Patents

Literature

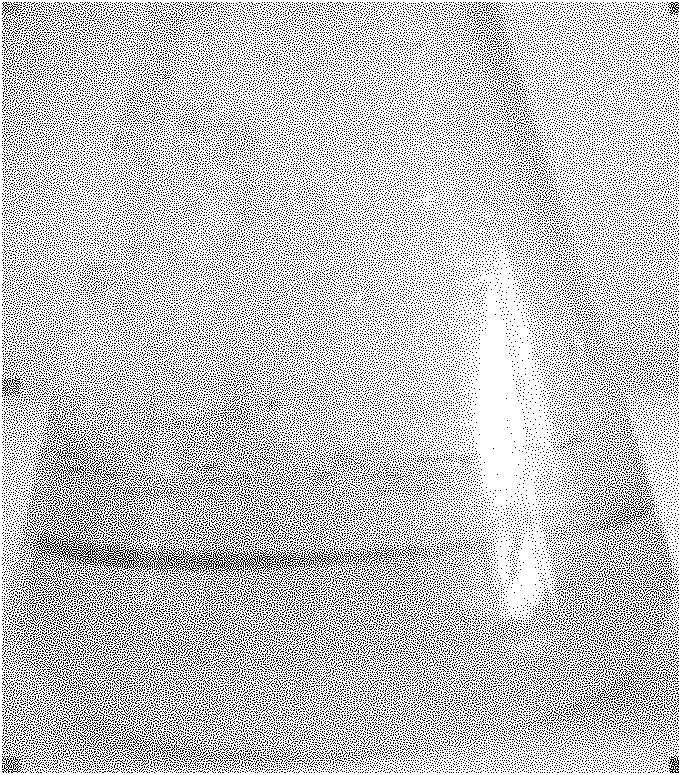

324 results about "Decane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Decane is an alkane hydrocarbon with the chemical formula C₁₀H₂₂. Although 75 structural isomers are possible for decane, the term usually refers to the normal-decane ("n-decane"), with the formula CH₃(CH₂)₈CH₃. All isomers, however, exhibit similar properties and little attention is paid to the composition. These isomers are flammable liquids. Decane is a component of gasoline (petrol) and kerosene. Like other alkanes, it is a nonpolar solvent, does not dissolve in water, and is readily combustible. Although it is a component of fuels, it is of little importance as a chemical feedstock, unlike a handful of other alkanes.

Asymmetric Gas Separation Membranes with Superior Capabilities for Gas Separation

InactiveUS20080143014A1Excellent permeation fluxHigh selectivityMembranesSemi-permeable membranesCellulose diacetatePolymer science

This invention relates to a method of making flat sheet asymmetric membranes, including cellulose diacetate / cellulose triacetate blended membranes, polyimide membranes, and polyimide / polyethersulfone blended membranes by formulating the polymer or the blended polymers dopes in a dual solvent mixture containing 1,3 dioxolane and a second solvent, such as N,N′-methylpyrrolidinone (NMP). The dopes are tailored to be closed to the point of phase separation with or without suitable non-solvent additives such as methanol, acetone, decane or a mixture of these non-solvents. The flat sheet asymmetric membranes are cast by the phase inversion processes using water as the coagulation bath and annealing bath. The dried membranes are coated with UV curable silicone rubber. The resulting asymmetric membranes exhibit excellent permeability and selectivity compared to the intrinsic dense film performances.

Owner:UOP LLC

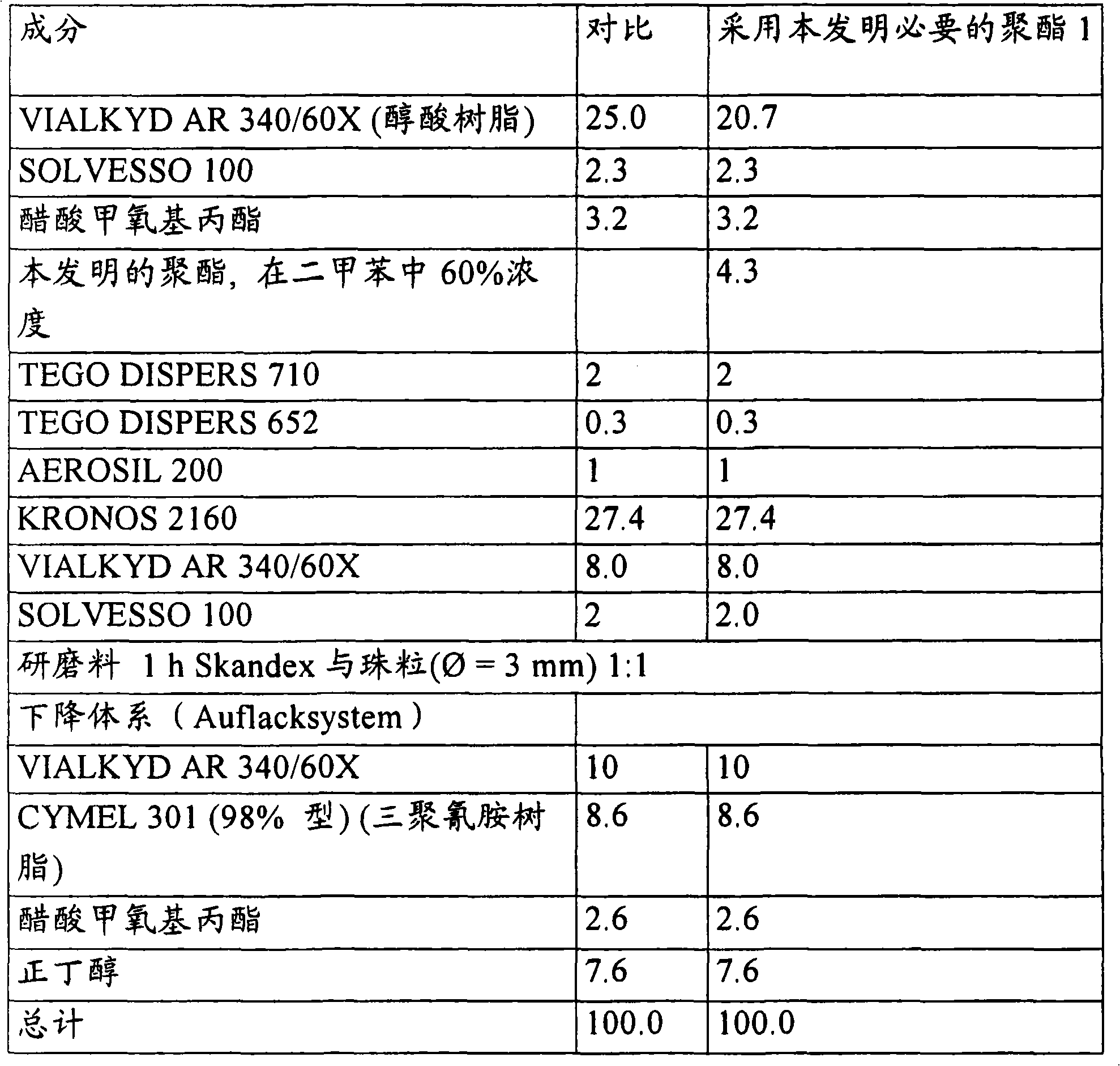

Coating material compositions

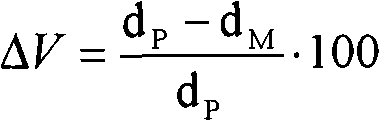

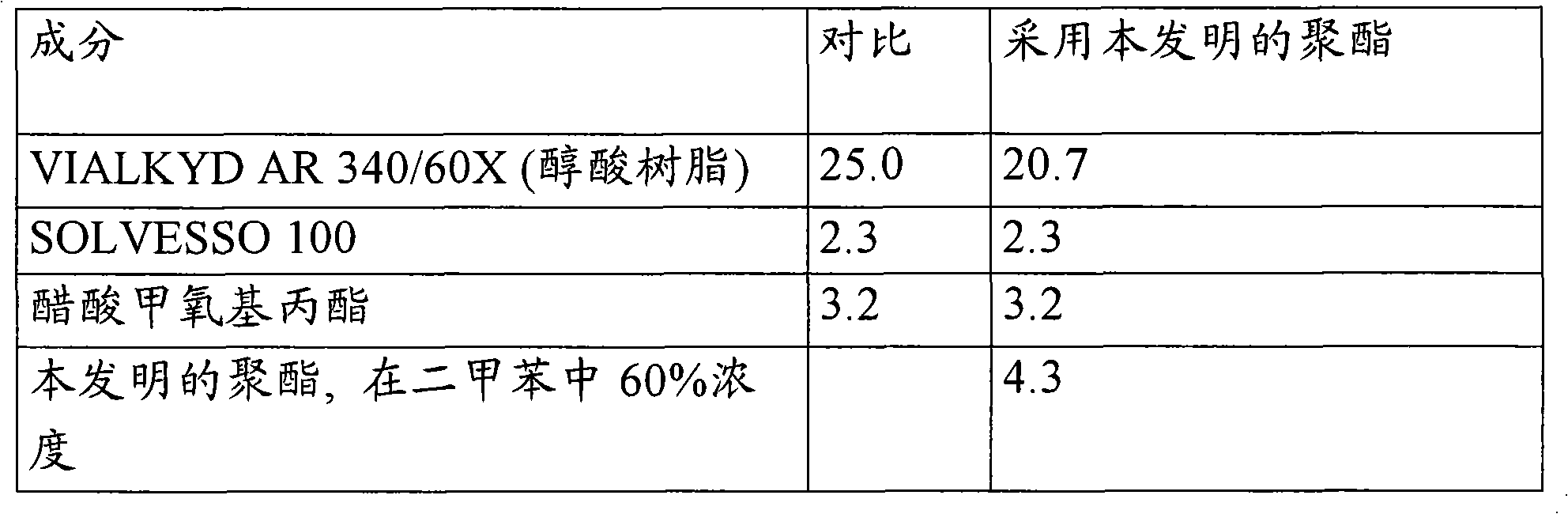

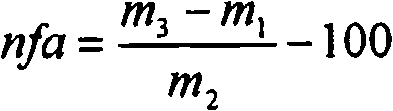

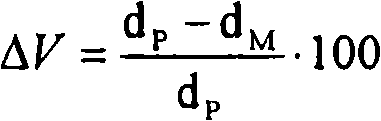

InactiveCN101353546AEffective adhesionImprove corrosion resistanceCosmetic preparationsLiquid surface applicatorsPolyesterAdditive ingredient

The invention relates to coating material compositions for, for example, metallic, mineral substrates or for substrates of wood, paper and plastics, which comprise yellowing-resistant, low-viscosity, unsaturated, amorphous polyesters which are very largely free of benzene and formaldehyde, as a result of which the adhesion of these coating material compositions is improved even under critical ambient conditions, and to a preparation process and use of said compositions. More specifically, the invention relates to coating material compositions, substantially including 1, yellowing-resistant, low-viscosity, unsaturated, amorphous polyesters which are very largely free of benzene and formaldehyde; 2, at least one other adhesive; 3, at least one accessory ingredient and / or additive; 4, at least one colorant and / or stuffing. The yellowing-resistant, low-viscosity, unsaturated, amorphous polyesters are composed by the following components: I. acid components, made up of A) at least one alpha, beta-unsaturated dicarboxilic acid, and B) at least one linear and / or branch fatty group and / or alicyclic and / or aromatic bifunctional and / or polyfunctional carboxyl acid, which is not provided with alpha, beta-unsaturated part; II. alcohol components, made up of C) bis(hydroxymethyl)tricyclo compounds and D) at least one bifunctional and / or polyfunctional alcohol, wherein, based on the polyesters, the content of benzene is lower than 10mg / kg and the content of formaldehyde is lower than 10mg / kg, the molecular weight distribution polydispersity of the polyesters is 1.3-4.5, the content of tricyclodecane(mono- / di-)aldehyde in the bis(hydroxymethyl)tricyclo compound C) is lower than 2 weight percent; mono(hydroxymethyl)tricyclo [5.2.1.0<2,6>] decane in the compound C) is lower than 10 weight percent, and the content of chromium, nickel, copper, cadmium and plumbum in the compound C) is lower than 2mg / kg.

Owner:EVONIK DEGUSSA GMBH

Impregnating solution of hydrogenation catalyst, its preparation method, hydrogenation catalyst and preparation method thereof

ActiveCN103055956AImprove hydrodesulfurization activityHigh activityMolecular sieve catalystsCatalyst activation/preparationHydrodesulfurizationDecane

The invention provides an impregnating solution of a hydrogenation catalyst and its preparation method. The method includes: preparing a VIII-th group metal compound and a first organic complexing agent into an aqueous solution A; preparing a VIB-th group metal compound into an aqueous solution B; and mixing the aqueous solution A and the aqueous solution B. Specifically, the ligand of the first organic complexing agent at least contains the coordination atom N. The invention also provides a hydrogenation catalyst and a preparation method thereof. Compared with current catalysts, the hydrogenation catalyst provided in the invention has high hydrodesulfurization activity. For example, a mixed solution of n-decane with a 4, 6-dimethyldibenzothiophene (4, 6-DMDBT) content of 0.59wt% is adopted as the raw material, and hydrodesulfurization activity contrast evaluation is performed on the catalyst provided in the invention and a contrast catalyst. In terms of a contrast catalyst activity of 100, the hydrodesulfurization activity of the catalyst provided in the invention can reach 120.

