Patents

Literature

24706 results about "Precipitation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In meteorology, precipitation is any product of the condensation of atmospheric water vapour that falls under gravity. The main forms of precipitation include drizzle, rain, sleet, snow, graupel and hail. Precipitation occurs when a portion of the atmosphere becomes saturated with water vapor, so that the water condenses and "precipitates". Thus, fog and mist are not precipitation but suspensions, because the water vapor does not condense sufficiently to precipitate. Two processes, possibly acting together, can lead to air becoming saturated: cooling the air or adding water vapor to the air. Precipitation forms as smaller droplets coalesce via collision with other rain drops or ice crystals within a cloud. Short, intense periods of rain in scattered locations are called "showers."

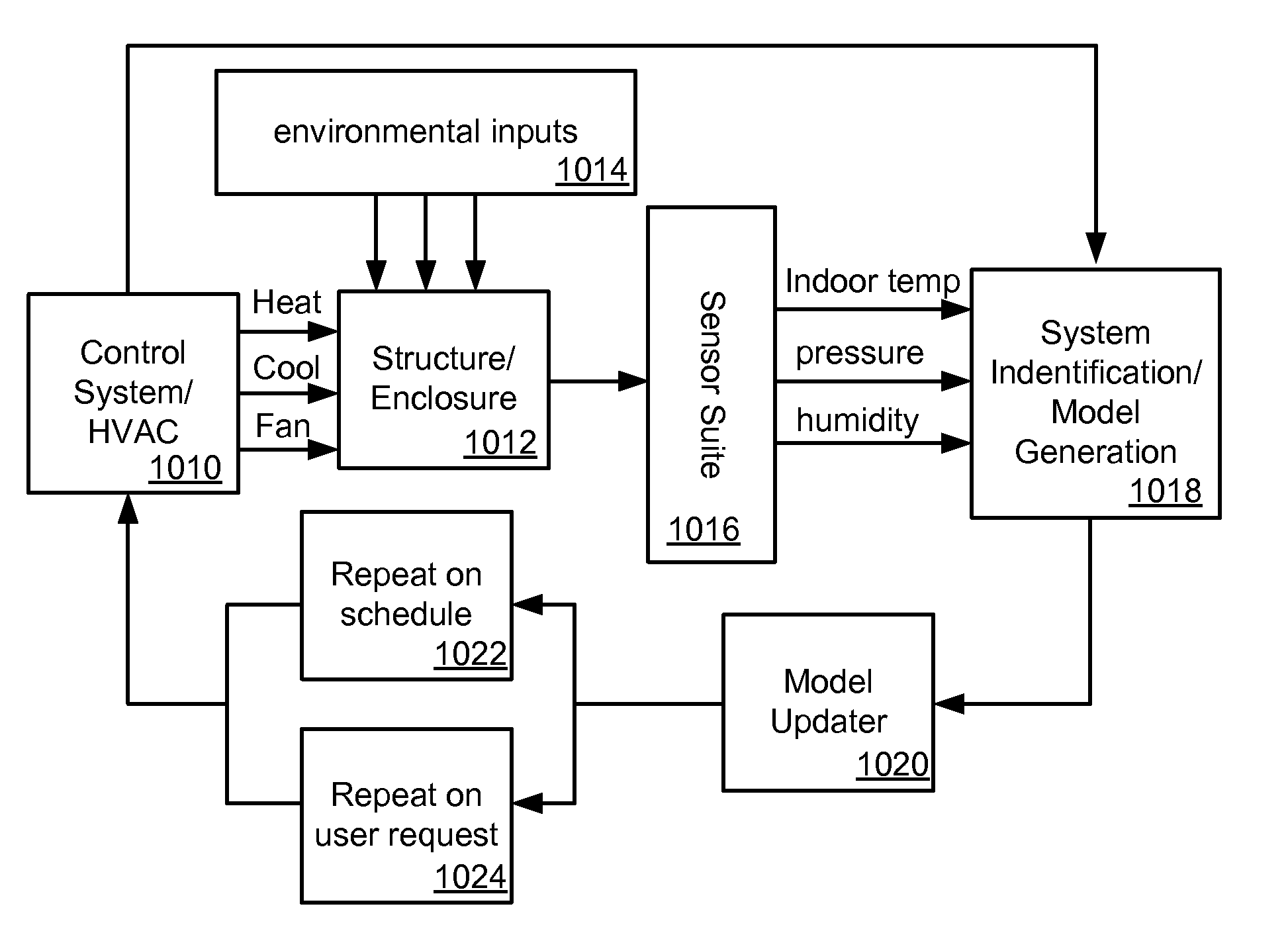

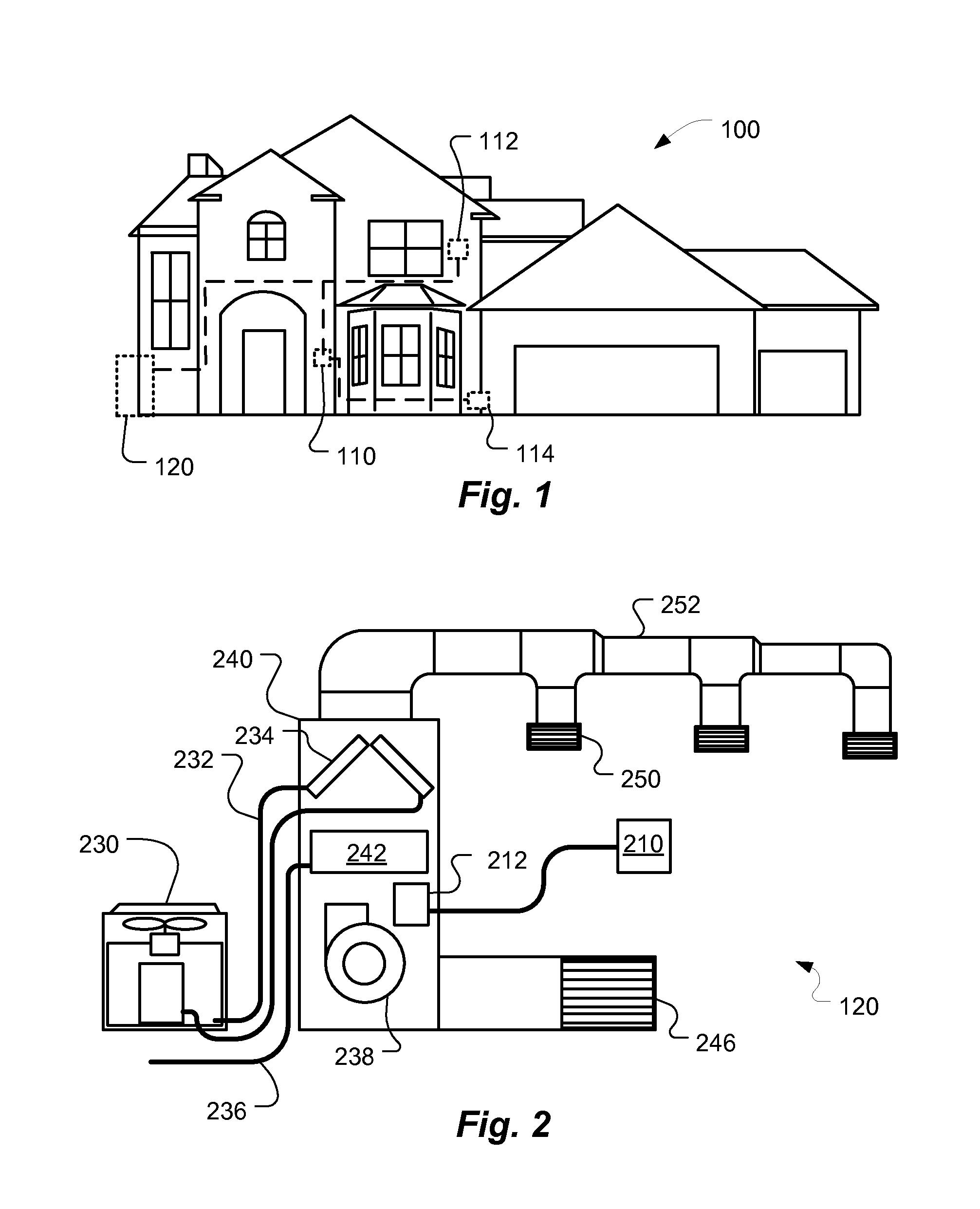

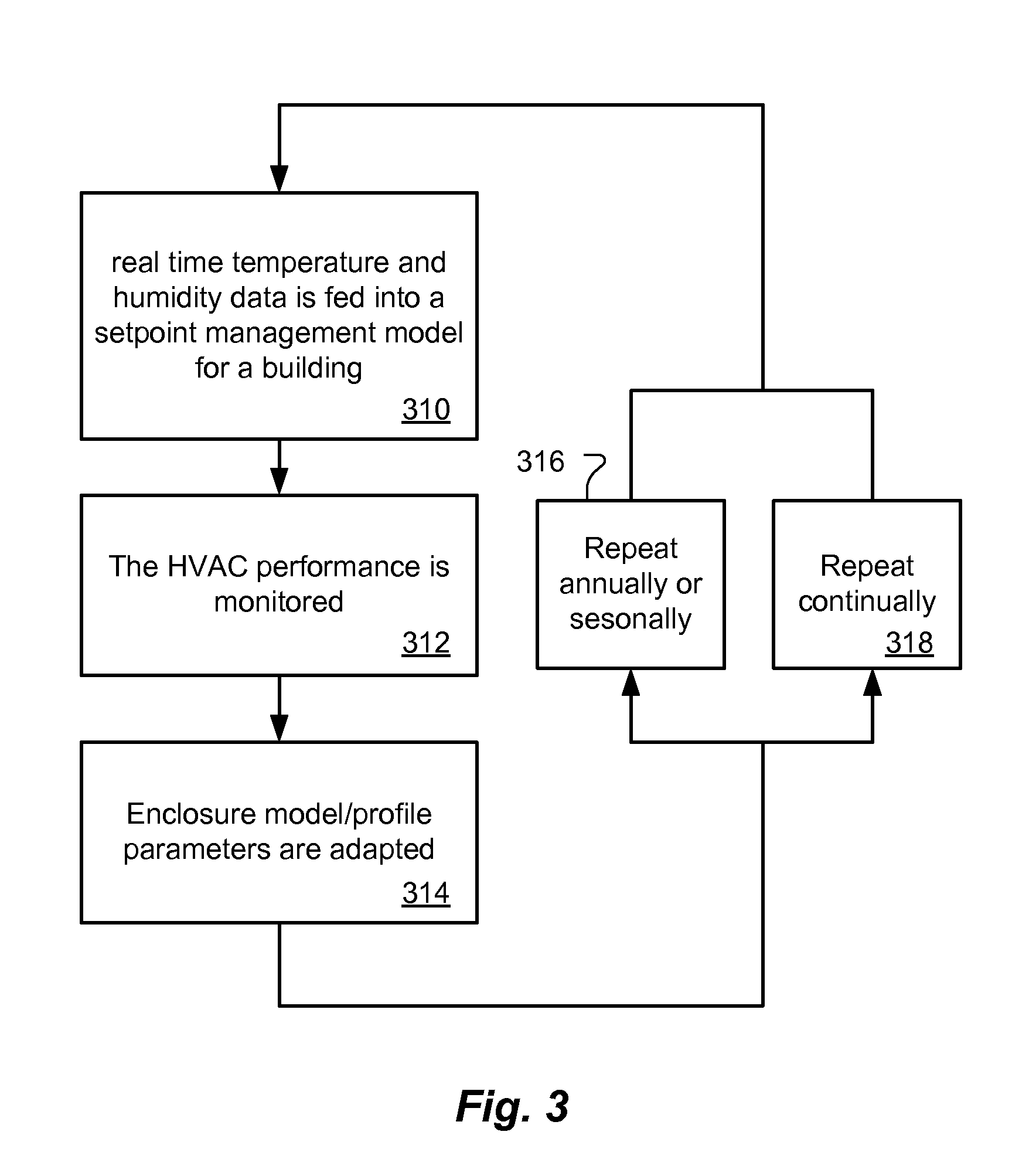

Thermodynamic modeling for enclosures

Systems and methods for modeling the behavior of an enclosure for use by a control system of an HVAC system are described. A model for the enclosure that describes the behavior of the enclosure for use by the control system is updated based on a weather forecast data. The weather forecast data can include predictions more than 24 hours in the future, and can include predictions such as temperature, humidity and / or dew point, solar output, precipitation. The model for the enclosure can also be updated based on additional information and data such as historical weather data such as temperature, humidity, wind, solar output and precipitation, occupancy data, such as predicted and / or detected occupancy data, calendar data, and data from the one or more weather condition sensors that sense current parameters such as temperature, humidity, wind, precipitation, and / or solar output. The model for the enclosure can be updated based also on an enclosure model stored in a database, and / or on enclosure information from a user. The model can be updated based on active testing of the enclosure which can be performed automatically or in response to user input. The testing can include heating and / or cooling the enclosure at times when the enclosure is not likely to be occupied.

Owner:GOOGLE LLC

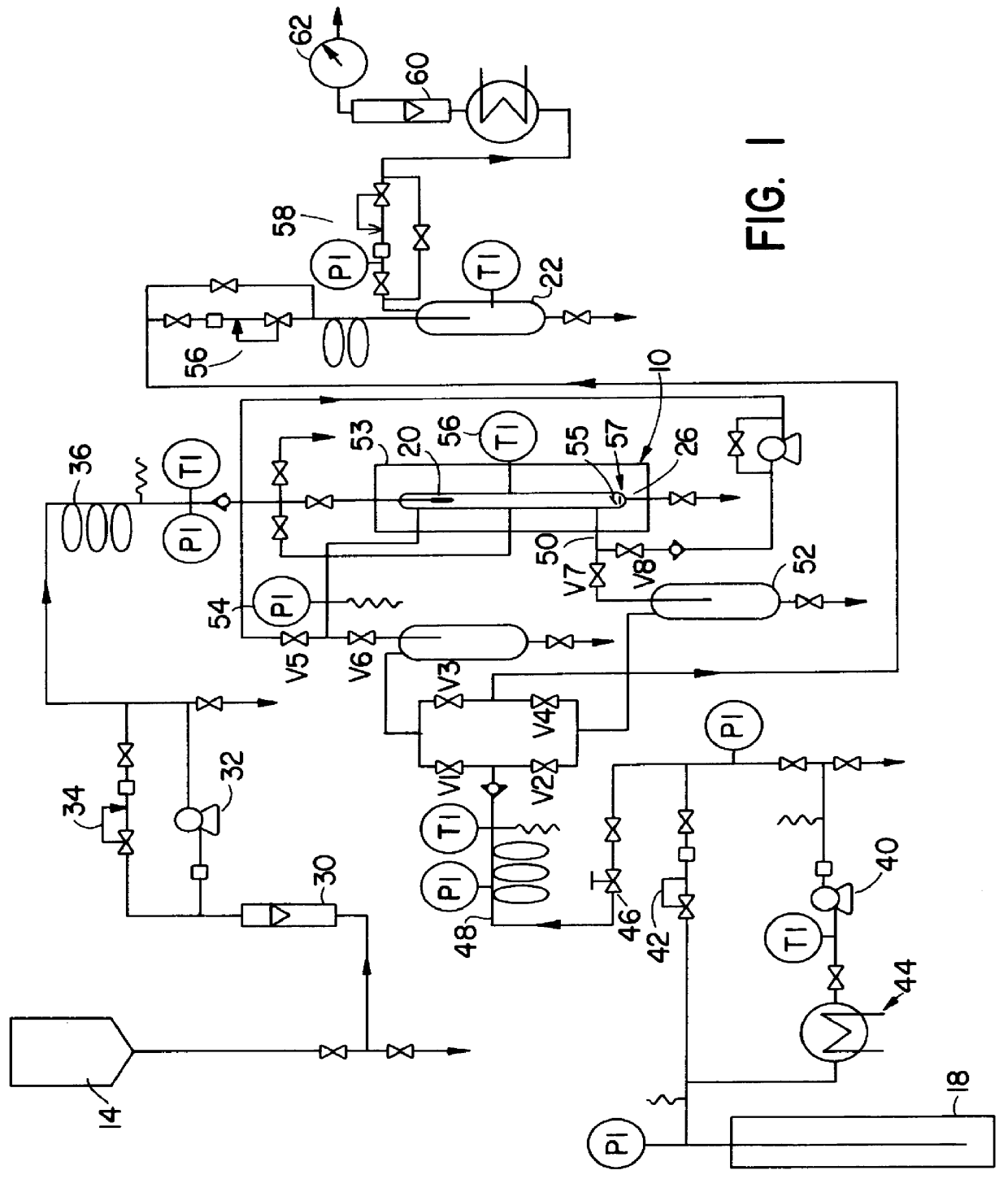

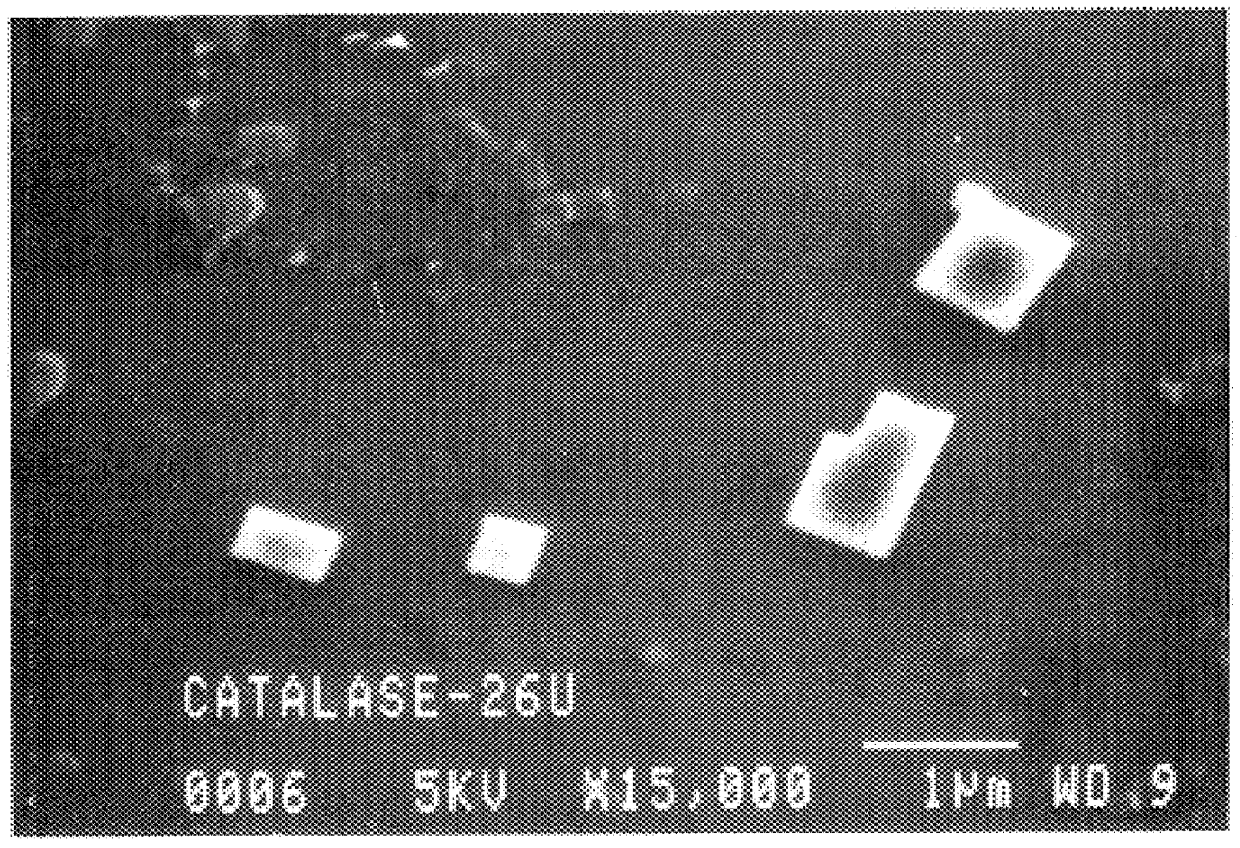

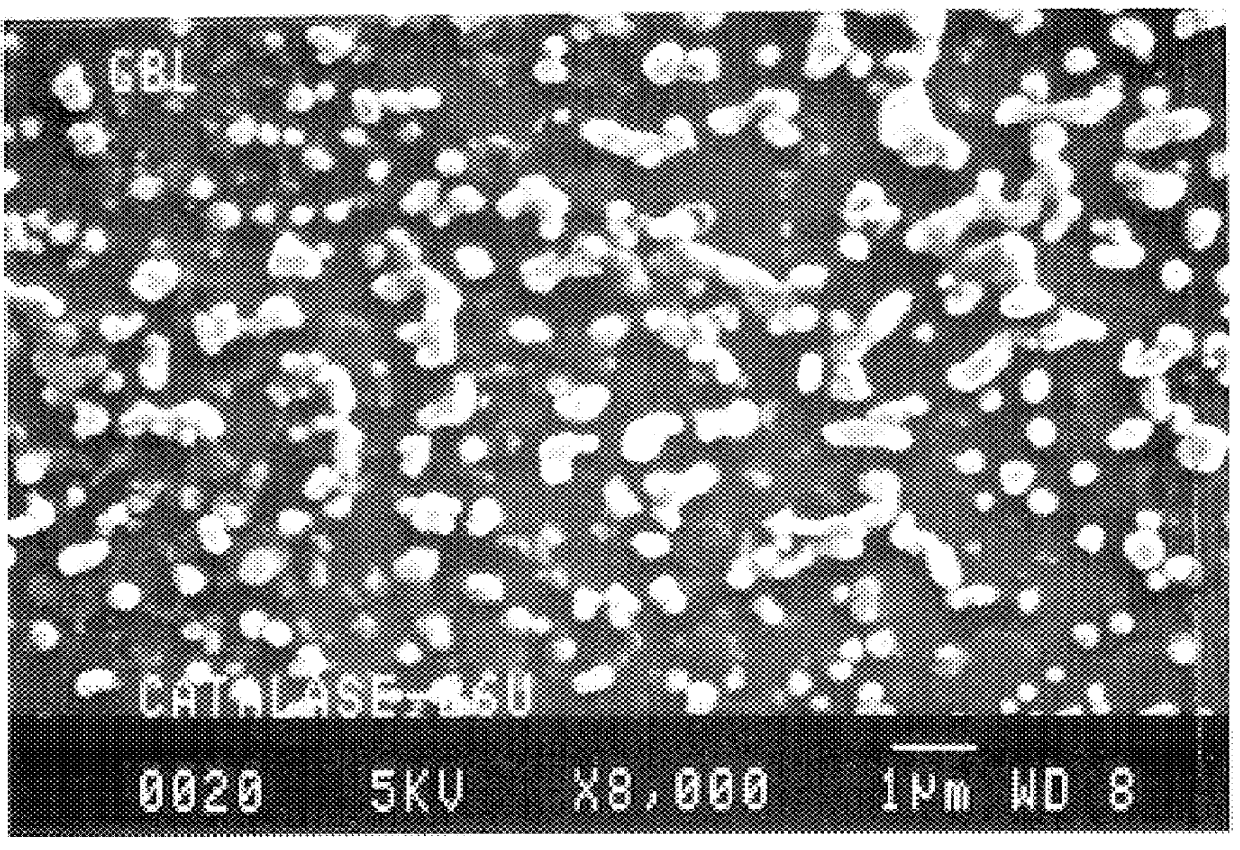

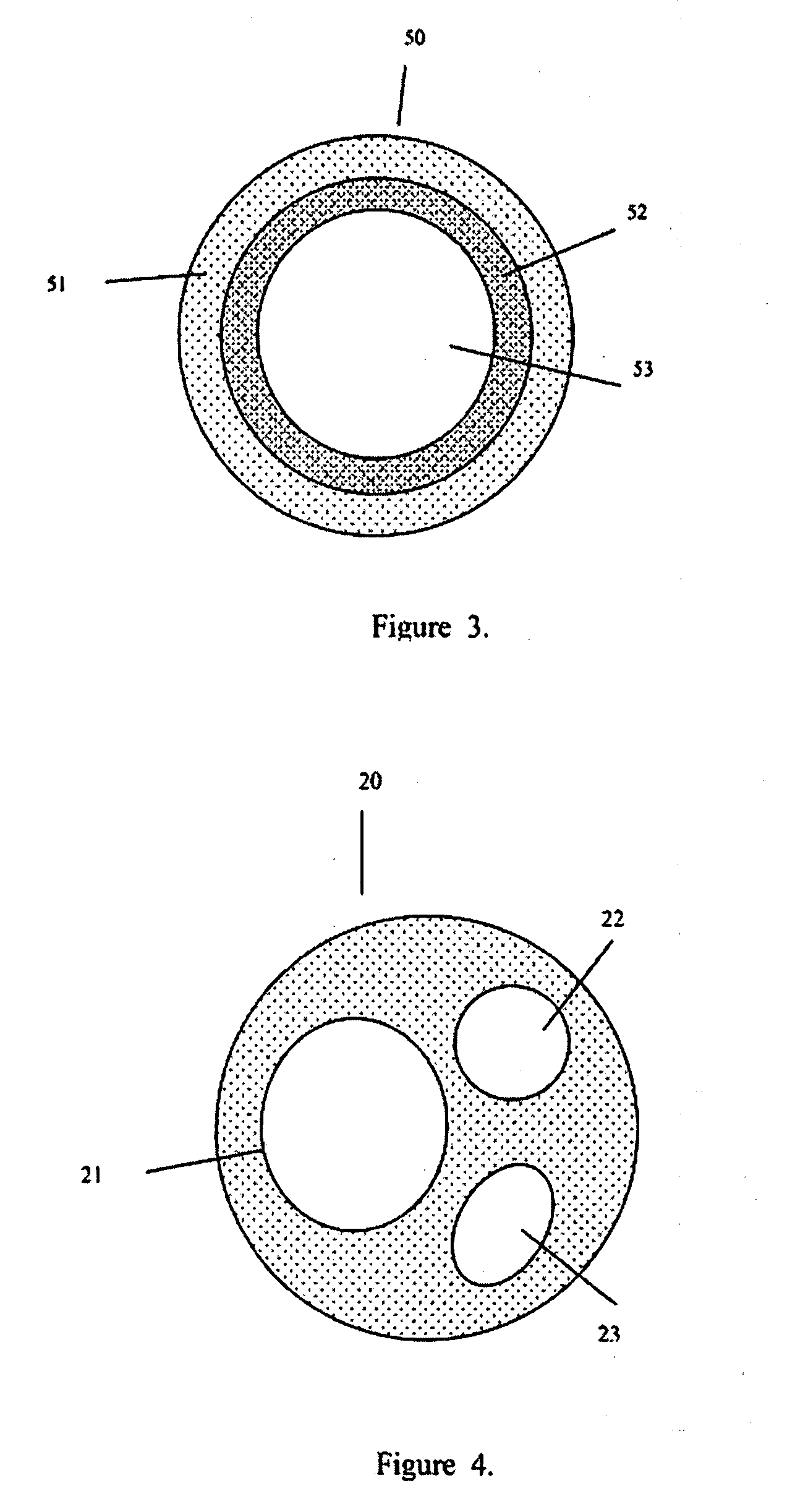

Preparation of protein microparticles by supercritical fluid precipitation

InactiveUS6063910AUniform and fine particle sizePowder deliveryPeptide/protein ingredientsMicroparticleSolvent

The present invention comprises passing a solution of a soluble material, preferably a protein, in a solvent through a continuum of supercritical antisolvent fluid and precipitating the soluble material. This can be conducted by passing the solution through the continuum of supercrital fluid in the form of droplets, which can be sprayed through the supercritical fluid. The plurality of droplets can be passed cocurrently or countercurrently with respect to a stream of antisolvent fluid. Alternatively, the solution can be passed through the continuum of supercritical antisolvent fluid in the form of a thin film or a plurality of fine streams.

