Patents

Literature

508 results about "Acesulfame potassium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

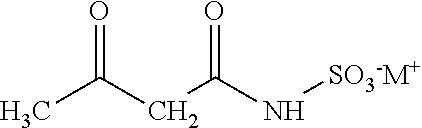

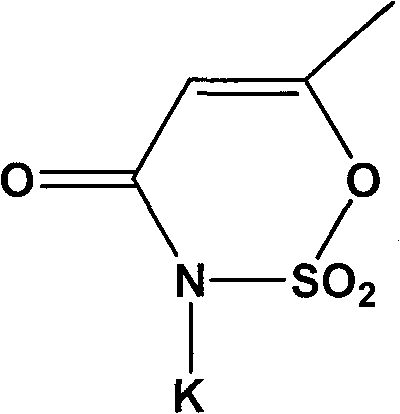

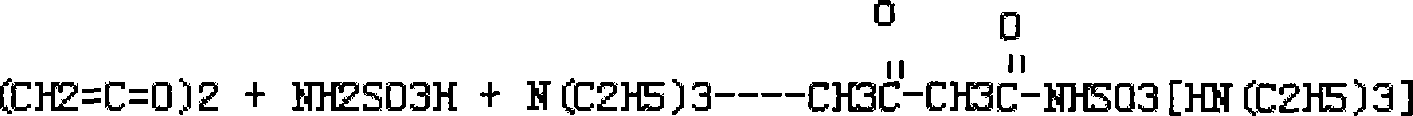

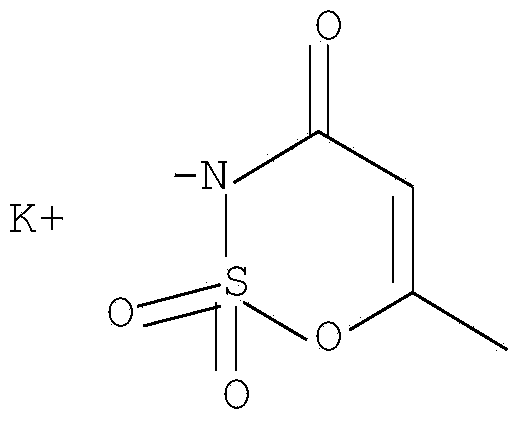

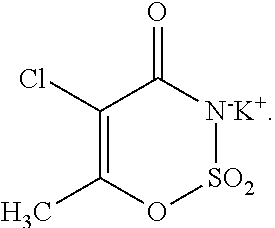

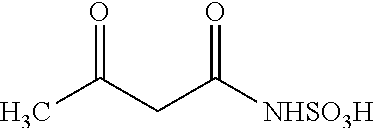

Acesulfame potassium (/ˌeɪsiːˈsʌlfeɪm/ AY-see-SUL-faym), also known as acesulfame K (K is the symbol for potassium) or Ace K, is a calorie-free sugar substitute (artificial sweetener) often marketed under the trade names Sunett and Sweet One. In the European Union, it is known under the E number (additive code) E950. It was discovered accidentally in 1967 by German chemist Karl Clauss at Hoechst AG (now Nutrinova). In chemical structure, acesulfame potassium is the potassium salt of 6-methyl-1,2,3-oxathiazine-4(3H)-one 2,2-dioxide. It is a white crystalline powder with molecular formula C₄H₄KNO₄S and a molecular weight of 201.24 g/mol.

Sweetener containing d-psicose and foods and drinks obtained by using the same

Providing a D-psicose-containing sweetener with the modification of the taste of D-psicose, comprising D-psicose, a sugar alcohol and / or a high intensity sweetener, preferably containing D-psicose as the main component, particularly a low-calorie sweetener and / or a sweetener giving refreshing feel in the oral cavity, as well as foods and drinks obtained by using the D-psicose-containing sweetener with the modification of the taste of D-psicose, and other products given with sweetness. The sugar alcohol is one or more sugar alcohols selected from the group consisting of sorbitol, mannitol, lactitol, maltitol, xylitol and erythritol, while the high intensity sweetener is one or more high intensity sweeteners as selected from aspartame, acesulfame K, sodium cyclamate, sodium saccharin, Sucralose (under trade name), stevia sweetener, dulcin, taumatin, neotame and monellin.

Owner:MATSUTANI CHEM INDS CO LTD +1

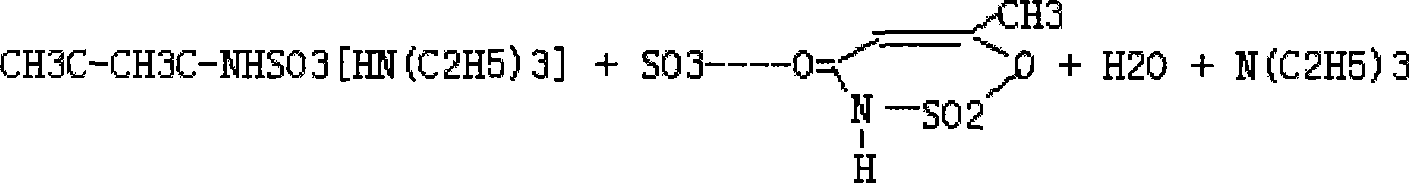

Process for reclaiming catalyst for use in synthesis of acesulfame potassium

InactiveCN1883790ANo pollutionHigh purityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsSulphate IonPotassium

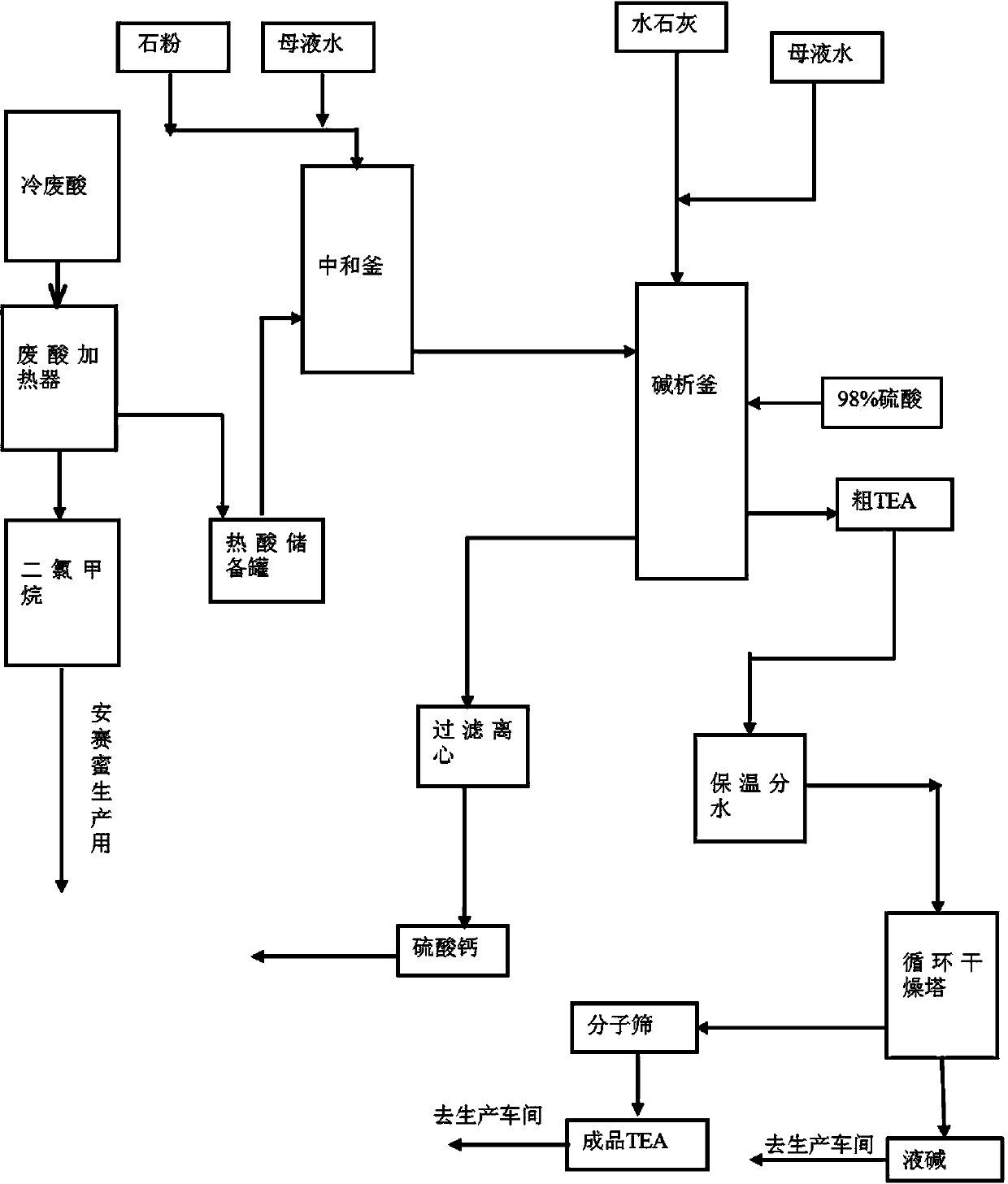

The invention discloses a process for recovering catalyst in synthesizing potassium acetylsulfanilate, which includes steps of: (1) neutralizing mixture containing triethylamine sulphate with base or basic salt, rising the temperature to 70-120 DEG C for distilling triethylamine. (2) removing water of triethylamine received in step (1) to obtain high purity triethylamine. In addition, acid could be added to the mixture of removing triethylamine in step (1) to neutralizing excess base, and gypsum is obtained by filtrating reactive liquid. The excellence of this method is that the process is simple, processing time is short, damage to the device is slight, having no contamination to environment, the retrieving triethylamine have high purity and can be used for synthesizing potassium acetylsulfanilate after removing water, and the byproduct such as gypsum also has some economic benefit

