Microcapsule sustained release agent and preparation method and application thereof

A technology for microcapsules and sustained-release agents, which is applied in the fields of microcapsules and sustained-release agents and their preparation and application fields, can solve the problems of short retention time of essences and the like, and achieve the effects of mild conditions, easy realization and prevention of volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Dissolve 5g of gelatin in 245ml of hot water at room temperature to prepare a 2% solution; dissolve 5g of gum arabic in 120ml of water to prepare a 4% aqueous solution of gum arabic, add 2ml of CO40 to the gum arabic solution and stir to dissolve, add 5g of essence , homogeneously emulsified at 3000rpm for 15min, add the gelatin solution prepared above to the emulsified emulsion, coagulate at 50°C, dropwise add acetic acid to adjust the pH to 4.0, stir for 30min, stop heating, let the temperature drop to room temperature, add 25% acetone 4ml of dialdehyde was solidified for 1h; adjusted the pH value of the system to 7, continued stirring for 30min, then stopped stirring, settled, and filtered to obtain a filter cake. Washed with ethanol and dried to obtain microcapsule sustained-release preparation. The encapsulation rate of the essence was 80%, and the drug loading was 20%.

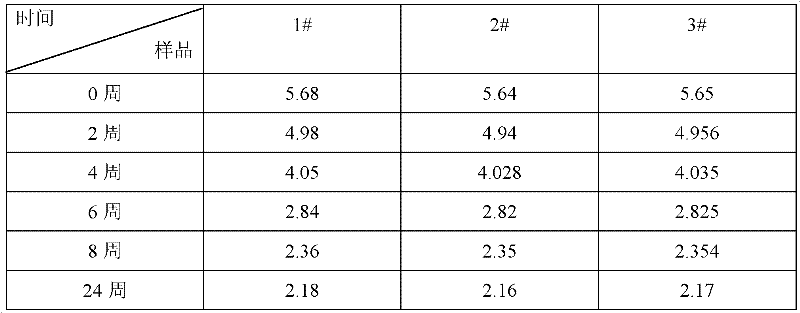

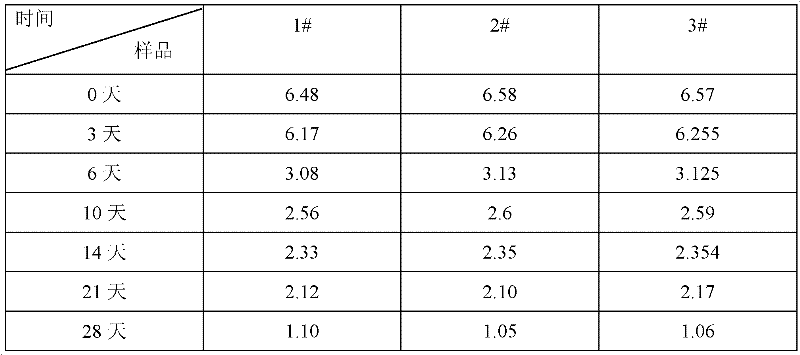

[0028] Take the microcapsule sustained-release preparation prepared in Example 1 and carry ou...

Embodiment 2

[0059] Dissolve 5g of natural polymer gelatin in 120ml of hot water at room temperature to prepare a 4% solution; dissolve 5g of gum arabic in 245ml of water to prepare a 2% aqueous solution of gum arabic, add 2ml of Tween-20 to the gum arabic solution Stir to dissolve, add 5g of essence, homogeneously emulsify at 3000rpm for 15min, add the prepared natural polymer gelatin solution to the emulsified emulsion, coagulate at 50°C, adjust the pH to 4.0, stir for 30min, stop heating, and reduce the temperature to At room temperature, add 4 ml of 25% glutaraldehyde to solidify for 1 hour; adjust the pH of the system to 7, continue stirring for 30 minutes, then stop stirring, settle, and filter to obtain a filter cake, which is soaked in a 1% concentration of tannic acid solution for 12 After 1 hour, suction-filtered again, washed with ethanol, and dried to obtain microcapsule powder. The encapsulation rate of the essence was 90%, and the drug loading was 25%.

Embodiment 3

[0061] Dissolve 5g of gelatin in 120ml of hot water at room temperature to prepare a 4% solution; dissolve 5g of gum arabic in 245ml of water to prepare a 2% aqueous solution of gum arabic, add 2ml of CO40 to the gum arabic solution and stir to dissolve, add 5g of essence , homogeneously emulsified at 3000rpm for 15min, add the prepared gelatin solution to the emulsified emulsion, coagulate at 50°C, adjust the pH value to 4.0, stir for 30min, stop heating, make the temperature drop to room temperature, add 4ml of 25% glutaraldehyde Solidify for 1 hour; adjust the pH value of the system to 7, continue stirring for 30 minutes, then stop stirring, settle, and suction filter to obtain a filter cake, soak the filter cake in a 1% concentration of tannic acid solution for 12 hours, then suction filter, wash with ethanol , microcapsule powder is obtained after drying. The encapsulation rate of the essence was 50%, and the drug loading was 10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com