Patents

Literature

2739 results about "Chlorobenzene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chlorobenzene is an aromatic organic compound with the chemical formula C₆H₅Cl. This colorless, flammable liquid is a common solvent and a widely used intermediate in the manufacture of other chemicals.

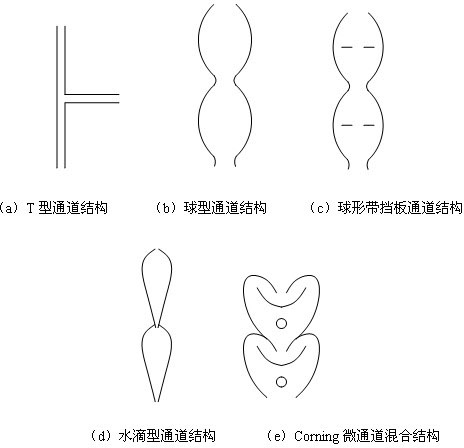

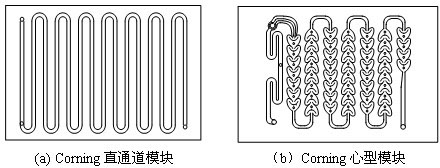

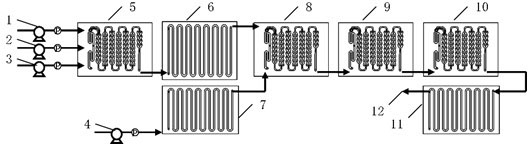

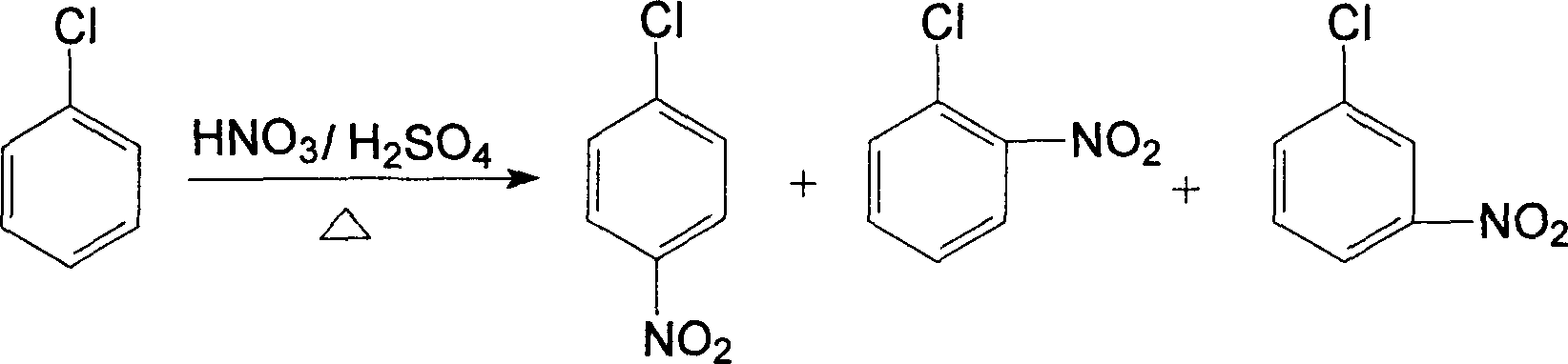

Method for undergoing chlorobenzene nitration reaction by using micro-channel reactor

ActiveCN102432471APrevent leakageAvoid dangerNitro compound preparationTemperature controlChlorobenzene

The invention relates to a method for undergoing a chlorobenzene nitration reaction by using a micro-channel reactor, belonging to the technical field of application of organic synthesis. In the method, nitric acid, sulfuric acid, water and chlorobenzene are taken as initial reaction raw materials, and processes such as mixed acid preparation, mixed acid and chlorobenzene preheating, mixed acid and chlorobenzene reacting and the like are completed in a micro-channel reactor system. In the reaction, nitro-sulfuric mixed acid is taken as a nitrating agent, the effective concentration of sulfuric acid in the mixed acid is 50-90 percent, the molar ratio of the nitric acid to the sulfuric acid in the mixed acid is 1:1-1:10, the molar ratio of the chlorobenzene to the nitric acid is 1:1.0-1:2.0, the reaction temperature is 50-100 DEG C, and the reaction time is 30-120 seconds. The chlorobenzene transformation ratio is up to 97 percent, the selectivity of nitrochlorobenzene serving as a product is over 96.5 percent, and the ratio of ortho-para nitrochlorobenzene is over 0.6. A strengthened mixed micro-channel reactor adopted in the invention is particularly suitable for undergoing a continuous nitration reaction, and has the characteristics of stable temperature control and safe process.

