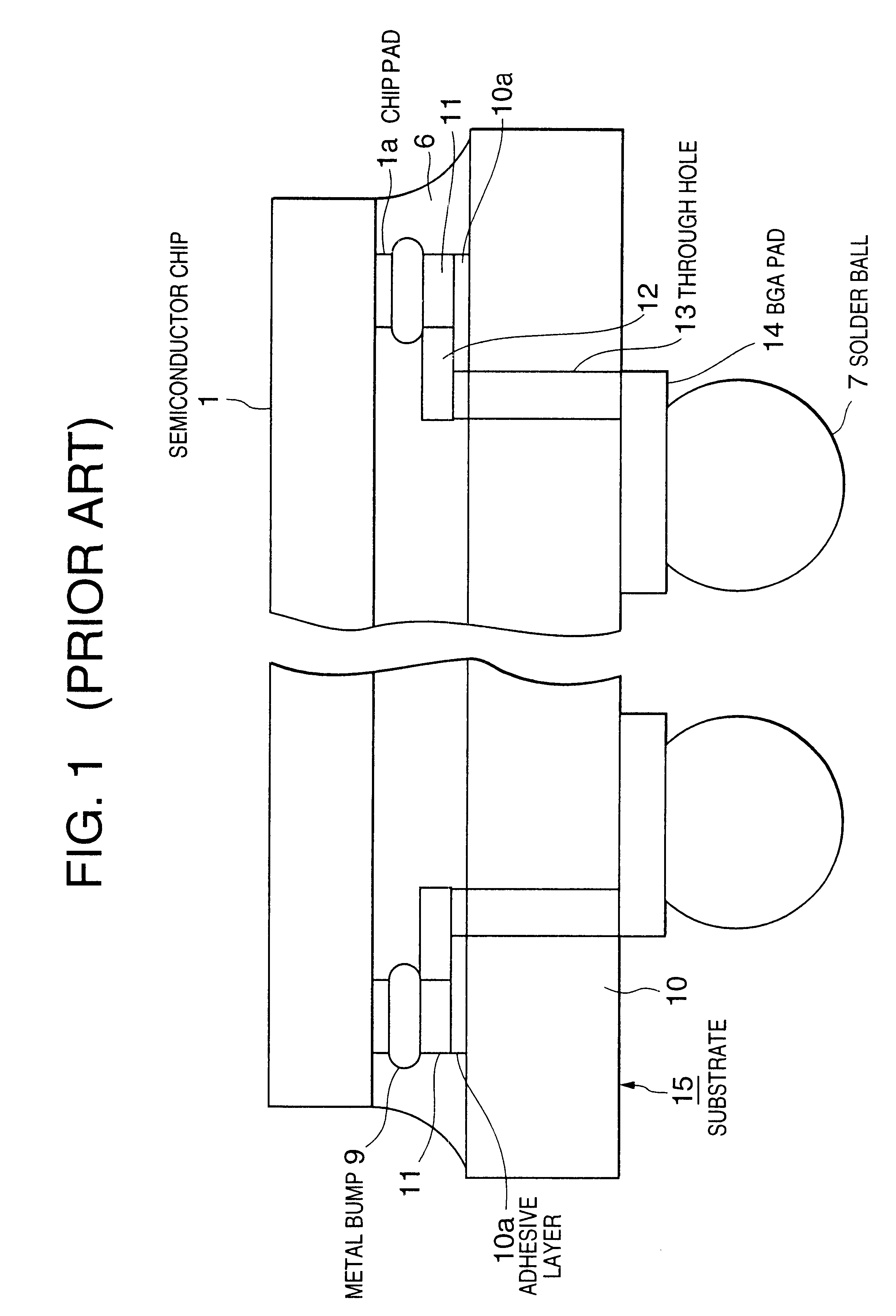

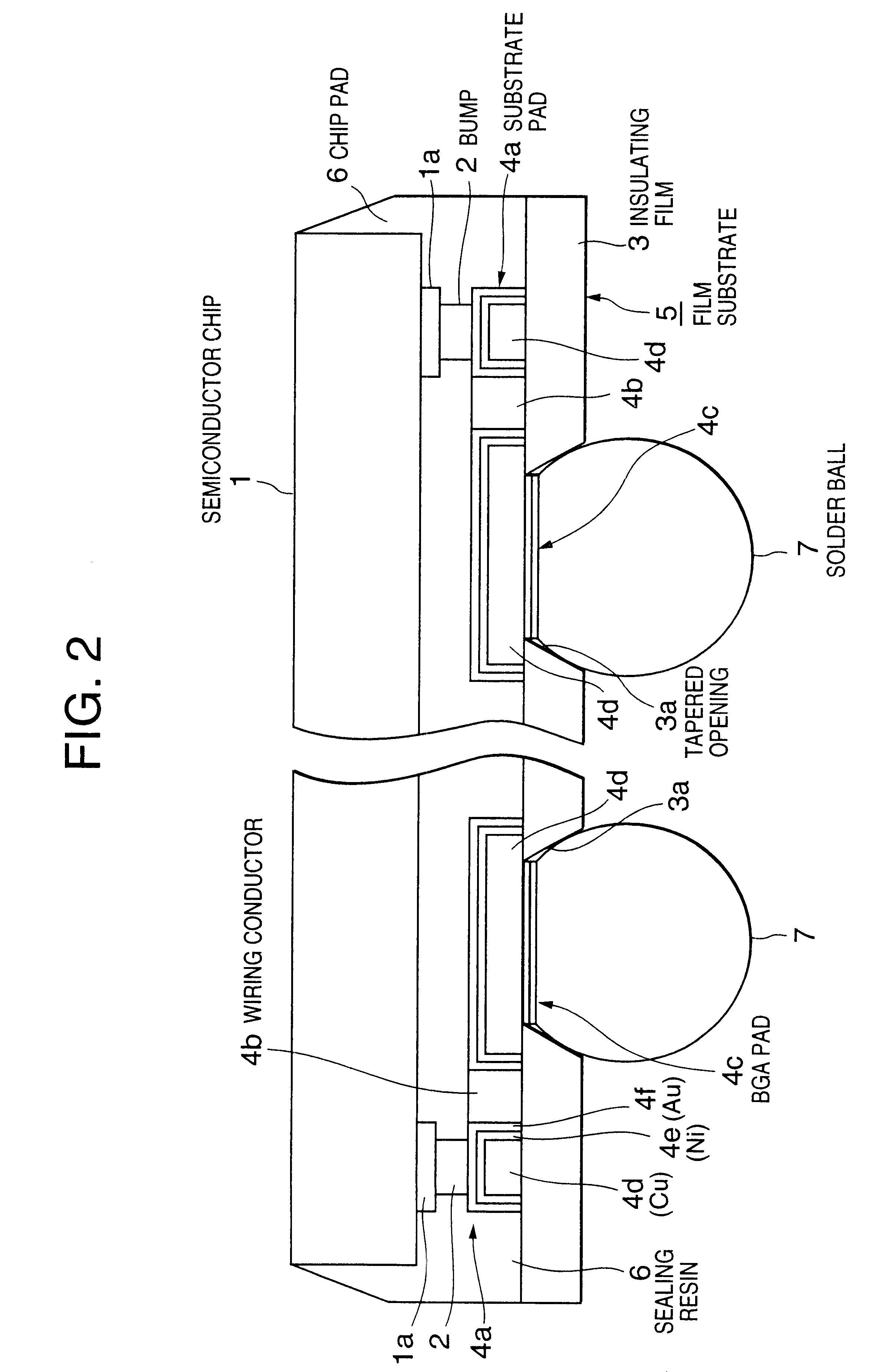

Semiconductor device

InactiveUS6400034B1Semiconductor/solid-state device detailsSolid-state devicesProduct inspectionDevice material

A semiconductor device allowing a finer terminal pitch, a low profile, and easy product inspection is disclosed. A semiconductor device includes a semiconductor chip and a film substrate having the semiconductor chip connected thereon. The film substrate includes an insulating film having a plurality of openings formed in a desired pattern and a wiring layer formed in a chip-connecting surface of the insulating film. Solder balls are each directly bonded to the external connection pads through the openings. The wiring layer includes substrate pads each being connected to the chip pads of the semiconductor chip, and external connection pads each being electrically connected to these substrate pads. The external connection pads are each formed over the openings so that the openings are covered with the external connection pads on the chip-connecting surface of the insulating film, respectively.

