Patents

Literature

2061 results about "Tannic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

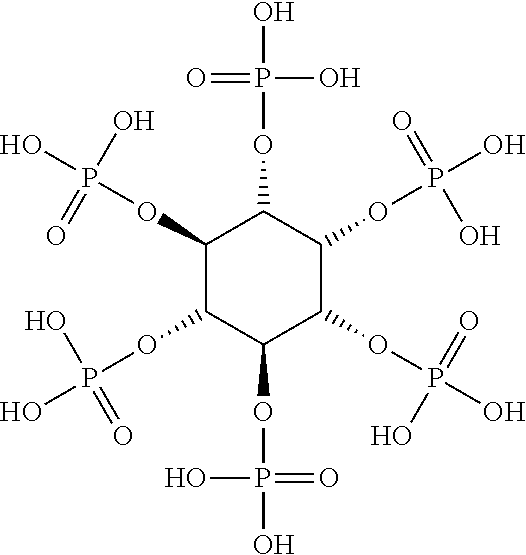

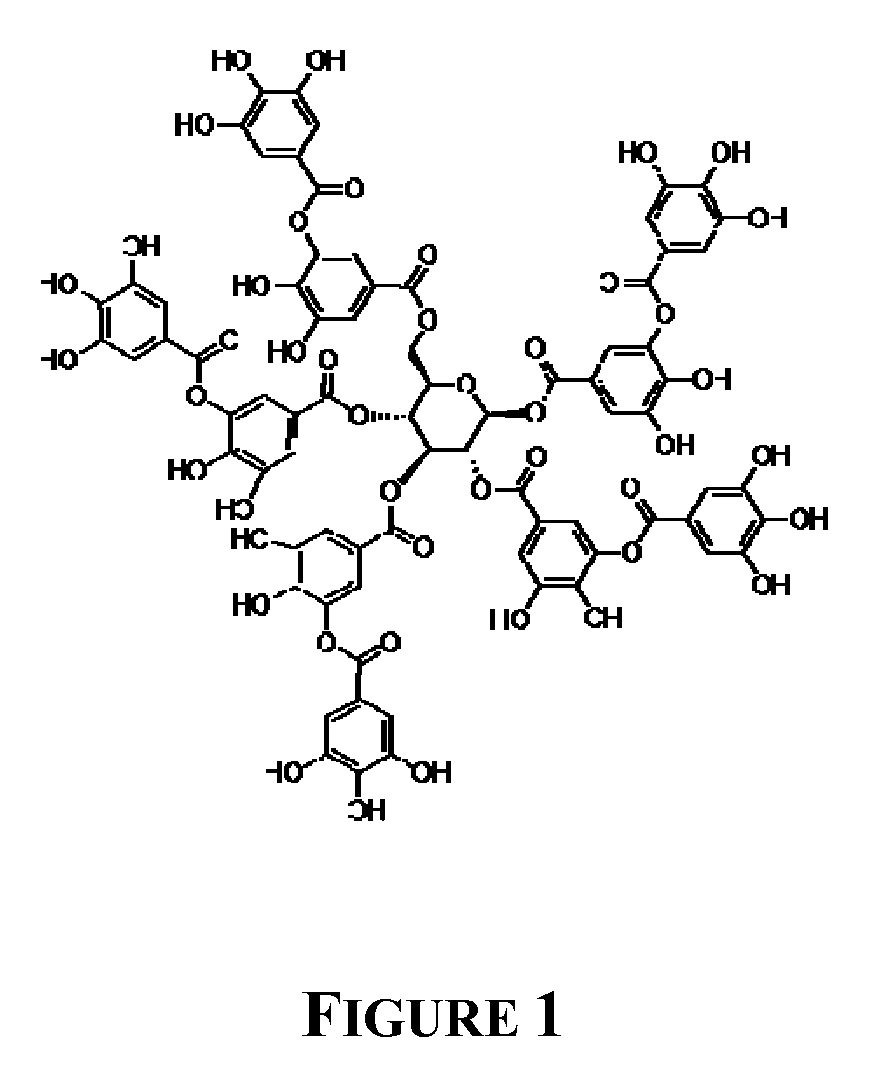

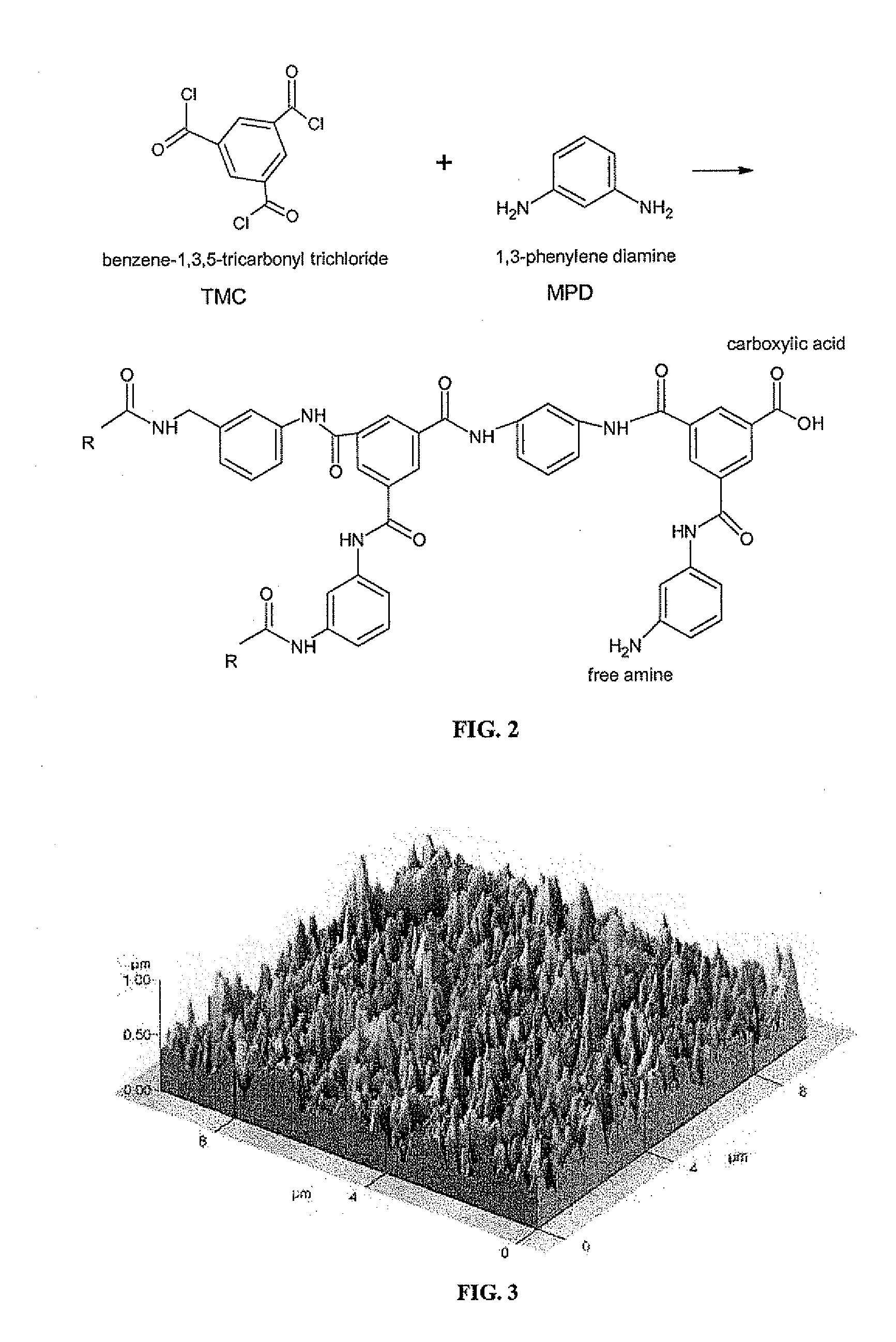

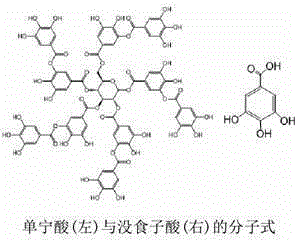

Tannic acid is a specific form of tannin, a type of polyphenol. Its weak acidity (pKₐ around 6) is due to the numerous phenol groups in the structure. The chemical formula for commercial tannic acid is often given as C₇₆H₅₂O₄₆, which corresponds with decagalloyl glucose, but in fact it is a mixture of polygalloyl glucoses or polygalloyl quinic acid esters with the number of galloyl moieties per molecule ranging from 2 up to 12 depending on the plant source used to extract the tannic acid. Commercial tannic acid is usually extracted from any of the following plant parts: Tara pods (Caesalpinia spinosa), gallnuts from Rhus semialata or Quercus infectoria or Sicilian Sumac leaves (Rhus coriaria).

Biodegradable activators to gel silica sol for blocking permeability

ActiveUS20130292120A1Risk of damageDrilling compositionSealing/packingButanedioic acidSalicylic acid

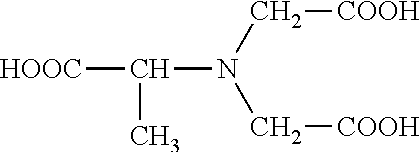

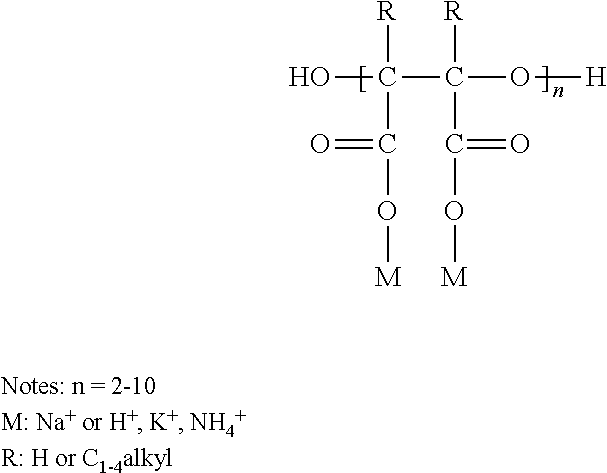

A method of treating a treatment zone in a well to reduce the permeability of the treatment zone including the steps of: introducing into the treatment zone a water-based treatment fluid comprising: an aqueous silica sol; and a water-soluble chemical activator for gelling the silica sol, wherein the chemical activator is selected from the group consisting of: phytic acid, methylglycinediacetic acid, a water-soluble polyepoxysuccinic acid, salicylic acid, ascorbic acid, tannic acid, and an alkali metal salt or ammonium salt of any of the foregoing; and shutting in treatment zone for at least a sufficient time to allow the treatment fluid to in-situ form a solid gel at a design temperature for the method. Alternatively, a first treatment fluid including the aqueous silica sol and a second treatment fluid including the chemical activator can be introduced into the treatment zone separately, in any order.

Owner:HALLIBURTON ENERGY SERVICES INC

Opiod tannate compositions

A composition comprising the tannate of an opioid. Suitable opioids include alfentanil, buprenorphine, butorphanol, carfentanil, cocaine, codeine, dezocine, diacetylmorphine, dihydrocodeine, dihydromorphine, diphenoxylate, diprenorphine, etorphine, fentanyl, heroin, hydrocodone, hydromorphone, beta-hydroxy-3-methylfentanyl, levo-alpha-acetylmethadol, levorphanol, lofentanil, meperidine, methadone, morphine, nalbuphine, nalmefene, o-methylnaltrexone, naloxone, naltrexone, oxycodone, oxymorphone, pentazocine, pethidine, propoxyphene, remifentanil, sufentanil, tilidine and tramadol. The opioid tannate may be readily prepared by reacting an opioid free base with tannic acid, either neat or in the presence of up to about 30 wt. % water, at a temperature of about 60 to about 150° C. and thereafter recovering the resultant opioid tannate. The opioid tannate may also be prepared by an alternative process that involves reacting the opioid free base with water at a temperature such that not more than about 10 wt. % of the opioid tannate will be decomposed and thereafter removing the water by freeze-drying.

Owner:JAME FINE CHEM

Compositions for Regulation of Hair Growth

InactiveUS20080254055A1Reduce frequencyImprove shaving efficiencyBiocideCosmetic preparationsPersonal carePhytic acid

Personal care composition comprising at least one hair growth regulating compound selected from the group consisting of glyceryl dilaurate, apigenin, tetrahydrocurcumin, oleanolic acid, azelaic acid, sulforaphane, canavanine, pyridoxal 5-phosphate, phytic acid, tannic acid, grape seed extract, NG-nitro-L-arginine-methyl ester, benzamidine, sodium butyrate, betulinic acid, polyornithine, polyarginine, fisetin, jasmonates, methyl-jasmonate, cis-jasmone, caffeic acid phenethyl ester, delphinidin, ethyl abietate, esculetin, sorbic acid methyl ester, canaline, N-formyl-methionine, N-formyl-alanine, taurine, palmitoyl carnitine, undecanol, undecylenic acid, rutin, fusidic acid, phenyl pyruvic acid, L-isoleucine, phenyl glycine, silibinin, silymarin, L-ascorbic acid-6-palmitate, N-undecylenoyl-L-phenylalanine, and salts, derivatives and mixtures of any of the foregoing; and a dermatologically-acceptable carrier.

Owner:THE PROCTER & GAMBLE COMPANY

Phenylephrine tannate and pyrilamine tannate salts in pharmaceutical compositions

Compositions of tannate salts of phenylephrine and pyrilamine produced by a method that allows for the in-situ conversion and incorporation of the tannate salts in a single dosage form. The conversion process includes dissolving a salts of phenylephrine and pyrilamine in a solvent and mixing with a dispersing agent and tannic acid to generate tannate salts. The tannate salts may be further processed to single dosage forms, such as tablets and suspensions.

