Patents

Literature

89results about How to "Not easy to be poisoned" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

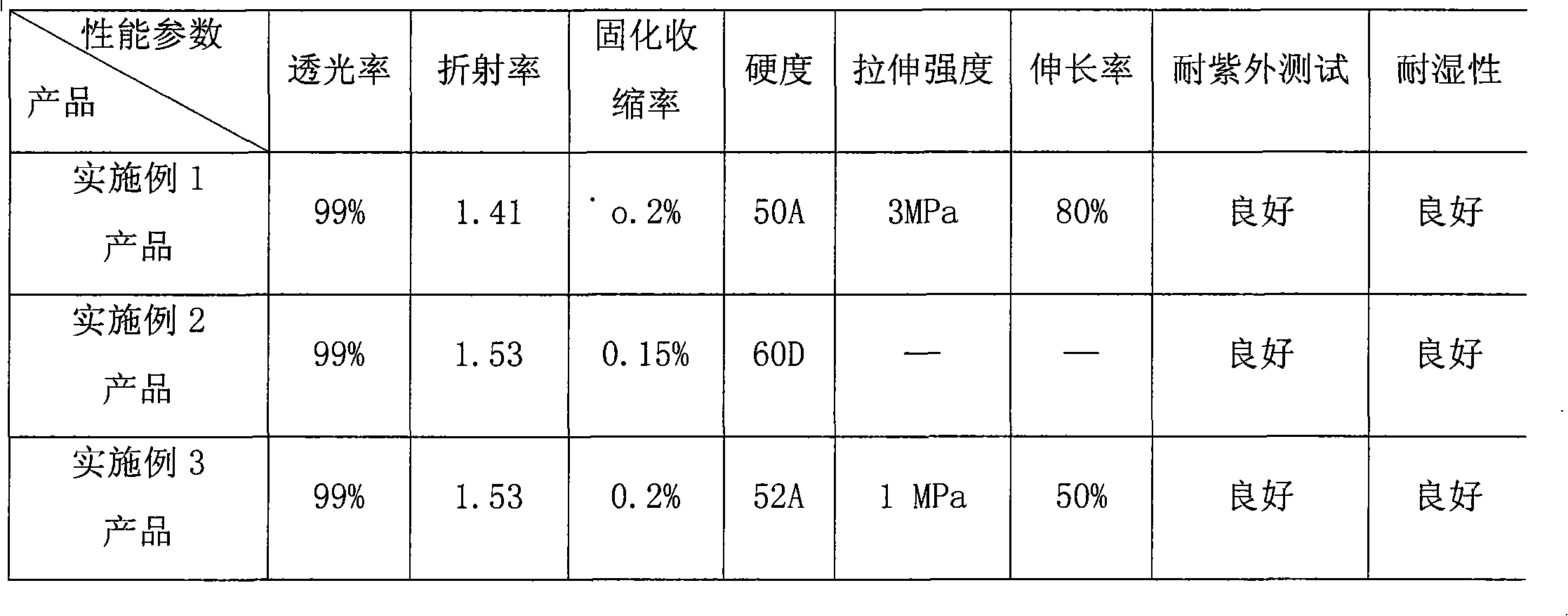

Organ silicon material for encapsulating power-type LED and synthetic method thereof

ActiveCN101608068AFully curedEven distribution of phenyl groupsSemiconductor devicesCross-linkMass ratio

The invention discloses an organ silicon material for encapsulating a power-type LED and a synthetic method thereof. The organ silicon material is mixed with a component A and a component B according to a mass ratio of 1:1 to 1:20, wherein the component A is a mixture of vinyl silicon polymer and a solidify catalyst, and the vinyl silicon polymer comprises vinyl silicon resin and polysiloxane with vinyl; and the component B comprises vinyl hydro silicon resin, poly hydro siloxane and an inhibitor. The organ silicon material has a higher refractive index, high transparency, excellent ultraviolet ageing resistance, good heat ageing resistance, and the like and is an ideal encapsulating material of the power type LED. The invention also discloses a synthetic method of an organ silicon material for encapsulating the power-type LED, the solidification of resin is more complete, and the light transmission and the hardness of the cross-link resin are effectively increased.

Owner:矽时代材料科技股份有限公司

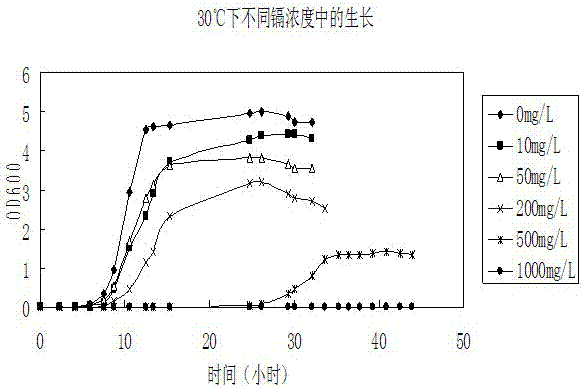

A kind of pseudomonas and its use and method for removing cadmium pollution in environment

ActiveCN102286405ASolve pollutionAdaptableBacteriaWater contaminantsBiotechnologyEnvironmental engineering

The invention relates pseudomonas, use thereof and a method for removing cadmium pollution to the environment. The pseudomonas class is named pseudomonas putidaHN103 and the collection number in a collection center is CCTCCNo.M2011184; and the shape and characteristics of the pseudomonas putidaHN103 comprise: 1) on a culture medium, a bacterial colony which used to be colorless and transparent turns white, smooth and convex-like with irregular edges; and 2) according to the result of bacterial microscopic examination, pseudomonas belongs to brevibacterium and is gram negative. The use of the bacteria is the use of the bacteria as a biological repair material for removing cadmium pollution. The method for removing cadmium pollution to the environment comprises the following steps: 1) regulating the cadmium ion concentration in sewage to a range in which pseudomonas can grow normally; 2) placing pseudomonas; 3) keeping the pseudomonas in the sewage for a certain time period; and 4) removing bacterial absorbing cadmium ions. The pseudomonas requires small investment, is low in cost, high in adaptability and capable of effectively removing cadmium, can quickly and obviously lower the concentration of cadmium ions in the environment and is suitable for biological remediation environments polluted by cadmium.

Owner:武汉华中农大资产经营有限公司

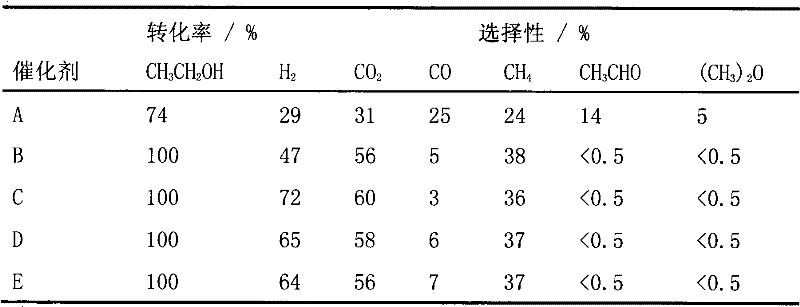

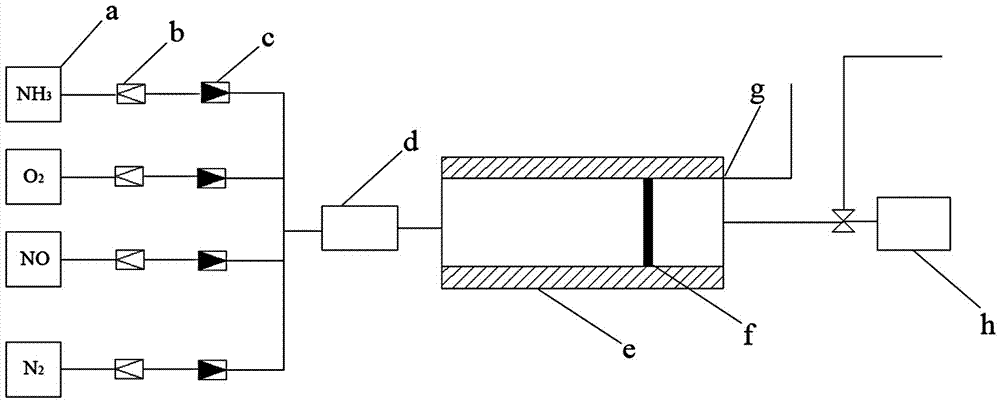

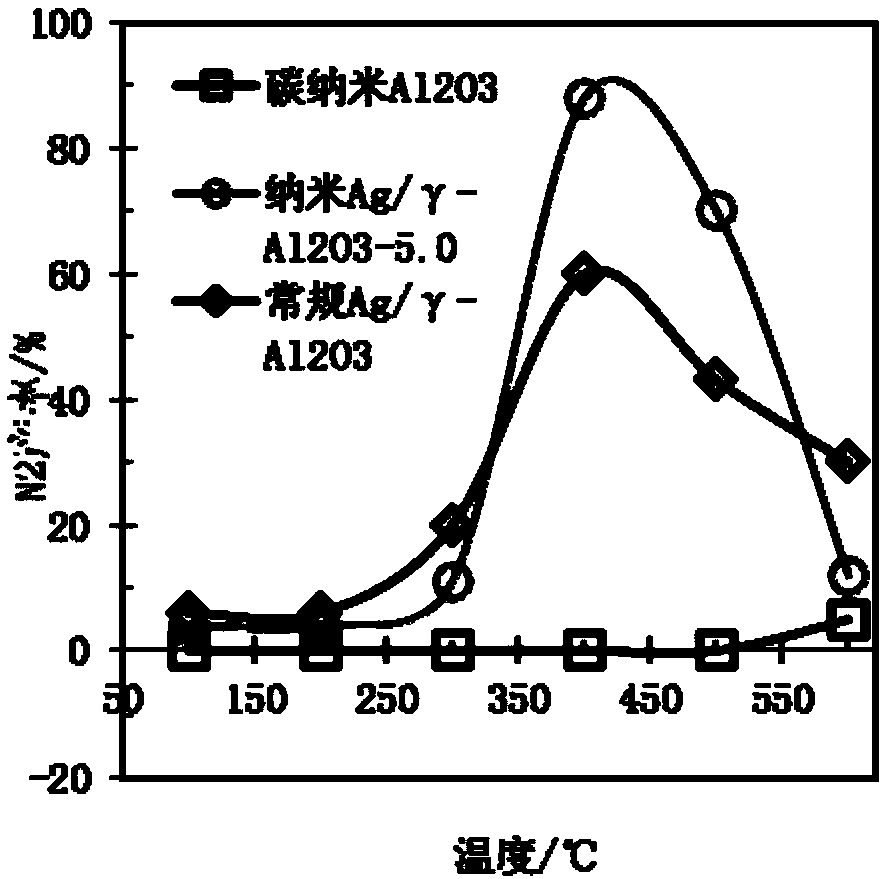

Hydrogen production catalyst

InactiveCN102513105AImprove stabilityGuaranteed service lifeHydrogenEnergy inputChemistryComposite oxide

The invention provides a cerium-based composite oxide loaded noble metal catalyst for catalyzing alcohols and hydrocarbons to carry out hydrogen production by reforming, comprising two parts including noble metal and a carrier. The noble metal is one or combination of more than two of rhodium, platinum, palladium, iridium, ruthenium and gold; and the carrier is a cerium-based composite oxide carrier which takes a cerium-lanthanum solid solution as a representative. The catalyst can be applied in the form of a grain state or a powder state and also can be coated on a porous integral ceramic to be used as a monolithic catalyst. The invention further provides a manufacturing method of the catalyst, which comprises the following steps of preparing a cerium-based composite oxide and loading the noble metal. Some preferable implementation schemes of the catalyst utilize biological ethanol as a raw material and the prepared hydrogen can be considered to a renewable energy source; and the catalyst can be applied to the condition of a high space velocity.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

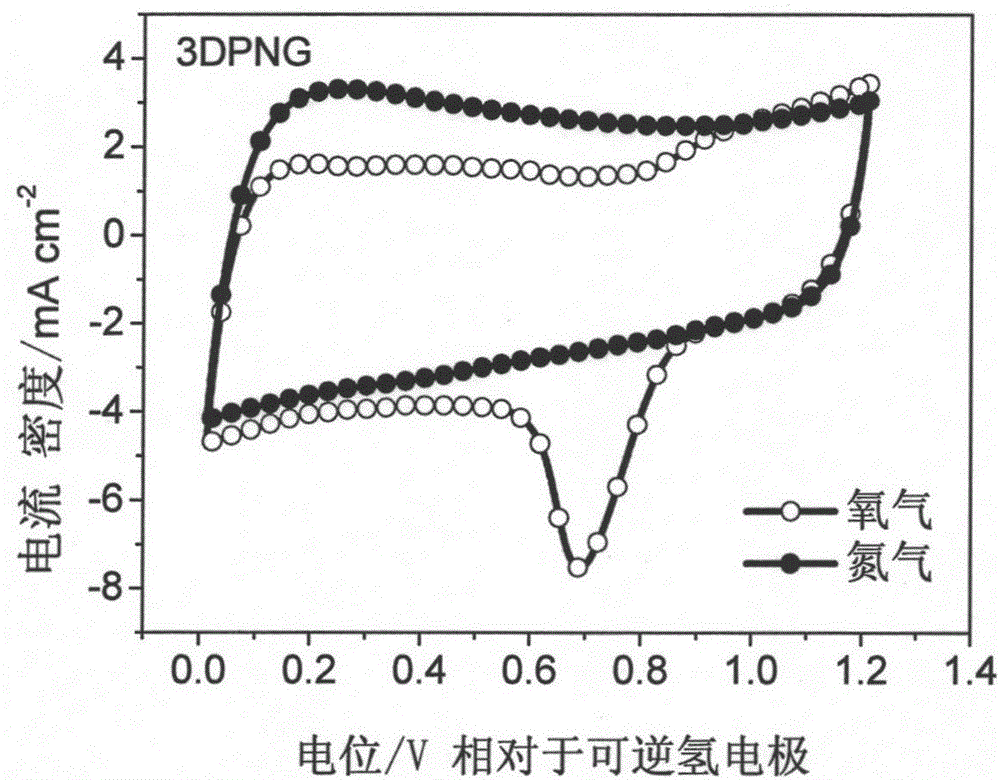

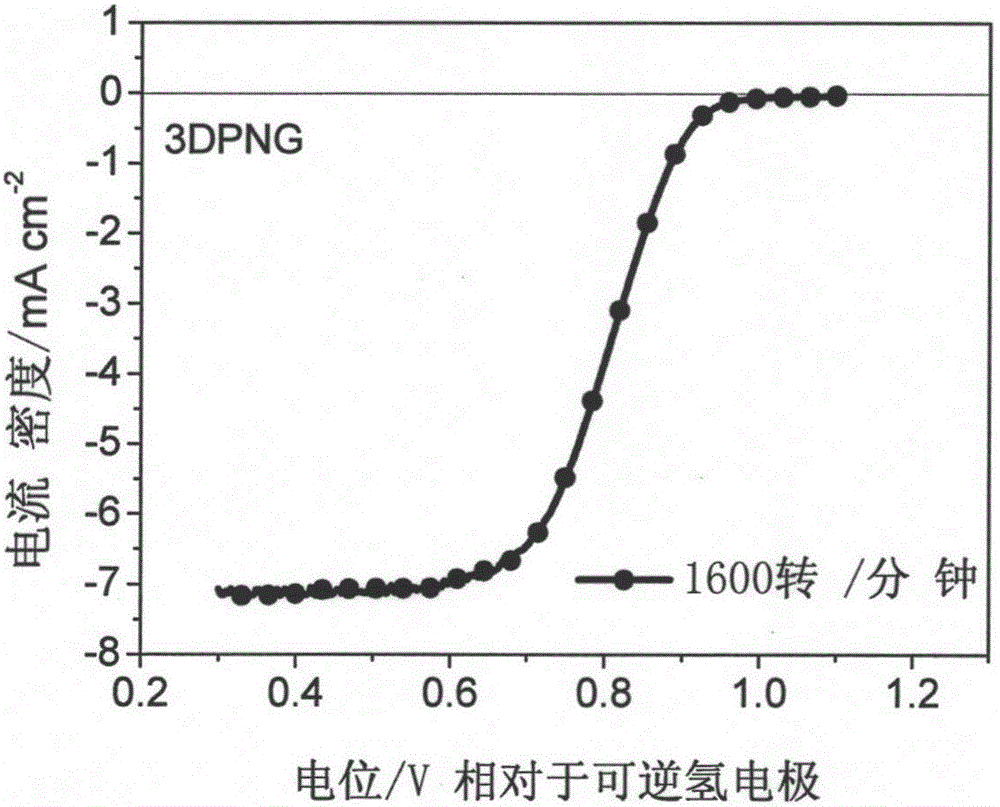

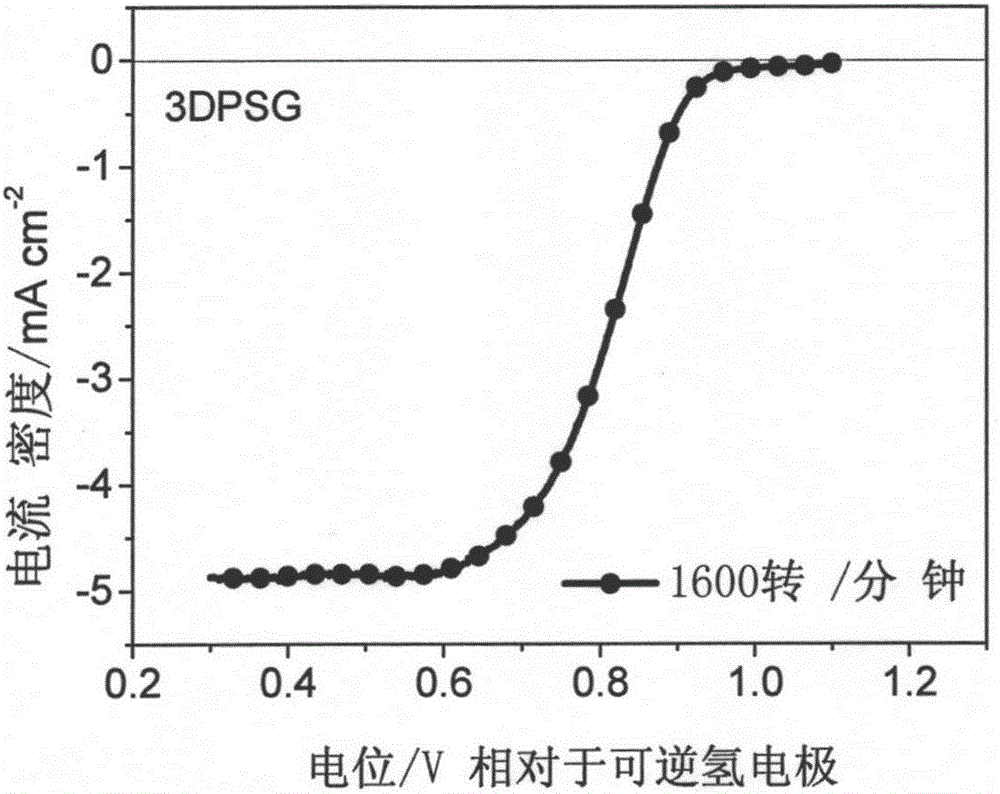

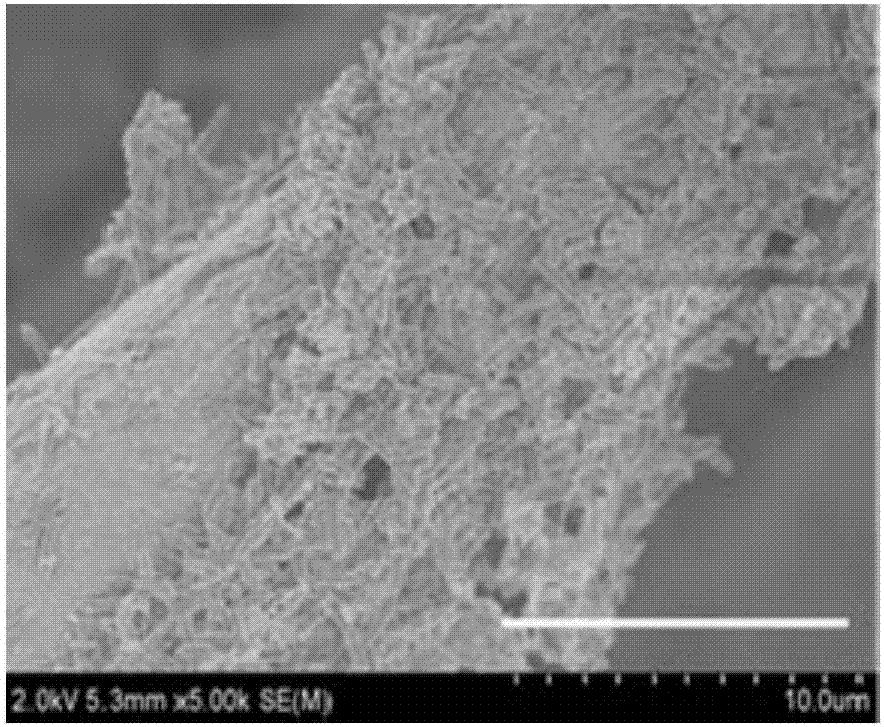

Preparation and application of nitrogen, sulphur or chlorine-doped three-dimensional porous graphene catalyst

