Waste acid treatment method and treatment system for acesulfame preparation technique by sulphuric anhydride cyclization method

A technology for waste acid treatment and acesulfame potassium, applied in chemical instruments and methods, neutralized water/sewage treatment, magnesium sulfate, etc., can solve the problems of difficult sales of building materials and chemical raw materials, high energy consumption, and low purity. , to achieve the effect of eliminating the discharge of high-salt sewage and solving environmental problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

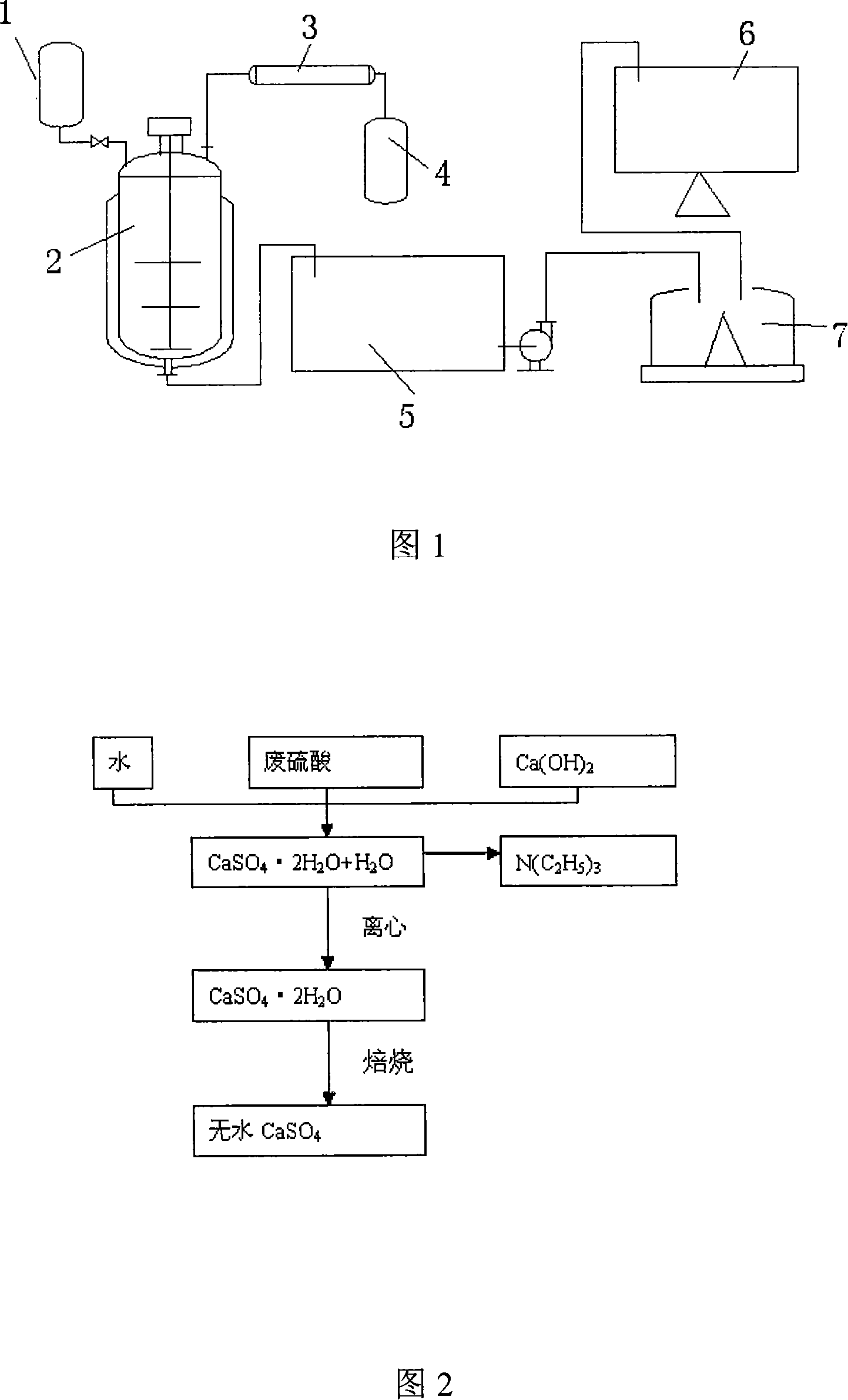

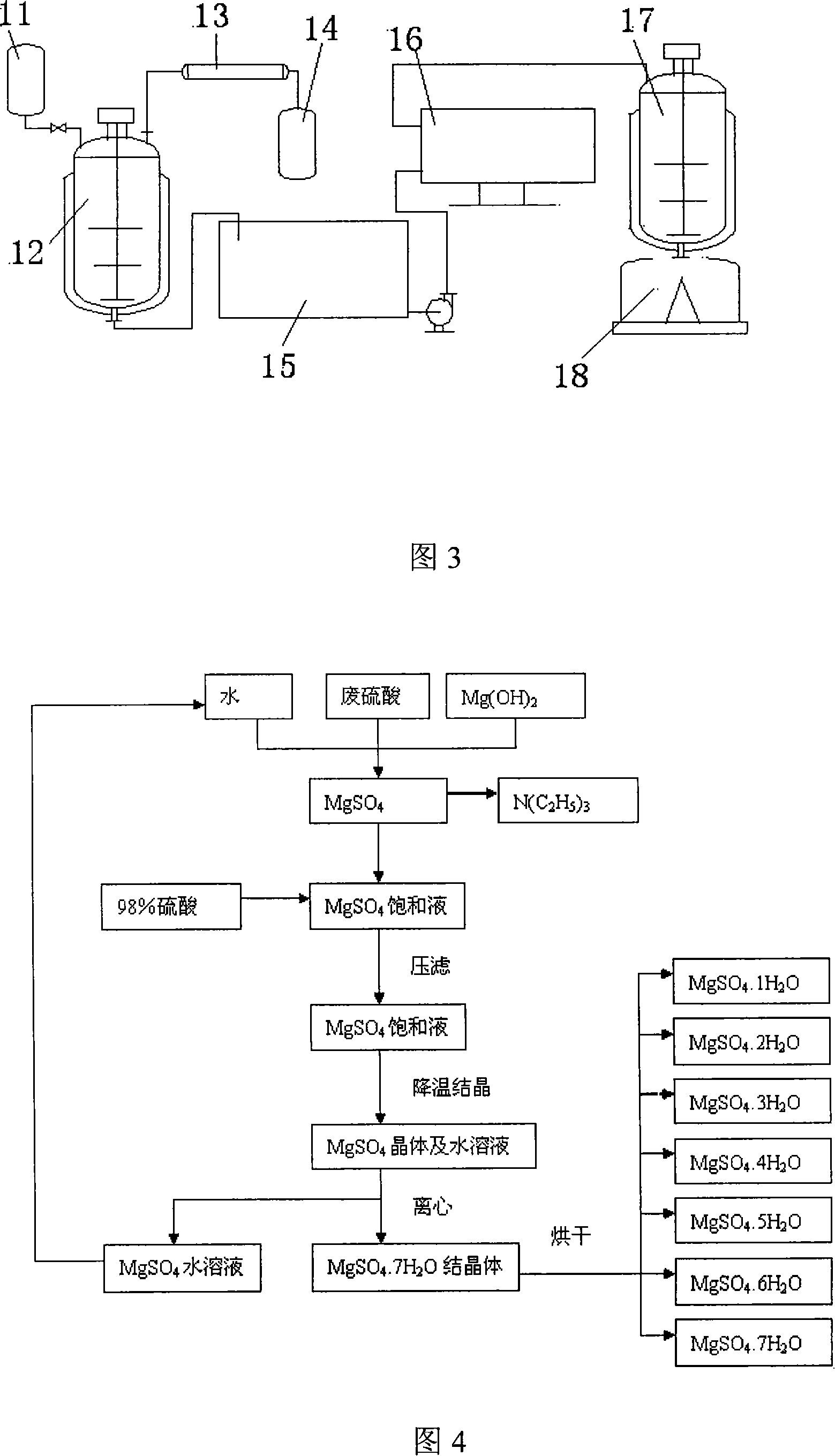

[0022] The present invention is described in detail below in conjunction with accompanying drawing:

[0023] Referring to accompanying drawing 2 and accompanying drawing 3, Fig. 2 has shown the schematic diagram of the system of using Mg(OH) 2 or MgO to treat waste acid of the present invention. The system includes a waste acid storage tank 11, a neutralization tank 12, a cooler 13, a triethylamine receiving tank 14, a pH value adjustment tank 15, a filter 16, a cooling tank 17, and a centrifuge 18, wherein the waste acid storage tank 1 passes through The valve leads into the neutralization kettle 12, the top of the neutralization kettle 12 is connected with a cooler 13, the other end of the cooler 13 is connected to receive the triethylamine receiving tank 14 cooled by the cooler, and the bottom of the neutralization kettle 12 is connected to the In the pH adjustment tank 15 containing the reacted materials, the pH adjustment tank 15 is connected to the cooling tank 17 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com