Owner:THE TRUSTEES FOR PRINCETON UNIV

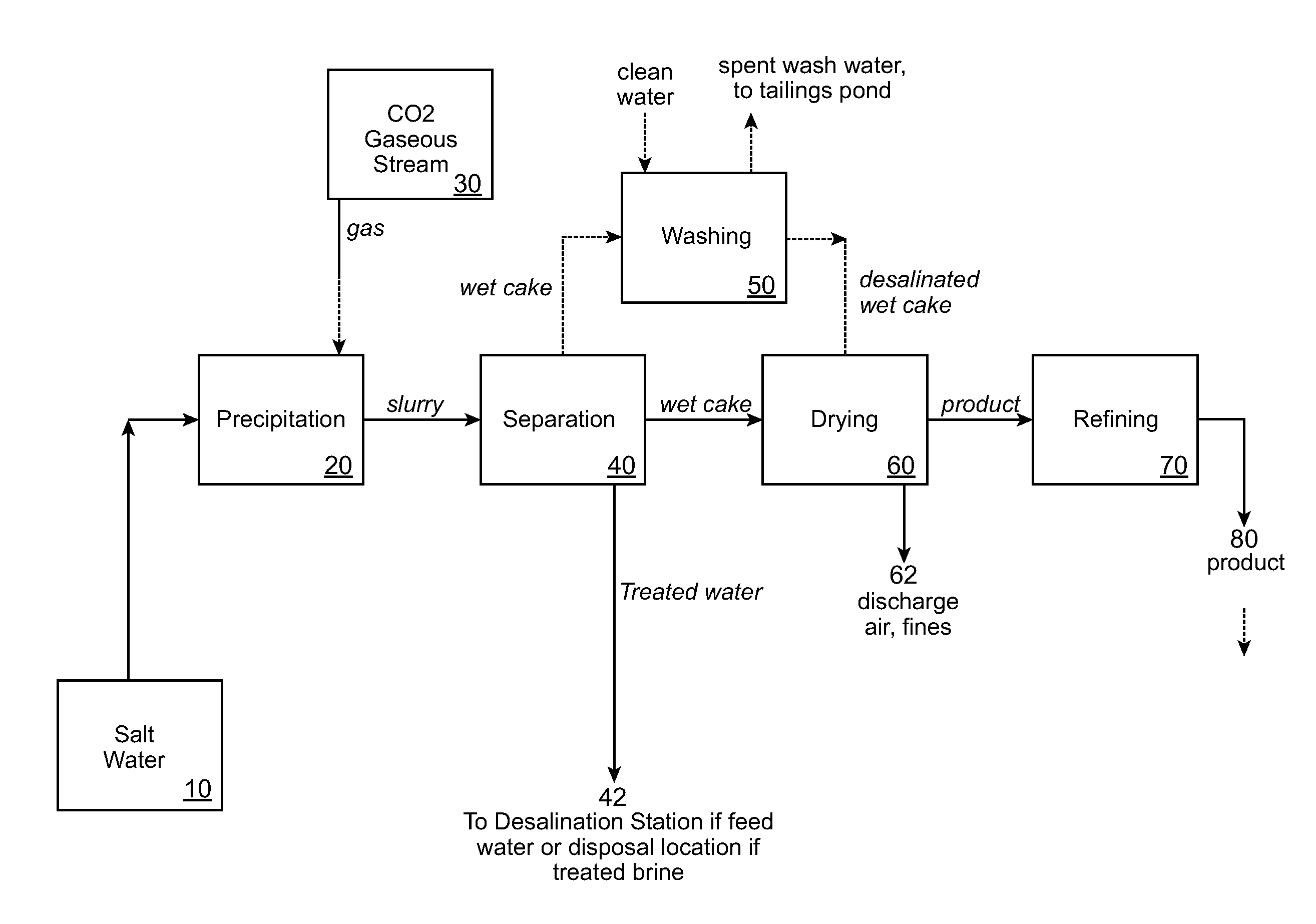

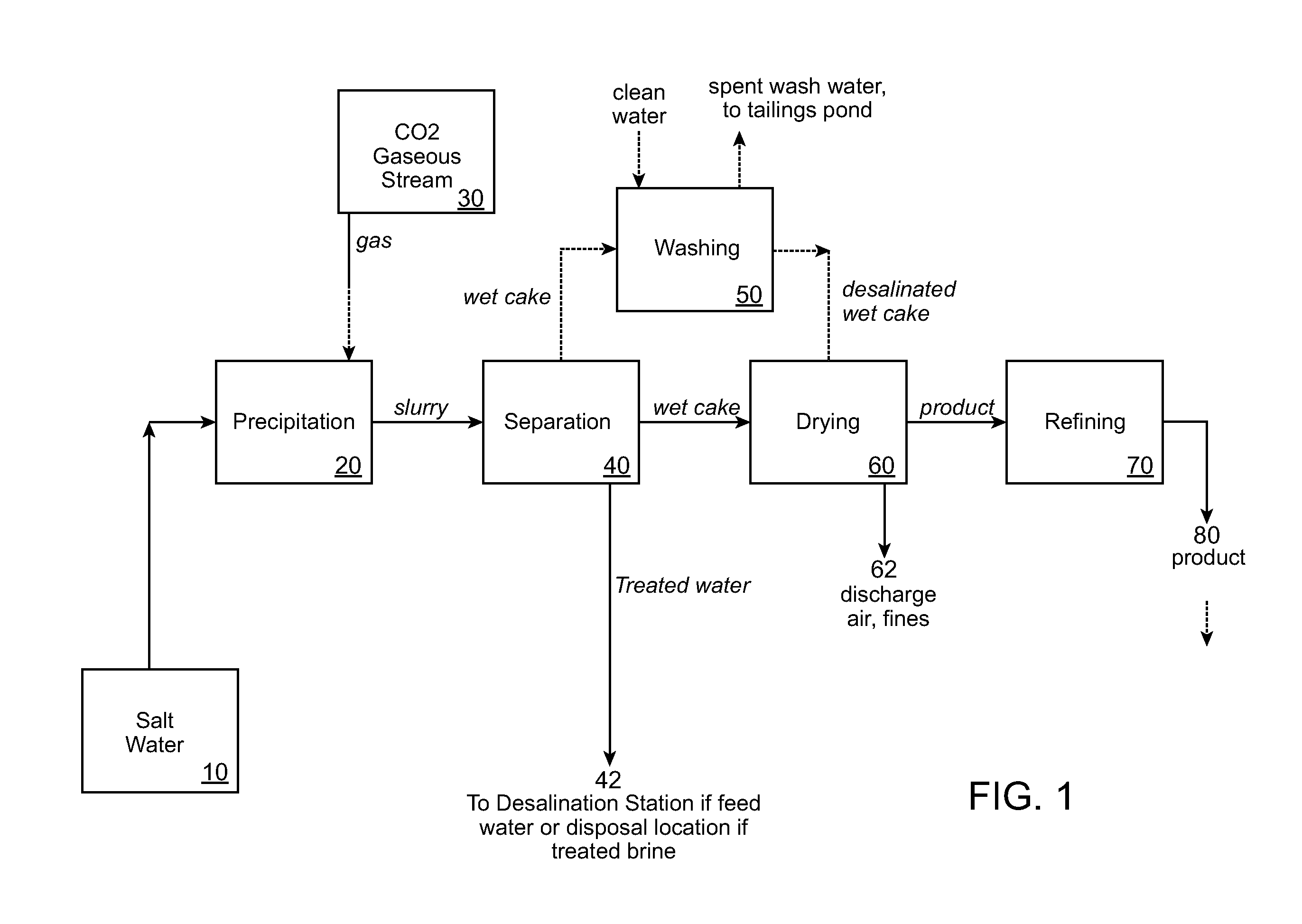

Desalination methods and systems that include carbonate compound precipitation

ActiveUS20090001020A1Easy complianceImprove desalination efficiencyGeneral water supply conservationSeawater treatmentSaline waterDesalination

Desalination methods that include carbonate compound precipitation are provided. In certain embodiments, feed water is subjected to carbonate compound precipitation conditions prior to desalination. In certain embodiments, desalination waste brine is subjected to carbonate compound precipitation conditions. In yet other embodiments, both feed water and waste brine are subjected to carbonate compound precipitation conditions. Aspects of embodiments of the invention include carbone dioxide sequestration. Embodiments of the invention further employ a precipitate product of the carbonate compound precipitation conditions as a building material, e.g., a cement. Also provided are systems configured for use in methods of the invention.

Owner:ARELAC INC

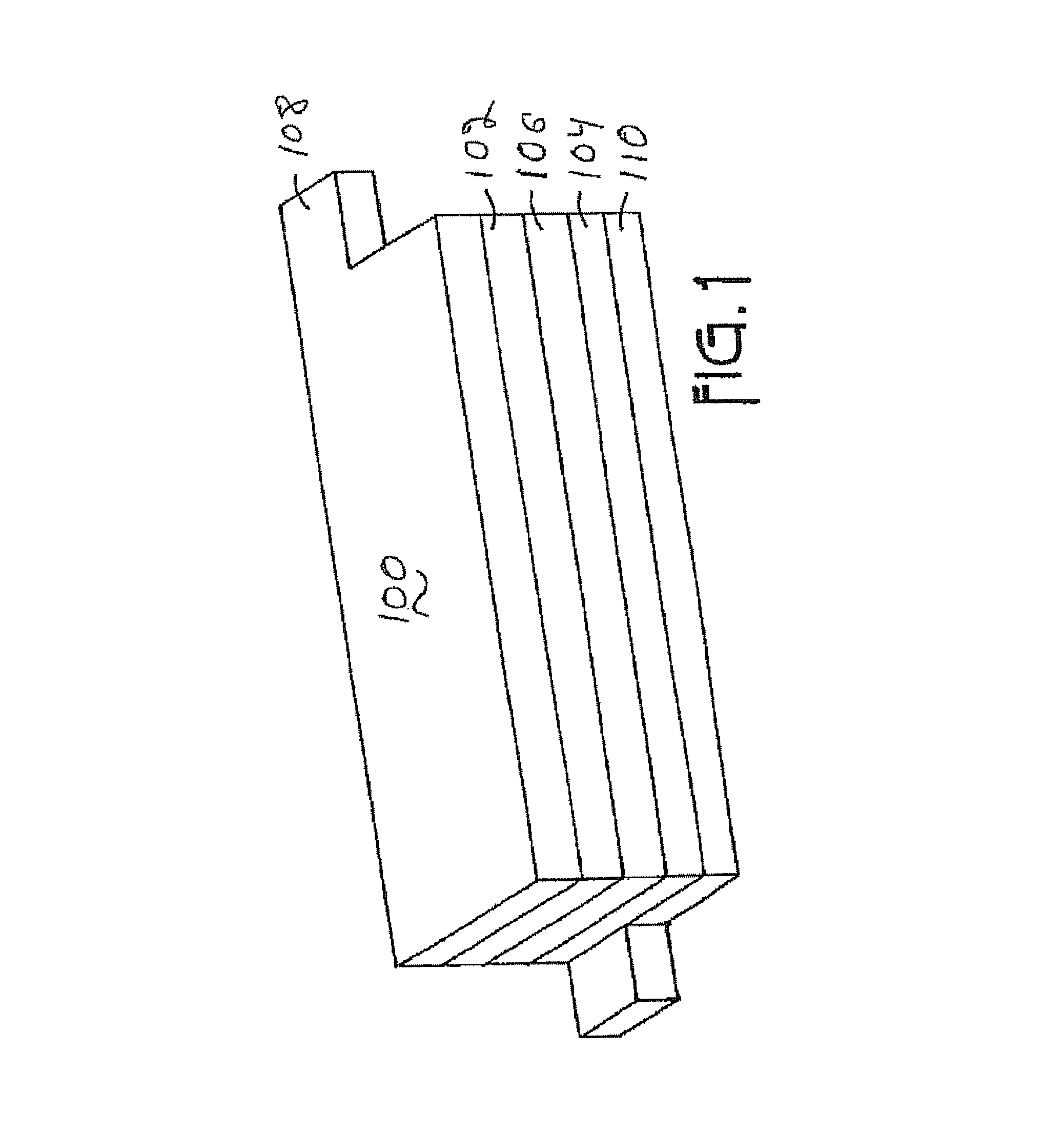

Positive electrode materials for lithium ion batteries having a high specific discharge capacity and processes for the synthesis of these materials

ActiveUS20100086853A1Electrode manufacturing processesAlkali metal oxidesDischarge rateLithium-ion battery

Owner:IONBLOX INC

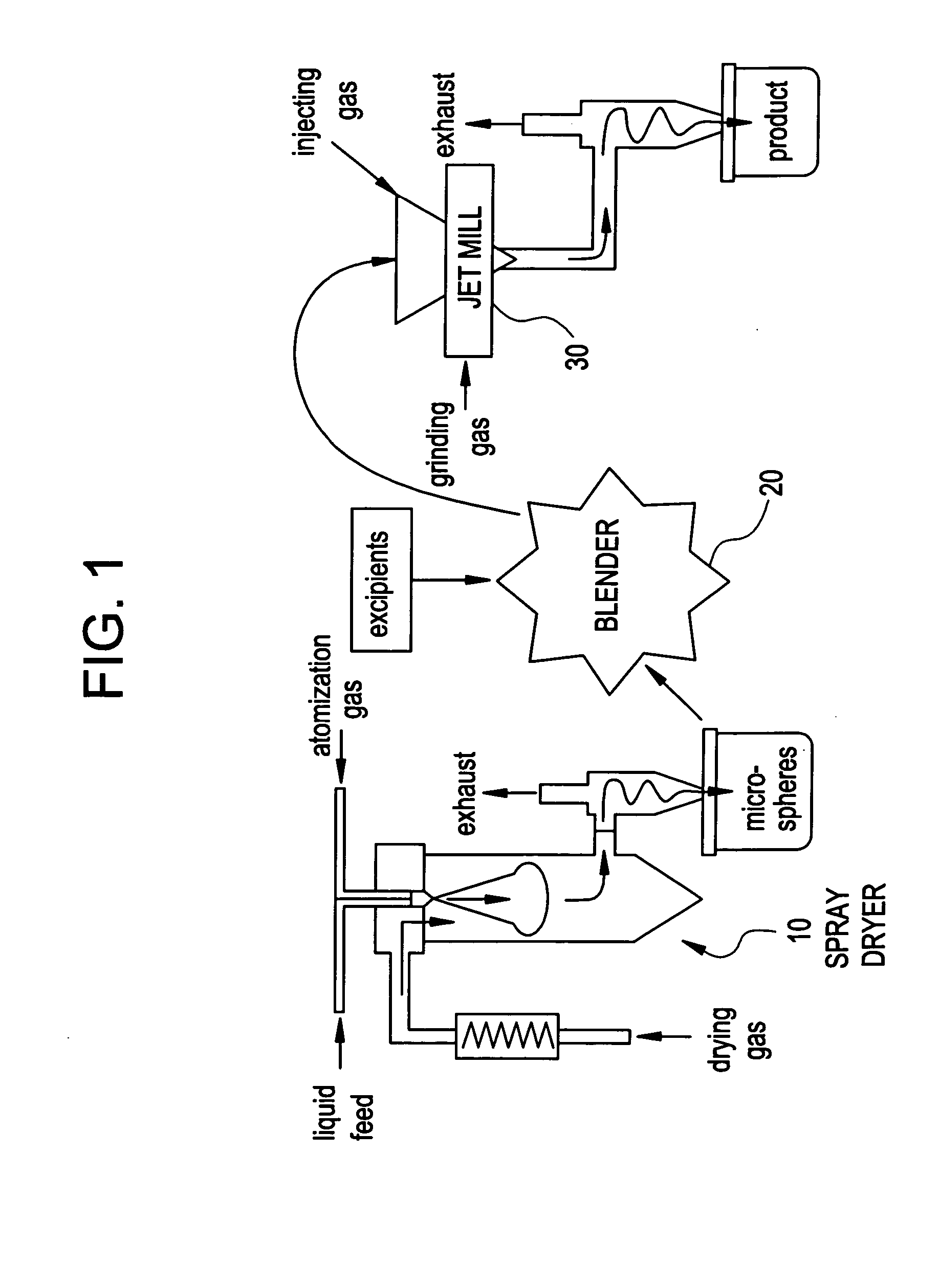

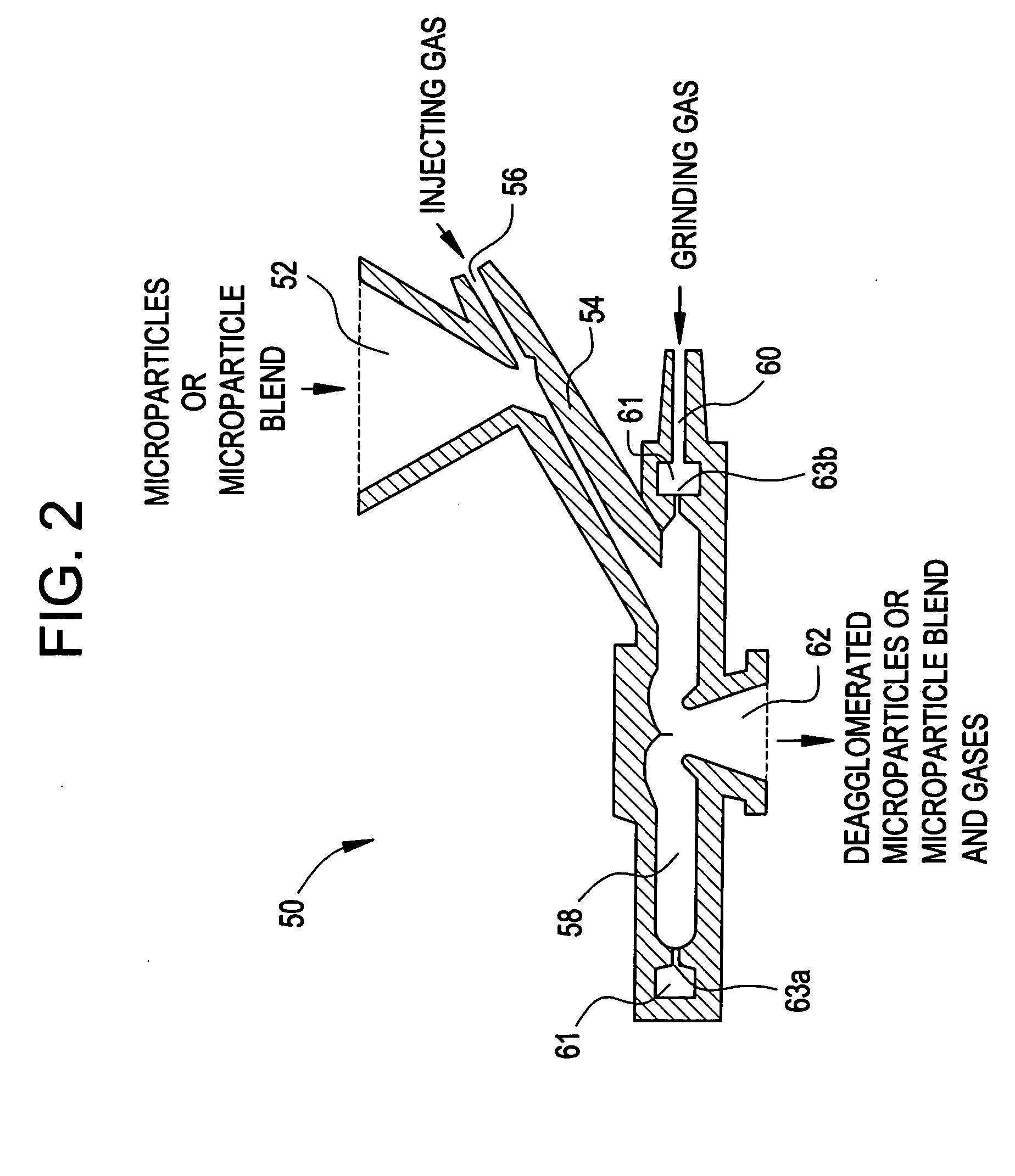

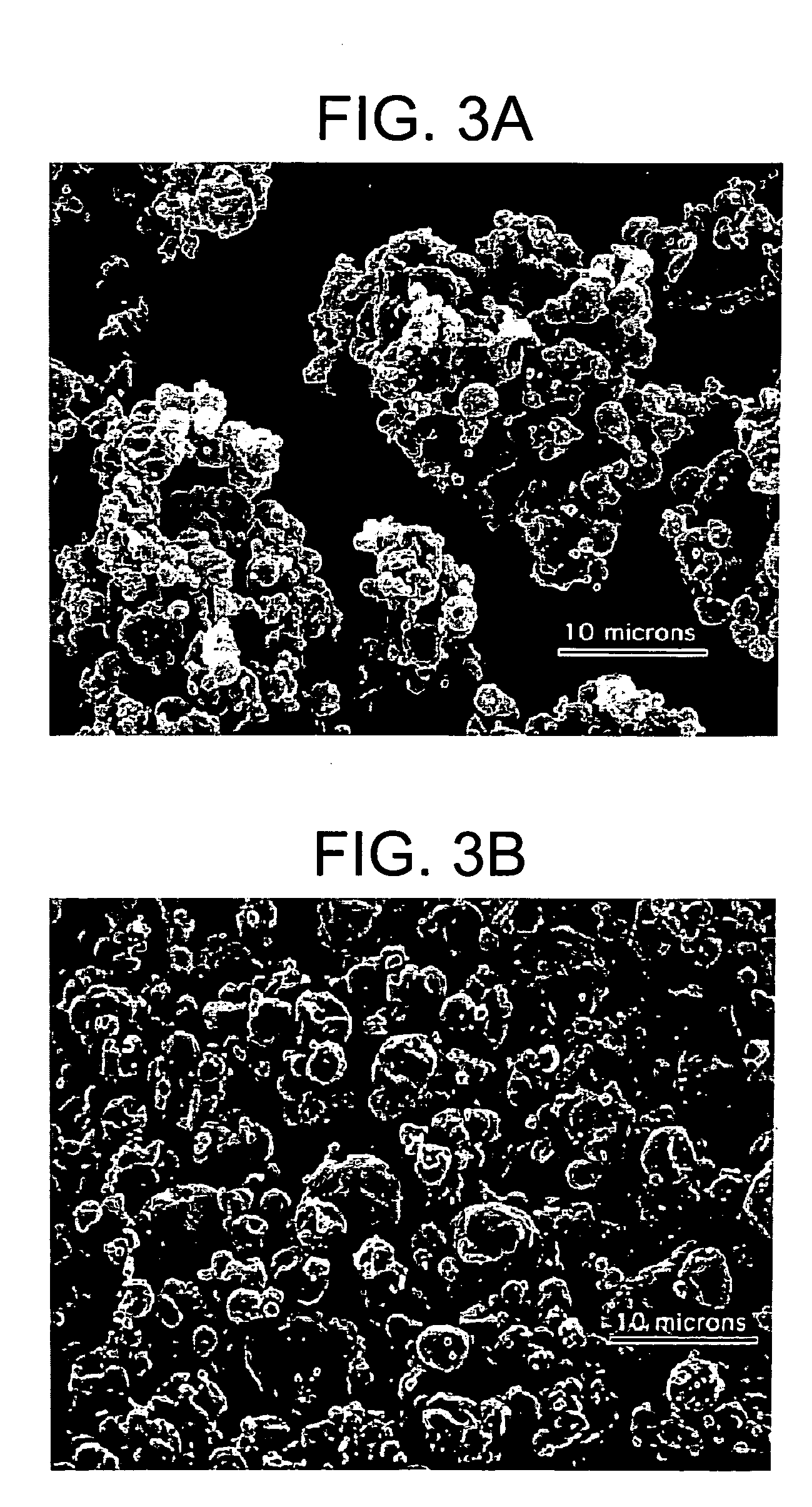

Methods for making pharmaceutical formulations comprising microparticles with improved dispersibility, suspendability or wettability

InactiveUS20050079138A1Good dispersibilityImproved suspendabilityPowder deliveryGranulation by liquid drop formationPowder mixtureMicroparticle

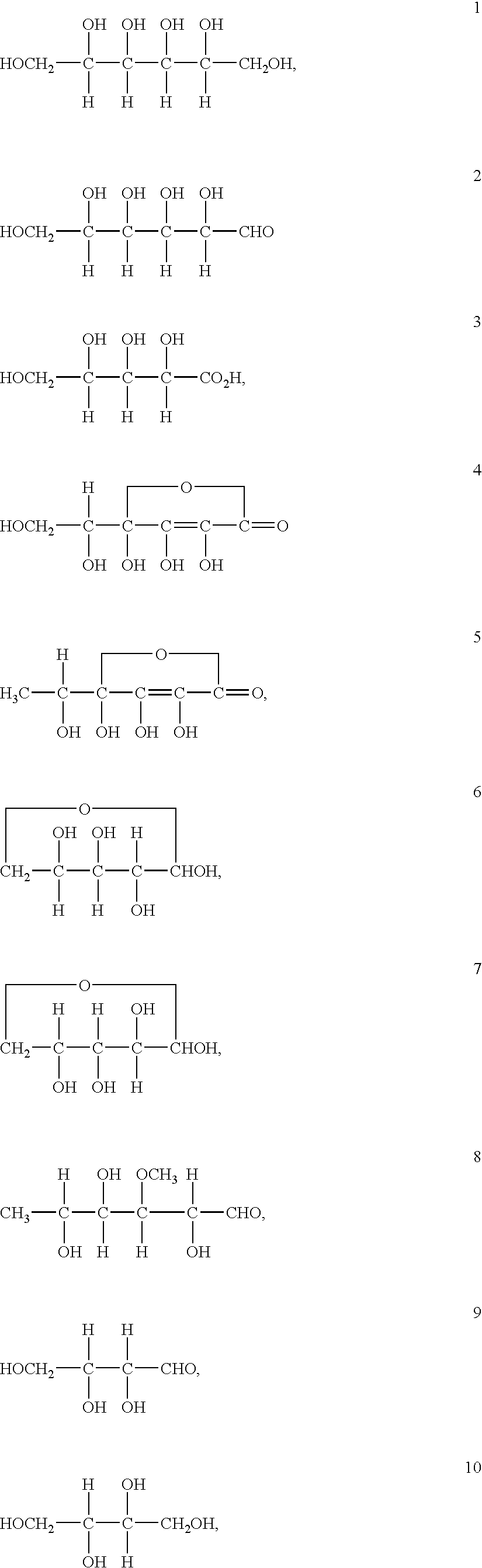

Methods are provided for making a dry powder blend pharmaceutical formulation, comprising the steps of: (a) providing microparticles which comprise a pharmaceutical agent; (b) blending the microparticles with at least one excipient in the form of particles to form a powder blend; and (c) jet milling the powder blend to form a dry powder blend pharmaceutical formulation having improved dispersibility, suspendability, or wettability as compared to the microparticles of step (a) or the powder blend of step (b). The method can further include dispersing the dry powder blend pharmaceutical formulation in a liquid pharmaceutically acceptable vehicle to make an formulation suitable for injection. Alternatively, the method can further include processing the dry powder blend pharmaceutical formulation into a solid oral dosage form. In one embodiment, the microparticles of step (a) are formed by a solvent precipitation or crystallization process.

Owner:ACUSPHERE INC

Stabilized vanadium electrolyte solutions for all-vanadium redox cells and batteries

InactiveUS6562514B1Effective amountEasy to modifyFinal product manufactureRegenerative fuel cellsRedoxPhysical chemistry

Owner:JD HLDG INC

Production of Soluble Protein Solutions from Soy ("S701")

ActiveUS20100098818A1Prevent oxidationMilk preparationProtein composition from vegetable seedsProtein solutionSports drink

A soy protein product, which may be an isolate, produces transparent heat-stable solutions at low pH values and is useful for the fortification of soft drinks and sports drinks without precipitation of protein. The soy protein product is obtained by extracting a soy protein source material with an aqueous calcium salt solution to form an aqueous soy protein solution, separating the aqueous soy protein solution from residual soy protein source, adjusting the pH of the aqueous soy protein solution to a pH of about 1.5 to about 4.4 to produce an acidified clear soy protein solution, which may be dried, following optional concentration and diafiltration, to provide the soy protein product.

Owner:BURCON NUTRASCI MB

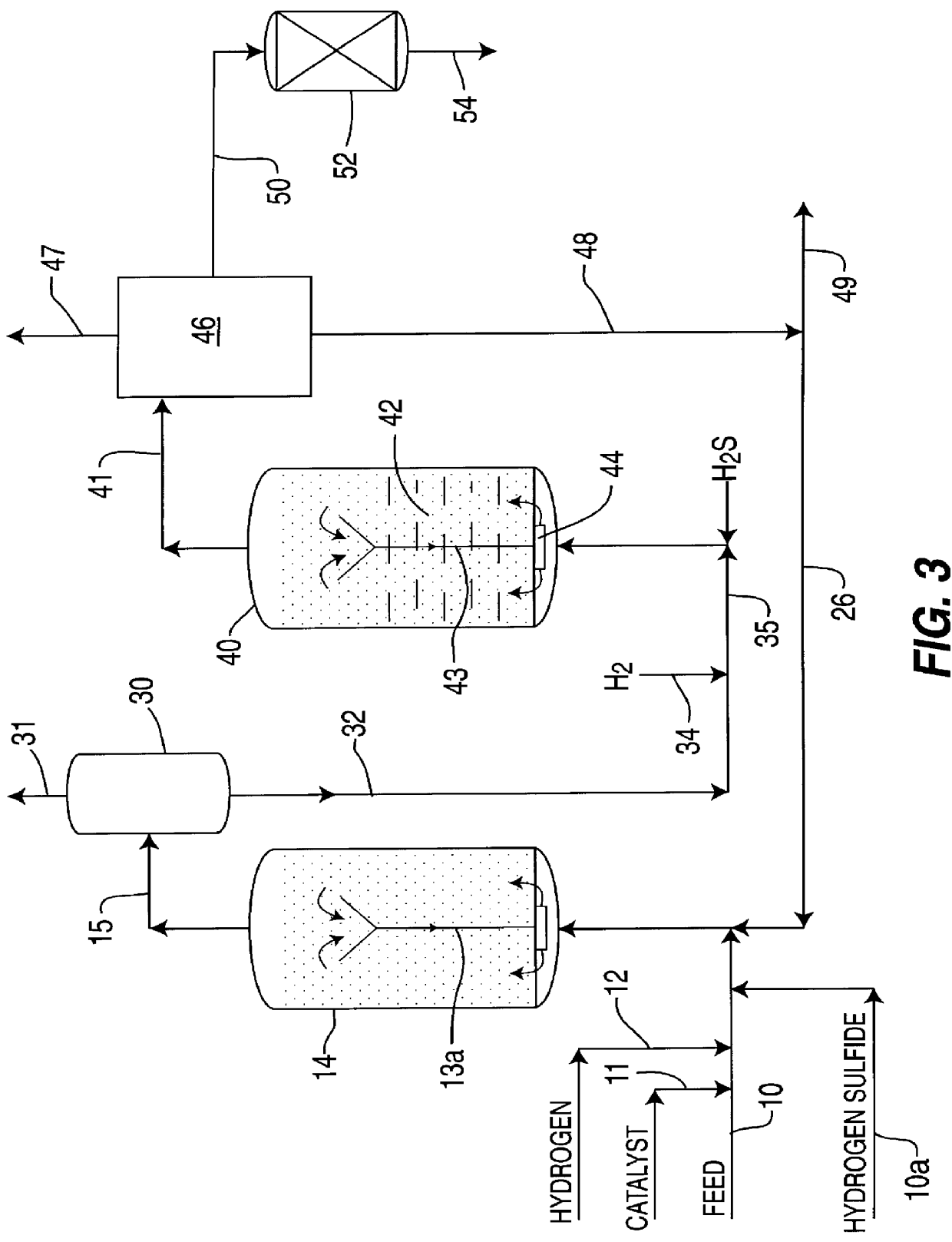

Iron-based ionic liquid catalysts for hydroprocessing carbonaceous feeds

InactiveUS6139723AIncrease hydrocracking ability of catalystIndirect and direct heating destructive distillationCatalyst activation/preparationLiquid productIron salts