Owner:CHANGZHOU UNIV

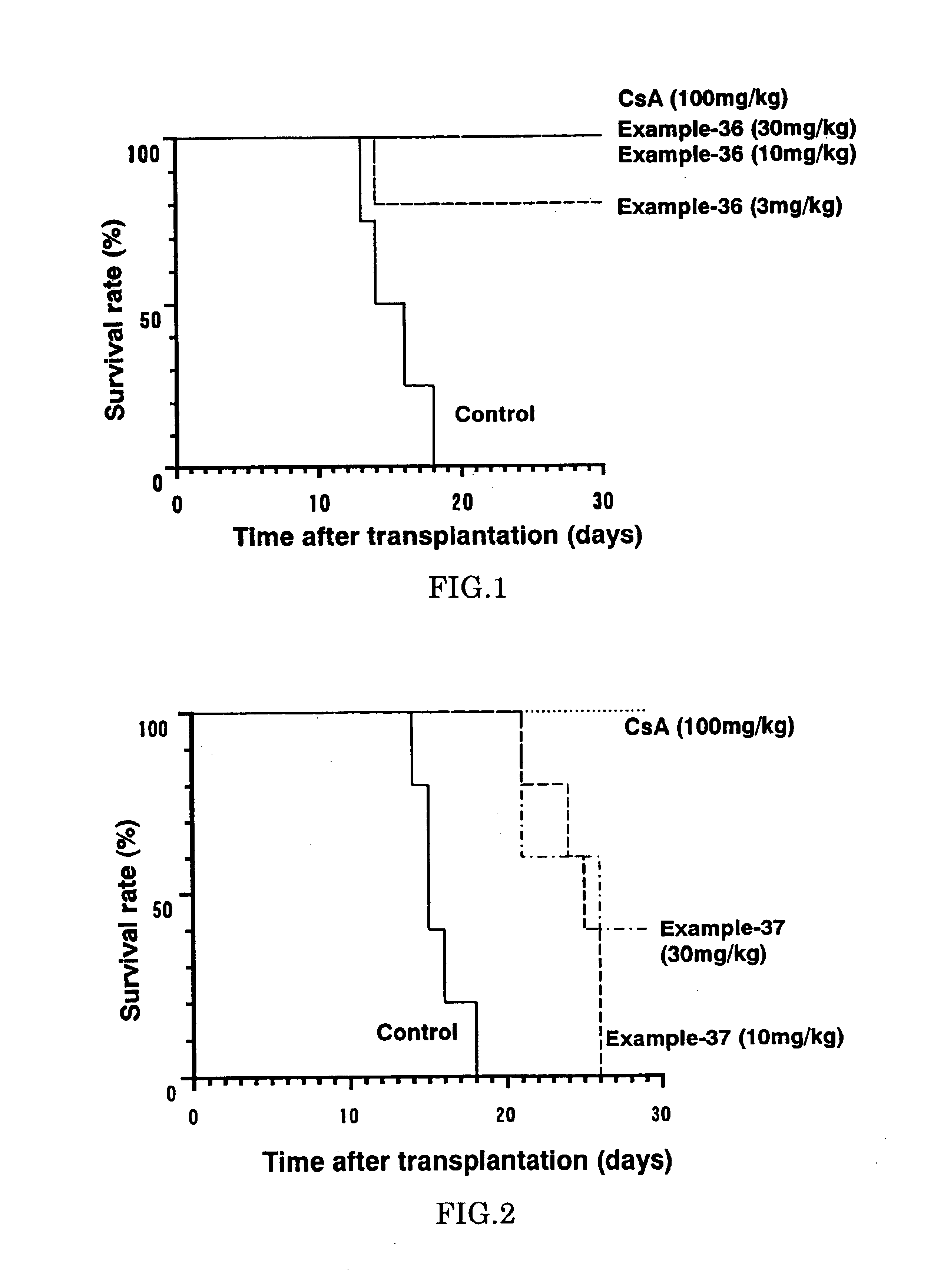

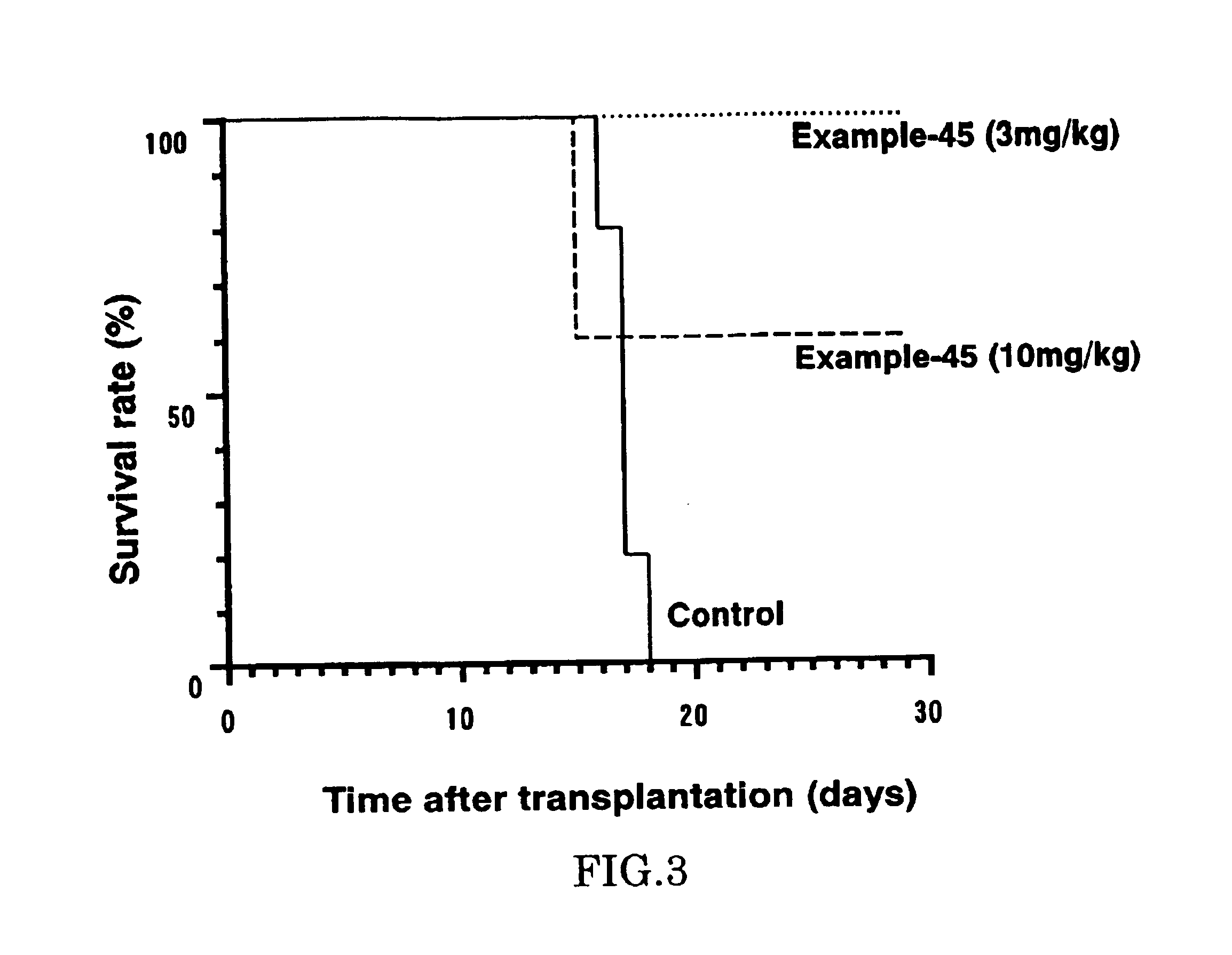

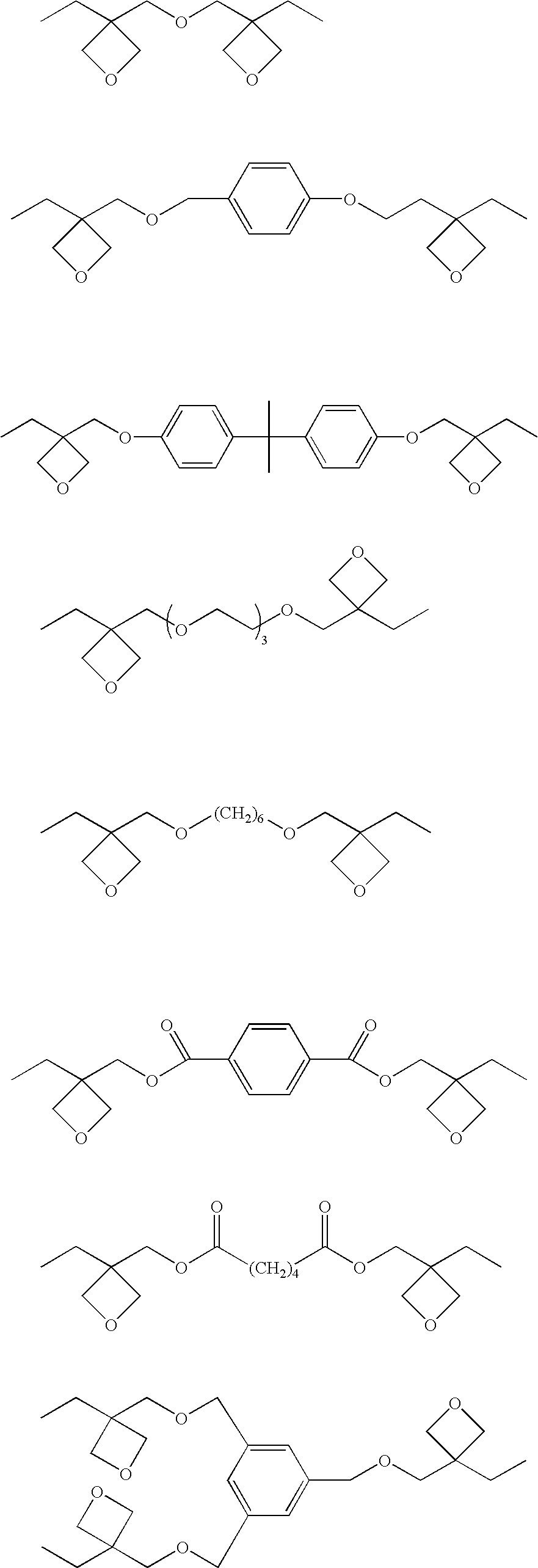

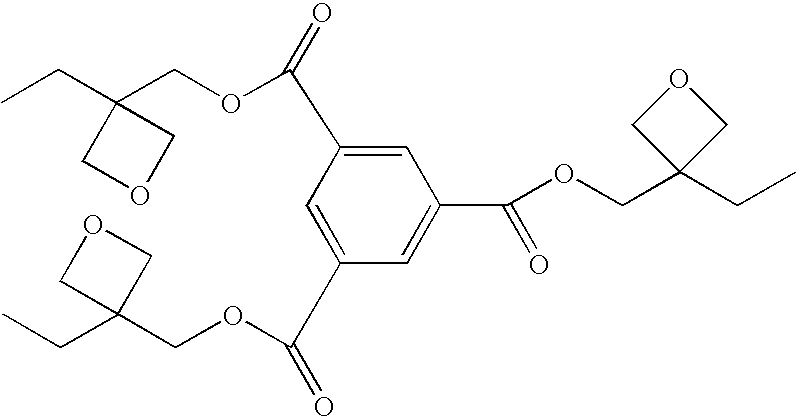

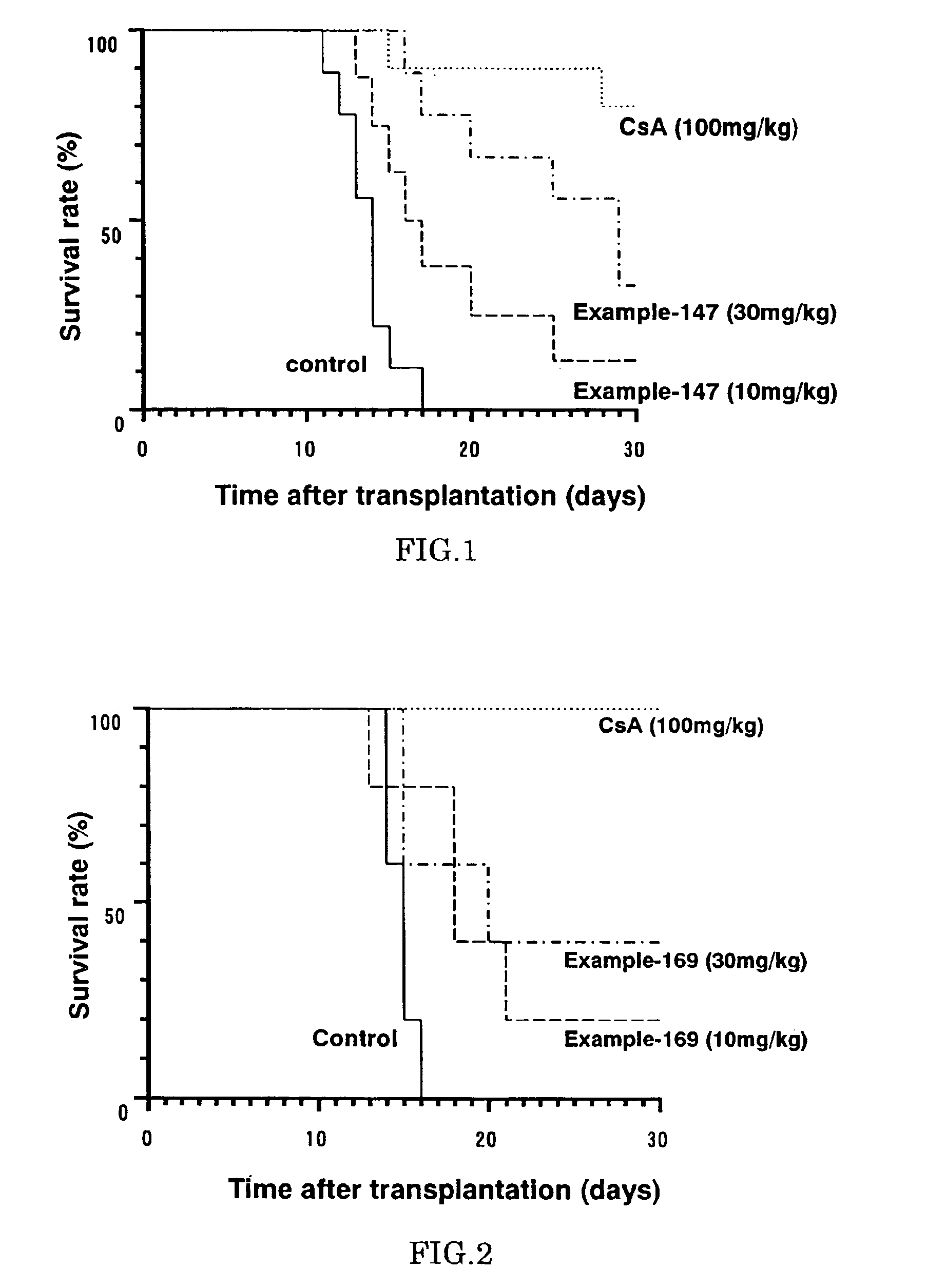

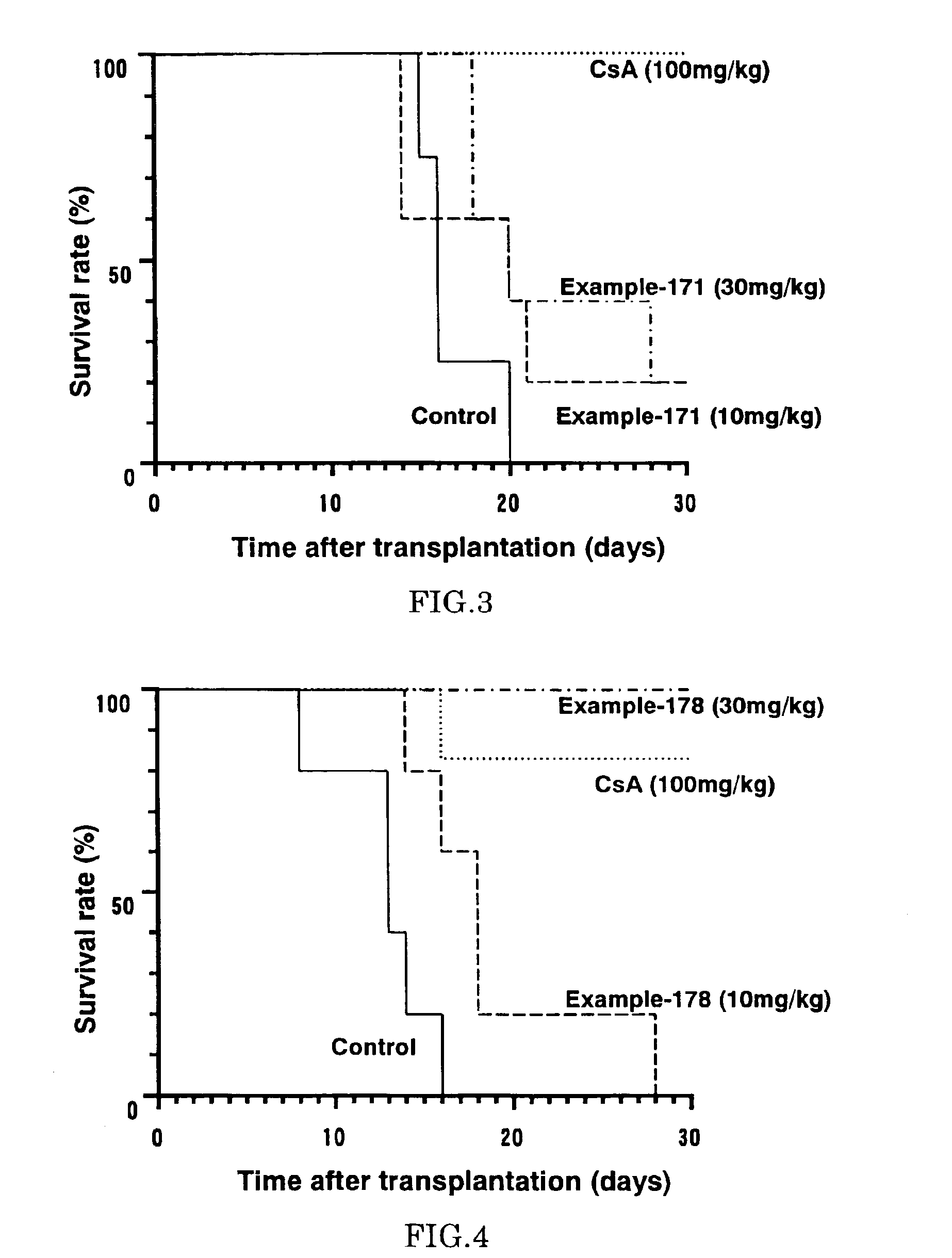

Diaryl sulfide derivative, addition salt thereof, and immunosuppressant

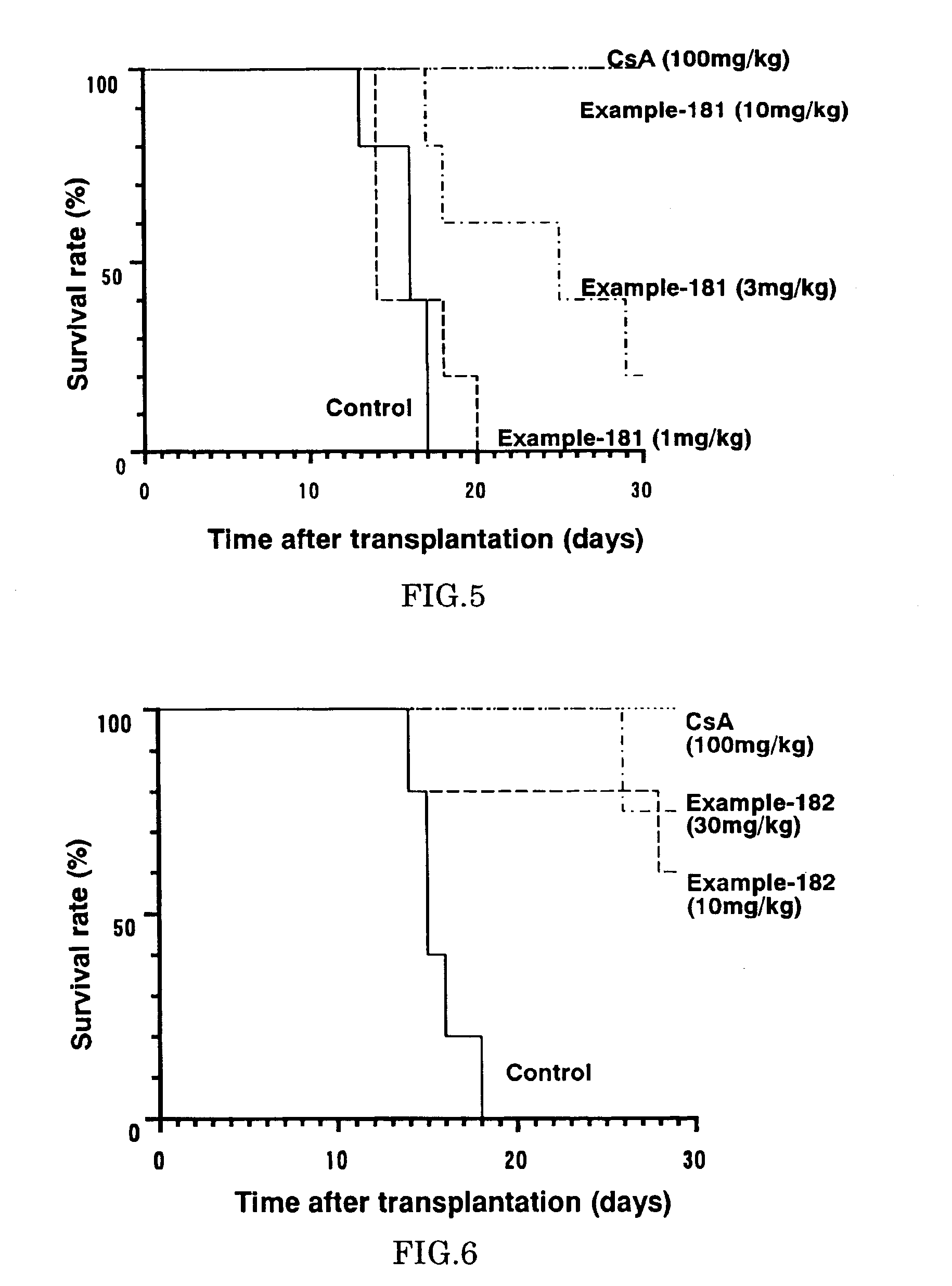

InactiveUS6960692B2Good effectLittle side effectsGroup 4/14 element organic compoundsBiocideArylSide effect

Owner:PRIOTHERA LTD

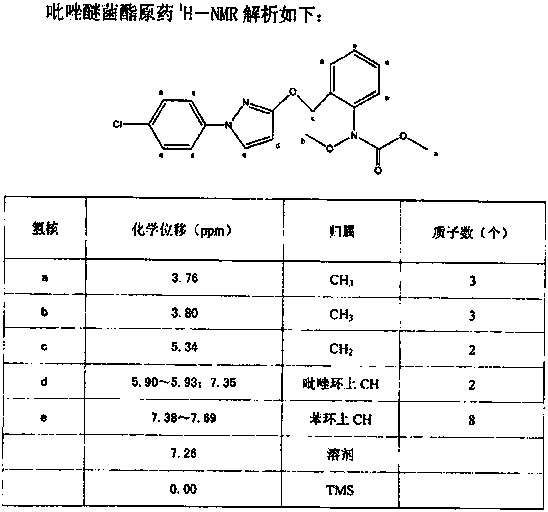

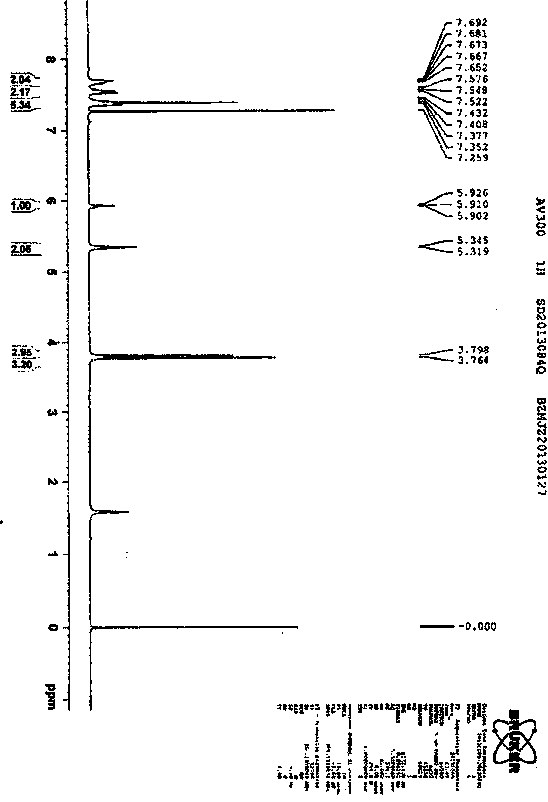

Synthetic technology for pyraclostrobin

ActiveCN104211641AFormation reaction is easy to controlSmooth responseOrganic chemistryMethylanilineChlorobenzene

The invention concretely relates to a synthetic technology for pyraclostrobin. The synthetic technology comprises: firstly performing cyclization to obtain 1-(4-chlorophenyl)-pyrazol-3-one, oxidizing the pyrazol ring under the effect of an oxidant to generate 1-(4-chlorophenyl)-3-hydroxypyrazole, then using 2-nitrobenzyl bromide to performing etherification to generate 1-(4-chlorophenyl)-3-[2-(nitrophenyl)methoxy]-1H-pyrazole, then using a reducing agent to perform nitro reducing, so as to generate N-hydroxyl-2-[N'-(4-chlorophenyl)pyrazol-3'-yloxymethyl]aniline, then using ClCO2CH3 to perform N-acylation reaction to generate methyl N-hydroxyl-N-2-{[N'-(4-chlorophenyl)pyrazol-3'-yloxymethyl]phenyl}formate, and finally performing hydroxyl methylation under an alkaline condition to generate pyraclostrobin. The technology enables all operations in the pyraclostrobin preparation process to be relatively controllable, helps to improve the stability of the preparation process and improve the product yield, successfully employs low-cost reagents and substantially reduces production cost, and also the employed reagents are relatively small in toxicity, is relatively beneficial for environment protection, and has no corrosivity on plastic pipes, so that the production safety is improved.

Owner:SHANDONG KANGQIAO BIO TECH CO LTD

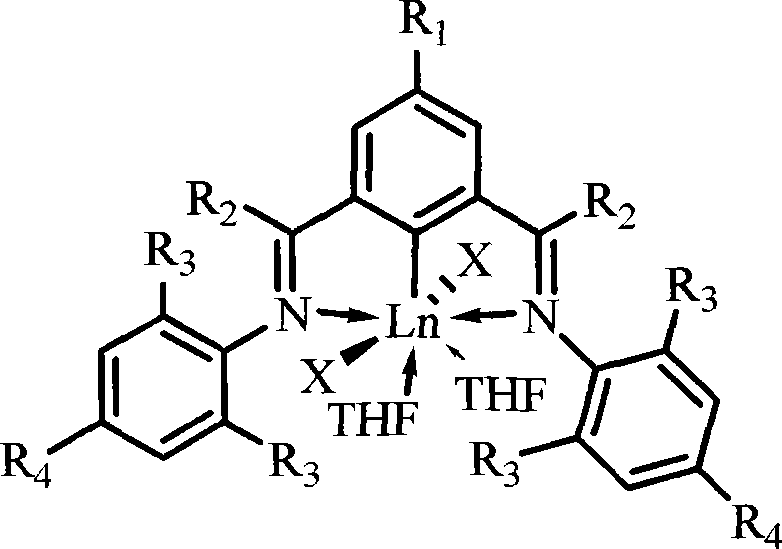

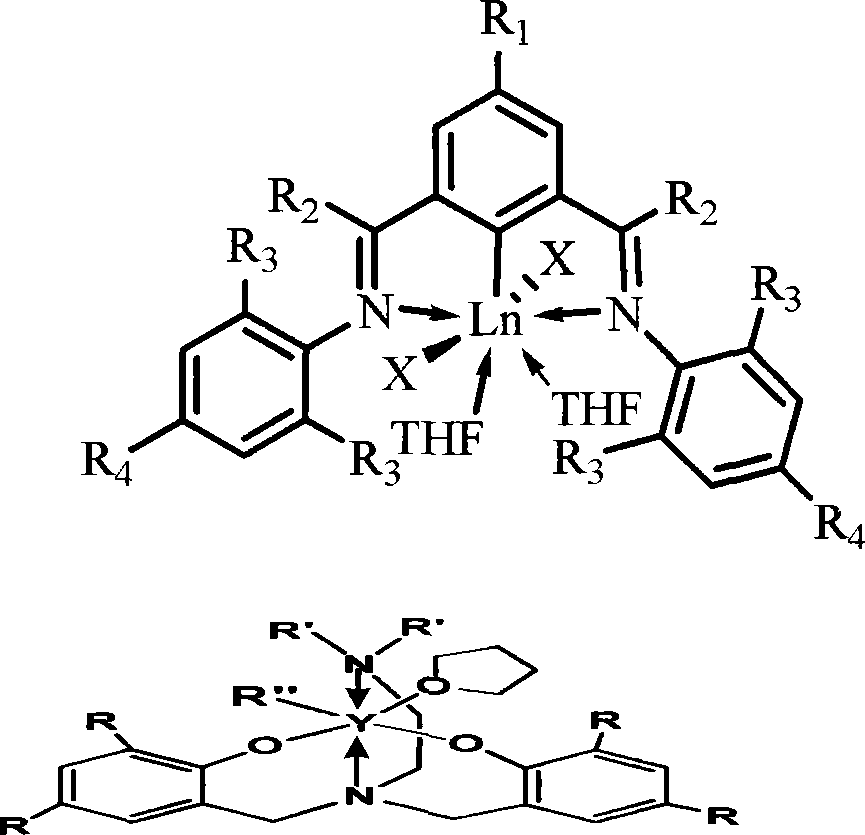

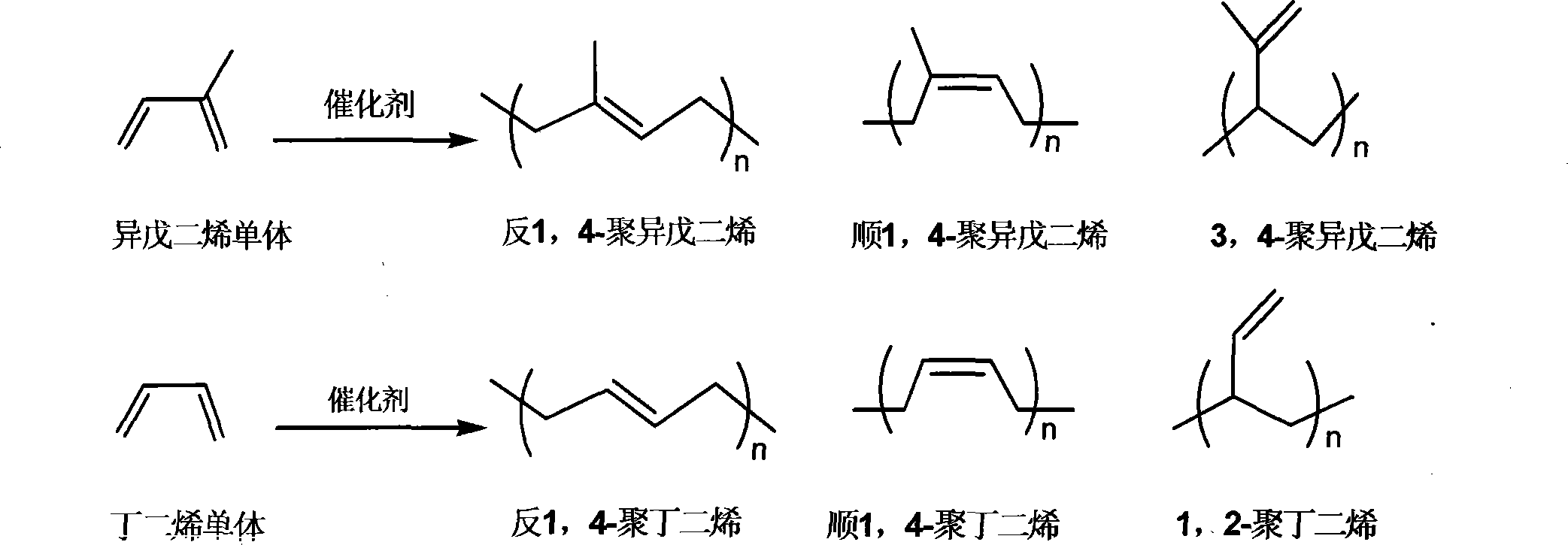

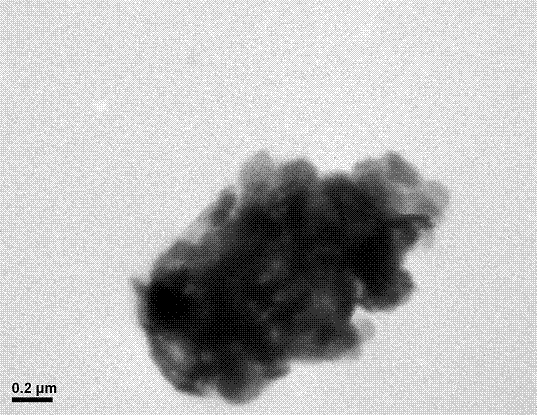

Rare earth catalyst for catalyzing syn form 1,4-selectivity polymerization of isoprene or butadiene

The invention relates to a rare-earth catalyst for catalyzing selective polymerization of isoprene or butadiene, while the catalyst system composed of the rare-earth catalyst can catalyze isoprene or butadiene to prepare polyisoprene or butadiene rubber with high cis-1, 4- structure. The rare-earth catalyst is composed of split-core type rare-earth complex, alkyl aluminium and organic boron salt. The solvent of polymerization is toluene or chlorobenzene. When catalyzes the polymerization of isoprene, the alkyl aluminium and split-core type rare-earth complex are rationed at 10-40, the organic boron salt and split-core type rare-earth complex are rationed at 1-3, the polymerization temperature is -20-80DEG C, the polymerization time is 0.5-2h, the monomer conversation ratio can reach 100% most, and the cis-1, 4 content of polymer is 55.0-98.8%, and when catalyzes the polymerization of butadiene, the alkyl aluminium and split-core type rare-earth complex are rationed at 10-40, the organic boron salt and split-core type rare-earth complex are rationed at 1-3, the polymerization temperature is -20-80DEG C, the polymerization time is 0.5-2h, the monomer conversation ratio can reach 100% most, and the cis-1, 4 content of polymer is 90.1-99.99%.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

New preparation method of 4,4-dichlorodiphenyl sulfone

InactiveCN102351758AReduce manufacturing costShort reaction timeOrganic chemistryOrganic compound preparationAcetic acidChlorobenzene

The invention discloses a new preparation method of 4,4-dichlorodiphenyl sulfone. The method comprises the following steps: 1) through using AlCl3 as a catalyst, and chlorobenzene and thionyl chloride as reaction raw materials, performing a Friedel-Crafts reaction at 25-35 DEG C, then hydrolyzing the mother liquor obtained through the Friedel-Crafts reaction, refluxing at 95-100 DEG C for 45-60 minutes, cooling the obtained mother liquor to less than 20 DEG C after refluxing to obtain an organic phase and an aqueous phase; 2) performing reduced pressure distillation on the organic phase, centrifuging, washing the obtained product to be neutral and be used as a product A for later use, wherein the main component of the product A is 4,4-dichlorodiphenyl sulfoxide; and 3) through using the product A and the oxidant hydrogen peroxide as raw materials and acetic acid as satalytic solvent, carrying out an oxidation reaction on the main component 4,4-dichlorodiphenyl sulfoxide of the product A to obtain crude 4,4-dichlorodiphenyl sulfone. Therefore, the existing synthesis method of 4,4-dichlorodiphenyl sulfone is changed, the production cost of 4,4-dichlorodiphenyl sulfone is low, the product quality is good and the reaction time is short.

Owner:WUJIANG BEISHE SHENGYUAN TEXTILE PROD AUXILIARIES PLANT

Method for preparing 4.4-dichlorodiphenyl sulfone by using sulfoxide oxidation

InactiveCN102351757AImprove qualityMild reaction conditionsOrganic chemistryOrganic compound preparationChlorobenzeneDistillation

The invention discloses a method for preparing 4.4-dichlorodiphenyl sulfone by using sulfoxide oxidation. The method comprises the following steps of: (1) performing Frieldel-Crafts reaction at the temperature of 25-35 DEG C by taking AlCl3 as a catalyst and chlorobenzene and thionyl chloride as reaction raw materials; next, hydrolyzing mother liquor after the Frieldel-Crafts reaction is finished; refluxing at the temperature of 95-100 DEG C for 45-60 minutes after hydrolysis is finished; cooling to be below 20 DEG C to divide into an organic phase and a water phase after refluxing is finished; performing reduced pressure distillation and centrifugal washing on the organic phase to be neutral to serve as a product A for later use, wherein a main component in the product A is 4.4-dichlorodiphenyl sulfone; and (2) performing oxidation reaction on the 4.4-dichlorodiphenyl sulfone by taking the product A as the raw material, hydrogen peroxide as a catalyst and dichloromethane as a reaction solvent to synthesize a 4.4-dichlorodiphenyl sulfone rough product. Thus, the method has the advantages of mild reaction conditions, high product quality and low three wastes (waste water, waste gas and industrial residues).

