Patents

Literature

196 results about "Stl file" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

STL (file format) STL (an abbreviation of "stereolithography") is a file format native to the stereolithography CAD software created by 3D Systems.

Method for forming refractory metal parts by using laser

InactiveCN101780544AHigh densityControl the degree of densificationIncreasing energy efficiencyMetallic material coating processesSelective laser meltingSoftware design

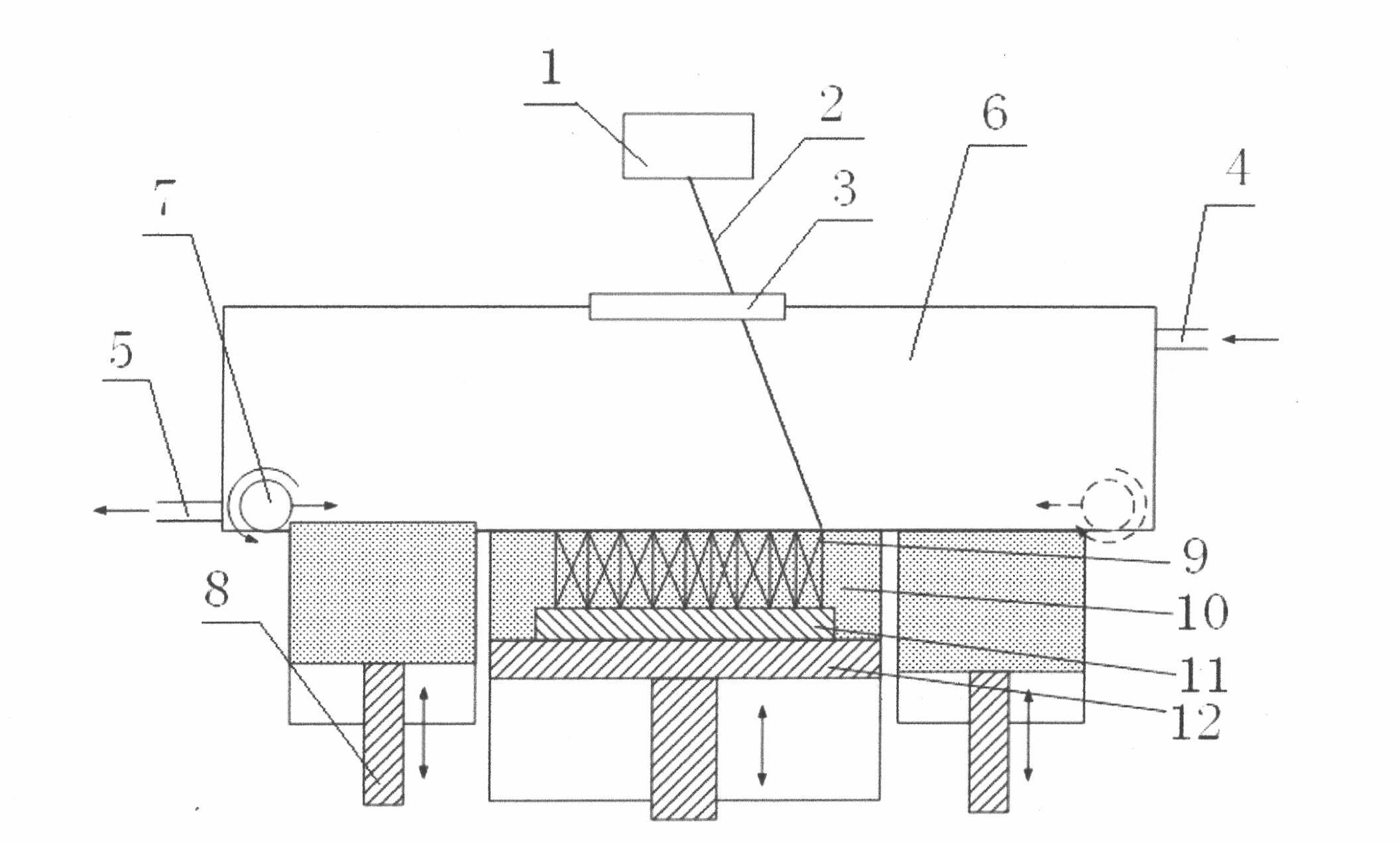

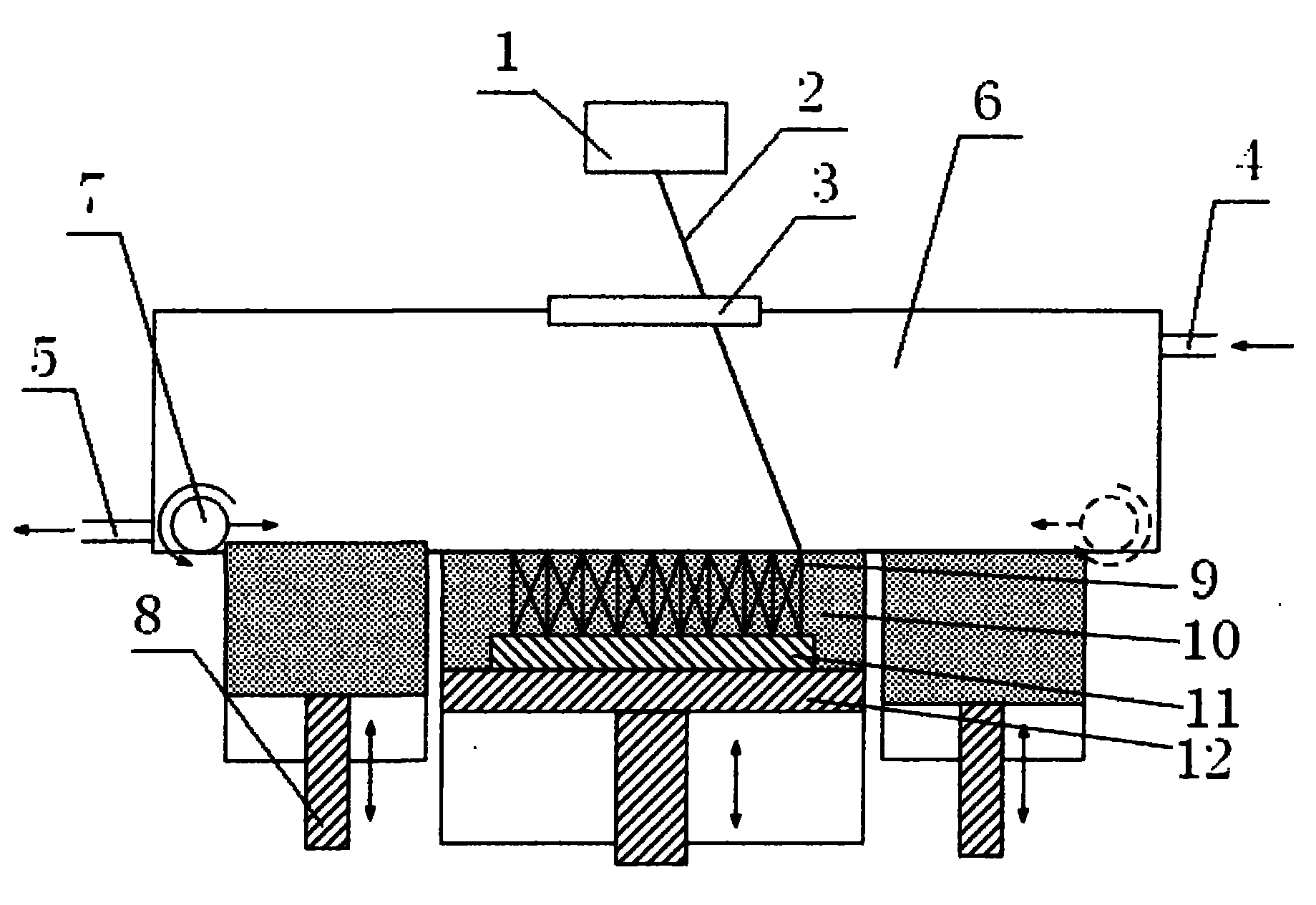

The invention provides a method for preparing parts with high-melting point metal powder and the method combines selective laser fusion rapid prototyping technology with powder sintering and forming technology. The method comprises the following steps: firstly, a three-dimensional modeling software is used to design the CAD models of parts, secondly, a slice processing software is used to generate multilayer slice information to be stored as STL files, the data of the STL files are transmitted to a selective laser melting rapid forming system; then in the selective laser melting rapid forming system, a layer of powder to be processed with the thickness of 0.05-0.2mm is laid on a platform by a powder-sending mechanism, a YAG laser or optical fiber laser with the laser power of more than 200W is used to scan the powder to be processed in a scanning speed of 20-300mm / s; and finally the powder is molten to accumulate the parts. The method does not need moulds and is characterized in that the technology has high controllability, does not adopt post-processing, is simple and practical and can be used to prepare parts with complicated shapes.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

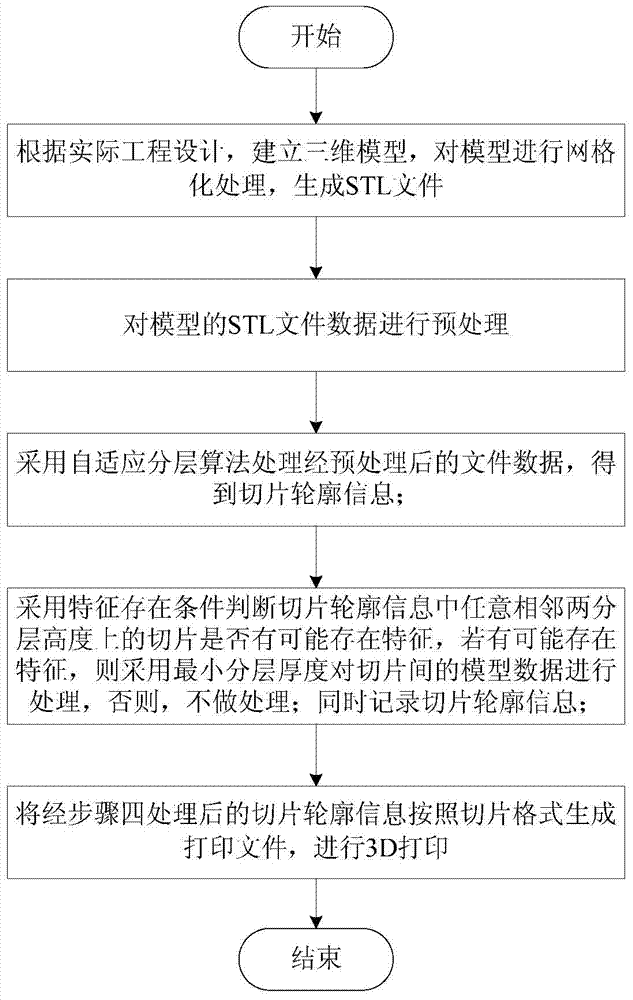

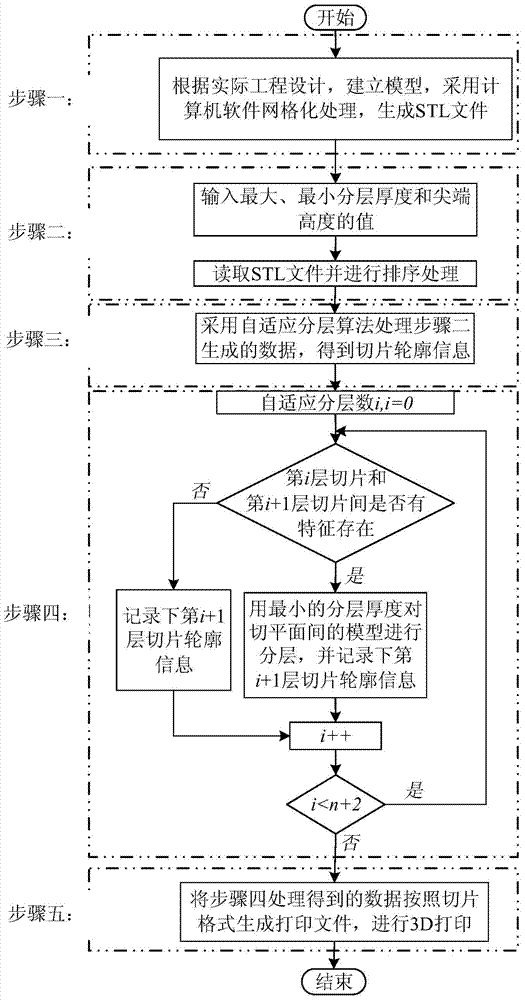

3D (three-dimensional) printing adaptive slicing method capable of reserving model features

ActiveCN104708824ASolve the lossResolve offsetAdditive manufacturing apparatusAlgorithmLayer thickness

The invention relates to a 3D (three-dimensional) printing adaptive slicing method capable of reserving model features, and belongs to the technical field of 3D printing. The method comprises the following steps: (1) according to an actual project design, establishing a 3D model, performing grid processing on the model, and generating STL (standard template library) file data; (2) performing preprocessing on the STL file data of the model; (3) processing the preprocessed file data by adopting an adaptive layer algorithm, and obtaining slice contour information; (4) judging whether the features possibly exist in slices at any two adjacent layer heights in the slice contour information or not by adopting a feature existence condition, if judging that the features possibly exist, performing secondary slicing on the model data of the slices by adopting the minimum layer thickness lmin, or otherwise, not performing processing, and recording the slice contour information; (5) generating a printing file in a slice format by the slice contour information processed in the step 4, and performing 3D printing. The method can effectively shorten printing time and reduce memory usage amount and calculated amount.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

Entirety quick manufacture method of hot isostatic pressing metal wrapps

InactiveCN101391302ARelief of restrictions that make it difficult to make complex envelopesHot isostatic pressing process goes smoothlyAdditive manufacturing apparatusIncreasing energy efficiencyVacuum pumpingData information

The invention discloses an integral rapid manufacturing method of a hot isostatic pressing metal sheath, comprising the steps: (1) a CAD three-dimensional model of the metal sheath is designed by adopting three-dimensional molding software, and is then processed by slicing software and saved as an STL file, and the data information of the STL file is transmitted to an SLM rapid forming machine; (2) a forming chamber is vacuumized; (3) a metal powder layer is spread on a work platform flatly; (4) a semiconductor pumping YAG laser or a fiber laser is adopted to scan the metal powder positioned at the boundary of the slice layer, and the powder material at the boundary is melted; and (5) the step (3) and the step (4) are repeated until the compact sheath is manufactured. Powder inlet holes can be reserved on the sheath when designing the three-dimensional model of the sheath, so as to facilitate the subsequent processes such as powder filling, compaction by vibration, vacuum pumping and encapsulation. The sheath is compact and has a controllable shape, and can form parts with any complex shapes and structures, and can realize the high utilization rate of material.

Owner:HUAZHONG UNIV OF SCI & TECH

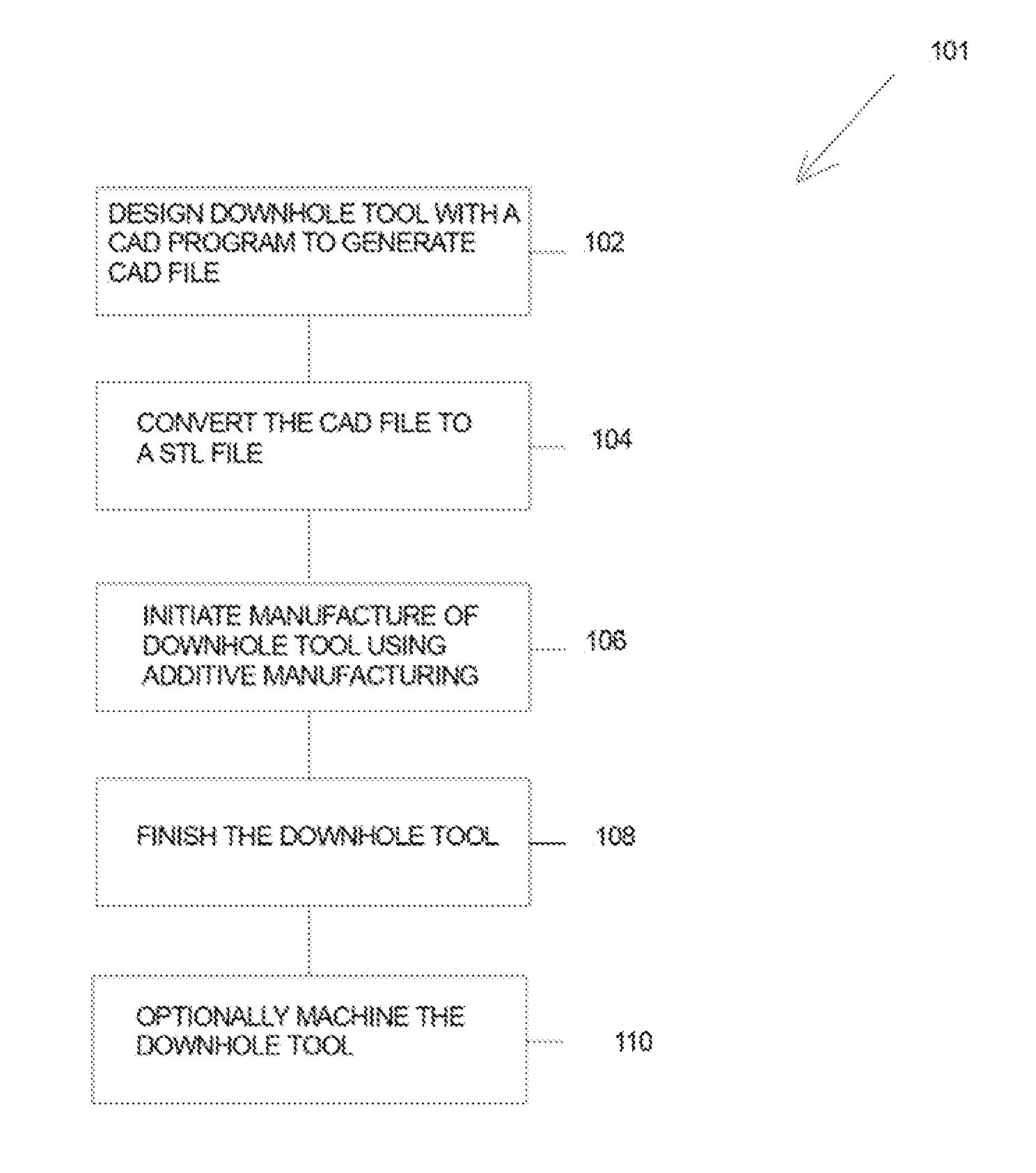

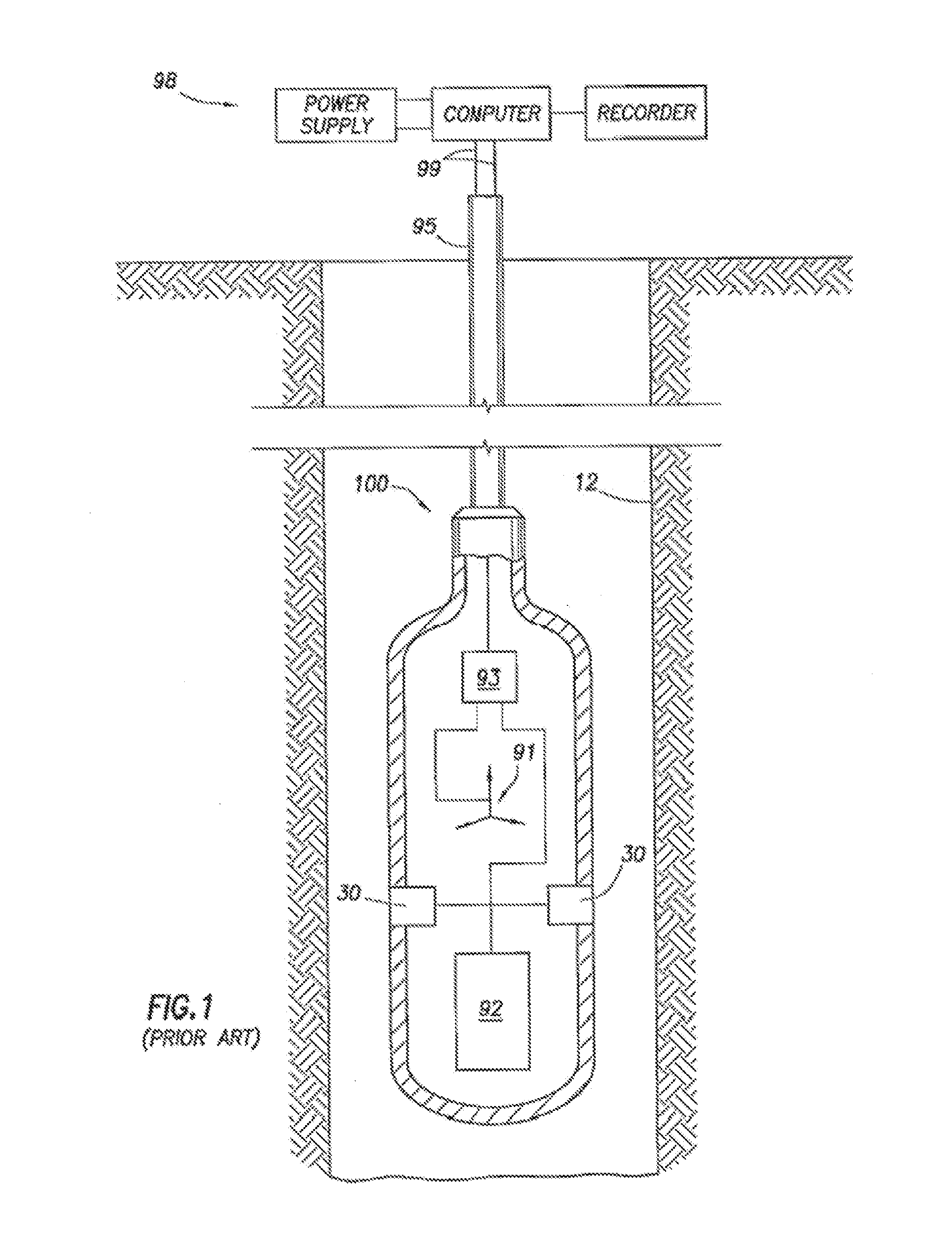

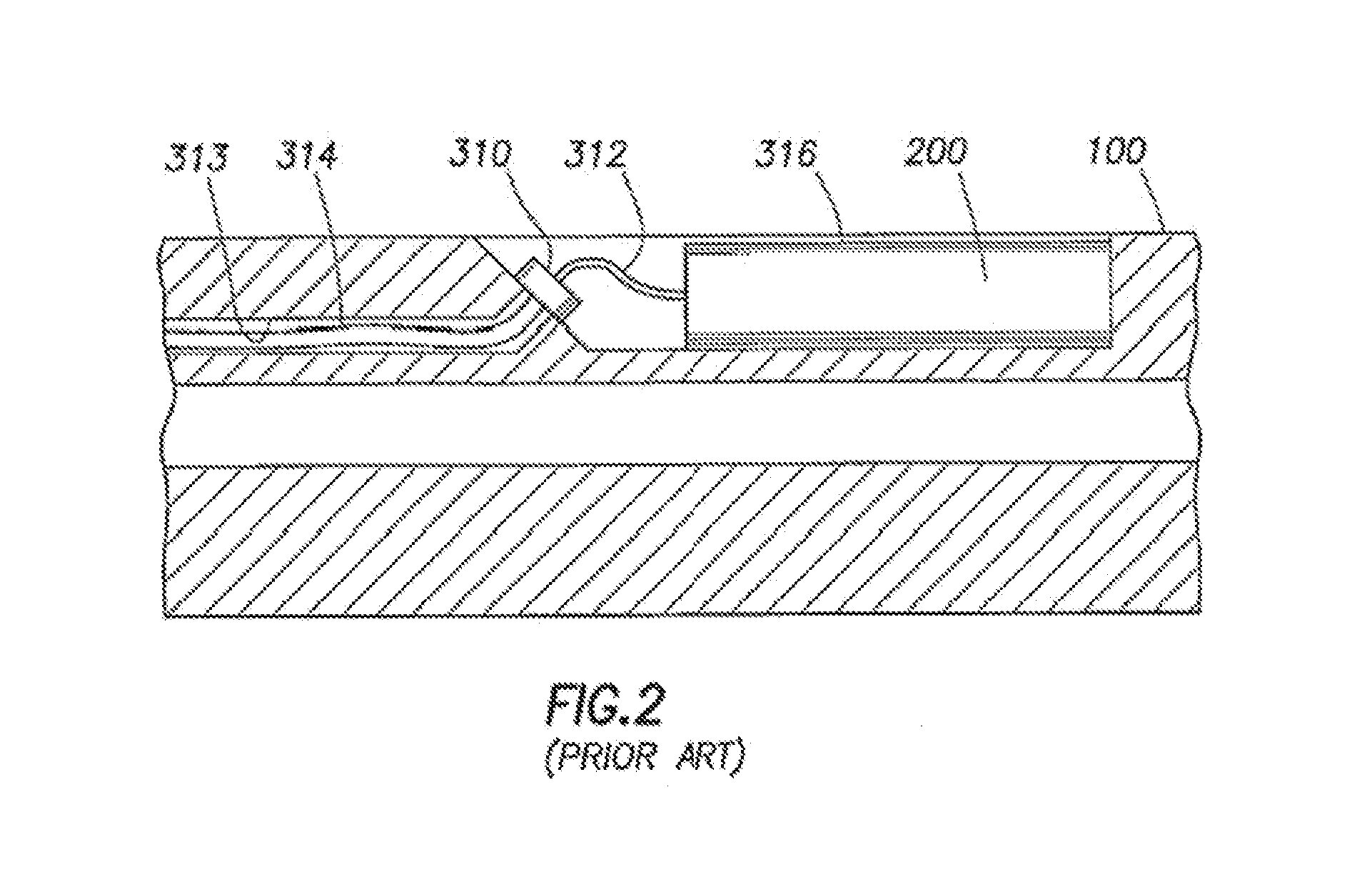

Addititve manufacturing of components for downhole wireline, tubing and drill pipe conveyed tools

InactiveUS20130310961A1Additive manufacturing apparatusIncreasing energy efficiencyDirect metal laser sinteringSelective laser sintering

Additive manufacturing may be used to manufacture components of downhole tools conveyed by downhole wireline, tubing, drill pipe and / or the like. A method in accordance with one or more aspects of the disclosure uses starting materials to incorporate one or more feedthroughs, passages, channels, chambers and the like in a downhole tool structure during the formation of the structure. A CAD may be made and then converted to a STL file, and then stereo lithography, selective laser sintering, fused deposition modeling, direct metal laser sintering and / or electron beam melting may be used to form the downhole tool. Subtractive manufacturing may be performed on the downhole tool after the downhole tool is formed by additive manufacturing.

