Patents

Literature

105results about How to "Avoid machining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

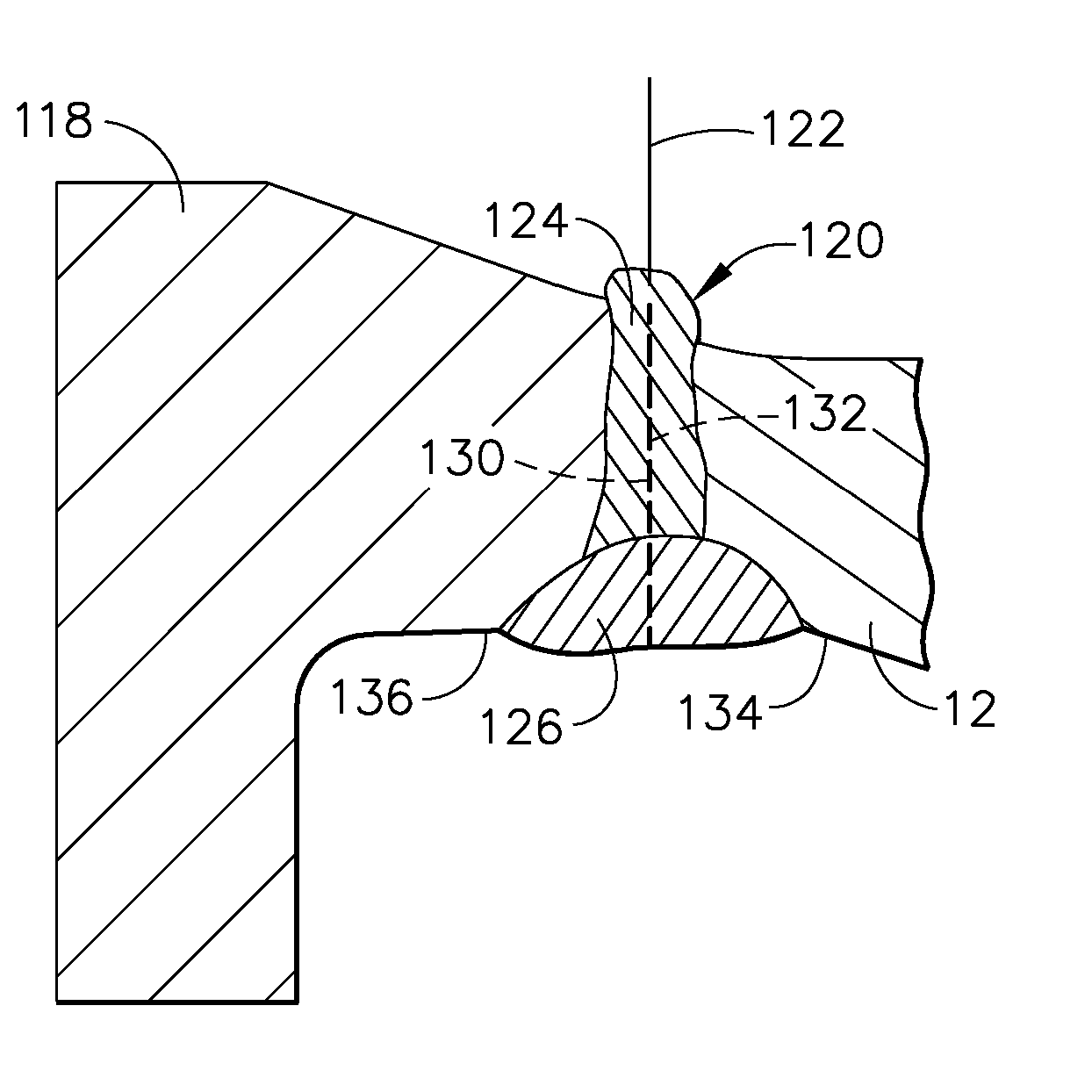

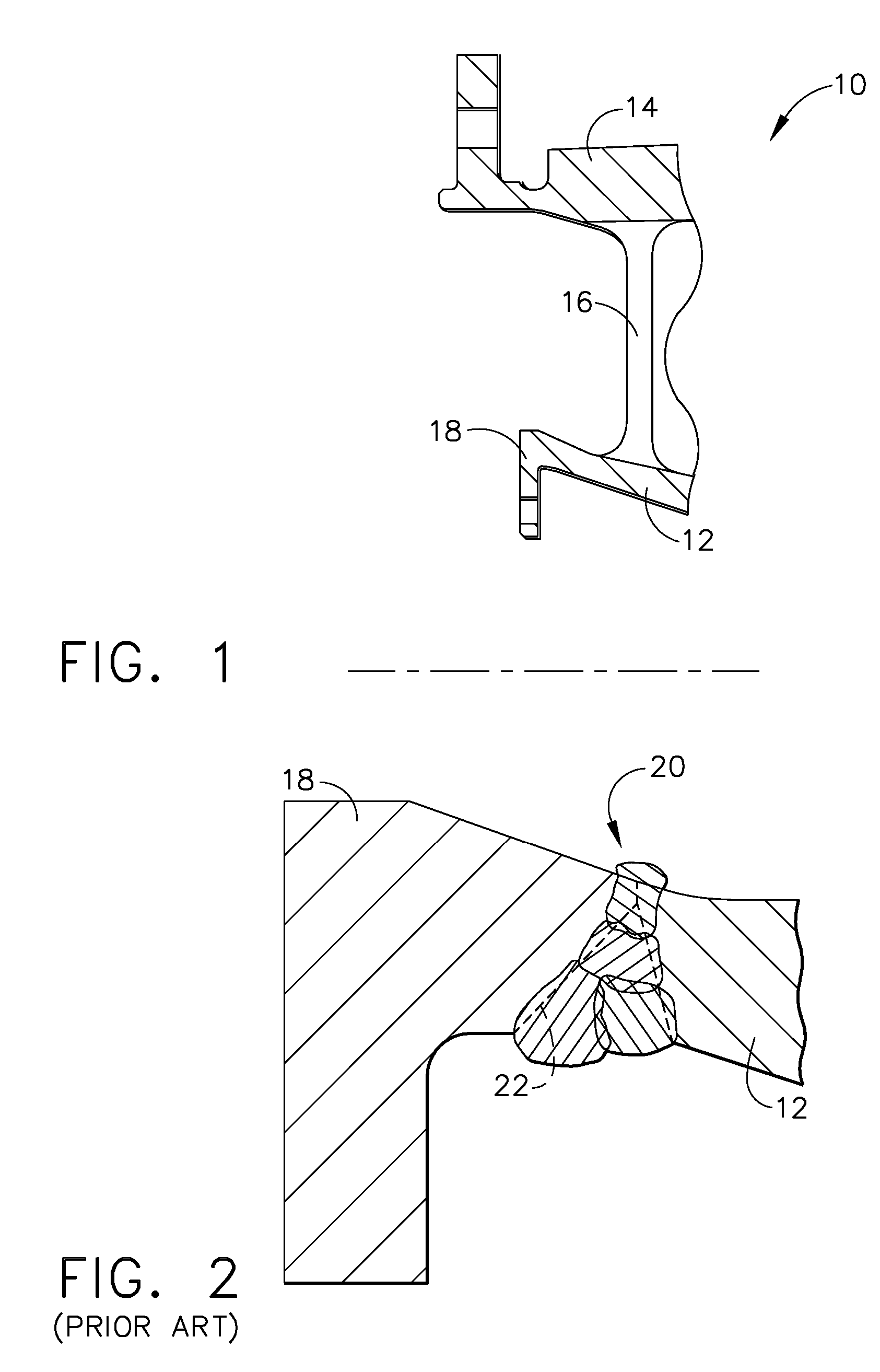

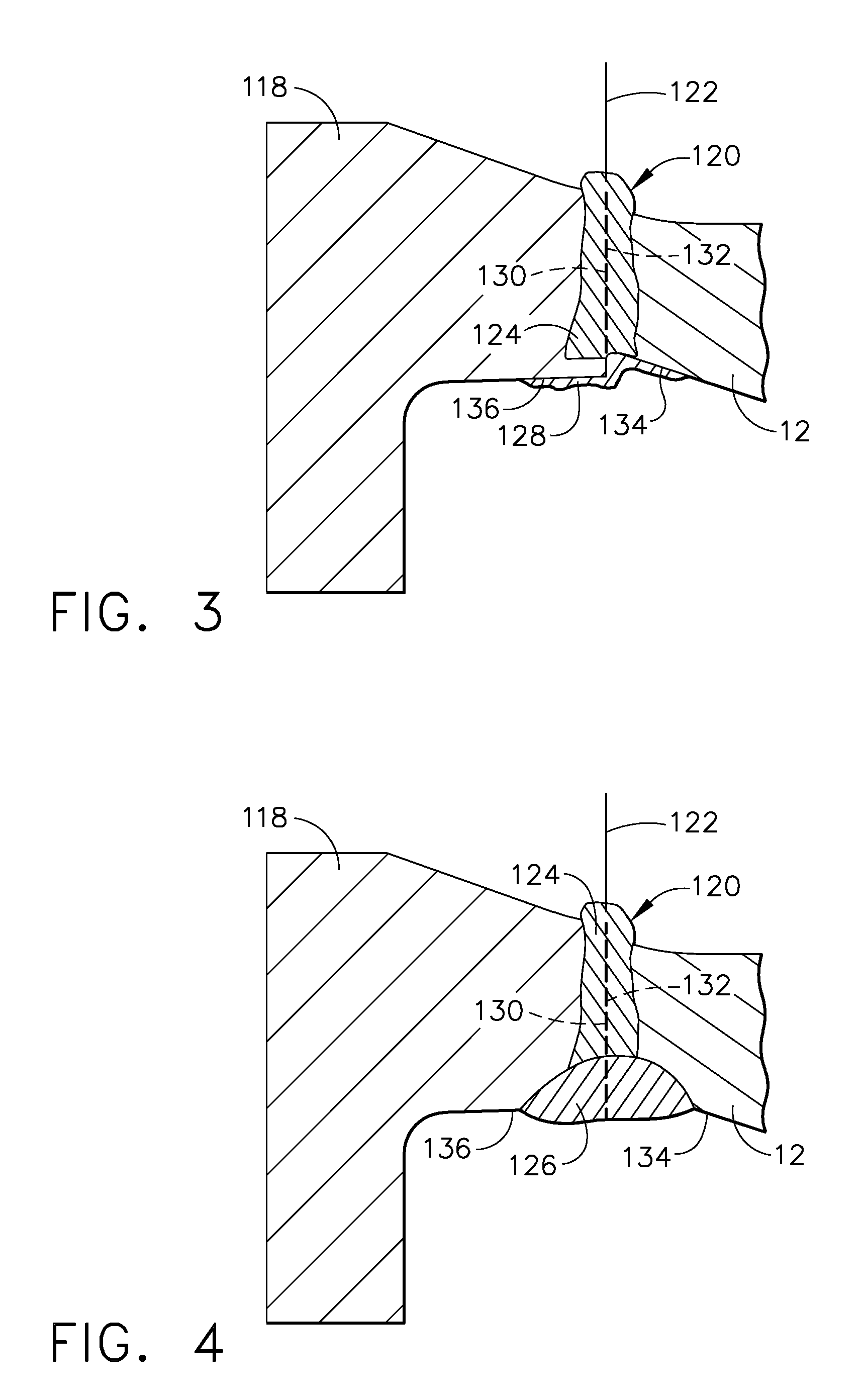

Welding process

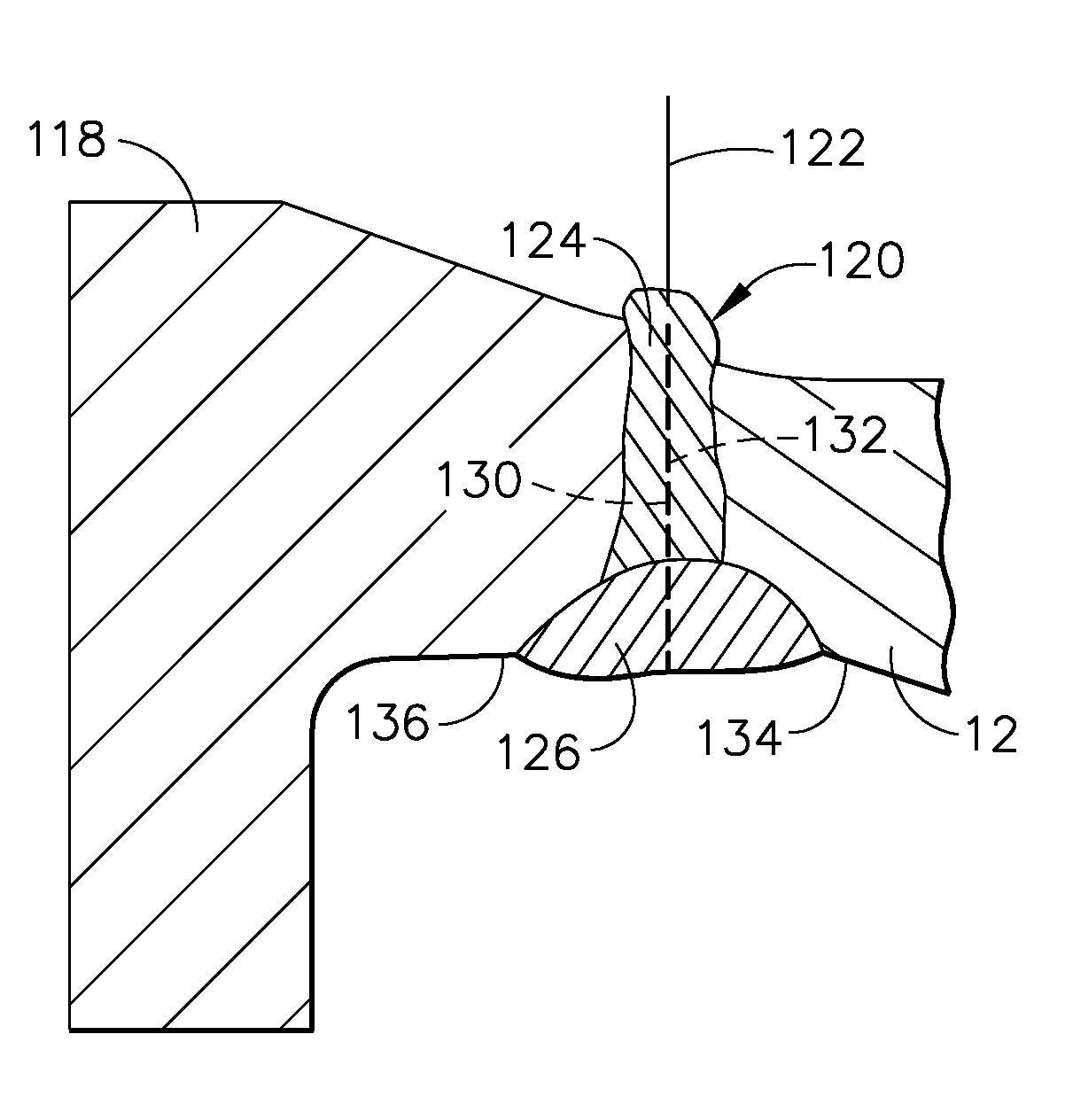

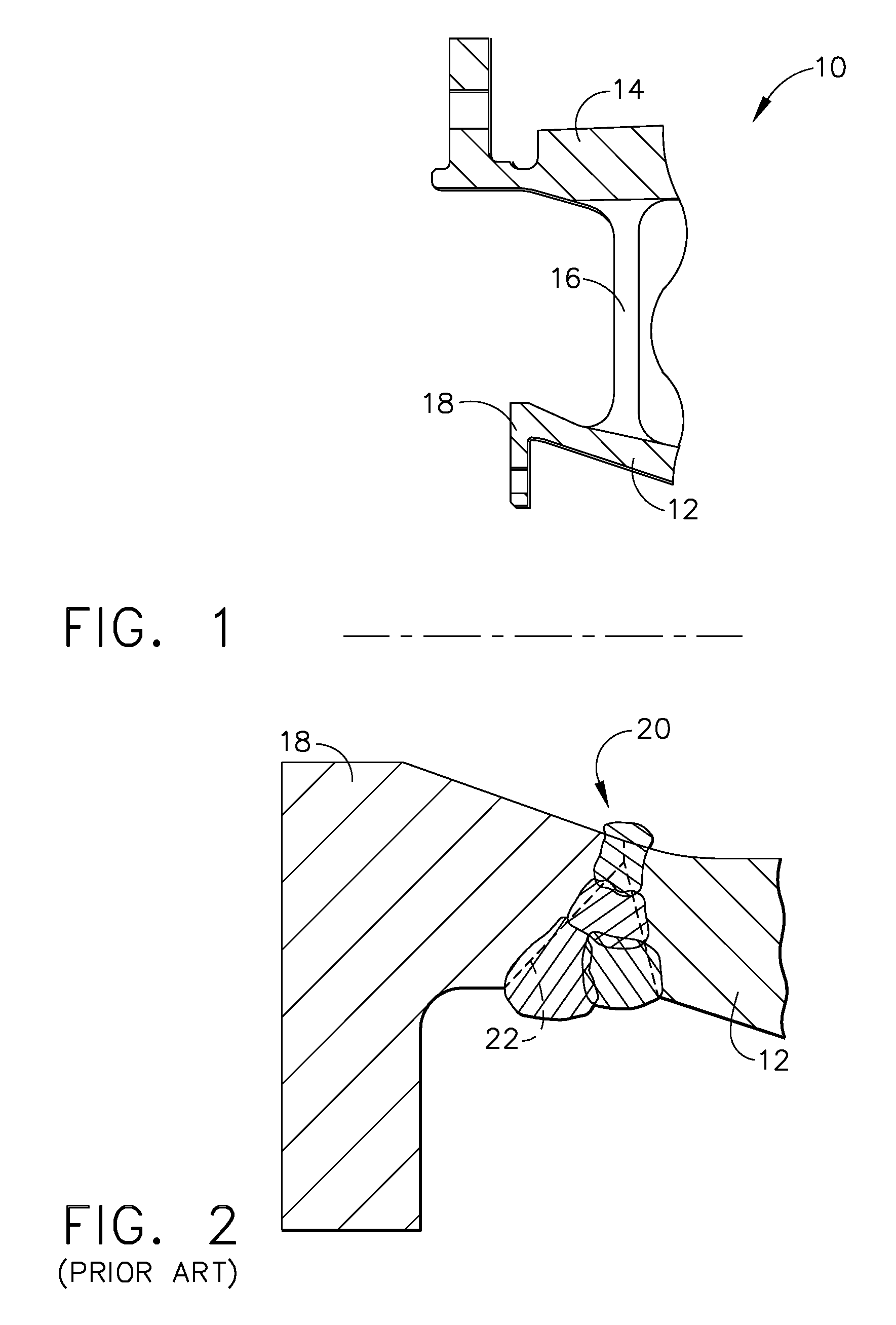

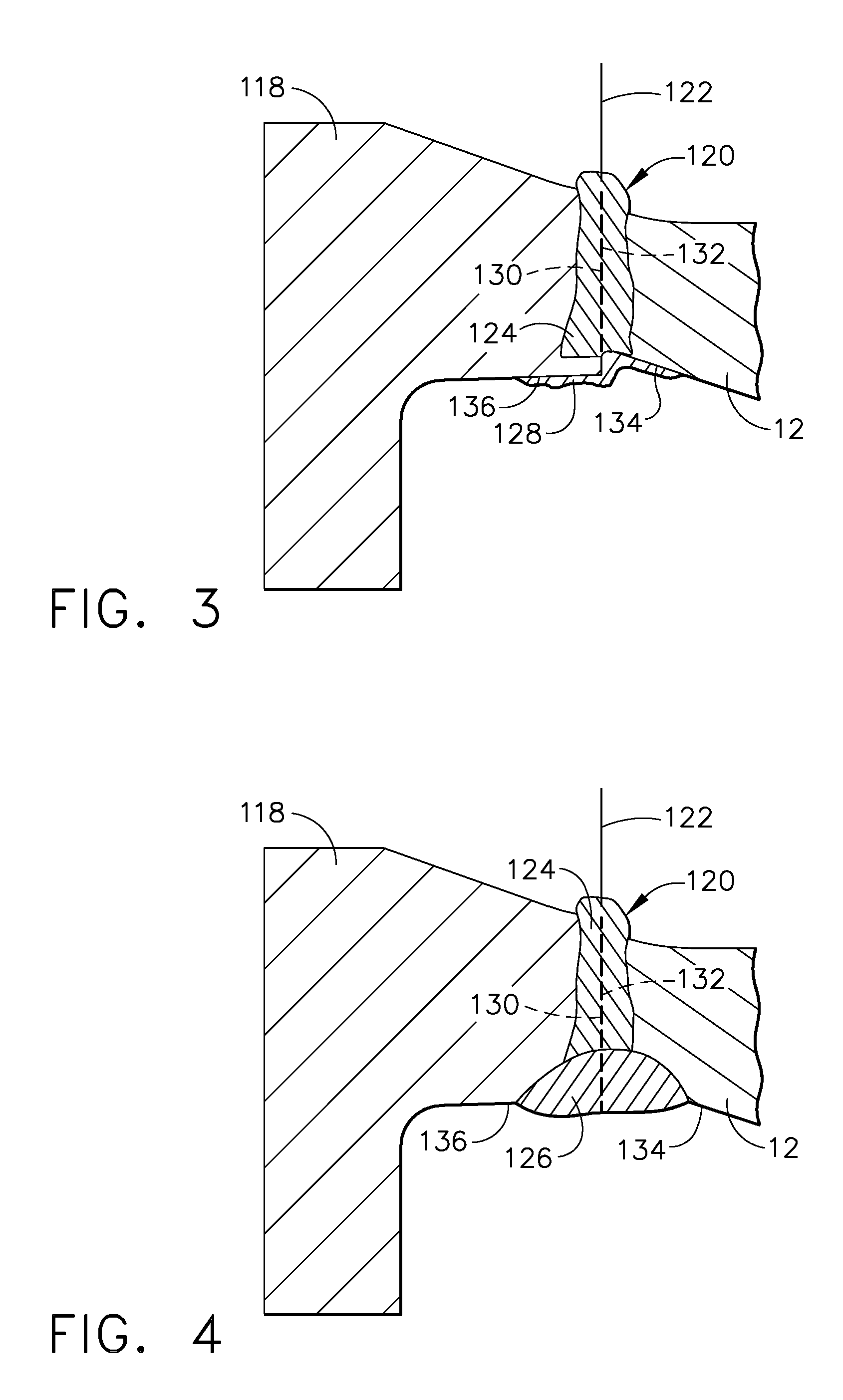

A process for repairing a compressor rear frame of a gas turbine engine. The process entails removing a seal flange from the inner casing wall of the frame to define an annular face on the casing wall, and fabricating a replacement flange to have an annular face with a radial width greater than the radial width of the annular face of the casing wall. The faces of the flange and wall are mated to form a joint, a penetration-enhancing flux is deposited adjacent the joint, and a single-pass gas tungsten arc welding operation is performed to form a root weldment that extends completely through the joint. The flux is then removed and a gas tungsten arc welding operation is performed to deposit a filler on the root weldment and form a second weldment that completely overlays but does not penetrate through the root weldment.

Owner:GENERAL ELECTRIC CO

Control Valve

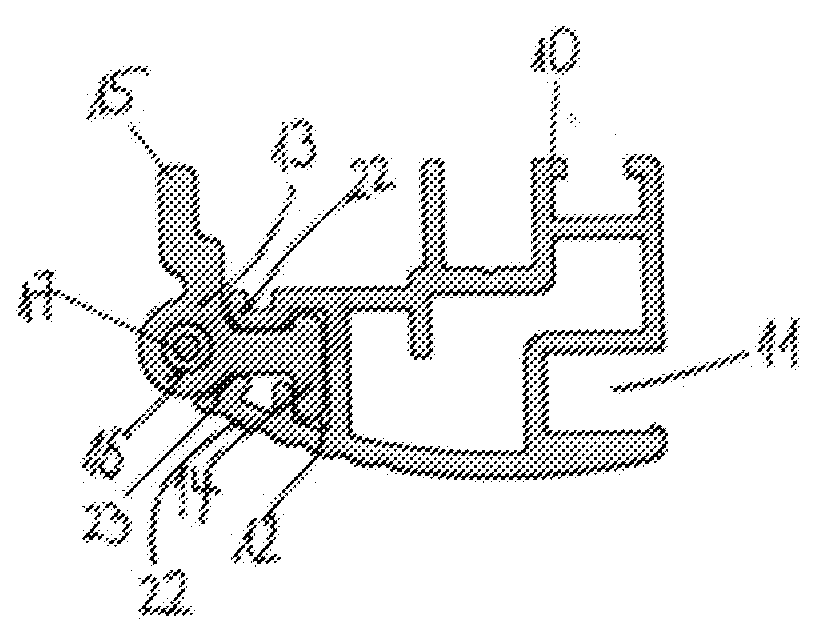

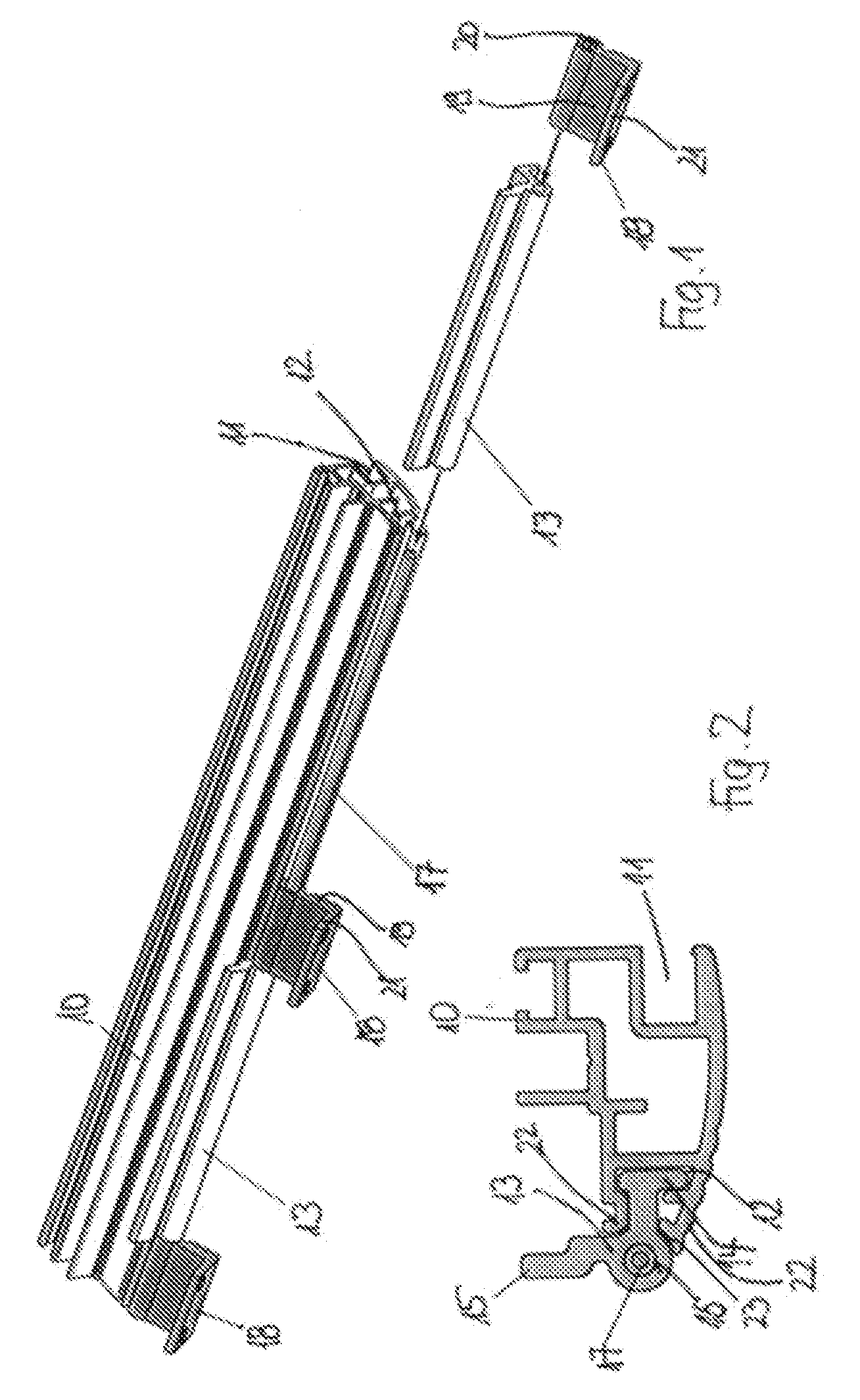

ActiveUS20110068284A1Easy to processSave materialOperating means/releasing devices for valvesSlide valveDifferential pressureEngineering