Owner:WUJIANG BEISHE SHENGYUAN TEXTILE PROD AUXILIARIES PLANT

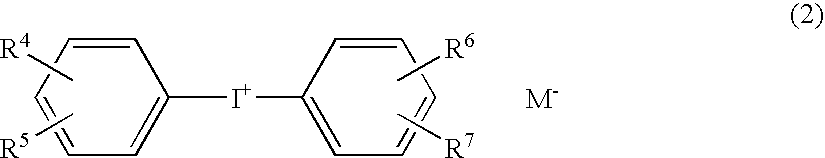

Photopolymerization initiator and photopolymerizable composition

InactiveUS20040186195A1High polymerization activityEasy to getImpression capsPhotomechanical apparatusDiketonePolycyclic compound

A photopolymerization initiator comprising (A) a photo acid-generating compound such as diaryliodonium salt (e.g., diphenyl iodonium, bis(p-chlorophenyl)iodonium, etc.), (B) a photo oxidation radical-generating compound such as diarylketone compound, alpha-diketone compound or ketocoumarin compound, and (C) a fused polycyclic aromatic compound such as 1,4-dimethylnaphthalene, 1-methylanthracene, 9-methylanthracene, 9,10-dimethylanthracene or 9,10-diethylanthracene. The photopolymerization initiator makes it possible to efficiently polymerize the cationically polymerizable monomer by the irradiation with visible light.

Owner:TOKUYAMA CORP +1

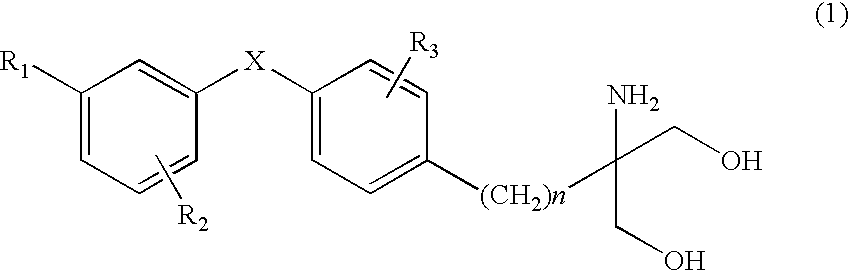

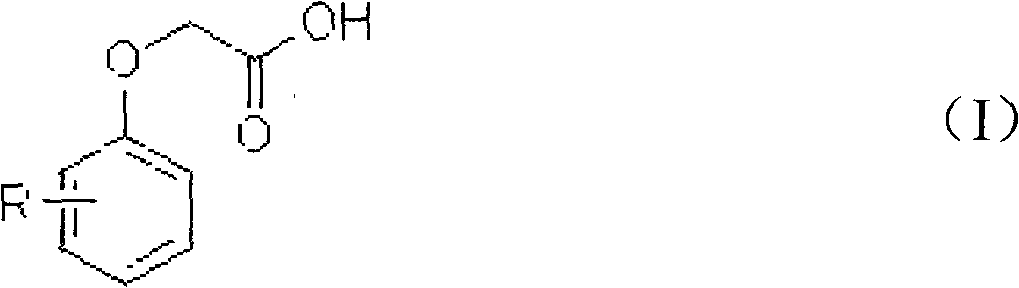

Diaryl ether derivative, addition salt thereof, and immunosuppressant

The present invention provides diaryl ether derivatives that exhibit significant immunosuppressive effects with less side effects.The diaryl derivatives of the present invention are represented by the following general formula (1): one example is 2-amino-2-[4-(3-benzyloxyphenoxy)-2-chlorophenyl]propyl-1,3-propanediol.

Owner:KYORIN PHARMA CO LTD

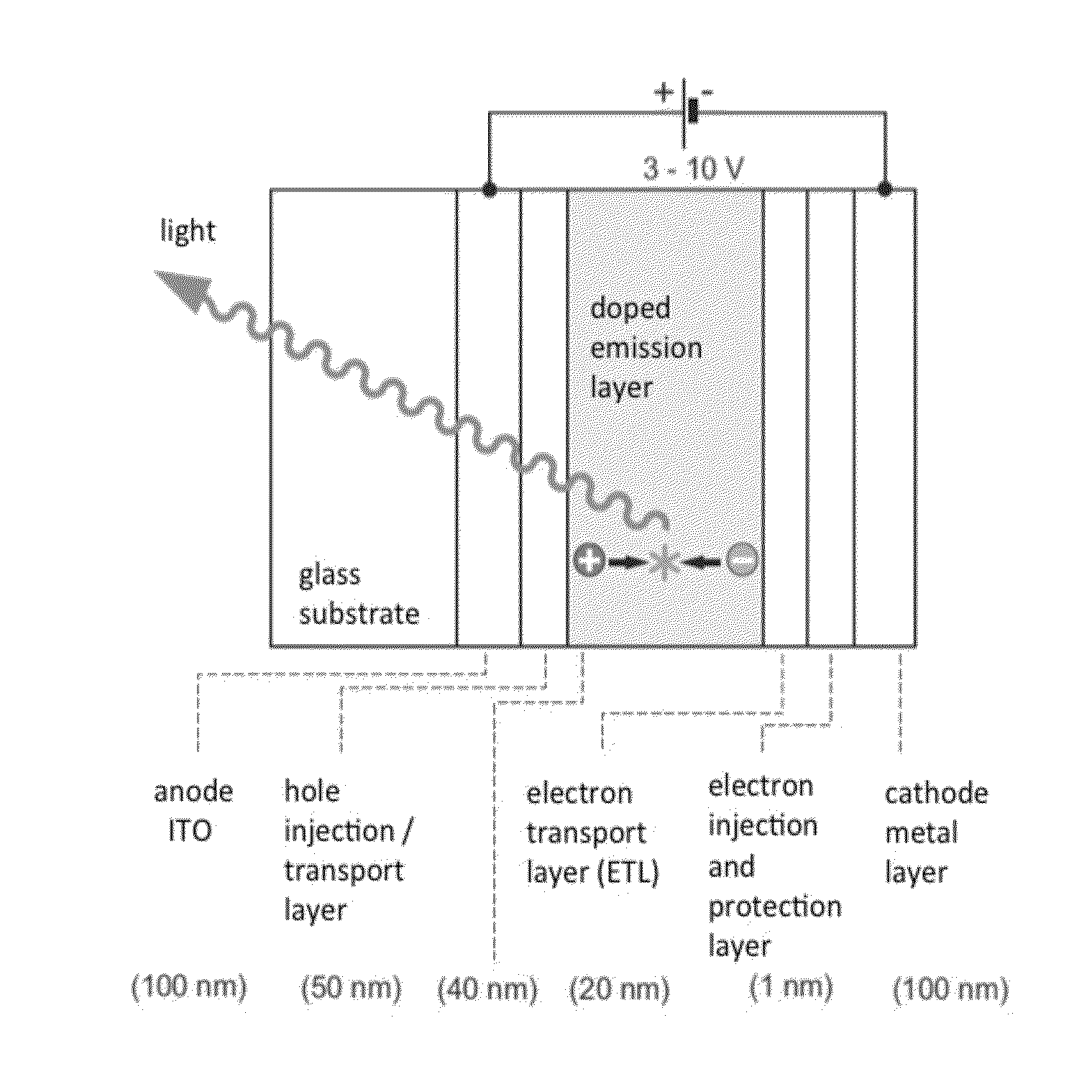

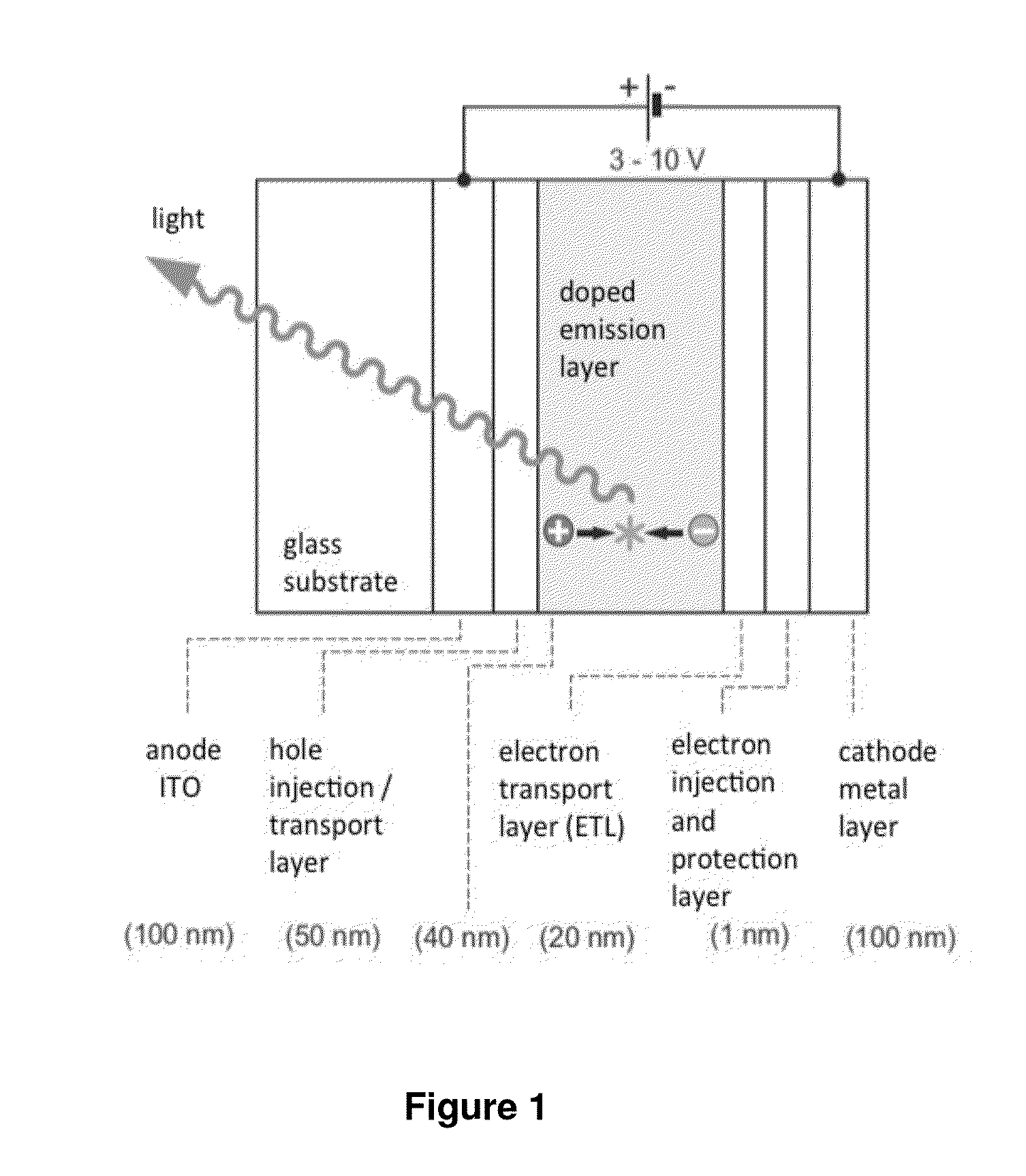

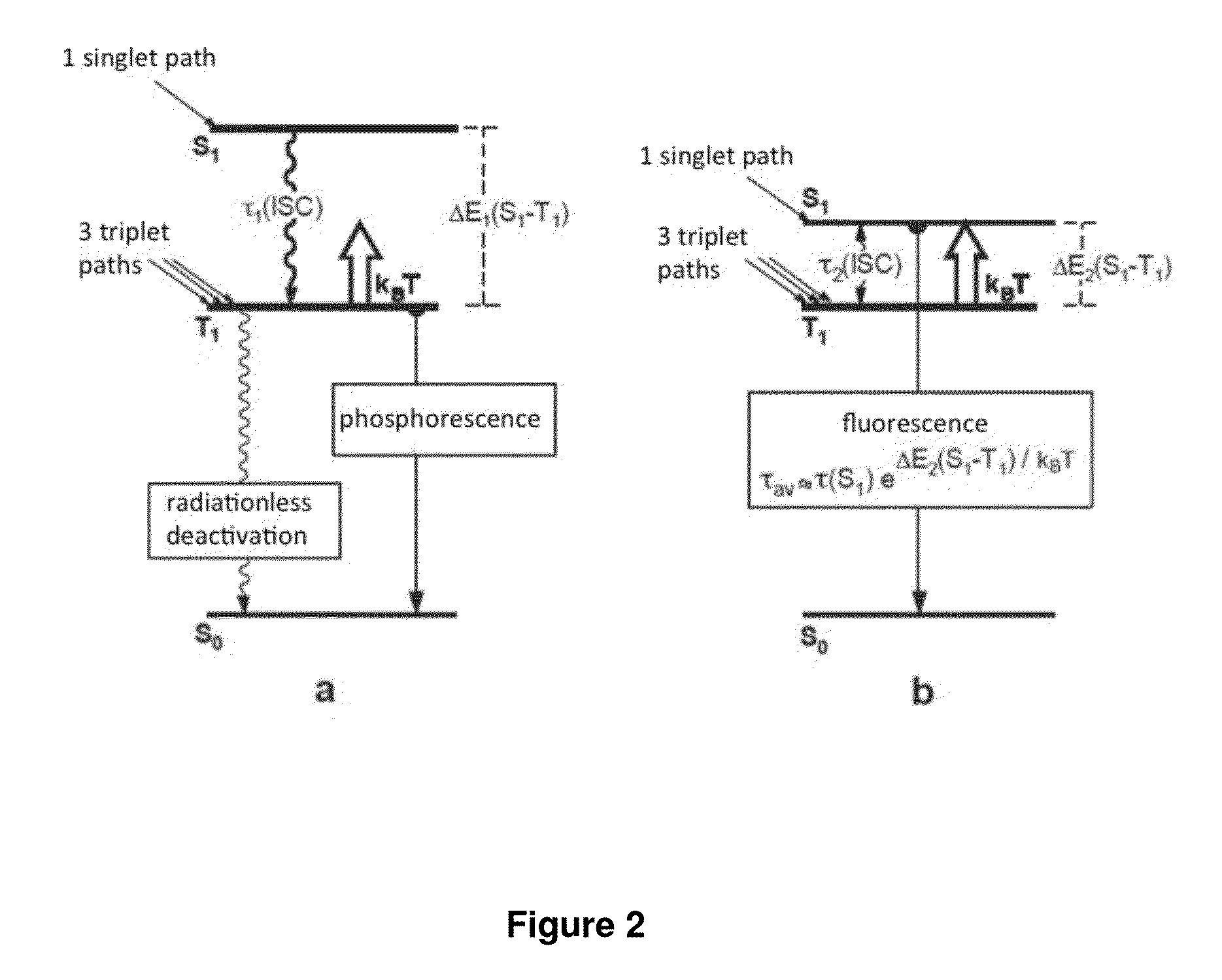

Copper (i) complexes for optoelectronic devices

ActiveUS20130150581A1Short possible emission decay timeDiminished roll-off behaviorFinal product manufactureGroup 5/15 element organic compoundsSolubilityChlorobenzene

The invention relates to neutral mononuclear copper (I) complexes for emitting light and with a structure according to formula (A) in which: M represents: Cu(I); L∩L represents: a single, negatively charged, bidentate ligand; N∩N represents: a diimine ligand (substituted with R and FG), in particular a substituted 2,2′-bipyridine derivative (bpy) or a substituted 1,10-phenanthroline derivative (phen); R represents: at least one sterically demanding substituent for preventing the planarisation of the complex in the excited state; FG=functional group, and represents: at least one second substituent for increasing solubility in organic solvents. The substituent can also be used for electron transport or alternatively for hole transport, said functional group being bound to the diimine ligands either directly or by means of suitable bridges; and the copper (I) complex: having a ΔE(S1−T1) value of less than 2500 cm−1 between the lowest excited singlet state (S1) and the triplet state (T1) which lies below; having an emission lifespan of at most 20 μs; having an emission quantum yield of greater than 40%, and a solubility of at least 1 g / L in organic solvents, in particular polar organic hydrocarbons such as acetone, methyl ethyl ketone, benzene, toluene, chlorobenzene, dichlorobenzene, dichloromethane, chloroform, dichloroethane, tetrachloroethylene, alcohols, acetonitrile or water.

Owner:SAMSUNG DISPLAY CO LTD

Synthetic process for efficiently and continuously producing 4,4-dichlorodiphenyl sulfone

InactiveCN108047101AAvoid cross usageAvoid pollutionOrganic chemistryOrganic compound preparationChlorobenzeneFiltration

The invention discloses a synthetic process for efficiently and continuously producing 4,4-dichlorodiphenyl sulfone, which comprises the following steps: carrying out Friedel-Crafts acylation on thionyl chloride and excessive chlorobenzene under the action of a lewis acid catalyst, carrying out pyrohydrolysis and adding chlorobenzene to carry out layering after the reaction is finished, adding anoxidizing agent into a sulfoxide organic layer to carry out oxidization, adding activated carbon to carry out decoloration and filtering; cooling filtrate and carrying out rejection filtration to obtain 4,4-dichlorodiphenyl sulfone. The synthetic process has the advantage that chlorobenzene not only is a raw material, but also is a reaction solvent, so that cross use of various solvents is avoided. Particularly, use of a great amount of acetic acid used as an oxidation reaction solvent is avoided, and corrosion to equipment and environmental pollution are avoided. In the integral process flow,separation and extraction of an intermediate 4,4-dichlorodiphenyl sulfoxide are avoided, so that production time of the product is greatly shortened, and production cost is saved. By using hydrogen peroxide, acetic acid and concentrated sulfuric acid as mixed oxidizing agents, oxidization capacity of hydrogen peroxide is greatly improved, yield and purity of the product are greatly improved, yield of the product reaches 90% or more, and purity of the product is greater than 99.8%.

Owner:九江中星医药化工有限公司

High oil absorption polyurethane foam and preparation method thereof

ActiveCN101987884AHigh oil absorptionFast oil absorptionOther chemical processesChemical recyclingChlorobenzeneKerosene

The invention relates to a high oil absorption polyurethane foam which comprises the following components in parts by weight: 20 to 40 parts of isocyanate, 35 to 60 parts of polyol, 0.5 to 3 parts of catalyst, 0.5 to 3 parts of foam stabilizer, 5 to 10 parts of foaming agent, 2 to 10 parts of opening agent,5 to 20 parts of flame retardant, 5 to 15 parts of silicon rubber spherical micro powder and 0.5 to 2 parts of coupling agent. The preparation method comprises the following technology steps of weighing, prepolymerization, dispersing, polymerization foaming reaction, curing and peeling at room temperature and cutting. The high oil absorption polyurethane foam can be used for the absorption and recycle of various oil products (crude oil, engine oil, diesel fuel, gasoline, kerosene and the like) on water surfaces, ground or surfaces of other objects, and various oil soluble organic compounds (benzene, methylbenzene, dimethylbenzene, chloroform, nitrobenzene, chlorobenzene and the like). The invention has the advantages of simple technology and low cost, obviously improves the dispersing effect of the silicon rubber spherical micro powder in a polymerization system by using ultrasonic technique, and greatly increase the oil absorption quantity and oil absorption rate of the polyurethane foam by adding the silicon rubber spherical micro powder.

Owner:CHINA BLUESTAR CHENGRAND CO LTD +1

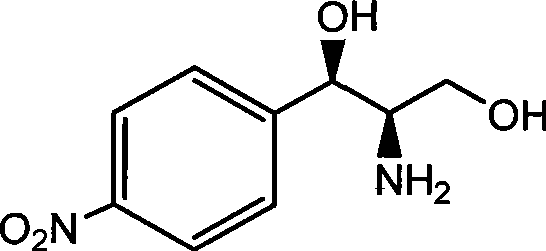

Method for preparing (S)-(4-chlorphenyl)-(pyridine-2-yl)-methanol by utilizing microbial catalysis

ActiveCN102559520AHigh excessLess side effectsFungiMicroorganism based processesPhosphateReaction temperature

The invention relates to a method for preparing (S)-(4-chlorphenyl)-(pyridine-2-yl)-methanol by utilizing microbial catalysis, and belongs to the technical field of biological catalysis. According to the method, 4-chlorphenyl-(pyridine-2-yl)-ketone is subjected to asymmetrical reduction by utilizing kluyveromycessp (CCTCCM 2011385) whole cells to synthesize the (S)-(4-chlorphenyl)-(pyridine-2-yl)-methanol. The method comprises the following steps of: sieving a microbe which has high-stereoselectivity carbonyl reductase activity on a prochiral ketone substrate, determining a series of conditions of asymmetrical reduction reaction, such as reaction temperature, pH, the concentration of cells, the concentration of the substrate and reaction time and additives (including various secondary solvents, polyethyleneglycol (PEG), phosphates and the like), wherein the enantiomer excess value and yield of the (S)-(4-chlorphenyl)-(pyridine-2-yl)-methanol serving as a product can reach 86.7 percent e.e and 92.1. The product is separated and extracted initially by silicagel column chromatography, so that the purity of the separated product is 99.2 percent, and the extraction yield is 56.7 percent.

