Patents

Literature

897results about "Molten metal supplying equipments" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

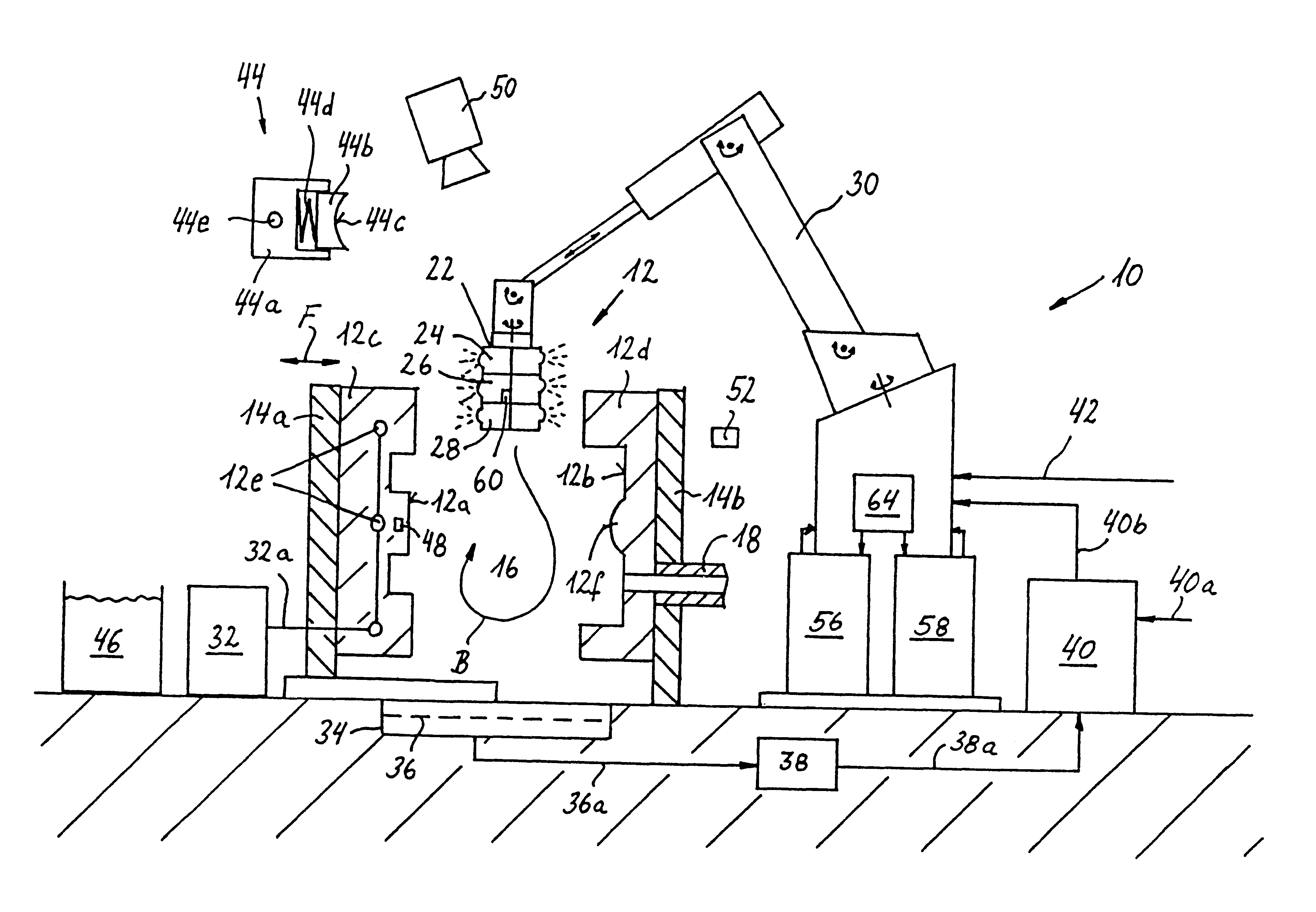

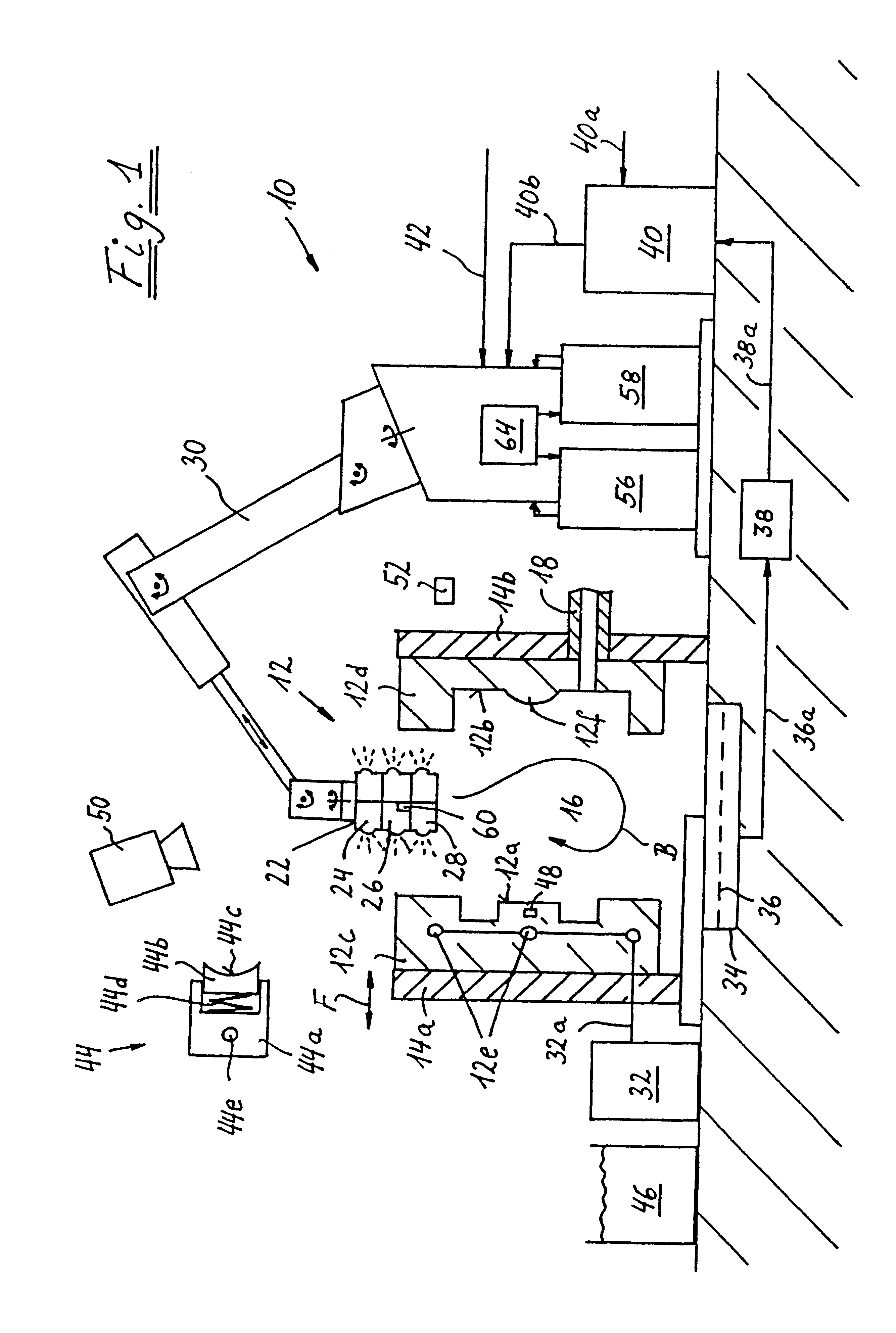

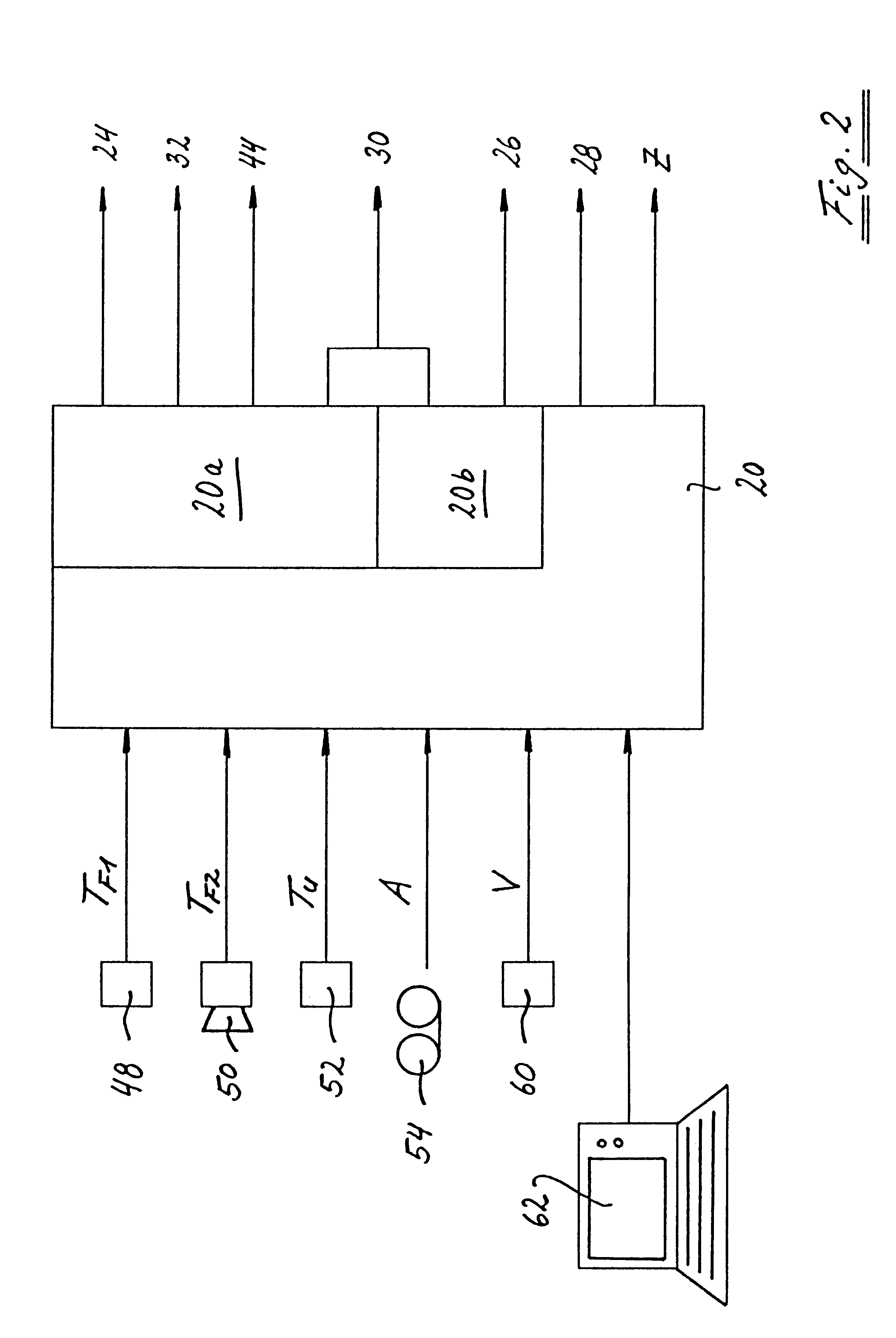

Transferring molten metal from one structure to another

ActiveUS20080314548A1Formation of dross in the ladle or launder are greatly reduced or eliminatedEliminate useMolten metal pouring equipmentsMolten metal supplying equipmentsDie castingMolten metal

