Patents

Literature

9323 results about "Materials processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Materials processing is defined as the series of steps or “unit operations” used in the manufacture of raw-materials into finished goods.

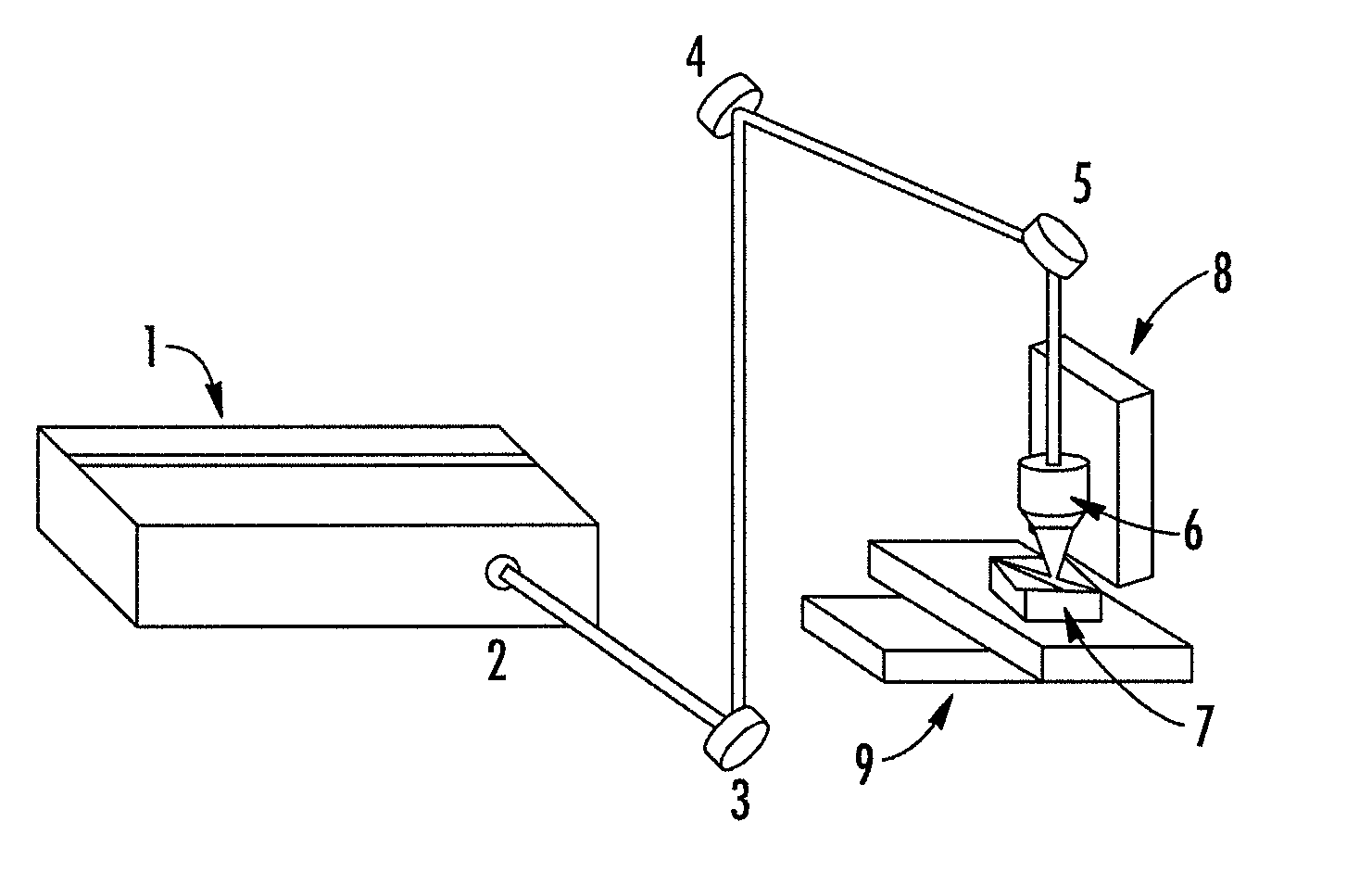

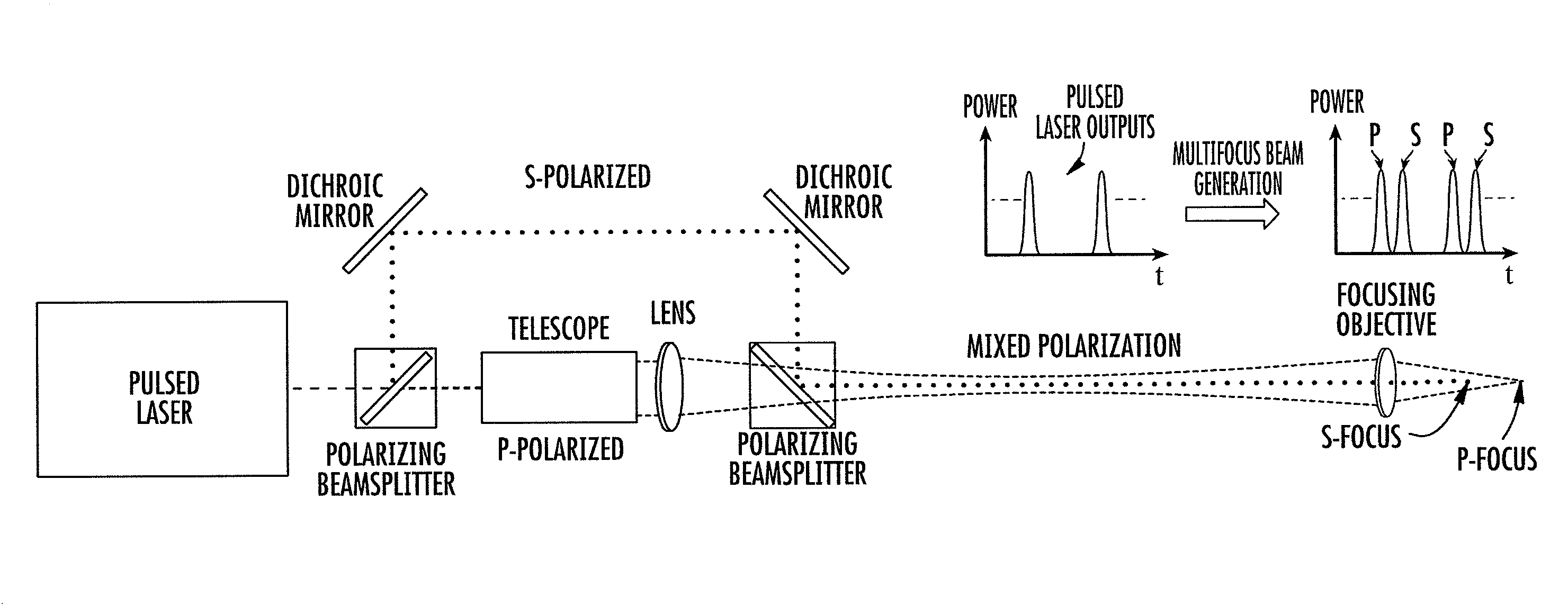

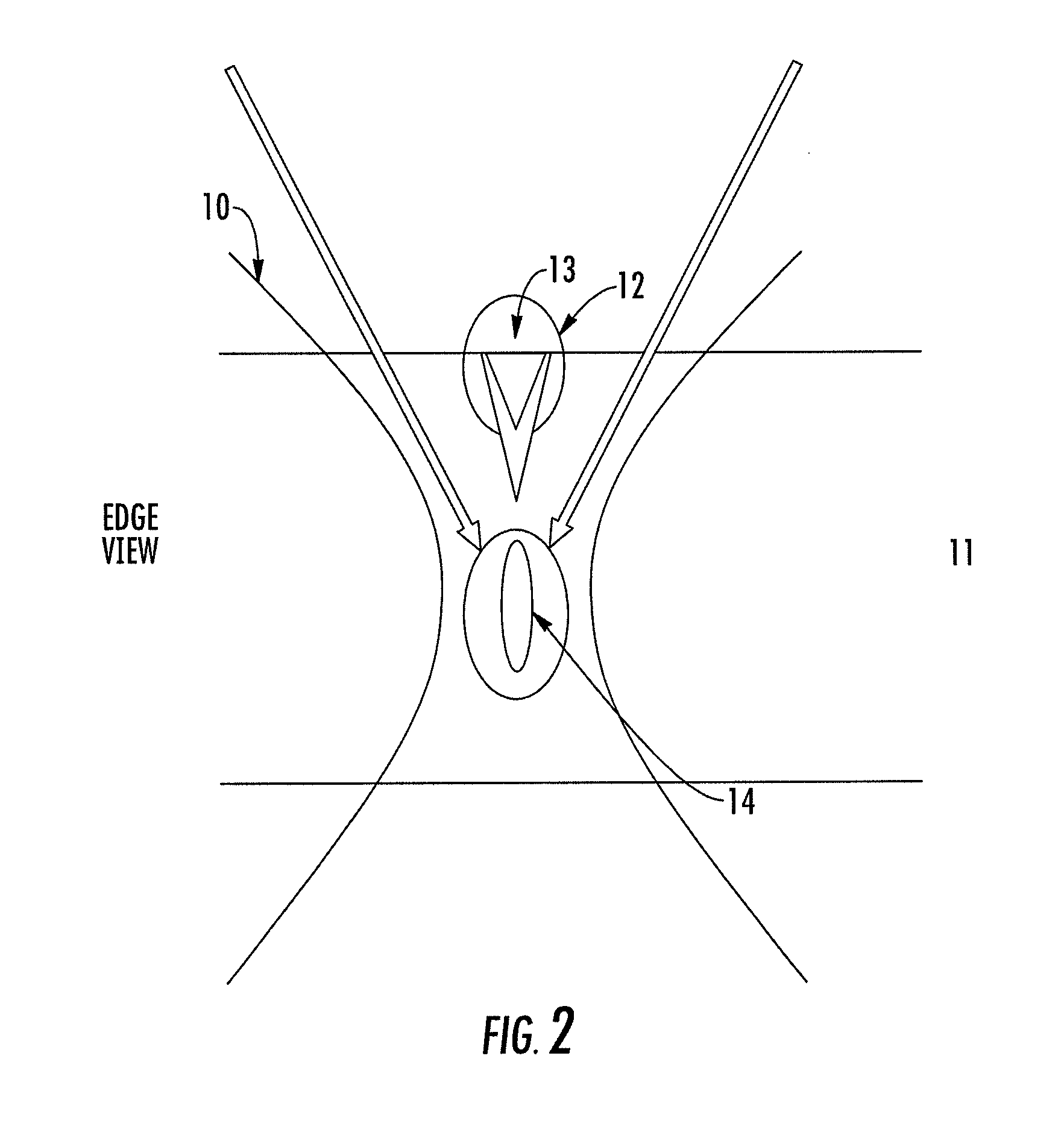

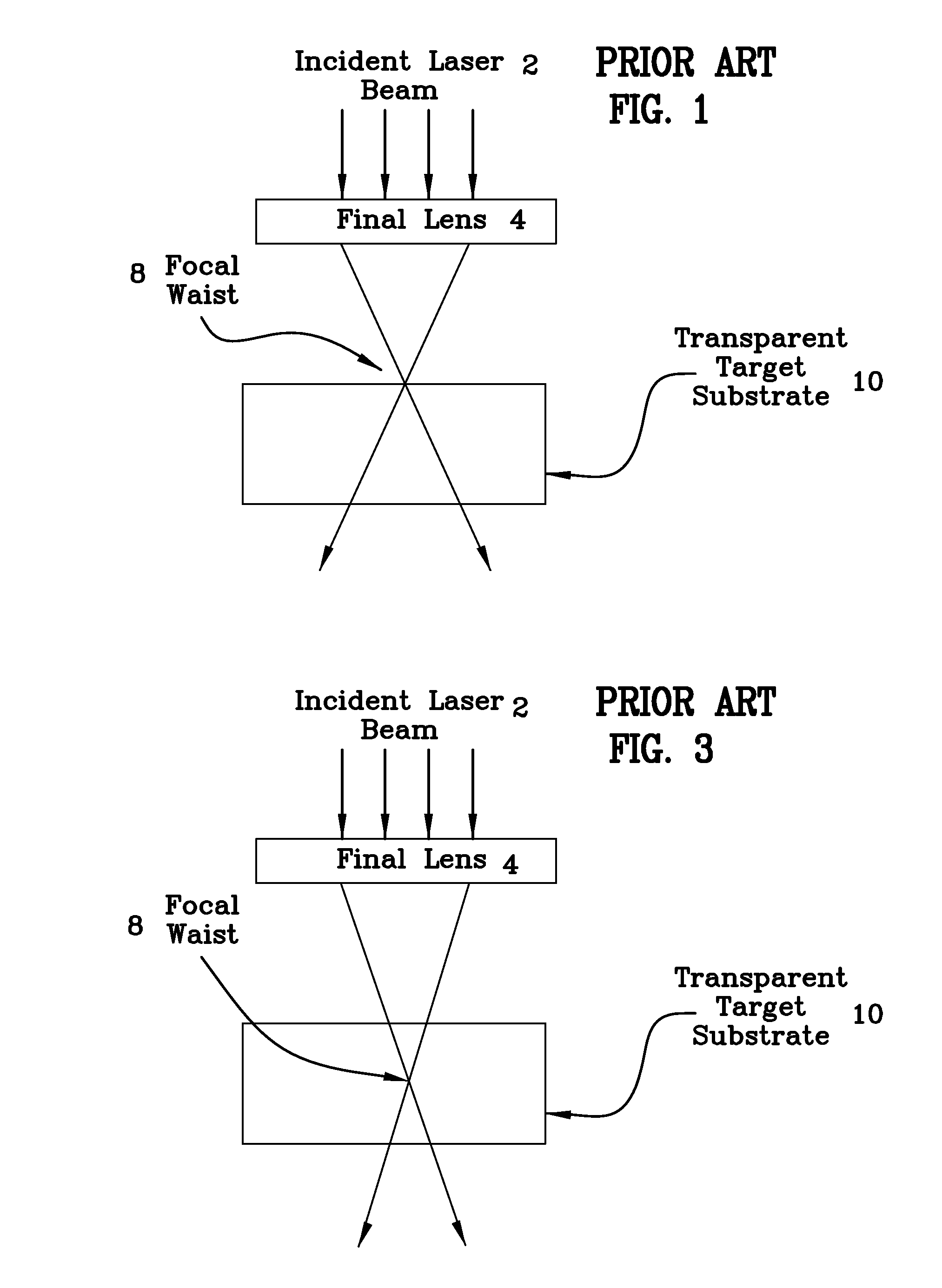

Transparent material processing with an ultrashort pulse laser

InactiveUS20100025387A1Reduce quality problemsPoor precisionSemiconductor/solid-state device manufacturingFine working devicesLight beamOptoelectronics

Methods, devices, and systems for ultrashort pulse laser processing of optically transparent materials are disclosed, with example applications in scribing, marking, welding, and joining. For example, ultrashort laser pulses create scribe features with one pass of the laser beam across the material, with at least one of the scribe features being formed below the surface of the material. Slightly modifying the ultrashort pulse laser processing conditions produces sub-surface marks. When properly arranged, these marks are clearly visible with correctly aligned illumination. Reflective marks may also be formed with control of laser parameters. A transparent material other than glass may be utilized. A method for welding transparent materials uses ultrashort laser pulses to create a bond through localized heating. In some embodiments of transparent material processing, a multifocus beam generator simultaneously forms multiple beam waists spaced depthwise relative to the transparent material, thereby increasing processing speed.

Owner:IMRA AMERICA

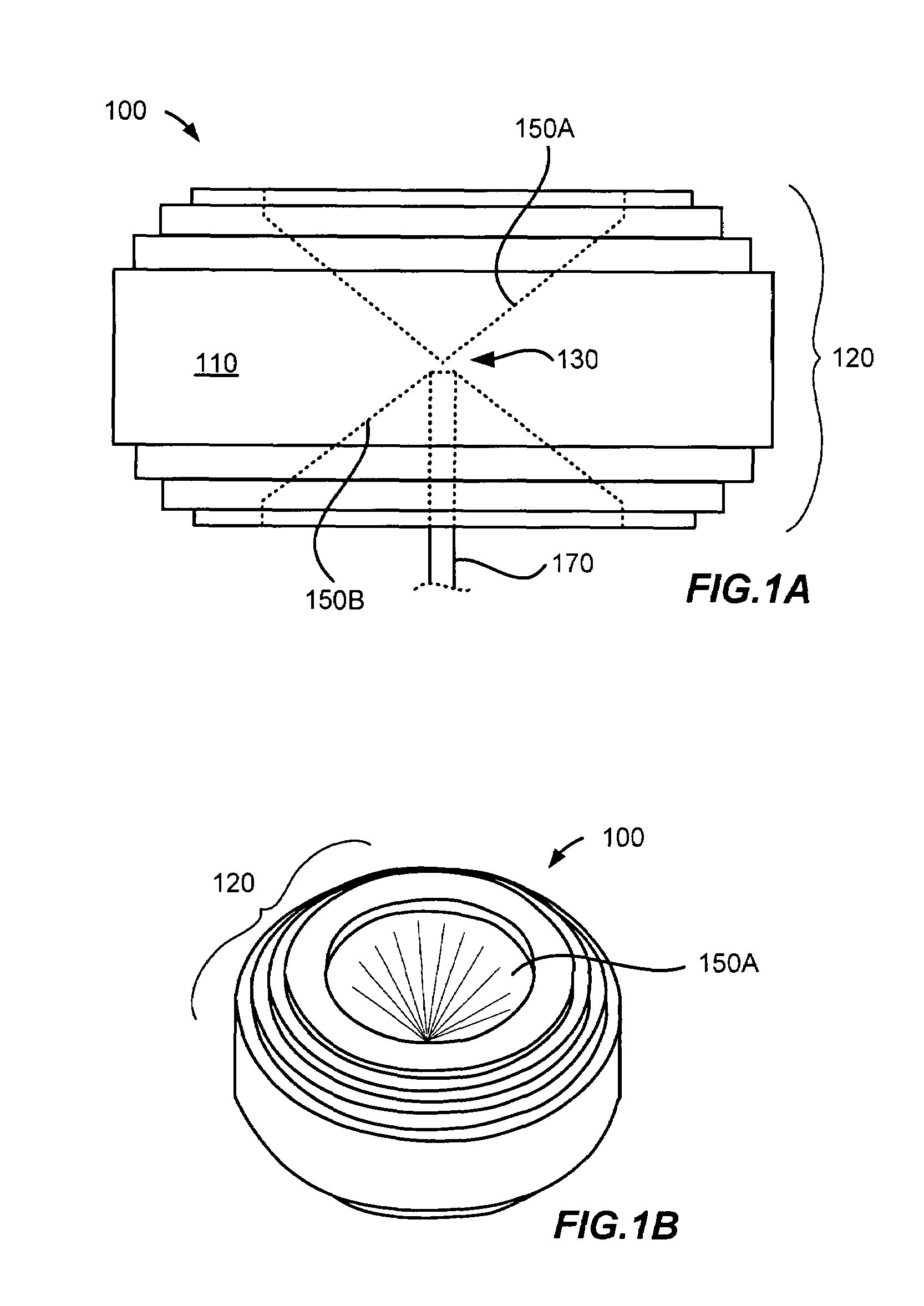

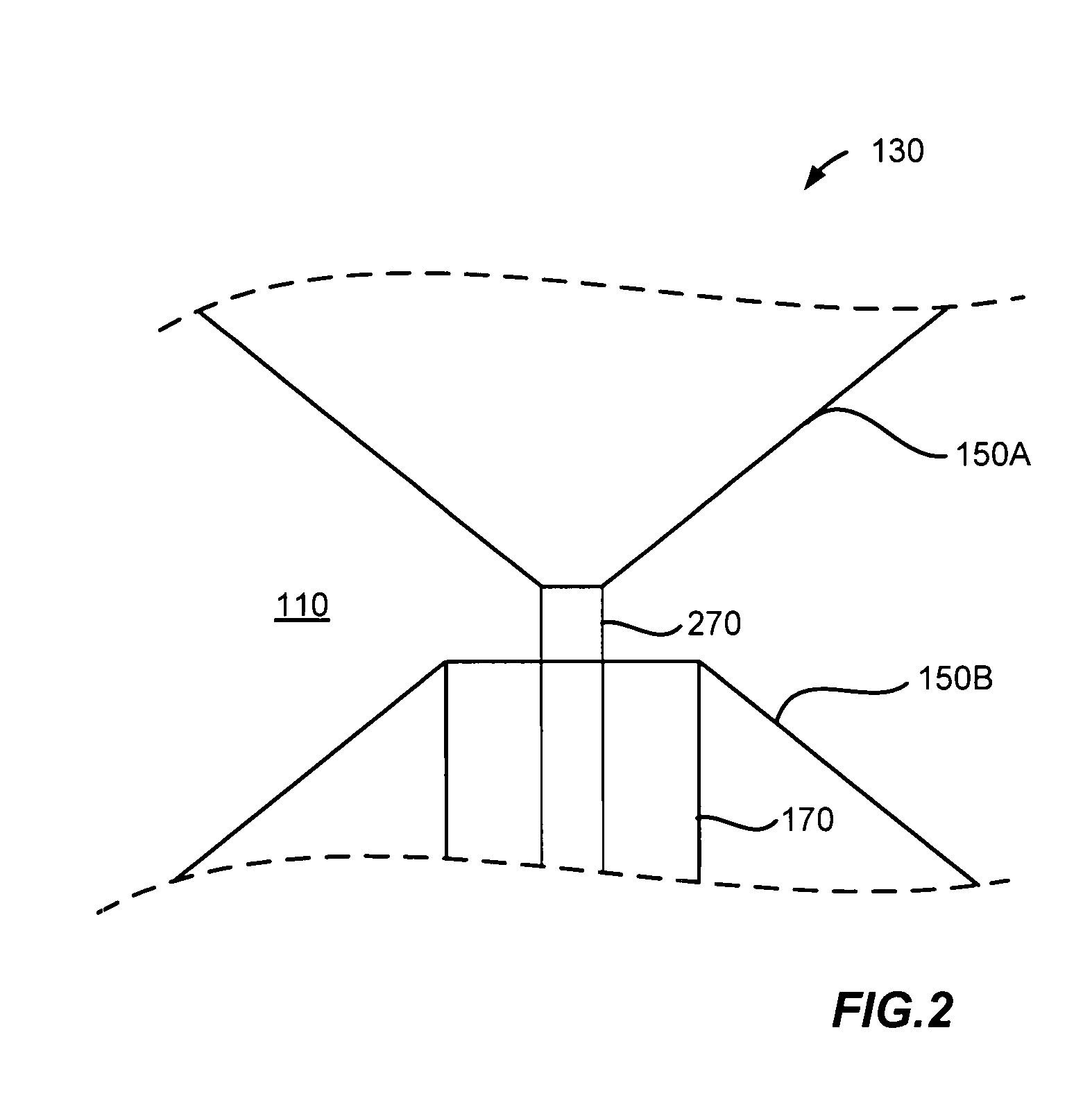

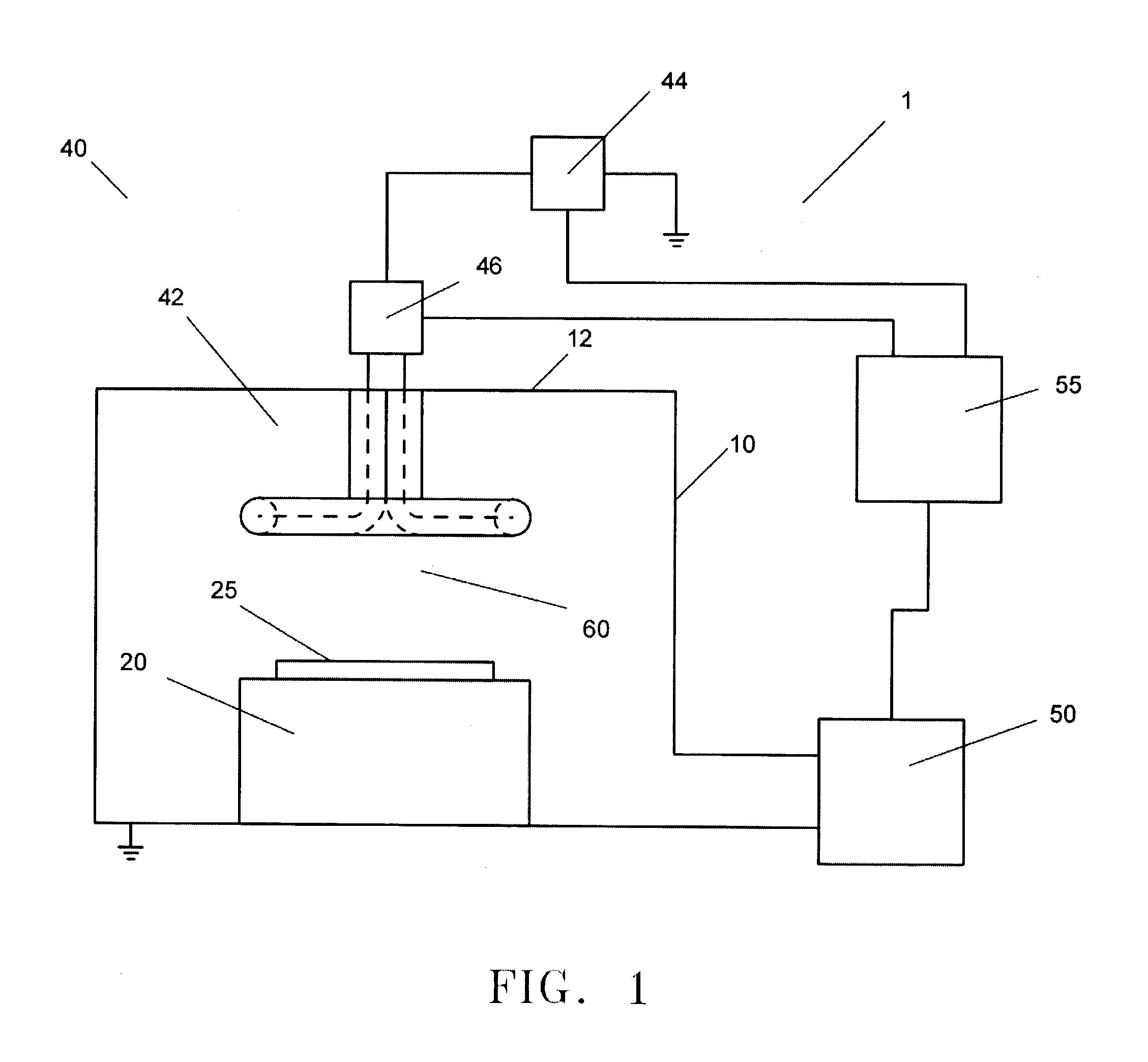

Bicone pattern shaping device

ActiveUS7525501B2Low costHigh gainAntenna feed intermediatesElectromagnetic radiationOmni directional

A broadband omni-directional bicone antenna. The antenna can comprise conductive surfaces of conical voids provided within a solid dielectric structure. The outside surface of the solid structure can support a radio frequency (RF) lens geometry operable for beam forming. The beam forming can modify the elevation pattern of the electromagnetic radiation from the bicone antenna. The solid dielectric structure may be machined or molded from a single piece of material. The conical voids provided within the solid structure can be metallized to provide conductive bicone radiators. The outer surface beam shaping lenses can be zoned or continuous and can provide elevation patterns with increased gain, cosecant squared falloff, or various other patterns. The beam shaping lens may be formed from any low-loss dielectric. Alternatively, the lens may be formed from a less dense material such as dielectric foam that can support radial conductive beam forming vanes.

Owner:EMS TECHNOLOGIES

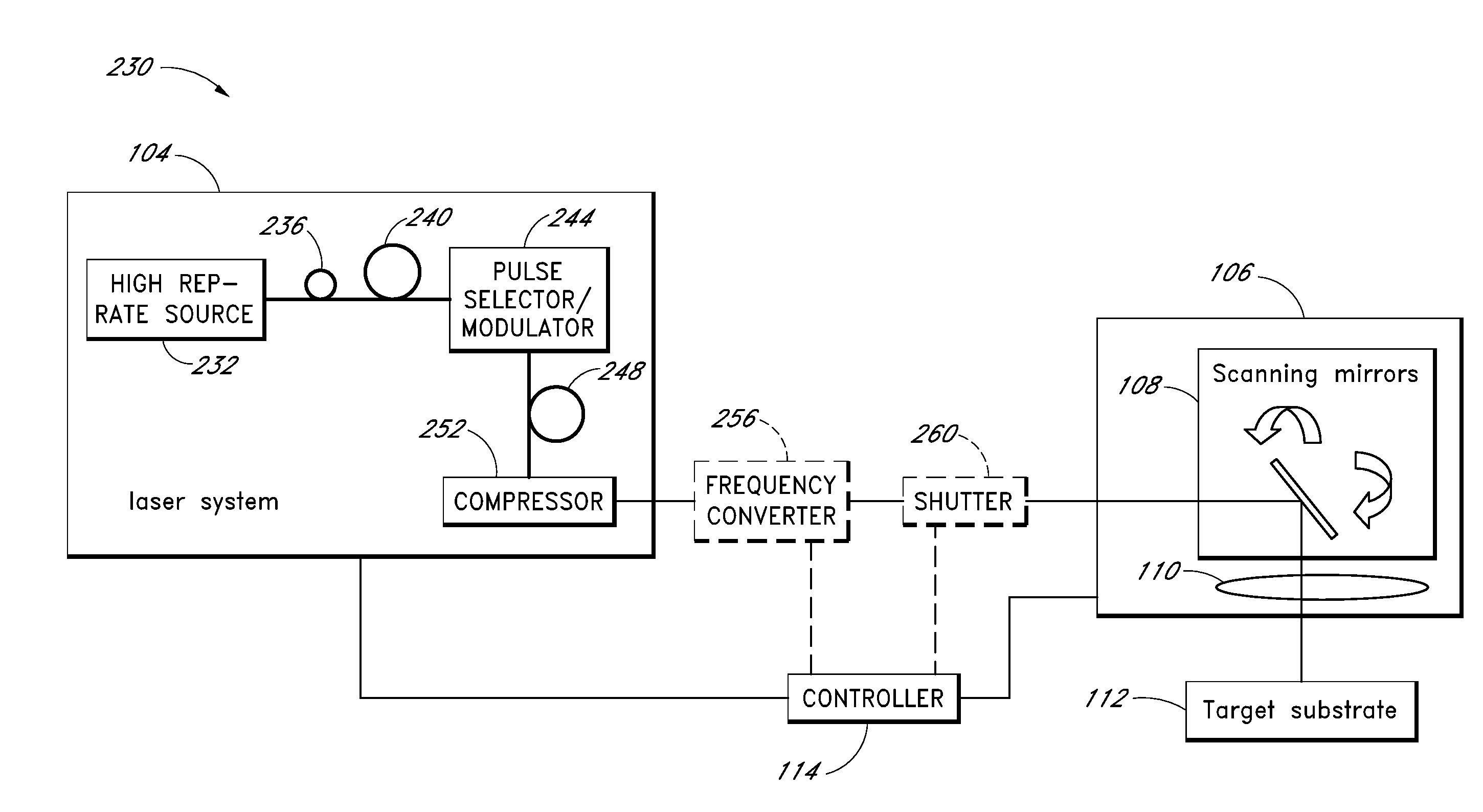

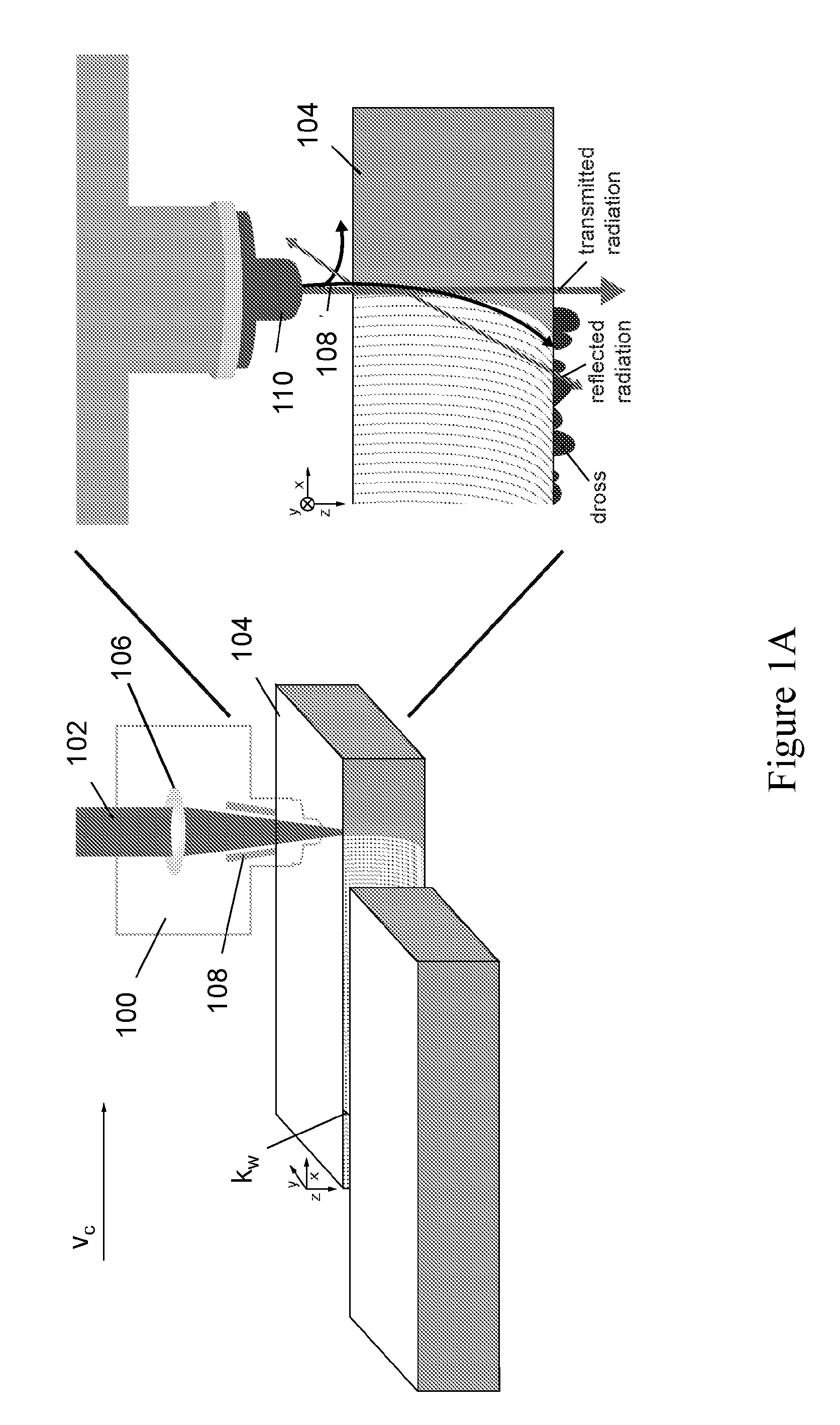

Laser-based material processing methods and systems

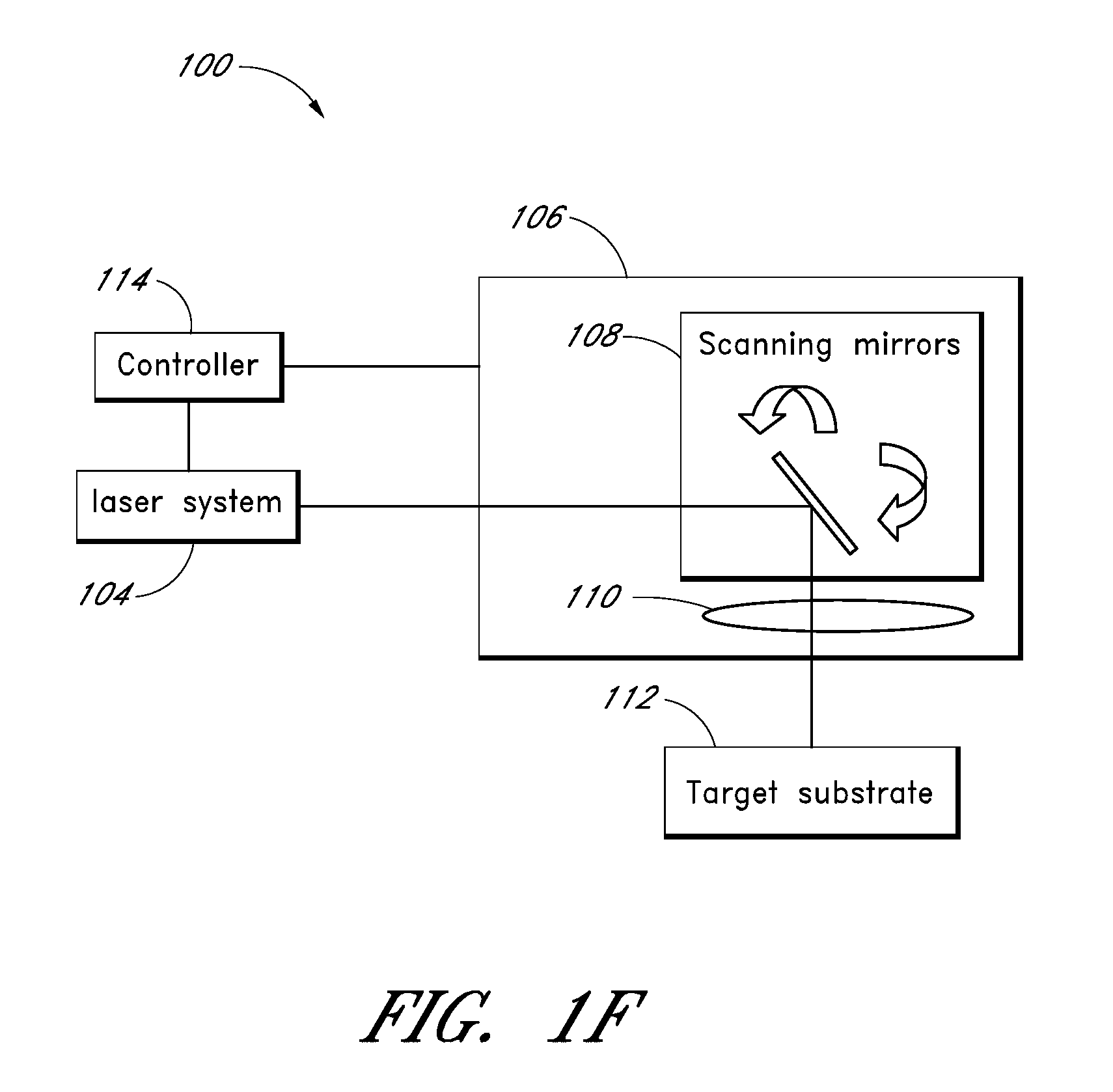

ActiveUS20100197116A1Efficient removalAvoid accumulationSemiconductor/solid-state device manufacturingWelding/soldering/cutting articlesDielectricMaterials processing

Various embodiments may be used for laser-based modification of target material of a workpiece while advantageously achieving improvements in processing throughput and / or quality. Embodiments of a method of processing may include focusing and directing laser pulses to a region of the workpiece at a pulse repetition rate sufficiently high so that material is efficiently removed from the region and a quantity of unwanted material within the region, proximate to the region, or both is reduced relative to a quantity obtainable at a lower repetition rate. In at least one embodiment, an ultrashort pulse laser system may include at least one of a fiber amplifier or fiber laser. Various embodiments are suitable for at least one of dicing, cutting, scribing, and forming features on or within a semiconductor substrate. Workpiece materials may also include metals, inorganic or organic dielectrics, or any material to be micromachined with femtosecond and / or picosecond pulses, and in some embodiments with pulse widths up to a few nanoseconds.

