Patents

Literature

598 results about "Anisole" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anisole, or methoxybenzene, is an organic compound with the formula CH₃OC₆H₅. It is a colorless liquid with a smell reminiscent of anise seed, and in fact many of its derivatives are found in natural and artificial fragrances. The compound is mainly made synthetically and is a precursor to other synthetic compounds. It is an ether.

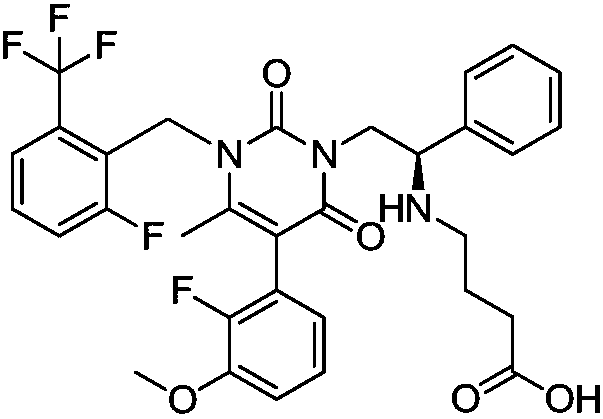

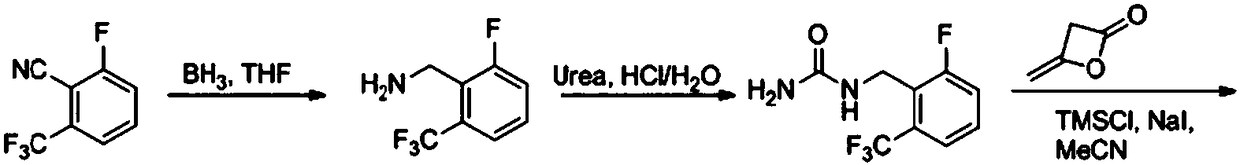

Elagolix synthesis method

The invention provides an elagolix synthesis method. The elagolix synthesis method comprises enabling a compound 5 and a compound 10 to participate in a condensation reaction to finish N-alkylation reaction to obtain a compound 11, and then implementing alkaline hydrolysis to obtain elagolix 12. The invention further discloses two synthesis methods of the compound 5: the method I comprises enabling a 5-bromine-6-methylpyrimidine-2,4(1H,3H)-diketone compound 1 and a 2-(brooethyl)-1-fluorin-3-(trifluoromethyl) benzene compound 2 to have a condensation reaction to obtain an intermediate 3, and then having a coupling reaction; the method II comprises enabling 1-halide-3-fluorin-2-anisole and acetoacetate 7 to have a coupling reaction to obtain a compound 8, and then having a condensation cyclization reaction with a compound 9; the improvements greatly shorten the route steps, the route efficiency is improved, the use of a noble metal catalyst is avoided, and the process cost is greatly lowered. The operation of the route is simple, the total yield is high, the purity of an obtained product is also relatively high, and the method is suitable for the enlarged production.

Owner:HANGZHOU CHEMINSPIRE TECH CO LTD

Container for 4-allylanisole and analog scolytid pesticides

A projectile can be used to administer pesticides such as one or more from the group consisting of 4-allylanisole, anisole, allylbenzene, 4-isopropylanisole, p-anisaldehyde, ethylbenzene, cumene, 4-methoxyacetophenone, 4-methylstyrene, 2-propylphenol, phenetole, and toluene, for scolytid infestation. Conifers, which are a target for scolytids, are protected by the application of the pesticides by use of a projectile containing the compound which explodes upon contact with the conifer thereby emitting the compound.

Owner:US SEC AGRI +1

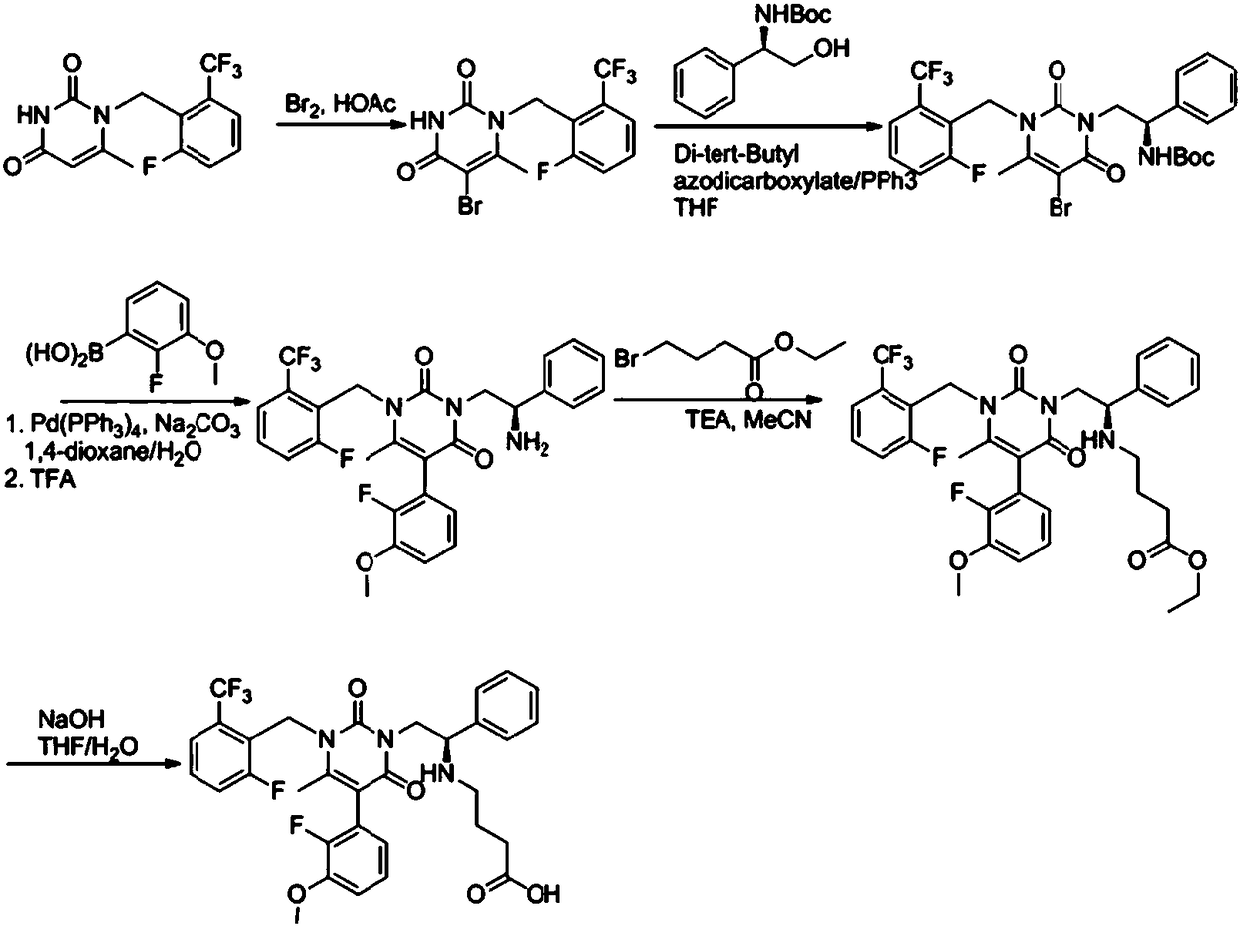

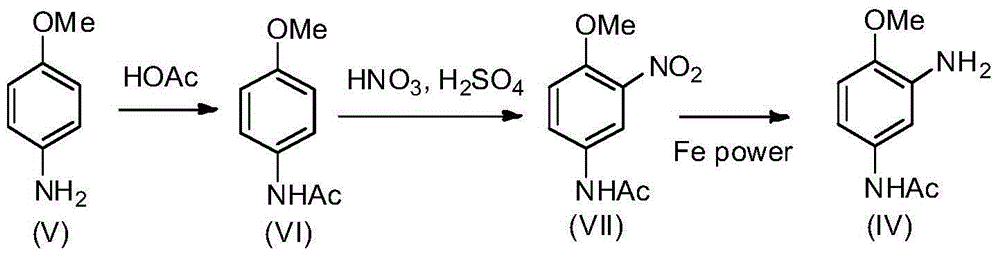

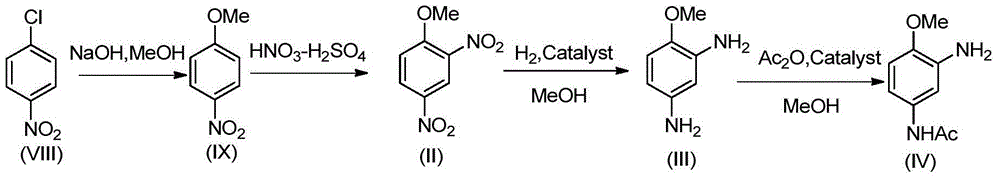

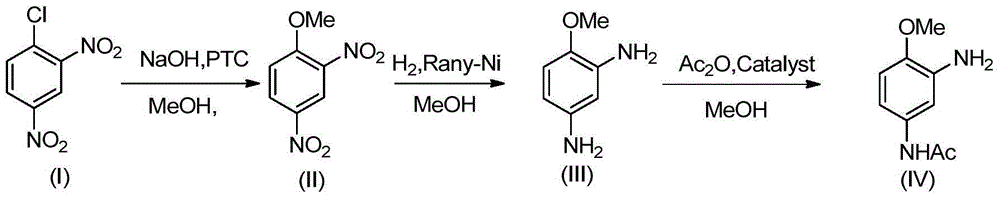

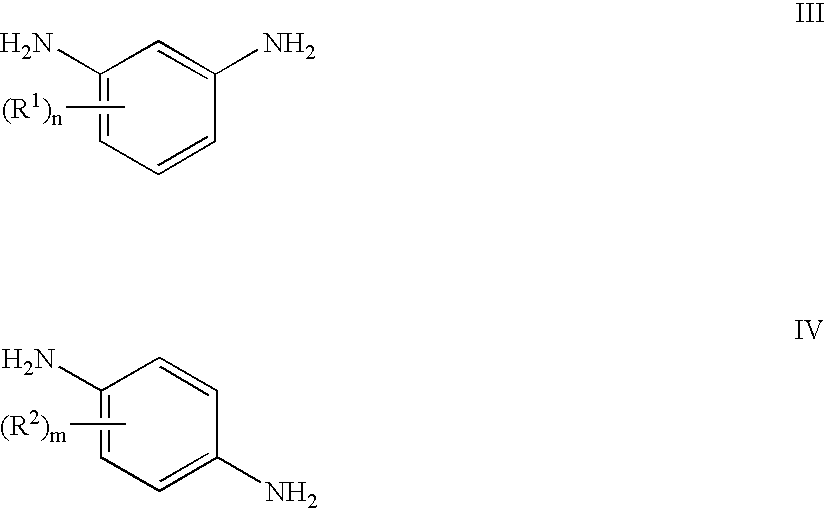

Synthesis process of 2-amino-4-acetamino anisole

InactiveCN104788334AReduce dosageReduce lossOrganic compound preparationCarboxylic acid amides preparationAcetic anhydrideEnergy consumption

The invention discloses a synthesis process of 2-amino-4-acetamino anisole. The synthesis process comprises the following steps: in methanol, under the action of an acid-binding agent, 2,4-diaminoanisole (III) and acetic anhydride are subject to acylation reaction shown in the description to obtain 2-amino-4-acetamino anisole (IV), wherein the molar ratio of the acid-binding agent to 2,4-diaminoanisole is (0.3 : 1)-(0.6 : 1). The synthesis process is low in energy consumption and cost, less in waste solids and waste liquid, environment-friendly, simple in operation, mild in reaction condition and high in industrial safety factor, the yield of the target compound is above 86% (counting according to original reaction raw materials), the HPLC purity is above 99.0%, the target compound is high in yield and good in quality, and the synthesis process is more suitable for industrial production.