Owner:SUZHOU HOPE TECH

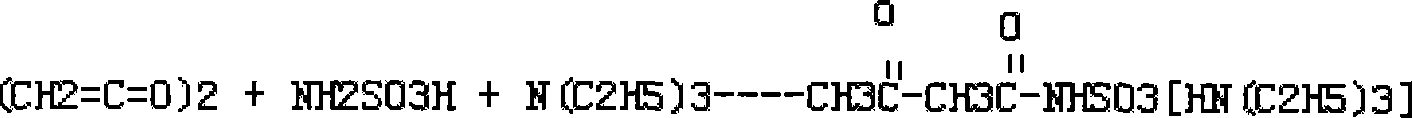

Process for producing acesulfame potassium

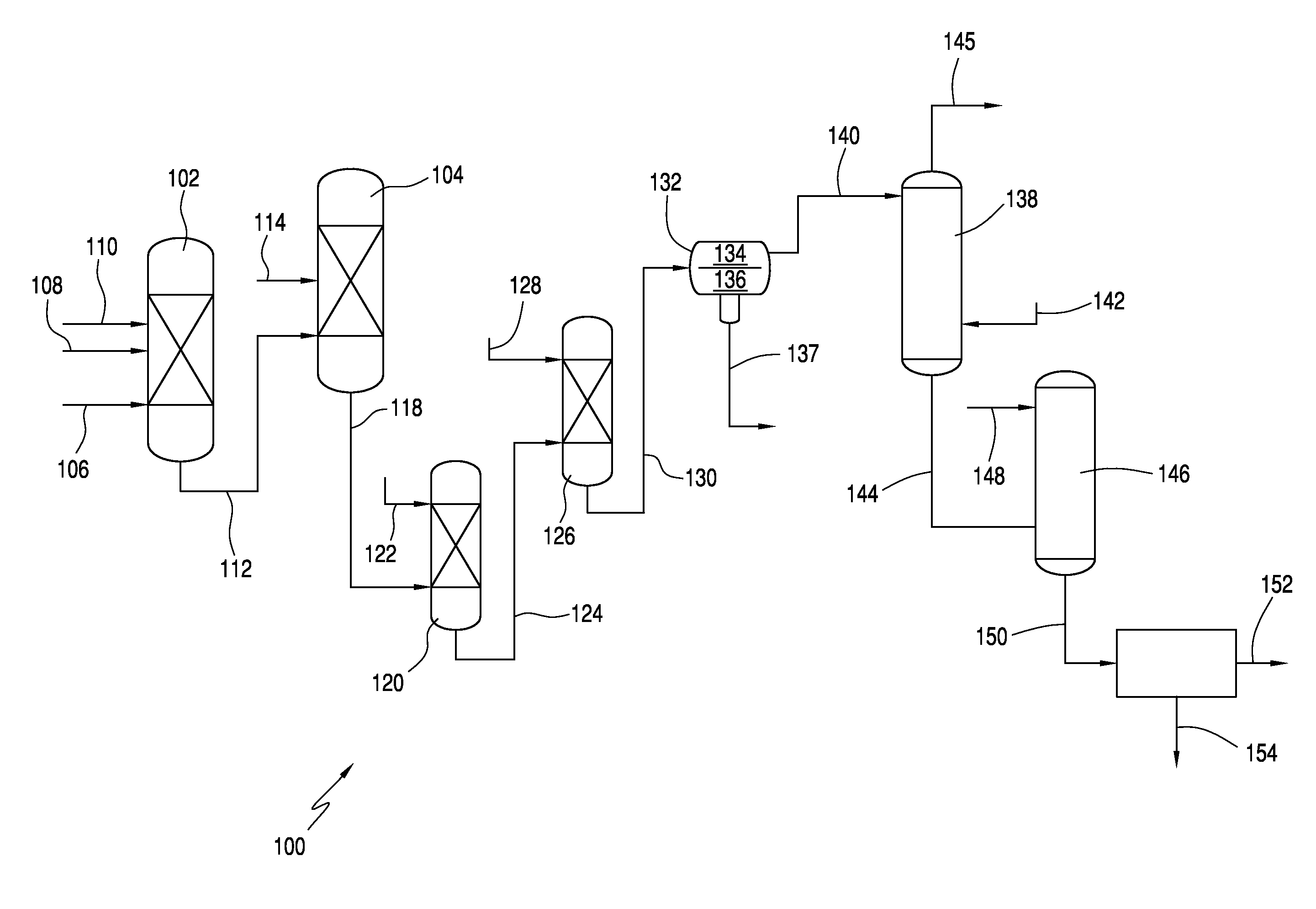

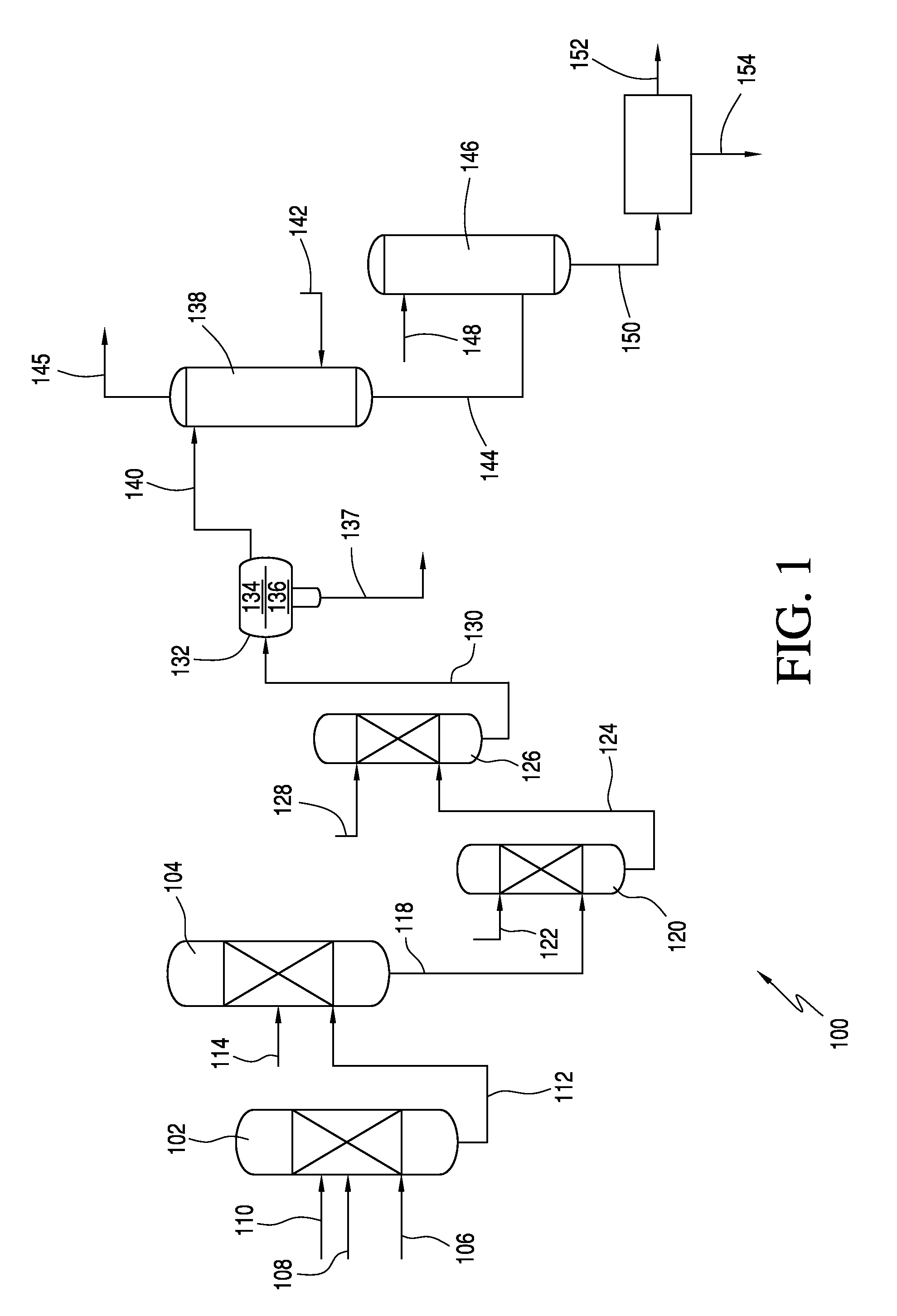

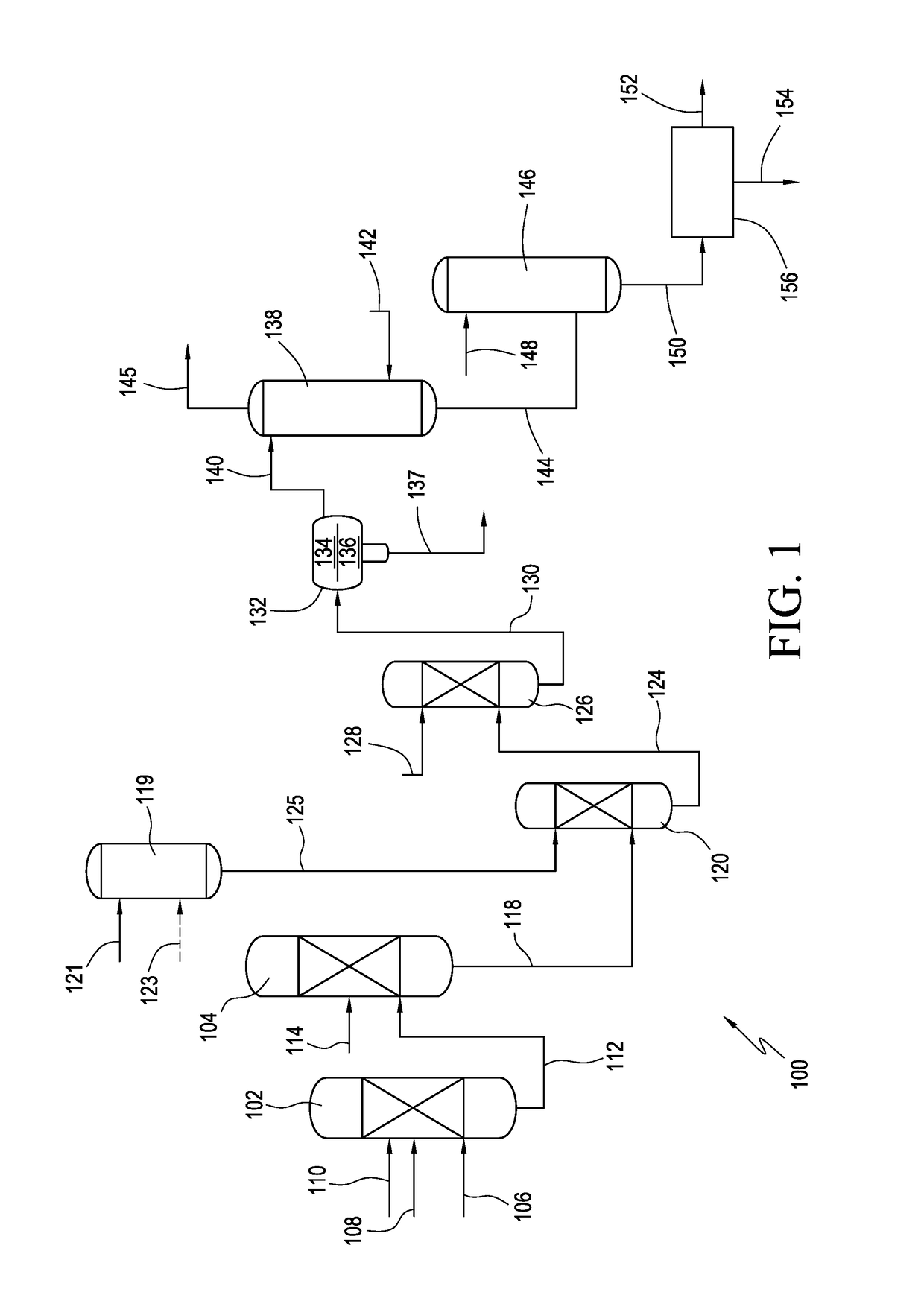

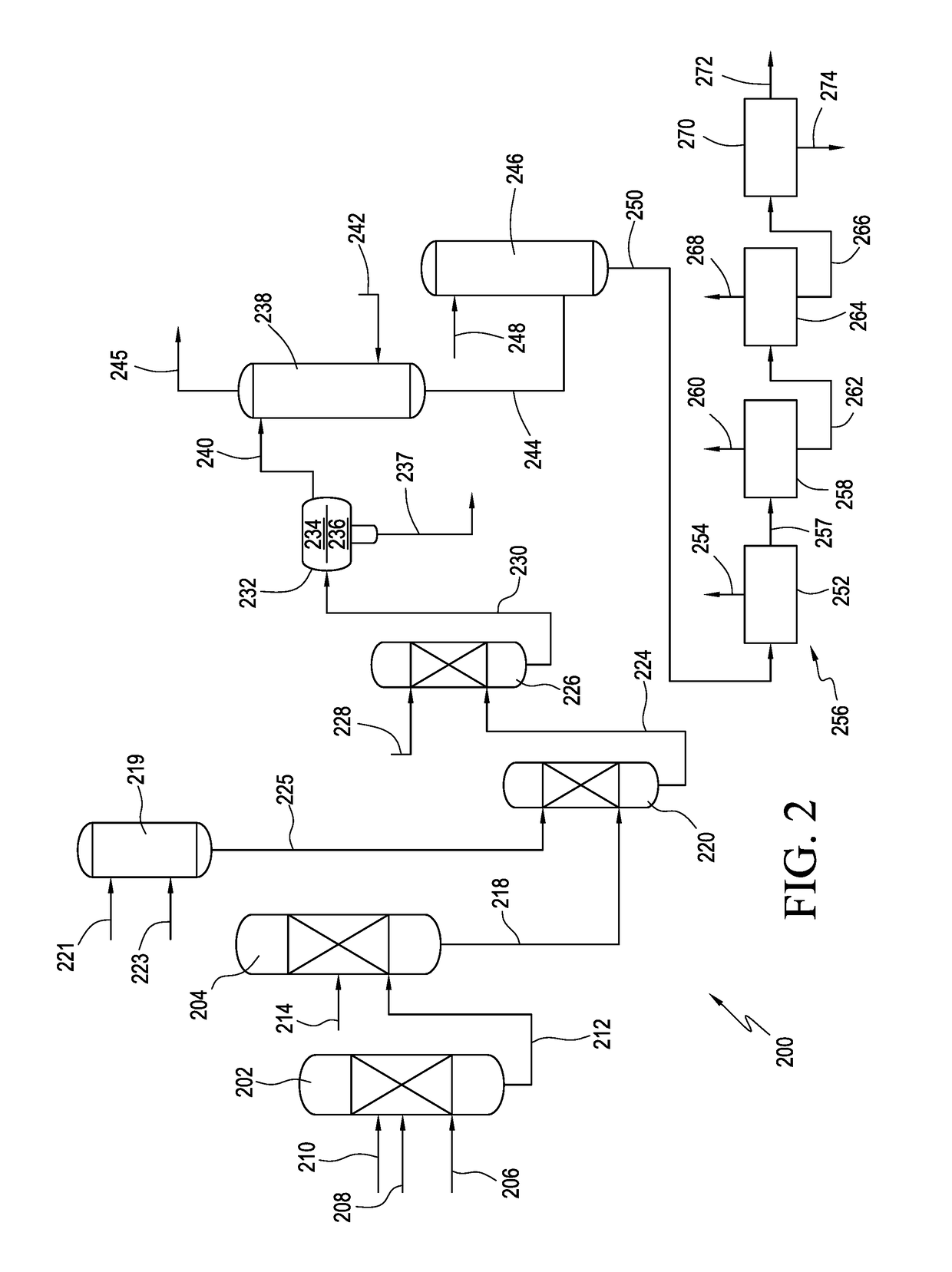

ActiveUS9024016B2Organic compound preparationSulfuric acid amide preparationAcetic acidSulfamic acid

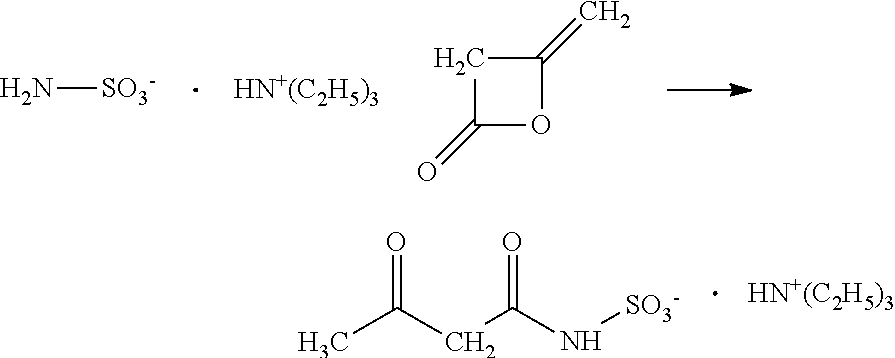

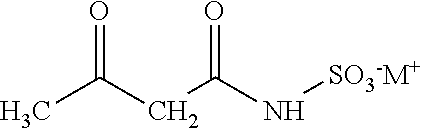

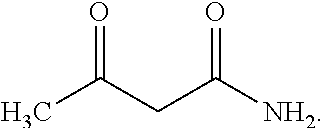

In one embodiment, the invention relates to processes for producing acesulfame potassium. In one embodiment, the process comprises the step of reacting a first reaction mixture to form an amidosulfamic acid salt such as a trialkyl ammonium amidosulfamic acid salt. The first reaction mixture comprises sulfamic acid, an amine, and smaller amounts, if any, acetic acid, e.g., less than 1 wt % (10000 wppm). In terms of ranges, the first reaction mixture may comprise from 1 wppm to 1 wt % acetic acid. The process further comprises the step of reacting the amidosulfamic acid salt with diketene to form an acetoacetamide salt. In preferred embodiments, the amidosulfamic acid salt formation reaction is conducted at pH levels from 5.5 to 7.0. The process further comprises the step of deriving the acesulfame-K from the acetoacetamide salt.

Owner:CELANESE SALES GERMANY

Synthesis process of acesulfame potassium

The invention discloses a synthesis process of acesulfame potassium, which uses acetylacetamide as raw material and inert organic solvent as solvent. Under the low temperature of -50-15 DEG C, catalyst and cyclizing reagent are added for ring closure reaction, after the reaction, the temperature is controlled in the range of -15-60 DEG C, and water is added for hydrolysis; after the hydrolysis, the reaction liquid stands to laminate, the water layer is extracted by the inert organic solvent to remove the aqueous phase and combine the organic phase, then water is added in the organic phase to wash and remove the aqueous phase, base is added in the organic phase for neutralizing and resting to laminate, the organic phase is recycled and the aqueous phase is decompressed and concentrated to obtain the crude acesulfame potassium, and finally the pure acesulfame potassium is obtained through decoloration by activated carbon and purification by recrystallization. The synthesis process of the acesulfame potassium uses the acetylacetamide as the raw material and has the characteristics of simple process, short procedure, low cost and good product quality.

Owner:GUANGDONG FOOD IND INST

Process for Producing Acesulfame Potassium

ActiveUS20130331565A1Organic compound preparationSulfuric acid amide preparationAcetic acidSulfamic acid

In one embodiment, the invention relates to processes for producing acesulfame potassium. In one embodiment, the process comprises the step of reacting a first reaction mixture to form an amidosulfamic acid salt such as a trialkyl ammonium amidosulfamic acid salt. The first reaction mixture comprises sulfamic acid, an amine, and smaller amounts, if any, acetic acid, e.g., less than 1 wt % (10000 wppm). In terms of ranges, the first reaction mixture may comprise from 1 wppm to 1 wt % acetic acid. The process further comprises the step of reacting the amidosulfamic acid salt with diketene to form an acetoacetamide salt. In preferred embodiments, the amidosulfamic acid salt formation reaction is conducted at pH levels from 5.5 to 7.0. The process further comprises the step of deriving the acesulfame-K from the acetoacetamide salt.

Owner:CELANESE SALES GERMANY

Yoghourt containing fruit material and its production method

ActiveCN101305750AGood for physical and mental healthWith weight loss effectMilk preparationFood preparationFlavorSucrose

The invention relates to a fruit paste-containing yoghurt, which is prepared from 0.5-2.0 kg of xylitol, 5-20 kg of fruit grain or jam, 0.1-10 kg of thickener, 0.01-0.05 kg of aspartyl-phenylalanine methyl ester (containing phenylalanine), 0.01-0.05 kg of Acesulfame K (Acesulfame Potassium), 0.01-0.03 kg of edible spice, and fresh milk and leaven in balancing amount per 100 weight parts of the yoghurt. The invention also provides a method for preparing the fruit paste-containing yoghurt. The fruit paste-containing yoghurt has low sucrose content, and abundant nutrition and good taste by adopting various fruits. BY adopting the preparation method, the fruit paste-containing yoghurt with different flavors can be prepared, and are suitable for long-term consumption of consumers.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

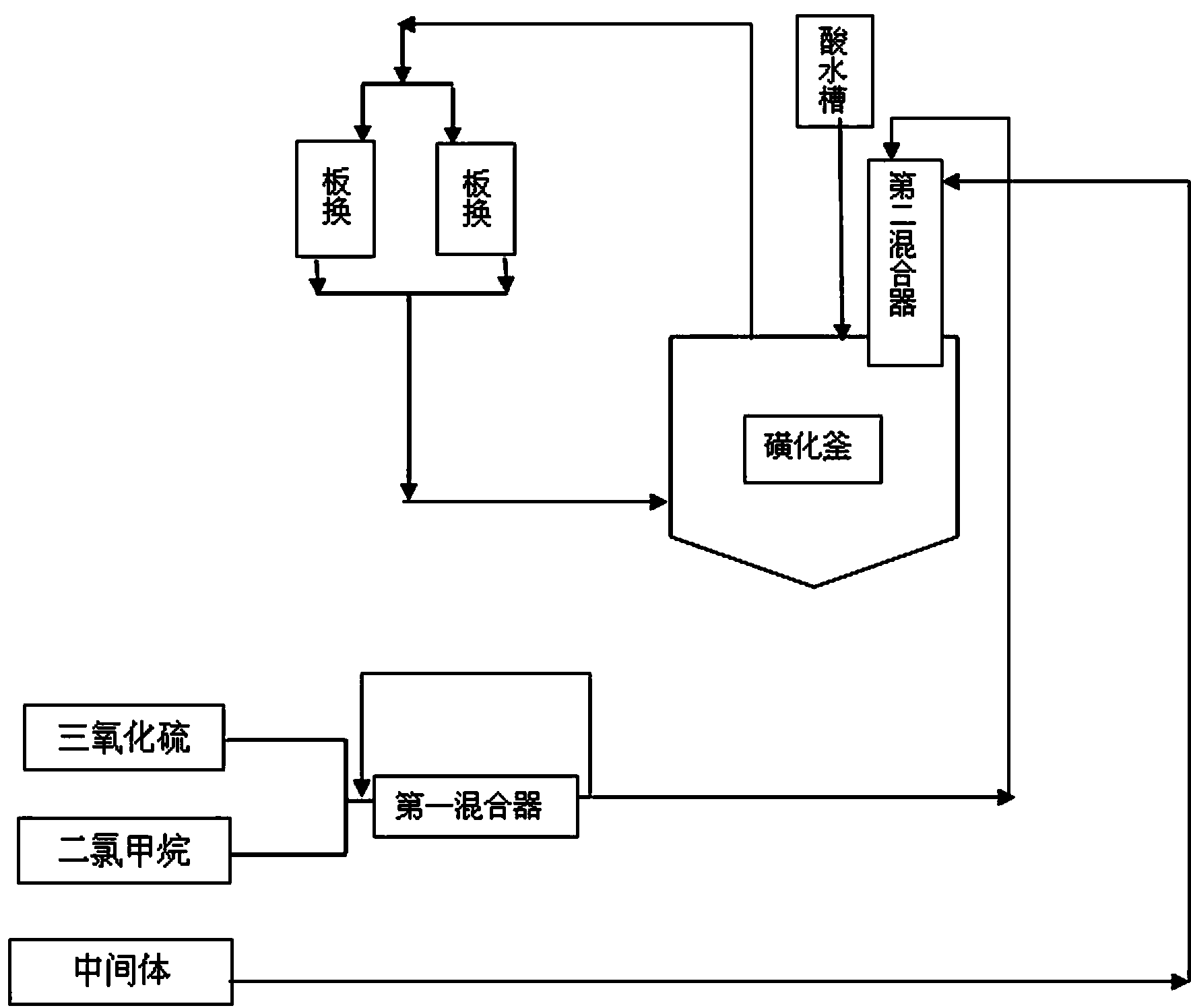

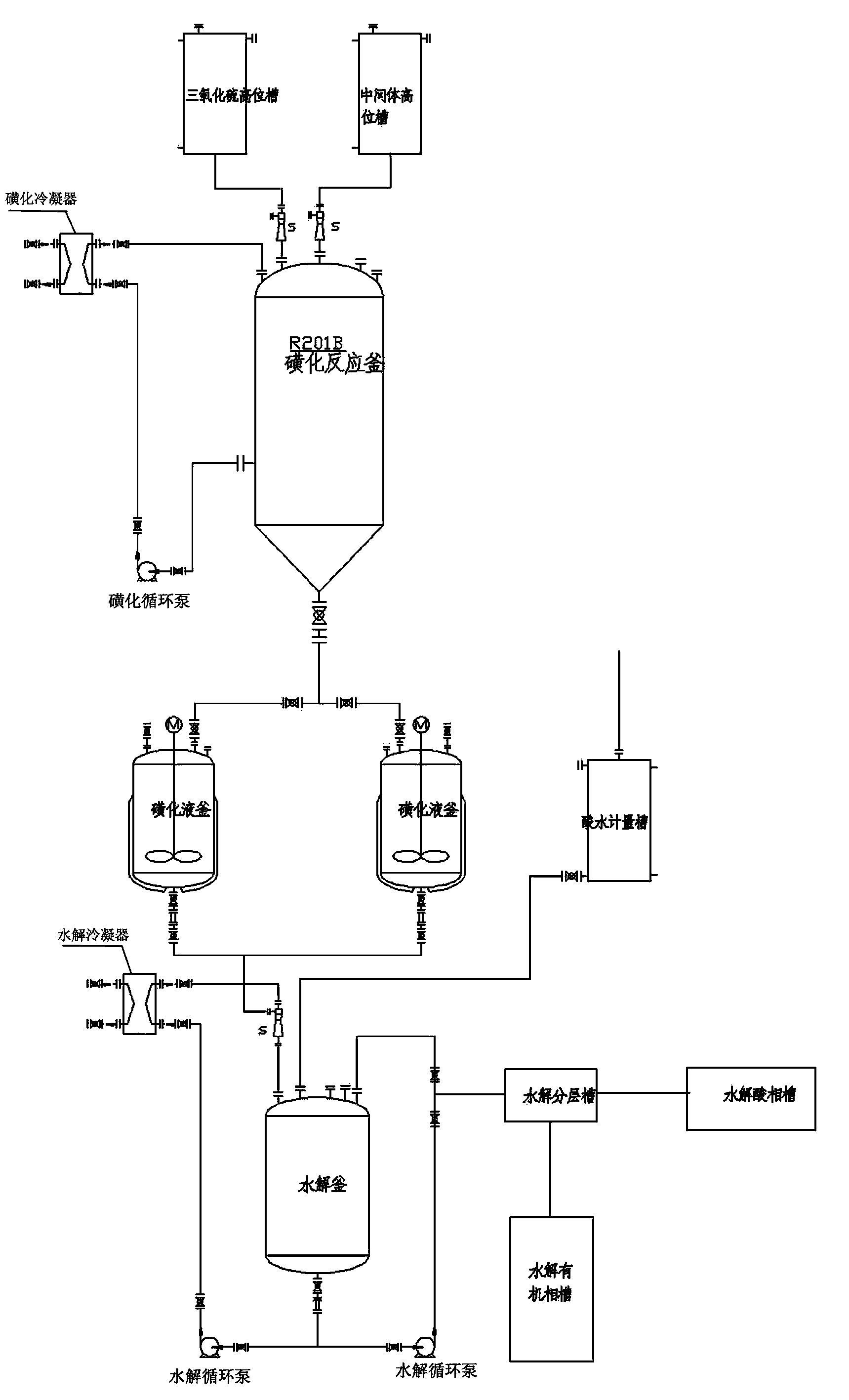

Acesulfame potassium cyclization continuous production method

ActiveCN103613566AImprove continuityReduce labor intensityOrganic chemistryReaction temperatureSulfur trioxide