Owner:IMRA AMERICA

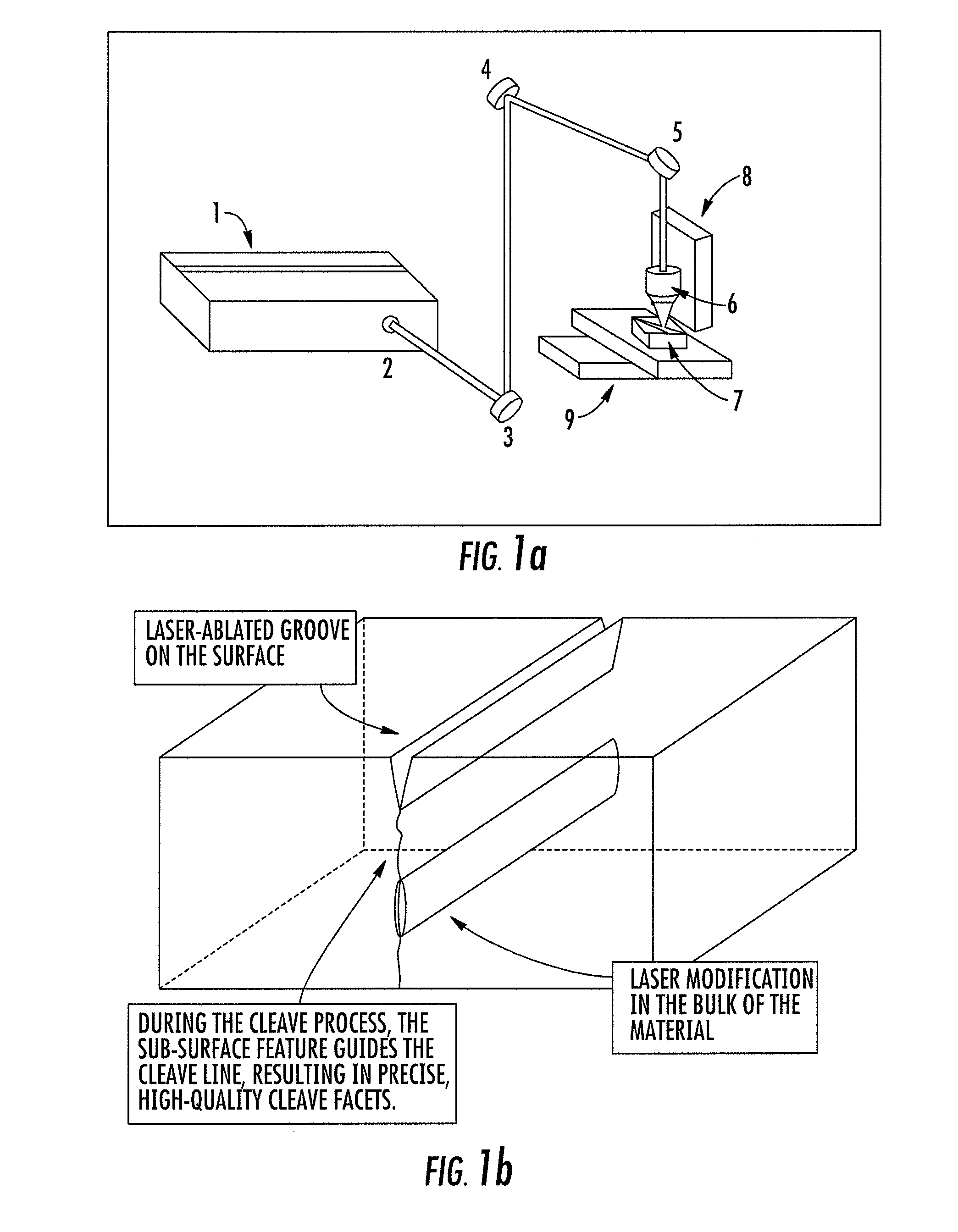

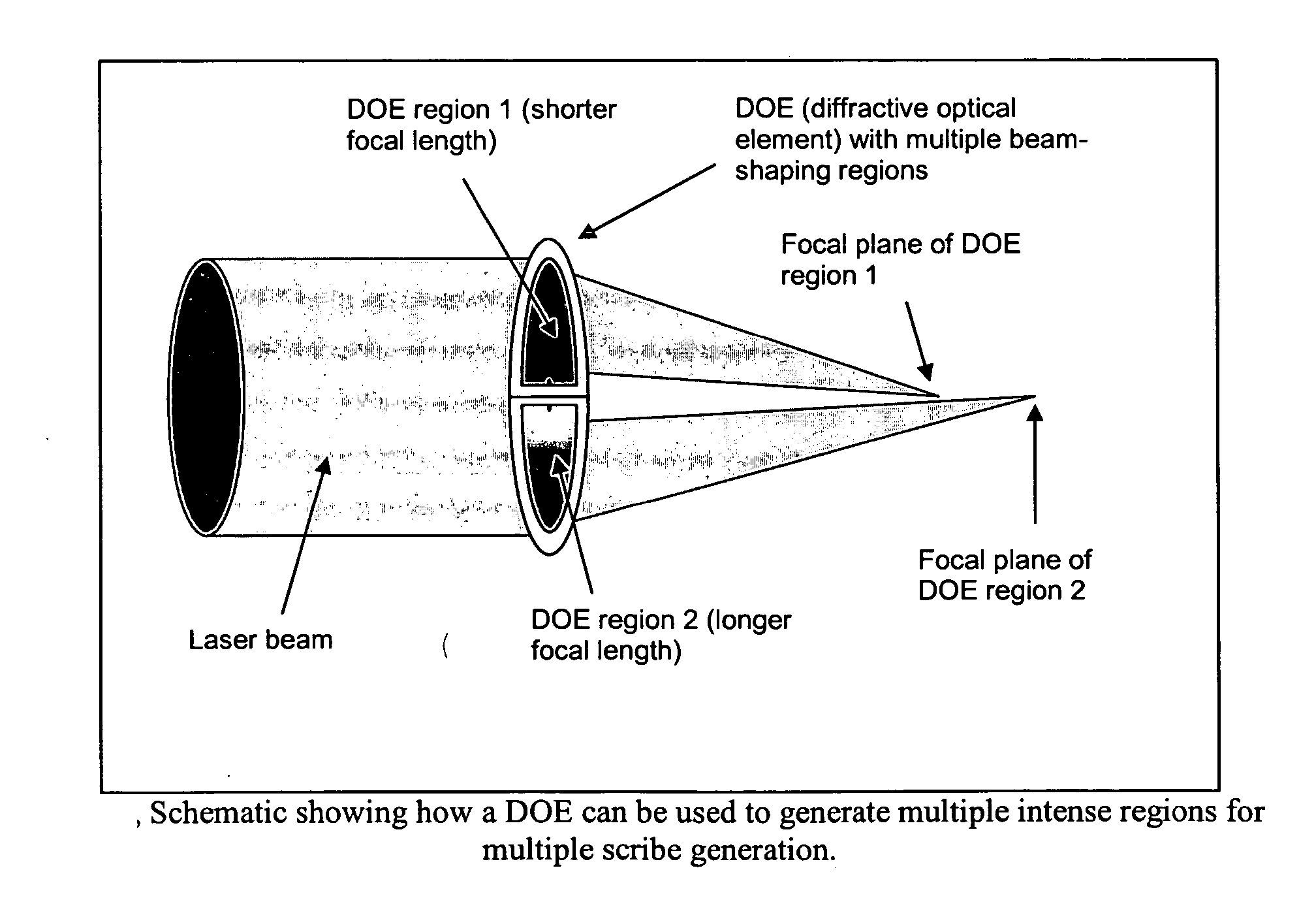

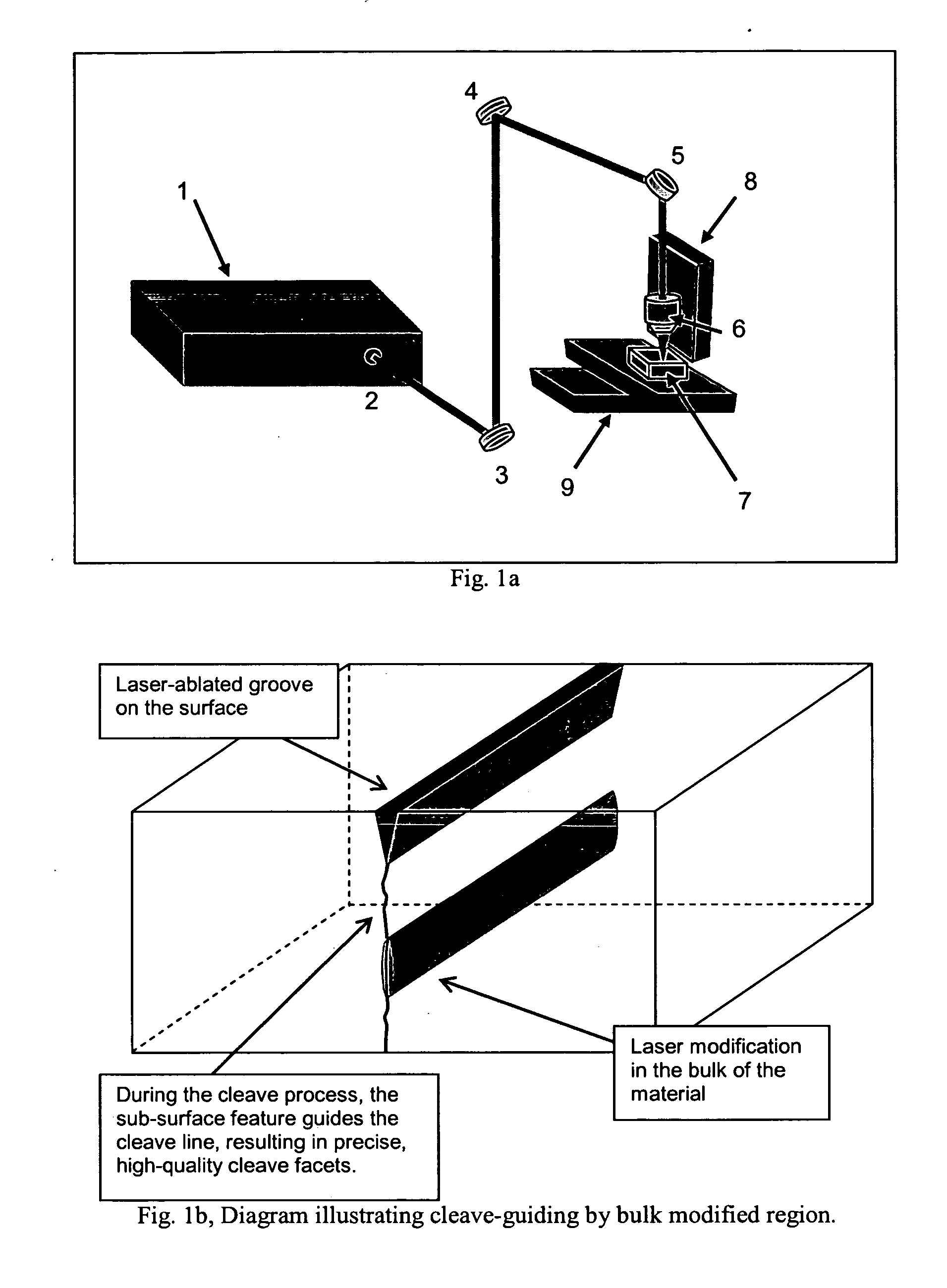

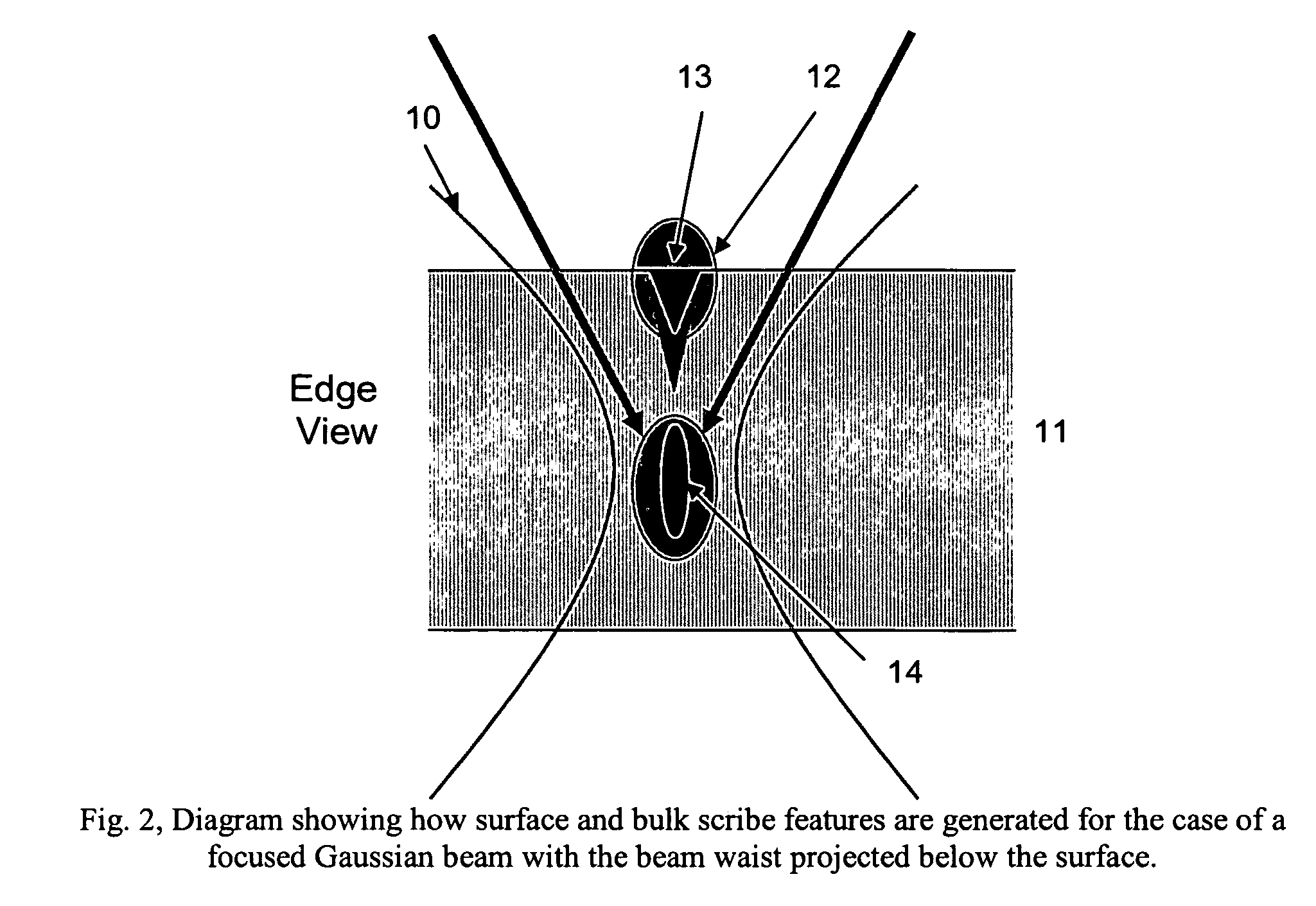

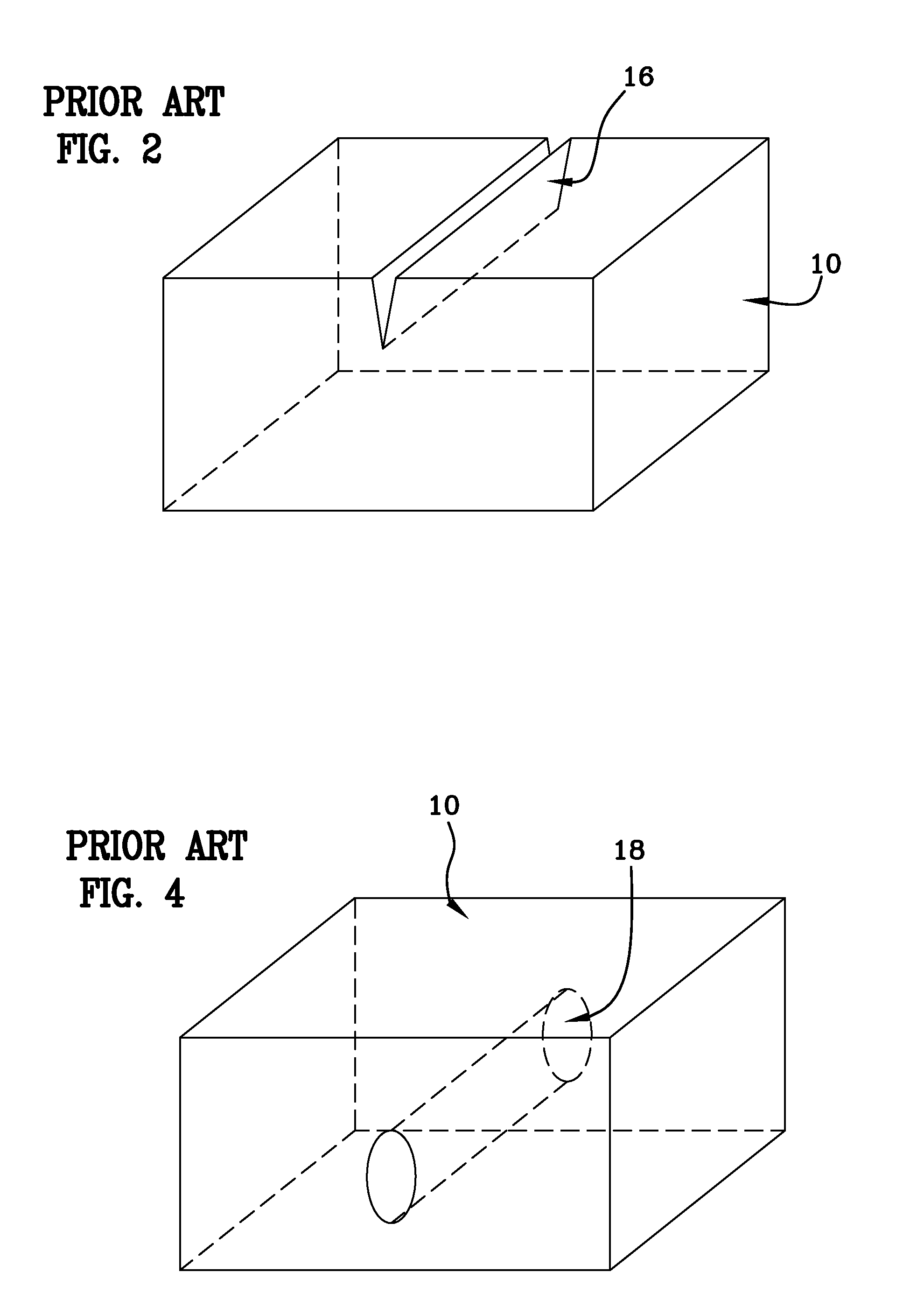

Transparent material processing with an ultrashort pulse laser

InactiveUS20070051706A1Reduce quality problemsPoor precisionFixed microstructural devicesThin material handlingHigh energyNonlinear absorption

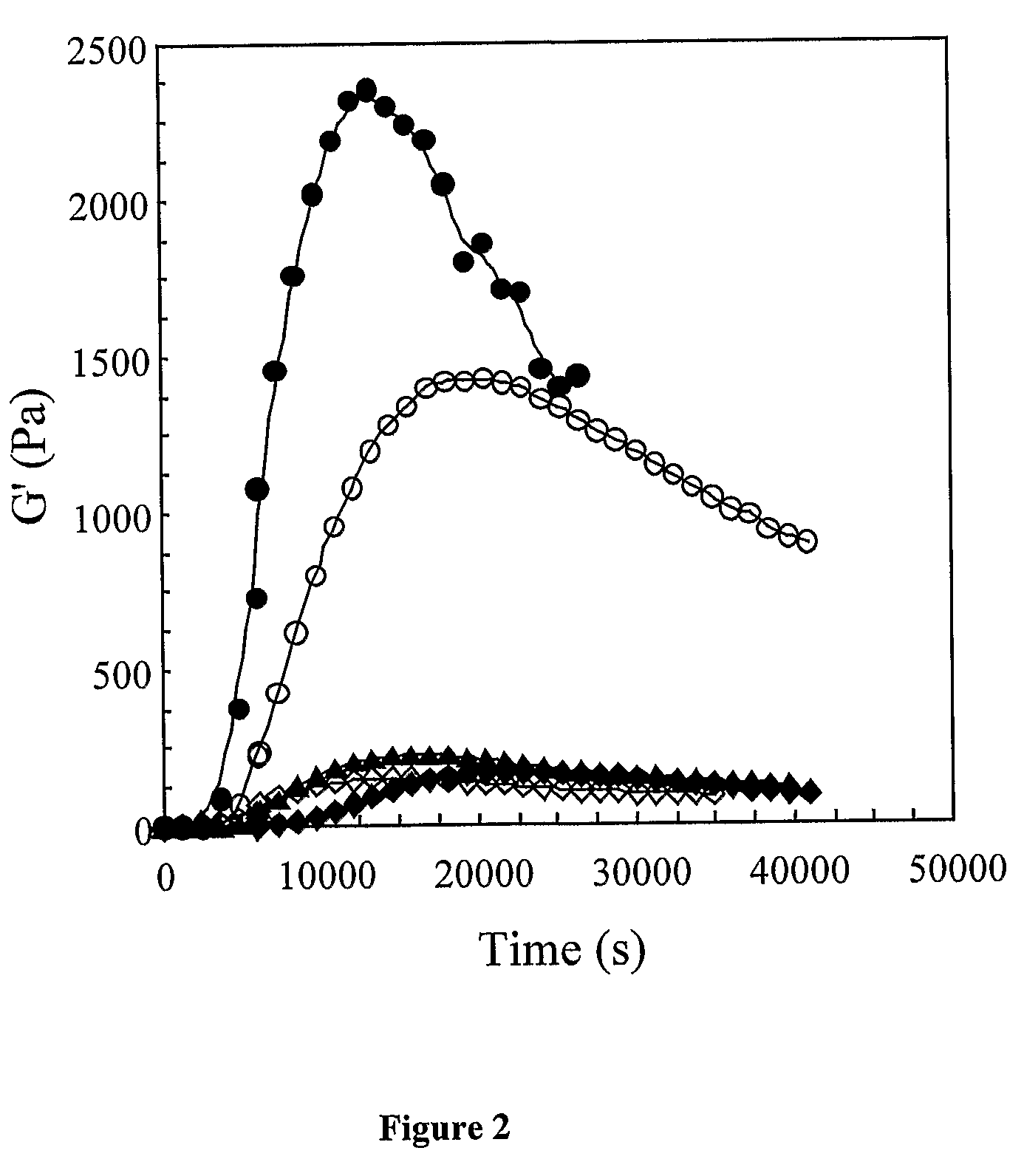

Methods for ultrashort pulse laser processing of optically transparent materials. A method for scribing transparent materials uses ultrashort laser pulses to create multiple scribe features with a single pass of the laser beam across the material, with at least one of the scribe features being formed below the surface of the material. This enables clean breaking of transparent materials at a higher speed than conventional techniques. Slightly modifying the ultrashort pulse laser processing conditions produces sub-surface marks. When properly arranged, these marks are clearly visible with side-illumination and not clearly visible without side-illumination. In addition, a method for welding transparent materials uses ultrashort laser pulses to create a bond through localized heating. The ultrashort pulse duration causes nonlinear absorption of the laser radiation, and the high repetition rate of the laser causes pulse-to-pulse accumulation of heat within the materials. The laser is focused near the interface of the materials, generating a high energy fluence at the region to be welded. This minimizes damage to the rest of the material and enables fine weld lines.

Owner:IMRA AMERICA

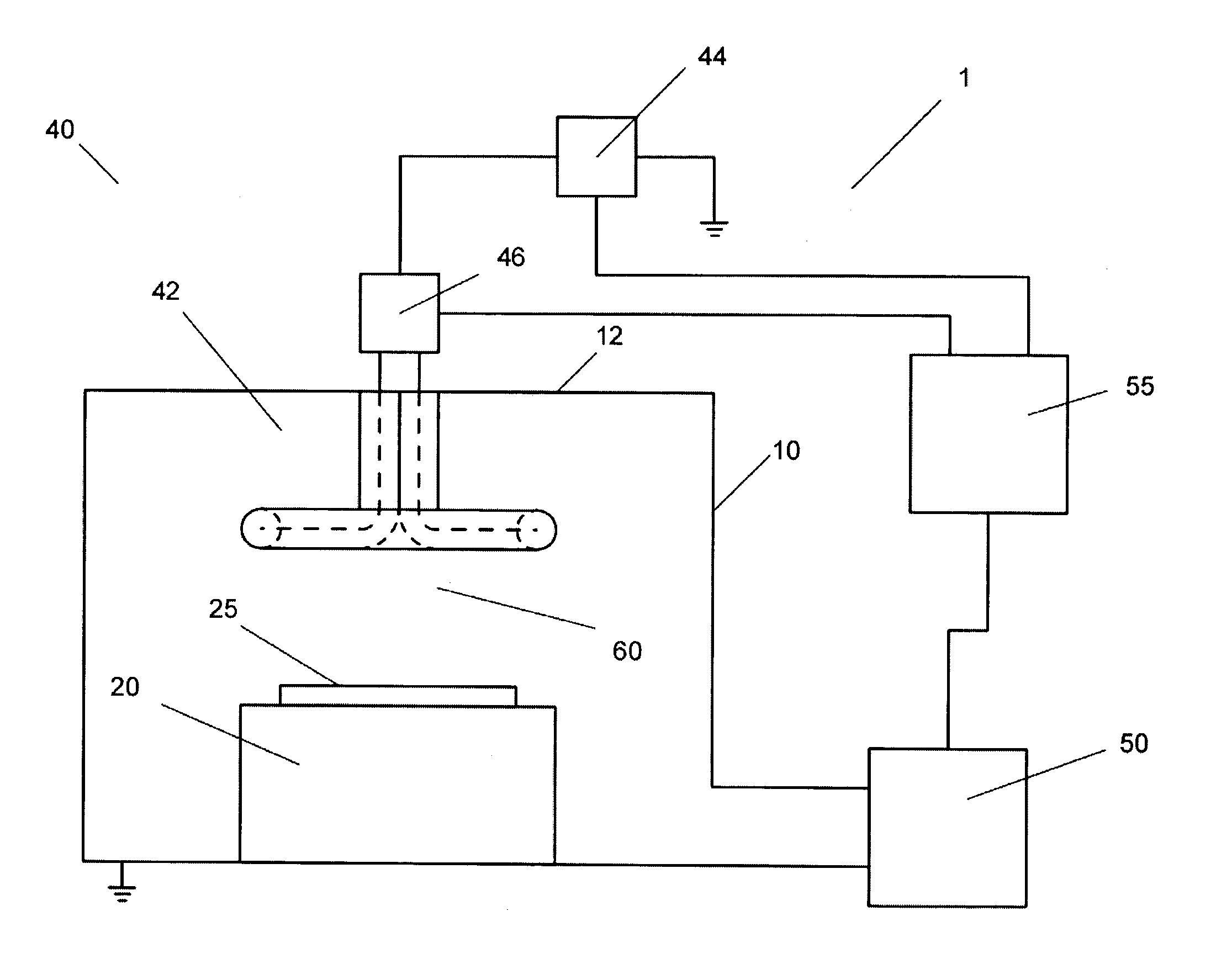

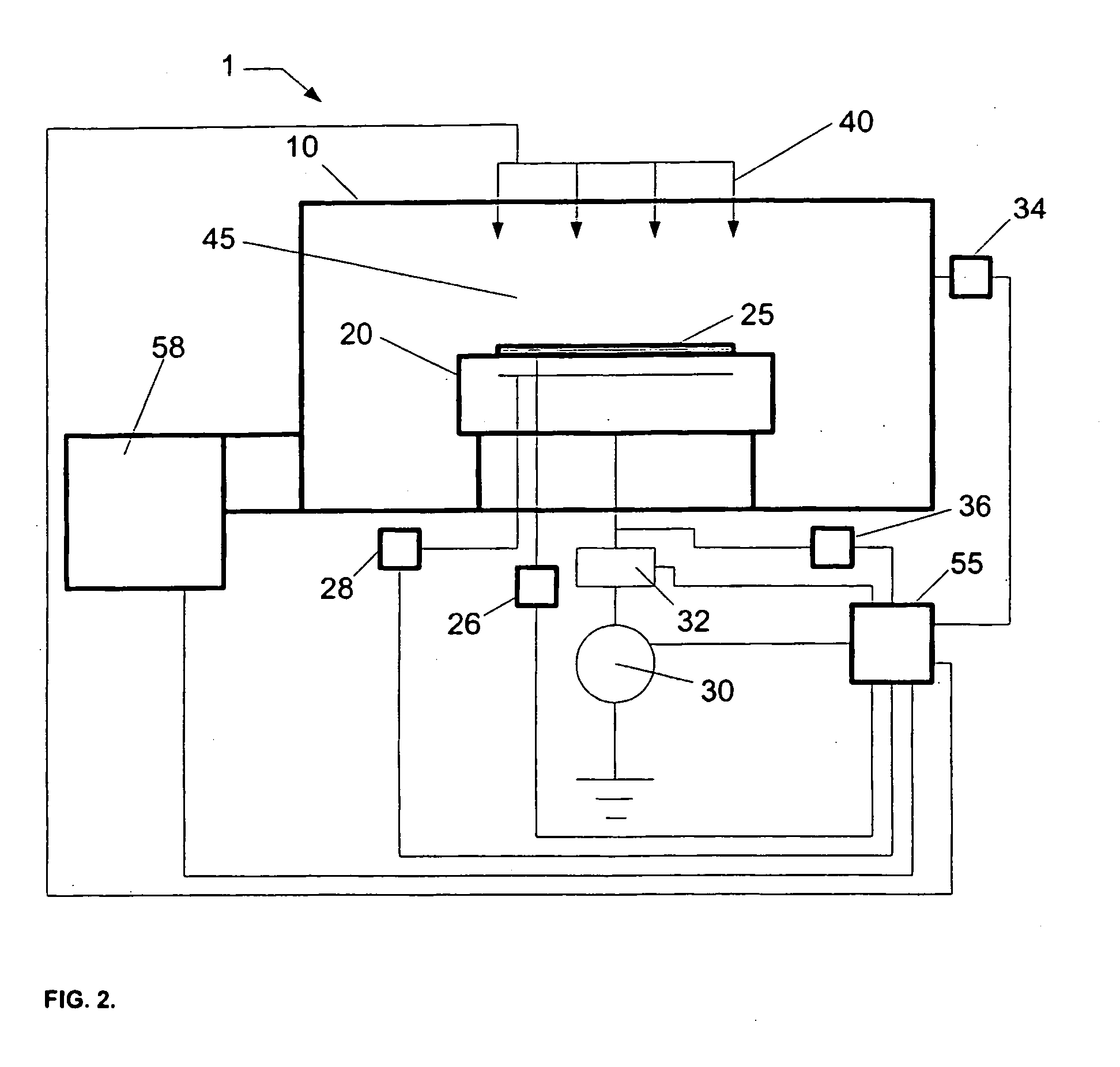

Inductively coupled plasma source for improved process uniformity

InactiveUS20030087488A1Electric discharge tubesSemiconductor/solid-state device manufacturingElectrical conductorEngineering

An improved apparatus for material processing, wherein the improved apparatus including a plasma processing system to process a substrate, the plasma processing system including a process chamber, a substrate holder, and a plasma source. The plasma source further includes an inductive coil assembly for inductively coupling RF power to plasma wherein the inductive coil assembly is arranged within a process chamber. The inductive coil assembly includes an inner conductor, a slotted outer conductor, and a dielectric layer. The inductive coil assembly can further include a second dielectric layer in order to protect the slotted outer conductor from plasma. The inner conductor is surrounded by the slotted outer conductor and, between which, resides the first dielectric layer. The second dielectric layer encapsulates the inner conductor, first dielectric layer and the slotted outer conductor.