Owner:JIANGNAN UNIV

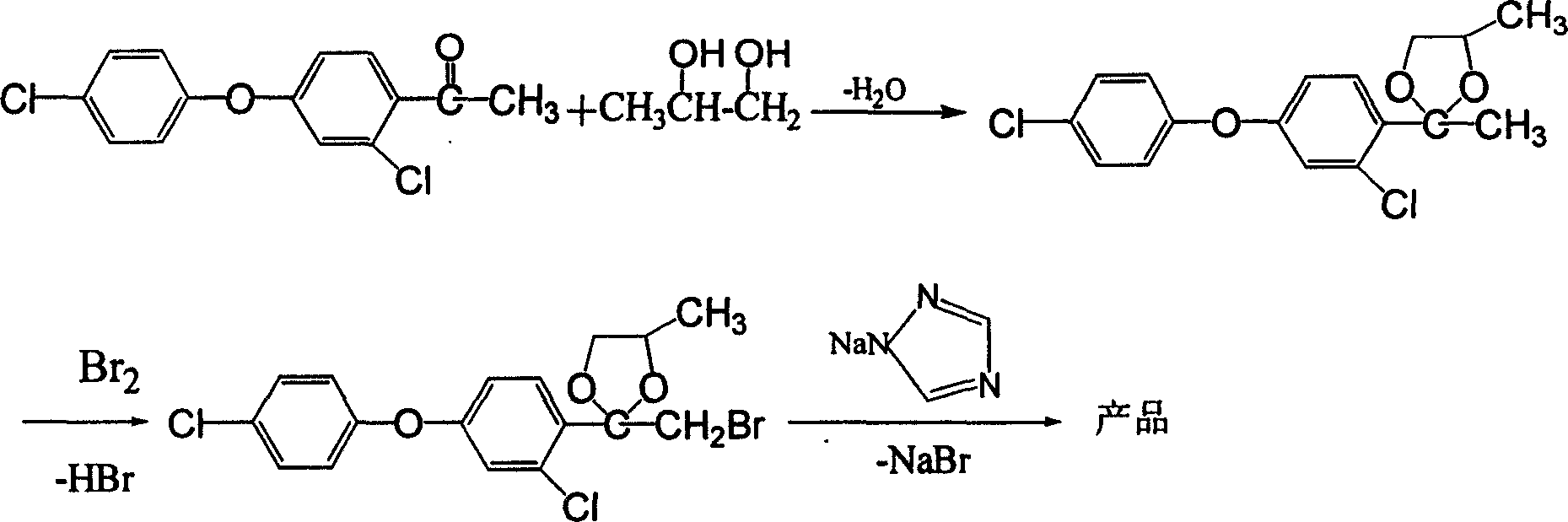

Preparation method of agricultural fungicide difenoconazole

A method for preparing agricultural germicid, include the steps: 4-(4-) -2-chloro acetophenone propylene glycol generate cyclics-3-chlorine-4-(2,4-dimethyl-1,3-dioxane-2-group)benz-4'-, the reaction happens with catalyst-paratoluenesulfonic acid existing in the solvent, the density mess ratio is 5-50%. When catalyst-paratoluenesulfonic acid exists, the cyclics reacts with bromine, generating bromide-3-chlorine-4-(4-methyl-2- -1,3-dioxane-2-group)benz-4'-chlorine, the bromidereacts with 1,2,4- with potassium bromide as catalysis in acutesolvent, whose density mess ratio is 15-50%, acquiring the target compound. The invention has increased the productive efficiency of by more than 20%.

Owner:JIANGSU GENGYUN CHEM CO LTD

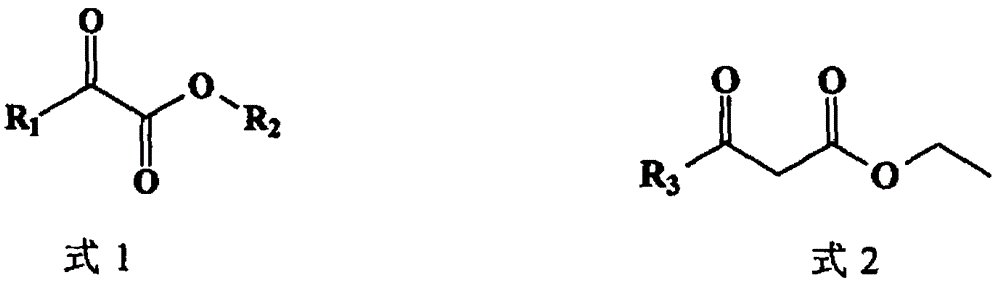

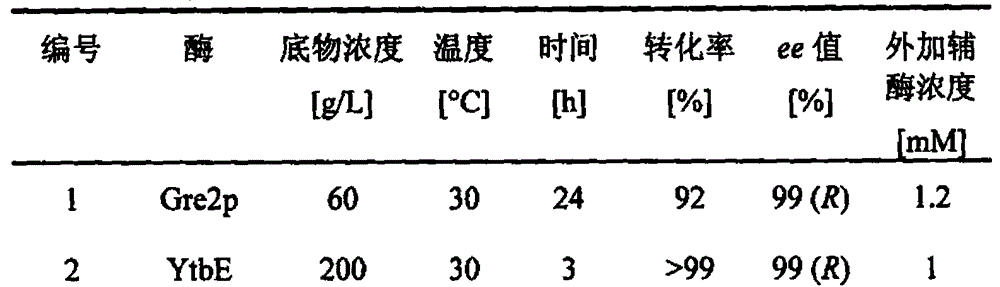

Carbonyl reductase mutant as well as gene and application thereof

InactiveCN104099305AImprove thermal stabilityIncreased reductase activityBacteriaOxidoreductasesMethyl o-chloromandelateMandelic acid

The invention relates to a carbonyl reductase CgKR1 mutant, a coding gene of the mutant, a recombinant expression vector containing the gene of the carbonyl reductase mutant, a recombinant expression transformant, a recombinase, a preparation method of the recombinase, and an application of the carbonyl reductase mutant to asymmetric reduction of ketonic ester for preparation of optically pure chiral hydroxyl ester, such as catalysis of o-cyano methyl phenylglyoxylate for asymmetric reduction to prepare (R)-o-chloro mandelic acid methyl ester. Compared with wild enzymes, the carbonyl reductase mutant has the advantages that the thermal stability is substantially improved, and the catalytic activity of part of the mutant to the o-chlorobenzoic acid formyl methyl ester is also obviously improved. The multiple mutants can be applied to catalysis of the ketonic ester for asymmetric reduction to prepare the optical purely-chiral hydroxyl ester, such as catalysis of the o-cyano methyl phenylglyoxylate for asymmetric reduction to prepare the optically pure (R)-o-chloro mandelic acid methyl ester. The carbonyl reductase mutants have the very good industrial application prospect.

Owner:EAST CHINA UNIV OF SCI & TECH

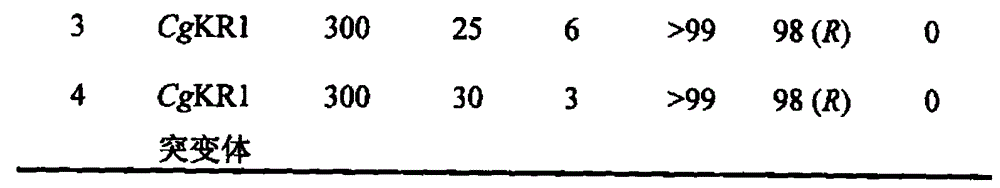

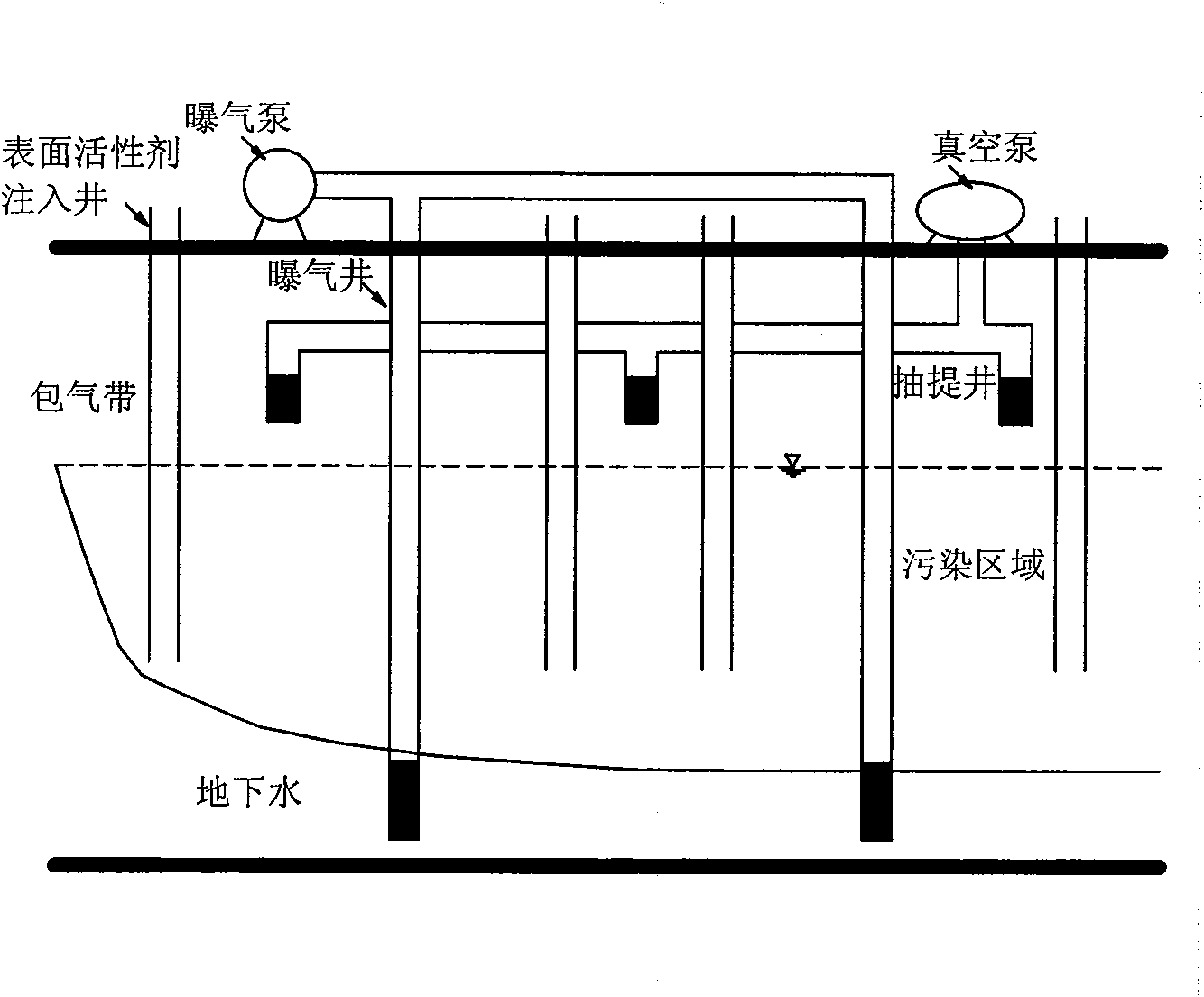

Method for recovery of contaminated groundwater through in situ enhanced aeration

InactiveCN101792214AReduce surface tensionIncrease air saturationWater aerationSustainable biological treatmentAeration rateChlorobenzene

The invention relates to a method for recovery of contaminated groundwater through in situ enhanced aeration, which comprises the following steps: digging more than one surfactant injection well, an aeration well and an extraction well in an area with the groundwater contaminated, injecting surfactant into the area with the groundwater contaminated through the surfactant injection well to dissolve the surfactant into the groundwater so as to form surface tension in the area with the groundwater contaminated, starting the extraction pump to pump an aeration zone into negative pressure, and starting the aeration pump for continuous aeration. The invention effectively solves the problem that the majority of pollutants can be removed only after flowing into the porous channel through diffusion due to the narrow porous channel near the aeration well, and improves the saturation degree of the air in the groundwater, thereby increasing opportunities of exposure the pollutants to the air. Tests show that, when the aeration rate is 100ml / min, the surface tension is reduced to 50.4dyn / cm from 70.5dyn / cm, the half-life for removal of the pollutant chlorobenzene is reduced to 16min from 31min, and simultaneously the trailing concentration is reduce to 5.1mg / L from 22.08mg / L. The removal rate can be increased to 98.5 percent from 89.2 percent after 420 minutes. The invention has the advantages of simple process, low cost, low surfactant injection and less impact on the environment.