Owner:KIEL JEFFREY S +2

Pharmaceutical compositions and methods for managing skin conditions

InactiveUS7018660B2Shorten the counting processBiocideCosmetic preparationsIrritationInflammatory dermatosis

This application relates to a stable pharmaceutical composition and methods for the cleansing of skin to facilitate the prevention, treatment, and management of skin conditions, such as seborrheic dermatitis, psoriasis, folliculitis, rosacea, perioral dermatitis, acne, impetigo and other inflammatory skin conditions, and the like, including a sufficient amount of an acidic component of a hydroxyacid or tannic acid, or a pharmaceutically acceptable salt thereof, to exfoliate a portion of the skin, a sufficient amount of stabilized hydrogen peroxide to facilitate cleansing of the skin without substantial irritation thereof, and an antimicrobial agent including at least one of an antibacterial agent, antimicrobial agent, antiviral agent, anthelmintic, or a combination thereof, in an amount sufficient to inhibit or reduce microorganisms on the skin.

Owner:MURAD

Pharmaceutical compositions and methods for managing skin conditions

InactiveUS20060051429A1Growth inhibitionPrevent skinBiocideCosmetic preparationsIrritationSeborrheic dermatitis

This application relates to a stable pharmaceutical composition and methods for the cleaning of skin to facilitate the prevention, treatment, and management of skin conditions, such as seborrheic dermatitis, psoriasis, folliculitis, rosacea, perioral dermatitis, acne, impetigo and other inflammatory skin conditions, and the like, including a sufficient amount of an acidic component of a hydroxyacid or tannic acid, or a pharmaceutically acceptable salt thereof, to exfoliate a portion of the skin, a sufficient amount of stabilized hydrogen peroxide to facilitate cleansing of the skin without substantial irritation thereof, and an antimicrobial agent including at least one of an antibacterial agent, antimicrobial agent, antiviral agent, anthelmintic, or a combination thereof, in an amount sufficient to inhibit or reduce microorganisms on the skin.

Owner:MURAD HOWARD

Methods for preparing metal and metal oxide nanoparticles

InactiveUS20100251856A1Material nanotechnologyTransportation and packagingMetal oxide nanoparticlesRoom temperature

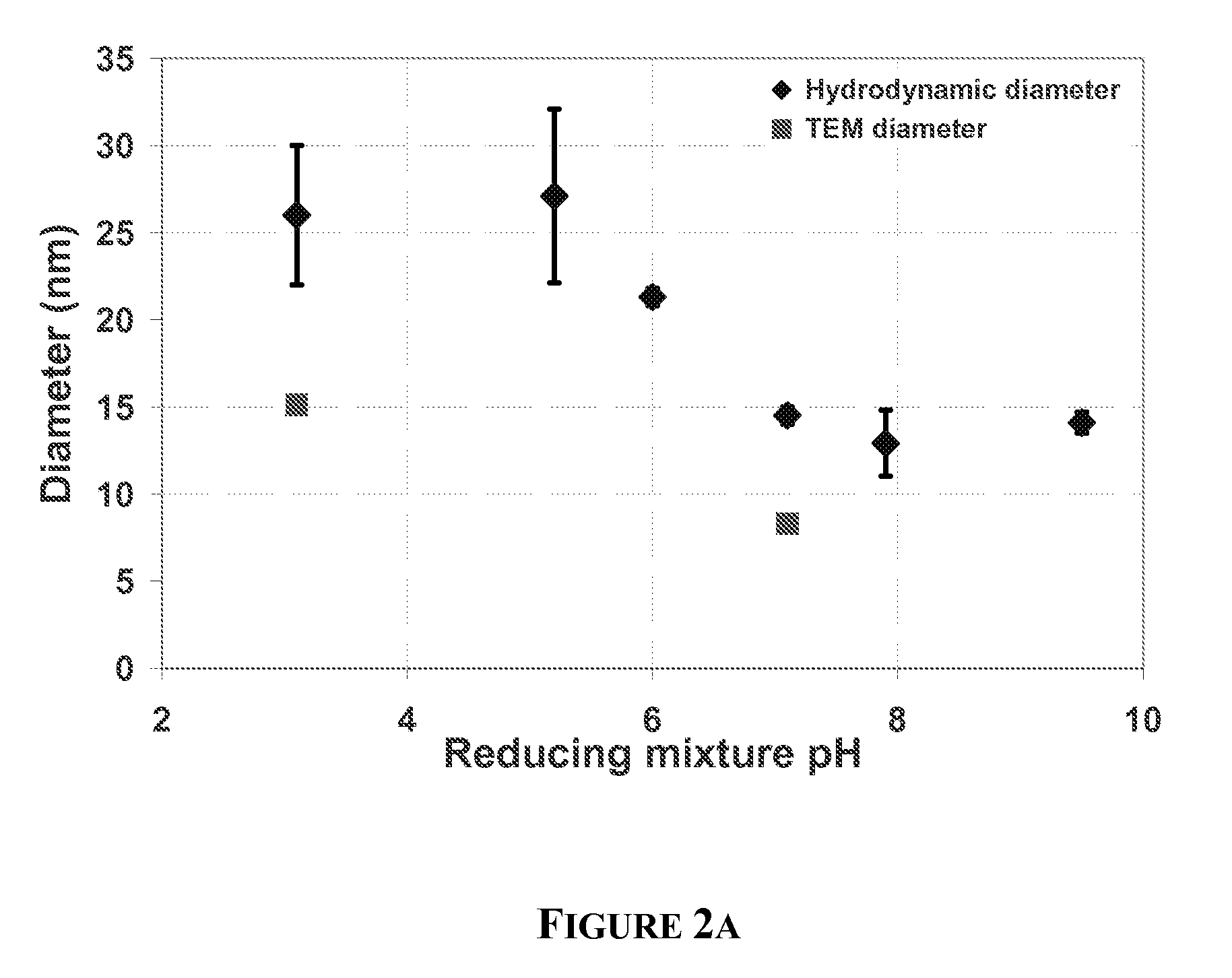

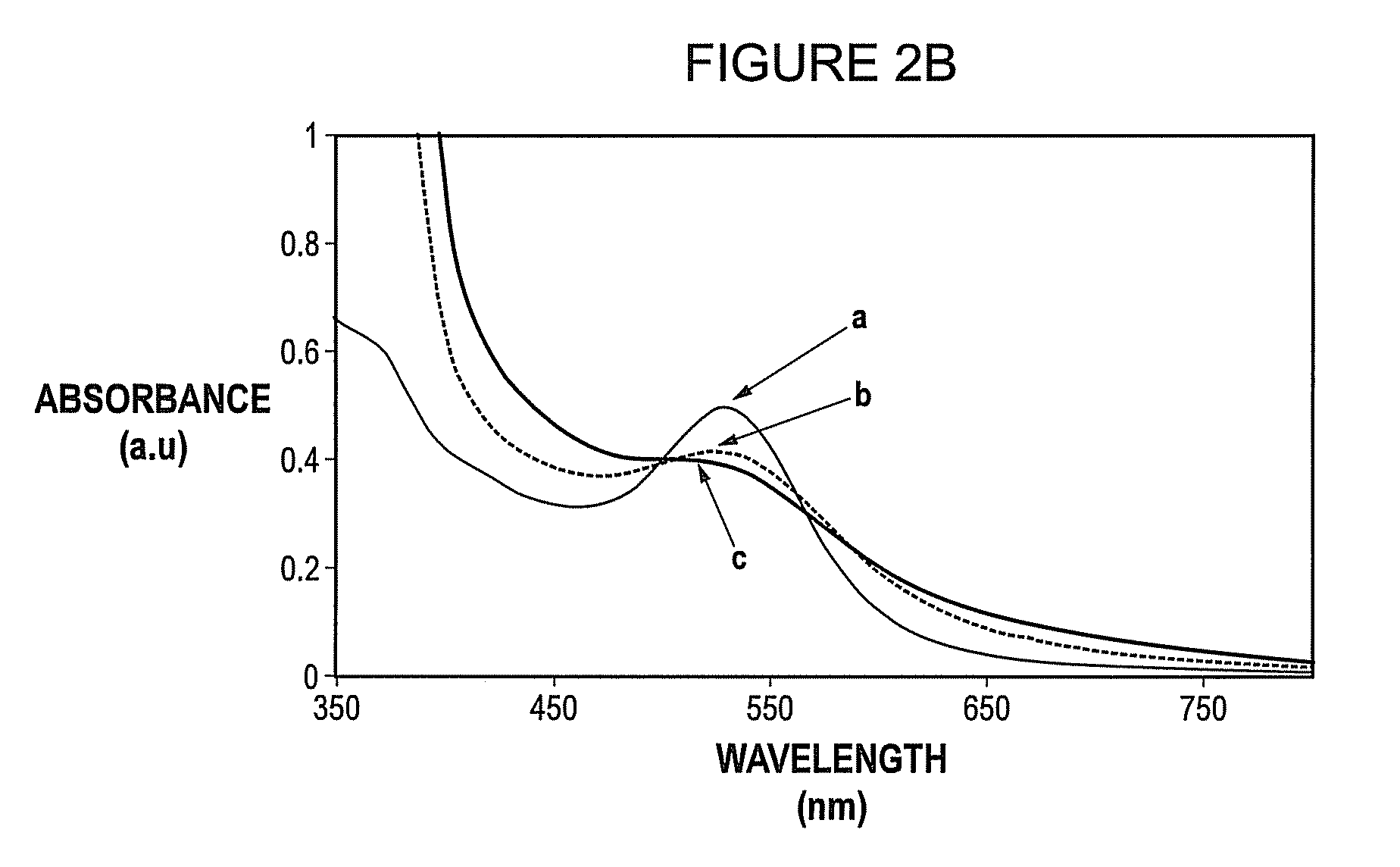

Metal and metal oxide nanoparticles can be prepared via a simple synthesis by using a hydrolysable gallotannin, such as tannic acid, to reduce a metal precursor compound and to act as a stabilizer for the resultant nanoparticles. By controlling the molar ratio of hydrolysable gallotannin to metal precursor and / or the initial pH of the reagents one can achieve control over the size and polydispersity of the resultant nanoparticles. In particular, the controlled addition of a metal precursor into a solution of the hydrolysable gallotannin, as described herein, can yield small nanoparticles, for example 1 nm to 40 nm diameter nanoparticles, with low polydispersity. The methods disclosed herein can be performed at room temperature.

Owner:INDIAN INSTITUTE OF SCIENCE

Aqueous rust-conversion rust-inhibiting primer

The invention relates to a water-based rust conversion antirust primer which is characterized in that: the primer comprises the following components with the corresponding percentage by weight : main conversion agent 5-35, auxiliary conversion agents 2-15, film forming material 40-55, penetrant 0.2-1.0, humectant 1-10, anti-forming agent 0.1-0.5, corrosion inhibitor 0.2-0.5 and solvent 0.5-8; the process is as follows: adding deionized water to a charging basket and heating the water to 60-80 DEG C with aliphatic alcohol polyethenoxy ether added, adding propylene glycol and starting a high-speed dispersion machine for agitation, later on adding tributyl phosphate, potassium sorbate, tannic acid and one of the auxiliary conversion agents and cooling down to 20-33 DEG C after agitating for 30-55 minutes, and adding vinyl chloride-modified acrylic resin latex and discharging material after agitating for 10-20 minutes. The invention has the advantages of direct application to steel surfaces with rust, thorough conversion of rust, excellent adhesive force of a conversion film, good flexibility, adaptation to various forms, and good compatibility with various top coatings.

Owner:安泰能(上海)高分子材料有限公司

Formative agent of protein complex

InactiveUS20020119946A1Keep for a long timePromote resultsBiocidePeptide/protein ingredientsCartilage cellsCuticle

The present invention proposes formative agent of protein complex, in which a polyphenol is useful component, and the agent is useful as gene complex, cell adhesion inhibitor or immune tolerogen. The polyphenol of forming the agent is selected from catechin group consisting of epigallocatechin-gallate, tannic acids, or proanto-dianisidine, a protein of the protein complex is selected from proteins consisting of animal proteins composed of polypeptide chain of peptide-combined amino acids, vegetative proteins, nucleus proteins, glycogen proteins, lipo-proteins and metal proteins, the gene complex comprises by compositing genes by polyphenol catechins in order to introduce genes to cells of animals or human bodies, a cell composed of the cell adhesion inhibitor is selected from cells consisting of an animal cell including a stem cell, skin cell, mucosa cell, hepatocyte, islet cell, neural cell, cartilage cell, endothelial cell, epidermal cell, osteocyte or muscle cell isolated from human or animal organism, or sperm, ovum or fertilized egg of domestic animals or fishes and a tissue or an organ for transplantation of the immune tolerogen is selected from the tissue or the organ consisting of skin, blood vessel, cornea, kidney, heart, liver, umbilical cord, bowels, nerve, lung, placenta or pancreas.