Owner:TOKYO ELECTRON LTD

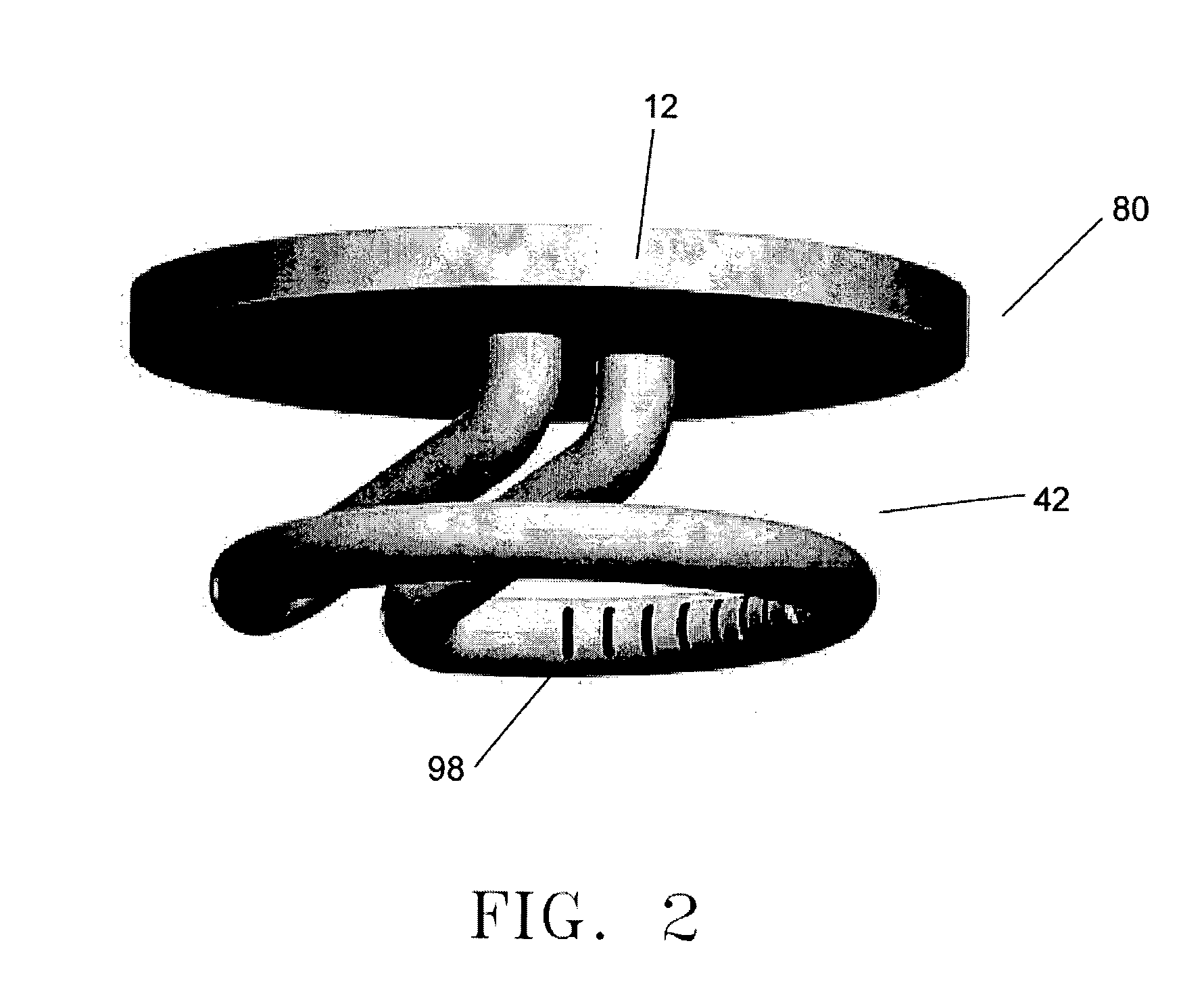

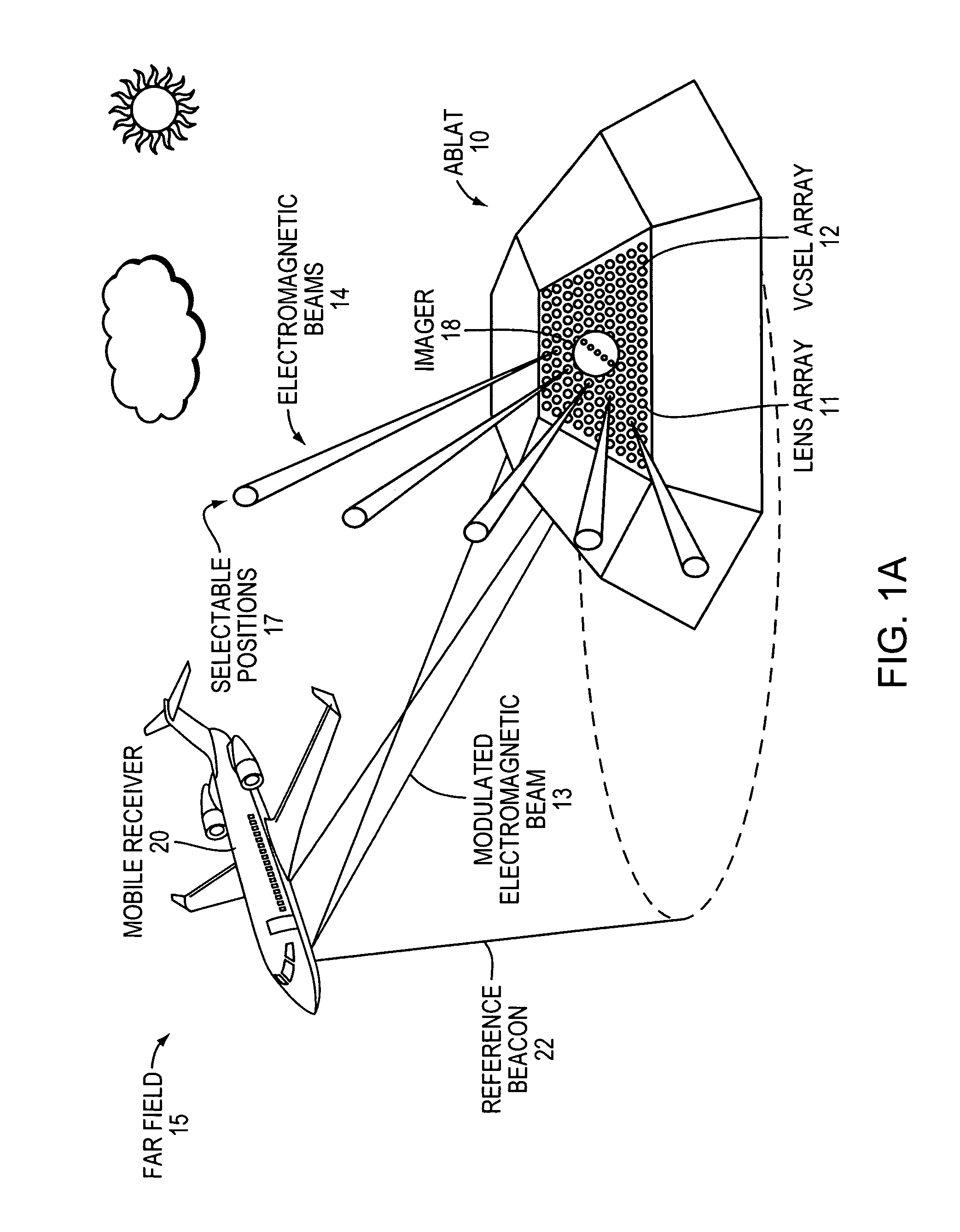

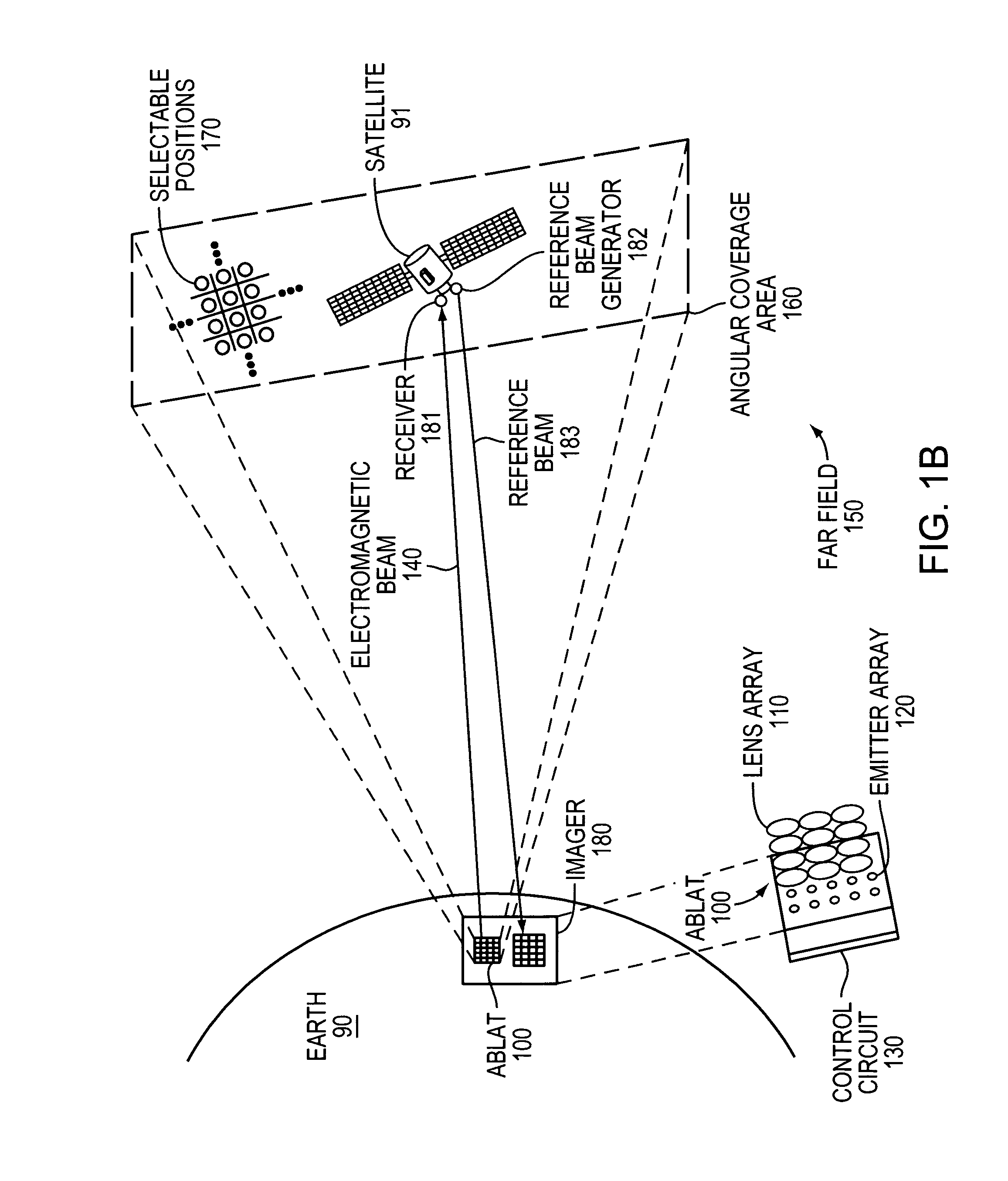

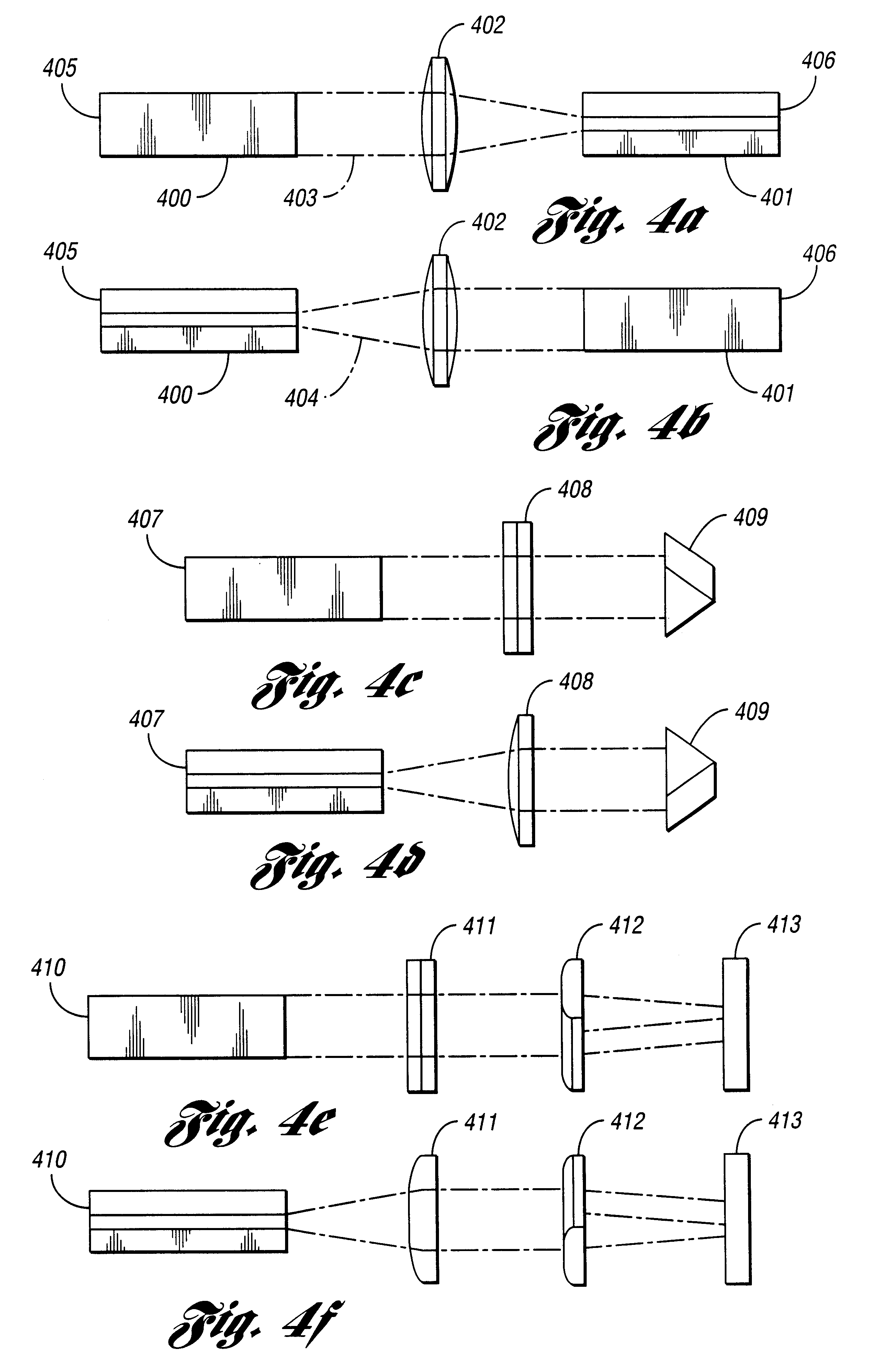

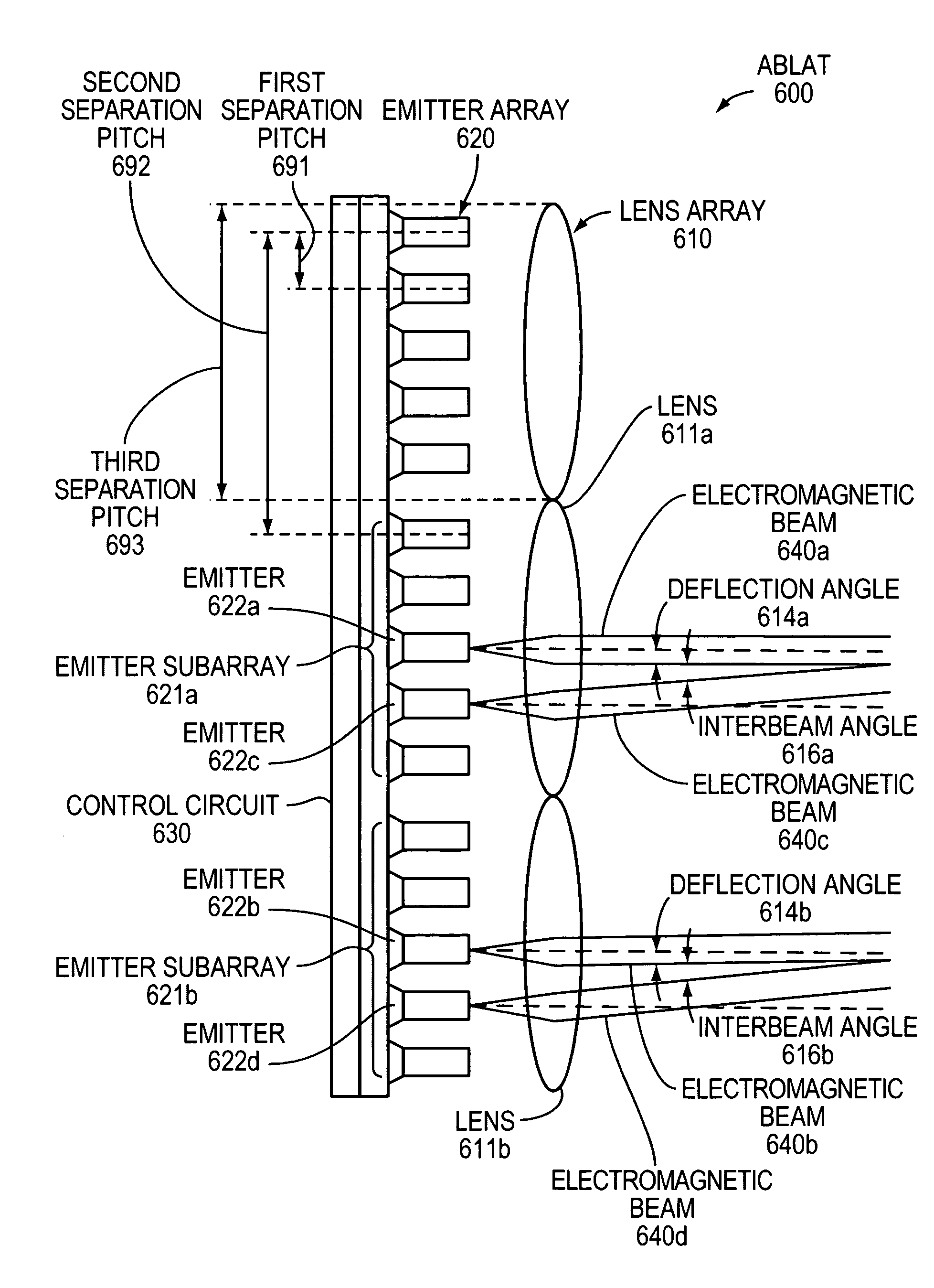

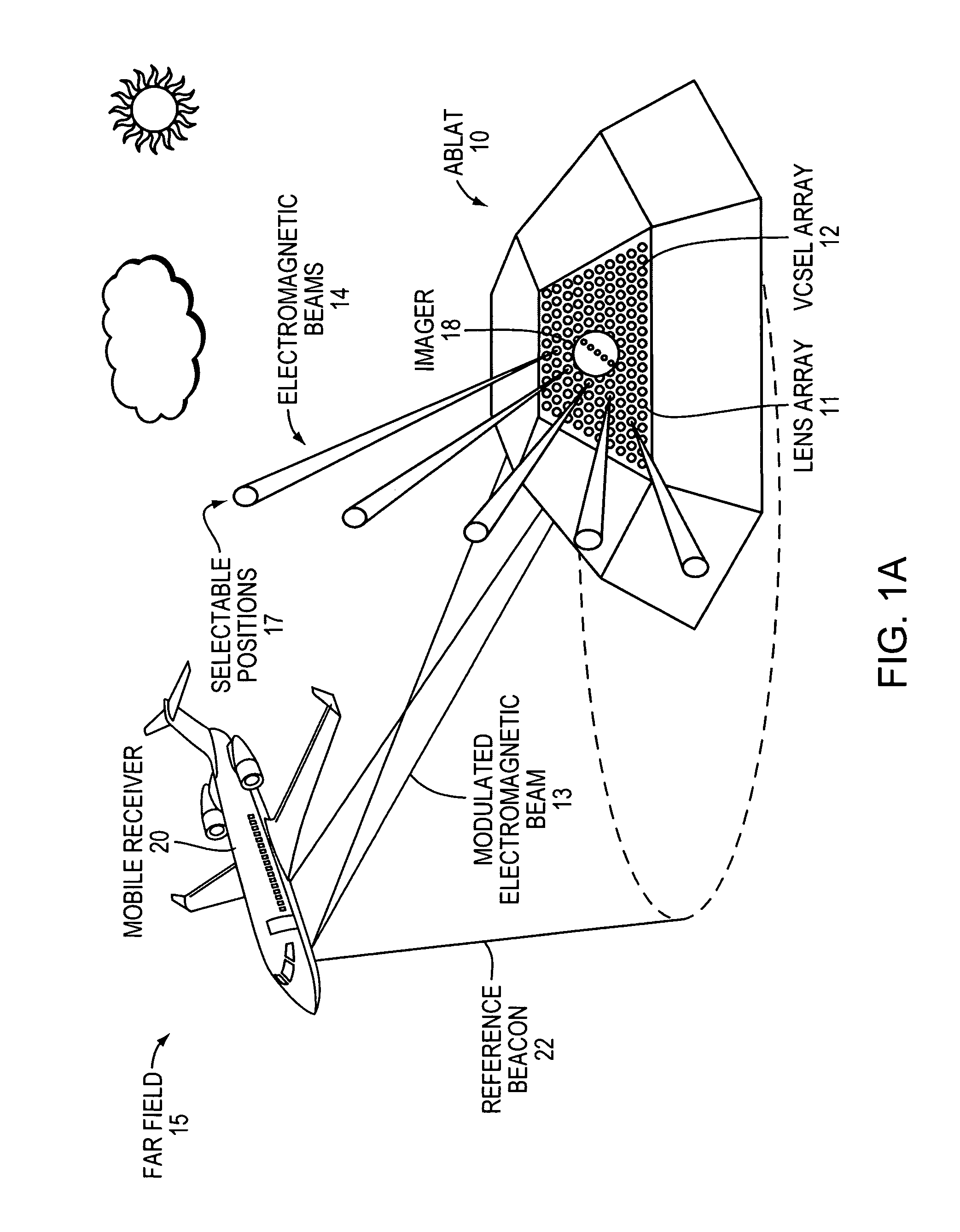

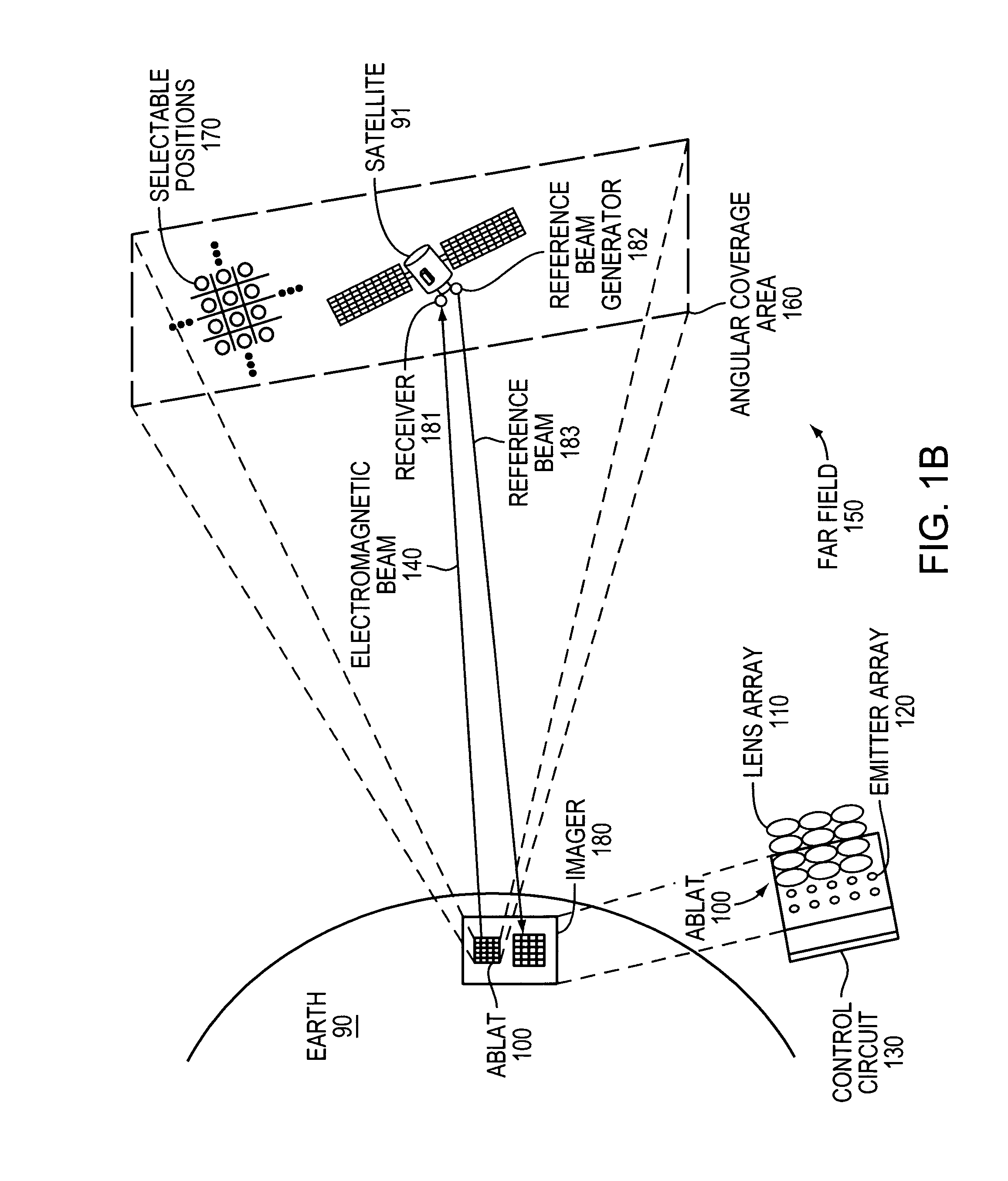

Agile-beam laser array transmitter

ActiveUS8301027B2Turn fasterWave based measurement systemsWavelength-division multiplex systemsLaser arrayBeam steering

An Agile-Beam Laser Array Transmitter (ABLAT) uses an array of emitters and an array of lenses to project electromagnetic beams over a wide angular coverage area in the far field. Differences in the separation pitches of the two arrays allows the ABLAT to project beams to contiguous and / or overlapping positions, depending on the ratio of the separation pitches and the lens focal length. Compared to other beam steering technology, the ABLAT is a smaller, lighter, and more efficient means of projecting beams over wider angular coverage areas. Various embodiments can be used in any beam steering application, including, but not limited to: free-space optical communications; light detection and ranging (lidar); optical scanning (e.g., retinal or bar-code scanning); display projection; image capture; optical character recognition; scanning laser microscopy; non-destructive testing; printing; facsimiles; map making; web inspection; color print processing; phototypesetting and platemaking; laser marking; material processing; DNA analysis; and drug discovery.

Owner:MASSACHUSETTS INST OF TECH

Method for closed-loop controlling a laser processing operation and laser material processing head using the same

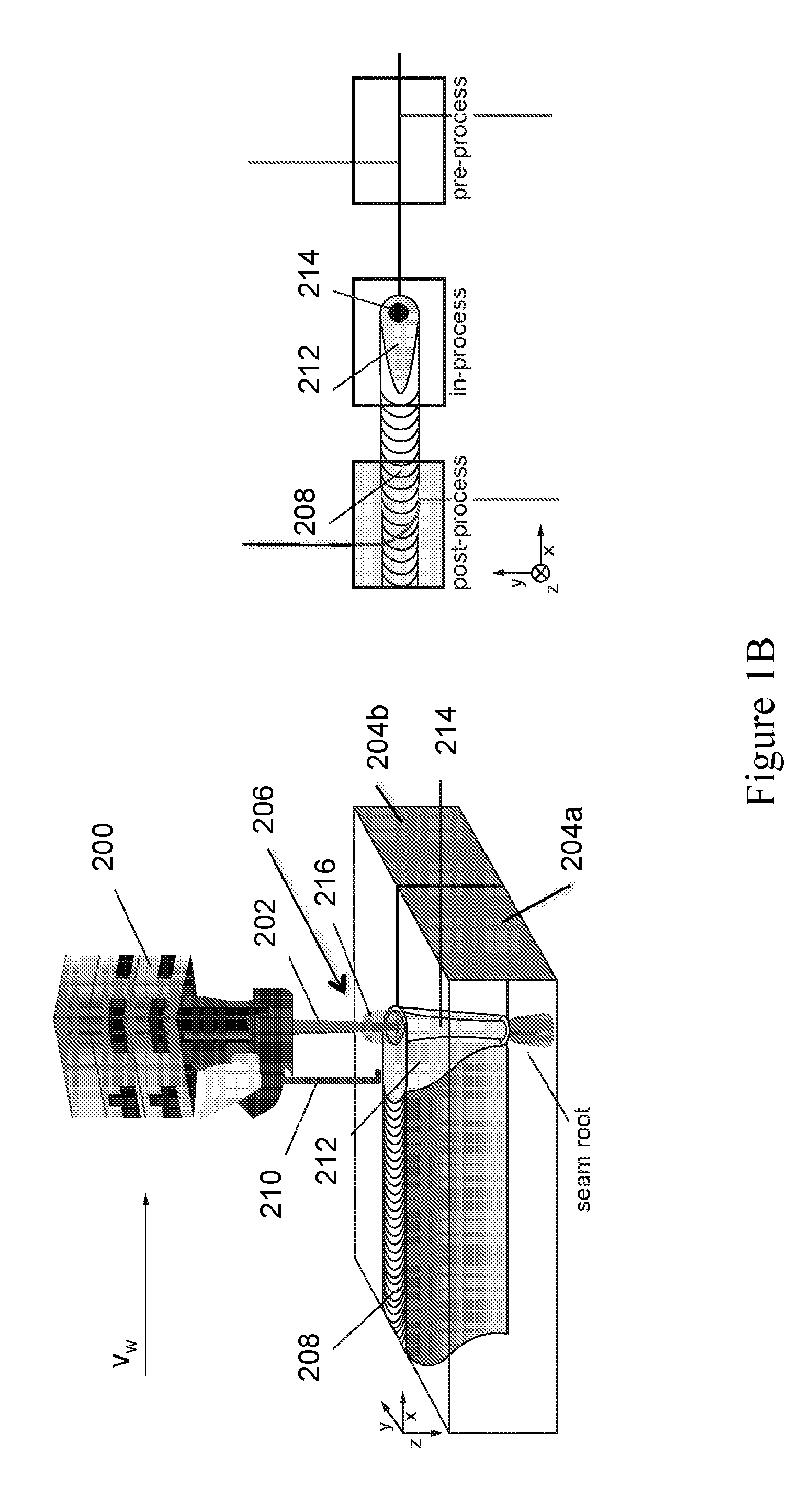

ActiveUS20130178952A1Reliable detectionSimilar levelImage analysisSoldering apparatusLaser processingAlgorithm

The present invention relates to a method for closed-loop controlling a processing operation of a workpiece, comprising the steps of: (a) recording a pixel image at an initial time point of an interaction zone by means of a camera, wherein the workpiece is processed using an actuator having an initial actuator value; (b) converting the pixel image into a pixel vector; (c) representing the pixel vector by a sum of predetermined pixel mappings each multiplied by a corresponding feature value; (d) classifying the set of feature values on the basis of learned feature values into at least two classes of a group of classes comprising a first class of a too high actuator value, a second class of a sufficient actuator value and a third class of a too low actuator value at the initial time point; (e) performing a control step for adapting the actuator value by minimizing the error et between a quality indicator ye and a desired value; and (f) repeating the steps (a) to (e) for further time points to perform a closed-loop controlled processing operation.

Owner:PRECITEC GMBH +1

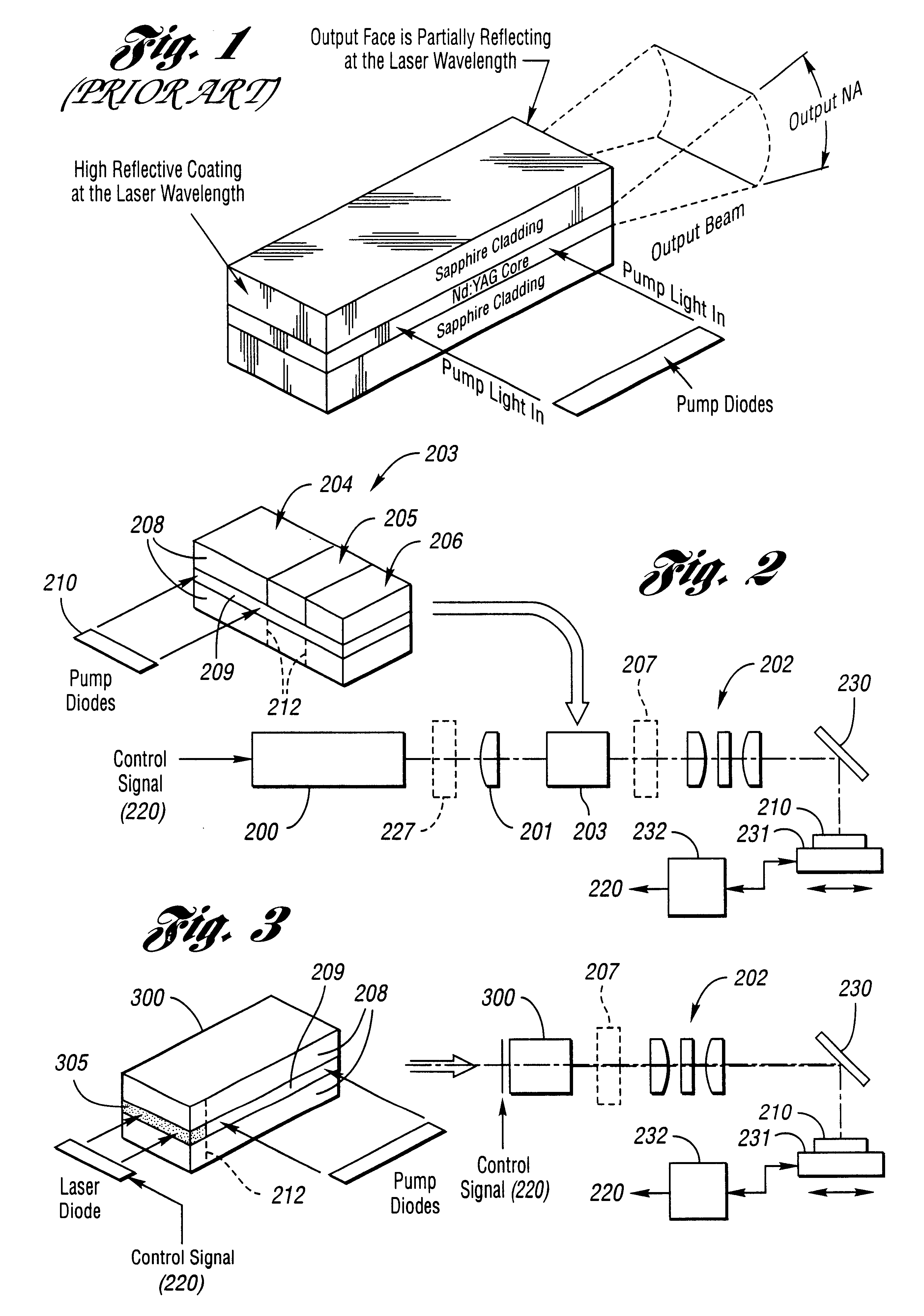

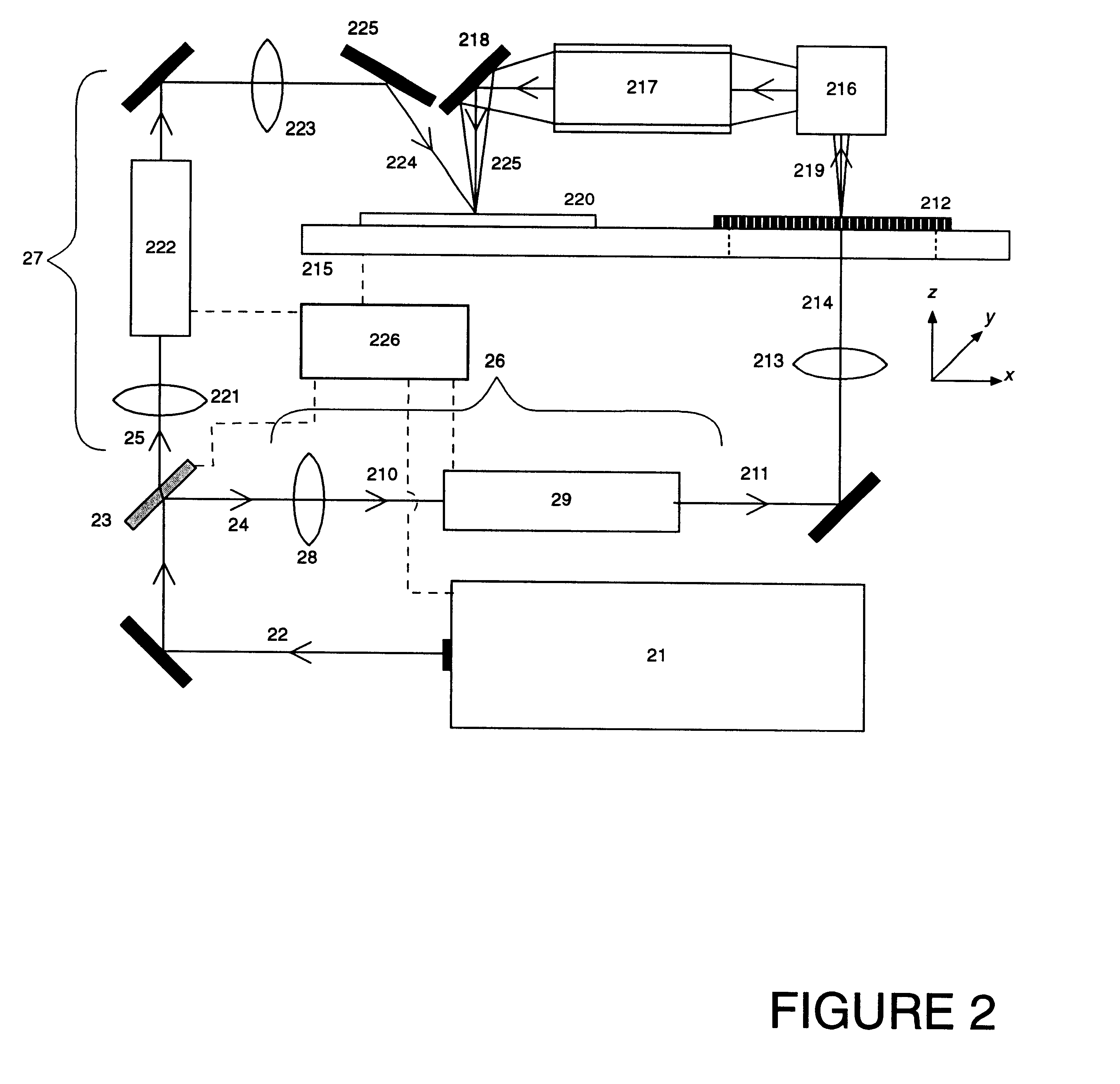

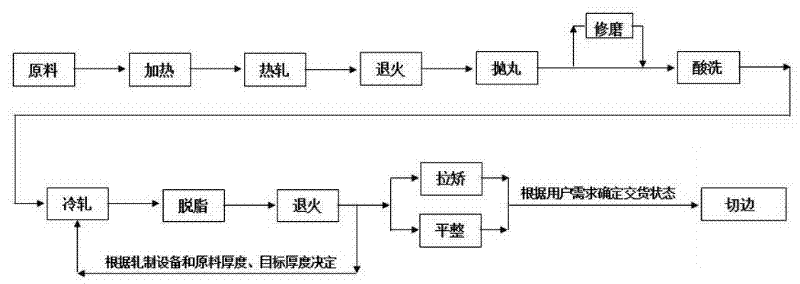

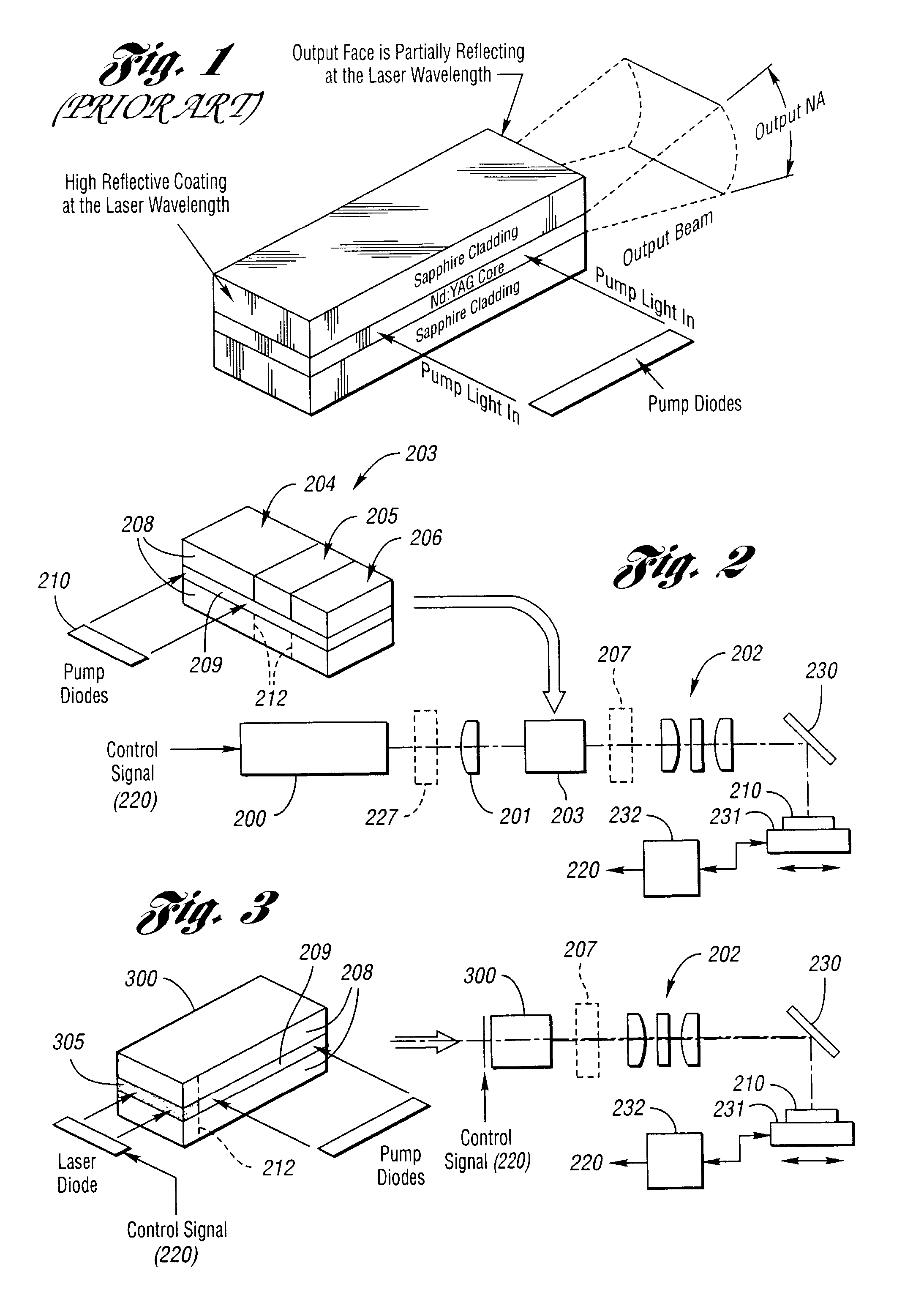

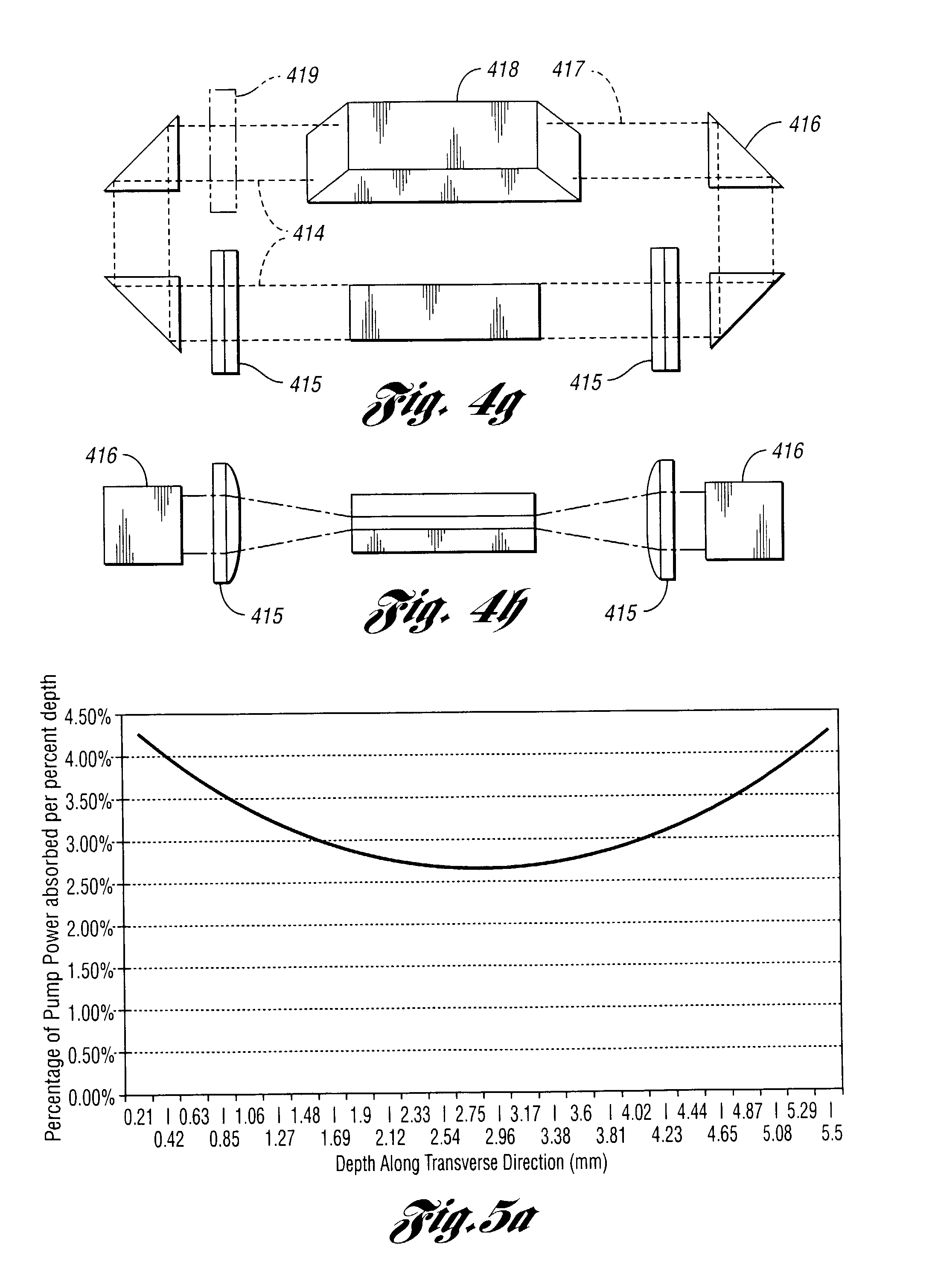

Laser based material processing methods and scalable architecture for material processing

InactiveUS6738396B2Improve stabilityLaser using scattering effectsOptical resonator shape and constructionPower applicationNanosecond

Methods and systems for laser-based processing of materials are disclosed wherein a scalable laser architecture, based on planar waveguide technology, provides for pulsed laser micromachining applications while supporting higher average power applications like laser welding and cutting. Various embodiments relate to improvements in planar waveguide technology which provide for stable operation at high powers with a reduction in spurious outputs and thermal effects. At least one embodiment provides for micromachining with pulsewidths in the range of femtoseconds to nanoseconds. In another embodiment, 100W or greater average output power operation is provided for with a diode-pumped, planar waveguide architecture.

