Patents

Literature

484results about How to "Avoid fatigue damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vibration inducing device for strengthening heat exchange of elastic tube bundle heat exchanger

InactiveCN101738129AAvoid fatigue damageImprove heat transfer efficiencyHeat transfer modificationEngineeringHeat exchanger

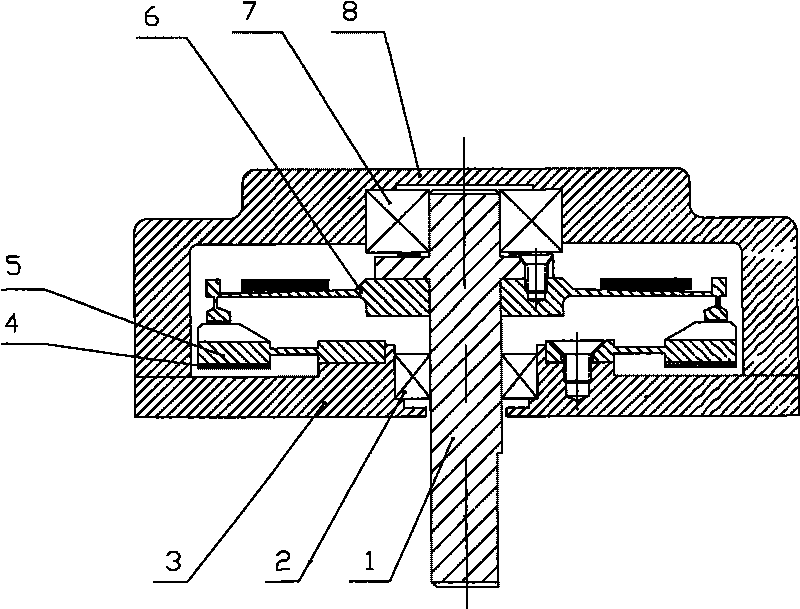

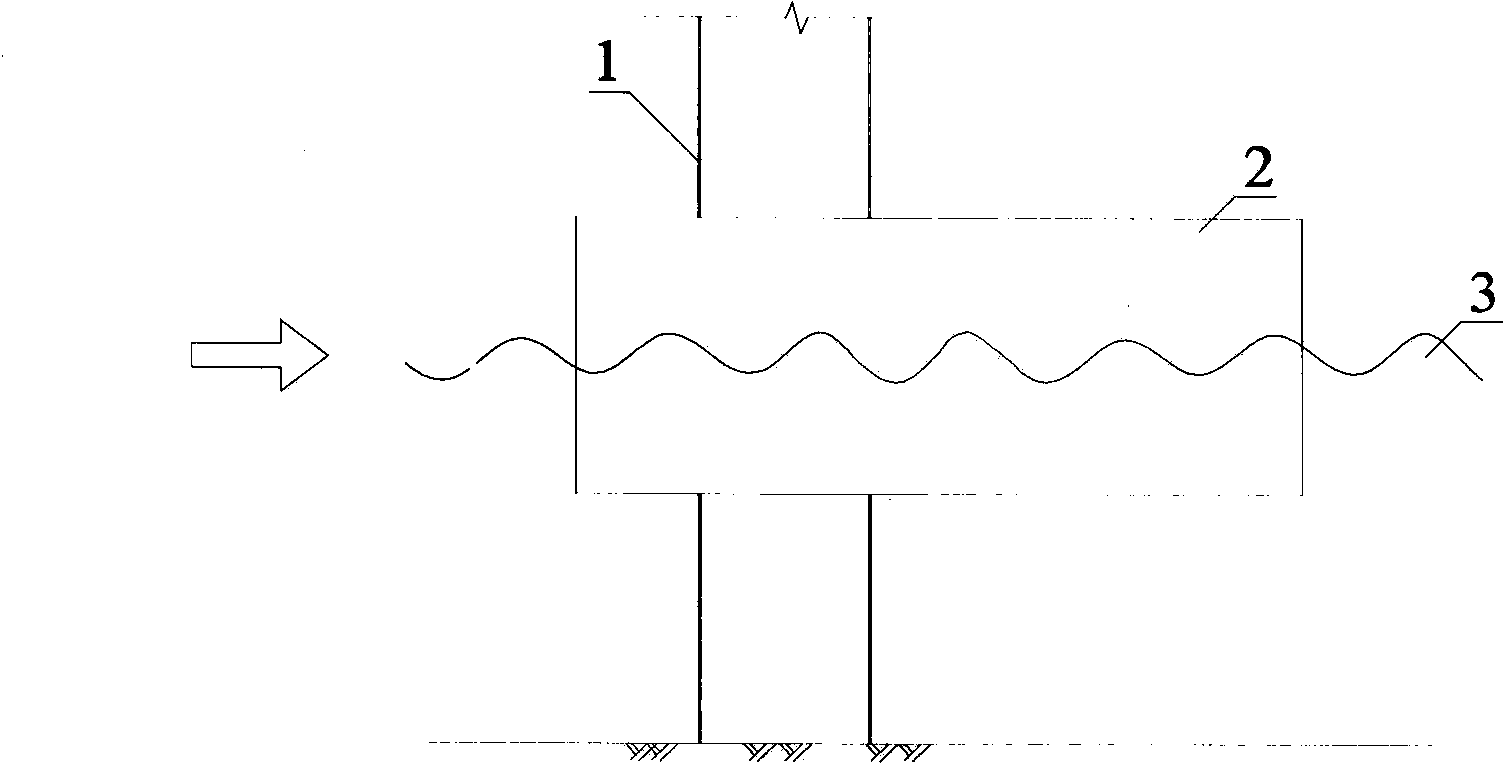

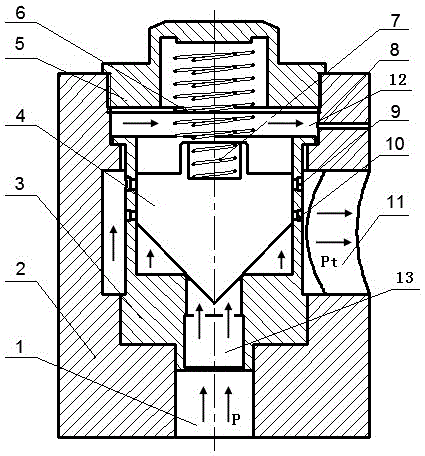

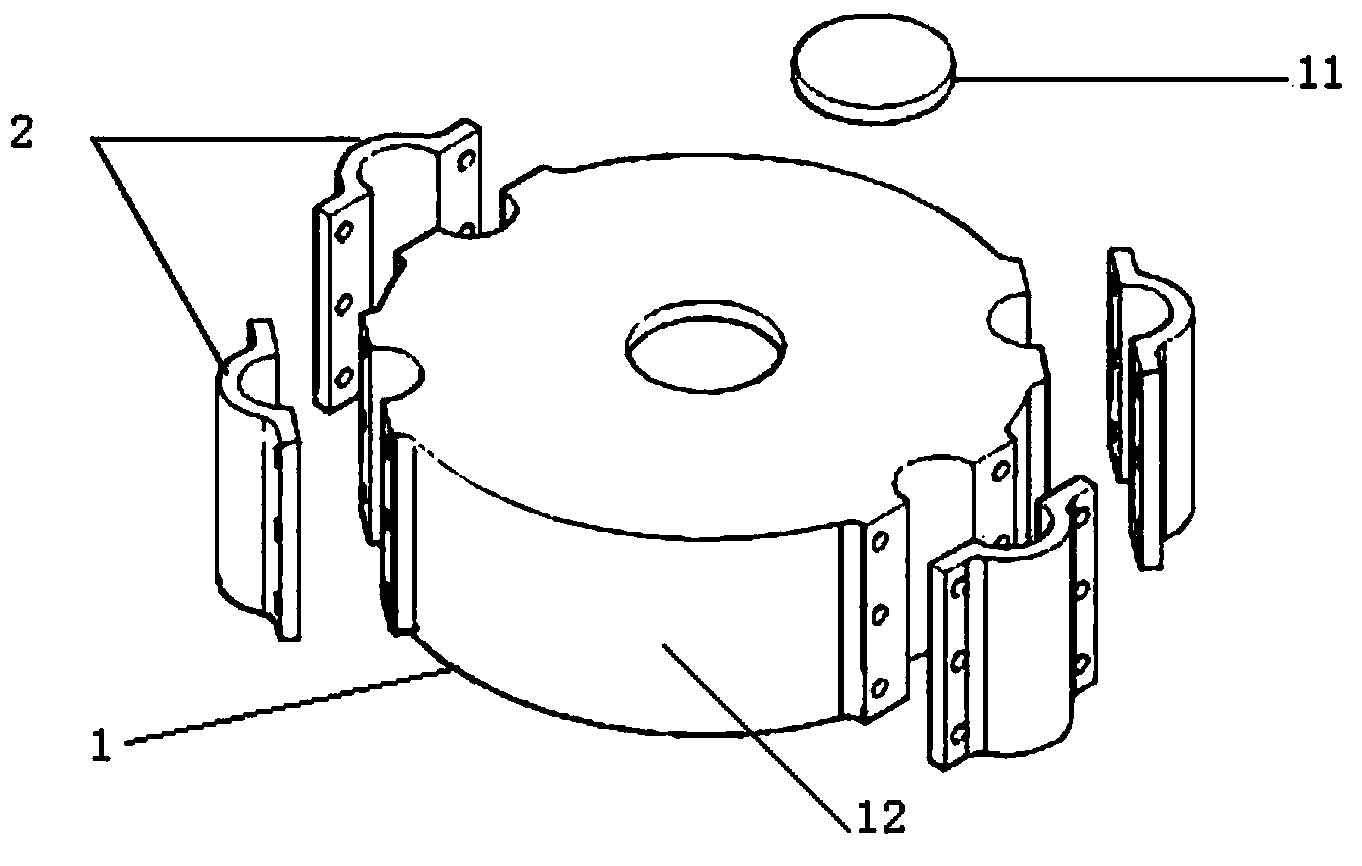

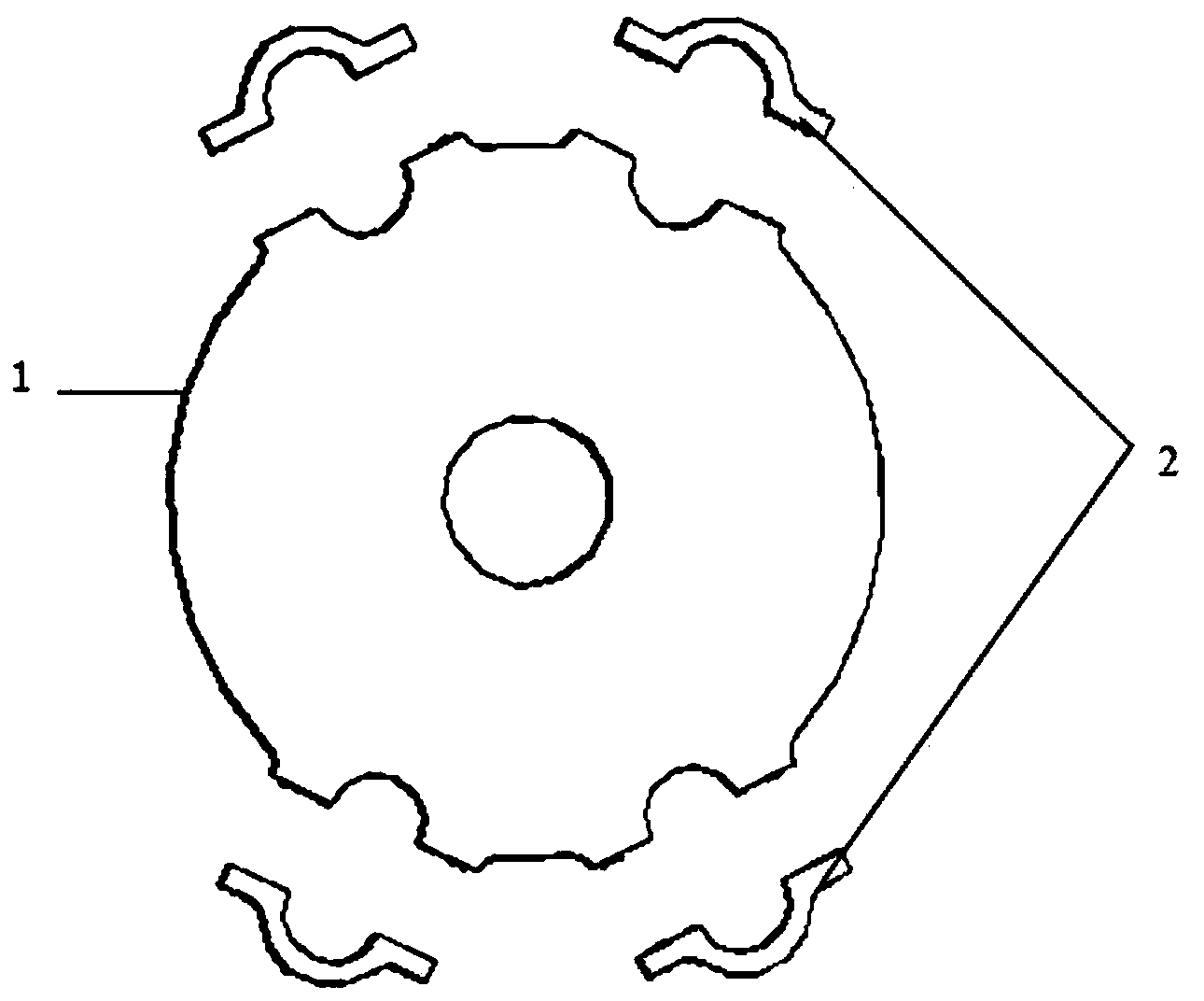

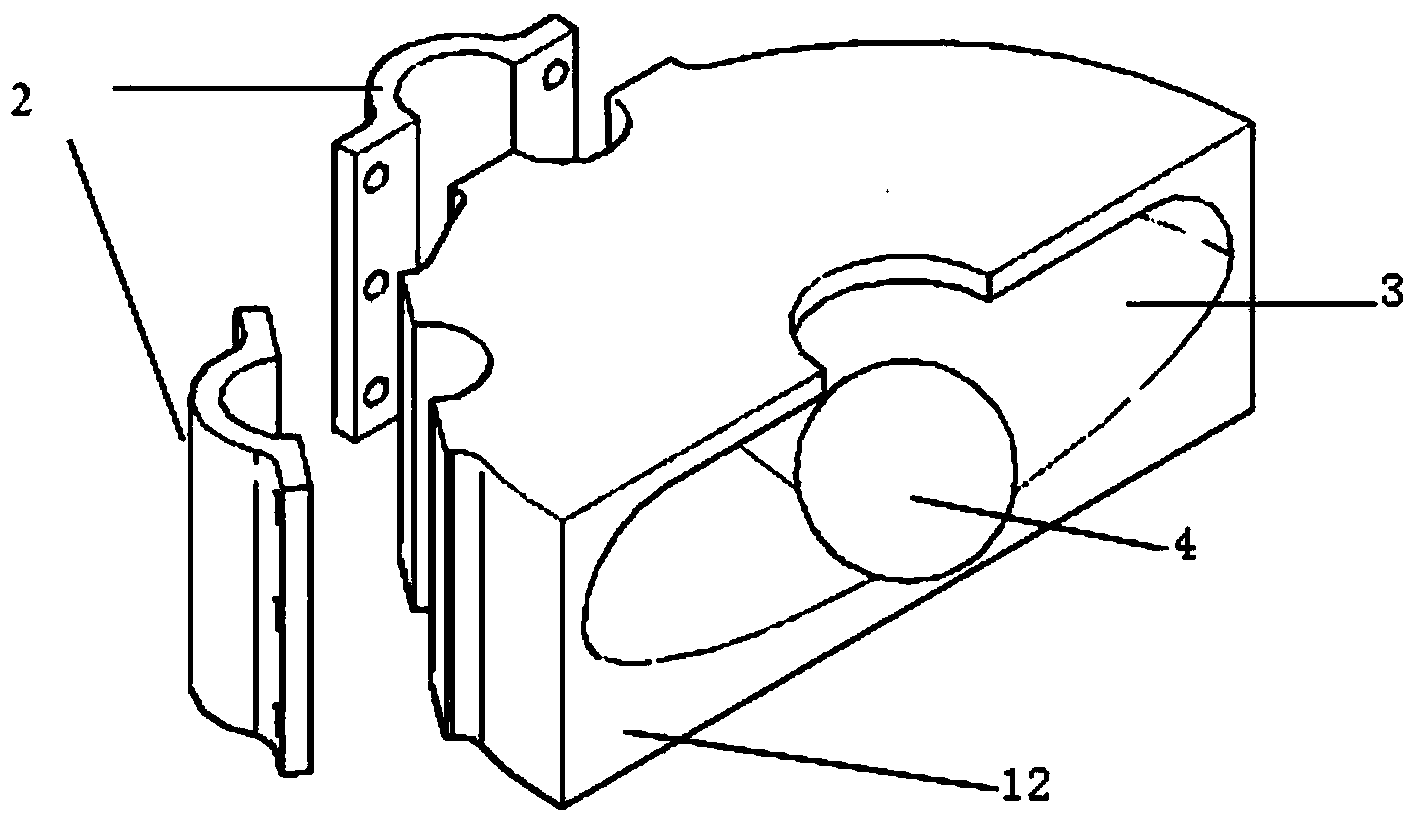

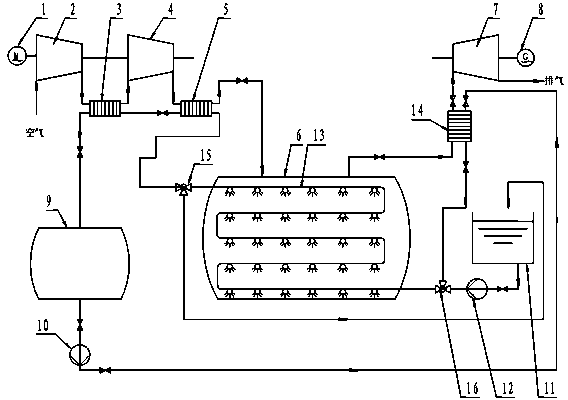

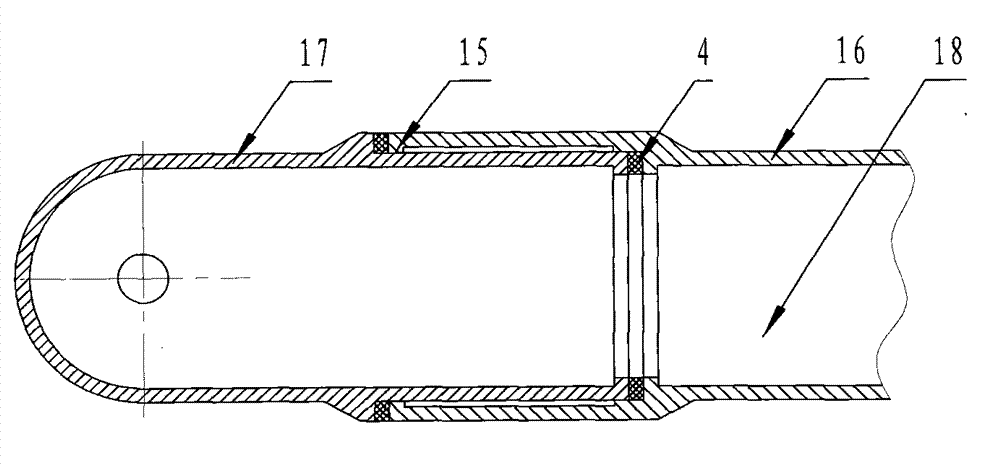

The invention discloses a vibration inducing device for strengthening the heat exchange of an elastic tube bundle heat exchanger. The vibration inducing device may have the vibration type, frequency and amplitude which are required by a heat exchanger bundle, improves the heat exchange efficiency and avoids damage to the heat exchanger bundle due to fatigue. The vibration inducing device comprises a water inlet tube and a pulse flow tube, wherein the water inlet tube and the pulse flow tube are both connected with a tube valve; the pulse flow tube is provided with a water outlet corresponding to floating mass block of the elastic heat exchanger bundle one by one; and a pulse flow generator is arranged on the pulse flow tube and / or the water outlet.

Owner:SHANDONG UNIV

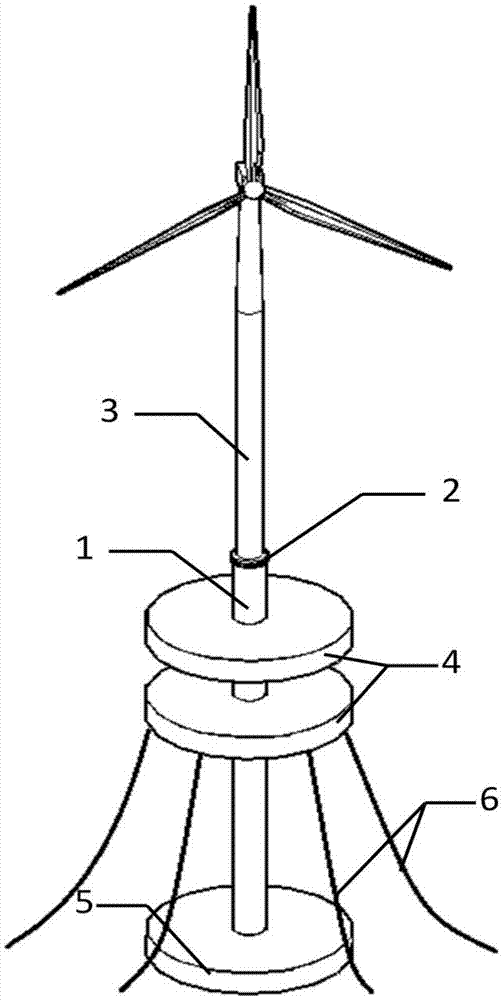

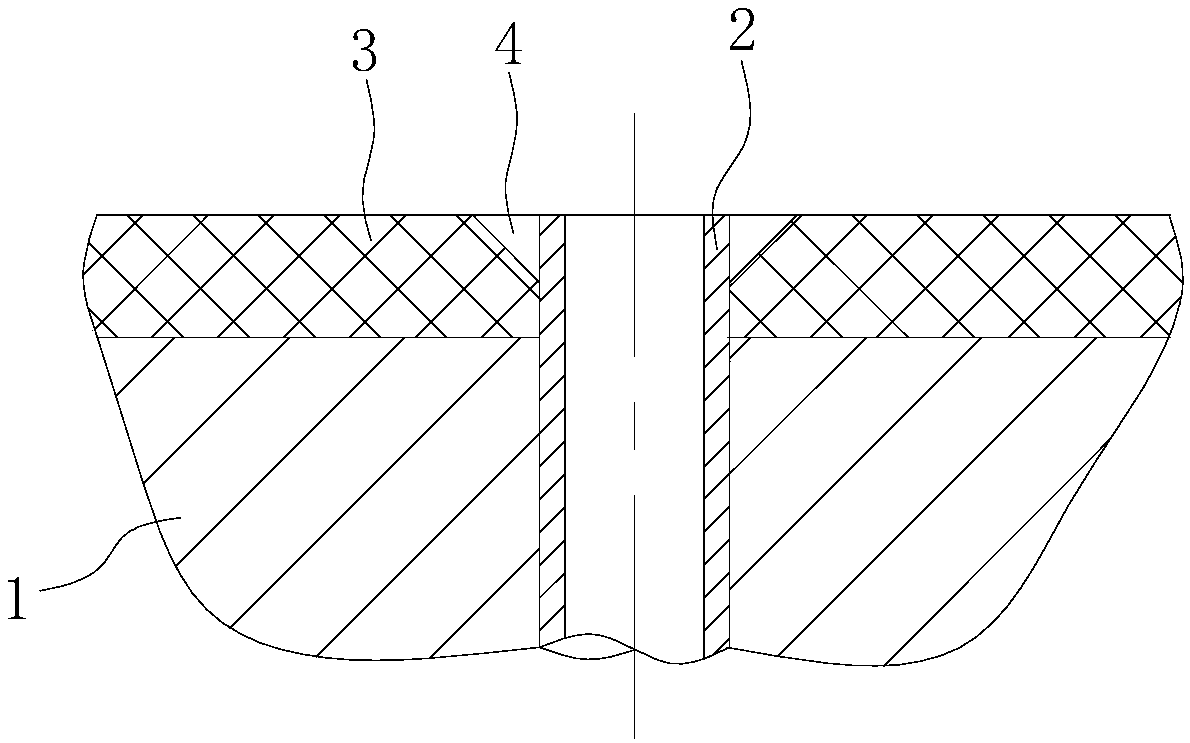

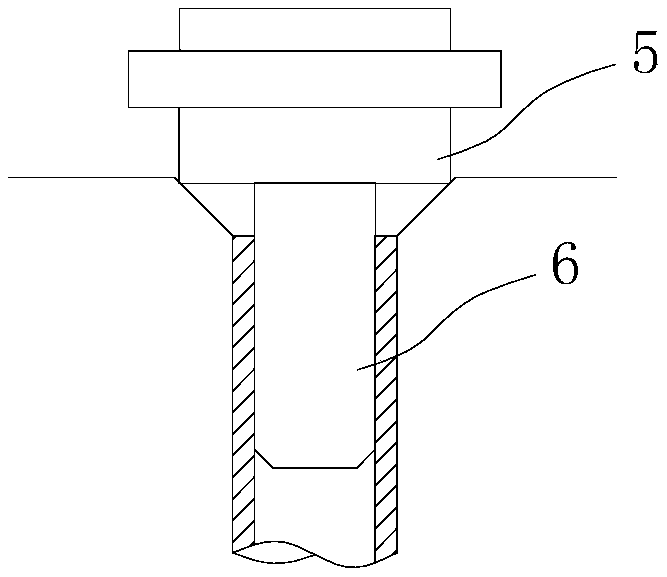

Offshore wind power spar buoyant foundation capable of towing

ActiveCN105438411AReduce resistanceSkip the dry mopping processFoundation engineeringFloating buildingsStress concentrationFatigue damage

The invention relates to an offshore wind power buoyant foundation form and in particular relates to an offshore wind power spar buoyant foundation capable of towing, which comprises a connecting column and is characterized in that the upper end of the connecting column is connected with a fan through a flange ring, a plurality of flat columnar closed air flotation boxes are arranged at the middle part of the connecting column, the closed air flotation boxes are not communicated with the connecting column, and the bottom of the connecting column is communicated with a loading cabin; a column body of the connecting column is provided with a detachable gear required for towing; and a mooring rope is arranged at the center of gravity of the buoyant foundation. Compared with the prior art, the offshore wind power spar buoyant foundation provided by the invention has the beneficial effects that the construction is convenient, rolling towage can be realized, the resistance of a wave flow is reduced, the stress concentration and fatigue damage caused by the traditional spar foundation in a wet towing process are avoided, the construction difficulty and construction cost are greatly reduced, and the offshore wind power spar buoyant foundation can be recycled. The additional mass and viscous damping of heave motion are effectively improved by virtue of the flat air flotation boxes, the water surface profile area of a buoy is effectively increased by virtue of the flat air flotation boxes on the water surface, a relatively large restoring moment is provided, the structure stability is relatively good, the center of gravity is lower than the center of flotation, and the resistance to capsizing is good.