Owner:SCHLUMBERGER TECH CORP

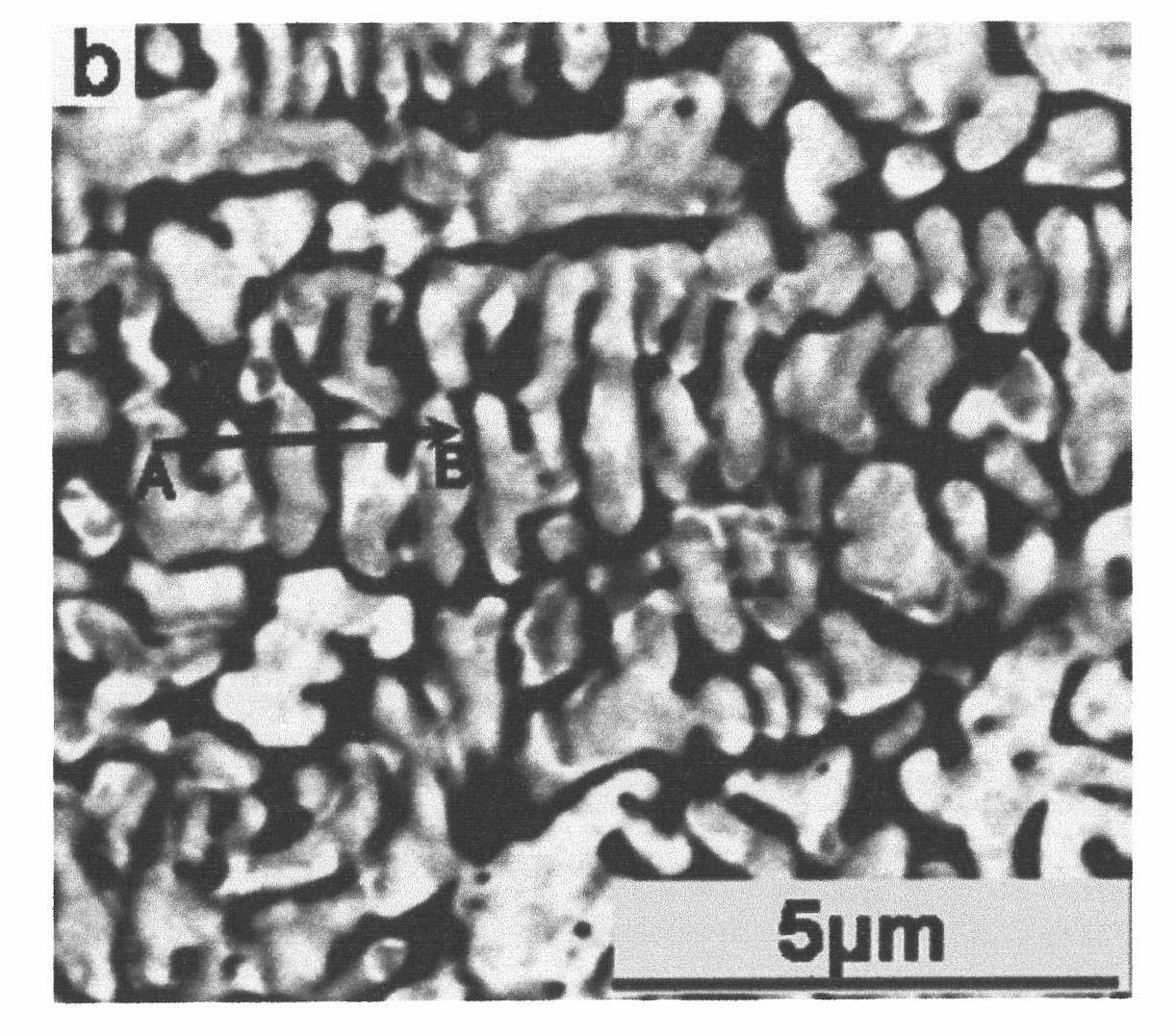

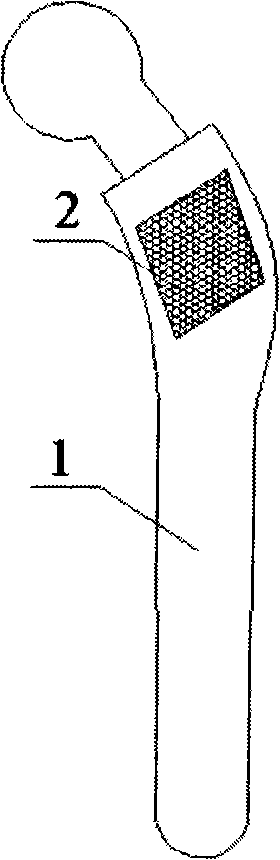

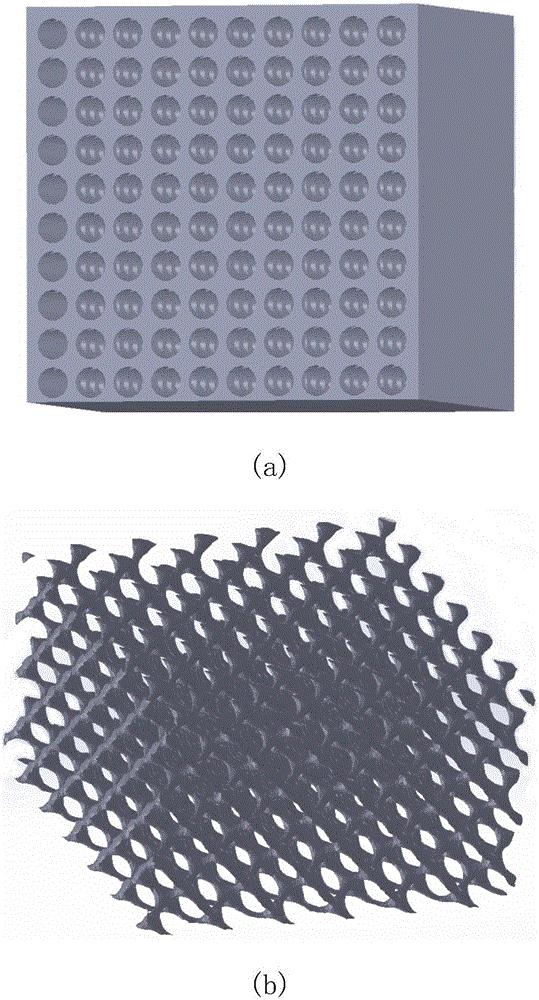

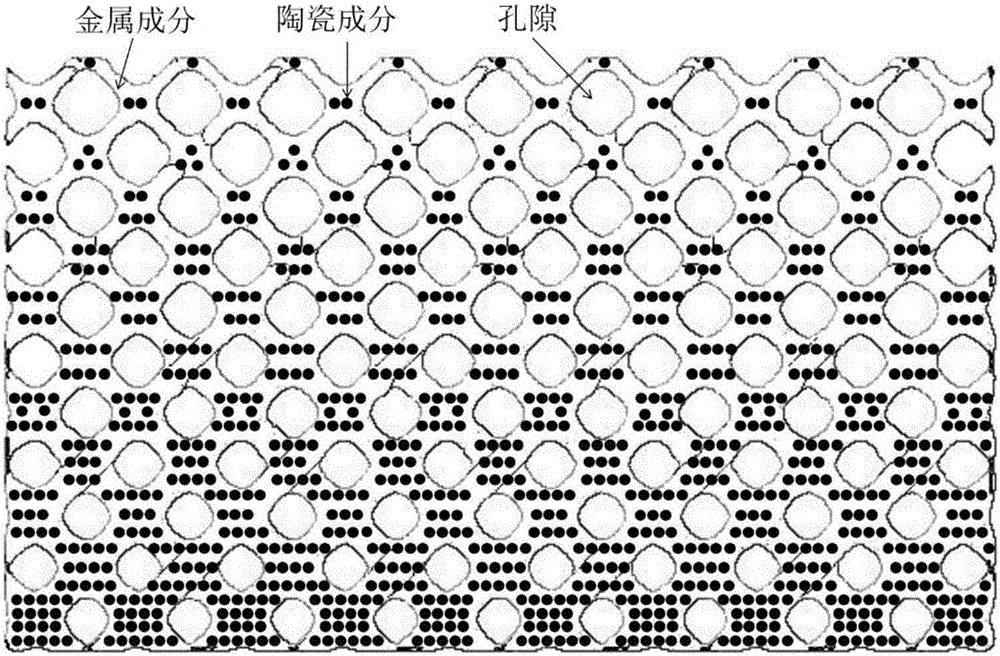

Preparation of artificial joint prosthesis with partially controllable porous structure

InactiveCN101301230AFacilitates biological immobilizationProtect high-strength mechanical propertiesJoint implantsSpecial data processing applicationsArtificial jointsSacroiliac joint

An artificial joint prosthesis with locally controllable porous structure and a method for making the same belong to the biomedical engineering field. The method comprises the following steps that: firstly, a porous structural body is designed by means of commercialized CAD software, and designed porous structural body CAD data is stored in an STL file format; secondly, a porous structural body CAD model is input into a quick forming system which is mainly used to control the scanning path of an electron beam, and the layering slicing processing of the CAD data is carried out by means of the Materialise's Magics software in the system so as to acquire the two-dimensional information data of the porous structural body and to carry out quick forming making; thirdly, the controllable porous structural body is welded on a predetermined position on the joint prosthesis by means of the laser welding technology so as to form the artificial joint prosthesis with locally controllable porous structure. The method overcomes the disadvantage that prosthesis self mechanical property is damaged during the prior making process of an artificial joint prosthesis surface porous structure.

Owner:SHANGHAI JIAO TONG UNIV

Method for selective laser sintering for quick and direct production of injection die

InactiveCN1970202AImprove sinterabilityHigh strengthIncreasing energy efficiencyTotal factory controlEpoxySelective laser sintering

A selective laser sintering quick manufacturing of the mold comprises CAD three dimension model design, storing STL files after treatment by the section software, sending the STL data to SLS quick forming machine. Spreading a composite powder of polyamide and copper on the power bed of selective laser sintering machine, with copper powder grain side 200--400, their weight ratio ranging 2:1-7:1, scanning and sintering in the selected zone of the laser harness, laser speckle 10-250 mum, scanning distance 0.04-0.1mm, scanning speed 1000- 3000mm / s, single layer thickness 70-150 mum, repeating till the formation of the complete mold inlaid, coating the surface with epoxide resin or acrylic acid series solidification system, polishing the surface thereafter. It is simple in process, short in processing period, low in cost, suitable for small volume plastic parts pilot run, testing and production.

Owner:HUAZHONG UNIV OF SCI & TECH

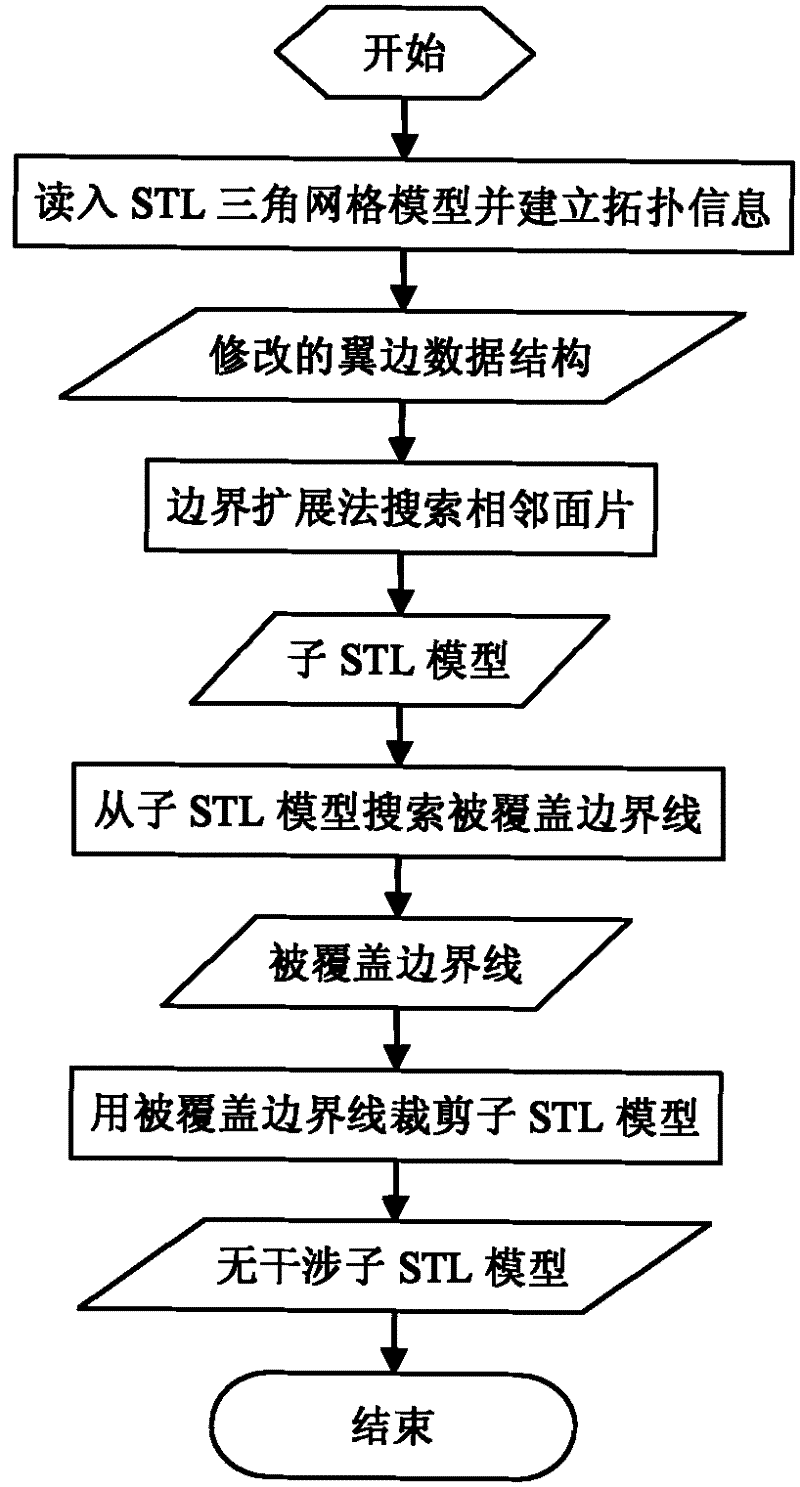

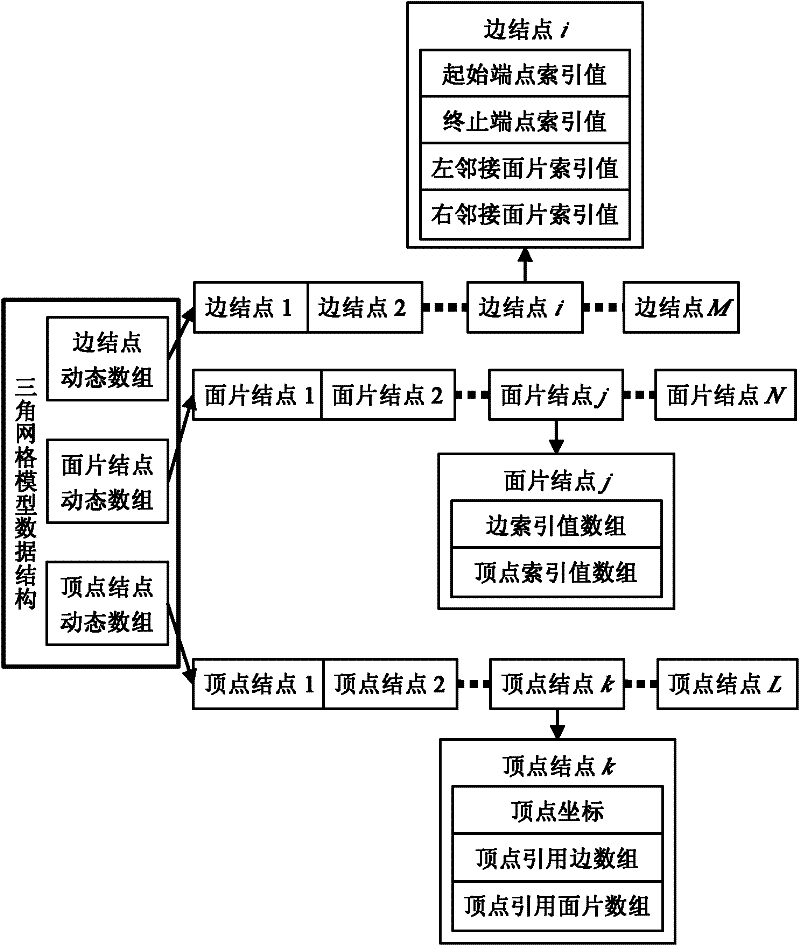

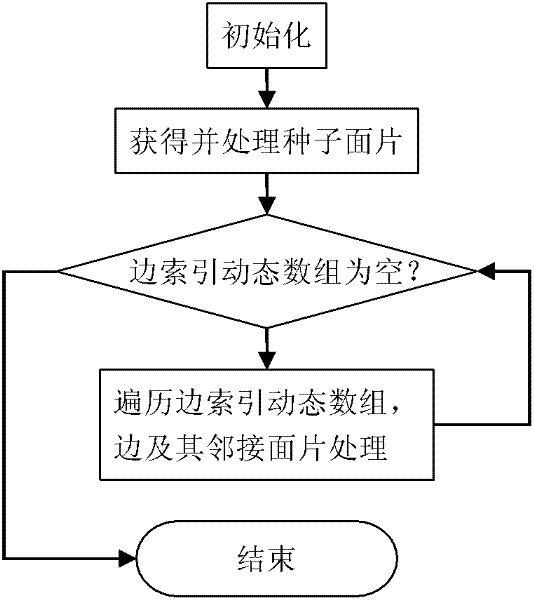

3D segmentation method for stl triangular mesh model

The invention discloses a three-dimensional segmenting method for an STL (Standard Template Library) triangular network model in rapid molding process. The three-dimensional segmenting method comprises the following steps of: firstly, reading the STL triangular network model from an STL file into an internal storage, and establishing complete topological information of a surface patch, a side and a peak in the STL model based on an improved wing-edge structure; secondly, repeatedly searching through information in the internal storage to obtain a highest position surface patch serving as a seed surface patch in an original STL model, and searching an adjacent surface patch having the same normal vector Z-axis component symbol as the seed surface patch with a boundary expansion method on the basis to obtain a plurality of sub-STL models having the same normal vector Z-axis component symbol; and lastly, checking the boundary of each sub-STL model, recognizing and extracting covered boundary lines, and segmenting the sub-STL model by using a vertical plane defined by the covered boundary lines to further generate non-interfered sub-STL models. By adopting the three-dimensional segmenting method, three-dimensional segmentation of the STL triangular network model can be realized effectively; and moreover, the triangular network model has the advantages of high adaptability, high efficiency and low resource consumption.

Owner:HUAQIAO UNIVERSITY

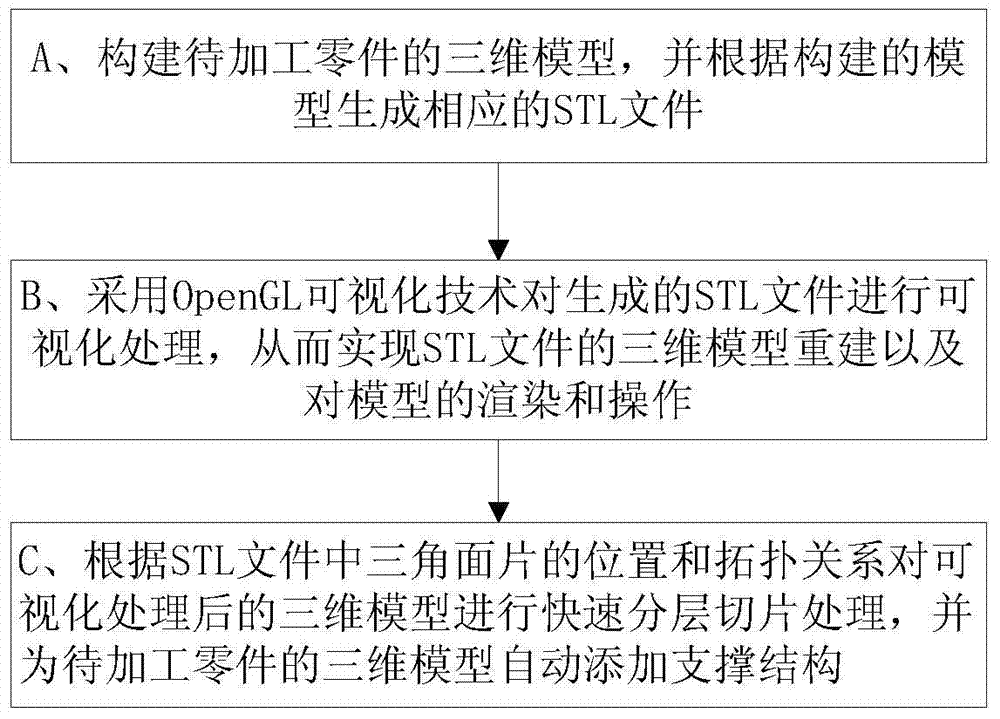

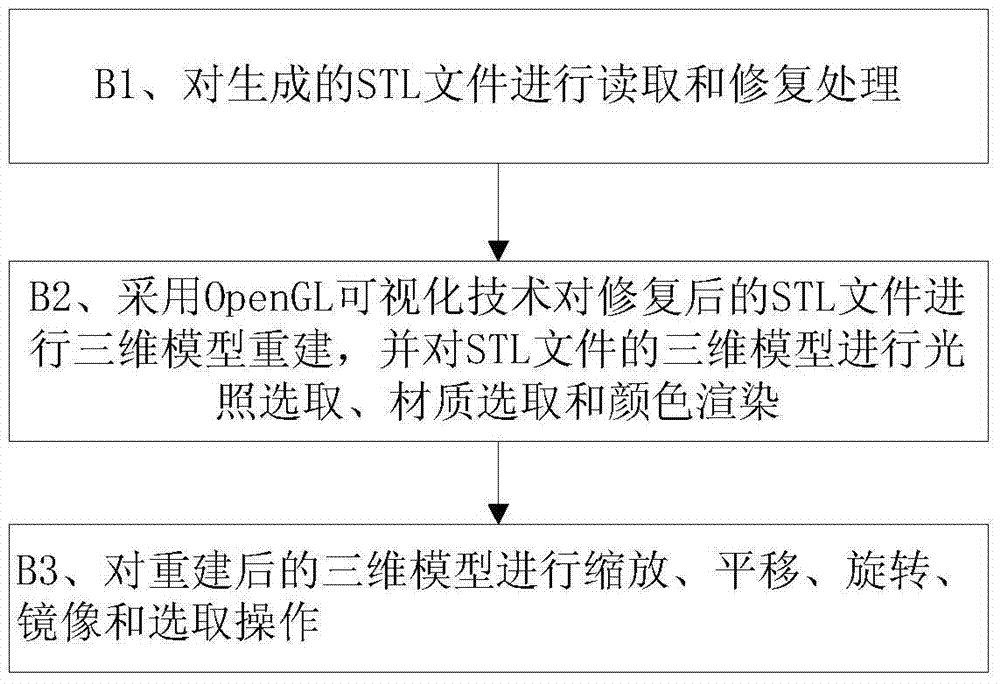

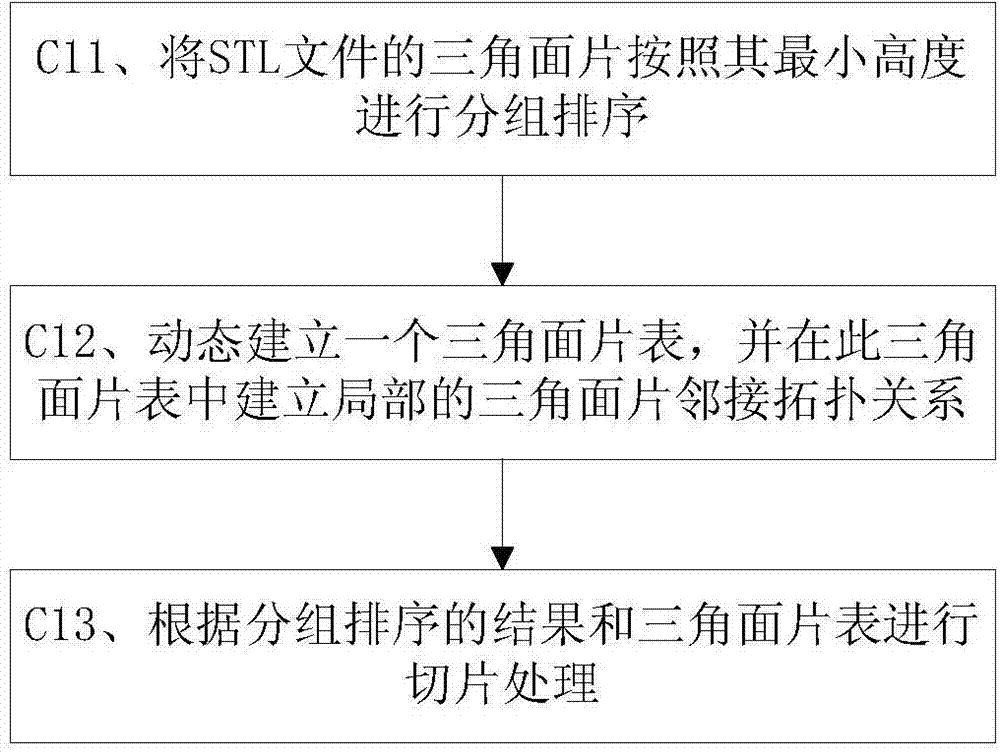

Implementation method based on 3D (Three Dimensional) printing data processing software platform

ActiveCN104504186AOvercome selected deficienciesQuality assuranceSpecial data processing applicationsSelective laser sinteringAutomatic control

The invention discloses an implementation method based on a 3D (Three Dimensional) printing data processing software platform. The implementation method based on the 3D printing data processing software platform comprises the following steps of establishing a 3D model of a part to be processed, and generating a corresponding STL (Standard Template Library) file according to the established model; adopting an OpenGL visualization technology to carry out visualization processing on the generated STL file; carrying out rapid hierarchical slicing processing on a 3D model subjected to the visualization processing according to the position and the topological relationship of a triangular patch in the STL file, and automatically adding a support structure for the 3D model of the part to be processed; according to the result of hierarchical slicing processing and the characteristics of processing materials, adopting a birth-death element method to simulate a processing process based on SLS (Selective Laser Sintering) and SLM (Selective Maping) technology processes for the part to be processed; carrying out parameter selection and model optimization on the part to be processed according to the simulation result, so that optimal printing parameters and an optimal processing model of the part to be processed are obtained. The implementation method based on the 3D printing data processing software platform has the advantages of high efficiency, low cost and good forming quality, and can be widely applied in the field of automatic control.