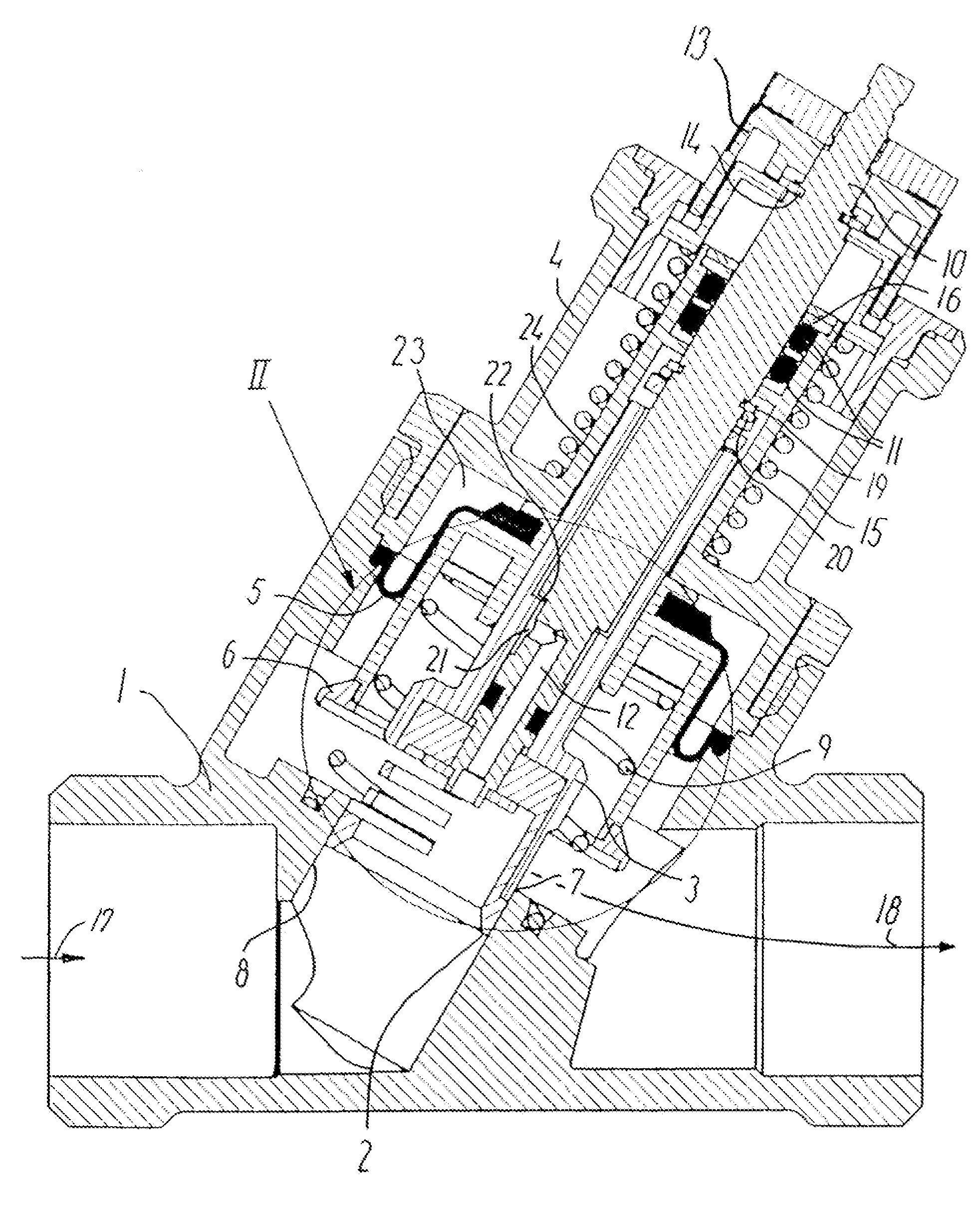

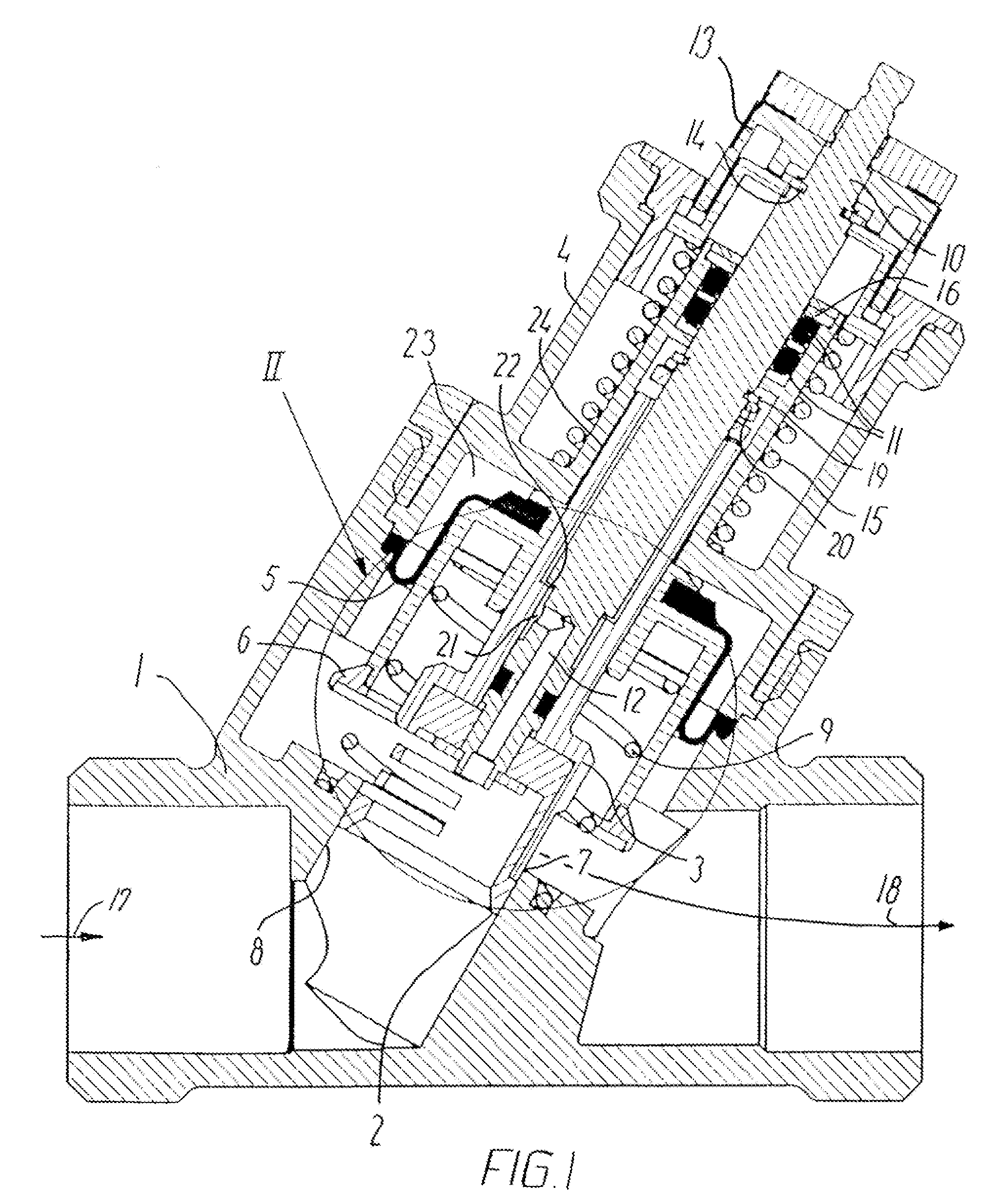

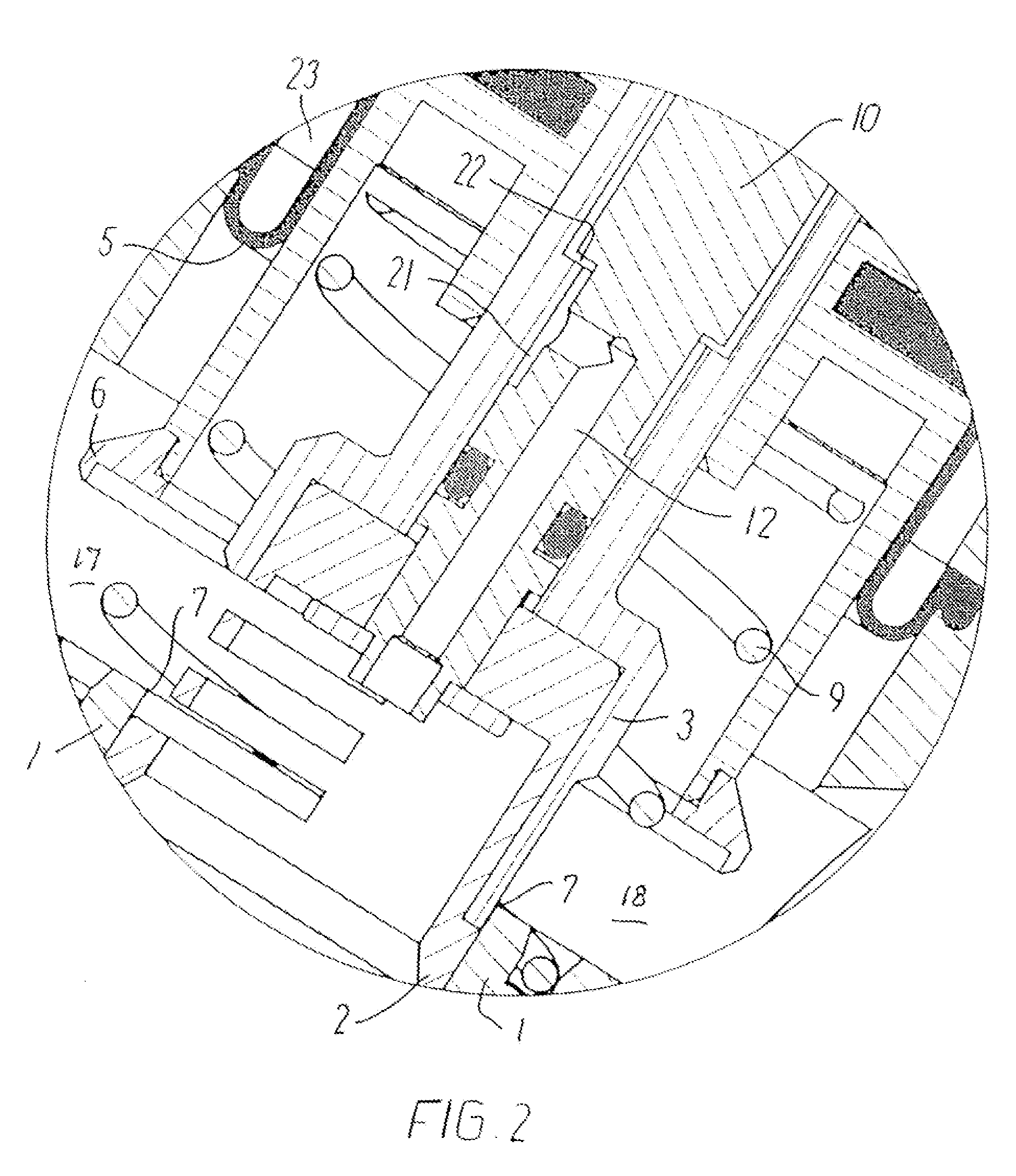

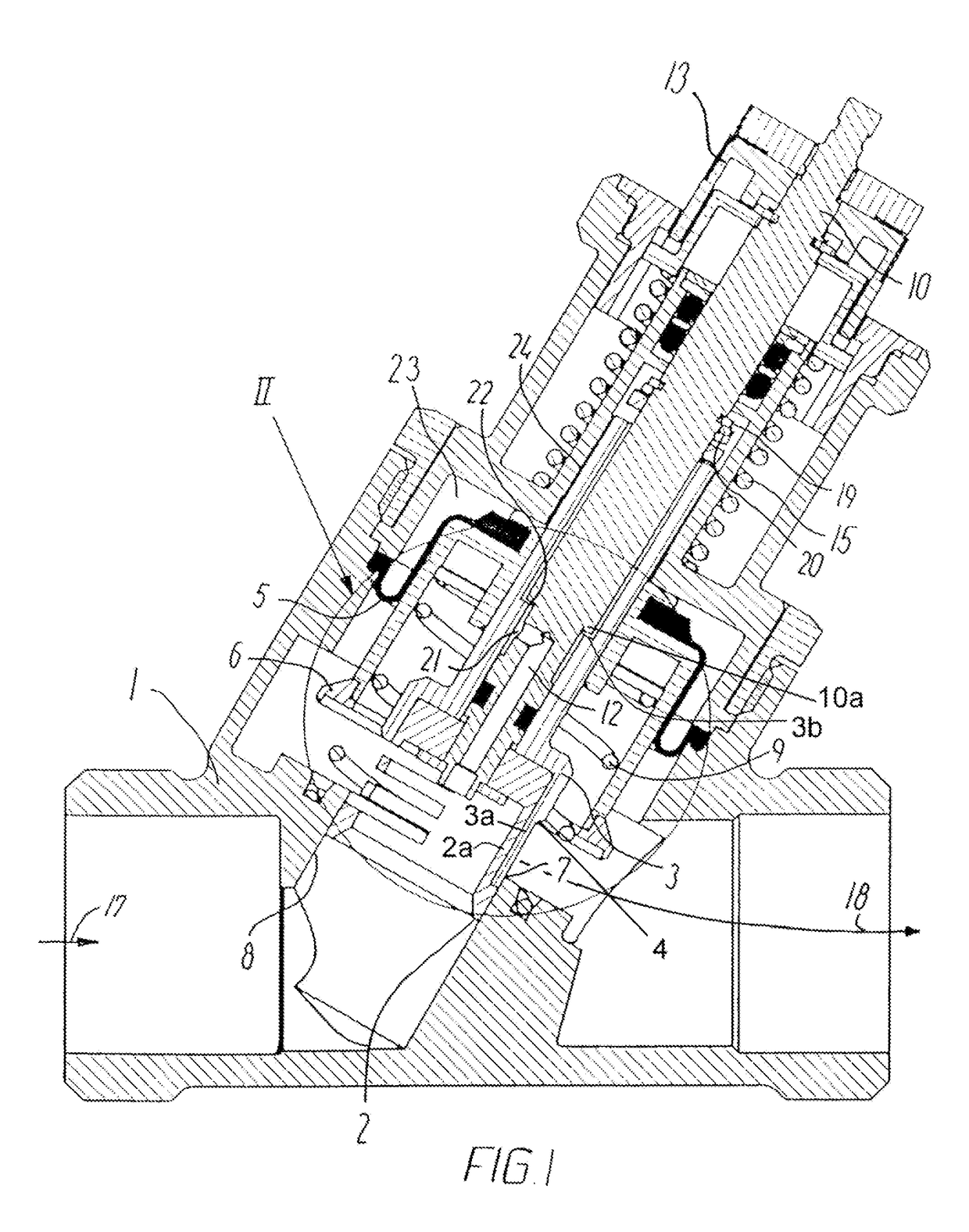

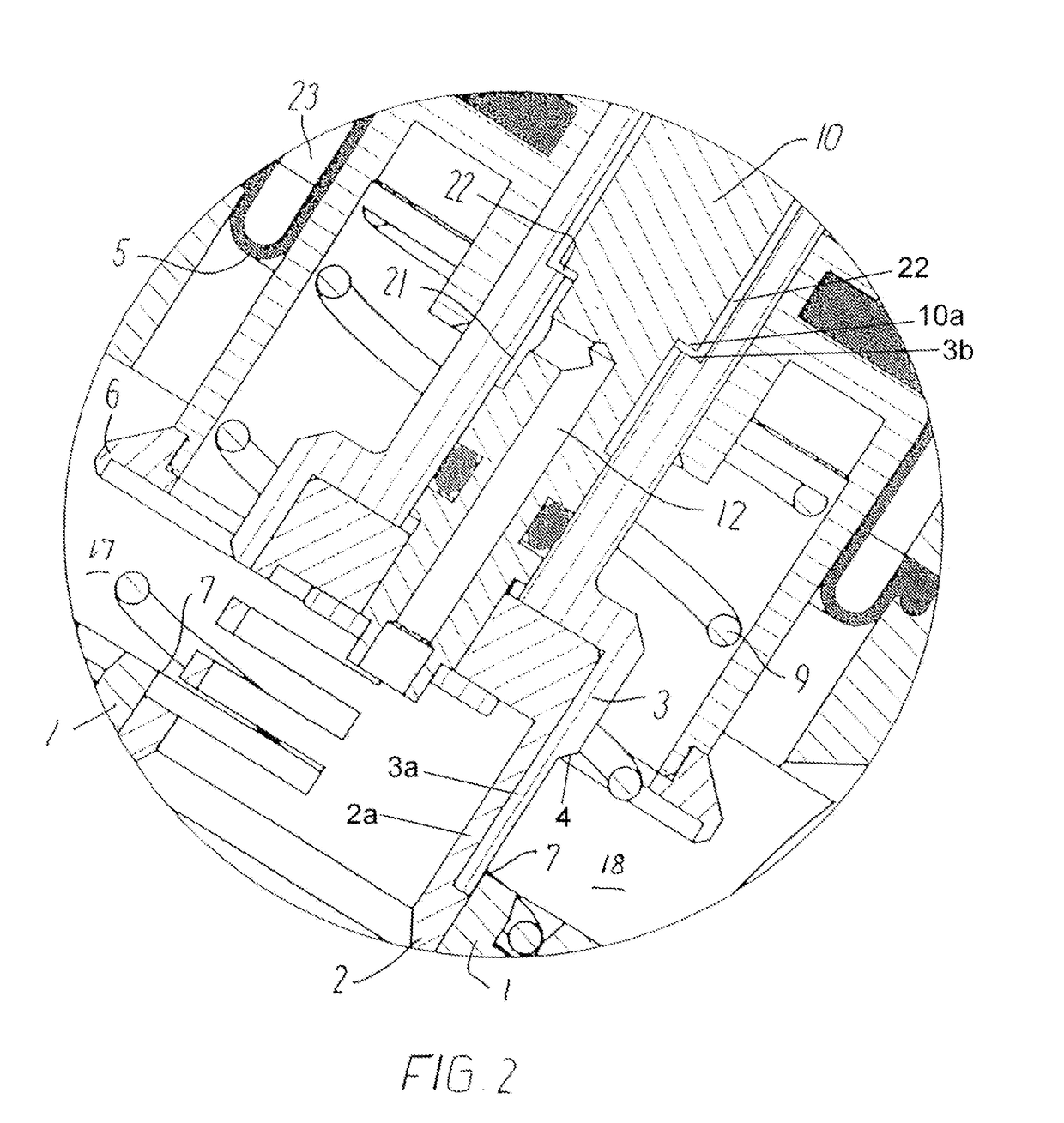

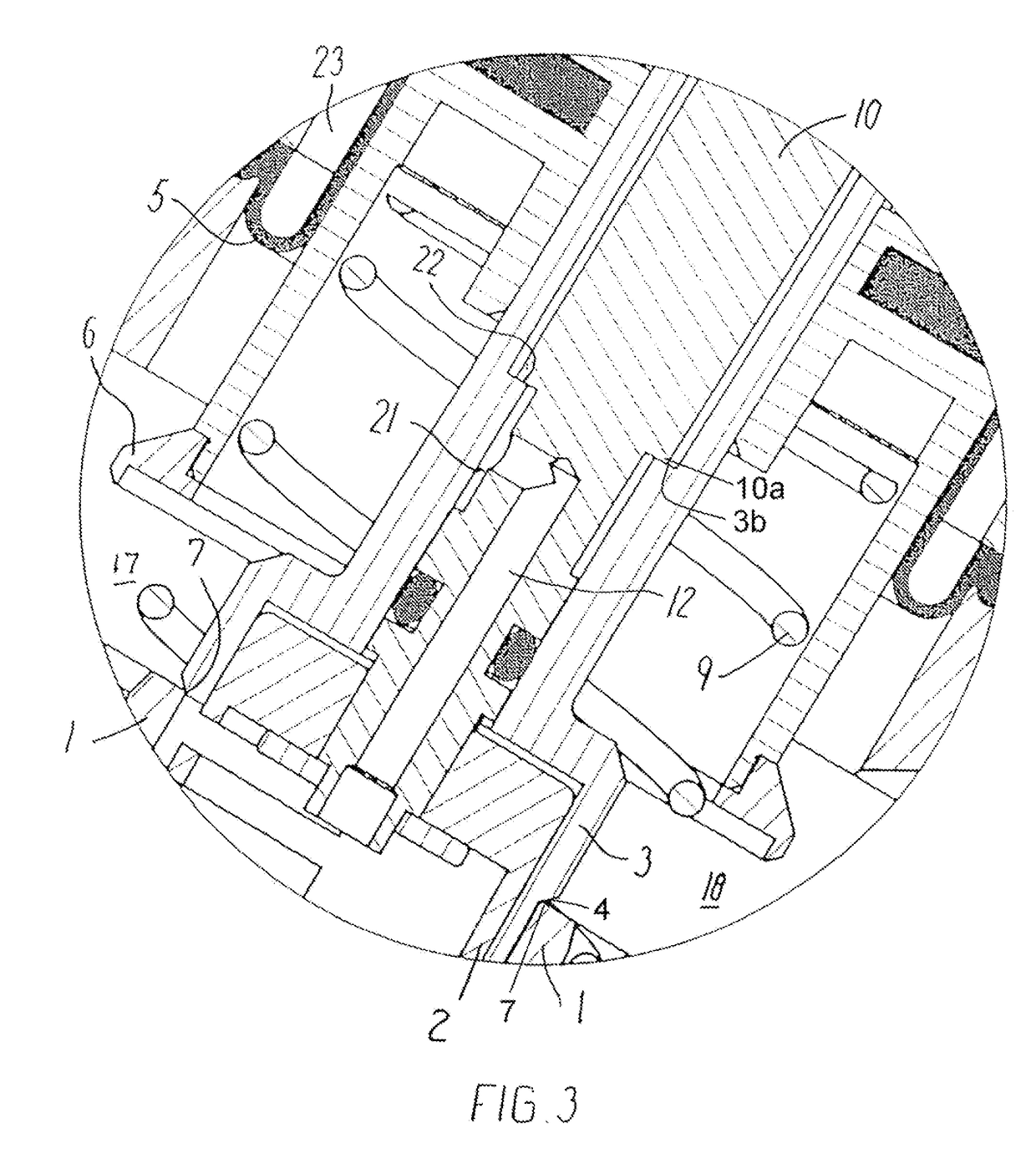

The control valve according to the invention is for use in liquid carrying systems. It comprises a valve housing (1) having an inlet side (17) and an outlet side (18), said valve housing being provided with a pressure maintaining arrangement for maintaining a constant differential pressure between the inlet and outlet sides, as well as an amount control arrangement for setting the maximum flow amount through the valve and adjustment of it. The control arrangement comprises two cylinder shell elements (2 and 3) cooperating in the flow path, both having material removed from otherwise overlapping areas, thereby generating an uncovered area (25) in the flow path of the control valve. The outer cylinder shell element (3) is stationary rotatable relative to the valve housing, while the inner cylinder shell element (2) may be rotated by means of a rotatable handle (13), whereby a larger or smaller opening (25) between the cooperating cylinder shell elements (2 and 3) may be provided. Both cylinder shell elements (2 and 3), which cooperate with the seat hole (8) of the valve housing, may also be displaced (26) in the axial direction, resulting in an increase or a decrease of the generated opening (25). Thereby, the flow amount may be adjusted prior to the presetting, e.g. by means of an actuator.

Owner:FRESE AS

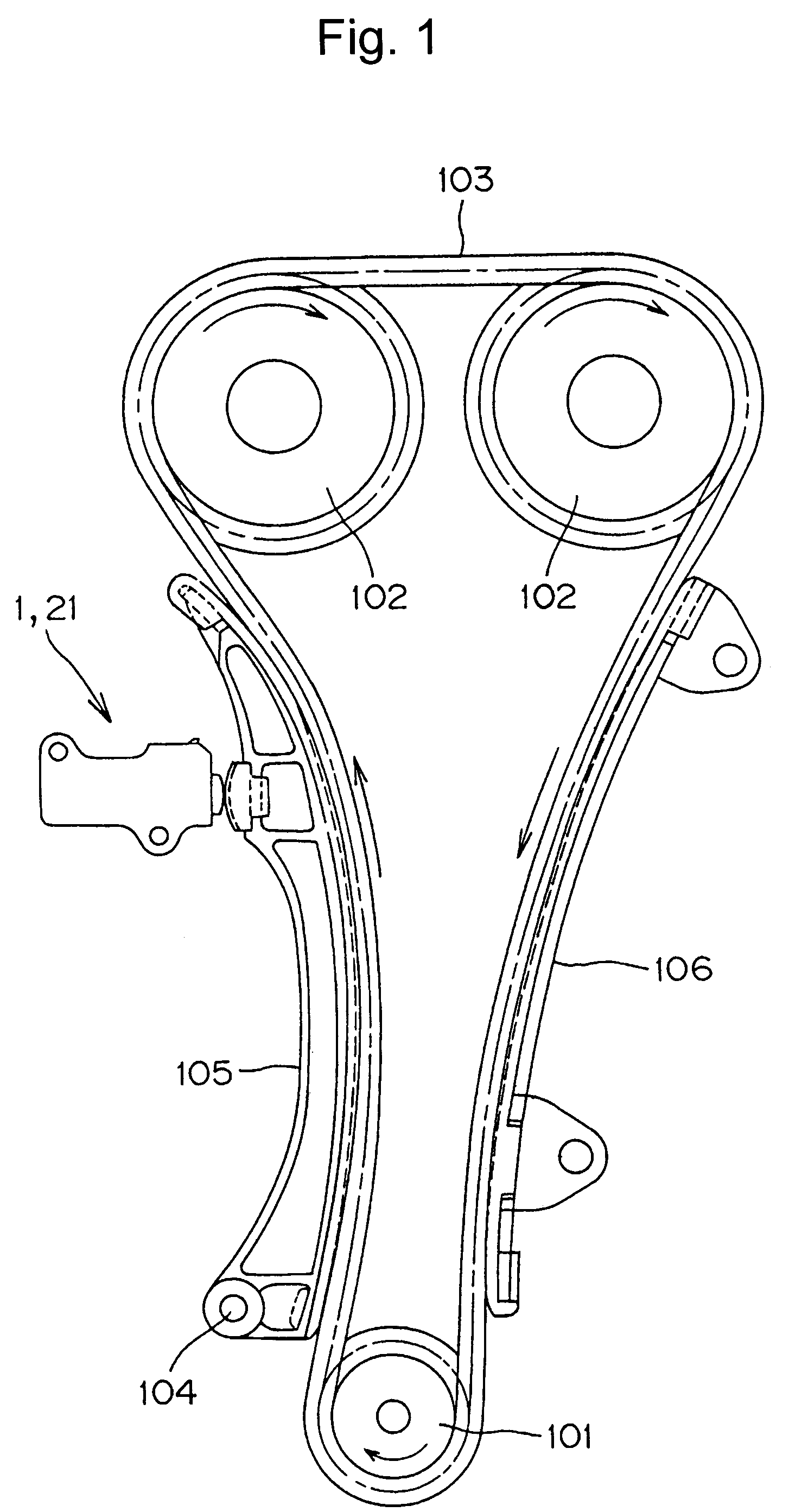

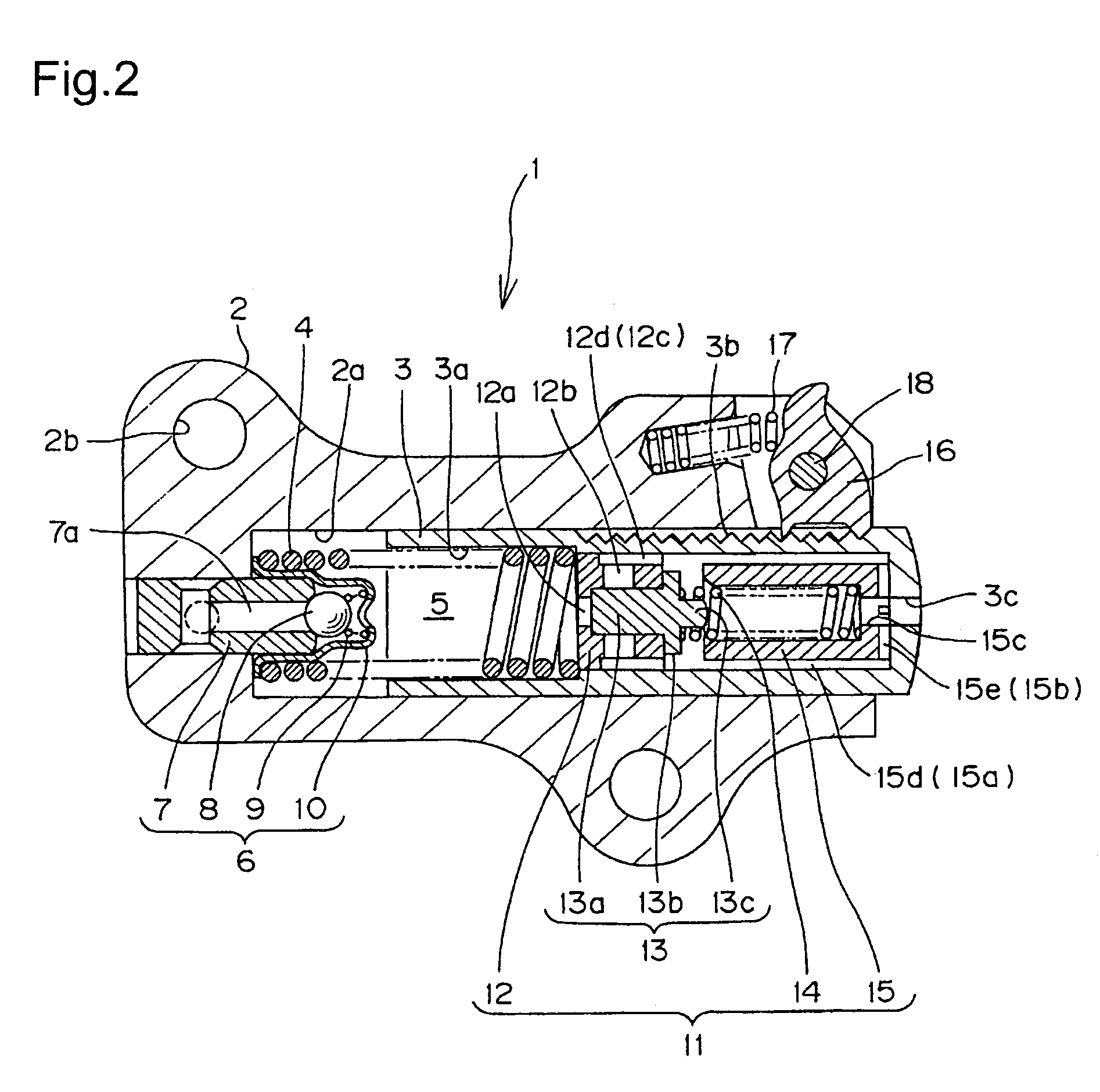

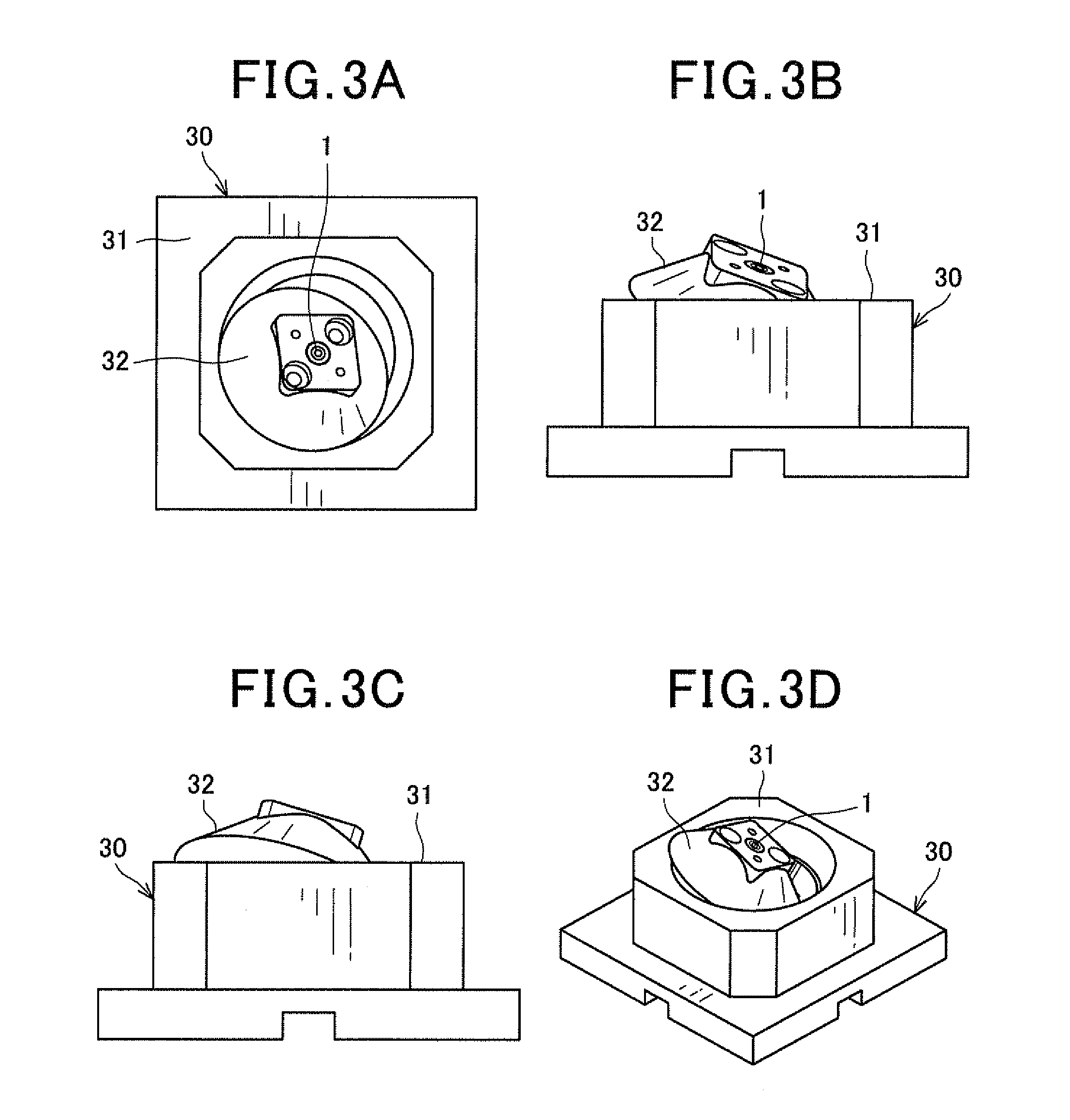

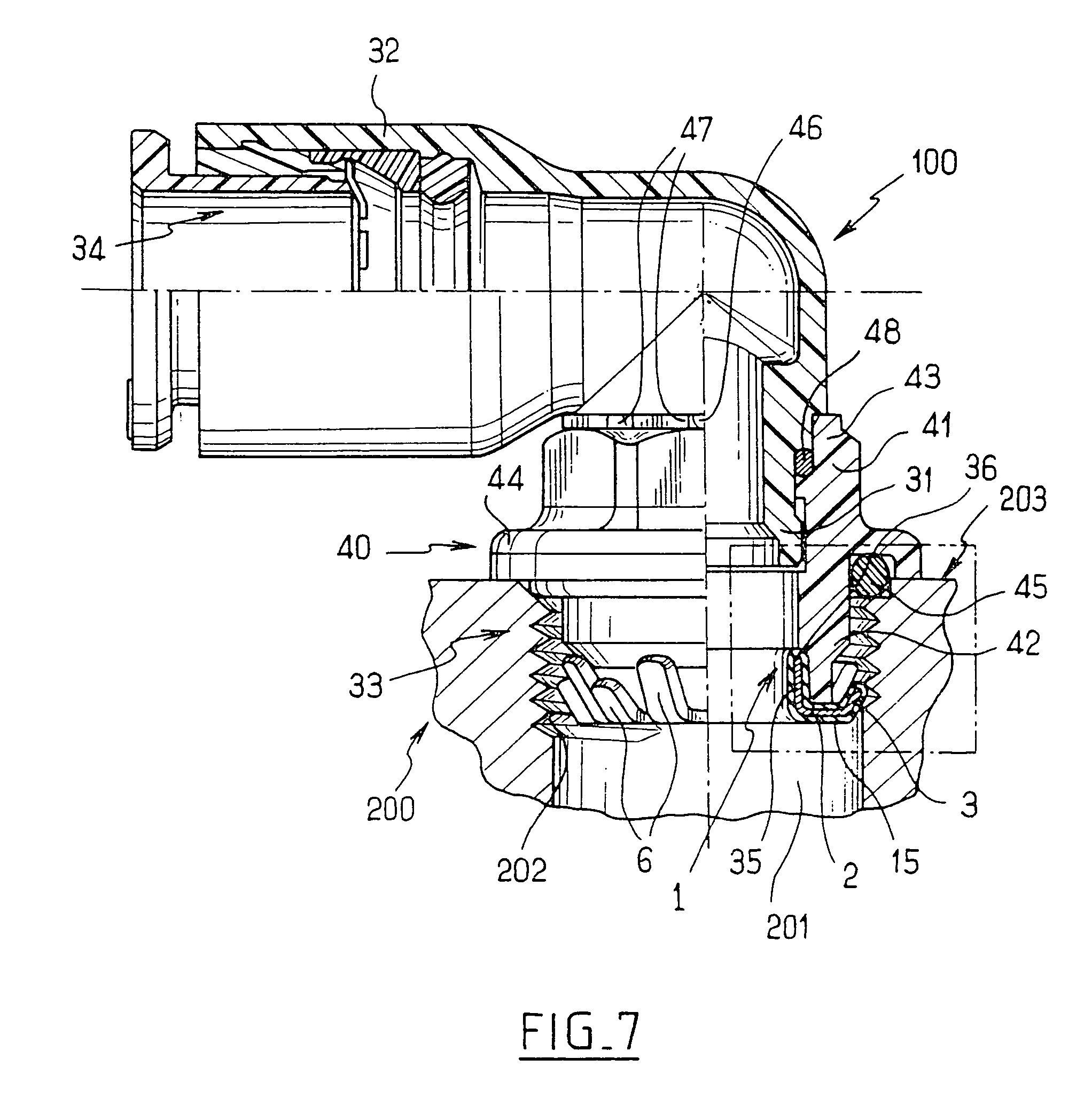

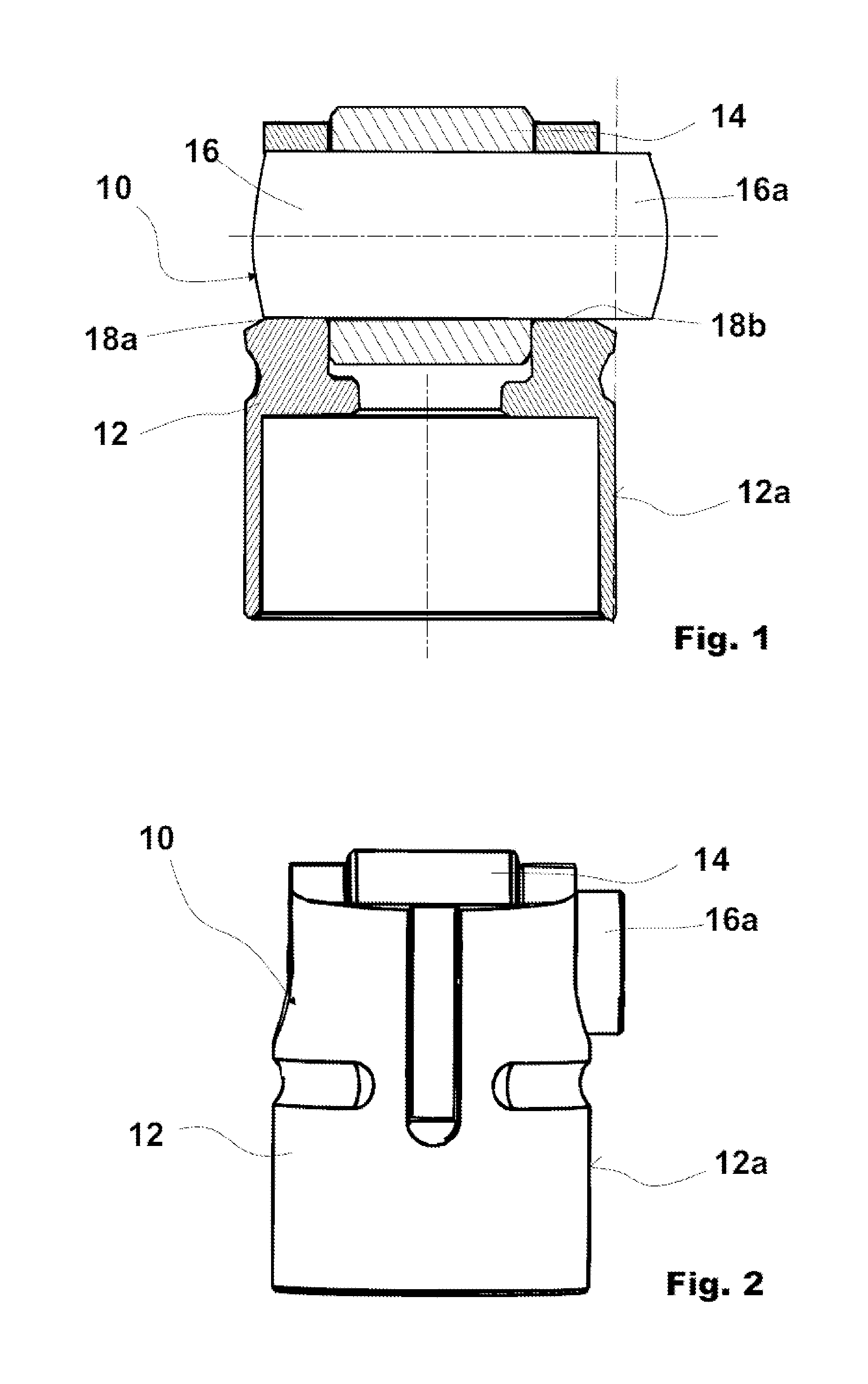

Hydraulic tensioner with improved relief valve

ActiveUS7618339B2Without impairing rigidity and integrityEasy to manufactureGearingValve drivesBungPlunger