Owner:BERTELSMANN MUSIC GROUP

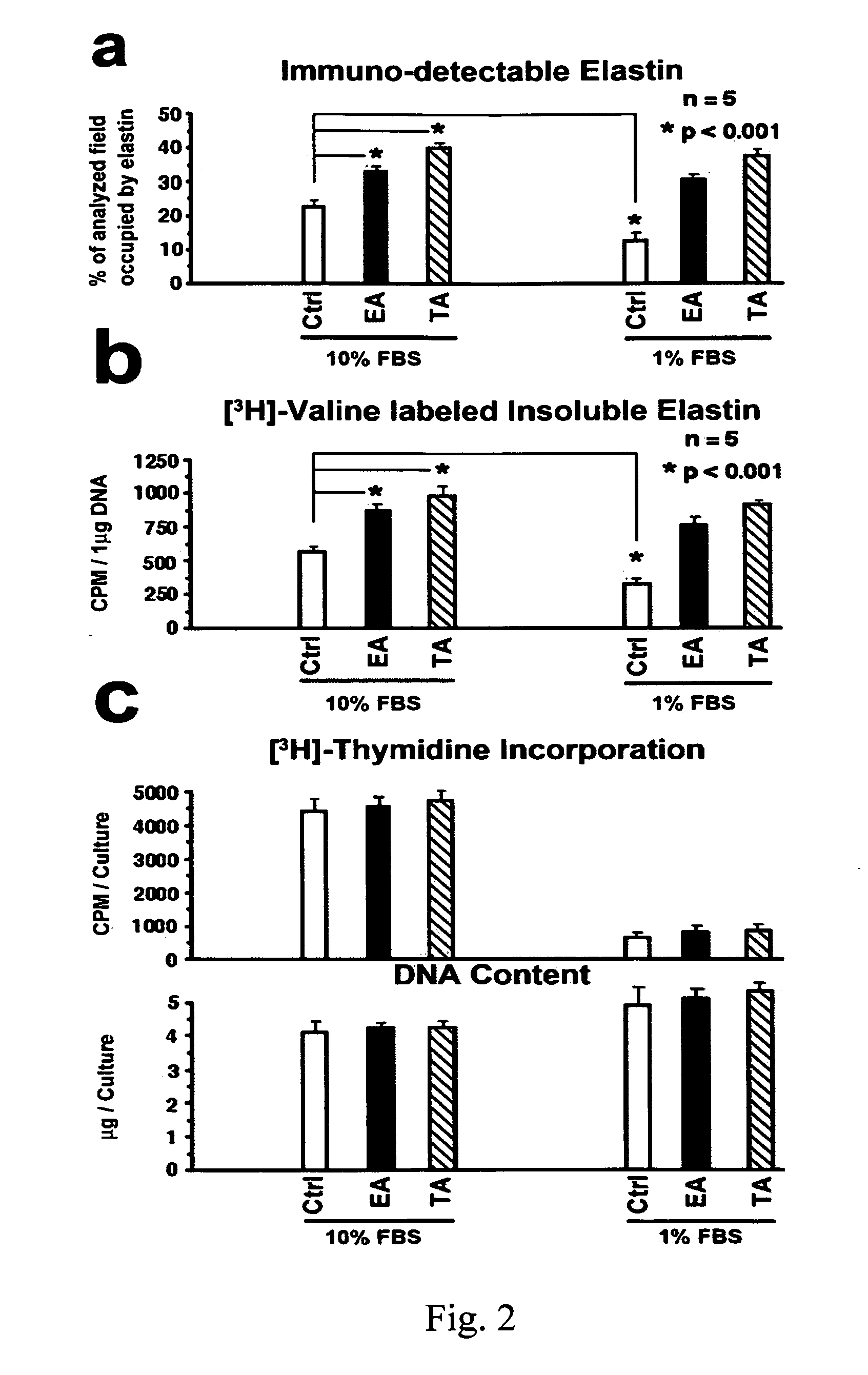

Elastin protective polyphenolics and methods of using the same

ActiveUS20090110709A1Prevent premature proteolyticEfficient elastogenesisCosmetic preparationsBiocideFiberPolyphenol

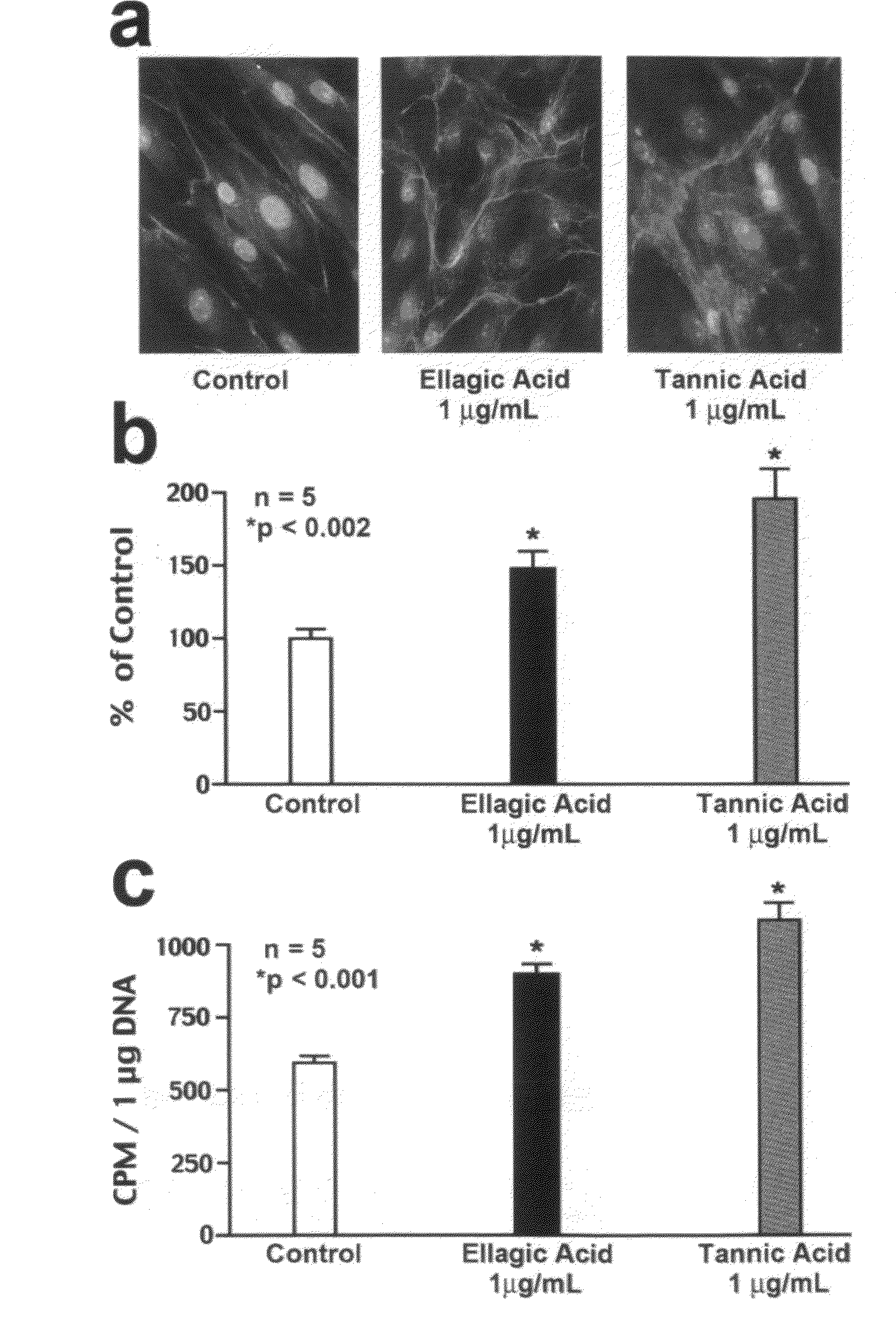

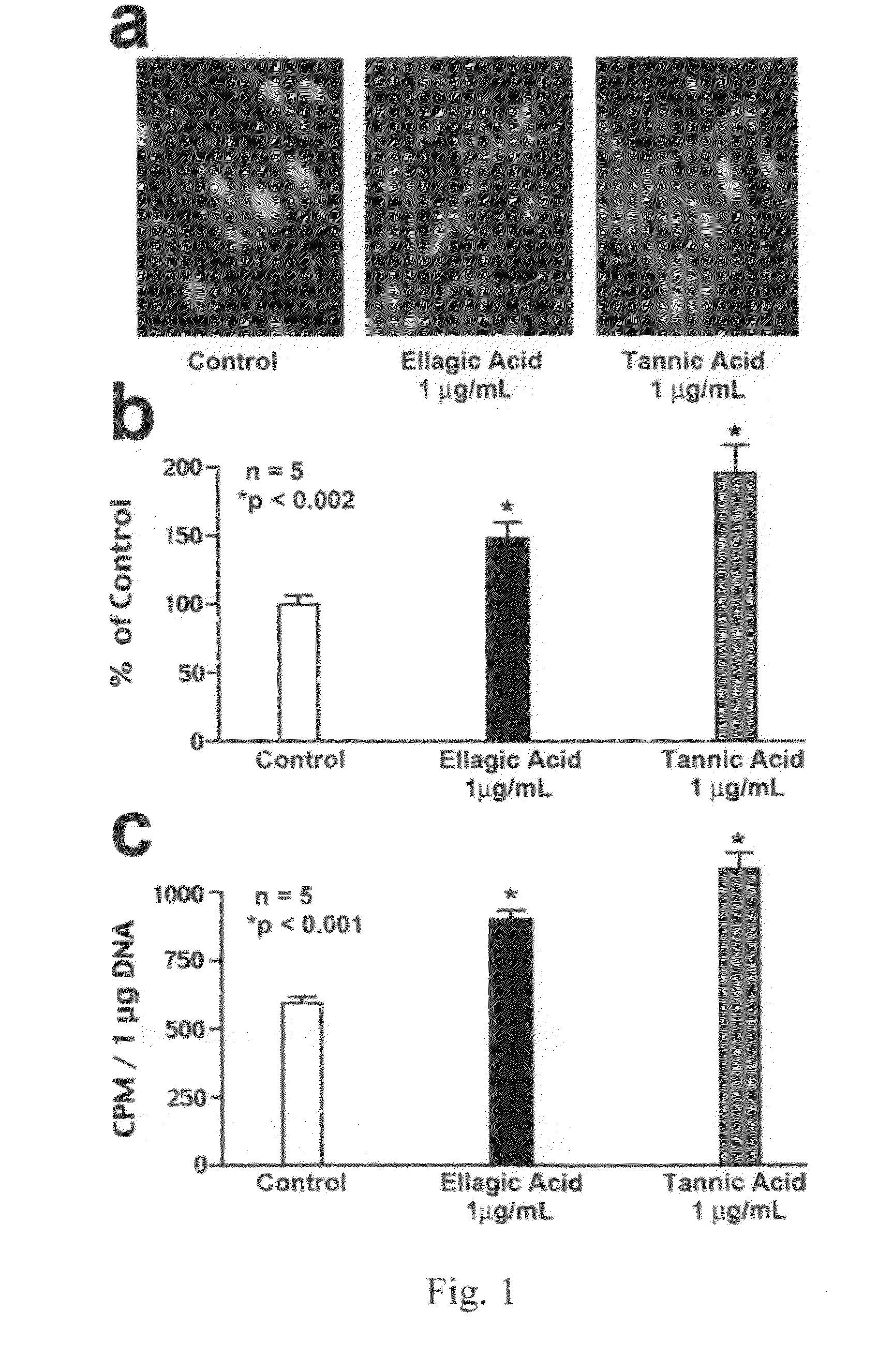

Dermal fibroblasts permanently loose their ability to synthesize elastin, the major component of elastic fibers, shortly after puberty. This progressive loss of elastic fibers cannot be replaced, resulting in the physical signs of aging. The present invention provides methods and compositions containing the polyphenols ellagic acid and / or tannic acid for protection against degradation of cutaneous elastic fibers by the elastolytic enzymes. The use of ellagic acid and / or tannic acid increased the overall deposition of elastic fibers in healthy and damaged skin cells. The protection of both intra-tropoelastin and extra-cellular mature elastic fibers from proteolytic enzymes by ellagic acid and tannic acid caused an increase in the net deposition of elastic fibers. Therefore, embodiments of the present invention provide methods and composition for the treatment of skin and prevention and treatment of degradation of dermal elastic fibers.