The invention relates to an acesulfame potassium cyclization continuous production method. The method is characterized in that the sulfonation reaction and hydrolysis reaction comprise the following steps: step a, separately pumping an intermediate generated during a synthesis reaction and sulfur trioxide into a sulfonation reactor in a certain speed, carrying out sulfonation reactions in the sulfonation reactor; step b, gasifying dichloromethane when the concentration of the reactants in the sulfonation reactor reach a certain level, spraying the sulfonation liquid into a hydrolysis reactor; step c, dropwise adding acidic water into the hydrolysis reactor to carry out hydrolysis reactions. The method has the advantages that an cyclization one-step reaction technology is adopted, thus the continuity of production operation is realized, and the work strength of workers is reduced; compared to the conventional intermittent production technology, the one-step reaction method has a higher stability, improves the service life of the reactor, shortens the reaction time, and reduces the side reactions. Furthermore, in the method, the sulfonation reaction temperature is raised, then dichloromethane gasification is utilized to reduce the reaction temperature, so that low temperature production is avoided, and a deep cooling ice machine is stopped, so the production efficient is greatly improved, and the energy consumption is largely reduced.

Owner:ANHUI JINGHE IND

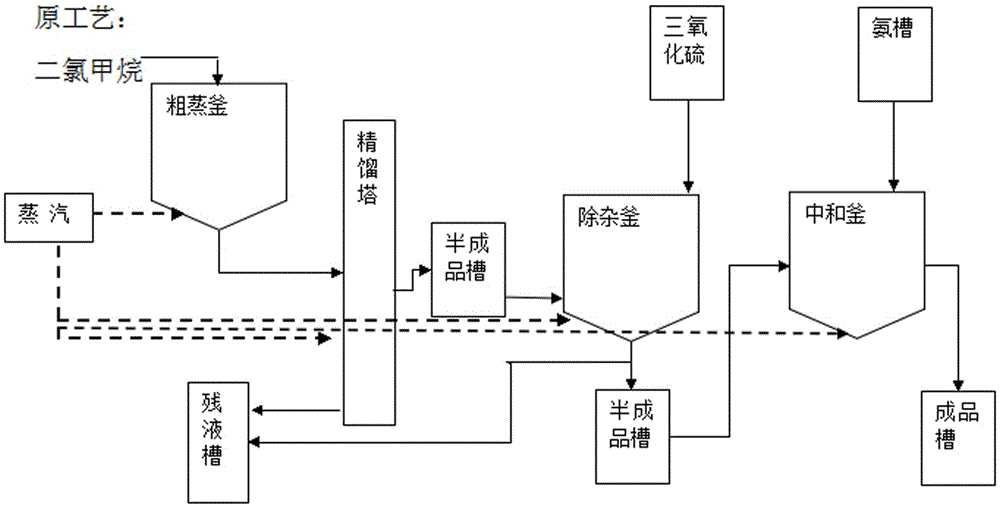

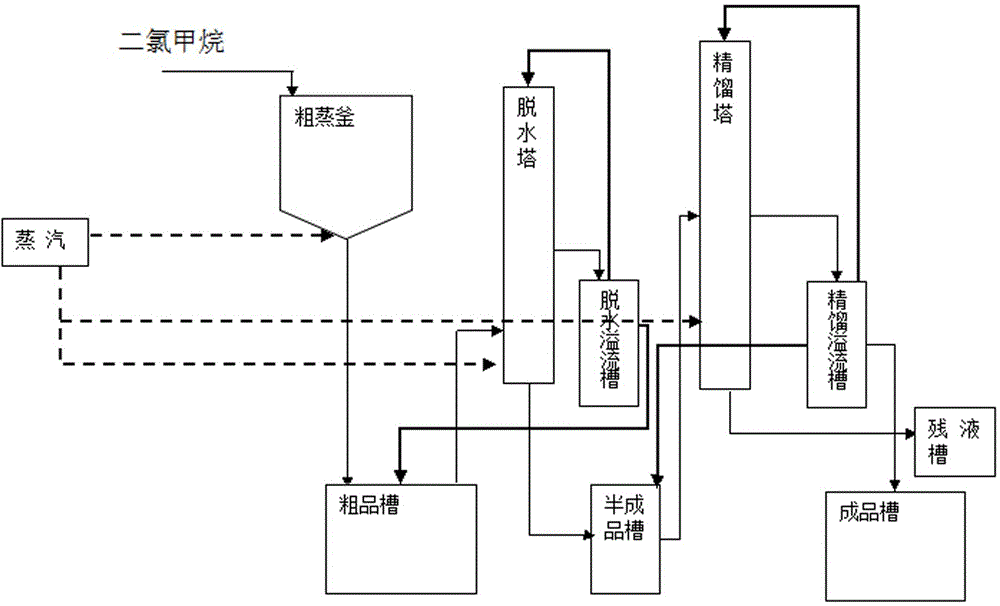

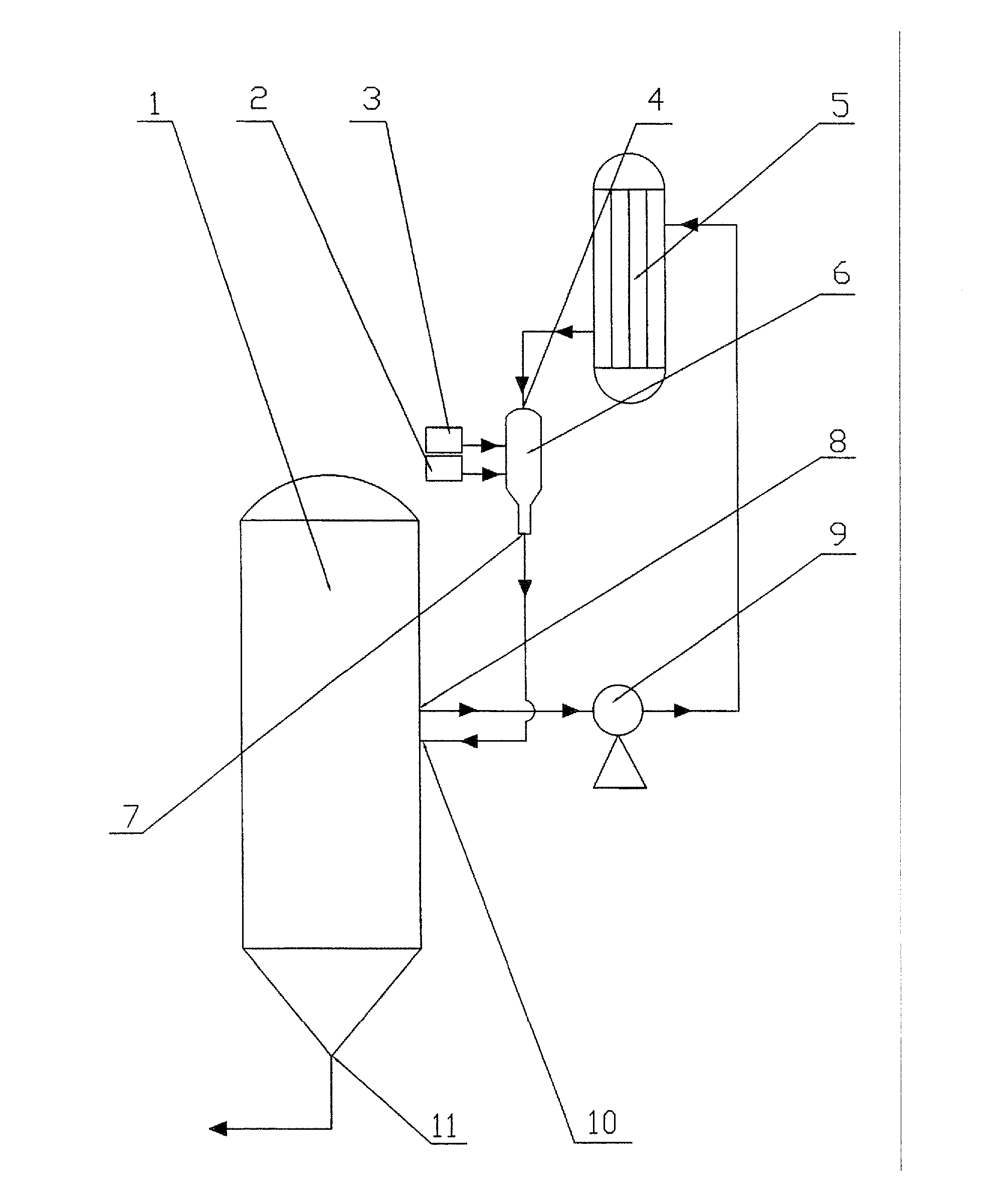

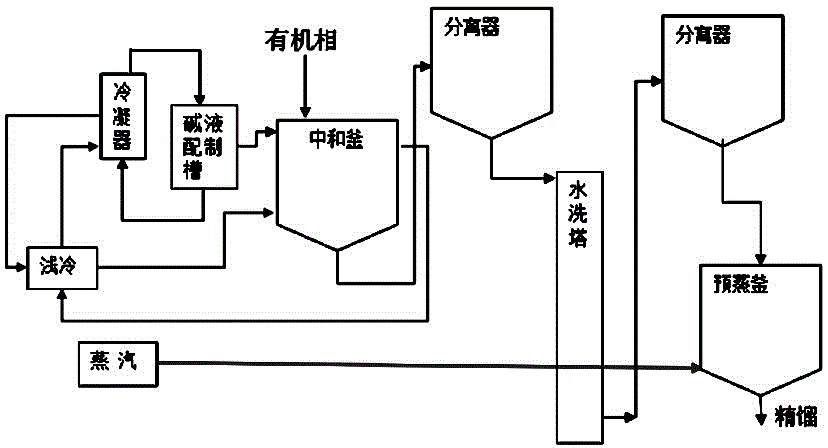

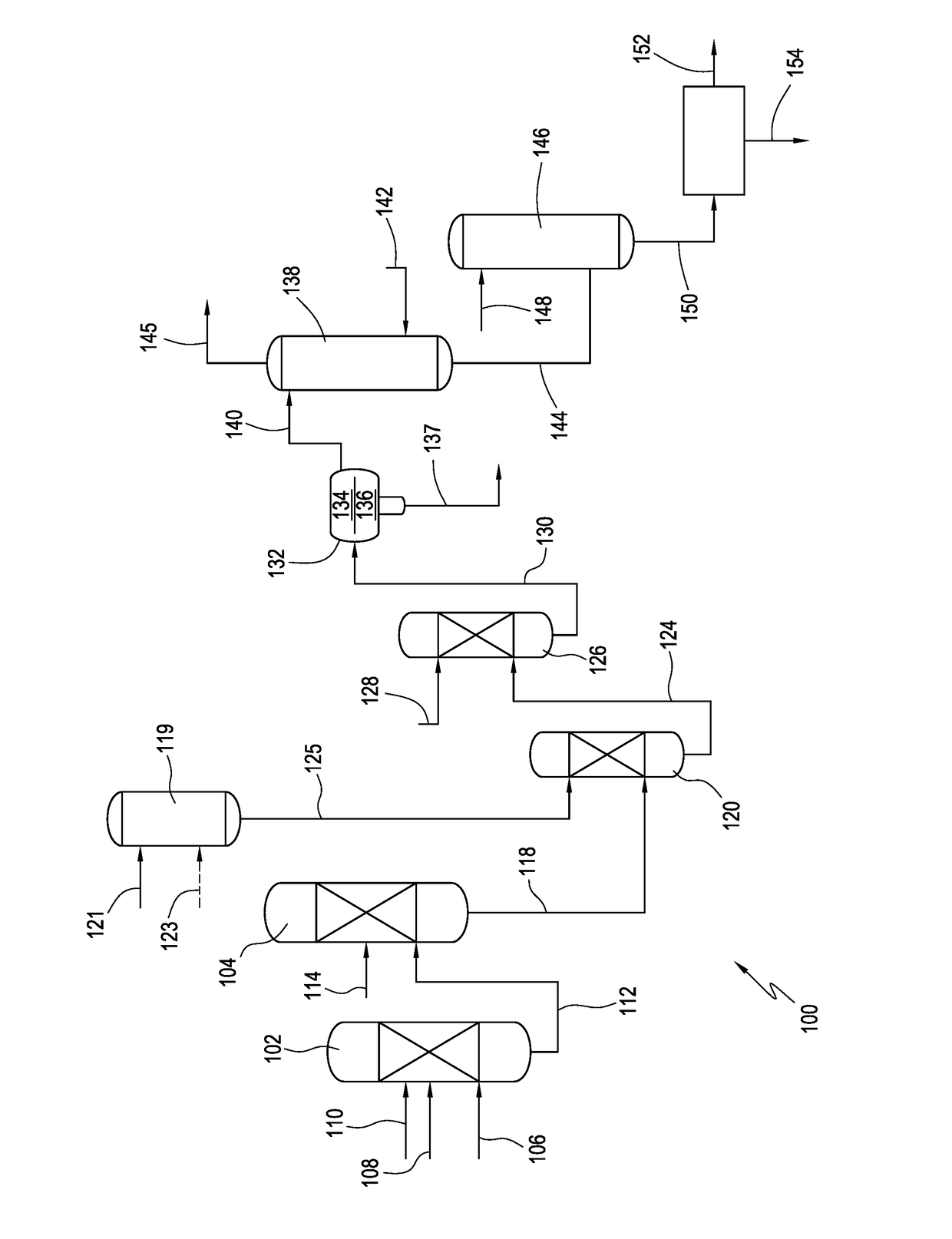

Method for recycling dichloromethane in acesulfame potassium synthesis process

InactiveCN105085160AImprove stabilityImprove product qualityHalogenated hydrocarbon preparationTowerHigh water content

The invention discloses a method for recycling dichloromethane in an acesulfame potassium synthesis process. The method comprises the steps of a, adding roughly distilled dichloromethane into a dehydrating tower, heating, condensing to enable steam of a mixed solution of dichloromethane and water to enter a dehydration overflow tank and dichloromethane containing qualified water at the bottom to enter a semi-finished product tank so as to be used by a rectifying tower; b, enabling dichloromethane containing unqualified water at the bottom of the overflow tank to enter the dehydrating tower again through backflow and dichloromethane with high water content at the top to enter a crude product tank, and regularly discharging layered water in the crude product tank; c, enabling dichloromethane containing qualified water in the semi-finished product tank to enter the rectifying tower, distilling to 45 DEG C, enabling dichloromethane steam to enter the dehydration overflow tank, and sucking dichloromethane with high impurity content at the bottom into a residual solution tank; and d, after detecting dichloromethane in the dehydration overflow tank to be qualified, placing dichloromethane into a finished product tank so as to be used for synthesizing and sulfonating, and enabling the unqualified dichloromethane to enter the rectifying tower so as to be rectified again.