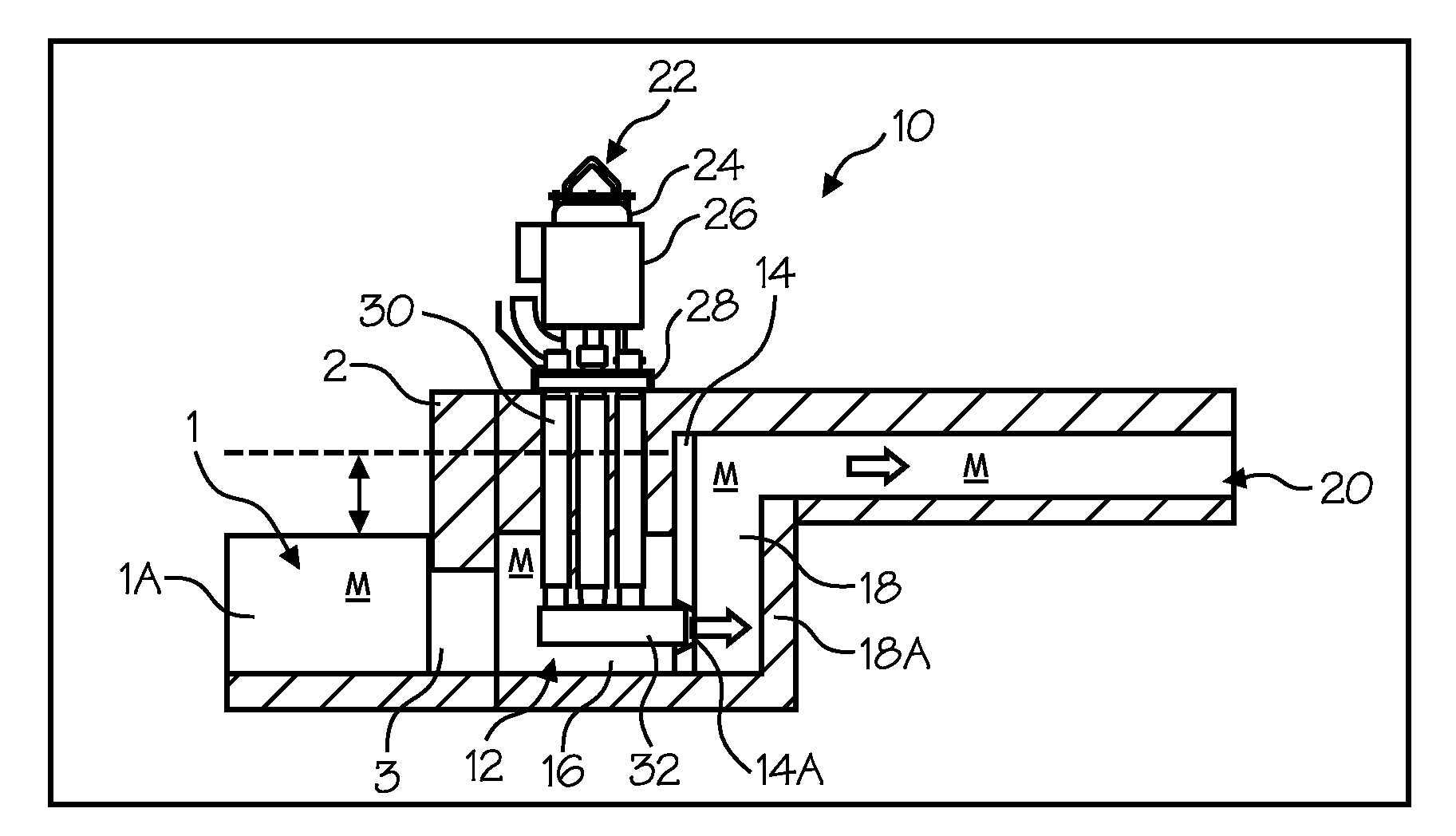

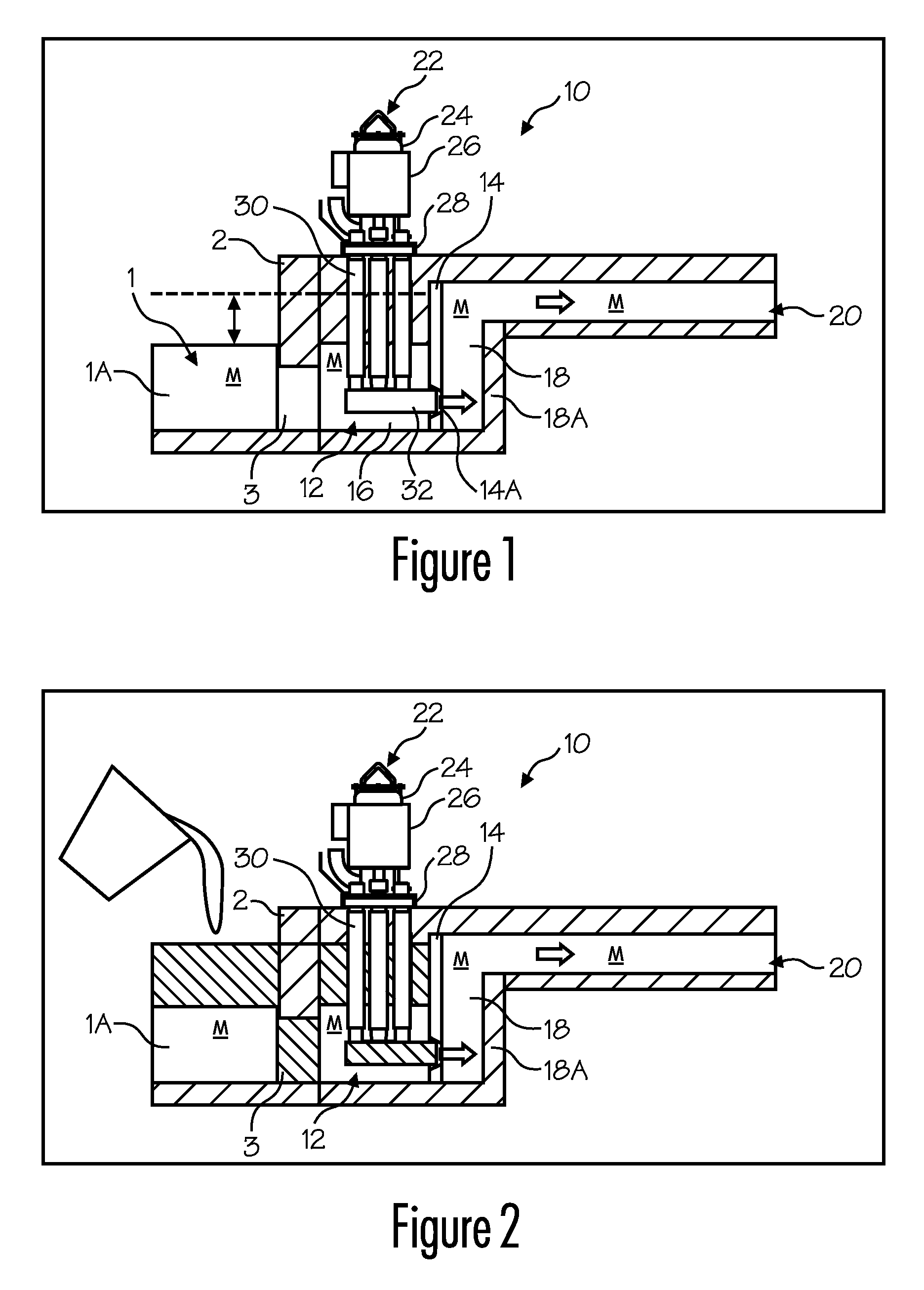

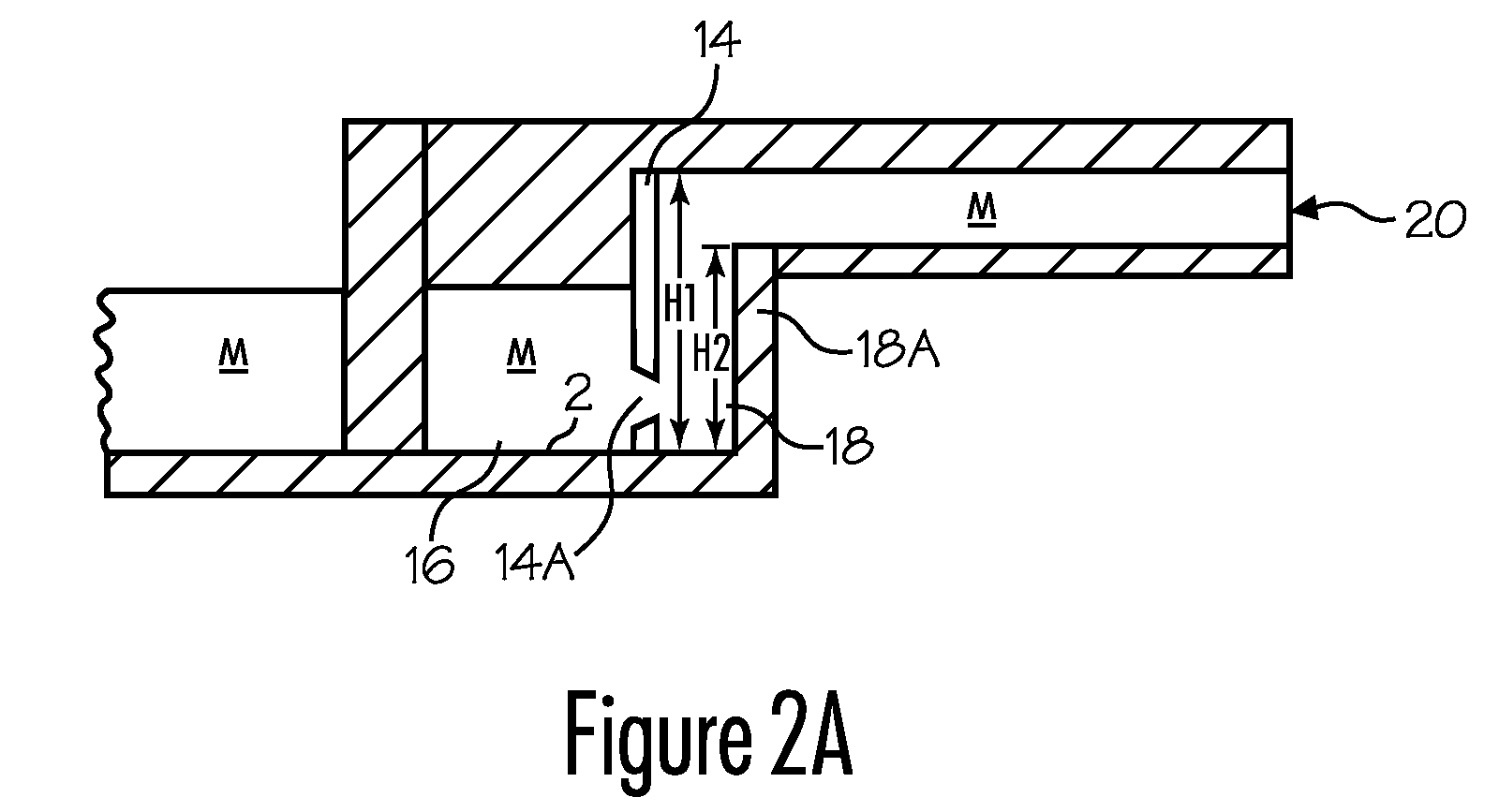

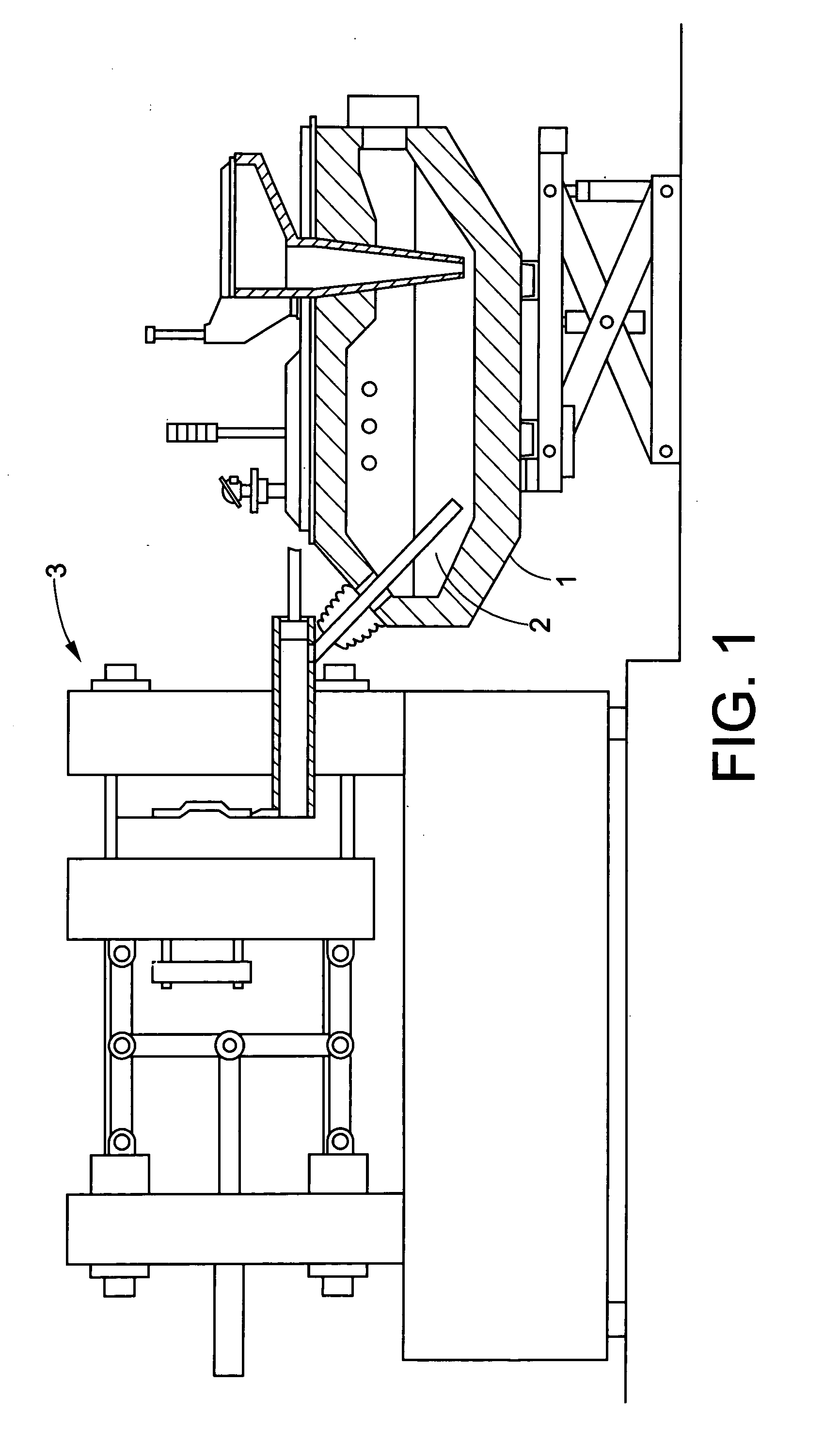

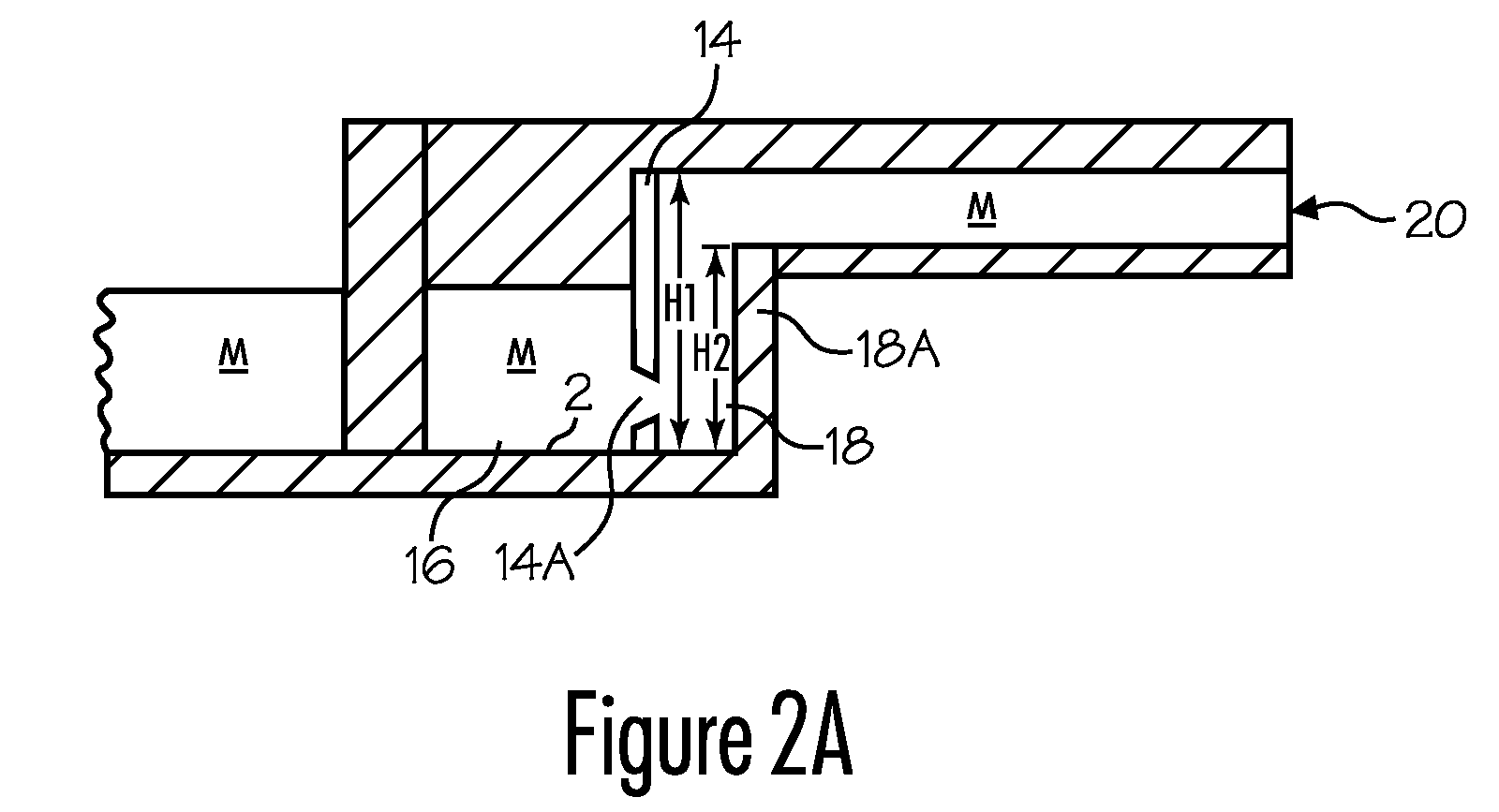

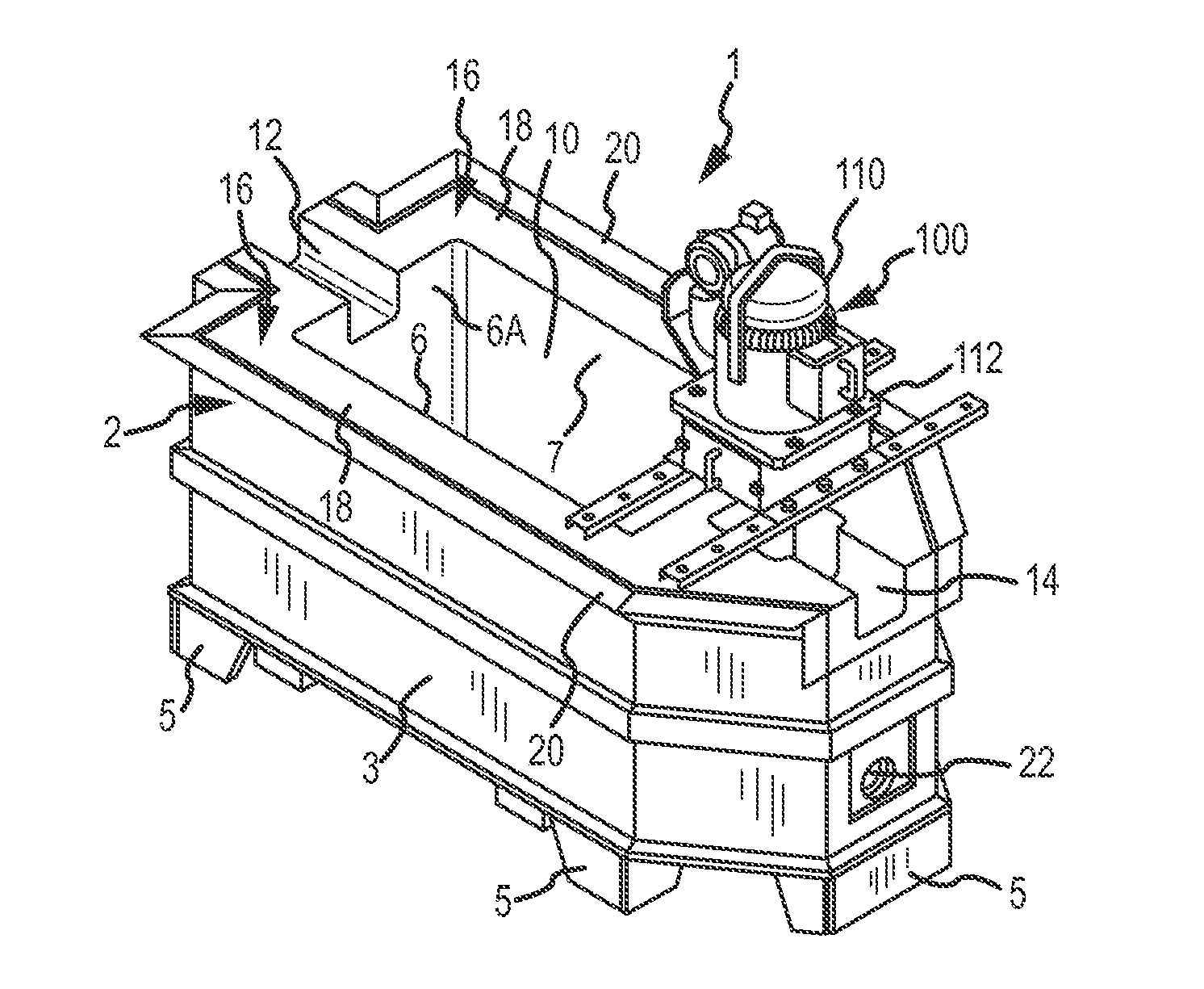

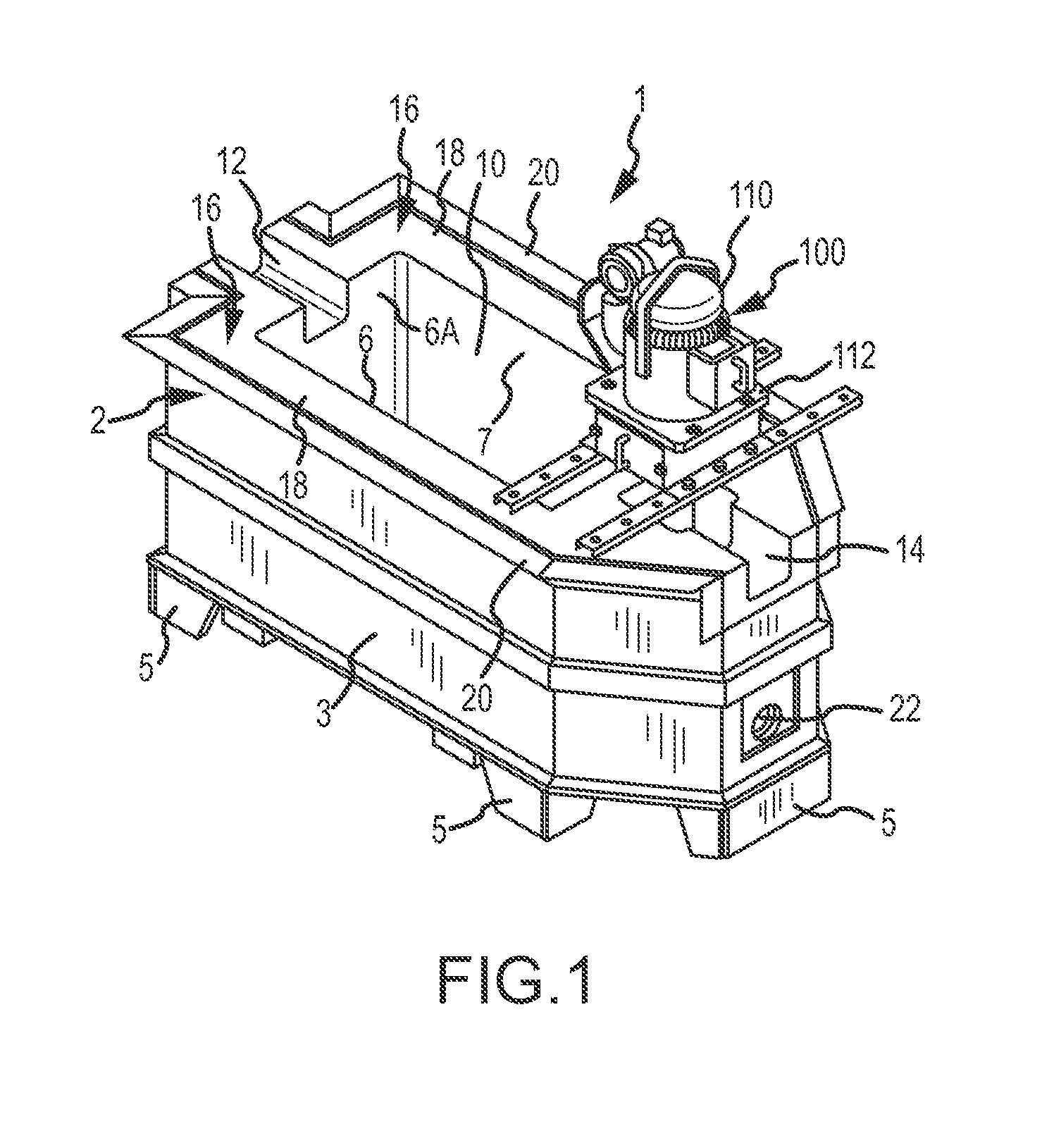

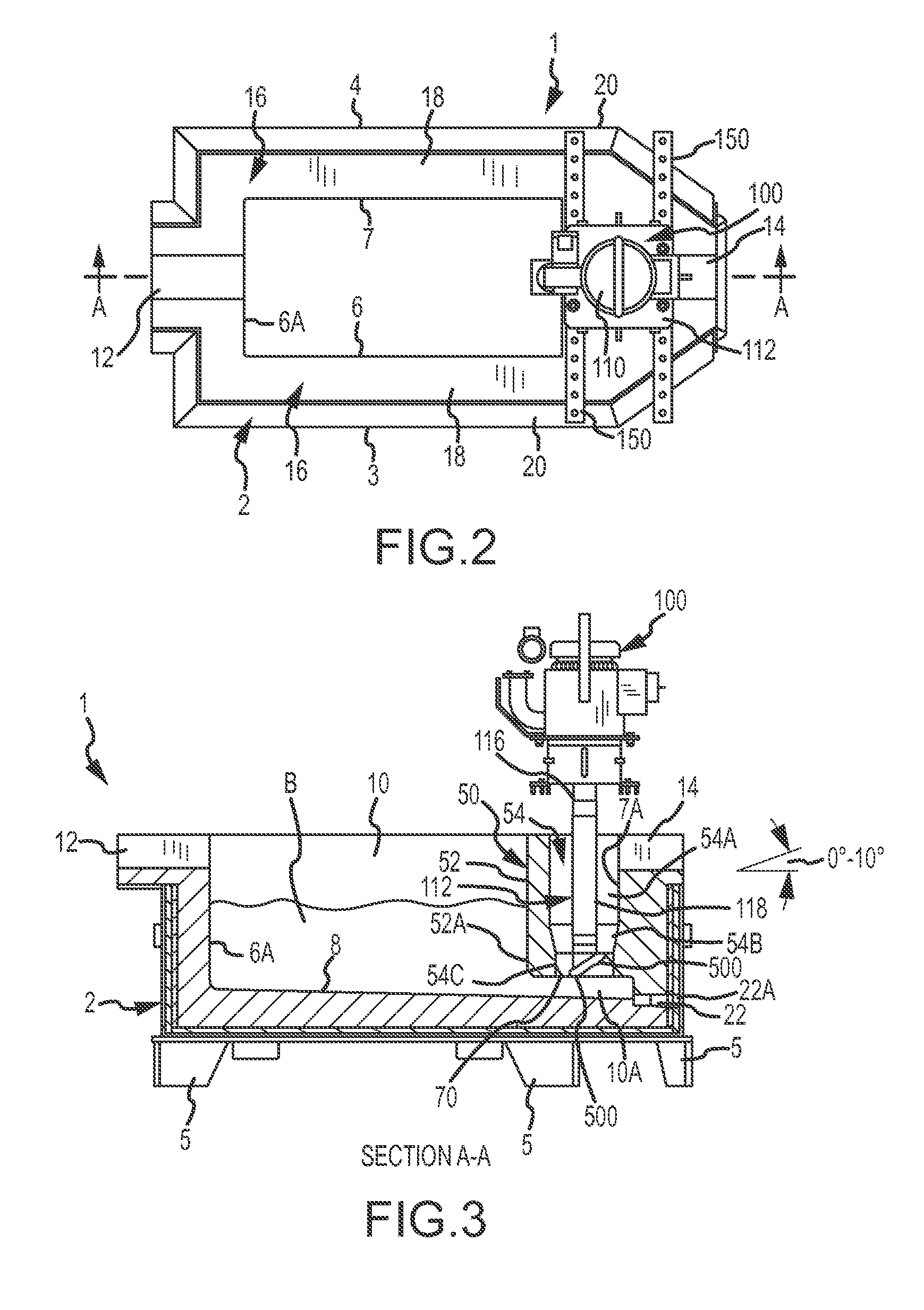

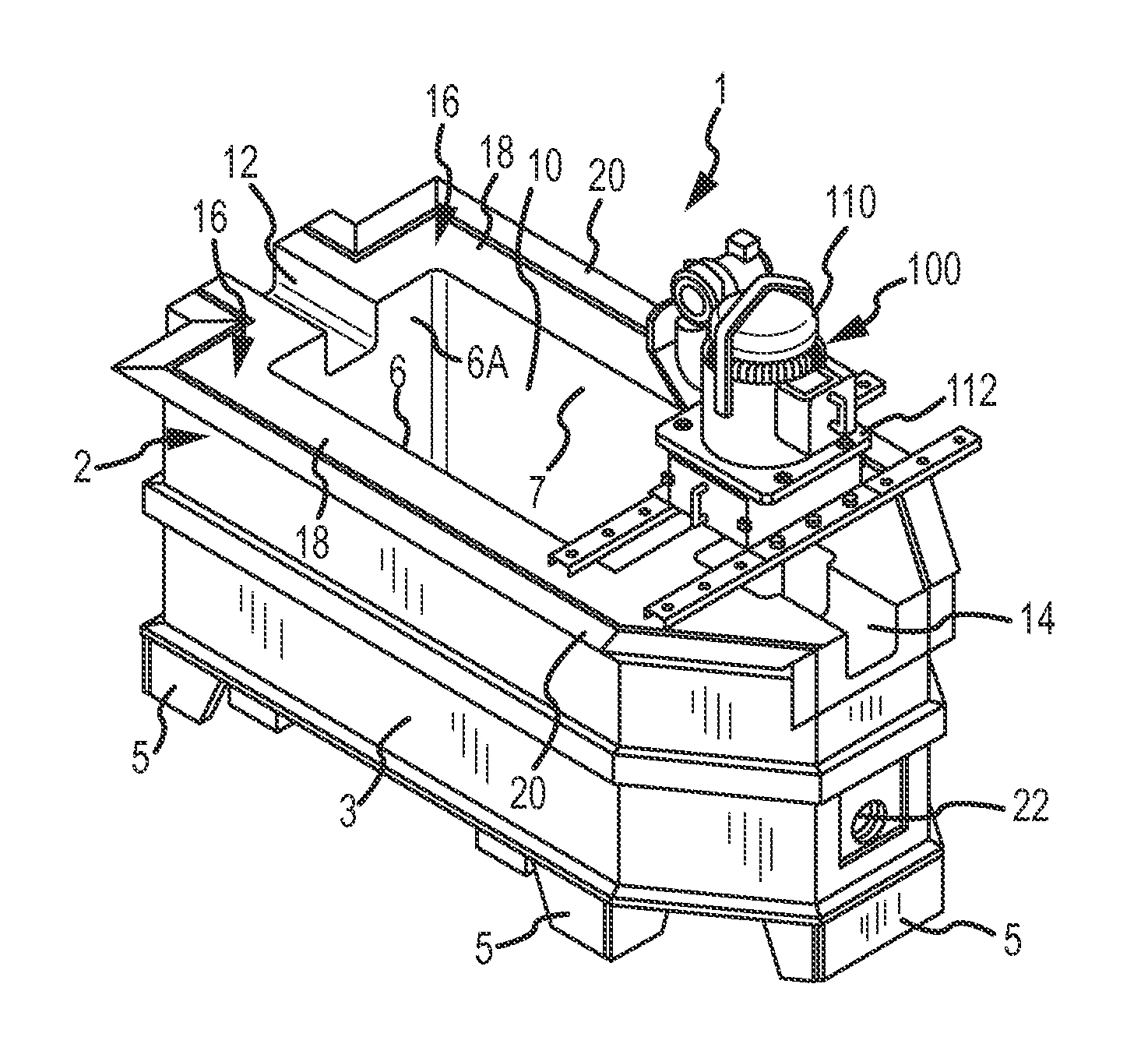

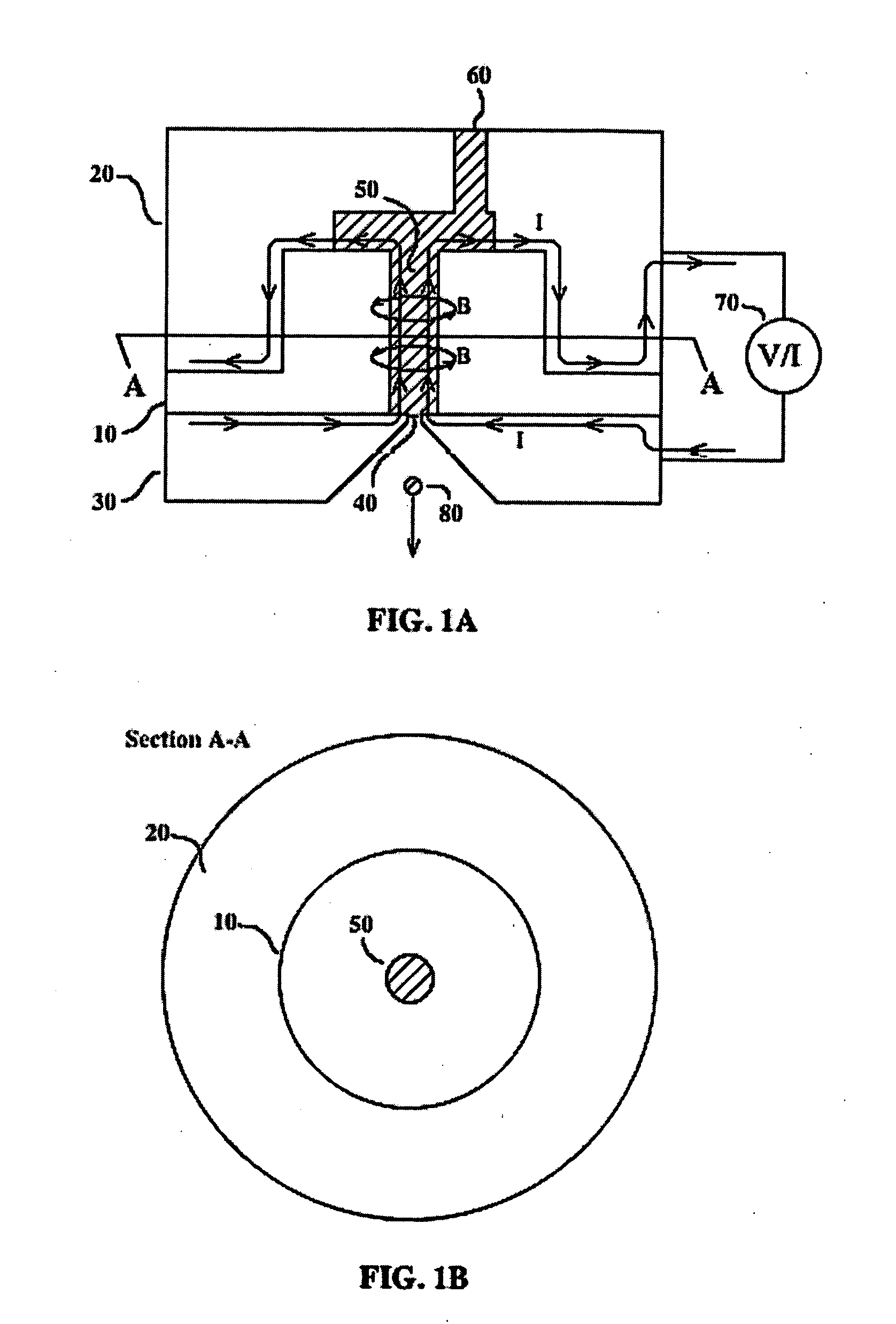

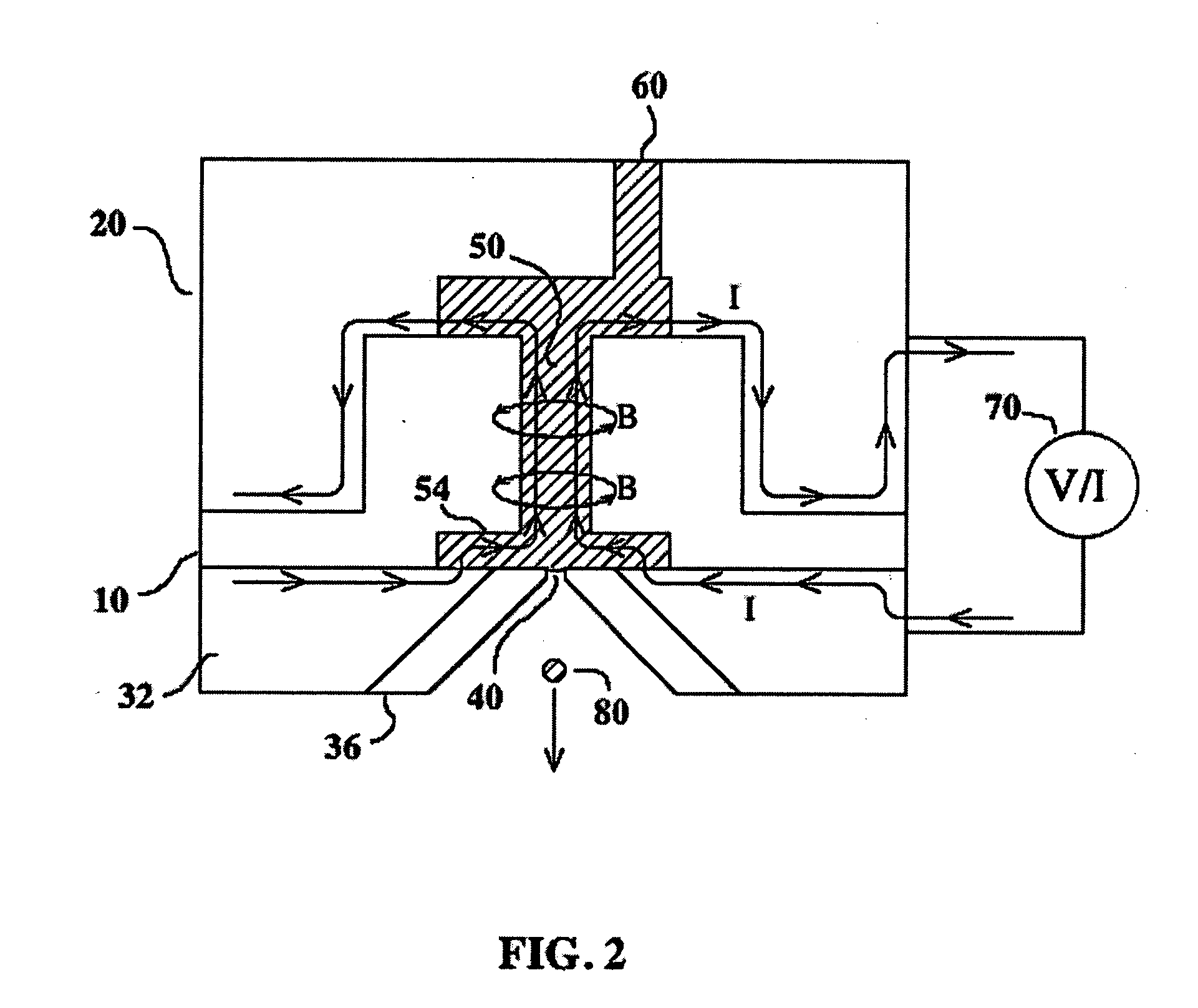

