Patents

Literature

353results about "Tar working-up by solvent extraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

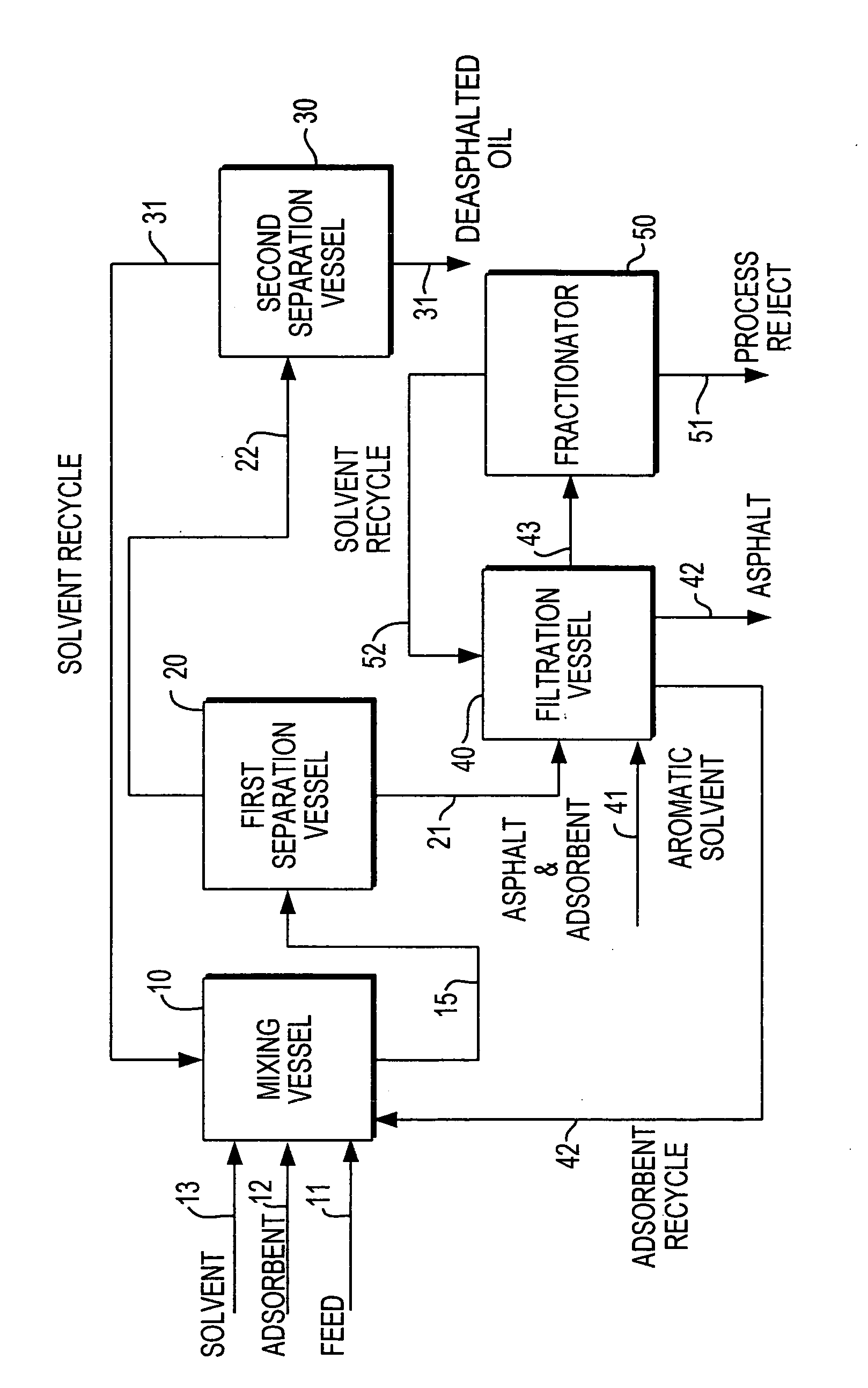

Enhanced solvent deasphalting process for heavy hydrocarbon feedstocks utilizing solid adsorbent

ActiveUS7566394B2Improve performanceImprove current efficiencyWorking-up pitch/asphalt/bitumen by selective extractionHydrocarbon distillationBenzeneActivated carbon

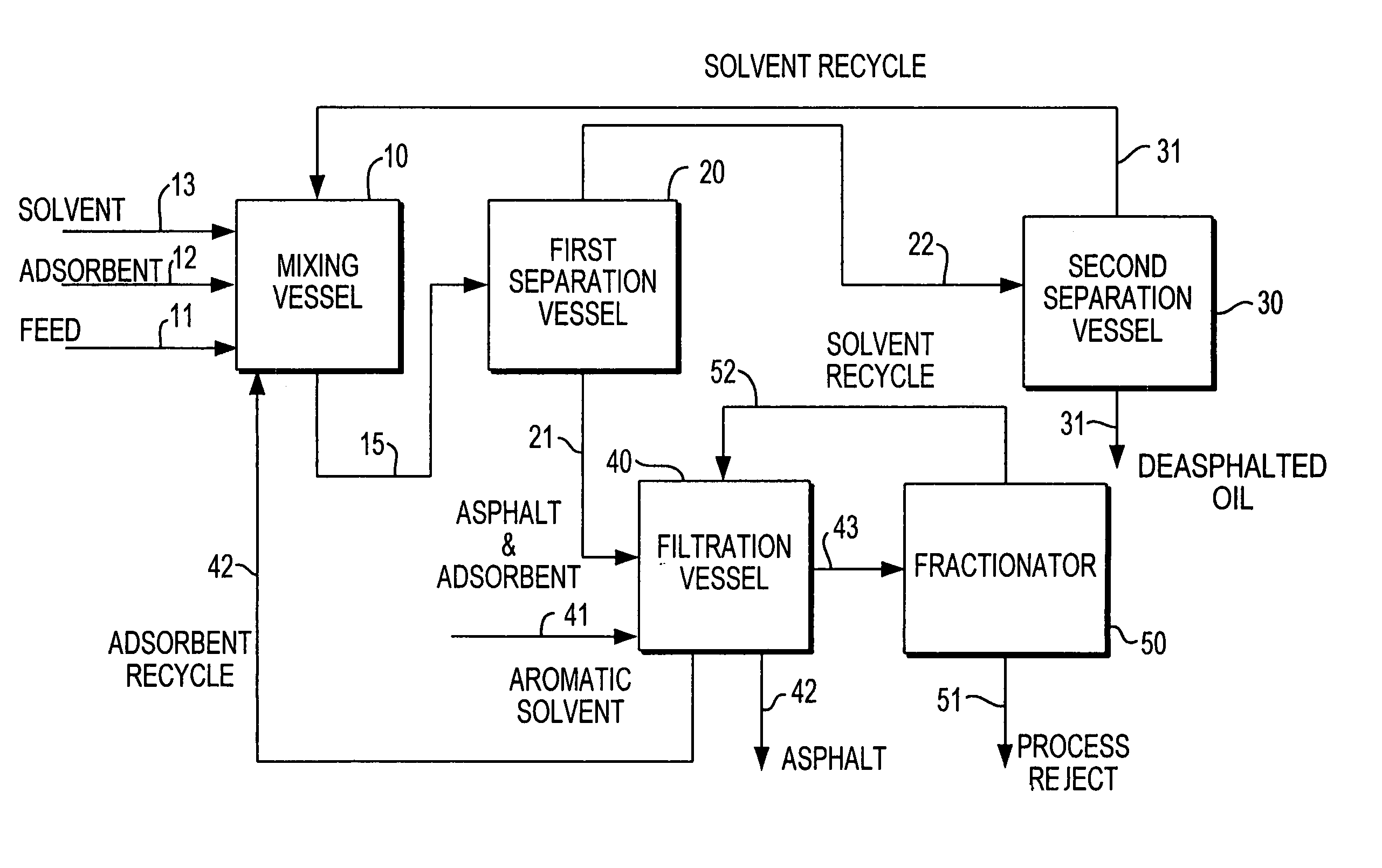

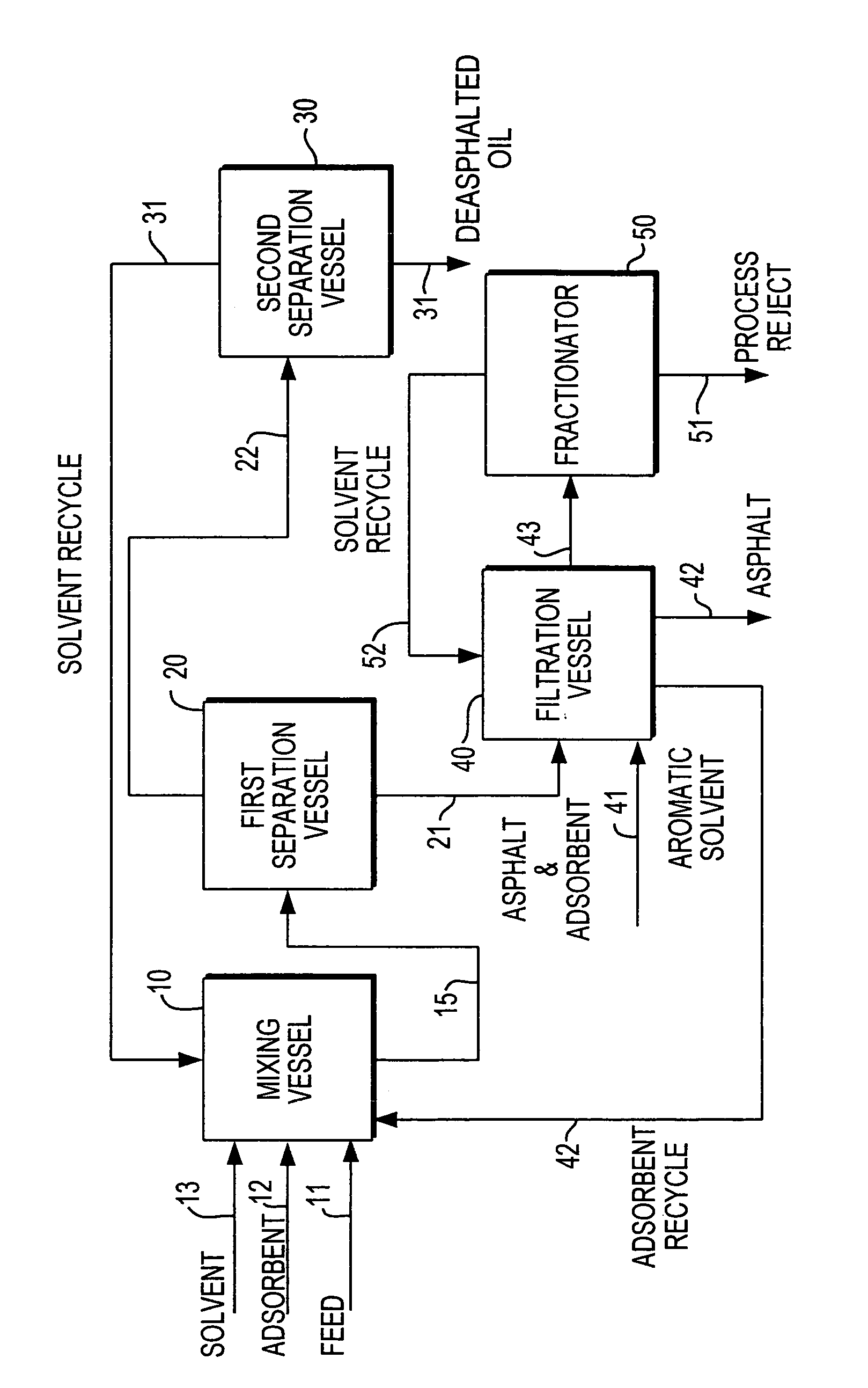

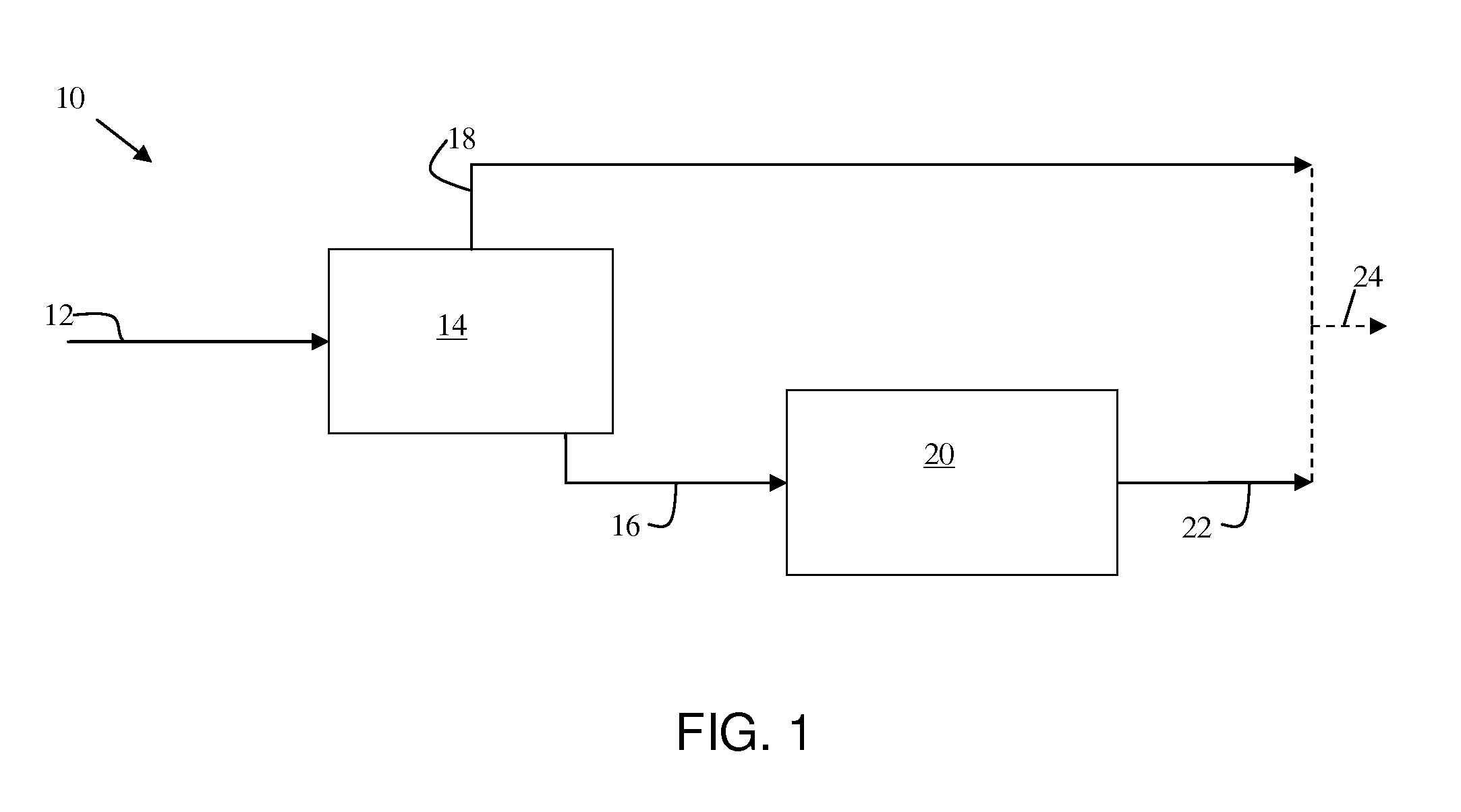

A solvent deasphalting of crude oil or petroleum heavy fractions and residues is carried out in the presence of a solid adsorbent, such as clay, silica, alumina and activated carbon, which adsorbs the contaminants and permits the solvent and oil fraction to be removed as a separate stream from which the solvent is recovered for recycling; the adsorbent with contaminants and the asphalt bottoms is mixed with aromatic and / or polar solvents to desorb the contaminants and washed as necessary, e.g., with benzene, toluene, xylenes and tetrahydrofuran, to clean adsorbant which is recovered and recycled; the solvent-asphalt mixture is sent to a fractionator for recovery and recycling of the aromatic or polar solvent. The bottoms from the fractionator include the concentrated PNA and contaminants and are further processes as appropriate.

Owner:SAUDI ARABIAN OIL CO

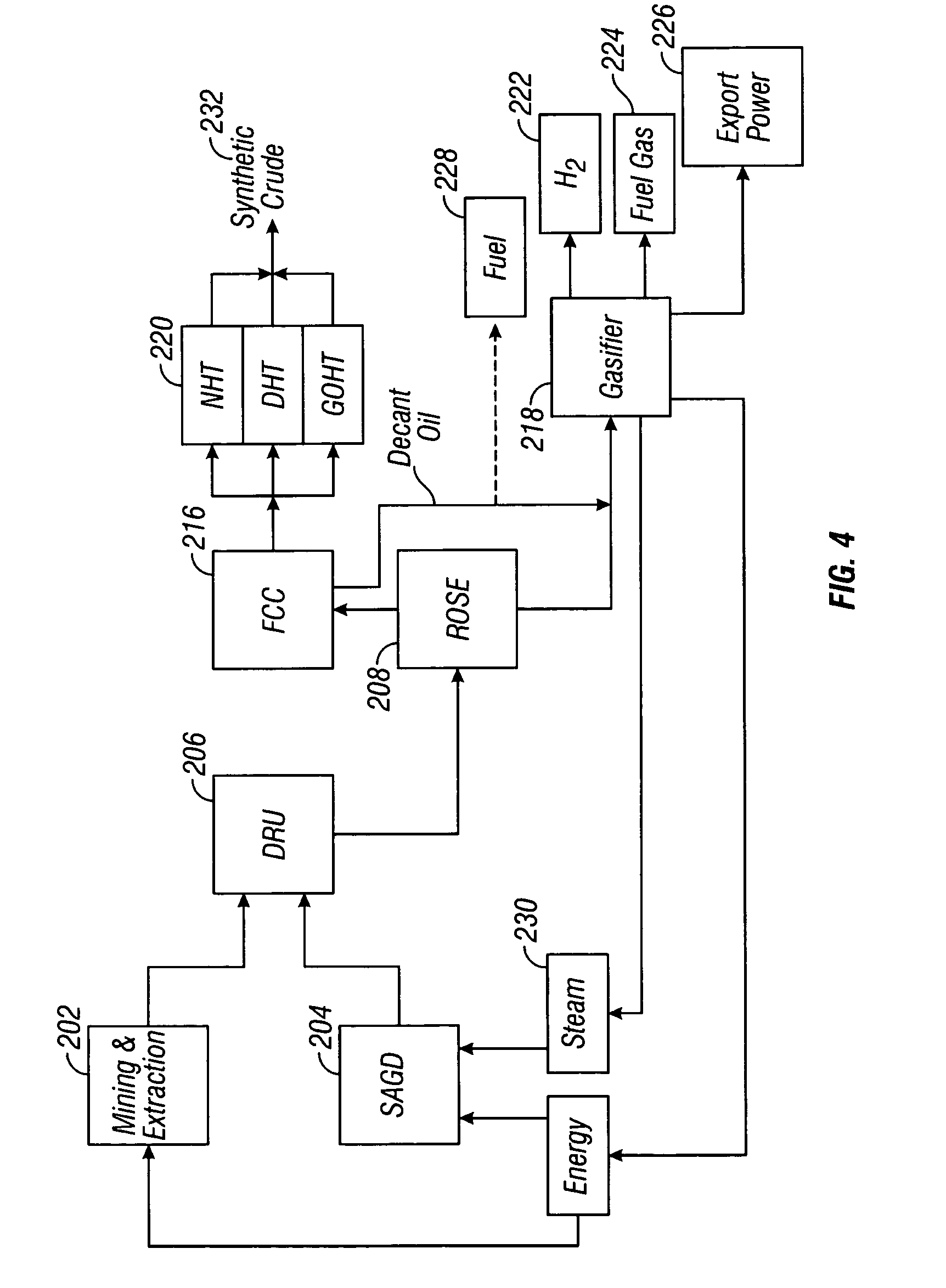

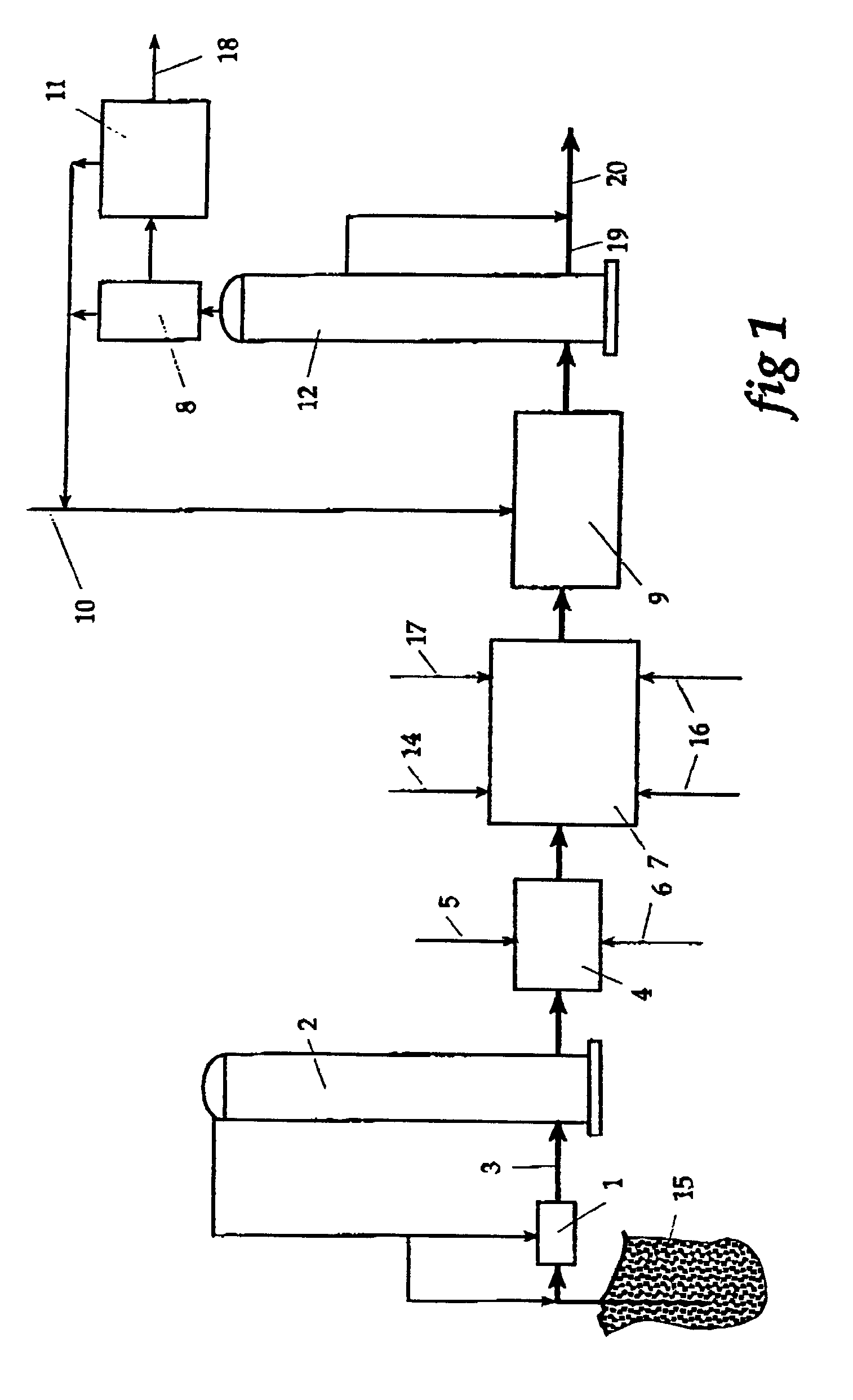

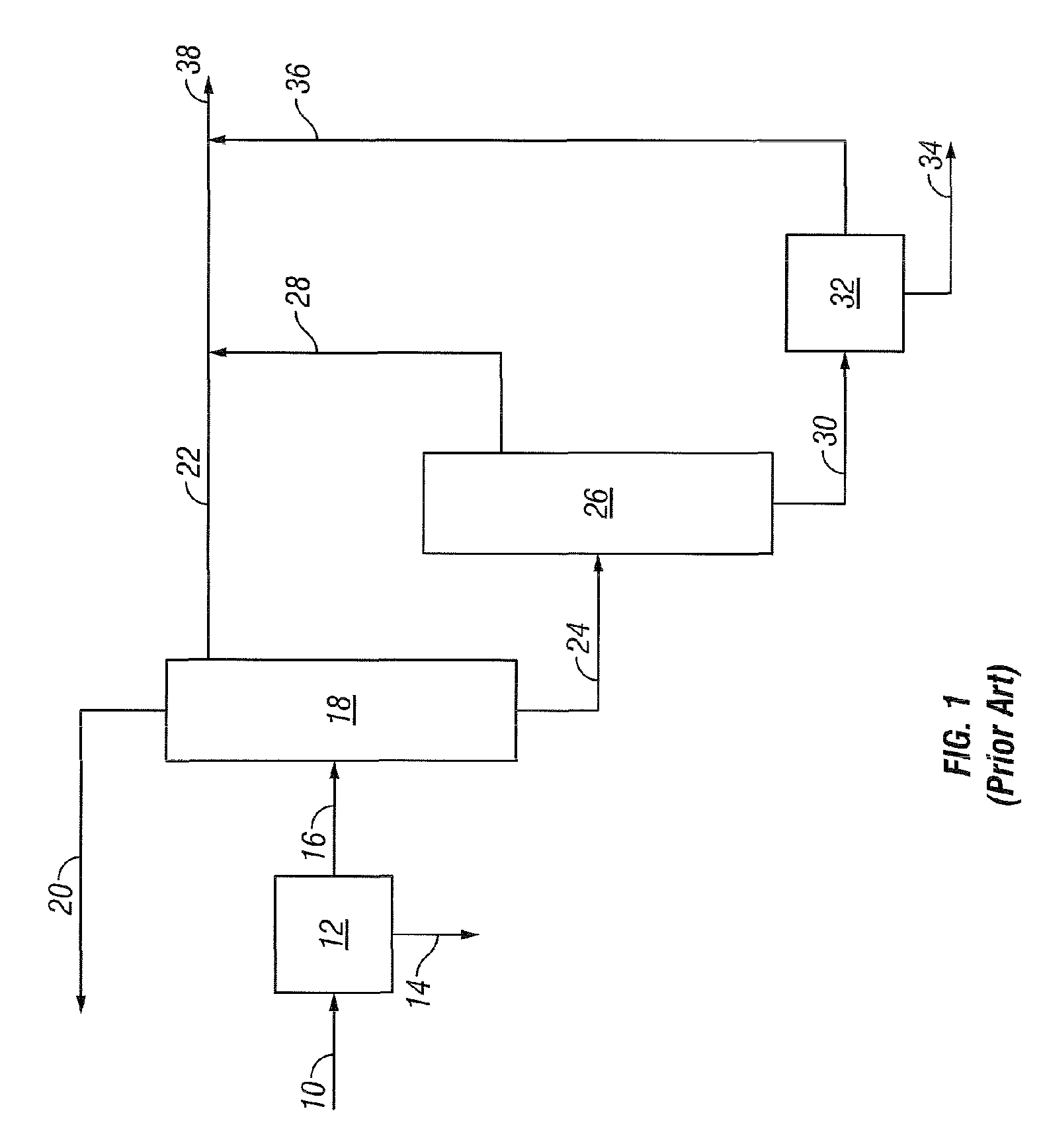

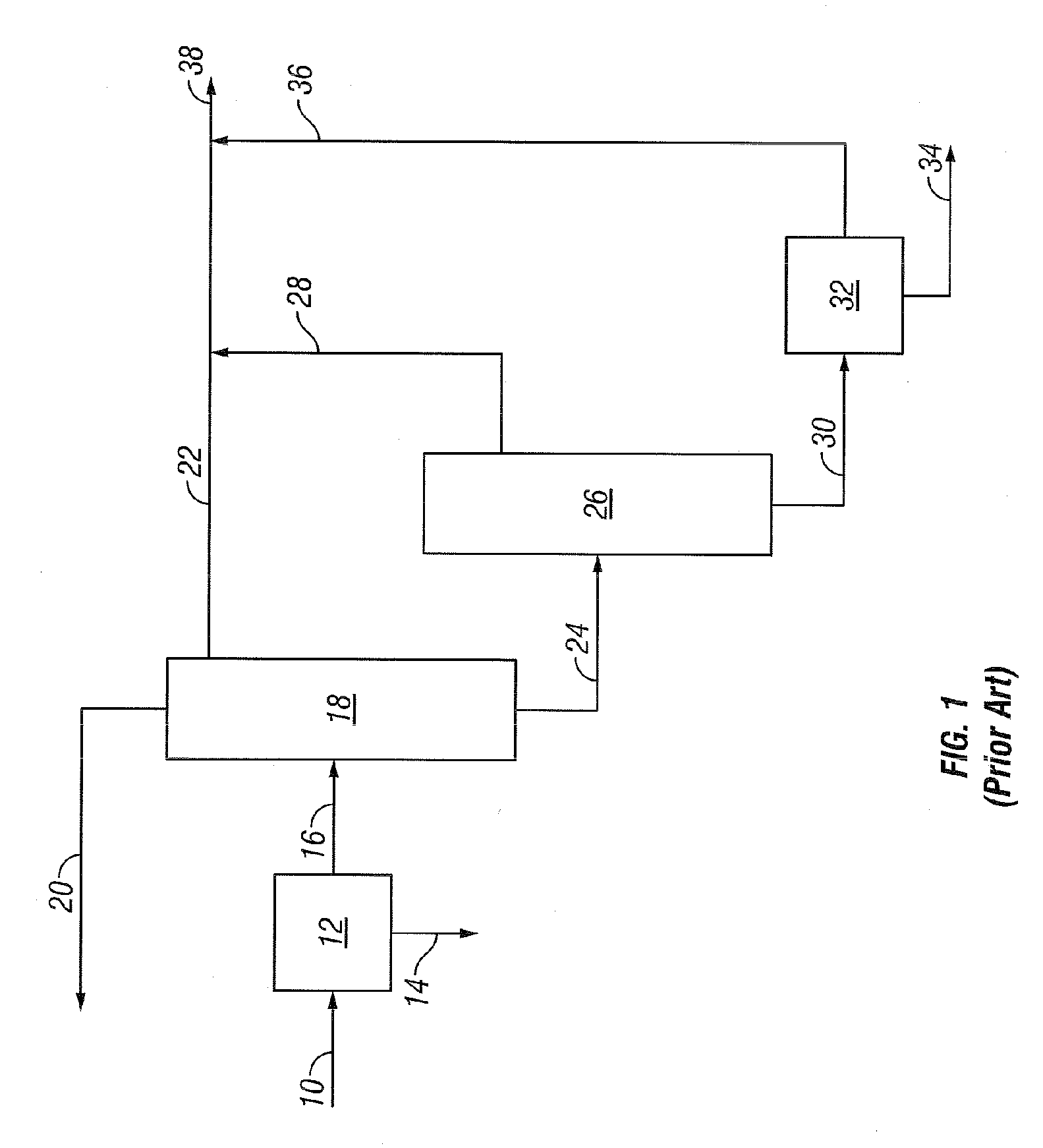

Heavy Oil and Bitumen Upgrading

ActiveUS20060042999A1Reduce metal contentEasy to liftThermal non-catalytic crackingWorking-up pitch/asphalt/bitumen by selective extractionNaphthaHydrogen

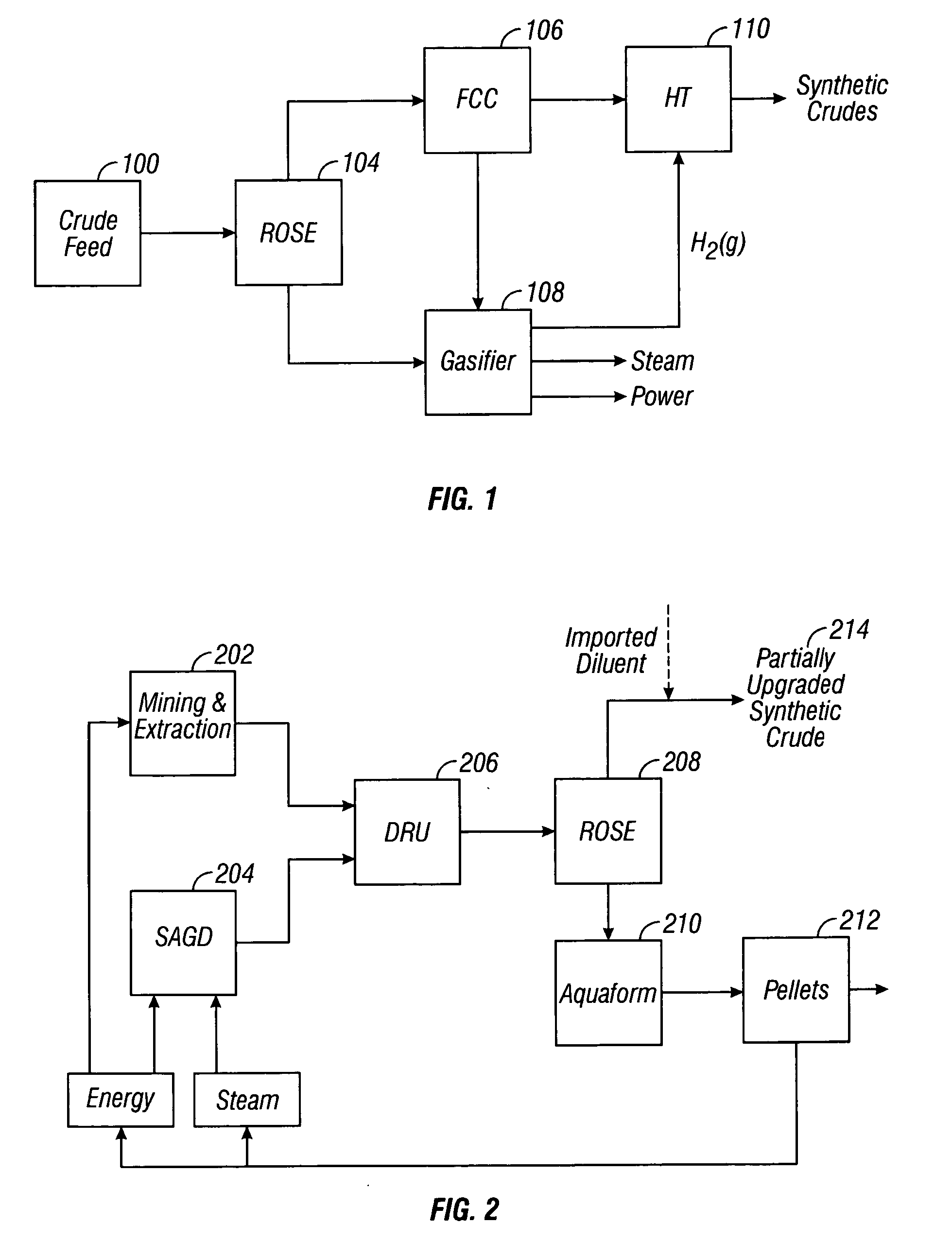

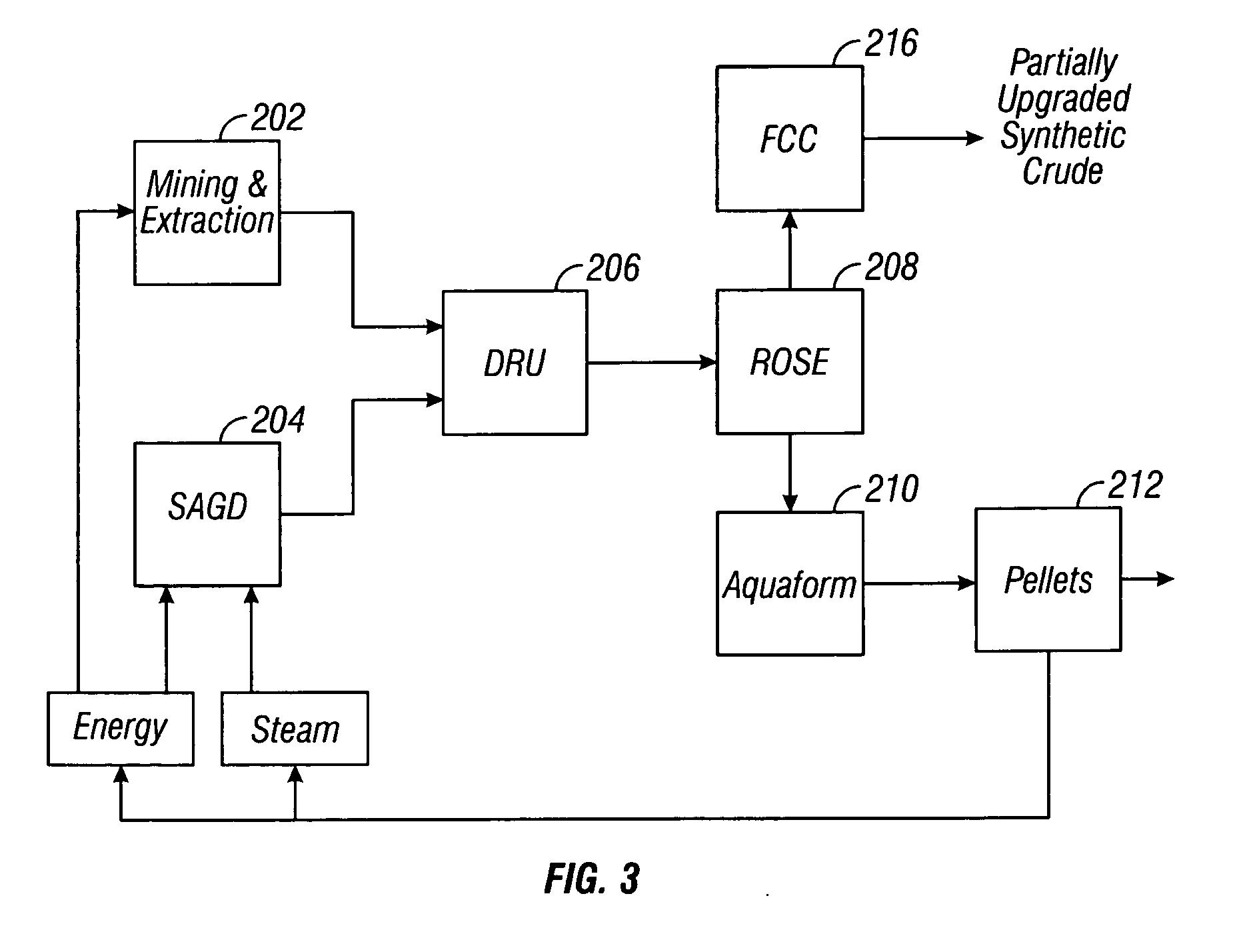

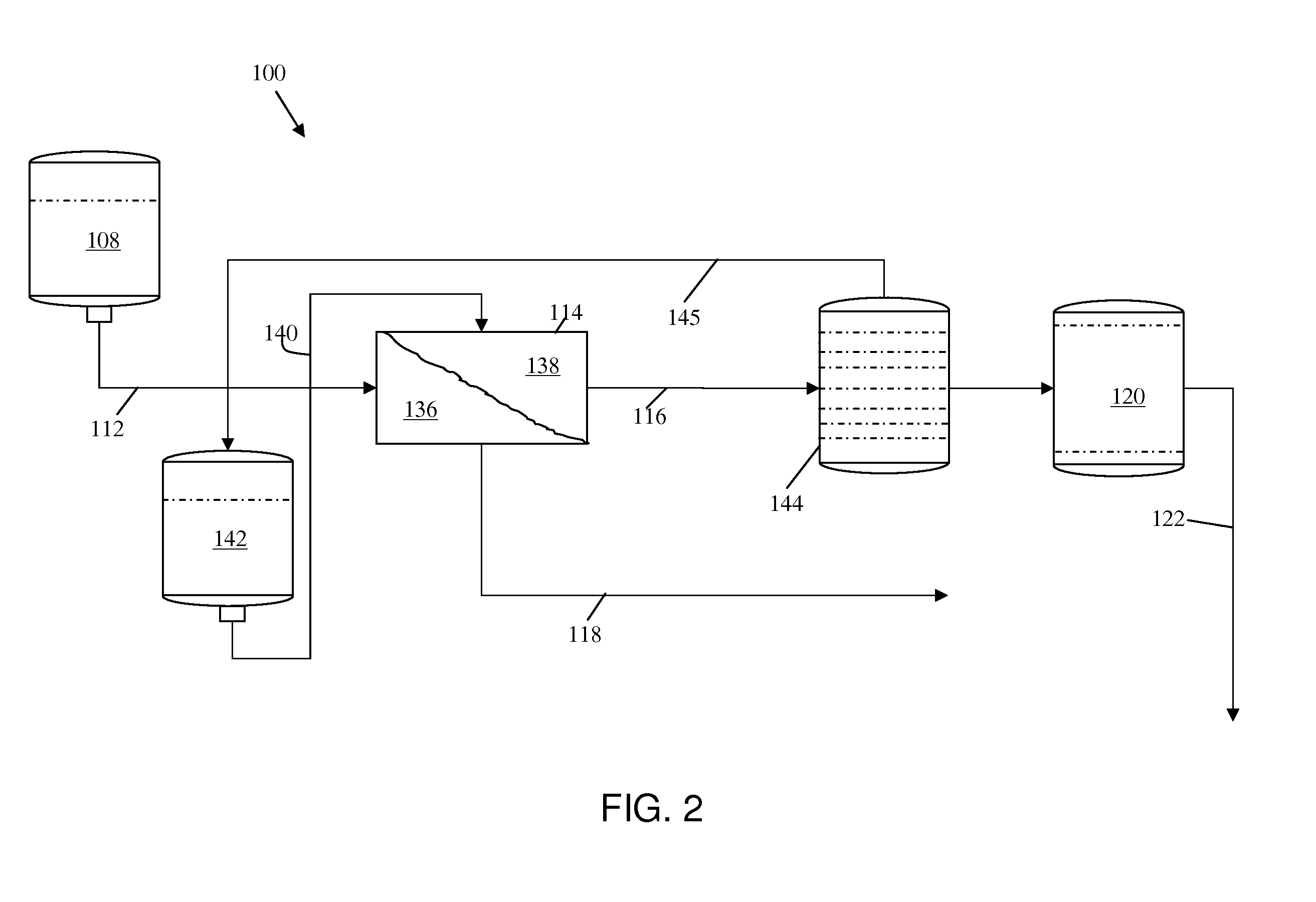

Disclosed is a process for the upgrading and demetallizing of heavy oils and bitumens. A crude heavy oil and / or bitumen feed is supplied to a solvent extraction process 104 wherein DAO and asphaltenes are separated. The DAO is supplied to an FCC unit 106 having a low conversion activity catalyst for the removal of metals contained therein. The demetallized distillate fraction is supplied to a hydrotreater 110 for upgrading and collected as a synthetic crude product stream. The asphaltene fraction can be supplied to a gasifier 108 for the recovery of power, steam and hydrogen, which can be supplied to the hydrotreater 110 or otherwise within the process or exported. An optional coker 234 can be used to convert excess asphaltenes and / or decant oil to naphtha, distillate and gas oil, which can be supplied to the hydrotreater 220.

