Patents

Literature

104results about How to "The polymerization reaction is fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

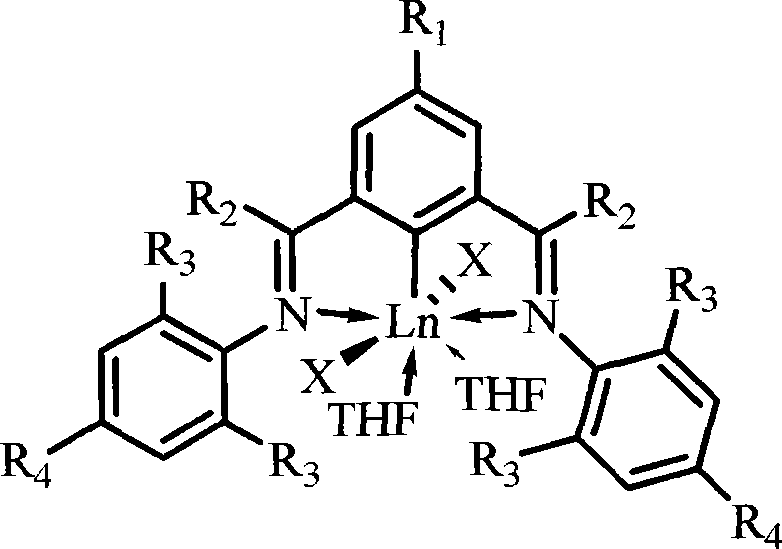

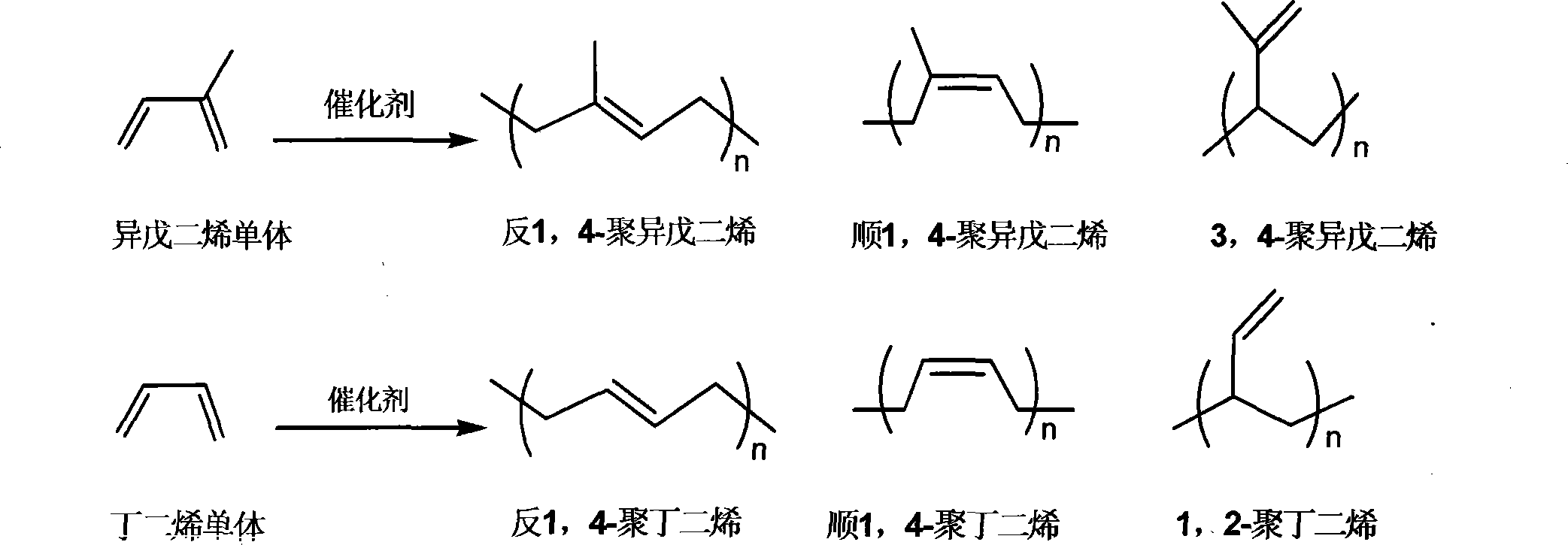

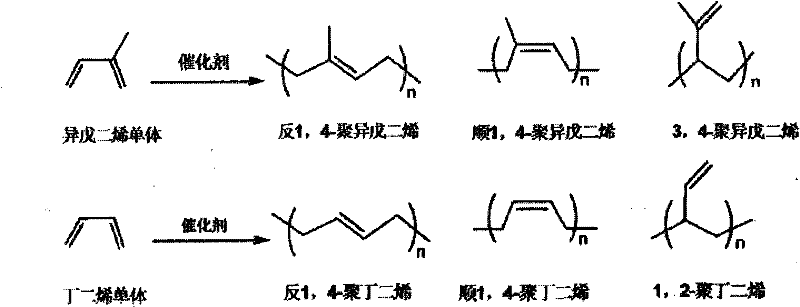

Rare earth catalyst for catalyzing syn form 1,4-selectivity polymerization of isoprene or butadiene

The invention relates to a rare-earth catalyst for catalyzing selective polymerization of isoprene or butadiene, while the catalyst system composed of the rare-earth catalyst can catalyze isoprene or butadiene to prepare polyisoprene or butadiene rubber with high cis-1, 4- structure. The rare-earth catalyst is composed of split-core type rare-earth complex, alkyl aluminium and organic boron salt. The solvent of polymerization is toluene or chlorobenzene. When catalyzes the polymerization of isoprene, the alkyl aluminium and split-core type rare-earth complex are rationed at 10-40, the organic boron salt and split-core type rare-earth complex are rationed at 1-3, the polymerization temperature is -20-80DEG C, the polymerization time is 0.5-2h, the monomer conversation ratio can reach 100% most, and the cis-1, 4 content of polymer is 55.0-98.8%, and when catalyzes the polymerization of butadiene, the alkyl aluminium and split-core type rare-earth complex are rationed at 10-40, the organic boron salt and split-core type rare-earth complex are rationed at 1-3, the polymerization temperature is -20-80DEG C, the polymerization time is 0.5-2h, the monomer conversation ratio can reach 100% most, and the cis-1, 4 content of polymer is 90.1-99.99%.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

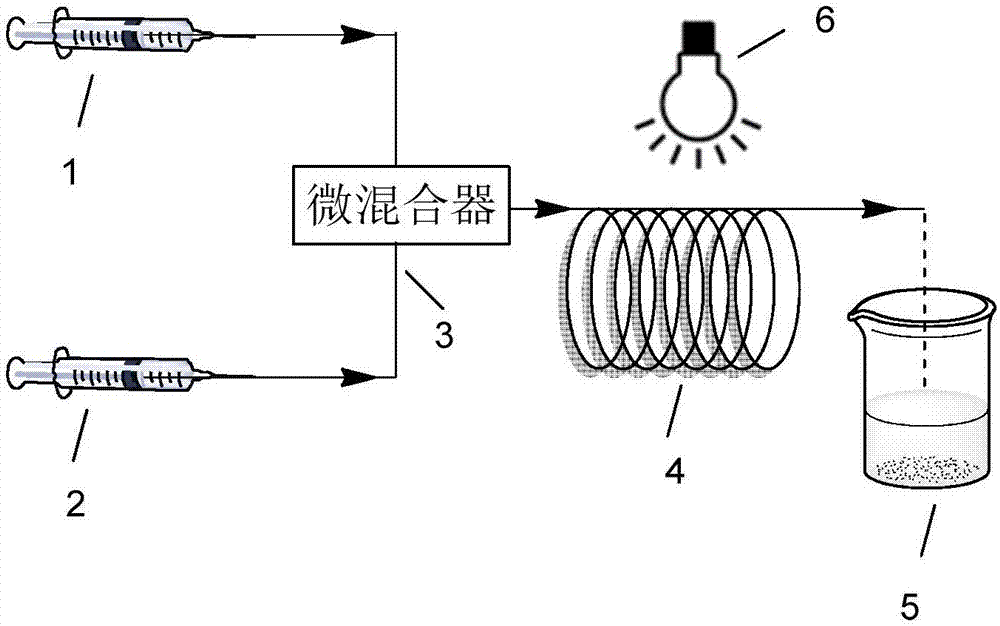

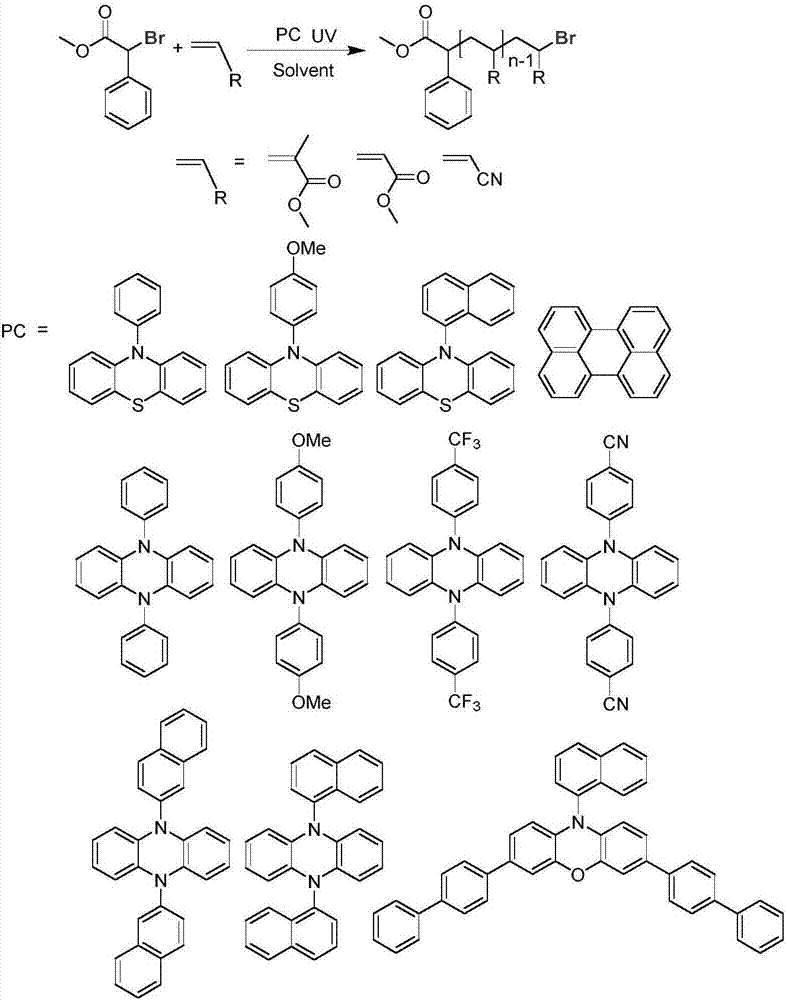

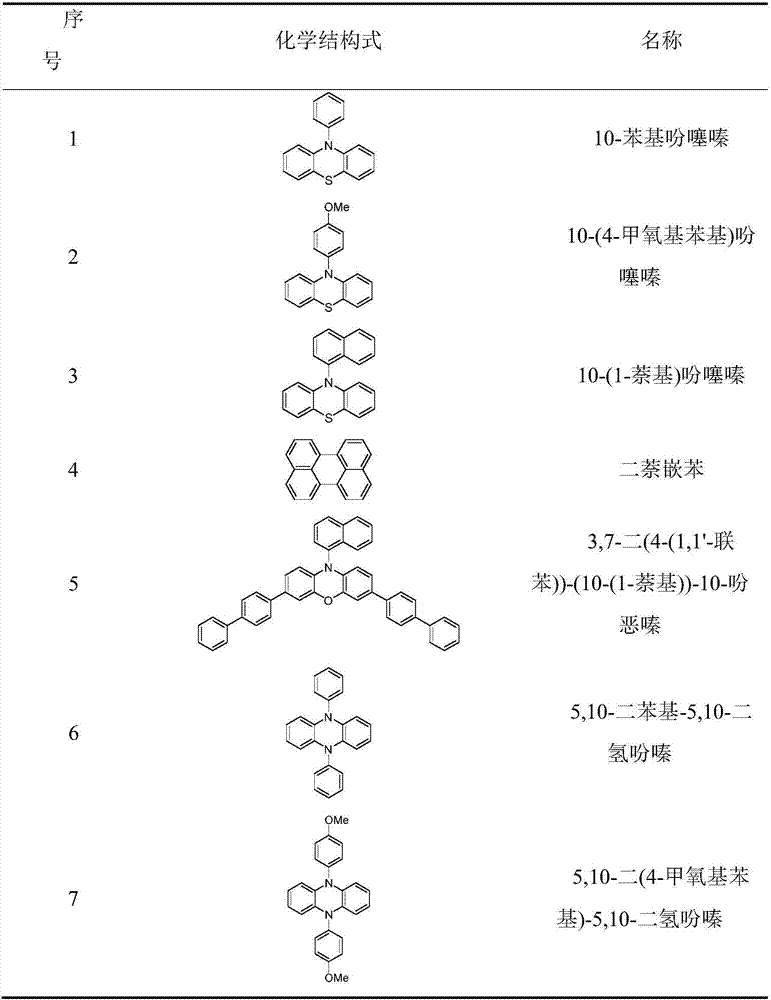

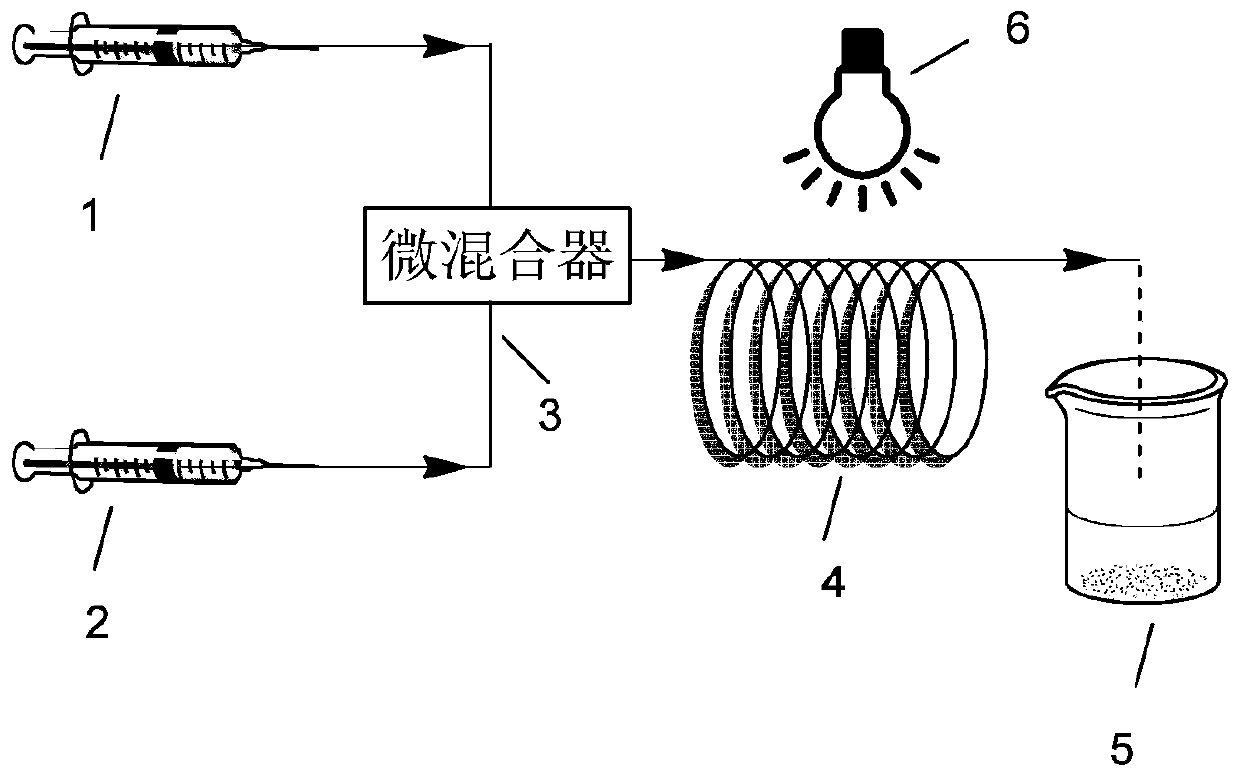

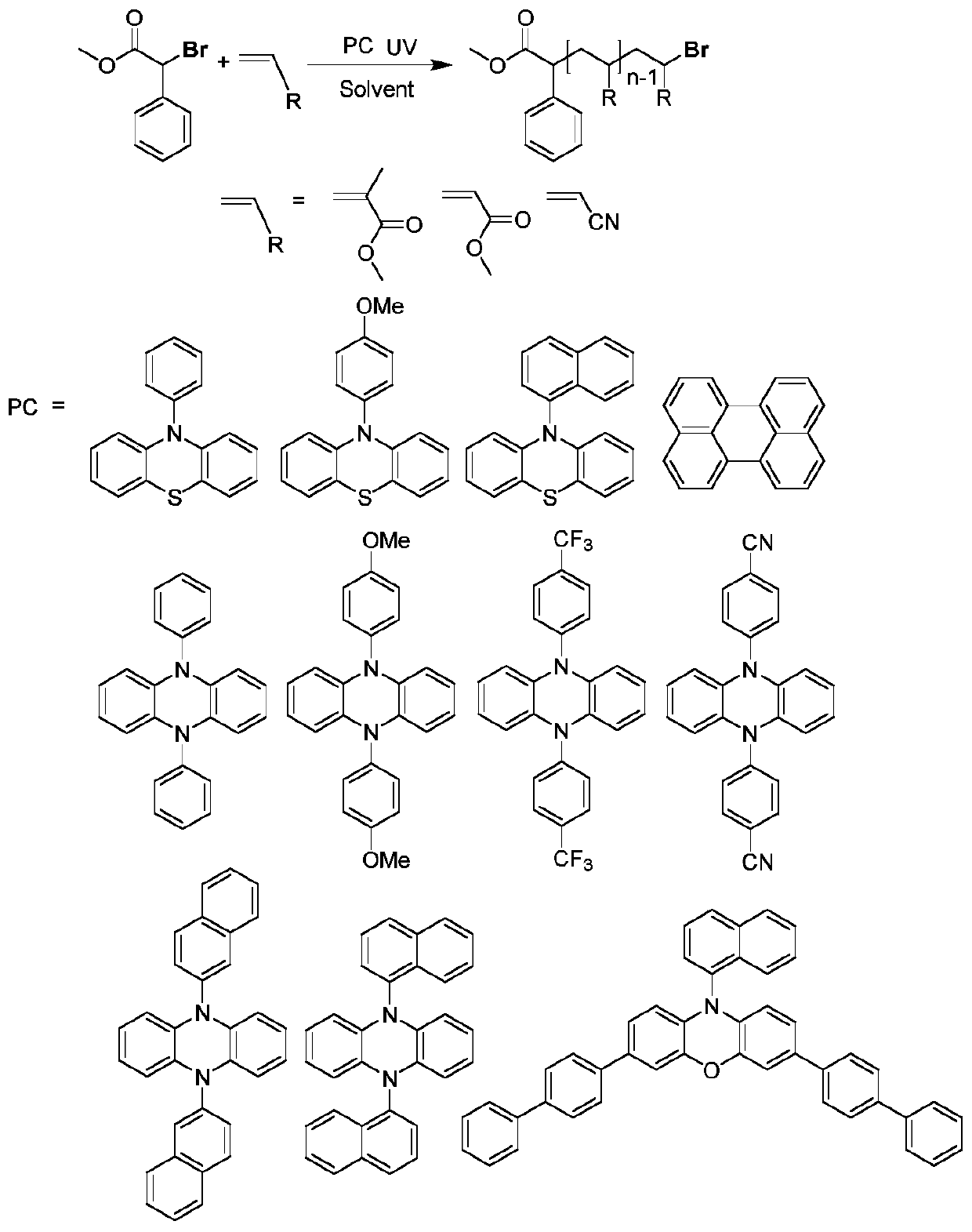

Method for preparing polymer by micro-scale photo-induced organic catalysis

ActiveCN106893015AImprove mixing efficiencyImprove mass transfer efficiencyChemical/physical/physico-chemical processesChemical/physical/physico-chemical microreactorsMicroreactorPolymer science

The invention discloses a method for preparing a polymer by micro-scale photo-induced organic catalysis. The method comprises the following steps: using alkyl halide as an initiator in a microreactor; and using an organic small molecule as a catalyst to catalyze atom-transfer radical-polymerization, so as to prepare the polymer. Compared with the prior art, the method provided by the invention has advantages of high reaction speed, controllable molecular weight and molecular weight distribution of a polymerization product, no residue, and wide application in fields of optoelectronic materials and biomedical materials.