InactiveCN105680060AIncrease the areaIncreased porous structureCell electrodesPorous grapheneReduction treatment

The invention provides a preparation and an application of a nitrogen, sulphur or chlorine-doped three-dimensional porous graphene catalyst. The preparation comprises the following steps: dissolving graphene oxide, an alkyl compound, a transition metal salt containing nitrogen, sulphur or chlorine and hydrochloric acid into a solvent, and carrying out ultrasonic treatment and drying to obtain a precursor; heating the precursor to 600-1,000 DEG C under inert gas protection and carrying out roasting reduction treatment for 1-3 hours to obtain primary carbide; carrying out pickling treatment on the obtained primary carbide with a mixed solution of hydrofluoric acid and hydrochloric acid at a room temperature for 12-24 hours, centrifuging the primary carbide, cleaning the primary carbide with deionized water and then drying the primary carbide to obtain the three-dimensional porous graphene material containing nitrogen, sulphur or chlorine; and heating the three-dimensional porous graphene material to 600-1,000 DEG C under inert gas protection, and carrying out roasting reduction treatment for 1-3 hours to obtain the nitrogen, sulphur or chlorine-doped three-dimensional porous graphene catalyst. The nitrogen, sulphur or chlorine-doped three-dimensional porous graphene catalyst has the characteristics of being high in stability, not easy to poison and the like, and has a good application prospect in the fields of wastewater treatment of a fuel cell, a metal-air cell, a super capacitor, an energy storage battery and a microbial fuel cell and the like.

Owner:DONGHUA UNIV

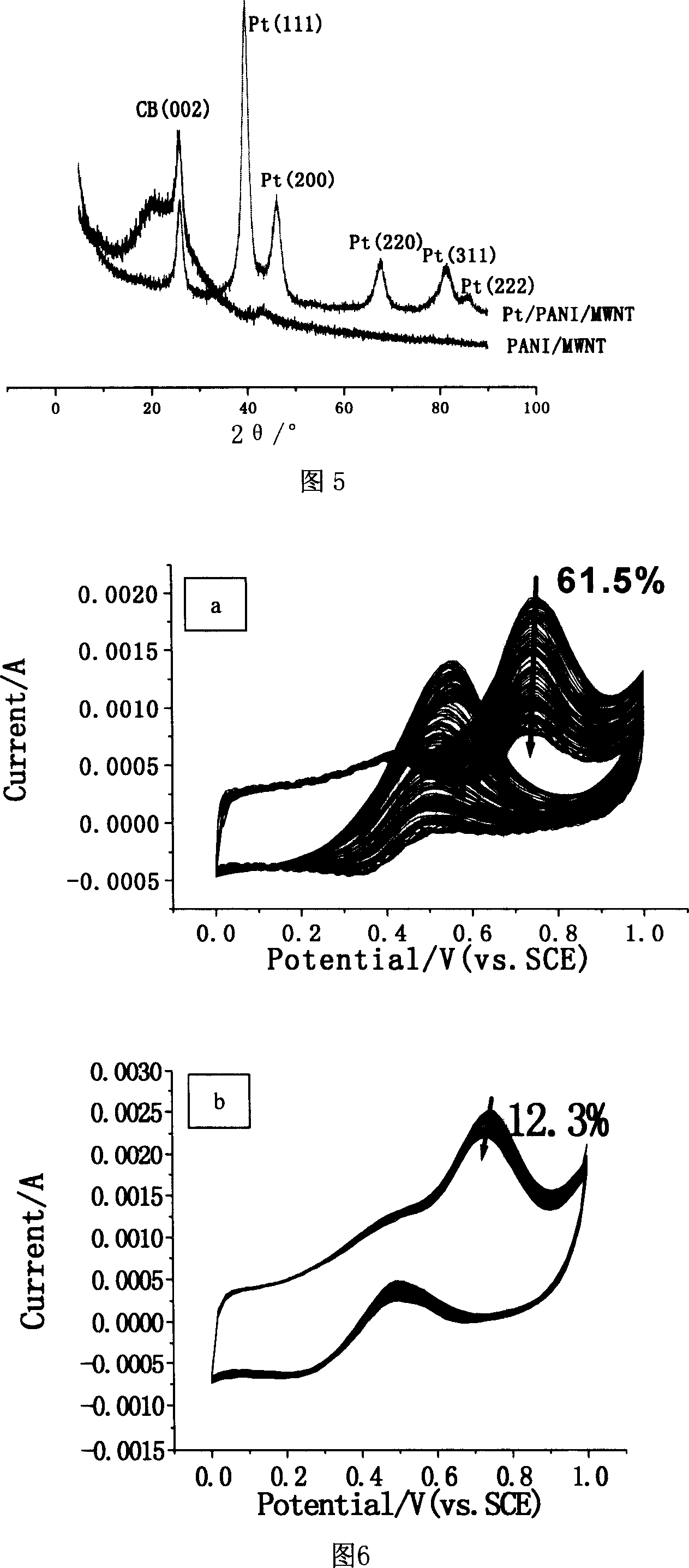

Method for preparing anode catalyst of direct methanol fuel cell

InactiveCN101003019AImprove deposition efficiencyGood catalytic activity for methanol oxidationCell electrodesMetal/metal-oxides/metal-hydroxide catalystsCarbon nanotubeAniline

A process for preparing the anode catalyst Pt / PANI / MWNT able to be directly used for methanol fuel battery includes such steps as adding sulfuric acid solution containing disperser into container, adding multi-wall carbon nanotubes, ultrasonic oscillating, adding phenylamine and ammonium persulfate solution, reacting, washing, baking to obtain polyphenylamine / multi-wall carbon nanotubes carrier, adding additive contained buffering solution of acetic acid, ultrasonic oscillating, adding chloroplatinic acid solution, continuous oscillating while heating and dropping sodium borohydride solution, reacting, filtering, washing and baking.

Owner:XIAMEN UNIV

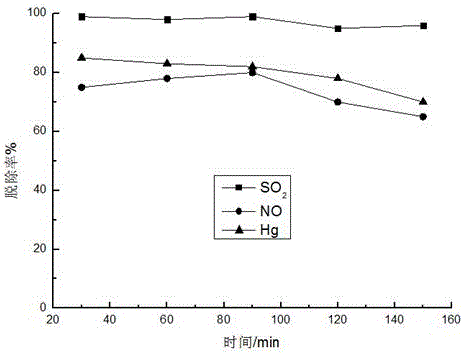

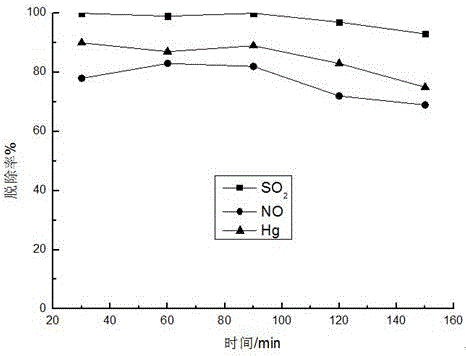

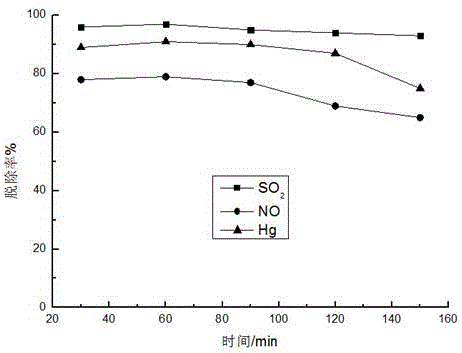

Method of utilizing copper smelting slag to remove SO2, NOx and Hg in nonferrous smelting flue gas

InactiveCN105771632AEasy to industrializeEffective absorptionGas treatmentDispersed particle separationFlue gasCatalytic oxidation

The invention discloses a method of utilizing copper smelting slag to remove SO2, NOx and Hg in nonferrous smelting flue gas. The method includes: using copper slag slurry prepared from the copper smelting slag as an absorbent to perform liquid-phase catalytic oxidation of SO2, NOx and Hg in the nonferrous smelting flue gas at normal temperature and normal pressure to achieve the objective of removing SO2, NOx and Hg in the nonferrous smelting flue gas. Oxidation of SO2, NOx and Hg is realized through catalytic oxidation action of metal oxide and transition metal ions contained in the copper smelting slag. The method is simple, raw materials are extremely large in reserve volume, easy to get, low in cost, easy for industrialized application and good in removal effect, and the objective of using waste to treat waste so as to realizing clean production can be achieved.