Owner:SHANGHAI ZONGXING CHEM TECH CO LTD

Compound feed for improving red drum flavor and preparation method thereof

The invention relates to a compound feed for improving red drum flavor and a preparation method thereof. The compound feed comprises fishmeal, high-gluten flour, soy protein concentrate, fermented peanut meal, beer yeast, corn meal, fish oil, vegetable oil, squid paste, soy lecithin, blood protein powder, binder carboxymethyl cellulose, composite vitamins, composite minerals, choline chloride, betaine, carnitine, sodium dehydroacetate, and butyl hydroxy anisole. The compound feed of the invention has advantages of good attractant effect, good palatability, high feed utilization rate, good-quality red drum. The compound feed can better prevent a feed from oxidative deterioration, improves the feed utilization rate, improves red drum growth, reduces environmental pollution and has a significant environment-protection effect.

Owner:ZHEJIANG MARINE DEV RES INST

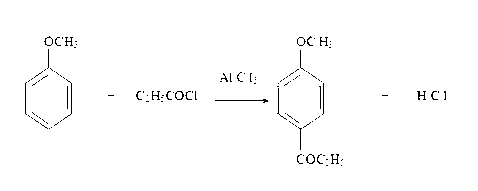

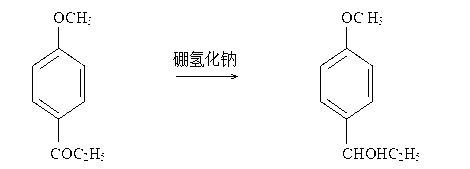

Synthetic method of anethole

InactiveCN103058835AReduce lossesLow costOrganic chemistryOrganic compound preparationSolventSide reaction

The invention discloses a synthetic method of anethole. Anisole and propionyl chloride serve as starting raw materials, are subjected to a friedel-crafts acylation reaction, then are restored through sodium borohydride, and then are catalyzed and dehydrated through organic acid and acid inorganic salt, and finally the anethole is manufactured through rectification. Side reaction is low through the adoption of acylation and reduction, a middle body is not needed to be purified and can be directly put into the next reaction, purification loss and purification cost of the middle body are reduced, yield coefficient is improved, and energy consumption is reduced. A chemical reduction method is utilized to replace a catalytic hydrogenation method, selectivity is high, response speed is fast, side reactions are small in number, and reduction yield coefficient can reach above 98%. Double catalysts are adopted to carry out ordinary pressure low temperature dehydration in dissolvent with a low boiling point, and compared with a negative pressure continuous dehydration method, dehydration time can be shortened by 90%, and the energy consumption is greatly reduced. The total yield coefficient of the method can reach 75%. A product quality index is higher than that of a natural product standard.

Owner:HUAIAN WAN BANG SPICE IND CO LTD +1

Compound fruit fragrance and flower fragrance essence for daily chemicals and preparation method thereof

InactiveCN105316109AImprove stabilityMeet the needs of material and cultural lifeEssential-oils/perfumesBenzoic acidDamascone

Owner:广东铭康香精香料有限公司

Polyene phosphatidyl choline injection and method for preparing the same

The invention discloses a polyene phosphatidyl choline injection and the preparation method. The components and the ratio (portion) of the polyene phosphatidyl choline injection of the invention is: 465 portion of polyene phosphatidyl choline injection, 88 portion of benzyl zlcohol, 50 to 800 portion of glycocholic acid, cholic acid or tween-80, 50 to 80 portion of alcohol, propanediol or glycerin, 15 to 200 portion of sodium hydroxide or sodium carbonate, 0.5 to 5 portion of 2,6-D-itert-butyl-p-cresol, 0.8 to 8 portion of Tertiary butyl-4-hydroxyl anisole, 3 to 25 portion of Vitamin E by weight. The polyene phosphatidyl choline injection of the invention has good clarity, high stability, simple preparation process and easy operation.

Owner:SICHUAN HAISCO PHARMA CO LTD +1

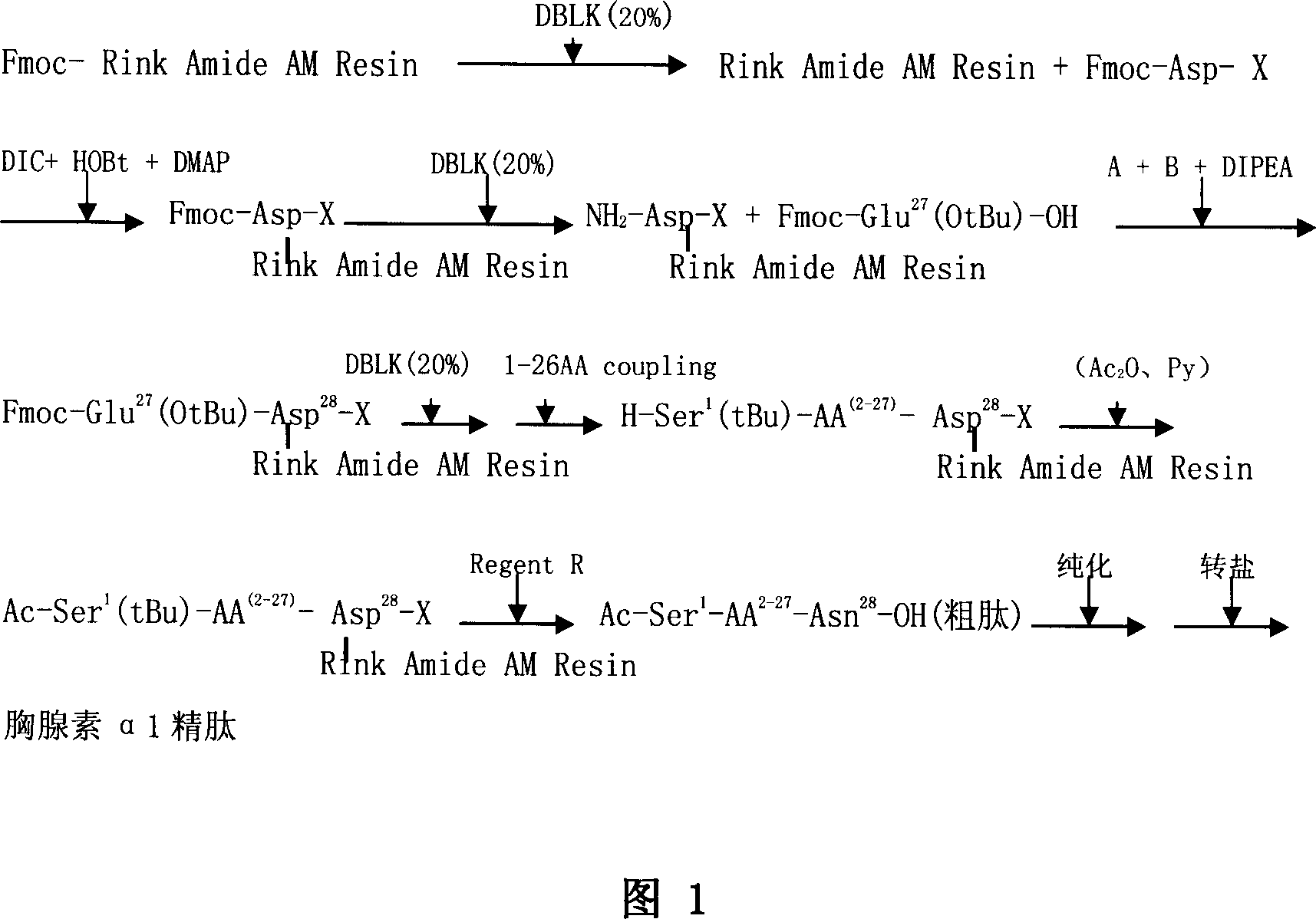

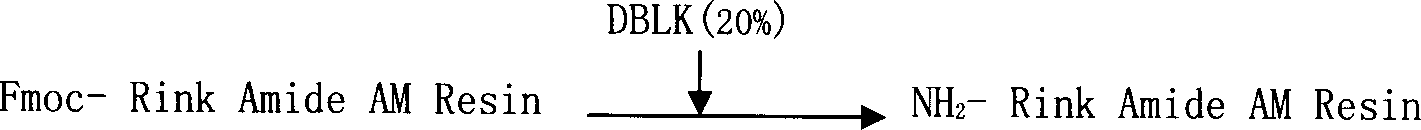

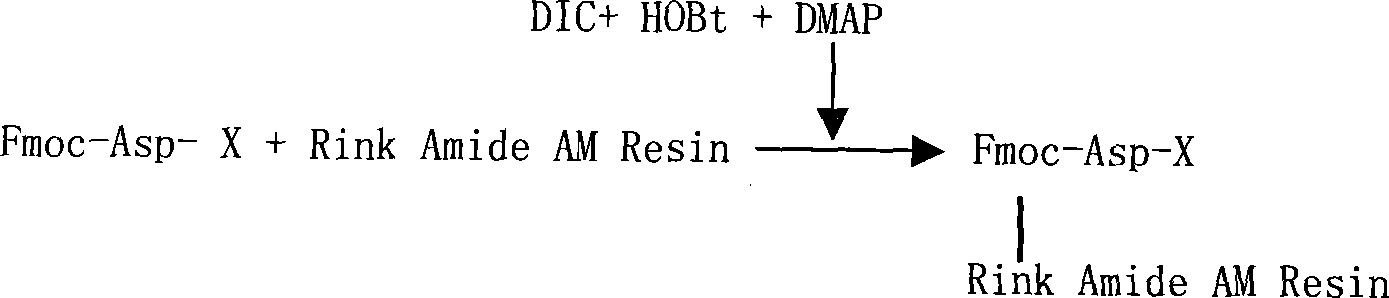

Solid phase synthetic technique for thymosin alpha1

ActiveCN101104638AAdvantages of solid phase synthesis processEasy to purifyThymopoietinsPeptide preparation methodsFluoroacetic acidAcetic anhydride

The invention relates to a solid-phase synthesis process of a thymosin alpha 1, belonging to the polypeptide solid-phase synthesis technical field. The invention comprises the following steps: a. a Fmoc-Rink Amide AM resin or a Fmoc-Rink Amide MBHA resin is used as carrier, an H2N-Rink Amide AM resin or an H2N-Rink Amide MBHA resin is obtained after deprotection of the Fmoc; b. side chain carboxyl group of Fmoc-Asp-X is connected with resin amino by the method of solid-phase synthesis to obtain the Fmoc-Asp (resin)-X; c. the left amino acid in the sequence is synthesized in solid-phase with the Fmoc strategy; d. after the amino protection group Fmoc of N terminal amino acid is removed, the N terminal amino acid is acetylated by acetic anhydride and pyridine; e. then the acetylated N terminal amino acid is cut by a cracking agent (tri fluoroacetic acid / benzoylate sulfide / 1, 2- dithioglycol / Anisole) to obtain the thymosin alpha 1; f. crude product of the thymosin alpha 1 is prepared and separated by HPLC to obtain the pure thymosin alpha 1. The invention can increase significantly the yield of the thymosin alpha 1 and decrease the production cost, which is helpful for scale production and has better industrialization prospect.