Owner:NANJING UNIV OF TECH

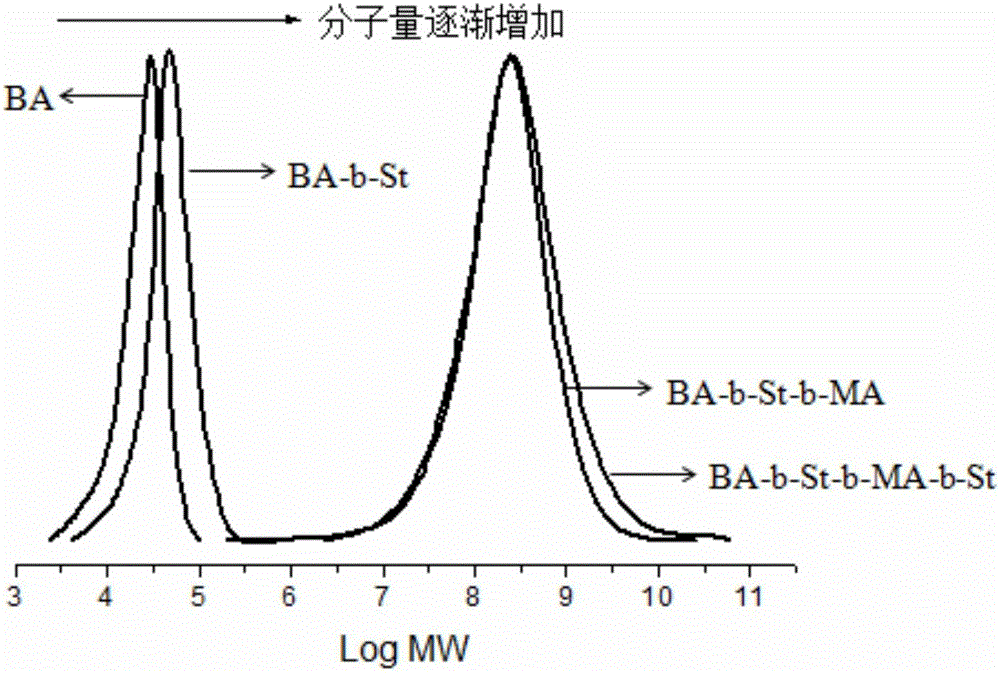

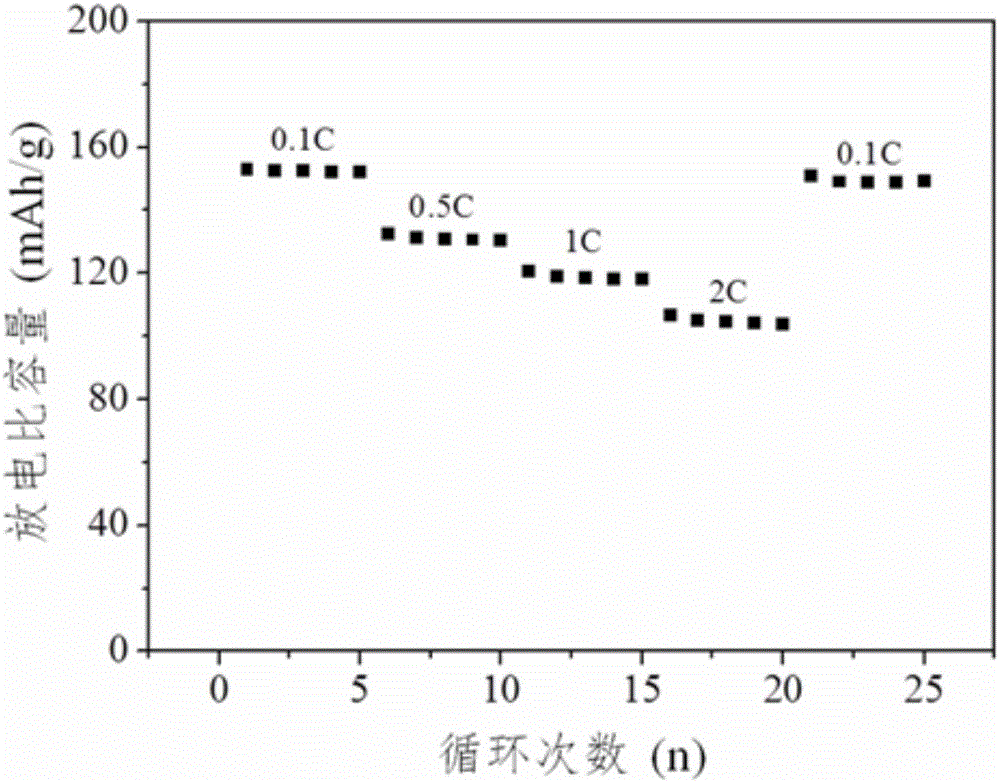

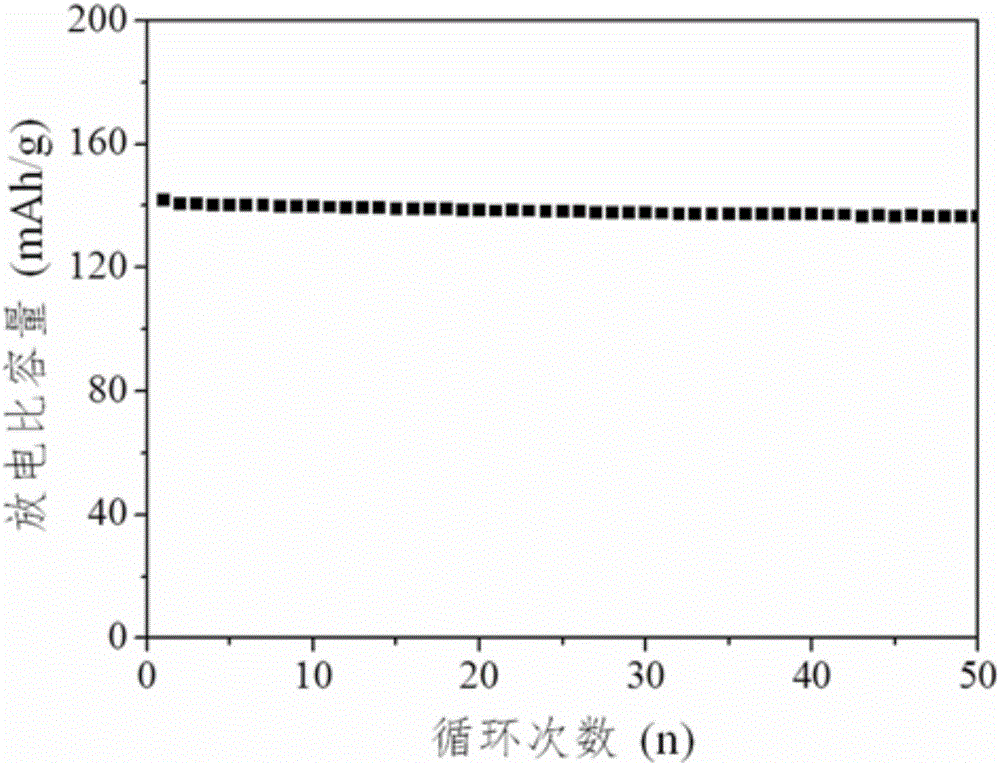

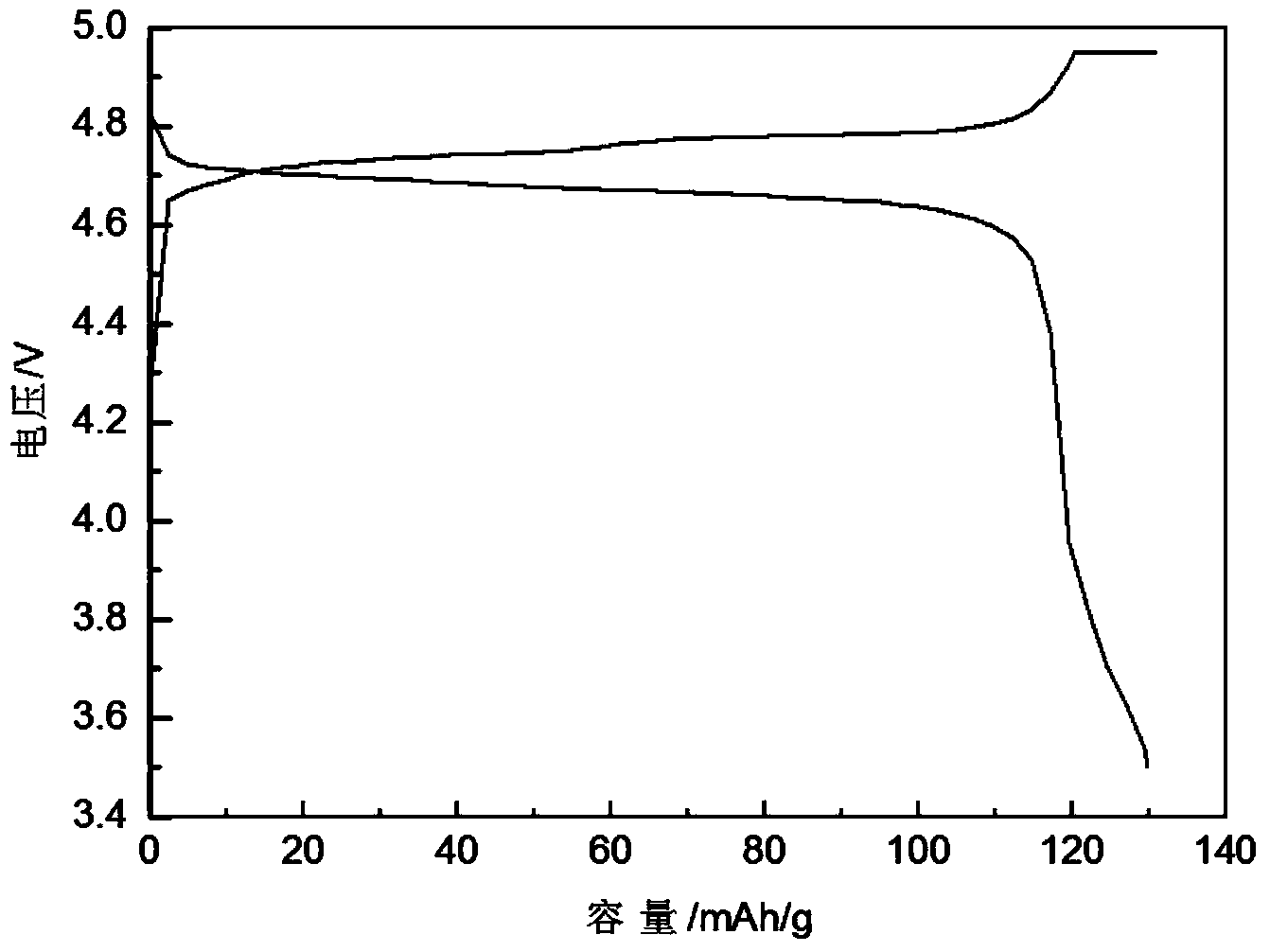

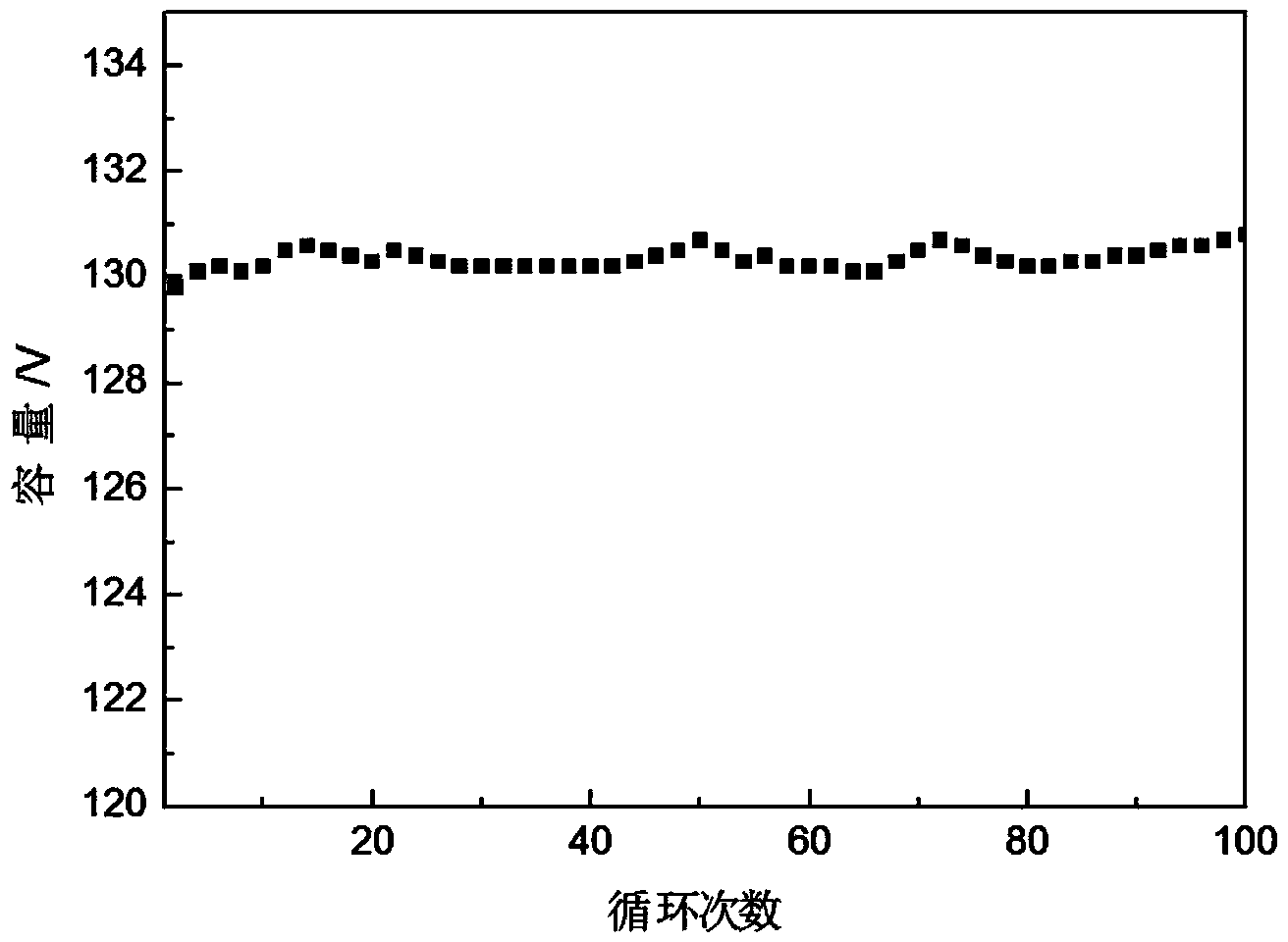

Water-based electrode binding agent and preparation method thereof

ActiveCN106281147AImprove mechanical propertiesGood compatibilityCell electrodesGraft polymer adhesivesWater basedPollution

The invention discloses a water-based electrode binding agent and a preparation method thereof. According to the water-based electrode binding agent, an emulsion polymerization system is adopted, and a reversible addition-fragmentation chain transfer free-radical polymerization technology is used for preparing butyl acrylate / styrene / methyl acrylate block copolymer latex which is used as the electrode binding agent. A preparation process has the advantages of energy saving and environment protection; compared with a traditional binding agent polyvinylidene fluoride, the water-based electrode binding agent has the advantages of low price, simple process, no pollution and the like; the discharge specific capacity of a used electrode in a lithium iron phosphate electrode can reach 153.4mAh / g, and the discharge specific capacity in a graphite electrode can reach 358.6mAh / g; and therefore, the water-based electrode binding agent has great application prospects.

Owner:浙江杰特维新材料有限公司

Synthesis method and application of water soluble chitosan-based flocculant

ActiveCN105622847ASpeed up homolysisThe polymerization reaction is fastWater/sewage treatment by flocculation/precipitationFunctional monomerAlcohol ethyl

The invention provides a synthesis method and application of a water soluble chitosan-based flocculant. The method comprises the steps of adding chitosan into acid solution, adding acylated monomer aqueous solution into the acid solution, uniformly stirring and mixing, performing vibration reaction for 1 to 10 h at 5 to 60 DEG C, performing precipitation and purification through ethyl alcohol and acetone, drying, and obtaining N-acylated chitosan; sequentially adding the N-acylated chitosan, deionized water, acrylamide and strong cation functional monomer into a reactor, uniformly stirring, leading nitrogen into homogenous solution to remove oxygen, adding a photoinitiator and a cosolvent, uniformly stirring and mixing, putting the raw materials into an ultraviolet light reaction device to perform polymerization reaction, drying, performing granulation and powder process, and obtaining the water soluble chitosan-based flocculant; the flocculant can be used for the removal treatment of alga in source water. The flocculant is good in solubility property, high in viscosity coefficient and short in synthesis time, does not need temperature reduction control, simplifies the production technology, reduces energy consumption, and reduces the production cost.

