Patents

Literature

754results about How to "High polymerization activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

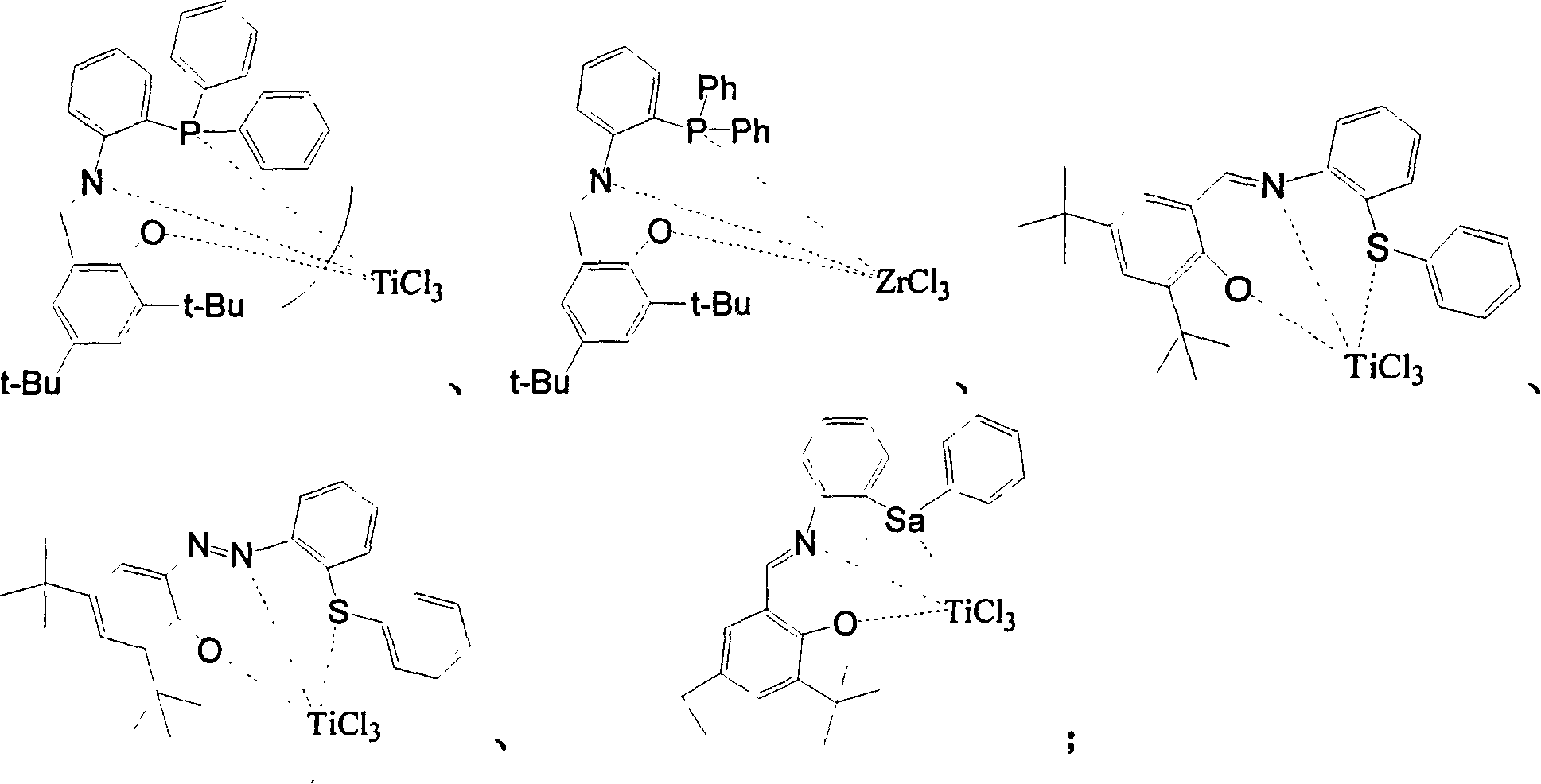

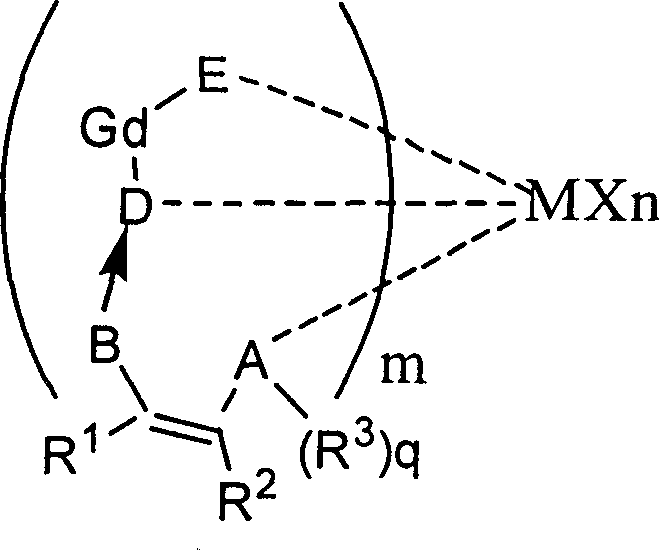

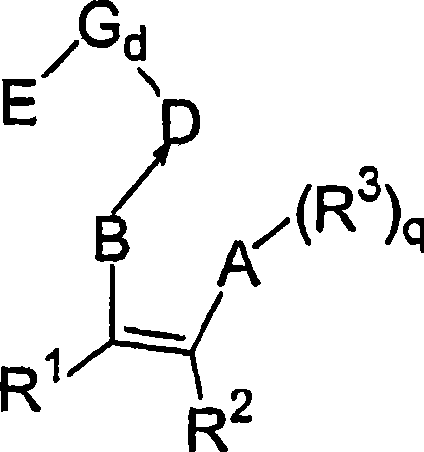

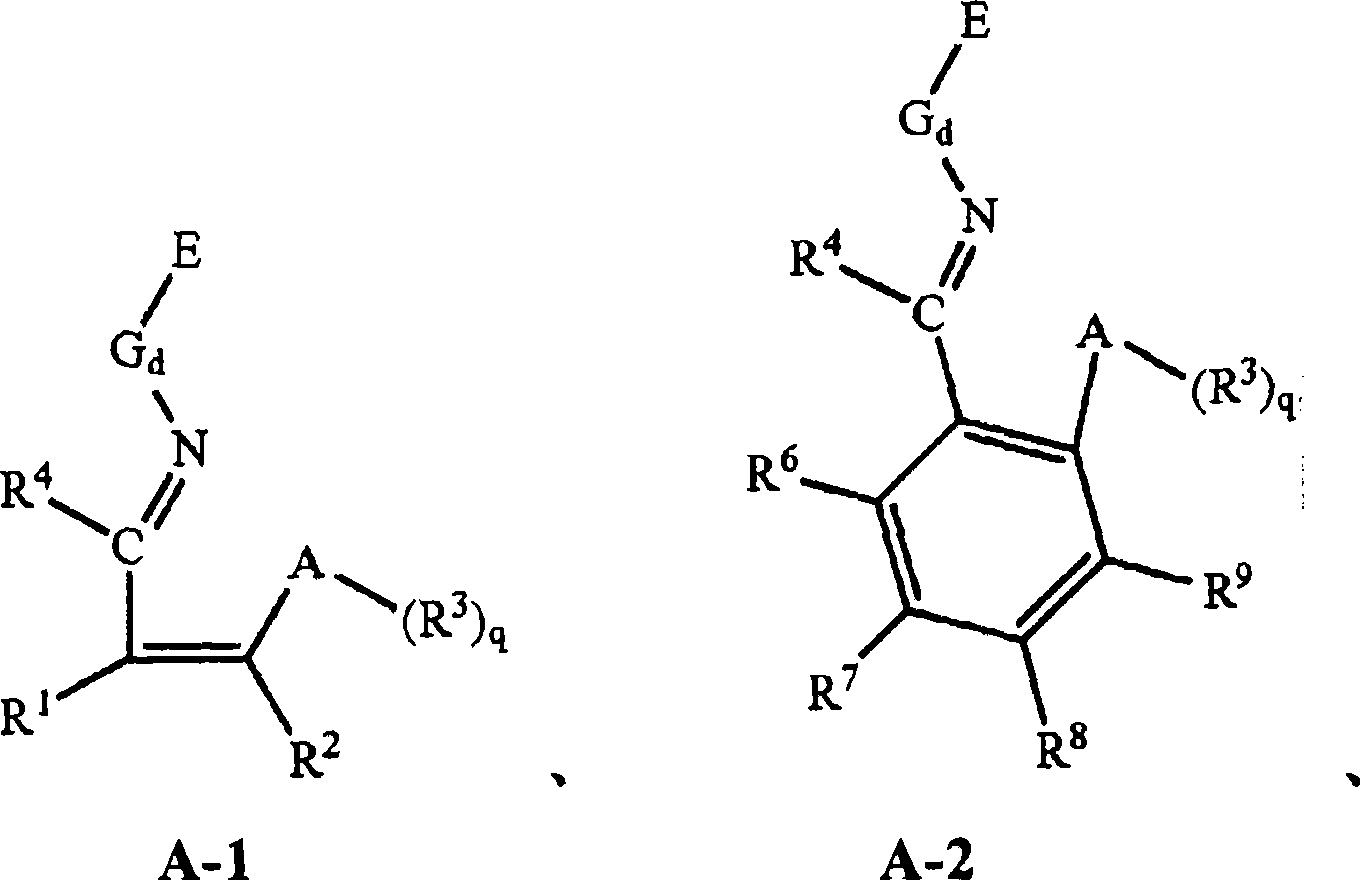

Carry type non-metallocene calalyst for polymerization of olefine, its preparation method and uses

The invention discloses an equivoluminal dipping loading method of non-metallocene olefin polymeric catalyst as well as application of copolymerizing course within two or more different olefins, which comprises the following steps: dissolving non-metallocene olefin polymeric catalyst in the solvent; mixing solution and carrier; stirring wet solid material evenly; drying; obtaining the load-typed non-metallocene olefin polymeric catalyst; making the solvent and carrier satisfy specific relationship.

Owner:SINOPEC YANGZI PETROCHEM

Olefinic polymerization and copolymerization method of supported non-metallocene catalyst

A method of alkene polymerization and copolymarization with f load non- metallocene catalyst: emplying the load non- metallocene catalyst and catalyst promoter forming the catalytic system, introducing polymer monomer or comonomer for alkene polymerization or copolymarization; adding the load non- metallocene catalyst into dissolvent and mixing with catalyst promoter and then transferring the mixture into polymerization reactor, or adding the load non- metallocene catalyst and catalyst promoter into the polymerization reactor in order or simultaneously. The catalyst promoter is chosen from: alkyl aluminium, aluminium oxane, Lewis acid, boralotano, alkyl borane or alkyl borane ammonium salt. The load non- metallocene catalyst is loaded to multiple poral solid by employing methods of solution dipping, equivoluminal dipping or solution dipping-before-equivoluminal dipping to form organic integral of property stable and strong binding force. The invention is characterized by the high alkene polymerization active, high fusion point and good normalization of the produced polymer, and the sastification of the demand of high level product production.

Owner:YANGZI PETROCHEM

Magnesium compound load type non-metallocene catalyst and preparation thereof

The invention relates to a magnesium compound supported non-metallocene catalyst, which is obtained by directly contacting a compound of catalytic active metal and a magnesium compound containing a non-metallocene ligand through an in-situ supporting method. The preparation method for the magnesium compound supported non-metallocene catalyst has simple, feasible and flexible process, and has more adjustable parameters to the polymerization activity of the catalyst. When the supported non-metallocene catalyst and a catalyst promoter are adopted to form a catalytic system for the homopolymerization / copolymerization of olefins, the obtained polymer has high bulk density and low ash, and the molecular weight distribution of the polymer has wide adjustable range.

Owner:SINOPEC YANGZI PETROCHEM

Magnesium compound load type non-metallocene catalyst and preparation thereof

The invention relates to a magnesium compound supported non-metallocene catalyst, which is obtained by directly contacting a non-metallocene ligand and a magnesium compound containing transition metal through an in-situ supporting method. The preparation method for the magnesium compound supported non-metallocene catalyst has simple and feasible process, and the supporting capacity and the polymerization activity of the catalyst have wide adjustable range. When the magnesium compound supported non-metallocene catalyst is combined with a catalyst promoter to catalyze the homopolymerization / copolymerization of olefins, high polymerization activities of the olefins can be obtained only by using small amount of the catalyst promoter.

