Load type non-metallocene catalyst and preparation thereof

A non-metallocene and non-metallocene ligand technology, which is applied to the combined supported non-metallocene catalyst. Specifically, it can solve problems such as high vacuum, low olefin polymerization activity, and high temperature in the loading process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

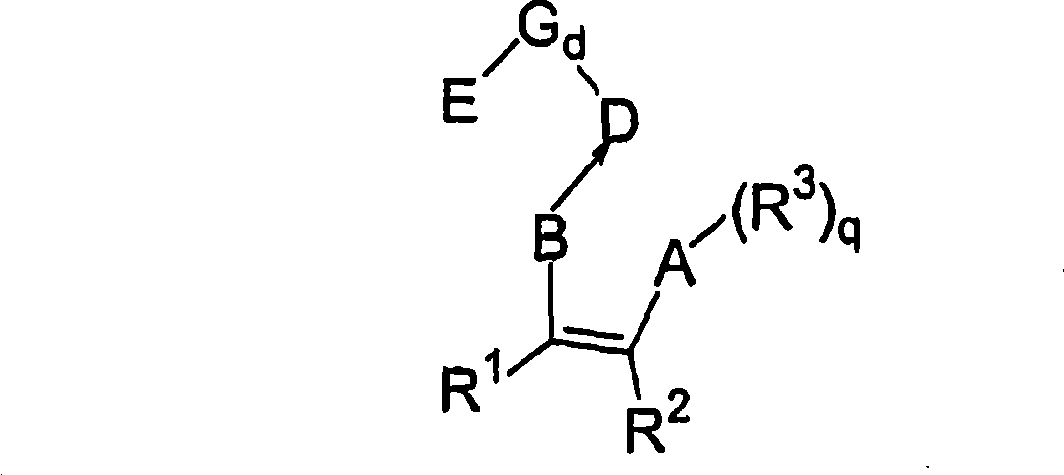

[0118]First, the present invention relates to a preparation method of a supported non-metallocene catalyst, comprising the following steps: dissolving a magnesium compound in a mixed solvent composed of tetrahydrofuran and alcohol to obtain a magnesium compound solution; making a porous carrier and the magnesium compound The steps of mixing the solutions to obtain a mixed slurry; adding a solvent for precipitation to the mixed slurry to precipitate it to obtain a composite carrier; treating the composite carrier with one selected from a chemical treatment agent and a non-metallocene ligand to obtain The treatment step of modifying the composite support, wherein the chemical treatment agent is selected from Group IVB metal compounds; and contacting the modified composite support with another party selected from the chemical treatment agent and the non-metallocene ligand , so as to obtain the contact step of the supported non-metallocene catalyst.

[0119] The steps to obtain th...

Embodiment 1

[0308] The porous carrier adopts silica gel, the model is ES757 of Ineos Company, and it is heated at 600°C and N 2 After continuous roasting under atmosphere for 4 h, it was ready for use.

[0309] Dissolve 5g of anhydrous magnesium chloride in a mixed system of tetrahydrofuran and ethanol, heat to 60°C and stir for 1.5 hours to form a solution, then add the heat-activated silica gel to the solution, and stir at 60°C for 2 hours to form a transparent system. Then 50ml of hexane was added to precipitate the magnesium compound, then filtered, washed once with 50ml of hexane, and dried to obtain a composite carrier.

[0310] Add 50ml of hexane to the composite carrier, stir and add titanium tetrachloride dropwise over 30 minutes, stir and react at 60°C for 4 hours, filter, wash with hexane for 3 times, each hexane consumption is 25ml, and then heat to 90°C Dry for 2 hours to obtain the modified composite carrier.