Owner:HONDA MOTOR CO LTD

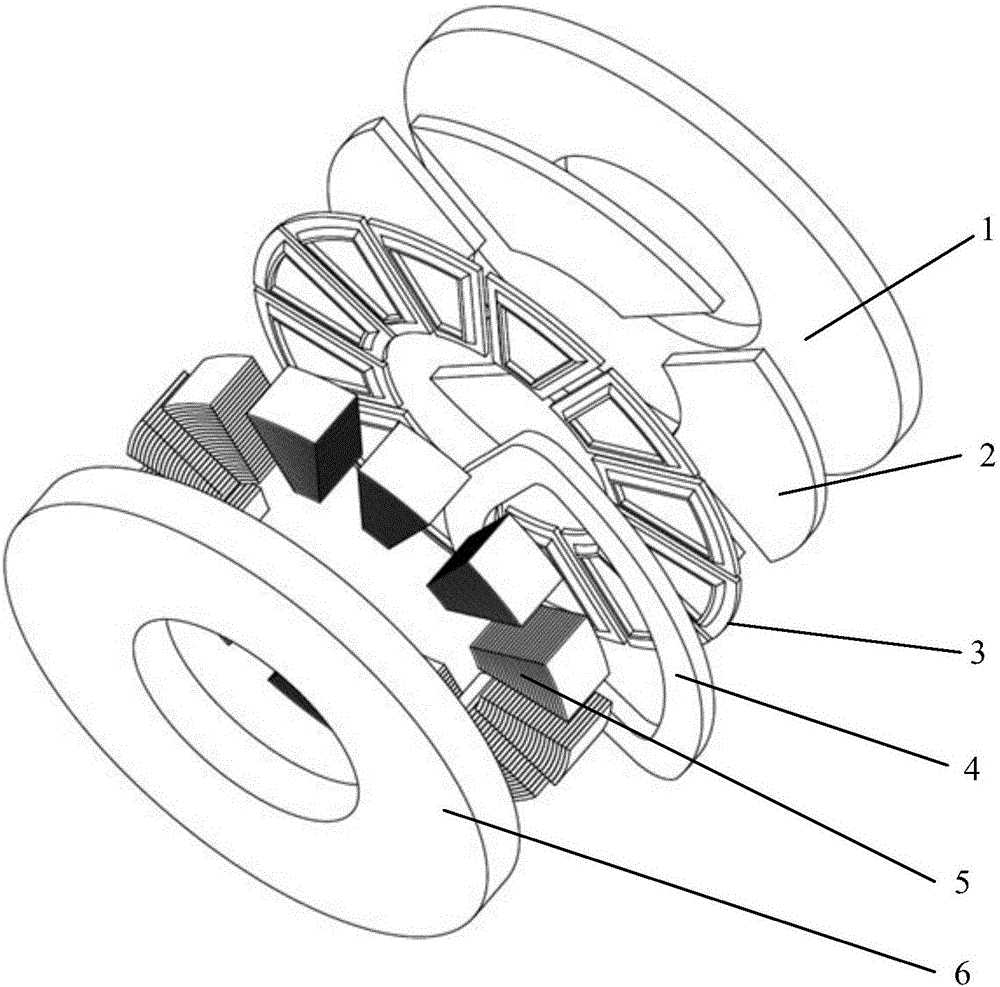

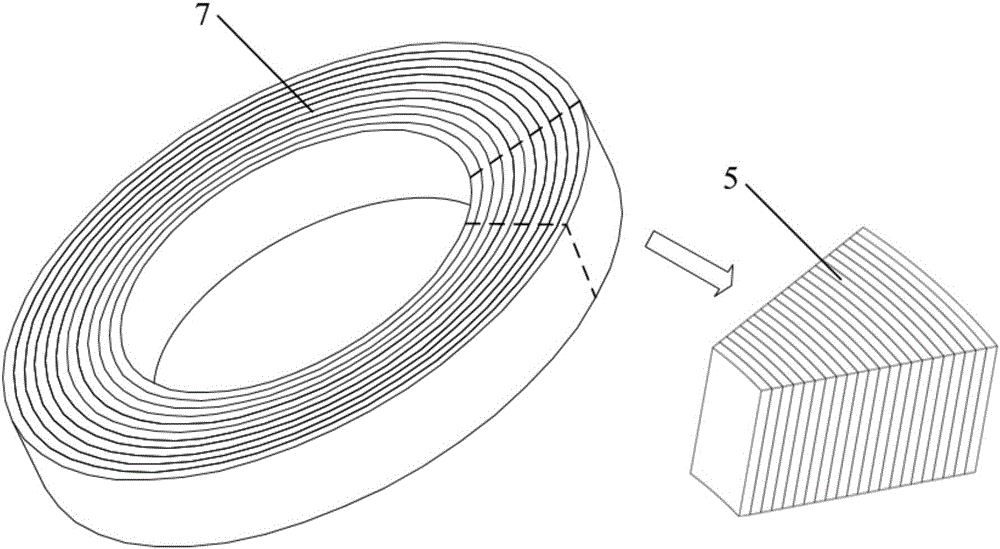

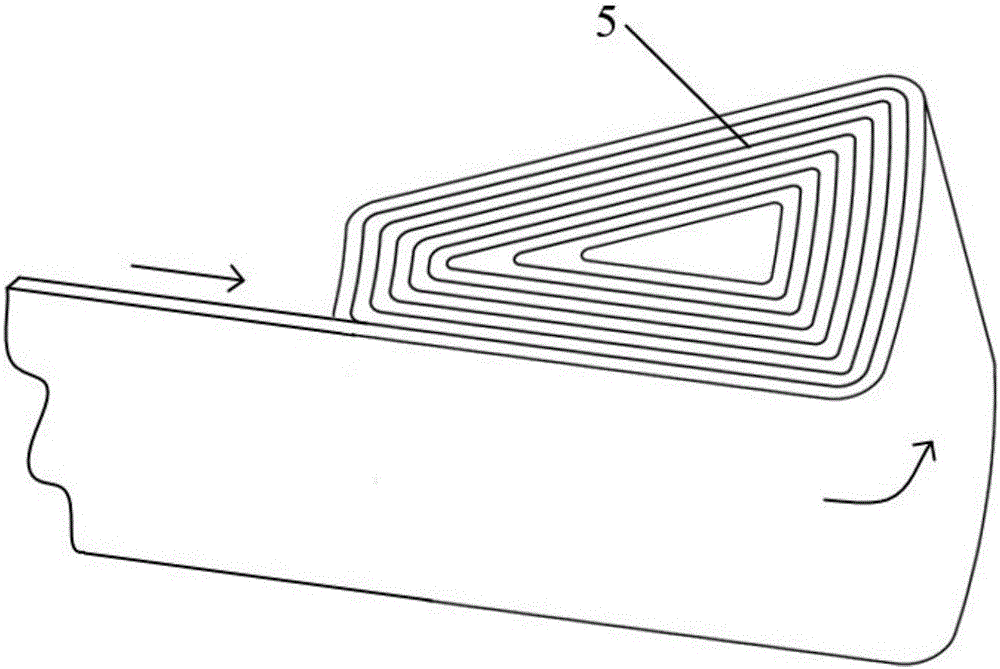

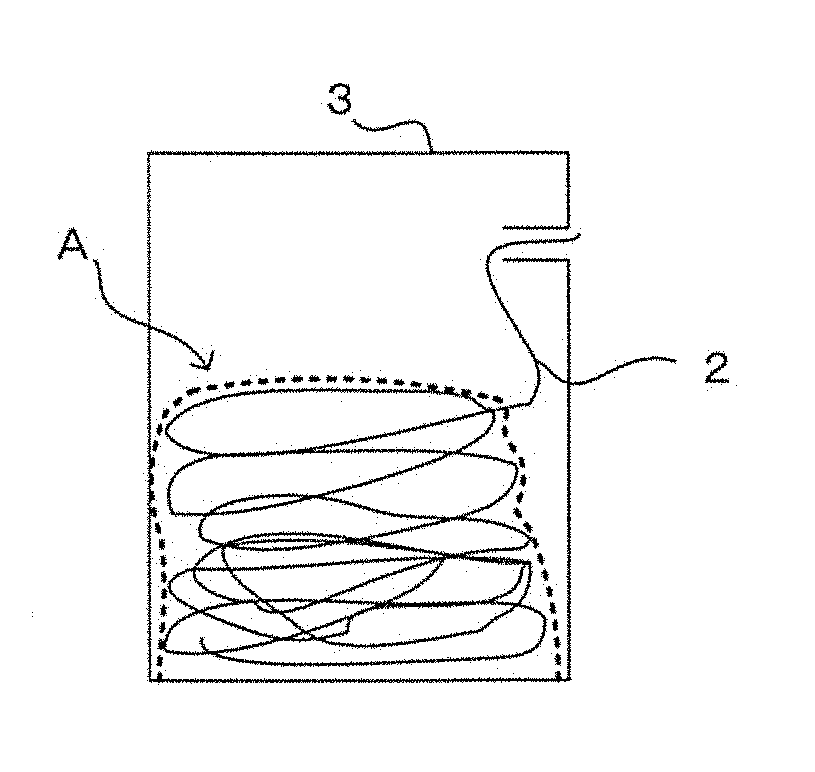

Axial magnetic field permanent magnetism motor and manufacturing method thereof

InactiveCN105762950AReduce lossAvoid machiningMagnetic circuit rotating partsSynchronous machine detailsAlloyMachining

The invention provides an axial magnetic field permanent magnetism motor, comprising a rotor and a stator, wherein the rotor is composed of a rotor yoke and a permanent magnet; the stator is composed of a gear body and a coil which are manufactured by amorphous alloy strips, and a gear top and a stator yoke which are manufactured by soft-magnetic composite materials. The scheme of preparing a permanent magnetism motor by amorphous alloy and soft-magnetic composite materials, and a corresponding manufacturing method can utilize advantages of two materials, and meanwhile avoid disadvantages of the two materials in machining.

Owner:SOUTHEAST UNIV

Control valve

ActiveUS8469052B2Easy to processSave materialOperating means/releasing devices for valvesSlide valveDifferential pressureEngineering

A control valve comprises a valve housing (1) having an inlet side (17) and an outlet side (18). The control valve also has a pressure maintaining arrangement for maintaining a constant differential pressure between the inlet and outlet sides, as well as an amount control arrangement for setting the maximum flow through the valve. A pair of cylinder shells located in the flow path have cooperating recesses which provide an uncovered area forming an opening (25). One cylinder shell is rotatable relative to the other cylinder shell by a rotatable handle (13), whereby a larger or smaller opening (25) between the cooperating cylinder shells may be provided. Both cylinder shells are axially displaceable within a seat hole (8), resulting in an increase or a decrease of the opening (25).

Owner:FRESE AS

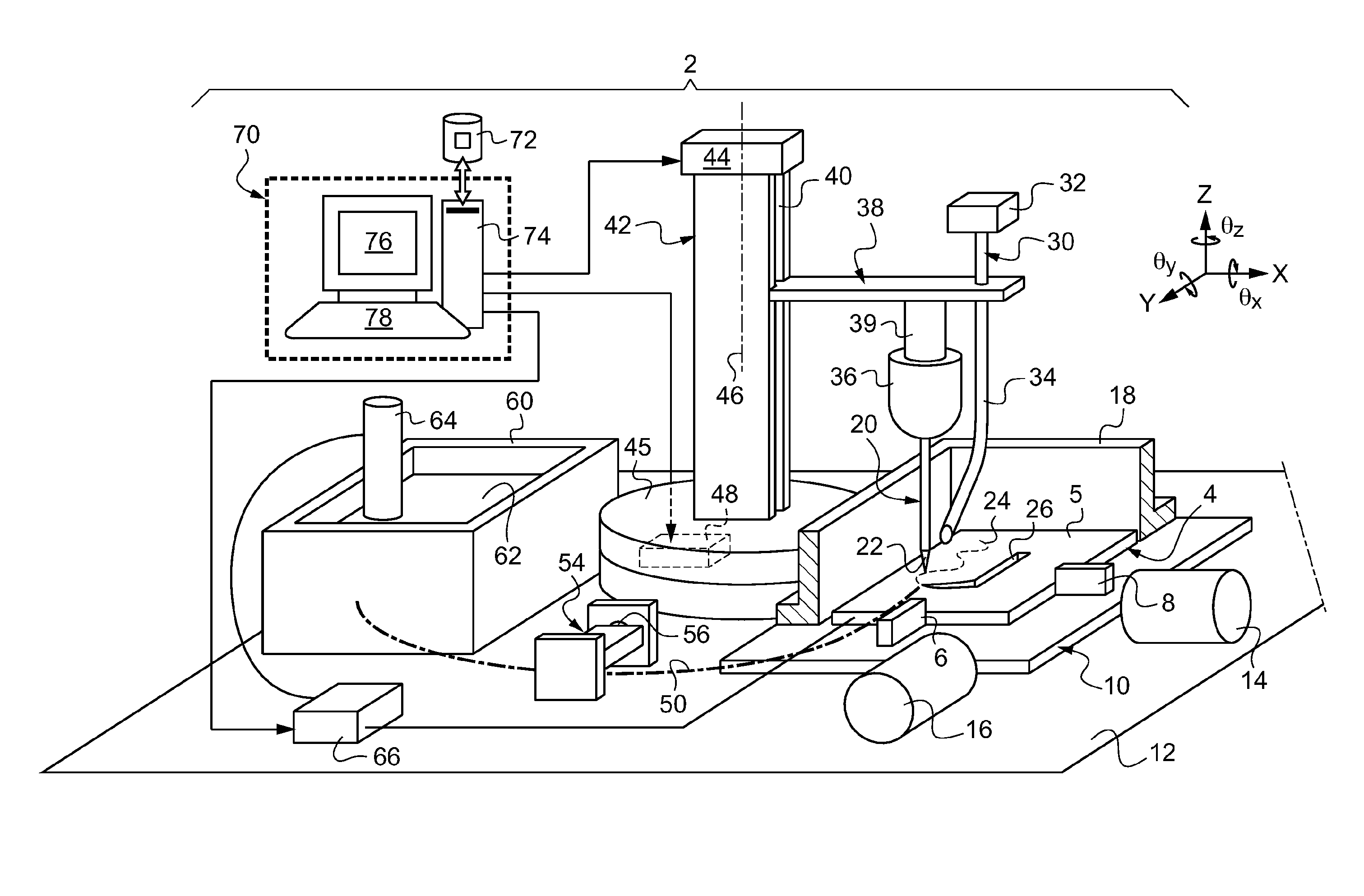

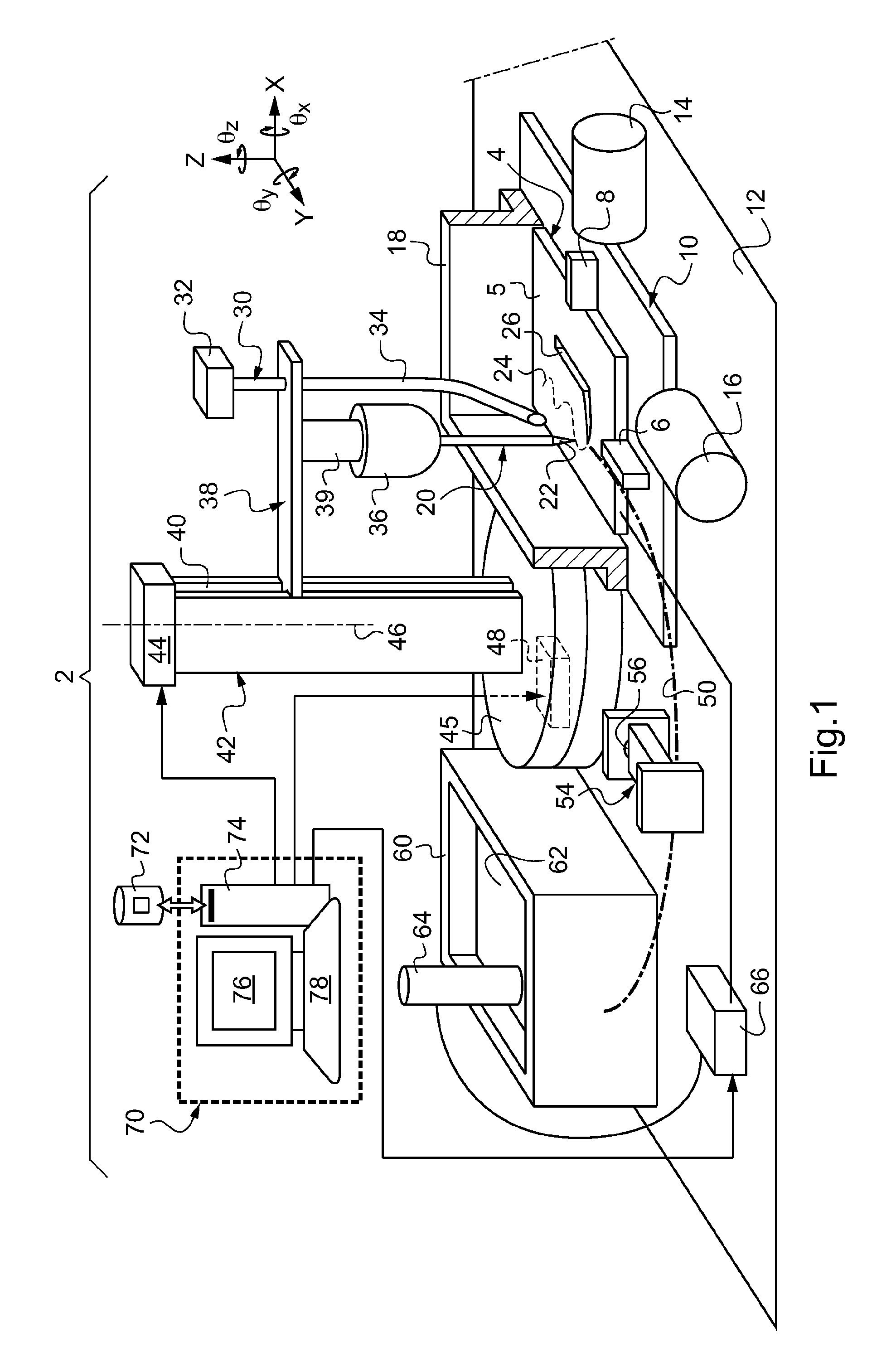

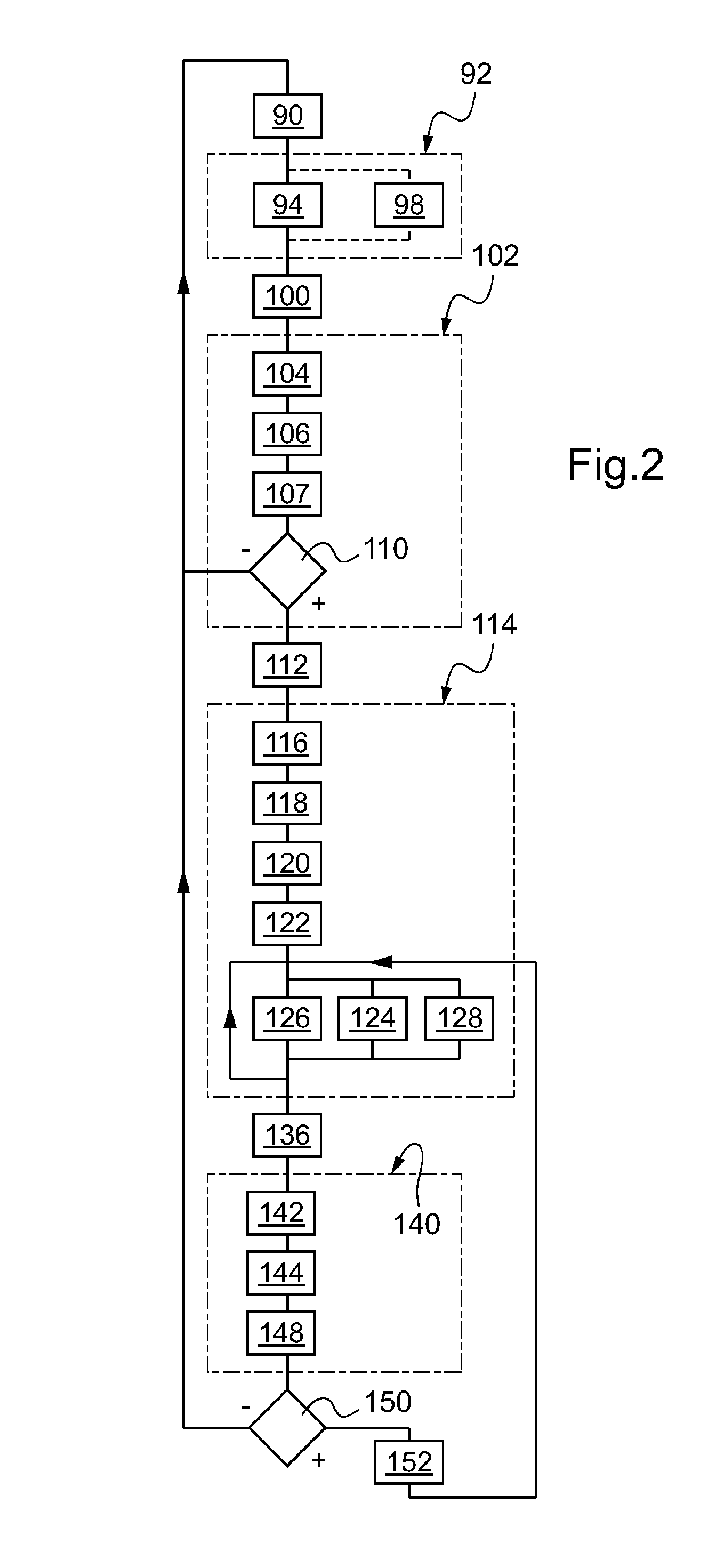

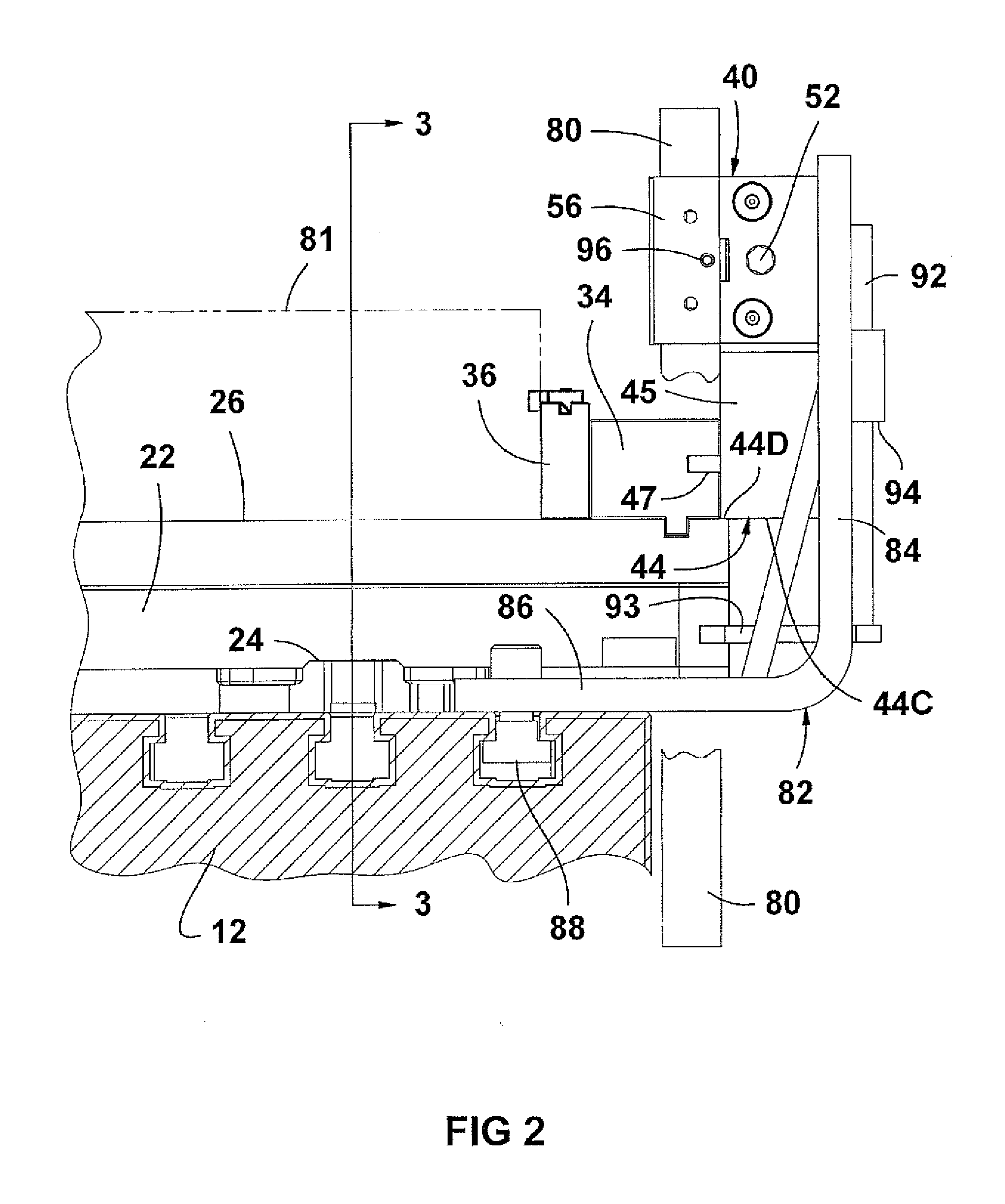

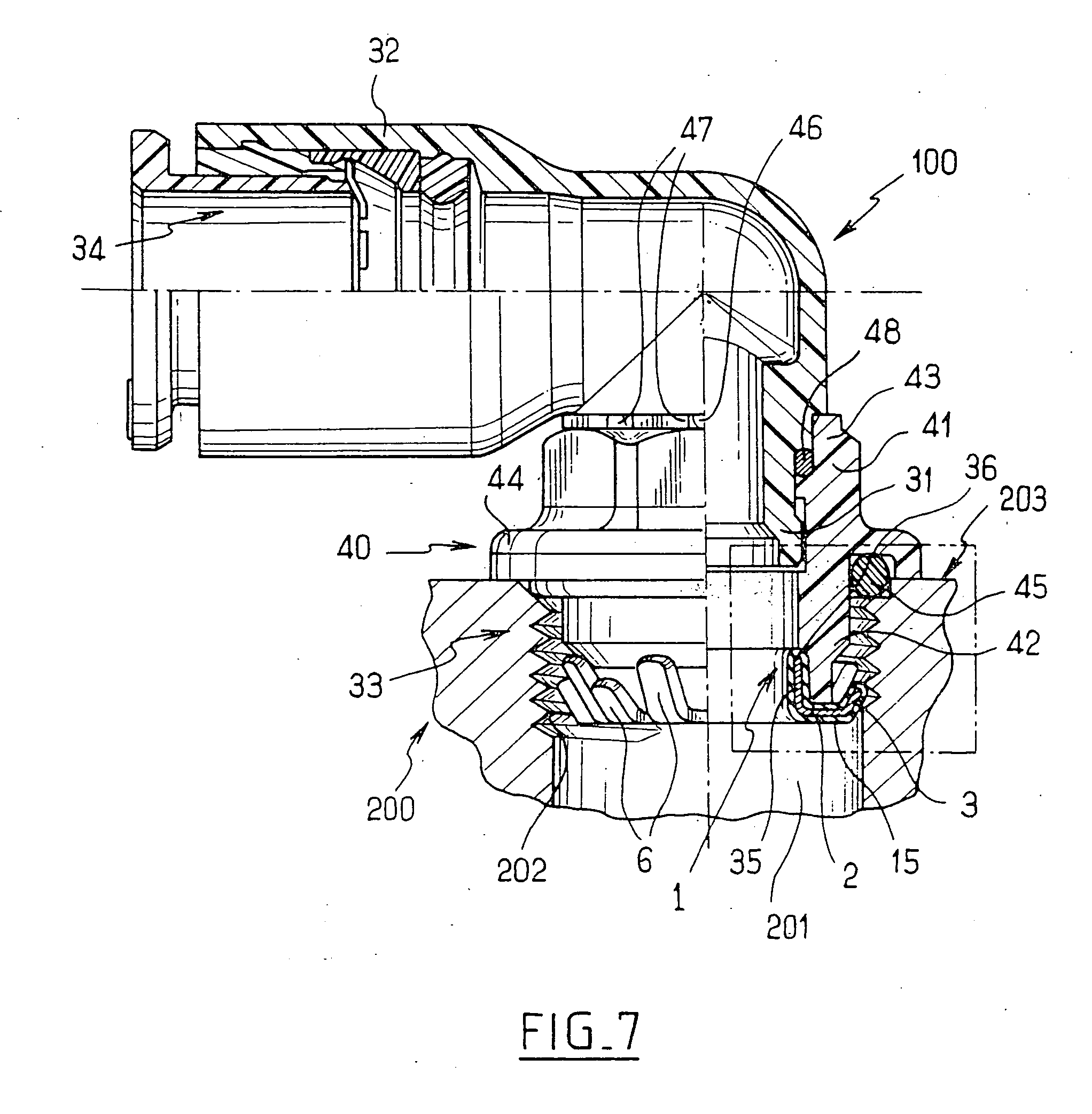

Machine and method for machining a part by micro-electrical discharge machining

InactiveUS20110174634A1Limit its operationImprove productivityMachining electrodesElectrolysis componentsEtchingElectrolysis

The invention relates to a machine for machining a part by micro-electrical discharge machining, said machine comprising a mechanism (44, 45, 46, 48) for modifying the configuration of the machine so as to alternatively and reversibly switch from a machining configuration to a sharpening configuration in which the tip of a same etching electrode (20) and another electrode (64) are dipped in an electrolyte bath in order to sharpen the tip of the etching electrode by electrochemnical corrosion.

Owner:UNIV DE LYON 1 CLAUDE BERNARD +2

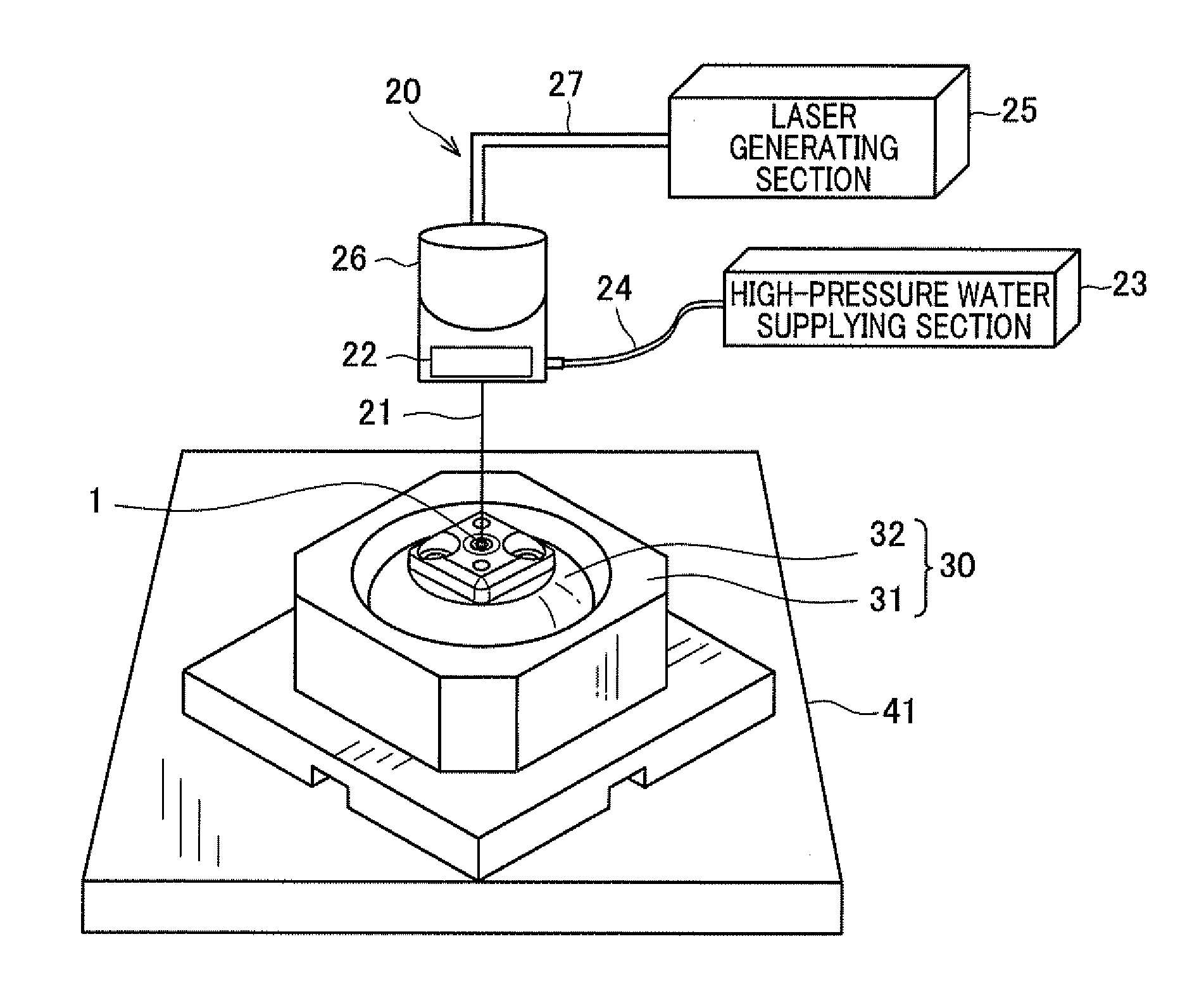

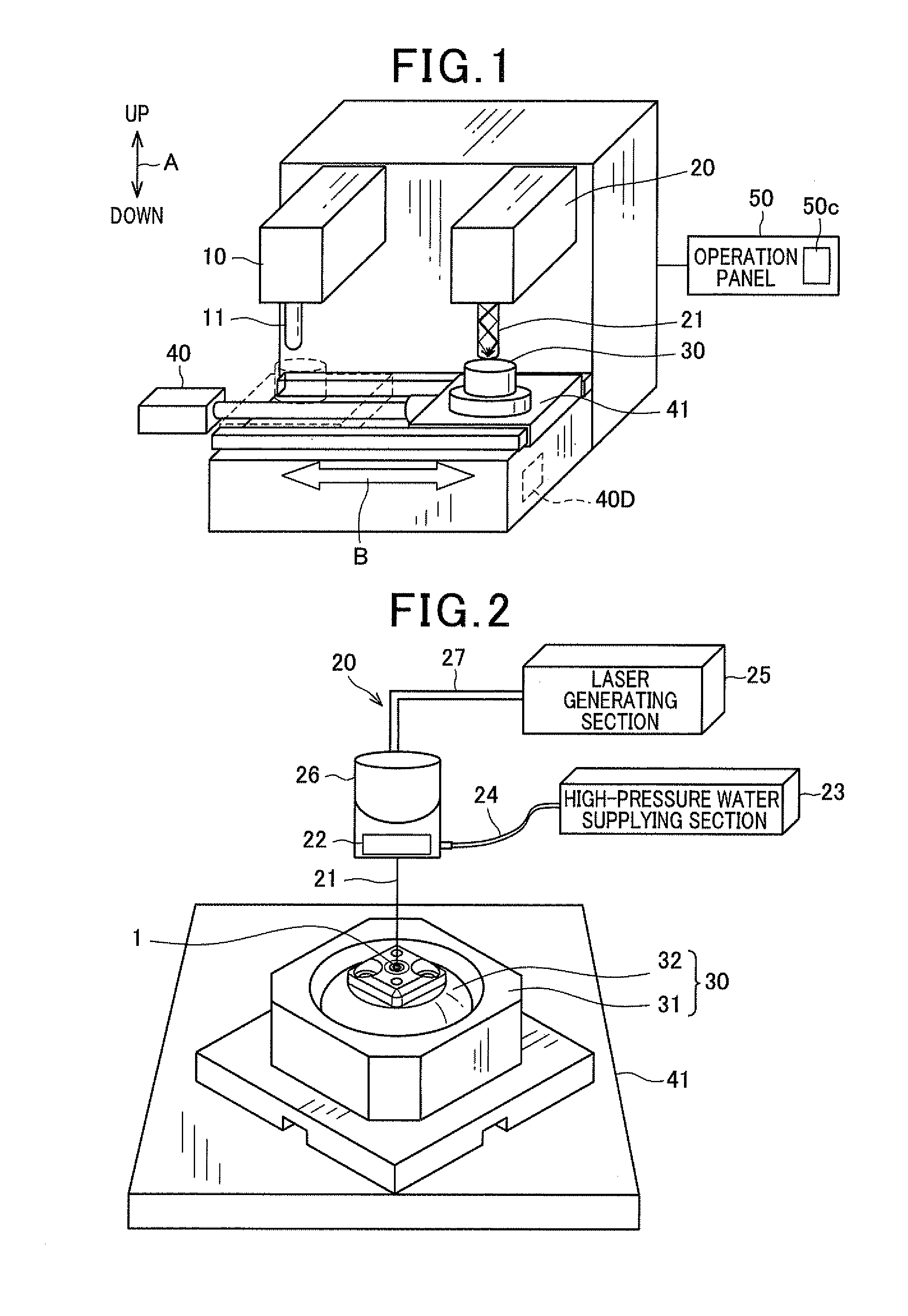

Device and method for machining workpiece with a laser beam

InactiveUS20110163078A1Avoid machiningImprove machine efficiencyFuel injection apparatusMachines/enginesLiquid jetEngineering

A laser machining device machines a workpiece having a machining portion where a hole is machined and a non-machining portion positioned on an extension of the hole. The laser machining device includes a nozzle that jets a column of liquid towards the hole of the machining portion and a laser head that introduces a laser beam into the column of liquid jetted towards the hole. The workpiece is held by a holding member. A laser beam blocking member is disposed in the non-machining portion. The laser beam blocking member blocks the laser beam that passes through the hole. Furthermore, a discharge path that discharges the liquid reaching the hole is provided in the laser beam blocking member.

