Method for titanium glycolate catalyzed synthesis of modified copolyester slice

A titanium glycol catalyzed, titanium ethylene glycol technology is applied in the field of titanium glycol catalyzed synthesis of modified copolyester chips, which can solve the problems of increased polyester production costs, high equipment requirements, and expensive prices, and achieve Increased polycondensation reaction speed, high intrinsic viscosity, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Add terephthalic acid, glycol, titanium glycolate and cobalt compound into the beating kettle according to the ingredient list, beat into a slurry, and then import it into the reaction kettle through a delivery pump, and carry out the esterification under 0.2Mpa nitrogen pressure at 255°C. reaction, the esterification stirring speed is 30rpm. After 150 min of reaction, 4.2 kg of esterification water was collected, and the esterification reaction was completed.

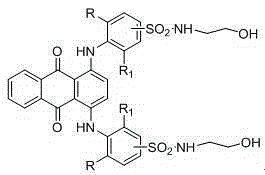

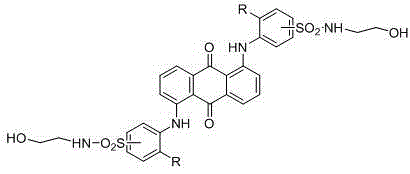

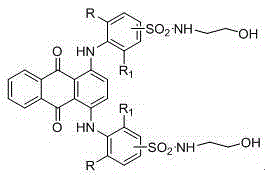

[0035] Using nitrogen pressure, the above-mentioned esterification reaction product is pressed into the polycondensation kettle. According to the ingredients list, add ethylene glycol, blue dye (R=1, R1=1), red dye with R as methyl, and trimethyl phosphate into the polycondensation tank at 265°C and 40rpm stirring , vacuumize the polycondensation kettle continuously, within 40 minutes, control the pressure inside the kettle to 200 Pa, then within 30 minutes, control the pressure inside the kettle to 50 Pa, cont...

Embodiment 2

[0037] Put terephthalic acid, ethylene glycol, 1,4-cyclohexanedimethanol, ethylene glycol titanium, and cobalt nitrate into the beating kettle according to the ingredient list, and after making slurry, add it to the reaction kettle via a delivery pump. The esterification reaction was carried out at 235° C. under a nitrogen pressure of 0.3 Mpa, and the stirring speed of the esterification was 30 rpm. After 140 min of reaction, 3.9 kg of esterification water was collected, and the esterification reaction was completed.

[0038] Using nitrogen pressure, the above-mentioned esterification reaction product is pressed into the polycondensation kettle. According to the ingredients list, add ethylene glycol, (R=2, R1=3) blue dye, R is ethyl red dye, and triphenyl phosphate into the polycondensation tank, and stir at 260 ° C and 40 rpm , vacuumize the polycondensation kettle continuously, within 30 minutes, control the pressure inside the kettle to 500 Pa, then within 40 minutes, cont...

Embodiment 3

[0040] Put terephthalic acid, ethylene glycol, isosorbide, ethylene glycol titanium, and cobalt acetate tetrahydrate into the beating kettle according to the ingredient list, and put it into the reaction kettle through a delivery pump after making a slurry. The esterification reaction was carried out at 258° C., and the stirring speed of the esterification was 30 rpm. After reacting for 180 min, 4.2 kg of esterification water was collected, and the esterification reaction was completed.

[0041] Using nitrogen pressure, the above-mentioned esterification reaction product is pressed into the polycondensation kettle. Add ethylene glycol, (R=3, R1=1) blue dye, red dye whose R is methoxy, and triethyl phosphate to the polycondensation tank according to the ingredients list, and stir at 265°C and 40rpm , vacuumize the polycondensation kettle continuously, within 30 minutes, control the pressure inside the kettle to 400 Pa, then within 40 minutes, control the pressure inside the ke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com