Owner:ANHUI JINGHE IND

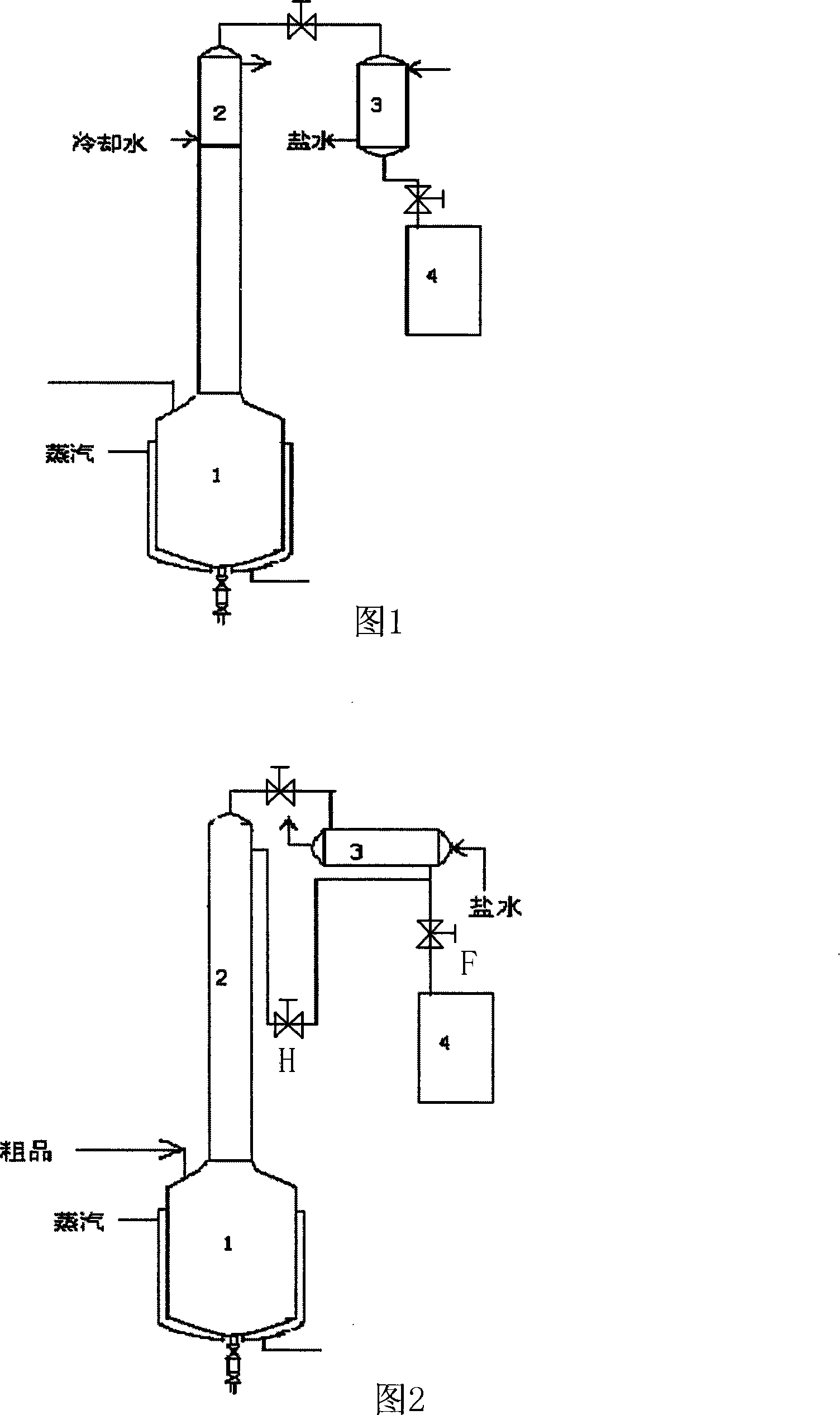

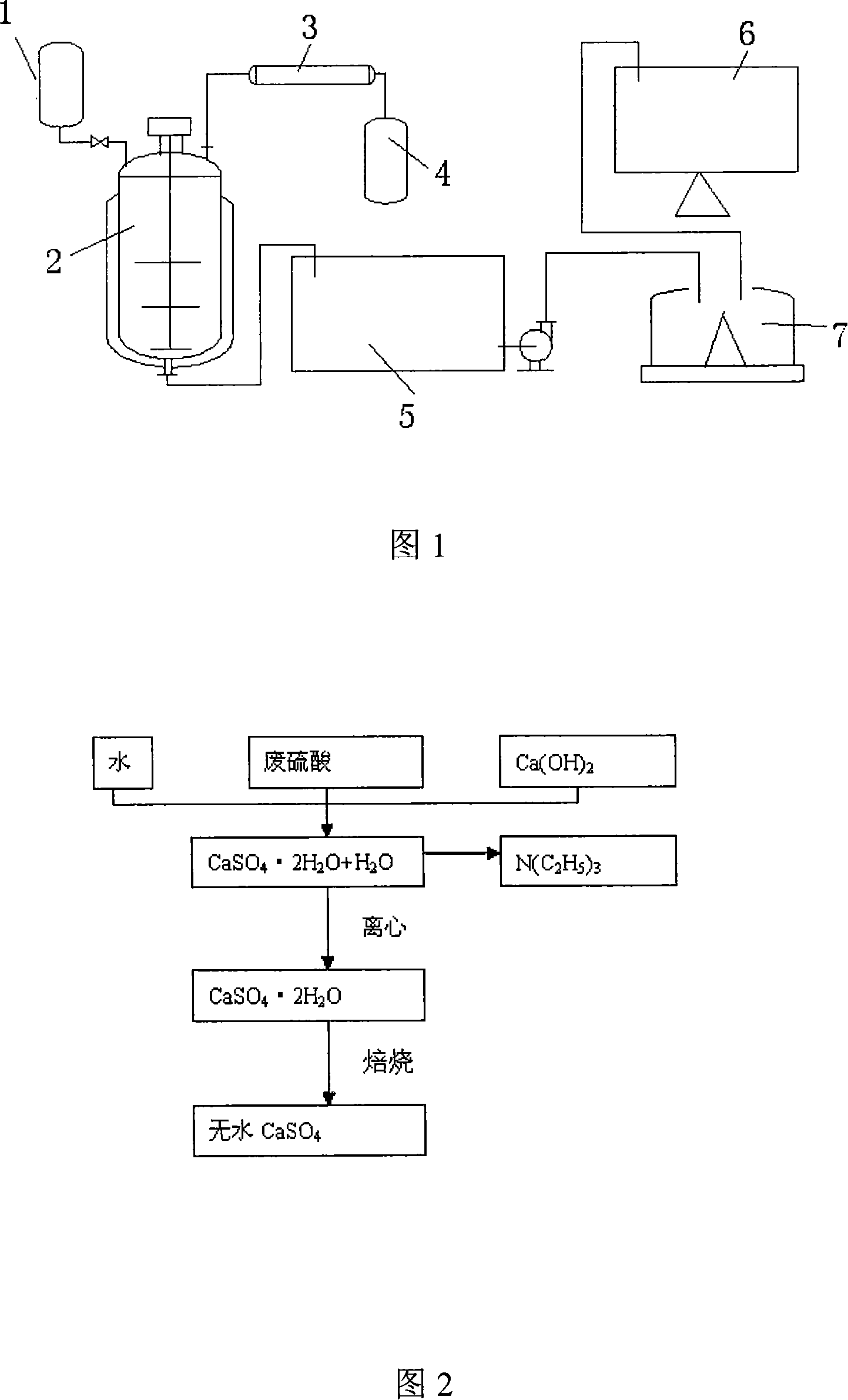

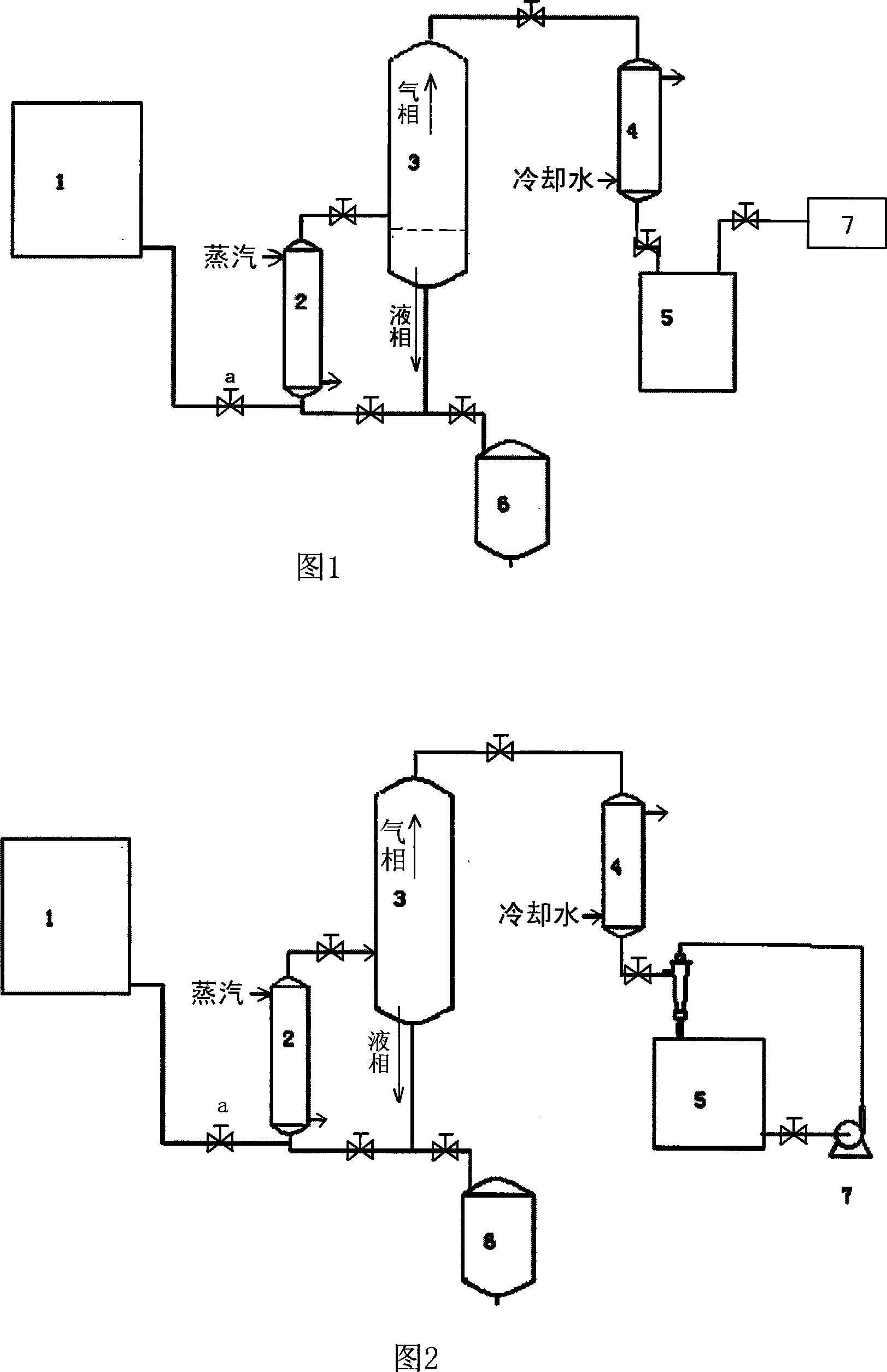

Triethylamine recovery processing method and device for production of acesulfame potassium

ActiveCN101157666AEasy to operateLow costAmino compound purification/separationMolecular sieveBoiling point

The invention relates to a triethylamine reclaim treatment method and the devices in the production of acesulfame-K, which is characterized in that the method includes the following steps: a. the crude triethylamine containing water is put into a distillation kettle (1), which is heated to the temperature of 38 DEG C to 42 DEG C, the time is about 20 to 40 minutes, the dichloromethane and other impurities with the low boiling points which are contained in the crude triethylamine are firstly evaporated, collected and then are condensed and collected by a condenser (3); b. the heating is carried out continually to about 83 DEG C, the temperature is kept for more than 30 minutes, which ensures that the water and triethylamine are placed still for layer separation, a lower layer is water, an upper layer is triethylamine, and triethylamine of the upper layer can be collected after the water is drained completely from the bottom of a kettle. Finally, the collected triethylamine is dried by the solid potassium hydroxide or a molecular screen, so the water content of triethylamine can be lower than 0.1 percent. The invention has the advantages of simple using equipment, convenient operation, safety, reliability, low cost, improved reclaim ratio of the product and significantly reduced operating cost.

Owner:ANHUI JINGHE IND

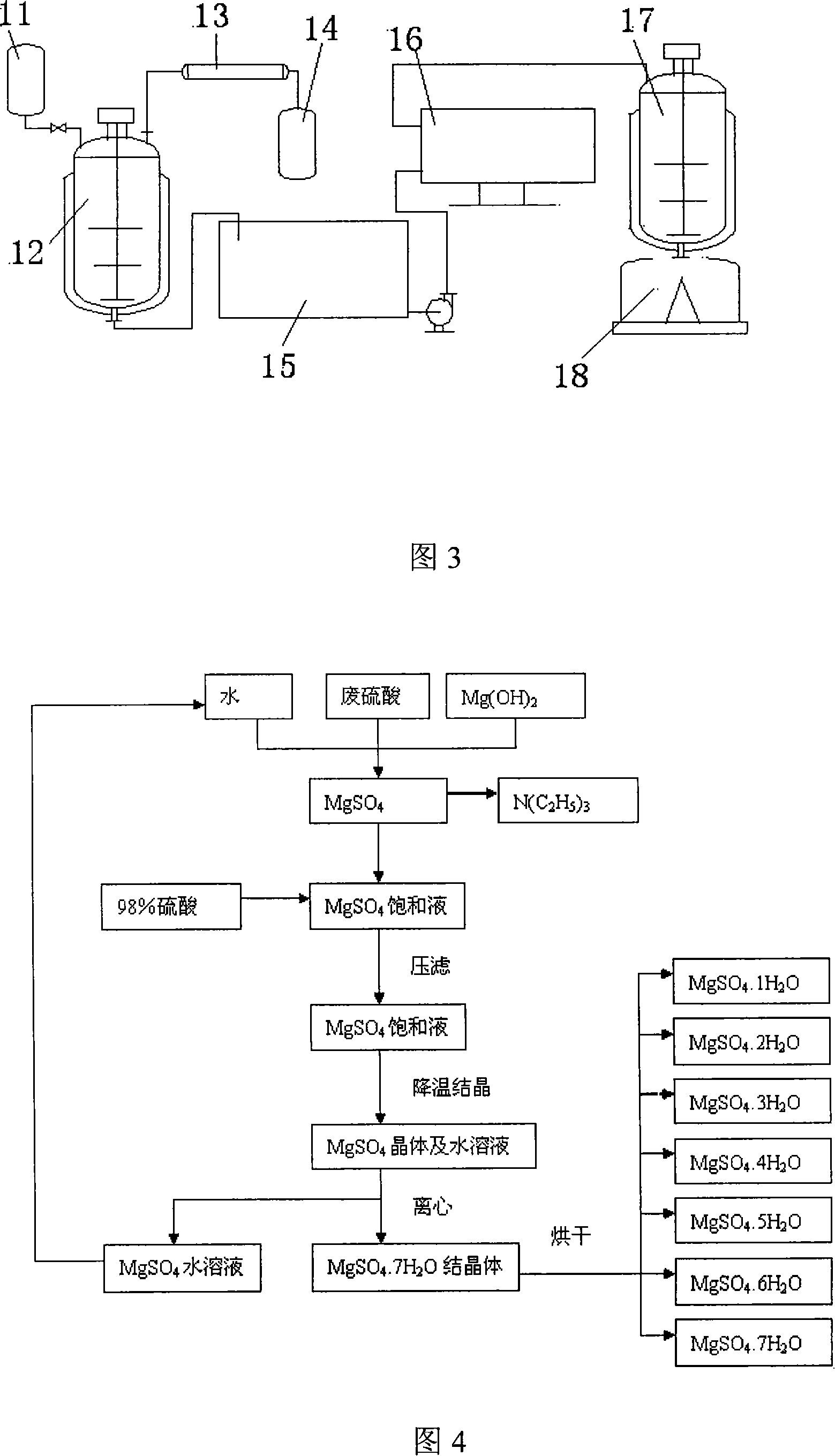

Waste acid treatment method and treatment system for acesulfame preparation technique by sulphuric anhydride cyclization method

ActiveCN101148300ASolve environmental problemsAchieve recyclingMagnesium sulfatesMultistage water/sewage treatmentSewageAcesulfame potassium

The present invention is process of treating waste acid solution from Acesulfame potassium preparing sulfuric anhydride cyclizing process. The process of treating waste acid solution includes the reaction of the waste acid solution and the mixture comprising Mg(OH)2 or MgO and water in a neutralizing reactor to produce triethylamine gas, cooling triethylamine gas in a cooler into triethylamine liquid and collecting in a tank, regulating the pH value of neutralizing reaction resultant in a regulating tank with 98 % concentration sulfuric acid solution into 5-7, filtering, cooling the filtrate in a MgSO4 cooling reactor to separate out MgSO4 hydrate. The present invention has MgSO4 yield up to 95 % and N(C2H5)3 recovering rate up to 95 % and can eliminate environmental pollution caused by Acesulfame potassium production.