Owner:NANJING UNIV OF TECH

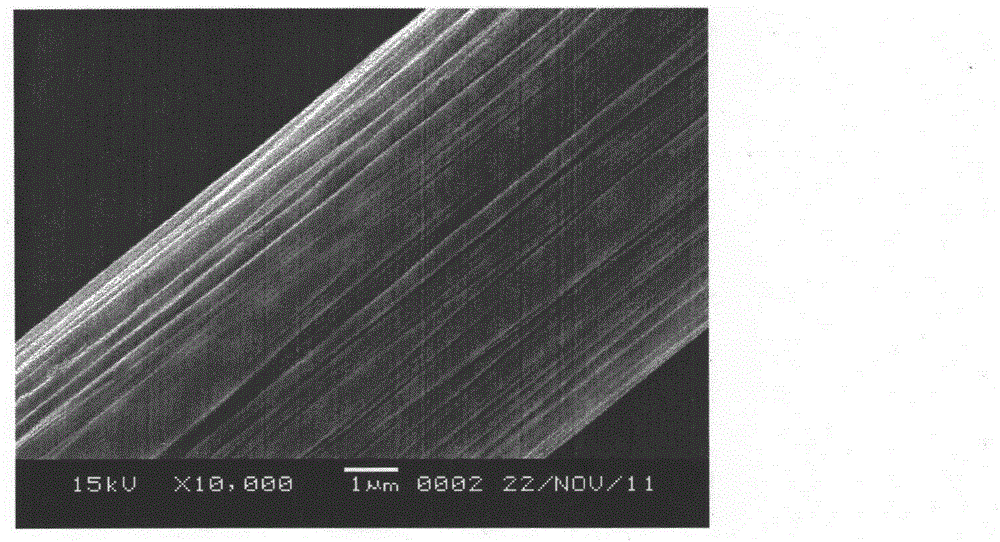

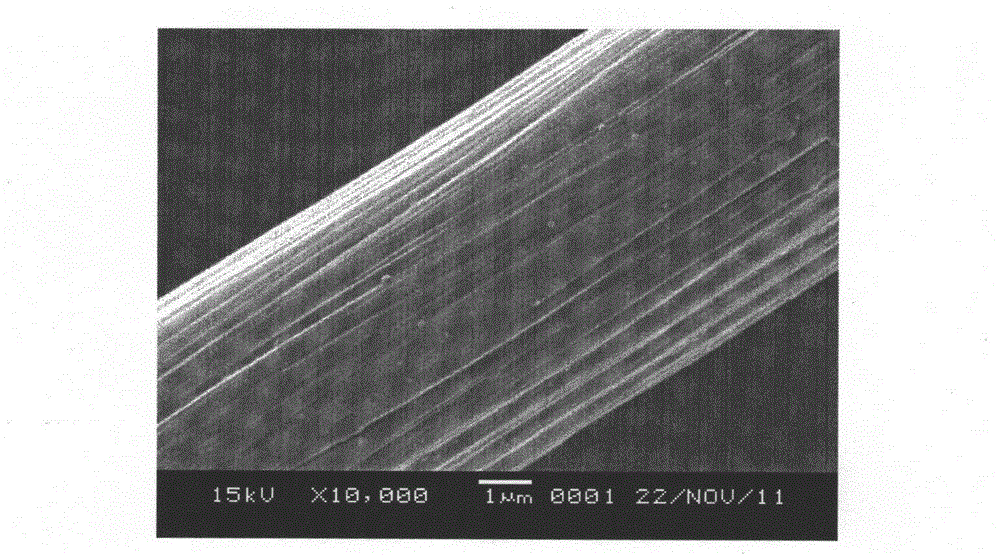

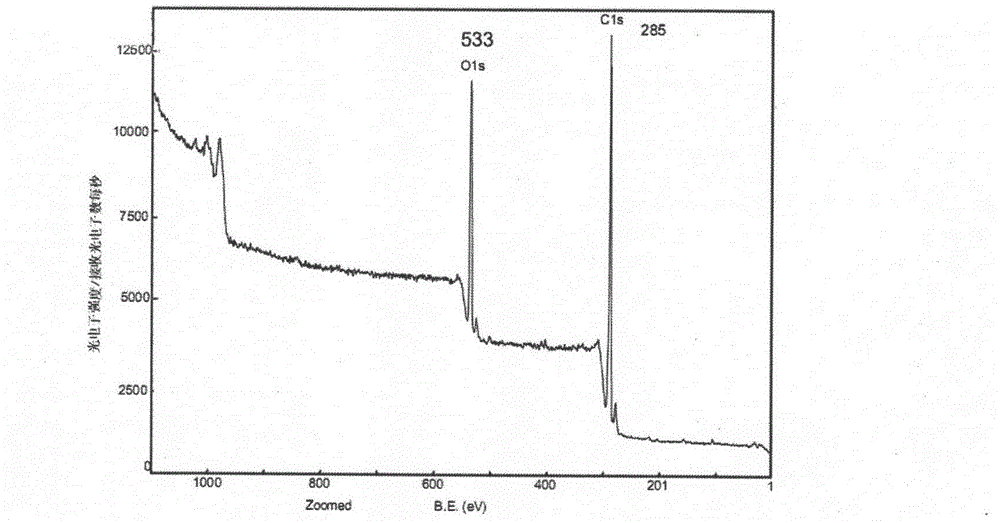

Preparation method for improving interfacial properties of carbon fiber composite material

InactiveCN102720061AImprove interface performanceThe polymerization reaction is fastFibre treatmentFiberOxygen

The invention provides a preparation method for improving interfacial properties of a carbon fiber composite material. The method is characterized by comprising the steps of firstly, preparing plasma activated carbon fiber; secondly, preparing a maleic anhydride dimethylbenzene solution; thirdly, subjecting the activated carbon fiber to ultrasonic infiltration; fourthly, performing grafting of maleic anhydride; and fifthly, purifying a crude product of the plasma activated carbon fiber which the maleic anhydride is grafted to. The method has the advantages that the free radicals formed on the surface of carbon fiber are processed through plasmas of argon-oxygen mixed gas, so that the polymerization reaction speed of the free radicals and the maleic anhydride is accelerated and the degree us improved; the reaction speed is accelerated through a high temperature, and the grafting reaction time is only 3 min to 7 min, so that grafting carbon fiber which is uniform in surface coating and high in grafting rate and has certain quantities of anhydride groups is obtained, the grafting carbon fiber and epoxy resin are subjected to reaction well, and the interfacial properties of the composite material is improved; and the method is energy-saving, environment-friendly and convenient to process.

Owner:DONGHUA UNIV

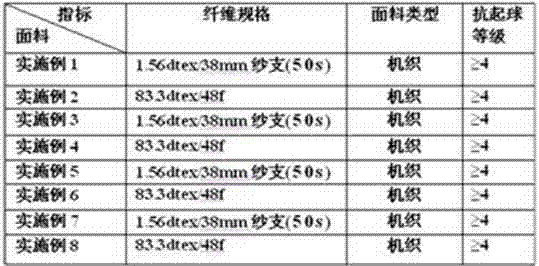

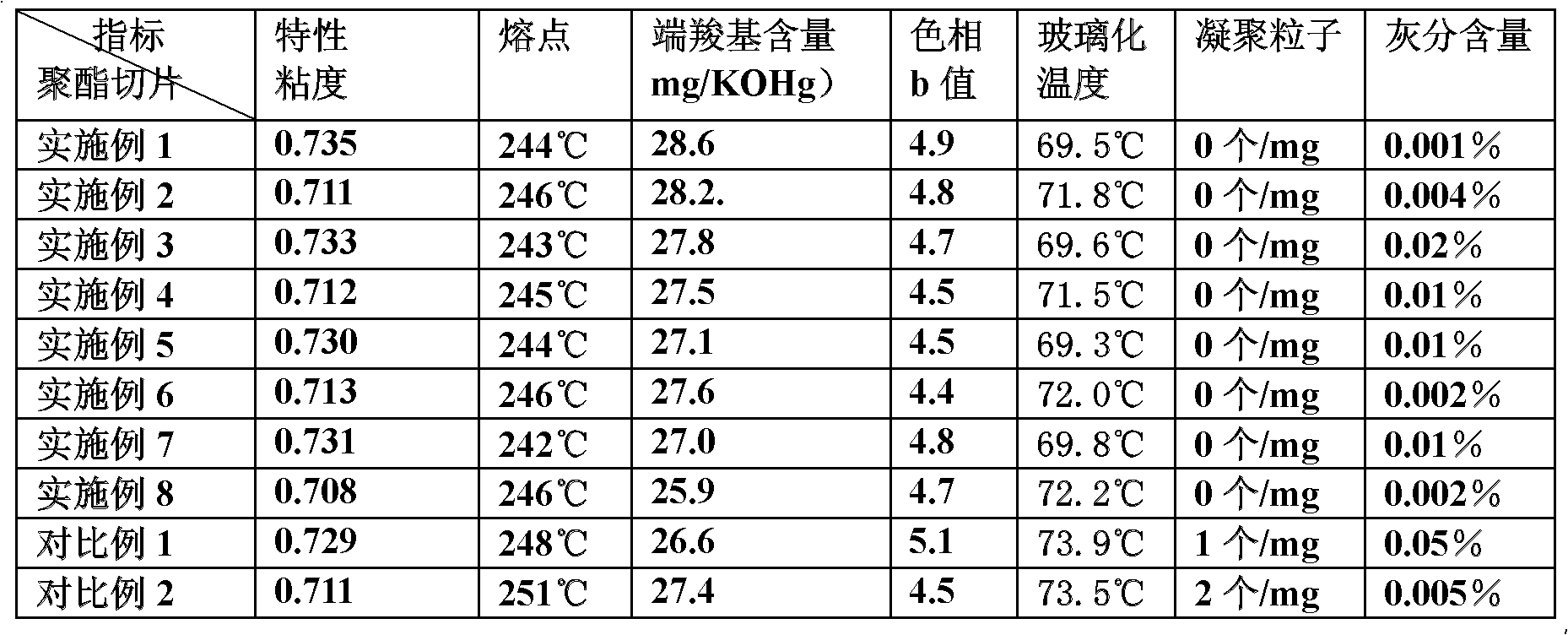

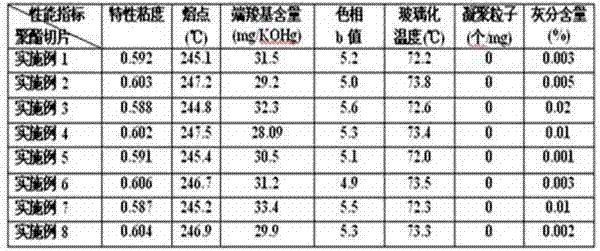

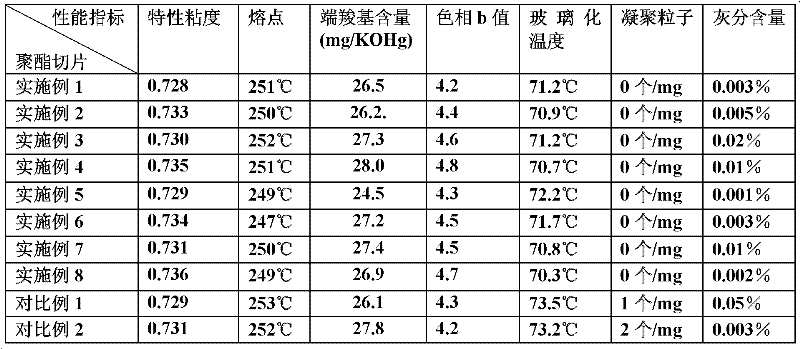

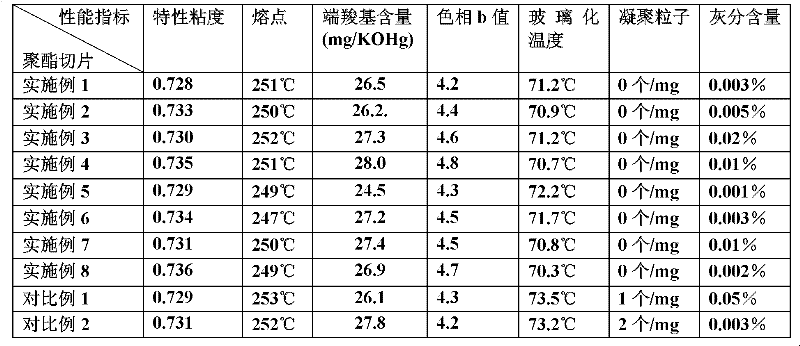

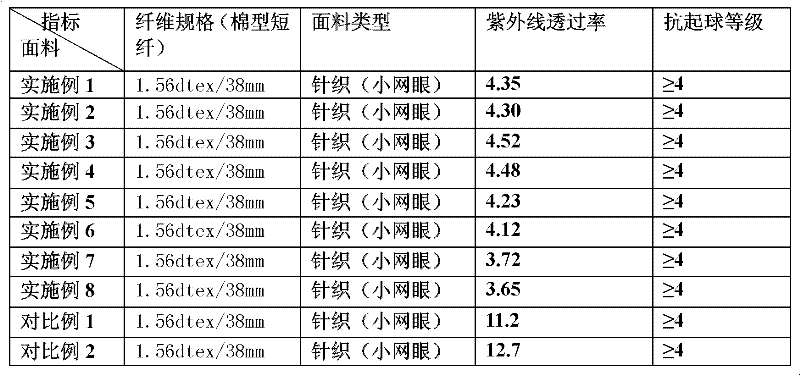

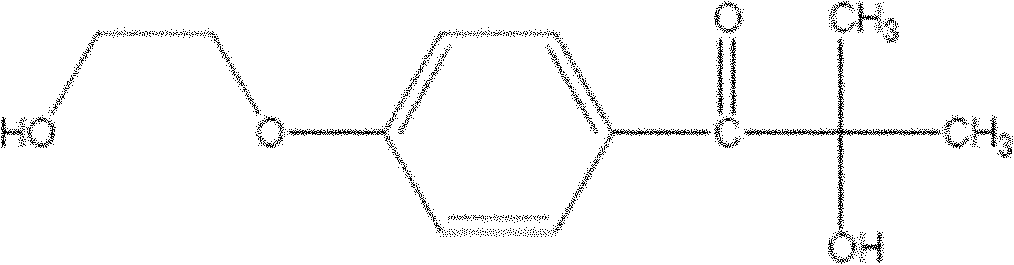

Preparation method for anti-pilling, anti-ageing and normal-pressure cation dyeable polyester chips

InactiveCN102391487AAvoid stickingAvoid self-polymerizationMonocomponent polyesters artificial filamentPolyesterTrans esterification

The invention relates to a preparation method for anti-pilling, anti-ageing and normal-pressure cation dyeable polyester chips. The preparation method comprises procedures of primary esterification, transesterification, secondary esterification and polymerization, wherein three monomers are added in the transesterification procedure; a hindered amine light stabilizer, a hindered phenol antioxidant and hydroxyl silicon oil are added after the secondary esterification and before prepolymerization; and the polyester slices are precrystallized and dried before the spinning procedure. A fabric prepared from fibers spun by the polyester chips has a high anti-pilling property and high light fastness; the polyester fibers can be dyed with various bright colors due to the normal-pressure cation dyeable property; the unified requirement of high-grade spring and summer clothing at present on functionality and color is met; and the polyester fibers and wool can be dyed in the same bath and a good clothing effect of the fibers blended with the wool is achieved. The polyester fibers spun by the polyester chips are important supplement for the cation dyeable polyester fiber market at present and have wide market prospect.

Owner:WUJIANG GANGYANG CHEM FIBER +1

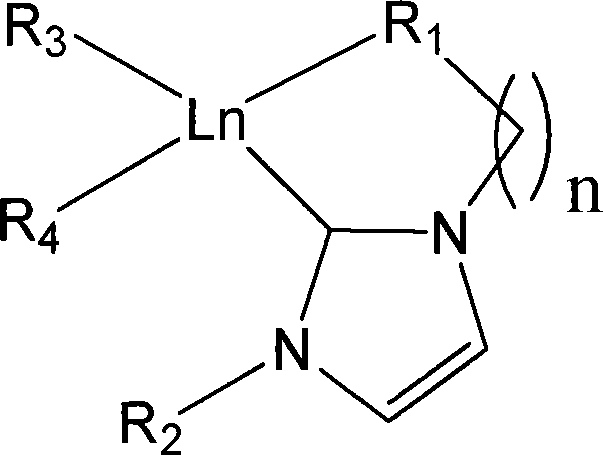

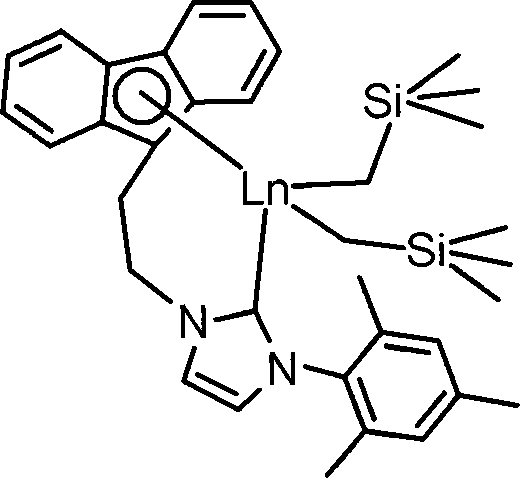

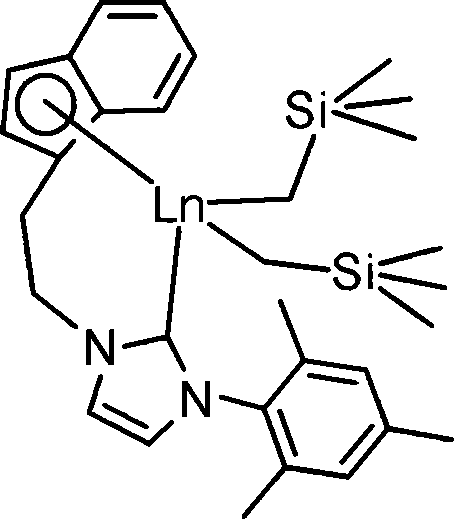

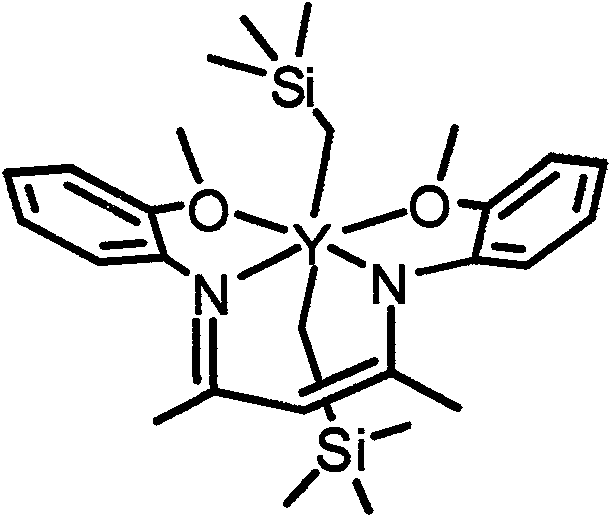

Aza cyclic carbine rear earth catalyst for crystallinity 3,4-polyisoprene

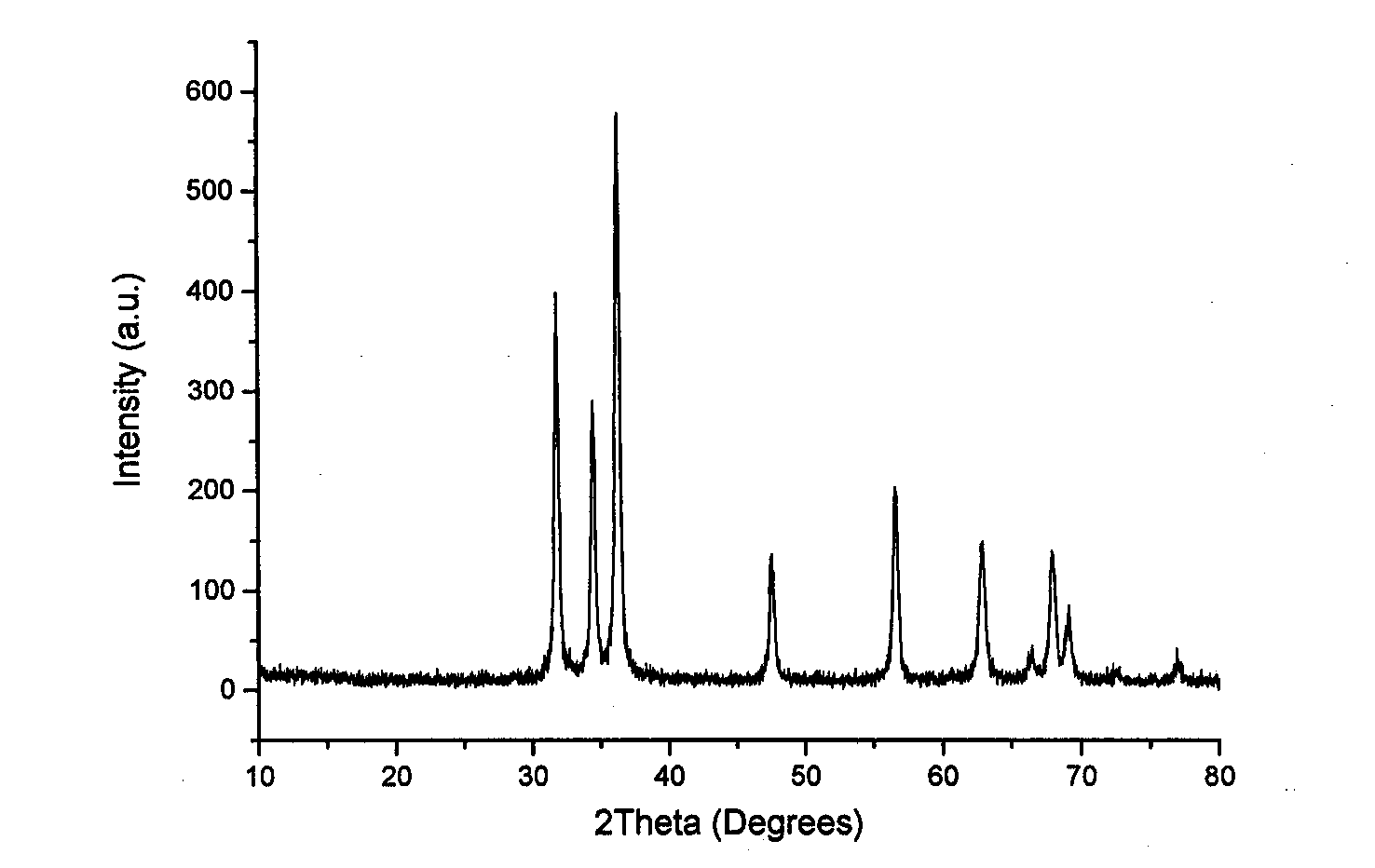

ActiveCN101157737AHigh molecular weightNarrow molecular weight distributionChlorobenzeneReaction temperature

