Multifunctional wide-flow high-efficiency gas-liquid separation device combining gravity and centrifugal technology

A gas-liquid separation device and combined technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., to achieve the effects of preventing fatigue damage, improving separation accuracy, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, the present invention will be described in more detail with examples in conjunction with the accompanying drawings:

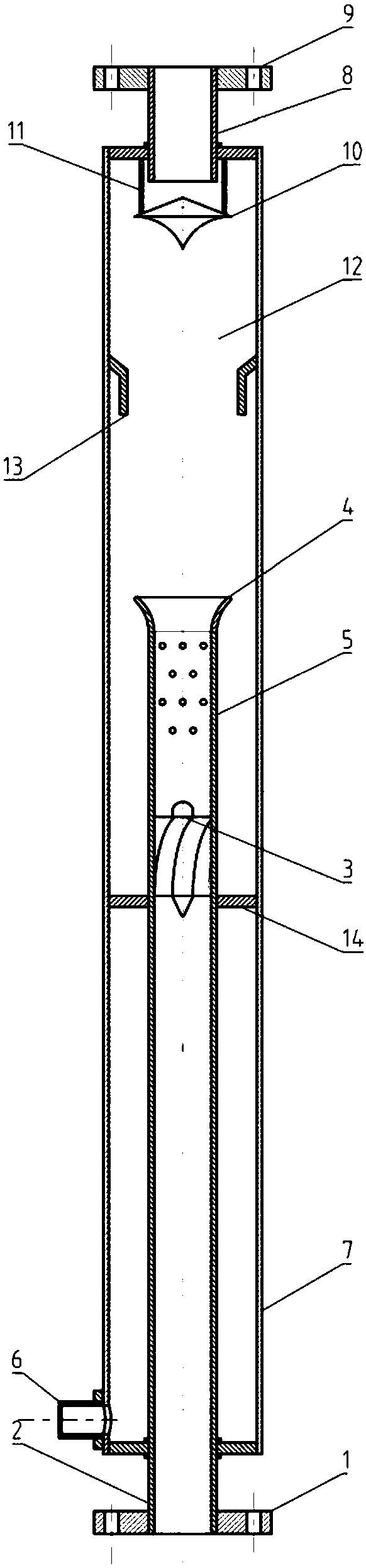

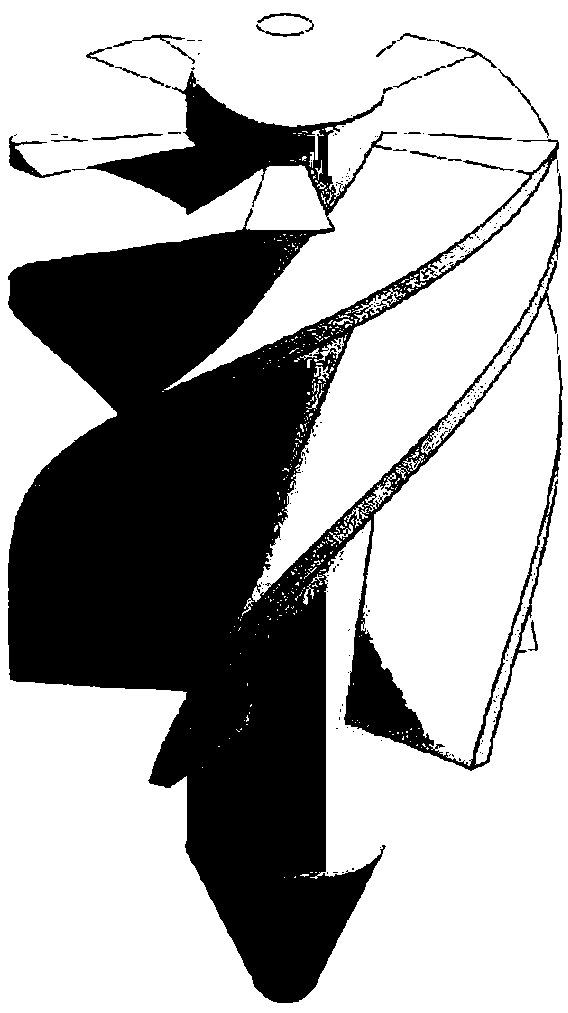

[0027] Combine Figure 1-4 , The present invention is a multifunctional wide-flow high-efficiency gas-liquid separation device that combines gravity and centrifugal technology. The main part is a sleeve structure and includes a core tube 2 and a sleeve 7. The core tube 2 is equipped with an impeller 3 inside; the inlet end of the core tube 2 is located outside the casing 7 and is connected to the inlet flange 1; a support structure 14 is provided between the core tube 2 and the casing 7; the outlet of the core tube 2 The end is located inside the casing 7 and is connected with the expansion section 4. The core tube 2 is located in the casing 7 and forms an annular descending space between the casing 7; the wall surface of the core tube 2 between the impeller 3 and the expansion section 4 An opening section 5 is provided on the upper part, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com