Owner:广东健齿生物科技有限公司

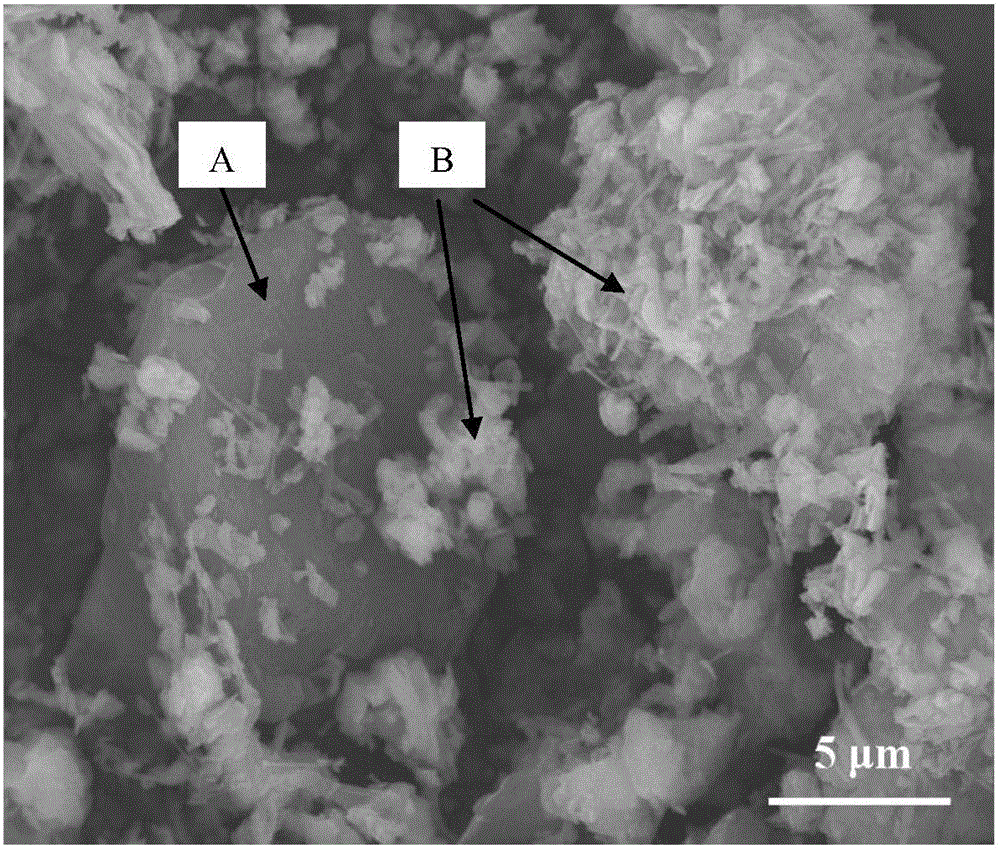

Selective laser sintering based preparation method of complex-structure porous ceramic

ActiveCN106316440AEasy to controlUnique microscopic pore structureCeramicwareMicro porosityCeramic composite

The invention discloses a selective laser sintering based preparation method of a complex-structure porous ceramic. The method comprises the following steps: 1) designing a CAD model for the porous ceramic with a complex structure, slicing to store an STL file, importing data information of the STL file into SLS equipment; 2) using an initial ceramic powder and a binder to prepare a binder / ceramic composite powder, and controlling the micro porosity character of the porous ceramic by adjusting the varieties and the added amount of the binder; 3) presetting the parameters of an SLS forming process, and combining with the data information to form a biscuit; 4) discharging glue and sintering the biscuit formed in the step 3), so as to obtain the needed porous ceramic. The porous ceramic with any complex macroscopic pore structure and the unique micro porosity character is prepared, and the preparation method has the advantages that the process is simple and efficient, no mold is needed, and the production cost is low.

Owner:HUAZHONG UNIV OF SCI & TECH +1

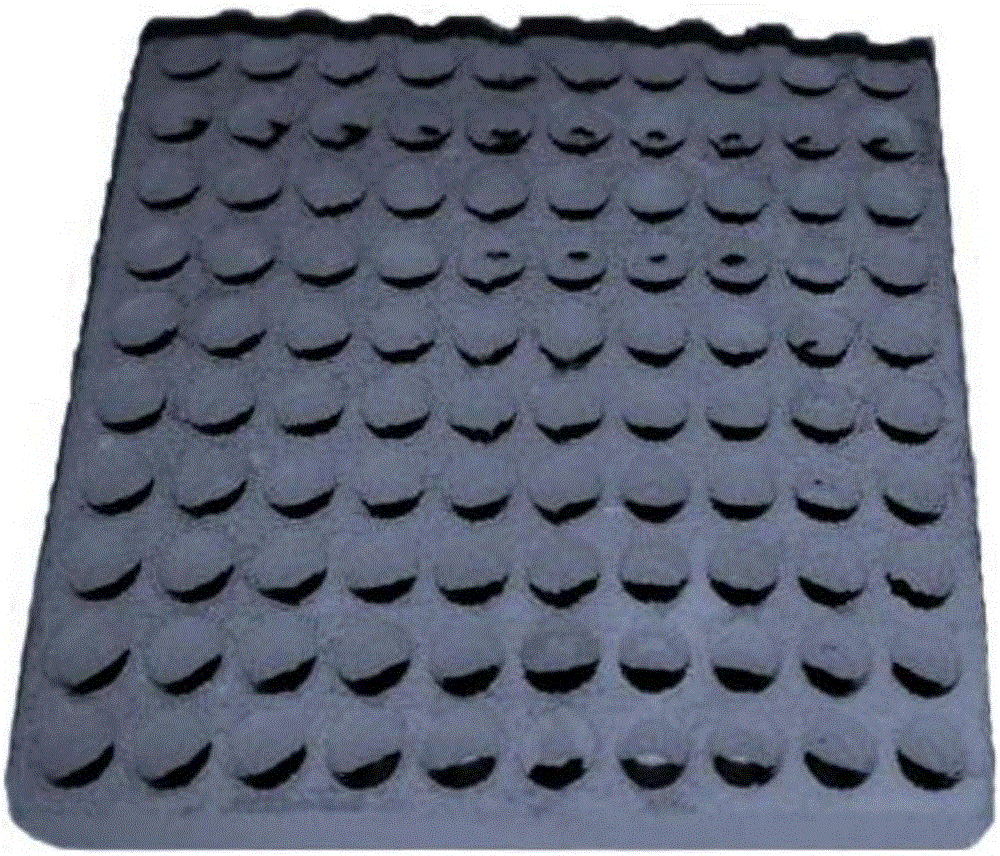

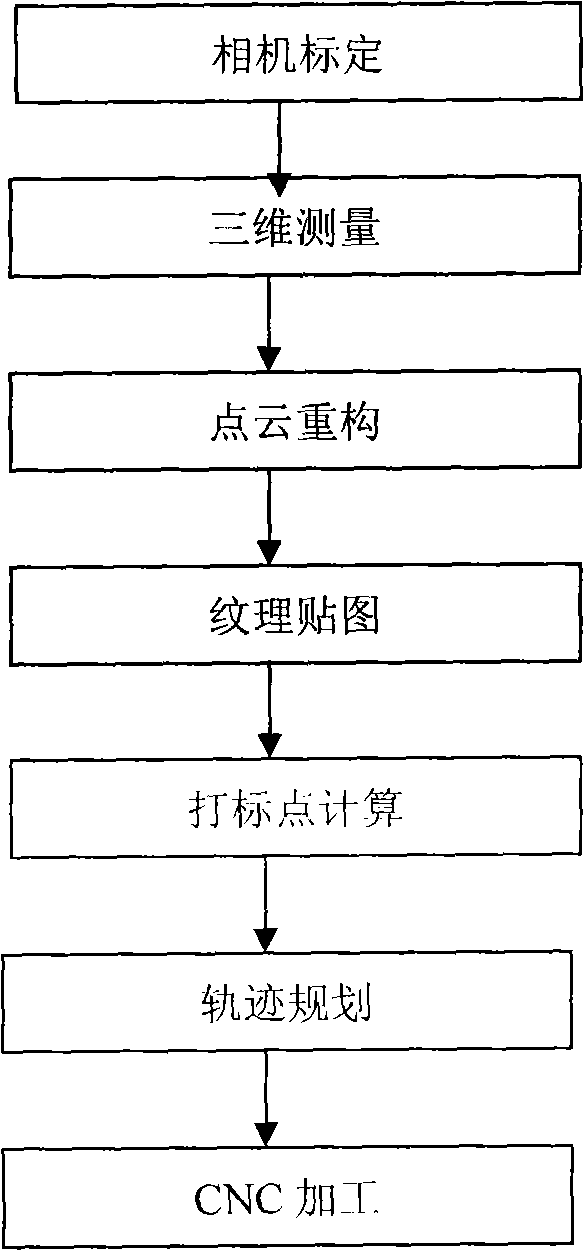

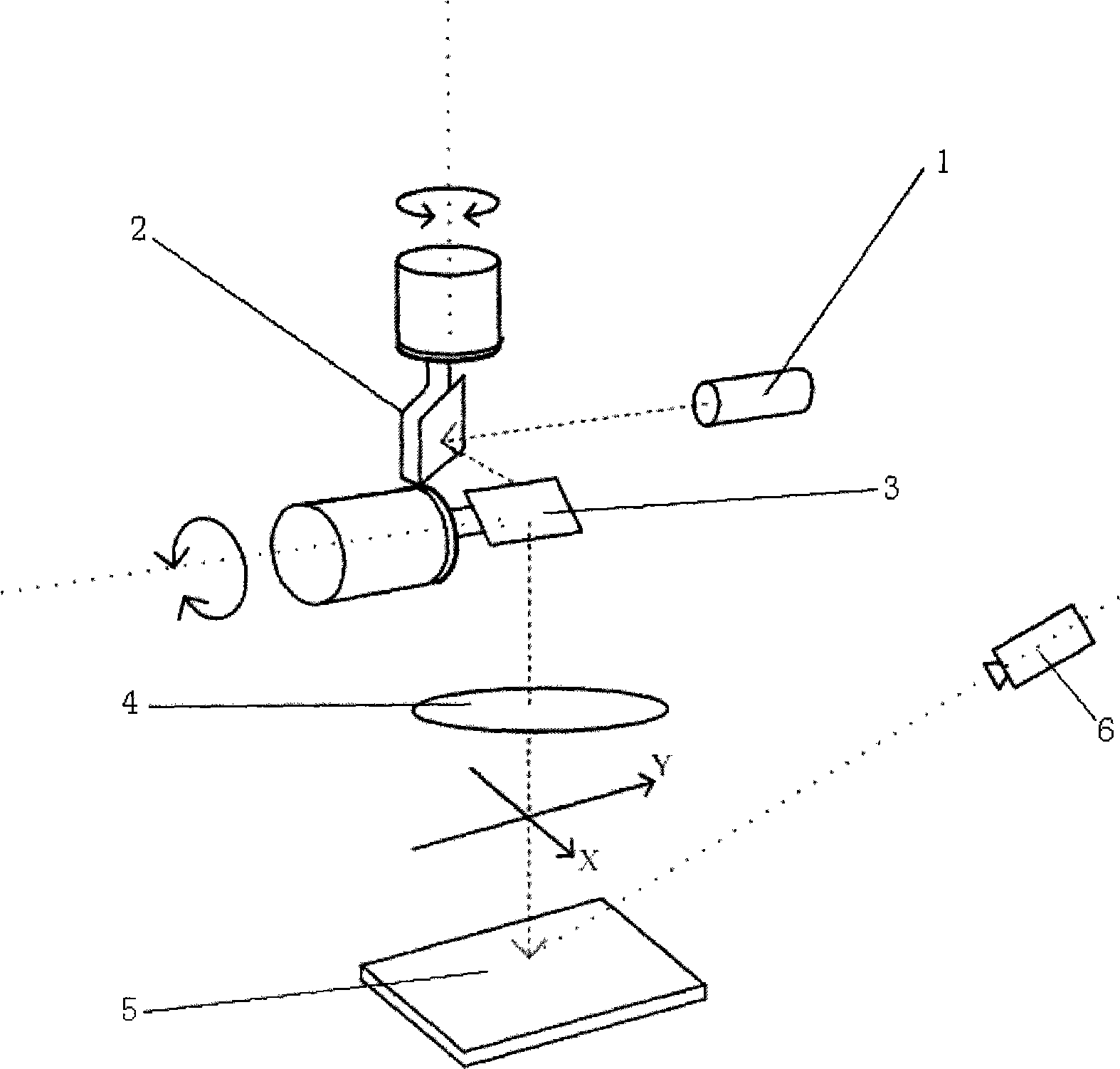

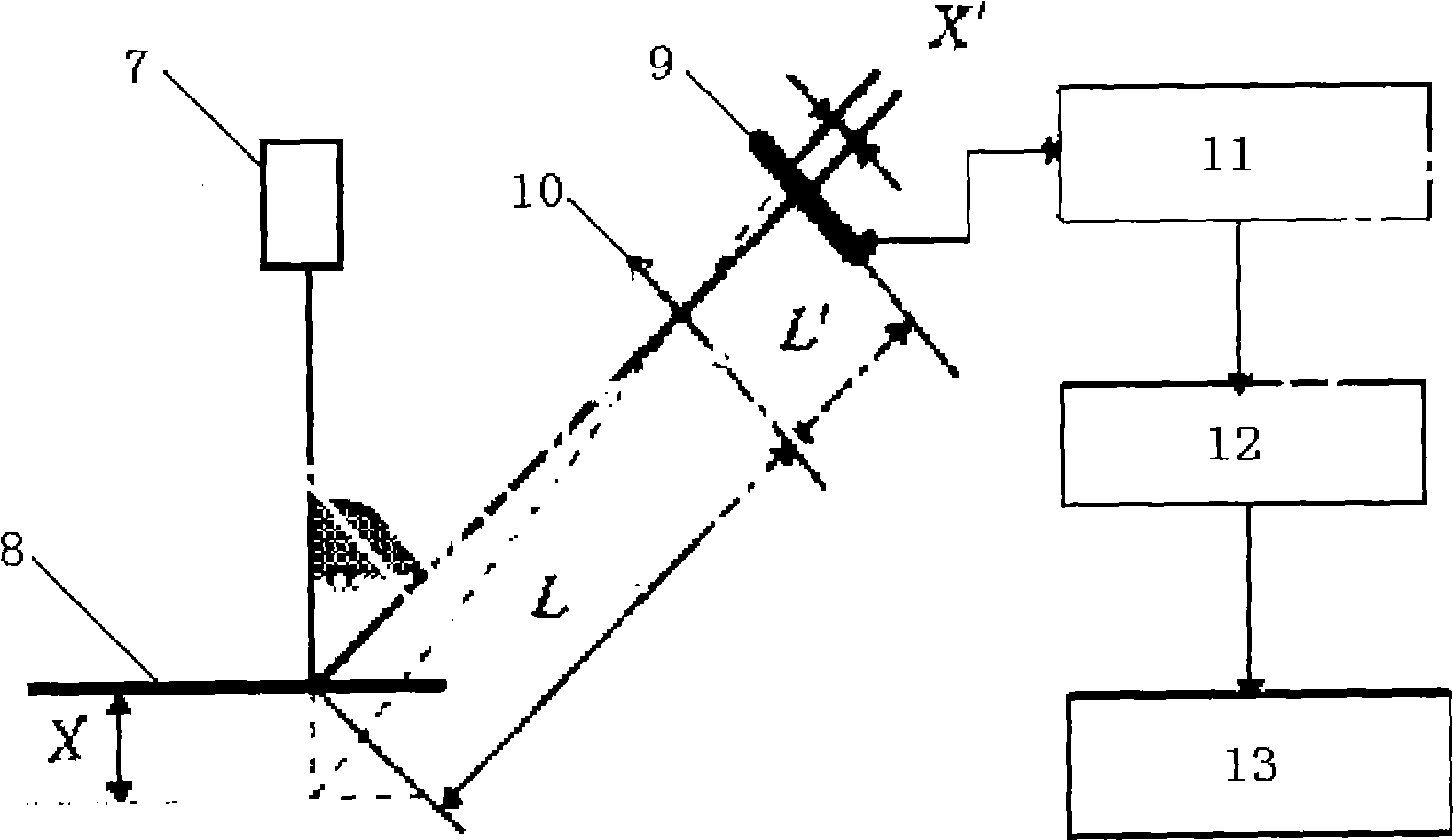

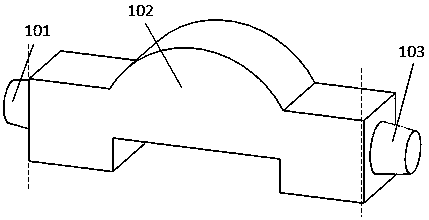

Measuring and machining integrated laser three-dimensional marking method and device

The invention provides a laser three-dimensional marking method and a device. The method comprises the following specific steps: installing and fixing a camera in a position pointing to a workbench of a laser inside-carving machine; calibrating structural parameters of the camera; placing a target part on the workbench, and measuring point cloud data of space three-dimensional coordinates of light spots on the surface to be processed of the target part; topologically reconstructing the point cloud data to form an STL triangular surface patch; inducing a part model STL document, taking an image to be marked as a grain, and pasting the grain on a triangular surface patch grid provided by the STL; iterating the triangular surface patch grid, judging the gray-scale value on the grid, and judging whether marking is needed or not according to the gray-scale value; recording the coordinates of points which need to be marked to form a marking point set list; sequencing the marking point set according to the magnitude of a Z value to generate marking point set data; and controlling the processing power of a laser to mark according to the marking point set data by CNC software. On the basis of the laser inside-carving machine, the laser three-dimensional marking device is provided with the optical camera.