The present invention relates to a nitrogen heterocyclic carbene rare earth complex, a catalyst system which consists of the present invention, aluminum alkyl and an organoboron salt can catalyse the isoprene to carry out the solution polymerization, so as to prepare the polyisoprene with the crystallization property, high 3, 4-structure and high glass transition temperature (Tg). The molar ratio of aluminum alkyl and the rare earth complex is within the scope of 1 to 100, the molar ratio of the organoboron salt and the rare earth complex is within the scope of 0.5 to 2.0; the solvent which is used for polymerization can be toluene, bromobenzene, n-hexane, dichloromethane or chlorobenzene; the polymerization temperature range is -20 DEG C to 80 DEG C, the reaction time of polymerization at minus 20 DEG C is 36 hours, the reaction time of polymerization at 80 DEG C is 1 hour, and the monomer conversion rate can be up to 100 percent. The reaction is characterized by active polymerization, the molecular weight of the product can be controlled by the molar ratio of the monomer and the catalyst, the molecular weight of the polyisoprene can achieve 360,000 at most, and the glass transition temperature Tg is equal to 5 DEG C to 50 DEG C. The content of the 3, 4 structure of the polyisoprene is affected by the spatial effect and the electronic effect of the rare earth complex, the solvent type for polymerization reaction and the polymerization reaction temperature and so on, which is changed between 76 percent and 99 percent.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

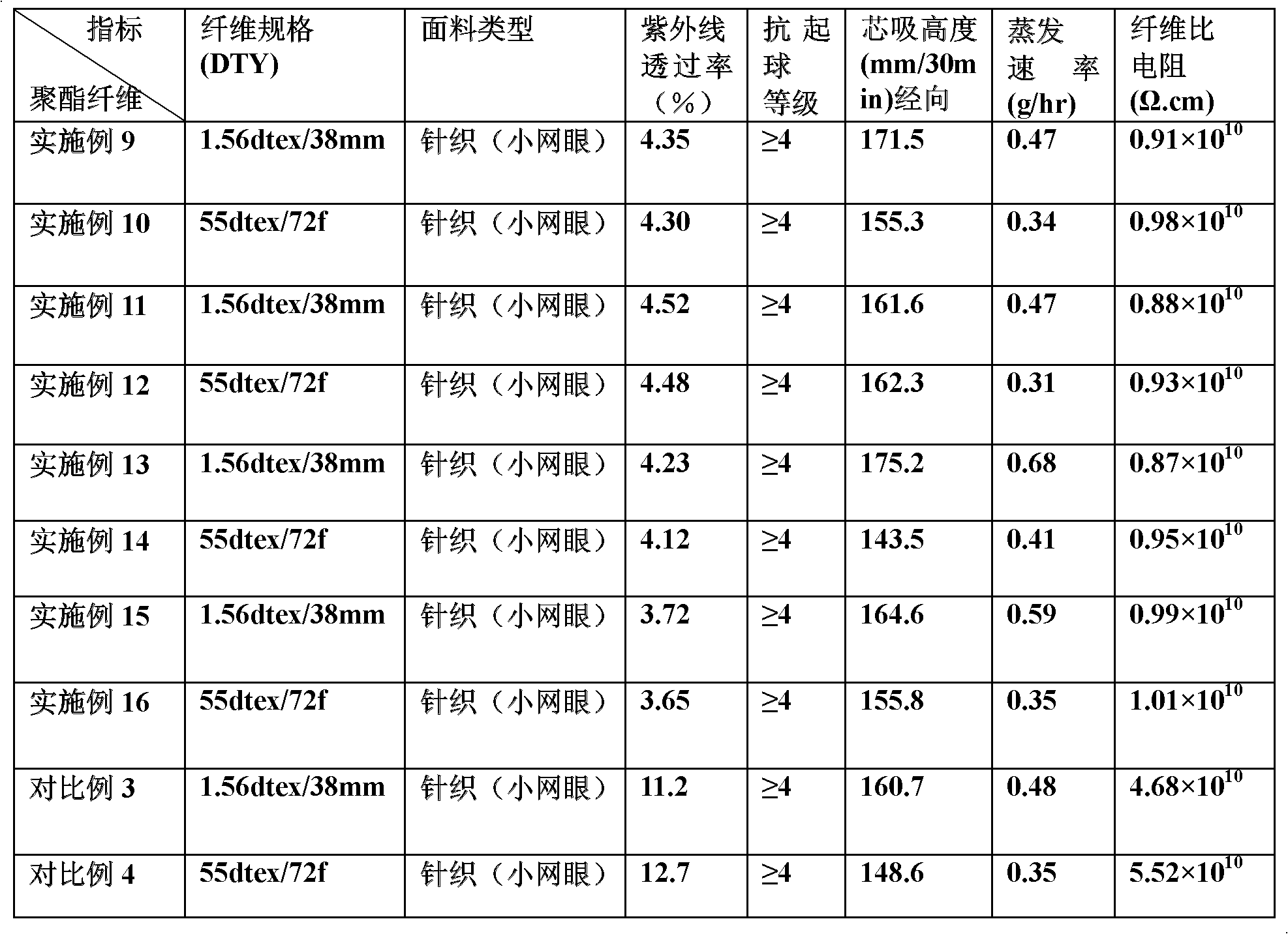

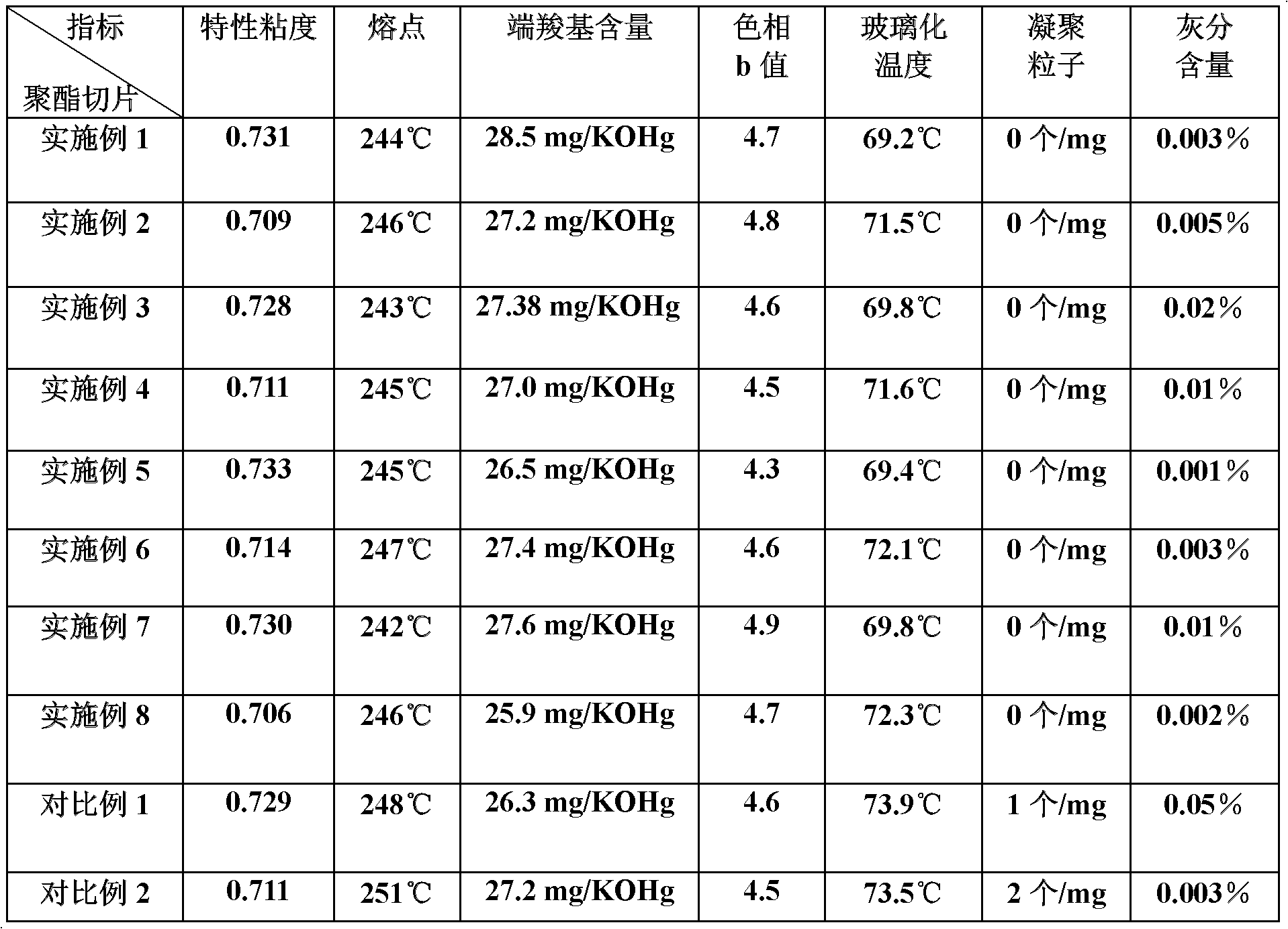

Method for preparing high-comfortable composite functional polyester fiber

ActiveCN102409429AReduce harmImproves UV resistanceElectroconductive/antistatic filament manufactureMonocomponent polyesters artificial filamentSolventAntistatic agent

The invention relates to a method for preparing a high-comfortable composite functional polyester fiber, comprising the steps of: first esterification reaction section, secondary esterification reaction section, polymerization reaction process and spinning process, wherein aliphatic dicarboxylic acid and / or non-centrosymmetrically aromatic dicarboxylic acid is led into the first esterification reaction section to serve as a third monomer; flexible polyethylene glycol is led into the secondary esterification reaction section to serve as a fourth monomer; after finishing the esterification reactions, hindered amine light stabilizer and hindered phenolic antioxidant which are respectively prepared by taking acetic acid and ethylene glycol as solvents and hydroxyl silicone oil are added; after finishing pre-polymerization and before final polymerization of the polymerization reaction process, ultraviolet light absorber and antistatic agent are added; and before finishing the spinning process, polyester slices are performed pre-crystallization and drying; fibers with odd-shaped cross sections of three-leaf, cross, five-leaf and the like are prepared by melt spinning. The obtained polyester fiber is anti-ultraviolet light, antistatic, anti-pilling and has wet-absorbing quick-drying performance; and the fabric has high comfort.

Owner:JIANGSU ZHONGLU TECH DEV +1

A method for photo-induced organocatalytic preparation of polymers at the microscale

ActiveCN106893015BAvoid it happening againQuick responseChemical/physical/physico-chemical processesMicroreactorPolymer science

The invention discloses a method for preparing a polymer by micro-scale photo-induced organic catalysis. The method comprises the following steps: using alkyl halide as an initiator in a microreactor; and using an organic small molecule as a catalyst to catalyze atom-transfer radical-polymerization, so as to prepare the polymer. Compared with the prior art, the method provided by the invention has advantages of high reaction speed, controllable molecular weight and molecular weight distribution of a polymerization product, no residue, and wide application in fields of optoelectronic materials and biomedical materials.

Owner:NANJING TECH UNIV

Method for modifying nickel lithium manganese anode material for lithium ion batteries

InactiveCN103474649AImprove performanceImprove electronic conductivityCell electrodesFiltrationPolypyrrole

The invention discloses a method for modifying a nickel lithium manganese anode material for lithium ion batteries. The method is characterized by including the steps of adding nickel lithium manganese and a surface modifier into water, carrying out ultrasonic dispersion for 10-20min, then, adding an oxidizing agent, carrying out ultrasonic dispersion for 5-15min, adding a pyrrole ethanol solution with the concentration of 0.1-0.5mol / L dropwise, continuing to carry out ultrasonic dispersion for 5-15min after adding, standing and aging the solution for 1-3h, and obtaining the modified nickel lithium manganese anode material wrapped with polypyrrole after suction filtration, washing and drying at the temperature of 80-100 DEG C. The wrapping amount of the polypyrrole is 0.5-5% of the total mass of the material. The specific surface of the prepared nickel lithium manganese anode material is reduced, and the nickel lithium manganese anode material has good processability and is better in cycle performance when applied to the lithium ion batteries.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Preparation method for polyester fibers with anti-static, anti-pilling and normal-pressure cation dyeable compound functions

InactiveCN102391486AAvoid self-polymerizationEasy-to-stain function guaranteeMonocomponent polyesters artificial filamentPolyesterFiber

The invention relates to a preparation method for polyester fibers with anti-static, anti-pilling and normal-pressure cationic dyeable compound functions. The preparation method comprises procedures of primary esterification, transesterification, secondary esterification and polymerization, wherein three monomers are added in the transesterification procedure; a hindered amine light stabilizer, a hindered phenol antioxidant and hydroxyl silicon oil are added after the secondary esterification and before prepolymerization; and an antistatic agent is added after the prepolymerization and before final polymerization. Fabric spun by the polyester fibers has high anti-static and anti-pilling properties; the polyester fibers can be dyed with various bright colors due to the normal-pressure cation dyeable property; the unified requirement of high-grade spring and summer clothing at present on functionality and color is met; and the fibers and wool can be dyed in the same bath and a good clothing effect of the fibers blended with the wool is achieved. The polyester fibers are important supplement for the cation dyeable polyester fiber market at present and have wide market prospect.

Owner:WUJIANG GANGYANG CHEM FIBER +1

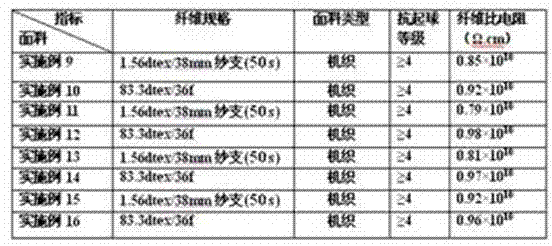

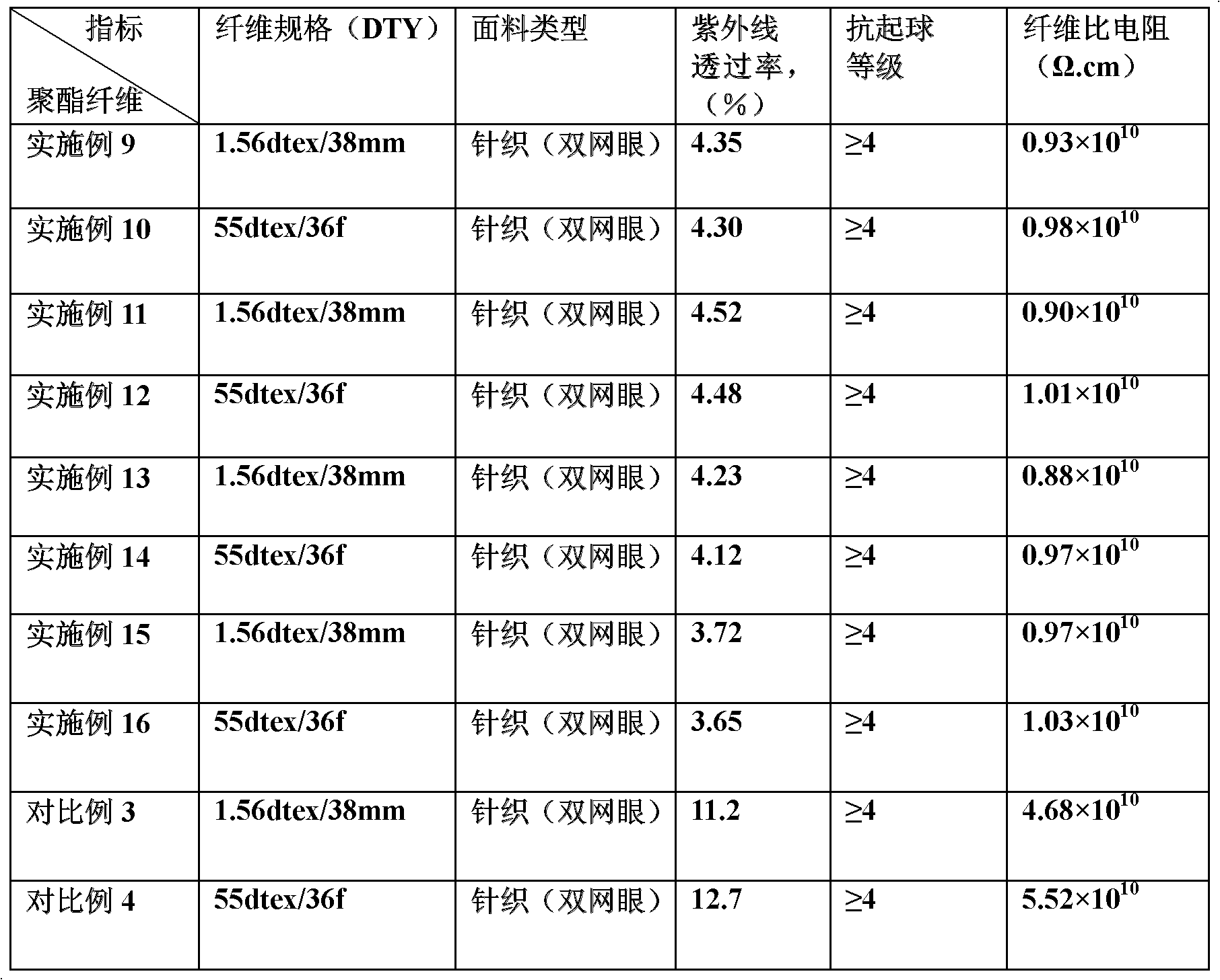

Preparation method for polyester fiber with composite ultraviolet, static electricity and pilling resisting functions

ActiveCN102409427AReduce harmImproves UV resistanceElectroconductive/antistatic filament manufactureArtificial filament heat treatmentSolventTransmittance

The invention relates to a preparation method for a polyester fiber with a composite ultraviolet, static electricity and pilling resisting function. The preparation method comprises an esterification reaction procedure, a polymerization reaction procedure and a spinning procedure. The esterification reaction procedure comprises a primary esterification reaction stage and a secondary esterification reaction stage, flexible polyethylene glycol is introduced as a third monomer in the secondary esterification reaction stage, and after esterification is finished, a hindered amine light stabilizer,a hindered phenol anti-oxidant and hydroxyl silicone oil are added, wherein the hindered amine light stabilizer and the hindered phenol anti-oxidant are prepared by taking an acetic acid and ethyleneglycol as solvents. In the polymerization reaction procedure, after prepolymerization and before final polymerization, an ultraviolet absorbent and an antistatic agent are added. Before the spinning procedure, polyester is sliced for pre-crystallization and drying. The polyester fiber obtained by the method has the outstanding ultraviolet, static electricity and pilling resisting functions, and after being woven into knitted machine-made fabrics, is tested to have related technical indexes comprising the ultraviolet light transmittance of less than or equal to 5.0%, the pilling resistance of more than or equal to level 4 and the fiber volume specific resistance of less than or equal to 10*10<10> ohm.cm.

