Patents

Literature

165 results about "Combined technique" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

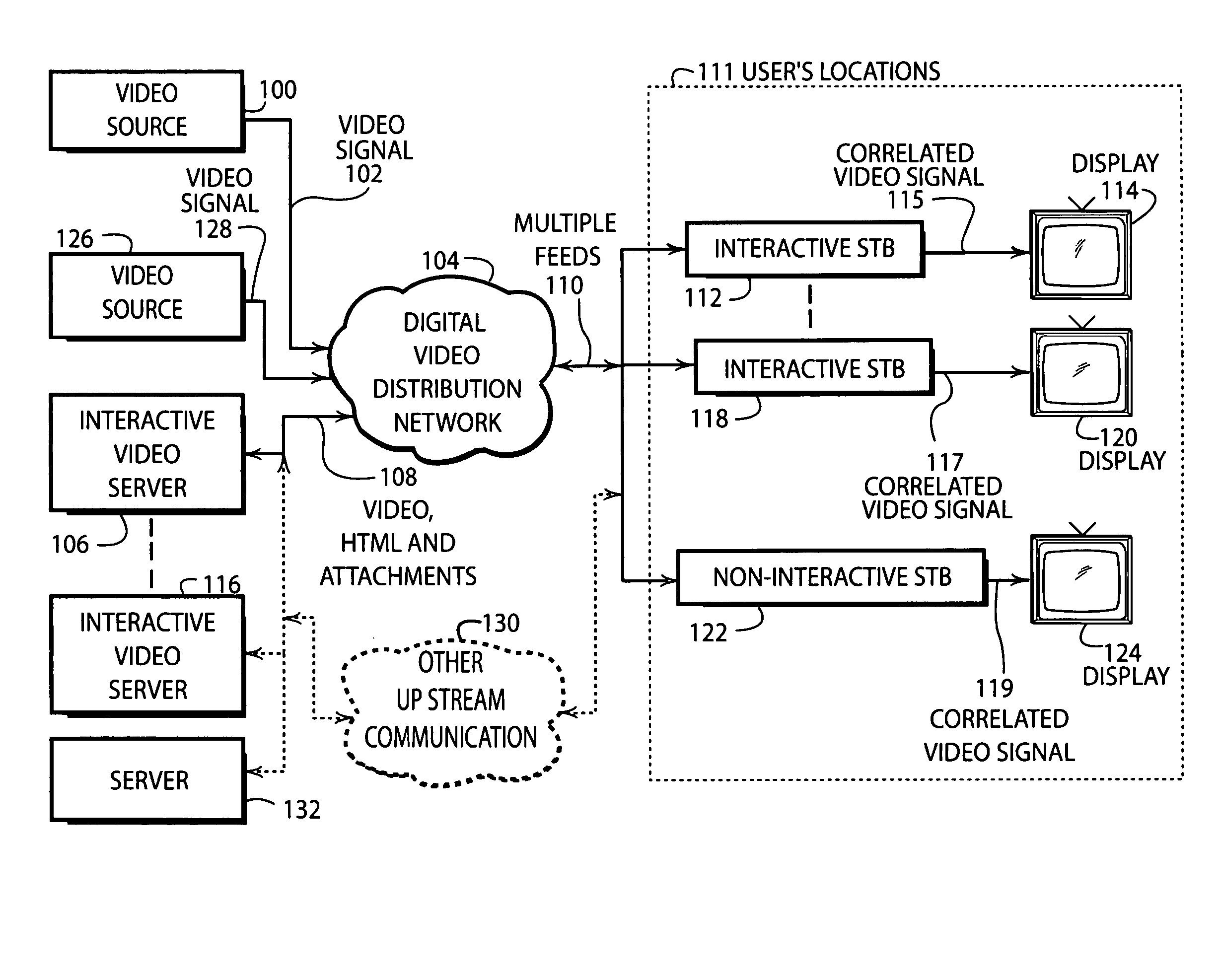

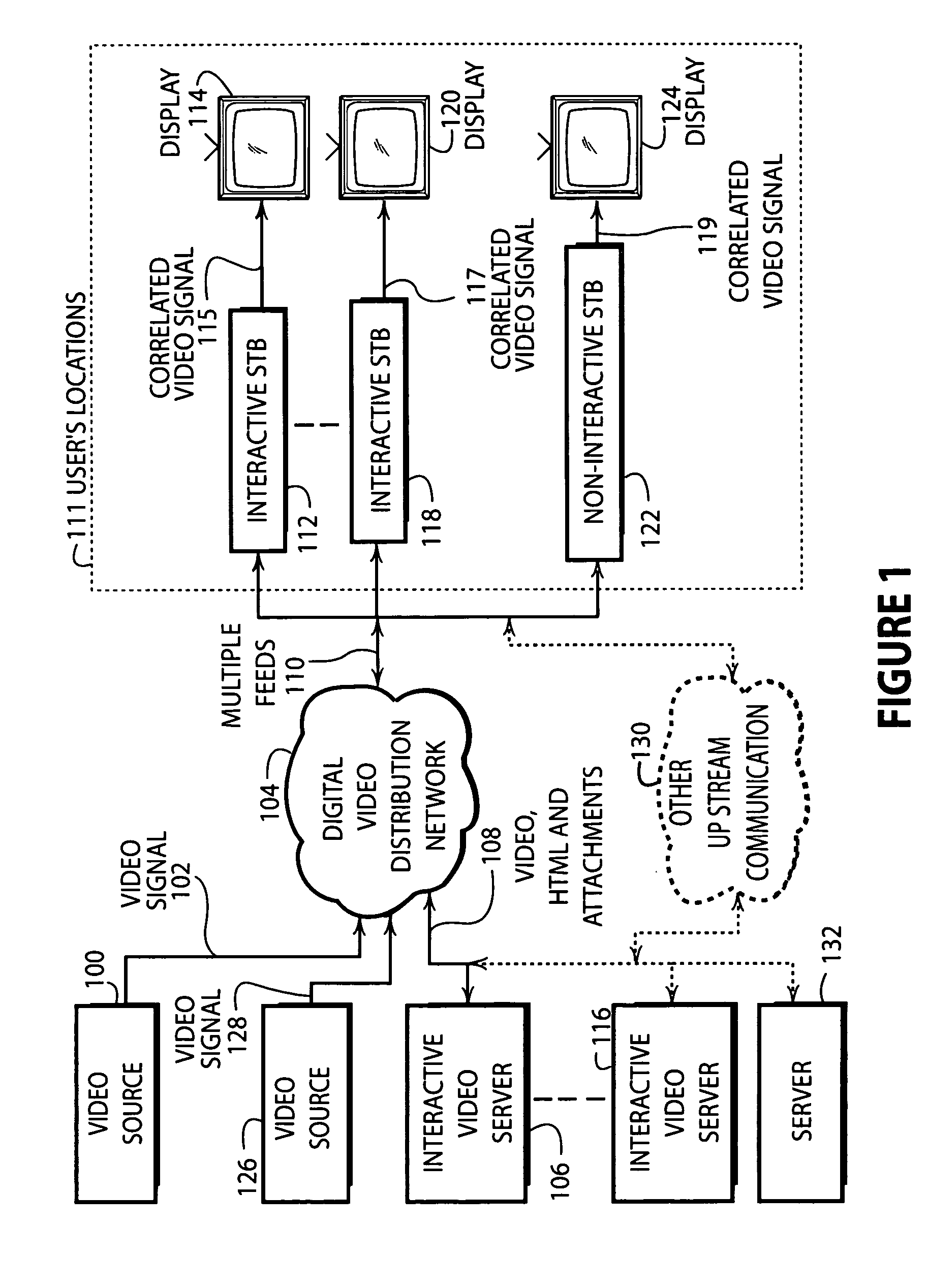

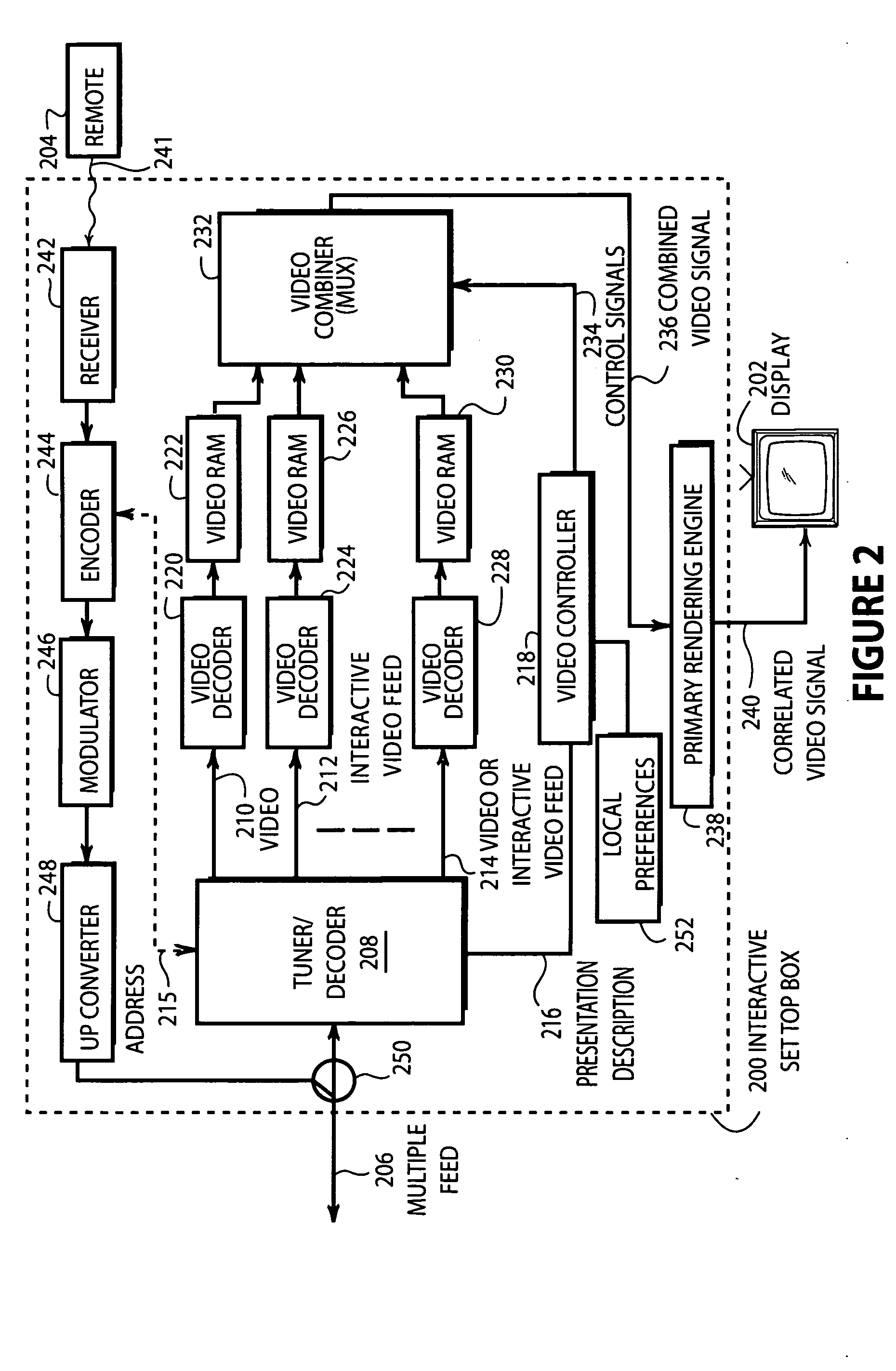

Advertising methods for advertising time slots and embedded objects

ActiveUS20050137958A1Increase flexibilityShort timeFinanceAdvertisementsCombined techniqueWorld Wide Web

Disclosed is a process for an advertising bidding system in which advertisers can bid on advertising time slots or enhanced ads that can be inserted in either prerecorded or live television programming. A high degree of flexibility is provided by allowing embedded ads to be purchased and displayed in a very short time period. This allows TV broadcasters to increase revenues and allows advertisers to have more flexibility in advertising. Objects can be inserted in the display video broadcast using enhancements such as by using mark-up language overlay pages or by video combination techniques. The effect of these ads can be evaluated for advertising campaigns.