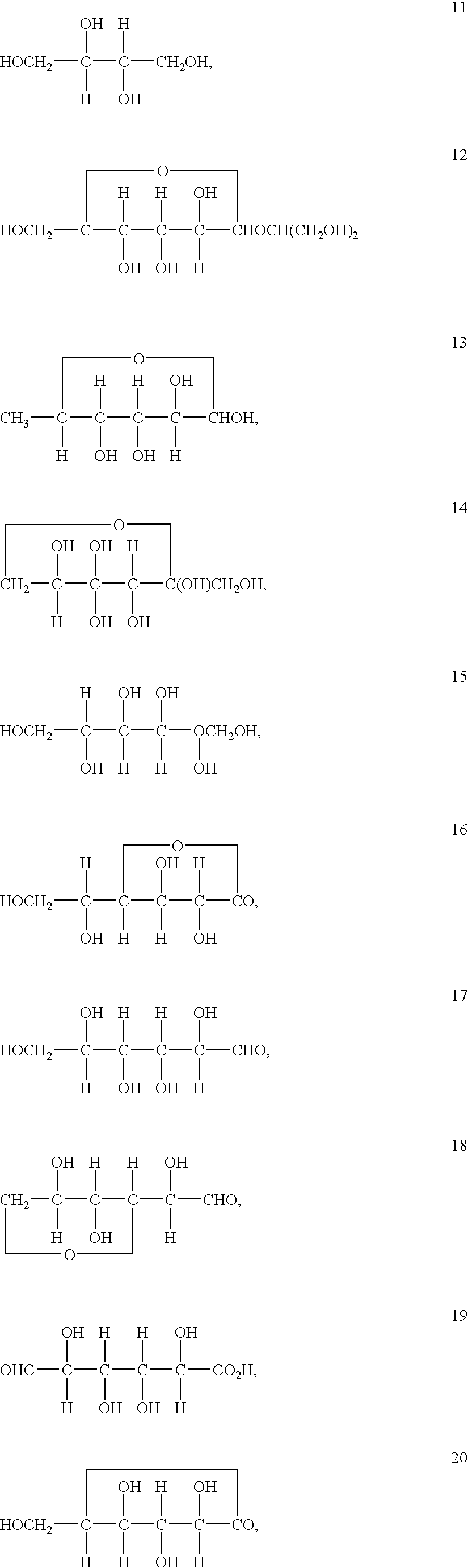

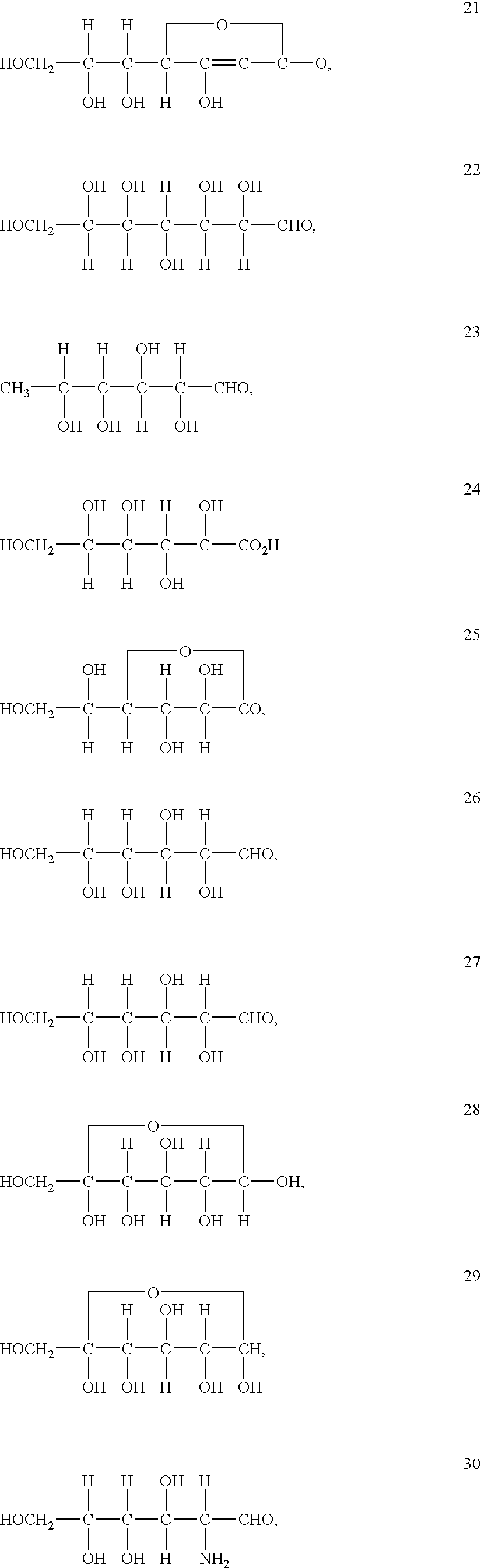

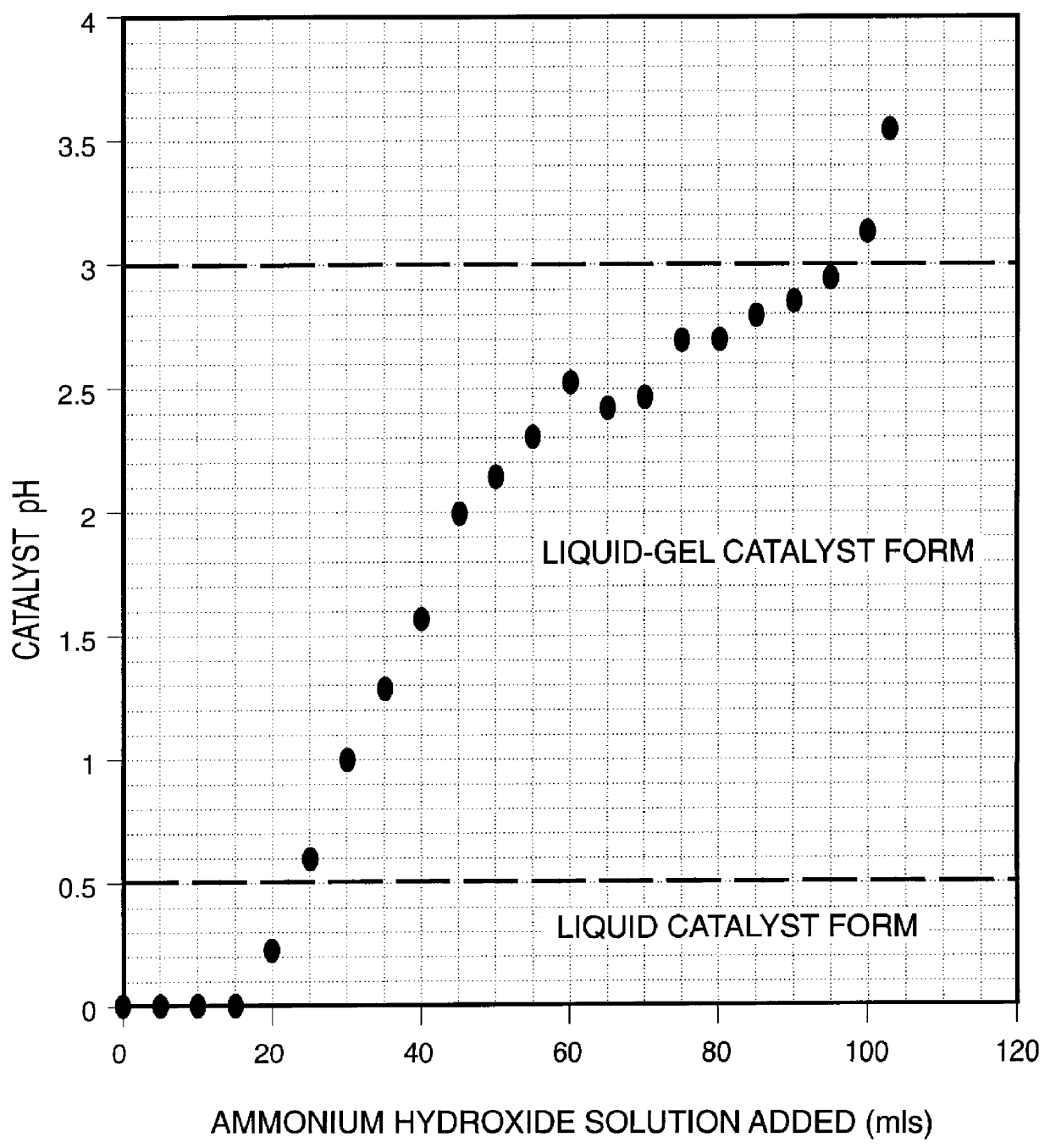

A highly dispersed iron-based ionic liquid or liquid-gel catalyst which may be anion-modified and metals-promoted has high catalytic activity, and is useful for hydrocracking / hydrogenation reactions for carbonaceous feed materials. The catalyst is produced by aqueous precipitation from saturated iron salt solutions such as ferric sulfate and ferric alum, and may be modified during preparation with anionic sulfate (SO42-) and promoted with small percentages of at least one active metal such as cobalt, molybdenum, palladium, platinum, nickel, or tungsten or mixtures thereof. The resulting catalyst may be used in a preferred ionic liquid form or in a liquid-gel form, and either fluidic form can be easily mixed and reacted with carbonaceous feed materials such as coal, heavy petroleum fractions, mixed plastic waste, or mixtures thereof. The invention includes methods for making the ionic liquid or liquid-gel catalyst, and processes for using the fluidic catalysts for hydroprocessing the carbonaceous feed materials to produce desirable low-boiling hydrocarbon liquid products.

Owner:HEADWATERS CTL

Method for producing carbon coated nano stage lithium iron phosphate by precipitation

InactiveCN101393982AAvoid synthetic stepsEasy to controlElectrode manufacturing processesIron saltsPhosphate

The invention discloses a precipitation method for preparing nanometer level iron phosphate lithium coated with carbon. The method comprises the following steps: firstly, weighing iron salt, deionized water and a compound of metallic elements; after the stirring and the mixing are performed, adding a phosphorous compound and citric acid diluted with water to the mixture; after the stirring is performed again, adding a precipitation agent to the mixture and controlling to the neutrality; stirring to react in a container, and after the static placement, respectively adding the deionized water, a carbon source and lithium salt to mix uniformly after the precipitate is filtered and washed; stirring again to react, and drying the water at 30 to 160 DEG C and warming up at the heating rate under the protection of non-oxidized gas after a product is crashed; baking at a constant temperature of 450 to 850 DEG C, cooling down to a room temperature at a cooling rate or with a stove, and finally obtaining the nanometer level ferric phosphate lithium coated with the carbon after crashing is performed. The precipitation method has the advantage that the raw material cost and the processing cost are low because bivalent iron is taken as the raw material. The iron phosphate lithium prepared by using the process has the characteristics of good physical processing performance and good electrochemistry performance, and is suitable for industrialized production.

Owner:南京海泰纳米材料有限公司

Method of producing effective bacterial cellulose-containing formulations

A new method to produce formulations of bacterial cellulose that exhibit improved viscosity-modifying properties particularly with low energy applied to effectuate viscosity changes therewith is provided. Such a method includes the novel co-precipitation with a water soluble co-agent that permits precipitation in the presence of excess alcohol to form an insoluble fiber that can than be utilized as a thickener or suspension aid without the need to introduce high energy mixing. Such bacterial cellulose properties have been available in the past but only through highly labor and energy intensive processes. Such an inventive method as now proposed thus provides a bacterial cellulose-containing formulation that exhibits not only properties that are as effective as those for previous bacterial celluloses, but, in some ways, improvements to such previous types. Certain end-use compositions and applications including these novel bacterial cellulose-containing formulations are also encompassed within this invention.

Owner:CP KELCO U S INC

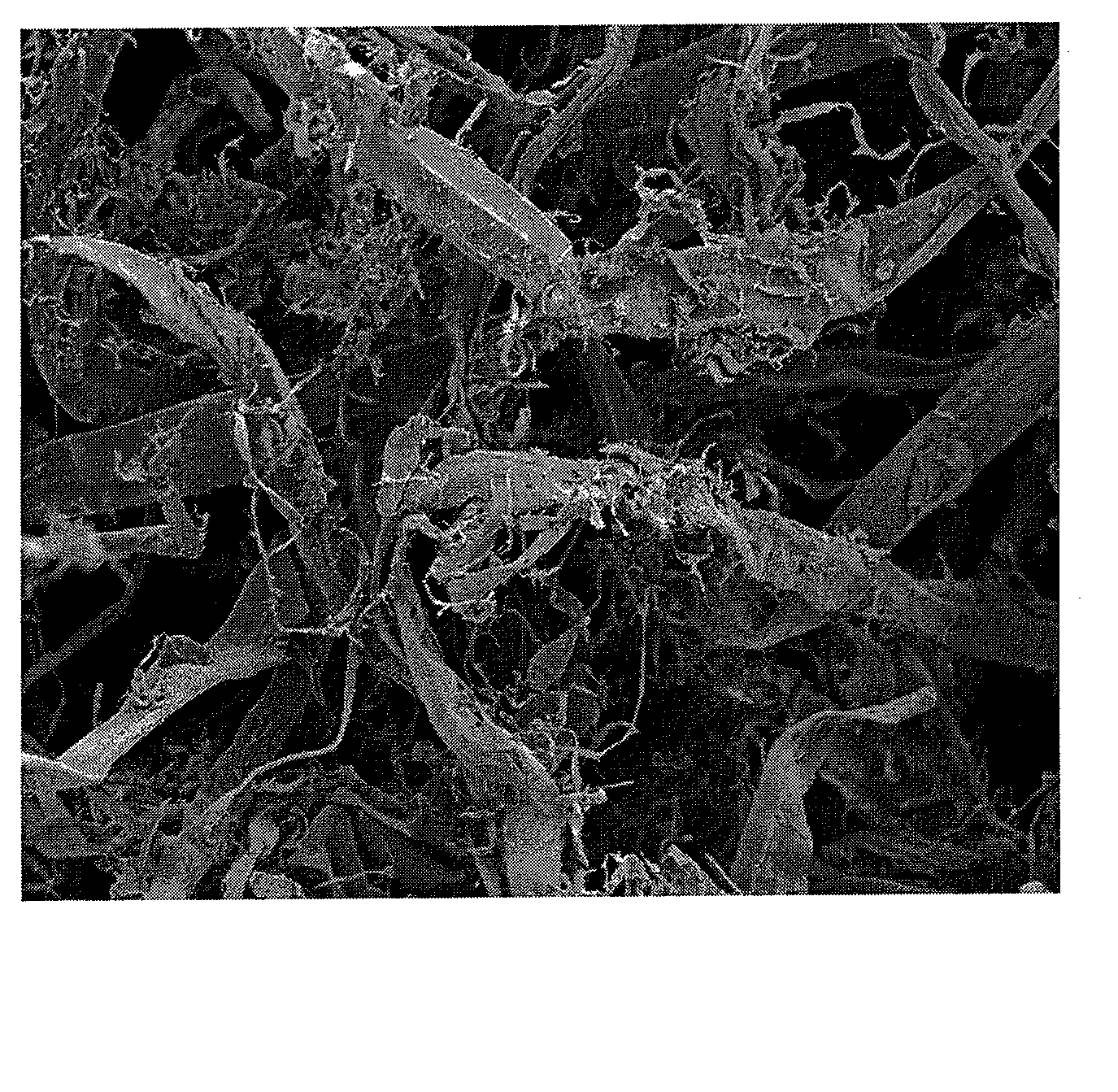

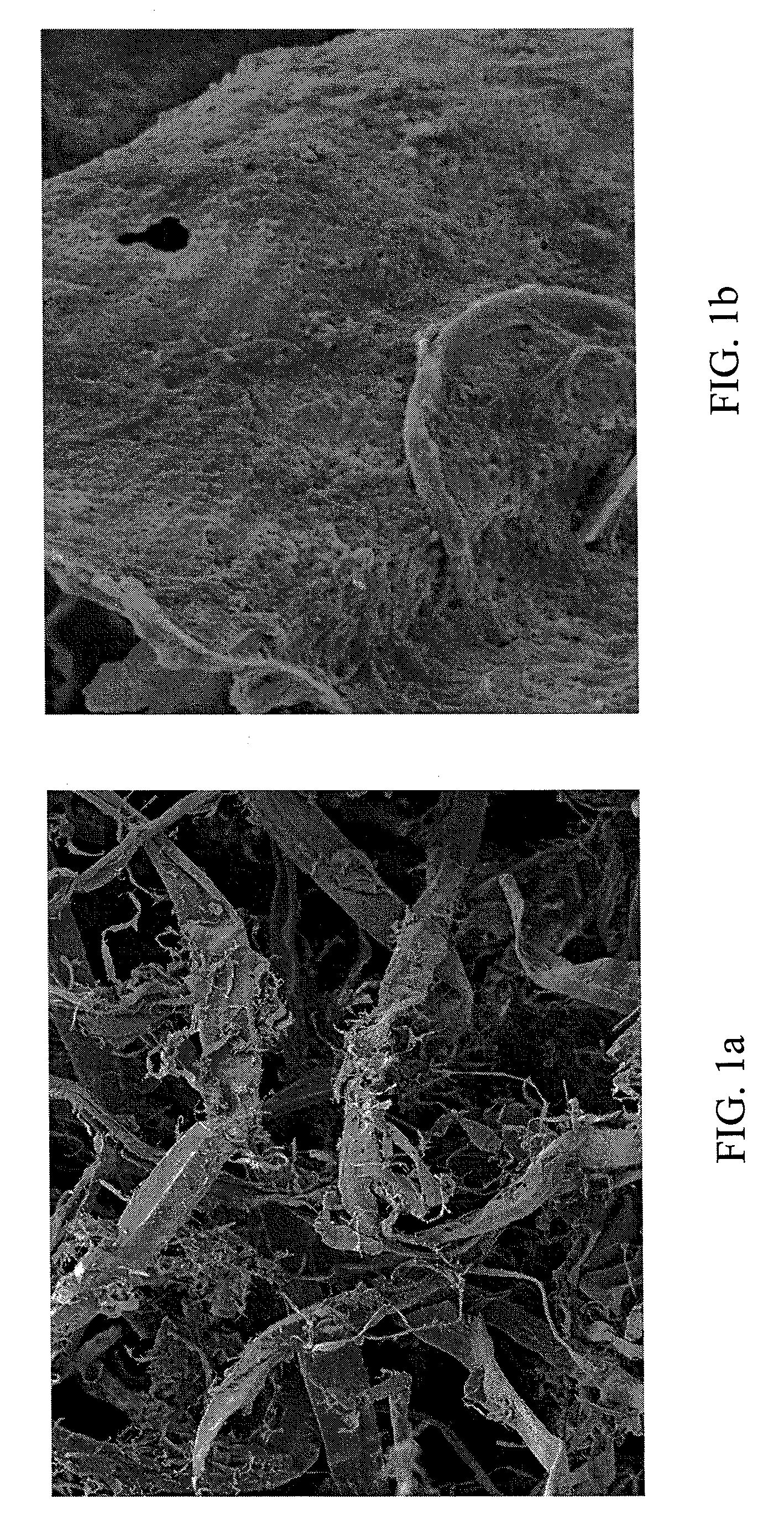

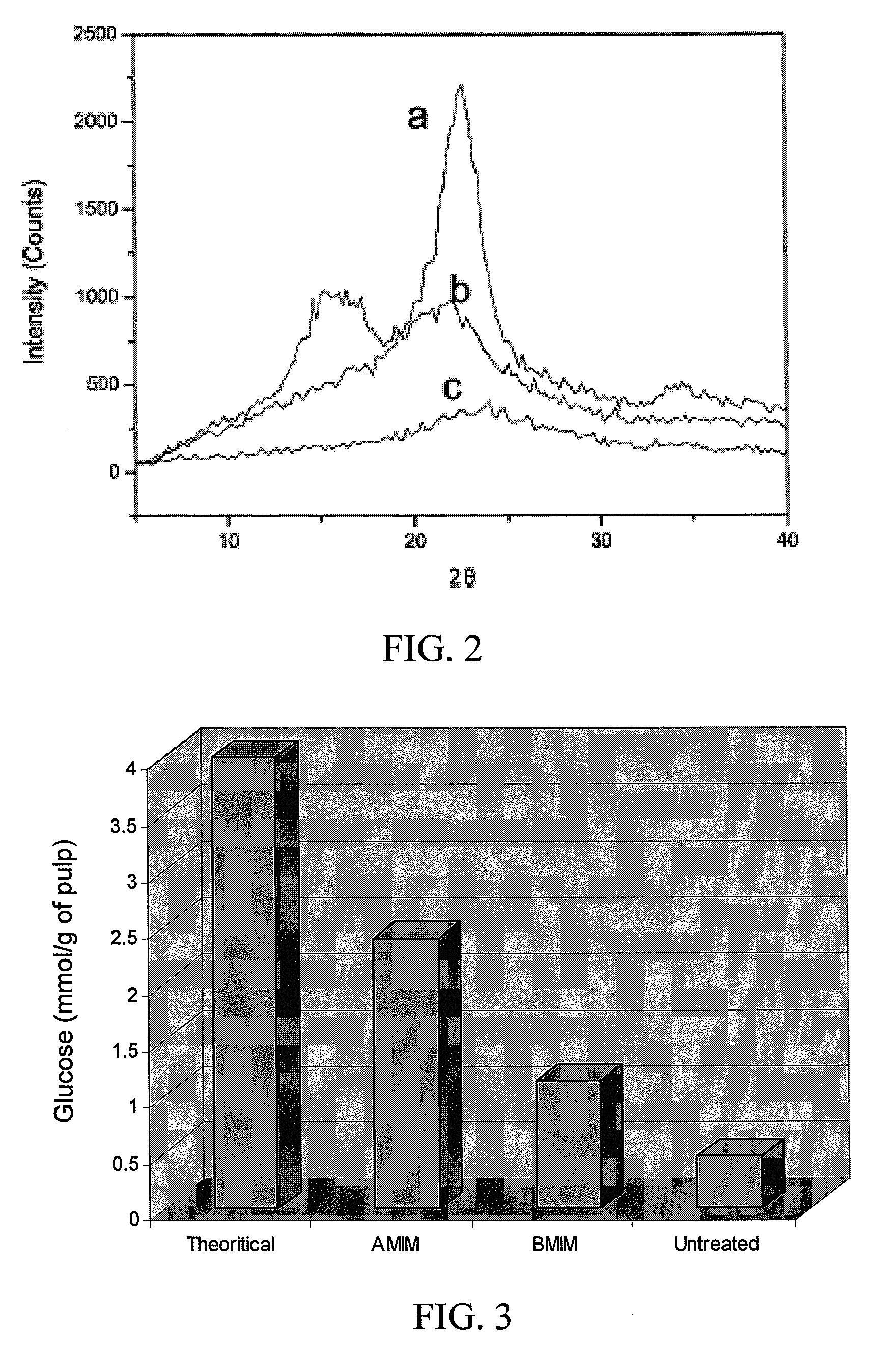

Use of lignocellulosics solvated in ionic liquids for production of biofuels

InactiveUS20080190013A1Guaranteed economic efficiencyReduced availabilityCellulosic pulp after-treatmentSugar productsBiofuelEvaporation

The present invention provides a method for converting lignocellulosic material into biofuel. In particular embodiments, the method comprises pre-treating lignocellulosic material by dissolving the material in ionic liquids. The pretreated lignocellulosic material can be isolated, such as by precipitation with a regenerating solvent (e.g., water), and be used directly in the formation of biofuel, including undergoing hydrolysis to form sugar and fermentation to form fuel, such as bioethanol. The ionic liquid can be recycled for further use, such as by evaporation of the water introduced during precipitation, and the recycling provides a route to a hemicellulose rich fraction and an ionic liquid of consistent quality and wood dissolution characteristics. The recovered hemicelluloses are of significant utilization potential toward commodity and specialty applications.

Owner:NORTH CAROLINA STATE UNIV

Reagent dispensing valve

A reagent dispensing valve particularly adapted for dispensing precise microfluidic quantities of fluids. The valve includes a valve portion and a solenoid actuator that are in fluid isolation from one another. The valve portion includes a plunger and seat combination and the actuator is substantially decoupled from the fluid path through the valve. The fluid path through the valve is substantially non-tortuous, thereby minimizing localized fluid pressure drops, and hence undesirable gaseous bubble precipitation within the fluid. The valve is also configured to substantially prevent bubble accumulation. The valve can further include a bubble trap for trapping and removing bubbles.