Owner:SINOPEC YANGZI PETROCHEM

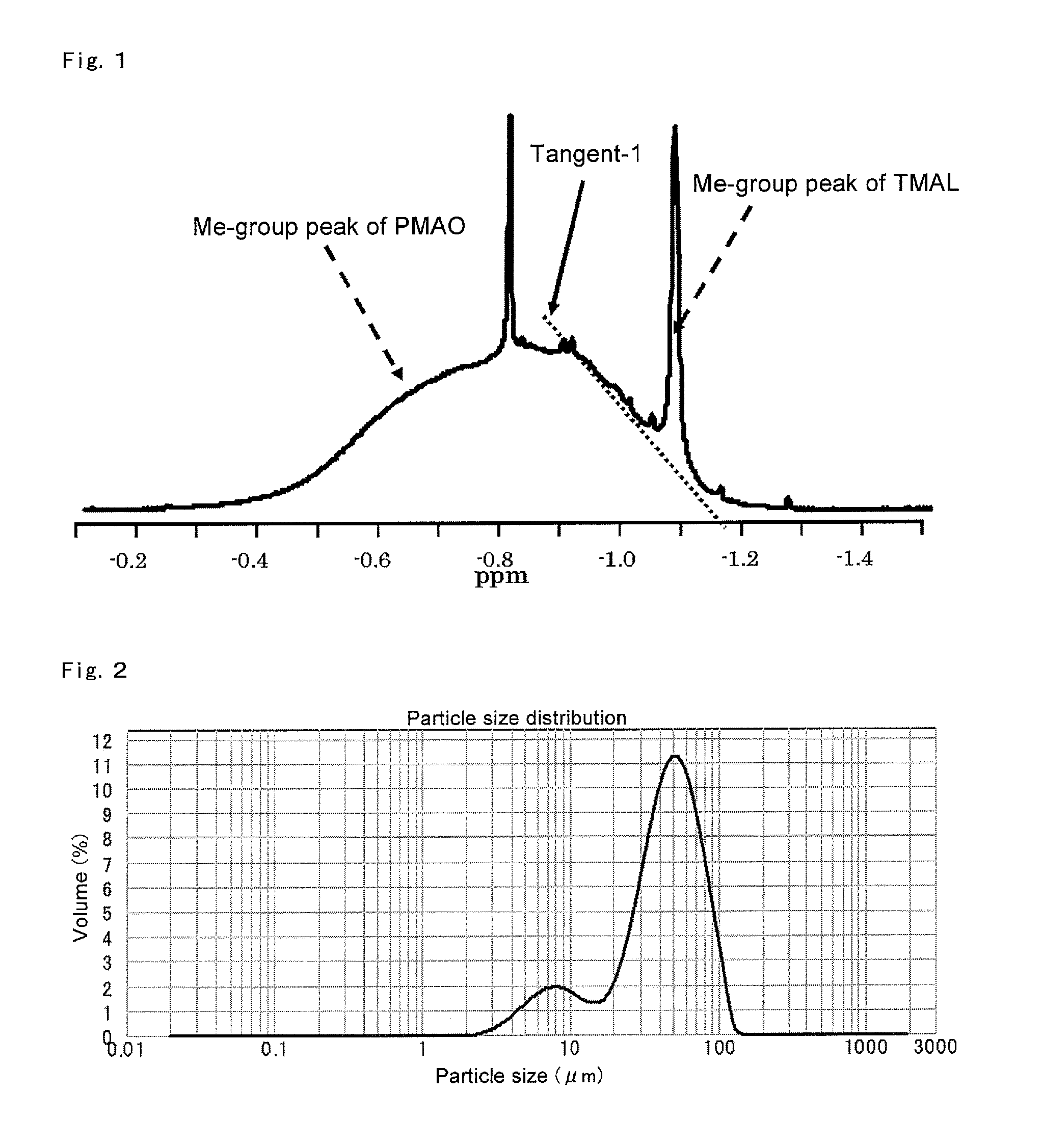

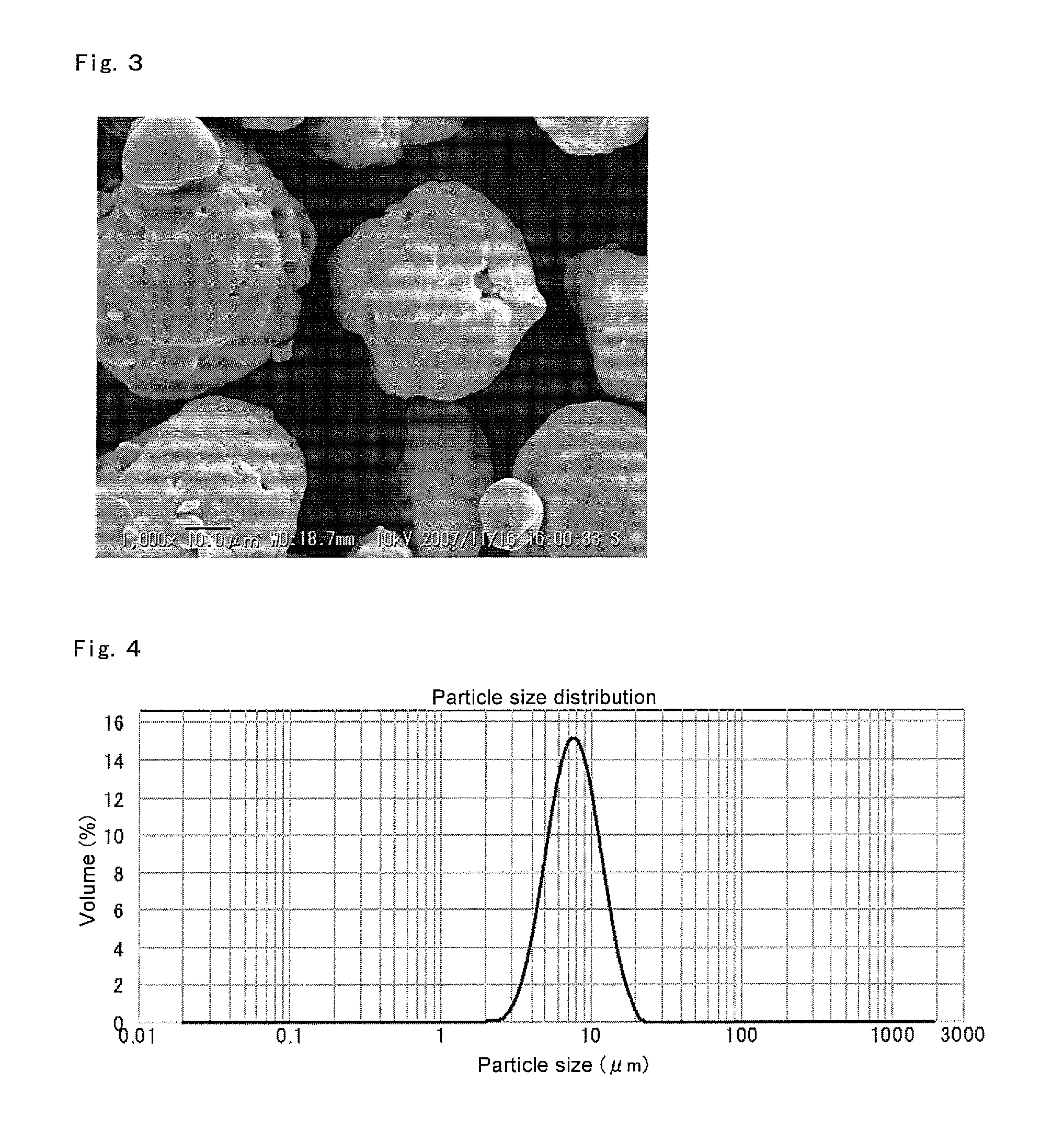

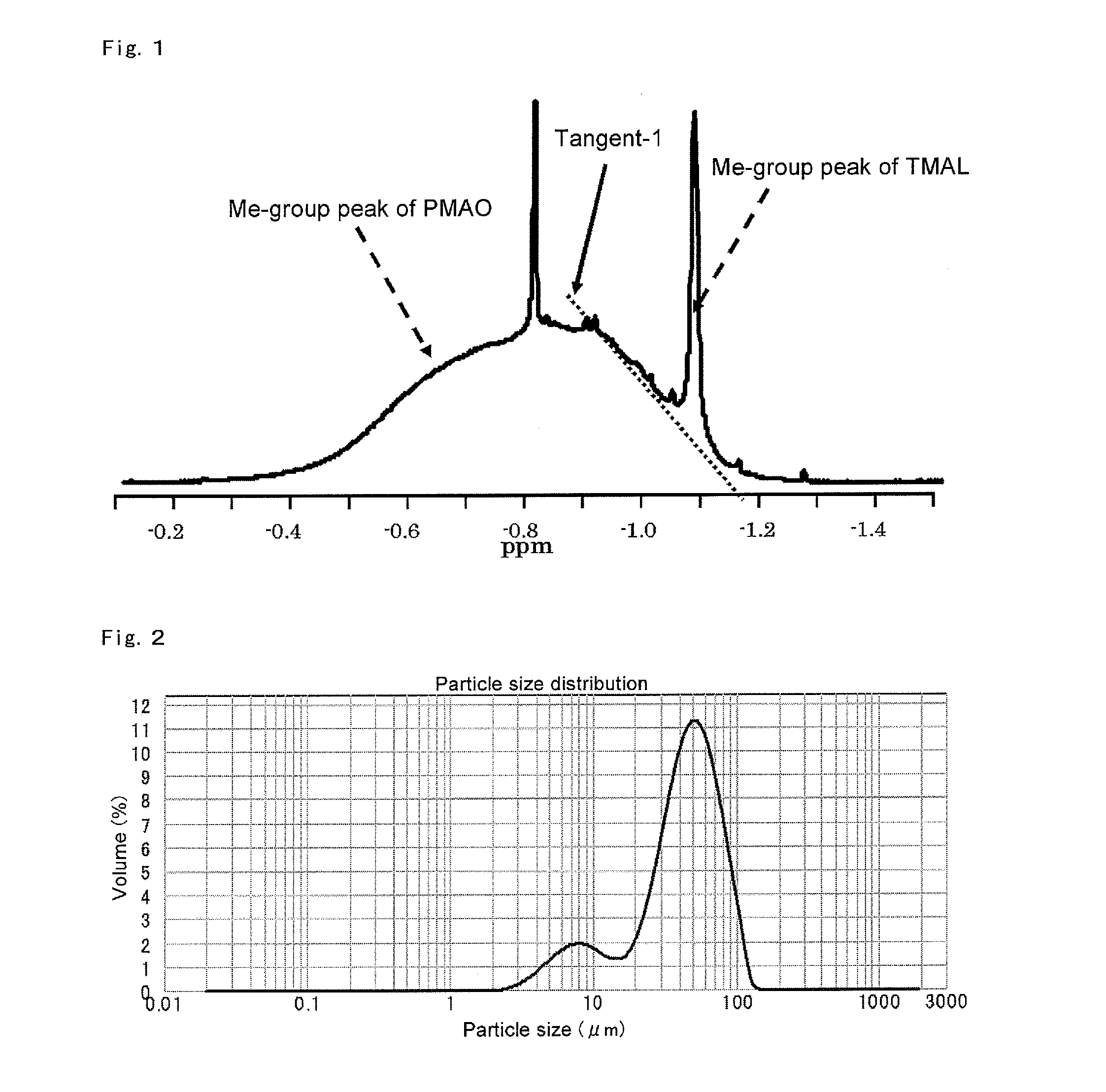

Solid polymethylaluminoxane composition and method for manufacturing same

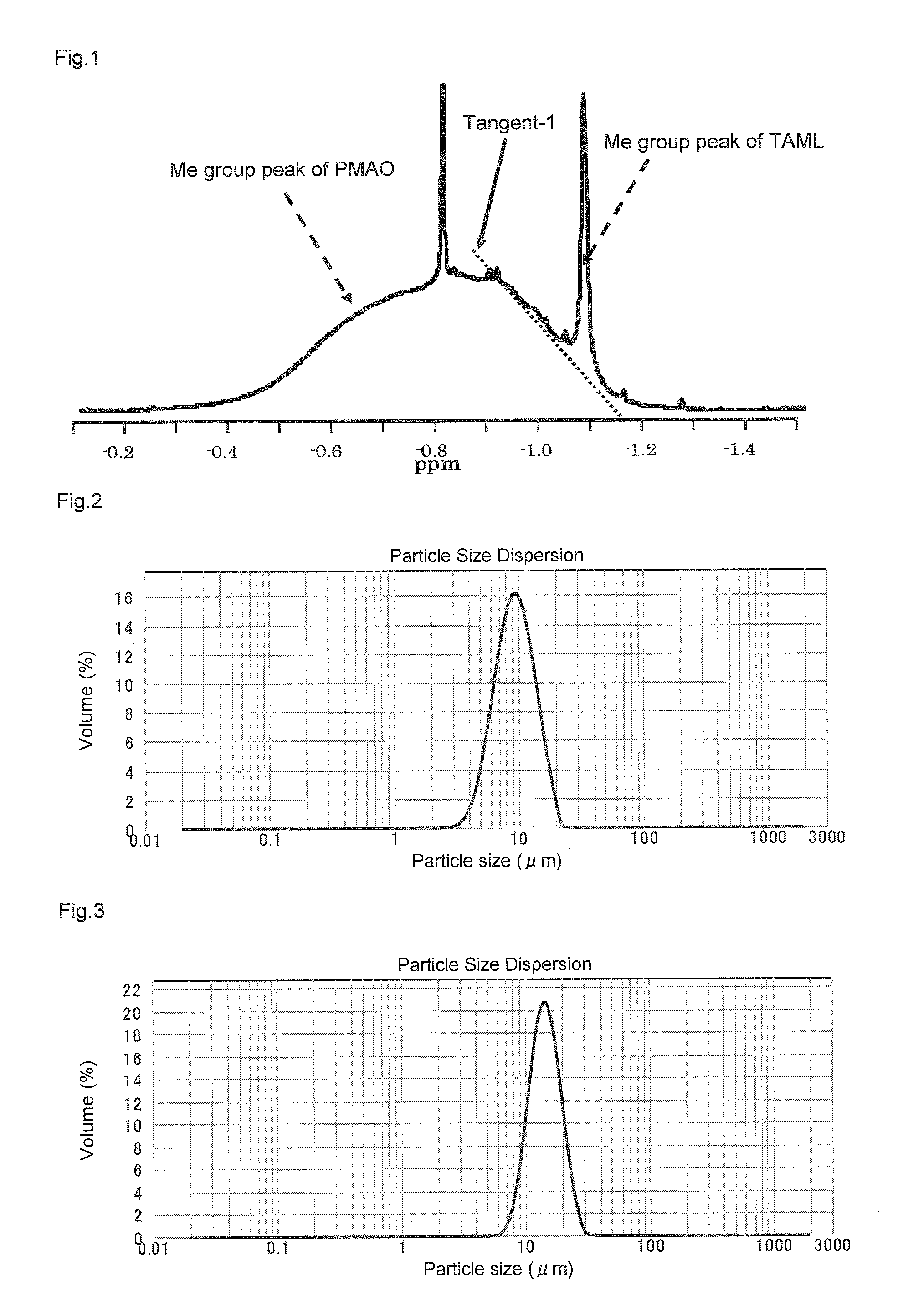

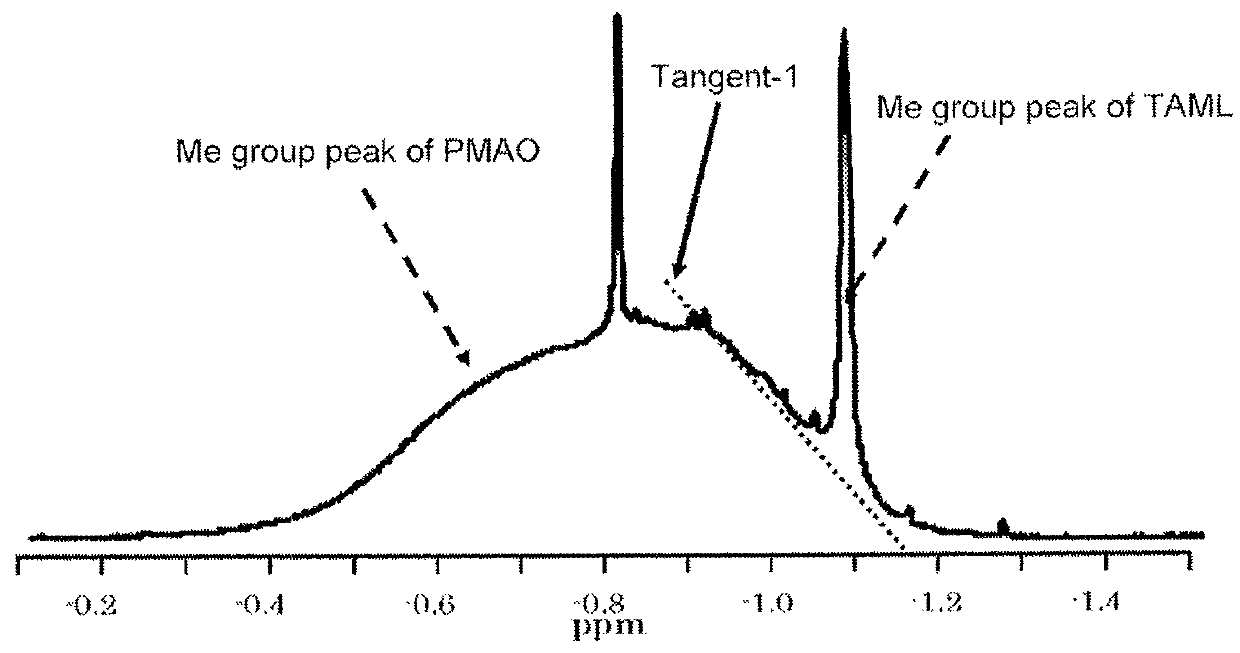

ActiveUS8404880B2High polymerization activityReduce solubilityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationOlefin polymerizationMethyl group

Owner:TOSOH FINECHEM CORP

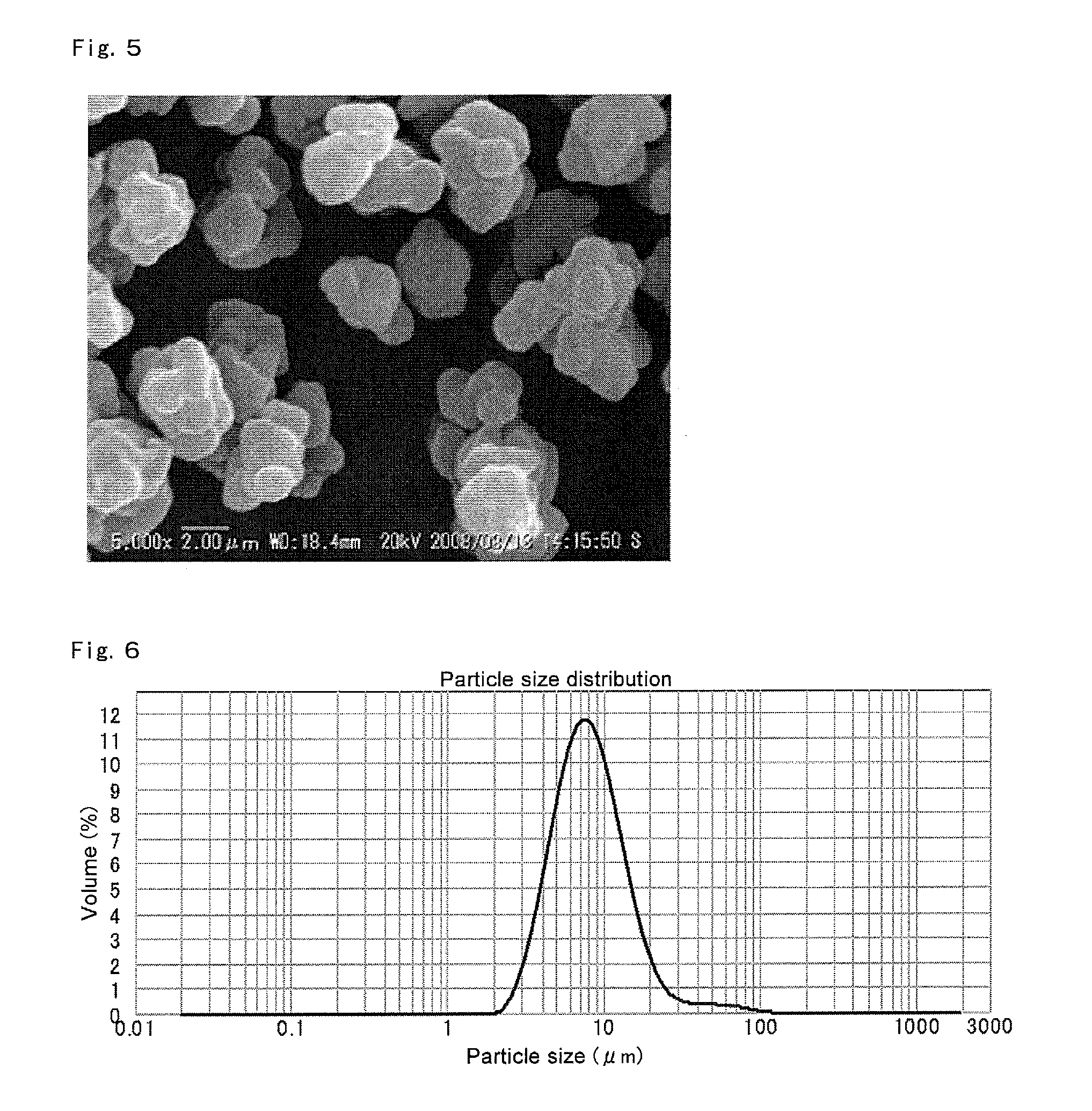

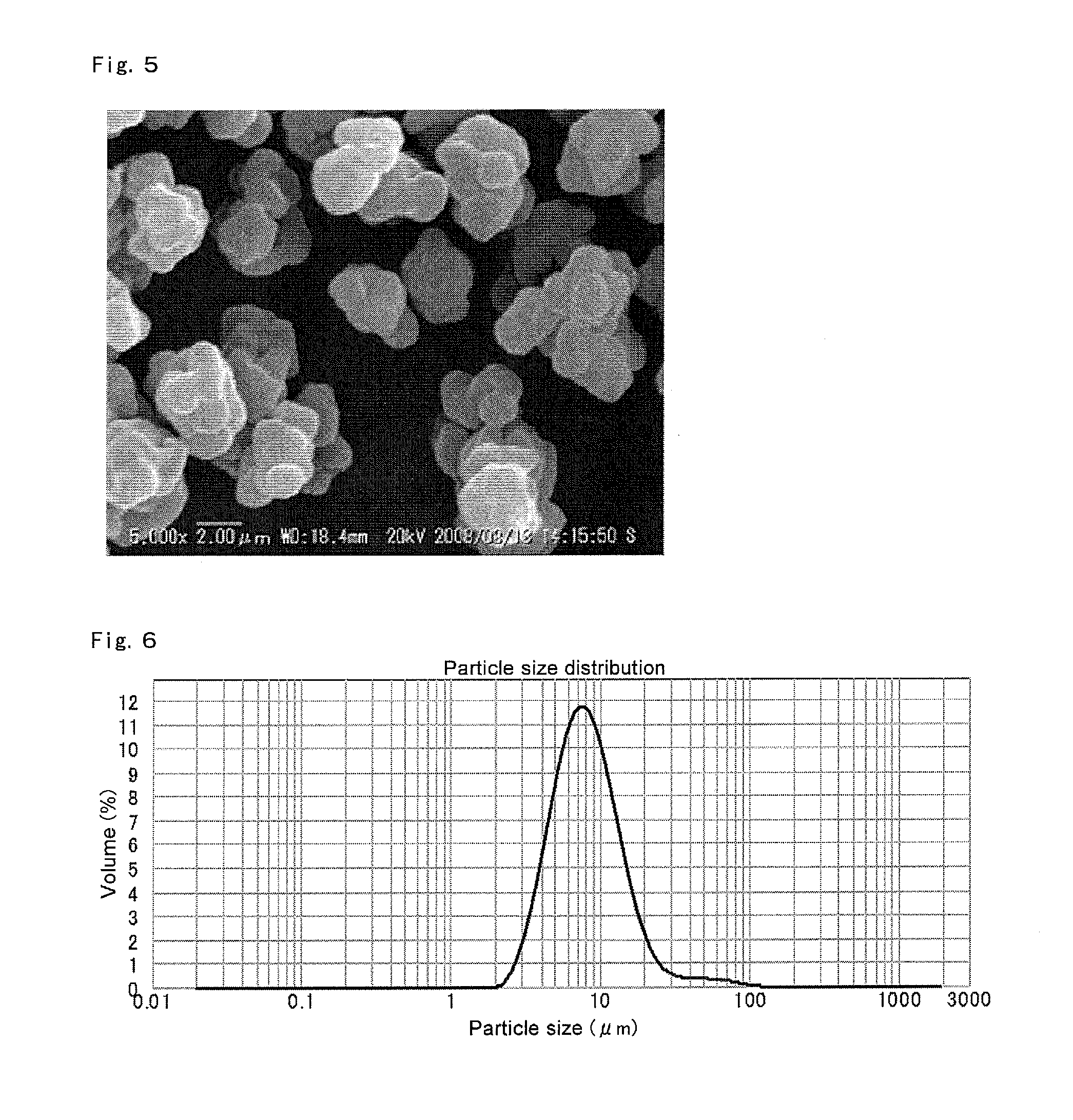

Method for manufacturing a small particle diameter product of solid polymethylaluminoxane composition

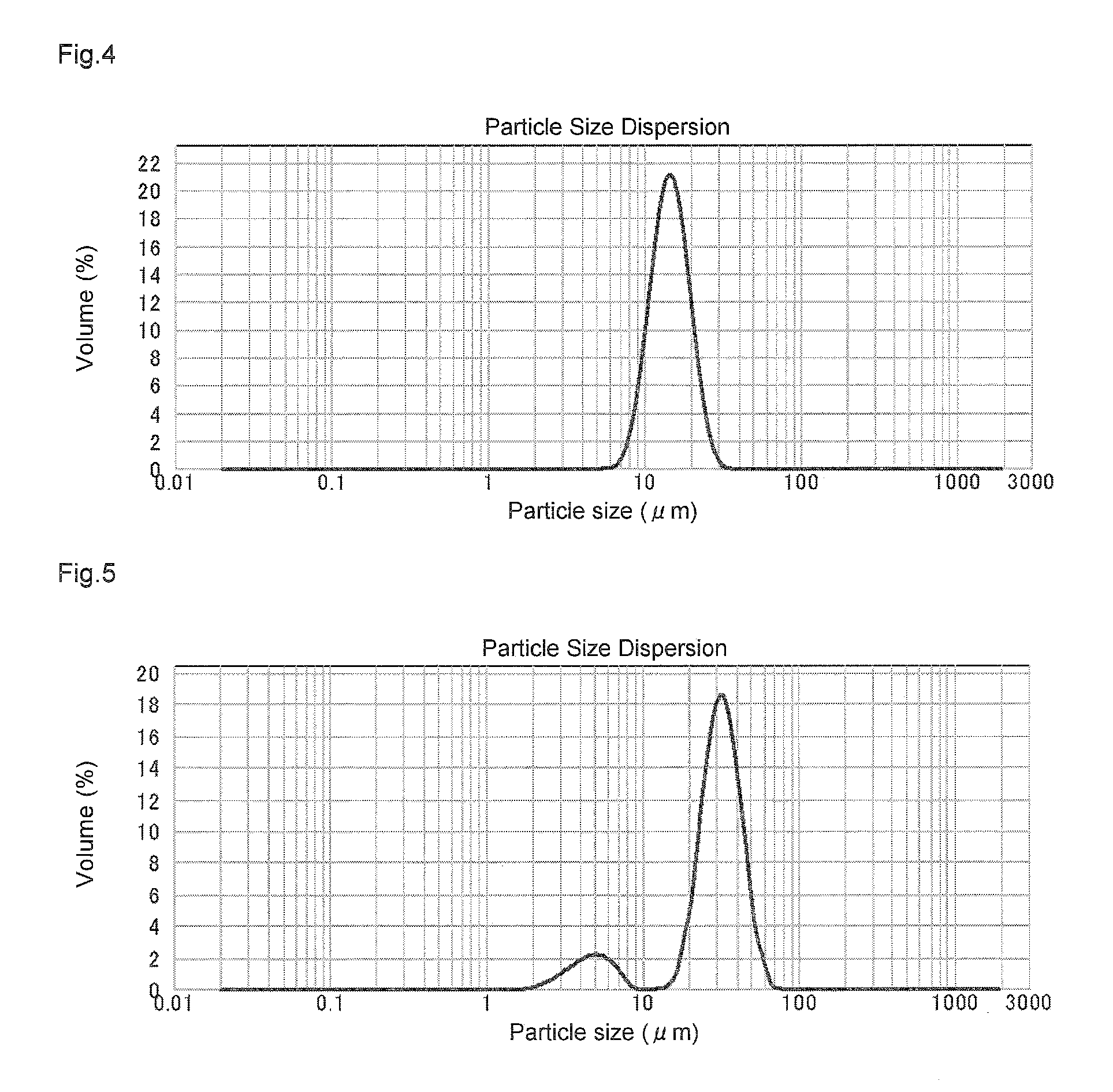

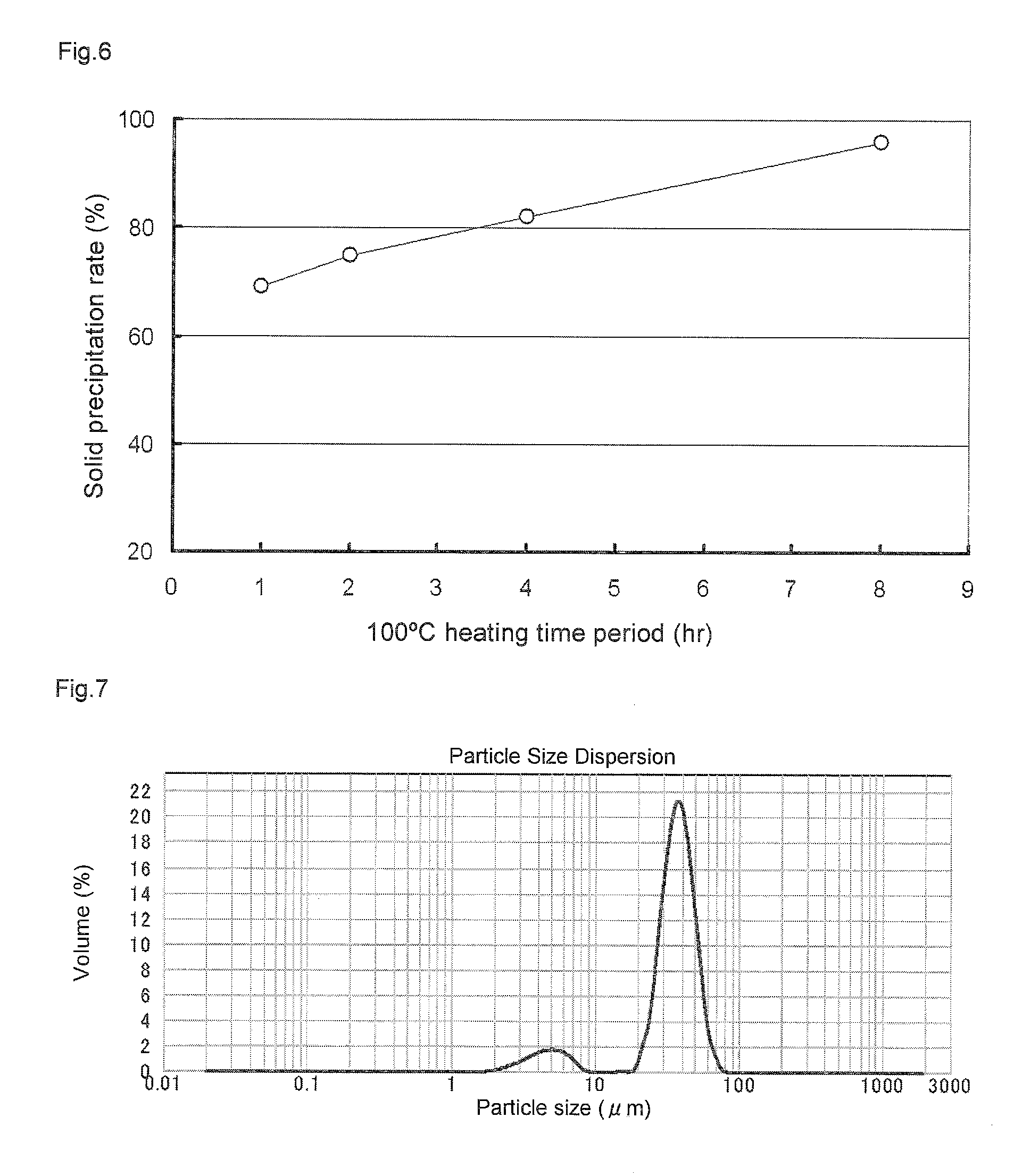

ActiveUS9340630B2Easy to optimizeHigh yieldGroup 3/13 element organic compoundsThin material handlingParticulatesDiameter product

A solid polymethylaluminoxane composition is provided having uniform particle diameter in the form of fine particles of less than 5 μm employed to polymerize olefins with high polymerization activity without silica. A method for manufacturing thereof, a polymerization catalyst, and a method for manufacturing a polyolefin are also provided. The solid polymethylaluminoxane composition: has an aluminum content within a range of 36 mass % to 43 mass %; has a mole fraction of methyl groups derived from trimethylaluminum moieties relative to the total number of mols of methyl groups of 12 mol % or less; and is particulate having a median diameter based on volume within a range of 0.1 μm to less than 5 μm. In a step of heating an aromatic hydrocarbon solution containing trimethylaluminum and the polymethylaluminoxane to cause solid polymethylaluminoxane composition to precipitate, prior to or during the heat treating step, a dry, inert gas is bubbled through.