Owner:RENESAS ELECTRONICS CORP

Sapphire mobile phone panel processing method

InactiveCN104088017AHigh hardnessHigh light transmittancePolycrystalline material growthAfter-treatment detailsStress concentrationWafer dicing

The invention discloses a sapphire mobile phone panel processing method. The process consists of material preparation, cutting, chamfering, rough grinding, annealing, DMP, CMP (chemical mechanical polishing), cleaning, coating, screen printing and finished product inspection, wherein in the step 1 of cutting, a crystal block is sliced to facilitate follow-up processing; in the step 2 of chamfering, the wafer edge is trimmed into an arc shape to improve the mechanical strength of the sheet edge and avoid stress concentration and consequent defect; in the step 3 of rough grinding, a wafer cutting damage layer caused by slicing is removed, and the flatness of the wafer is improved; in the step 4 of annealing, the stress concentration and large BOW caused by mechanical processing are improved; in the step 5 of DMP, the damage layer caused by rough grinding is improved, and the surface roughness of the wafer is reduced; in the step 6 of CMP, the wafer roughness is improved so that the surface reaches the nanoscale precision; in the step 7 of coating, the wafer is subjected to anti-fingerprint coating treatment; and in the step 8 of screen printing, the single side of the wafer is subjected to screen printing treatment to enhance light absorption. By adopting the method, a sapphire mobile phone panel without damage layer on surface and with nanoscale roughness can be obtained; moreover, the preparation period is greatly shortened, the production cost is saved, and the labor productivity is improved.

Owner:CHANGZHOU C PE PHOTO ELECTRICITY SCI & TECHN

Manufacturing method for rolling titanium-steel composite plate

InactiveCN104138903AAvoid recombinationGuarantee normal productionMetal rolling arrangementsOxygenComposite plate

The invention provides a manufacturing method for rolling a titanium-steel composite plate. A high-performance composite plate can be obtained through the steps of make-to-order conversion, basic shroud plate surface treatment, blank assembling, blank welding, vacuum pumping, heating (by a car bottom furnace, a pit type soaking furnace or a bell type furnace), descaling, rolling, straightening, plate separating, finishing, product inspection, surface treatment, packaging, goods delivering and the like. By adopting a composite blank making and vacuum pumping mode, a shroud plate is enabled to be in a sealed oxygen-free environment, a cladding steel plate can be protected to the maximum, and the cladding steel plate can be prevented from being subjected to high-temperature oxidation; by adopting the car bottom furnace, the pit type soaking furnace or the bell type furnace, the defect that the heating temperature of a steel pushing type or walking beam furnace is difficult to control can be avoided, the temperature control accuracy is higher, a titanium plate is enabled to be always rolled in an alpha phase region, and the composite quality and the surface quality are ensured; due to an innovated blank assembling, heating and rolling technology, the whole rolling preparation of a high-combination strength titanium / steel composite plate is realized, the online control on performance is realized, a follow-up thermal treatment technology is avoided, and the energy consumption and the production cost are reduced.