Owner:BIODOT

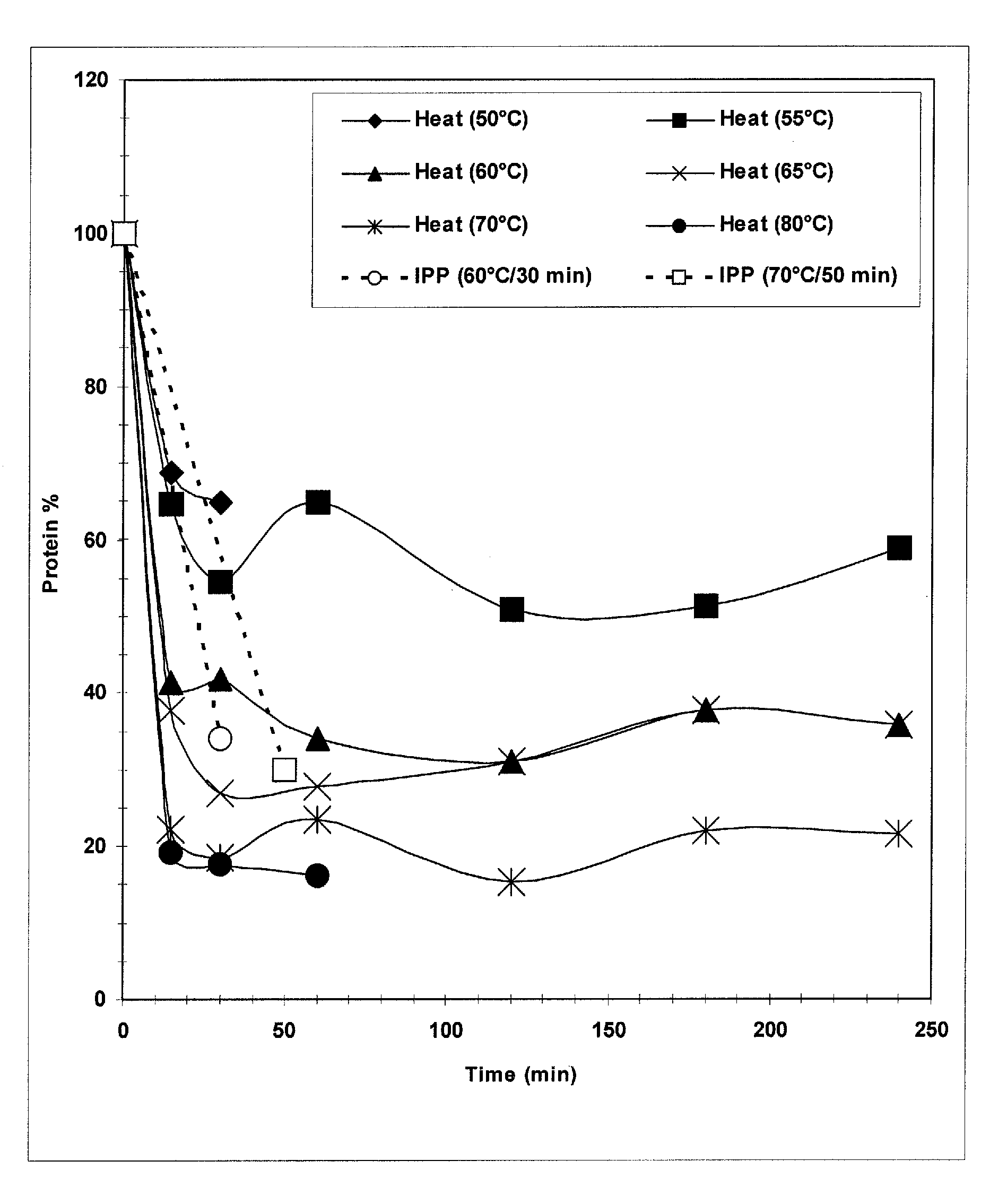

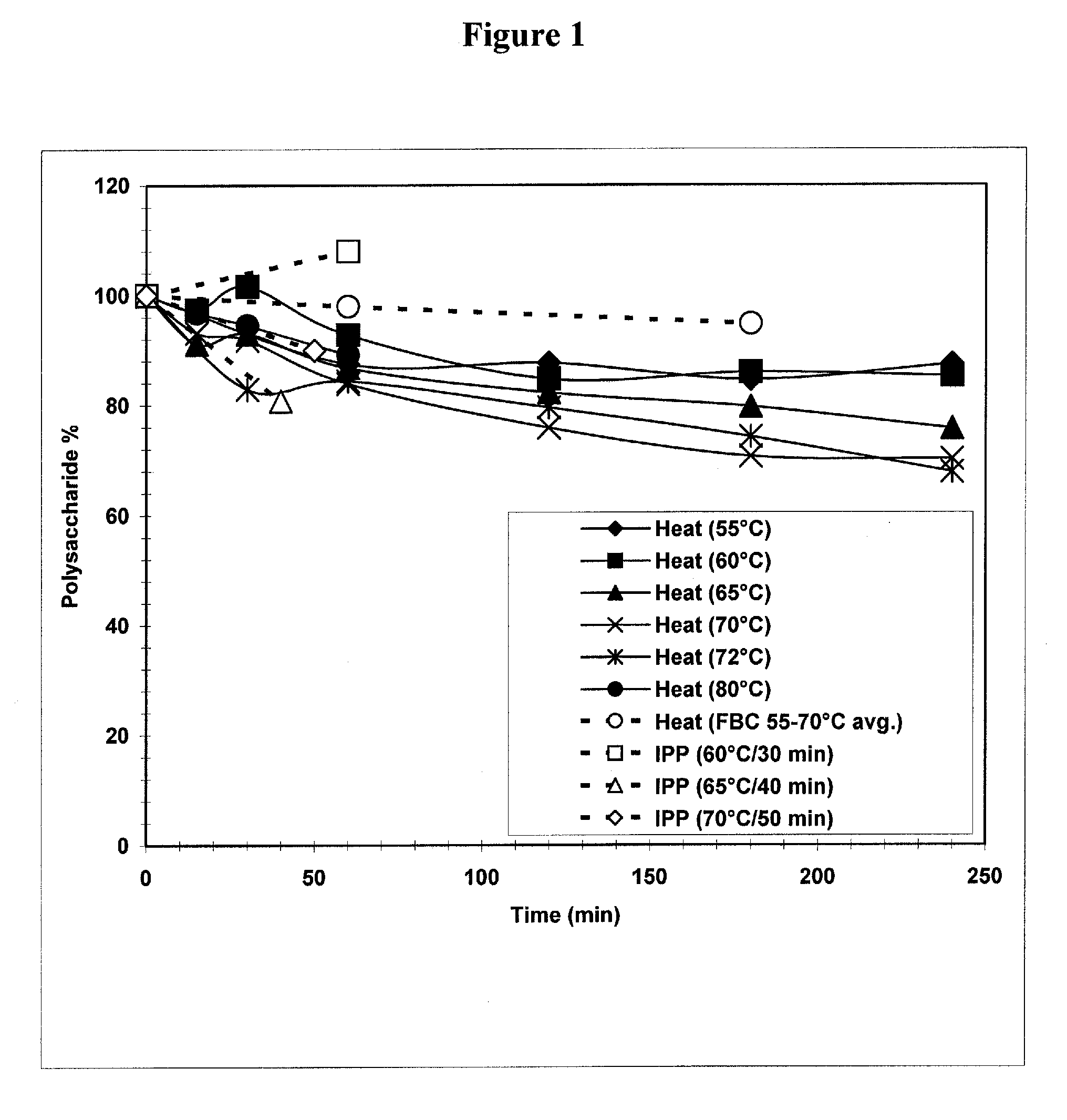

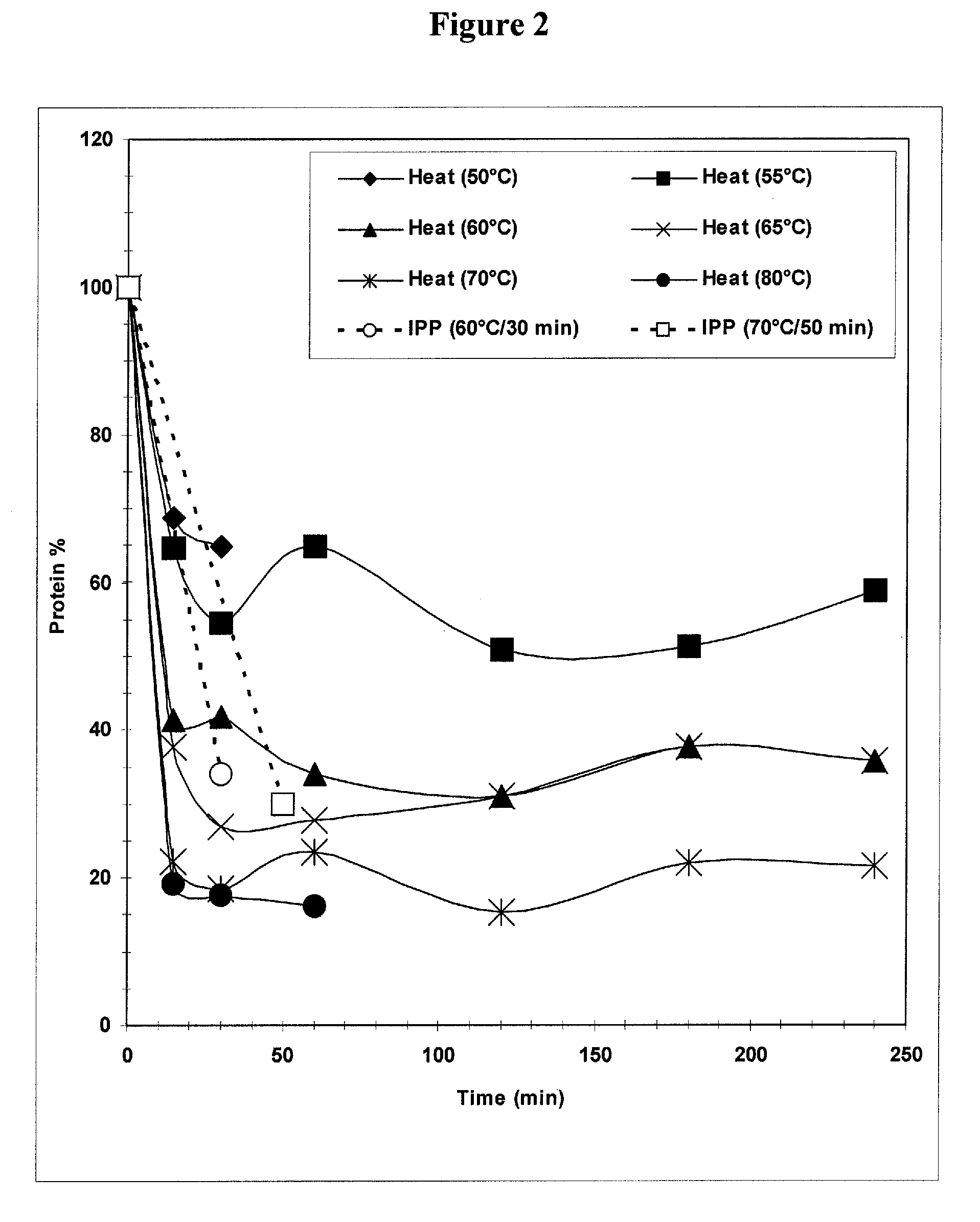

Methods for the separation of streptococcus pneumoniae type 3 polysaccharides

ActiveUS20080102498A1Reducing and removing impurityImprove filtering effectAntibacterial agentsOrganic active ingredientsStreptococcus pneumoniaeLysis

The present invention provides improved methods for the reduction or removal of protein impurities from a complex cellular Streptococcus pneumoniae lysate or centrate comprising serotype 3 polysaccharides involving steps relating to post-lysis heating or pH adjustment. In certain methods, the lysate is heated for a time and at a temperature sufficient to denature proteins present in the lysate and cause their aggregation and precipitation. In one embodiment, the lysate is heated to at least 60° C. for at least 30 minutes to cause protein aggregation and precipitation, more particularly about 60° C. to about 70° C. for about 30 to about 50 minutes, and even more particularly about 65° C. for about 40 minutes. In other methods, the pH of the lysate or centrate is increased to at least 8.0 to improve filterability, more particularly about 8.0 to 8.4, and even more particularly about 8.2. In further methods, heating and pH adjustment steps are combined to cause the aggregation and precipitation of proteins as well as to improve filterability of the lysates or centrates. In other methods, the pH of the lysate or centrate is lowered to about 3.0 to about 5.0 to cause protein aggregation and precipitation. Such methods allow for the production of substantially purified serotype 3 polysaccharide-containing lysates or centrates.

Owner:WYETH LLC

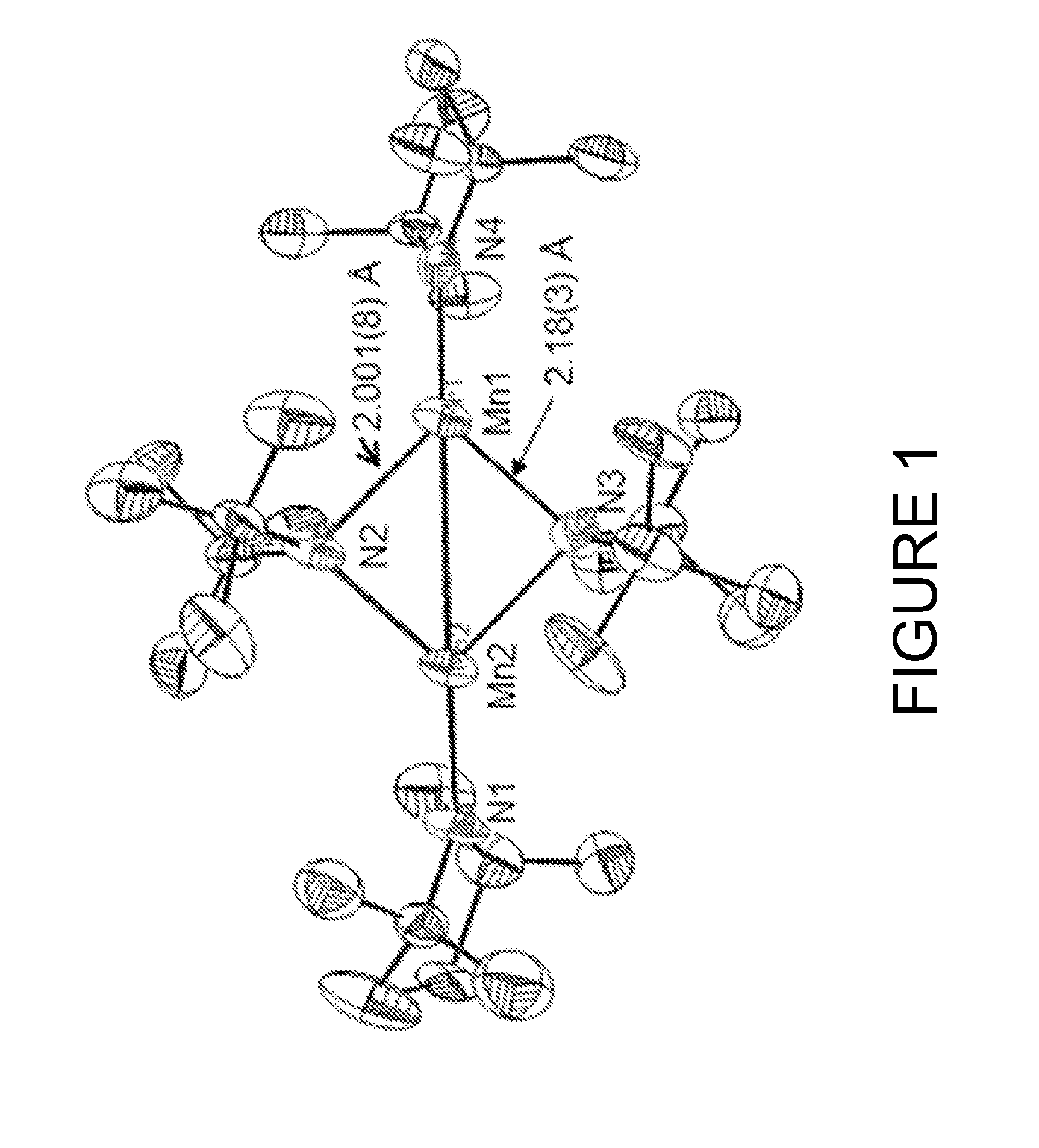

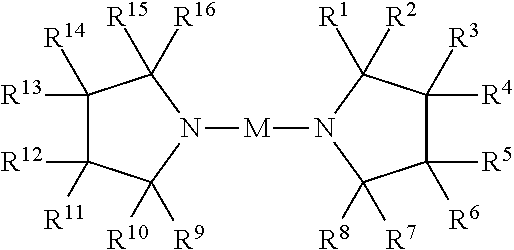

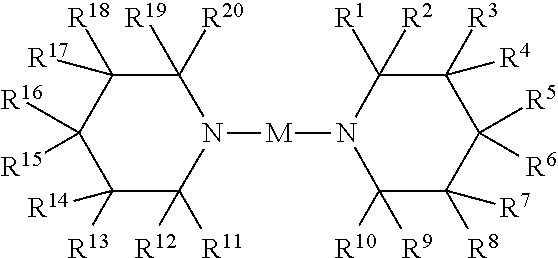

Metal amides of cyclic amines

ActiveUS20160152649A1Improve thermal stabilityImprove conductivityIron group organic compounds without C-metal linkagesNickel organic compoundsGermanideMetal silicide

Compounds, and oligomers of the compounds, are synthesized with cyclic amine ligands attached to a metal atom. These compounds are useful for the synthesis of materials containing metals. Examples include pure metals, metal alloys, metal oxides, metal nitrides, metal phosphides, metal sulfides, metal selenides, metal tellurides, metal borides, metal carbides, metal silicides and metal germanides. Techniques for materials synthesis include vapor deposition (chemical vapor deposition and atomic layer deposition), liquid solution methods (sol-gel and precipitation) and solid-state pyrolysis. Suitable applications include electrical interconnects in microelectronics and magnetoresistant layers in magnetic information storage devices. The films have very uniform thickness and high step coverage in narrow holes.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

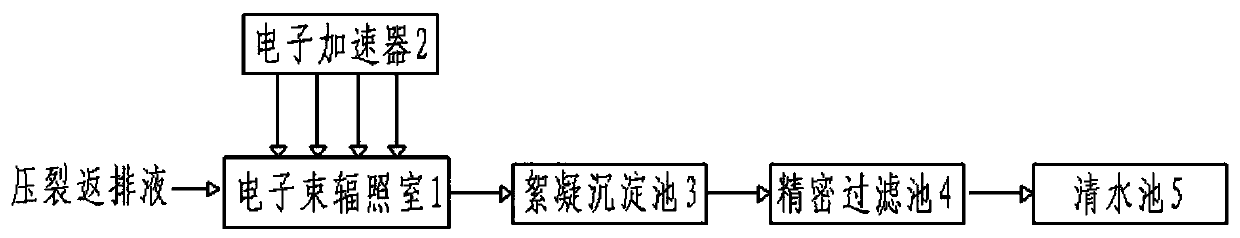

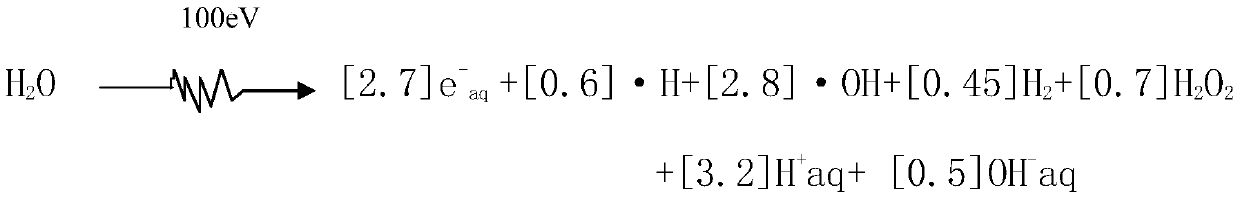

Rapid treatment method for fracturing flowback fluid

PendingCN110467298ARealize online processingLittle side effectsWaste water treatment from quariesTreatment involving filtrationFlocculationFiltration

Owner:RUIJIE ENVIRONMENTAL PROTECTION TECH CO LTD

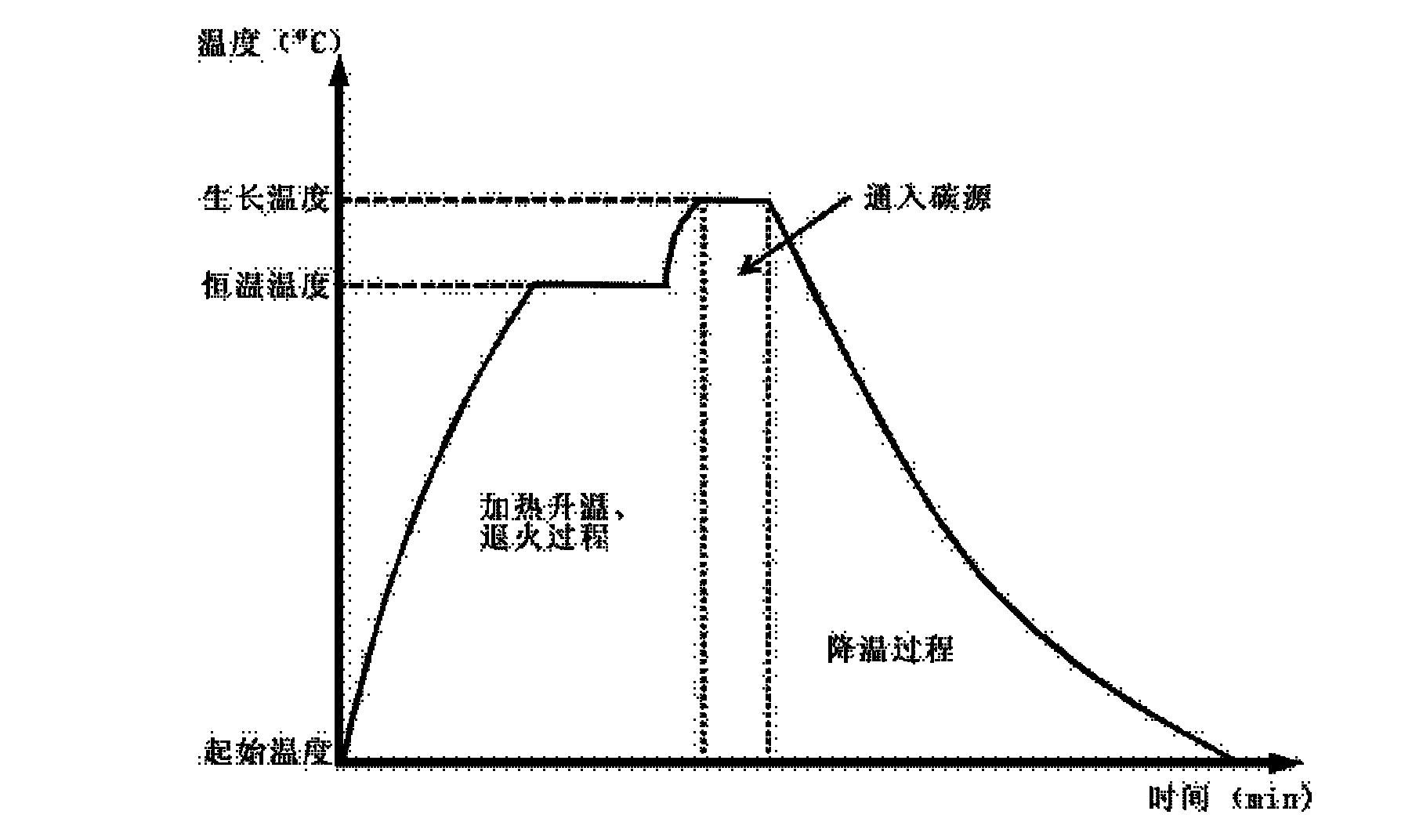

Method for preparing single-layer graphene

The invention discloses a method for preparing single-layer graphene. The method comprises the following steps of: 1) preparing an alloy substrate; and 2) in the hydrogen and inert atmosphere, catalyzing to grow graphene on the surface of the alloy substrate obtained in the step 1) by a chemical vapor deposition method, thereby finishing the preparation of the single-layer graphene. The method makes use of the characteristics of two or more alloy metals in the alloy substrate, realizes control on the decomposition, diffusion and precipitation processes of a carbon source, simply and efficiently restrains the precipitation process of carbon dissolved in the metal substrate to enable the graphene to be capable of growing in a surface catalytic manner to obtain the single-layer graphene withuniform layer distribution, and is suitable for industrial production and particularly for the controllable preparation of single-layer or few-layer graphene.

Owner:PEKING UNIV

Adherent biologically active ingredient carrier granule

InactiveUS20070280981A1Reduce total usageEasy to useBiocideAnimal repellantsBULK ACTIVE INGREDIENTMoisture

A composition is provided that includes an inventive biologically active ingredient carrier granule that adheres to the surface of plants, grasses, and weeds using a moisture-active coating, illustratively including gum Arabic, guar gum, gum karaya, gum tragacanth and locust bean gum. Upon application of the inventive granule onto a plant surface, water from precipitation, irrigation, dew, co-application with the granules from special application equipment, or guttation water from the plant itself, provides sufficient moisture for adherence of the granule to the plant surface.

Owner:THE ANDERSONS

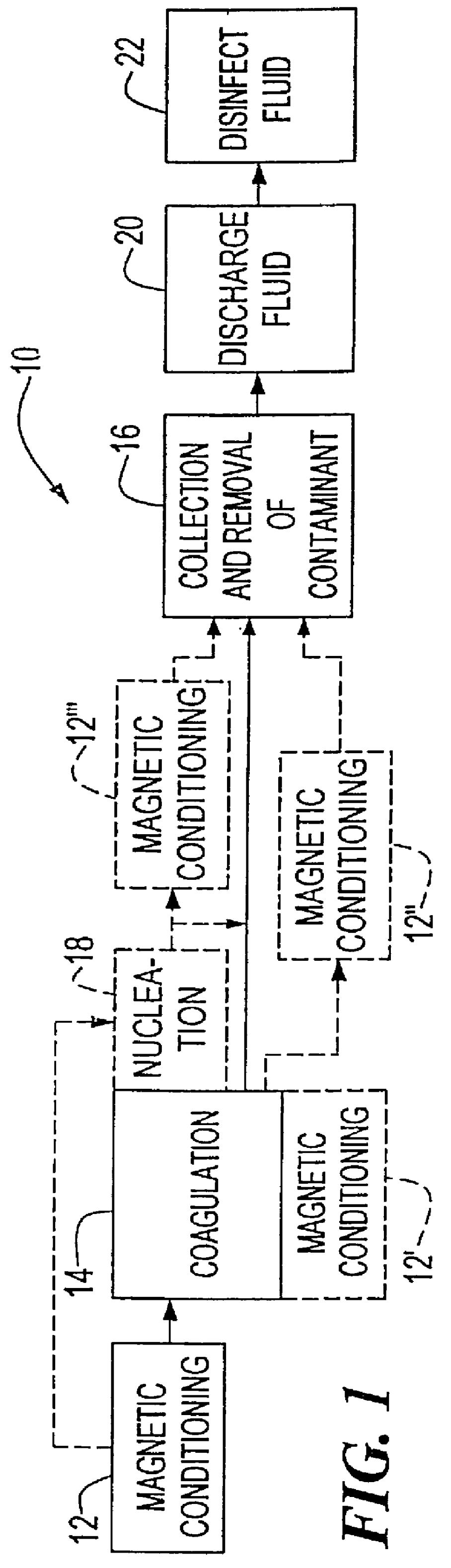

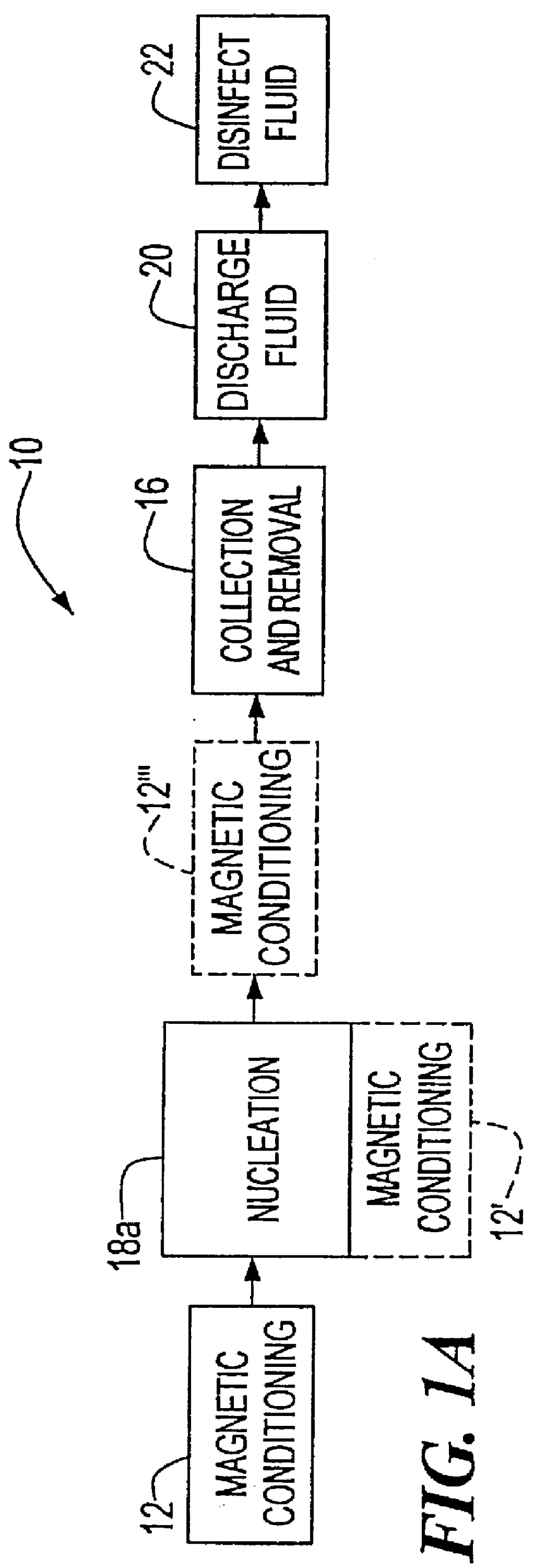

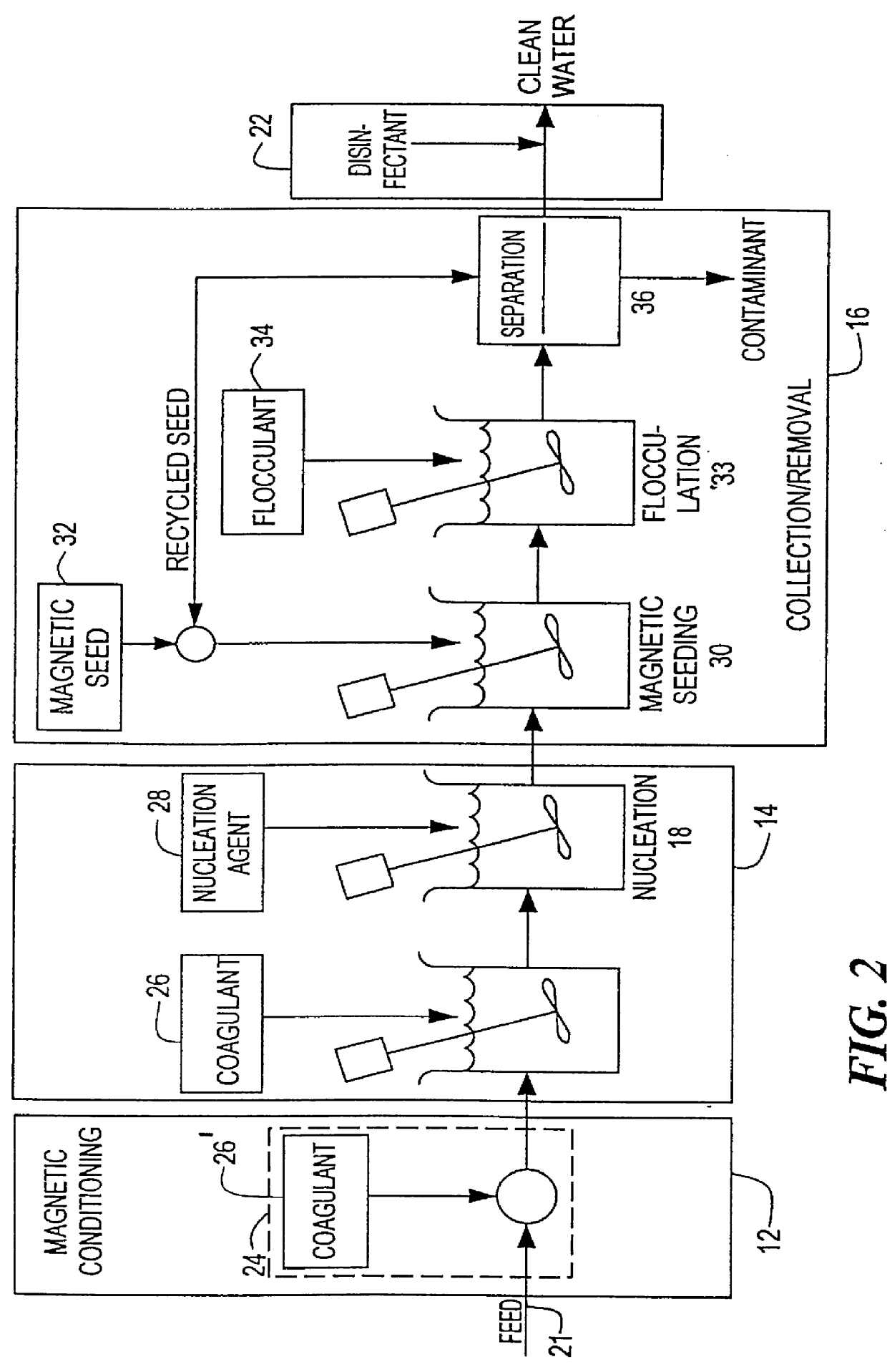

Method and system for removing solutes from a fluid using magnetically conditioned coagulation

InactiveUS6099738AImprove performanceEffective treatmentWater treatment compoundsWater contaminantsColloidEngineering

A method for removing a solute from a fluid using magnetically conditioned coagulation includes magnetically conditioning the fluid by applying a conditioning magnetic field to enhance the precipitation of solute particles for coagulation; adding a coagulant to the fluid before, during, or after application of the conditioning magnetic field to coagulate the increased available solute particles to form colloids; and collecting the colloids for removal from the fluid.

