Patents

Literature

279results about "Refining by solvent de-asphalting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

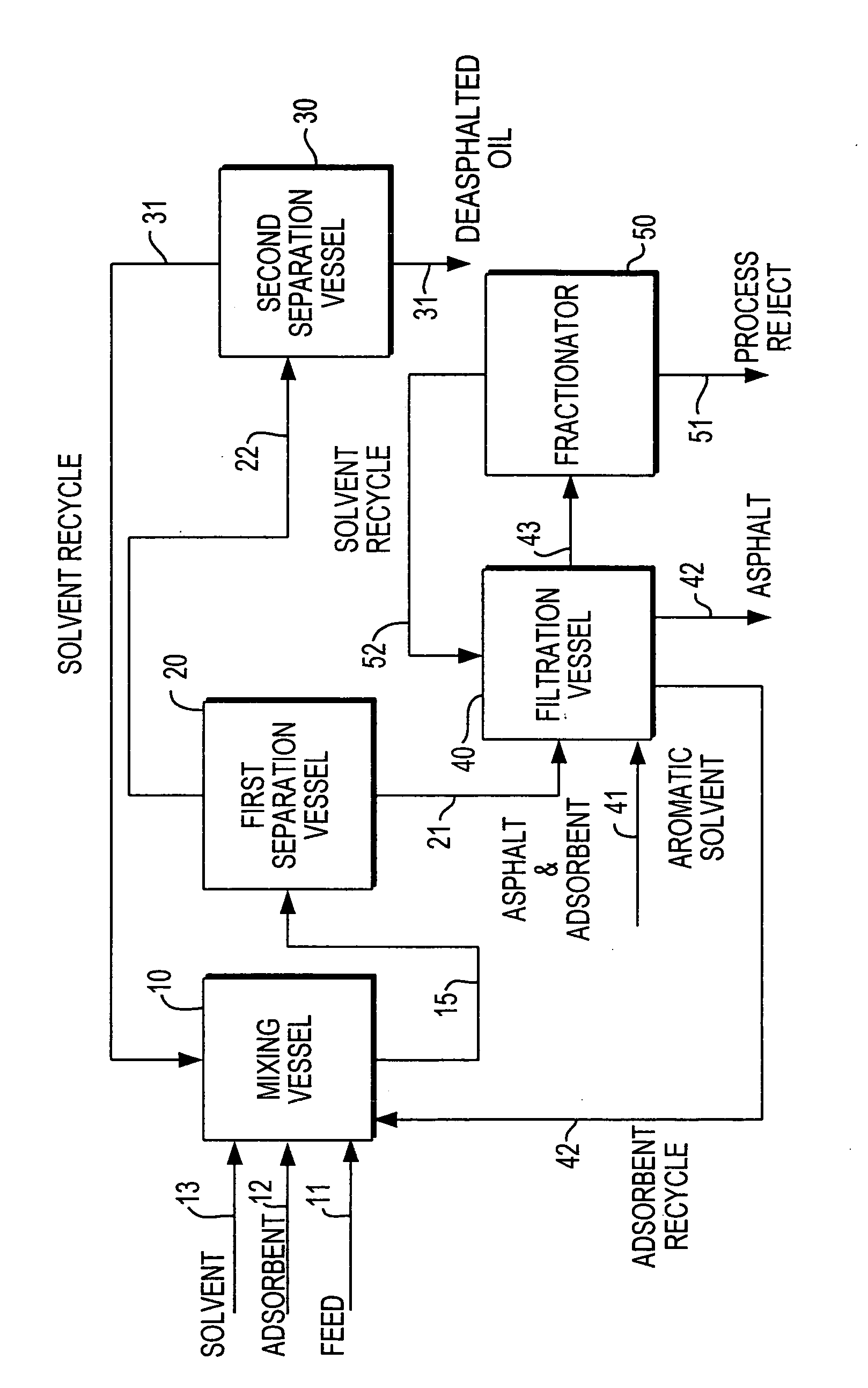

Enhanced solvent deasphalting process for heavy hydrocarbon feedstocks utilizing solid adsorbent

ActiveUS7566394B2Improve performanceImprove current efficiencyWorking-up pitch/asphalt/bitumen by selective extractionHydrocarbon distillationBenzeneActivated carbon

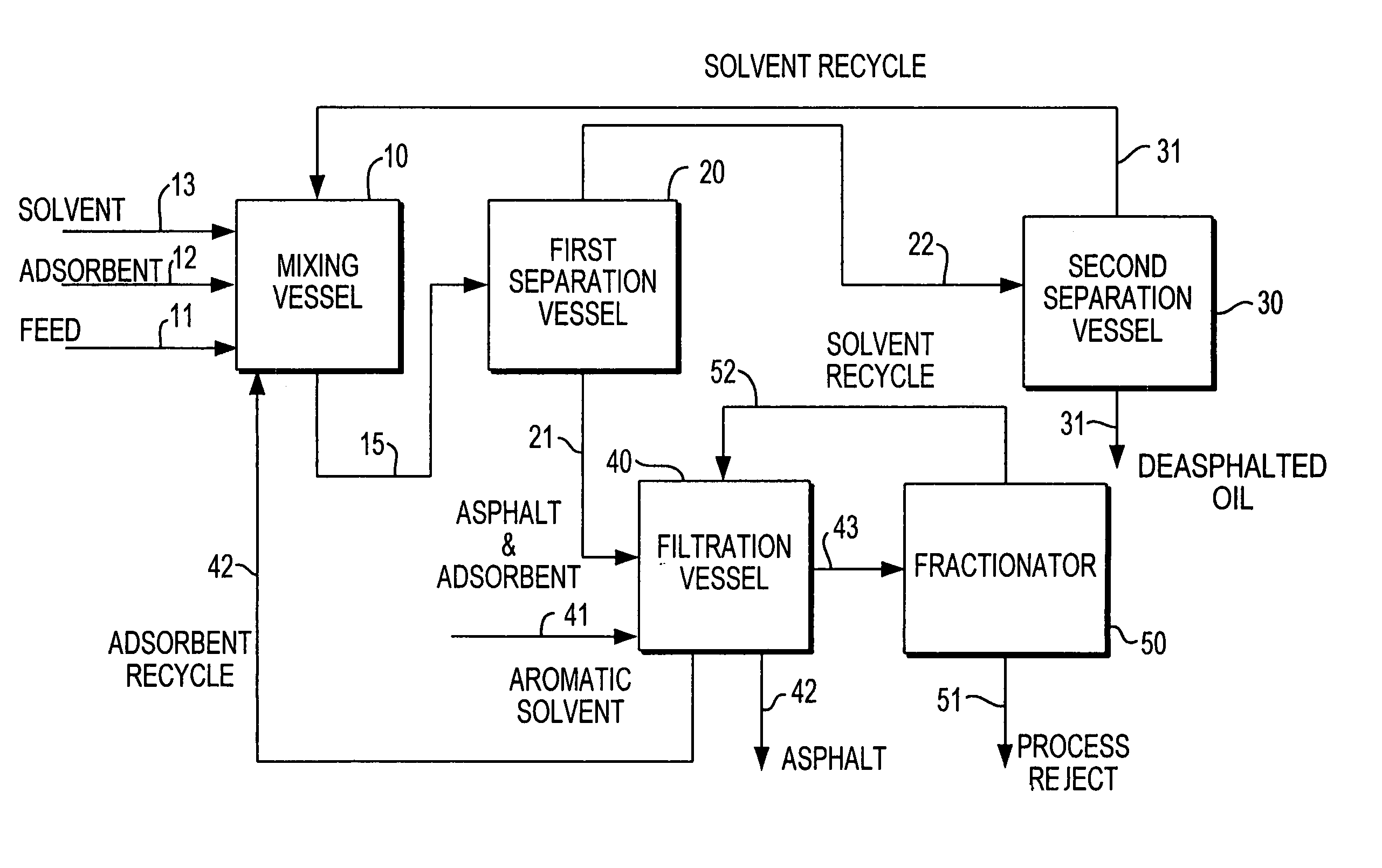

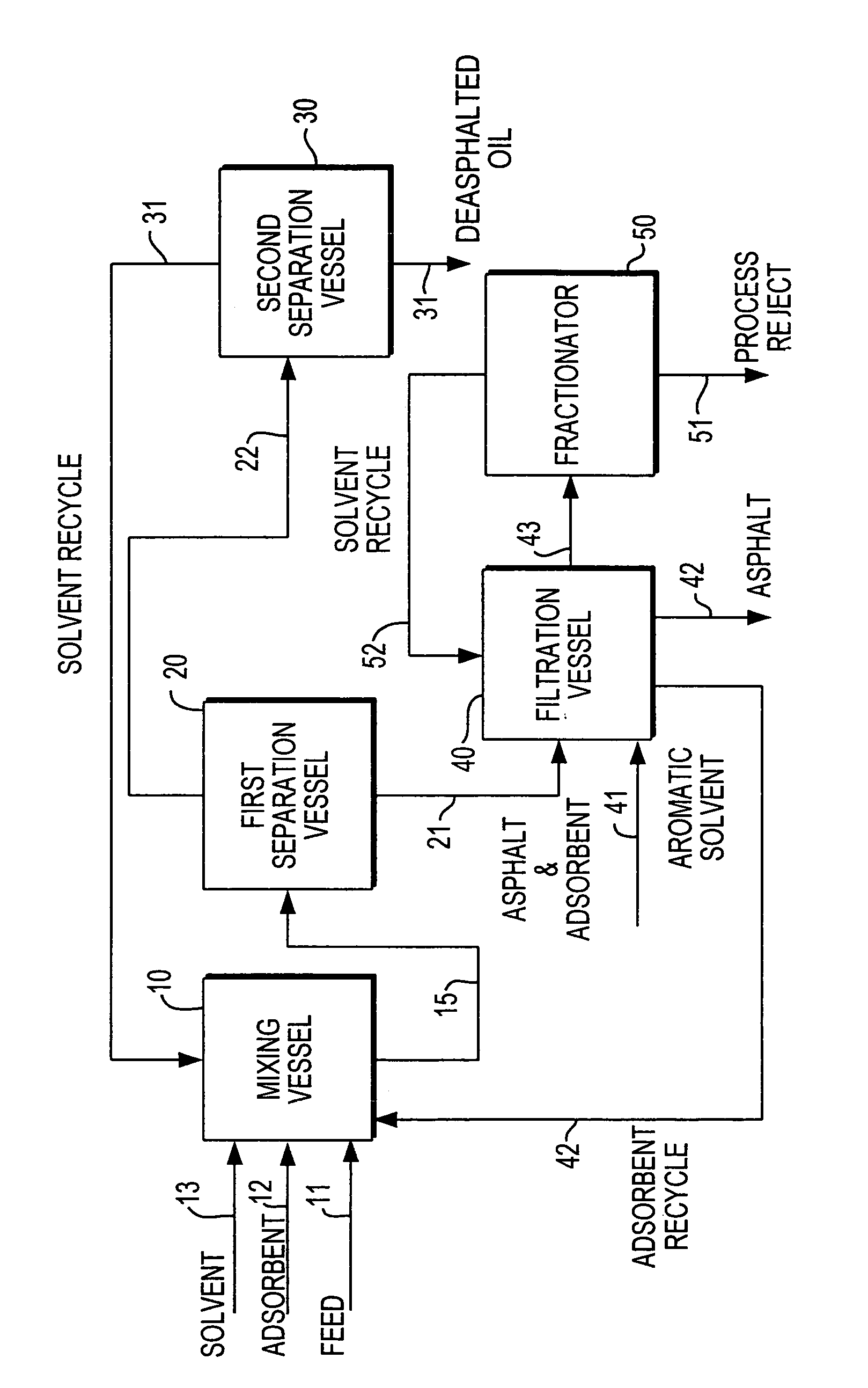

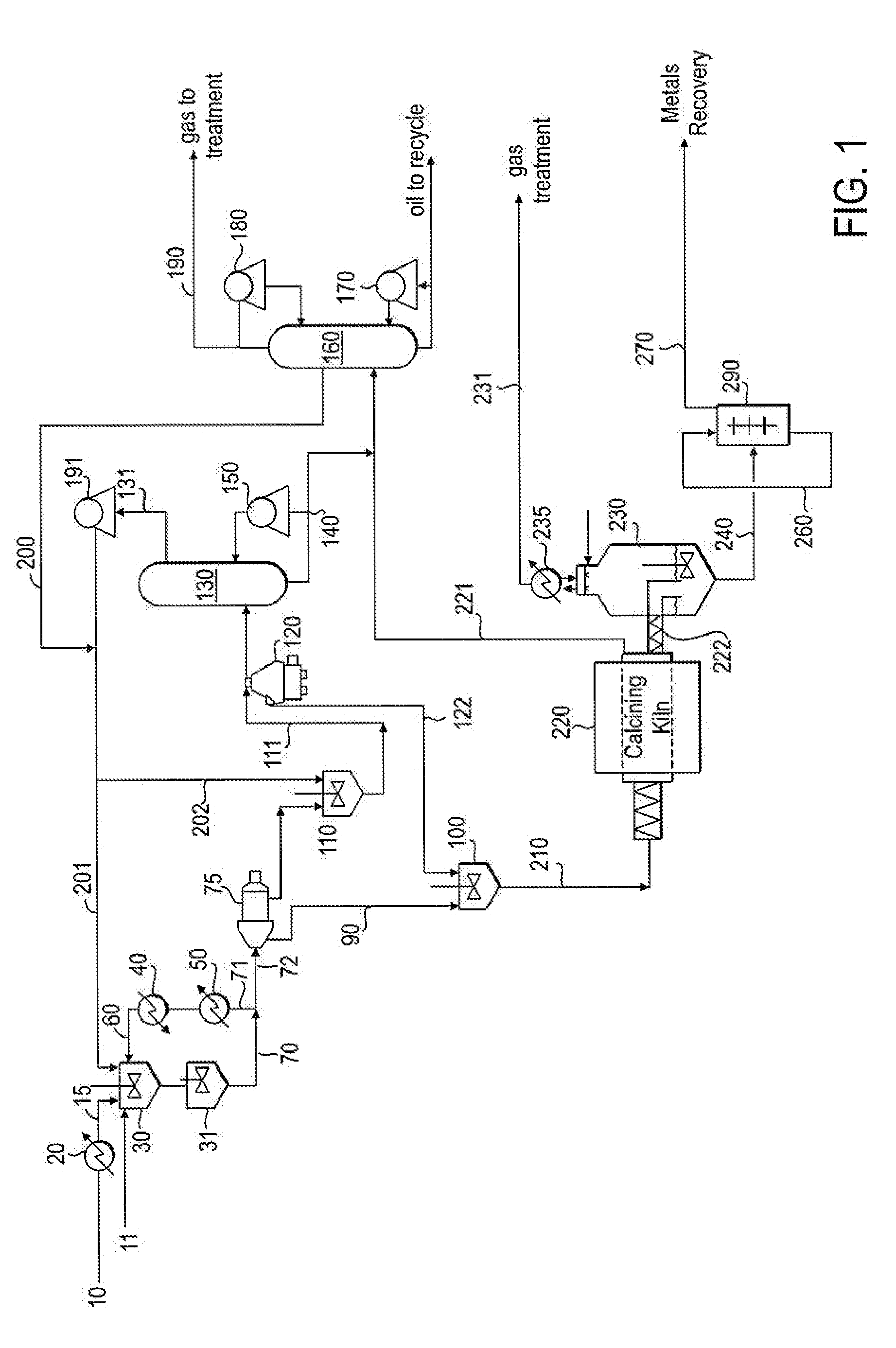

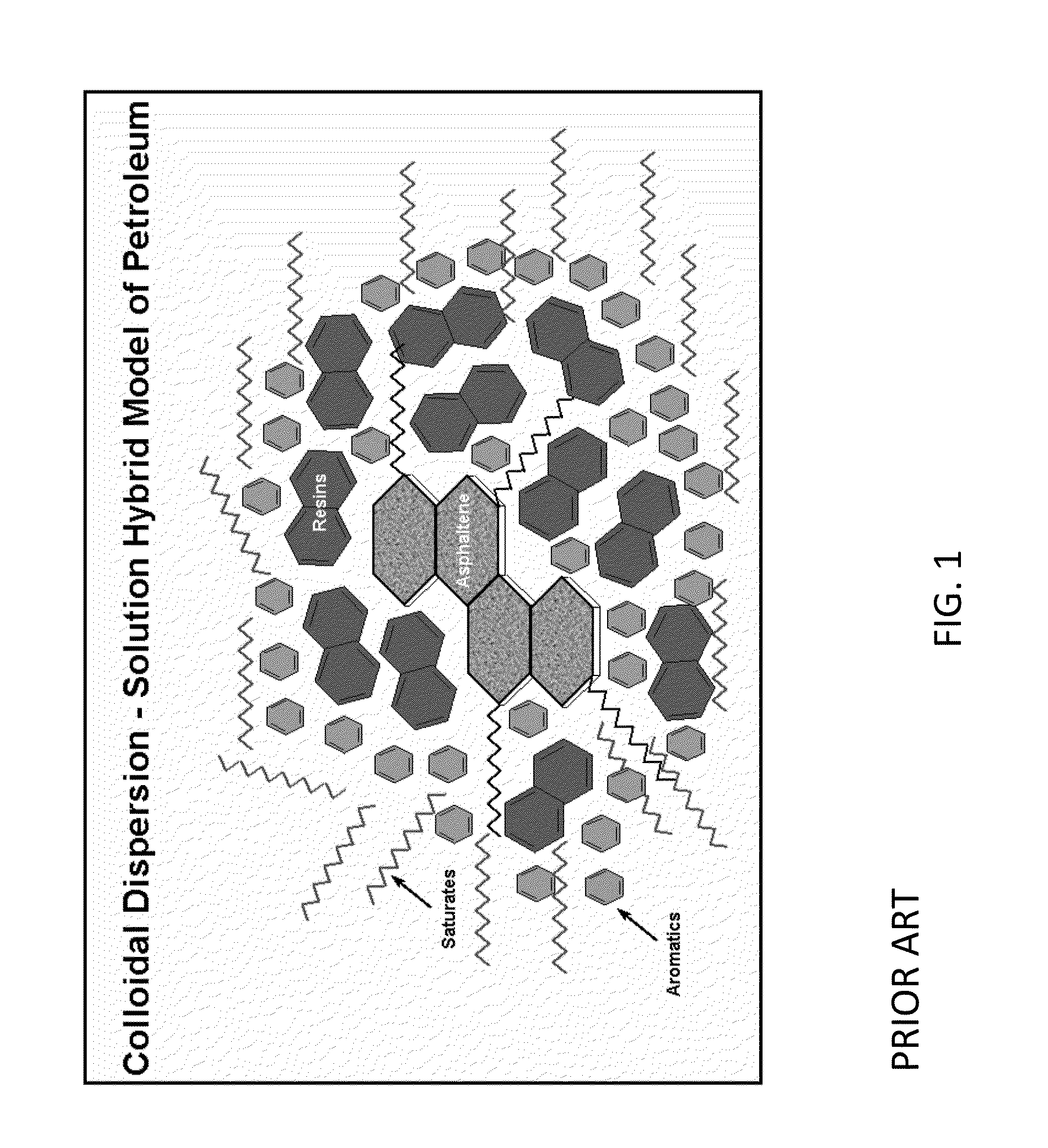

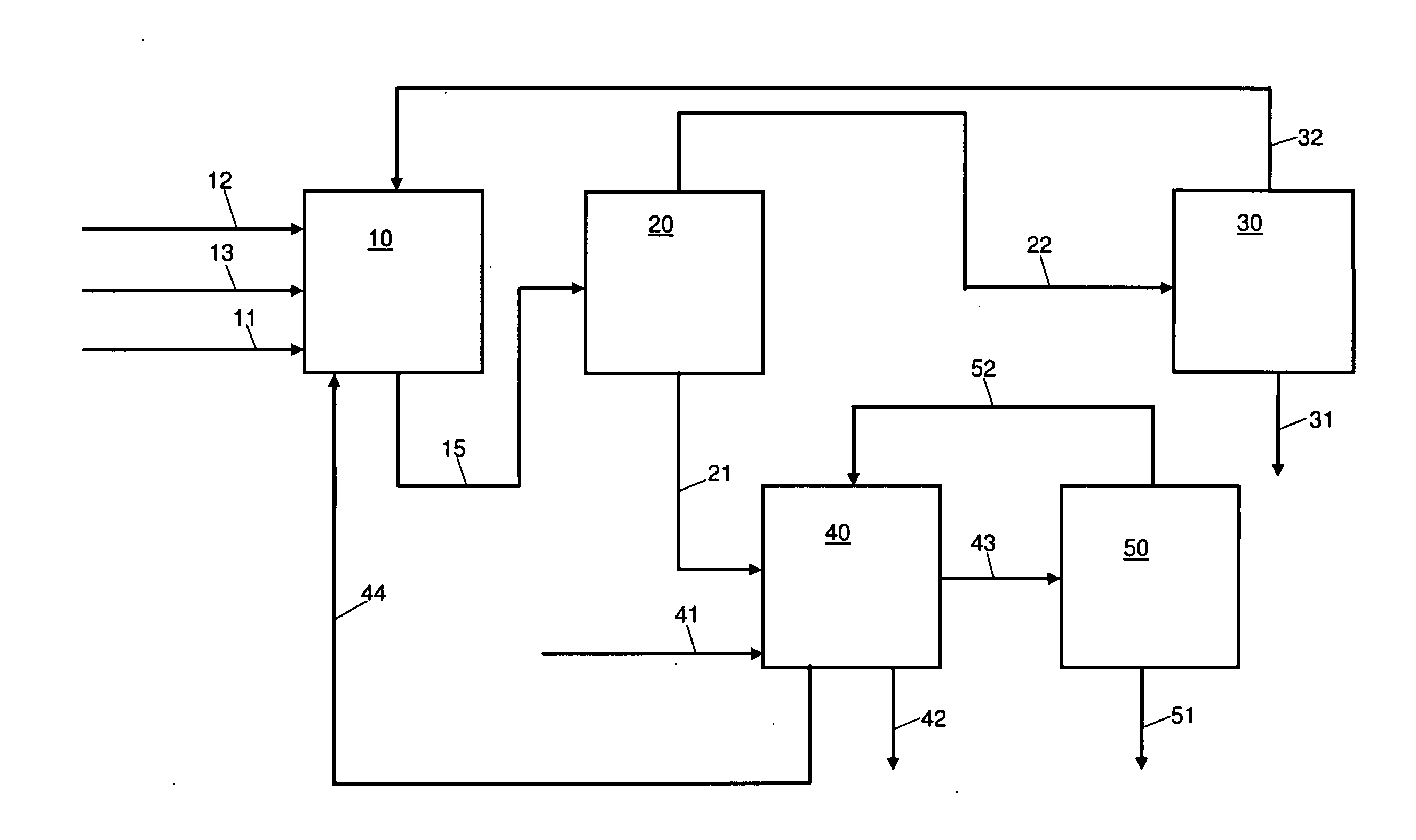

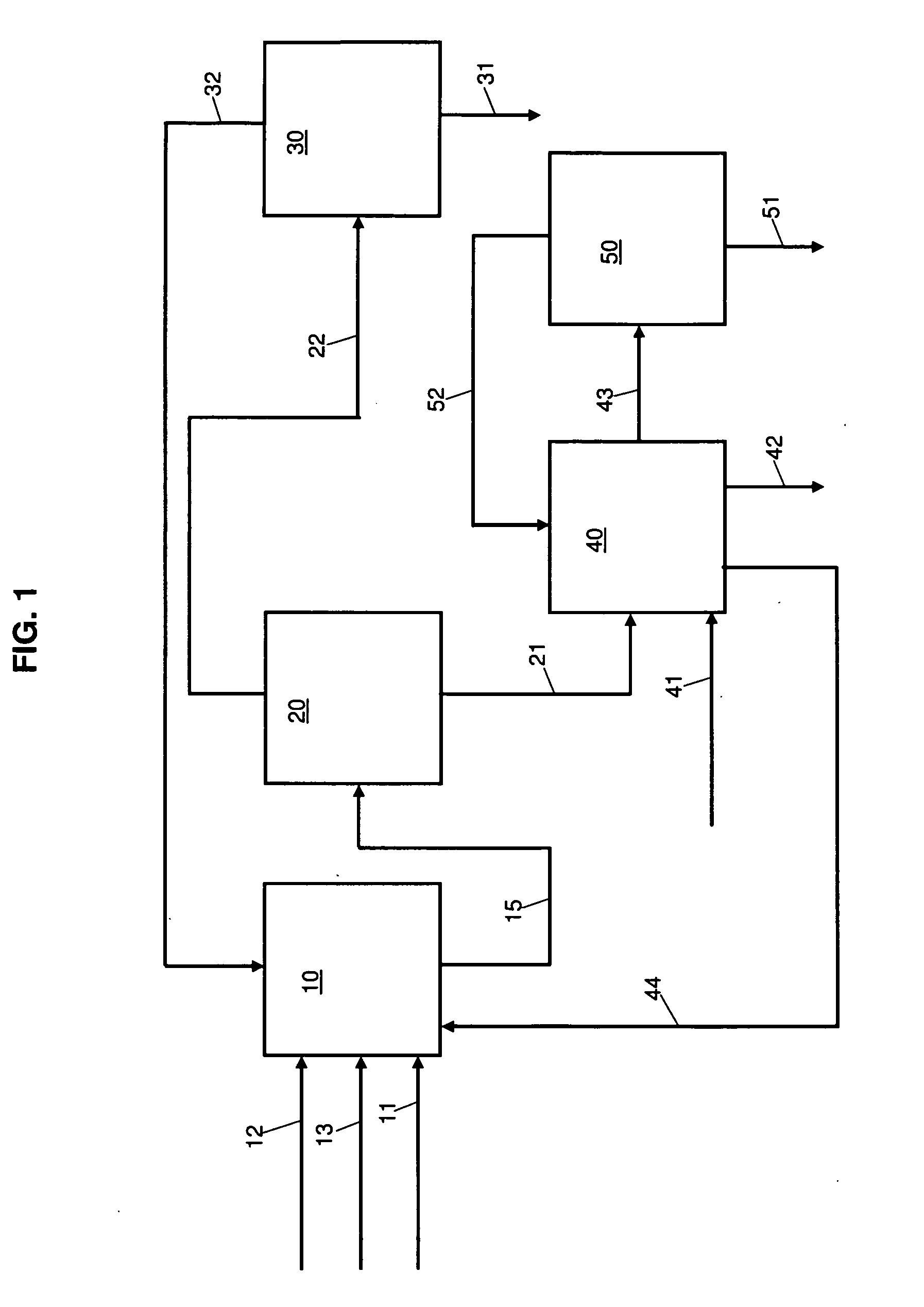

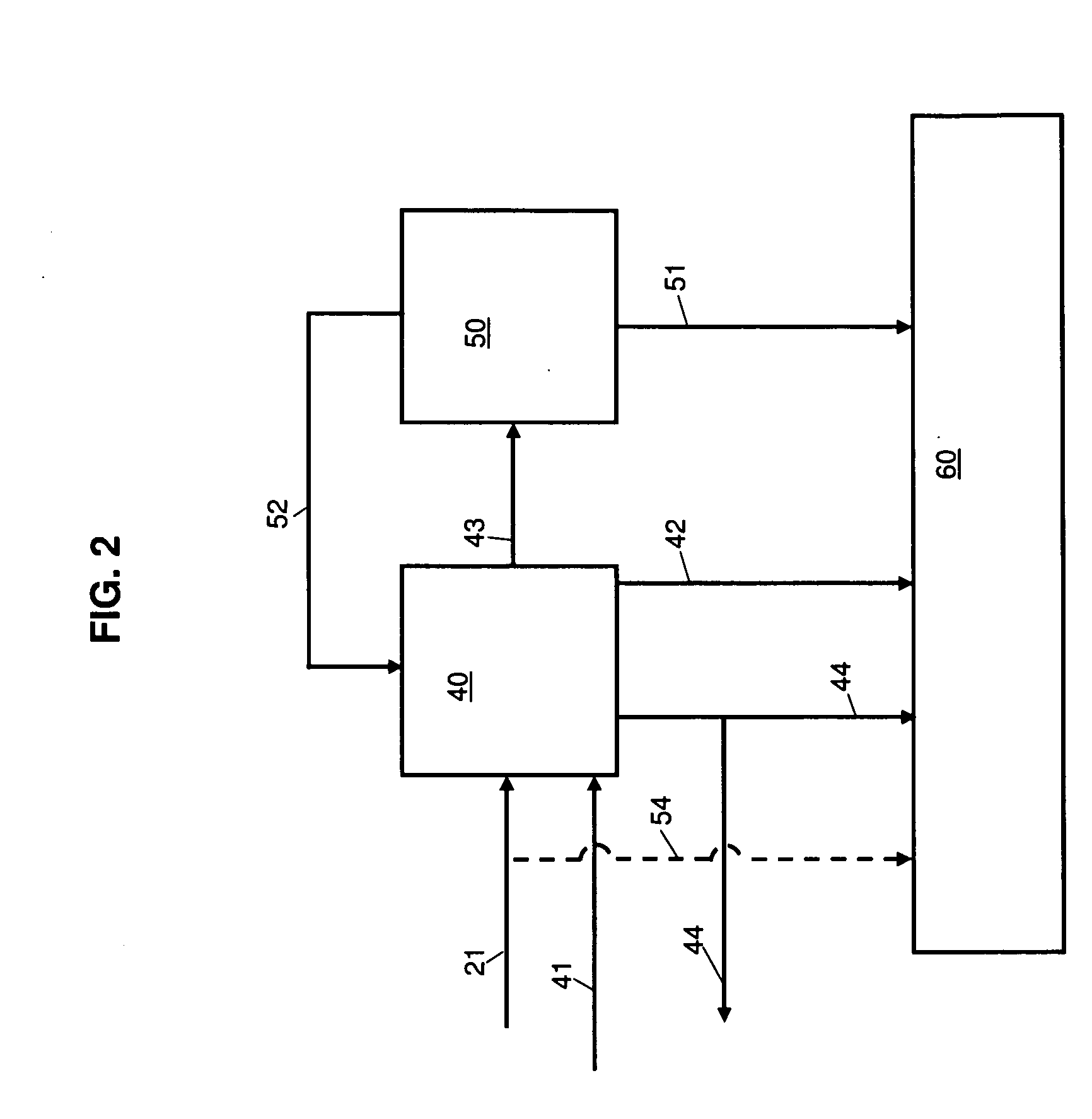

A solvent deasphalting of crude oil or petroleum heavy fractions and residues is carried out in the presence of a solid adsorbent, such as clay, silica, alumina and activated carbon, which adsorbs the contaminants and permits the solvent and oil fraction to be removed as a separate stream from which the solvent is recovered for recycling; the adsorbent with contaminants and the asphalt bottoms is mixed with aromatic and / or polar solvents to desorb the contaminants and washed as necessary, e.g., with benzene, toluene, xylenes and tetrahydrofuran, to clean adsorbant which is recovered and recycled; the solvent-asphalt mixture is sent to a fractionator for recovery and recycling of the aromatic or polar solvent. The bottoms from the fractionator include the concentrated PNA and contaminants and are further processes as appropriate.