Owner:JIGANG GRP +1

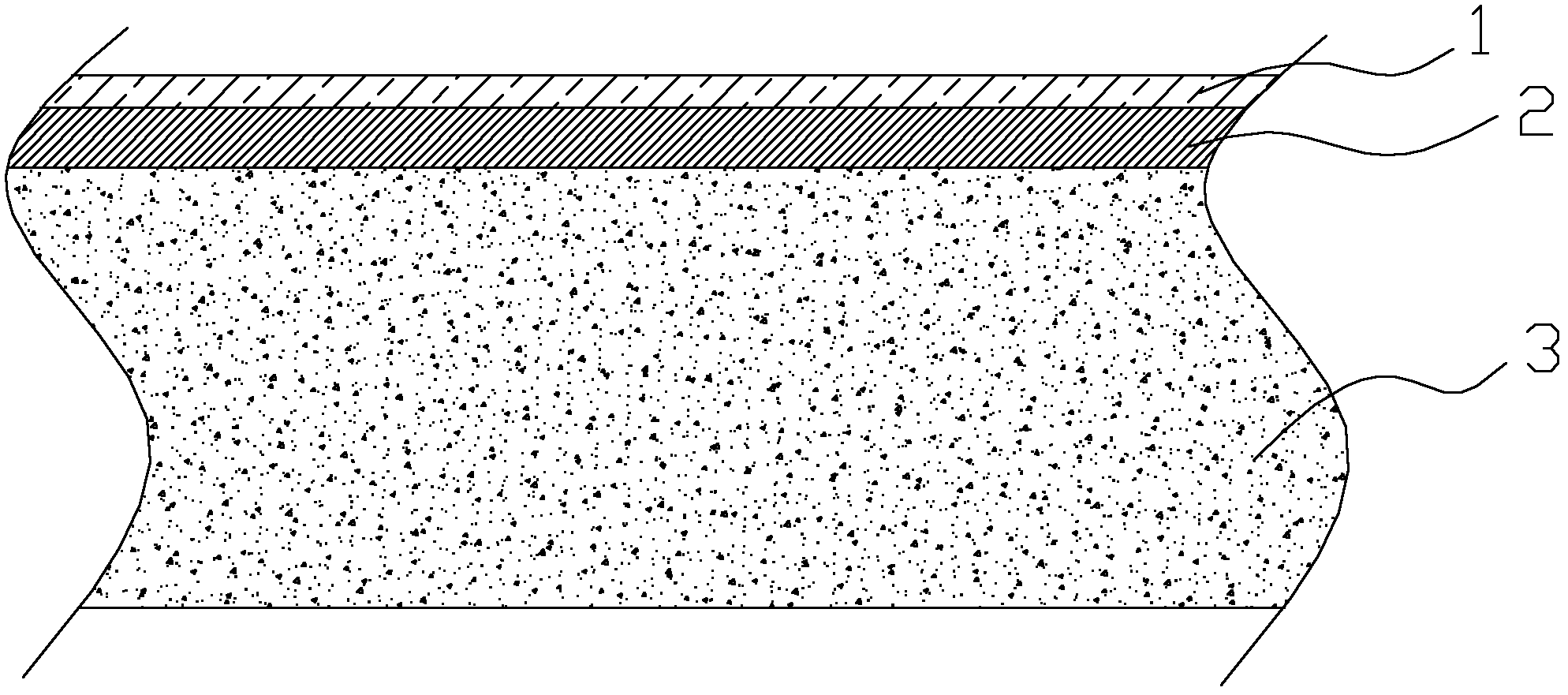

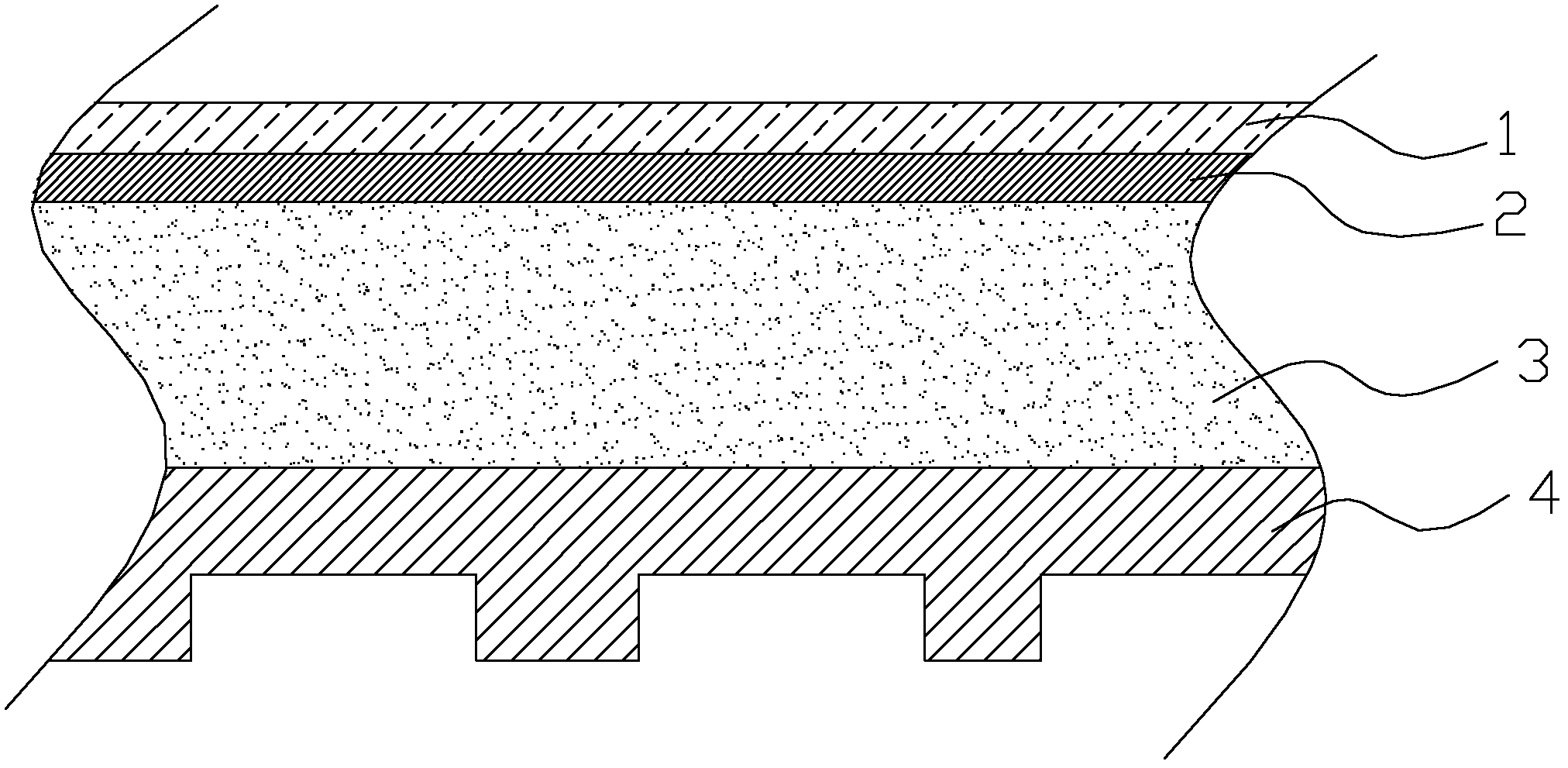

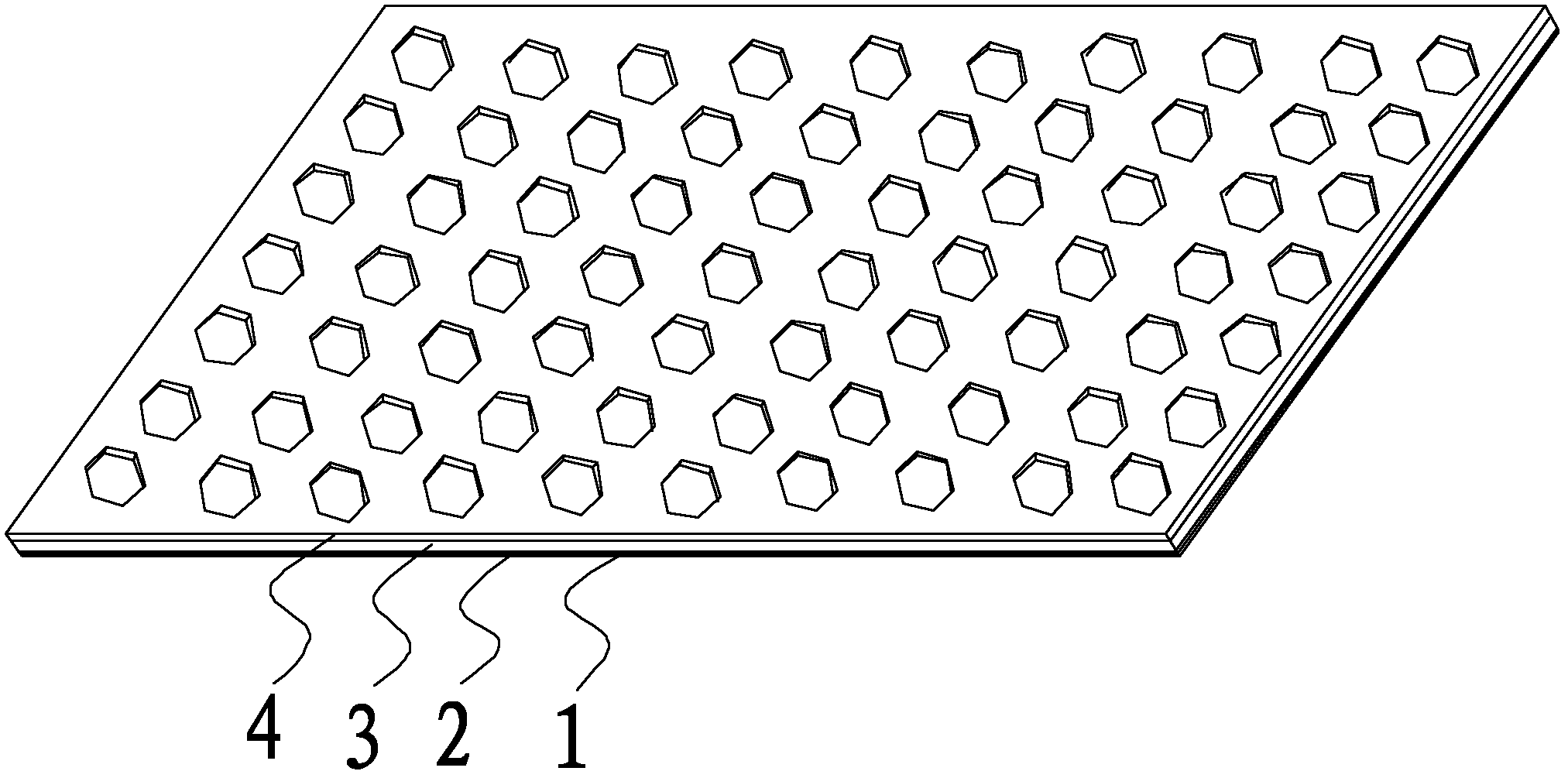

Production process of high-grade fir melamine ecological board

ActiveCN105459221AReduces surface white bloomsReduce defects such as carbonizationOther plywood/veneer working apparatusLaminationInfraredProduct inspection

The invention belongs to the field of board machining and particularly relates to a production process of a high-grade fir melamine ecological board. The process particularly includes the following steps of poplar middle plate selection, poplar middle plate splicing, fir core veneer selection, fir core veneer sanding, fir core veneer slotting, core veneer gluing, infrared ray board arrangement for forming a blank, cold pressing, core cutting, hot pressing, putty application, maintenance, sanding, semi-checking, secondary putty application, secondary sanding, gluing and veneering, base board cold pressing, base board edge cutting, base board hot pressing, base board putty application, base board fixed-thickness sanding, base board edge sawing, base board inspection, repairing, melamine impregnated paper hot pressing and finished product inspection, packaging and warehousing of finished products. The production process has the advantages that fir core veneers are adopted, the hardness, nail-holding ability and static bending strength of the board is improved; eucalyptus middle plates are replaced with poplar middle plates, and the defects that the surface of the finished products is stained and carbonized caused by multiple burrs and scabs on the surfaces of the gum wood are reduced effectively.