Owner:ROKU INCORPORATED

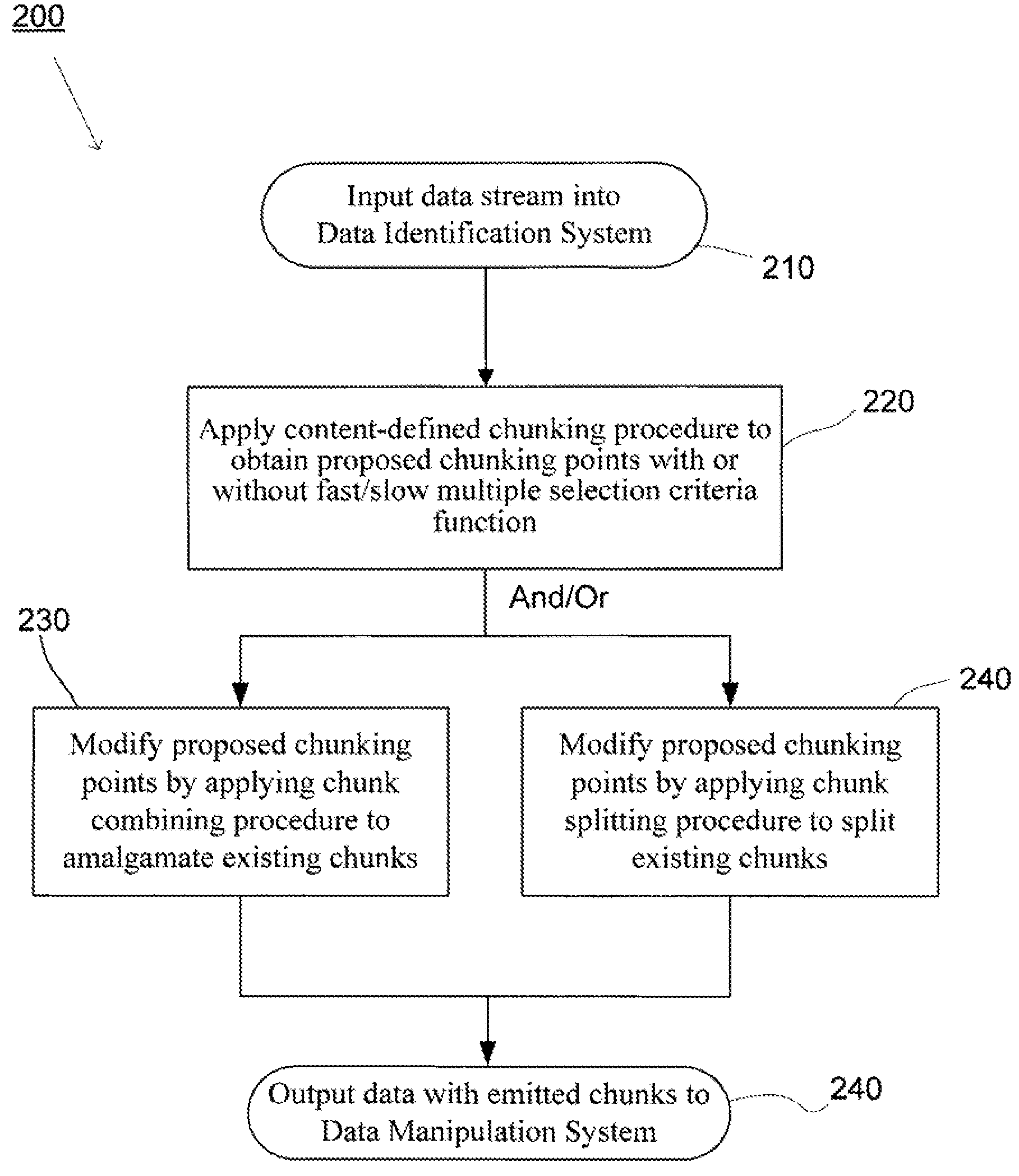

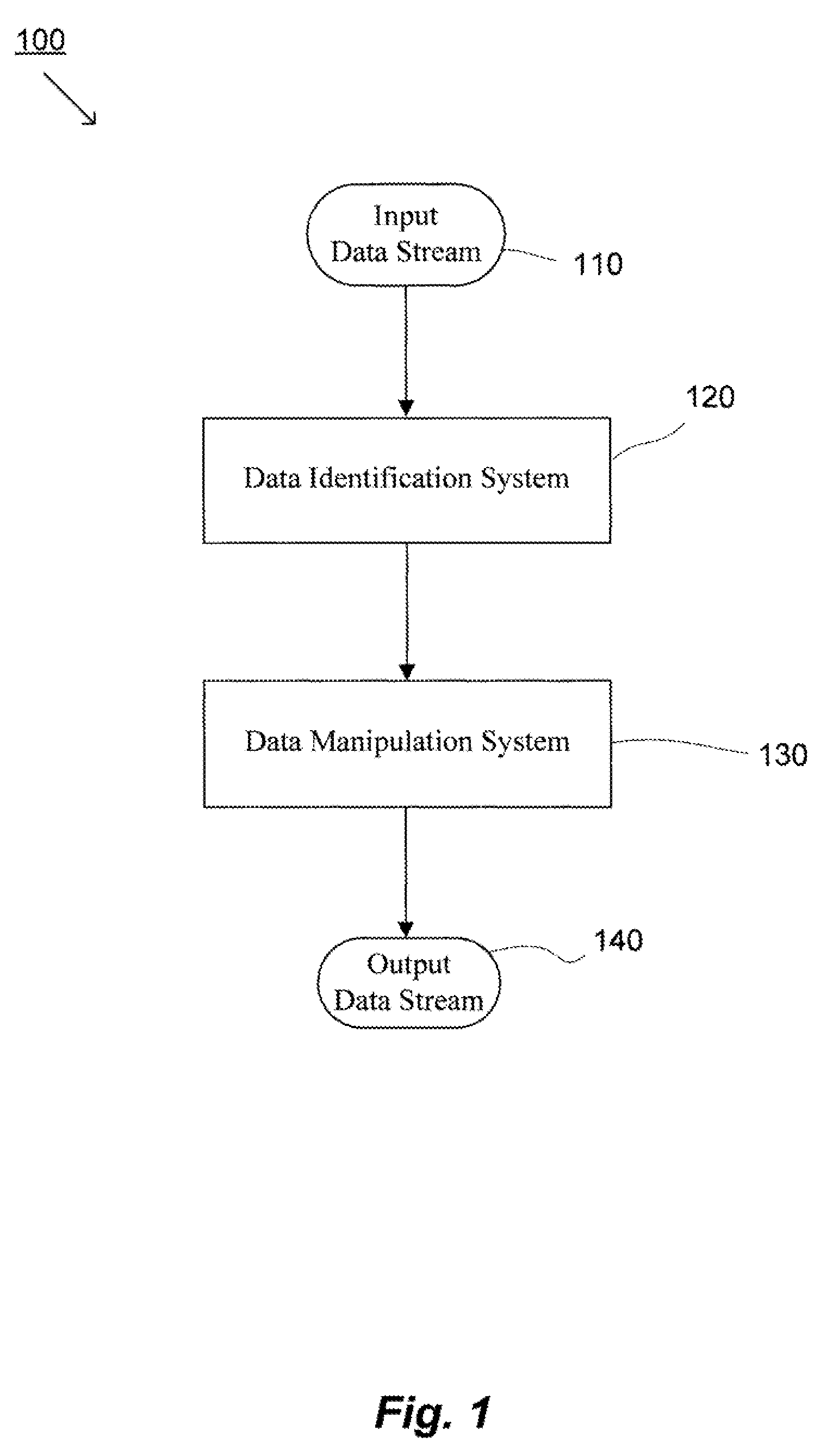

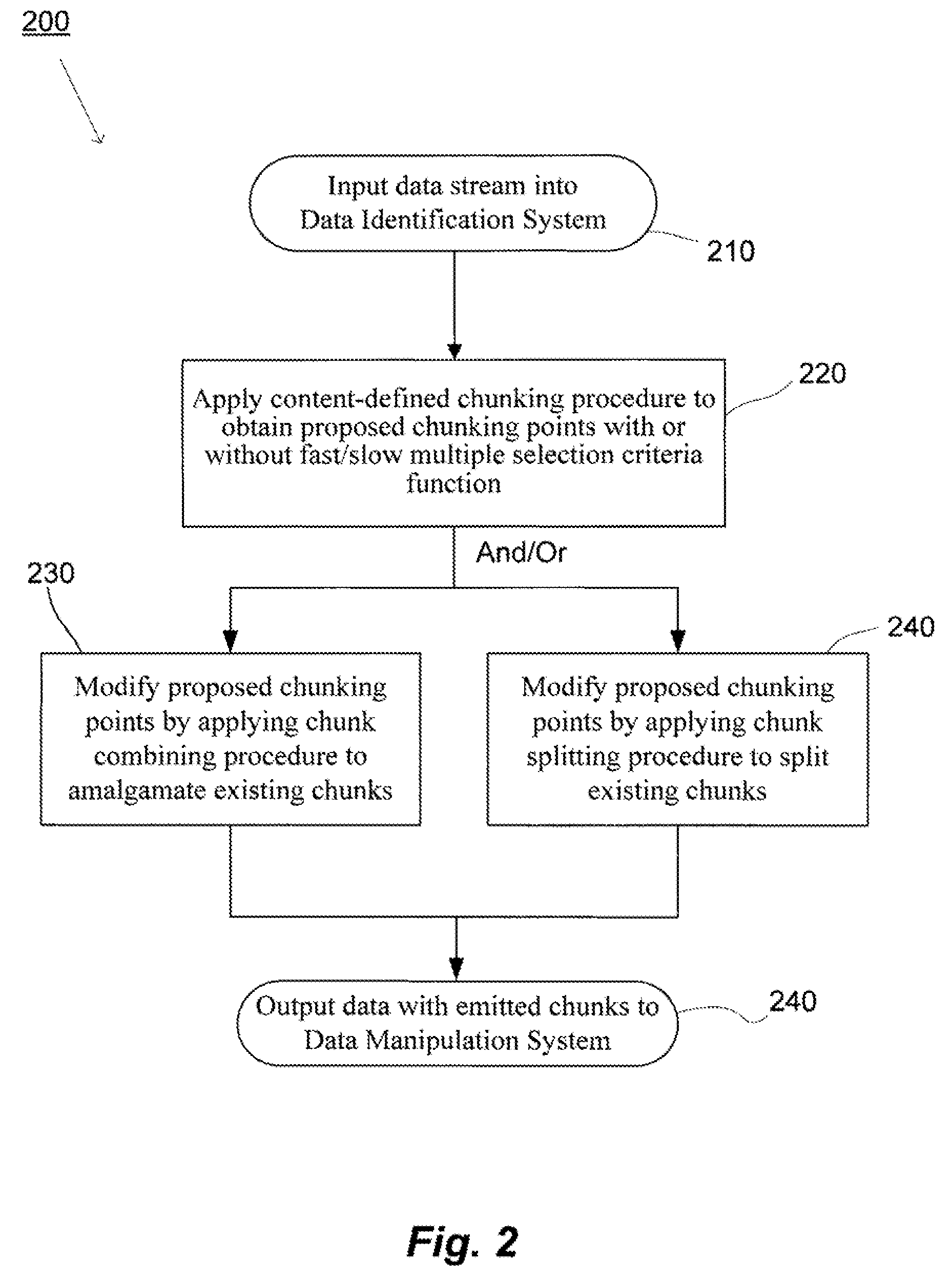

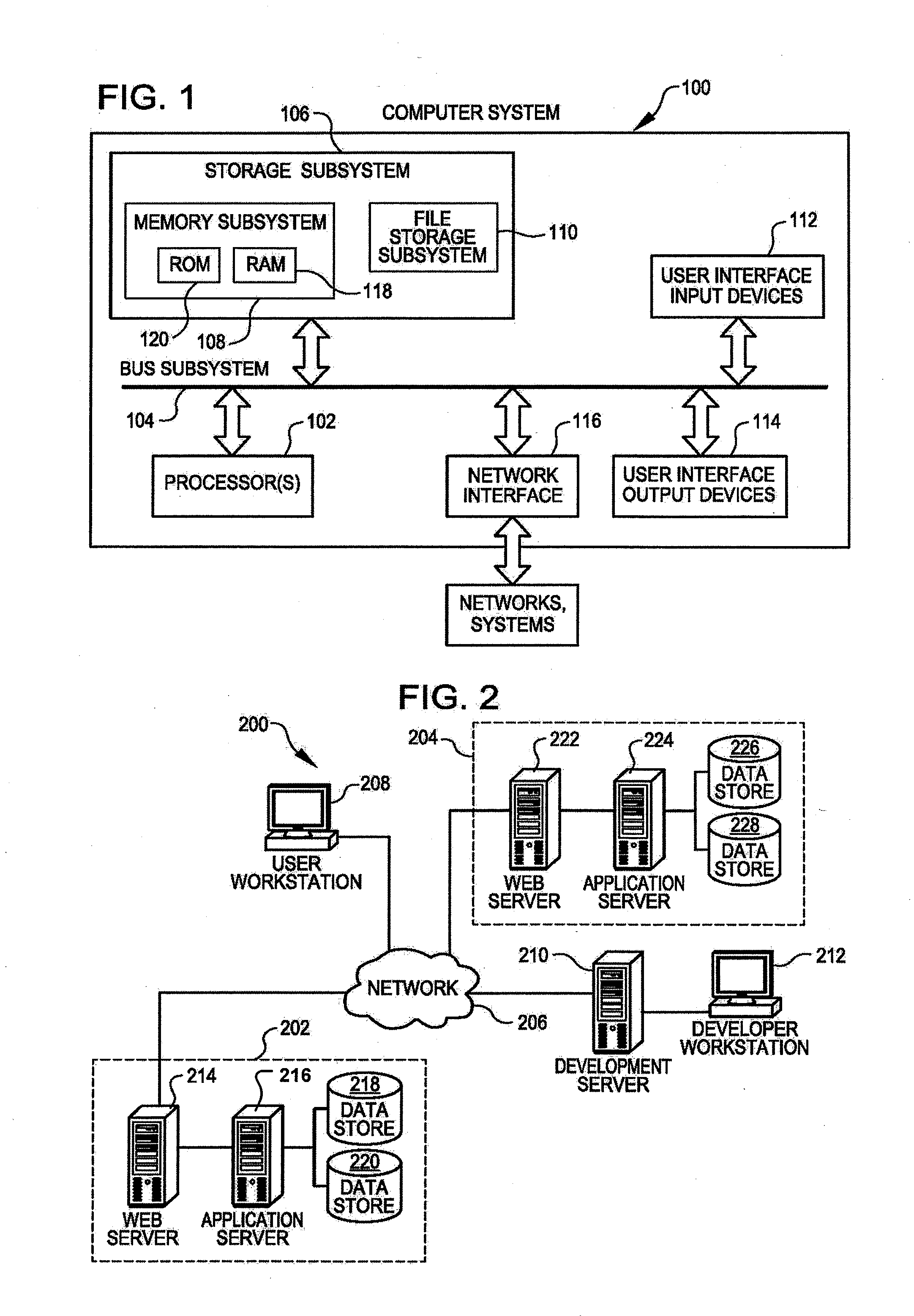

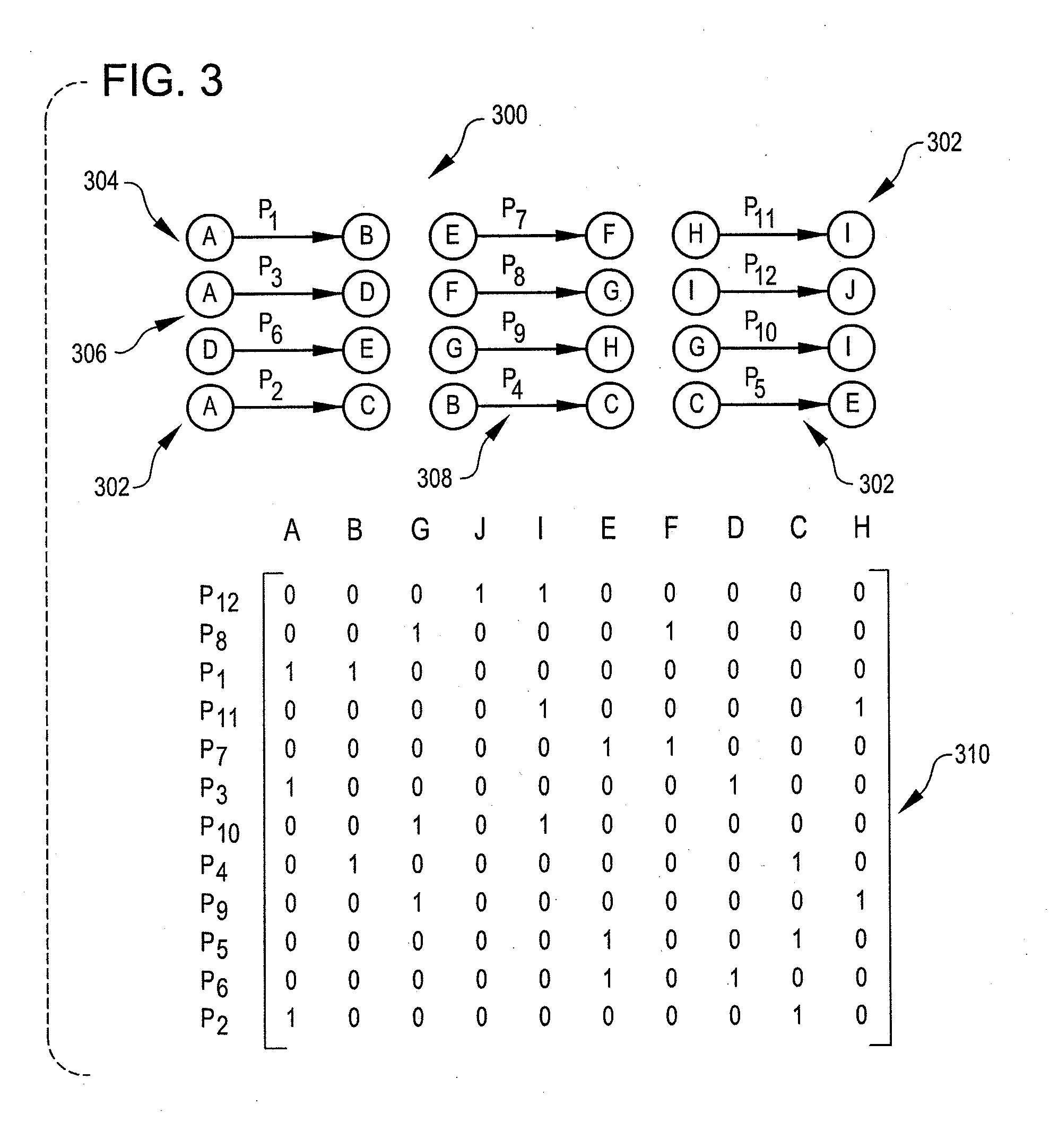

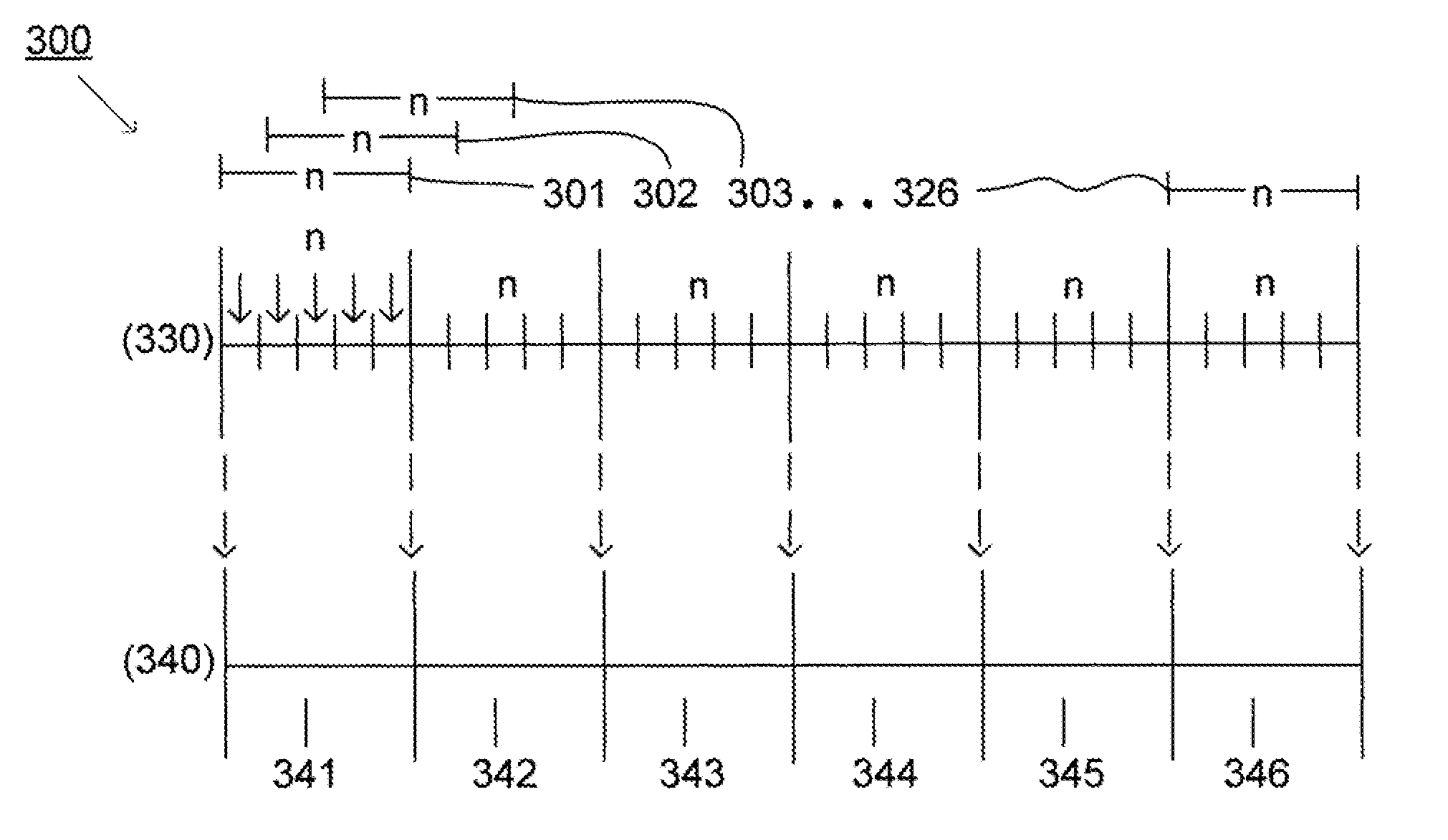

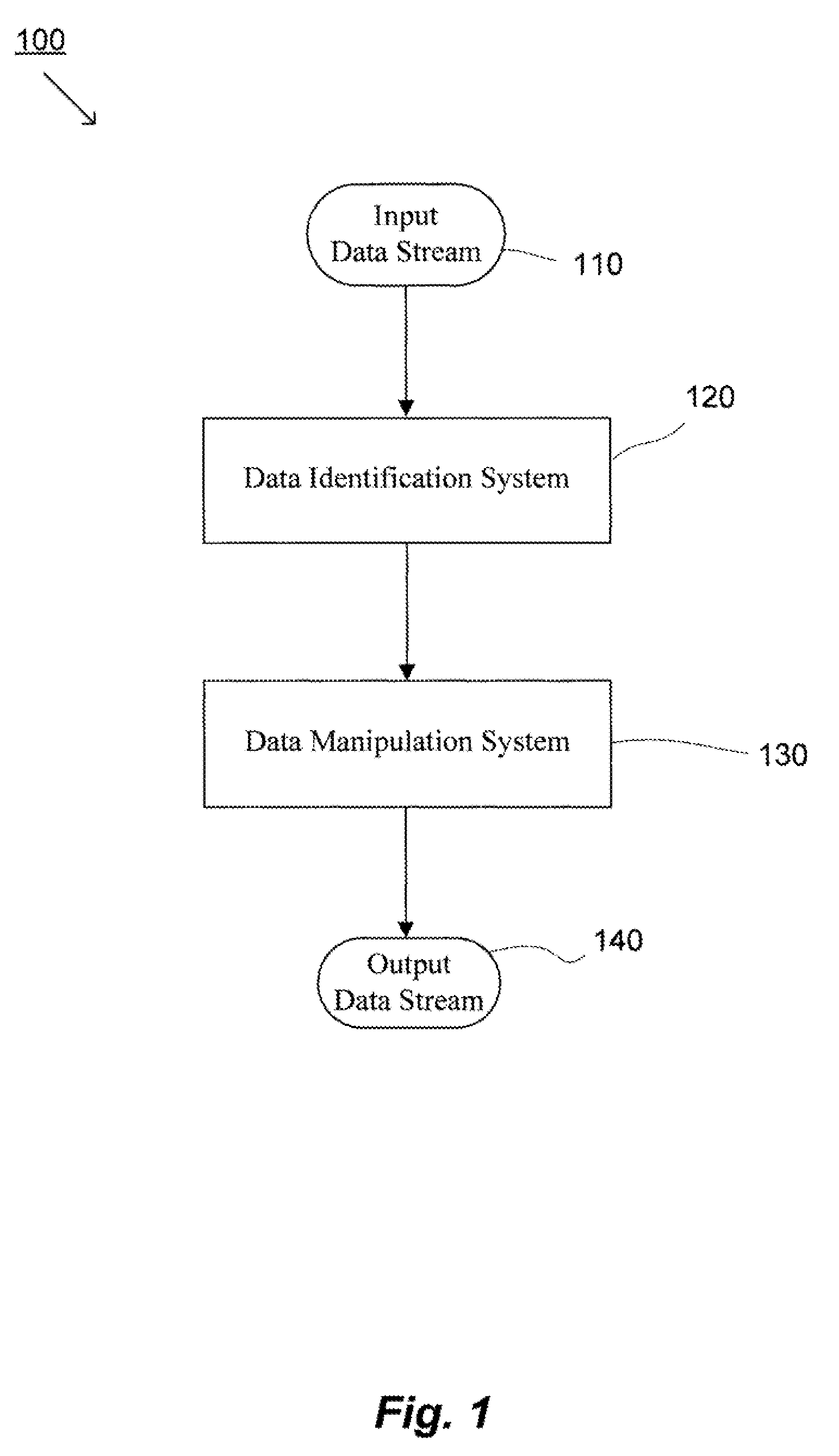

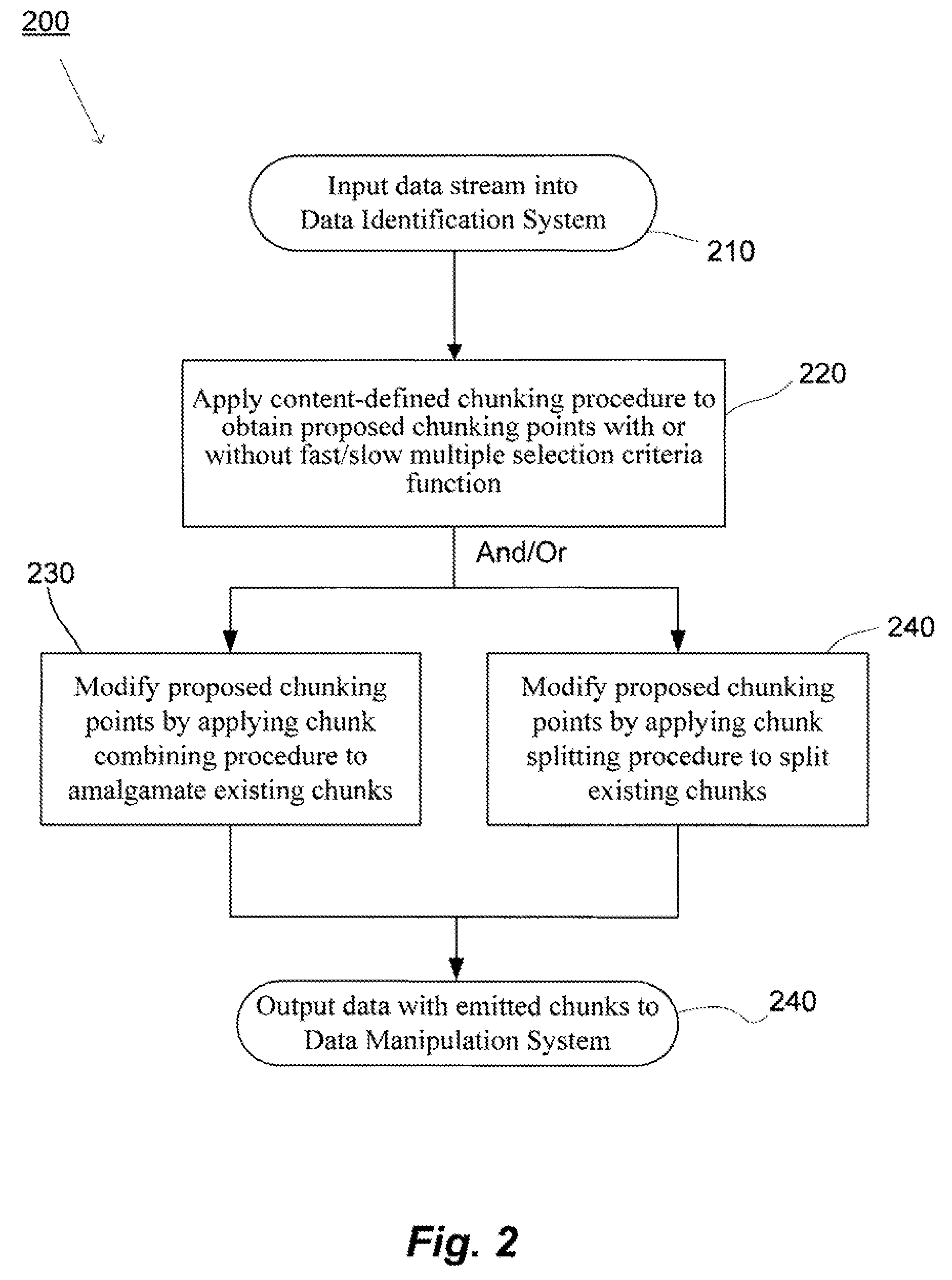

Methods and systems for quick and efficient data management and/or processing

ActiveUS20080133561A1Improve data processing efficiencyReduce quality problemsDigital data information retrievalProgram control using stored programsData managementCombined technique

System(s) and method(s) are provided for data management and data processing. For example, various embodiments may include systems and methods relating to relatively larger groups of data being selected with comparable or better performing selection results (e.g., high data redundancy elimination and / or average chunk size). In various embodiments, the system(s) and method(s) may include, for example a data group, block, or chunk combining technique or / and a data group, block, or chunk splitting technique. Various embodiments may include a first standard or typical data grouping, blocking, or chunking technique and / or data group, block, or chunk combining technique or / and a data group, block, or chunk splitting technique. Exemplary system(s) and method(s) may relate to data hashing and / or data elimination. Embodiments may include a look-ahead buffer and determine whether to emit small chunks or large chunks based on characteristics of underlying data and / or particular application of the invention (e.g., for backup).

Owner:NEC CORP

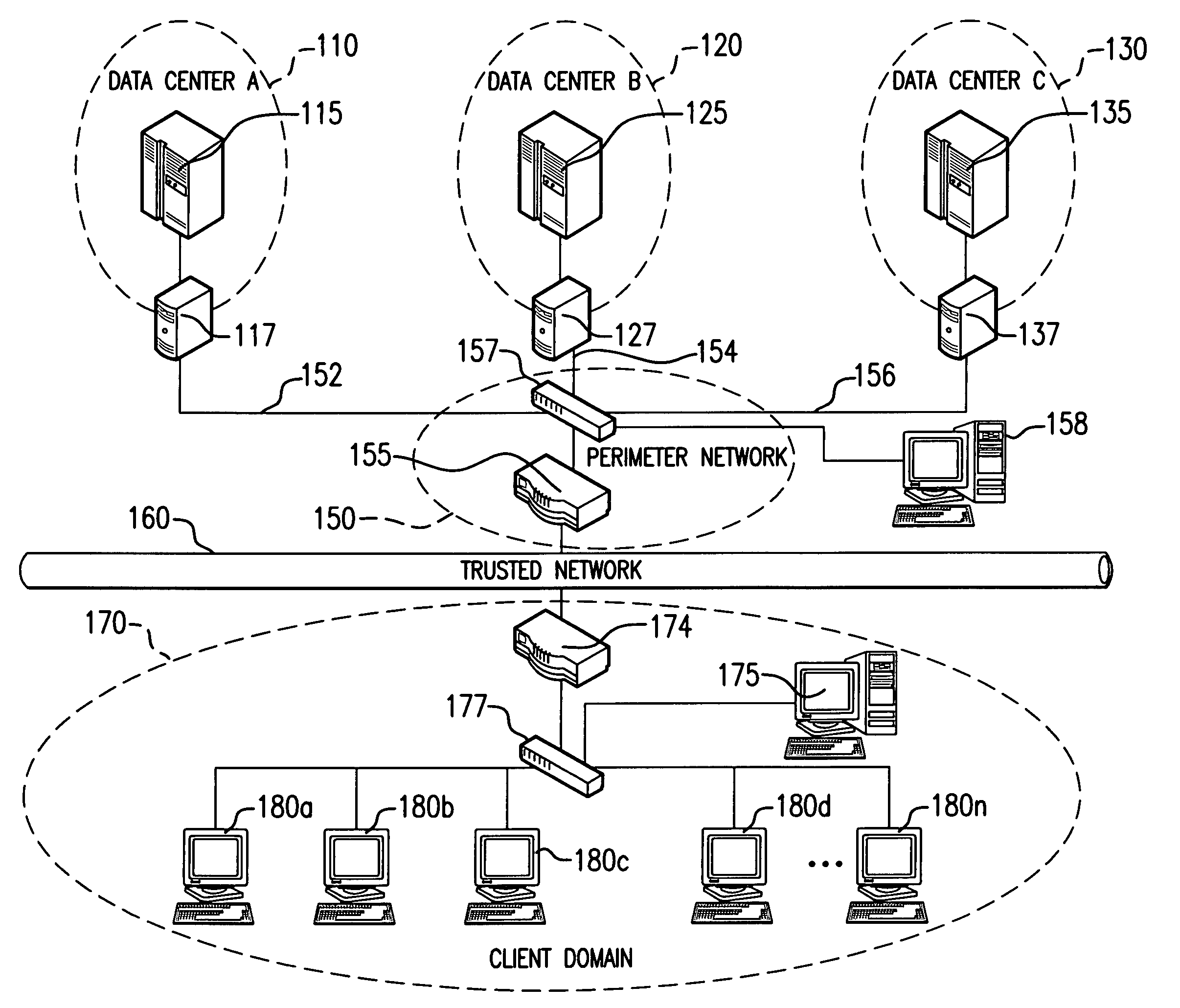

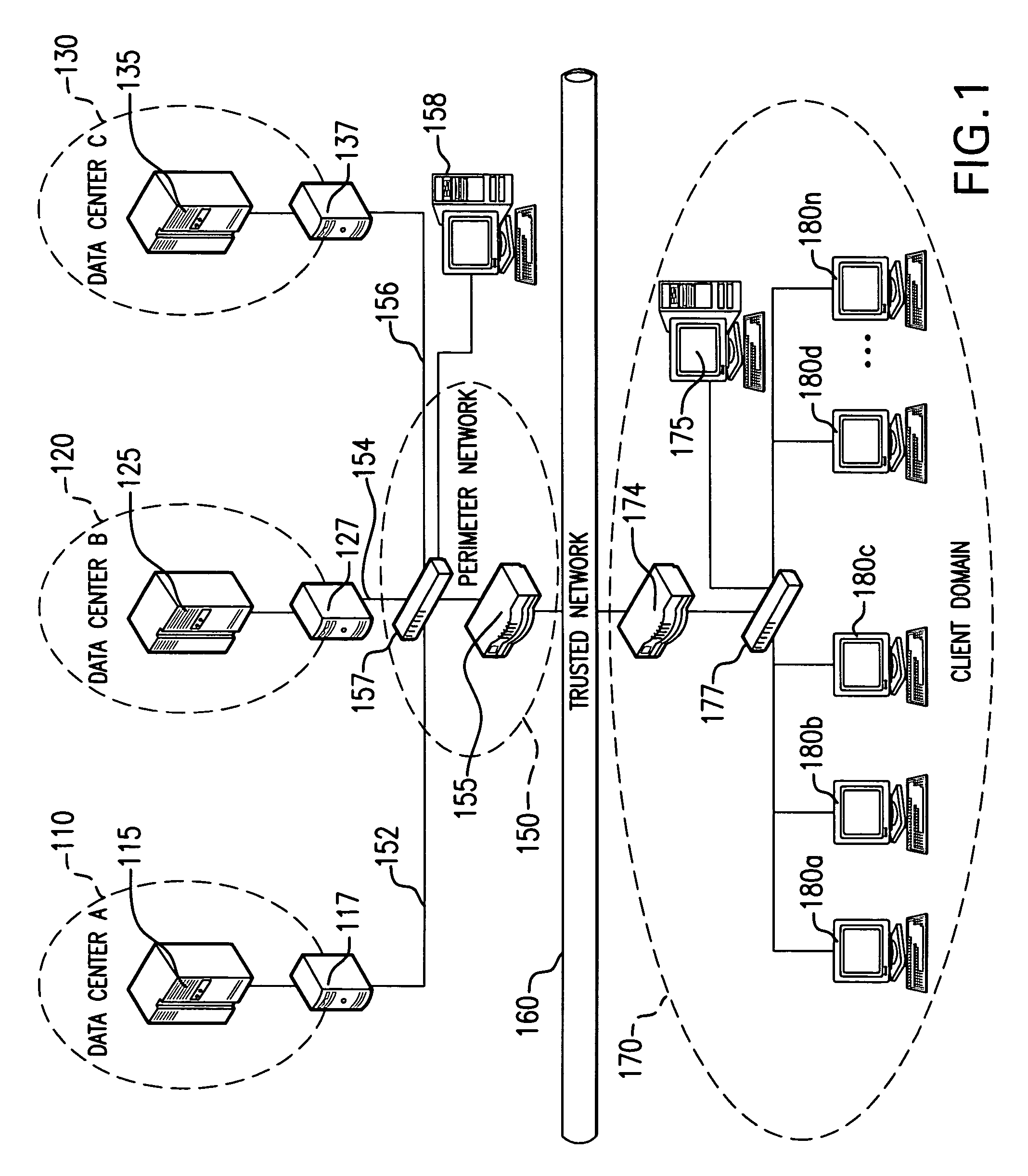

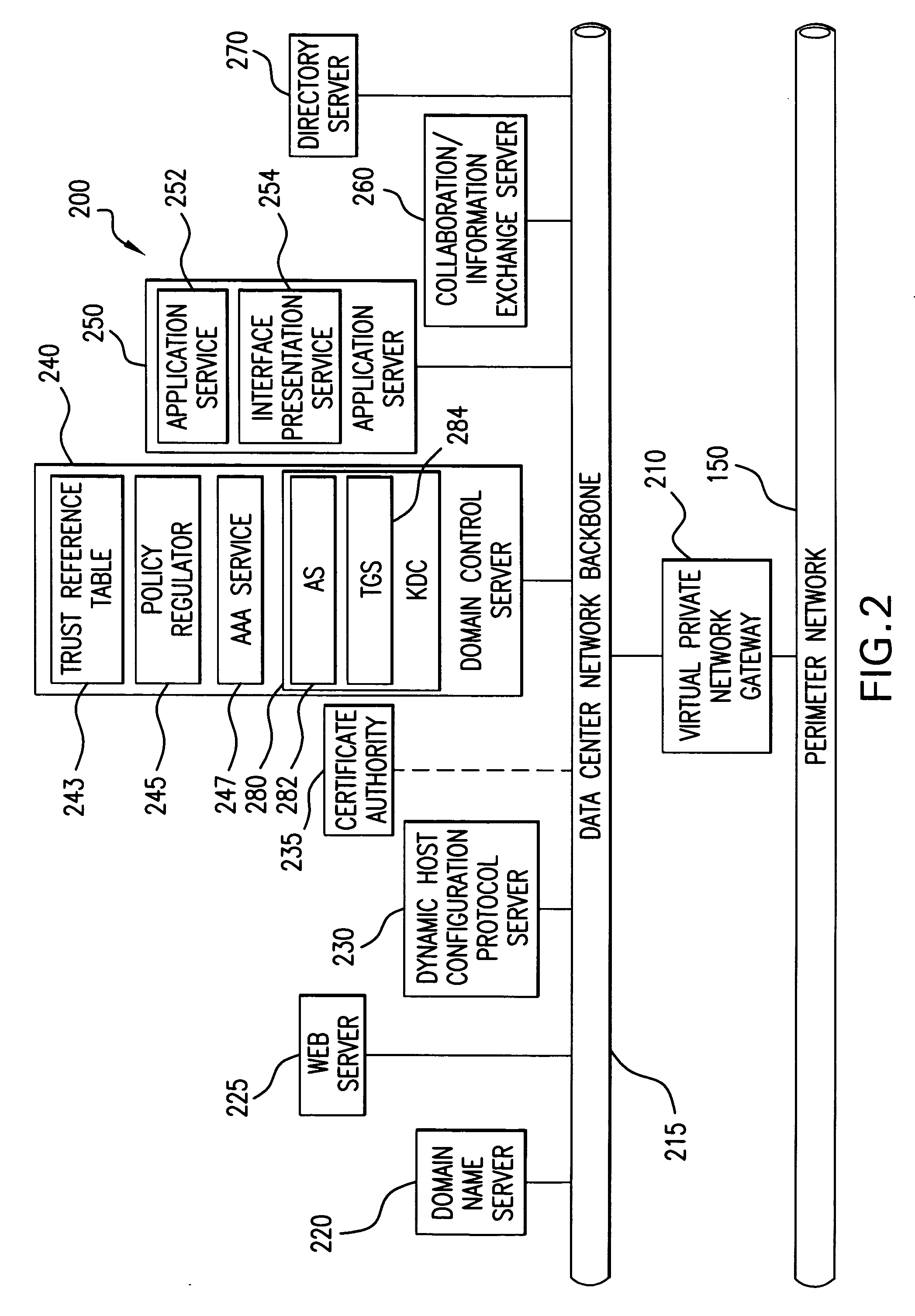

System for secure computing using defense-in-depth architecture

ActiveUS20060041761A1Key distribution for secure communicationUnauthorized memory use protectionPrivate networkCombined use

A secure computing system is provided which utilizes a unique combination of Public Key Infrastructure (PKI), Virtual Private Networking (VPN), and server-based computing on thin client devices. The combination of technology and components provide secure computing through Defense-in-Depth using commercial off-the-shelf components.