Owner:THE GSI GRP LLC

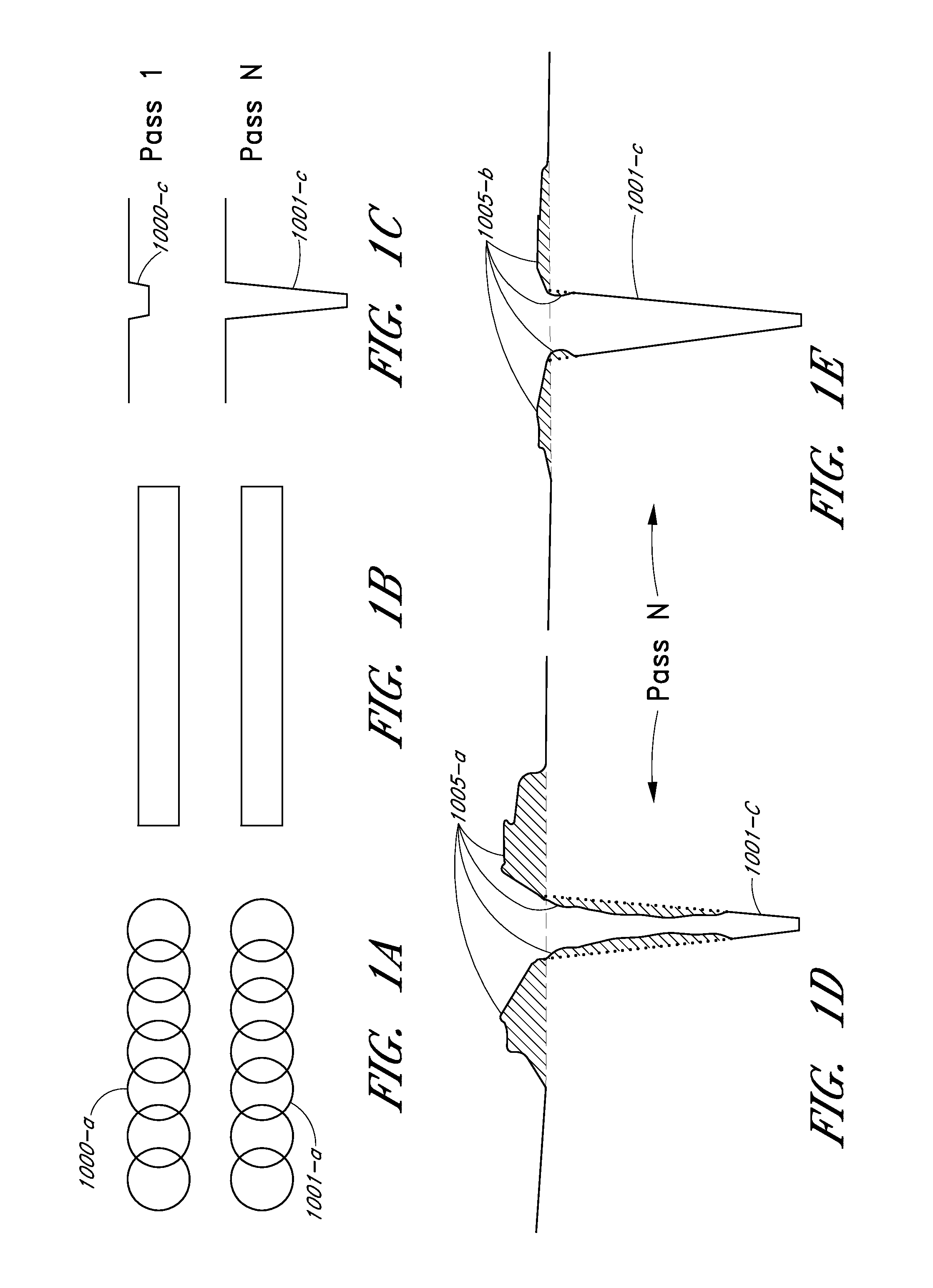

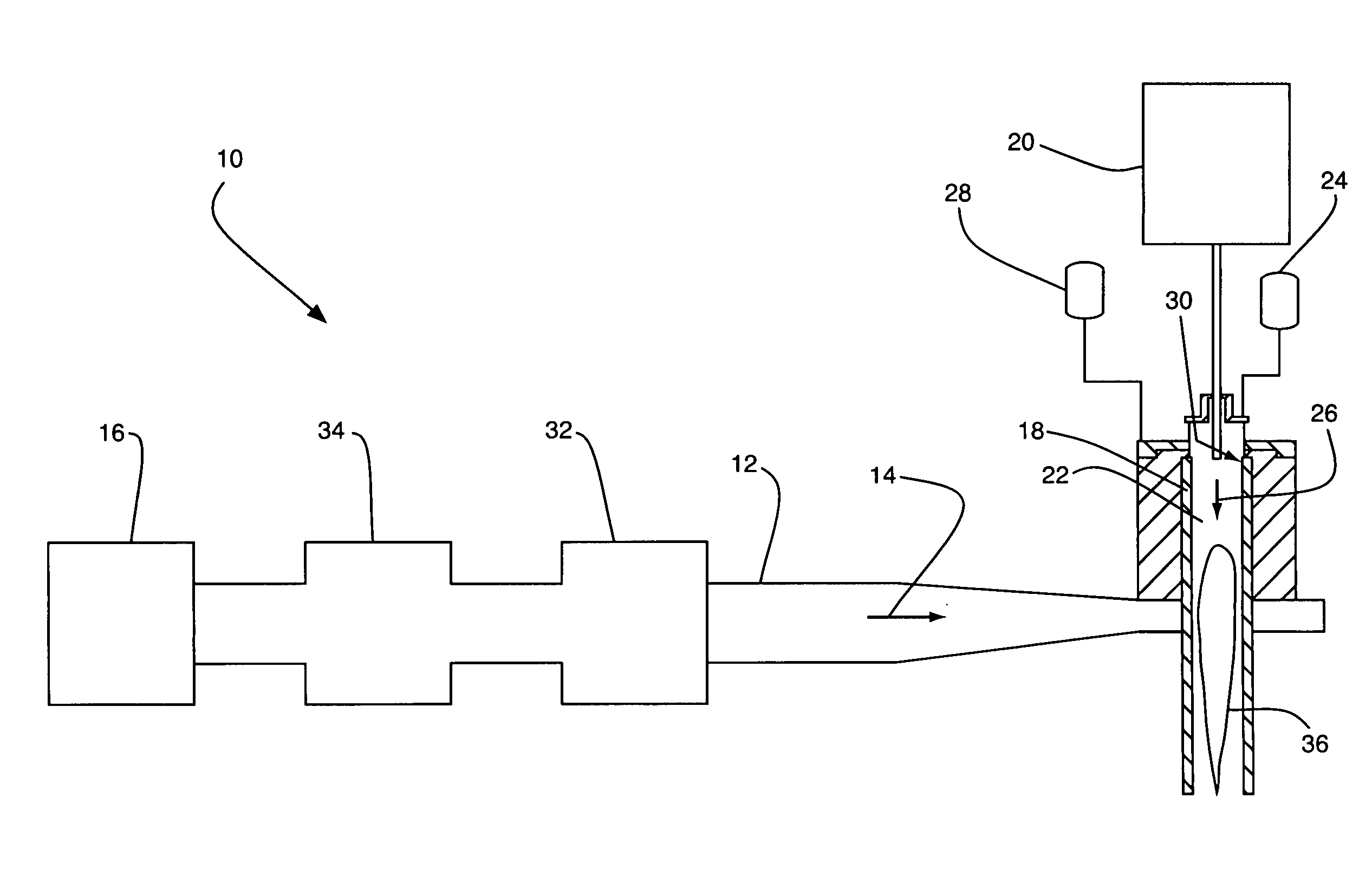

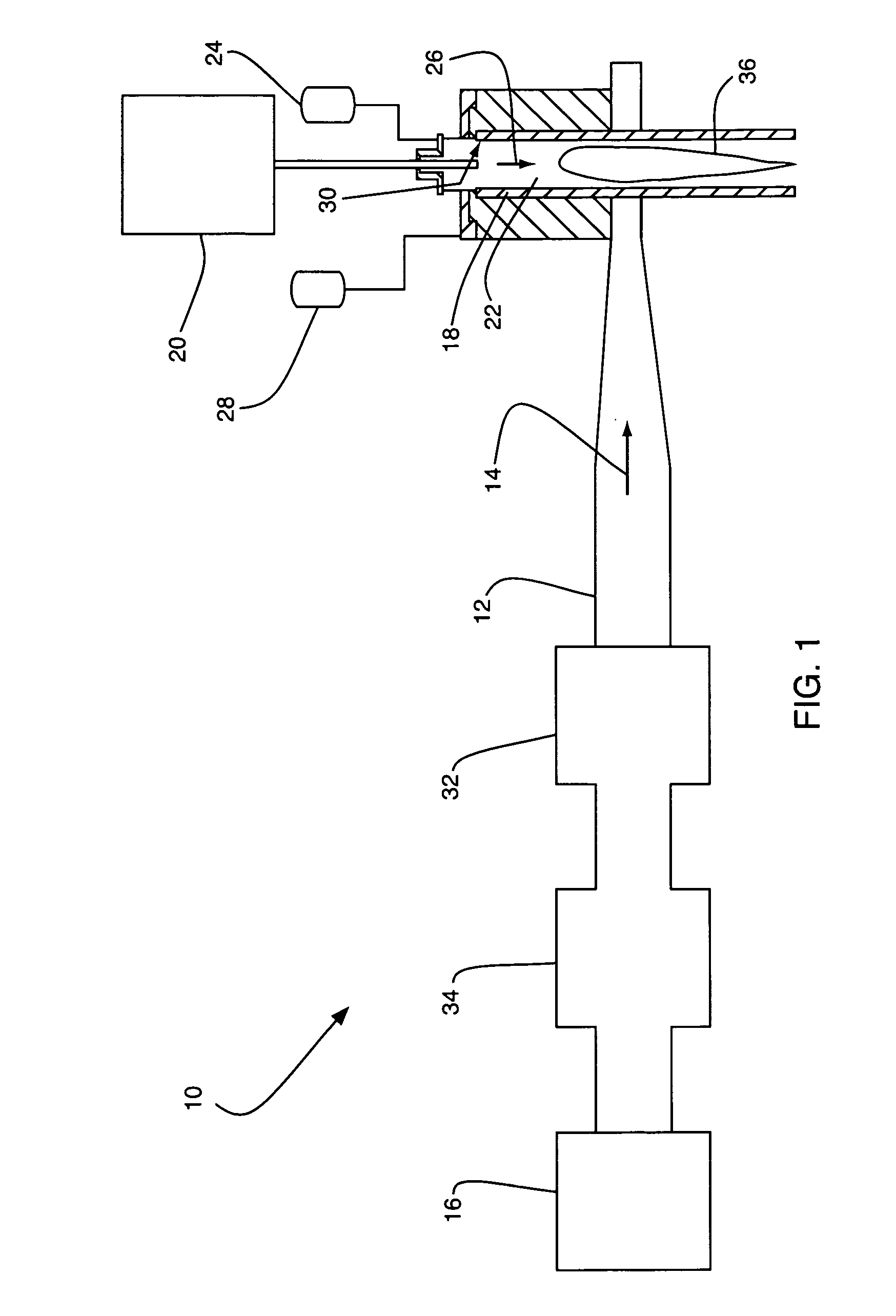

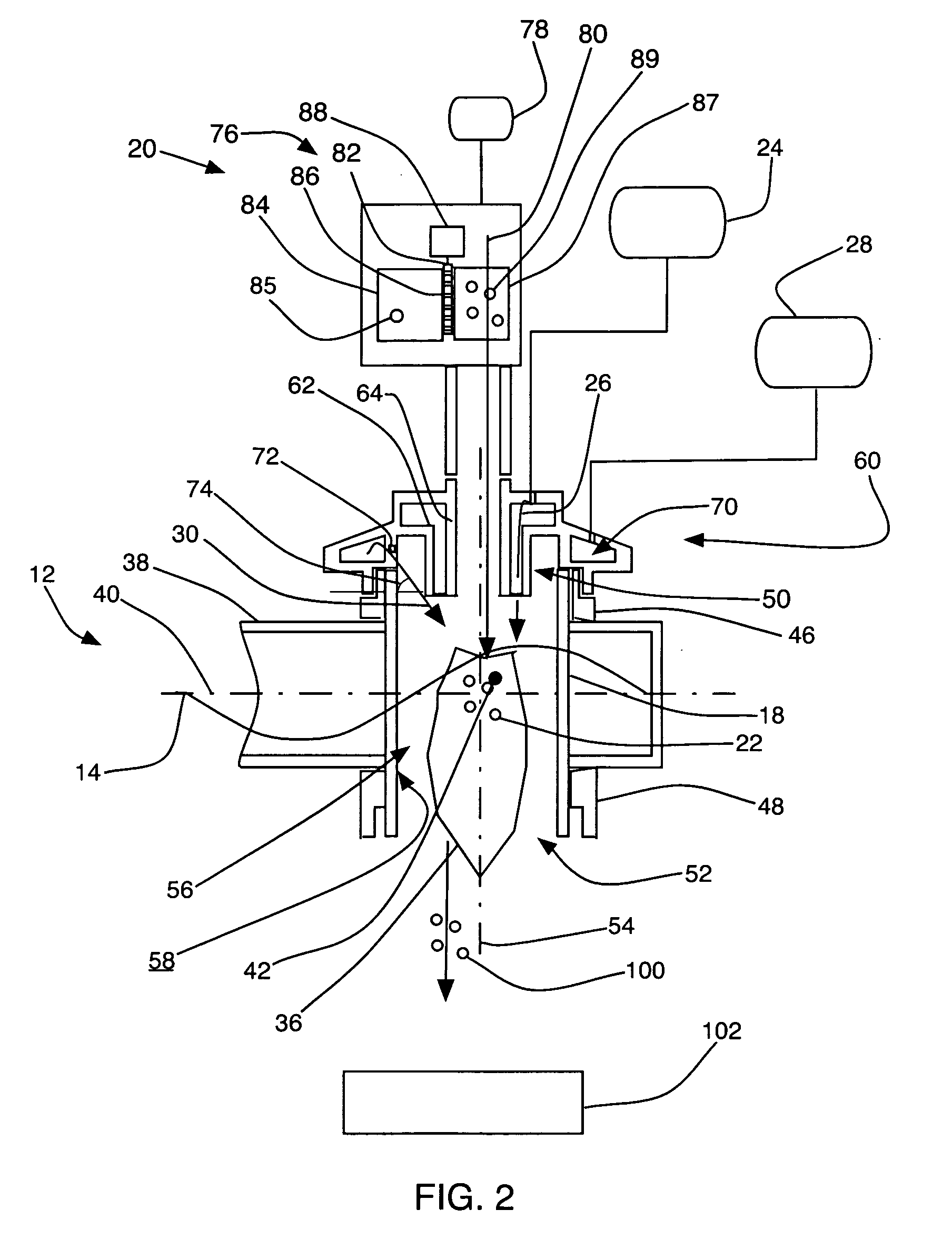

System and method for improved material processing using a laser beam

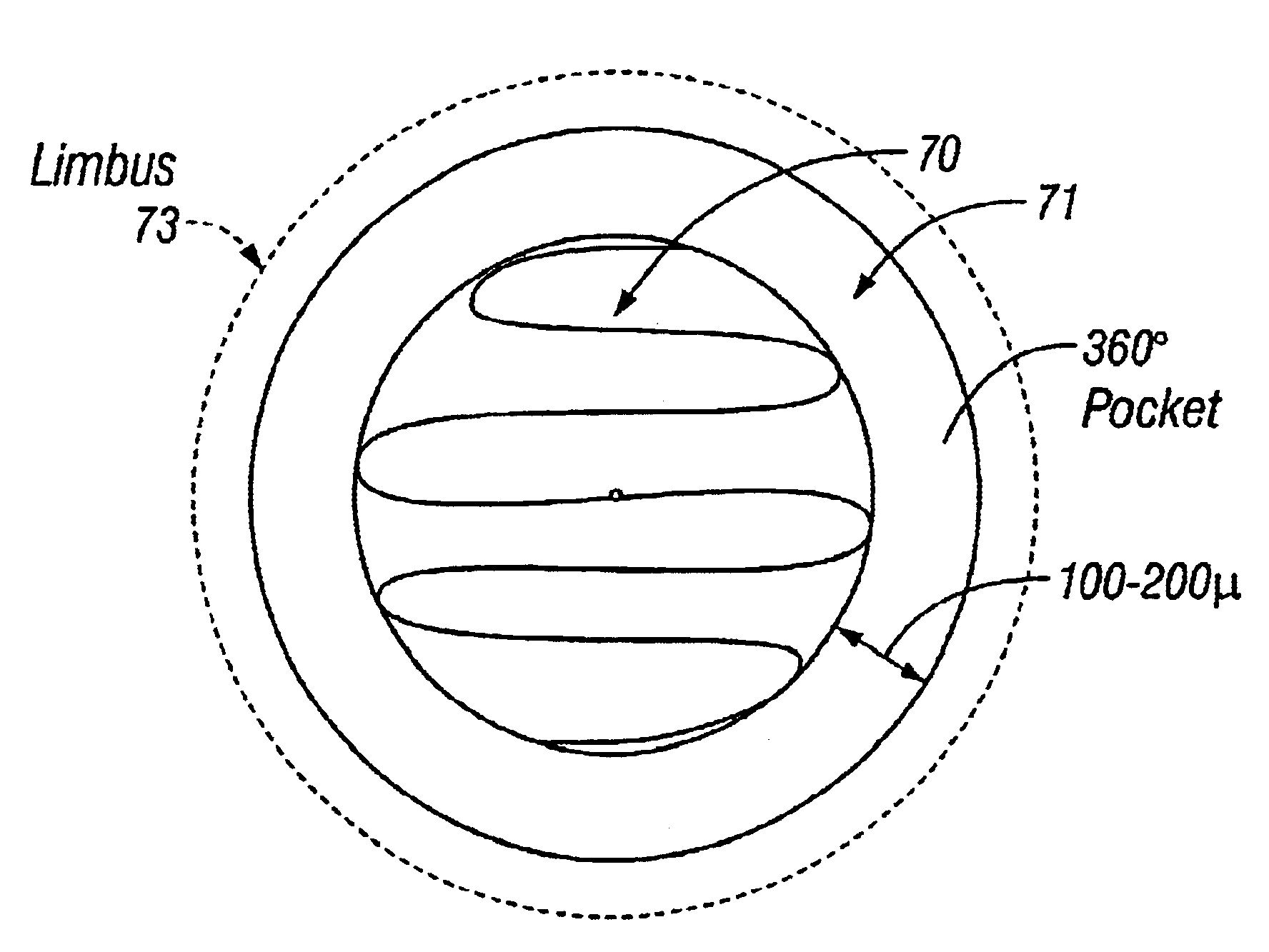

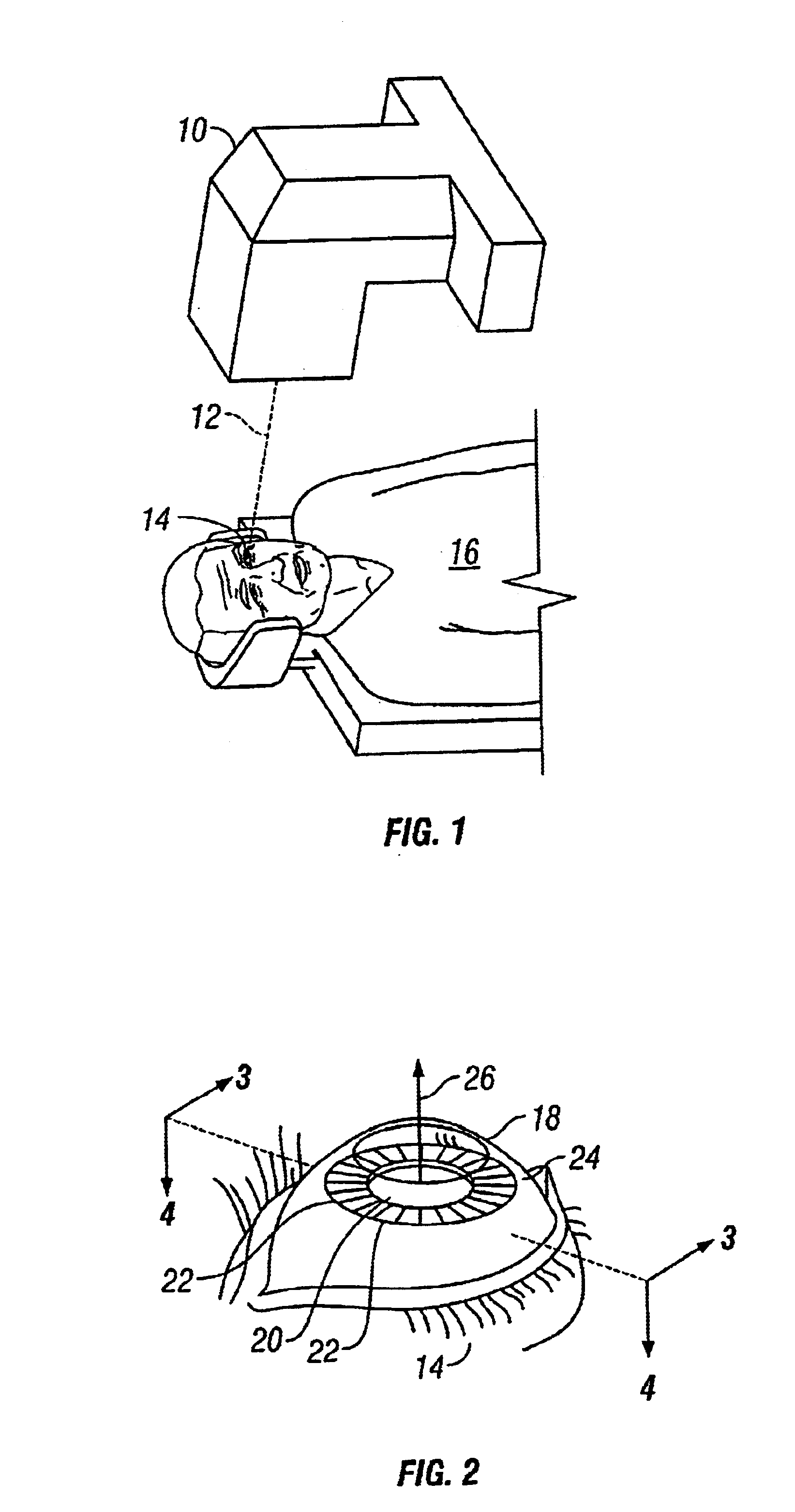

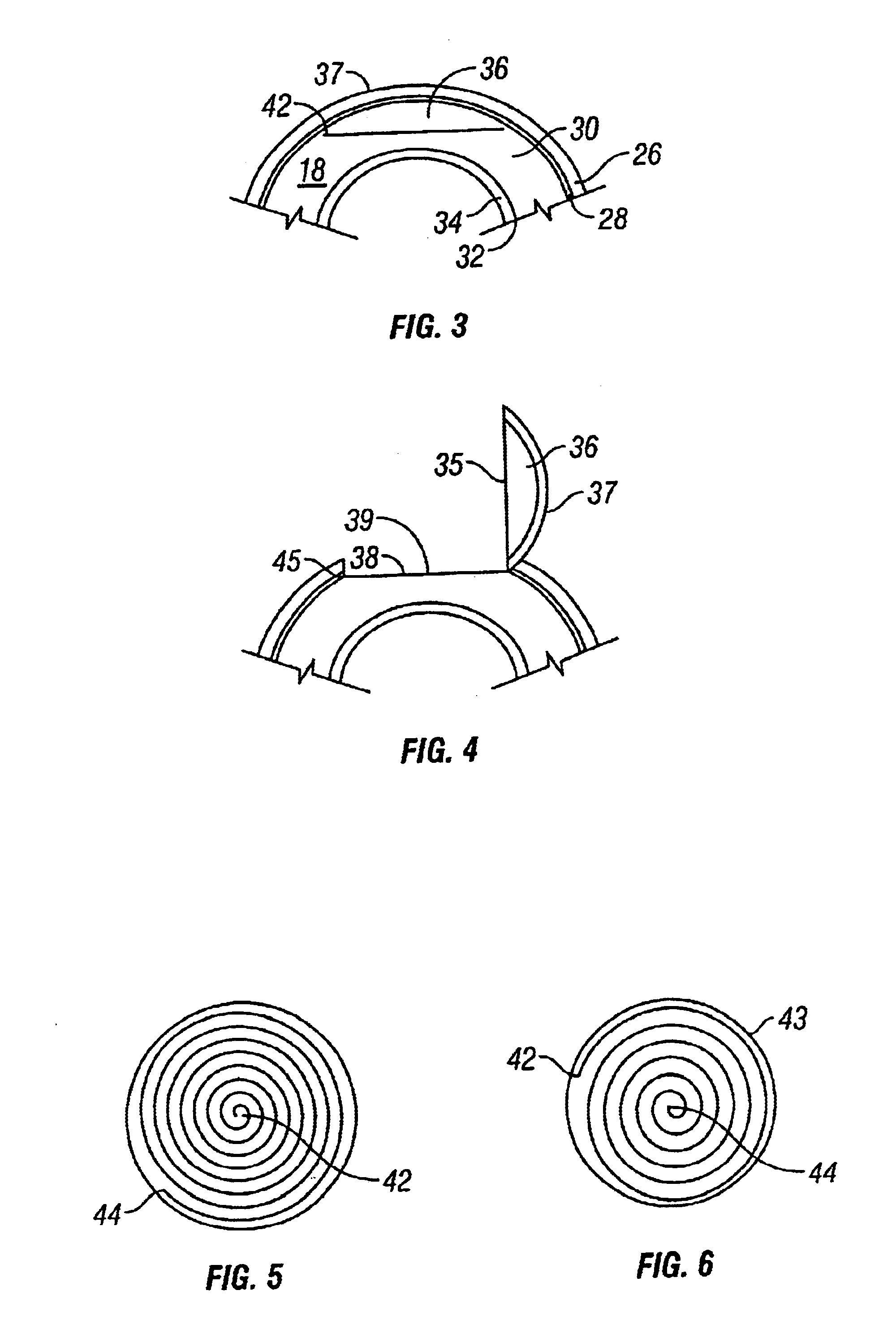

InactiveUS6902561B2Reduce impactSpeed up the processLaser surgeryDiagnosticsPulse characteristicsOptoelectronics

A method and system for improved material processing using a laser beam. The method and system includes directing a laser beam above, at or below the surface of the material in one or more preferred patterns and with preferred laser pulse characteristics specific to the material to reduce or mitigate the accumulation or effects of gas, debris, fluid, or other by-products of photodisruption either at the location where additional laser pulses are being placed or in other sensitive locations in the material.

Owner:AMO DEVMENT

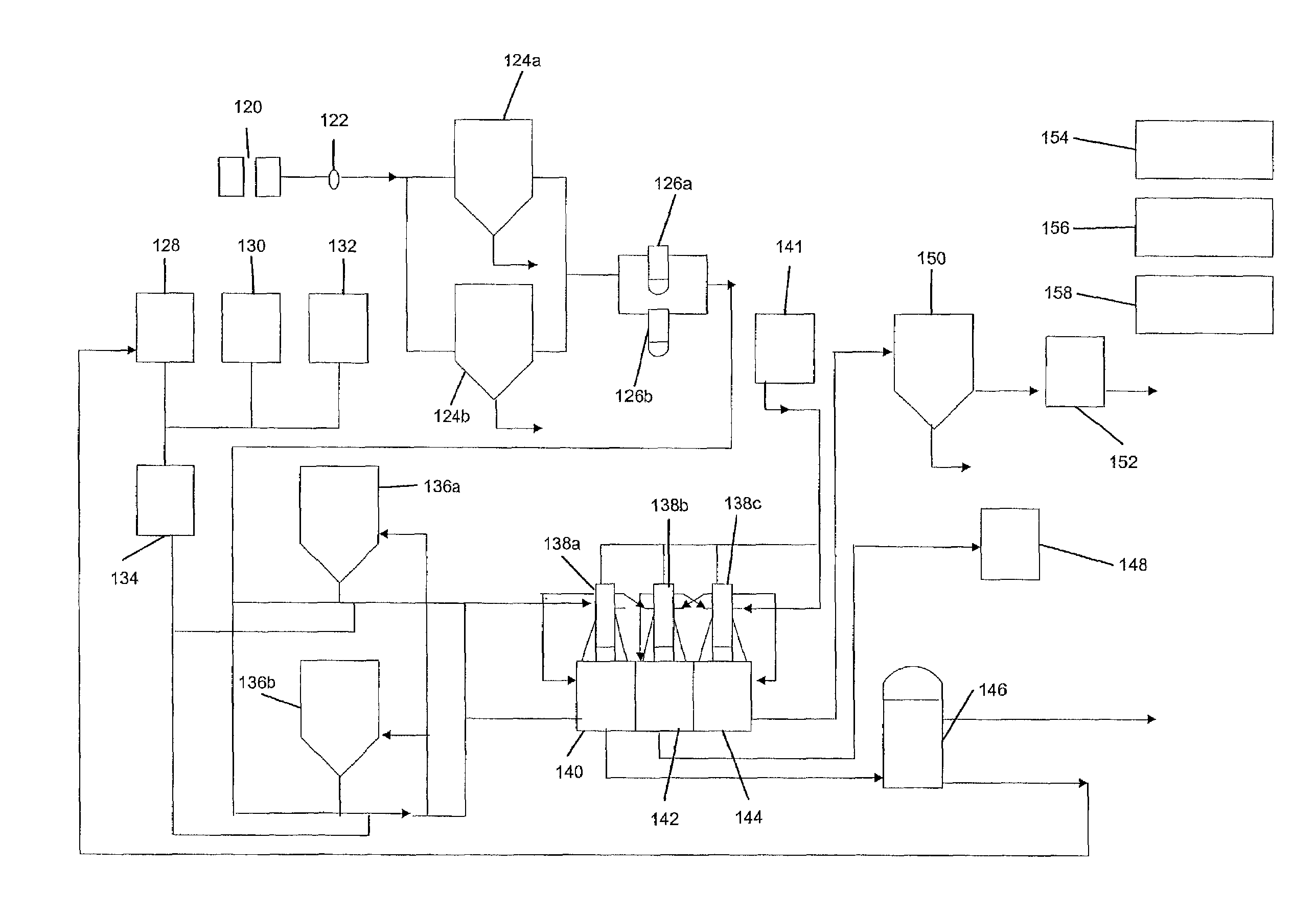

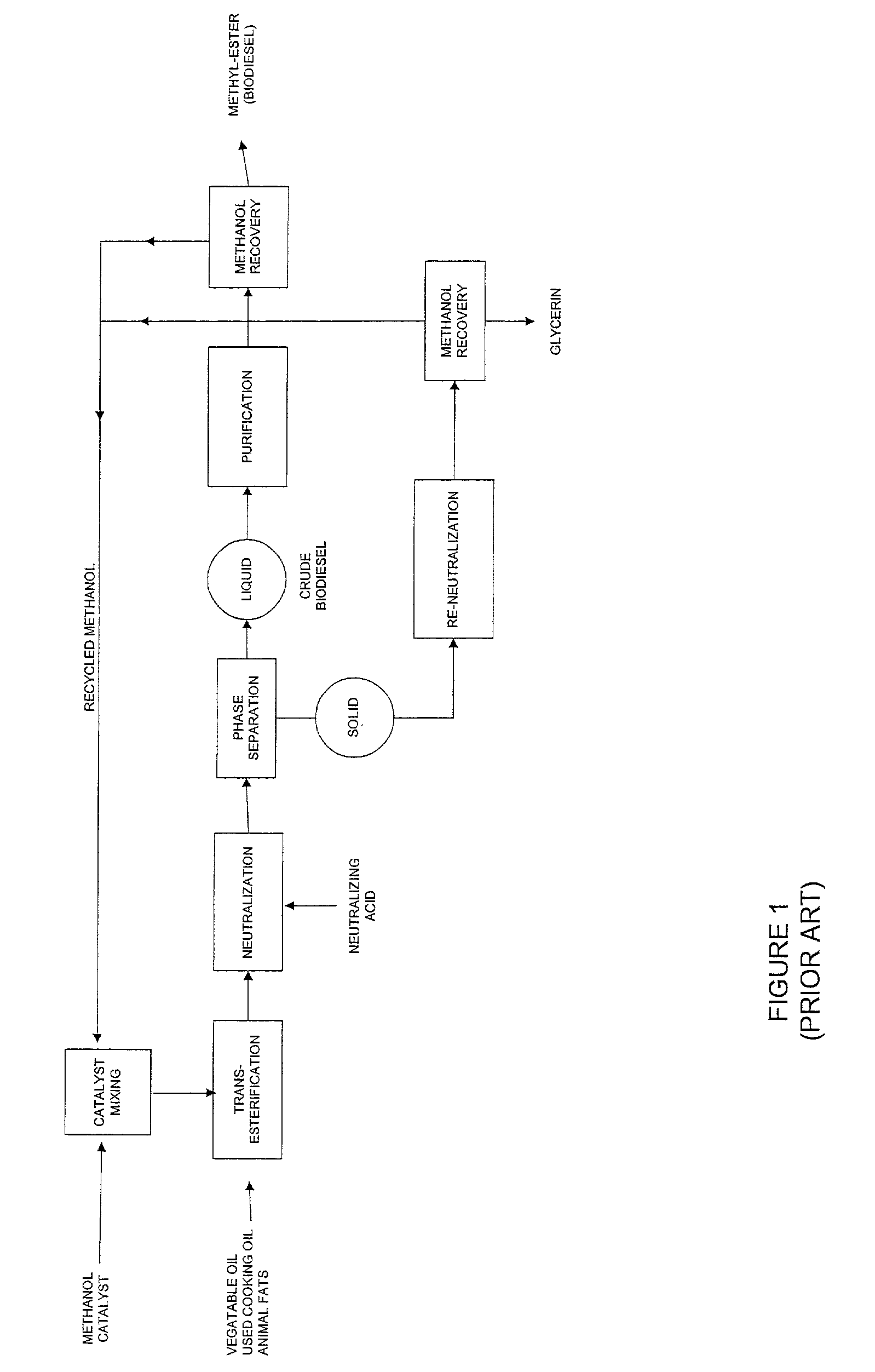

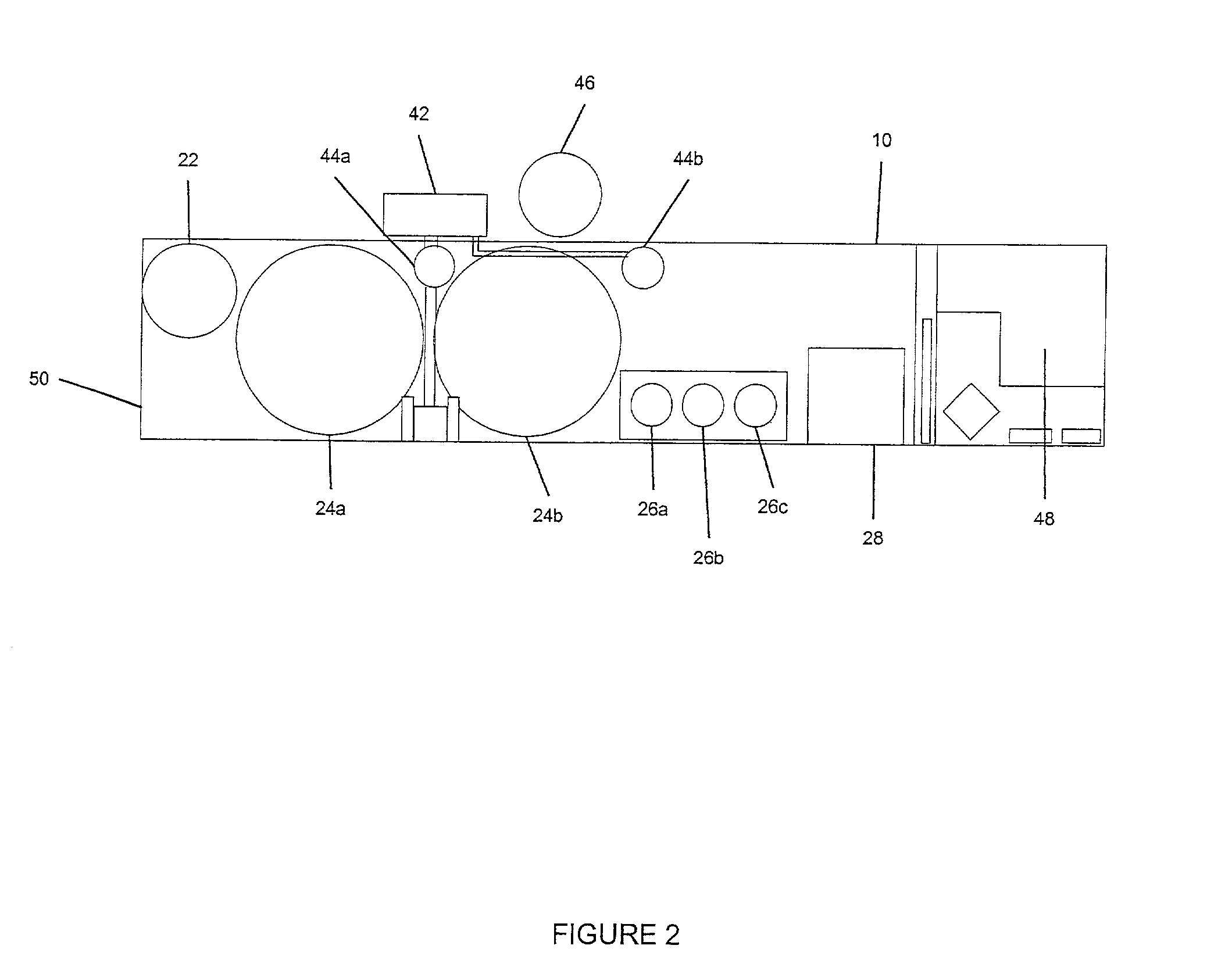

Biodiesel production unit

In a first aspect, systems and methods for producing biodiesel fuel include a modular production unit incorporated onto a single platform or into a housing for ease of relocatability. The modular production unit preferably includes a mixing unit, a reactor unit, a separation unit, a distillation unit, and a filtering unit, all incorporated onto or into a self-contained platform or housing that is able to be easily relocated. In a second aspect, the modular production unit is combined with additional fixed and / or relocatable components to provide a biodiesel processing plant. In a third aspect, a raw materials processing system and method includes a roller barrel adapted for recovery, transportation, and introduction of recycled oil feedstock into a biodiesel manufacturing process. The raw materials processing system preferably includes a hot box for filtering and heating the raw recycled oil feedstock.