Owner:CEEC JIANGSU ELECTRIC POWER DESIGN INST

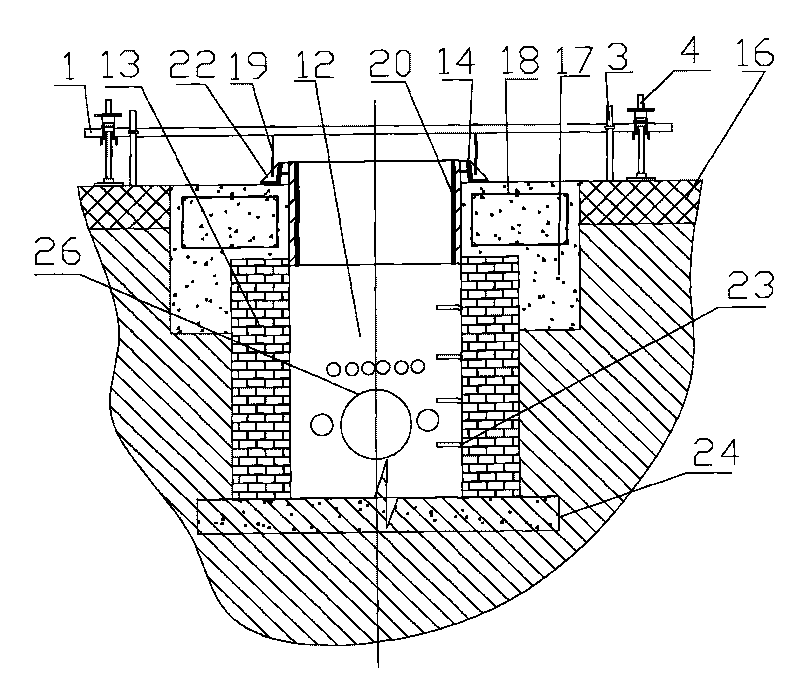

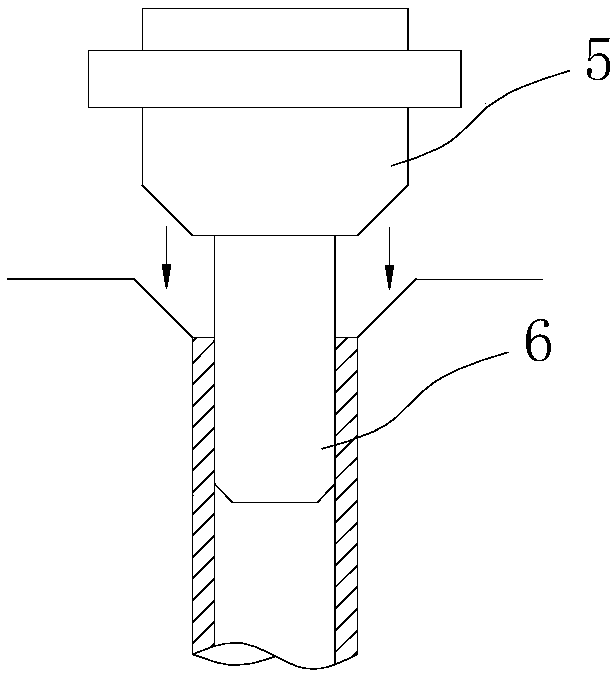

Concrete integral pouring construction method and device for road inspection well

InactiveCN101718101APrevent slippingResistance to the effects of horizontal thrustArtificial islandsUnderwater structuresProduct inspectionReinforced concrete

The invention provides concrete integral pouring construction method and device for a road inspection well. The method comprises advance constructions and post constructions, wherein the advance constructions comprise the following steps of: measuring and paying off; excavating a wellhole; pouring a reinforced concrete foundation bottom and building a wellhole protection wall; connecting pipelines; building a well chamber; mounting a tread; backfilling well perimeters; reserving a branch pipe; building a close up section; mounting a cover plate; building the wellhole; covering and protecting; backfilling cement and stone dust to the well perimeters; and constructing a pavement basic layer. The post constructions comprise the following steps of: excavating the pavement basic layer covered on the wellhole to expose the wellhole, dismantling the cover plate and excavating a concrete foundation pit by using the wellhole as a center, wherein the radius of the excavated foundation pit two times larger than or equal to that of the wellhole; laying reinforcing steel bars in the foundation pit and supporting an inner mold in the wellhole; overhanging a well cover on the wellhole by a fixing bracket overhanging device; adjusting the altitude of the well cover; pouring concrete into the foundation pit and keeping the height of the concrete parallel to the bottom of the well cover; building the perimeters of the well cover into a cement slope by concrete; carrying out acceptance checks; paving a bituminous pavement on the perimeters of the well cover and keeping the bituminous pavement parallel to the well cover.

Owner:JINAN URBAN CONSTR GRP

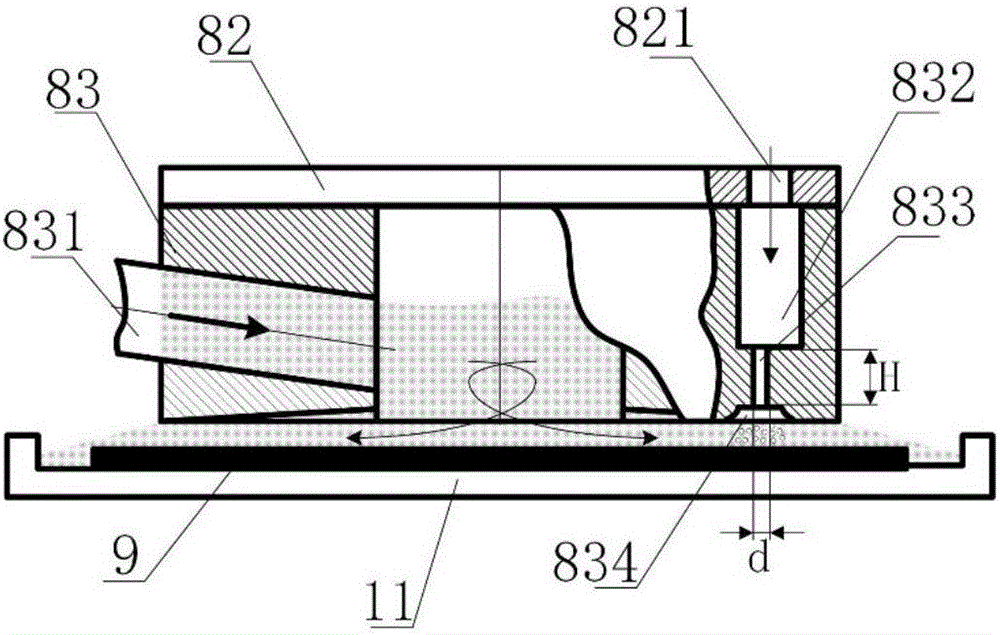

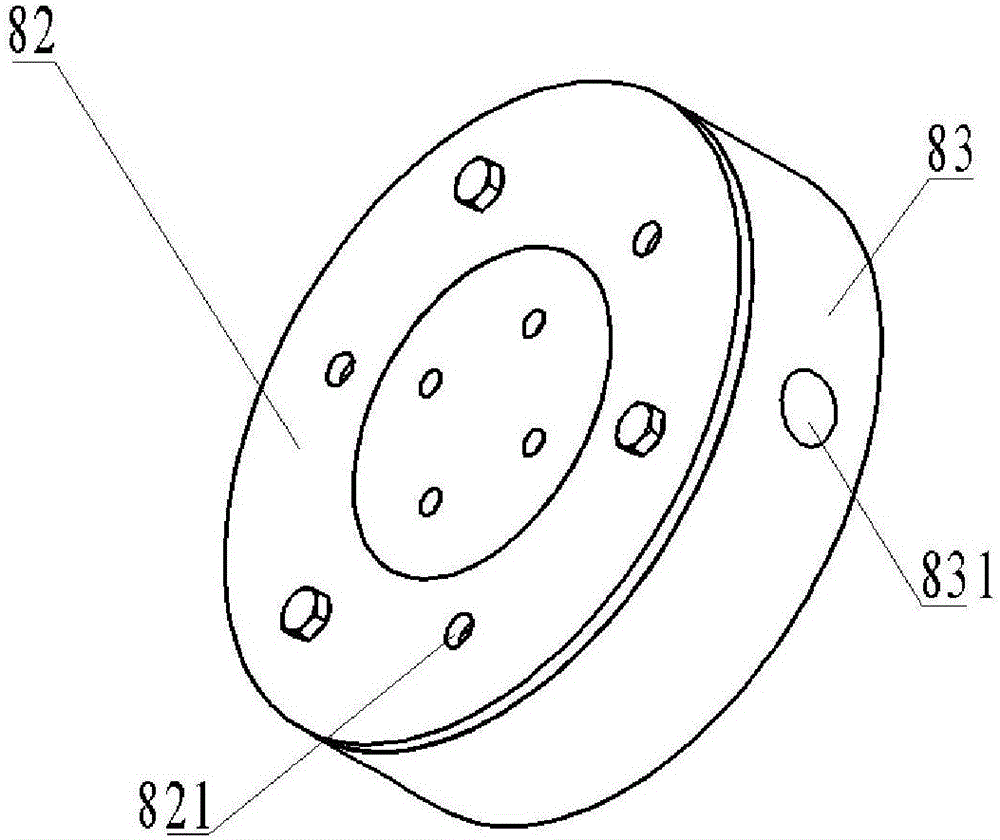

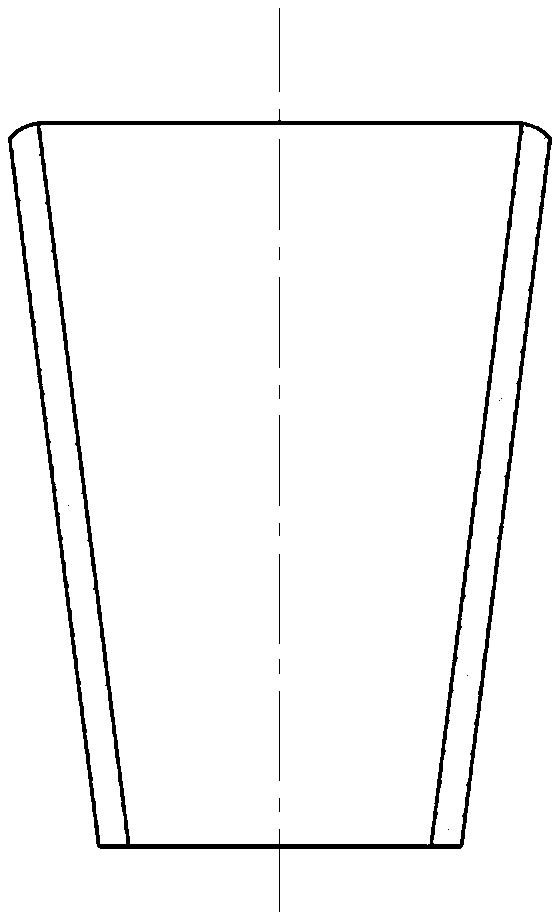

Efficient fluid finishing method and device based on structure cavitation effect

ActiveCN106392863ACollapse drive effect is obviousSimple structureEdge grinding machinesPolishing machinesBubble cavitationWear particle

The invention discloses an efficient fluid finishing method based on the structure cavitation effect. According to the efficient fluid finishing method, the Venturi tube cavitation effect is introduced to fluid finishing, strong bubble cavitation action is formed in the effective polishing area formed between a processing tool and a workpiece to be processed by arranging a Venturi tube structure on the processing tool, and the bubble cavitation action is utilized to drive a liquid-solid abrasive flow in the formed effective polishing area to move in a high-speed turbulent vortex mode to achieve processing on the surface of the workpiece to be processed through abrasive particles. According to the efficient fluid finishing method based on the structure cavitation effect, the Venturi tube structure is utilized to achieve growth and collapse of bubbles in the microspur gap between the processing tool and the workpiece to be processed so as to achieve unordered and high-speed turbulent flow of the abrasive particles; compared with processing equipment adopting ultrasonic waves, the structure is simpler and the cost is lower; and compared with normal bubble-free-collapse processing equipment, the controllability is better, and the bubble collapse driving effect is more obvious.

Owner:ZHEJIANG UNIV OF TECH

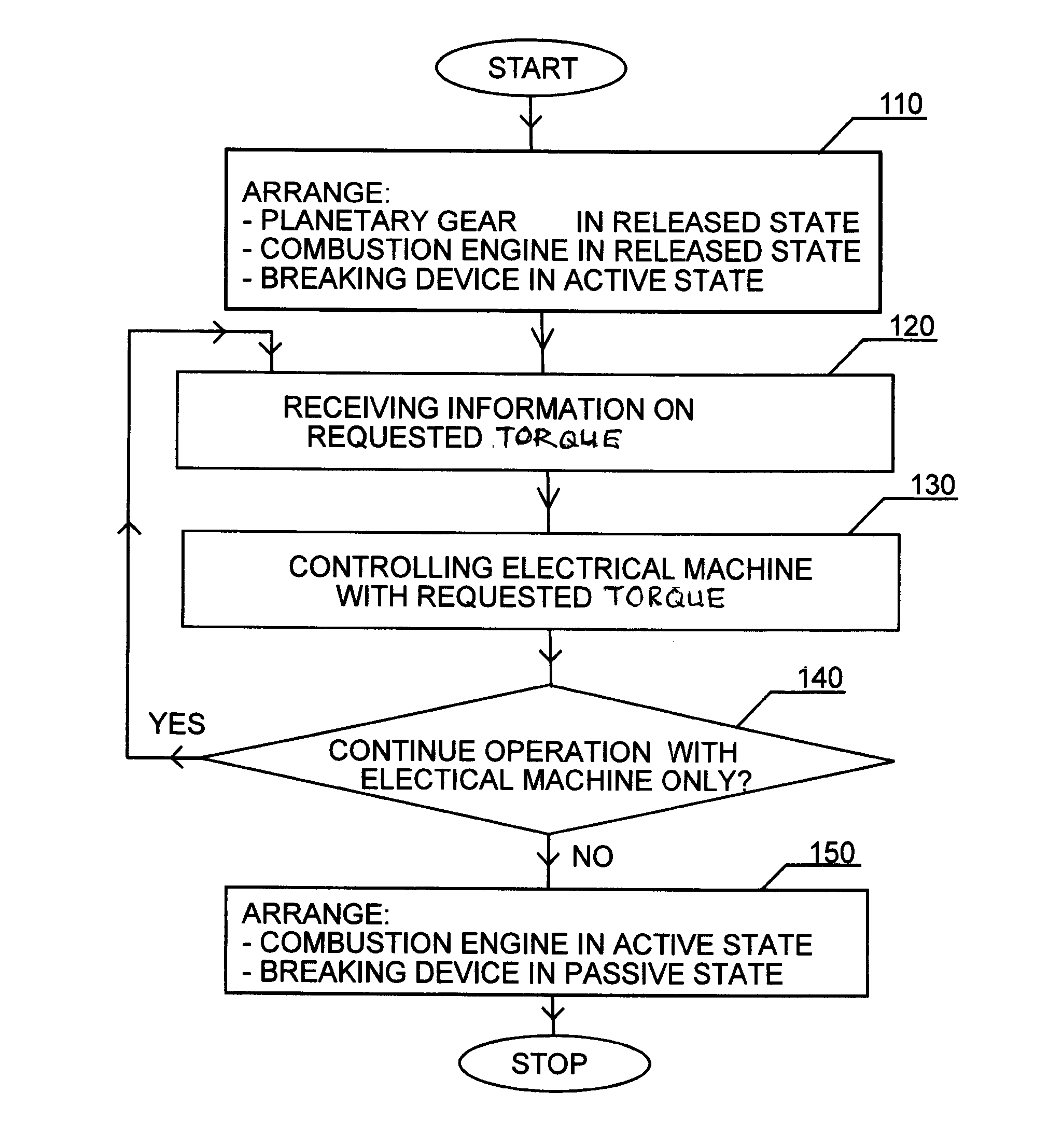

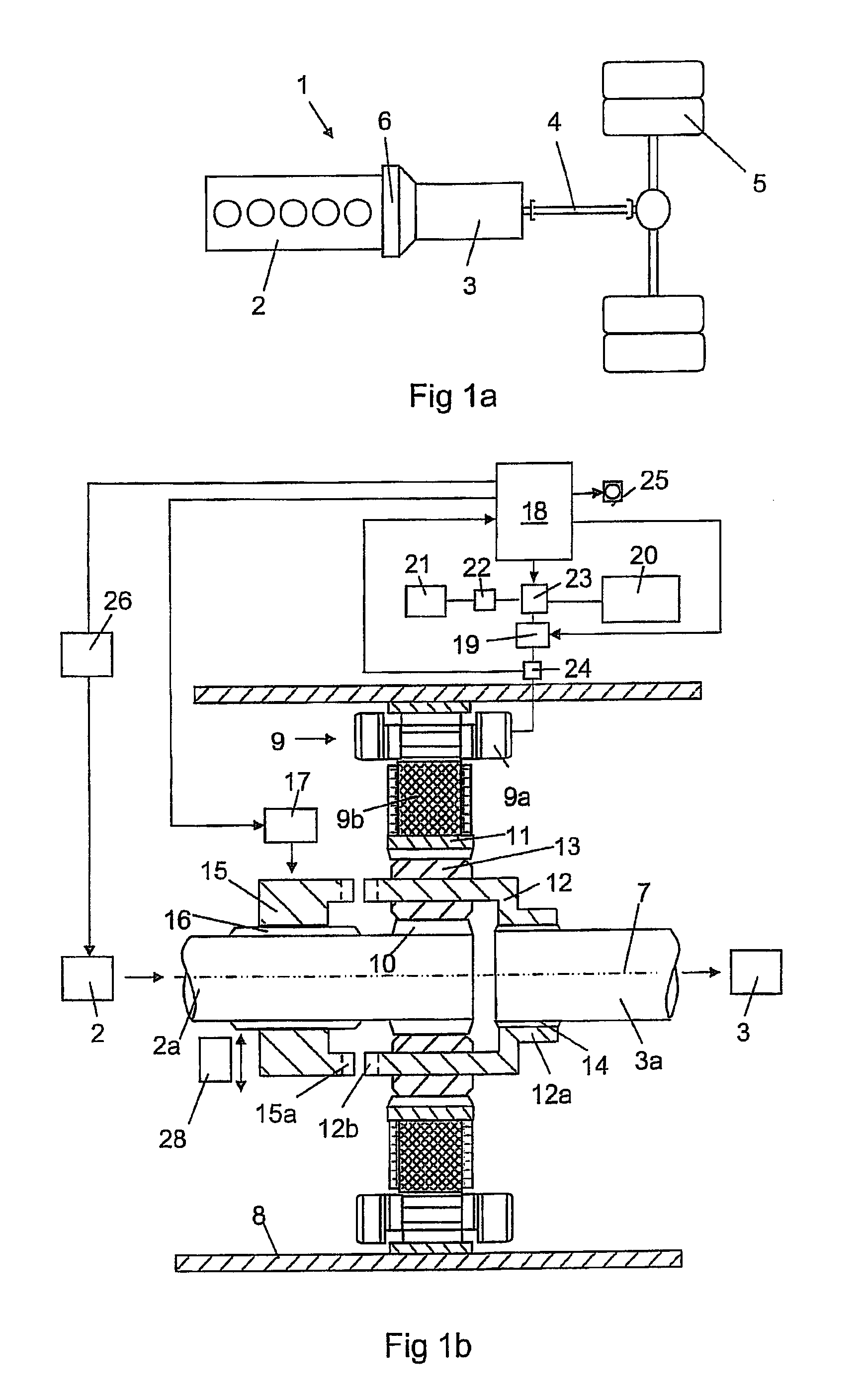

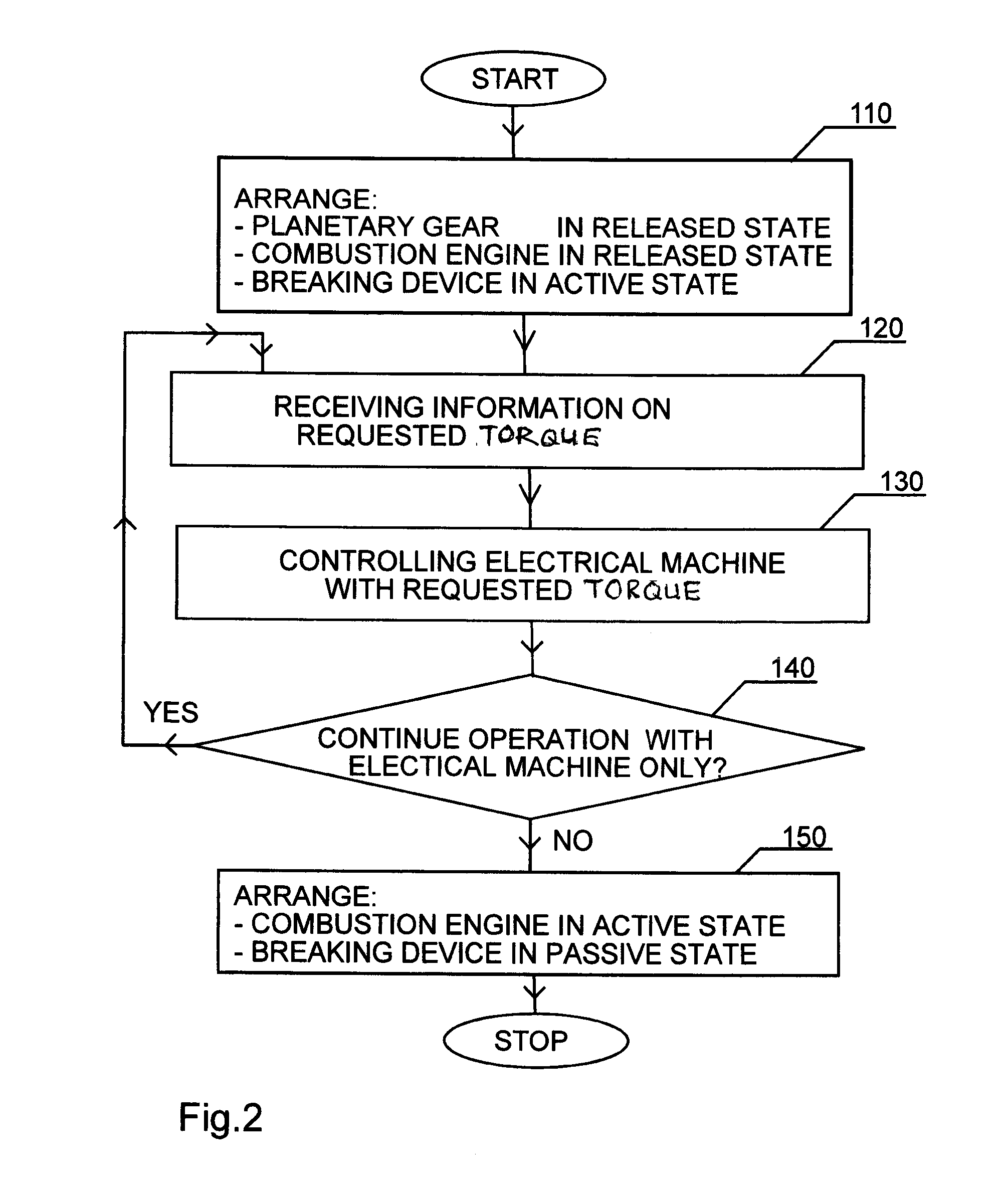

Method for controlling a drive system of a vehicle, a drive system, a computer program, a computer program product and a vehicle

ActiveUS20150375734A1Increase torqueReduce energy lossDigital data processing detailsVehicle sub-unit featuresCombustionElectric machine

A method for controlling a drive system of a vehicle, the drive system including a combustion engine with an output shaft, a gearbox with an input shaft, an electrical machine including a stator and a rotor, and a planetary gear with a sun gear, a ring gear and a planet wheel carrier. The combustion engine may be active or inactive. A braking device may be active or passive. The planetary gear may be released or locked. The method includes arranging the planetary gear in the released state, the combustion engine in inactive state, the braking device in active state, and, when information on a requested torque for the operation of the vehicle is received, controlling the electrical machine to provide the requested torque with the combustion engine inactive, the braking device active and the planetary gear released.