Owner:MITRE SPORTS INT LTD

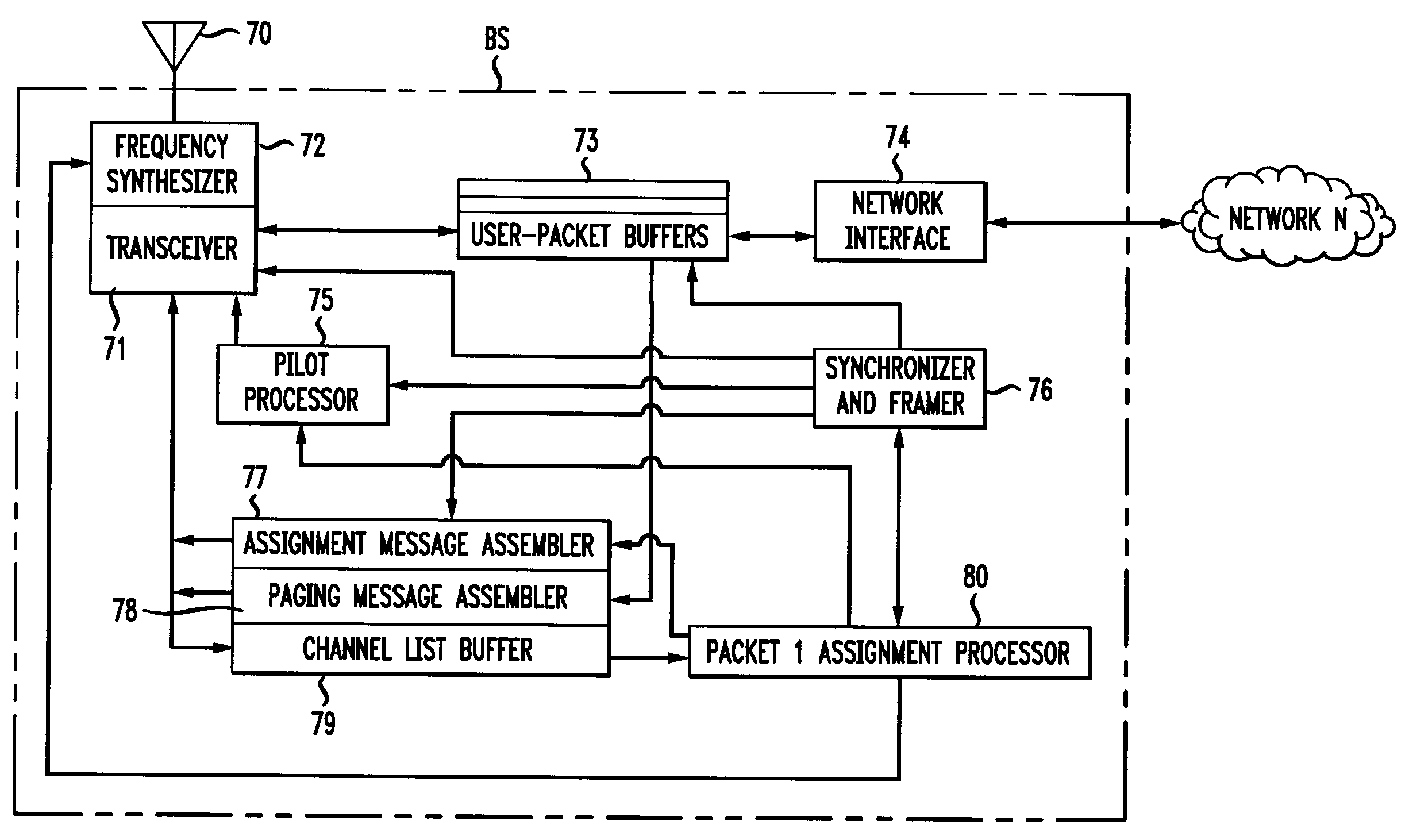

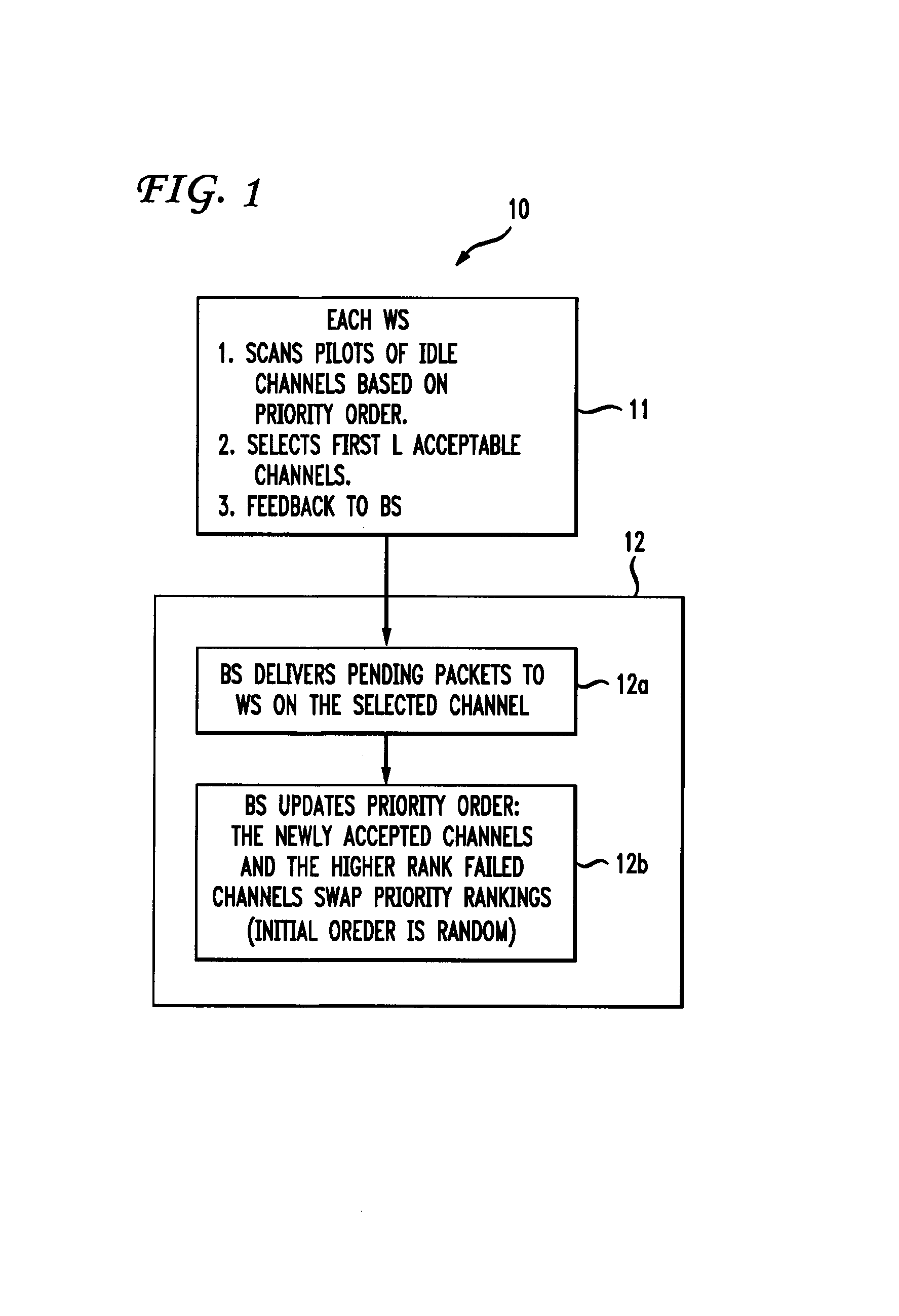

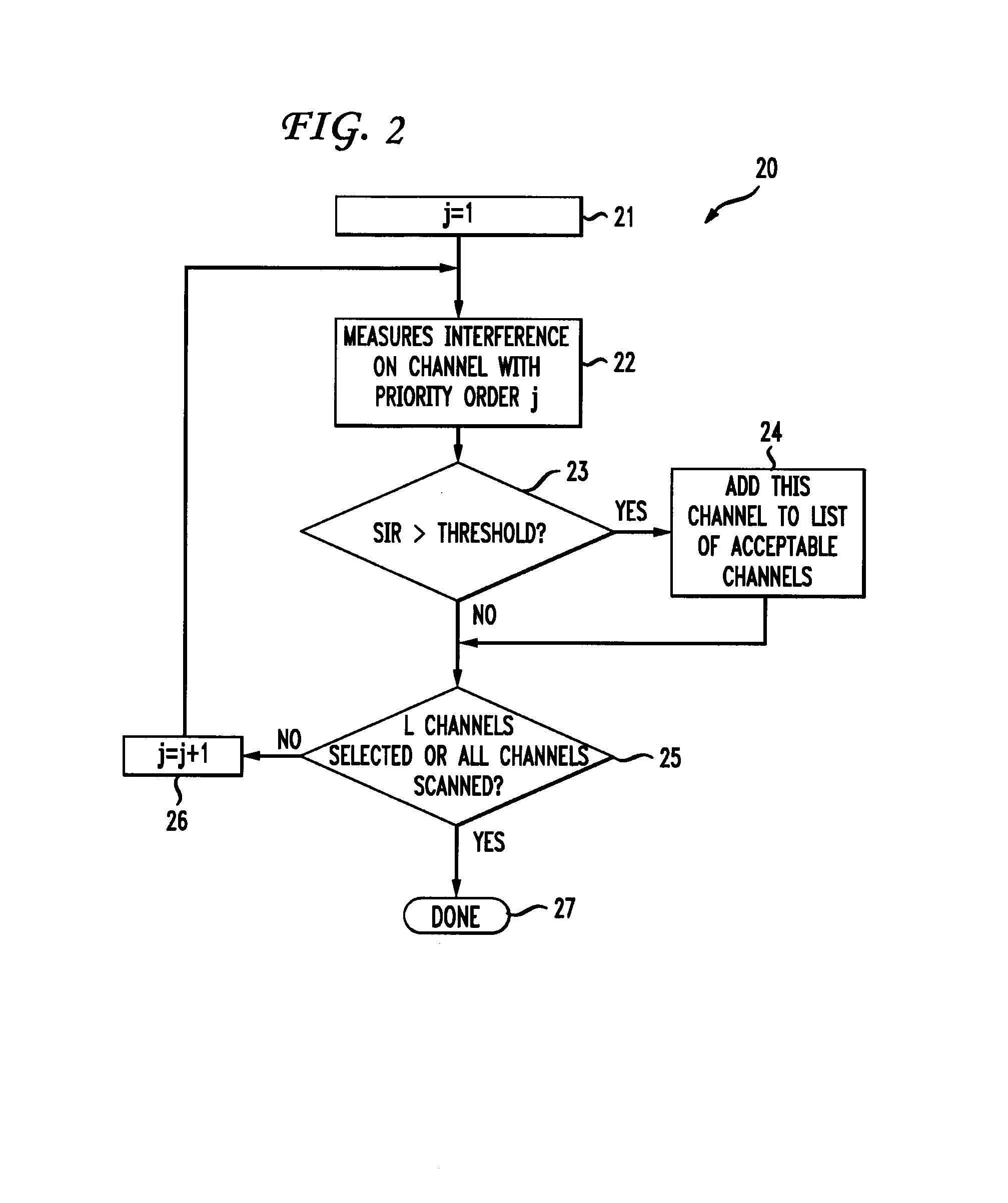

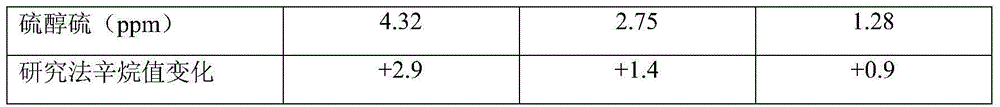

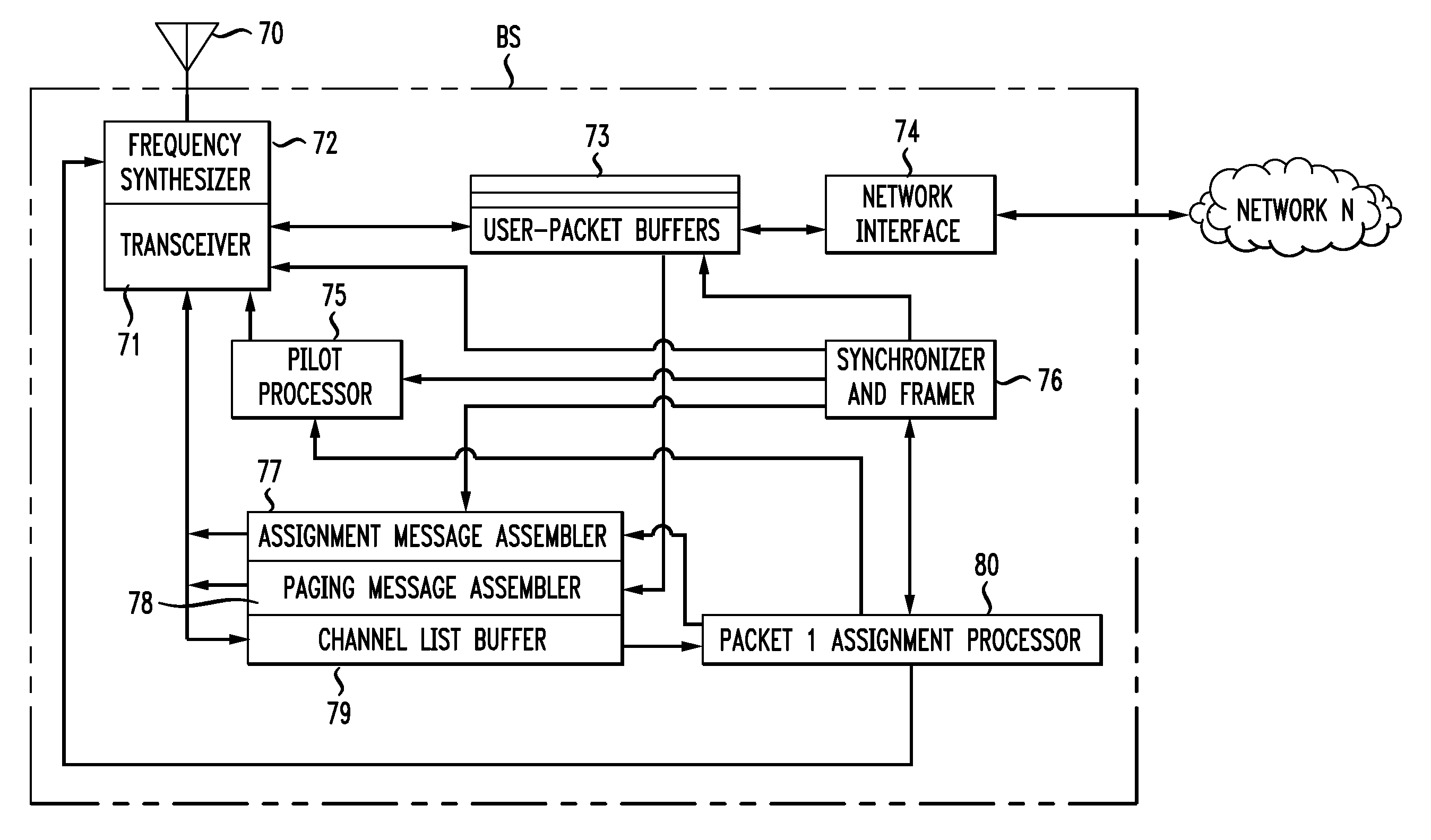

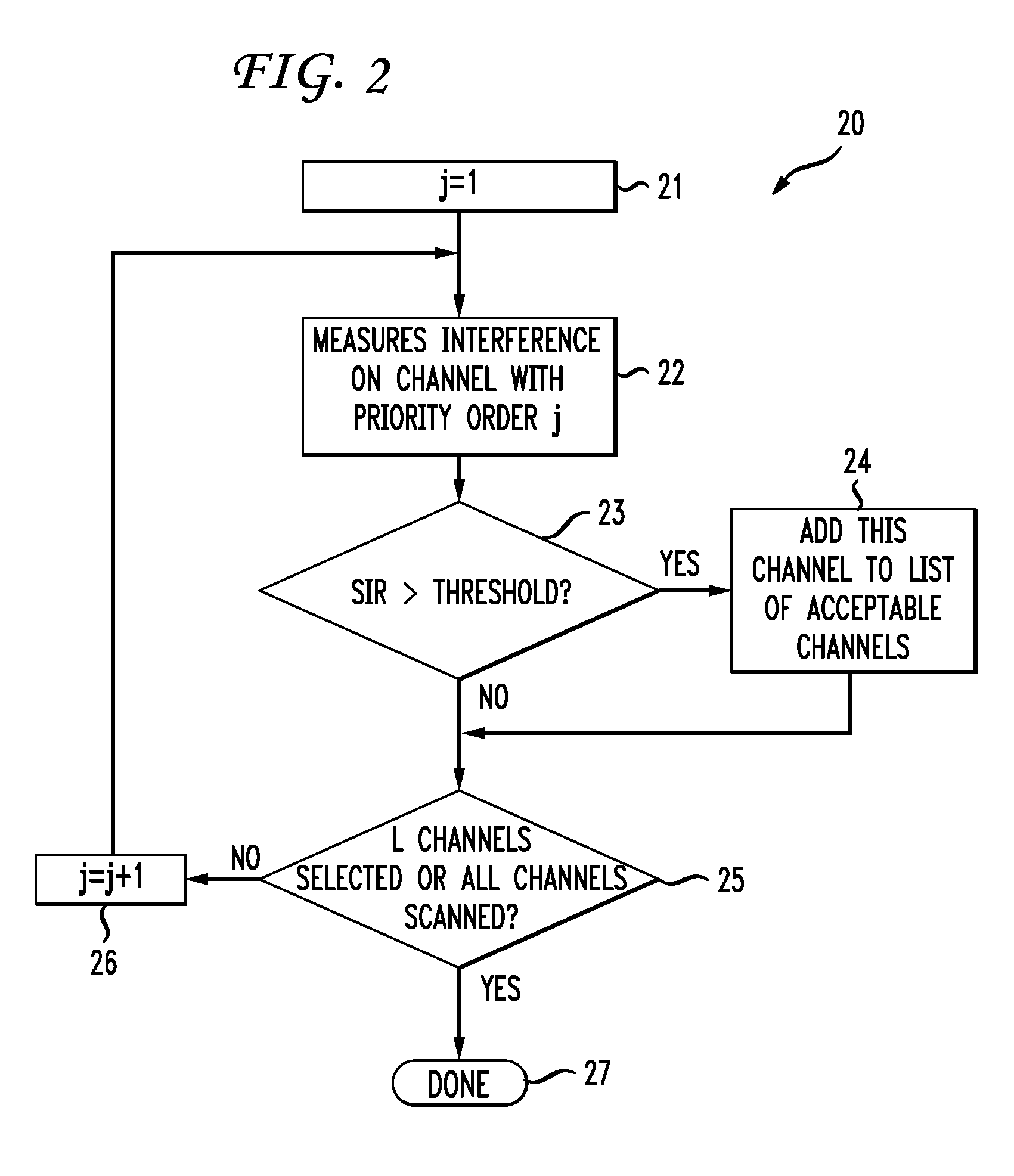

System and method for selecting a transmission channel in a wireless communication system that includes an adaptive array

InactiveUS7133380B1Spatial transmit diversityFrequency-division multiplexCommunications systemTransmission channel

A method for establishing wireless communication between a transmitter and a receiver in a wireless communication system. The receiver includes an adaptive array that has at least two antennas. Each antenna receives a signal and produces a received signal. The transmitter includes at least two transmission channels for communicating the signal from the transmitter to the receiver. The wireless communication system suppresses interference at the receiver by applying an interference suppression technique when combining the received signals. The selection of a channel at the transmitter is based on the channel performance at the receiver for each transmission channel. The channel performance is based on a combining technique different from the interference suppression technique.

