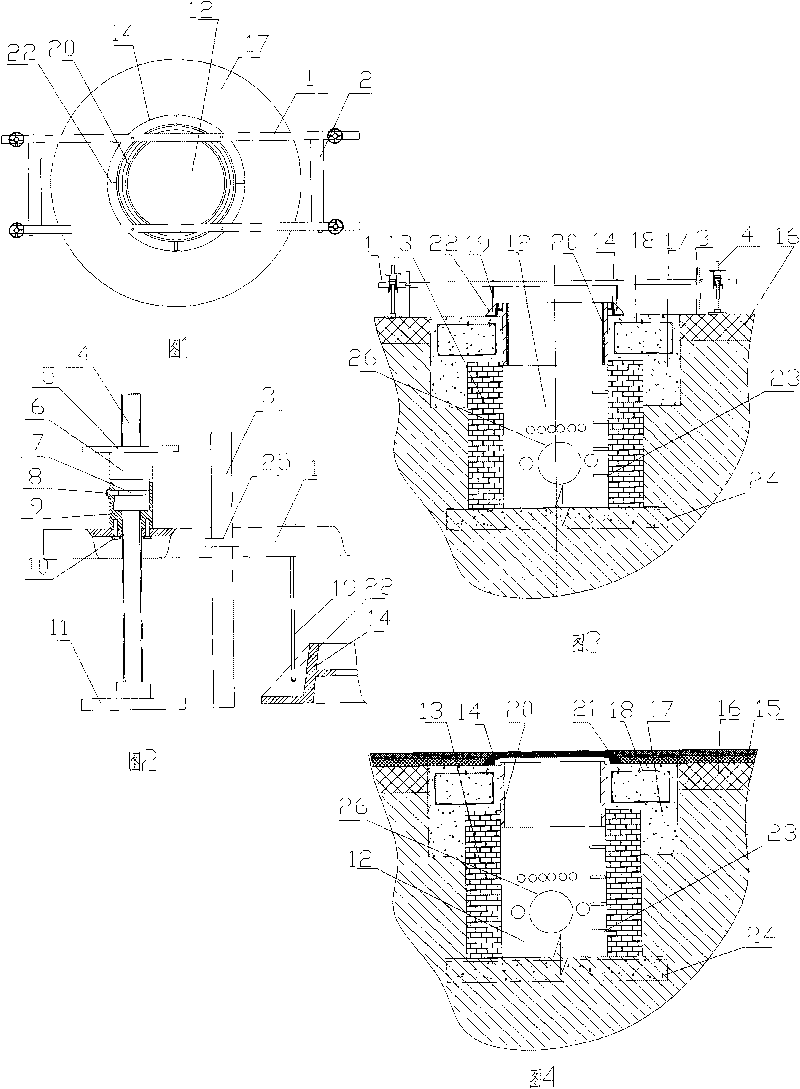

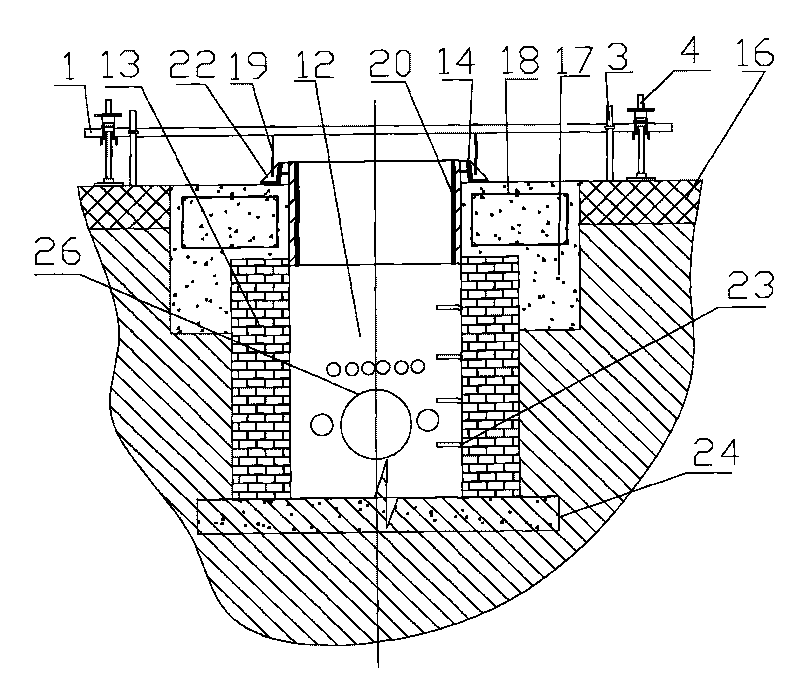

Concrete integral pouring construction method and device for road inspection well

A technology of integral pouring and construction method, which is applied in construction, artificial islands, water conservancy projects, etc., can solve the problems of inability to ensure the overall flatness of the road surface, inaccurate control of the elevation of the manhole cover, looseness around the inspection well, etc., and achieve easy control of the elevation of the manhole cover, Avoid fatigue damage, fast construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] After years of continuous improvement by our company, the construction method of integrally pouring reinforced concrete ring beams with suspension supports and inspection manhole covers for support installation has been formed, which has completely solved the common quality problems of municipal road inspection wells. This construction method has been widely used in Jinan Jingshi Road widening and reconstruction and environmental improvement project, Jinan Dawei 2nd Road widening and reconstruction project, Erhuan East Road surface road and BRT rapid transit system construction project second bid section, Jinan Daminghu Road road reconstruction project Among them, Jinan Jingshi Road widening and reconstruction and environmental improvement project won the Luban Award, and Jinan Dawei 2nd Road widening and reconstruction project won the National Gold Cup Award. The phenomenon of car jumping and noise from time to time, the road pavement inspection well cover is well conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com