Owner:KELLOGG BROWN & ROOT LLC

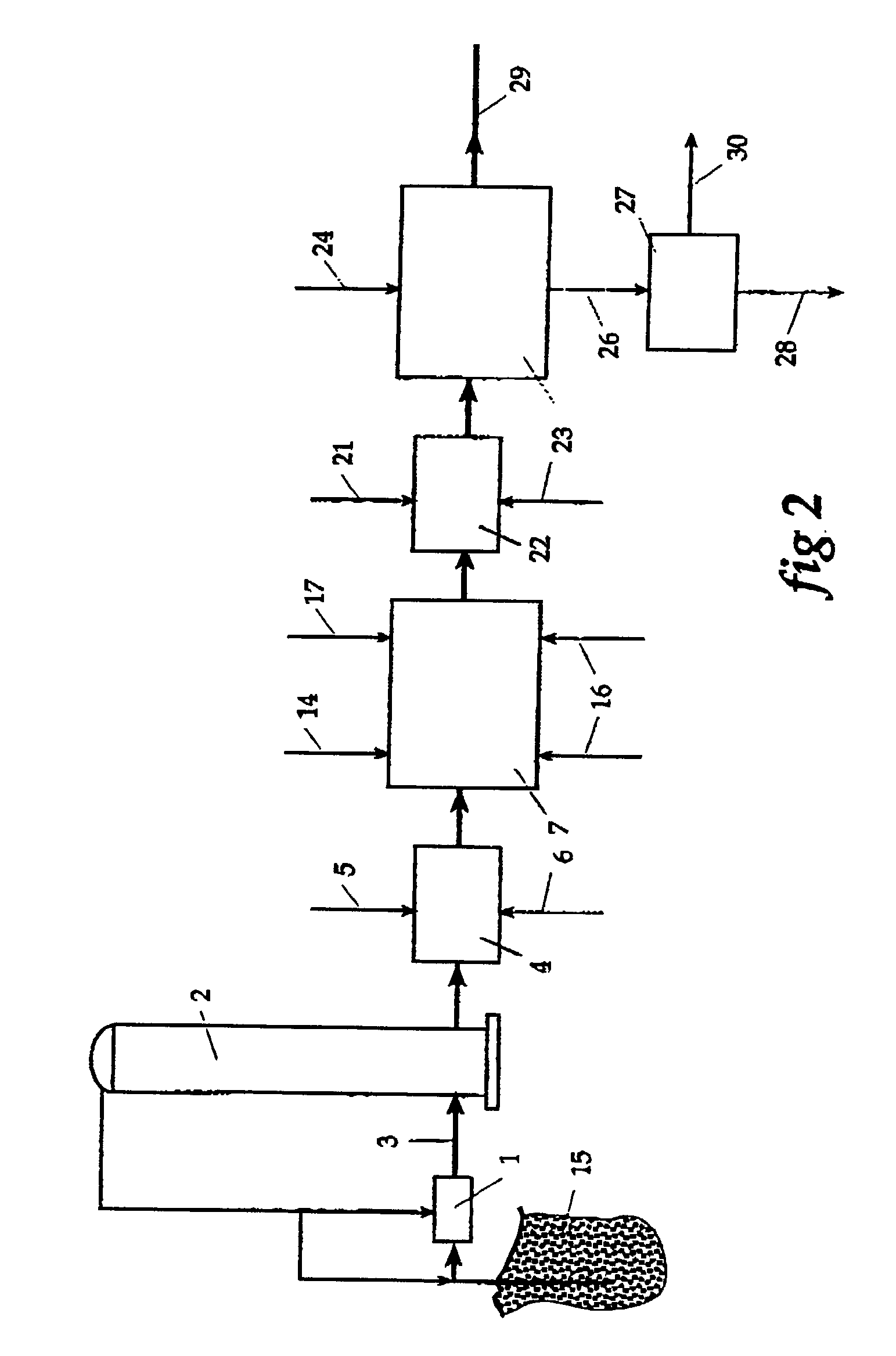

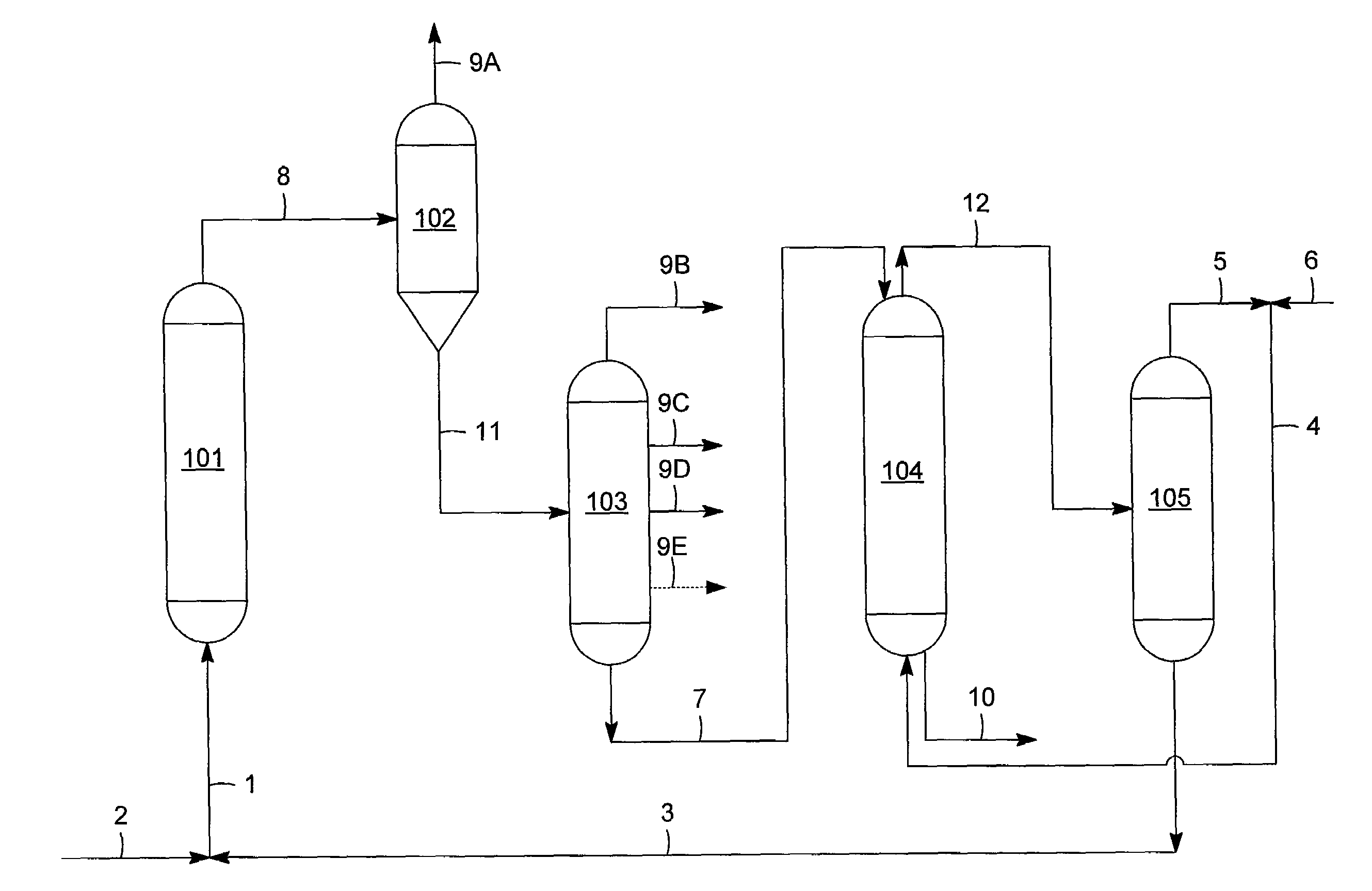

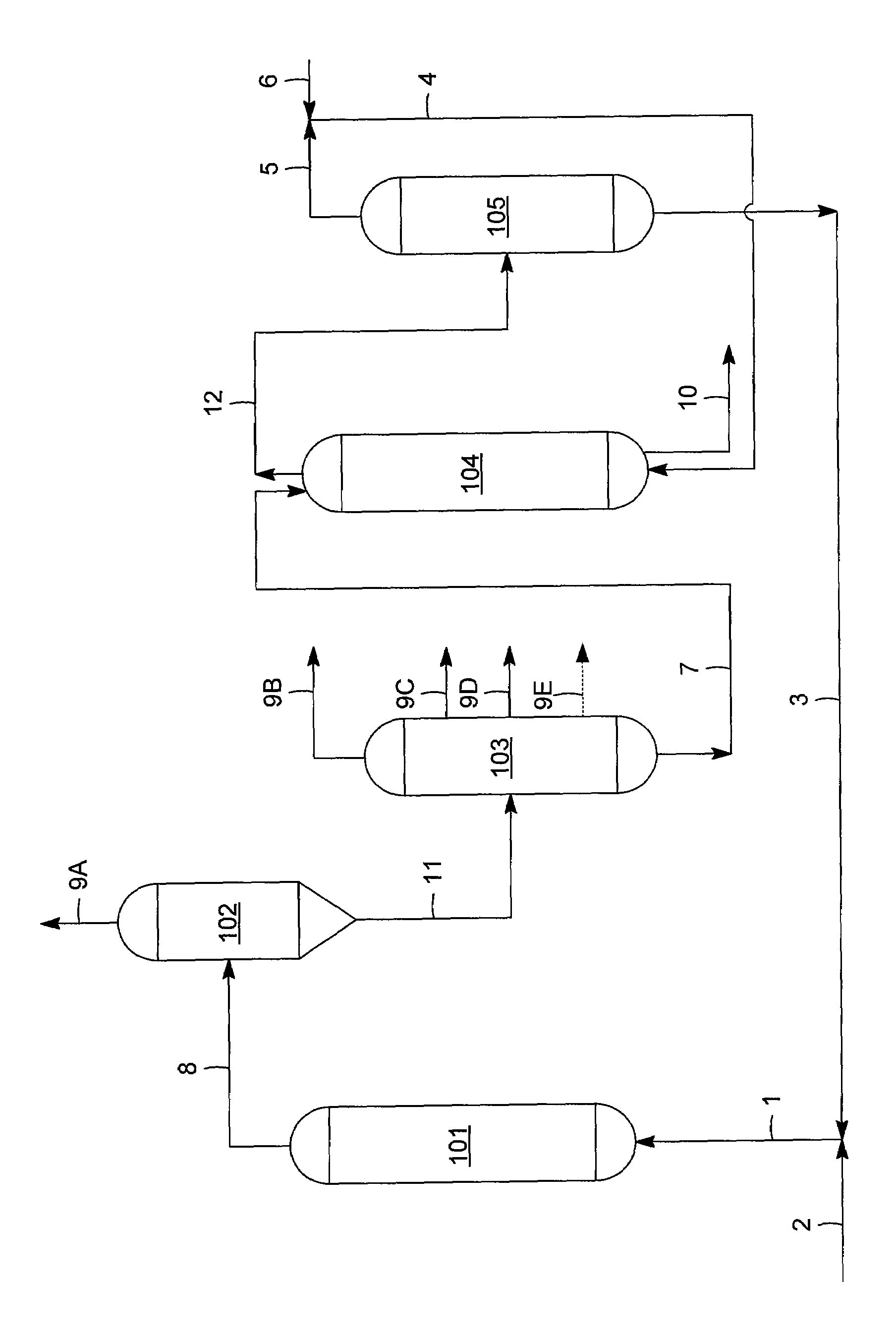

Systems and methods for residue upgrading

ActiveUS20080223754A1Thermal non-catalytic crackingWorking-up pitch/asphalt/bitumen by selective extractionNaphthaReaction zone

Systems and methods for processing hydrocarbons are provided. A hydrocarbon can be distilled to provide a distillate, a gas oil, and a residue. The residue can include, but is not limited to asphaltenes and non-asphaltenes. The residue can be mixed with a solvent to provide a mixture. The asphaltenes can be selectively separated from the mixture to provide a deasphalted oil. At least a portion of the deasphalted oil and at least a portion of the gas oil can be hydroprocessed to provide a hydroprocessed hydrocarbon. At least a portion of the distillate and at least a portion of the hydroprocessed hydrocarbon can be cracked in a first reaction zone to provide a first cracked product comprising C2 hydrocarbons, C3 hydrocarbons, C4 hydrocarbons, and naphtha.

Owner:MARVELL TECHNOLOGY GROUP LTD +1

Dearomatized asphalt

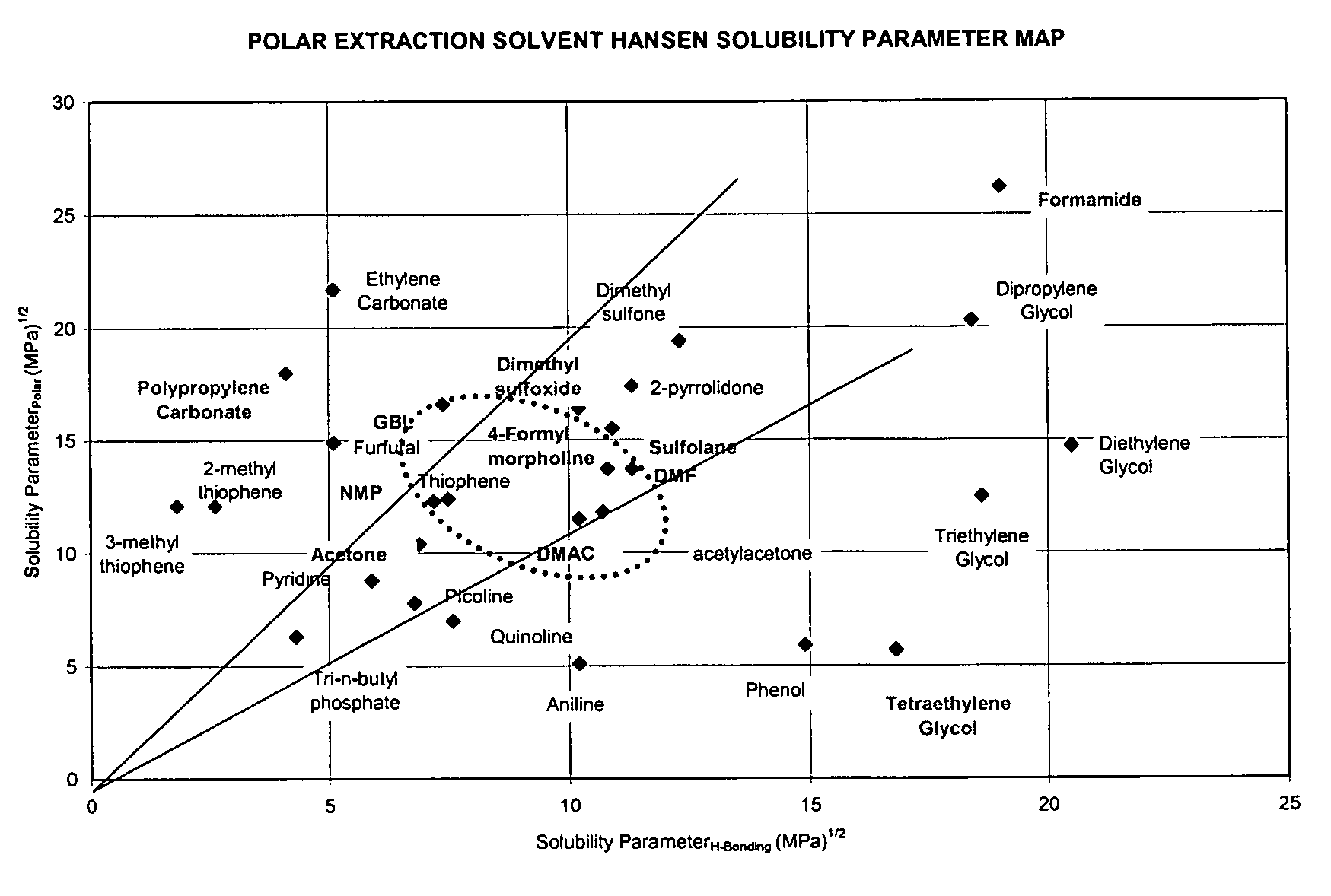

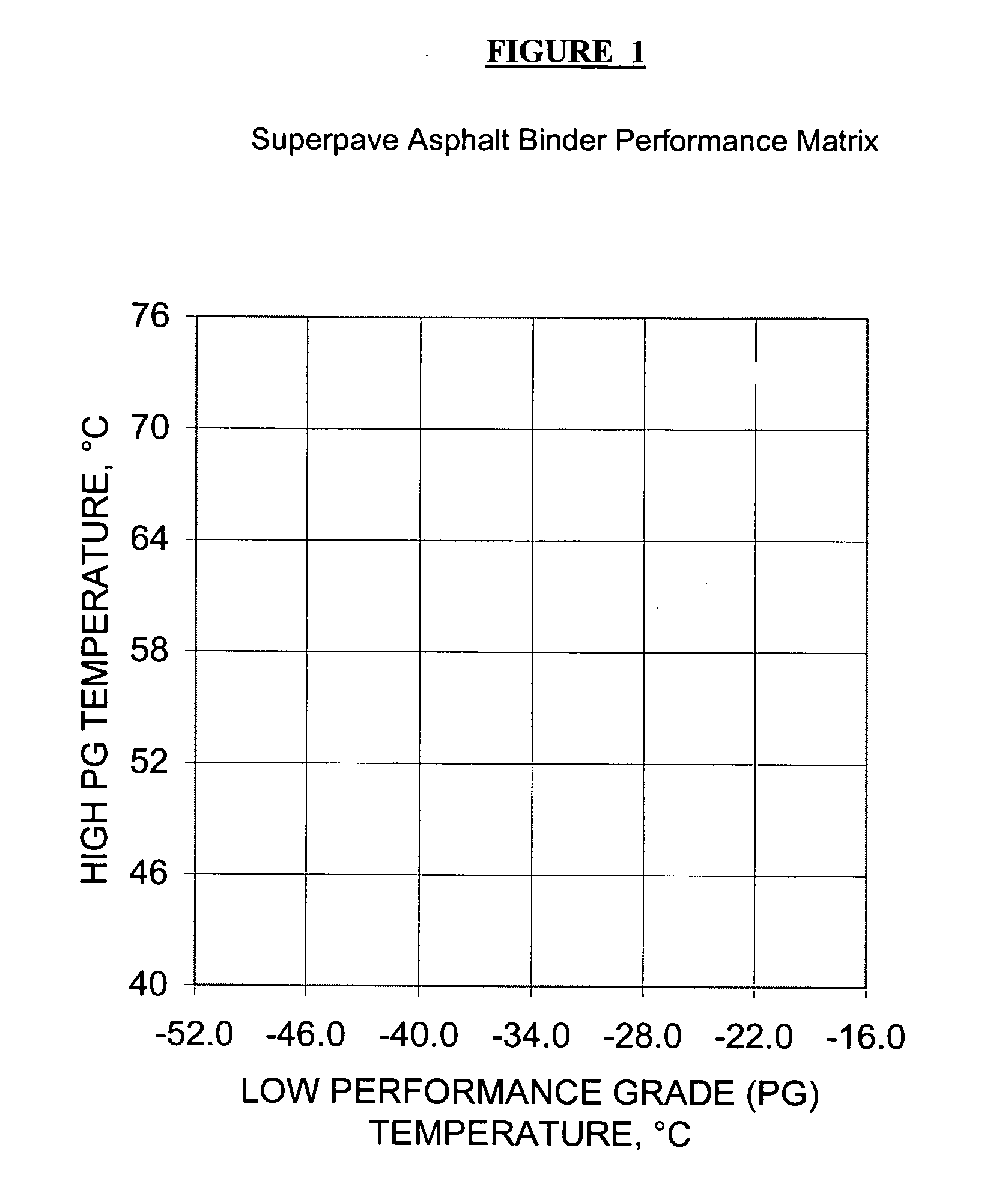

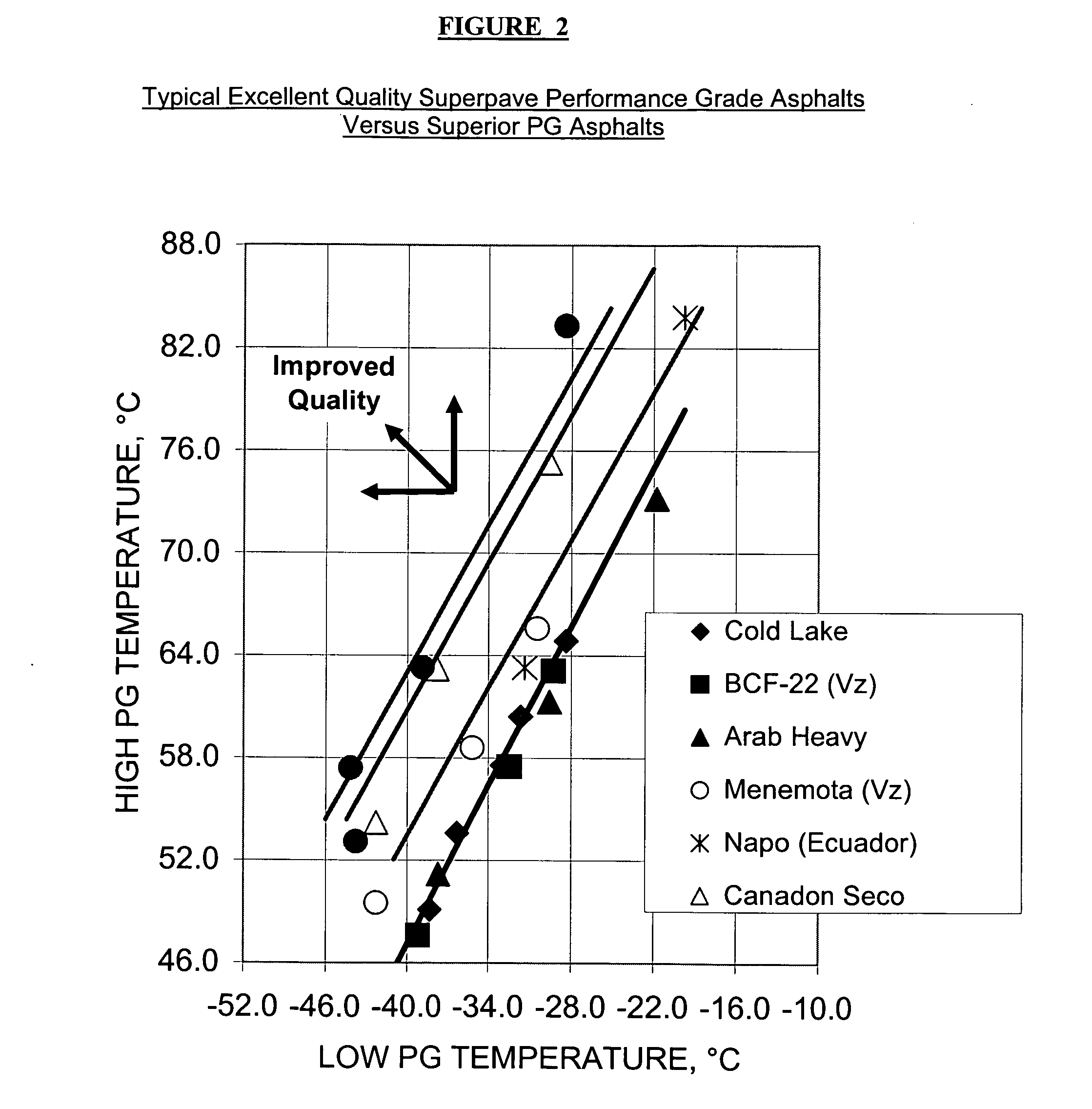

InactiveUS20080006561A1Improving neat asphalt propertyHigh-temperature stiffnessWorking-up pitch/asphalt/bitumen by selective extractionSolid sorbent liquid separationSolventAsphalt

This invention relates to a dearomatized asphalt. More particularly, an asphalt is extracted with a aromatic extraction solvent to produce an asphalt-rich phase and a solvent rich phase. The asphalt rich phase is stripped of solvent to produce dearomatized asphalt that has superior properties for paving and roofing applications.

Owner:MORAN LYLE E +1

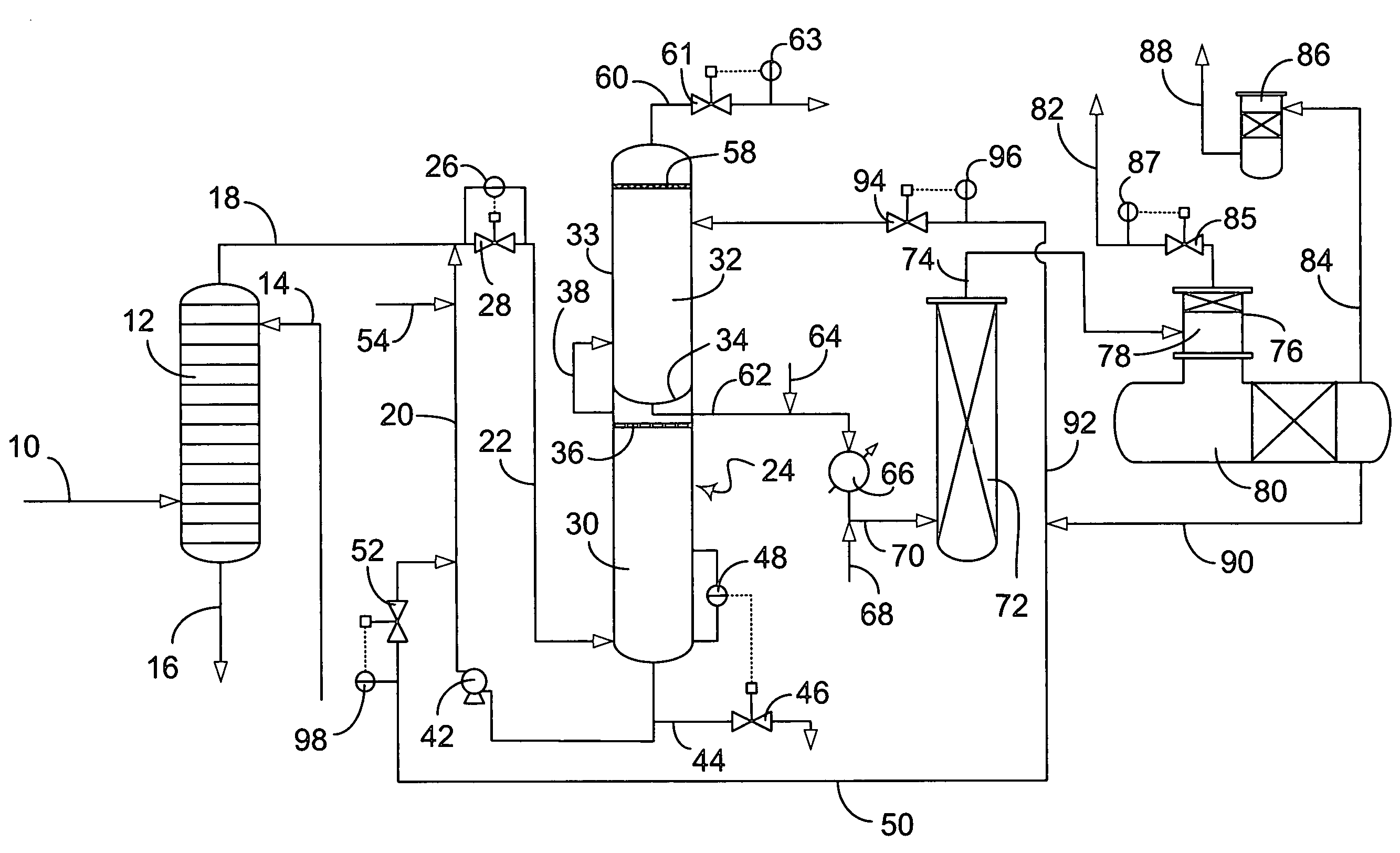

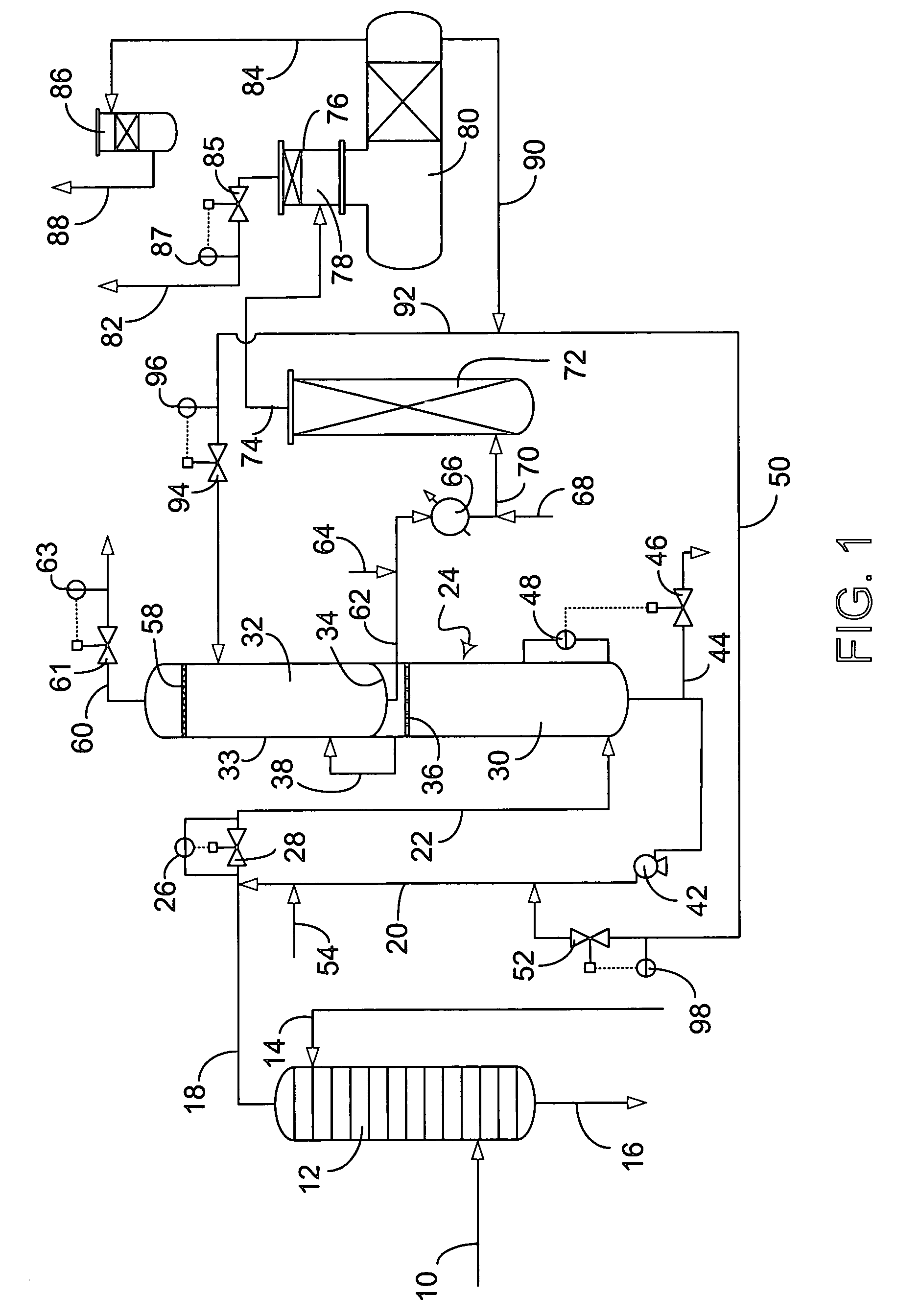

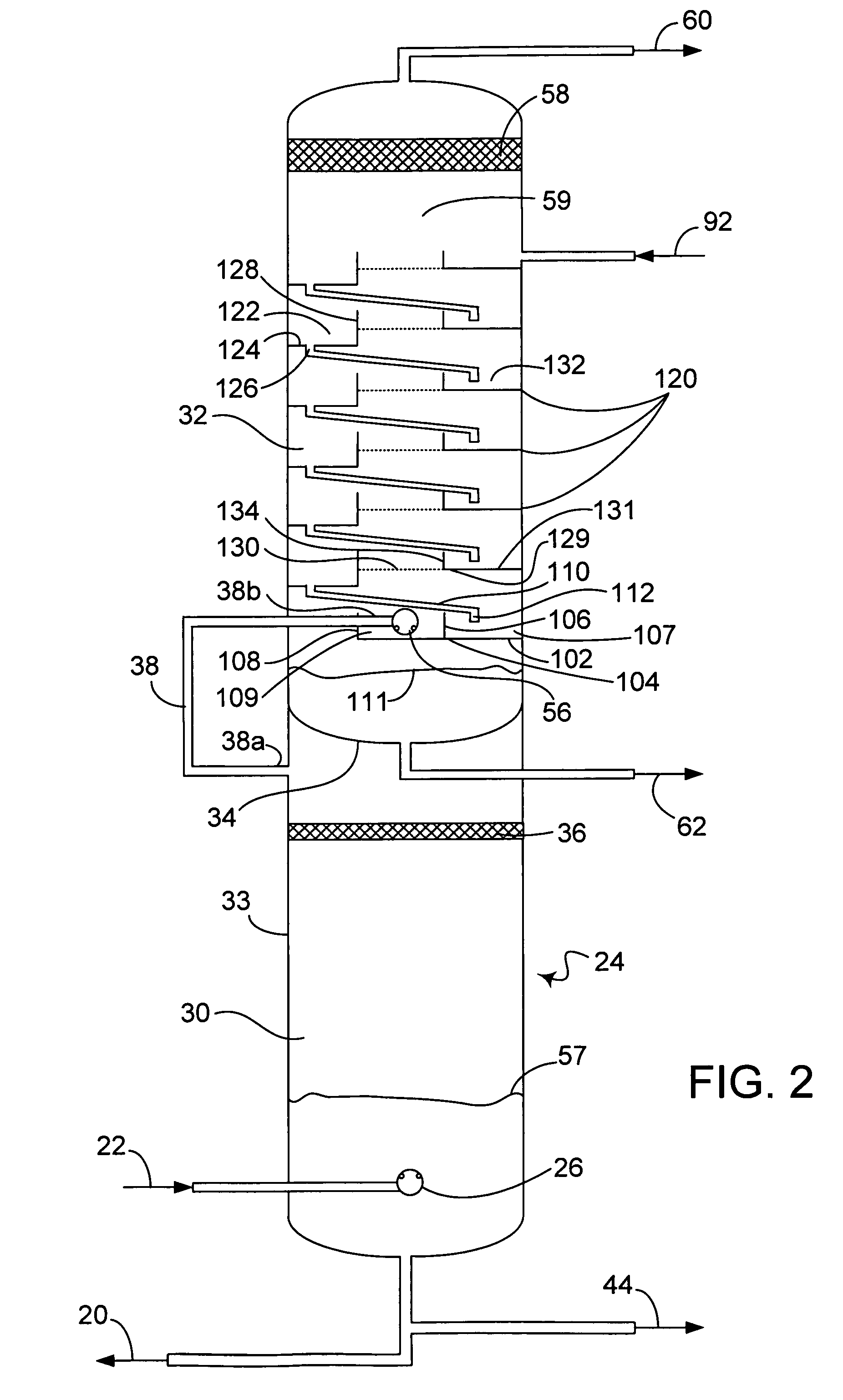

Enhanced solvent deasphalting process for heavy hydrocarbon feedstocks utilizing solid adsorbent

ActiveUS20080093260A1Improve performanceImprove current efficiencyWorking-up pitch/asphalt/bitumen by selective extractionHydrocarbon distillationBenzeneActivated carbon

A solvent deasphalting of crude oil or petroleum heavy fractions and residues is carried out in the presence of a solid adsorbent, such as clay, silica, alumina and activated carbon, which adsorbs the contaminants and permits the solvent and oil fraction to be removed as a separate stream from which the solvent is recovered for recycling; the adsorbent with contaminants and the asphalt bottoms is mixed with aromatic and / or polar solvents to desorb the contaminants and washed as necessary, e.g., with benzene, toluene, xylenes and tetrahydrofuran, to clean adsorbant which is recovered and recycled; the solvent-asphalt mixture is sent to a fractionator for recovery and recycling of the aromatic or polar solvent. The bottoms from the fractionator include the concentrated PNA and contaminants and are further processes as appropriate.