Owner:SAUDI ARABIAN OIL CO

Heavy Oil and Bitumen Upgrading

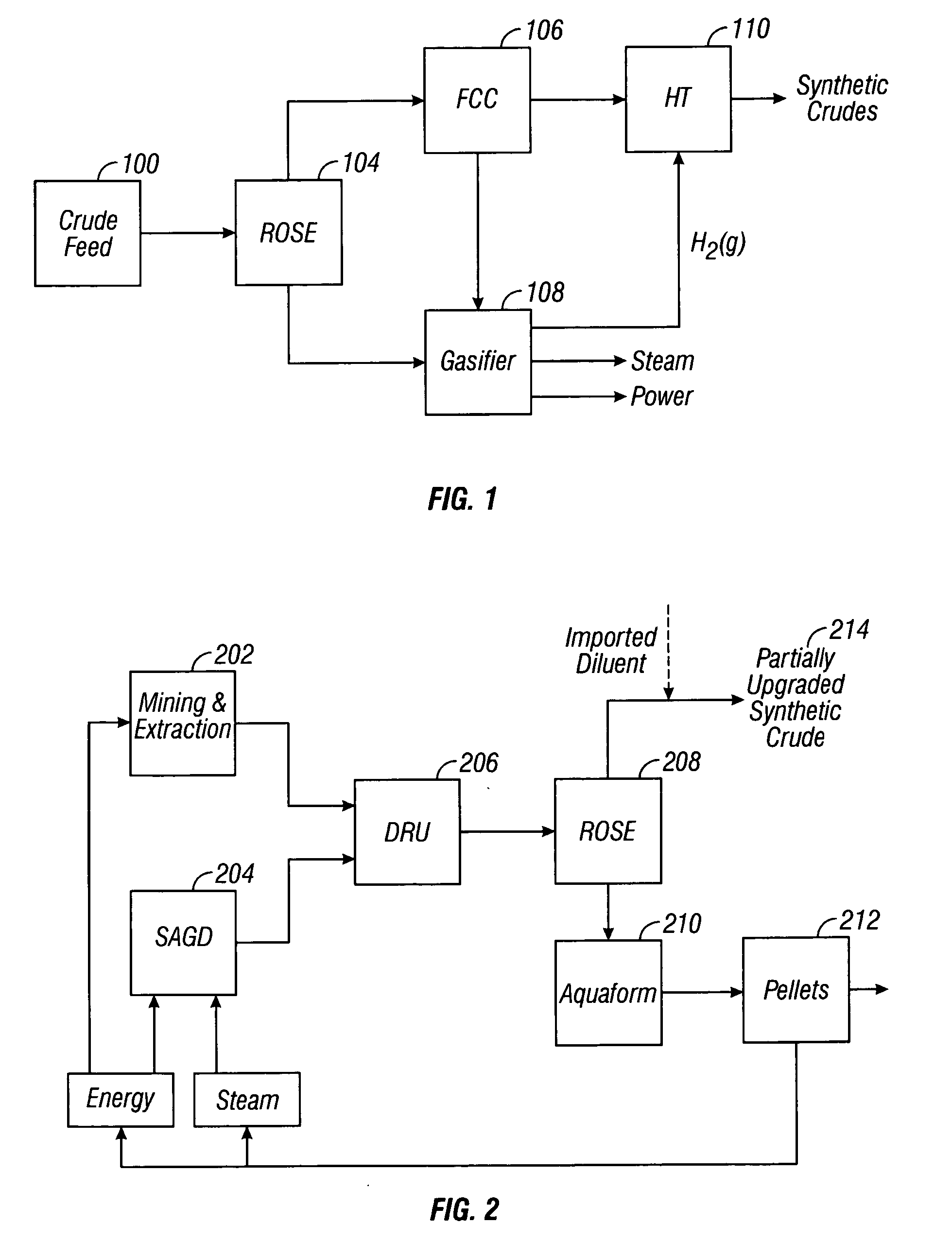

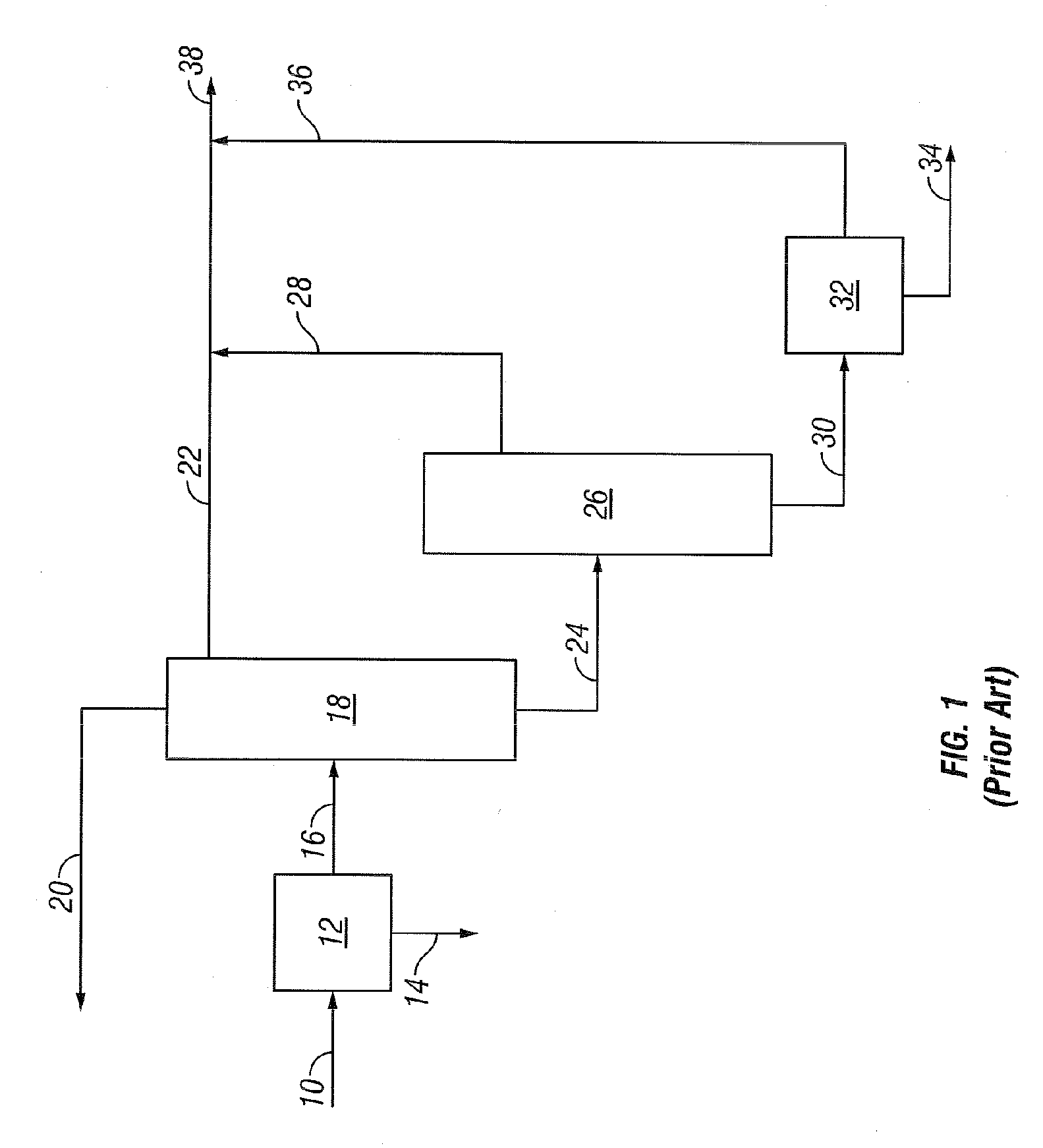

ActiveUS20060042999A1Reduce metal contentEasy to liftThermal non-catalytic crackingWorking-up pitch/asphalt/bitumen by selective extractionNaphthaHydrogen

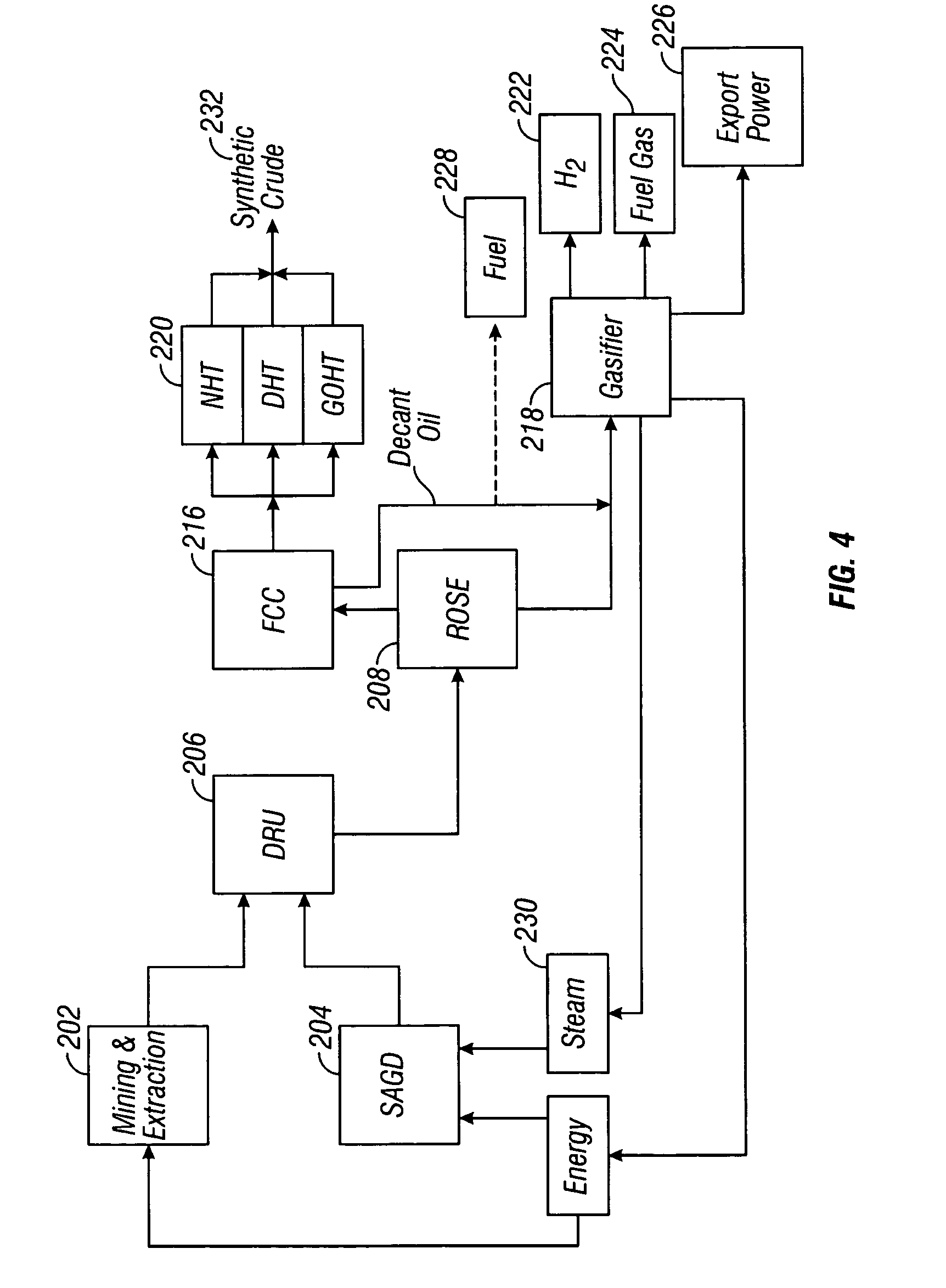

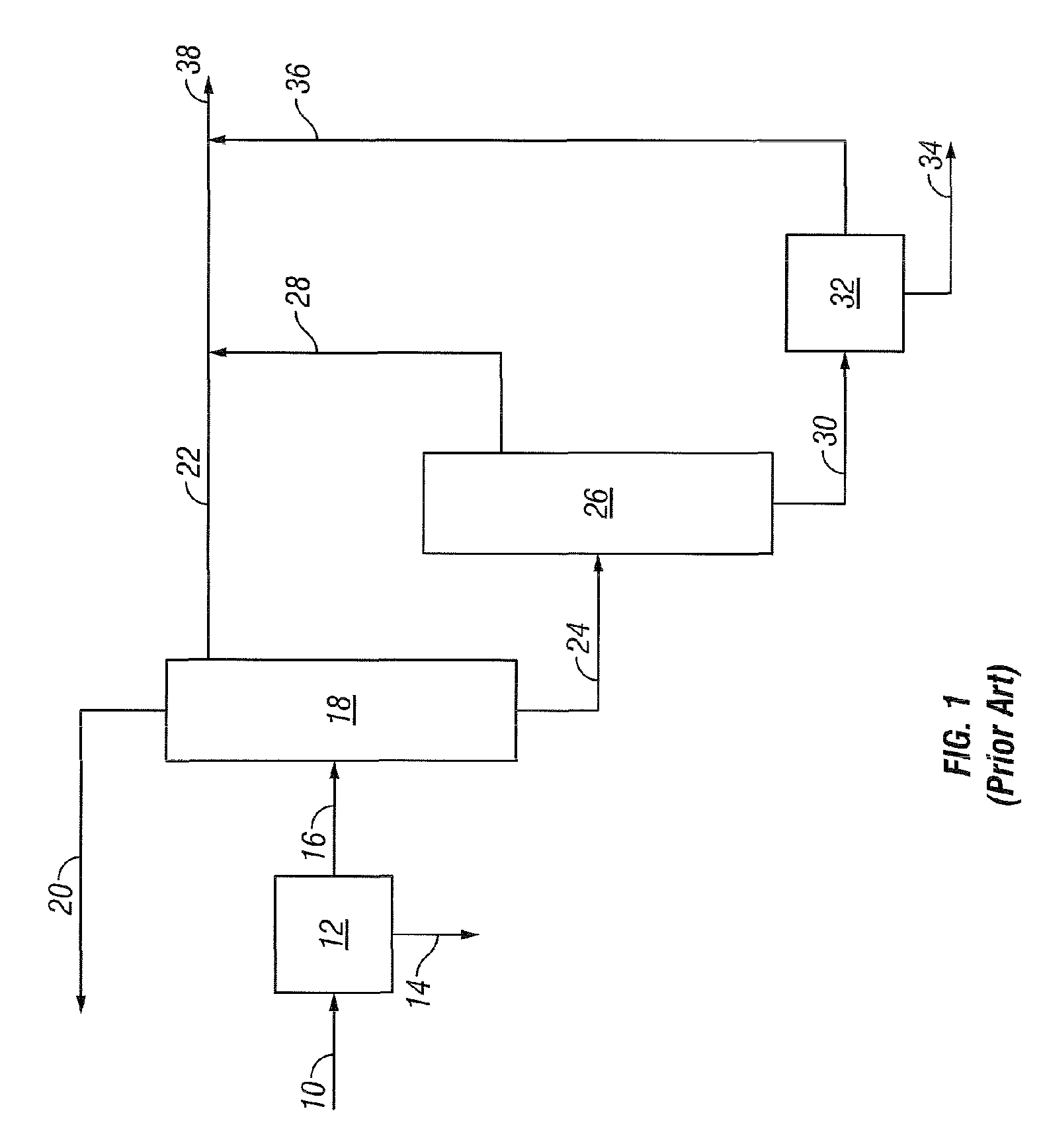

Disclosed is a process for the upgrading and demetallizing of heavy oils and bitumens. A crude heavy oil and / or bitumen feed is supplied to a solvent extraction process 104 wherein DAO and asphaltenes are separated. The DAO is supplied to an FCC unit 106 having a low conversion activity catalyst for the removal of metals contained therein. The demetallized distillate fraction is supplied to a hydrotreater 110 for upgrading and collected as a synthetic crude product stream. The asphaltene fraction can be supplied to a gasifier 108 for the recovery of power, steam and hydrogen, which can be supplied to the hydrotreater 110 or otherwise within the process or exported. An optional coker 234 can be used to convert excess asphaltenes and / or decant oil to naphtha, distillate and gas oil, which can be supplied to the hydrotreater 220.

Owner:KELLOGG BROWN & ROOT LLC

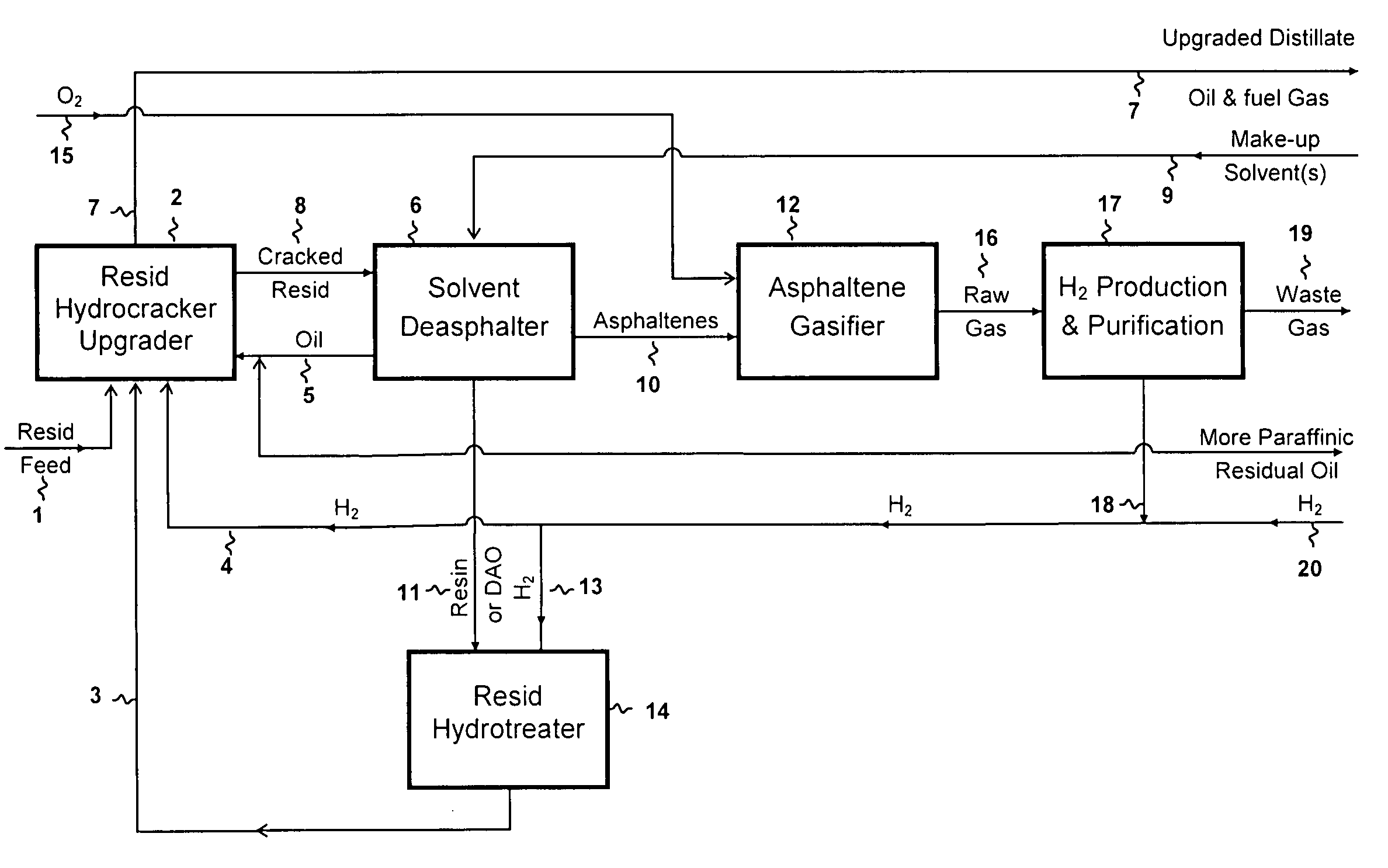

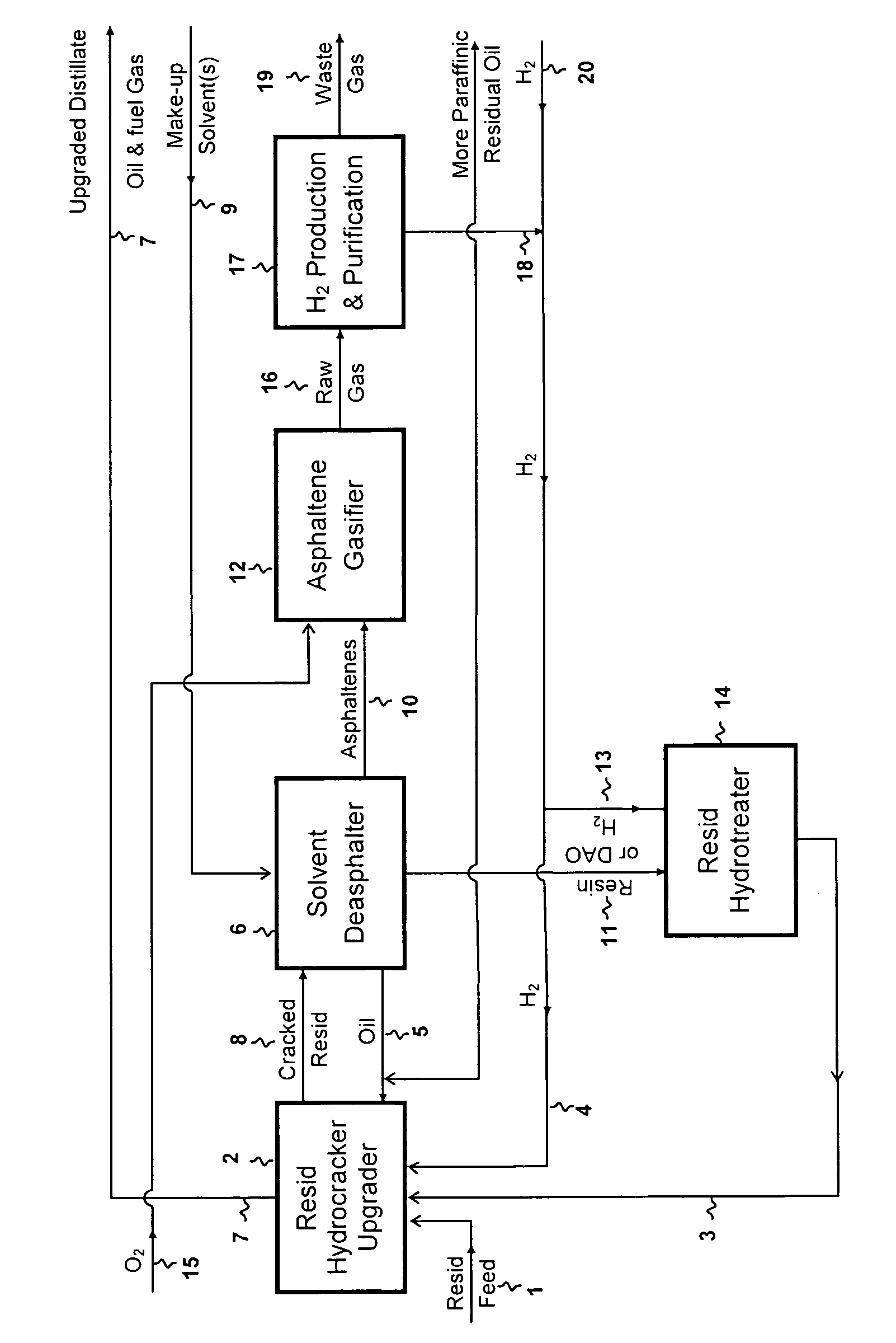

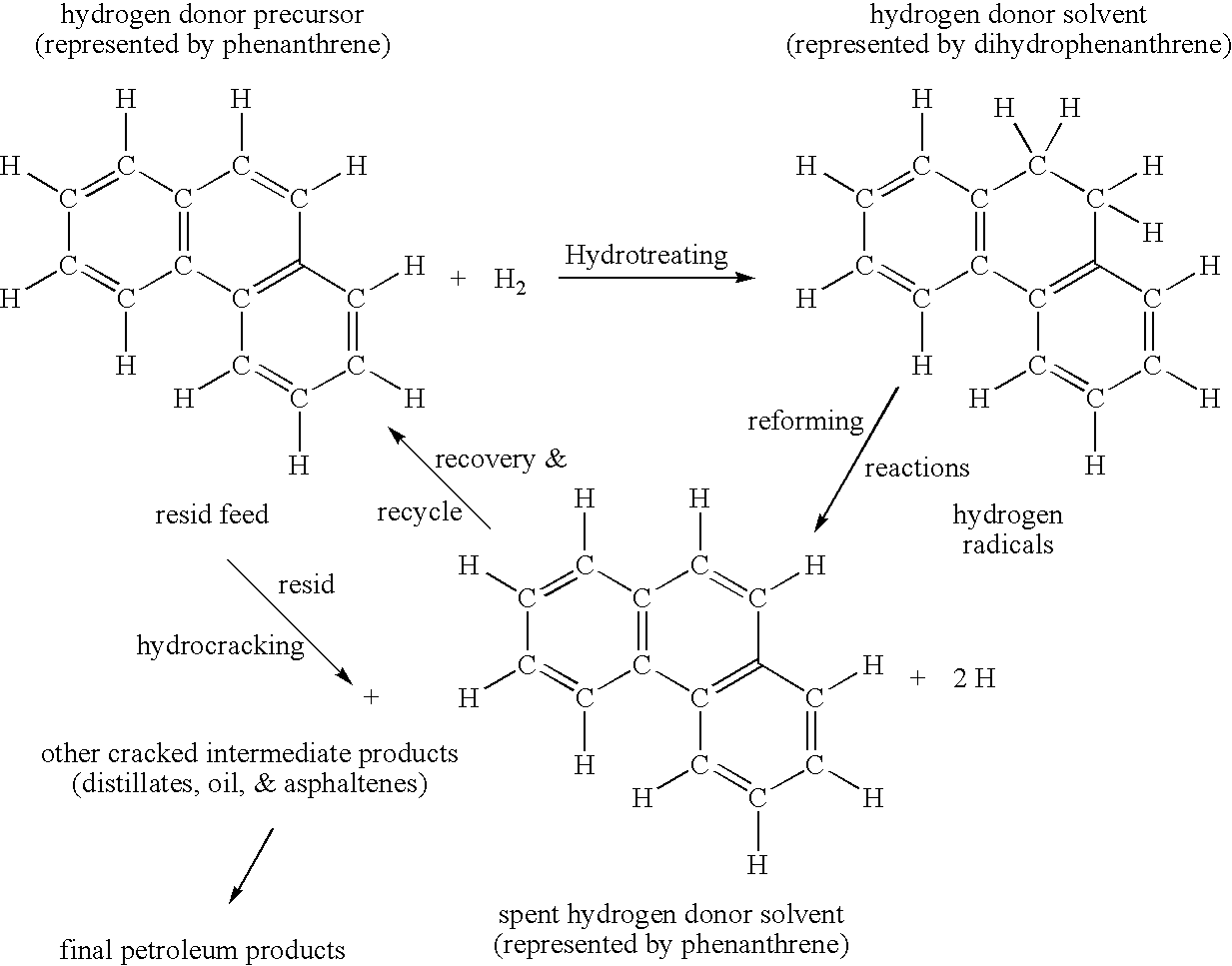

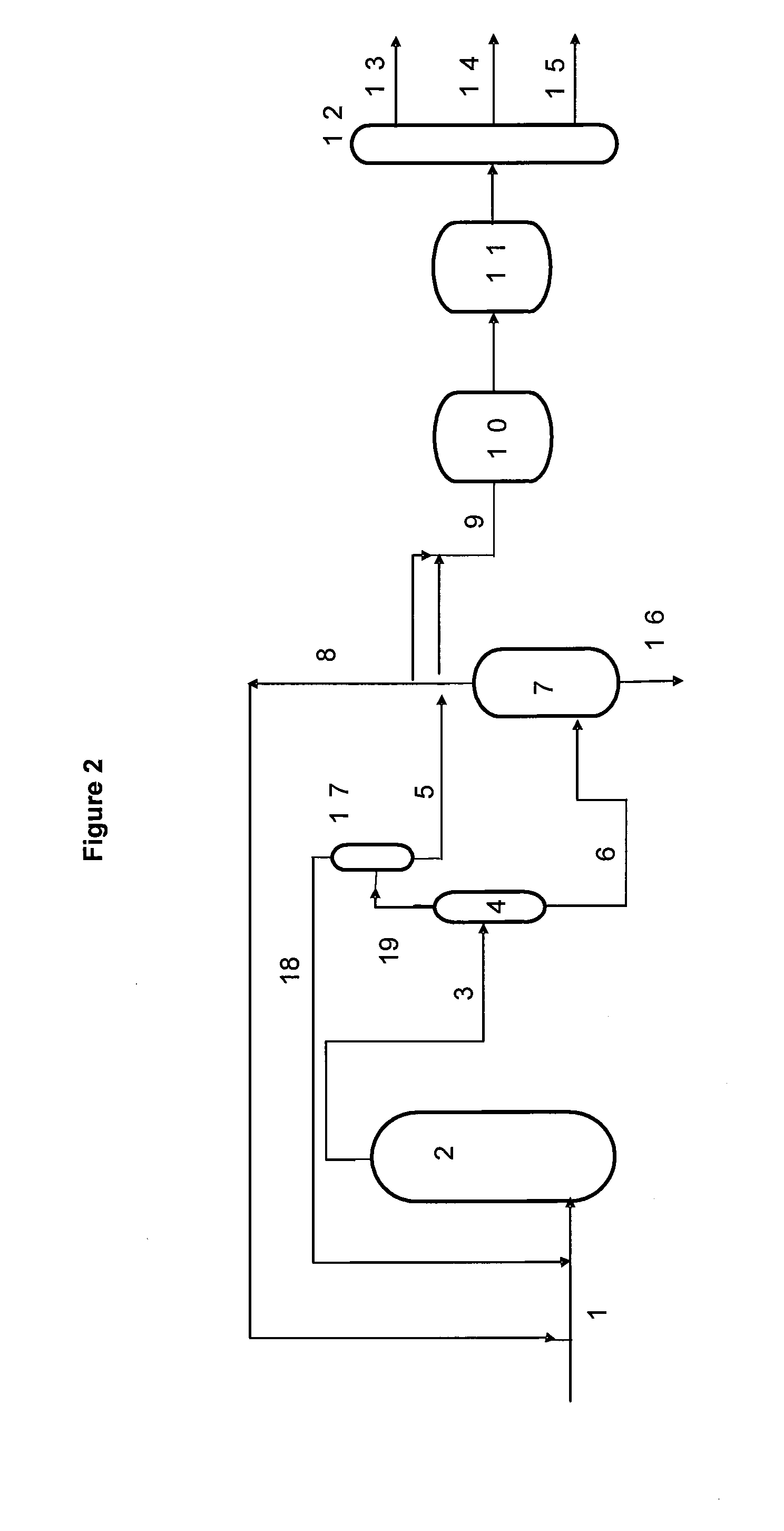

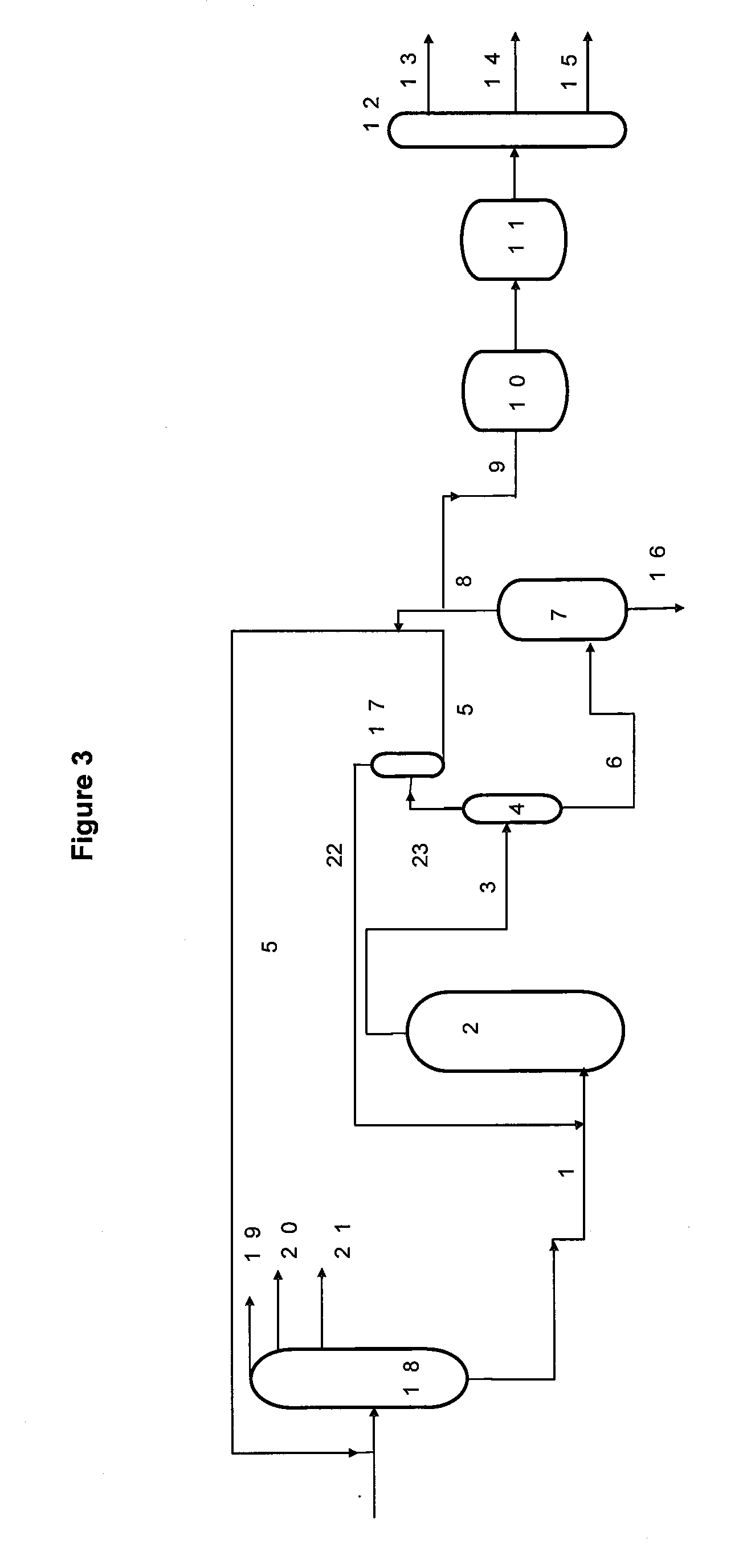

Hydrogen donor solvent production and use in resid hydrocracking processes

InactiveUS20070108100A1Treatment with plural serial cracking stages onlyCoke ovensHydrogenBoiling point

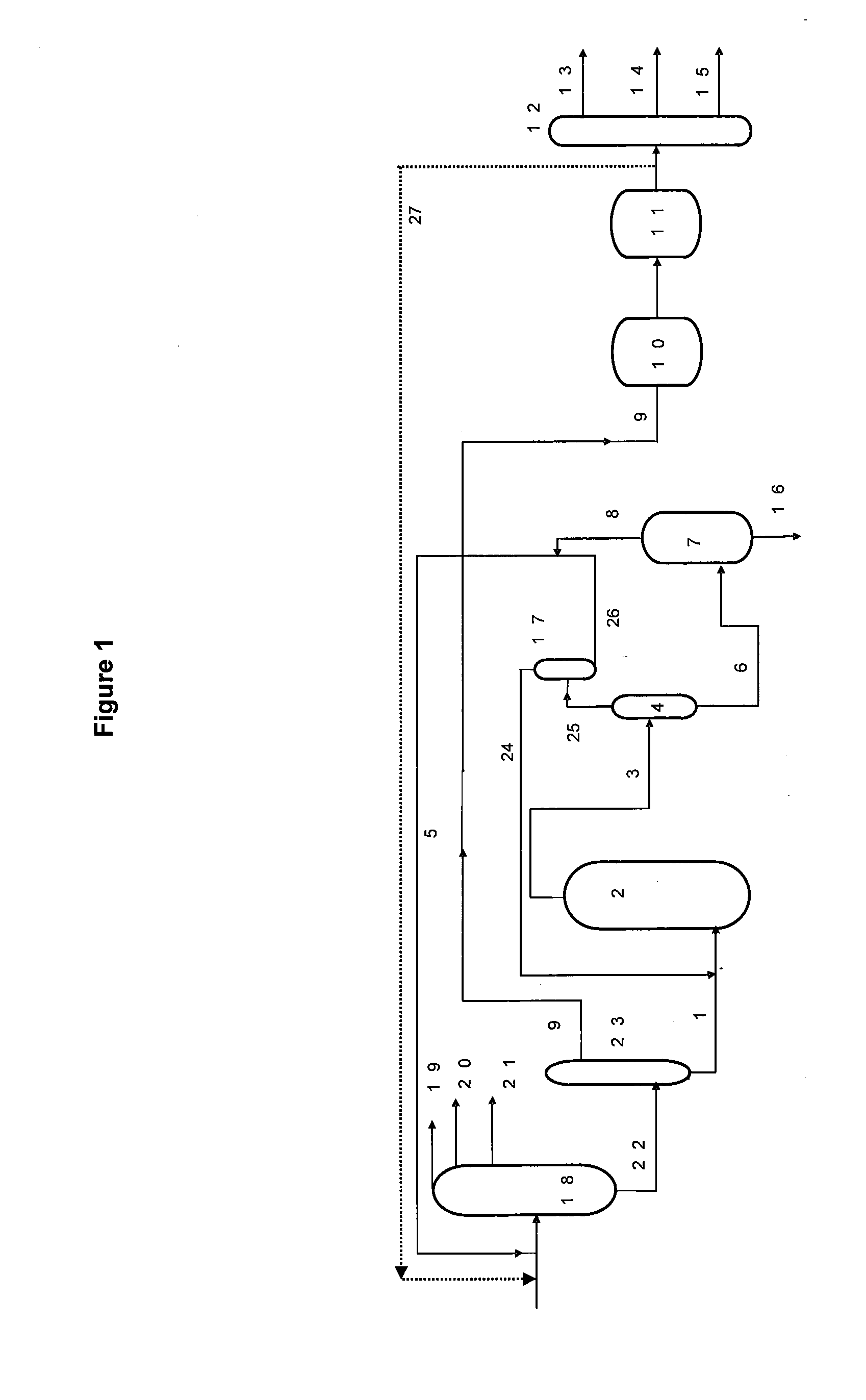

A process derived hydrogen donor solvent is used to increase the maximum resid conversion and conversion rate in an ebullated bed resid hydrocracker. The hydrogen donor solvent precursor is produced by hydroreforming reactions within the resid hydrocracker, recovered as the resin fraction from a solvent deasphalting unit, regenerated in a separate hydrotreater reactor, and recycled to the ebullated bed resid hydrocracker. The major advantage of this invention relative to earlier processes is that hydrogen is more efficiently transferred to the resin residual oil in the separate hydrotreater and the hydrogen donor solvent effectively retards the formation of coke precursors at higher ebullated bed resid hydrocracker operating temperatures and resid cracking rates.

Owner:BOC GRP INC

Enhanced solvent deasphalting process for heavy hydrocarbon feedstocks utilizing solid adsorbent

ActiveUS20080093260A1Improve performanceImprove current efficiencyWorking-up pitch/asphalt/bitumen by selective extractionHydrocarbon distillationBenzeneActivated carbon

A solvent deasphalting of crude oil or petroleum heavy fractions and residues is carried out in the presence of a solid adsorbent, such as clay, silica, alumina and activated carbon, which adsorbs the contaminants and permits the solvent and oil fraction to be removed as a separate stream from which the solvent is recovered for recycling; the adsorbent with contaminants and the asphalt bottoms is mixed with aromatic and / or polar solvents to desorb the contaminants and washed as necessary, e.g., with benzene, toluene, xylenes and tetrahydrofuran, to clean adsorbant which is recovered and recycled; the solvent-asphalt mixture is sent to a fractionator for recovery and recycling of the aromatic or polar solvent. The bottoms from the fractionator include the concentrated PNA and contaminants and are further processes as appropriate.