Owner:CHINA PETROLEUM & CHEM CORP +1

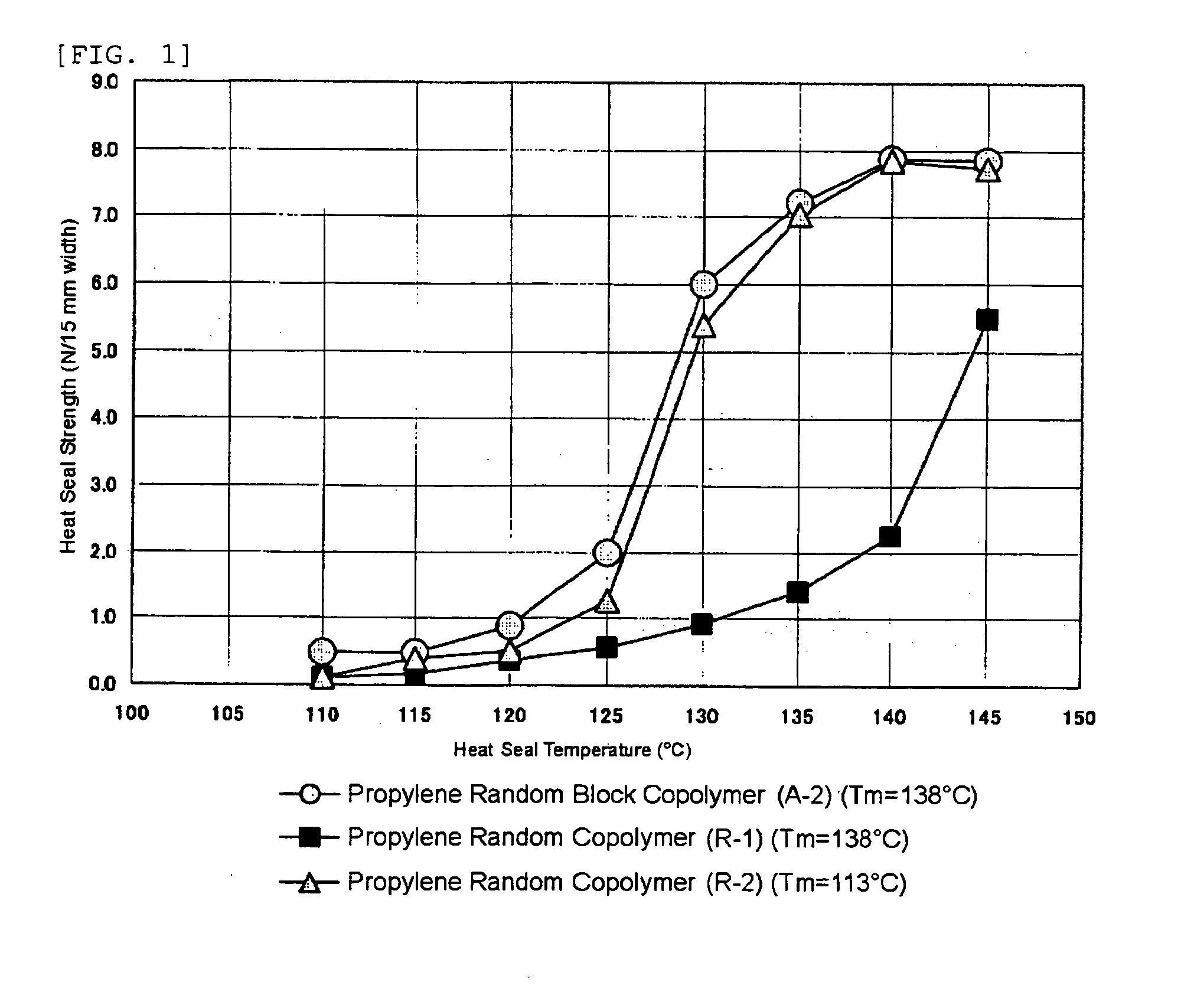

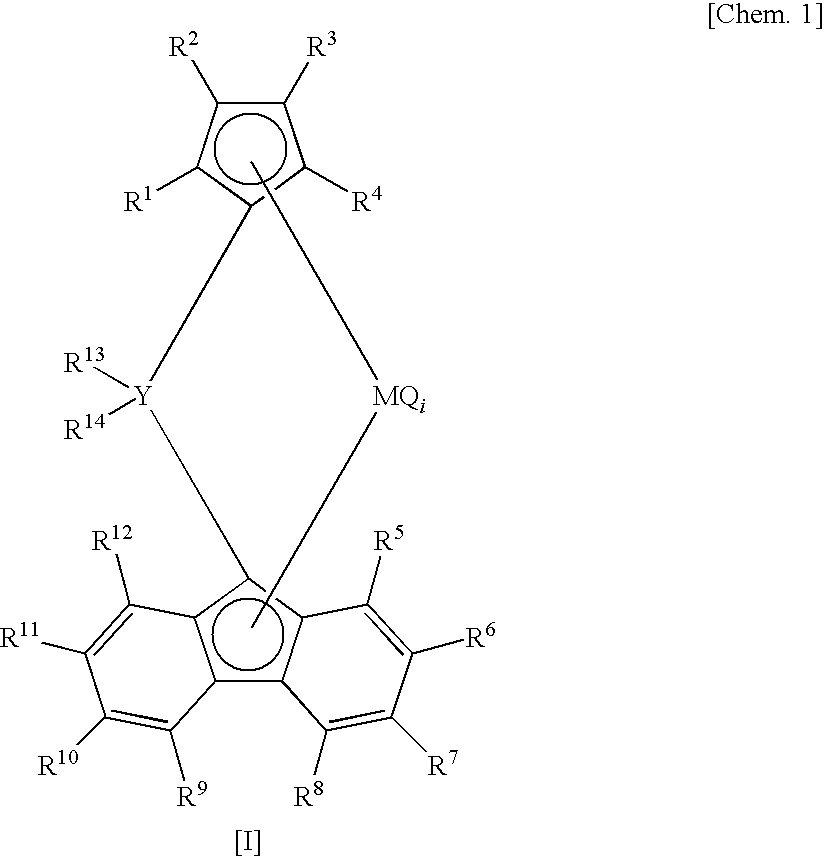

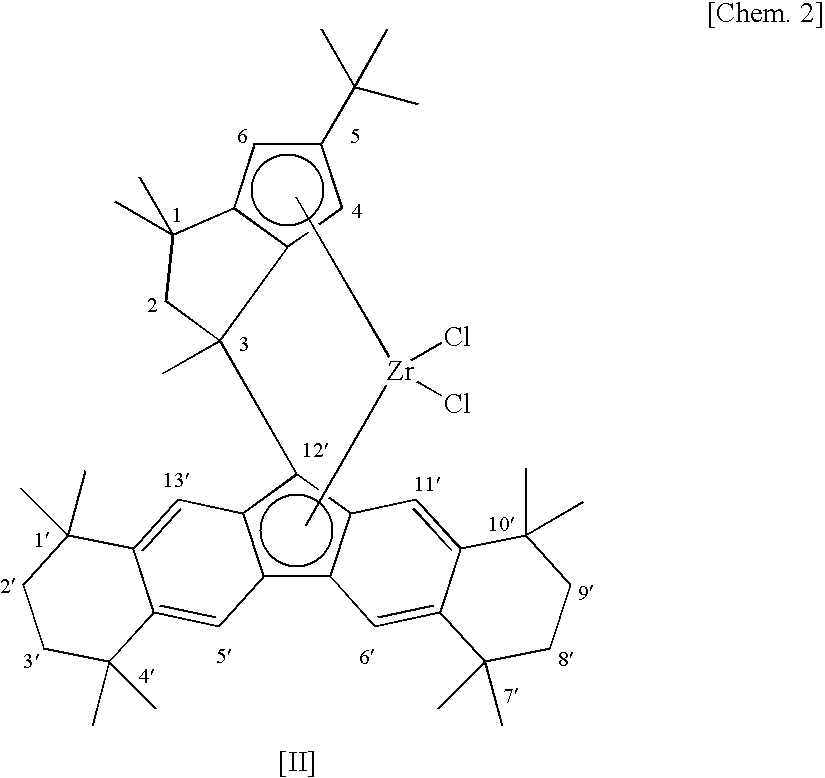

Propylene Random Block Copolymer, Resin Composition Containing the Copolymer and Molded Article Made Thereof

The invention provides a propylene random block copolymer (A) that has a melt flow rate from 0.1 to 100 g / 10 min and a melting point from 100 to 155° C. and includes 90 to 60% by weight of a portion insoluble (Dinsol) in n-decane at room temperature and 10 to 40% by weight of a portion soluble (Dsol) in n-decane at room temperature, wherein the Dinsol satisfies the following requirements (1) through (3) and the Dsol satisfies the following requirements (4) through (6). The invention further provides molded articles such as sheets, films, injection molded articles, hollow molded articles, injection blow molded articles and fibers, which are formed of the propylene random block copolymer (A) or a propylene resin composition containing the propylene random block copolymer (A). (1) The molecular weight distribution (Mw / Mn) obtained by GPC of the Dinsol is from 1.0 to 3.5, (2) the content of skeletons derived from ethylene in the Dinsol is from 0.5 to 13% by mole, (3) the total amount of 2,1- and 1,3-propylene units in the Dinsol is 0.2% by mole or less, (4) the molecular weight distribution (Mw / Mn) obtained by GPC of the Dsol is from 1.0 to 3.5, (5) the intrinsic viscosity [η] in decalin at 135° C. of the Dsol is from 1.5 to 4 dl / g and (6) the content of skeletons derived from ethylene in the Dsol is from 15 to 35% by mole.

Owner:MITSUI CHEM INC +1

Dispersions of amorphous urethanized unsaturated polyester resins based on particular dicidol isomers

An aqueous dispersion, contains: a) an amorphous urethanized, unsaturated polyester resin, b) a nonvolatile content of from 20% to 60% by weight, c) from 0 to 60% by weight of a solvent, d) a pH of between 5.0 and 9.5, and e) a viscosity at 20° C. of from 20 to 500 mPas. The polyester resin is obtained from I. an alcohol component, II. i) from 20 to 100 mol % of an α,β-unsaturated carboxylic acid component, and ii) from 0 to 80 mol % of a further carboxylic acid component, and III. at least one isocyanate component. The alcohol component contains a dicidol mixture of the isomeric compounds 3,8-bis(hydroxymethyl)tricyclo[5.2.1.02,6]decane, 4,8-bis(hydroxymethyl)tricyclo[5.2.1.02,6]decane and 5,8-bis(hydroxymethyl)tricyclo[5.2.1.02,6]decane. Each isomer is present in a fraction of from 20 to 40% in the dicidol mixture. The sum of the three isomers in the dicidol mixture is from 90 to 100%. The dicidol mixture is present from 10 to 100 mol % in the alcohol component of the polyester.

Owner:EVONIK DEGUSSA GMBH

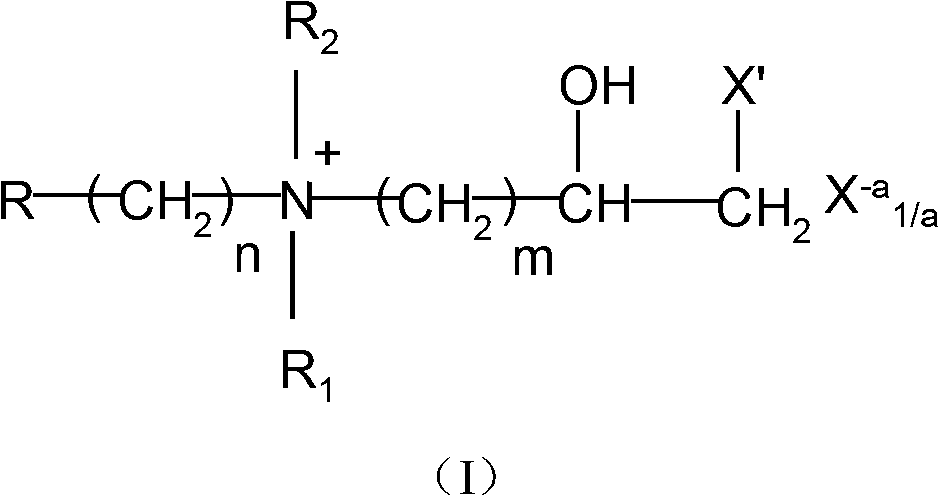

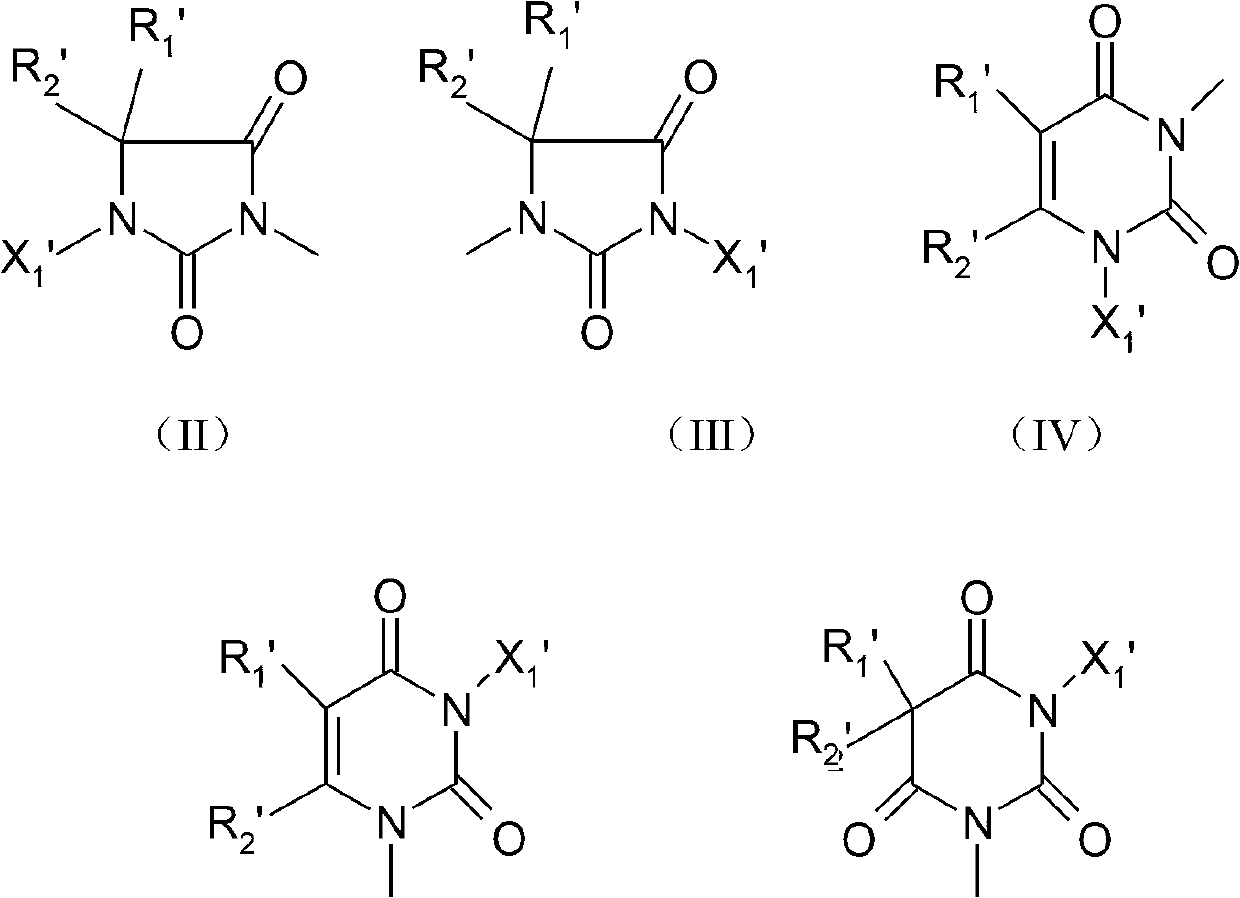

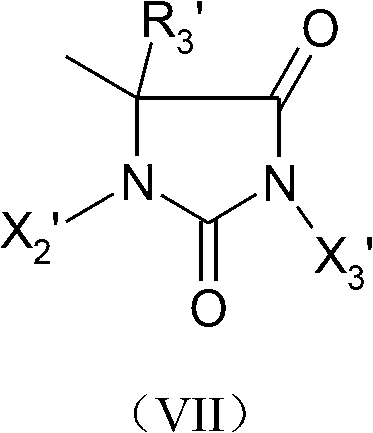

Hydroxy halogen amine compound containing quaternary ammonium salt functional group and preparation method and application thereof

