Method for producing GH4169 high-temperature alloy multiply laminate structure

A GH4169, superalloy technology, applied in the field of material processing, can solve the problem of inability to manufacture multi-layer structure GH4169 superalloy, and achieve the effect of shortening preparation time and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

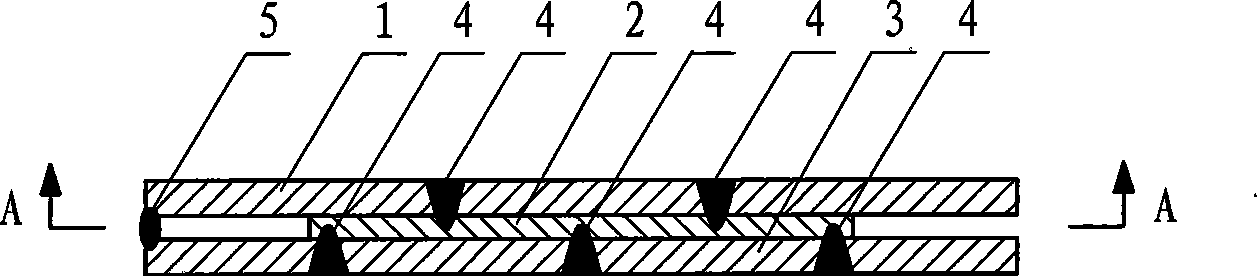

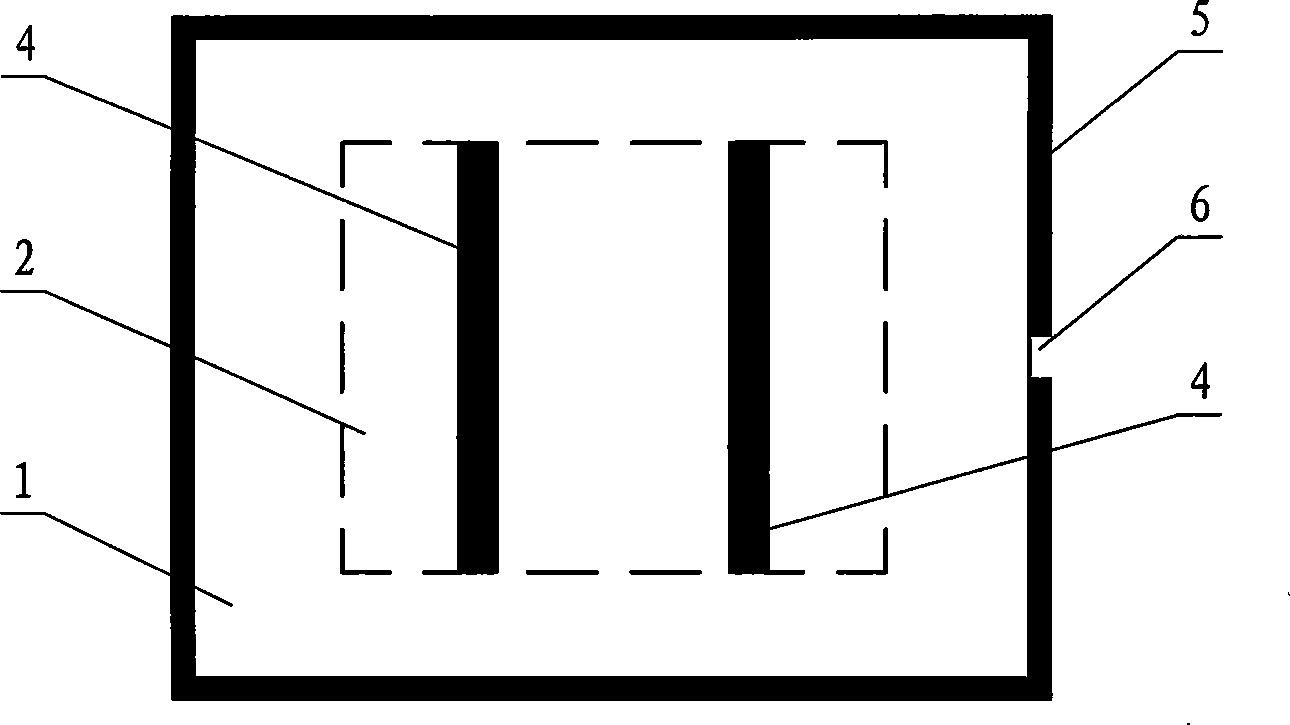

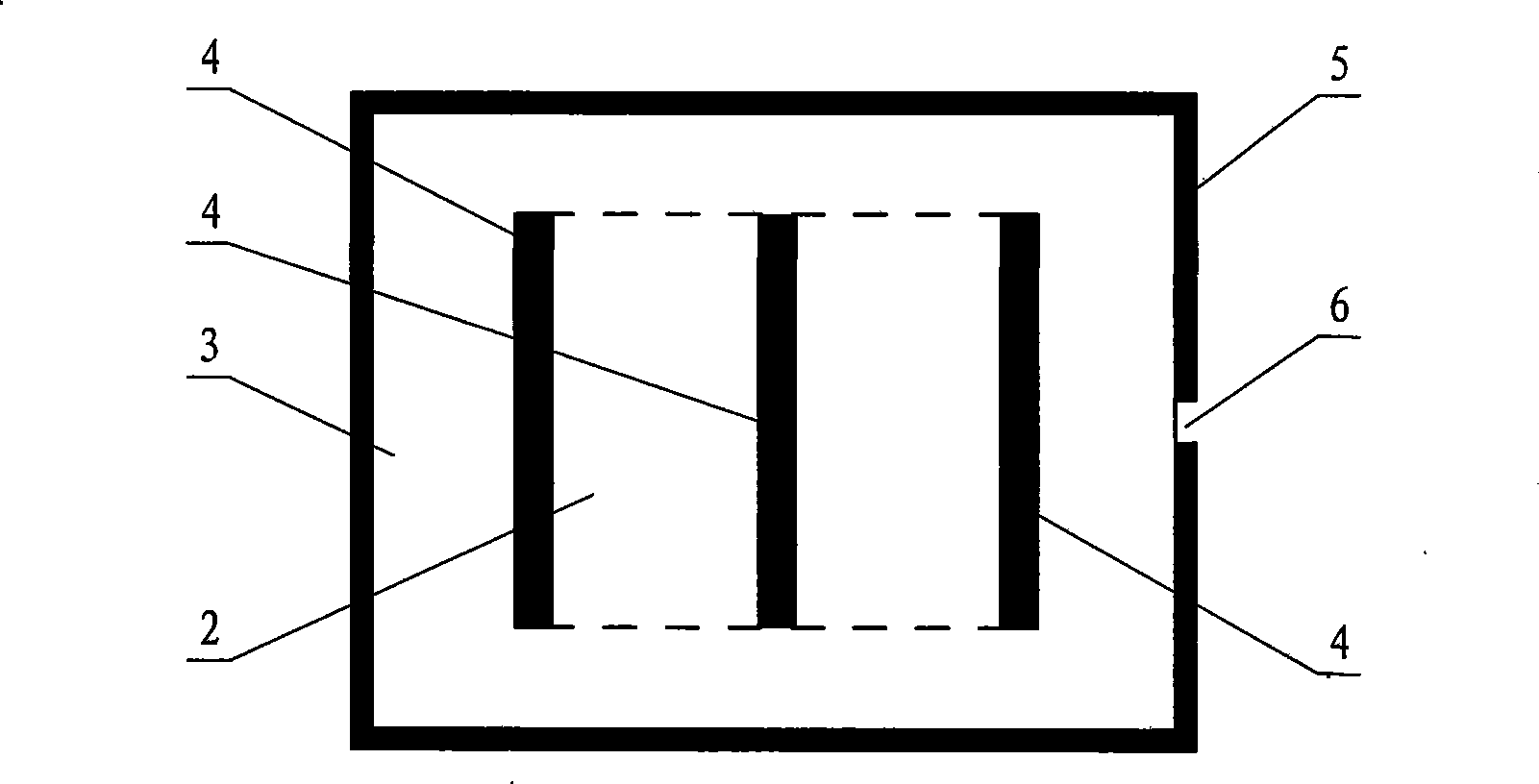

[0014] Specific implementation mode one: see Figure 1 to Figure 7 Describe this embodiment, a method for manufacturing a GH4169 superalloy multilayer plate structure, and the steps for realizing the method include:

[0015] Step 1: Put the panel 1, bottom panel 3 and N core panels 2, which are all made of GH4169 superalloy, into an acetone solution with a purity of 99.9% (mass) or more and ultrasonically clean it for 1min to 5min, then use a stainless steel brush and sandpaper Polish the surfaces of panel 1, base plate 3 and N core plates 2 for 8 minutes to 20 minutes, and then put panel 1, base plate 3 and N core plates 2 into an acetone solution with a purity of 99.9% (mass) or more for 5 minutes to 20 minutes. 15min, N=1 or N=2K, K is a positive integer;

[0016] Step 2: Fix the panel 1, bottom plate 3 and N core plates 2 on the workpiece table, and use laser deep penetration welding to respectively install the panel 1, bottom plate 3 and N cores from the side of the pane...

specific Embodiment approach 2

[0026] Specific embodiment two: the difference between this embodiment and embodiment one is that in step one, the panel 1, the core plate 2 and the bottom plate 3 that are all made of GH4169 superalloy are put into the glass with a purity of more than 99.9% (mass) respectively. Ultrasonic cleaning in acetone solution for 2min to 3min, then use stainless steel brush and sandpaper to polish the surface of panel 1, core panel 2 and bottom panel 3 for 10min to 15min respectively, then put panel 1, core panel 2 and bottom panel 3 into % (mass) above the acetone solution for 10min to 15min, and other steps and technical parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0027] Embodiment 3: The difference between this embodiment and Embodiment 1 is that in Step 4, the upper mold 7 and the lower mold 8 are provided with 1 to 3 vent holes, and other steps and technical parameters are the same as Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com