Owner:ELASTOGENESIS LLC +1

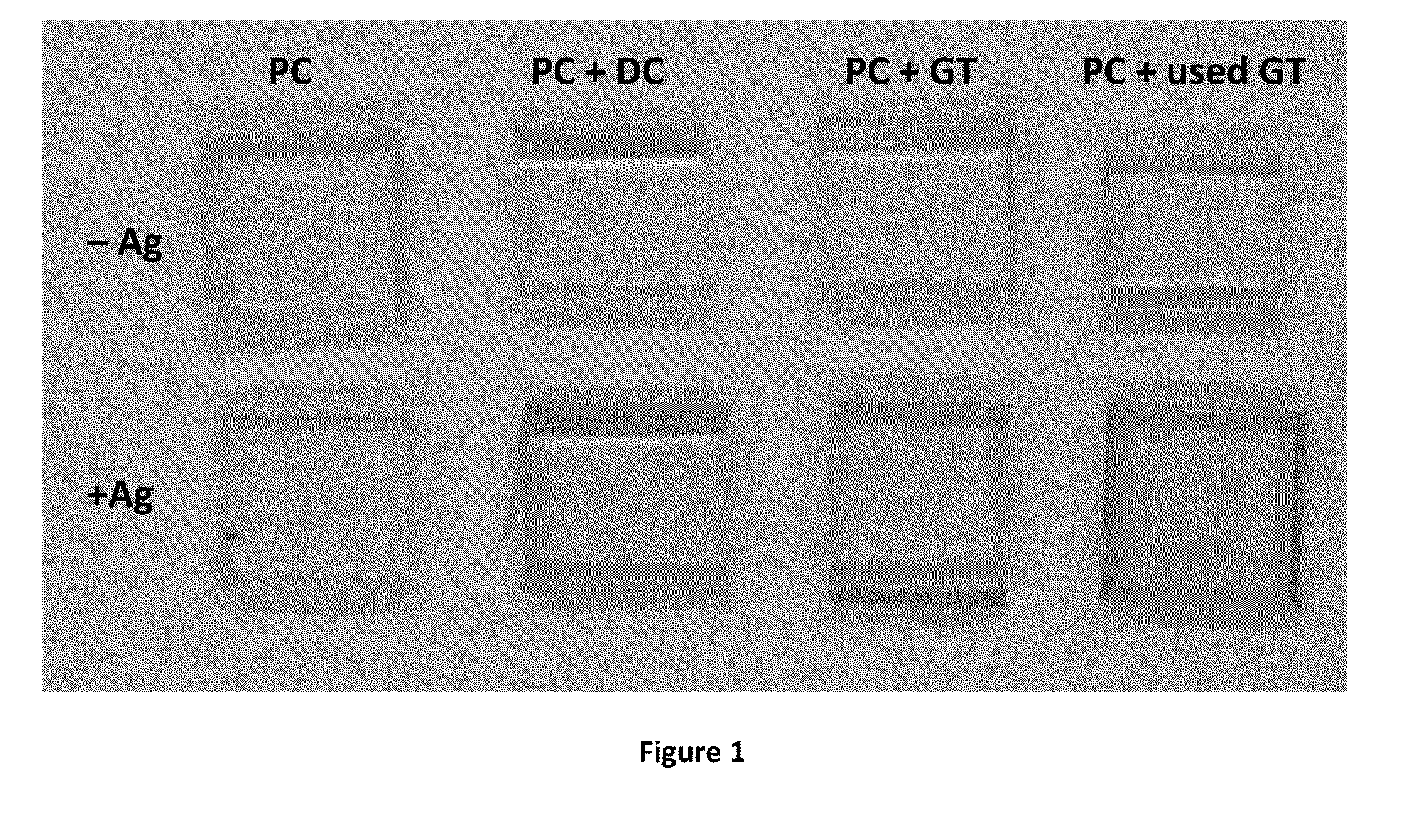

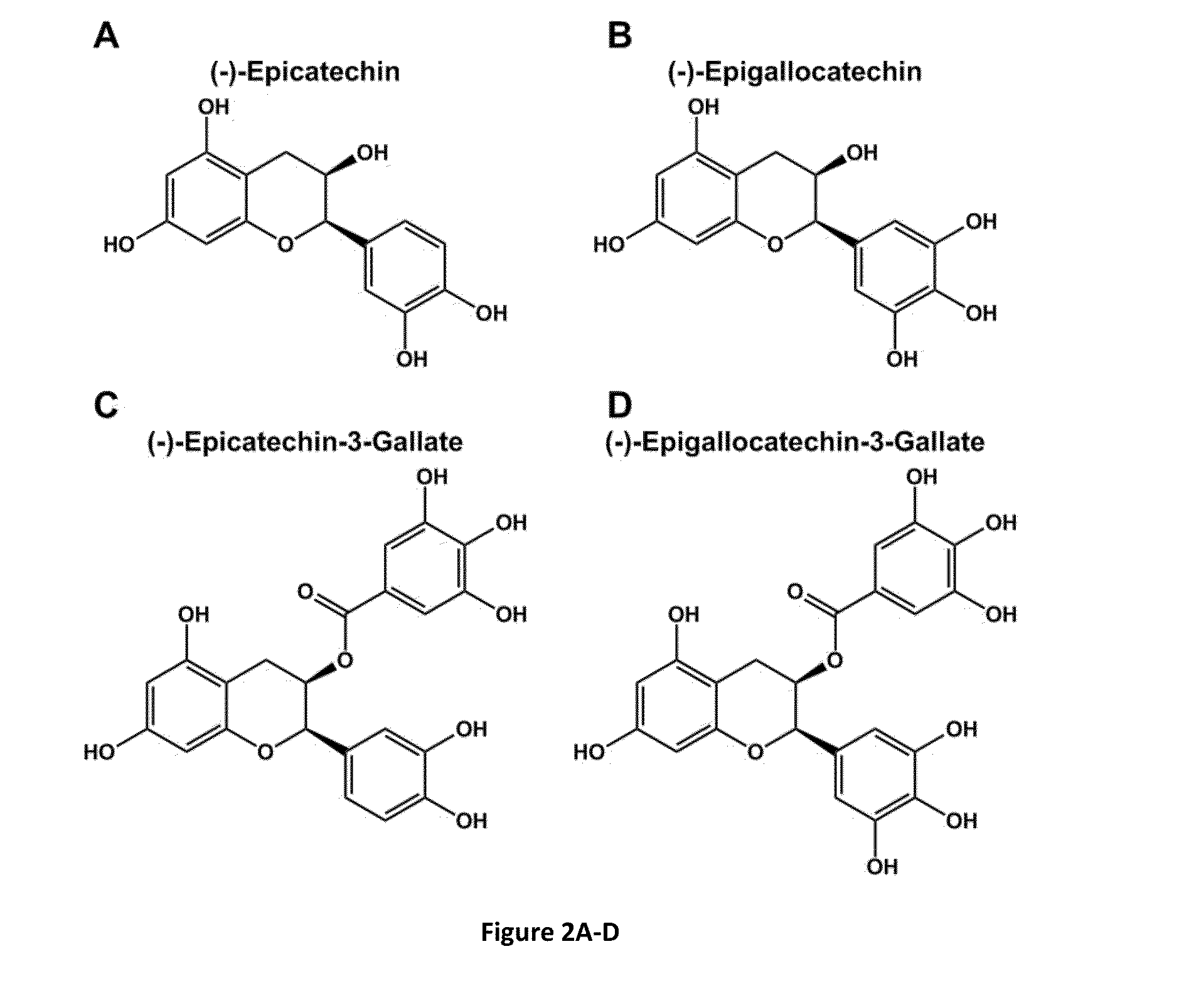

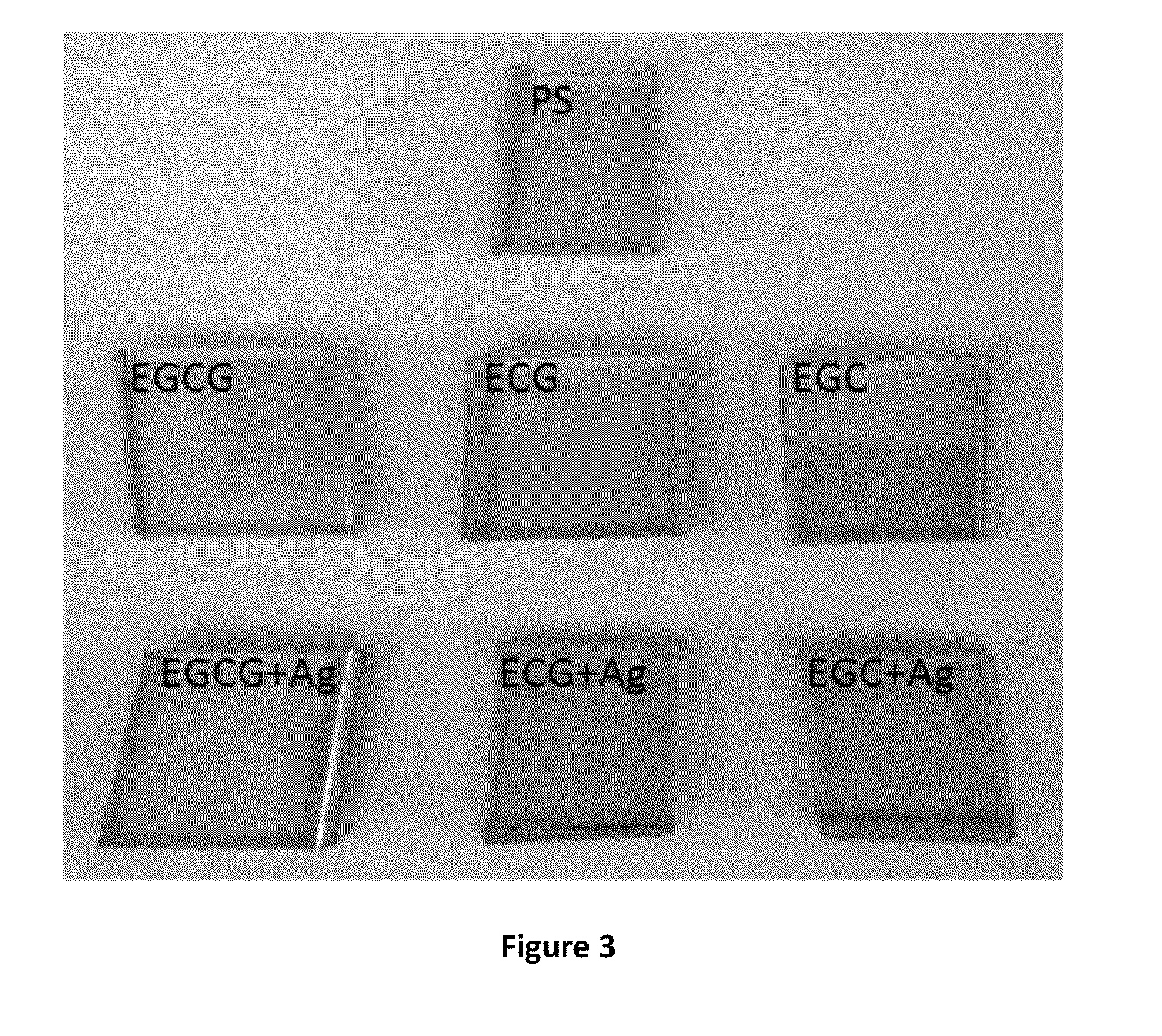

Phenolic Coatings and Methods of Making and Using Same

InactiveUS20140206630A1Little and no discolorationEasy to functionalizeBiocideHydroxy compound active ingredientsGallic acid esterChemical compound

A method of making a facile, surface-independent, polyphenol coating is disclosed. In general, the method includes contacting at least a portion of the substrate to be coated with an aqueous solution containing one or more salts and one or more nitrogen-free phenolic compounds. Substrates of all kinds may be used, and compounds used to make the coating may include epigallocatechin-3-gallate (EGCG), epigallocatechin (EGC) and epicatechin-3-gallate (ECG), tannic acid, gallic acid, pyrogallol, and / or other nitrogen-free phenolic compounds. The coating made using the method, methods of using the coating, and kits comprising the coating precursors are also disclosed.