Owner:SCANIA CV AB

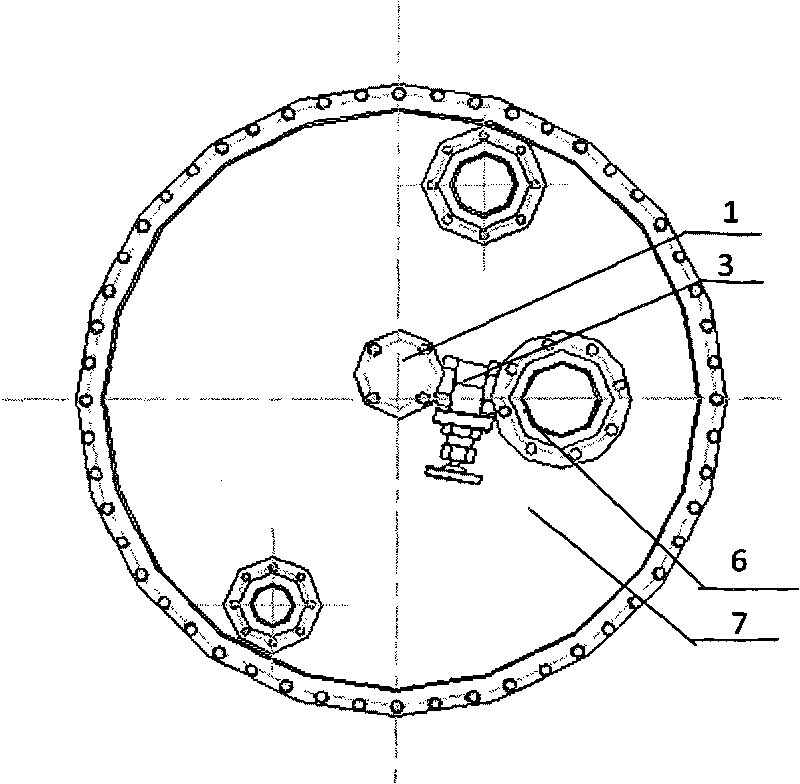

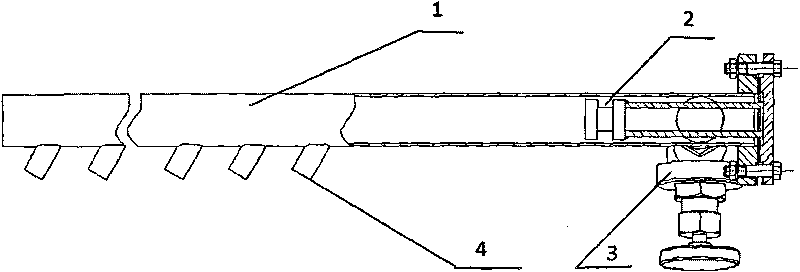

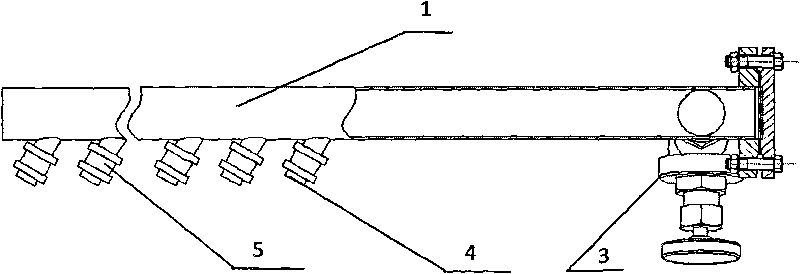

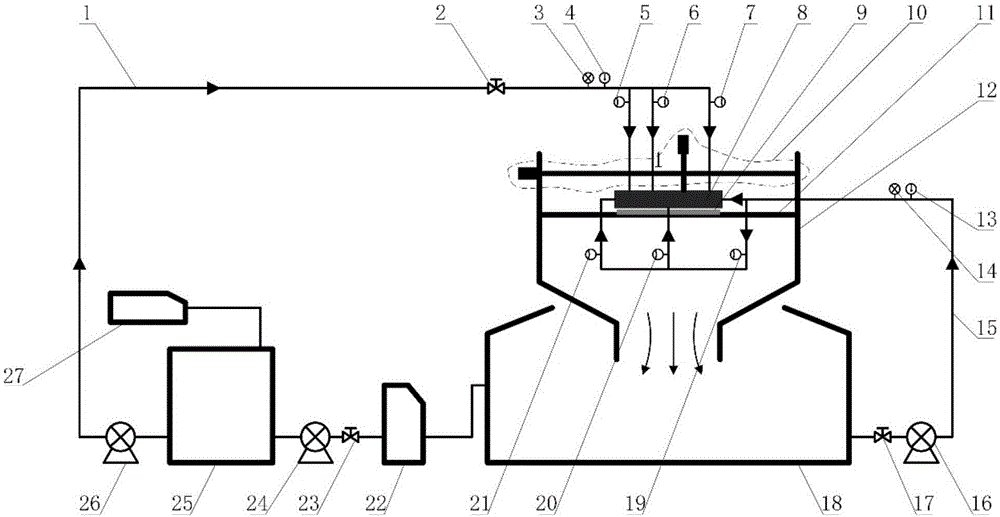

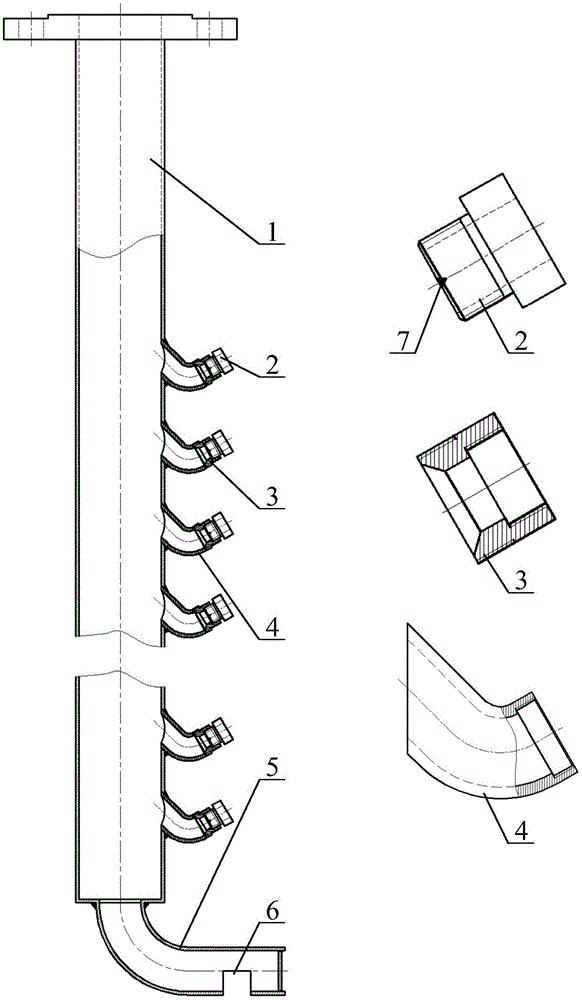

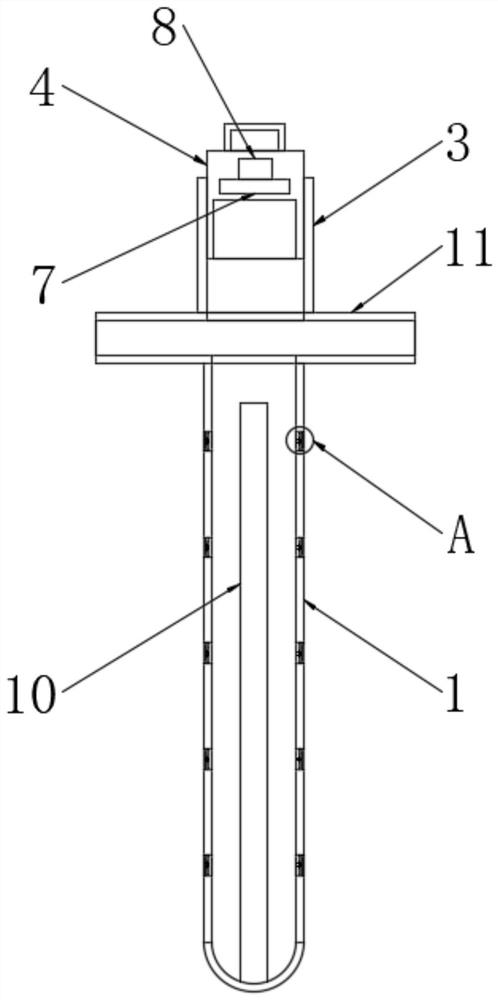

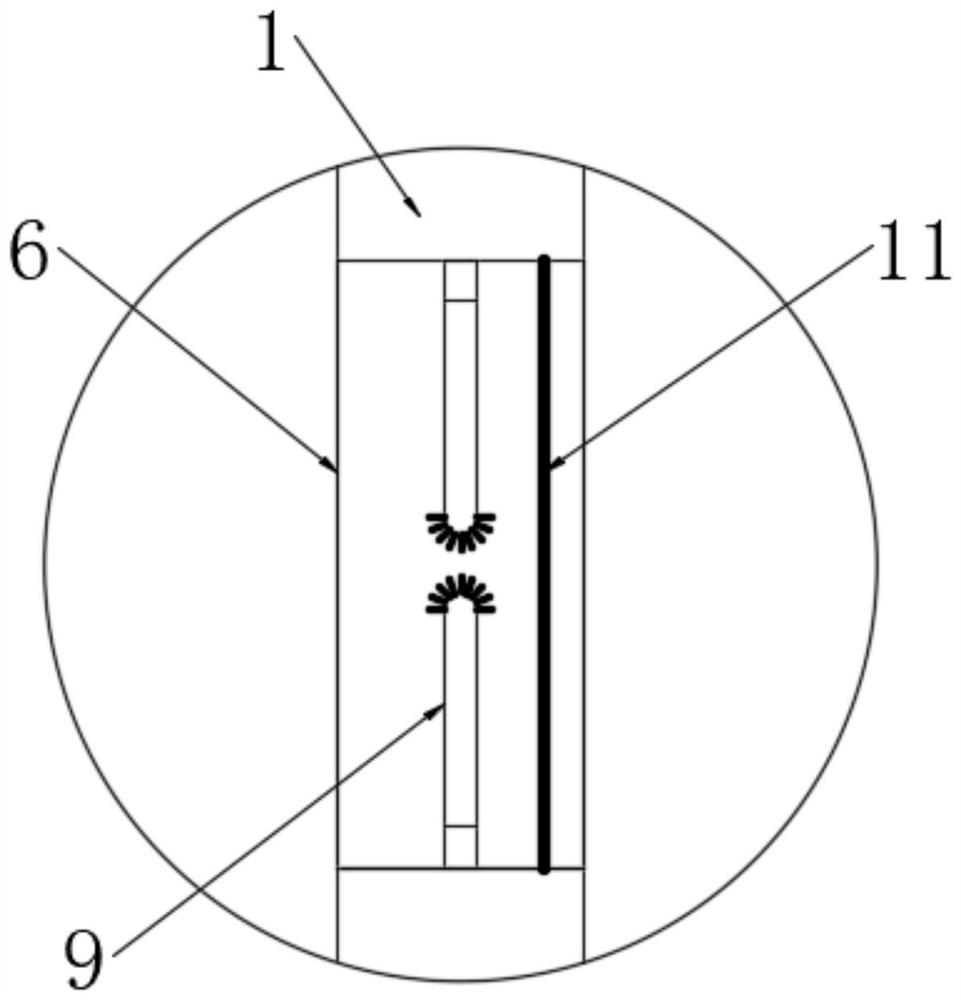

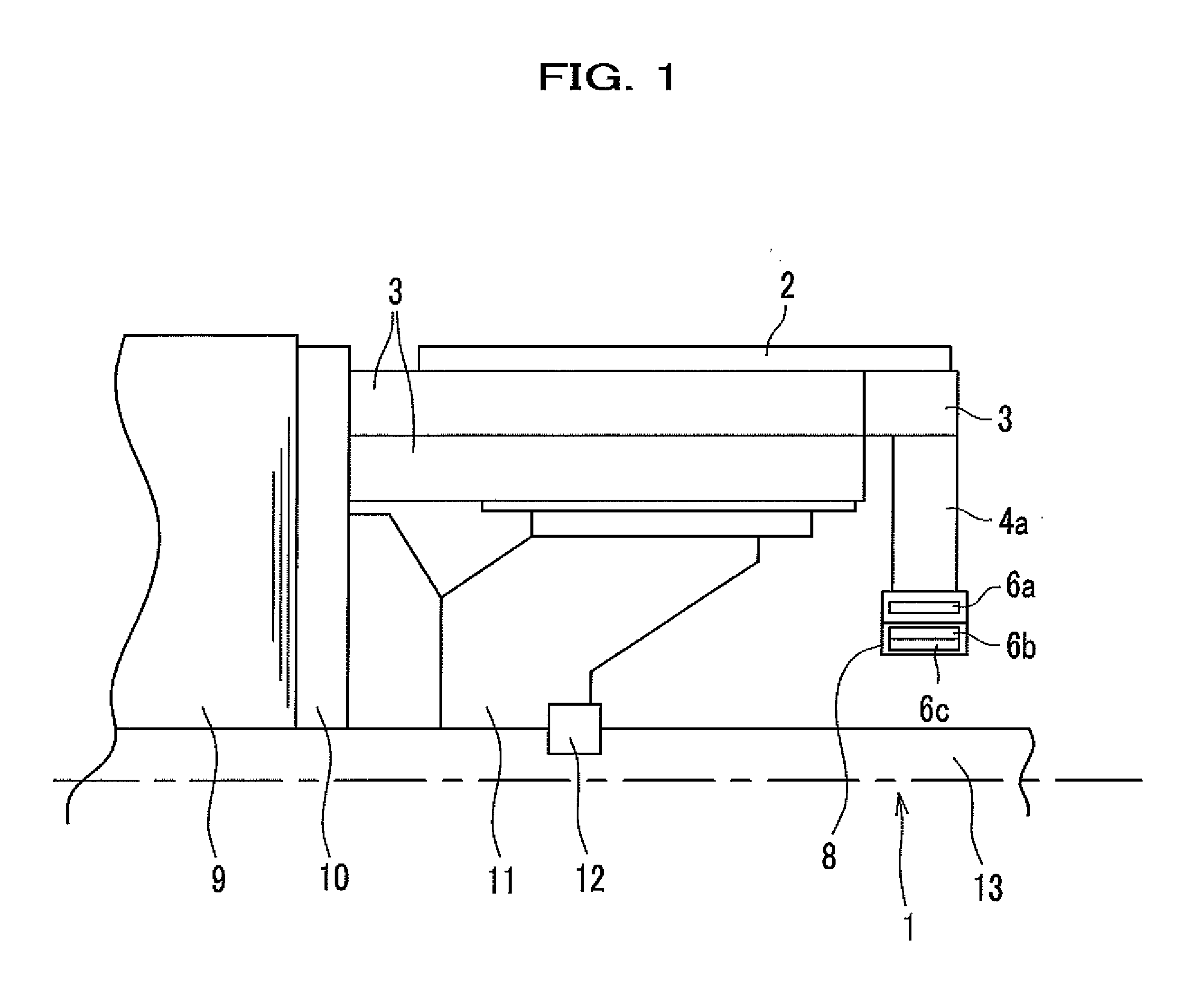

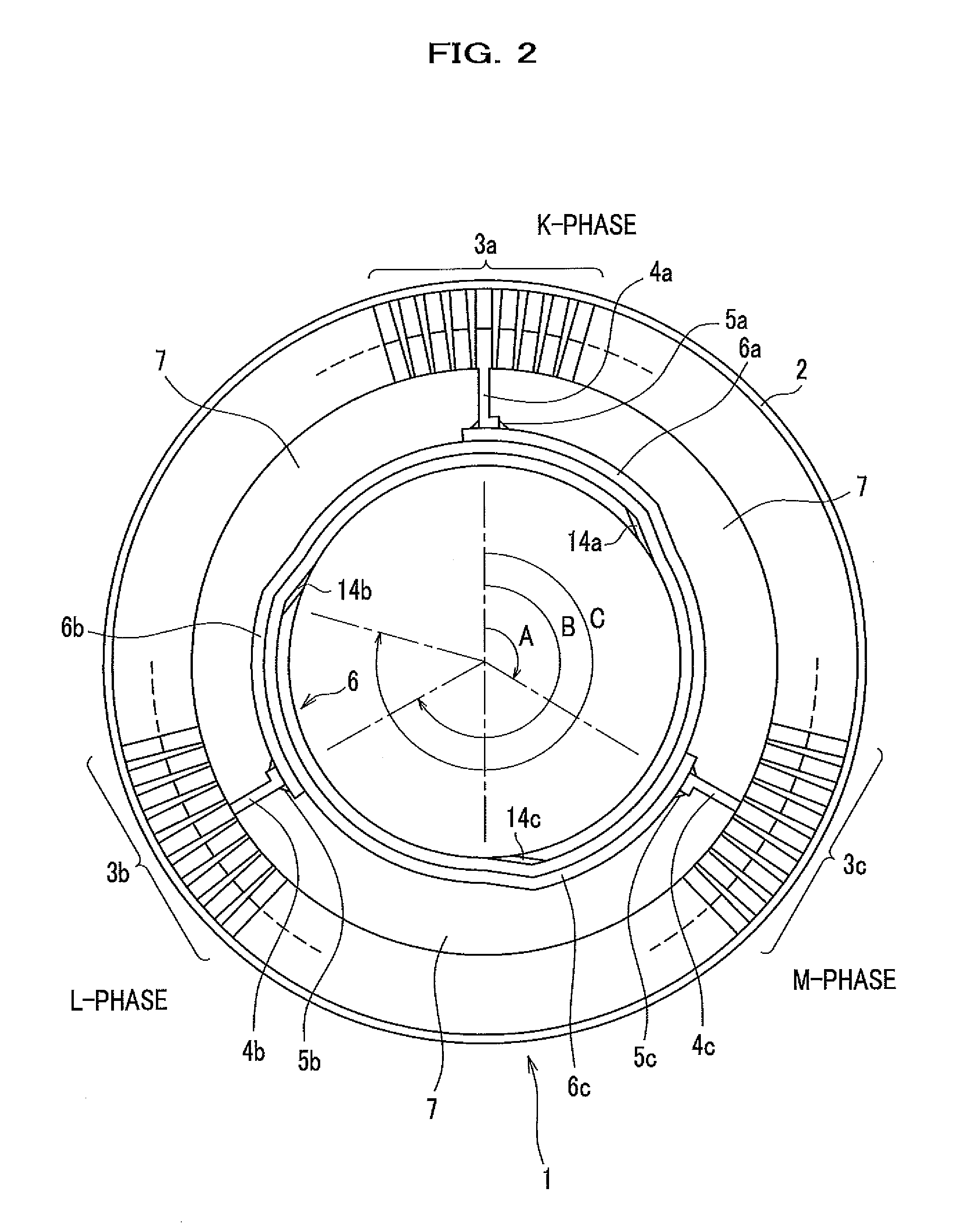

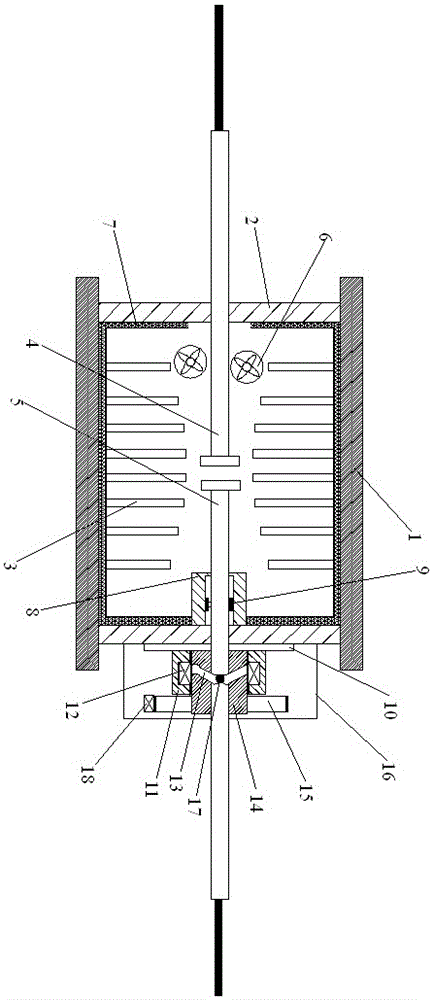

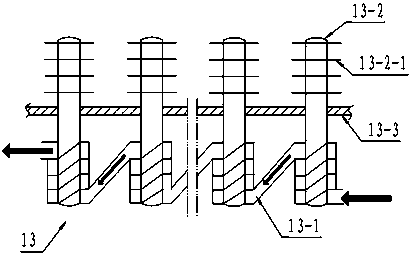

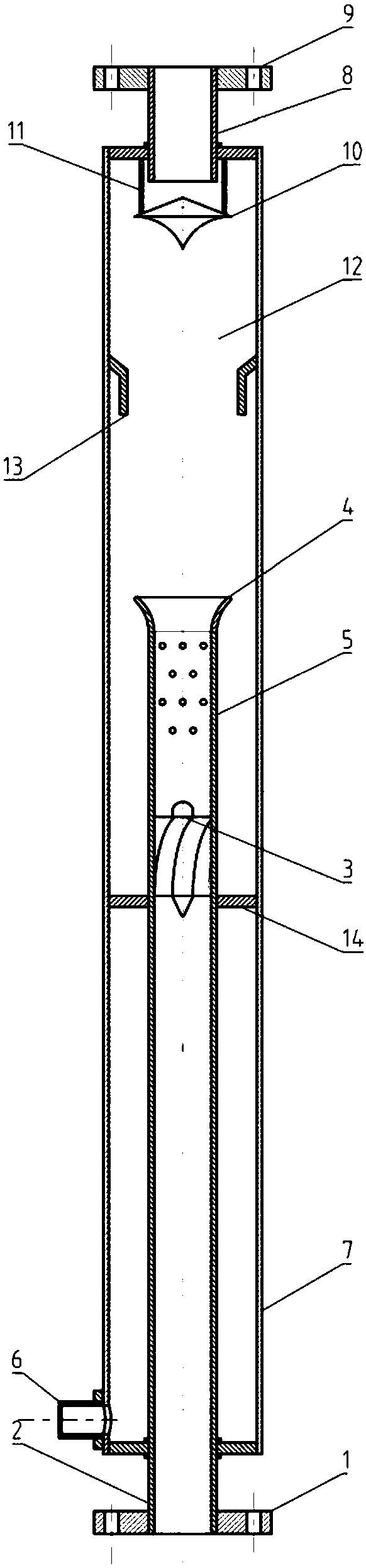

Uniform distribution type pulsating flow generating device for vibration induction of elastic tube bundles inside heat exchanger

ActiveCN105135931AImprove heat transfer effectRealize rationalityHeat transfer modificationEngineeringUltimate tensile strength

A uniform distribution type pulsating flow generating device for vibration induction of elastic tube bundles inside a heat exchanger comprises a vertical pipe, branch bent pipes, guide pipes, pulsating flow pipes, turbulator bodies and a shell pass water inlet pipe. The branch bent pipes consistent in spacing are distributed on the vertical pipe, the guide pipes are connected to the corresponding branch bent pipes, the pulsating flow pipes are connected to the guide pipes, and the turbulator bodies are arranged on the pulsating flow pipes. The shell pass water inlet pipe is arranged at the bottom end of the vertical pipe. When the uniform distribution type pulsating flow generating device is used, one end of the uniform distribution type pulsating flow generating device is fixed to an upper seal head of the heat exchanger, and the other end of the uniform distribution type pulsating flow generating device is suspended at the bottom of the heat exchanger. The uniform distribution type pulsating flow generating device can generate uniform and consistent pulsating flow having certain frequency and strength at outlets of the pulsating flow pipes by controlling the flow of a fluid flowing into the vertical pipe, induces the elastic tube bundles inside the elastic tube bundle heat exchanger to vibrate evenly, can achieve expected vibration required for heat transfer strengthening of the elastic tube bundle heat exchanger and avoids fatigue failures of the tube bundles due to vibration.