Owner:KUNMING UNIV OF SCI & TECH

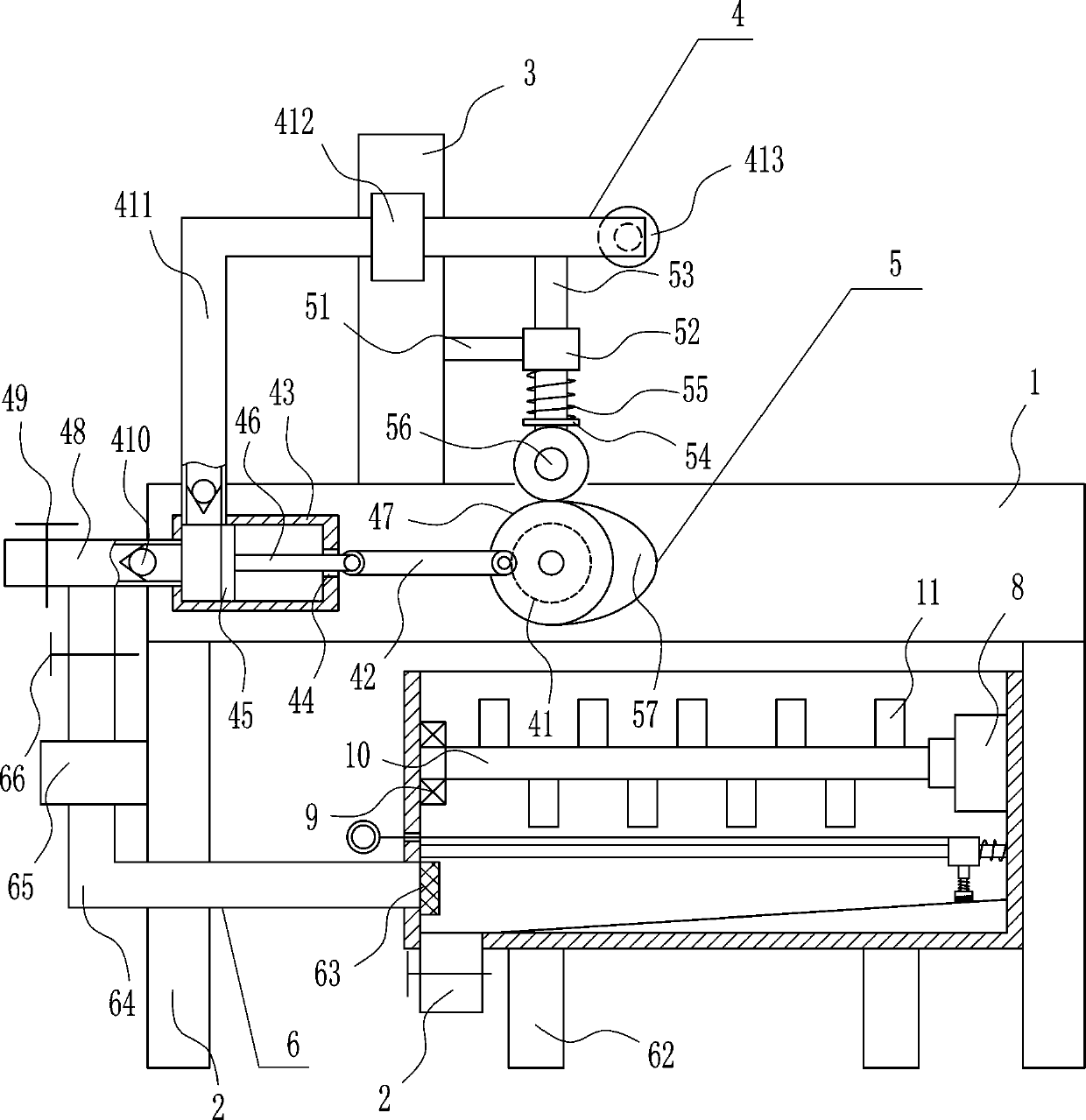

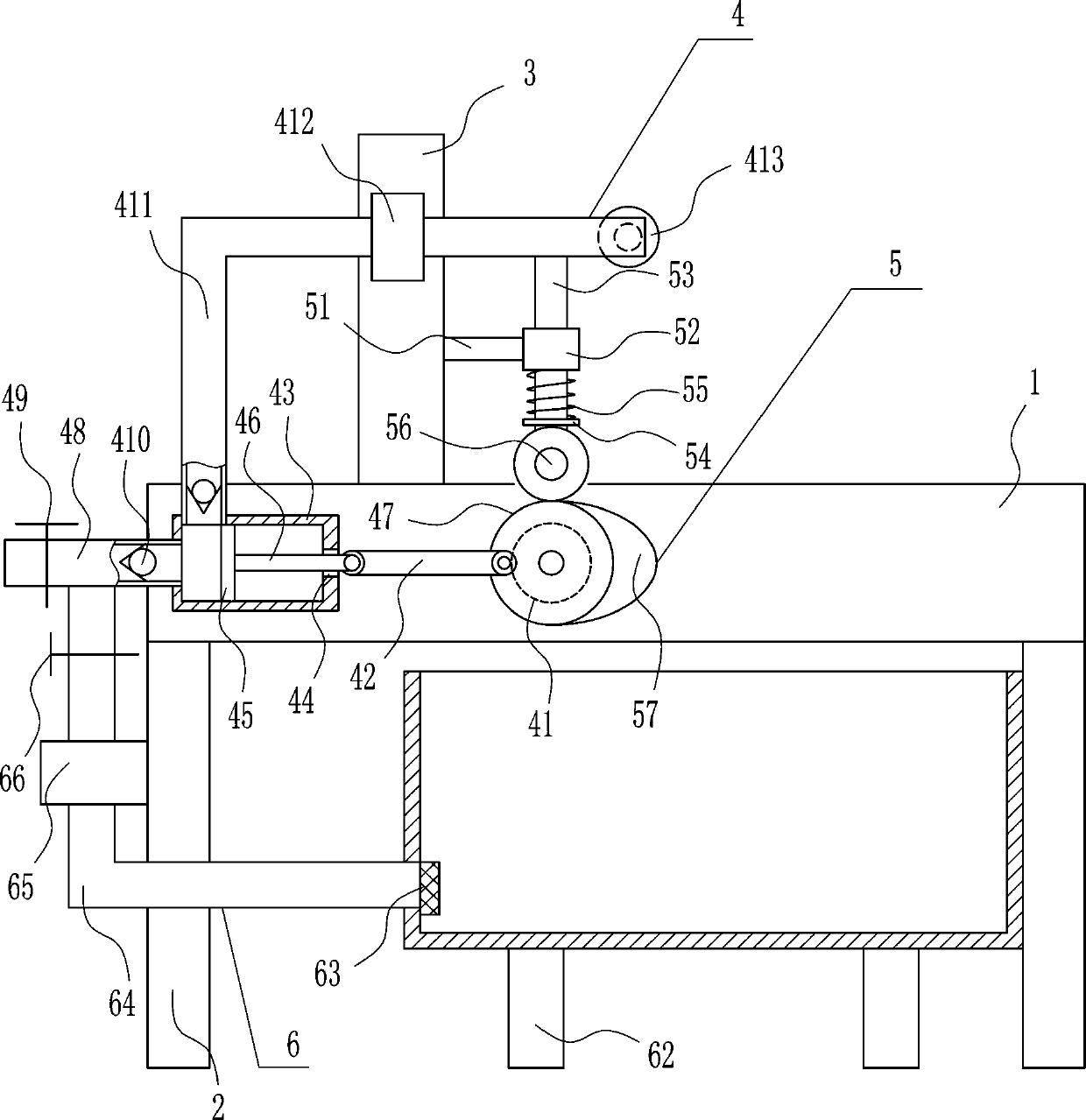

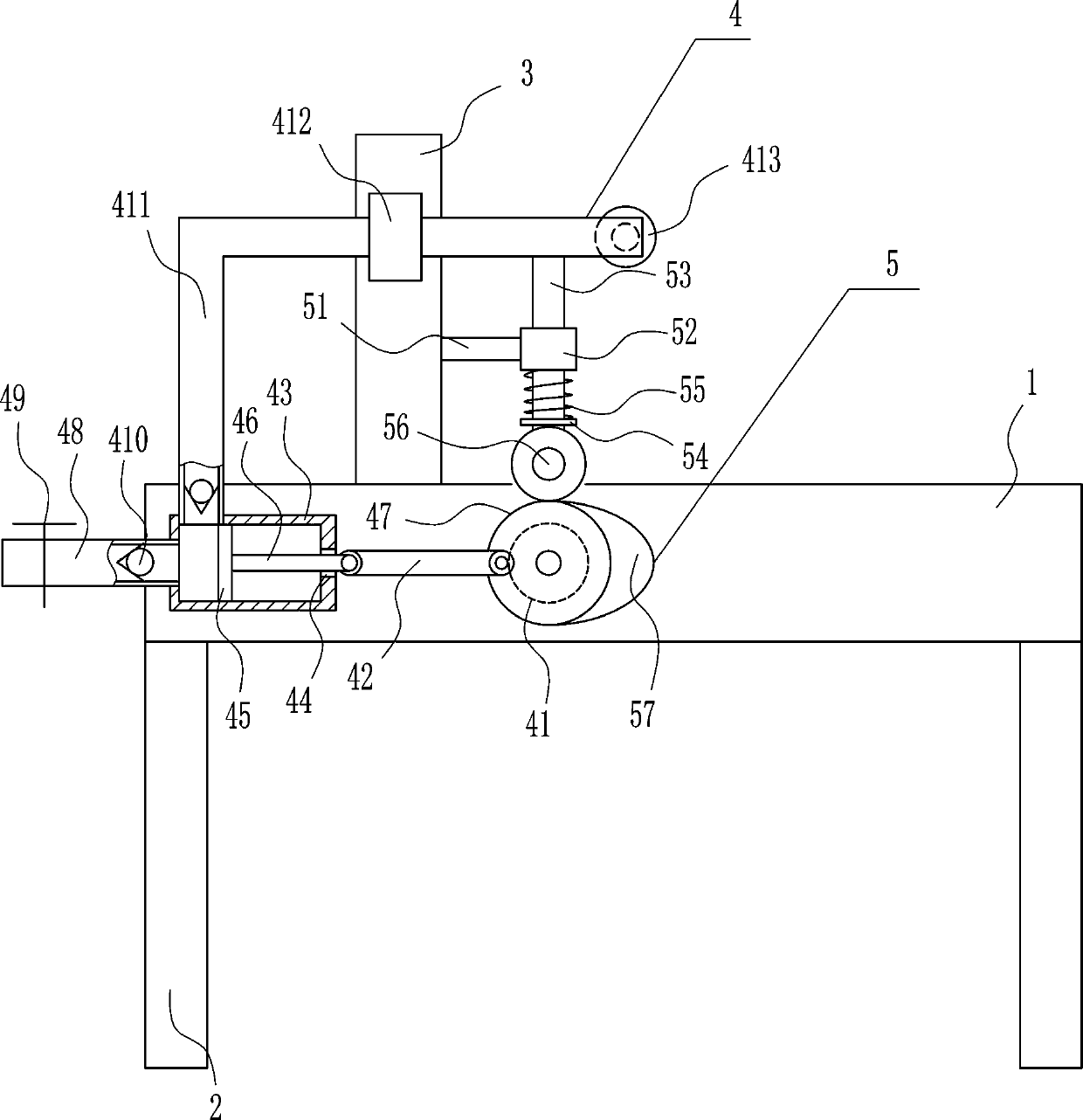

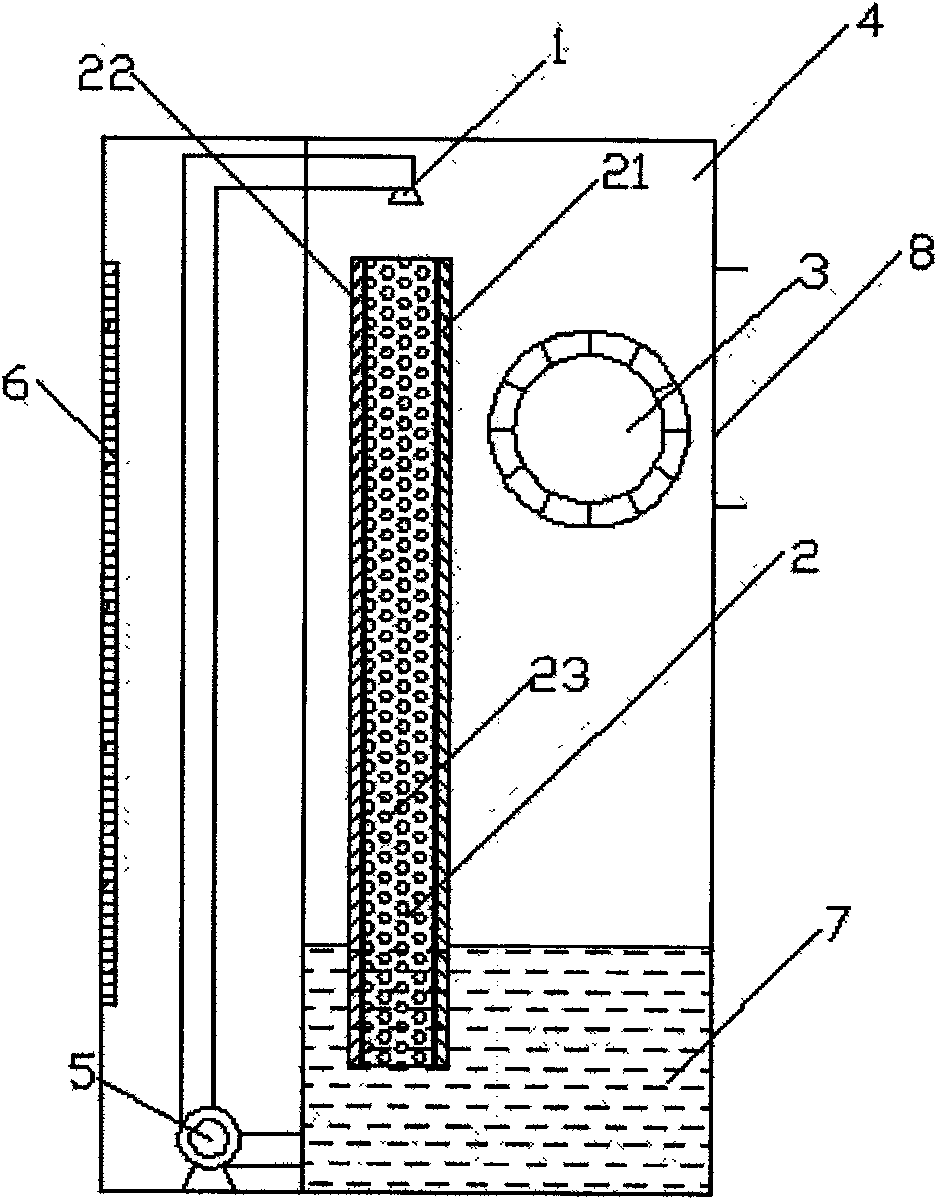

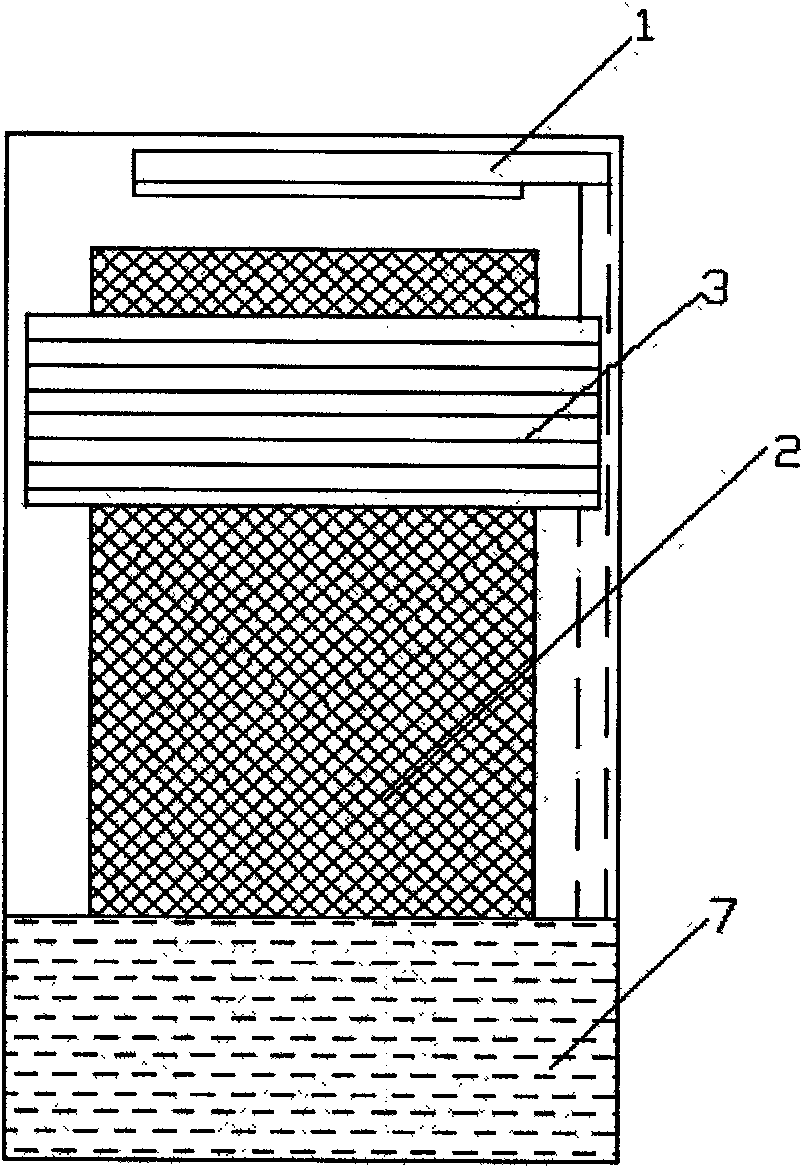

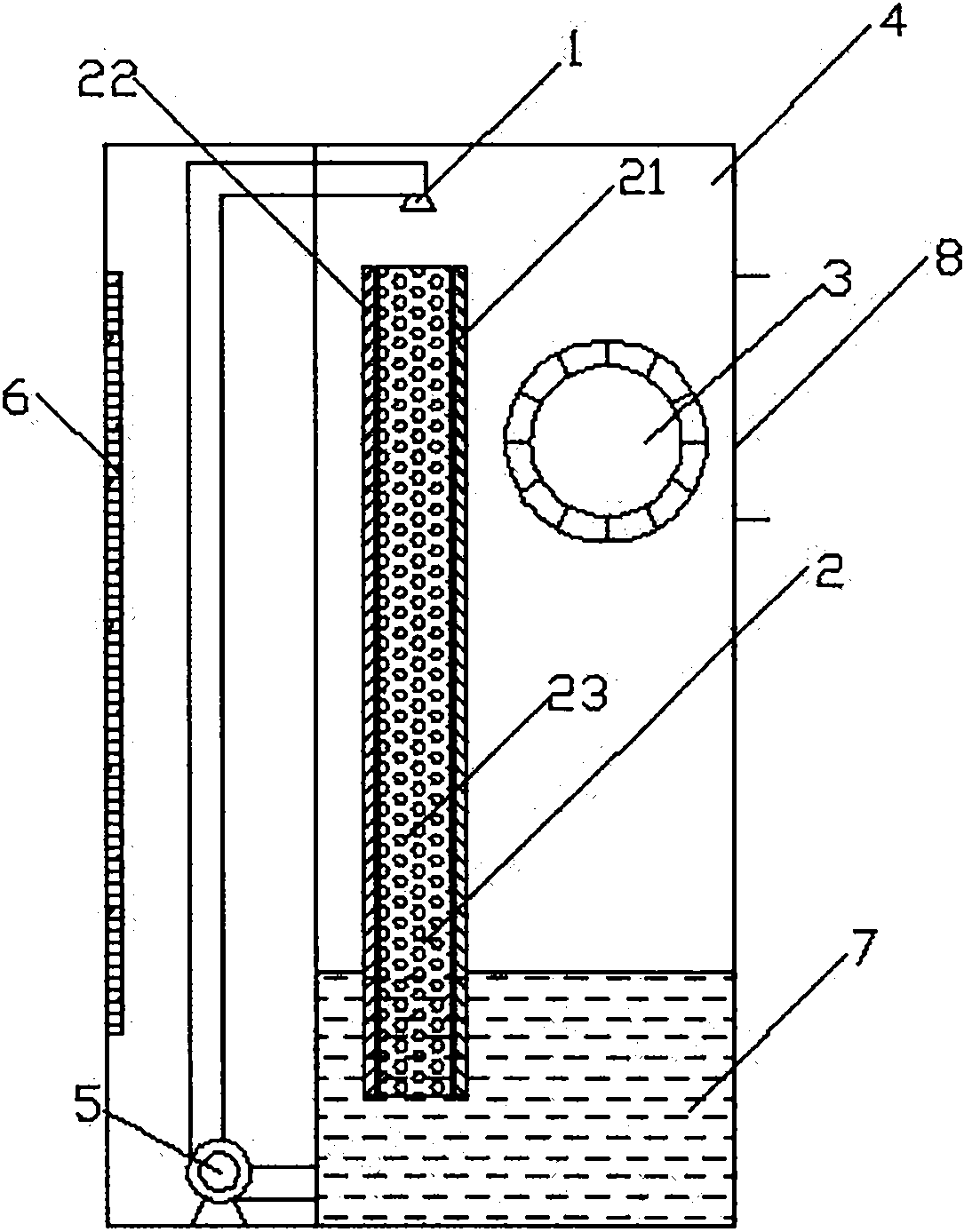

Radioactive rare earth waste transport vehicle cleaning equipment

The invention relates to cleaning equipment, in particular to radioactive rare earth waste truck cleaning equipment. The technical problem to be solved by the invention is to provide radioactive rareearth waste transport vehicle cleaning equipment which has the beneficial effects that both the time and the labor are saved, not only can a transport vehicle be cleaned, but also cleaned water can befiltered and then reused, and the transport vehicle is not required to be mutually cleaned and is hard to poison. In order to solve the technical problem, the invention provides the radioactive rareearth waste truck cleaning equipment which comprises a bottom plate and the like; supporting legs are symmetrically mounted on the left side and the right side at the bottom of the bottom plate, a vertical plate is mounted on the left side at the top of the bottom plate, and a water spray device is arranged between the upper part on the front side surface of the vertical plate and the left side onthe front side surface of the bottom plate. The radioactive rare earth waste truck cleaning equipment provided by the invention has the beneficial effects that through a circulating device, the cleaned water can be filtered and then reused, so that water resources are saved; the effects that both the time and the labor saved, not only can the transport vehicle be cleaned, but also the cleaned water can be filtered and then reused, and the transport vehicle is not required to be mutually cleaned and is hard to poison are achieved.

Owner:赣州清亦华科科技有限公司

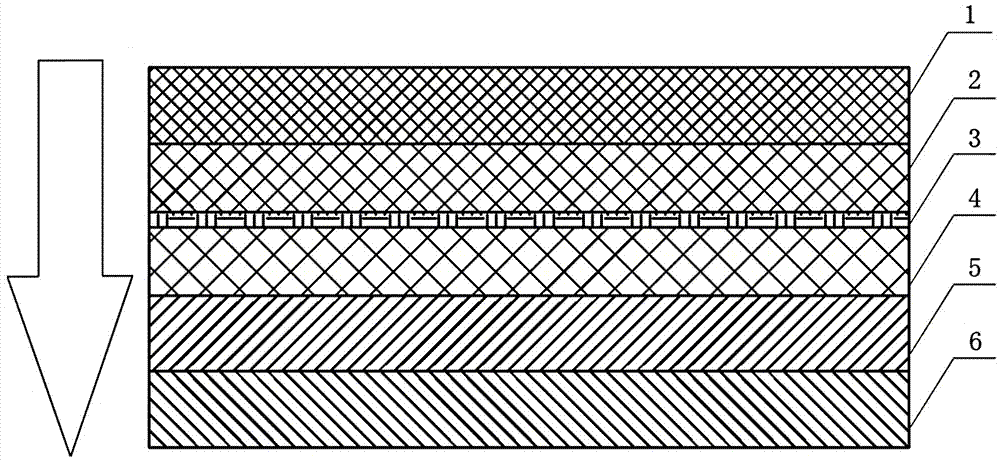

High-temperature-resistant filtering material with ultra-clean filtering and low-temperature catalytic denitration functions, and preparation method thereof

ActiveCN106914064ALarge specific surface areaHigh porosityOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationChemistryFiber layer

The invention discloses a high-temperature-resistant filtering material with ultra-clean filtering and low-temperature catalytic denitration functions, and a preparation method thereof. The filtering material successively comprises, from a dust-facing surface, an island-type or fragment-type extremely superfine fiber layer, a superfine fiber layer, a PTFE sewing-thread base-cloth layer, a fine-denier fiber layer, a high-temperature-resistant adhesive layer and a catalyst coating. The high-temperature-resistant filtering material provided by the invention has the excellent characteristics of a large specific surface area, high porosity and the like, can realize ultralow dust discharge and has superhigh filtration accuracy and good filtering effect; a catalyst is uniform in distribution, firm in loading, high in catalysis efficiency, good in anti-sulfur effect and long in service life; the preparation method for the filtering material is simple in process and easy for realization of industrialization; the catalyst is not prone to poisoning and long in service life; and the high-temperature-resistant filtering material is applicable to flue gas filtering under complex conditions like high working temperature, great dust content and high requirements on filtration accuracy, and can realize low-temperature denitration of nitrogen oxides in flue gas without extra heating while realizing high-precision filtering.