Owner:AT&T INTPROP II L P

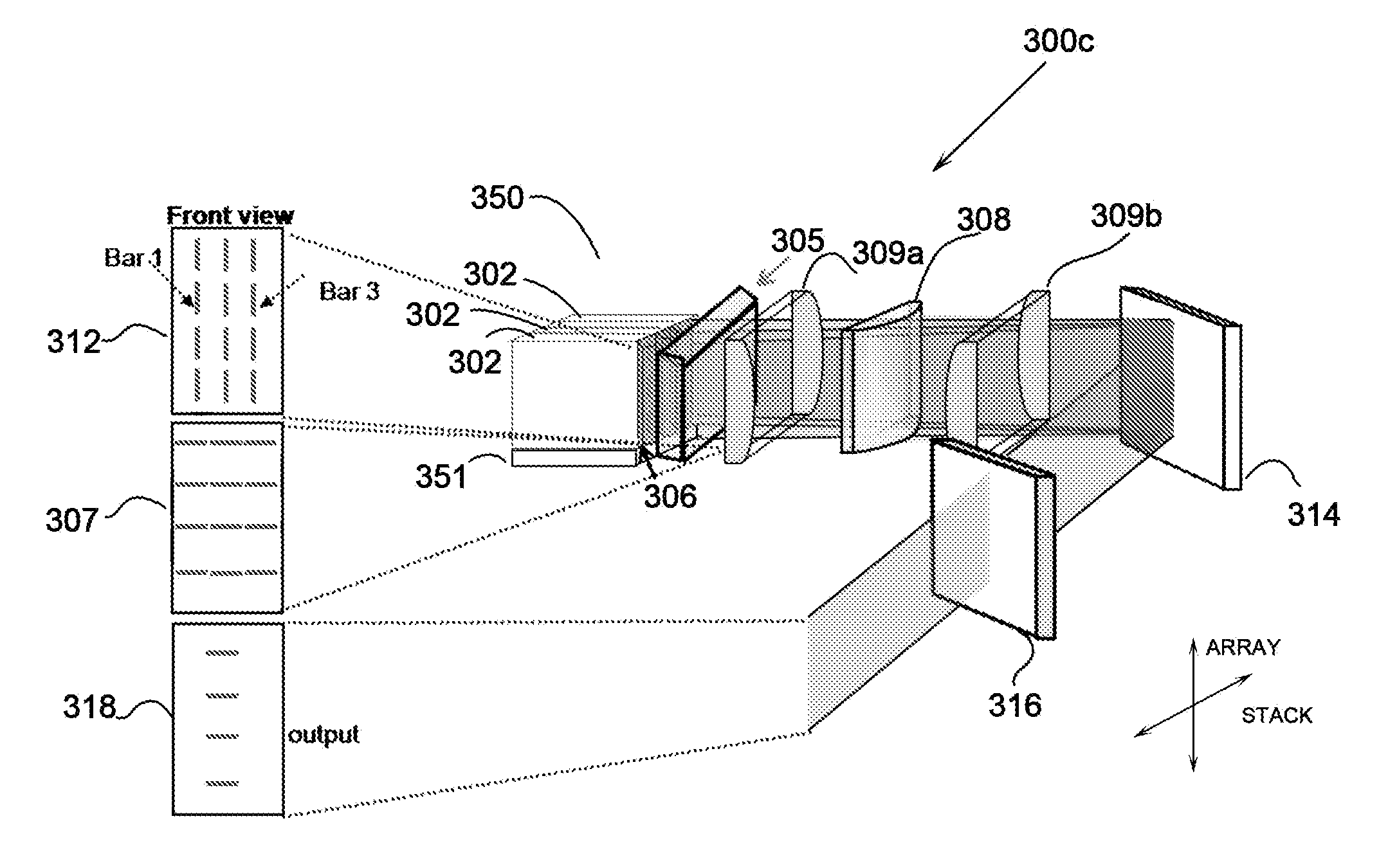

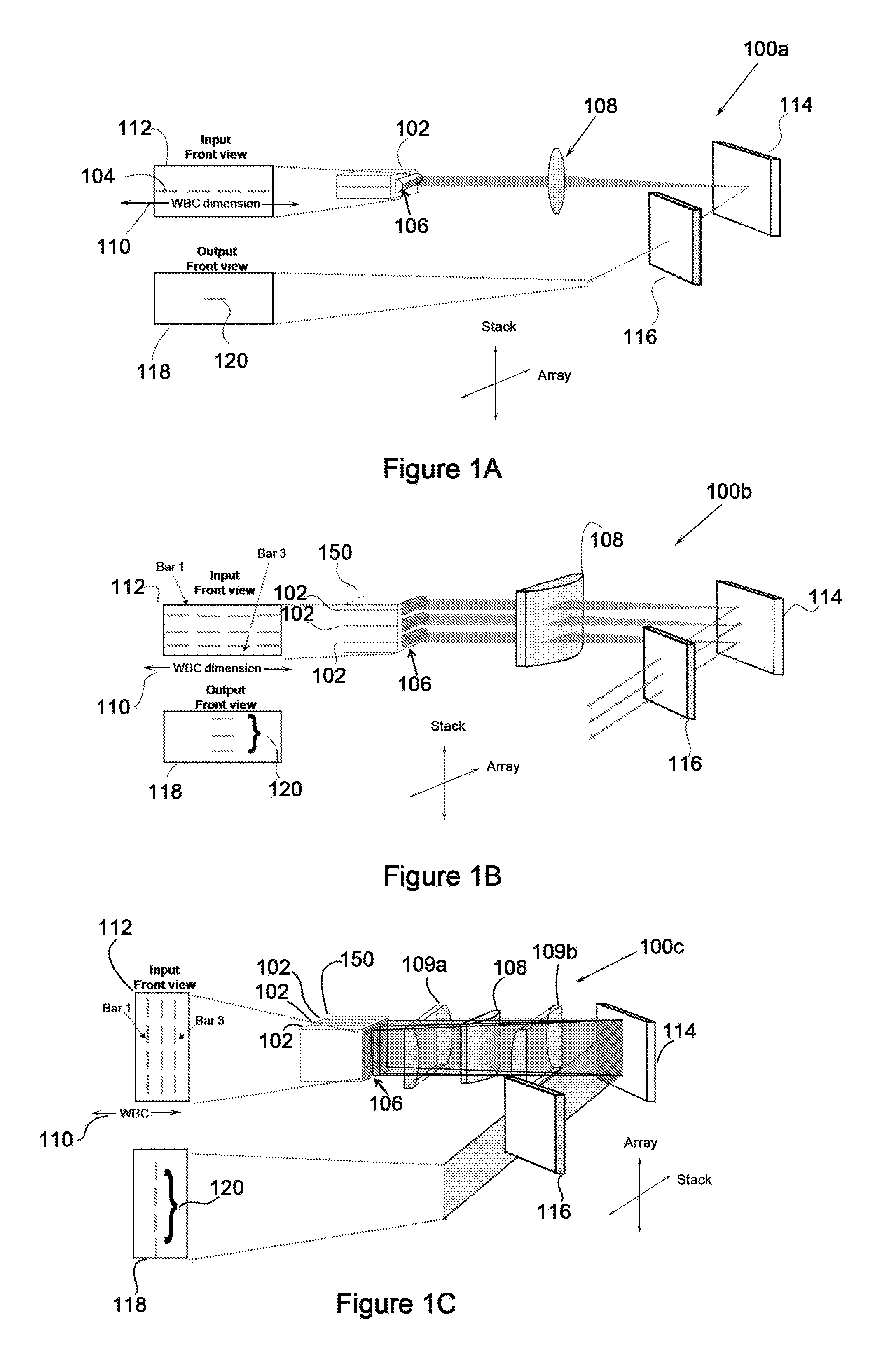

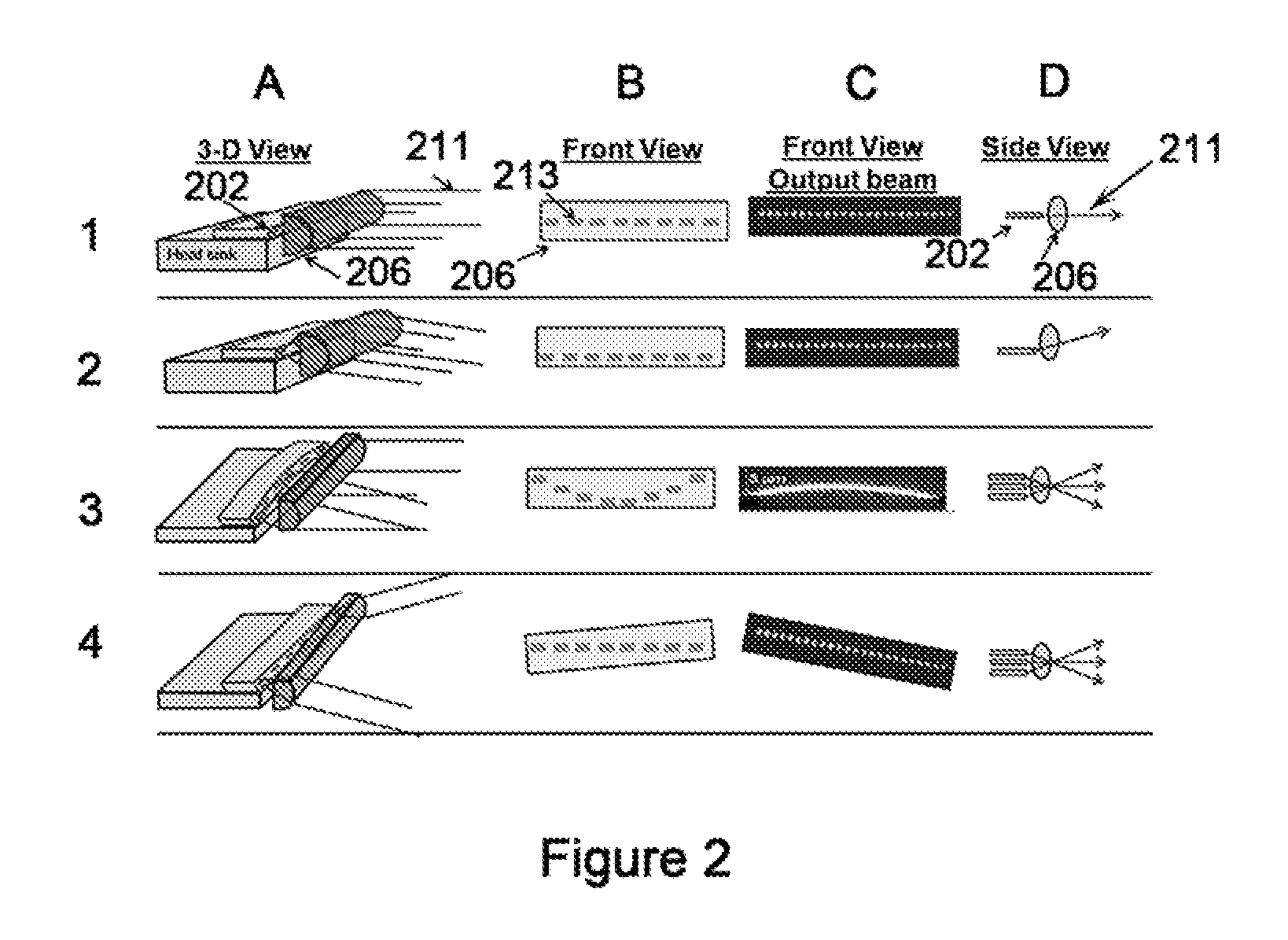

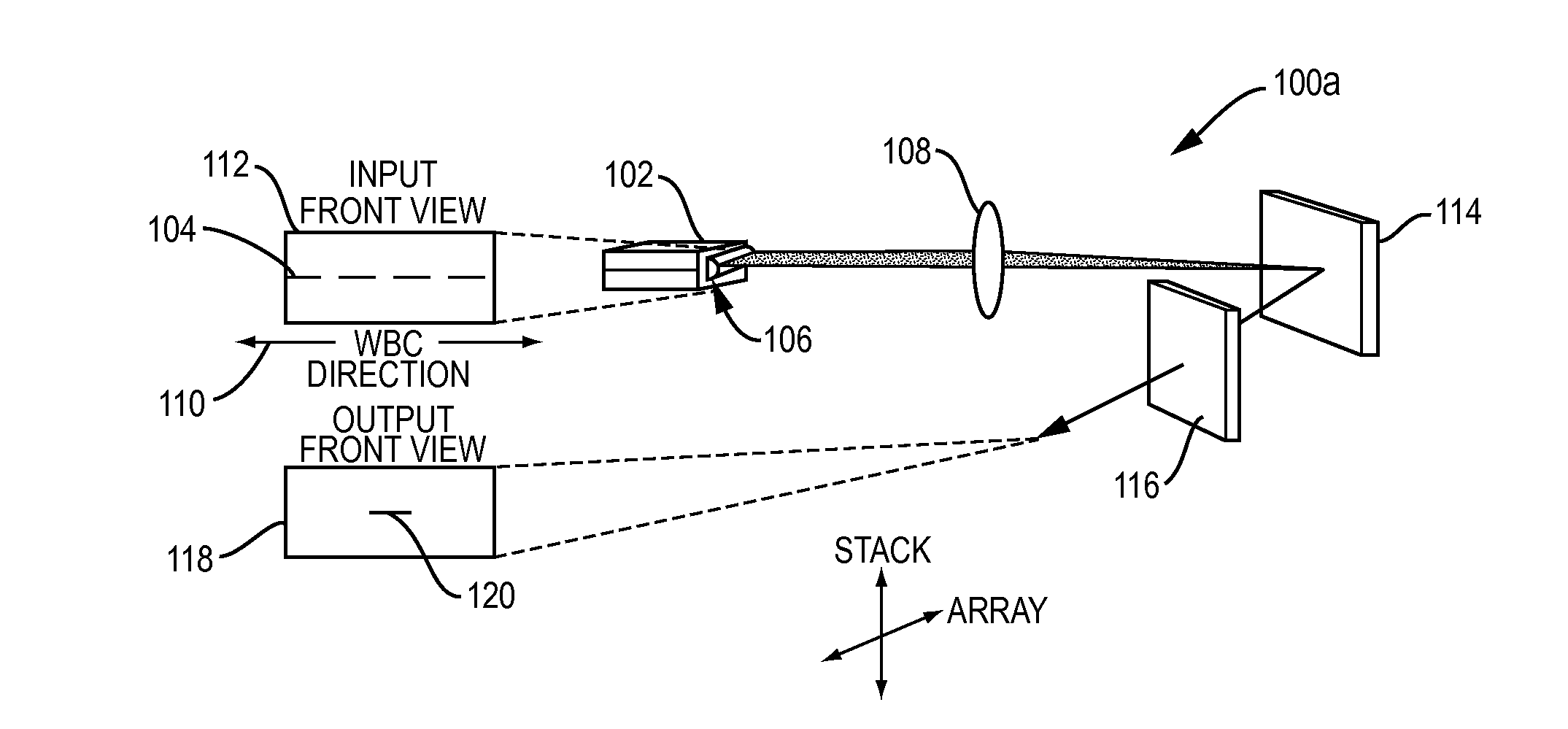

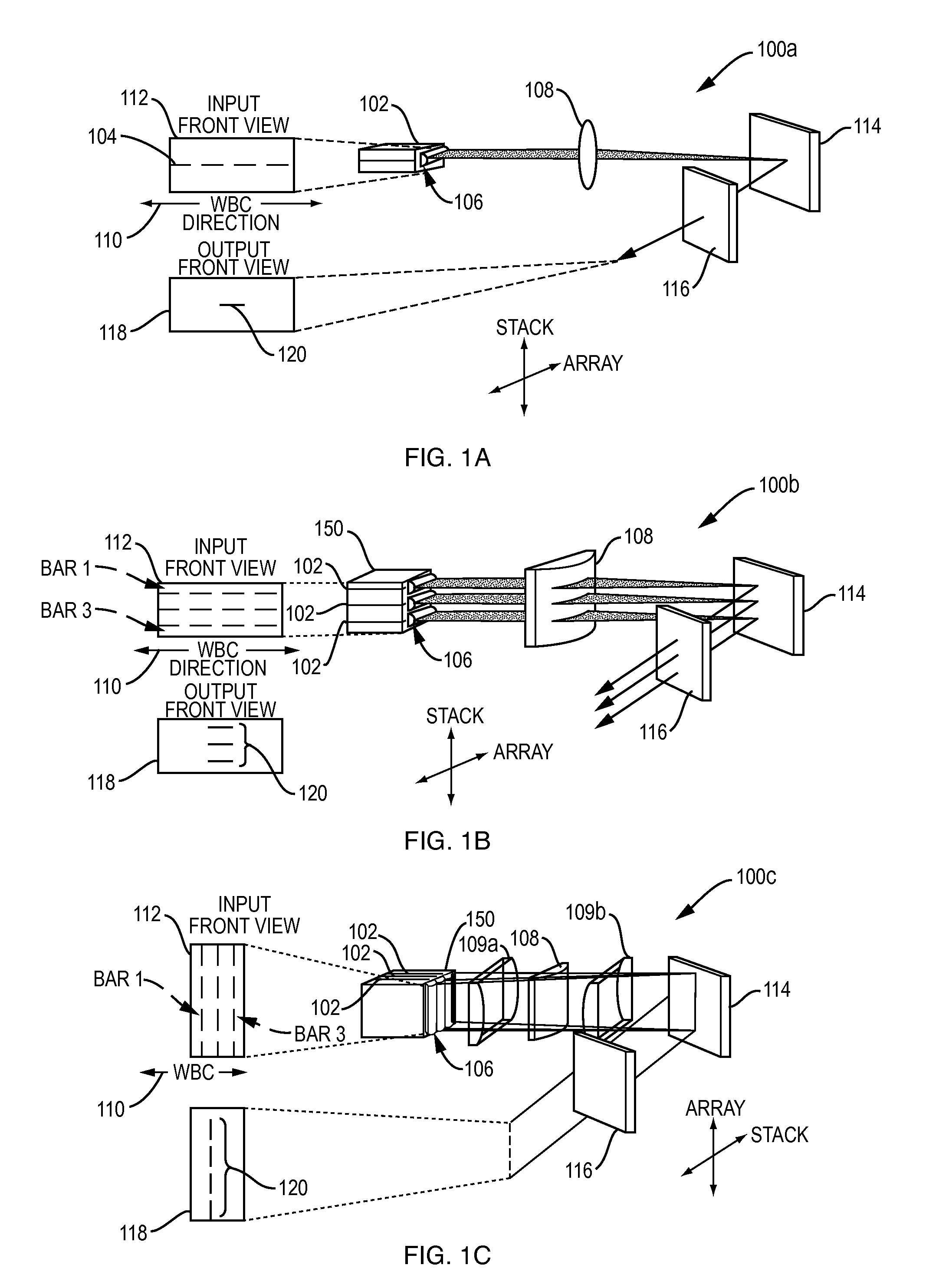

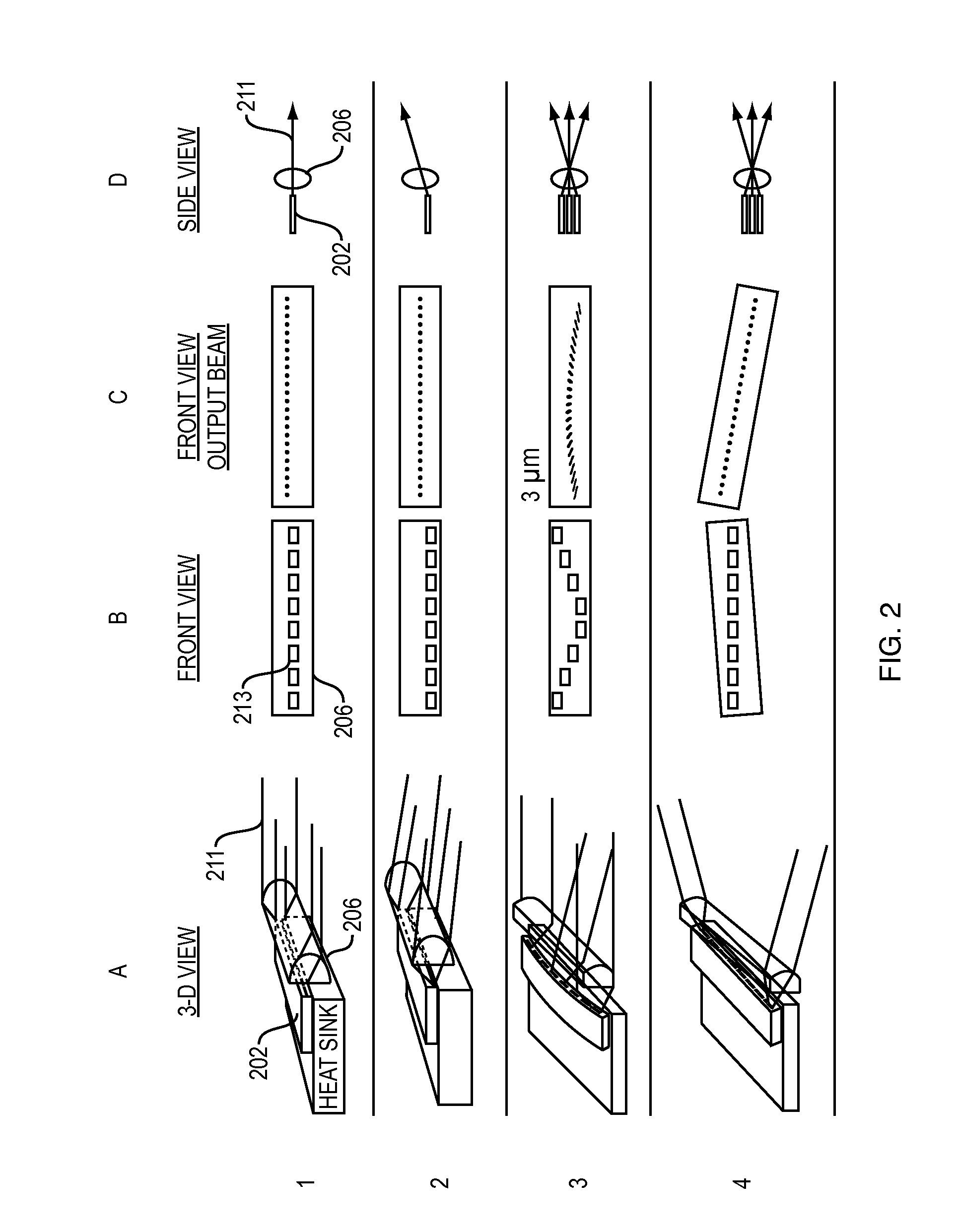

Selective Repositioning and Rotation Wavelength Beam Combining System and Method

A system and method for reconfiguring a plurality of electromagnetic beams to take advantage of various wavelength beam combining techniques. The reconfiguring of beams includes individual rotation and selective repositioning of one or more beams with respect to beam's original input position.

Owner:PANASONIC OF NORTH AMERICA

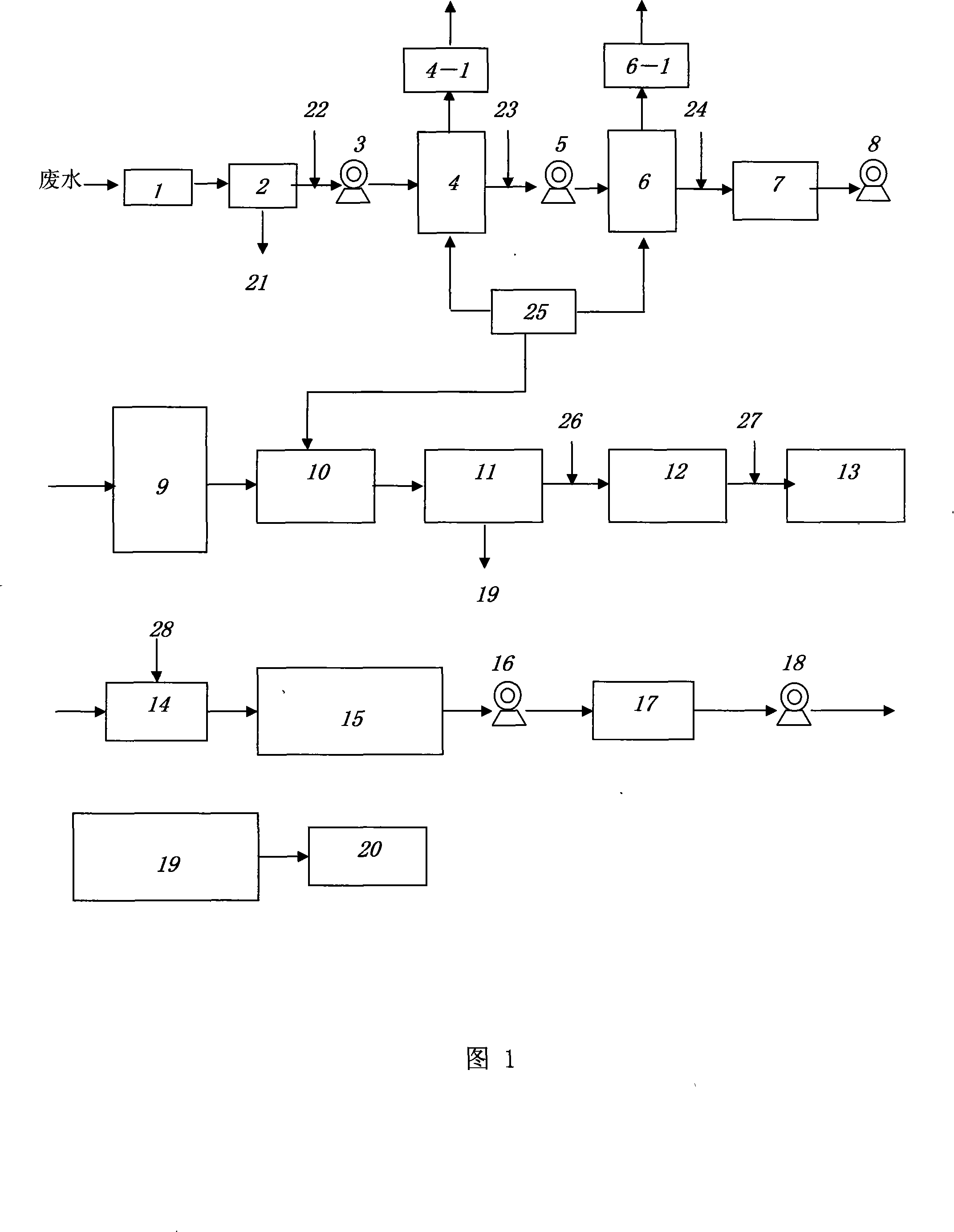

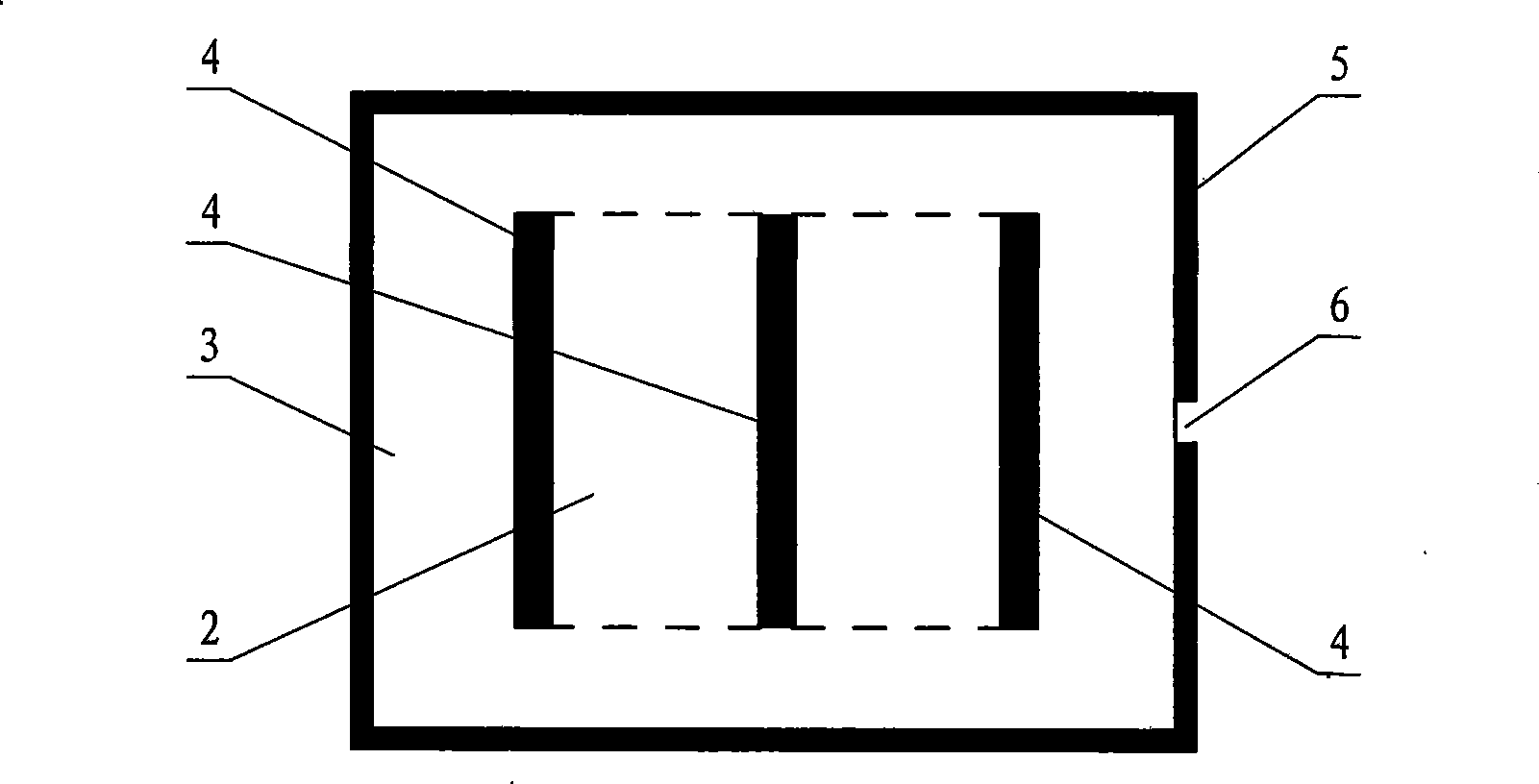

Combination technique for processing and recycling high-cyanogen high-ammonia high-salt organic waste water

InactiveCN101172743AProcess Combination ScienceReasonable process combinationWater contaminantsWater/sewage treatment bu osmosis/dialysisIndustrial waste waterCombined technique

The invention relates to a combined technique of treating and reusing the organic sewage which is rich in cyanogen, ammonia and salt, and adopts the combined techniques of acidified decyanation (with the sodium cyanide recollected), basified ammonia blowing (with ammonium salt recollected), oxidation by adding chlorine, biological treatment, precipitation and clarification, deep oxidation, biological active carbon filtering, one-time brine refining, microstraining film, and other combined techniques, and then the chlorine alkali is produced after the secondary brine refining in the chlorine alkali industry and the entrance into the ionic membrane electrobath. The combined technique can be used for treating the industrial sewage in the tricyanogen chloride, chlorine alkali, gold mine, galvanization and other industries and conduct recovery of the resources, thereby overcoming the disadvantages that the prior art has narrow applicability and treatment function and disappointing treatment result, cannot recollect the resources, and has high treatment cost and unobvious economical benefit. The combination of the technique is scientific and reasonable, the technique is novel, unique and mature, the treatment is good, and the combined technique has a plurality of functions, strong applicability, wide use range and remarkable environmental and economical benefit.

Owner:HAINAN CHENGTAI ENVIRONMENT ENG

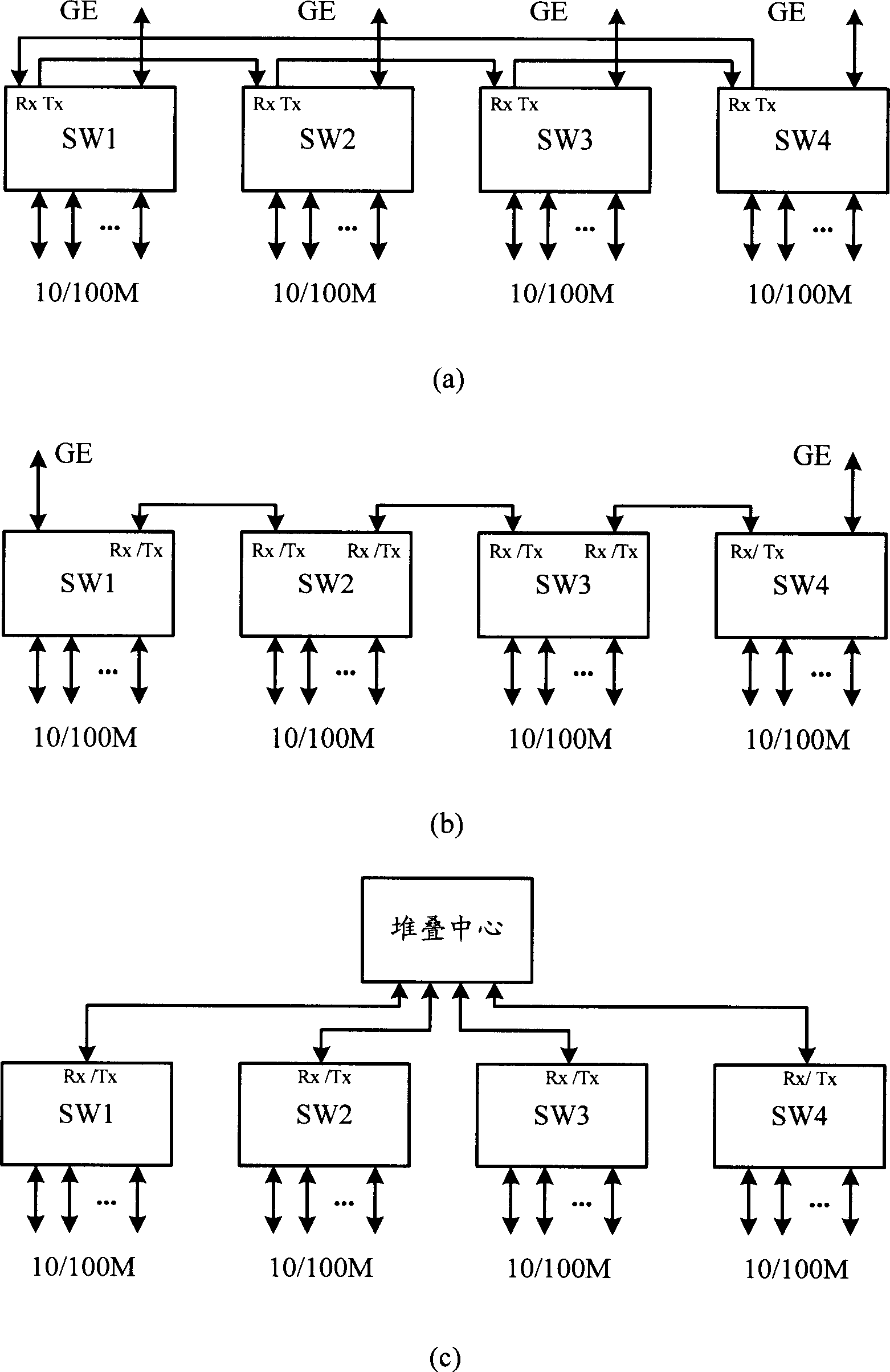

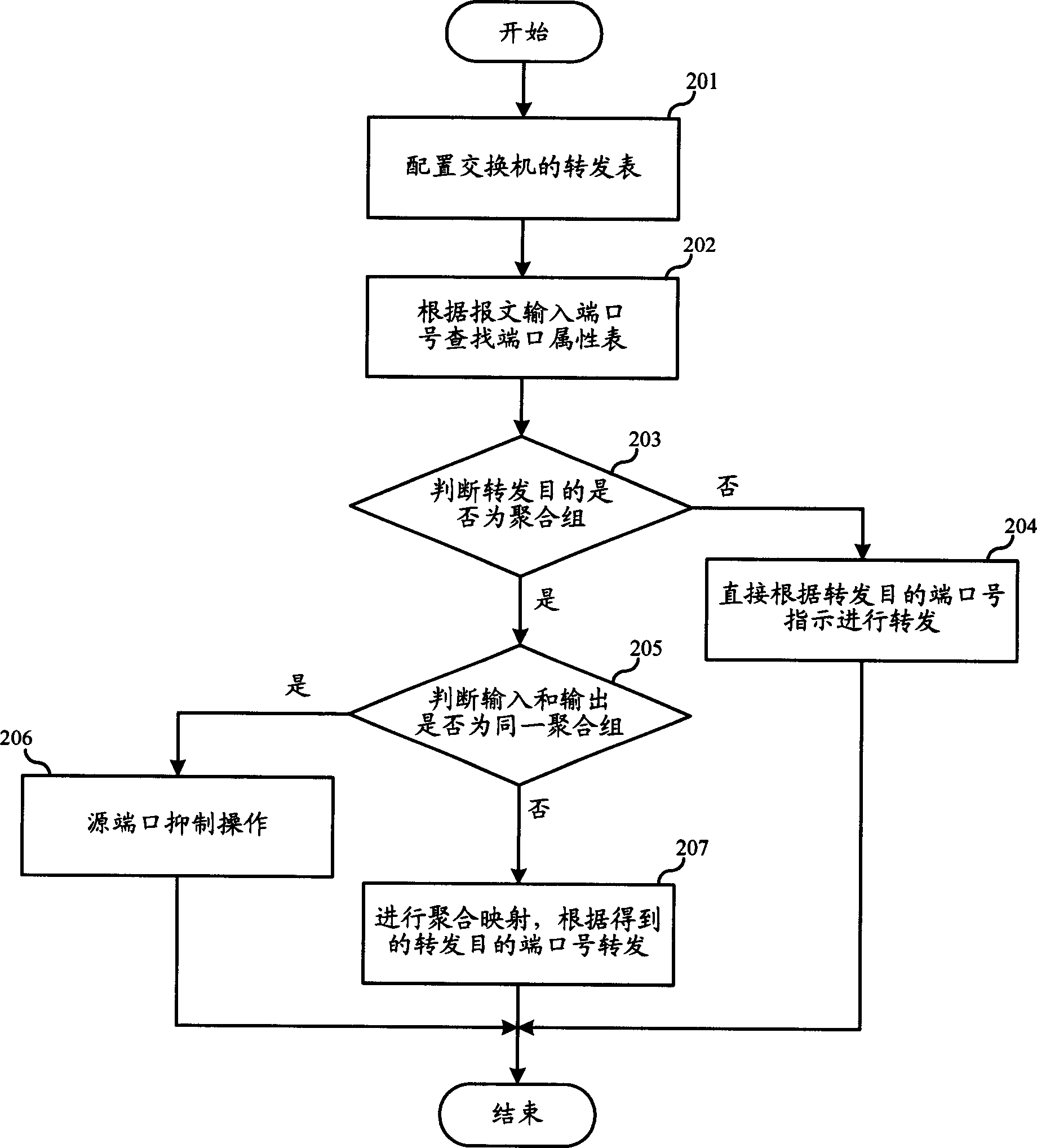

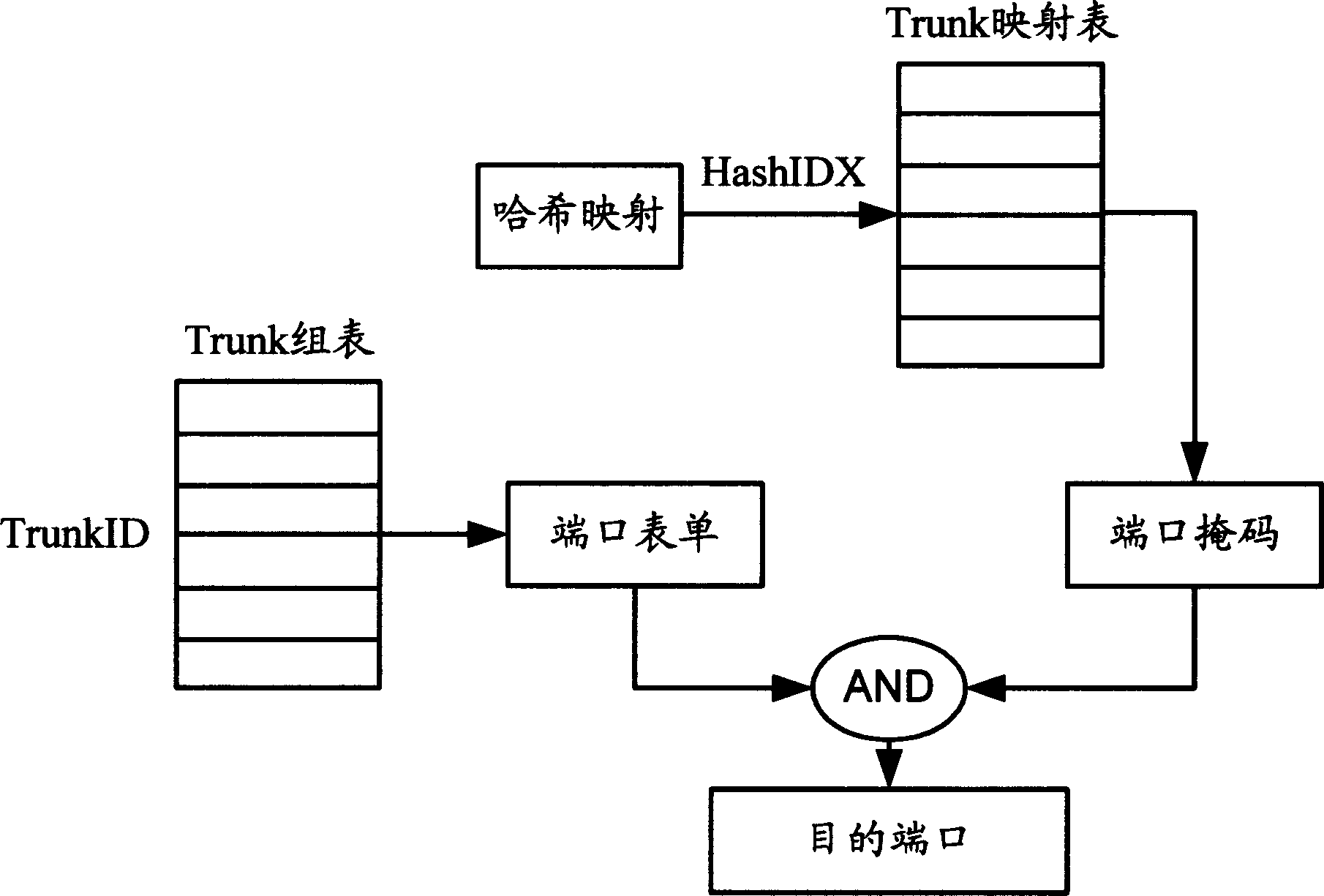

Ethernet device stacking method and its system

ActiveCN1809022AUniform polymerizationLoad balancingData switching networksLink aggregationCombined technique

This invention relates to communication combined technique and discloses one Ethernet device overlap method and its system to freely dispatch higher band connection with multiple devices to realize high effective overlapping. This invention adopts linkage polymer method on multiple overlap terminals as stack linkage Ethernet devices. The linkage polymer method realizes linkage polymer and load even through terminal property list, Trunk list, mapping list and message transfer process.