Owner:SHANDONG UNIV

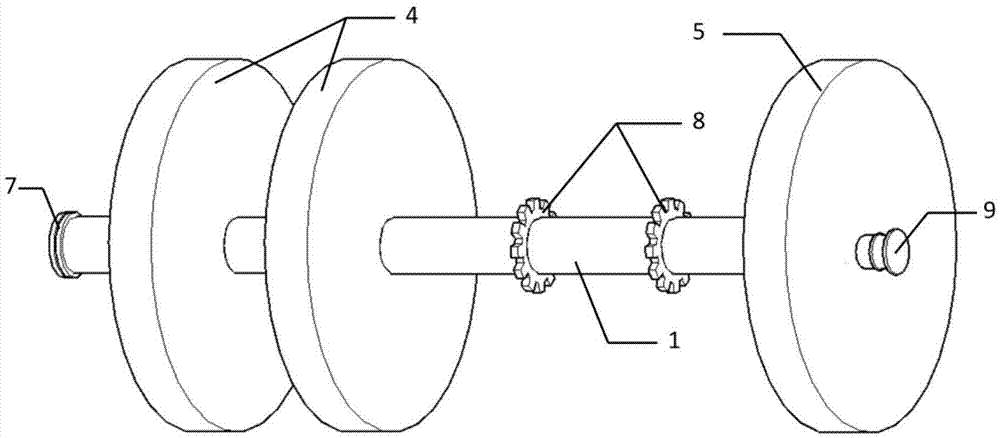

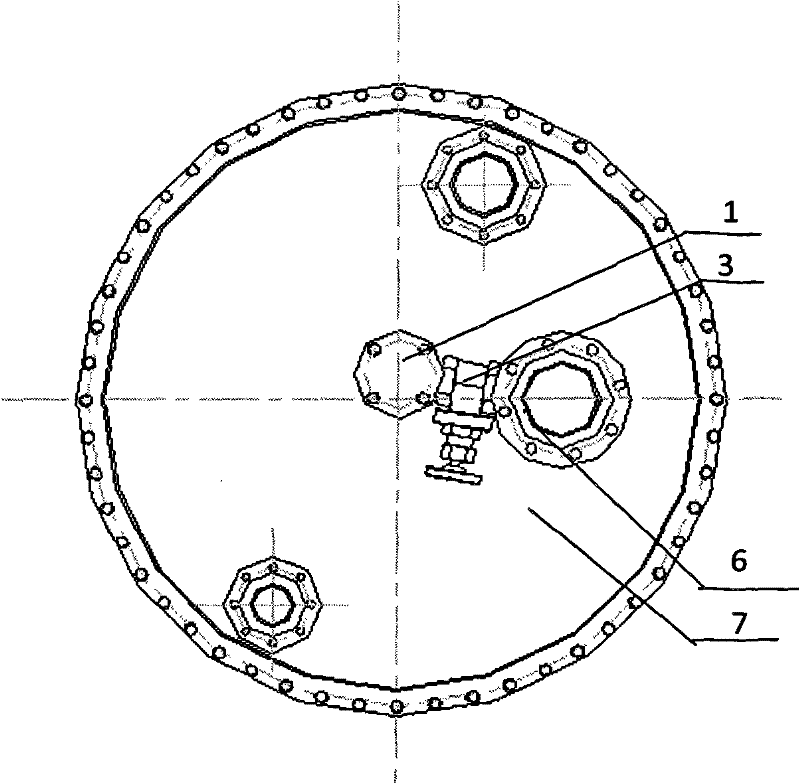

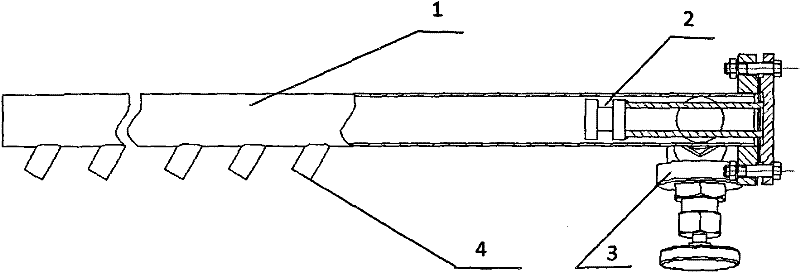

Travelling wave ultrasound motor with dual stator and rotor multi-diameter shaft structure

InactiveCN101702592ALarge output torqueImprove mechanical efficiencyPiezoelectric/electrostriction/magnetostriction machinesThrust bearingEngineering

A travelling wave ultrasound motor with a dual stator and rotor multi-diameter shaft structure belongs to the technical field of ultrasound motor. Two groups of stators and rotors are arranged between the external fixing structure and the internal supporting structure of the motor, wherein the external fixing structure is composed of two stator seats arranged opposite to each other, and a drum-shaped shell arranged between the stator seats, the internal supporting structure is formed by limiting the shaft position of the multi-diameter shaft by thrust bearings in the stator seats. The invention not only maintains the advantages of the existing ultrasound motor with single stator and rotor, but also is easier to operate, has more contact structure, higher torque to capacity ratio and stronger anti-interference capacity to external load, thus being especially suitable for fields of aerospace and biomedicine.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

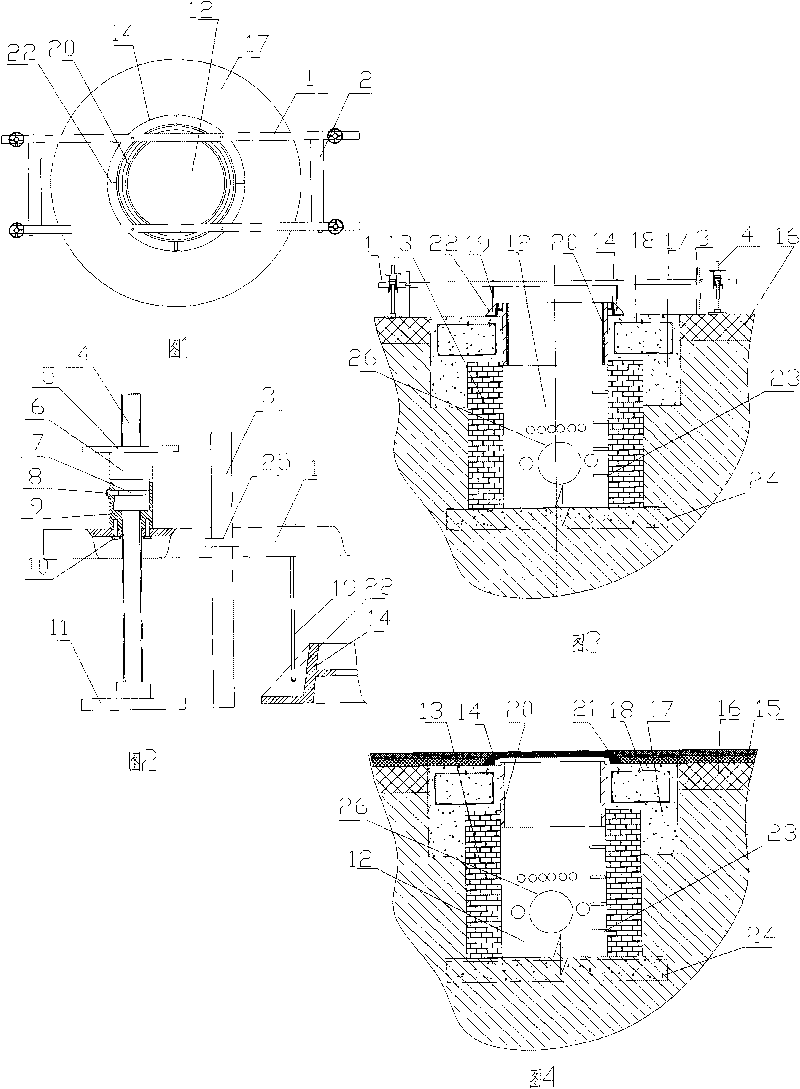

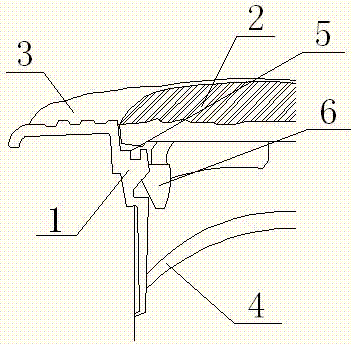

Anti-settling manhole cover and construction method thereof

InactiveCN103114607ALoss does not happenNo subsidenceArtificial islandsUnderwater structuresRoad surfaceIndustrial engineering

The invention belongs to the technical field of municipal engineering, and particularly relates to an anti-settling manhole cover and a construction method of the anti-settling manhole cover. The anti-settling manhole cover comprises a support seat and a cover plate which is arranged on the support seat in a buckled mode. The anti-settling manhole cover is characterized in that the support seat is fixedly provided with a flange plate in a connected mode, the lower portion of the support seat is inserted into an adjusting ring, adhesive tape is arranged between the support seat and the cover plate, and an elastic locking device mounted on the support seat is arranged below the adhesive tape. The anti-settling manhole cover and the construction method of the anti-settling manhole cover have the advantages that the problems that the periphery of a manhole is loose, cracks and is settled, the manhole cover is missing, a vehicle bumps when passing through the manhole cover, noise is generated, and the like are solved; the manhole cover is perfectly connected with a road surface around the manhole cover, the height of the manhole cover is the same as that of the road surface around the manhole cover, the flatness can meet road surface acceptance criteria, the overall flatness of the road surface is guaranteed, and the good effects that the road surface is attractive and a driver feels comfortable when driving on the road surface are solved; the structural integrity is improved, the periphery of the manhole does not sink, and the manhole cover is not prone to loss and damage; and the anti-settling manhole cover and the construction method of the anti-settling manhole cover have a wide application scope in manhole cover installation and reinforcement projects in the municipal engineering and have popularization value.

Owner:JINAN URBAN CONSTR GRP

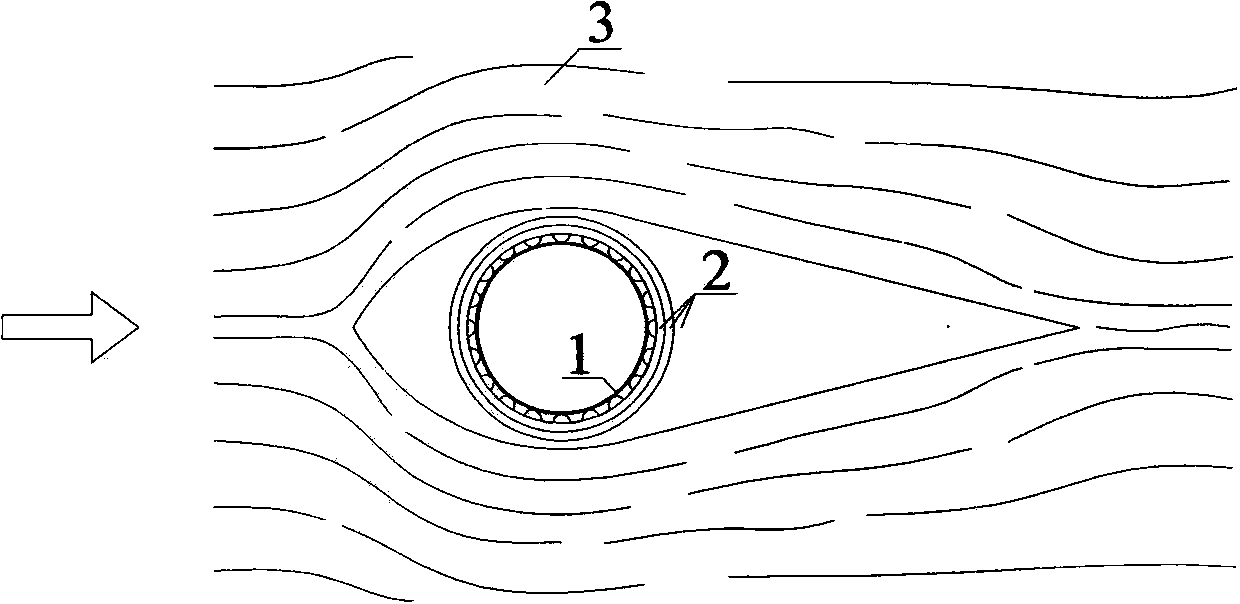

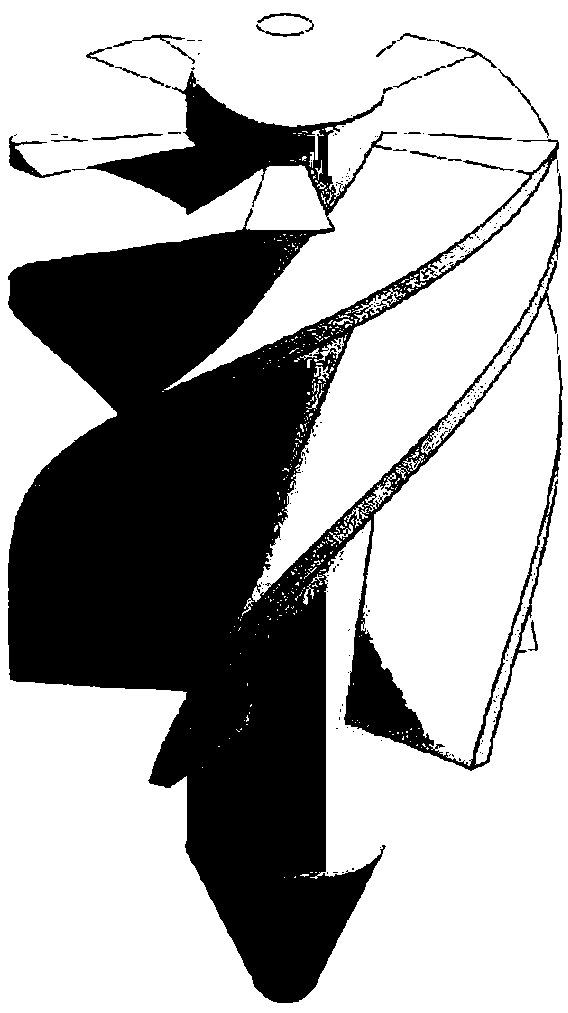

Reduction method for basic wave current vibration of offshore wind power single pile

ActiveCN103469830AReduce vibration responseAvoid fatigue damageProtective foundationViscoelastic dampingSuction force

The invention relates to a reduction method for basic wave current vibration of an offshore wind power single pile. A flexible damping device is arranged outside the basic wall surface of the single pile, wave currents are smoothed and flowing states are improved by utilizing a wing-shaped wall surface with a short head and a long tail, various water power stimulations are reduced from vibration sources, and passed loads are separated and absorbed through viscoelastic damping materials, so that the purpose of reducing pile foundation vibration is achieved. According to the reduction method for the basic wave current vibration of the offshore wind power single pile, the damping device which automatically moves up and down along water level change is always in a main stimulation area of the wave currents by changing water body weights inside a balancing water tank and adjusting relative position of a device and the water surface and under combined actions of the gravity and buoyancy force, the damping device enables the head and tail to be maintained consistent with wave current directions and plays role in damping flexibly along with change of wave current directions under combined actions of head pressure and tail suction of the wing-shaped overflowing wall surface. The reduction method for the basic wave current vibration of the offshore wind power single pile has the advantages of enabling the pile foundation vibration to be reduced by more than 70 % and being simple in structure and convenient to achieve.

Owner:NANJING HYDRAULIC RES INST

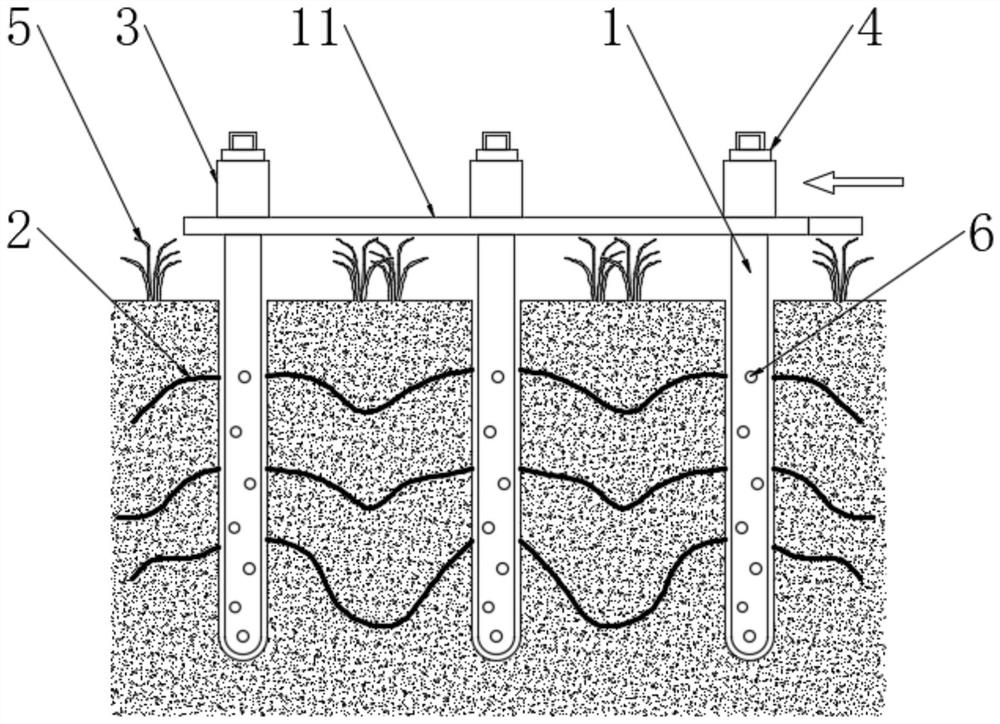

A parallel restoration method for farmland heavy metal pollution

ActiveCN111589851BImprove propertiesImprove repair efficiencyContaminated soil reclamationSoil-working methodsMagnetic effectSoil science

The invention discloses a parallel restoration method for heavy metal pollution in farmland, which belongs to the technical field of heavy metal pollution restoration. It can be implemented by embedding repair rods in the soil, and uniformly discharging and collecting materials through the soil filter screen, so as to directly The way of water injection penetrates into the soil autonomously, and is doped with heavy metal scavenger and repair microspheres. The heavy metal scavenger uses the infiltration of water to capture the heavy metal ions in the soil and forms insoluble substances, while the repair microspheres infiltrate simultaneously In the process of peeling off the surface, the nutrients are continuously released into the soil to improve the soil properties. At the same time, the insoluble heavy metals are adsorbed and captured, and the magnetic effect of the repair microspheres is used to assist diffusion in the soil and intersect to form a tight repair. Finally, the residual repair microspheres and heavy metals are recovered through a magnetic field, which not only significantly reduces the cost of repair, but also greatly improves the efficiency and effect of repairing heavy metal pollution in farmland.

Owner:广西盎之然环保科技有限公司

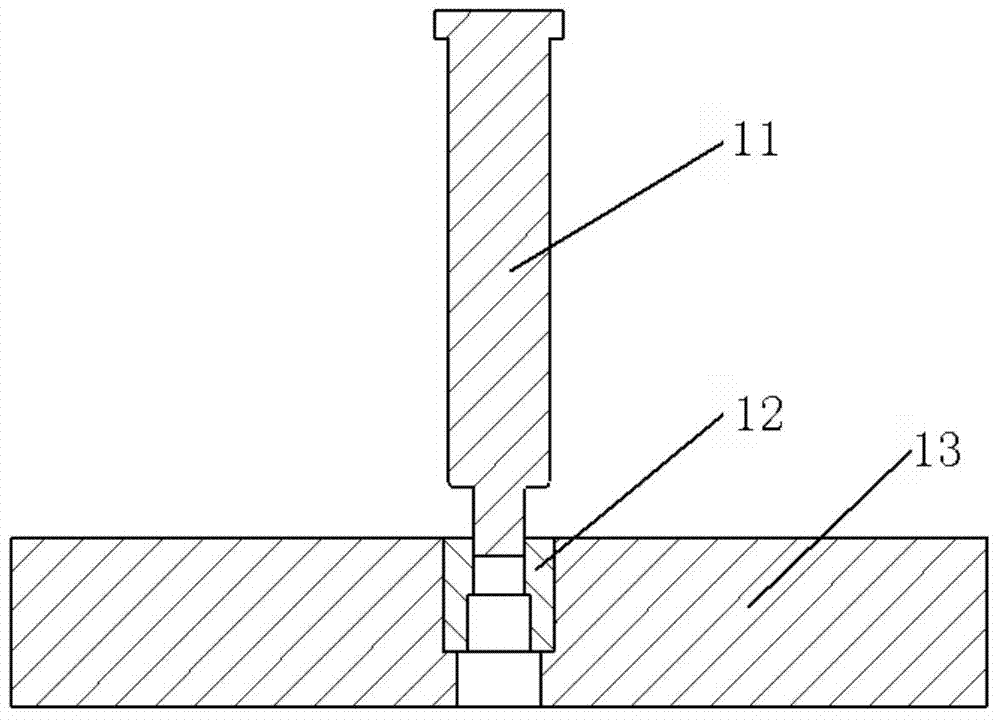

Connecting processing technology for tube and tube plate

ActiveCN108971710AClosely connectedImprove wear resistanceWelding accessoriesCorrosionHeat exchanger

The invention discloses a connecting processing technology for a tube and a tube plate. The technology comprises the following steps: performing bead weld on the tube plate, and forming a bead weldinglayer; chamfering a tube hole of the bead welding layer on the tube plate; enabling the tube to penetrate into the tube hole in the tube plate, wherein the end part of the tube is aligned to the beadwelding layer; performing expanded connection on a welding area of the tube and the tube plate; welding the tube and the tube plate, and welding by using an autopulse argon tungsten-arc welding filling wire; and performing the expanded connection on a non-welding area of the tube and the tube plate. The connecting processing technology for the tube and the tube plate is capable of increasing wearresistance and corrosion resistance of the tube plate through the bead welding layer, eliminating a gap of the welding area of the tube and the tube plate through the first expanded connection beforewelding, improving welding quality, welding by using the chamfering filling wire, reducing a leakage risk, eliminating a gap of the non-welding area of the tube and the tube plate through the secondexpanded connection after welding, preventing liquid or impurities from entering so that corrosion is generated to cause a failure welding joint, through the previous and later two times of the expanded connection and chamfering filling wire welding, guaranteeing connecting quality of the tube and the tube plate. The connecting processing technology for the tube and the tube plate is suitable forthe field of heat exchangers.