Owner:SAUDI ARABIAN OIL CO

Process for producing fuel

InactiveUS20060027488A1Low costHigh thermal efficiencyWorking-up pitch/asphalt/bitumen by selective extractionSolid fuelsAlkaneSorbent

A fuel is produced from bitumen by precipitating a substantial portion of asphaltenes from bitumen by contacting the bitumen with a lower alkane solvent. Suitable burners include a fluidized bed boiler, a circulating fluidized bed boiler and a pitch boiler which utilize either pre-combustion sulfur sorbents or post-combustion flue gas desulfurization. The sulfur in emissions can be used to produce sulfuric acid. The process uses a low cost fuel, generates steam, power and sulfuric acid and meets all emission requirements for SO2, NOx and PM.

Owner:GAUTHIER RICHARD

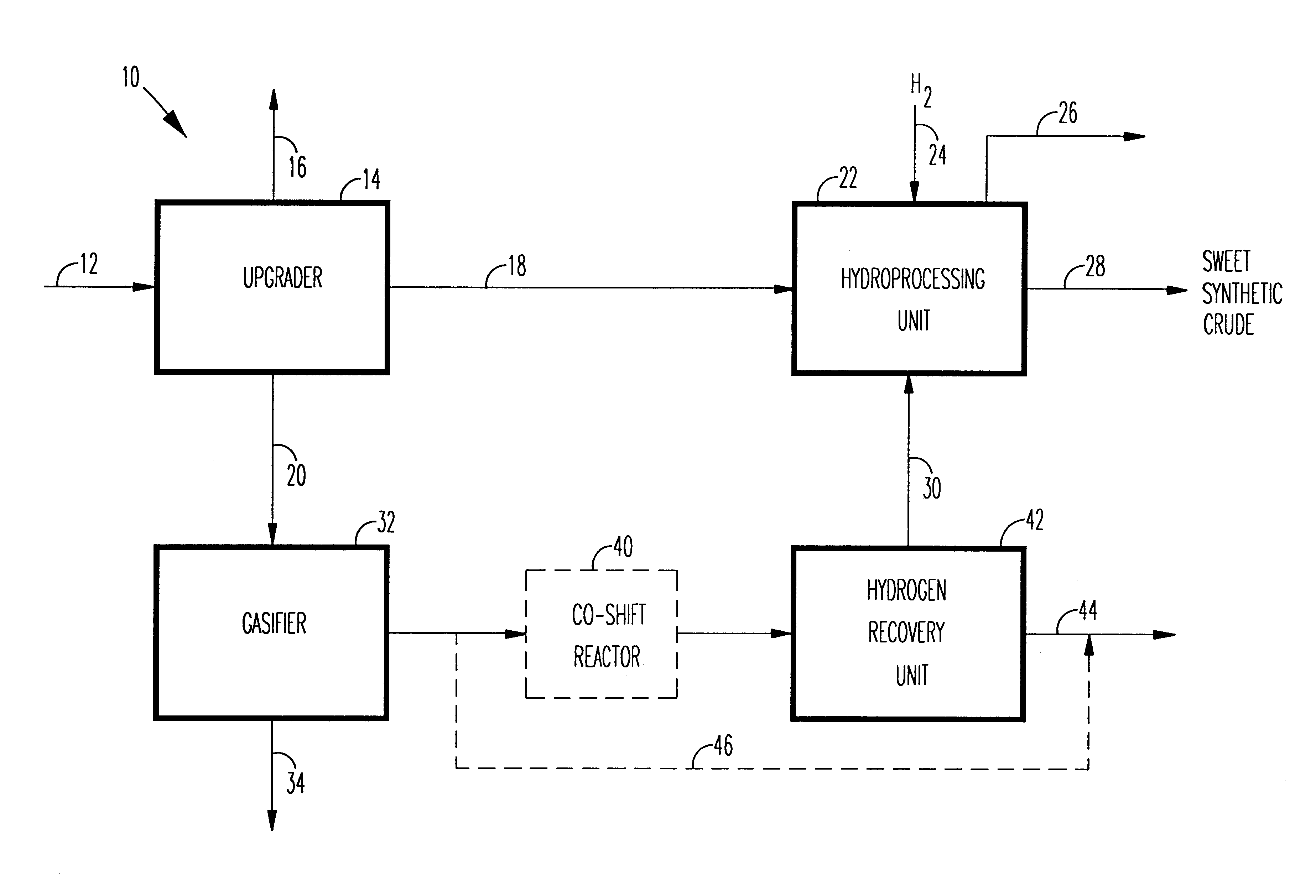

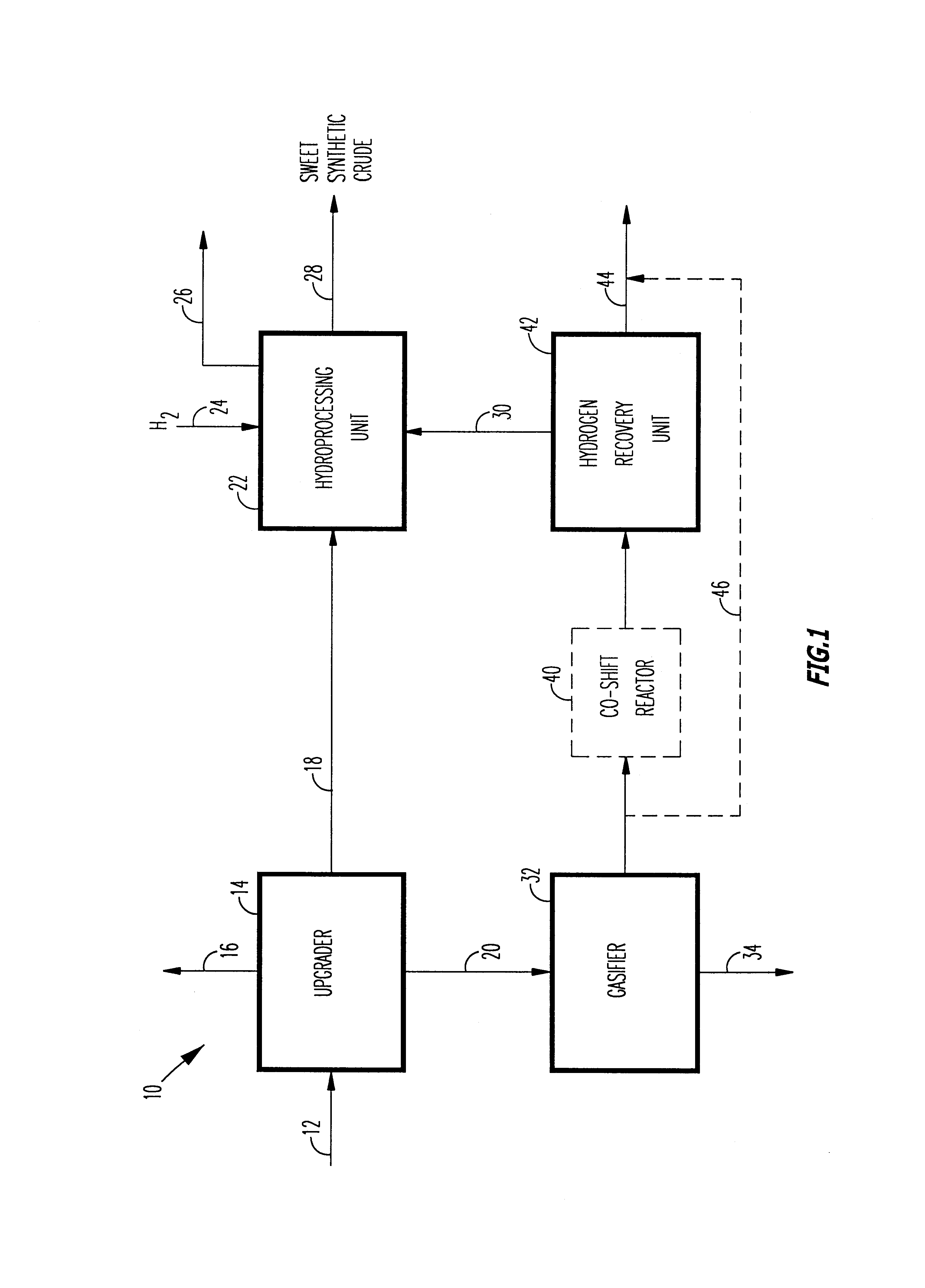

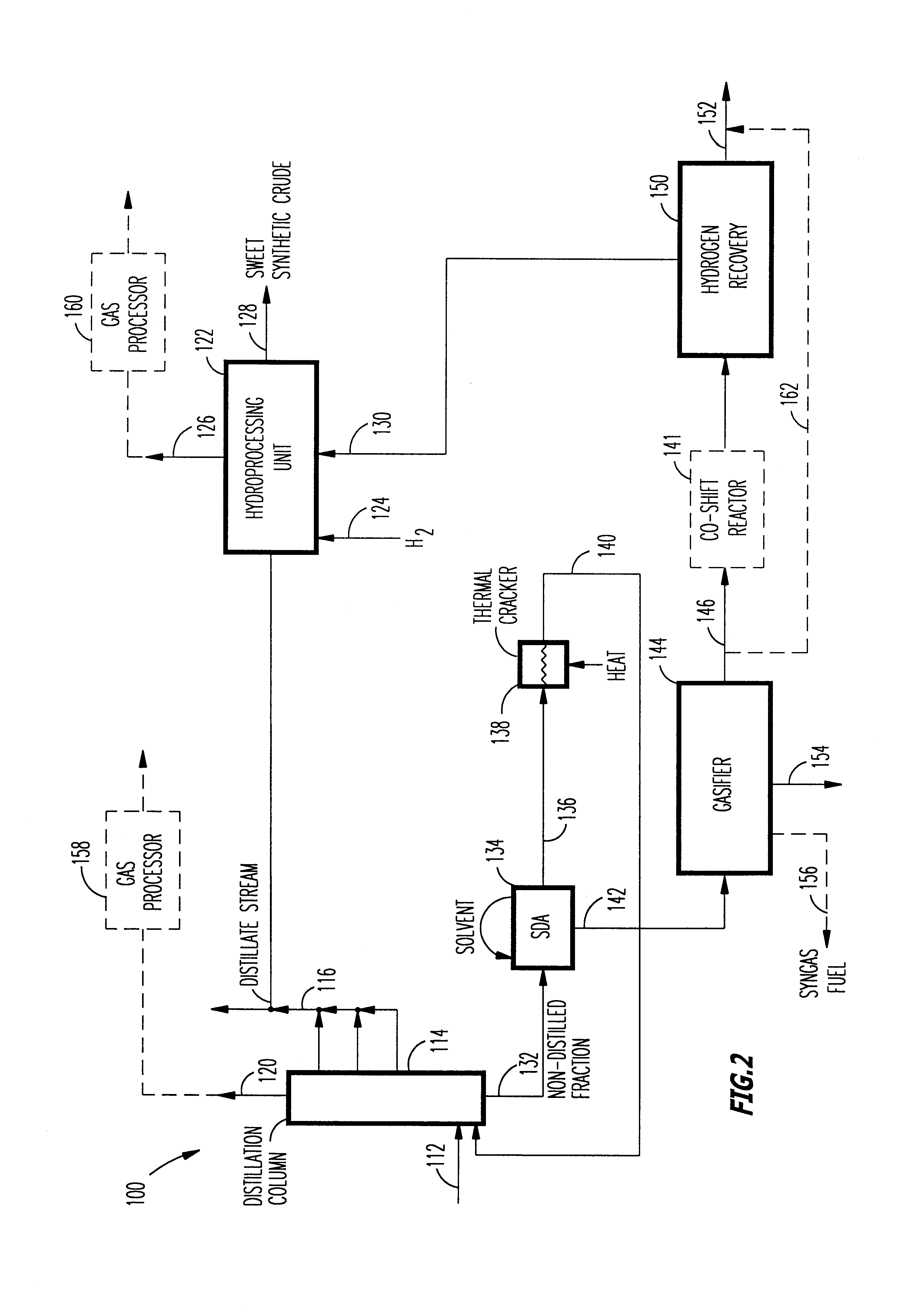

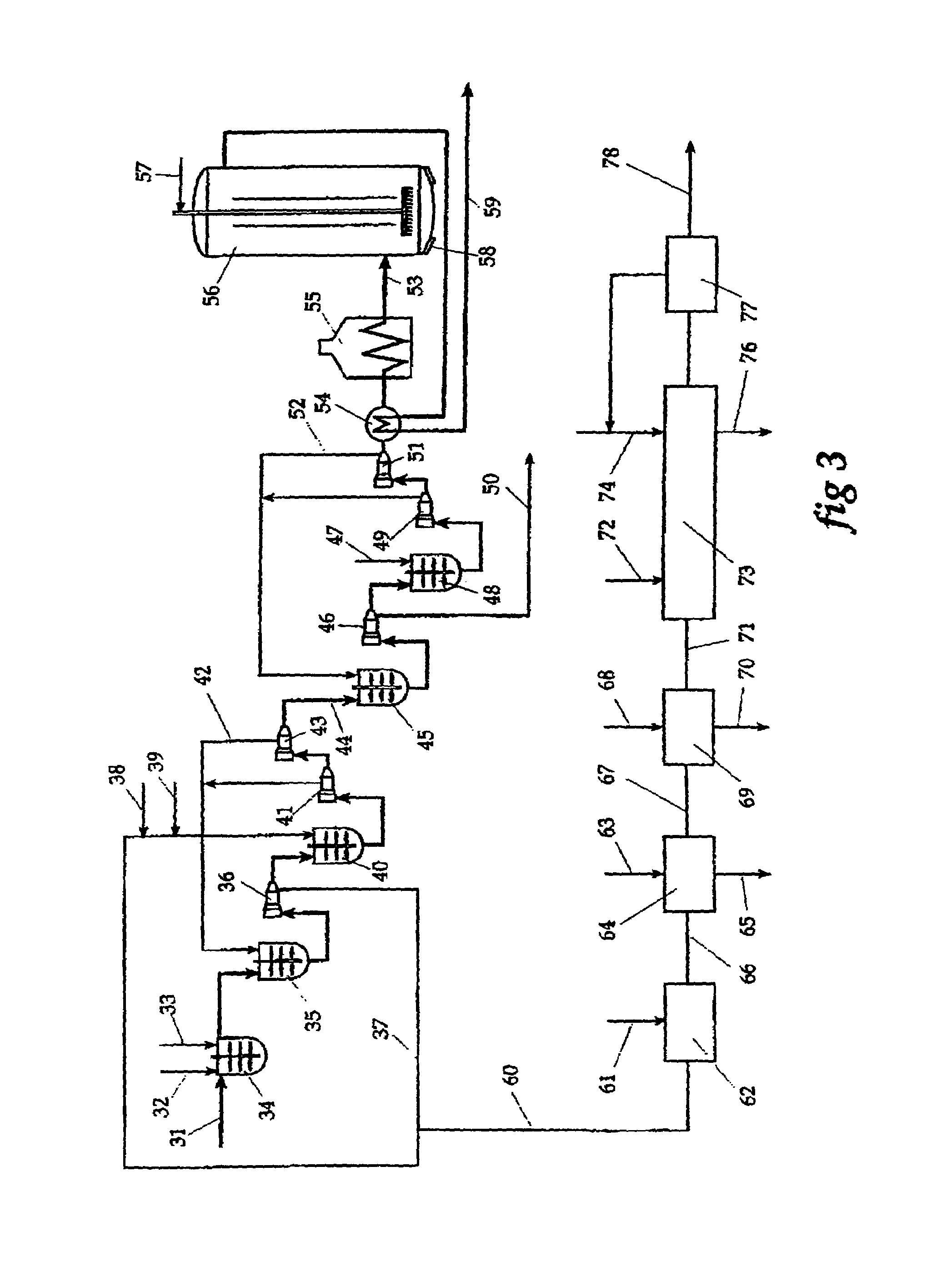

Method of and apparatus for upgrading and gasifying heavy hydrocarbon feeds

A novel apparatus for producing sweet synthetic crude from a heavy hydrocarbon feed comprising: an upgrader for receiving said heavy hydrocarbon feed and producing a distillate fraction including sour products, and high-carbon content by-products; a gasifier for receiving the high-carbon content by-products and producing synthetic fuel gas and sour by-products; a hydroprocessing unit for receiving the sour by-products and hydrogen gas, thereby producing gas and sweet crude; and a hydrogen recovery unit for receiving said synthetic fuel gas and producing further hydrogen gas and hydrogen-depleted synthetic fuel gas, said further hydrogen gas being supplied to said hydroprocessing unit.

Owner:ORMAT IND LTD

Membrane desulfurization of liquid hydrocarbons using an extractive liquid membrane contactor system and method

InactiveUS20110000823A1Transfer rate is not hinderedEasy to transportWorking-up pitch/asphalt/bitumen by selective extractionSolvent extractionOrganosulfur compoundsLiquid hydrocarbons

The process of the present invention is directed to the desulfurization of a sulfur-containing hydrocarbon stream with a membrane contactor, where sulfur compounds are concentrated in a sulfur-rich stream on a permeate side of the membrane using an extractive liquid, and a sulfur-lean stream is recovered as a retentate. The sulfur-rich stream, which has a small volume relative to the original hydrocarbon stream, is conveyed to a recovery zone to recover extractive liquid, and the remaining hydrocarbon stream having an increased concentration of sulfur compounds is passed to a downstream desulfurization apparatus or system, such as a hydrotreating system, to recover the hydrocarbons associated with the organosulfur compounds.

Owner:SAUDI ARABIAN OIL CO

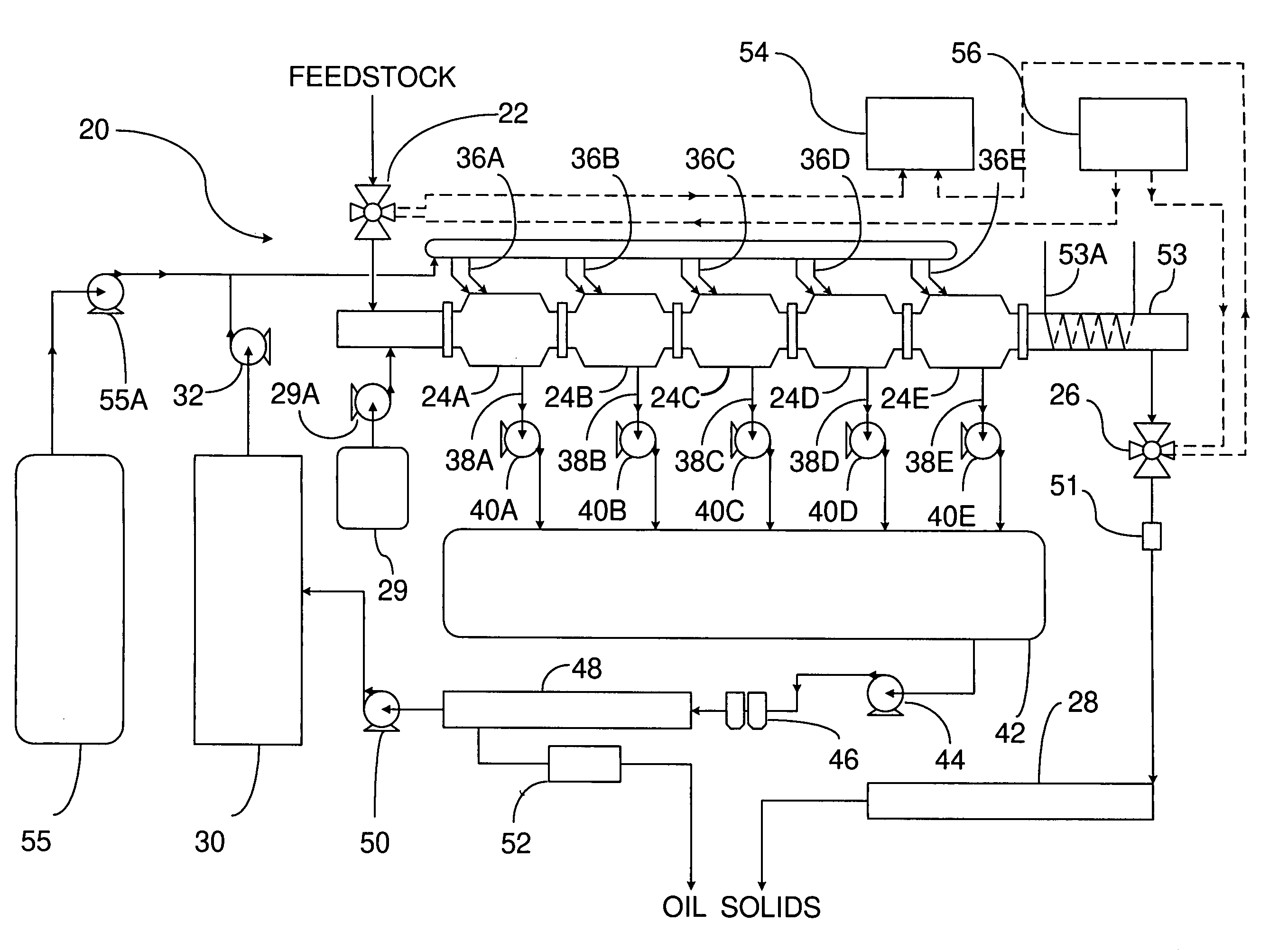

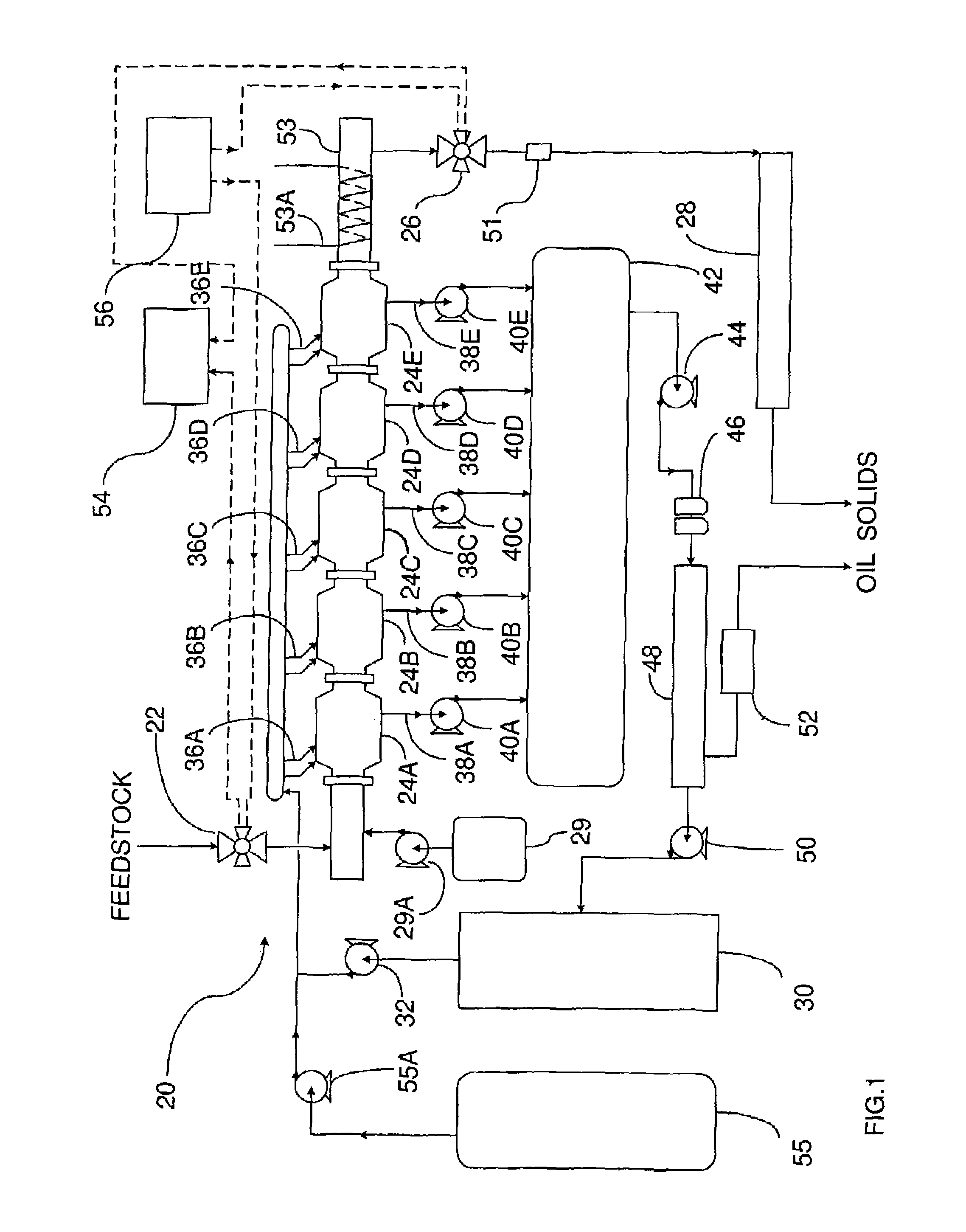

Process for upgrading tar

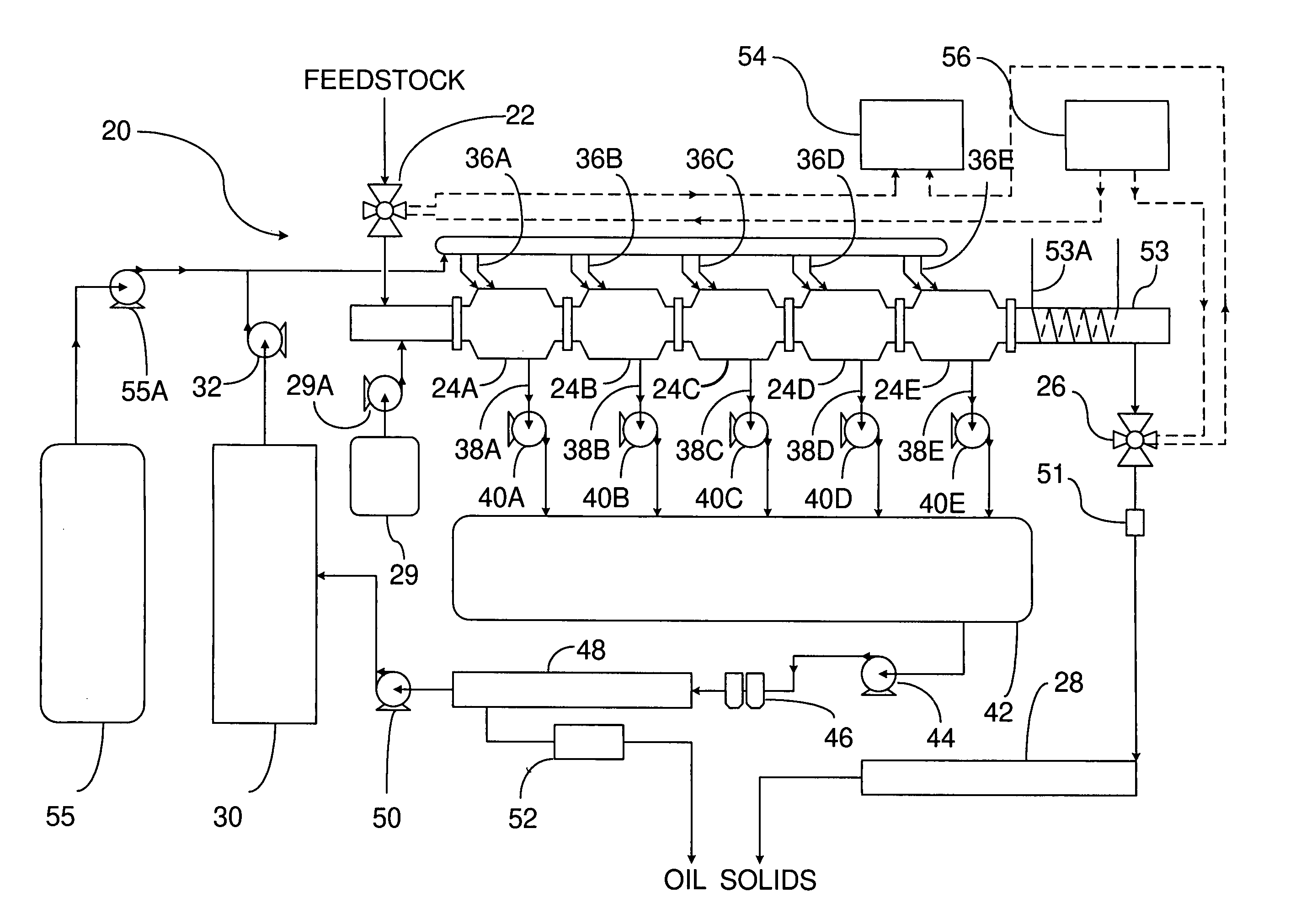

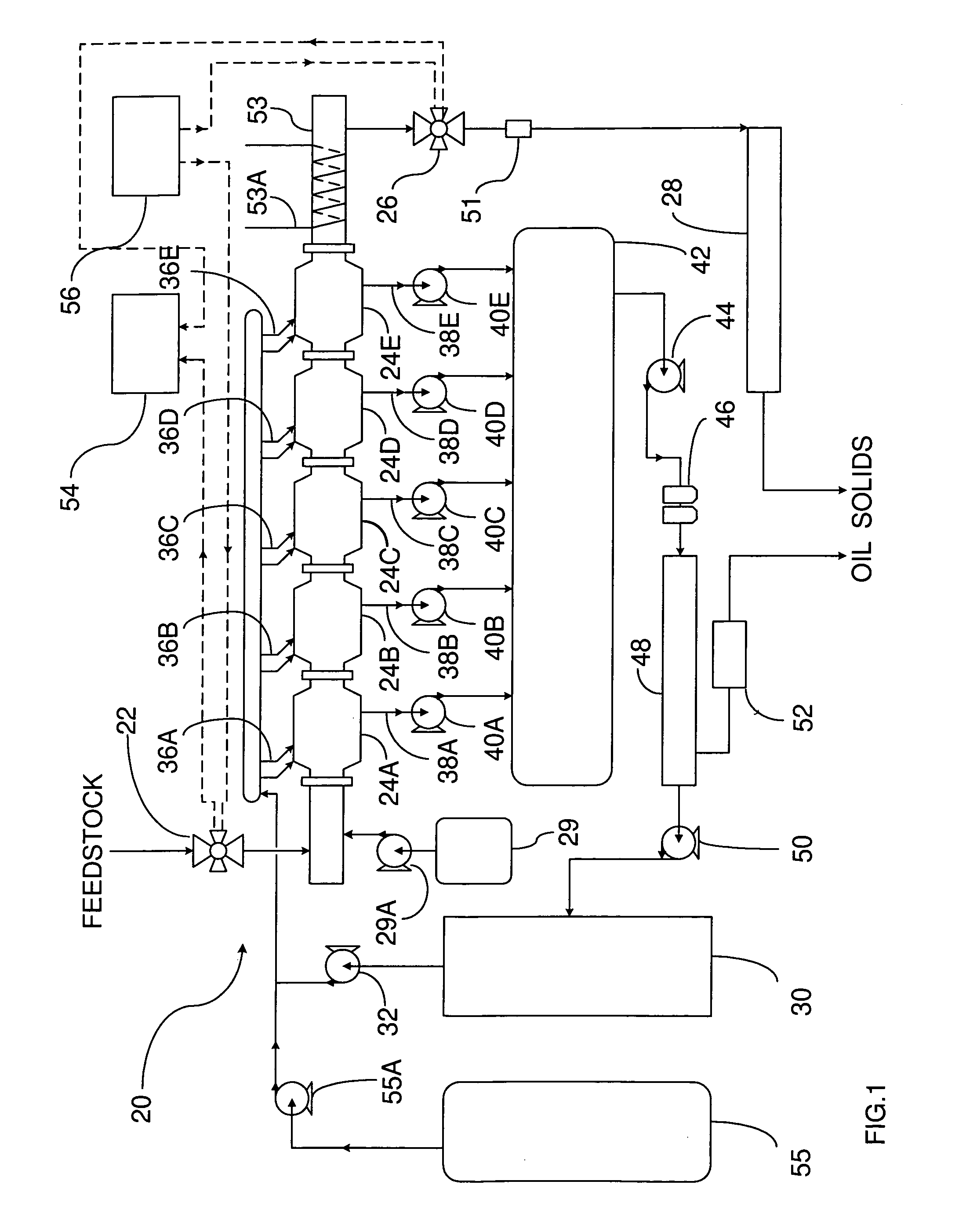

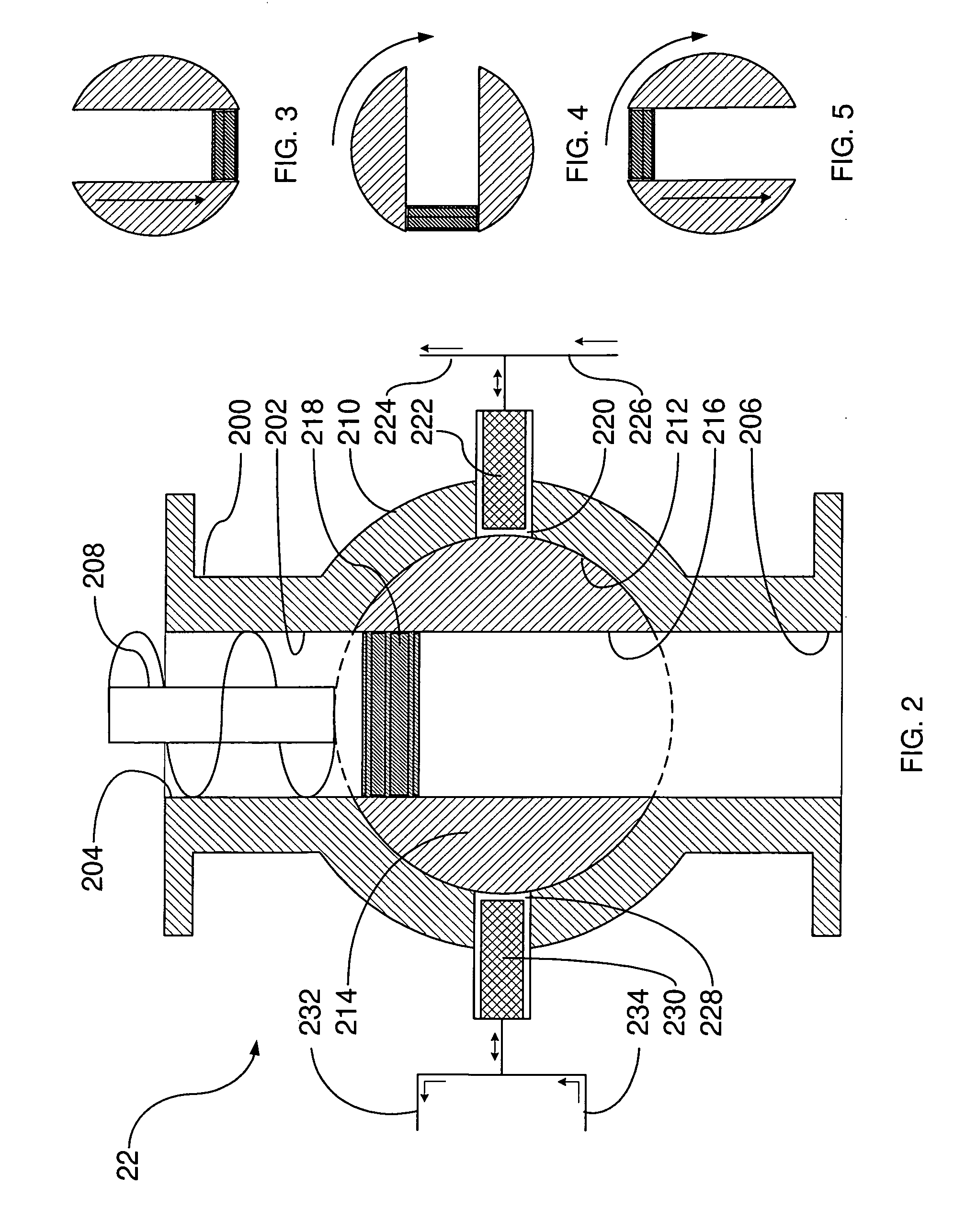

ActiveUS20080099371A1Thermal non-catalytic crackingLiquid hydrocarbon mixture productionDistillationTar

A feedstream comprising tar is feed to a solvent deasphalter wherein it is contacted with a deasphalting solvent or fluid to produce a composition comprising a mixture or slurry of solvent containing a soluble portion of the tar, and a heavy tar fraction comprising the insoluble portion of the tar. These fractions may be separated in the deasphalter apparatus, such as by gravity settling wherein the heavy tar fraction is taken off as bottoms, and the solvent-soluble fraction taken as overflow or overheads with the solvent. The overflow or overheads is sent to a solvent recovery unit, such as a distillation apparatus, wherein solvent is recovered as overheads and a deasphalted tar fraction is taken off as a sidestream or bottoms. The solvent or a portion thereof, recovered as overheads, may be then be recycled to the solvent deasphalter, or in a preferred embodiment, at least a portion of the solvent is steam cracked to produce a product comprising light olefins.