Owner:EVOQUA WATER TECH LLC

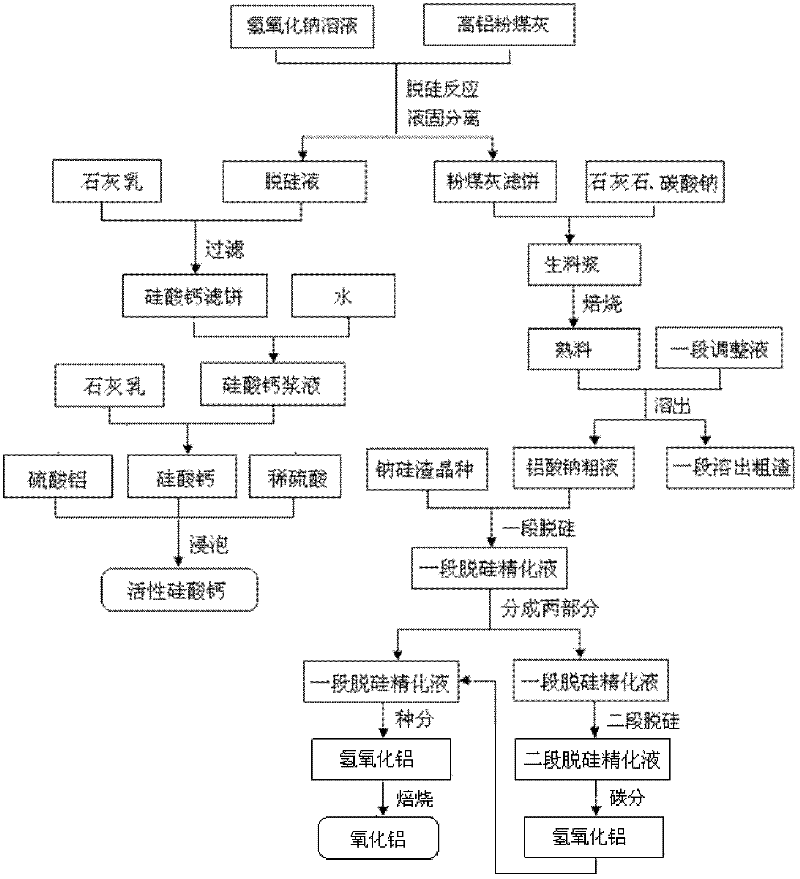

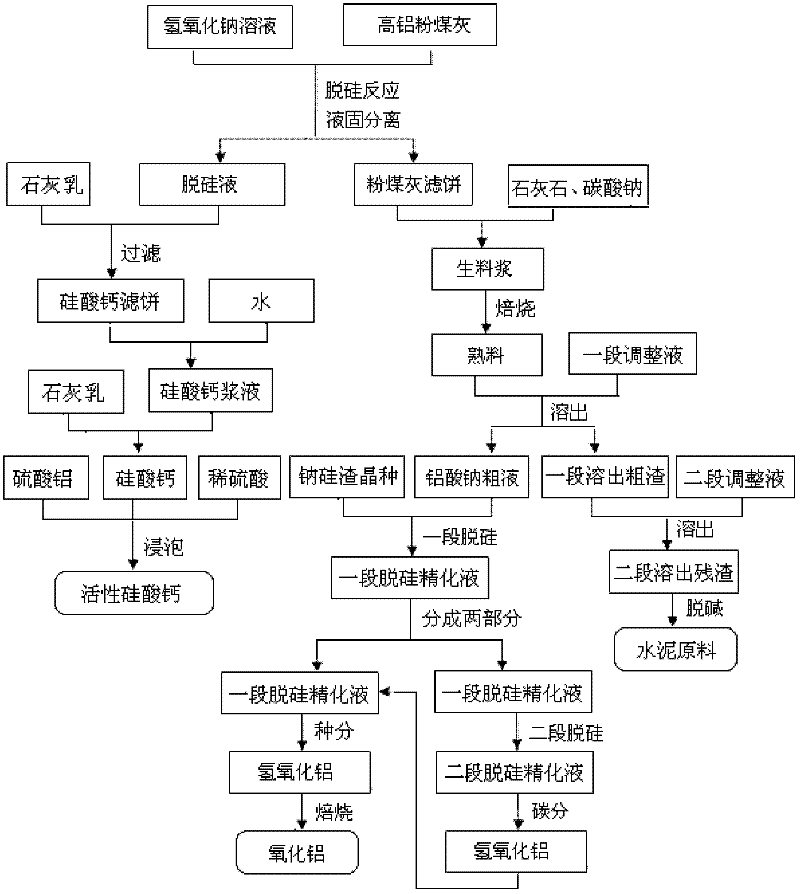

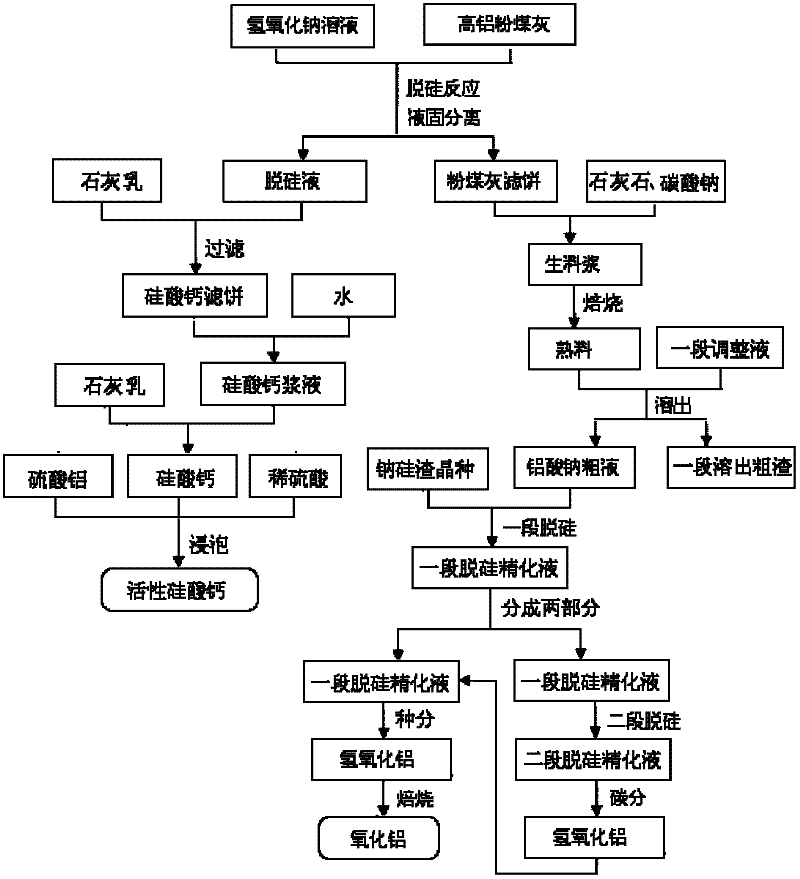

Method for producing aluminum oxide and co-producing active calcium silicate through high-alumina fly ash

ActiveCN102249253AExtraction is effective and cheapIncrease Al-Si RatioAlkaline-earth metal silicatesAluminium oxide/hydroxide preparationCalcium silicateSodium aluminate

The invention provides a method for producing aluminum oxide and co-producing active calcium silicate through high-alumina fly ash. The method comprises the following steps that: the high-alumina fly ash firstly reacts with a sodium hydroxide solution to carry out pre-desilication to obtain a liquid-phase desiliconized solution and a solid-phase desiliconized fly ash; lime cream is added to the liquid-phase desiliconized solution to carry out a causticization reaction, the resulting solid phase is active calcium silicate which is prepared through carrying out filter pressing, flash evaporation and drying to obtain the finished product; limestone and a sodium carbonate solution are added to the desiliconized fly ash to blend qualified raw slurry, then the blend qualified raw slurry is subjected to baking into the clinker, the liquid phase generated from dissolution of the clinker is a crude solution of sodium aluminate; the crude solution of the sodium aluminate is subjected to processes of first-stage deep desilication, second-stage deep desilication, carbonation, seed precipitation, baking and the like to obtain the metallurgical grade aluminum oxide meeting requirements. According to the present invention, the defects in the prior art are overcome; purposes of less material flow and small amount of slaggling are achieved; energy consumption, material consumption and production cost are relative low; extraction rate of the aluminum oxide is high; the calcium silicate with high added value is co-produced; the method provided by the present invention can be widely applicable for the field of chemical engineering.