Owner:BIODIESEL IND

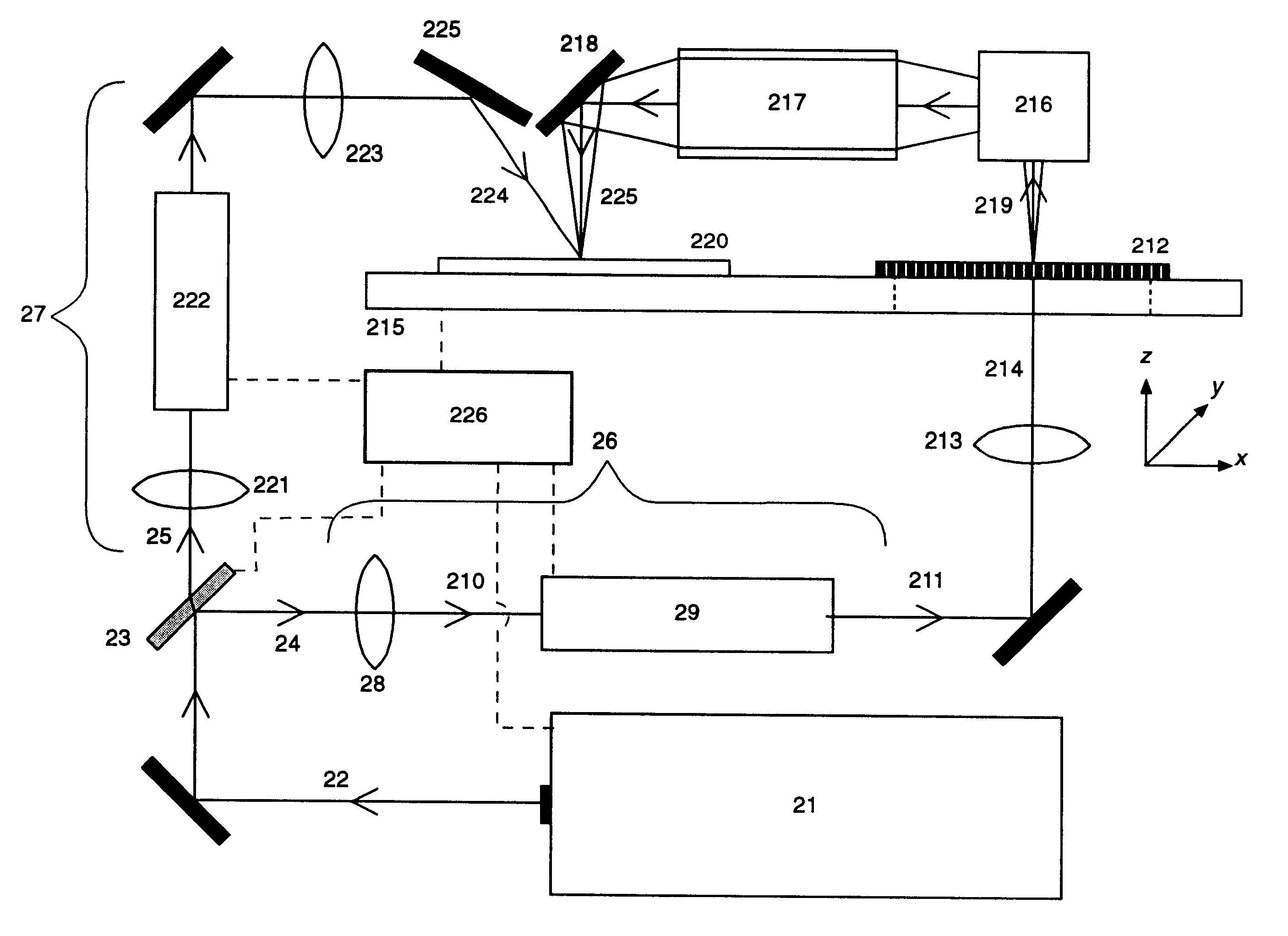

Dual-beam materials-processing system

InactiveUS6621044B2Improve throughputProlong lifePhotomechanical exposure apparatusLight therapyDual beamLight beam

Apparatus and method for patterned sequential lateral solidification of a substrate surface, avoiding the need for demagnification to avoid mask damage from fluence sufficient to overcome the threshold for sequential lateral solidification, while using the high throughput of a common stage presenting both 1:1 mask and substrate simultaneously for patterning. The radiation source provides imaging beam and non-imaging beam, each of fluence below the threshold of sequential lateral solidification, but with aggregate fluence above the threshold. The imaging beam path includes a relatively delicate 1:1 mask and 1:1 projection subsystem, with optical elements including a final fold mirror proximate to the substrate surface, put the below-threshold mask pattern on the substrate surface. The non-imaging beam bypasses the delicate elements of imaging beam path, passing through or around the final fold mirror, to impinge on the substrate surface at the same location. Where the radiation patterns of the masked imaging beam and non-imaging beam coincide, their aggregate fluence exceeds the threshold for sequential lateral solidification. The dual selection provides pattern without damage to delicate optical elements.

Owner:ANVIK CORP

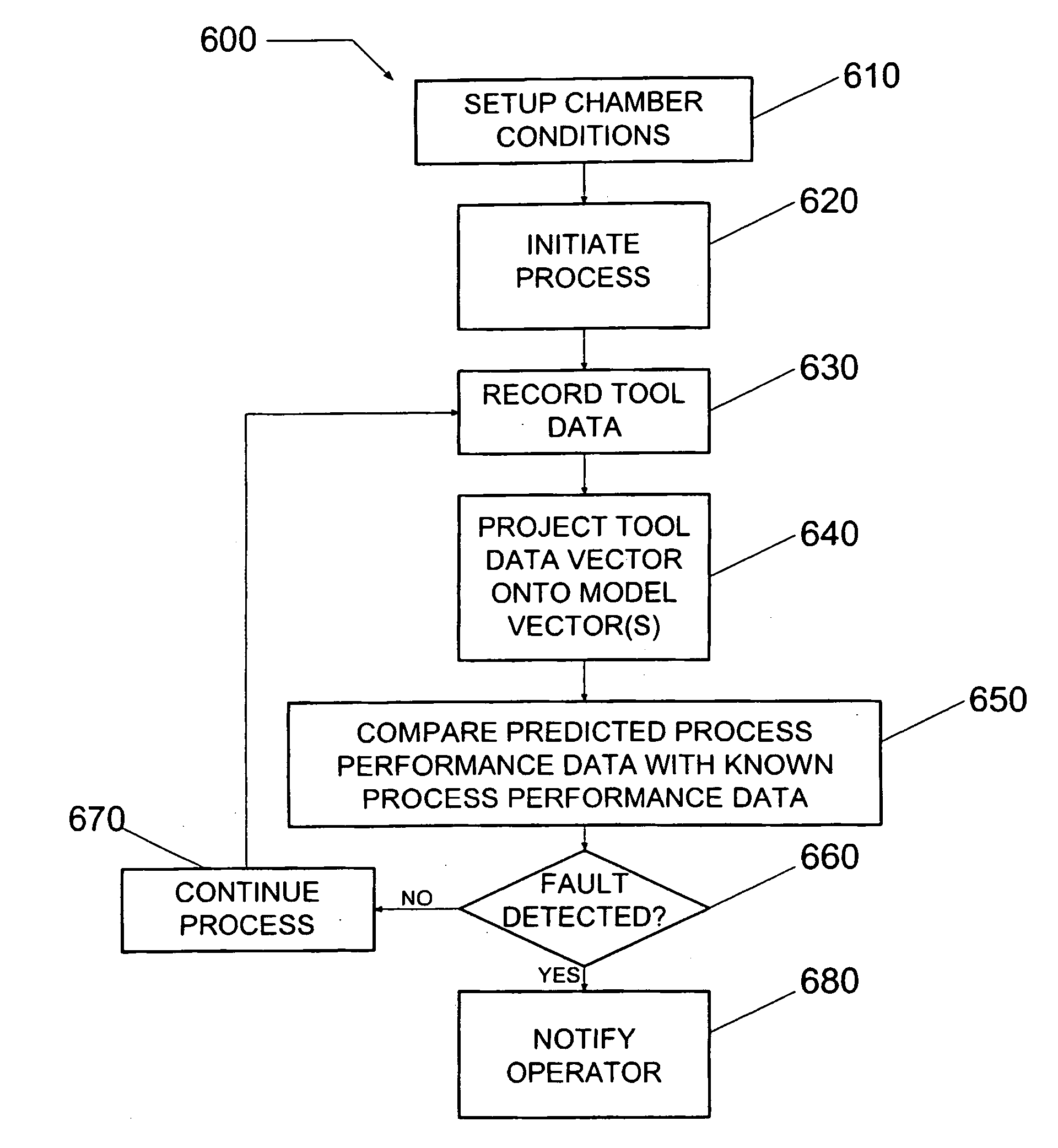

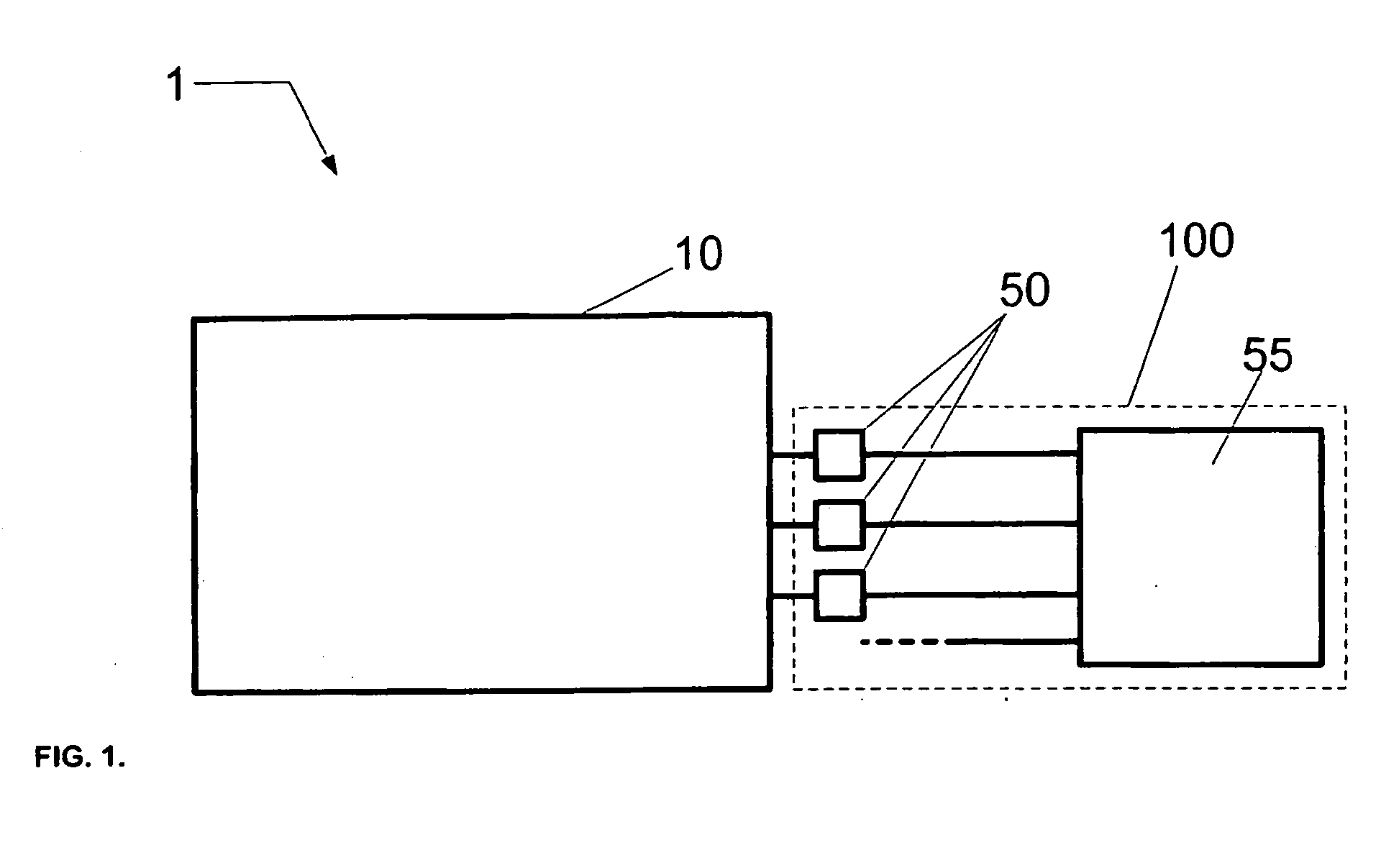

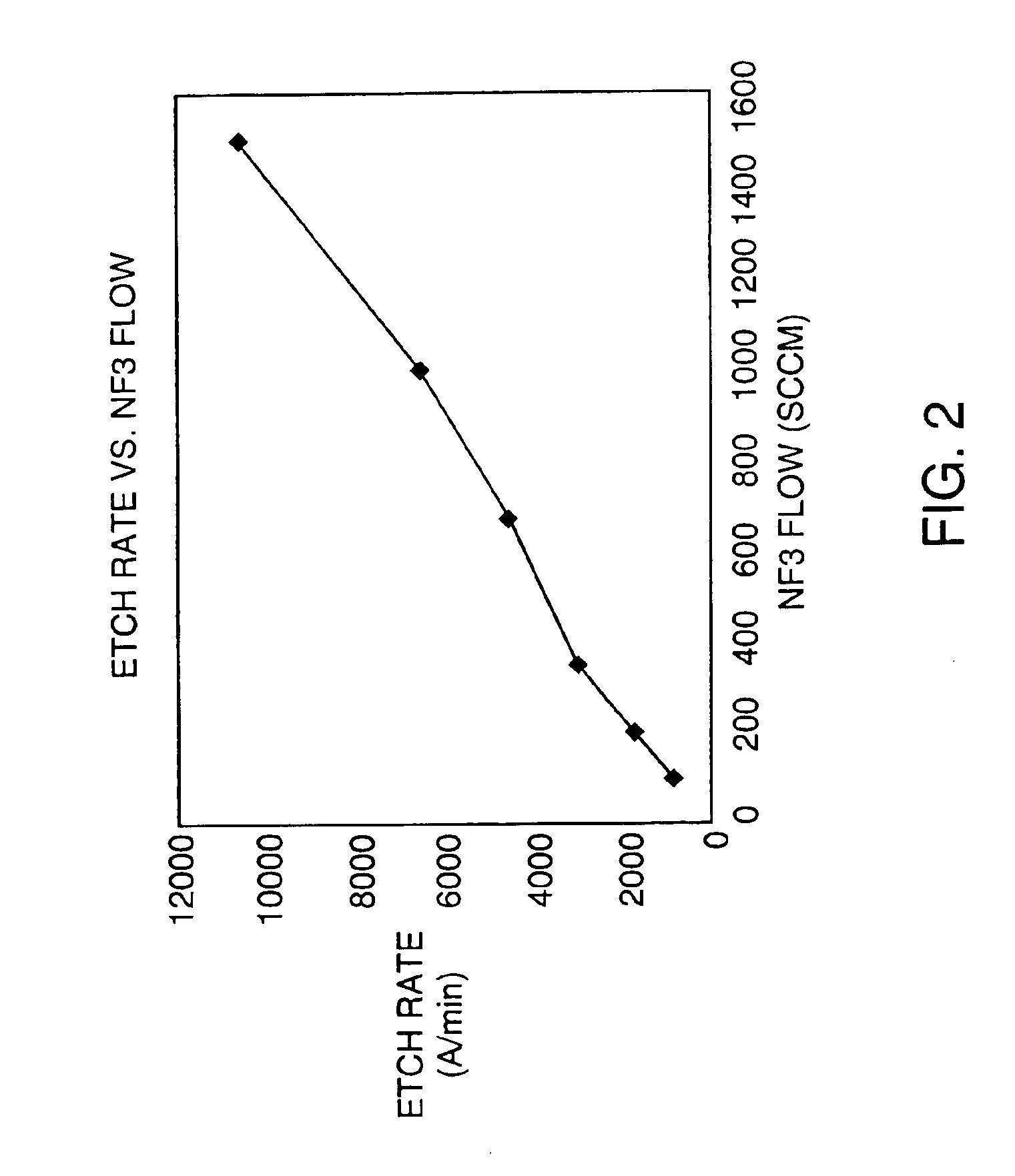

Method and system for predicting process performance using material processing tool and sensor data

InactiveUS20050252884A1Semiconductor/solid-state device testing/measurementElectric discharge tubesEngineeringMaterials processing

A material processing system including a process tool and a process performance prediction system. The performance prediction system includes sensors coupled to the tool to measure tool data and a controller coupled to the sensors to receive tool data, where the controller is configured to predict the process performance for the tool using the tool data. A method for detecting a fault in a material processing system using a process performance prediction model is also provided. The method includes preparing the tool, initiating a process in the tool, and recording tool data to form to a tool data matrix. The method also includes performing a matrix multiplication of the tool data matrix and a correlation matrix to form predicted process performance data, where the correlation matrix includes the performance prediction model, comparing the predicted data with target data, and determining a fault condition of the processing system from the comparing step.

Owner:TOKYO ELECTRON LTD

Agile-beam laser array transmitter

ActiveUS20100046953A1Turn fasterWide field of viewWave based measurement systemsWavelength-division multiplex systemsLaser arrayColor printing

An Agile-Beam Laser Array Transmitter (ABLAT) uses an array of emitters and an array of lenses to project electromagnetic beams over a wide angular coverage area in the far field. Differences in the separation pitches of the two arrays allows the ABLAT to project beams to contiguous and / or overlapping positions, depending on the ratio of the separation pitches and the lens focal length. Compared to other beam steering technology, the ABLAT is a smaller, lighter, and more efficient means of projecting beams over wider angular coverage areas. Various embodiments can be used in any beam steering application, including, but not limited to: free-space optical communications; light detection and ranging (lidar); optical scanning (e.g., retinal or bar-code scanning); display projection; image capture; optical character recognition; scanning laser microscopy; non-destructive testing; printing; facsimiles; map making; web inspection; color print processing; phototypesetting and platemaking; laser marking; material processing; DNA analysis; and drug discovery.

Owner:MASSACHUSETTS INST OF TECH

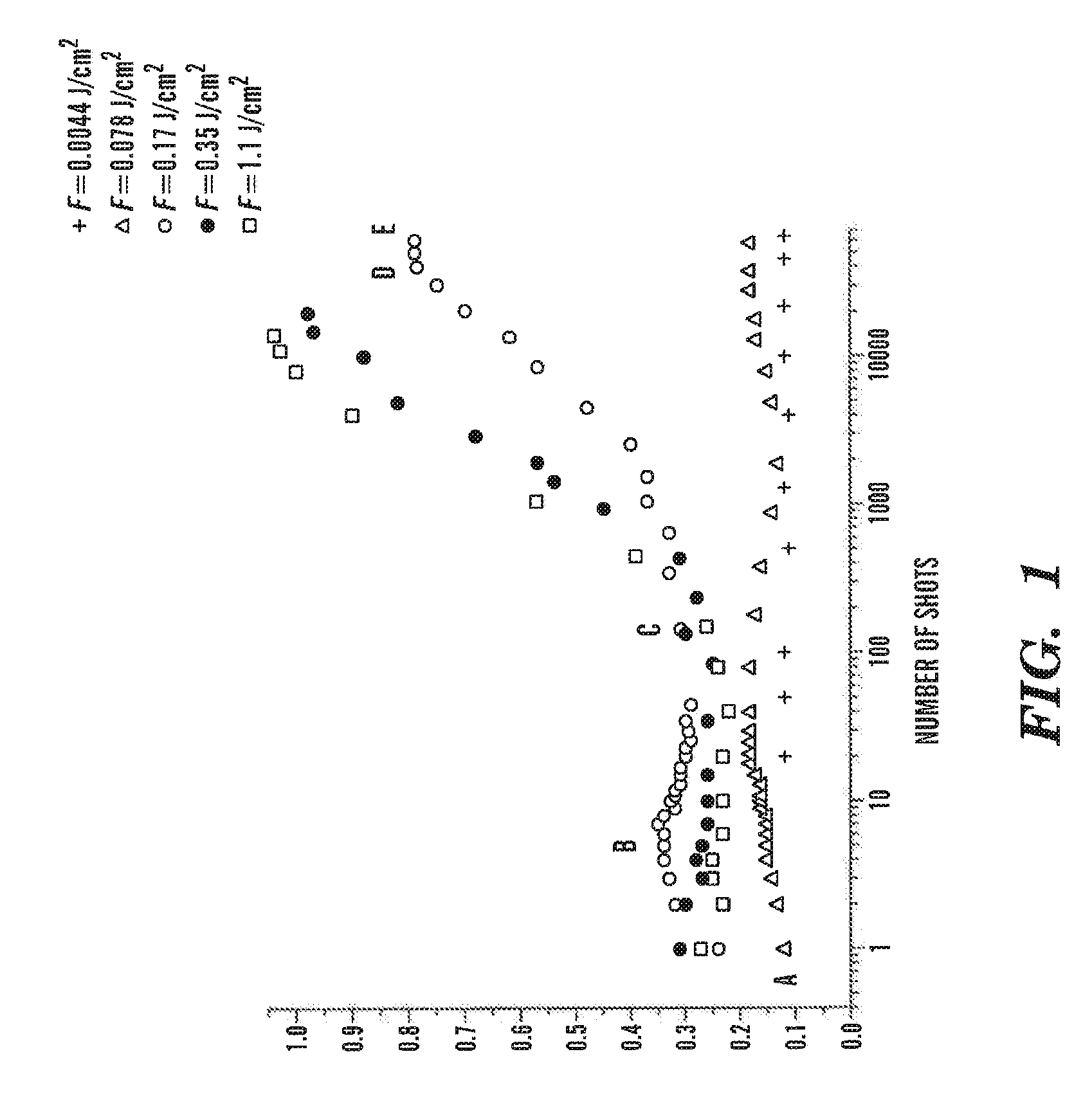

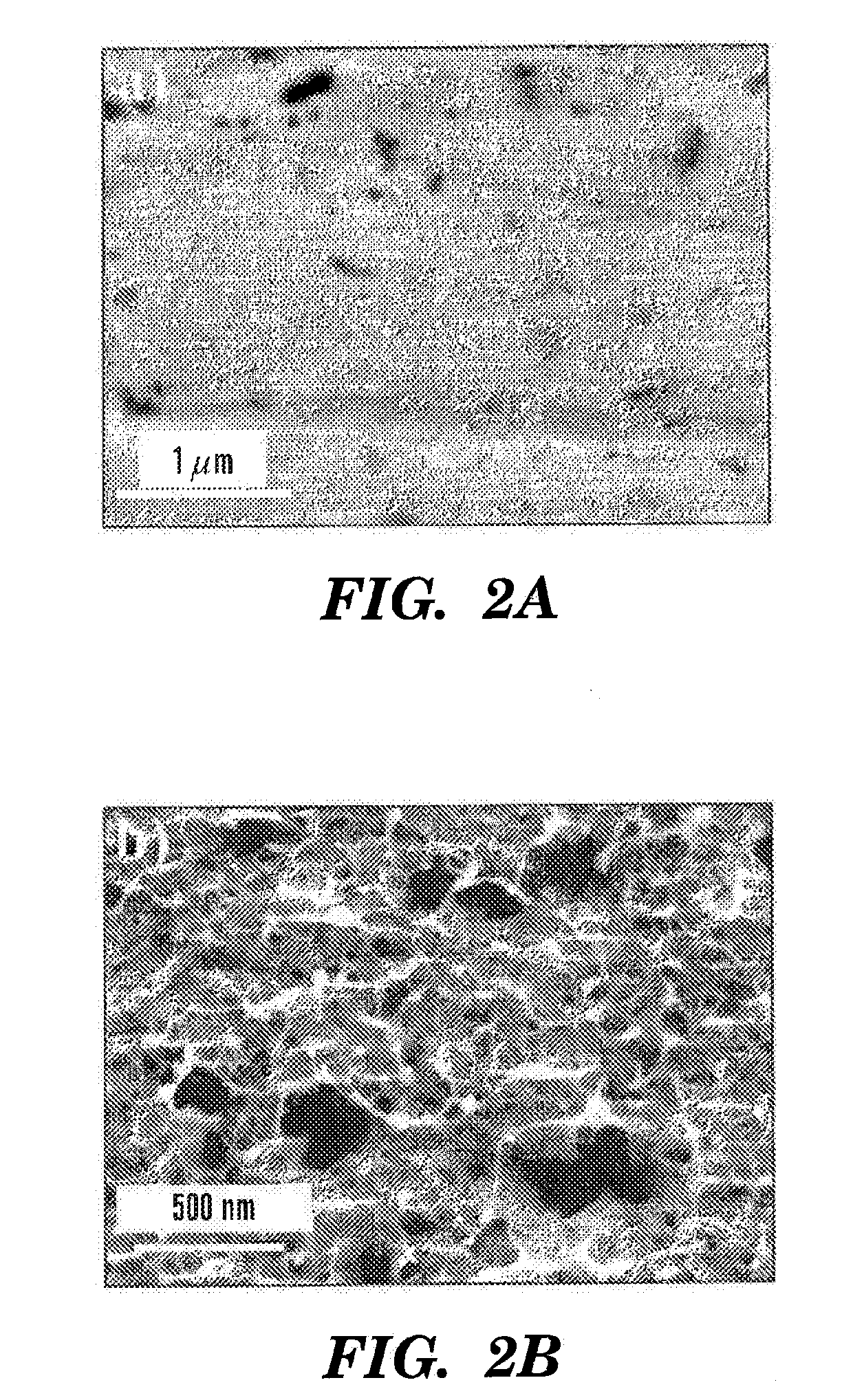

Femtosecond Laser Pulse Surface Structuring Methods and Materials Resulting Therefrom

InactiveUS20080299408A1Material nanotechnologyEngine sealsBiocompatibility TestingMaterials processing

Embodiments of the present invention are generally directed to materials processing methods using femtosecond duration laser pulses, and to the altered materials obtained by such methods. The resulting nanostructured (with or without macro- and micro-structuring) materials have a variety of applications, including, for example, aesthetic applications for jewelry or ornamentation; biomedical applications related to biocompatibility; catalysis applications; and modification of, for example, the optical and hydrophilic properties of materials including selective coloring.

Owner:UNIVERSITY OF ROCHESTER

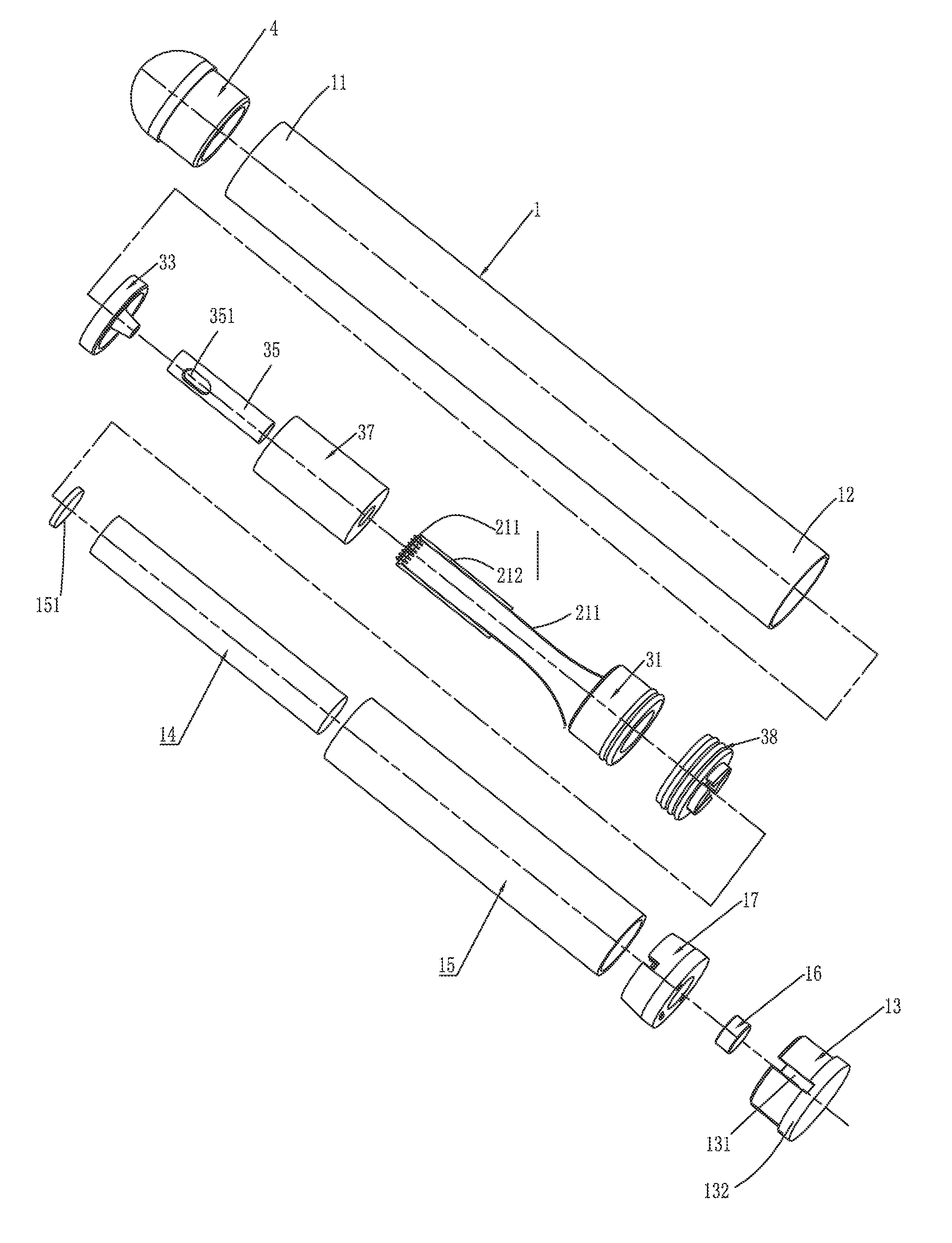

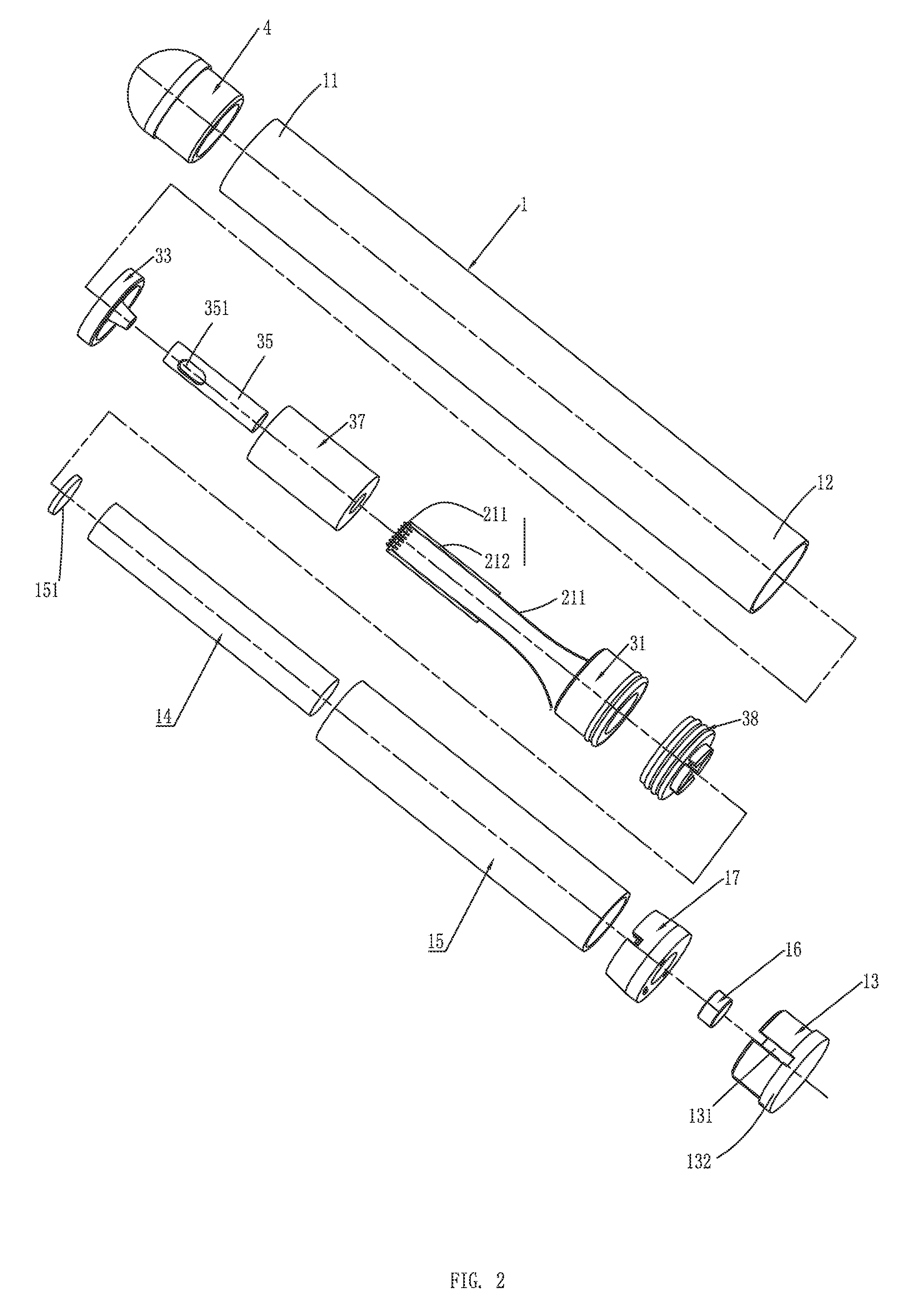

Electronic cigarette and electronic cigarette device

This invention relates to an electronic cigarette and an electronic cigarette device, the electronic cigarette includes a sucking cylinder, a sucking nozzle configured at an end of the sucking cylinder; wherein the sucking cylinder and / or the sucking nozzle are processed with wooden material; wherein the wooden material is natural timber. The electronic cigarette device includes the above-mentioned electronic cigarette, and further includes an electronic cigarette casing, for accommodating and charging the electronic cigarette; the electronic cigarette casing includes a bottom box and a box cover, the bottom box and / or the box cover are made of the wooden material. The electronic cigarette and the electronic cigarette casing are of health, hygiene, environmental protection and good taste and good feel.