A system for transferring molten metal from a vessel and into one or more of a ladle, ingot mold, launder, feed die cast machine or other structure is disclosed. The system includes at least a vessel for containing molten metal, an overflow (or dividing) wall, and a device or structure, such as a molten metal pump, for generating a stream of molten metal. The dividing wall divides the vessel into a first chamber and a second chamber, wherein part of the second chamber has a height H2. The device for generating a stream of molten metal, which is preferably a molten metal pump, is preferably positioned in the first chamber. When the device operates, it generates a stream of molten metal from the first chamber and into the second chamber. When the level of molten metal in the second chamber exceeds H2, molten metal flows out of the vessel and into another structure, such as into one or more ladles and / or one or more launders.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

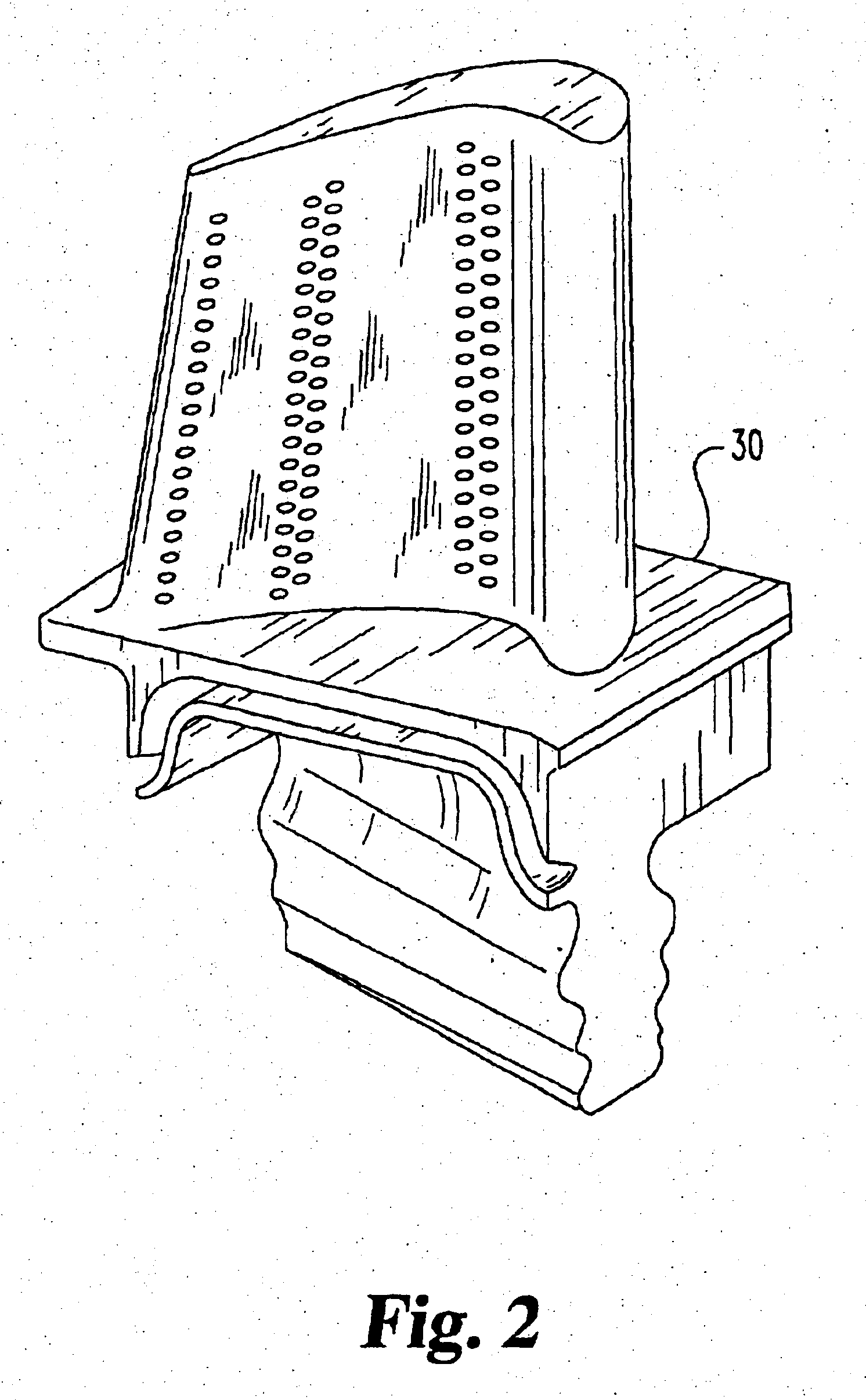

Bonded particle filters

InactiveUS7157043B2Significant portionMelt-holding vesselsMolten metal pouring equipmentsMolten metalMaterials science

An apparatus for filtering molten metal held in a vessel before the metal enters the dosing tube. The filtering apparatus includes an attachment portion that mounts to the dosing tube, a filter body connected to the attachment portion and a planar surface attached to an end of the filter body opposite the attachment portion. The filter body can include a beveled end opposite the attachment portion where the planar surface is attached. The apparatus can be made from a bonded-particle material made from silicon carbide or aluminum oxide held together by an aluminum-resistant binder.