Owner:苏州天马医药集团天吉生物制药有限公司

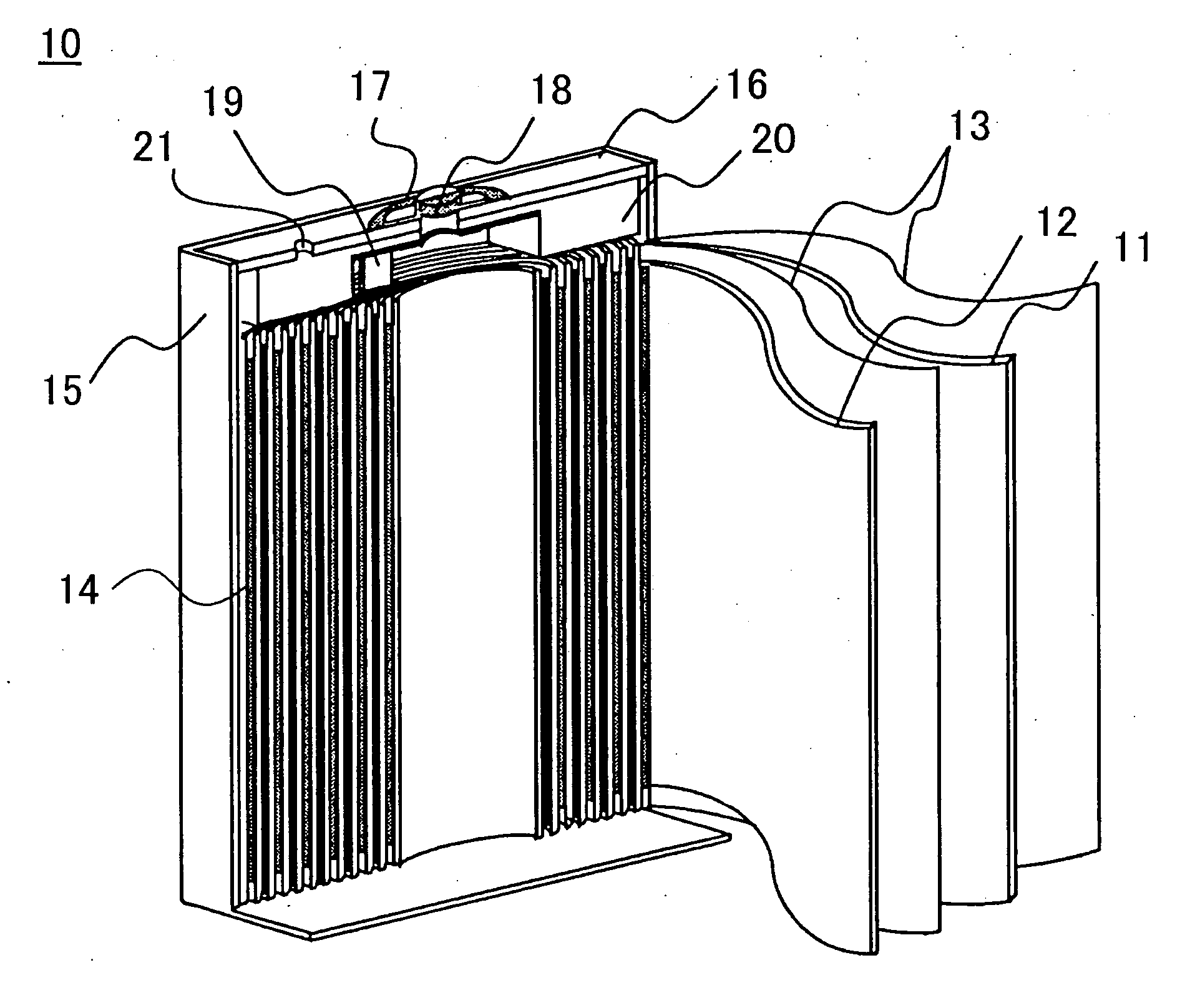

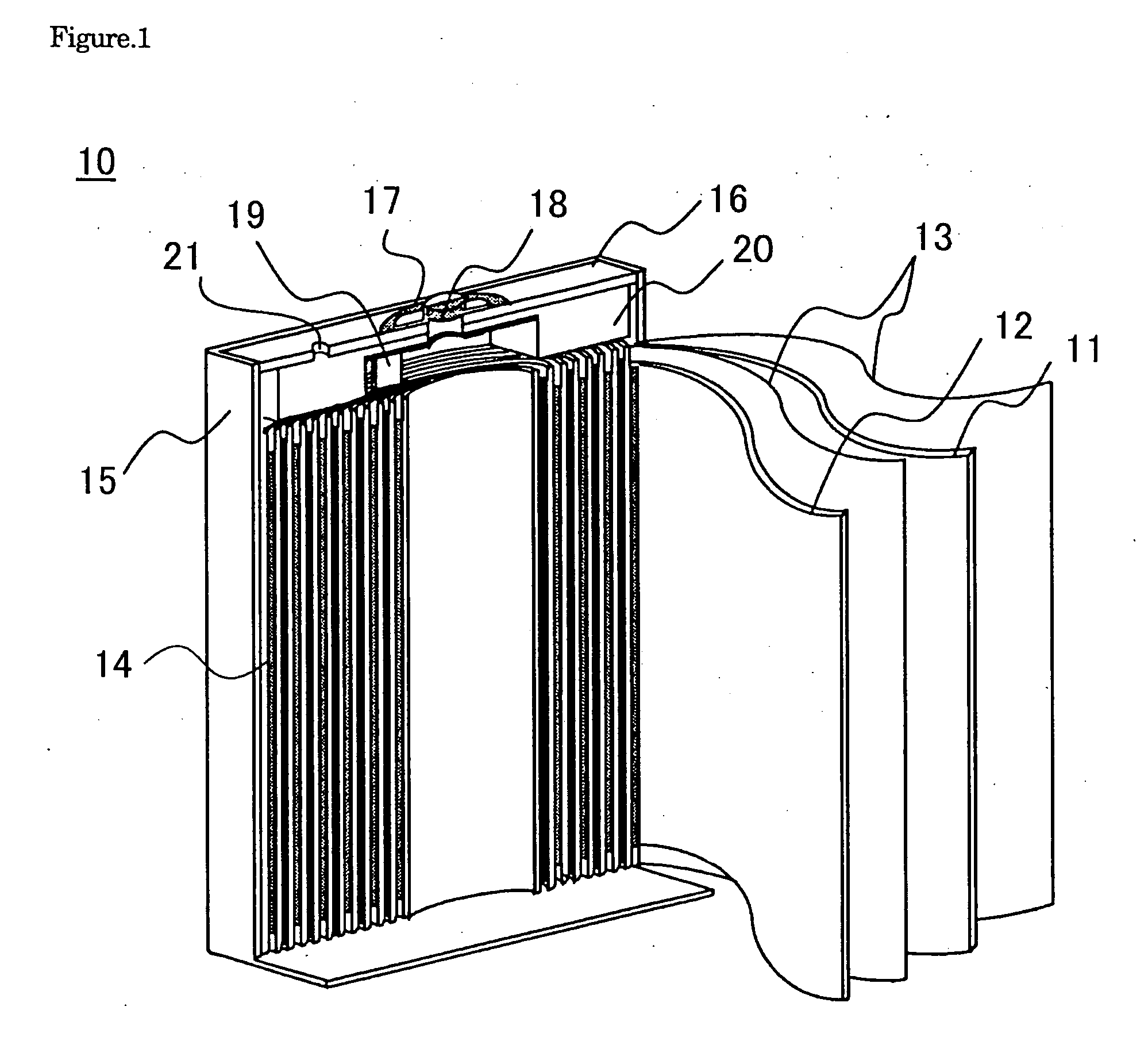

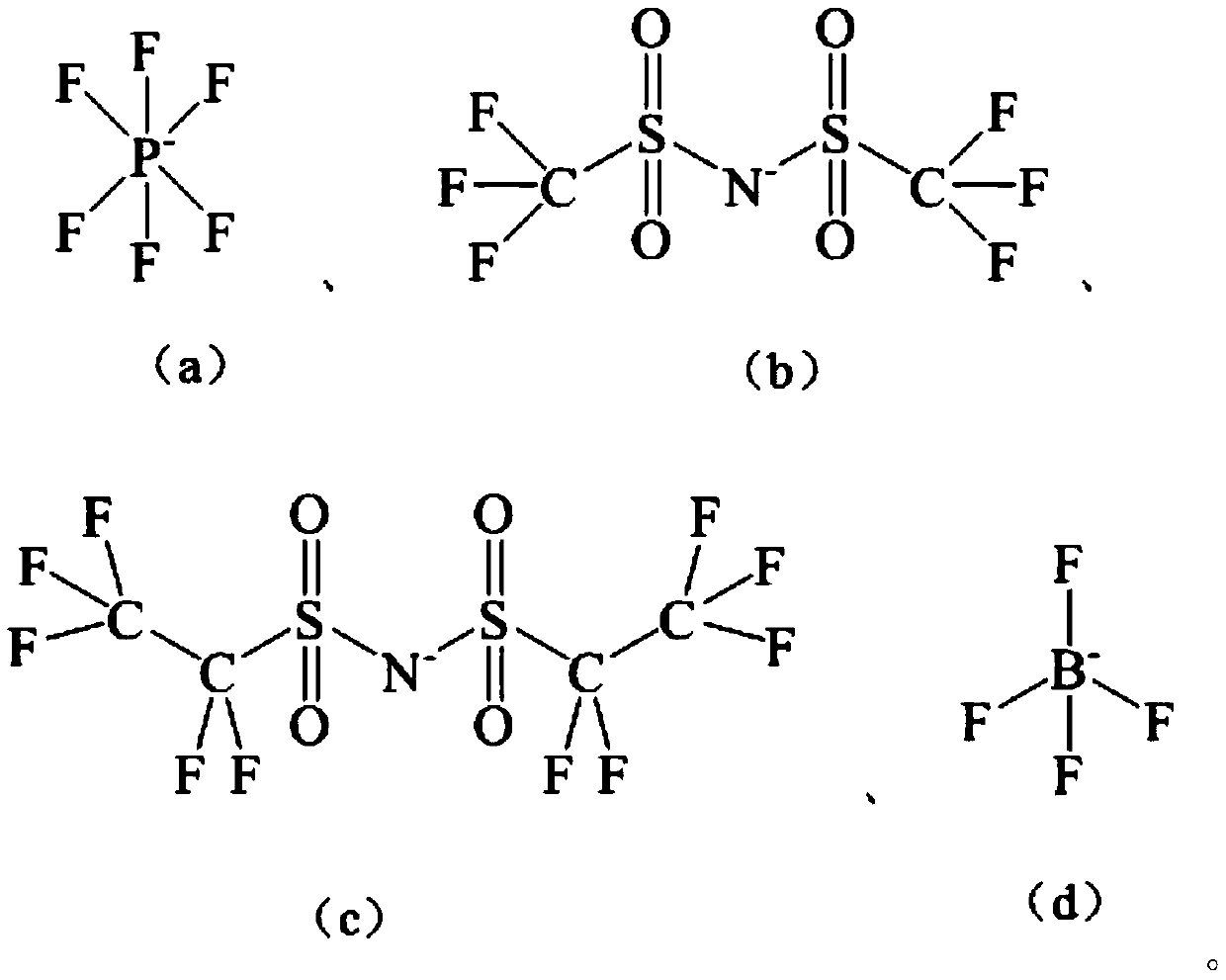

Non-aqueous electrolyte secondary battery

InactiveUS20060199077A1Reduce oxidative decompositionIncrease charging voltageDrying solid materials without heatOrganic electrolyte cellsManganeseSolvent