Owner:TOSOH FINECHEM CORP

Supported non-metallocene catalyst as well as preparation method and application thereof

ActiveCN102039184AComposition is easy to controlThe content is easy to controlOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationChemical treatmentAlkene

The invention relates to a supported non-metallocene catalyst and a preparation method thereof. The catalyst has the characteristics of simple and practical preparation method, flexible and adjustable polymerization activity and the like, and the non-metallocene compound in the catalyst and the chemical treatment agent have synergy beneficial to giving play to activity. The invention also relatesto an application of the supported non-metallocene catalyst in olefin homopolymerization / copolymerization. Compared with the prior art, the catalyst is characterized in that the dosage of the promoter is less in the application.

Owner:CHINA PETROLEUM & CHEM CORP +1

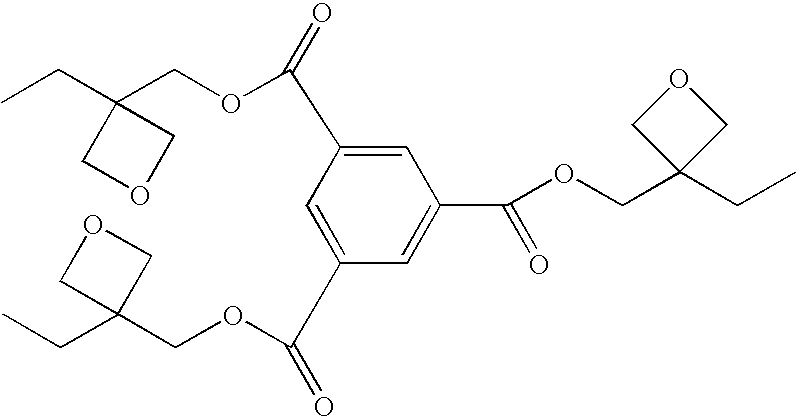

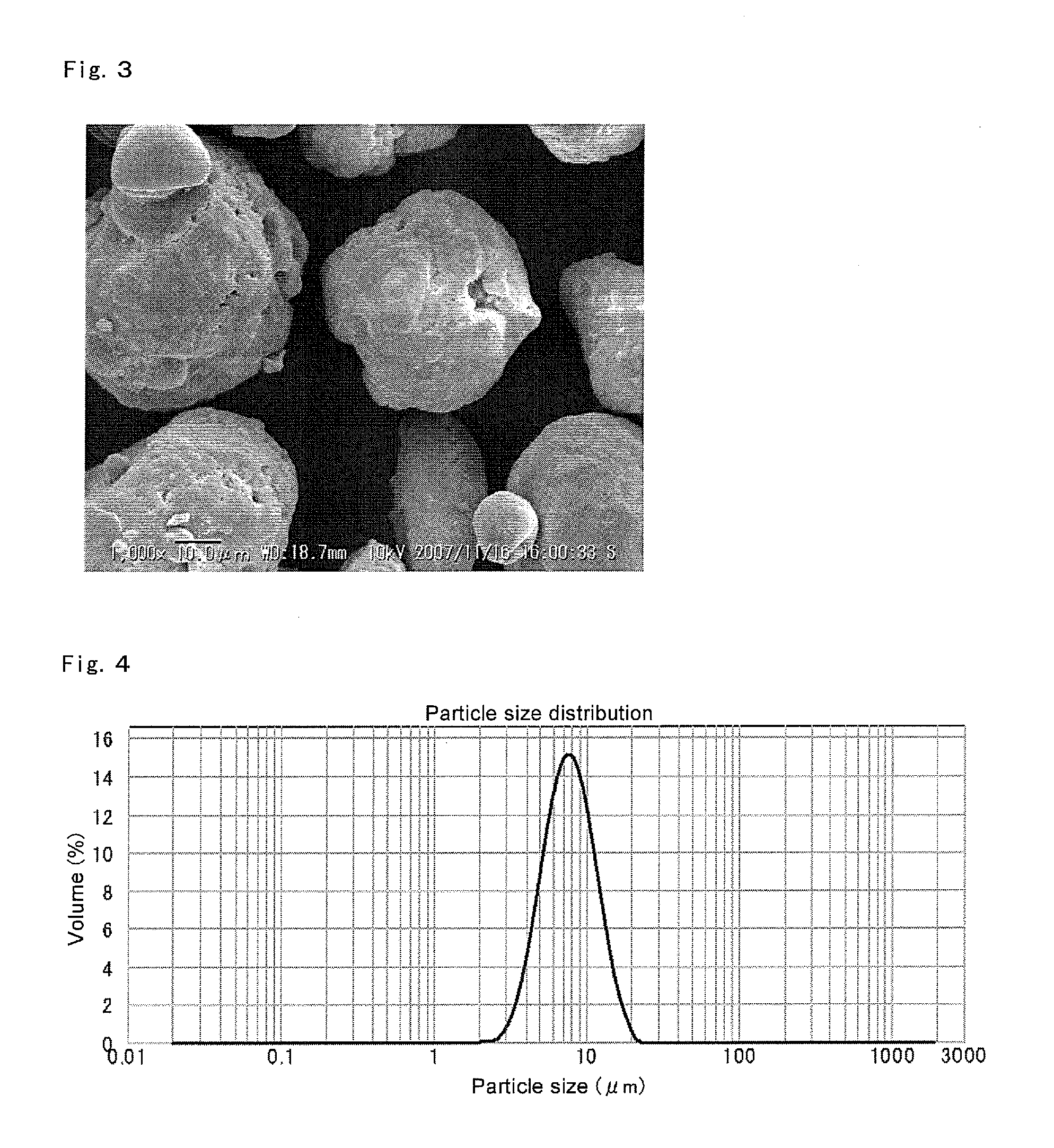

Solid support-polymethylaluminoxane complex, method for producing same, olefin polymerization catalyst, and method for producing polyolefin

ActiveUS8975209B2Conveniently obtainHigh polymerization activityOrganic-compounds/hydrides/coordination-complexes catalystsOrganic chemistry methodsPolyolefinOlefin polymerization

Disclosed is a solid support-polymethylaluminoxane complex exhibiting a higher polymerization activity than a conventional substance and being homogeneous. Also disclosed is a method for producing an olefin-based polymer having a favorable quality using the complex and a transition metal compound. The complex comprises a coating layer containing polymethylaluminoxane and trimethylaluminum on the surface of a solid support. The coating layer comprises a solid polymethylaluminoxane composition in which (i) the content of aluminum is in a range of 36 to 41 mass % and (ii) the molar fraction of methyl groups derived from a trimethylaluminum moiety to the total number of moles of methyl groups is 12 mol % or less. Also disclosed is an olefin polymerization catalyst comprising the complex and a transition metal compound represented by general formula (III): MR5R6R7R8 as catalyst components, and a method for producing a polyolefin comprising polymerizing an olefin using the catalyst.

Owner:TOSOH FINECHEM CORP

Supported non-metallocene catalyst, its preparation method and uses

ActiveCN102039188AThe load is easy to controlSimple processOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationChemical treatmentCompound (substance)

The invention relates to a supported non-metallocene catalyst and its preparation method. The supported non-metallocene catalyst is characterized by simple preparation method, flexible polymerization activity etc. In addition, non-metallocene complexes in the catalyst cooperate with the chemical disposal agent to enhance the activity. The invention also relates to the application of the supportednon-metallocene catalyst in alkene homopolymerization / copolymerization. Less amount of co-catalyst is required in use compared with the prior art.

Owner:CHINA PETROLEUM & CHEM CORP +1

Load type non-metallocene catalyst, preparation method and application thereof

ActiveCN102039191AComposition is easy to controlThe content is easy to controlOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationChemical treatmentOrganic chemistry

The invention relates to a load type non-metallocene catalyst and a preparation method thereof. The load type non-metallocene catalyst has the characteristics of simple preparation method, flexible and adjustable polymerization activity and the like, and synergistic reaction which is beneficial to activity development is formed between non-metallocene complexes and chemical conditioning agents inthe catalyst. The invention also relates to the application of the load type non-metallocene catalyst in olefin homopolymerization / copolymerization. Compared with the prior art, the application has the characteristic of less cocatalyst amount.

Owner:CHINA PETROLEUM & CHEM CORP +1

Loaded non-metallocene catalyst and preparation method and application thereof

ActiveCN102059149AThe load is easy to controlWidening or narrowing of molecular weight distributionOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationAlkeneMetallocene

The invention relates to a loaded non-metallocene catalyst and a preparation method and application thereof. The loaded non-metallocene catalyst has the characteristics of simple and practicable preparation method, flexible and adjustable polymerization activity and the like. The invention also relates to the application of the loaded non-metallocene catalyst to the homopolymerisation / copolymerization of olefin. Compared with the prior art, the application has the characteristic of small using amount of a cocatalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Loaded non-metallocene catalyst and preparation method and application thereof

ActiveCN102059153AThe load is easy to controlAdjust molecular weightOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationMetalloceneChemistry

The invention relates to a loaded non-metallocene catalyst and a preparation method and application thereof. The loaded non-metallocene catalyst has the characteristics of simple and practicable preparation method, flexible and adjustable polymerization activity and the like. The invention also relates to the application of the loaded non-metallocene catalyst to the homopolymerisation / copolymerization of olefin. Compared with the prior art, the application has the characteristic of small using amount of a cocatalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Loaded non-metallocene catalyst and preparation method and application thereof

ActiveCN102059150AThe load is easy to controlAdjust viscosity average molecular weightOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationAlkeneMetallocene

The invention relates to a loaded non-metallocene catalyst and a preparation method and application thereof. The loaded non-metallocene catalyst has the characteristics of simple and practicable preparation method, flexible and adjustable polymerization activity and the like. The invention also relates to the application of the loaded non-metallocene catalyst to the homopolymerisation / copolymerization of olefin. Compared with the prior art, the application has the characteristic of small using amount of a cocatalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

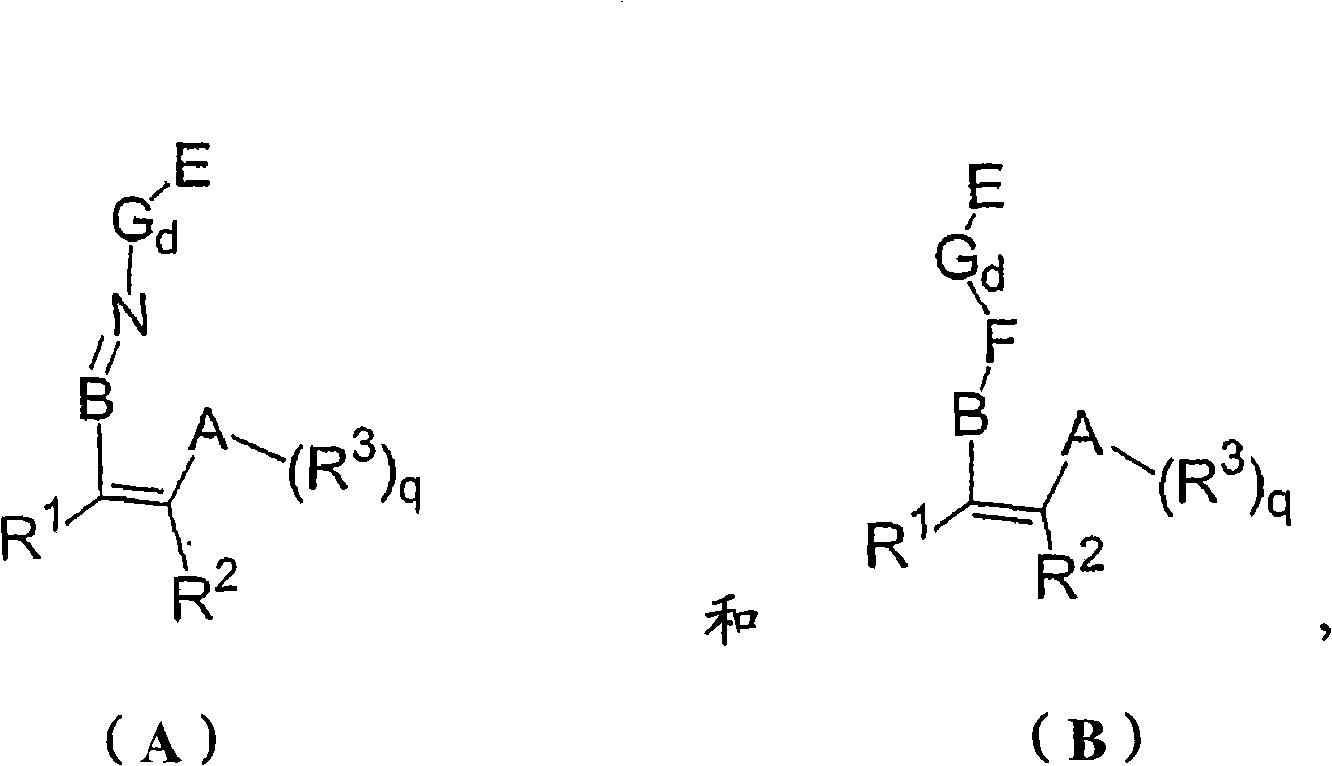

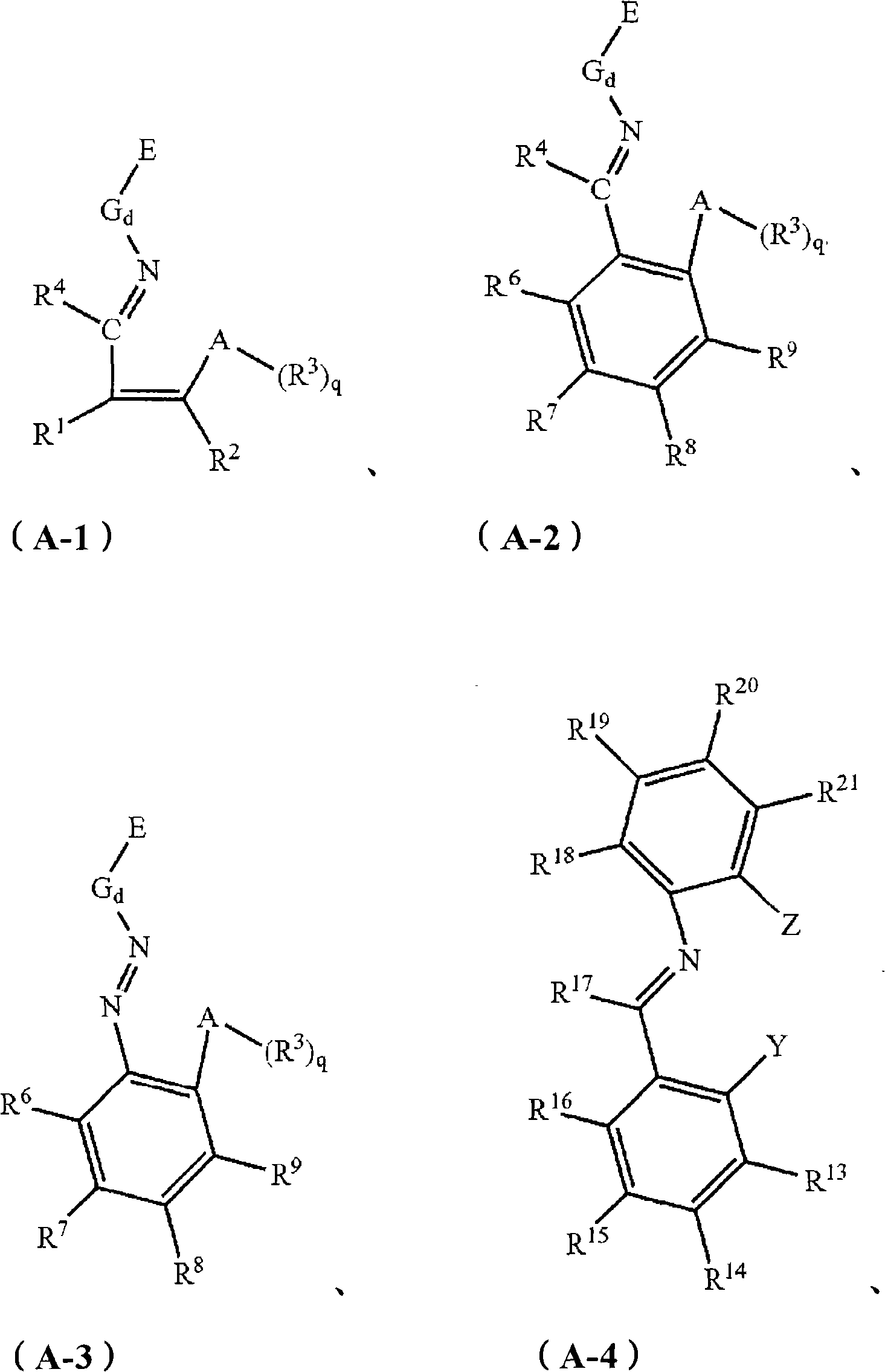

Radical polymerization catalyst and adhesive kit for dental use

InactiveUS20050009946A1High polymerization activityEasy to handleImpression capsPhysical/chemical process catalystsArylVanadium Compounds

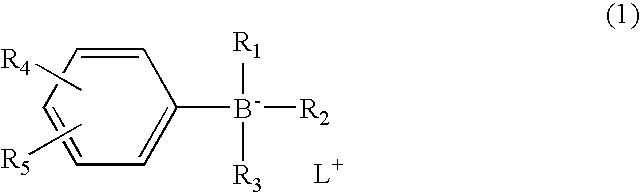

According to the present invention, there are disclosed a radical polymerization catalyst comprising an aryl borate compound, an acidic compound and a +tetravalent and / or +pentavalent vanadium compound; and a curable composition, a dental composition, a dental adhesive, a dental pretreatment agent, a dental adhesive kit, etc. all containing the radical polymerization catalyst.

Owner:TOKUYAMA CORP +1

Load type non-metallocene catalyst and preparation thereof

The invention relates to a supported non-metallocene catalyst. The supported non-metallocene catalyst is obtained by a non-metallocene ligand and a transition metal compound which directly react on a carrier through an in-situ supporting method. The preparation method for the supported non-metallocene catalyst has simple and feasible process, and the supporting capacity and the polymerization activity of the catalyst have wide adjustable range. When the supported non-metallocene catalyst is combined with a catalyst promoter to catalyze the homopolymerization / copolymerization of olefins, high polymerization activities of the olefins can be obtained only by using small amount of the catalyst promoter.