Owner:ANHUI WEIDUO FOOD INGREDIENTS CO LTD

Concentrating method and device in acesulfame potassium production

Owner:ANHUI JINGHE IND

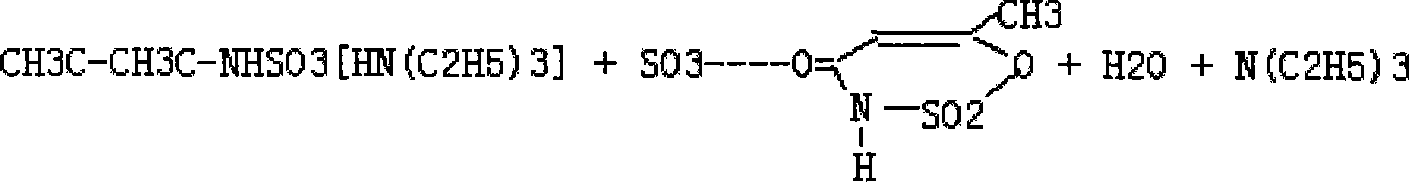

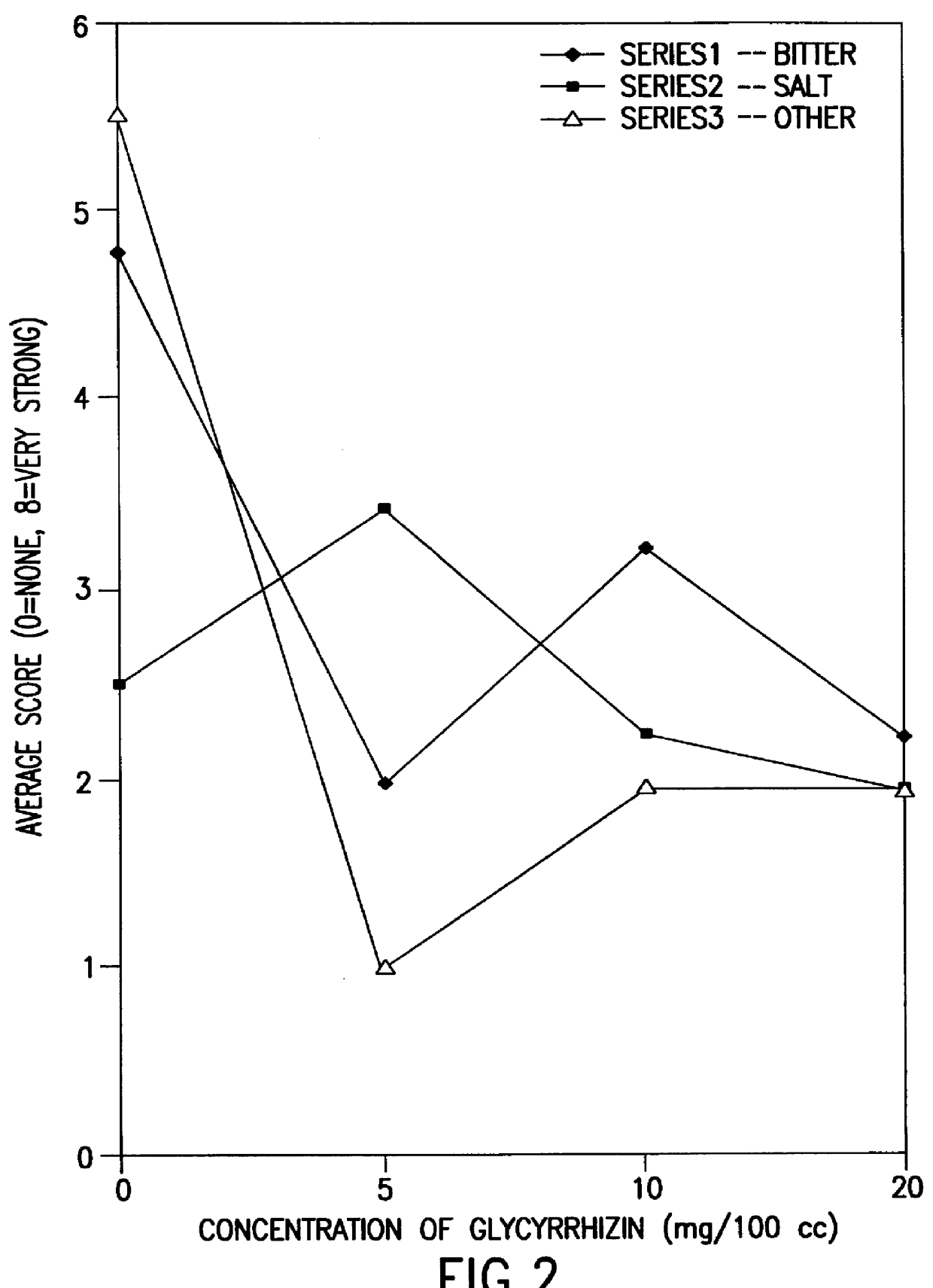

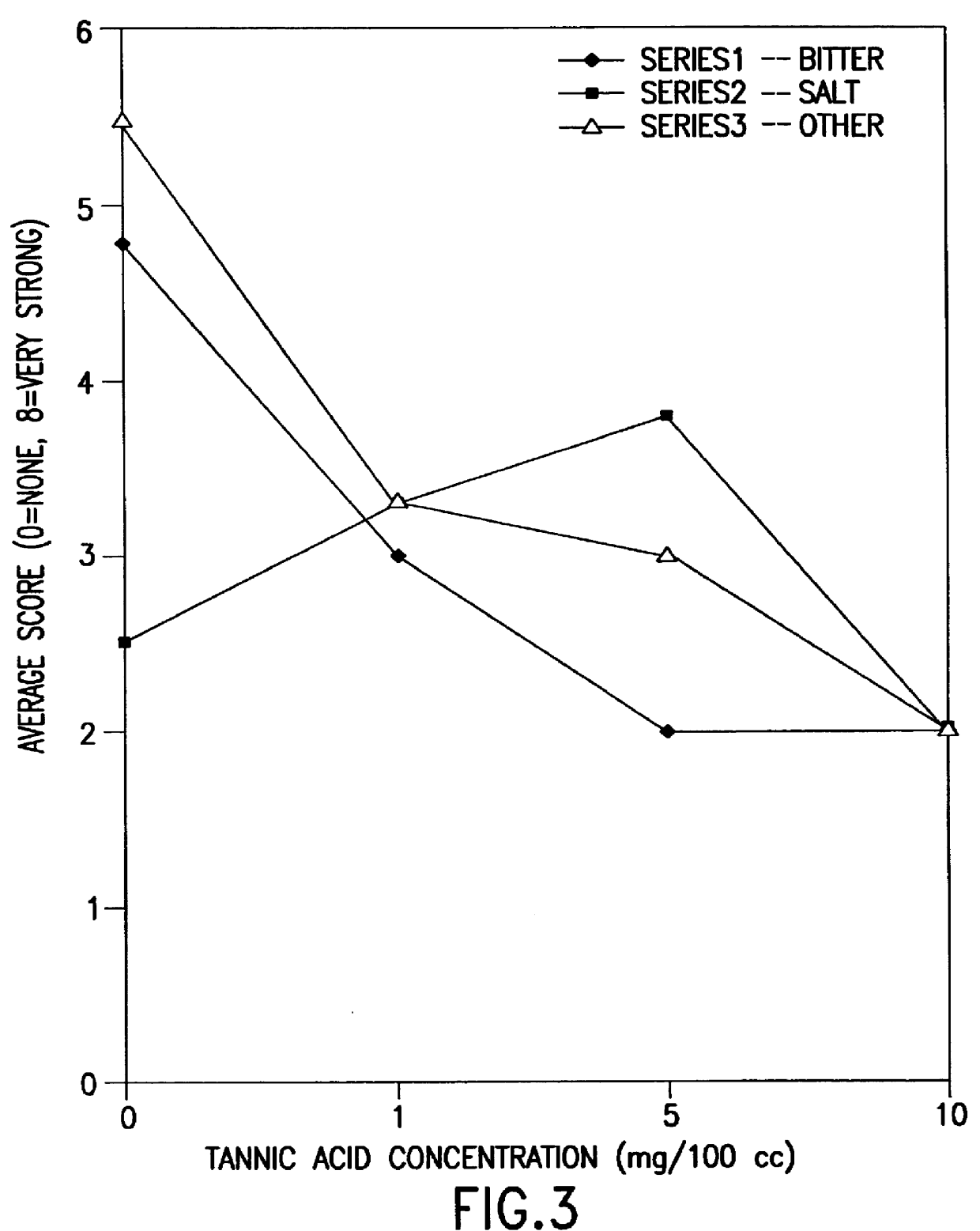

Method and composition for masking mineral taste

InactiveUS6156332AReduce aftertasteReduce tastePharmaceutical delivery mechanismUrinary disorderPotassiumTannic acid

The invention relates to methods and compositions for masking the taste of minerals in ingestible products. In particular, tannic acid glycyrrhizin and acesulfame potassium are added to compostions comprising minerals such as potassium, calcium, magnesium, iron, copper, chromium, zinc and mixtures in order to reduce or eliminate the unpleasant taste or aftertase associated with these minerals.

Owner:AMBI

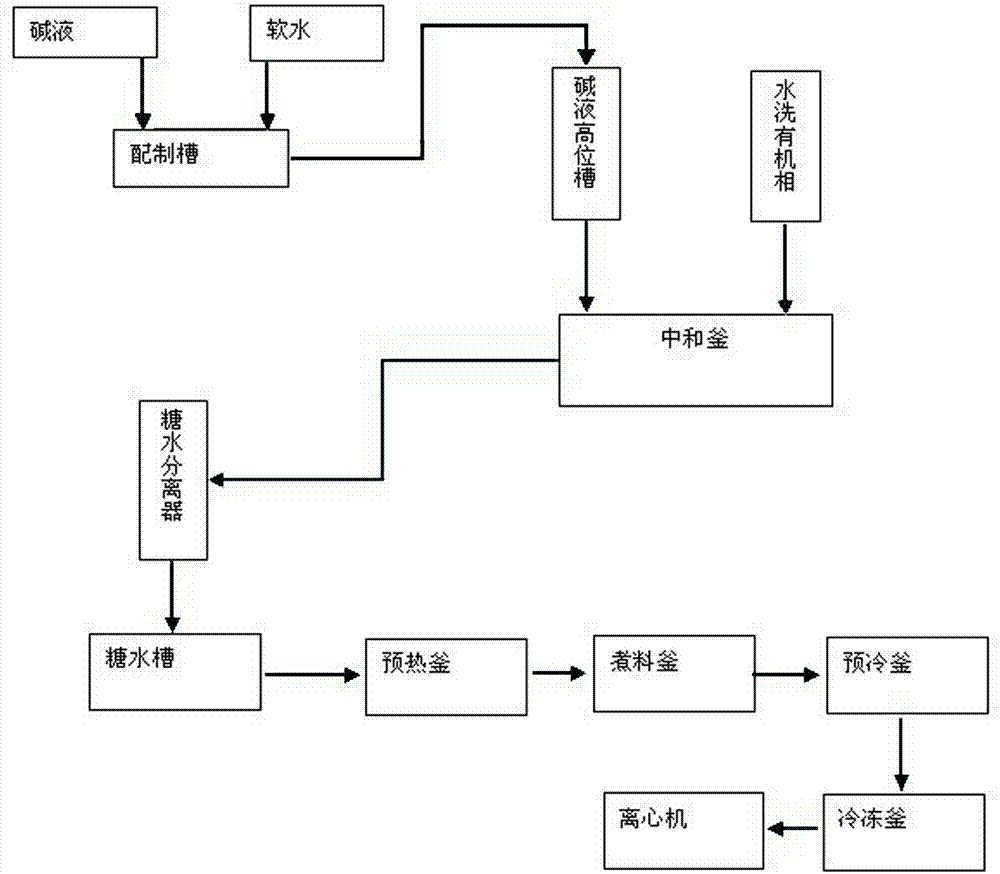

Neutralization direct crystallization production technology of acesulfame potassium

ActiveCN103588728AReduce labor intensityAdvanced technologyOrganic chemistryCentrifugationEvaporation

The invention relates to a neutralization direct crystallization production technology of acesulfame potassium, the neutralization direct crystallization production technology of the acesulfame potassium includes neutralization reaction, separation and hydrolysis rough crystallization reaction stepS, and the neutralization direct crystallization production technology is characterized in that: a neutralization direct crystallization method is used in the neutralization reaction, an original alkali is directly added into a water-wash organic phase of a neutralization tank for stirring for reaction, after precipitation and stratification, acesulfame potassium crystals are directly separated to a crude evaporation kettle for heating to evaporate dichloromethane which is carried out, and then an acesulfame potassium crude product is obtained by freezing and centrifugation. The neutralization direct crystallization production technology has the advantages that: through use of the neutralization direct crystallization production technology, the production operation is simplified and the worker labor intensity is reduced; and compared with traditional production technologies in the prior art, the neutralization direct crystallization production technology removes alkali preparation, concentration and other operation, simplifies the operation, reduces the labor intensity, and saves a large amount of water and steam.

Owner:ANHUI JINGHE IND

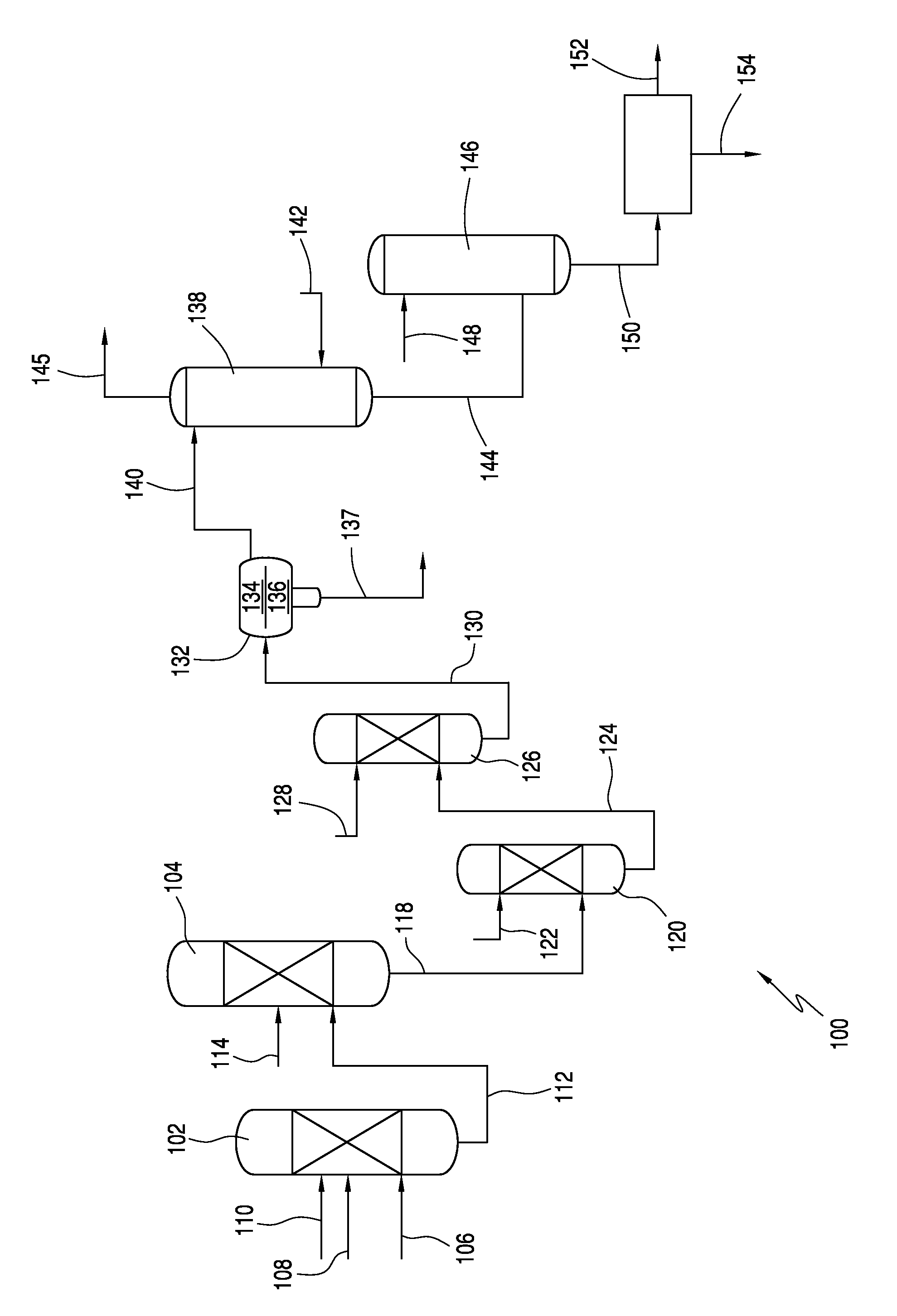

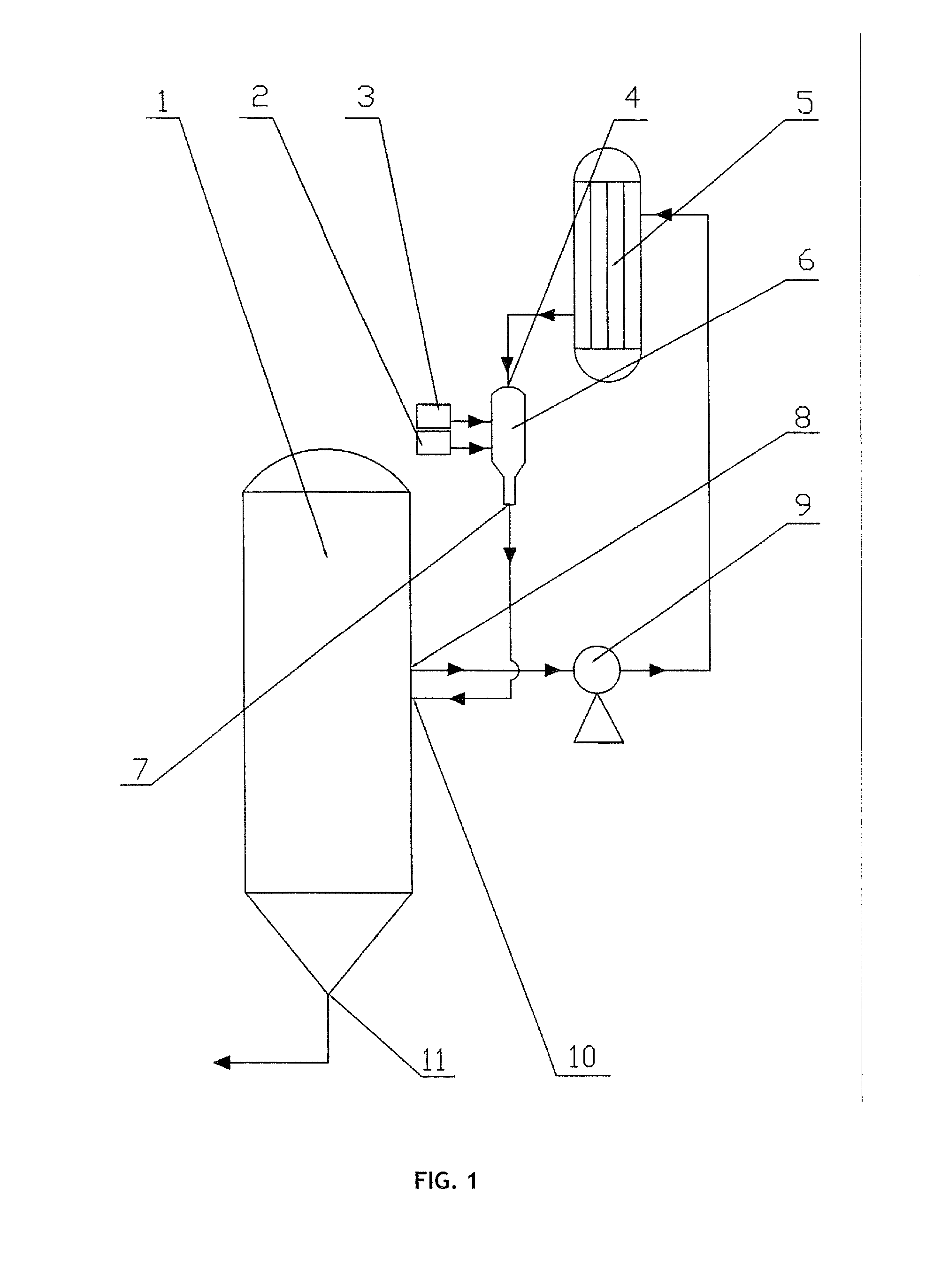

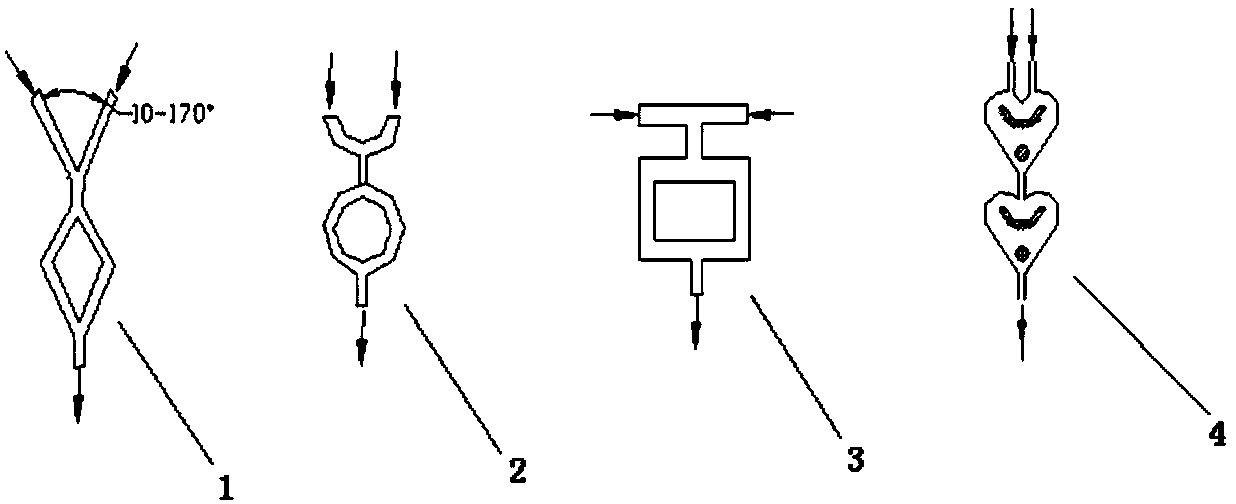

Process and apparatus for producing an intermediate in the synthesis of acesulfame potassium

The invention discloses a kind of sulfonation cyclization technique for synthesizing acesulfame potassium for continuous production without stirring and special equipment for this technique. An injection pump is adopted to directly inject the sulfonation raw material and sulfonating agent into autoclave for sulfonation cyclization reaction under high velocity. Moreover, the reciprocating pump is adopted to deliver part of materials in autoclave to condenser designed outside the autoclave for cooling, followed by delivering the cooled materials to another input end of injection pump which together with sulfonation raw material and sulfonating agent is injected into autoclave through high-velocity injection by injection pump. The apparatus is composed of autoclave, injection pump, reciprocating pump and condenser.