A non-aqueous electrolyte secondary battery with excellent discharge cycle characteristics and a charging termination potential ranging from 4.4 to 4.6 V based on lithium, consisting of a positive electrode comprising a positive electrode active material, a negative electrode, and a non-aqueous electrolyte containing a non-aqueous solvent and an electrolyte salt, in which the positive electrode active material comprises a mixture of a lithium-cobalt composite oxide containing at least both zirconium and magnesium in LiCoO2, and a lithium-manganese-nickel composite oxide having a layered structure and containing at least both manganese and nickel, and the potential of the positive electrode active material ranges from 4.4 to 4.6 V based on lithium, and the non-aqueous electrolyte contains at least one of aromatic compounds selected from the group consisting at least of toluene derivatives, anisole derivatives, biphenyl, cyclohexyl benzene, tert-butyl benzene, tert-amyl benzene, and diphenyl ether.

Owner:SANYO ELECTRIC CO LTD

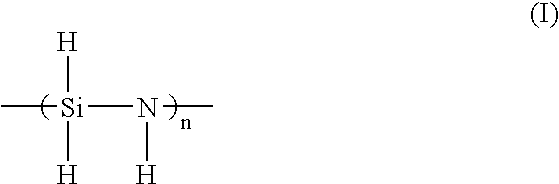

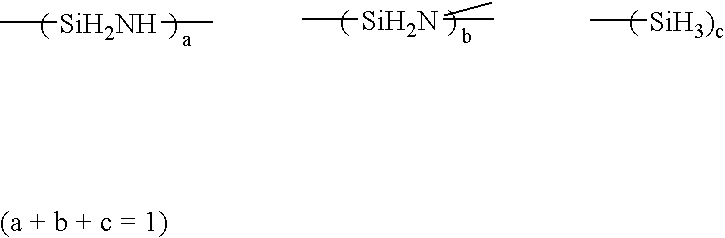

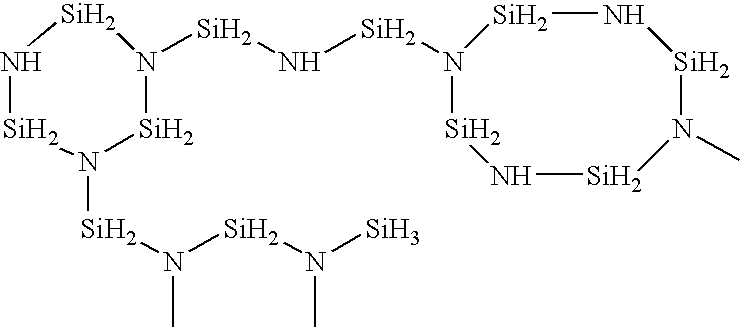

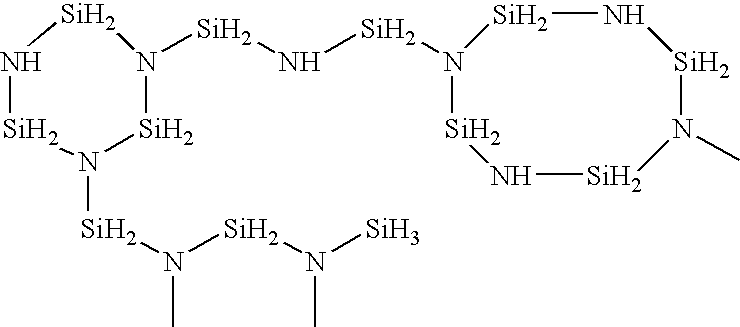

Solvent for treating polysilazane and method of treating polysilazane with the solvent

InactiveUS7344603B2Improve abilitiesAvoid adversely affecting the properties of a groundSemiconductor/solid-state device manufacturingDetergent compounding agentsAlkaneNonane

Polysilazane is treated with a single or mixed solvent comprising one or more members selected from the group consisting of xylene, anisole, decalin, cyclohexane, cyclohexene, methylcyclohexane, ethylcyclohexane, limonene, hexane, octane, nonane, decane, a C8-C11 alkane mixture, a C8-C11 aromatic hydrocarbon mixture, an aliphatic / alicyclic hydrocarbon mixture containing 5 to 25% by weight of C8 or more aromatic hydrocarbons, and dibutyl ether, wherein the number of 0.5 micron or more fine particles contained in 1 ml of the solvent is 50 or less. As the treatment of polysilazane, there are illustrated, for example, edge-rinsing and back rinsing of a polysilazane film formed by spin coating polysilazane on a semiconductor substrate. The water content of the solvent is preferably 100 ppm or less.

Owner:MERCK PATENT GMBH

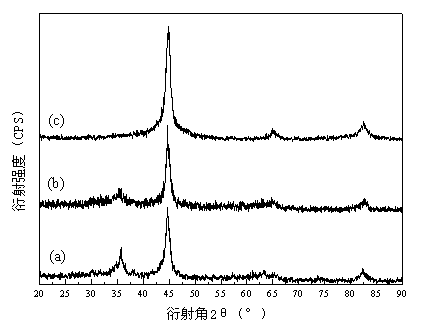

Dispersant modified nano zero-valent iron and preparing method and application thereof

The invention discloses a preparing method for dispersant modified nano zero-valent iron. Through a polymerization inhibitor, MEHQ or PEI serves as a dispersant to modify nano zero-valent iron; through the space steric hindrance effect and the electrostatic steric hindrance effect, the agglomeration phenomenon of the nano zero-valent iron is reduced; in the preparing process of the nano zero-valent iron, the surface of the nano zero-valent iron is modified, agglomeration of the nano zero-valent iron is reduced, dispersibility of the nano zero-valent iron is improved, and the nano zero-valent iron with the higher dispersibility is prepared; nano zero-valent iron particles prepared through the method have the good dispersion stability, inoxidizability and higher reducibility; in the synthetic process of the nano zero-valent iron particles, protection by nitrogen or other inert gases is not needed; and the method is low in cost, easy to operate and environment-friendly. Chlorinated organic compounds, heavy metal, antibiotics, coloring matter and the like in water can be effectively degraded, and the method has a wide application prospect.

Owner:KUNMING UNIV OF SCI & TECH

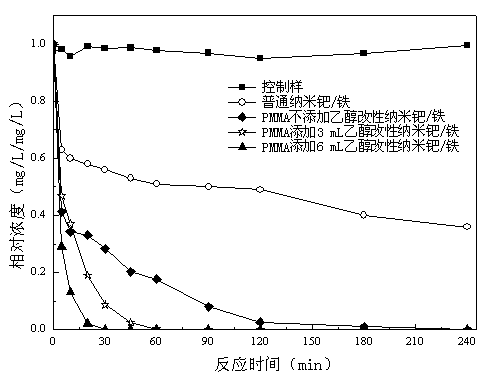

Method for preparing modified nanometer-palladium/iron duplex-metal particles

InactiveCN103100721AGood dispersionImprove antioxidant capacityPolymethyl methacrylateMetal particle

The invention discloses a method for preparing modified nanometer-palladium / iron duplex-metal particles. Macromolecule polymer polymethyl methacrylate is used as a modifying agent, absolute ethyl alcohol is used as cosolvent, and particle surfaces are modified in the process of nanometer-palladium / iron double duplex-metal particle preparation. The preparation method includes that anisole is adopted as solvent of the polymethyl methacrylate, the absolute ethyl alcohol is used as the cosolvent, ferrous saline solution is a precursor solution of zero-valent iron, wherein the zero-valent iron is prepared proportionally through aqueous phase the according to a certain proportion, the precursor solution forms nanometer zero-valent iron particles under the action of reducing agent hydroboration, and then an impregnation method is adopted to conduct palladiumizing to the nanometer zero-valent iron particles, and finally high polymer which is added with the nanometer-palladium / iron duplex-metal particles modified by ethanol is prepared. The nanometer-palladium / iron duplex-metal particles prepared through the method have good dispersity, inoxidizability, and dechlorinating reactivity. The method can be achieved simply in common temperature and common pressure, is simple and convenient to manufacture, and has wide application prospects.

Owner:KUNMING UNIV OF SCI & TECH

Solvent for treating polysilazane and method of treating polysilazane with the solvent

InactiveUS20050027089A1Excellent propertyImprove trimming effectSemiconductor/solid-state device manufacturingDetergent compounding agentsAlkaneNonane

Polysilazane is treated with a single or mixed solvent comprising one or more members selected from the group consisting of xylene, anisole, decalin, cyclohexane, cyclohexene, methylcyclohexane, ethylcyclohexane, limonene, hexane, octane, nonane, decane, a C8-C11 alkane mixture, a C8-C11 aromatic hydrocarbon mixture, an aliphatic / alicyclic hydrocarbon mixture containing 5 to 25% by weight of C8 or more aromatic hydrocarbons, and dibutyl ether, wherein the number of 0.5 micron or more fine particles contained in 1 ml of the solvent is 50 or less. As the treatment of polysilazane, there are illustrated, for example, edge-rinsing and back rinsing of a polysilazane film formed by spin coating polysilazane on a semiconductor substrate. The water content of the solvent is preferably 100 ppm or less.

Owner:MERCK PATENT GMBH

Extraction of phenol-containing effluent streams

InactiveUS20050240065A1Organic compound preparationWater contaminantsPHENOL LIQUIDMethyl isobutyl ketone

A process for extracting phenol from a phenol-containing aqueous solution is disclosed. The process entails contacting the aqueous solution with an extracting agent that comprise a mixture of 60 to 99% of methyl isobutyl ketone, 1 to 40% of anisole and 0 to 20% of mesitylene.