Owner:王晓宇

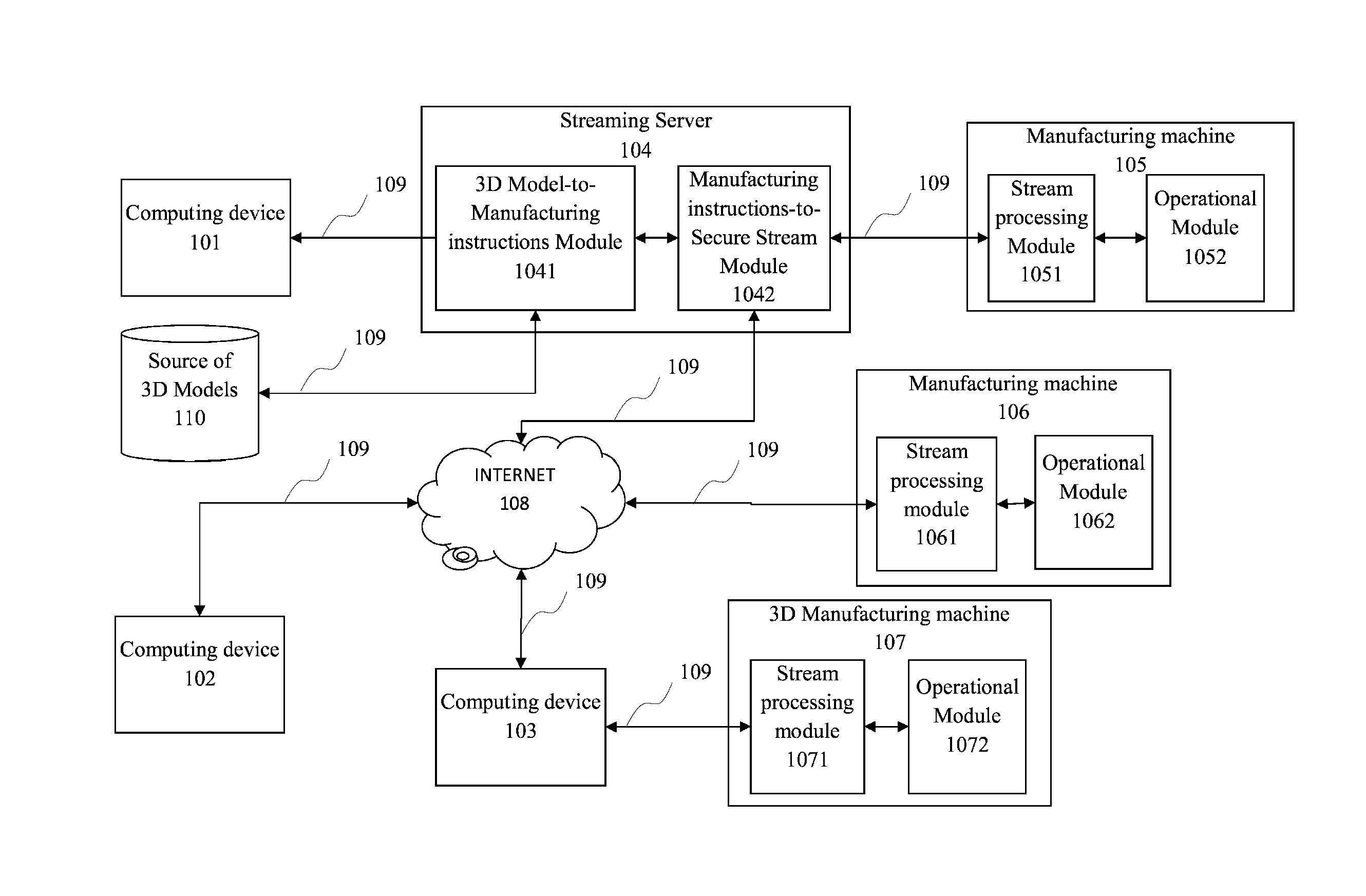

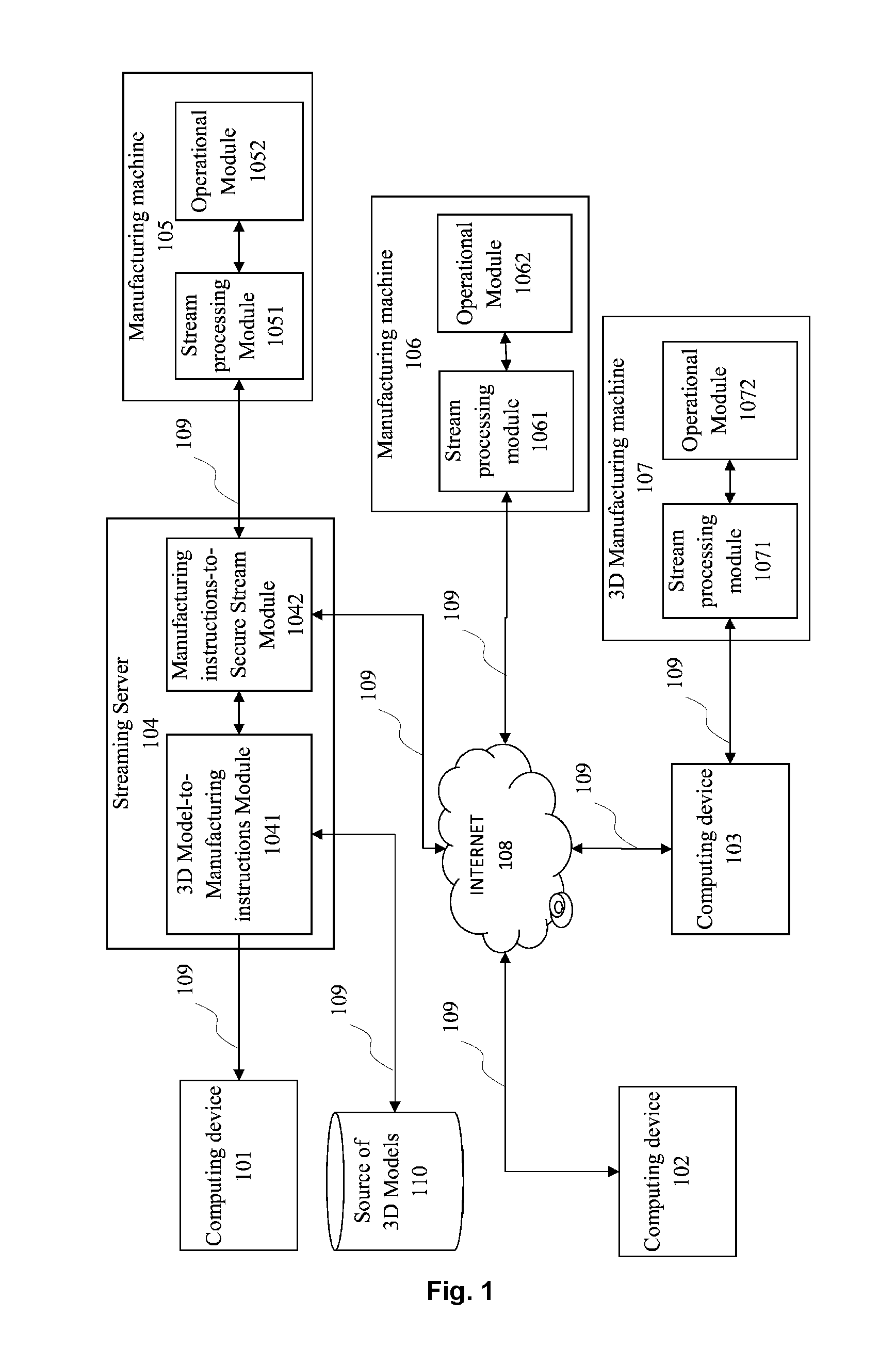

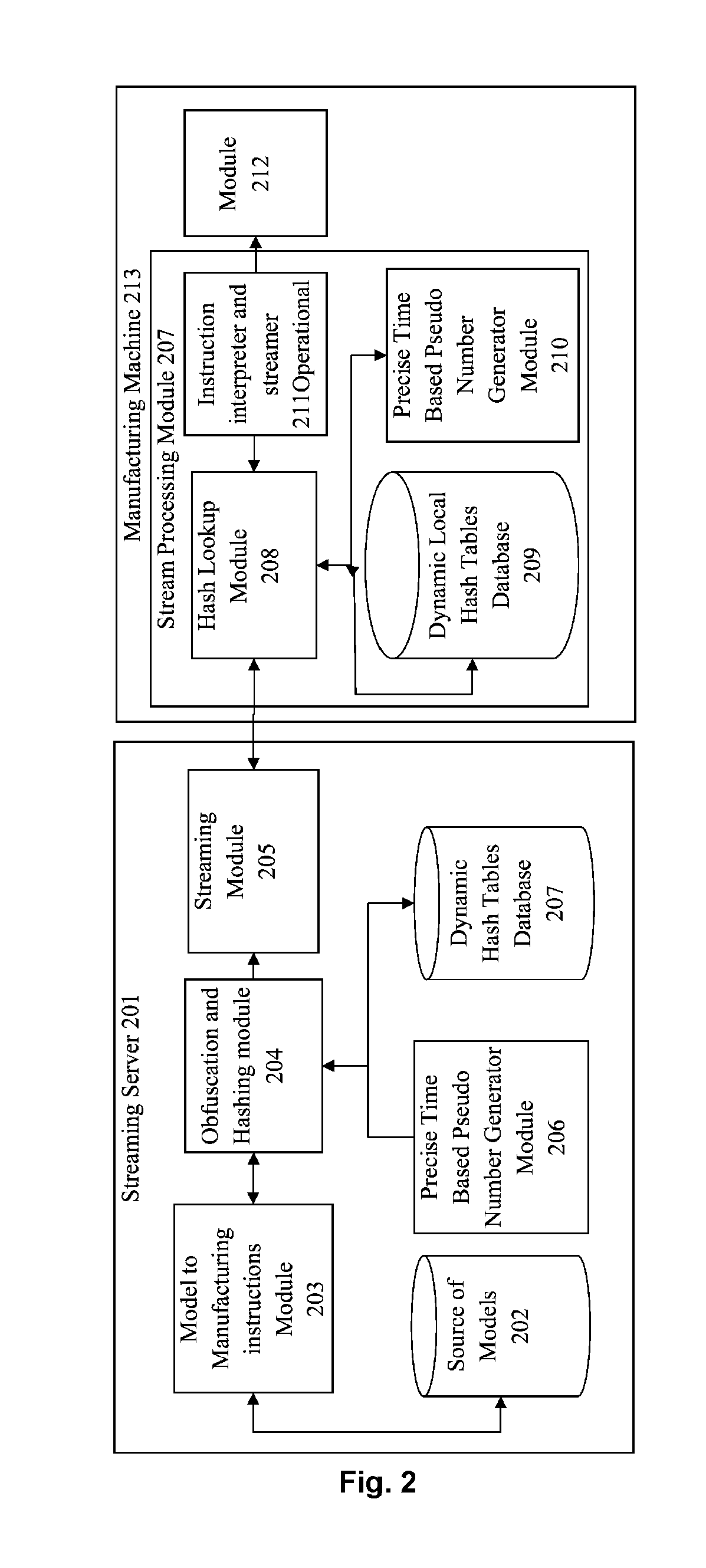

Secure streaming method in a numerically controlled manufacturing system, and a secure numerically controlled manufacturing system

InactiveUS20150350278A1Improve securityProgramme controlAdditive manufacturing apparatusG-codeComputer science

Secure streaming method in a numerically controlled manufacturing system, where the 3D file of the 3D object such as a CAD file or STL file is not sent to the manufacturing machine, but is kept in asecured system. Instead, only the instructions for controlling the manufacturing machine (e.g., so called G-codes) are streamed to the manufacturing machine. Such instructions are secured so that only a specific manufacturing machine can make use of them. To this end, the set of instructions may be encoded, e.g., hashed on a secure server, using a server hash table while the manufacturing machine is provided with a local lookup hash table that is synchronized, e.g., loosely synchronized with the serve's hash table for converting the hashed instructions back to instructions suitable for operating the manufacturing machine.

Owner:TRONDERT OU

Rapid precise constructing and shaping method for complex curved face product

InactiveCN101025831AAvoid self-intersectionAvoid inclusionSpecial data processing applications3D modellingPre treatmentComputer science

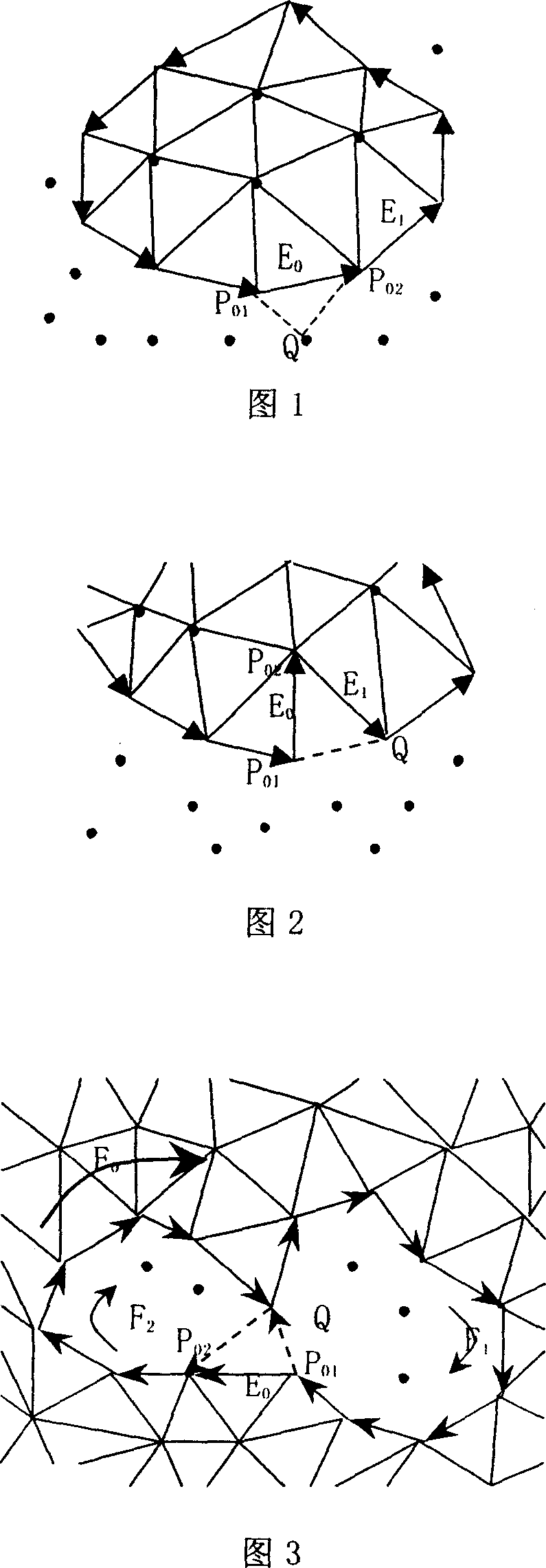

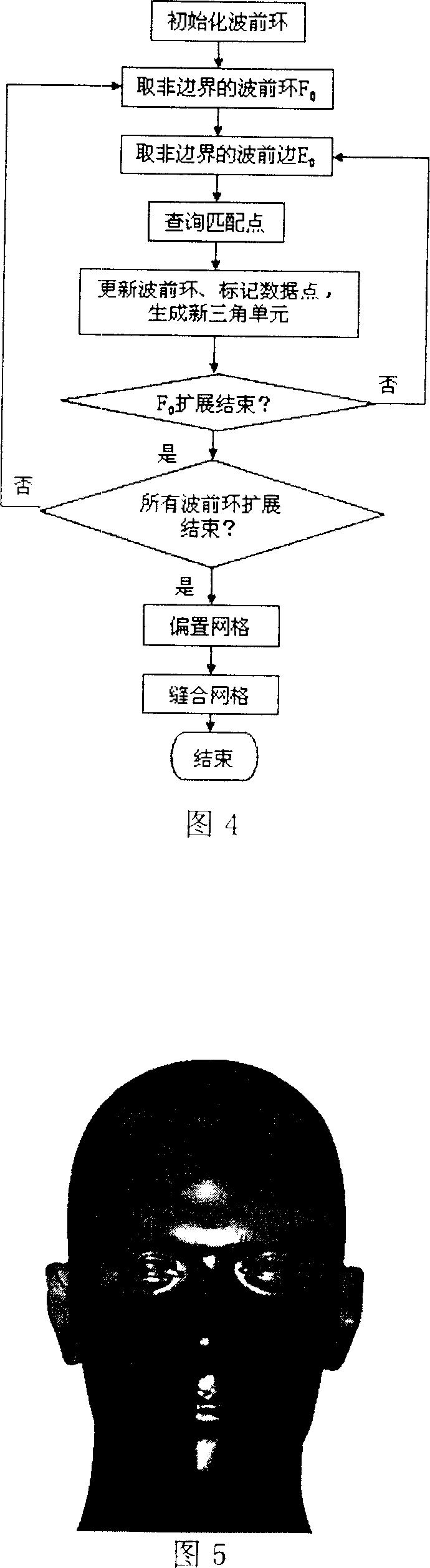

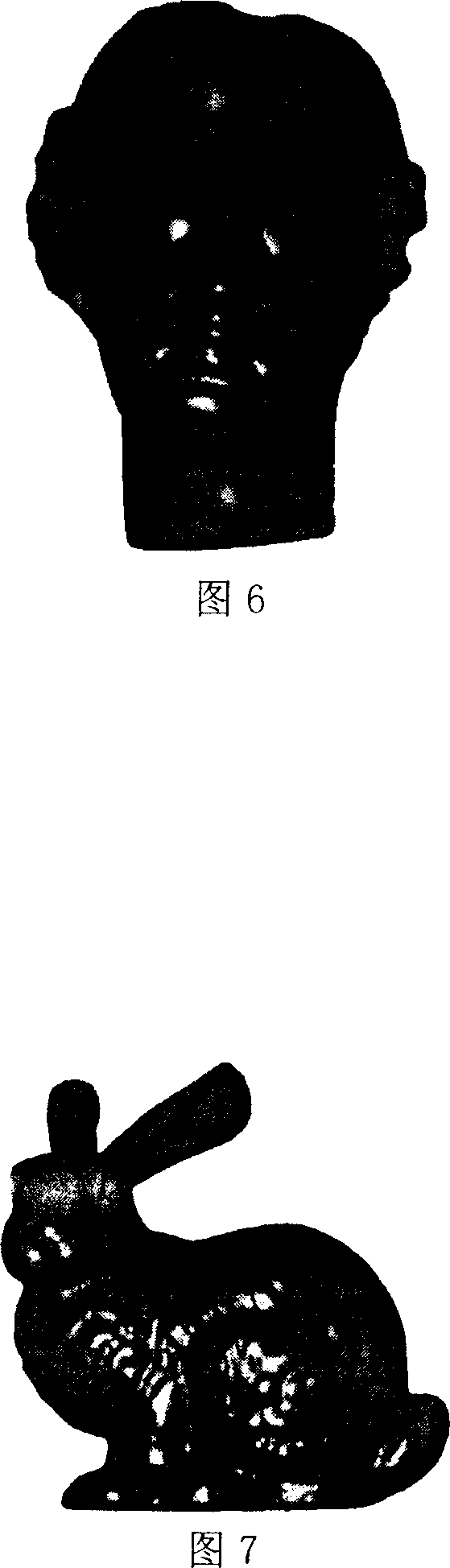

This invention provides a fast and accurate building and molding method for complex surface products, which is characterized with the steps: (1) collecting data and pre-treating them, (2) creating the initial wave pre-ring, (3) defining saturation point, freedom point, wave-front side, wave-front point , wave-front wings and side angle, to generate grid model of the initial measurement data, (4) calculating arrows of all the node and the offset data coordinates values along arrows to generate the triangular grid unit of data points in offset layer, (5) suturing the boundary of original layer and offset layer, ( 6) outputting STL file, producing the prototype.

Owner:SHANDONG UNIV OF TECH

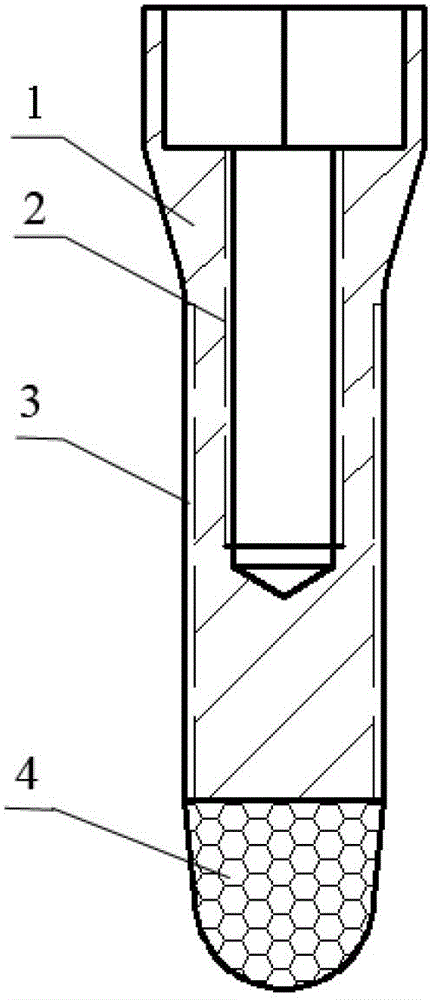

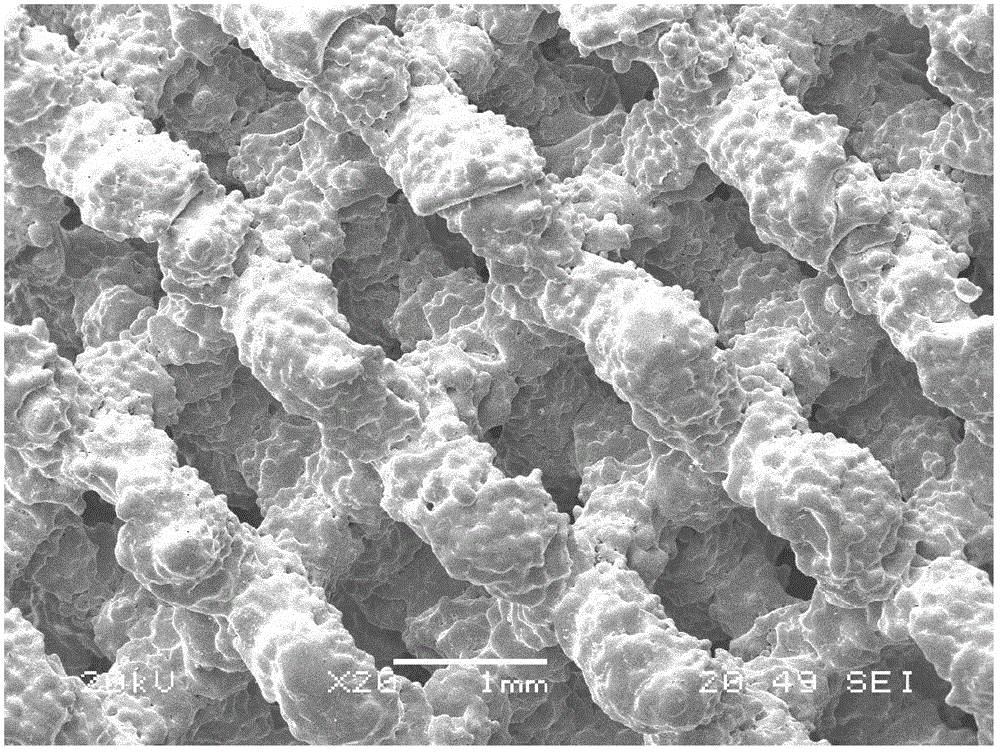

Dental implant and preparation method thereof

Provided is a dental implant and a preparation method of the dental implant. The dental implant comprises a dental implant body and a porous structure body; the dental implant body is internally provided with an inner threaded hole connected with a base station, external threads connected with an alveolar bone are arranged on the outer surface of the dental implant body, the porous structure body is connected to the bottom of the dental implant body, pores of the porous structure body are mutually and completely communicated, the size of the pore is 300-1000 micrometers, and the porosity is 60-90%. The preparation method is as follows: designing a dental implant structure by a commonly known CAD software and storing CAD design data in a STL file layout; inputting the CAD design data into a rapid forming system which carries out layered slicing treatment to obtain two-dimension information data, and rapidly forming and making the dental implant; and machining the inner threaded hole and the outer screw thread on the dental implant body of the dental implant. As the porous structure is arranged at the bottom of the dental implant, into which bones can well grow, and the surface of the porous structure is rough, the bonding strength between the dental implant and the alveolar bone is improved.

Owner:SHANGHAI JIAO TONG UNIV

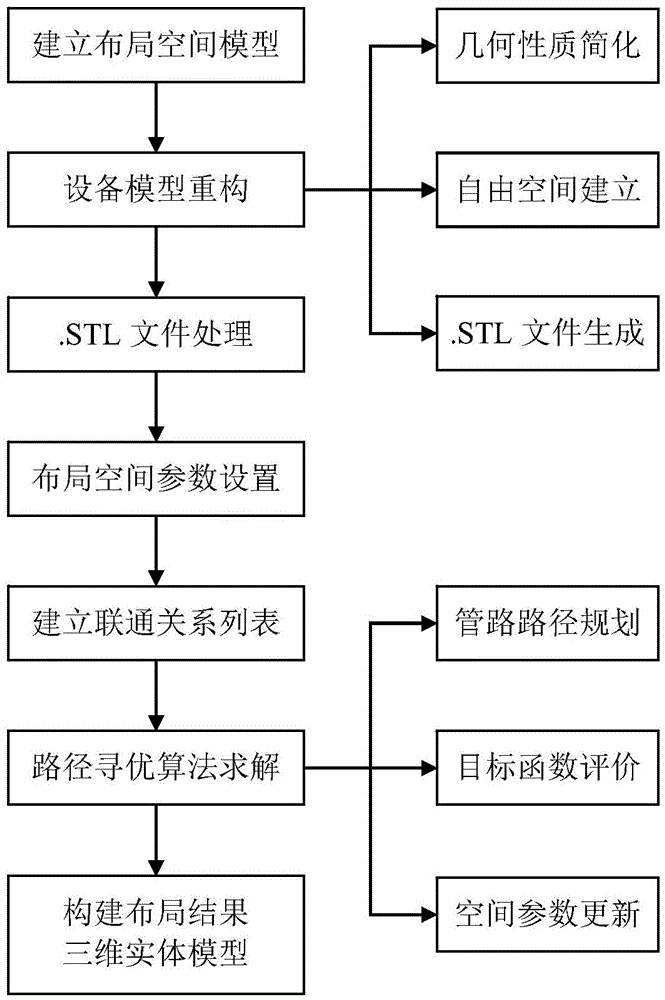

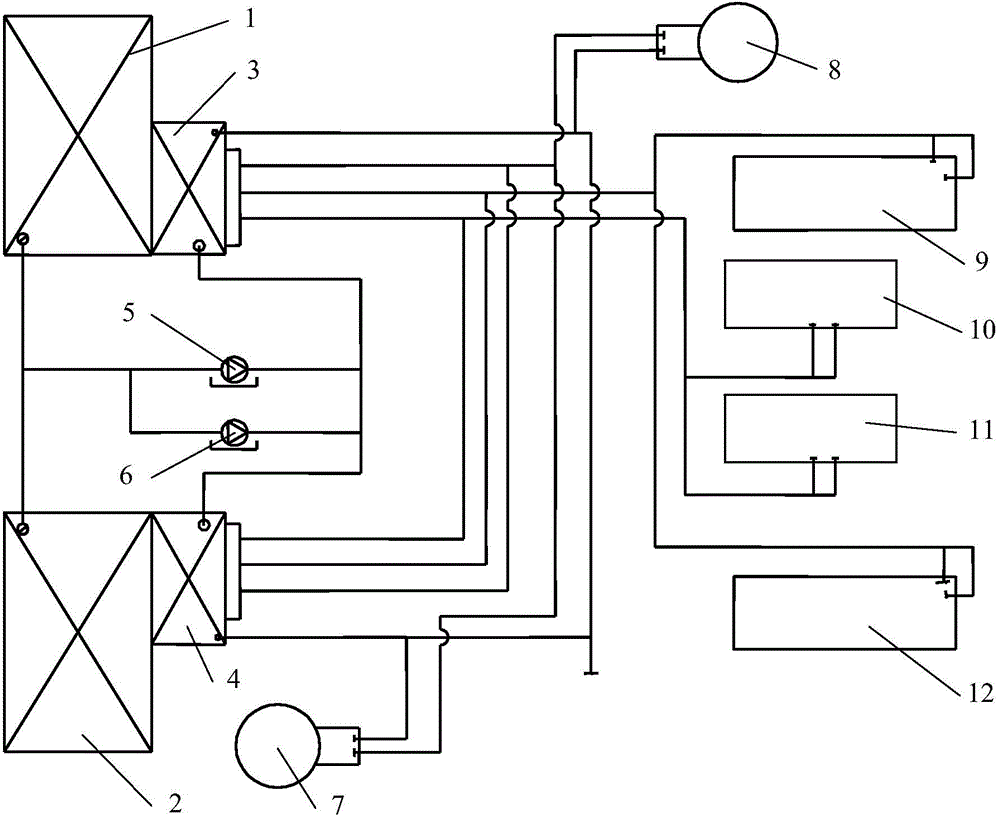

Ship pipeline route optimum design method

ActiveCN104699899AShorten the design cycleImprove Design PerformanceSpecial data processing applicationsSorting algorithmSimulation

The invention discloses a ship pipeline route optimum design method which comprises the following steps: establishing a pipeline layout space three-dimensional entity model according to the ship structure and the equipment layout parameters; establishing an equipment model free space and generating an STL form file of an equipment model; processing the STL file of the model to obtain the coordinates and vector coordinates of the vertexes of all triangular plates in the file, and determining the layout space range occupied by the equipment; setting pipeline layout space parameters and constructing a layout space mathematic model; analyzing a pipeline system principle diagram, determining the communication relationship among the equipment connection points and establishing a ship equipment communication relation and pipeline diameter information list; carrying out pipeline route planning by utilizing an optimization algorithm; according to the pipeline diameter and the number of the connection points, planning the pipeline route to obtain a preferred resolution by utilizing a pipeline route optimum design method of combining a maze algorithm, an improved non-dominated sorting algorithm and a concerted evolution algorithm; and constructing a ship pipeline system three-dimensional entity model. The ship pipeline route optimum design method has the advantage of effectively improving the design efficiency of the ship pipeline system.