Owner:HUIZHOU KIMREE TECH

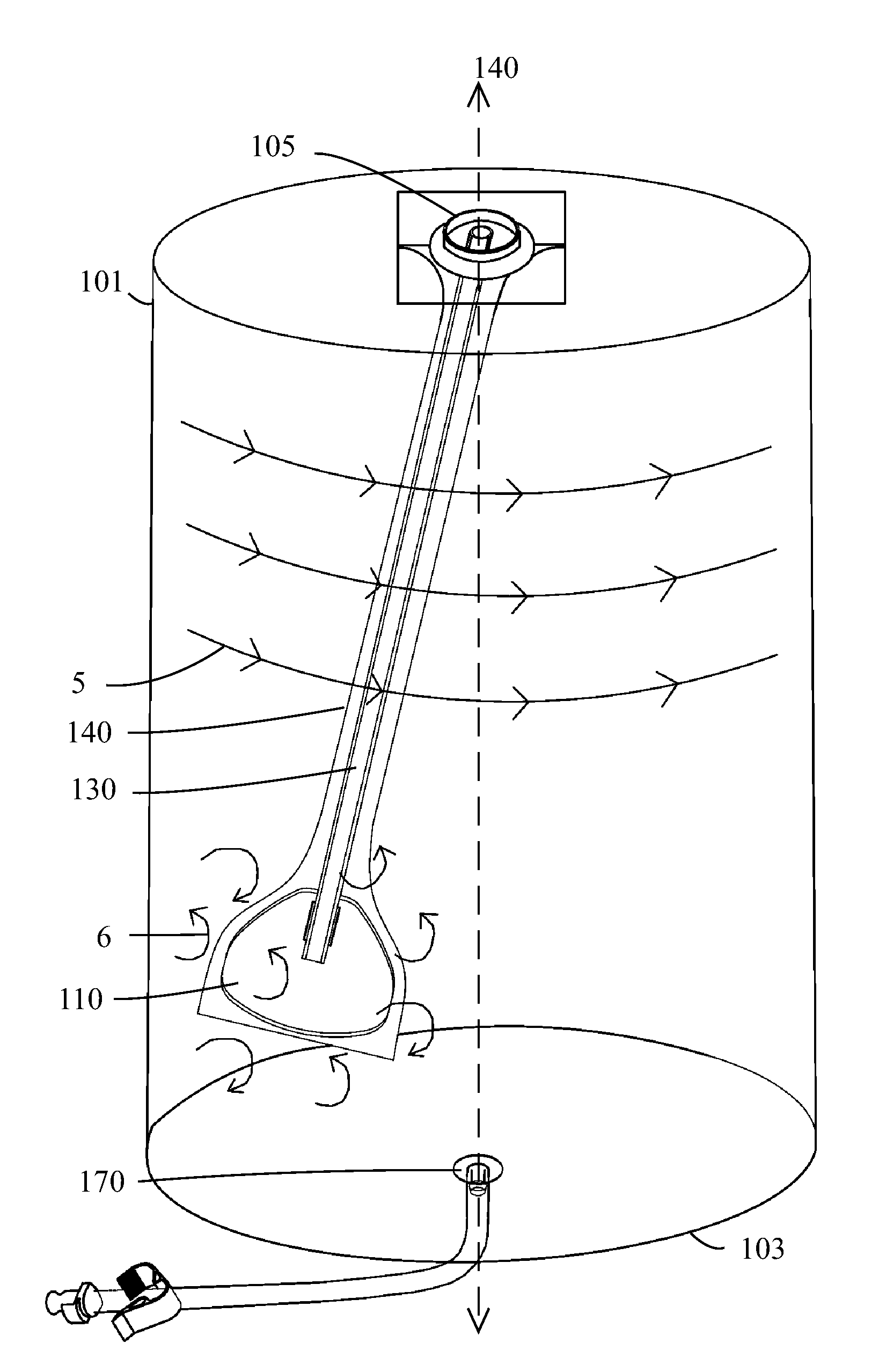

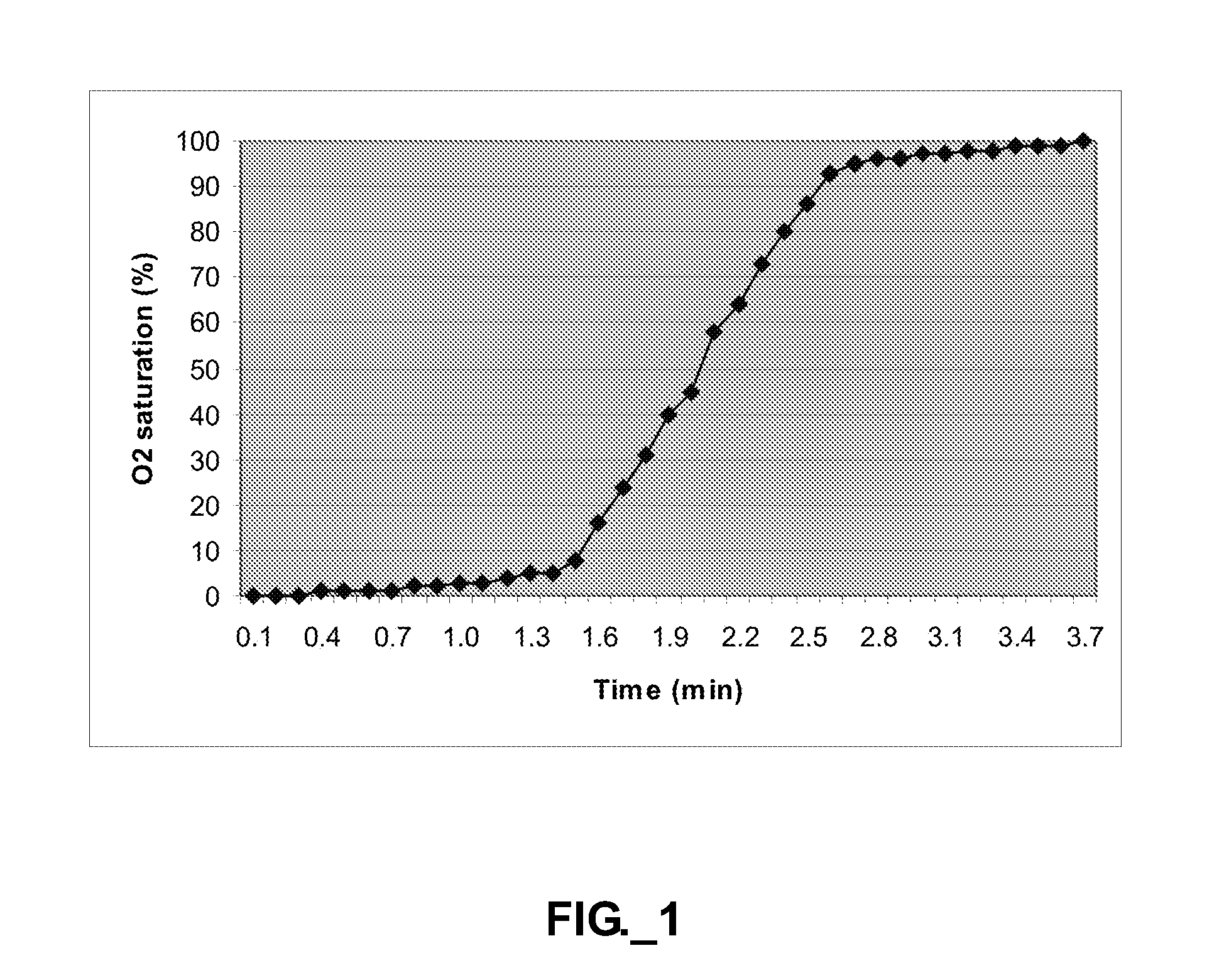

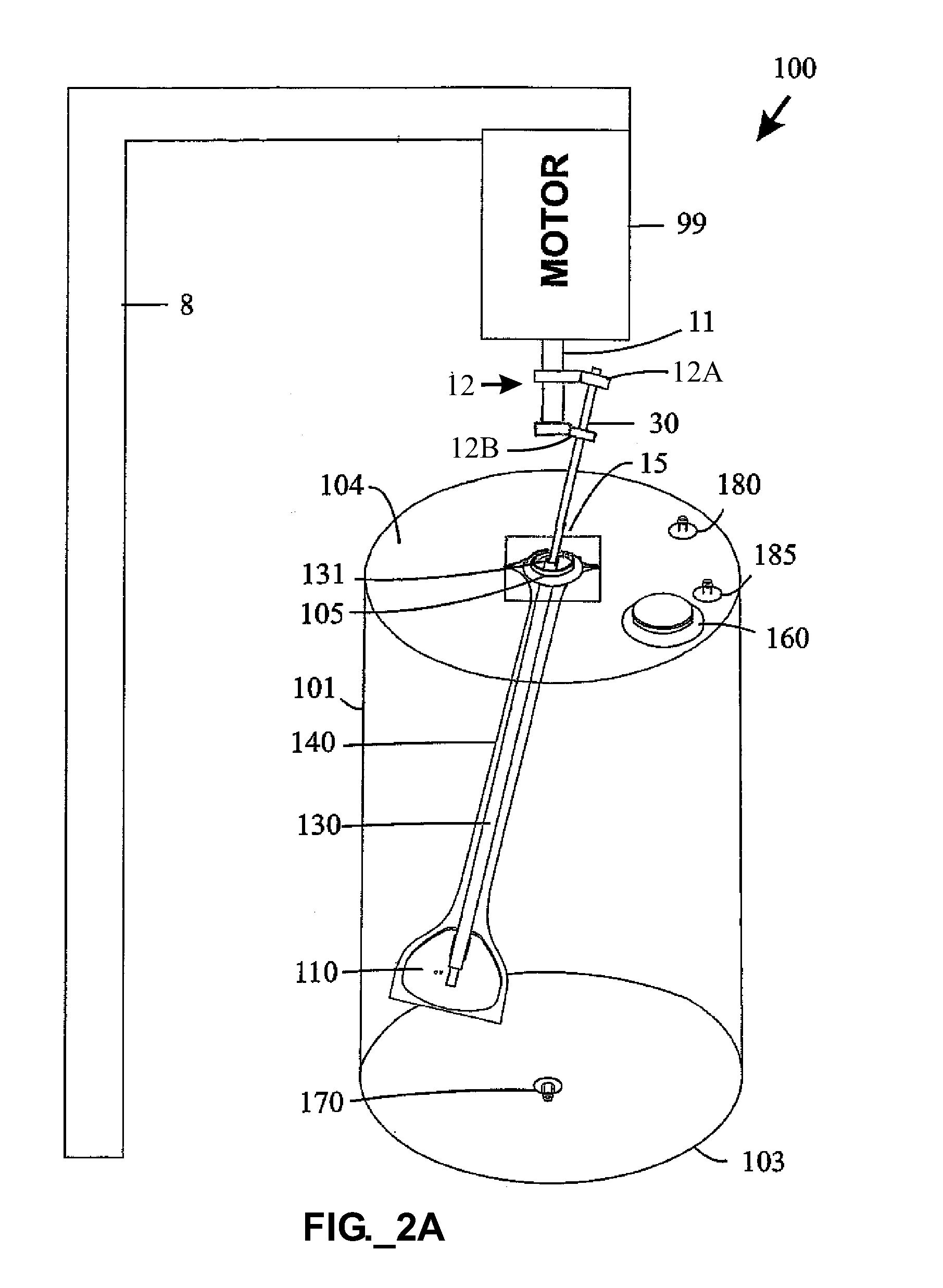

Disposable bioreactor

ActiveUS20100015696A1Bioreactor/fermenter combinationsBiological substance pretreatmentsCatheterEngineering

A disposable material processing apparatus, useable as a bioreactor or fermenter, includes a hollow tank (101) and a mixing paddle (110) disposed within the interior of the tank and adapted to mix contents therein. The paddle may be isolated within a flexible sleeve (140). Various functional elements, such as a sparger, sensor, material extraction conduit, material addition conduit, and / or heat exchange element may be provided, and optionally arranged to travel with the paddle within the tank interior. Baffles may protrude into a mixing tank to enhance mixing. A tank and / or sleeve may comprise polymeric film materials.

Owner:PALL LIFE SCI BELGIUM

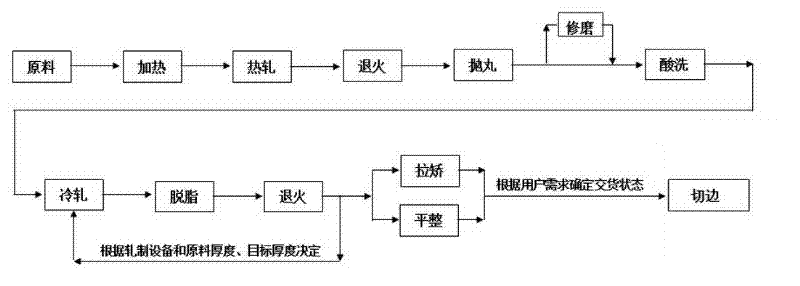

Processing method of titanium and titanium alloy strip coils

ActiveCN102310314ASolve the shortage of titanium-free surface processing technologyImprove processing efficiencyWork treatment devicesMetal rolling arrangementsSingle plateTitanium

The invention provides a processing method of titanium and titanium alloy strip coils, which comprises the steps of raw material preparation, heating, rolling, annealing, shot blasting treatment, coping, pickling, cold rolling, derosination, annealing, straightening or flattening, edge scraping, and product obtaining. According to the method, existing large steel rolling equipment of various types in the steel processing industry is fully utilized, the defect that no titanium material surface processing and treatment technology exists in the steel processing industry is overcome, the advantages of the steel processing industry are combined with the uniqueness of the titanium material processing industry, and the essential leap of titanium material processing from single plate rolling to long strip rolling plus collection and coiling is completed. By using the method, goods can be delivered in a coiled state as well as a flat plate state, the titanium material processing efficiency is improved, the titanium material processing yield is increased, and conditions are created and high quality raw materials are provided for the processing of titanium welded pipes with various diametersand longer lengths, so high efficiency, energy conservation and economization of titanium material processing are realized.

Owner:YUNNAN TITANIUM IND

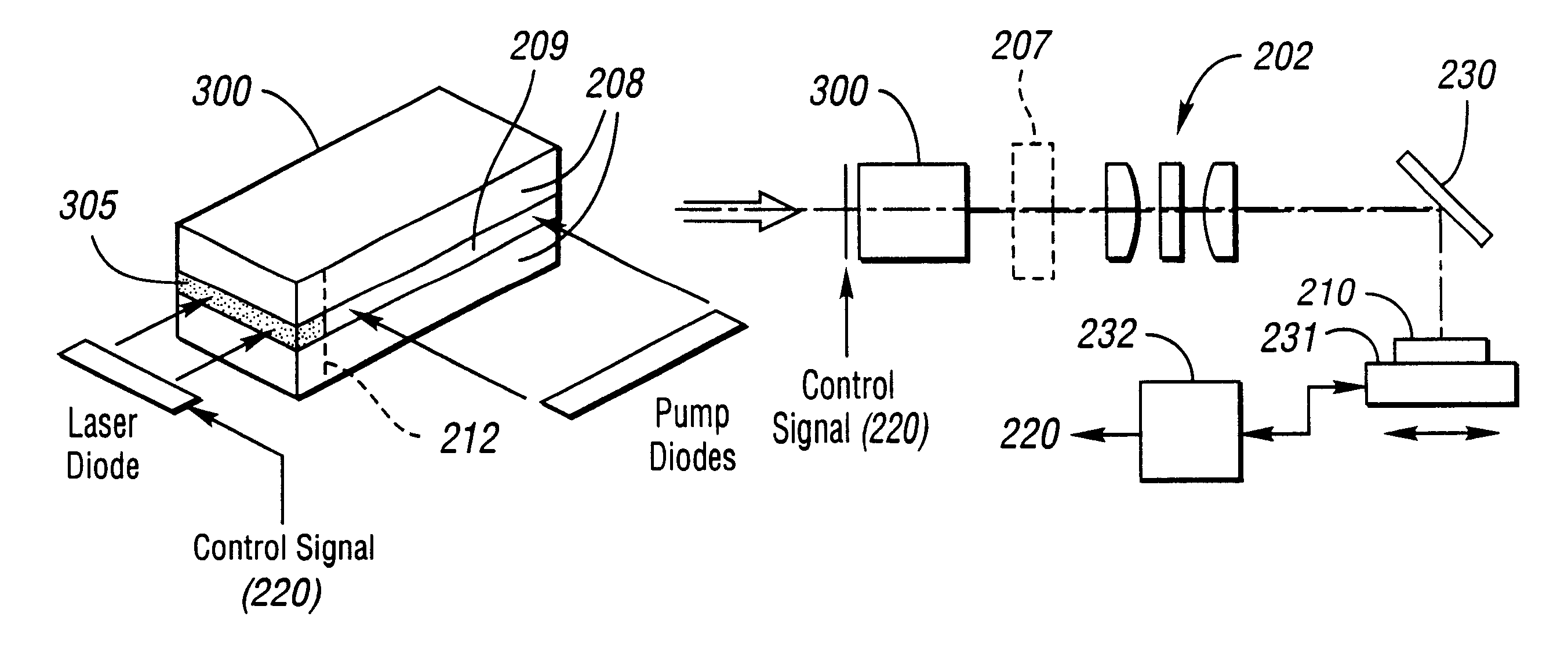

Laser based material processing methods and scalable architecture for material processing

InactiveUS20030160034A1Improve stabilityLaser using scattering effectsOptical resonator shape and constructionPower applicationNanosecond

Methods and systems for laser-based processing of materials are disclosed wherein a scalable laser architecture, based on planar waveguide technology, provides for pulsed laser micromachining applications while supporting higher average power applications like laser welding and cutting. Various embodiments relate to improvements in planar waveguide technology which provide for stable operation at high powers with a reduction in spurious outputs and thermal effects. At least one embodiment provides for micromachining with pulsewidths in the range of femtoseconds to nanoseconds. In another embodiment, 100W or greater average output power operation is provided for with a diode-pumped, planar waveguide architecture.

Owner:THE GSI GRP LLC

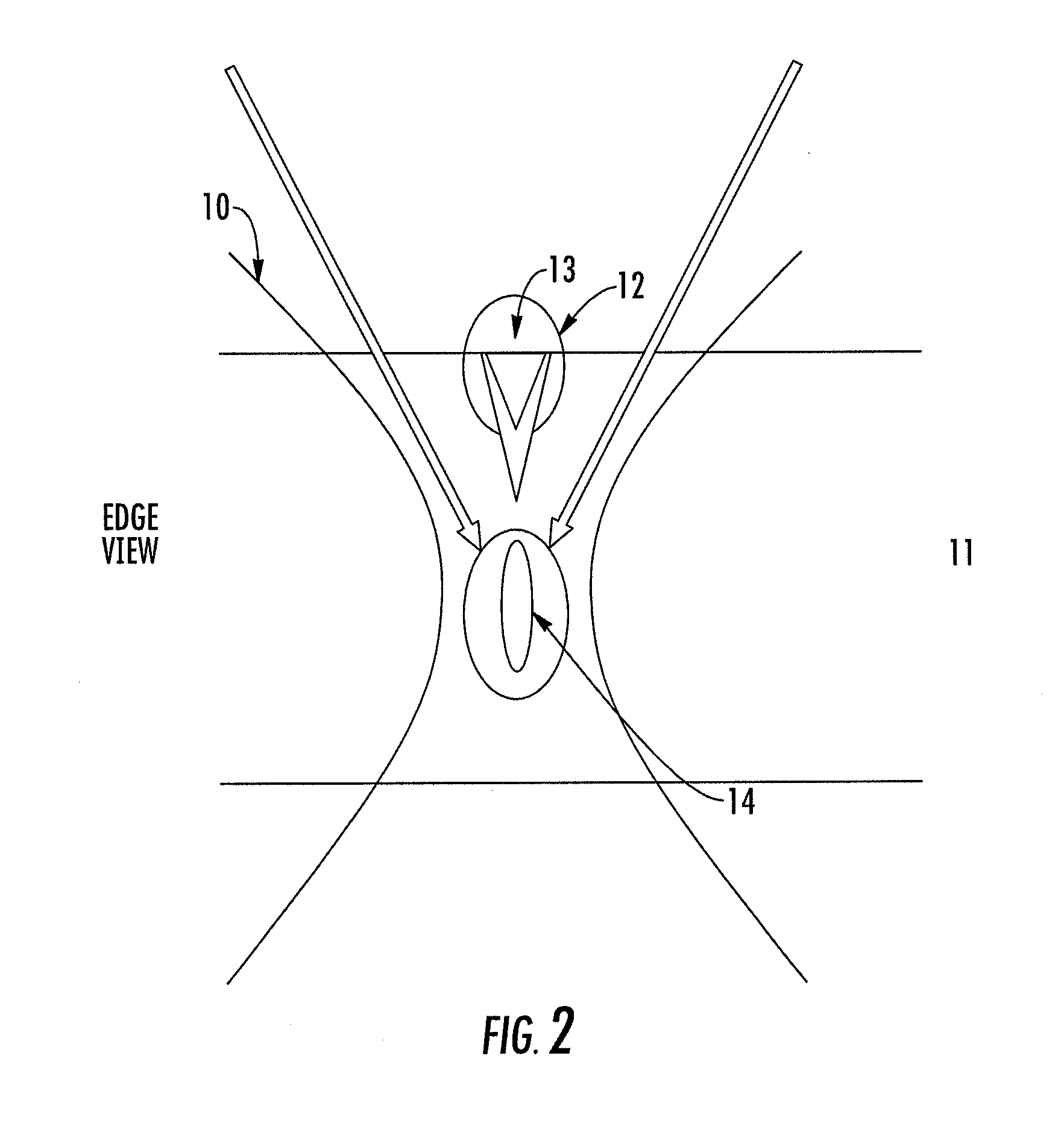

Transparent material processing with an ultrashort pulse laser

InactiveUS9138913B2Reduce quality problemsPoor precisionAircraft componentsSemiconductor/solid-state device manufacturingLight beamLight reflection

Methods, devices, and systems for ultrashort pulse laser processing of optically transparent materials are presented, with example applications in scribing, marking, welding, and joining. For example, ultrashort laser pulses create multiple scribe features with one pass of the laser beam across the material, with at least one of the scribe features being formed below the surface of the material. Slightly modifying the ultrashort pulse laser processing conditions produces different types of sub-surface marks. When properly arranged, these marks are clearly visible with correctly aligned illumination through either light scattering or light reflection and nearly invisible without illumination. Transparent material other than glass may be utilized. A method for welding transparent materials uses ultrashort laser pulses to create a bond through localized heating. In some embodiments of transparent material processing, a multifocus beam generator simultaneously forms multiple beam waists spaced depthwise relative to the transparent material, thereby increasing processing speed.

Owner:IMRA AMERICA

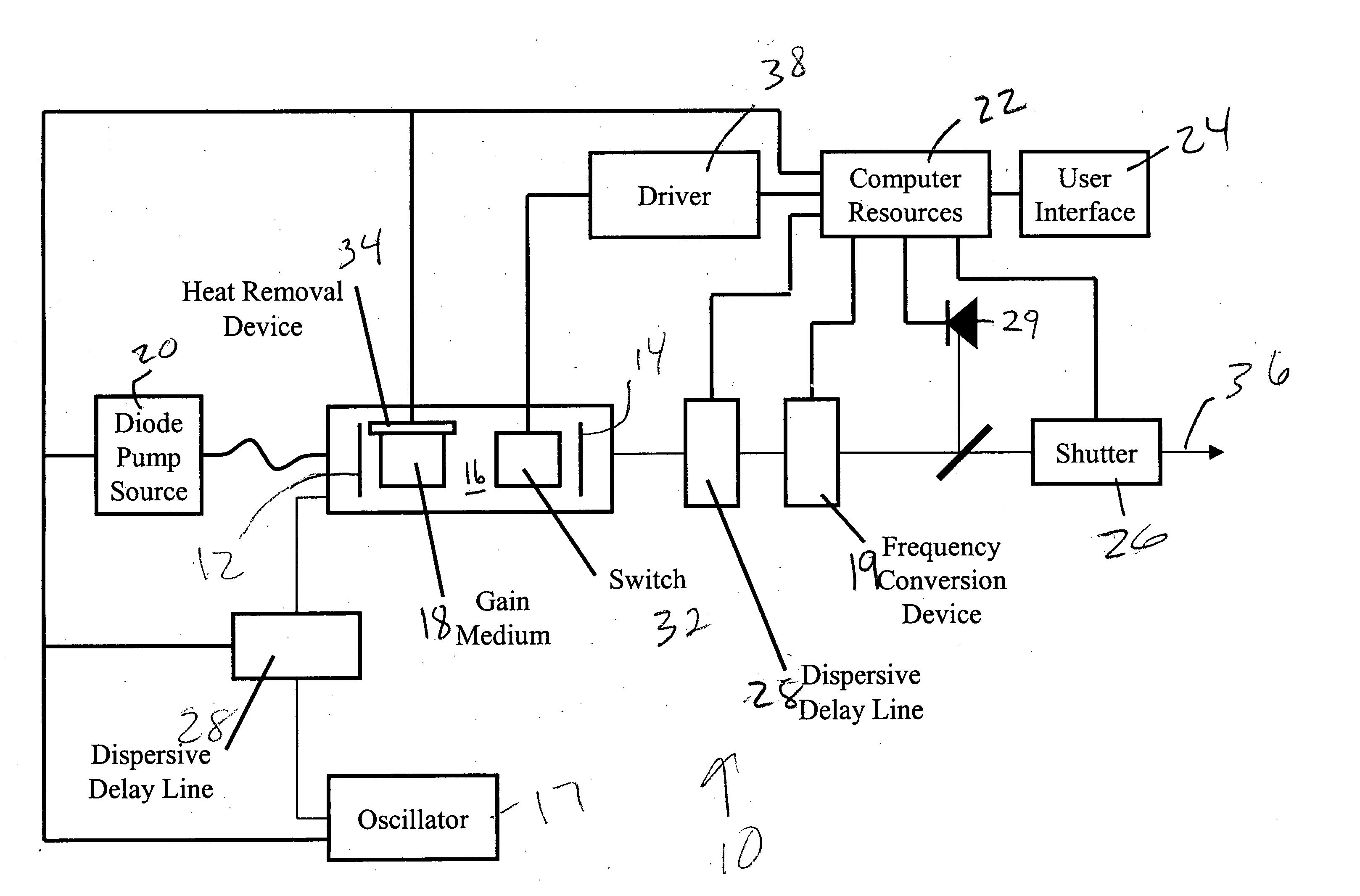

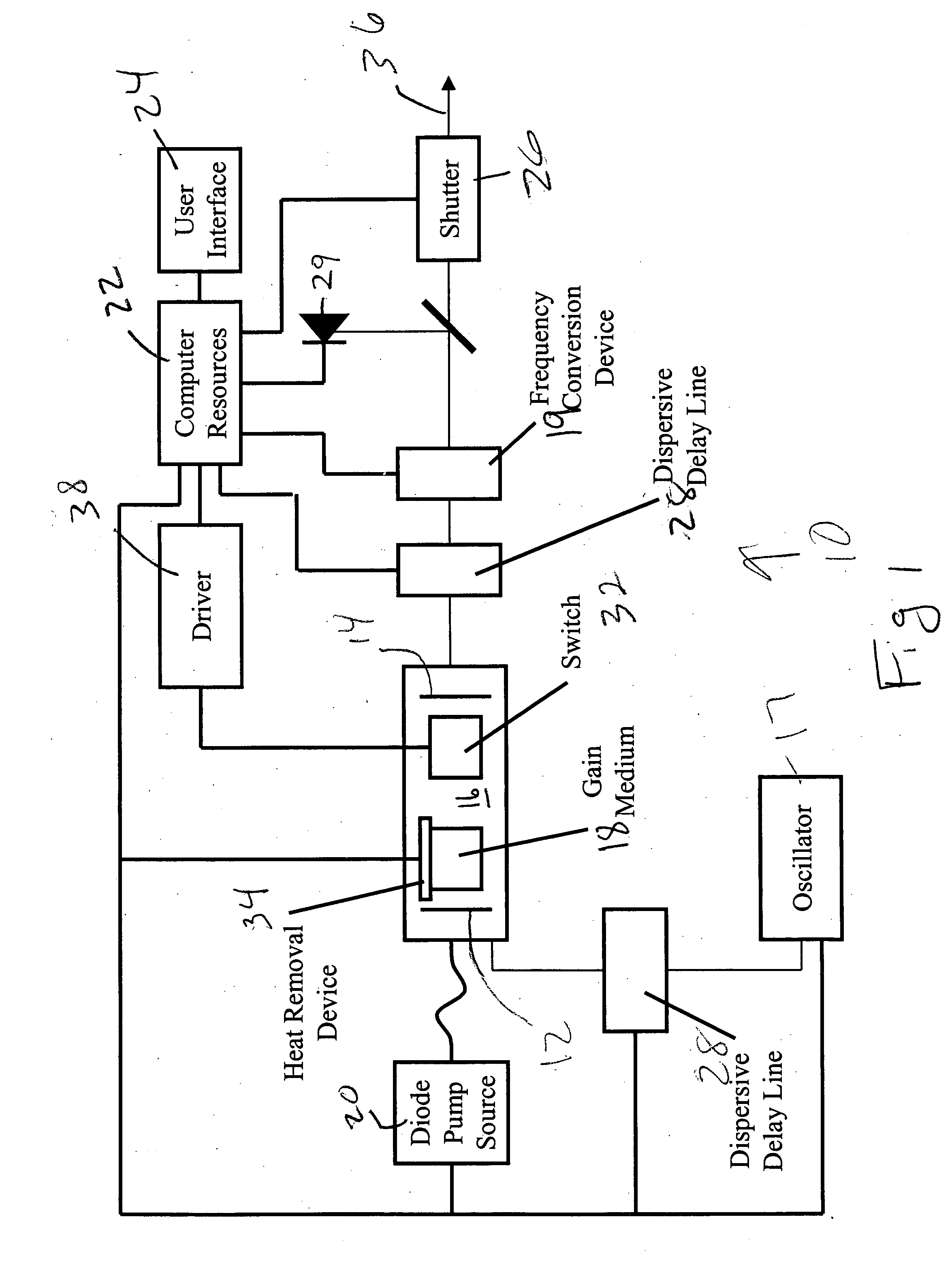

Industrial directly diode-pumped ultrafast amplifier system

InactiveUS20050157382A1Provide controlLaser arrangementsActive medium materialComputer resourcesAudio power amplifier

A directly diode-pumped amplifier system is disclosed which produces sub-picosecond pulses with an output power of 2 watts or more. Computer resources are coupled to the amplifier system and are configured to provide control of operating parameters of the amplifier system. An optional second harmonic generator is supplied to increase the contrast ratio and reduce the minimum focal spot size. This amplifier system can be utilized for material processing applications.

Owner:SPECTRA PHYSICS

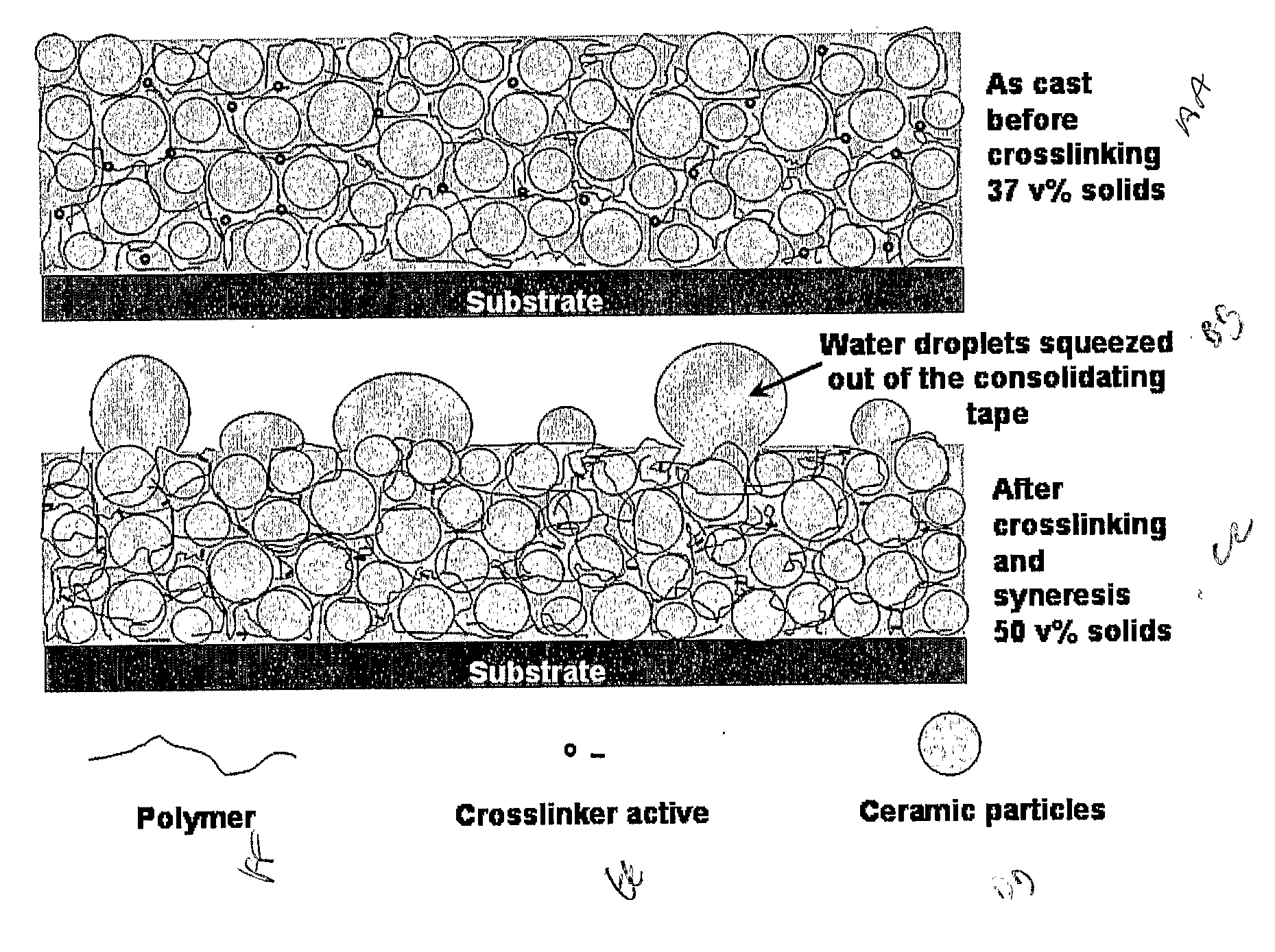

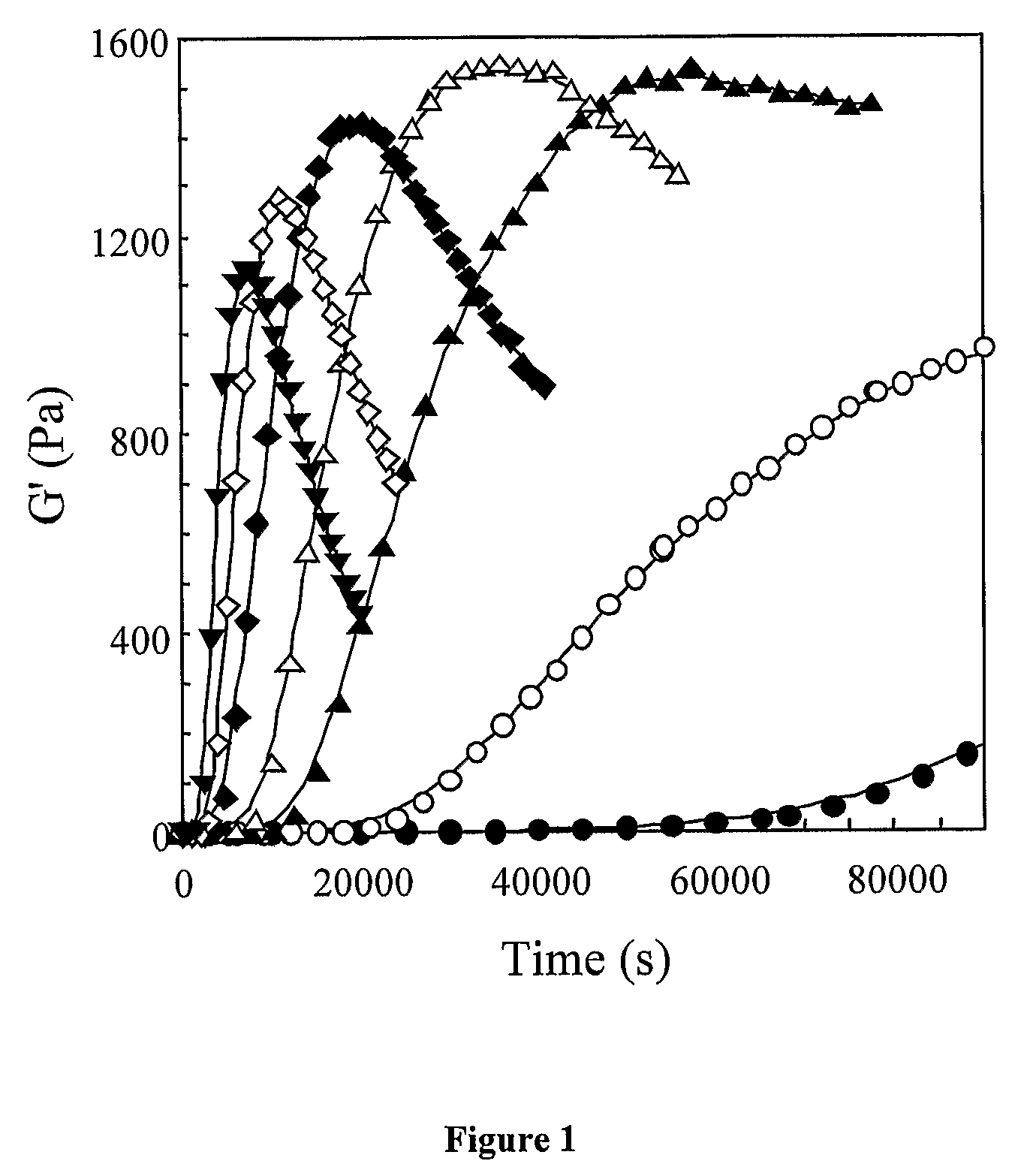

Ceramic and Metallic Components and Methods for Their Production from Flexible Gelled Materials

InactiveUS20080286590A1High viscosityIncrease the degree of cross-linkingMaterial nanotechnologySynthetic resin layered productsCross-linkFuel cells

Owner:ALBRIGHT & WILSON AUSTRALIA +4

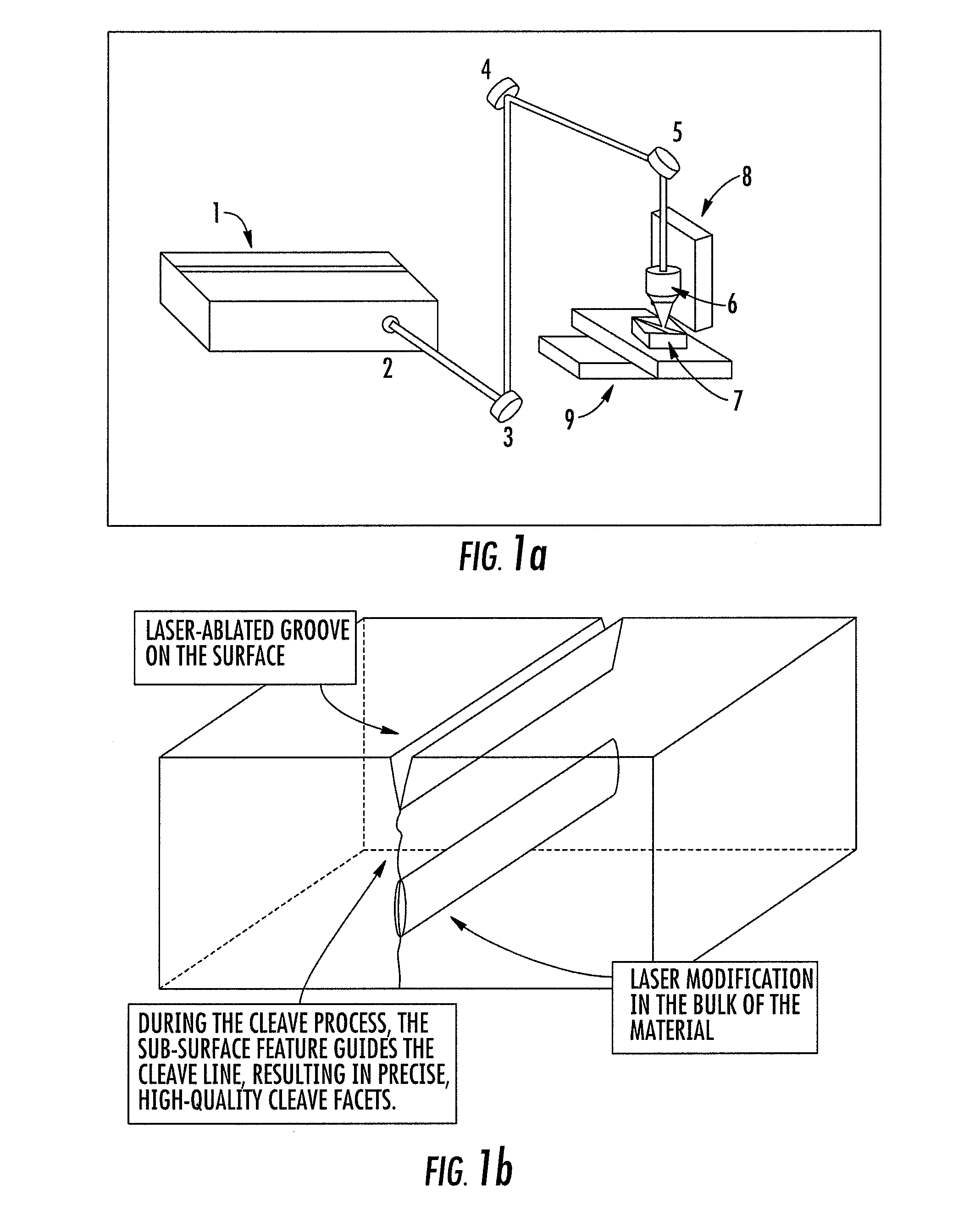

Method of material processing by laser filamentation

ActiveCN103079747ASemiconductor/solid-state device manufacturingGlass severing apparatusFilamentationExtra-location

A method is provided for the internal processing of a transparent substrate in preparation for a cleaving step. The substrate is irradiated with a focused laser beam that is comprised of pulses having an energy and pulse duration selected to produce a filament within the substrate. The substrate is translated relative to the laser beam to irradiate the substrate and produce an additional filament at one or more additional locations. The resulting filaments form an array defining an internally scribed path for cleaving said substrate. Laser beam parameters may be varied to adjust the filament length and position, and to optionally introduce V-channels or grooves, rendering bevels to the laser-cleaved edges.; Preferably, the laser pulses are delivered in a burst train for lowering the energy threshold for filament formation, increasing the filament length, thermally annealing of the filament modification zone to minimize collateral damage, improving process reproducibility, and increasing the processing speed compared with the use of low repetition rate lasers.