Owner:COVESTRO DEUTSCHLAND AG

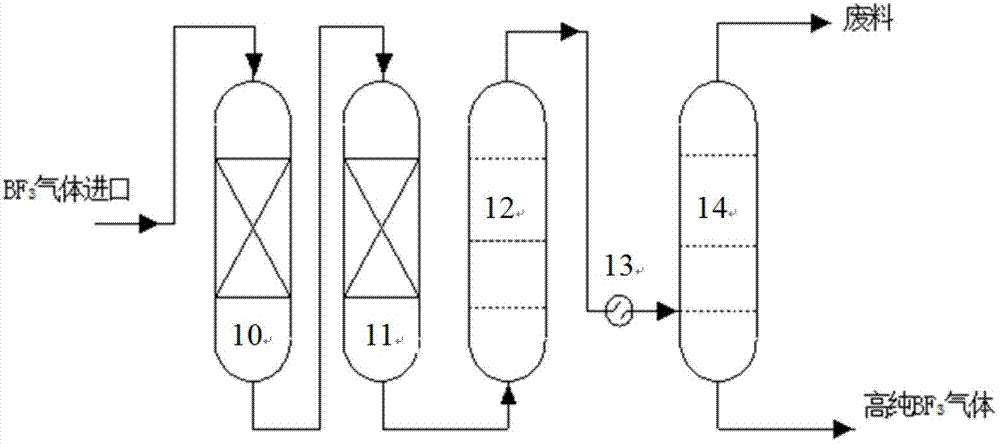

Method for producing enriched boric-10 acid from trifluoride-anisole complex and application thereof

The invention relates to a method for producing enriched boric-10 acid from a trifluoride-anisole complex and application thereof. The method comprises the following steps: reacting a boron trifluoride-anisole complex with excessive sodium methoxide methanol solution, operating in an ice bath for 5-25 minutes, carrying out thermostatic water bath, reacting for 40-60 hours while keeping the reaction temperature within the range of 40-60 DEG C, stopping heating, and carrying out centrifugal stratification; fractionating the centrifugated supernatant: heating the mixture, starting to collect the fraction when the temperature rises to 50 DEG C, and stopping collecting the fraction when the temperature rises to 60 DEG C; and carrying out salting-out stratification on the collected fraction, mixing with deionized water, carrying out vacuum filtration on the mixture to obtain a solid, and drying to obtain the boric acid. The enriched boric-10 acid is used in the field of production of 10B-isotope-enriched downstream boric acid products, nuclear-grade boric acids and other enriched boric-10 acids by an anisole chemical exchange fractionation process. The production raw materials are from a closed system; and the invention has the impurity removal link, so the product purity is higher, thereby lowering the difficulty of subsequent boric acid production.

Owner:TIANJIN UNIV

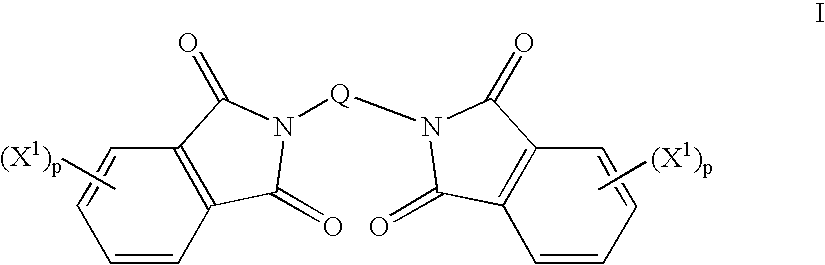

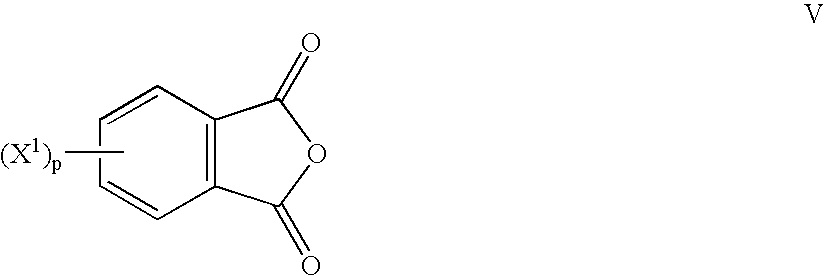

Method to prepare bis(haloimides)

Bis(halophthalimides) are prepared in mixture in an organic liquid such as ortho-dichlorobenzene or anisole, by a reaction at a temperatire of at least 150° C. between at least one diamine compound and at least one halophthalic anhydride in the presence of imidization catalyst. The reaction mixture is maintained at about 15% by weight solids content and rich in the halophthalic anhydride by constantly monitoring the reaction mixture using analytical methods such as high performance liquid chromatography. The product mixture may be directly employed in the direct preparation of polyetherimides, and similar slurries may be employed to prepare other polyether polymers.

Owner:SHPP GLOBAL TECH BV

Method for the production of alpha-alane

A method of forming α-alane. The method includes reacting aluminum trichloride and an alkali metal hydride to form an alane-ether complex solution. An aqueous diethyl ether solution is optionally added to the alane-ether complex solution to form a partially hydrolyzed ether / alane-ether complex solution. A solution of a first crystallization additive is added to the alane-ether complex solution or to the aqueous ether / alane-ether complex solution to form a crystallization solution. The first crystallization additive is selected from the group consisting of polystyrene, polybutadiene, polystyrene-co-polybutadiene, polyisoprene, poly-alpha-methylstyrene, polystyrene-co-polyindene, poly-alpha-pinene, and mixtures thereof. Optionally, a second crystallization additive is added to the crystallization solution. The second crystallization additive is selected from the group consisting of squalene, cyclododecatriene, norbornylene, norbornadiene, a phenyl terminated polybutadiene, 2,4-dimethyl anisole, 3,5-dimethyl anisole, 2,6-dimethyl anisole, polydimethyl siloxane, and mixtures thereof. Solvents are removed from the crystallization solution to crystallize the α-alane.

Owner:NORTHROP GRUMMAN SYST CORP

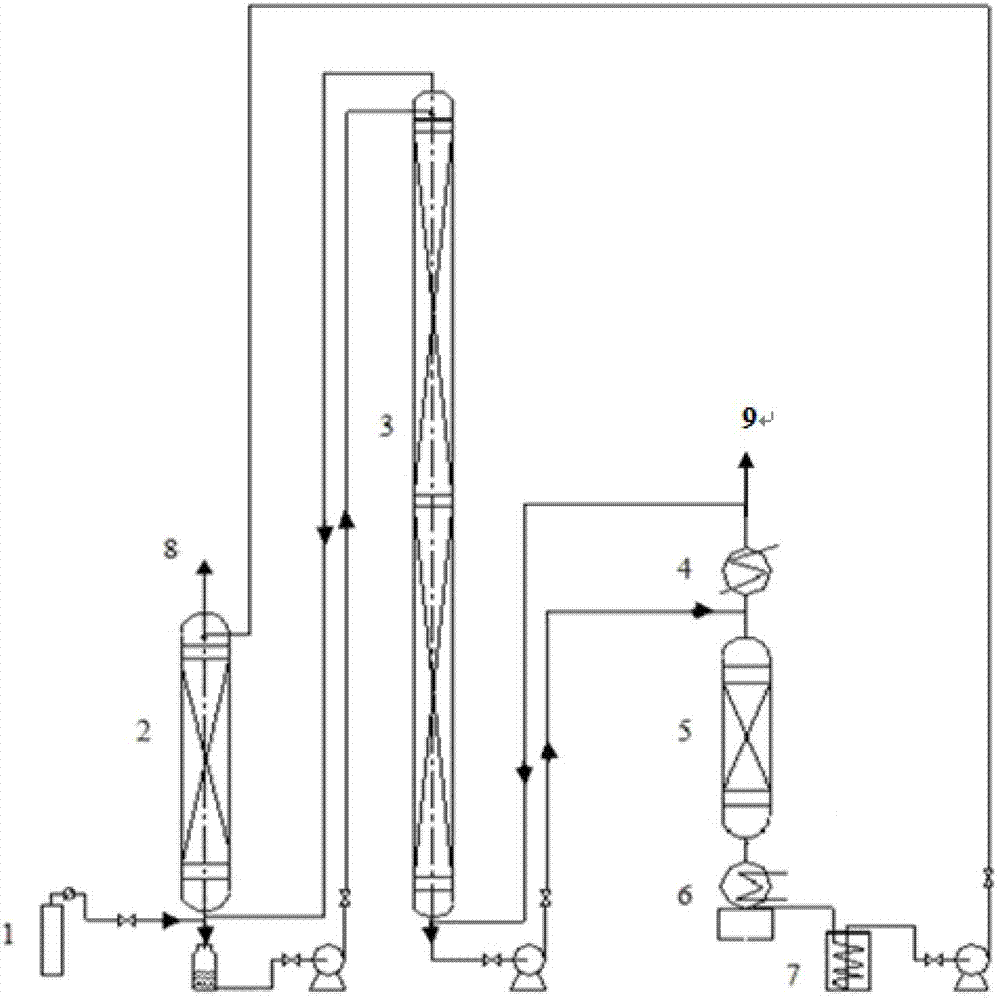

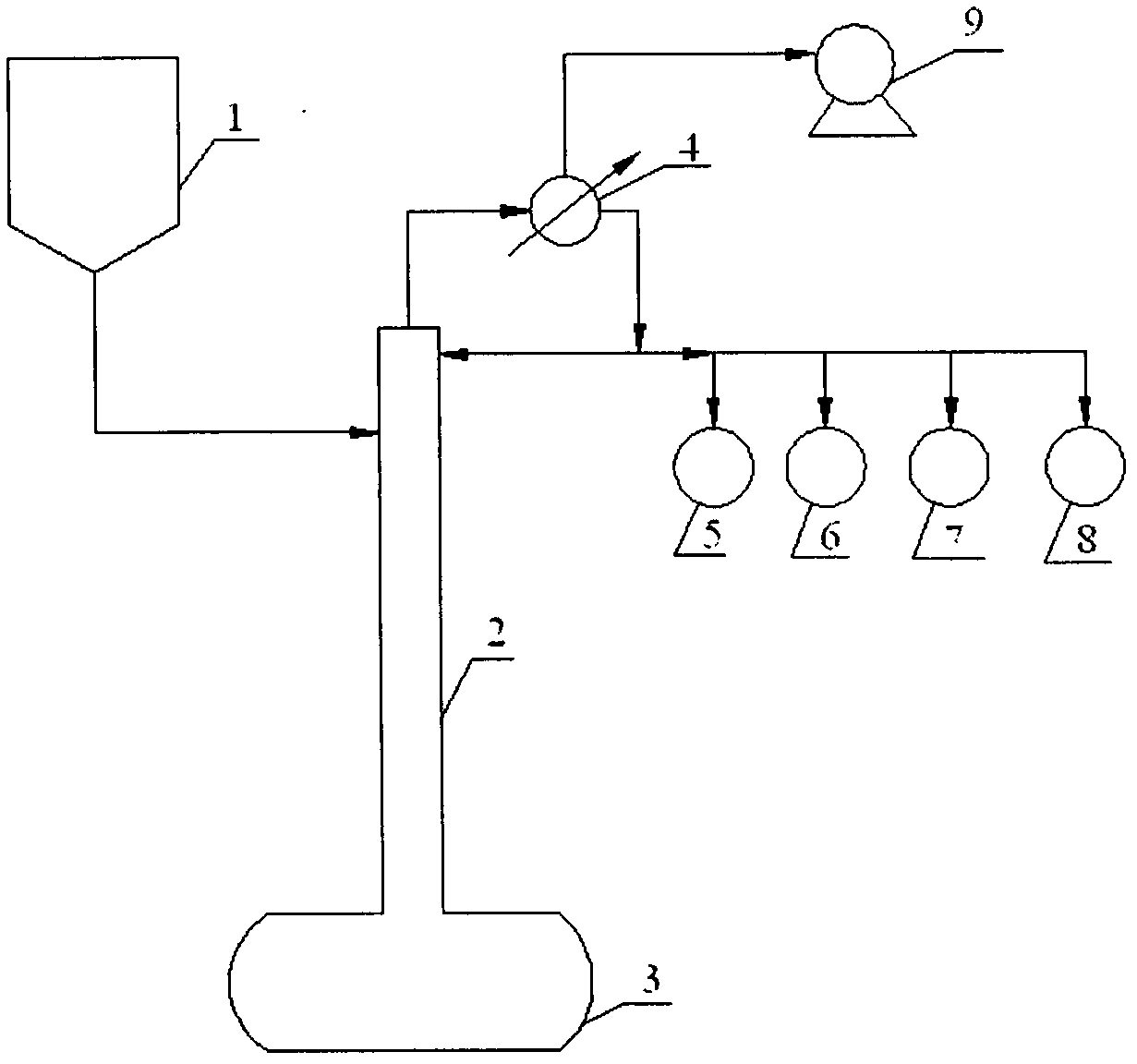

Device and method for producing boron trifluoride-11 electronic specific gas

InactiveCN102774845AFulfil requirementsMeet production requirementsBoron halogen compoundsCounter flowBoron trifluoride

