A mechanical refrigeration cold trap system for pharmaceutical factory sewage source

A sewage source, mechanical technology, applied in refrigerators, refrigeration components, mechanical equipment, etc., can solve the problems of insufficient use of high-grade energy, increase heat transfer resistance, difficult to control, etc., to improve energy utilization efficiency, save Energy, the effect of eliminating ice blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further explained below in conjunction with accompanying drawing, it is necessary to point out here that the following specific embodiments are only used to further illustrate the present application, and should not be interpreted as limiting the protection scope of the present application. Application content Some non-essential improvements and adjustments are made to this application.

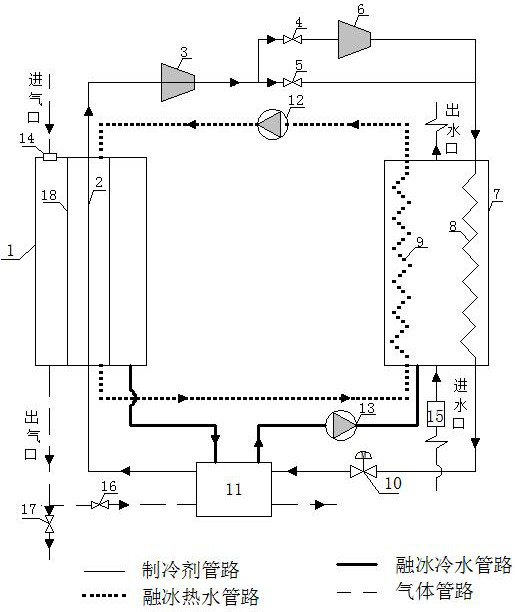

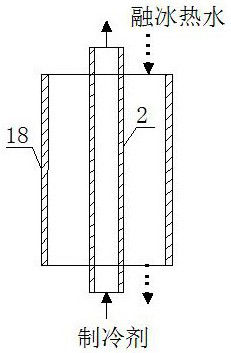

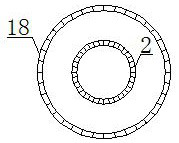

[0025] Please refer to the accompanying drawings, a pharmaceutical factory sewage source mechanical refrigeration cold trap system, which includes a sewage source refrigeration cold trap system, a jacketed ice melting system, and a waste cold recovery system.

[0026] First, the gas is separated and processed. When the condensation temperature required for the gas to be captured in the cold trap 1 is relatively high, the sewage source refrigeration cold trap system starts the cold trap 1, the evaporator coil 2, the low-level refrigeration compressor 3, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com