A bonded chromatographic column stationary phase and preparation method thereof

A chromatographic column and stationary phase technology, applied in the field of chromatographic separation, can solve the problems of unstable alkaline medium, complicated modification process, small specific surface area, etc., achieve stability and good hydrolysis resistance, simple process route, high ratio The effect of surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

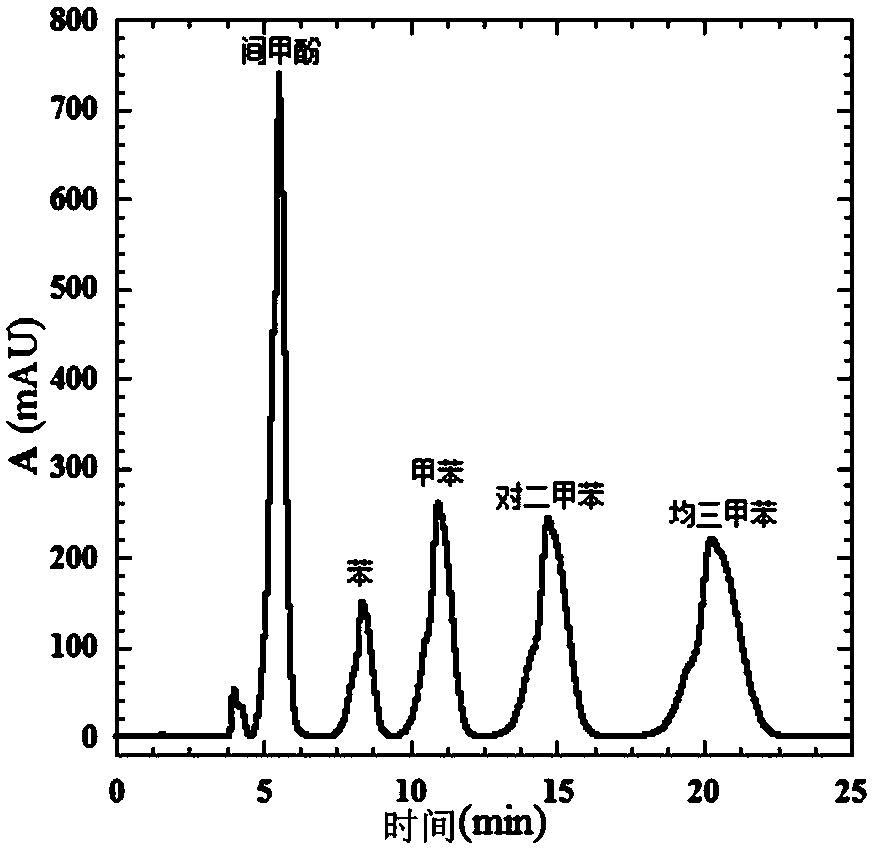

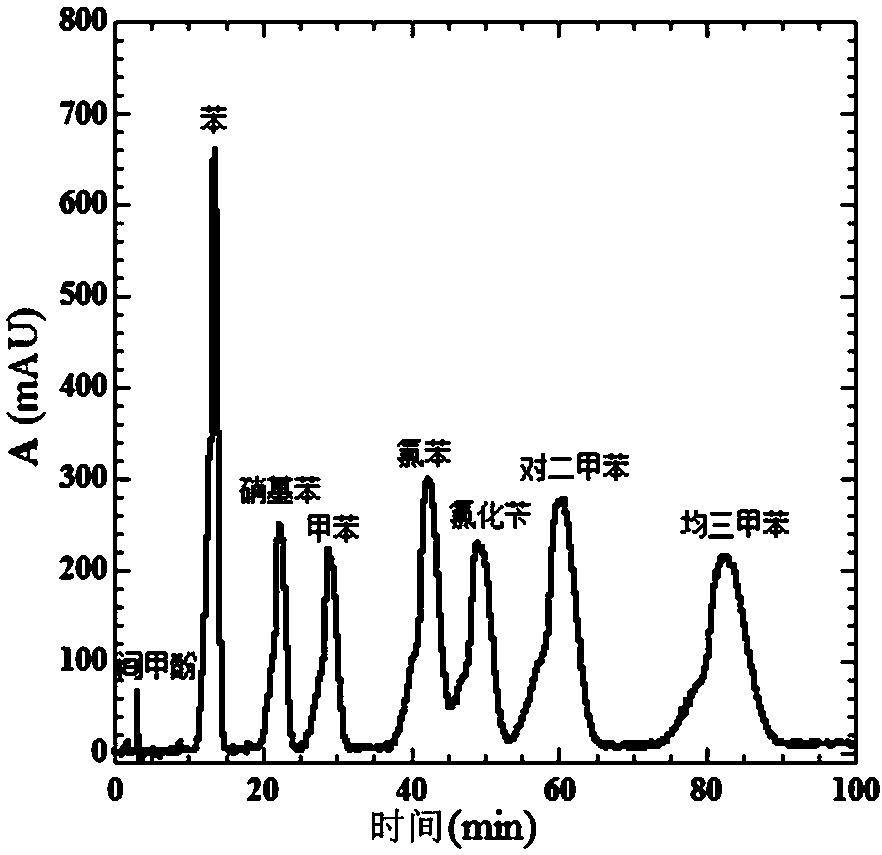

Examples

Embodiment 1

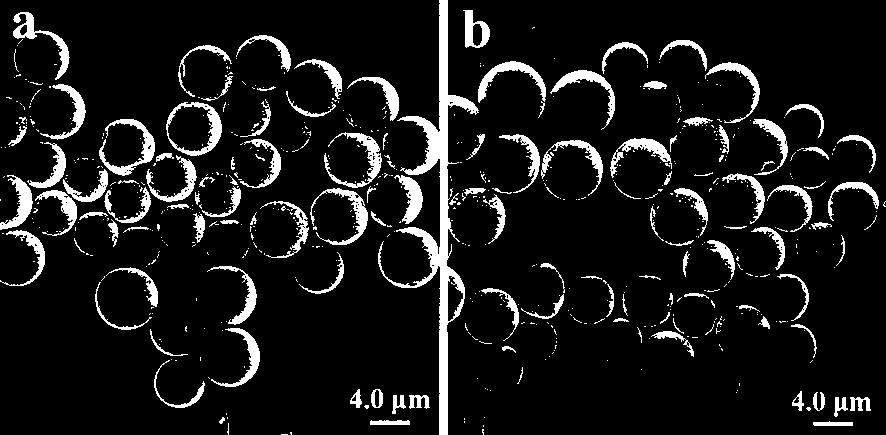

[0034] 1. Weigh 4 g of silica gel balls with a particle size of 5 mm and place them in an eggplant-shaped bottle, add 50 mL of 4 mol / L hydrochloric acid aqueous solution, and reflux at room temperature for 2 hours to obtain a mixture;

[0035] 2. Suction filter the mixture obtained above, wash the filter cake obtained by suction filtration with a large amount of deionized water until the filtrate is neutral, then wash the solid with acetone and ether respectively, and finally place it in a vacuum drying oven, at room temperature dry overnight;

[0036] 3. Ultrasonically disperse 450 mg of the solid obtained in step 2 in 25 mL of deionized water, add 335 mg of surfactant cetyltrimethylammonium bromide, 135 mL of absolute ethanol, 200 mL of deionized water, 2.5 In the mixed solution of mL saturated ammonia water;

[0037] 4. Quickly add 225 µL of 4,4'-bis(triethoxysilyl)-1,1'-biphenyl to the mixed solution obtained in step 3 under the stirring condition of 1500rmp, and keep sti...

Embodiment 2

[0042] 1. Weigh 4 g of silica gel balls with a particle size of 5 mm and place them in an eggplant-shaped bottle, add 50 mL of 4 mol / hydrochloric acid aqueous solution, and reflux for 2 hours to obtain a mixture;