Owner:TIANJIN UNIV

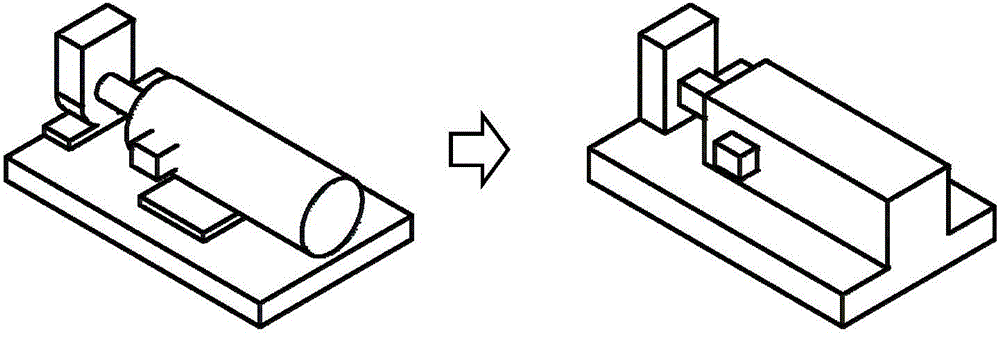

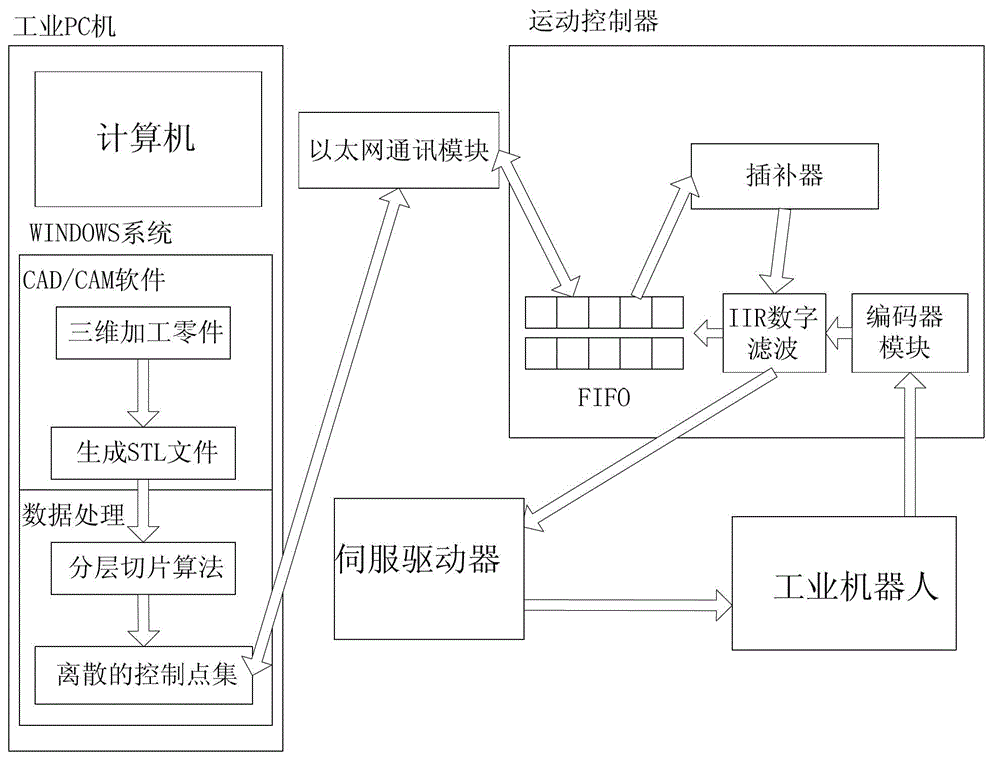

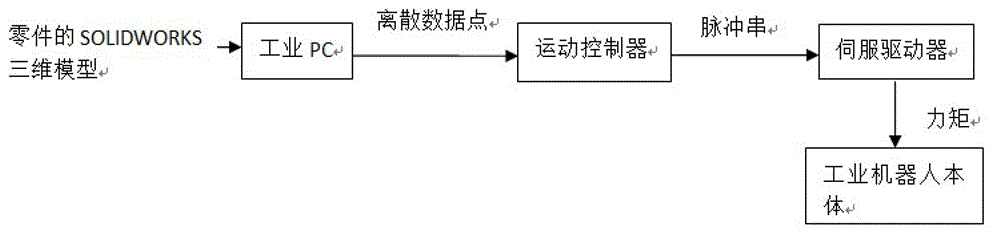

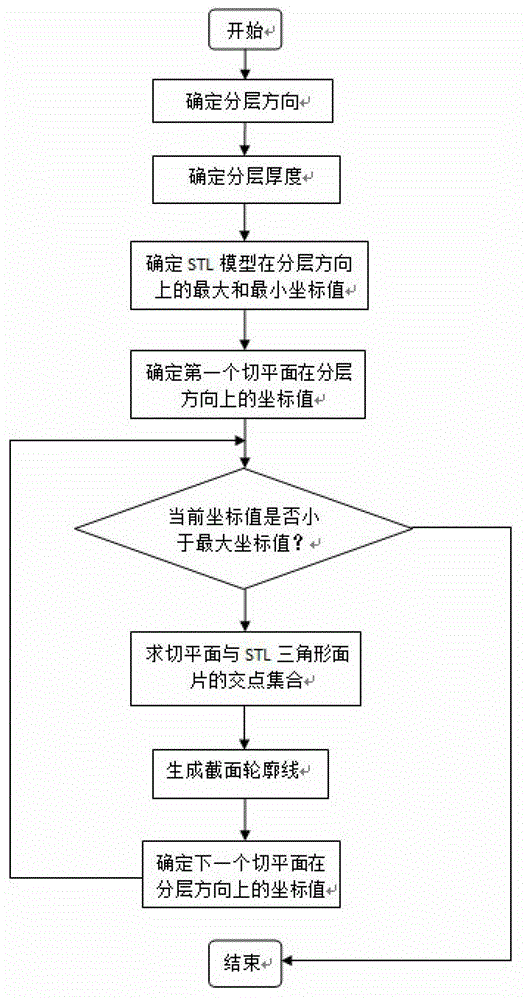

Track generating method facing toward complex curved surface processing and track generating system thereof

InactiveCN103064343AOvercoming the inability to resolve model voidsReduce the number of timesProgramme controlComputer controlIntersection of a polyhedron with a lineMotion controller

The invention discloses a track generating method facing toward complex curved surface processing and a track generating system thereof. The track generating method includes that a to-be-processed complex curved surface is chosen and a standard template library (STL) file is generated; layer dividing direction and layer dividing thickness are determined; group dividing is conducted on a triangular patch; the point of intersection is obtained by an incremental method; a coordinate minimum value point of each section point of intersection gather in the direction of being vertical to the layer dividing direction is found out, another point of intersection of the same triangular patch is searched and connected with the minimum value point, and the process continues until the outline of each tangent plane is obtained and eventually the generating route track is obtained. The track generating system comprises an industrial personal computer (PC), a motion controller, a servo driver and an industrial robot body. The industrial PC generates three-dimensional to-be-processed components into a scattered control point set and transmits the control point set to the motion controller. The motion controller conducts an interpolation calculation on the control point set and outputs pulse trains to the servo driver, and drives the industrial robot body to conduct coordinated movement in a torque control mode. The track generating method facing toward complex curved surface processing and the track generating system thereof have the advantages of small calculation quantity, short calculation time, and high calculation efficiency.

Owner:SOUTH CHINA UNIV OF TECH

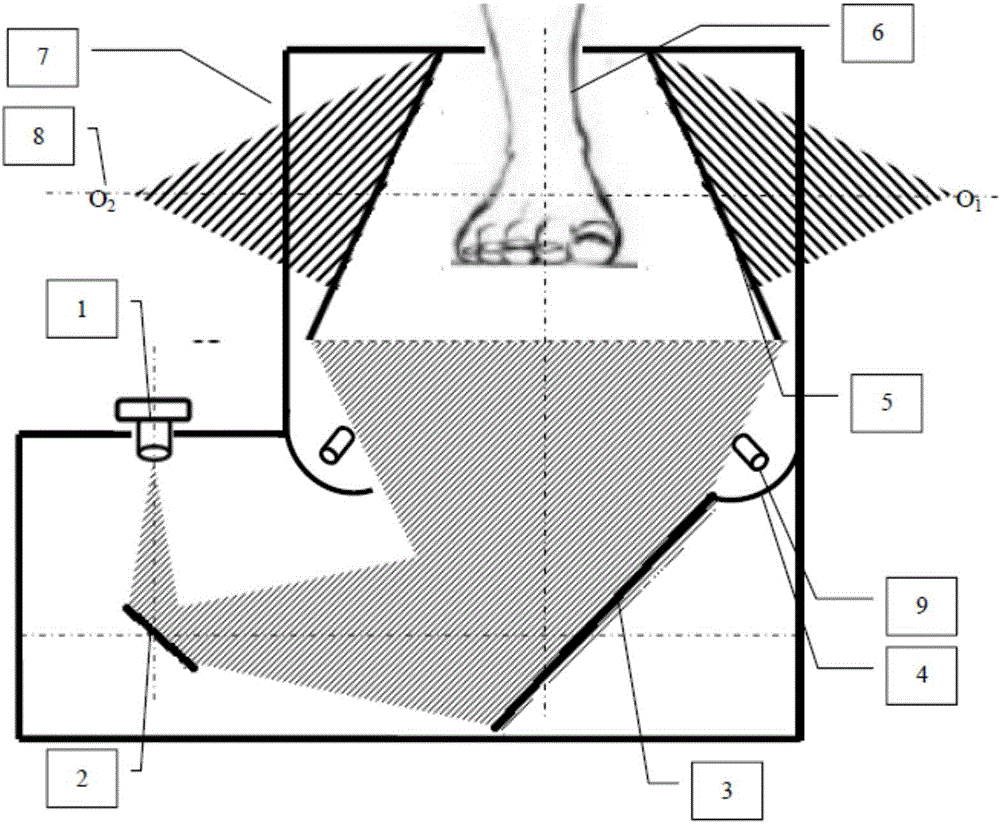

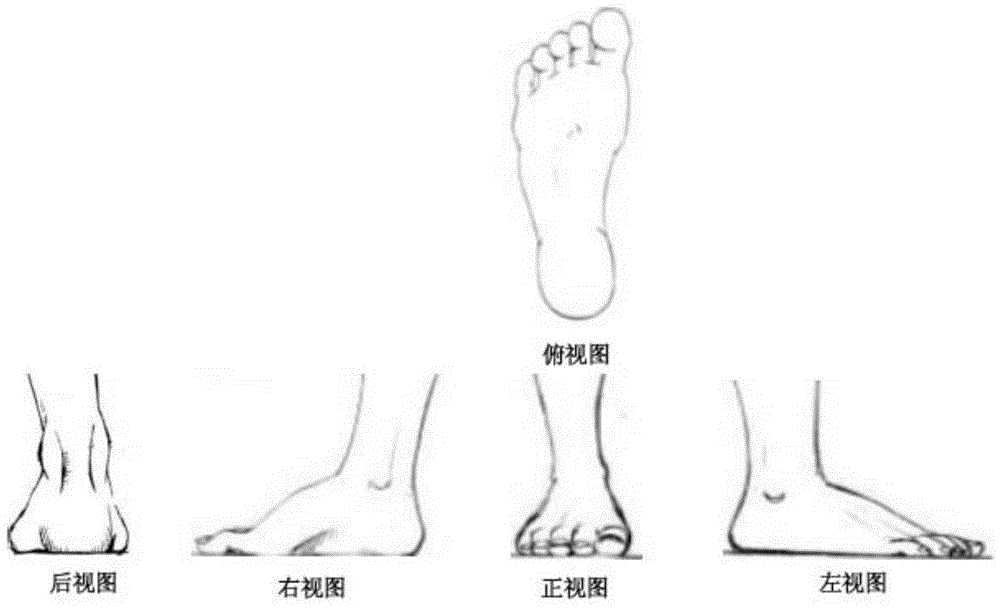

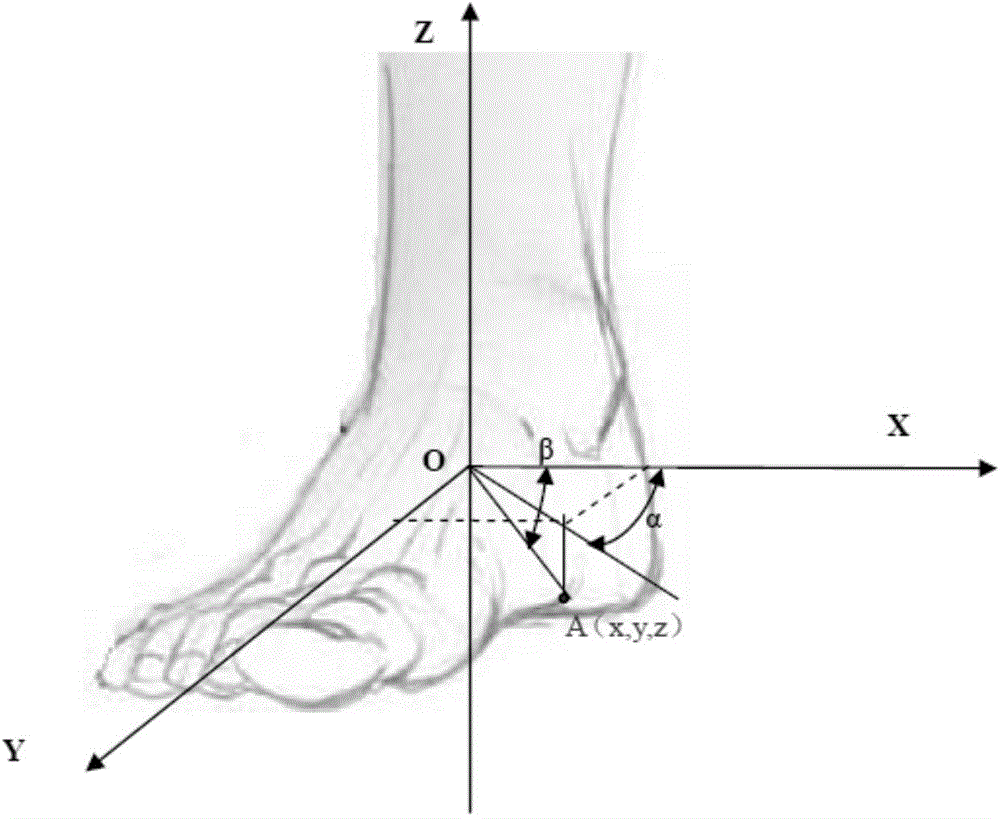

Real-person shoe type copying device and shoe tree manufacturing method based on single-eye multi-angle-of-view robot vision

InactiveCN104573180AIncrease silhouetteConstraints for adding silhouettesSpecial data processing applications3D modellingPlane mirrorImage segmentation

The invention discloses a real-person shoe type copying device based on single-eye multi-angle-of-view robot vision. The device comprises a single-eye multi-angle-of-view 3D (Three-dimensional) vision box and a computer, wherein the single-eye multi-angle-of-view 3D vision box is used for shooting images of a foot of a real person at five different angles of view; the computer is used for achieving the 3D reconstruction of the foot of the real person and automatically generating a 3D printing file; a plane mirror rectangular bucket-type cavity is formed inside the single-eye multi-angle-of-view 3D vision box and consists of four trapezoidal mirror planes; the upper part of a mirror body is large, and the lower part of the mirror body is small; the mirror planes face the inner side of a cavity body; a light source used for providing uniform soft lighting for the foot of the real person is arranged at the lower part of the plane mirror rectangular bucket-type cavity; cameras used for obtaining the images of the foot of the real person at multiple angles of view according to the refraction and reflection principle of the mirror planes are further arranged in the single-eye multi-angle-of-view 3D vision box; the computer comprises a single-eye multi-angle-of-view 3D vision calibrating unit, an image division, conversion and correction unit, a real person foot surface shape measurement unit and an automatic STL (Standard Template Library) file generation unit. The invention further discloses a shoe tree manufacturing method based on the single-eye multi-angle-of-view robot vision.

Owner:ZHEJIANG UNIV OF TECH

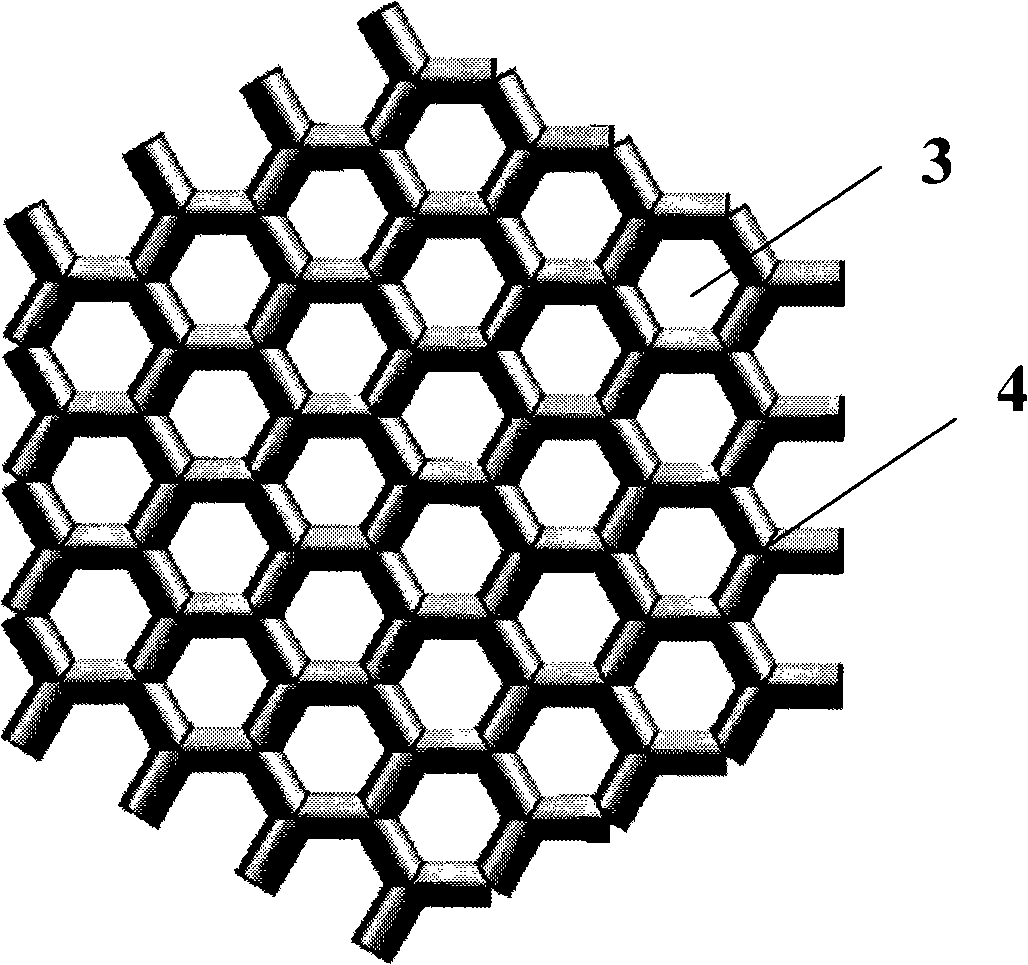

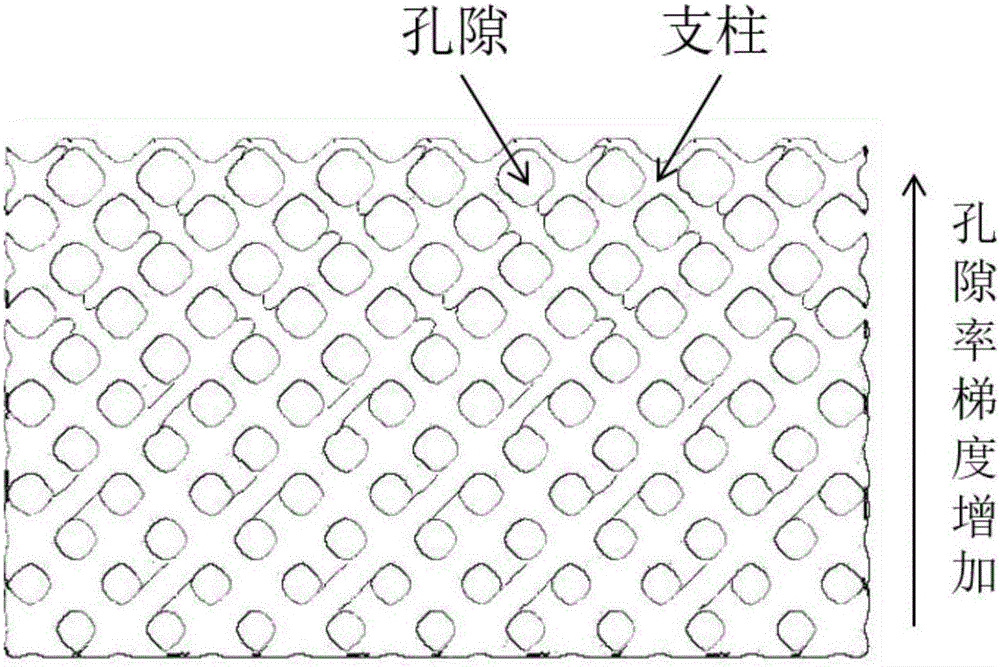

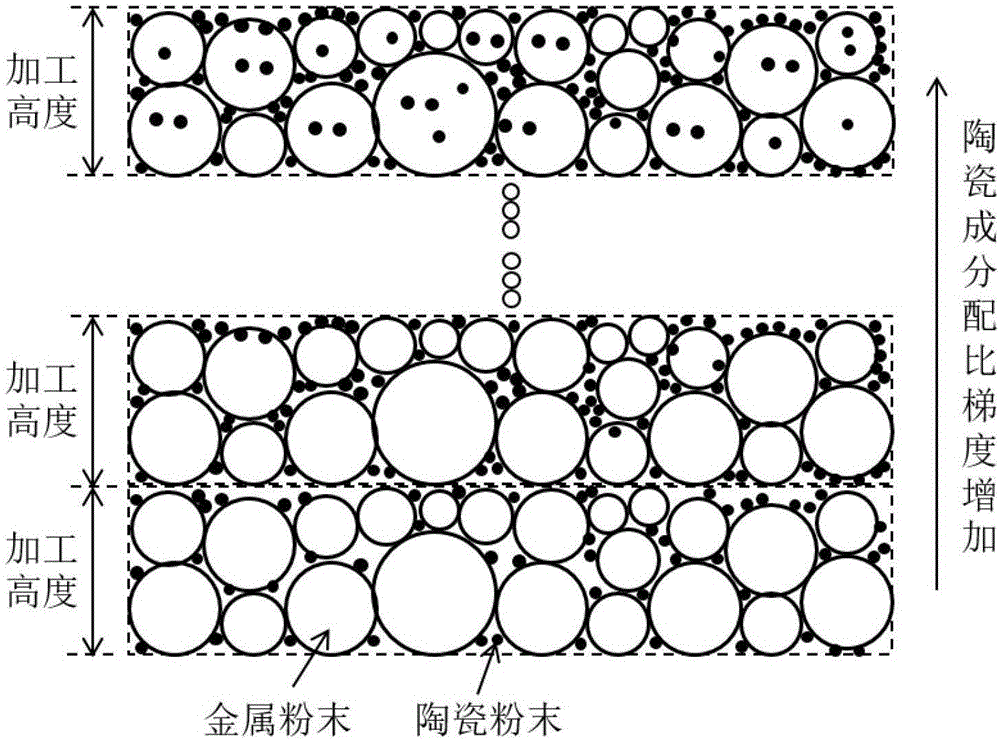

Preparation method for reticulate structural part provided with component and pore double gradient transition layers

ActiveCN106270517AUniform mechanical propertiesImprove osseointegration performanceAdditive manufacturing apparatusLaser scanningTransition layer

The invention discloses a preparation method for a reticulate structural part provided with component and pore double gradient transition layers. The method comprises the following steps that (1) a three-dimensional model of a reticulate structure with bionic unit topology and gap dimension gradient changes is design, the three-dimensional model is subjected to slicing treatment and then converted into an STL document, and the STL document is input into SLM forming equipment; (2) various powders are evenly mixed according to a preset ratio, and a mixed powder is fed and laid; (3) a current slice layer of the reticulate structural part is subjected to laser scanning forming and is descended by the thickness of a laid power layer after forming is finished, and then the mixed powder in the current ratio is adopted for forming the next slice layer; (4) the step (3) is repeated until forming of the layers with the set height is completed through the powder in the current ratio, mixing of powder in another ratio is completed, and powder feeding and laying are conducted; and (5) the step (3) and (4) are repeated until forming of the whole reticulate structure with various components being in gradient transition is completed. The preparation method has the advantages of being high in preparation efficiency, simple in preparation technological process, low in cost and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

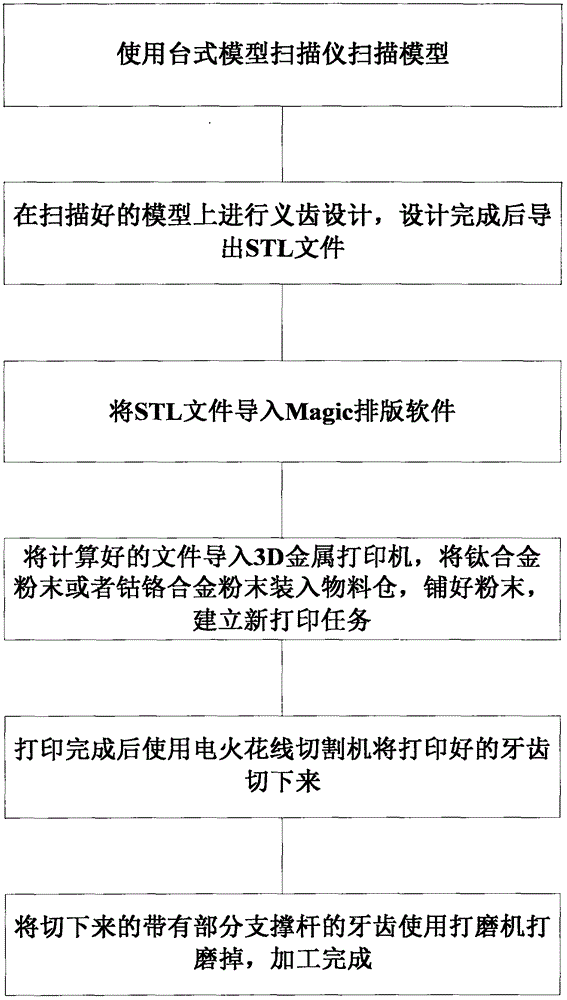

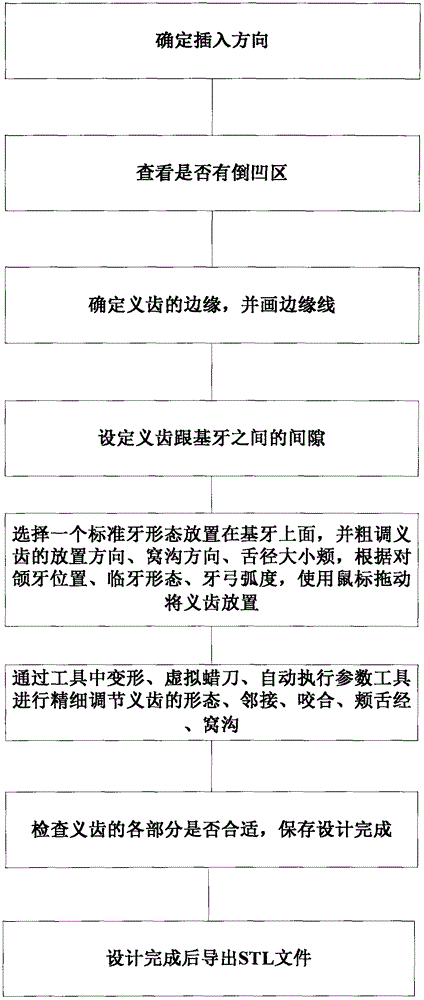

Manufacturing method of false tooth based on 3D (three dimensional) printing

ActiveCN105030357AIn line with the concept of environmental protection developmentThere will be no problems of deformation and incomplete castingArtificial teethSanderElectric discharge

The invention provides a manufacturing method of a false tooth based on 3D (three dimensional) printing. The method comprises the steps of scanning a model by using a desktop model scanner; designing the false tooth on a scanned model, exporting a STL file when the design is finished; importing the exported STL file into a Magic publishing software, overturning the imported tooth crown by 180 degrees along the direction of a Y axis by a location moving tool, and moving 1.5 mm along the positive direction of a Z axis; then, checking whether the file is damaged through a checking tool, inserting a support rod through a part tool, performing split layer treatment on the file through a platform tool, and calculating the file; importing the calculated file into a 3D metal printer, putting titanium alloy powder or cobalt-chromium alloy powder into a stock bin, spreading the powder, and creating a new print job; using a wire cut electric discharge machine to cut off a printed tooth after the printing is completed; polishing off the part of a cut-off false tooth with the support rod by using a sander, and the processing is completed.