Owner:ROFIN SINAR TECH

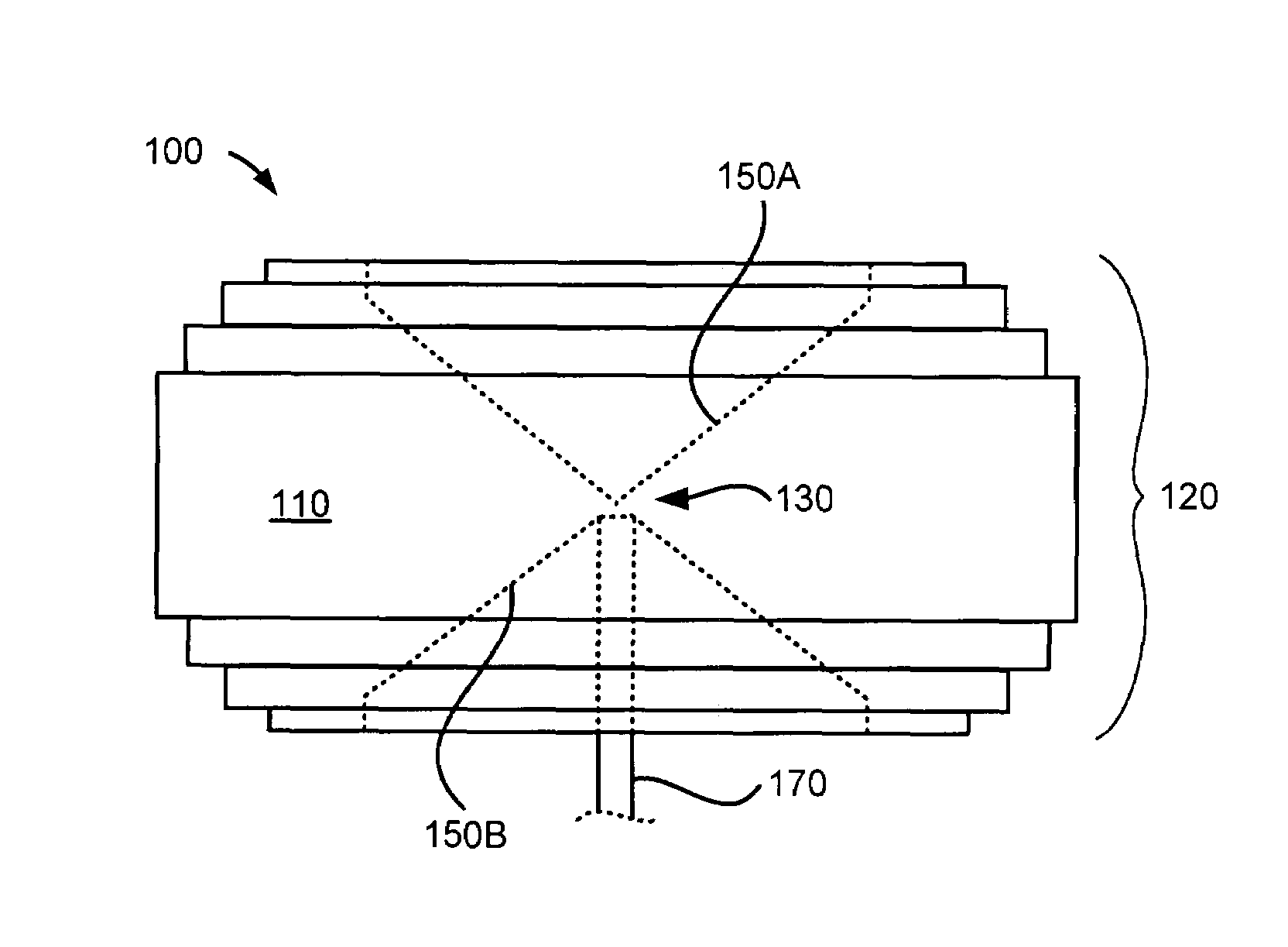

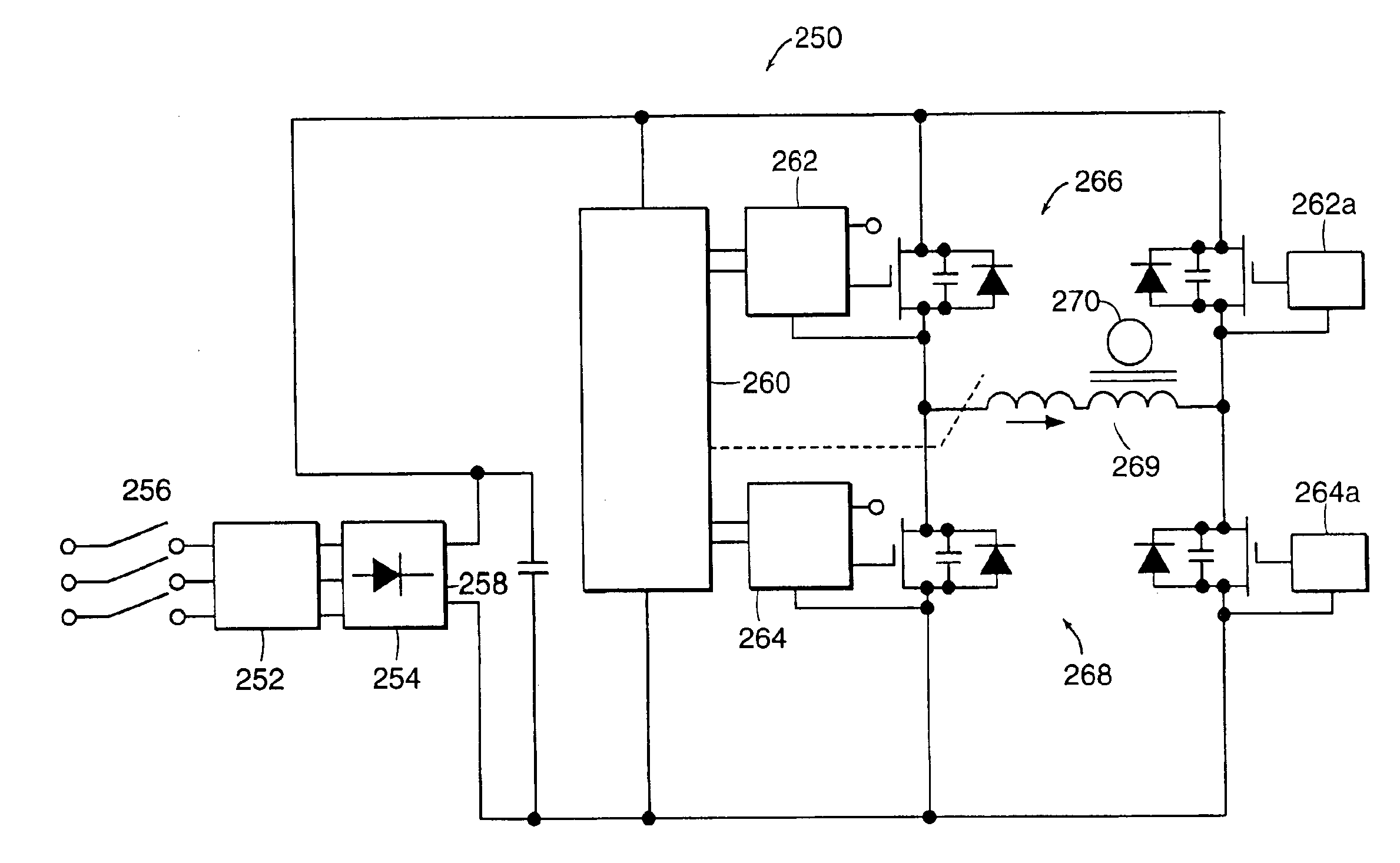

Integrated plasma chamber and inductively-coupled toroidal plasma source

InactiveUS6924455B1Improve efficiencyHigh rateCellsVacuum evaporation coatingEngineeringMaterials processing

A material processing apparatus having an integrated toroidal plasma source is described. The material processing apparatus includes a plasma chamber that comprises a portion of an outer surface of a process chamber. A transformer having a magnetic core surrounds a portion of the plasma chamber. The transformer has a primary winding. A solid state AC switching power supply comprising one or more switching semiconductor devices is coupled to a voltage supply and has an output that is coupled to the primary winding. The solid state AC switching power supply drives an AC current in the primary winding that induces an AC potential inside the chamber that directly forms a toroidal plasma that completes a secondary circuit of the transformer and dissociates the gas.

Owner:MKS ASTEX PROD GRP +1

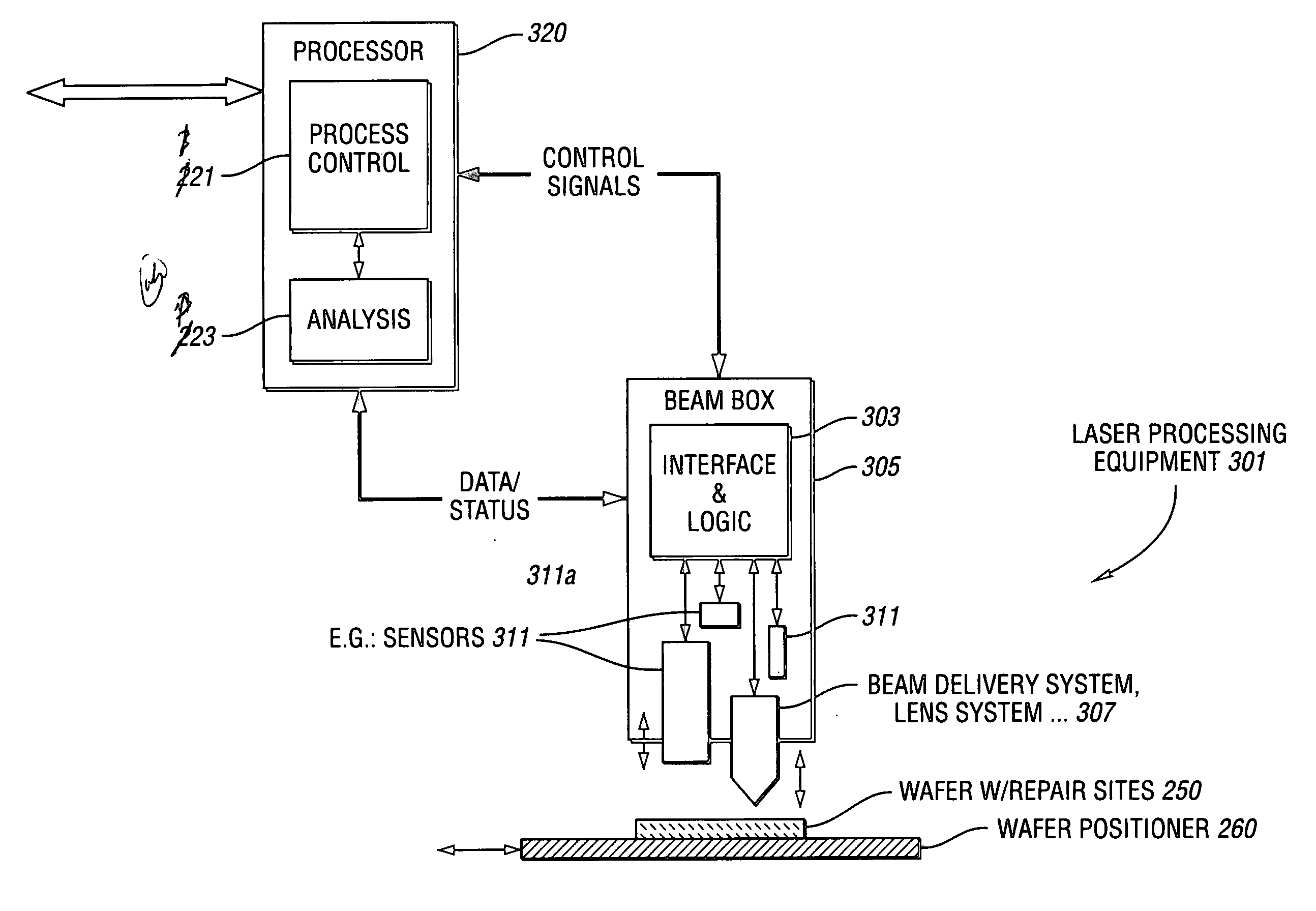

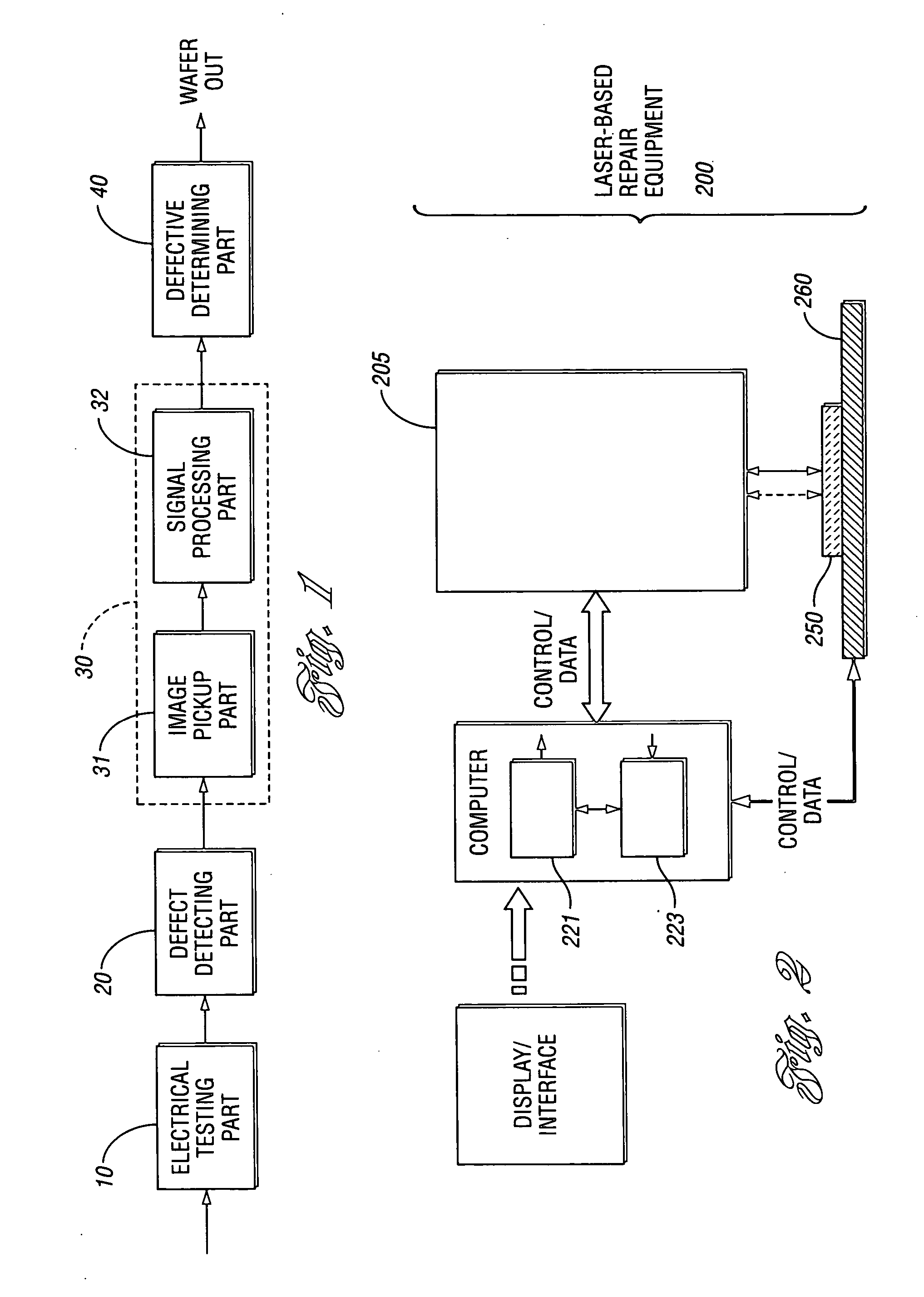

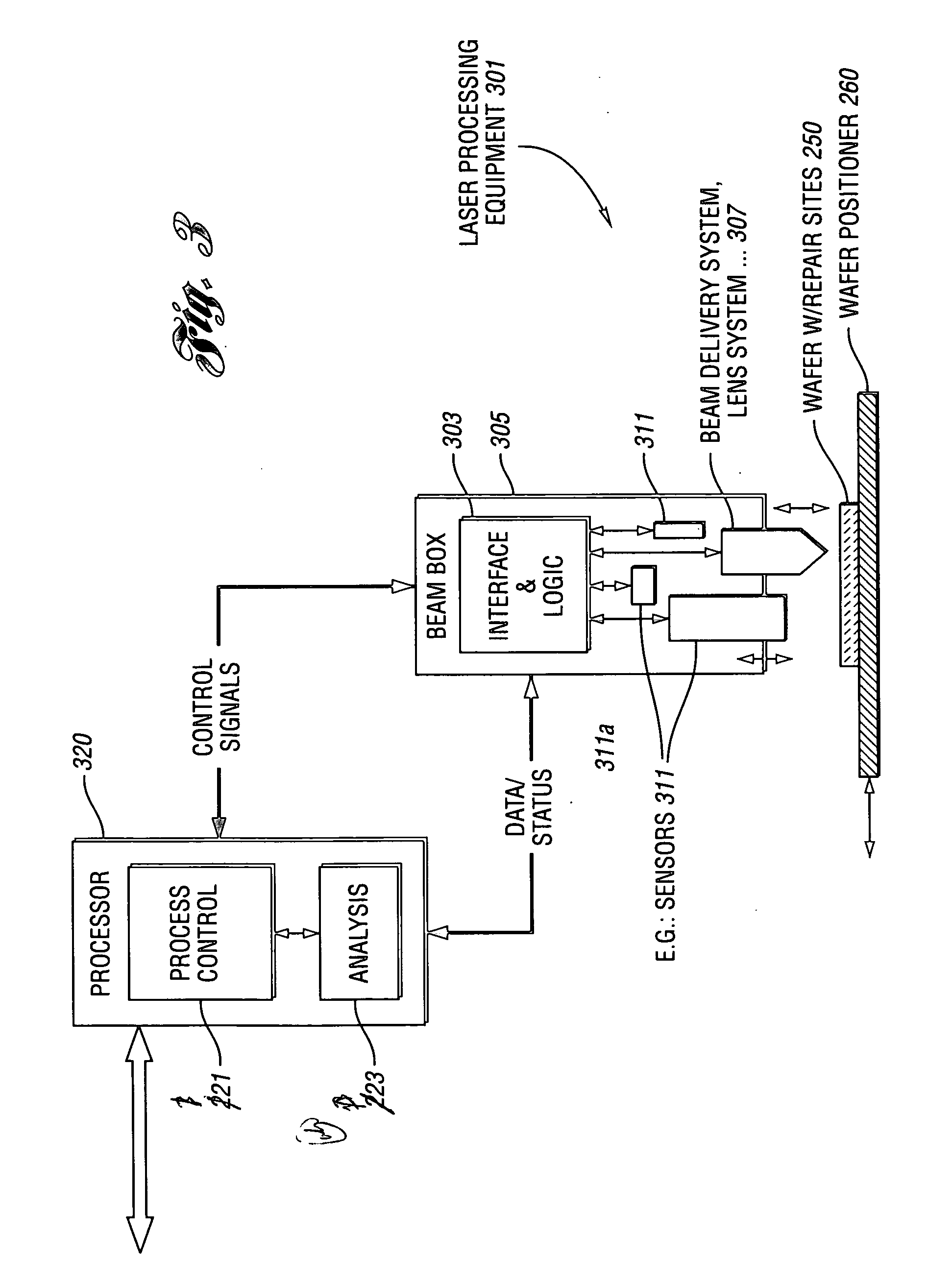

Method and system for adaptively controlling a laser-based material processing process and method and system for qualifying same

InactiveUS20070106416A1Increase productionEliminate unnecessary test stepSemiconductor/solid-state device testing/measurementComputer controlControl systemMaterials processing

A method and system for adaptively controlling a laser-based material processing process are provided. The system includes sensing equipment to measure a process variable or condition of at least one of a laser-based material processing system and a workpiece processed by the material processing system and to provide a corresponding measurement signal. The control system also includes a signal processor for processing the measurement signal to obtain a processed signal which initiates, at least semi-automatically, an action associated with at least one of the material processing system and the workpiece. A method and system for at least semi-automatically qualifying a laser-based material processing system which delivers laser energy to locations on or adjacent a plurality of microstructures formed on a workpiece to at least partially process the microstructures are also provided.

Owner:ELECTRO SCI IND INC

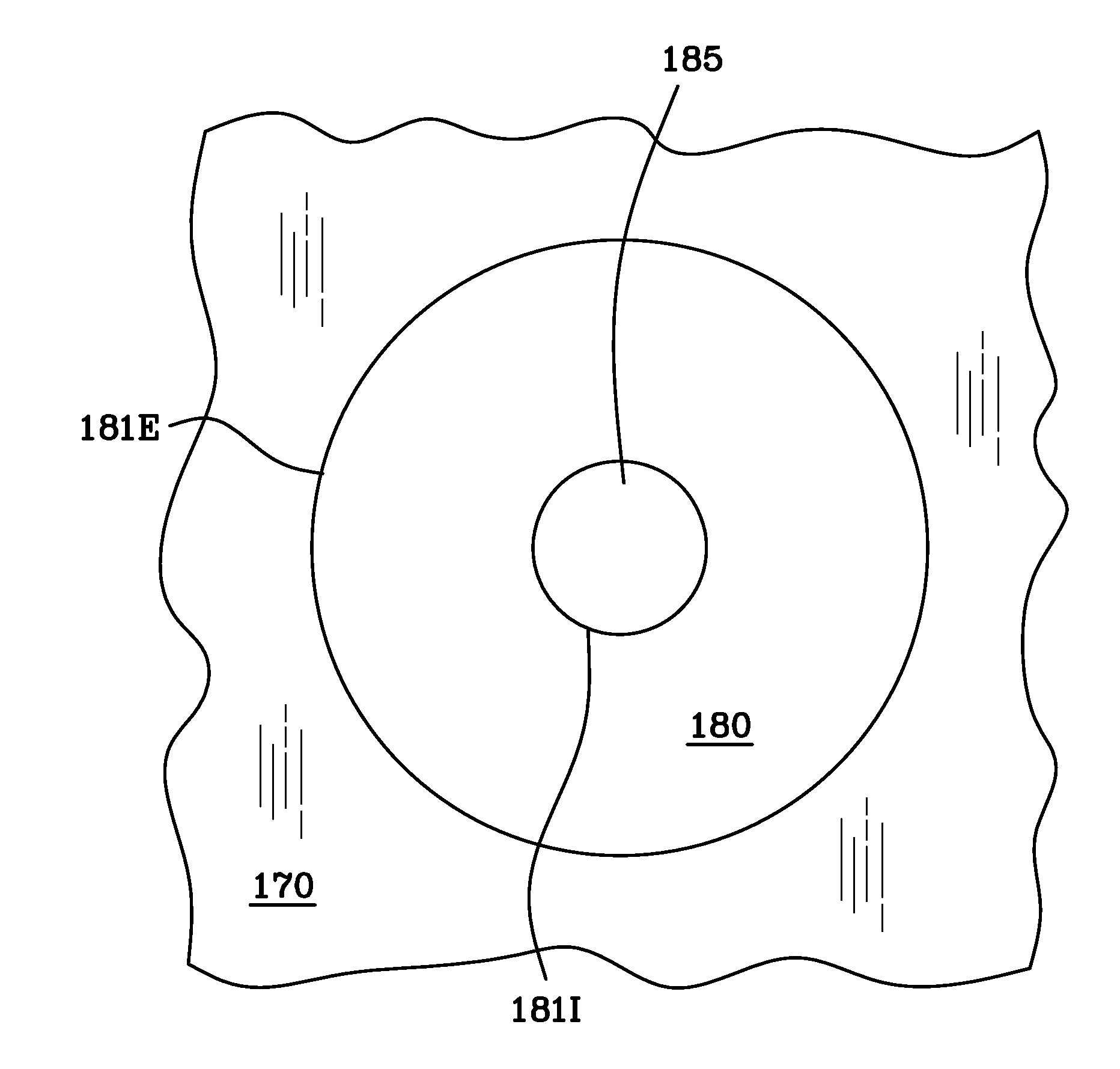

Method of fabricating a glass magnetic hard drive disk platter using filamentation by burst ultrafast laser pulses

ActiveUS20150118522A1Reduce manufacturing costExtreme precisionMagnetic materials for record carriersGlass furnace apparatusHard disc driveNon ablative

A non-ablative method and apparatus for making an economical glass hard disk (platter) for a computer hard disk drive (HDD) using a material machining technique involving filamentation by burst ultrafast laser pulses. Two related methods disclosed, differing only in whether the glass substrate the HDD platter is to be cut from has been coated with all the necessary material layers to function as a magnetic media in a computer's hard drive. Platter blanks are precisely cut using filamentation by burst ultrafast laser pulses such that the blank's edges need not be ground, the platter's geometric circularity need not be corrected and there is no need for further surface polishing. Thus the platters can be cut from raw glass or coated glass. As a result, this method reduces the product contamination, speeds up production, and realizes great reductions in the quantity of waste materials and lower production costs.

Owner:ROFIN SINAR TECH

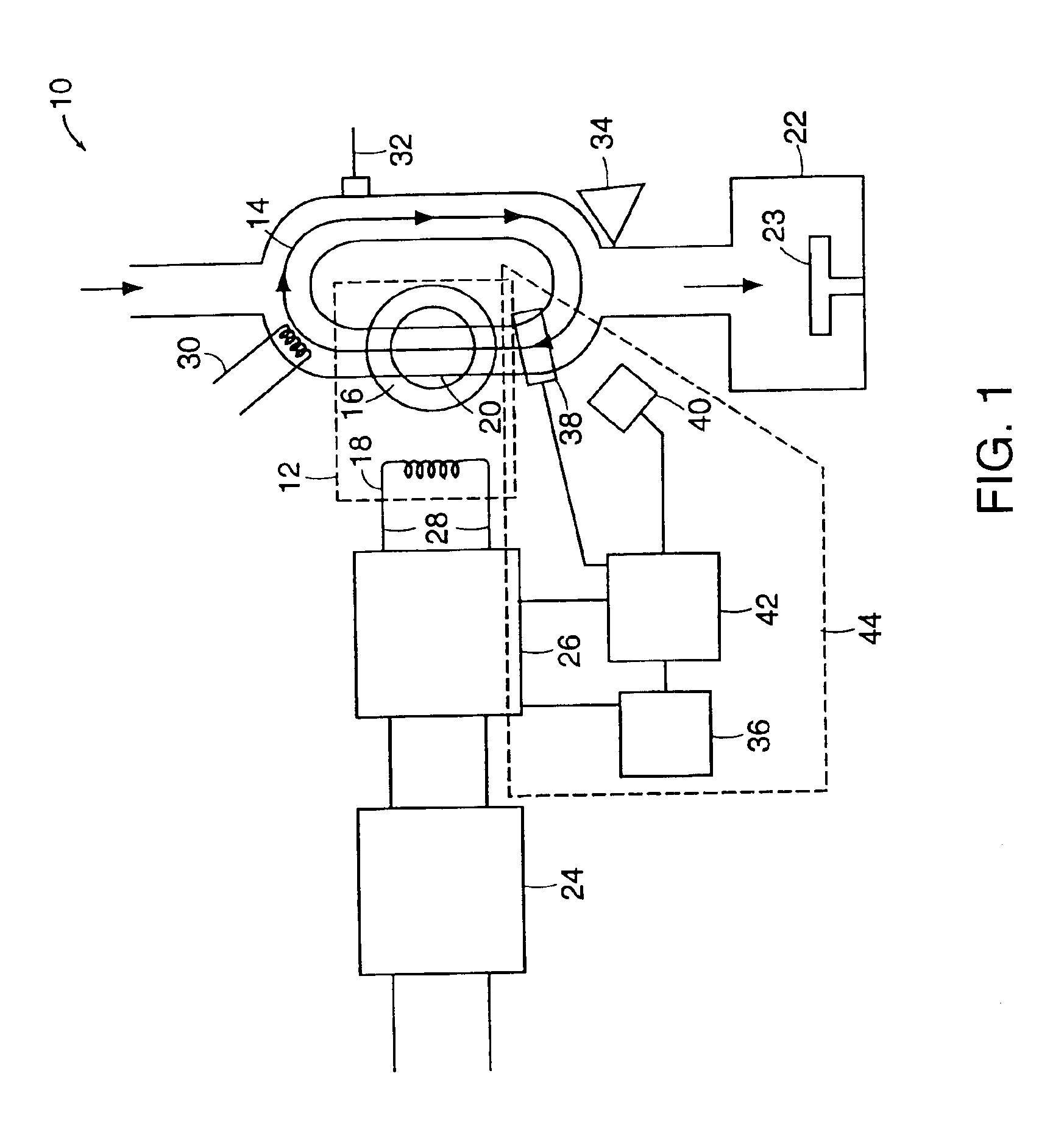

Microwave plasma apparatus and method for materials processing

ActiveUS20080173641A1Enhanced couplingReduce leakageMolten spray coatingArc welding apparatusMolten statePlasma jet

A microwave plasma apparatus for processing a material includes a plasma chamber, a microwave radiation source, and a waveguide guiding microwave radiation from the microwave radiation source to the plasma chamber. A process gas flows through the plasma chamber and the microwave radiation couples to the process gas to produce a plasma jet. A process material is introduced to the plasma chamber, becomes entrained in the plasma jet, and is thereby transformed to a stream of product material droplets or particles. The product material droplets or particles are substantially more uniform in size, velocity, temperature, and melt state than are droplets or particles produced by prior devices.

Owner:6K INC +1

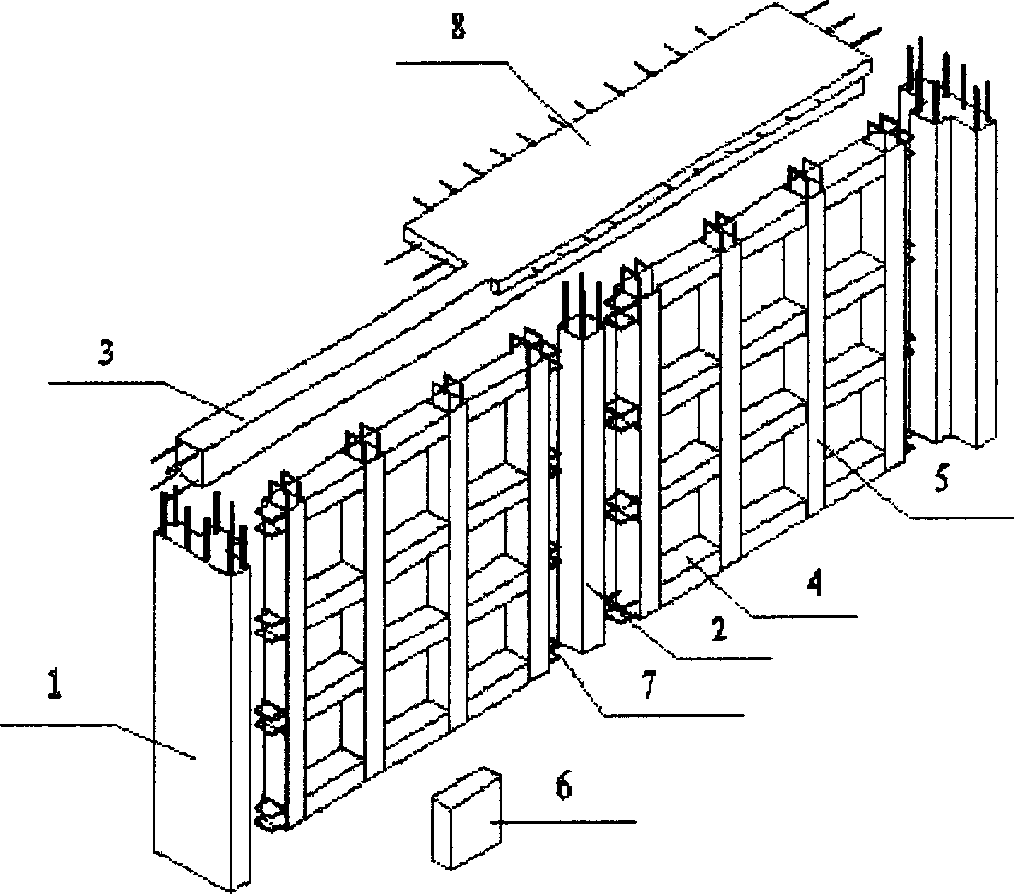

Multi-rib structure system and its connection construction method

InactiveCN1804263AAchieve graded releaseMeet the energy-saving requirements of light buildingsWallsFloor slabPre stressing

The invention relates to a ribbed structure which comprises a ribbed composite wall plate, a hidden frame and a floor. Wherein, the ribbed composite wall plate is a network construction element formed by reinforced steel concrete and light material and divided by the reinforced steel concrete beam as rib beam and rib post in small sections with embedding light material stuffing blocks into the grid; the ribbed composite wall plate also comprises the goatee bar extending from the rib beam and rib post, which is four steel bars with certain anchoring length extending from each rib beam and post and is longitude steel bar whose end is a hook in connection to hook hidden frame; or else the goatee bars are two U-shape closed ring extending from each rob beam an post and is inserted with longitude steel bars in connection; the hidden frame is formed by outer frame post, connection post, and hidden beam which are embedded outside the ribbed composite wall plate while using common concrete, profiled bar concrete or steel structural beam and post; the stuffing material is made from light material with certain strength, volume weight and little elastic modulus; and the floor can select on-situ irrigating concrete, on-sit or prefabricated ribbed composite floor, pre-stress layered floor or special-shaped pre-stress hollow floor.