Owner:HUAWEI TECH CO LTD

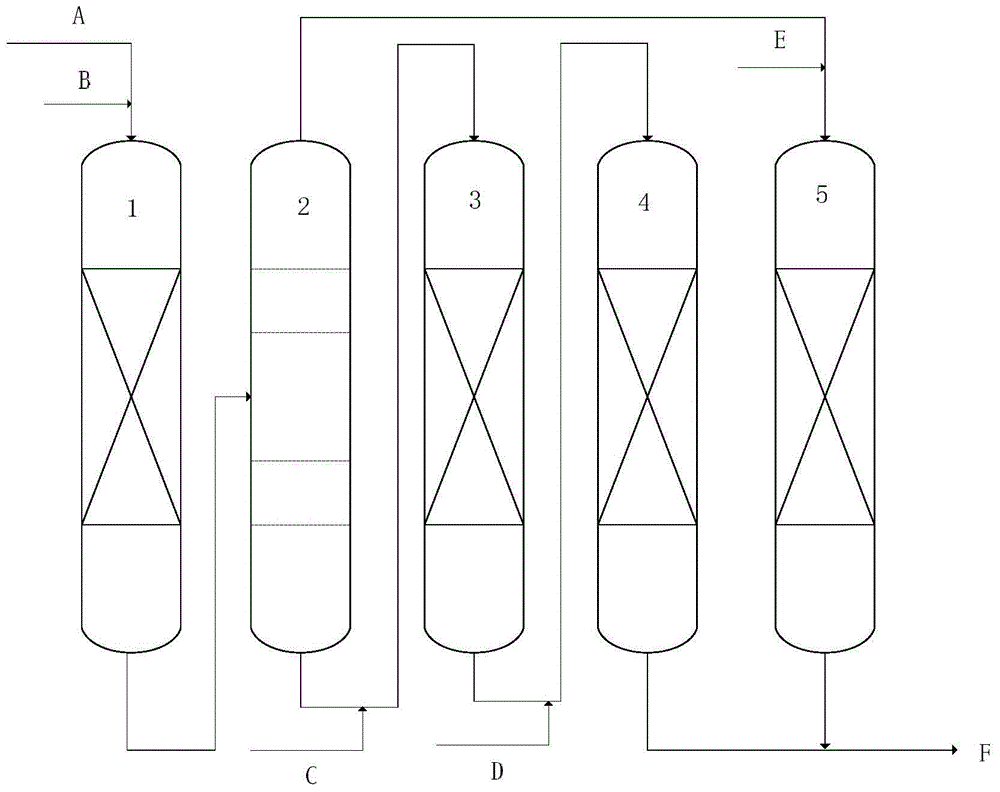

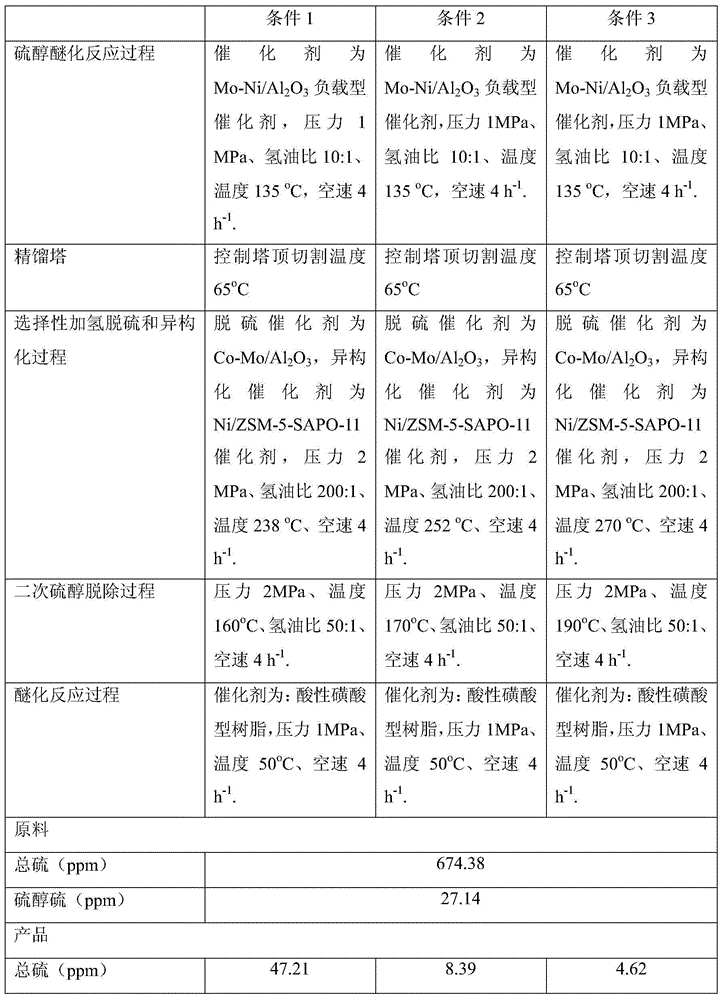

Catalytically cracked gasoline deep desulfurization combined technique

InactiveCN104479738ASolution to short lifeSimple principleTreatment with hydrotreatment processesHydrocarbon oils treatment productsIsomerizationSludge

The invention relates to a catalytically cracked gasoline deep desulfurization method which comprises the following steps: 1. carrying out thiolation reaction, wherein the gasoline is divided into a light component and a heavy component by a rectification tower after reaction; 2. carrying out selective hydrodesulfurization and isomerization on the heavy component; 3. after the selective hydrodesulfurization process, carrying out hydrodesulfurization on secondary mercaptan; 4. etherifying the light gasoline; and 5. finally, blending the light and heavy components to obtain the ultralow-sulfur gasoline product which conforms to the national V gasoline quality standard. The technique is suitable for hydrogenation modification of the catalytically cracked gasoline, and has the advantages of high desulfurization percent, high liquid yield, high catalyst stability of all units, long service life and no discharge of caustic sludge in the whole process.

Owner:XI'AN PETROLEUM UNIVERSITY

System and method for selecting a transmission channel in a wireless communication system that includes an adaptive array

InactiveUS8036164B1Spatial transmit diversityFrequency-division multiplexCommunications systemTransmission channel

A method for establishing wireless communication between a transmitter and a receiver in a wireless communication system is disclosed. The receiver includes an adaptive array that has at least two antennas. Each antenna receives a signal and produces a received signal. The transmitter includes at least two transmission channels for communicating the signal from the transmitter to the receiver. The wireless communication system suppresses interference at the receiver by applying an interference suppression technique when combining the received signals. The selection of a channel at the transmitter is based on the channel performance at the receiver for each transmission channel. The channel performance is based on a combining technique different from the interference suppression technique.

Owner:AT&T INTPROP II L P

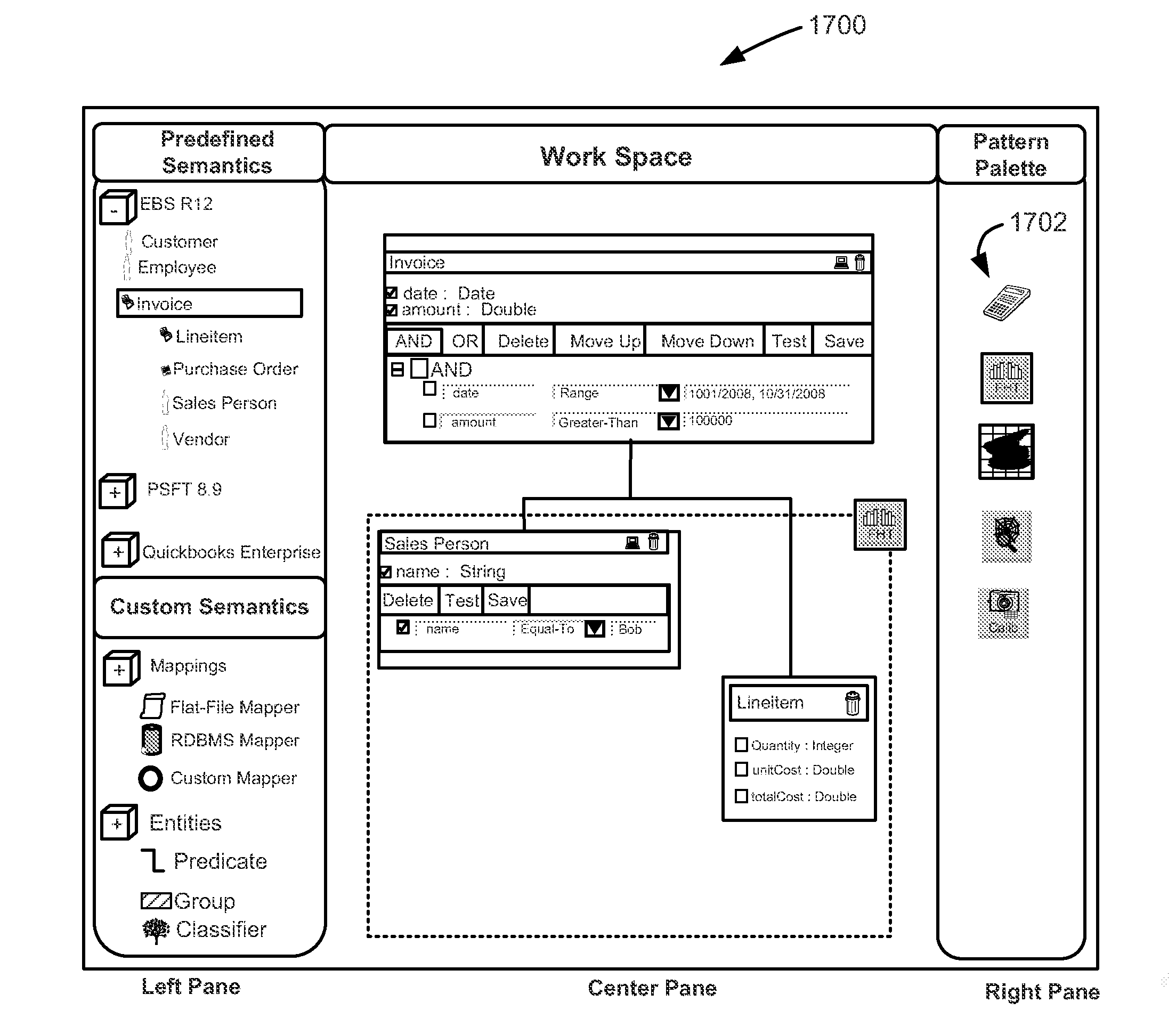

Techniques for semantic business policy composition

ActiveUS20100218134A1Well formedOffice automationVisual/graphical programmingCombined techniqueApplication software

Owner:ORACLE INT CORP

Methods and systems for quick and efficient data management and/or processing

ActiveUS8214517B2Reduce quality problemsHigh data redundancyDigital data information retrievalProgram control using stored programsCombined techniqueData management

System(s) and method(s) are provided for data management and data processing. For example, various embodiments may include systems and methods relating to relatively larger groups of data being selected with comparable or better performing selection results (e.g., high data redundancy elimination and / or average chunk size). In various embodiments, the system(s) and method(s) may include, for example a data group, block, or chunk combining technique or / and a data group, block, or chunk splitting technique. Various embodiments may include a first standard or typical data grouping, blocking, or chunking technique and / or data group, block, or chunk combining technique or / and a data group, block, or chunk splitting technique. Exemplary system(s) and method(s) may relate to data hashing and / or data elimination. Embodiments may include a look-ahead buffer and determine whether to emit small chunks or large chunks based on characteristics of underlying data and / or particular application of the invention (e.g., for backup).

Owner:NEC CORP

Casting and forging combined technique of aluminum alloy linkage rod

InactiveCN101486087AEnsure billet qualitySimplify the traditional die forging processEngine componentsRheniumRare-earth element

The invention discloses technology for casting and forging an aluminum alloy connecting rod, wherein an aluminum alloy composition of the connecting rod is adjusted by addition of rare earth element in casting technology, and the addition of the rare earth element is 2 to 5 percent of an aluminum liquid; the aluminum alloy connecting rod is guaranteed to comprise the following compositions: 88 to 94 percent of aluminum, 3.8 to 4.9 percent of copper, 0.5 to 1.5 percent of silicon, 0.4 to 1.2 percent of manganese, 0.4 to 1.0 percent of magnesium, 0.8 to 1.8 percent of rhenium and 0.4 to 0.14 percent of iron; and a casting head is not cut off and reheated in the casting technology and taken as one part or a scrapped part of a forged piece, and casting afterheat is utilized for forging. The technology simplifies the prior die forging technology, improves reasonable floatation, the streamline and mechanical properties of casting metals, improves a metallurgical structure close to the casting head on the forged piece, and has the effects of high technological utilization rate of materials, shortened technological process and energy conservation and consumption reduction. Moreover, the casting and forging technology can obviously improve the internal quality and the mechanical properties of casting blanks, and the production cost of the casting blanks is lower than that of the prior die forging.

Owner:DANYANG RONGJIA PRECISION MACHINERY

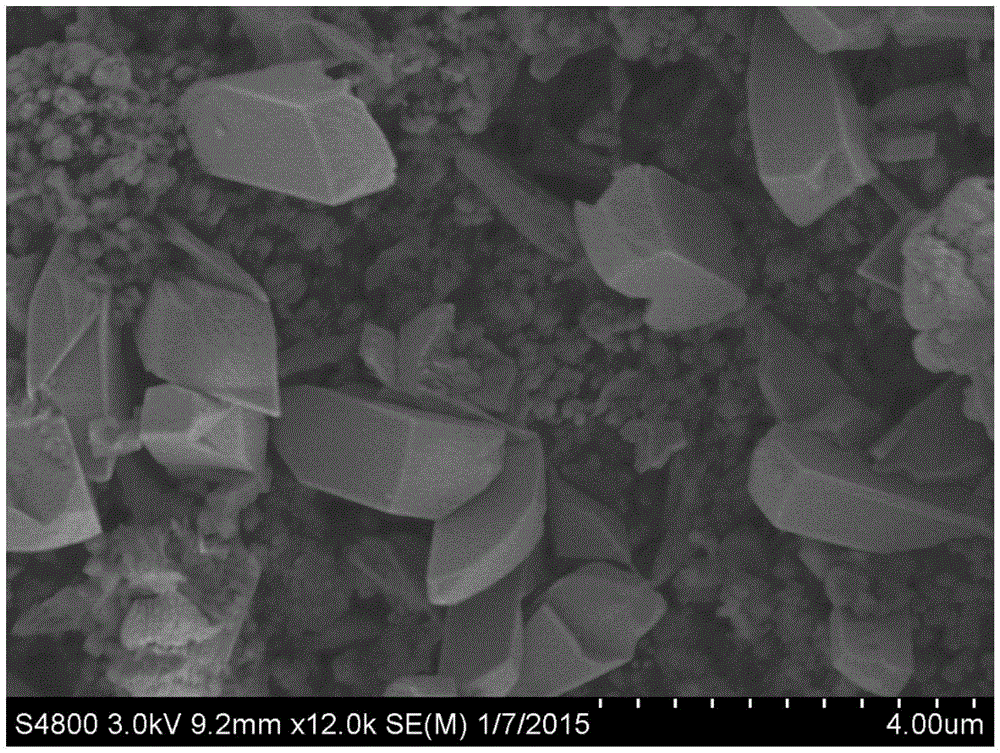

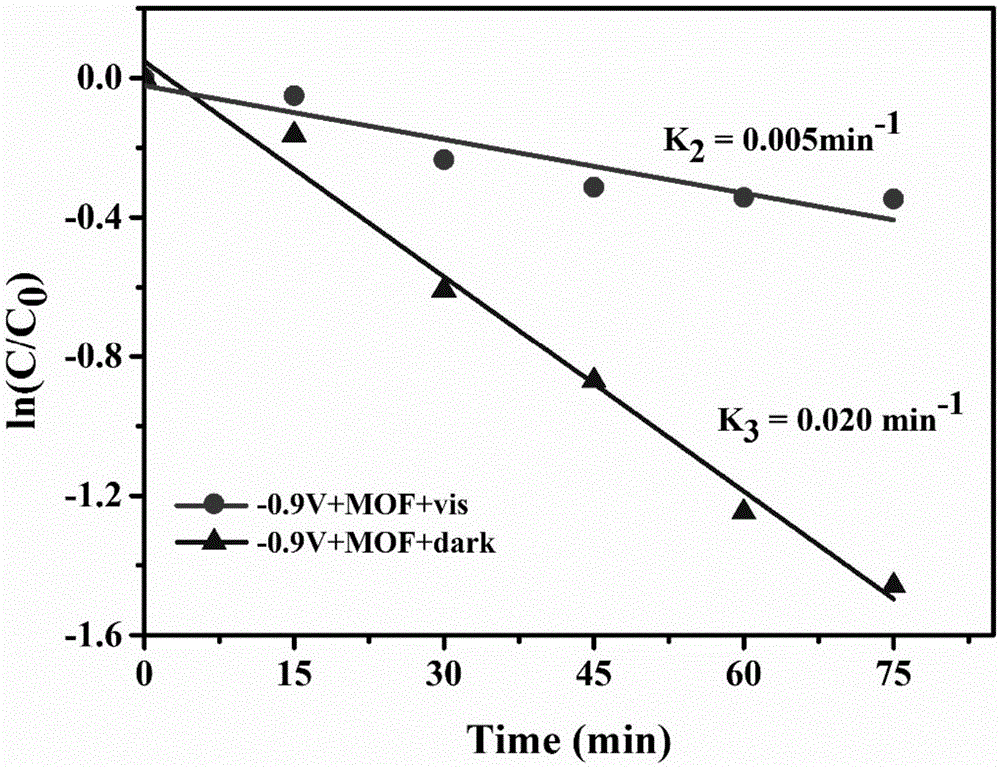

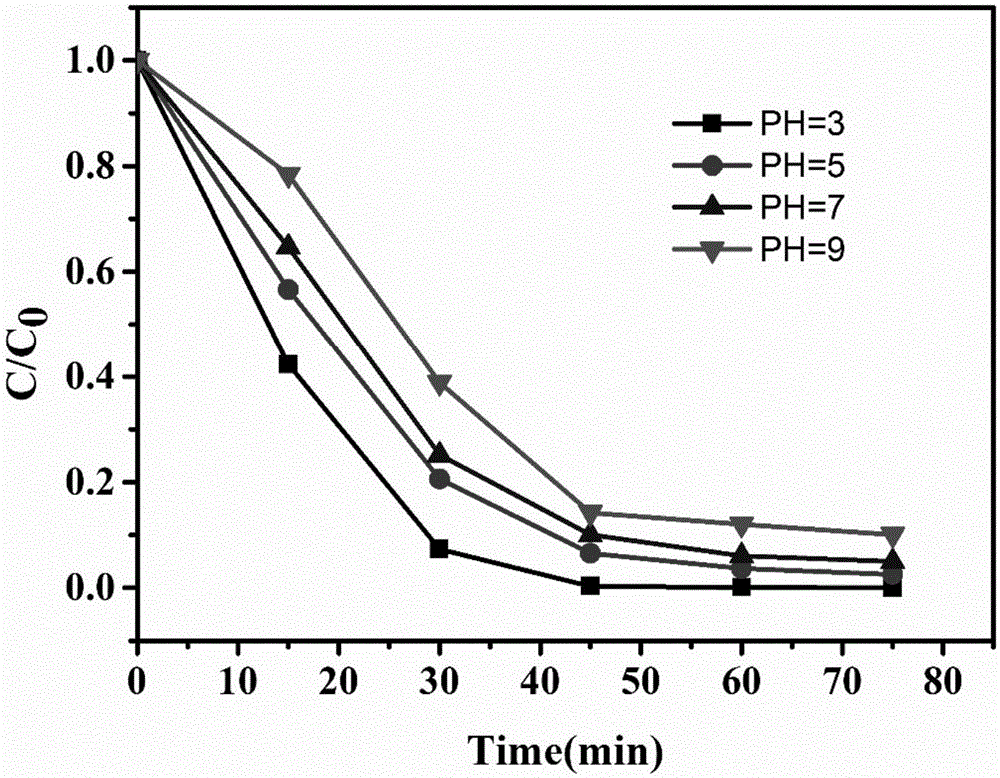

Carbon-aerogel-carried bimetal organic framework electro-Fenton cathode and preparation method thereof

ActiveCN105110423AEfficient degradationReduce energy consumptionWater/sewage treatment by irradiationWater contaminantsMetal-organic frameworkCombined technique

The invention relates to a carbon-aerogel-carried bimetal organic framework electro-Fenton cathode and a preparation method thereof. The preparation method comprises the following steps: by using a block carbon aerogel as a substrate electrode, carrying out hydrothermal reaction to load a bimetal organic framework onto the substrate electrode, filtering, washing, and carrying out vacuum drying to obtain the carbon-aerogel-carried bimetal organic framework electro-Fenton cathode, wherein the bimetal organic framework is a Fe / Co bimetal organic framework. Compared with the prior art, by combining the photocatalytic technique and electro-Fenton, the carbon-aerogel-carried bimetal organic framework electro-Fenton cathode can degrade organic pollutants by using the higher-efficiency low-energy-consumption advanced oxidation technique, thereby providing a new way for using the electro-Fenton cathode in the photocatalytic / electro-Fenton combined technique for treating nondegradable organic pollutants. The carbon-aerogel-carried bimetal organic framework electro-Fenton cathode has the advantages of simple technical operation, energy saving and high efficiency, and has very wide application range in the field of actual water treatment.

Owner:TONGJI UNIV

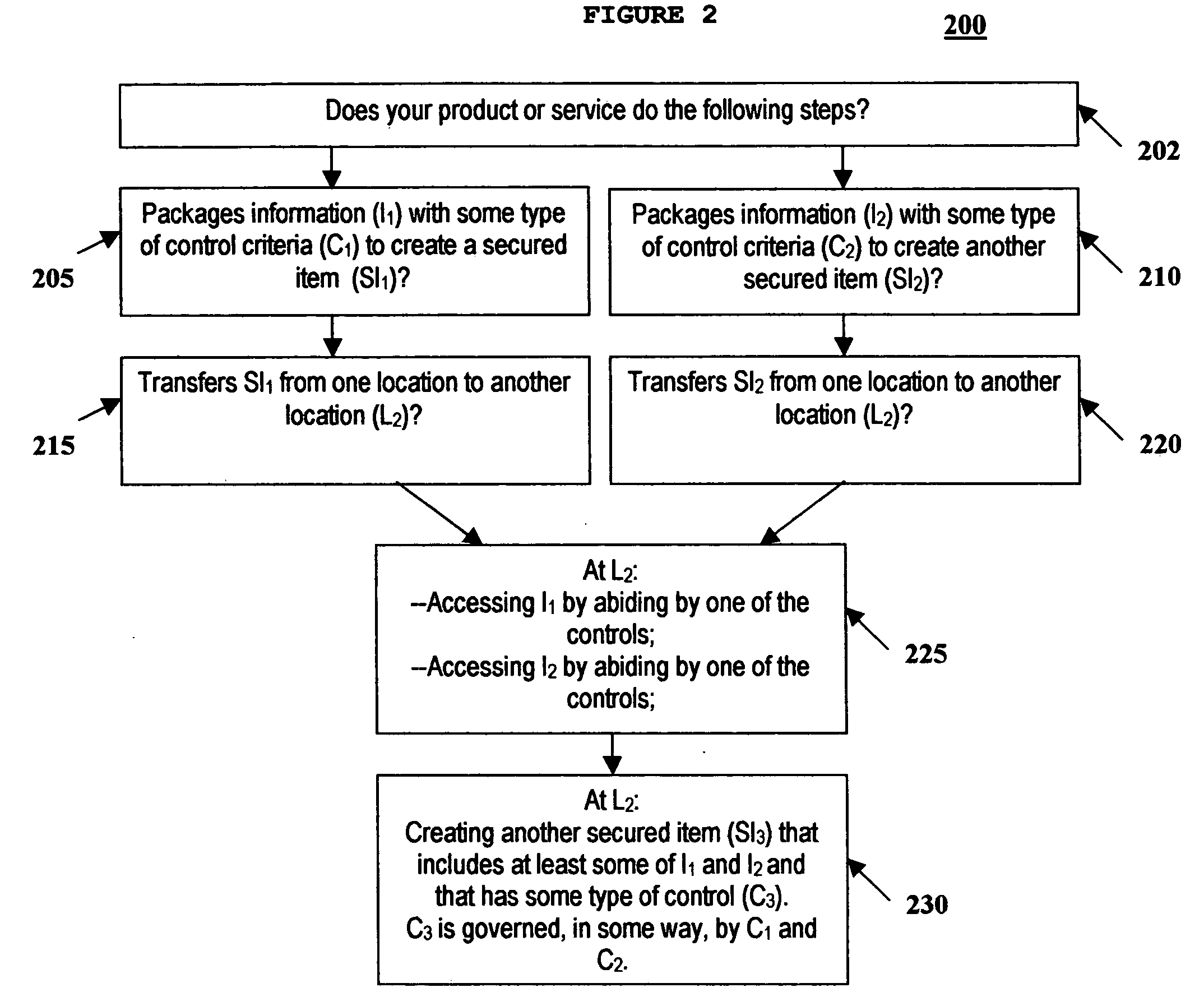

Systems and methods for evaluating information to identify, and act upon, intellectual property issues

InactiveUS20050114169A1Office automationSpecial data processing applicationsIntellectual propertyCombined technique

The systems and methods of the present invention enable users to identify whether a composition of matter, technical design, product, service, component, technology, feature, business model or any other item may have intellectual property issues associated therewith. The present invention includes a set of screens, filters, comparison sheets, and / or questionnaires (referred to generically as screens) which are derived from patent claims and used to evaluate whether a composition of matter, technical design, product, service, component, technology, feature, business model or any other item may have intellectual property issues associated therewith. The present invention further comprises systems and methods designed to help groups of people, in a collaborative environment, manage the use of screens.