Owner:INNER MONGOLIA DATANG INT RENEWABLE RESOURCES DEV

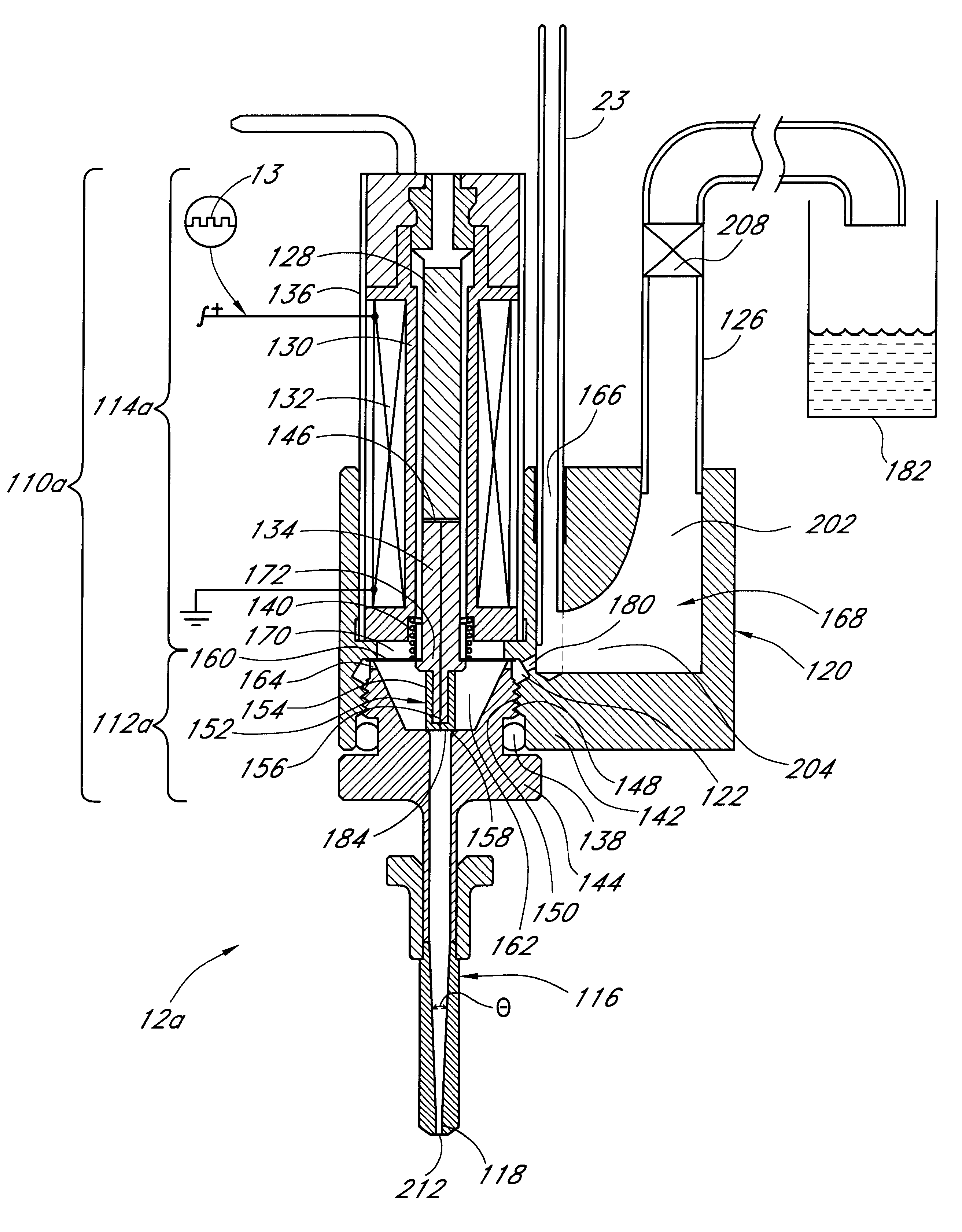

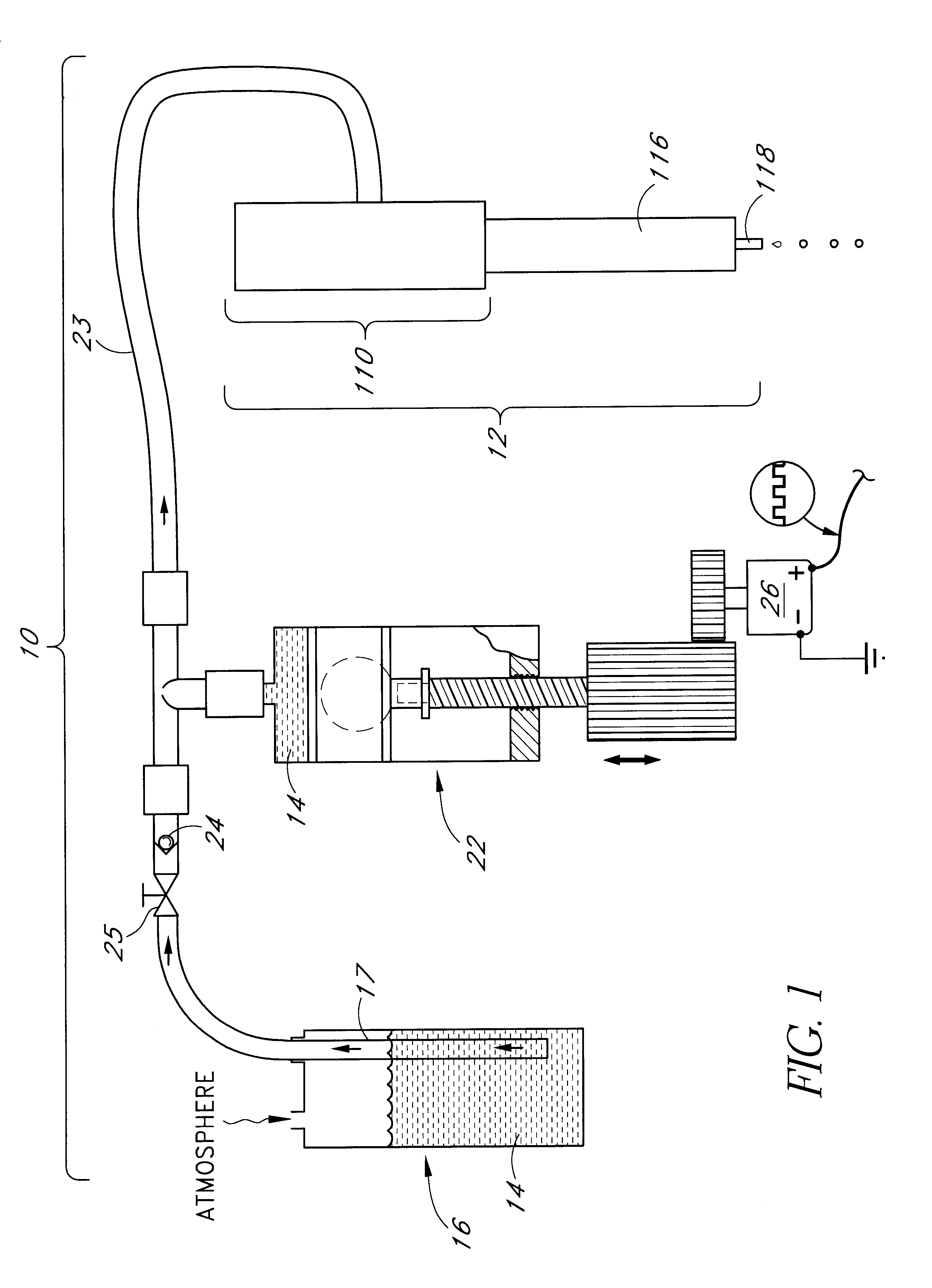

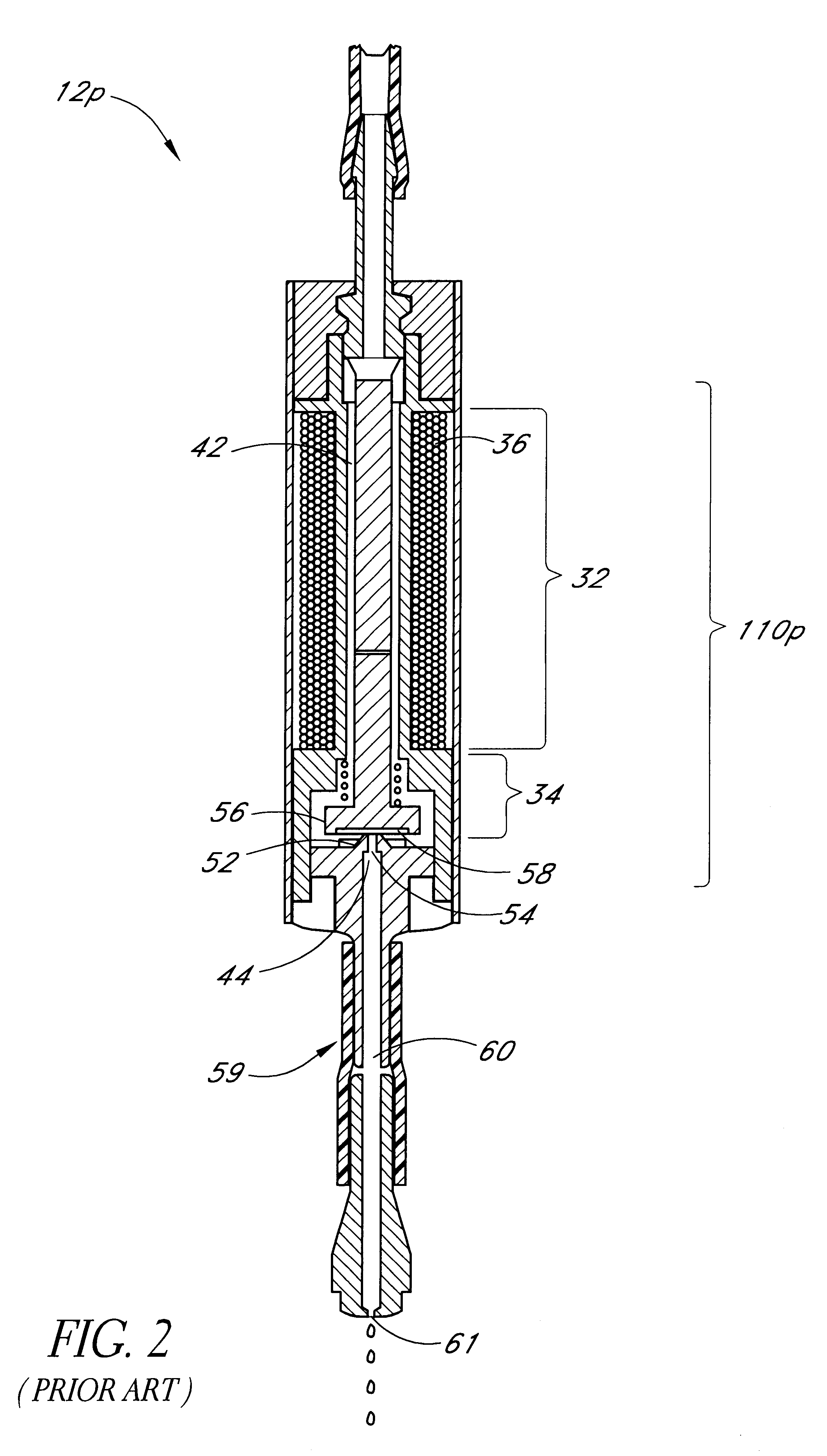

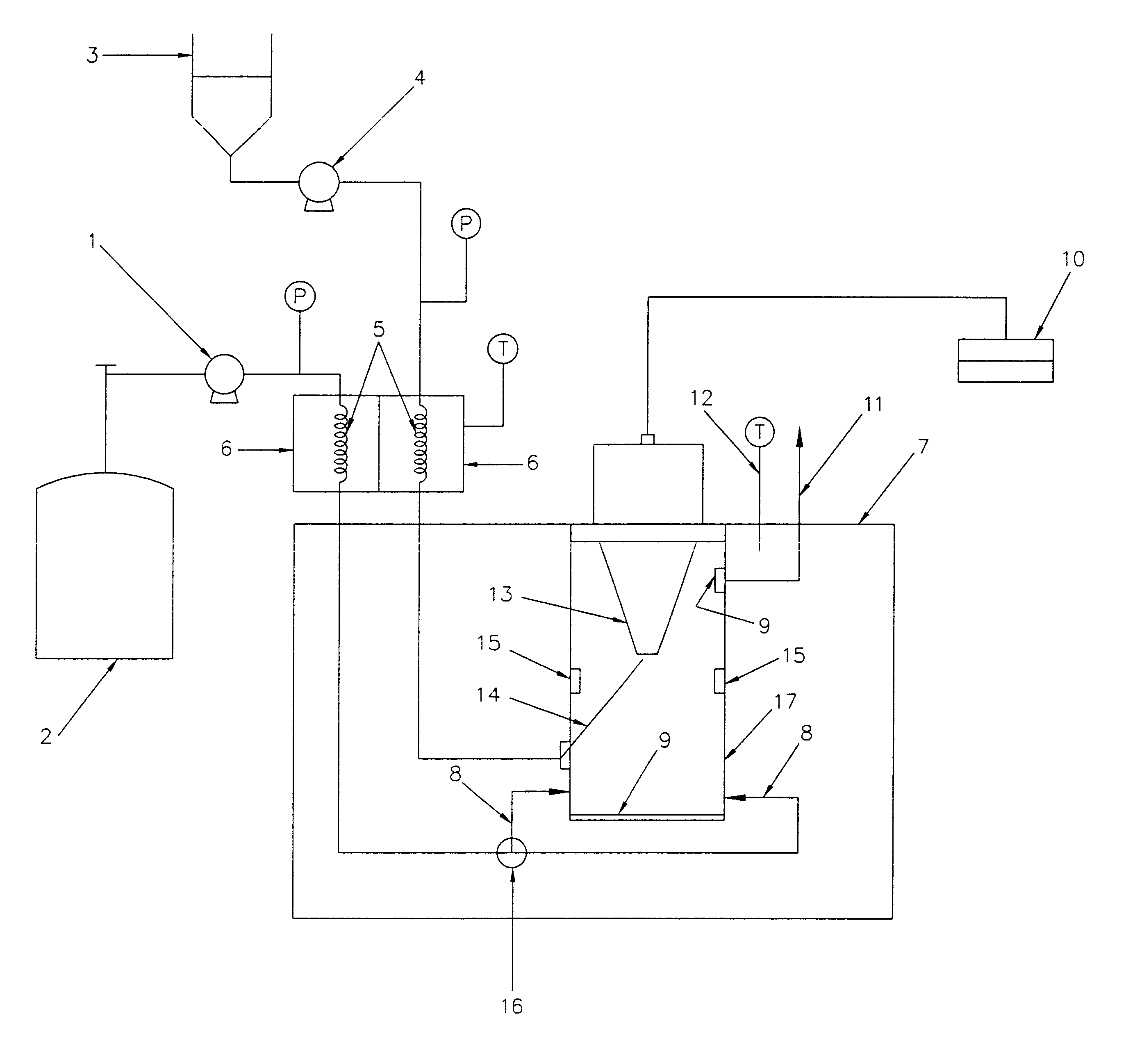

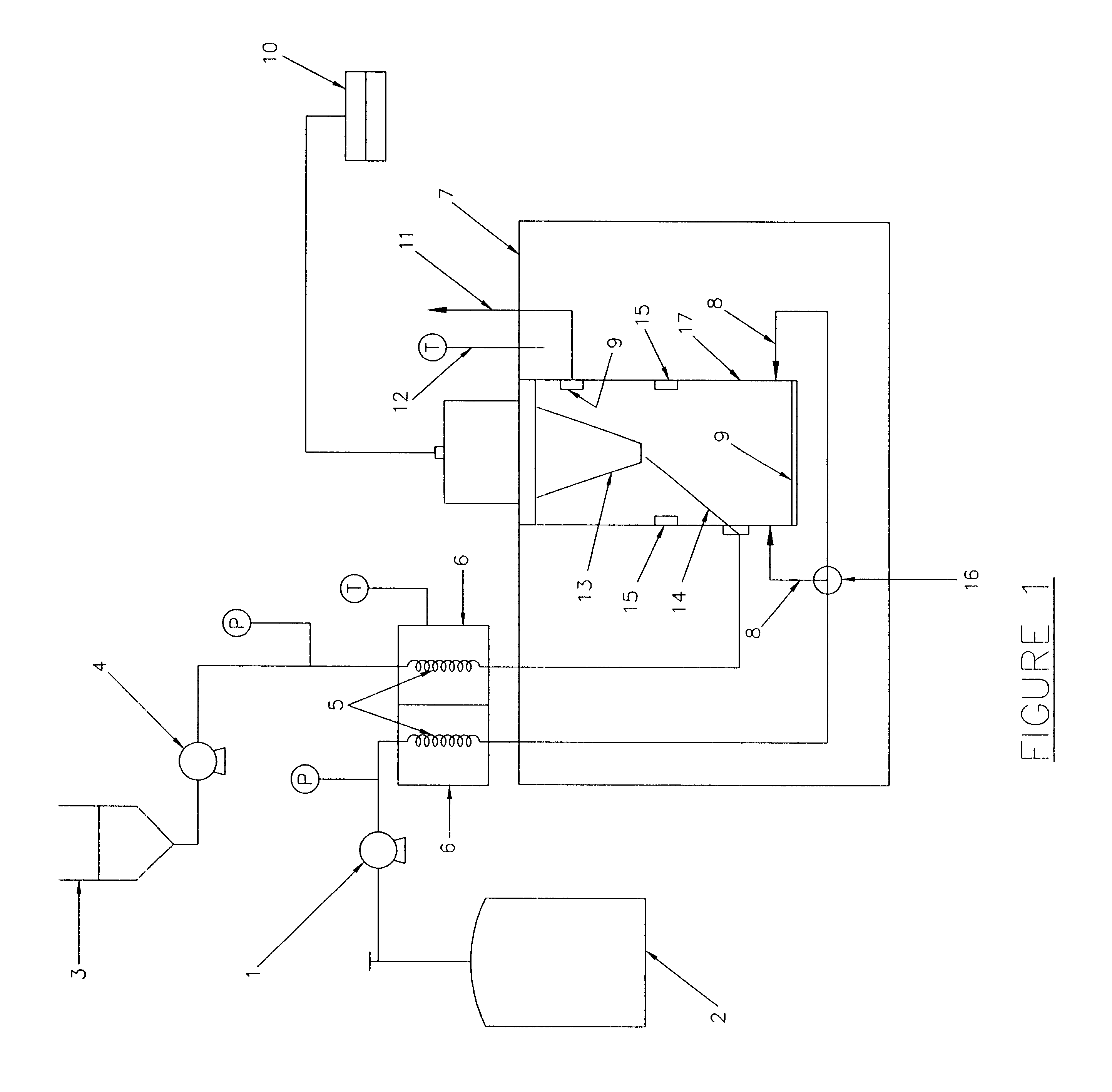

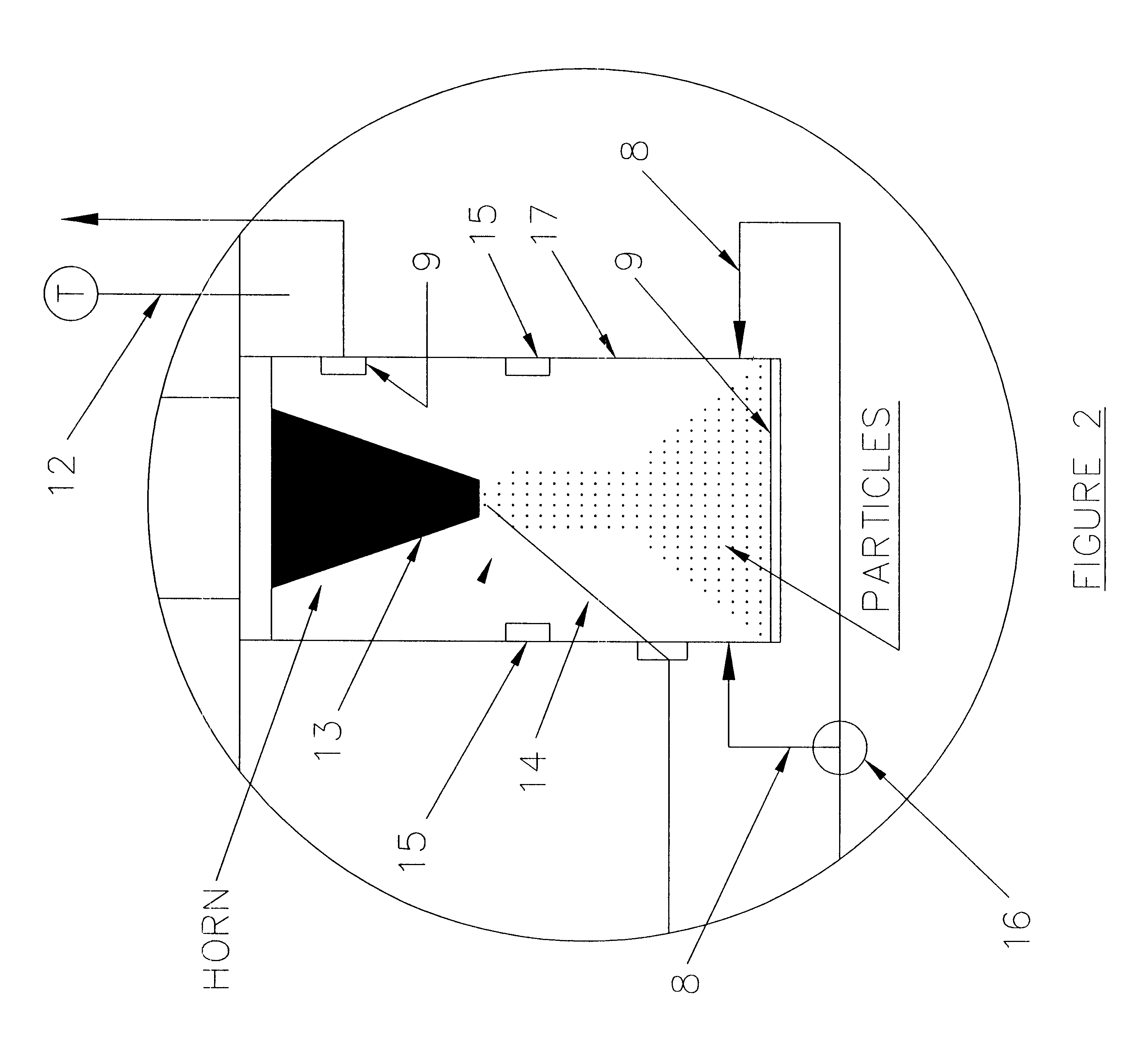

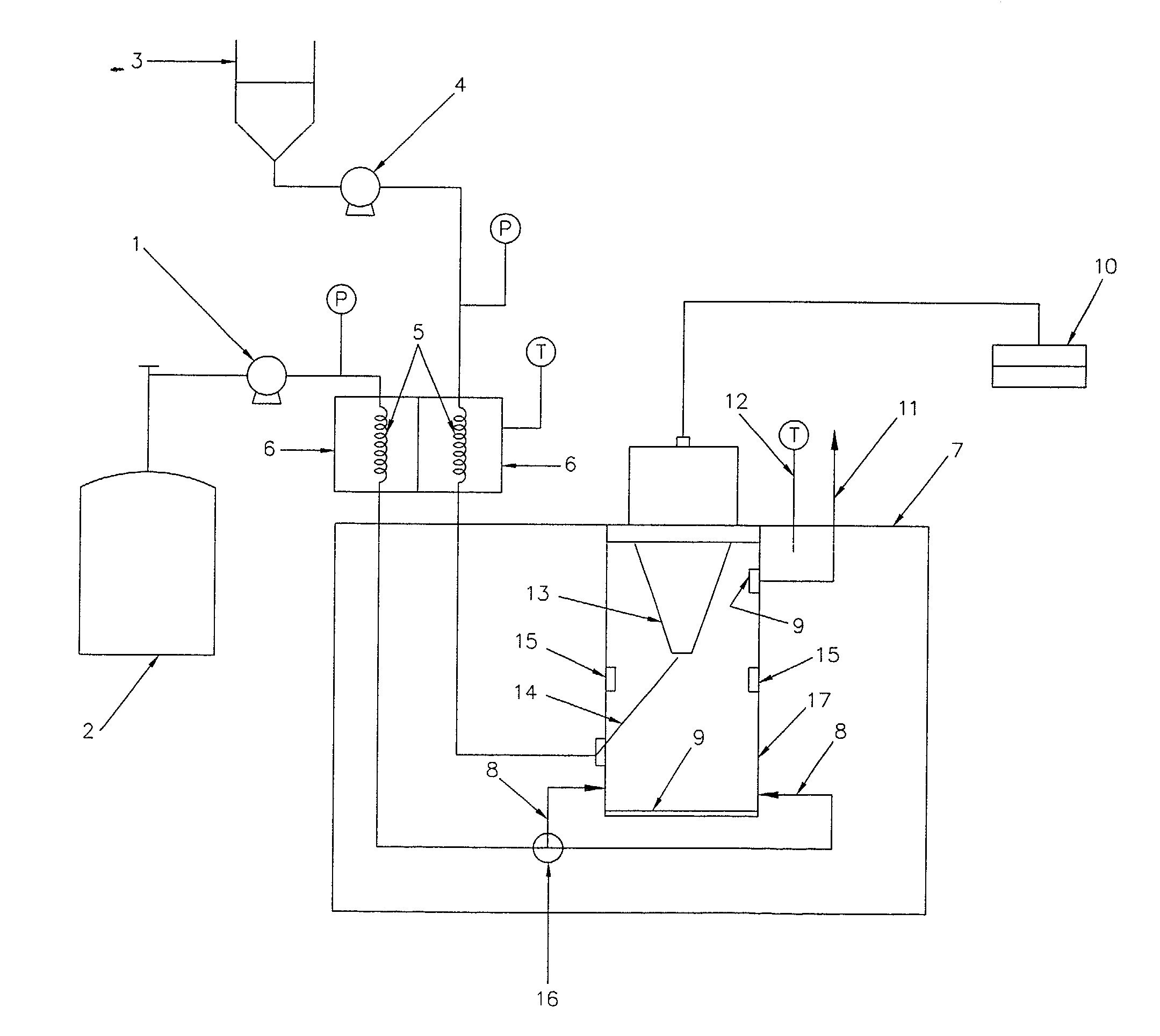

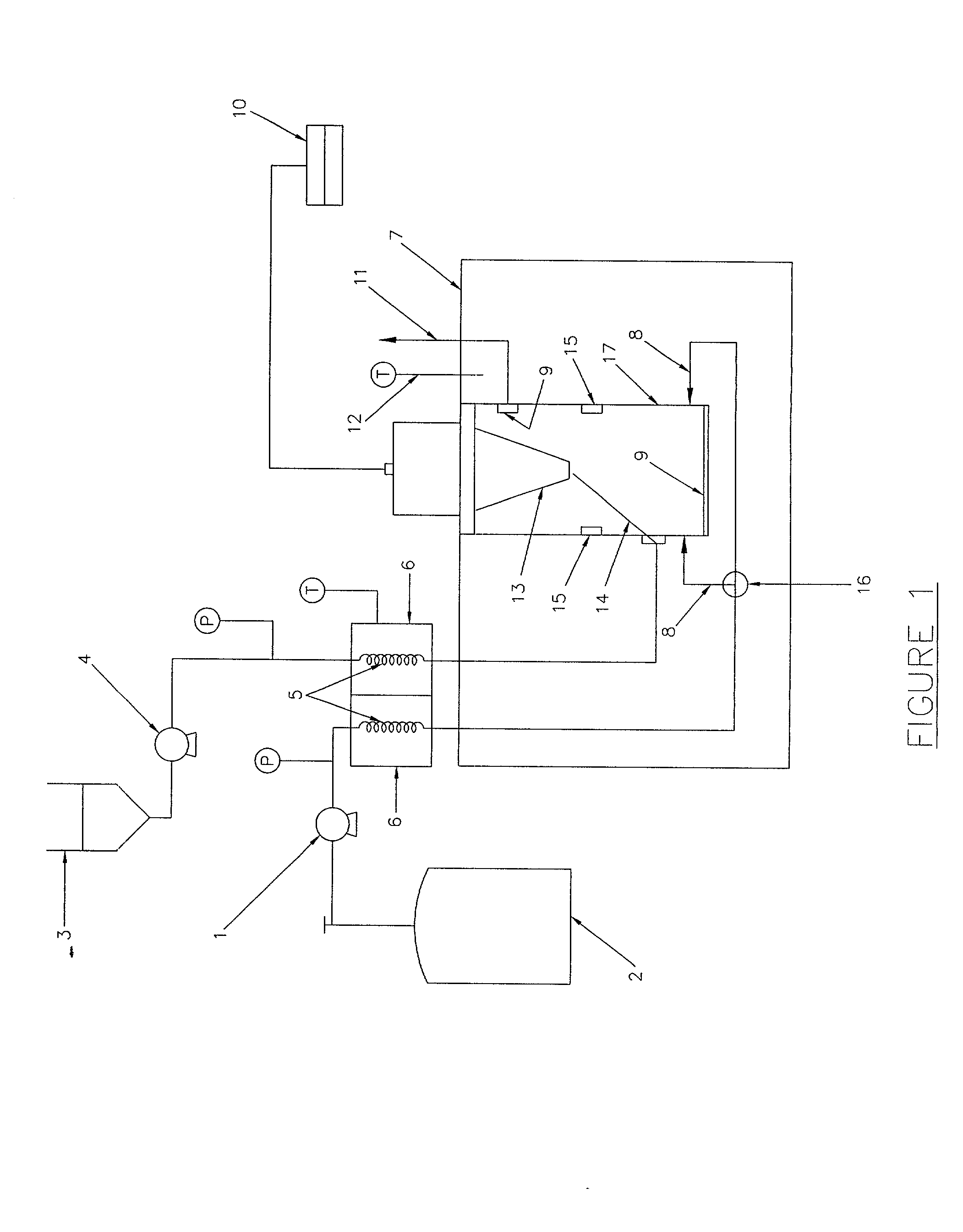

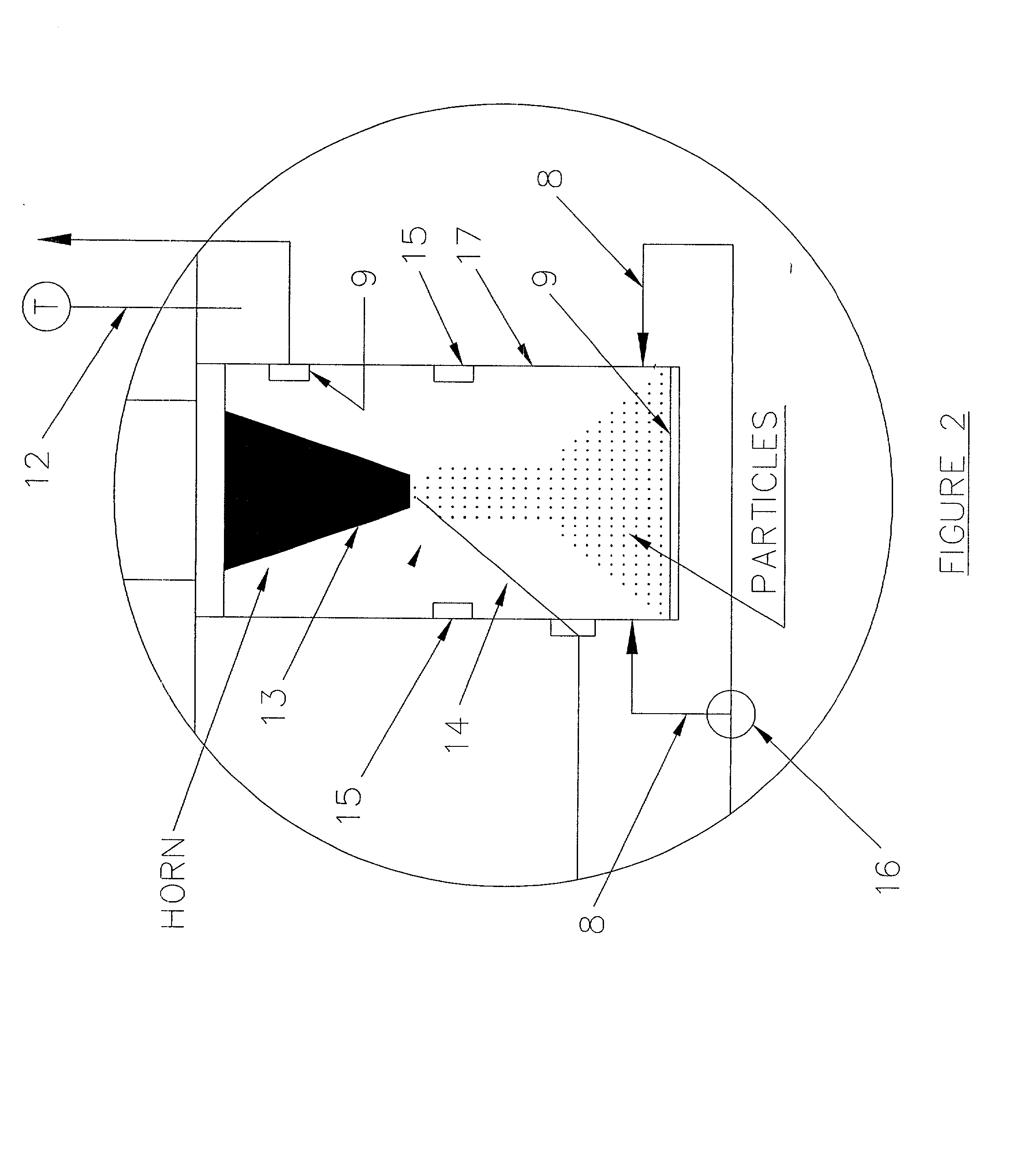

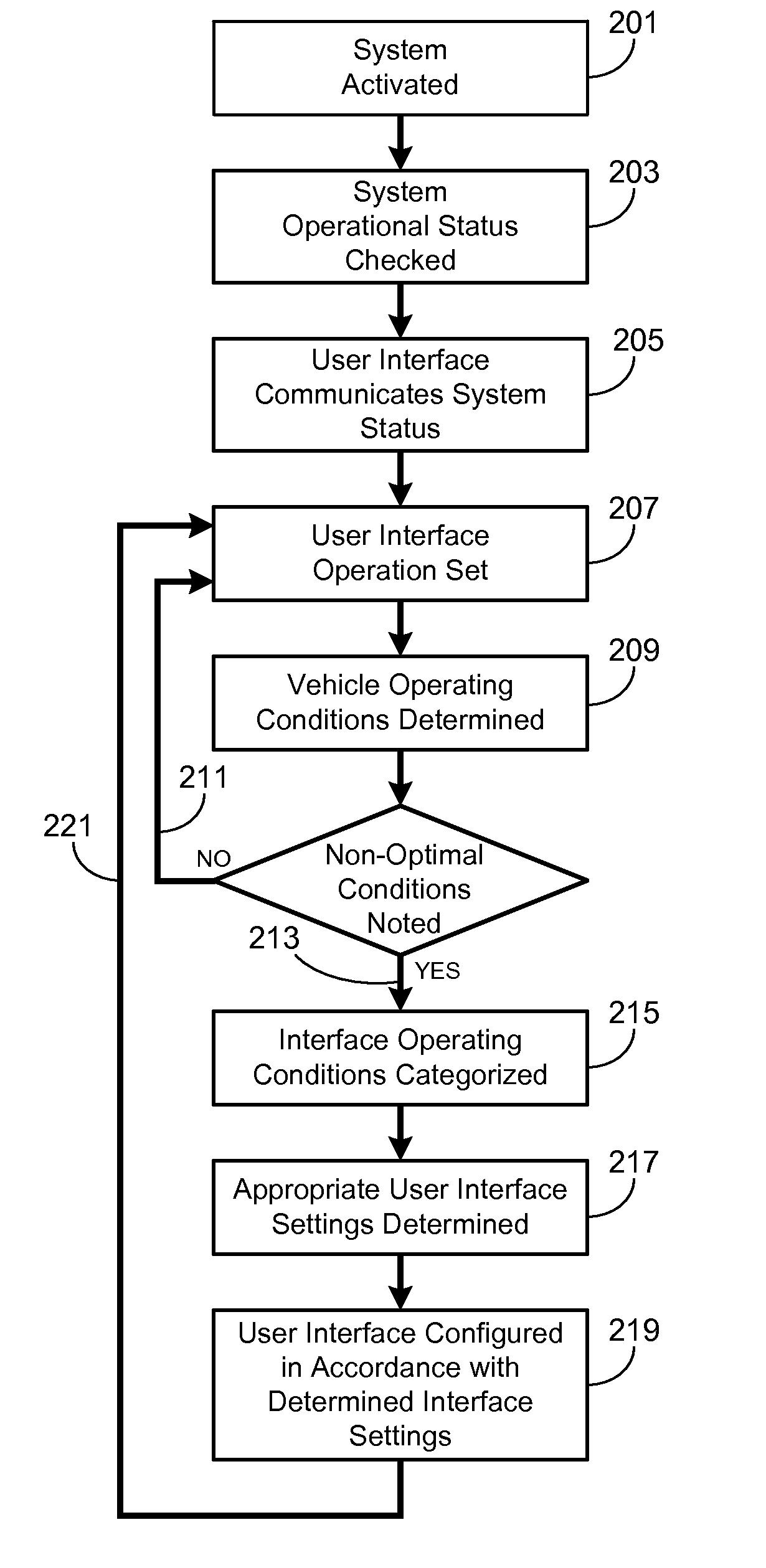

Method of forming nanoparticles and microparticles of controllable size using supercritical fluids with enhanced mass transfer

The current invention, Supercritical Antisolvent Precipitation with Enhanced Mass Transfer (SAS-EM) provides a significantly improved method for the production of nano and micro-particles with a narrow size distribution. The processes of the invention utilize the properties of supercritical fluids and also the principles of virbrational atomization to provide an efficient technique for the effective nanonization or micronization of particles. Like the SAS technique, SAS-EM, also uses a supercritical fluid as the antisolvent, but in the present invention the dispersion jet is deflected by a vibrating surface that atomizes the jet into fine droplets. The vibrating surface also generates a vibrational flow field within the supercritical phase that enhances mass transfer through increased mixing. Sizes of the particles obtained by this technique are easily controlled by changing the vibration intensity of the deflecting surface, which in turn is controlled by adjusting the power input to the vibration source. A major advantage of the SAS-EM technique is that it can be successfully used to obtain nanoparticles of materials that usually yield fibers or large crystals in SAS method. Microencapsulation via coprecipitation of two or more materials can also be achieved using the SAS-EM technique.

Owner:UNIV AUBURN

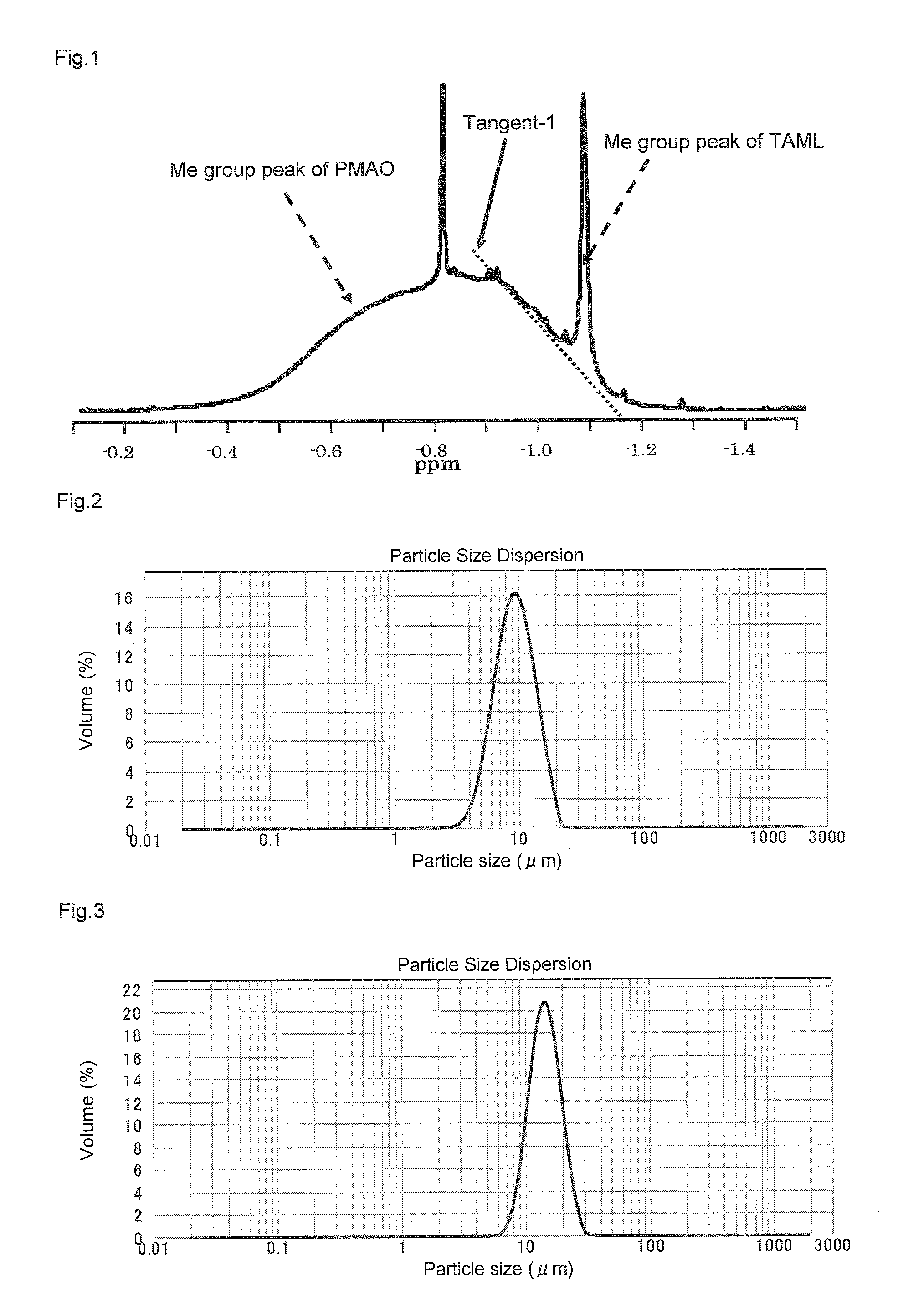

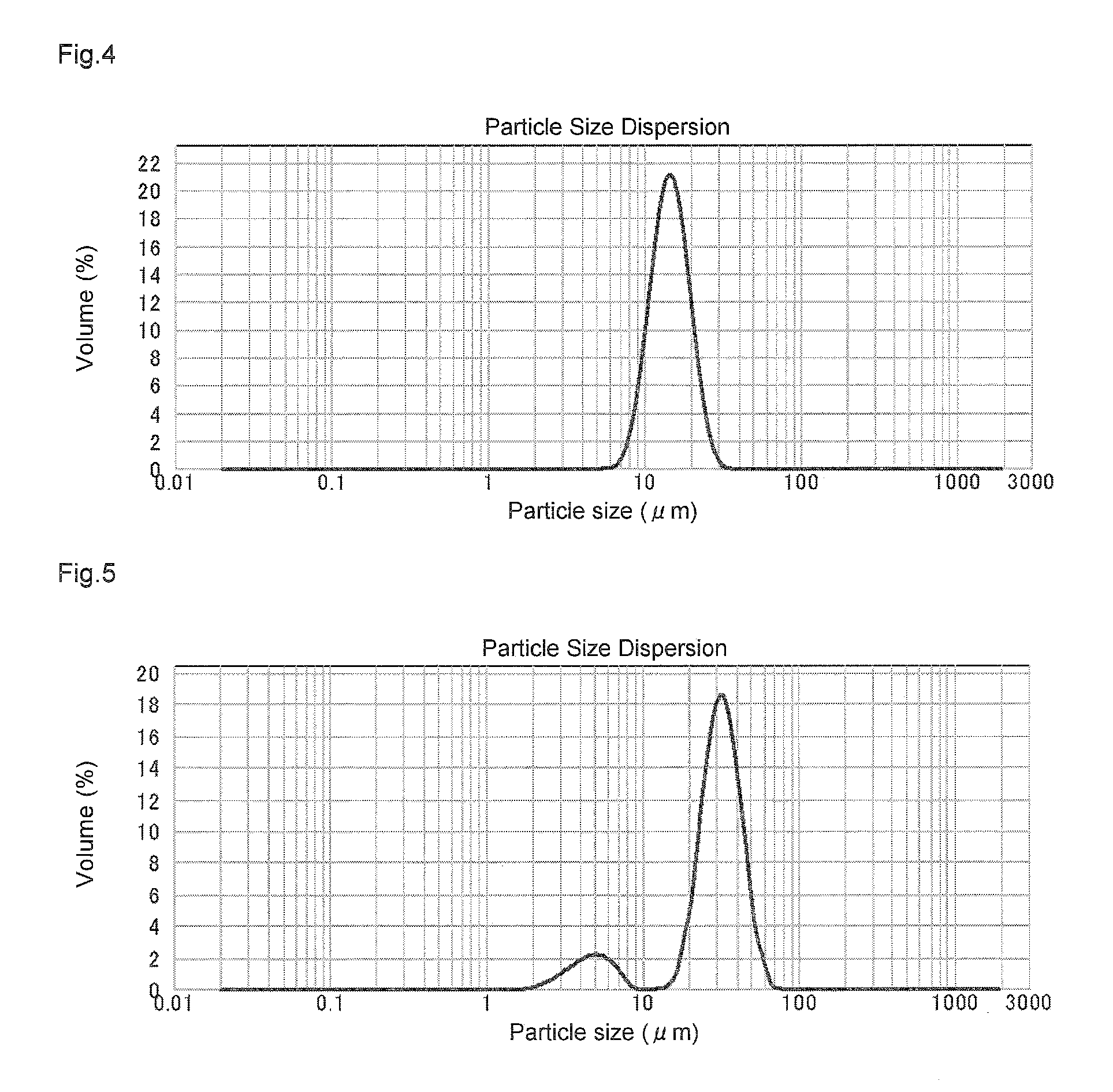

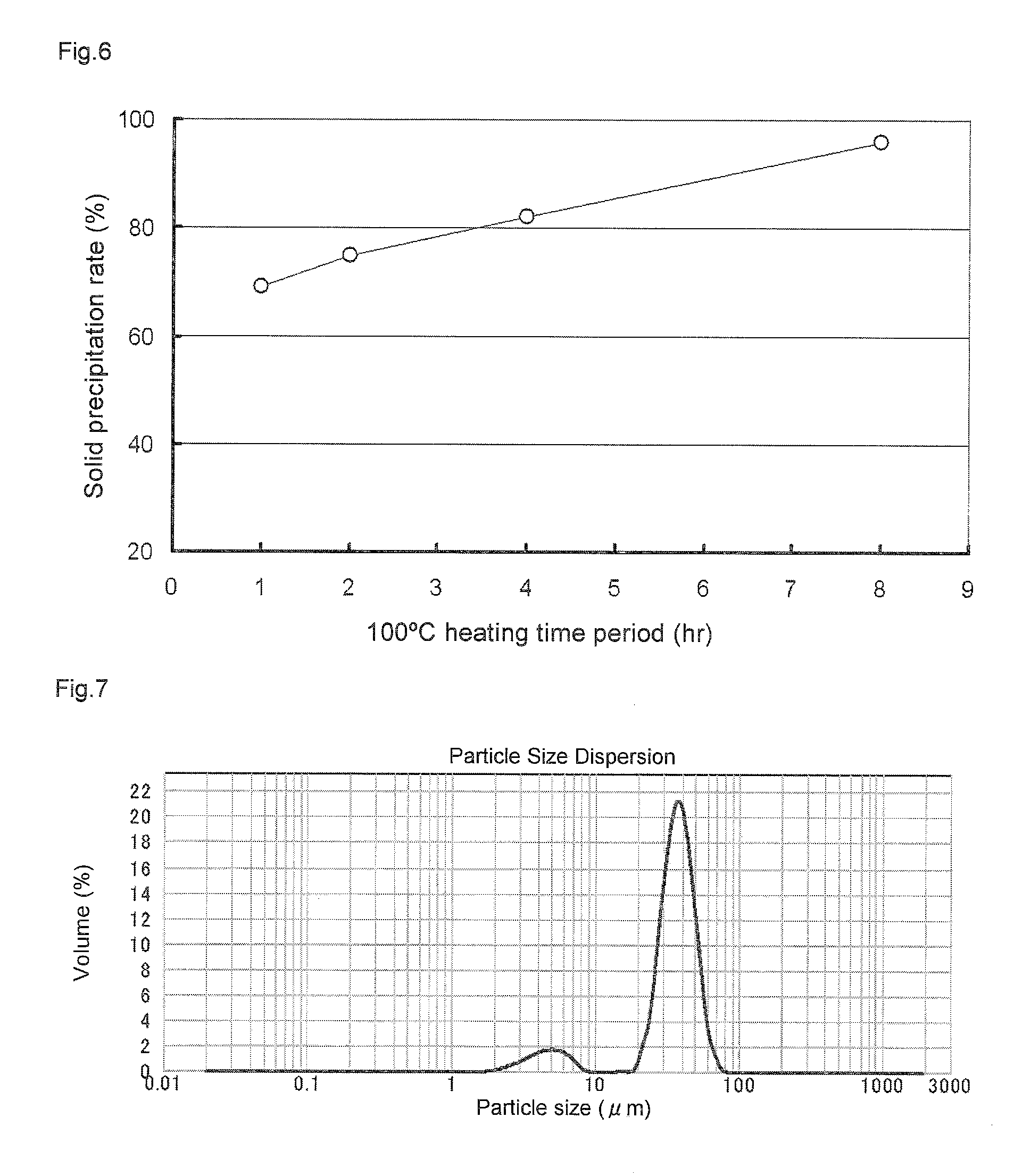

Solid polymethylaluminoxane composition and method for manufacturing same

ActiveUS8404880B2High polymerization activityReduce solubilityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationOlefin polymerizationMethyl group

Owner:TOSOH FINECHEM CORP

Method of forming nanoparticles and microparticles of controllable size using supercritical fluids and ultrasound

The current invention, Supercritical Antisolvent Precipitation with Enhanced Mass Transfer (SAS-EM) provides a significantly improved method for the production of nano and micro-particles with a narrow size distribution. The processes of the invention utilize the properties of supercritical fluids and also the principles of virbrational atomization to provide an efficient technique for the effective nanonization or micronization of particles. Like the SAS technique, SAS-EM, also uses a supercritical fluid as the antisolvent, but in the present invention the dispersion jet is deflected by a vibrating surface that atomizes the jet into fine droplets. The vibrating surface also generates a vibrational flow field within the supercritical phase that enhances mass transfer through increased mixing. Sizes of the particles obtained by this technique are easily controlled by changing the vibration intensity of the deflecting surface, which in turn is controlled by adjusting the power input to the vibration source. A major advantage of the SAS-EM technique is that it can be successfully used to obtain nanoparticles of materials that usually yield fibers or large crystals in SAS method. Microencapsulation via coprecipitation of two or more materials can also be achieved using the SAS-EM technique.