Owner:XIAMEN ZHONGCHUANG ENVIRONMENTAL TECH CO LTD

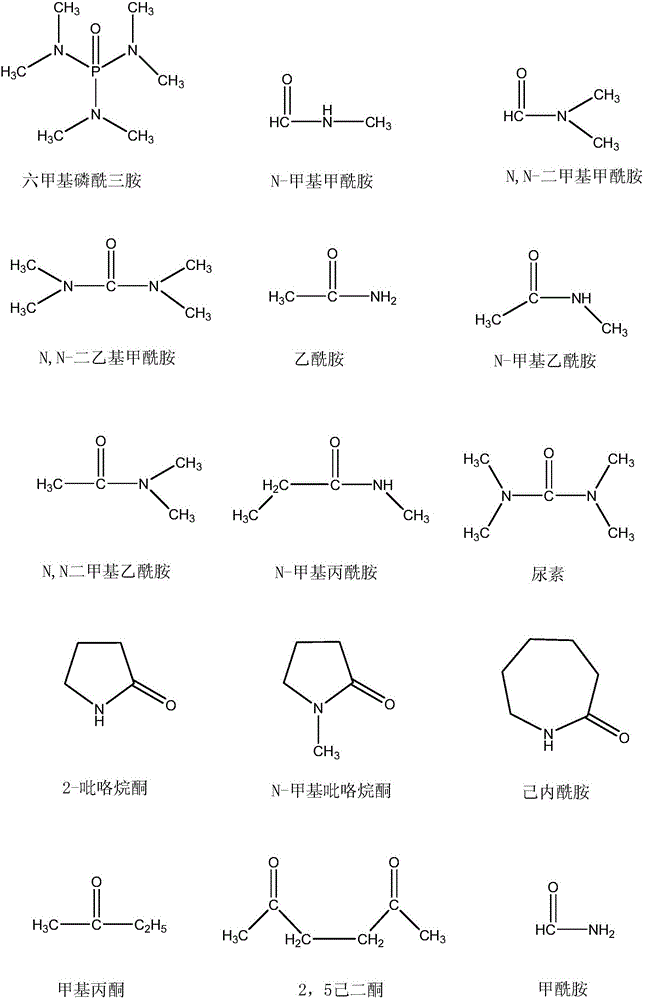

Production method of pentafluoroethane

InactiveCN1724490AImprove conversion rateHigh selectivityHalogenated hydrocarbon preparationHydrogen fluorideTetrafluoroethylene

The invention relates to a process for synthesizing pentafluoroethane (HFC-125) from tetrafluoroethylene and hydrogen fluoride at the presence of catalyst, wherein the catalyst is a dual system comprising tertiary amine compounds and carbonyl-containing compounds by the proportion of 1:0.05-10, the reaction condition being, the reaction temperature 10-150 deg. C, the reaction pressure 0.6-2.5 MPa, the reacting time 1-10 hours. The invention can realize high conversion rate of tetrafluoroethylene and good selectivity of pentafluoroethane.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

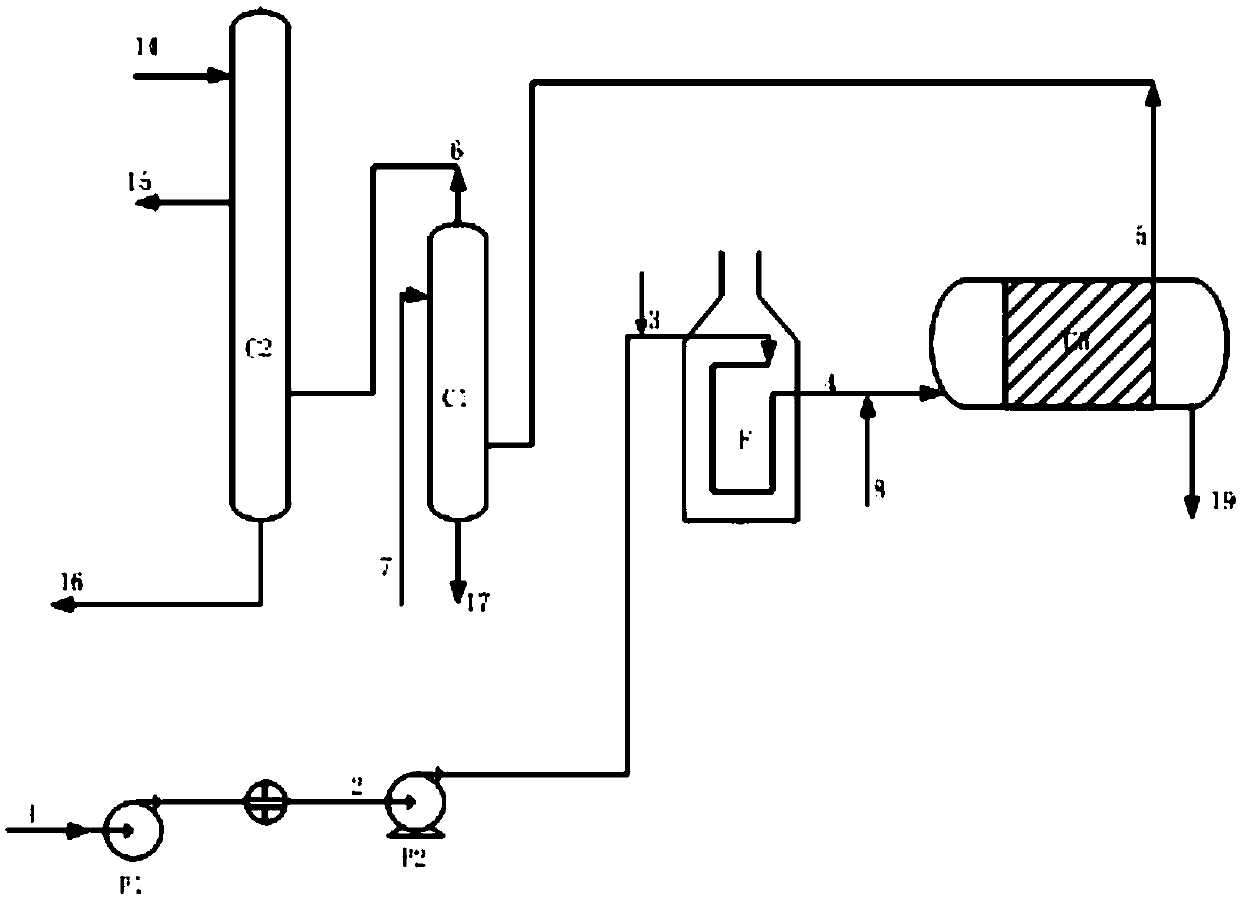

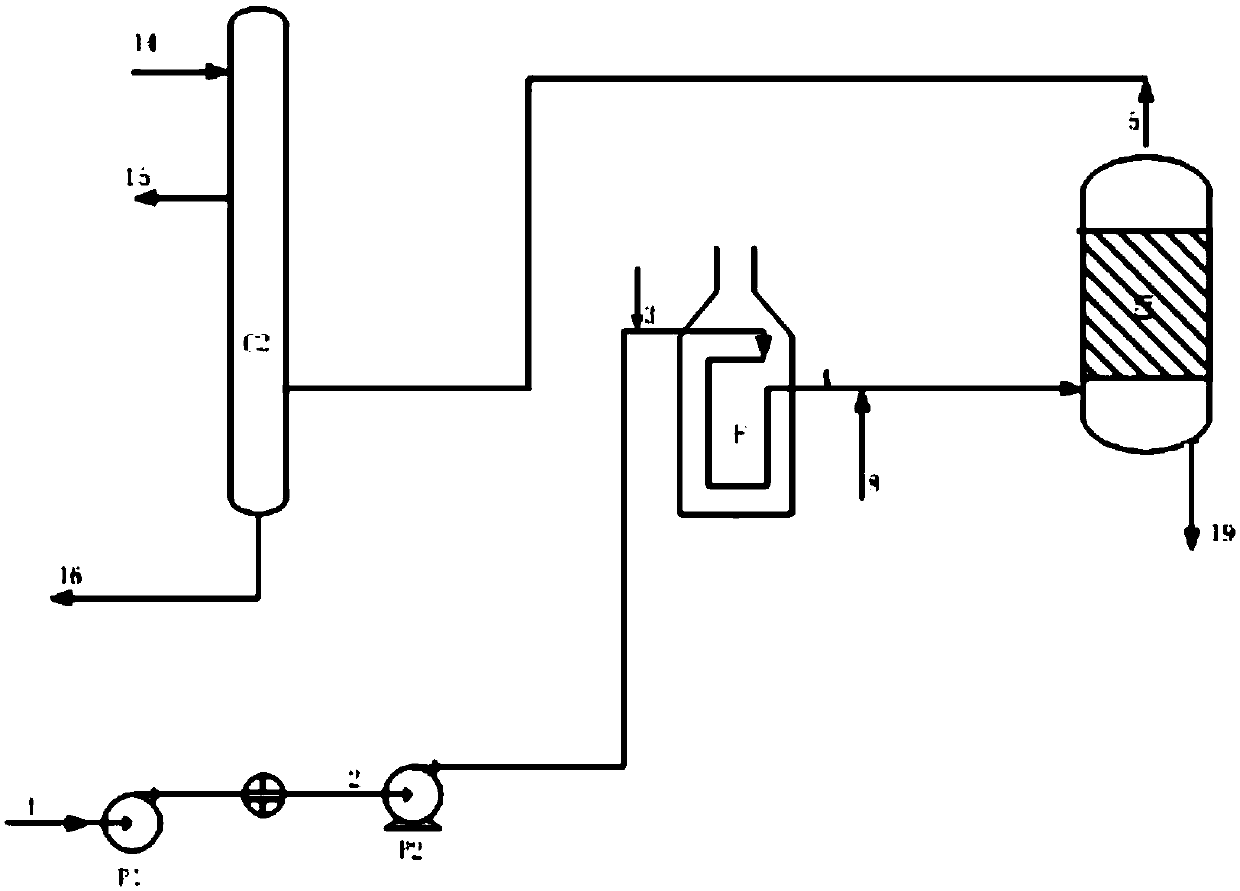

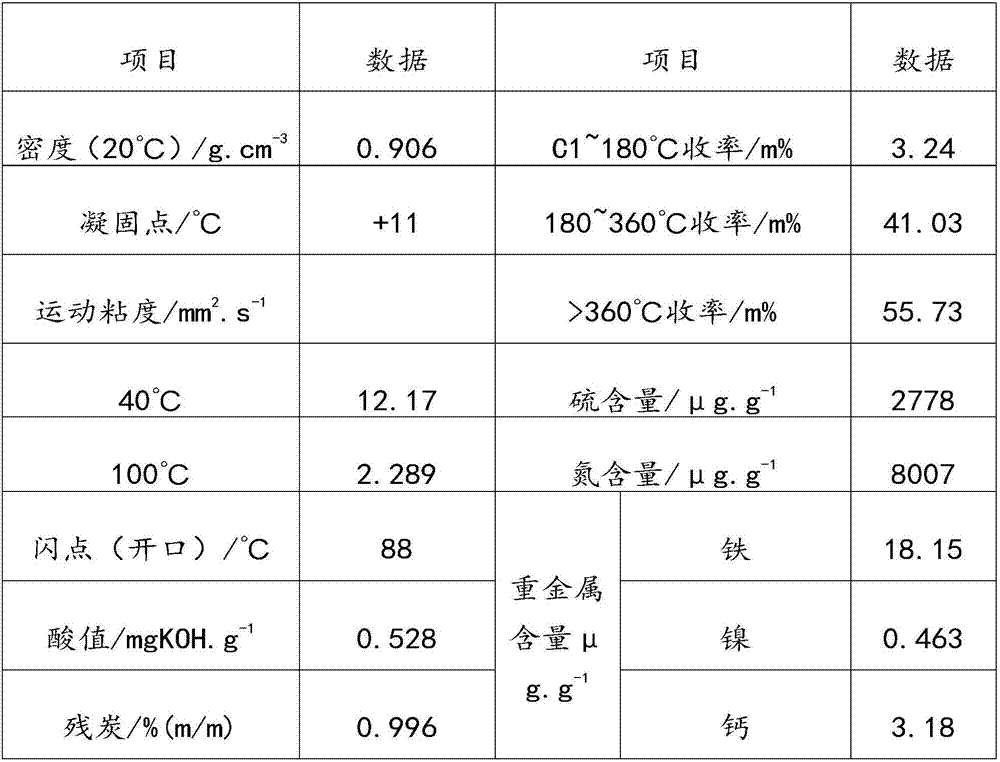

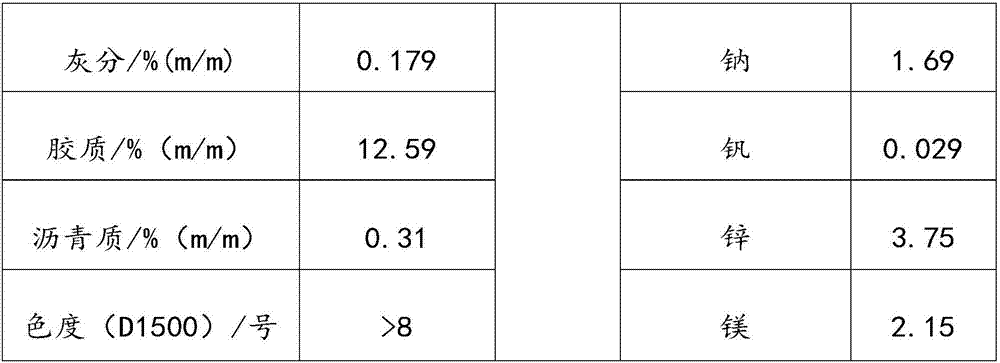

Process for delayed coking of undoped full-fraction ethylene tar

PendingCN109609182AReduce processDelayed coking productionThermal non-catalytic crackingTreatment with plural serial stages onlyDistillationTar

The invention discloses a process for delayed coking of undoped full-fraction ethylene tar. The process comprises the following steps: injecting water into preheated ethylene tar, and feeding the ethylene tar into a heating furnace for heating, wherein the temperature of an outlet of a furnace tube of the heating furnace is 440-470 DEG C; feeding the heated ethylene tar into a coking kettle for carrying out a reaction; and then feeding the reaction products into a normal-pressure fractionating tower for carrying out distillation separation to obtain a light fraction, petroleum coke and tail oil. The invention aims to provide the process which has simple steps, does not need catalysts, pre-treatment or doping, and is used for delayed coking of full-fraction ethylene tar, so that continuousproduction of delayed coking process of full-fraction ethylene tar is realized. The obtained fraction sections all can be processed according to a conventional production process of a refinery plat, the processing steps are simple, no catalyst is needed, operation conditions of existing deep processing do not need to be changed, economic cost is saved, and production efficiency is improved.