Owner:SHANDONG MAIER DENTAL MATERIALS CO LTD

Near-net-shape method for porous metal part

The invention discloses a near-net-shape method for a porous metal part. The method comprises the following steps: (1) firstly, designing a three-dimensional CAD model of the part, saving the model as an STL file, and transmitting the file to SLM quick shape equipment; (2) introducing protective gas into the equipment after the equipment is vacuumized; (3) spreading a layer of metal powder with thickness of between 0.05 and 0.15millimeter and grain diameter of between 10 and 100 mu m on a metal substrate by a powder feeding mechanism; (4) scanning the outer profile of the boundary of a slice by adopting a laser beam of which the laser power is more than or equal to 100W to ensure that the profile is melted; (5) repeating the step (3) to (4) until shaping is completed; and (6) integrally placing a shell of the shaped part and powder loaded in the shell in a high temperature sintering furnace for sinter shaping. The method does not need a die, and has the characteristics of simple and easy technical process and complicated shape manufacture.

Owner:HUAZHONG UNIV OF SCI & TECH

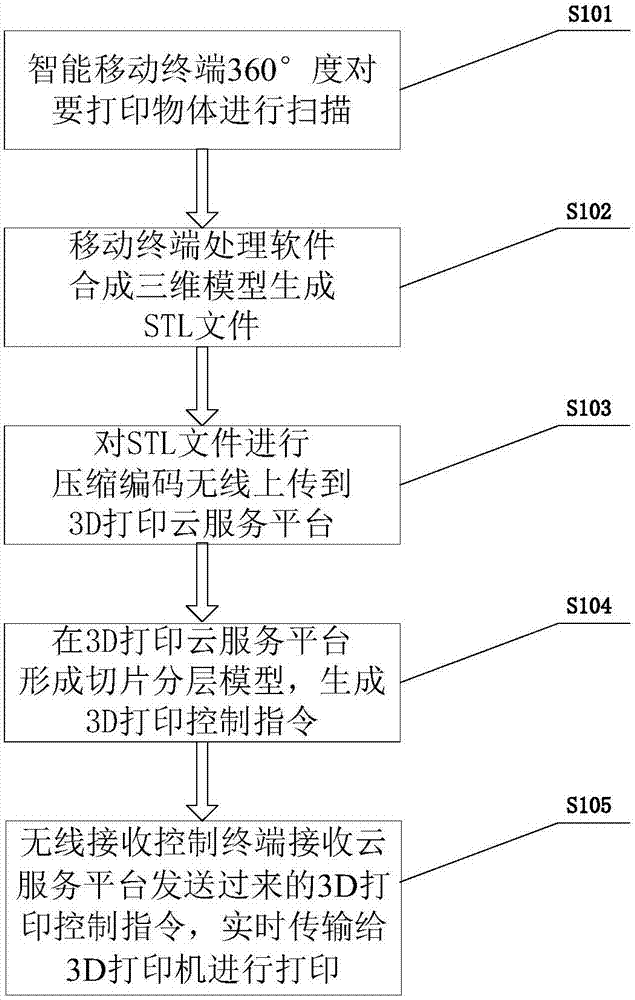

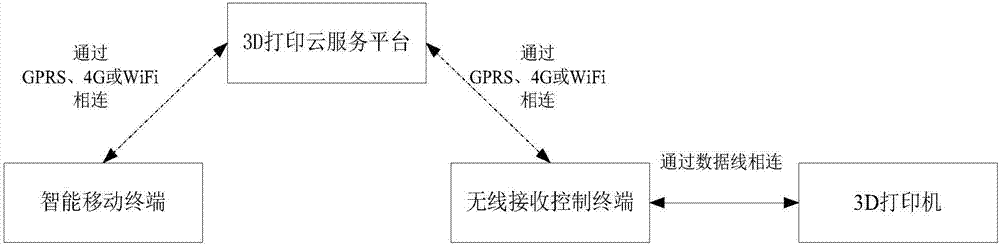

Remote 3D printing method and system

InactiveCN106933522AAchieve real-time 3D printingEasy to callAdditive manufacturing apparatusDigital output to print unitsComputer graphics (images)Computer terminal

The present invention belongs to the technical field of 3D printing, and relates to a remote 3D printing method. The method comprises that a to-be-printed object is scanned by using an intelligent mobile terminal; a 3D model is synthesized to generate an STL file; the Huffman coding compression is carried out on the STL file, and the processed STL file is wirelessly uploaded to a 3D printing cloud service platform; a slice hierarchical model is formed on the 3D printing cloud service platform, and a 3D print control instruction is generated; the 3D print control instruction is transmitted to a wireless receiving control terminal; and the wireless receiving control terminal transmits the 3D print control instruction to the 3D printer in real time, so that printing is carried out by the 3D printer. According to the method disclosed by the present invention, 3D data of the printed object is stored on the cloud service platform, so that subsequent calling at any time can be facilitated, and requirements of mobile, remote, real-time 3D printing are effectively solved.

Owner:武汉中天元科技有限公司

Sectioning method of three-dimensional model and three-dimensional printing device

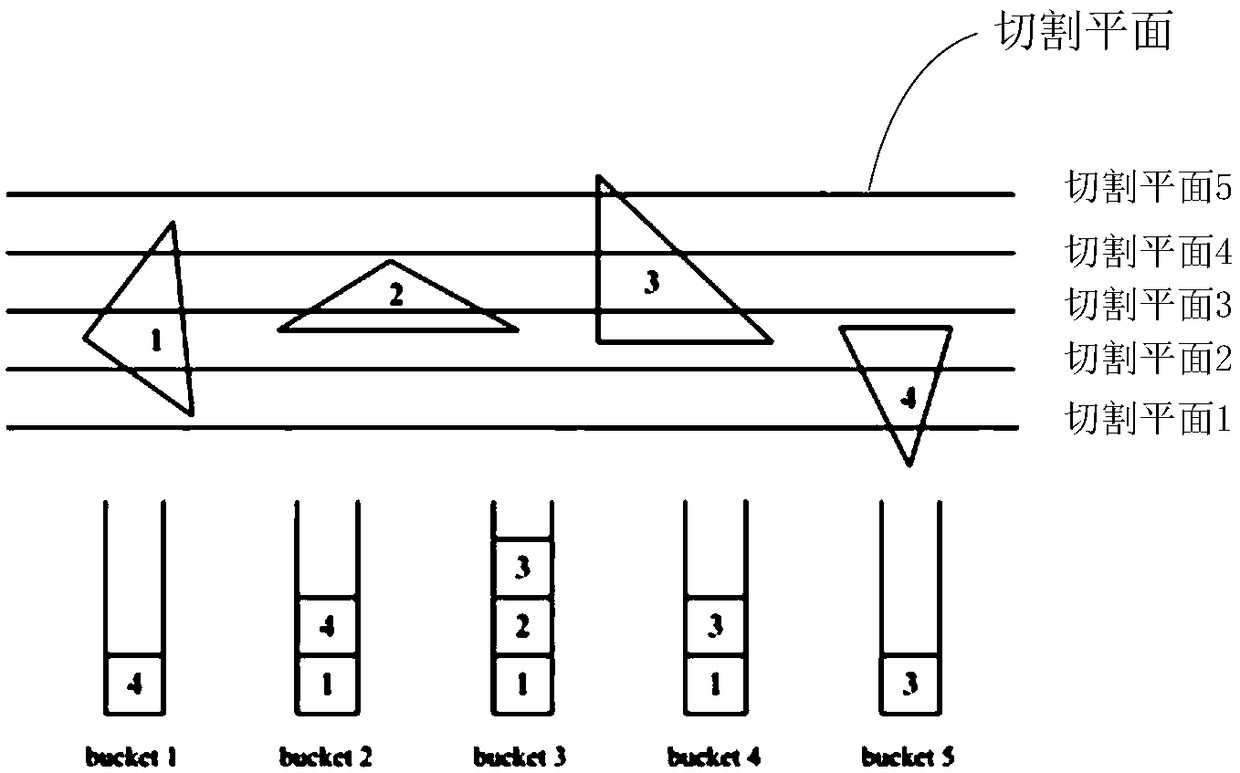

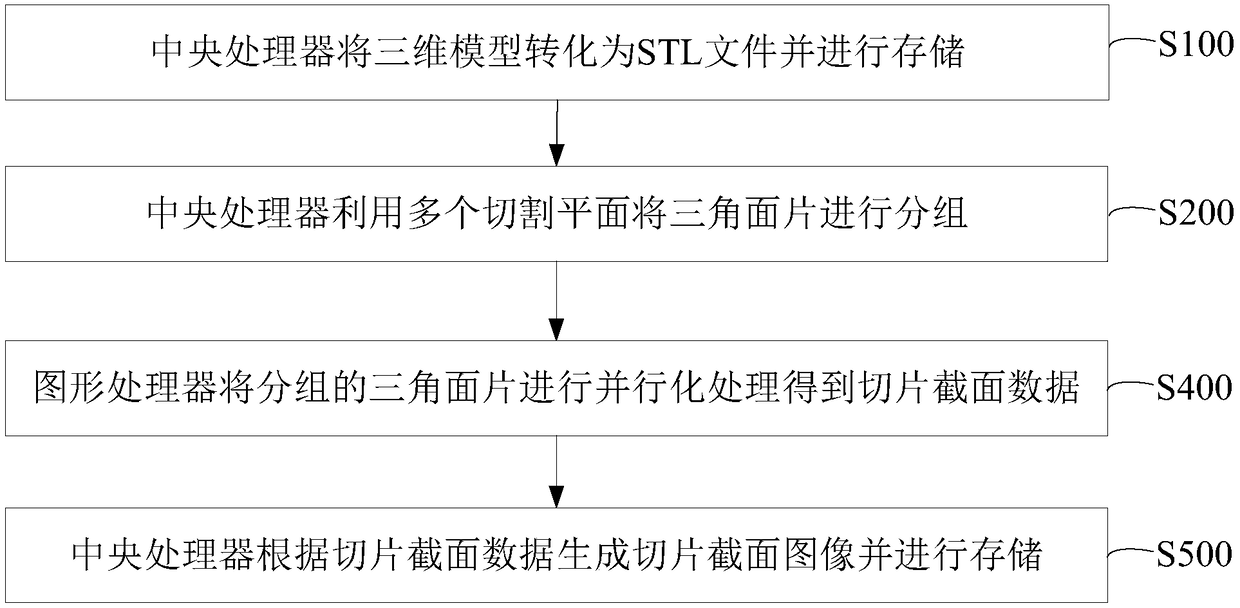

ActiveCN109159425AImprove slice calculation efficiencyImprove printing efficiencyAdditive manufacturing apparatusManufacturing data aquisition/processingGraphicsIntersection of a polyhedron with a line

The invention relates to a sectioning method of a three-dimensional model and a three-dimensional printing device. The three-dimensional printing device comprises a central processor and a graph processor. The method comprises the following steps: the central processor converts the three-dimensional model into an STL file and stores the STL file; the central processor groups triangular patches bymeans of a plurality of cutting planes, so that the triangular patches intersected with the same cutting plane are in a same group; the graph processor processes the grouped triangular patches in parallel to obtain slice section data, wherein the slice section data is intersection data of the cutting planes and the triangular patches; the central processor generates slice section images accordingto the slice section data and stores the slice section images. By grouping the triangular patches by the cutting planes by means of the central processor and processing the grouped triangular patchesin parallel by means of the graph processor, the sectioning calculating efficiency of the three-dimensional efficiency can be improved effectively, so that the 3D printing efficiency is further improved, and efficient manufacturing demands are met.

Owner:CLOUD COMPUTING CENT CHINESE ACADEMY OF SCI

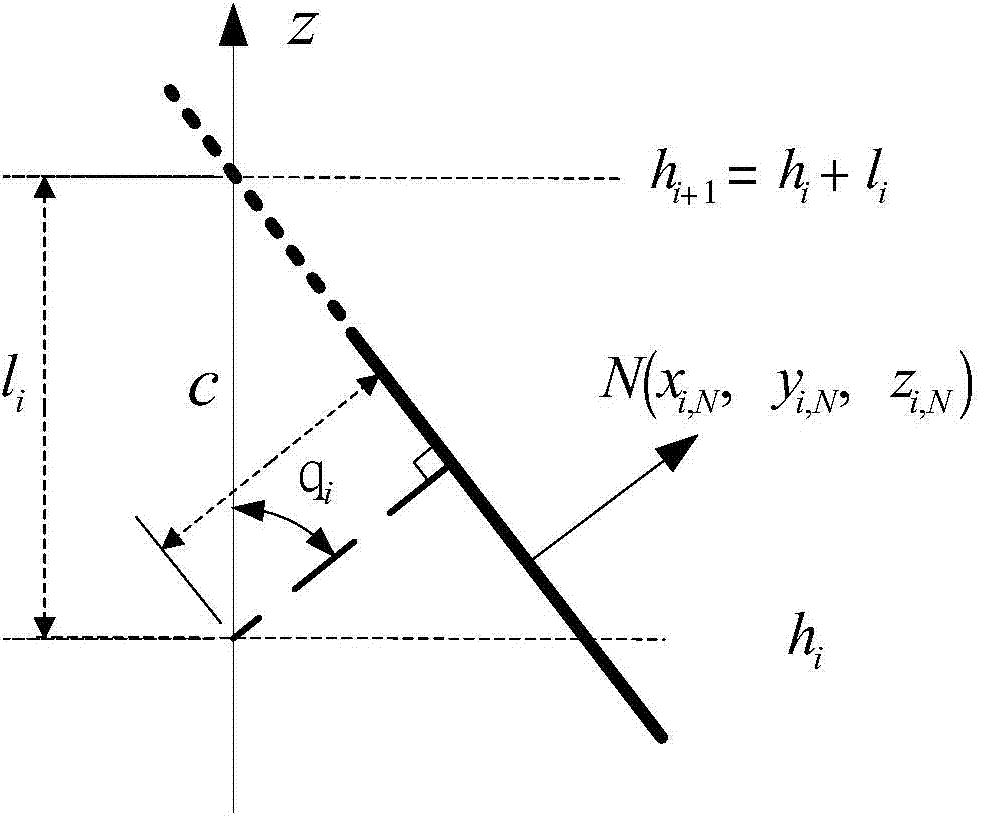

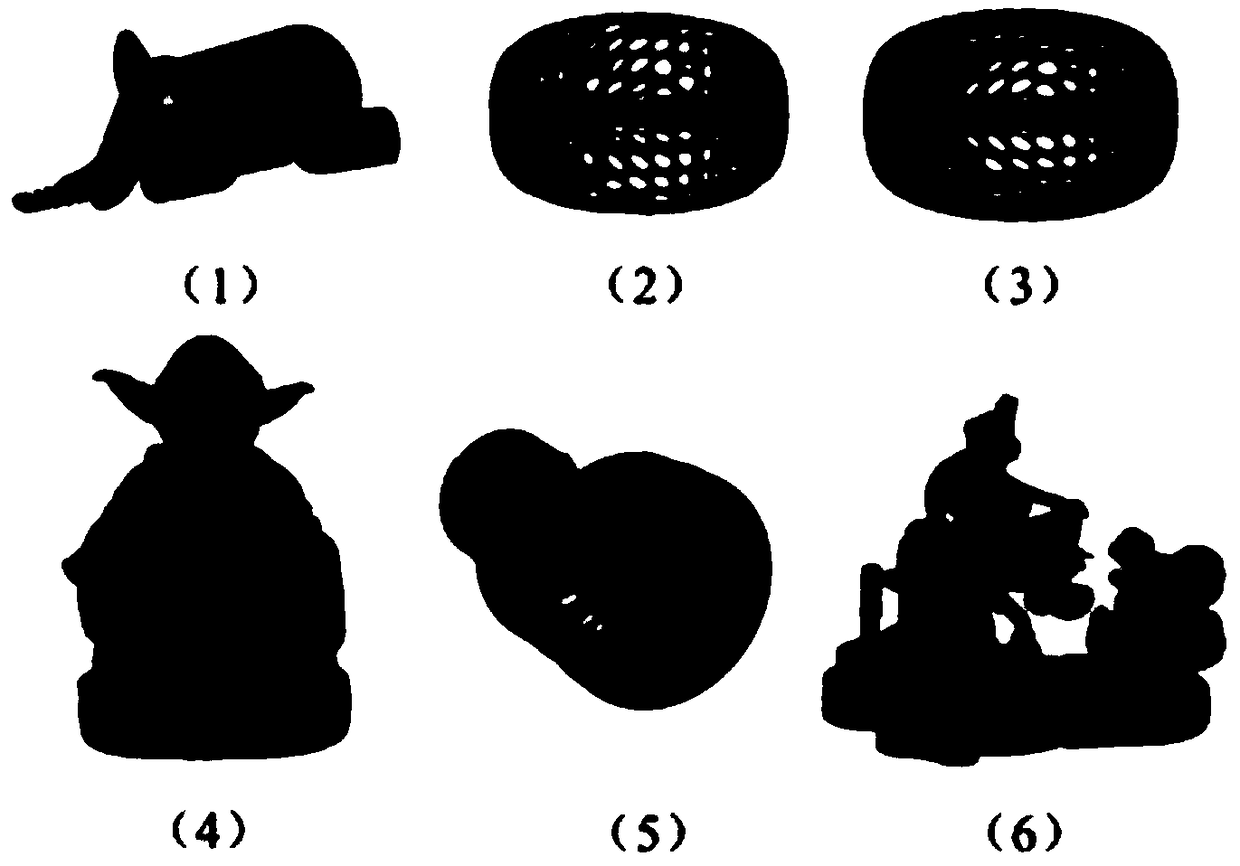

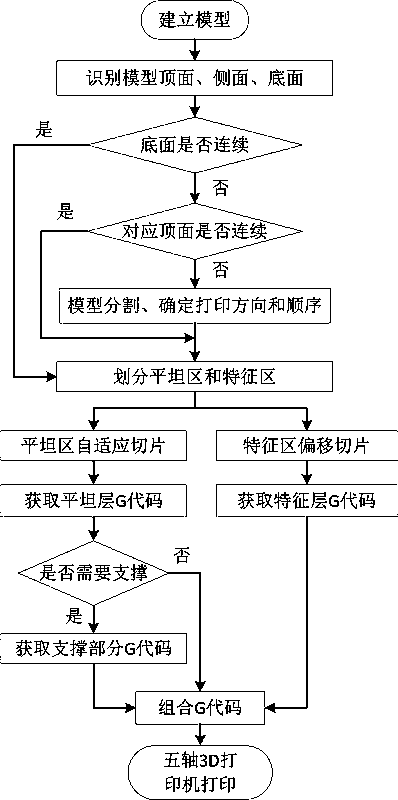

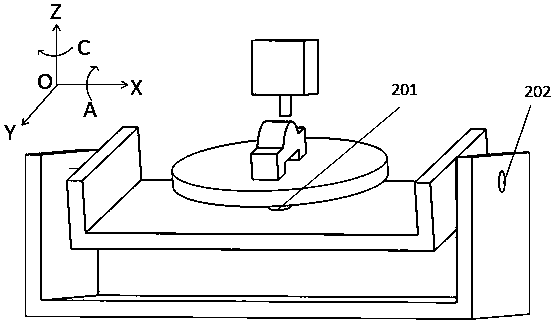

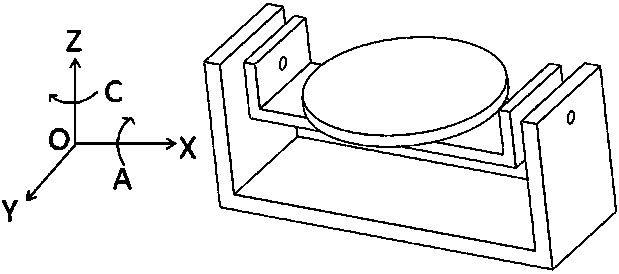

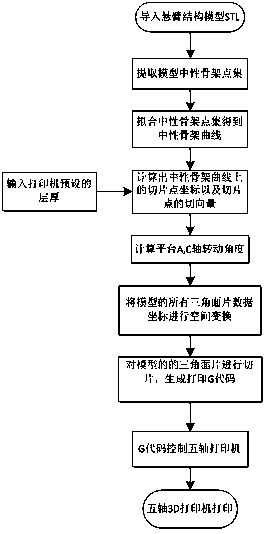

Model surface characteristic-based five-axis linked 3D printing method of adaptive hybrid section

ActiveCN108312548AHigh strengthImprove mechanical propertiesAdditive manufacturing apparatusManufacturing data aquisition/processingComputer Aided DesignEngineering

The invention relates to a model surface characteristic-based five-axis linked 3D printing method of an adaptive hybrid section. The model surface characteristic-based five-axis linked 3D printing method comprises the following steps: firstly establishing a workpiece three-dimensional model by using computer-aided design software, classifying the surfaces of the model into a top surface, side surfaces and a bottom surface according to normal vector information in an STL file, and segmenting the model according to continuity; classifying each model part into a flat area for plane printing and acharacteristic area for space printing according to surface characteristics; performing plane slicing for the flat area, acquiring a route code G according a preset sharp-corner height value adaptivesection, and acquiring a code G of a supporting part if the support is needed; performing the deviation slicing for the characteristic area, and acquiring a route code G; and combining and sequencingall route codes G, and inputting into a five-axis linked 3D printing machine to realize the printing. According to the method, by utilizing the five-axis linked printing machine, the space 3D printing is realized according to the workpiece surface characteristics. The method is a 3D printing production method which is high in workpiece surface precision, high in structural performance and capableof saving time and materials.