Owner:SUZHOU HOPE TECH

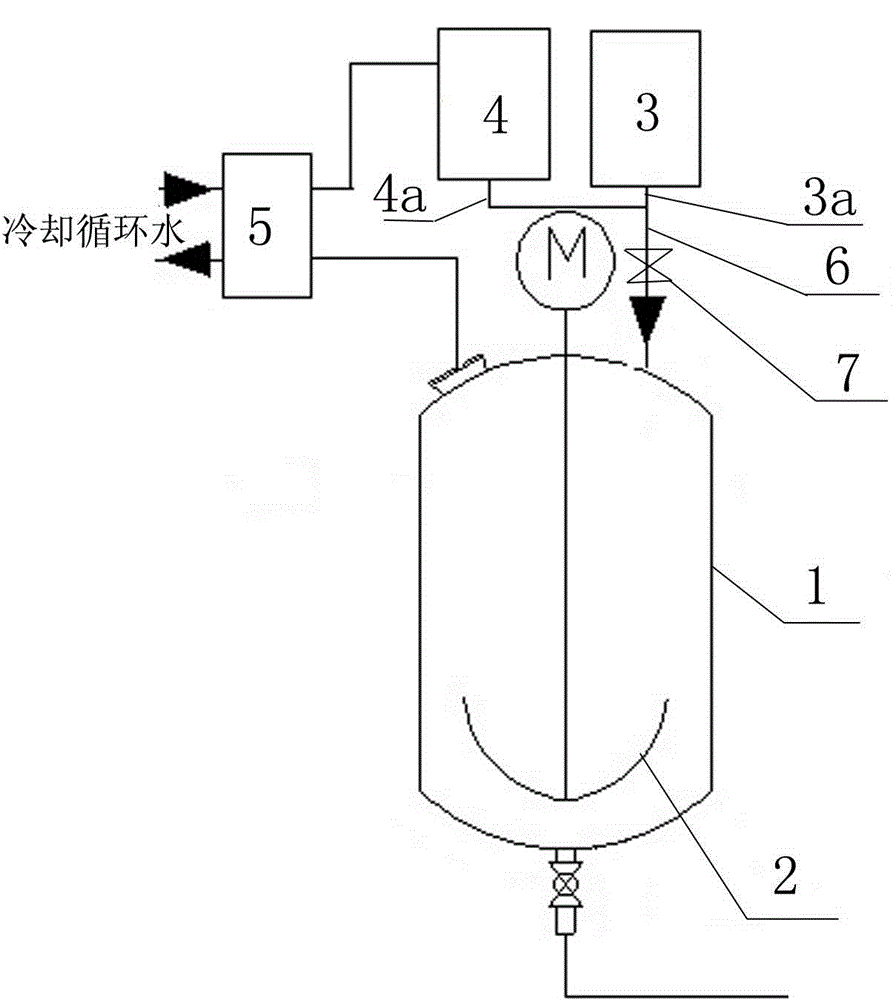

Acesulfame potassium synthesis section acylation reaction process

ActiveCN105198778AIncrease temperatureShort reaction timeSulfuric acid amide preparationDichloromethaneAcesulfame potassium

The invention discloses an acesulfame potassium synthesis section acylation reaction process. The process includes the following steps that a, a stirring machine of an acylation kiln and circulating cooling water flowing through a plate heat exchanger are started; b, objects obtained through the synthesis reaction of sulfamic acid and triethylamine are placed in an acylation kiln. C, dichloromethane and diketene with the volume ratio of 1 to 1 are evenly mixed, and a mixture of dichloromethane and diketene is dropwise added into the acylation kiln according to the ingredient amount, wherein the dropwise adding flow is 500 L / H; d, vaporized dichloromethane returns to a container for containing dichloromethane after passing through the plate heat exchanger, the mixture of dichloromethane and diketene is dropwise added into the acylation kiln, the acylation reaction temperature is raised, the reaction time is shortened, and the production efficiency is improved; meanwhile, dichloromethane is evaporated through the acylation reaction, evaporated dichloromethane is liquefied after being cooled through circulating cooling water, and liquefied dichloromethane returns to the container for containing dichloromethane to be recycled. The process is simplified, and the energy consumption is lowered.

Owner:ANHUI JINGHE IND

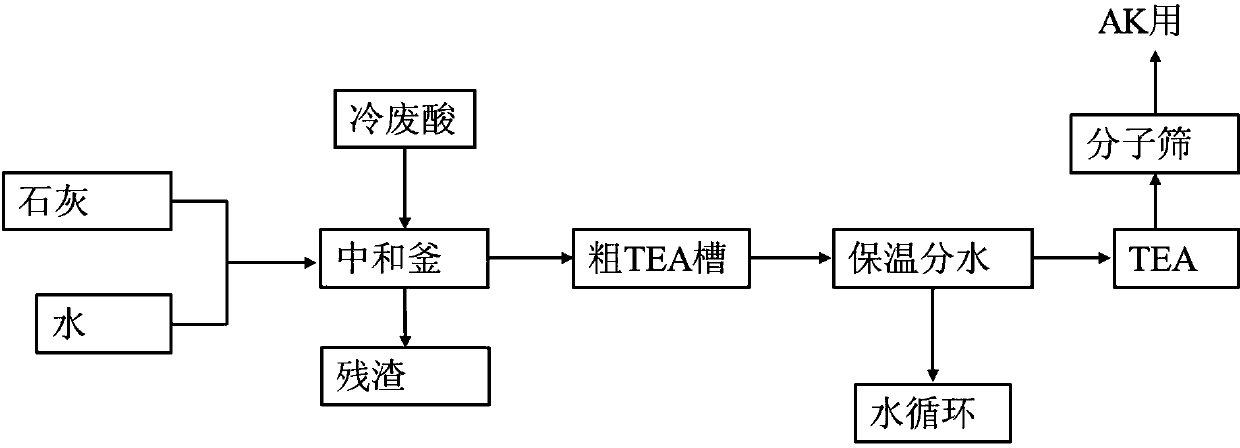

Recovery method of catalyst triethylamine in acesulfame potassium production

ActiveCN104193625ANo lossEfficient use ofAmino compound purification/separationCalcium/strontium/barium sulfatesPtru catalystMethylene Dichloride

The invention belongs to the technical field of acesulfame potassium production and relates to a recovery method of catalyst triethylamine in the acesulfame potassium production. A one-step one-kettle reaction is changed into a two-kettle three-step reaction, and the purpose of recovering triethylamine is achieved by the following steps: (1) preheating, and recovering methylene dichloride; (2) carrying out neutralization reaction; (3) reacting in an alkali separation kettle and dropwise adding sulfuric acid; (4) carrying out heat preservation and water distribution. Compared with a traditional method, the recovery method has the advantages that the recovery rate is greatly improved, the labor intensity of workers is reduced at the same time, and produced wastes also reach the environmental treatment standards.

Owner:ANHUI JINGHE IND

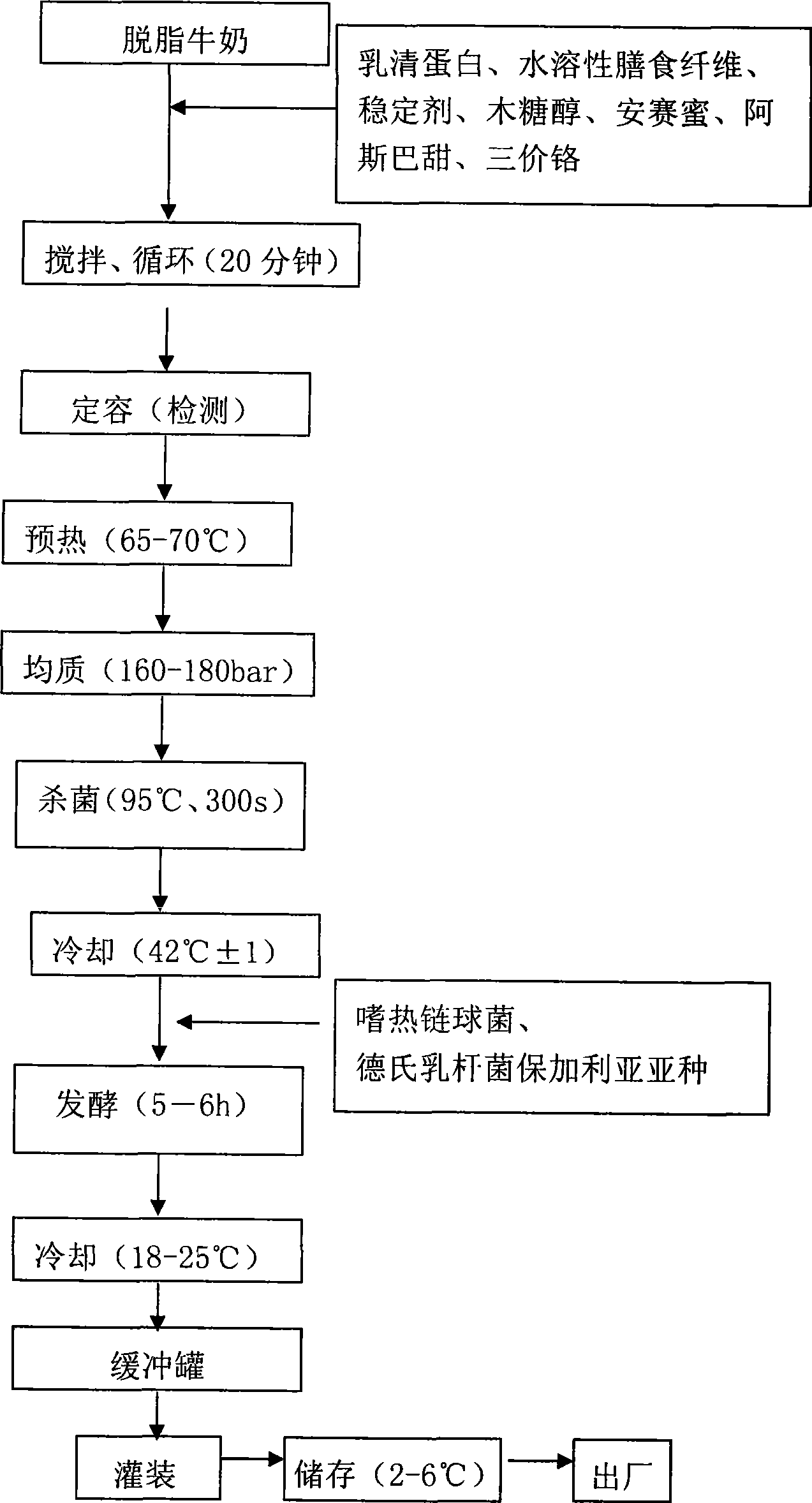

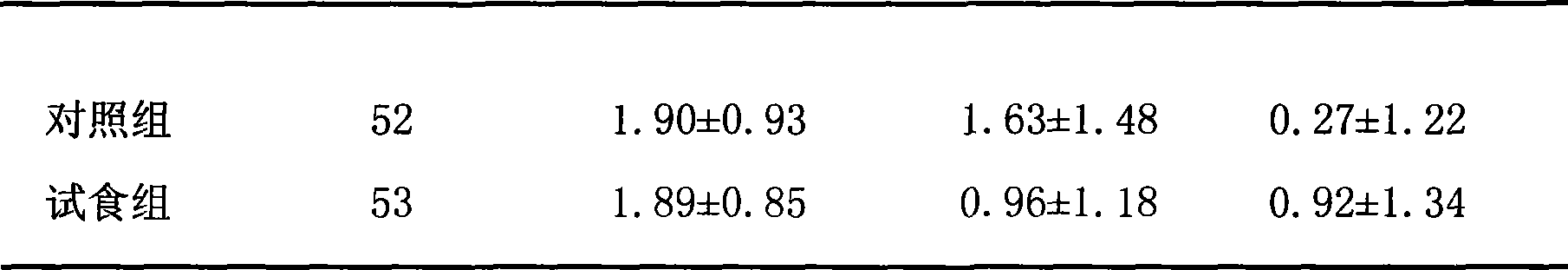

Yoghourt for reducing blood sugar and method for producing the same

The invention relates to a food, in particular to a yogurt manufacturing method, more particularly to a yogurt for assisting to reduce the blood sugar, and a production method thereof. The product comprises skimmed fresh milk, water-soluble dietary fiber, xylitol, lactoalbumin, stabilizer, aspartame, acesulfame potassium, trivalent chromium, streptococcus thermophilus and Lactobacillus delbrueckii subsp. Bulgaricus. The trivalent chromium for reducing the blood sugar is added in the yogurt, thereby the product plays the role of reducing the blood sugar, and not only has the abundant nutrition, but also plays the role of health care for assisting to reduce the blood sugar when the consumers with diabetes drink the yogurt. The product is effective after clinical test and has higher security.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

