Multi-rib structure system and its connection construction method

A dense rib and system technology, applied in building components, building structures, walls, etc., can solve the problems of low seismic resistance and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

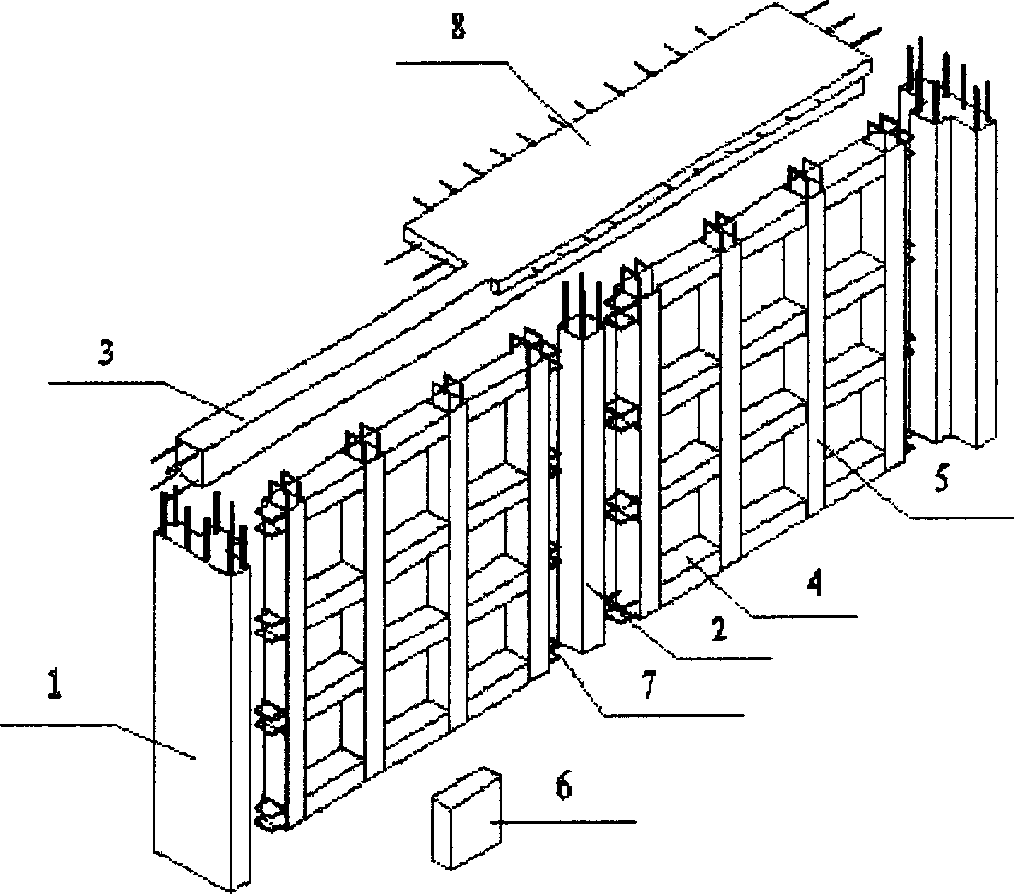

[0035] The dense-rib structure system of the present invention adopts an assembled integral structure scheme, and is mainly composed of dense-rib composite wall panels, invisible frames 1, 2, 3 and floor slabs 8 .

[0036] 1. Composite ribbed wall panel: the structural wall is divided by reinforced concrete beams and columns with smaller cross-sections, that is, ribbed beams and columns 4 and 5, to form grid-like wall pieces, and light-weight material filling blocks are embedded in the grid 6. Form a building component composed of reinforced concrete and lightweight materials. There are connecting steel bars protruding from the reinforced concrete girder columns on the side of the wall panel. During the construction process, the composite wall panel with dense ribs is assembled, and it is firmly connected with the invisible frame 1, 2, and 3 to form a dense rib structure. The reinforced concrete beam with a small cross-section The columns are called rib beam columns 4,5.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com