Owner:JIANGSU ZHONGLU TECH DEV +1

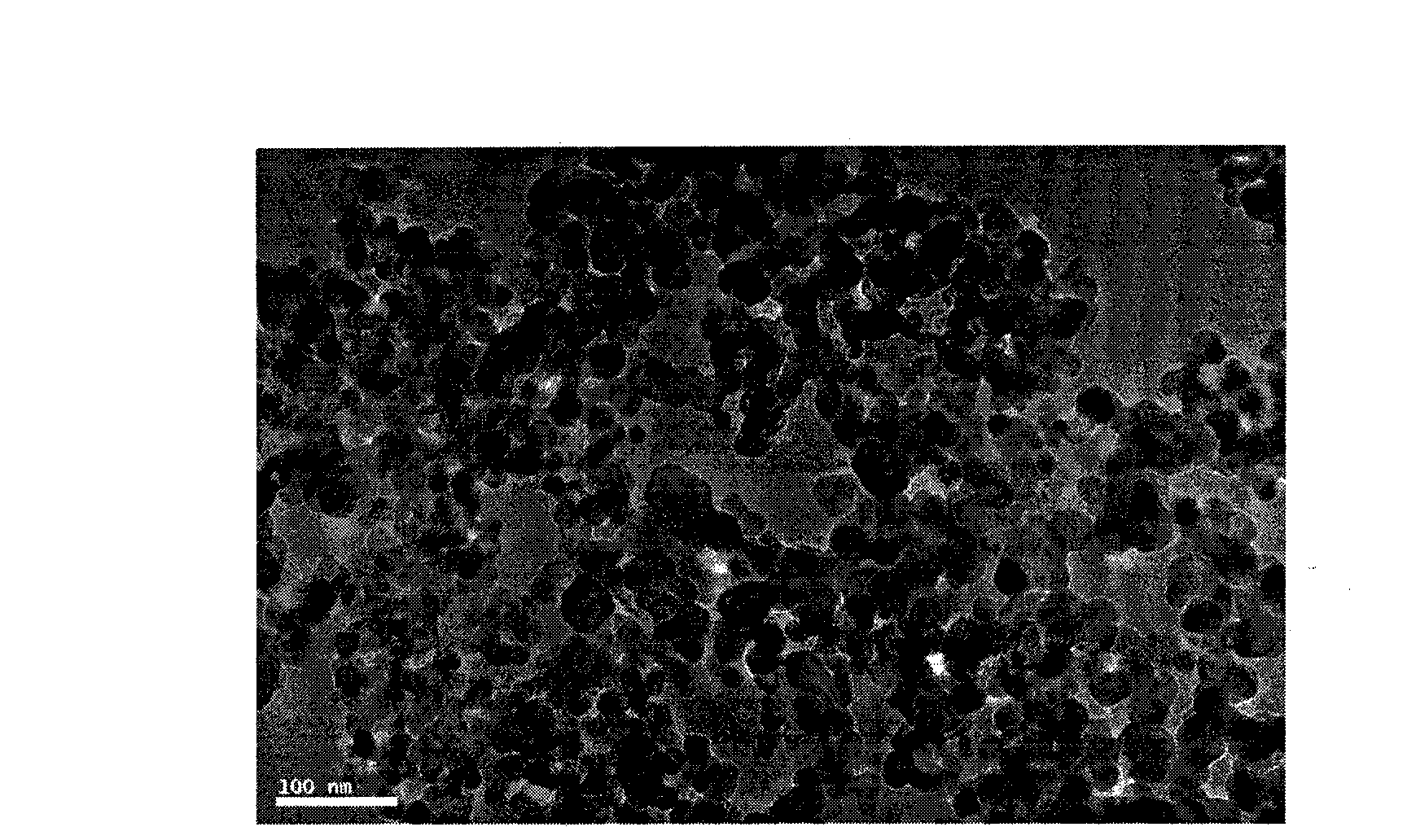

Method for preparing n-type doped zinc oxide nanometer powder

InactiveCN101665235AUniform sizeCalcination temperature is lowNanostructure manufactureAntistatic MaterialsAqueous solution

The invention discloses a method for preparing n-type doped zinc oxide nanometer powder, belonging to the preparation of nanometer materials. A general formula of the n-type doped zinc oxide is ZnO: M, wherein M is selected from Ga, In and Al. The preparation method comprises the following steps: adding M-containing soluble salt and Zn-containing soluble salt to aqueous solution of acrylic acid according to a certain proportion; adding aqueous solution of peracetic initiators; heating at 60-100 DEG C to ensure the system to completely polymerized; drying, cooling, grinding, and calcining in amuffle; and treating the obtained product at high temperature in reducing atmosphere. The invention has simple technique and is suitable for large-scale preparation and industrial mass production. Theprepared powder has good dispersibility, uniform size in the range from 20 to 120 nm, homogeneous phase without impurity, lighter color and higher conductivity and is particularly applied to the fields of transparent heating insulating materials, light color antistatic materials and the like.

Owner:SHIJIAZHUANG RAILWAY INST

Superhydrophobic polyester resin powder paint

InactiveCN105694682AIncrease the degree of diffusionHigh purityPowdery paintsBituminous coatingsAluminium hydroxideAntioxidant

The invention discloses a superhydrophobic polyester resin powder coating, the raw materials of which include by weight: 45-50 parts of polyester resin, 22-26 parts of phenolic resin, 17-20 parts of hydroxyl acrylic resin, 13-20 parts of fluorine-containing hydrophobic material 16 parts, 8-12 parts of asphalt, 6-9 parts of magnesium carbonate, 6-8 parts of aluminum hydroxide powder, 1-3 parts of barium sulfate, 2-3 parts of zinc powder, 3-5 parts of curing agent, 2 parts of leveling agent -5 parts, 1-2 parts of matting agent, 1-3 parts of antioxidant, 1-2 parts of pigment dispersant. The superhydrophobic polyester resin powder coating proposed by the invention has excellent hydrophobic performance and is a powder coating with good antirust performance.

Owner:安徽圣德建材科技有限公司

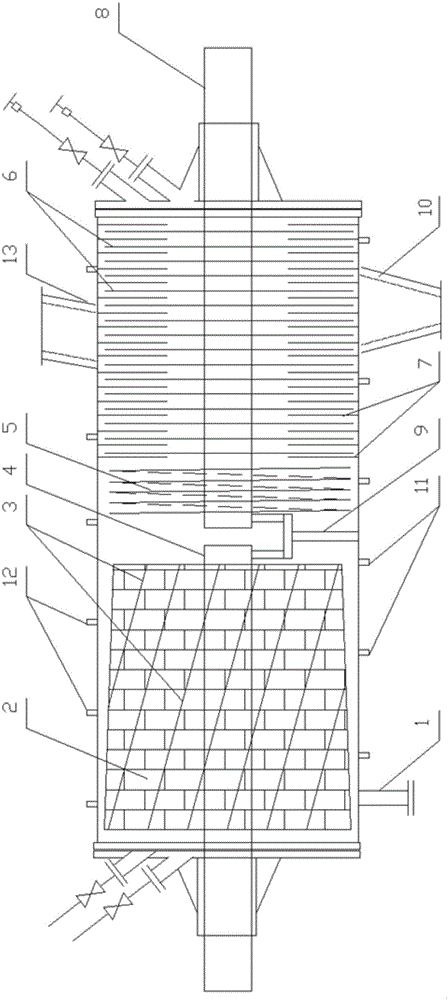

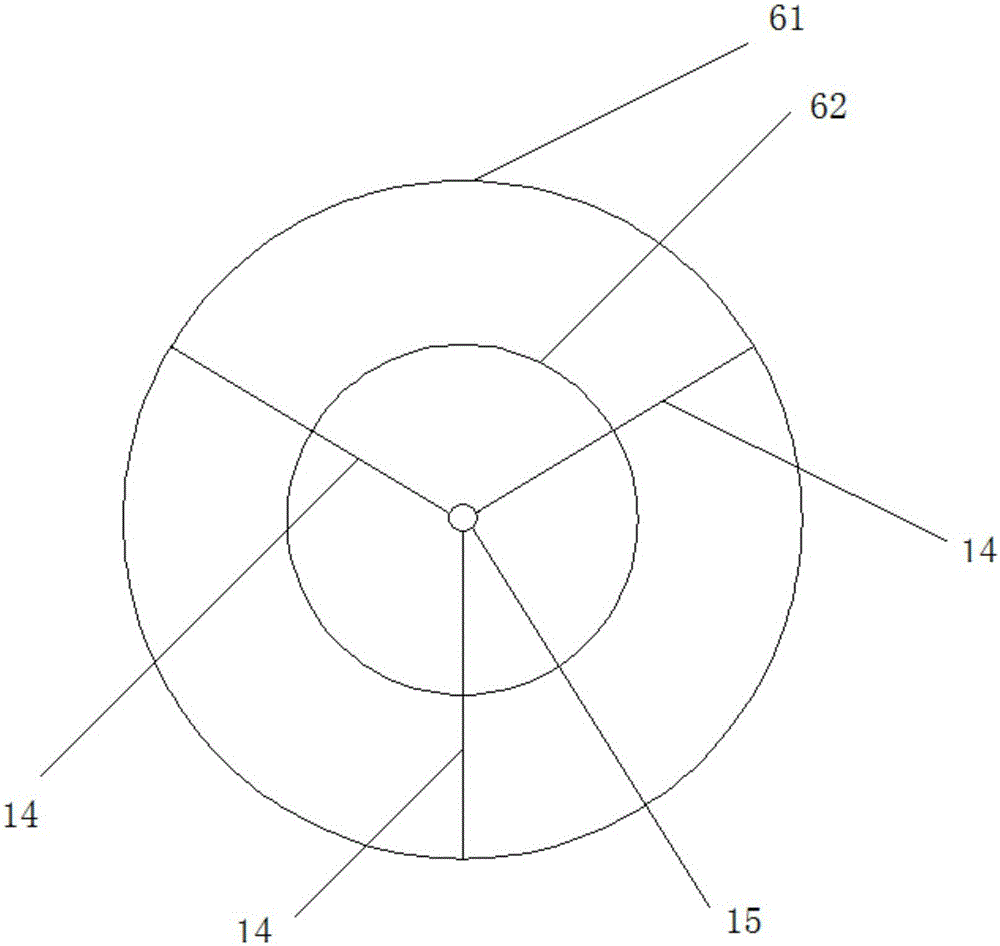

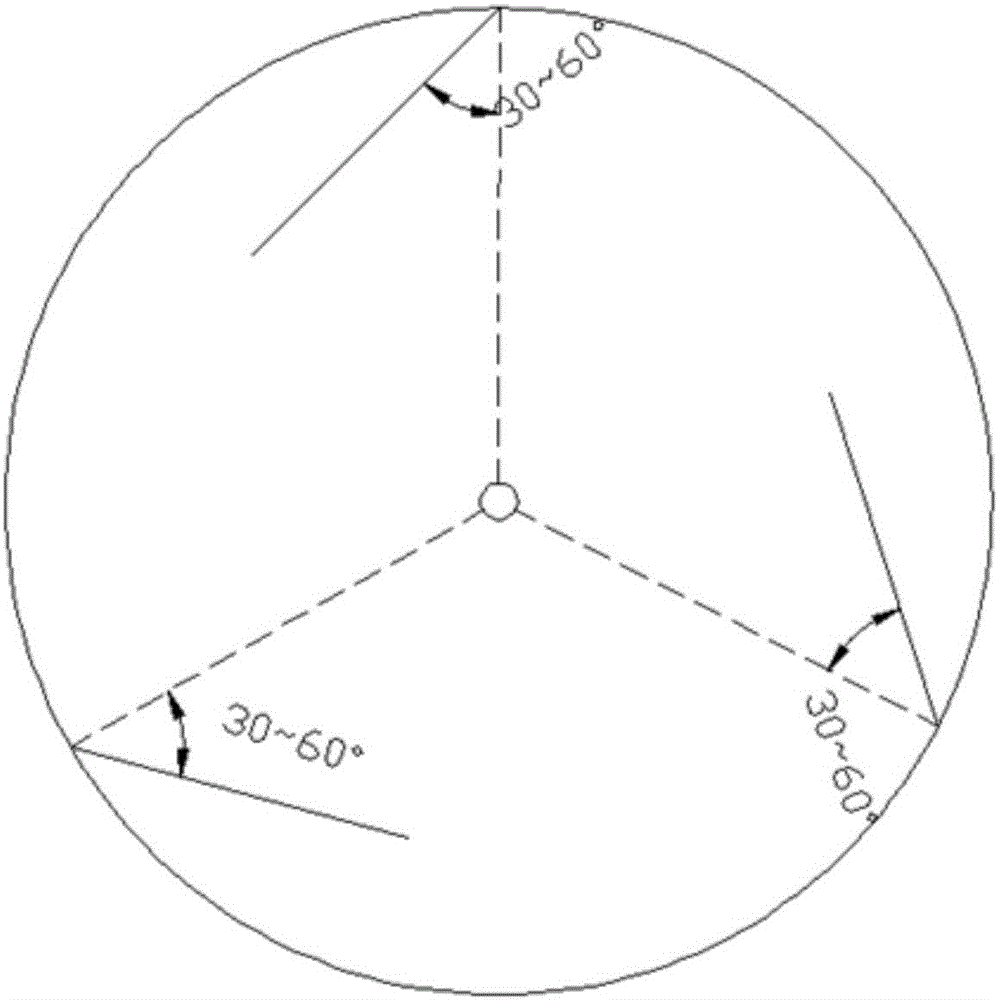

Polymeric reactor and polyester production method

ActiveCN106268591AHigh viscosityIncrease the devolatilization areaChemical/physical/physico-chemical stationary reactorsCircular discPolyester

The invention discloses a polymeric reactor and a polyester production method. The polymeric reactor comprises a closed horizontal cylinder. A front end rotating shaft is arranged at the portion, close to a material inlet, inside the cylinder. One end of the front end rotating shaft stretches out from the cylinder and is connected with a first power device. A rear end rotating shaft is arranged at the portion, close to a material outlet, of the cylinder, and one end of the rear end rotating shaft stretches out from the cylinder and is connected with a second power device. A supporting structure for supporting the front end rotating shaft and the rear end rotating shaft is arranged inside the cylinder. A cage frame type stirrer is arranged on the front end rotating shaft. A section of screw-type disc is arranged at the portion, close to the front end rotating shaft, of the rear end rotating shaft. A plurality of sets of coaxial circular rings are arranged at the other parts of the rear end rotating shaft. A plurality of scrapers parallel to the faces of the circular rings are arranged among the circular rings. According to the method, the polymeric reactor is used for performing polyester production to obtain a high-viscosity polyester melt. The cage frame type stirrer is arranged at the front end, the multiple circular rings are arranged at the rear end, and the devolatilization efficiency of equipment can be effectively improved.

Owner:SHANGHAI JUYOU CHEM ENG

Method for preparing polyacrylate-2-acrylamide-2-methyl propane sulfonic acid

The invention discloses a method for preparing polyacrylic acid-2-acrylamide-2-methyl propanesulfonic acid. The method mainly comprises the following steps: 5 to 30 mass percent of crylic acid, 1 to 15 mass percent of 2-acrylamide-2-methyl propanesulfonic acid, 0.5 to 6 mass percent of persulfate, 0.2 to 3 mass percent of sodium sulfite, 0.05 to 3 mass percent of L-ascorbic acid, 0.5 to 9 mass percent of ethanol, 0.5 to 3 mass percent of dodecyl mercaptan and 50 to 85 mass percent of water are mixed to have polymerization reaction for not less than one hour at a temperature of between 35 and 60 DEG C to obtain the polyacrylic acid-2-acrylamide-2-methyl propanesulfonic acid. The method has the advantages the polyacrylic acid-2-acrylamide-2-methyl propanesulfonic acid with low molecular weight is synthesized once, has low starting reaction temperature, less energy consumption, rapid reaction speed, high utilization efficiency of equipment, a simple process and convenient operation.