Owner:TIANJIN DONGSHENG IND & TRADE

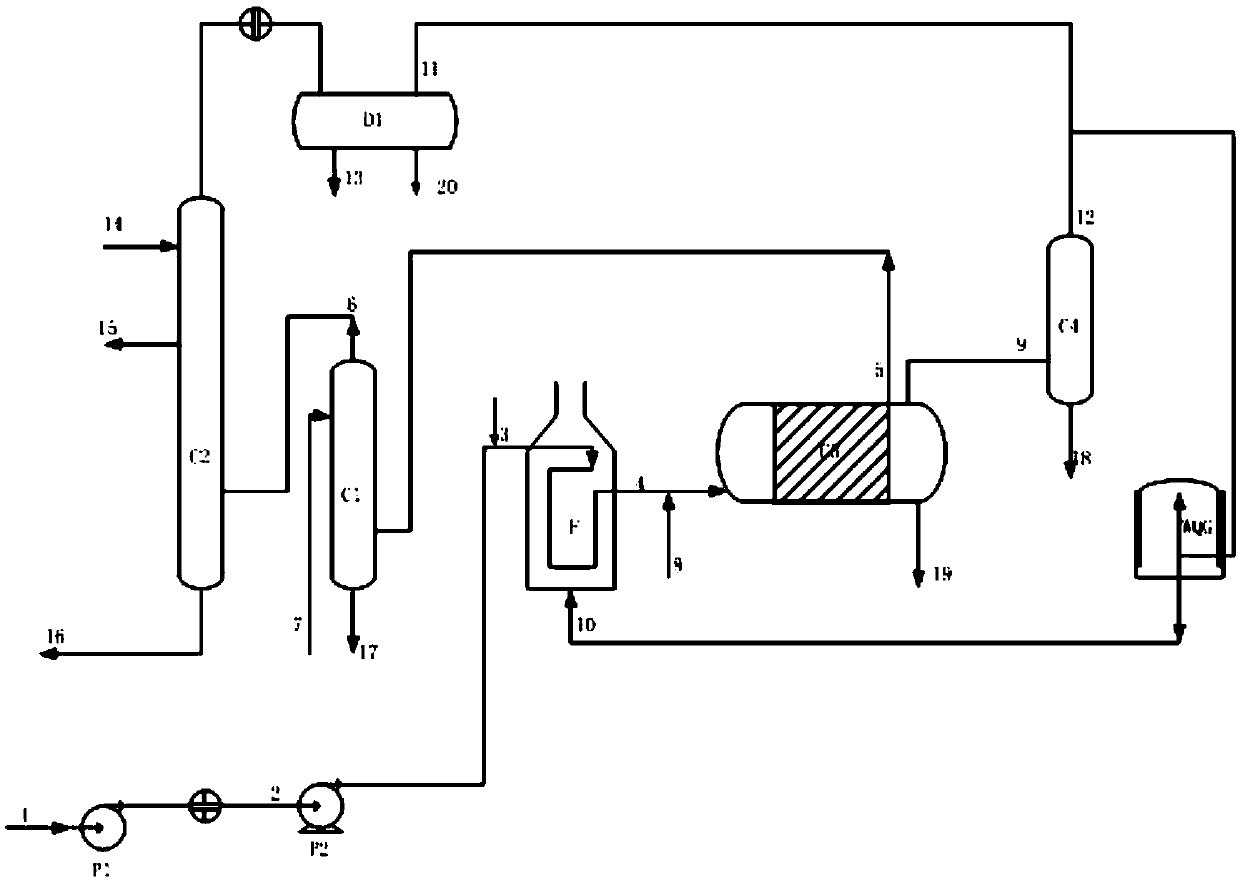

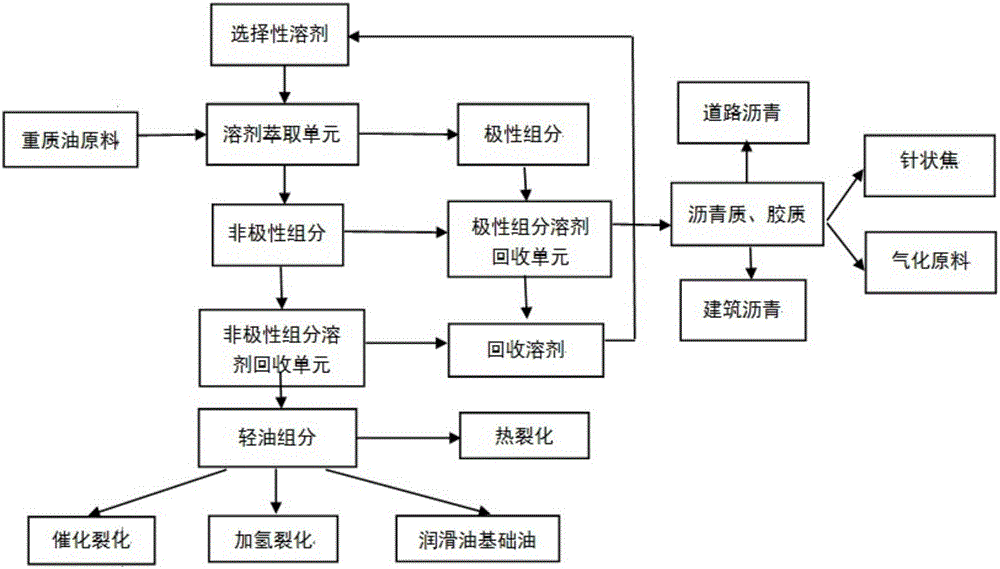

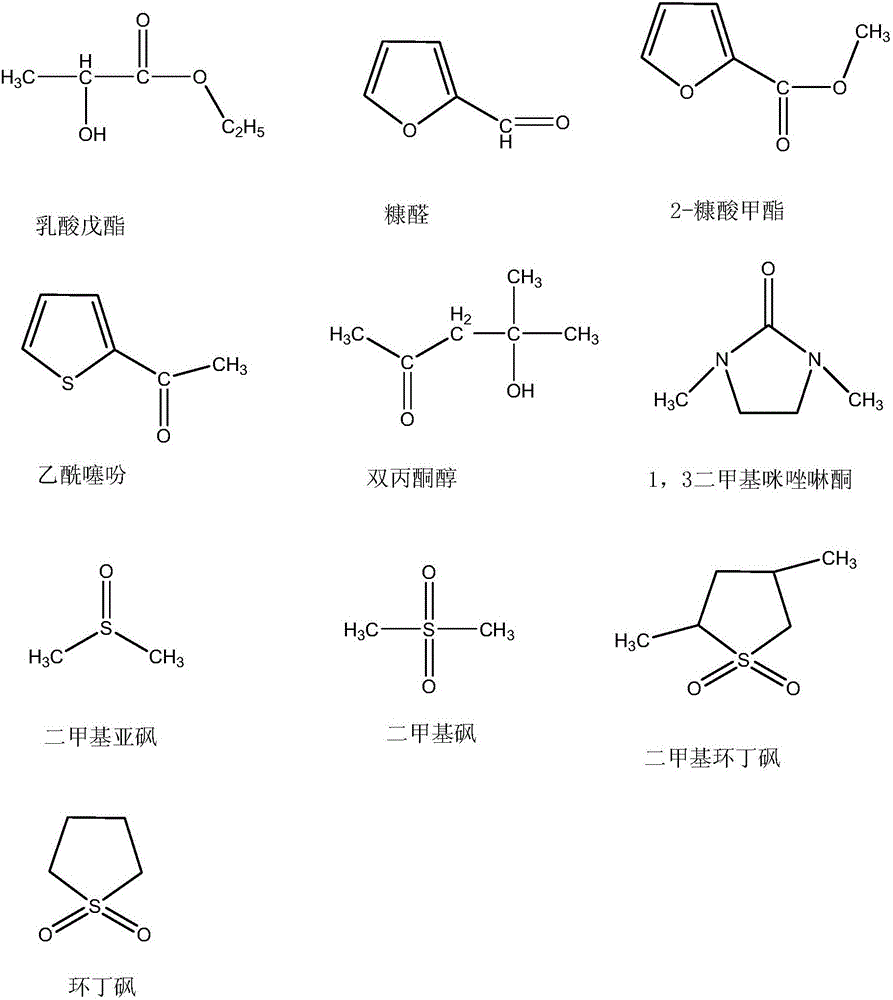

Method of extracting and separating crude oil

InactiveCN106833719AAvoid cokingInhibit aggregationRefining by solvent de-asphaltingHydrocarbon oils treatmentDistillationSolvent

The invention provides a method of extracting and separating crude oil. The method comprises the step of extracting the crude oil by adopting a selective solvent, wherein the selective solvent comprises a polar non-proton solvent. According to a polarity effect and hydrogen-bond interaction, the crude oil is divided into polar and nonpolar two components. During solvent separation, an inorganic salt component in the crude oil is enriched, and corrosion of Cl to equipment is reduced. A demulsifier can be added into the solvent extraction process so that moisture in the crude oil can be removed through the solvent better. While the crude oil is separated, the content of S, N and metal in a light component can be reduced at the same time, and the processing pressure of subsequent devices is reduced. According to the method of extracting and separating the crude oil, not only is energy consumption far lower than that of distillation, but also coking, polymerization or dissociation of heavy distillates of petroleum in the process can be avoided, a high-vacuum apparatus during reduced pressure distillation is not needed either, and the operation cost and equipment cost are remarkably reduced.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method for preparing nano-scale catalyst through ultrasonic atomization plasma reaction

InactiveCN109590028AImprove catalytic oxidation performanceHigh selectivityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsNano catalystHigh pressure

The invention discloses a method for preparing a nano-scale catalyst through ultrasonic atomization plasma reaction. The method comprises the following steps: (1) introducing an active component intoan ultrasonic atomizer, and introducing carrier gas into the ultrasonic atomizer for bubbling to bring out atomized gas containing active component precursor, so as to form aerosol; putting a catalystcarrier into a discharging gap of a plasma reactor, uniformly mixing aerosol flowing from the ultrasonic atomizer with supplemented carrier gas, enabling the mixture to continuously flow through thedischarging gap, heating gas in the plasma reactor, starting a high-voltage discharging device, continuously keeping atomization and high-voltage discharging states to reduce metal ions in active components of the aerosol into metal monomers loaded to the catalyst carrier. Compared with traditional methods, the catalyst prepared by virtue of the method has the advantages that the catalytic activity is high, the preparation cost of the catalyst is low, the preparation process is simple, and the catalyst has an extremely high industrial application value.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

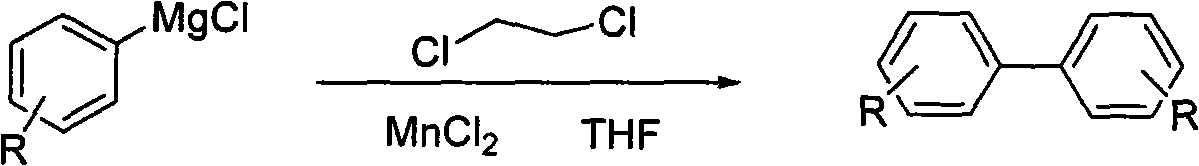

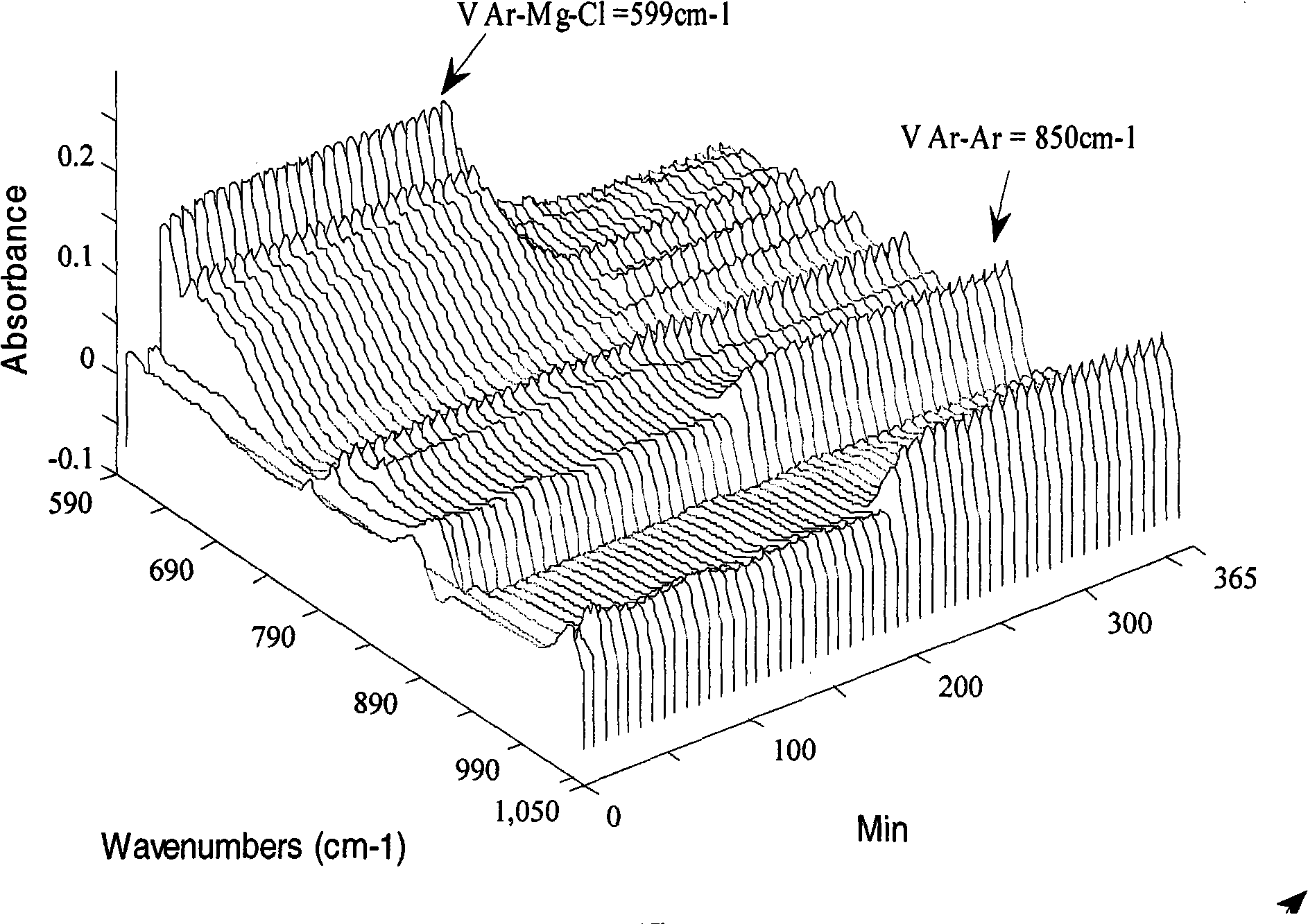

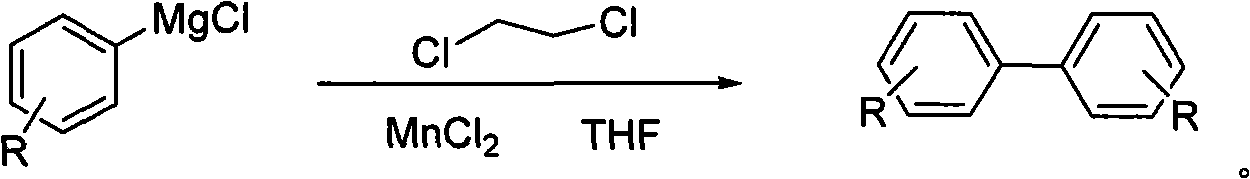

Self-coupling reaction method of manganses-catalyzed and oxidized chlorobenzene grignard reagent

InactiveCN101284753ALow priceAir stabilizationOrganic compound preparationOrganic chemistry methodsGrignard reagentManganese

The invention provides a synthetic method which uses manganese chloride as a catalyst and adopts1, 2-ethylene dichloride as a secondary oxidant to catalyze the homo-coupling reaction of a chlorine aryl compound grignard reagent, so as to further obtain a biaryl compound with the corresponding symmetric structure. In the synthesis route, the method uses various chlorine aryl compounds and activated magnesium to generate the grignard reagent, and adds the manganese chloride and the 1,2-ethylene dichloride as the catalyst and the secondary oxidant to catalyze the grignard reagent and obtain the homo-coupling reaction. The synthesis route is simple, the raw materials and the catalyst are cheap, the production rate is high, the operation is convenient, and the purification is easy. The method is applicable to agrochemicals, drugs, natural products, conduction materials and asymmetric synthesis of catalysts.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

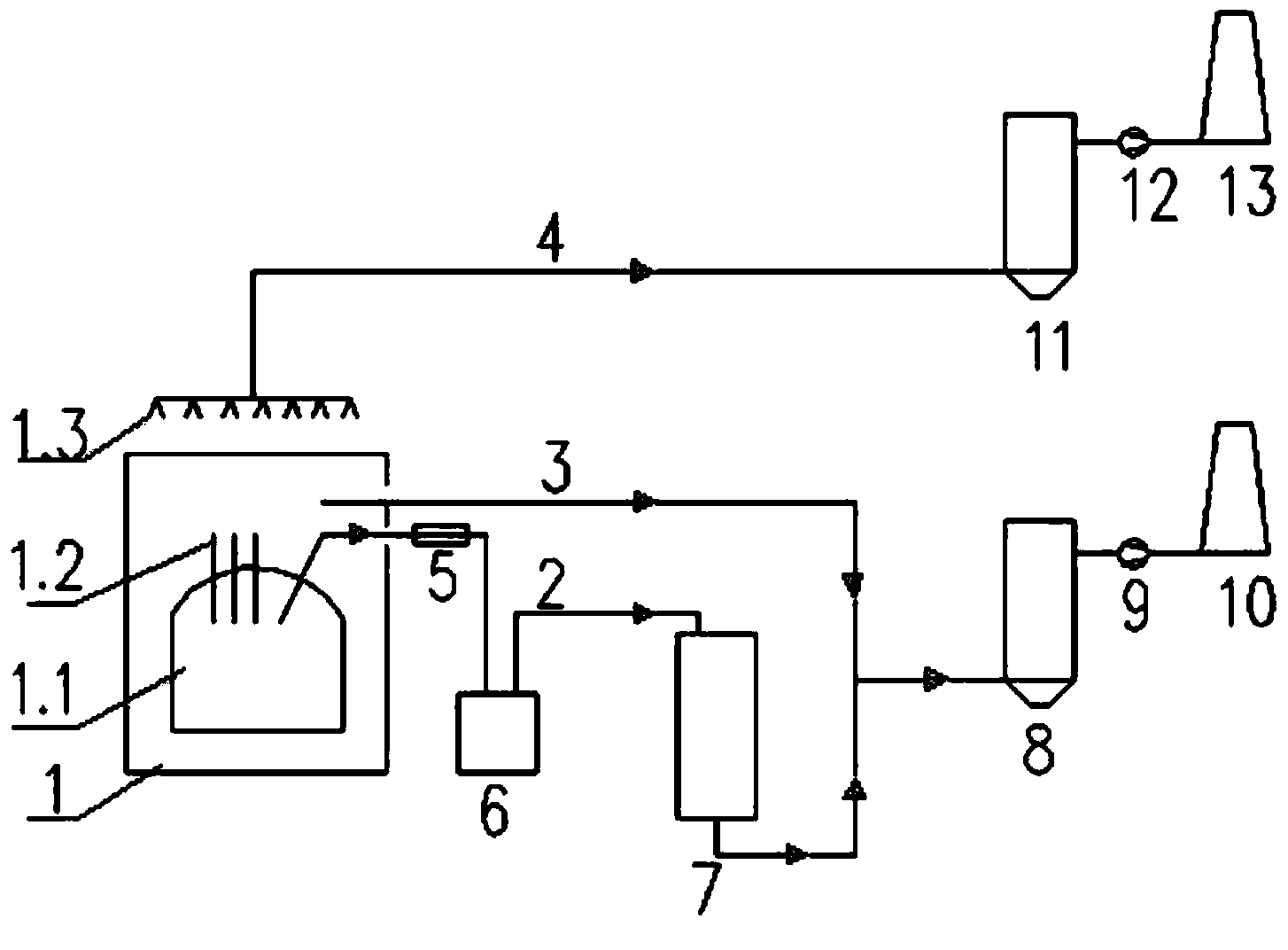

Method for preparing fuel oil through catalytic hydrogenation of shale oil

The invention relates to a method for preparing fuel oil through catalytic hydrogenation of shale oil. The method comprises the following steps: (a) removing impurities of which the particle size is greater than 20 mu m from the shale oil, mixing the shale oil with a sulfur-containing assistant and then mixing the shale oil with hydrogen, thus obtaining hydrogen mixed raw oil; (b) enabling the hydrogen mixed raw oil to react in a hydrogenation protective reactor and a hydrorefining reactor in sequence, carrying out gas-liquid separation on a reaction output object, mixing a liquid separation object of a low-pressure separator with desalted water containing an ammonia catcher, and entering a hydro-upgrading reactor for reacting; (c) carrying out primary separation on the reaction output object through a second high-pressure separator, and carrying out secondary separation on a separation object at the lower part of the second high-pressure separator through a second low-pressure separator; (d) separating materials in the second low-pressure separator, recycling a gas separation object at the top part, and feeding the liquid separation object at the bottom part to a fractionating tower; (e) fractionating in the fractionating tower, thus obtaining a final product. By using the method disclosed by the invention, the problem of coking can be effectively solved, poisoning cannot be easily caused by a catalyst, and the production cost is low.

Owner:FUSHUN XINRUI CATALYST

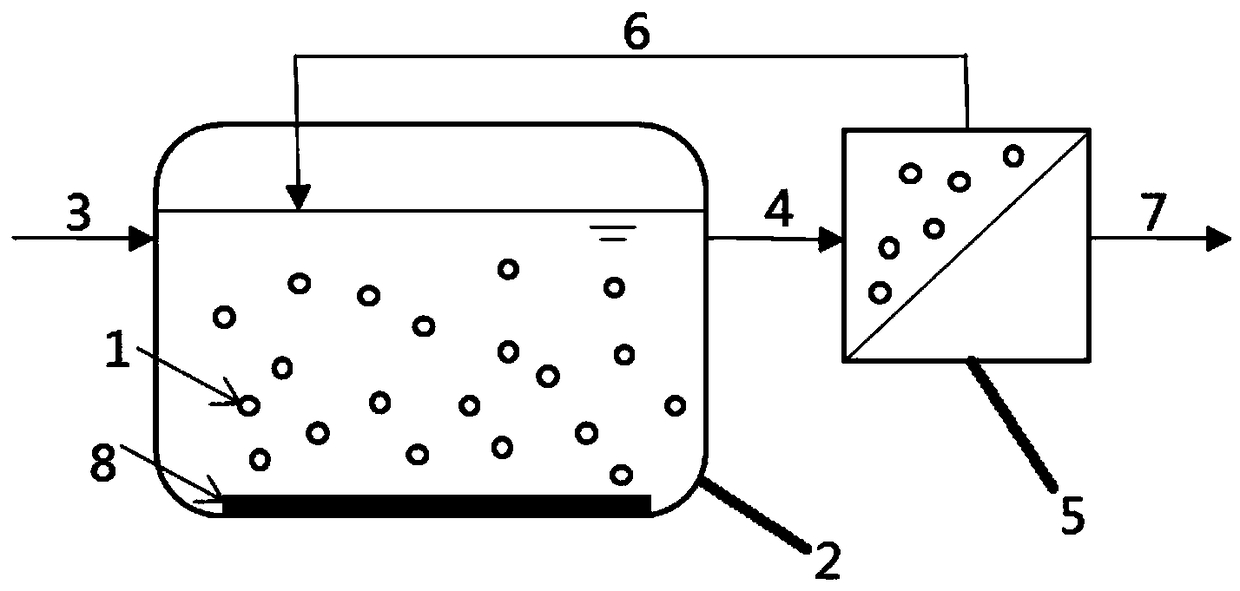

Method and device for treating pollutant and dust in gas

InactiveCN101804294AIncrease negative ionsAdd fragrance ingredientsUsing liquid separation agentElectrolysisProduct gas

The invention belongs to the environment protection field and discloses a method and a device for treating pollutant and dust in gas. The method is electrochemical means, solution-electrode is adopted as reaction system, gas is guided into the solution-electrode reaction system, and electrolysis reaction is carried out to degrade pollutant. The adopted electrode is a three-dimensional foam electrode with openings, and foam filler is filled between anode and cathode. The invention also provides a device applicable to the method, liquid cycle and effective distribution are adopted, so that gas and liquid can be effectively distributed and mixed on the surface of the three-dimensional electrode, effective area of reaction is greatly increased, and gas purification efficiency is improved.