Owner:NORTHWESTERN UNIV

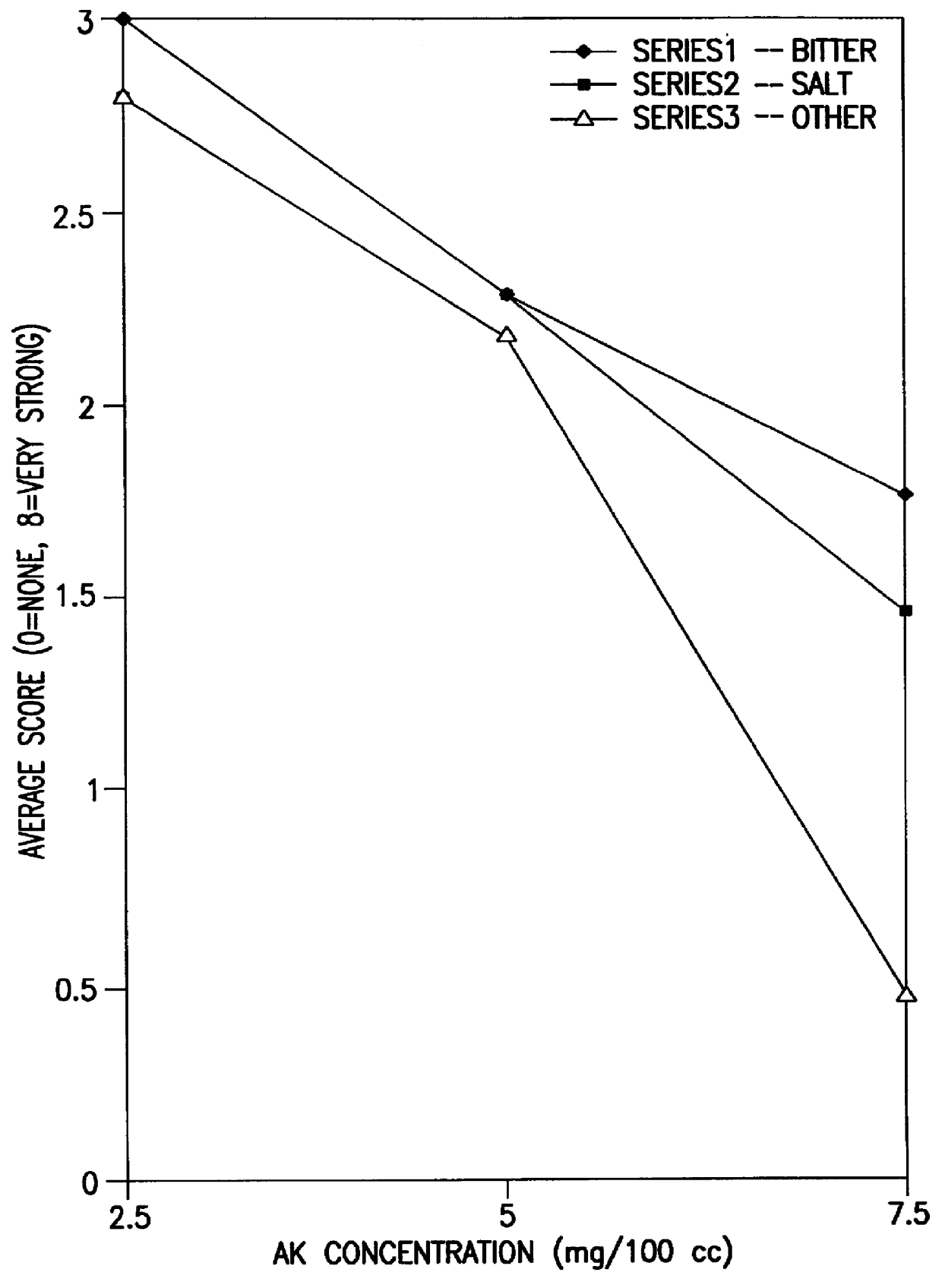

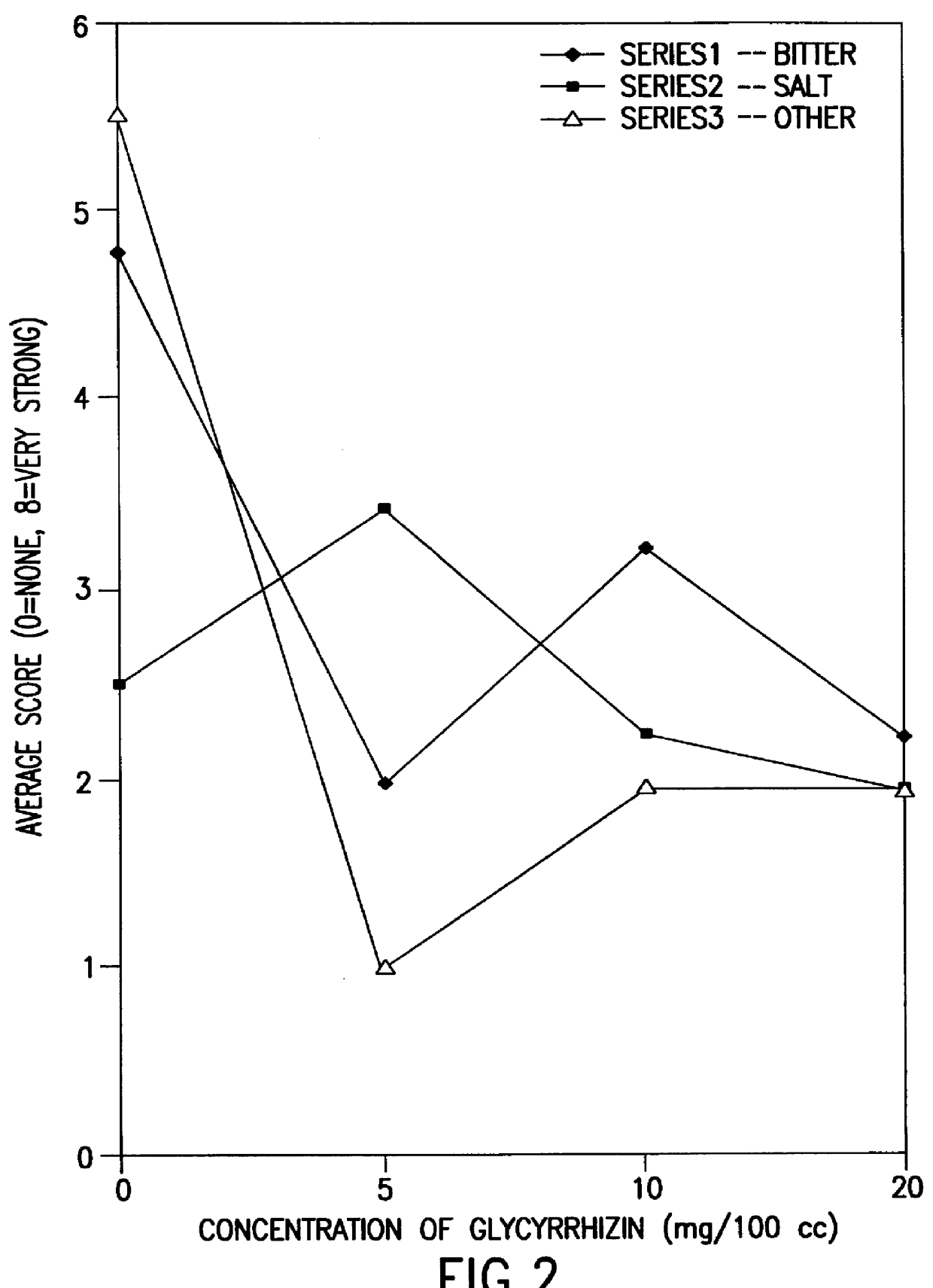

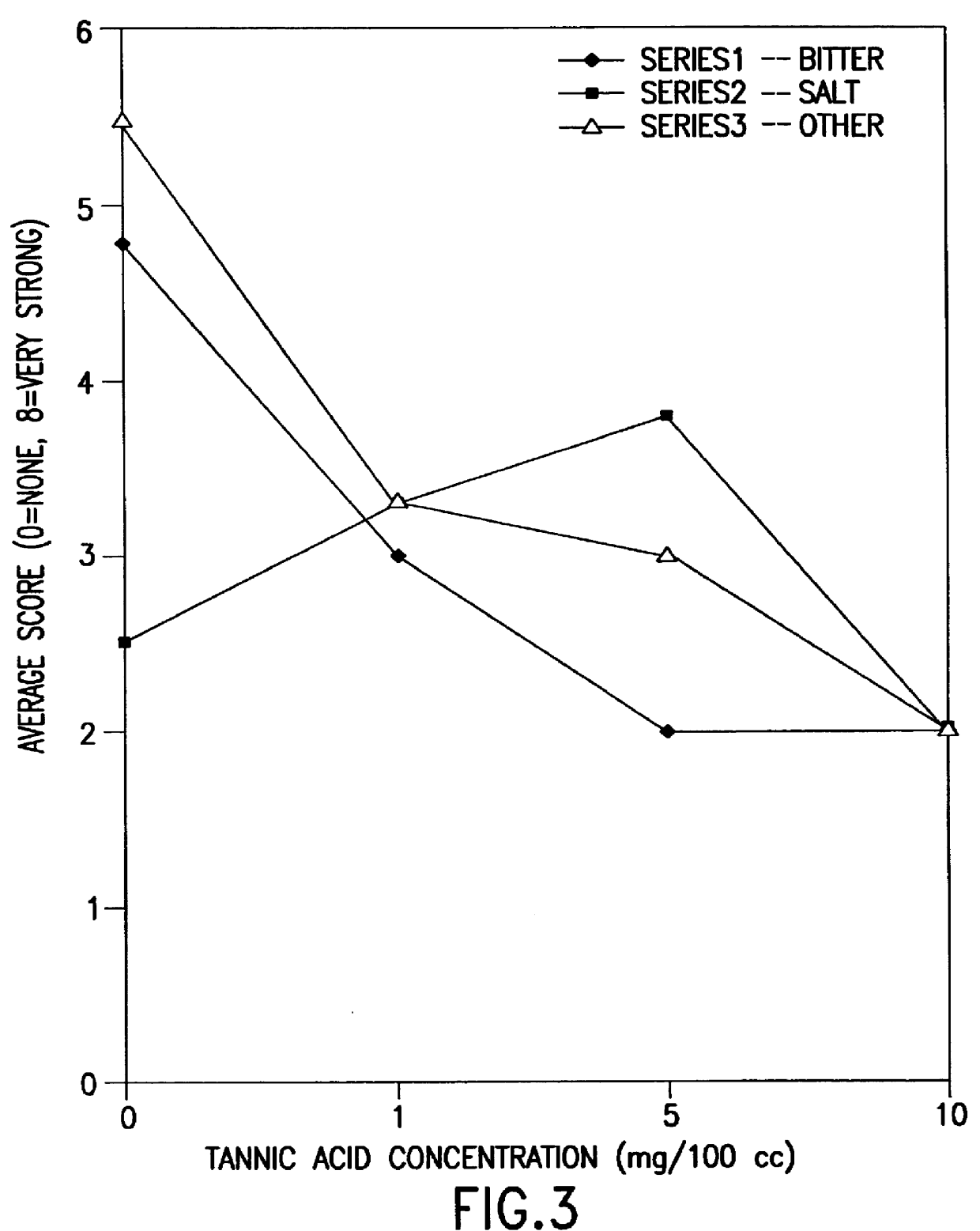

Method and composition for masking mineral taste

InactiveUS6156332AReduce aftertasteReduce tastePharmaceutical delivery mechanismUrinary disorderPotassiumTannic acid

The invention relates to methods and compositions for masking the taste of minerals in ingestible products. In particular, tannic acid glycyrrhizin and acesulfame potassium are added to compostions comprising minerals such as potassium, calcium, magnesium, iron, copper, chromium, zinc and mixtures in order to reduce or eliminate the unpleasant taste or aftertase associated with these minerals.

Owner:AMBI

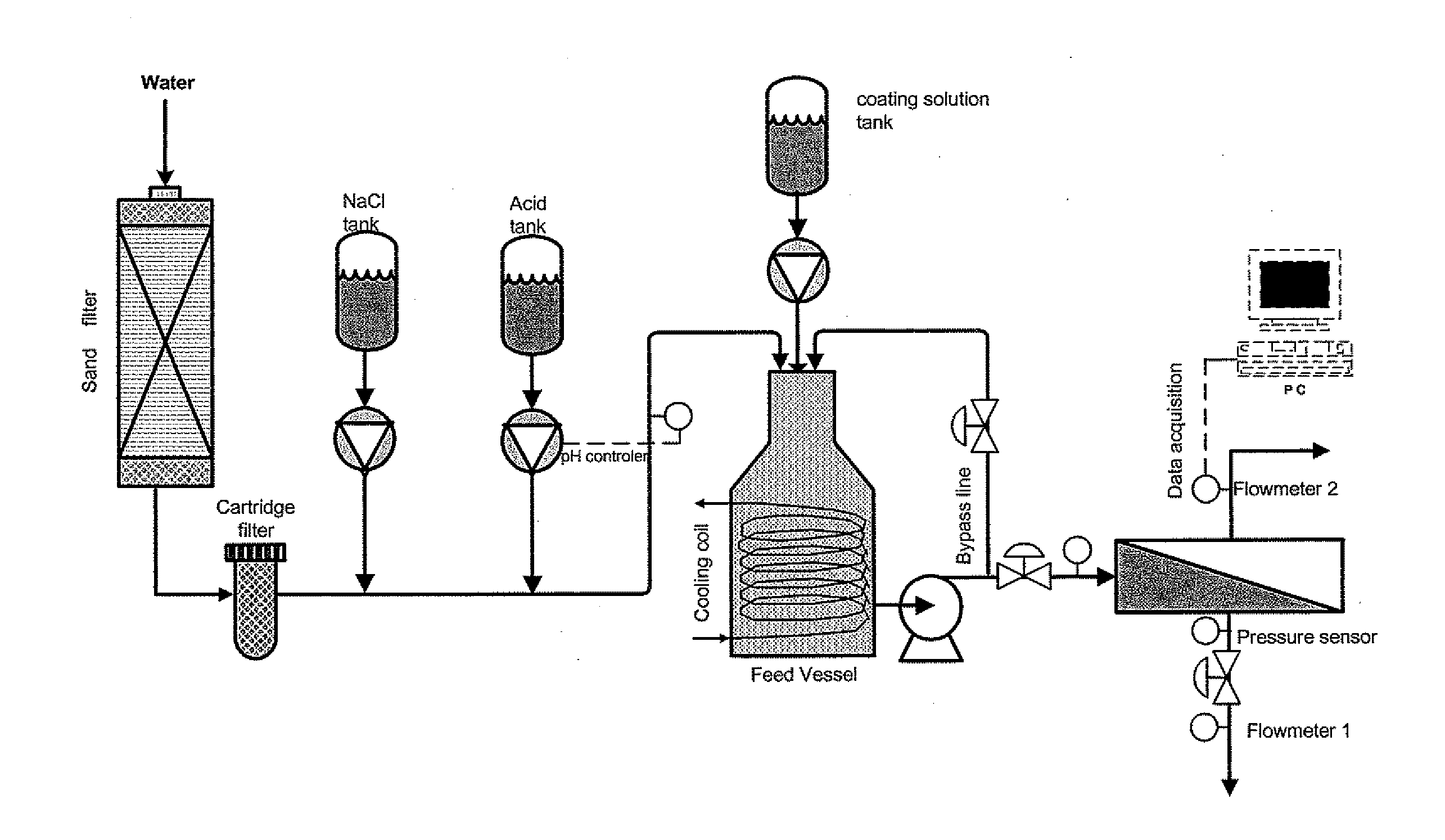

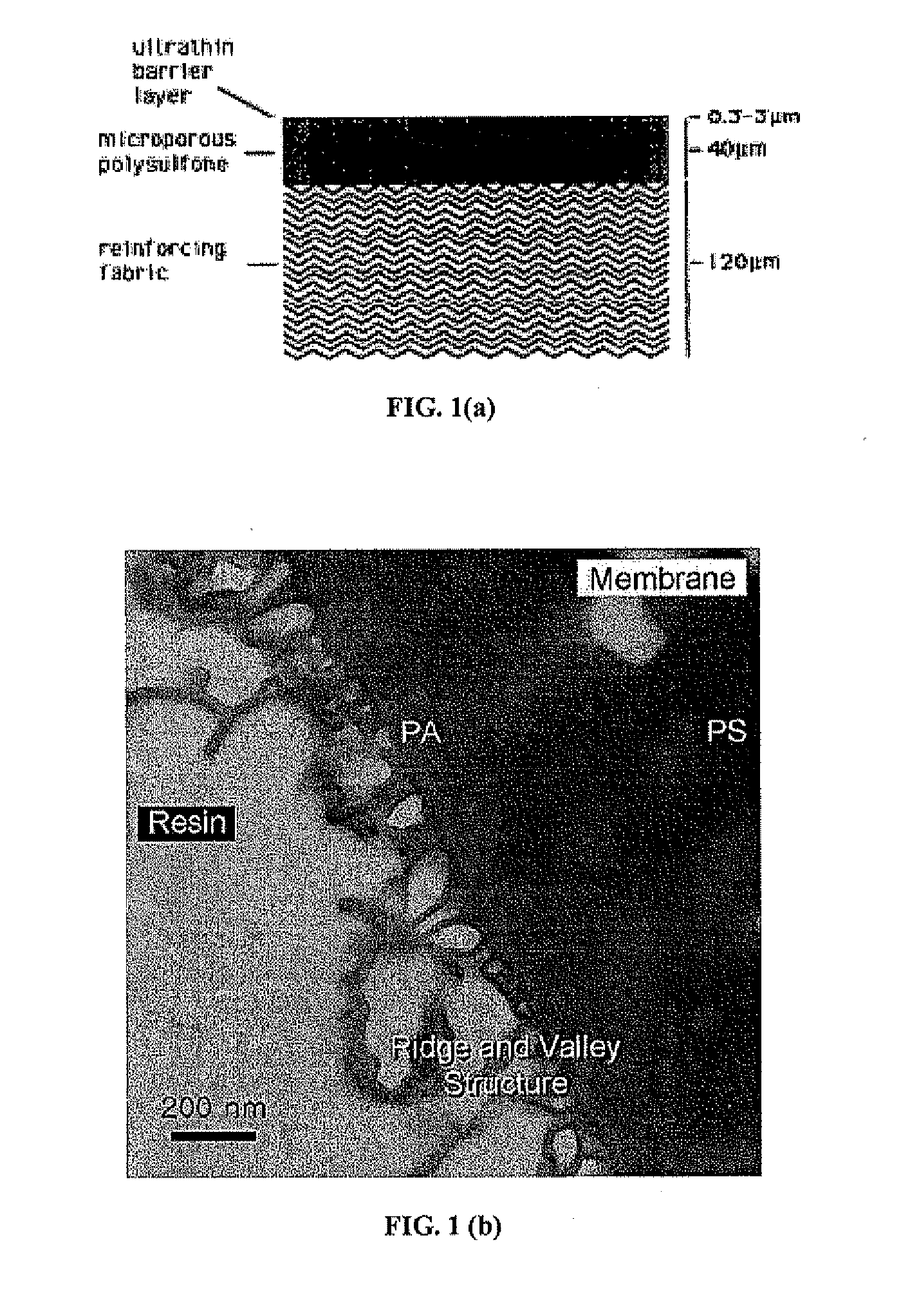

Application of Rejection Enhancing Agents (REAs) that do not have Cloud Point Limitations on Desalination Membranes

Methods of treating used or degraded reverse osmosis membranes post-production are provided. The membranes can be treated online or offline. The reverse osmosis membranes are cleaned and then contacted with a rejection enhancing agent solution that includes polyvinylpyrrolidone or polyvinylalcohol. The reverse osmosis membrane is then contacted with a tannic acid solution to produce a reconditioned reverse osmosis membrane having reduced defects. The treatment can take place at temperatures greater than 34° C. because the polyvinylpyrrolidone and polyvinylalcohol rejection enhancing agents used do not have cloud point limitations.