Owner:娄底市裕德科技有限公司

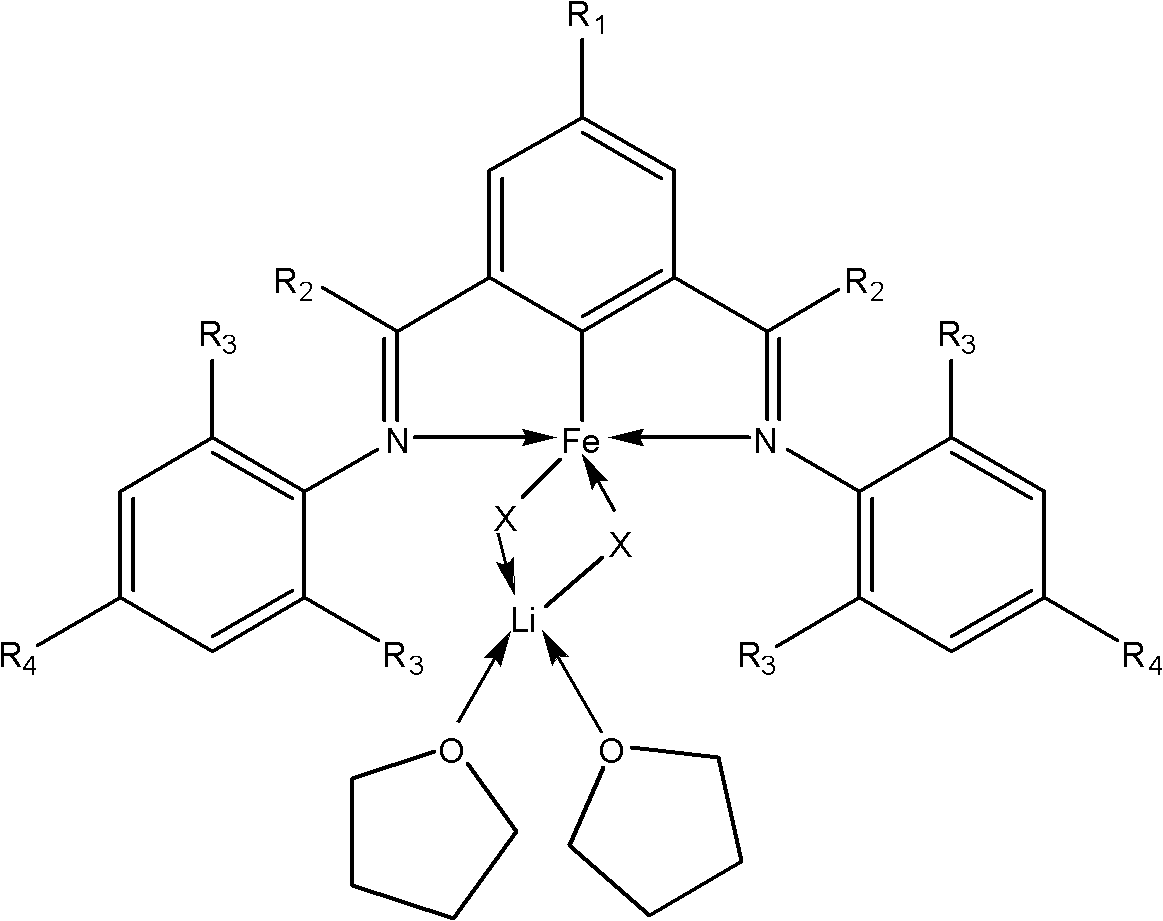

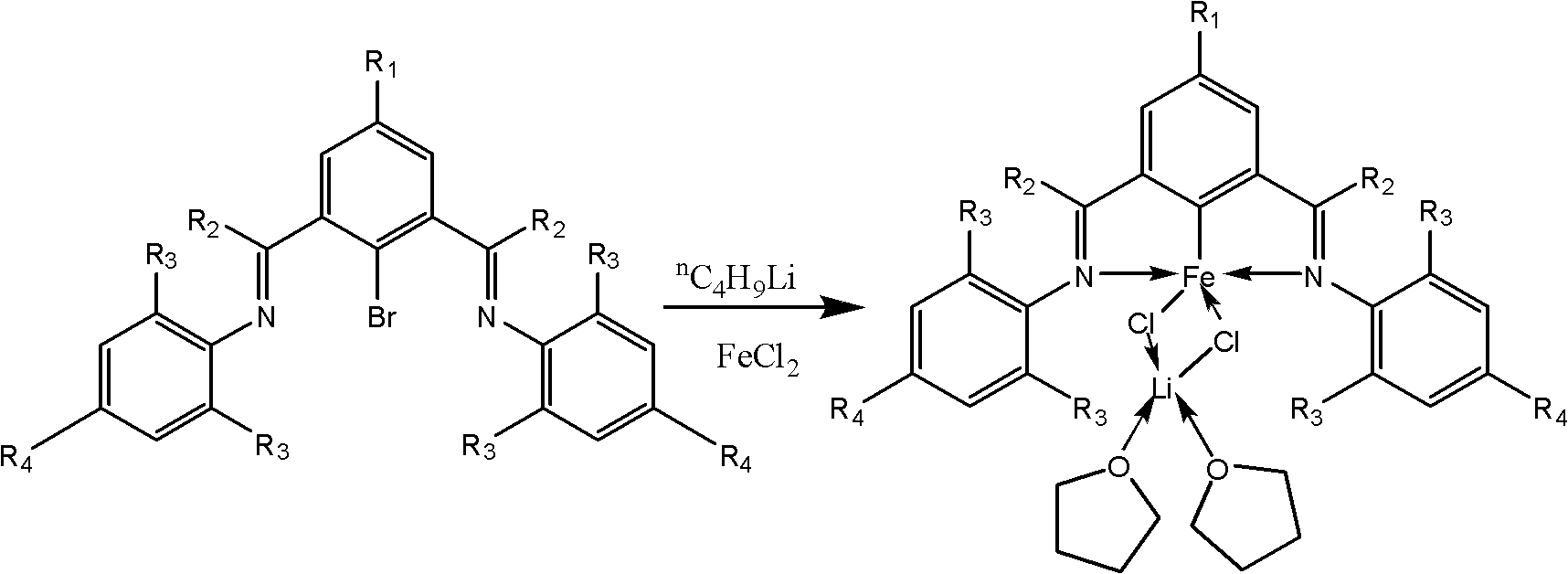

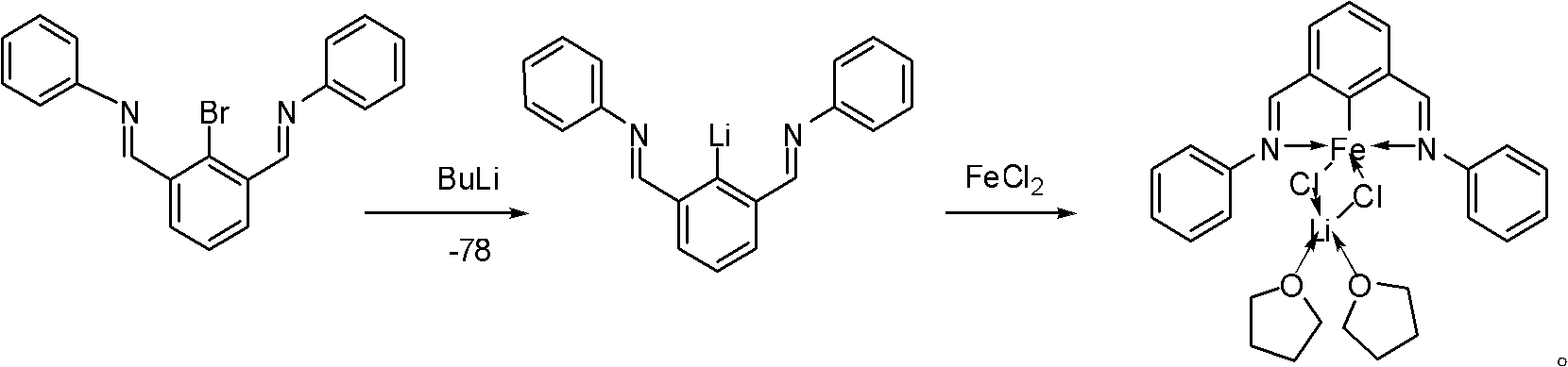

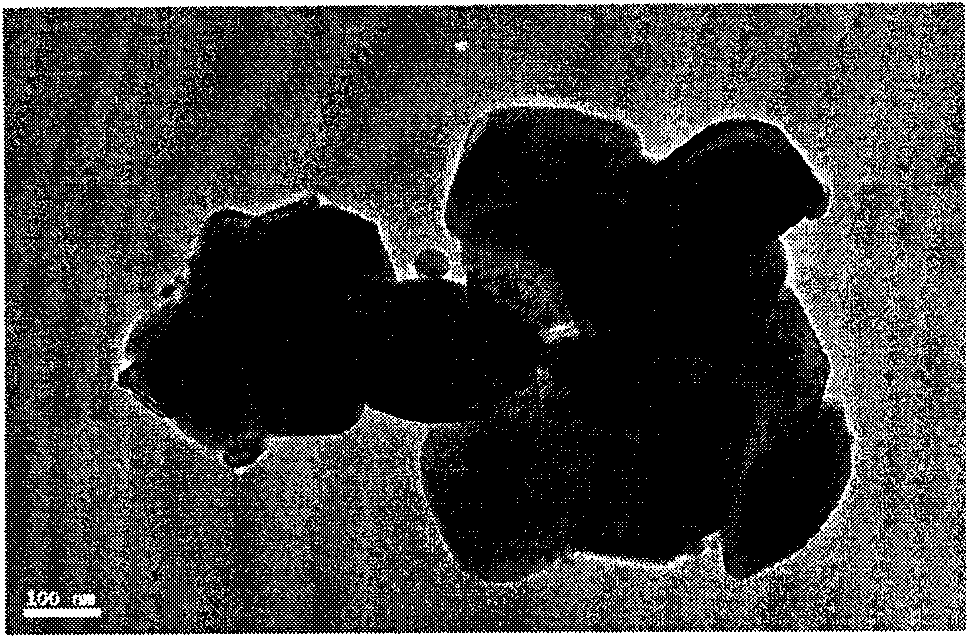

Clamp-type iron complex and preparation method and application thereof

InactiveCN102633840AEasy to manufactureImprove stabilityIron organic compoundsFiltrationRoom temperature

The invention discloses a clamp-type iron complex and a preparation method and application thereof, and belongs to the field of catalysis technologies. The clamp-type iron complex is based on [NCN]-coordination. The preparation method comprises the following steps of: adding a butyl lithium solution into a ligand solution under the condition of the temperature of -78 to -40 DEG C, and reacting to obtain a reaction solution; adding ferrous chloride into the reaction solution, naturally raising the temperature to room temperature, and continuing reaction; and adding hexane to perform filtration and recrystallization. A catalyst consisting of the [NCN]-coordination clamp-type iron complex and alkyl aluminum is used for catalyzing butadiene syn-1,4 to perform selective polymerization. The clamp-type iron complex is convenient to prepare and high in stability; during selective polymerization of the butadiene under the catalyst, the using amount of the catalyst is small, the polymerization reaction speed is high, the conversion efficiency is high, and syn-1,4 selectivity is relatively high, and polymer molecule weight and molecule weight distribution are controllable; the system formed by the catalyst is homogeneous; the clamp-type iron complex is convenient to use; during polymerization, the temperature fluctuation range is small; and the reaction is easy to control.

Owner:JILIN UNIV

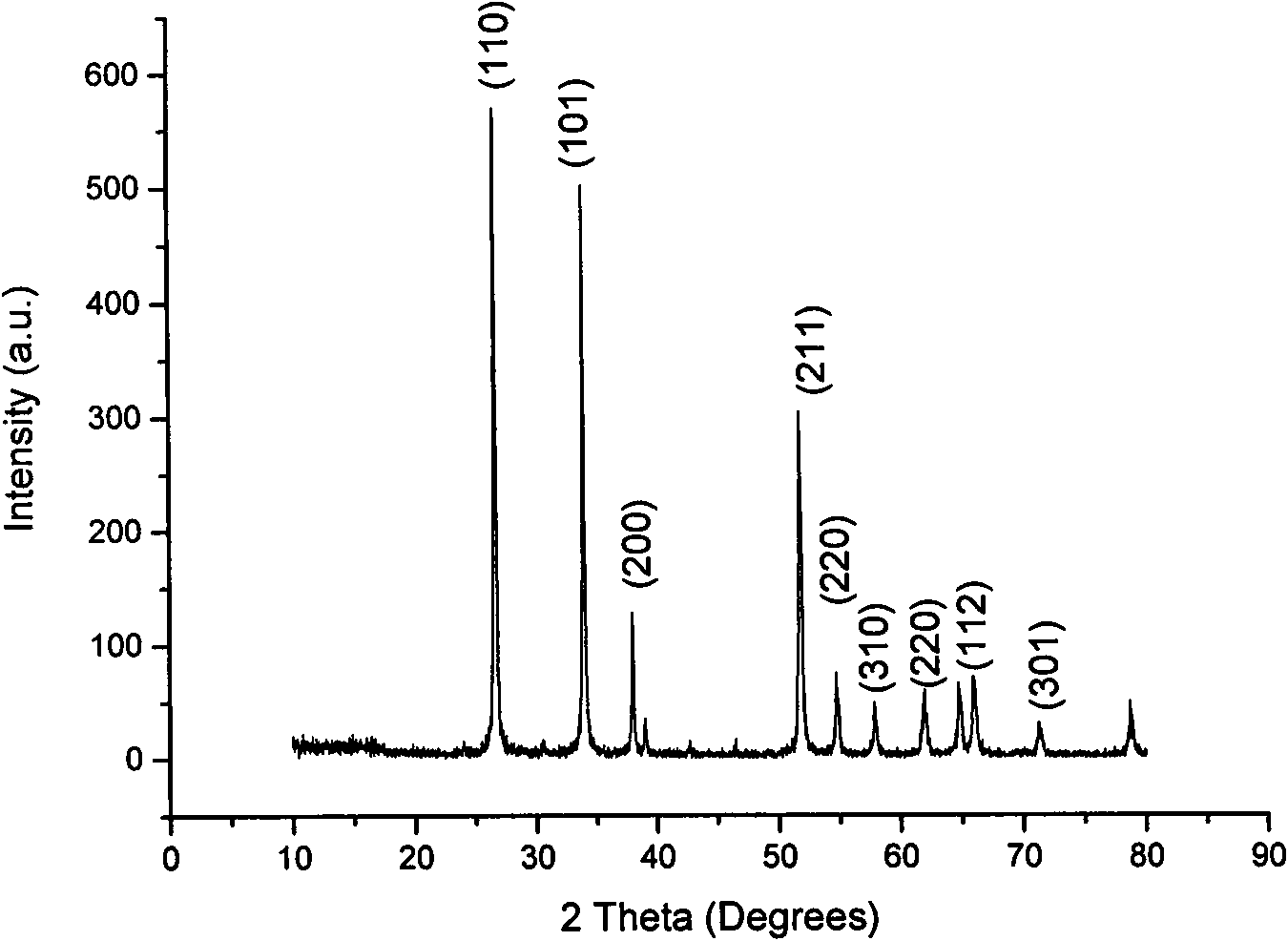

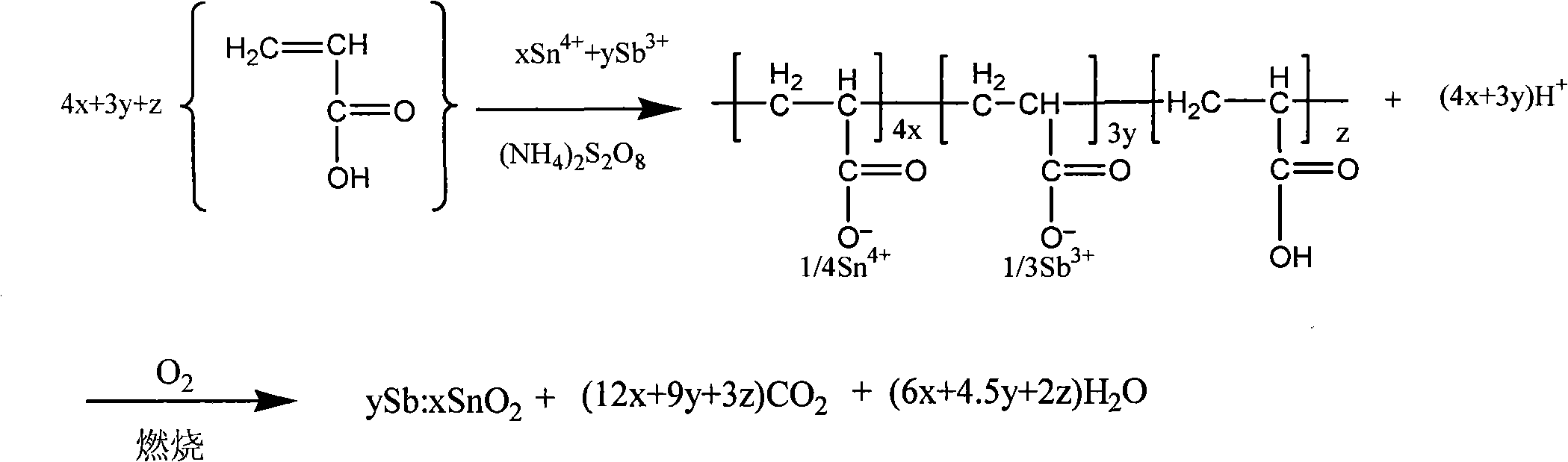

Preparation method of antimony-doped tin oxide nano-powder

InactiveCN101643200AAvoid emissionsGood dispersionNanostructure manufactureAir atmosphereAqueous solution

The invention discloses a preparation method of antimony-doped tin oxide nano-powder, which belongs to the field of preparation of nanomaterials. The preparation method comprises the following steps:(1) mixing propenoic acid with water according to the ratio of 1-4:1 in parts by weight, and obtaining solution A; (2) weighing soluble antimony salt and tin salt, adding into the solution A, dissolving and obtaining a homogeneous system B, wherein, the ratio of Sb<3+>: Sn<4+> by molar fraction is 1-15:100, and the ratio of tin salt: solution A in parts by weight is 1-25:100; (3) adding water solution of peroxide initiator with weight content of 2-10% into the homogeneous system B for obtaining solution C under the stirring condition; and (4) heating the solution C for 0.1-3h at the temperature of 60-100 DEG C, then drying at the temperature of 80-150 DEG C for obtaining solids, grinding after cooling, and calcining for 1-10h in an air atmosphere at the temperature of 450-900 DEG C. The method has simple process flow, and the prepared powder has even distribution of particle size and higher purity.

Owner:SHIJIAZHUANG RAILWAY INST

Method for titanium glycolate catalyzed synthesis of modified copolyester slice

The invention discloses a method for titanium glycolate catalyzed synthesis of a modified copolyester slice. The method includes: subjecting terephthalic acid and diol in a mole ratio of 1:1.2-2.0, a titanium glycolate catalyst and a cobalt compound to esterification, subjecting the esterification product to polycondensation with blue dye, red dye, an organic compound stabilizer of phosphorus and a small amount of ethylene glycol, then utilizing nitrogen to extrude a melt, and performing casting strip dicing to obtain a modified copolyester slice, wherein the titanium glycolate catalyst is obtained by under the protection of nitrogen, mixing tetrabutyl titanate with ethylene glycol to form a clarified solution, performing heating to 160DEG C, carrying out reaction for 9h, distilling off and collecting the reaction generated n-butanol, cooling the reaction solution to room temperature, conducting filtering and collecting solid, washing the solid with acetone repeatedly, and carrying out drying. The method accelerates the polymerization reaction, and the synthesis process of titanium glycolate does not generate hydrogen chloride or other toxic gases, the process is simple and is convenient for industrialization, and the prepared copolyester slice has neutral tone.

Owner:JIANGSU JINGHONG NEW MATERIAL TECH

Preparation method of antistatic, anti-balling, and ordinary pressure cation dyeable polyester chip

InactiveCN102433605AAvoid self-polymerizationEasy-to-stain function guaranteeElectroconductive/antistatic filament manufactureMonocomponent polyesters artificial filamentPolyesterFiber

The invention relates to a preparation method of an antistatic, anti-balling, and ordinary pressure cation dyeable polyester chip, comprising the following steps: a primary esterification reaction step, an ester exchange reaction step, a secondary esterification reaction step, and a polymerization reaction step, wherein, a ternary-monomer is added in the ester exchange reaction step, hindered anime light stabilizers, hindered phenol antioxygens and hydroxyl silicone oil are added after the ester exchange reaction and before a prepolymerization reaction, and an antistatic agent is added after the prepolymerization of the polymerization reaction step and before a final polymerization. Fabrics prepared from polyester fibers produced by using the polyester chips disclosed herein have good antistatic behavior and good anti-balling behavior, and have unlimited dyeing possibilities by using the ordinary pressure cation dyeability, thus the uniform requirements of present high-grade spring and summer clothes for functionality and colors can be satisfied. The obtained fibers can be dyed with wool together, and the blending of the fibers with wool has good dress effect. The polyester chips and fibers disclosed herein are an important supplement of present cation dyeable polyester fiber market, and have a wide market prospect.

