Hydrogen production catalyst

A catalyst and reforming hydrogen production technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, hydrogen, etc., can solve low ethanol conversion rate, poor stability, low hydrogen selectivity, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

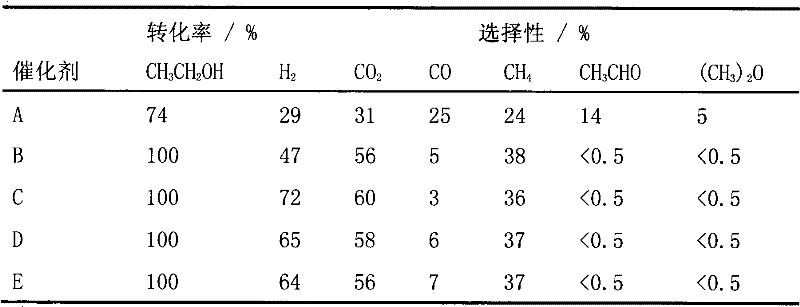

Embodiment 1

[0087] Make a solution of cerium nitrate and lanthanum nitrate at a ratio of 9:1, add excess urea to the solution, and stir continuously at 90°C for 12 hours, then suction filter and wash, put the filter cake in an oven and dry at 110°C Dry overnight, and finally calcine in air at 500°C for 5 hours in a muffle furnace to obtain a powder. An appropriate amount of rhodium chloride solution is added, and an impregnation method is used to prepare a supported rhodium catalyst with a loading capacity of 1%. The loaded product was dried in an oven at 110°C overnight, and finally calcined in air at 500°C for 3 hours in a muffle furnace to obtain a powdered catalyst.

[0088] The prepared catalyst was pressed into tablets, crushed, sieved, and 40-60 meshes were taken for later use, which was called catalyst A.

Embodiment 2

[0090] Other conditions were the same as in Example 1, but the Ce / La molar ratio was changed to 8:2 to prepare catalyst B.

Embodiment 3

[0092] Catalyst C was prepared by changing the Ce / La molar ratio to 7:3 with other conditions unchanged as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com