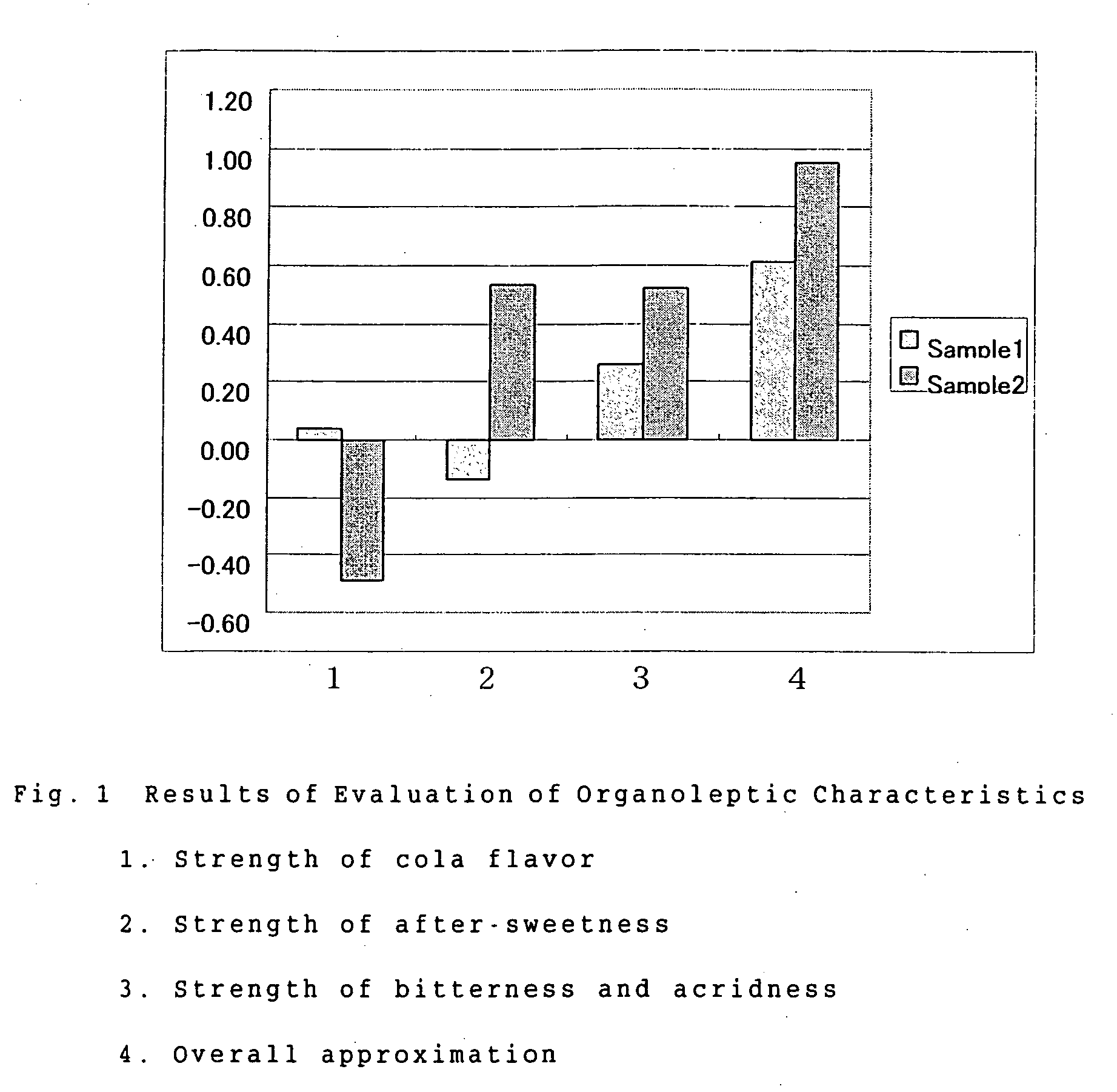

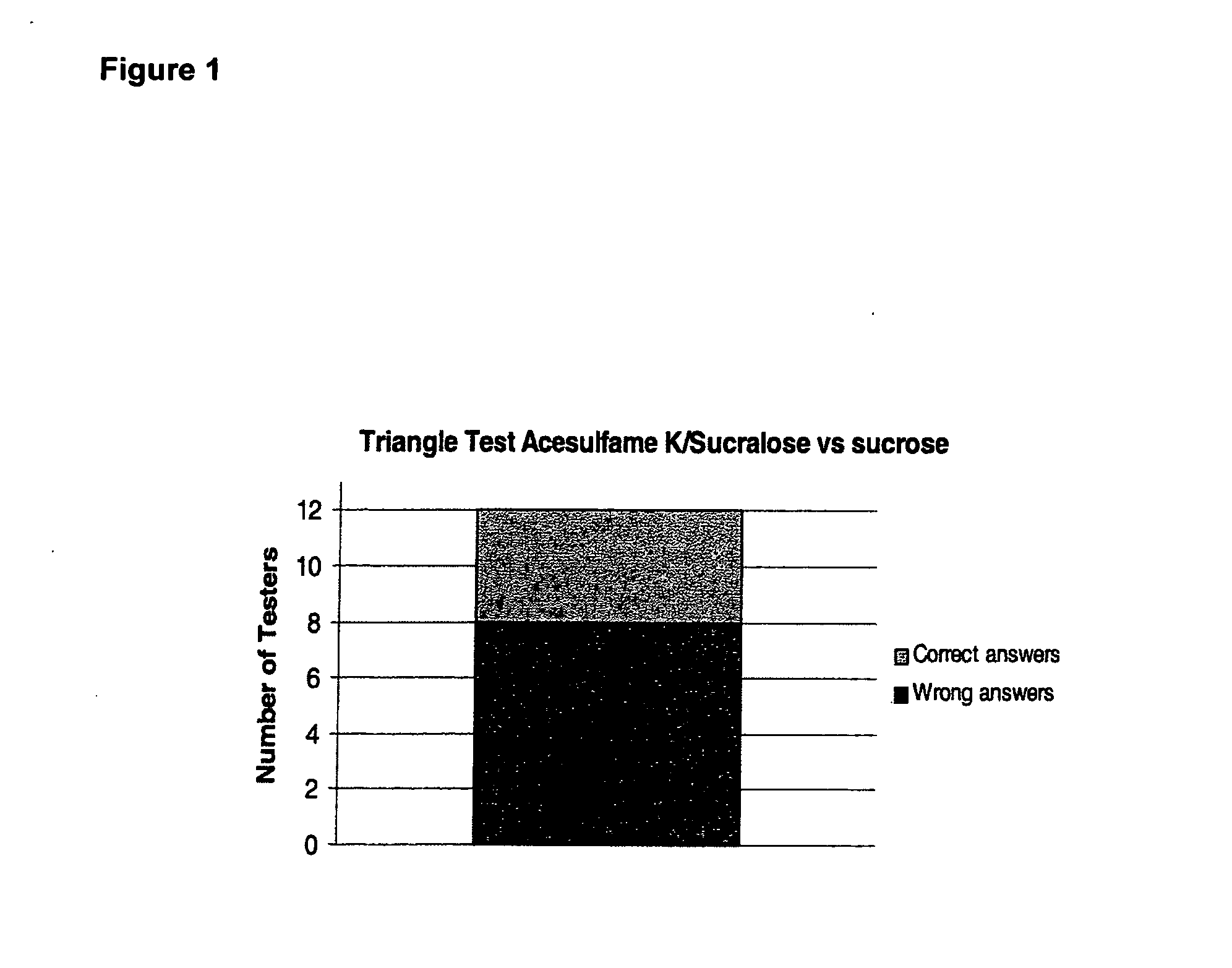

Low-calorie beverages and sweetener composition with improved palatability

InactiveUS20050238779A1Improve palatabilityLimited in calorieFood ingredient functionsFood preparationLow calorieLarge Calorie

The invention described herein provide beverages which have excellent palatability and are limited in calorie content and a sweetener composition having the same characteristics, which contain sucralose and acesulfame K.

Owner:AJINOMOTO CO INC

Process for manufacturing water treatment ceramsite filter by waste gypsum generated in acesulfame potassium production

ActiveCN101913898ACorrosion resistanceAntioxidantSolid waste disposalCeramicwareSludgeExpanded clay aggregate

The invention relates to a process for manufacturing a water treatment ceramsite filter by waste gypsum generated in acesulfame potassium production, which is characterized by comprising the following steps: a) pre-treatment: cleaning, drying and dewatering the waste gypsum generated in the acesulfame potassium production; b) mixing and homogenizing: mixing the treated waste gypsum with flyash and biological sludge to serve as a base stock, wherein base stock comprises 40-60% of waste gypsum by mass, 20-35% of flyash by mass and 5-20% of biological sludge by mass; and adding 8-15% of clay by mass and 1-12% of pore-forming material by mass, and evenly mixing; c) pelletizing; d) expanding; and e) screening: crushing the expanded product into the ceramic product with the particle size of 3-15mm, namely obtaining the product in the invention. The ceramic filter obtained in the invention can be suitable for enterprises needing water treatment like sewage treatment plants and the like.

Owner:南通宏信化工有限公司

Low carbohydrate ice cream

A low carbohydrate ice cream formulation that is rich in fiber is provided. The subject ice cream base formulation is free of milk and, hence, lactose and is comprised of heavy cream, water, maltodextrin soluble fiber, polydextrose, whey protein concentrate, glycerin, egg yolks, lecithin, xanthan gum, microcellulose gum, a mixture of locust bean gum and carrageenan gum, a mixture of mono- and di-glycerides of short chain fatty acids and an artificial sweetener that is a combination of acesulfame potassium and sucralose. Ice cream prepared by blending a suitable flavor into the subject base formulations is esthetically comparable to conventional premium ice cream.

Owner:KETO

Anti-blocking agent for acesulfame potassium and application method thereof

InactiveCN103960558AAvoid clumpingEasy to processTransportation and packagingMixingFood additiveAnticaking agent

The invention particularly relates an anti-blocking agent for acesulfame potassium and an application method thereof and belongs to the field of food additives. The anti-blocking agent is prepared from the following raw materials by weight percent: 20-60% of sodium polyacrylate solution, 30-70% of surface active agent and 10-20% of simethicone. The application method comprises the following steps: successively adding the sodium polyacrylate solution, the surface active agent and the simethicone at weight ratio into a right amount of water, and then stirring and dissolving, thereby obtaining the anti-blocking agent for acesulfame potassium. When the anti-blocking agent related by the invention is applied, the addition amount of the anti-blocking agent accounts for 0.1wt%-0.5wt% of the acesulfame potassium.

Owner:SOUTHEAST UNIV

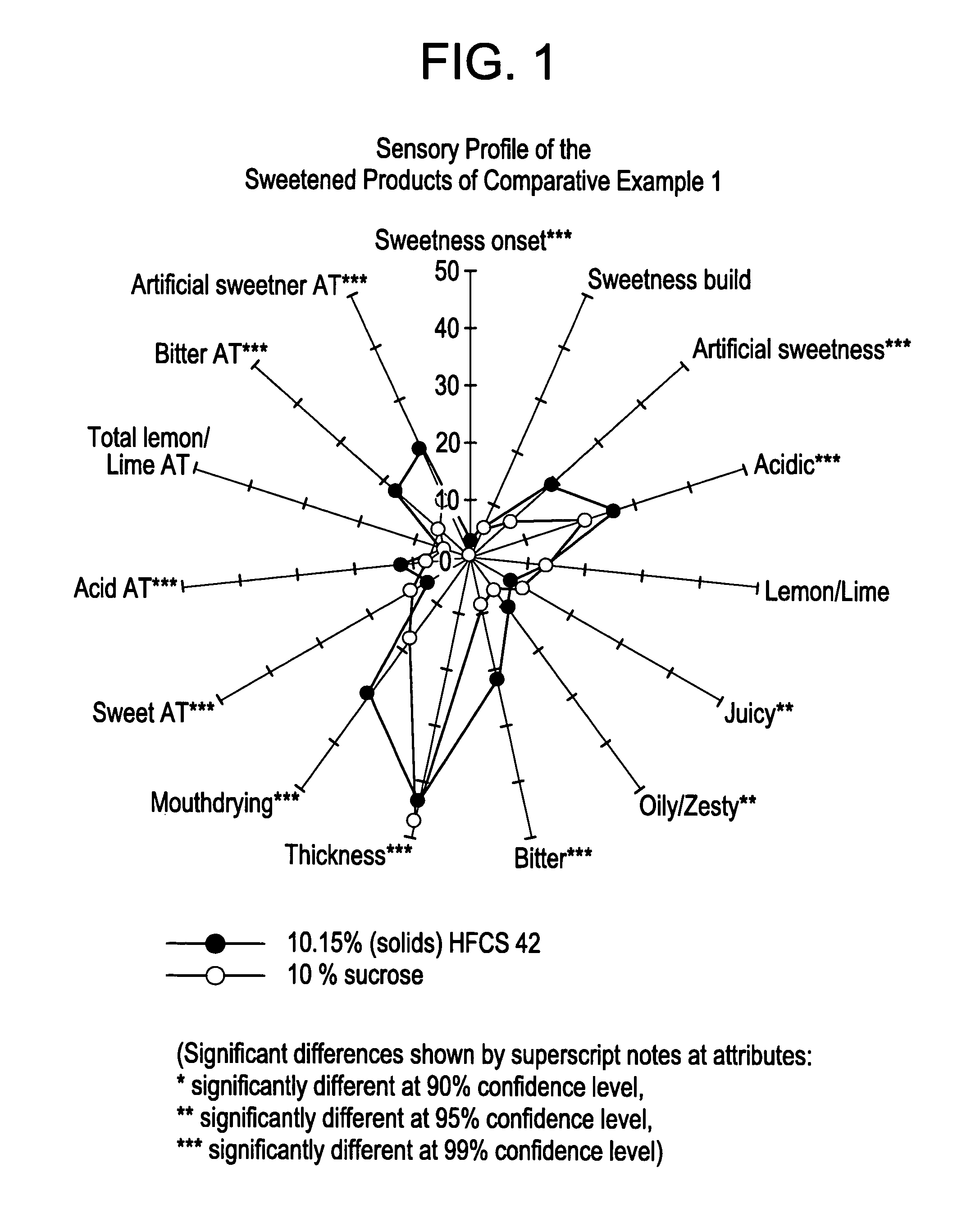

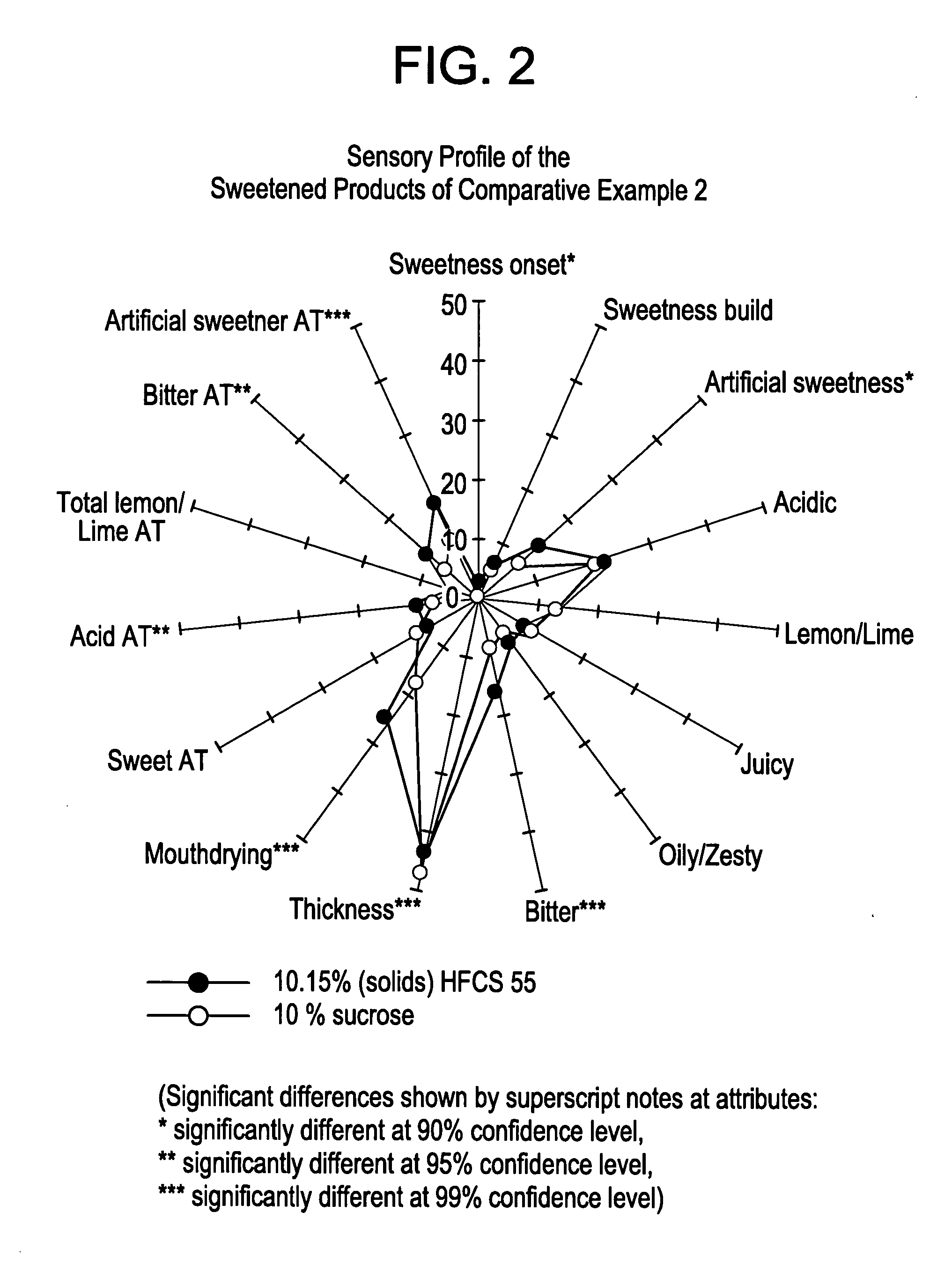

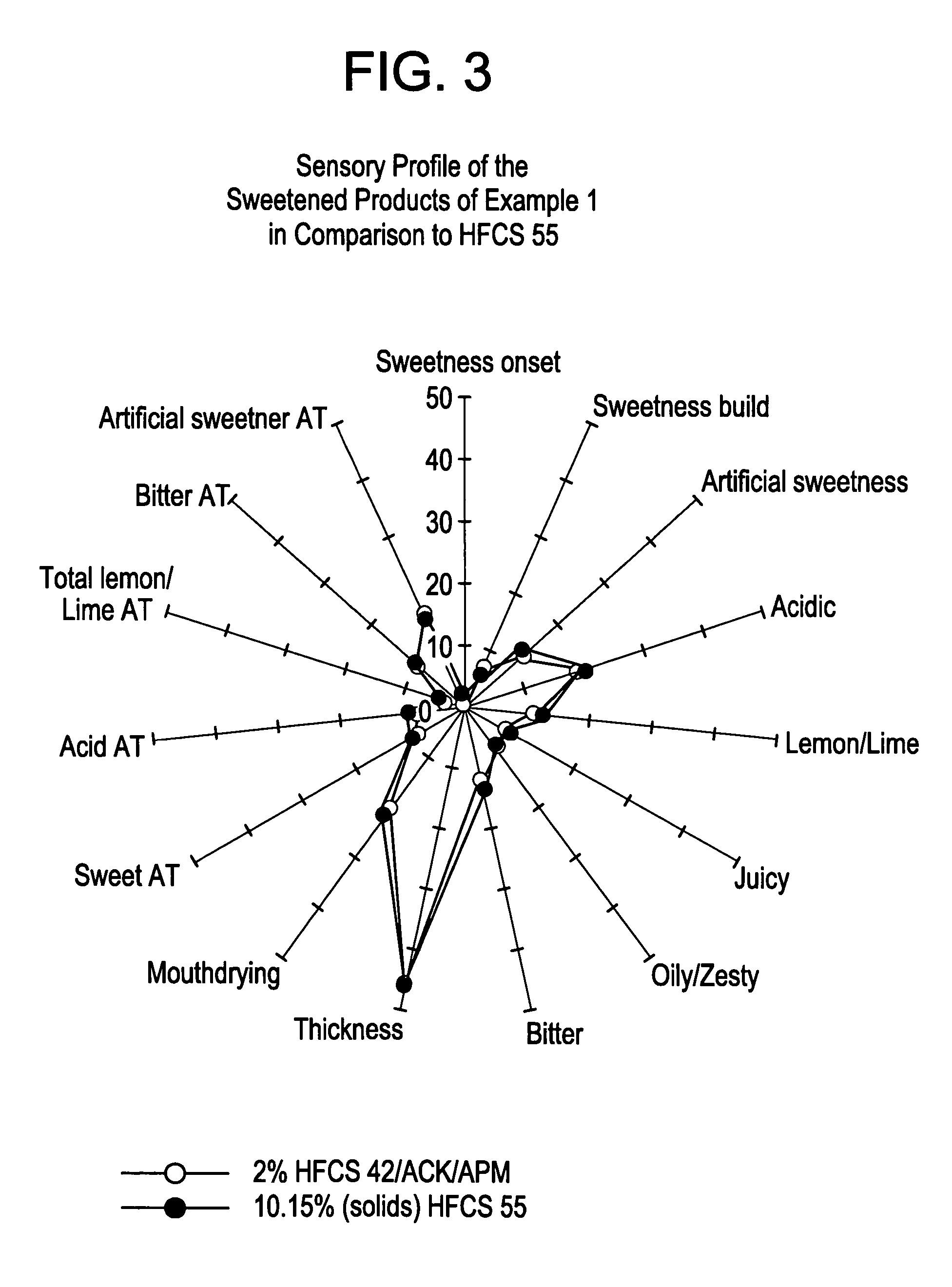

Sweetener compositions with a sweetness and taste profile comparable to HFCS 55

This invention relates to sweetening compositions used to produce foodstuffs with a sweetness and taste profile comparable to HFCS 55. The sweetener compositions generally include at least one carbohydrate sweetener selected from the group consisting of HFCS 55, HFCS 42 and sucrose along with an effective amount of a high intensity sweetener composition. The high intensity sweetener composition includes acesulfame K and one of either aspartame, sucralose or neotame. Foodstuffs formed using the reduced-calorie sweetener compositions of the invention exhibit a taste profile comparable to HFCS 55 and a calorie reduction of 50% or more.