Owner:WUJIANG GANGYANG CHEM FIBER +1

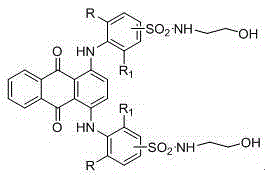

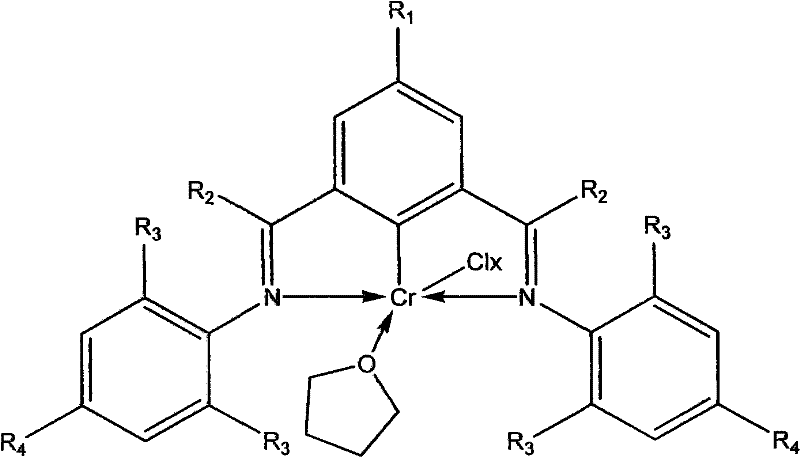

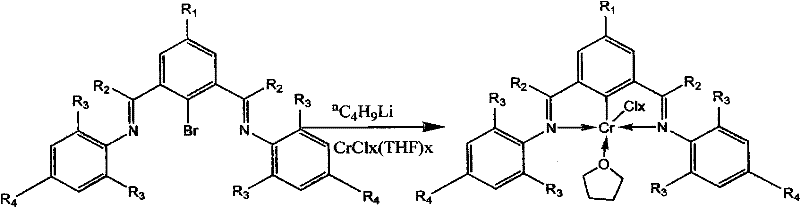

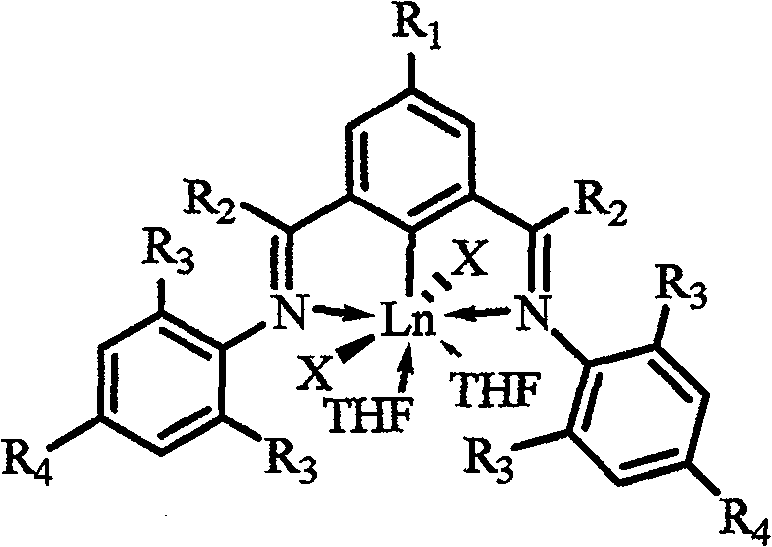

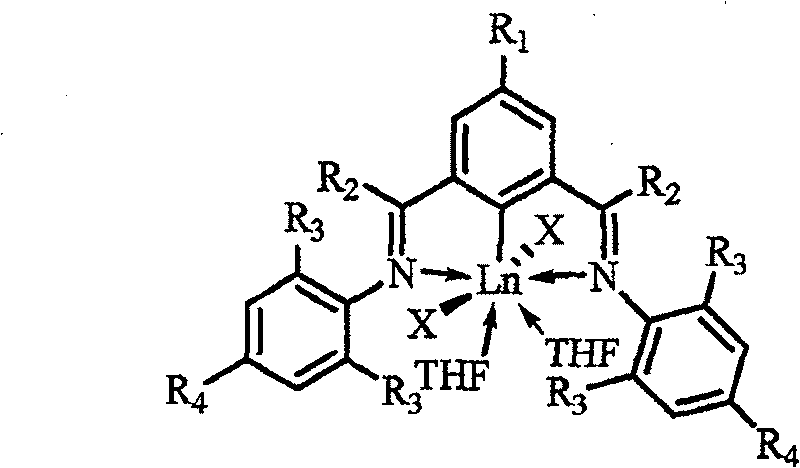

Caliper type chromium complex and preparation method and application thereof

InactiveCN102127116AImprove stabilityGood stability and easy preparationGroup 6/16 element organic compoundsButyl lithiumAdduct

The invention relates to a caliper type chromium complex and a preparation method and application thereof, and belongs to the technical field of catalysts. The caliper type chromium complex is a [NCN]-ligand-based caliper type chromium complex. The preparation method comprises the following steps of: adding hexane solution of butyl lithium into tetrahydrofuran solution of a ligand dropwise for reaction; adding a tetrahydrofuran adduct of chromium trichloride or chromium dichloride; and heating the mixture to room temperature naturally and reacting to obtain the caliper type chromium complex. The ligand can be 2,6-bis(N-2,6- phenyl)imido bromobenzene. The caliper type chromium complex, alkyl aluminum and organic boron salt serving as catalysts are used for catalyzing selective polymerization of isoprene or butadiene. The caliper type chromium complex has high stability and is convenient to prepare; the catalytic system can be used for selectively catalyzing polymerization of the isoprene or the butadiene, and has low using amount of a cocatalyst, high polymerization speed, high conversion rate and high anti-1,4 selectivity; and the caliper type chromium complex can be applied actually by replacing natural trans-1,4 rubber.

Owner:JILIN UNIV

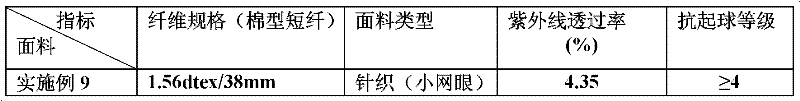

Method for preparing polyester fibers with ultraviolet-resistant and anti-pilling composite function

ActiveCN102443877AImprove the diffusion effectReduce transmittanceArtificial filament heat treatmentMelt spinning methodsPolyesterFiber

The invention relates to a method for preparing polyester fibers with ultraviolet-resistant and anti-pilling composite function. The method comprises an esterification reaction procedure, a polymerization reaction procedure and a spinning procedure, wherein the esterification reaction procedure comprises a primary esterification reaction stage and a secondary esterification reaction stage, and aliphatic dicarboxylic acid or non-p-aryl dicarboxylic acid serving as a third monomer is introduced in the primary esterification reaction stage; flexible polyethylene glycol serving as a fourth monomer is introduced in the secondary esterification reaction stage; a hindered amine light stabilizer and a hindered phenol antioxidant which are respectively prepared by using acetic acid and ethylene glycol as solvents and hydroxy silicone oil are added after the esterification is completed; and after the pre-polymerization of the polymerization reaction procedure is completed and before final polymerization, an ultraviolet absorbent is added. Before the spinning procedure, polyester slices are pre-crystallized and dried. The polyester fibers obtained by the method have excellent ultraviolet-resistant and anti-pilling function; and after the polyester fibers are woven into knitted fabrics and woven fabrics, tests show the related technical indexes that: the ultraviolet transmission rate is less than or equal to 5.0 percent, and the anti-pilling performance is more than or equal to level 4.

Owner:JIANGSU GUOWANG HIGH TECH FIBER CO LTD

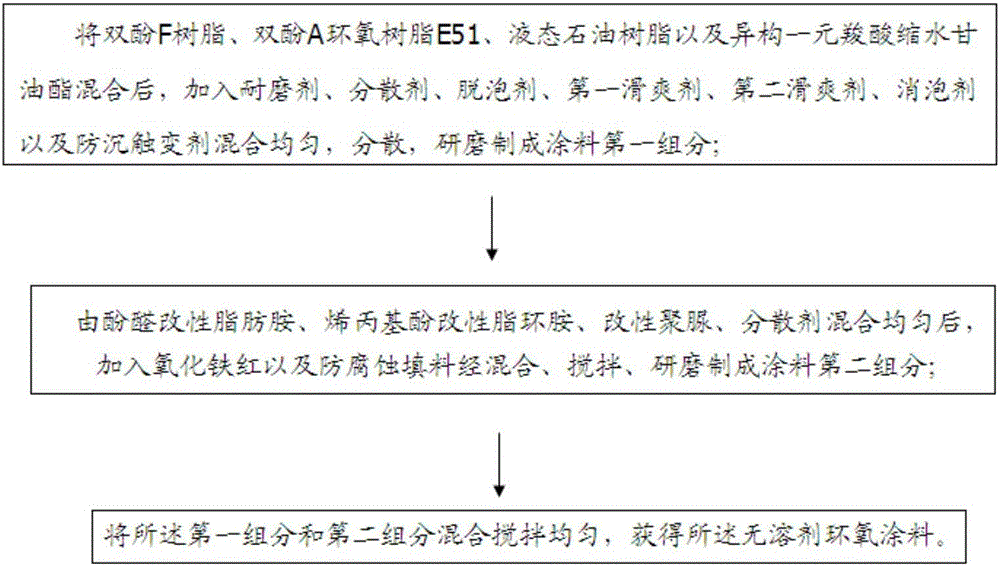

Solvent-free epoxy coating material and preparation method thereof

ActiveCN106554705ALow viscosityImprove compactnessFireproof paintsAnti-corrosive paintsSolvent freeAliphatic amine

The invention provides a solvent-free epoxy coating material and a preparation method thereof. The solvent-free epoxy coating material comprises a first component and a second component, wherein the first component comprises the following components in parts by weight: 1 part of bisphenol F resin, 0.8-1.0 part of bisphenol A epoxy resin E51, 0.1-0.2 part of liquid petroleum resin, 0.15-0.3 part of isomerous monocarboxylic acid glycidyl ester, 0.2-0.7 part of an anti-wear agent, 0.1-0.3 part of a dispersant, 0.02-0.1 part of an air-release agent, 0.01-0.1 part of a first slip agent, 0.05-0.1 part of a second slip agent, 0.05-0.1 part of a defoaming agent and 0.01-0.02 part of an anti-settling thixotropic agent; and the second component comprises the following components in parts by weight: 1 part of phenolic aldehyde modified aliphatic amine, 0. 8-1.2 parts of allylphenol modified alicyclic amine, 0.015-0.03 part of modified polyurea, 0.01-0.03 part of a dispersant, 0.1-0.3 part of iron oxide red and 0.15-0.35 part of anti-corrosion packing. A coating formed by the solvent-free epoxy coating material has an excellent thin-coating property, the one-step film-forming thickness of the solvent-free epoxy coating material can be equal to or less than 100 mu m, and the coating has high apparent quality.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

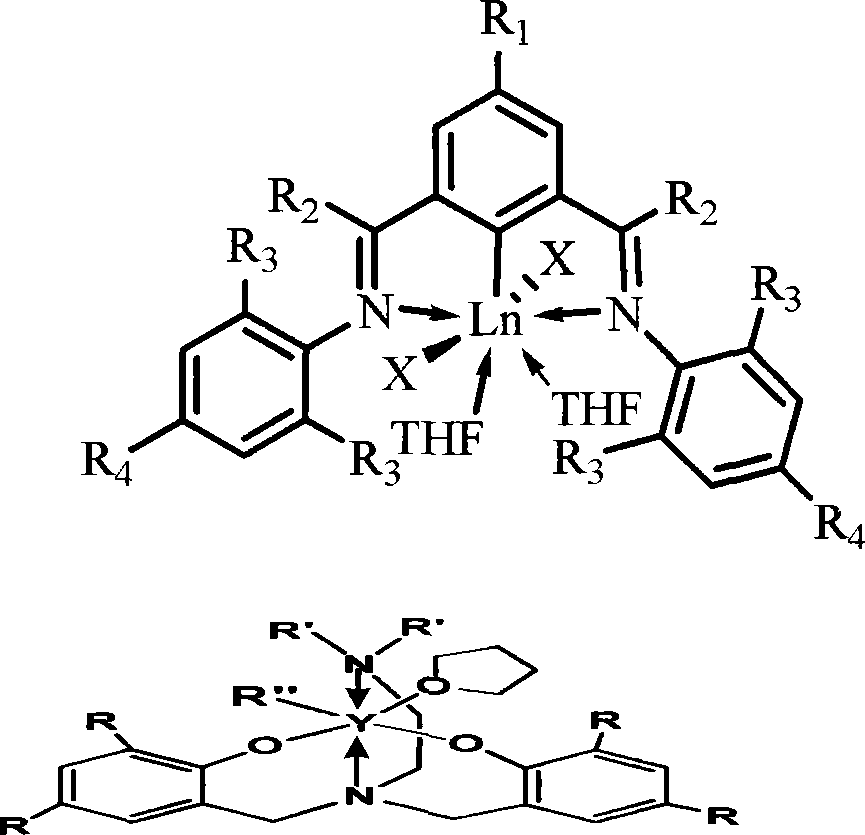

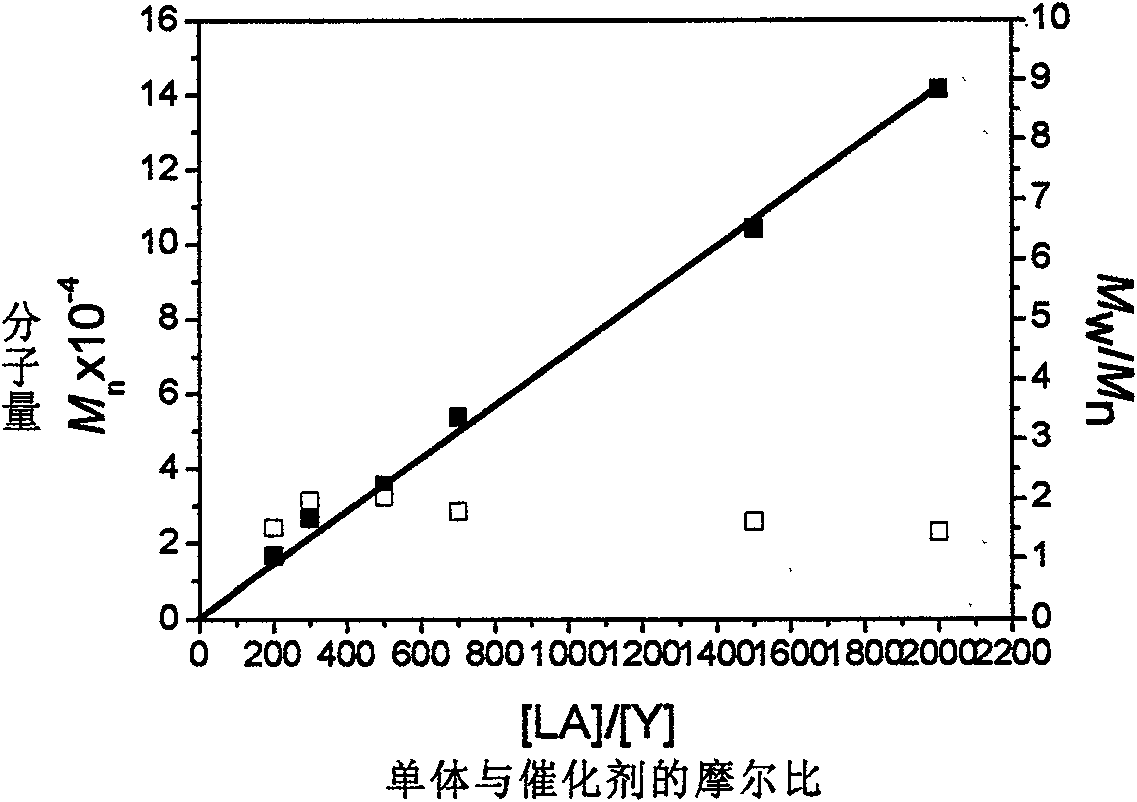

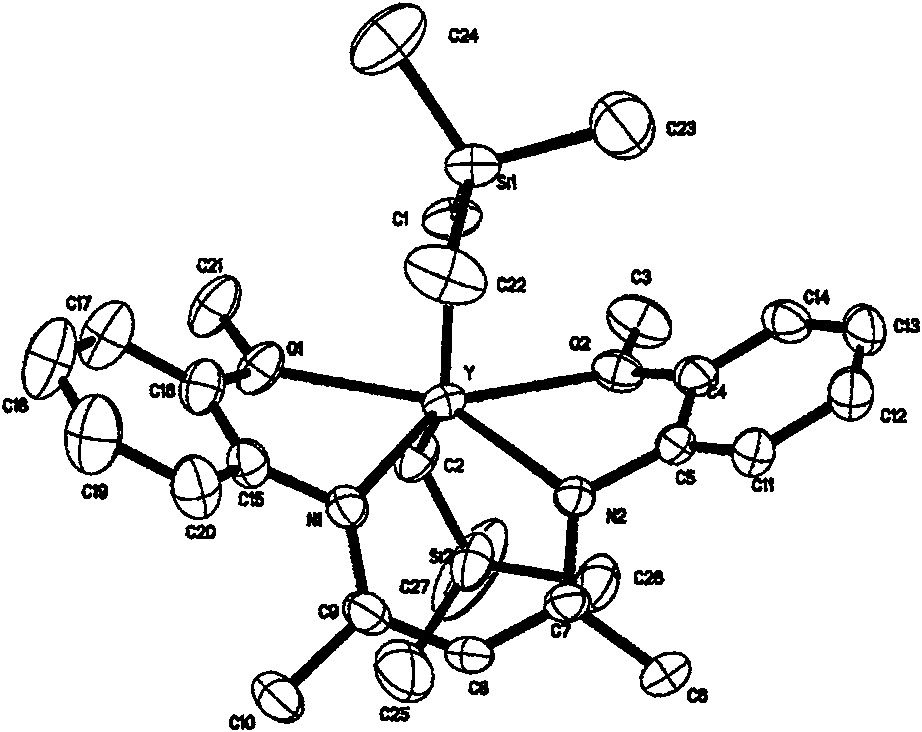

Rare earth alkyl coordination compound for configuration maintenance of catalytic levorotatory lactide and ring-opening polymerization as well as preparation method and use method thereof

ActiveCN101619080AThe polymerization reaction is fastLow reaction temperatureSilicon organic compoundsGroup 3/13 element organic compoundsLactideRare earth

The invention relates to a rare earth alkyl coordination compound for configuration maintenance of catalytic levorotatory lactide and ring-opening polymerization as well as a preparation method and a use method thereof. The rare earth alkyl coordination compound can be used for initiating levorotatory lactide to carry out configuration maintenance and ring-opening polymerization of a solution, has high activity and can use tetrahydrofuran, methylene chloride or toluene as an organic solvent. In a tetrahydrofuran solution, a levorotatory lactide ring-opening polymerization reaction is carried out at 20-70 DEG C, and the monomer conversion rate reaches 100% after the reaction is carried out for 0.1-5 hours; in a toluene solvent, the levorotatory lactide ring-opening polymerization reaction is carried out at 20-100 DEG C, and the monomer conversion rate reaches 100% after the reaction is carried out for 0.1-5 hours. The molecular weight of a product is controlled by the mol ratio of a monomer and an initiator, the activity of the lactide polymerization reaction is influenced by the space effect and the electronic effect of a catalyst, the solvent, the temperature and the actualizing method of the polymerization reaction and the like, and the configuration maintenance of the poly-levorotatory lactide is obtained.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Method for preparing polyacrylic acid or sodium polyacrylate

InactiveCN101423577BLower the starting temperatureReduce energy consumptionPersulfateReaction temperature

Owner:娄底市裕德科技有限公司

Rare earth catalyst for catalyzing 1,4-selectivity polymerization of isoprene or butadiene

The invention relates to a rare-earth catalyst for catalyzing selective polymerization of isoprene or butadiene, while the catalyst system composed of the rare-earth catalyst can catalyze isoprene orbutadiene to prepare polyisoprene or butadiene rubber with high cis-1, 4- structure. The rare-earth catalyst is composed of split-core type rare-earth complex, alkyl aluminium and organic boron salt.The solvent of polymerization is toluene or chlorobenzene. When catalyzes the polymerization of isoprene, the alkyl aluminium and split-core type rare-earth complex are rationed at 10-40, the organicboron salt and split-core type rare-earth complex are rationed at 1-3, the polymerization temperature is -20-80DEG C, the polymerization time is 0.5-2h, the monomer conversation ratio can reach 100% most, and the cis-1, 4 content of polymer is 55.0-98.8%, and when catalyzes the polymerization of butadiene, the alkyl aluminium and split-core type rare-earth complex are rationed at 10-40, the organic boron salt and split-core type rare-earth complex are rationed at 1-3, the polymerization temperature is -20-80DEG C, the polymerization time is 0.5-2h, the monomer conversation ratio can reach 100%most, and the cis-1, 4 content of polymer is 90.1-99.99%.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