Owner:SAUDI ARABIAN OIL CO

Beverage contg. juice of cerasus humilis sok fruit and its preparing method

A P.humilis fruit juice beverage rich in Ca and Fe is prepared from P.humilis fruit juice, through enzymolyzing by pectinase, filtering, adding clarifying agent prepared from chitosan, gelatin, tannic acid, bentonite, EDTA and honey, clarifying, centrifugal separation of supernatant, adding sugar, and homogenizing.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

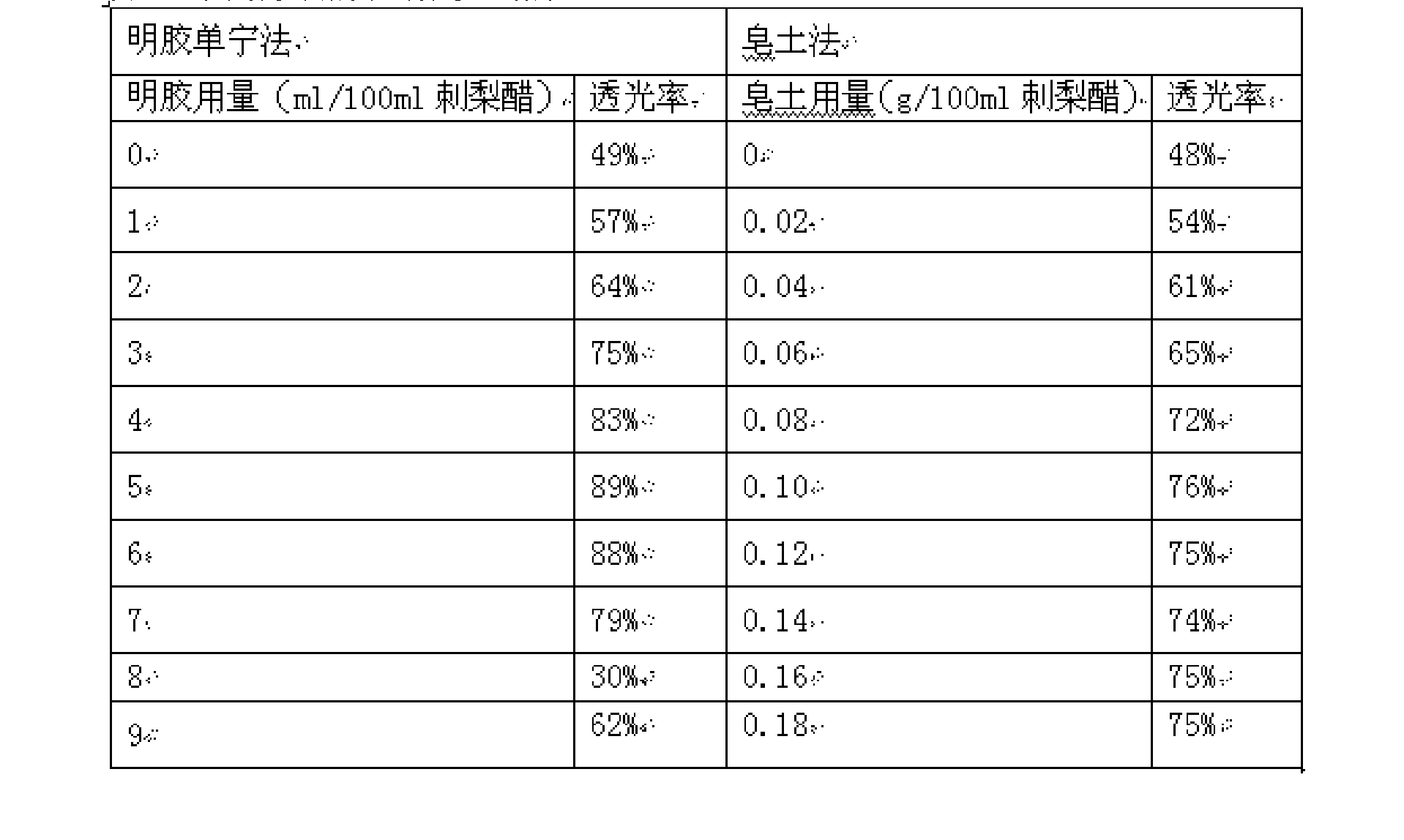

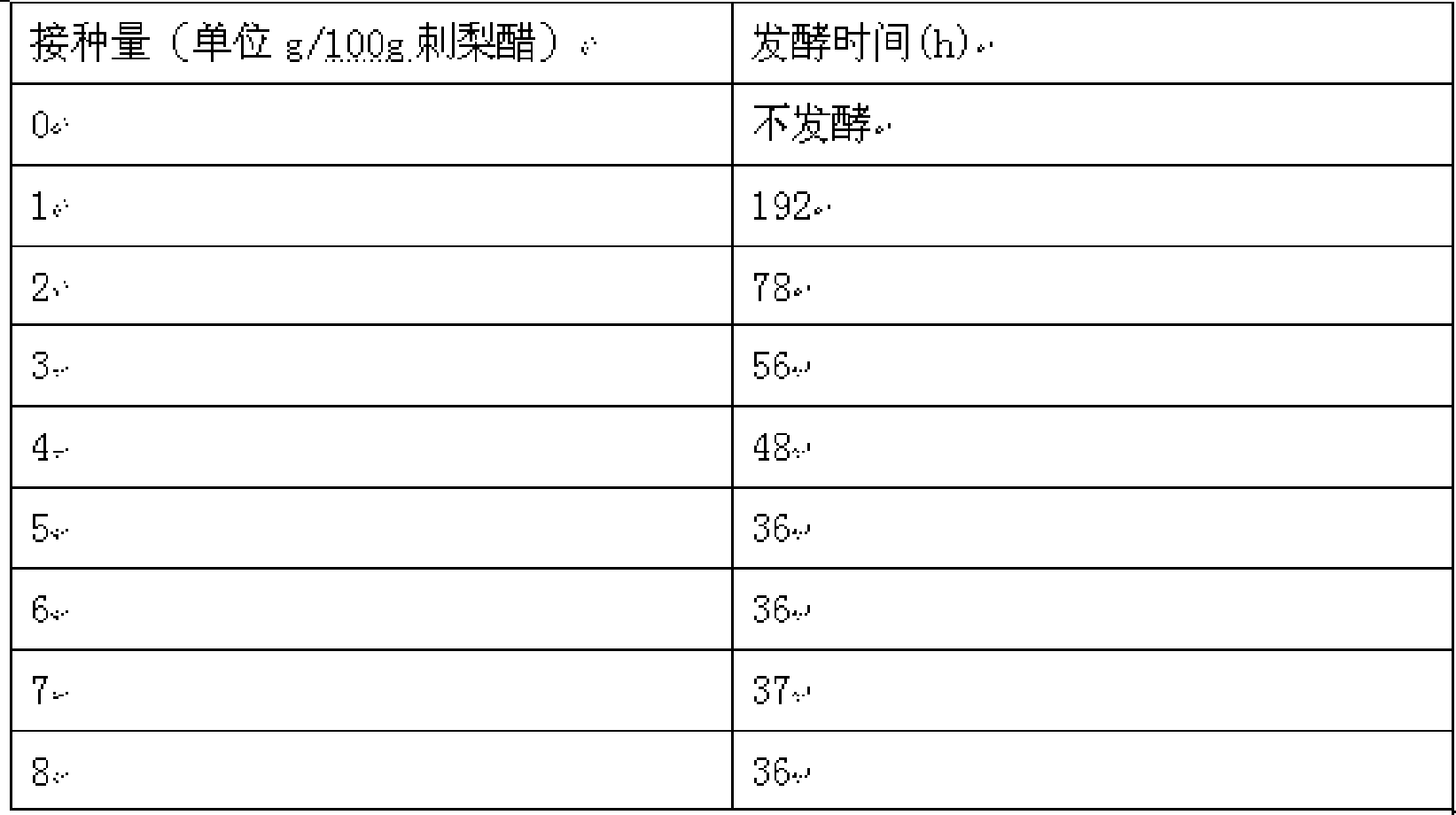

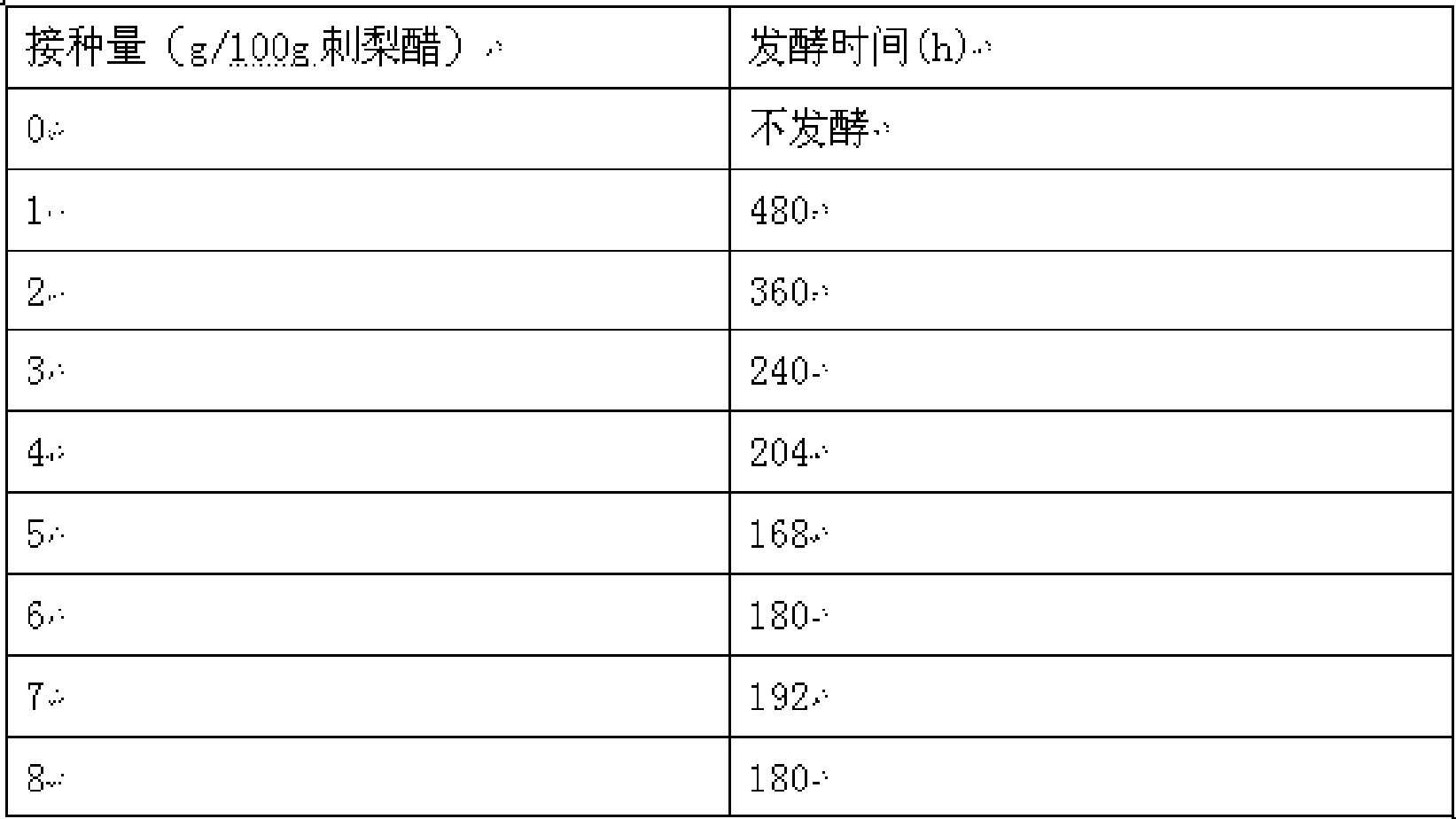

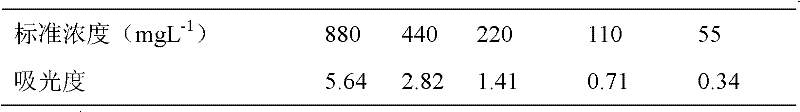

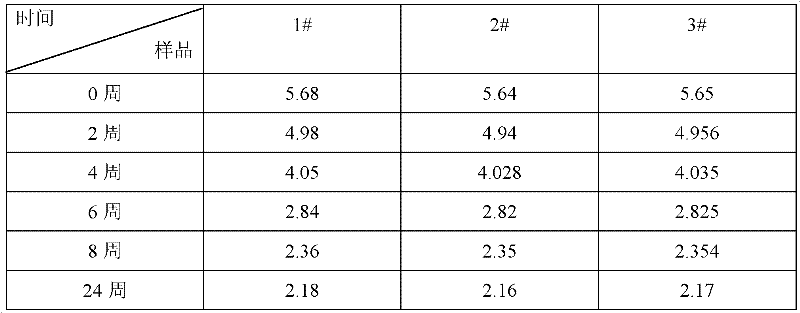

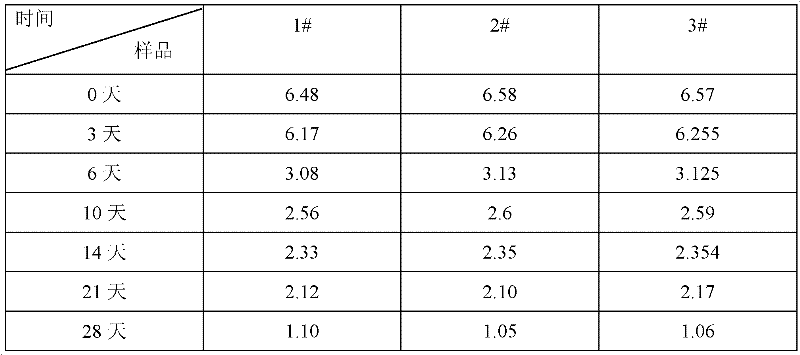

Rosa roxburghii vinegar beverage and preparation method thereof

InactiveCN101380130AMellow tasteChange the tasteVinegar preparationFood preparationPectinaseFully developed