Owner:UNIV AUBURN

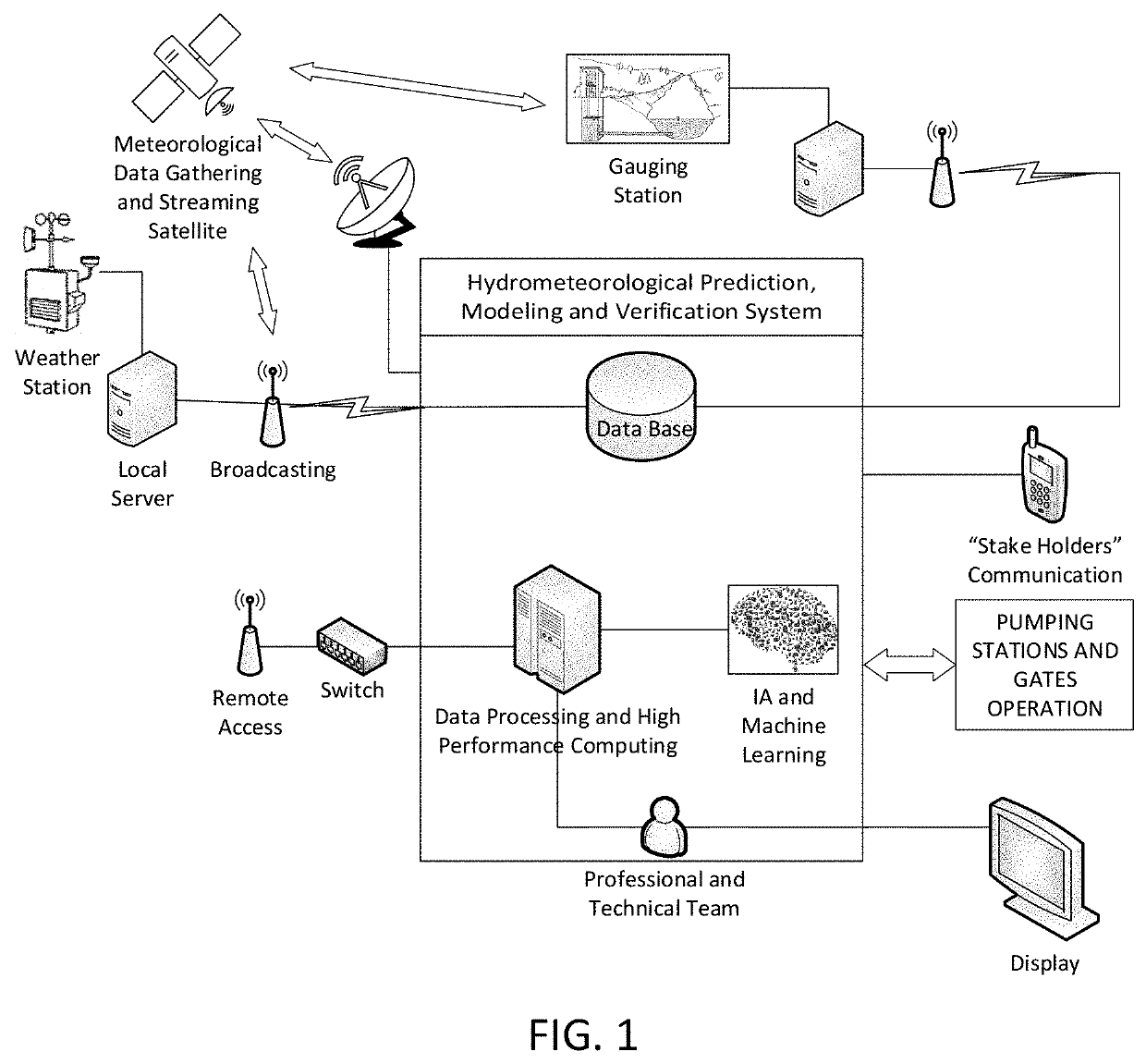

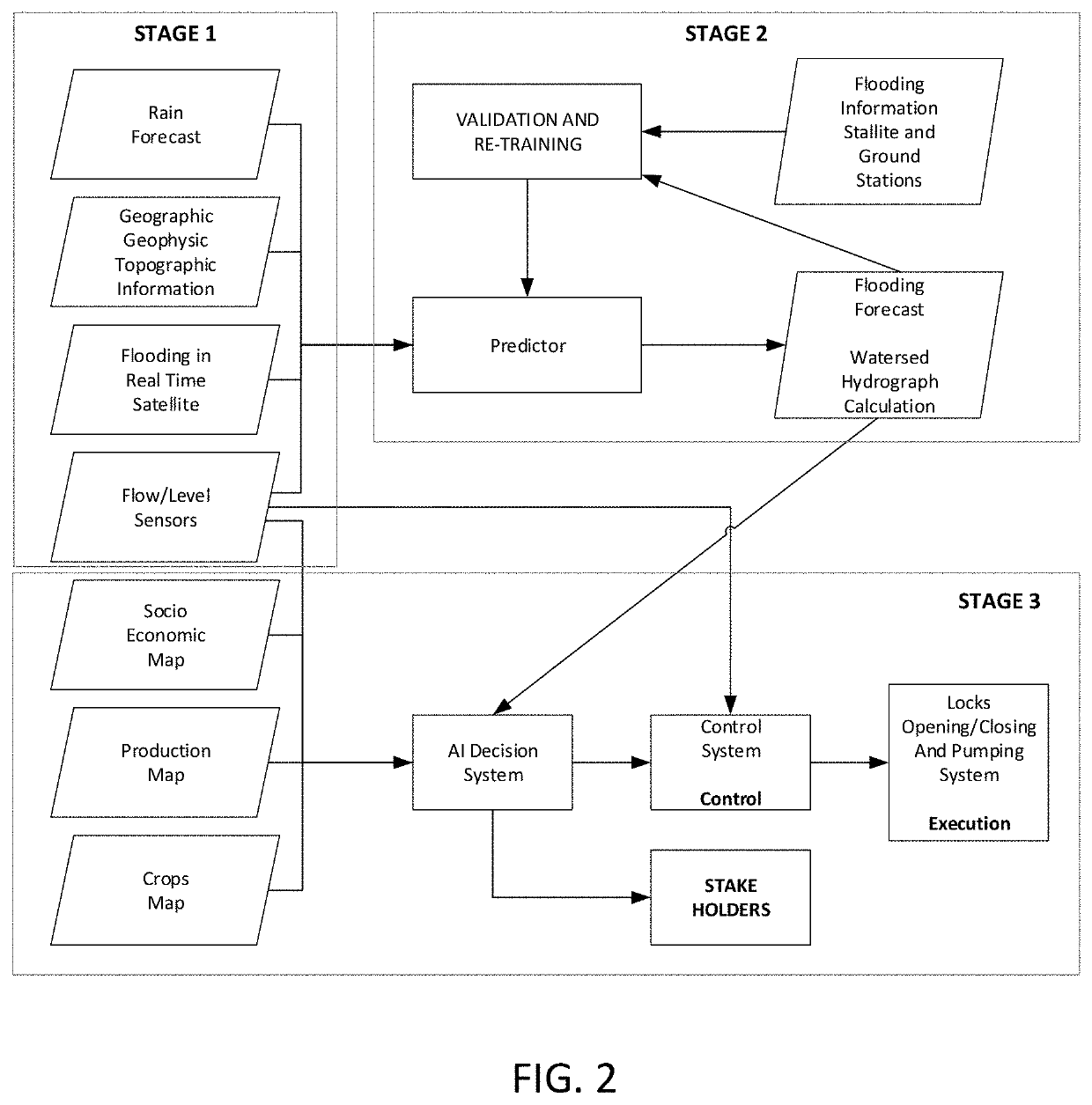

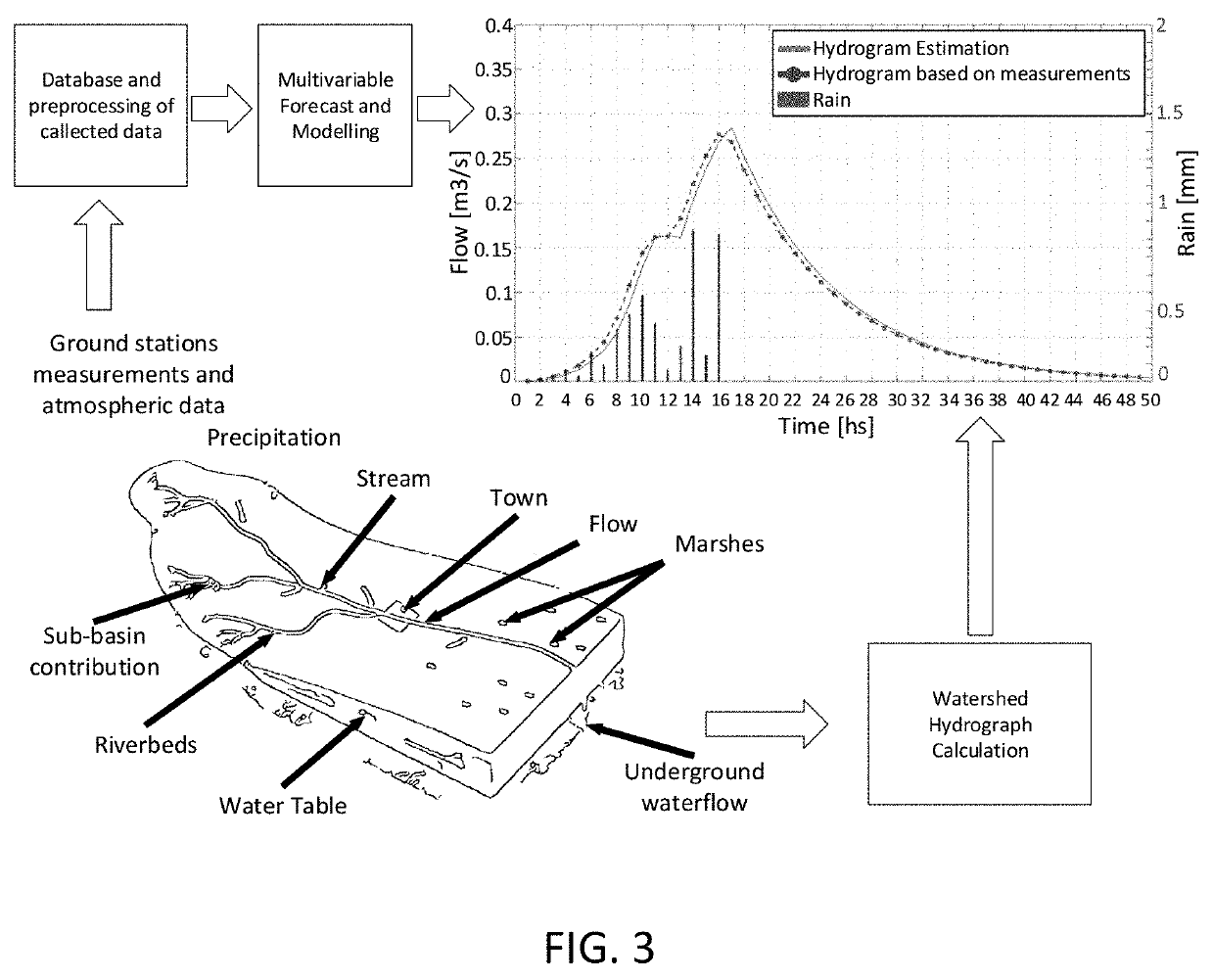

Analysis system and hydrology management for basin rivers

ActiveUS20190354873A1Minimize impactWeather condition predictionClimate change adaptationSocio economyWater quality

Watershed hydrology analysis and management process and system with a network of weather stations and artificial drainage systems with artificial and natural reservoir management through locks and pumping stations. It evaluates potential hydrologic risk in each area and analyses the possible consequences of future precipitations using simulations. To make the simulation, it calculates hydrographs for each sub-basin, streams and rivers in the basin. It simulates the behavior of the basin under different scenarios corresponding to different types of management of the operation of locks and / or pumps and compares its results in terms of loss of flooded area, economic loss in each area, loss for flooding of urban areas, etc. Optimization of the simulation through artificial intelligence (AI, meta-heuristic algorithms, neural networks, etc.) allows it to act as a search engine to find better solutions and the best configuration of resource management that allows minimizing the socio-economic impact on each basin.

Owner:PESCARMONA LUCAS

Injectable hollow tissue filler

The present invention comprises a plurality of injectable hollow particulate fillers suspended in a biocompatible fluid carrier to significantly improve the clumping resistance and injectability of the composition. The hollow particulate fillers have a lower effective density and are able to suspend in the carrier without precipitation. The loss of skin volume as a result of aging, diseases, weight loss, and injury can lead to uneven skin surface (e.g. wrinkle, etc.). The uneven skin can be repaired by injecting appropriate amount of hollow fillers underneath the skin. Some cases of urinary incontinence occur when the resistance to urine flow has decreased excessively. Continence is restored by injecting the present invention to the urethra tissue to increase resistance to urine outflow. Similarly, the present invention allows for the control of gastric fluid reflux by submucosal injections of the fillers to the esophageal-gastric and gastric-pyloric junction. For patients with vesicoureteral reflux, it can be treated by injection of the present invention into patients' ureteral tissue. This invention can also be used to repair defective or inadequately functioning muscles of the anal sphincter by administering an effective amount of injectable hollow fillers into the defect or anal sinuses.

Owner:CHU JACK FA DE

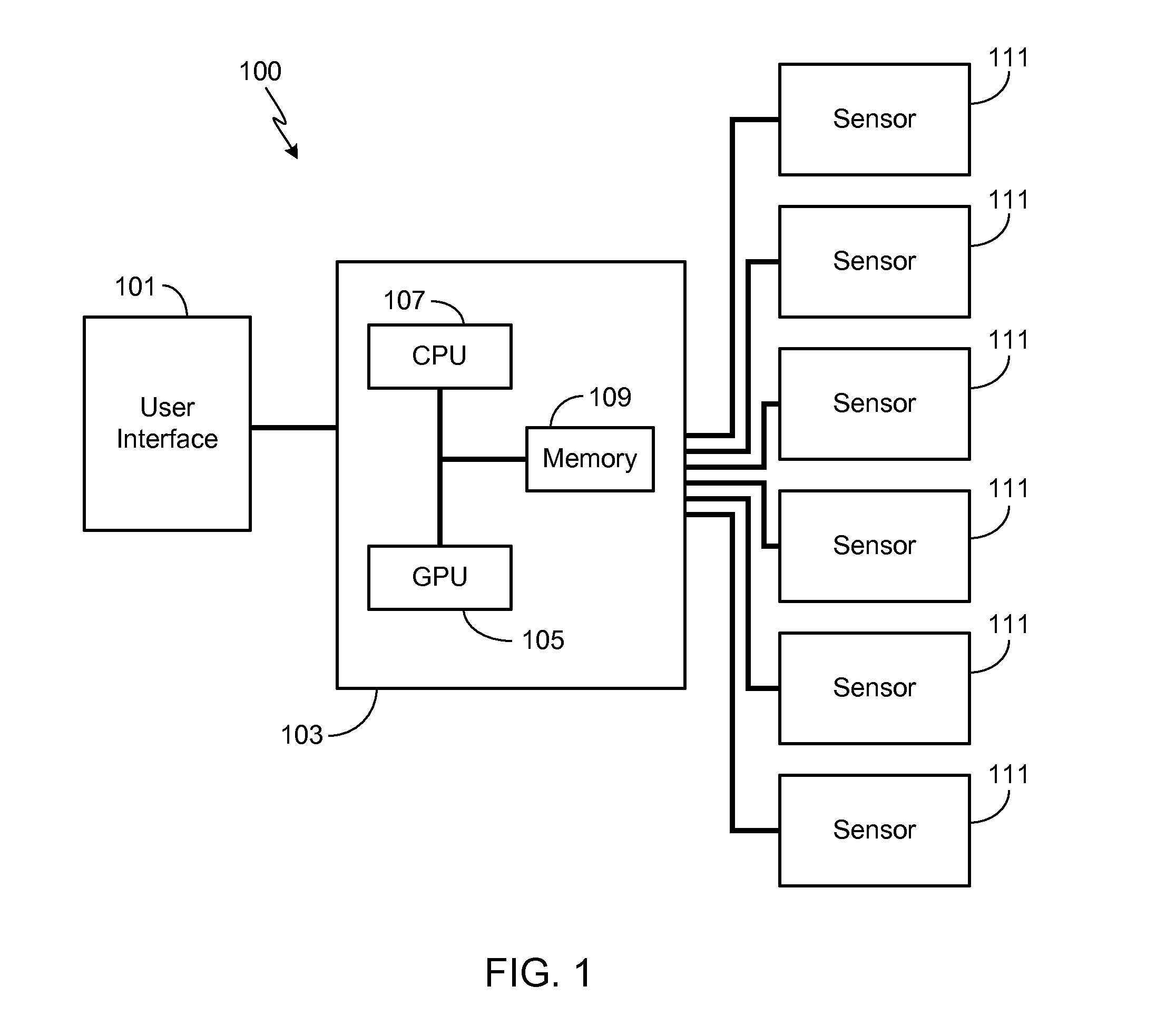

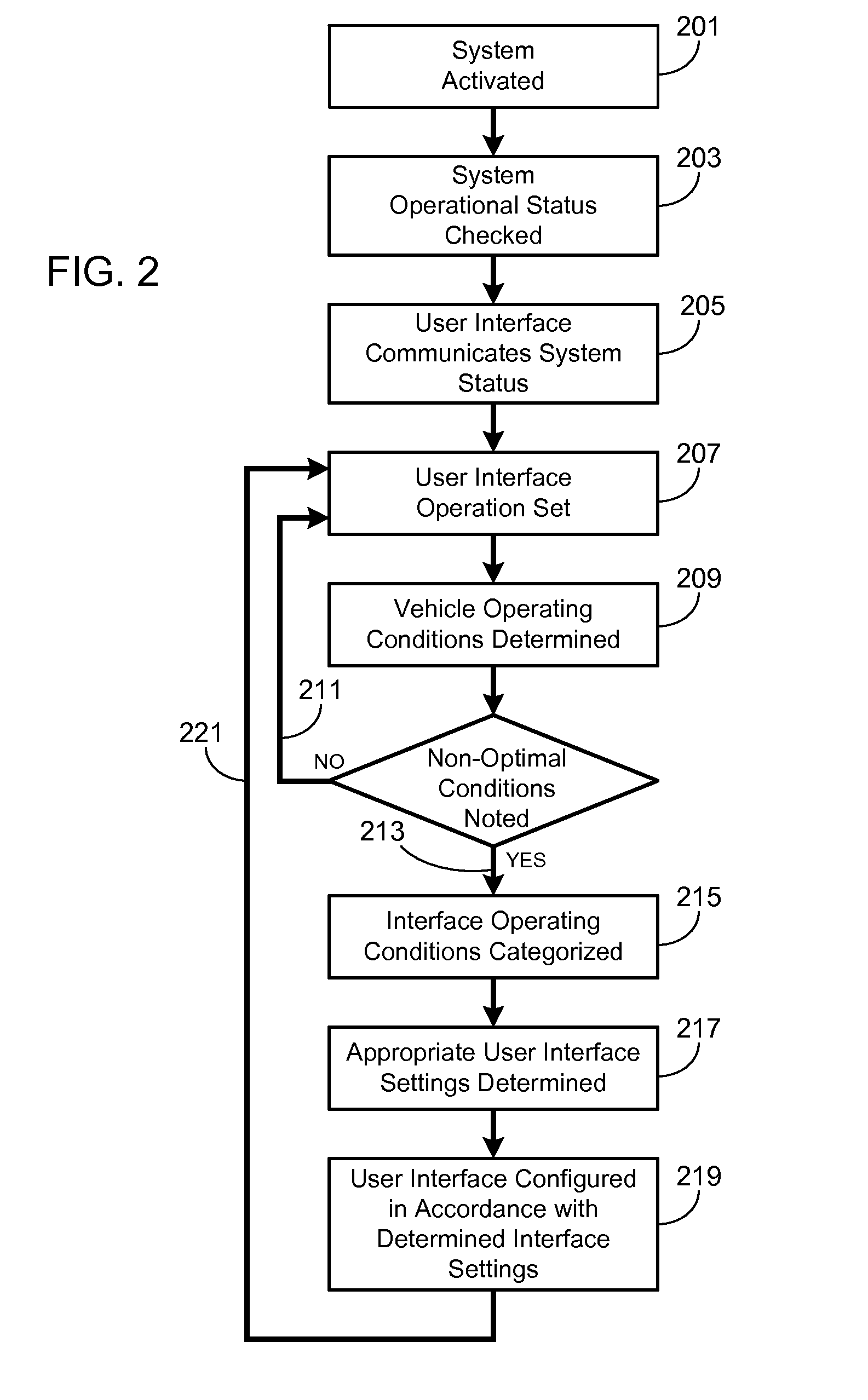

Adaptive Vehicle User Interface

A method is provided for configuring a vehicle interface in response to a monitored vehicle condition. For example, the vehicle condition sensor may be a precipitation sensor, in which case the set of vehicle subsystem touch-sensitive soft buttons correspond to windshield wiper controls when the precipitation sensor indicates a non-zero precipitation level. Alternately, the vehicle condition sensor may be a GPS sensor, in which case the set of vehicle subsystem touch-sensitive soft buttons correspond to activation controls an external system such as a garage door controller, a home lighting controller, or a home security controller. Alternately, the vehicle condition sensor may sense driving style, for example by monitoring vehicle speed, acceleration, lateral force or the output of a performance mode selector, in which case the set of vehicle subsystem information graphics correspond to essential vehicle operating controls.

Owner:TESLA INC

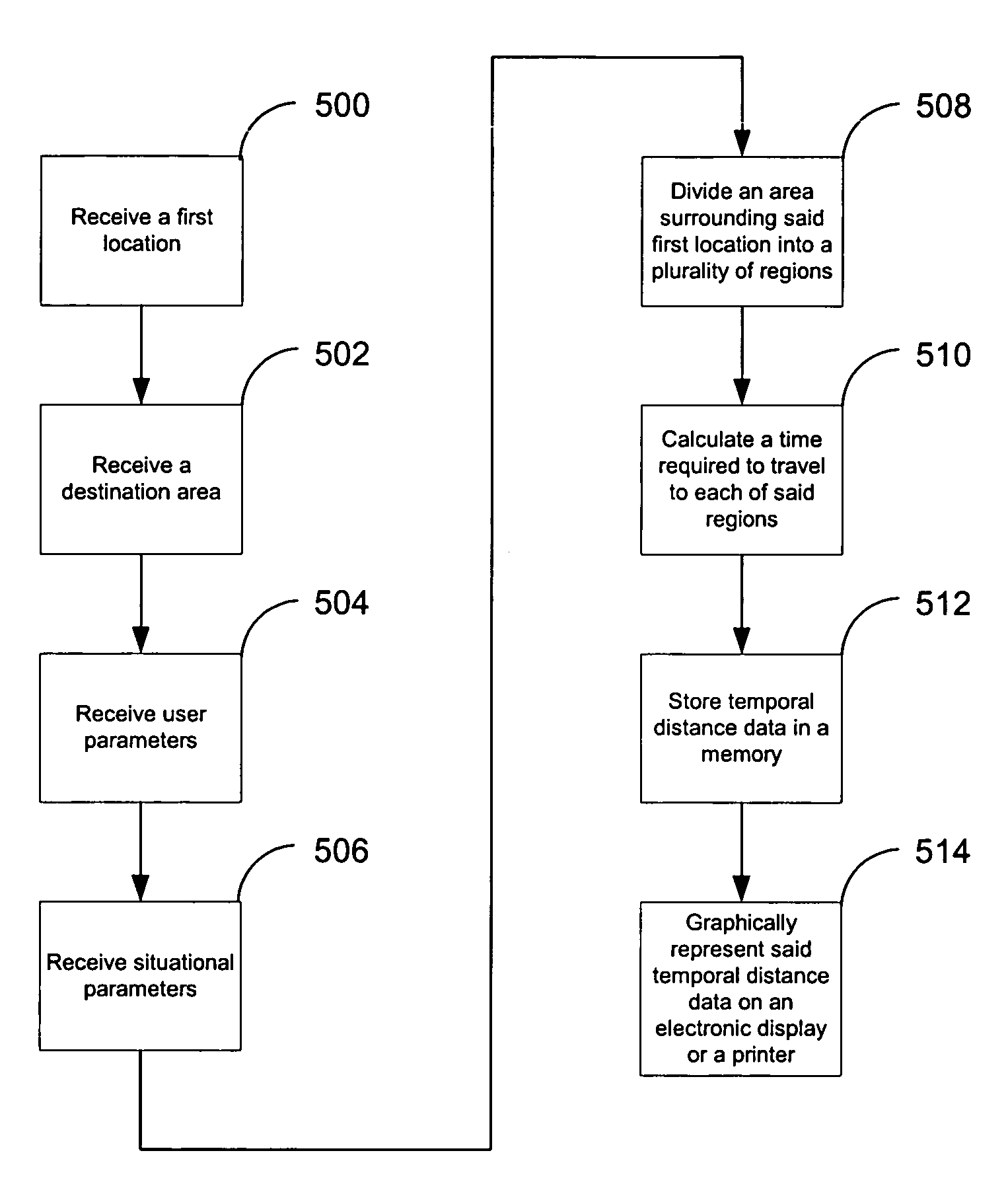

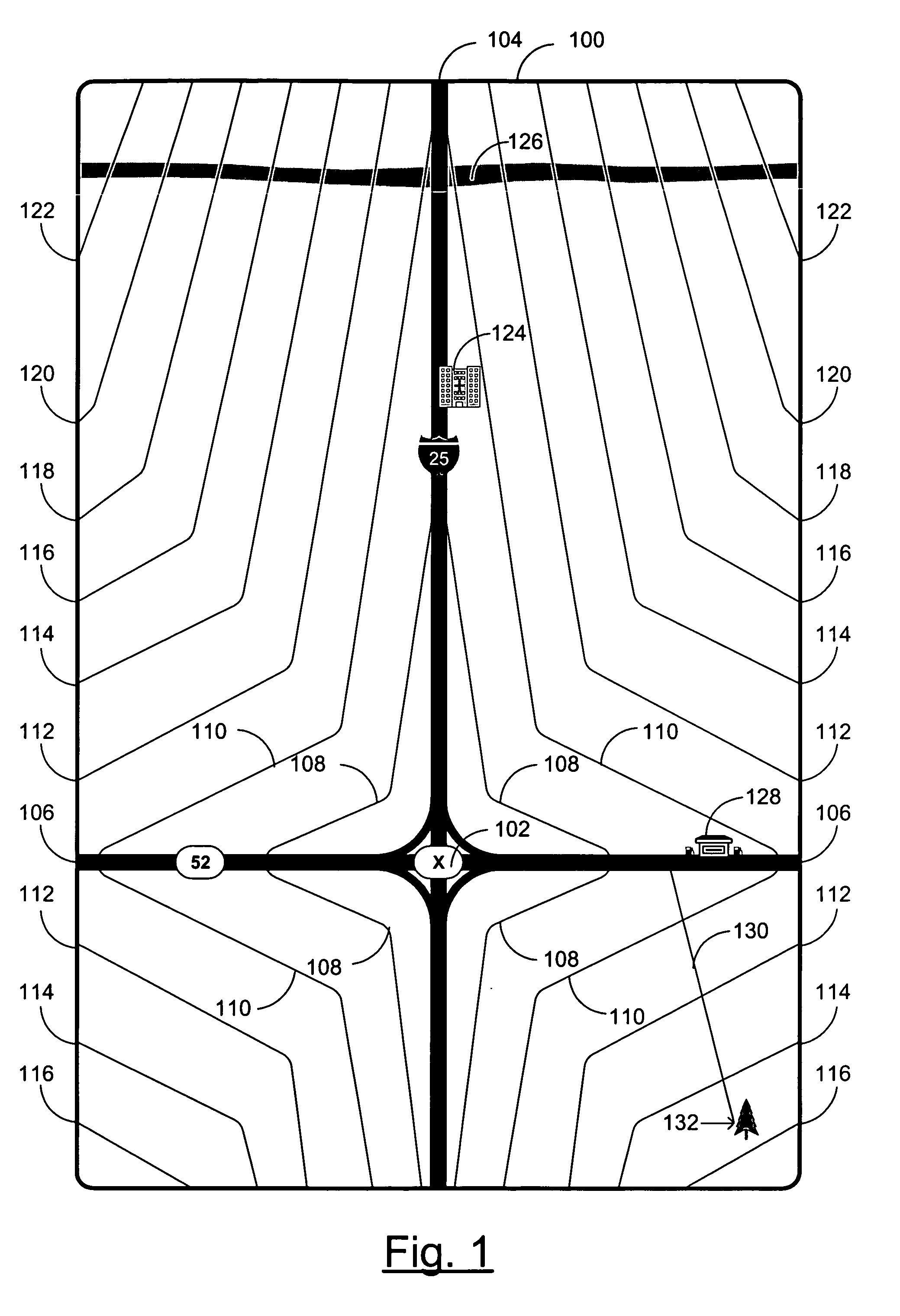

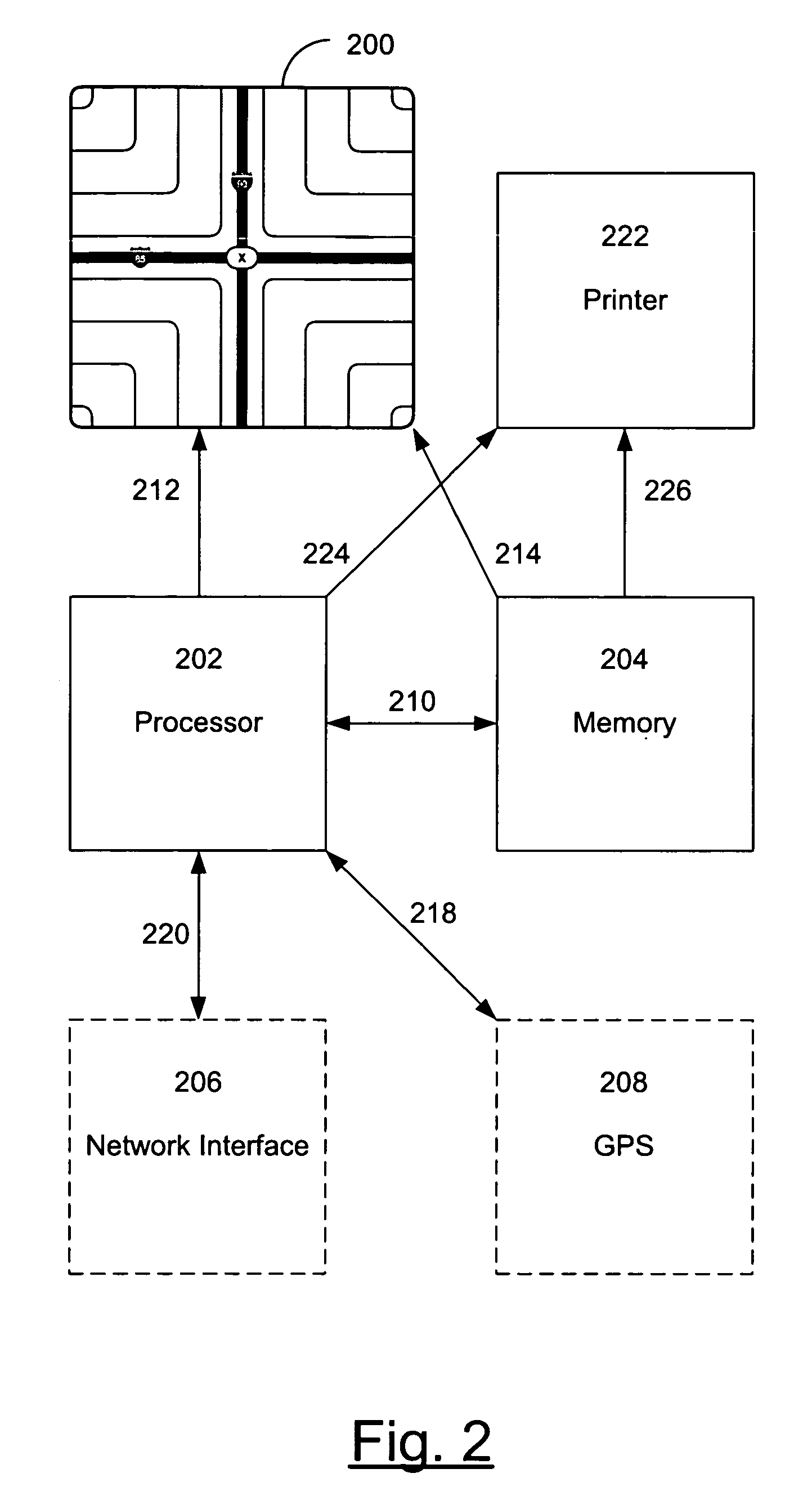

Method and apparatus for the display of temporal distance data

An electronic device is built including a memory, a processor, and a display. The processor is configured to calculate an array of estimated travel time data from a first location to a plurality of locations within a destination area from a set of situational parameters and a set of user parameters. These situational parameters may include data such as: the location, condition, and speed limits of roads and paths; the availability of public transportation; terrain information such as elevation, slope, the presence of trails and vegetation; and weather information such as wind speed and precipitation. User parameters may include data such as: the user's mode of transportation, the user's physical abilities, and the load the user is carrying.

