Method for forming refractory metal parts by using laser

A refractory metal and laser forming technology, which is applied in the field of metal parts forming and processing, can solve the problems affecting the dimensional accuracy of parts, difficult to directly form parts, and inability to directly form, so as to avoid dimensional deviation, avoid machining and save materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

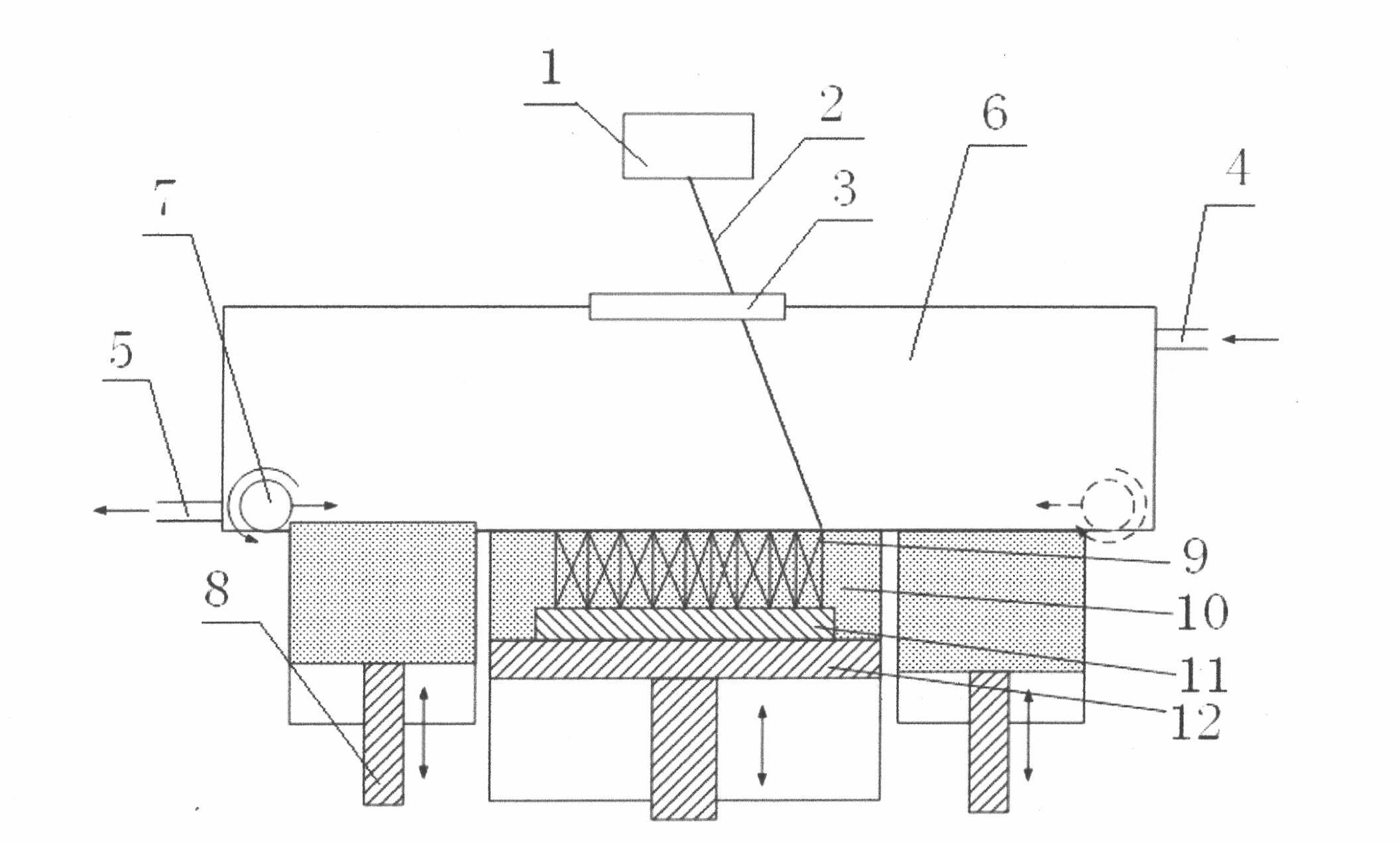

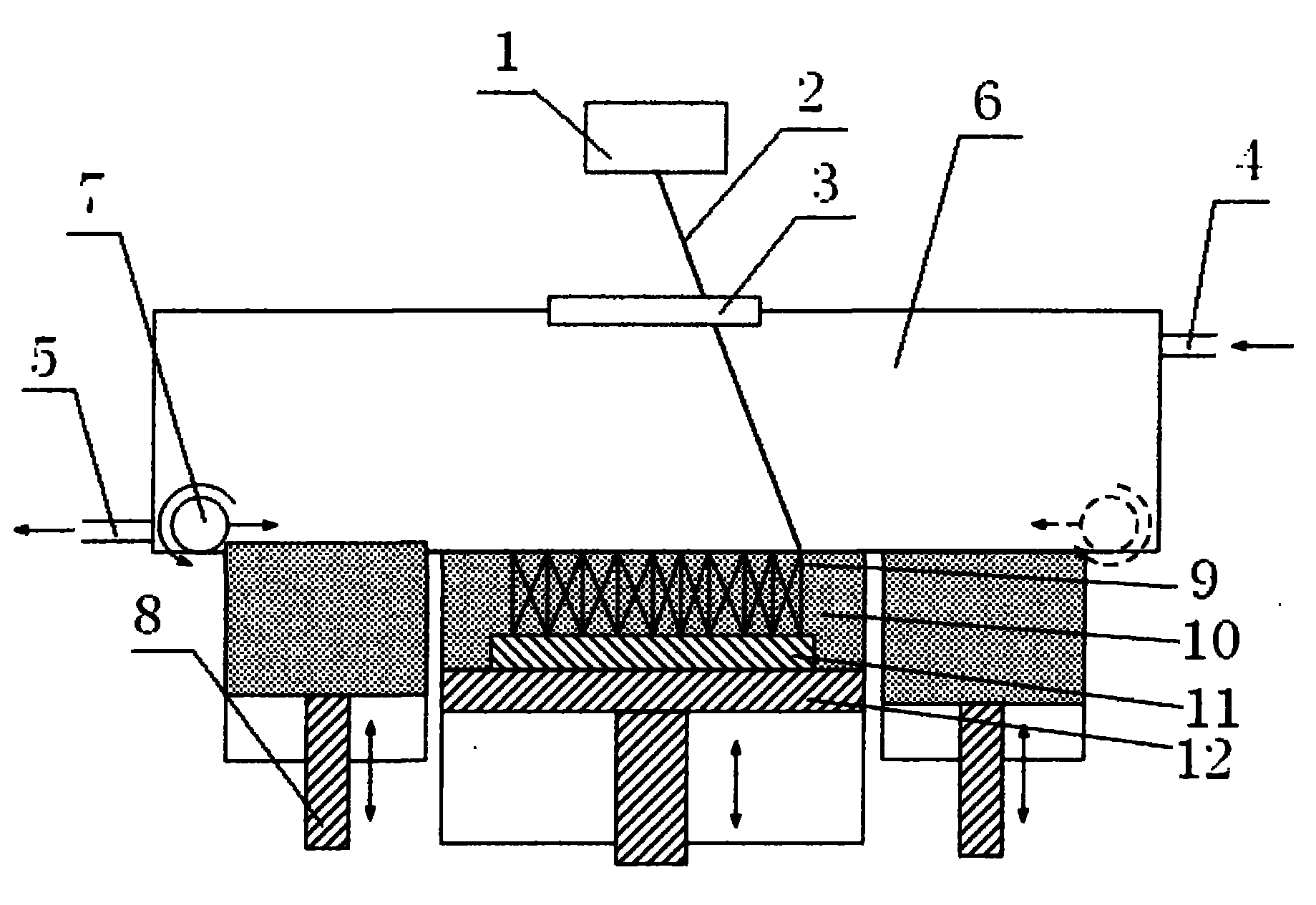

[0030] (1) The computer uses 3D modeling software (such as UG, Pro / E, etc.) to design the CAD 3D model of the part, and then it is processed by the slicing software and saved as an STL file, and the data information of the STL file is input to the SLM rapid prototyping system.

[0031] (2) In the SLM rapid prototyping system, a layer of W-Ni mixed powder with a thickness of about 0.1-0.2 mm is spread on the metal substrate by the powder feeding mechanism (wherein the mass fraction of W is ≥ 80%, and the particle size is about 10 ~100μm).

[0032] (3) Use a YAG laser or a fiber laser with a laser power of 200W to scan the slice after selecting the scanning path to melt the refractory mixed metal powder, wherein the scanning speed is 100-300mm / s.

[0033] (4), repeat the above steps (2)-(3), until the shell processing of the whole part is completed, at this time, the SLM processing of the W-Ni refractory metal complex metal part is completed.

[0034] Finally, follow-up process...

example 2

[0036] (1) Use 3D modeling software (such as UG, Pro / E, etc.) to design the CAD 3D model of the refractory part, then process it with the slicing software and save it as an STL file, and input the data information of the STL file into the SLM rapid prototyping system .

[0037] (2) Spread a layer of tungsten powder with a thickness of about 0.05~0.15mm (particle size about 10~100μm) on the metal substrate by the powder feeding mechanism.

[0038](3) Use a YAG laser with a laser power of 200W to scan the slice after selecting the processing path to melt the tungsten powder, wherein the scanning speed is 50-100 mm / s.

[0039] (4) Steps (2)-(3) are repeated until the tungsten metal part with a certain complex shape is processed.