Owner:JILIN UNIV

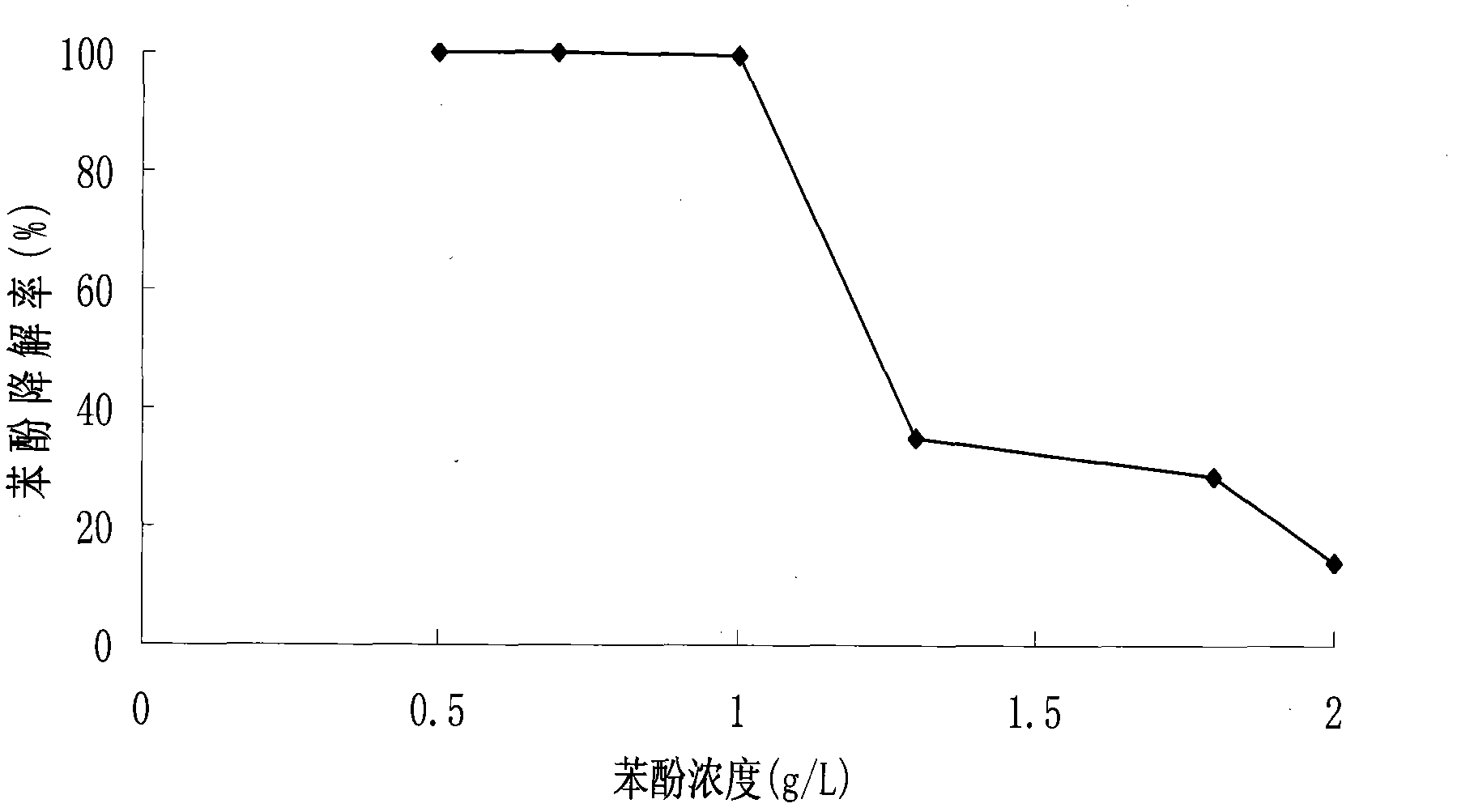

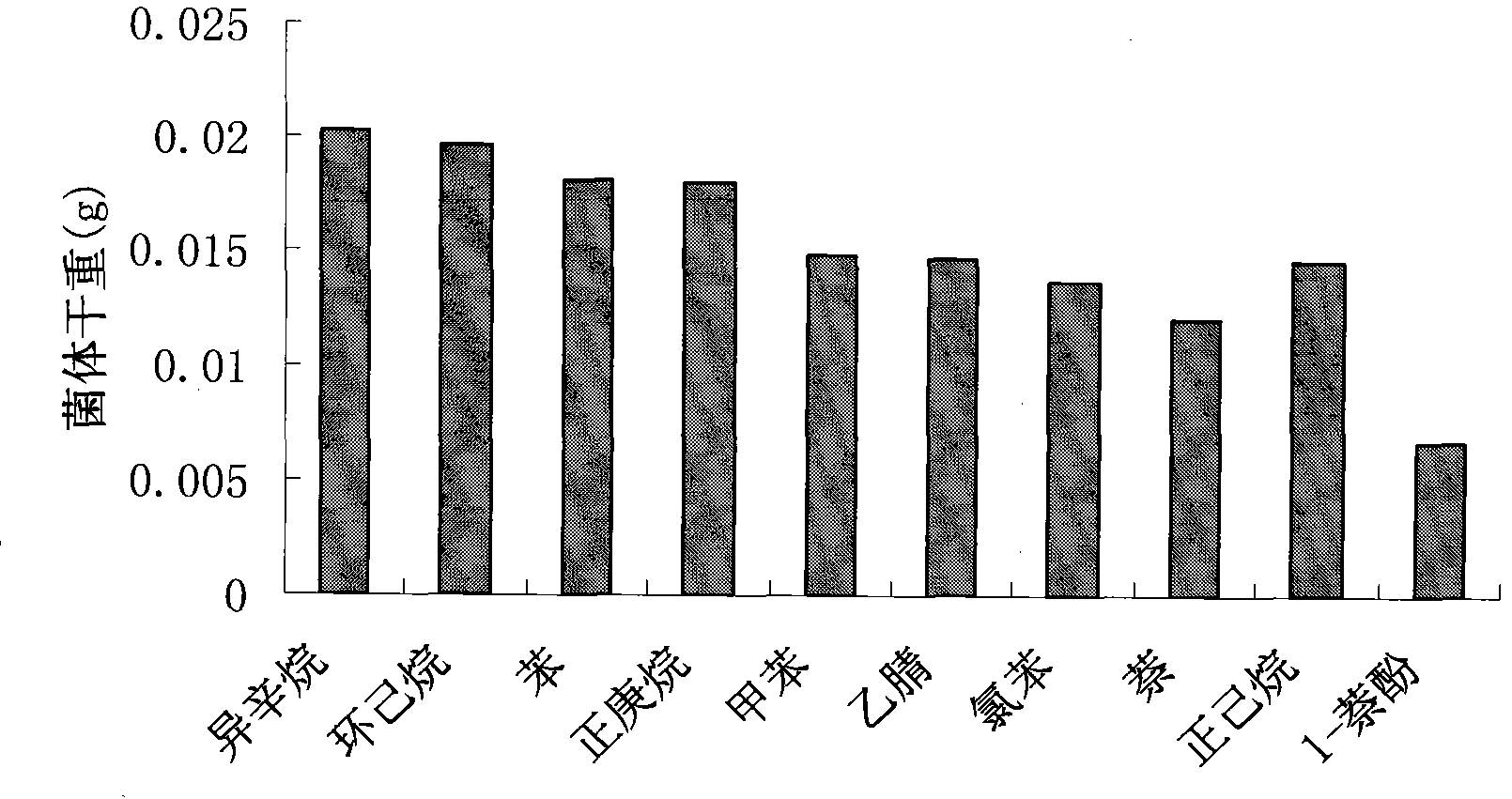

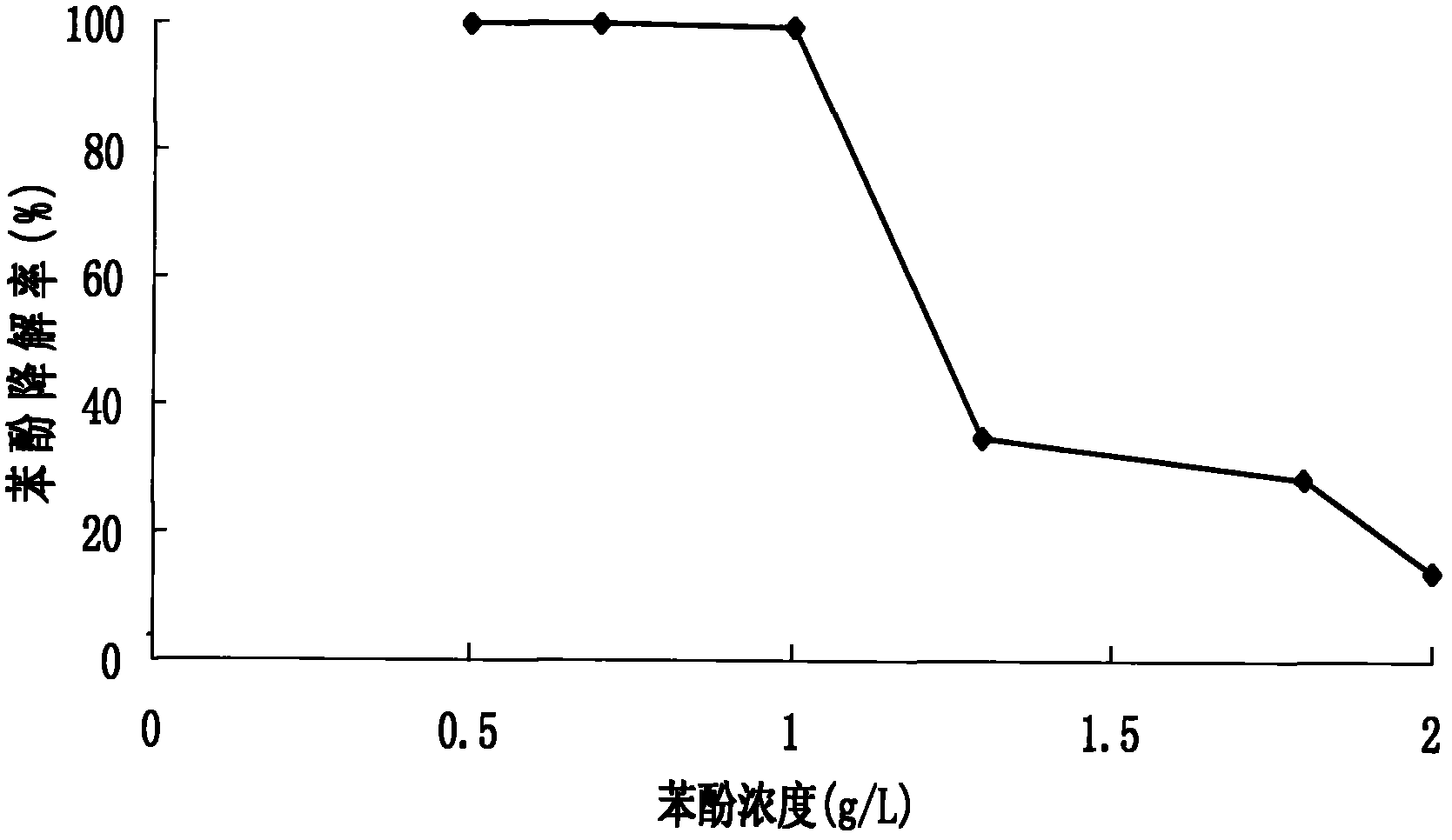

Rhodococcus ruber and application thereof in degradation of phenol pollutants

ActiveCN102604875ABroad-spectrumEfficientBacteriaMicroorganism based processesBenzeneInorganic salts

The invention relates to Rhodococcus ruber and application of Rhodococcus ruber in degradation of phenol pollutants. The Rhodococcus ruber is designated as Rhodococcus ruber SD3, which is preserved in a preservation unit appointed by SIPO (State Intellectual Property Office), wherein the preservation unit is a China Center for Type Culture Collection, the preservation date is February 26, 2012, the accession number is CCTCC NO: M 2012035, and the Latin name is Rhodococcus ruber SD3. The Rhodococcus ruber has the following technical effect: after Rhodococcus ruber SD3 in an inorganic salt medium of phenol (phenol concentration is 1.0g / L) is subjected to shaking table vibration culture at 35 DEG C and 200r / min for 72h, the phenol degradation rate is 99.73%. The Rhodococcus ruber SD3 can also degrade substances such as isooctane, cyclohexane, benzene, n-heptane, methylbenzene, acetonitrile, chlorobenzene, naphthalene, n-hexane, and 1-naphthol.

Owner:JIANGXI NORMAL UNIV

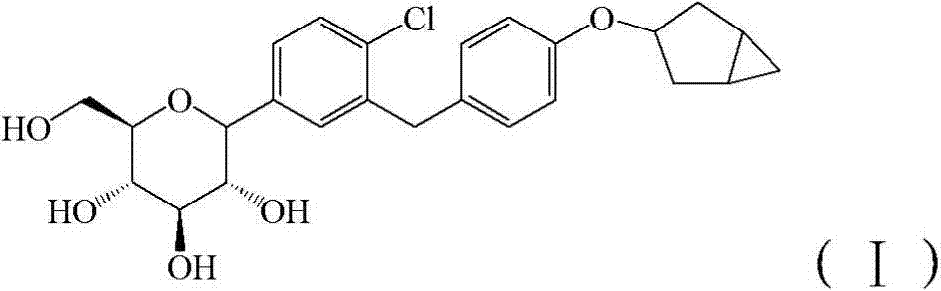

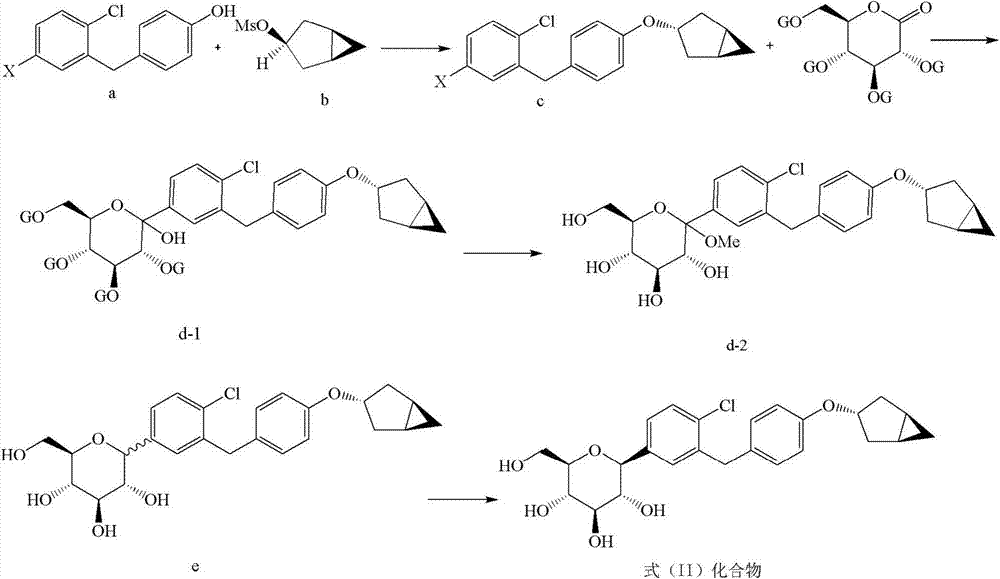

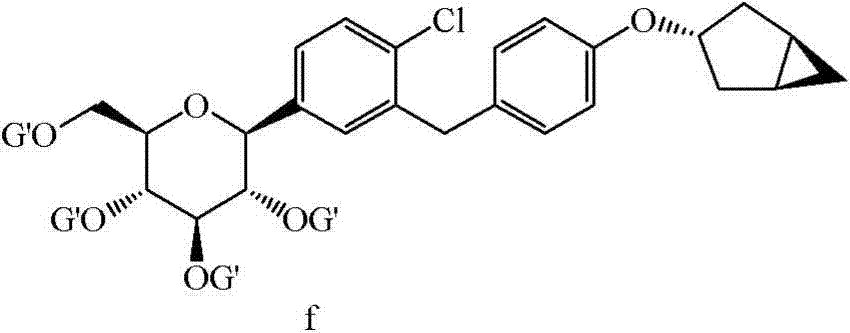

Optically pure benzyl-4-chlorophenyl C-glucoside derivatives

ActiveCN104761522AGood choicePrevent diabetesOrganic active ingredientsMetabolism disorderInsulin dependent diabetesDisease

The invention belongs to the technical filed of medicines, and concretely relates to optically pure benzyl-4-chlorophenyl C-glucoside derivatives represented by formula (II) and formula (III), a method for preparing the above compounds and intermediates thereof, a medicinal preparation and a medicinal composition containing the compounds, and an application of the optically pure benzyl-4-chlorophenyl C-glucoside derivatives in the preparation of medicines for treating and / or preventing insulin-dependent diabetes, non-insulin dependent diabetes, insulin resistance diseases or obesity, various diabetes and relevant diseases as a sodium-glucose cotransporter (SGLT) inhibitor.

Owner:JILIN HUISHENG BIOPHARMACEUTICAL CO LTD +1

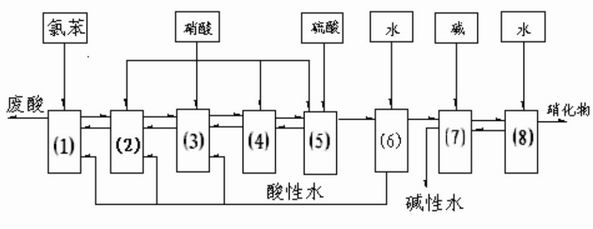

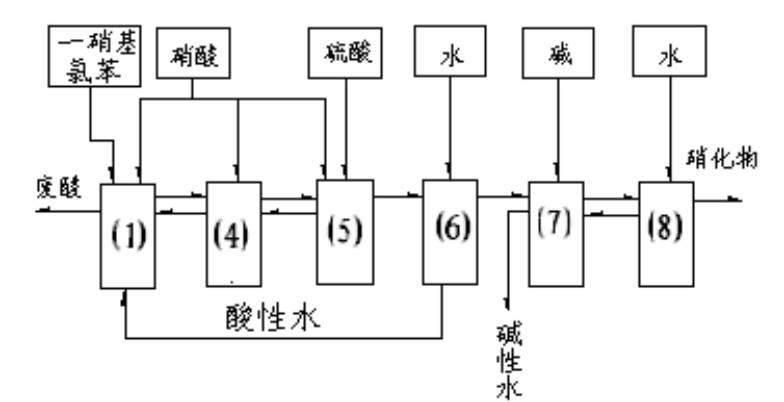

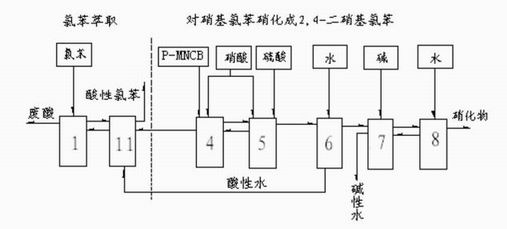

Method for continuously preparing dinitrochlorobenzene

ActiveCN102070457AIncrease profitIncrease production capacityNitro compound preparationNitrateChlorobenzene

The invention discloses a method for continuously preparing dinitrochlorobenzene. Multiple dinitration reactors are connected in series for reaction, and mononitrochlorobenzene is continuously added to the first dinitration reactor, and continuously flows through all the dinitration reactors and flows out; a mixed acid nitrating agent is prepared from 75-85% of sulfuric acid, 2-7% of nitric acid and 5-15% of water; the reaction temperature is 40-95 DEG C; and each dinitration reactor is provided with a separation device for separating an organic phase from an inorganic phase, and the inorganic phase is returned into the reactor, thereby keeping the inorganic phase and the organic phase in the required proportion. In the invention, the dinitrochlorobenzene is prepared by continuous reactions, and the reactions are continuously carried out and sequentially completed; chlorobenzene is used for extracting nitrates and nitric acid in an acid phase, thereby lowering the content of the nitric acid in the acid phase and recycling the nitrates in the acid phase; by the invention, the dinitrochlorobenzene can be continuously prepared from two raw materials (chlorobenzene and p-nitrochlorobenzene) by using one set of devices; and the invention has the advantages of low raw material consumption and high production capacity.

Owner:LIANYUNGANG DIPU CHEM

Treatment technique of tetrabromobisphenol A production wastewater

InactiveCN102583849AReduce CODReduce processing loadWater/sewage treatment by electrochemical methodsMultistage water/sewage treatmentTetrabromobisphenol AChlorobenzene

The invention discloses a treatment technique of tetrabromobisphenol A production wastewater, belonging to organic chemical industry wastewater recycling and harmless environmental-protection treatment technologies. The treatment technique of tetrabromobisphenol A production wastewater is an acidification precipitation-resin adsorption-advanced oxidation combined technique, and mainly comprises the following steps: 1. regulating the pH value of the wastewater to recycle the tribromophenol in the wastewater by acidification precipitation; 2. filling the wastewater, in which abundant tribromophenol is removed, into an adsorption column by using a macroporous adsorbent resin subjected to conventional pretreatment, and passing the wastewater through a bed bottom at a certain flow rate so that chlorobenzene is adsorbed by the resin, wherein the resin adsorption is utilized to remove most chlorobenzene, bisphenol A and other nondegradable organic substances in the recycled wastewater, thereby effectively reducing COD (chemical oxygen demand) of the wastewater and relieving the treatment load of the wastewater; and 3. carrying out electrocatalytic oxidation on the wastewater subjected to acidification precipitation-resin adsorption to finally remove harmful and nondegradable substances in the wastewater, thereby achieving the goal of harmless discharge after reaching the standard.

Owner:TIANJIN POLYTECHNIC UNIV

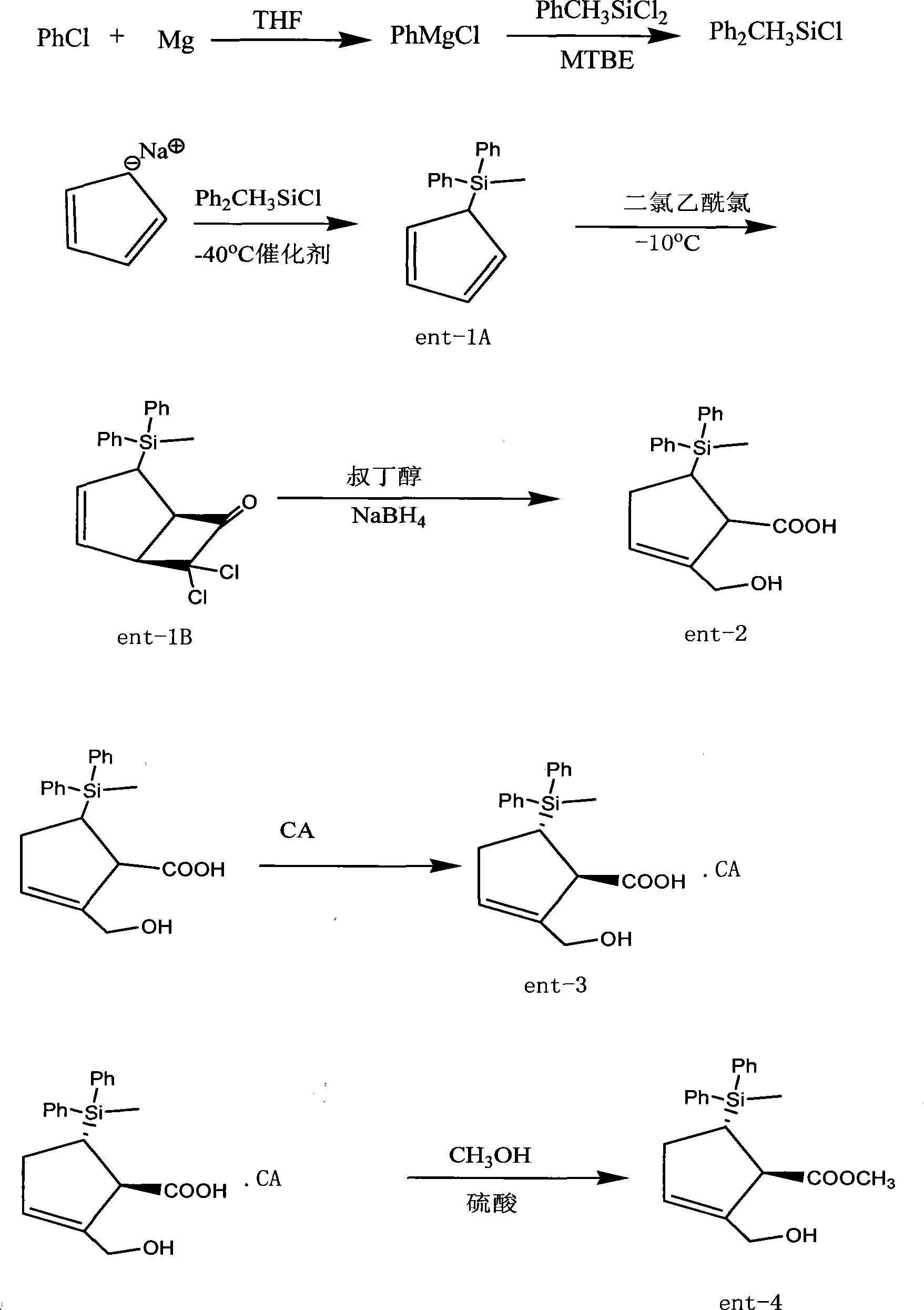

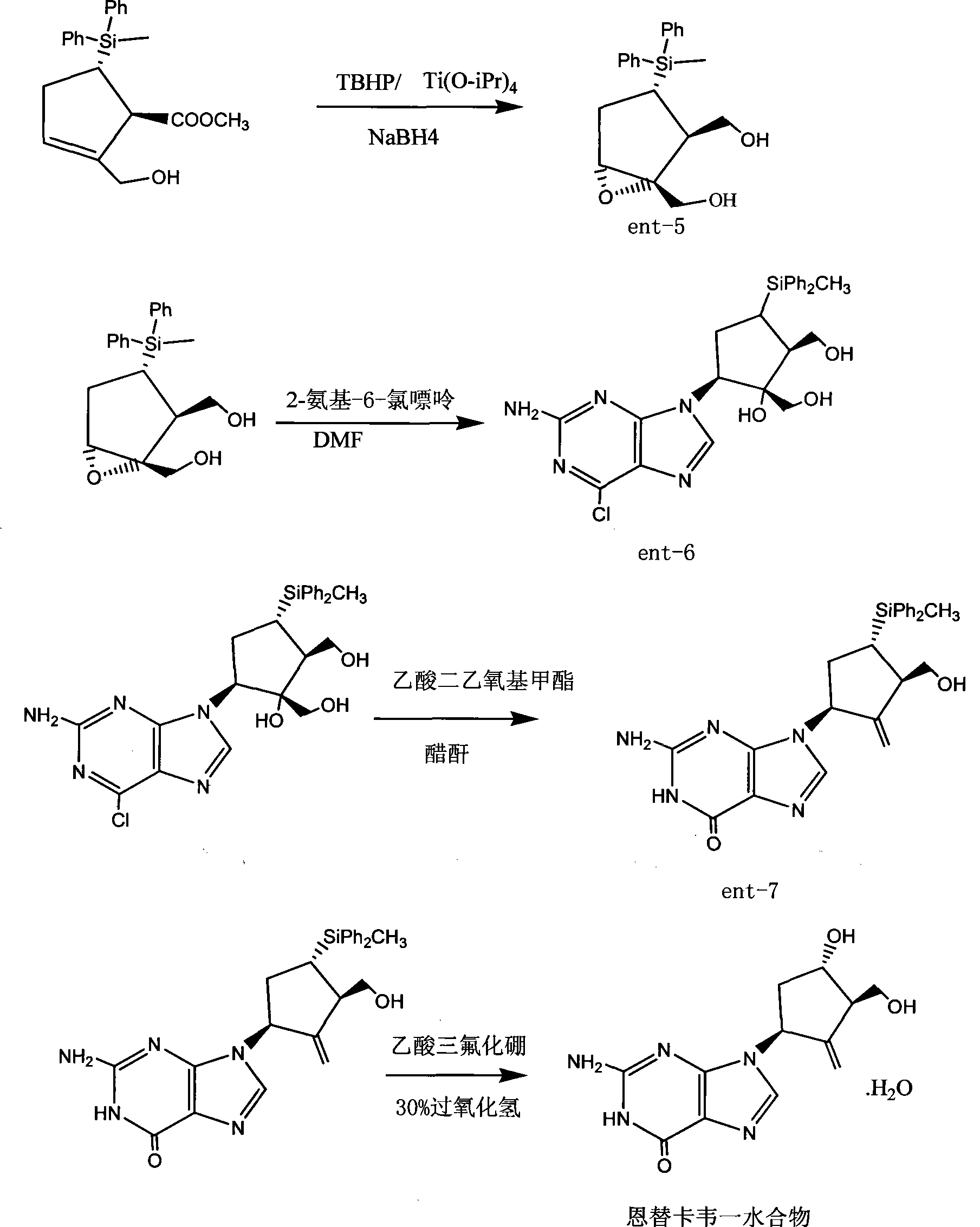

Industrialization production process of entecavir-monohydrate

ActiveCN101531660ALower synthesis costRaw materials are cheap and easy to getGroup 4/14 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsChlorobenzeneGrignard reagent

The invention provides an industrialization production process of entecavir-monohydrate. The special features of the process different from the other process are that: methyldiphenylchlorosilane is used as the silanization protector and special catalyst, thus the reaction temperature is -40 DEG C and the object product is smoothly produced (the reaction temperature is -78 DEG C in the prior process). Thus the production process is more suitable for industry production and because the silanization protector is cheaper and easily obtained, the production cost is greatly reduced. The invention comprises the preparation of methyldiphenylchlorosilane as the silanization protector which is obtained by directly synthesizing the methylphenyldichlorosilane and Grignard reagent of chlorobenzene under the action of special catalyst.