Owner:SHANGHAI UNIV

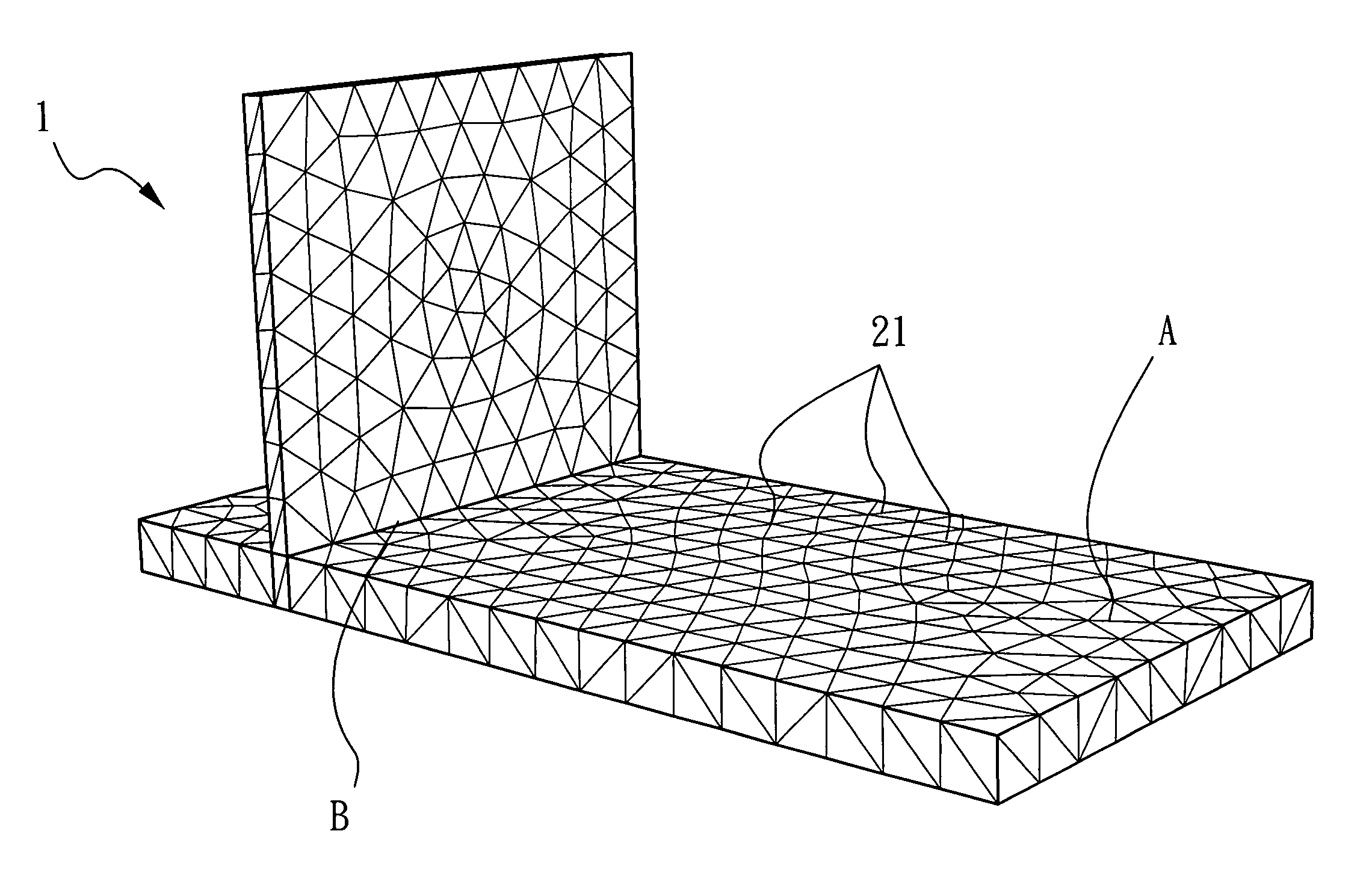

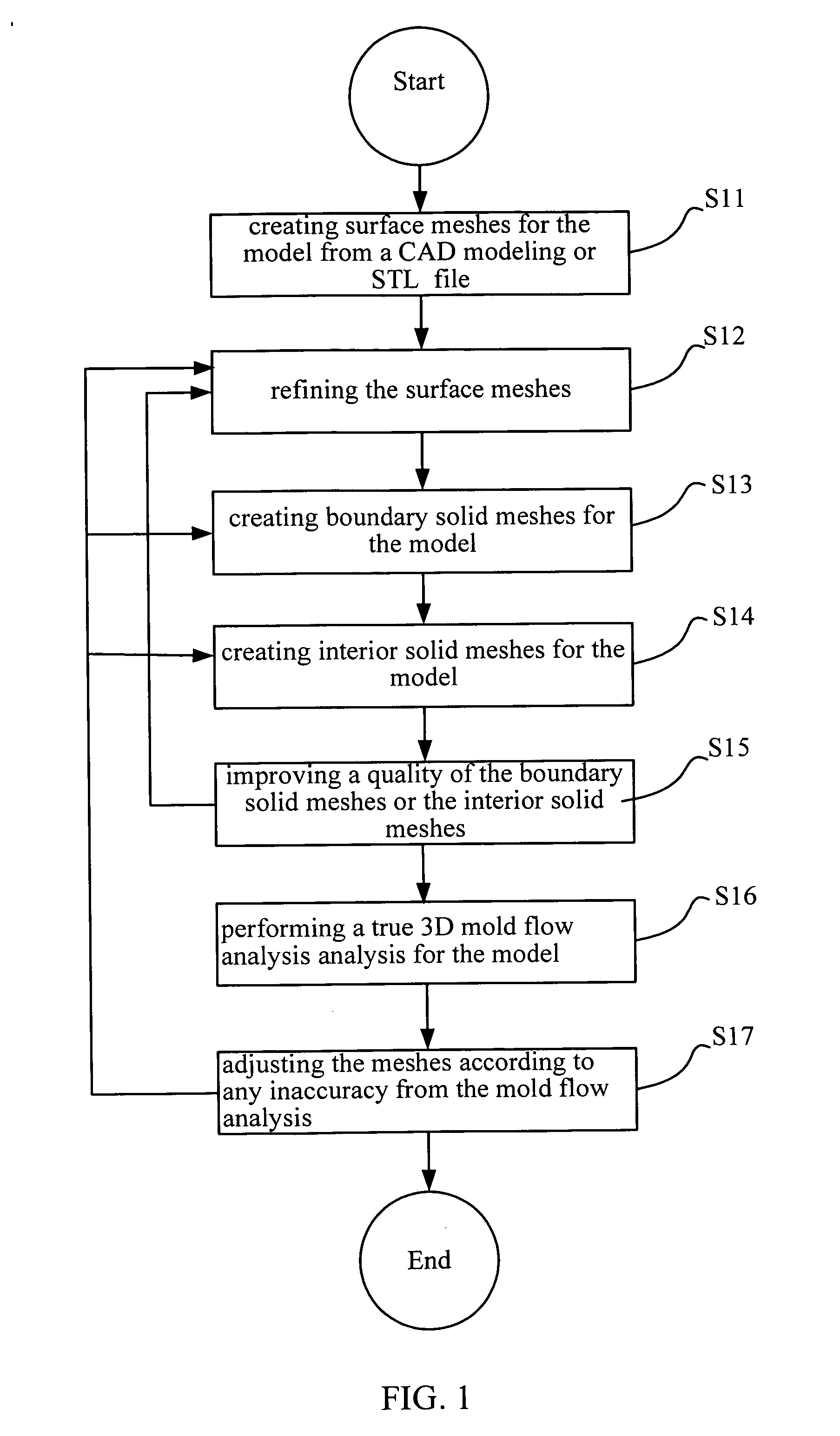

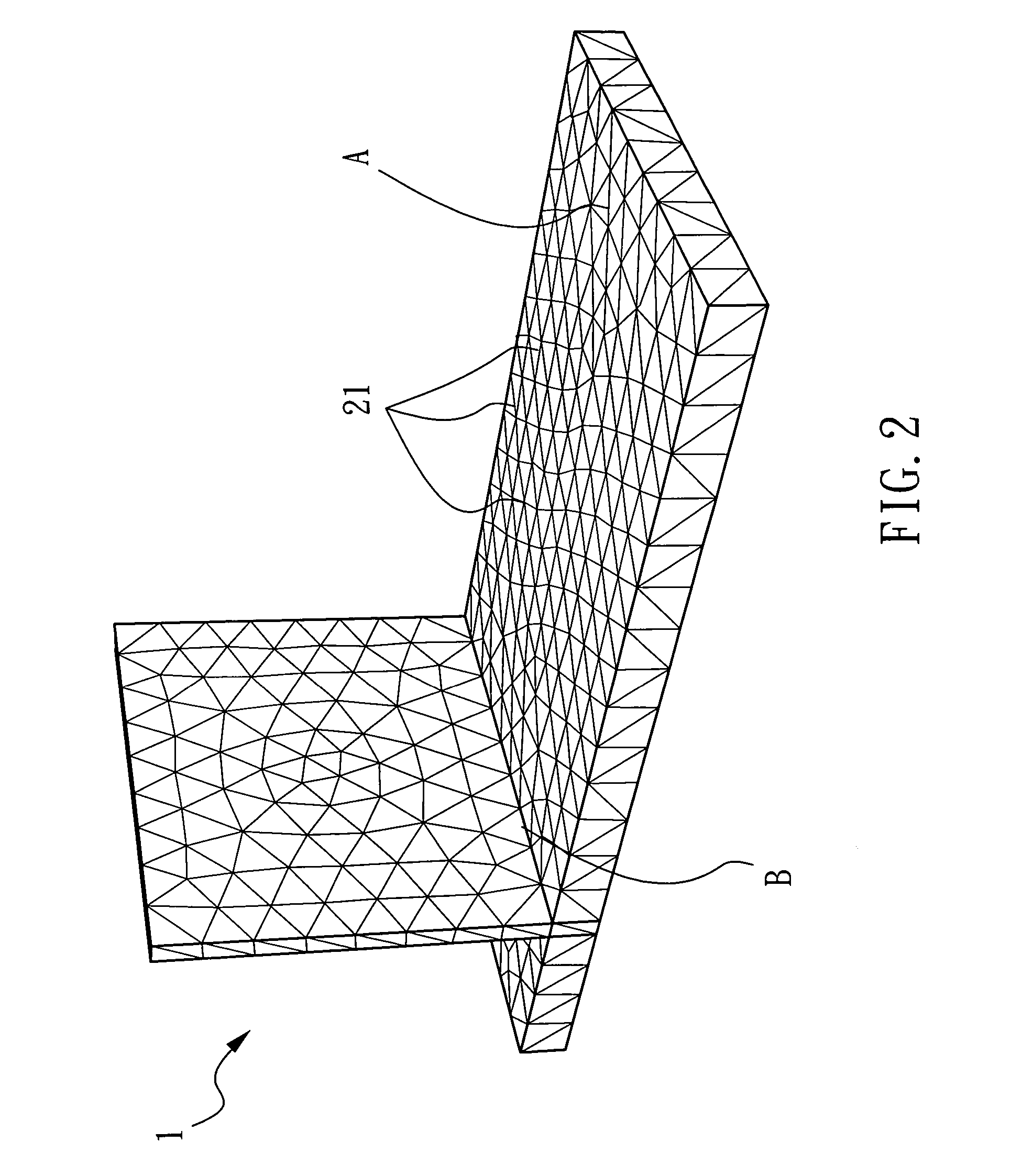

Automated mesh creation method for injection molding flow simulation

An automated mesh creation method for automatically creating meshes for a model that may be applied in a mold flow analysis. The method includes the steps of creating surface meshes for the model from a CAD model or a STL file; refining the surface meshes; creating boundary solid meshes for the model; creating interior solid meshes for the model; improving the quality of the boundary solid meshes or the interior solid meshes; performing a true 3D model flow analysis for the model according to the surface meshes, the boundary solid meshes and the interior solid meshes; and adjusting the surface meshes, the boundary solid meshes or the interior solid meshes according to any inaccuracy of the mold flow analysis.

Owner:CORETECH SYST

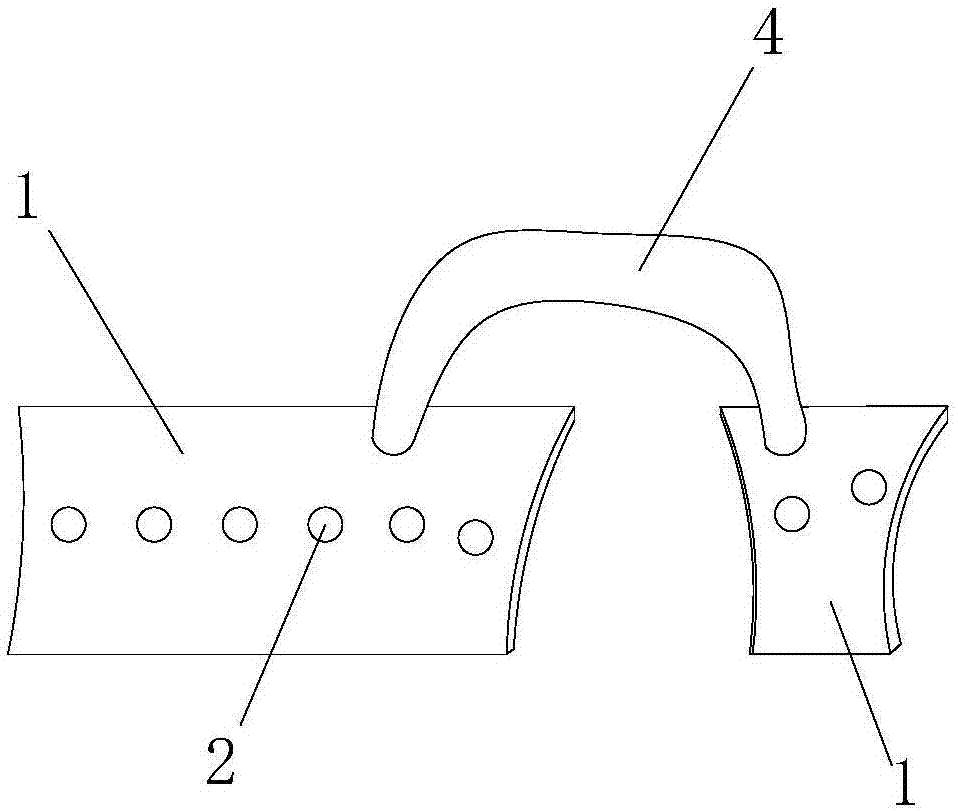

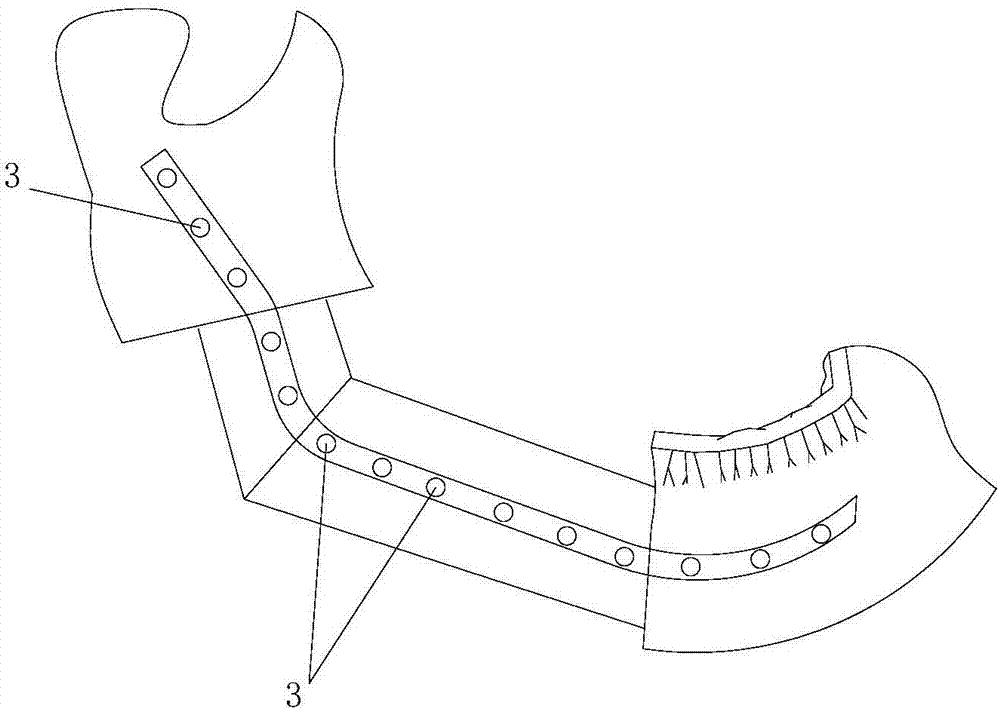

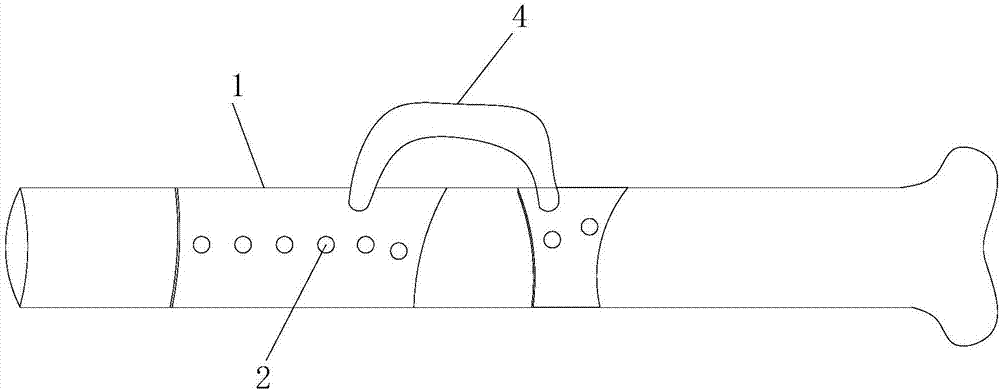

Production method of 3D printing fibula reconstruction jaw surgical tool combining bone excision with titanium-plate positioning

ActiveCN107951538AAccurately restore the occlusal relationshipStable condyle positionAdditive manufacturing apparatusComputer-aided planning/modellingJaw osteotomyMandible osteotomy

The invention discloses a production method of a 3D printing fibula reconstruction jaw surgical tool combining bone excision with titanium-plate positioning. The method comprises the steps that a jawthree-dimensional model and a fibula three-dimensional model are reconstructed; according to the lesion range, the jaw osteotomy plane is determined, and an expected jaw model is designed; a preforming titanium plate is fixed to the target portion of an expected jaw model entity and subjected to secondary scanning; a titanium plate-expected jaw composite model and a titanium plate model are obtained; the titanium plate-expected jaw composite model, the titanium plate model and an STL file of the expected jaw model are subjected to rectification and alignment; a mandible osteotomy guide plate and a fibula osteotomy guide plate are designed, tack holes in the titanium plate model are correspondingly mapped to the mandible osteotomy guide plate and the fibula osteotomy guide plate, and a special quickly-formed guide plate is formed. According to the produced fibula osteotomy tool, the obtained fibula can be precisely positioned in the tack holes and can be accurately transferred to the jaw according to the design expectation, and the pre-bent titanium plate is used for directly and accurately positioning an acquired bone segment.

Owner:XIANGYA HOSPITAL CENT SOUTH UNIV

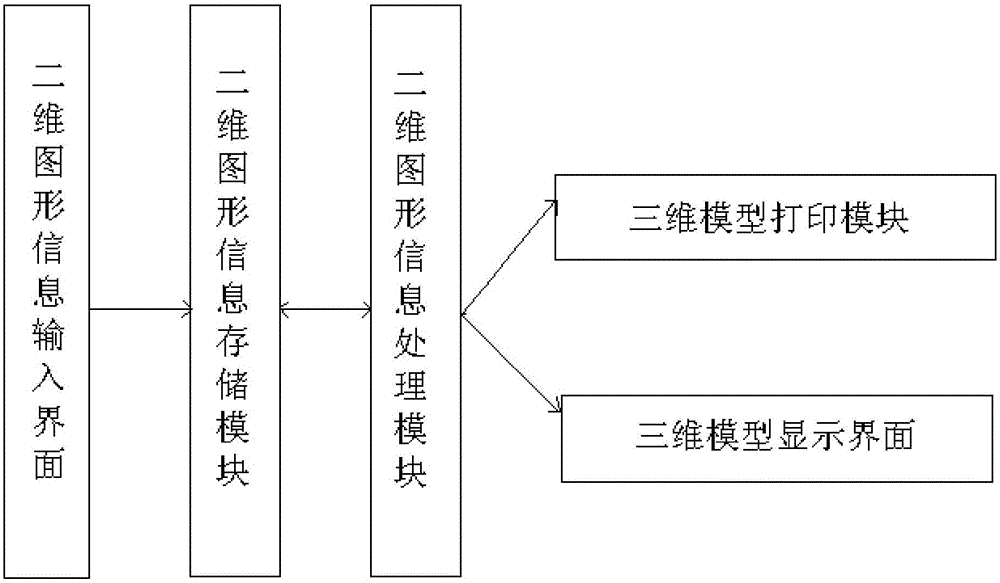

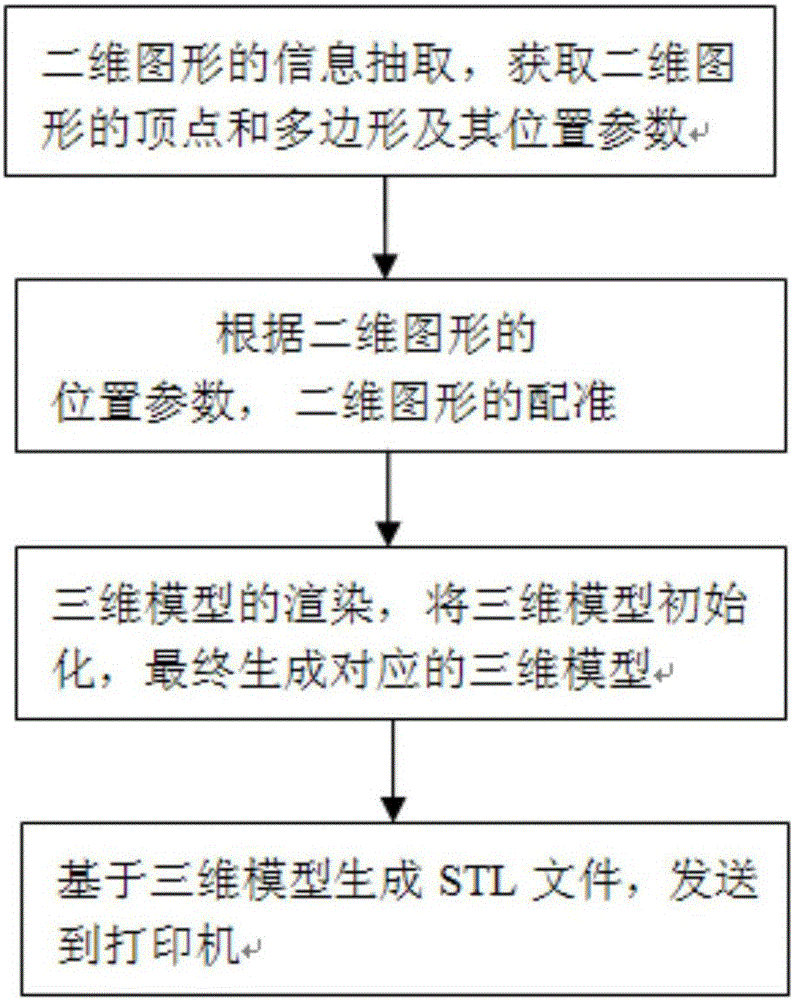

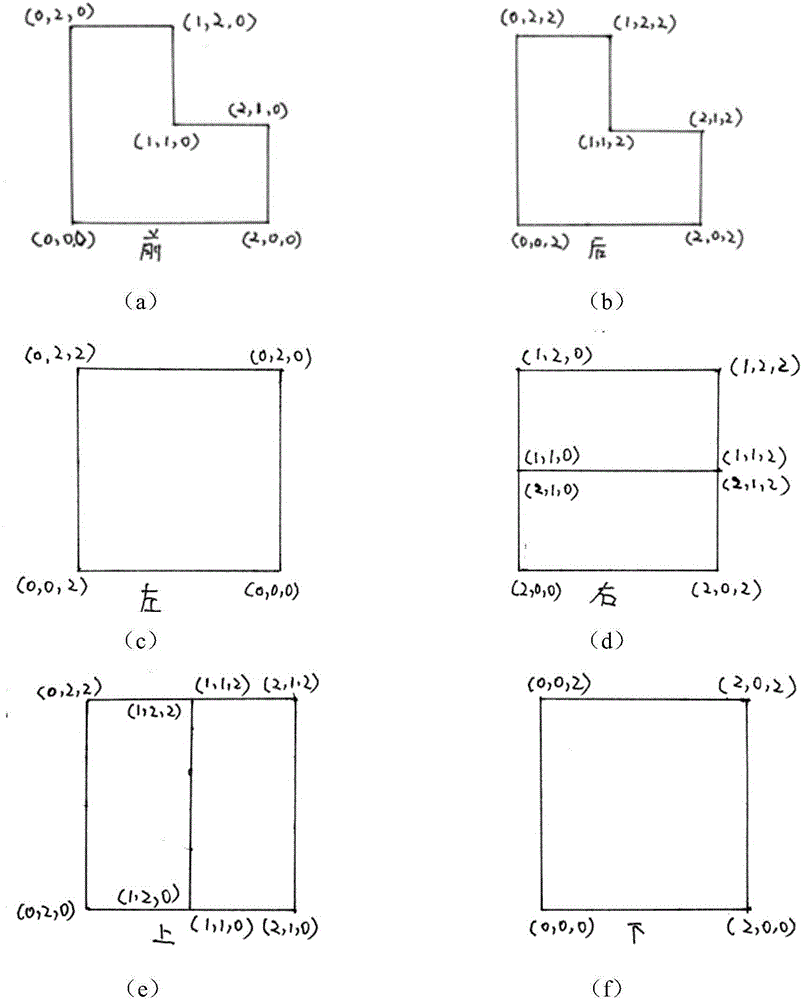

3D printing device based on two-dimensional image, and three-dimensional modeling method for 3D printing device

The invention discloses a 3D printing device based on a two-dimensional image, and the 3D printing device comprises a two-dimensional graphic information input interface, a two-dimensional graphic information storage module, a two-dimensional graphic information processing module, a three-dimensional model display interface, and a three-dimensional model printing module. The invention also discloses a three-dimensional modeling method based on a two-dimensional graph, and the method comprises the steps: firstly extracting views of six surfaces of a to-be-printed object; secondly respectively extracting and storing the two-dimensional graphic information of the views of the six surfaces; thirdly carrying out the registration of the two-dimensional graphic information, and generating a three-dimensional model; finally generating an STL file for 3D printing according to the three-dimensional model. According to the invention, the whole modeling process is completed automatically, and the device and method are convenient for operation, are high in production rate, and have certain precision. The device and method exert low requirements for hardware, can be used for platforms and terminals, and is low in resource consumption.