Owner:SUN YAT SEN UNIV

Method for on-site detecting and metering fume discharge total amount and fume concentration on-site detecting and metering instrument

InactiveCN1587973AReduce volumePromote decompositionRelative volume flow measurementsSpecific gravity measurementAutomatic controlEngineering

A method of onsite detecting and metering total amount of lampblack discharged and lampblack density onsite detecting and metering instrument are disclosed. Collect a part from air current, lampblack contained in which is completely oxided to be carbon dioxide and water; and before hand quantitative relation of density of lampblack and density of carbon dioxide created in oxidation reaction is built up; then detected density change of carbon dioxide before and after oxidation reaction is converted into density value of lampblack; density value of lampblack collected in each time quantum are accumulated and total amount of lampblack discharged is calculated according to sectional area and air current velocity of air outlet. Lampblack density onsite detecting and metering instrument is consisted of probe unit and discharge capacity, its main parts consist of detecting tube, data processing controller, automatic control switch, carbon dioxide tester, heating element, temperature tester, air current flow velocity and lampblack collection blower fan. The invention can test and calculate total amount of lampblack discharged, benefiting for environmental protecting sector to charge according to discharge capacity.

Owner:何宗彦

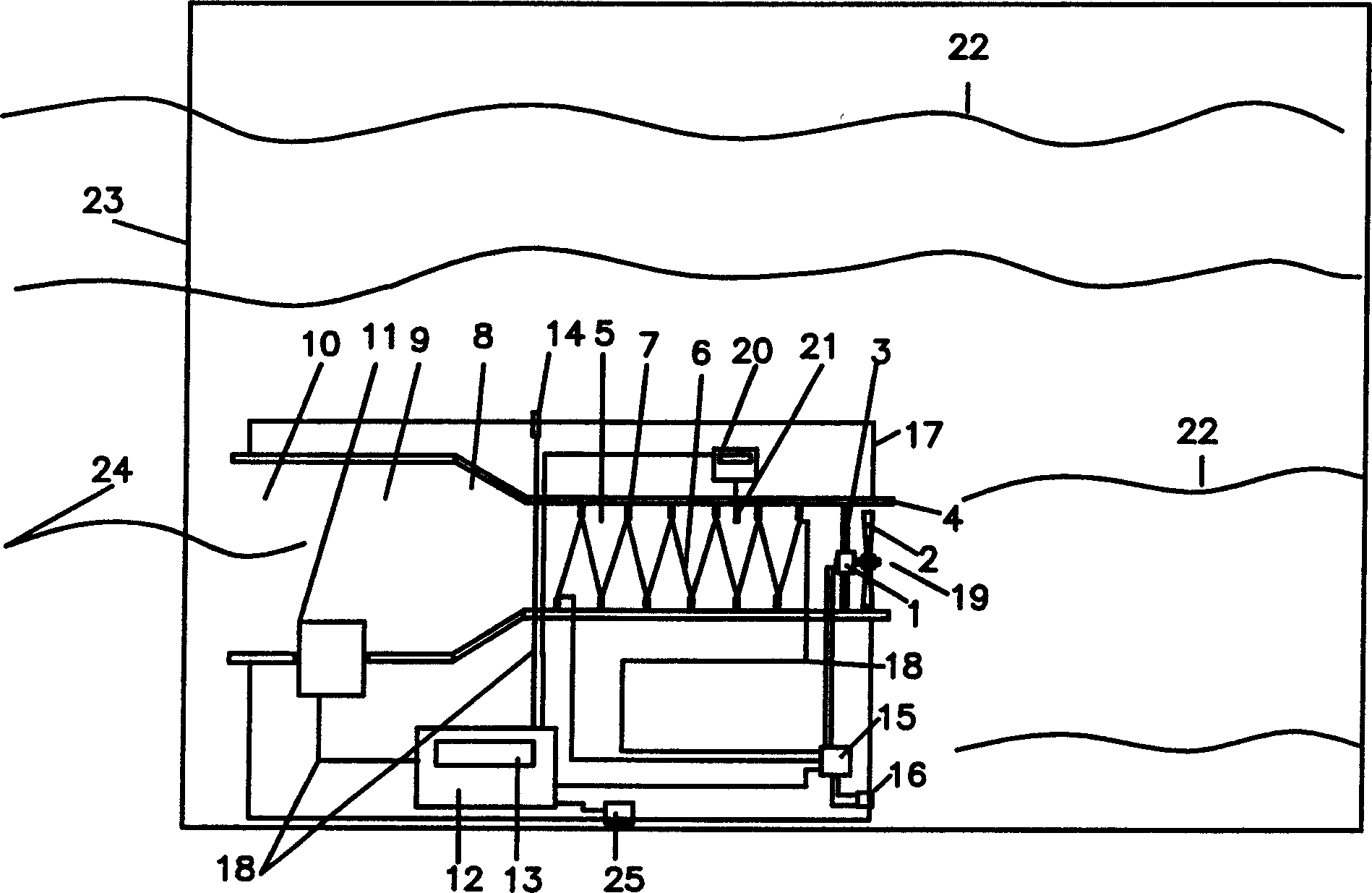

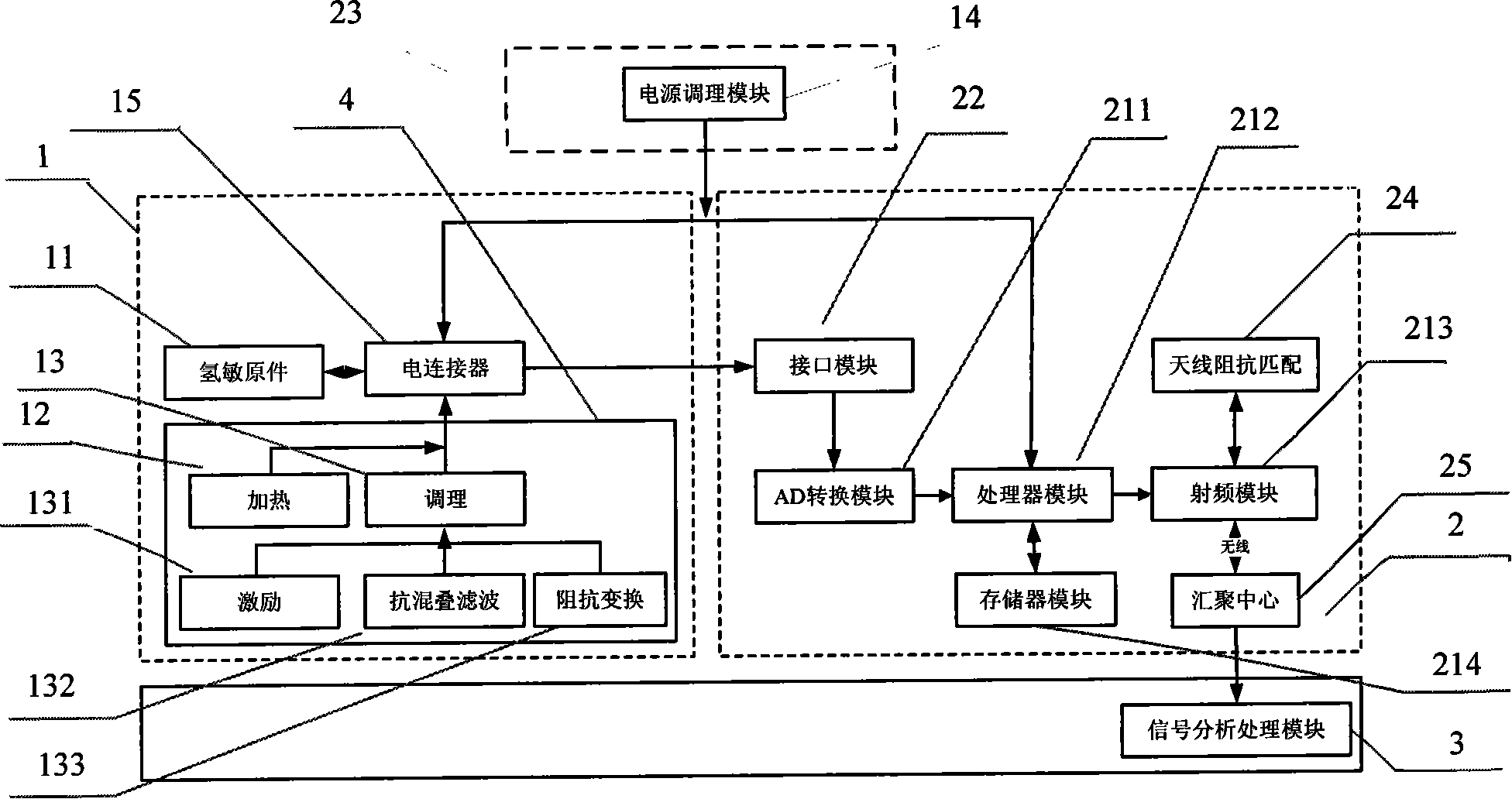

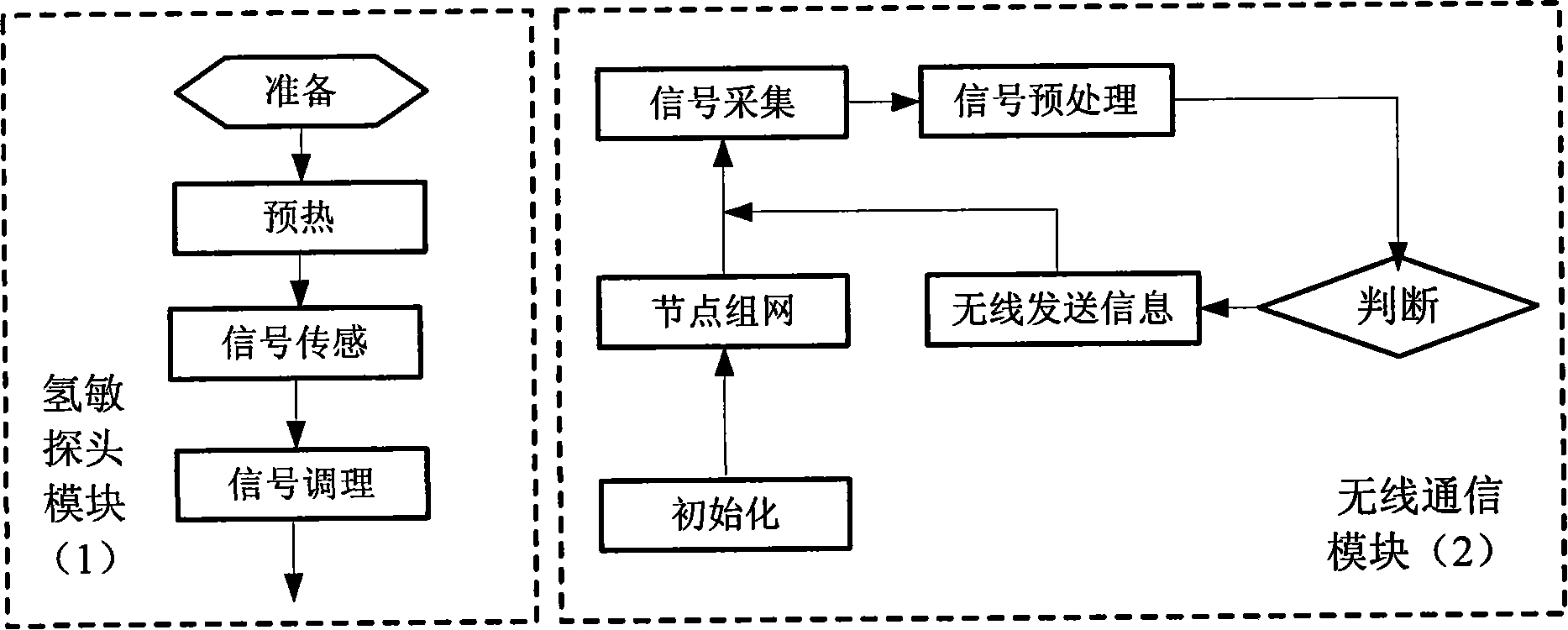

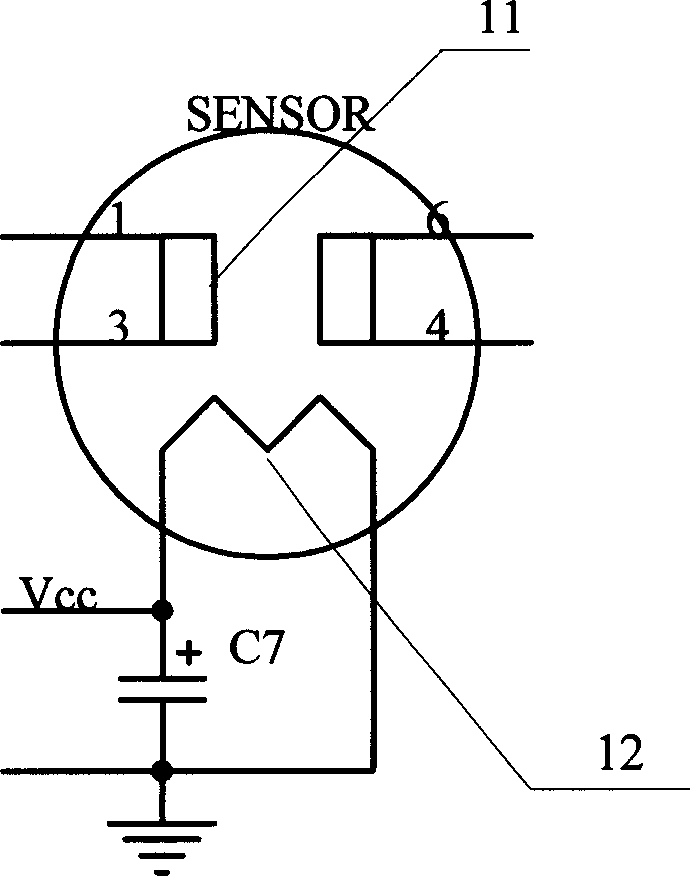

Intelligent hydrogen leakage detecting system based on wireless sensing network

InactiveCN101174355AWide detection rangeFunctionalTransmission systemsTransmissionHydrogenInformation analysis

The invention discloses a hydrogen leakage intelligent detection system based on a wireless sensing network, which comprises a hydrogen sensitive probe module, a wireless communication network module and a signal analysis processing module. The hydrogen sensitive probe module is connected with the signal analysis processing module through the wireless communication network module, after completing calibration, the hydrogen sensitive probe module makes filtering and modulation to a data signal, the wireless communication network module acquires and converses the analog data signal, makes processing according to the calibration result, makes judgment according to the processing result, transmits the processing result to a concourse center in a wireless way, and then transmits to a information analysis processing module. The hydrogen leakage intelligent detection system based on a wireless sensing network has the advantages of small size, low cost, convenient installation, strong anti-interference capability, quick response speed, and high safety.

Owner:NAT UNIV OF DEFENSE TECH

Treatment method of nonbiodegradable organic wastewater

ActiveCN108751490ALow costNot easy to be poisonedWater contaminantsWater/sewage treatment by magnetic/electric fieldsOxygenOperating cost

The invention discloses a treatment method of nonbiodegradable organic wastewater, which comprises the following steps of: injecting the organic wastewater to be treated into a reactor filled with catalyst particles, allowing organic matter in the organic wastewater to be oxidized by oxygen by the action of the catalyst particles to form inorganic matter, conveying effluent of the reactor to a separator, separating the catalyst particles from the effluent of the reactor by membrane separation or magnetic field separation, and entrapping the effluent to allow the effluent to flow back to the reactor, and taking effluent of the separator as final effluent. According to the method, a noble metal catalyst is not required to adopted; a low-cost transition metal is taken as a catalyst raw material; the cost of the catalyst is lowered; the catalyst is high in activity and stability; the possibility of poisoning is low; in addition, low temperature and atmospheric pressure reaction conditionsare only required in a reaction process; a pressure vessel is not required; technical difficulty and operating cost are greatly reduced; and the nonbiodegradable organic matter can be degraded into the inorganic matter such as CO2, N2 and H2O under the low temperature and atmospheric pressure conditions.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

De-carbon monoxide catalyst and preparation method thereof

ActiveCN109513447AEvenly dispersedUniform distribution of poresGas treatmentHeterogenous catalyst chemical elementsPore distributionSulfur

The invention discloses a de-carbon monoxide catalyst and a preparation method thereof. The catalyst comprises a carrier and an active component loaded on the carrier, wherein the carrier is a composite of titanium dioxide and active aluminium oxide and the active component comprises manganese oxide and copper oxide. The catalyst has the beneficial effects that the carrier adopts the titanium dioxide as a main component, so that the catalyst has excellent sulfur resistance; in the meantime, the titanium dioxide is modified by adopting the active aluminium oxide to ensure that the specific surface area of the carrier is up to 150-180m<2> / g and the pore volume is up to 0.3-0.38m<3> / g, so that the ability of the carrier adopting the titanium dioxide as the main component to load the active component is effectively enhanced and more catalytically active centers are contained in the catalyst; and after the active aluminium oxide and the titanium dioxide are composited, molecules in the composite of the titanium dioxide and the active aluminium oxide can be kept to be uniformly dispersed due to electric charge carried on the surface of the titanium dioxide and the stability of the dispersion system is excellent and finally the carrier in which the titanium dioxide is uniformly dispersed and the pore distribution is uniform is obtained.

Owner:沈炳龙

Method for preparing magnesium-based nanocomposite hydrogen storage material

InactiveCN111515405ATo achieve the purpose of hydrogen storageNot easy to explodeMaterial nanotechnologyReversible hydrogen uptakeCarbon nanotubeChemical adsorption

The invention relates to a method for preparing a magnesium-based nanocomposite hydrogen storage material, and belongs to the technical field of hydrogen storage materials. In the method, carbon nanotubes are grown in situ on the surface of a molecular sieve to serve as a substrate, rare earth lanthanum is used as a target, a layer of lanthanum hydride film is formed on the surface of the substrate by sputtering to serve as a filler of the hydrogen storage material, and with magnesium hydride as a raw material, the magnesium-based nanocomposite hydrogen storage material is prepared by mechanical ball milling. When hydrogen molecules make contact with the material, the hydrogen molecules are adsorbed on the alloy surface, H-H bonds of the hydrogen molecules dissociate into atomic hydrogen,hydrogen atoms diffuse inwards from the material surface to be immersed into metal atoms with the radius much larger than that of the hydrogen atoms and among crystal lattices in the gaps of metal toform a solid solution, hydrogen solidly dissolved in the metal continues to diffuse inwards, the diffusion must have activation energy of conversion from chemical adsorption to dissolution, after thesolid solution is saturated by hydrogen, excess hydrogen atoms react with the solid solution to produce metal hydride, and thus the purpose of hydrogen storage is achieved.