Owner:ANHUI BIOCHEM UNITED PHARMA CO LTD

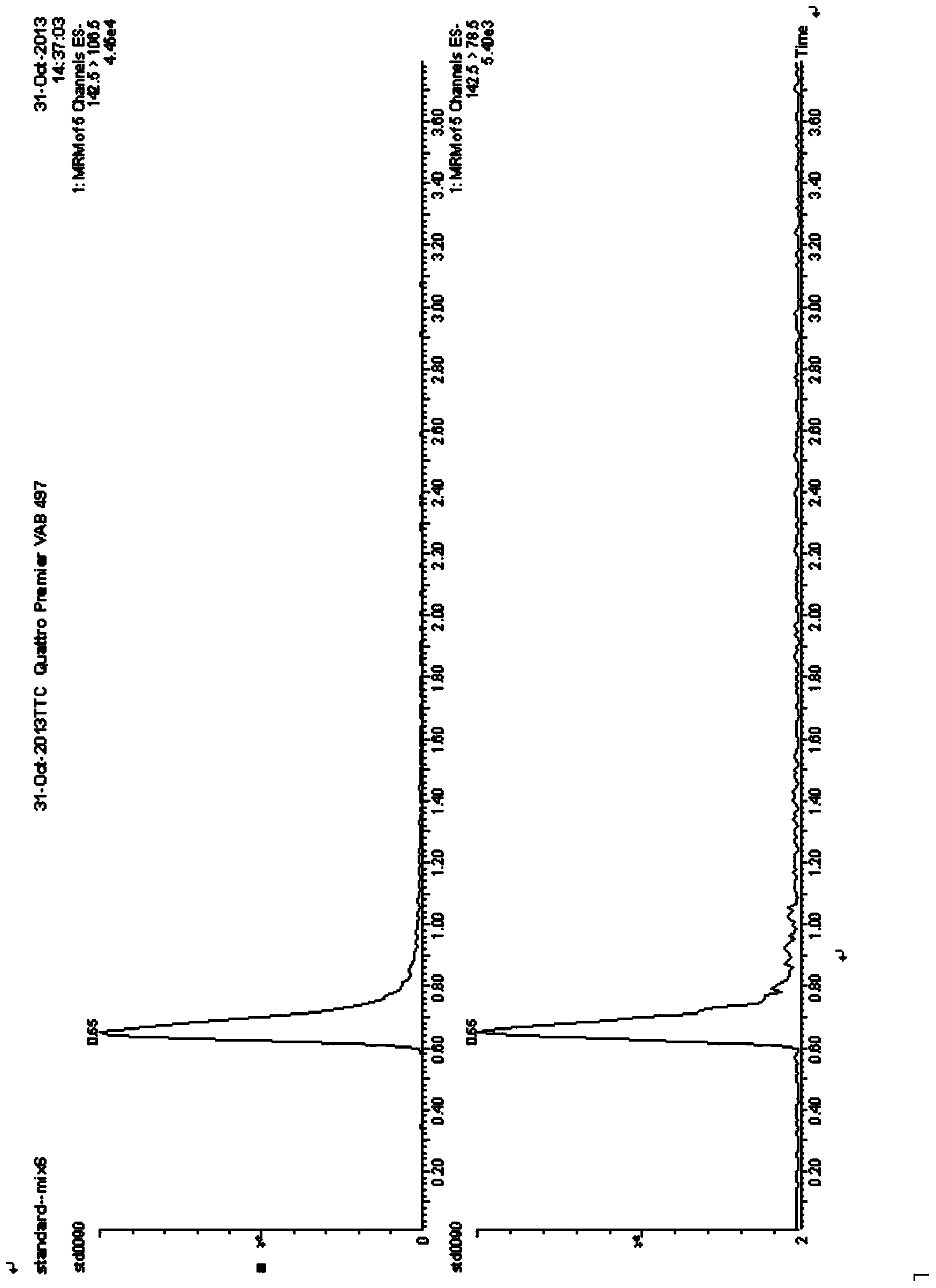

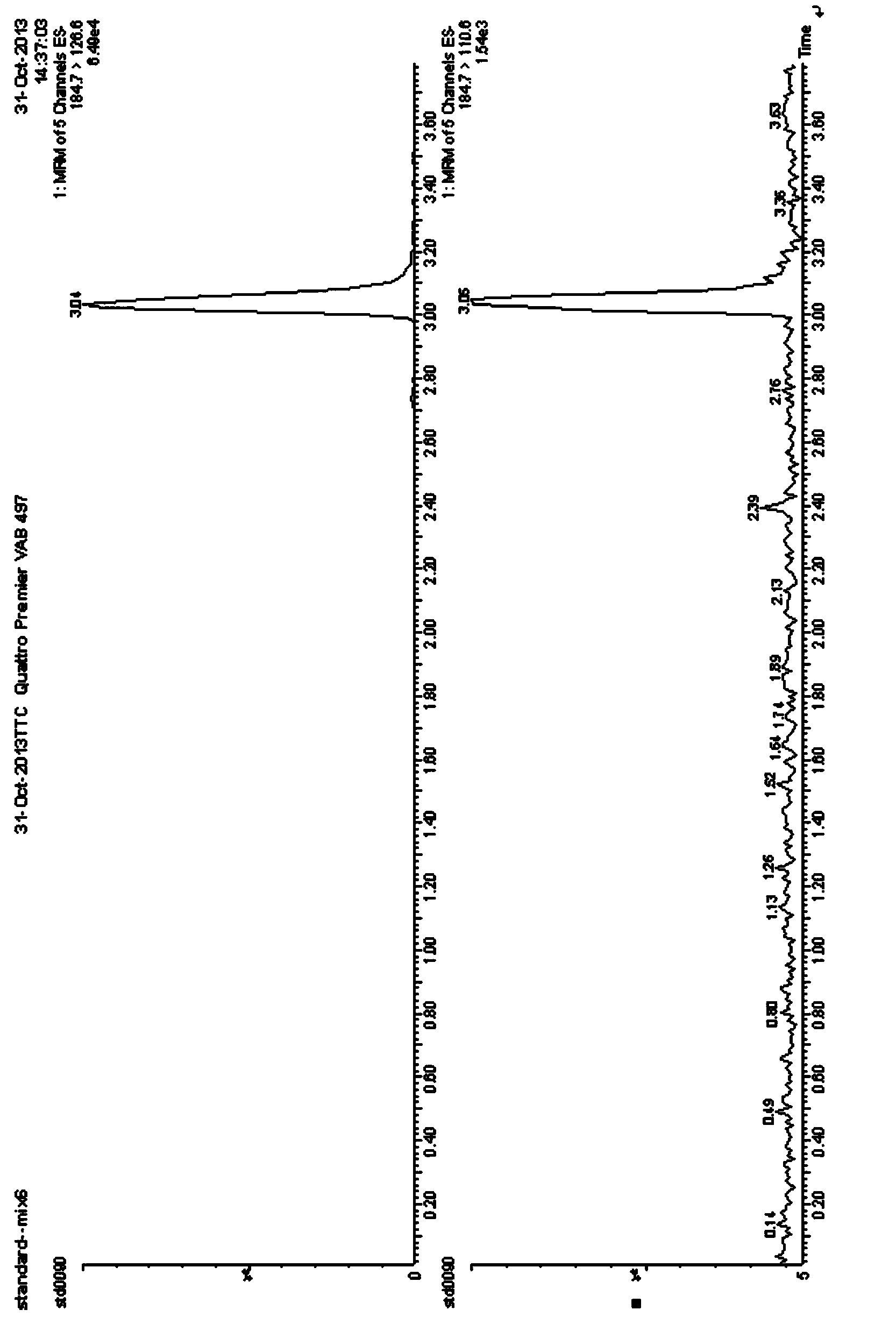

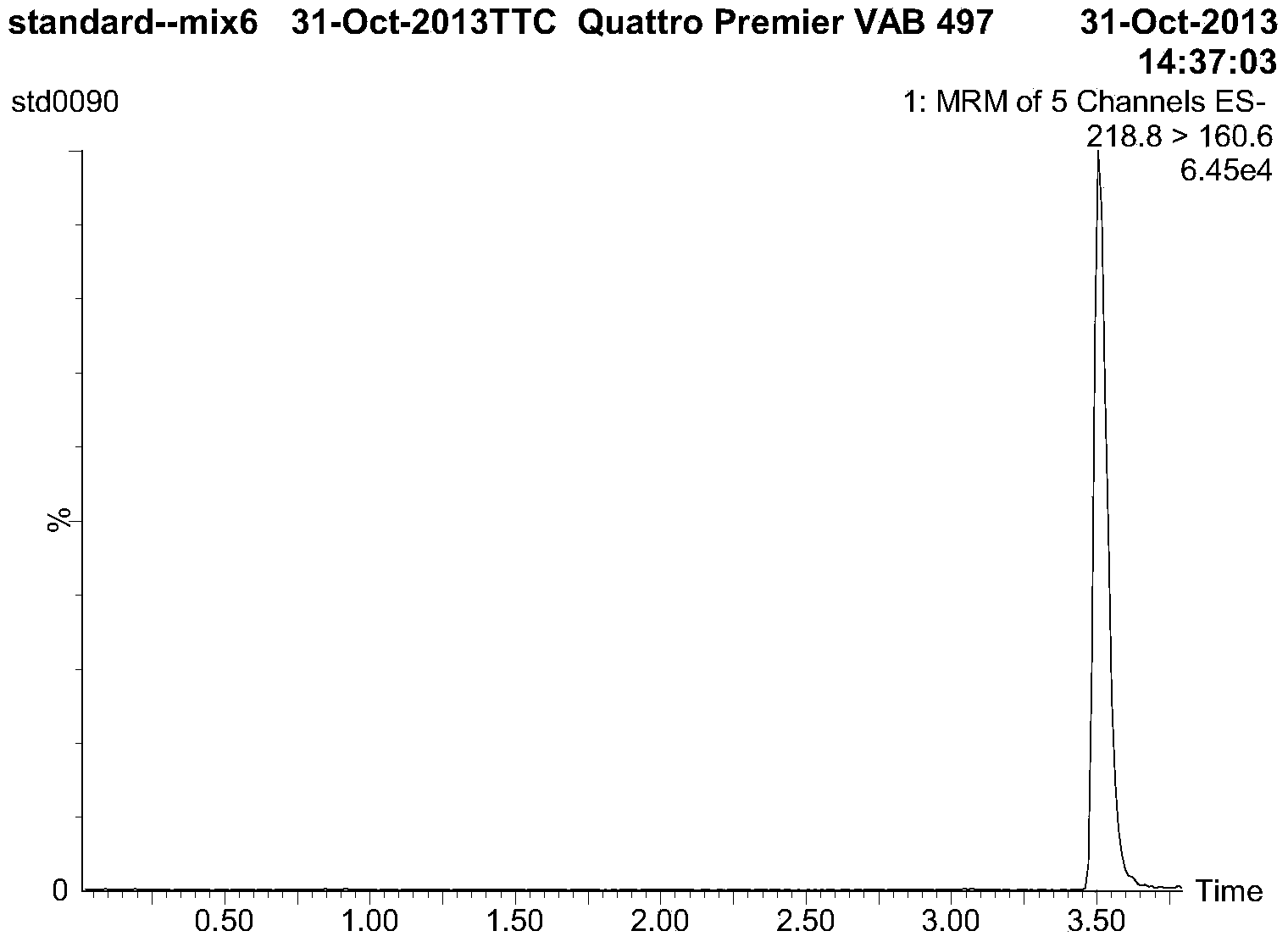

Detection method for plant growth regulator residues in fruits

InactiveCN103969363AStable recoveryAchieving Simultaneous DetectionComponent separationSodium acetateGrowth plant

The invention relates to a detection method for plant growth regulator residues in fruits. The detection method comprises the following steps: the QuEChERS method is adopted to extract and purify the plant growth regulator residues in fruits, so as to enable the adding standard recovery rate of the target compound to reach 71%-98%; the RSD ( relative standard deviation) is not higher than 6%; the sensitivity and selectivity are favorable and the recovery rate is stable; the liquid chromatograph tandem mass spectrogram detection method is adopted to simultaneously detect forchlorfenuron, ethephon, 4-sodium chlophenoxycetate and 2,4- sodium acetate-dichlorobenzene oxygen; the detection limits range from 0.5 microgram / kg to 100 microgram / kg respectively; the sensitivity requirement of national limited standard is met. The detection method has favorable sensitivity and selectivity and can serve as a method for detecting the plant growth regulator residues in fruits.

Owner:WENZHOU INST OF TECH TESTING & CALIBRATION

Method for catalyzing dynamic kinetic resolution of arylamine via racemization catalyst

InactiveCN102533922AGood stability for repeated useMild reaction conditionsOrganic chemistry methodsChemical recyclingChlorobenzenePtru catalyst

The invention discloses a method for catalyzing dynamic kinetic resolution of arylamine via a racemization catalyst, comprising the following steps of: 1) adding p-chlorophenol, n-pentanoic acid, dicyclohexylcarbodiimide and 4-dimethylamino-pyridine, and carrying out mixing, filtration, drying, concentration and column chromatography to obtain a pentanoic acid p-chlorophenyl ester acyl donor; 2) carrying out coprecipitation on magnesium chloride solution and aluminum chloride solution and carrying out water-heat treatment to obtain chloridion intercalated hydrotalcite, adding the chloridion intercalated hydrotalcite in lauryl sodium sulfate aqueous solution, and carrying out backflow, cooling, centrifugation, water washing, acetone washing and drying to obtain a carrier; 3) adding palladium salt and the carrier, and carrying out heating, ascorbic acid addition, centrifugation, water washing, acetone washing and freeze-drying to obtain the racemization catalyst; and 4) adding arylamine, the acyl donor, lipase and the racemization catalyst in toluene and placing in a stainless steel reactor to add hydrogen so as to obtain amide. The method provided by the invention is used for catalyzing the dynamic kinetic resolution of arylamine, has rapid reaction rate, low temperature, high conversion rate and high product optical purity, and has great application value.

Owner:ZHEJIANG UNIV

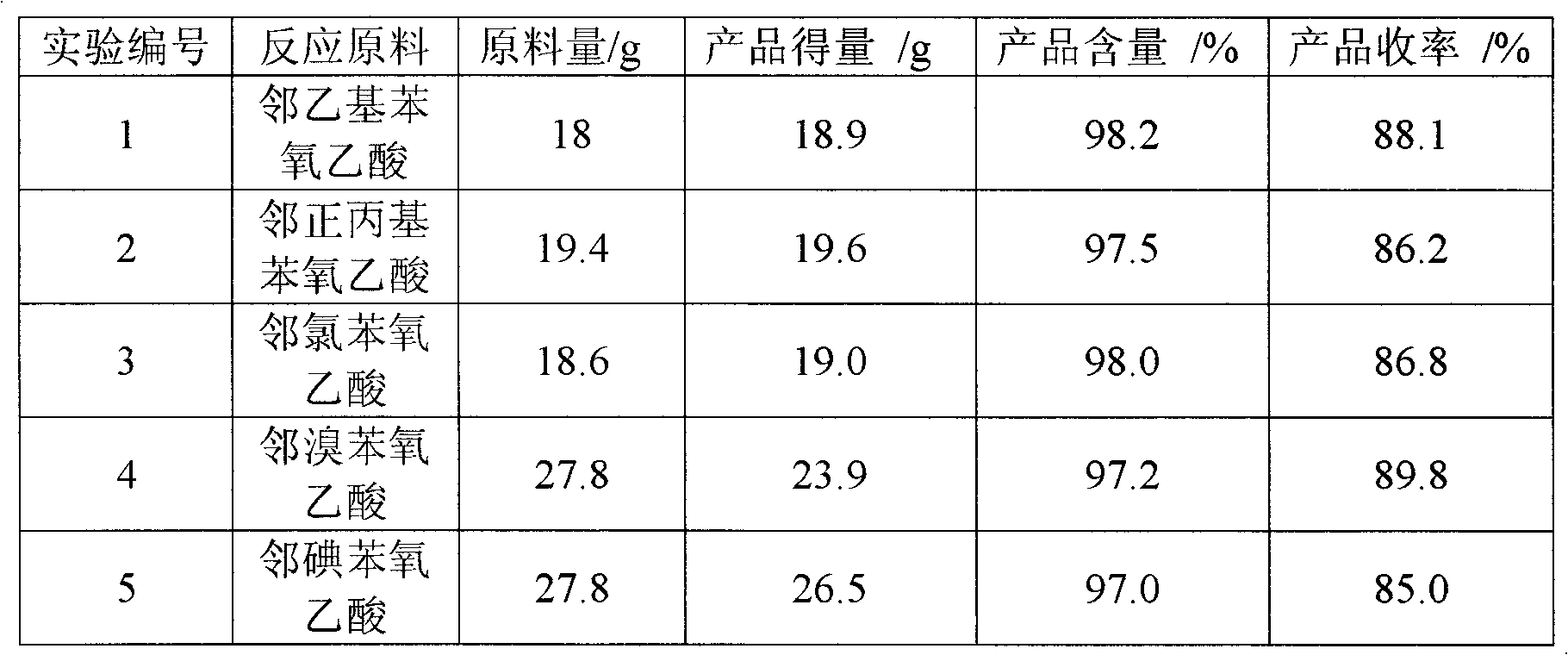

Chloration method for phenoxyacetic acid and derivatives thereof

InactiveCN102336654AEasy to industrializeOrganic compound preparationCarboxylic compound preparationChlorobenzeneIndustrial waste water

The invention provides a chloration method for phenoxyacetic acid and derivatives thereof, which comprises the following steps that: raw materials of the phenoxyacetic acid or the derivatives of the phenoxyacetic acid and chlorinating agents take reaction at a certain temperature in organic solvents under the effect of catalysts, wherein the chlorinating agents can be chlorine gas, sodium hypochlorite, calcium hypochlorite and sulfuryl chloride, the catalysts can be lewis acid and sulfurated substances, and solvents can be dichloromethane, dichloroethane, trichloromethane, carbon tetrachloride, formic acid, ethyl acetate, benzene, toluene, dimethylbenzene, chlorobenzene and o-dichlorobenzene. The method has the advantages that the operation can be carried out under the waterless condition, the generation of a large amount of industrial waste water is avoided, the used catalysts are safe and are easy to obtain, the solvents can be cyclically used, and the industrialization is easy.