Owner:SAUDI ARABIAN OIL CO

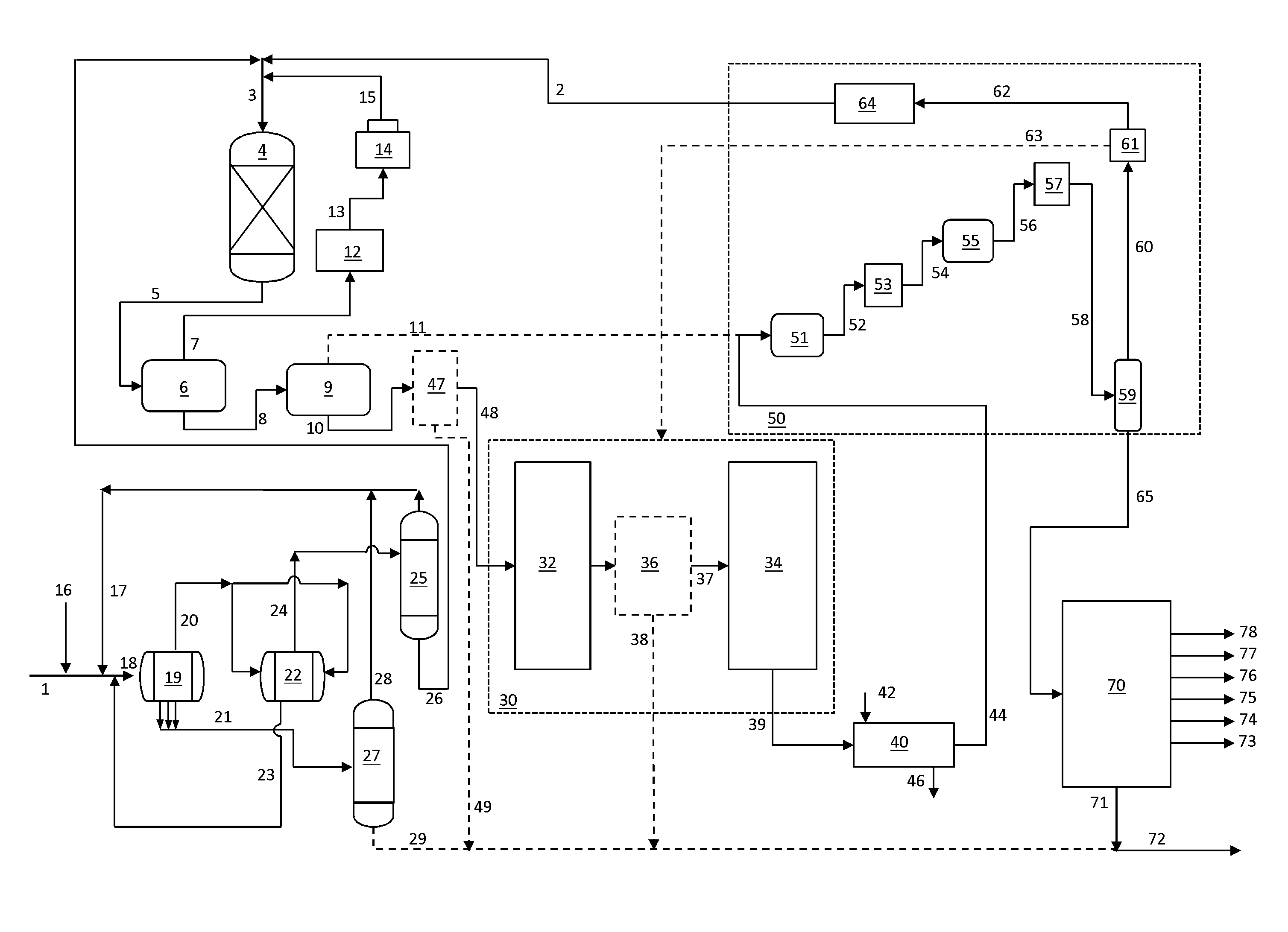

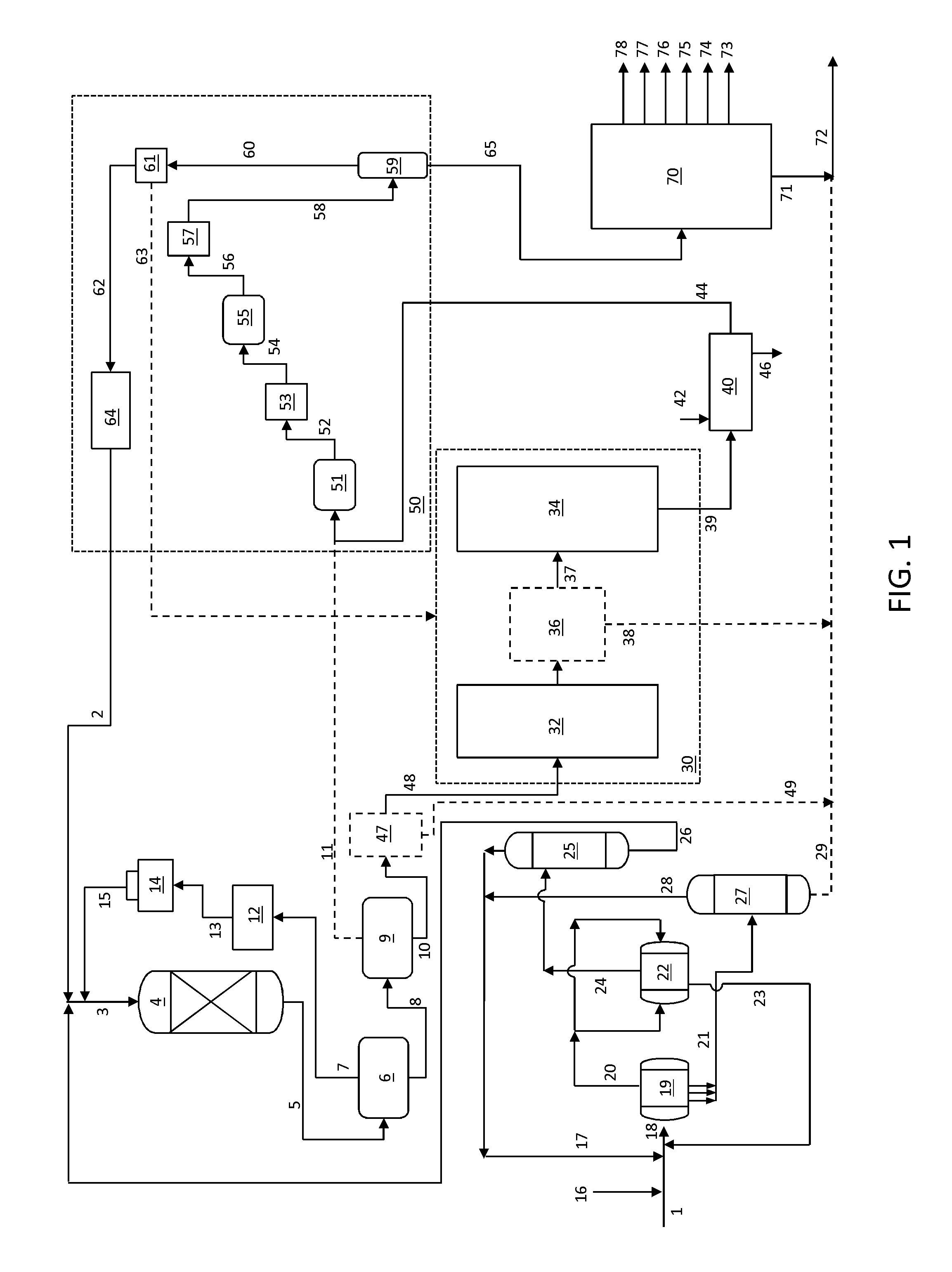

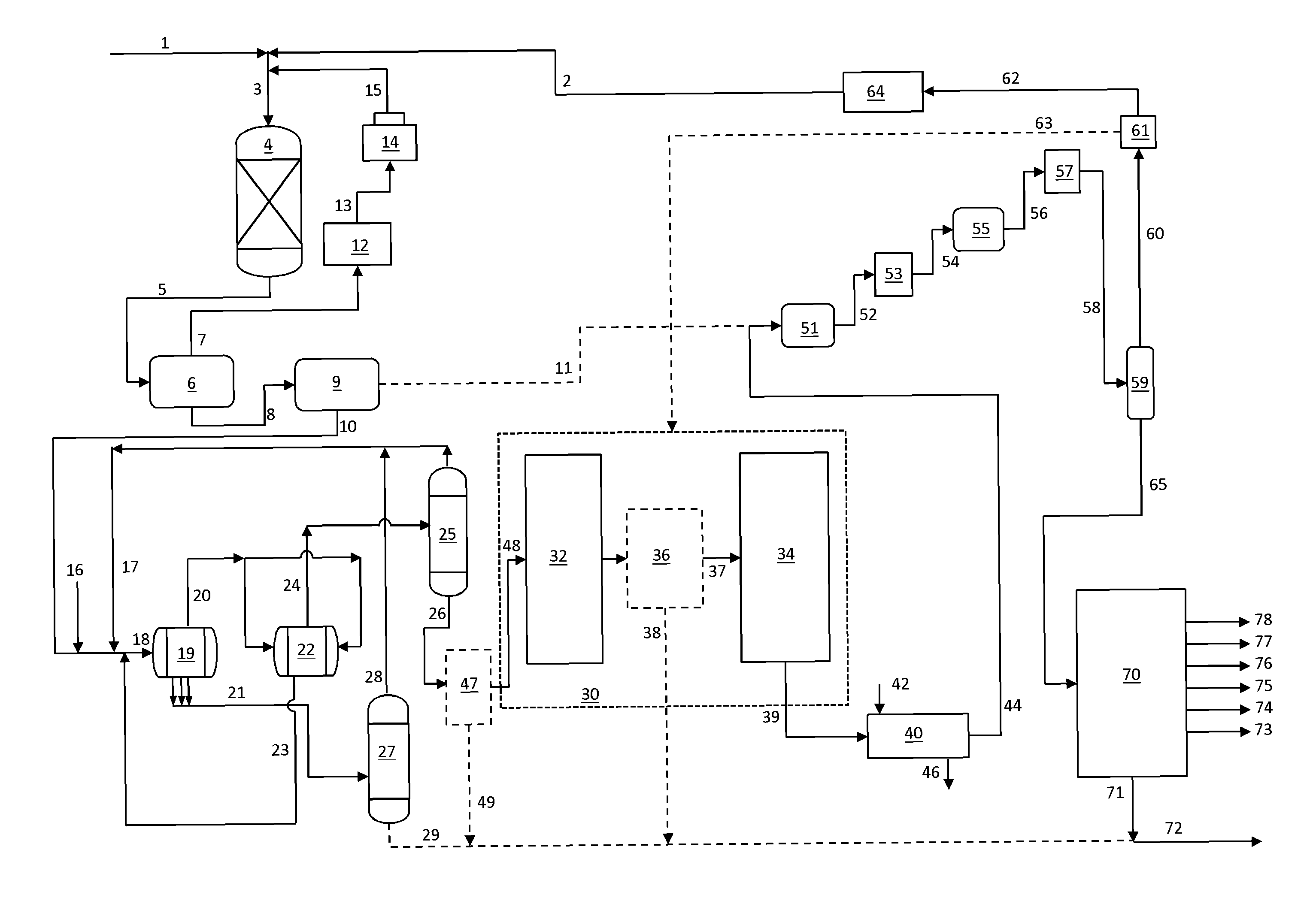

Integrated solvent deasphalting, hydrotreating and steam pyrolysis process for direct processing of a crude oil

ActiveUS9284502B2Thermal non-catalytic crackingTreatment with plural serial cracking stages onlySteam pyrolysisFuel oil

A process is provided that is directed to a steam pyrolysis zone integrated with a solvent deasphalting zone and a hydrotreating zone to permit direct processing of crude oil feedstocks to produce petrochemicals including olefins and aromatics. The integrated solvent deasphalting, hydrotreating and steam pyrolysis process for the direct processing of a crude oil to produce olefinic and aromatic petrochemicals comprises: charging the crude oil to a solvent deasphalting zone with an effective amount of solvent for producing a deasphalted and demetalized oil stream and a bottom asphalt phase; charging the deasphalted and demetalized oil stream and hydrogen to a hydroprocessing zone operating under conditions effective to produce a hydroprocessed effluent reduced having a reduced content of contaminants, an increased paraffinicity, reduced Bureau of Mines Correlation Index, and an increased American Petroleum Institute gravity; thermally cracking the hydroprocessed effluent in the presence of steam to produce a mixed product stream; separating the mixed product stream; purifying hydrogen recovered from the mixed product stream and recycling it to the hydroprocessing zone; recovering olefins and aromatics from the separated mixed product stream; and recovering pyrolysis fuel oil from the separated mixed product stream.

Owner:SAUDI ARABIAN OIL CO

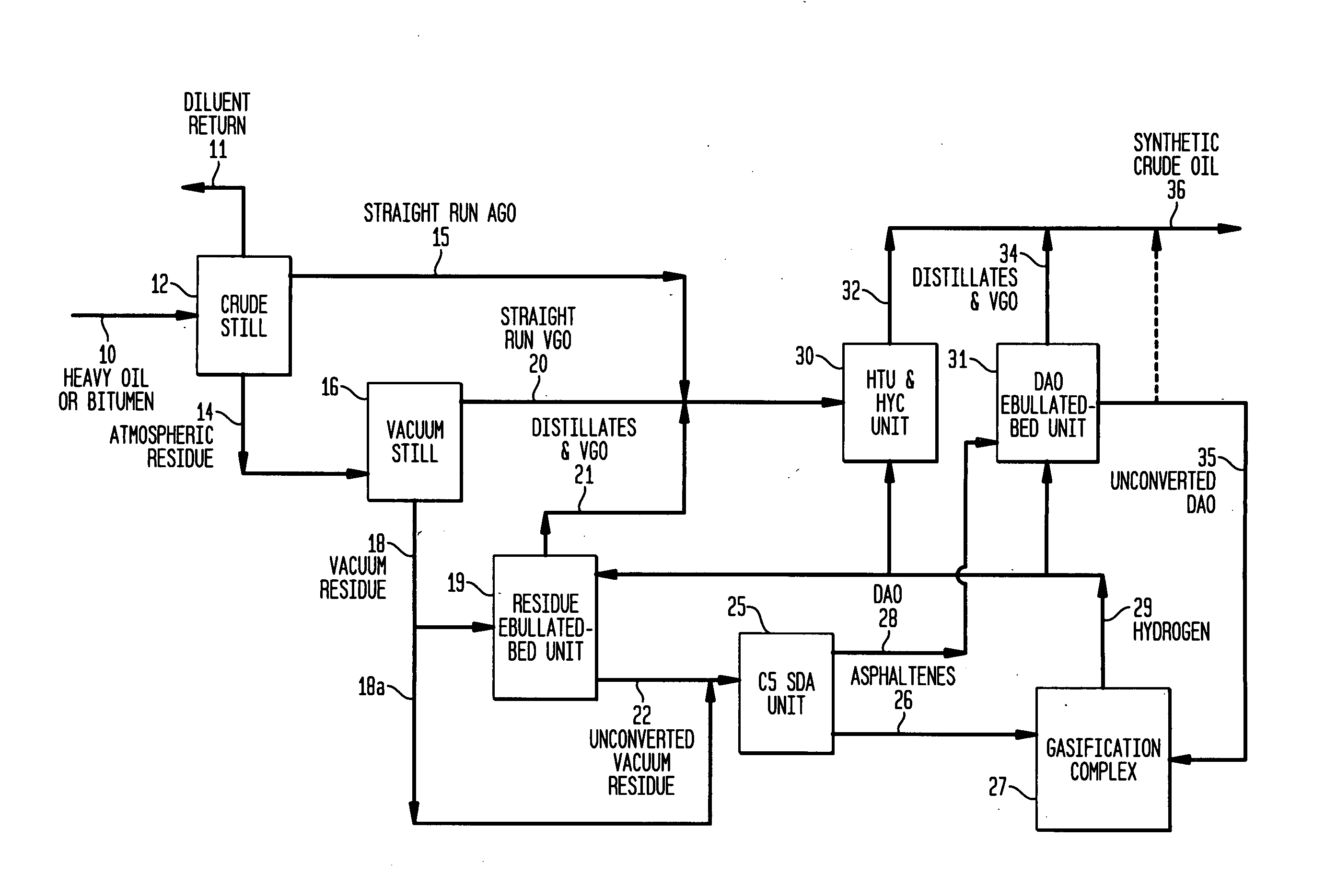

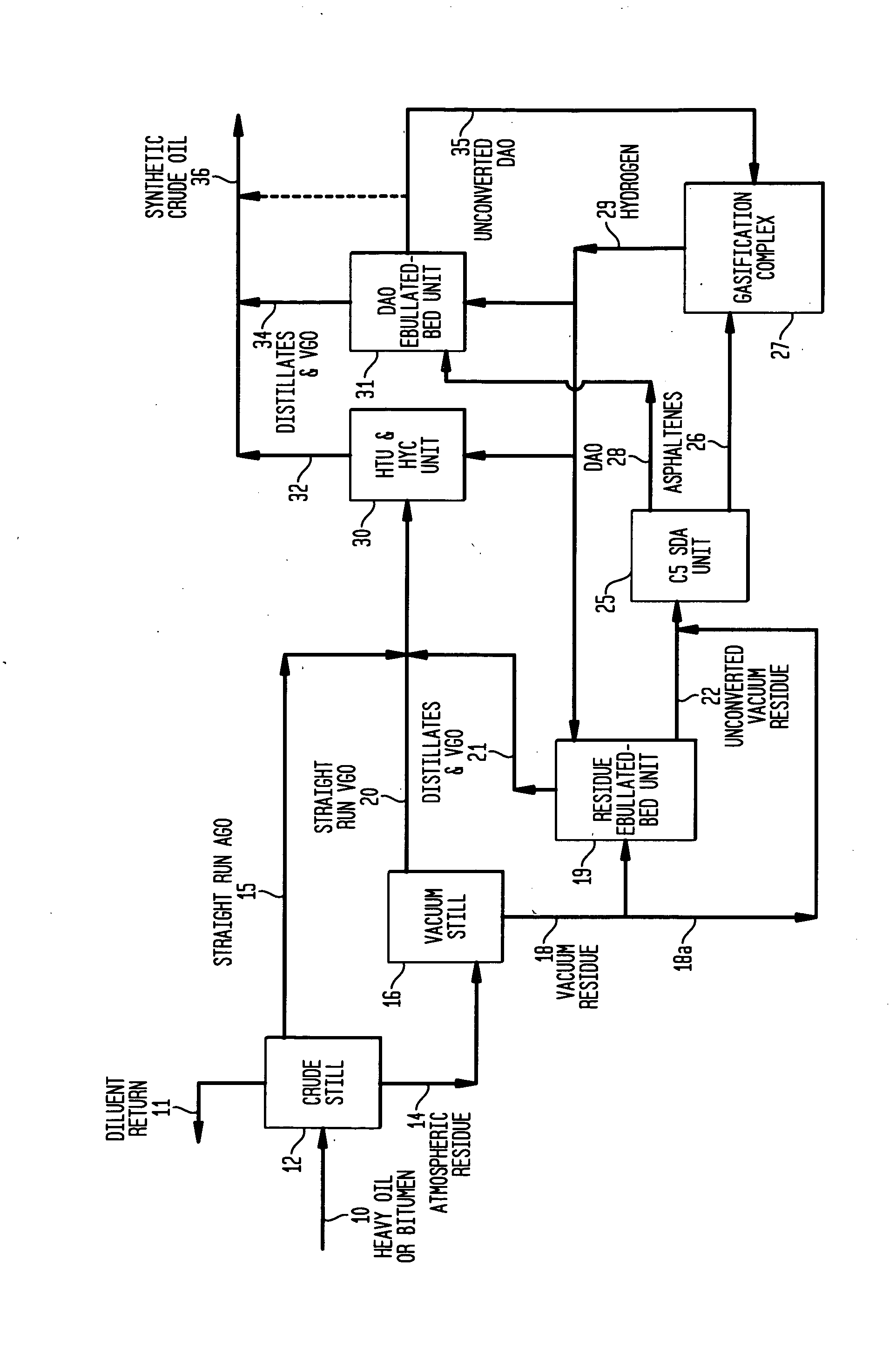

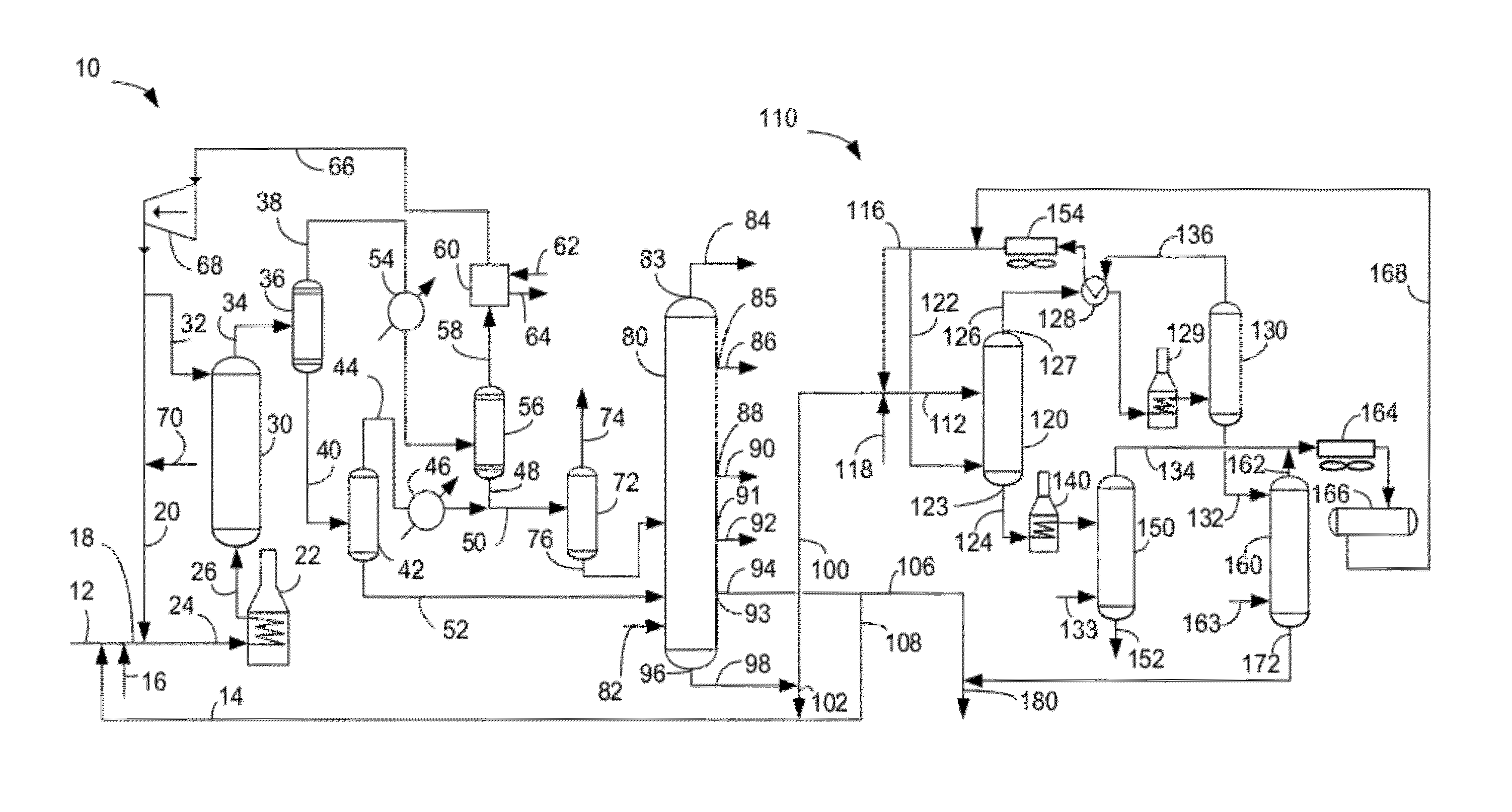

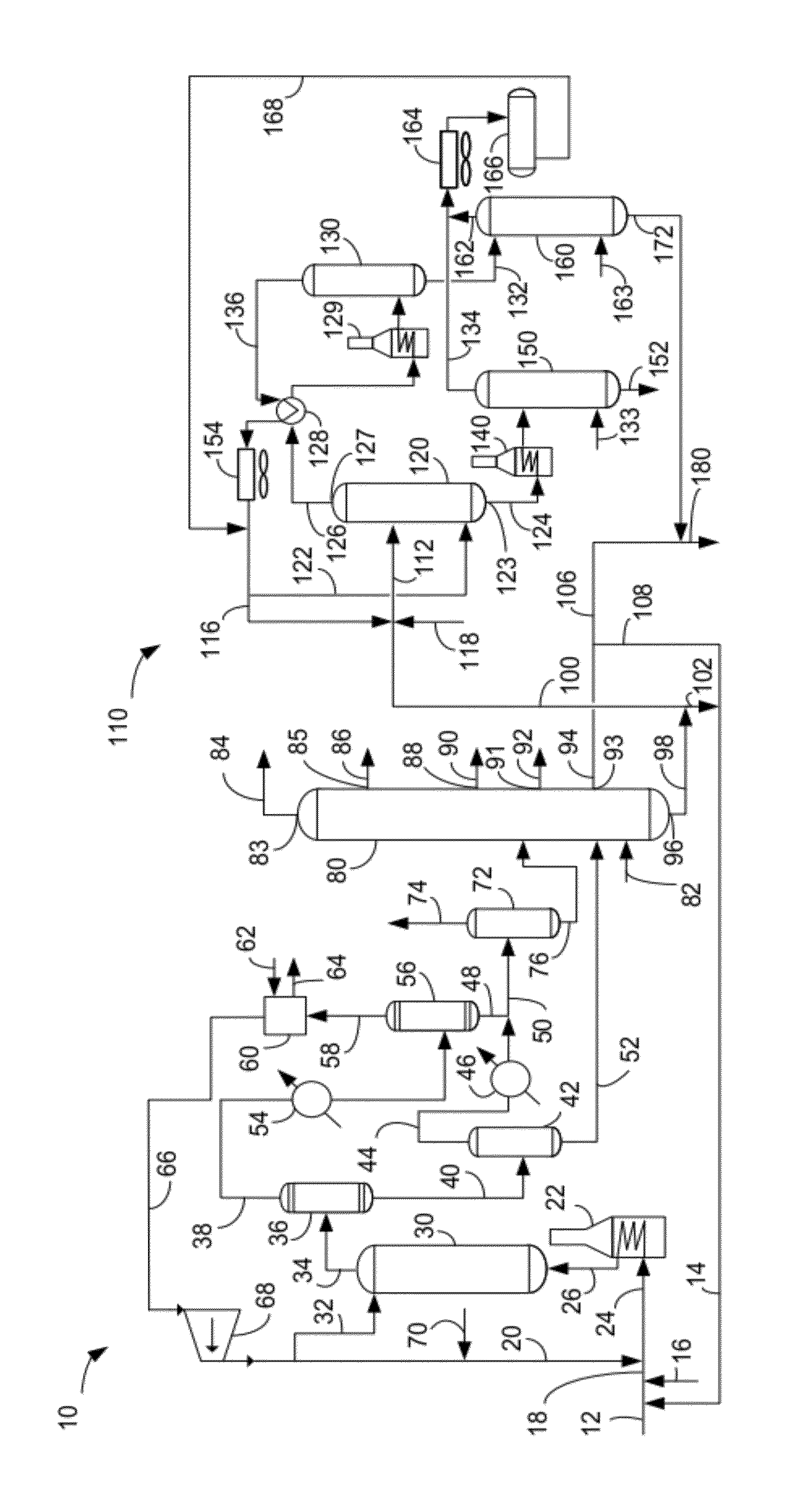

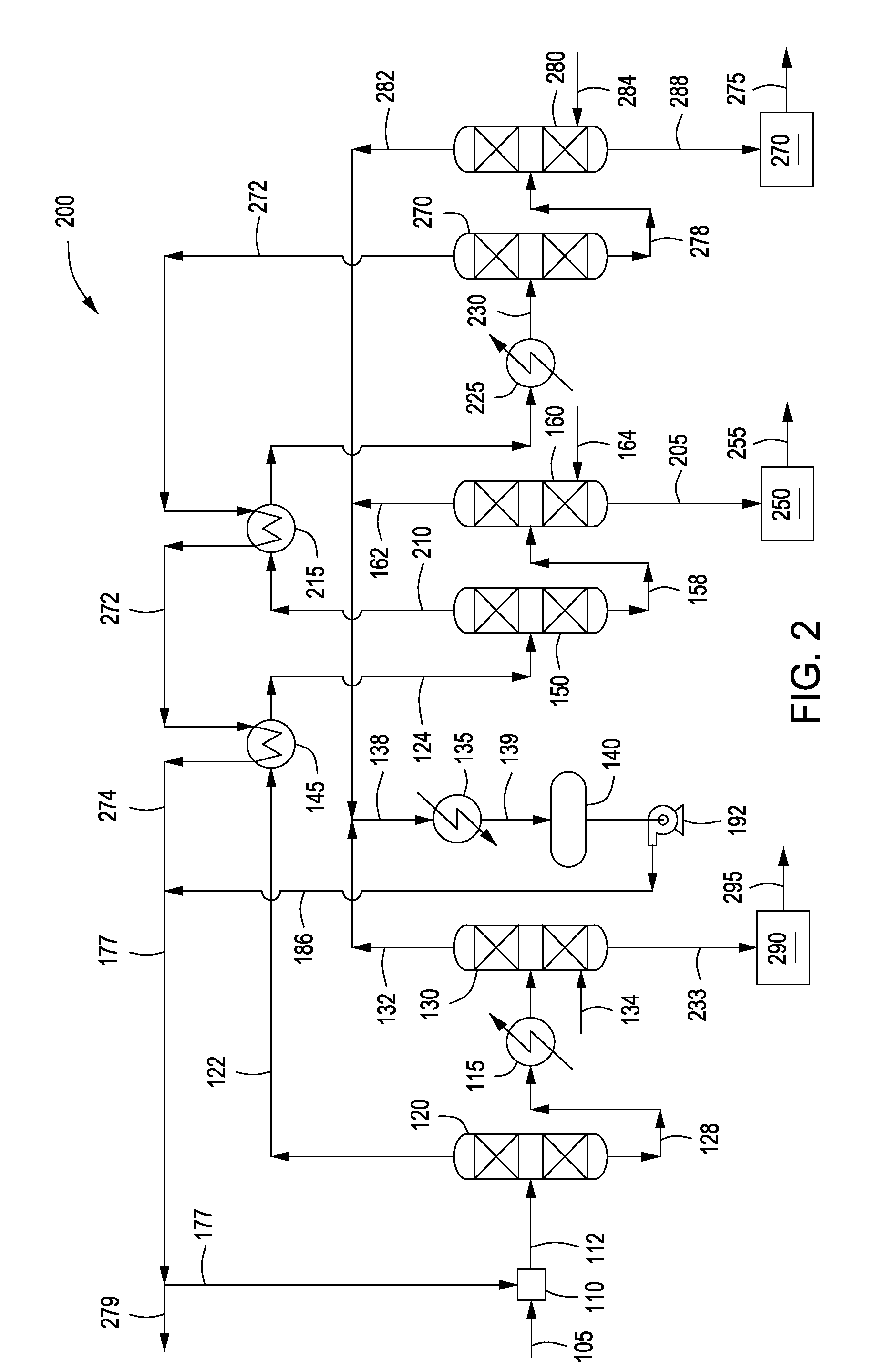

Innovative heavy crude conversion/upgrading process configuration

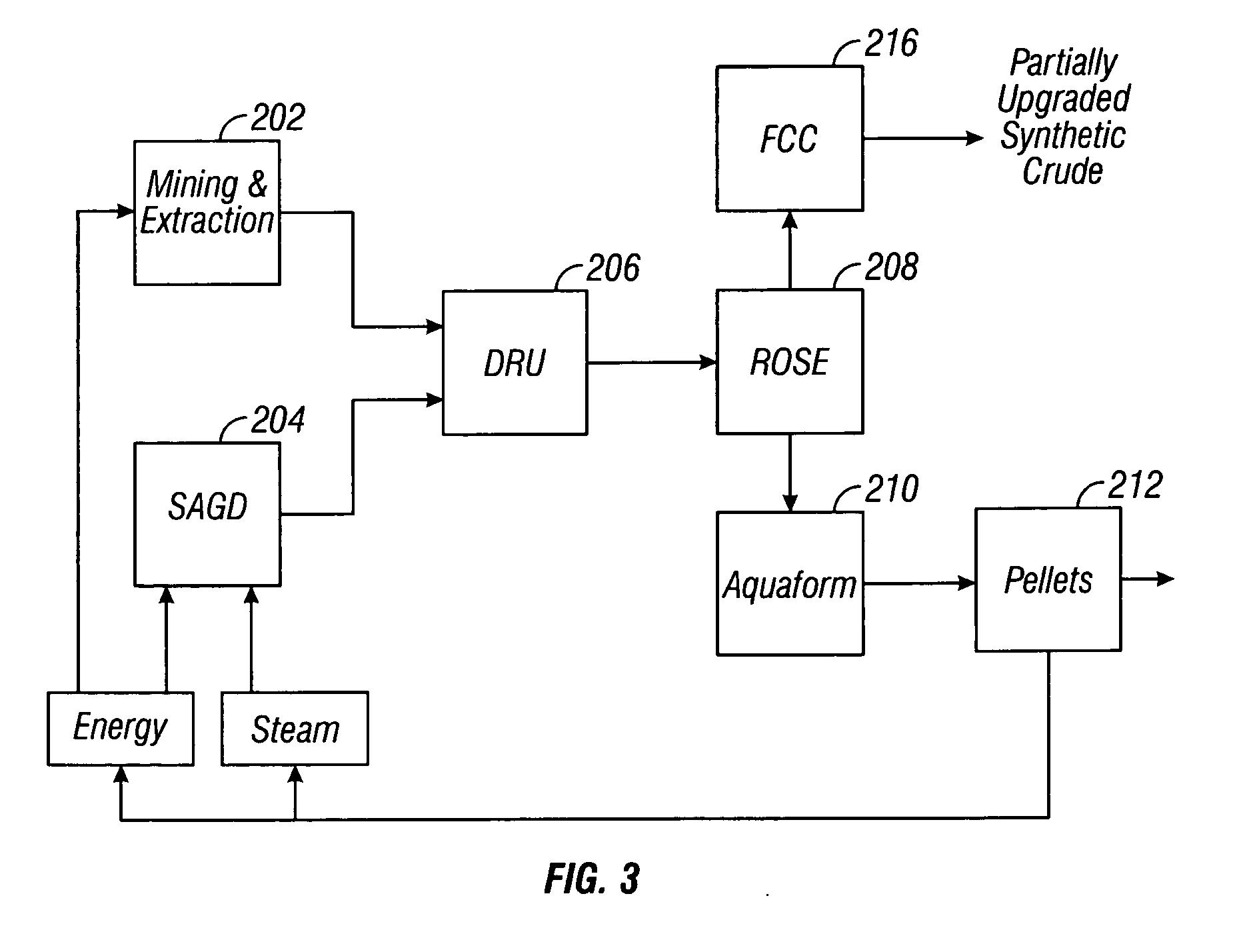

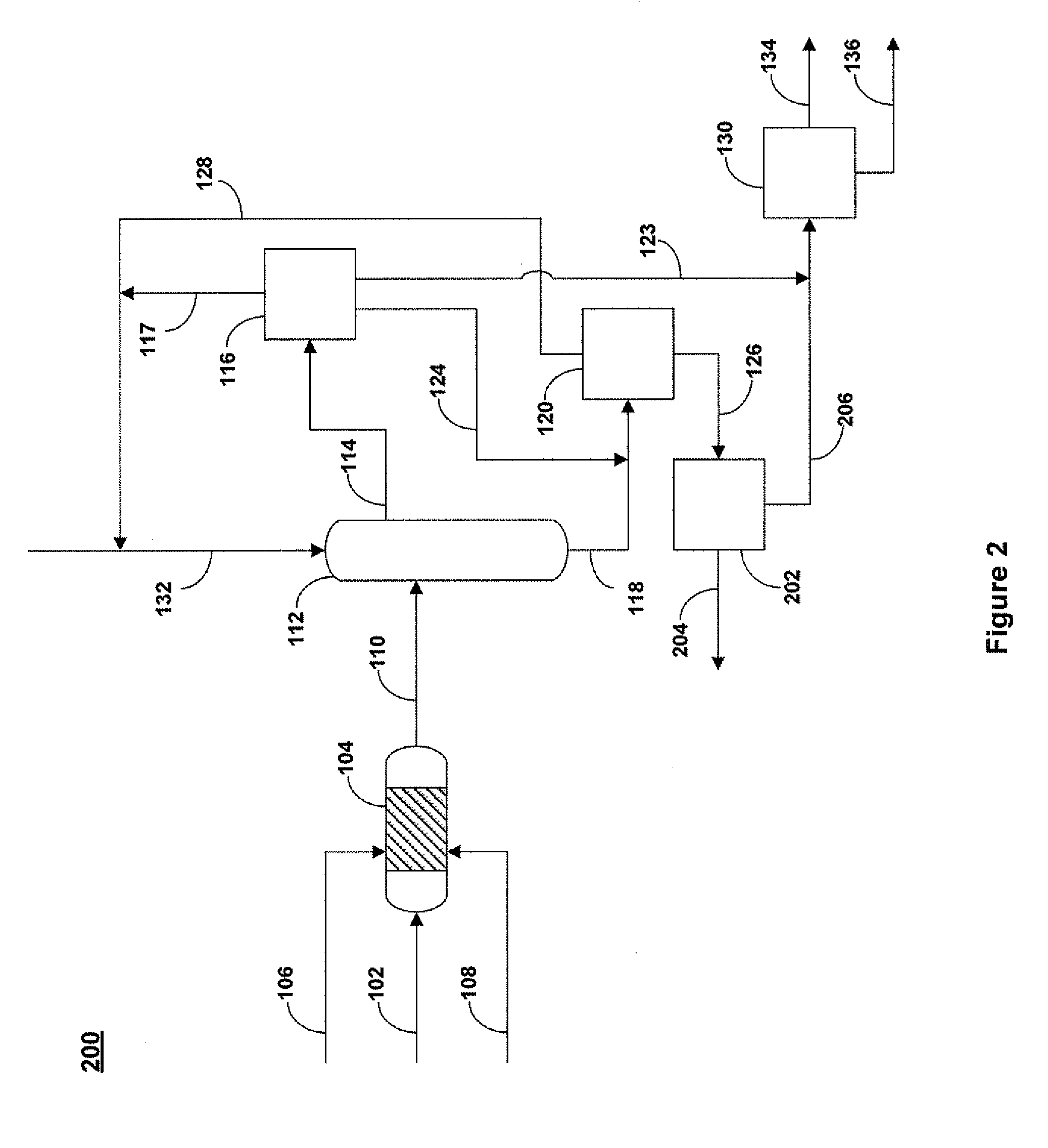

InactiveUS20110198265A1Maximizing liquid SCO yieldYield maximizationHydrocarbon oil crackingTreatment with hydrotreatment processesFuel oilProcess configuration

The described invention discloses an innovative solvent deasphalter and hydroconversion-processing configuration for converting bitumen or heavy oils to produce a transportable synthetic crude oil (SCO). The innovative processing scheme disclosed herein maximizes the synthetic crude oil yield at a minimal investment compared to currently known methods.