Owner:SINOPEC YANGZI PETROCHEM

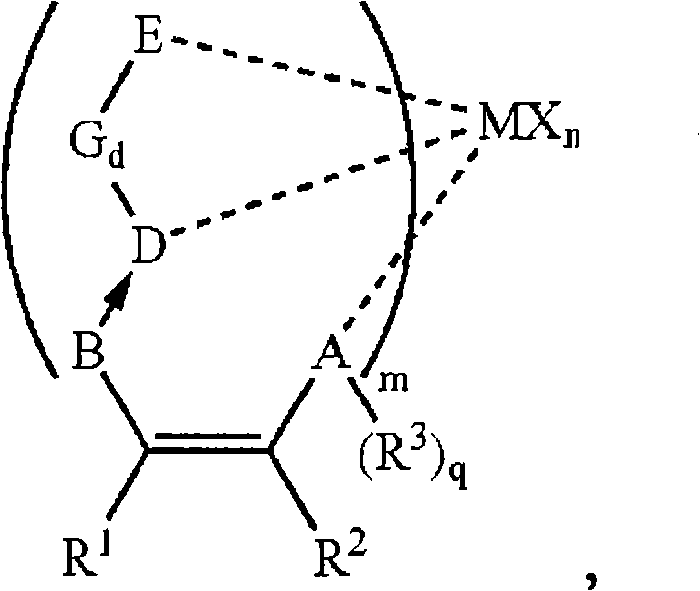

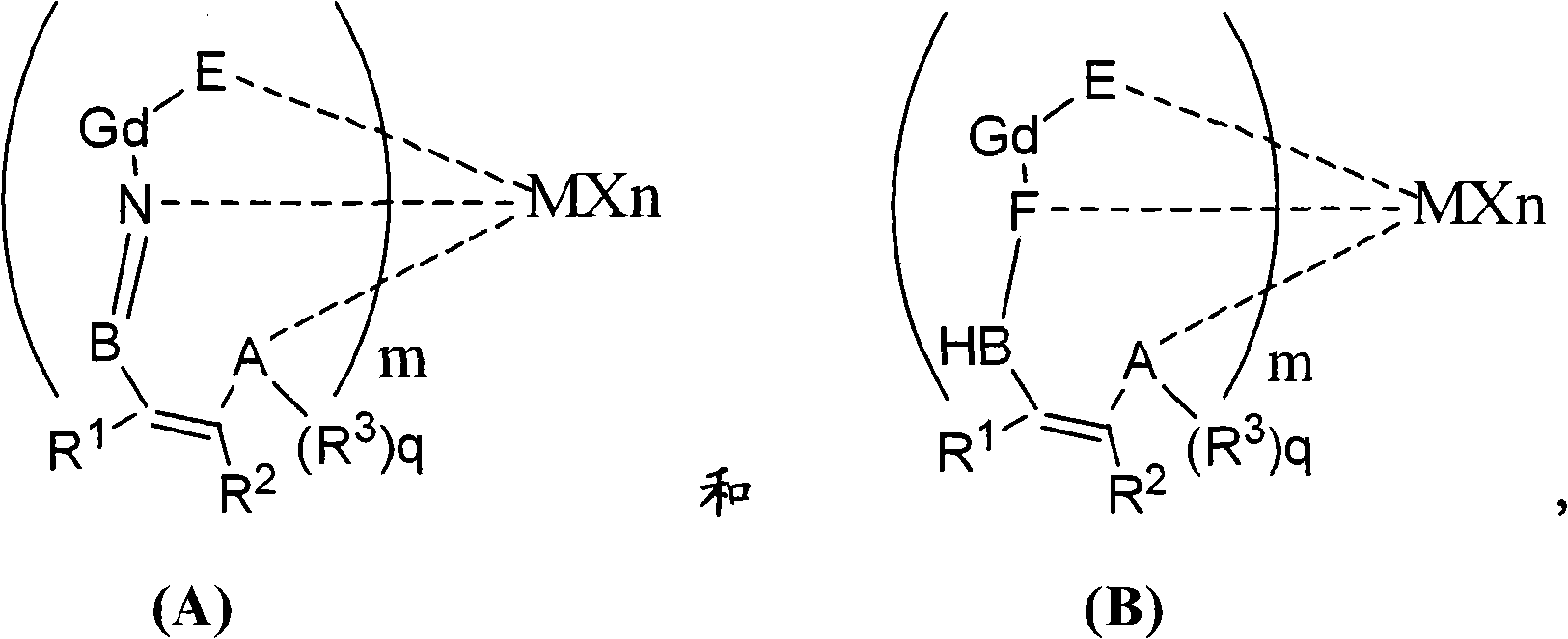

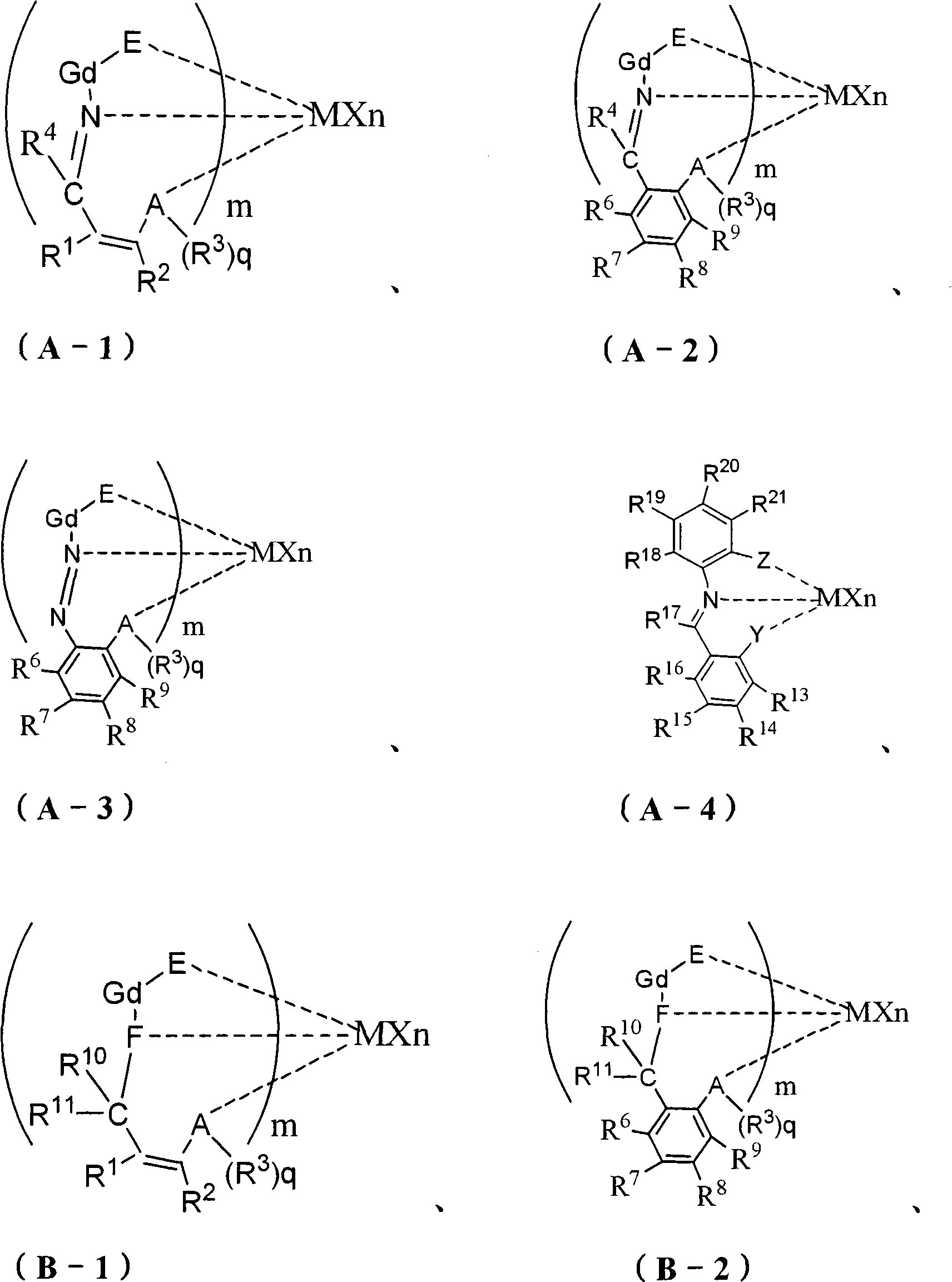

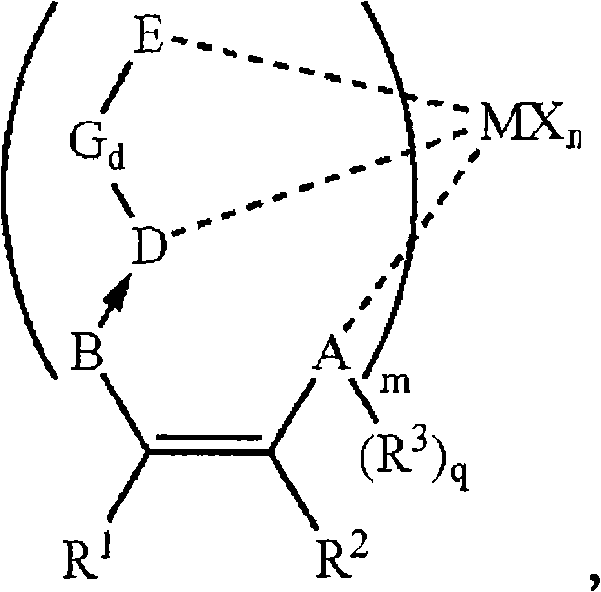

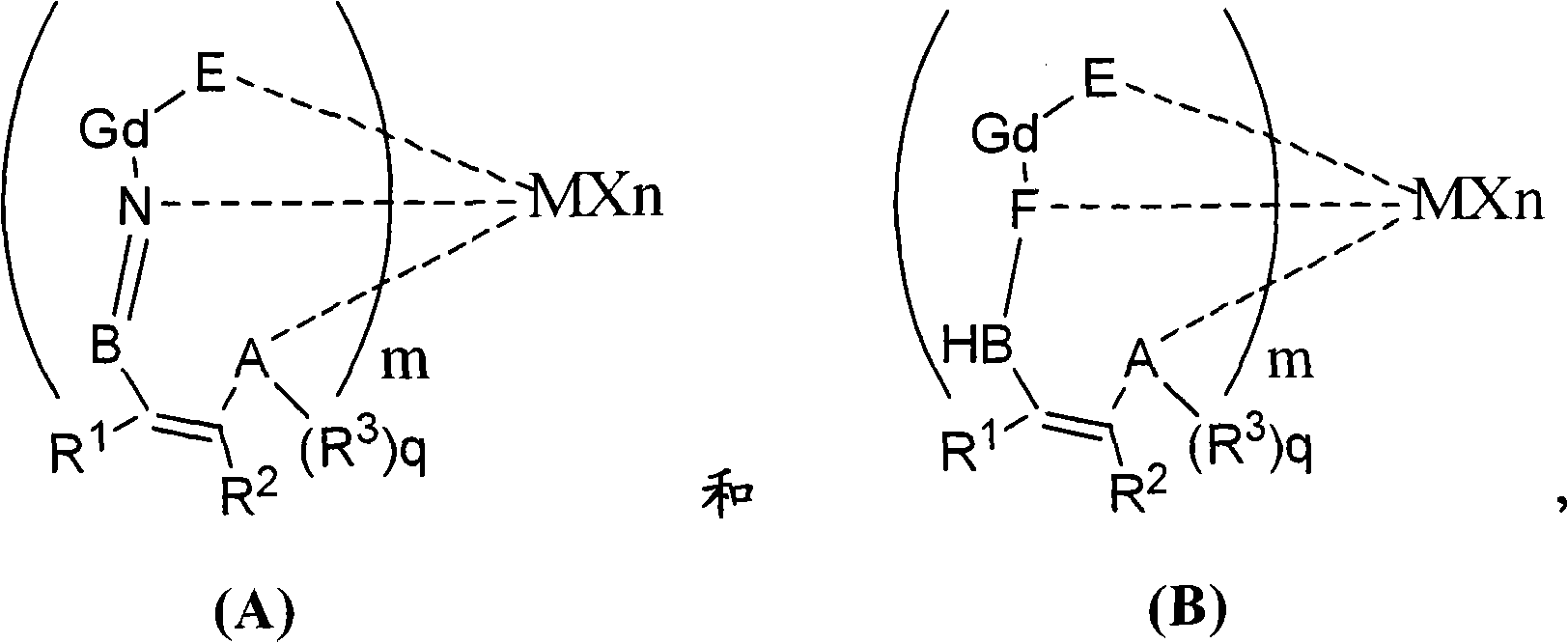

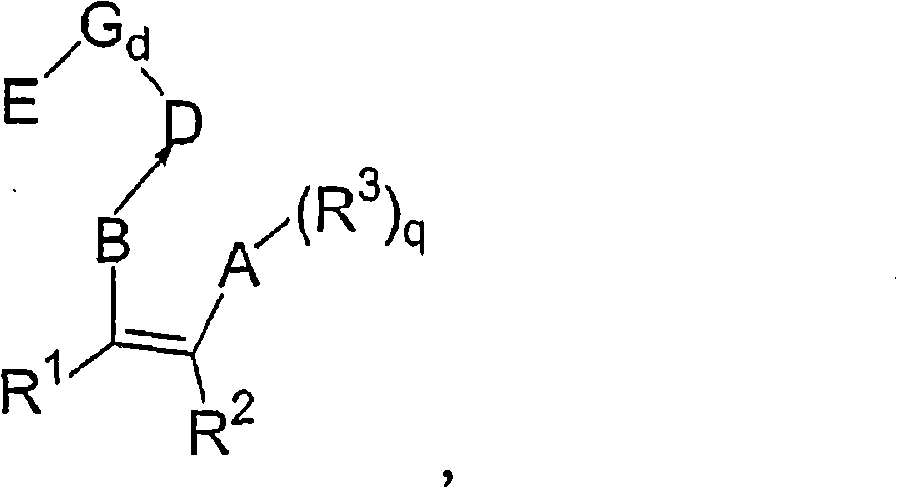

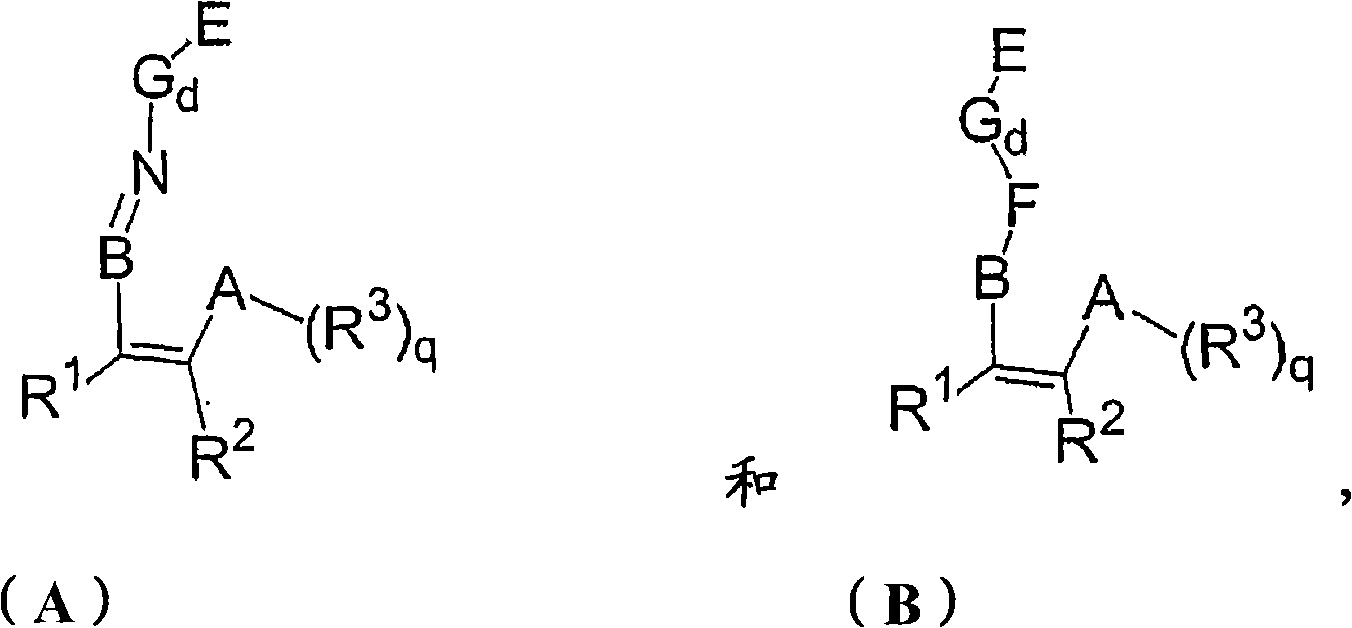

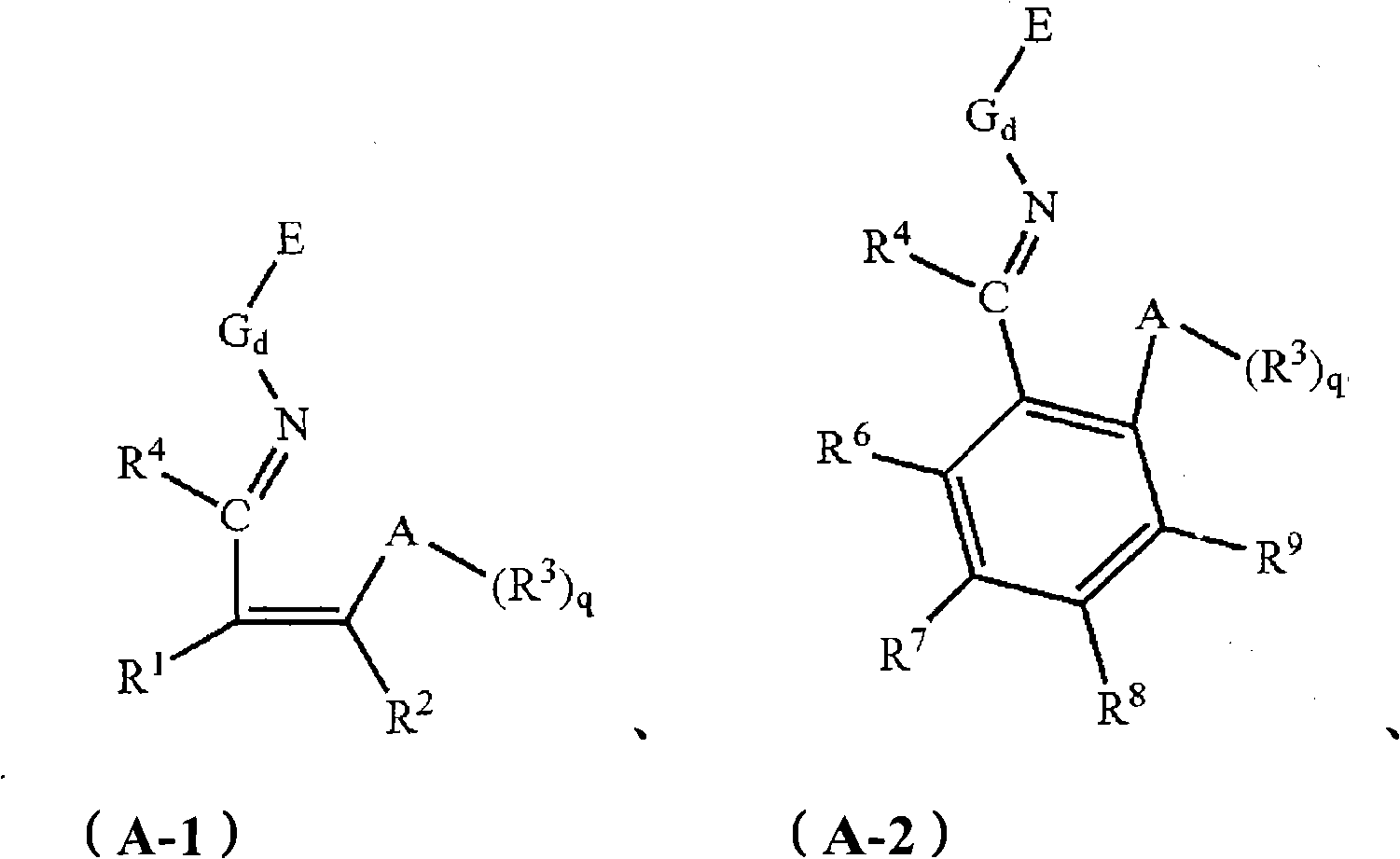

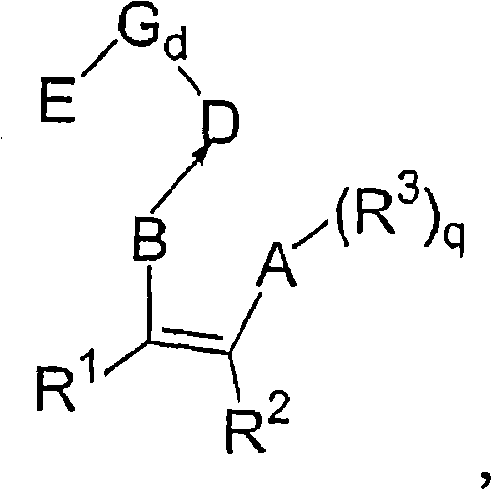

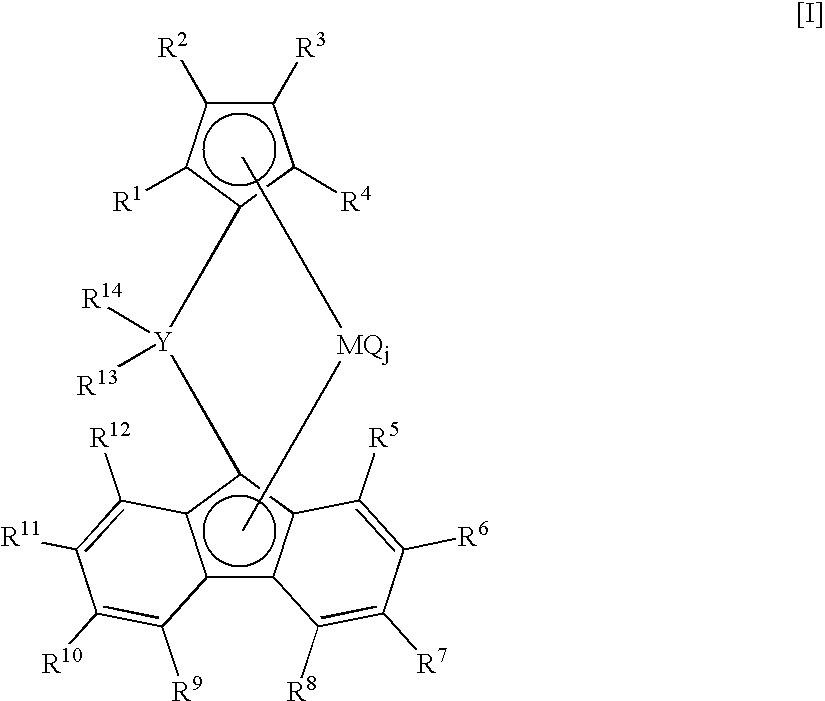

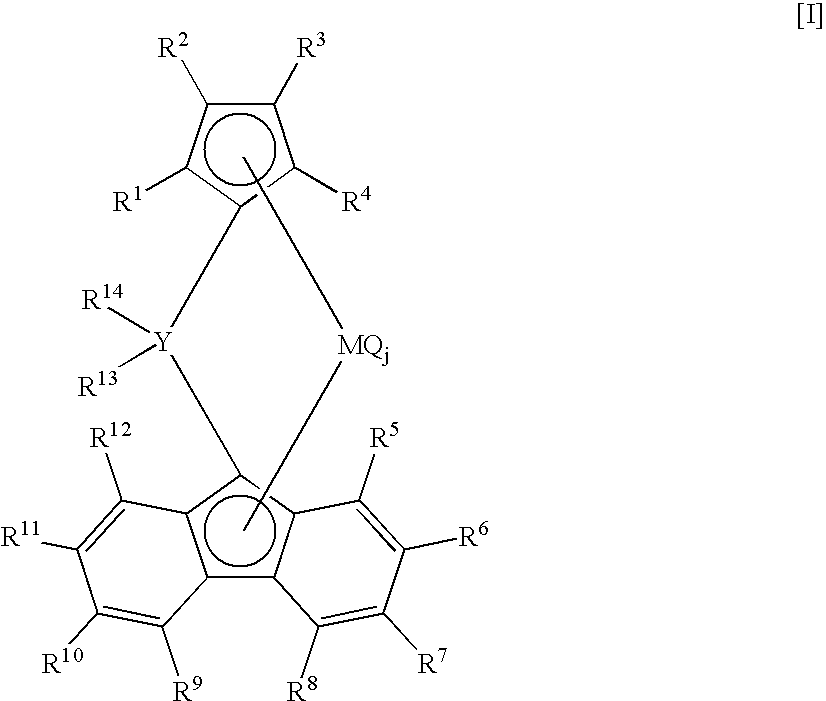

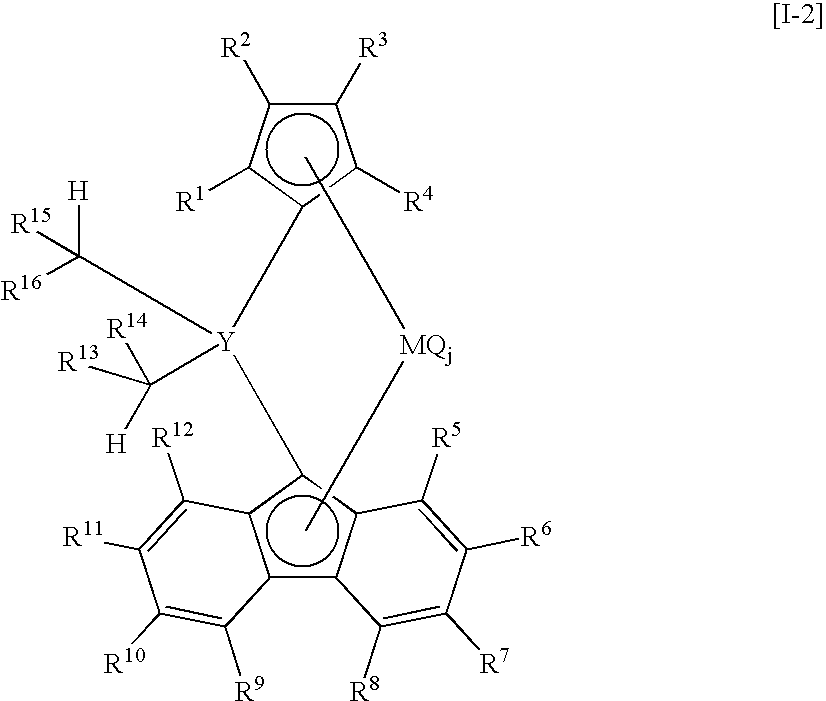

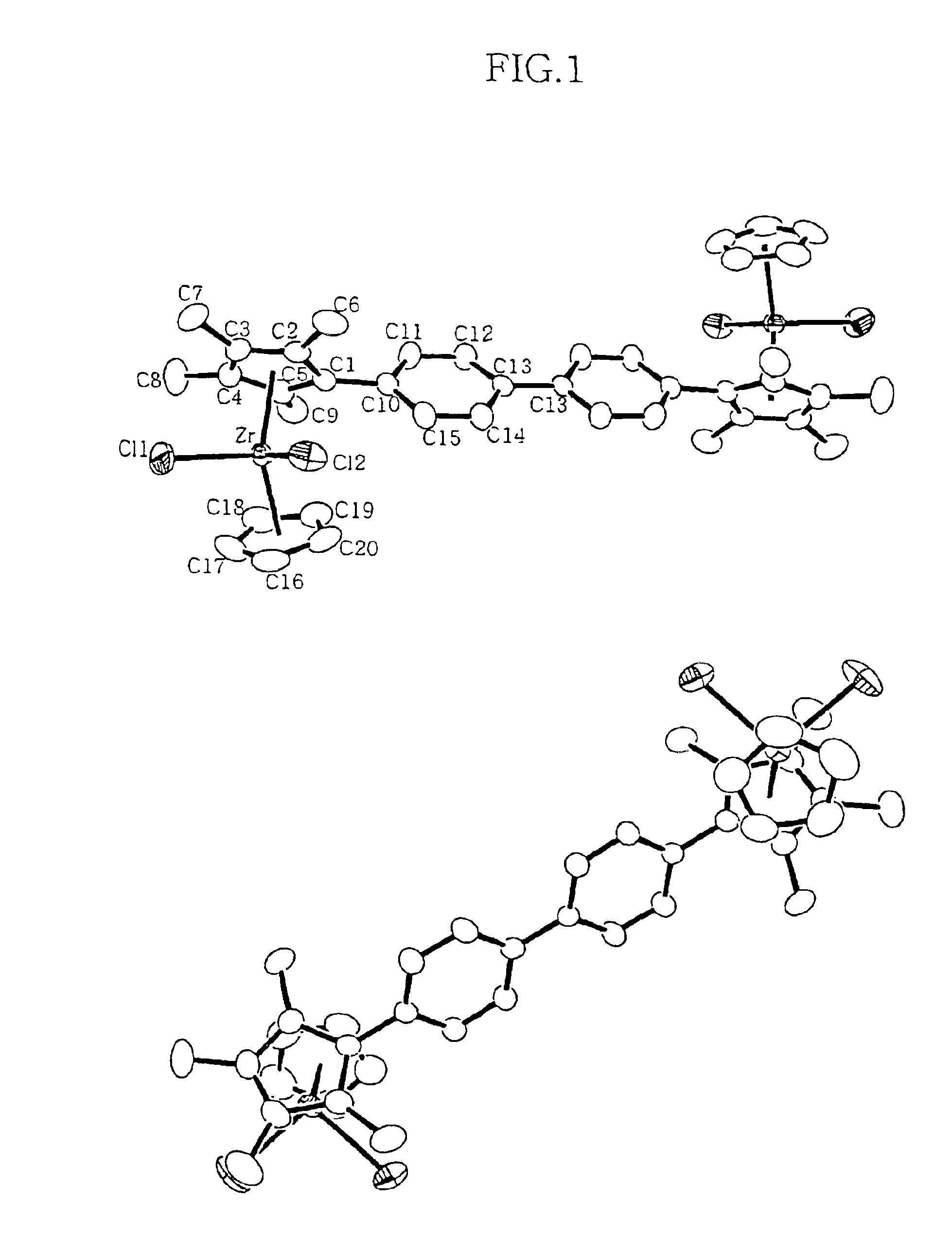

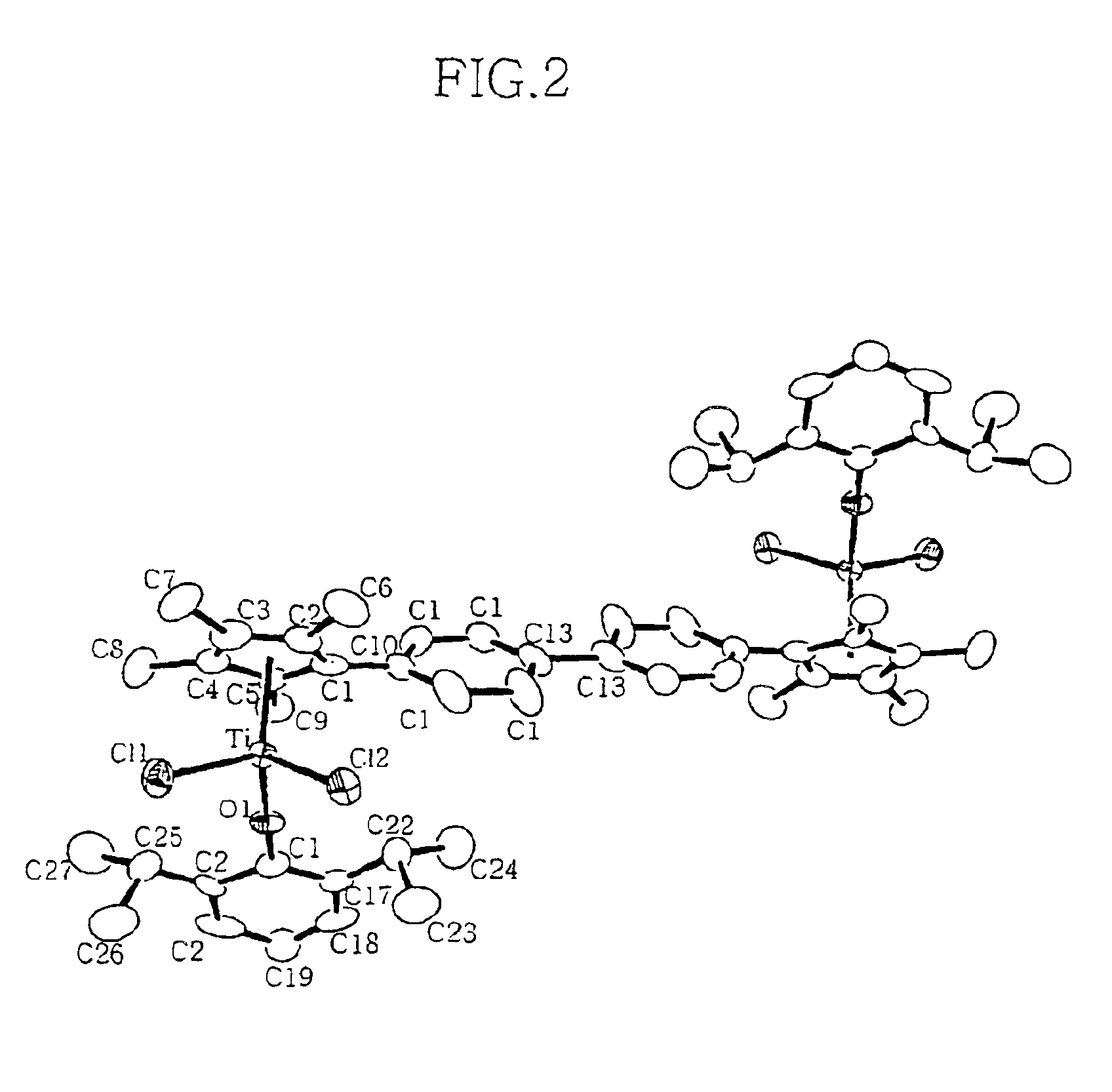

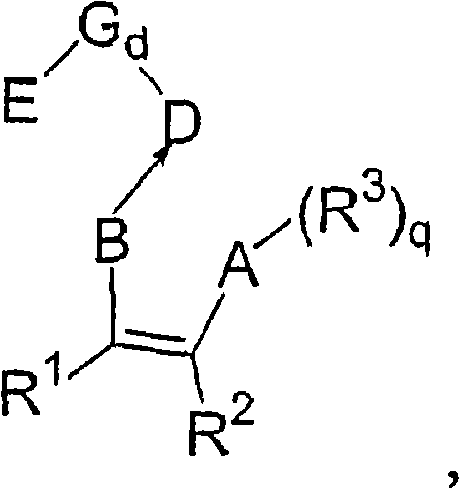

Polyolefin production catalyst and method of preparing polyolefins

InactiveUS6121182AHigh polymerization activityImprove rigidityOrganic-compounds/hydrides/coordination-complexes catalystsPolymer sciencePolyolefin

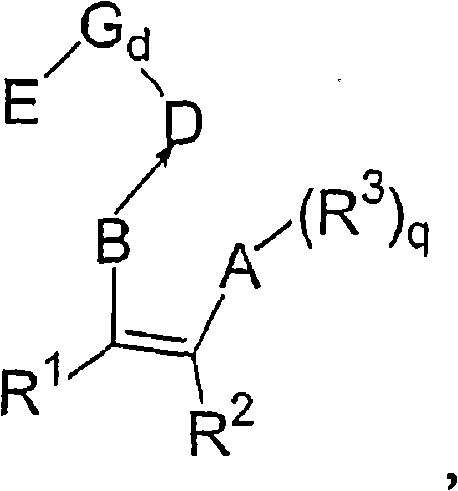

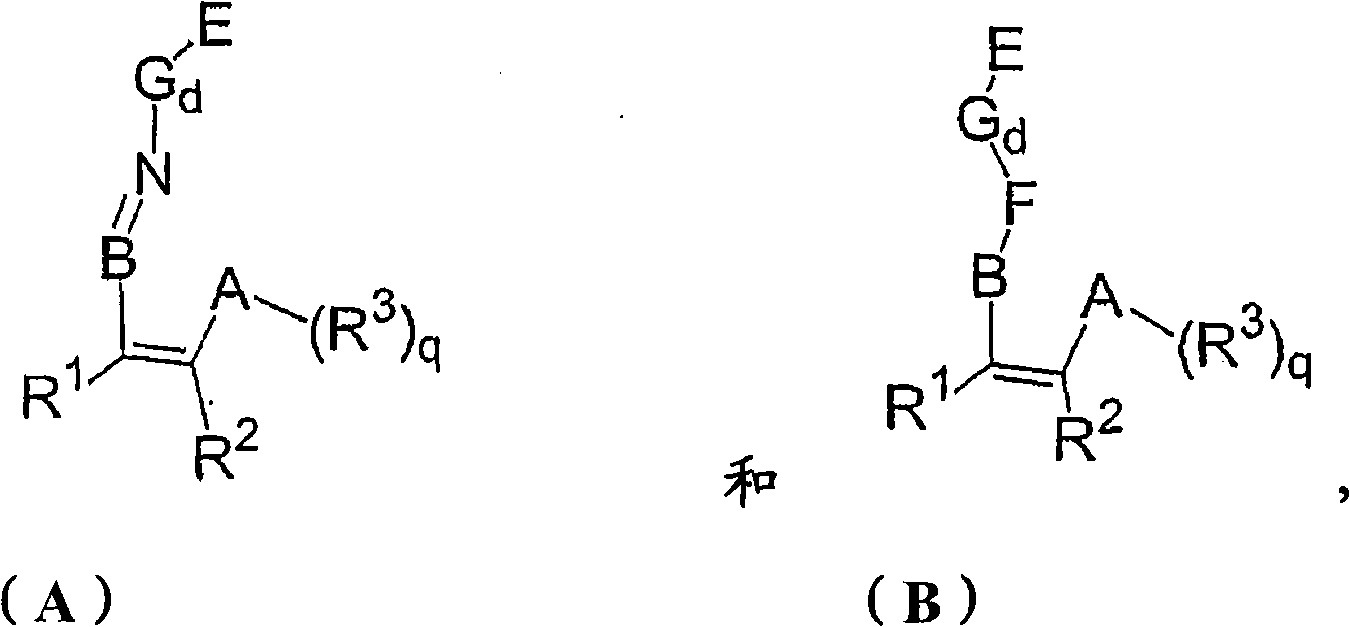

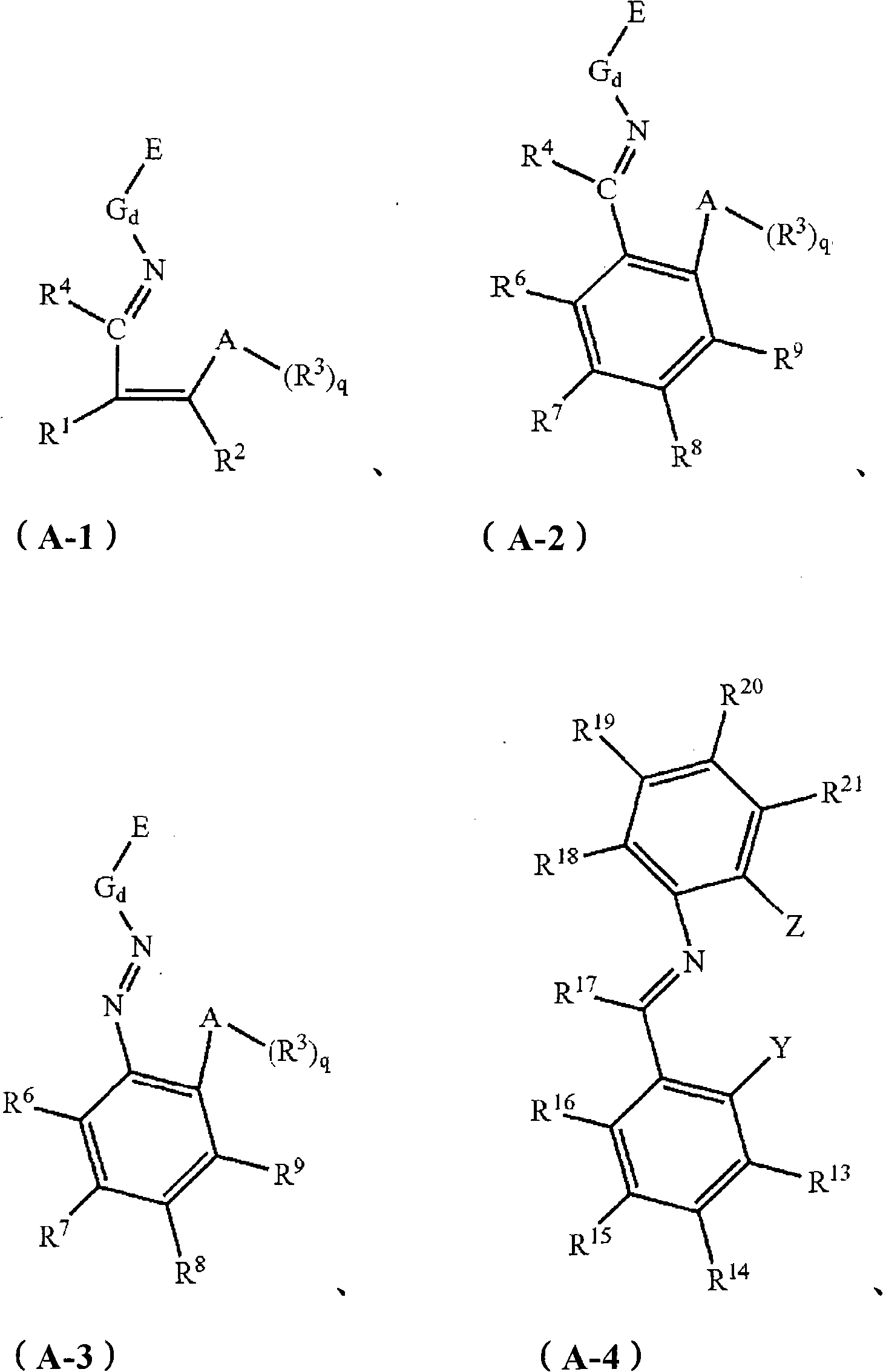

PCT No. PCT / JP97 / 01387 Sec. 371 Date Dec. 11, 1997 Sec. 102(e) Date Dec. 11, 1997 PCT Filed Apr. 22, 1997 PCT Pub. No. WO97 / 40075 PCT Pub. Date Oct. 30, 1997A catalyst component for polyolefin production catalysts comprising a