Owner:DONGFANG (GUANGZHOU) HEAVY MASCH CO LTD

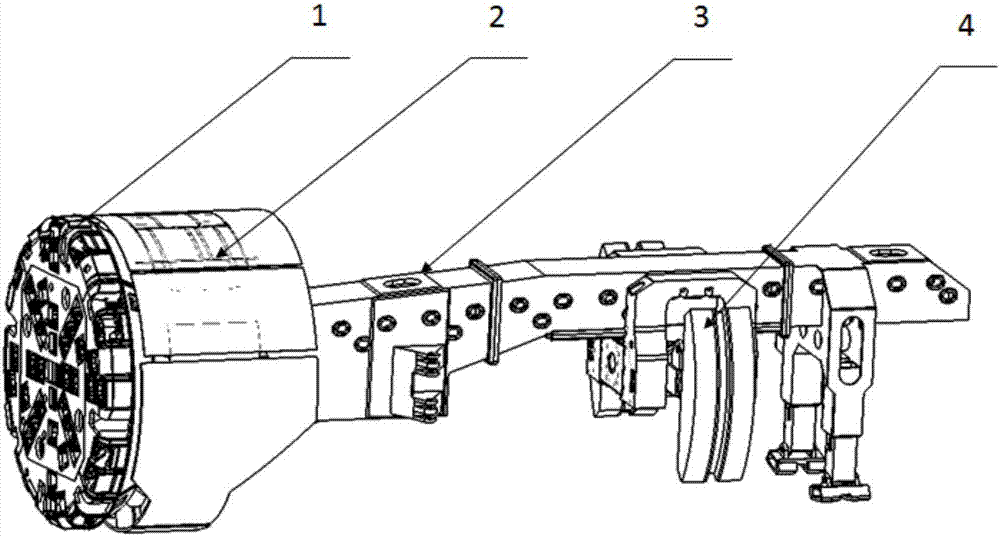

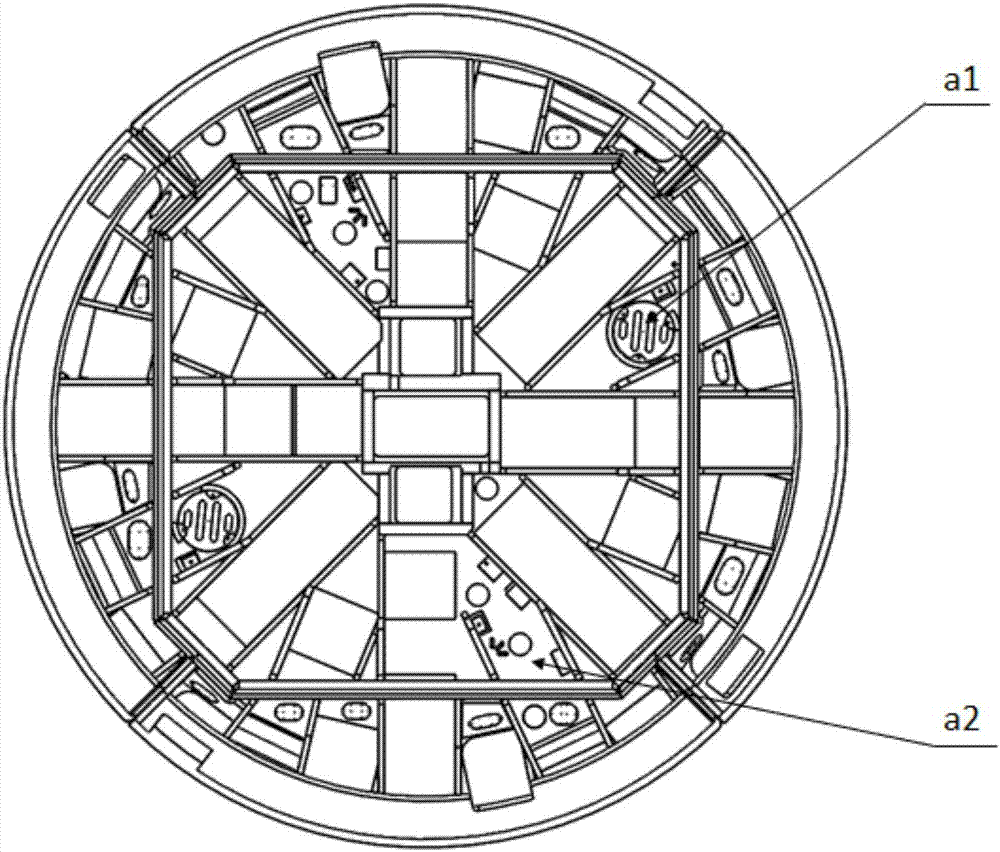

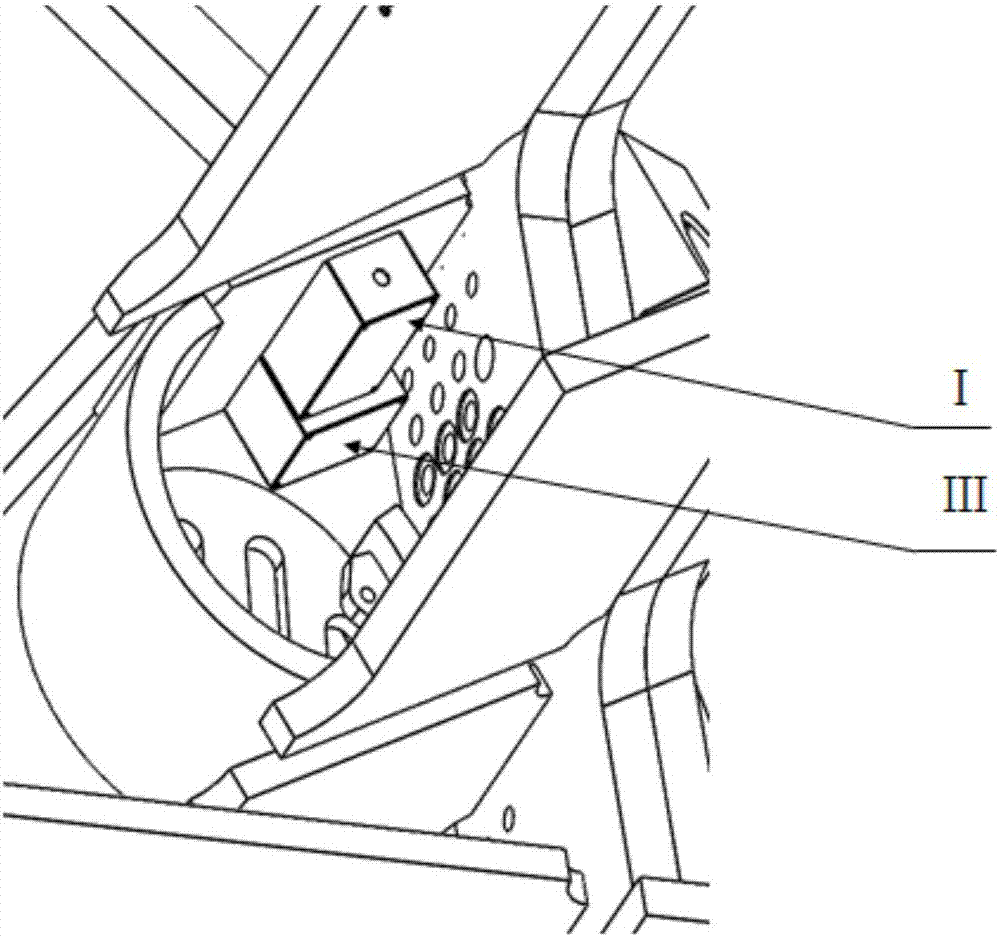

Method for monitoring vibration and strain of key parts of full-face rock tunnel boring machine

ActiveCN107420105ASafe and reliable workTimely reminder for maintenance and overhaulTunnelsFatigue damageUnit system

The invention provides a method for monitoring vibration and strain of key parts of a full-face rock tunnel boring machine and belongs to the technical field of real-time monitoring of underground construction for full-face rock tunnel boring machines. The invention is intended to provide a monitoring device and an all-weather monitoring warning system thereof. A vibration and strain sensor and a wireless data transmission system therein are used to acquire monitoring data in order to provide long-term real-time monitoring for vibration and strain states of key parts of a TBM (tunnel boring machine) main unit system during operating, operators can be reminded of performing maintaining in time, fatigue damage of key weak parts of the TBM main unit system is prevented, and operational safety and reliable of the TBM are ensured. The invention also provides a method for evaluating strain state of parts unable to be measured, namely, an equivalent mapping method. Therefore, a complete system for monitoring vibration and strain of key parts of the TBM main unit system in the whole process is constructed.

Owner:DALIAN UNIV OF TECH

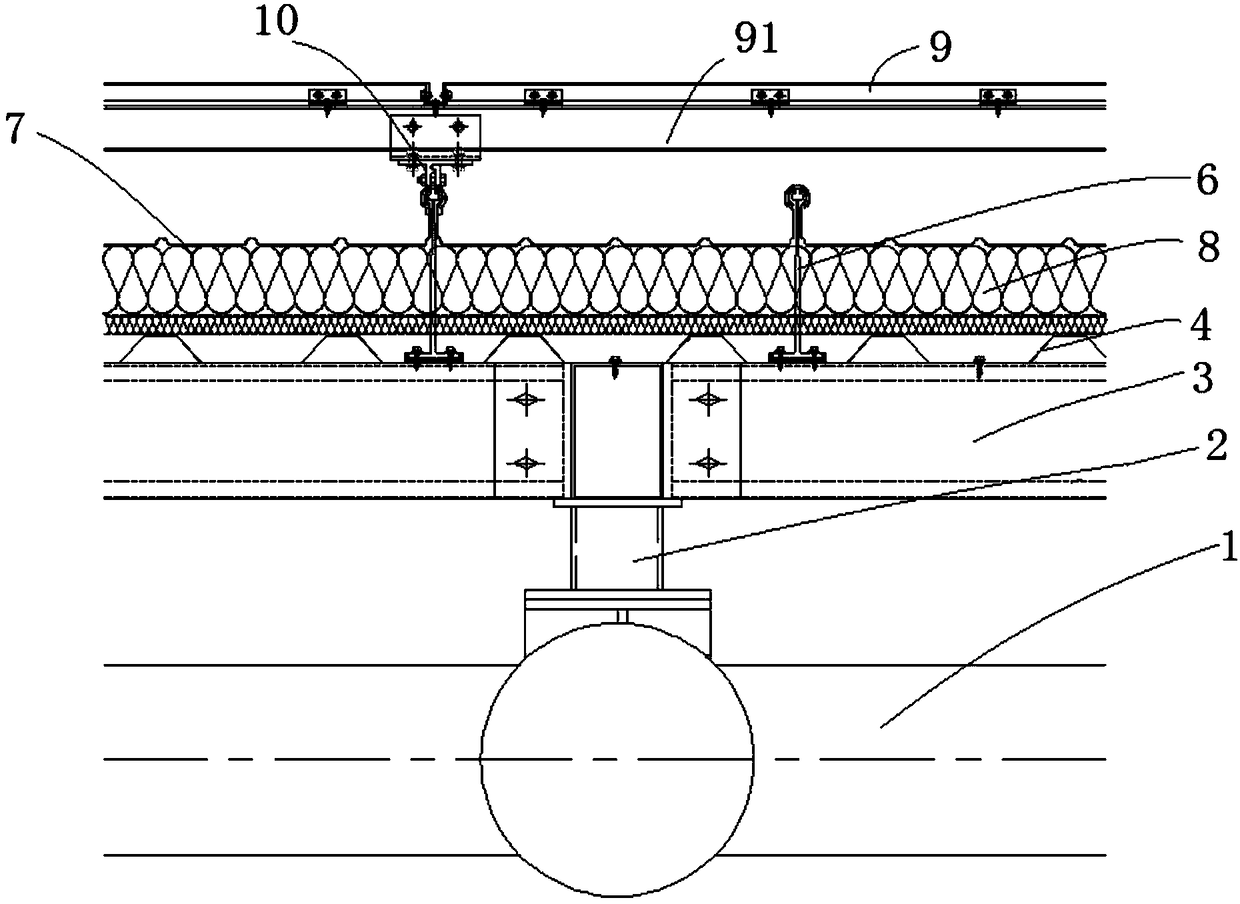

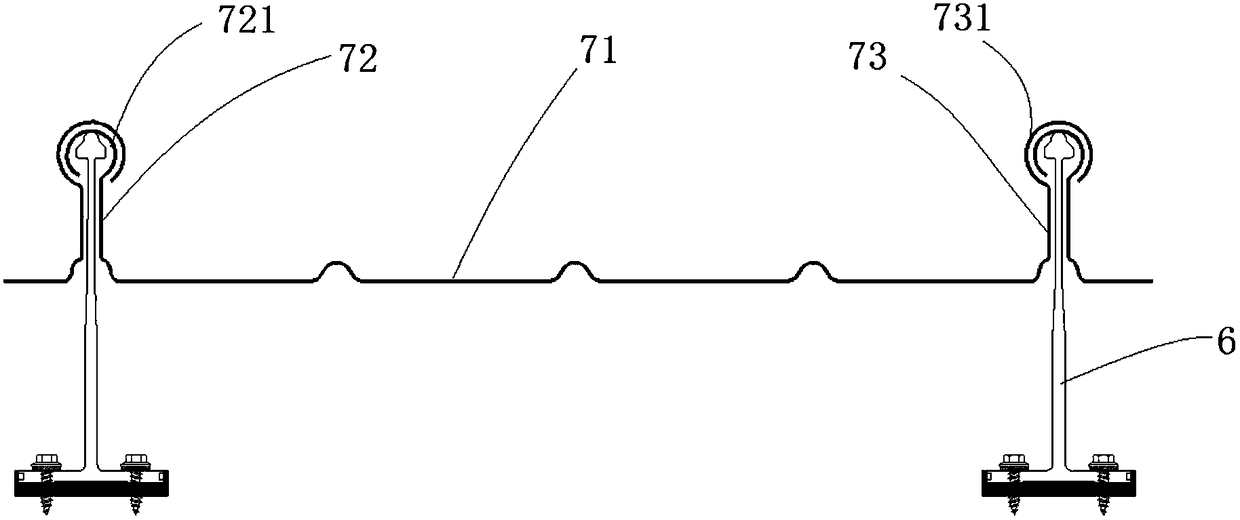

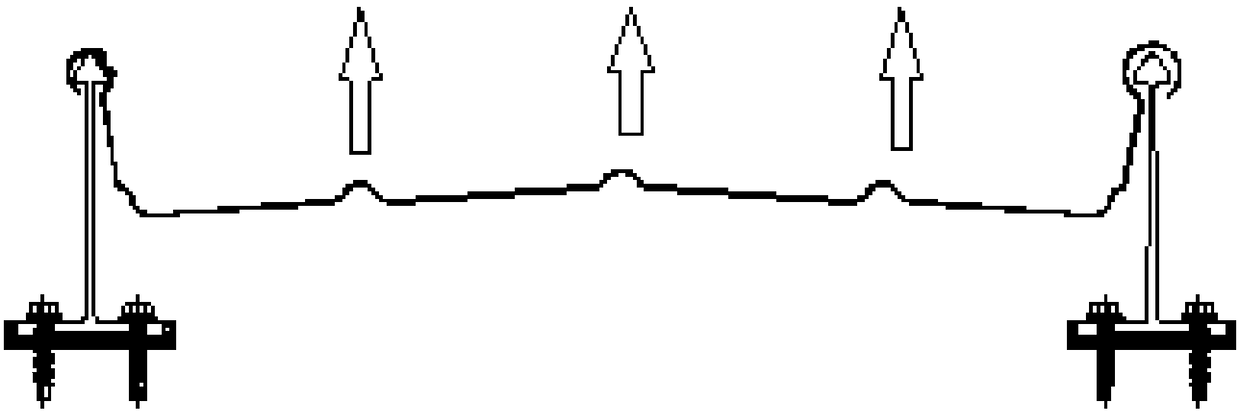

Anti-typhoon and anti-leakage metal roof system

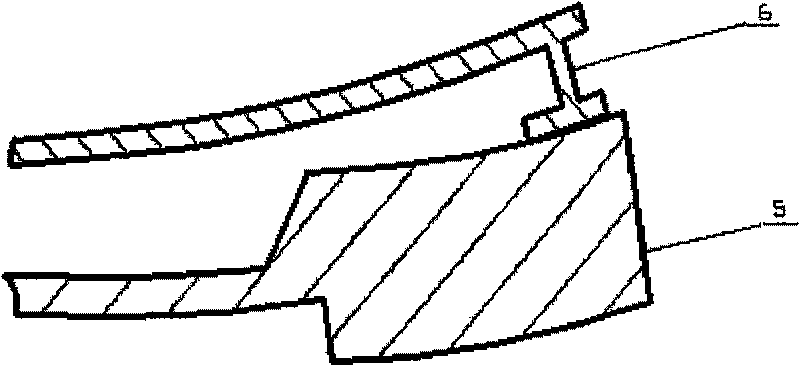

PendingCN108590007AAvoid fatigue damageNo stress concentration problemsBuilding roofsRoof covering insulationsThermal insulationEngineering

The invention discloses an anti-typhoon and anti-leakage metal roof system. The metal roof system sequentially comprises a main steel structure, main roof purline, secondary roof purline, pressed steel bottom plates and purline laid on the pressed steel bottom plates from top to bottom. A plurality of fixed seats are fixed to the purline at intervals, concave roof plates which are engaged with thefixed seats are arranged between the fixed seats, and multiple layers of sound-insulation and vapor-proof thermal insulation materials are laid on the pressed steel bottom plates. The fixed seats include fixed supporting seats and panel engaging plates, wherein the purline is fixedly connected with the lower ends of the fixed supporting seats; the panel engaging plates are fixedly connected withthe fixed supporting seats, and small angles are formed between the panel engaging plates and the fixed supporting seats in the length direction of the roof plates so that the panel engaging plates and the fixed supporting seats can rotate relatively; and panel engaging parts are formed in the upper parts of the panel engaging plates, and the panel engaging parts and both side edges of the roof plates form engaging connection. The anti-typhoon and anti-leakage metal roof system solves the problems that a traditional metal roof system with vertical lockrands has low wind resistance, and is prone to leaking and prone to producing expansion deformation damage, and the safety of upper supporting facilities is affected.

Owner:CENT INT GROUP +1

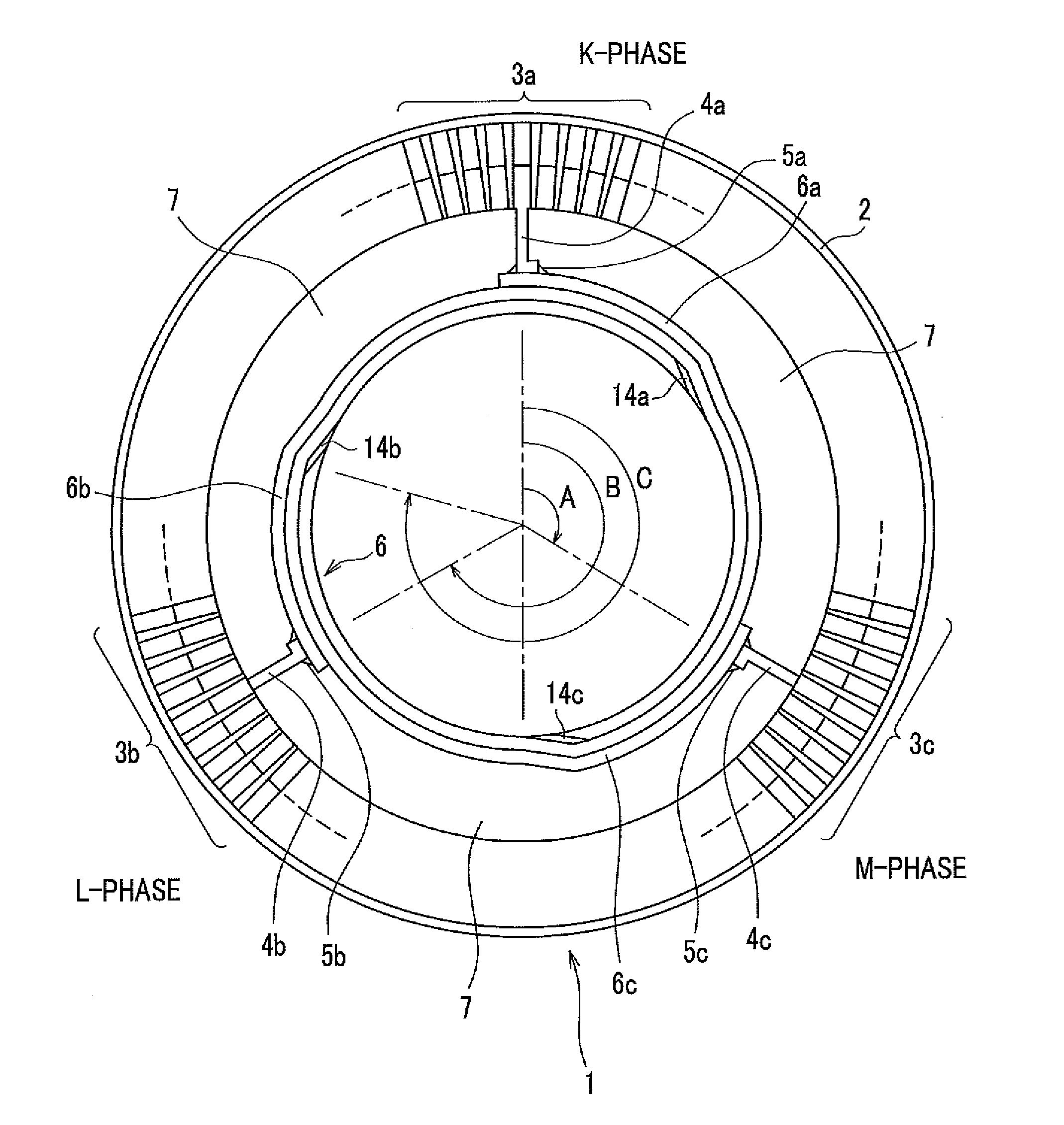

Neutral Ring for Use in Rotating Electrical Machine and Method for Manufacturing the Same

ActiveUS20160043603A1Relieve pressureAvoid fatigue damageManufacturing stator/rotor bodiesApplying solid insulationElectrical and Electronics engineeringEngineering

A rotating electrical machine includes a rotor core, a rotor shaft, a coil, a bind, a lead-out wire of which one end is connected to the coil and the other end is connected to a neutral ring. A filling is filled between the coil and the neutral ring. The neutral ring is formed with a plurality of members that are connected with one another to have flexibility.

Owner:HITACHI IND PROD LTD

Vibration inducing device for strengthening heat exchange of elastic tube bundle heat exchanger

InactiveCN101738129BAvoid fatigue damageImprove heat transfer efficiencyHeat transfer modificationEngineeringHeat exchanger

The invention discloses a vibration inducing device for strengthening the heat exchange of an elastic tube bundle heat exchanger. The vibration inducing device may have the vibration type, frequency and amplitude which are required by a heat exchanger bundle, improves the heat exchange efficiency and avoids damage to the heat exchanger bundle due to fatigue. The vibration inducing device comprises a water inlet tube and a pulse flow tube, wherein the water inlet tube and the pulse flow tube are both connected with a tube valve; the pulse flow tube is provided with a water outlet correspondingto floating mass block of the elastic heat exchanger bundle one by one; and a pulse flow generator is arranged on the pulse flow tube and / or the water outlet.

Owner:SHANDONG UNIV

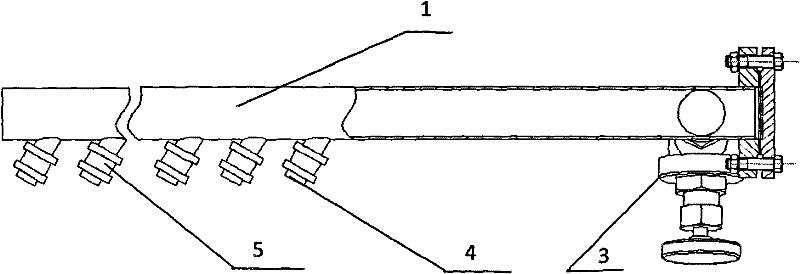

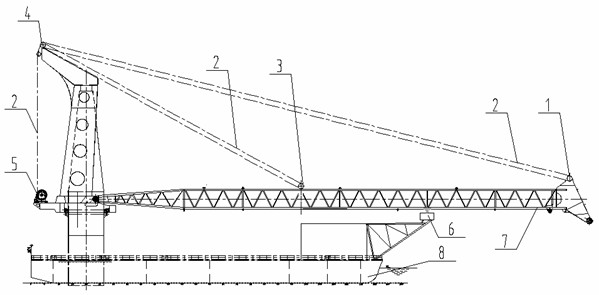

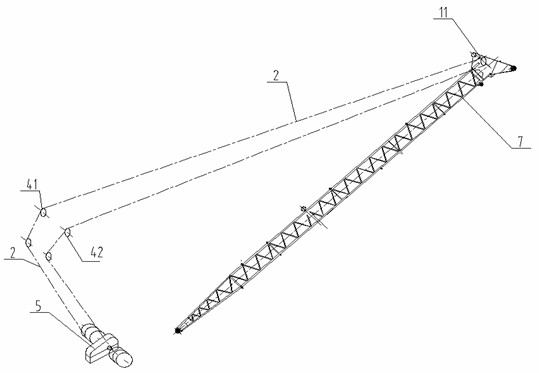

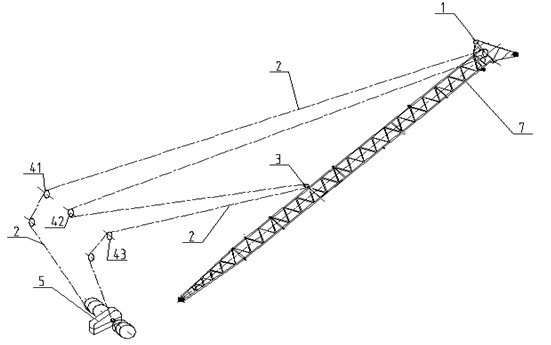

Pretension and lay-off method and device of crane jib for ship

InactiveCN101983894AReduce supportAvoid fatigue damageCargo handling apparatusPassenger handling apparatusEngineeringWinch

The invention relates to a pretension and lay-off method of a crane jib for a ship, belonging to the technical field of a crane. The crane comprises a luffing mechanism composed of a top pulley block, a jib, a winch, a luffing wire rope and a jib head pulley block and a bracket. The method comprises the following steps: A. operating the winch in the forward direction, loosening the jib and layingoff the jib onto the bracket; and B, operating the winch in the reverse direction, pulling the jib upwards to enable the pressure of the jib on the bracket to be less than the pressure on the bracketbefore being subjected to the upward pull, and stopping and shutting off the winch. The invention also relates to a pretension and lay-off device of a crane jib for a ship. The luffing mechanism alsocomprises a middle pulley arranged at the middle of the jib, and the luffing wire rope is connected with the jib head pulley block and the middle pulley through the top pulley block. The pretension and lay-off method and device of a crane jib for a ship can produce a pretension force on the jib by means of the luffing wire rope, thereby reducing the self-weight load of the jib as well as the influence and the destruction on the jib structure as a result of the shock load and the changing load of the bracket on the jib. Besides, the invention has the advantages of simple method and structure, convenient operation and low cost.