The invention relates to a device and a method for producing boron trifluoride-11 (11BF3) electronic specific gas, wherein boron trifluoride raw gas is fed from the bottom of a synthesizer, anisole is downwards sprayed from the top of the synthesizer, and at the operation temperature of 10-25 DEG C, complex reaction is carried out to produce a boron trifluoride-anisole complex; a BF3 gas which is cracked from a cracking device is fed from the bottom of a chemical exchange tower, the gas and the liquid counter flow to fully contact with each other, and at the operation temperature of 15-30 DEG C, the chemical exchange reaction is carried out; heavier 11B isotope is enriched at the top of the tower in a gaseous state, and lighter 10B isotope is enriched in the liquid complex in the bottom of the tower; the enriched 11BF3 gas enters the synthesizer from the bottom, and is synthesized with the anisole again to form the liquid complex; the liquid complex of the enriched 10B isotope enters a decomposer, is heated to decompose into 11BF3 lean gas at 140-170 DEG C, and enters the chemical exchange tower to be subjected to chemical exchange; and the operation is repeated until the 11B abundance of the 11BF3 gas reaches above 99.7%, and the product is recovered from an 11BF3 product outlet.

Owner:TIANJIN UNIV

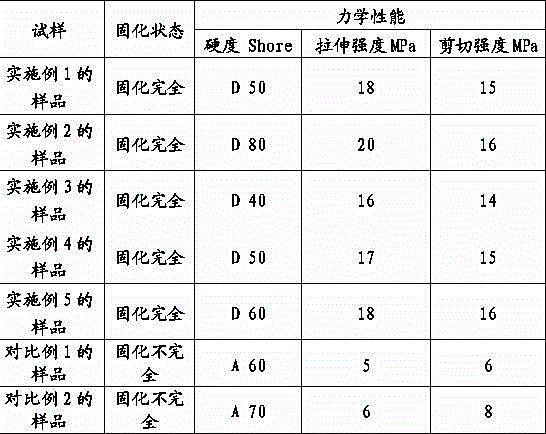

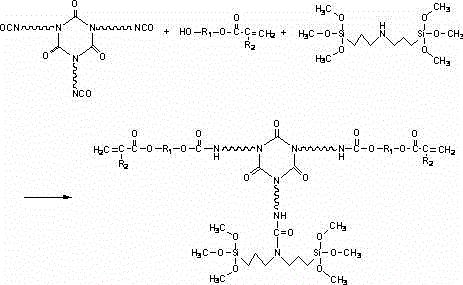

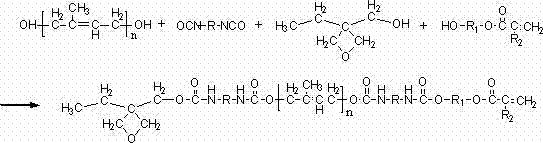

UV/moisture dual-curing resin and synthesis method thereof

ActiveCN104788644ASpecial chemical structureSolve problems that cannot be curedPtru catalystSpectrograph

The invention provides a synthesis method of UV / moisture dual-curing resin. The method comprises the following steps: placing HDI tripolymer, hydroxied acrylates, polymerization inhibitor hydroquinone monomethylether and catalyst dibutyltin dilaurate into a three-mouth flask with a thermometer, heating the three-mouth flask to 65 DEG C, dropwise adding bis(gamma-trimethoxysilyl propyl)amine, controlling the temperature at 70 to 75 DEG C, and carrying out the reaction for 2 to 3 hours; analyzing NCO groups by utilizing an infrared spectrograph, and stopping the heating reaction when the NCO value is not changed, thereby obtaining the UV / moisture dual-curing resin. The resin can be optically cured by virtue of UV and also can be cured by virtue of moisture, so that the problem that a shadow part cannot be cured in the optical polymerization process; moreover, compared with the resin adopting isocyanate as a reaction group curing-sealing end, the resin adopting methoxylsilane as the moisture curing reaction group is more stable in reaction speed and cured resin effect, and the further curing effect of the product is better.

Owner:YANTAI DARBOND TECH

Resin with mixing and solidification functions and synthetic method thereof

The invention provides a synthetic method of resin with mixing and solidification functions. The synthetic method of the resin with the mixing and the solidification functions comprises the steps that 80-110 g of polyisoprene dibasic alcohol, 4-10 g of 3-ethyl-3-hydroxymethyleneoxetane, 5-12 g of hydroxyl acrylate, 0.1 g of polymerization inhibitor para hydroxybenzene methyl ether and 0.01 g of catalyst dibutyltin dilaurate are added into a three-mouth flask with a thermometer, the temperature is raised to 65 degrees, then 18-32 g of diisocyanate starts to be dropwise added, the temperature is controlled to be 70-75 degrees, and reaction is performed for 2-3 h. The content of NCO perssad is analyzed by an infrared spectrometer, until the NCO peak disappears completely, the heating reaction is stopped, and the urethane acrylate modified by oxetane can be obtained. The resin with the mixing and the solidification functions can manufacture three-dimensional products with low shrinking percentage, low warping, good flexibility, ageing resistance, high machining precision, good photocuring performance and excellent mechanical strength; in addition, the synthetic reaction is simple in technology and easy to control, no special equipment is needed to be used, no solvent is needed, and the production cost is low.

Owner:YANTAI DARBOND TECH

Method for the production of alpha-alane

ActiveUS20050222445A1Reduce impurityHydrogenThiosulfates/dithionites/polythionitesCyclododecatrienePolydimethyl siloxane

A method of forming alpha-alane. The method includes reacting aluminum trichloride and an alkali metal hydride to form an alane-ether complex solution. An aqueous ether solution is optionally added to the alane-ether complex solution to form a partially hydrolyzed ether / alane-ether complex solution. A solution of a crystallization additive is added to the alane-ether complex solution or to the aqueous ether / alane-ether complex solution to form a crystallization solution. The crystallization additive is selected from the group consisting of squalene, cyclododecatriene, norbomylene, norbomadiene, a phenyl terminated polybutadiene, 2,4-dimethyl anisole, 3,5-dimethyl anisole, 2,6-dimethyl anisole, polydimethyl siloxane, and mixtures thereof. Ether is removed from the crystallization solution to crystallize the alpha-alane.

Owner:NORTHROP GRUMMAN SYST CORP

Container for 4-allylanisole and analog scolytid pesticides

A projectile which can be a paint ball, capsule or the like can be used to administer pesticides such as one or more from the group consisting of 4-allylanisole, anisole, allylbenzene, 4-isopropylanisole, p-anisaldehyde, ethylbenzene, cumene, 4-methoxyacetophenone, 4-methylstyrene, 2-propylphenol, phenetole, and toluene, for scolytid infestation or a pheromone or a mixture of the foregroup. Conifers, which are a target for scolytids, are protected by the application of the pesticides and attractants by use of a projectile containing the compounds which explodes or sufficiently disintegrates upon contact with the conifer thereby emitting the compounds.

Owner:MISSISSIPPI STATE UNIVERSITY +1

Intermittent extractive distillation separation method of methanol-methyl propionate azeotropic mixtures

InactiveCN102584525AFlexible operationReduce cost inputOrganic compound preparationCarboxylic acid esters preparationChlorobenzeneExtractive distillation

The invention discloses an intermittent extractive distillation separation method of methanol-methyl propionate azeotropic mixtures, which belongs to the separation technology of the methanol-methyl propionate azeotropic mixtures and includes: ethylene glycol, 1,2-propylene glycol, glycerol, anisole and toluene or chlorobenzene are used as extracting agents, under operation conditions of an extracting rectifying tower, mass ratio of the extracting agents and overhead distillate is 0.5:1-10:1at ordinary pressure or reduced pressure, feeding temperature of the extracting agents is 20-60 DEG C, different temperatures and different reflux ratios at the top of the extracting rectifying tower are controlled, methanol products, a methanol-methyl propionate transition section I, methyl propionate products and a methyl propionate-extracting agent transition section II are respectively picked out through the extracting rectifying tower, and when extracting agent components of a heating kettle meet requirements, the extracting agents are pumped into a high-level storage groove and materials are fed for the next intermittent extractive distillation separation. The intermittent extractive distillation separation method has the advantages that the single tower is low in device cost and flexible in operation, and the extracting agents are adopted to damage a methanol-methyl propionate azeotropic system to separate out high-purity methanol products and high-purity methyl propionate products.