Owner:INST FR DU PETROLE

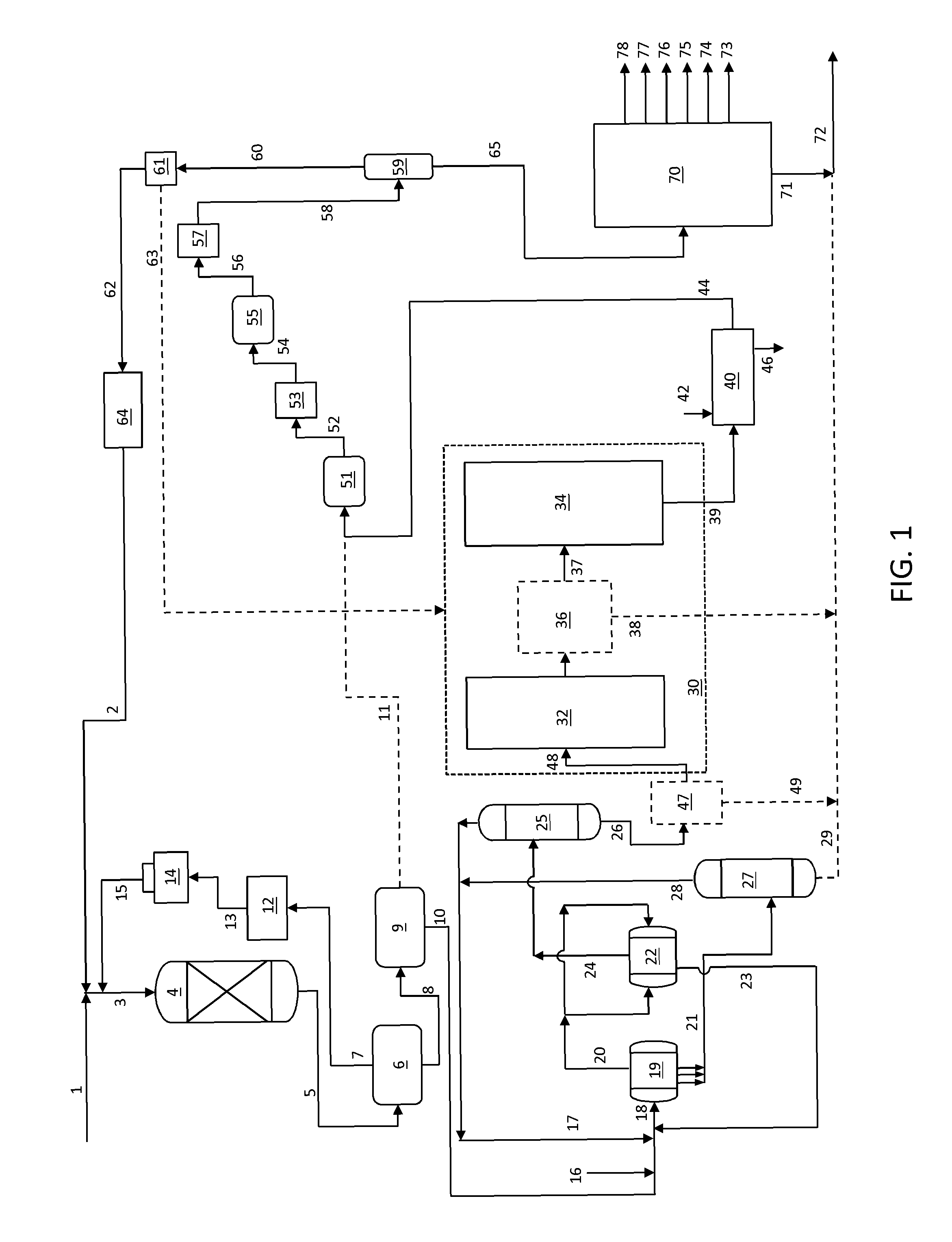

Integrated solvent deasphalting and steam pyrolysis process for direct processing of a crude oil

ActiveUS9284497B2Thermal non-catalytic crackingTreatment with plural serial stages onlyFuel oilSteam pyrolysis

A process is provided that is directed to a steam pyrolysis zone integrated with a solvent deasphalting zone to permit direct processing of crude oil feedstocks to produce petrochemicals including olefins and aromatics. The integrated solvent deasphalting and steam pyrolysis process for the direct processing of a crude oil to produce olefinic and aromatic petrochemicals comprises charging the crude oil to a solvent deasphalting zone with an effective amount of solvent to produce a deasphalted and demetalized oil stream and a bottom asphalt phase; thermally cracking the deasphalted and demetalized oil stream in the presence of steam to produce a mixed product stream; separating the mixed product stream; recovering olefins and aromatics from the separated mixed product stream; and recovering pyrolysis fuel oil from the separated mixed product stream.

Owner:SAUDI ARABIAN OIL CO

Process for producing fuel

InactiveUS20060027488A1Low costHigh thermal efficiencyWorking-up pitch/asphalt/bitumen by selective extractionSolid fuelsAlkaneSorbent

A fuel is produced from bitumen by precipitating a substantial portion of asphaltenes from bitumen by contacting the bitumen with a lower alkane solvent. Suitable burners include a fluidized bed boiler, a circulating fluidized bed boiler and a pitch boiler which utilize either pre-combustion sulfur sorbents or post-combustion flue gas desulfurization. The sulfur in emissions can be used to produce sulfuric acid. The process uses a low cost fuel, generates steam, power and sulfuric acid and meets all emission requirements for SO2, NOx and PM.

Owner:GAUTHIER RICHARD

Process for upgrading tar

ActiveUS20080099371A1Thermal non-catalytic crackingLiquid hydrocarbon mixture productionDistillationTar

A feedstream comprising tar is feed to a solvent deasphalter wherein it is contacted with a deasphalting solvent or fluid to produce a composition comprising a mixture or slurry of solvent containing a soluble portion of the tar, and a heavy tar fraction comprising the insoluble portion of the tar. These fractions may be separated in the deasphalter apparatus, such as by gravity settling wherein the heavy tar fraction is taken off as bottoms, and the solvent-soluble fraction taken as overflow or overheads with the solvent. The overflow or overheads is sent to a solvent recovery unit, such as a distillation apparatus, wherein solvent is recovered as overheads and a deasphalted tar fraction is taken off as a sidestream or bottoms. The solvent or a portion thereof, recovered as overheads, may be then be recycled to the solvent deasphalter, or in a preferred embodiment, at least a portion of the solvent is steam cracked to produce a product comprising light olefins.

Owner:EXXONMOBIL CHEM PAT INC

Integrated hydrotreating, solvent deasphalting and steam pyrolysis process for direct processing of a crude oil

ActiveUS20130220884A1Reduce contentIncreased paraffinicityThermal non-catalytic crackingTreatment with plural serial stages onlySteam pyrolysisFuel oil

A process is provided that is directed to a steam pyrolysis zone integrated with a hydrotreating zone and a solvent deasphalting zone to permit direct processing of crude oil feedstocks to produce petrochemicals including olefins and aromatics. The integrated hydrotreating, solvent deasphalting and steam pyrolysis process comprises charging the crude oil to a hydroprocessing zone operating under conditions effective to produce a hydroprocessed effluent reduced having a reduced content of contaminants, an increased paraffinicity, reduced Bureau of Mines Correlation Index, and an increased American Petroleum Institute gravity; charging the hydroprocessed effluent to a solvent deasphalting zone with an effective amount of solvent to produce a deasphalted and demetalized oil stream and a bottom asphalt phase; thermally cracking the deasphalted and demetalized oil stream in the presence of steam to produce a mixed product stream; separating the mixed product stream; purifying hydrogen recovered from the mixed product stream and recycling it to the hydroprocessing zone; recovering olefins and aromatics from the separated mixed product stream; and recovering pyrolysis fuel oil from the separated mixed product stream.

Owner:SAUDI ARABIAN OIL CO

Process for recovering ultrafine solids from a hydrocarbon liquid

ActiveUS20080156700A1Good curative effectSemi-permeable membranesCatalytic naphtha reformingFlocculationParticulates

A method for separating and recovering ultrafine particulate solid material from a suspension or slurry of the solid material and a hydrocarbon liquid by precipitation or flocculation of a heavy fraction of the hydrocarbon liquid with an effective amount of a precipitation or flocculation agent such that the precipitated heavy fraction encapsulates the particulate solid material. The method further comprises coking the precipitated heavy fraction and grinding the coked product to an ultrafine size.

Owner:CHEVROU USA INC

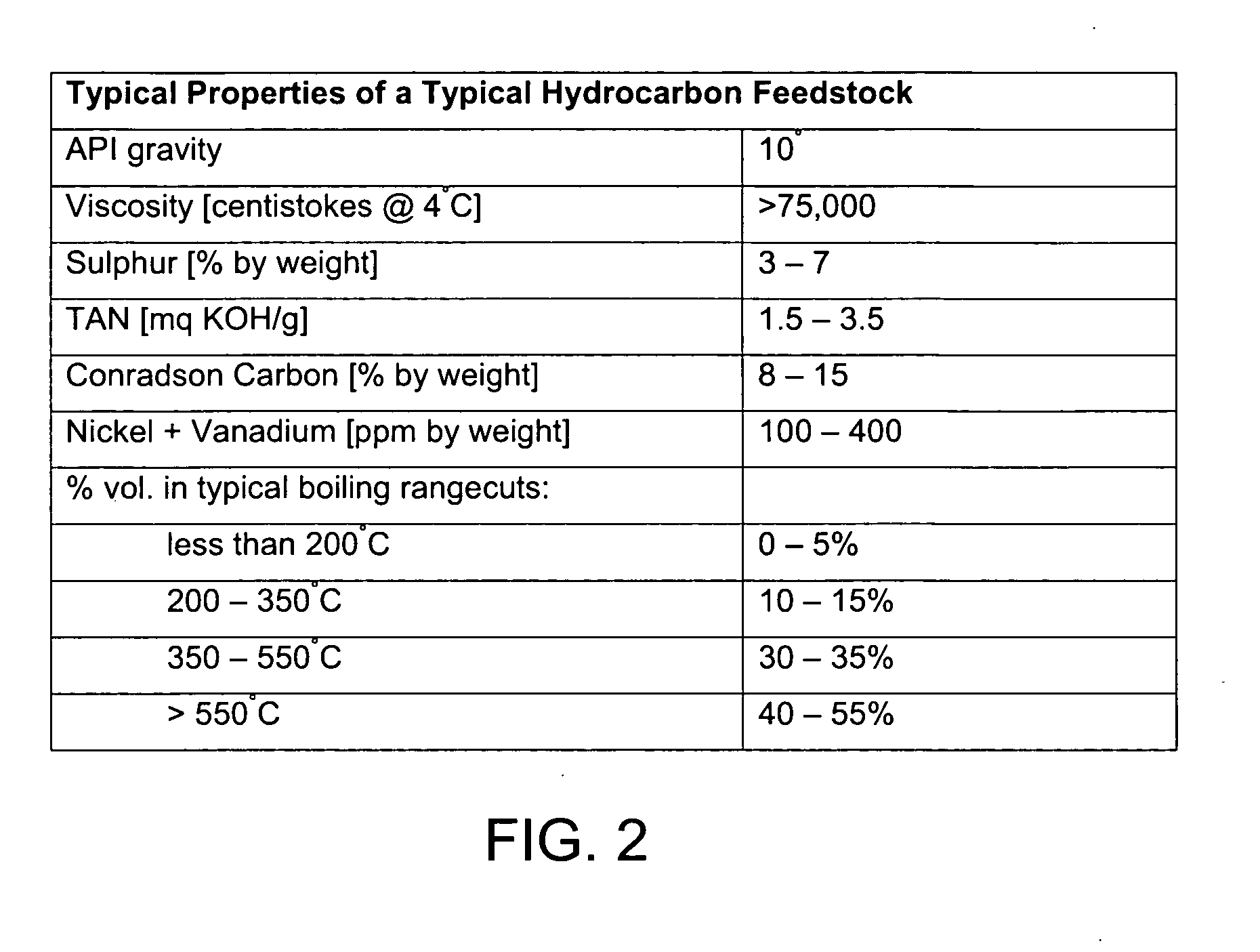

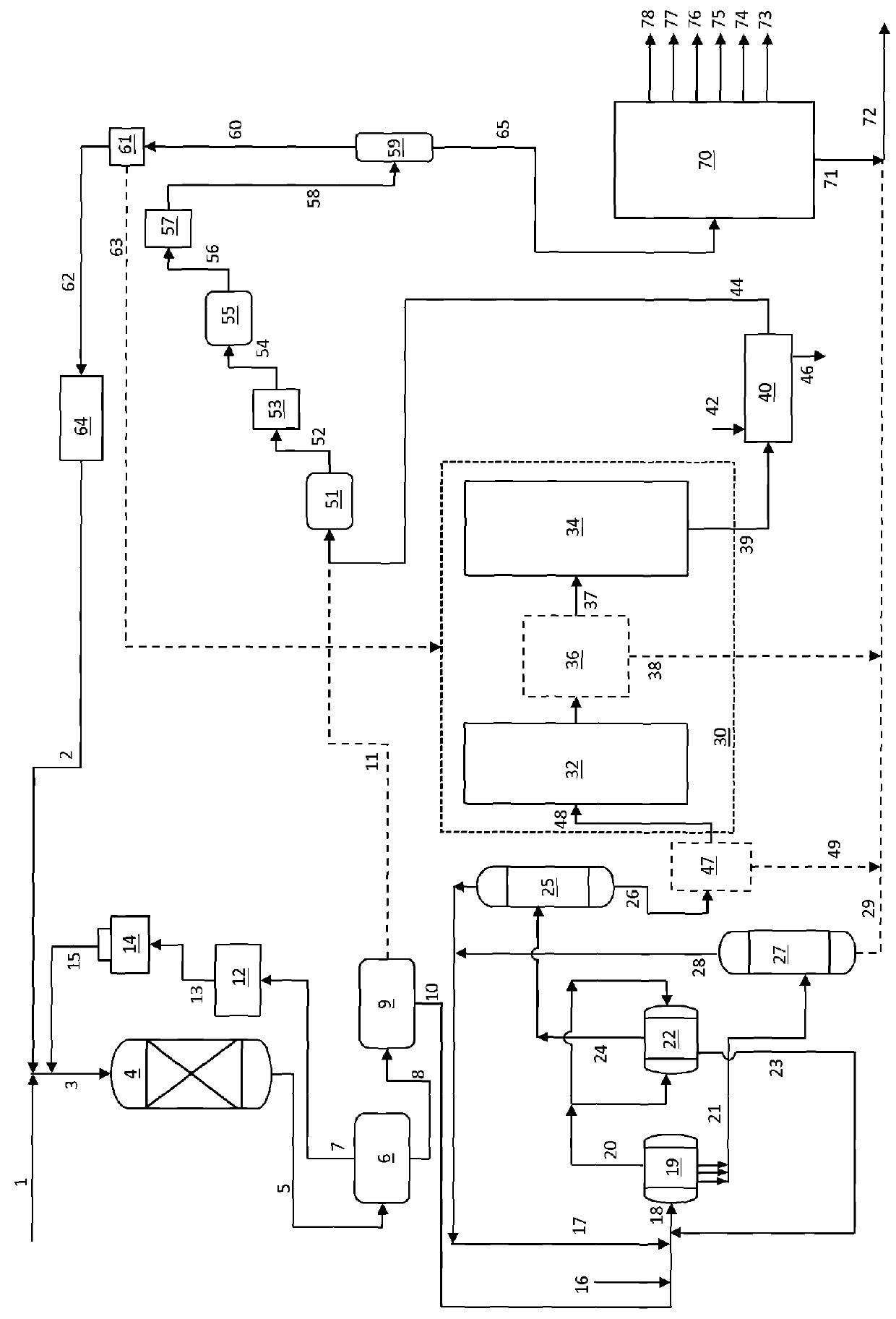

Integrated process for the treatment of oil feeds for the production of fuel oils with a low sulphur and sediment content

InactiveUS9650580B2Easy to integrateSave energyLiquid carbonaceous fuelsTreatment with hydrotreatment processesSulfurBoiling point

Treating a hydrocarbon feed having a sulphur content of at least 0.5% by weight, an asphaltenes content of at least 1% by weight, an initial boiling point of at least 340° C. and a final boiling point of at least 480° C., in order to obtain at least one deasphalted oil fraction with a sulphur content of 0.5% by weight or less and a sediment content of 0.1% by weight or less.

Owner:INST FR DU PETROLE

Integrated Solvent Deasphalting and Slurry Hydrocracking Process

InactiveUS20100122934A1High value distillateEfficient integrationWorking-up pitch/asphalt/bitumenLiquid hydrocarbon mixture productionParticulatesHydrogen

Integrated slurry hydrocracking (SHC) and coking methods for making slurry hydrocracking (SHC) distillates are disclosed. Representative methods involve passing a slurry comprising a deasphalted oil (DAO) produced in a solvent deasphalting (SDA) process, optionally with recycled SHC gas oil and recycled SHC pitch, and a solid particulate through an SHC reaction zone in the presence of hydrogen to obtain the SHC distillate. Recovery and recycle of SHC gas oil and pitch from the SHC effluent improves the overall conversion to naphtha and distillate products and decreases catalyst requirements.

Owner:UOP LLC

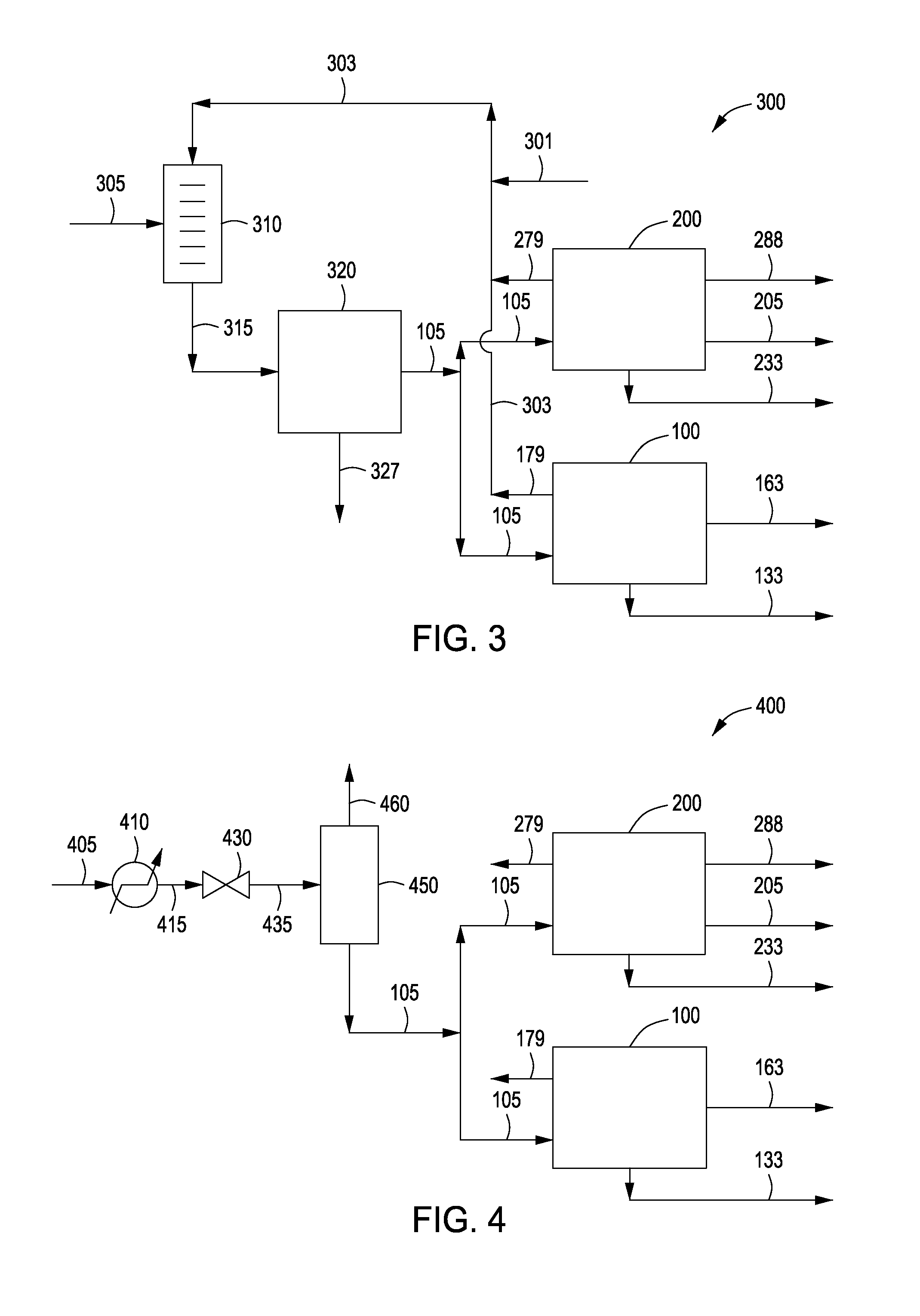

System for upgrading of heavy hydrocarbons

Systems and methods for processing one or more hydrocarbons are provided. One or more hydrocarbons can be selectively separated to provide one or more heavy deasphalted oils. At least a portion of the heavy deasphalted oil can be cracked using a fluidized catalytic cracker to provide one or more lighter hydrocarbon products.