The invention provides a method for preparing a roxburgh rose vinegar beverage. The method comprises steps of treating raw materials, adding pectinase, adjusting total sugar degree, inoculating pre-activated alcohol active dry yeast for alcohol fermentation, inoculating pre-activated acetic acid bacteria suspension for acetic acid fermentation, and clarifying, removing acerbity and filtering by gelatin-tannic acid method. Compared with the prior art, the invention develops a new roxburgh rose product, namely roxburgh rose vinegar beverage. Compared with the other table vinegar, the roxburgh rose vinegar beverage has richer nutrition, mellow taste, intense flavor and unique efficiency, is tasty and refreshing, and has the functions of relaxing blood vessels and reducing blood lipid. By adopting the gelatin-tannic acid method, the acerbity taste of the roxburgh rose is completely removed, the taste of the roxburgh rose is changed, the interest of the people in eating the roxburgh rose is improved, and the functions of the roxburgh rose such as beautifying and skin maintaining, and nourishing and building health are fully developed. The product can be stored for 18 months at room temperature while maintaining nutritious and health-care ingredients of the roxburgh rose very well.

Owner:季晓燕

Microcapsule sustained release agent and preparation method and application thereof

InactiveCN102373110ASimple process routeMild conditionsEssential-oils/perfumesAnimal housingDispersityFirming agent

The invention provides a microcapsule sustained release agent and a preparation method and application thereof. The microcapsule sustained release agent is prepared by embedding essence with gelatin and Arabic gum, and is applied to sanitary towels or sanitary cushions or panty-shape diapers or pet cushions. The microcapsule sustained release agent consists of a core material and a wall material, wherein the wall material consists of natural high molecular gelatin, Arabic gum and a curing agent; the core material consists of essence and essential oil; the curing agent consists of tannic acid and glutaraldehyde; and microencapsulation is performed on the core material and the wall material in the ratio 1:2. The invention further provides a preparation method of the microcapsule sustained release agent. The preparation method comprises the following steps of: adding an emulsifier into Arabic gum for mixing; adding essence or essential oil into an emulsion for homogenizing and emulsifying; adding a gelatin solution into the emulsified emulsion; agglomerating into a capsule; curing with a curing agent; and drying to obtain a high-dispersity microcapsule sustained release agent. By adding the microcapsule sustained release agent into the space between a skin contact layer and a water-absorbing layer of a sanitary towel or sanitary cushion or panty-shape diaper or pet cushion, the effect of keeping fragrance for a long time can be achieved.

Owner:TIANJIN SINOSH NEW MATERIAL TECH

Preparation method of composite flat membrane for adsorbing heavy metal ions and product thereof

InactiveCN103480347AImprove adsorption capacityLittle change in costSemi-permeable membranesOther chemical processesPhysical chemistryWastewater

The invention relates to a preparation method of a composite flat separation membrane and a product thereof, wherein the composite flat separation membrane has good adsorption ability on heavy metal ions such as nickel, molybdenum, mercury and the like as well as large adsorption capacity and high adsorption efficiency and can be cleaned for recycling. The product provided by the invention is prepared from water-washed and acid-washed attapulgite by modifying attapulgite with tannic acid and compounding with polyvinylidene fluoride. The composite flat membrane provided by the invention has a good adsorption effect on the heavy metal ions such as lead, cadmium, nickel, molybdenum and the like in wastewater, the adsorption rate on nickel ions of the composite membrane in which the mass ratio of polyvinylidene fluoride to modified attapulgite is 1:0.01 is close to 40%, and the adsorption rate on mercury ions is close to 60%. The product provided by the invention integrates the advantages of a polyvinylidene fluoride separation membrane as well as the adsorption performance of attapulgite; the preparation technology is simple and low in cost, does not need special equipment and is easy to implement industrially; the membrane has stable physical performance, and the pure water flux is increased.

Owner:TIANJIN CNCLEAR ENVIRONMENTAL PROTECTION SCI & TECH CO LTD

Graphene and preparation method thereof

ActiveCN106477559AGood dispersionGood prospects for biological applicationsGrapheneHigh concentrationEther

The invention provides a preparation method of graphene. The preparation method includes the steps of firstly, preparing graphene oxide; secondly, using a silane coupling agent to modify the graphene oxide; thirdly, adding an initiator in the presence of the modified graphene oxide obtained in the second step, and copolymerizing N-vinyl pyrrolidone and polyethylene glycol monoallyl ether to obtain silane coupling agent modified graphene oxide dispersing liquid using copolymer as the dispersing agent; fourthly, adding gallic acid and tannic acid into the modified graphene oxide dispersing liquid obtained in the third step to perform reduction reaction so as to obtain the end-product graphene. The prepared graphene is promising in bio-application prospect and capable of forming stable and high-concentration dispersing liquid.

Owner:刘果

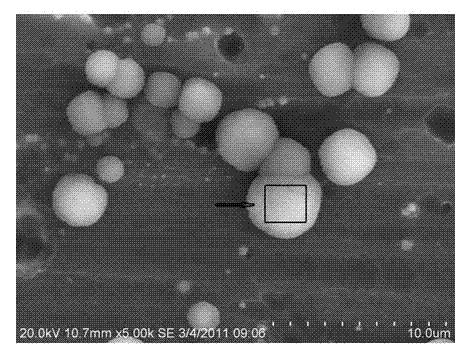

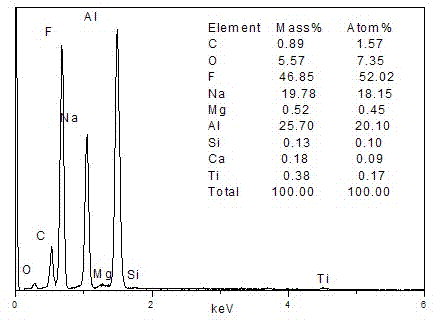

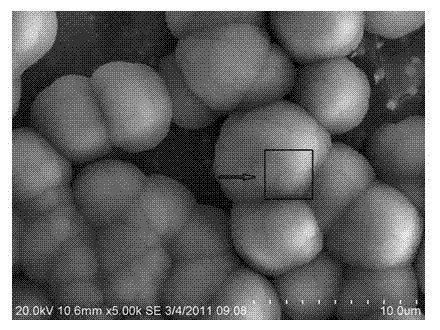

Treatment solution and treatment method for preparing golden cryolite conversion film on surface of aluminum alloy

InactiveCN102242358ASimple recipeSimple processMetallic material coating processesManganeseToxic material

The invention discloses a treatment solution and a treatment method for preparing a golden cryolite conversion film on the surface of aluminum alloy. The composite conversion film prepared by the invention has a double-layer structure: an outer layer mainly containing organic complexes and an inner layer mainly containing Na3AlF6. The treatment solution comprises the following components in concentration: 1-5.0 g / L fluotitanic acid, 0.5-5.0 g / L fluorozirconic acid, 1-5.0 g / L tannic acid, 2-5.0 g / L film-forming accelerator fluoride and 2-5.0 g / L manganese salt; and the treatment solution is regulated with a base until the pH value is 3.0-5.0. The treatment solution disclosed by the invention is free of chromium and other toxic substances; the conversion and treatment process does not need heating and has the advantages of short treatment time, room-temperature treatment and simple process; and the chemical conversion film prepared by the treatment method has the advantages of excellentcorrosion performance, high binding strength with a base body, and no hexavalent or trivalent chromium harmful to environment and human bodies.

Owner:SOUTH CHINA UNIV OF TECH

Tannic acid modified bean powder adhesion agent and method of manufacturing the same

InactiveCN101108958AReduce acidityHigh bonding strengthProtein adhesivesGlue/gelatin preparationWater bathsAdhesive

A tannic acid modified soybean powder adhesive and the preparation method are provided, which relates to an adhesive and the preparation method. The invention solves the problems of poor water resistance, high alkaline and strong corrosion of the current soy-adhesive. Based on the weight portion, the product of the invention consists of 100 soybean powder, 600 water and 2 to 14 tannic acid. The preparation method is as follows: the soybean powder is dissolved in the water of 30 DEG C. to 35 DEG C. and insulated in the water for 3min to 8min, and is added with tannic acid solution to react for 10min to 20min under the temperature of 30 DEG C. to 35 DEG C. after stirring evenly. Compared with the prior art, the invention has the adhesive with low pH value, reduces the stimulation and corrosion on the bonded materials and the production workers and the production cost and increases the bonding strength. The soybean powder adhesive manufactured by the invention can be used for the production of the plywood and other packing materials and has no formaldehyde releasing, low corrosion and good water resistance, which belongs to the environmental adhesive with high bonding strength, safe use and simple production technology.

Owner:NORTHEAST FORESTRY UNIVERSITY

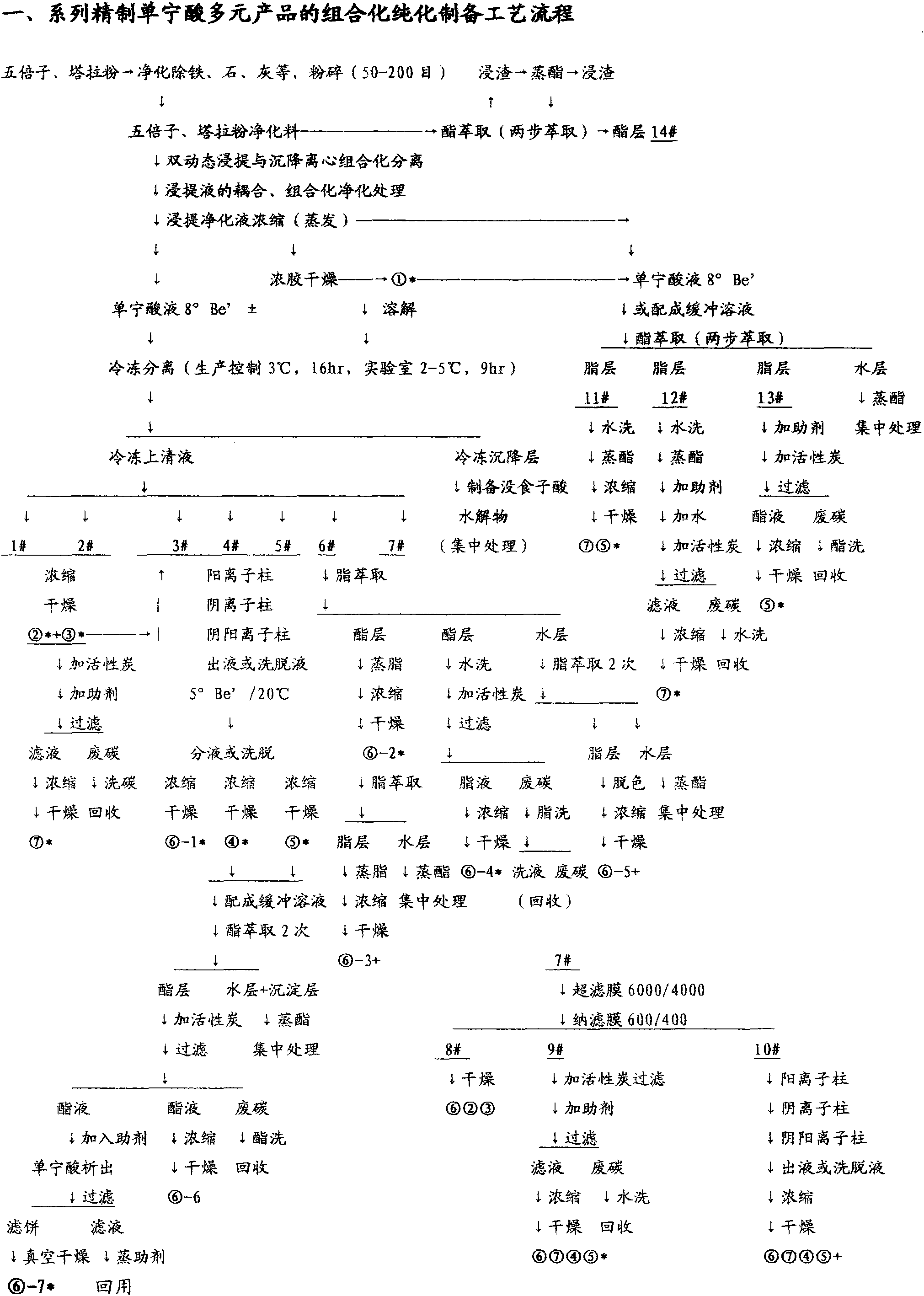

Multielement combined purification preparation process of refined tannic acid serie and combined preparation of products

InactiveCN102127125AIncreased tannic acid contentImprove exchange capacityEsterified saccharide compoundsSugar derivativesActivated carbonTannic acid

The invention relates to a multielement combined purification preparation process of a refined tannic acid serie and a combined preparation of the products. Gallnut or tara ultrarfine grinding material or industrial tannic acid is used as raw material and the multielement combined purification process, equipment and technologies such as extraction, freezing separation, solvent extraction, resin column separation, activated carbon absorption decoloring separation, complexation separation, membrane separation and refining separation to prepare a serie of tannic acid multielement products such as industrial tannic acid, dye tannic acid, beer tannic acid, edible tannic acid, medicinal tannic acid, reagent tannic acid, high purity tannic acid and electronic grade tannic acid, thus the integration and innovation of the green, low-carbon, environmentally friendly and energy-saving industrialized technology that tannic acid raw material is refined and processed deeply can be effectively realized. The combined technology is adopted to effectively realize the integration and innovation of the high, sophisticated, deep and sharp integrated technology that the raw material is used to prepare the serie of refined tannic acid multielement products, which is an achievement of the high and innovative technologies.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Method for preventing and treating avian influenza in human

A method and composition for preventing and treating Avian Influenza in Humans utilizes an effective quantity of polyphenolic(s) and / or its derivatives in combination with a carrier. The anti-avian influenza ingredient having a composition selected from the group consisting of theaflavin, theaflavin-3,3′-digallate, theaflavin-3-monogallate, theaflavin-3 gallate, theaflavin-3′-gallate, thearubigin, gallic acid, tannic acid, (−)-epigallocatechin gallate (EGCG), (−) epigalloatechin (EGC), (+)-epicatechin (EC), (−)-gallocatechin gallate (GCG), and catechin.