Owner:EXXONMOBIL CHEM PAT INC

Treatment of crude oils

InactiveUS6955753B1Quality improvementImprove efficiencyWorking-up pitch/asphalt/bitumen by selective extractionSolvent extractionHydrogenPetroleum

A process and apparatus to extract and recover heavy metals and sulfur from crude oil or petroleum fuel products including the steps of emulsifying the crude oil with an emulsifying agent, adding a leach solution to the emulsified crude oil and leaching the emulsified crude oil at elevated temperature and pressure to give a leached emulsified crude oil. The leach solution may be acid or alkali. A proportion of the leach solution is extracted for recovering heavy metals. There can also be a microwave hydro-treating step using hydrogen gas at a temperature below 220° C. to ensure there is no quality degradation in the crude feed to produce a desulfurized crude oil and a hydrogen sulphide by-product and recovering sulfur from the hydrogen sulphide by-product.

Owner:RODOLFO ANTONIO M GOMEZ

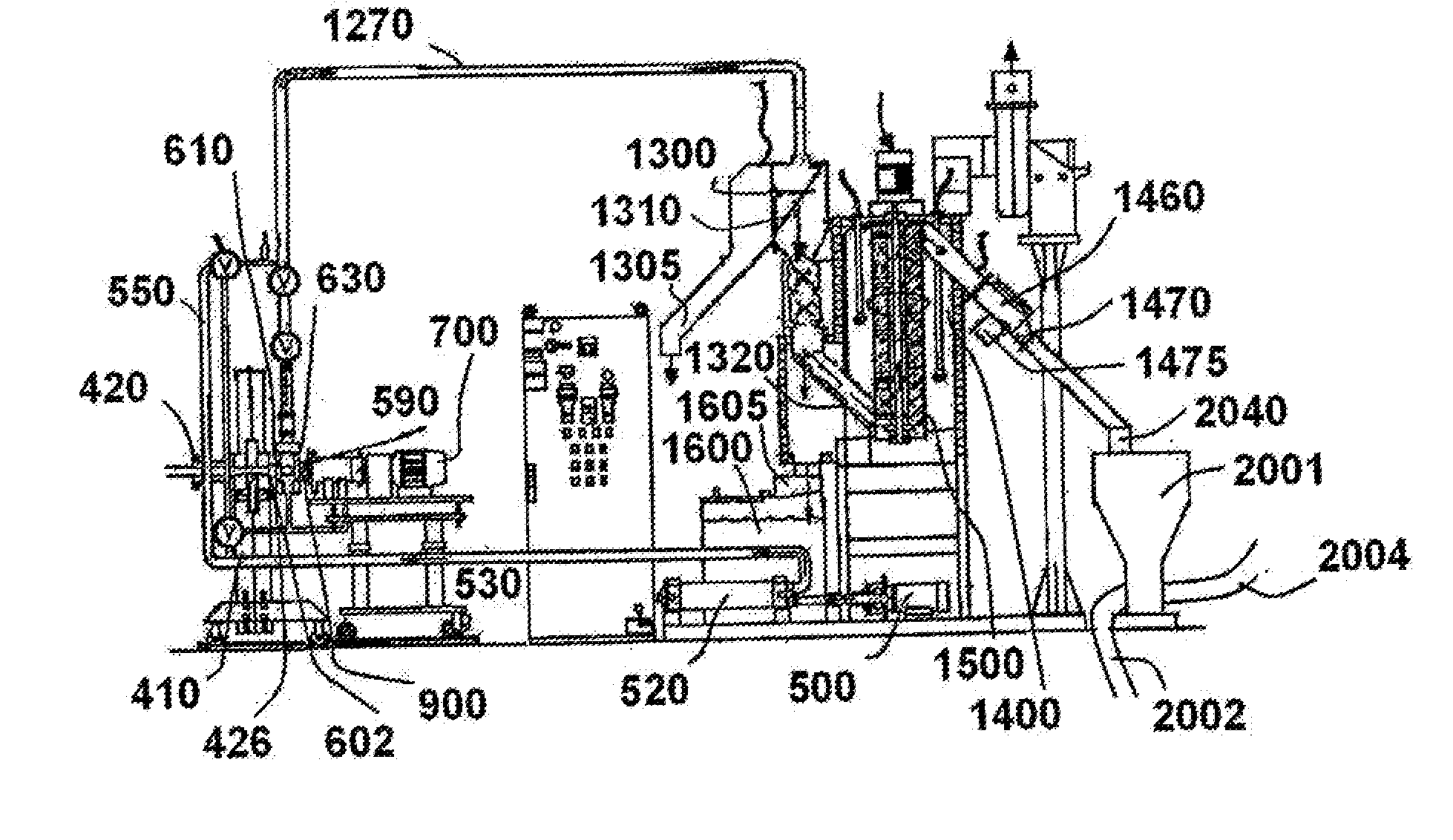

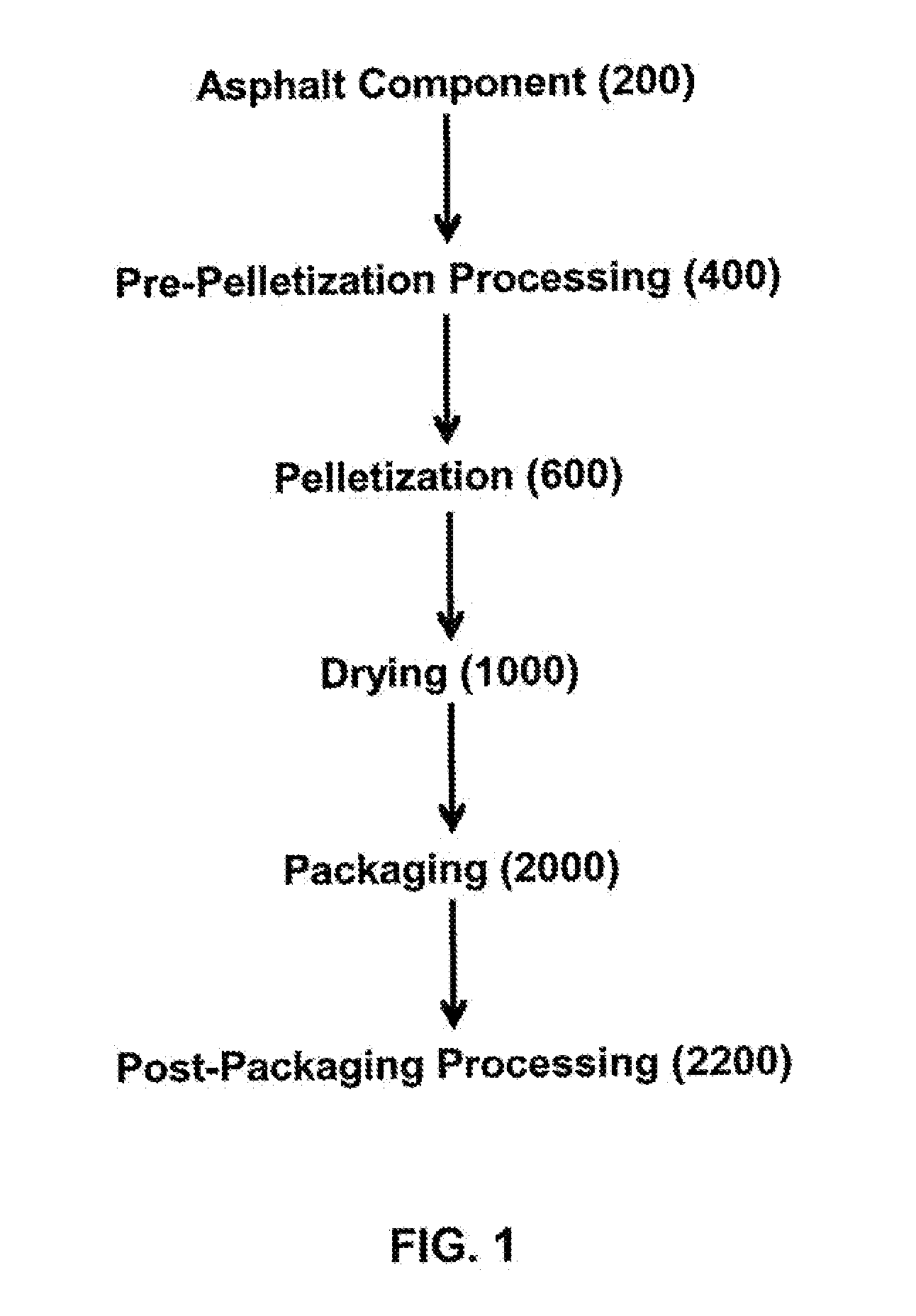

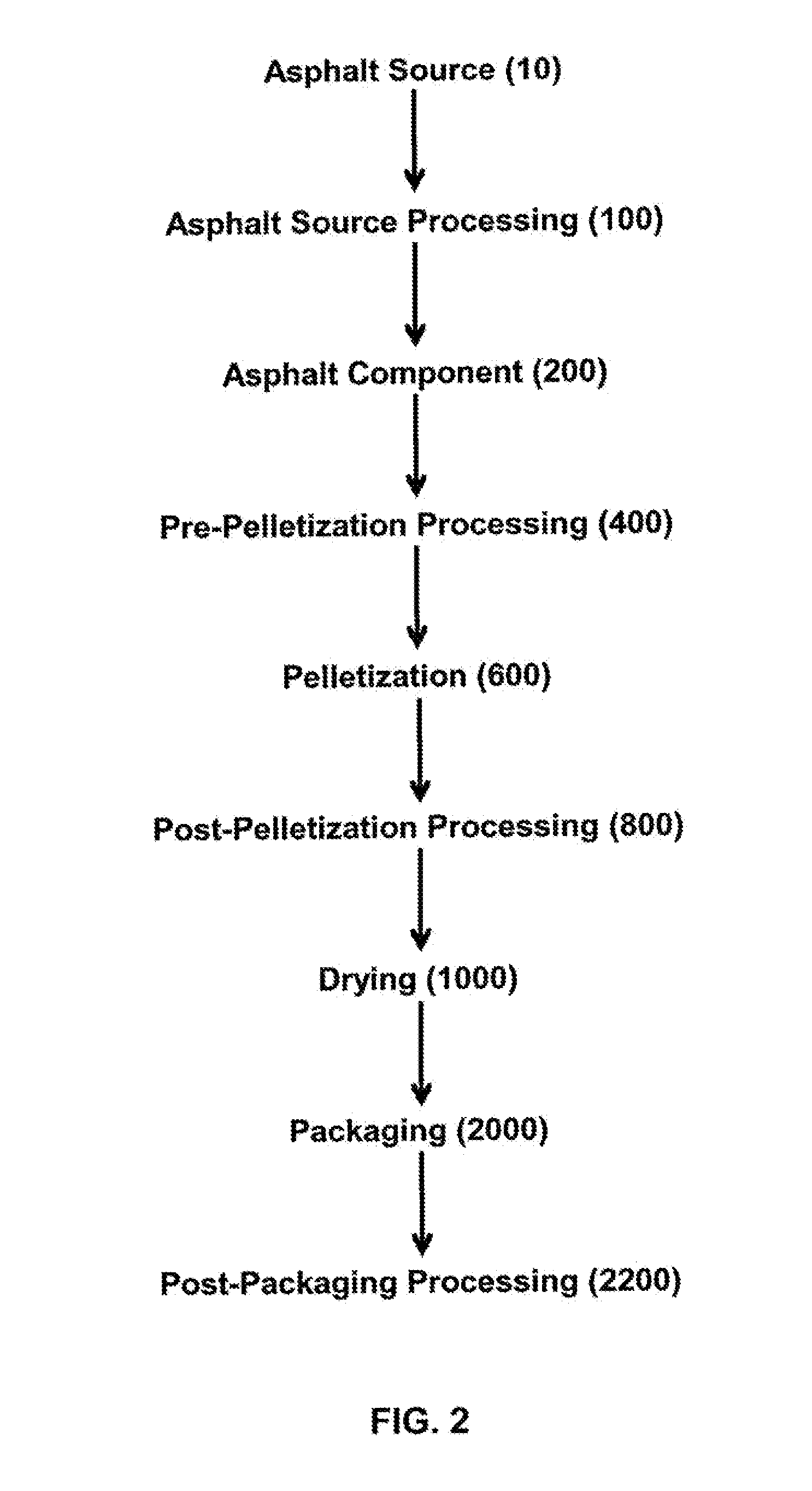

Continuous process for fractioning, combination, and recombination of asphalt components for pelletization and packaging of asphalt and asphalt-containing products

ActiveUS20130036714A1Prevent movementWorking-up pitch/asphalt/bitumen by distillationLiquid surface applicatorsEngineeringAsphalt

A continuous process for fractioning, combination, and recombination of asphalt sources into asphalt components for pelletization of asphalt and asphalt-containing products such that the pellets formed are generally uniform in dimension, freely flowing, free from agglomeration, and the pelletized asphalt is packaged, and preferably compatibly packaged, for additional processing and applications.

Owner:GALA INDUSTRIES INC

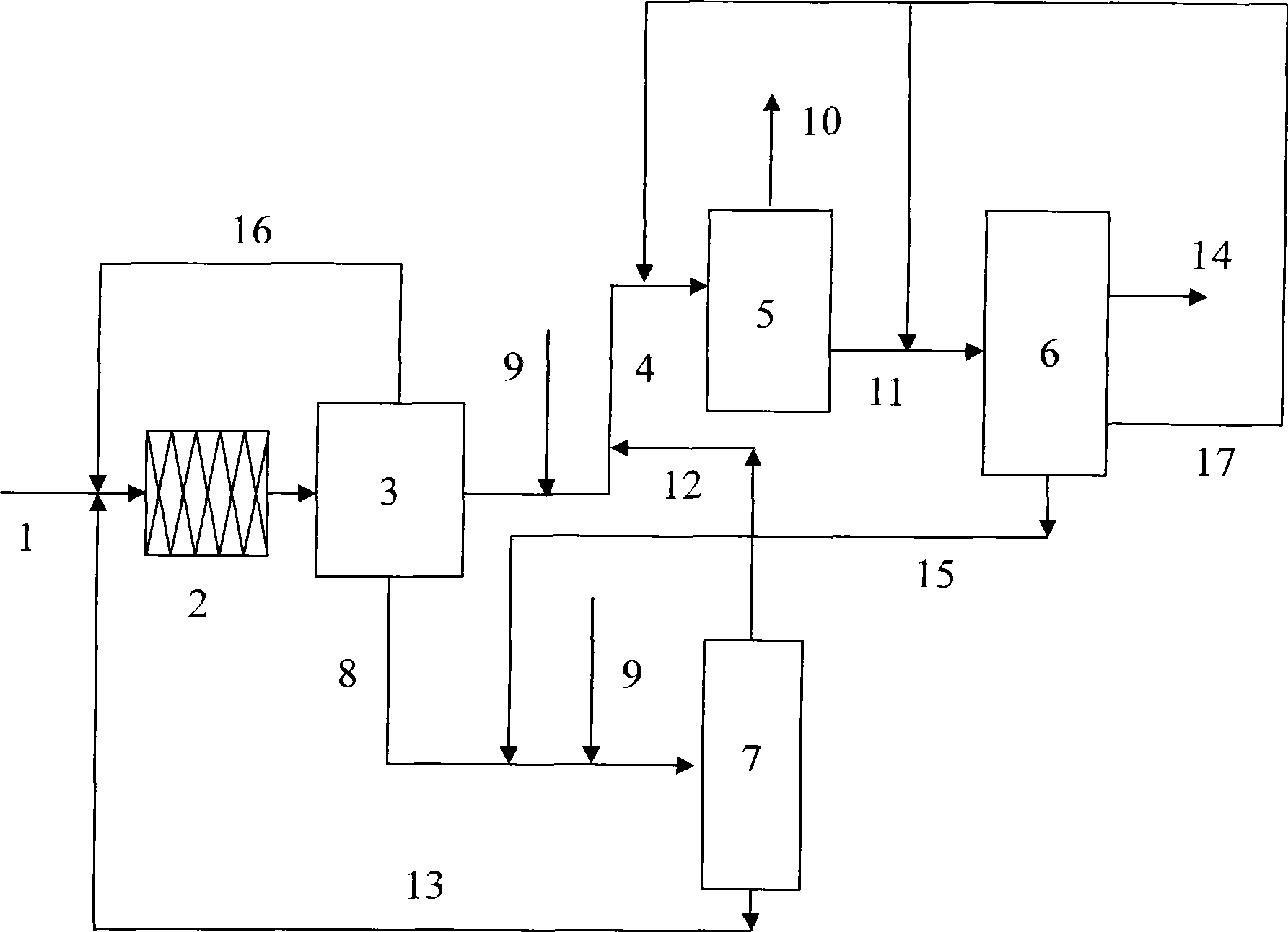

Composite process for treatment of inferior residual oil

ActiveCN101418222AWide adaptability of raw materialsAchieve maximum light weightTreatment with hydrotreatment processesTar working-up by solvent extractionDistillationHydrogenation process

The invention discloses a combined process method for treating inferior residual oil. The method comprises the following steps: a residual oil material enters a solvent deasphalting device to obtain DAO and deoil asphalt; the obtained DAO enters a hydrogenation device of a boiling bed and is treated to obtained a lightweight distillation fraction and hydrogenated tail oil; the hydrogenated tail oil enters a catalytic cracking device and is treated to obtain a lightweight distillation fraction and oil slurry; at least partial oil slurry and the deoil asphalt are mixed, enter a hydrogenation device of a suspension bed and are treated to obtain a lightweight distillation fraction and unconverted tail oil, wherein the unconverted tail oil circularly returns the solvent deasphalting device; and the lightweight distillation fraction and the DAO are mixed and enter the hydrogenation device of the boiling bed. The combined process course organically combines a decarbonization process and a hydrogenation process; and according to different properties of raw materials, a corresponding process and operation condition is adopted so as to maximize conversion of the residual oil material while minimizing equipment investment.

Owner:CHINA PETROLEUM & CHEM CORP +1

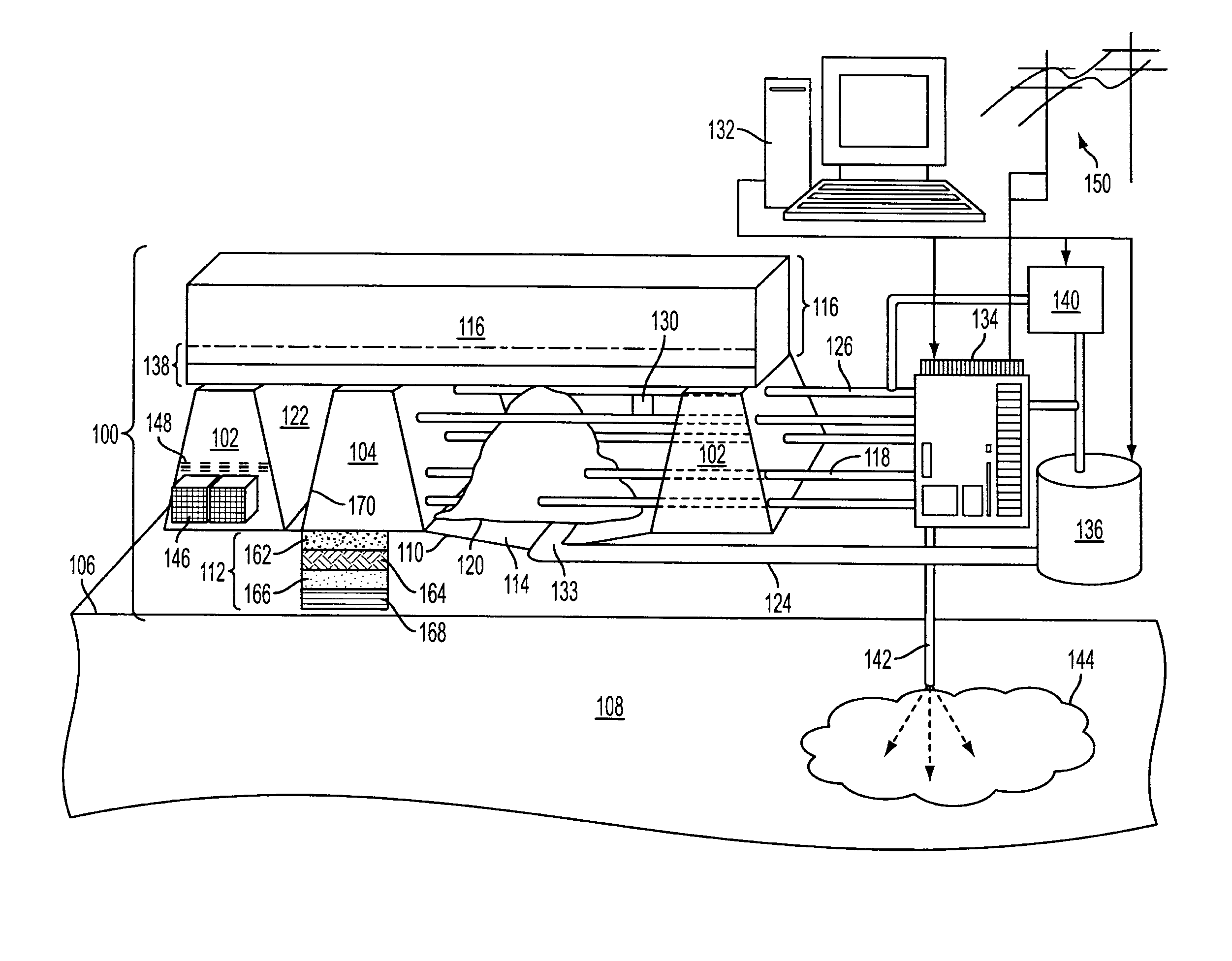

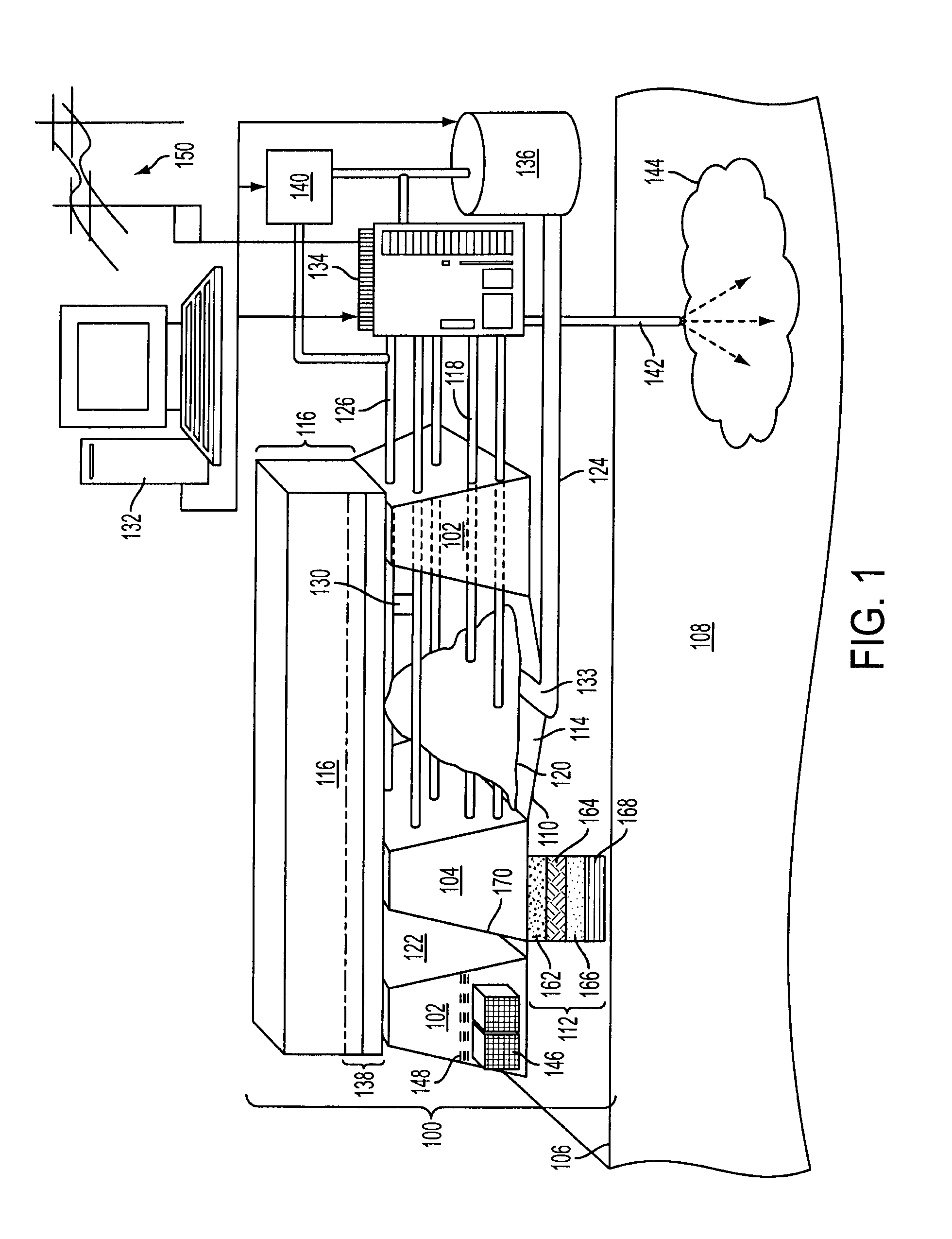

Methods of recovering hydrocarbons from hydrocarbonaceous material using a constructed infrastructure having permeable walls and associated systems

ActiveUS20080190815A1Easy to produceLarge movementThermal non-catalytic crackingUnderground chambersHydrocotyle bowlesioidesEngineering

A method of recovering hydrocarbons from hydrocarbonaceous materials can include forming a constructed permeability control infrastructure. This constructed infrastructure defines a substantially encapsulated volume having substantially permeable side walls and a substantially impermeable cap. A comminuted hydrocarbonaceous material can be introduced into the control infrastructure to form a permeable body of hydrocarbonaceous material. The permeable body can be heated sufficient to remove hydrocarbons therefrom without contamination or substantial leaching of materials outside of the impoundment. During heating the hydrocarbonaceous material is substantially stationary as the constructed infrastructure is a fixed structure. Removed hydrocarbons can be collected for further processing, use in the process, and / or use as recovered.