Owner:DENSO CORP

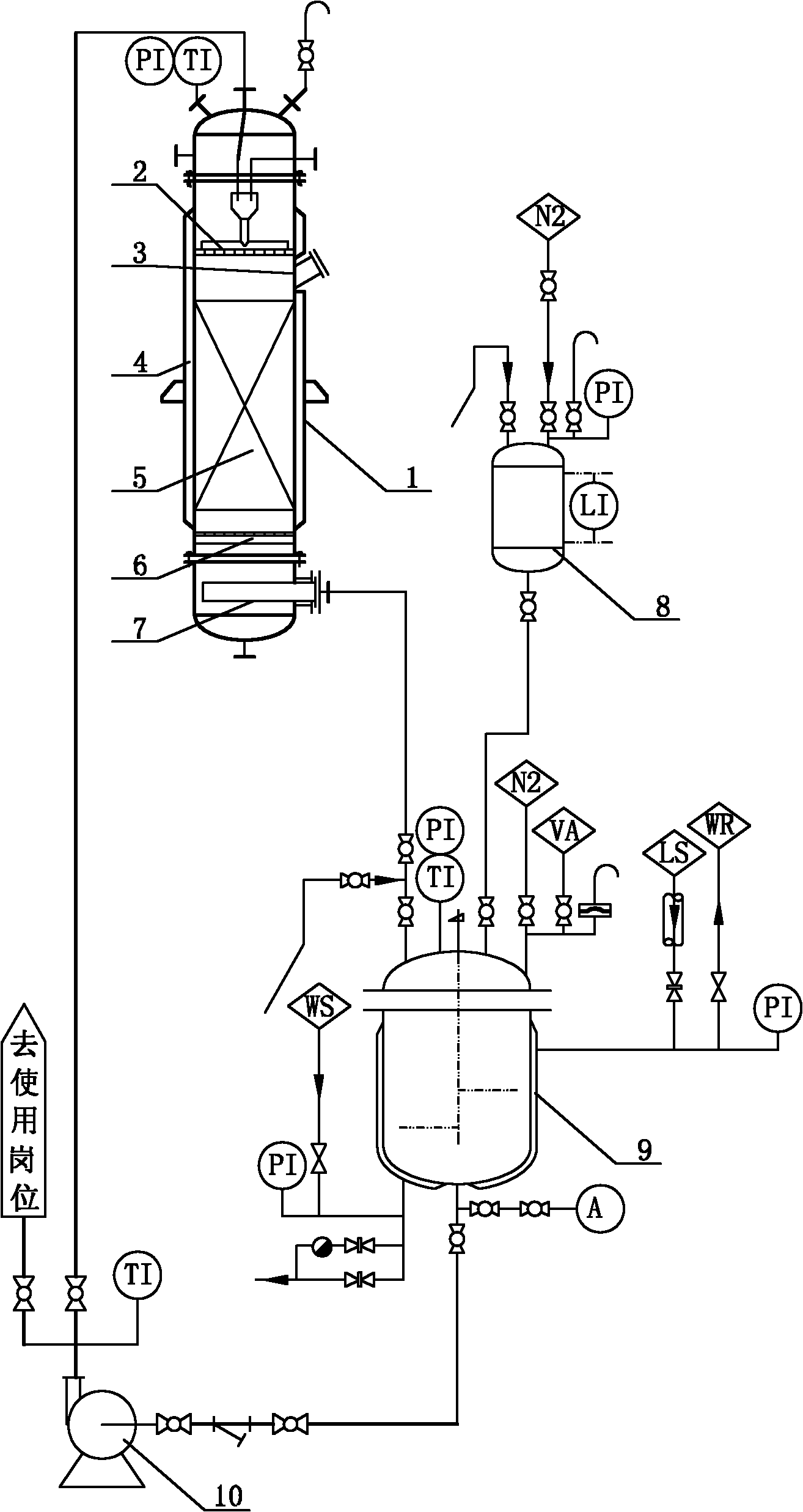

Method for preparing Grignard reagent

ActiveCN102093396AReduce unit consumptionEmission reductionChemical/physical/physico-chemical stationary reactorsMagnesium organic compoundsHalohydrocarbonGrignard reagent

The invention discloses a method for preparing a Grignard reagent. In the conventional method for preparing the Grignard reagent by using magnesium powder, the magnesium content of the common magnesium ingot can reach over 99 percent; after the magnesium ingot forms the magnesium powder by cutting processing, the magnesium content of the magnesium powder is about 95 percent; 4 percent of metal magnesium is oxidized during the cutting processing; an oxidation film of the oxidized magnesium can delay the occurrence of a Grignard reaction to cause initiation difficulty; and if the dropping speed of halogenated hydrocarbon is increased, instant reaction is generated to release a great deal of reaction heat and a production accident occurs. The method for preparing the Grignard reagent is characterized in that: large-particle magnesium or magnesium ingot with nominal diameter of more than 1 mm serves a raw material; and the Grignard reaction is performed in a kettle reaction mode or an external circulation reaction mode. The large-particle magnesium or magnesium ingot serves the raw material, so the quantity of magnesium oxide in the magnesium is greatly reduced, proportion of byproducts formed by the magnesium oxide and an initiator is reduced, the quality of the Grignard regent is improved, and utilization ratio of the metal magnesium and utilization ratio of the halogenated hydrocarbon are increased.

Owner:ZHEJIANG NHU CO LTD

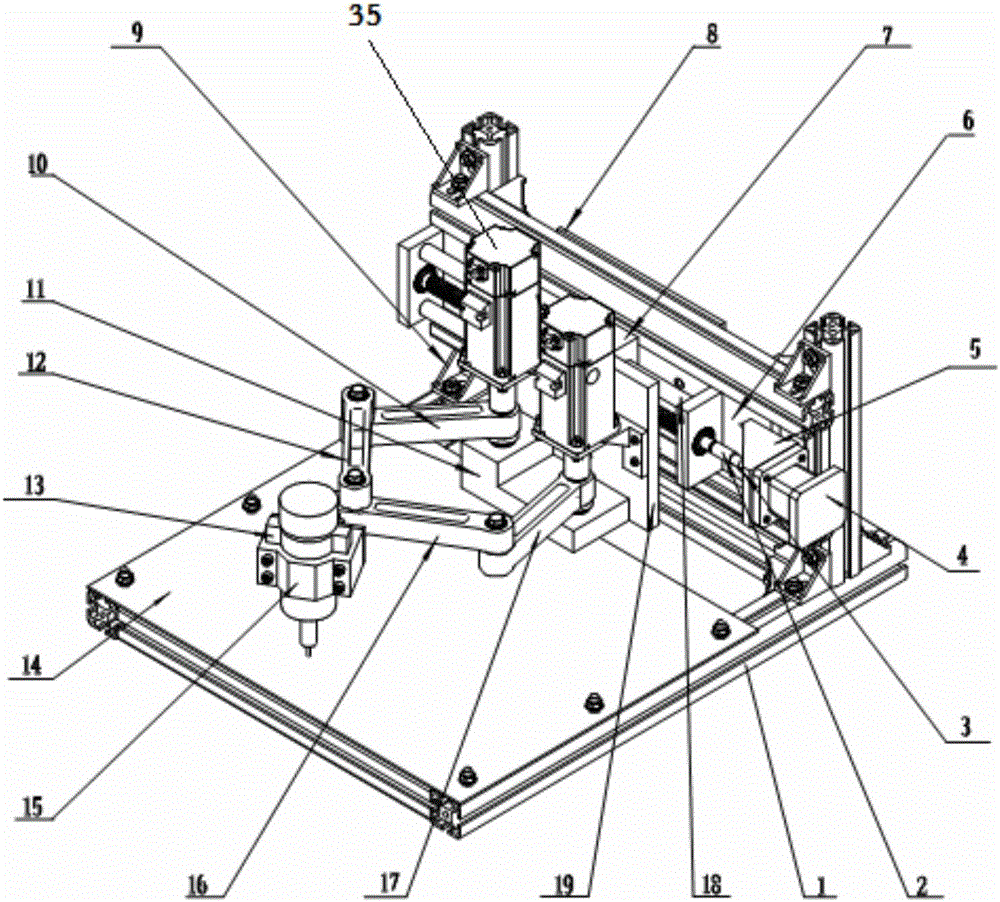

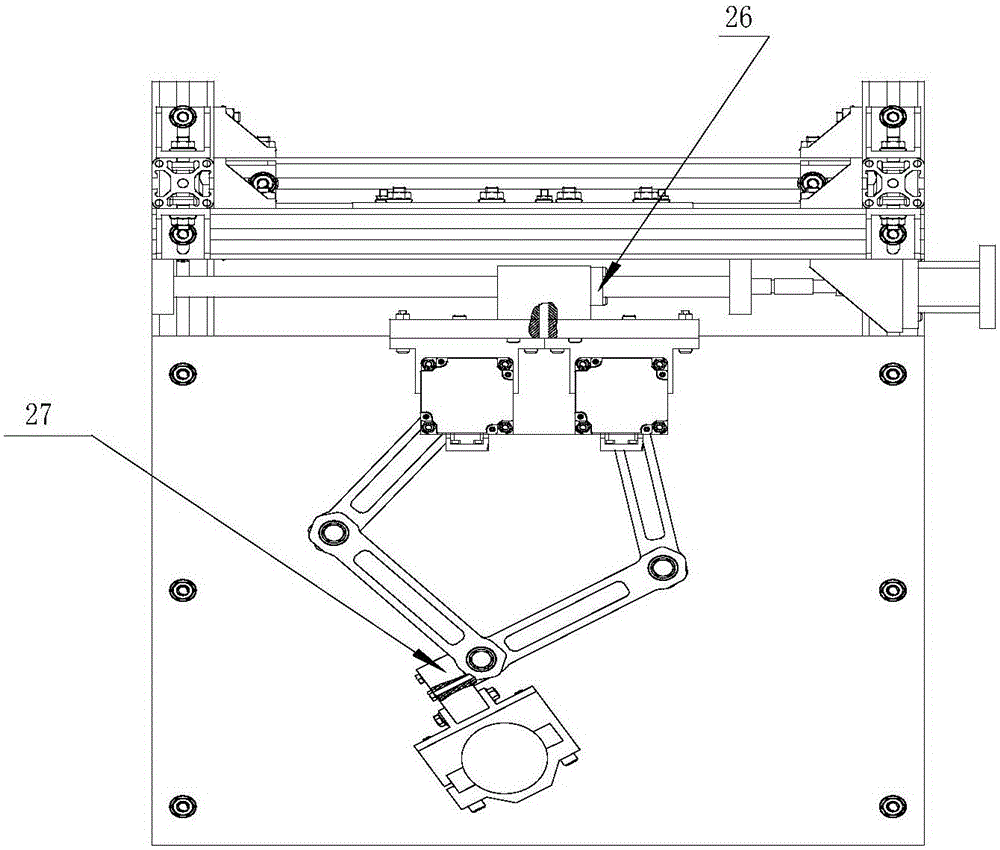

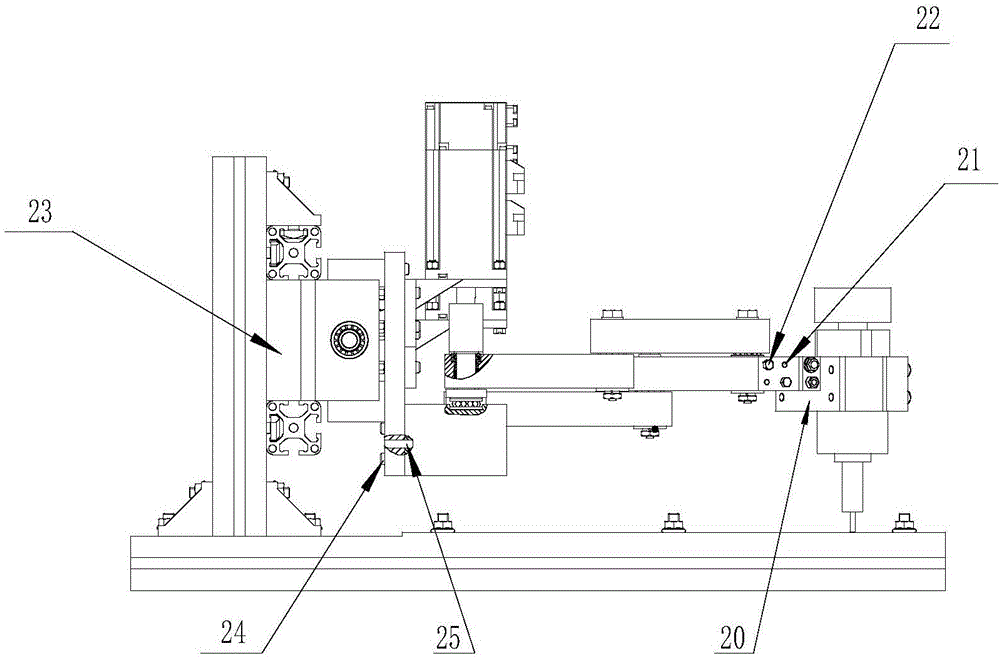

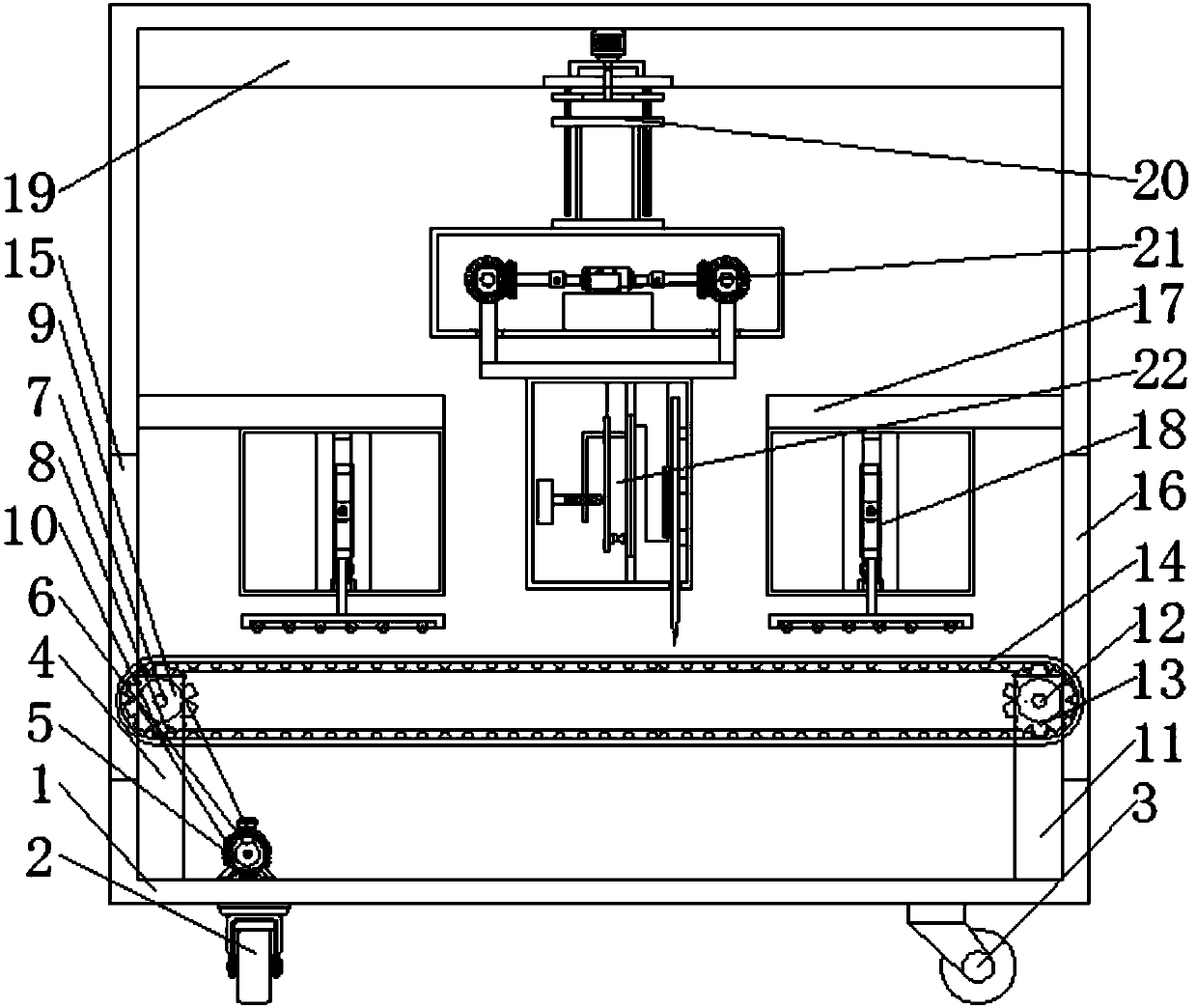

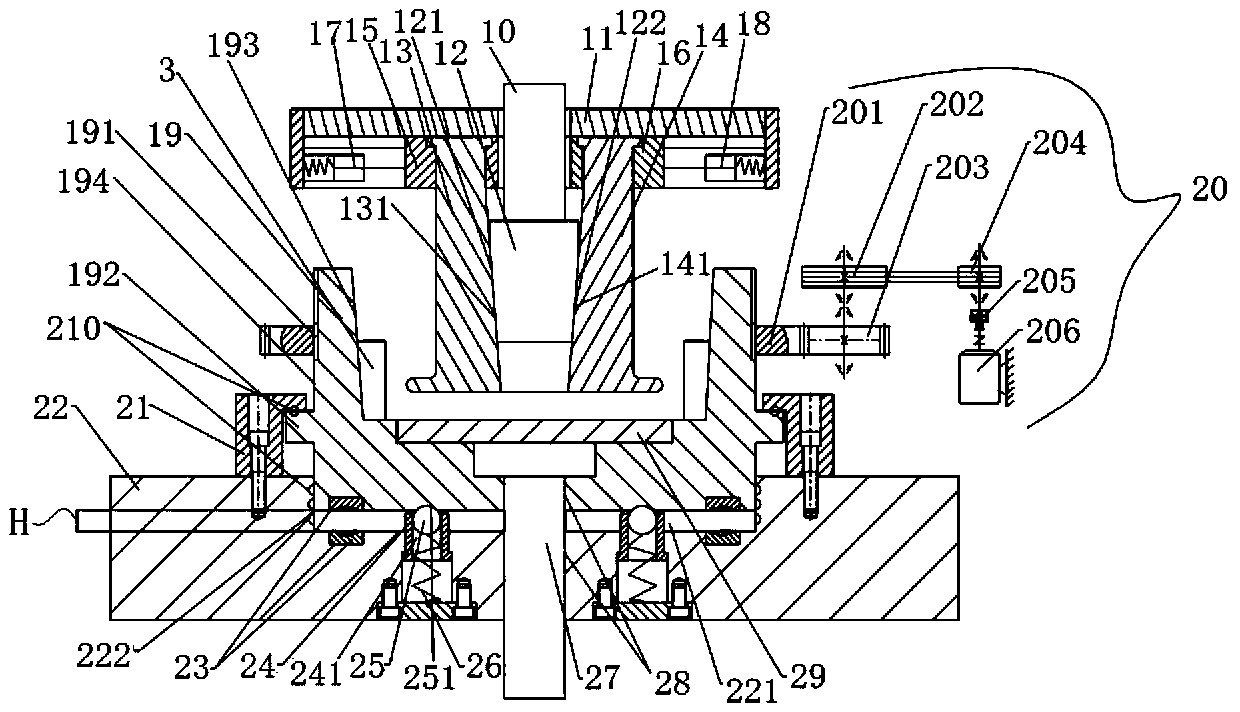

Vertical type reconfigurable multifunctional parallel mechanism

ActiveCN106671066AWide range of working planesSmooth movementProgramme-controlled manipulatorBall screwEngineering

In order to solve the problems that in the prior art, 5R parallel mechanisms are small in movement space, incapable of fast reconfiguration and large in rod and rod connection friction, the invention discloses a vertical type reconfigurable multifunctional parallel mechanism. The vertical type reconfigurable multifunctional parallel mechanism comprises a working platform, a five-rod mechanism, a reconfigurable end effector and a rack position adjusting device. A rack is fixed on the position adjusting device, and the end effector is installed on connecting rods of the parallel mechanism. The rack position adjusting device drives a ball screw through a stepping motor, then the position of the rack is changed, and thus the whole parallel mechanism moves in the axis direction of the ball screw so as to obtain larger working space. The reconfigurable end effector is of the structure that the clamping range is changeable and disassembling is easy, so that clamping of different components such as an electric spindle, a 3D printing head and a laser sintering head is achieved, and fast reconfiguration is achieved so as to realize different processing technologies.

Owner:NORTHEASTERN UNIV

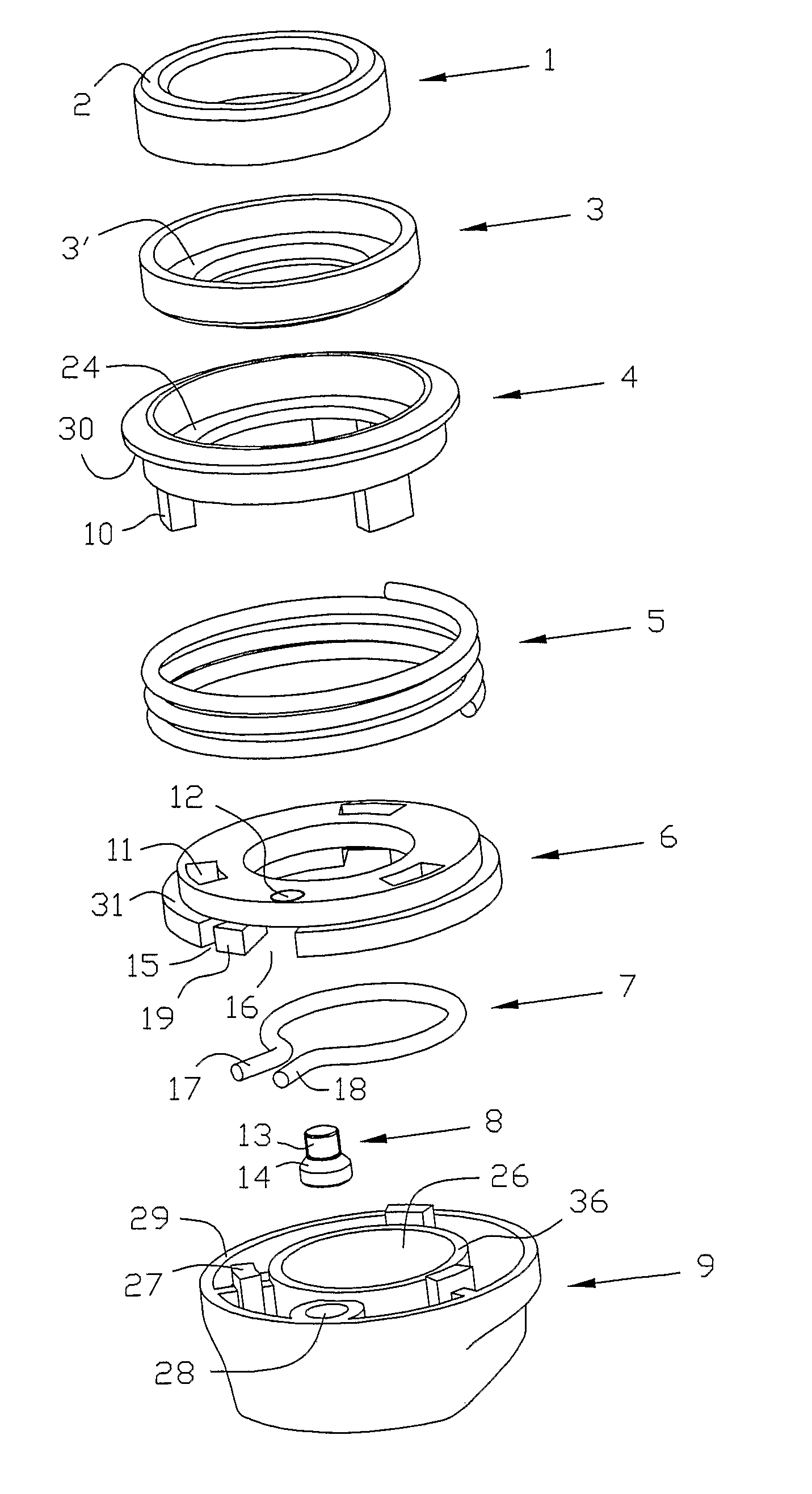

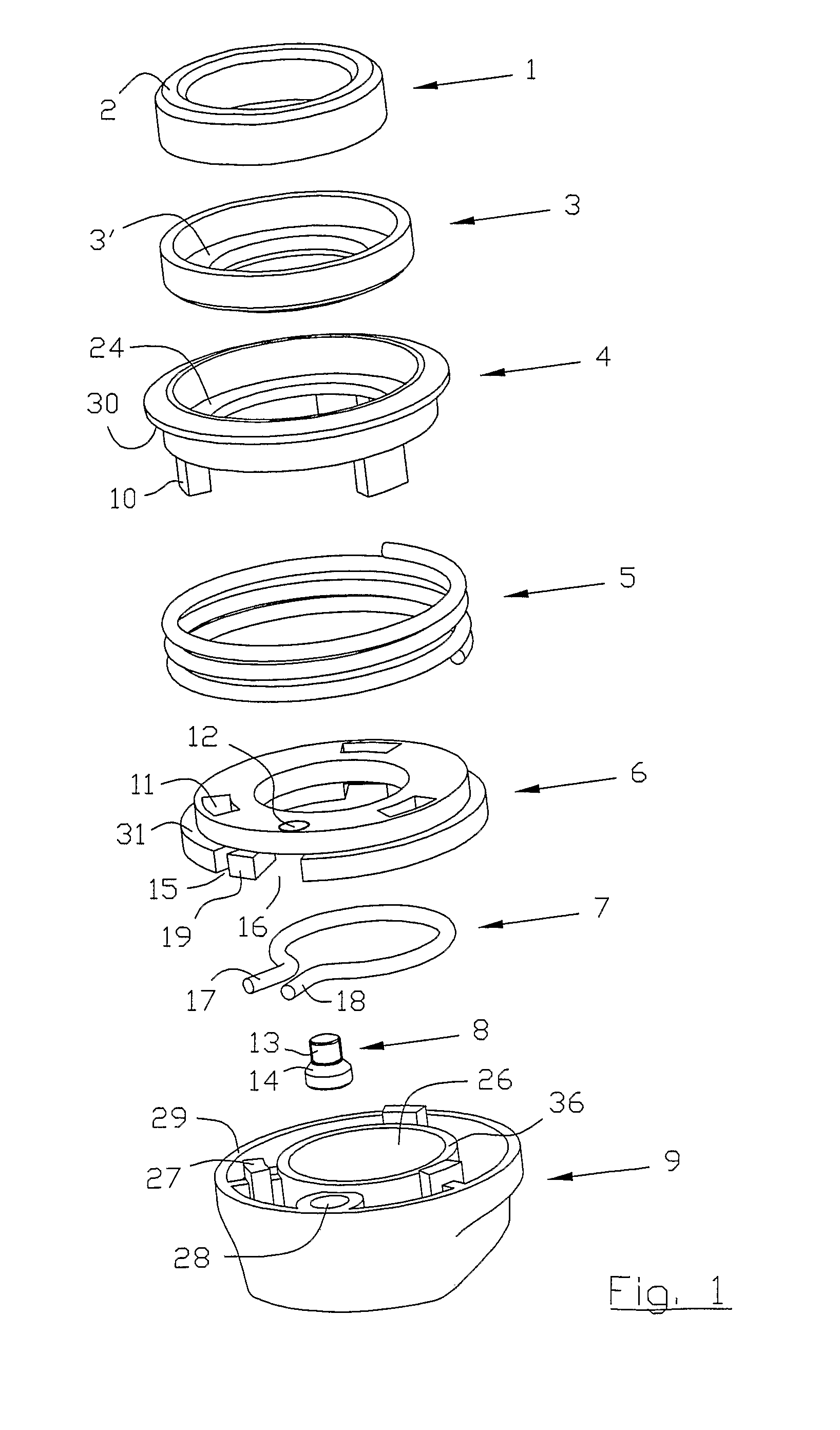

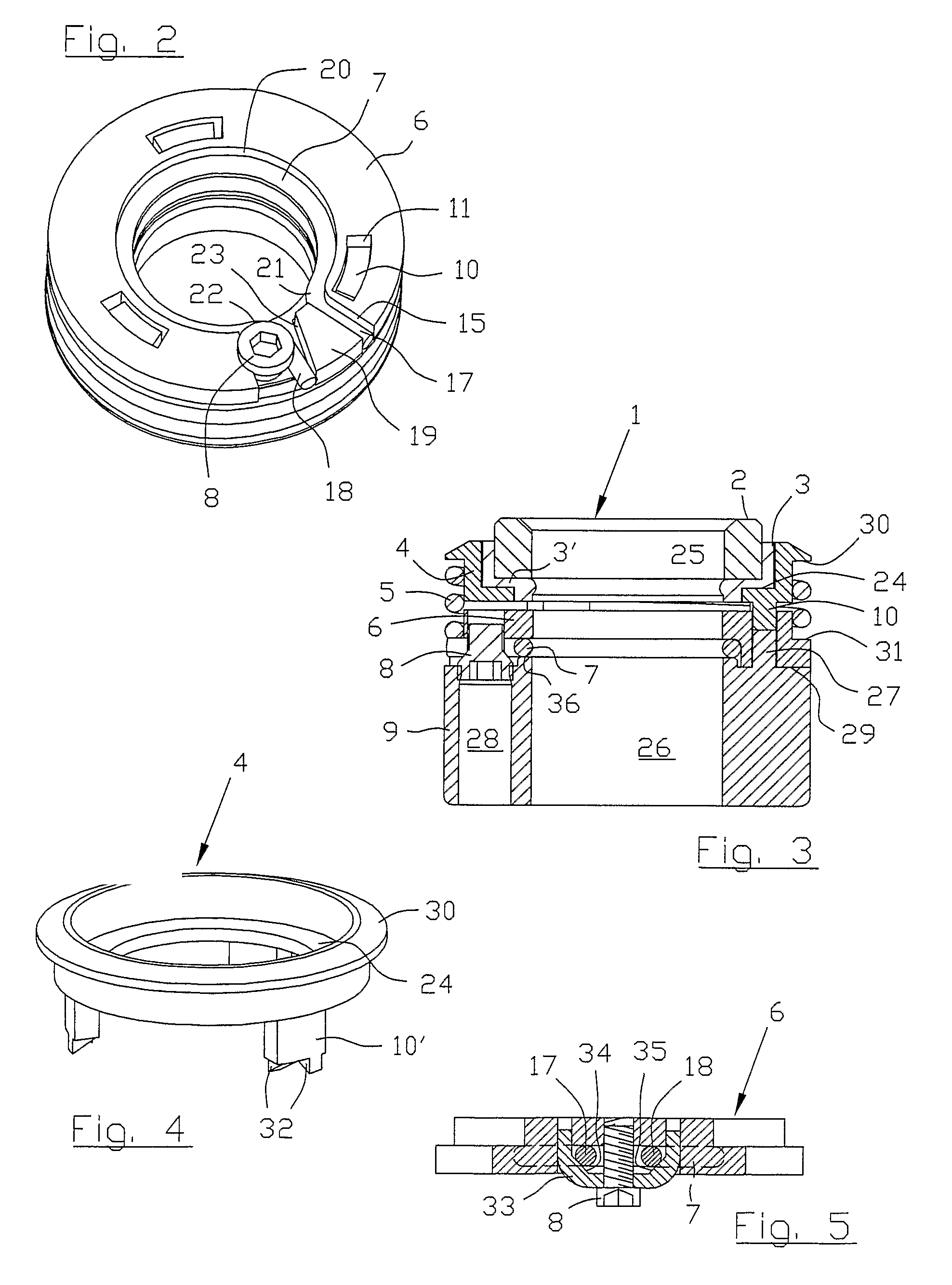

Axial face seal assembly, mounting method and mounting fixture

An axial face seal assembly including a seal member which is seated in a carrier, the carrier being non-rotatably connected to a base member but movable axially thereto and biased from the base member by means of a compression spring interposed between the base member and the carrier, the base member being axially and non-rotatably securable to a drive shaft by means of an open ring clamp having first end second ends. The ring clamp is supported on the base member, at least one of said first and second ends being movable relative to the other end in a circumferential direction; and wherein tightening means is rotatably journalled on the base member for adjusting the relative distance between the first and second ends of the ring clamp. A mounting fixture is likewise disclosed and cooperating with the seal assembly in a mounting procedure.