Owner:ZHEJIANG SHENGHUA YUNFENG GREENEO

Production method for antistatic Raschel blanket

The invention relates to the field of blanket preparation, and discloses a production method for an antistatic Raschel blanket. The production method comprises the following steps: 1) weaving: carrying out warping, weaving and fine hair cutting on plush yarns and ground yarns sequentially, thereby preparing an antistatic Raschel blanket semi-finished product; 2) carrying out pre-finishing: setting, brushing, lustring and rolling fabric; 3) dyeing and finishing: dyeing the fabric, reducing and cleaning the fabric, neutralizing the fabric with an acetic acid solution, washing the fabric and discharging the fabric out of a cylinder, drying the fabric, ageing the fabric for fixation, carrying out soft and smooth treatment, and re-drying the fabric; 4) carrying out after treatment: drying and setting the fabric, lustring, brushing, ironing and shearing the front surface of the fabric, napping, brushing, lustring, shearing and re-setting the back surface of the fabric, ironing and shearing the front surface of the fabric, ironing and shearing the back surface of the fabric, slitting and stitching the fabric; 5) carrying out finished product inspection, packaging and warehousing. The antistatic Raschel blanket disclosed by the invention has the characteristics of being flexible and straight in naps, good in elasticity, excellent in fabric skin-friendliness, moisture absorption and desorption and gas permeability, and anti-static.

Owner:ZHEJIANG TRUELOVE CARPET IND SCI & TECH

Ceramic-plastic floor and processing method thereof

InactiveCN102966231AStrong attachmentHigh attachmentSynthetic resin layered productsFlooringProduct inspectionWear resistant

The invention relates to a floor and discloses a ceramic-plastic floor with an imitative ceramic effect. The ceramic-plastic floor comprises a PVC (polyvinyl chloride) transparent wear-resistant layer, a PVC pattern printing layer and a base material layer which are sequentially stacked from top to bottom. The base material layer is prepared by using the following components in parts by weight: 100 parts of PVC resin, 10-25 parts of plasticizer, 2.0-5.0 parts of stabilizer, 35-55 parts of microsphere powder, 80-100 parts of stone powder, 0.5-2.0 parts of rosin and a proper amount of coloring agent. The invention additionally discloses a processing method of the ceramic-plastic floor. The ceramic-plastic floor comprises the following processing steps of: 1) base material layer processing; 2) pattern printing; 3) hot-press molding; 4) surface treatment; 5) heat treatment; and 6) finished product inspection and packaging. The ceramic-plastic floor provided by the invention has the advantages of small shrinkage distortion, easiness in processing, good fireproof and damp-proof performance, simplicity and convenience in assembling, environmental friendliness, higher impact strength, higher bending strength and the like.

Owner:SHENZHEN JIANCHEN INDAL

CSP production process of steel for automobile crossbeam

ActiveCN1974823ALow costEasy stability controlTemperature control deviceWork treatment devicesProduct inspectionChemical composition

The production process of SCP for automobile crossbeam includes the steps of converter smelting, LF refining, continuous casting and rolling, coiling and product inspection. The steel of SCP for automobile crossbeam consists of C 0.16-0.20 wt%, Si 0.3-0.5 wt%, Mn 1.3-1.5 wt%, P not more than 0.015 wt%, S not more than 0.010 wt%, Ti 0.01-0.03 wt%, Als 0.020-0.035 wt%, N not more than 65 PPm. Compared with available technology, the present invention has the advantages of relatively low alloy content in the steel, easy control of the chemical comprise, short production process and low production cost.