Owner:QINGDAO HAIXI HEAVY DUTY MASCH CO LTD

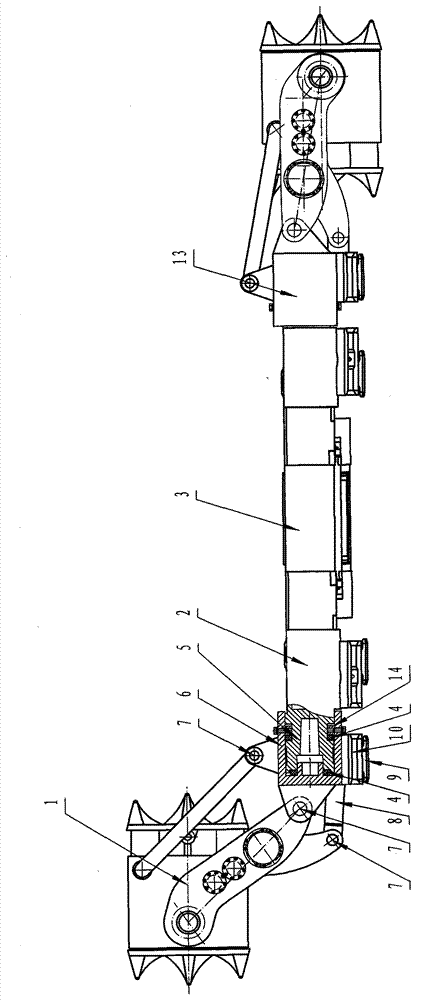

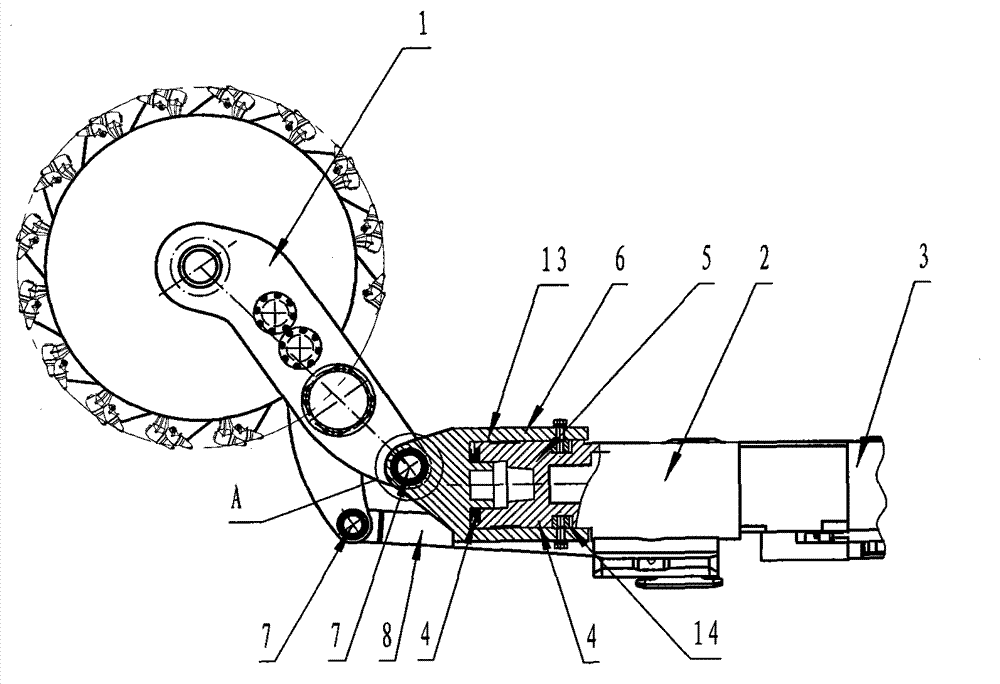

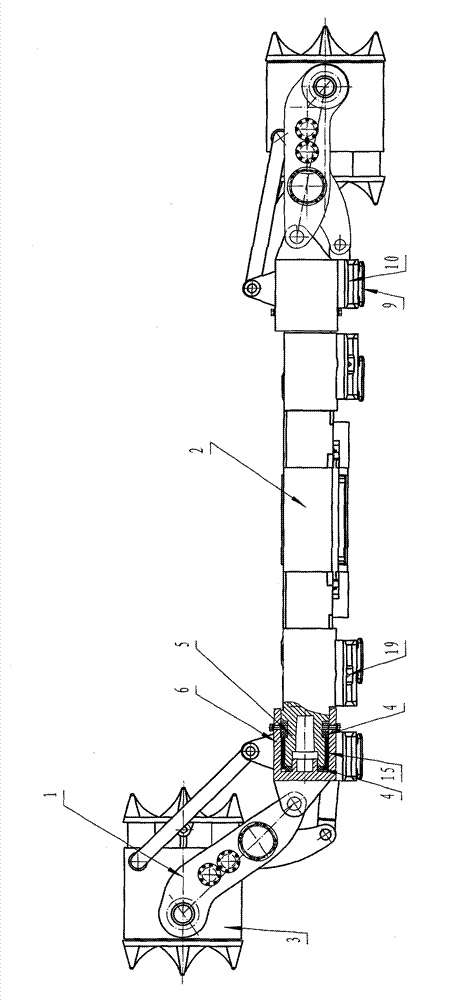

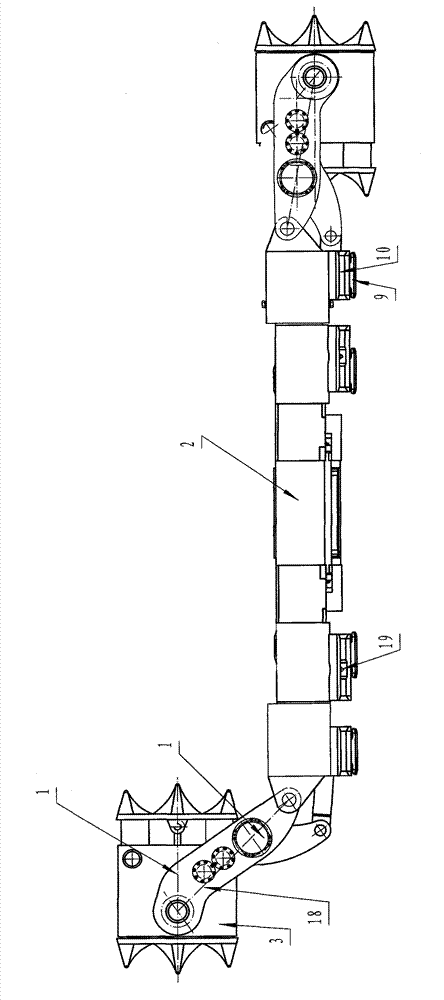

Vibration isolation coal cutter

ActiveCN103016003AWon't twist and cutTwist shearNon-rotating vibration suppressionSlitting machinesFatigue damageFailure rate

The invention relates to a vibration isolation coal cutter, which comprises a cutting mechanism and a body, wherein a buffer mechanism is arranged between the cutting mechanism and the body; the body comprises a traction box; the traction box is provided with a guide piece; the buffer mechanism is provided with a guide sleeve matched with the guide piece; and a buffer is arranged between the guide piece and the guide sleeve. According to the vibration isolation coal cutter, the impact vibration generated by a cutting part can be isolated, the impact on a traction part and the body is reduced, each connecting and fixing piece is prevented from loosening, the fatigue damage of each connecting piece is avoided, the failure rate of the coal cutter is reduced, and the working efficiency of the coal cutter is improved.

Owner:刘素华

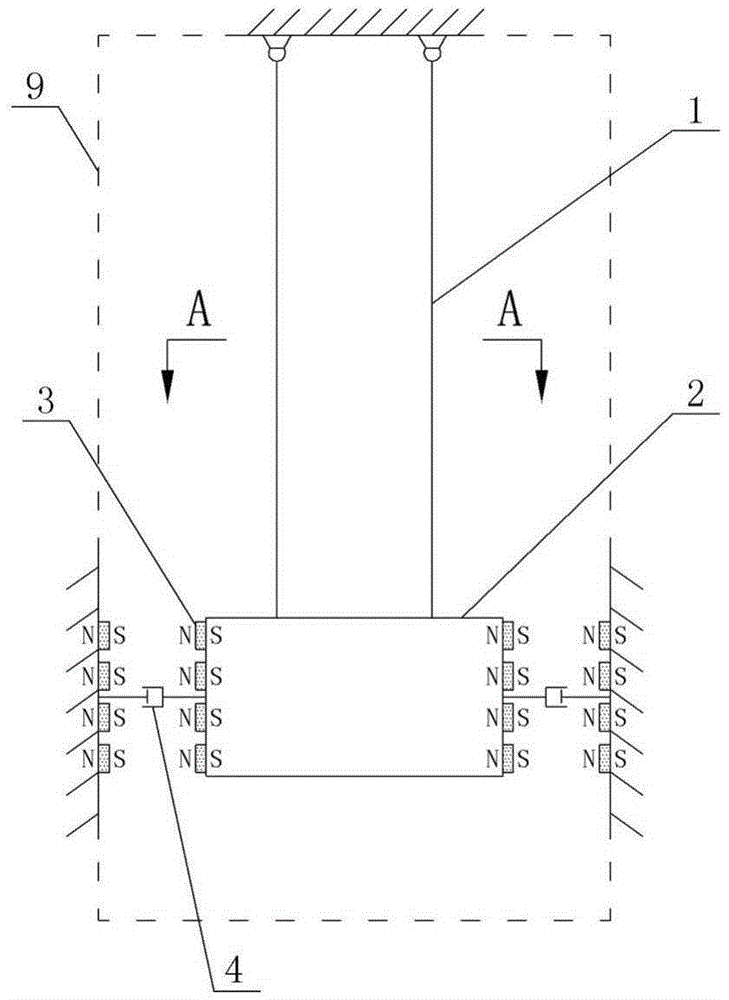

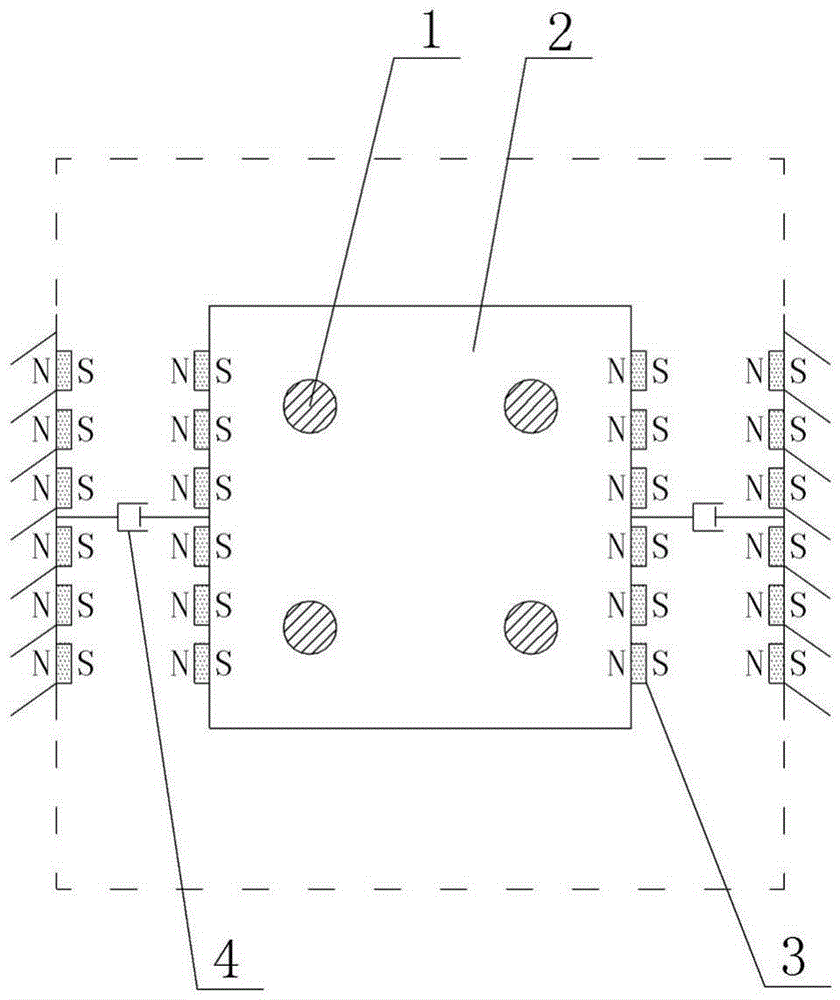

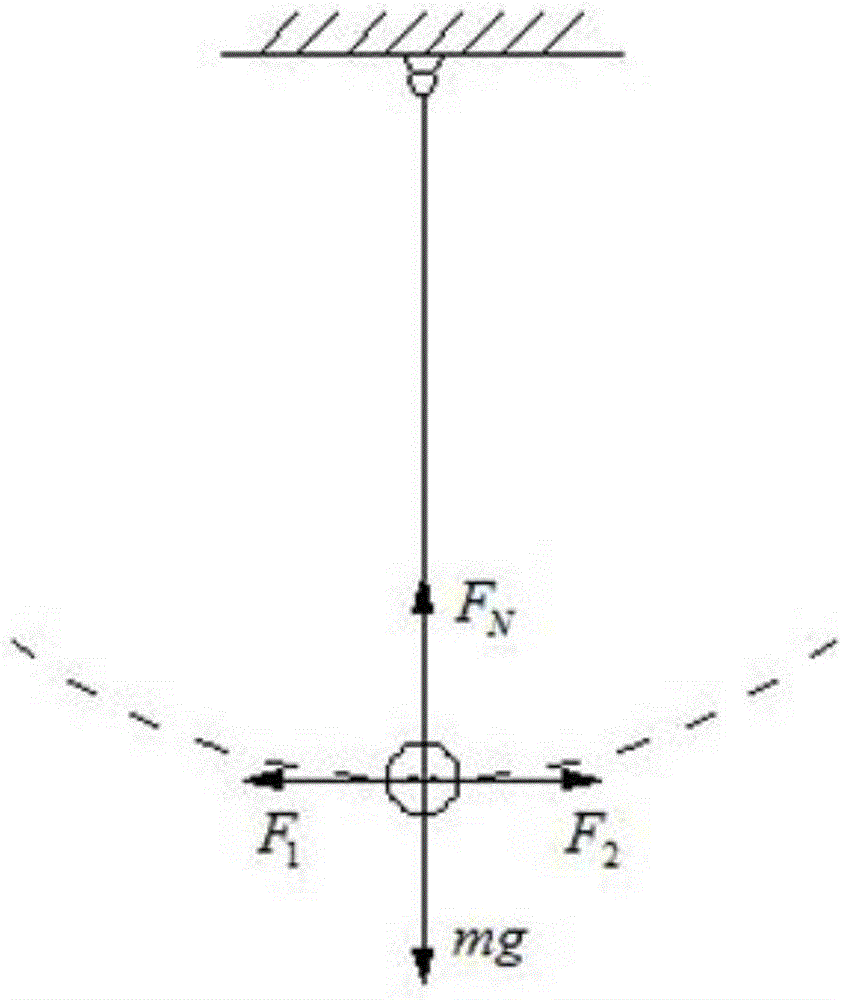

Ultralow frequency swinging type tuning mass damper and achieving method thereof

ActiveCN104612279AShorten pendulum lengthExpand the scope of engineering applicationsShock proofingEngineeringNegative stiffness

The invention belongs to the technical field of structure vibration control and discloses an ultralow frequency swinging type tuning mass damper and an achieving method thereof. The novel tuning mass damper is formed through an added negative stiffness adjusting device with a novel structure, meanwhile, the achieving method of the tuning mass damper is disclosed, accordingly the swinging length of the ultralow frequency swinging type tuning mass damper (TMD) can be effectively shortened, the mounting space of the TMD is decreased, and the engineering application range of the ultralow frequency swinging type TMD is expanded.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Power switch device

InactiveCN106206109AExtended service lifeImprove reliabilityContact driving mechanismsSwitch power arrangementsFatigue damageAutomatic control

The invention discloses a power switch device. The power switch device comprises a cover plate, an outer shell, a static contact, a moving contact and a moving contact drive assembly, wherein the outer shell is covered with the cover plate; the outer shell is internally provided with the static contact and the moving contact which are coaxial; the moving contact is driven and connected by the moving contact drive assembly so as to realize connection and disconnection with the static contact; and the moving contact drive assembly is driven by using a cam. According to the power switch device, the moving contact is driven by using the cam, the service life of the power switch can be prolonged, a spring is prevented from being used for a long time to cause fatigue damage of the spring, the reliability of the power switch is improved, the operating state of the power switch is guaranteed, a cylinder and a timer are arranged, automatic control of the power switch can be realized, and timing control is realized; and moreover, arc chutes can reduce the influence of internal arcs, radiator fans can effectively adjust heat and moisture inside the power switch, the operating environment of the power switch is guaranteed, and the service life of the power switch is further prolonged.

Owner:XIHUA UNIV

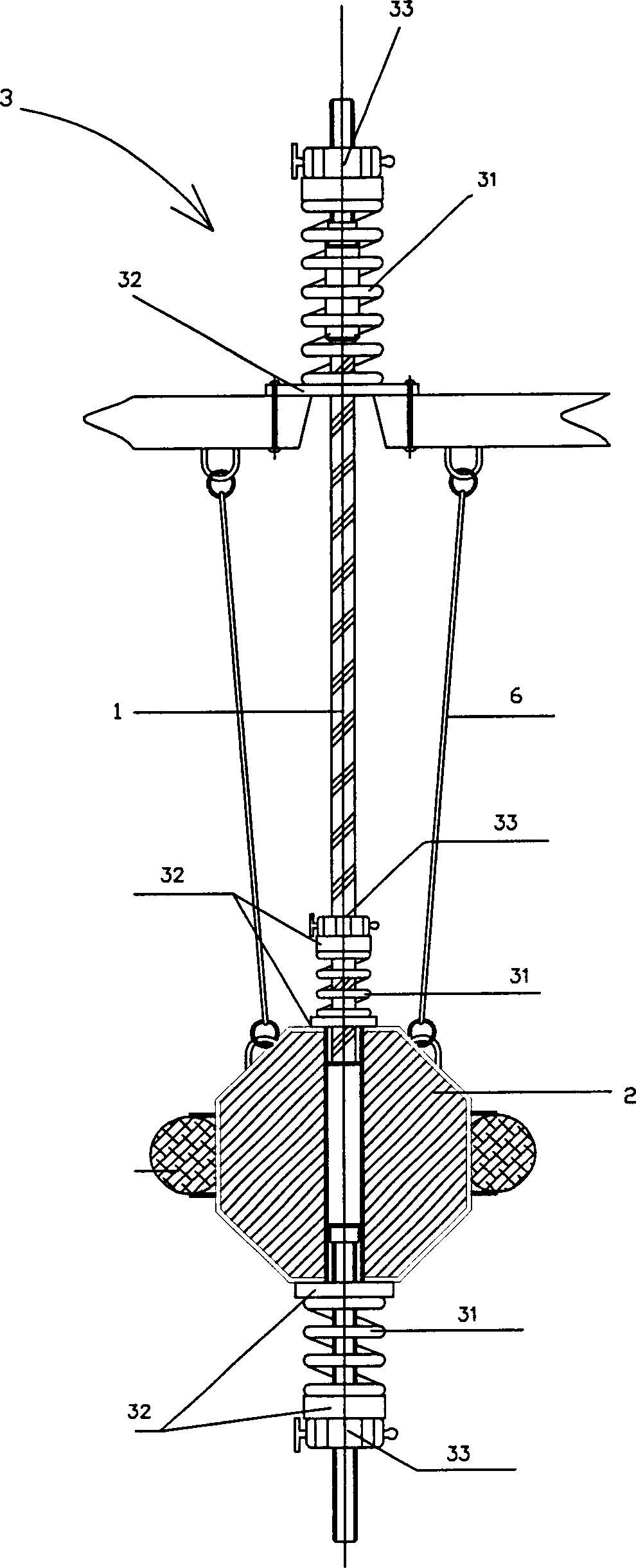

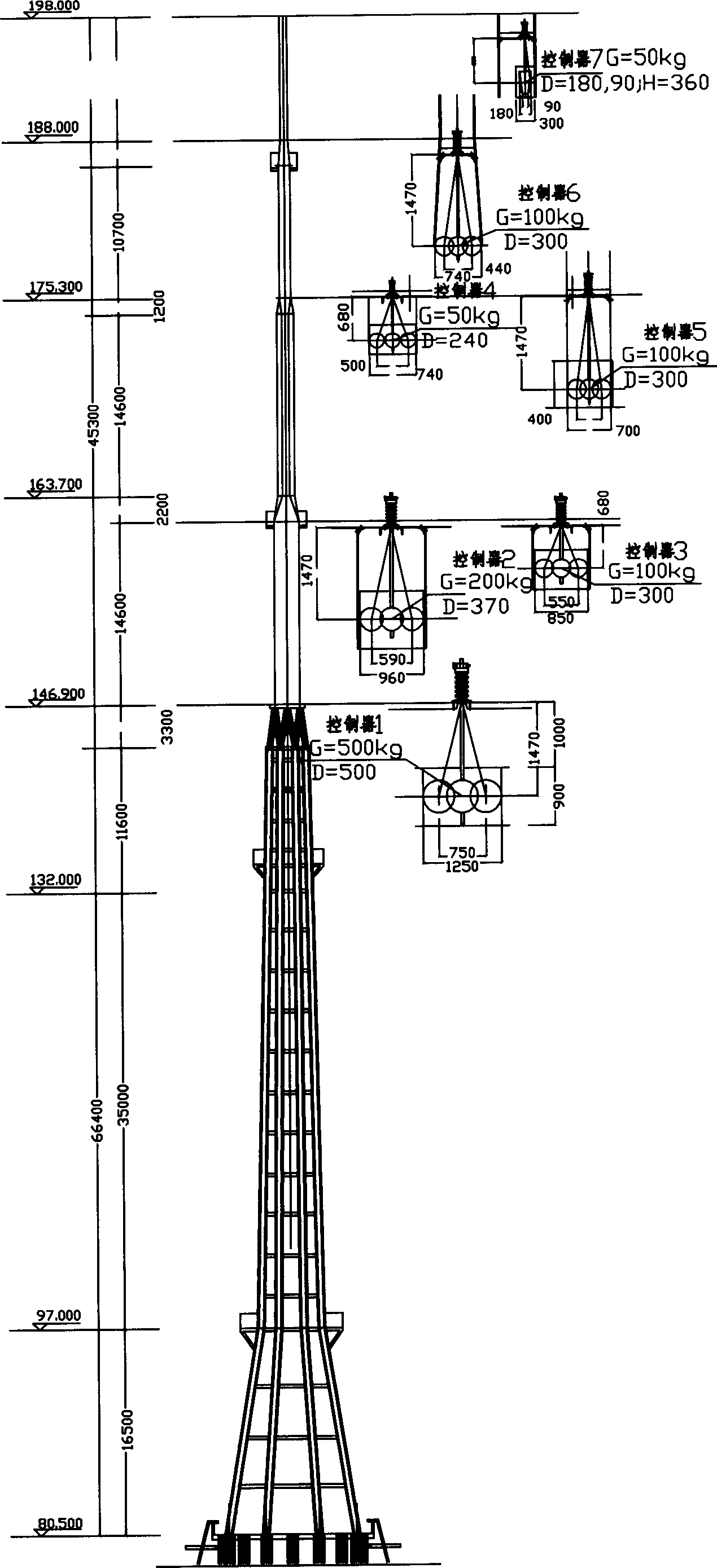

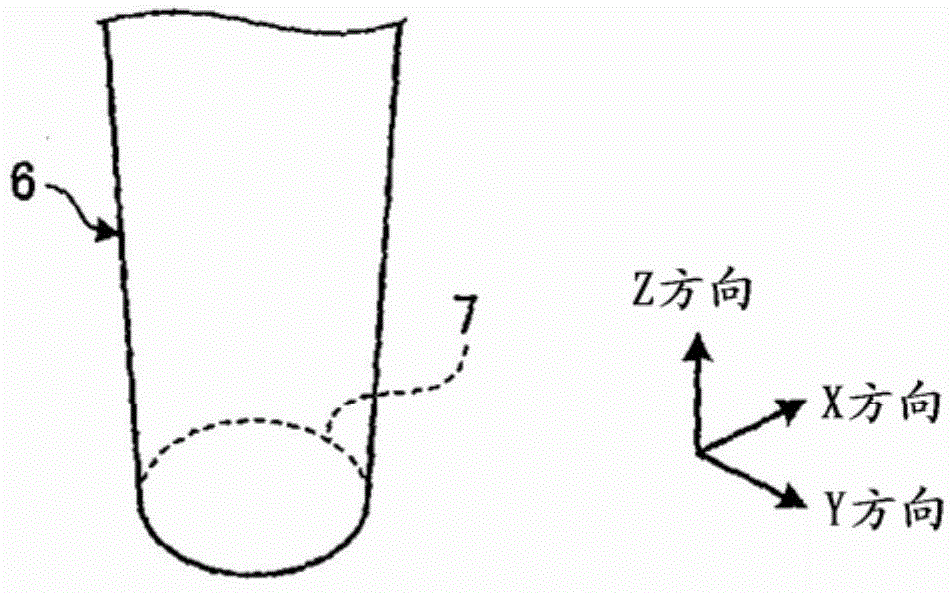

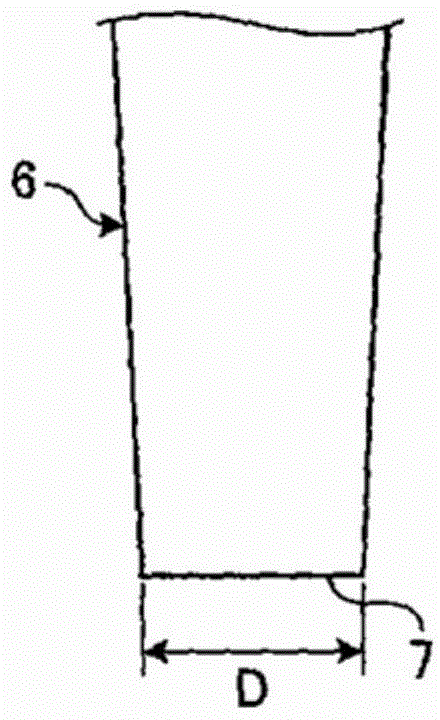

Dynamic vibration absorption and energy consumption apparatus for reducing wind vibration response of high tower structure