Owner:上海术理智能科技有限公司

Near-net-shape forming method of refractory metal part

InactiveCN102773479APromote absorptionImprove bindingAdditive manufacturingIncreasing energy efficiencySelective laser meltingSoftware design

The invention discloses a near-net-shape forming method of a refractory metal part, aiming at solving the complexity and the time consumption of a PM (power metallurgy) molding mode, and compensating the technical defect that the comprehensive property of an alloy cannot brought into play completely due to the fact that an SLM (selective laser melting) method liquid phase quantity cannot achieve the technical index of 30-35Vol / % of the densification. The method provided by the invention is as follows: 1, three-dimensional modeling software is adopted to design a CAD (computer-aided design) of a part, subsequently multiple layer slicing information is generated by slicing processing software, and an STL (Standard Template Library) file is stored, and the data of the STL file is transmitted to an SLM rapid molding system; 2, a layer of metal powder to be machined (the thickness ranges from 0.02-0.2mm, and the particle diameter is about 10-100 micrometer) is paved on a working platform by a powder conveying mechanism; 3, an optical fiber laser is adopted to scan the slicing, and the metal powder to be machined paved in the step 2 is completely melted, wherein the scanning speed is 50-1000mm / s; and 4, the steps (2) and (3) are repeated till the whole part machining is ended. The method has the beneficial effects that the powder is subjected to alloying, the bonding property of the alloy is improved, thereby being beneficial for the filling and the molding densification of the liquid, and improving the comprehensive property of the alloy.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

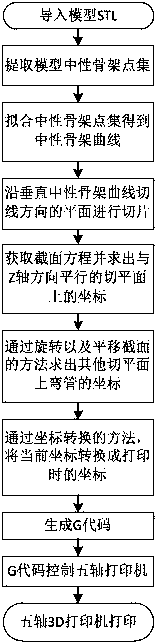

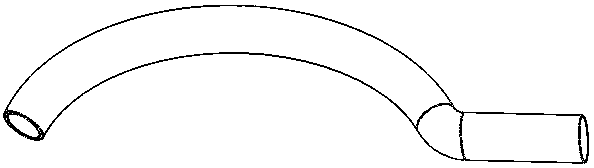

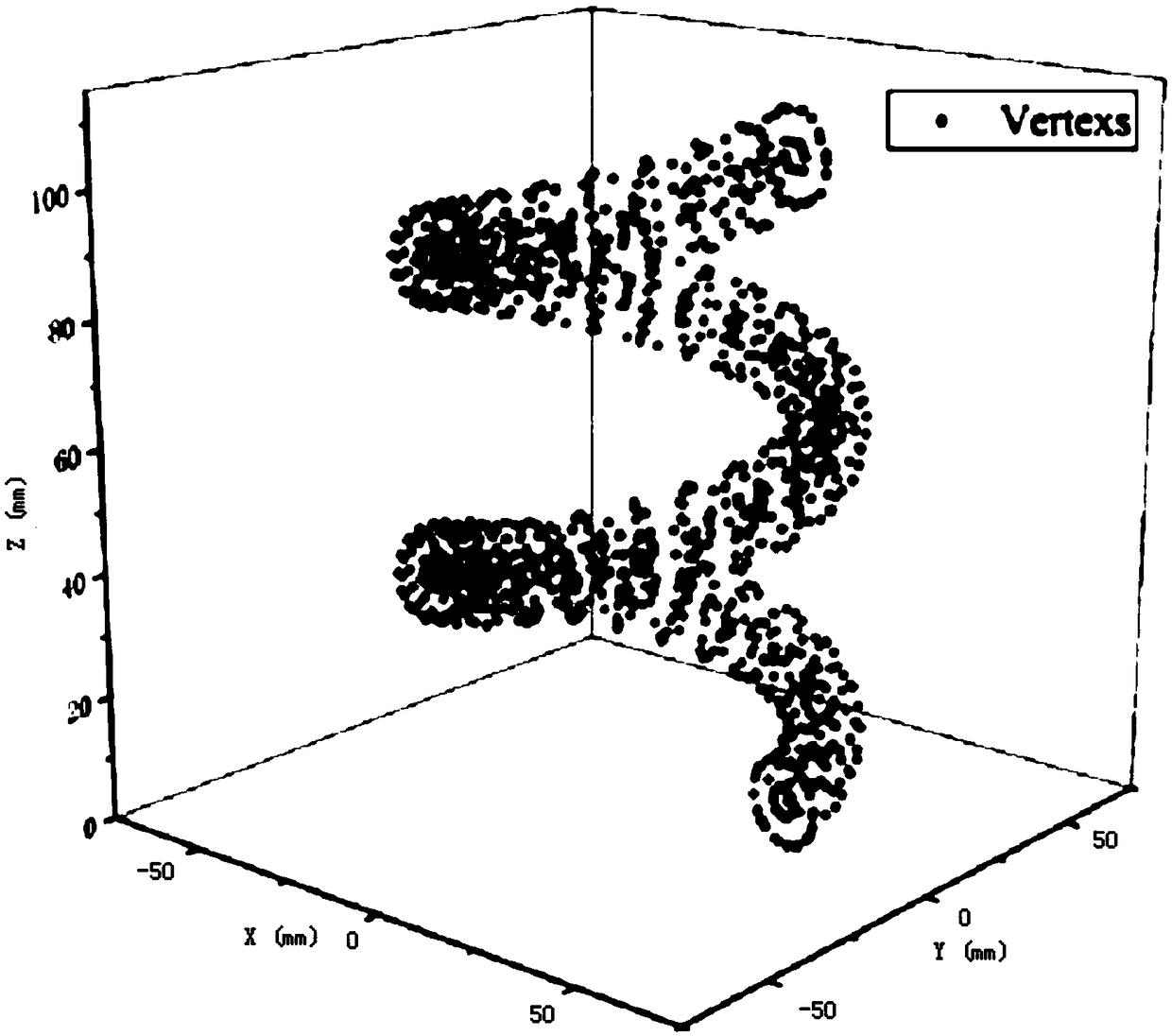

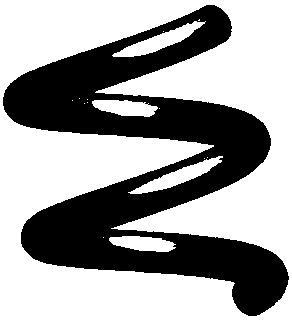

3D printing method used for printing elbow pipe in axial direction based on five-axis printing platform

ActiveCN109367014AAchieve readAchieve axial printingAdditive manufacturing apparatusManufacturing data aquisition/processingCurve fittingEngineering

The invention relates to a 3D printing method used for printing an elbow pipe in the axial direction based on a five-axis printing platform. The method comprises the following specific steps that a model neutral skeleton point set is extracted according to triangular patch data of a model STL file, curve fitting is performed on the neutral skeleton point set to obtain a neutral skeleton curve, slicing points are selected on the neutral skeleton curve of a model, and slicing is performed along a plane perpendicular to the tangential direction of the neutral skeleton curve; a cross section pointset is obtained according to the slicing method and the triangular patch data, and fitting is performed on the point set to obtain a cross section equation; a coordinate on a tangent plane parallel to the Z axis is calculated through the cross section equation; the coordinates of the elbow pipe on the other tangent planes are calculated through rotating and a cross section translating method, andall the coordinates of the elbow pipe are read; the coordinates of the position where the elbow pipe is located currently are converted into printing coordinates through a coordinate converting method; and finally, G codes recognized by a five-axis 3D printer are generated and input into the printer, and printing is completed on exhausting supports.

Owner:SHANGHAI UNIV

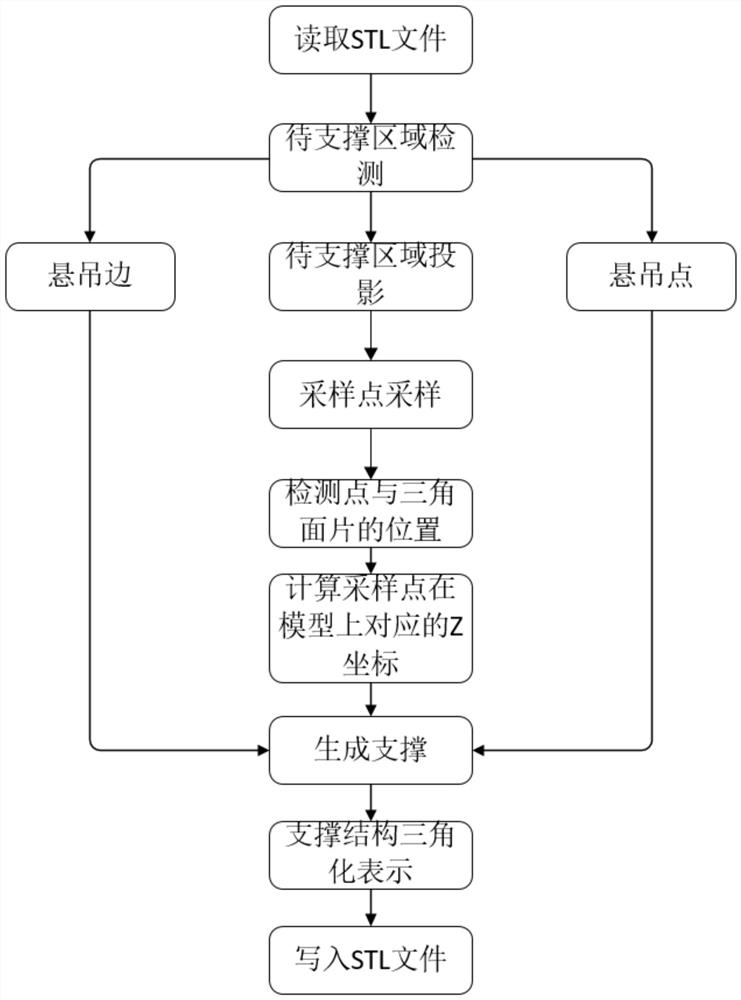

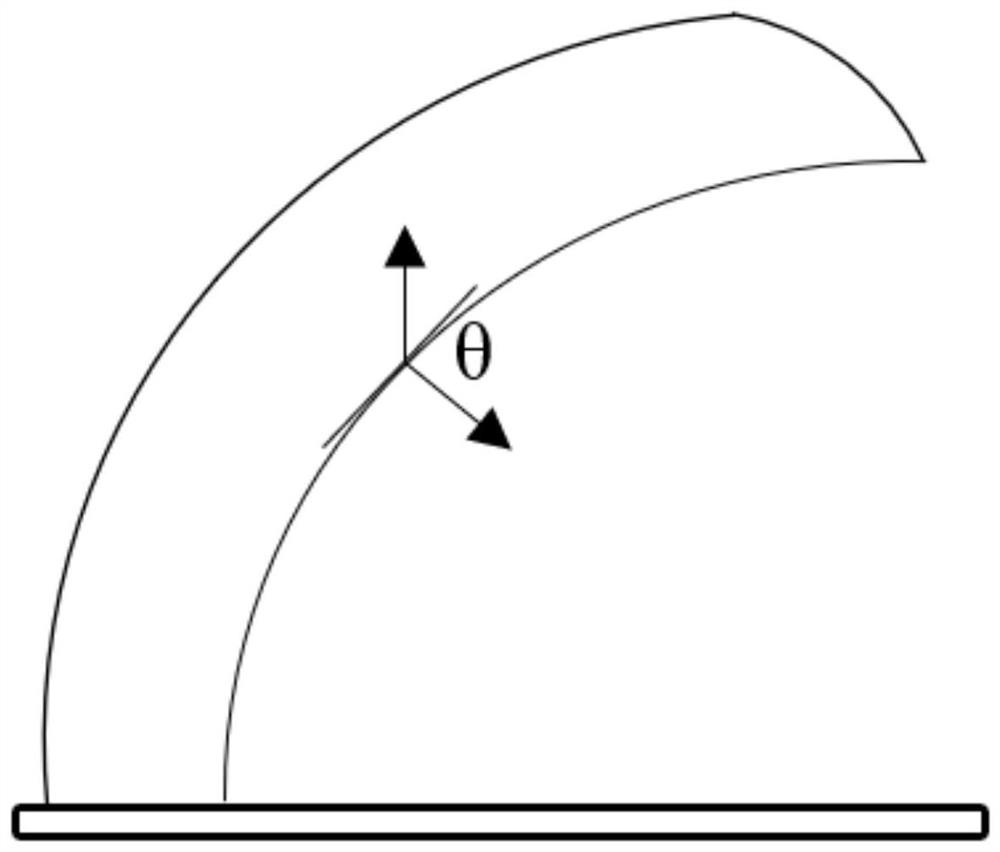

3D printing supporting structure design method based on STL file

PendingCN112590198AGood removal effectStable printingAdditive manufacturing apparatus3D object support structures3d printAlgorithm

A 3D printing supporting structure design method based on an STL file comprises the following steps that 3D modeling software is used for conducting three-dimensional modeling on a model, the STL fileis exported, the STL file is read, triangular patch vertex and normal vector information in the STL file is read, a critical angle is defined, the read triangular patch information is integrated, a to-be-supported area is projected to a working plane to form a two-dimensional projection area to obtain a part needing to be supported, sampling point sampling is carried out to generate a supportingstructure, and all vertex coordinates and normal vector coordinates are written into an STL file. Compared with the prior art, the problems that a traditional supporting structure is excessive in useamount, materials are wasted, the supporting structure is difficult to remove, and a to-be-supported area of a sharp-angled model including a suspension edge, a suspension point and the like cannot bedetected are solved, by means of the 3D printing supporting structure design method based on the STL file, the calculation efficiency is improved on the premise of guaranteeing that the model is tender and is consolidated and stably printed, the printing cost is saved, and the supporting structure is easier to remove.

Owner:HANGZHOU DIANZI UNIV

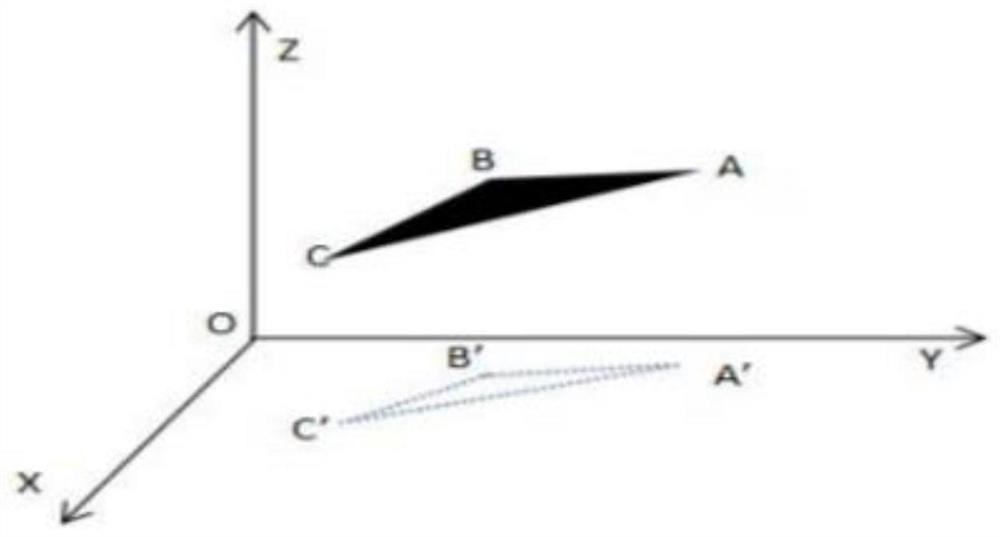

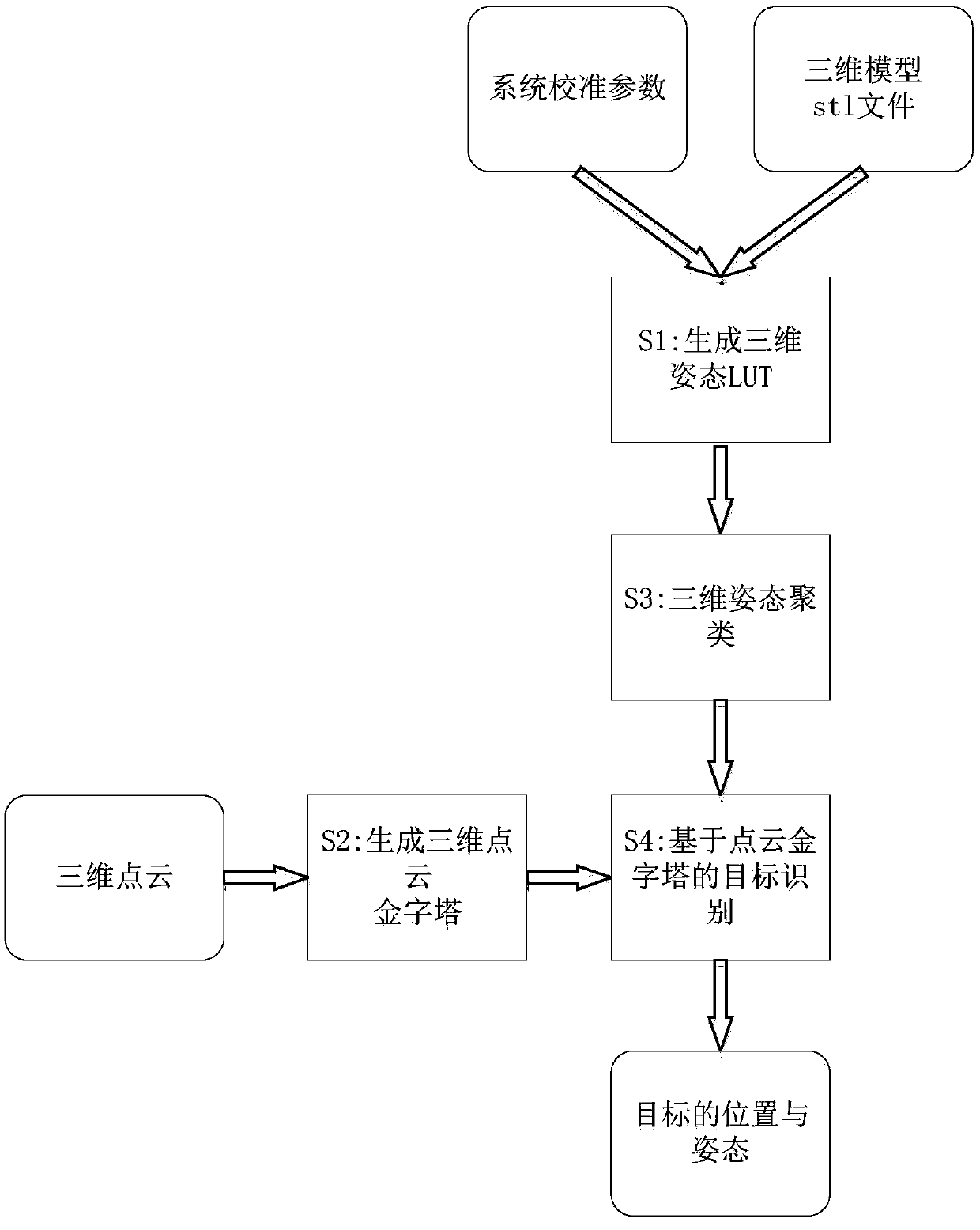

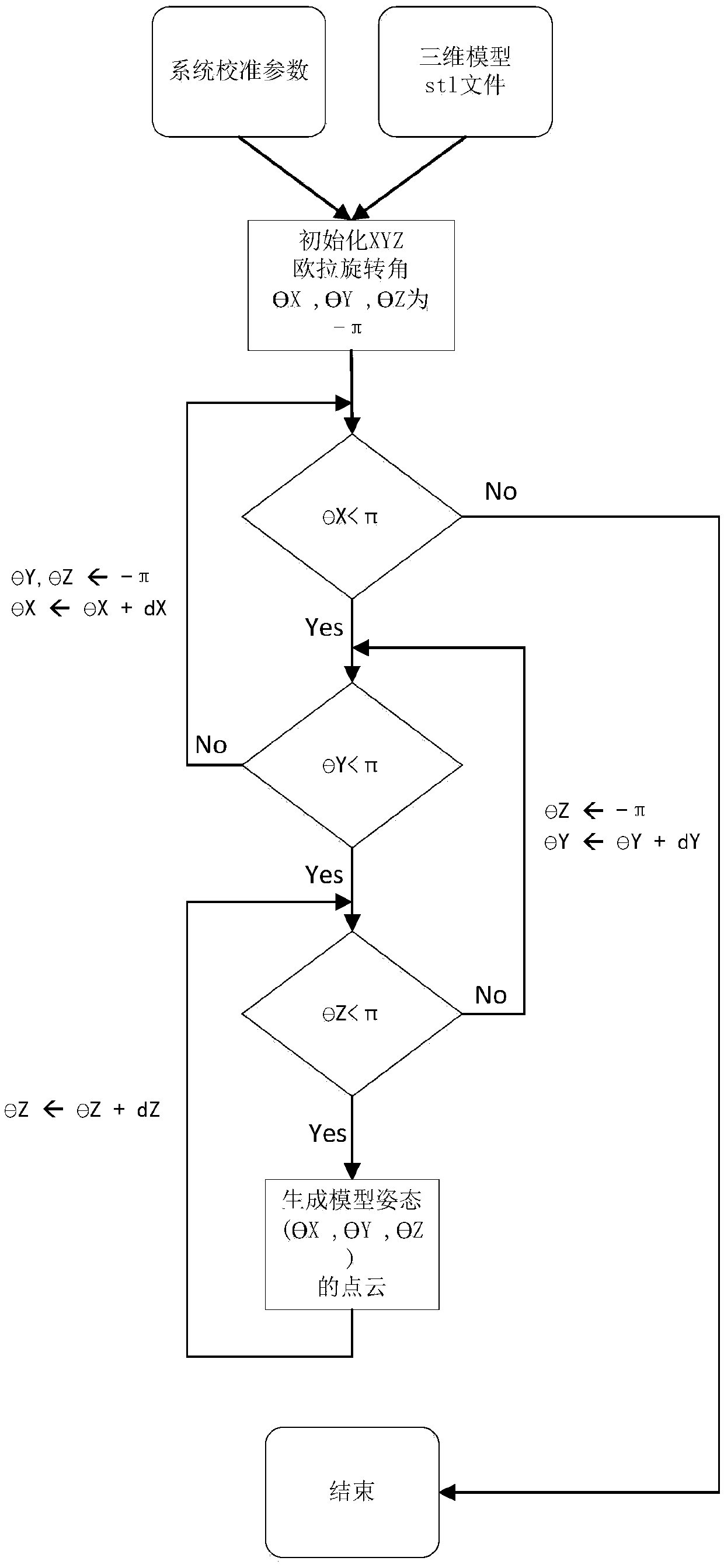

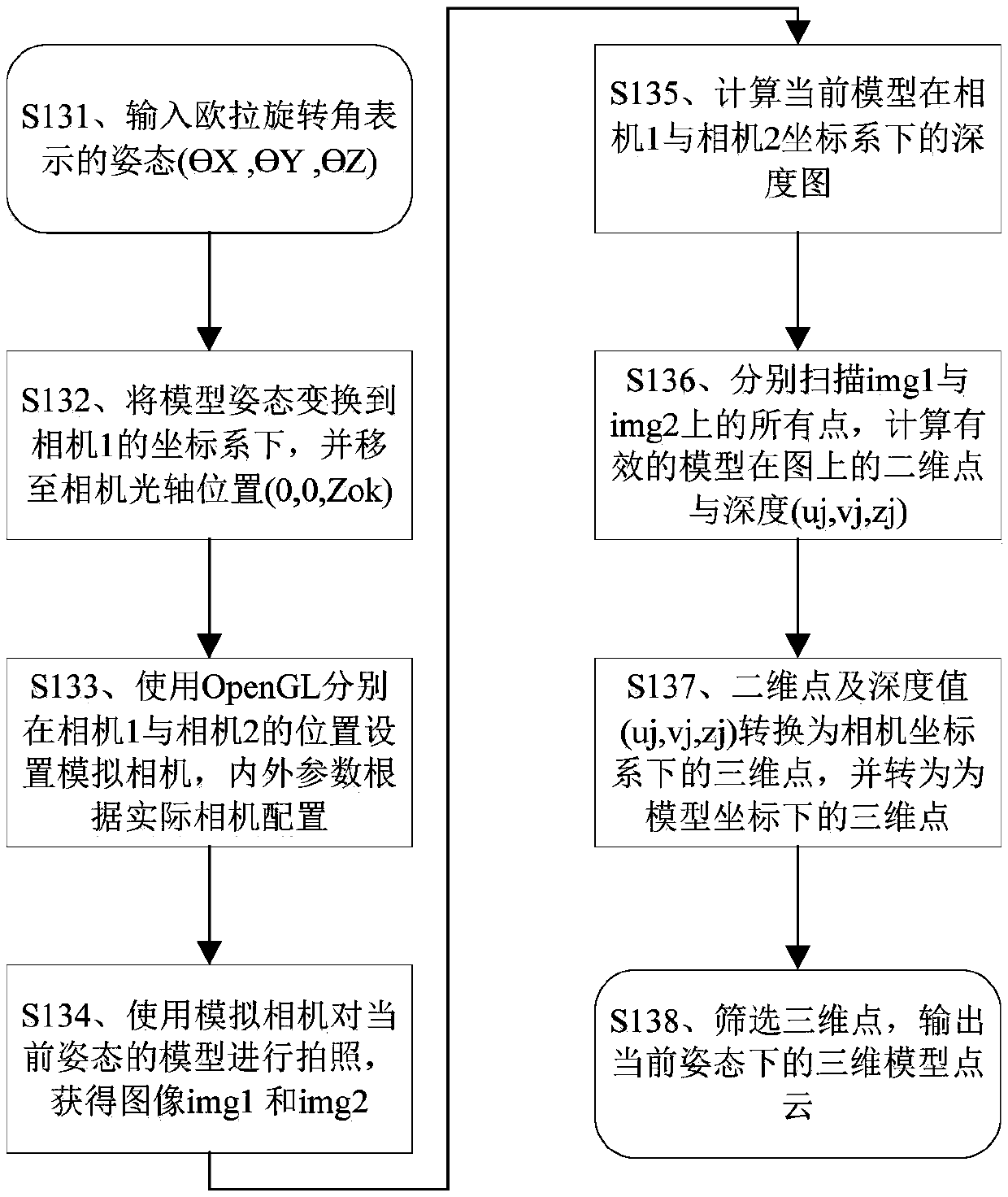

Target recognition method and device based on three-dimensional point cloud and storage medium

ActiveCN109033989ARecognition time is shortImprove recognition accuracyImage enhancementImage analysisPoint cloudGoal recognition

The embodiment of the invention provides a target recognition method and device based on a three-dimensional point cloud and a storage medium. The method comprises the following steps: generating a three-dimensional pose LUT of a model; generating a three-dimensional point cloud pyramid; clustering a 3D pose; performing target recognition based on point cloud pyramid. By adopting the method of theembodiment of the invention, the identification and grasping of the disordered target in industry can be well solved, and the position and the posture of the target can be quickly recognized in the current three-dimensional point cloud scene by using the target stl file to be recognized, the recognition time is short, and the recognition accuracy is high.

Owner:深圳辰视智能科技有限公司

Unsupported 3D printing method based on dynamic slicing algorithm

ActiveCN109228353ATurn real-time controlAvoid structureAdditive manufacturing apparatusManufacturing data aquisition/processingCurve fittingTime control

The invention relates to an unsupported 3D printing method based on a dynamic slicing algorithm. The unsupported 3D printing method comprises the following steps: extracting a neutral skeleton point set of a model according to triangular patch data in an STL document of the model; performing curve fitting on the neutral skeleton point set to obtain a neutral skeleton curve; selecting a slicing point on the neutral skeleton curve of the model and calculating a tangent vector of the point, wherein the slicing direction is always perpendicular to the Z-axis direction of a five-axis 3D printer through real-time control on the spatial rotation of a five-axis 3D printing receiving platform; finally generating a G code identified by the five-axis 3D printer to realize spatial printing. The unsupported 3D printing method provided by the invention mainly focuses on the unsupported printing of a cantilever structure with continuous holes or grooves, simultaneously avoids external and internal supporting structures of cantilever mechanism printing parts, reduces the printing supply and time, avoids the stripping support post-treatment process and improves the flexibility of an unsupported printing process.

Owner:SHANGHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com