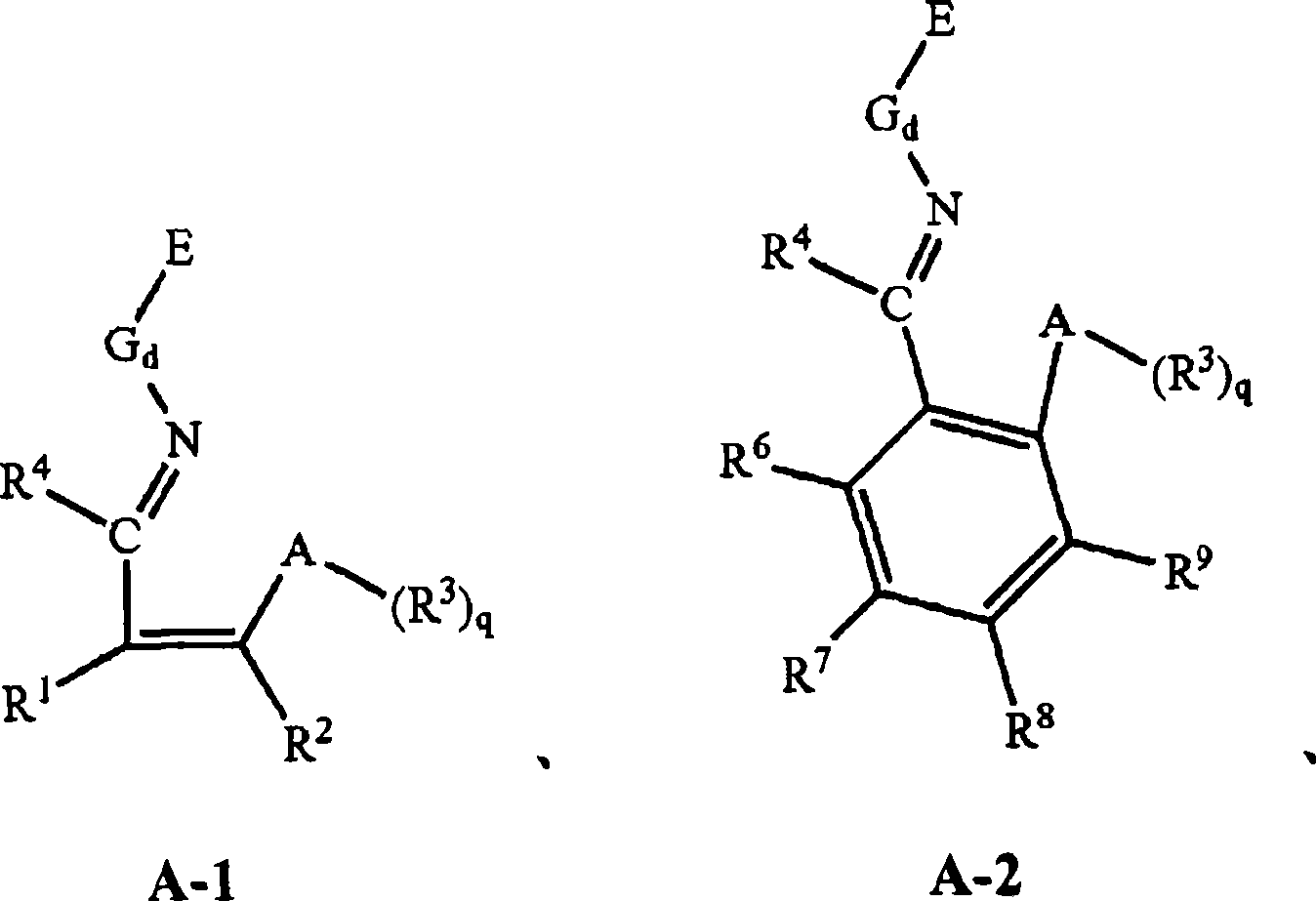

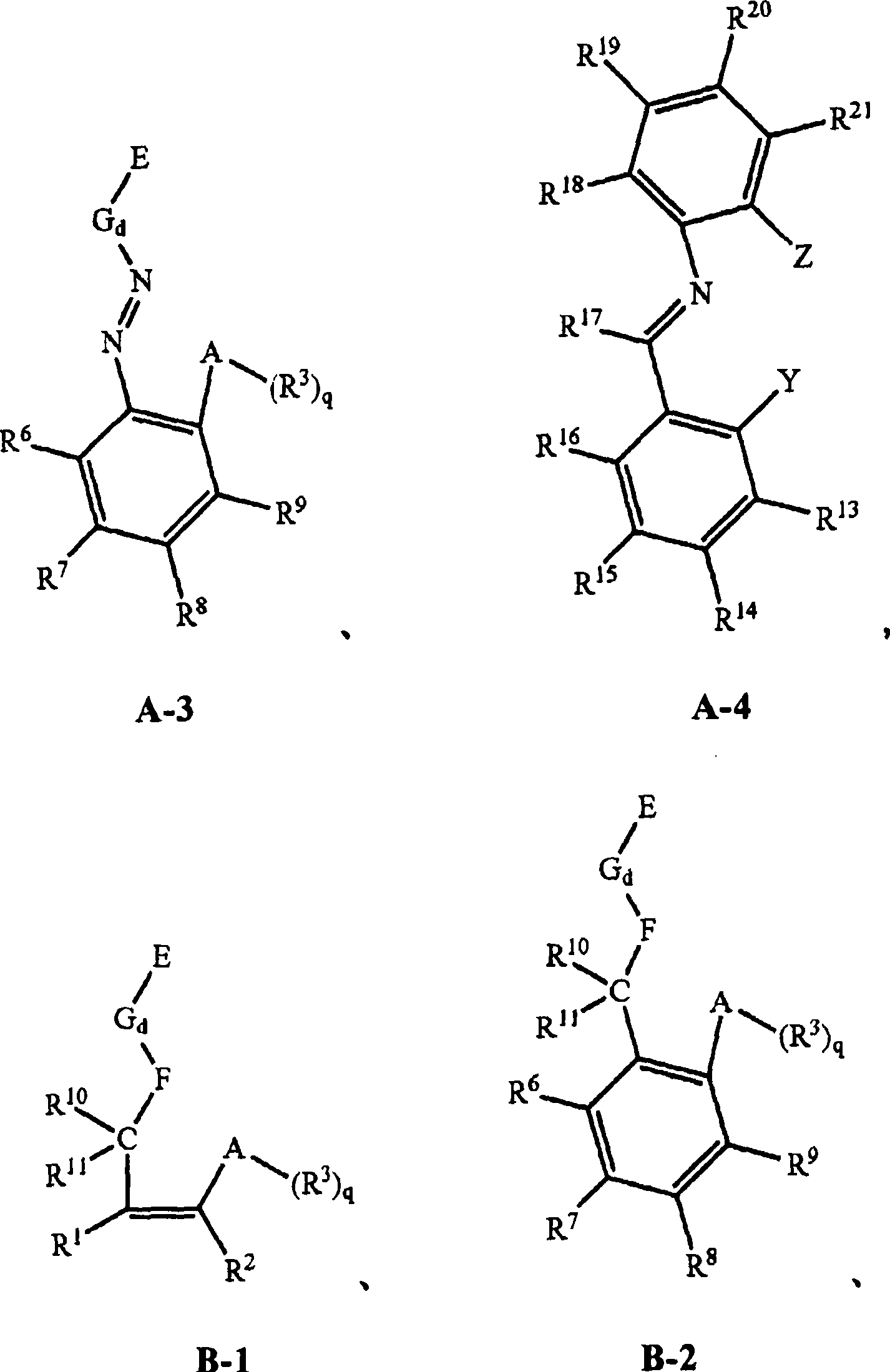

[0311] the structural formula The non-metallocene ligand was...

Embodiment 1-1

[0315] Basically the same as Example 1, but with the following changes:

[0316] Magnesium chloride was changed to magnesium bromide.

[0317] Ethanol was changed to propanol.

[0318] Magnesium compounds were precipitated with decane and washed 3 times with decane.

[0319] The non-metallocene ligand is changed to

[0320] Wherein, the mass ratio of magnesium bromide to the porous carrier is 1:2, the molar ratio to tetrahydrofuran is 1:40, the molar ratio to ethanol is 1:0.57, and the proportioning ratio of titanium tetrachloride to the composite carrier is 15.2 mmol : 1 gram. The mass concentration of the non-metallocene ligand is 0.11 g / ml, the mass ratio of the non-metallocene ligand to the modified composite carrier is 0.22:1, and the solvent for dissolving the non-metallocene ligand is changed to toluene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com