Owner:KELLOGG BROWN & ROOT LLC

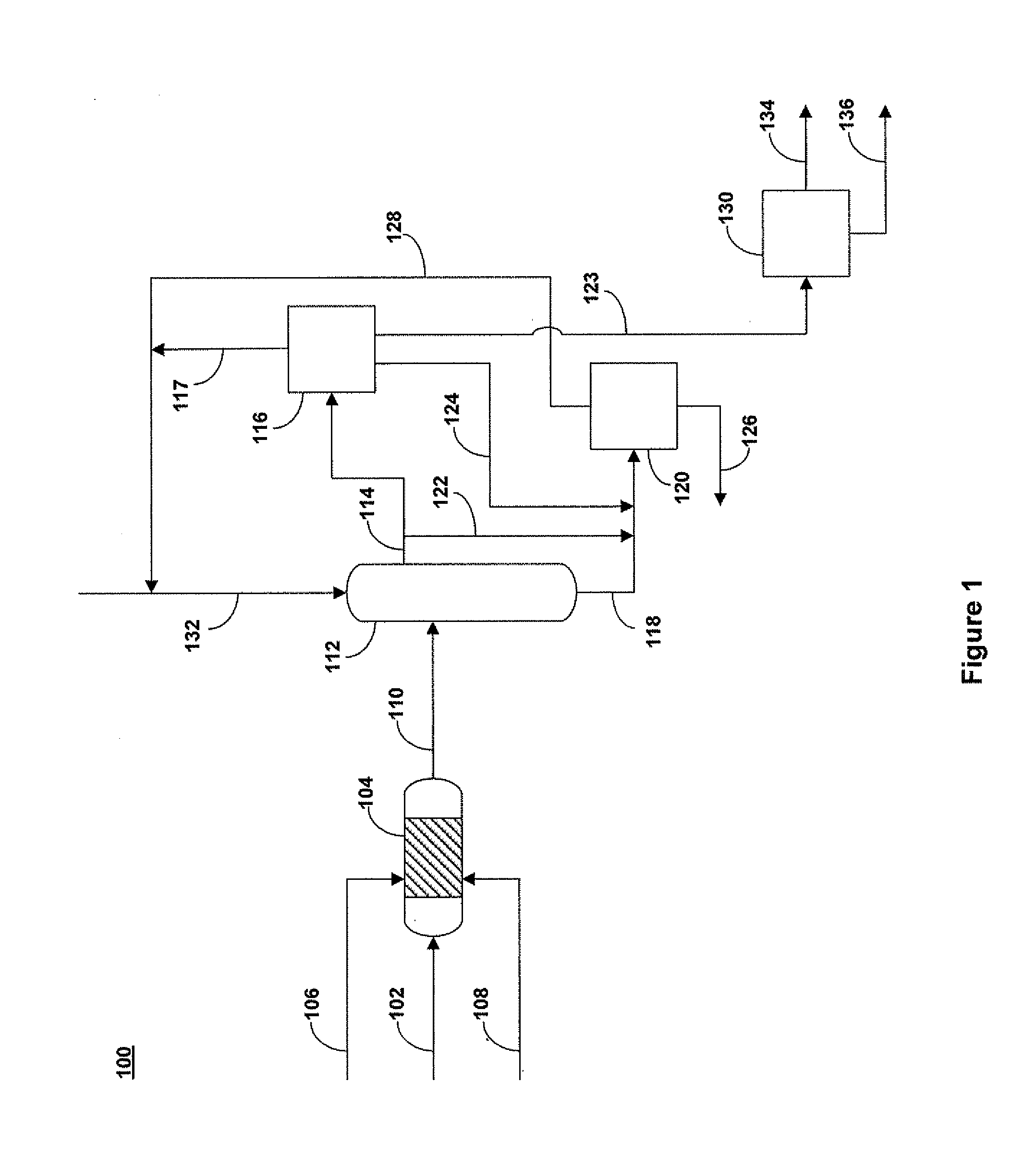

Bitumen production-upgrade with common or different solvents

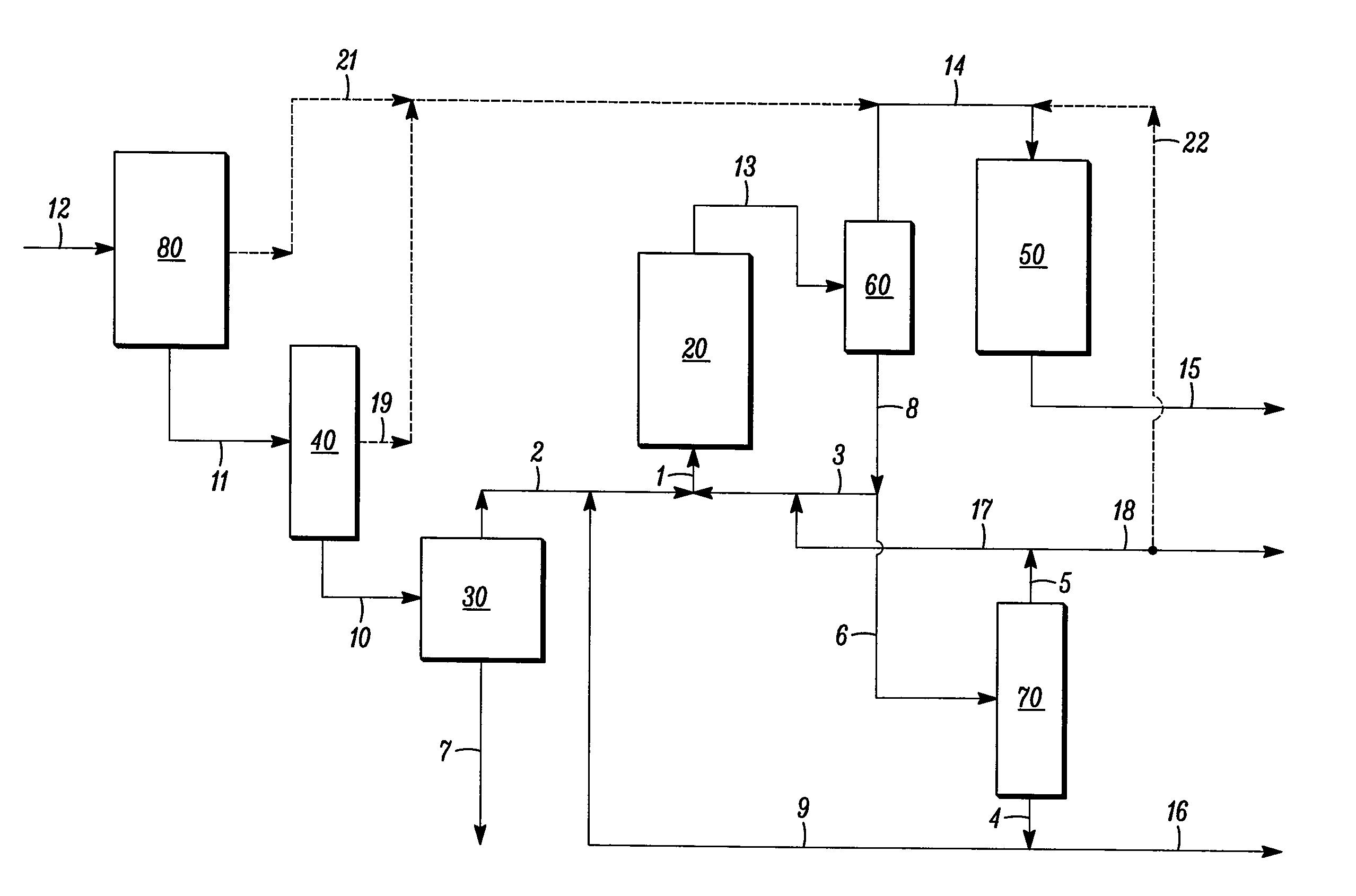

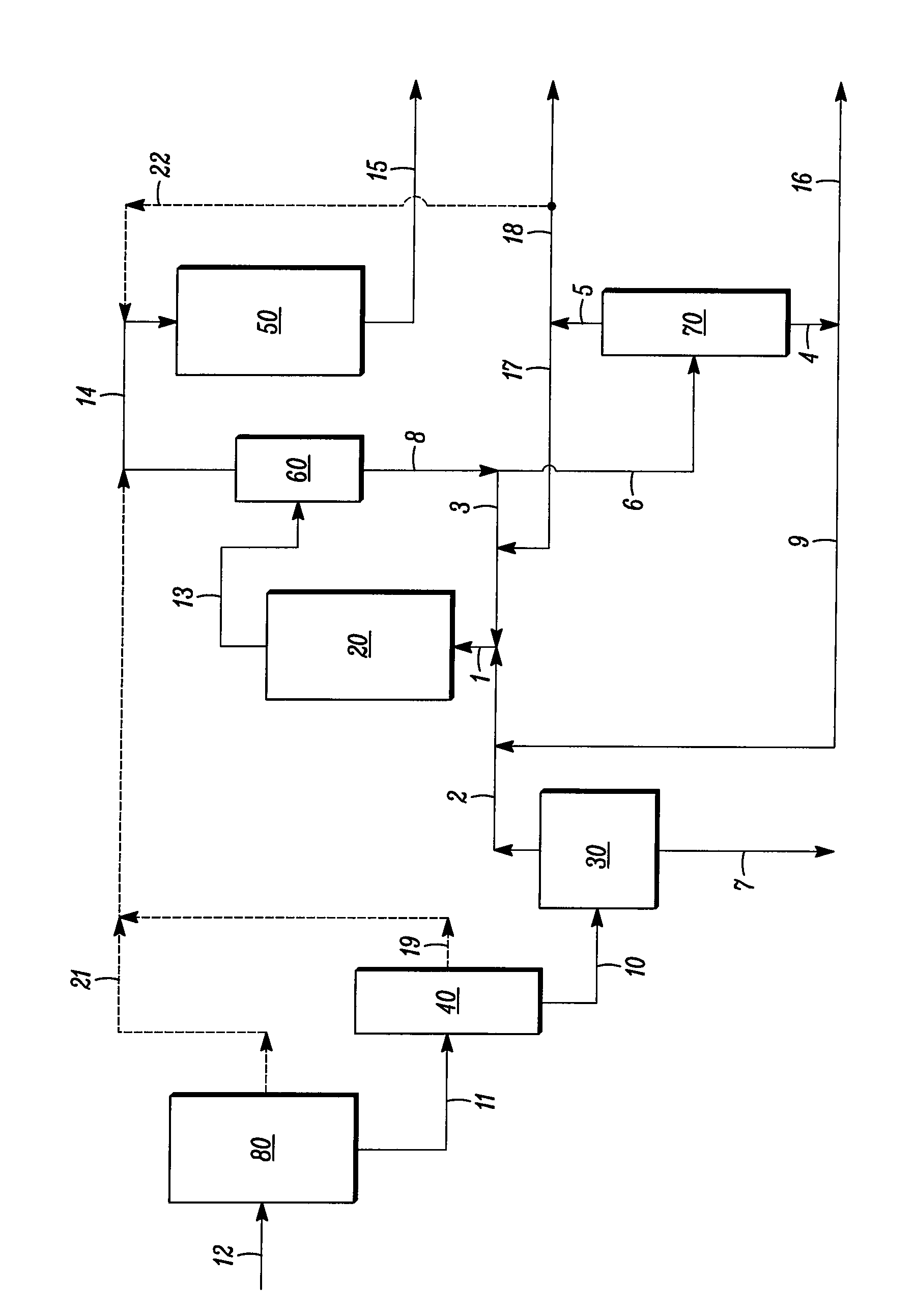

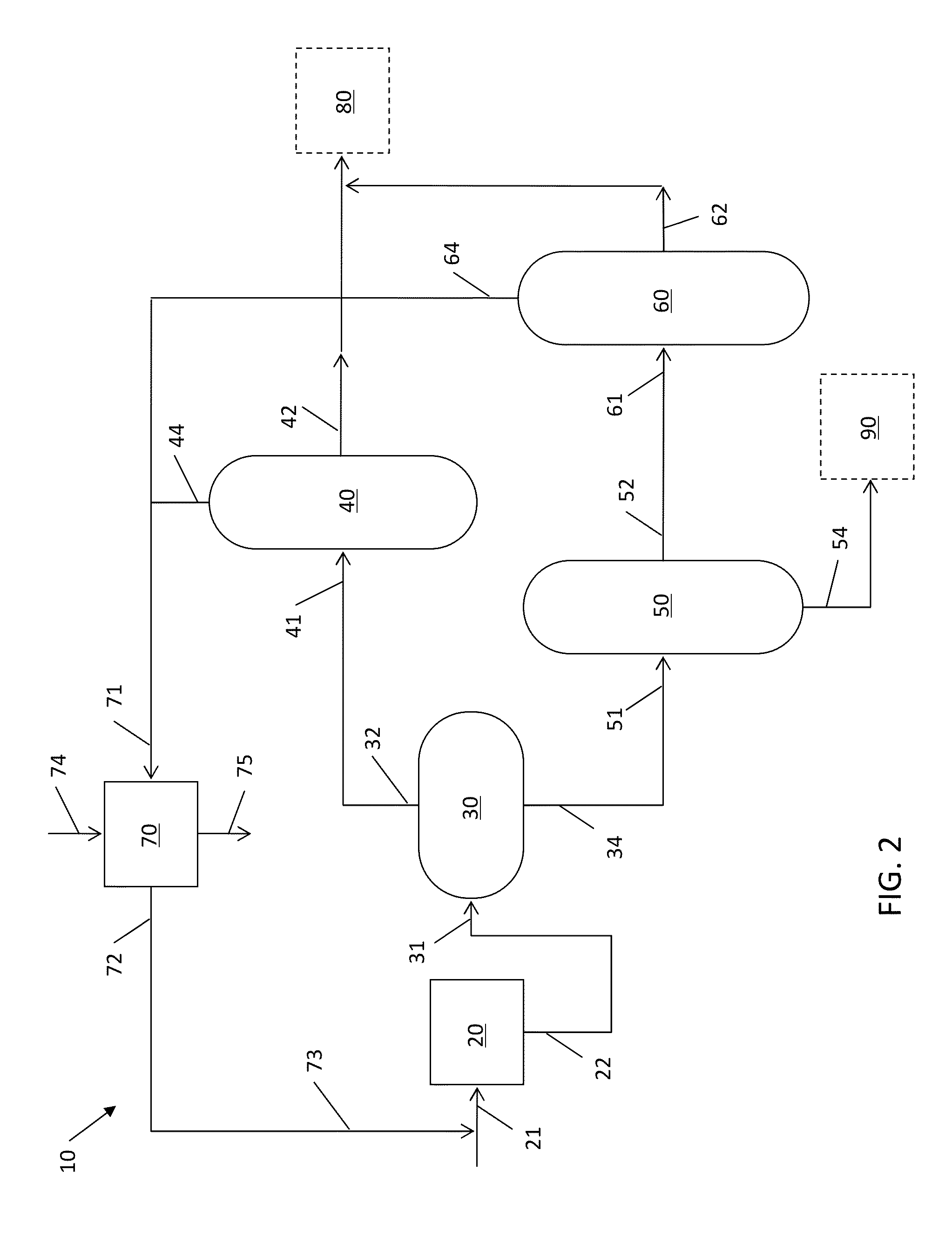

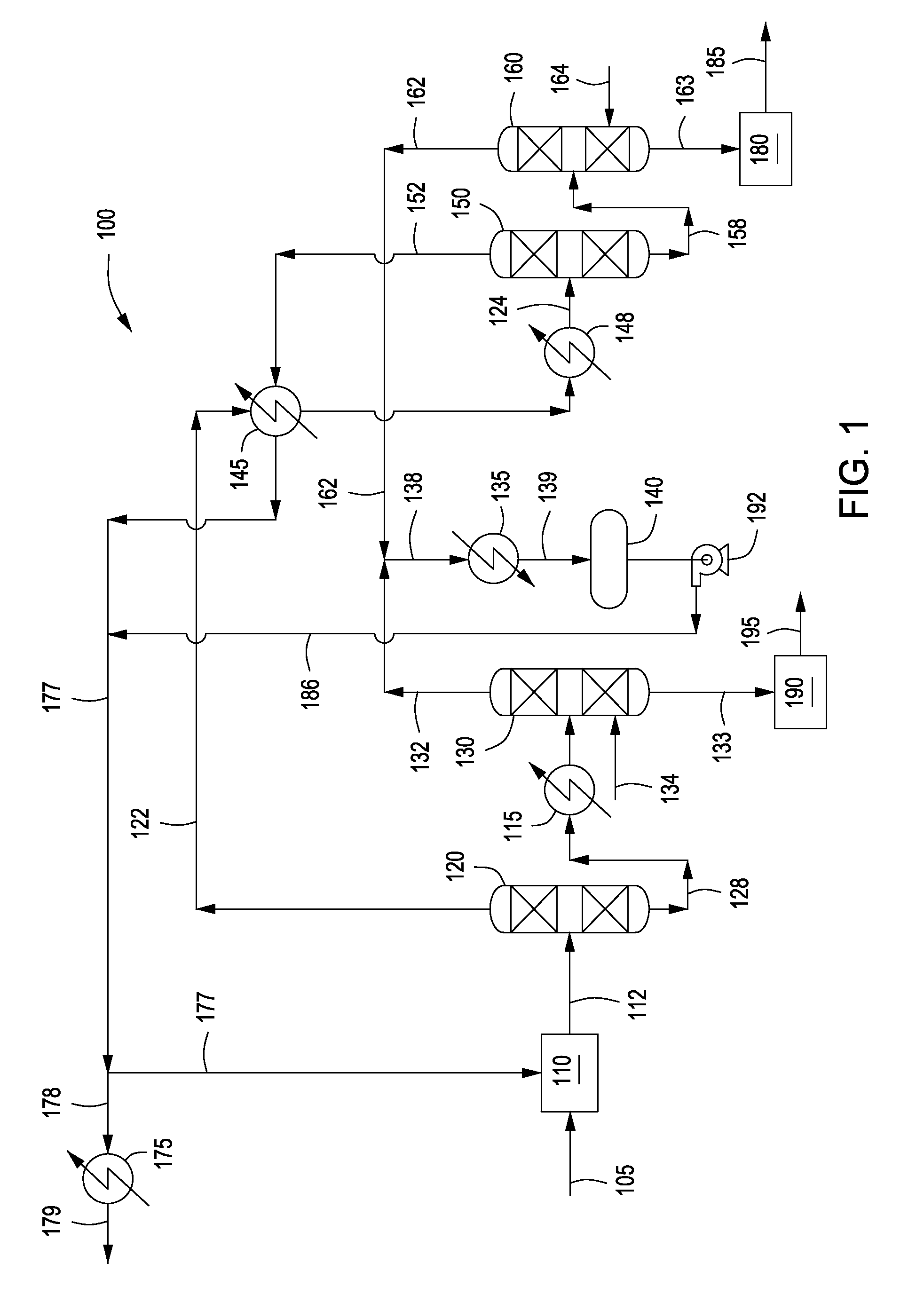

ActiveUS7749378B2Reduce capital investmentReduce operating expensesWorking-up pitch/asphalt/bitumen by selective extractionRefining by water treatmentDiluentWater fraction

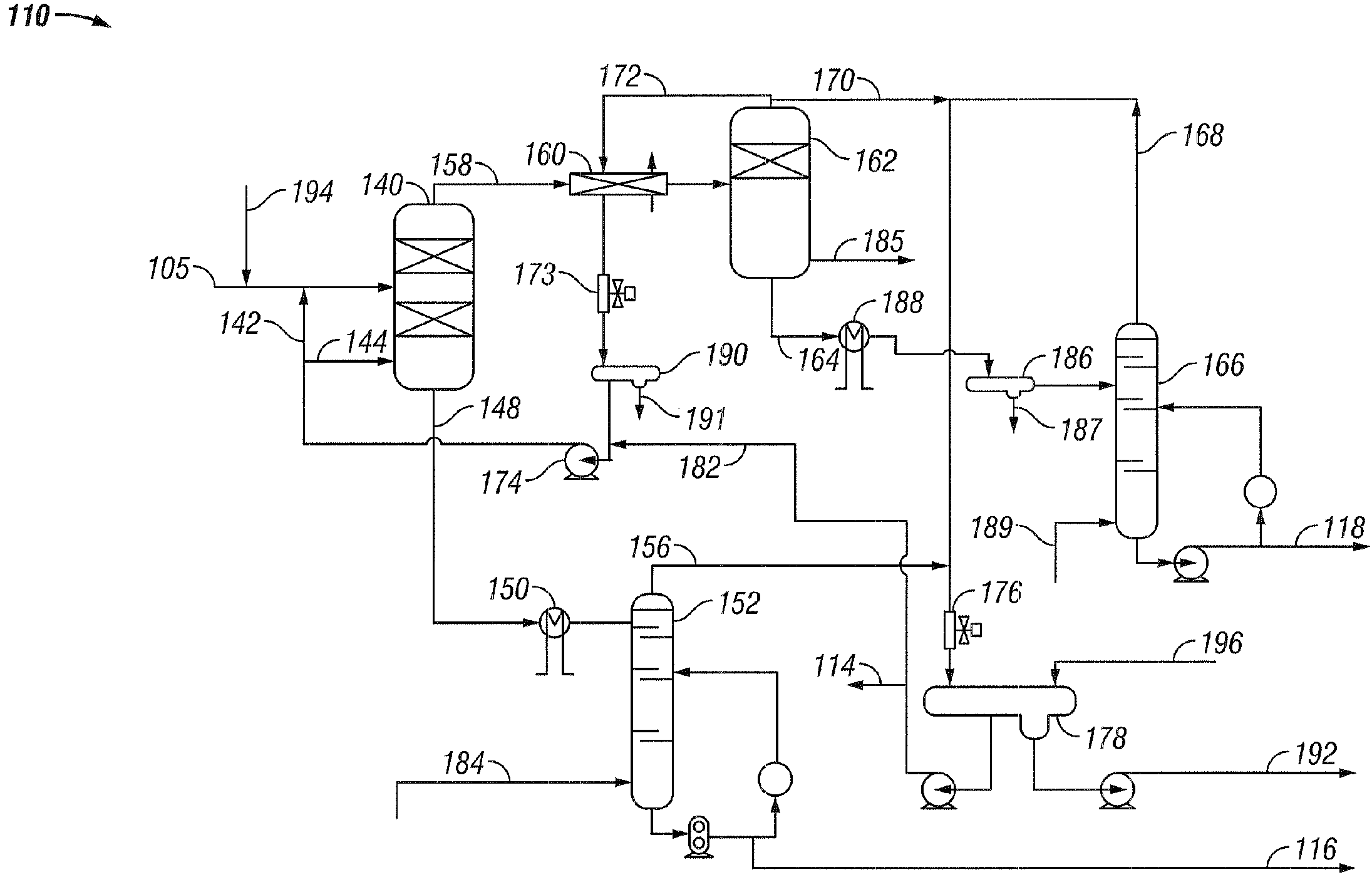

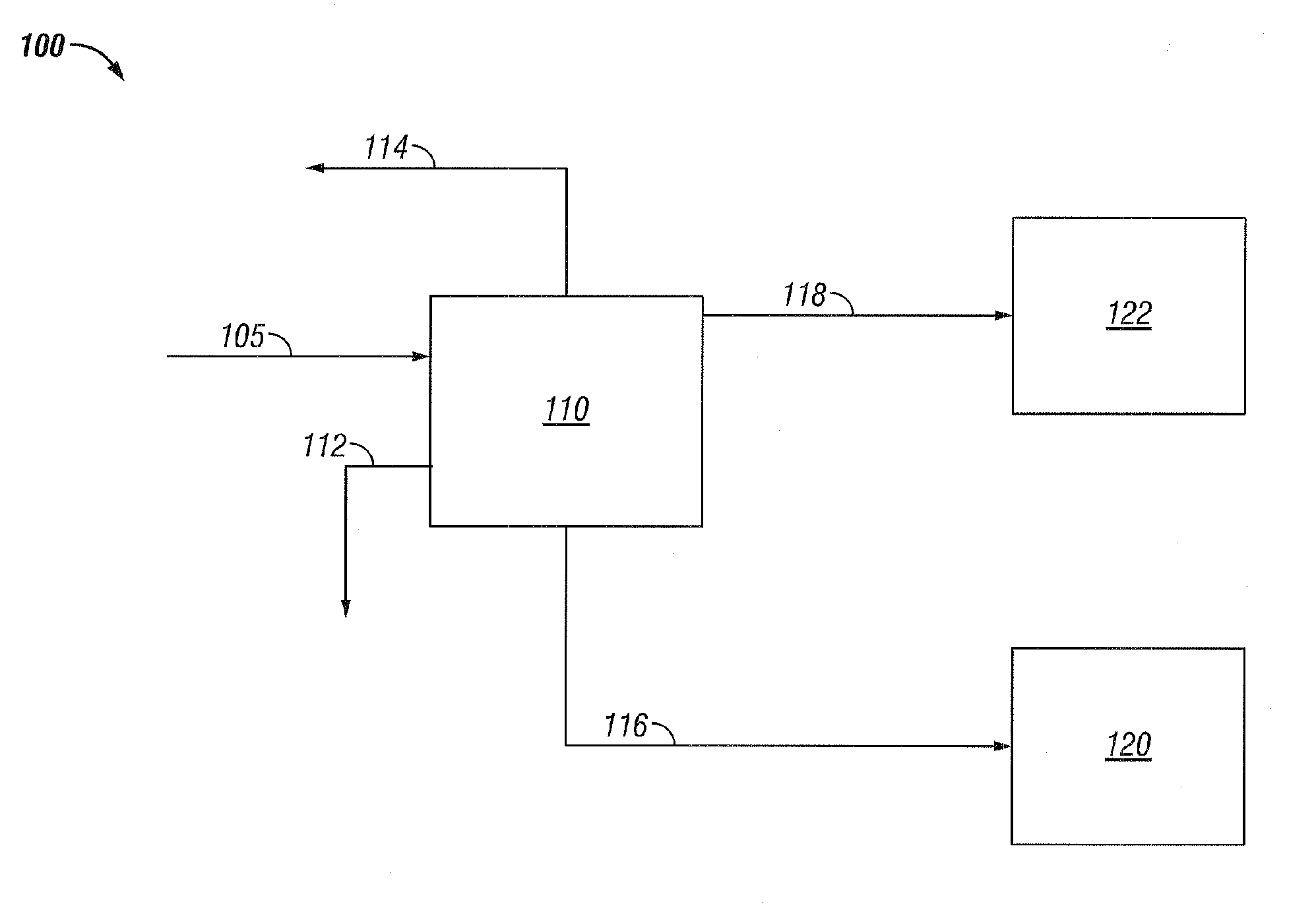

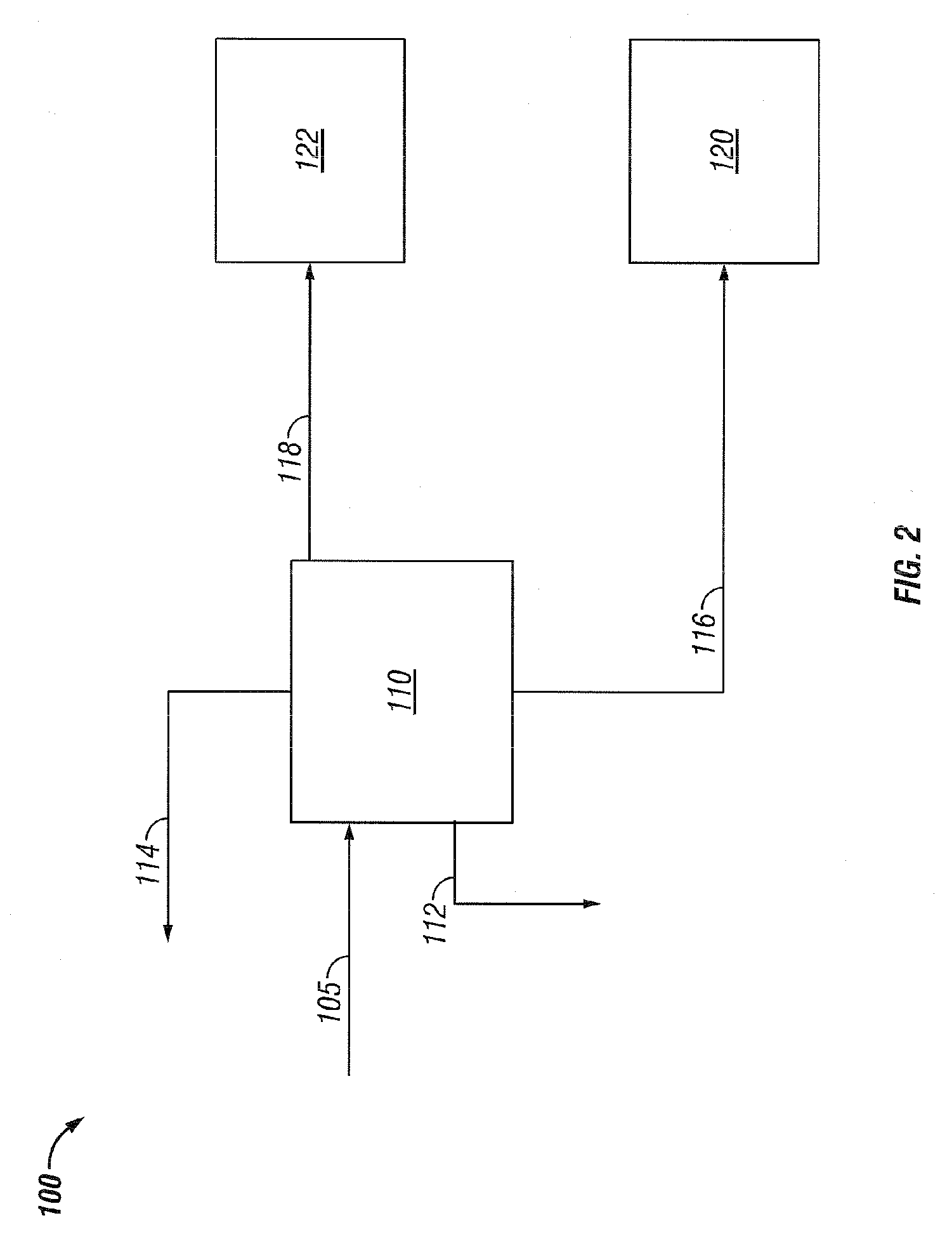

Disclosed is a process for the upgrading of heavy oils and bitumens, where the total feed to the process can include heavy oil or bitumen, water, and diluent. The process can include the steps of solvent deasphalting 110 the total feed 105 to recover an asphaltene fraction 116, a deasphalted oil fraction 118 essentially free of asphaltenes, a water fraction 112, and a solvent fraction 114. The process allows removal of salts from the heavy oils and bitumens either into the aqueous products or with the asphaltene product.

Owner:KELLOGG BROWN & ROOT LLC

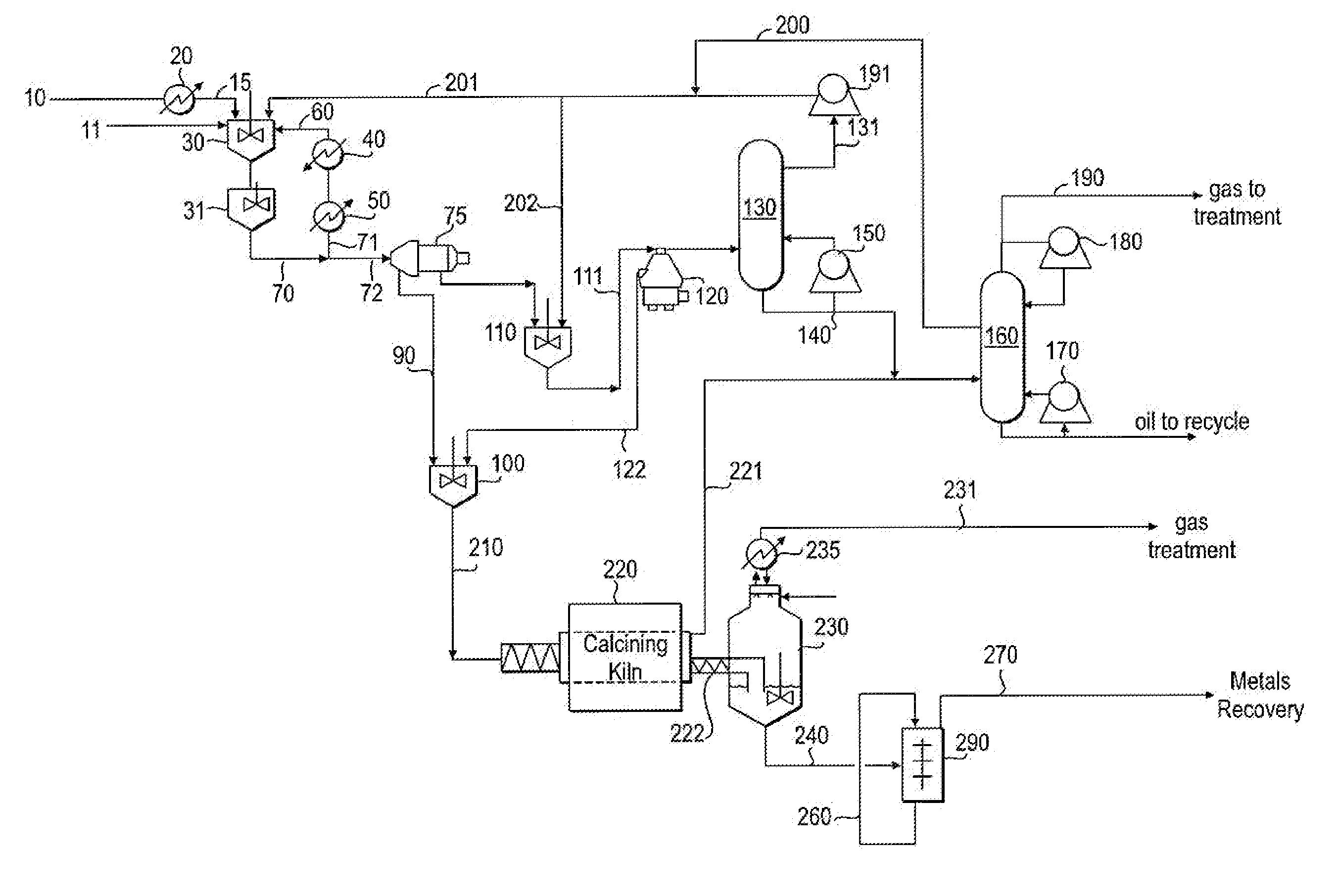

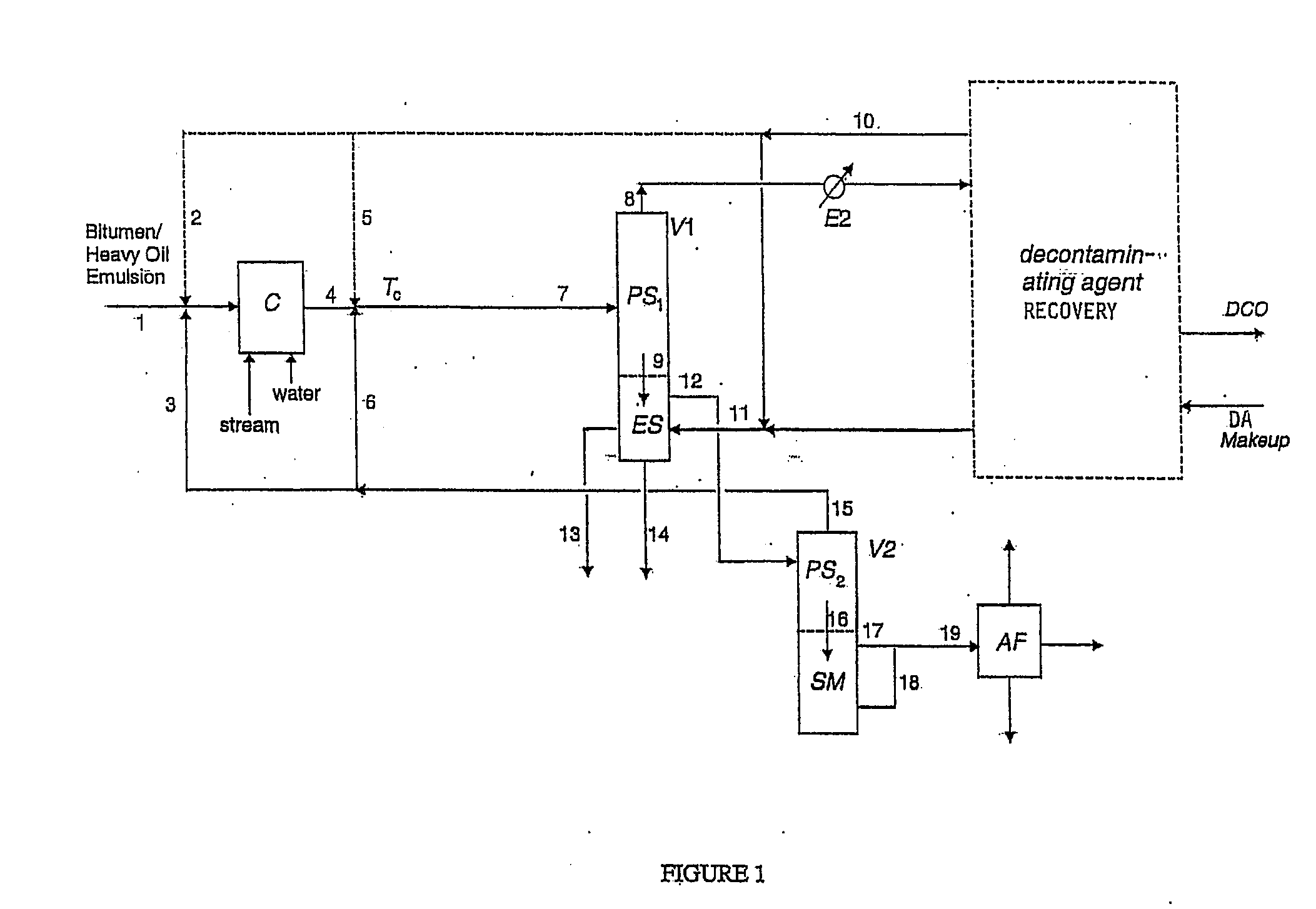

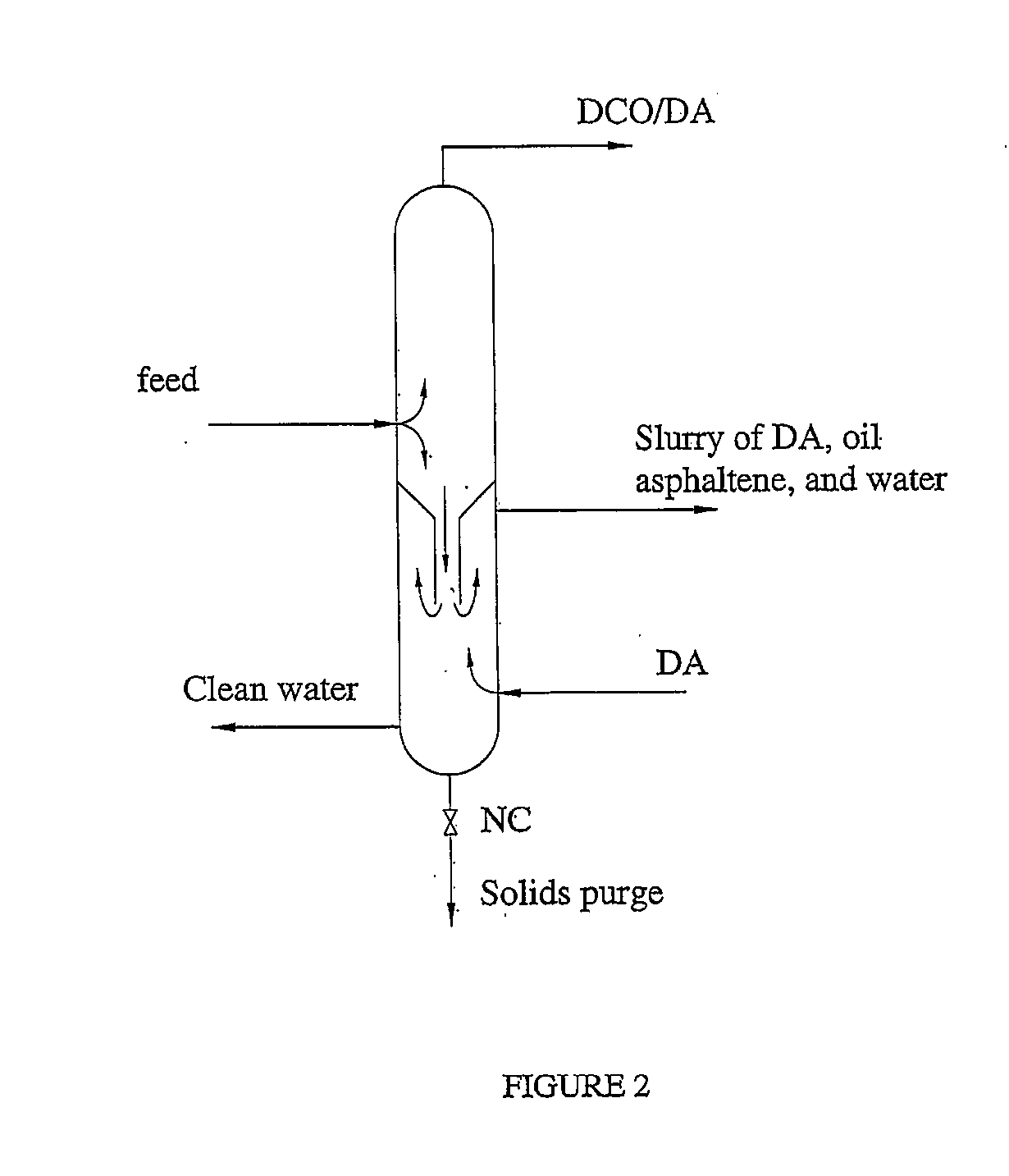

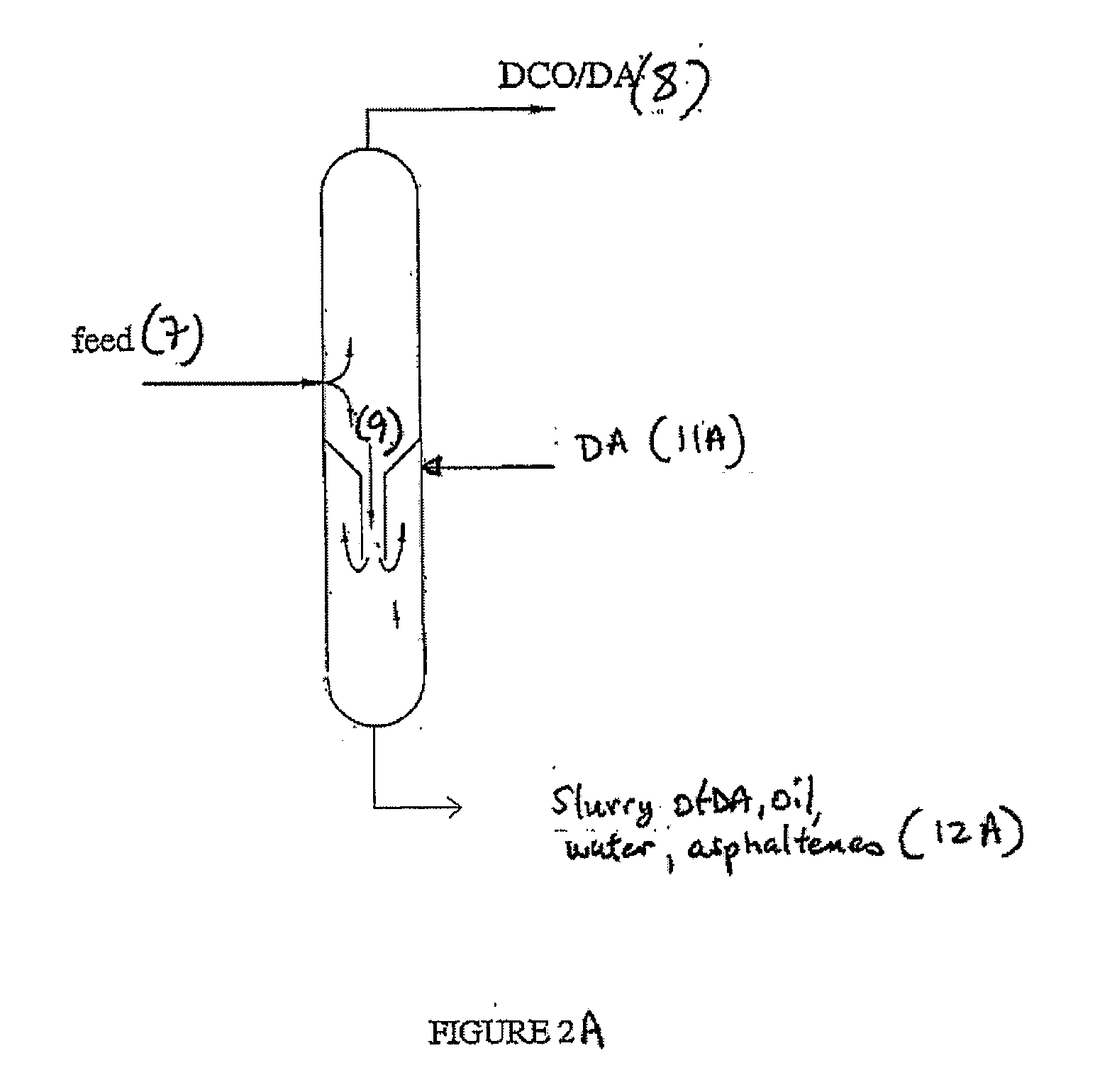

Decontamination of asphaltic heavy oil and bitumen

ActiveUS20060260980A1Distillation regulation/controlHydrocarbon distillationPetroleum productFuel oil

Owner:VALUE CREATION +1

Process for stabilization of heavy hydrocarbons

ActiveUS20130026074A1Prevent further sediment formationReduces sludge formationWorking-up pitch/asphalt/bitumen by selective extractionRefining by heating/coolingCarbon numberAlkane

A process for stabilization of heavy hydrocarbons to reduce sludge formation in storage tanks and / or transportation lines and to enhance the hydrocarbon yield includes mixing a paraffinic or heavy naphtha solvent having carbon numbers in the range 10 to 20 with the feedstock to solvent-flocculate a relatively small, predetermined portion of asphaltenes present in the feedstock, separating and flashing the sediment to recover a light hydrocarbon fraction, flashing the heavy hydrocarbon / solvent phase and recycling the solvent to stabilize the heavy hydrocarbons without significantly affecting the yield of valuable products.