Owner:RED LEAF RESOURCES

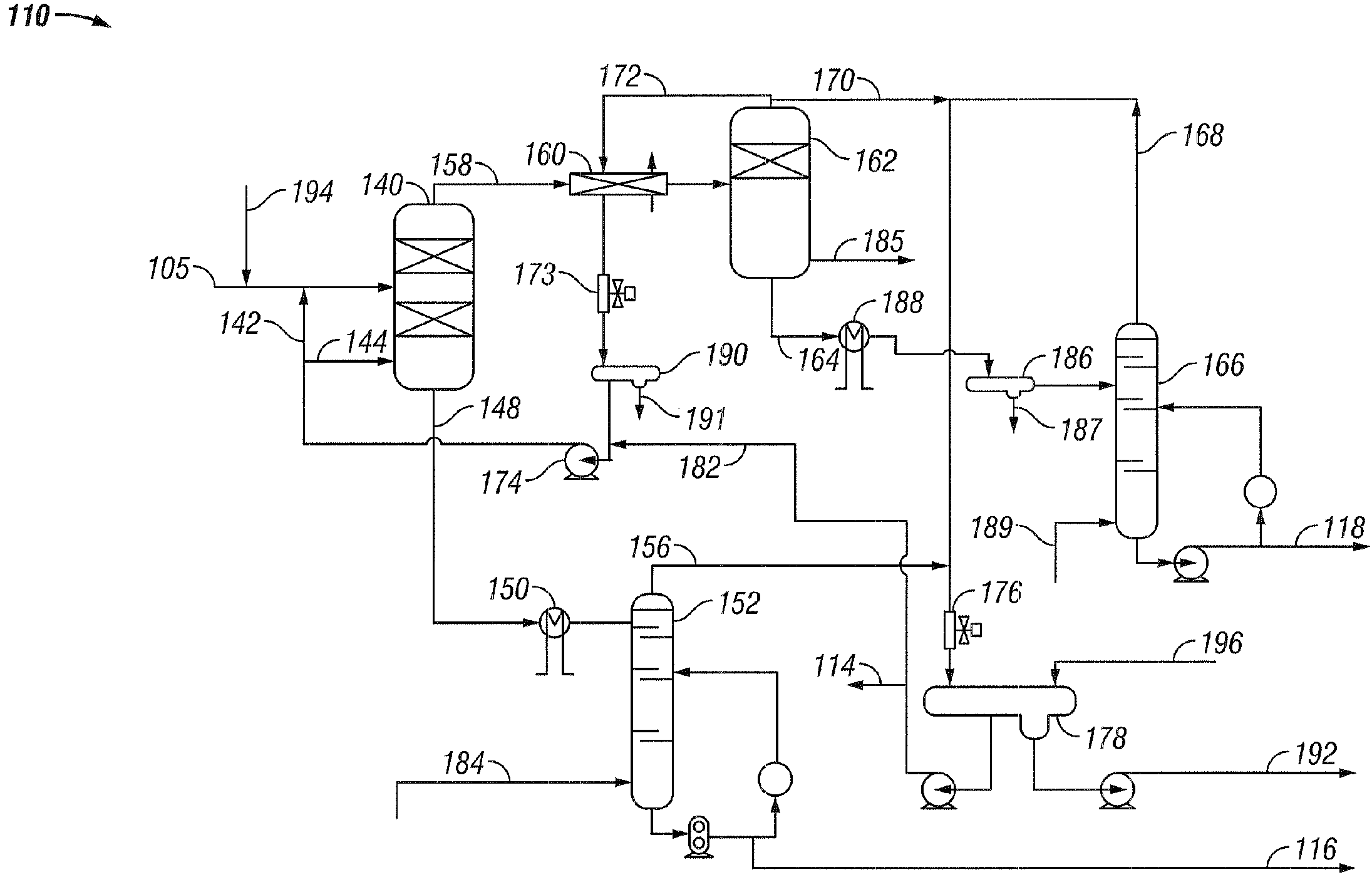

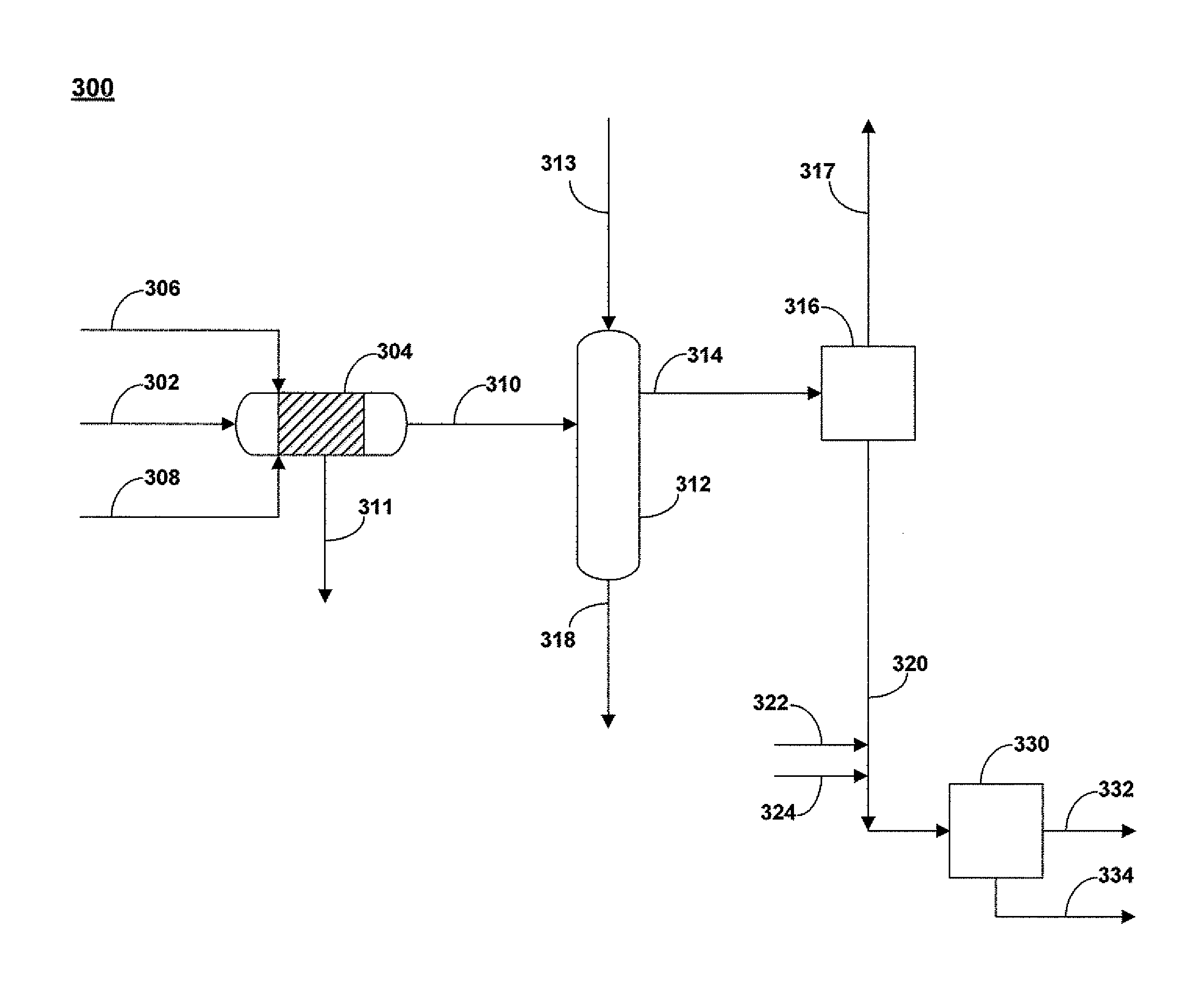

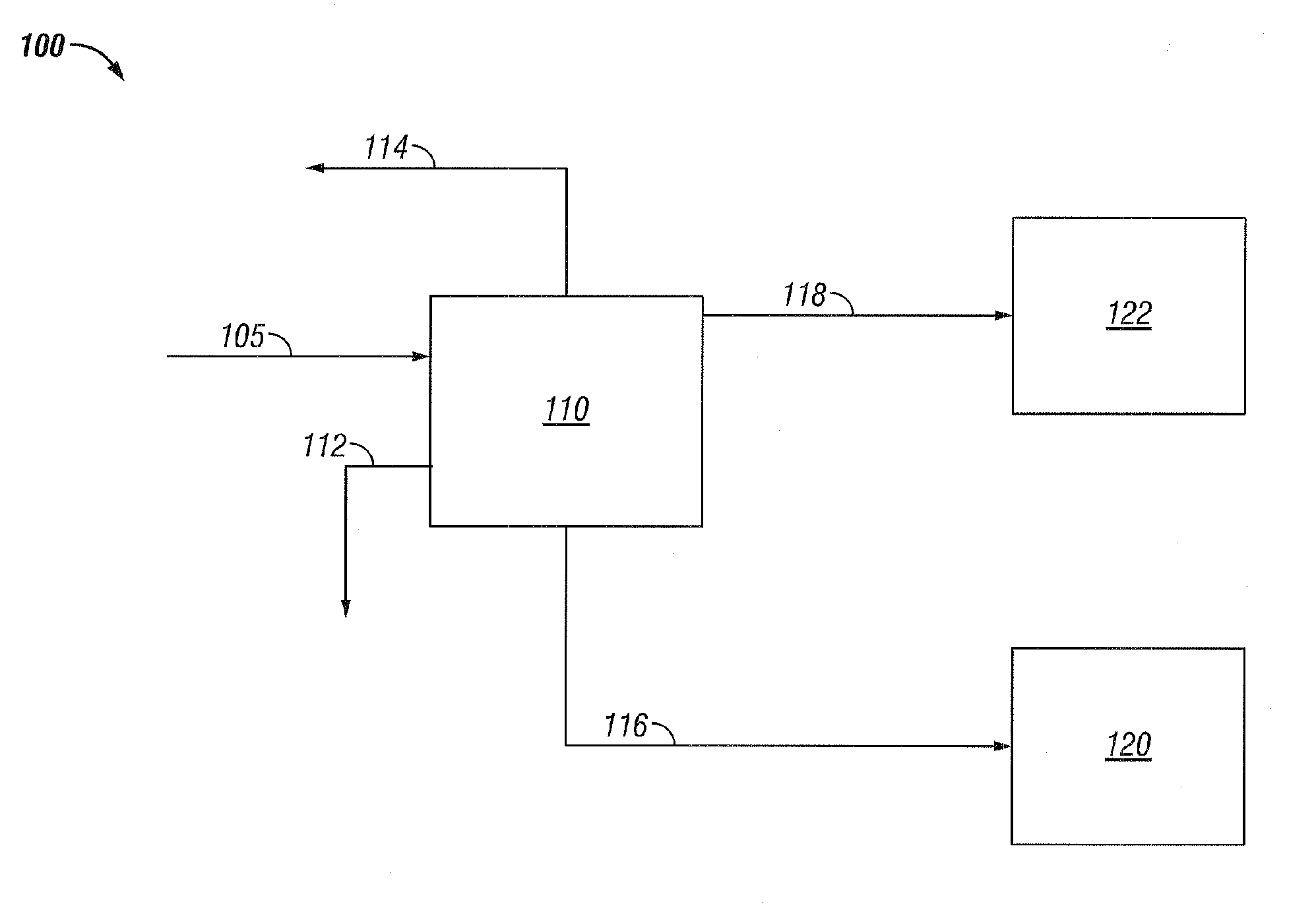

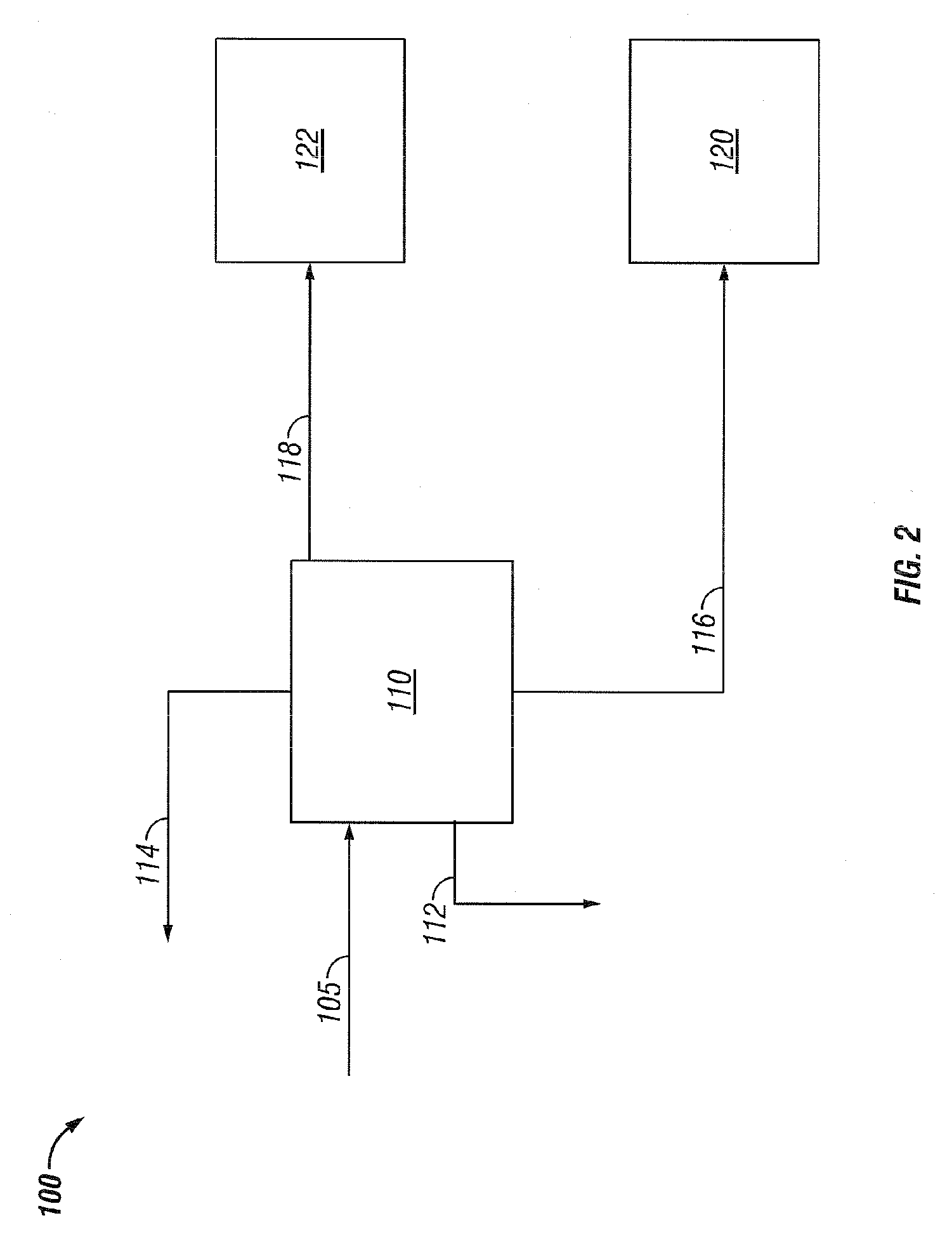

Bitumen production-upgrade with common or different solvents

ActiveUS7749378B2Reduce capital investmentReduce operating expensesWorking-up pitch/asphalt/bitumen by selective extractionRefining by water treatmentDiluentWater fraction

Disclosed is a process for the upgrading of heavy oils and bitumens, where the total feed to the process can include heavy oil or bitumen, water, and diluent. The process can include the steps of solvent deasphalting 110 the total feed 105 to recover an asphaltene fraction 116, a deasphalted oil fraction 118 essentially free of asphaltenes, a water fraction 112, and a solvent fraction 114. The process allows removal of salts from the heavy oils and bitumens either into the aqueous products or with the asphaltene product.

Owner:KELLOGG BROWN & ROOT LLC

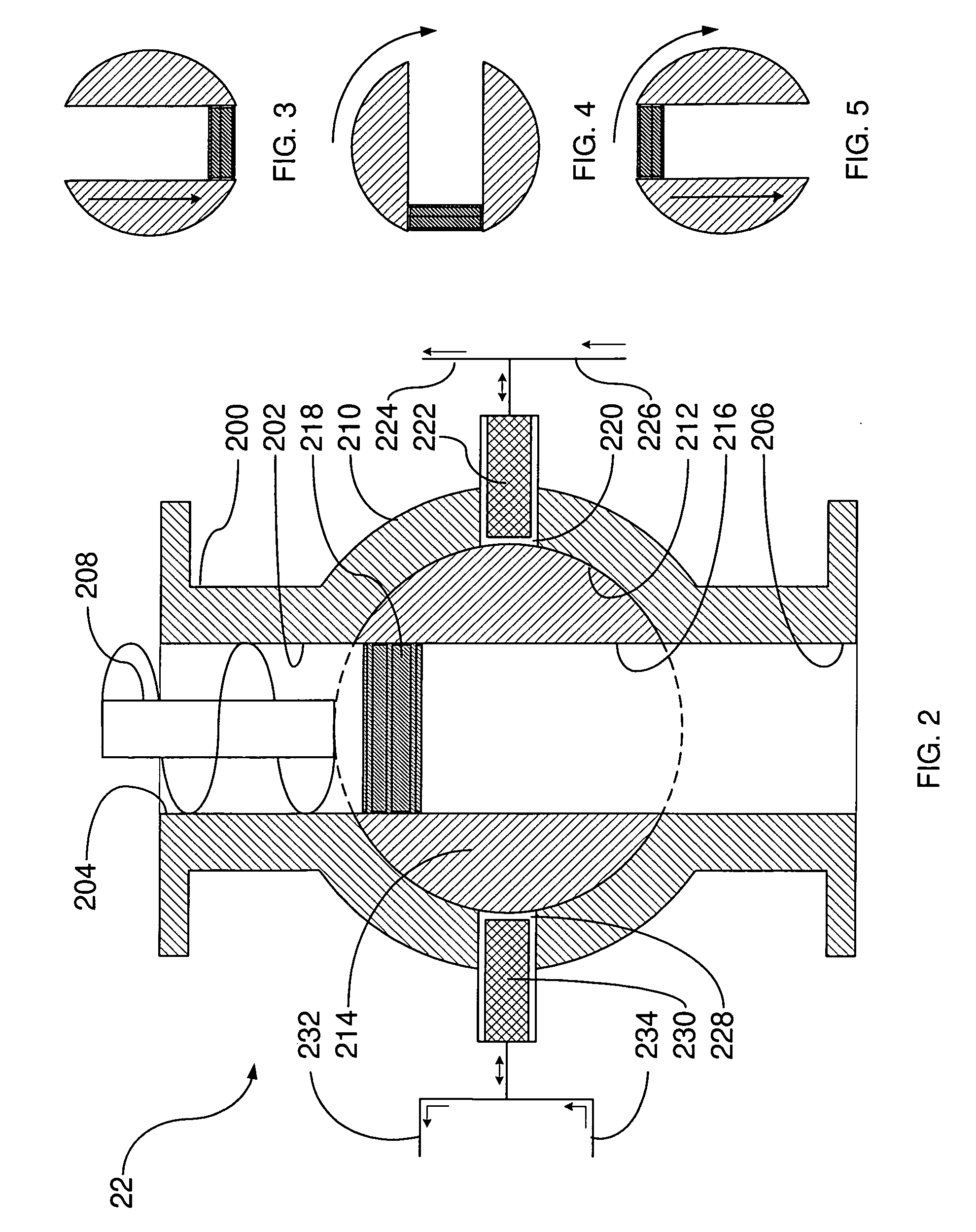

Method and apparatus for removing solute from a solid solute-bearing product

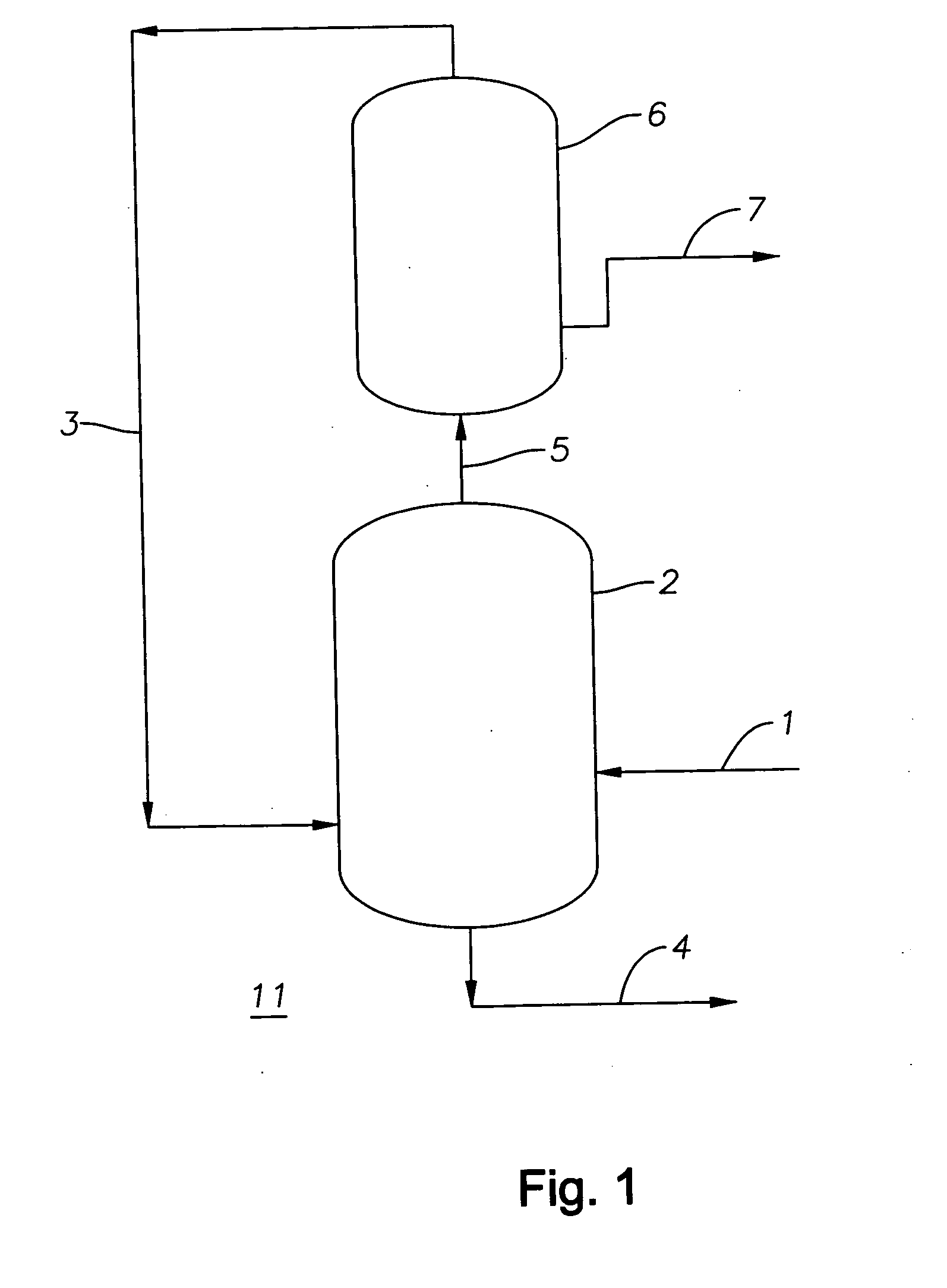

ActiveUS7384557B2Obstruct passageLiquid separation auxillary apparatusSolid sorbent liquid separationSolid massLiquid state

The process and apparatus are for removing a solute from a solute-bearing solid product by means of a solvent which remains in liquid state throughout the entire oil extraction process. In one embodiment, the solvent is normally in gazeous state at ambient temperature and pressure values, but is used mainly in liquid state within the method and apparatus of the present invention by maintaining such pressure and temperature values within the apparatus so that the solvent will remain in this liquid state.

Owner:APPLIED AMBIENT EXTRACTION PROCESS CONSULTANTS

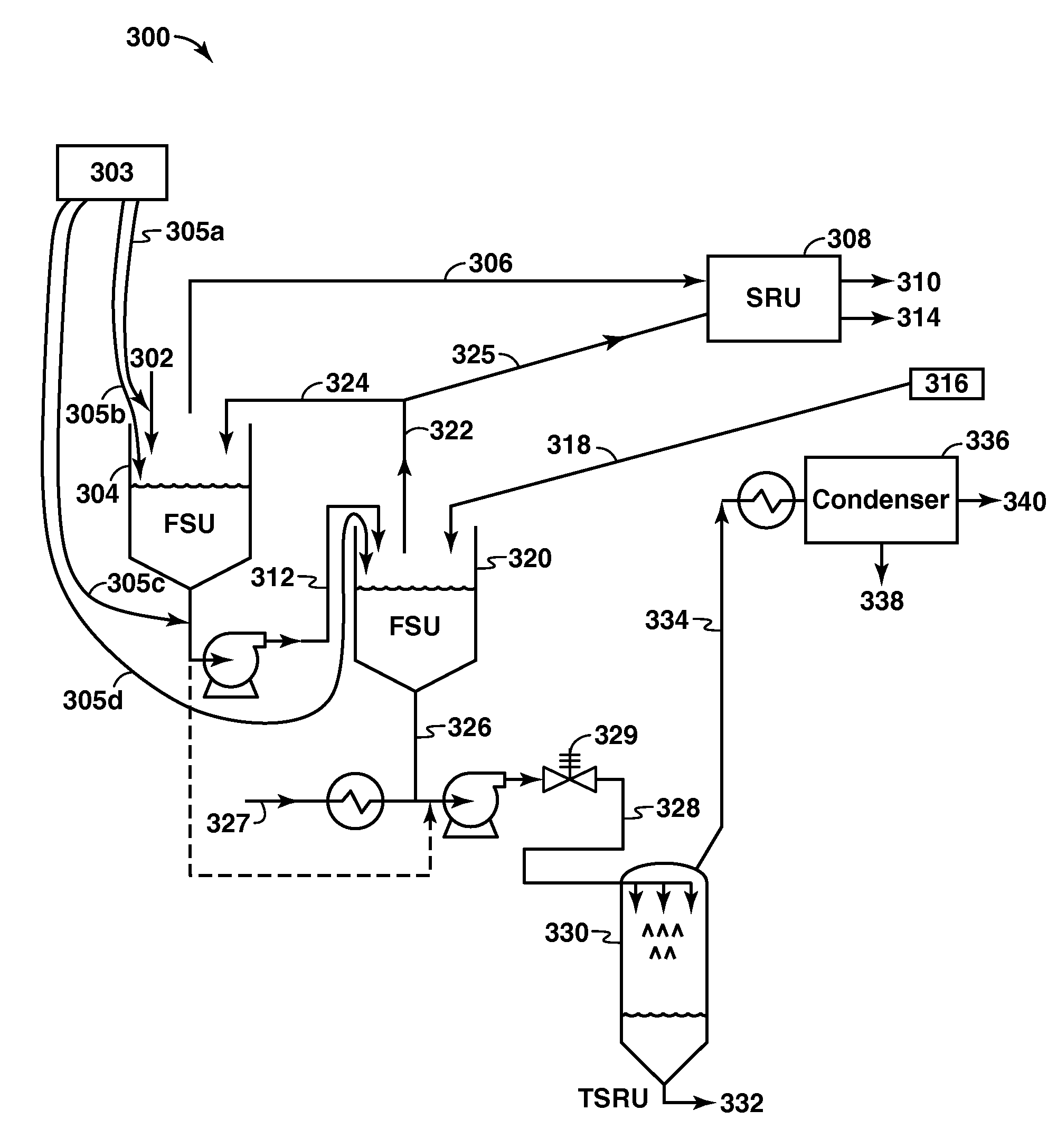

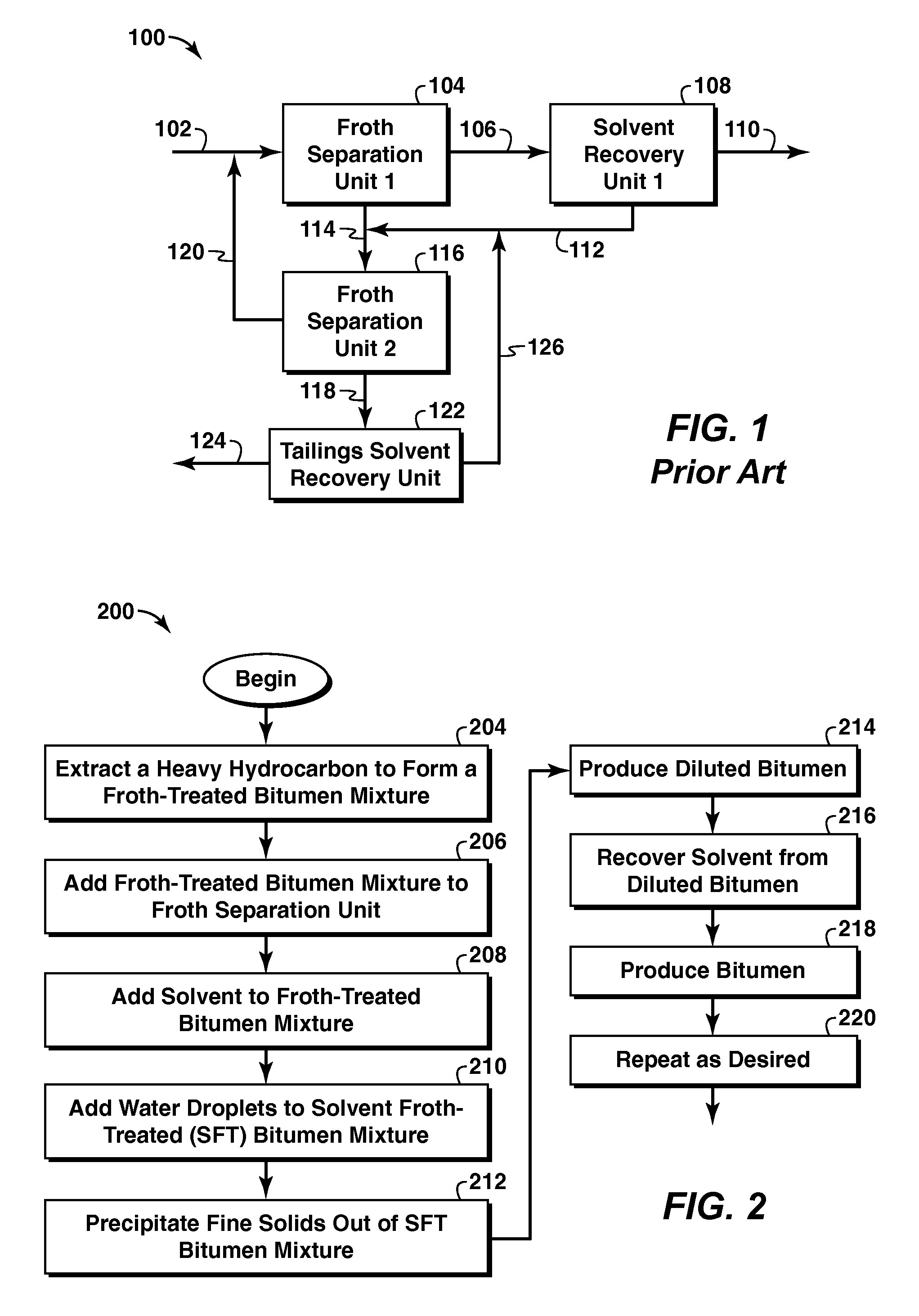

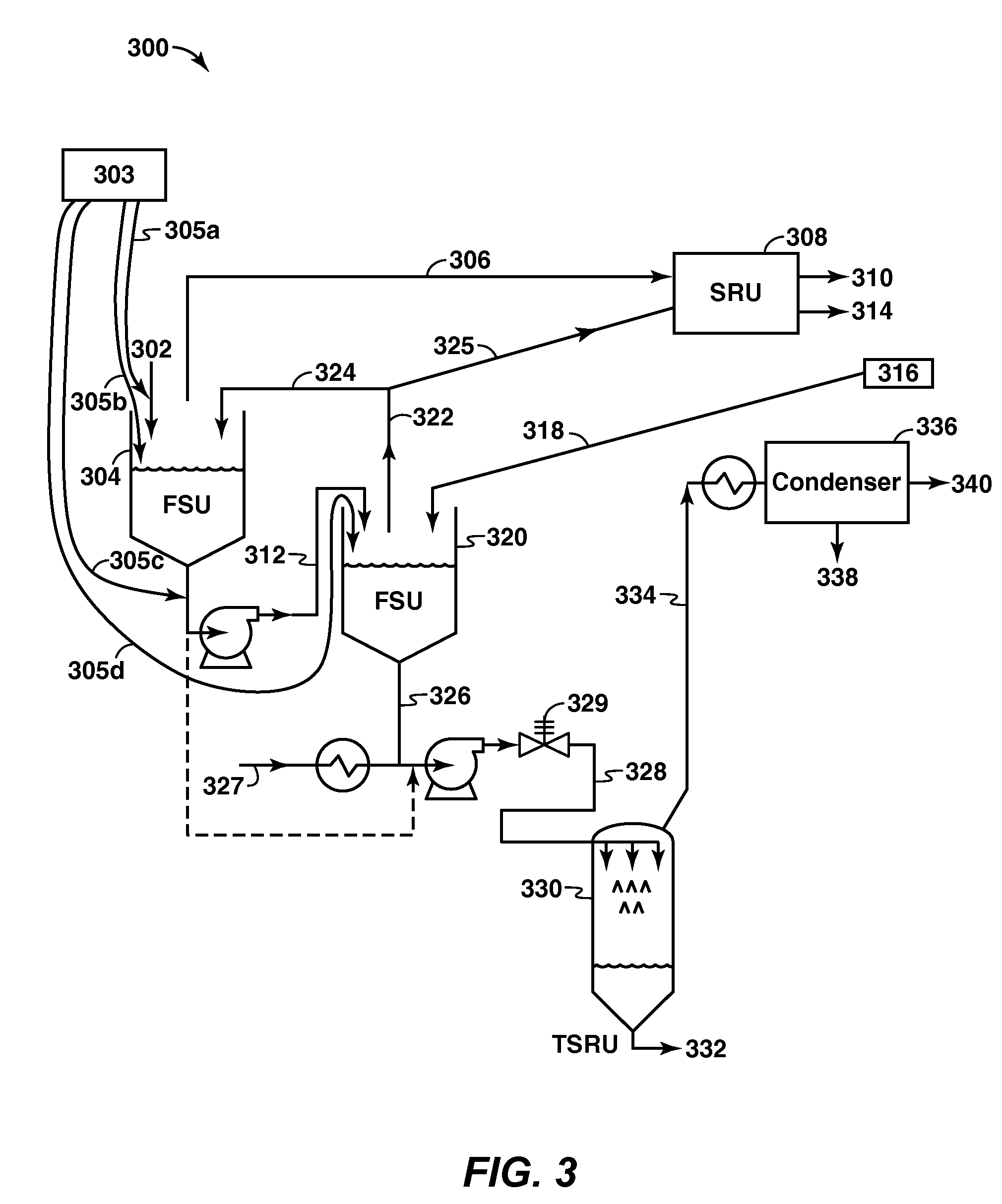

Upgrading Bitumen In A Paraffinic Froth Treatment Process

ActiveUS20090200209A1Increase settlement rateWorking-up pitch/asphalt/bitumen by selective extractionSolvent extractionParaffin waxPipeline transport

The invention relates to an improved bitumen recovery process. The process includes adding water to a bitumen-froth / solvent system containing asphaltenes and mineral solids. The addition of water in droplets increases the settling rate of asphaltenes and mineral solids to more effectively treat the bitumen for pipeline transport, further enhancement, refining, or any other application of reduced-solids bitumen.

Owner:EXXONMOBIL UPSTREAM RES CO

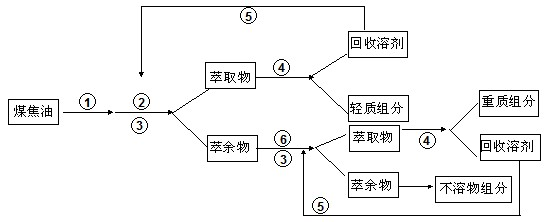

Extracting and separating method of high-temperature coal tar

InactiveCN102492451AHigh purityEfficient separationTar working-up by solvent extractionTime rangeDistillation

An extracting and separating method of high-temperature coal tar belongs to a coal tar separation method. The extracting and separating method includes the step of adding No.1 or No.2 solvent into the coal tar at the ordinary pressure for secondary extraction and separation. Extraction processes are carried out under the pretreatment condition of sufficiently mixing and heating, heating temperature is lower than 150 DEG C, raw materials of the coal tar are respectively mixed with the No.1 or No.2 solvent according to the volume proportion of 1:2 to 4, extraction time ranges from 1 to four hours, extracts and raffinate are obtained after the No.1 solvent and the coal tar are filtered and separated when the system is balanced, and the No.1 solvent is recovered by distillation and recycled. The extracting and separating method has the advantages that energy saving effect of equipment is evident, process is simple and convenient, operation conditions are moderate, manufacturing cost and investment of the equipment are low and benefits are evident. Adding quantity of the solvent and extraction operation parameters are changed, separation depth and process capacity of the coal tar can be flexibly mastered and selectively controlled.

Owner:CHINA UNIV OF MINING & TECH

Process for Oxidative Desulfurization and Sulfone Disposal Using Solvent Deasphalting

ActiveUS20120055843A1High purityWorking-up pitch/asphalt/bitumen by selective extractionSulfur-dioxide/sulfurous-acidSulfurSolvent

A method and apparatus for upgrading a hydrocarbon feedstock is provided. The method includes the steps of (a) supplying a hydrocarbon feedstock to an oxidation reactor, wherein the hydrocarbon feedstock is oxidized in the presence of a catalyst under conditions sufficient to selectively oxidize sulfur compounds present in the hydrocarbon feedstock; (c) separating the hydrocarbons and the oxidized sulfur compounds by solvent extraction; (d) collecting a residue stream that includes the oxidized sulfur compounds; and (e) supplying the residue stream to a deasphalting unit.

Owner:SAUDI ARABIAN OIL CO

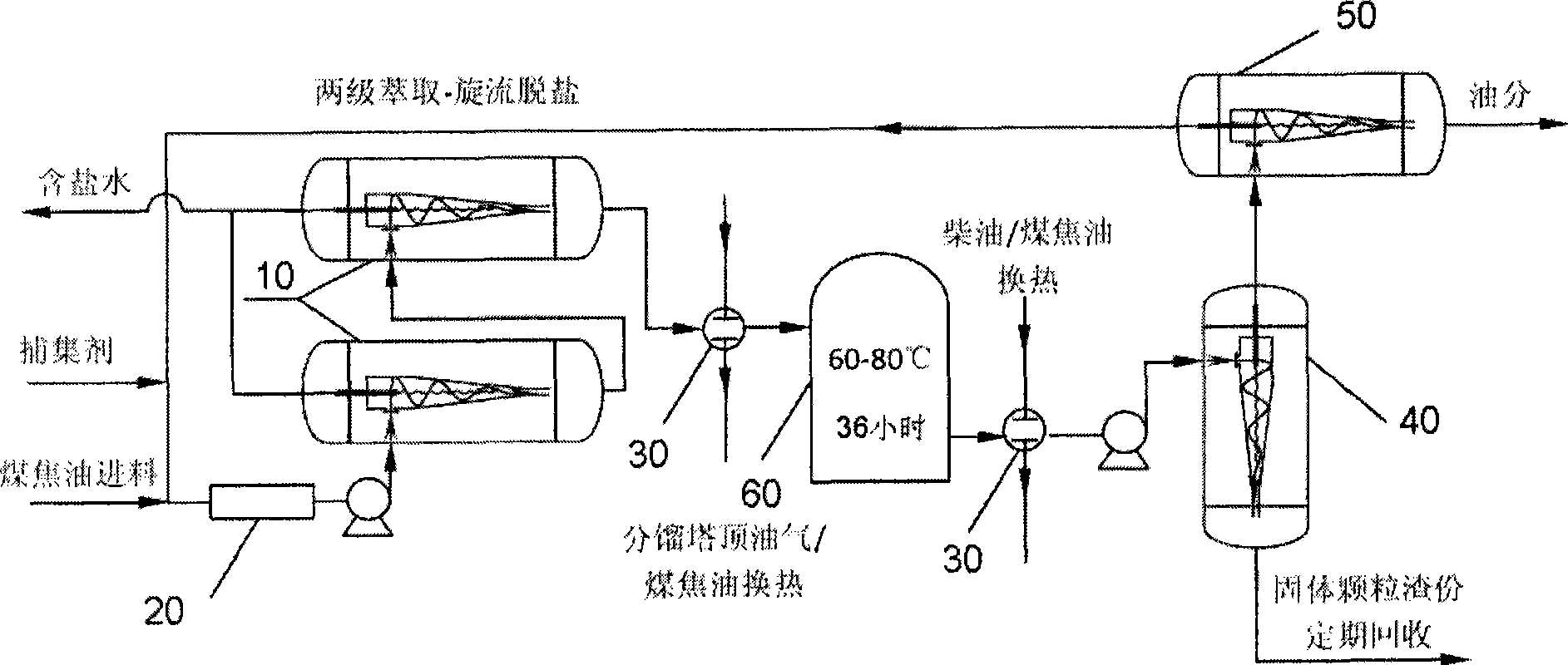

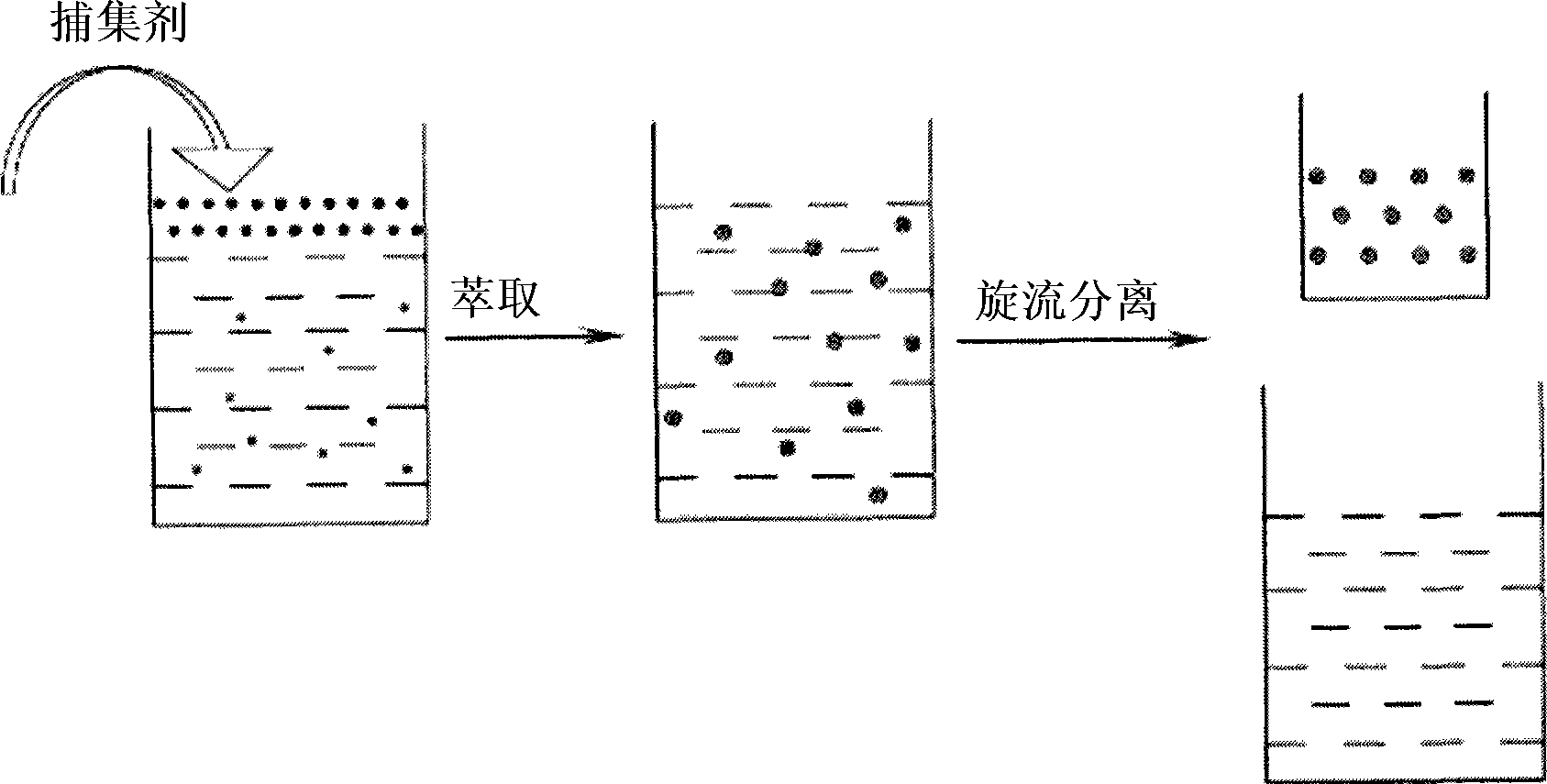

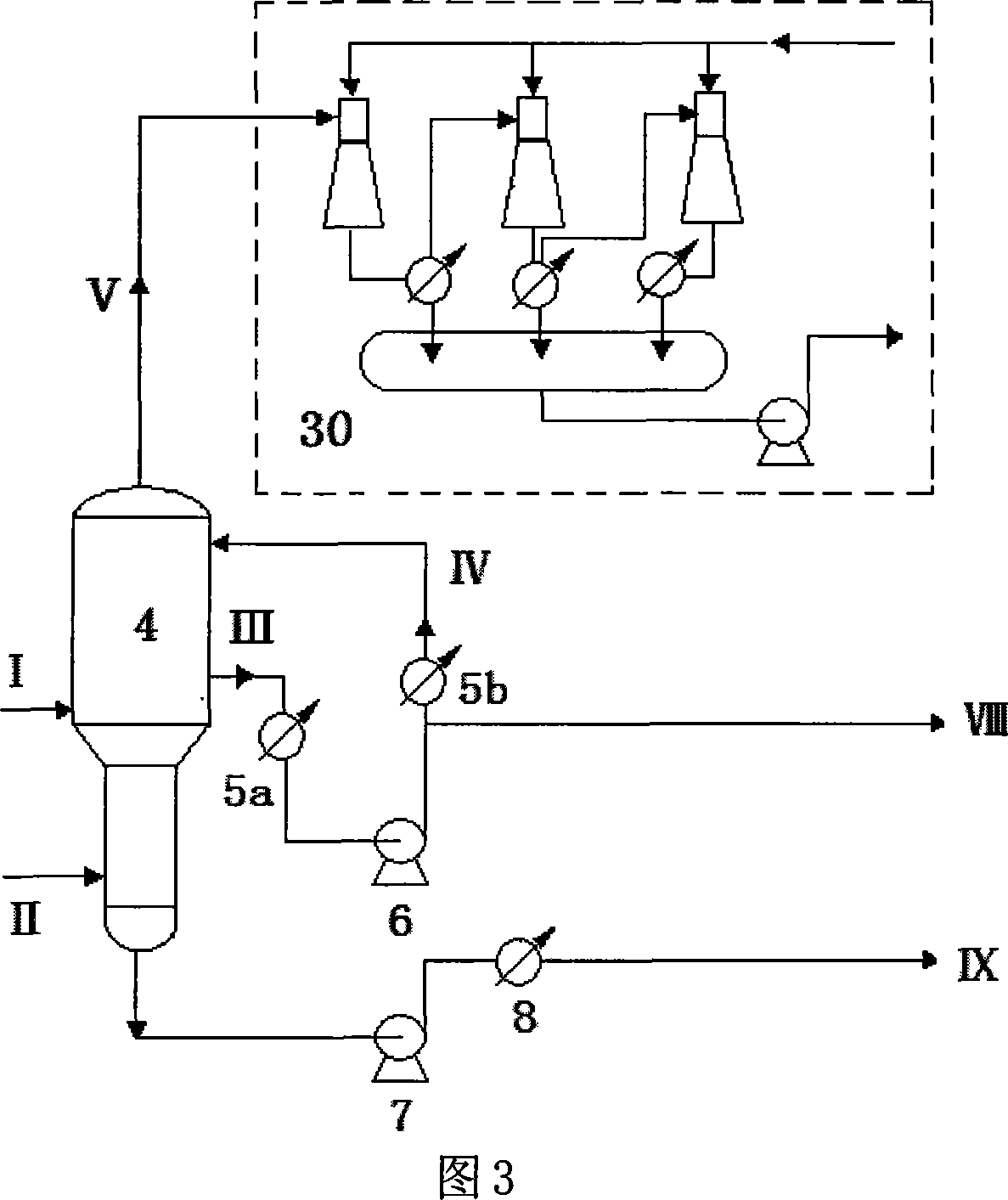

Coal tar coupled rotational flow purification method and apparatus

ActiveCN101475818AReduce heat consumptionReduce resistanceTar working-up by water removalTar working-up by solvent extractionPurification methodsPhysical chemistry

The invention relates to a method and a device for purifying coal tar through coupling rotational flow, wherein the method for purifying the coal tar through coupling rotational flow comprises the following steps: (a) mixing coal tar feed with a trapping agent sufficiently so as to extract out saline matters dispersed in the coal tar; (b) performing liquid-liquid rotational flow separation on thecoal tar in which the dispersed saline matters are extracted out for separating out the saline matters so as to obtain desalinated coal tar; (c) keeping stand and depositing the desalinated coal tar so as to remove the moisture therein and obtain dehydrated coal tar; (d) performing solid-liquid rotational flow separation on the dehydrated coal tar so as to remove solid particles therein and obtain the coal tar without the solid particles; and (e) performing micro rotational flow separation on the coal tar without the solid particles so as to remove the micro moisture therein. The invention also provides a device for purifying the coal tar through the coupling rotational flow.