InactiveCN102786477AEfficientImprove surface hydrophilicityBiocideOrganic chemistryQuaternary ammonium cationOrganic synthesis

The invention relates to the field of organic synthesis and discloses hydroxy halogen amine compound containing quaternary ammonium salt functional group with a structure shown in a formula (I), wherein R1 and R2 are C1-C20 alkyl or alkene groups, C1-C8 haloalkyl or alkenyl halide groups or C1-C8 hydroxy alkyl, or R1 and R2 are combined into C3-C7 naphthene base or cycloalkene group, and R is selected from hydantoins group, 2-imidazole ketone group, 4-imidazole ketone group, isocyanurates group, 1,3,8-tri-azaspiro [4.5] decane-2,4-diketones group, and piperidines group. The compound can be used for preparing an antibacterial agent and an antibacterial material.

Owner:SHANGHAI NORMAL UNIVERSITY

Method for preparing 5A molecular sieve for straight-chain paraffin adsorption through adopting attapulgite

ActiveCN103170304AGood saturated adsorption capacityOther chemical processesAluminium silicatesAlkaneIon exchange

The invention relates to a method for preparing a 5A molecular sieve for straight-chain paraffin adsorption through adopting attapulgite, and belongs to the technical field of molecular sieve adsorbents. The method comprises the following steps: 1, calcining attapulgite at a high temperature, and immersing in a hydrochloric acid solution; 2, fully dissolving attapulgite in an aqueous solution of sodium hydroxide; 3, fully dissolving sodium hydroxide and sodium metaaluminate in water; 4, rapidly mixing a solution obtained in step 2 with a solution obtained in step 3, violently stirring to obtain a milky colloid, crystallizing the colloid at 80-95DEG C for 4-6h, cooling, filtering, washing until the pH value is less than 9, and drying to obtain raw powder of a 4A molecular sieve; and 5, carrying out ion exchange of the raw powder of a 4A molecular sieve and a calcium chloride solution to obtain the 5A molecular sieve. The static saturated adsorption capacities of the 5A molecular sieve to n-decane and n-pentadecane reach 0.0716g / g and 0.123g / g respectively. The method for preparing the 5A molecular sieve through adopting a cheap and easily available attapulgite resource is used to substitute a traditional chemical raw material method, and the 5A molecular sieve has a good saturated adsorption capability to straight-chain paraffin.

Owner:CHANGZHOU UNIV

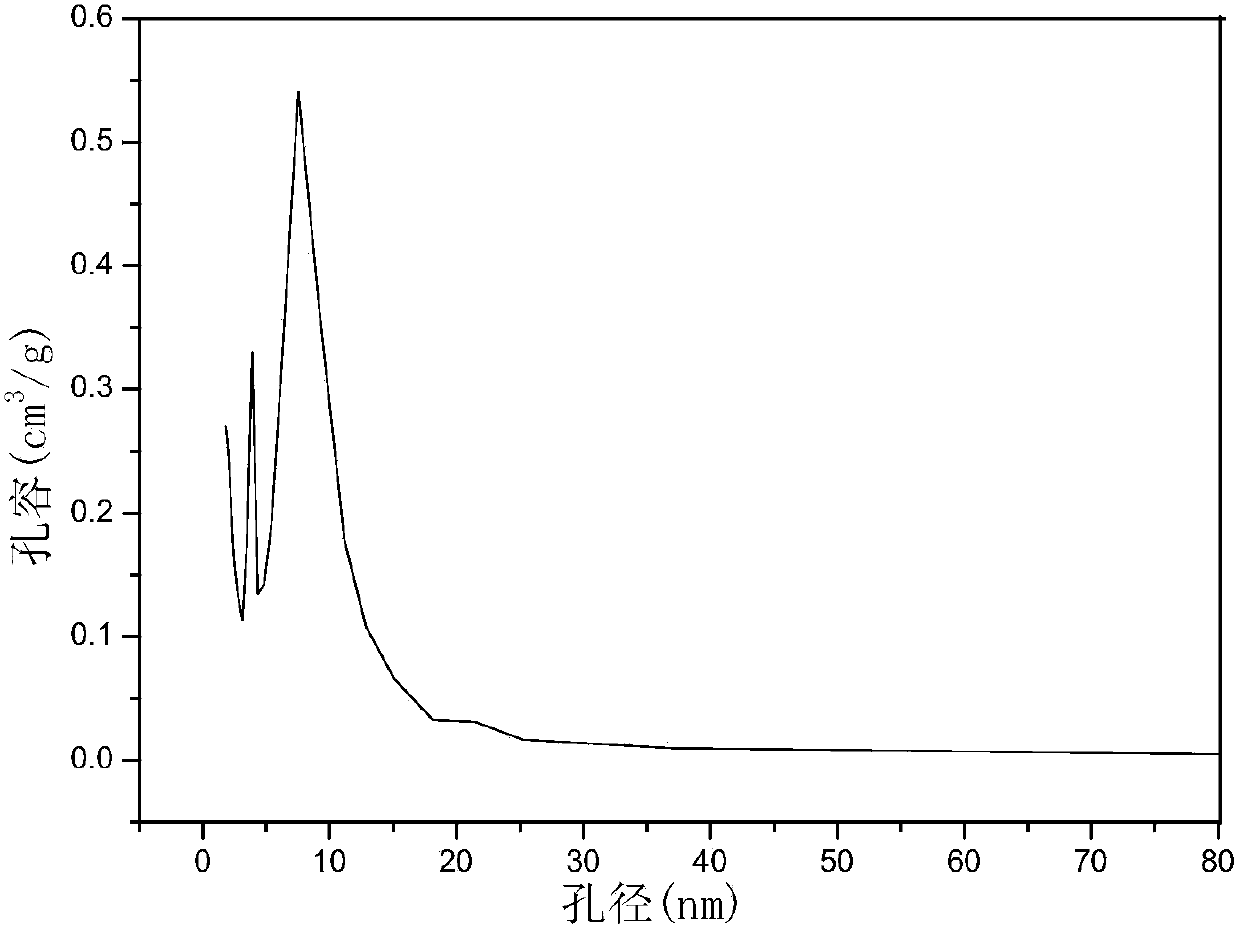

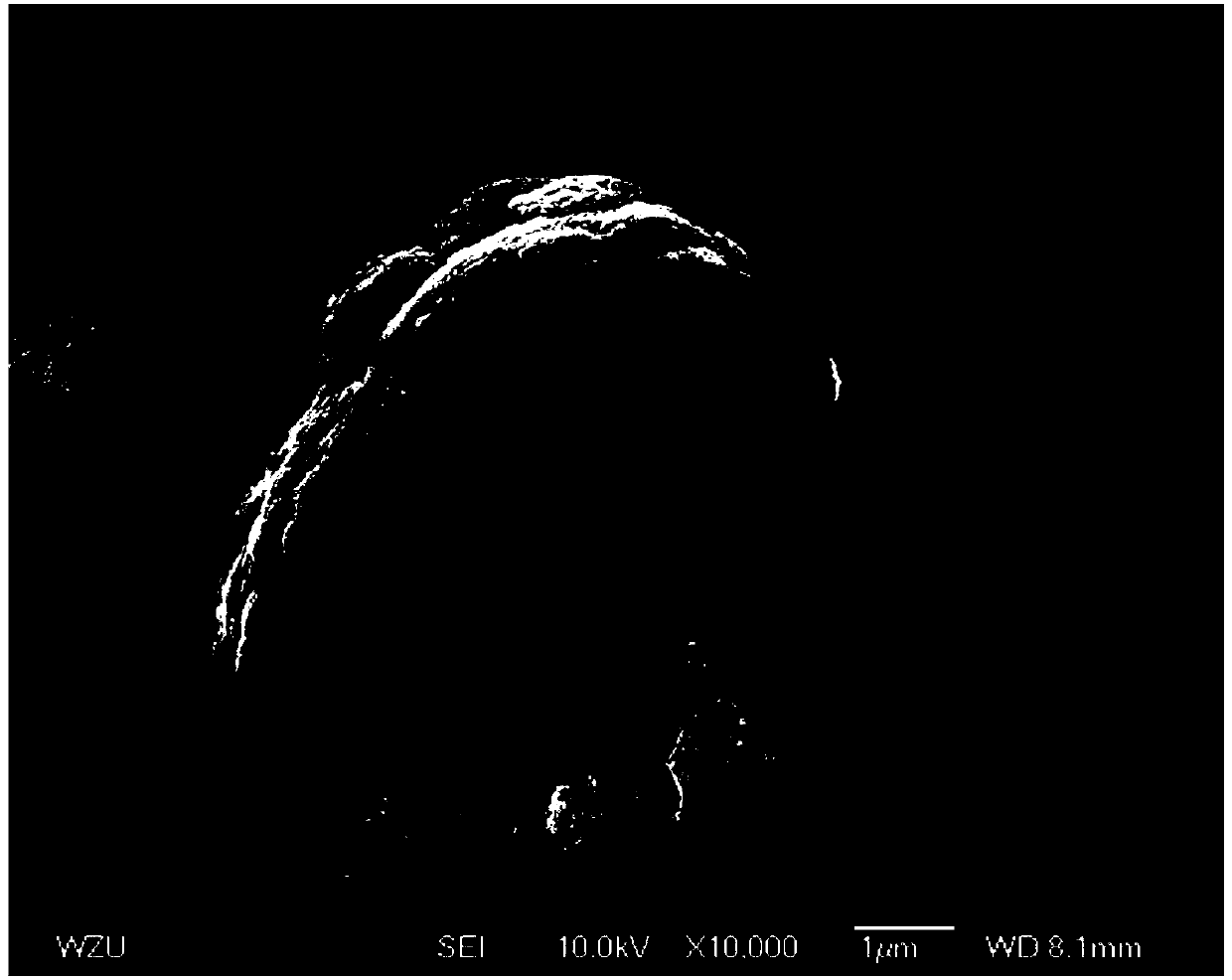

Mesoporous ZSM-5 zeolite, mesoporous ZSM-5 zeolite-loaded metal sulfide catalyst and application

ActiveCN103787368ALower synthesis costThe synthesis method is simpleMolecular sieve catalystsHydrocarbon oil crackingMethyl carbamateHydrodesulfurization

The invention discloses mesoporous ZSM-5 zeolite, a mesoporous ZSM-5 zeolite-loaded metal sulfide catalyst and an application. The synthesizing method of the mesoporous ZSM-5 zeolite comprises the following steps: (1) after uniformly mixing diallylamine and concentrated hydrochloric acid, adding dimethyl diallyl ammonium chloride, uniformly stirring and reacting for 1-6 hours at 60-120 DEG C, and cooling to obtain a template agent DMMC (Dimethylol Methyl Carbamate); (2) preparing acidified aluminum sulfate liquor by aluminum sulfate, concentrated sulfuric acid and water; (3) adding water into water glass, uniformly stirring, adding NaOH, adding the template agent DMMC after cooling to room temperature, continuously stirring for 2-5 hours, then adding the acidified aluminum sulfate liquor under stirring, and stirring for 2-8 hours to obtain a gel in a final state; (4) crystallizing the gel in the final state obtained in the step (3), filtering, drying and calcining to obtain the mesoporous ZSM-5 zeolite. The mesoporous ZSM-5 zeolite-loaded metal sulfide catalyst prepared by taking the mesoporous ZSM-5 zeolite as a carrier is applied to hydrodesulfurization of 4, 6-dimethyl dibenzothiophene and hydrocracking reaction of n-decane, thereby greatly improving the raw material conversion ratio.

Owner:WENZHOU UNIVERSITY

Preparation method of porous 5A molecular sieve for straight-chain alkane adsorption

InactiveCN104045095AHave diversityGood saturated adsorption capacityOther chemical processesAluminosilicate zeolite type-AAlkaneSilicic acid

The invention discloses a preparation method of a porous 5A molecular sieve for straight-chain alkane adsorption and belongs to the technical field of molecular sieve adsorbents. The preparation method comprises the following steps of adding ethyl orthosilicate into a sodium hydroxide aqueous solution, carrying out stirring for some time, fully dissolving sodium metaaluminate in water, fast mixing the two solutions, carrying out violent stirring to obtain milky colloid, carrying out crystallization on the colloid at a temperature of 80-95 DEG C for 4-6h, carrying out cooling, carrying out filtration, carrying out washing until a pH value is less than 9, carrying out drying by an oven to obtain 4A molecular sieve raw powder, carrying out ion exchange on the 4A molecular sieve raw powder and a calcium chloride solution to obtain the 5A molecular sieve. The 5A molecular sieve has n-decane static saturated adsorption capacity of 0.538g / g and n-pentdecne static saturated adsorption capacity of 0.647g / g. The 5A molecular sieve is prepared from an organic silicon source ethyl orthosilicate replacing an inorganic silicon source sodium silicate so that the channels of the 5A molecular sieve have diversity. The 5A molecular sieve has a good saturation adsorption amount of straight-chain alkanes.