Owner:DALIAN RES & DESIGN INST OF CHEM IND

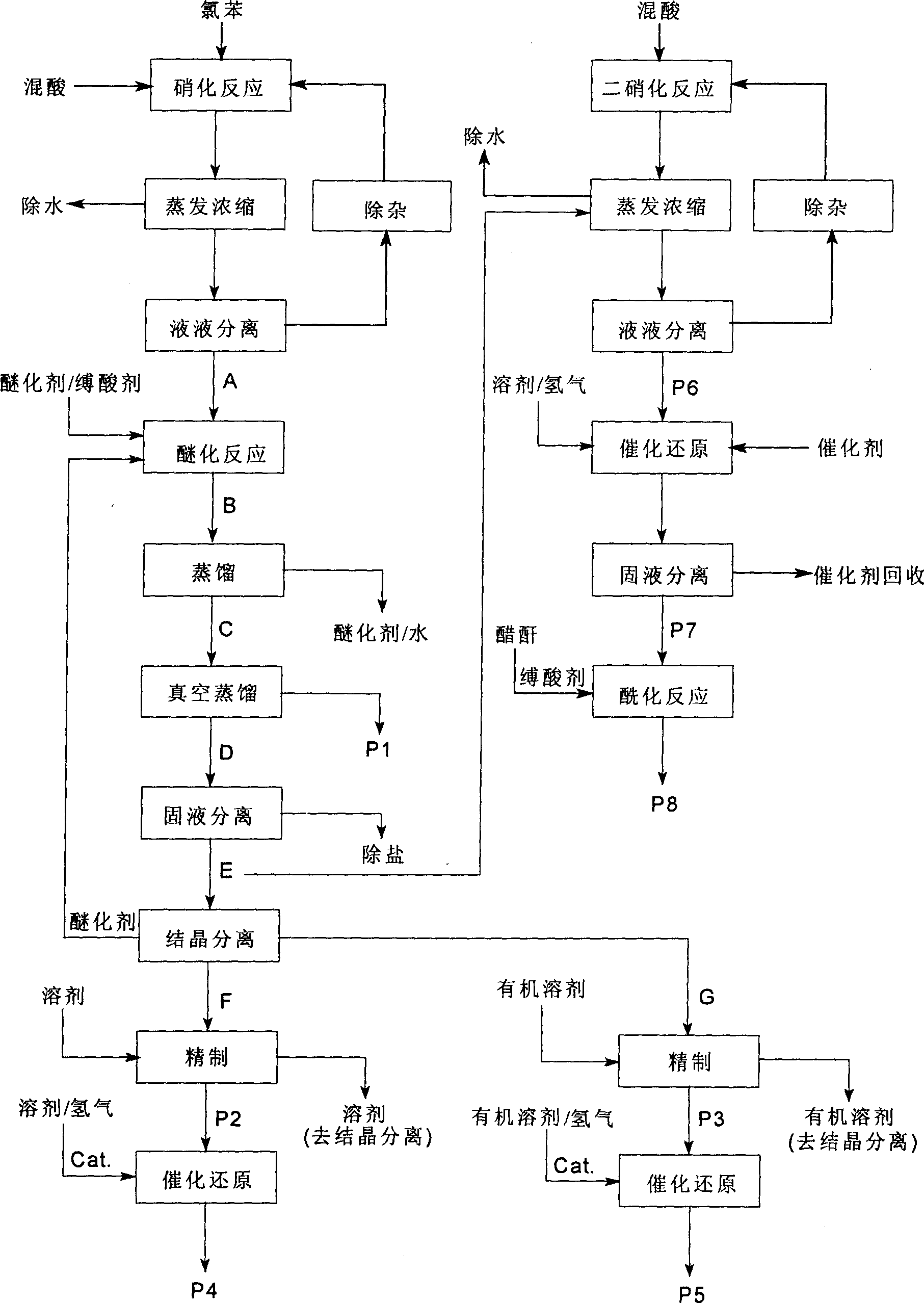

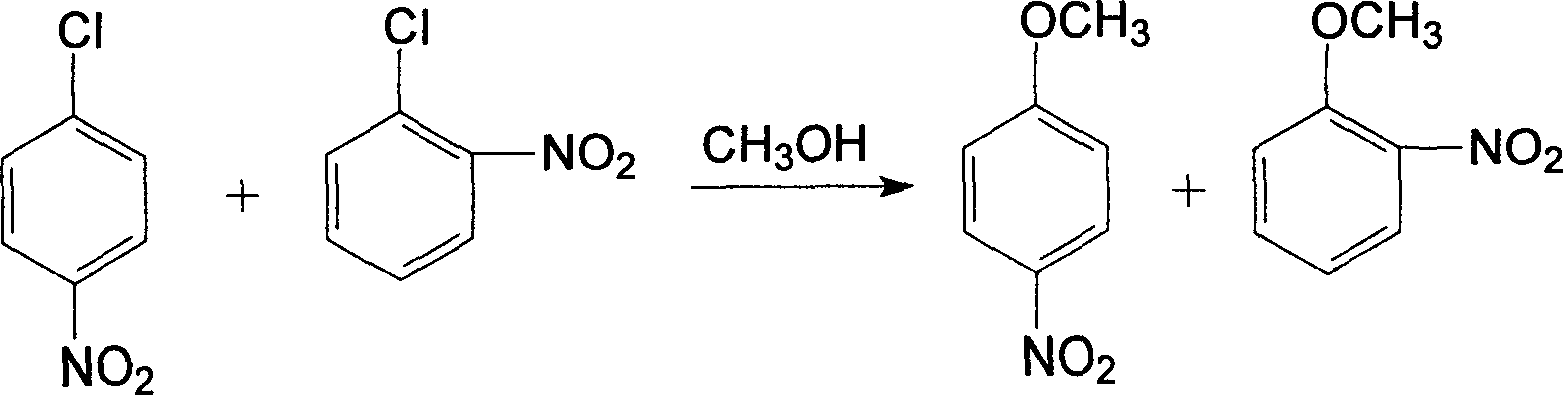

Process of producing nitrobenzether aminobenzether amidobenzether from chlorobenzene

InactiveCN1861562AAvoid conditionsAvoid investment in equipmentOrganic compound preparationCarboxylic acid amides preparationO-nitrochlorobenzeneChloride salt

A process for preparing nitrophenylether, aminophenylether and amidophenylether between chlorobenzene and acid mixture removing water, liquid-liquid separation to obtain organic phase consisting of o-, p- and meta-nitro chlorobenzene compounds, etherifying said mixture, recovering etherifying agent, vacuum distilling, separating and refining meta-nitro chlorobenzene, removing chloride salt generated in etherification, crystallizing separation, recrystallizing p- and o-nitro phenylether compounds, catalytic hydrogenating reaction, nitrifying reaction to obtain 2,4-drinitro phenylether, catalytic hydroreducing reaction to obtain 2,4-diamino phenylether, and aceylating reaction to obtain 2-amino-4-acetylamino phenylether.

Owner:CHANGZHOU JIASEN CHEM +1

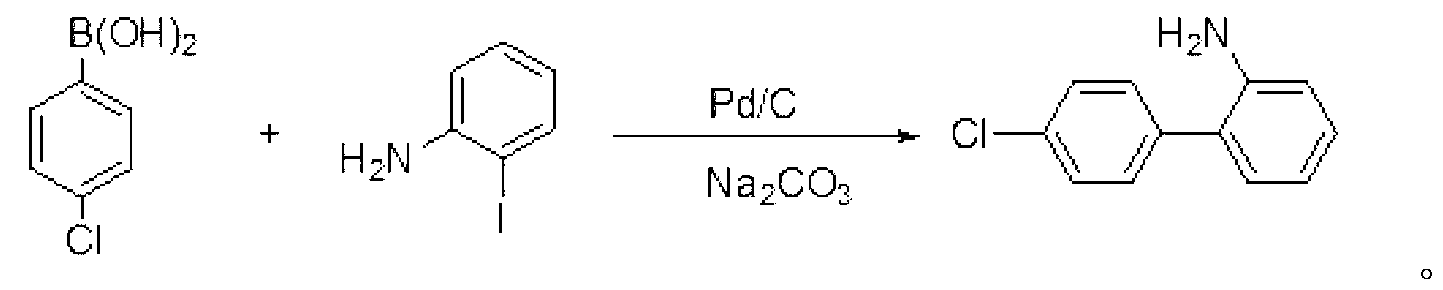

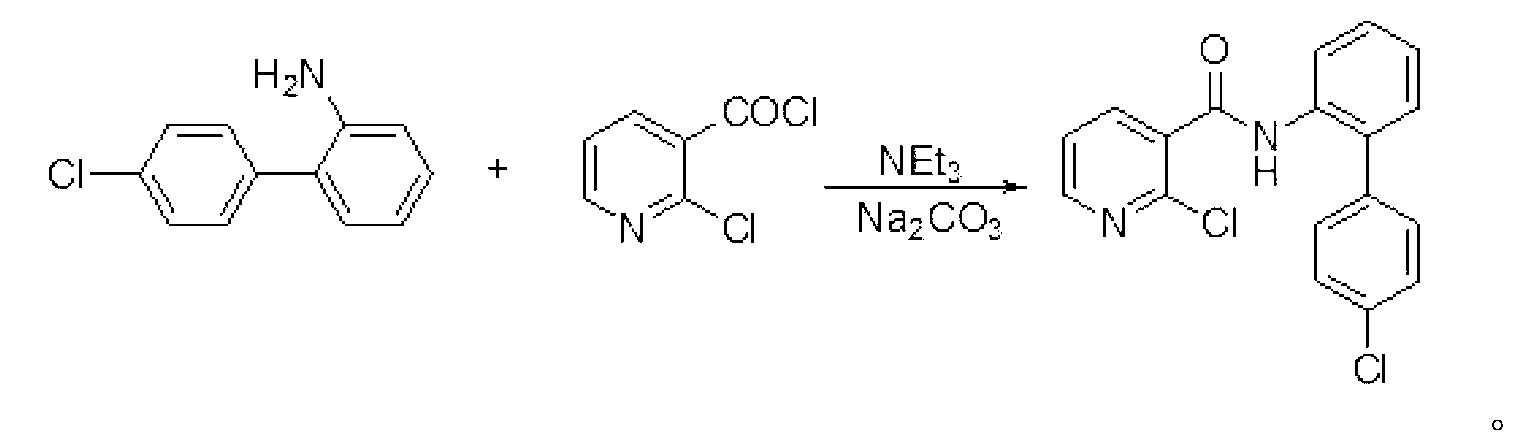

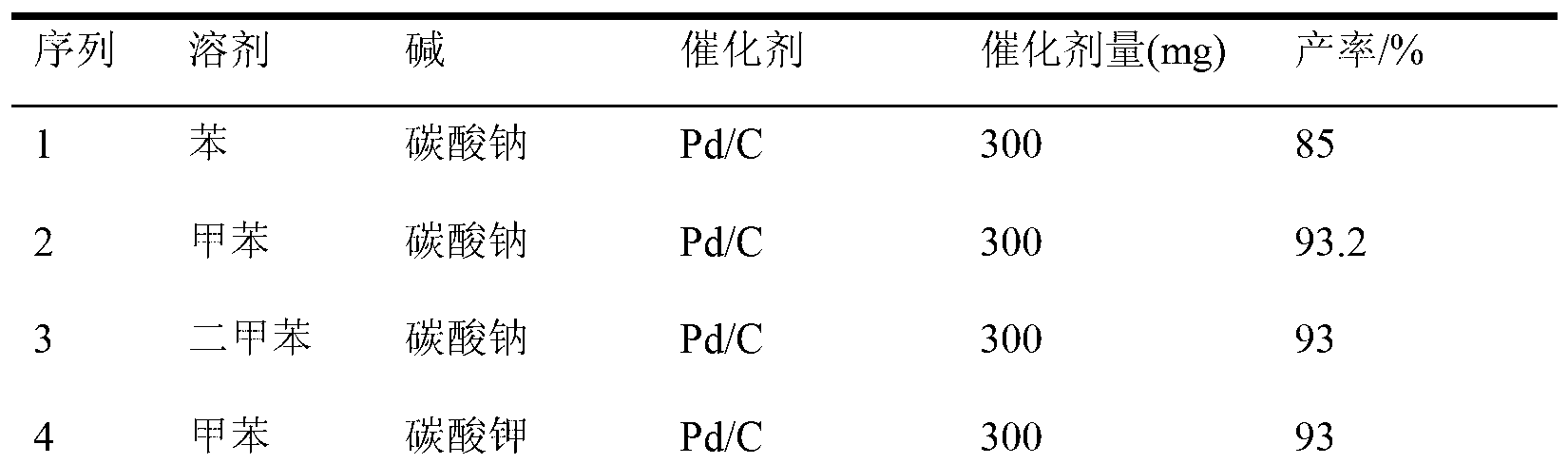

Preparation method of Boscalid

InactiveCN103073489AReduce manufacturing costHigh yieldAmino preparation from aminesAlkaline waterChlorobenzene

The invention discloses a preparation method of Boscalid, which comprises the following steps that Suzuki coupling reaction occurs between o-iodoaniline and 4-chlorobenzene boronic acid to produce an intermediate product 4'-chlorinated biphenyl-2-amine under the catalytic effect of Pd / C by using methylbenzene and alkaline water as mixed solvent; and condensation reaction occurs between the 4'-chlorinated biphenyl-2-amine and 2-chloronicotinyl chloride to produce the Boscalid. The preparation method of the Boscalid has the advantages that the production cost is reduced, the yield of the intermediate product 4'-chlorinated biphenyl-2-amine is improved, the total yield of the two steps exceeds 84 percent and the industrial production is expected to be realized.

Owner:LIMIN CHEM CO LTD

Preparation method of BPPO and PVA-based organic-inorganic hybrid anion exchange membrane

InactiveCN102698616AGood flexibilityFully quaternizedSemi-permeable membranesChlorobenzenePolyvinyl alcohol

The invention discloses a preparation method of a BPPO (Brominated Polystyrene) and PVA (Polyvinyl Alcohol)-based organic-inorganic hybrid anion exchange membrane. The preparation method comprises the following steps: (1), dissolving the BPPO in chlorobenzene, and adding DMF (Dimethyl Formamide), tertiary amine solution, two micromolecule alkoxy silanes and water so as to obtain BPPO (+) / SiO2 materials; (2) dissolving the obtained BPPO (+) / SiO2 materials into DMF mixed solution so as to BPPO (+) / SiO2 solution; (3) dropping the BPPO (+) / SiO2 solution into PVA solution so as to prepare coating liquid; and (4) coating the coating liquid on a basal body so as to form a diaphragm, and drying the diaphragm to obtain the organic-inorganic hybrid anion exchange membrane. According to the invention, quaternary ammonium BPPO, PVA and micromolecule alkoxy silanes are utilized to prepare the hybrid anion exchange membrane containing the quaternary ammonium group and-OH base, the content of the PVA in the membrane can be controlled, and a cross-linked structure can be formed, so that the stability and mechanical performance of the membrane can be reinforced; and moreover, the -OH base in the PVA can promote the H+ ion to transfer, so that the prepared hybrid anion exchange membrane is particularly suitable for diffusion dialysis process, and can separate and recycle acid waste liquid.

Owner:YANCHENG TEACHERS UNIV

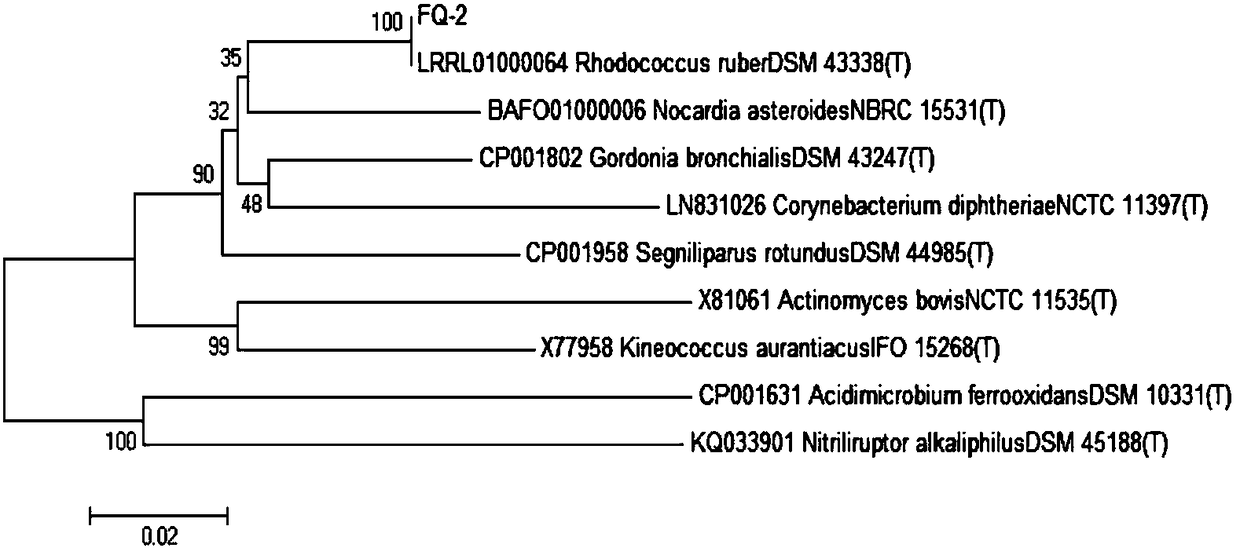

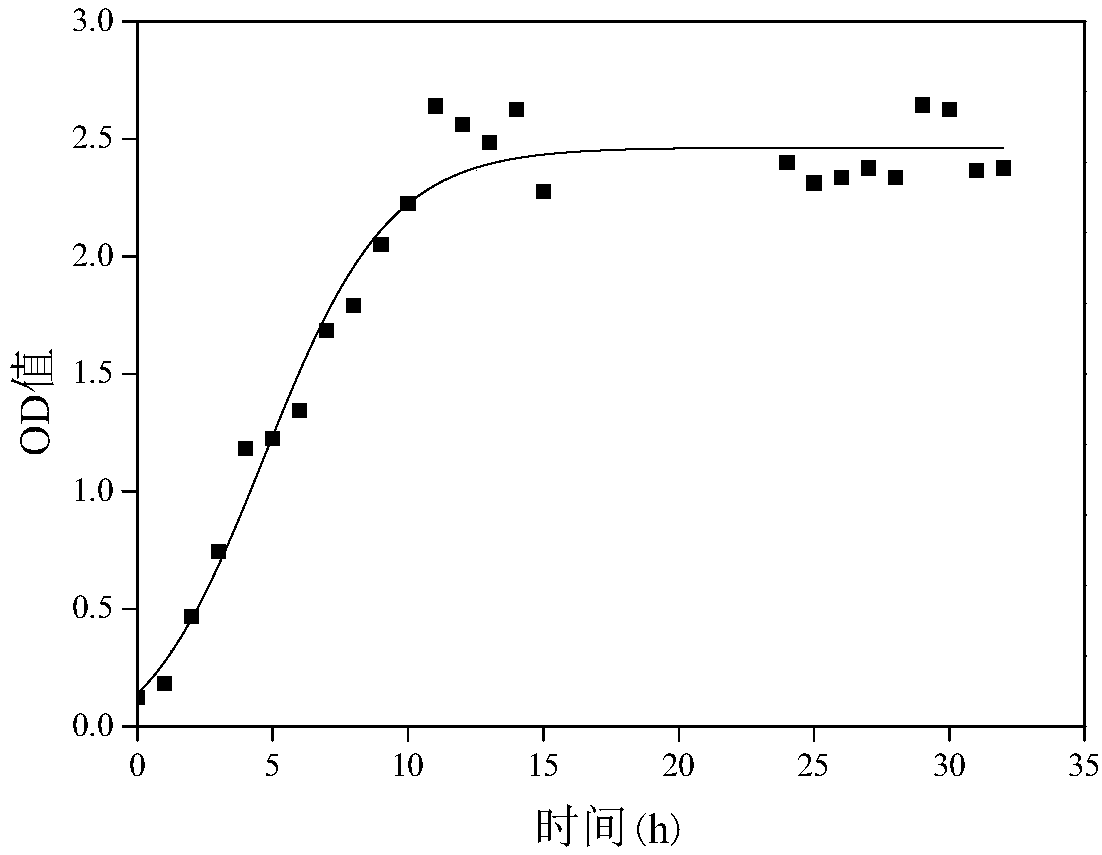

Rhodococcus ruber and application thereof in degradation of organic pollutants

The invention discloses rhodococcus ruber FQ-2 and an application thereof in degradation of acetone and other common industrial organic pollutants. The application method comprises the steps: an inorganic salt culture medium containing acetone and other common industrial pollutants is inoculated with the rhodococcus ruber FQ-2, a degradation reaction is carried out under the conditions of the temperature of 30 DEG C and the rotating speed of 160 r / min, and thus the organic pollutants are degraded; the common organic pollutants comprise acetone, n-hexane, carbon disulfide, chlorobenzene, butylacetate, ethyl acetate or alpha-pinene. The rhodococcus ruber FQ-2 is taken from activated sludge of an aeration tank of a pharmaceutical factory in Zhejiang province, has good degradation effect on VOCs organic pollutants, especially acetone, and can completely convert acetone into harmless substances such as CO2, H2O, cell biomass and the like; at the same time, the bacterial strain also can degrade common industrial pollutants such as carbon disulfide and chlorobenzene in different extent, so the bacterial strain has broad application prospects in biological purification of industrial wastegas and wastewater.