Owner:SICAN VENTURES

Resist calcification modified method of heterogeneity biological organization material

InactiveCN101161293AReduce degradationImprove anti-calcification propertiesProsthesisFiberTissue material

The present invention discloses a method of calcification-resisting modifying for the heterologous biology tissue material, in the method the tannic acid solution is used to immerse the tissue; the concentration of the tannic acid is between 1 and 6%, the pH value of the solution is between 4.0 and 6.0, the immersing temperature is between 18 and 32 DEG C, and the immersing time is between 24 and 96 hour. The method of the invention can simultaneously crosslink the collagen fiber, the elastic fiber and glycosaminoglycan in the cell epimatrix of the tissue material, reduce the degradation when the tissue is implanted to the body, compensate the insufficiency that the pentanedial only crosslinks the collagen fiber and remarkably increase the calcification-resisting capability of the material; has the effect of antibacterial and reducing the protein antigenicity, and helps to increase the calcification-resisting capability and bioavailability of the material. The intercrossed tissue material has the advantages of good biostability, reinforced biomechanical property and long service lifetime.

Owner:胡盛寿 +2

Anti-corrosion plaster for ocean steel facilities

The invention relates to the anticorrosion material which is the anticorrosion cream for the steel device used in the sea, river and lake. The component is mineral lipid 10-45%, antirust 5-10%, lubricant 30-40% and bulking agent 20-40%. The anticorrosion cream covered on the steel surface has good compactability. It adds the tannic acid and metal sub-sulphonate into the anticorrosion cream to improve the anticorrosion used in the sea, river and lake.

Owner:株式会社那卡波技工 +1

Iron rust conversion agent and preparation method thereof

InactiveCN103173757AStrong weather resistanceImprove mechanical propertiesMetallic material coating processesAtmospheric airSolvent

The invention relates to an iron rust conversion agent for removing and preventing rust on the surface of steel. The iron rust conversion agent can be coated on a rusty surface of the steel, the iron rust is conversed into a layer of a protective film, the complicated components of the rust layer are converted into stable products, and the stable products show no rust in the relatively long time in the atmosphere, therefore, the rusty surface of the steel can be directly coated and constructed without removing the rust. A synthetic resin emulsion is used as a main film-forming agent, pyrogallic acid and tannic acid are used as main conversion agents, citric acid is used as an auxiliary conversion agent, and a film-forming auxiliary agent is adopted to realize the curing film-forming at room temperature, thus the compactness and water resistance of the film are improved; and moreover, isopropyl alcohol is used as a solvent and penetrating agent, so as to stabilize the rusty layer. The iron rust conversion agent is sprayed to the rusty surface of the steel, thus a compact and uniform black film is formed on the surface of the steel in short time. In addition, the iron rust conversion agent has advantages of simple preparation process, low cost, stable performance, economy and practicality, safety and environmental friendliness, not containing of toxic and harmful ingredients such as formaldehyde, benzene and nitrite, and no simulation on operating personnel and the like.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Color regulator special for improving appearance of recombinant tobacco and preparation method of same

The invention discloses a color regulator special for improving appearance of recombinant tobacco and a preparation method of the color regulator and belongs to the technical field of preparation of food colorants. The color regulator is prepared by mixing three natural pigments including beta-carotene, lycopene and caramel and five additive aids including guar gum, tannic acid, citric acid, sodaand methyl acetate according to a certain ratio, wherein the natural pigments are separated and purified by a supercritical CO2 extraction technology and a reverse osmosis technology; and oil-solublebeta-carotene and lycopene are modified into water-soluble pigments by an emulsification embedding technology. The preparation method is simple and easy to implement. The color regulator has the advantages of high water solubility, strong coloring power, stable performance and safety and no toxicity in combustion. High-quality recombinant tobacco can be prepared by the color regulator.

Owner:HUBEI CHINA TOBACCO IND +1

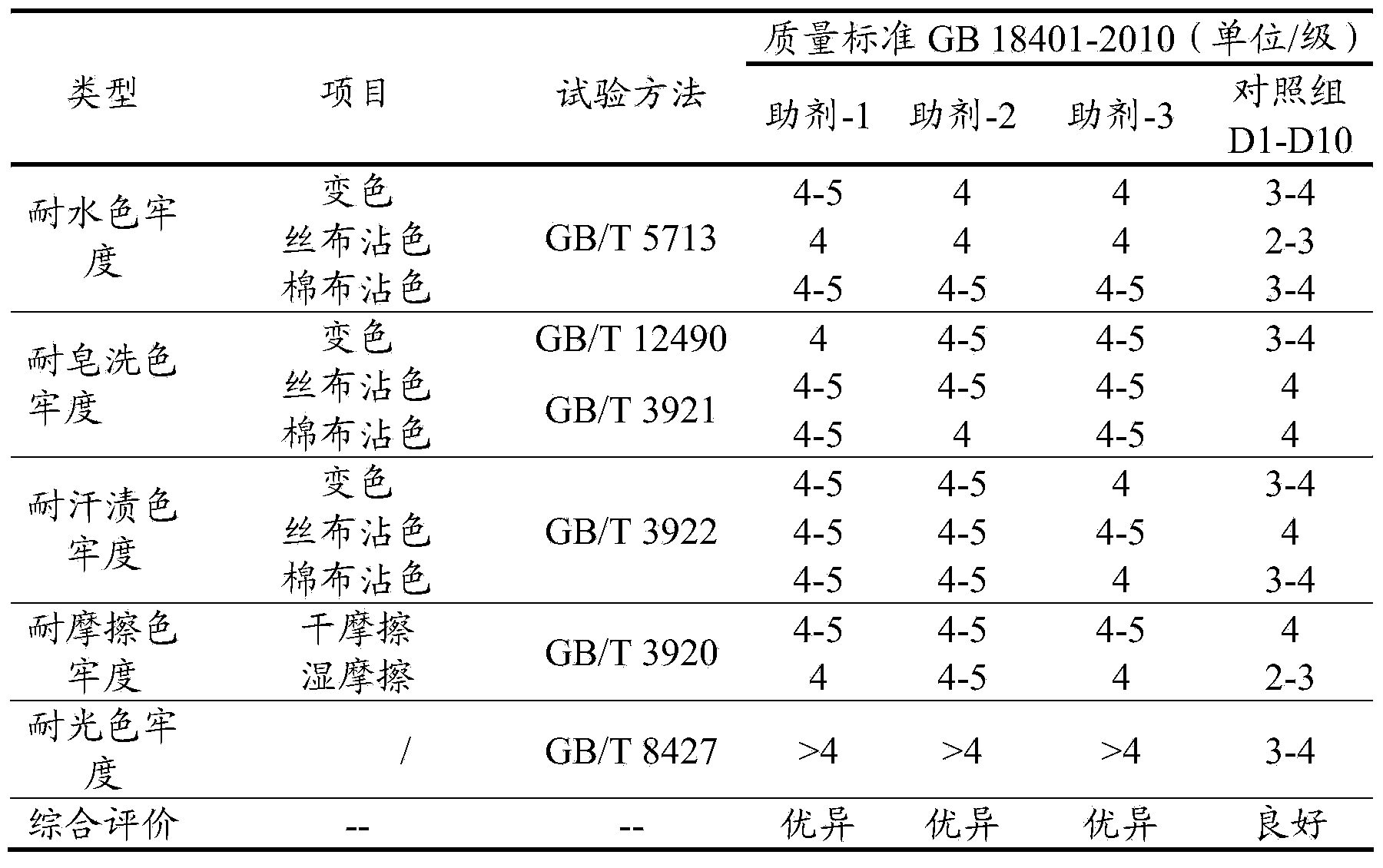

Composite printing and dyeing auxiliary as well as preparation method and application of auxiliary

The invention relates to a composite printing and dyeing auxiliary as well as a preparation method and an application of the auxiliary. The composite printing and dyeing auxiliary is prepared by compounding polyethylene glycol diamine, N-methylol acrylamide, sodium dodecyl benzene sulfonate, ammonium persulfate, di-rhamnolipid, a plant extract, tannic acid, sodium taurate, 1-carboxyl-N,N,N-trimethyl polycrylactone, tetradecyl dimethyl ammonium chilride, 1-phenoxy-2-propyl alcohol, 2-p-toluene sulfonic acid phenylamino-4-chloro-6-beta-naphthoxy triazine, silicon dioxide, europium chloride, ethanol and polyethylene glycol 600. As specific polymer components, the plant extract, quaternary ammonium salt, natural amino acid and natural esters are introduced, a rare earth complex is formed and other suitable components are added under compounding and synergistic effects, the composite printing and dyeing auxiliary has excellent technical effects of burnishing, protecting the color and improving the color fastness, and has the certain antibacterial and antistatic functions, and therefore, the composite printing and dyeing auxiliary has a wide industrial application prospect in the textile printing and dyeing industry.

Owner:傅科杰

Micro-arc oxidation electrolyte and micro-arc oxidation method for titanium alloys

InactiveCN103911644AGood degreasingNo pollution in the processSurface reaction electrolytic coatingElectrolytic agentMicro arc oxidation

The invention relates to a micro-arc oxidation electrolyte and micro-arc oxidation method for titanium alloys. The electrolyte comprises phytic acid or phytate, and one or more of electrolytes such as bioactive element containing calcium salts, magnesium salts, zinc salts or organic additives such as tannic acid and hydroxides also can be added. The micro-arc oxidation method comprises the steps of pretreatment, micro-arc oxidation, and post-processing. The micro-arc oxidation electrolyte disclosed by the invention does not contain Cr<6+>, F<-> and PO4<3->, therefore, the electrolyte has no pollution to the environment. A coating prepared according to the micro-arc oxidation method disclosed by the invention is of a typical microporous structure, and has good antimicrobial properties, biological activity, corrosion resistance and wear resistance; the method is easily-obtained in raw materials, and suitable for industrial production.

Owner:JIANGXI SCI & TECH NORMAL UNIV

Water-based white sealed primer and preparation method thereof

The invention relates to a water-based white sealed primer and a preparation method thereof. The water-based white sealed primer comprises the following components in part by weight: 350 to 600 parts of water-based resin and 50 to 100 parts of modified barium metaborate. The water-based white sealed primer provided by the invention has performance of sealing wood tannic acid and has a durable and good sealing effect after construction on the base material containing the tannic acid, nicotine blot and water-based pigment. Water-based white wood coating is coated on the primer, so the water-based white wood coating is not polluted by the pollutants and is not discolored, and the primer has high rubbing property, covering power and corrosion resistance and can prevent wood from being rotten and deteriorated.

Owner:BEIJING ZHANCHEN CHEM +2

Method for extracting germanium from high-impurity low-grade complex zinc oxide powder

ActiveCN102191391AAvoid interferenceAvoid harmPhotography auxillary processesProcess efficiency improvementIndiumHydrometallurgy

The invention provides a method for extracting germanium from high-impurity low-grade complex zinc oxide powder, and belongs to the technical field of hydrometallurgical processes. The method comprises the following steps of: under the process conditions that the PH value is 0.5 to 1.5 and the temperature is 55 to 75 DEG C, adding sulfite into aqueous solution of zinc sulfate which contains 8,000to 15,000mg / L iron, 300 to 1,000mg / L Fe<3>, and 30 to 135mg / L germanium so as to convert Fe<3> into Fe<2>, complexing and precipitating the germanium by adopting tannic acid to ensure that the germanium in the aqueous solution of zinc sulfate is subjected to a phase change reaction to form [GeO(C75H52O46)2<2>], pretreating, and calcining in a calcining kiln to obtain a germanium concentrate with the germanium content of between 8 and 22.36 percent which is used for producing germanium series products; and removing iron from solution of zinc sulfate obtained after the separation, and feeding into the conventional electrolytic zinc production system to recover valuable metals such as zinc, cadmium, indium and the like. By the method, the interference of the Fe<3> to a multi-metal recovery system can be effectively avoided, the production cost is reduced, and the smooth production process flow is ensured. The method has great significance for comprehensively recovering and recycling the valuable metals in low-grade high-impurity complex zinc oxide raw materials.

Owner:NANHUA MAOSEN REGENERATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com