Automatic quantitative weighing device and quantitative weighing method for molten metal

A molten metal, quantitative weighing technology, applied in equipment for supplying molten metal, measuring devices, weighing equipment with special properties/forms, etc. The effect of reducing manual operation and simple and lightweight mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

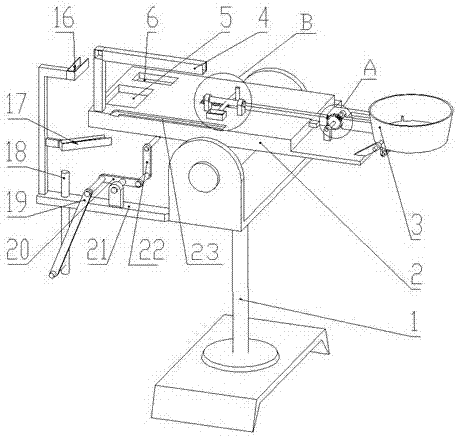

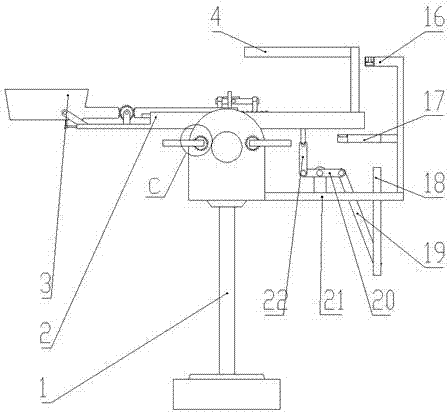

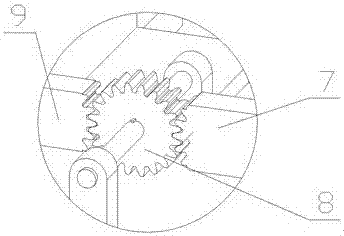

[0038] The embodiment of the present invention provides an automatic quantitative weighing device for molten metal, such as figure 1 , figure 2 with Figure 6As shown, it includes a bracket 1, a balance board 2 that is movably arranged on the bracket 1 through a rotating shaft, a pouring bucket 3 that is movably arranged at one end of the balance board 2, a weight storage box 5 that is arranged at the other end of the balance board 2, and the The driving mechanism of the pouring barrel connected to the barrel 3; the pouring barrel 3 is used to receive the molten metal in the external ladle or crucible, and is eccentrically arranged on the balance plate 2 through the rotating shaft, and its center of gravity is located outside the balance plate 2. The pouring barrel drive mechanism includes a positioning assembly for limiting the turning of the pouring barrel 3 and a trigger assembly for releasing the limiting assembly.

[0039] It also includes a metal ball circulation mech...

Embodiment 2

[0060] An embodiment of the present invention provides an automatic quantitative weighing method for molten metal, the method comprising:

[0061] Step S1: Obtain the weight of the prefabricated casting, place an equal amount of counterweights in the counterweight holding box 6 of the balance board according to the weight of the prefabricated casting, the balance board 2 tilts, and the pouring bucket 3 is hinged on the balance board 2 and keep level;

[0062] Step S2: Pouring the molten metal into the positioned pouring barrel 3, when the weight of the molten metal gradually increases until the balance plate 2 tilts in the opposite direction, the pouring barrel 3 eccentrically arranged on the edge of the balance plate 2 will be released And it rotates under the action of its own gravity, and the molten metal liquid in the pouring barrel 3 is poured into the mould; at the same time, the metal ball returns to the initial end of the metal ball release groove under the action of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com