Owner:XYLEM IP HLDG

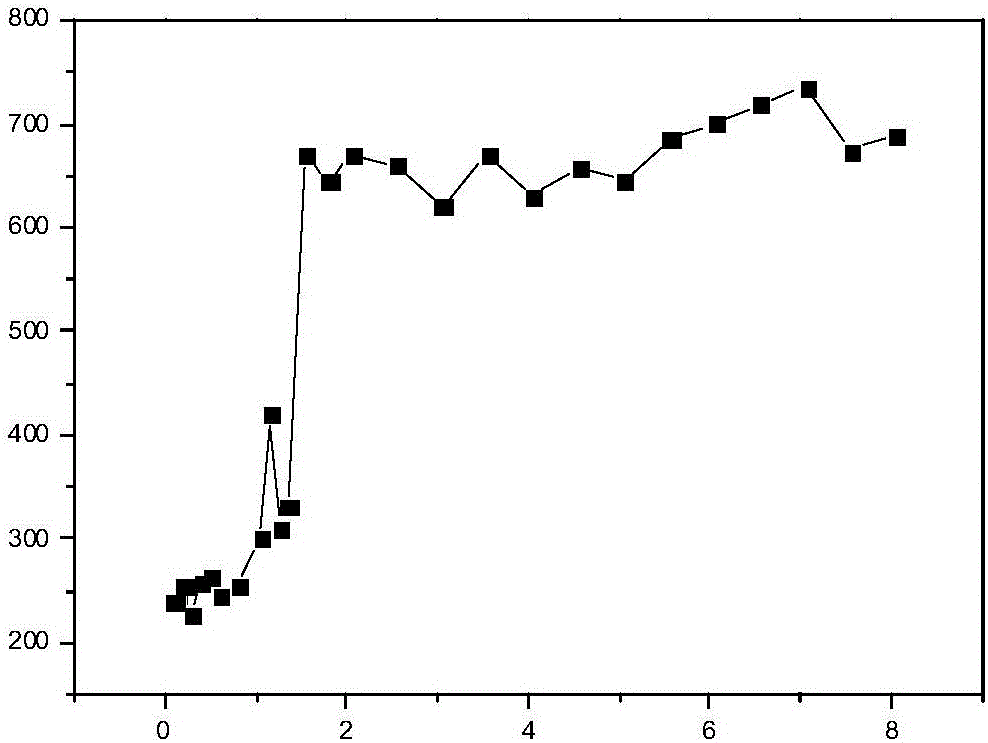

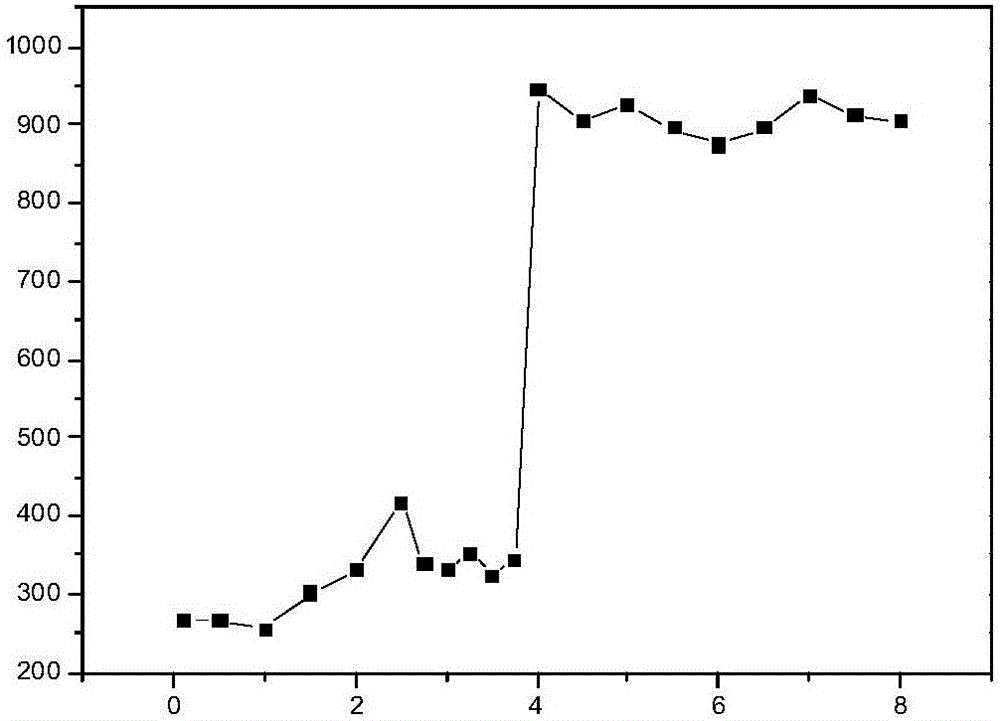

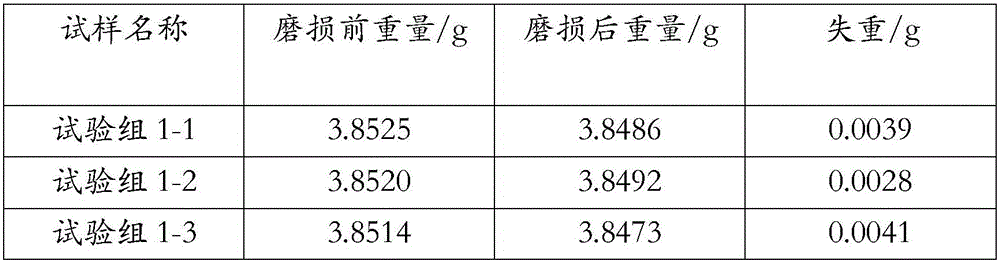

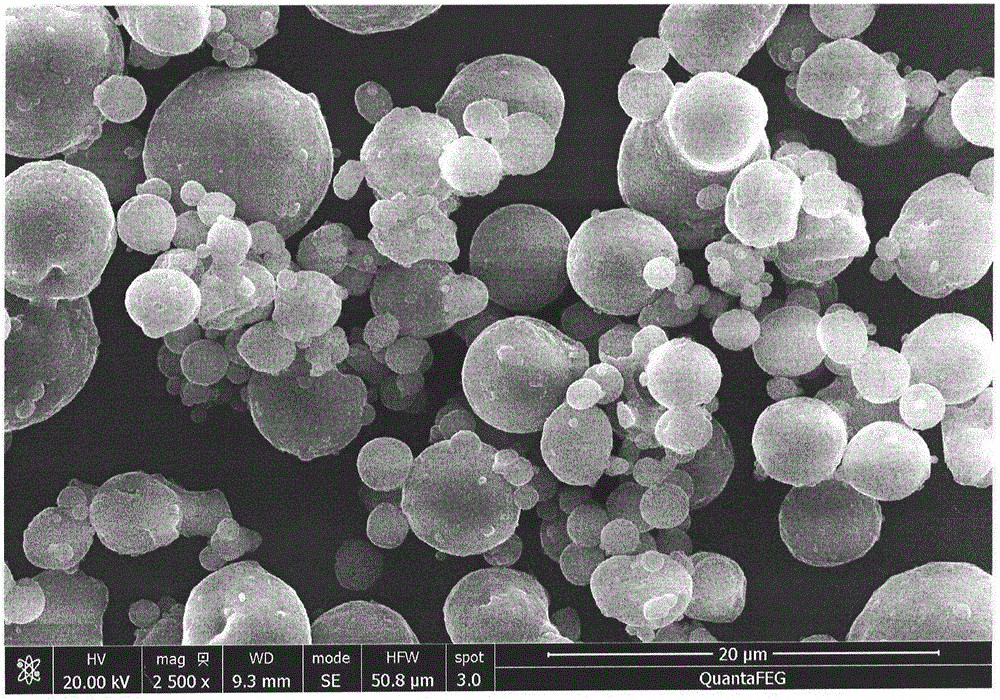

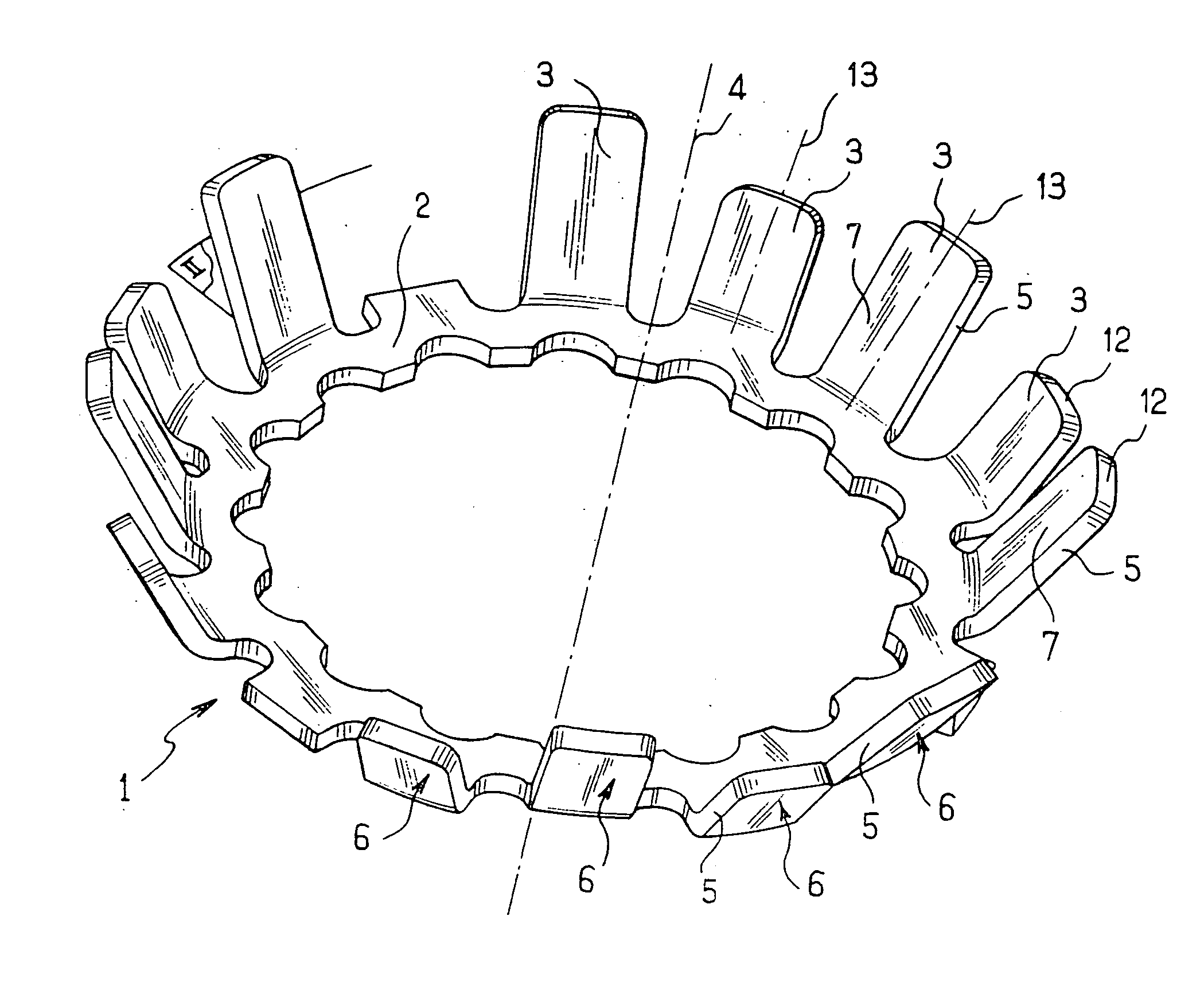

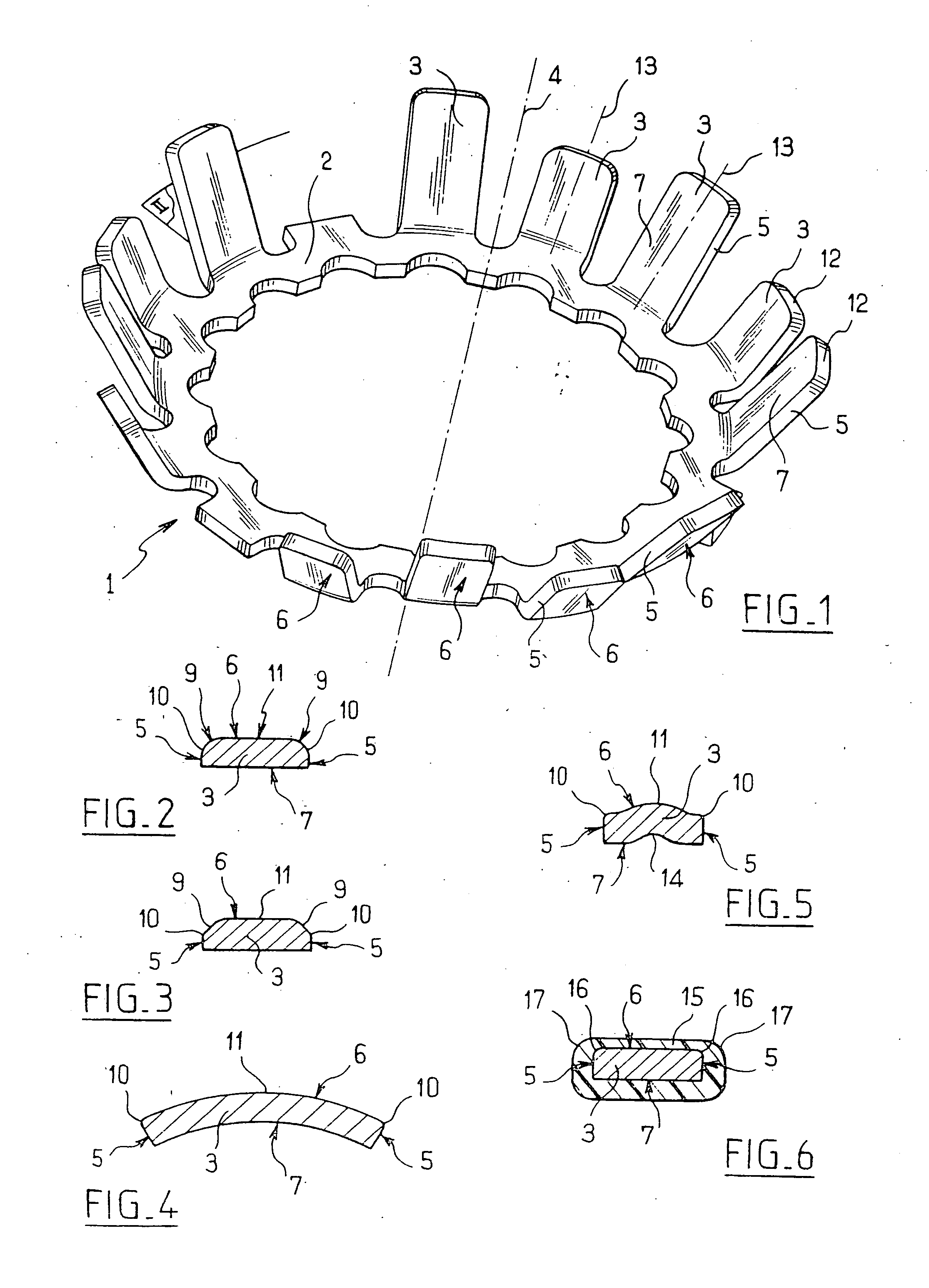

3D printing repair method of chain wheel

ActiveCN105728724AReduce wasteAvoid machiningAdditive manufacturing apparatusIncreasing energy efficiencyThree dimensional modelDouble coating

The invention discloses a 3D printing repair method of a chain wheel. The method comprises following steps: firstly, scanning, wherein the chain wheel is scanned, and space coordinates of the chain wheel surface are obtained; secondly, model processing and code generation, wherein the space coordinates of the chain wheel surface are compared with standard space coordinates of the chain wheel surface, a three-dimensional model required to be repaired is obtained, and the three-dimensional model is sliced to generate numerical control codes; thirdly, 3D printing; wherein the initial stage is printed, power of a laser device is set to range from 1200 W to 1500 W, and after 0.5 mm to 1.5 mm is printed, the power of the laser device is set to range from 600 W to 800 W; and fourthly, aftertreatment, wherein the chain wheel obtained after 3D printing is subject to sand blasting and polishing processing. According to the repair method, the wear portion can be precisely repaired, a double-coating cladding method is adopted, it is ensured that a cladding layer and a base body are completely in metallurgical bonding, and meanwhile hardness and wear resistance of the surface of the repaired position of the chain wheel can be superior to those of a new product.

Owner:SHANDONG ENERGY HEAVY EQUIP MFG GRP CO LTD +1

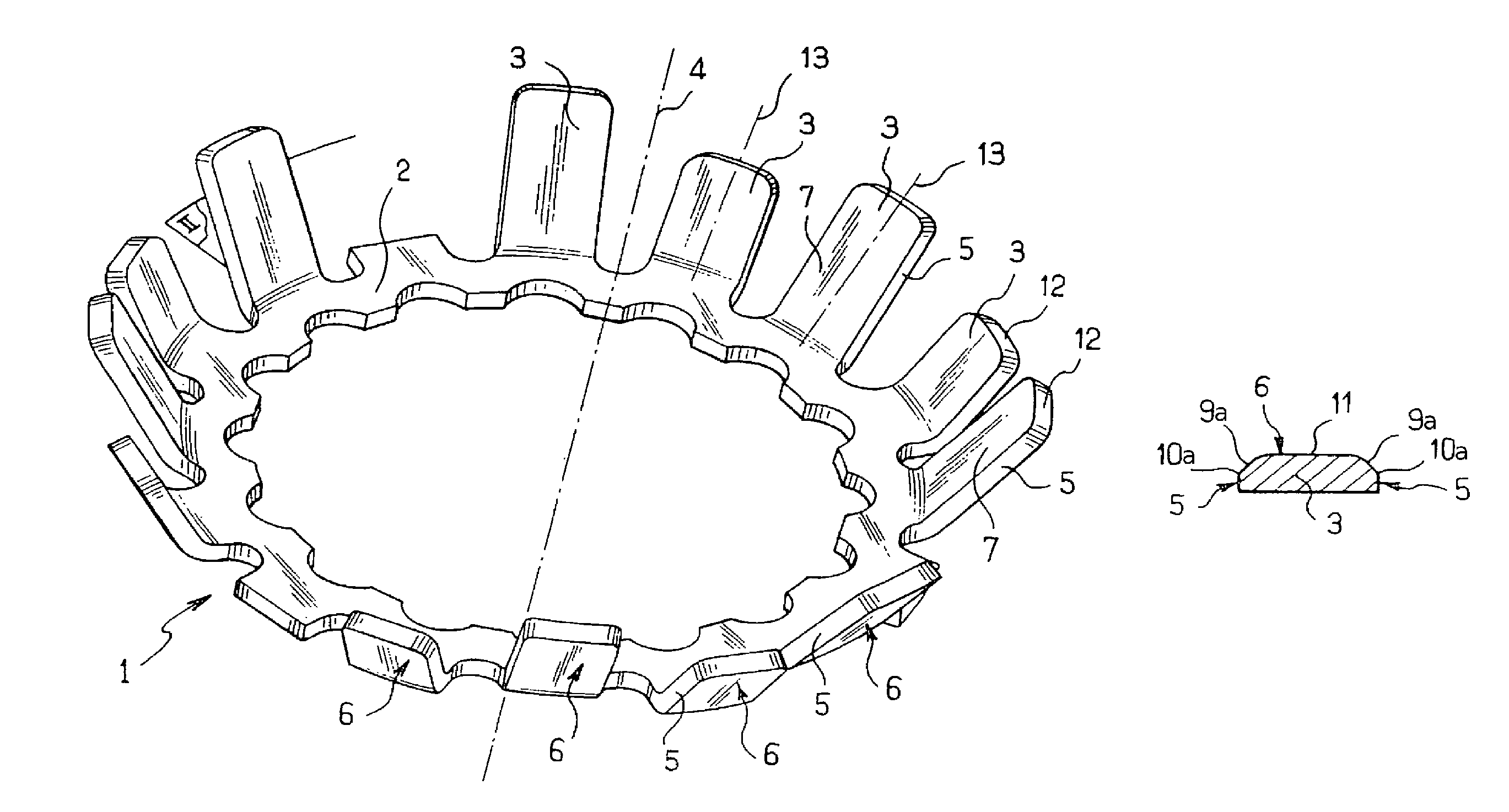

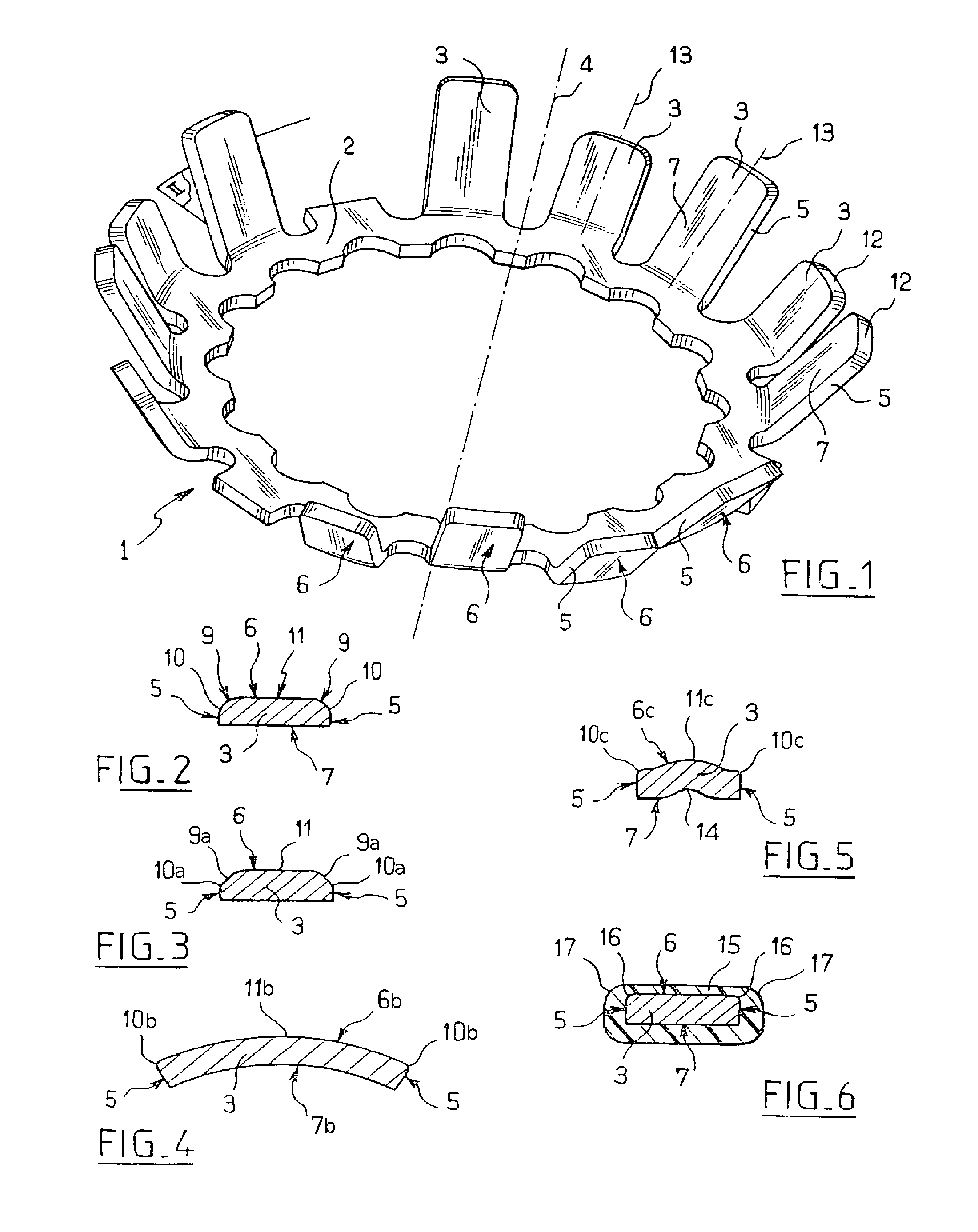

Non-aggressive anchor washer

InactiveUS7878554B2Avoid machiningSleeve/socket jointsSnap-action fastenersCouplingClassical mechanics

Owner:LEGRIS

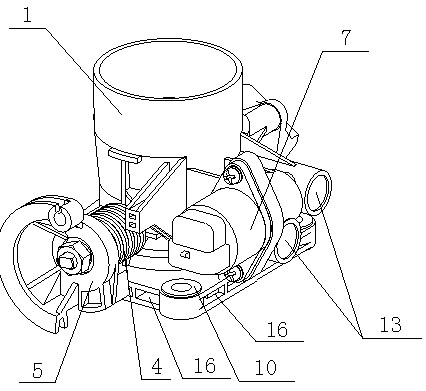

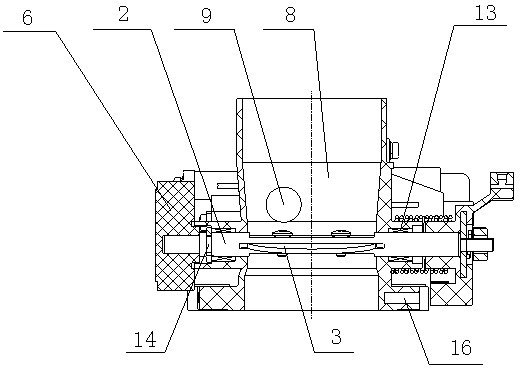

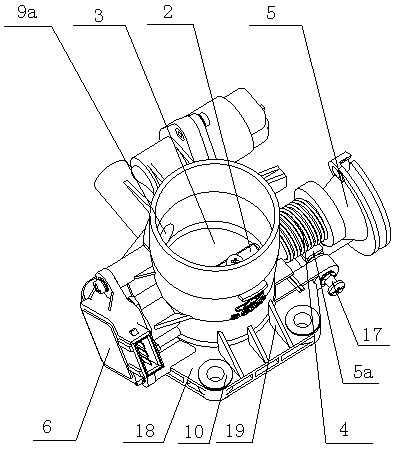

Plastic electric-spraying throttle valve body assembly

InactiveCN102003290AAvoid sizeAvoid stabilityEngine controllersMachines/enginesMain channelThermal expansion

The invention discloses a plastic electric-spraying throttle valve body assembly, comprising a throttle valve body (1), a throttle valve spindle (2), a throttle valve piece (3), a torsion spring (4), a swing frame (5), a position sensor (6), a stepping motor (7), a flange plate metal insert (10), an idle screw mounting hole metal insert (11), stepping motor and position sensor mounting hole metal inserts (12), a card (14) and an idle adjusting screw (17), wherein a main channel (8) and an idle side channel (9) are arranged inside the throttle valve body (1), and a base of the throttle valve body (1) is provided with a flange plate (18). The plastic electric-spraying throttle valve body assembly has the beneficial effects that the defect of easy deformation of the main channel of the plastic throttle valve body can be effectively overcome, the fast interchange of a metal throttle valve body assembly and a plastic throttle valve body assembly in the process of assembly and after-sale maintenance of an engine is realized, and the leak problem of the side channel of the throttle valve body caused by different coefficients of thermal expansion is solved.

Owner:SICHUAN HONGGUANG AUTO MACHINERY ELECTRONICS

Welding process

InactiveUS20050224487A1Suitable for repairAvoid machiningTurbinesPump componentsGas tungsten arc weldingGas turbines

A process for repairing a compressor rear frame of a gas turbine engine. The process entails removing a seal flange from the inner casing wall of the frame to define an annular face on the casing wall, and fabricating a replacement flange to have an annular face with a radial width greater than the radial width of the annular face of the casing wall. The faces of the flange and wall are mated to form a joint, a penetration-enhancing flux is deposited adjacent the joint, and a single-pass gas tungsten arc welding operation is performed to form a root weldment that extends completely through the joint. The flux is then removed and a gas tungsten arc welding operation is performed to deposit a filler on the root weldment and form a second weldment that completely overlays but does not penetrate through the root weldment.

Owner:GENERAL ELECTRIC CO

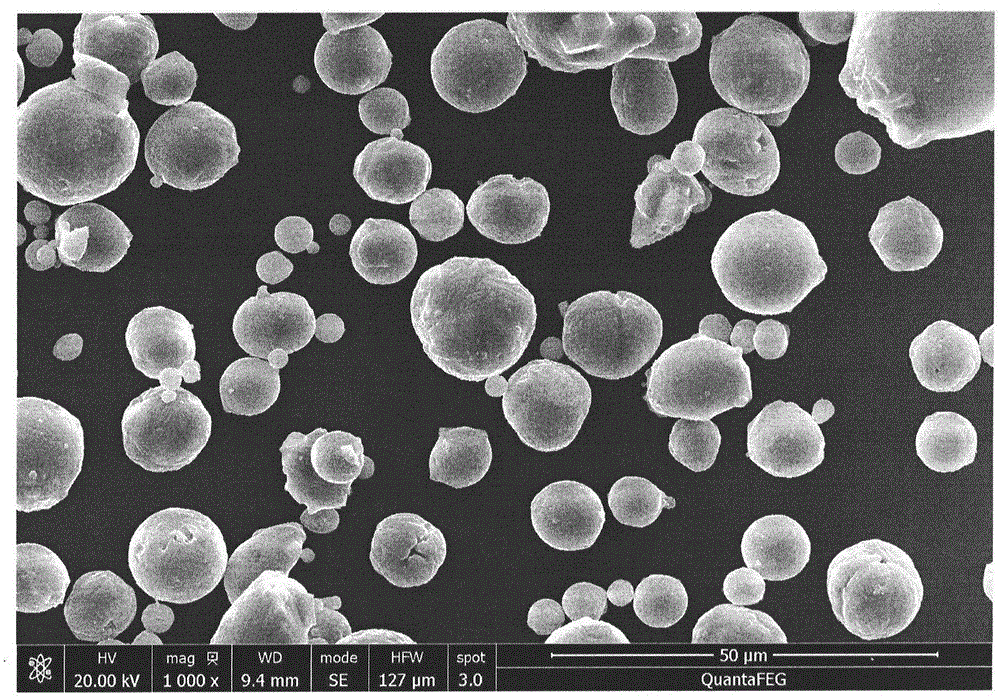

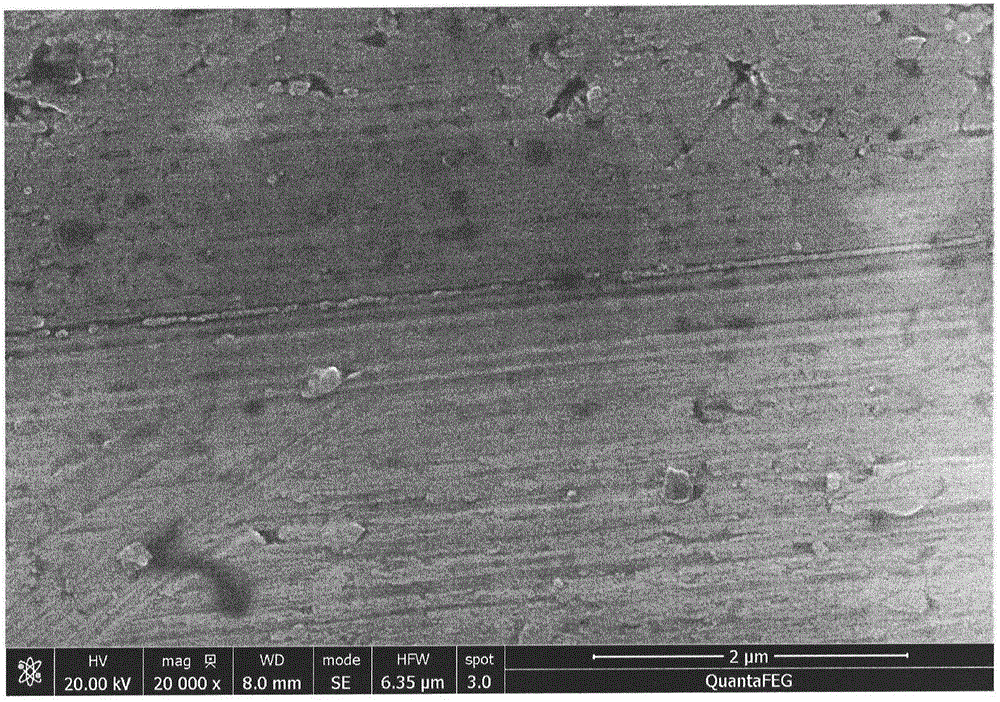

Method for preparing silicon-aluminum alloy electronic packaging material by virtue of rapid injection molding

The invention relates to a method for preparing a silicon-aluminum alloy electronic packaging material by virtue of rapid injection molding. The silicon-aluminum alloy comprises the following components in percentage by weight: 10%-60% of Si and the balance of Al. The method comprises the following steps of preparing according to the components of the alloy, mixing the prepared silicon-aluminum alloy powder and a binder at a certain ratio in an internal mixer to obtain a uniform compound feedstock, carrying out injection molding on the feedstock to obtain a green body, removing the binder from the green body and sintering to obtain the silicon-aluminum alloy electronic packaging material of which the relative density is greater than 99%. The silicon-aluminum alloy material has the advantages of uniform alloy components and uniform and dense microstructures and can be prepared into the silicon-aluminum alloy electronic packaging material which has continuously adjustable thermal expansion coefficient range of (6-12)*10<-6> / K, the thermal conductivity range of 110-150W / mK and the specific gravity of 1.7-2.6g / cm<3> and complex and diversiform structure, the complicated machining processes such as lathing, milling, planing and grinding are avoided and the method has the advantages of high production efficiency, simple process, low cost, excellent product performance and the like.

Owner:苏州中宝复合材料股份有限公司

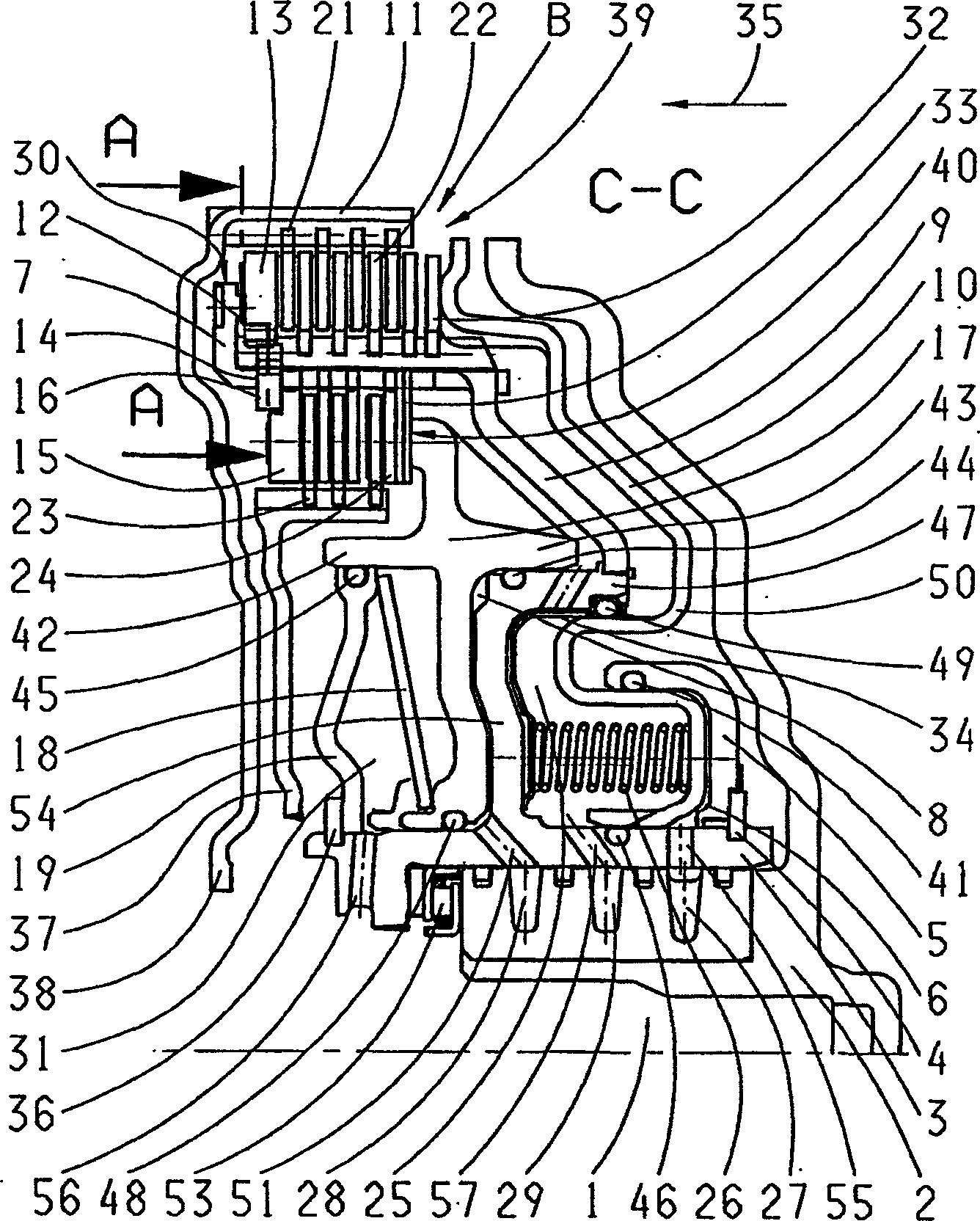

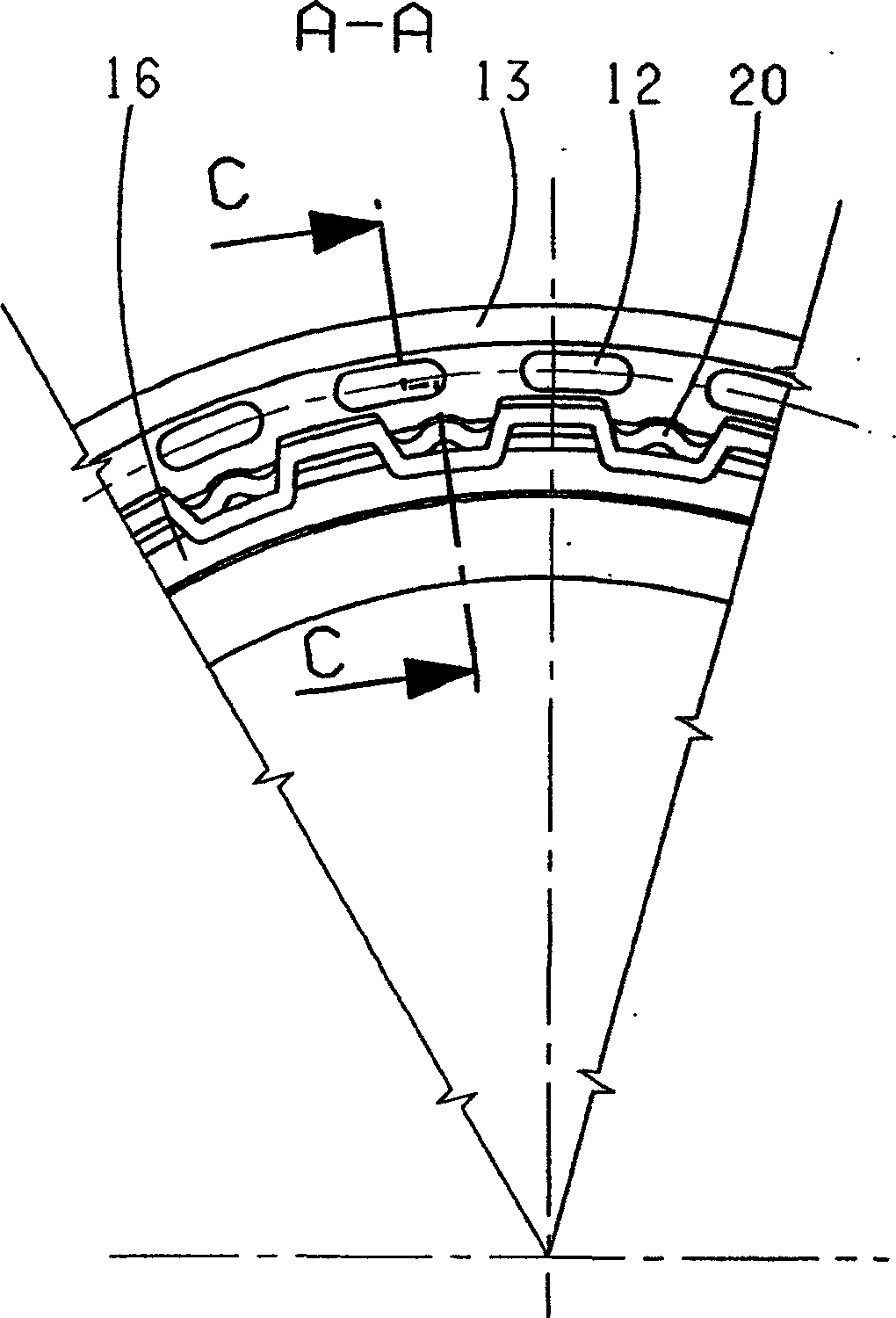

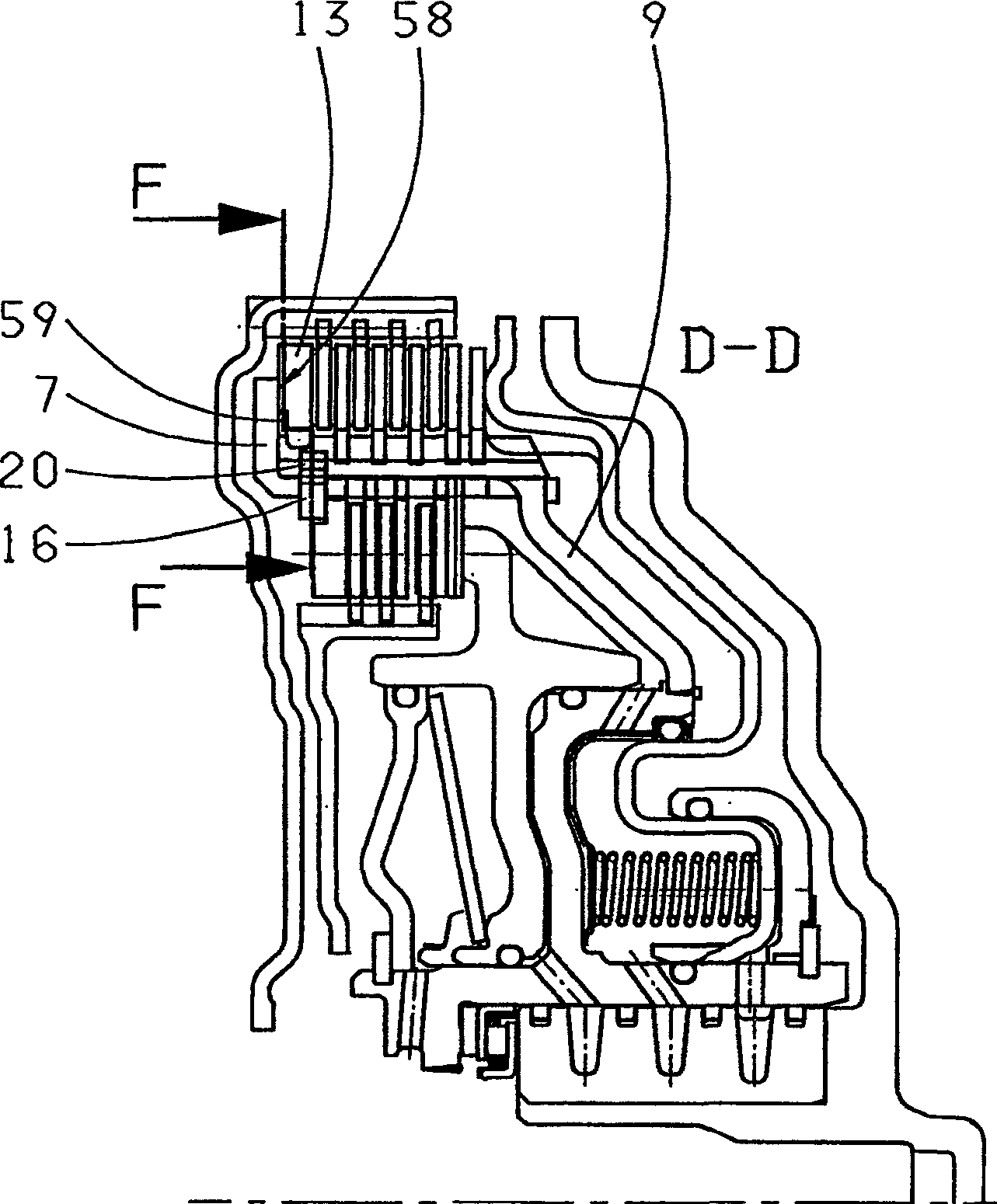

Clutch assembly in a gearbox comprising two axially and radially adjoining clutches

InactiveCN1875201AShorten the axial lengthArbitrary and simple choiceFluid actuated clutchesFriction clutchesAutomatic transmissionEngineering

The invention relates to a clutch assembly in a gearbox, in particular an automatic gearbox or automated manual gearbox of the double-clutch type, comprising two axially and radially adjoining multi-plate clutches (B, E). The inner plates (23) of the radial inner clutch (E) are located on an inner clutch-plate carrier (37) and the outer plates (21) of the radial outer clutch (B) are located on an outer clutch-plate carrier (38), whilst the inner plates (22) of the radial outer clutch (B) and the outer plates (24) of the radial inner clutch (E) are located on a common clutch-plate carrier (9). In addition, the plates (23, 24) of the radial inner plate stack (40) are supported axially against a circlip (16) that is fixed to the common clutch-plate carrier (9). The aim of the invention is to provide a space-saving, cost-effective clutch assembly. To achieve this, the plates (21, 22) of the radial outer plate stack (39) can be pressed in an axial direction against a bearing section (7) of the common clutch-plate carrier (9), said section consisting of an end piece of the common clutch-plate carrier (9) that faces radially outwards.