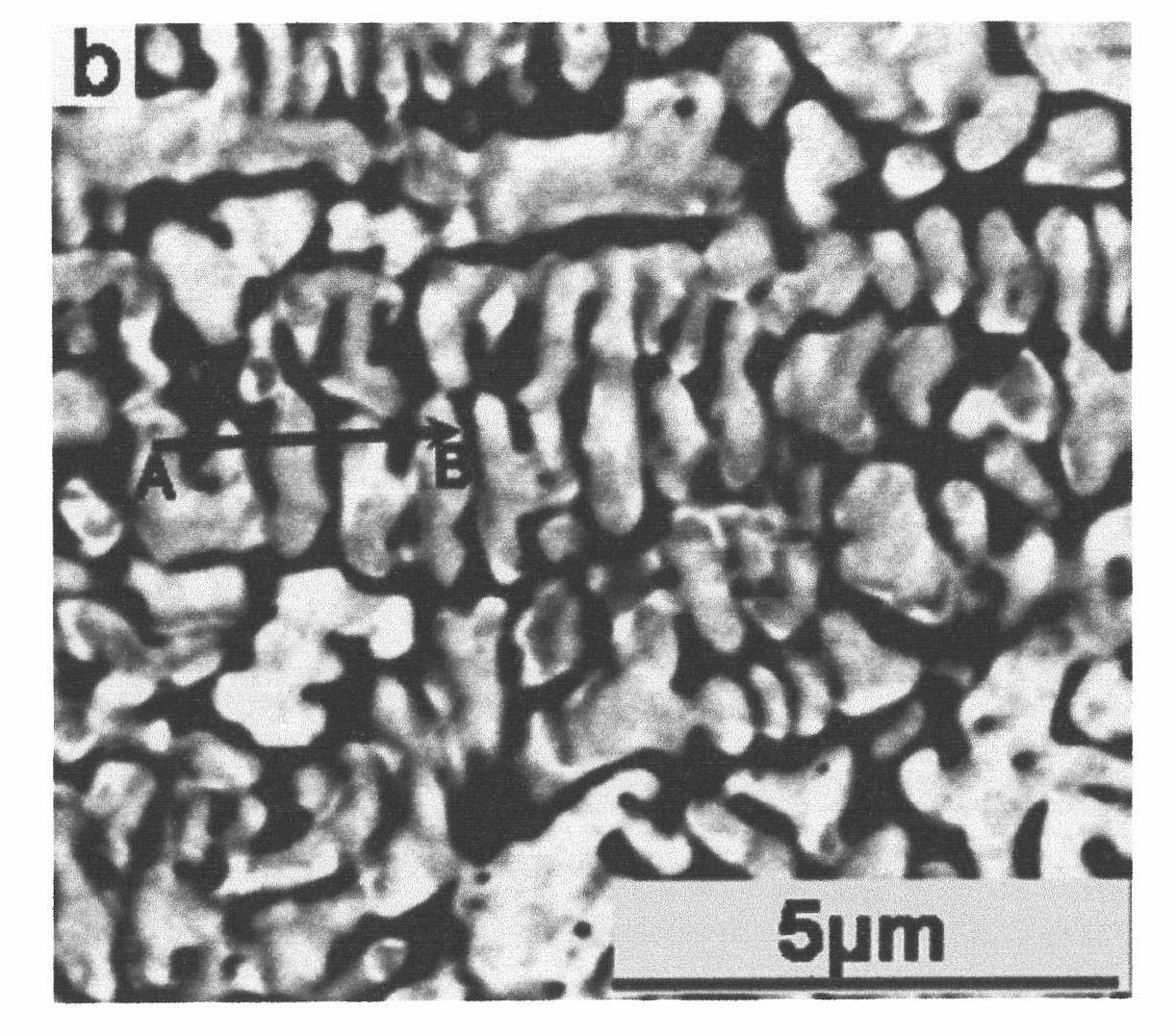

[0040] like figure 2 Shown is the metallographic diagram after the 200W YAG laser is used to scan and select the processing path to melt the tungsten powder.

[0041] After processing the obtained tungsten metal parts with complex shapes through mec...

example 3

[0043] (1) Use 3D modeling software (such as UG, Pro / E, etc.) to design the CAD 3D model of the refractory part, then process it with the slicing software and save it as an STL file, and input the data information of the STL file into the SLM rapid prototyping system .

[0044] (2) Spread a layer of Mo-Si mixed powder (with a particle size of about 10-100 μm) with a thickness of about 0.02-0.15 mm on the metal substrate by a powder feeding mechanism.

[0045] (3) A fiber laser with a laser power of 200W is used to scan the slice after the selected processing path to melt the Mo-Si mixed powder, wherein the scanning speed is 50-100 mm / s.

[0046] (4) Steps (2)-(3) are repeated until the molybdenum metal parts with a certain complex shape are processed.

[0047] After processing the obtained tungsten metal parts with complex shapes through mechanical polishing and other steps, MoSi with certain complex shapes and sizes can be obtained. 2 Refractory metal parts.

[0048] In th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com