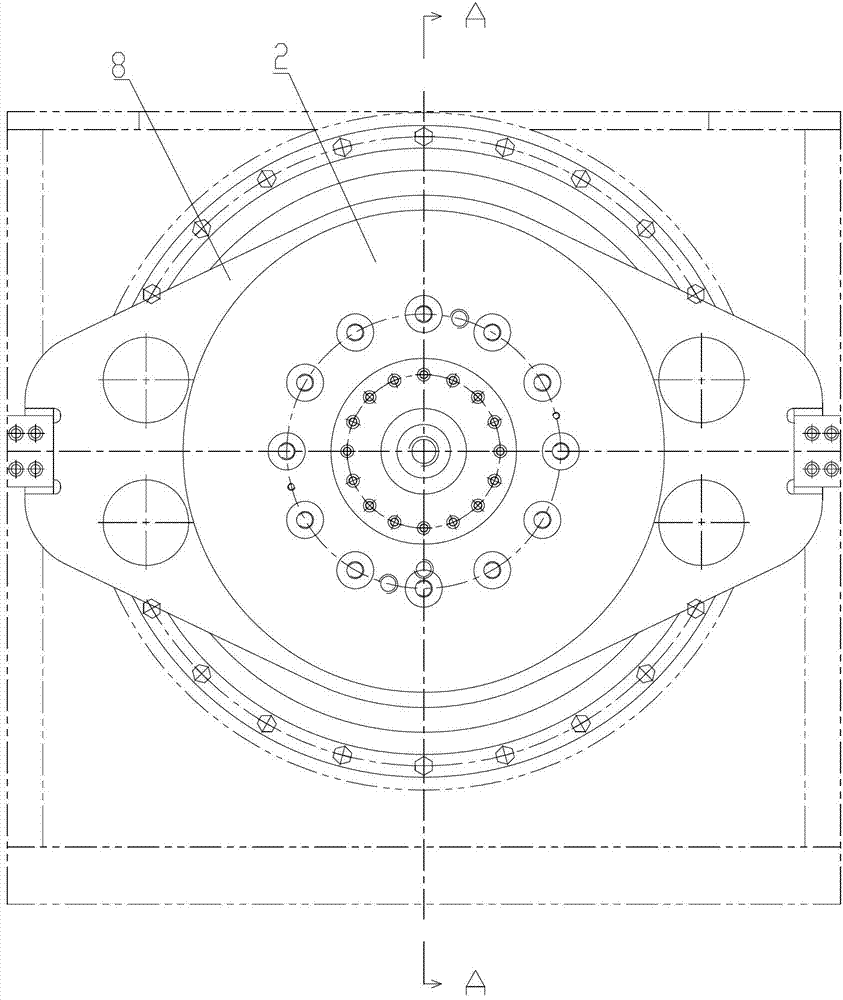

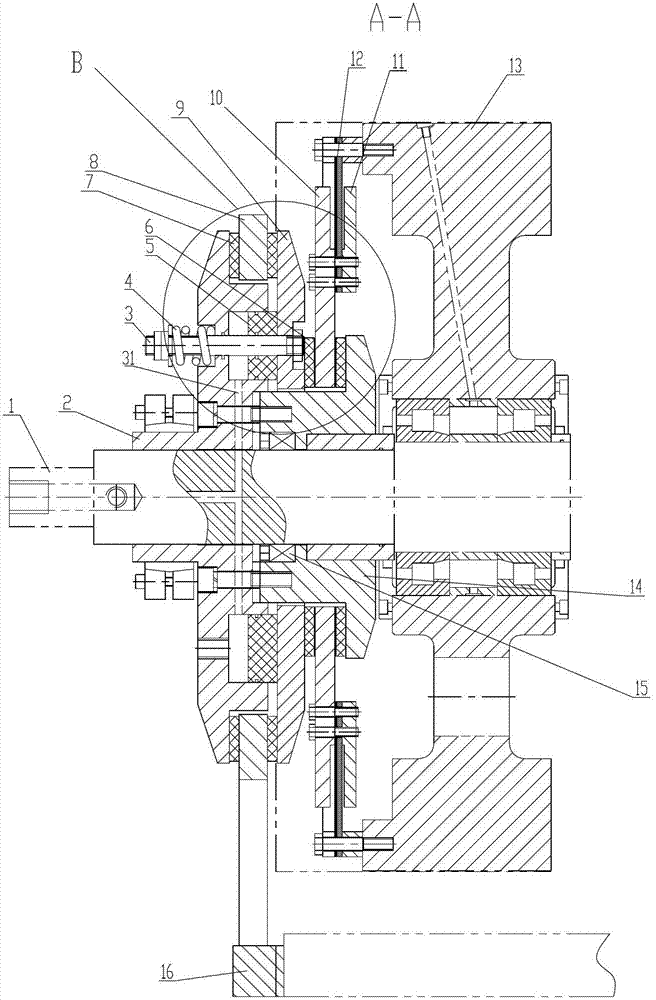

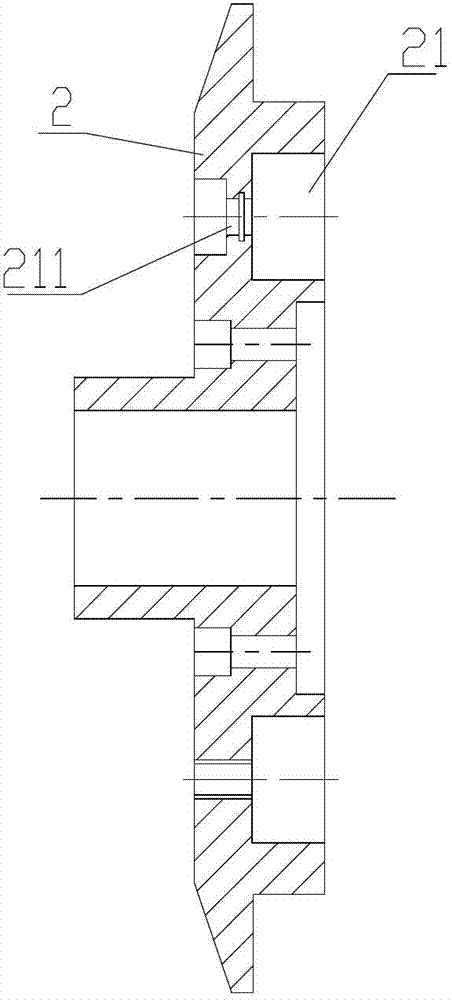

The invention discloses a dynamic shock-absorbing and dissipating energy device of reducing high tower structure wind vibration response, which comprises the following parts: steel pendulum tie1 whose one end hangs on the structure6, another end hangs with mass block2; the block2 can be used for boring iron shot or casting aluminum steel ball; the pendulum tie1 crosses the hole; the antifatigue damage device is installed in suspension construction; the pendulum tie1 crosses cylindrical compression spring31, whose both extremities of perforated bearing plate32 are clamped by fastener33; the upper, lower end of pendulum tie on mass block2 install antifatigue damage device3; the periphery of mass block is fixed with bump amortization dissipating energy component rubber ring4 whose amortization is more than 5%; There is a protection and repair suspender5 between structure6 and mass block. The control structure is effective, simple and reliable, which is installed in the mast cartridge for vibration damping control the mast structure shacking; the invention improves the control effect, which avoids the big and complicated device.

Owner:深圳中建院建筑科技有限公司

Method for minimizing fatigue damage in welded structure, tool for forming strike mark, and welded structure

ActiveCN103958116AAvoid fatigue damageFurnace typesWelding/soldering/cutting articlesFatigue damagePeening

A method for minimizing fatigue damage in a welded structure by minimizing the fatigue damage produced in the welded portion of the welded structure. In this method, a substantially linear weld bead is curved in an arc-shape along a direction that transverses the weld bead at a right angle on the surface of a base material adjacent to the bead in the welded portion, and a strike mark is formed through hammer peening or ultrasonic shock peening using a tool for forming a strike mark having at the tip a strike-mark-forming surface with the center of curvature skewed to one side of two end surfaces mutually parallel along the weld bead; a strike mark is formed on the surface of the base material adjacent to the substantially linear and curved weld bead through hammer peening or ultrasonic shock peening using a tool for forming a strike mark having at the tip a planar strike-mark-forming surface with an overall circular or elliptical shape; and fatigue damage on the welded portion is minimized by introducing compressive residual stress in the vicinity of a weld bead toe with the tool for forming a strike mark.

Owner:JFE STEEL CORP

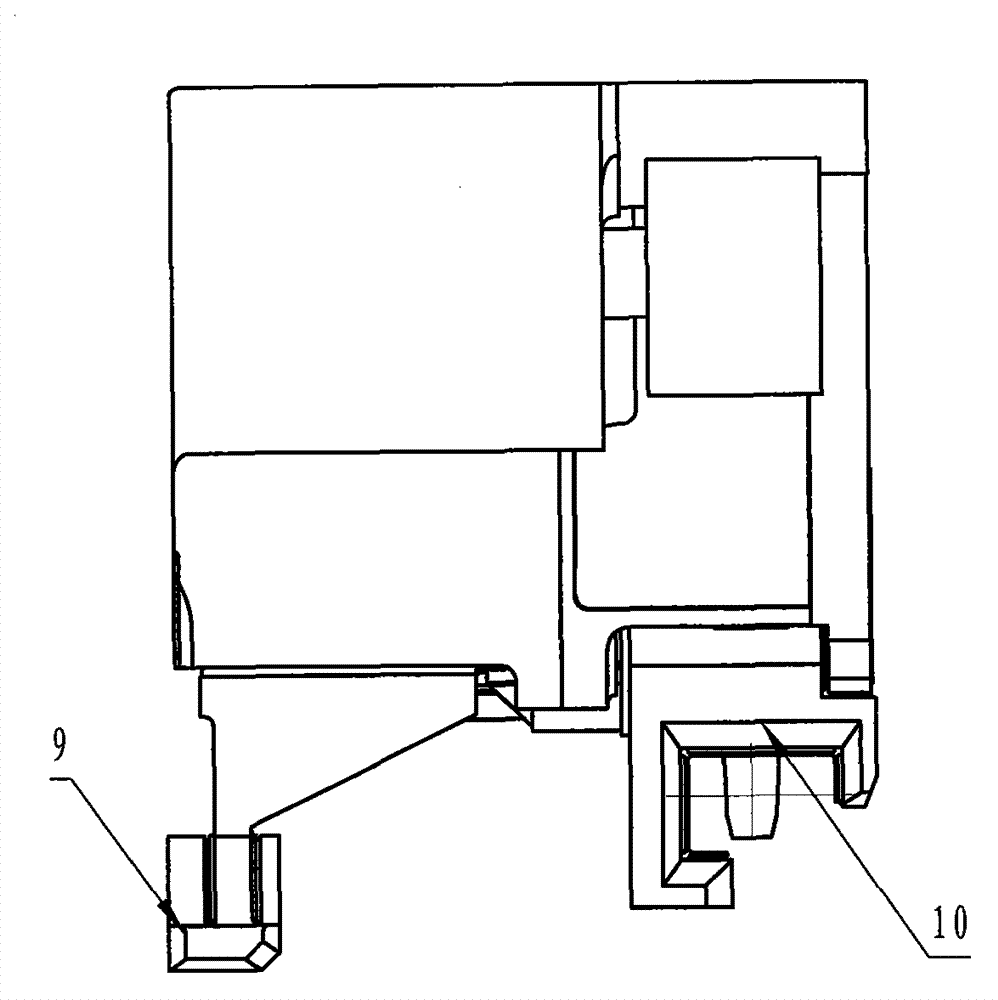

Hydraulic clutch brake device of punch press

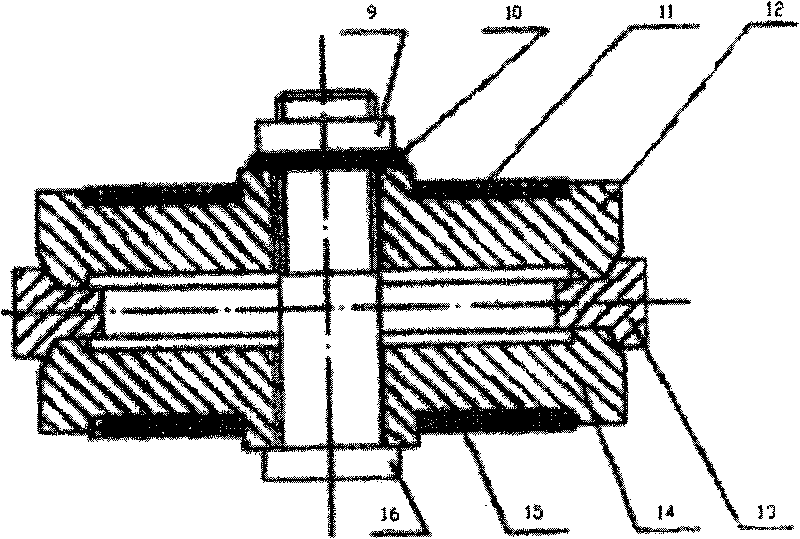

ActiveCN102767584AReduce processing stepsSimple processing technologyCoupling-brake combinationPressesClutchFlywheel

The invention discloses a hydraulic clutch brake device of a punch press and relates to improvement of the hydraulic clutch brake device of the punch press. According to the hydraulic clutch brake device of the punch press, a forward driving mechanism and a reverse driving mechanism are integrated, so that the whole structure is simple, the stress state can be improved, and the service life of parts can be prolonged. The punch press comprises a machine body, a flywheel, a crankshaft and a hydraulic source, the hydraulic clutch brake device is arranged between the crankshaft and the flywheel, a brake ring is fixedly arranged on the machine body, a hydraulic cylinder is connected with an operating ring through an axial opening / closing moving driving mechanism, the axial opening / closing moving driving mechanism comprises a piston rod, a piston and a return spring, and the piston rod also serves as a return guide rod. According to the hydraulic clutch brake device of the punch press, the return rod and the piston rod are integrated, and in order to ensure that the separation is clear, a clutch plate of the device and the flywheel of the device are connected through a steel spring plate, so that the clutch plate is effectively separated from a starting friction plate.

Owner:YANGZHOU FORGING MACHINE TOOL

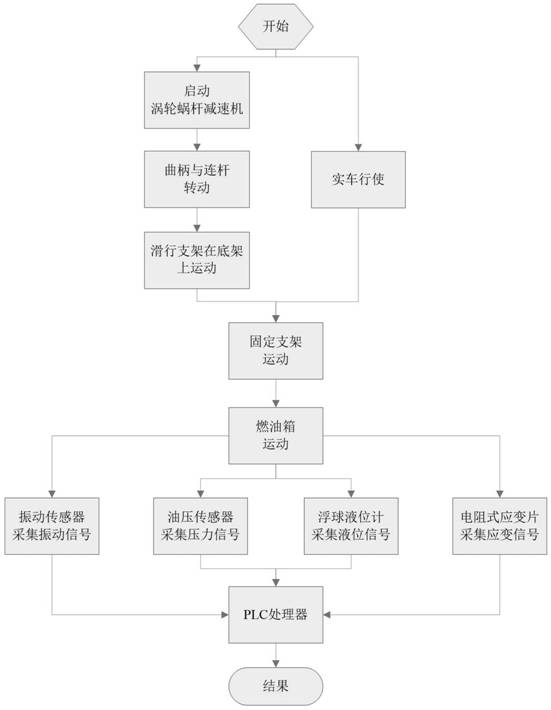

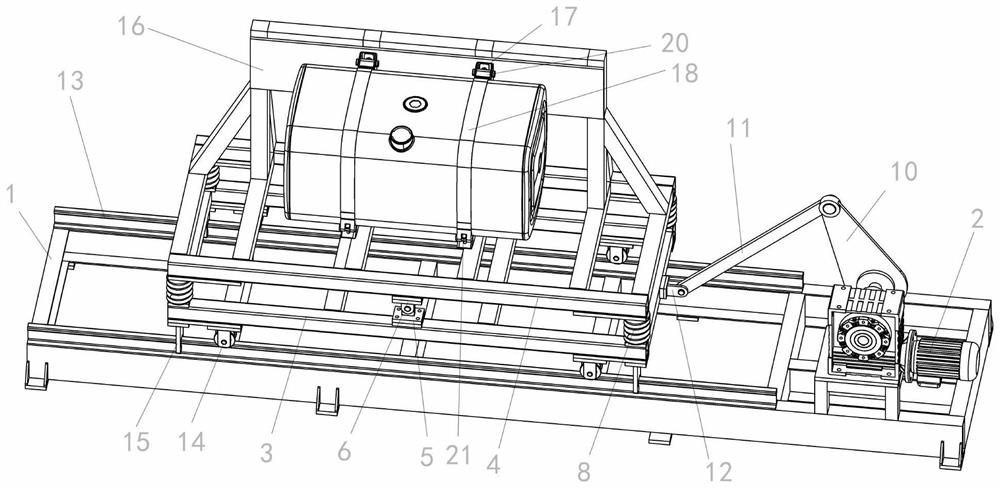

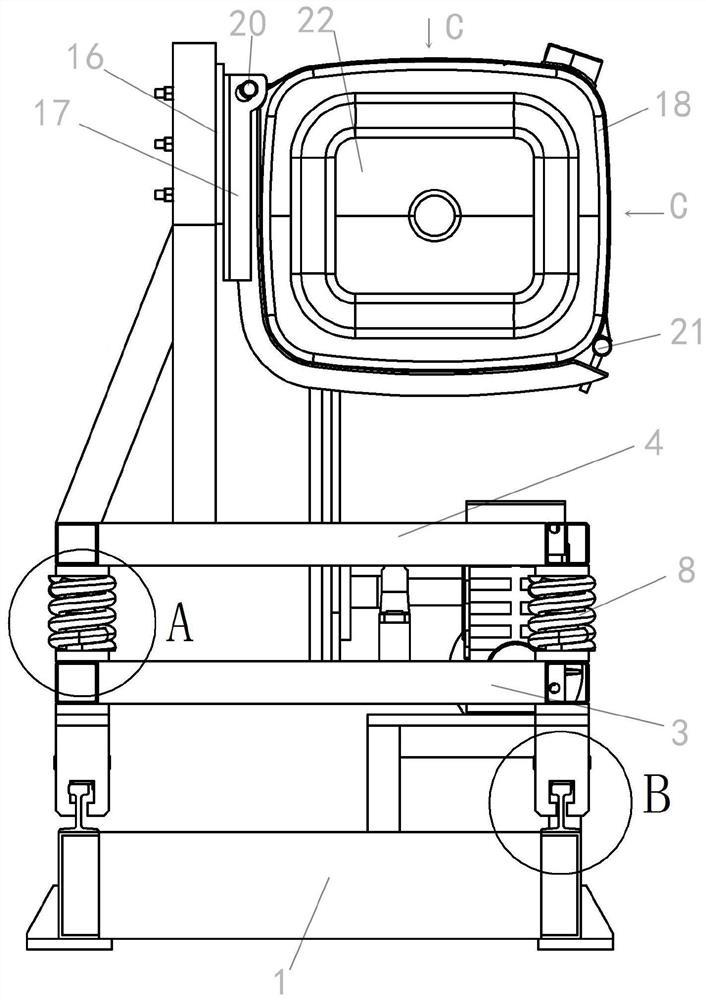

Heavy truck fuel tank oil shaking characteristic test device and test method

The invention discloses a heavy truck fuel tank oil shaking characteristic testing device and method, and belongs to the technical field of oil tank testing. The device comprises a power unit and a test piece connecting unit, the power unit comprises a bottom frame and a driver, the bottom frame is fixedly arranged on the ground, the driver is installed on the bottom frame, and a reciprocating transmission mechanism is arranged at the output end of the driver; the test piece connecting unit comprises a sliding bracket, a fixed bracket and an oil tank connecting piece; the sliding support is slidably arranged on the bottom frame, the sliding bracket is movably connected with the reciprocating transmission mechanism; first hinge supports are fixedly connected to the middle positions of the front side and the rear side of the sliding bracket, second hinge supports are fixedly connected to the middle positions of the front side and the rear side of the fixed bracket, the two second hinge supports and the corresponding first hinge supports are jointly connected with connecting pins, an elastic buffer structure is connected between the fixed bracket and the sliding bracket, and the oil tank connecting piece is fixedly installed on the fixed bracket. The motion condition of the fuel tank of the heavy truck is truly simulated, and a positive effect is achieved for the structural improvement or research and development of the fuel tank.

Owner:ANHUI FUMA AUTO PARTS GRP CO LTD

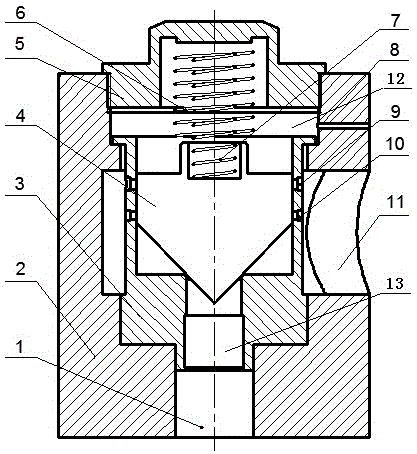

Two-stage double-spring direct relief valve and control method thereof

InactiveCN105090152ARegulating pressureTwo stage pressure regulationServomotor componentsEqualizing valvesInternal pressureValve seat

The invention relates to a two-stage double-spring direct relief valve and a control method thereof. The two-stage double-spring direct relief valve comprises a valve body internally provided with an oil inlet and an oil outlet. A valve seat is sleeved with the valve body in a sliding manner. A valve element is sleeved with the valve seat in a sliding manner. The width of the upper portion of the valve element is smaller than that of the middle of the valve element. The lower portion of the valve element is conical, the conical lower portion of the valve element is in matching connection with a conical hole penetrating the bottom of the valve seat, and the conical hole is communicated with the oil inlet. A second damping hole and a first damping hole are sequentially and vertically formed in the two sides of the valve seat in a transverse penetrating manner respectively. A pressure adjusting screw is further included and arranged at the top end of the valve body and is in threaded fit with the inner side of the valve body. An outer pressure adjusting spring is arranged in a rod portion of the pressure adjusting screw in the length direction, an inner pressure adjusting spring is coaxially sleeved with the outer pressure adjusting spring, and one end of the inner pressure adjusting spring is connected with the top end of the valve element. The two-stage double-spring direct relief valve has the beneficial effects that collisions between the valve body and the valve seat can be reduced, and the service life of the valve can be prolonged.

Owner:FUZHOU UNIV

Damping vibration attenuation frame for sling

ActiveCN103924517AReduce vibration responseReduce collisionBridge structural detailsUltrasound attenuationVibration attenuation

The invention provides a damping vibration attenuation frame for a sling. The damping vibration attenuation frame is used for increasing damping of the suspension bridge sling. The damping vibration attenuation frame comprises a box type attenuation frame body and a sling clamp. The sling clamp is used for being connected with a sling strand of the sling. The box type attenuation frame body is connected with the sling strand through the sling clamp in a fastening mode. The box type attenuation frame body is of a box type structure, and a cavity is formed in the box type attenuation frame body and filled with viscous fluid. At least one inertia mass ball used for vibration attenuation is arranged in the cavity and immersed into the viscous fluid wholly or partially. The damping vibration attenuation frame for the sling is used for increasing damping of the suspension bridge sling, has the functions of the vibration attenuation frame and a damper, and reduces the vibration response of the sling; the damping vibration attenuation frame is not provided with mechanical motion parts, and therefore the problem of fatigue rupture generated when a common viscoelastic damper or a viscous damper is used for vibration attenuation of the sling.