Owner:CHANGZHOU UNIV

Preparation and uses of tumor-targeted carrier material RGD-fatty alcohol series of compounds

The invention discloses a method for preparing RGD-fatty alcohol series compounds as tumor targeting carrier materials and application thereof. The method comprises the following steps: conjugating n-octa alkyl fatty alcohol, decane-based fatty alcohol, dodecyl fatty alcohol, tetradecyl fatty alcohol, hexadecane fatty alcohol, and octadecyl fatty alcohol with RGD peptide segment respectively, and performing hydrophobic modification on the compounds to synthesize a peptide conjugated compound with different amphiphilic long-chain alkyls and RGD, namely Arg-Gly-Asp-O-CnH[2n +1] (n is equal to 8, 10, 12, 14, 16, or 18), and synthesize a compound of Gly-Gly-Asp-O-C4H29 simultaneously, thus the effectiveness of the targeting materials is further confirmed.

Owner:CAPITAL UNIVERSITY OF MEDICAL SCIENCES

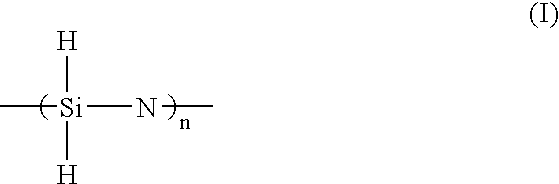

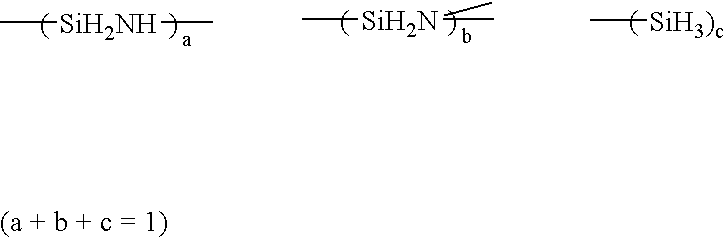

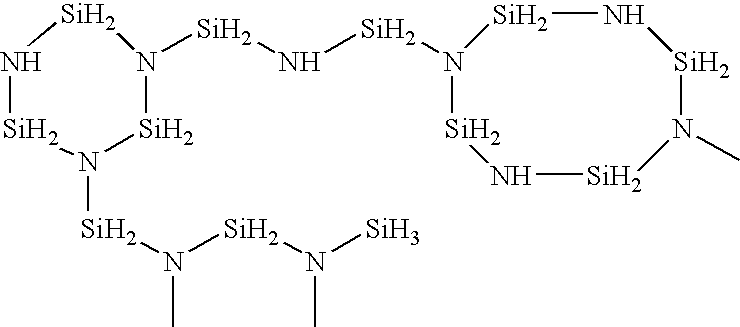

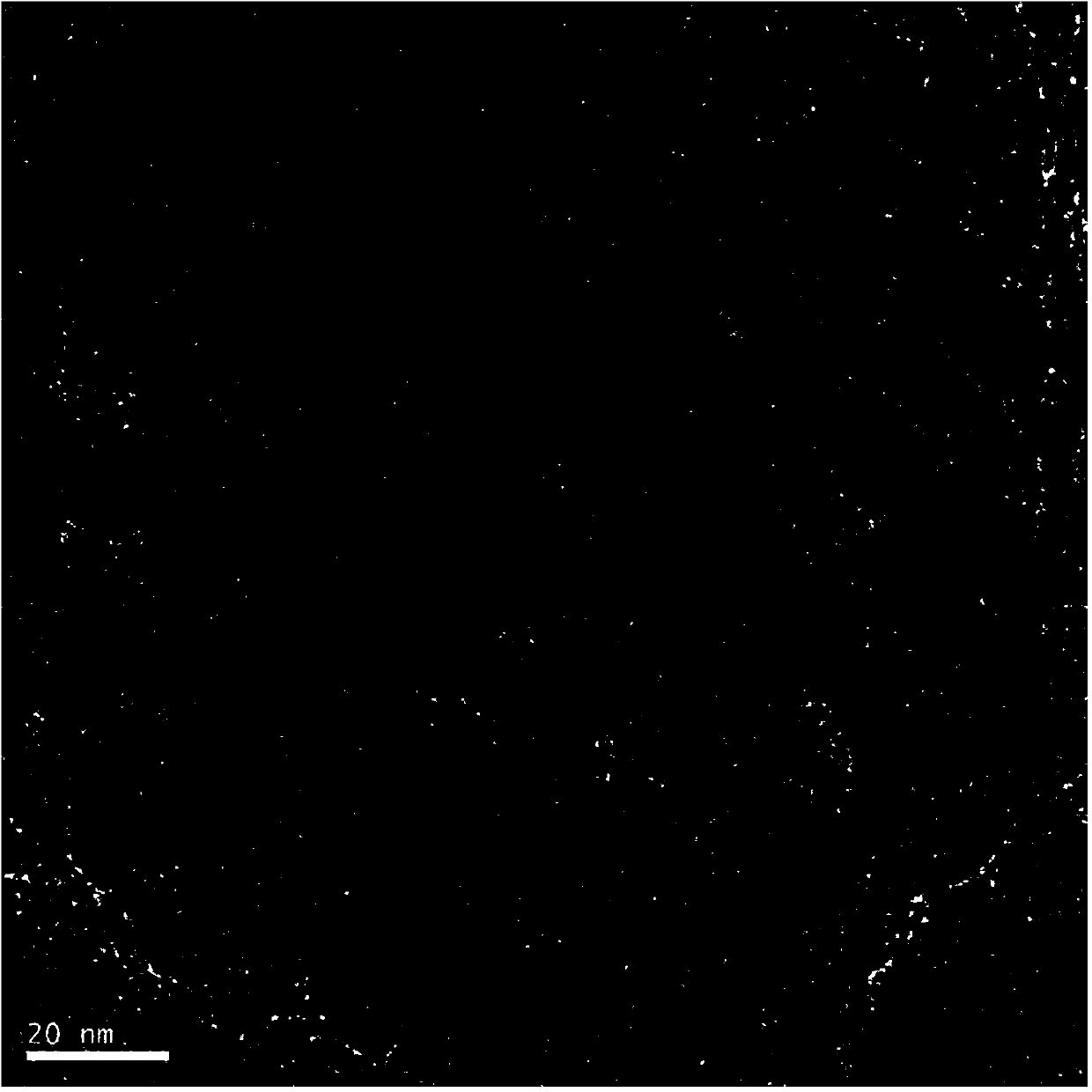

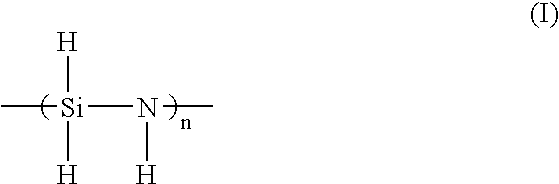

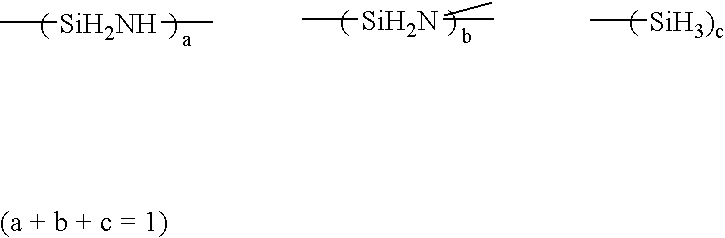

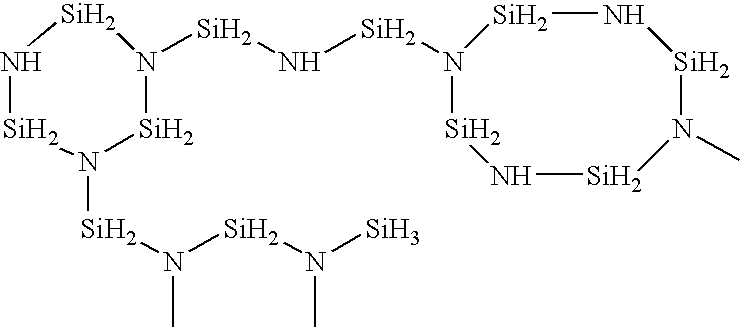

Solvent for treating polysilazane and method of treating polysilazane with the solvent

InactiveUS7344603B2Improve abilitiesAvoid adversely affecting the properties of a groundSemiconductor/solid-state device manufacturingDetergent compounding agentsAlkaneNonane

Polysilazane is treated with a single or mixed solvent comprising one or more members selected from the group consisting of xylene, anisole, decalin, cyclohexane, cyclohexene, methylcyclohexane, ethylcyclohexane, limonene, hexane, octane, nonane, decane, a C8-C11 alkane mixture, a C8-C11 aromatic hydrocarbon mixture, an aliphatic / alicyclic hydrocarbon mixture containing 5 to 25% by weight of C8 or more aromatic hydrocarbons, and dibutyl ether, wherein the number of 0.5 micron or more fine particles contained in 1 ml of the solvent is 50 or less. As the treatment of polysilazane, there are illustrated, for example, edge-rinsing and back rinsing of a polysilazane film formed by spin coating polysilazane on a semiconductor substrate. The water content of the solvent is preferably 100 ppm or less.

Owner:MERCK PATENT GMBH

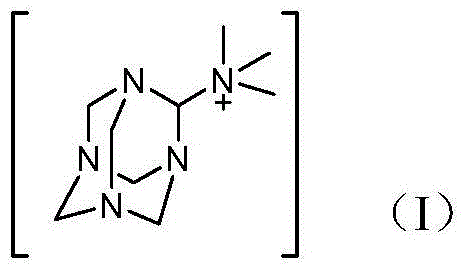

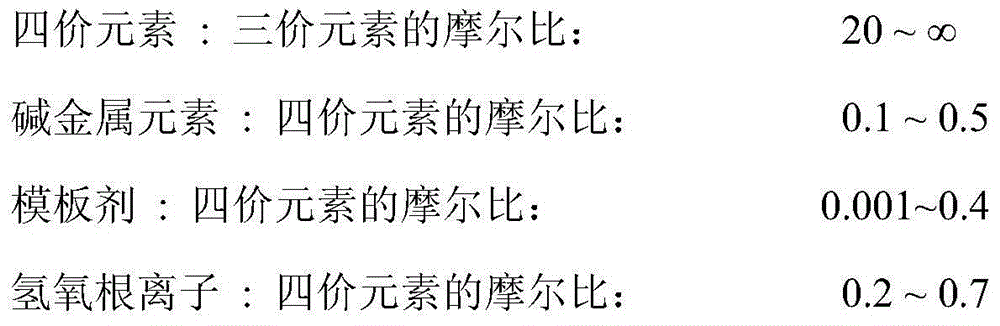

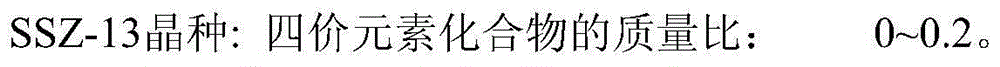

A synthetic method of an SSZ-13 molecular sieve

ActiveCN105645426AEasy to removeReduce usageCrystalline aluminosilicate zeolitesQuaternary ammonium cationHydroxyl ion

A synthetic method of an SSZ-13 zeolite molecular sieve is disclosed. The method includes preparing SSZ-13 crystals under crystallization conditions from raw materials comprising an oxide of at least one quadrivalent element or a quadrivalent element mixture, an oxide of at least one trivalent element and a trivalent element mixture, at least one alkali metal compound, N,N,N-trimethyl-1,3,5,7-tetraazatricyclo[3.3.1.1]decane-2-ammonium hydroxide or a mixture of the N,N,N-trimethyl-1,3,5,7-tetraazatricyclo[3.3.1.1]decane-2-ammonium hydroxide and the SSZ-13 molecular sieve crystal seeds, hydroxyl ions and water. The method is a method of synthesizing the SSZ-13 molecular sieve by adopting a novel and cheap template. The method avoids adoption of traditional expensive N,N,N-trimethyladamantan-1-ammonium cations or benzyl trimethyl quaternary ammonium cations as templates to synthesize the SSZ-13 molecular sieve, thus significantly reducing the cost of synthesizing the SSZ-13 zeolite molecular sieve.