Owner:UNIV OF JINAN

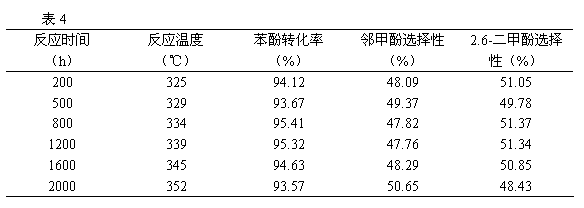

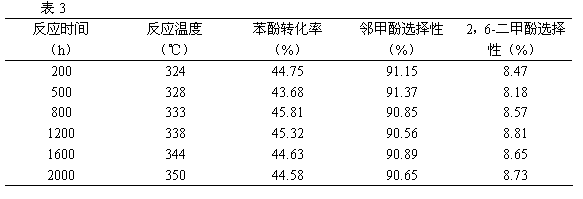

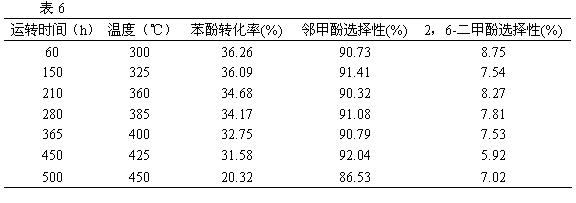

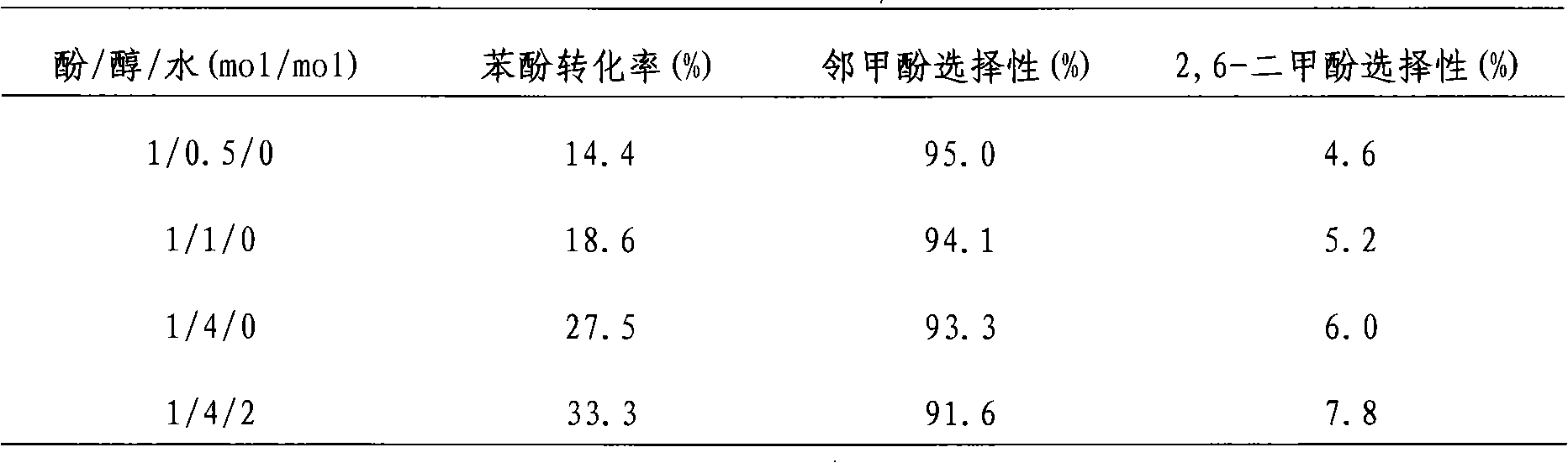

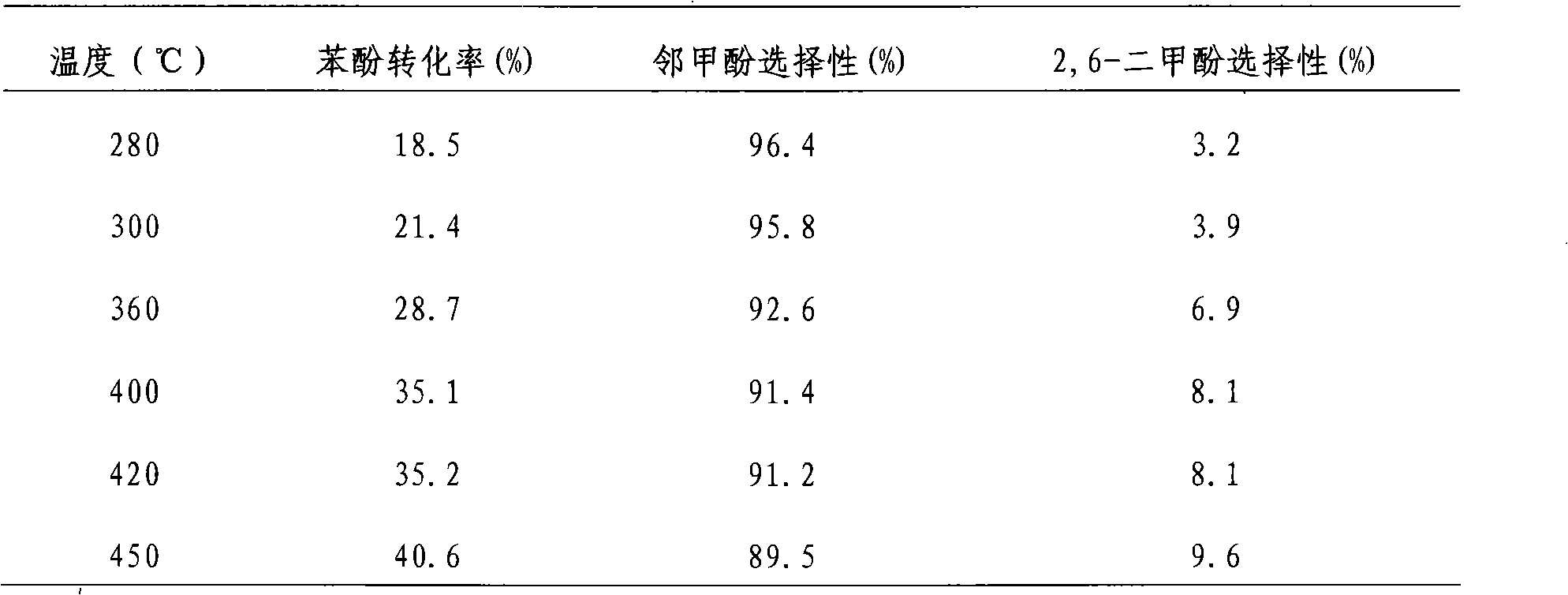

Method for preparing ortho-cresol and 2,6-dimethylphenol

InactiveCN102826960AAdjustable pHHigh activityOrganic chemistryOrganic compound preparationPtru catalystOrtho position

The invention discloses a method for preparing ortho-cresol and 2,6-dimethylphenol and is characterized in that a reaction mixed liquid at the mole ratio of phenol to methanol to water being 1: (2-5): (1-3) is pumped the into a reactor by the use of a pump at the feeding space velocity of 0.5-2 hr<-1>; N2 with the flow velocity of 10-25 mL / min is used as a carrier gas; and a vapor-phase alkylation reaction is carried out at the reaction pressure of normal pressure to 0.5 MPa at the reaction temperature of 320-380 DEG C and under the condition of an alkaline Fe / Mg / Sb composite oxide used as a catalyst. The method provided by the invention has advantages as follows: high average conversion rate of phenol, long one-way service life of the catalyst, high ortho-selectivity, and no generation of impurities m.p-cresol and anisole. In addition, the process is simple, and the method is suitable for continuous large-scale production of ortho-cresol, or reallocation of 2,6-dimethylphenol, or co-production of ortho-cresol and 2,6-dimethylphenol.

Owner:HUNAN XINLING CHEM CO LTD

Method for the production of alpha-alane

ActiveUS20070066839A1Lower the volumeMultiple metal hydridesGroup 3/13 element organic compoundsAlkaneCyclododecatriene

A method of forming α-alane. The method includes reacting aluminum trichloride and an alkali metal hydride to form an alane-ether complex solution. An aqueous diethyl ether solution is optionally added to the alane-ether complex solution to form a partially hydrolyzed ether / alane-ether complex solution. A solution of a first crystallization additive is added to the alane-ether complex solution or to the aqueous ether / alane-ether complex solution to form a crystallization solution. The first crystallization additive is selected from the group consisting of polystyrene, polybutadiene, polystyrene-co-polybutadiene, polyisoprene, poly-alpha-methylstyrene, polystyrene-co-polyindene, poly-alpha-pinene, and mixtures thereof. Optionally, a second crystallization additive is added to the crystallization solution. The second crystallization additive is selected from the group consisting of squalene, cyclododecatriene, norbornylene, norbornadiene, a phenyl terminated polybutadiene, 2,4-dimethyl anisole, 3,5-dimethyl anisole, 2,6-dimethyl anisole, polydimethyl siloxane, and mixtures thereof Solvents are removed from the crystallization solution to crystallize the α-alane.

Owner:NORTHROP GRUMMAN SYST CORP

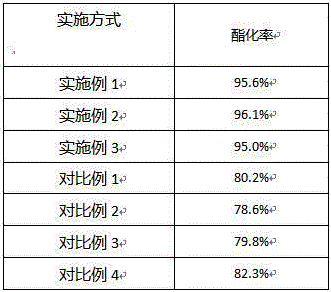

Preparation technology of tert-butyl acrylate

InactiveCN104987288AHigh yieldIncrease profitOrganic compound preparationCarboxylic acid esters preparationPolymer sciencePtru catalyst

The invention discloses a preparation technology of tert-butyl acrylate. Acrylic acid, isobutene, an acidic catalyst and a polymerization inhibitor undergo an esterification reaction at 40-120DEG C under 1.0-5.0MPa under an isobutene volume space velocity of 0.5-5.0 / h according to a molar ratio of acrylic acid to isobutene of 1.0:1.0-5.0:1.0, the polymerization inhibitor comprises tert-butylcatechol, p-hydroxyanisole, 2,5-di-tert-butylhydroquinone and diphenylamine according to a weight ratio of 1:3:2:7, and the acidic catalyst is strong-acid cation exchange resin. The method can substantially improve the yield of tert-butyl acrylate.