Owner:ZF FRIEDRICHSHAFEN AG

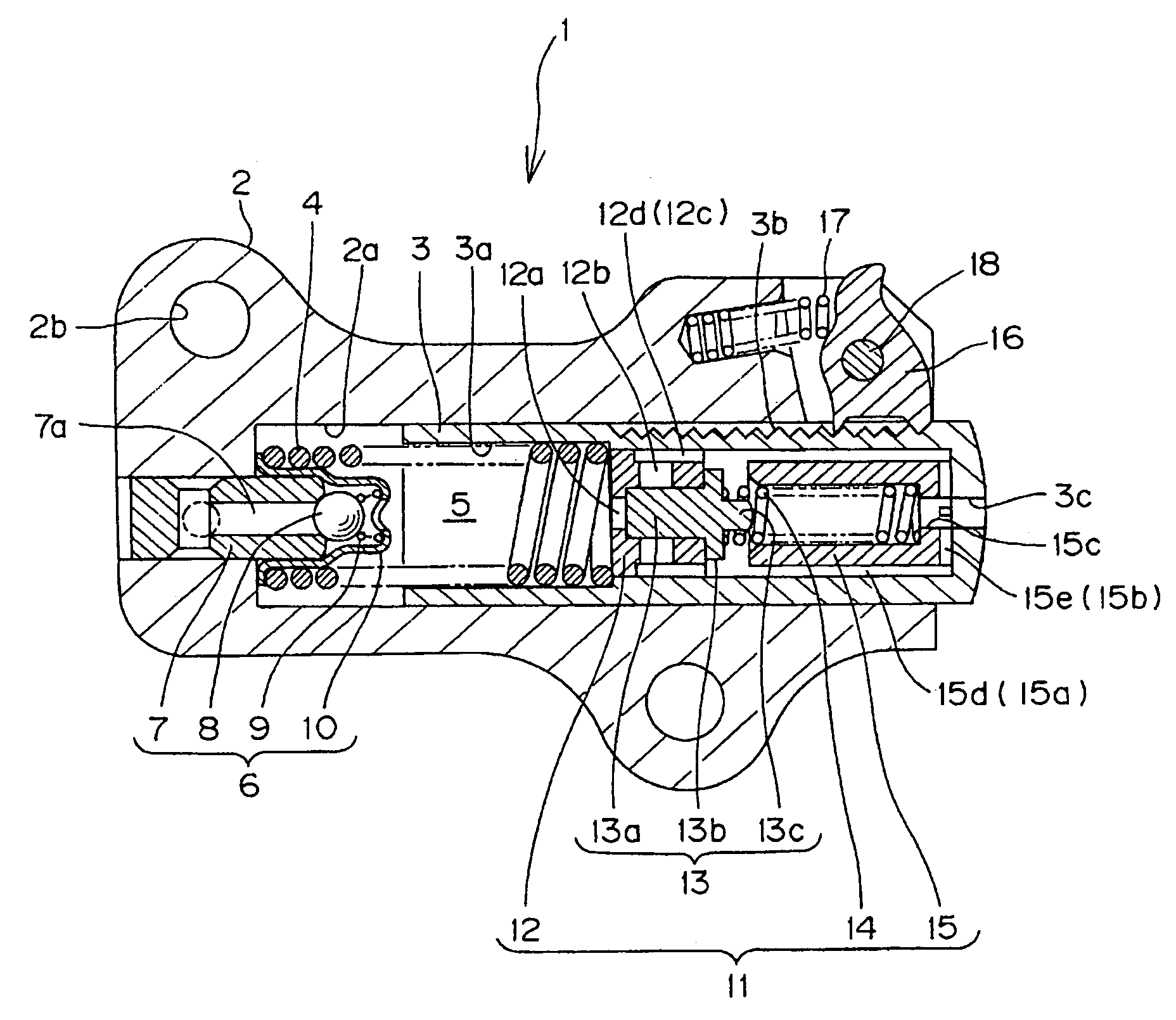

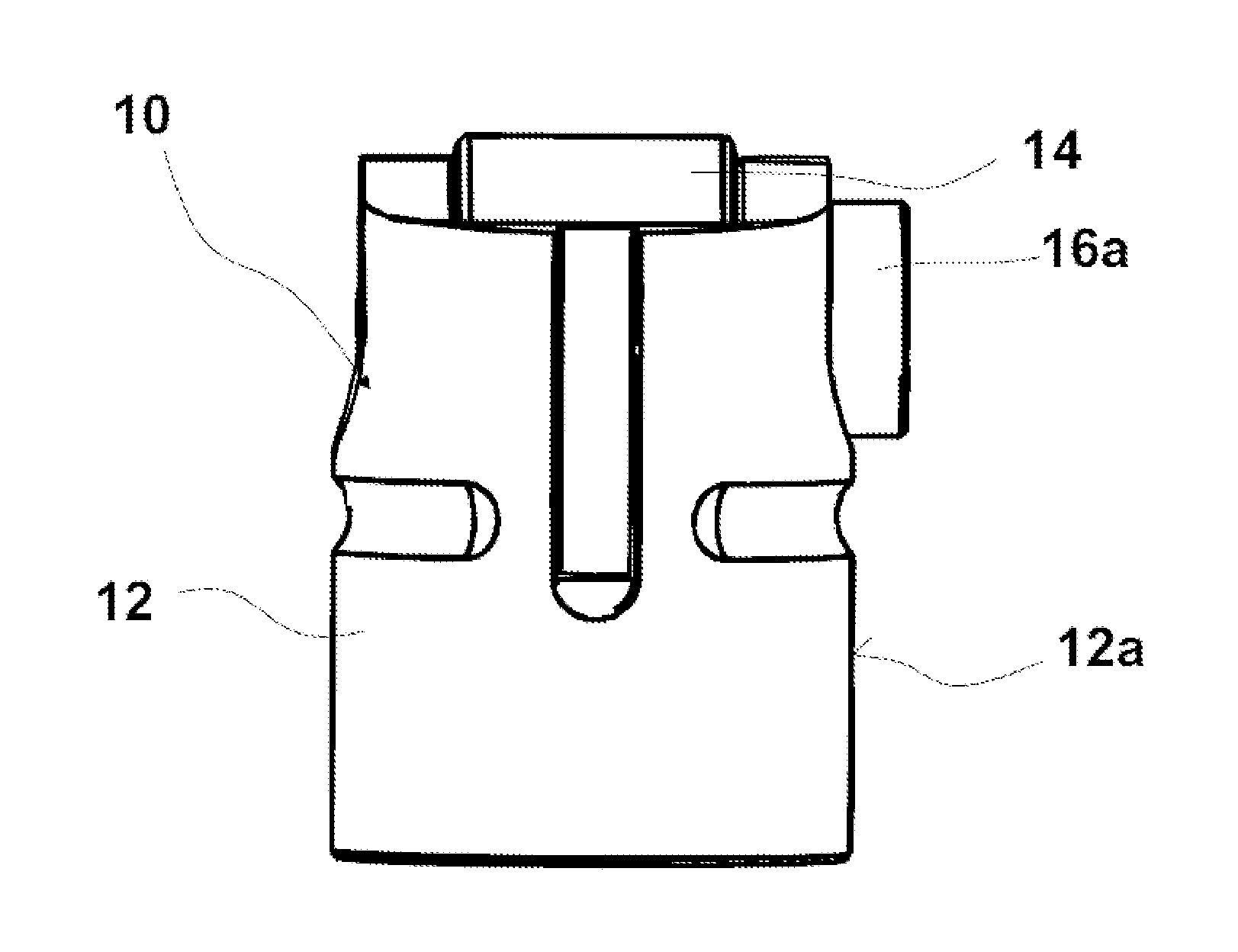

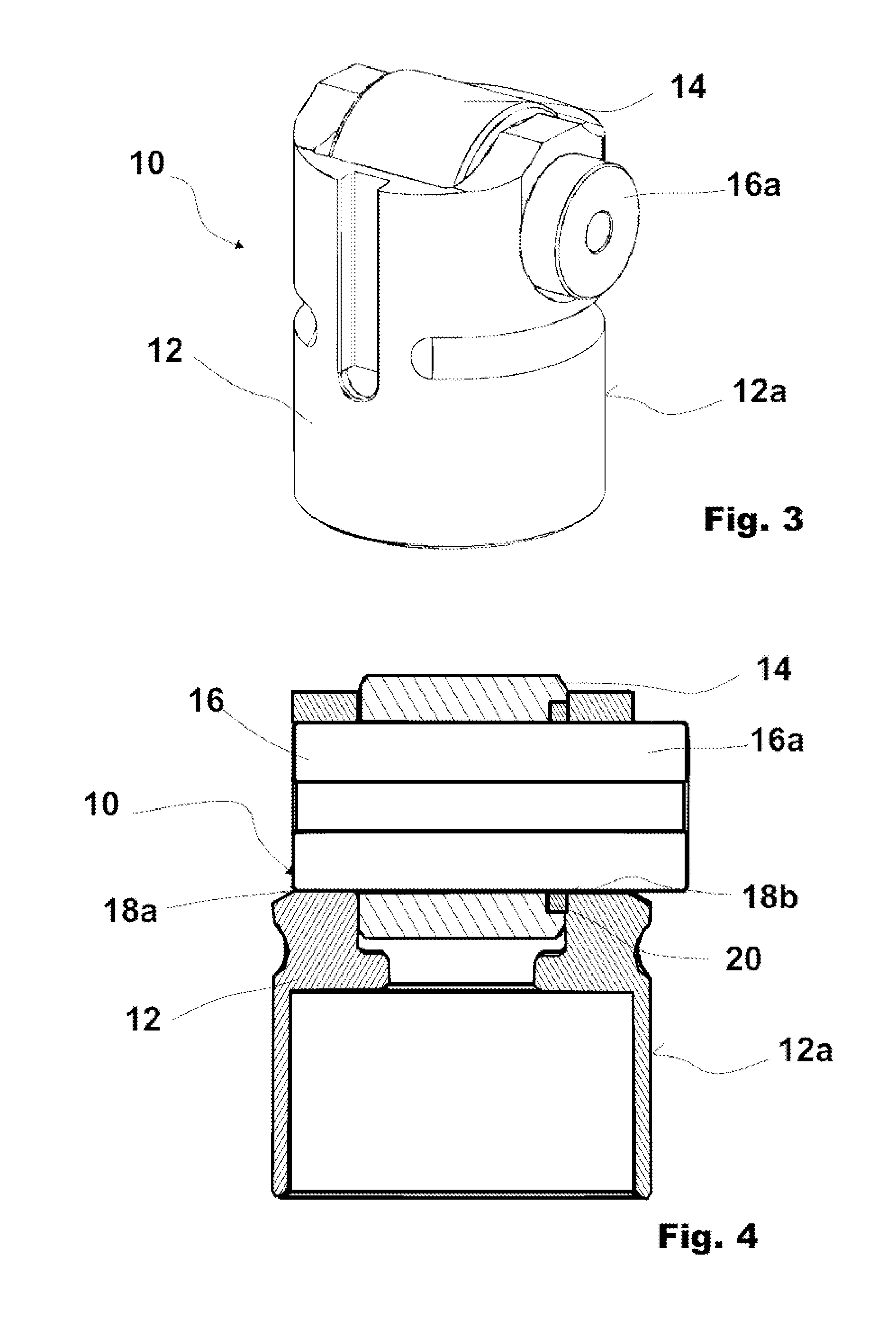

Cam follower with Anti-rotation device

ActiveUS20150337939A1Easy to slidePrevent rotationValve arrangementsCam-followersReciprocating motionCam

A cam follower including a plunger intended to execute a reciprocating movement in an exterior body. The plunger includes a plunger body having a cylindrical exterior surface, an anti-rotation device extending radially beyond the cylindrical exterior surface of the pusher body and engaging via a matching structure in the exterior body, a roller providing the contact with a cam, and a sleeve rotatably supporting the roller in the plunger body. The plunger body includes at least one lateral bore and the sleeve is inserted in the bore. In order to avoid additional components and assembly steps to constitute the anti-rotation device, the present invention proposes to use one end of the sleeve as the anti-rotation device.

Owner:AB SKF

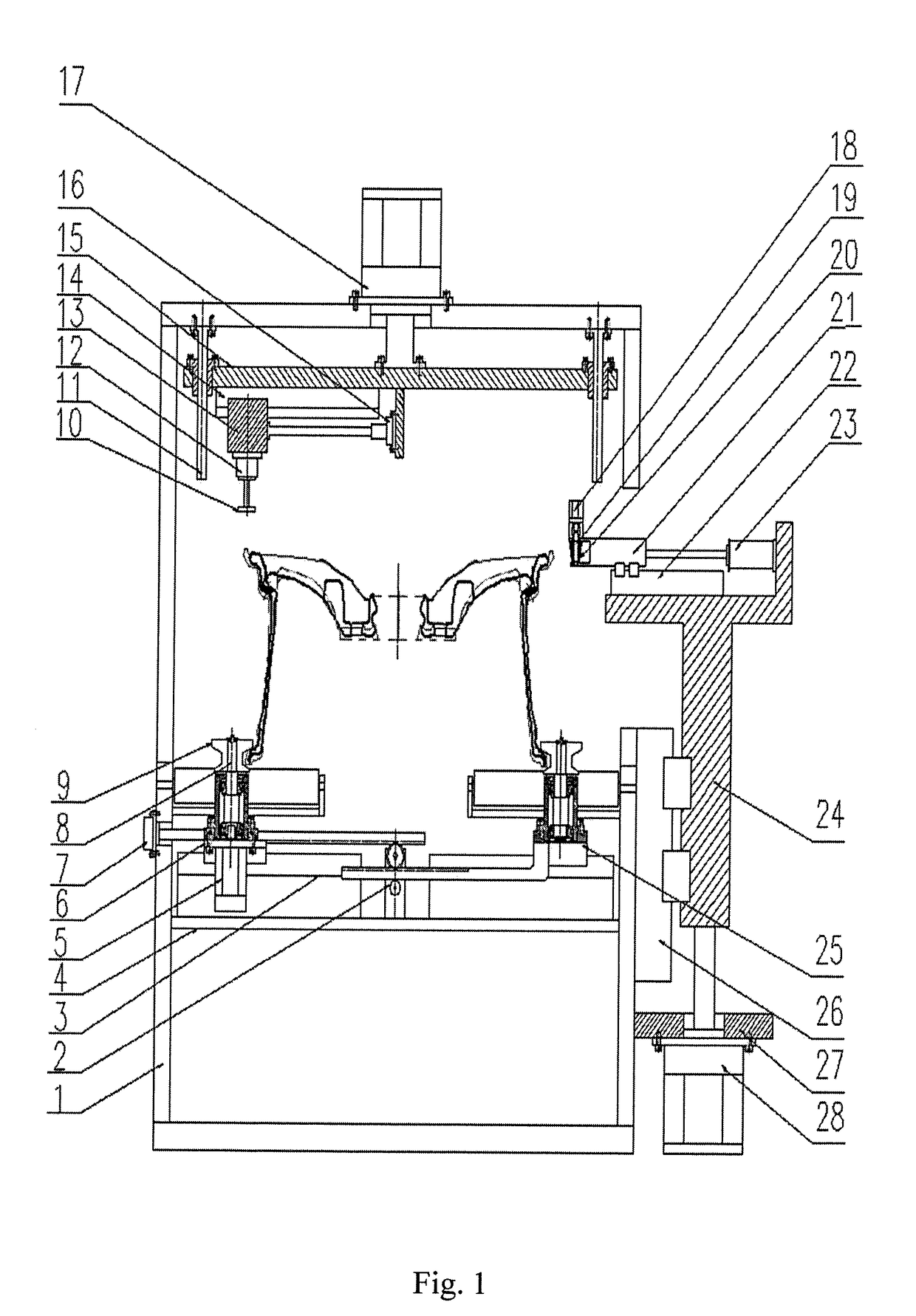

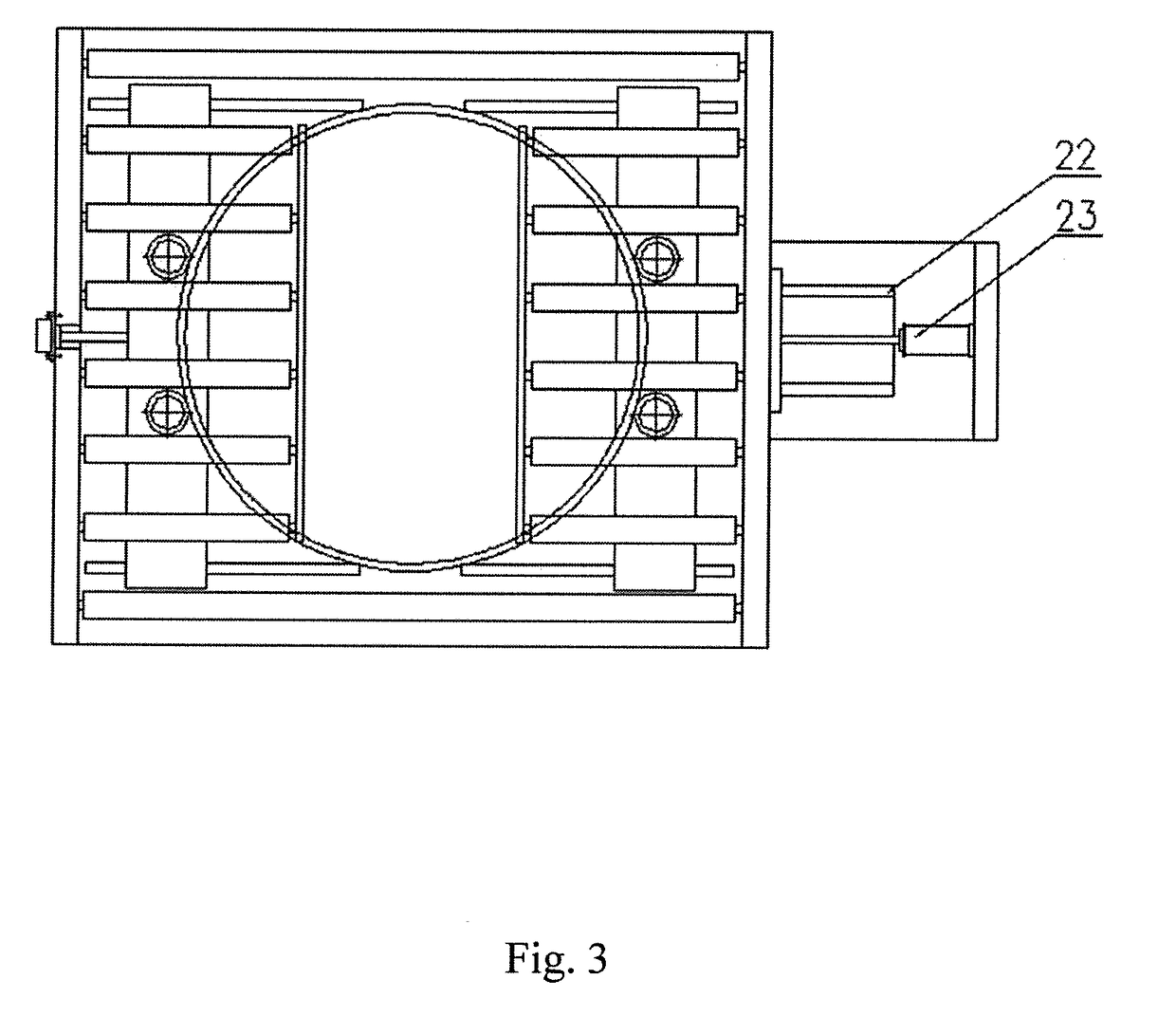

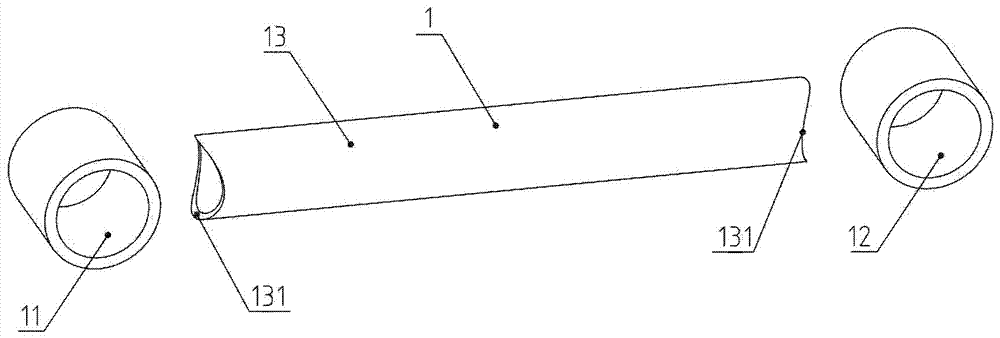

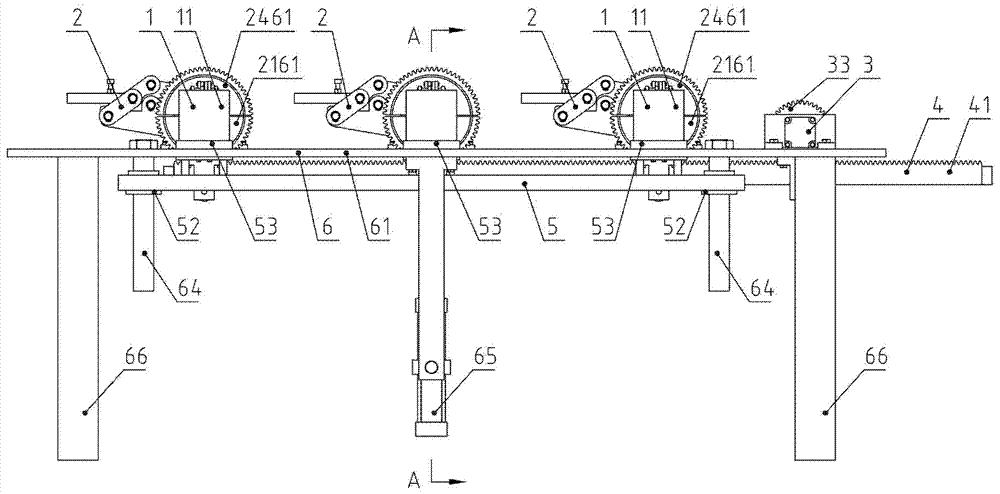

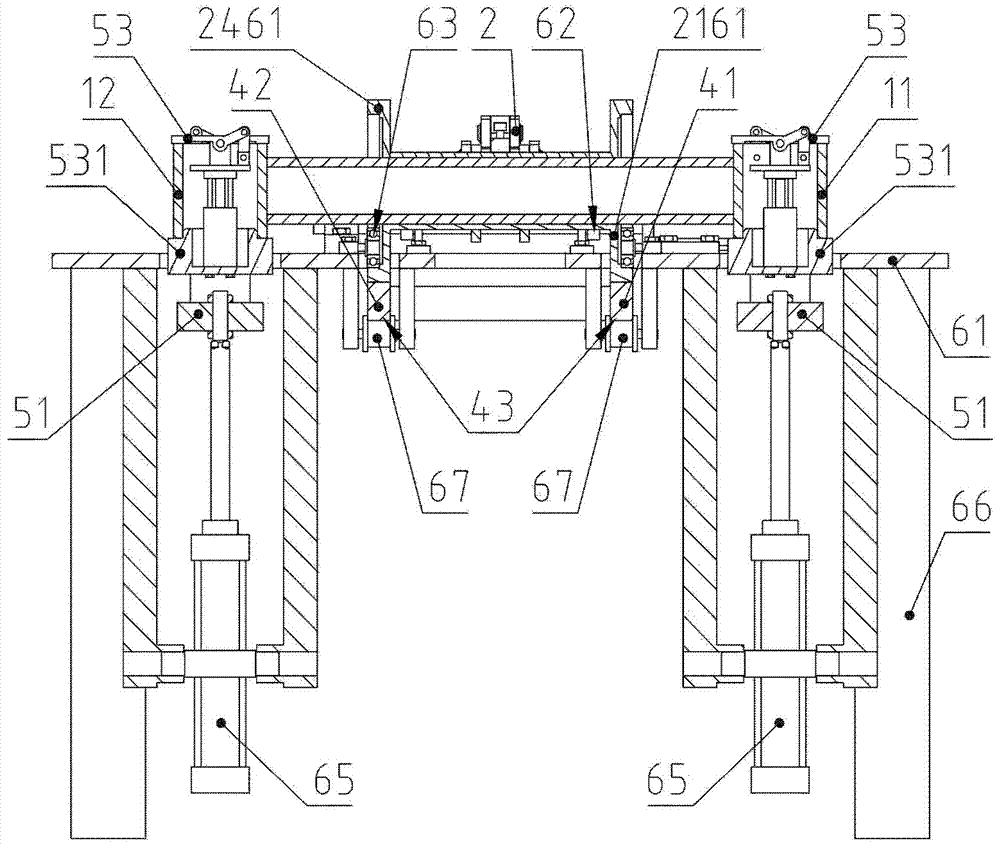

Wheel blank positioning lip correction device

ActiveUS20190022823A1Correction of deformationAvoid machiningEdge grinding machinesPolishing machinesEngineeringSlide plate

Disclosed is a wheel blank positioning lip correction device, comprising a frame, a gear rack structure, a guide rail I, a clamping system support plate, a servo motor I, a left slide plate, a clamping cylinder, a rotating shaft, rotating wheels, an end mill, guide posts, a servo motor II, an inner slide block, a guide rail II, a feeding slide plate, a linear motor II, a linear motor I, a servo motor III, a shaft, a grinding wheel, an outer slide block, a guide rail III, a linear motor III, a lifting table, a right slide plate, a lifting guide rail, a motor support plate and a lifting linear motor.

Owner:CITIC DICASTAL

Thermal cutting device for chemical fabric

InactiveCN107604629APrevent affecting processing qualityAvoid wrinklesSevering textilesWrinkle skinEngineering

The invention relates to a thermal cutting device for chemical fabric. The device comprises a tank body, a first motor is fixedly connected to the portion, close to a first supporting column, of the bottom of an inner cavity of the tank body, and a first belt wheel is connected with the outer surface of a second belt wheel through a first belt in a sliding mode; a first gear is meshed with the outer surface of a second gear through a gear belt in a transmission mode, a pressing device is fixedly connected with the side, away from the tank body, of the bottom of a supporting plate, and a lifting device is fixedly connected with the middle of one side of the top, away from the inner cavity of the tank body, of a connection block; a horizontal mobile device is fixedly connected to the side, away from the connection block, of the lifting device, and a thermal cutting device body is fixedly connected to the side, away from the lifting device, of the horizontal mobile device. The invention relates to the technical field of chemical fabric processing. The device can process chemical fabric products of various specifications, replacement and further cutting processing are avoided, the timeis saved, the cost is lowered, wrinkles are prevented, and the situation is avoided that the phenomenon of easy silk falling-off of cutting edges of the chemical fabric happens and accordingly the processing quality is influenced.