Owner:CHINA CATALYST HLDG CO LTD

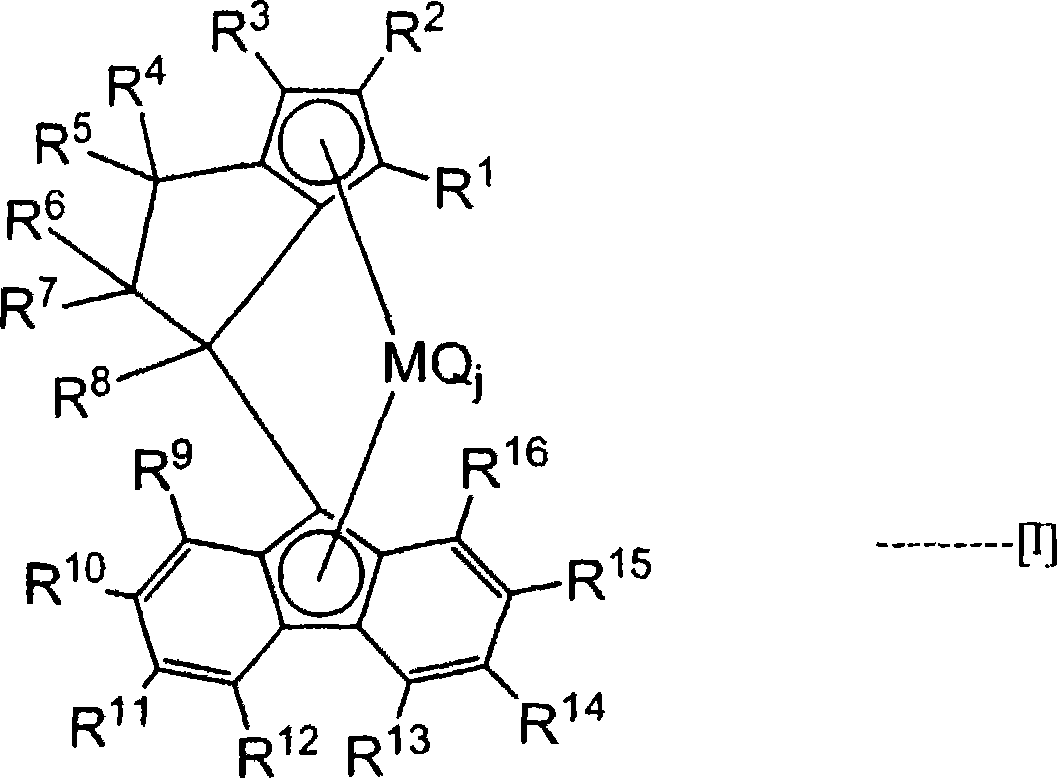

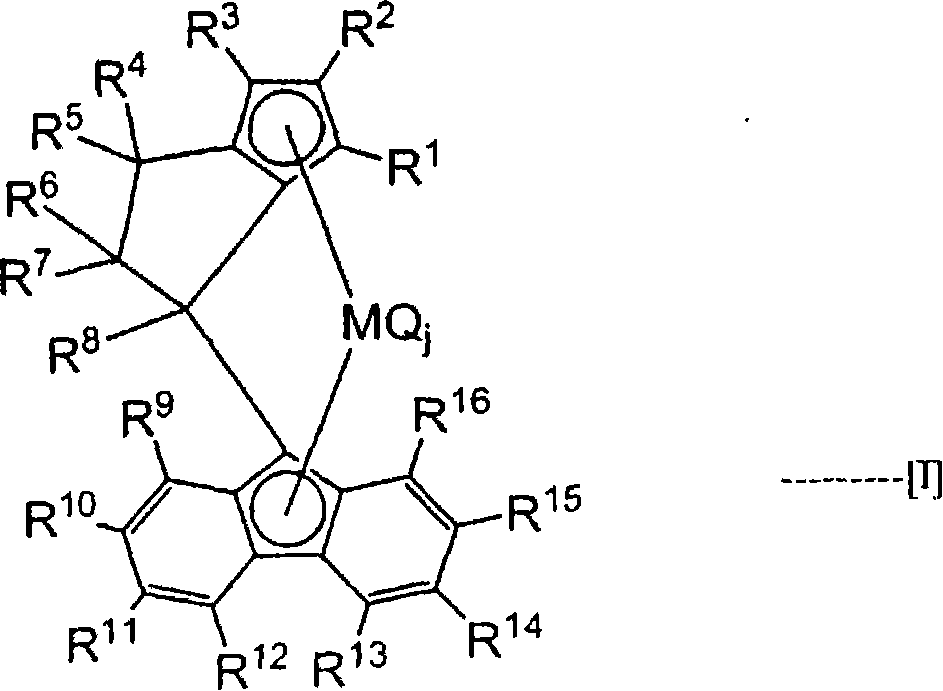

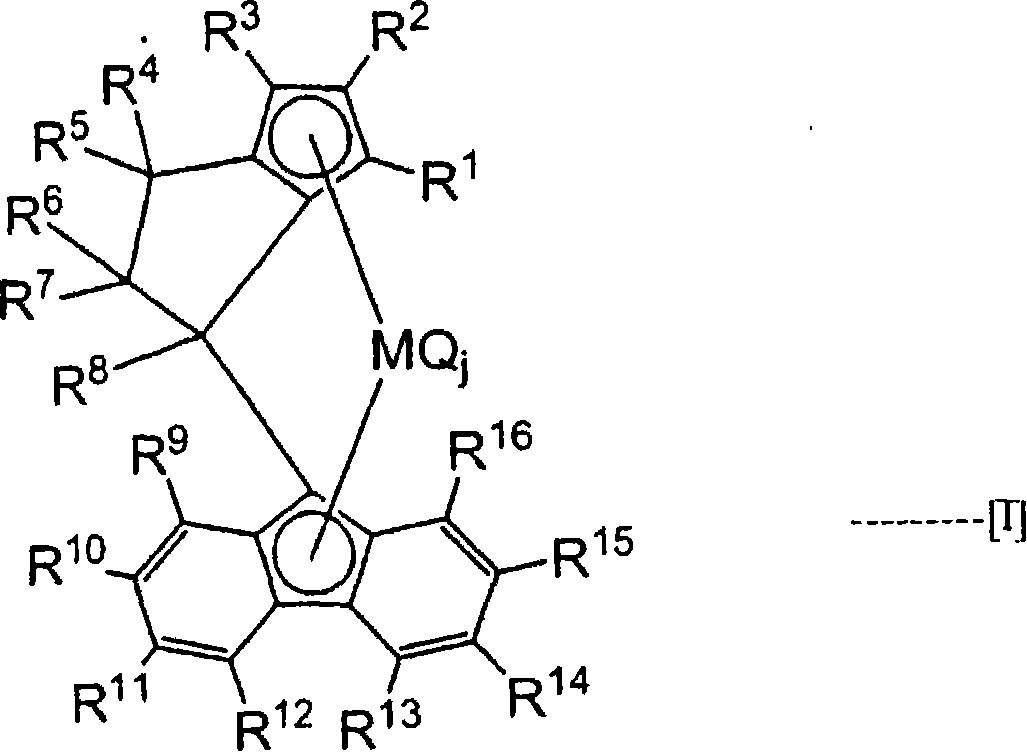

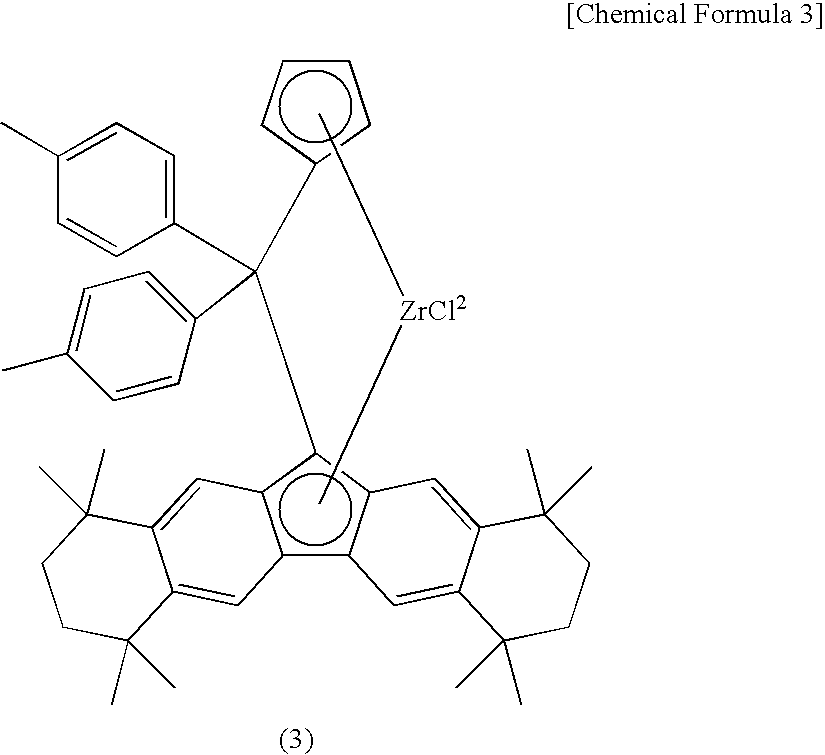

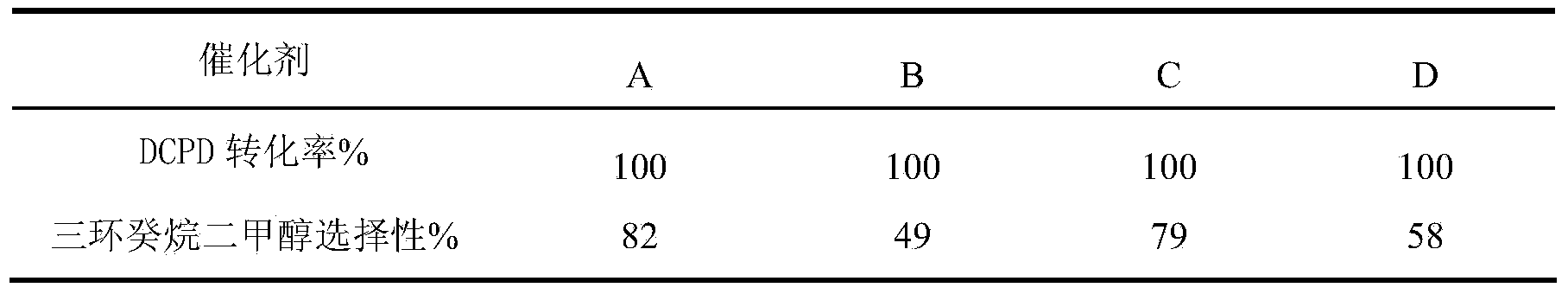

Azaspiro[4.5] decane derivatives and use thereof

The invention provides azaspiro[4.5]decane derivatives of Formula (A): and pharmaceutically acceptable salts, solvates, hydrates, N-oxides, and diastereomers thereof, wherein A1, X, A2, Rr, R2′, W1, R3′, R4′, a, and b are defined in the disclosure. The invention also provides compounds of Formulae I, and B-G, and pharmaceutically acceptable salts, solvates, hydrates, N-oxides, and diastereomers thereof. Further, the invention provides use of the compounds of Formulae A-G and I, and the pharmaceutically acceptable salts, solvates, hydrates, N-oxides, and diastereomers thereof, to treat pain. In certain embodiments, Compounds of the Disclosure are useful for treating a disorder responsive to blockade of one or more sodium channels.

Owner:PURDUE PHARMA LP

Solvent for treating polysilazane and method of treating polysilazane with the solvent

InactiveUS20050027089A1Excellent propertyImprove trimming effectSemiconductor/solid-state device manufacturingDetergent compounding agentsAlkaneNonane

Polysilazane is treated with a single or mixed solvent comprising one or more members selected from the group consisting of xylene, anisole, decalin, cyclohexane, cyclohexene, methylcyclohexane, ethylcyclohexane, limonene, hexane, octane, nonane, decane, a C8-C11 alkane mixture, a C8-C11 aromatic hydrocarbon mixture, an aliphatic / alicyclic hydrocarbon mixture containing 5 to 25% by weight of C8 or more aromatic hydrocarbons, and dibutyl ether, wherein the number of 0.5 micron or more fine particles contained in 1 ml of the solvent is 50 or less. As the treatment of polysilazane, there are illustrated, for example, edge-rinsing and back rinsing of a polysilazane film formed by spin coating polysilazane on a semiconductor substrate. The water content of the solvent is preferably 100 ppm or less.

Owner:MERCK PATENT GMBH

Asymmetric gas separation membranes with superior capabilities for gas separation

InactiveUS20100244306A1Excellent permeation fluxHigh selectivityProductsSemi-permeable membranesCellulose diacetatePolyimide membrane

This invention relates to a method of making flat sheet asymmetric membranes, including cellulose diacetate / cellulose triacetate blended membranes, polyimide membranes, and polyimide / polyethersulfone blended membranes by formulating the polymer or the blended polymers dopes in a dual solvent mixture containing 1,3 dioxolane and a second solvent, such as N,N′-methylpyrrolidinone (NMP). The dopes are tailored to be closed to the point of phase separation with or without suitable non-solvent additives such as methanol, acetone, decane or a mixture of these non-solvents. The flat sheet asymmetric membranes are cast by the phase inversion processes using water as the coagulation bath and annealing bath. The dried membranes are coated with UV curable silicone rubber. The resulting asymmetric membranes having a skin thickness of less than 100 nm, exhibit excellent permeability and selectivity compared to the intrinsic dense film performances.