Owner:EAST CHINA UNIV OF SCI & TECH

Apparatus for prewashing a hydrocarbon stream containing hydrogen sulfide

Disclosed is an apparatus for extracting sulfur compounds from a hydrocarbon stream. A prewash section for converting hydrogen sulfide to sodium sulfide by reaction with an alkali such as caustic prepares the hydrocarbon stream for extraction. Spent alkali is continuously withdrawn and regenerated alkali is continuously added to the prewash section.

Owner:UOP LLC

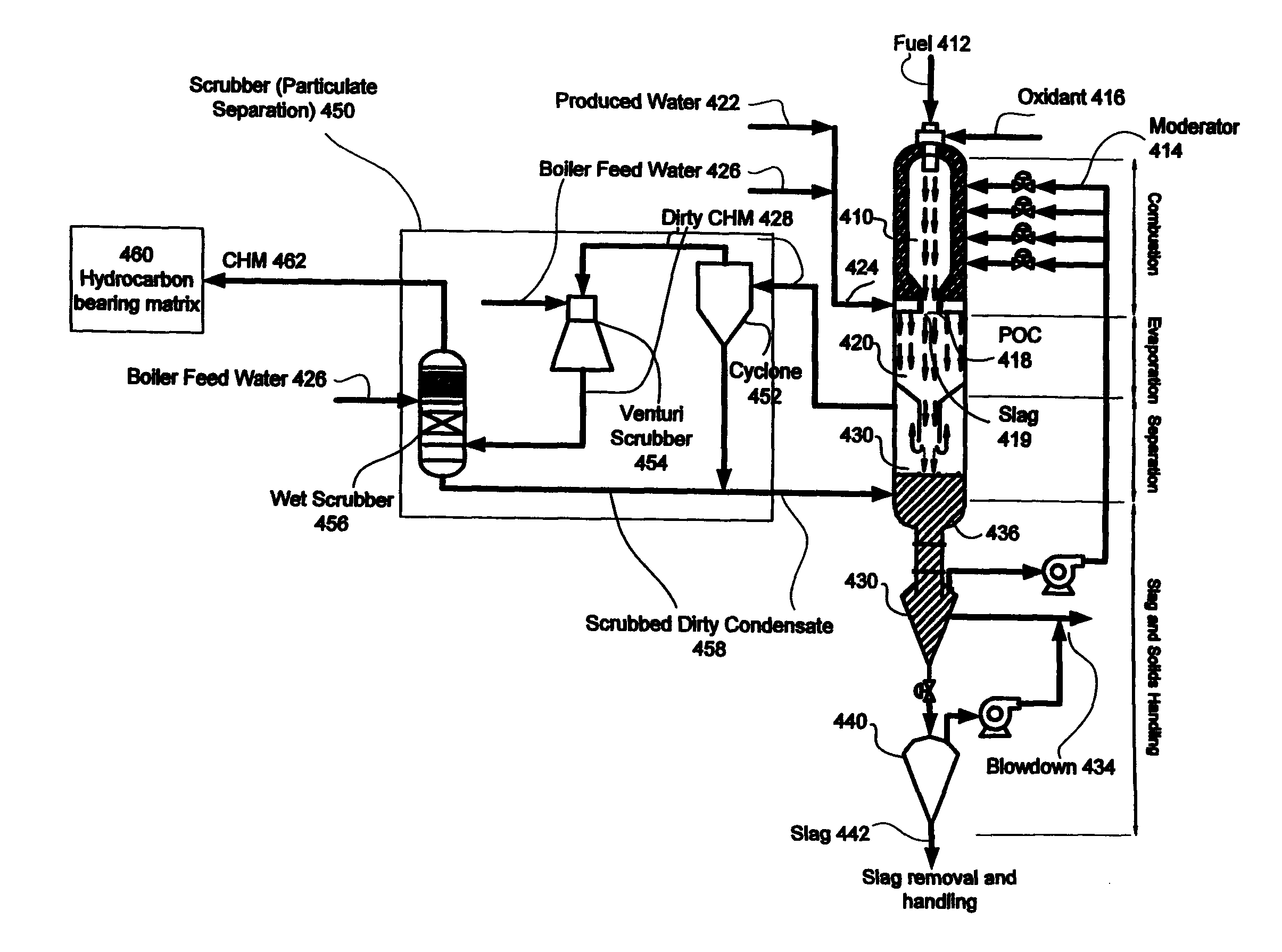

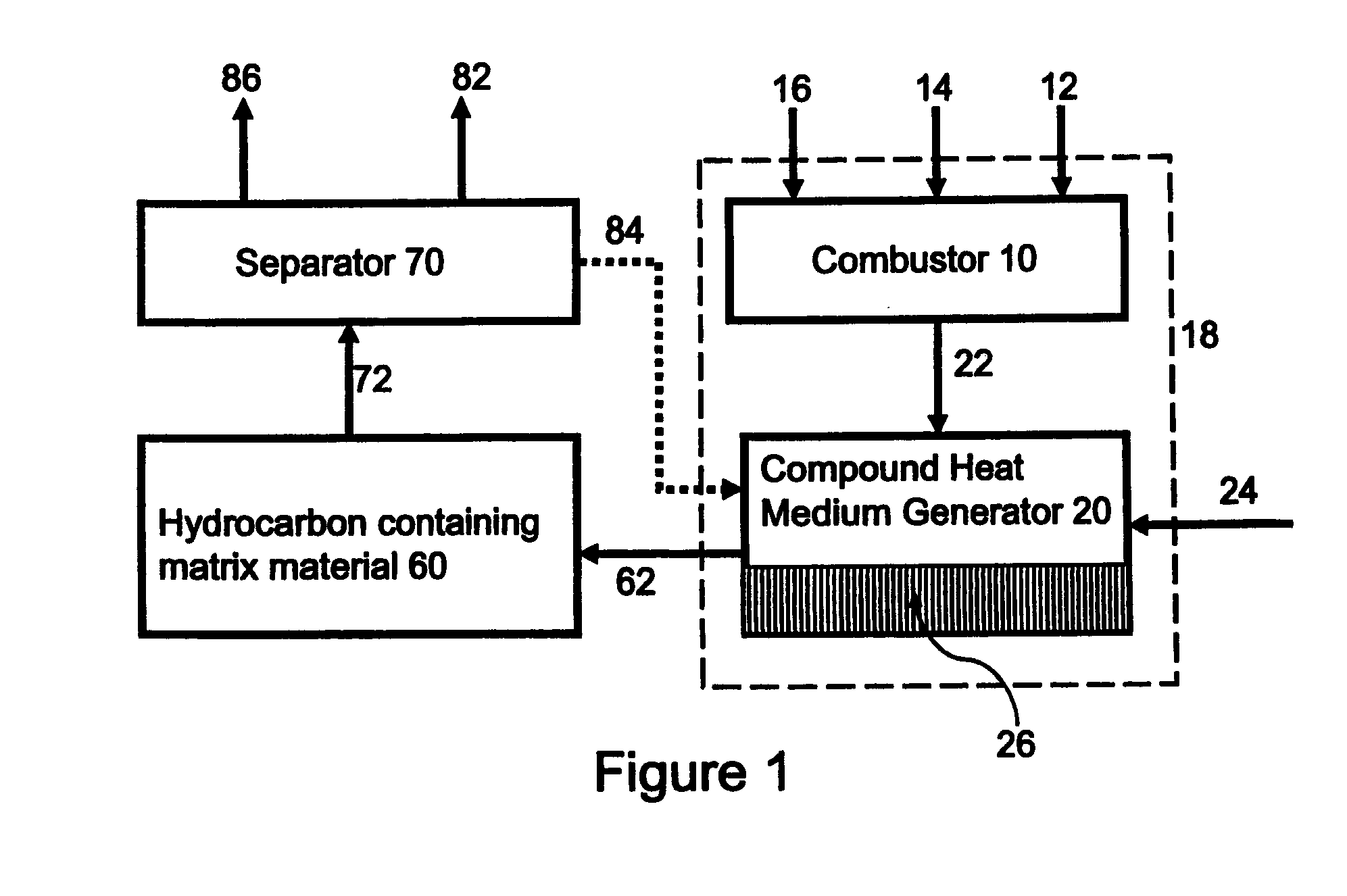

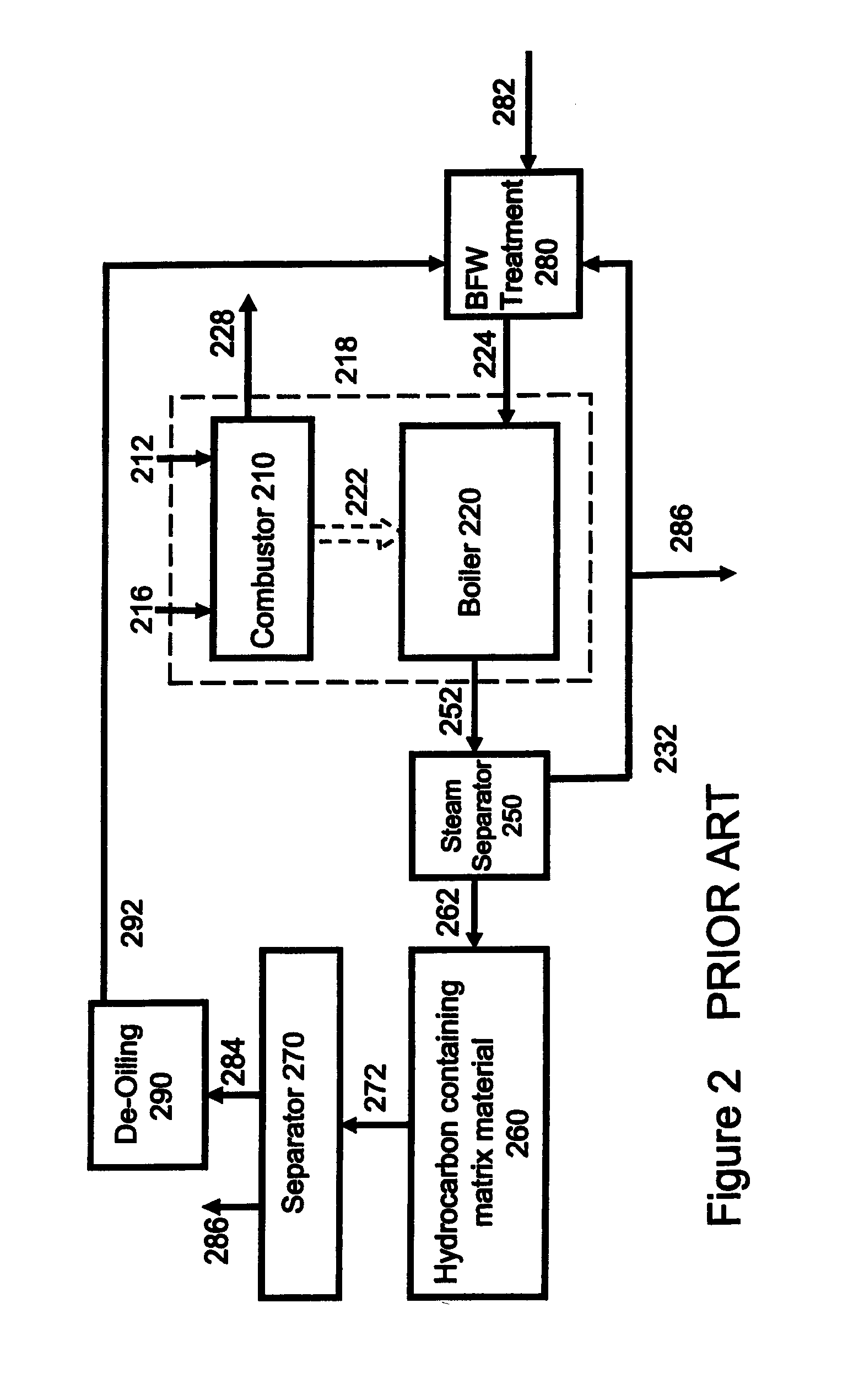

Systems and Methods for Low Emission Hydrocarbon Recovery

InactiveUS20100282644A1Emission reductionReduce other environmental impactWorking-up pitch/asphalt/bitumen by selective extractionSolvent extractionEmulsionFuel oil

Systems and methods are provided for low emission (in-situ) heavy oil production, using a compound heat medium, comprising products of combustion of a fuel mixture with an oxidant and a moderator, mixed with steam generated from direct contact of hot combustion products with water, under pressure. The compound heat medium, comprising mainly CO2 and steam, is injected at pressure into a hydrocarbon reservoir, where steam condenses out of the compound heat medium releasing heat to the reservoir. The condensate is produced with the hydrocarbon as a hydrocarbon / water mixture or emulsion. Non-condensable gases, primarily CO2, from the compound heat medium may remains in the reservoir through void replacement, leakage to adjacent geological strata. Beneficially, any CO2 produced is recovered at pressure, for use in other processes, or for disposal by sequestration. Produced water is recovered and recycled as a moderator and steam generating medium.

Owner:ORION PROJECTS

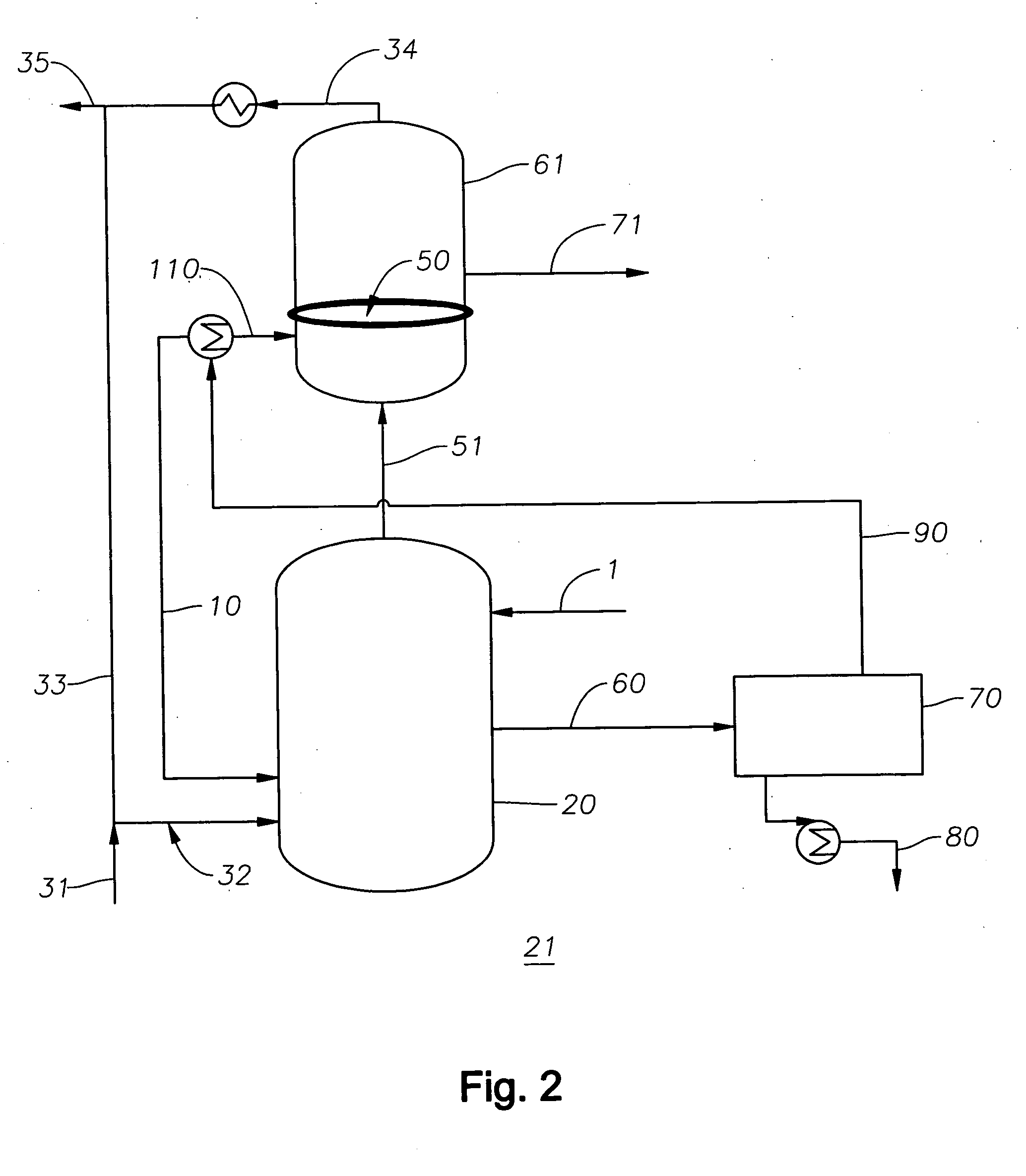

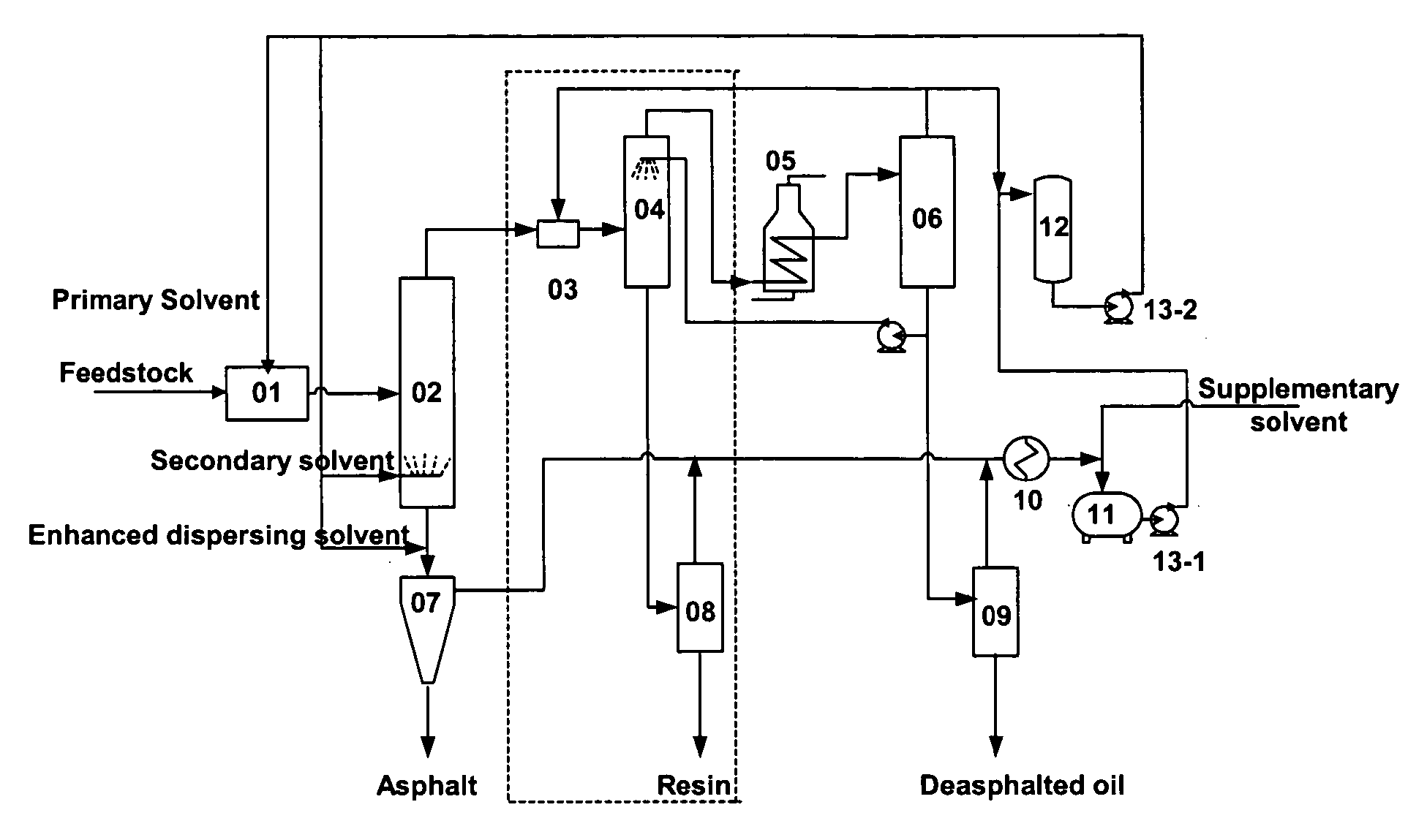

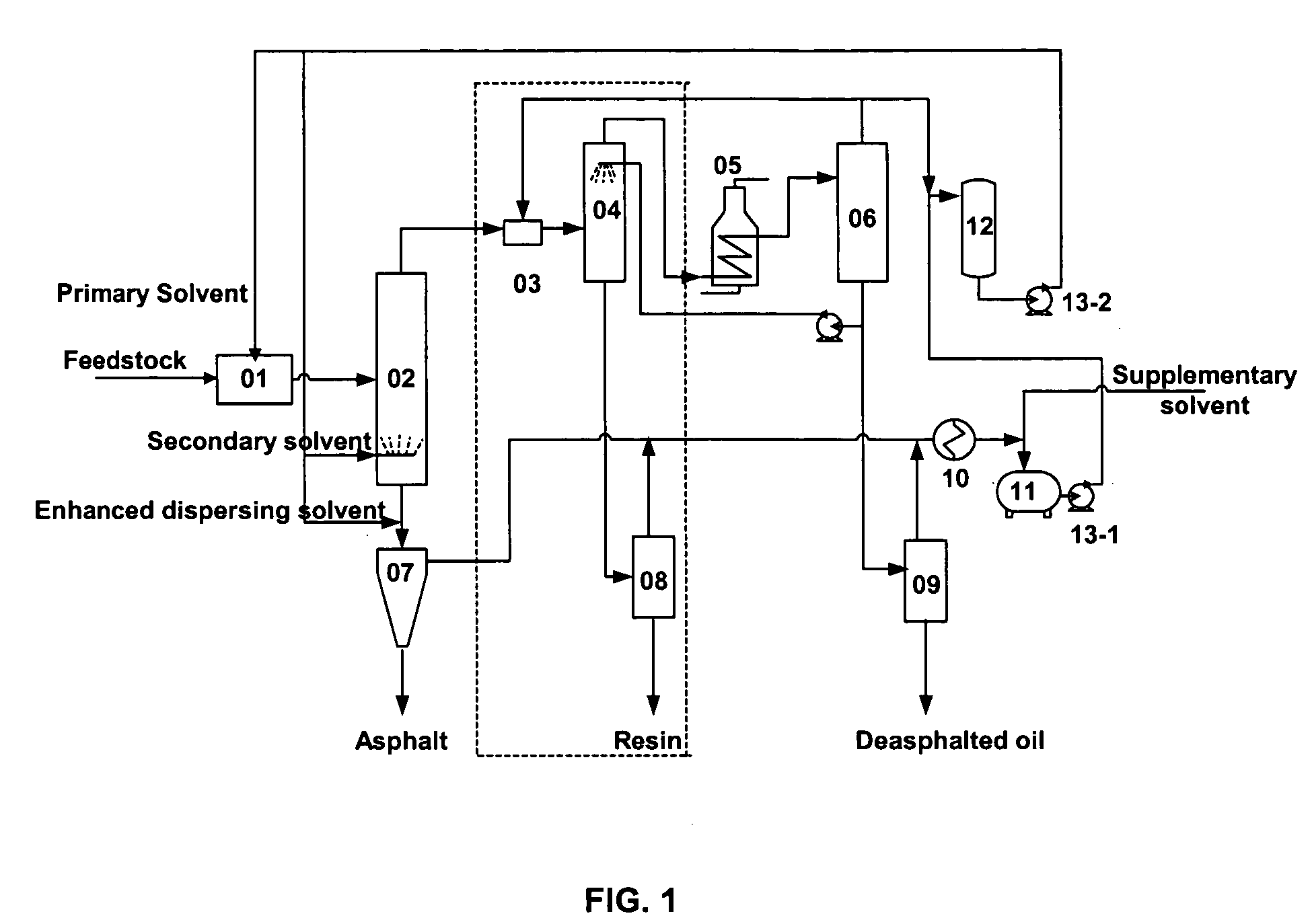

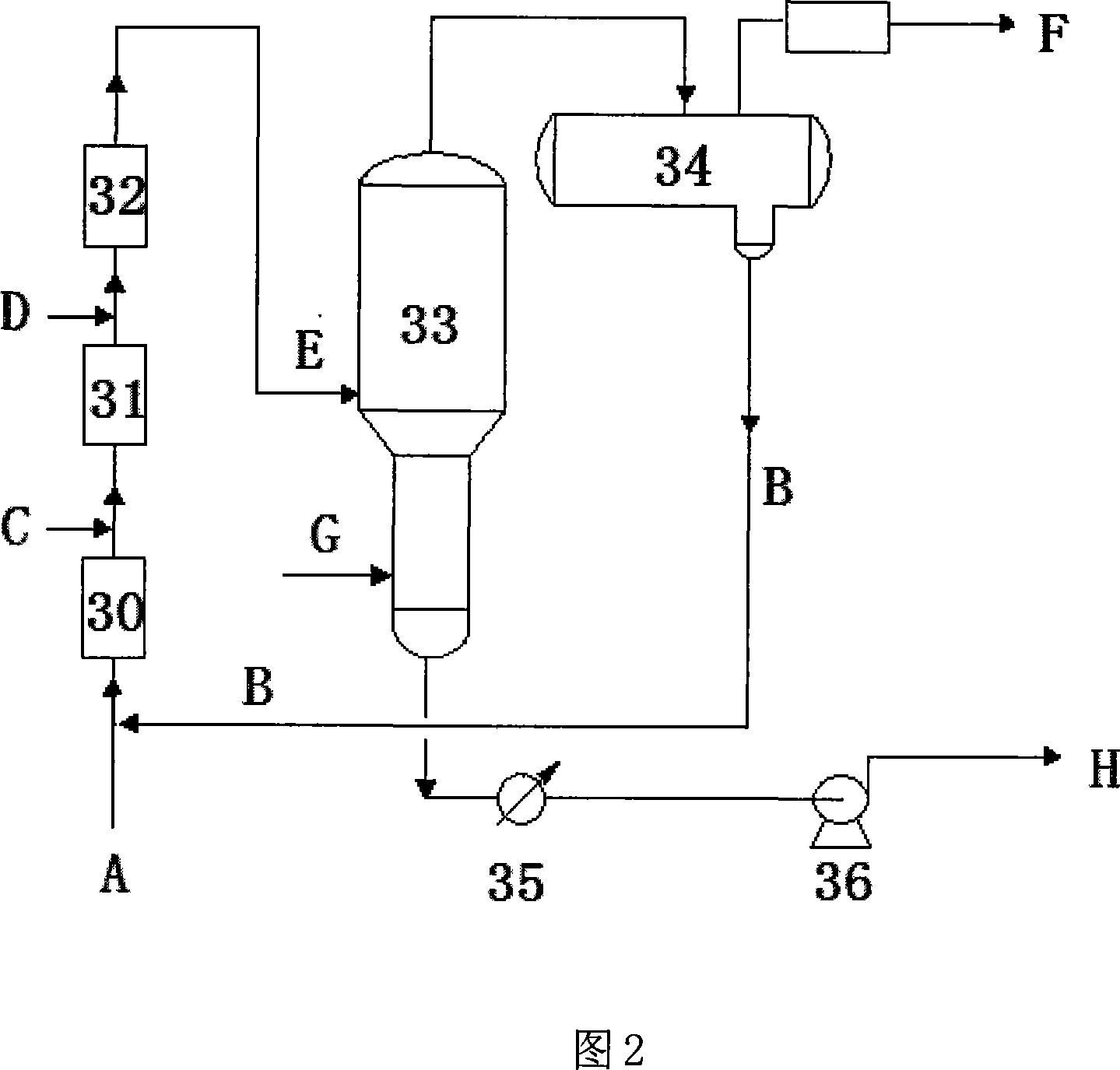

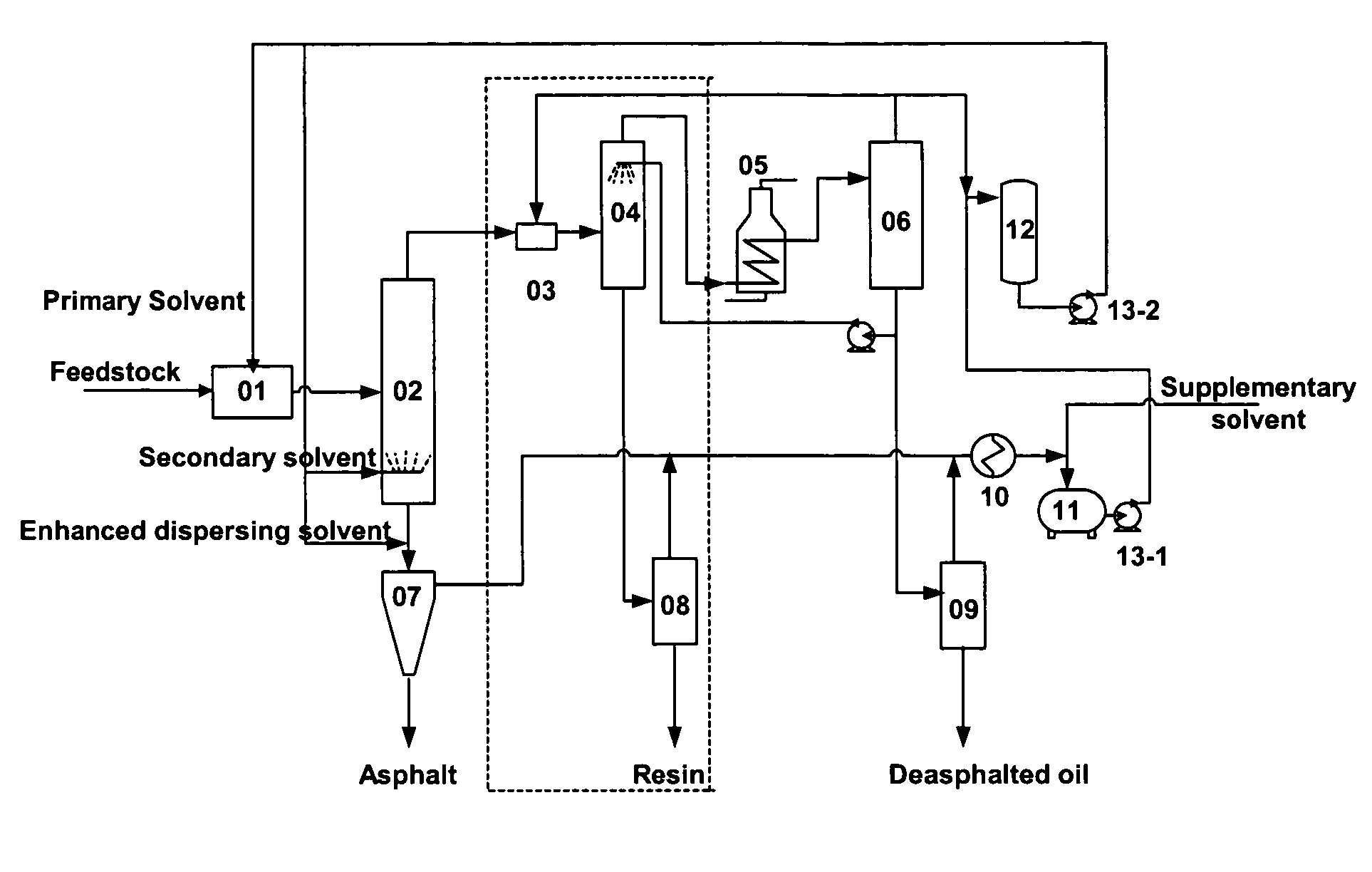

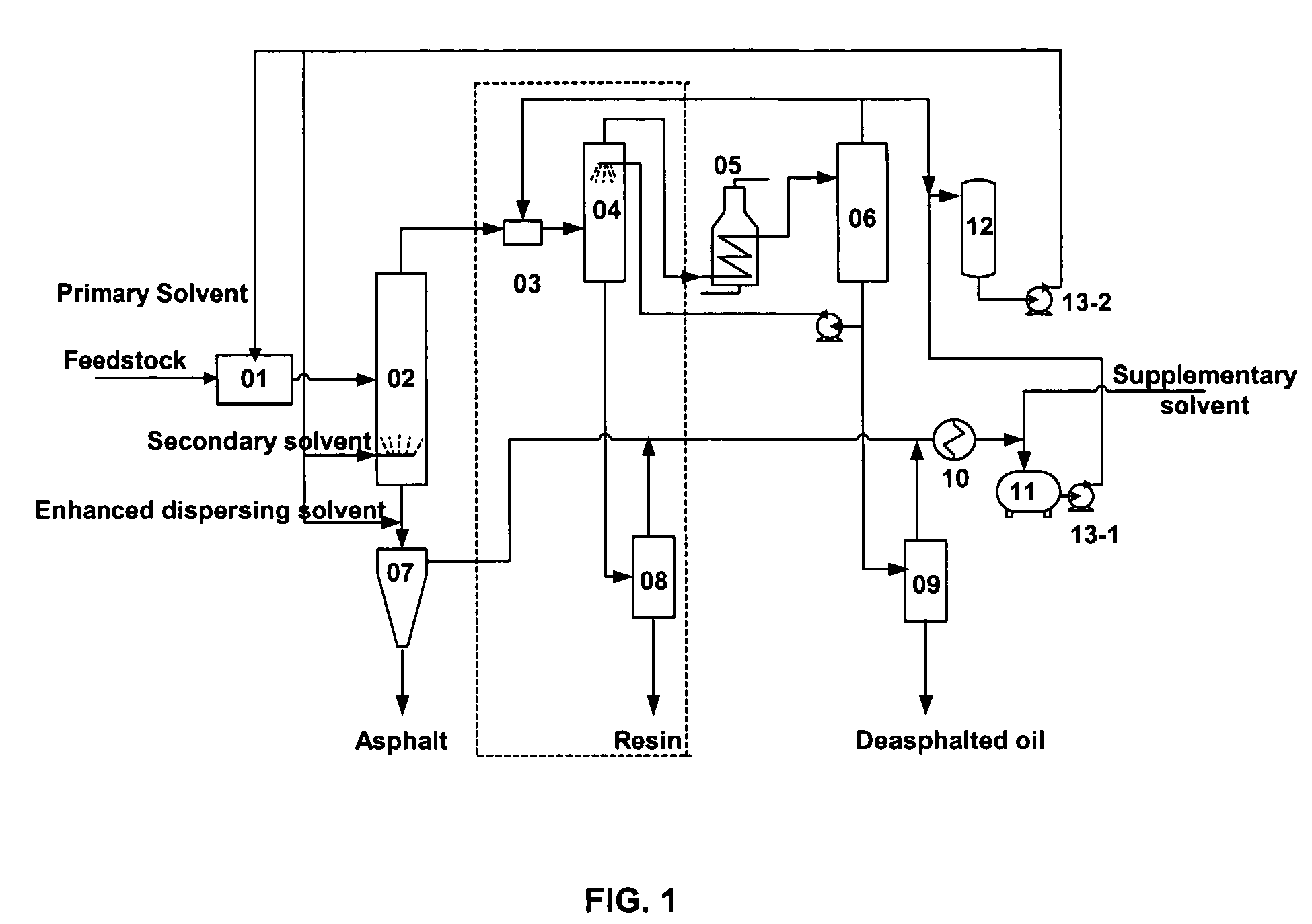

Deep separation method and processing system for the separation of heavy oil through granulation of coupled post-extraction asphalt residue