Owner:姚谦峰

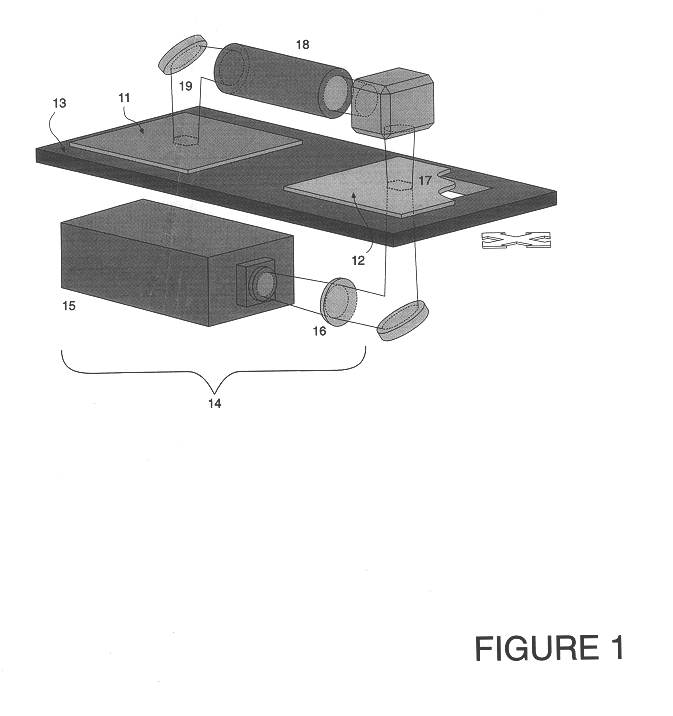

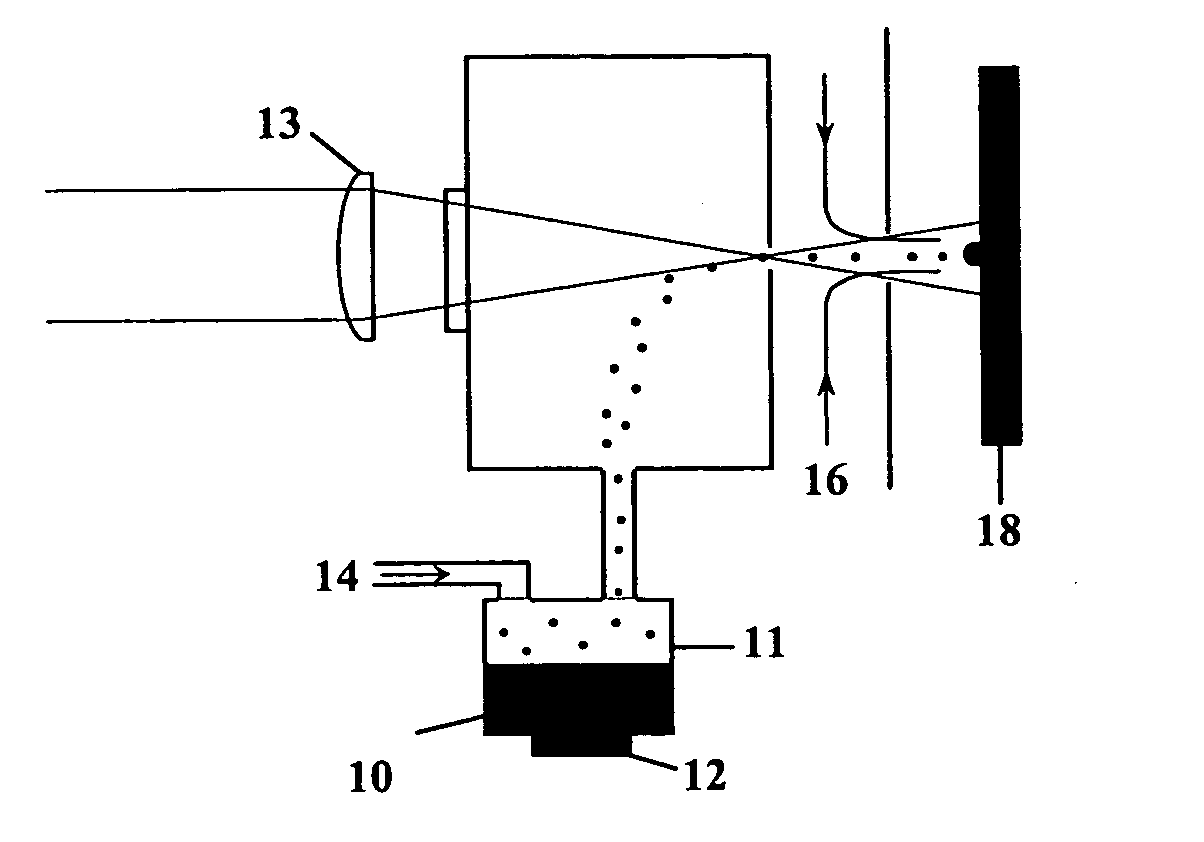

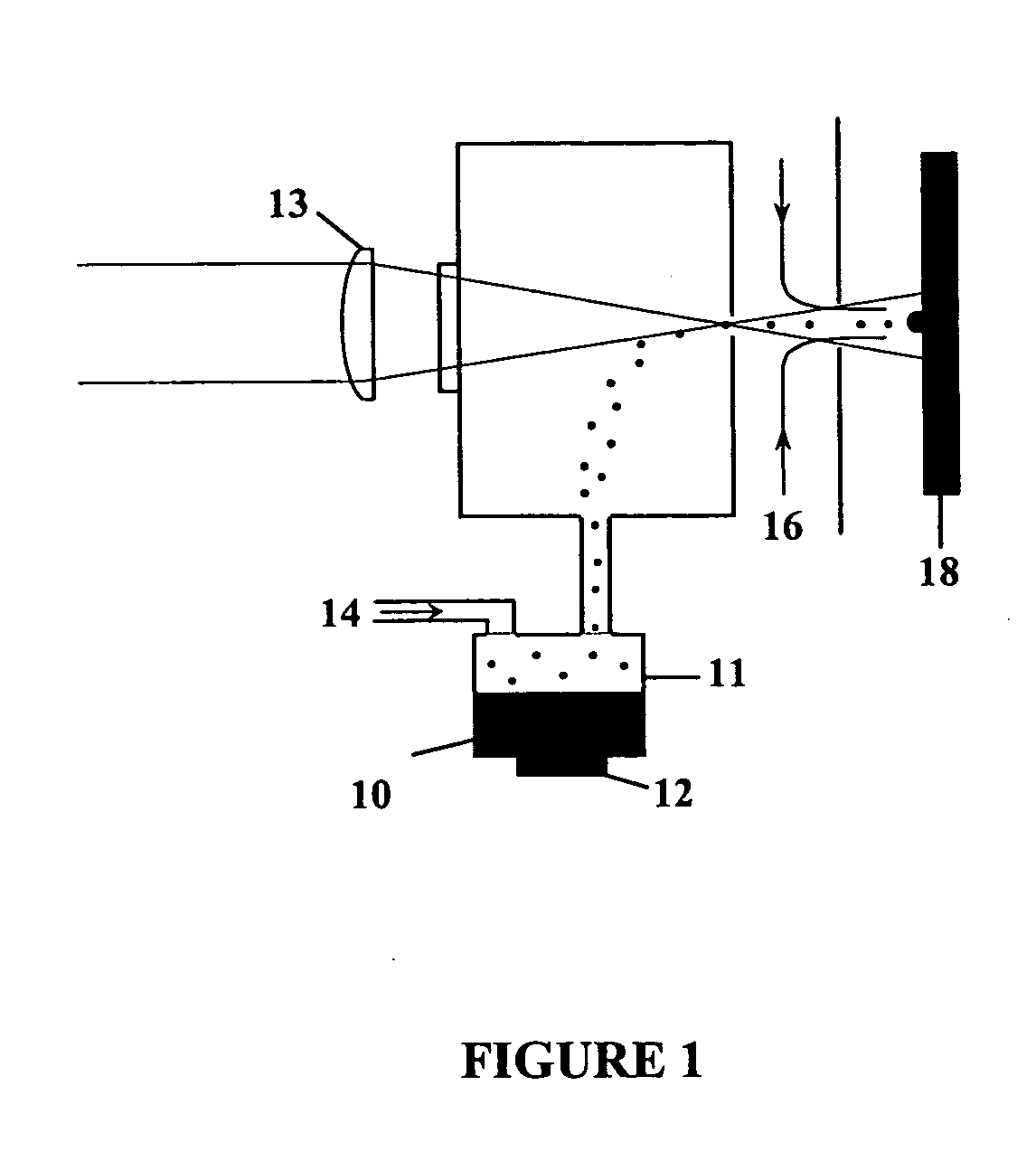

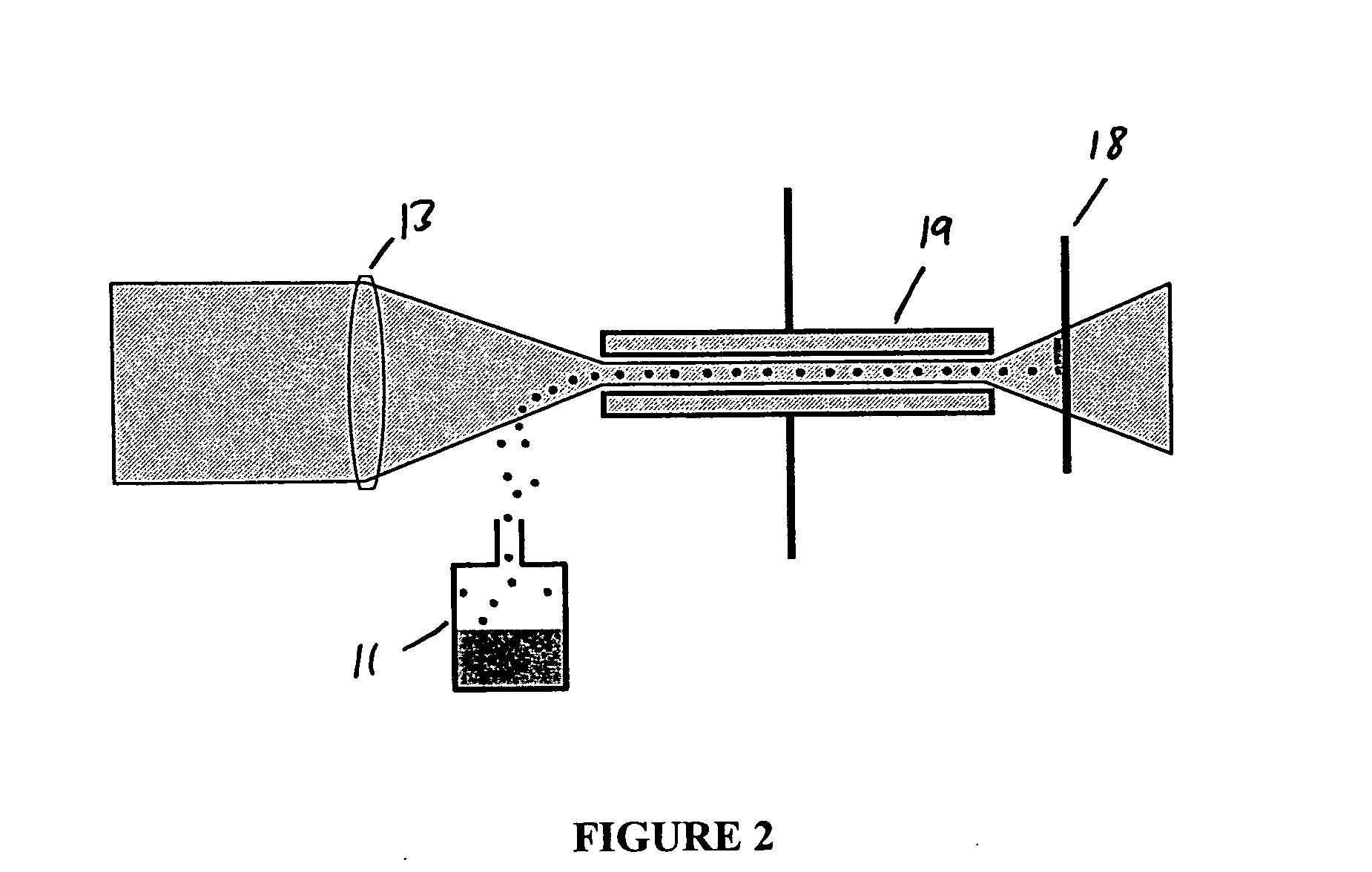

Maskless direct write of copper using an annular aerosol jet

InactiveUS20050156991A1Prevent crystallizationLower decomposition temperatureSolid-state devicesLiquid/solution decomposition chemical coatingLaser processingSource material

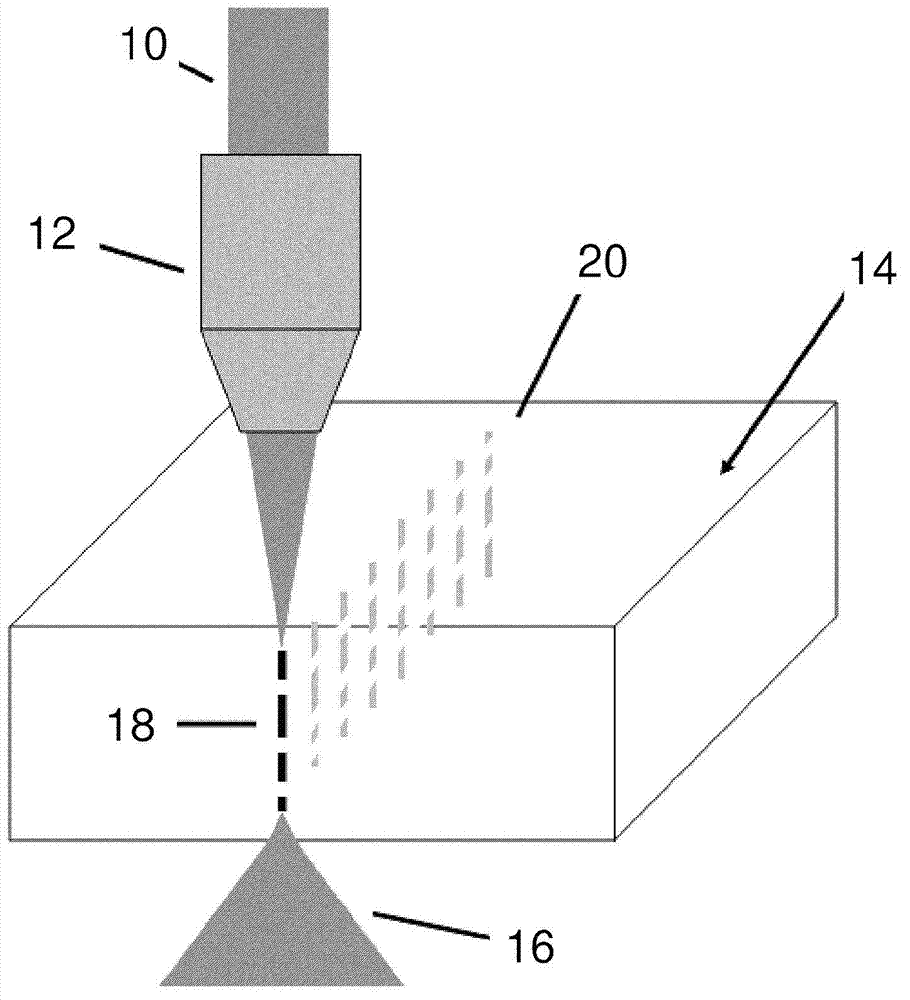

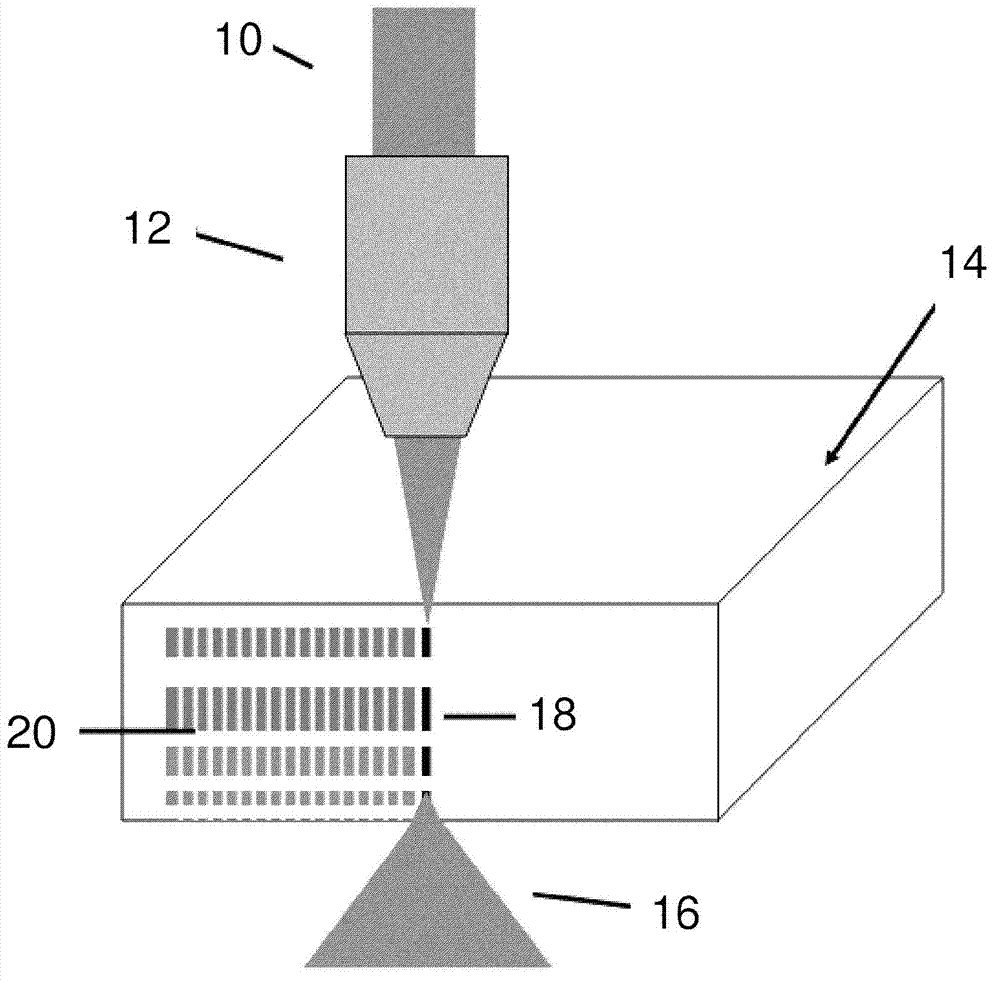

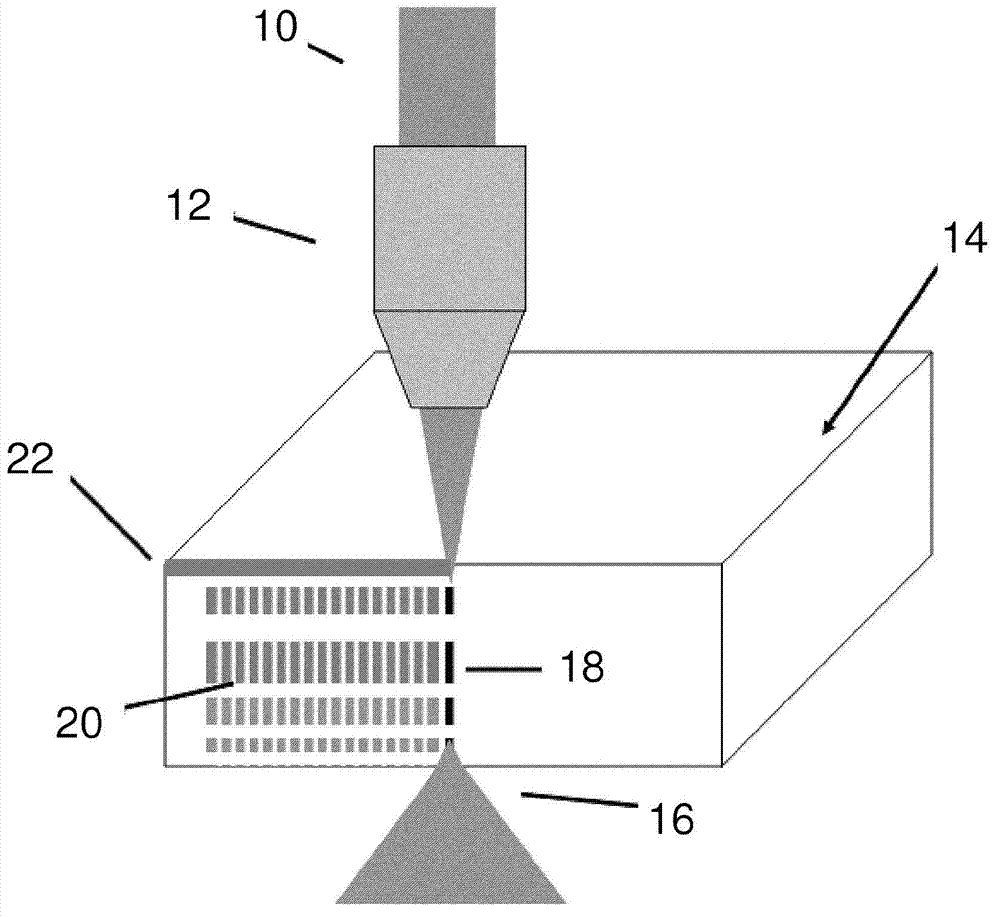

Methods and apparatus for the deposition of a source material (10) are disclosed. An atomizer (12) renders a supply of source material (10) into many discrete particles. A force applicator (14) propels the particles in continuous, parallel streams of discrete particles. A collimator (16) controls the direction of flight of the particles in the stream prior to their deposition on a substrate (18). In an alternative embodiment of the invention, the viscosity of the particles may be controlled to enable complex depositions of non-conformal or three-dimensional surfaces. The invention also includes a wide variety of substrate treatments which may occur before, during or after deposition. In yet another embodiment of the invention, a virtual or cascade impactor may be employed to remove selected particles from the deposition stream. Also a method and apparatus for maskless deposition of copper lines on a target, specifically relating to localized solution-based deposition of copper using an annular aerosol jet and subsequent material processing using conventional thermal techniques or laser processing.

Owner:OPTOMEC DESIGN CO

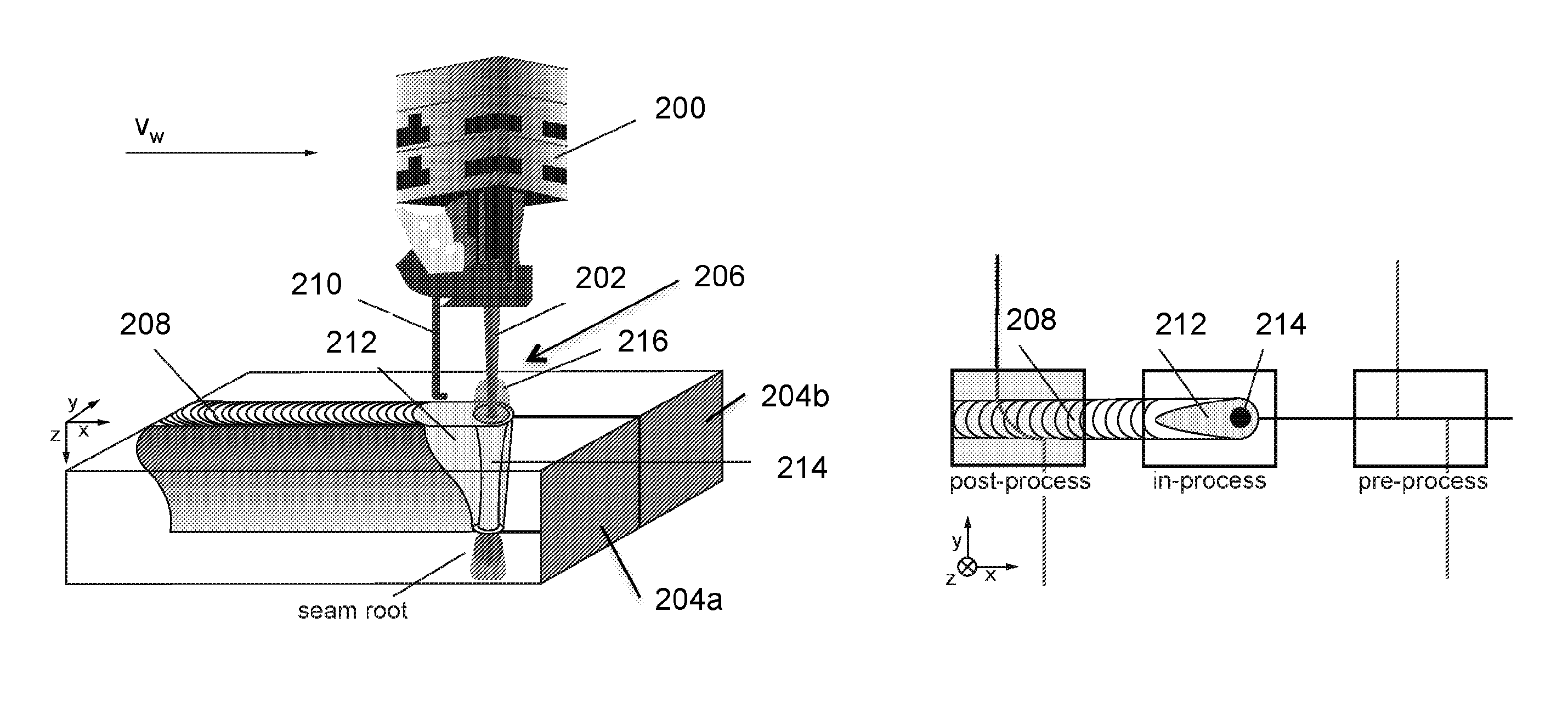

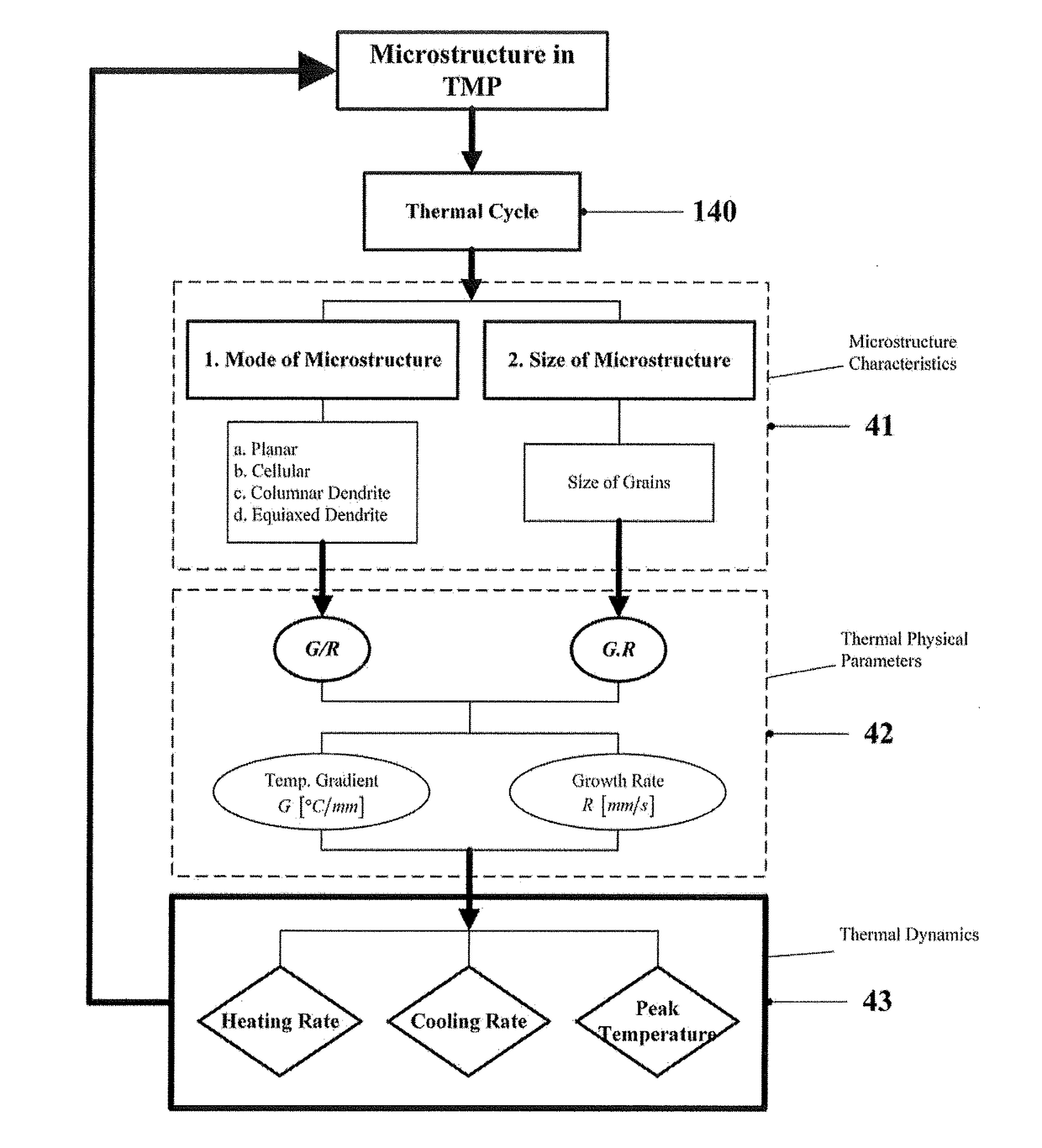

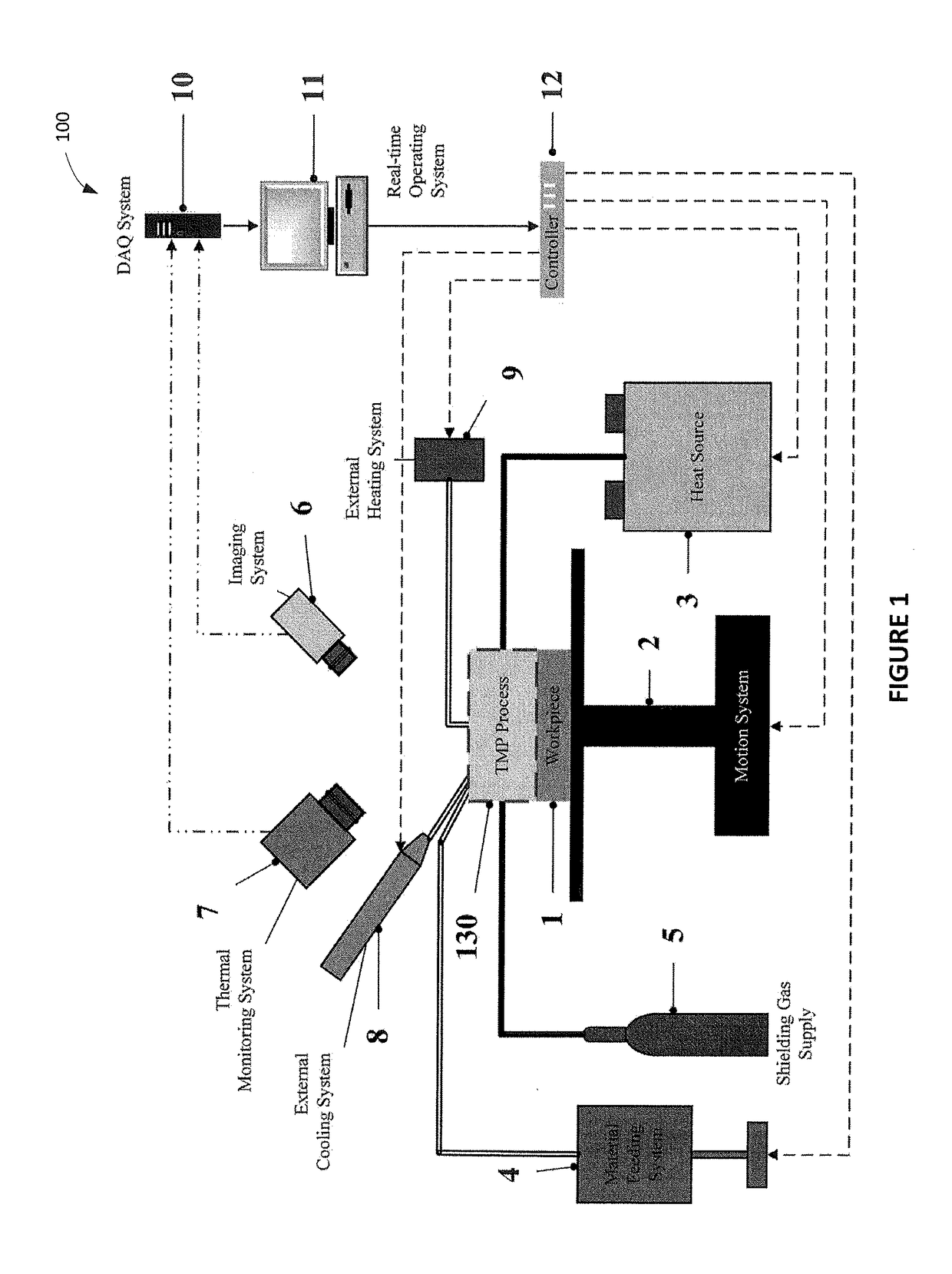

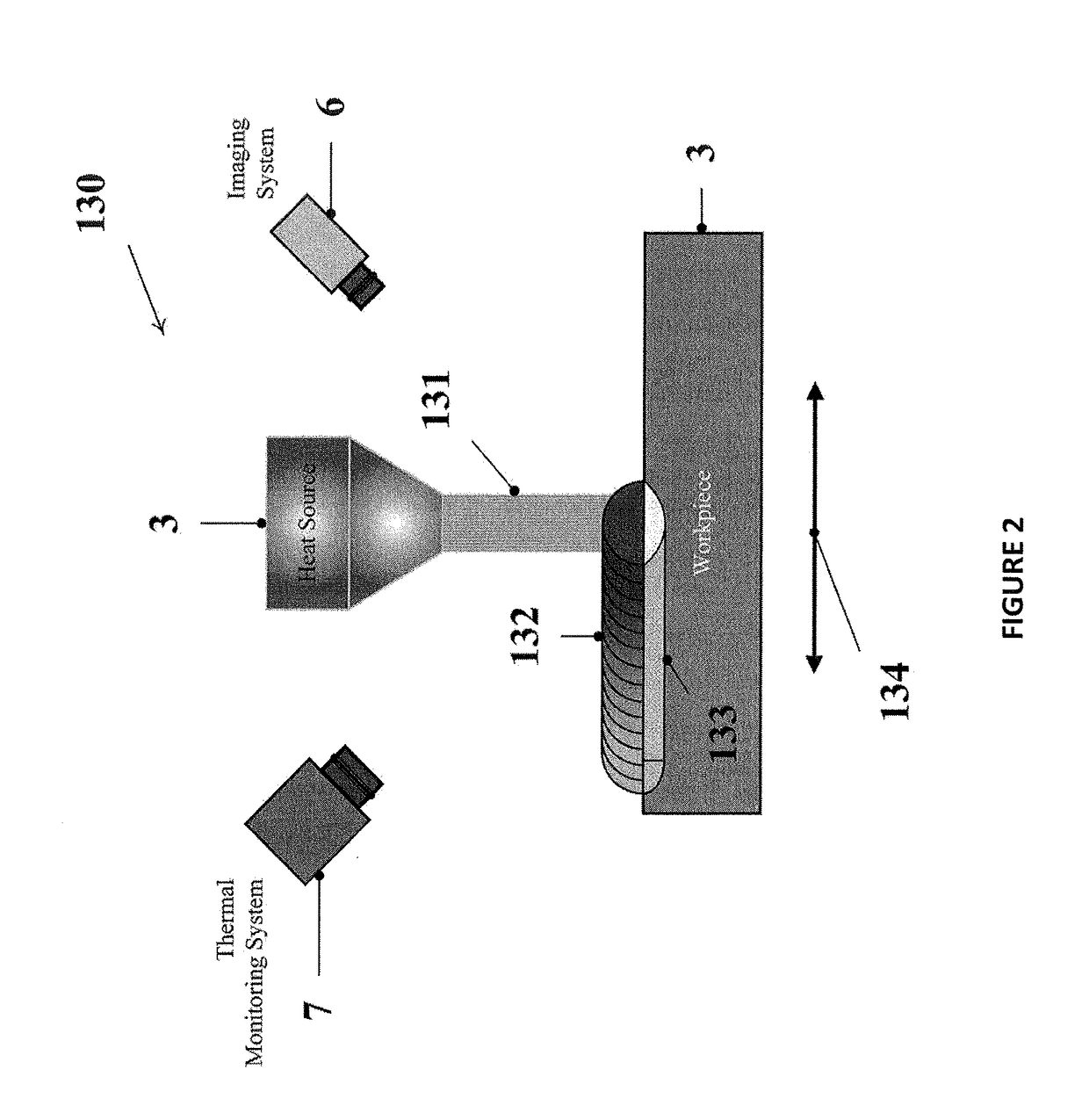

System and method for real time closed-loop monitoring and control of material properties in thermal material processing

ActiveUS20170102689A1Programme controlAdditive manufacturing apparatusProcess engineeringMonitoring and control

The disclosure is directed at a method and apparatus for integrated real-time monitoring and control of microstructure and / or geometry in thermal material processing (TMP) technologies. The method includes obtaining real-time thermal dynamic variables, such as, but not limited to the cooling rate, peak temperature and heating rate, and geometry of the thermal material process. These real-time thermal variables are then analyzed along with a thermal model to determine a microstructure / geometry model. This microstructure / geometry model can then be used to provide the real-time monitoring and control of a finished state for the material being processed by the thermal material processing procedure.

Owner:KHAJEPOUR AMIR +2

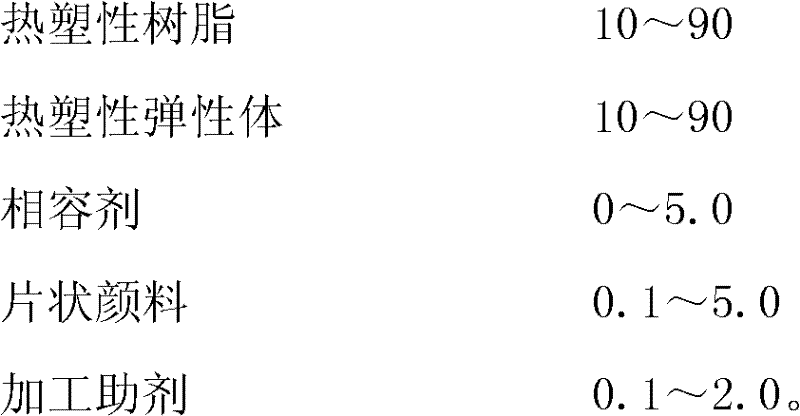

Resin composition for temperature control indication

ActiveCN102516789ARepeatable and reversible instructionsFlexible color designTemperature controlElectron probe microanalysis

The invention relates to a resin composition for temperature control indication. The resin composition comprises the following ingredients, by weight: 10-90 parts of thermoplastic resin, 10-90 parts of thermoplastic elastomer, 0-5.0 parts of compatilizer, 0.1-5.0 parts of sheet pigment and 0.1-2.0 parts if processing auxiliary agent. Compared with a prior art, the thermoplastic resin composition prepared by the invention can be used for temperature control and alarm indication; compared with traditional temperature display methods of electron microprobe, infrared radiation and mercury thermometer, the preparation method has advantages of simpleness, effectiveness, sensitive reaction and low cost, can be widely applied to temperature control alarm of large and small machinery equipment and apparatuses and has huge market prospect in fields of machinery and material processing, chemical engineering, electronic apparatus and monitor on various experiment processes, etc.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com