Owner:UOP LLC

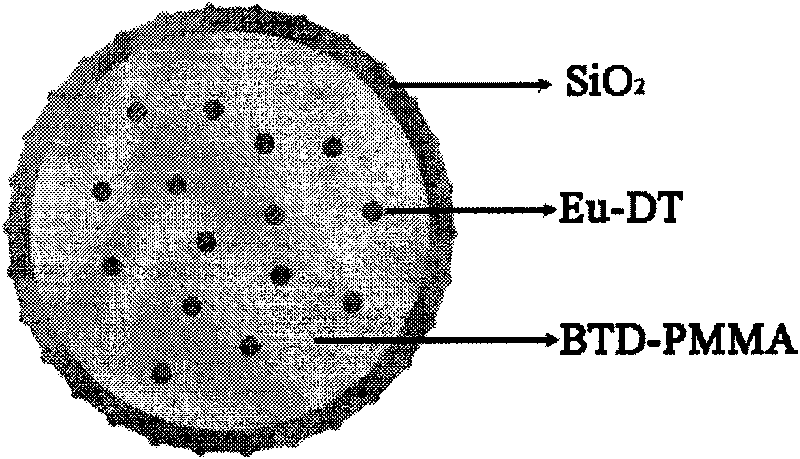

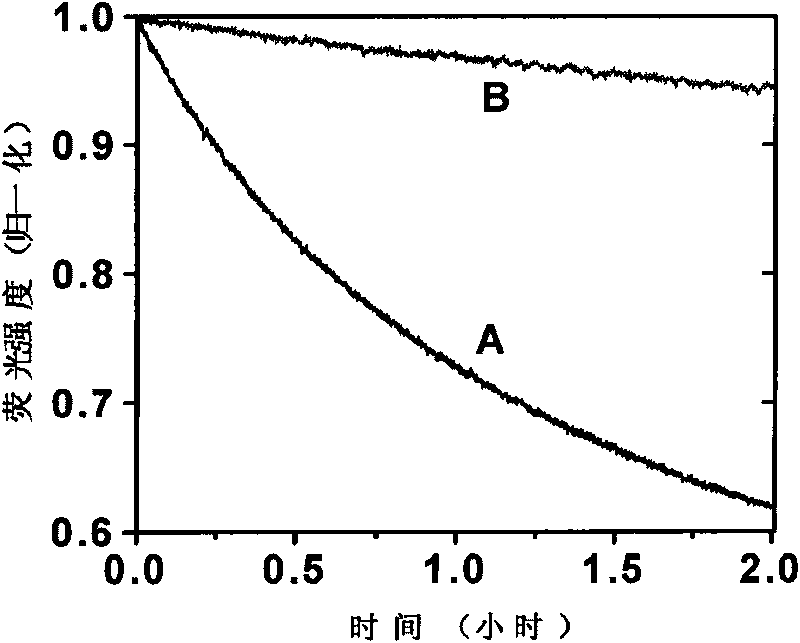

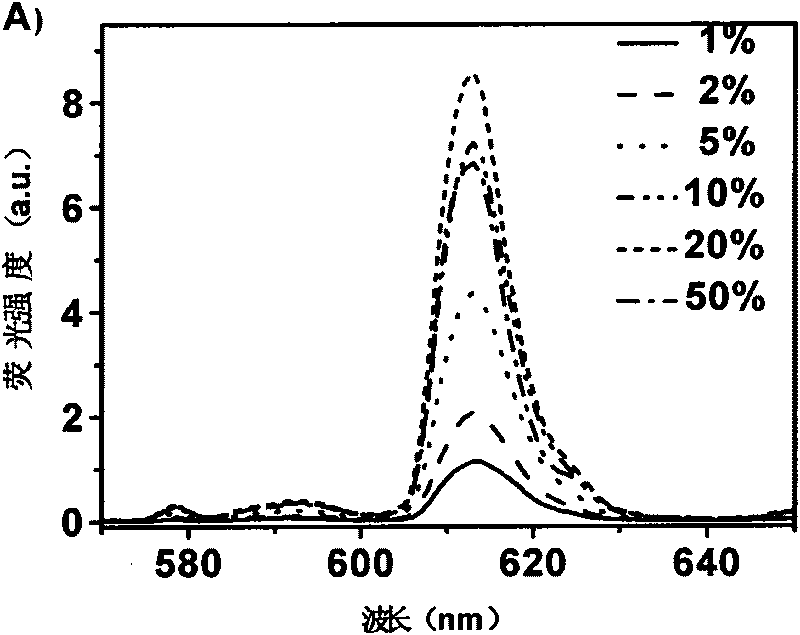

Bioluminescent nanoparticle, temperature sensing film and preparation method thereof

InactiveCN101724394AReduce volumeGood compatibilityThermometers using physical/chemical changesLuminescent compositionsBiological bodyNanoparticle

The invention relates to a bioluminescent nanoparticle, a temperature sensing film and a preparation method thereof, and belongs to the technical field of biological temperature sensors. The bioluminescent nanoparticle comprises a silicon dioxide shell and a hybrid core, wherein the hybrid core is formed by randomly dispersing Eu-DT in 2-bis(trimethoxysilyl)decane and polymethyl methacrylate; and the silicon dioxide shell is formed by performing hydrolytie polycondensation on the 2-bis(trimethoxysilyl)decane. The bioluminescent temperature sensing film comprises the bioluminescent nanoparticles and PVA film vectors in a weight ratio of 0.01 to 0.03 percent. The sensing film has tiny particle volume and excellent temperature resolution ratio; and the Eu-DT probe is encapsulated in a nanometer protective layer which cannot cause organism repulsion, so that the material has good organism compatibility, and the encapsulation ensures that the probe has resistance to external interference.

Owner:BEIJING JIAOTONG UNIV

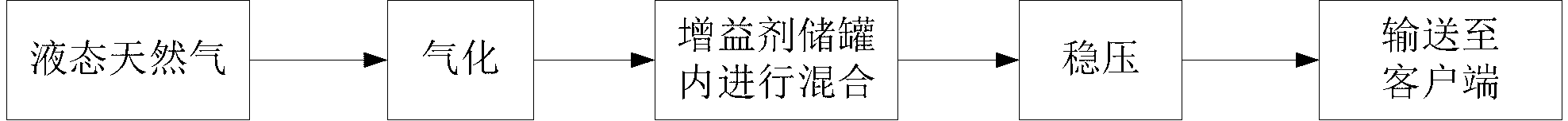

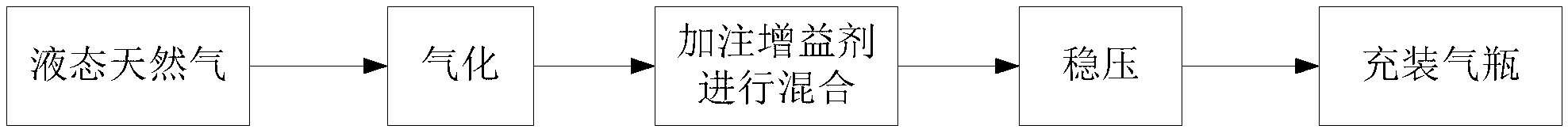

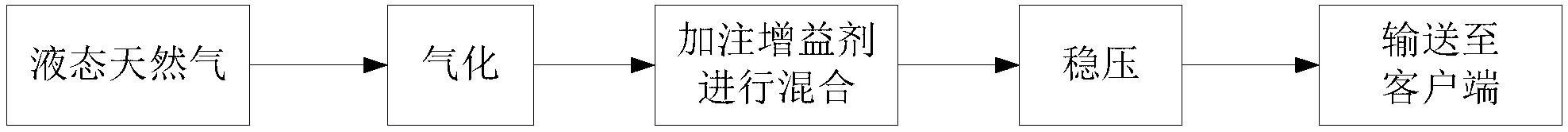

Welding and cutting gas and preparation method thereof

InactiveCN103320190AEasy to prepareNo pollution in the processGaseous fuelsNonaneRare earth metal compounds

The invention discloses a welding and cutting gas which consists of a natural gas and a gain agent, wherein the gain agent consists of a rare earth metal compound, a transition metallocene compound, methanol, toluene, methyl tertiary butyl ether, cyclohexane, nonane, decane and water. Compared with acetylene and propane, the welding and cutting gas is more economical, more energy-saving, more environment-friendly, safer and cleaner. The invention also provides a preparation method of the welding and cutting gas.

Owner:CANGXI COUNTY CHASE GAS INVESTMENT

Propylene polymer, composition containing the polymer, and molded objects obtained from these

Owner:MITSUI CHEM INC

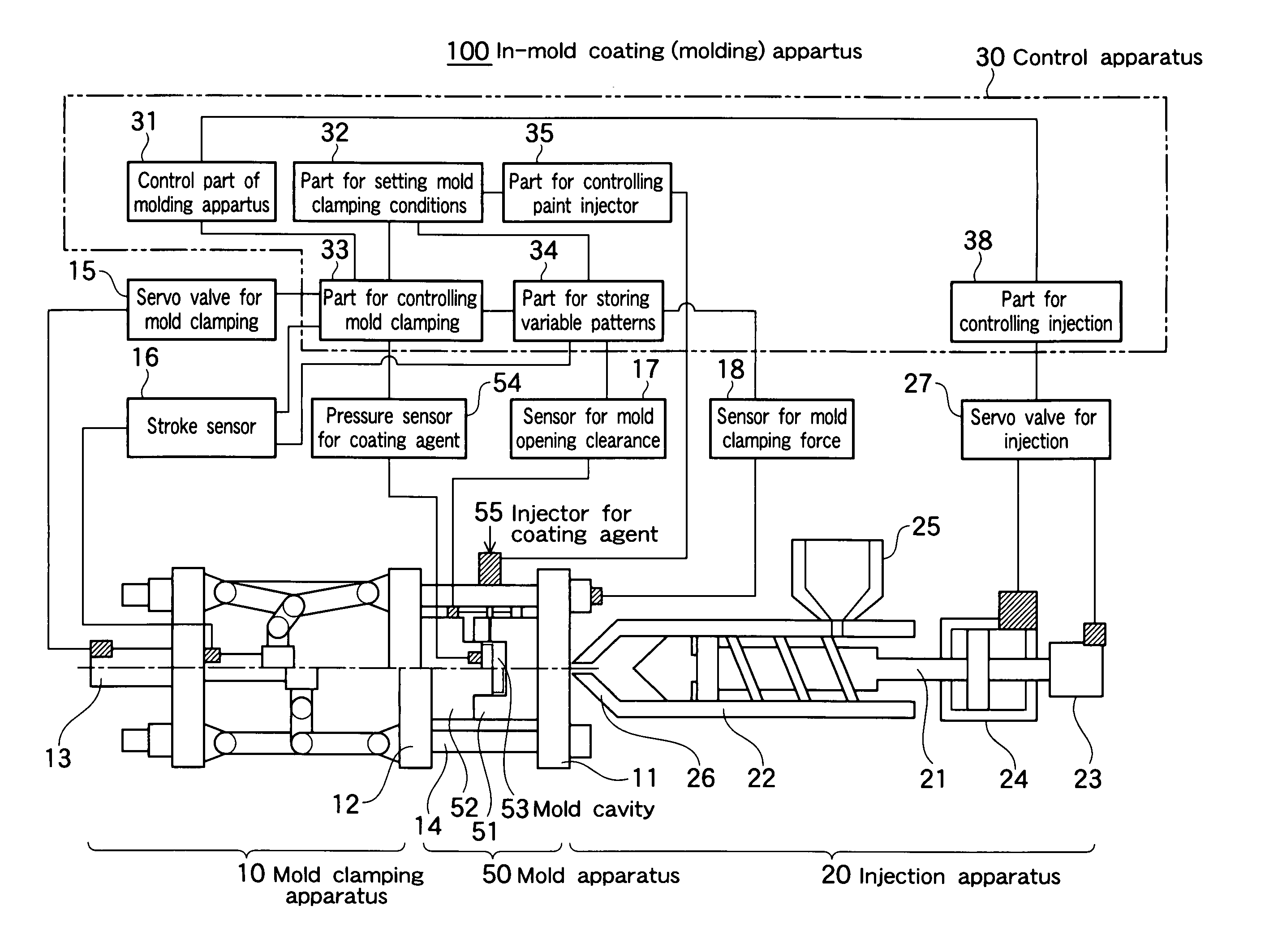

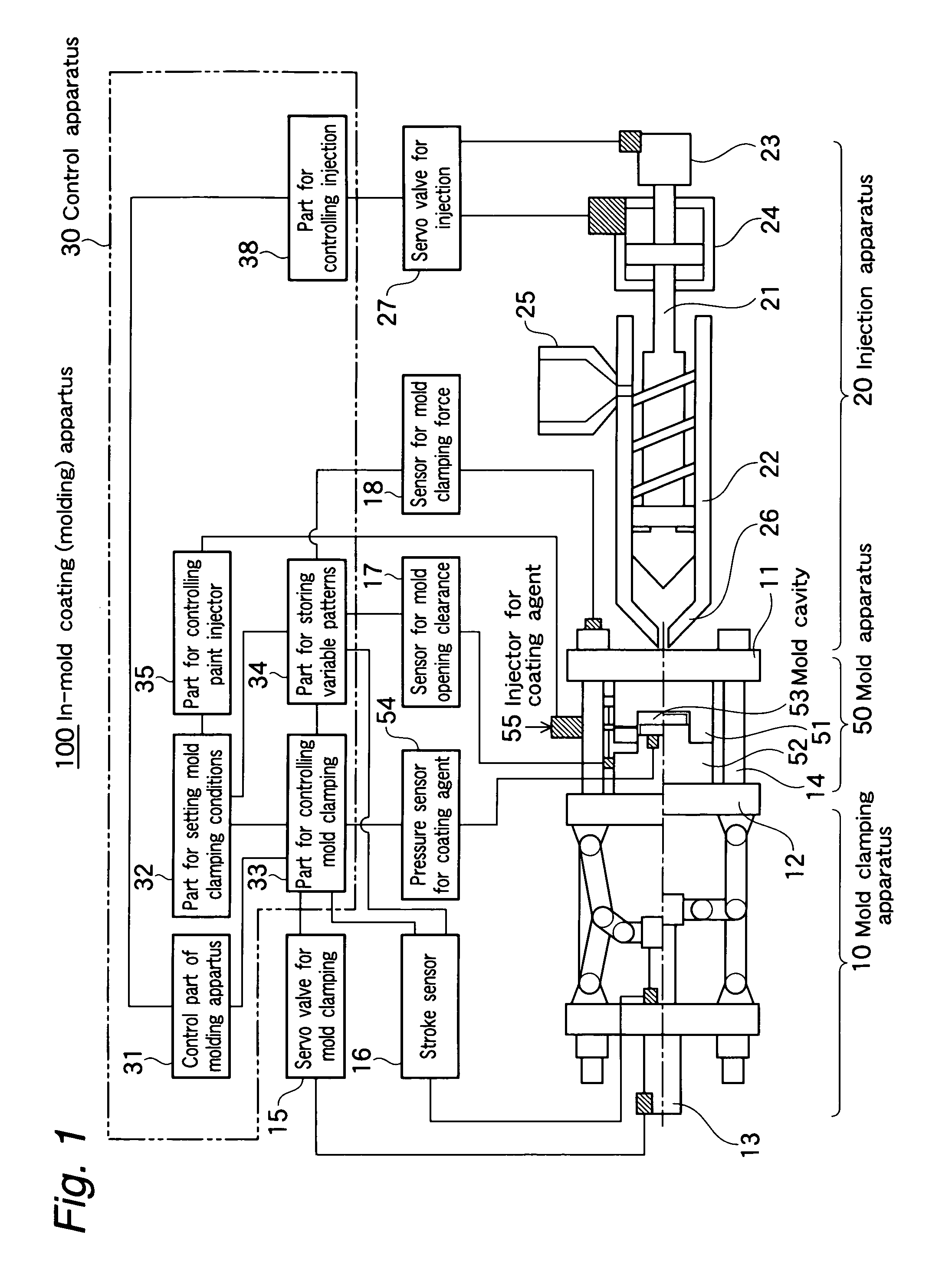

Molded object obtained by in-mold coating and process for producing the same

InactiveUS20050214559A1Improve adhesionHigh bonding strengthTailstocks/centresMouldsMethacrylatePolymer science

An in-mold coating molded article is obtained by coating the surface of a resin molded product comprising a hydroxyl group-containing polypropylene resin composition (A) with a paint composition for in-mold coating, wherein the composition (A) comprises a polypropylene resin (i), an additive rubber (ii) and optionally a polymer compound (iii) other than the polypropylene resin (i) and the additive rubber (ii), the total hydroxyl value of the polypropylene resin (i), the additive rubber (ii) and the optional polymer compound (iii) is from 1 to 40, the composition (A) has a rubber component content (total of the amount of the additive rubber (ii) and the amount of components soluble in n-decane at 23° C. of the polypropylene resin (i) and the optional polymer compound (iii)) of from 15 to 80% by mass based on 100% by mass of the total amount of the rubber component and the resin component other than the rubber component, the paint composition comprises a vehicle component comprising 10 to 70% by mass of an oligomer having at least two (meth)acrylate groups and 90 to 30% by mass of an ethylenically unsaturated monomer copolymerizable with the oligomer, a (meth)acryl modified chlorinated polyolefin having a chlorine content of from 2 to 40% by mass, an organic peroxide polymerization initiator, and a polyisocyanate compound in a specific proportion. In the process for preparing the article, the article is prepared by injection molding method, injection compression molding method or injection press molding method. Accordingly, there can be provided an in-mold coating molded article such that the paint composition is monolithically formed on the surface of the resin molded product of the composition with good adhesion and a process for preparing the same.