Owner:ANSARI HAZIM

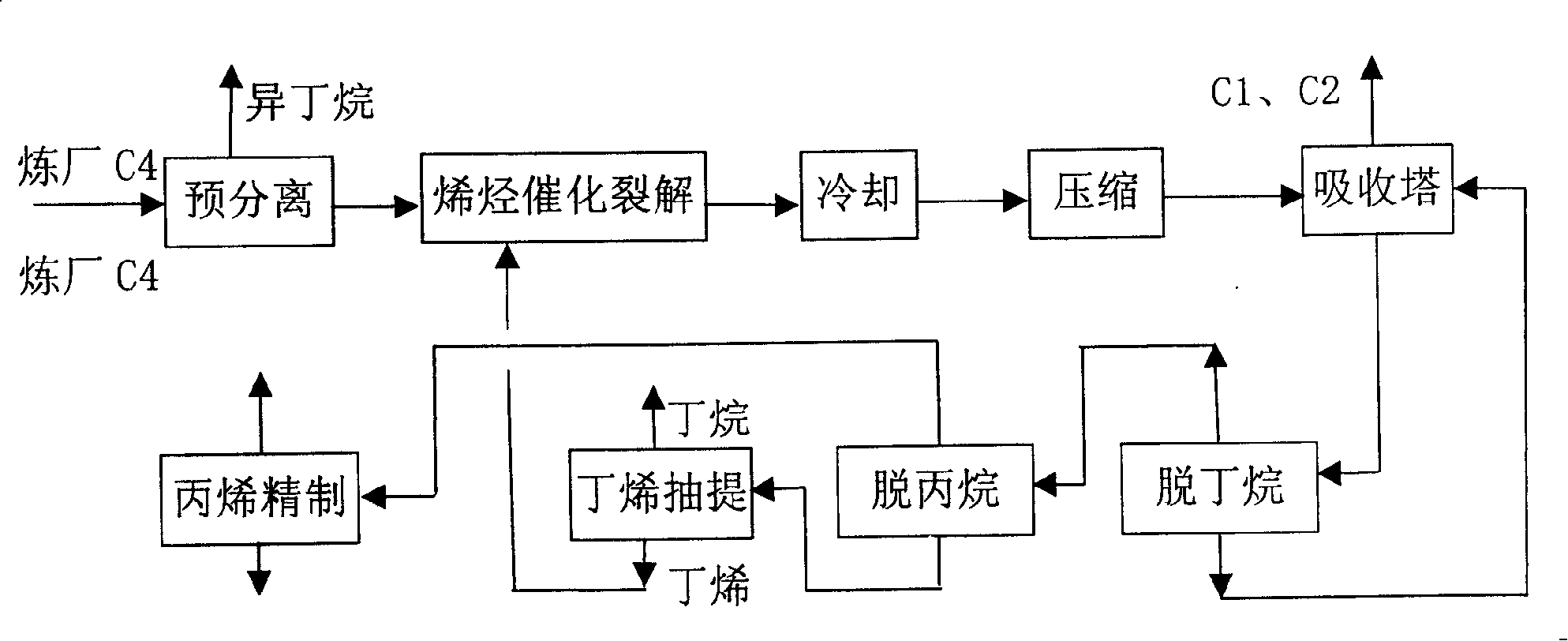

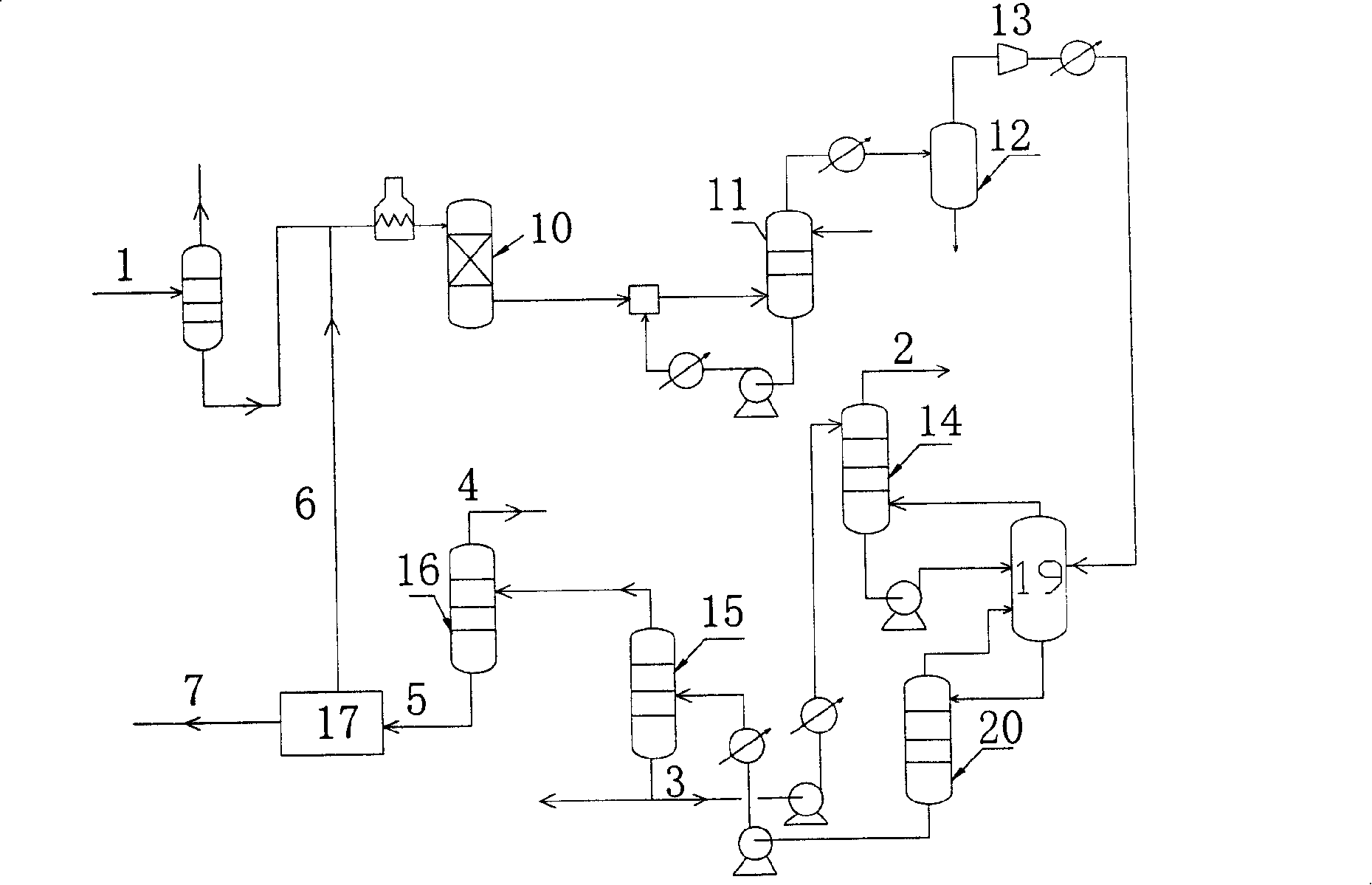

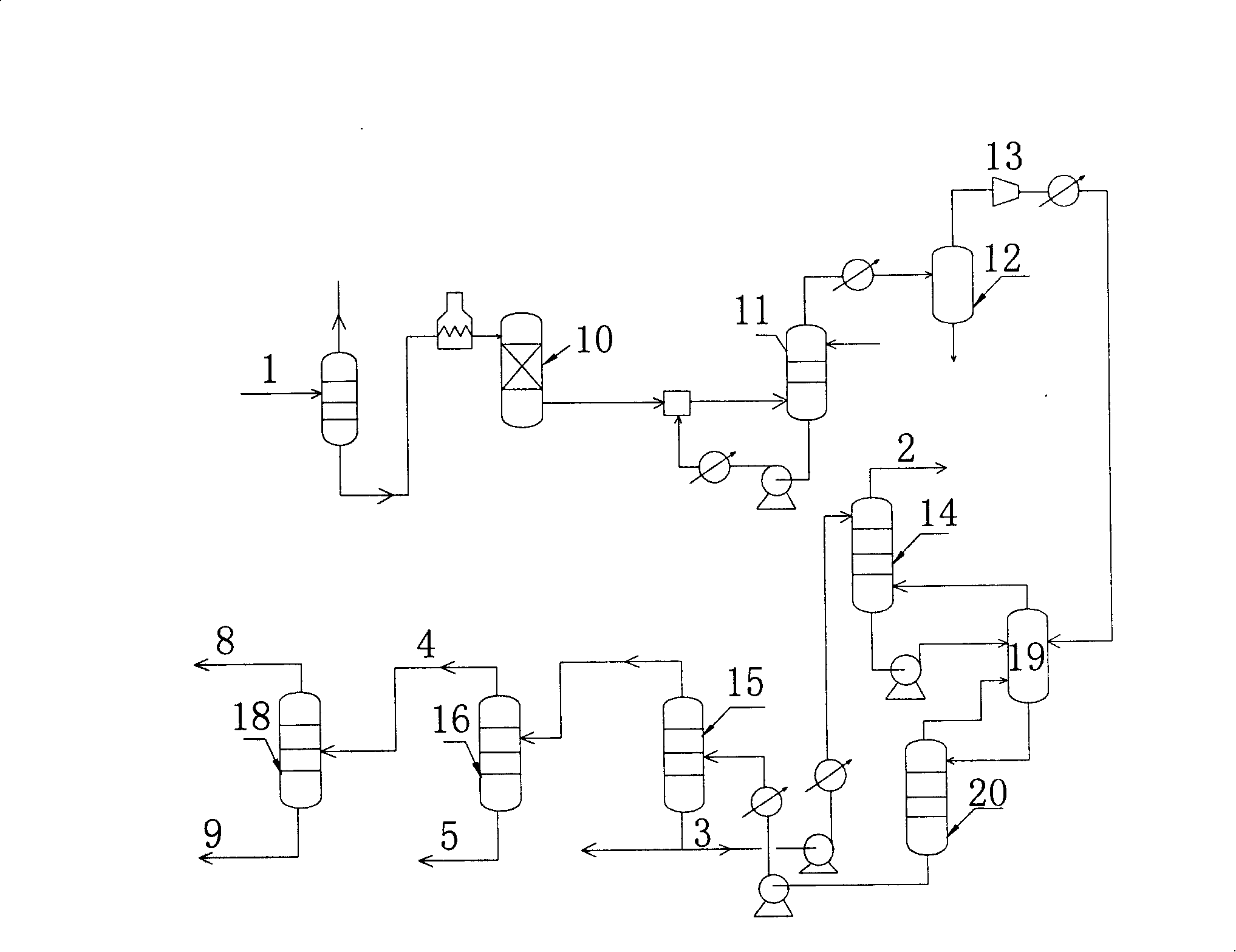

Combined technique for preparing olefins by using refinery C4

ActiveCN101205162ASolve real problemsGood industrial valueMolecular sieve catalystsEthylene productionHydrogenCombined technique

A method for utilizing the C4 raffinate to prepare the olefin of the invention belongs to the technical field of olefin preparation. In order to solve the problem that the C4 raffinate can not be sufficiently utilized, the invention proposes that the C4 raffinate is first pre-separated so as to remove the propane, the propylene and the isobutene in the C4 raffinate and then the treated C4 raffinate is delivered to an olefin catalytic cracking system, and the generated cracking gas mixtures go into a cooling system to be cooled down and then are compressed with entering a compression section; the compressed catalytic cracking gas goes into an absorption tower and the light components such as the methane, the C2, etc. are produced from the top of the absorption tower and the column bottom matters flow through a separation system with being separated so as to respectively obtain the C3 components, the C4 components and the C5 components and heavier components with the C5 and heavier components as absorbents. The combined process of the invention has the advantages of sufficient utilization of the C4 raffinate, few hydrogen circulations, low energy consumption, high propylene yield, simple operation, low investment, etc.

Owner:CHINA PETROLEUM & CHEM CORP +1

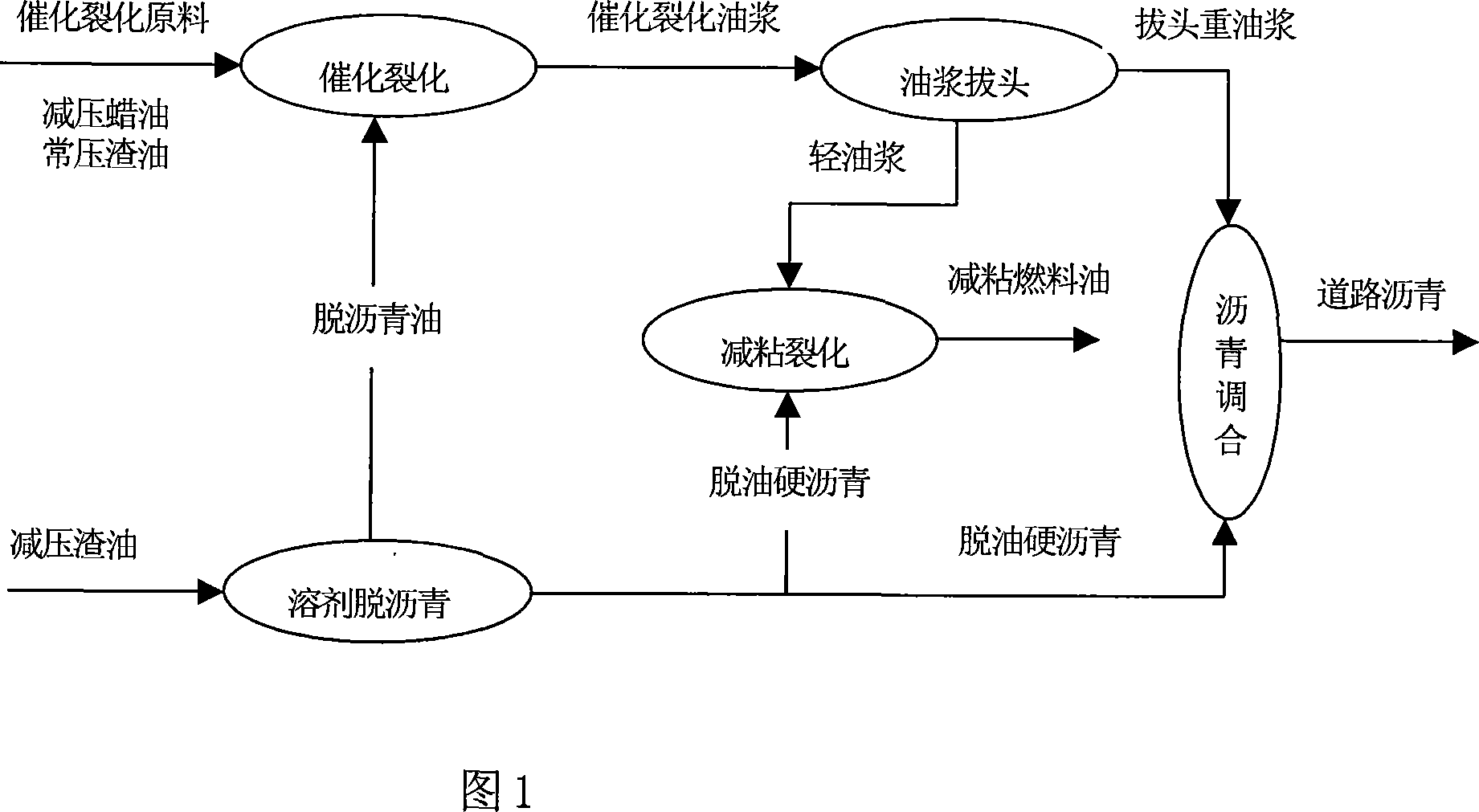

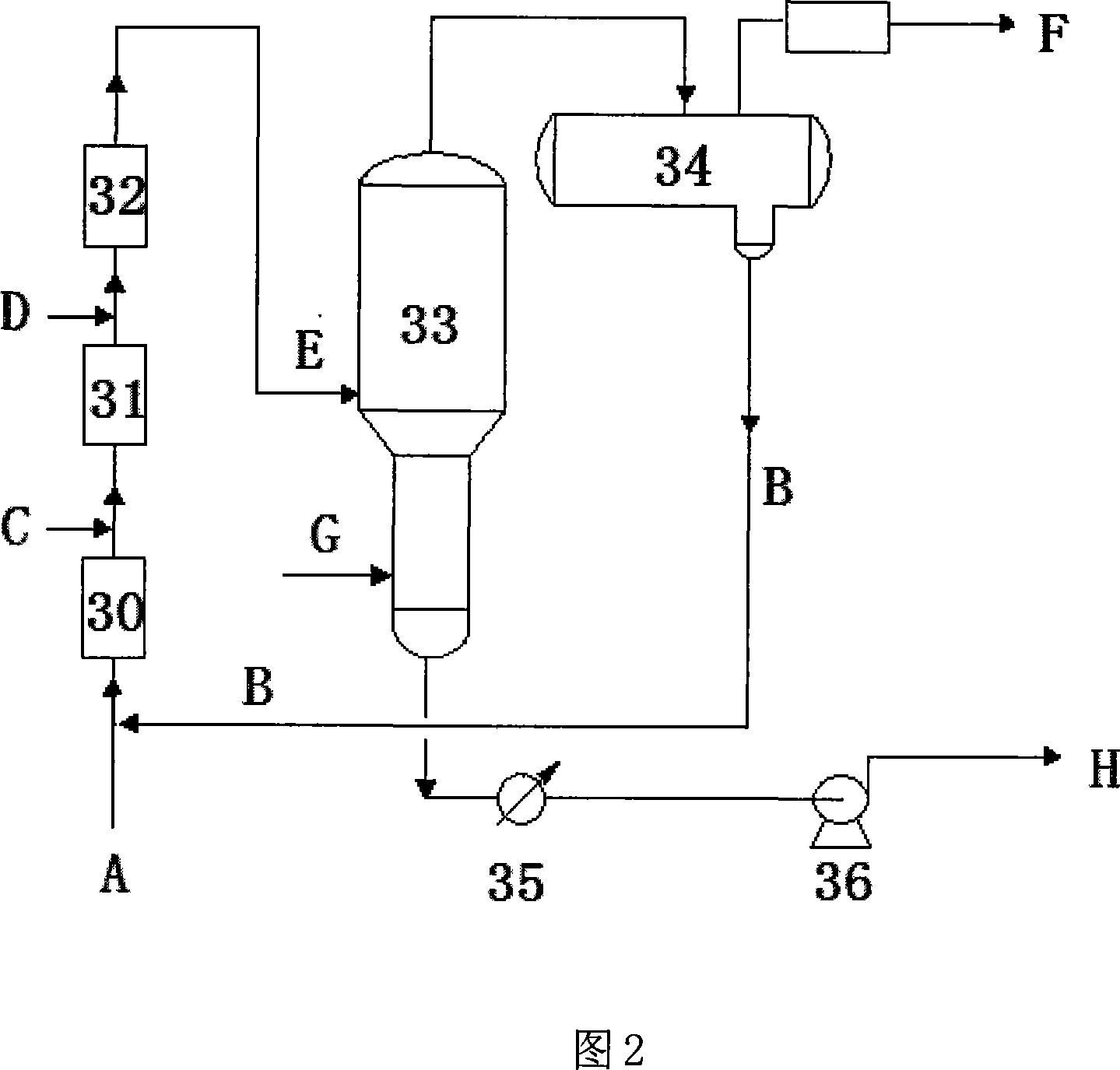

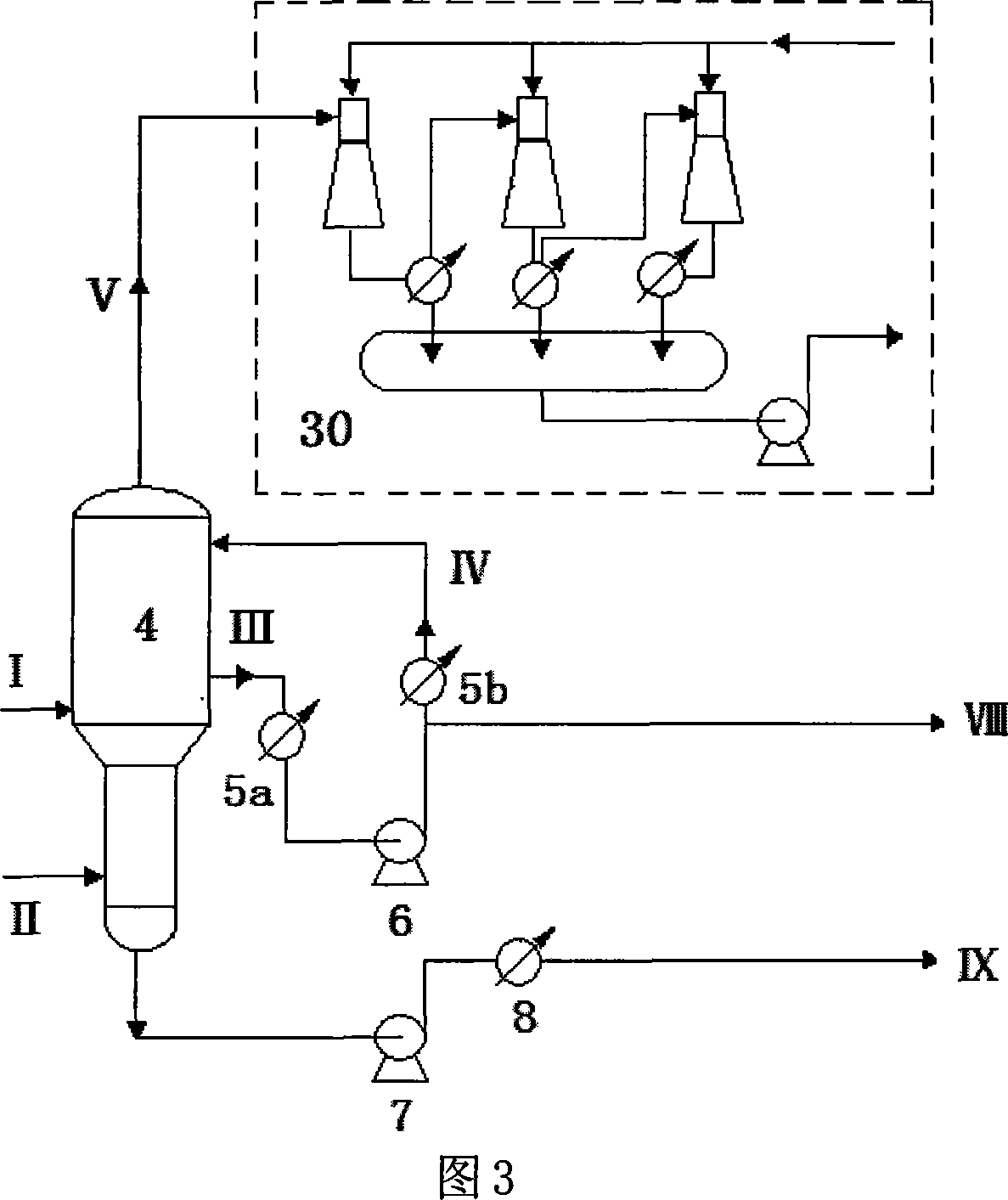

Combined technique for processing heavy oil

InactiveCN101050383AHigh yieldQuality improvementTreatment with plural serial stages onlyTar working-up by solvent extractionSlurryCombined technique

This invention relates to a process for processing heavy oil. The process comprises: removing asphalt from vacuum residual oil by butane deasphalting to obtain asphalt-free oil and oil-free hard asphalt, mixing asphalt-free oil with one or two of atmospheric residual oil and vacuum wax oil, catalytically pyrolyzing to obtain light hydrocarbons, gasoline and diesel oil with high added values, vacuum-distilling residual oil slurry to obtain light oil slurry and tapped heavy oil slurry, mixing light oil slurry with part of oil-free hard asphalt, pyrolyzing to obtain 7# commercial fuel oil, and adequately mixing tapped heavy oil slurry with the other part of oil-free hard asphalt in a static mixer to obtain advanced petroleum asphalt for road construction.

Owner:CHINA PETROLEUM & CHEM CORP

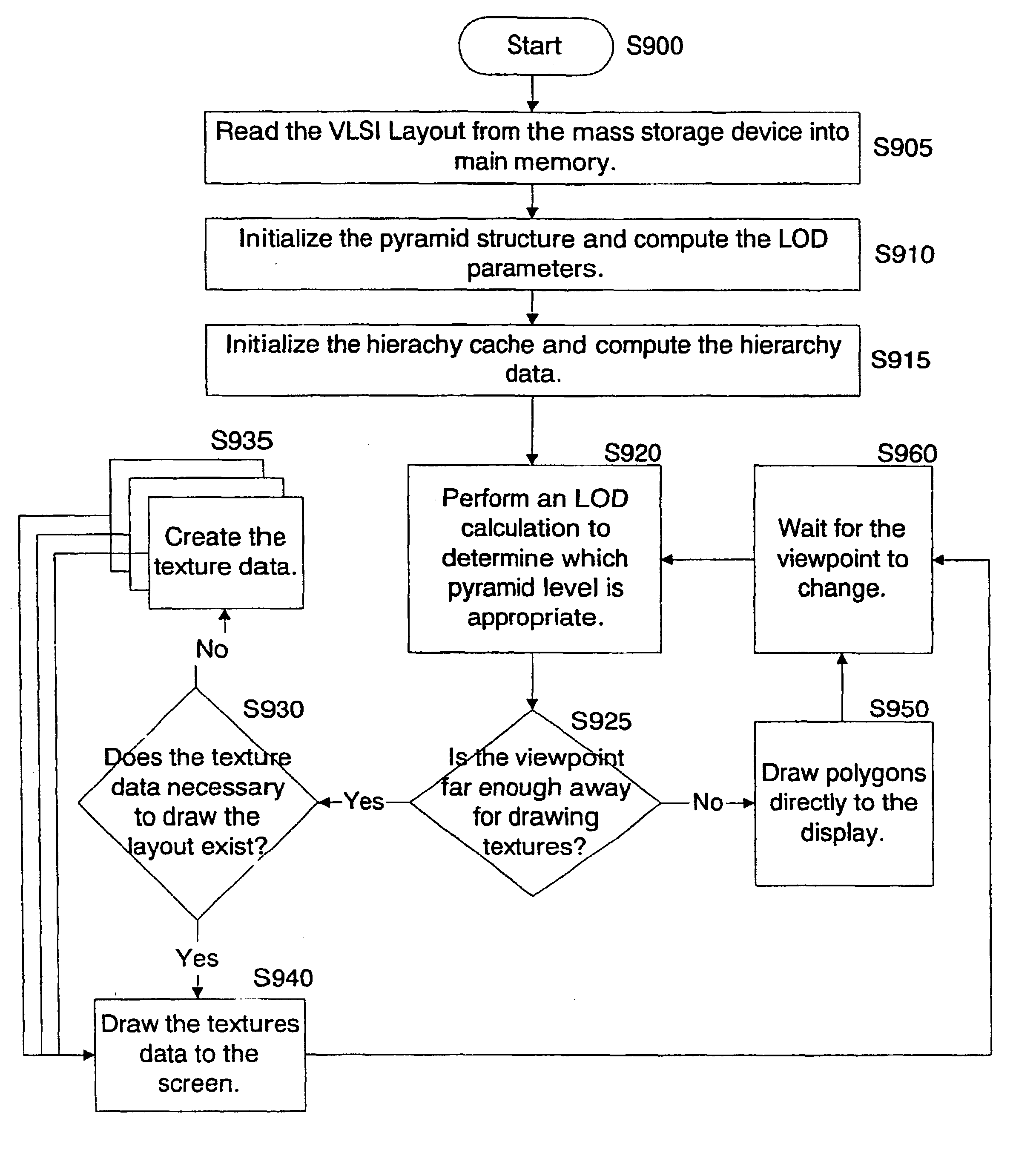

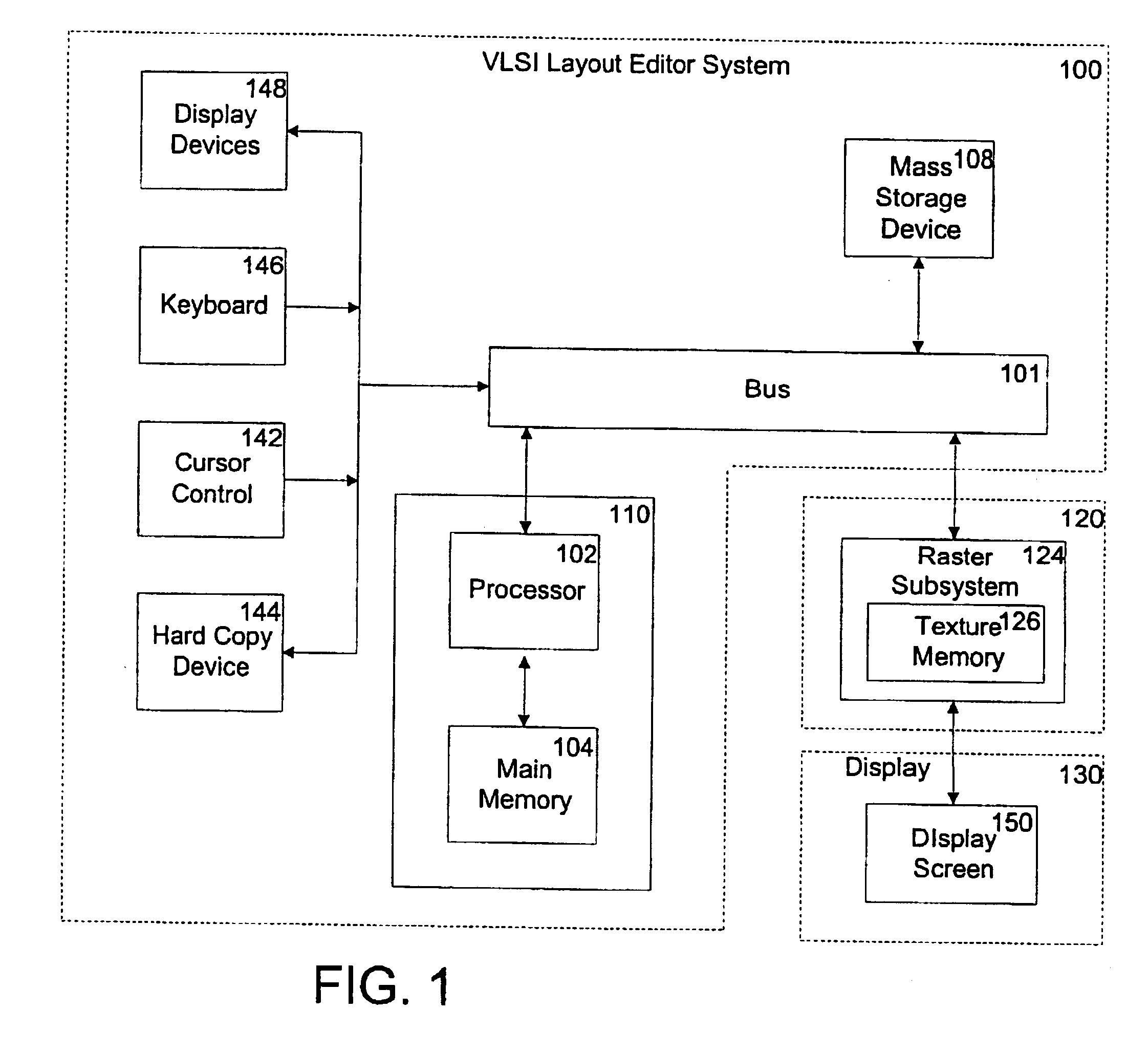

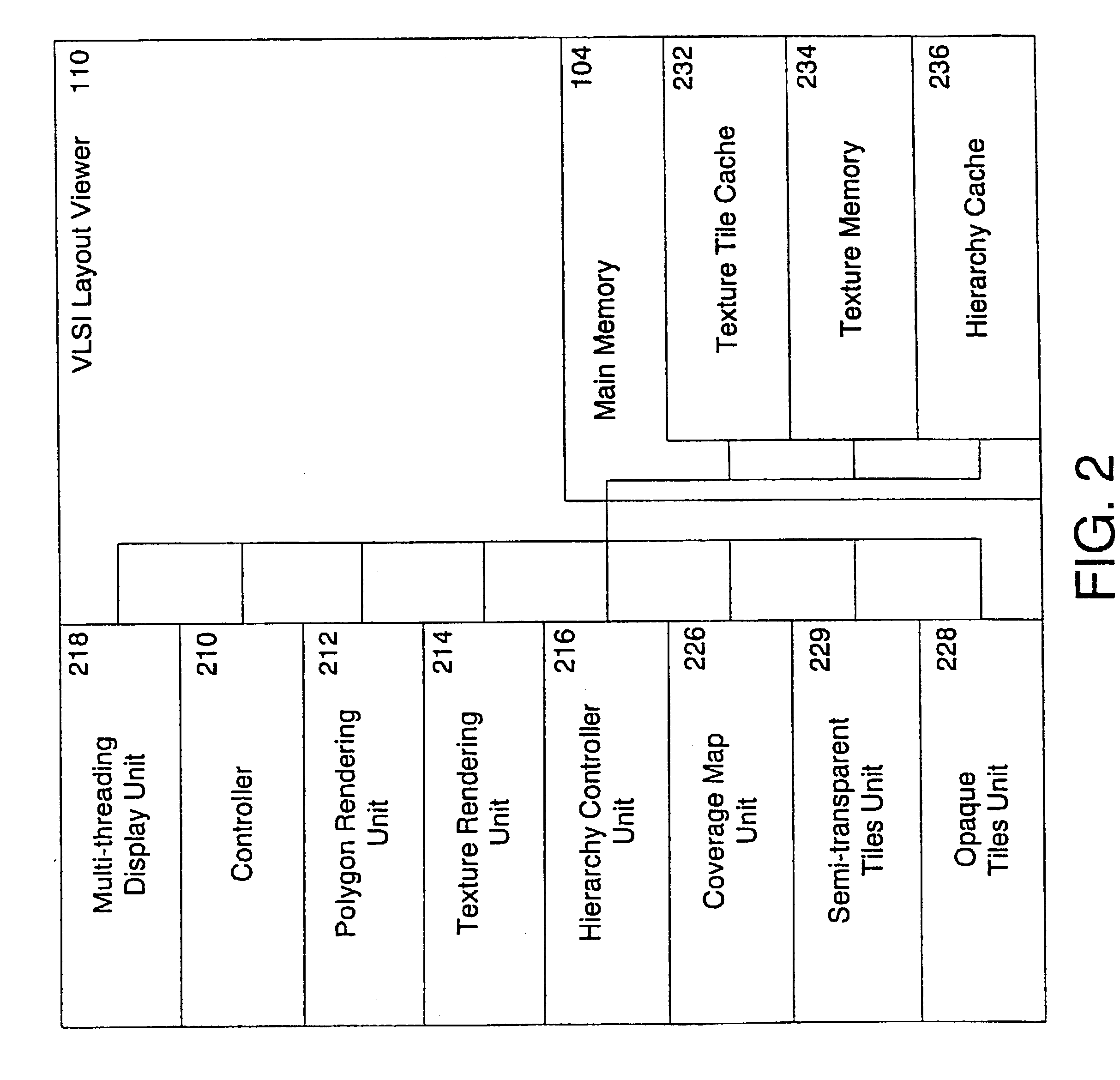

Method and system for displaying VLSI layout data

InactiveUS6886148B2Accurate photo-realistic representationAccurate real-time navigationDigital storageComputer programmed simultaneously with data introductionGeometric propertyComputer graphics (images)