metallocene compound represented by general formula (1) (symbols have the meanings as described in the specification), polyolefin production catalyst containing the component, and method for producing polyolefin with the catalyst are provided. Use of a catalyst containing the novel metallocene compound as a catalyst component of the invention in polymerization of alpha -olefin, particularly propylene, enables one to prepare high rigid, high melting point isotactic polypropylene useful as an industrial material for automobiles and the like, more specifically isotactic polypropylene having highly controlled stereoregulartity and regioregularity, particularly the one having a high regioregularity that has been difficult to achieve with conventional metallocene catalysts.

Owner:SUNALLOMER

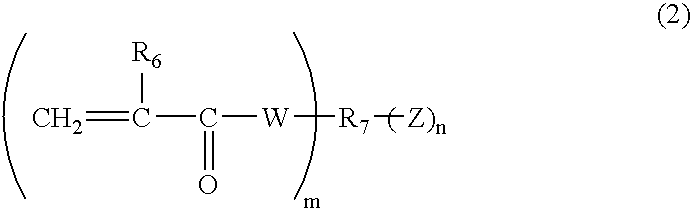

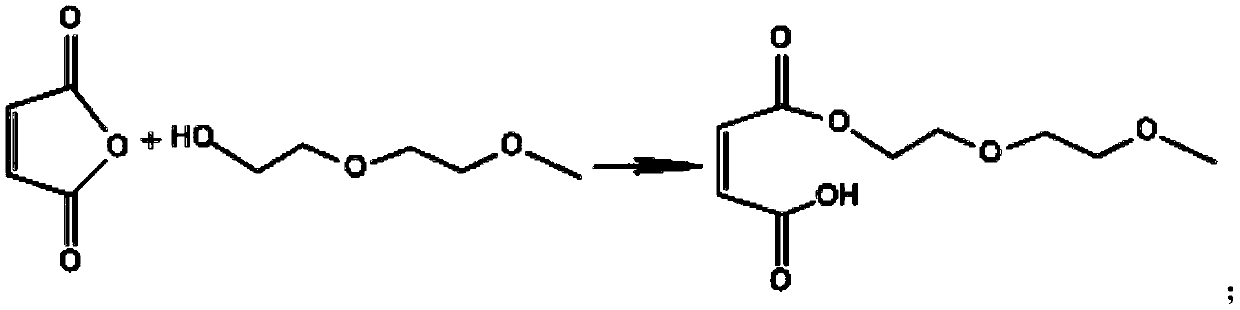

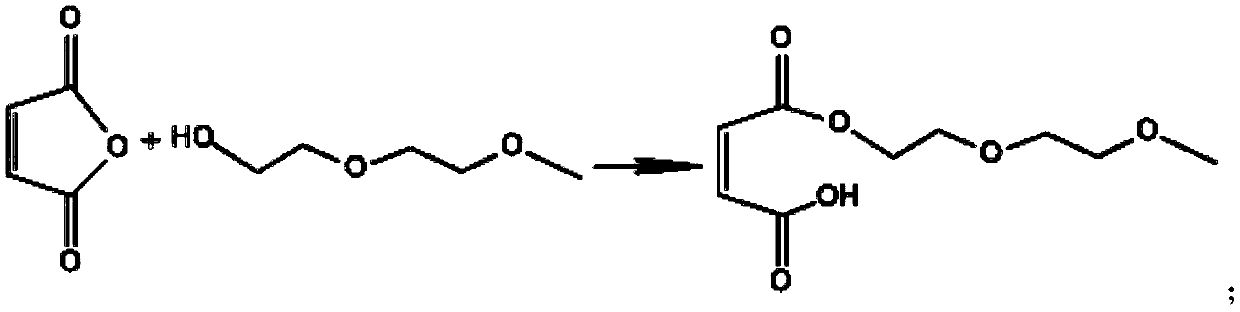

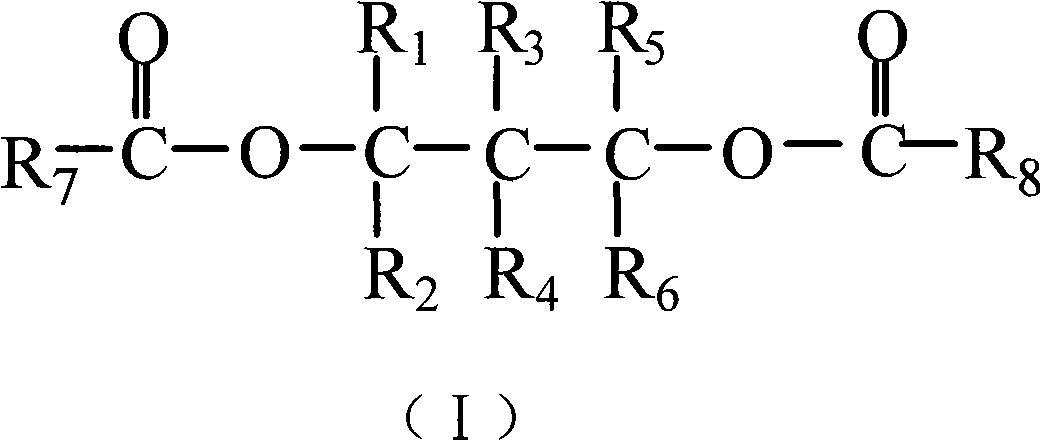

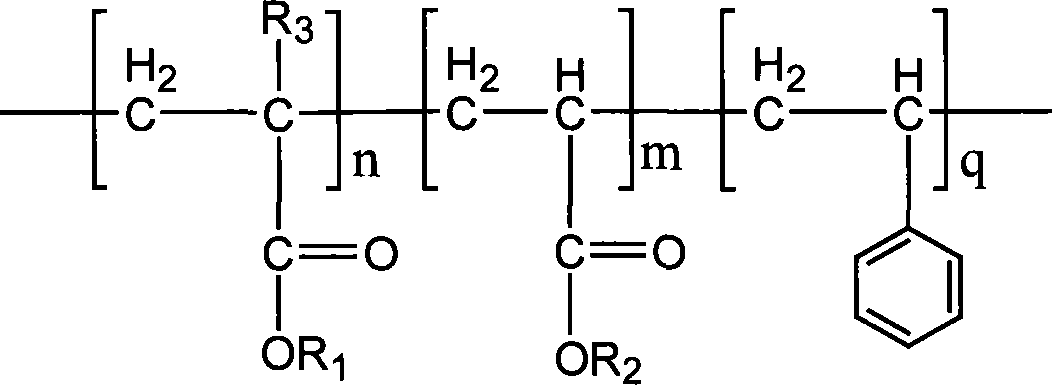

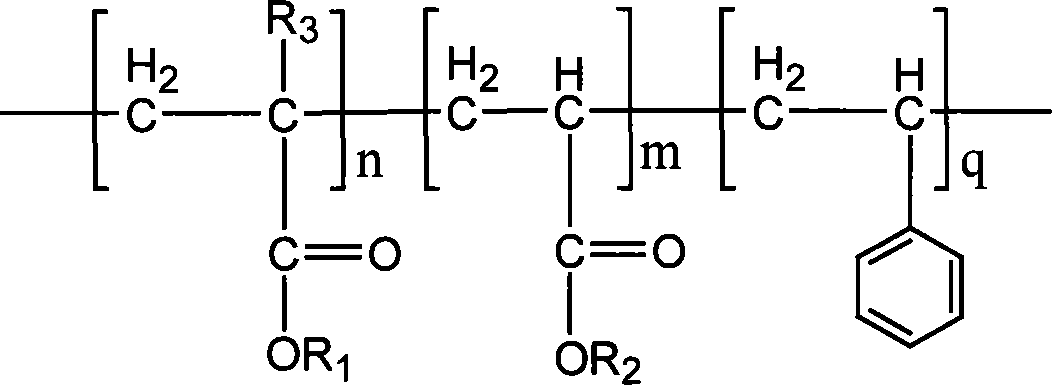

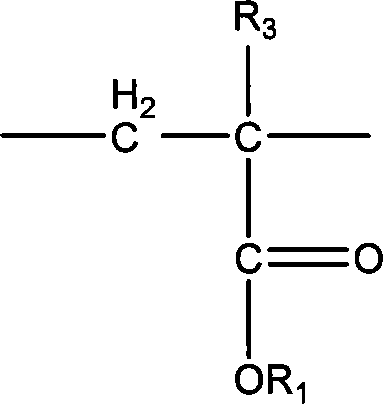

Mud-proof slump-retaining type polycarboxylate superplasticizer with low shrinkage and high adaptability and low-temperature preparation method thereof