Owner:SAUDI ARABIAN OIL CO

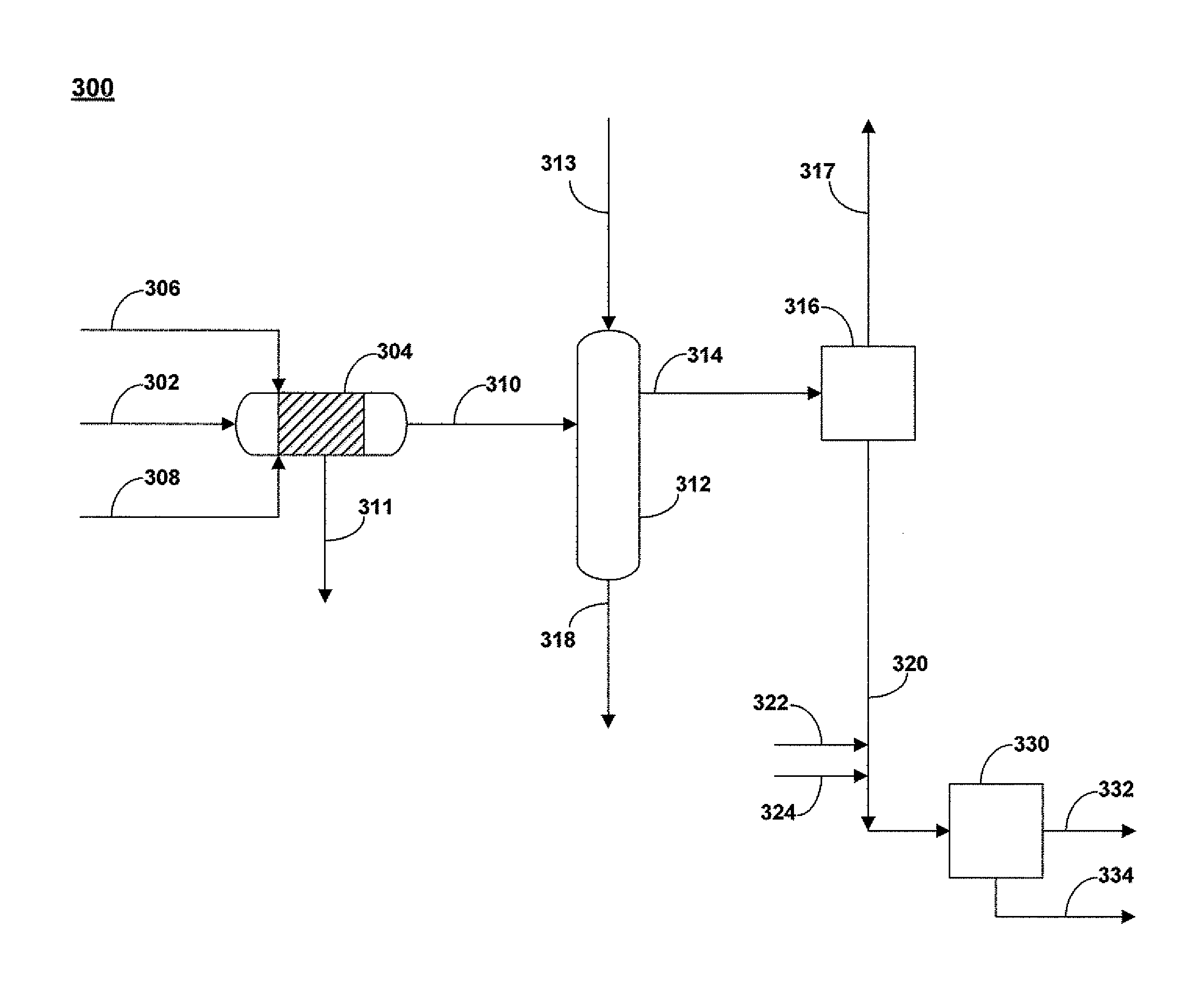

Process for Oxidative Desulfurization and Sulfone Disposal Using Solvent Deasphalting

ActiveUS20120055843A1High purityWorking-up pitch/asphalt/bitumen by selective extractionSulfur-dioxide/sulfurous-acidSulfurSolvent

A method and apparatus for upgrading a hydrocarbon feedstock is provided. The method includes the steps of (a) supplying a hydrocarbon feedstock to an oxidation reactor, wherein the hydrocarbon feedstock is oxidized in the presence of a catalyst under conditions sufficient to selectively oxidize sulfur compounds present in the hydrocarbon feedstock; (c) separating the hydrocarbons and the oxidized sulfur compounds by solvent extraction; (d) collecting a residue stream that includes the oxidized sulfur compounds; and (e) supplying the residue stream to a deasphalting unit.

Owner:SAUDI ARABIAN OIL CO

Process for treating a heavy hydrocarbon feedstock and a product obtained therefrom

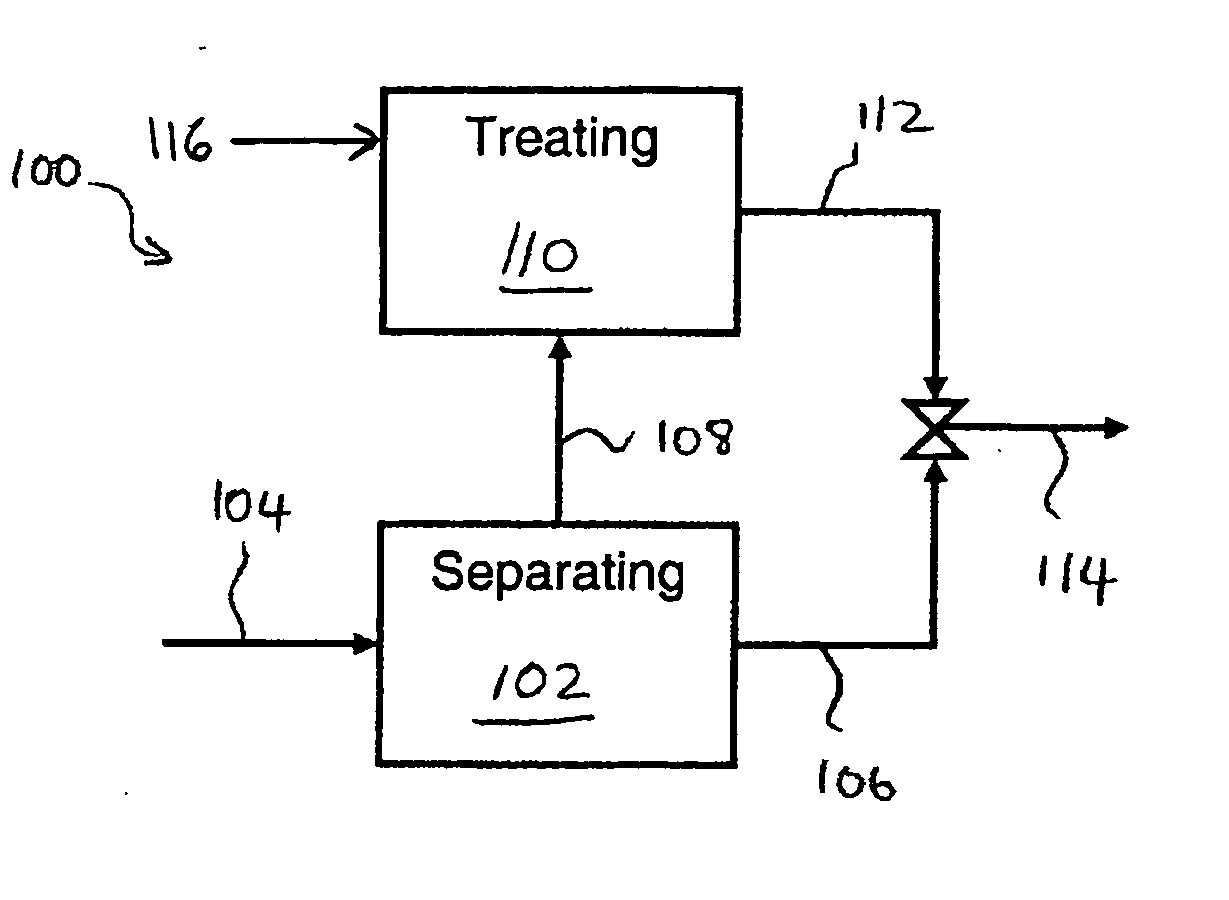

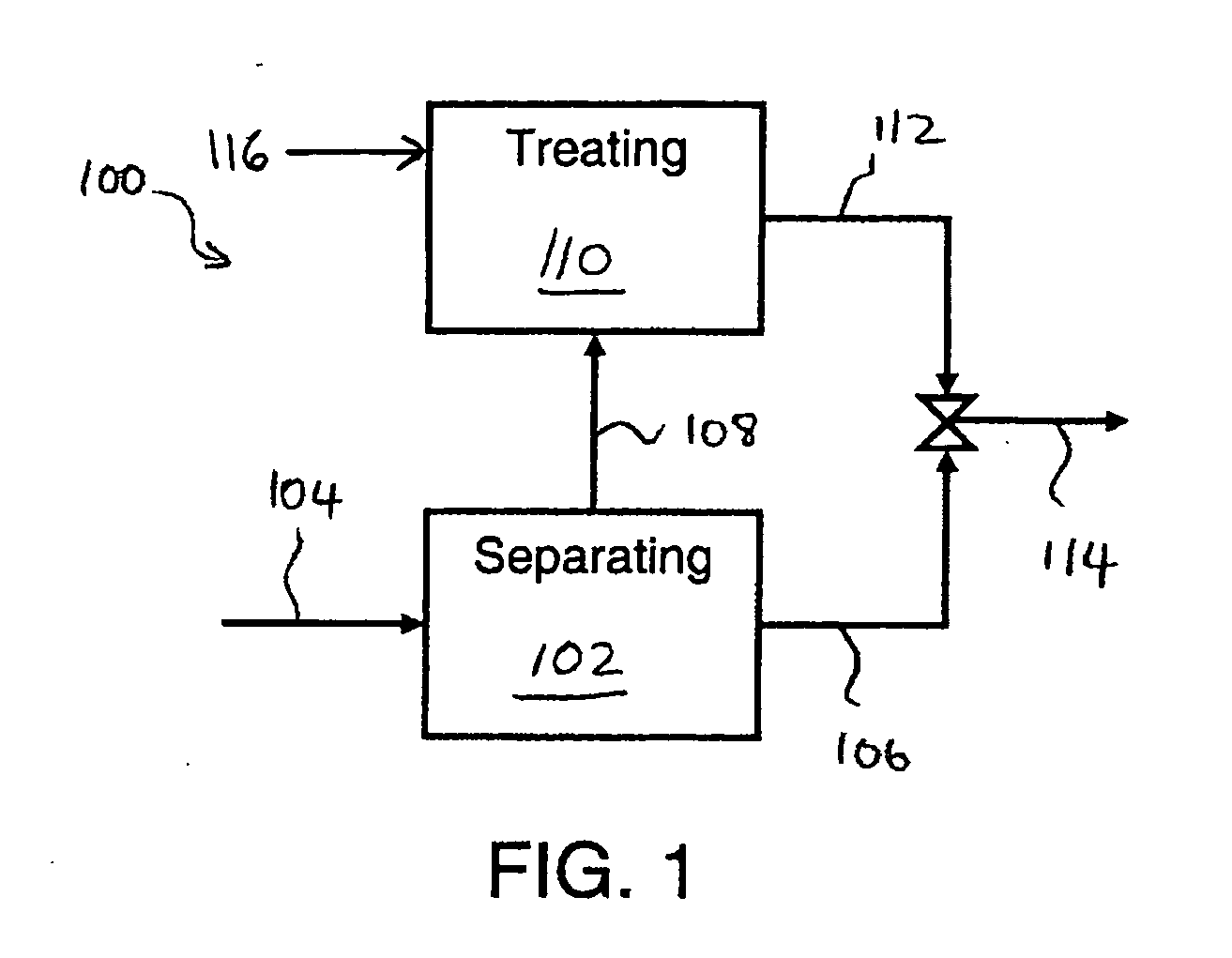

InactiveUS20070108098A1Thermal non-catalytic crackingCatalytic crackingAPI gravityPipeline transport

A process for treating a heavy hydrocarbon feedstock is disclosed. The process involves separating the feedstock into a residue component and a light component, the residue component having a lower API gravity than the light component and treating at least a portion of the light component to produce a synthetic transport diluent suitable for combining with at least a portion of the residue component to produce a product which meets applicable criteria for pipeline transport.

Owner:STATOIL CANADA

Composition of hydrocarbon fuel

Slurry hydrocracking a heavy hydrocarbon feed produces a HVGO stream and a pitch stream. At least a portion of the pitch stream is subjected to SDA to prepare a DAO stream low in metals. The DAO is blended with at least a portion of the HVGO stream to provide turbine or marine fuel with acceptable properties for combustion in gas turbines or for marine fuel grades.

Owner:UOP LLC

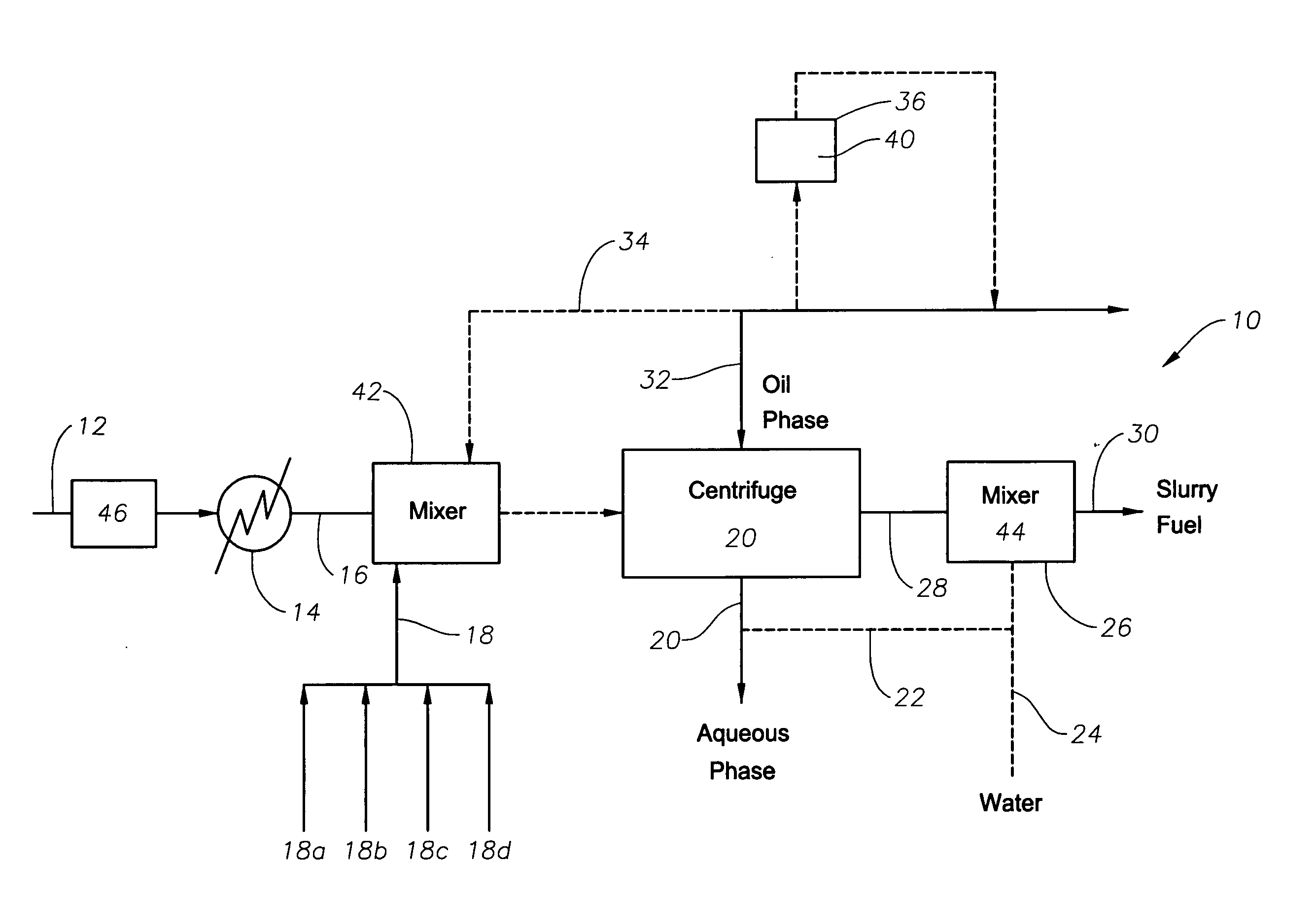

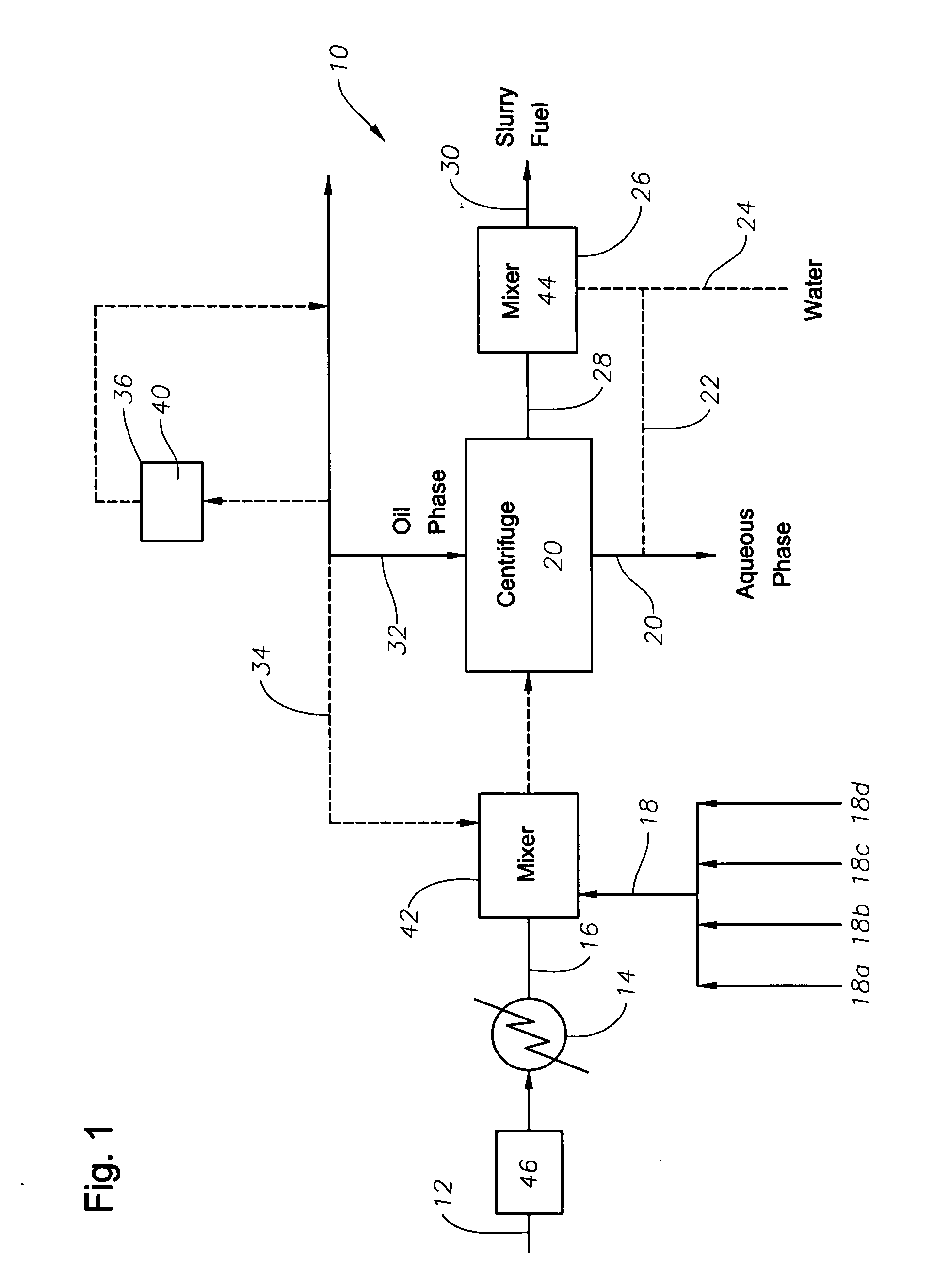

Method for utilizing hydrocarbon waste materials as fuel and feedstock

ActiveUS20060070912A1Low costDewatering/demulsification with mechanical meansRefining by heating/coolingFiberCarbon fibers

The fuel properties of petroleum hydrocarbon waste having an API gravity varying from about 5 to 30 are improved by heating the hydrocarbon to a temperature of about 35° C. to 90° C. and mixing the heated hydrocarbon stream with a suitable solvent to reduce the viscosity of the hydrocarbon, which is then separated by a centrifuge to obtain an aqueous phase stream, an oil phase stream, and a separated solids stream. The oil phase stream has a viscosity range of about 250 centipoise (cP) to about 1000 cP. The oil phase stream is utilized in a refinery, while a slurry fuel is prepared with the separated solids stream and aqueous phase stream as a feedstock for road asphalt, a fuel for a combustor, or a fuel for a gasification process. The oil phase stream is used for fuels and feedstock for making carbon fiber.

Owner:SAUDI ARABIAN OIL CO

Bitumen Production-Upgrade with Common or Different Solvents

ActiveUS20060283776A1Reduce operating expensesOperational reliability is increasedWorking-up pitch/asphalt/bitumen by selective extractionRefining by water treatmentDiluentFuel oil

Disclosed is a process for the upgrading of heavy oils and bitumens, where the total feed to the process can include heavy oil or bitumen, water, and diluent. The process can include the steps of solvent deasphalting 110 the total feed 105 to recover an asphaltene fraction 116, a deasphalted oil fraction 118 essentially free of asphaltenes, a water fraction 112, and a solvent fraction 114. The process allows removal of salts from the heavy oils and bitumens either into the aqueous products or with the asphaltene product.

Owner:KELLOGG BROWN & ROOT LLC

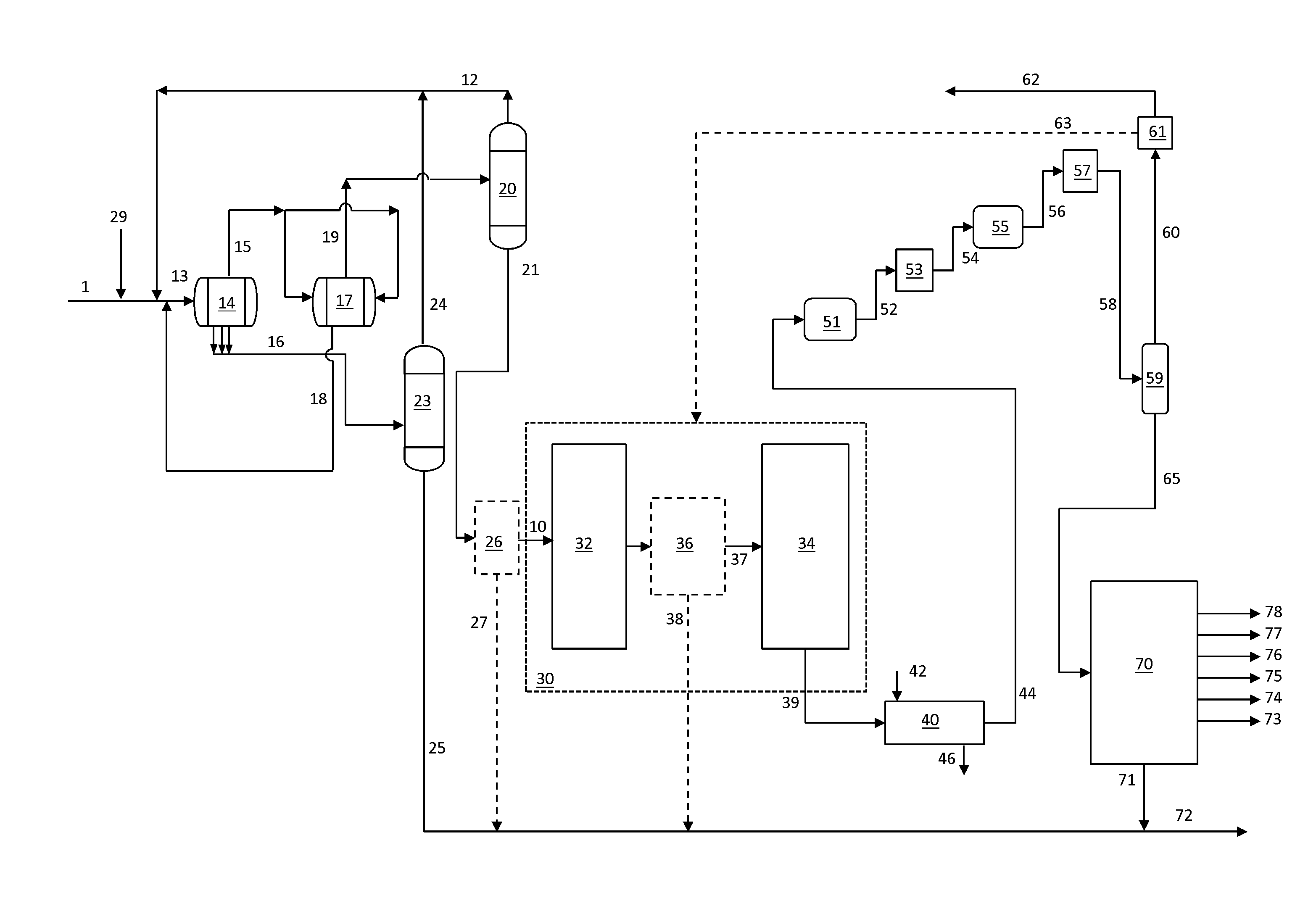

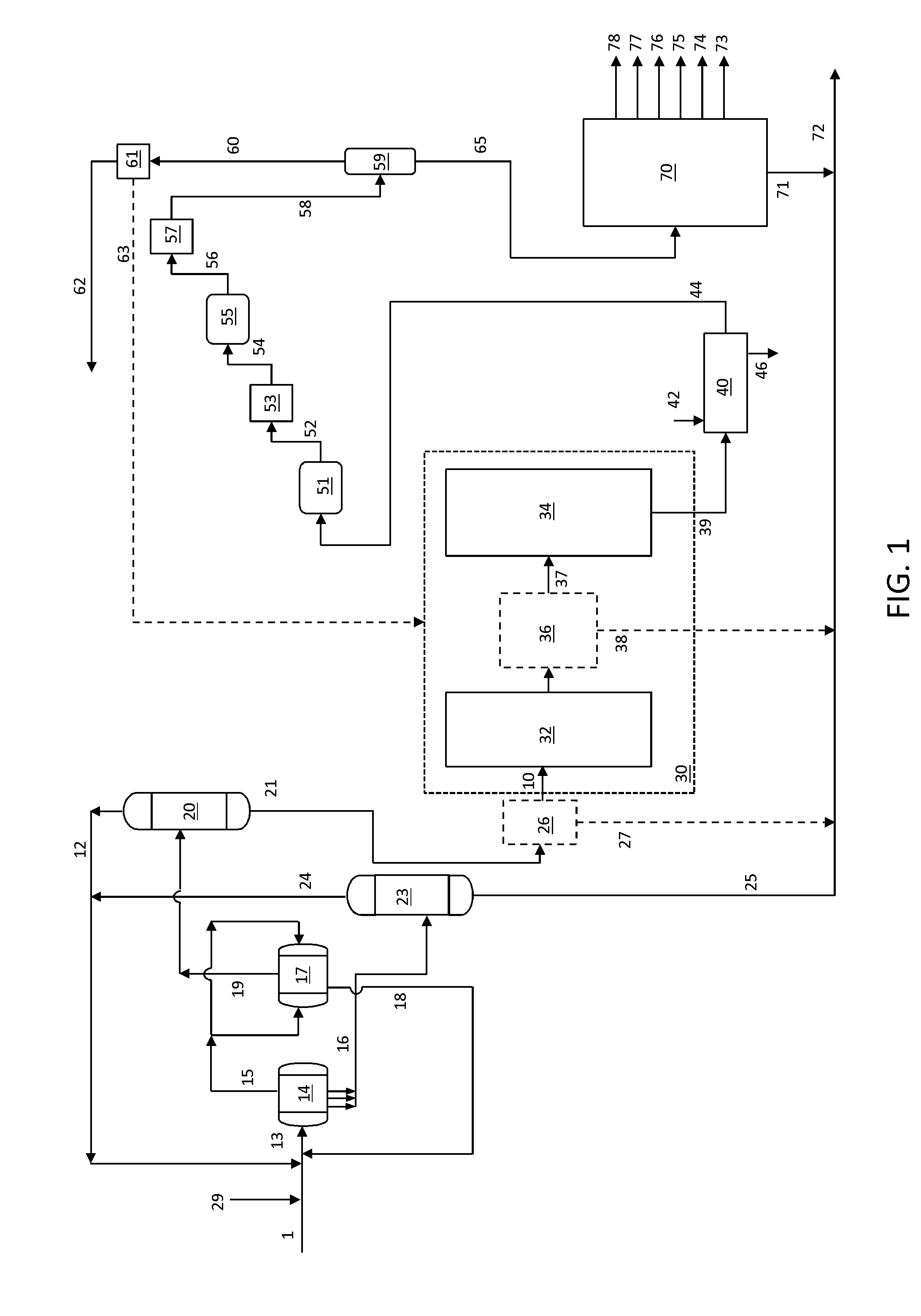

Residue conversion process that includes a deasphalting stage and a hydroconversion stage with recycling of deasphalted oil