Owner:ZHEJIANG UNIV OF TECH

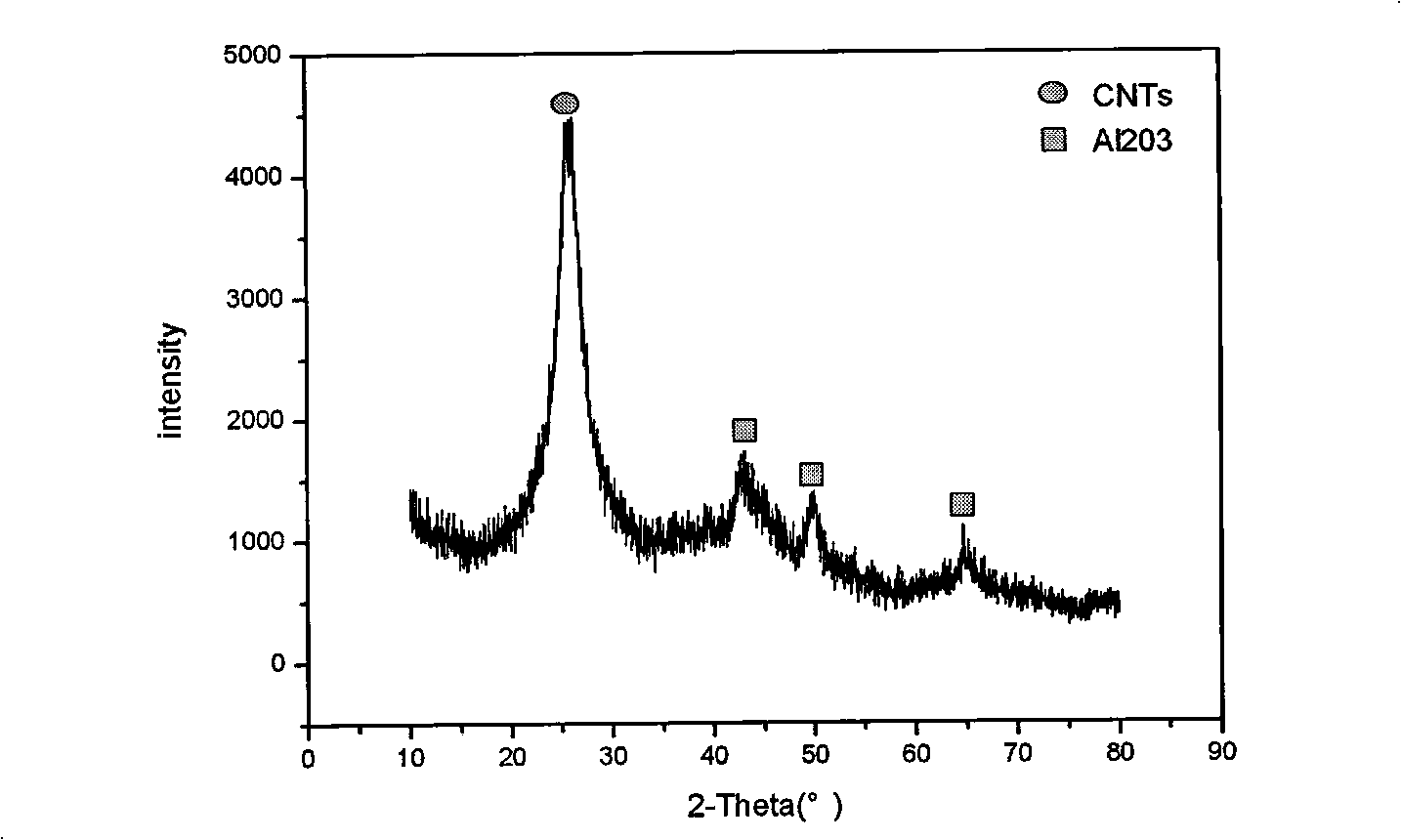

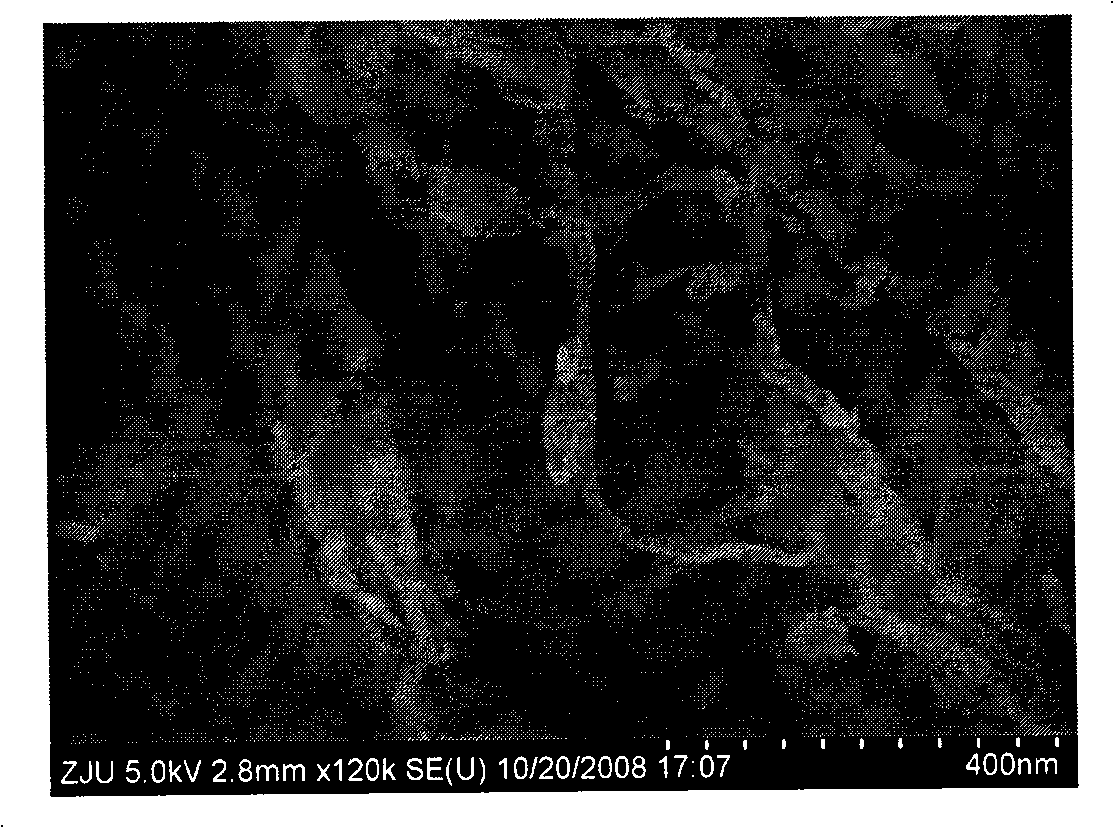

Catalyst for removing nitrogen oxide and organic pollutant discharged in burning and method for preparing same

InactiveCN101513612AGuarantee structureExcellent low temperature SCR characteristicsDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsChlorobenzeneCarbon nanotube

The invention discloses a catalyst for removing nitrogen oxide and organic pollutant discharged in burning, comprising carbon nanotube and alumina as the carrier and manganese oxide as the active ingredient, the active ingredient in the catalyst accounts for 1 to 10% of the total catalyst mass. The catalyst is prepared by a solvent-thermal method. In the inventive catalyst, CNTs and Al2O3 are simultaneously used as the carrier for the first time, thus the catalyst has big specific surface area and high mechanical strength, at the same tine the temperature of the selective catalytic reaction is reduced, 94.2% of chlorobenzene removing ratio can be obtained at the temperature of 150 DEG C, 88.8% of NOx removing ratio is obtained at the temperature of 200 DEG C. The catalyst can be used for removing the nitrogen oxide (NOx)and dioxin organic pollutant discharged in the high-temperature process in the fire coal power plant, metallurgy industry, garbage burning and the like.

Owner:ZHEJIANG UNIV

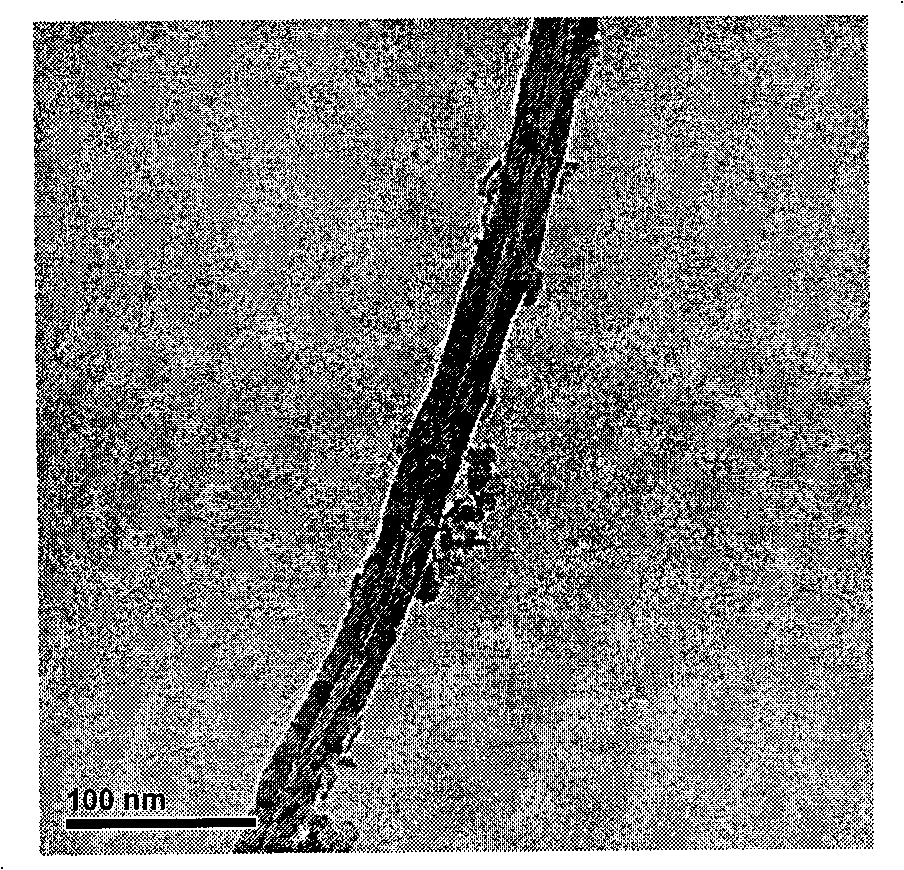

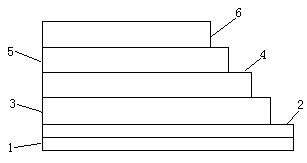

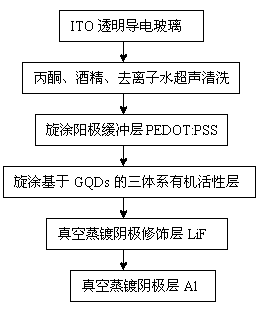

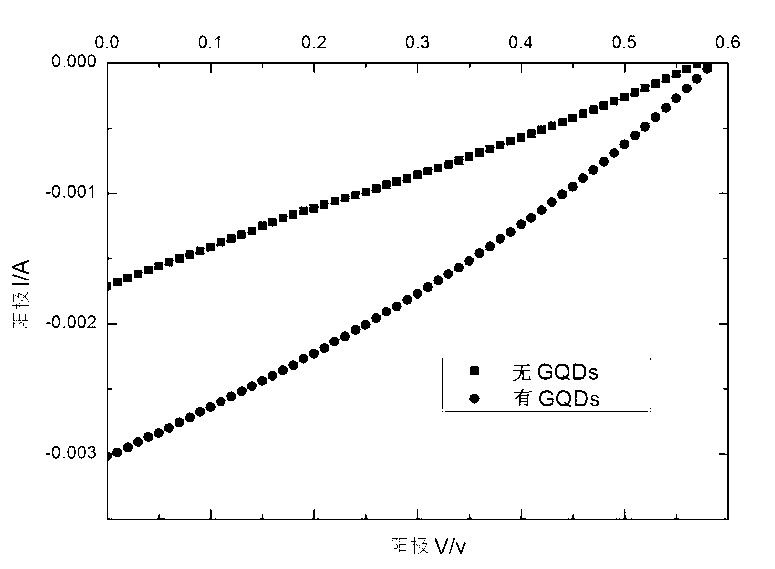

Three-system organic photovoltaic device based on graphene quantum dots and preparation method of three-system organic photovoltaic device

InactiveCN103022357AIncrease short circuit currentHigh dissociation efficiencyFinal product manufactureSolid-state devicesChlorobenzeneEvaporation

The invention relates a three-system organic photovoltaic device based on graphene quantum dots and a preparation method of the three-system organic photovoltaic device. According to the preparation method, the design limitation of an original binary organic photovoltaic device is broken through, and a spin coating technique and a thermal evaporation film plating technique are adopted on transparent conductive glass to reach the purpose of enhancing the device energy conversion efficiency. The three-system organic photovoltaic device uses a three-system coexistence system including an organic donor and an organic acceptor as well as the graphene quantum dots as an organic active layer, the donor and the acceptor are dissolved in chlorobenzene containing the graphene quantum dots in a certain proportion, and a three-system coexistence structure active layer is prepared only by only requiring the spin coating, so that the cost is low, the operation is simple and the conversion efficiency of the organic photovoltaic device is effectively improved.

Owner:FUZHOU UNIV

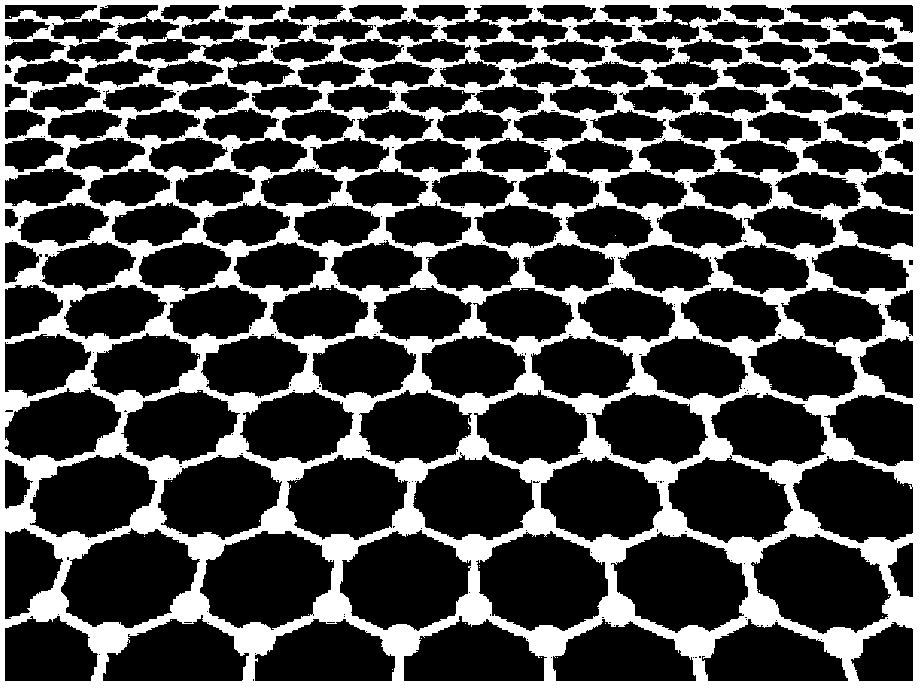

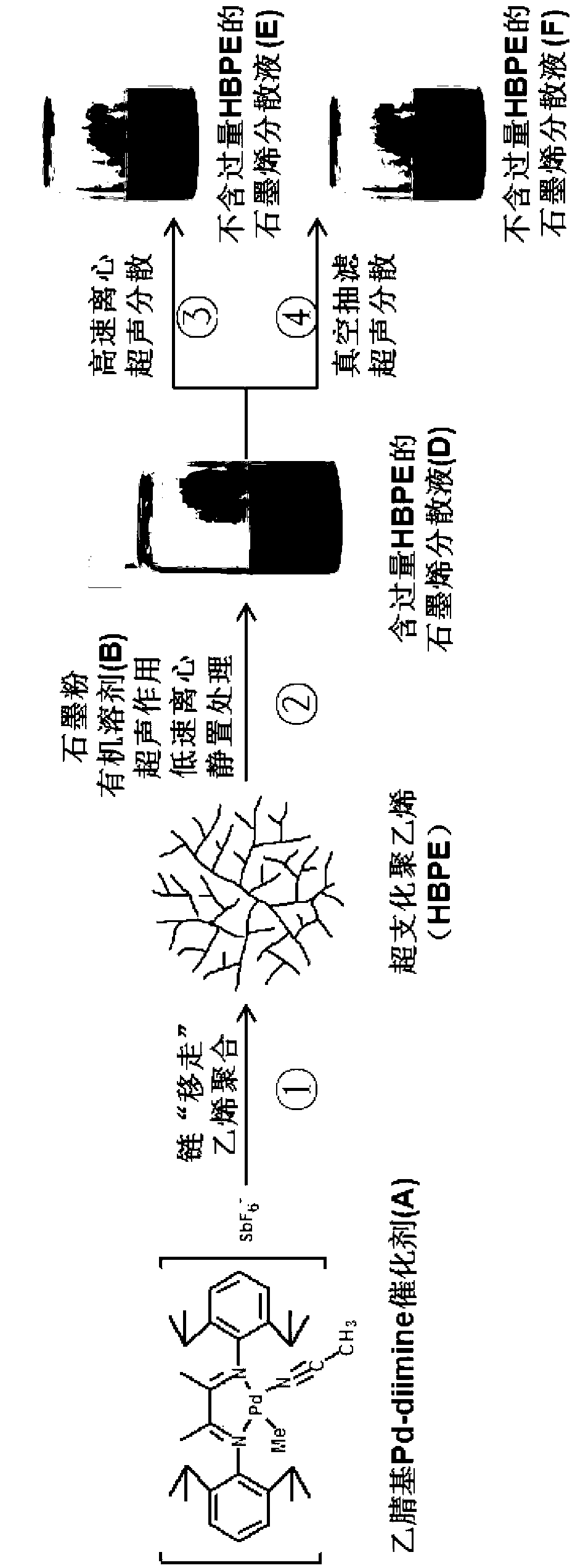

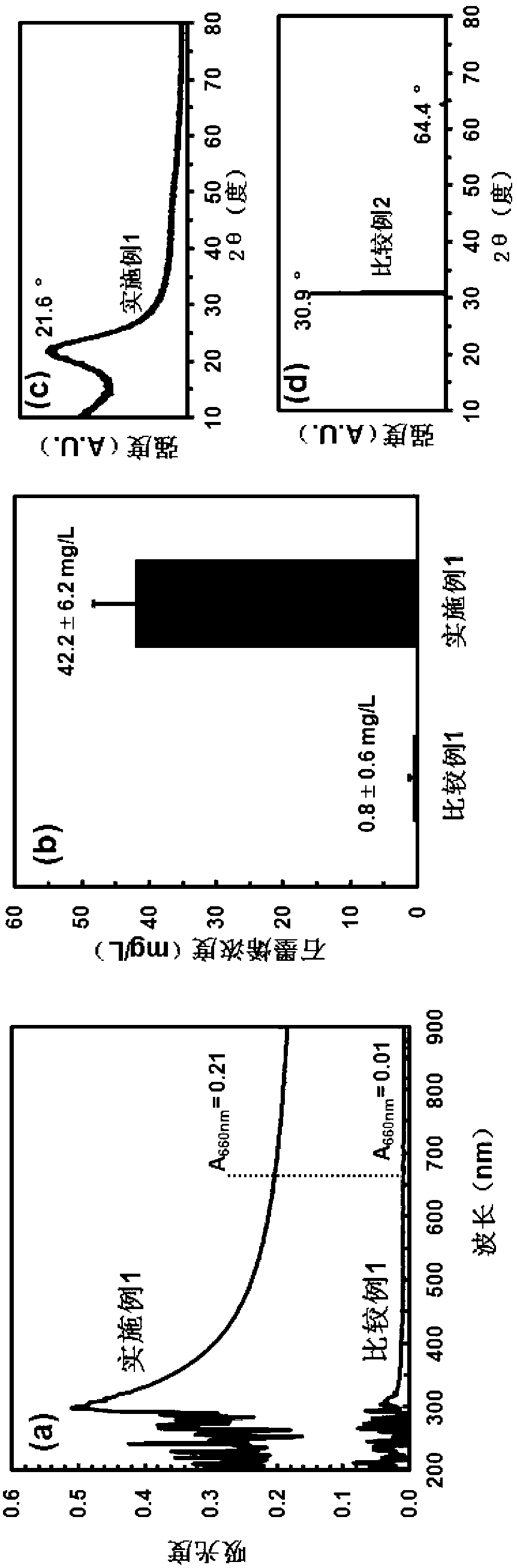

Method for preparing graphene organic dispersion solution from hyperbranched polyethylene

ActiveCN103087335ALow concentration of surface defectsLess destructive to the surface structureGrapheneChlorobenzeneLow speed

The invention discloses a method for preparing a graphene organic dispersion solution from hyperbranched polyethylene, which comprises the following steps: (1) proportionally mixing graphite powder, organic solvent B and hyperbranched polyethylene, and then performing ultrasonic dispersion on the obtained mixture to obtain a graphene initial dispersion solution C; and further performing low-speed centrifugation and standing treatment to obtain a graphene dispersion solution D containing excessive hyperbranched polyethylene, wherein the organic solvent B is selected from one of the following chemically pure or analytically pure agents: tetrahydrofuran, trichloromethane, n-heptane, chlorobenzene and dichloromethane; and (2) performing ultra-high-speed centrifugation or vacuum filtration on the graphene dispersion solution D obtained in the steps (1) to remove the contained excessive hyperbranched polyethylene, and further performing ultrasonic dispersion in the organic solvent B to obtain the graphene organic dispersion solution. The preparation process causes less damage to the surface structure of graphene; and the obtained graphene is low in surface defect concentration and can better take the performance advantages.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com