CdS/g-C3N4 composite visible light catalyst, preparation method and application

A composite catalyst, g-c3n4 technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of poor stability of CdS catalysts, inability to achieve recycling, and reduced photocatalytic activity. problems, to achieve the effect of solving energy crisis, reducing the probability of photocorrosion and oxidation, and solving environmental problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

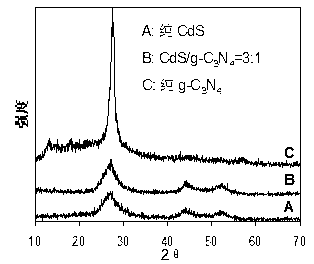

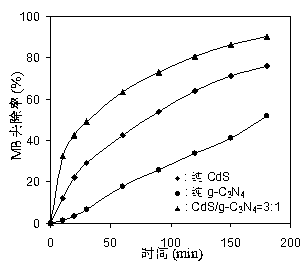

[0028] Example 1: CdS / g-C 3 N 4 =3:1 (mass ratio), g-C 3 N 4 Preparation and Application of Composite Visible Light Catalyst at Calcination Temperature of 520 °C

[0029] (1) Put melamine in a crucible and bake it in a muffle furnace at 500 °C for 2 h with a heating rate of 10 °C min -1 ; then heated up to 520 ℃, roasted for 2 h, cooled and ground to obtain g-C 3 N 4 ;

[0030] (2) Add 1 g g-C 3 N 4 Add to 1 mol L -1 In NaOH solution, ultrasonically make it form a uniformly dispersed suspension;

[0031] (3) Under constant stirring conditions, 0.1mol L -1 CdCl 2 Add the solution into (2), and keep stirring for 30 min; then add 0.1 mol L -1 Na 2 S solution and keep stirring for 30 min;

[0032] (4) The product obtained in (3) was centrifuged, washed with deionized water until neutral, dried in vacuum at 70 °C, cooled, ground and dried to obtain CdS / g-C 3 N 4 =3:1.

[0033] (5) Based on the obtained CdS / g-C 3 N 4 =3:1 is a photocatalyst, which catalyzes the...

Embodiment 2

[0043] Example 2: CdS / g-C 3 N 4 =3:1 (mass ratio), g-C 3 N 4 Preparation and Application of Composite Visible Light Catalyst at Calcination Temperature of 320 °C

[0044] In Example 2, the step (1) in Example 1 was changed to: put melamine in a crucible, bake it in a muffle furnace at 300 °C for 2 h, and the heating rate was 10 °C min -1 ; then heated up to 320 ℃, roasted for 2 h, cooled and ground to obtain g-C 3 N 4 . Other steps are as embodiment 1, obtain CdS / g-C 3 N 4 =3:1 composite visible light catalyst.

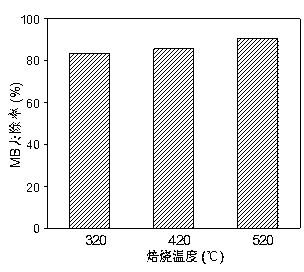

[0045] The CdS / g-C 3 N 4 =3:1 is used for visible light catalytic degradation MB solution, under the same reaction conditions as in Example 1, the degradation efficiency of MB after 3 h is 83.45% (see image 3 ).

Embodiment 3

[0046] Example 3: CdS / g-C 3 N 4 =3:1 (mass ratio), g-C 3 N 4 Preparation and Application of Composite Visible Light Catalyst at Calcination Temperature of 420 °C

[0047] In Example 3, the step (1) in Example 1 is changed to: put melamine in a crucible, bake it in a muffle furnace at 400 °C for 2 h, and the heating rate is 10 °C min -1 ; then heated up to 420 ℃, roasted for 2 h, cooled and ground to obtain g-C 3 N 4 . Other steps are as embodiment 1, obtain CdS / g-C 3 N 4 =3:1 composite visible light catalyst.

[0048] The CdS / g-C 3 N 4 =3:1 is used for visible light catalytic degradation MB solution, under the same reaction conditions as in Example 1, the degradation efficiency of MB after 3 h is 85.66% (see image 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com