A VLSI layout editor and method for using same that increases display and re-display speed and accuracy uses properties inherent to VLSI layouts that allows them to be displayed efficiently and accurately independent of the canonical expression of the VLSI design. The VLSI layout editor and methods for using same use precomputed images that each represent a portion of the VLSI layout, a hierarchy cache that includes multiple LOD versions of selected sub-designs in the pre-computed images, and selected direct determination of the viewable representation from the canonical expression for at least one LOD. Apparatus and methods according to the present invention can render a particular type of data whose canonical form is smaller than its corresponding displayed image thereof when the displayed image has geometric properties that allow heuristics and rasterization for dynamic and accurate expansion using selected combined techniques. Texture mapping and mipmapping can be used to accurately reduce, expand and reorder layers in a viewable image expanded from a canonical expression of the VLSI layout.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

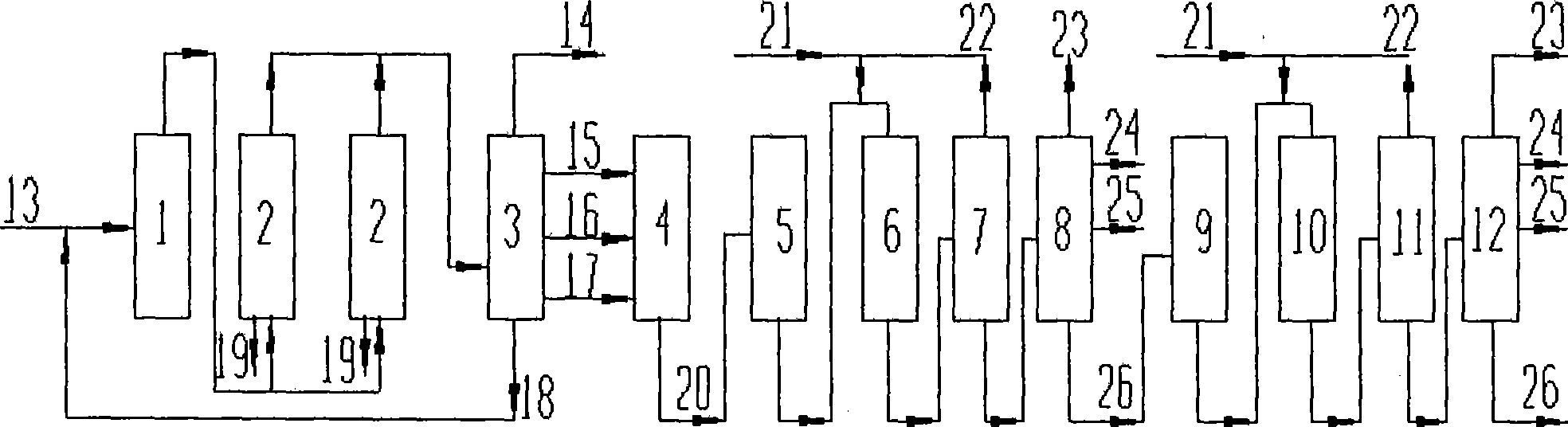

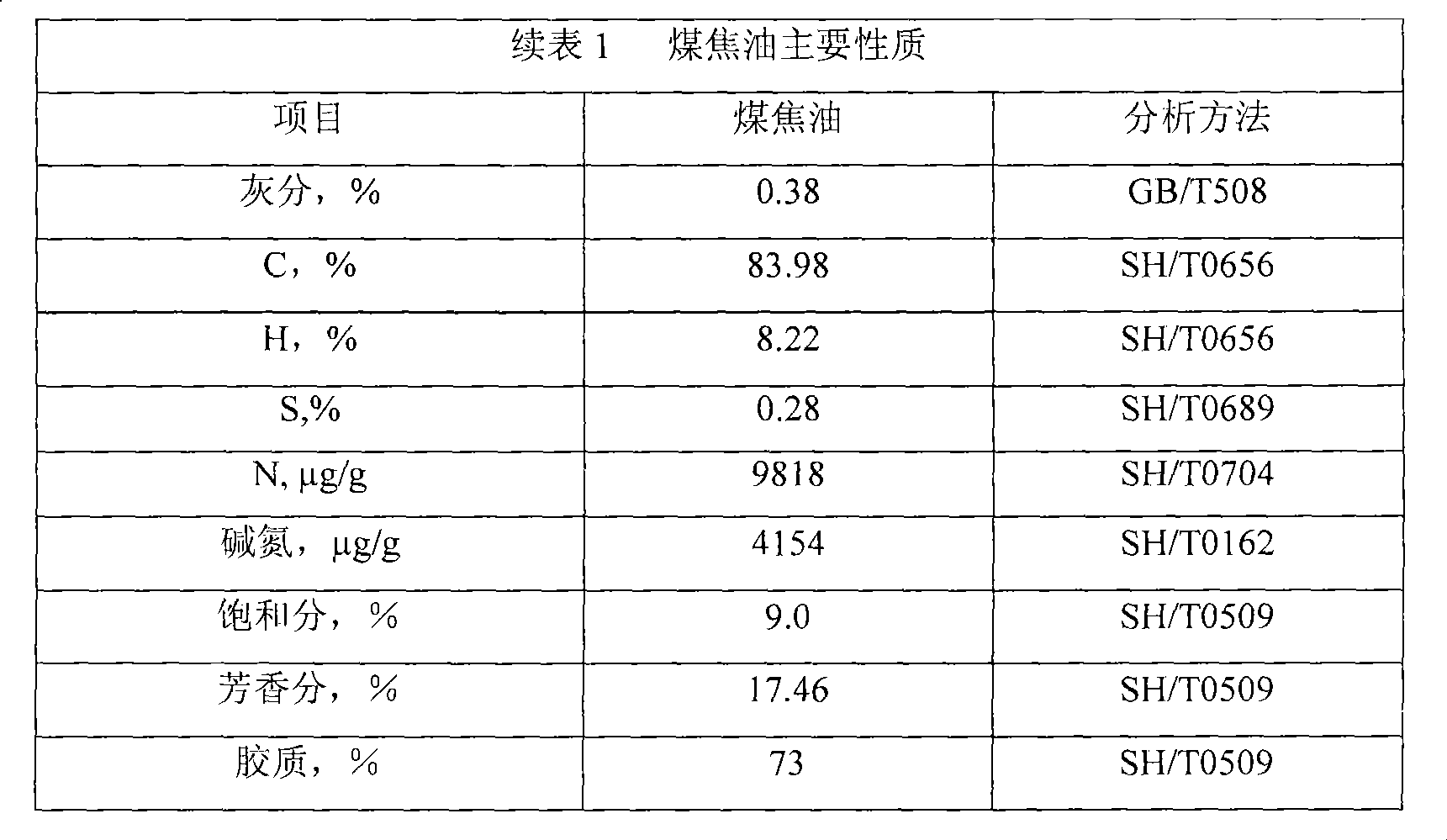

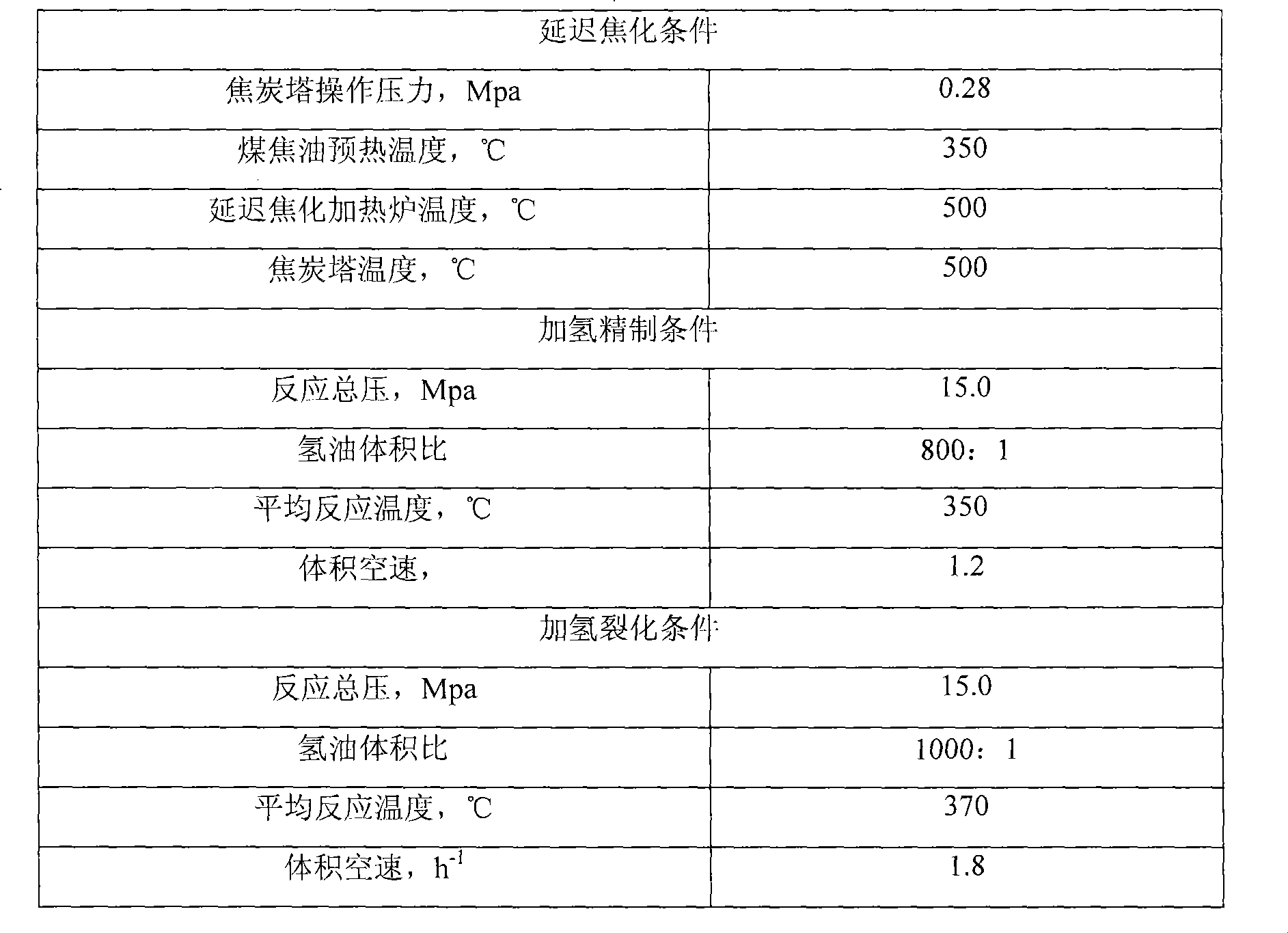

Delay coking hydrogenation combined process for coal oil

ActiveCN101429456AReduce pollutionIncrease added valueTreatment with hydrotreatment processesGasolineHydrogenation process

The invention provides a combined technique for delayed coking and hydrogenation of coal tar. The combined technique adopts the delayed coking and hydrogenation method to perform delayed coking, hydrogenation and final refining on the coal tar, wherein the hydrogenation process comprises hydrotreating, hydrorefining and hydrocracking; and liquefied gas, fuel oil and lube base oil are finally obtained. The key point of the combined technique is to utilize the combined technique of delayed coking and hydrogenation to adjust the technological conditions of the delayed coking technology and the hydrogenation technology, so as to realize final aim of modification of the coal tar. The combined technique converts the coal tar with low value and high pollution into clean and superior liquefied gas, gasoline, diesel fuel, lube and so on, improves the added value of products, and reduces environmental pollution.

Owner:SHAANXI COAL & CHEM IND GRP SHENMU TIANYUAN CHEM IND

Integrated technology quality model

InactiveUS20070078702A1Low costSimple methodHardware monitoringOffice automationProgram planningCombined technique

Owner:LIBERTY PEAK VENTURES LLC

Three-dimensional braided carbon fiber reinforced polyetheretherketone composite material and preparation method thereof

InactiveCN102134372AAvoid difficultiesGood mechanical propertiesCarbon fibresPoly ether ether ketoneDistilled water

The invention relates to a three-dimensional braided carbon fiber reinforced polyetheretherketone composite material and a preparation method thereof. Carbon fiber reinforced polyetheretherketone fiber, and carbon fiber which is used as the raw material and accounts for 18-54% by volume, are mixed and braided in a three-dimensional five-direction mode to obtain the three-dimensional braided carbon fiber reinforced polyetheretherketone composite material. The three-dimensional braided carbon fiber reinforced polyetheretherketone composite material is prepared from fibers by a braiding and hot compaction combined technique. The technological process comprises the following steps: carrying out three-dimensional mixing and braiding on the polyetheretherketone fiber and carbon fiber, carrying out solution oxidation pretreatment on the mixed fabric, repeatedly flushing with distilled water, drying, putting the mixed fabric into a die, and carrying out hot compaction. The invention can effectively overcome the difficulties in the preparation of the three-dimensional braided composite material due to the thermoplastic property of the polyetheretherketone, thereby obtaining the three-dimensional braided carbon fiber reinforced polyetheretherketone composite material which has the advantages of sufficient fiber immersion and excellent mechanical properties.

Owner:江苏飞荣达新材料科技有限公司

Treatment technique of tetrabromobisphenol A production wastewater

InactiveCN102583849AReduce CODReduce processing loadWater/sewage treatment by electrochemical methodsMultistage water/sewage treatmentTetrabromobisphenol AChlorobenzene

The invention discloses a treatment technique of tetrabromobisphenol A production wastewater, belonging to organic chemical industry wastewater recycling and harmless environmental-protection treatment technologies. The treatment technique of tetrabromobisphenol A production wastewater is an acidification precipitation-resin adsorption-advanced oxidation combined technique, and mainly comprises the following steps: 1. regulating the pH value of the wastewater to recycle the tribromophenol in the wastewater by acidification precipitation; 2. filling the wastewater, in which abundant tribromophenol is removed, into an adsorption column by using a macroporous adsorbent resin subjected to conventional pretreatment, and passing the wastewater through a bed bottom at a certain flow rate so that chlorobenzene is adsorbed by the resin, wherein the resin adsorption is utilized to remove most chlorobenzene, bisphenol A and other nondegradable organic substances in the recycled wastewater, thereby effectively reducing COD (chemical oxygen demand) of the wastewater and relieving the treatment load of the wastewater; and 3. carrying out electrocatalytic oxidation on the wastewater subjected to acidification precipitation-resin adsorption to finally remove harmful and nondegradable substances in the wastewater, thereby achieving the goal of harmless discharge after reaching the standard.

Owner:TIANJIN POLYTECHNIC UNIV

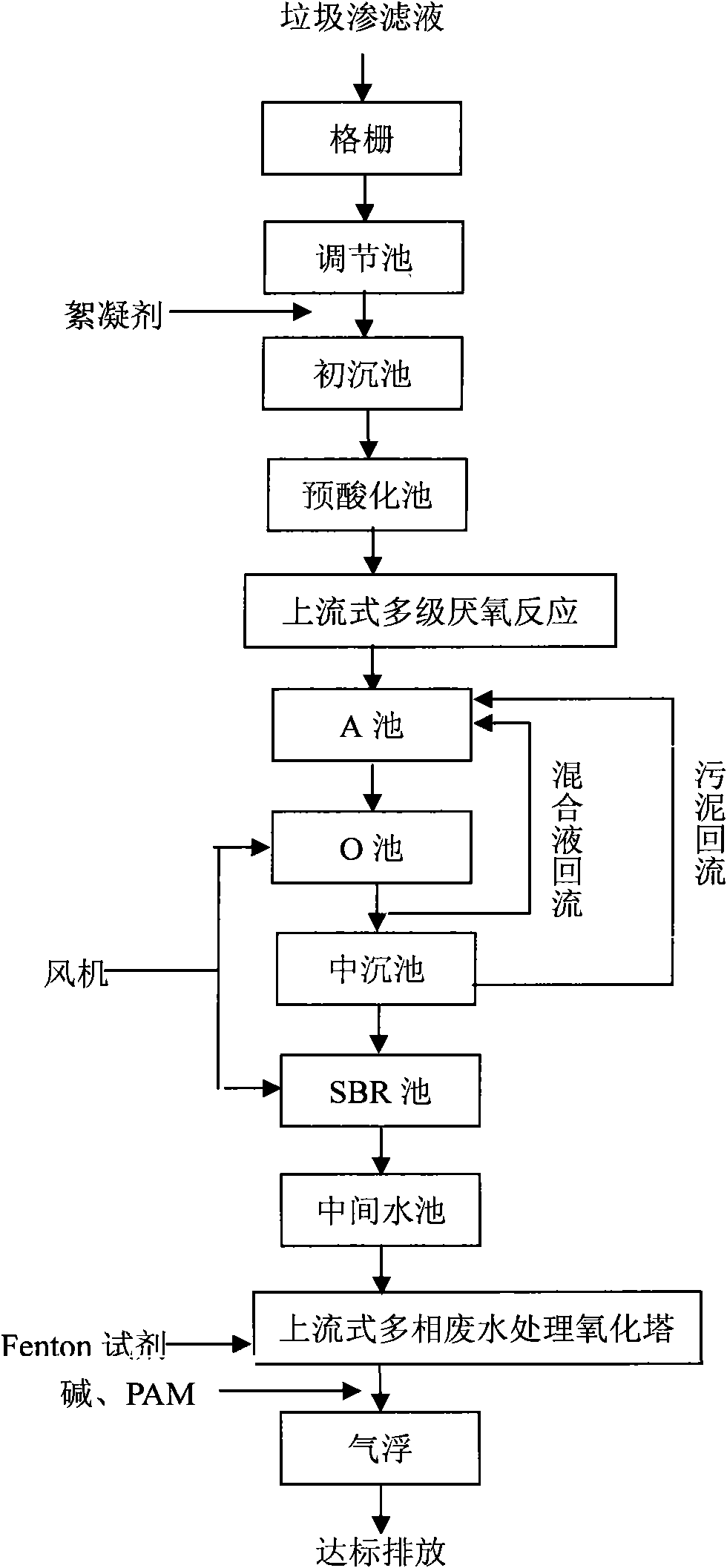

Method for treating garbage leachate

ActiveCN101767914ASimple and fast operationLow running costTreatment with anaerobic digestion processesTreatment with aerobic and anaerobic processesTreatment effectCombined technique

The invention discloses a method for treating garbage leachate. The method treats the garbage leachate by using the combined technique of pretreatment, biochemical treatment and advanced treatment, wherein the pretreatment adopts a method of coagulating sedimentation, reduces the concentration of organic matters, ammonia nitrogen and metallics, and reduces the inhibiting effect on the subsequent biochemical treatment; the biochemical treatment uses an anaerobic process, an A / O process and SBR to biochemically degrade wastewater, thereby simultaneously removing the organic matters and achieving the goal of denitrification; and finally, Fenton advanced oxidation and air flotation are used for carrying out the advanced treatment, and the strong oxidizing property of hydroxyl free radicals is utilized to oxidize the organic matters, which are difficult to be biochemically degraded, in waste water, thereby ensuring that the outlet water is discharged after reaching the standard. The invention has the advantages of simple operation of the technique, low operating cost, good treatment effect, no secondary pollution and the like, and the advanced treatment can ensure that the outlet water is discharged after reaching the standard. The outlet water meets the standard for pollution control on the landfill site of municipal solid waste (GB 16889-2008).

Owner:GUANGXI BOSSCO ENVIRONMENTAL PROTECTION TECH

Multiple combined technique for high concentration hard-degraded organic waste water treatment

InactiveCN101041531AEfficient removalAchieve mineralizationTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentHigh concentrationFiltration

The invention discloses a multiple compositing craft to high density hard degraded organic waste water, which comprises the following steps: (a) proceeding aeration coagulation-aeration micro-electrolytic treatment; adopting intensified and materialized compositing craft; removing most of COD in organic waste water; improving biological property; (b) proceeding anaerobic-hydrolytic decomposition acidify biochemistry treatment; leading organic waste water into highly effective hydrolyze acidifying tank; cutting off macromolecule; increasing biological property; removing part of COD; transiting valent state of nitrogen; (c) intensifying microbe aerobic biological disposing craft; passing the waste water into aerobic tank with intensified microbe; removing remain COD, ammonia nitrogen and SS contaminant; (d) proceeding twice materialized treatment; adopting highly effective active oxygen to sterilization and disinfection; further stripping colourity, COD; reaching recycling water stander through sand filtration.