Owner:QUALCOMM INC

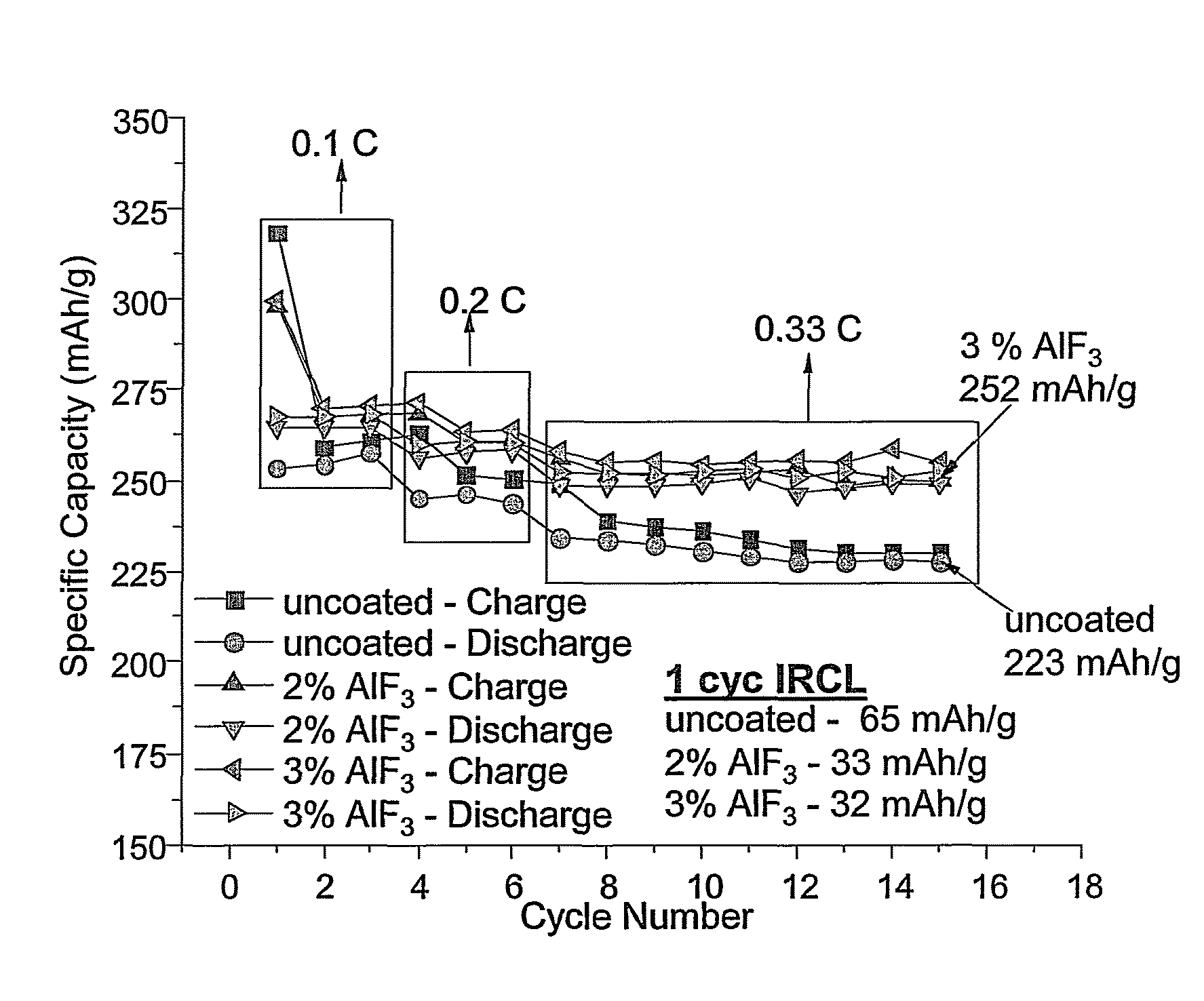

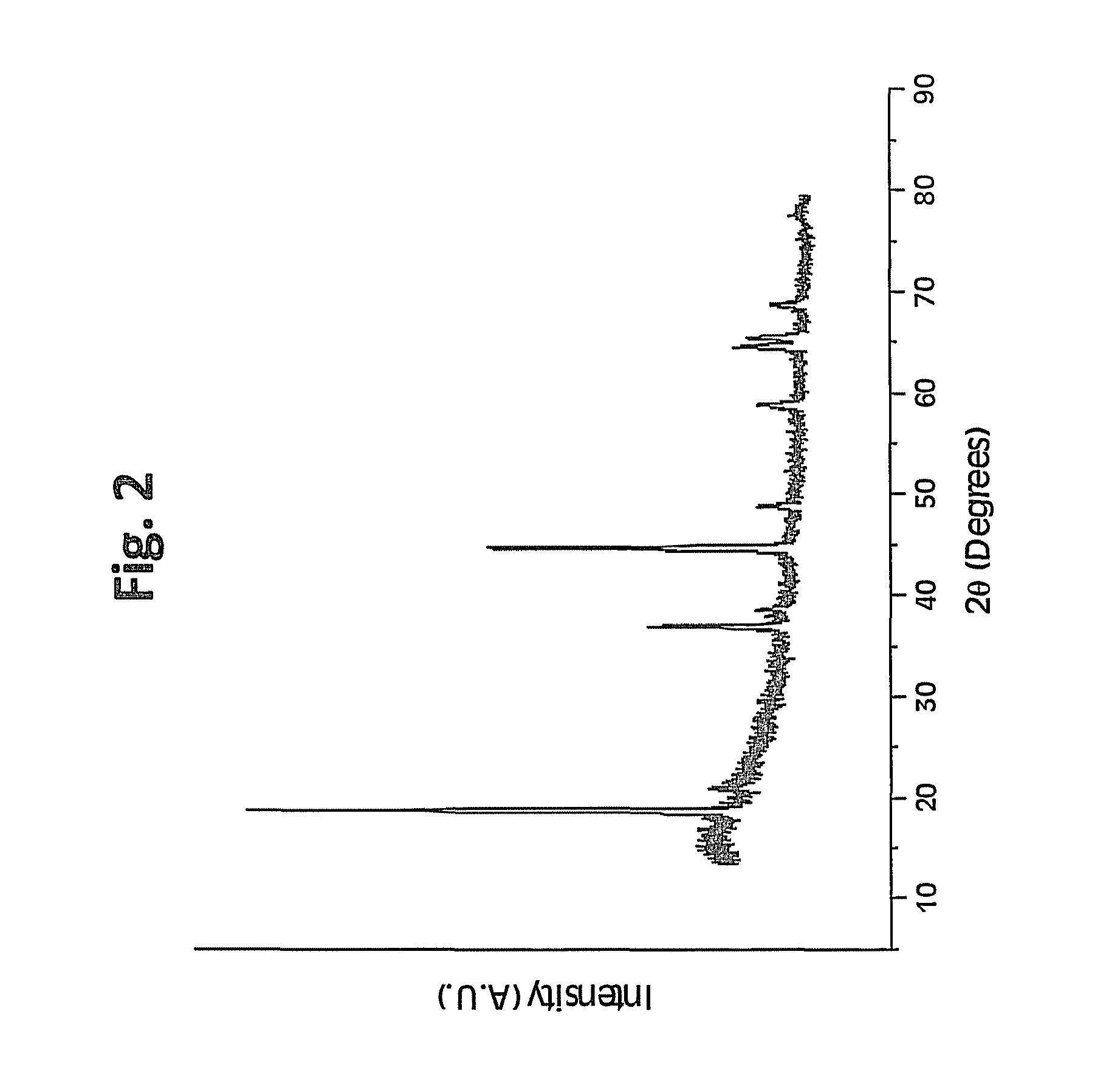

Positive electrode materials for lithium ion batteries having a high specific discharge capacity and processes for the synthesis of these materials

ActiveUS8389160B2Electrode manufacturing processesAlkali metal oxidesElectrical batteryDischarge rate

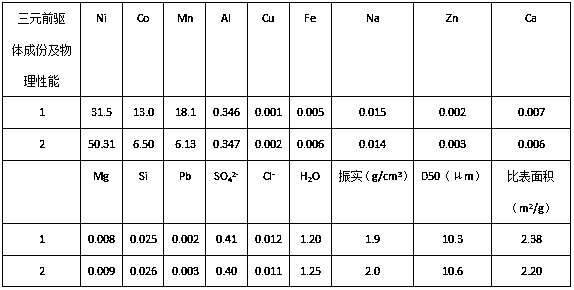

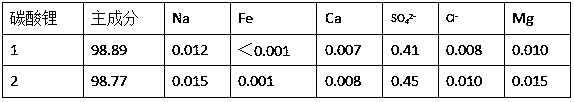

Positive electrode active materials are described that have a very high specific discharge capacity upon cycling at room temperature and at a moderate discharge rate. Some materials of interest have the formula Li1+xNiαMnβCOγO2, where x ranges from about 0.05 to about 0.25, α ranges from about 0.1 to about 0.4, β ranges from about 0.4 to about 0.65, and γ ranges from about 0.05 to about 0.3. The materials can be coated with a metal fluoride to improve the performance of the materials especially upon cycling. Also, the coated materials can exhibit a very significant decrease in the irreversible capacity lose upon the first charge and discharge of the cell. Methods for producing these materials include, for example, a co-precipitation approach involving metal hydroxides and sol-gel approaches.

Owner:IONBLOX INC

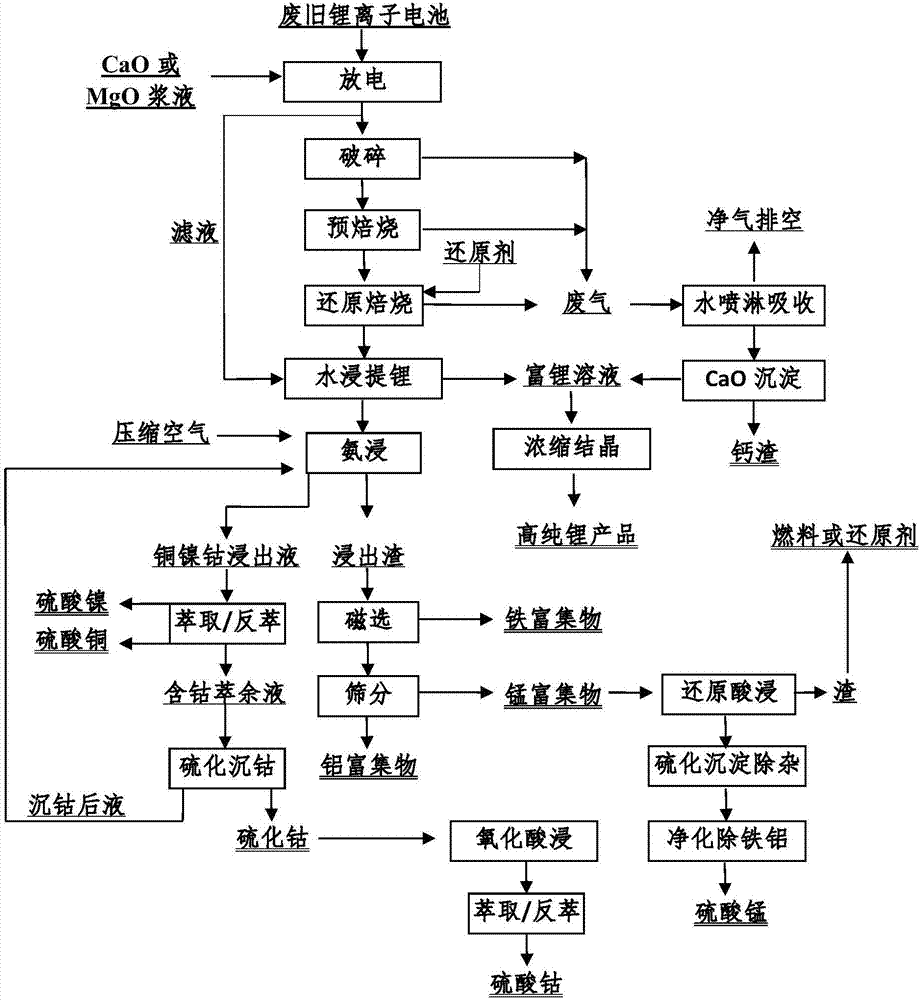

Method for comprehensively recycling valuable metals from spent lithium ion battery

ActiveCN107017443AThe pre-processing process is simpleHigh recovery rateWaste accumulators reclaimingProcess efficiency improvementVulcanizationSlag

The invention discloses a method for comprehensively recycling valuable metals from a spent lithium ion battery. The method comprises the following steps: carrying out electric discharge treatment on a spent battery, crushing, pre-roasting at 300-400 DEG C, adding a reducing agent, and carrying out reduction roasting at 450-700 DEG C; carrying out water extraction and evaporative crystallization on fine aggregates obtained through the reduction roasting, so as to obtain a high-purity lithium product, leaching copper, nickel and cobalt from leached slag and roasted lump materials by virtue of ammonia oxide, carrying out magnetic separation and sieving on ammonia leaching slag so as to obtain iron and aluminum enriched products, and carrying out reduction acid leaching, purification and edulcoration on sieved products, so as to obtain a high-purity manganese sulfate solution; and carrying out extraction and selective reverse extraction on ammonia leaching liquid, so as to obtain a high-purity nickel sulfate solution and a high-purity copper sulfate solution, and carrying out vulcanization cobalt precipitation, oxidation acid leaching and extraction purification on raffinate, so as to obtain a high-purity cobalt sulfate solution. The method is high in extraction rate of valuable metals and applicable to the treatment of multiple waste lithium ion battery raw materials and efficient utilization of multiple elements, and sorting is not required.

Owner:GUANGDONG GUANGHUA SCI TECH

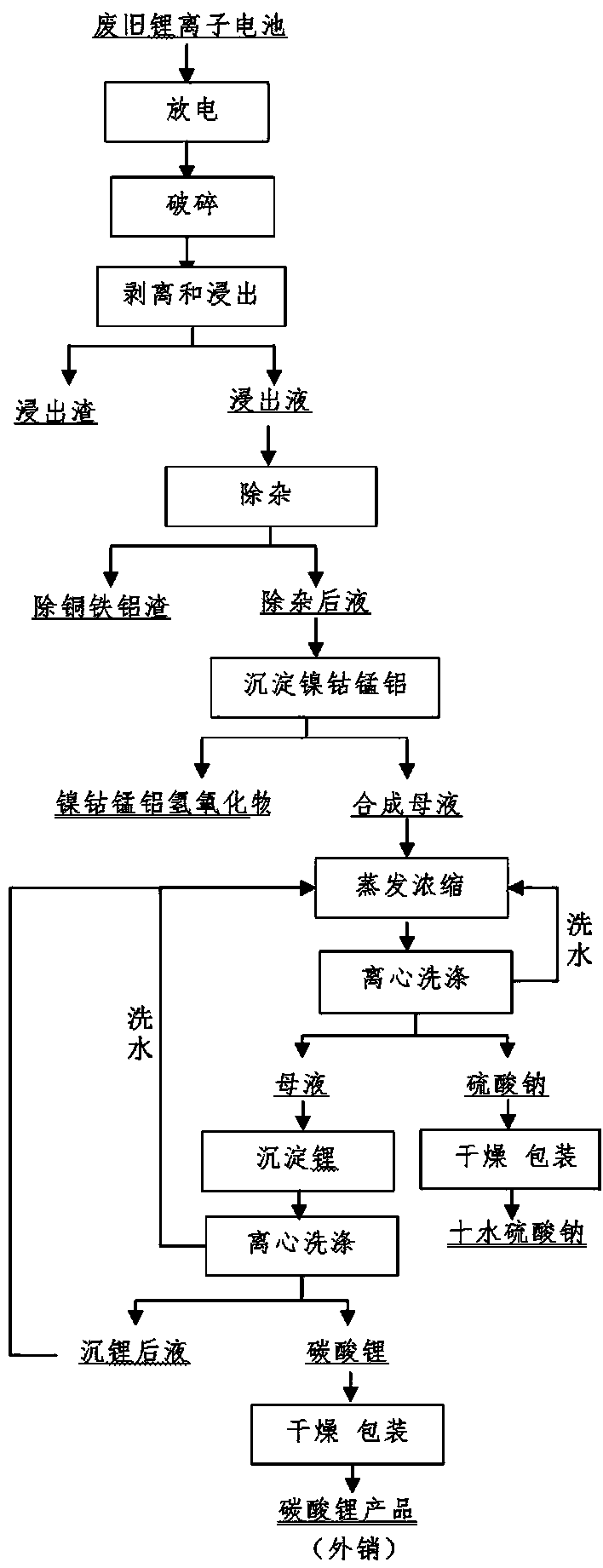

Recycling method for valuable metal from waste nickel-cobalt-manganese lithium ion battery

InactiveCN107653378AReduce lossesLess investmentWaste accumulators reclaimingProcess efficiency improvementSlagManganese

The invention relates to a method for recycling valuable metal from a waste nickel-cobalt-manganese lithium ion battery. The method comprises the following steps of: dismounting, discharging and crushing the battery, soaking crushed waste nickel-cobalt-manganese lithium ions into sulfuric acid with certain concentration, adding a reducing agent to strip positive and negative pole pieces, and leaching valuable metals of nickel, cobalt, manganese and lithium; and replacing leach liquor with iron powder to remove copper, carrying out hydrolyzing to remove iron and aluminum, and dosing an impurity-removed solution to synthesize an aluminum coated nickel, cobalt and manganese ternary positive electrode material precursor, evaporating and concentrating the synthesized solution, adding carbonateor introducing carbon dioxide to recycle lithium. According to the method disclosed by the invention, stripping and leaching are synchronously completed, chemical precipitation is performed to removecopper, iron and aluminum, slag amount is small, slag filter performances are good, and the impurity-removed solution is used for synthesizing the aluminum coated nickel, cobalt and manganese ternaryprecursor, so that the recovery rate of valuable metal is increased; and the recovery rate for nickel, cobalt and manganese is 96% or higher in the whole process, the total recovery rate of lithium is90% or higher, the technological process is short, operation is simple, equipment is less, and the cost is low.

Owner:JINCHUAN GROUP LIMITED +1

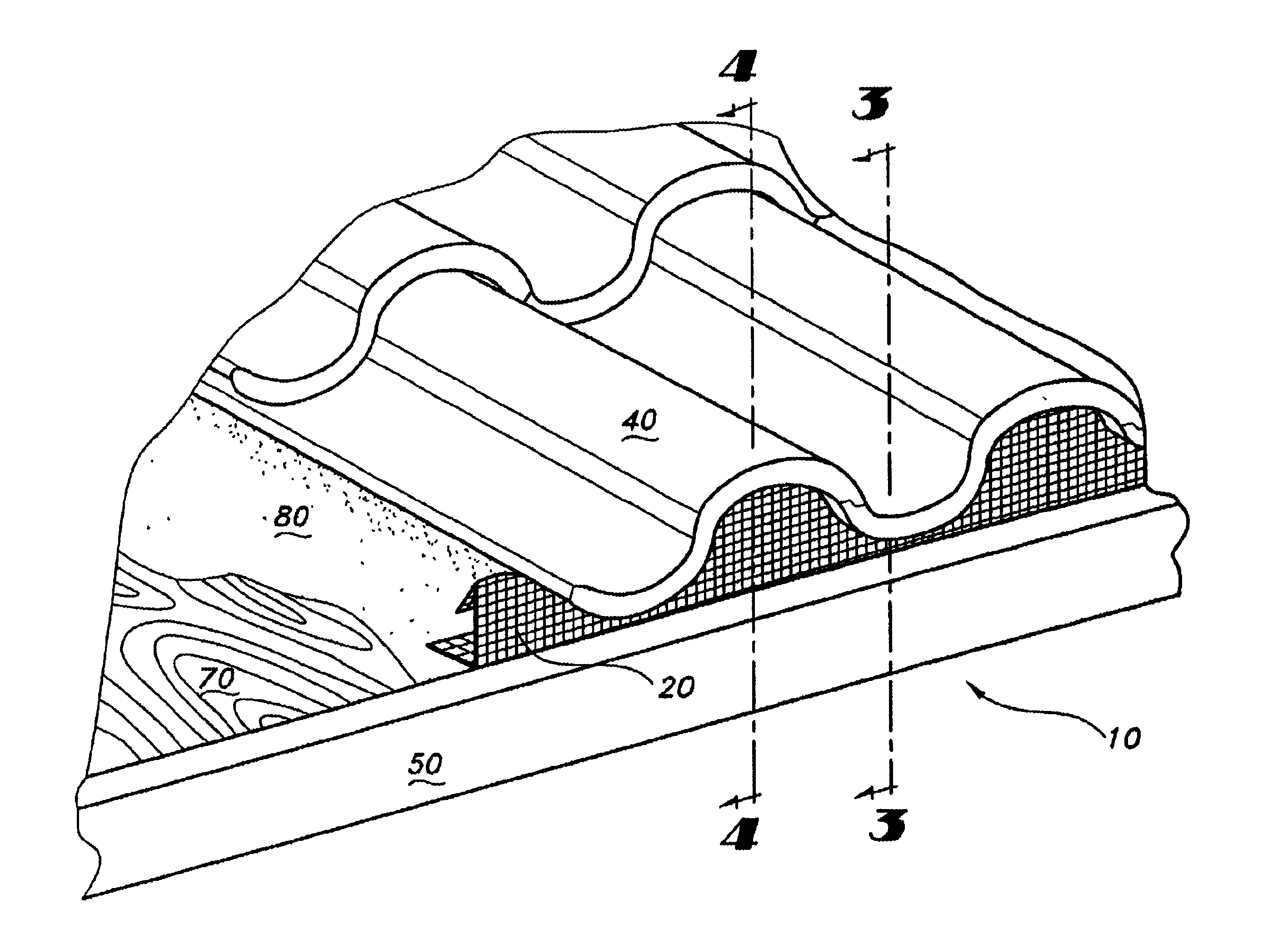

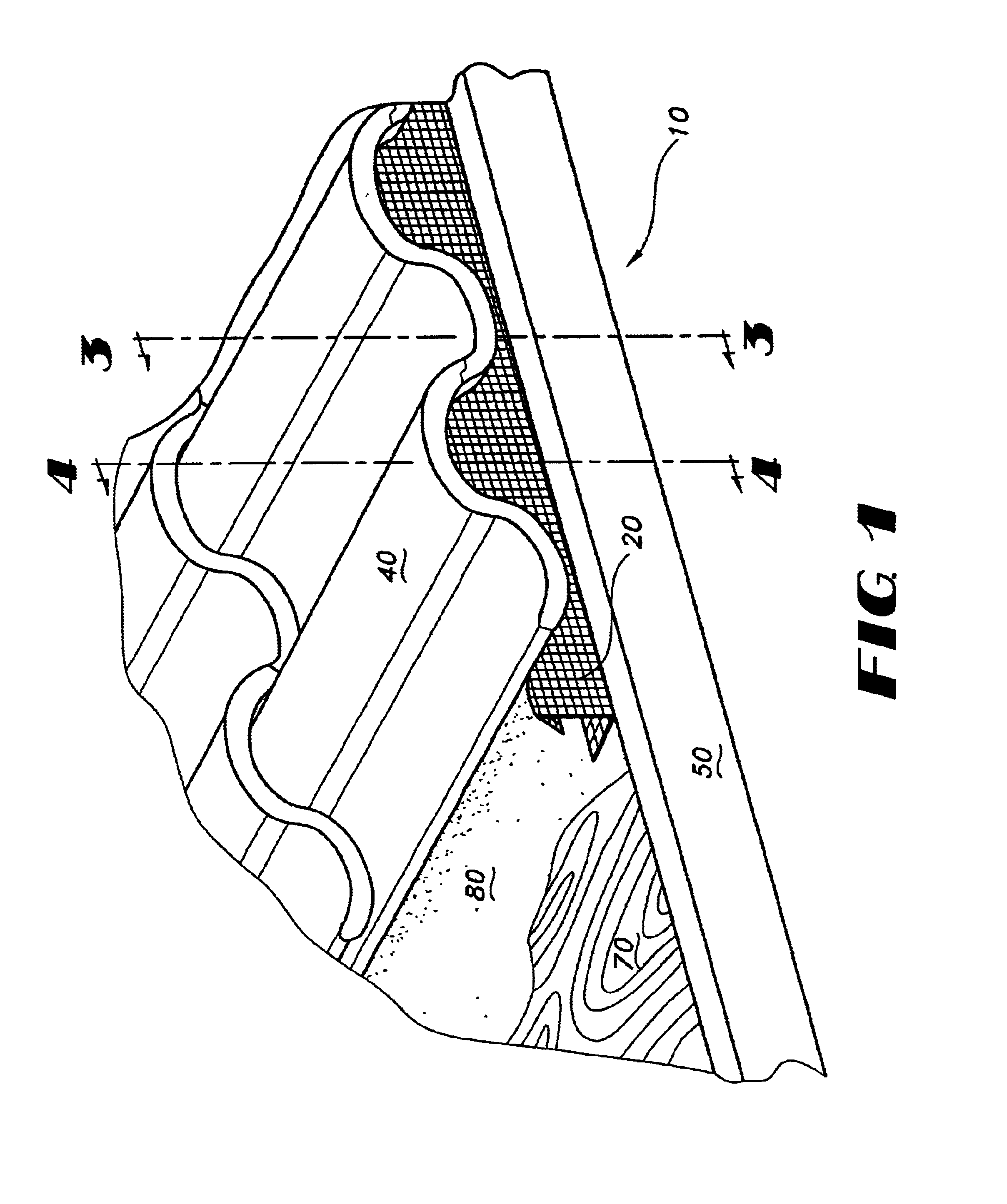

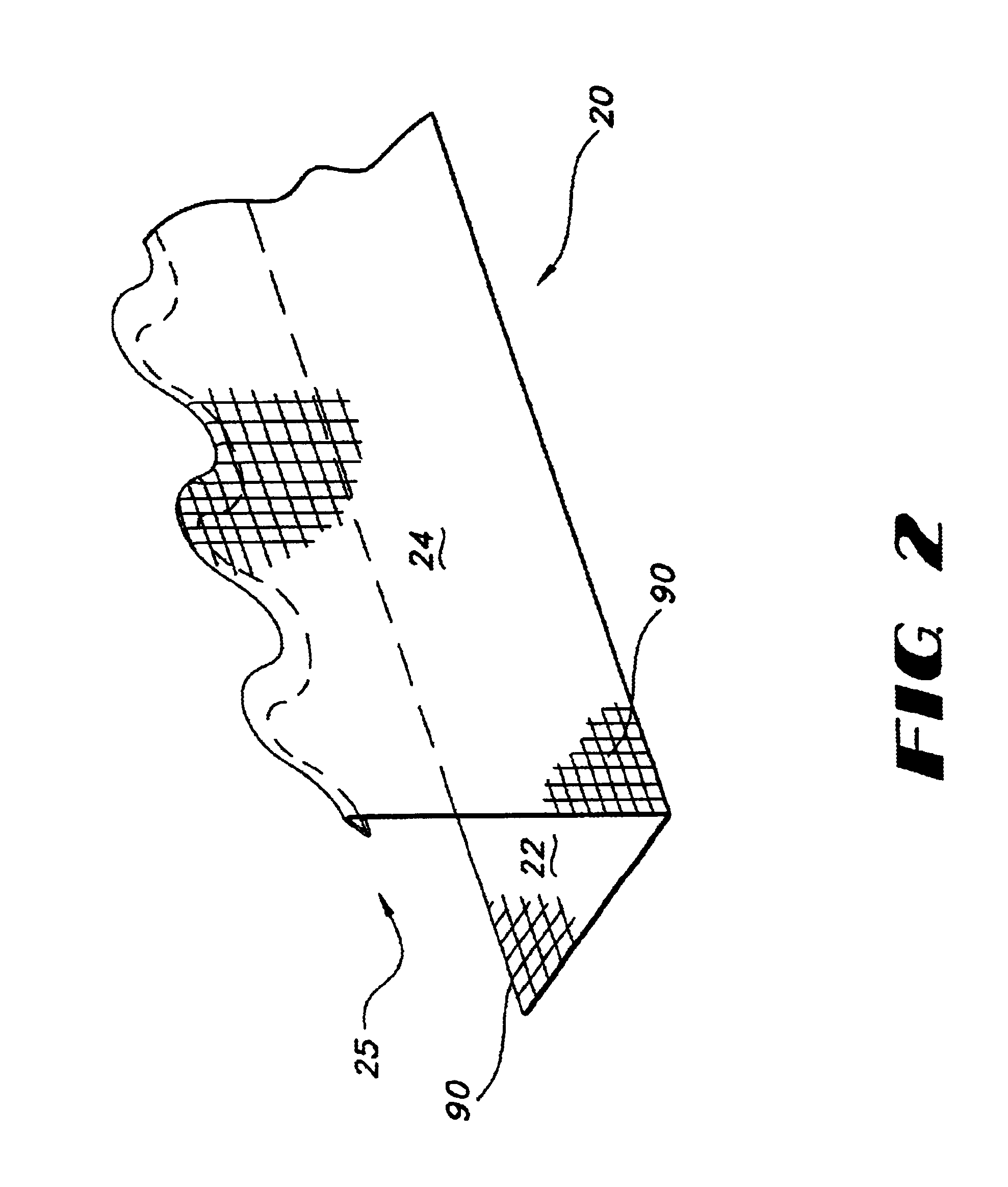

Vented eaves closure

InactiveUS6941706B2Increase air circulationMinimize heat transferRoof covering using slabs/sheetsBuilding roofsWind drivenRoof tile

A method is provided for installing a ventilated eaves closure and tile support apparatus along the eaves of a roof. A vented eaves closure apparatus is disposed along the eaves to support the first course of roof tiles at a desired pitch. The apparatus provides support, ventilation, and drainage, while also providing a barrier to wind-driven precipitation, bird nesting, and animal invasion. The apparatus includes an array of openings configured to allow drainage and facilitate the flow of air beneath the tiles and throughout the air space between the roof deck and the tiles. The method and apparatus can be adapted to fit a variety of roof types and roof tiles having different sizes, shapes, and profiles.

Owner:BORAL LIFETILE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com