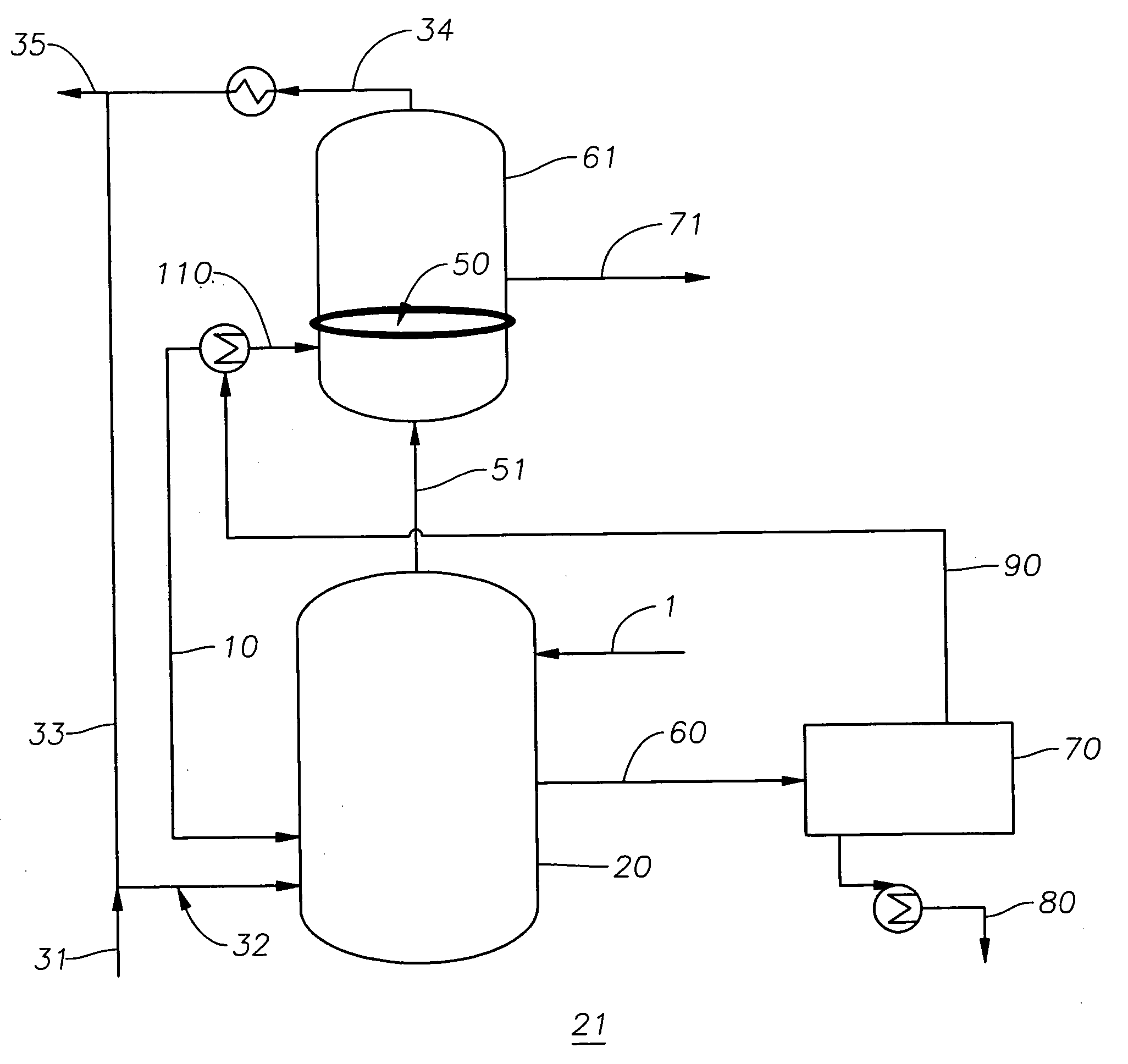

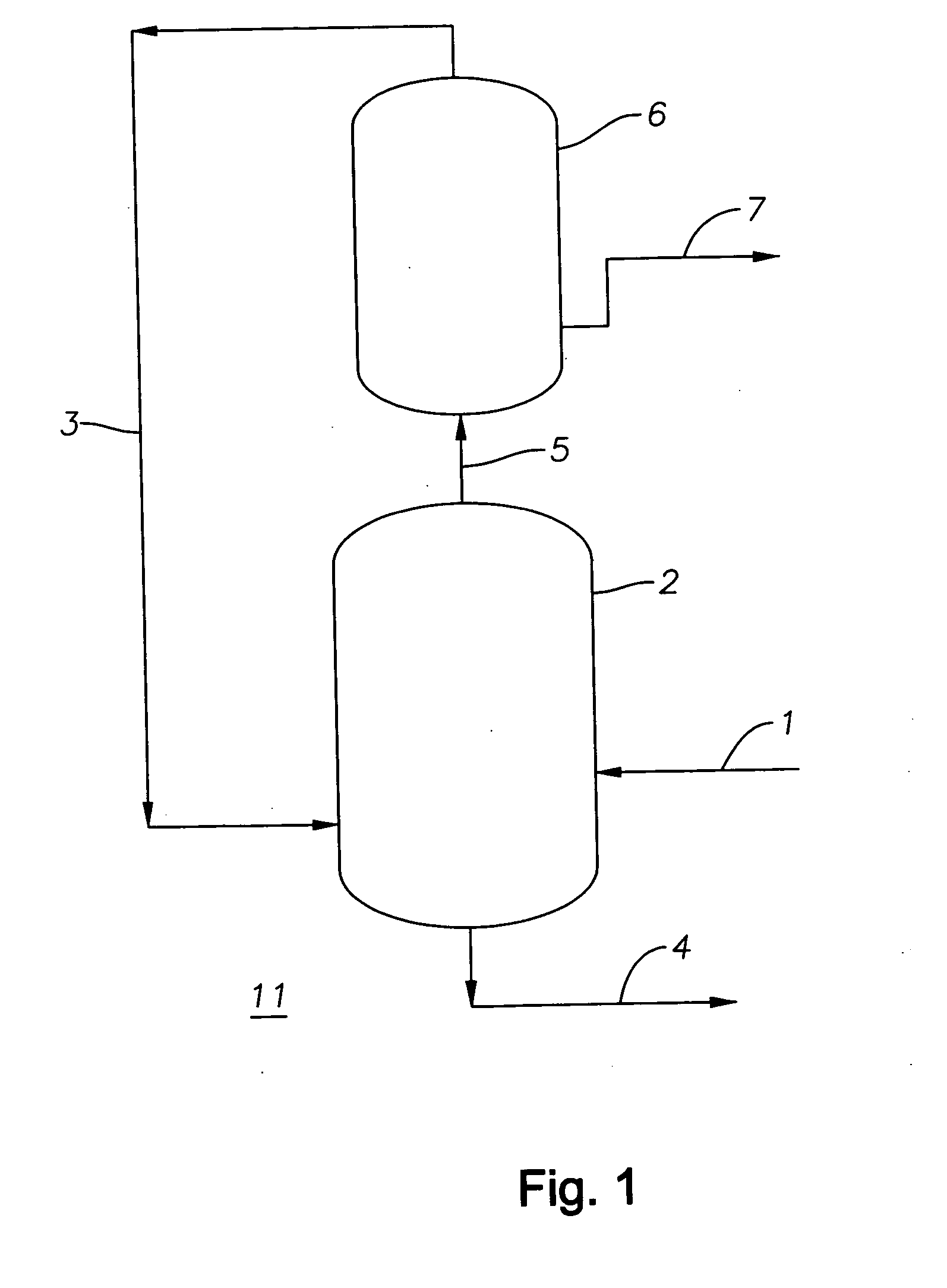

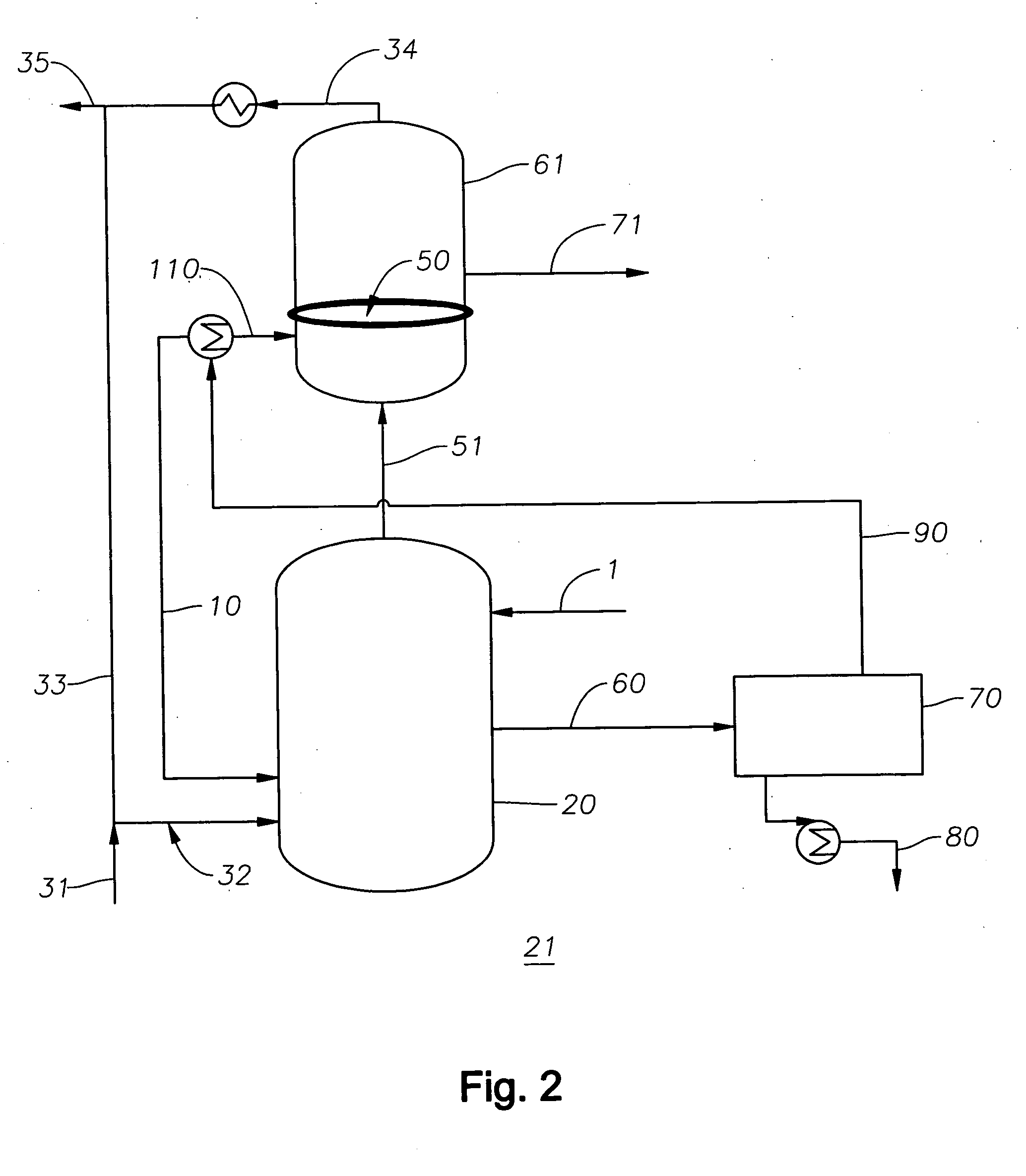

ActiveUS20120061292A1Improve product qualitySimple and economical processTreatment with hydrotreatment processesMetal/metal-oxides/metal-hydroxide catalystsBoiling pointThree-phase

Owner:INST FR DU PETROLE

Integrated hydrotreating, solvent deasphalting and steam pyrolysis process for direct processing of a crude oil

ActiveUS9382486B2Thermal non-catalytic crackingTreatment with plural serial stages onlySteam pyrolysisFuel oil

A process is provided that is directed to a steam pyrolysis zone integrated with a hydrotreating zone and a solvent deasphalting zone to permit direct processing of crude oil feedstocks to produce petrochemicals including olefins and aromatics. The integrated hydrotreating, solvent deasphalting and steam pyrolysis process comprises charging the crude oil to a hydroprocessing zone to produce a hydroprocessed effluent; charging the hydroprocessed effluent to a solvent deasphalting zone to produce a deasphalted and demetalized oil stream and a bottom asphalt phase; thermally cracking the deasphalted and demetalized oil stream in the presence of steam to produce a mixed product stream; separating the mixed product stream; purifying hydrogen recovered from the mixed product stream and recycling it to the hydroprocessing zone; recovering olefins and aromatics from the separated mixed product stream; and recovering pyrolysis fuel oil from the separated mixed product stream.

Owner:SAUDI ARABIAN OIL CO

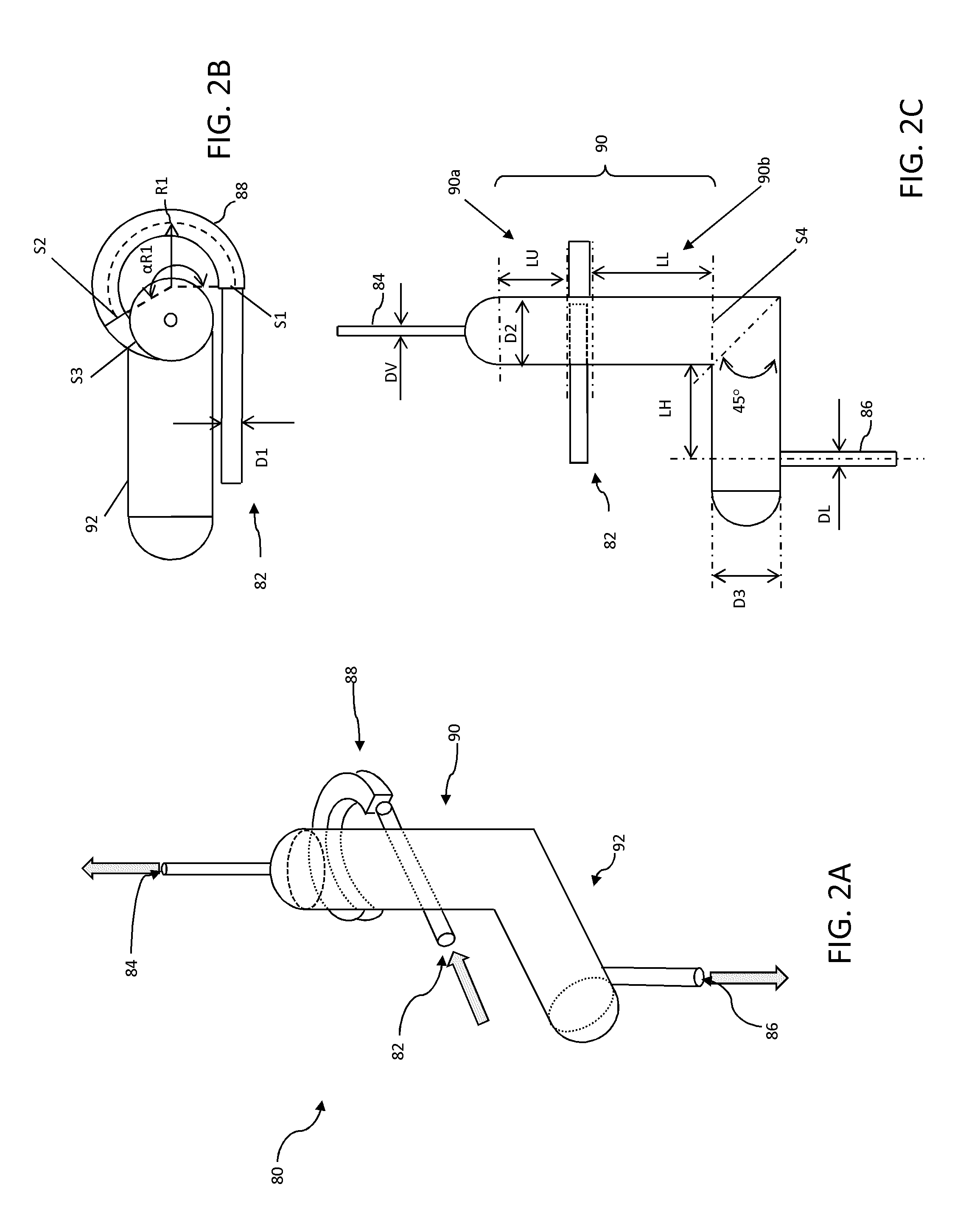

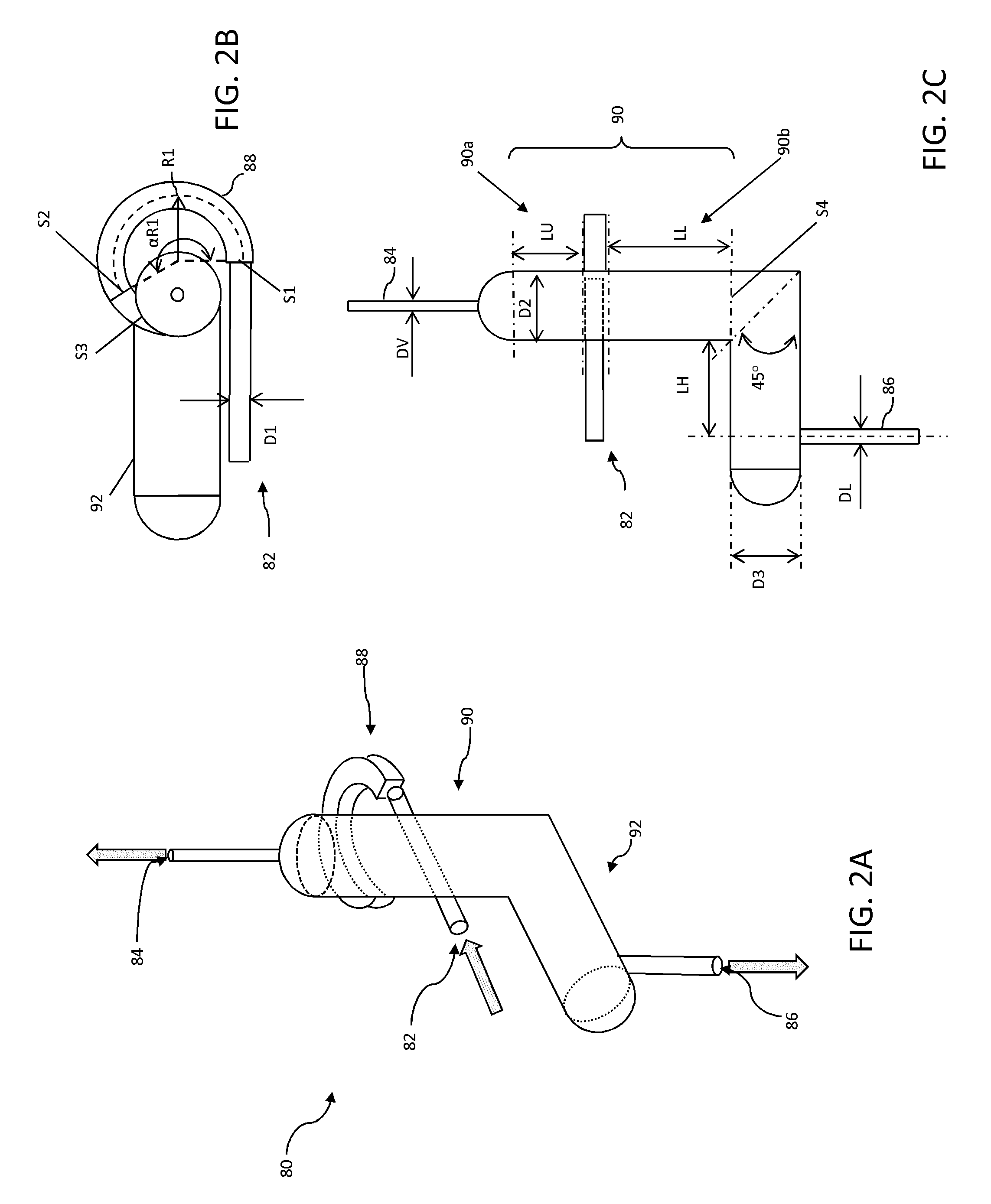

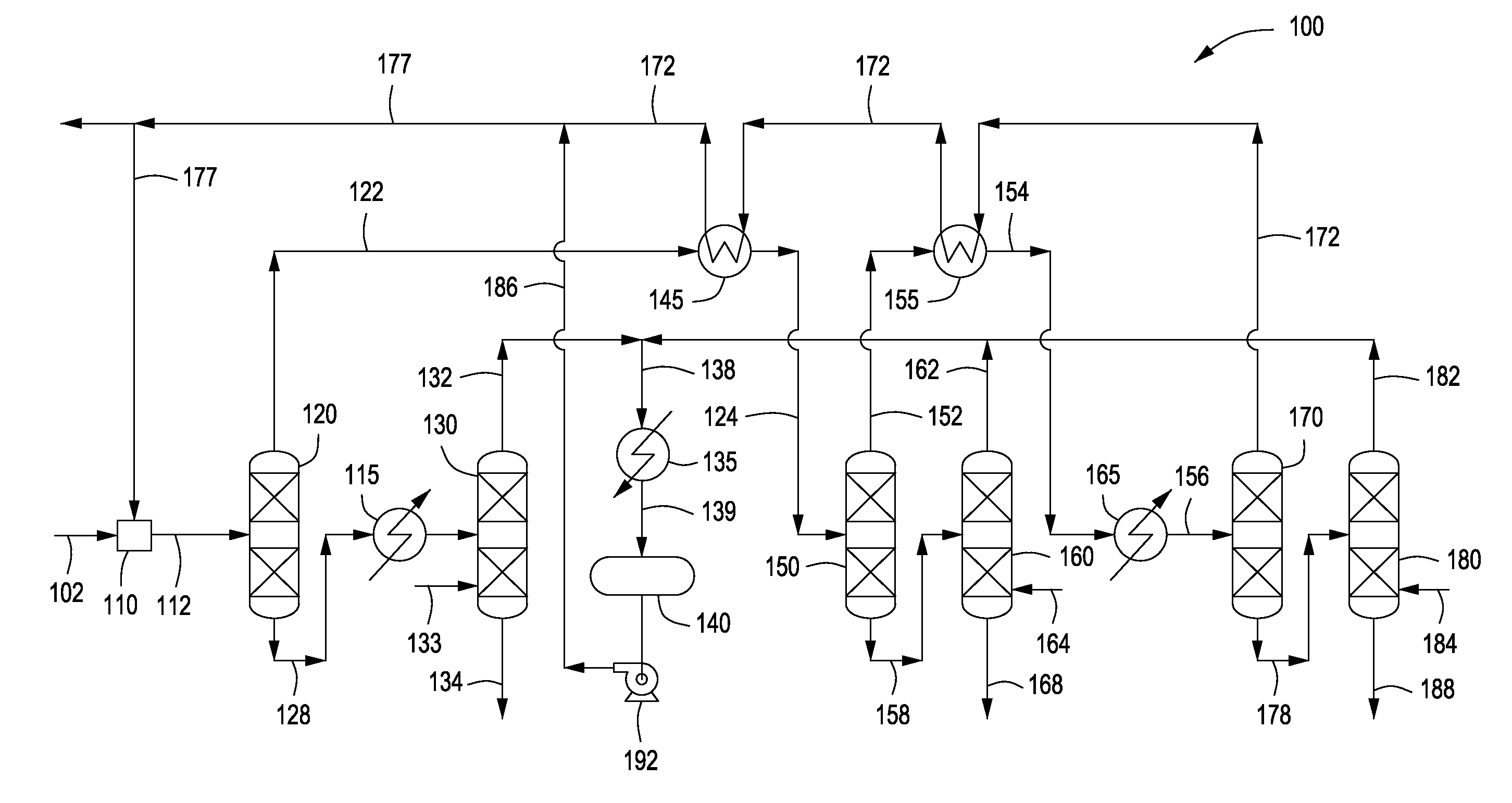

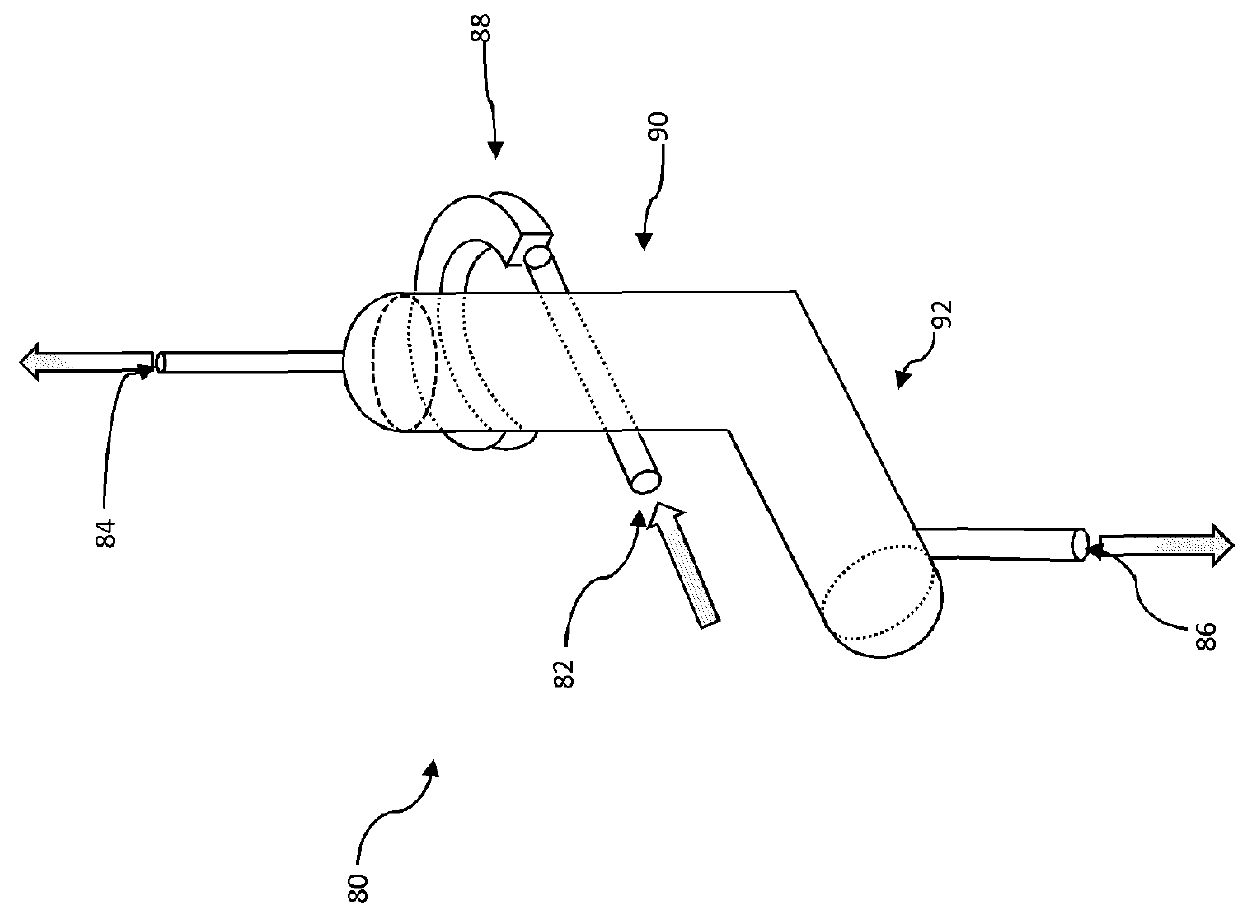

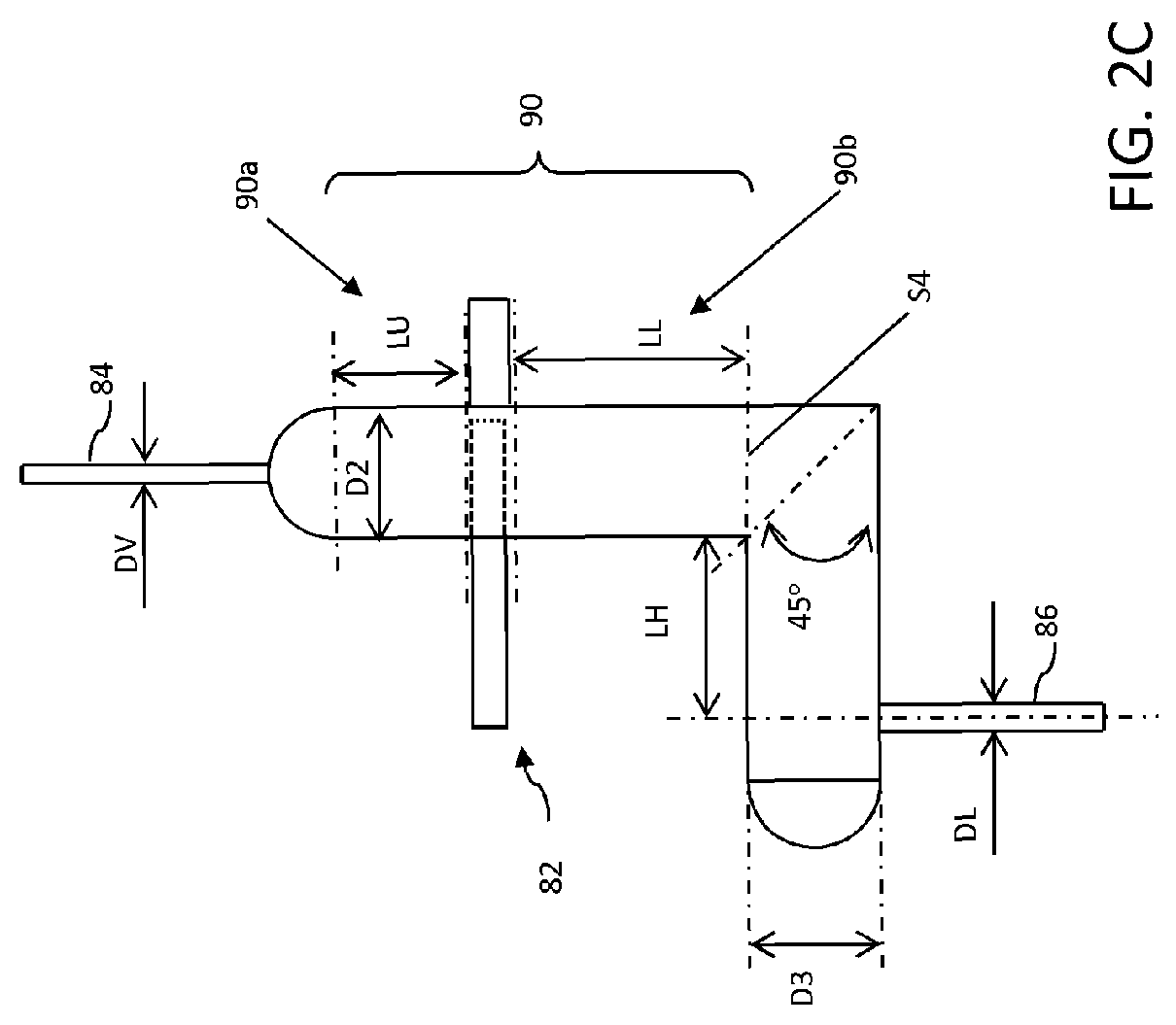

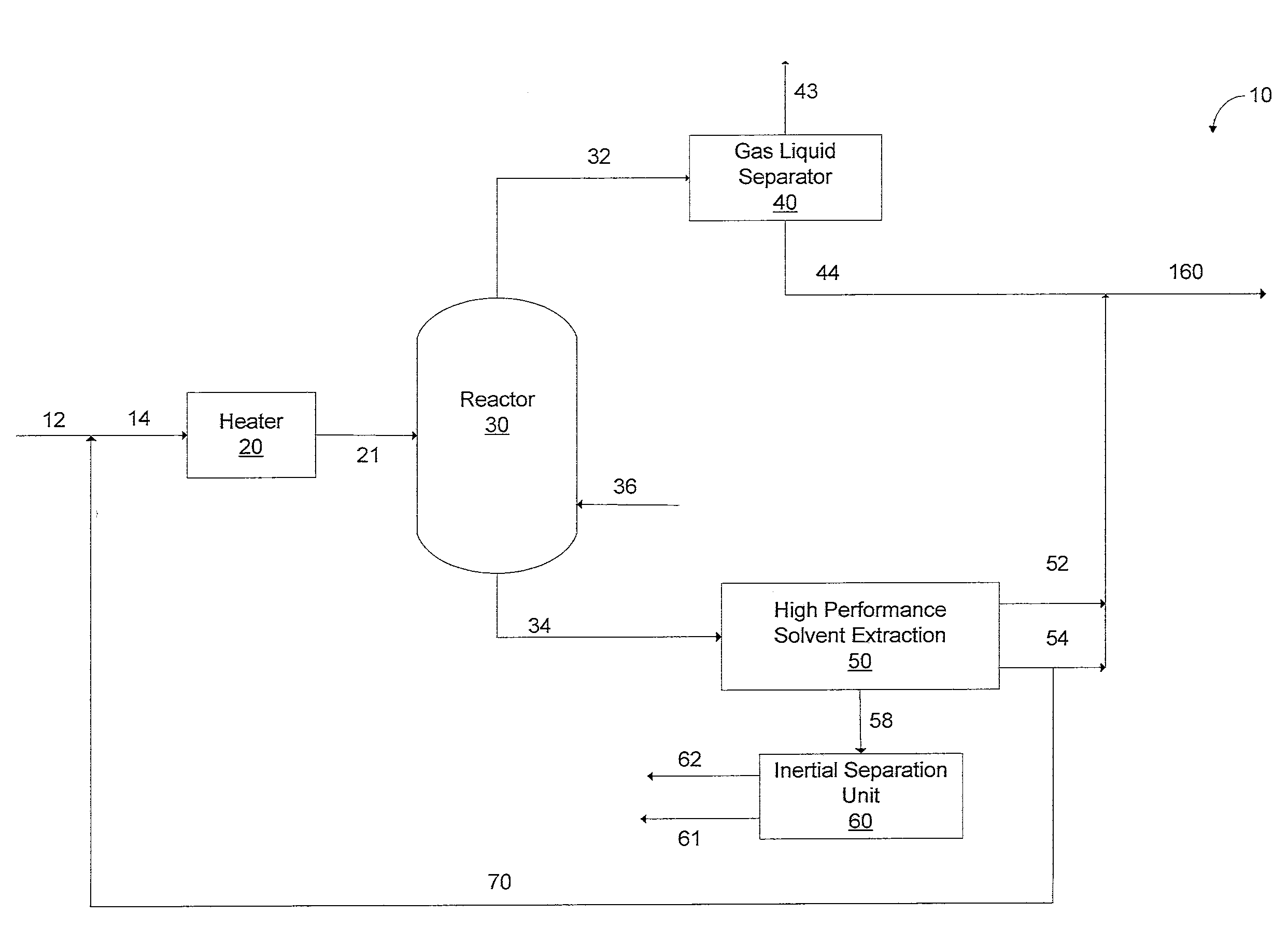

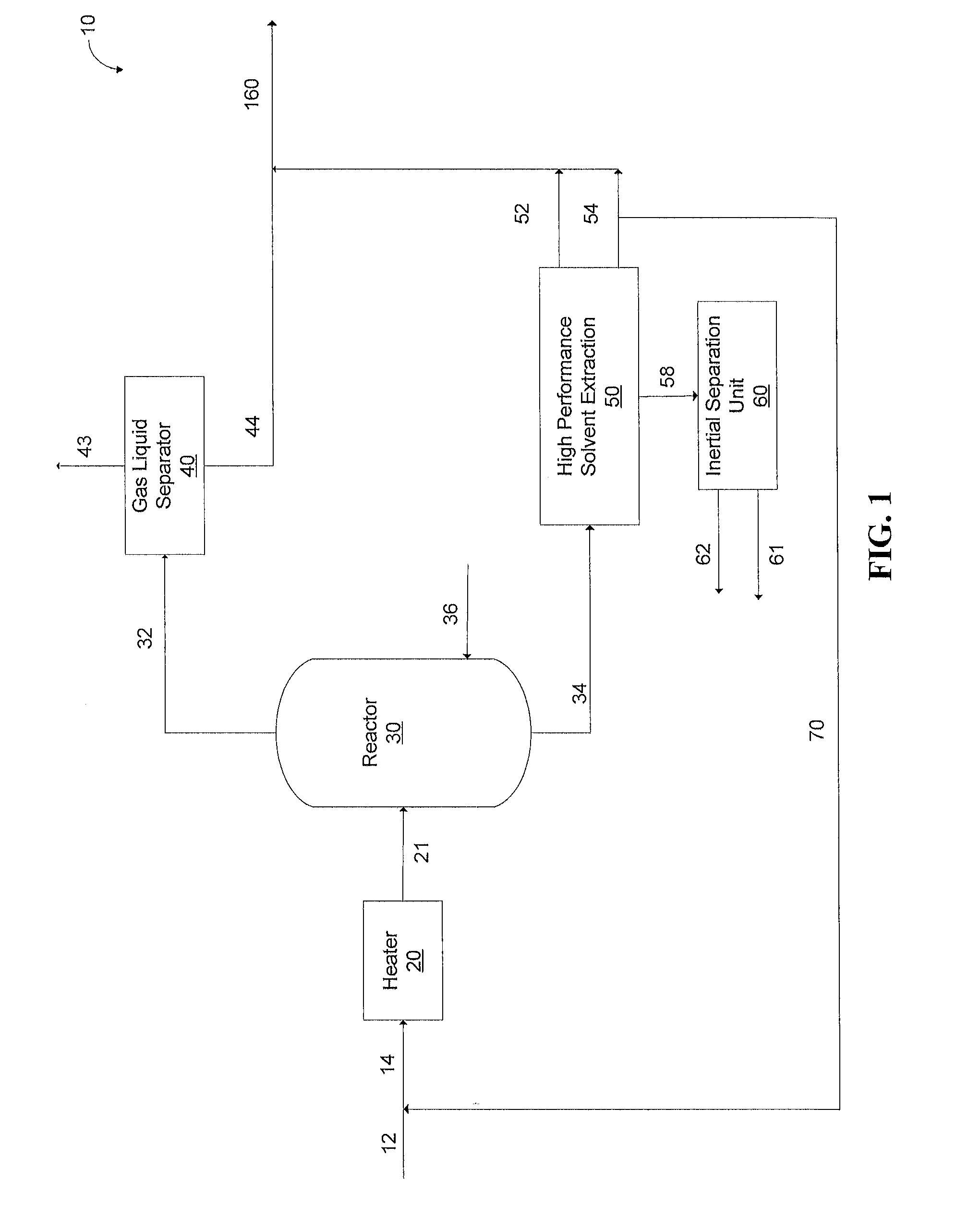

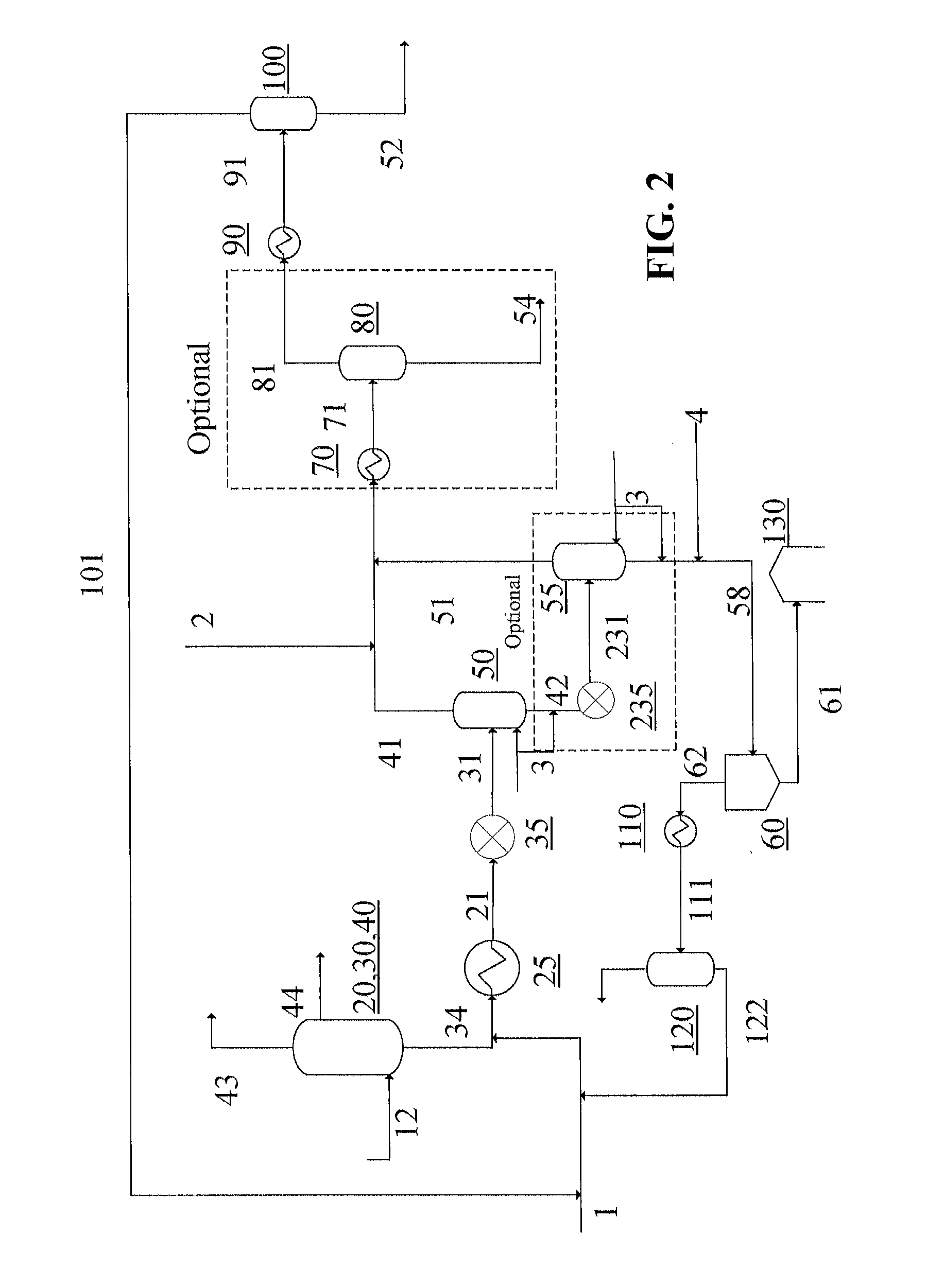

Low complexity, high yield conversion of heavy hydrocarbons

ActiveUS20130180888A1Assist in removingImproved solvent-extraction performanceWorking-up pitch/asphalt/bitumen by distillationThermal non-catalytic crackingSolventAsphaltene