Owner:NUTRINOVA NUTRITION SPECIALTIES & FOOD ENGREDIENTS GMBH

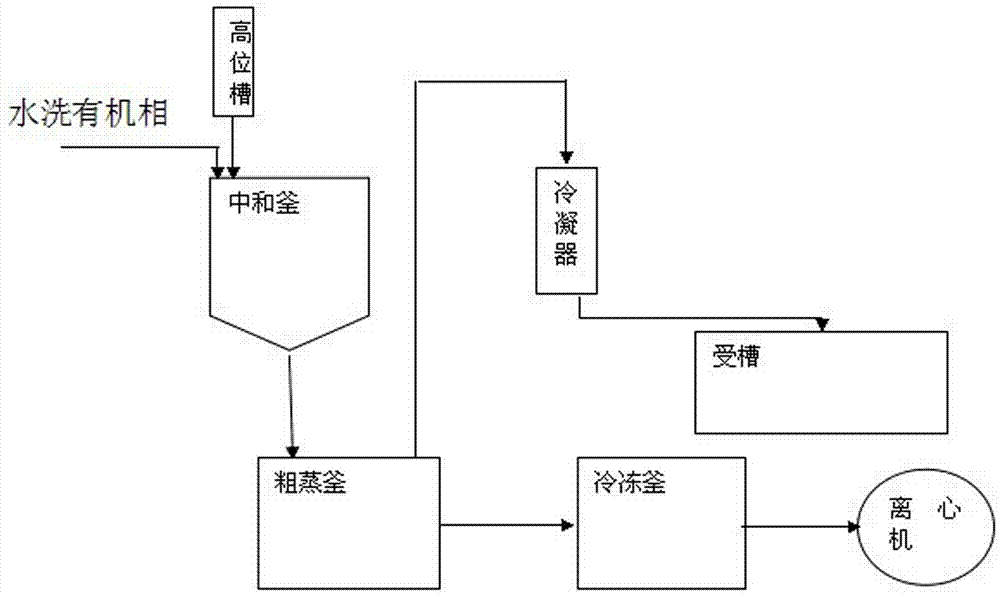

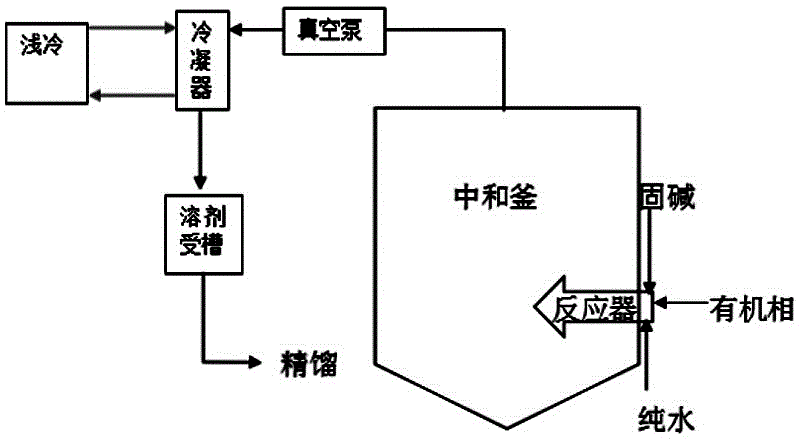

Method for solvent self-heating separation in acesulfame potassium synthesis

ActiveCN106365952ALow boiling pointReduce usageHalogenated hydrocarbon separation/purificationTemperature controlBoiling point

The invention discloses a method for solvent self-heating separation in acesulfame potassium synthesis. The method includes the following steps of pumping solid potassium hydroxide and water of the conventional adding percents into a reactor to make potassium hydroxide and water dissolved in a neutralization kettle and release heat till the temperature is naturally raised to 60 DEG C, starting a vacuum pump connected with the neutralization kettle to vacuumize the neutralization kettle to the negative pressure of -0.4 MPa, pumping an organic phase of the conventional adding percent into the reactor to make the temperature in the kettle naturally decrease and then increase, starting the vacuum pump to conduct vacuumization till a condenser valve when the temperature of the kettle is raised to 50 DEG C, starting the condenser brine valve, controlling the temperature of the kettle at 45 DEG C by controlling the feeding ratio of the organic phase to sodium carbonate, and discharging condensed dichloromethane to a solvent collecting tank through a condenser. The method has the advantages that solvent is pressurized in the reactor and depressurized after getting out of the reactor, the boiling point of the solvent is reduced, original processes of separating, washing, separating, pre-boiling and the like are omitted through temperature control, operation is simplified, labor intensity is reduced, machines and pumps are less used, and meanwhile lots of steam is saved.

Owner:ANHUI JINGHE IND

Sweetener compositions with a sweetness and taste profile comparable to HFCS 55

InactiveUS20060159820A1Reduction in foodstuff calorieHigh strengthFood ingredientsFood preparationSucroseSweetness

This invention relates to sweetening compositions used to produce foodstuffs with a sweetness and taste profile comparable to HFCS 55. The sweetener compositions generally include at least one carbohydrate sweetener selected from the group consisting of HFCS 55, HFCS 42 and sucrose along with an effective amount of a high intensity sweetener composition. The high intensity sweetener composition includes acesulfame K, aspartame and sucralose. Foodstuffs formed using the reduced-calorie sweetener compositions of the invention exhibit a taste profile comparable to HFCS 55 and a calorie reduction of 50% or more.

Owner:NUTRINOVA NUTRITION SPECIALTIES & FOOD ENGREDIENTS GMBH

Sugar substitute and bulking agent and chocolate

InactiveUS20060088637A1Reduce and eliminate laxative effect and effectReduce and eliminate effect and flatulence effectCocoaFood ingredient functionsButter cocoaAdditive ingredient

The invention relates to a solid, low calorie, palatable sugar substitute with the following ingredients, by weight: inulin 21.6%-48.3%; polydextrose 21.6%-59.0%; maltodextrin 2.0%-48.0%; trace amounts of an antiagglomerant, and the balance being one or more intense sweeteners, for example, sucralose or acesulfame-K or a combination of acesulfame-K and neohesperidin dihydrochalone. A solid, low calorie, chocolate comestible is provided as follows: inulin 12.0-20.0%; polydextrose 15.0-25.0%; maltodextrin 2.0-8.0%; milk 0-22% dependent upon flavor (dark, milk, etc.); cocoa mass 10-50% dependent upon flavor; cocoa butter 8-25% dependent upon flavor; trace amounts of lecithin and flavor; and the balance being one or more intense sweeteners such as aspartame, acesulfame-K or sucralose or a combination of acesulfame-K and neohesperidin dihydrochalone.

Owner:SWEETABUE

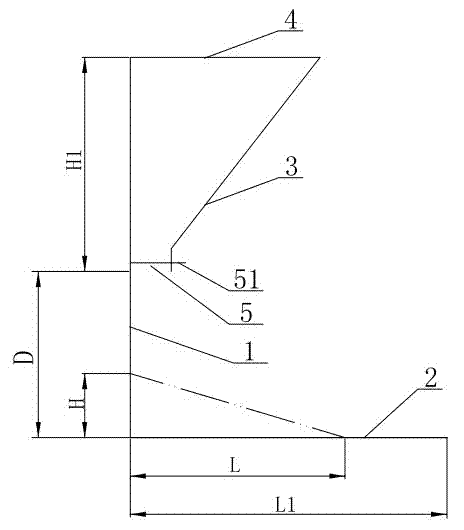

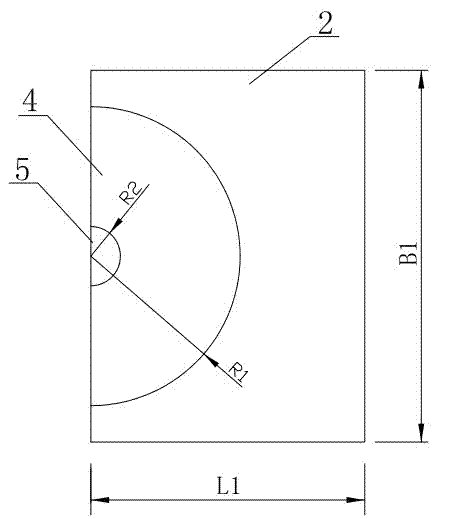

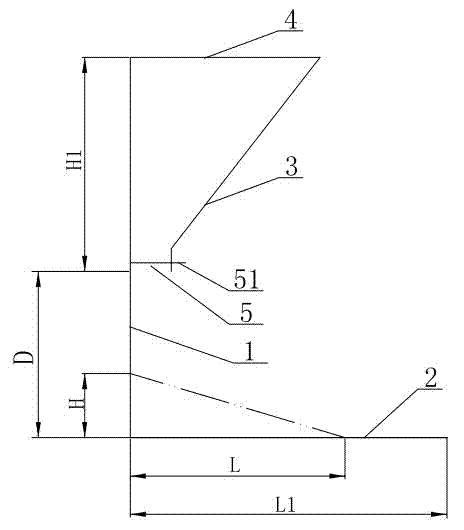

Method for measuring and calculating acesulfame potassium agglomeration period

ActiveCN102359926ASimple methodAccurate calculationDirect flow property measurementAcesulfame potassiumChemistry

The present invention discloses a method for measuring and calculating an acesulfame potassium agglomeration period. The method comprises the following steps: (1) preparing a measurement and calculation device for the acesulfame potassium agglomeration period, wherein the structure of the device comprises: a L-shaped baffle and a semi-conical funnel; (2) pouring 100 g of acesulfame potassium to the device, and timing until the acesulfame potassium is completely poured in the device, measuring the falling time t, substituting the t into the following formula: T1=-40.56*t+462.63, and calculating a first period T1; (3) measuring the vertical height H and the pavement length L of the acesulfame potassium, wherein of the vertical height and the pavement length are formed after the acesulfame potassium is completely leaked, calculating a H / L value, substituting the H / L value into the following formula: T2 =-752.58*H / L+544.41, and calculating a second period T2; (4) calculating the arithmetic mean of the T1 and the T2 to obtain the acesulfame potassium agglomeration period T. According to the present invention, the method of the present invention is simple; with the method, the acesulfame potassium agglomeration period can be accurately measured and calculated, such that the storage, the transport and the use can be effective arranged so as to substantially improve the work efficiency and reduce the labor cost.

Owner:南通宏信化工有限公司

Acesulfame potassium compositions and processes for producing same

A process for producing acesulfame potassium, the process comprising the steps of providing a cyclizing agent composition comprising a cyclizing agent and a solvent and having an initial temperature, cooling the cyclizing agent composition to form a cooled cyclizing agent composition having a cooled temperature less than 35° C., reacting an acetoacetamide salt with the cyclizing agent in the cooled cyclizing agent composition to form a cyclic sulfur trioxide adduct composition comprising cyclic sulfur trioxide adduct; and, forming from the cyclic sulfur trioxide adduct in the cyclic sulfur trioxide adduct composition the finished acesulfame potassium composition comprising non-chlorinated acesulfame potassium and less than 39 wppm 5-chloro-acesulfame potassium. The cooled temperature is at least 2° C. less than the initial temperature.

Owner:CELANESE INT CORP

Acesulfame potassium compositions and processes for producing same

Compositions and processes for producing high purity acesulfame potassium are described. One process comprises the steps of providing a crude acesulfame potassium composition comprising acesulfame potassium and acetoacetamide, concentrating the crude acesulfame potassium composition to form a water stream and an intermediate acesulfame potassium composition comprising acesulfame potassium and less than 33 wppm acetoacetamide, and separating the intermediate acesulfame potassium composition to form the finished acesulfame potassium composition comprising acesulfame potassium and less than 33 wppm acetoacetamide. The concentrating step is conducted at a temperature below 90° C. and the separating step is conducted at a temperature at or below 35° C.

Owner:CELANESE INT CORP

Sweetener combination for sweetening preserved fruit

The invention relates to a sweetener combination of acesulfame-K and sucralose in a weight ratio of at least 75 / 25 for sweetening preserved fruit. The invention further relates to a process for the at least partial replacement of sucrose (sugar) in preserved fruit.

Owner:NUTRINOVA NUTRITION SPECIALTIES & FOOD ENGREDIENTS GMBH

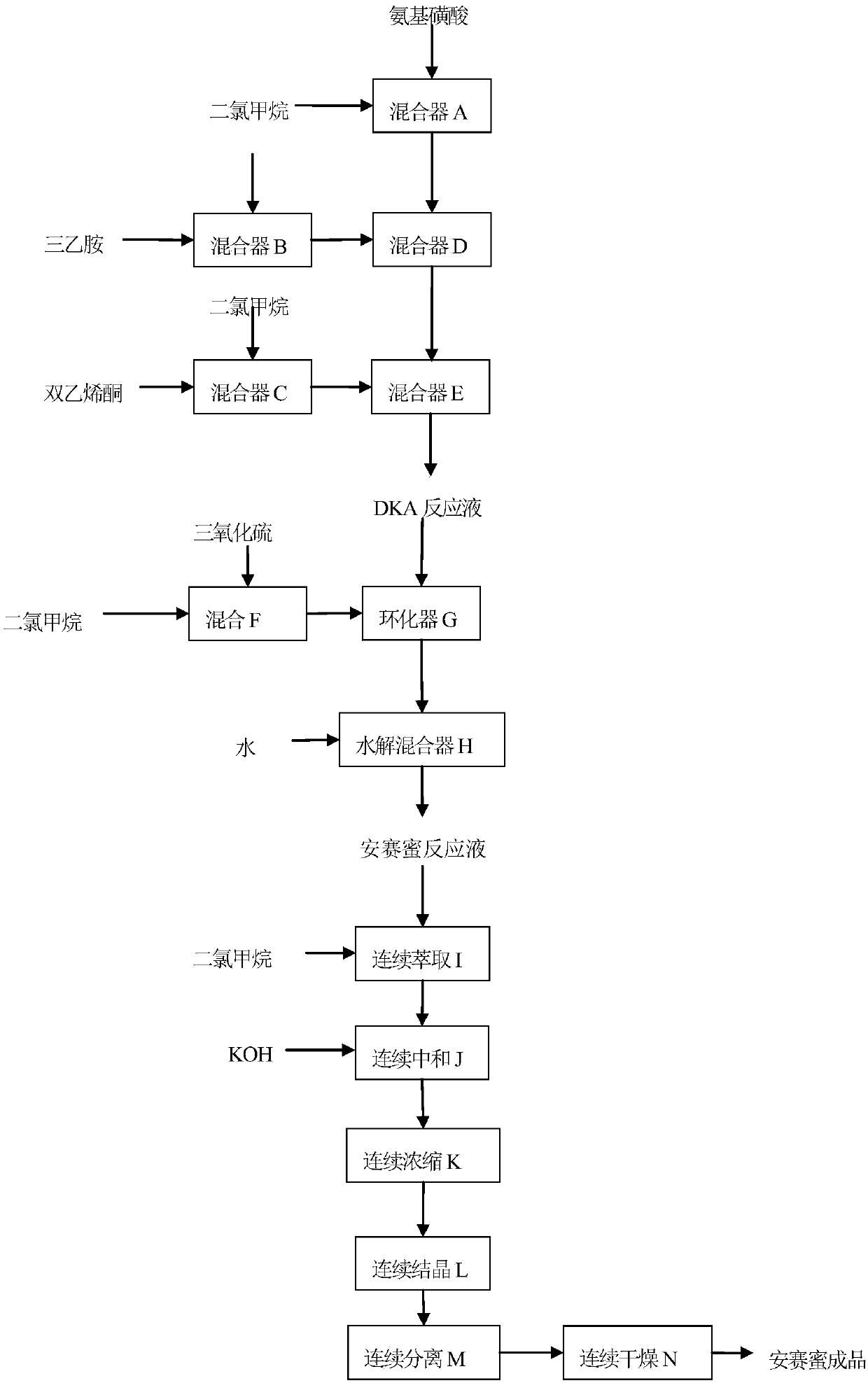

Method for continuously producing acesulfame potassium

The invention belongs to the field of chemical production, and provides a method for continuously producing acesulfame potassium, which comprises the following steps: continuously mixing and dissolving sulfamic acid and dichloromethane, continuously neutralizing with a triethylamine solution, introducing the neutralized reaction solution and ketene dimer into a continuous reactor, and carrying outaddition acylation reaction to obtain a DKA reaction solution; sulfur trioxide and solvent micro-mixing: S03, enabling dichloromethane to enter a micro-mixer, so as to prepare a cyclizing agent; cyclization and hydrolysis: continuously feeding the DKA reaction solution and a cyclizing agent into a cyclization microreactor to generate a cyclization reaction solution, and continuously feeding the cyclization reaction solution into a hydrolysis microreactor to obtain an acesulfamic acid reaction solution; enabling the acesulfame acid reaction liquid and dichloromethane to enter continuous extraction equipment, enabling an extracted organic phase and a potassium hydroxide aqueous solution to enter a continuous neutralization reactor to obtain acesulfame acid potassium reaction liquid, and subjecting the acesulfame acid potassium reaction liquid to continuous concentration, continuous crystallization, continuous separation and continuous drying to obtain the acesulfame acid potassium finished product. The process has the characteristics of simple process, low cost, good product quality, continuous whole process and the like.

Owner:NANTONG ACETIC ACID CHEM +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com