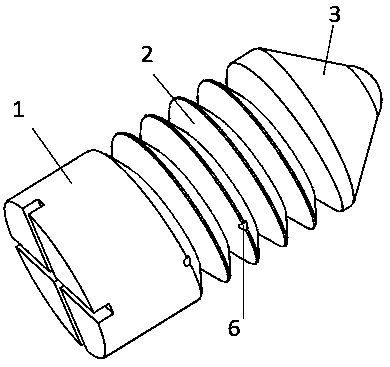

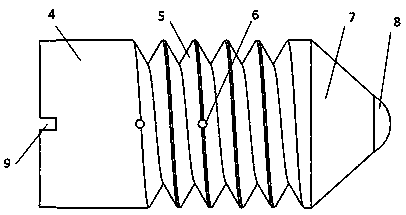

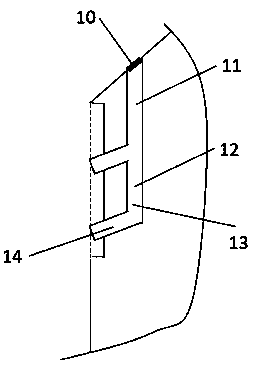

Degradable bioactive screw and manufacturing method thereof

A bioactive, screw technology, applied in the field of biodegradable bioactive screws and their manufacturing, can solve the problems of low mechanical strength, tunnel expansion, screw loosening, etc., and achieve high mechanical strength, fast and low-cost manufacturing, and good ligament fixation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] 1) Mix the calcium magnesium silicate powder and the photosensitive resin solution uniformly according to the mass percentage of 1.1:1 to obtain a uniformly dispersed bio-ink, and mix atorvastatin with a 5% polyvinyl alcohol solution to obtain Drug-loaded polyvinyl alcohol solution.

[0072] 2) According to the shrinkage rate of the material before and after sintering, the final shape and size of the screw, design the model before calcination, and convert the model into an STL file format that can be recognized by the light-curing printer, and then import it into the light-curing printer.

[0073] 3) Add the bio-ink configured in step 1) into the liquid storage tank of the light-curing printer, start the light-curing printer, and the printer will cure the bio-ink layer by layer according to the designed parameters, and finally get the screw blank.

[0074] 4) Wash the screw blank in step 3) with water to remove the uncured bio-ink on the surface of the screw blank and i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com