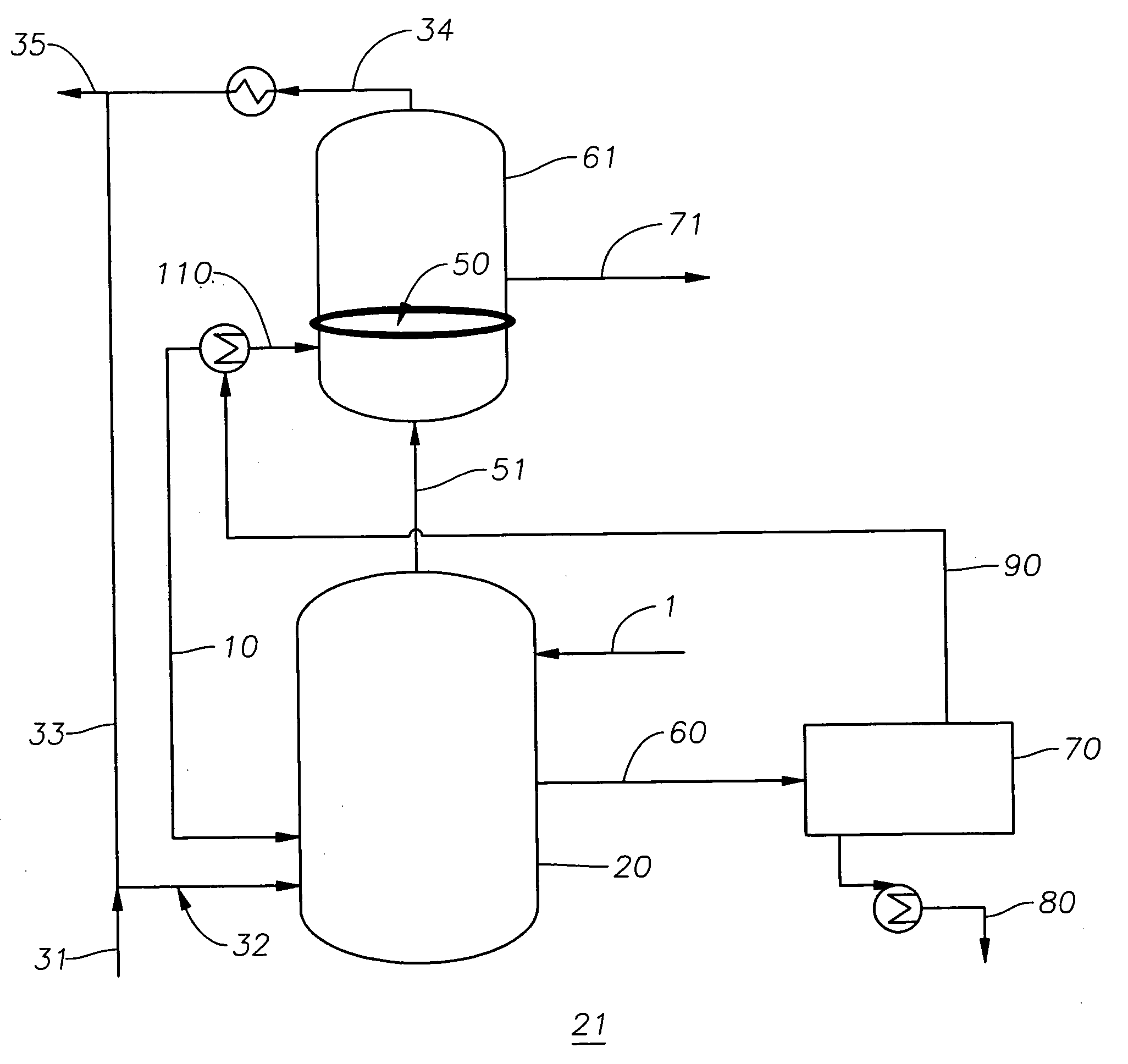

ActiveUS20070007168A1High yieldSimple processWorking-up pitch/asphalt/bitumen by selective extractionWorking-up pitch/asphalt/bitumen by solidifying/disintegratingSolid particleOil phase

The present invention is a separation method and system in which granulation of coupled post-extraction asphalt residue is used to achieve deep separation of heavy oil. A dispersion solvent is introduced into the asphalt phase after separation by solvent extraction and the asphalt phase undergoes rapid phase change in a gas-solid separator and is dispersed into solid particles while the solvent vaporizes, resulting in low temperature separation of asphalt and solvent with adjustable size of the asphalt particles. The separation method of this invention also includes a three-stage separation of heavy oil feedstock, in which the deasphalted oil phase separated from heavy oil is treated with supercritical solvent and results in the further separation of the resin portion of the deasphalted oil, maximizing the yield and quality of the deasphalted oil. The processes and systems in this invention use atmospheric pressure and a low temperature gas-solid separator instead of a high temperature and high pressure furnace and do not require the feed pre-heating or heat exchange equipment at the inlet of resin separator column, resulting in a simplified process flow and reduced investment.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

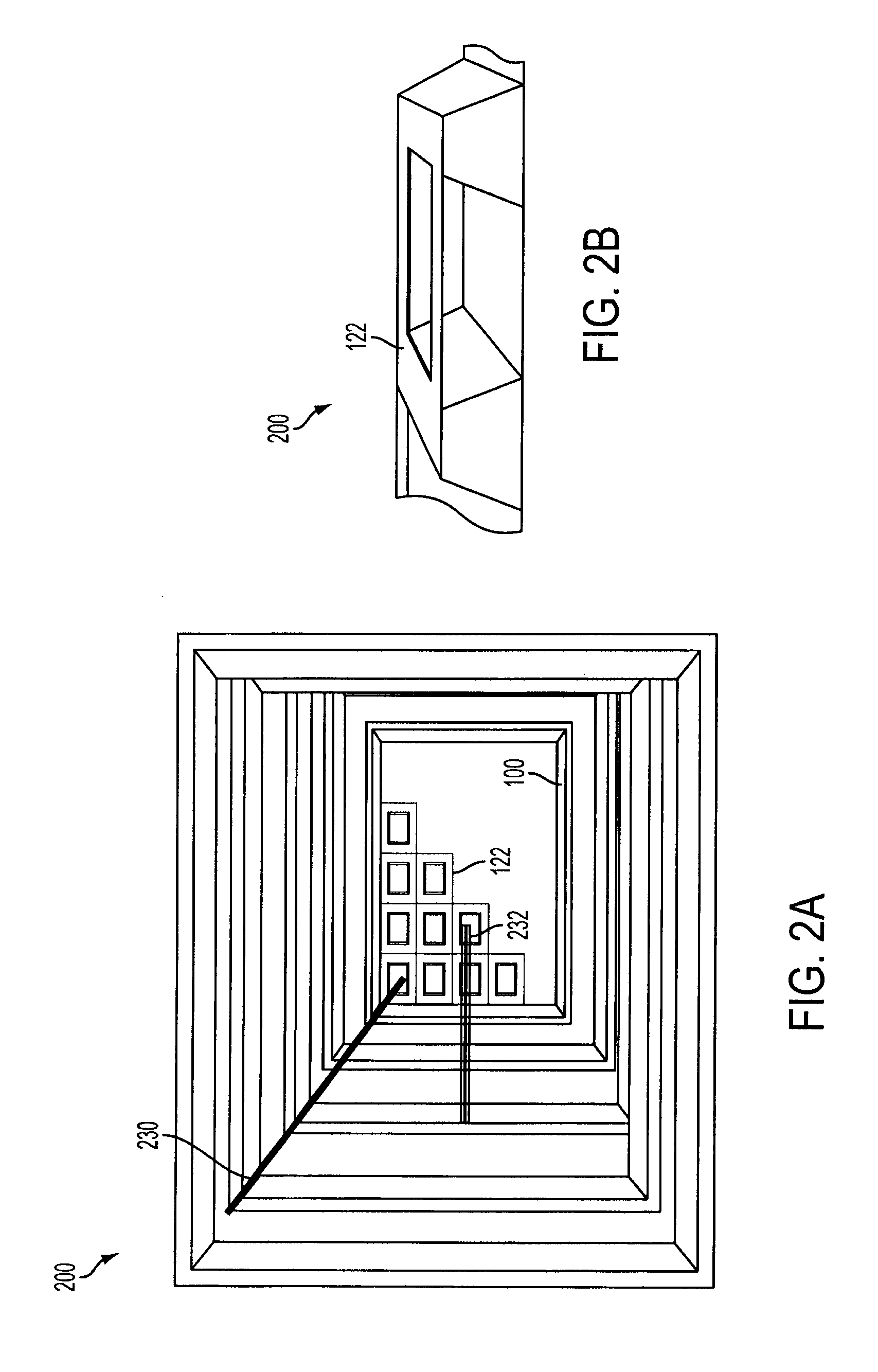

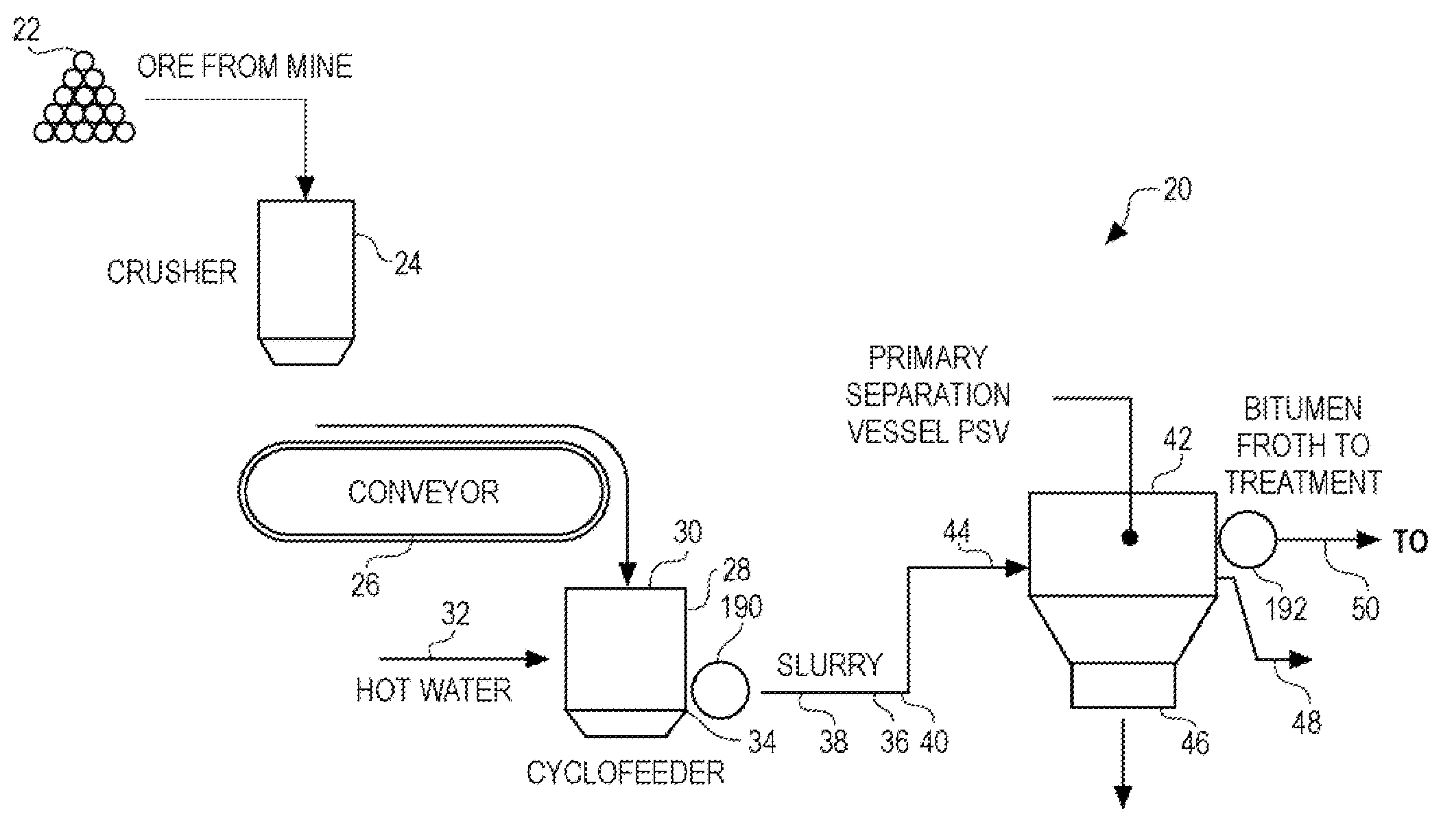

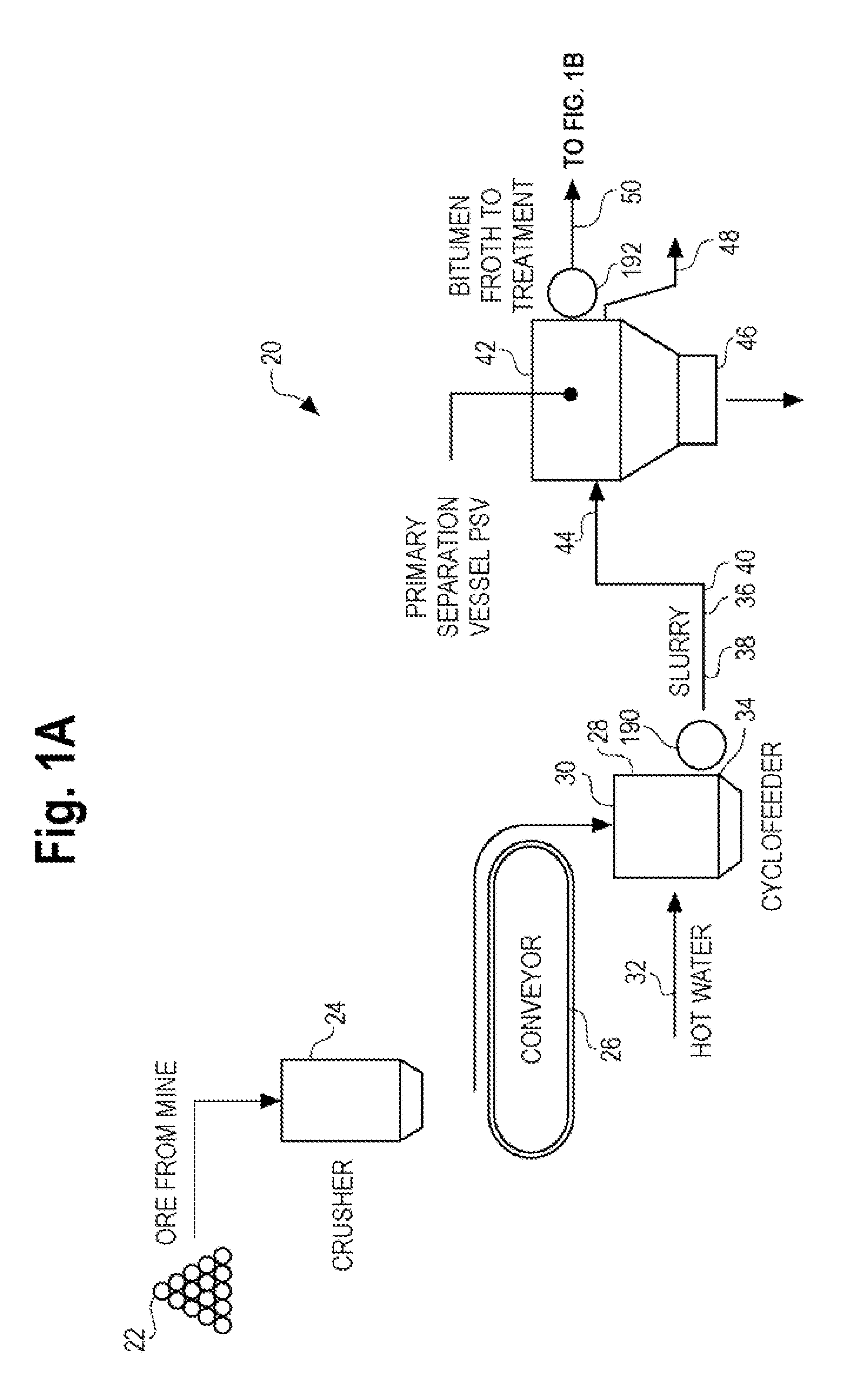

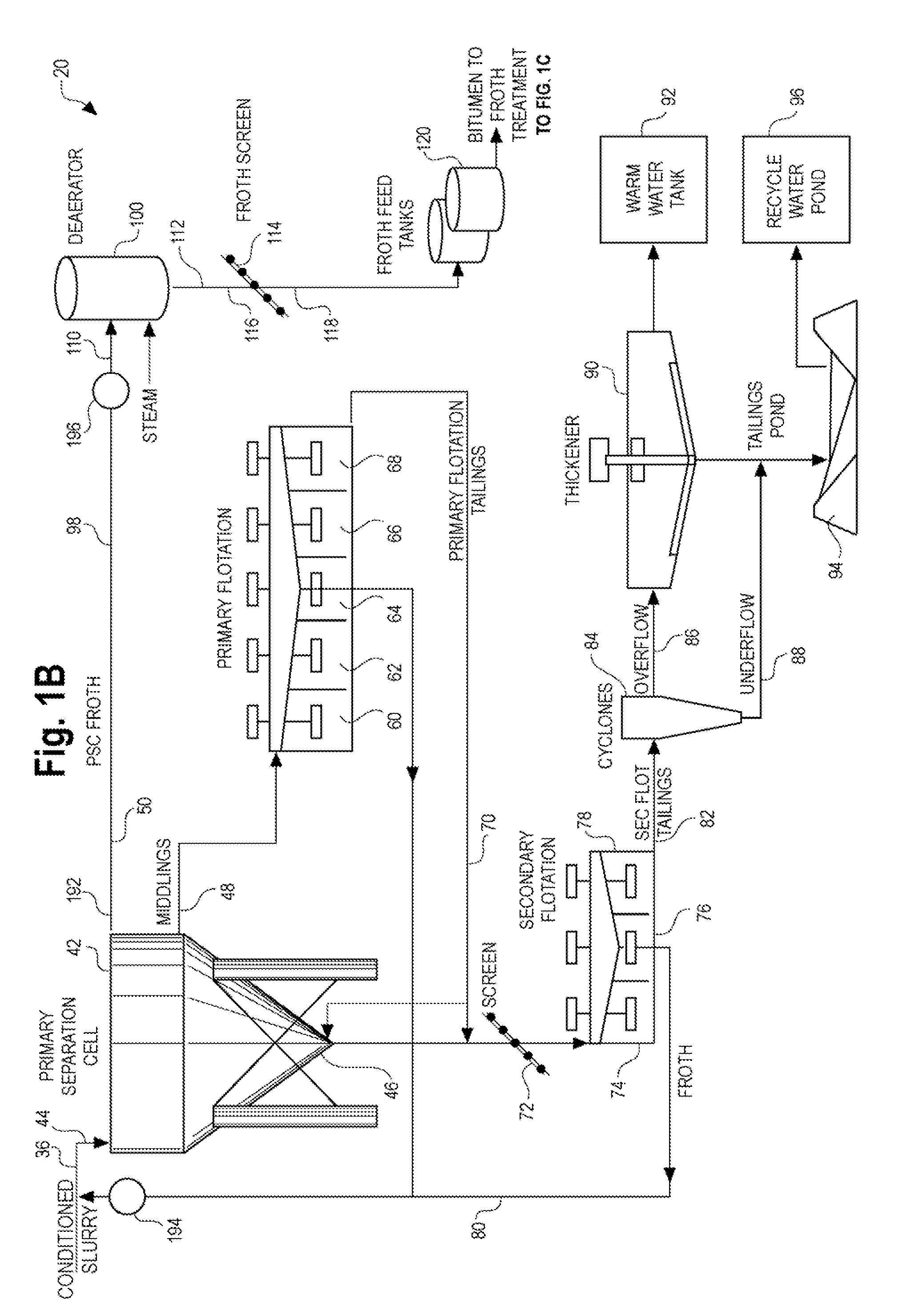

RF heating to reduce the use of supplemental water added in the recovery of unconventional oil

ActiveUS20100219105A1Selective heatingWorking-up pitch/asphalt/bitumen by selective extractionLiquid hydrocarbon mixture recoveryEngineeringSlurry

Equipment and a process for separating bitumen from oil sand in a process stream are disclosed. The equipment includes several processing vessels and one or more local area radio frequency applicators to selectively heat the process stream in local areas of the equipment. The local area can be adjacent to an input or output of a component of the equipment. Also disclosed is equipment for processing an oil sand—water slurry, including a slurrying vessel, a slurry pipe, and a local area radio frequency applicator. The local area radio frequency applicator is located outside of the slurry pipe, and heats the local area without significantly heating the contents of the slurrying vessel or of the downstream portion of the slurry pipe.

Owner:HARRIS CORP

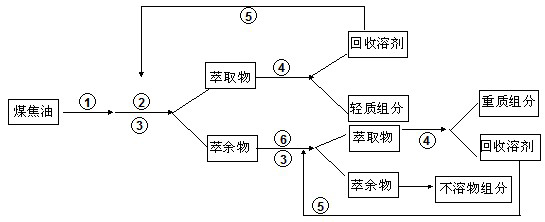

Deasphalting of Gas Oil from Slurry Hydrocracking

ActiveUS20100243518A1High value distillateIncrease valueWorking-up pitch/asphalt/bitumen by selective extractionTreatment with hydrotreatment processesSlurryProcess engineering

Integrated slurry hydrocracking (SHC) and solvent deasphalting (SDA) methods for making slurry hydrocracking (SHC) distillates are disclosed. Representative methods involve passing a slurry comprising a vacuum column resid, a recycled, deasphalted oil obtained from SDA, and a solid particulate through an SHC reaction zone in the presence of hydrogen to obtain the SHC distillate. Fractionation or distillation in the SHC product recovery section yields a combined SHC gas oil / SHC pitch stream that is sent to SDA. In a representative embodiment, vacuum distillation in the SHC product recovery is avoided, thereby eliminating equipment that is often most susceptible to fouling.

Owner:UOP LLC

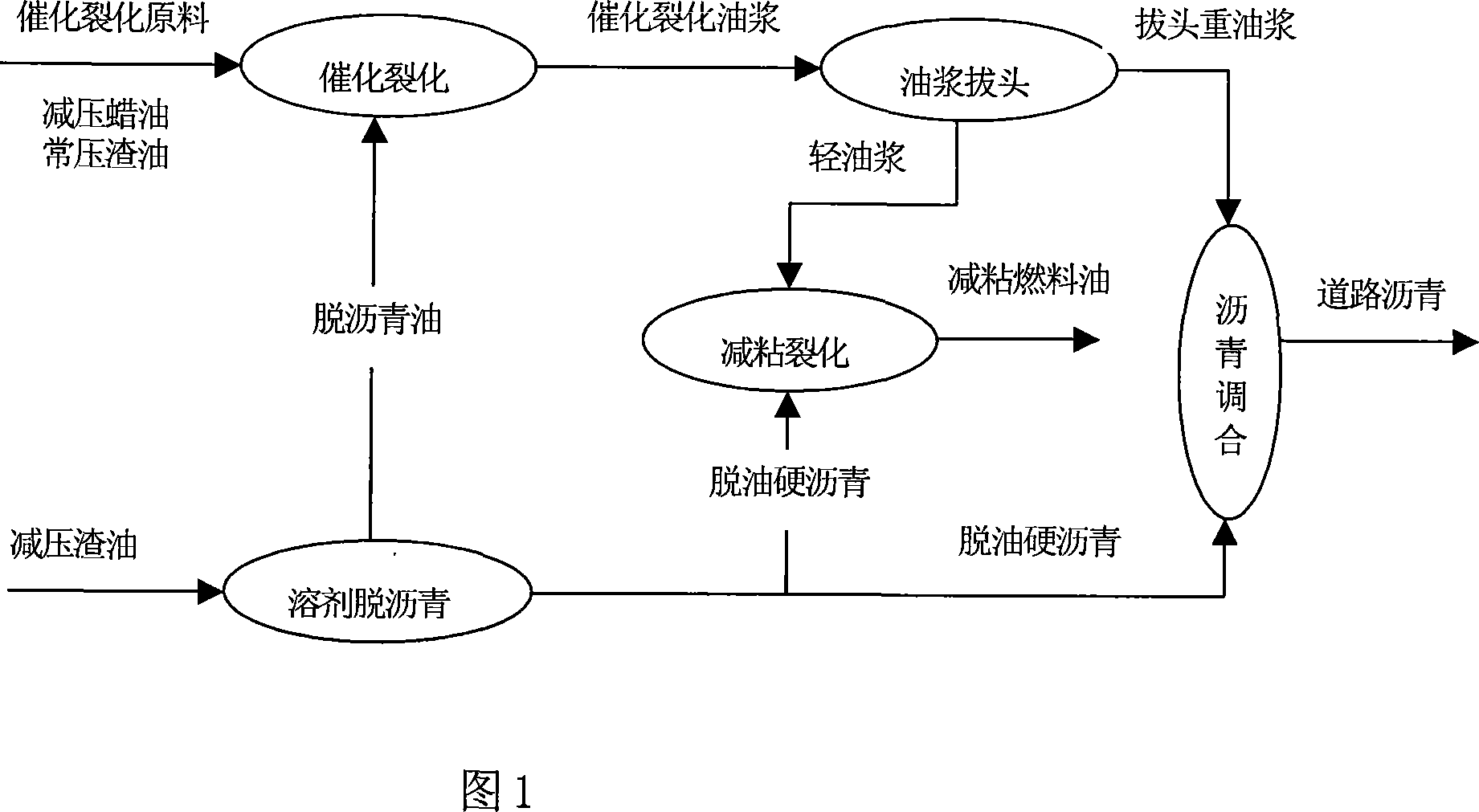

Combined technique for processing heavy oil

InactiveCN101050383AHigh yieldQuality improvementTreatment with plural serial stages onlyTar working-up by solvent extractionSlurryCombined technique

This invention relates to a process for processing heavy oil. The process comprises: removing asphalt from vacuum residual oil by butane deasphalting to obtain asphalt-free oil and oil-free hard asphalt, mixing asphalt-free oil with one or two of atmospheric residual oil and vacuum wax oil, catalytically pyrolyzing to obtain light hydrocarbons, gasoline and diesel oil with high added values, vacuum-distilling residual oil slurry to obtain light oil slurry and tapped heavy oil slurry, mixing light oil slurry with part of oil-free hard asphalt, pyrolyzing to obtain 7# commercial fuel oil, and adequately mixing tapped heavy oil slurry with the other part of oil-free hard asphalt in a static mixer to obtain advanced petroleum asphalt for road construction.