Owner:深圳市亚环环保科技有限公司

Concentrated feed for cattle

InactiveCN106721203ASlow down the rate of degradationAbundant resourcesFood processingAnimal feeding stuffChemistryShrimp

The invention provides concentrated feed for cattle. The concentrated feed is prepared from raw materials including wheat bran, a caragana microphylla fermented product, a urea phosphate complex, vinasse, shell meal, dried small shrimp, tangerine peel, table salt, a premix additive and the like. According to the concentrated feed for the cattle, provided by the invention, non-protein nitrogen is converted into animal body protein by adopting a urea slow-release technology and the price of the concentrated feed is reduced, so that the aim of reducing the feeding cost is realized.

Owner:天津市盛鑫肉牛养殖有限公司

Preparation method of heavy metal ion removal sieve

InactiveCN102698706AImprove efficiencyNot easy to be poisonedOther chemical processesWaste water treatment from metallurgical processChemistrySodium silicate

The invention discloses a preparation method of a heavy metal ion removal sieve. The preparation method comprises the steps as follows: firstly, synthesizing a pyrophosphate polyoxometalate type exchanger-titanium silicate pyrophosphate by potassium pyrophosphate, sodium silicate and titanium tetrachloride; and secondly, preparing the titanium silicate pyrophosphate, a mixed solution of trivalent chromic ions, copper ions, zinc ions and cadmium ions with a certain concentration, and nitric acid into the heavy metal ion removal sieve according to the chemical sieve preparation means by using the embedding-extraction technology. The heavy metal ion removal sieve prepared by the preparation method can directly purify pollution in electroplated wastewater, particularly heavy metal pollution in the electroplated wastewater, and cannot bring new pollution; compared with the conventional chemical precipitation method and the ion resin exchange method, the specific ion sieve technology of the heavy metal ion removal sieve has the advantages of high efficiency, low possibility of poisoning, low cost, easiness in operation, low energy consumption and the like, and the heavy metal ion removal sieve can be recycled; and the electroplated wastewater treated with the heavy metal ion removal sieve is used, so that the national emission standard can be completely complied and safety emission or cyclic utilization can be realized. Therefore, the heavy metal ion removal sieve has a broad prospect of application.

Owner:SHENZHEN HUASHUI ENVIRONMENTAL PROTECTION TECH

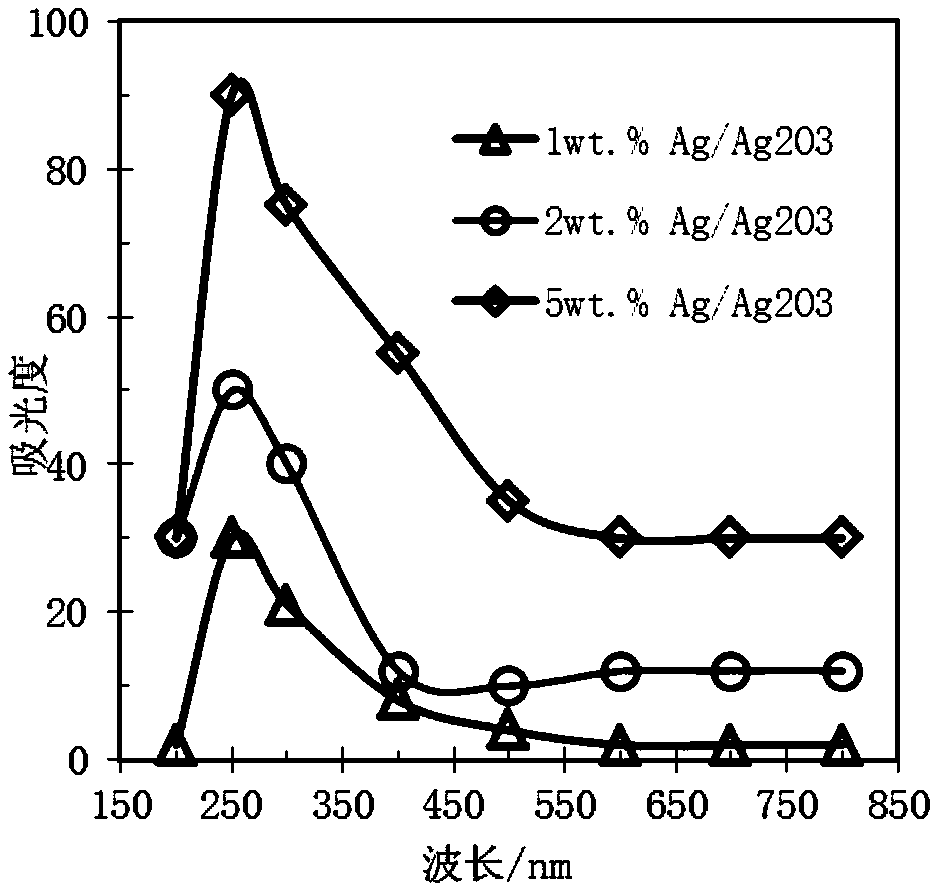

Preparation method of gluconic acid and its salt

InactiveCN1319930CHigh catalytic activityImprove catalytic selectivityOrganic compound preparationCarboxylic acid salt preparationCatalytic oxidationGluconic acid

The invention relates to the preparation method of gluconic acid and its salt, wherein Au / C catalyst liquid phase catalytic oxidation glucose is employed to synthesize calcium gluconae through calcium hydrate neutralization, based on this, the replacing reaction of magnesium, zinc and ferrous sulfate is utilized to obtain the corresponding glucoheptonates, and glucose acid is obtained through sulfuric acid replacement reaction.

Owner:KUNMING INST OF PRECIOUS METALS

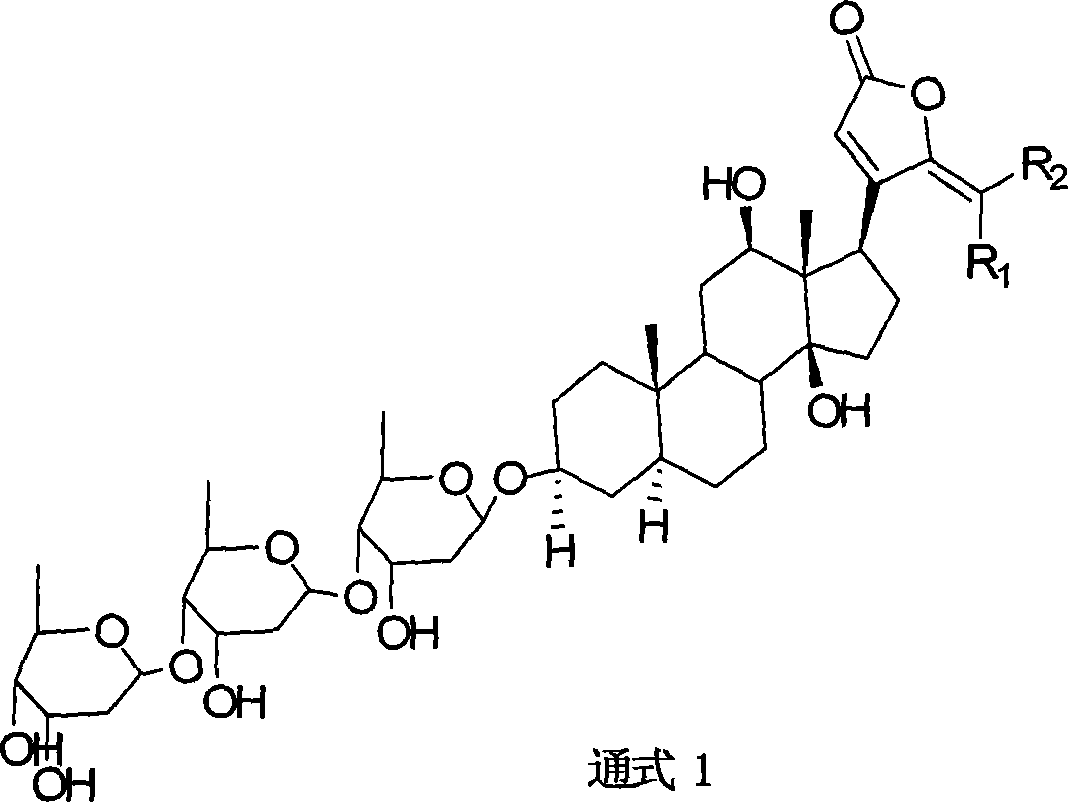

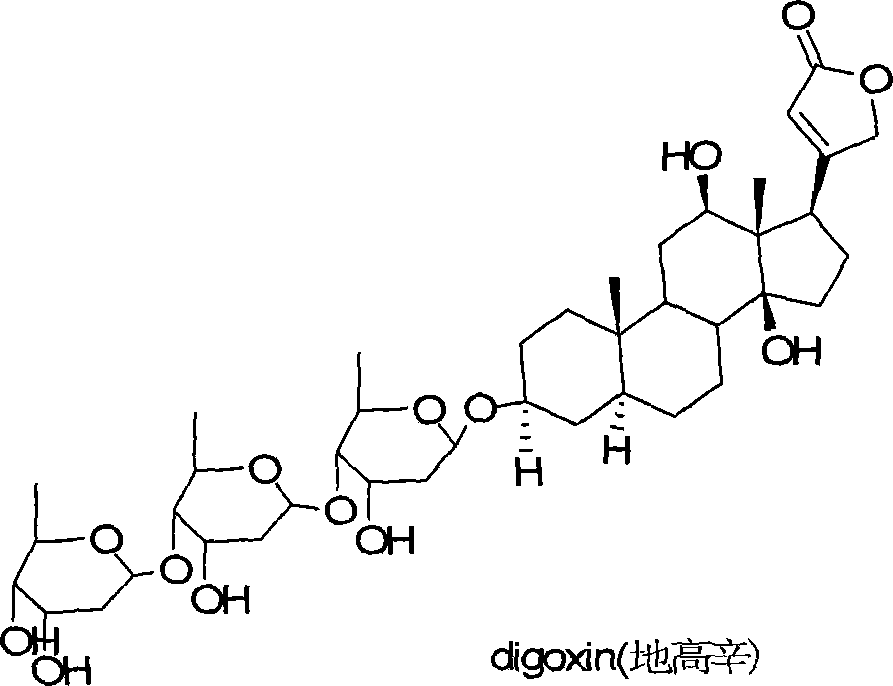

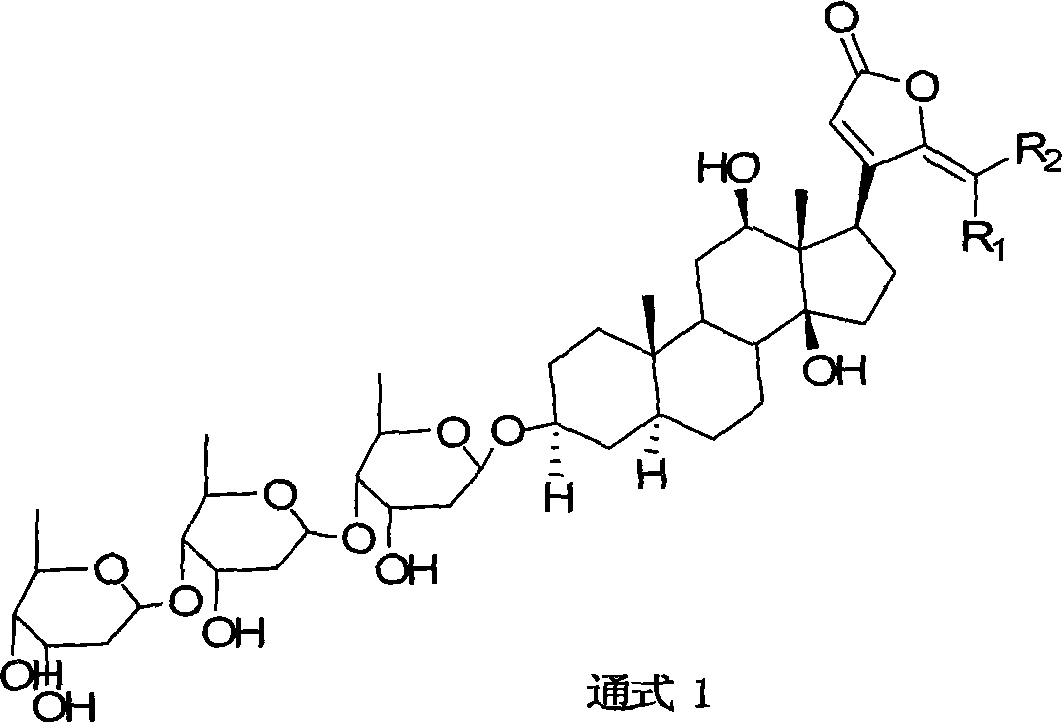

21-subunit digoxin derivative and preparation method thereof

InactiveCN101041683AEnhance myocardial contractilityLarge shrinkageOrganic active ingredientsSteroidsDigoxinStructural unit

Owner:ZHENGZHOU UNIV

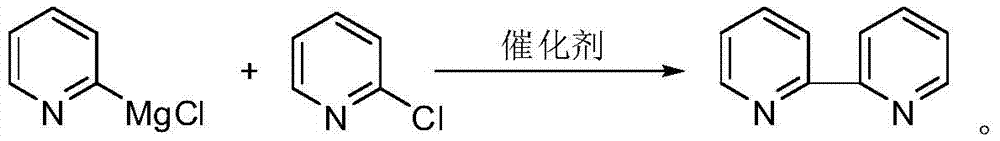

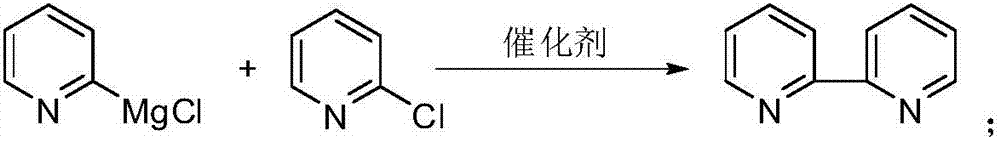

A kind of preparation method of 2,2'-bipyridine

ActiveCN104151231BReduce usageRaw materials are easy to getOrganic chemistryGrignard reagentManganese

The invention discloses a preparation method of 2, 2'-bipyridyl. In the preparation method, with a manganese salt or a cobalt salt as a catalyst, 2-chloropyridine Grignard reagent reacts with 2-chloropyridine to produce the 2, 2'-bipyridyl. The invention further discloses a method for performing Grignard reaction and coupling reaction with the 2-chloropyridine as a raw material by one-pot method to produce the final 2, 2'-bipyridyl. The preparation method of the 2, 2'-bipyridyl has the advantages of easily available raw materials, inexpensive and stable catalyst, environmental protection, and being low in cost, and simple and convenient to operate; by the preparation method, needs of large-scale industrial production can be met; the preparation method has a wide market prospect.