Owner:HUZHOU WUTENG NEW MATERIAL

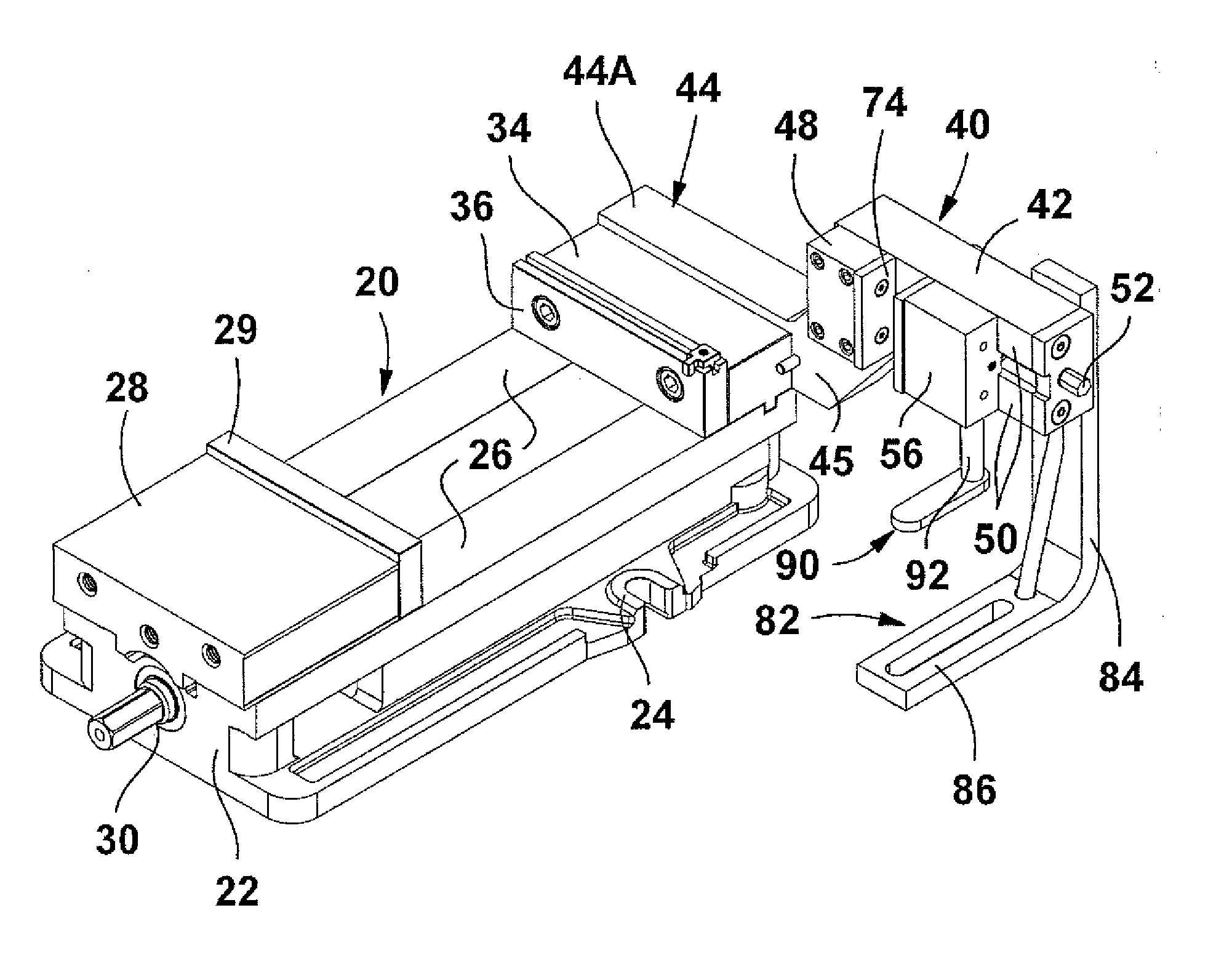

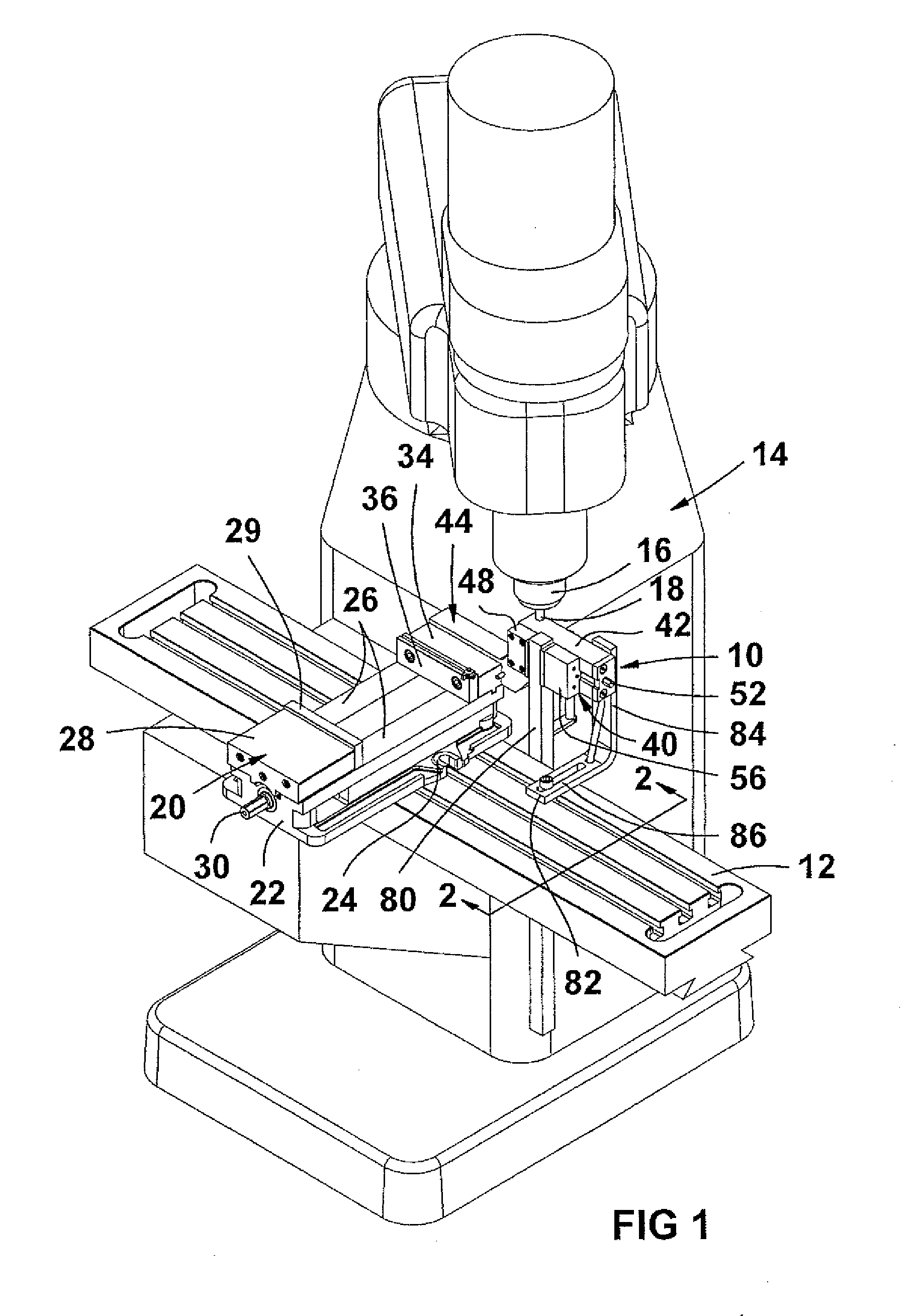

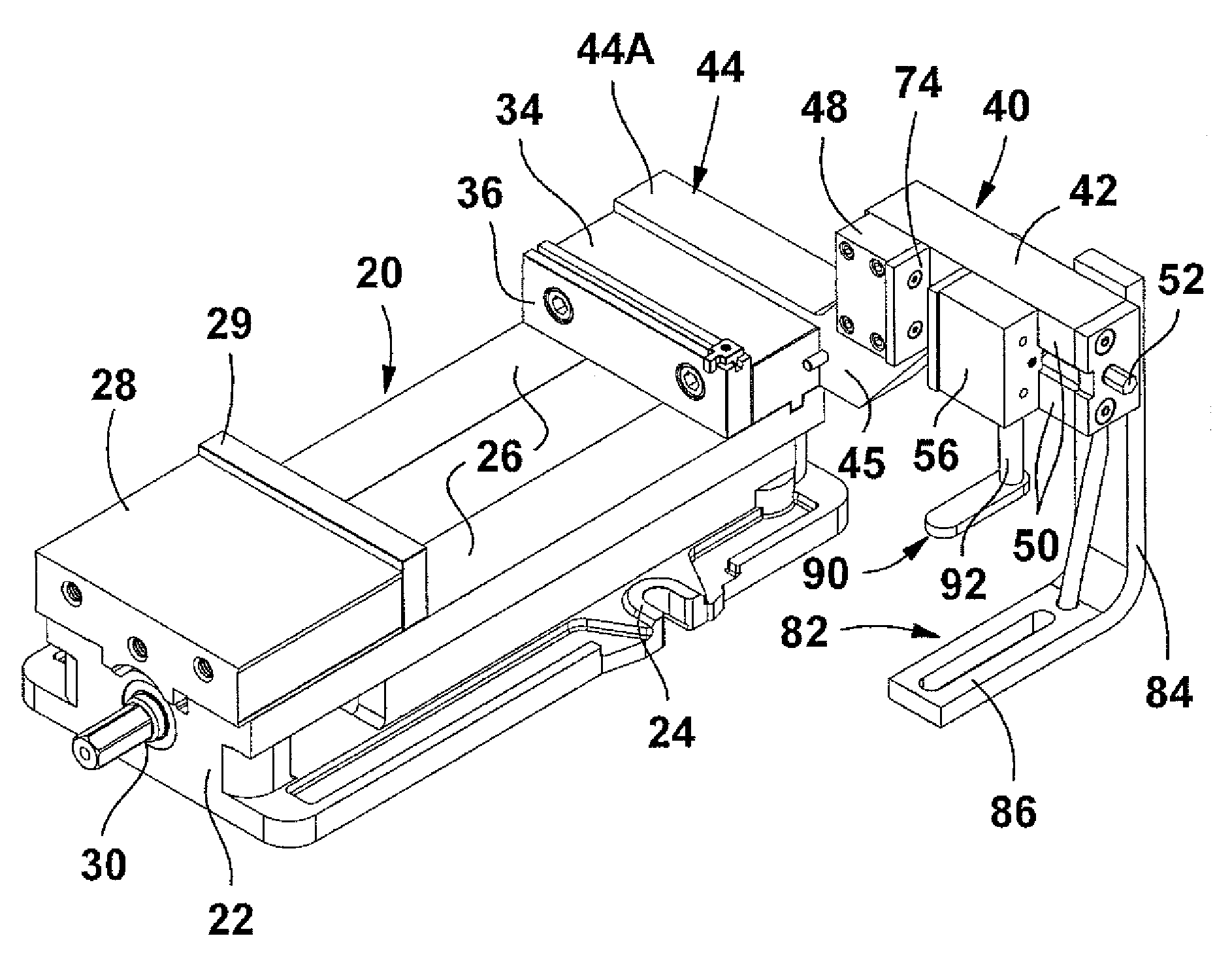

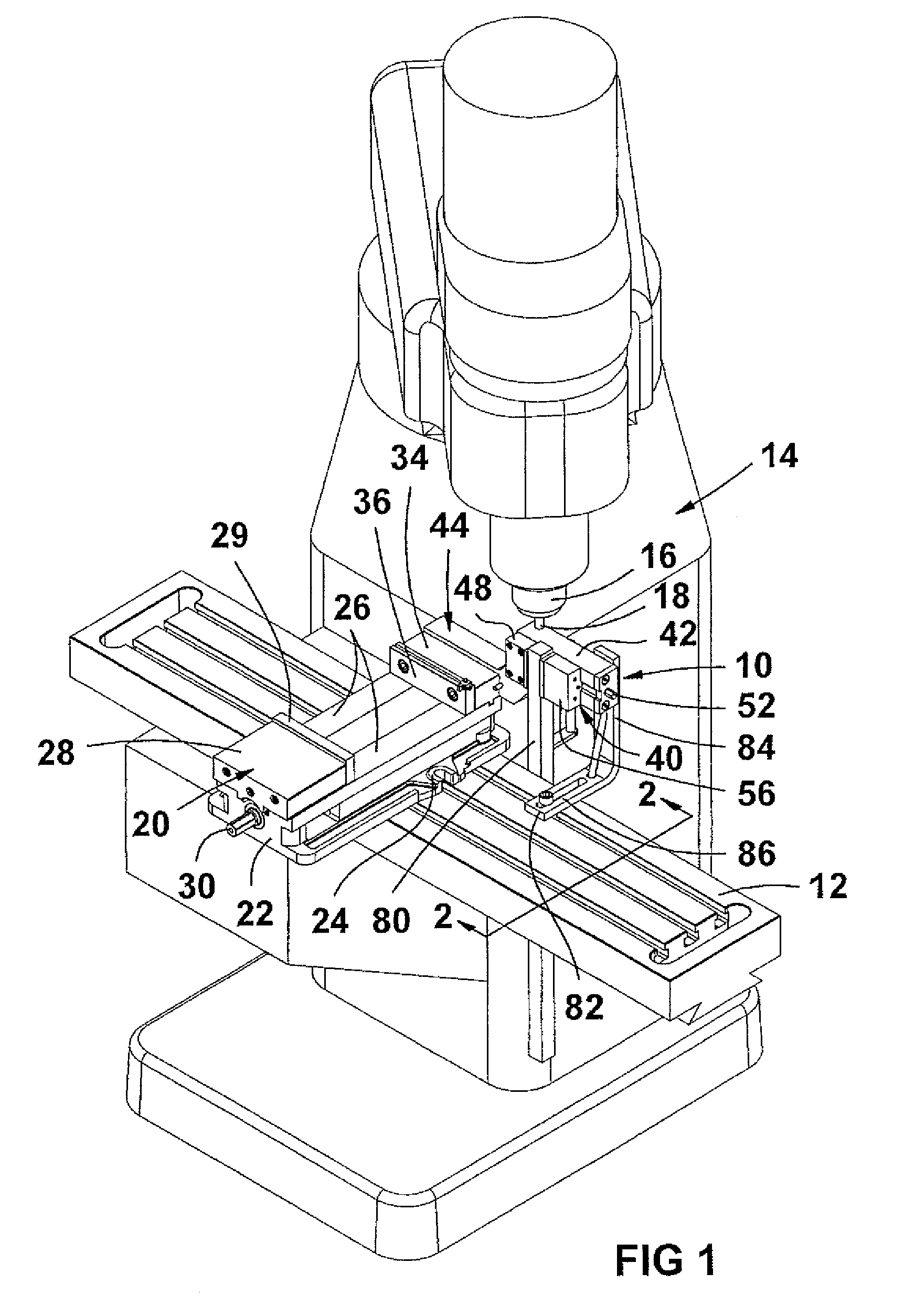

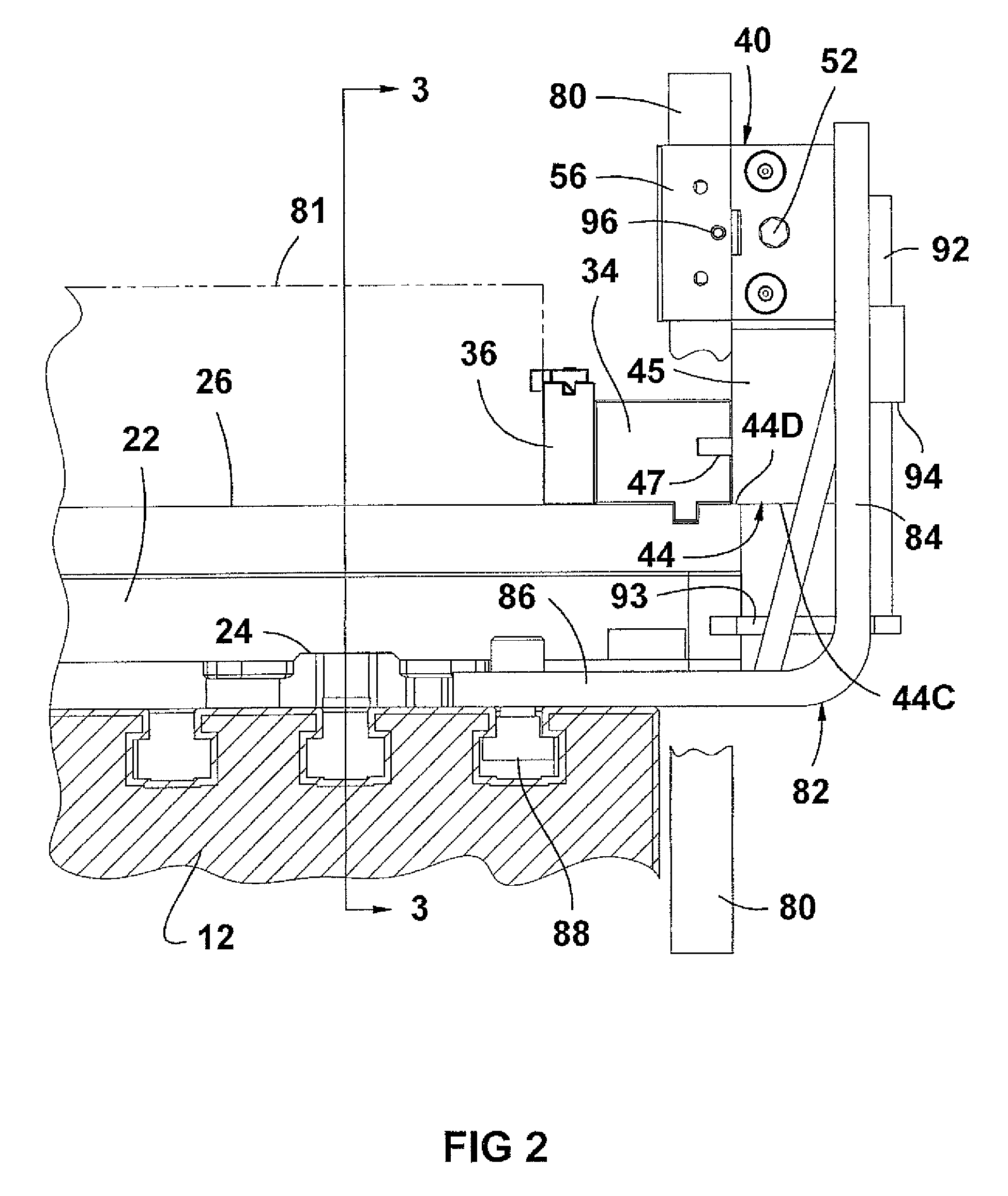

Machine vise attachment

ActiveUS20140054835A1Improve processingAvoid machiningPositioning apparatusMetal working apparatusEngineeringMachine tool

A main machine vise has a second auxiliary vise having independently movable clamping jaws attached to it with the auxiliary vise set to one side of the main machine vise and above a supporting surface of a machine tool table on which the main machine vise is mounted. The auxiliary vise has a movable jaw that moves in a plane generally perpendicular to the tool table on which it is mounted, while the main machine vise has a movable jaw that moves in a plane parallel to the tool table or surface on which it is mounted. The auxiliary vise is mounted on a bracket that offsets the clamping jaws of the auxiliary vise from the main machine vise so that work pieces can be independently clamped in each of the vises. The auxiliary vise includes a vibration reducing stabilizer for attaching to the tool table or support.

Owner:KURT MANUFACTURING COMPANY INC

Non-aggressive anchor washer

InactiveUS20070092852A1Increase in costComplicated to manufactureDental implantsSleeve/socket jointsCouplingEngineering

An anchor washer for anchoring a first element and a second element in relative engagement, includes an annular portion from which there extends at least one tooth that is inclined relative to a central axis of the annular portion, the annular portion being designed for mounting on the first element, and the tooth having two side faces between which there extends a rubbing surface for being oriented substantially towards the second element, the surface being connected to the side faces via coupling portions, the tooth being shaped so that at least one of the coupling portions is set back from at least a portion of the surface so that the coupling portion is kept at a distance from the second element. A coupling device including such a washer is also disclosed.

Owner:LEGRIS

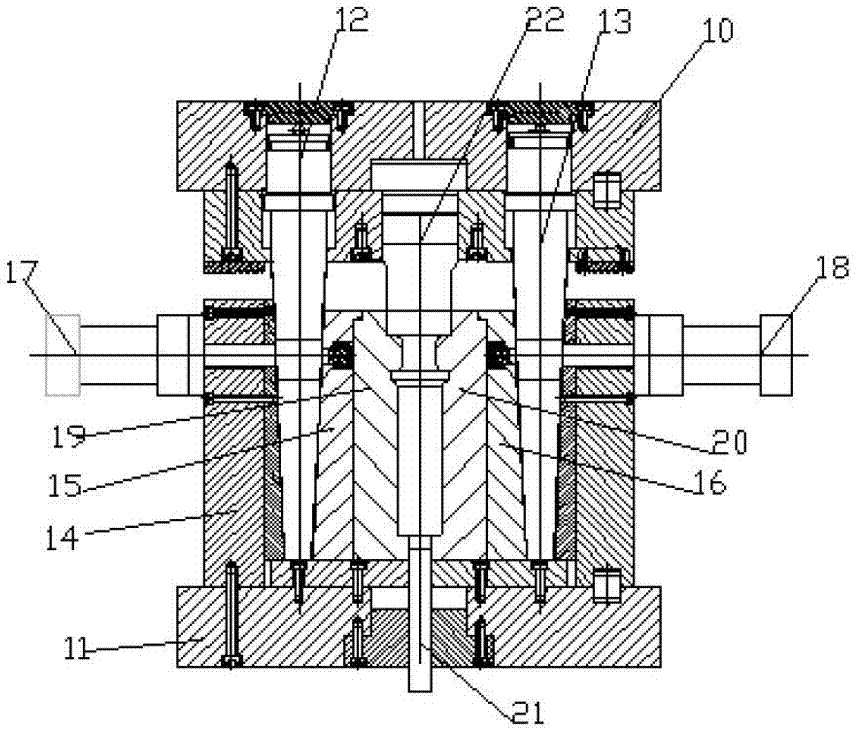

Rotating extrusion forming die for cabin workpiece

InactiveCN110624972AIncrease profitImprove mechanical propertiesExtrusion diesVertical axisMachining

The invention provides a rotating extrusion forming die for a cabin workpiece. The rotating extrusion forming die comprises a male die, a female die, an upper die assembly and a lower die base; a diecavity is formed in the female die, the die cavity can be used for placing a blank, and the female die is rotatably arranged on the lower die base about a vertical axis; the male die is arranged on the upper die assembly and can extend into the die cavity along with the upper die assembly; and the upper die assembly can drive the male die to run in the vertical direction and horizontal direction so as to carry out extrusion forming on the blank in the die cavity. According to the scheme, the cutting machining is avoided, the material utilization rate is greatly improved, the later machining consumption is reduced, then the production cost is reduced, the production efficiency is improved, the mechanical performance of a workpiece main body part is improved, the bearing capacity descendingproblem caused by flow line cutting is avoided, the deformation uniformity is improved, and the wall thickness difference is reduced.

Owner:ZHONGBEI UNIV

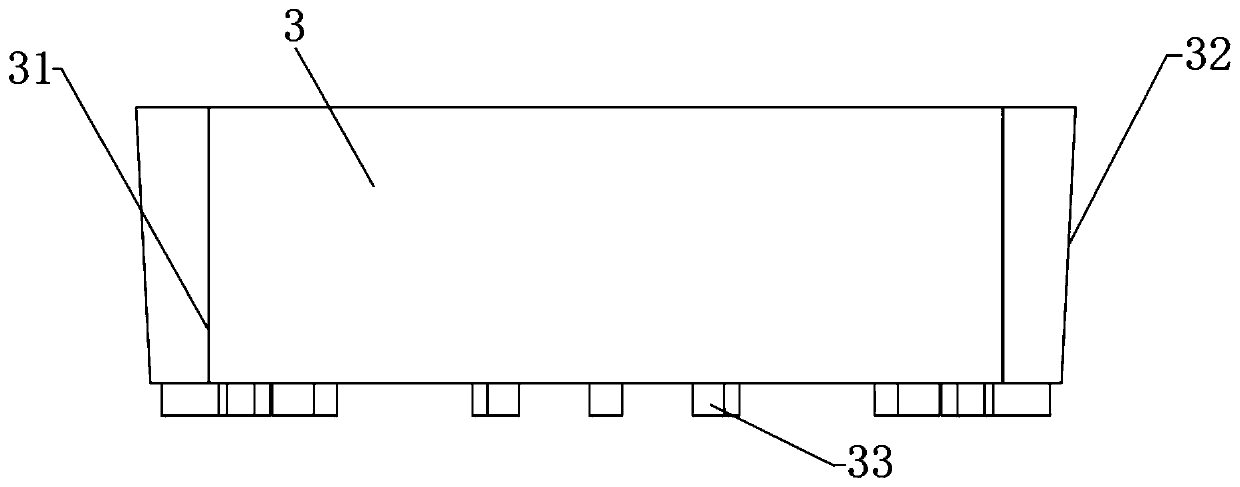

Profiled Frame as a Component of a Window or Door

InactiveUS20070245648A1Produced economicallyAvoid machiningDoors/windowsWing accessoriesEngineeringMechanical engineering

A profiled frame, as a component of a window or door, for holding a plate-like panel supported in a circumferential frame, and comprising a profiled frame member having a profiled chamber that extends over at least a portion of the longitudinal length of the profiled frame member; molded elements to be inserted into, and positively held by, the profiled chamber; a hinge shaft for insertion through bores of the molded elements; and at least one monolithic hinge to be disposed between molded elements for mounting the profiled frame on a supporting component, wherein the hinge has a hinge bore via which the hinge can be threaded onto the hinge shaft, and wherein the hinge is fixed in position on the hinge shaft via adjoining molded elements.

Owner:EMKA BESCHLAGTAILE GMBH & CO KG

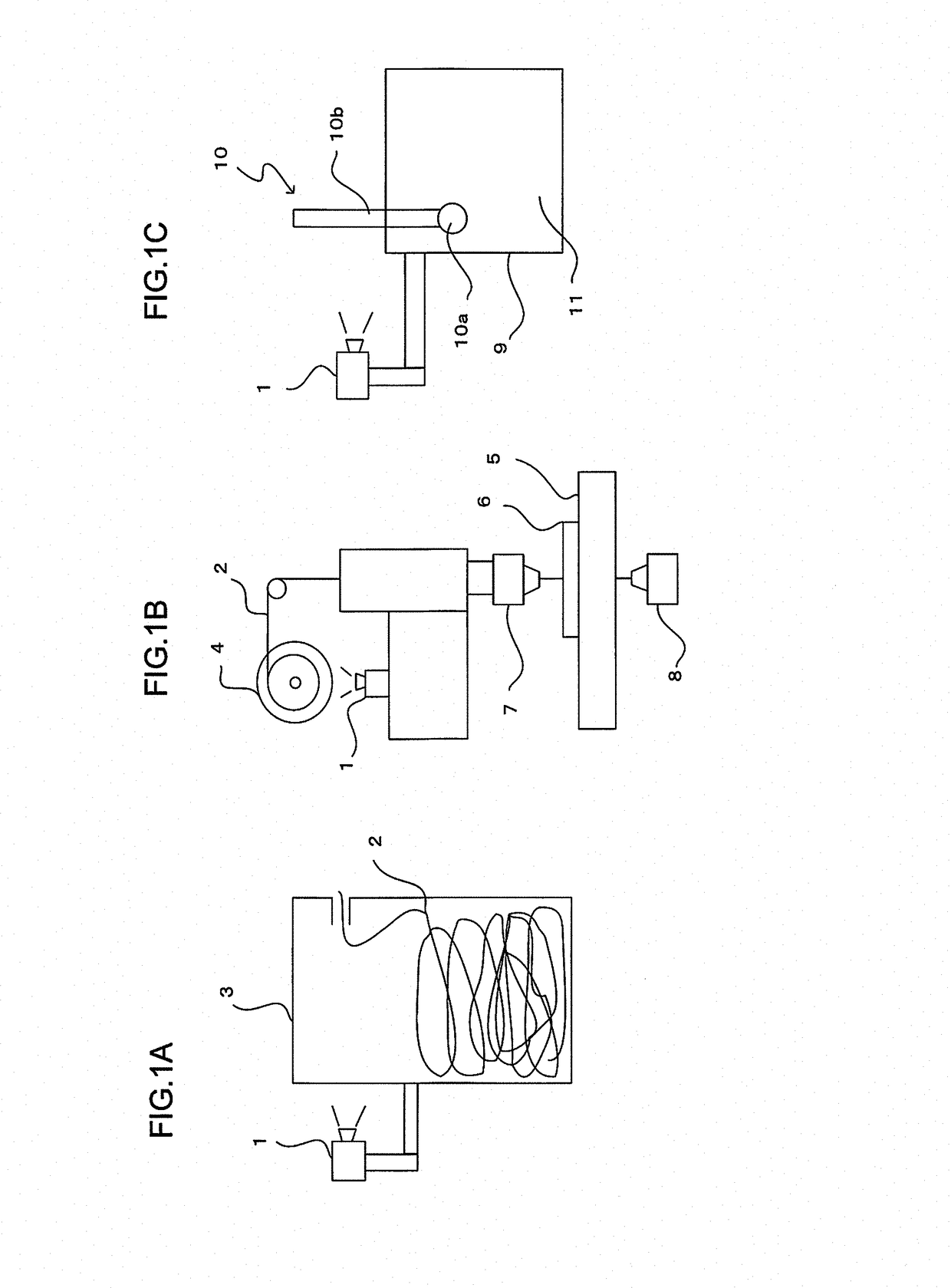

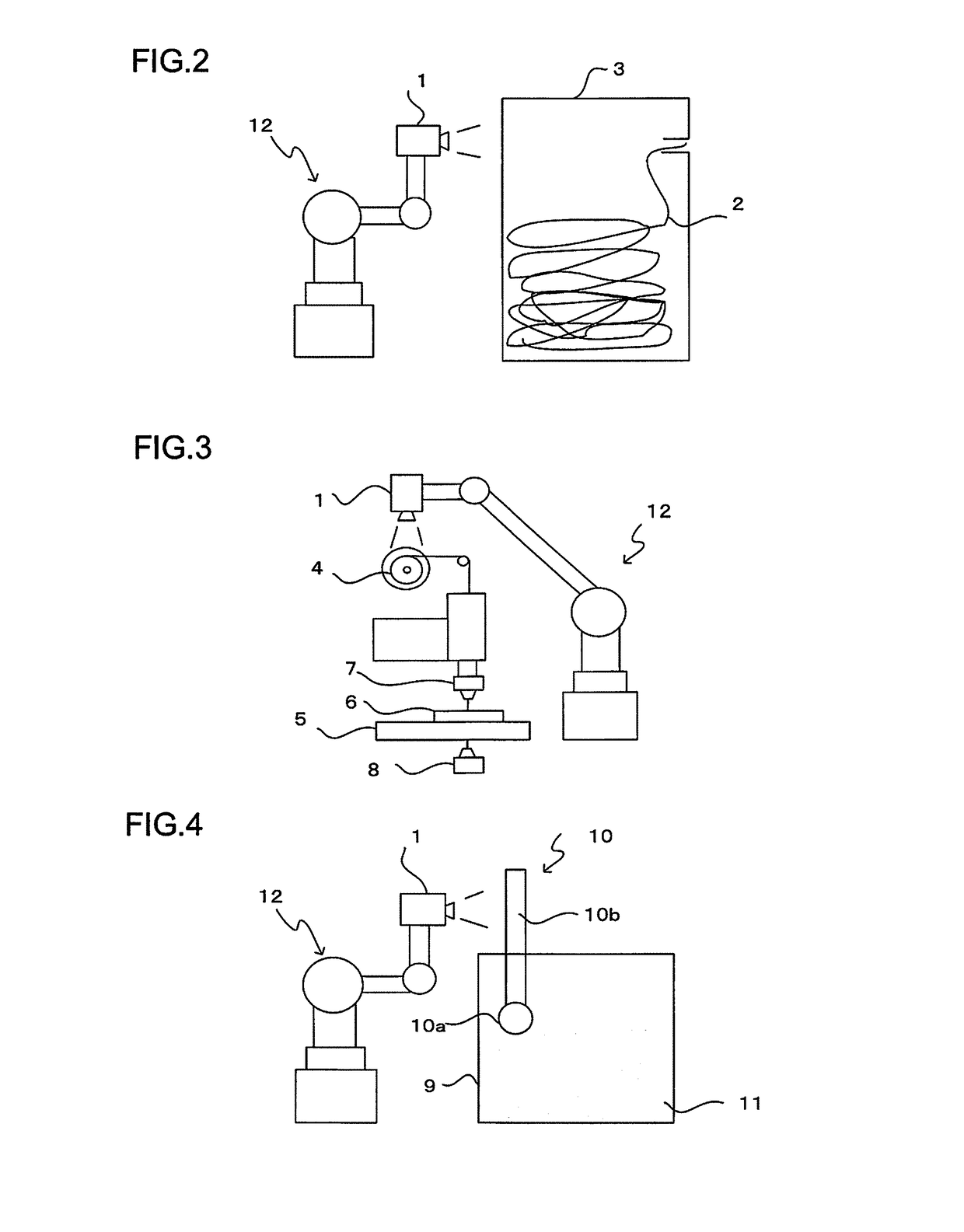

Wire electric discharge machine

InactiveUS20170193654A1Avoid stopAvoid it happening againImage enhancementImage analysisElectric dischargeBobbin

A wire electric discharge machine according to invention prevents occurrence of failure beforehand and prevents machining stop. This can be effected by acquiring an image of a part using an image information collection unit such as a visual sensor with respect to matters, which requires inspection management of the amount of a wire accumulated in a wire electrode storage box, a remaining amount of a wire of a wire bobbin, a level of a machining liquid of a water reservoir and the like, and issuing warning when it is determined, based on the obtained image information, that the failure is highly likely to occur as the wire deposition amount is close to a limit of the wire electrode storage box, the wire remaining amount is small, or the machining liquid level falls below a set value to deal with the state based on this warning.

Owner:FANUC LTD

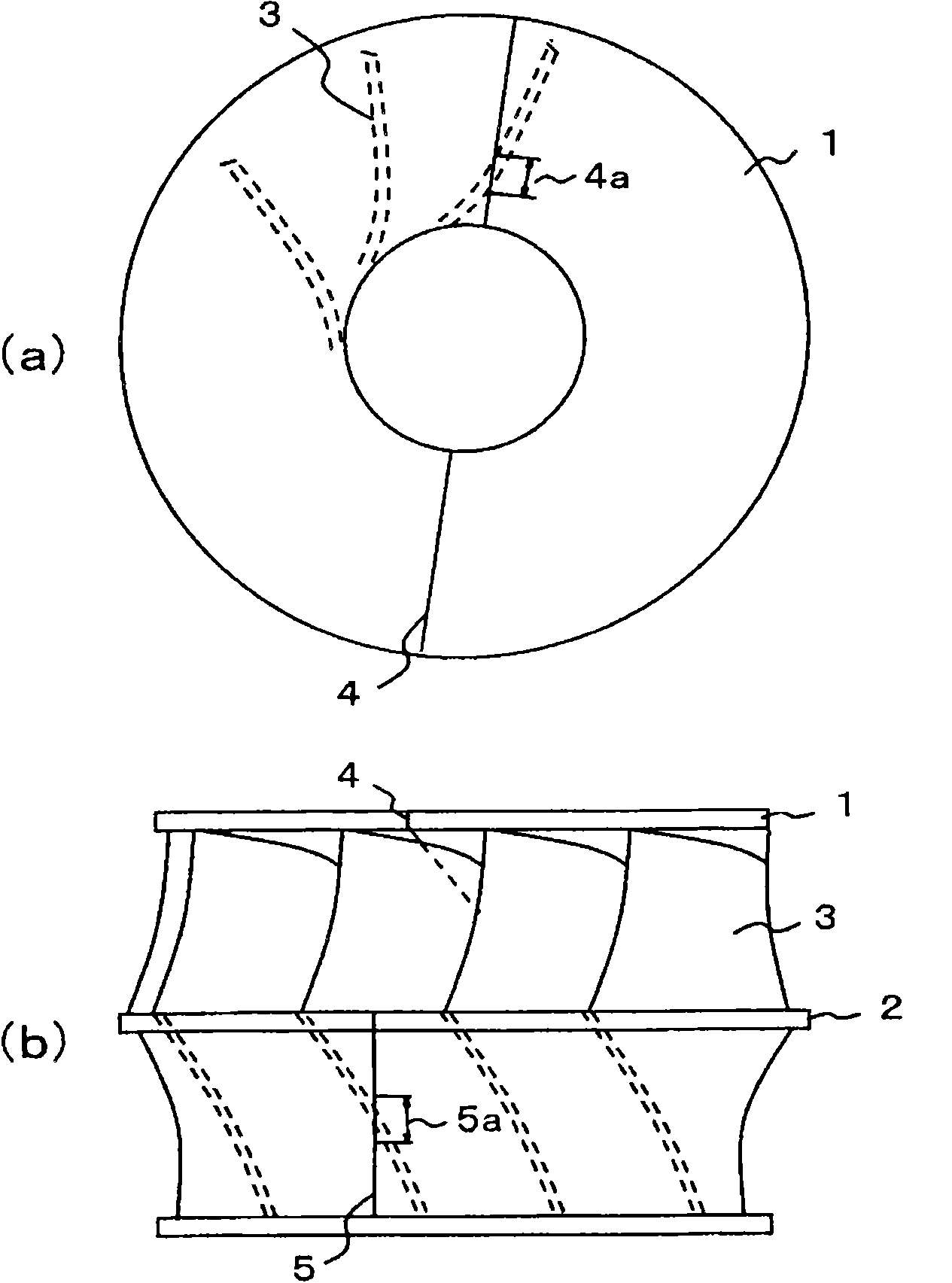

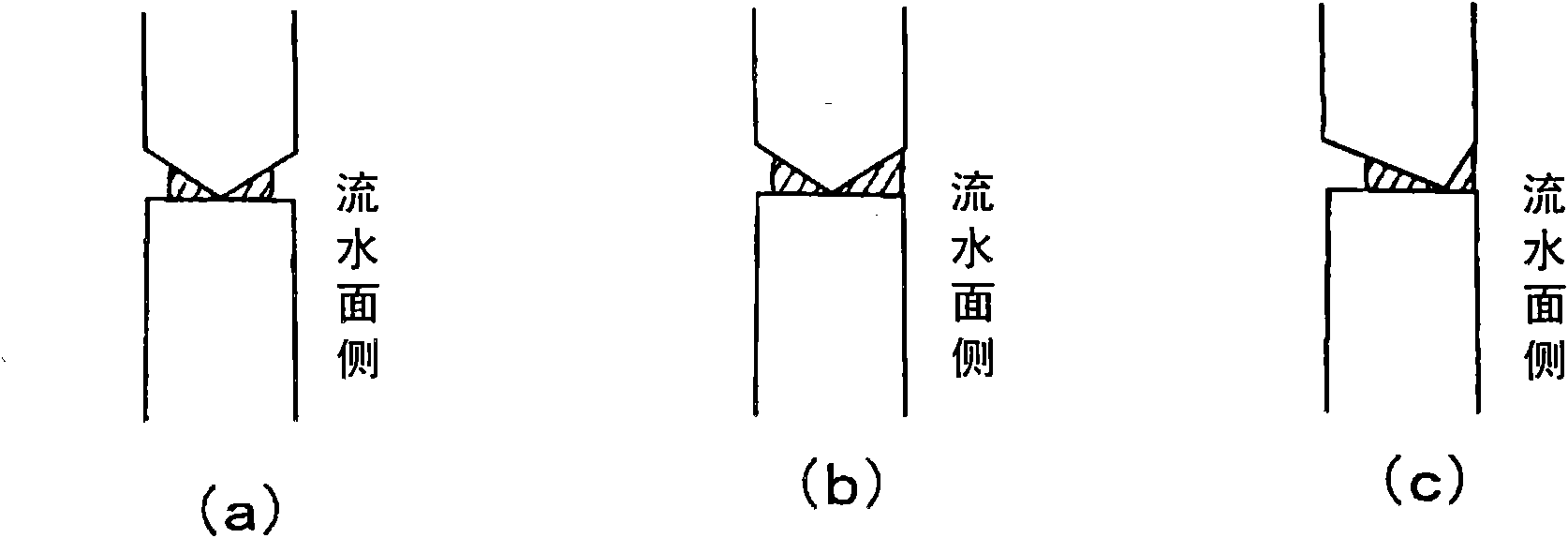

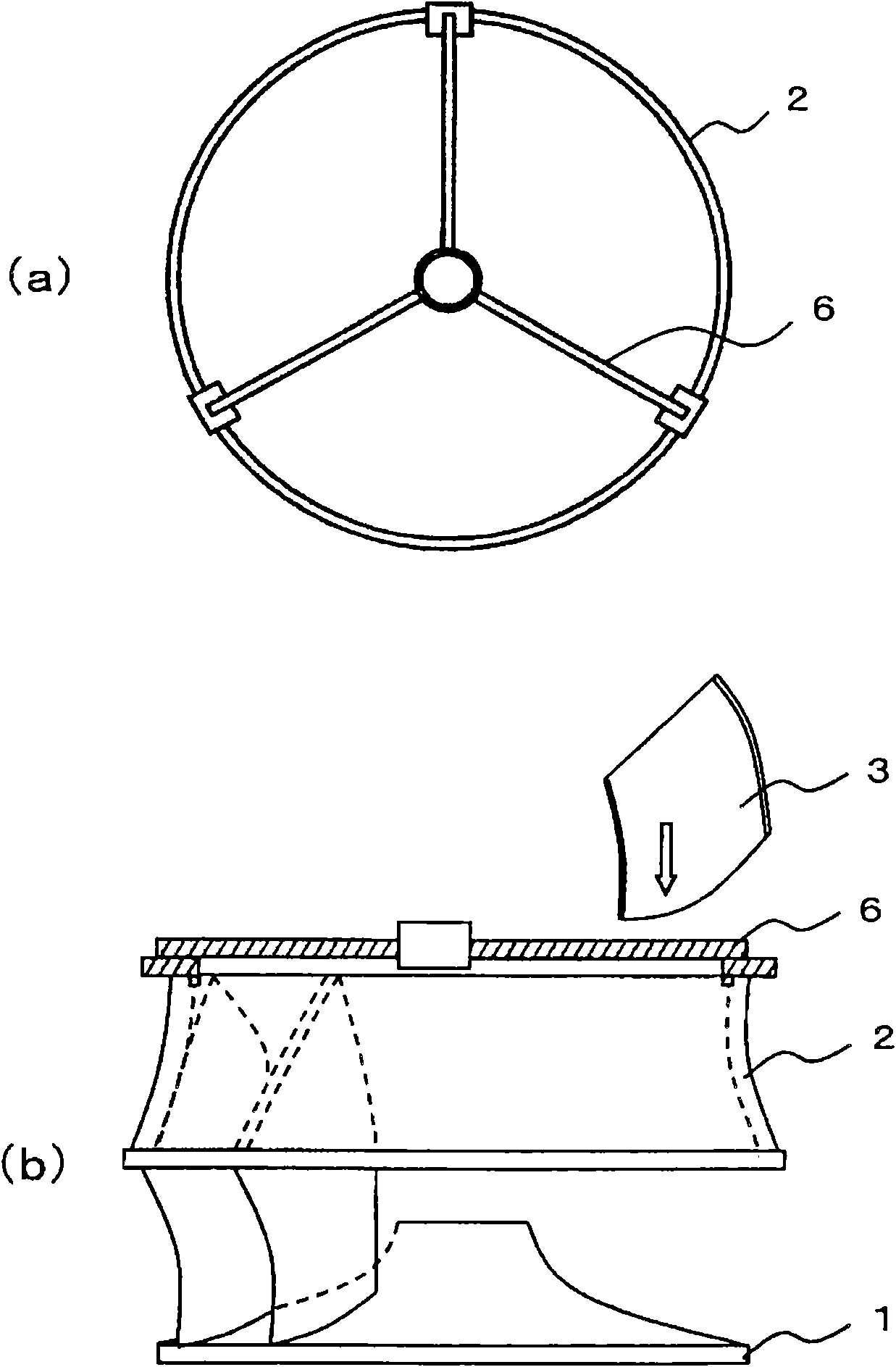

Assembling method of upper canopy or lower ring and assembling method of runner

ActiveCN101865068AAvoid deformationNo welding defectsEngine manufactureFinal product manufactureSplit linesEngineering

The present invention provides an assembling method of upper canopy or lower ring of Francis runner, which restrains welding deformation for preventing large-scale machining and welding defect while the upper canopy or lower ring that are divided into a plurality of members for integrally welding. Particularly, the assembling method of the lower ring (2) of a runner composed of the upper canopy (1), the lower ring (2) and blades (3) in a Francis hydraulic turbine or Francis pump-turbine comprises the following steps: a temporary welding step of performing welding with a welding quantity less than the welding quantity of full groove area of dividing line section and performing surfacing welding next to the crossed part of the blades (3) to a water surface; and a step of grinding and shaping the welding part at the periphery (5a) of the crossed part to the water surface. The upper canopy is assembled similarly.