Owner:QILU UNIV OF TECH

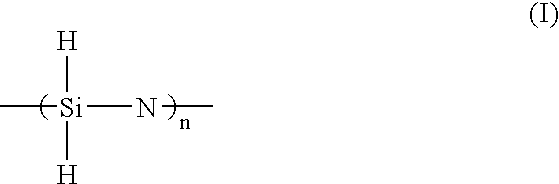

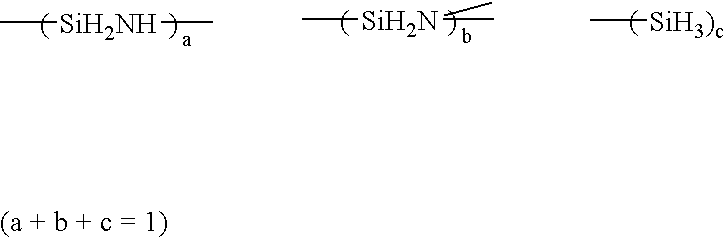

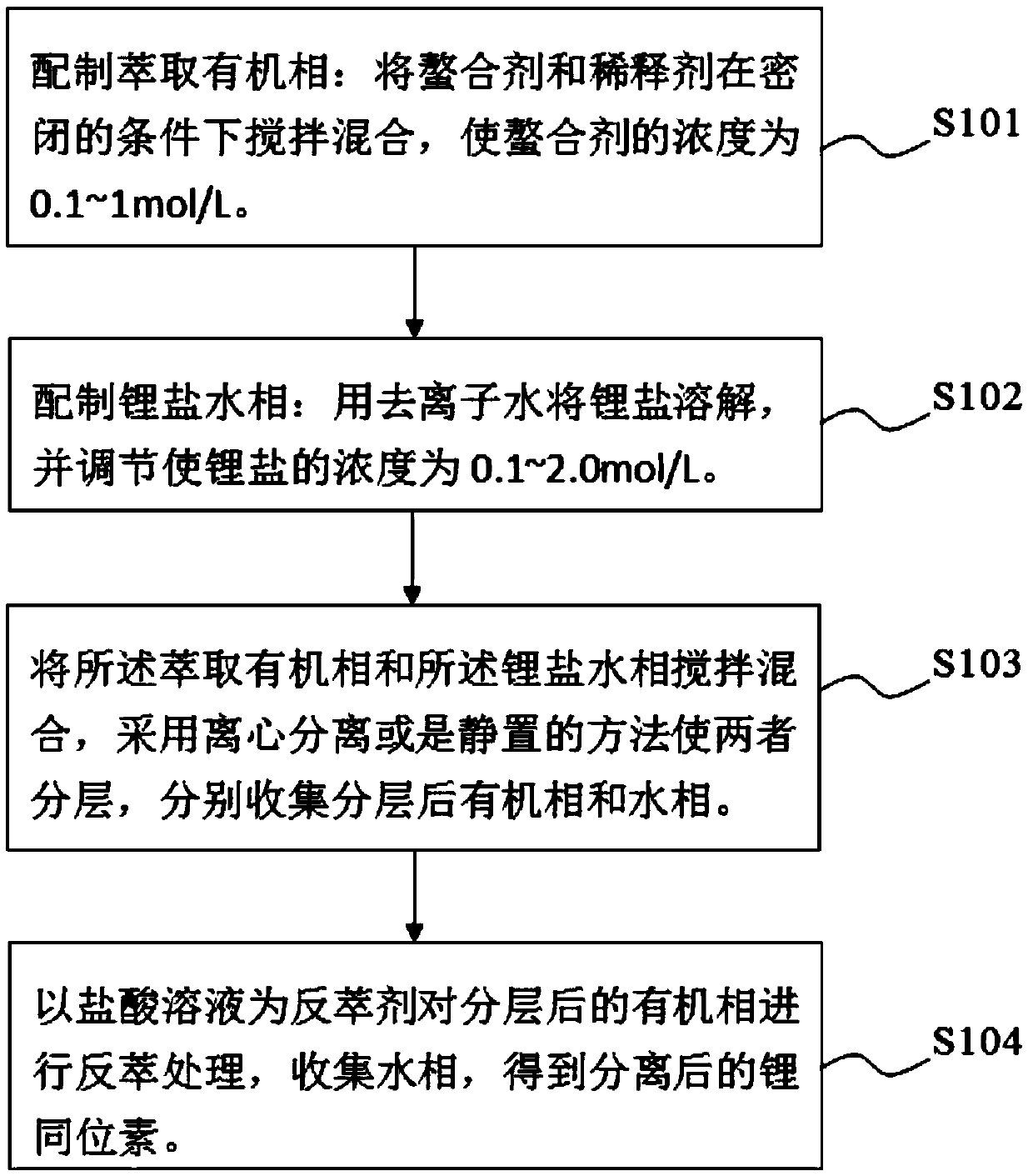

Method for extracting lithium isotopes

ActiveCN105498542AIncrease single-stage extraction rateEasy to separateIsotope separationChlorobenzeneKerosene

The invention discloses a method for extracting lithium isotopes. A chelating agent and a diluent are prepared into an extractive organic phase, and the lithium isotopes are extracted from and separated out of a lithium salt water phase. Hydrophobic ionic liquid with a crown ether structure is adopted as the chelating agent and composed of positive ions and negative ions, wherein positive ions with a structural formula I and / or a structural formula II are adopted as the positive ions. One or more of PF6<->, (SO2CF3)2N<->, (SO2CF2CF3)2N<-> and BF4<-> is / are adopted as the negative ions. One or more of kerosene, octanone, chloroform, dichloromethane, carbon tetrachloride, tetrachloroethylene, nitrobenzene, methylbenzene, dimethylbenzene, diethylbenzene, bromobenzene, anisole, nitromethane, 2-methylcyclohexanone, methylisobutylketone, chlorobenzene, dichlorobenzene, trichlorobenzene and diphenyl ether is / are adopted as the diluent. The method has the advantages of being safe, green, efficient and good in stability and can be used for multi-stage enrichment and separation of the lithium isotopes.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Composite material for dental prosthesis and preparation method of composite material

InactiveCN105232340AHigh mechanical strengthHigh strengthImpression capsDentistry preparationsBiocompatibilitySILICONE DIOXIDE

The invention discloses a composite material for dental prosthesis and a preparation method of the composite material. The composite material is prepared from the following components in parts by weight: 20-40 parts of polyethylene, 25-40 parts of xanthan gum, 20-25 parts of hydroxy calcium phosphate, 2-8 parts of chitosan, 1-6 parts of tributyl citrate, 4-8 parts of a phase transfer agent, 2-6 parts of divinyl tetramine, 25-35 parts of 2-methyl-2-propenoic acid 2-(phosphonooxy) ethyl ester, 4-8 parts of silver lactate, 7-20 parts of titanium dioxide, 10-15 parts of silicon dioxide, 3-8 parts of an antioxidant, 4-8 parts of hydroxyanisole, 1-13 parts of calcium fluophosphate, 8-23 parts of ethanol and 25-45 parts of double distilled water. The tooth filling material disclosed by the invention is good in mechanical strength, high in intensity and good in biocompatibility, and the safety of the material to human bodies is improved. The preparation method disclosed by the invention is simple and easy to implement, and is suitable for industrial production.

Owner:SUZHOU COSMETIC MATERIALS

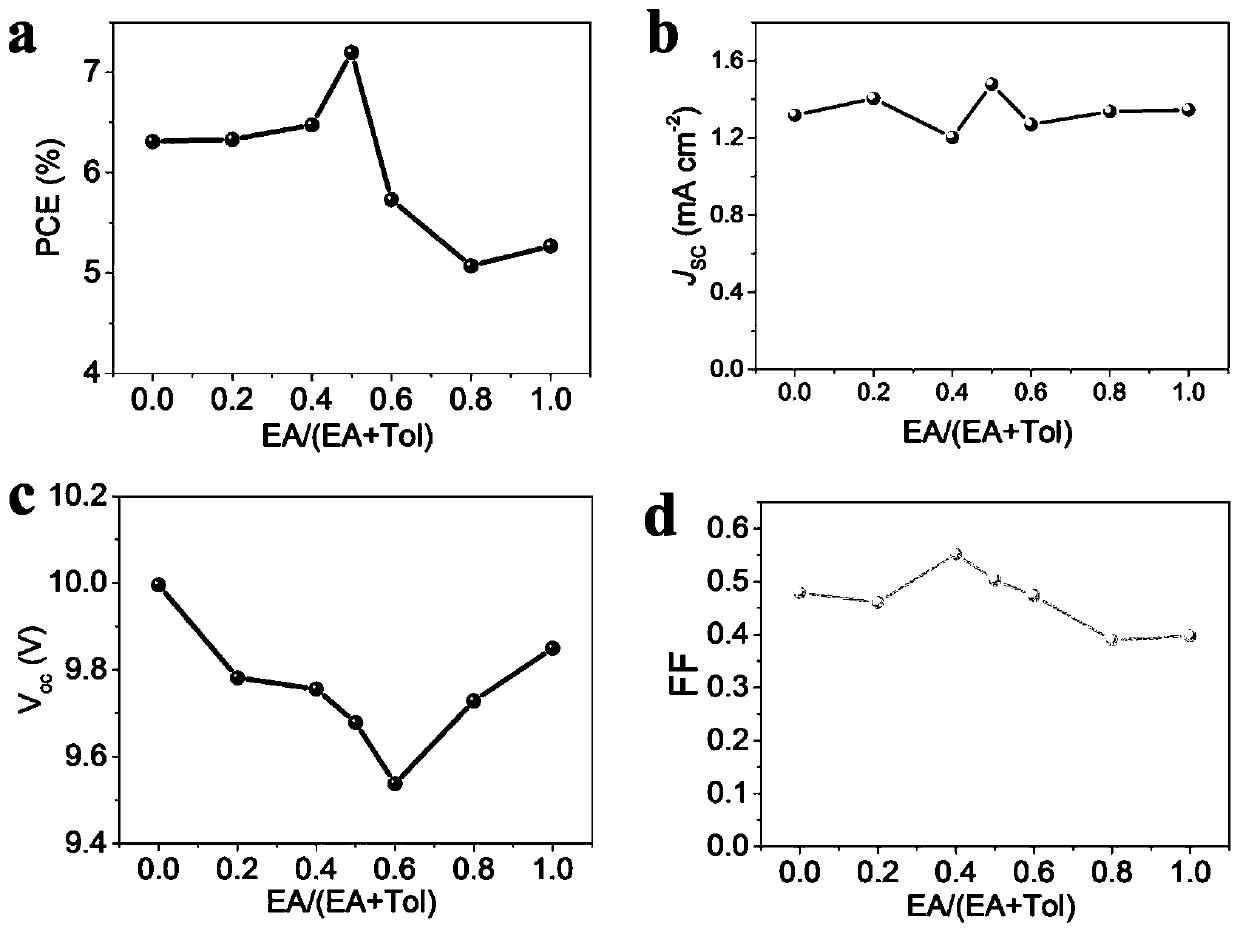

Method for preparing large-area perovskite layer and perovskite solar cell

PendingCN110718632ARefine the grain sizeReduce supersaturationSolid-state devicesSemiconductor/solid-state device manufacturingChlorobenzenePerovskite solar cell

The invention discloses a method for preparing a large-area perovskite layer and a perovskite solar cell. The method comprises the following steps of coating a perovskite precursor solution on a substrate to form a perovskite precursor layer; adding a mixed anti-solvent, and carrying out annealing treatment to obtain the perovskite layer, wherein the mixed anti-solvent is a mixed solvent formed bymixing a solvent A and a solvent B; the solvent A is selected from any one of methylbenzene, chlorobenzene, dichloromethane, ethyl acetate, anisole and diethyl ether, the solvent B is selected from any one of methylbenzene, chlorobenzene, dichloromethane, ethyl acetate, anisole and monohydric alcohol with 3-6 carbon atoms, the solvent A and the solvent B are different, and a volume ratio of the solvent A to the mixed anti-solvent is 10%-90%. In the invention, a supersaturation degree of the perovskite precursor solution in a crystallization process is reduced by using the mixed anti-solvent so that crystallization nucleation sites are uniformly generated, the perovskite thin film with uniform film formation and a large grain size is finally obtained, and a good application prospect is possessed in the field of preparation of large-area perovskite devices.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

Method for preparing o-cresol

ActiveCN101514145AHigh selectivityLow selectivityOrganic chemistryOrganic compound preparationReaction temperatureP-Cresol

The invention discloses a method for preparing o-cresol, which is characterized by comprising the following steps: uniformly mixing phenol with methanol by a mass ratio 1: (0.5-4), and then pumping the mixture into a reaction tube containing alkylate catalyst, introducing inert carrier gas into the reaction tube, and obtaining o-cresol after condensing and recycling the reaction product. The reaction conditions comprise normal atmosphere, reaction temperature of 280 to 450 DEG C, and the airspeed of incoming stock of 0.8-1.8h. The method has advantages of simple technical process, high selectivity of o-cresol, no generation of by-products such as meta-cresol, p-cresol and anisole relatively low selectivity of 2, 6-dimethyl phenol and long service life of the catalyst.

Owner:HUNAN XINLING CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com