Owner:刘景峰

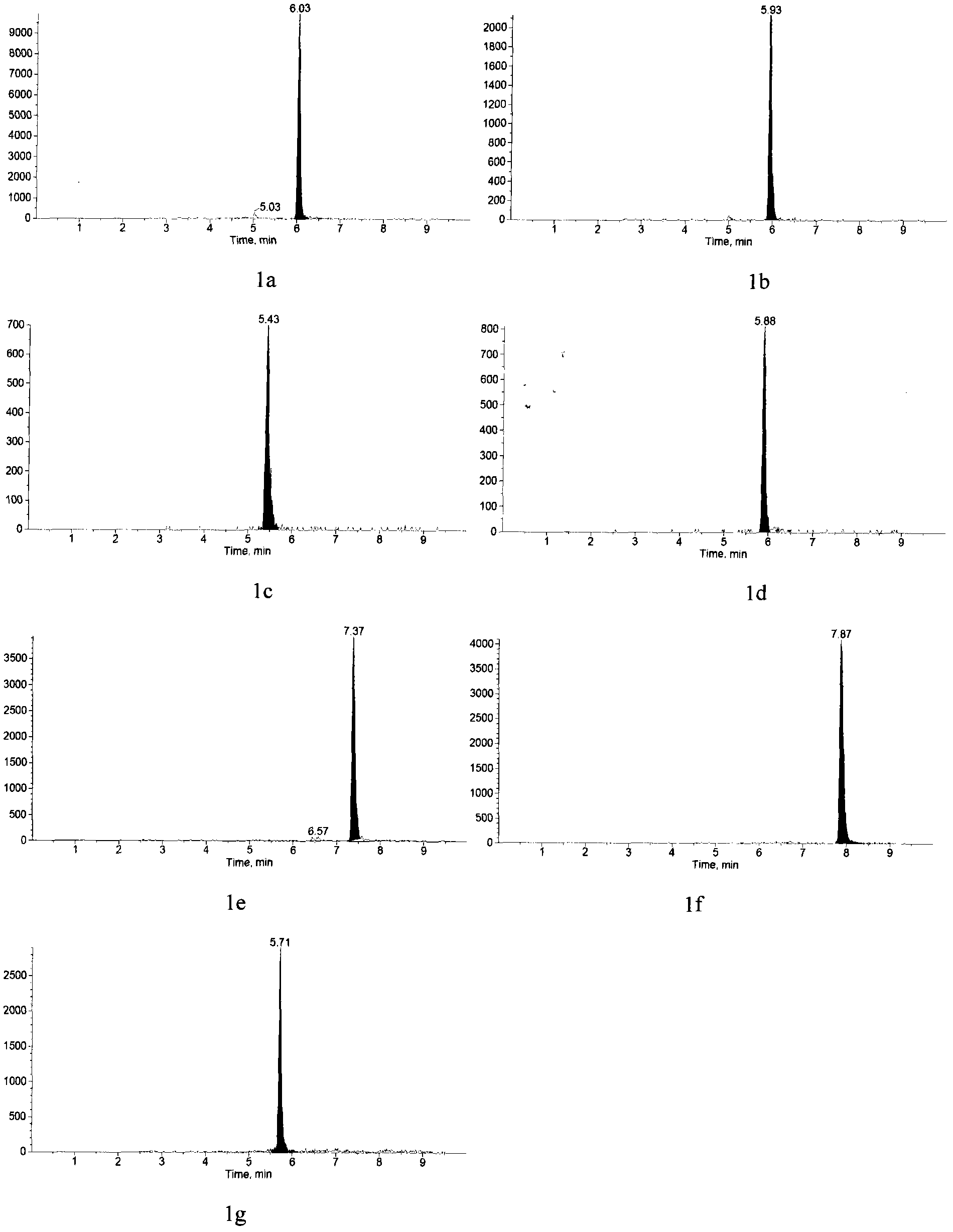

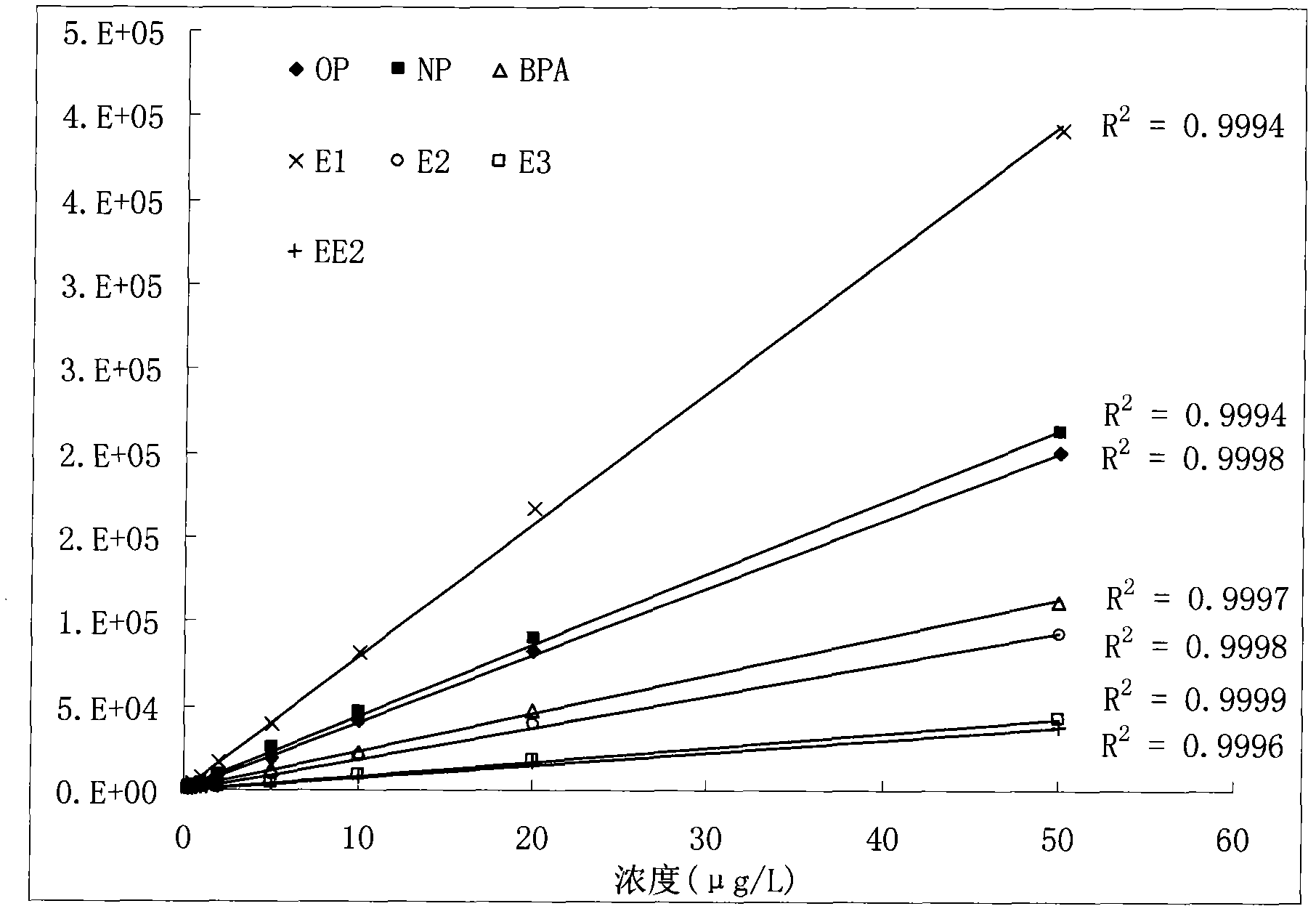

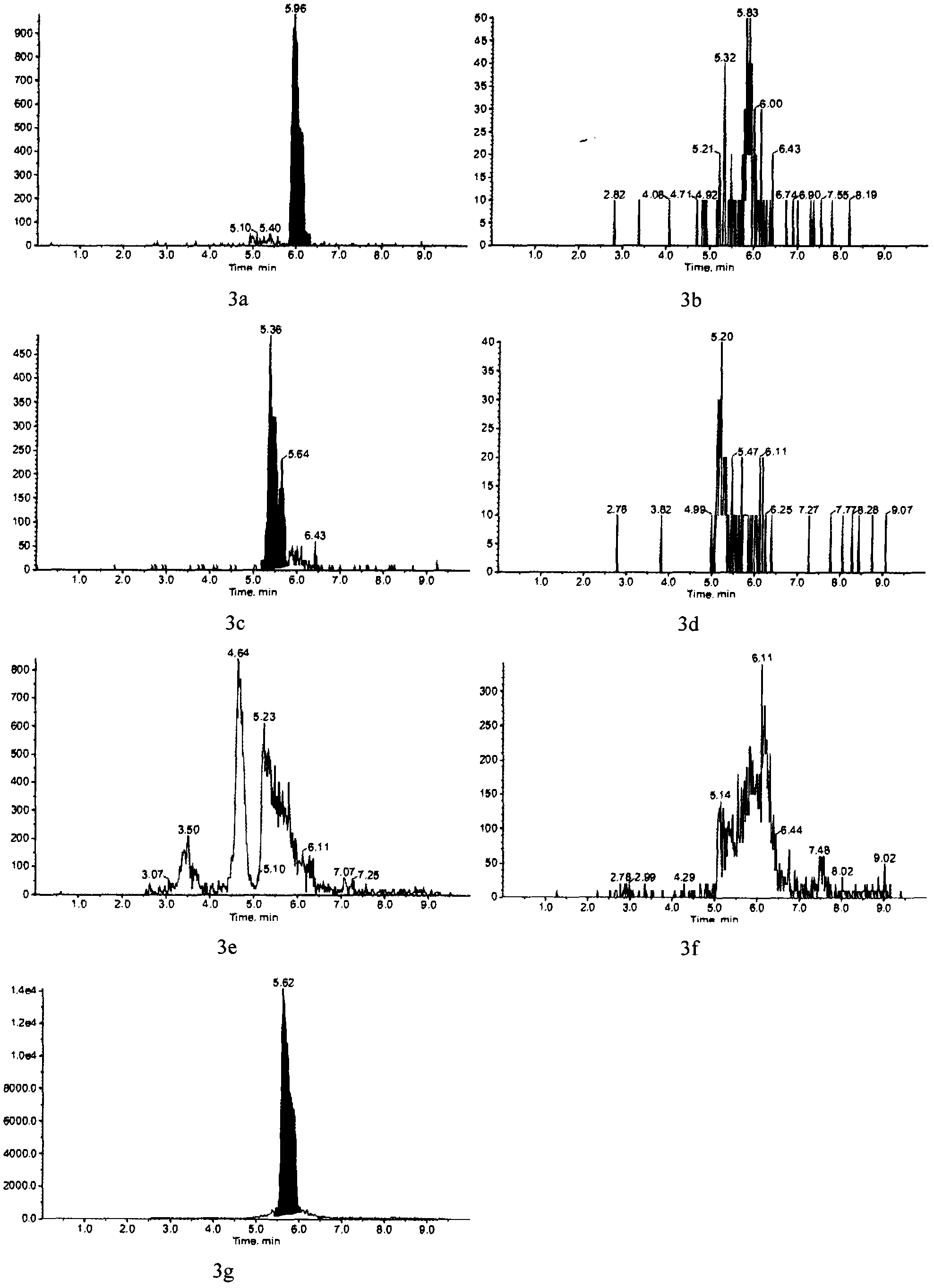

Method for jointly detecting estrogen, nonyl phenol, octylphenol and bisphenol A in complex substrate water sample

The invention relates to a detecting technique of endocrine disrupters in water environment and particularly relates to a technique for quantitative analysis on oestrone, 17beta-estradiol, estriol, 17alpha-ethinyl estradiol, nonyl phenol, octylphenol and bisphenol A in a complex substrate water sample by adopting a liquid chromatogram-tandem mass spectrum combined technique. The method comprises the following steps: enriching a collected water sample by using a HLB (Hydrophile-Lipophile Balance) solid-phase extraction column and washing with carbinol; drying elution liquid nitrogen and purifying by using Florisil; and finally, analyzing by utilizing the liquid chromatogram-tandem mass spectrum combined technique. The method is environment-friendly, easy to operate and high in recovery rate. The method can quickly analyze the trace amount of oestrone, 17beta-estradiol, estriol, 17alpha-ethinyl estradiol, nonyl phenol, octylphenol and bisphenol A in the complex substrate water sample.

Owner:BEIJING NORMAL UNIVERSITY

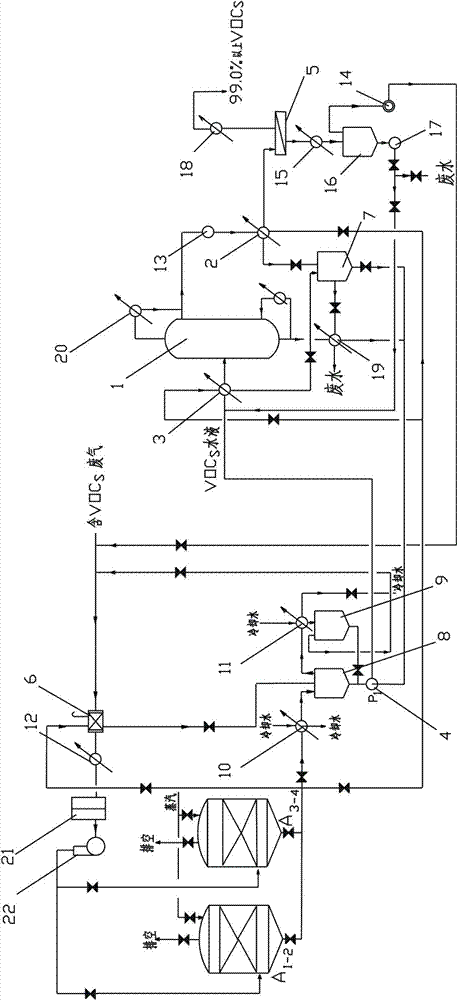

Combined technique of separating and recycling VOCS (volatile organic compounds) from industrial waste gas by adsorption-desorption-rectification-pervaporation

ActiveCN102764559AReduce dosageReduce cooling water consumptionOrganic compound preparationDispersed particle separationFiberCombined technique

The invention relates to a combined technique of separating and recycling VOCS (volatile organic compounds) from industrial waste gas by adsorption-desorption-rectification-pervaporation, which comprises the following steps: drying, cooling and filtering the industrial waste gas containing the VOCS, then conveying into a plurality of adsorption-desorption groups to carry out adsorption-desorption operation, uniformly spraying through upper parts of adsorption-desorption devices by saturated vapor with the pressure at 0.15-0.5MPa, heating GAC (granular active carbon) or ACF (active carbon fiber) to desorb the adsorbed VOCS; after finishing the desorption, entering the next adsorption, using the VOCS-containing saturated vapor desorbed by the vapor in a pervaporation membrane for separation and heat supply. The combined technique provided by the invention forms an impact and enclosed circulation to sufficiently recycle the VOCS from the waste gas. The VOCS-containing saturated vapor desorbed by the saturated vapor contains large amount of latent heat and sensible heat, and the sensible heat of residual liquid on the bottom of a rectification tower is utilized sufficiently.

Owner:武汉旭日华环保科技股份有限公司

Forming method for large high-modulus ellipsoidal molded surface hemispherical shell of aluminum alloy storage box

The invention relates to a forming method of a large high-modulus thin-wall ellipsoidal molded surface hemispherical shell of an aluminum alloy storage box for spaceflight and belongs to the technicalfield of storage box forming. A round plate blank is used for direct precise numerical-control spinning forming of the large high-modulus ellipsoidal molded surface hemispherical shell of the aluminum alloy storage box, and auxiliary working procedures such as pre-forming and intermediate heat-treatment are not needed; through the technical design and precise control, the combined technique of heat conventional spinning and then heat power spinning at the first stage and heat conventional spinning at the second stage is adopted, and the large high-modulus ellipsoidal molded surface hemispherical shell of the aluminum alloy storage box can be precisely formed only by using a spinning block, through clamping at a time and in one numerical-control program, so that the technical process is shortened, the production efficiency is improved, and the forming precision of a member can be greatly improved; and a unilateral gap between the inner molded surface of the formed ellipsoidal molded surface hemispherical shell and a theoretical molded surface template is smaller than 0.2 mm, and the wall thickness difference of the inner molded surface of the formed ellipsoidal molded surface hemispherical shell and the theoretical molded surface template is smaller than 0.2 mm.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

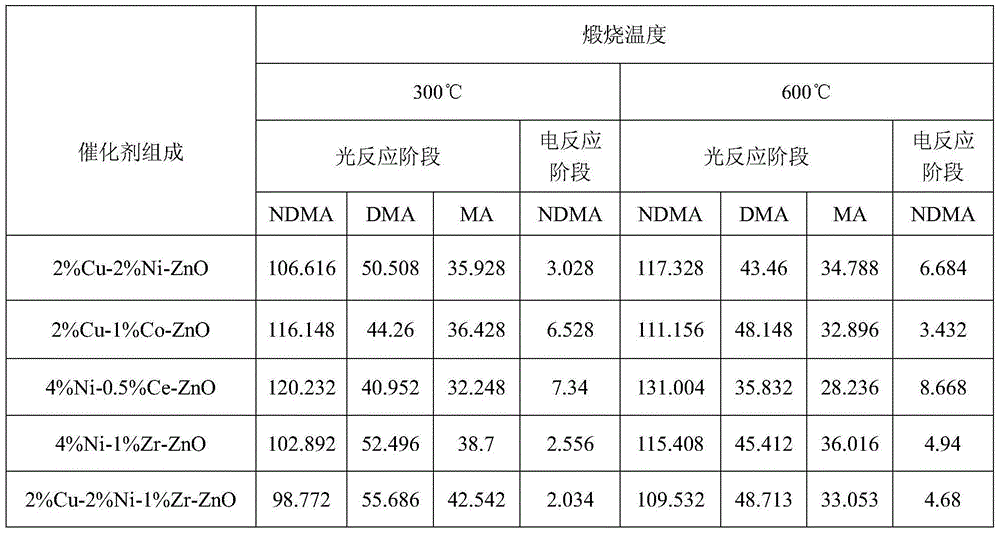

Method for treating organic wastewater by photoelectric combined technique

ActiveCN104628200AHigh removal rateEfficient degradationWater treatment parameter controlWater/sewage treatment by irradiationFiberChemical oxygen demand

Owner:SOUTHEAST UNIV

Selective Repositioning and Rotation Wavelength Beam Combining System and Method

InactiveUS20140036375A1Increase brightnessIncrease powerLaser detailsTelescopesLight beamClassical mechanics

A system and method for reconfiguring a plurality of electromagnetic beams to take advantage of various wavelength beam combining techniques. The reconfiguring of beams includes individual rotation and selective repositioning of one or more beams with respect to beam's original input position.

Owner:TERADIODE

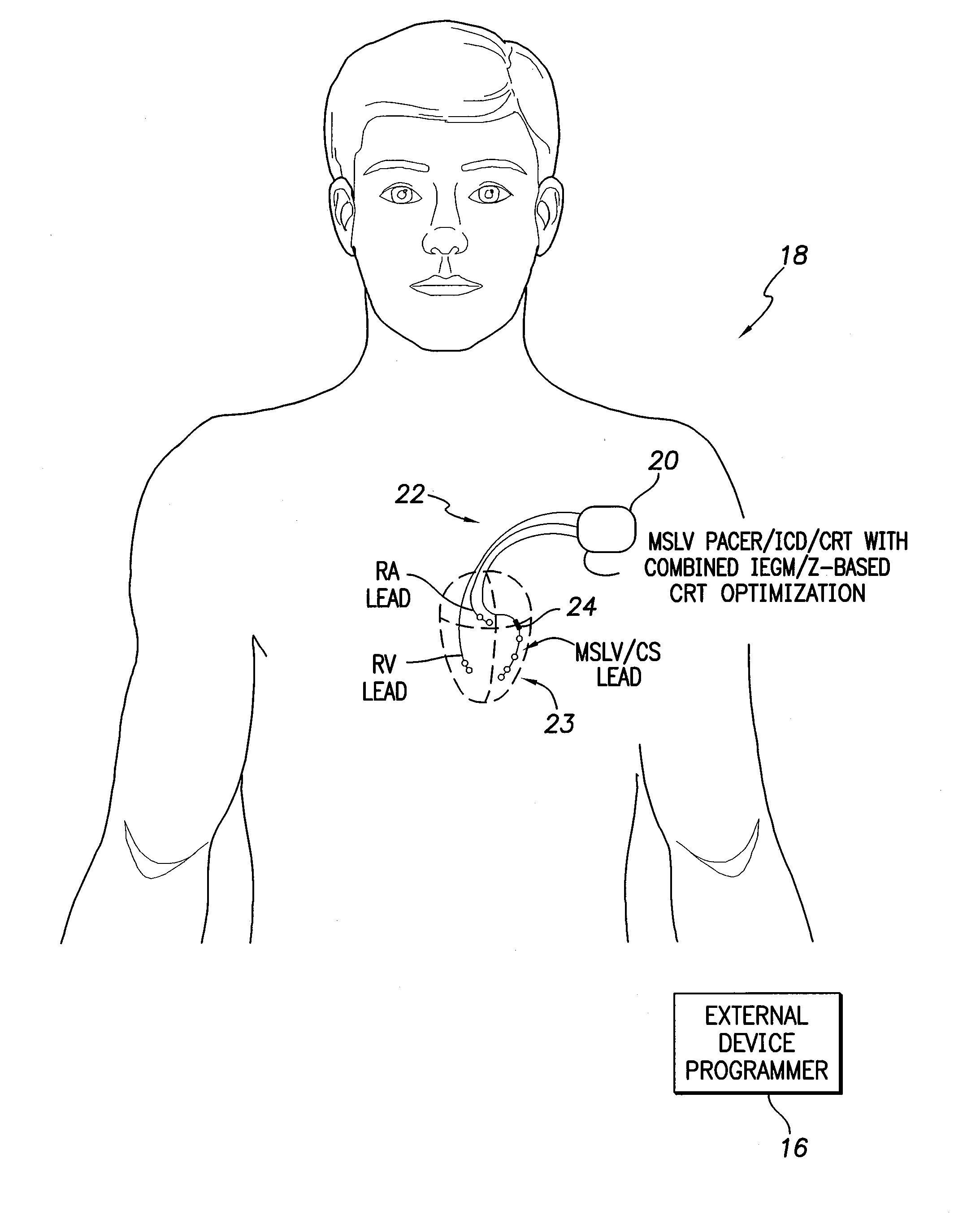

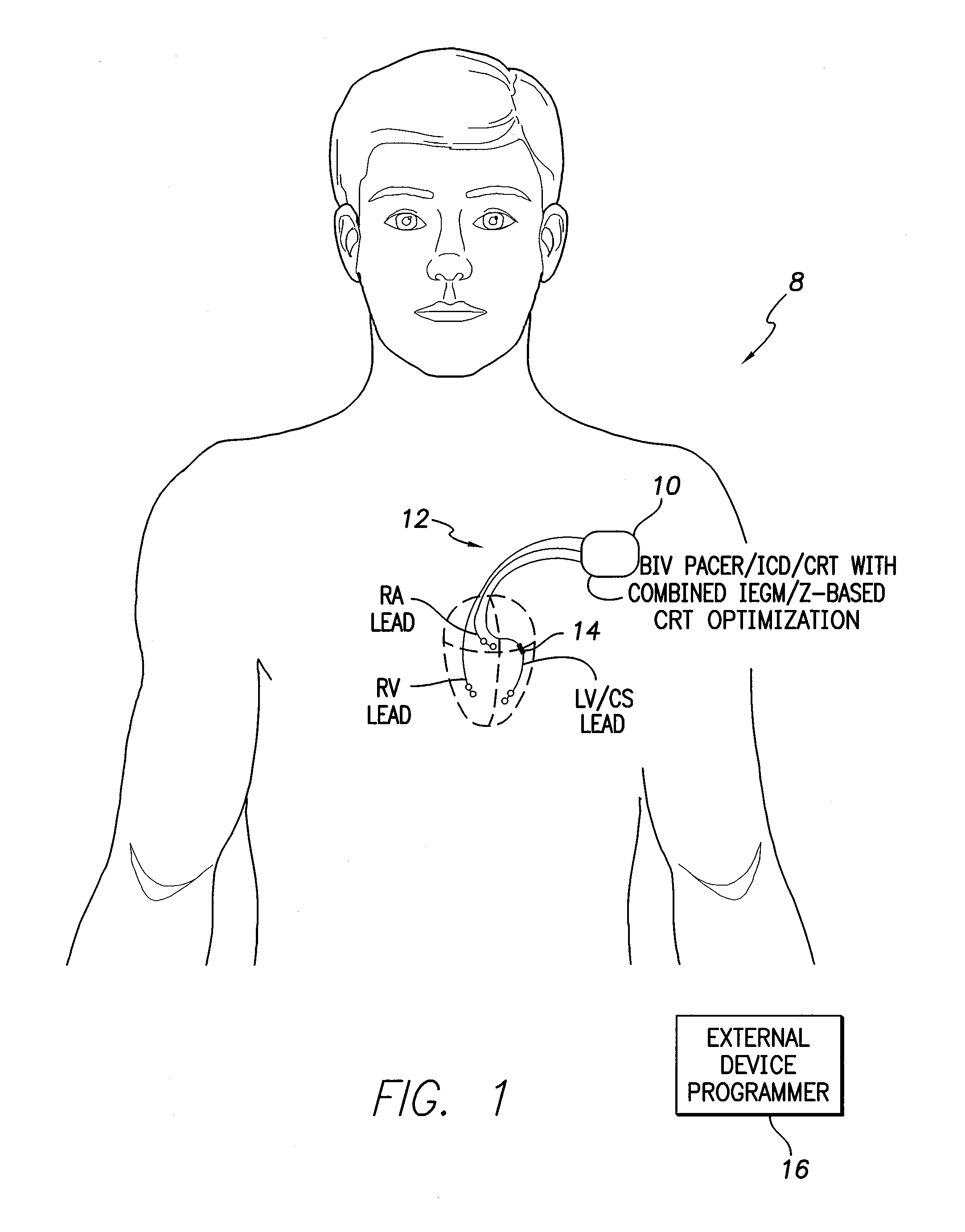

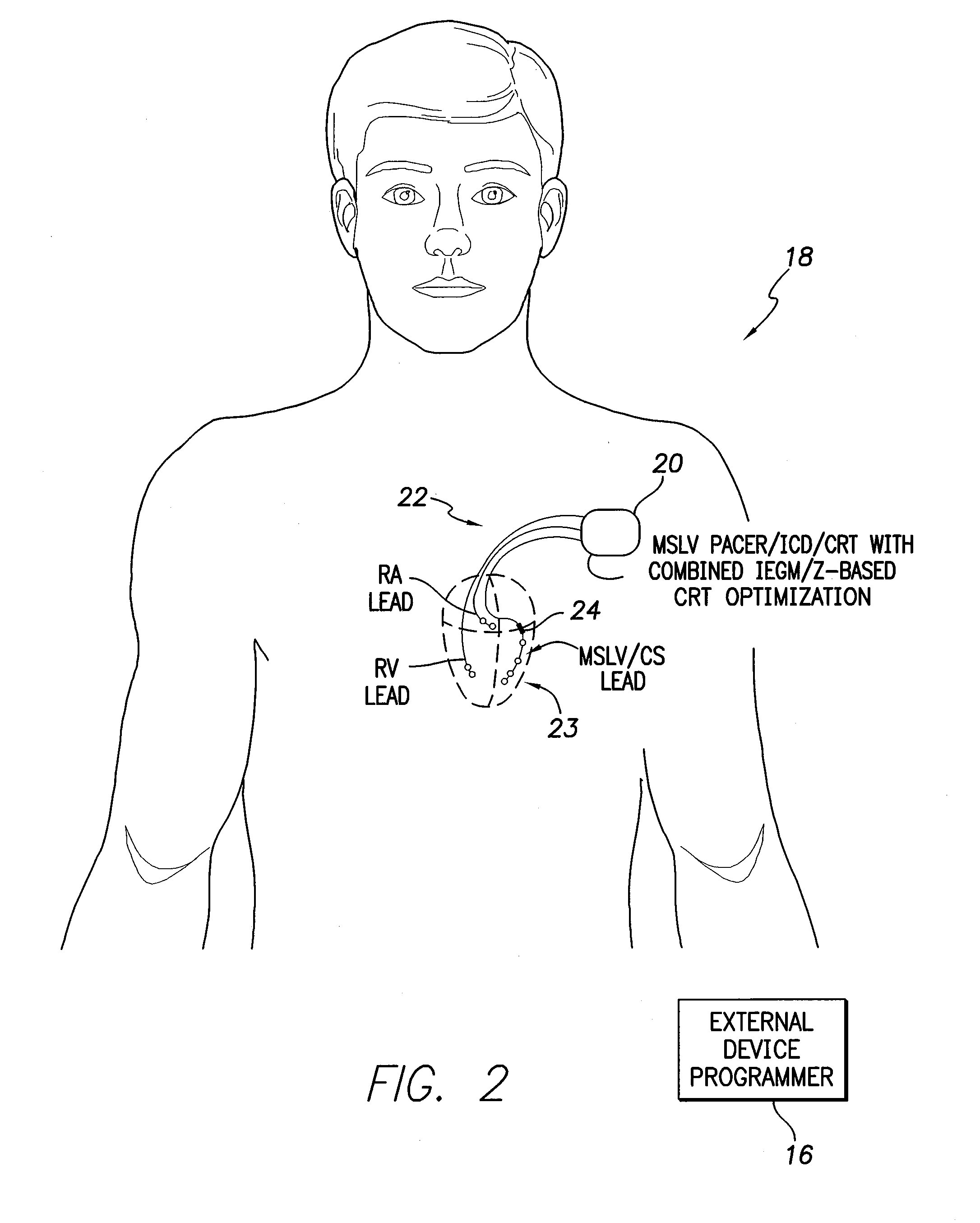

Systems and methods for optimizing AV/VV pacing delays using combined IEGM/impedance-based techniques for use with implantable medical devices

Systems and methods are provided wherein intracardiac electrogram (IEGM) signals are used to determine a set of preliminary optimized atrioventricular (AV / PV) and interventricular (VV) pacing delays. In one example, the preliminary optimized AV / VV pacing delays are used as a starting point for further optimization based on impedance signals such as impedance signals detected between a superior vena cava (SVC) coil electrode and a device housing electrode, which are influenced by changes in stroke volume within the patient. Ventricular pacing is thereafter delivered using the AV / VV pacing delays optimized via impedance. In another example, parameters derived from IEGM signals are used to limit the scope of an impedance-based optimization search to reduce the number of pacing tests needed during impedance-based optimization. Biventricular and multi-site left ventricular (MSLV) examples are described.

Owner:PACESETTER INC

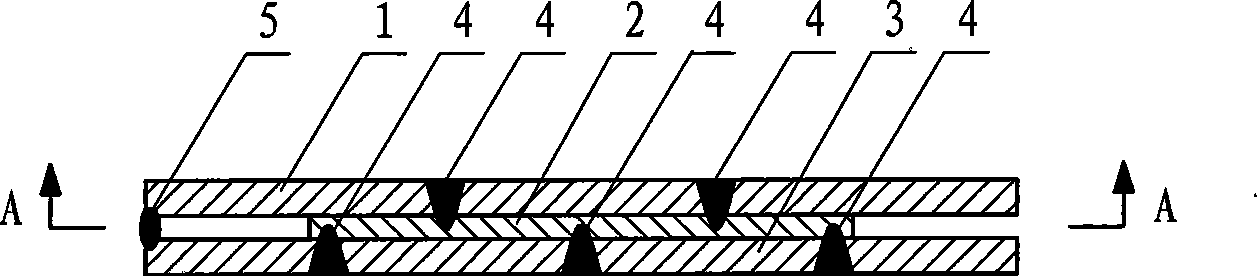

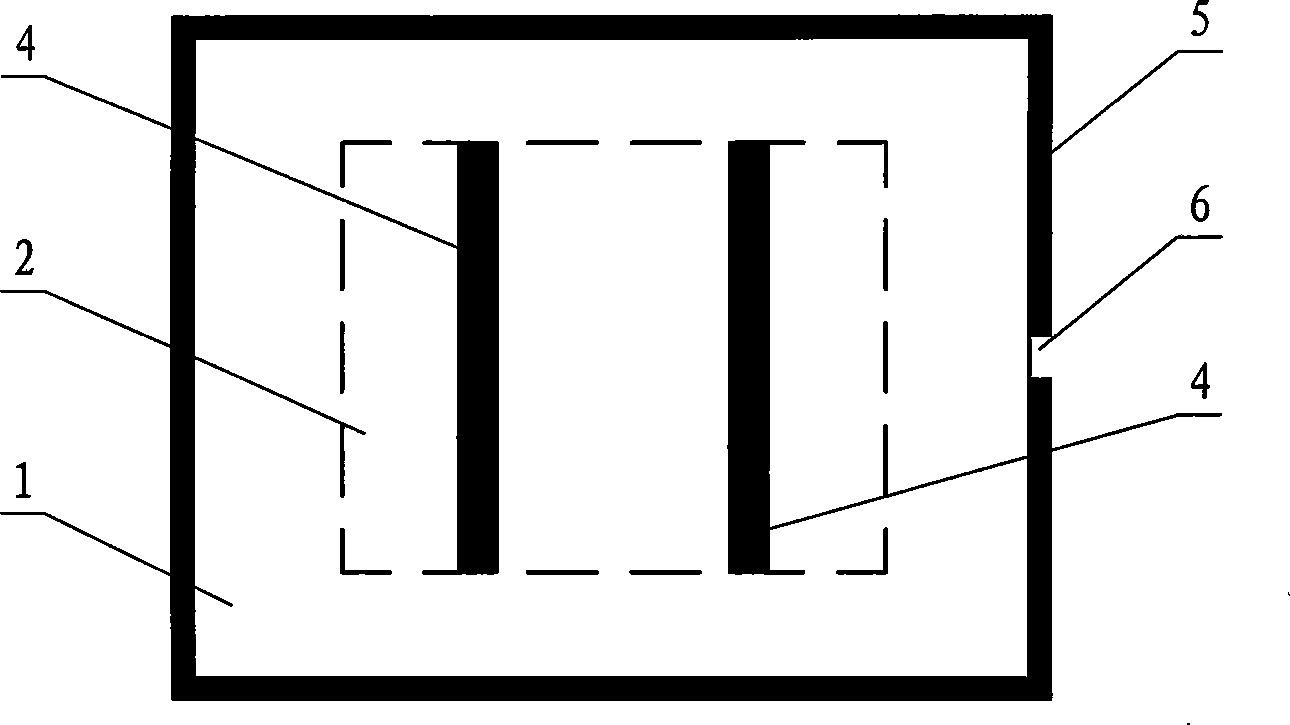

Method for producing GH4169 high-temperature alloy multiply laminate structure

InactiveCN101412155AShort manufacturing timePracticalArc welding apparatusLaser beam welding apparatusRoom temperatureAlloy

The invention provides a method for manufacturing the GH4169 high-temperature alloy sandwich panel structure, which belongs to the field of material processing. The aim of the invention is to solve the problems in manufacturing the GH4169 high-temperature alloy with a multi-layer structure by SPF / DB. The method comprises the following steps: 1. the ultrasonic cleaning is performed; 2. by adopting the laser deep penetration welding, various workpieces are welded together; 3. by adopting the argon-arc welding, a sealed space is formed, and only a vent hole is reserved; 4. the welded workpieces are placed in a die; 5. the die is placed in a heating furnace, heated at a temperature of between 950 and 980 DEG C and subjected to heat preservation for 25 and 40 minutes; 6. the inert gas is filled in for the superplastic bulging treatment; and 7. the die is cooled down to the room temperature. In the invention, by adopting the laser connection / superplastic bulging combined technique, the GH4169 high-temperature alloy sandwich panel structure is successfully manufactured; and by utilizing the quickness and the accuracy in the laser connection, the manufacturing time of the sandwich panel is shortened.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com