Owner:CHINA PETROLEUM & CHEM CORP

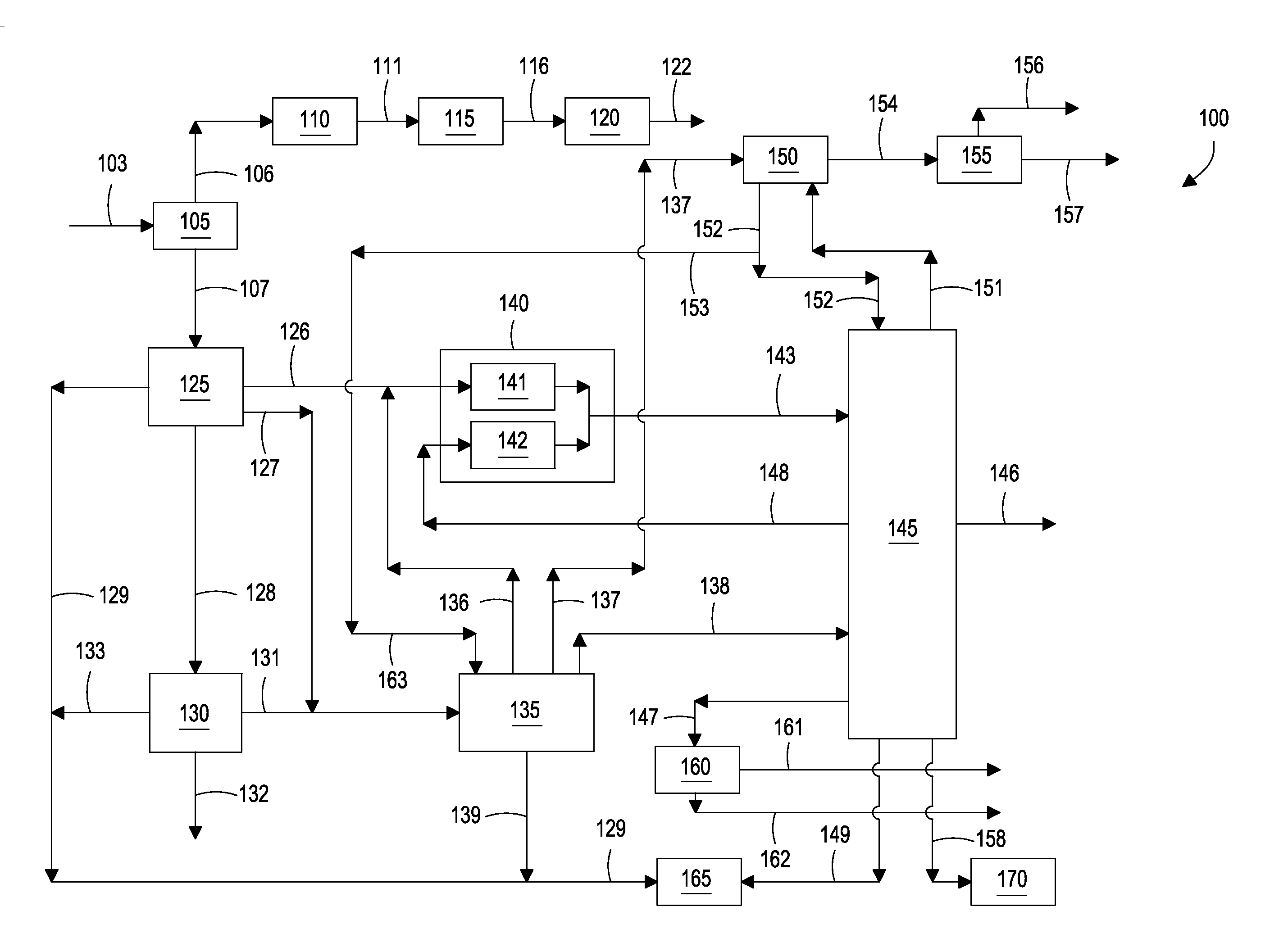

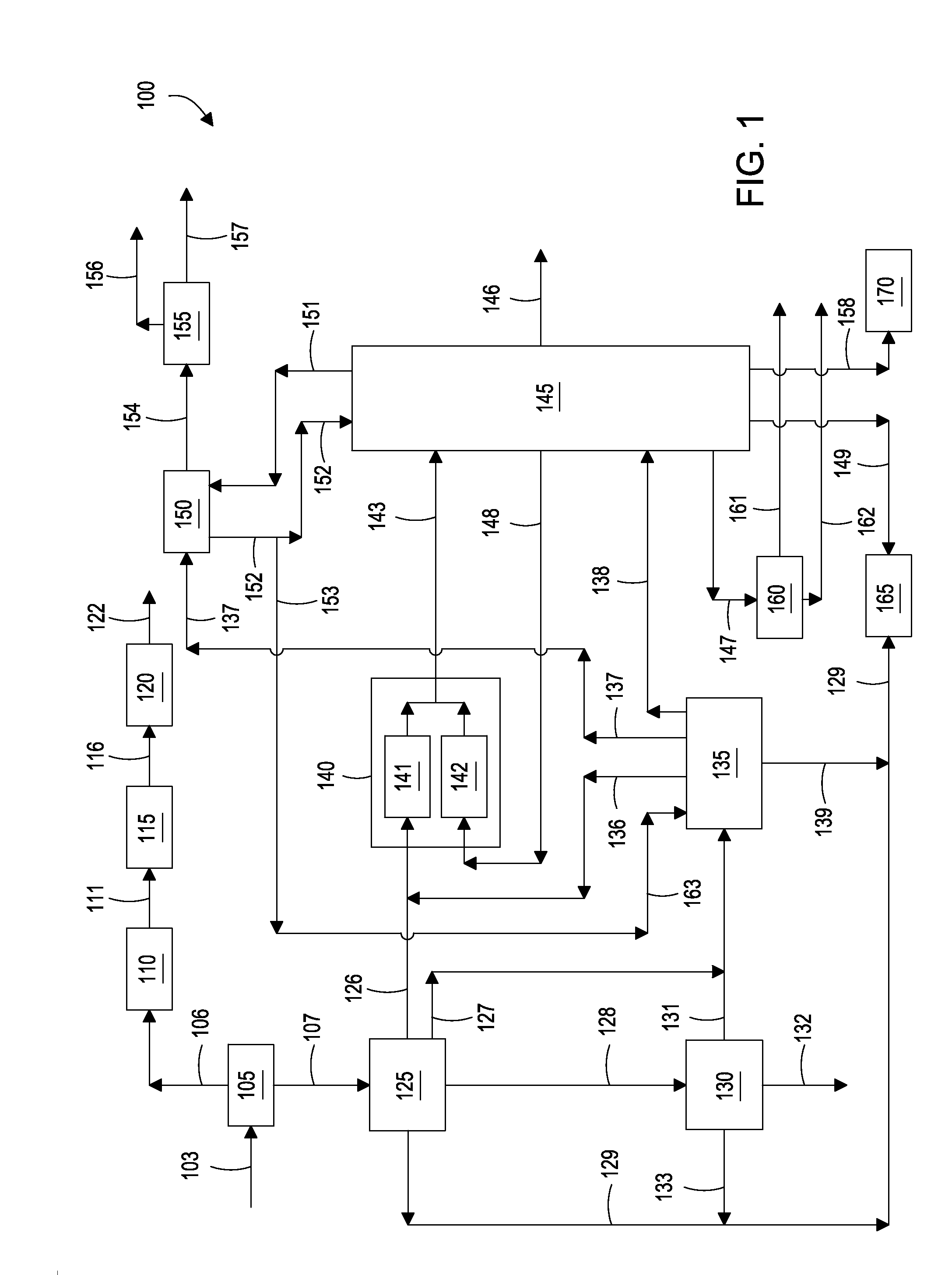

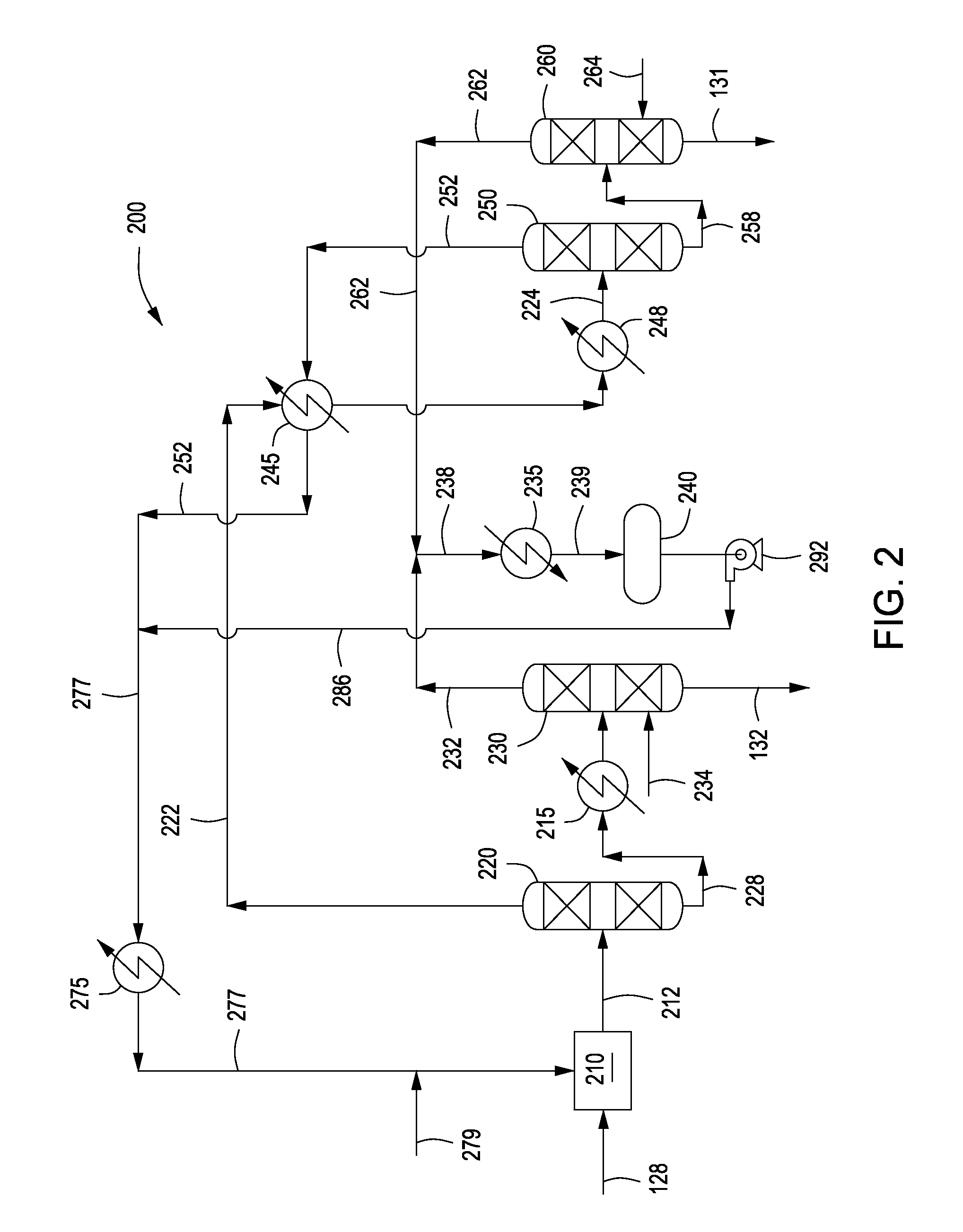

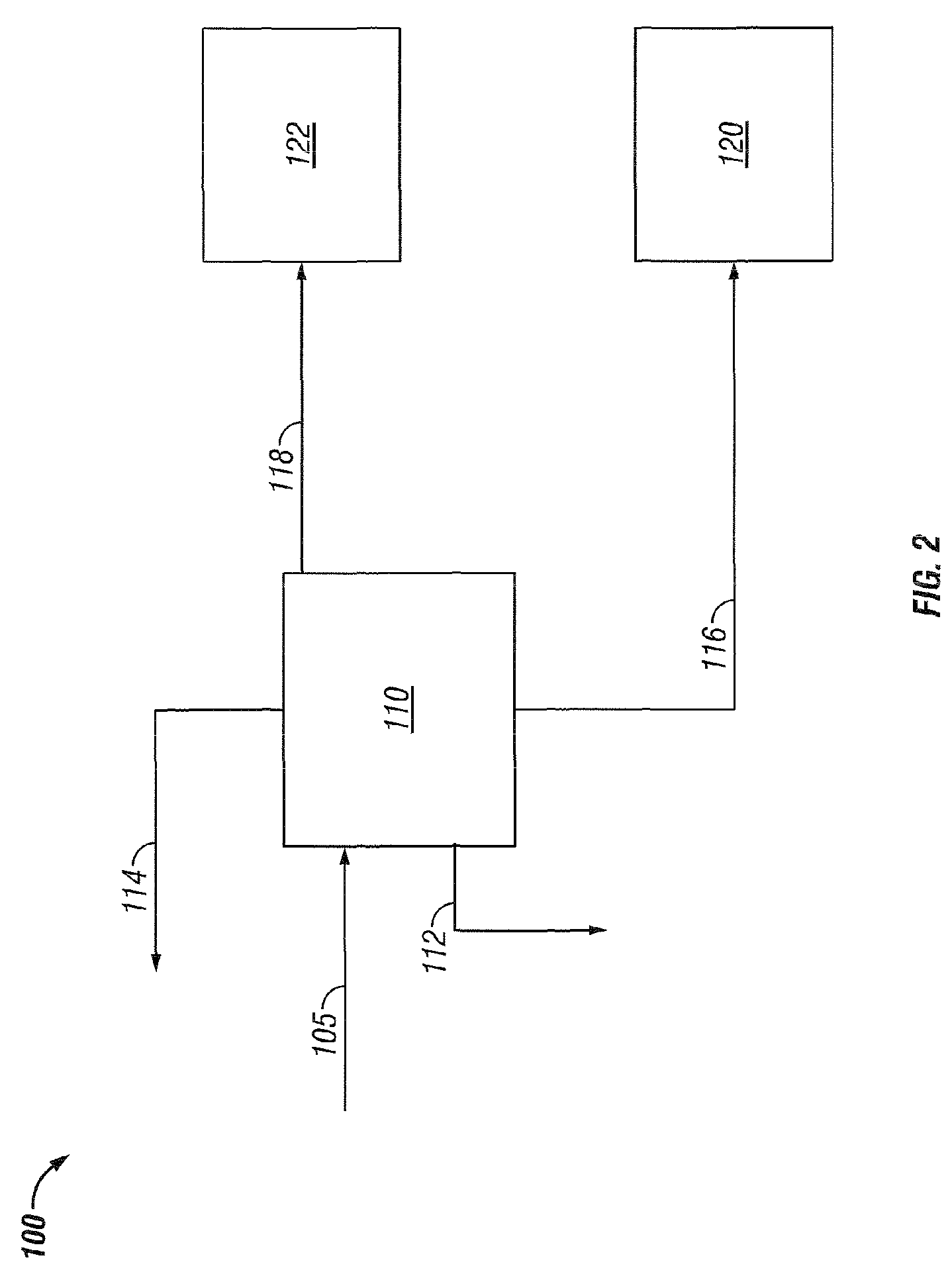

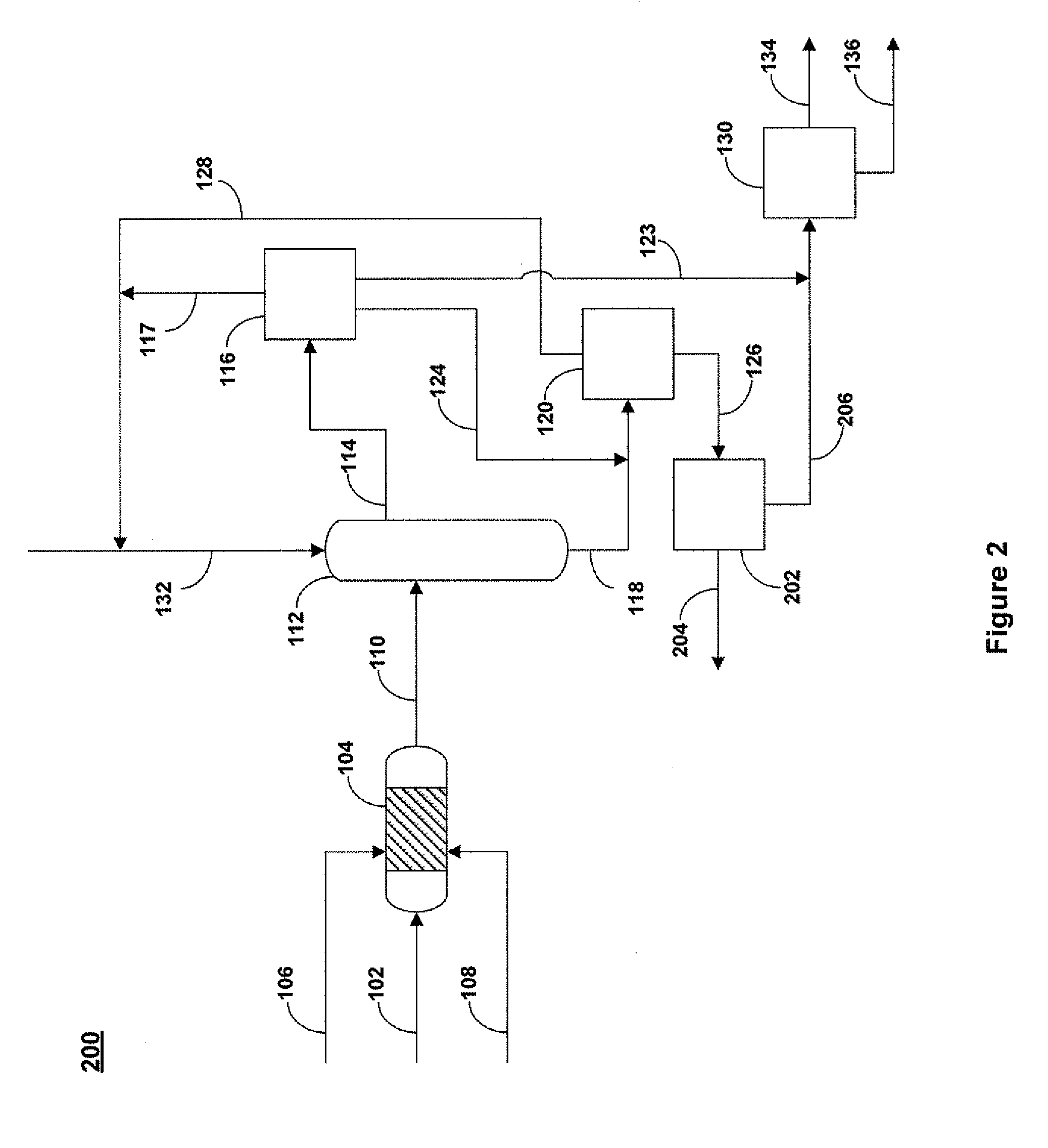

Bitumen Production-Upgrade with Common or Different Solvents

ActiveUS20060283776A1Reduce operating expensesOperational reliability is increasedWorking-up pitch/asphalt/bitumen by selective extractionRefining by water treatmentDiluentFuel oil

Disclosed is a process for the upgrading of heavy oils and bitumens, where the total feed to the process can include heavy oil or bitumen, water, and diluent. The process can include the steps of solvent deasphalting 110 the total feed 105 to recover an asphaltene fraction 116, a deasphalted oil fraction 118 essentially free of asphaltenes, a water fraction 112, and a solvent fraction 114. The process allows removal of salts from the heavy oils and bitumens either into the aqueous products or with the asphaltene product.

Owner:KELLOGG BROWN & ROOT LLC

Method and apparatus for removing solute from a solid solute-bearing product

ActiveUS20050092682A1Obstruct passageLiquid separation auxillary apparatusValve arrangementsSolid massLiquid state

The process and apparatus are for removing a solute from a solute-bearing solid product by means of a solvent which remains in liquid state throughout the entire oil extraction process. In one embodiment, the solvent is normally in gazeous state at ambient temperature and pressure values, but is used mainly in liquid state within the method and apparatus of the present invention by maintaining such pressure and temperature values within the apparatus so that the solvent will remain in this liquid state.

Owner:APPLIED AMBIENT EXTRACTION PROCESS CONSULTANTS

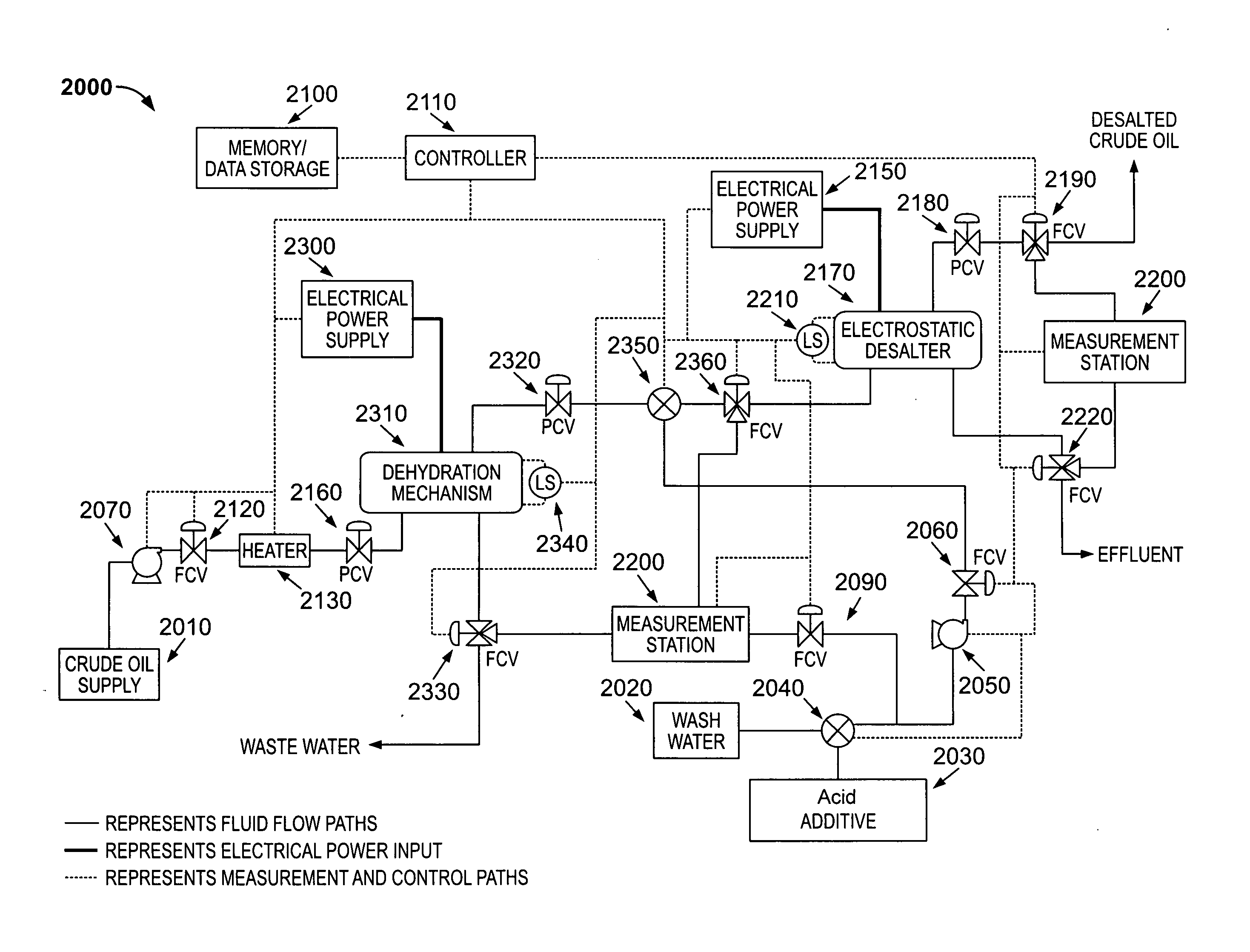

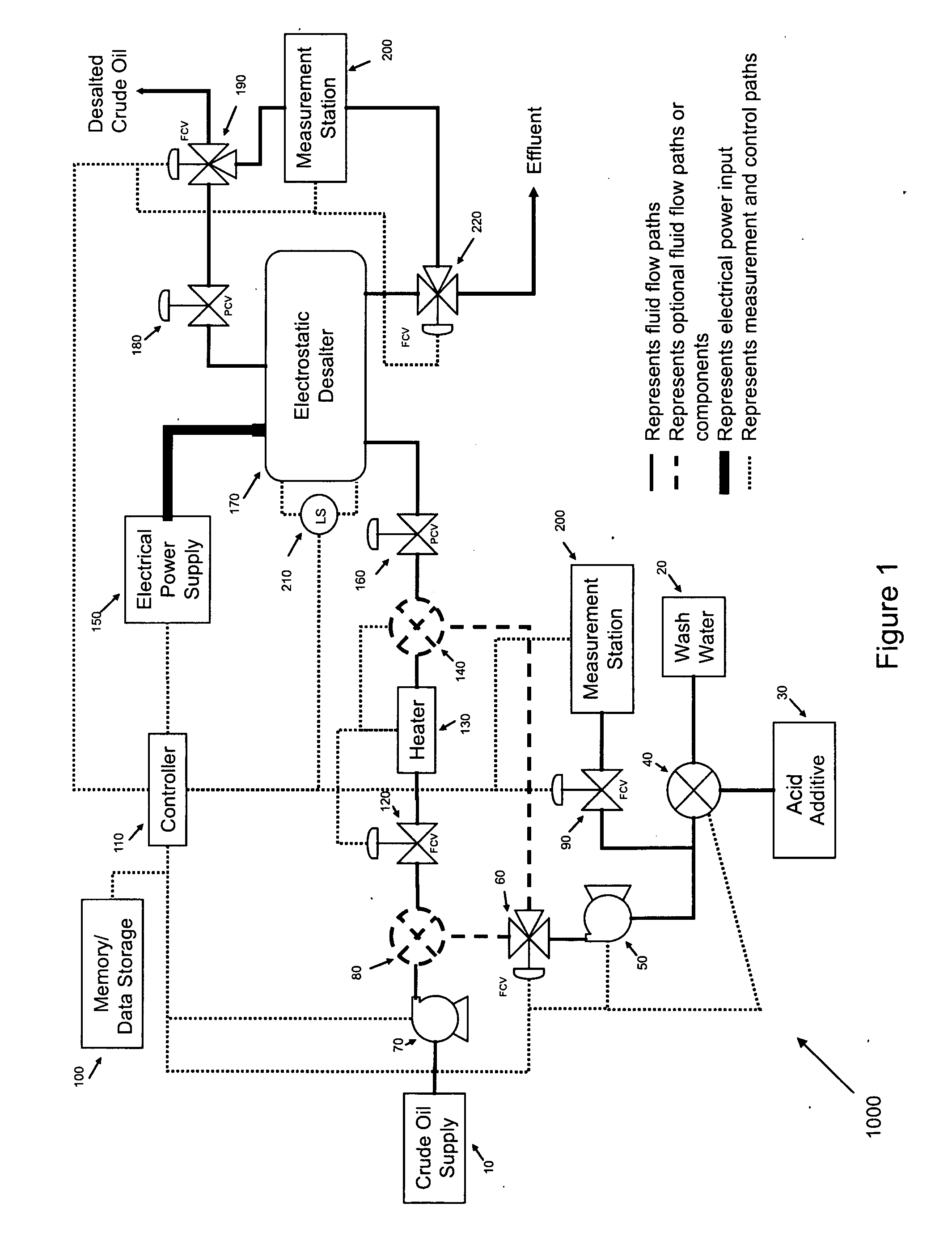

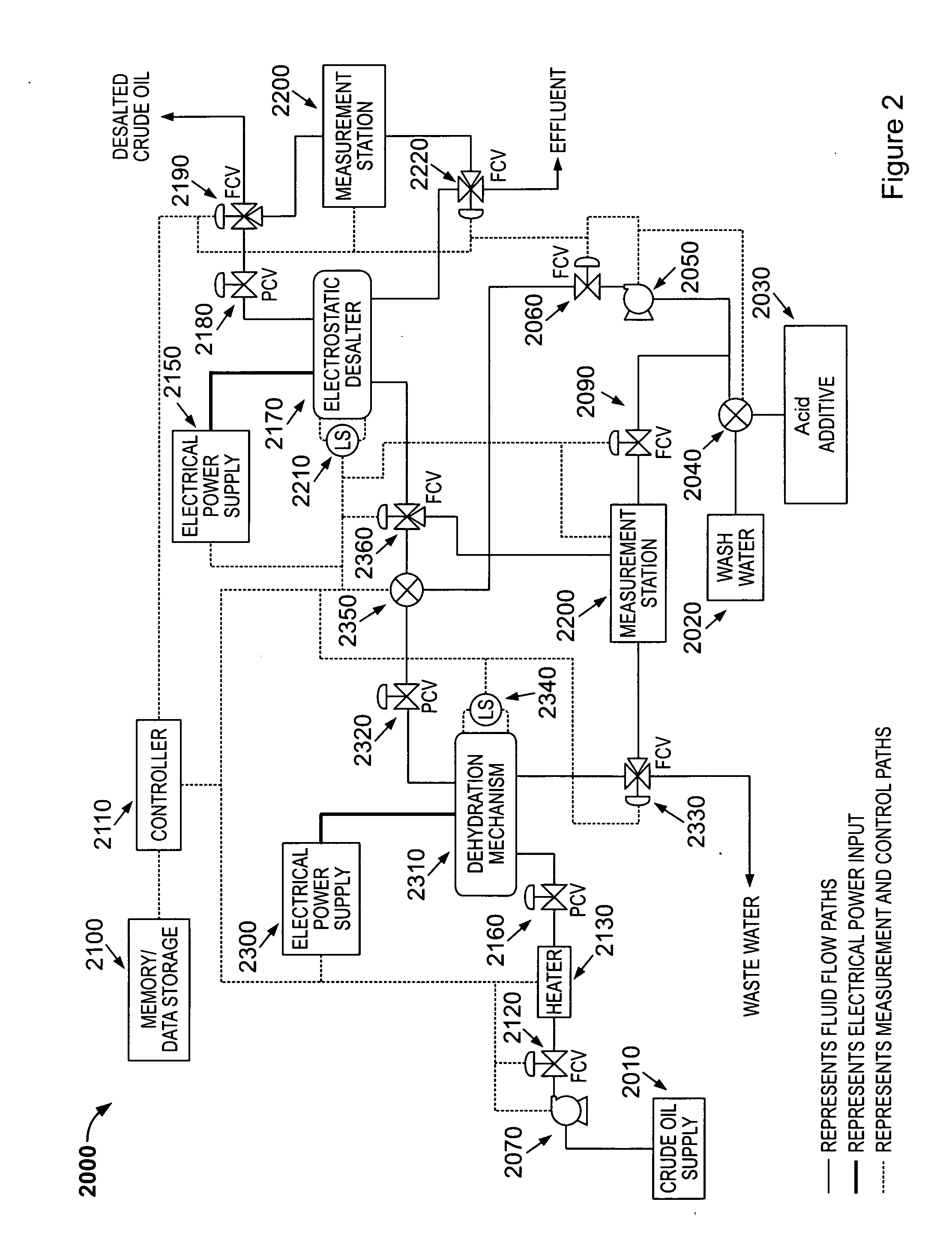

Method and device for automated control of enhanced metal and amine removal from crude oil

InactiveUS20110100877A1Sampled-variable control systemsWorking-up pitch/asphalt/bitumen by selective extractionAutomatic controlWash water

A method for removing calcium, iron, other metals, and amines from crude oil in a refinery desalting process includes the steps of adding a wash water to the crude oil; adding the wash water to the crude oil to create an emulsion; adding to the wash water, the crude oil or the emulsion an acid additive consisting of at least one of the following: oxalic acid, citric acid, water-soluble hydroxyacid selected from the group consisting of glycolic acid, gluconic acid, C.sub.2-C.sub.4 alpha-hydroxy acids, malic acid, lactic acid, poly-hydroxy carboxylic acids, thioglycolic acid, chloroacetic acid, polymeric forms of the above hydroxyacids, poly-glycolic esters, glycolate ethers, and ammonium salt and alkali metal salts of these hydroxyacids, and mixtures thereof; heating at least one of the crude oil, the wash water or the emulsion to a desired temperature; resolving the emulsion containing the acid additive into a hydrocarbon phase and an aqueous phase using electrostatic coalescence, the metals and amines being transferred to the aqueous phase; measuring at least one desalting process characteristic at at least one process point; performing a statistical calculation of the desalting process performance based upon the measuring; and adjusting a control setting of the desalting process as a function of the statistical calculation. Other methods and devices are also provided.

Owner:ASSATEAGUE OIL

Deep separation method and processing system for the separation of heavy oil through granulation of coupled post-extraction asphalt residue

ActiveUS7597794B2High yieldSimple processWorking-up pitch/asphalt/bitumen by selective extractionWorking-up pitch/asphalt/bitumen by solidifying/disintegratingSolid particleOil phase

The present invention is a separation method and system in which granulation of coupled post-extraction asphalt residue is used to achieve deep separation of heavy oil. A dispersion solvent is introduced into the asphalt phase after separation by solvent extraction and the asphalt phase undergoes rapid phase change in a gas-solid separator and is dispersed into solid particles while the solvent vaporizes, resulting in low temperature separation of asphalt and solvent with adjustable size of the asphalt particles. The separation method of this invention also includes a three-stage separation of heavy oil feedstock, in which the deasphalted oil phase separated from heavy oil is treated with supercritical solvent and results in the further separation of the resin portion of the deasphalted oil, maximizing the yield and quality of the deasphalted oil. The processes and systems in this invention use atmospheric pressure and a low temperature gas-solid separator instead of a high temperature and high pressure furnace and do not require the feed pre-heating or heat exchange equipment at the inlet of resin separator column, resulting in a simplified process flow and reduced investment.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

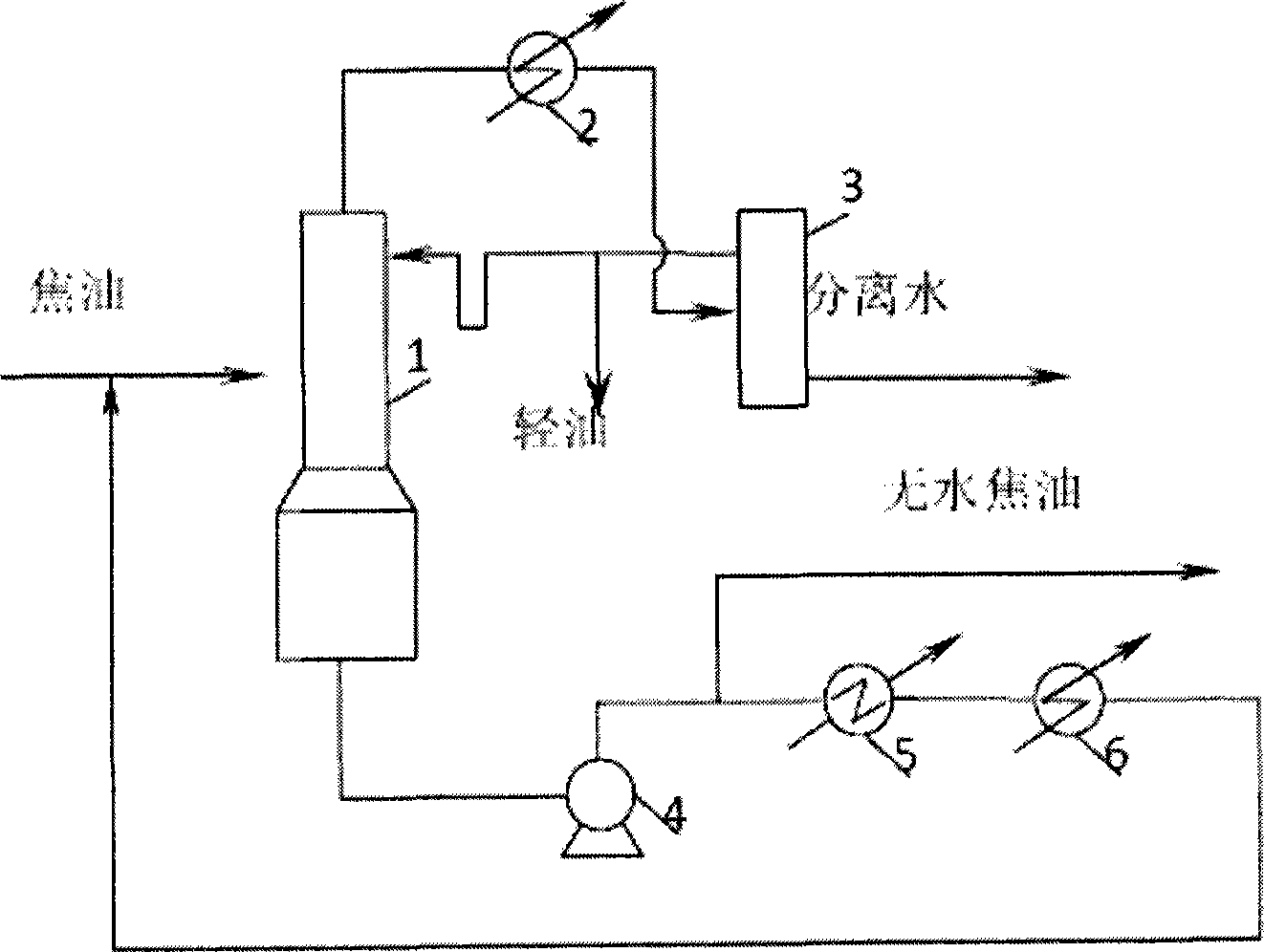

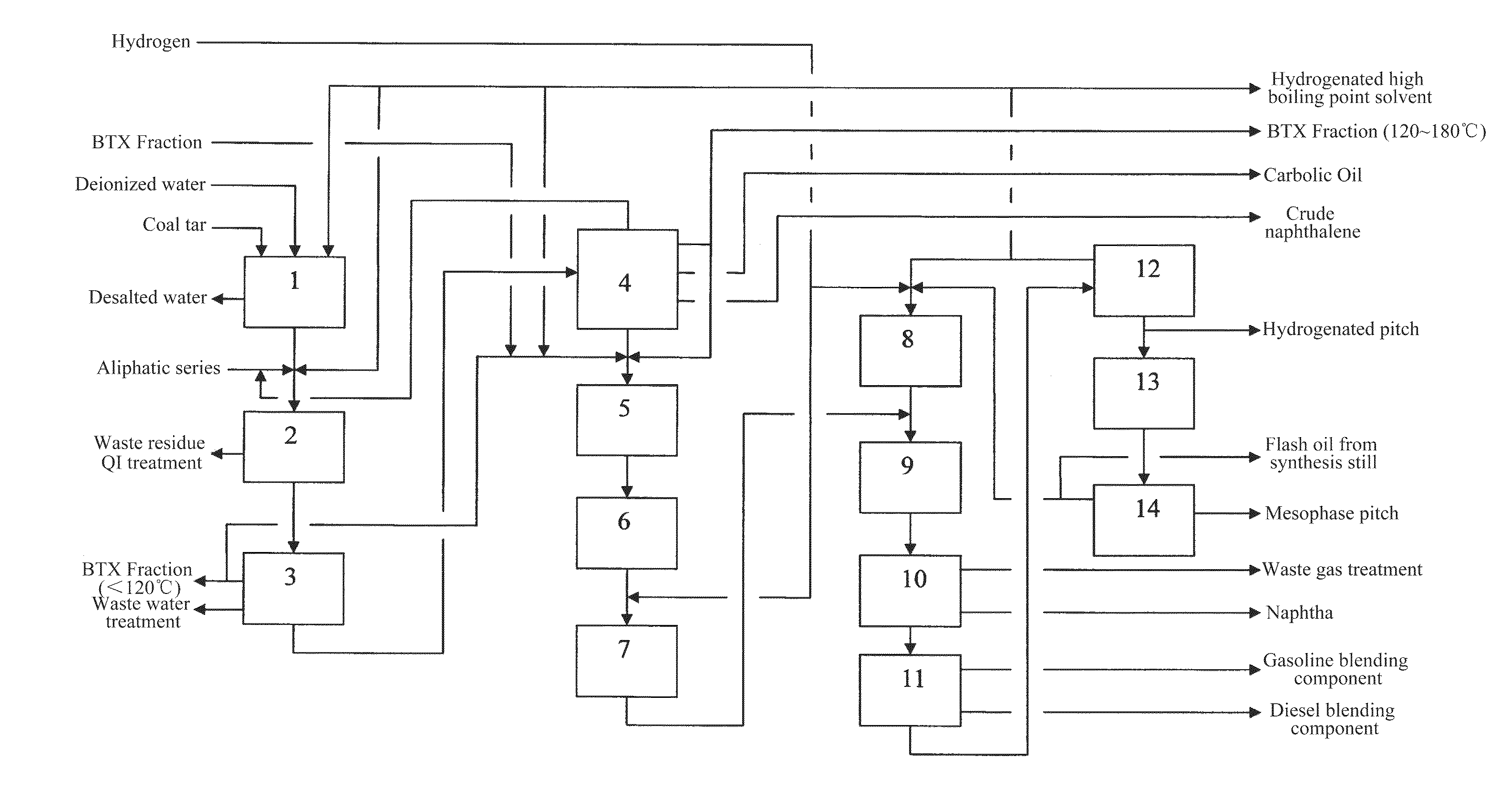

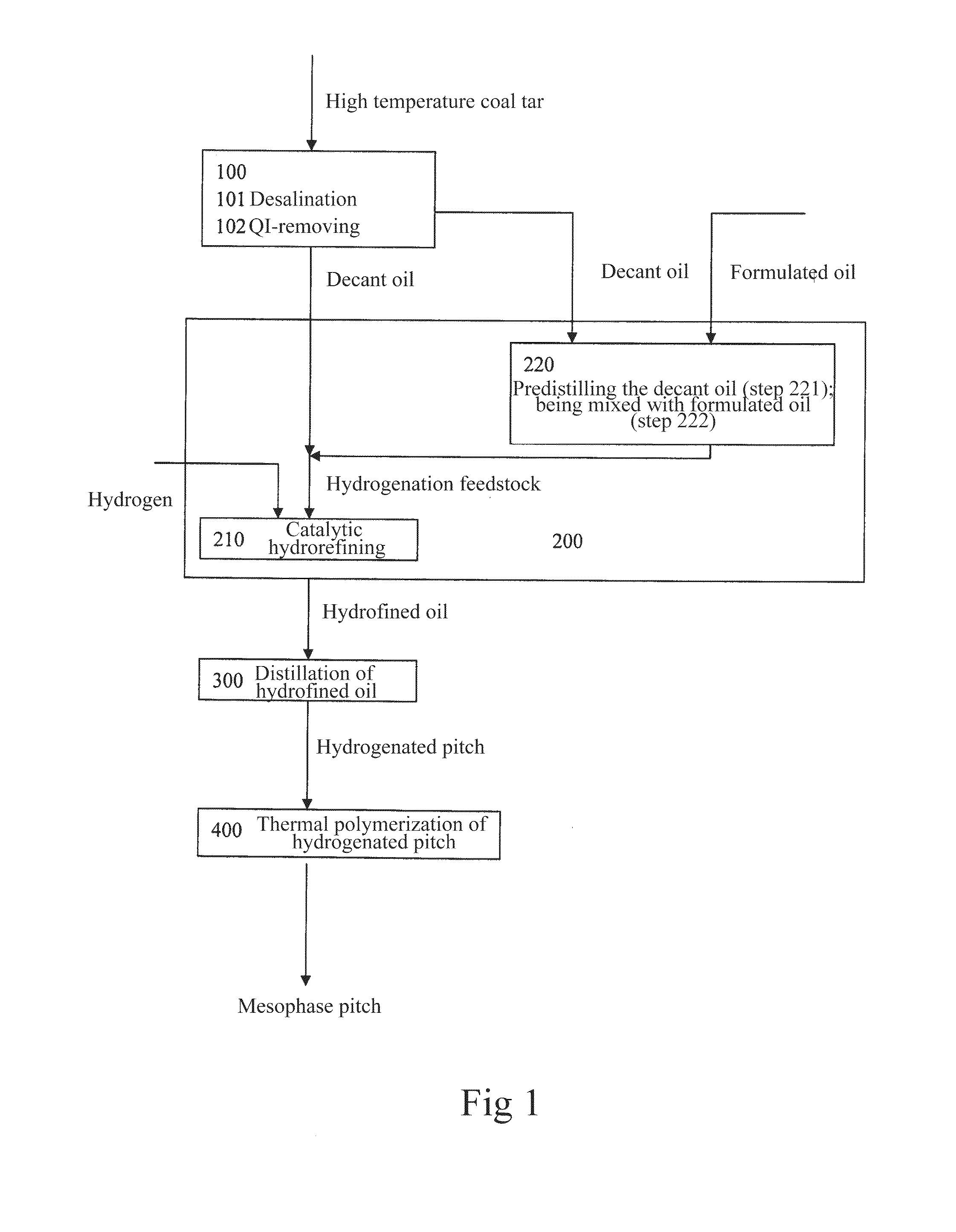

Process for Producing Mesophase Pitch by Hydrogenation of High-temperature Coal Tar

ActiveUS20150076031A1Increase H/C ratioHigh content of mesophase pitchWorking-up pitch/asphalt/bitumen by distillationLiquid hydrocarbon mixtures productionBoiling pointCoal tar

A process for producing mesophase pitch from high-temperature coal tar comprises: removing salts and quinoline insoluble fraction from a high-temperature coal tar to obtain a decant oil; using the decant oil as a hydrogenation feedstock, or pre-distilling the decant oil to obtain a residue with a boiling point higher than 230 and formulating the residue into a hydrogenation feedstock; catalytic hydrorefining the hydrogenation feedstock to obtain a hydrofined oil; distilling the hydrofined oil to obtain hydrogenated pitch; and subjecting the hydrogenated pitch to the thermal polymerization to obtain the mesophase pitch. The process has features such as an easily controllable degree of hydrogenation, complete removal of impurities, good raw material flowability, not tending to form the carbon deposition and the coking during the process, and not tending to jam the reactor. The product has a high content of mesophase pitch, a low softening point and a low impurity content.

Owner:ECO CARBON MATERIALS HLDG (SHENZHEN) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com