Owner:METAULLICS SYST +1

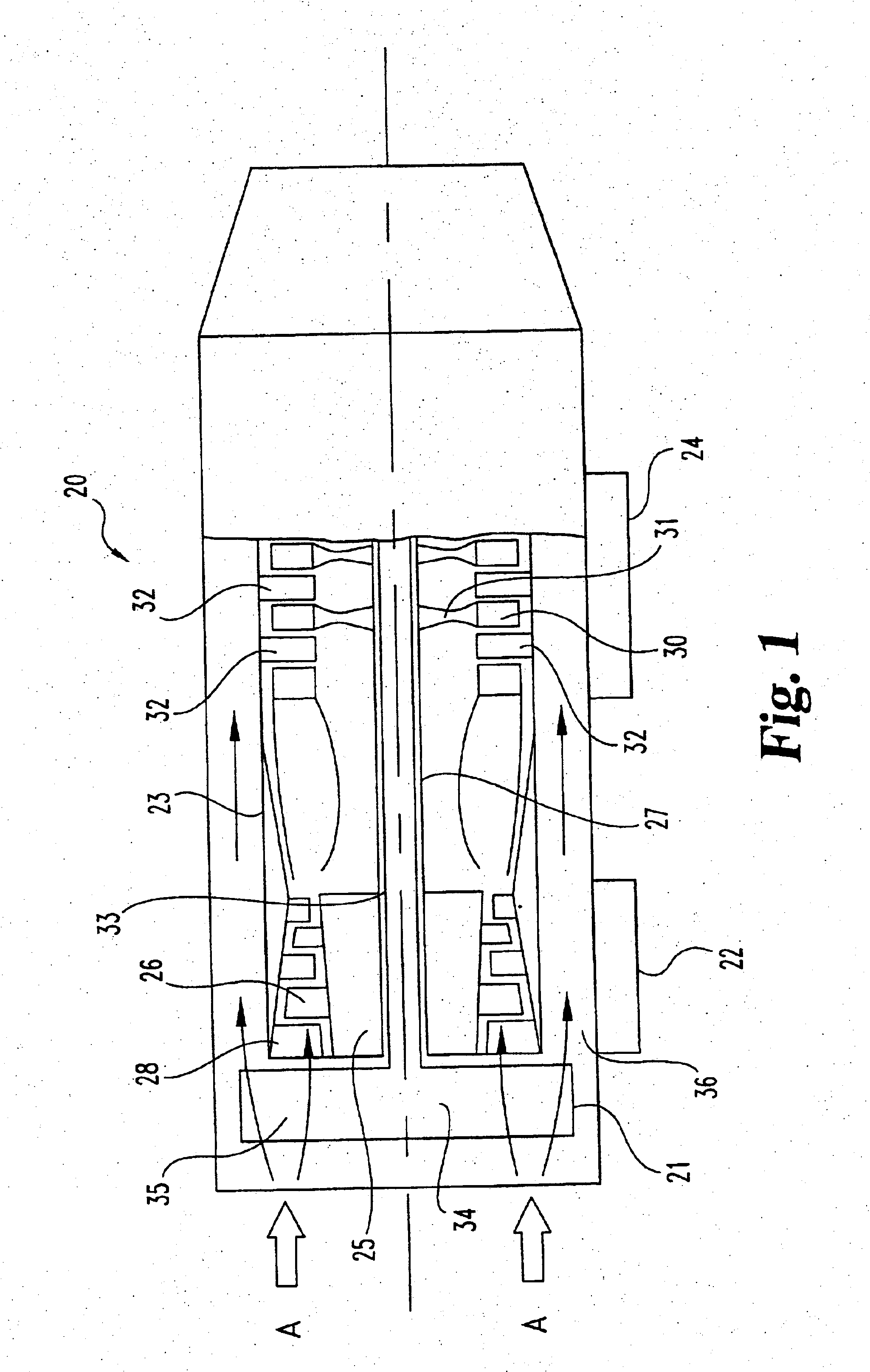

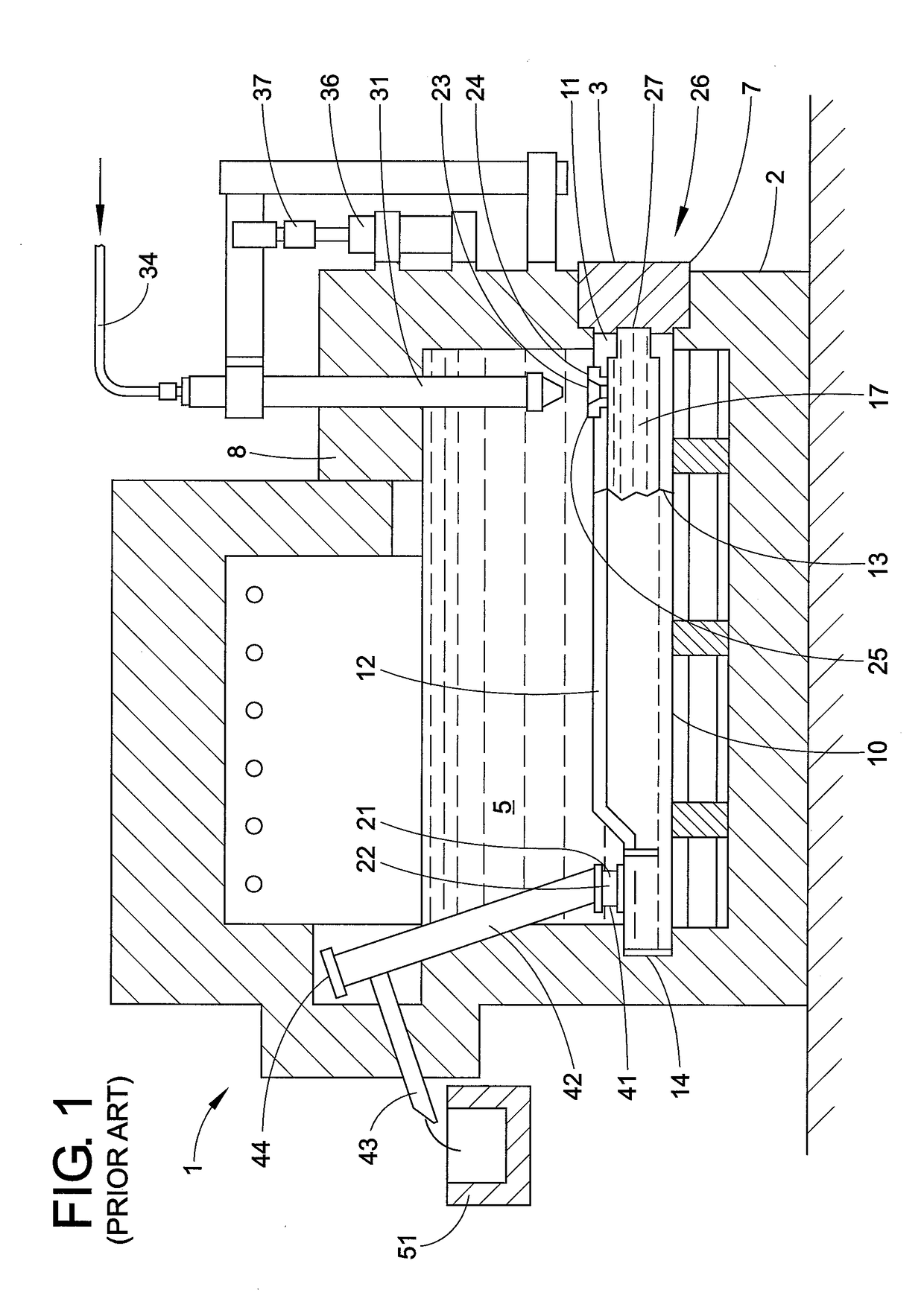

Molten metal pressure pour furnace and metering valve

InactiveUS7279128B2Avoid flowMelt-holding vesselsMolten metal pouring equipmentsDifferential pressureMetallurgy

An apparatus and process are provided for discharging a dose of a molten metal from a pressure pour furnace. A heating chamber of the furnace is used to keep the molten metal at a selected temperature. A sealing port between the heating chamber and a pressure chamber allows selectively filling of the pressure chamber with molten metal from the heating chamber by inserting or removing a sealing means from the sealing port. The sealing means inserted in the sealing port also provides a means for preventing back flow of the molten metal to the heating chamber when the pressure chamber is pressurized. Differential pressure sensing of the pressure of the molten metal in the pressure chamber and the pressure of the pressurizing gas in the pressure chamber can optionally be used to achieve an accurate measured discharge from the pressure chamber as the level of molten metal decreases from repeated discharges of doses from the furnace. The sealing plate in which the sealing port is disposed and the sealing means selectively inserted or removed from the sealing port can be used as a metering valve between two molten metal containing components such as a launder and a pressure chamber of a pressure pour furnace.