InactiveCN110003402AImprove adaptabilityImprove mud slump performanceSuperplasticizerCarboxylic acid

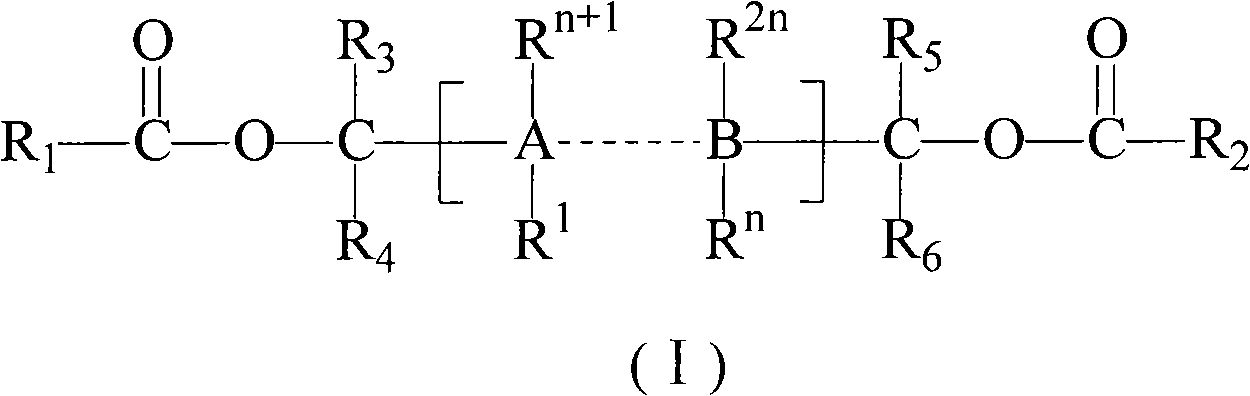

The invention discloses a mud-proof slump-retaining type polycarboxylate superplasticizer with low shrinkage and high adaptability and a low-temperature preparation method thereof. The polycarboxylatesuperplasticizer is mainly prepared by the following steps: carrying out free radical polymerization on 4-hydroxybutylvinyl polyoxyethylene ether, unsaturated carboxylic acid, an unsaturated amide-type monomer, dipolyethylene glycol maleate, an unsaturated quaternary ammonium cationic monomer, an oxidizing agent, a catalyst, a reducing agent, a chain transfer agent and deionized water at 5-15 DEGC through an aqueous solution, regulating pH value by adding a sodium hydroxide solution, and supplementing water. The preparation method of the invention has advantages of low-temperature production, no heat source, simple equipment, no pollution, short reaction time and high production efficiency. The prepared mud-proof slump-retaining type polycarboxylate superplasticizer endows concrete withgood workability, good adaptability, low shrinkage and high strength, has excellent mud-proof slump-retaining property, and greatly reduces construction difficulty.

Owner:SICHUAN TONGZHOU CHEM TECH

Crosslinked metallocene compound for olefin polymerization and method of polymerizing olefin with the same

InactiveUS20060161013A1High polymerization activitySilicon organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsPolymer sciencePolyolefin

The bridged metallocene compound or the olefin polymerization catalyst which comprises the compound, enables high polymerization activity in polymerizing one or more monomers selected from ethylene and α-olefins. The bridged metallocene compound contains specific substituted cyclopentadienyl and fluorenyl groups which are linked via carbon or silicon atoms. In the method for the preparation of polyolefins, one or more monomers, preferably ethylene as an essential monomer, selected from ethylene and α-olefins are copolymerized in the presence of the olefin polymerization catalyst comprising the bridged metallocene compound, so that an ethylene based polymer with an ethylene content of more than 50 mol % is obtained.

Owner:MITSUI CHEM INC

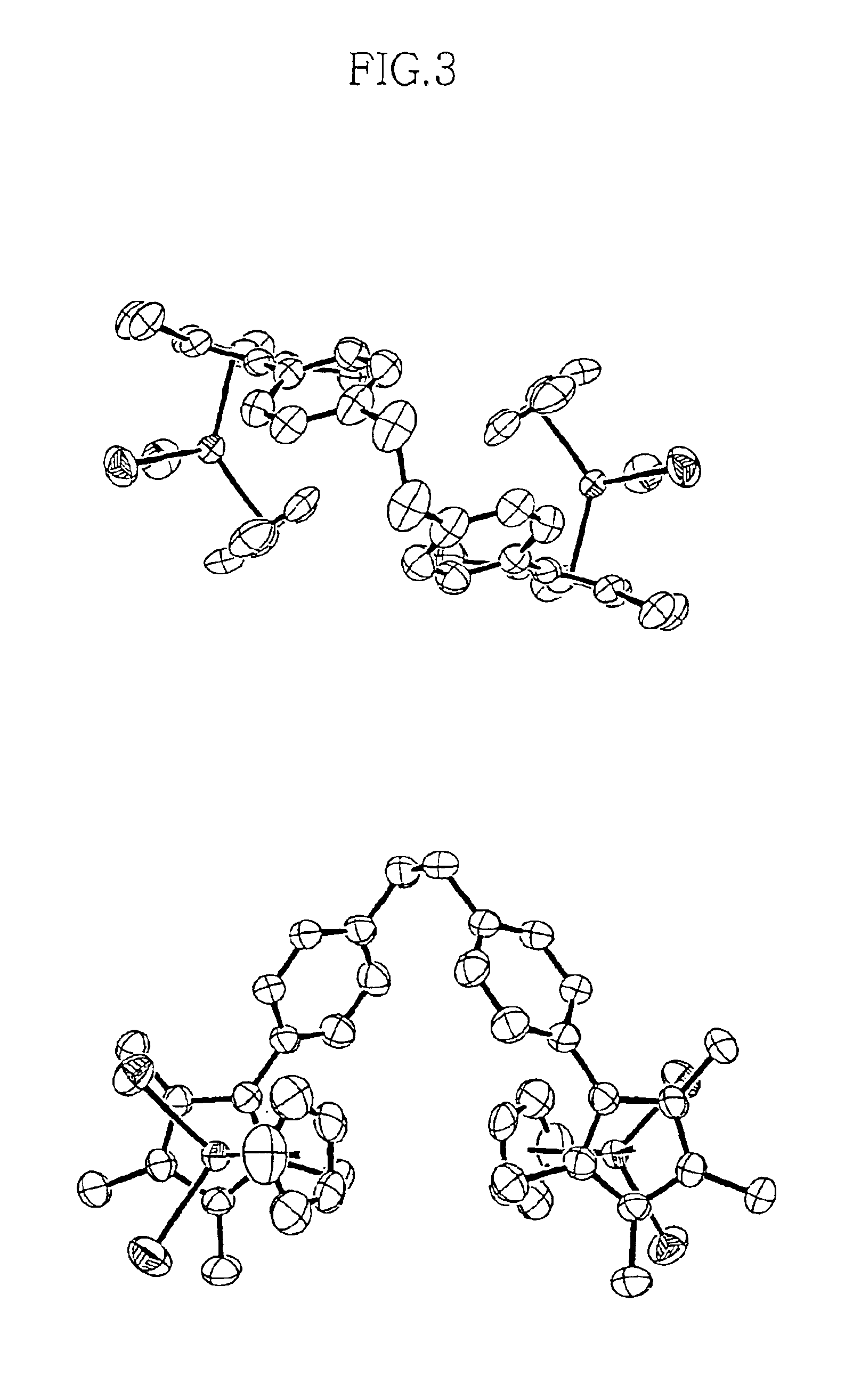

Multinuclear metallocene catalyst

InactiveUS6943225B2High polymerization activityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationAluminoxaneOlefin polymerization

The present invention relates to a multinuclear metallocene catalyst for olefin polymerization and a process for olefin polymerization using the same, in which the multinuclear metallocene catalyst for olefin polymerization comprises, as a main catalyst, a transition metal compound that contains at least two metal atoms in the groups III to X of the periodic table as central metals and a ligand having a cyclopentadienyl structure bridging between the two metal atoms, and, as a cocatalyst, an aluminoxane compound, an organoaluminum compound or a bulky compound reactive to the transition metal compound to impart a catalytic activity to the transition metal compound.

Owner:HONAM PETROCHEM

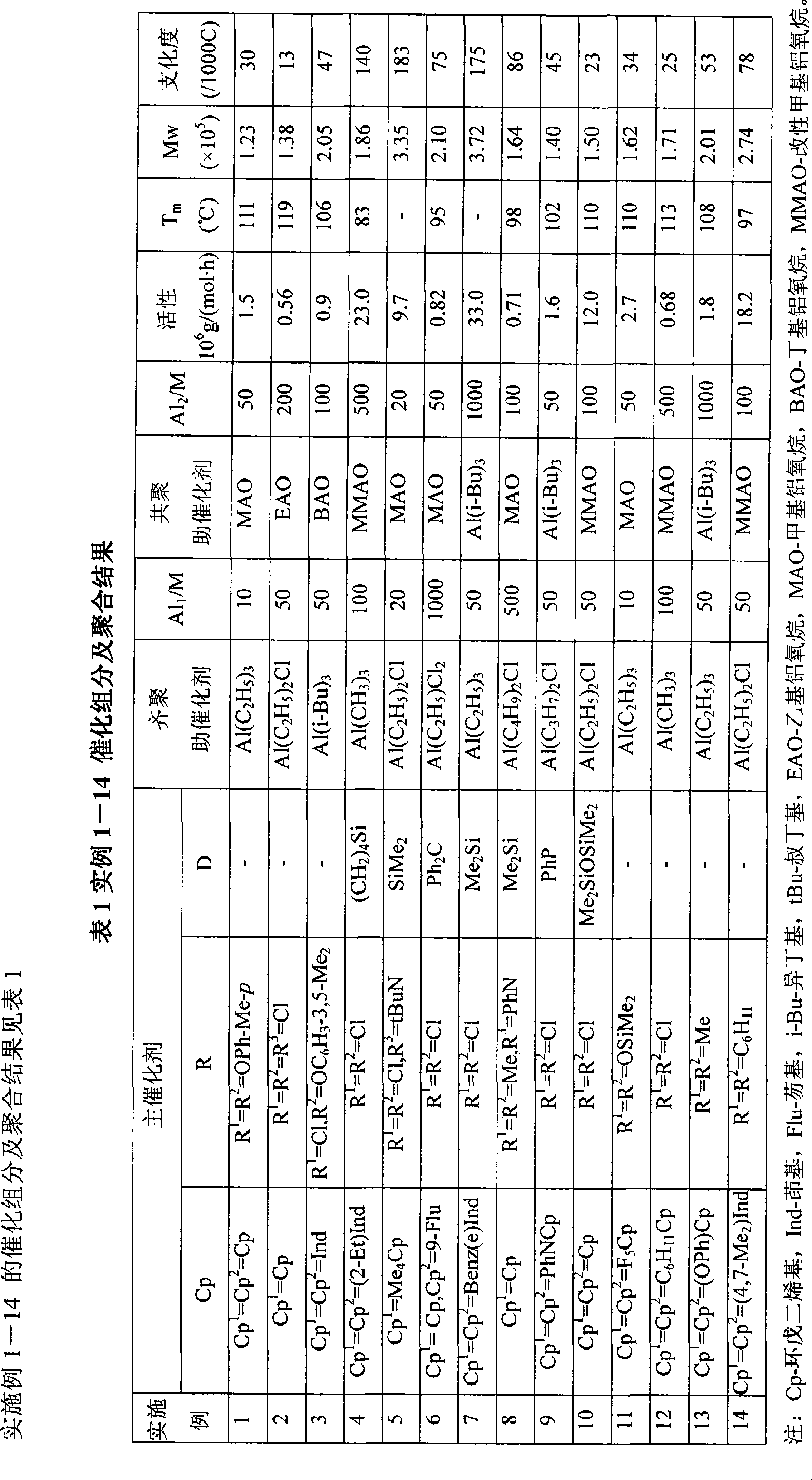

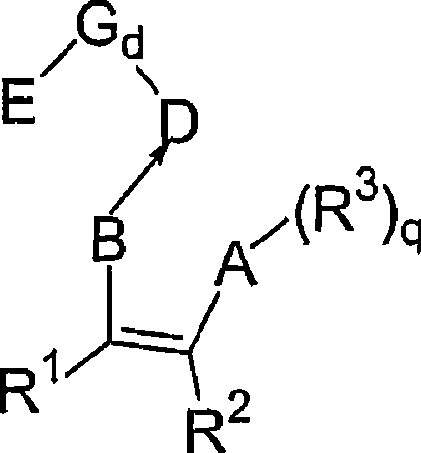

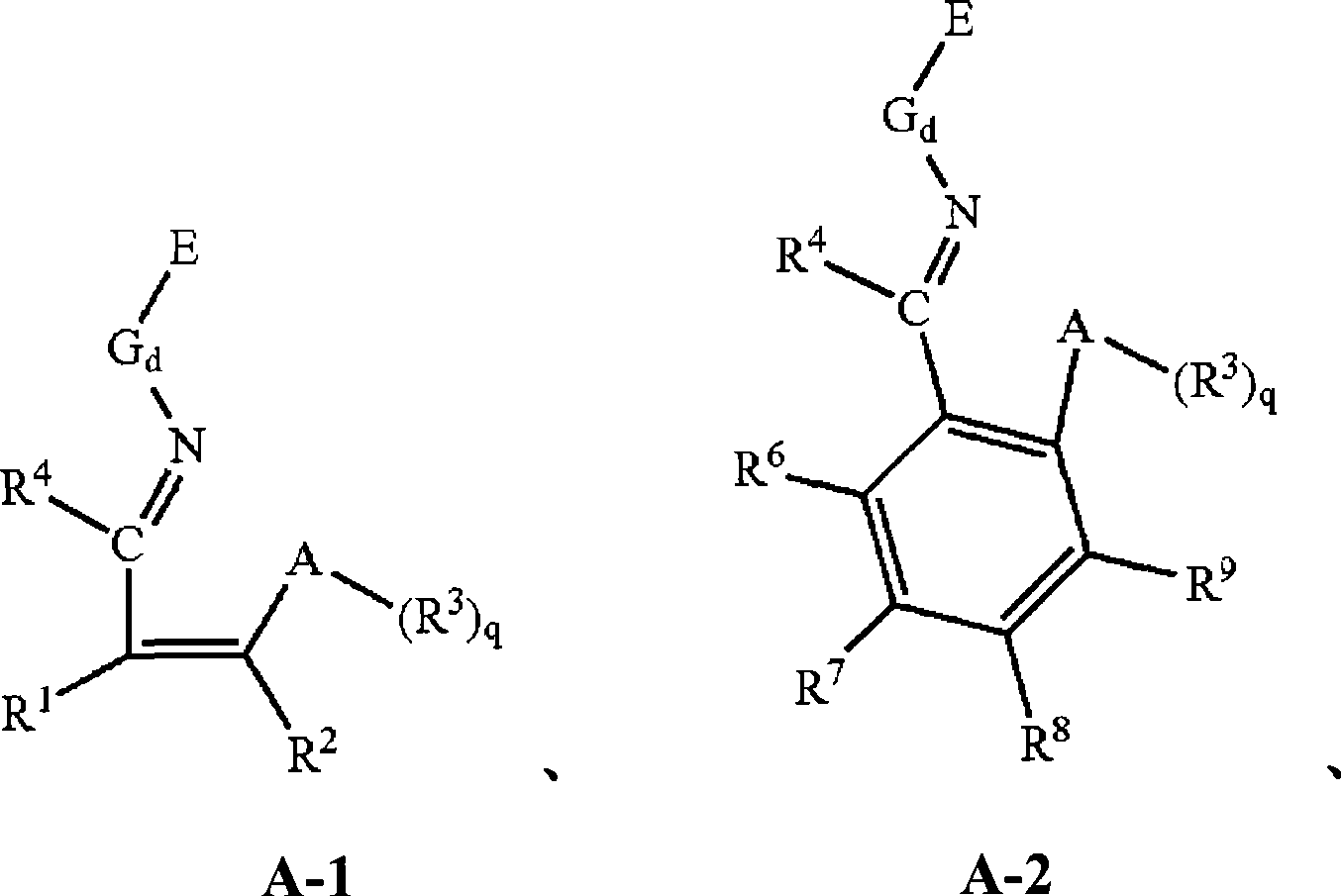

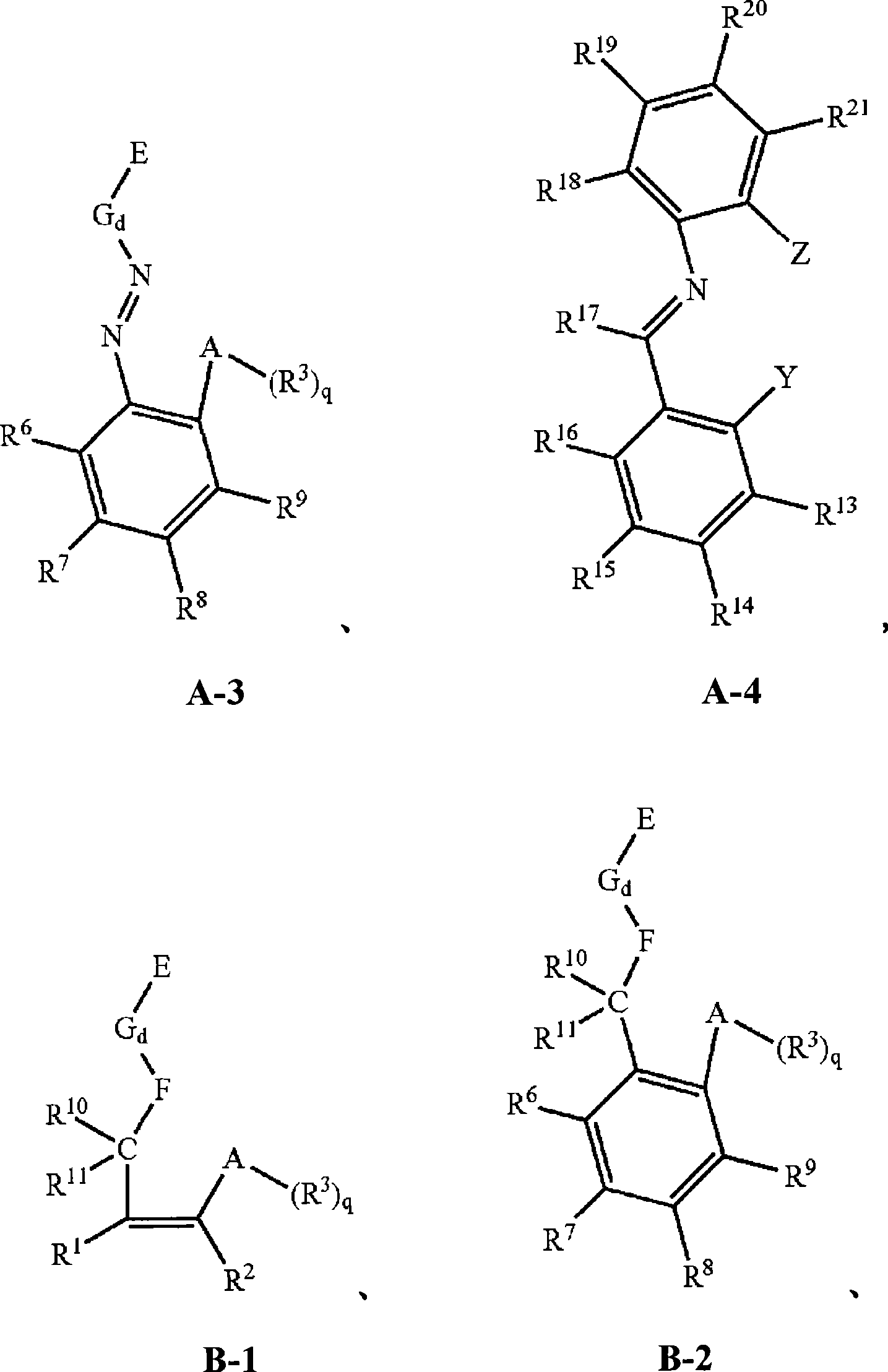

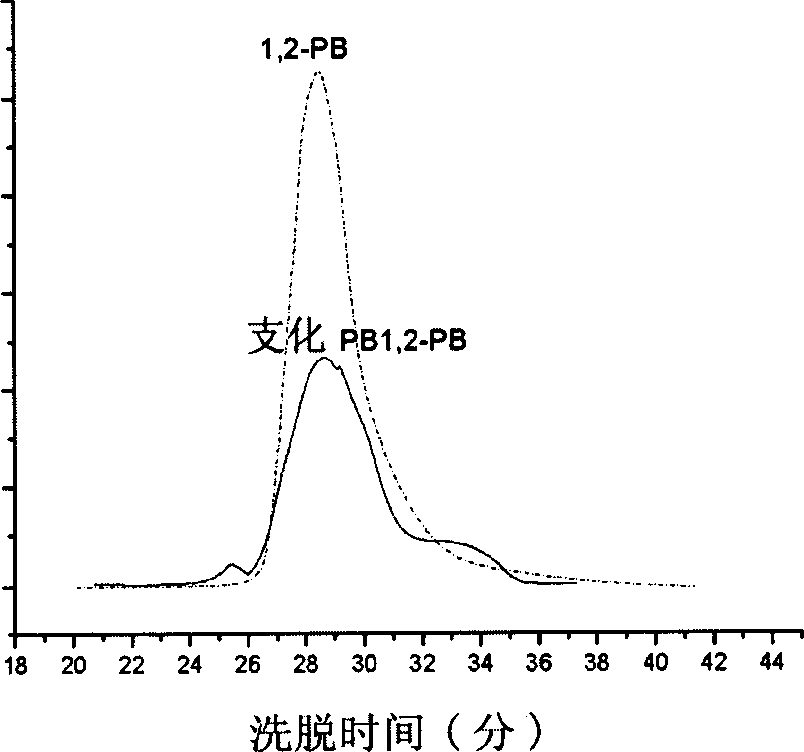

Metallocene domino catalytic system for preparing branched polyethylene using ethylene as only monomer and use thereof