[0043] 2. Suction filter the mixture obtained above, wash the solid obtained by suction filtration with a large amount of deionized water until the filtrate is neutral, then wash the solid with acetone and ether respectively, and finally place it in a vacuum drying oven at 25 °C Dry overnight at room temperature;

[0044] 3. Ultrasonically disperse 450 mg of the solid obtained in step 2 in 25 mL of deionized water, add 288 mg of surfactant cetyltrimethylammonium chloride, 135 mL of absolute ethanol, 200 mL of deionized water, 2.5 In the mixed solution of mL saturated ammonia water;

[0045] 4. Quickly add 225 µL of 3,3'-bis(triethoxysilyl)-1,1'-biphenyl to the mixed solution obtained in step 3 under the stirring condition of 1500rmp, and keep stirring for 8 hours ...

Embodiment 3

[0049] 1. Weigh 4 g of silica gel balls with a particle size of 5 mm and place them in an eggplant-shaped bottle, add 50 mL of 4 mol / hydrochloric acid aqueous solution, and reflux at room temperature for 4 hours to obtain a mixture;

[0050] 2. Suction filter the mixture obtained above, wash the solid obtained by suction filtration with a large amount of deionized water until the filtrate is neutral, then wash the solid with acetone and ether respectively, and finally place it in a vacuum drying oven at 25 °C Dry overnight at room temperature;

[0051] 3. Ultrasonically disperse 450 mg of the solid obtained in step 2 in 25 mL of deionized water, and add 353 mg of surfactant octadecyltrimethylammonium bromide, 120 mL of anhydrous methanol, 200 mL of deionized water, and 3.5 In the mixed solution of mL saturated ammonia water;

[0052] 4. Quickly add 242 µL of 1,4-bis(triethoxysilyl)benzene to the mixed solution obtained in step 3 under the stirring condition of 1500 rpm, keep ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com