Owner:KK TOSHIBA

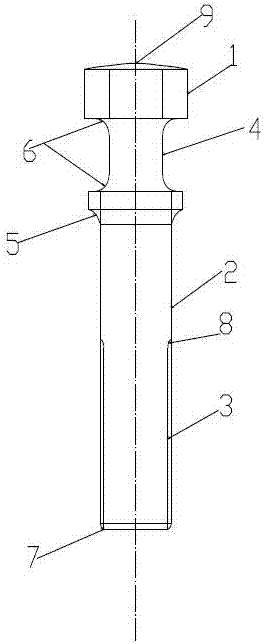

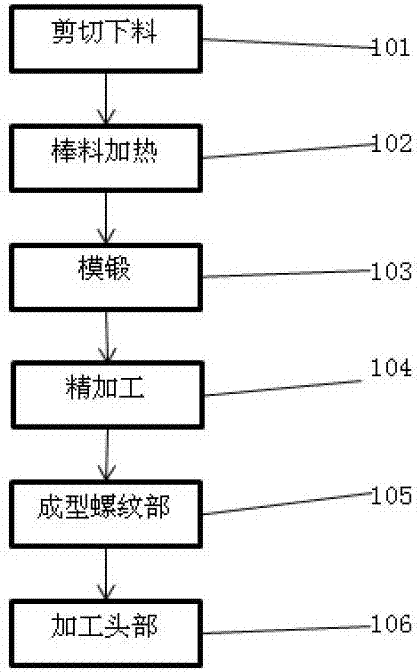

Processing method for valve assembly

The invention relates to a T-shaped valve rod, a processing method thereof and a special forging and pressing die. The valve rod is a rod-like body and comprises a head, a central polish rod part and a threaded part; a trapezoidal slot is formed in each of the left and right sides of the head, a sealing surface is formed at the junction of the head and the polish rod part, the upper and lower ends of the trapezoidal slots, the junctions of the polish rod part and the threaded part and the ends of the threaded part are arc chamfers, and the sealing surface is arc-shaped; and the upper end surface of the head is an arc-shaped convex surface. The processing method of the valve assembly sequentially comprises the steps: shearing and blanking, heating, die forging, finishing, threaded part forming and head processing. The T-shaped valve rod disclosed by the invention has the advantages of simple processing process, capability of realizing little cutting and even no cutting, reducing the cost and increasing the production efficiency of a product and low material consumption.

Owner:RUGAO CITY SHUANGYA ENVIRONMENTAL PROTECTION TECH CO LTD

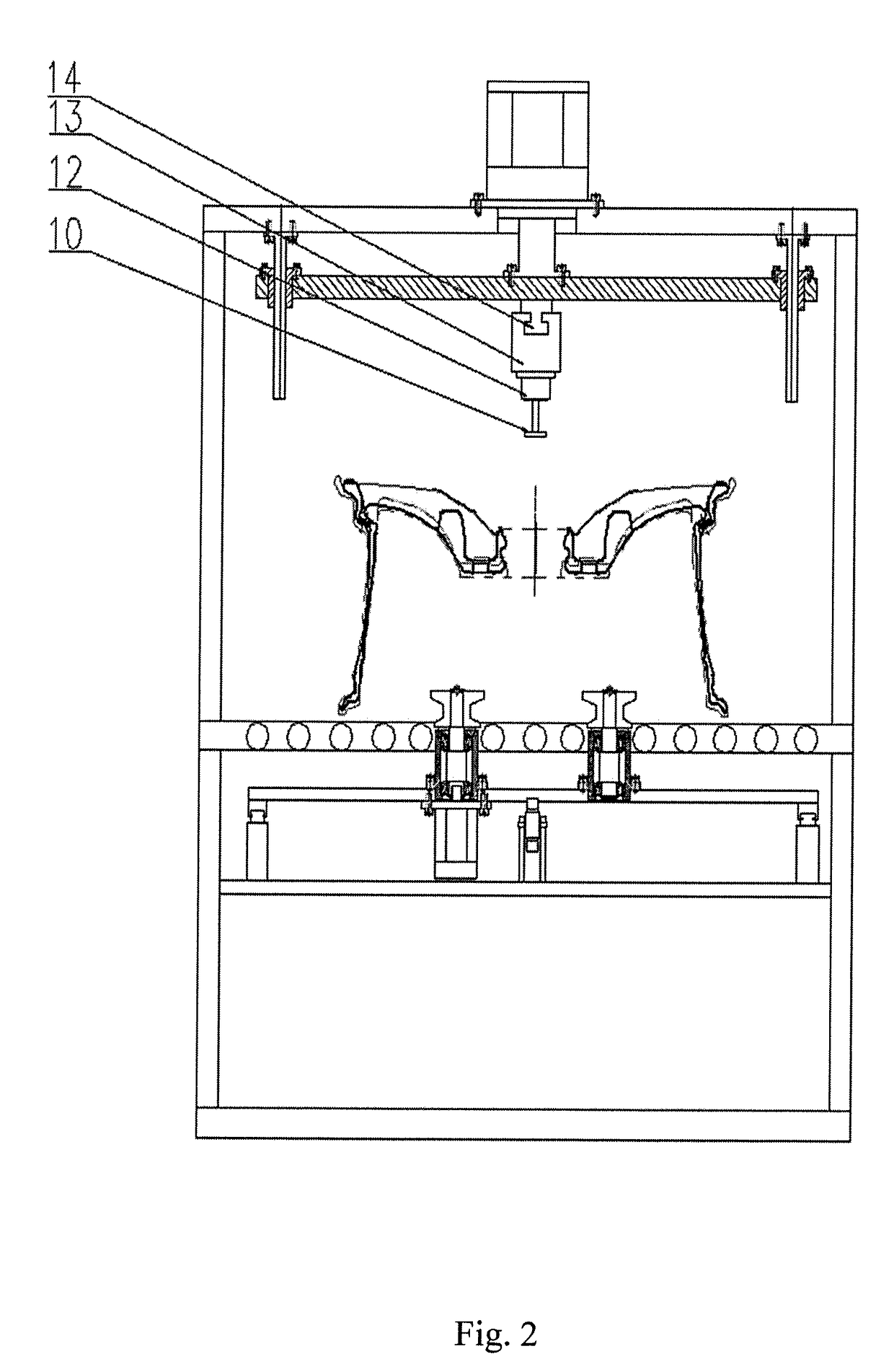

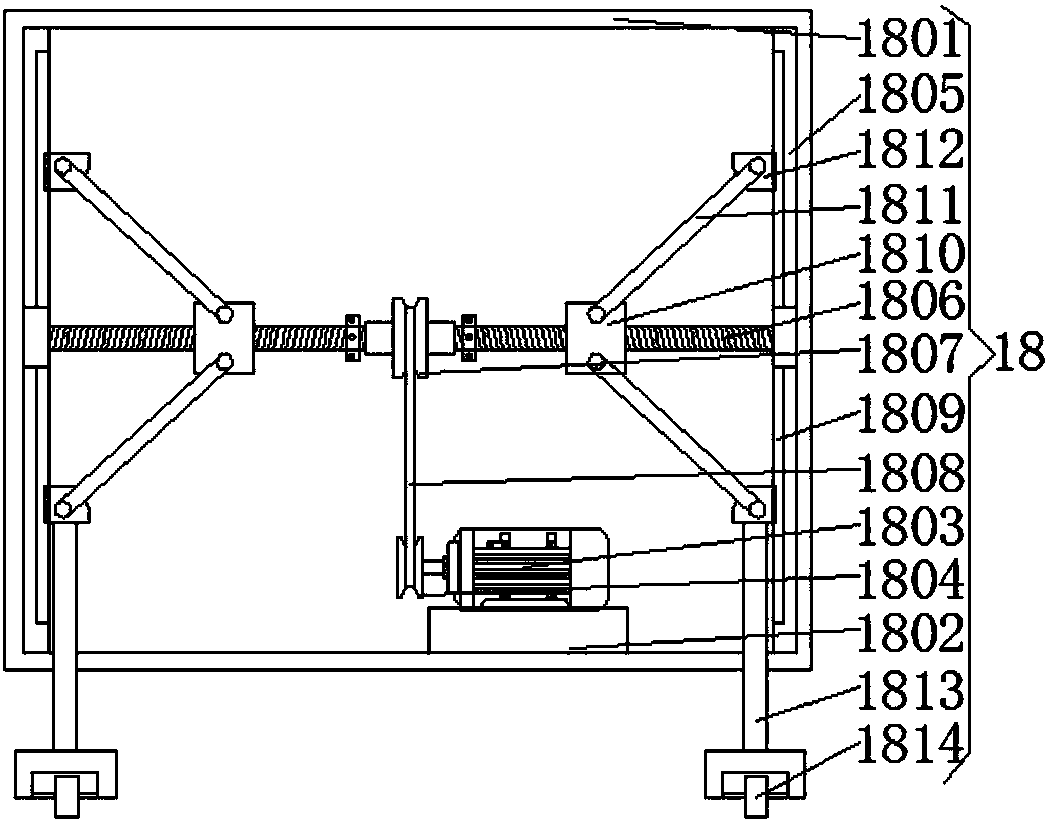

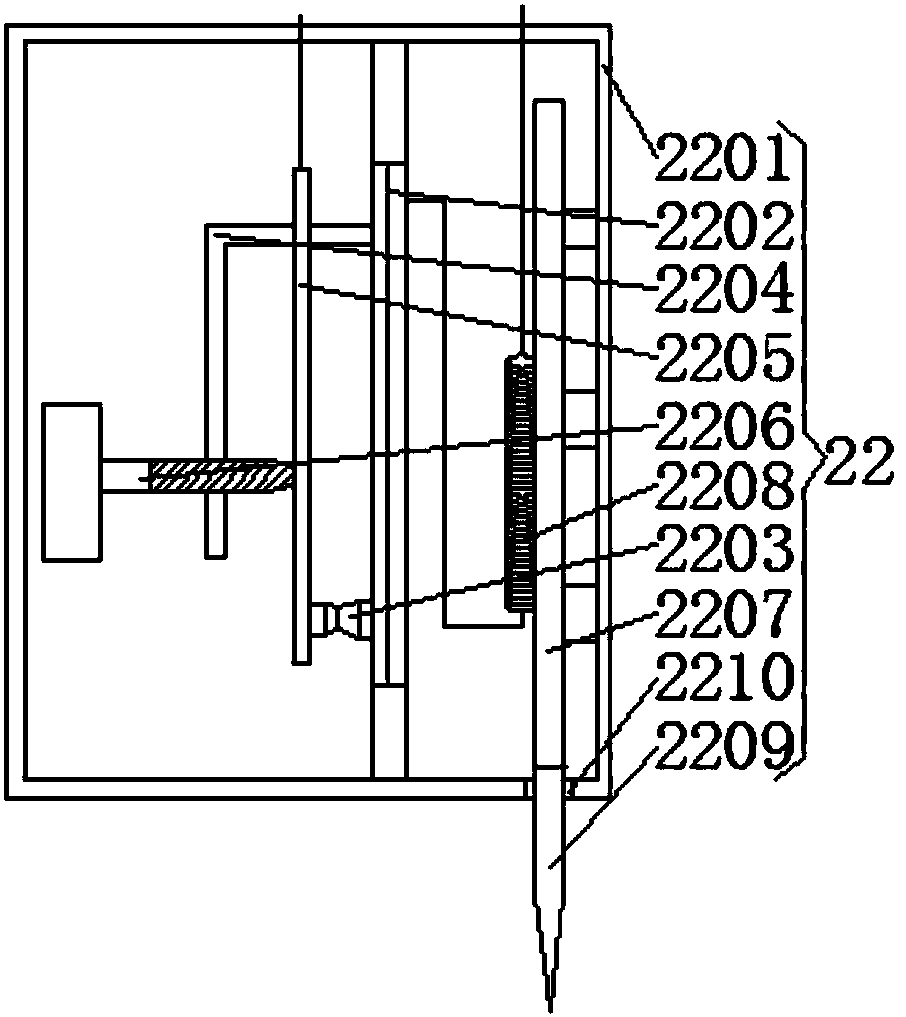

Semi-automatic welding positioner of double-lug-ring connecting rod

ActiveCN107984156ARestricted degrees of freedomFully contactedWelding/cutting auxillary devicesAuxillary welding devicesMotor driveMechanical components

The invention belongs to the technical field of mechanical part design and manufacturing, and relates to a manufacturing tool for a universal double-lug-ring connecting rod, in particular to a semi-automatic welding positioner of a double-lug-ring connecting rod. A lug ring positioning assembly of an air cylinder drive is used for precisely positioning two lug rings, and a planar four-bar linkagemechanism with a dead point is used for precisely positioning and clamping a middle connecting rod; and a servo motor drives a workpiece to rotate through a gear-rack transmission mechanism, so that full-welding during rotating is performed. The semi-automatic welding positioner disclosed by the invention is efficient and intelligent, saves labor power, is small in welding seam dimension, is smallin specification of a needed machine tool, and saves materials.

Owner:昌松智能科技(上海)有限公司

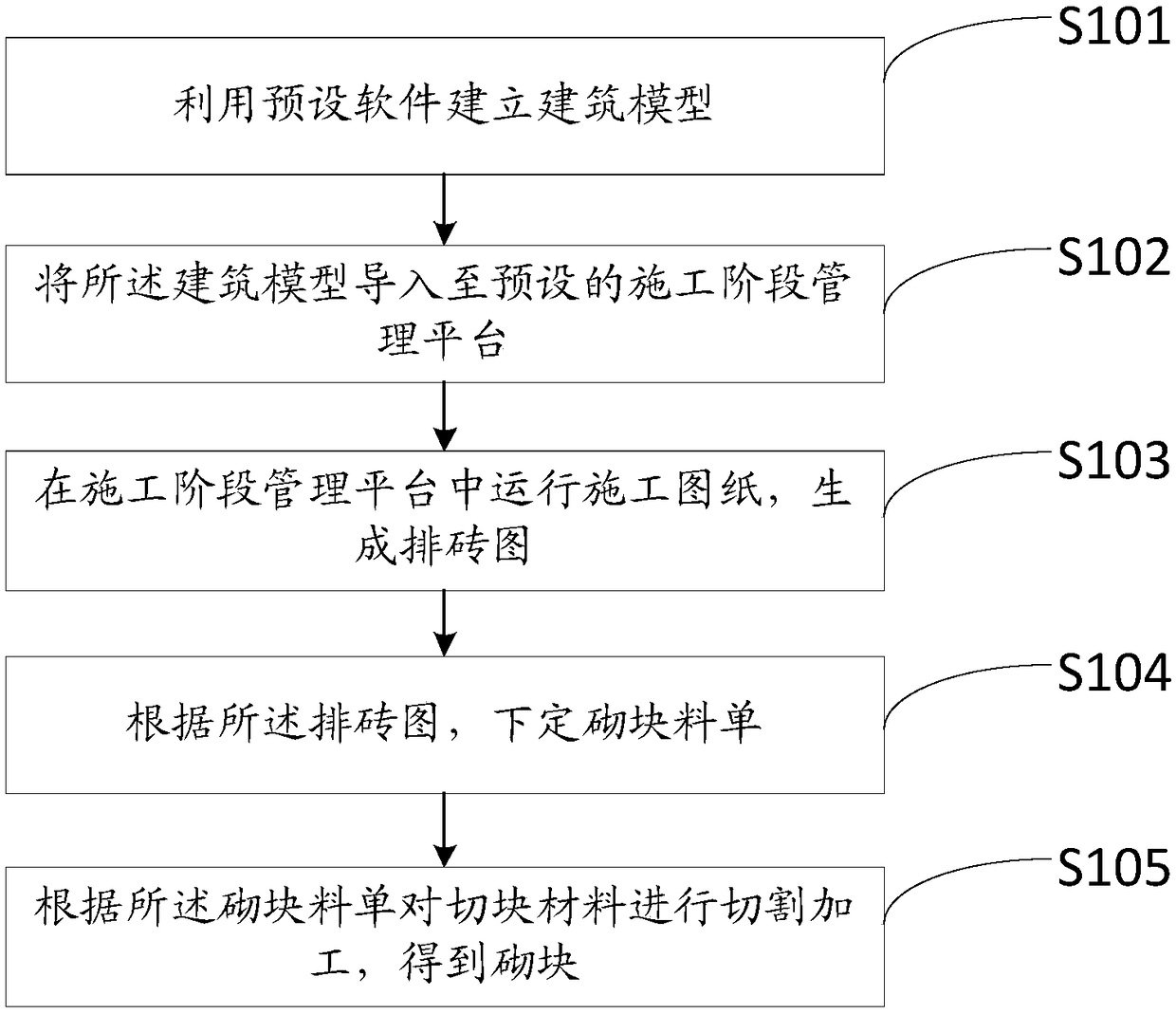

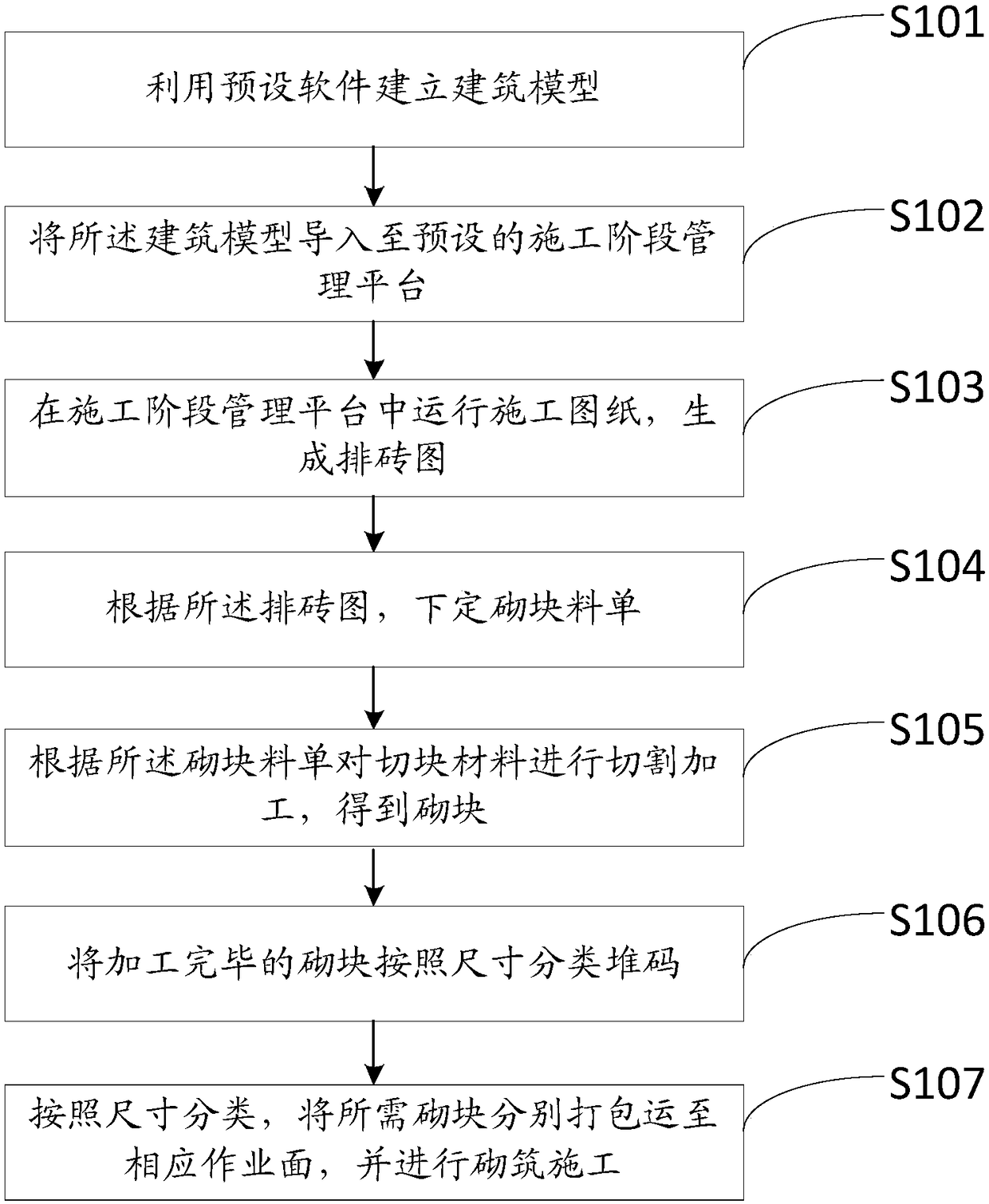

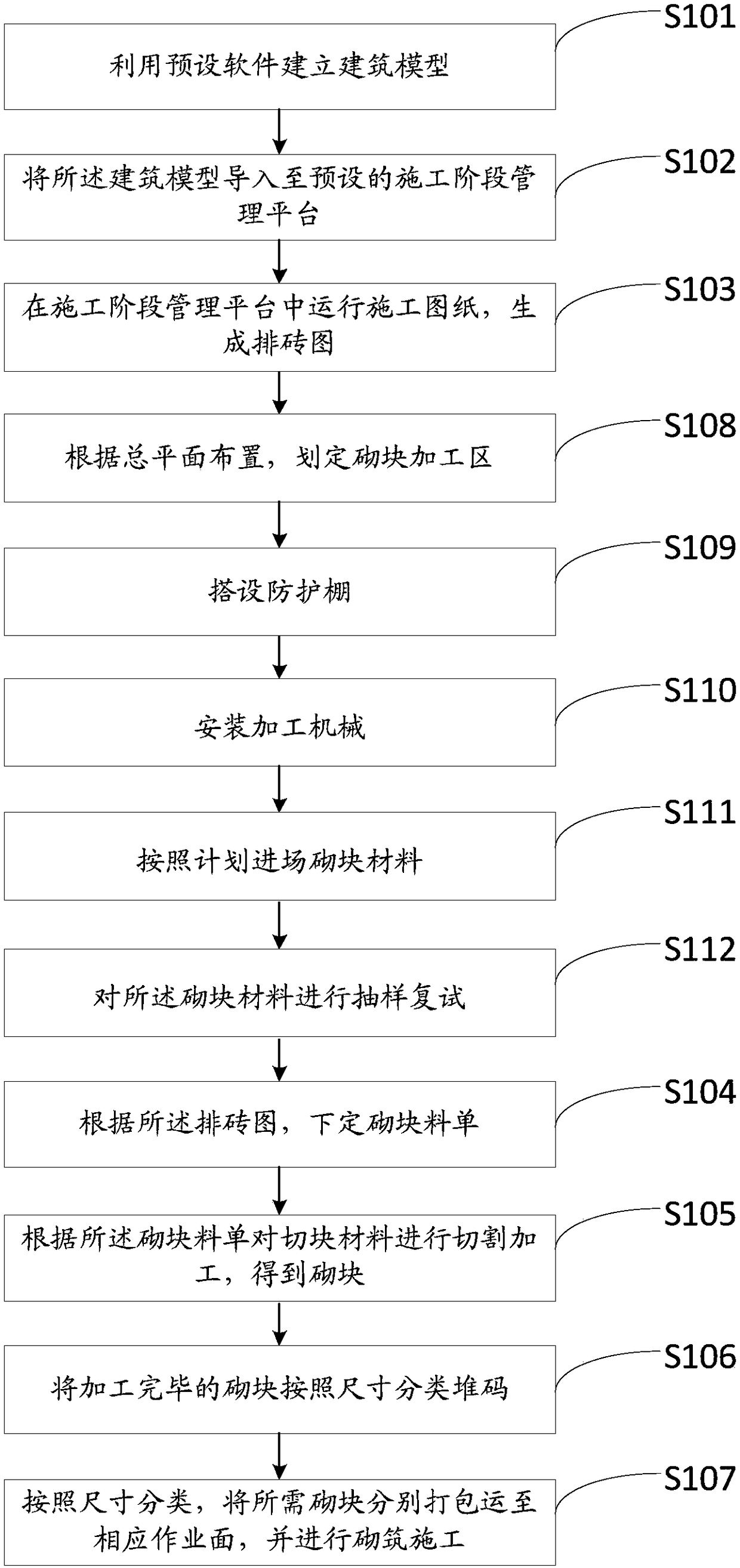

BIM based block cutting preprocessing construction method and block

InactiveCN108086573AAvoid machiningReduce investmentGeometric CADBuilding componentsBrickArchitectural engineering

The invention provides a BIM based block cutting preprocessing construction method and a block. The BIM based block cutting preprocessing construction method comprises the following steps of utilizinga preset software to establish a building model; importing the building model into a preset construction stage management platform; operating a construction drawing in the construction stage management platform, and producing a brick arrangement drawing; according to the brick arrangement drawing, ordering a block material order; and performing cutting processing on a block cutting material according to the block material order to obtain a block. By adopting the BIM based block cutting preprocessing construction method has the technical effects that block loss is reduced; the operation is simple, and the produced brick arrangement drawing is high in operability; centralized cutting processing is performed on all the blocks in a processing region, the process intermittent time of cutting the blocks on an operation surface is avoided, and the construction period of field masonry is effectively saved; cutting processing is performed on all the blocks with a special cutting machine, the error caused by manual processing on the operation surface is effectively avoided, and the construction quality is ensured; and the blocks are saved, the loss rate is lowered, the construction efficiency is greatly improved, the construction progress is effectively accelerated, and dust pollution is effectively reduced.

Owner:THE THIRD CONSTR CO LTD OF CHINA CONSTR THIRD ENG BUREAU

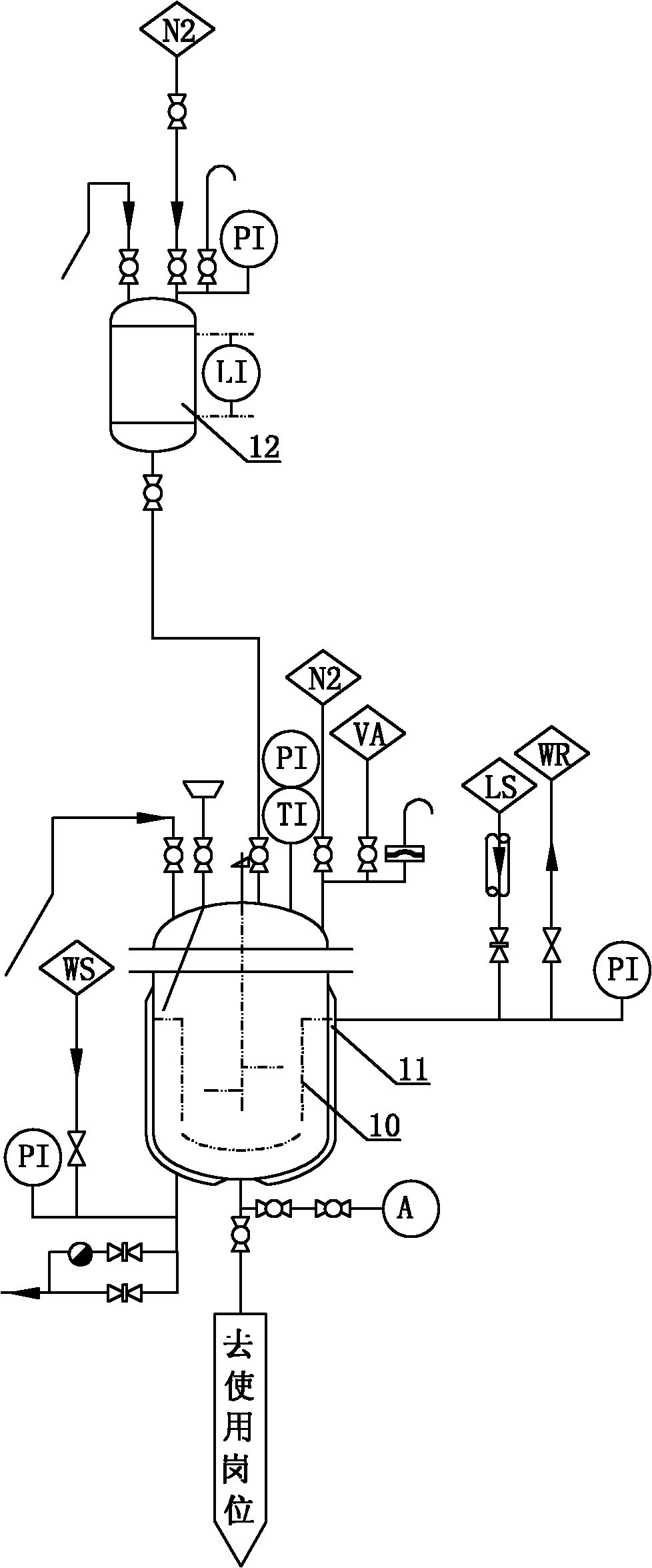

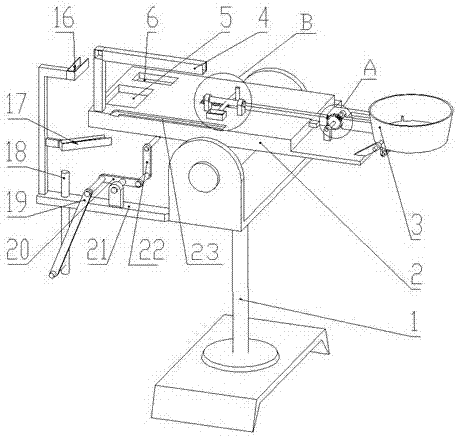

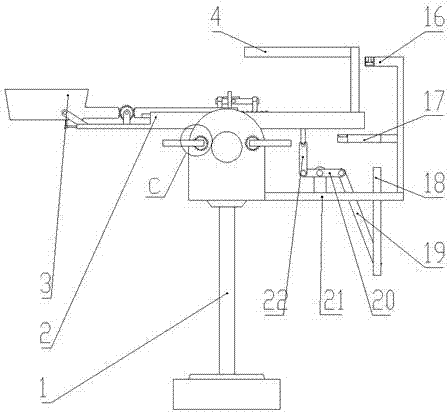

Automatic quantitative weighing device and quantitative weighing method for molten metal

ActiveCN107414064APrevent over pouringSimple and fast operationMolten metal supplying equipmentsWeighing apparatus for materials with special property/formEngineeringMechanical engineering

The invention provides an automatic quantitative weighing device and quantitative weighing method for molten metal. The automatic quantitative weighing device for molten metal comprises a support, a balance plate, a pouring bucket, a weight storage box and a pouring bucket driving mechanism, wherein the balance plate is movably arranged on the support through a rotating shaft, the pouring bucket is movably arranged at one end of the balance plate, the weight storage box is arranged at the other end of the balance plate, and the pouring bucket driving mechanism is connected with the pouring bucket; the pouring bucket is eccentrically arranged on the balance plate through the rotating shaft, and the center of gravity of the pouring bucket is located outside the balance plate; and the pouring bucket driving mechanism comprises a positioning assembly used for limiting turning of the pouring bucket, a triggering assembly used for releasing the limiting assembly, and a metal ball circulating mechanism used in cooperation with the triggering assembly. The automatic quantitative weighing device and quantitative weighing method for molten metal have the beneficial effects that molten metal can be quantitatively weighed accurately, the working efficiency is improved, the quality of castings is improved, and materials are saved.

Owner:YANTAI ENG & TECH COLLEGE YANTAI TECHNICIAN INST

Machine vise attachment

ActiveUS9193040B2Sufficient forceReduce vibrationPositioning apparatusMetal working apparatusEngineeringMachine tool

A main machine vise has a second auxiliary vise having independently movable clamping jaws attached to it with the auxiliary vise set to one side of the main machine vise and above a supporting surface of a machine tool table on which the main machine vise is mounted. The auxiliary vise has a movable jaw that moves in a plane generally perpendicular to the tool table on which it is mounted, while the main machine vise has a movable jaw that moves in a plane parallel to the tool table or surface on which it is mounted. The auxiliary vise is mounted on a bracket that offsets the clamping jaws of the auxiliary vise from the main machine vise so that work pieces can be independently clamped in each of the vises. The auxiliary vise includes a vibration reducing stabilizer for attaching to the tool table or support.

Owner:KURT MANUFACTURING COMPANY INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com