Owner:MAANSHAN IRON & STEEL CO LTD

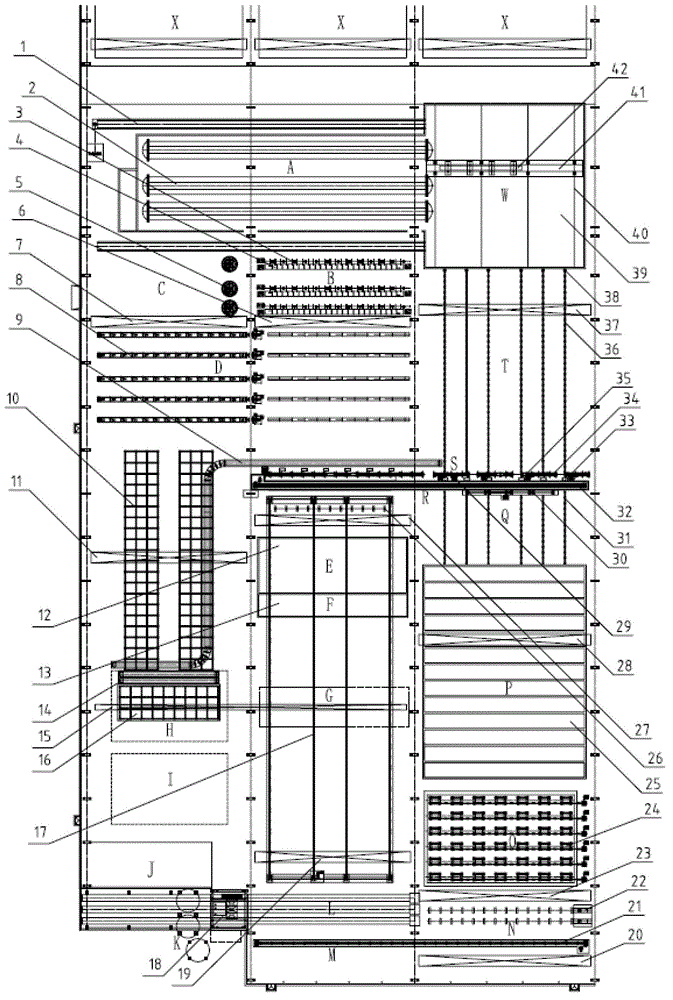

PHC (prestressed concrete pipe pile) pile streamline conveying production line

ActiveCN102744779AEasy to moveReduce incidenceCeramic shaping plantsShaping reinforcementsProduct inspectionProduction line

The invention belongs to a production process of a PHC pile and relates to a PHC pile streamline conveying production line. The production line is characterized by comprising a whole production workshop formed by a left area, a middle area and a right area, wherein from the front part to the back part of the workshop, the left area is sequentially provided with a blending floor, an end plate processing area, a steel reinforcement cage, an end plate assembling area and a steel reinforcement cage roll welding area, the middle area is sequentially provided with a concrete spreading area, a cage loading area, an oil spraying pool, a die-cleaning pool, a die-detaching area, and a steel rod precisely cutting and heading area, and the right area is sequentially provided with a tensioning area, a centrifugal molding area, a steaming area, a pipe pile expanding area, a product inspection and code-spraying identifier area, a to-be-high pressure steamed semi-finished pipe pile storing area and a high pressure kettle-entering transition carriage pit. The production line has the beneficial effects that plane circular arrangement is adopted, and the occurrence rate of accidents is reduced due to the adoption of a stereo lifting technical mode that the upper surface and the lower surface are mutually moved; and due to the adoption of a slope platform and a slope rail, the pipe pile is moved, the distance of carriage movement is greatly shortened, and the energy consumption is reduced.

Owner:TIANJIN PORT & CHANNEL PILE IND

Method and apparatus for mobile quality management inspections

A mobile Quality Management / Control system for performing mobile product inspections is provided. A mobile device, such as a tablet, is configured to communicate with one or more databases and allow for real time entry (and subsequent access) of the details of product inspections for quality control and management purposes. The details of such inspections are maintained and available for all subsequent inspections. The mobile device is further configured to provide inspectors with inspection procedures and / or tutorials associated with the inspections being performed.

Owner:LIFETIME BRANDS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com