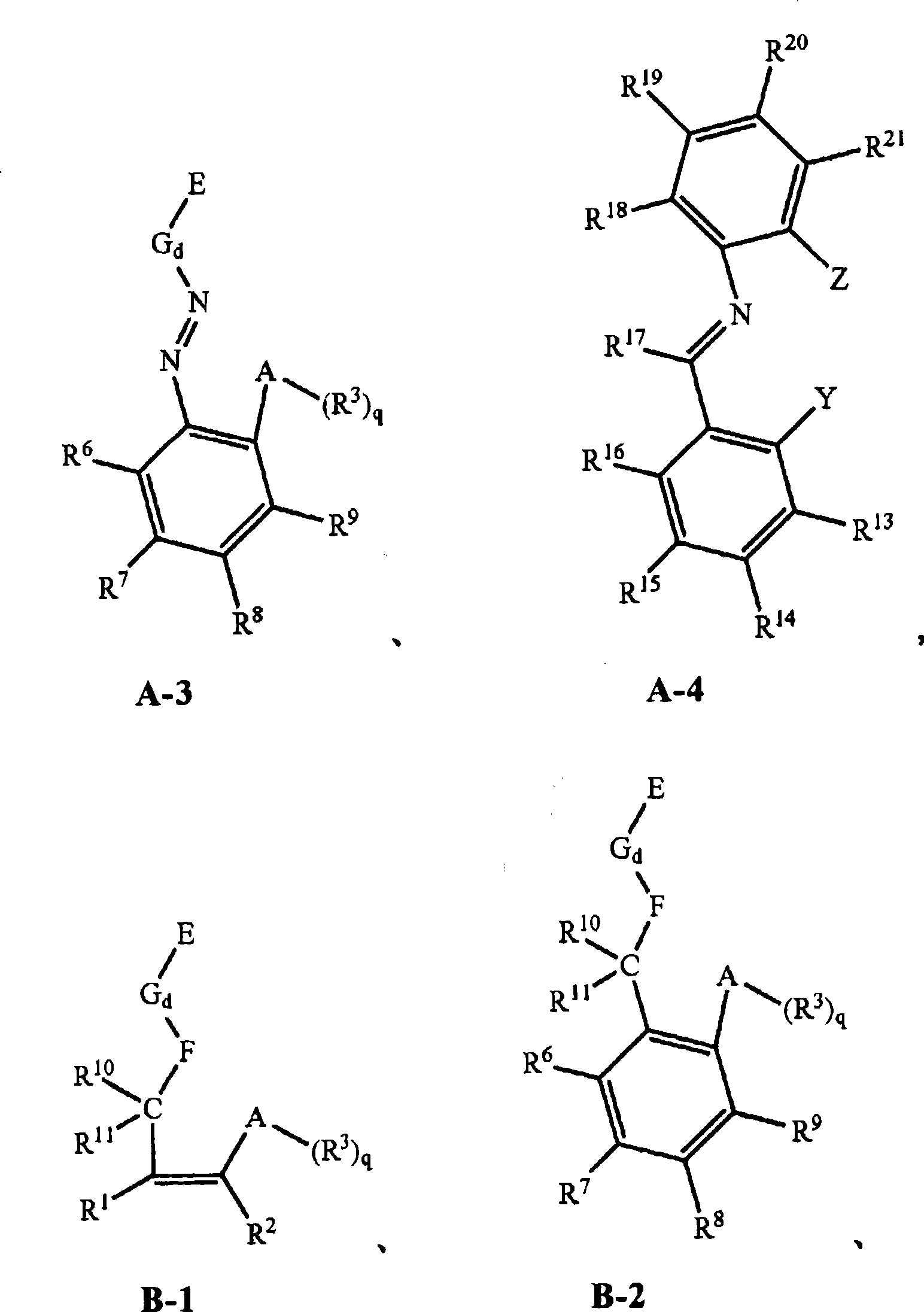

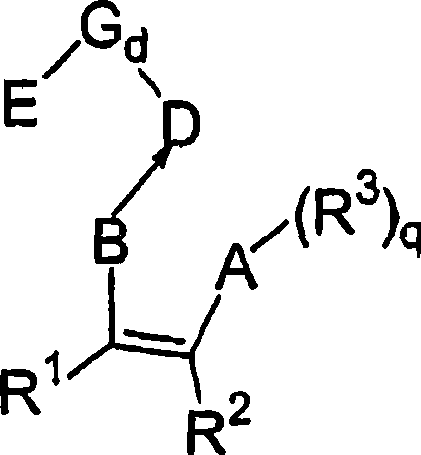

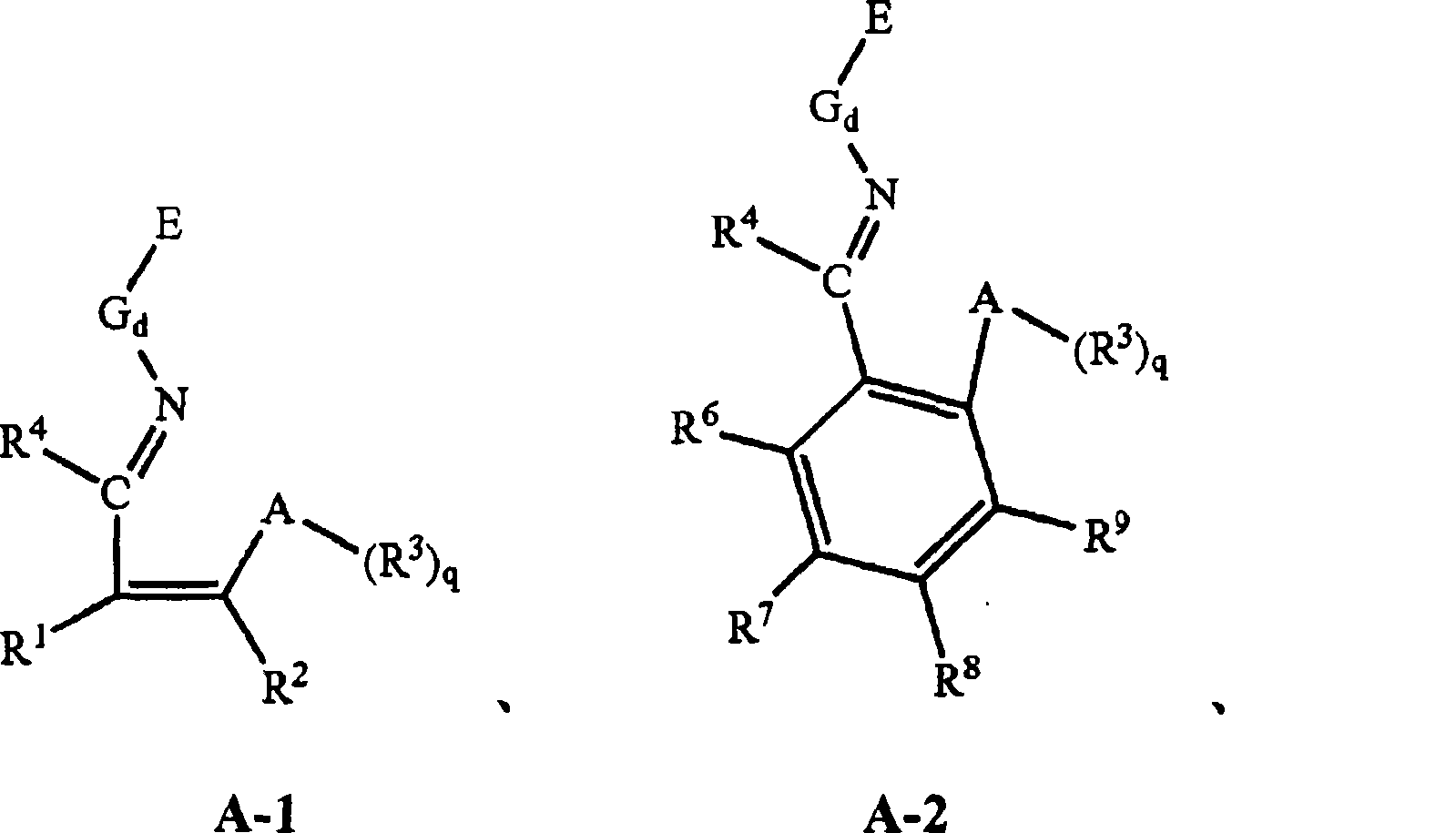

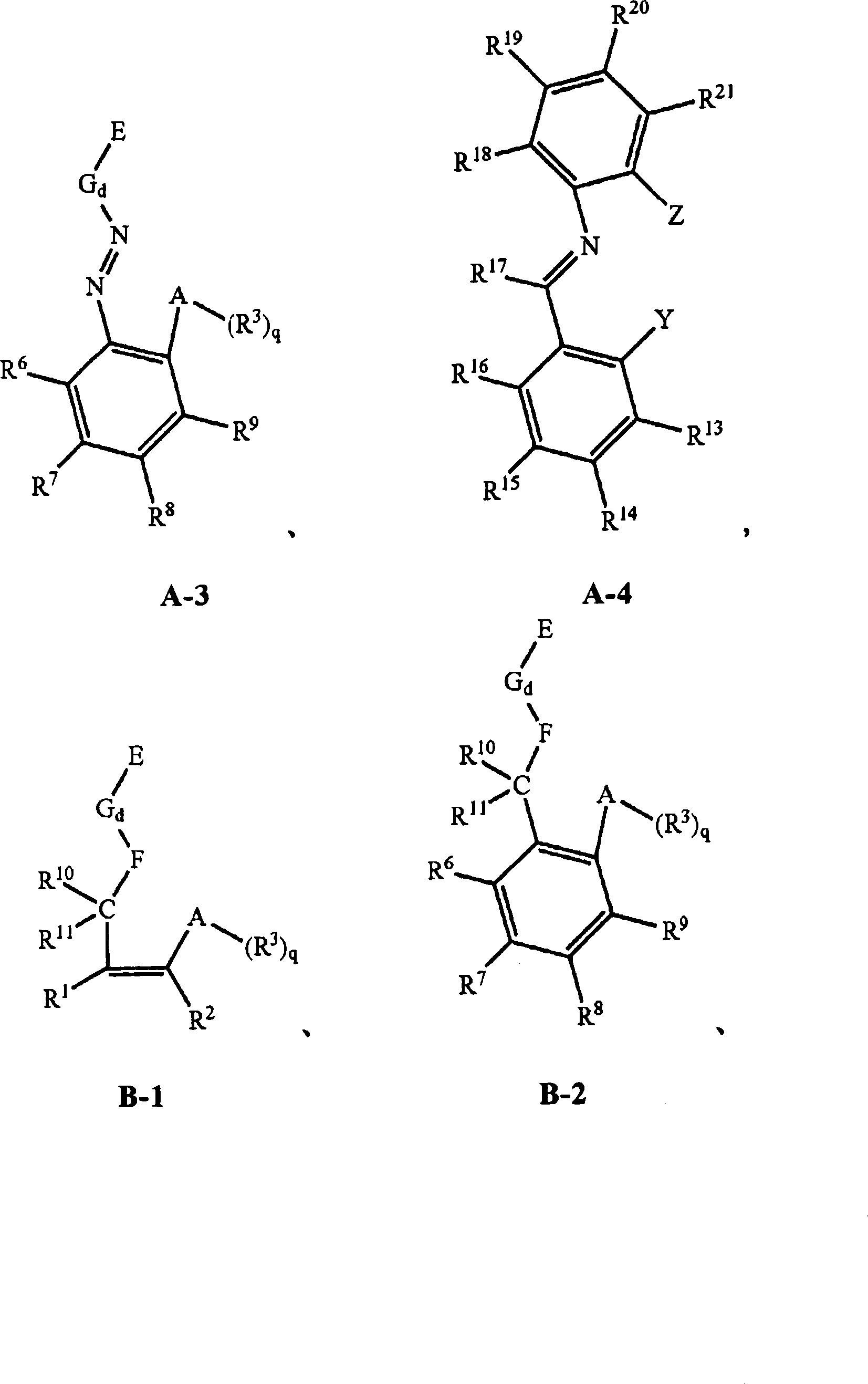

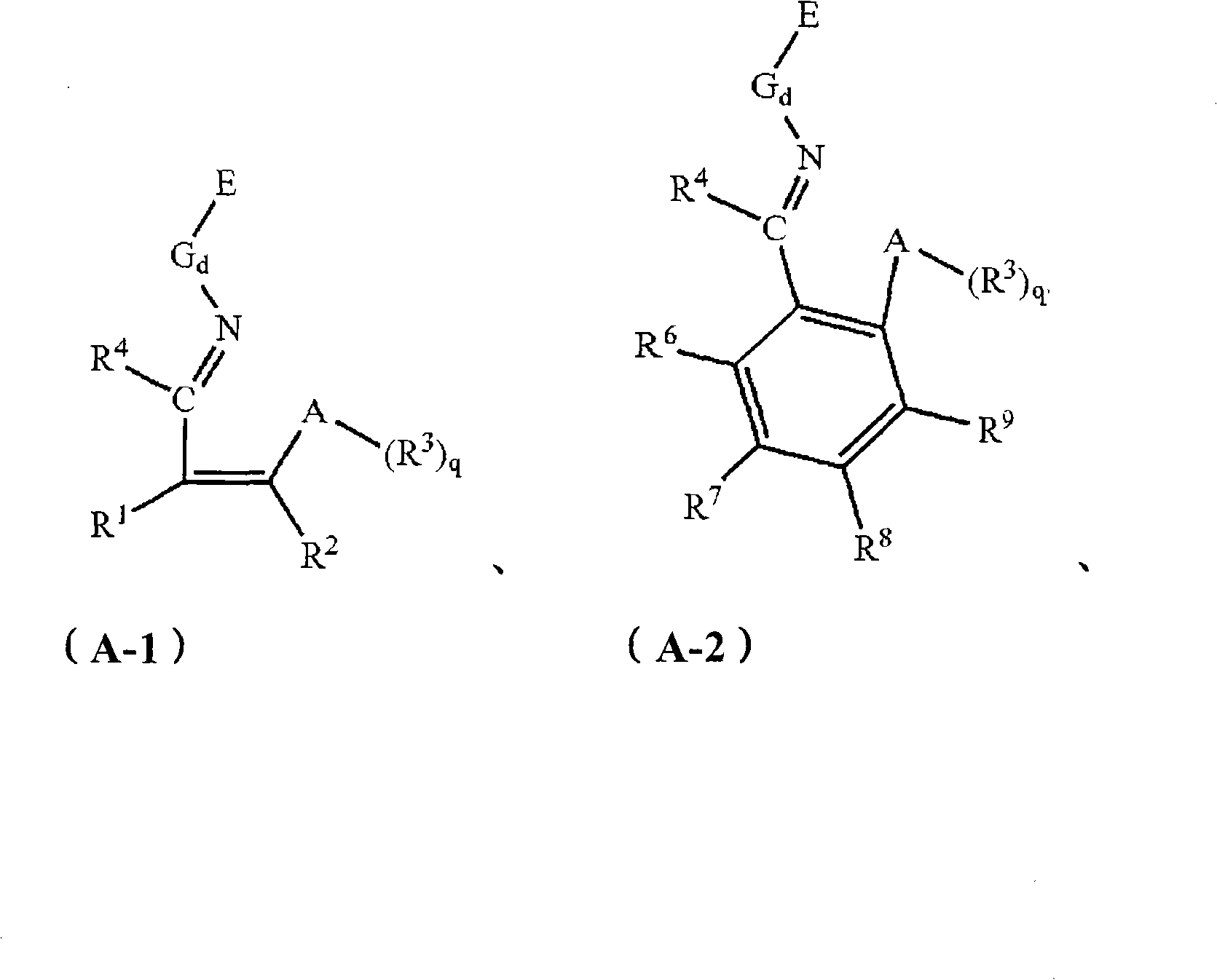

InactiveCN101392036ALower synthesis costAchieve the effect of molecular tailoringTriisobutylaluminiumStructural formula

The invention discloses a domino catalyzing system of a primary metallocene catalyst, which takes ethane as a sole monomer to prepare branched polyethylene, and the application thereof, which relates to vinyl copolymer. the catalyzing system is a compound catalyzing system consisting of the single primary metallocene catalyst and two different catalyst promoters, wherein, the primary catalyst is a metallocene catalyst with a structural formula of Cp<1>MR<1>R<2>R<3>, Cp<1>Cp<2>MR<1>R<2> or Cp<1>-D-Cp<2>MR<1>R<2>; alkyl aluminium acts as an oligomerization catalyst promoter; methylaluminoxane or triisobutyl aluminium or triethyl aluminum that is not used together with the oligomerization catalyst promoter acts as a copolymerization catalyst promoter; the mole ratio between the oligomerization catalyst promoter and the primary catalyst is 10-1000 to 1, and the mole ratio between the copolymerization catalyst promoter and the primary catalyst is 20-1000 to 1. The catalytic activity of the metallocene domino catalyzing system for preparing the branched polyethylene is 5 multiplied by 10<5> to 5 multiplied by 10<7>gPE / (molM per hour), the degree of branching is 10-200 / 1000C, the molecular weight of the branched polyethylene prepared under the effect of the catalyzing system ranges from 1 multiplied by 10<5> to 4 multiplied by 10<5> and the melting point is below 120 DEG C or even no melting point exists.

Owner:HEBEI UNIV OF TECH

Load type non-metallocene catalyst and preparation thereof

The invention relates to a supported non-metallocene catalyst. The supported non-metallocene catalyst is obtained by a non-metallocene ligand and a transition metal compound which directly react on a carrier through an in-situ supporting method. The preparation method for the supported non-metallocene catalyst has simple and feasible process, and has wide adjustable range of the supporting capacity and the polymerization activity of the catalyst. When the supported non-metallocene catalyst is combined with a catalyst promoter to catalyze the homopolymerization / copolymerization of olefins, high polymerization activities of the olefins can be obtained only by the less using amount of the catalyst promoter.