Owner:ZHIXING S&T

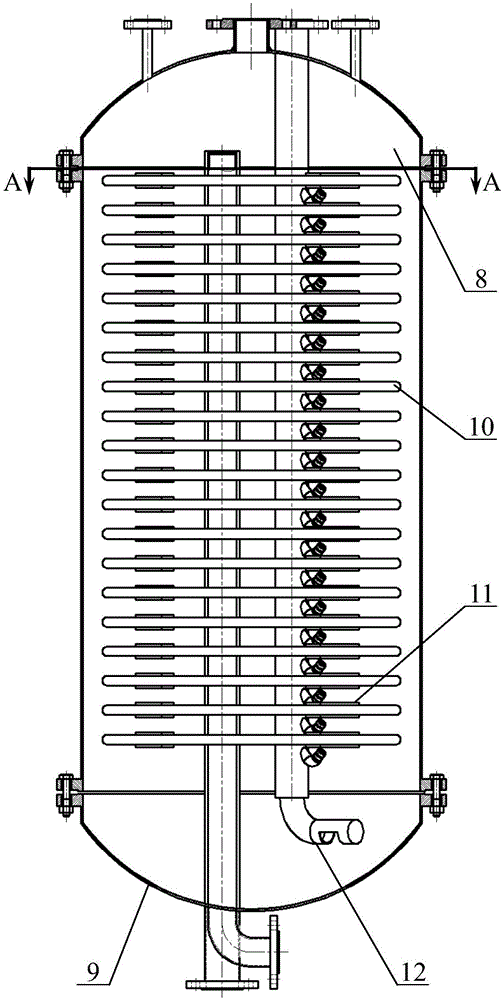

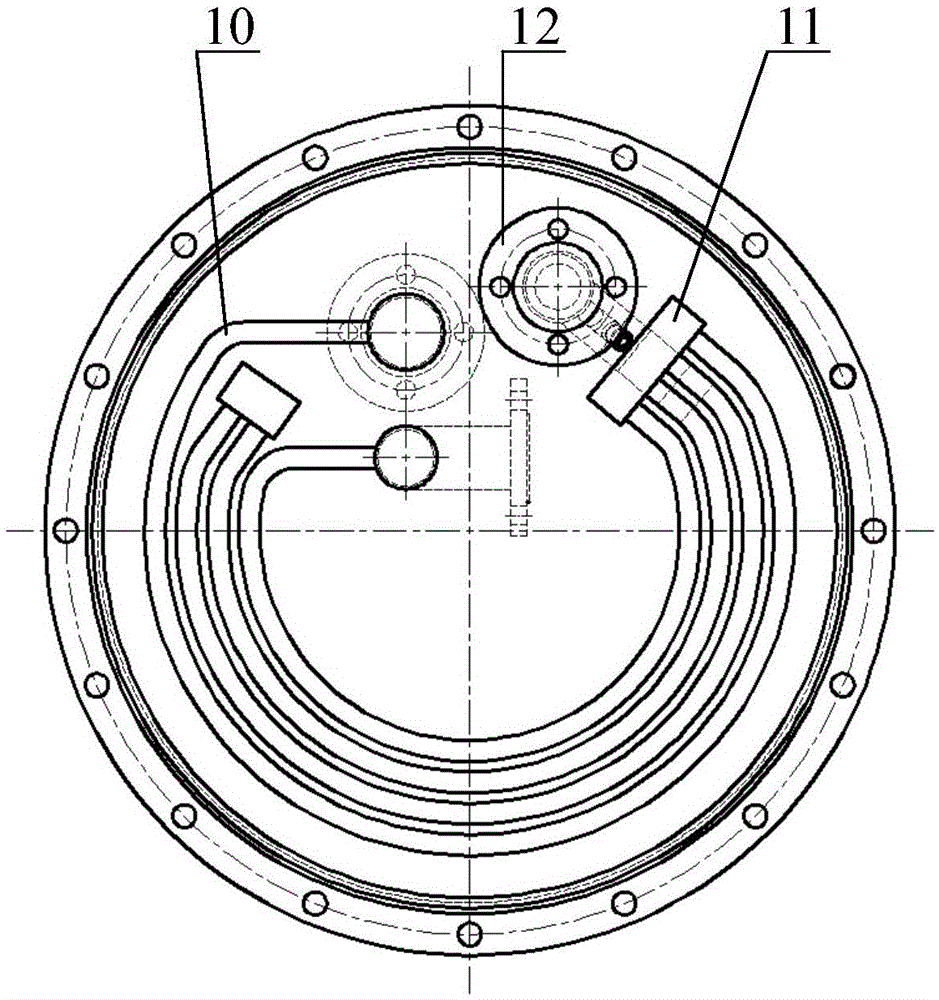

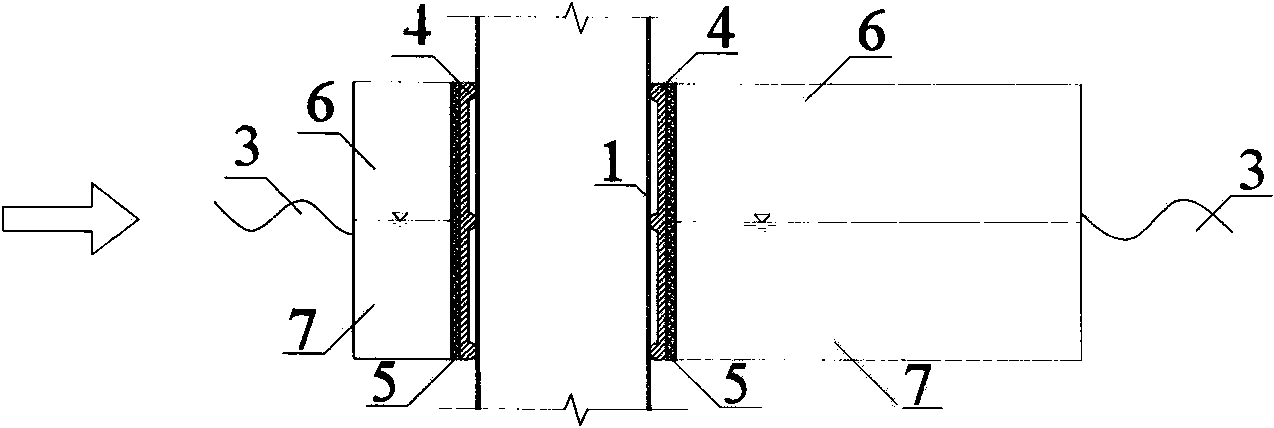

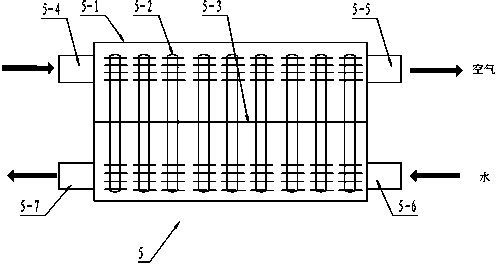

Stably-operating adiabatic compressed air storage power generation method and system

InactiveCN103775207AStable air temperatureAvoid fatigue damageGas turbine plantsPiston pumpsPower gridLoad following power plant

The invention discloses a stably-operating adiabatic compressed air storage power generation method and system. The technical scheme is as follows: when a power grid is in a valley load, by using a sinuous coil heat pipe exchanger arranged at a gas storage chamber and a countercurrent gas-liquid heat pipe exchanger arranged at an outlet of a gas compressor, through forced circulation, compression heat in a gas compression and energy storage process is absorbed by steps, and the absorbed heat is stored in the heat storage device; and when the power grid is in a peak load, the heat of the heat storage device is released, by using a gas release countercurrent gas-liquid heat pipe exchanger arranged at a turbine motor inlet and the sinuous coil heat pipe exchanger arranged at the gas storage chamber, through forced circulation, the temperature of a gas entering a turbine motor is increased, expansion cold of the gas storage chamber is absorbed, and the temperature of the gas storage chamber is kept relatively stable. According to the stably-operating adiabatic compressed air storage power generation method and system, the compression heat in a gas compression and energy storage process and expansion cold generated in a gas release and power generation process are absorbed by steps, thus a constant temperature of air in the gas storage chamber can be kept, the whole operation efficiency of the system is improved, the safety of the gas storage chamber can be ensured, and continuous and stable operation of a unit is ensured.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

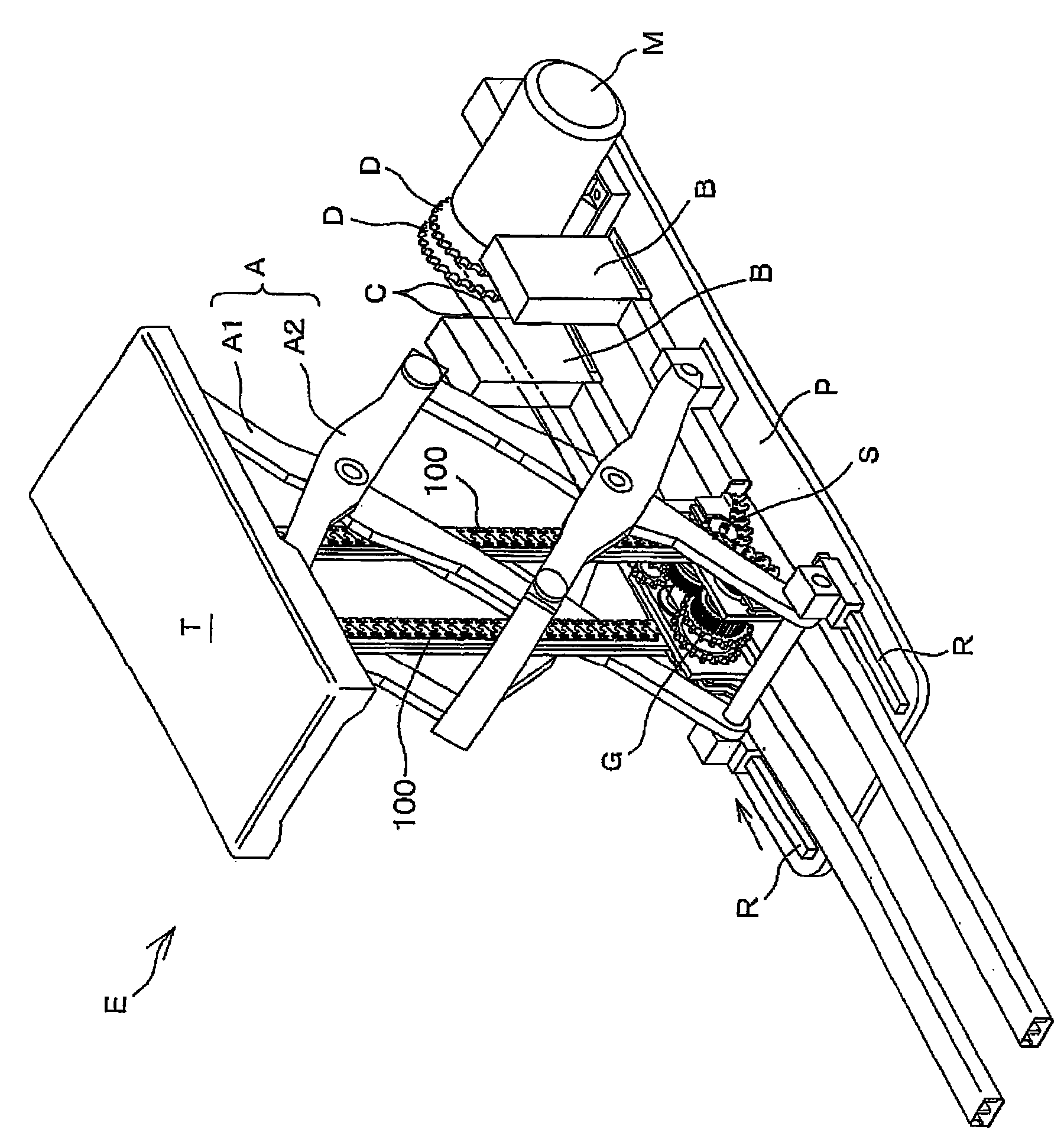

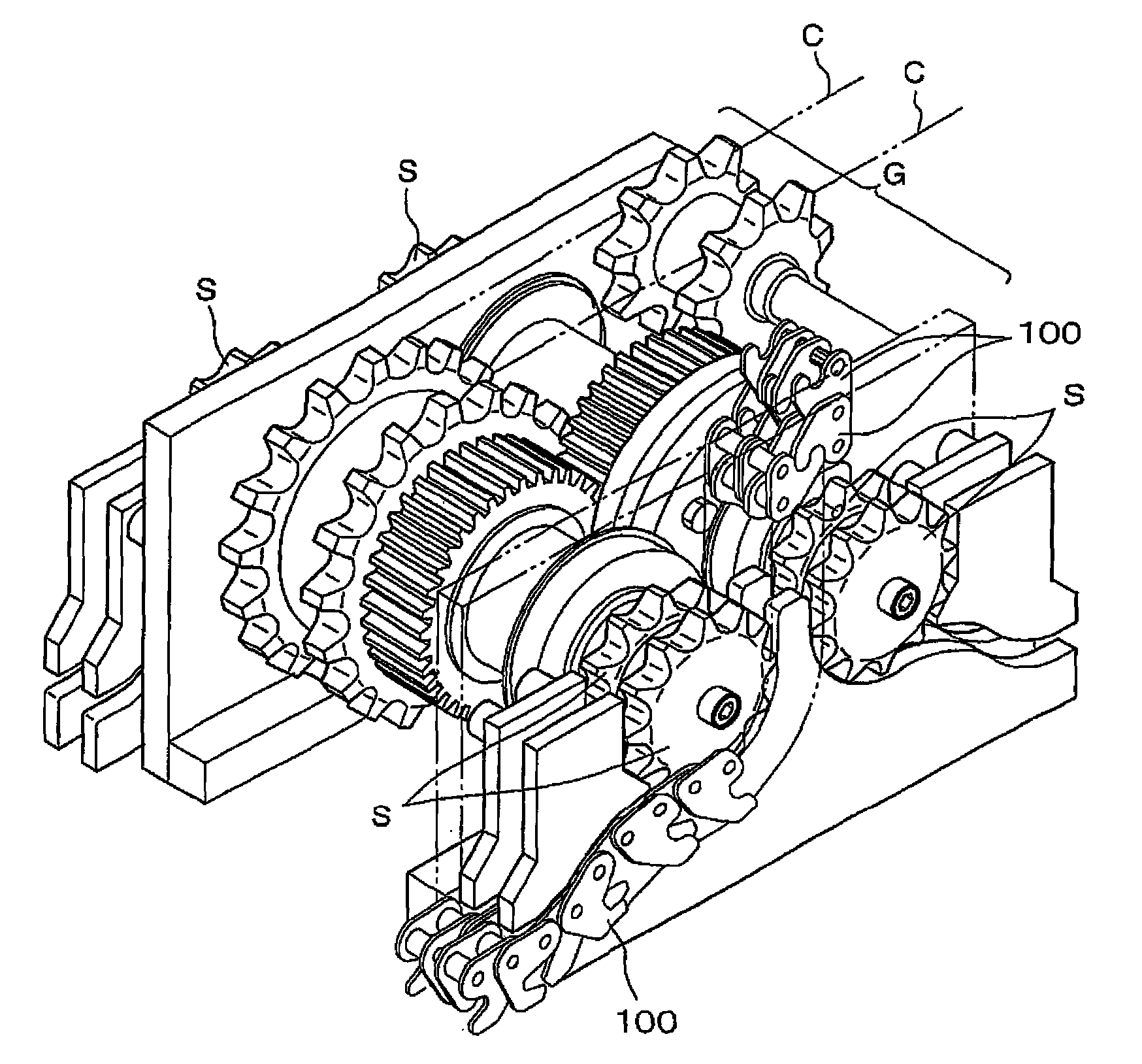

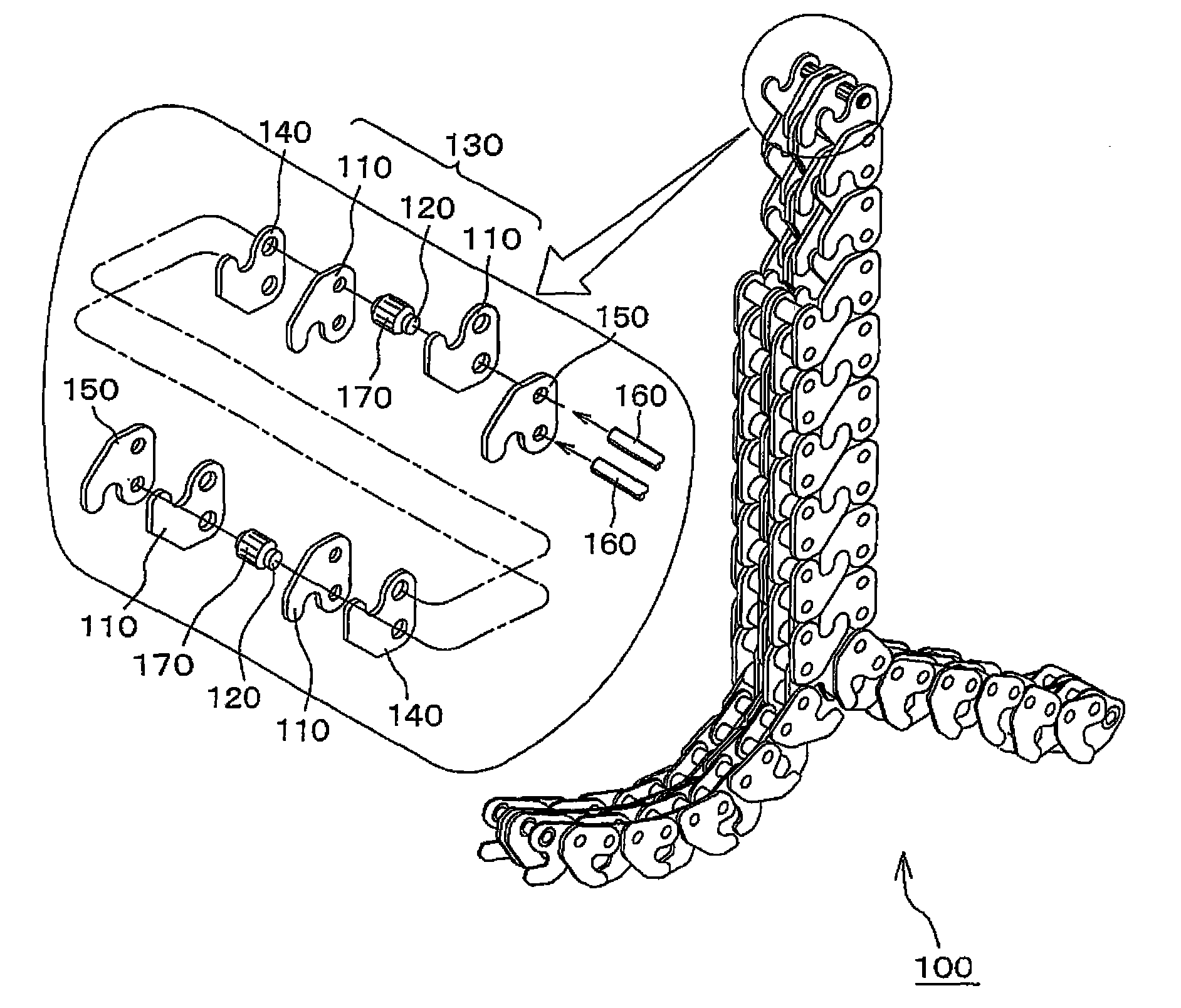

Hoisting and lowering driving engagement multi-row chain

InactiveCN101654214ACurb bendingImprove mesh balanceLifting framesFriction gearingsMiniaturizationEngineering

Aspects of the invention provide a hoisting and lowering driving engagement multi-row chain in which the weight of the chain is balanced across the chain width direction so as to improve the load balance. This allows the weight of articles to be hoisted and lowered more stably hoisted and at higher positions, and results in an improvement of endurance of the chain, reduction of driving noise, miniaturization of the chain size, while the biasing or deflecting of intermediate tooth plates and inner tooth plates in the chain width direction is suppressed. The hoisting and lowering driving engagement mluti-row chain 100 includes, inner tooth plates 110, a bushing 120, intermediate tooth plates 140, outer tooth plates 150 and connecting pins 160, and the inner tooth plates 110, the intermediate tooth plates 140 and the outer tooth plates 150 are manufactured by blanking with molds in same shape from a same direction, and at least one of the inner tooth plates 110, the intermediate tooth plates 140 and the outer tooth plates 150 are connected with other plates in a state of back reversion.

Owner:TSUBAKIMOTO CHAIN CO

Buffering guide method by reciprocating impact reactive force and vibration isolation mining machine

ActiveCN103016004AWon't twist and cutTwist shearSlitting machinesCutting machinesFatigue damageVibration isolation

The invention relates to a buffering guide method by reciprocating impact reactive force and a vibration isolation mining machine. The vibration isolation mining machine comprises a lifting part, a reciprocating impact part, a machine body and a traveling part, wherein a buffering device is arranged on the lifting part or between the lifting part and the machine body or between the lifting part and the reciprocating impact part; the impact reactive force is applied on a buffering supporting piece and a fixed supporting piece or a buffering guide sleeve and a buffering guide piece; the buffering piece is deformed to absorb the impact reactive force; a direction guide piece controls a buffering direction to be reciprocating linear buffering, so that non-directional swinging of the buffering piece is prevented, and the buffering piece is prevented from being separated from the lifting part or the machine body; and impact vibration produced by a cutting stop part can be isolated; impact on a traction part and the machine body is reduced; looseness of connection fixing pieces is prevented; fatigue damage to the connection pieces is avoided; the fault rate of the mining machine is reduced; and the working efficiency of the mining machine is improved.

Owner:刘素华

Multifunctional wide-flow high-efficiency gas-liquid separation device combining gravity and centrifugal technology

ActiveCN108815927AMeet separation needsEfficient dischargeDispersed particle separationFatigue damageGas phase

The invention aims to provide a multifunctional wide-flow high-efficiency gas-liquid separation device combining gravity and centrifugal technology. The device comprises a sleeve and a core tube, wherein the inlet end of the core tube is located outside the sleeve, and the outlet end of the core tube extends into the sleeve; a support structure is arranged between the core tube and the sleeve, animpeller is mounted in the core tube, a water retaining ring is arranged on the inner wall of the sleeve above the outlet end of the core tube, a gas phase lead-out port is formed in the upper end ofthe sleeve, and a liquid phase lead-out port is formed in the lower end of the sleeve. By means of an opening section, oscillation caused by change of the gas-liquid two-phase flow pattern is weakened, liquid phase can flow into the annular descending space between the core tube and the sleeve as soon as possible, and accordingly, separation efficiency is improved, fatigue damage is prevented, andthe service life is prolonged; liquid droplets carried in the gas core can be blocked by a separation baffle and diverted to the inner wall surface of the sleeve, and liquid on the wall surface can be effectively prevented from going uprush too high and being carried by gas due to an annular cavity formed by the water retaining ring and the inner wall of the sleeve. Therefore, separation efficiency can be effectively improved by the structures.

Owner:HARBIN ENG UNIV

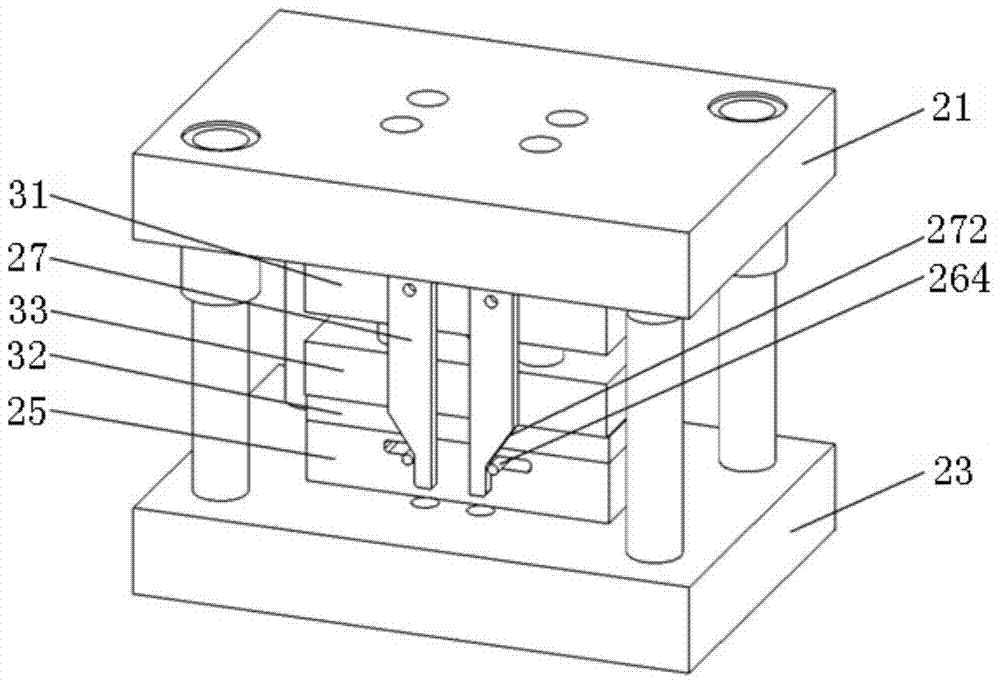

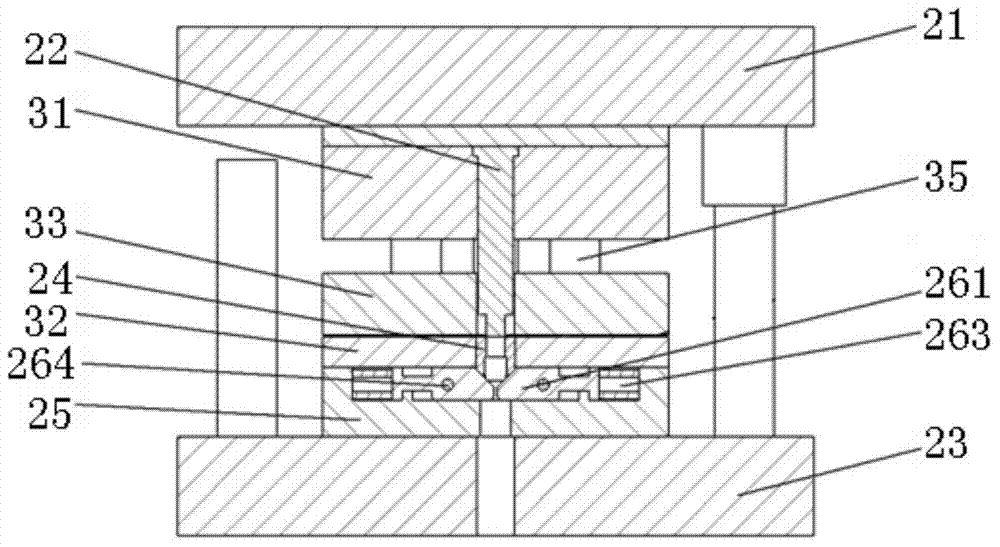

Hole flanging die

The invention discloses a hole flanging die. The hole flanging die comprises a male die body fixedly connected to an upper die base, and a female die sleeve fixedly connected to a lower die base and matched with the male die body. The male die body comprises a hole flanging part close to the upper die base, and a punching part far away from the upper die base, and the female die sleeve is matched with the punching part. The hole flanging die further comprises a movable limiting mechanism, the female die sleeve moves in the opening and closing direction of the die through the movable limiting mechanism and is fixed to the preset position, and when the female die sleeve is located at the lower limit position, a preset distance is formed between the upper end face of the female die sleeve and the lower end face of the hole flanging part. Accordingly, the hole flanging die can achieve the pre-punching and hole flanging procedures in the same die, and therefore the usage amount of the die is reduced, the tool cost of the die is reduced, the production cost is reduced, and the production efficiency is improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com