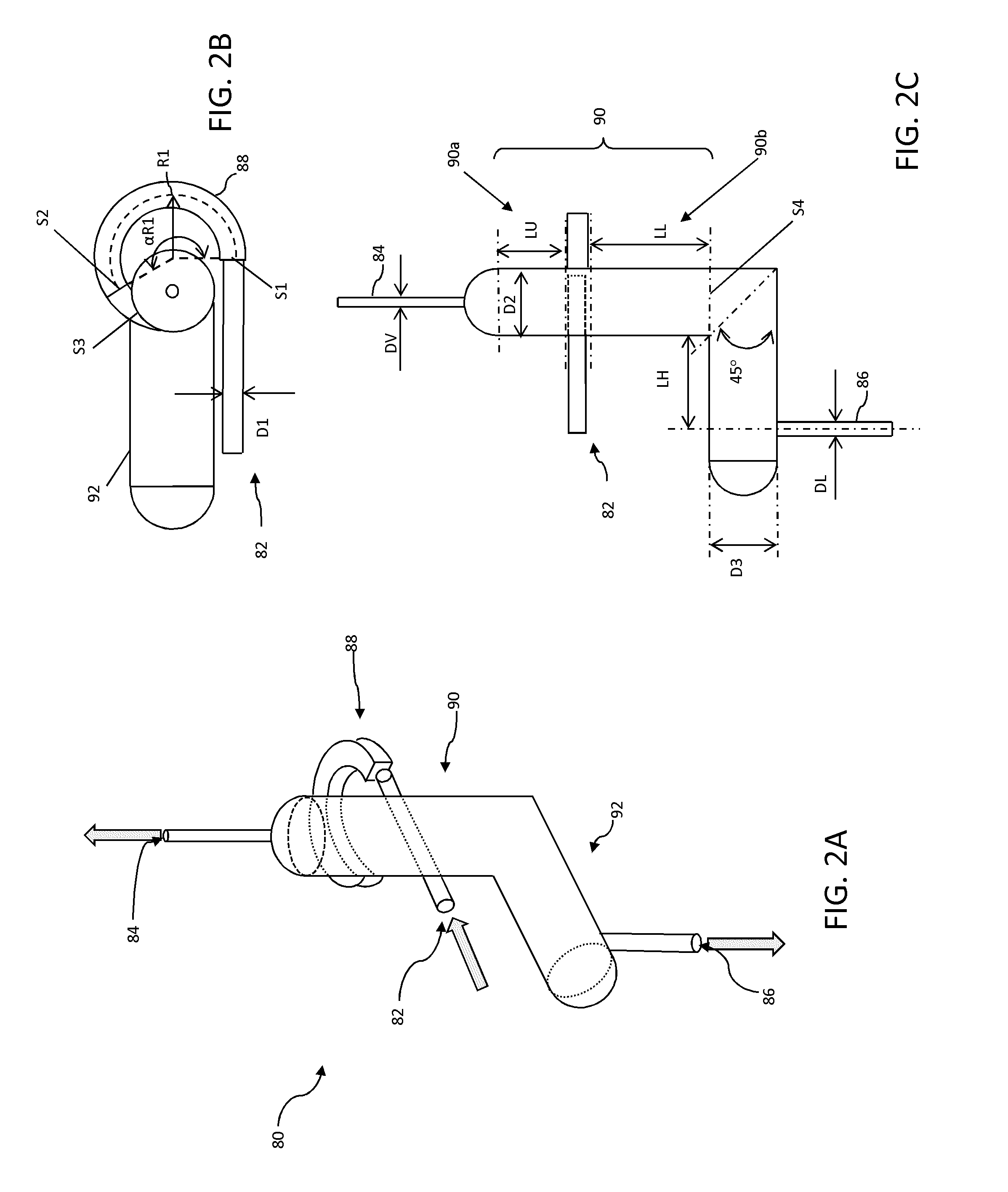

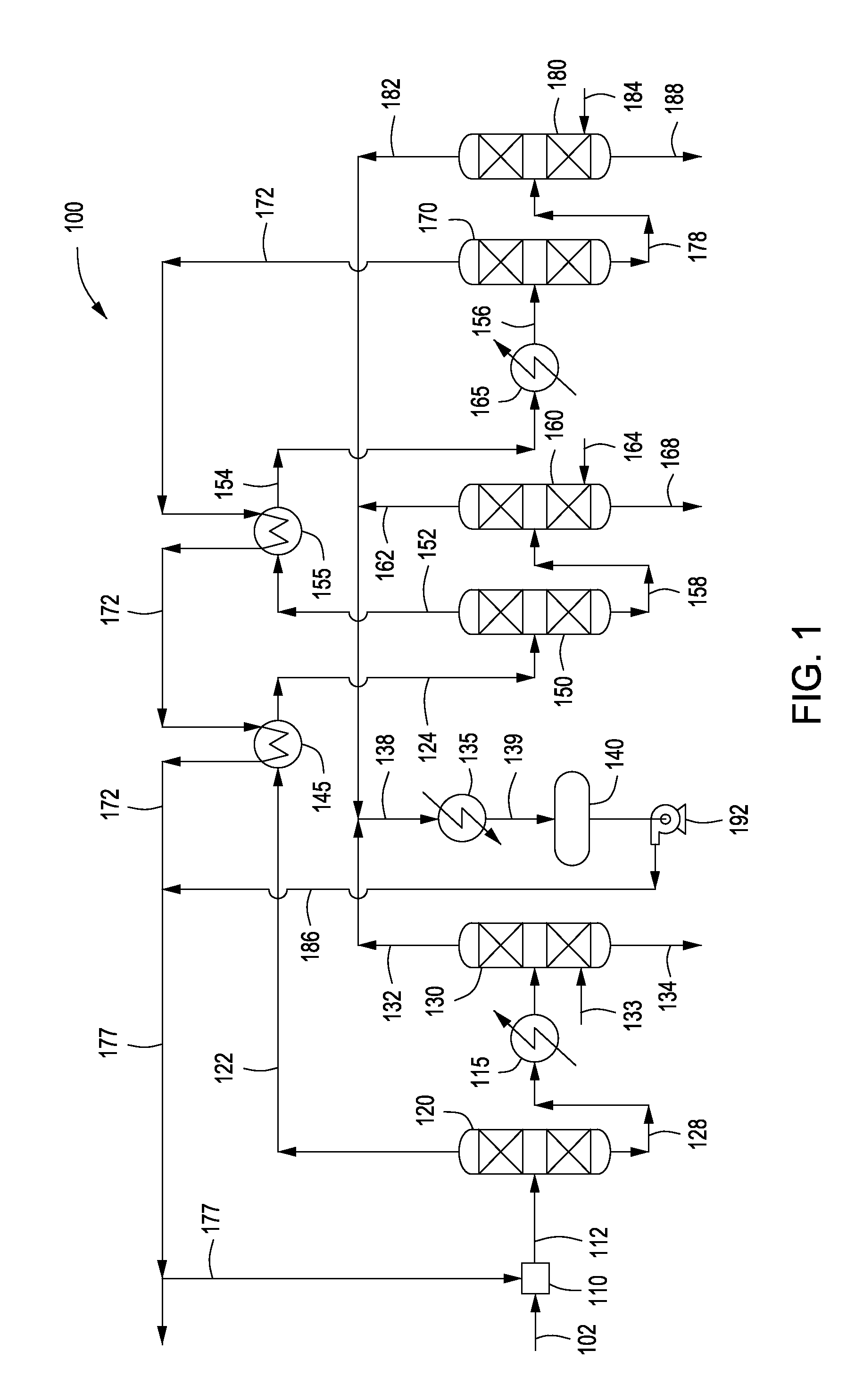

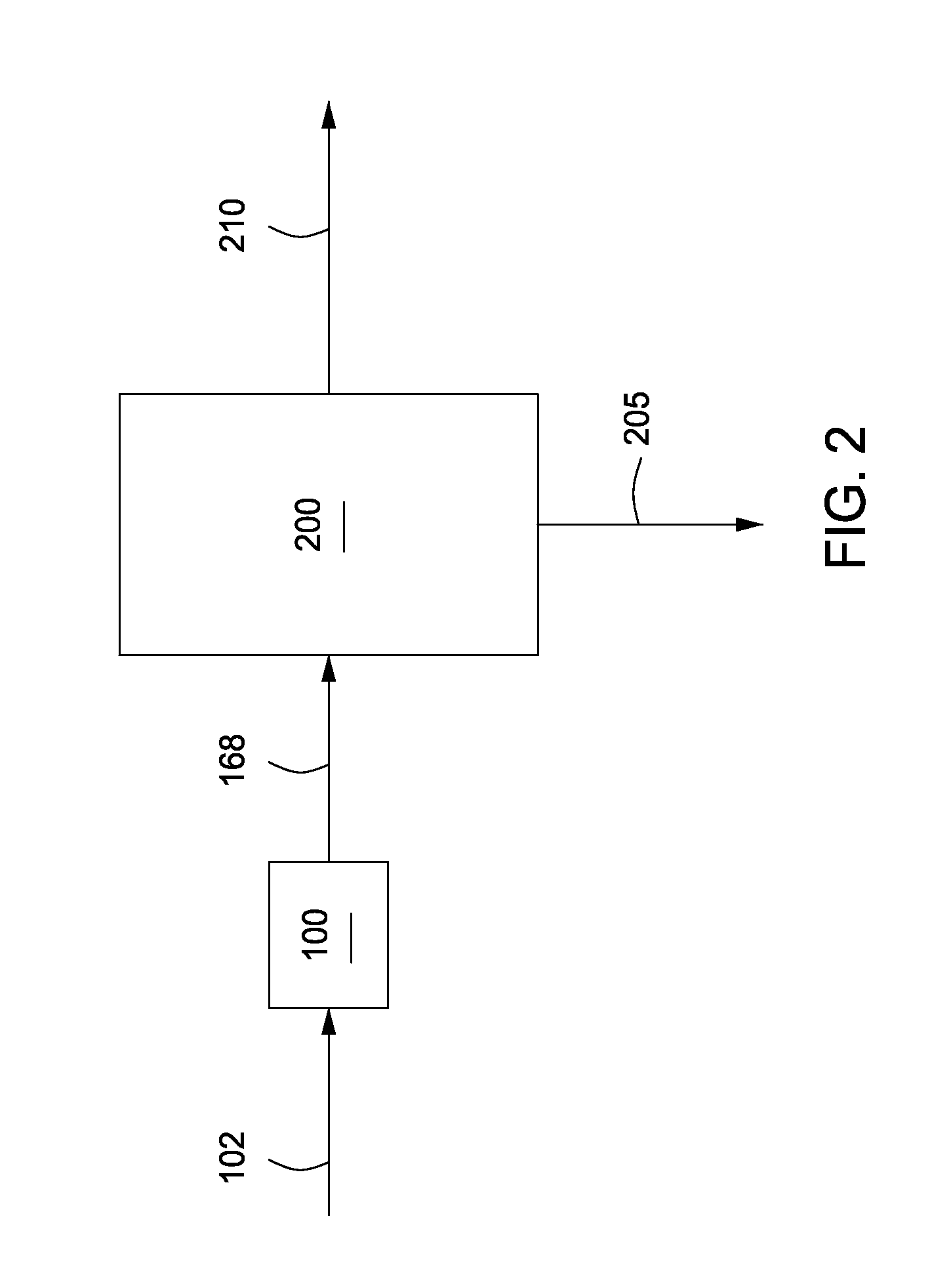

A process for producing pipeline-ready or refinery-ready feedstock from heavy hydrocarbons using a high-performance solvent extraction process with high local solvent-to-process fluid ratios yet maintaining low overall solvent-to-process fluid ratios, by first performing mild thermal cracking on the heavy hydrocarbons and then separating asphaltene-rich fractions from a resulting thermally affected fluid so that the high solvent-to-oil ratio portion of the process acts only on those asphaltene-rich fractions, and producing a dry, solid asphaltene as an end-product.

Owner:SUNCOR ENERGY INC

Asphalt production from solvent deasphalting bottoms

ActiveUS20090301931A1Minimizing conventional waste handling demandEliminate wasteWorking-up pitch/asphalt/bitumen by selective extractionWorking-up tarEffective solutionDesorption

A cost-effective solution is provided for eliminating refinery process waste, including spent catalytic and non-catalytic adsorbent materials, as well as adsorbate process reject materials derived from desorption, while minimizing conventional waste handling demands. An asphalt composition includes asphalt and spent adsorbent material from a solvent deasphalting unit. The asphalt can comprise asphaltic material obtained from a solvent deasphalting unit, and spent adsorbent material in the asphalt composition was previously utilized in the solvent deasphalting unit. The asphalt composition can also include process reject materials.

Owner:SAUDI ARABIAN OIL CO

Residuum Oil Supercritical Extraction Process

InactiveUS20110094937A1Working-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by chemical meansProcess systemsAsphaltene

Systems and methods for processing one or more hydrocarbons are provided. A hydrocarbon can be selectively separated to provide one or more finished products and an asphaltenic hydrocarbon using a pretreatment process. The asphaltenic hydrocarbon can be selectively separated to provide a deasphalted oil and one or more asphaltenes. At least a portion of the deasphalted oil can be converted to one or more first products using a first post-treatment process. At least a portion of the one or more asphaltenes can be converted to one or more second products using a second post-treatment process.

Owner:KELLOGG BROWN & ROOT LLC

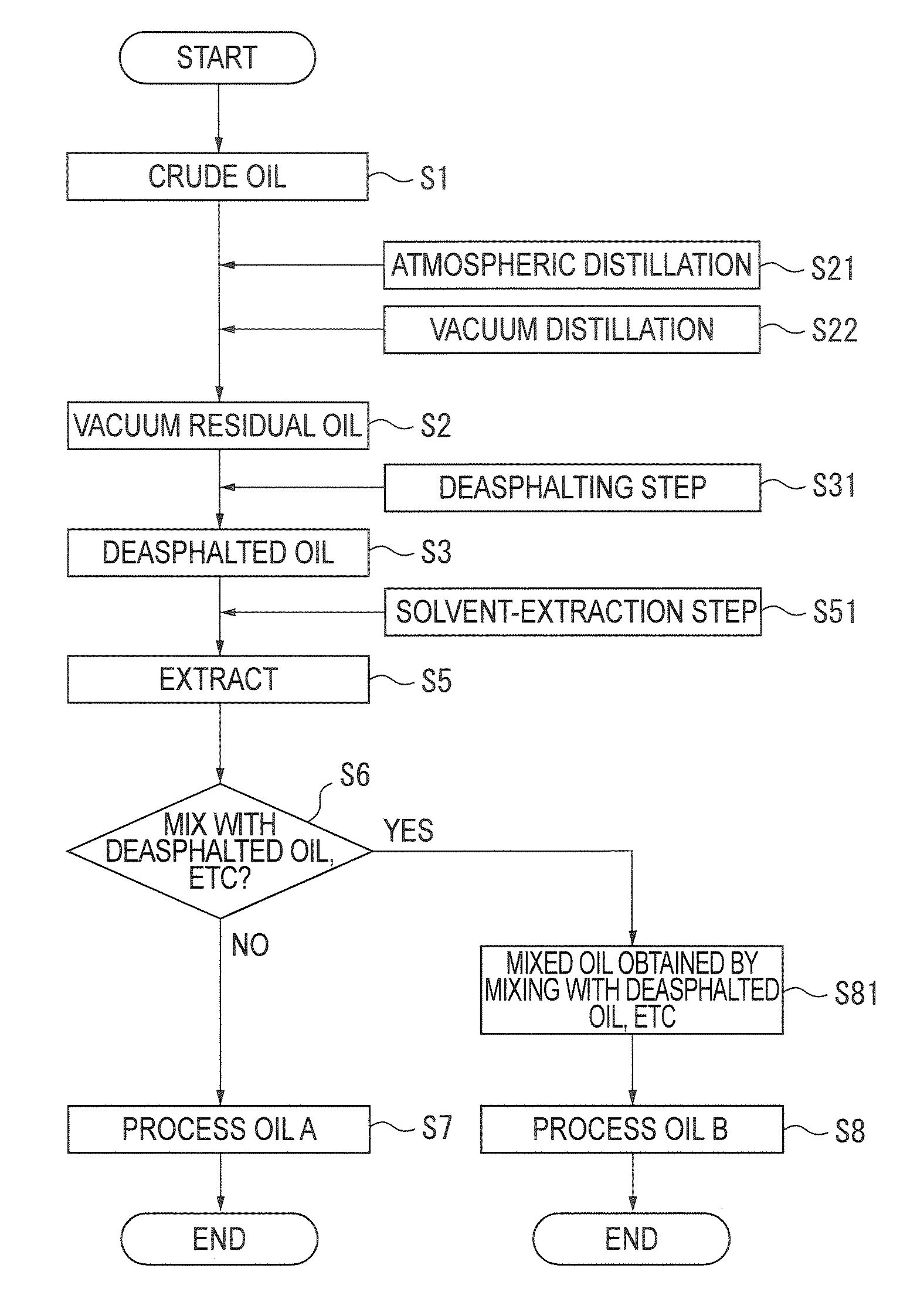

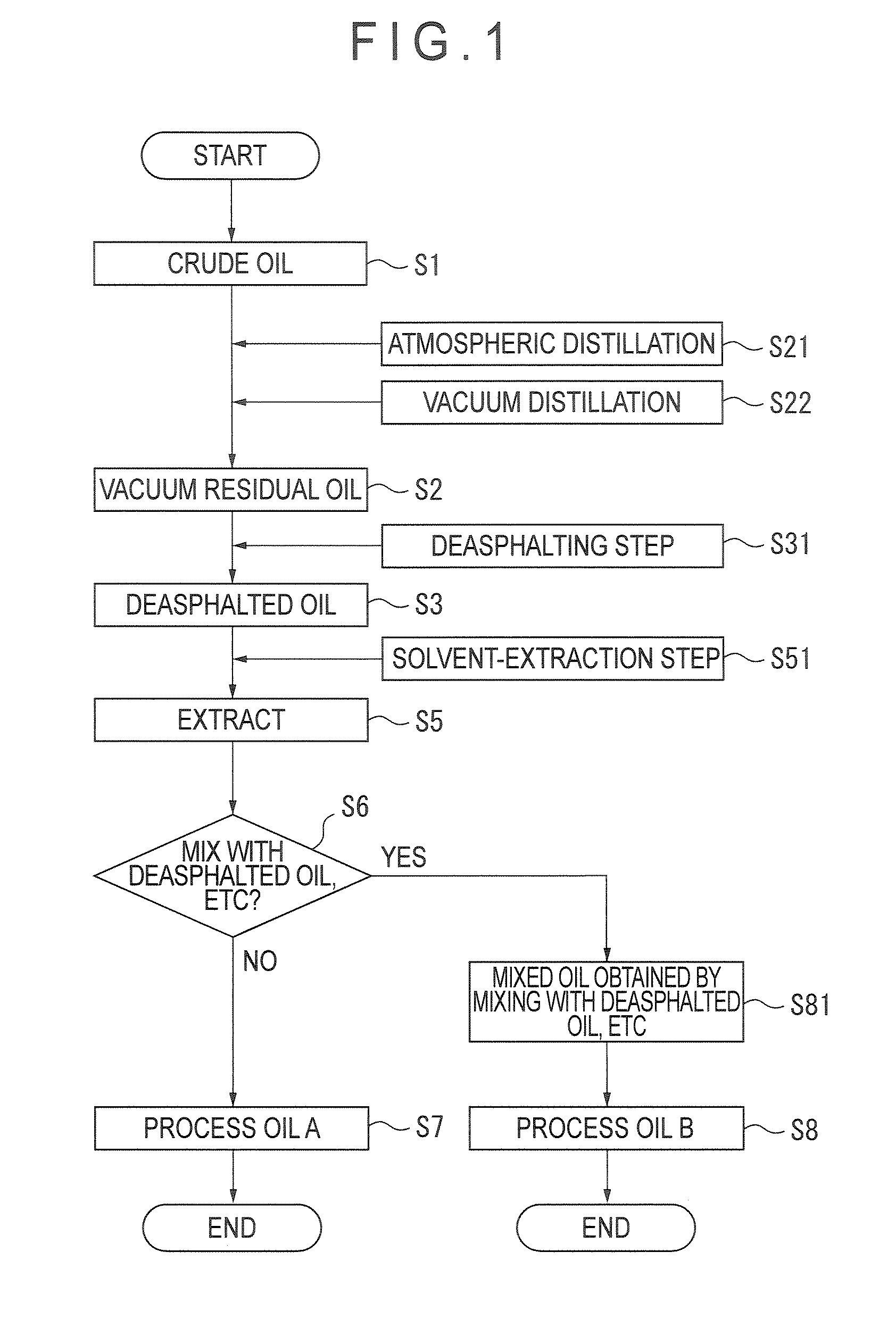

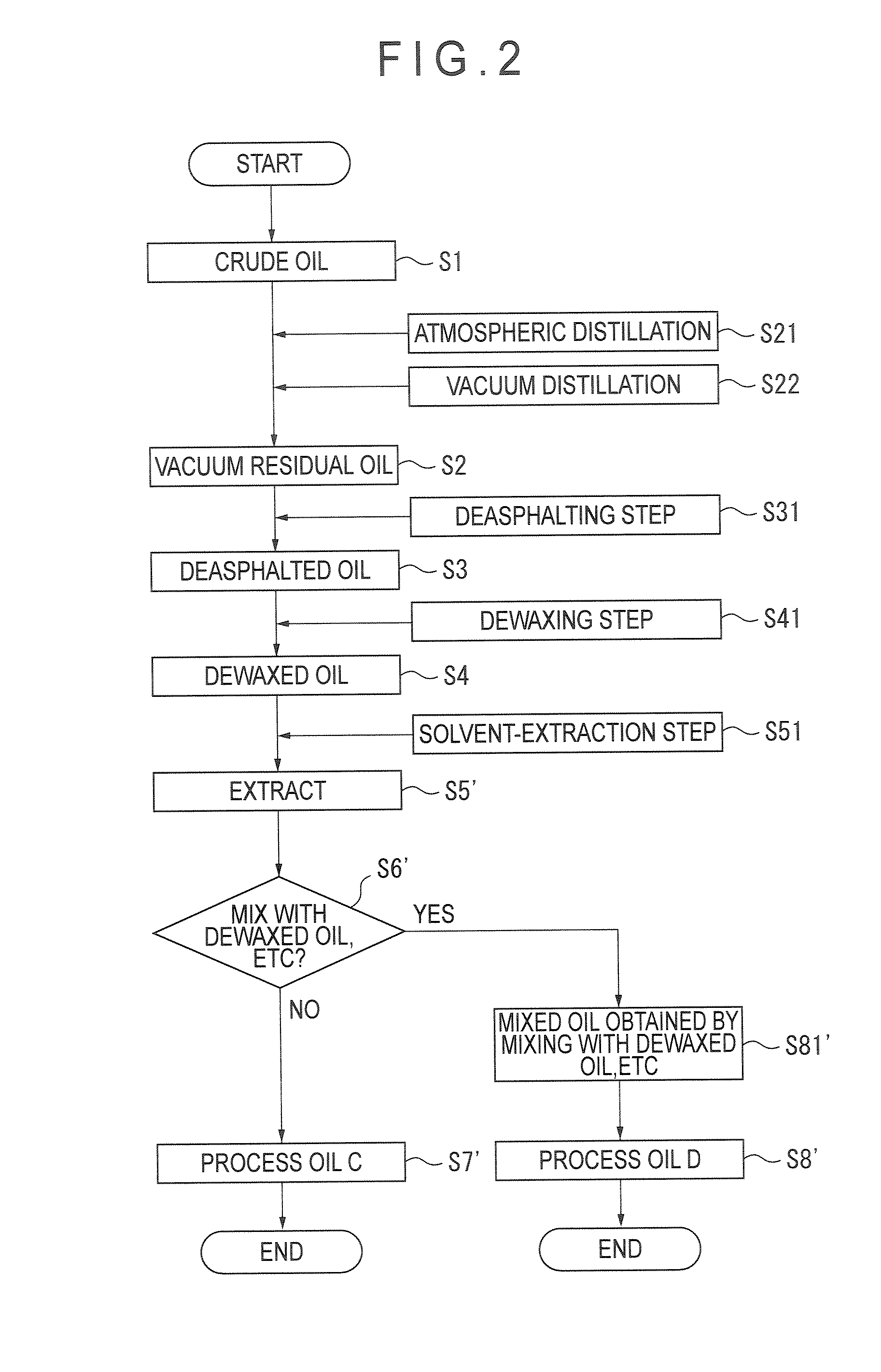

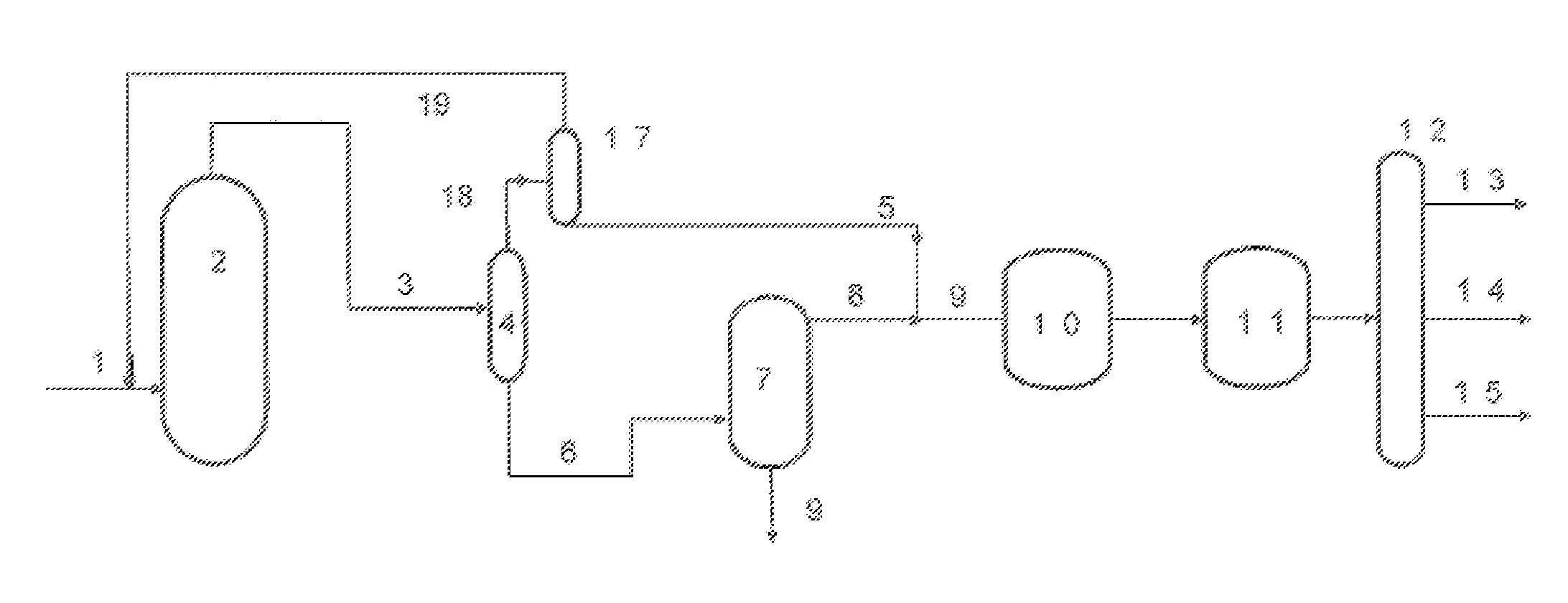

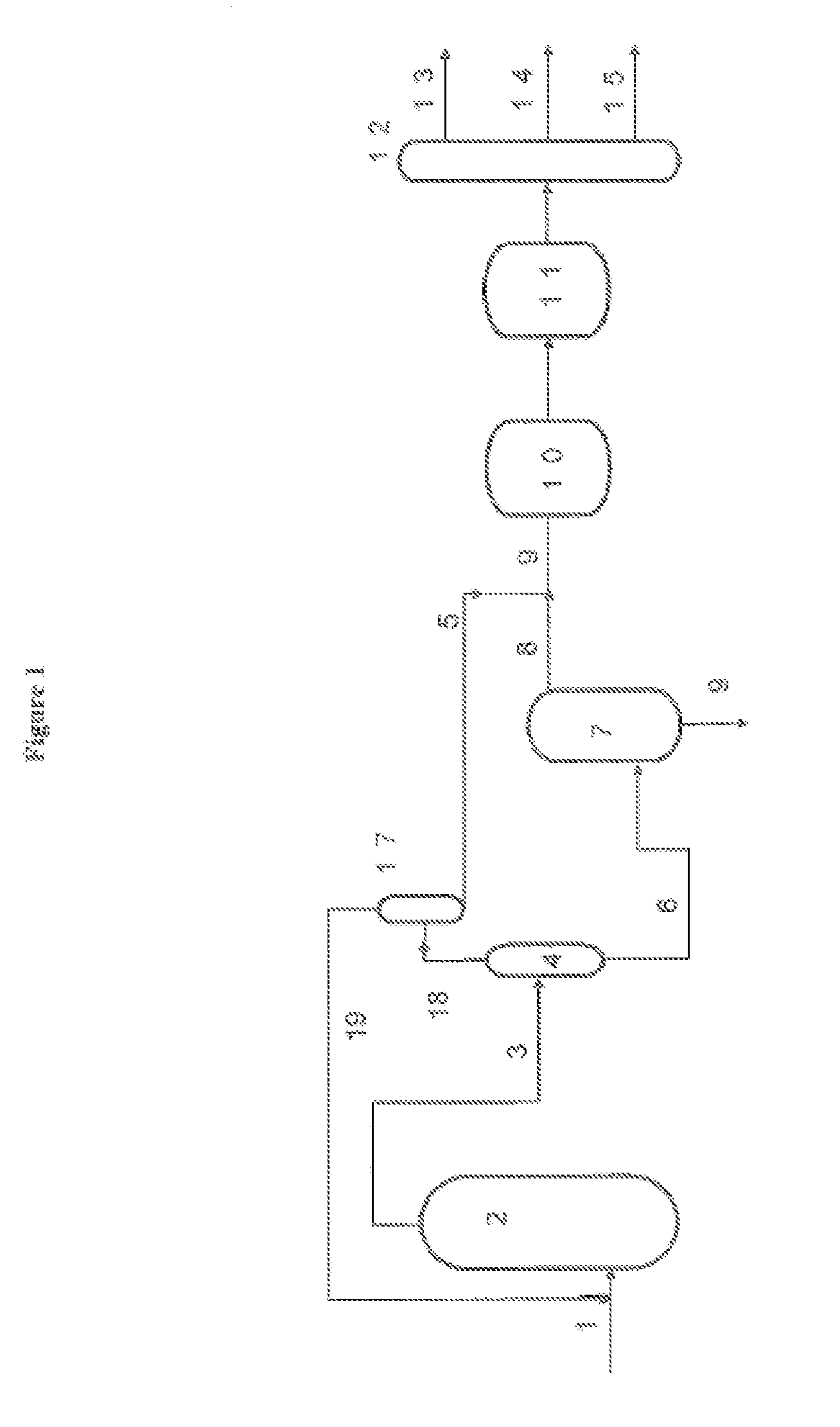

Process oil, process for production of deasphalted oil, process for production of extract, and process for production of process oil

InactiveUS20090020453A1Improve securityProvide accuratelyWorking-up pitch/asphalt/bitumen by selective extractionLiquid carbonaceous fuelsAniline pointResidual oil

The present invention is related to a process oil using as a raw material a deasphalted oil obtained by deasphalting a vacuum residual oil of a crude oil and a manufacturing method of the process oil, the process oil having properties of:(a) a polycyclic aromatics (PCA) content of less than 3 mass %;(b) a viscosity (100° C.) of 40 to 70 mm2 / s;(c) an aniline point of 85 to 100° C.;(d) a flash point of 250° C. or higher;(e) an aromatic hydrocarbon content of 40 to 55 mass %; and(f) a polar substance content of 10 to 15 mass %.The present invention is also related to a process oil and a manufacturing method of the process oil, the process oil obtained by mixing: an extract obtained by deasphalting and solvent-extracting a vacuum residual oil of a crude oil; and a lubricant base oil having a polycyclic aromatics (PCA) content of less than 3 mass %, and having properties of:(a) a polycyclic aromatics (PCA) content of less than 3 mass %;(i) a viscosity (100° C.) of 30 to 80 mm2 / s;(j) an aniline point of 90° C. or lower;(k) a flash point of 240° C. or higher;(l) a benzo(a)pyrene content of 1 mass ppm or less;(m) a specified aromatic compound content of 10 mass ppm or less; and(n) a polar substance content of 10 to 30 mass %.

Owner:IDEMITSU KOSAN CO LTD

Residue conversion process that includes a deasphalting stage and a hydroconversion stage

ActiveUS20120061293A1Quality improvementReduce contentTreatment with hydrotreatment processesMetal/metal-oxides/metal-hydroxide catalystsHydrogenDistillation

Owner:INST FR DU PETROLE

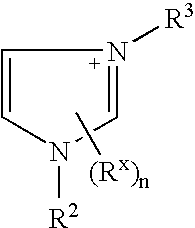

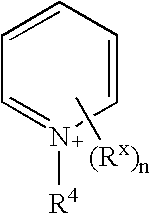

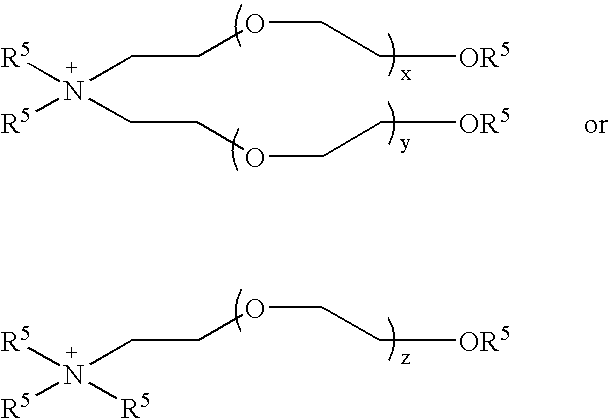

Upgrading of petroleum resid, bitumen or heavy oils by the separation of asphaltenes and/or resins therefrom using ionic liquids

Petroleum resid, bitumen and / or heavy oil is upgraded by the separation of asphaltenes and / or resins from such resids, bitumen and / or heavy oils by contacting them with an ionic liquid with which the asphaltenes and / or resins interact.

Owner:EXXON RES & ENG CO

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com