Owner:SINOPEC YANGZI PETROCHEM

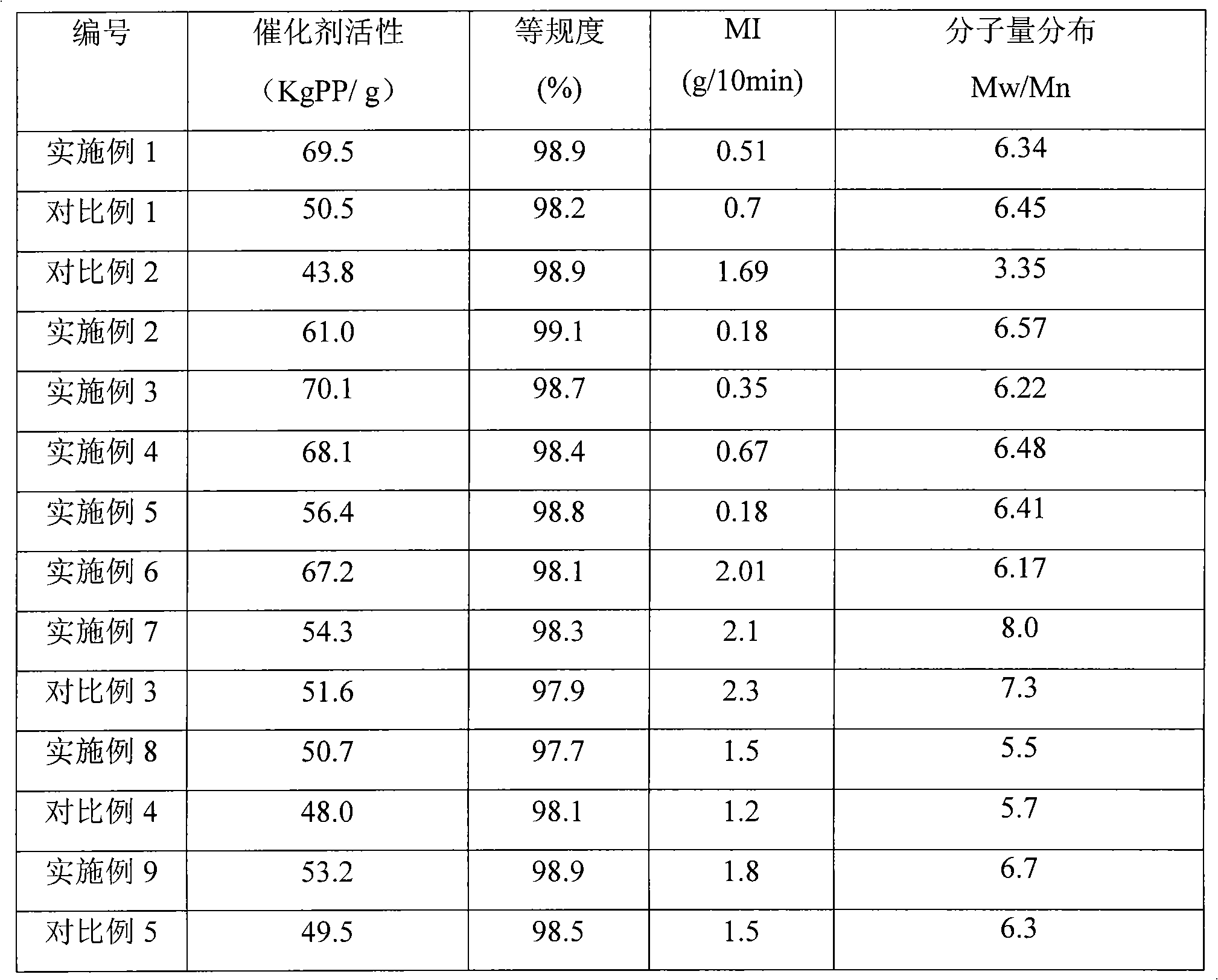

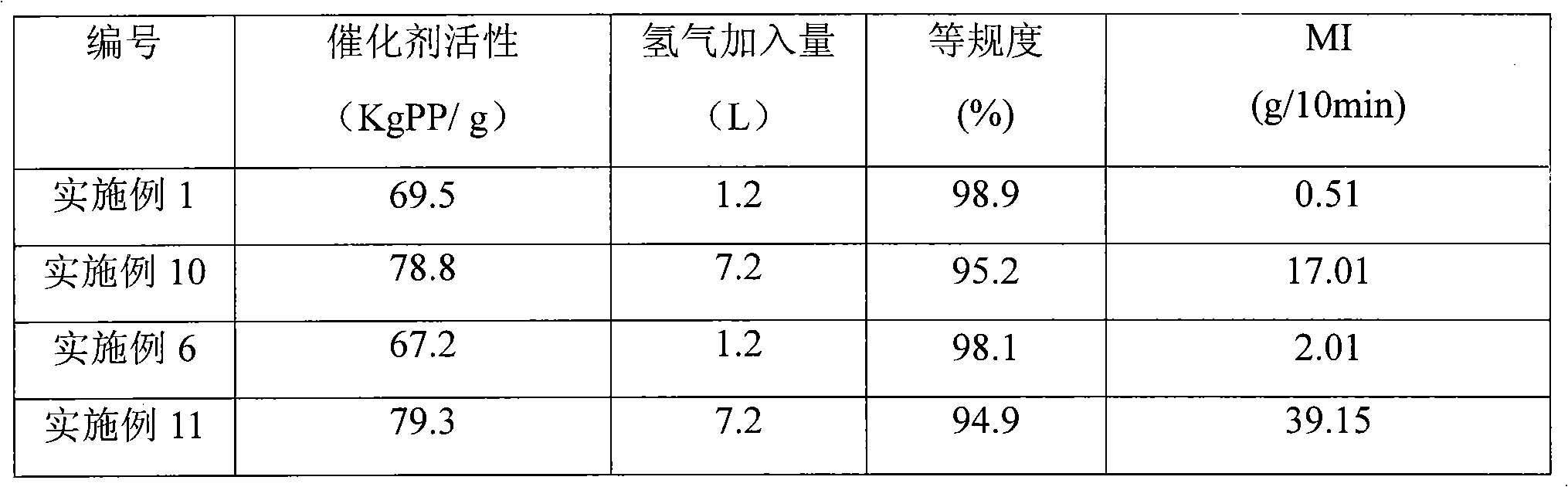

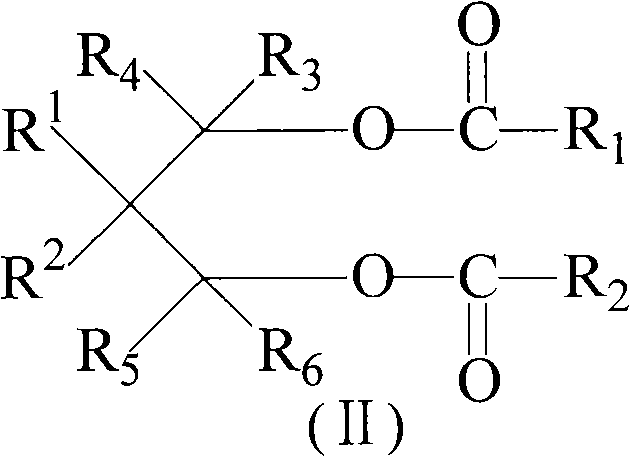

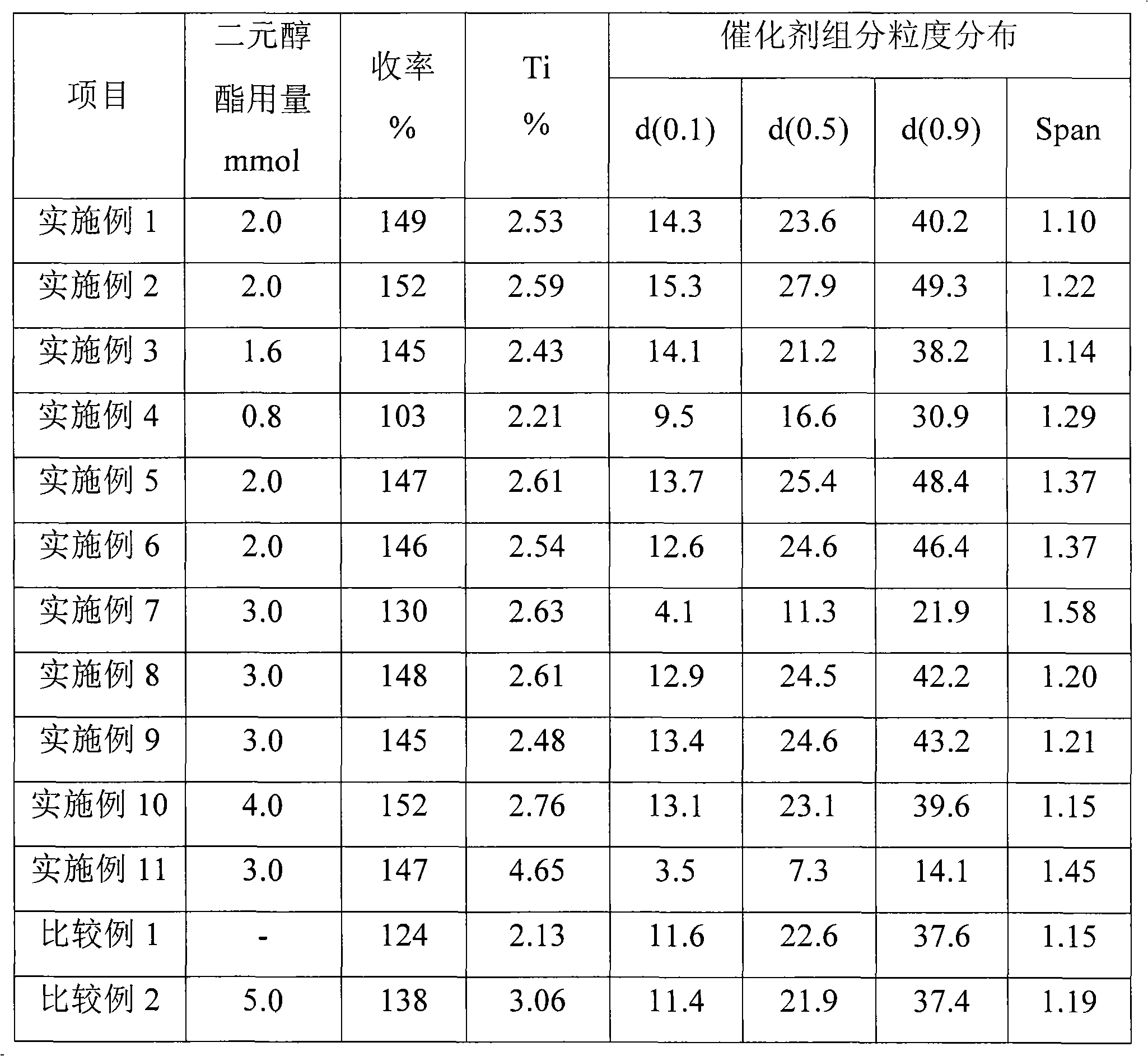

Catalyst component for olefin polymerization and catalyst thereof

The invention provides a catalyst component for olefin polymerization. The method for preparing the catalyst component comprises the following steps of: (1) dissolving magnesium halides into a solvent system consisting of an organic epoxy compound, an organic phosphorous compound and an inert diluent to obtain a uniform solution, mixing the uniform solution and a titanium compound, precipitating solids in the presence of an auxiliary precipitation agent, and adding an organic alcoholic compound before the solids are precipitated; and (2) treating the precipitated solids by using at least one electron donor compound diatomic alcohol ester compound to make the compound attached to the solids; and treating the solids by using the titanium compound and the inert diluent. The catalyst of the invention has a simple preparation method; when the catalyst is used for the olefin polymerization, particularly propylene polymerization, the polymerization activity of the catalyst is obviously improved; and the molecular weight distribution of the polymers obtained from the catalyst is quite wide.

Owner:CHINA PETROLEUM & CHEM CORP +1

Loaded non-metallocene catalyst and preparation method and application thereof

ActiveCN102059152AThe load is easy to controlAdjust molecular weightOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationAlkeneMetallocene

The invention relates to a loaded non-metallocene catalyst and a preparation method and application thereof. The loaded non-metallocene catalyst has the characteristics of simple and practicable preparation method, flexible and adjustable polymerization activity and the like. The invention also relates to the application of the loaded non-metallocene catalyst to the homopolymerisation / copolymerization of olefin. Compared with the prior art, the application has the characteristic of small using amount of a cocatalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

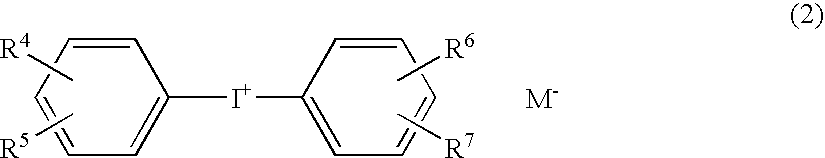

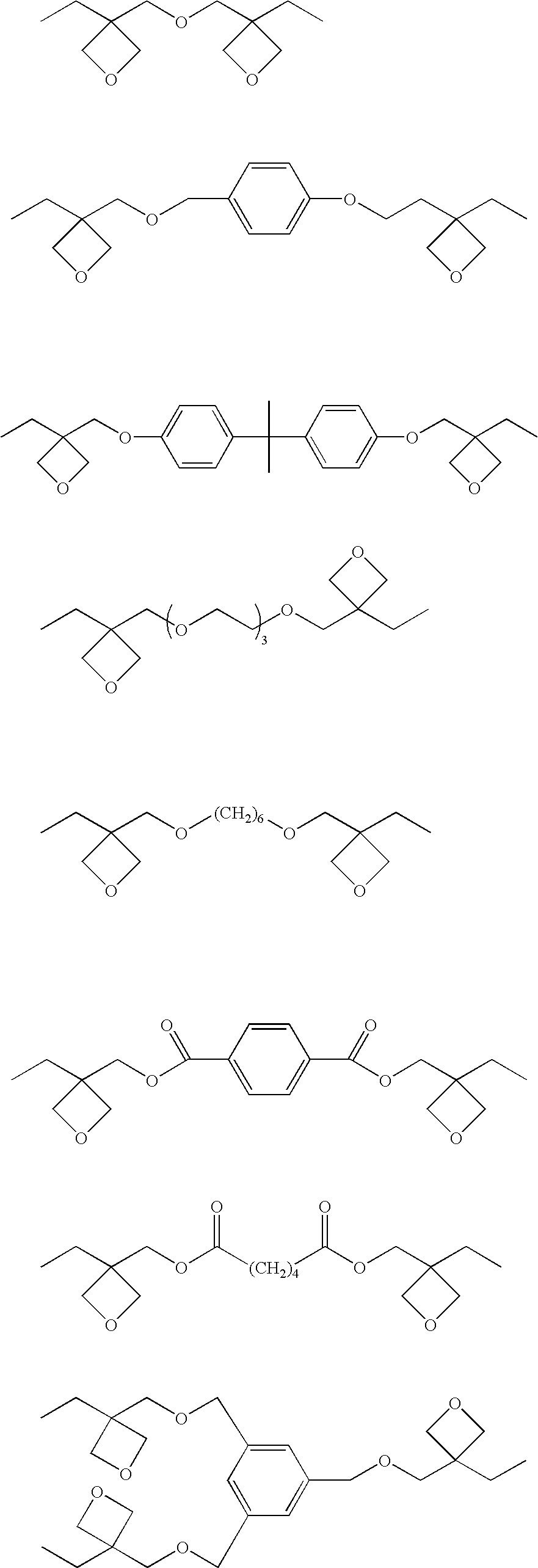

Photopolymerization initiator and photopolymerizable composition

InactiveUS20040186195A1High polymerization activityEasy to getImpression capsPhotomechanical apparatusDiketonePolycyclic compound

A photopolymerization initiator comprising (A) a photo acid-generating compound such as diaryliodonium salt (e.g., diphenyl iodonium, bis(p-chlorophenyl)iodonium, etc.), (B) a photo oxidation radical-generating compound such as diarylketone compound, alpha-diketone compound or ketocoumarin compound, and (C) a fused polycyclic aromatic compound such as 1,4-dimethylnaphthalene, 1-methylanthracene, 9-methylanthracene, 9,10-dimethylanthracene or 9,10-diethylanthracene. The photopolymerization initiator makes it possible to efficiently polymerize the cationically polymerizable monomer by the irradiation with visible light.

Owner:TOKUYAMA CORP +1

Solid support-polymethylaluminoxane complex, method for producing same, olefin polymerization catalyst, and method for producing polyolefin

ActiveUS20130059990A1High yieldHigh polymerization activityOrganic chemistry methodsOrganic-compounds/hydrides/coordination-complexes catalystsPolyolefinOlefin polymerization

Disclosed is a solid support-polymethylaluminoxane complex exhibiting a higher polymerization activity than a conventional substance and being homogeneous. Also disclosed is a method for producing an olefin-based polymer having a favorable quality using the complex and a transition metal compound. The complex comprises a coating layer containing polymethylaluminoxane and trimethylaluminum on the surface of a solid support. The coating layer comprises a solid polymethylaluminoxane composition in which (i) the content of aluminum is in a range of 36 to 41 mass % and (ii) the molar fraction of methyl groups derived from a trimethylaluminum moiety to the total number of moles of methyl groups is 12 mol % or less. Also disclosed is an olefin polymerization catalyst comprising the complex and a transition metal compound represented by general formula (III): MR5R6R7R8 as catalyst components, and a method for producing a polyolefin comprising polymerizing an olefin using the catalyst.

Owner:TOSOH FINECHEM CORP

Loaded non-metallocene catalyst and preparation method and application thereof

ActiveCN102059148AThe load is easy to controlAdjust viscosity average molecular weightOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationMetalloceneChemistry

The invention relates to a loaded non-metallocene catalyst and a preparation method and application thereof. The loaded non-metallocene catalyst has the characteristics of simple and practicable preparation method, flexible and adjustable polymerization activity and the like. The invention also relates to the application of the loaded non-metallocene catalyst to the homopolymerisation / copolymerization of olefin. Compared with the prior art, the application has the characteristic of small using amount of a cocatalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of catalyst component for polymerization reaction of olefins and catalyst thereof

The invention provides a method for preparing a catalyst component for the polymerization reaction of olefins, which comprises the following steps: (1) dissolving magnesium halide in a solvent system comprised of an organic epoxy compound, an organic phosphorus compound and an inert diluent to form uniform solution; (2) mixing a titanium compound with the uniform solution formed by the step (1) and adding a precipitant to form a mixture, or adding the precipitant into the uniform solution formed by the step (1) first and mixing the uniform solution with the titanium compound to form a mixture; and (3) heating the mixture obtained by the step (2), adding any selected electronic donor compound during heating or after heating, and washing the resulting product with an inert diluent to obtain a magnesium / titanium-containing solid material, wherein the precipitant is a glycol ester compound. The catalyst component has high polymerization activity and stereoselectivity and causes little polymer fine powder when used in the polymerization reaction of olefins.

Owner:CHINA PETROLEUM & CHEM CORP +1

High oil absorption resin and synthetic method thereof

The invention discloses a high oil absorbing resin, and a process for preparation comprises utilizing short-chain ester of (metyl group) acrylic acid, long-chain ester of acrylic acid and styrene monomer to be monomers, adding dispersing agent and surface active agent, and getting through suspension polymerization and random copolymerization under the condition of the existence of cross linker and initiating agent. The process for synthesizing has lithe time consumption, which can be industrialized, and high oil absorbing resin which is got has high oil absorbing efficiency, fast oil absorbing speed, and which can be recycled to be repeatedly used.

Owner:SUZHOU TIMELYBLUE ENVIRONMENTAL TECH

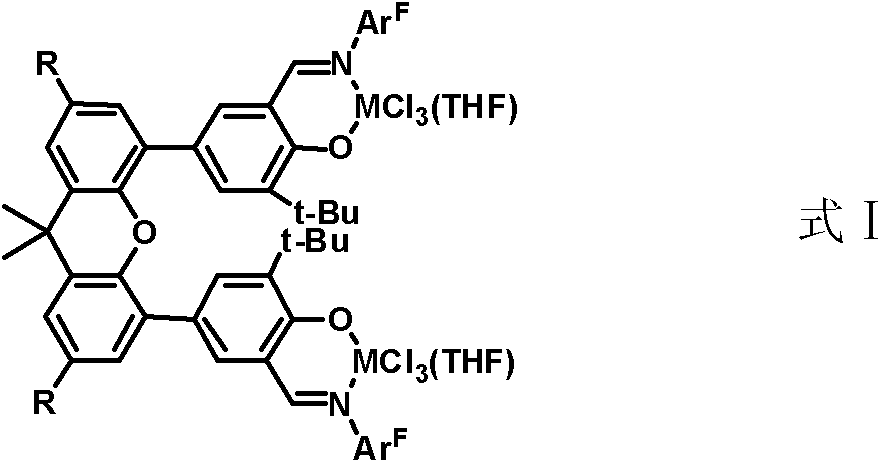

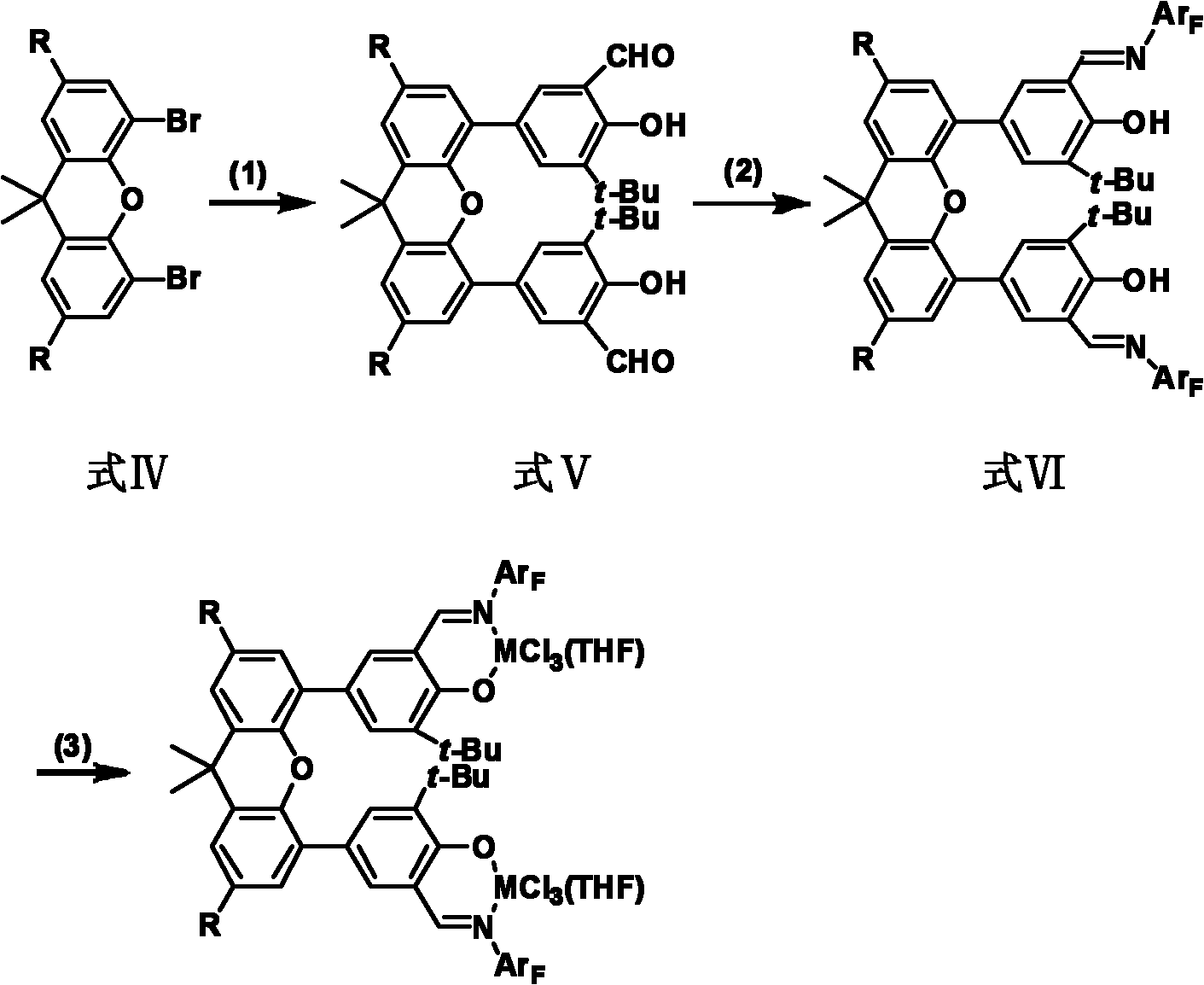

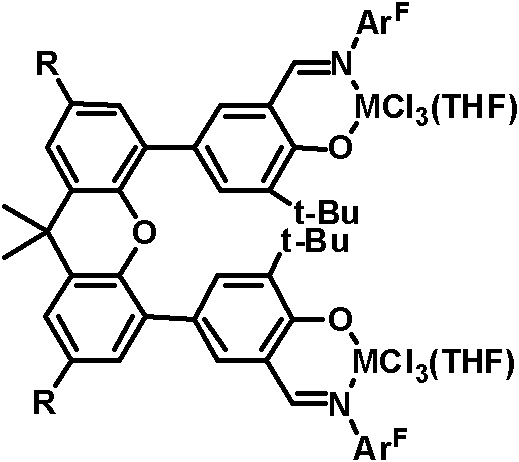

Bimetallic catalyst precursor and application thereof to olefin polymerization or copolymerization

ActiveCN101864010AHigh catalytic efficiencyHigh polymerization activityAluminoxaneCoordination polymerization

The invention discloses a bimetallic catalyst precursor for catalyzing olefin to polymerize or copolymerize and belongs to the field of olefin coordination polymerization. The catalyst precursor is based on a salicvlaldimine ligand and an IV group transition metal. Compared with a monometallic catalyst, with the synergistic effect of bimetals, a catalyst consisting of the precursor and alkyl aluminum has higher activity when used for catalyzing the olefin to homopolymerize or copolymerize; particularly, the activity of the catalyst can reach 5.2*104g / mol<-1>h<-1> at the ethylene pressure of 1atm when used for catalyzing 1,5-hexadiene to be copolymerized with the ethylene; and in addition, the catalyst has higher ratio of inducing a comonomer into a polymer.

Owner:PEKING UNIV

Method for preparing branched high vinyl polybutadiene rubber using molybdenum series catalysis

The invention relates to a method for preparing branched high ethenyl butadiene rubber with molybdenum catalyst, recombining macromolecular monomer prepared through polymerization of molybdenum catalyst butadiene atom free radical or butadiene anion initiated by organic lithium, naphthalene sodium, with coordinate polymerization of butadiene or original position polymerization, to prepare said product with controllable construction. The method is characterized by simple process, special construction of polymer, proper molecular weight and molecular distribution, more than 80% of ethenyl content, controllable property, length, distribution and degree of branching of branch chain in a certain range, good processing behavior and physical mechanics property and low production cost.

Owner:QINGDAO UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com