Owner:DAI NIPPON TORYO CO LTD

Gordonia alkanivorans and application in oil degradation

InactiveCN101974466AGood use effectBroad application prospect of bioremediationBacteriaMicroorganism based processesBioremediationNonadecane

The invention discloses a Gordonia alkanivorans and application in oil degradation, and belongs to the field of biotechnology. The Gordonia alkanivorans S104 is separated from a sea mud sample in Dalian area, and was collected in the Chinese General Microbial Culture Collection (CGMCC) on October 12th, 2010, wherein the collection number is 4224. The Gordonia alkanivorans is gram positive bacteria, has a rodlike shape, is determined by 16SrDNA sequence, and has high similarity (99.7 percent) with Gordonia alkanivorans, so the Gordonia alkanivorans is named Gordonia alkanivorans; however, the colonial morphology and the physiological and biochemical characters of the Gordonia alkanivorans are different from those of the model strains of the Gordonia alkanivorans. A plurality of hydrocarbons and aromatic compounds can be used by the Gordonia alkanivorans as sole carbon source, which comprises decane, undecane, hexadecane, nonadecane, docosane, octacosane, naphthalene, anthracene, phenanthrene, fluorene and terphenyl; the Gordonia alkanivorans can degrade oil, such as crude oil, diesel oil, soybean oil, olive oil and the like; and the Gordonia alkanivorans grows better in the diesel oil at 2 percent concentration, can degrade the crude oil, and has a promising application prospect in bioremediation of pollution of the crude oil and the diesel oil.

Owner:DALIAN UNIV OF TECH

Soapberry vegetable-fruit washing-up liquid

ActiveCN103242976ALess irritatingGood decontamination and washing effectAmpholytes/electroneutral surface-active compoundsDetergent compounding agentsBetaineIrritation

The invention discloses soapberry vegetable-fruit washing-up liquid. The soapberry vegetable-fruit washing-up liquid comprises the following raw materials in parts by weight: 4-6 parts of lauryl dimethyl sulfo glycine betaine, 4-6 parts of tallowacryl sodium tamphoacetate, 2-4 parts of N,N-dimethyl decane-N-amine oxide, 5-7 parts of dodecyl-beta-D-maltoside, 0.05-0.15 part of soapberry peel extract and 80 parts of water. The soapberry vegetable-fruit washing-up liquid is compounded by non-ionic surfactant and ampholytic surfactant, so that conventional anionic surfactant is abandoned, and therefore, the irritation to hand surfaces is greatly lowered when a good decontamination washing-up effect is ensured; and meanwhile, natural soapberry essence is added, so that bacteria can be effectively inhibited and killed, and therefore, the skin is moistened.

Owner:ZHEJIANG SHENYING TECH CO LTD

Bath salt plaster for women and children

ActiveCN101152123AElasticPromote blood circulationCosmetic preparationsToilet preparationsDiseaseGeneral function

The present invention discloses a bathing salt gypsum used for women and children, which is characterized in that the bathing salt gypsum comprises salt, surface active agents, plant extracts, perfumery, essential oil, moisture agents, pearling agent, superfatting agent, pH value regulating agent and distilled water. The surface active agents refer to negative ion type, nonionic type or amphion type; the moisture agent refers to 6501, glycerin, wool grease, macromolecule emulsified silicon oil, phenyl silicone oil, ring silicone oil; the pearling agent refers to ethyl glycol stearate; the pH value regulating agent refers to citric acid; the superfatting agent refers to polyglycerol-3-decane ester or capric acid polyglycerol-4 ester. The present invention not only has such general functions as sterilizing and stopping itch, restraining harmful bacterium growth on skin surface, but also keeps skin smooth, soft and elastic; when eliminating body dirt, meanwhile, the invention speeds up body blood circulation and purifies appreciate, which keeps the skin in a state of soft, smooth, comfortable and elastic, and is capable of curing some illness as well.

Owner:中盐东兴盐化股份有限公司

Method for preparing cerium trifluoride using neutral phosphoras (phosphine) extraction system

InactiveCN1911814AImprove recycling ratesLiquid solutions solvent extractionRare earth metal compoundsHydrazine compoundKerosene

The process of preparing cerium trifluoride micro powder with neutral phosphorus extracting system adopts the material solution of RE sulfuric acid and / or nitric acid solution containing Ce(IV) and F and with acidity of 0.2-6.0 mol / L; extractant comprising Cyanex923 and one or several of TBP, P350, PBBP, DEHEHP, ODOP, Cyanex921, Cyanex925, Cyanex471 and TOEDPO in arbitrary proportion; diluting solvent of n-hexane, n-heptane, octane, noane, decane or sulfonated kerosene to constitute extracting composition together with the extractant; and the back extracting solution of hydrogen peroxide, hydrazine hydrate, hydroxylamine hydrochloride or their mixture with sulfuric acid and / or nitric acid. The extracted composition is washed and back extracted to obtain the cerium trifluoride micro powder with purity of 90-99.9999 % and granularity of 1-4000 nm.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Propylene random copolymers and use thereof

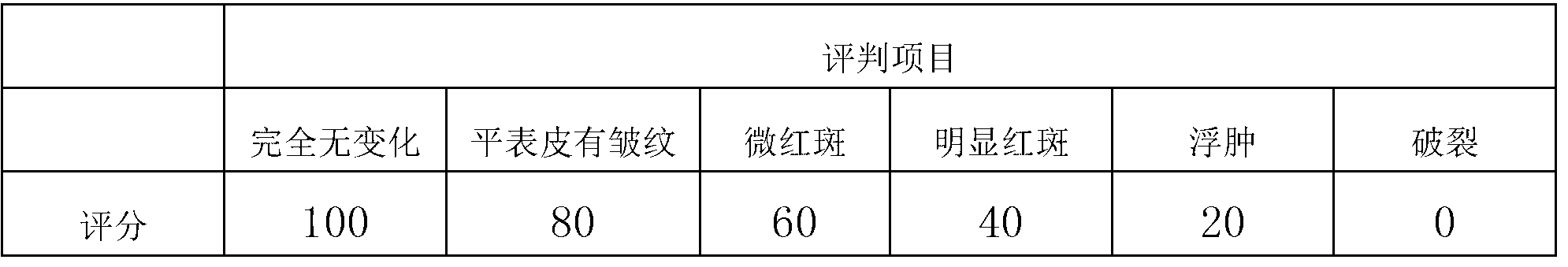

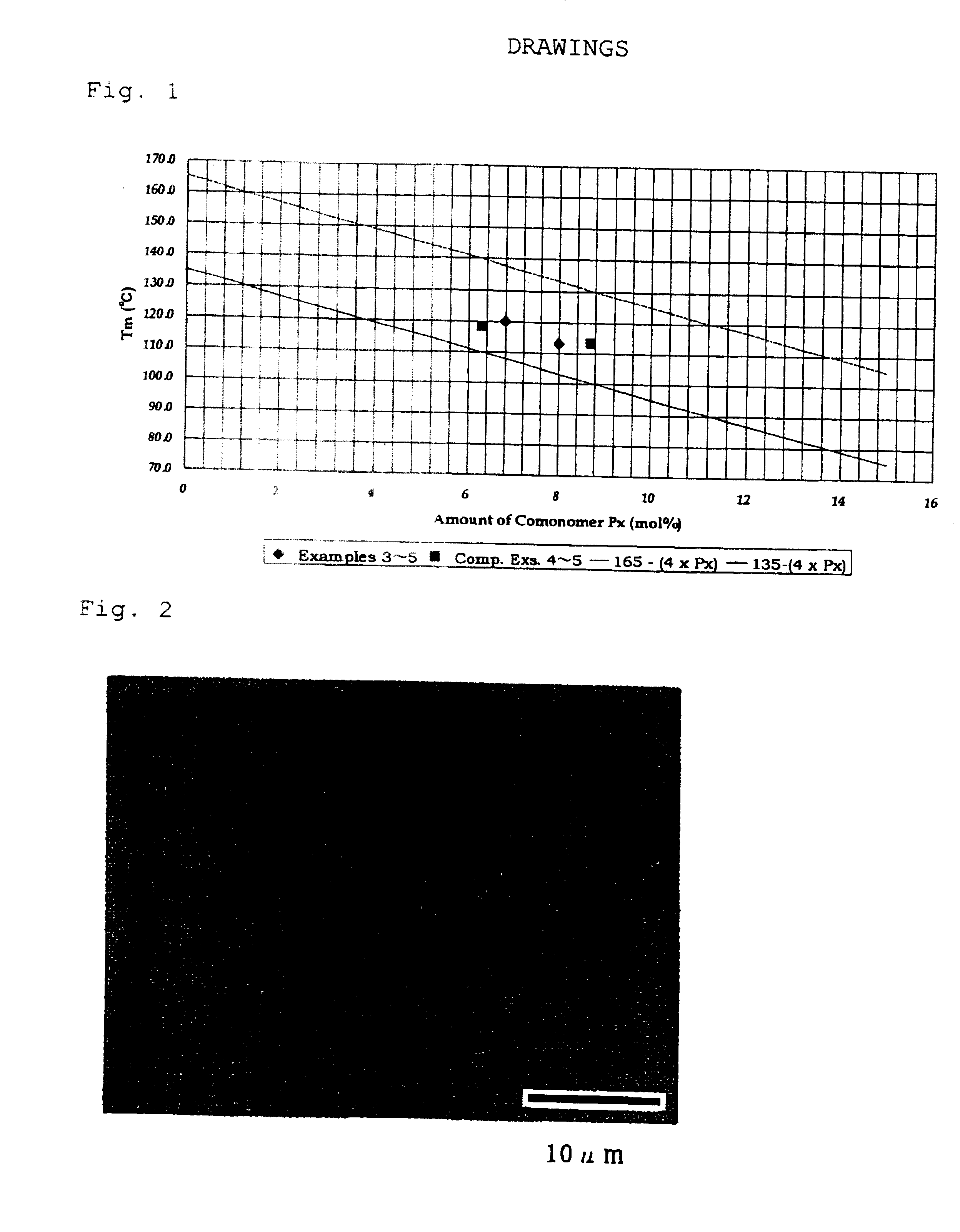

ActiveUS20060222849A1Low melting pointLess deteriorationOrganic-compounds/hydrides/coordination-complexes catalystsSynthetic resin layered productsDecaneCopolymer

The present invention relates to a propylene random copolymer which satisfies the following requirements [1] to [4], and to various useful molded products obtained by molding the propylene random copolymer: [1] the concentration (Pa, % by mole) of a skeletal constituent derived from propylene (a), and the concentration (Px, % by mole) of a skeletal constituent derived from at least one olefin selected from ethylene (b) and α-olefins having 4 to 20 carbon atoms (c), each of which is contained in the propylene random copolymer, satisfy the following relational expressions (Eq-1) to (Eq-3): 85≦Pa<100 (Eq-1) 0<Px≦15 (Eq-2) Pa+Px=100 (Eq-3); [2] the concentration (Pa, % by mole) of the skeletal constituent derived from propylene (a) contained in the propylene random copolymer, and the melting point (Tm) measured with a differential scanning calorimeter satisfy the following relational expression (Eq-4): 135−4×(100−Pa)<Tm<165−4×(100−Pa) (Eq-4); [3] the total amount of 2,1-bonded and 1,3-bonded non-stereoregular fractions is less than or equal to 0.2% by mole; and [4] the amount of the n-decane (nC10)-soluble fraction is less than or equal to 2.0% by weight.

Owner:MITSUI CHEM INC

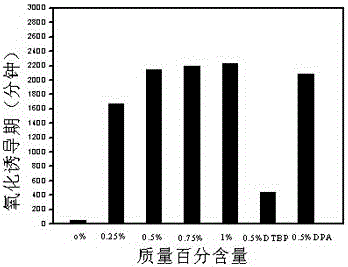

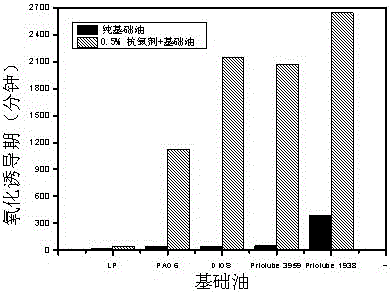

High-temperature anti-oxidant for lubricating oil and preparation method of high-temperature anti-oxidant

ActiveCN105038904AExtension of timeImprove solubilityOrganic compound preparationAdditivesTert butyl phenolPtru catalyst

The invention discloses a preparation method of a high-temperature anti-oxidant for lubricating oil. 2,6-di-tert-butyl phenol and substituted diphenylamine are taken as raw materials, and n-decane is taken as a high-boiling-point solvent. The materials above are reacted at 120-170 DEG C for 2-4 h under the action of a catalyst and in the presence of a noble gas to obtain a product, and the product is treated to obtain the target product. Anti-oxidants, of 2,6-di-tert-butyl phenol and substituted diphenylamine, with excellent antioxidant performance are used in the invention. The use temperature of the anti-oxidant is increased, and the working time of lubricating oil is greatly prolonged. The high-temperature anti-oxidant for lubricating oil has advantages of high temperature resistance, good anti-oxidant performance, and good solubility in lubricating oil. It is proved through a high-temperature antioxidant experiment that the high-temperature anti-oxidant has excellent properties and a bright application prospect.