Owner:GUANGAN LIER CHEM CO LTD

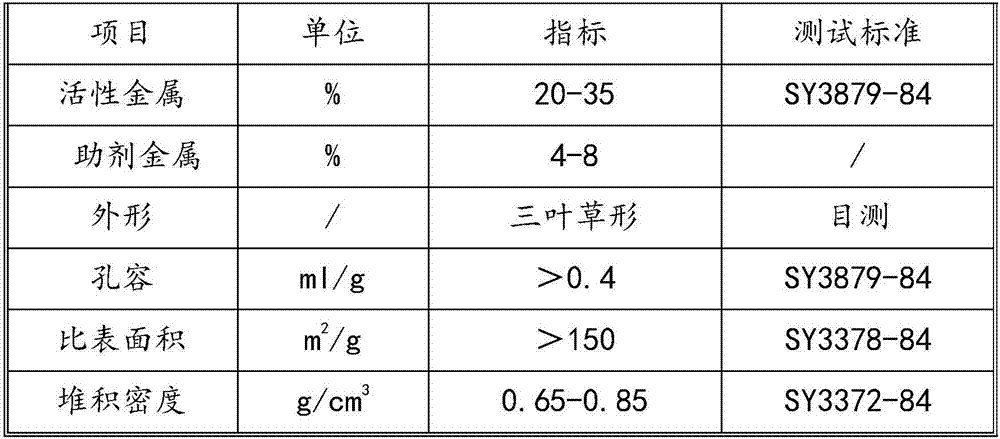

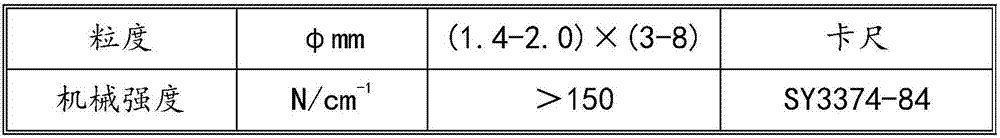

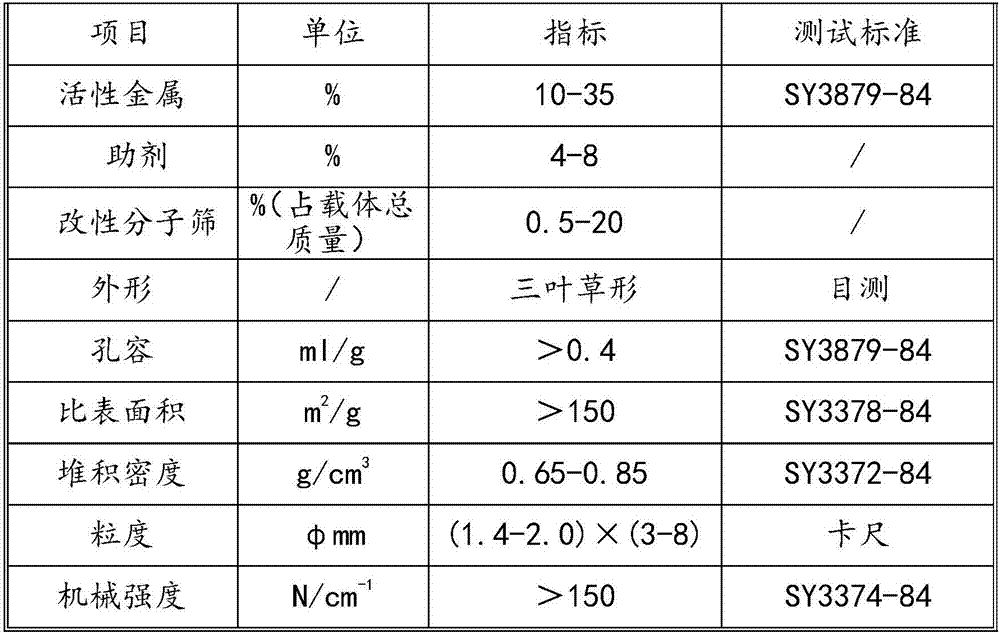

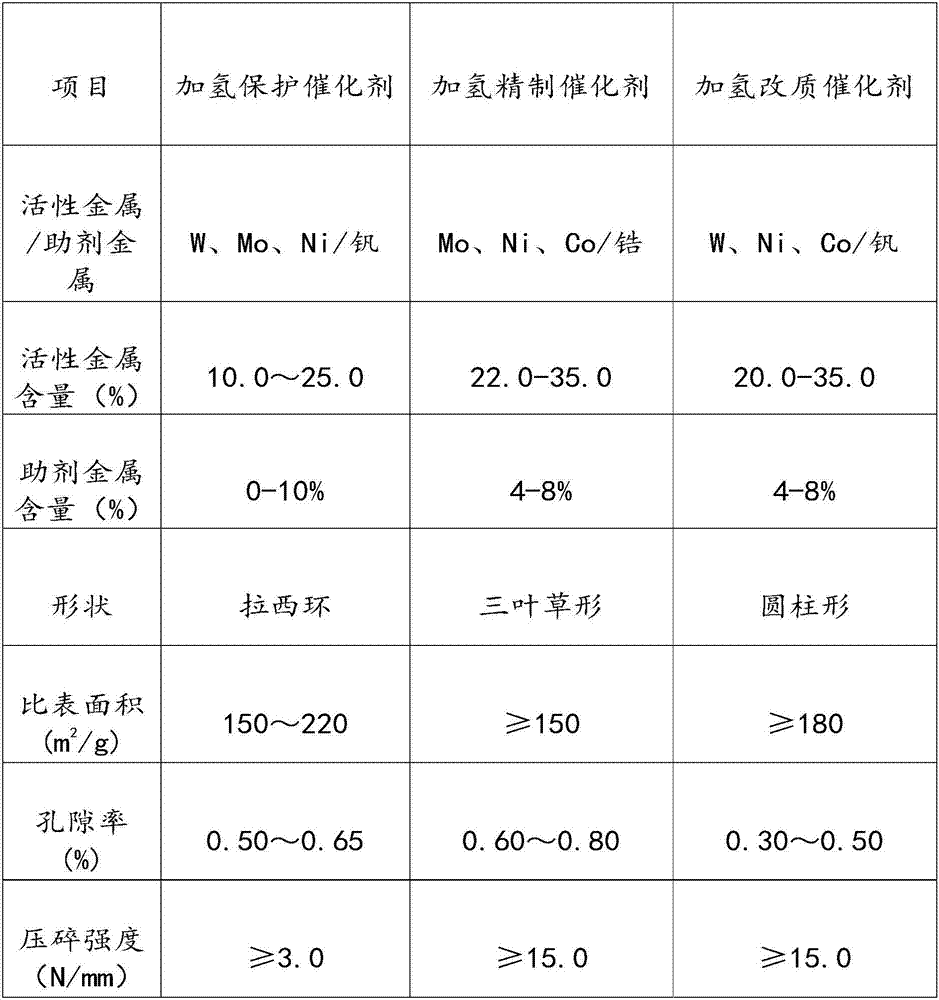

Catalyst system for preparing fuel oil from shale oil through catalytic hydrogenation and use method of catalyst system

ActiveCN107983360AHigh yieldHigh catalytic efficiencyMolecular sieve catalystsMetal/metal-oxides/metal-hydroxide catalystsMolecular sieveOxidation state

The invention relates to a catalyst system for preparing fuel oil from shale oil through catalytic hydrogenation and a use method of the catalyst system. The catalyst system comprises a hydrogenationprotection catalyst, a hydrogenation refining catalyst and a hydrogenation modification catalyst, wherein the hydrogenation protection catalyst comprises a first carrier, a first active metal and a first aid metal; the hydrogenation refining catalyst comprises a second carrier, a second active metal and a second aid metal; the hydrogenation modification catalyst comprises a third carrier, a thirdactive metal and a third aid metal; both the first carrier and the second carrier are macropore aluminum oxide; the third carrier is aluminum oxide with a modified molecular sieve; the first active metal, the second active metal and the third active metal are selected from one or more of W, Mo, Ni and Co in an oxidation state; and the first aid metal, the second aid metal and the third aid metal are selected from one or more of vanadium series meals, zirconium series metals or lanthanide series metals. By adopting the catalyst system and the method, the problems of coking and catalyst poisoning are effectively solved, and the catalyst system is low in cost and safe and stable.

Owner:FUSHUN XINRUI CATALYST

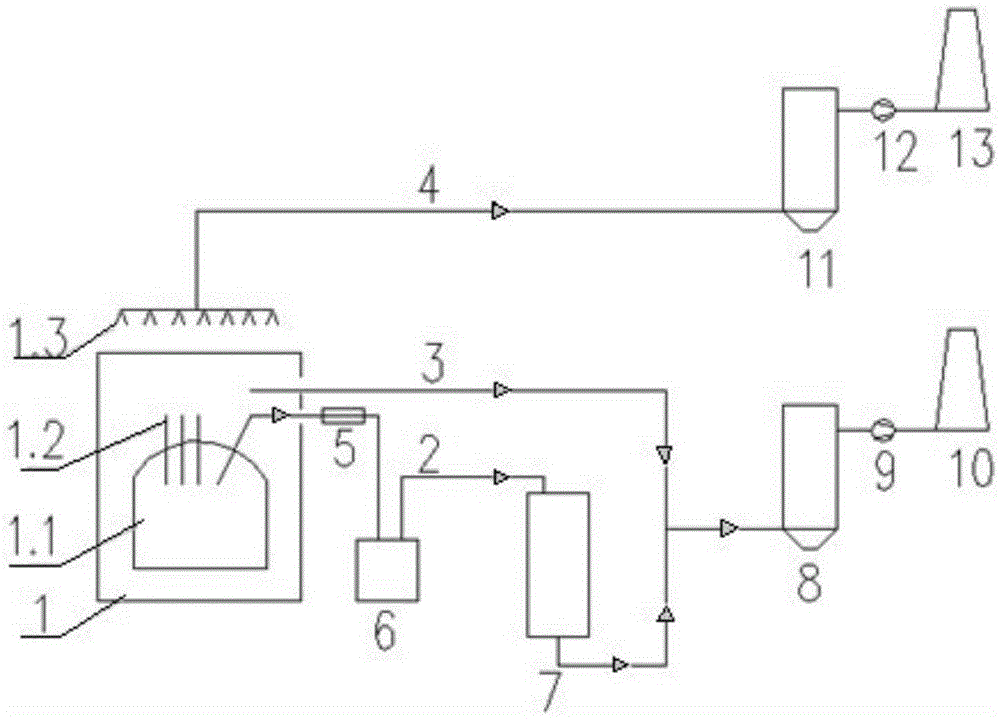

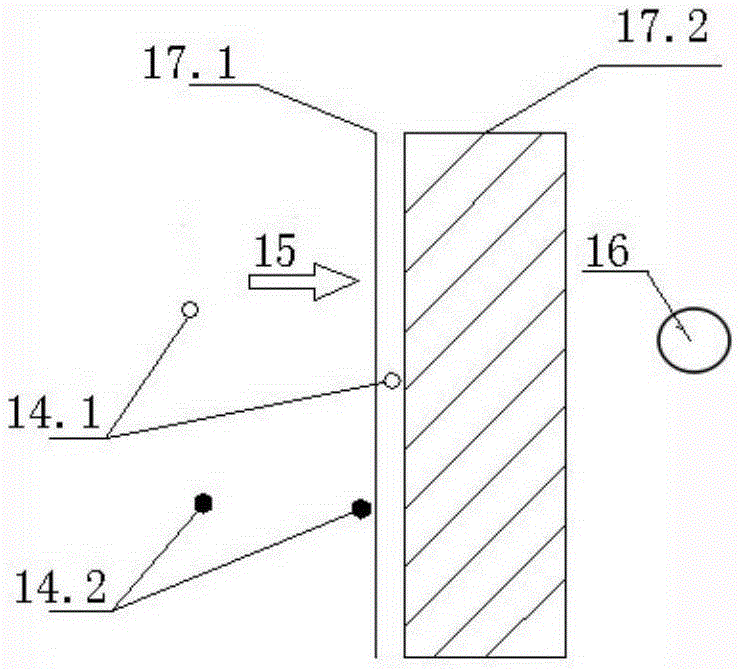

Process and equipment for co-operatively removing dust and dioxin

ActiveCN104075586AGuaranteed concentrationNo secondary pollutionDispersed particle filtrationIncreasing energy efficiencyParticulatesAtmospheric air

The invention discloses a process and equipment for co-operatively removing dust and dioxin, and belongs to the technical field of fume purification. According to the process, four-hole exhausted fume, doghouse fume and roof hood fume in an electric furnace doghouse sealing hood are simultaneously treated in three channels, and the process particularly comprises the steps as follows: the four-hole exhausted fume and the doghouse fume converge after passing through channels I and II respectively under the action of an induced draft fan I, and are cooled and introduced to a deduster I; in the deduster I, dust particles in the four-hole exhausted fume and the doghouse fume are filtered on the surface of the filter bag of the deduster I, then are degraged via a powdery catalyst, and finally are exhausted from a chimney I; the roof hood fume enters a deduster II via a channel III under the action of an induced draft fan II, and the purified dust particles are exhausted to the atmosphere from a chimney II. The process and the equipment co-operatively remove the dust and dioxin in the electric furnace fume, and ensure that the concentration of the dioxin and the dust concentration of the particles can meet the national environmental protection standards. The equipment is simple in structure, stable and reliable in running, less in investment and low in running and maintenance costs.

Owner:CISDI ENG CO LTD

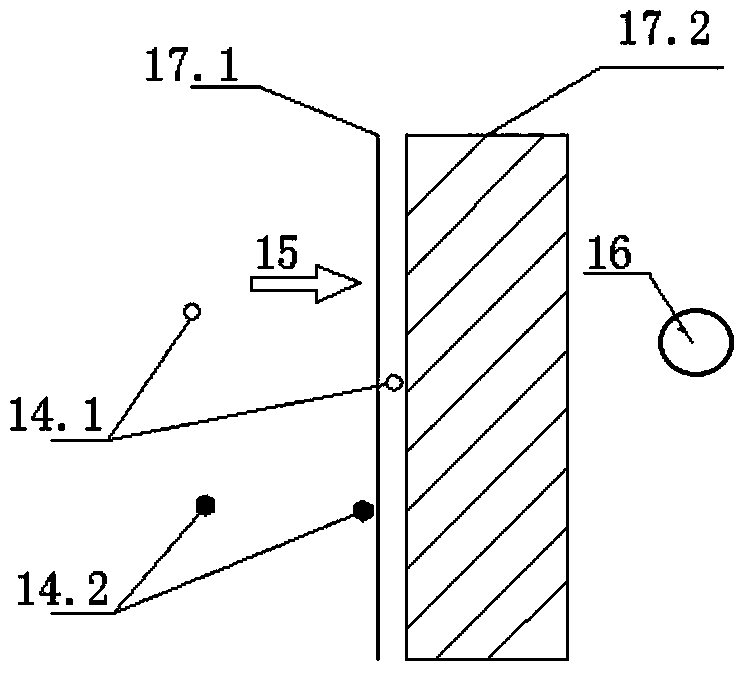

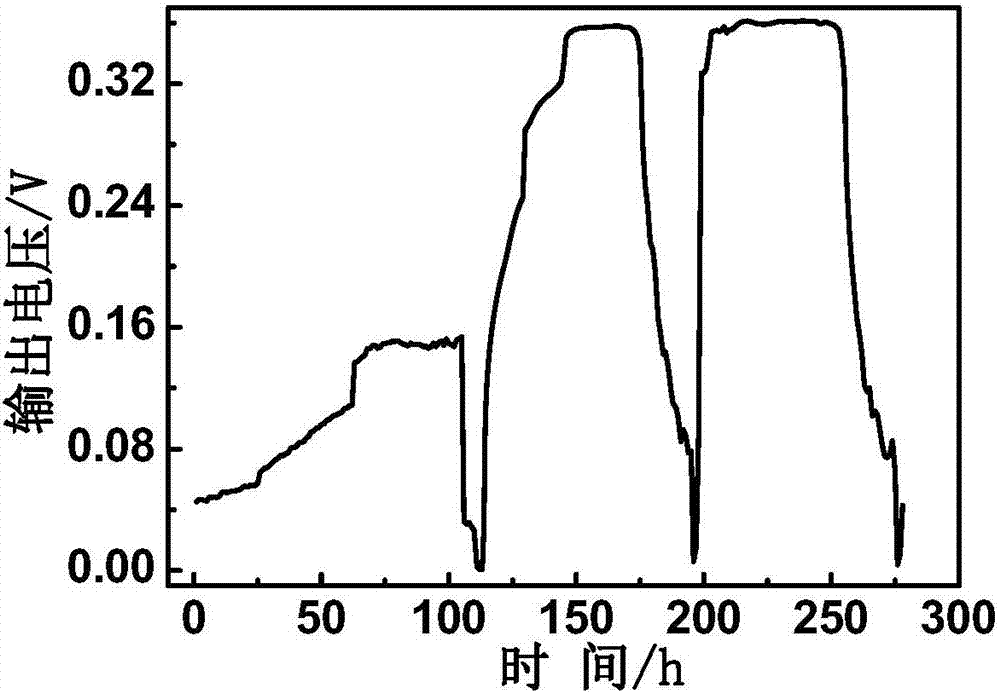

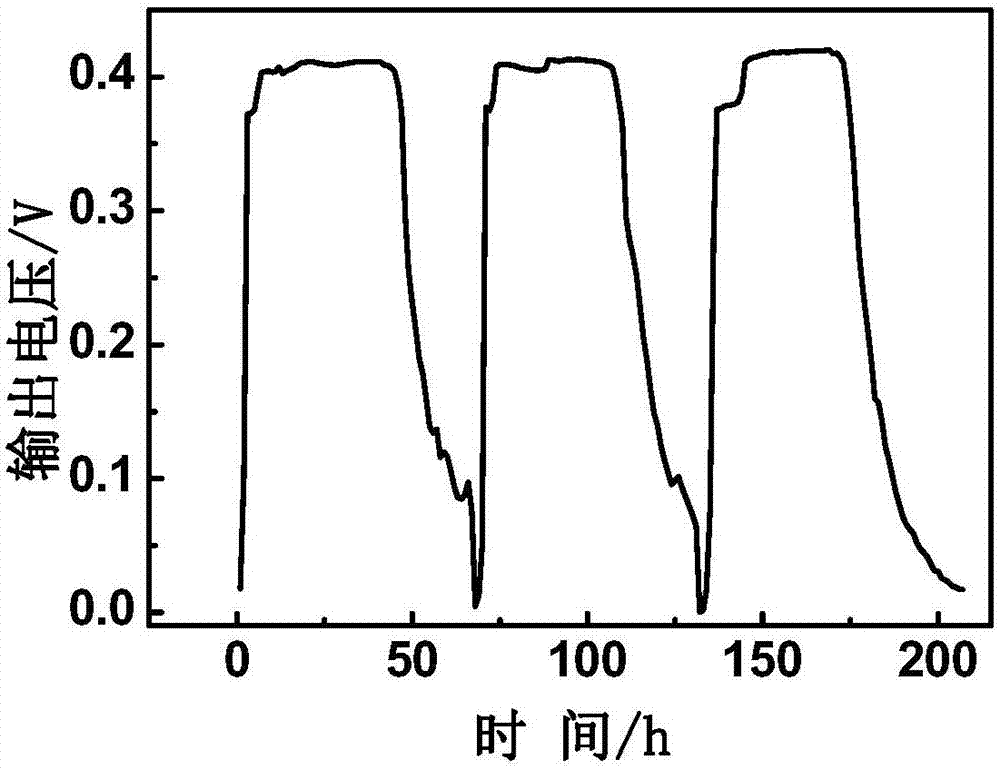

Rhodococcus pyridinovorans and application thereof in microbial fuel cell

ActiveCN106967653AElectrogenic activityLow running costBacteriaMicroorganism based processesEngineeringFacultative anaerobic organism

The invention discloses Rhodococcus pyridinovorans and application thereof in a microbial fuel cell. The Rhodococcus pyridinovorans HR-1 is preserved in China General Microbiological Culture Collection Center (CGMCC) in No.3 Microbiology Research Institute of China Science Academy, No.1 Yard, Beichen West Road, Chaoyang District, Beijing, on April13th, 2017, with a preservation number of CGMCC NO.14021. The Rhodococcus pyridinovorans HR-1 disclosed by the invention is facultative anaerobe, has the functions of effectively decomposing multiple organic matters and obtaining electric energy at the same time and improving the output voltage of the microbial fuel cell, has better adaptability to extreme organic wastewater such as landfill leachate and industrial wastewater, and can be used as an anode catalyst of the microbial fuel cell for treating the extreme organic wastewater.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

A process and equipment for synergistically removing dust and dioxin

ActiveCN104075586BGuaranteed concentrationNo secondary pollutionDispersed particle separationIncreasing energy efficiencyParticulatesExhaust fumes

The invention discloses a process and equipment for co-operatively removing dust and dioxin, and belongs to the technical field of fume purification. According to the process, four-hole exhausted fume, doghouse fume and roof hood fume in an electric furnace doghouse sealing hood are simultaneously treated in three channels, and the process particularly comprises the steps as follows: the four-hole exhausted fume and the doghouse fume converge after passing through channels I and II respectively under the action of an induced draft fan I, and are cooled and introduced to a deduster I; in the deduster I, dust particles in the four-hole exhausted fume and the doghouse fume are filtered on the surface of the filter bag of the deduster I, then are degraged via a powdery catalyst, and finally are exhausted from a chimney I; the roof hood fume enters a deduster II via a channel III under the action of an induced draft fan II, and the purified dust particles are exhausted to the atmosphere from a chimney II. The process and the equipment co-operatively remove the dust and dioxin in the electric furnace fume, and ensure that the concentration of the dioxin and the dust concentration of the particles can meet the national environmental protection standards. The equipment is simple in structure, stable and reliable in running, less in investment and low in running and maintenance costs.

Owner:CISDI ENG CO LTD

Preparation method of acyloin compounds

ActiveCN106397151AImprove securityGood choiceOrganic-compounds/hydrides/coordination-complexes catalystsCarbonyl compound preparation by condensationState of artSide reaction

The invention relates to a preparation method of acyloin compounds, and belongs to the field of fine chemical industry. A new catalyst 1-n butyl benzimidazole hydrochloride is provided for synthesis of the acyloin compounds, and the products have the advantages of good quality and less side reactions; deficiencies existed in the prior art are overcome.

Owner:濮阳天源生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com