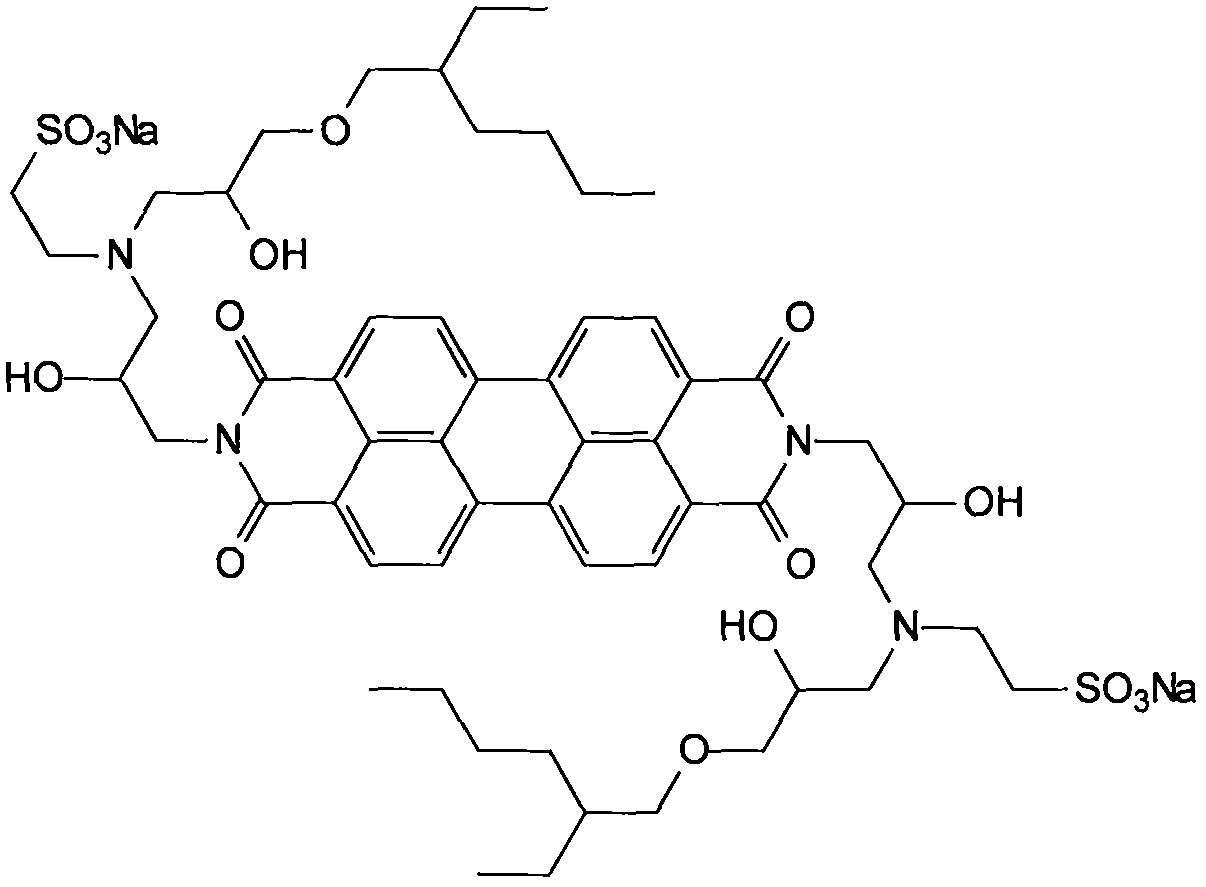

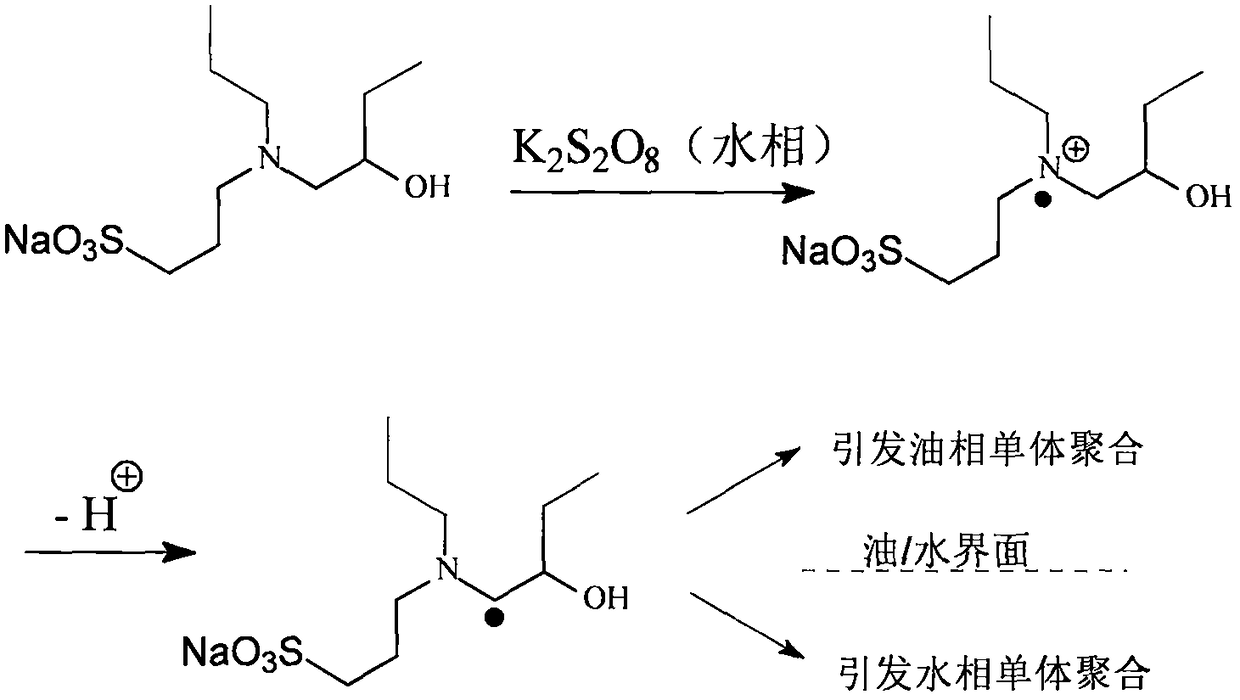

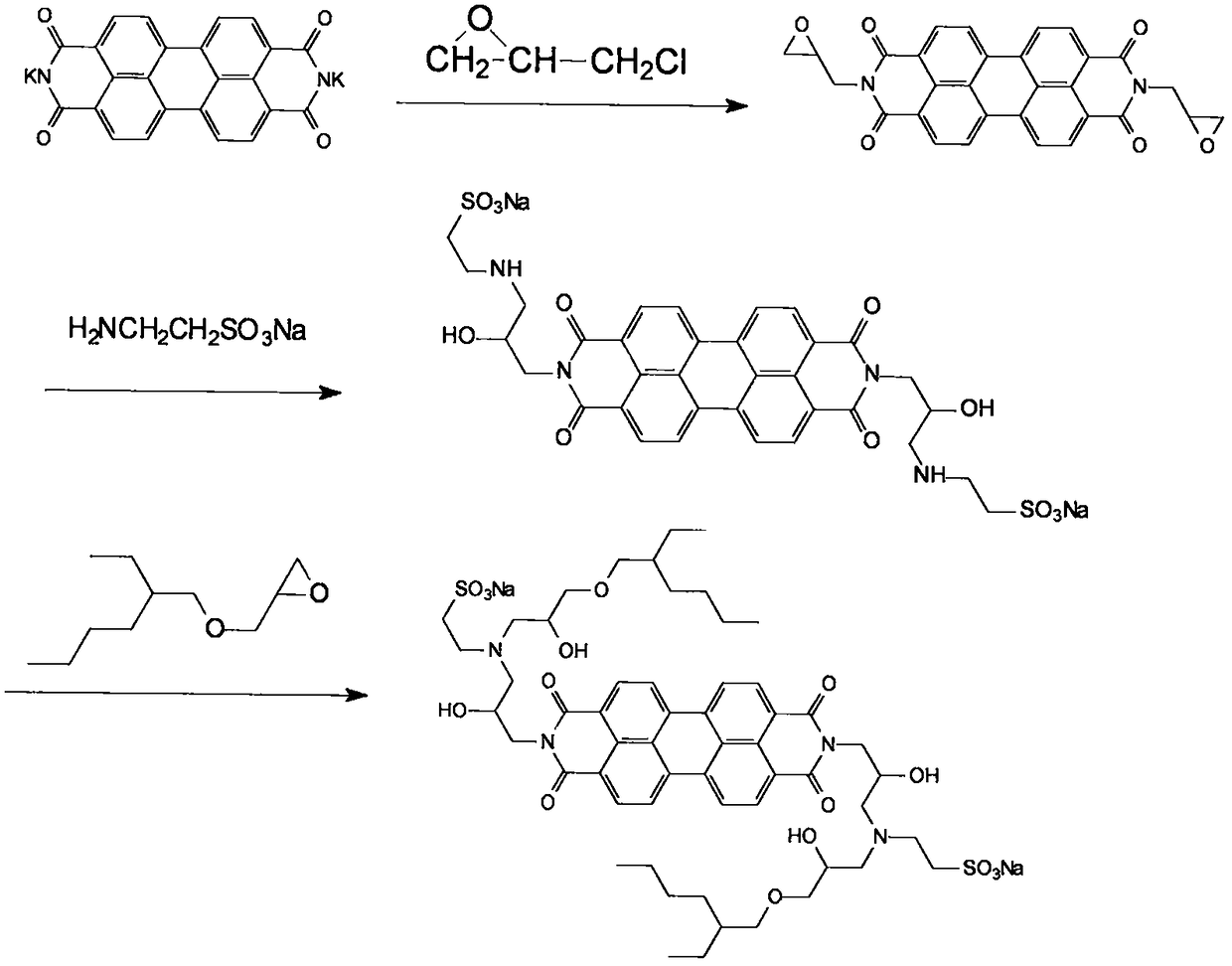

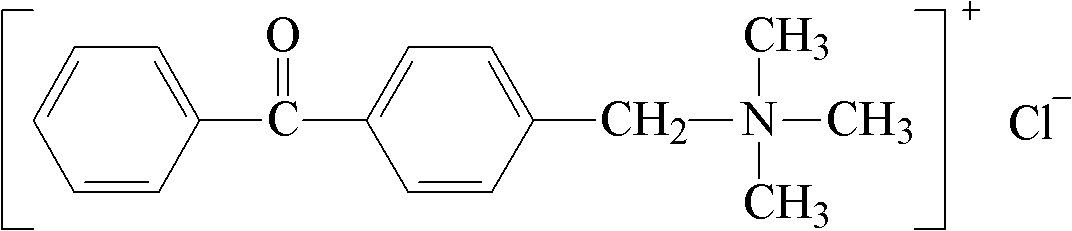

Polymerization method of perylene diimide fluorochrome

The invention relates to a polymerization method of perylene diimide fluorochrome. An amphiphilic compound containing perylene diimide fluorophores and a tertiary amine structure is synthesized, whichcan be used as an initiator for free radical polymerization; tertiary amine can be subjected to a redox reaction with potassium persulfate at the normal temperature to generate active free radicals multiple times, both oil-soluble monomer methyl acrylate polymerization and water-soluble monomer vinylpyrrolidone polymerization can be initiated on a water / oil interface, and then the the purpose ofpolymerizing the perylene diimide fluorochrome is achieved. By means of the mode, the functionalization and the polymerization reaction do not interfere with each other, the degree of freedom of operation is high, more kinds of products are obtained, the polymerization reaction conditions are mild, neither organic solvent nor emulsifier is needed, and the method meets the requirements of green chemistry.

Owner:NINGBO UNIV

Preparation method of anti-ultraviolet anti-pilling polyester slices

ActiveCN102443153AImprove the diffusion effectReduce transmittanceMonocomponent polyesters artificial filamentPolyesterUltraviolet lights

The invention relates to a preparation method of anti-ultraviolet anti-pilling polyester slices. The preparation method comprises an esterification reaction working procedure and a polymerization reaction working procedure, wherein the esterification reaction working procedure comprises a primary esterification reaction section and a secondary esterification reaction section; in the primary esterification reaction section, aliphatic dicarboxylic acid and / or non-para-aryl dicarboxylic acid are / is introduced to serve as a third monomer; in the secondary esterification reaction section, flexiblepolyethylene glycol is introduced to serve as a fourth monomer; after esterification is completed, a hindered amine light stabilizer and a hindered phenol antioxidant which are respectively prepared from acetic acid and ethylene glycol as a solvent and hydroxy silicone oil are added; and after prepolymerization and before final polymerization in the polymerization reaction working procedure, an ultraviolet absorbent is added. The polyester fibers spun from the polyester slices prepared by the method provided by the invention have excellent anti-ultraviolet and anti-pilling performances; and after the polyester fibers are knitted / woven into knitted / woven fabric, test shows that the fabric has the following correlated technical indexes: the ultraviolet light transmittance is not more than 5.0%, and the anti-pilling performance is not less than 4-level.

Owner:JIANGSU ZHONGLU TECH DEV +1

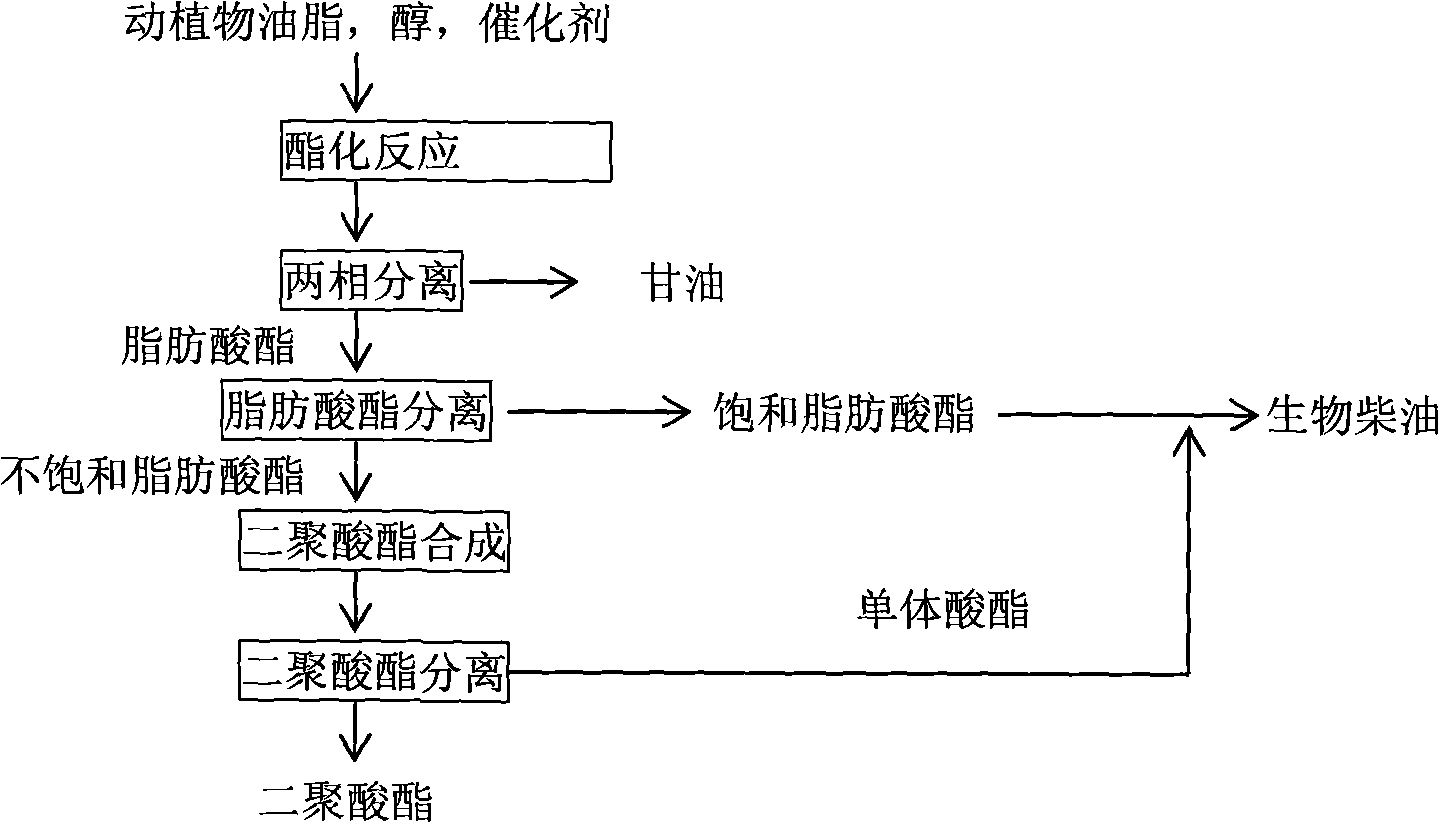

Method for coproducing biological diesel oil and dimeric dibasic acid ester by using animals and plants grease

InactiveCN101260311AThe polymerization reaction is fastShort reaction timeFatty acid esterificationBiofuelsSolventUrea

The invention provides a method to produce bio-diesel and dimerized acid ester from combination of animal and plant lipids. Esterification is performed between animal / plant lipids and a lower alcohol containing 1-4 carbons, the product of esterification is separated into saturated and un-saturated lipid acids through urea inclusion. The condition of urea inclusion includes the ratio of lipid acid esters: urea: solvent (w / w / w) is 1: (0.6-4): (2-10), with the temperature of 0-25 DEG C and the time of 5-30 hours. The unsaturated lipid acids react for 1-12 hours under 150-300 DEG C with the presence of an acid catalyst, and the product undergoes vacuum distillation to obtain monomer lipid acid ester and dimerized acid ester. The combination of the monomer lipid ester and the saturated lipid acid ester obtained through urea inclusion is the bio-diesel. The invention increases the reaction speed, shortens the reaction time, and improves the quality of the product of dimerized lipid acid ester, because a great deal of saturated lipid acid ester does not participate in the polymerization reaction.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

Method for preparing water-soluble polymer by auto-deposition polymerization initiated by ultraviolet light

The invention discloses a method for preparing a water-soluble polymer by auto-deposition polymerization initiated by ultraviolet light, belonging to the technical field of aqueous dispersion polymerization. The method comprises the following steps of: firstly, preparing reaction liquid: proportionally mixing a photoinitiator, a water-soluble monomer and a solvent in a straight tube glass reaction flask to prepare the reaction liquid, and introducing nitrogen for removing oxygen for 20-40 minutes, wherein the concentration of the photoinitiator in the reaction liquid is 0.1-10mmol / L, and the concentration of the monomer in the reaction liquid is 0.5-6mmol / L; and then, carrying out illumination reaction: putting the reaction flask containing the reaction liquid below an ultraviolet lamp for irradiating for 10-120 minutes. According to the invention, polymers formed in the reaction process are continuously precipitated out, gathered and deposited at the bottom of the reactor, so that the light shielding effect is relieved or eliminated; and meanwhile, the supernatant liquid can be recycled, so that the reaction efficiency is high, and the method is economic and rapid. Through simple decantation, a product can be separated, the method is simple and convenient, and the product is pure and can be dried easily, thereby being favorable for subsequent applications.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com