Owner:道骐科技有限公司

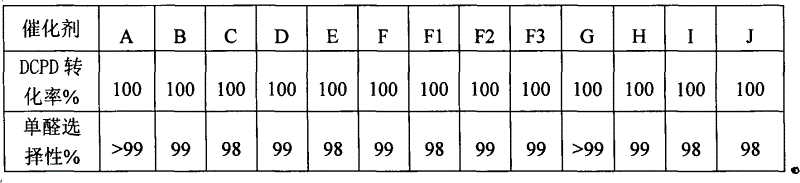

Method for synthesizing tricyclic decane unsaturated monoaldehyde

InactiveCN102617311ALow priceEasy to makeOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide reactionDecaneCoprecipitation

The invention relates to a method for synthesizing a tricyclic decane unsaturated monoaldehyde. According to the method, a dicylopentadiene is catalyzed under the action of a catalyst at the low temperature and pressure without using a solvent to synthesize a tricyclic unsaturated monoaldehyde, the catalyst is a metal phosphonic complex catalyst which is carried by a ferromagnetic oxide, and an impregnation method and a coprecipitation method are used to prepare the tricyclic decane unsaturated monoaldehyde. By means of the method, the conversion rate of the dicylopentadiene (DCPD) can reach to above 99%, and the selectivity of the tricyclic decane unsaturated monoaldehyde can reach to above 98%.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

Ethylenic Polymer and Molded Article Obtained Therefrom

InactiveUS20090018299A1Good moldabilityHigh transparencySynthetic resin layered productsPolymer scienceFractionation

An ethylene-α-olefin copolymer for a film or sheet satisfying the following requirements [1] to [5] simultaneously is excellent in transparency and moldability and is suitably used for a film or sheet excellent in mechanical strength.[1] The density (d) is in the range of 890 to 980 kg / m3.[2] The intrinsic viscosity ([η]) measured at 135° C. in decalin is in the range of 0.5 to 10 dl / g.[3] The ratio of weight average molecular weight (Mw) to number average molecular weight (Mn) (Mw / Mn) measured by GPC is in the range of 2.0 to 50.[4] In an elution temperature-elution amount curve given by cross fractionation chromatography (CFC), the difference between a temperature at which the integrated elution amount is 1% by mass and a temperature at which the integrated elution amount is 40% by mass is 12° C. or less, wherein the total elution amount is 100% by mass.[5] The amount of a component soluble in decane is 0.5% by mass or less.

Owner:MITSUI CHEM INC +1

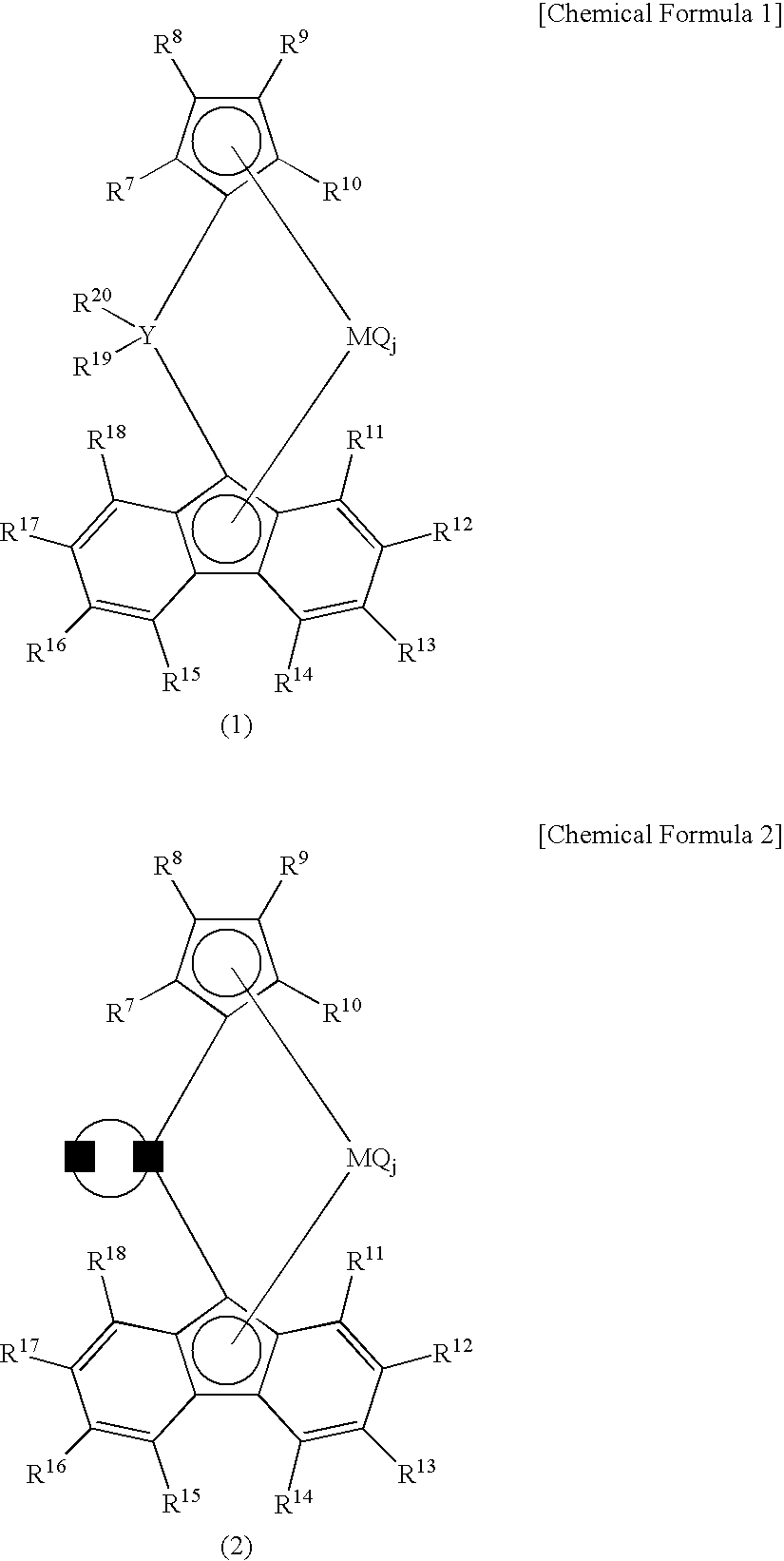

Method of synthesizing tricyclic decane dimethyl carbinol

InactiveCN103396293ALow priceEasy to makePreparation by oxo-reaction and reductionOrganic-compounds/hydrides/coordination-complexes catalystsCobalt(II,III) oxideDecane

The invention relates to a method of synthesizing tricyclic decane dimethyl carbinol. The method comprises the following steps of: preparing a cobaltosic oxide-supported nanogold catalyst, and modifying the obtained catalyst by a phosphine ligand; and catalyzing dicyclopentadiene to synthesize tricyclic decane dimethyl carbinol by a one-step method under the relatively low temperature and pressure, wherein the conversion rate of the dicyclopentadiene (DCPD) by the method is 99% or higher, and the selectivity of the tricyclic decane dimethyl carbinol can reach 80% or higher.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

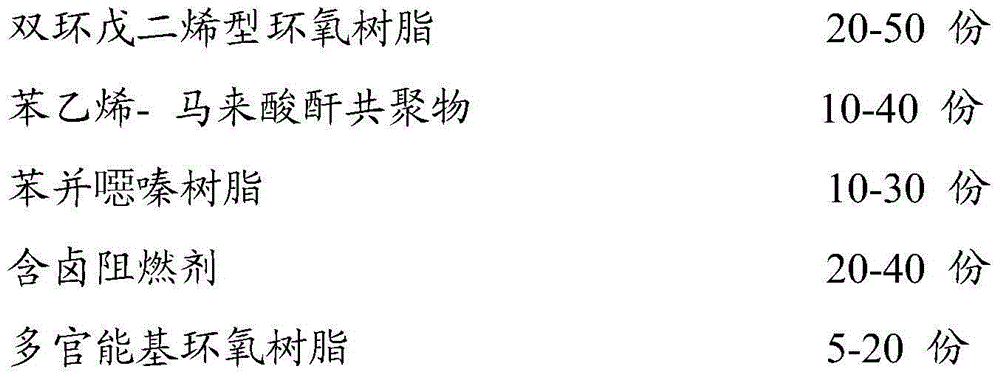

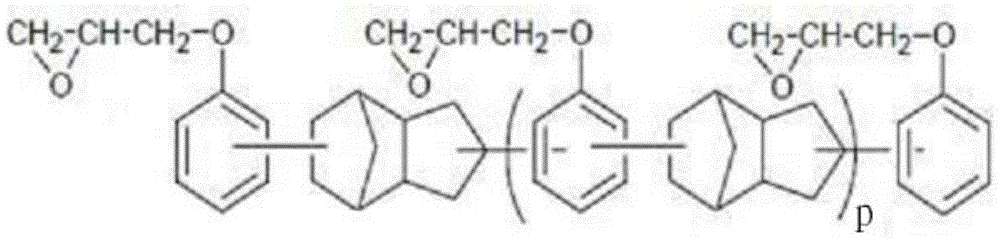

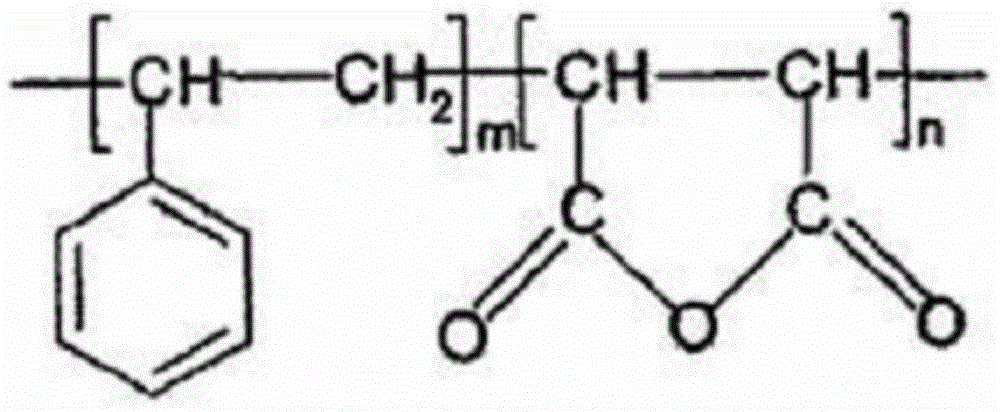

Halogen resin composition and application thereof

The invention relates to a halogen resin composition and an application thereof. The halogen resin composition is prepared from the following raw materials in parts by weight: 20-50 parts of dicyclopentadiene epoxy resin, 10-40 parts of styrene-maleic anhydride copolymer, 10-30 parts of benzoxazine resin, 20-40 parts of halogenous fire retardant, and 5-20 parts of multi-functional group epoxy resin, wherein the halogenous fire retardant is at least one of the decabrominated dipheny ethane, tri(tribromophenyl) triazine, brominated polyolefin, brominated polystyrene, ethyl-di(tetrabromobenzene o-dicarboximide), decabromodiphenyl ether, hexabromocyclododecane, eight bromo ether, tetrachlorophthalic anhydride, Hexachlorocyclopentadiene and perchlorinated cyclopentyl decane. A metal foil substrate made of the halogen resin composition has the advantages of low dielectric constant and dielectric loss, excellent heat resistance, good machinability and low swelling coefficient and can be well applied to a composite board.

Owner:GUANGZHOU GRACE ELECTRON CORP

Unsaturated polyesters

InactiveCN101353419AImprove hydrolysis resistanceHigh glossCosmetic preparationsOther chemical processesPolyesterCompound c

The present invention relates to unsaturated polyesters, more specifically to yellowing-resistant, low-viscosity, unsaturated, amorphous polyesters which are very substantially free of benzene and formaldehyde, and to a process for preparation thereof and to the use thereof as an adhesive component in coating compositions. The yellowing-resistant, low-viscosity, unsaturated, amorphous polyesters are composed of acid components and alcohol components, which is characterized in that based on the polyesters, the content of benzene is lower than 10mg / kg and the content of formaldehyde is lower than 10mg / kg; the molecular weight distribution polydispersity of the polyesters is 1.3-4.5; the content of tricyclodecane(mono- / di-)aldehyde in the bis(hydroxymethyl)tricyclo compound C) is lower than 2 weight percent; mono(hydroxymethyl)tricyclo [5.2.1.0<2,6>] decane in the compound C) is lower than 10 weight percent; and the content of chromium, nickel, copper, cadmium and plumbum in the compound C) is lower than 2mg / kg.

Owner:EVONIK DEGUSSA GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Azaspiro[4.5] decane derivatives and use thereof Azaspiro[4.5] decane derivatives and use thereof](https://images-eureka.patsnap.com/patent_img/5888e493-d037-4d7b-90ca-32369c464ef6/US20160207923A1-20160721-C00001.PNG)

![Azaspiro[4.5] decane derivatives and use thereof Azaspiro[4.5] decane derivatives and use thereof](https://images-eureka.patsnap.com/patent_img/5888e493-d037-4d7b-90ca-32369c464ef6/US20160207923A1-20160721-C00002.png)

![Azaspiro[4.5] decane derivatives and use thereof Azaspiro[4.5] decane derivatives and use thereof](https://images-eureka.patsnap.com/patent_img/5888e493-d037-4d7b-90ca-32369c464ef6/US20160207923A1-20160721-C00003.PNG)