Owner:HI T E Q

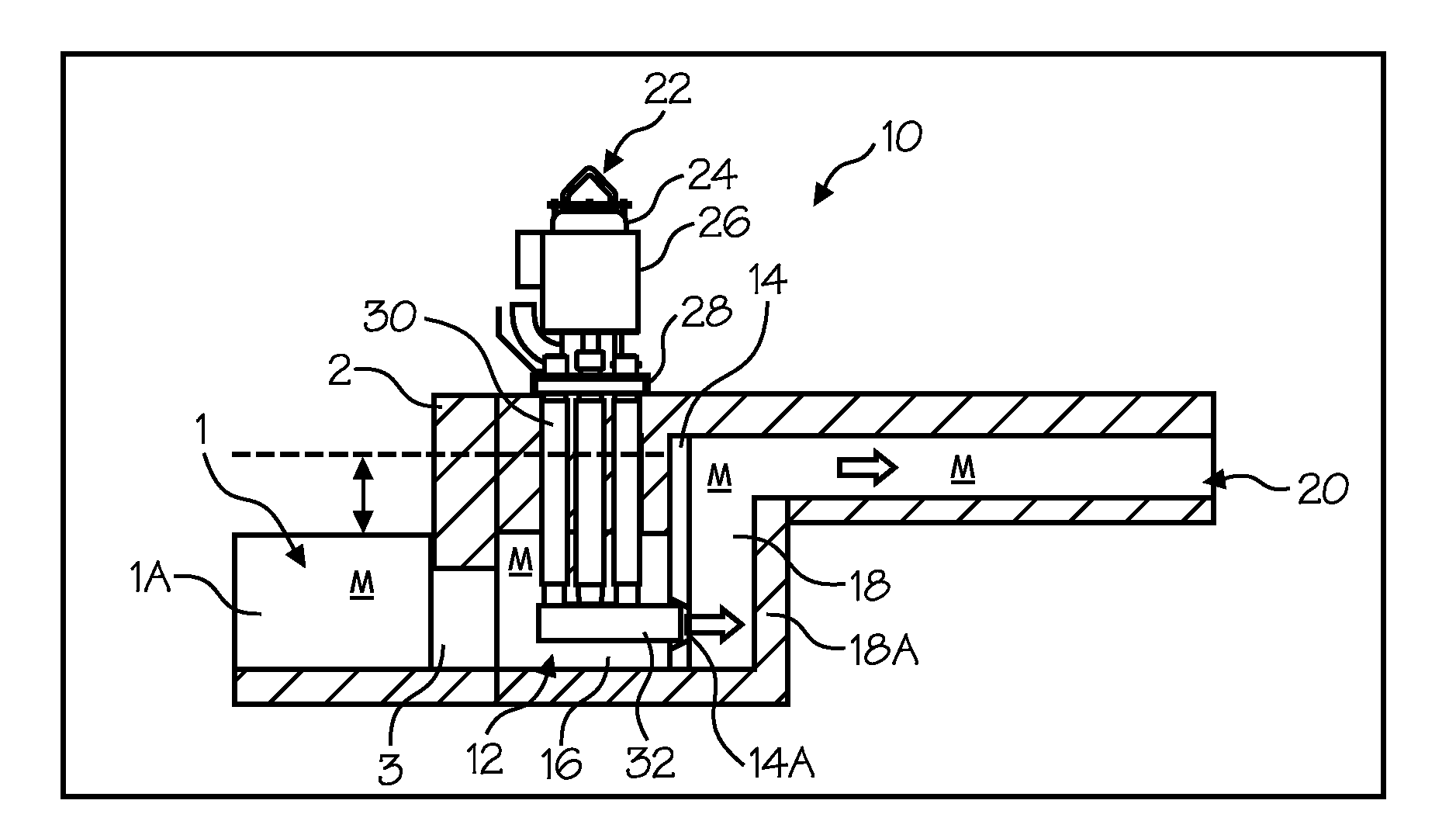

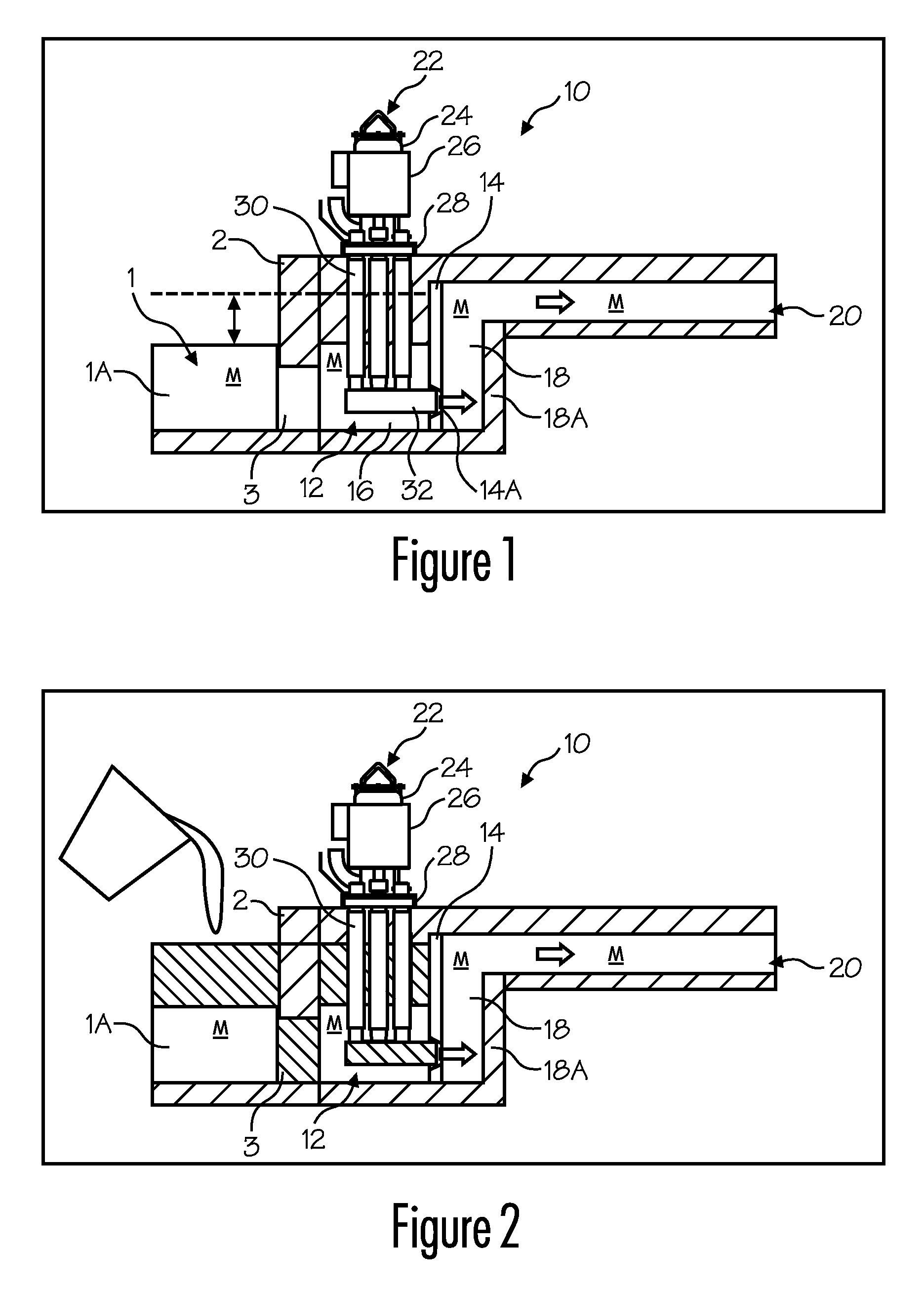

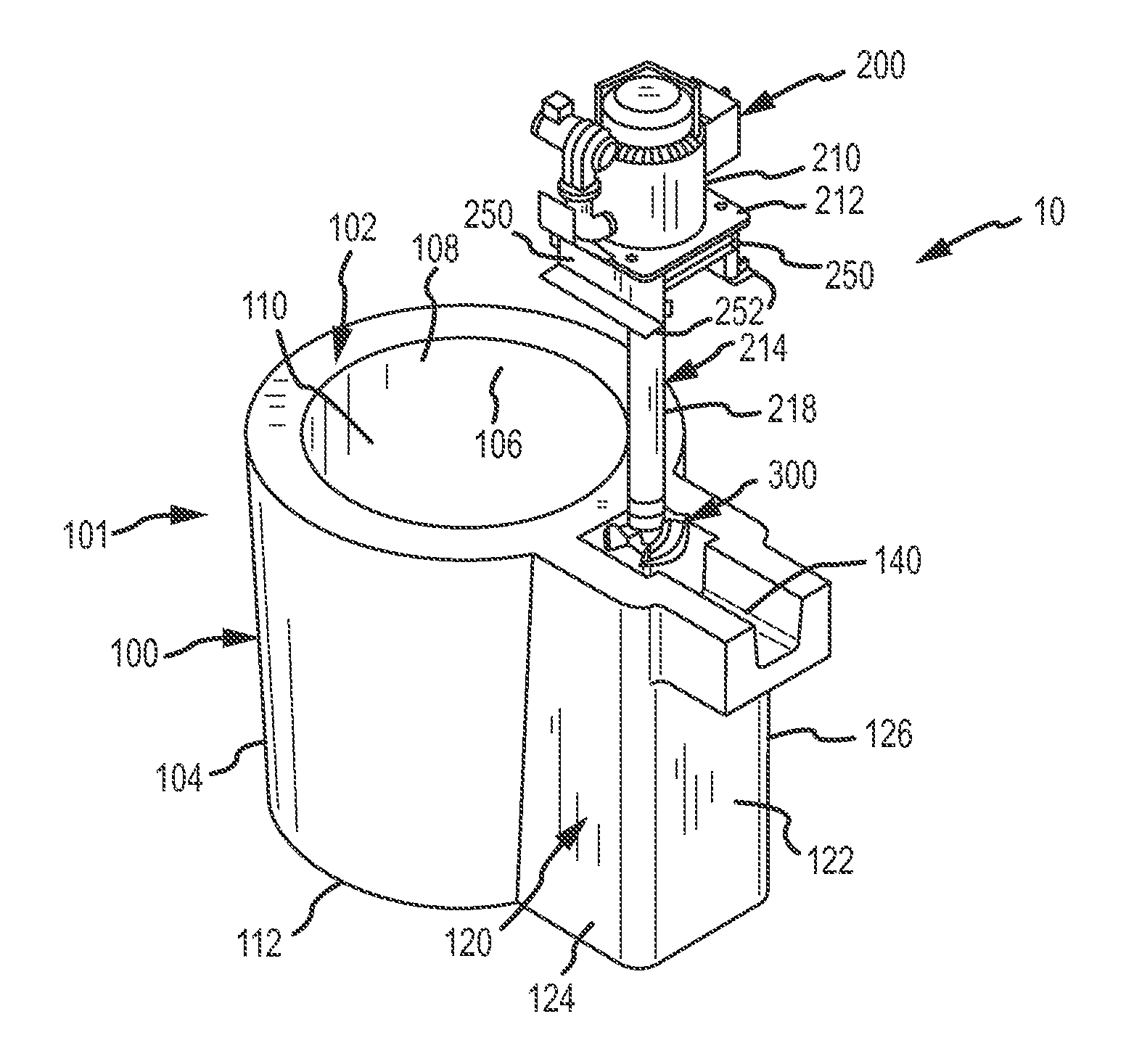

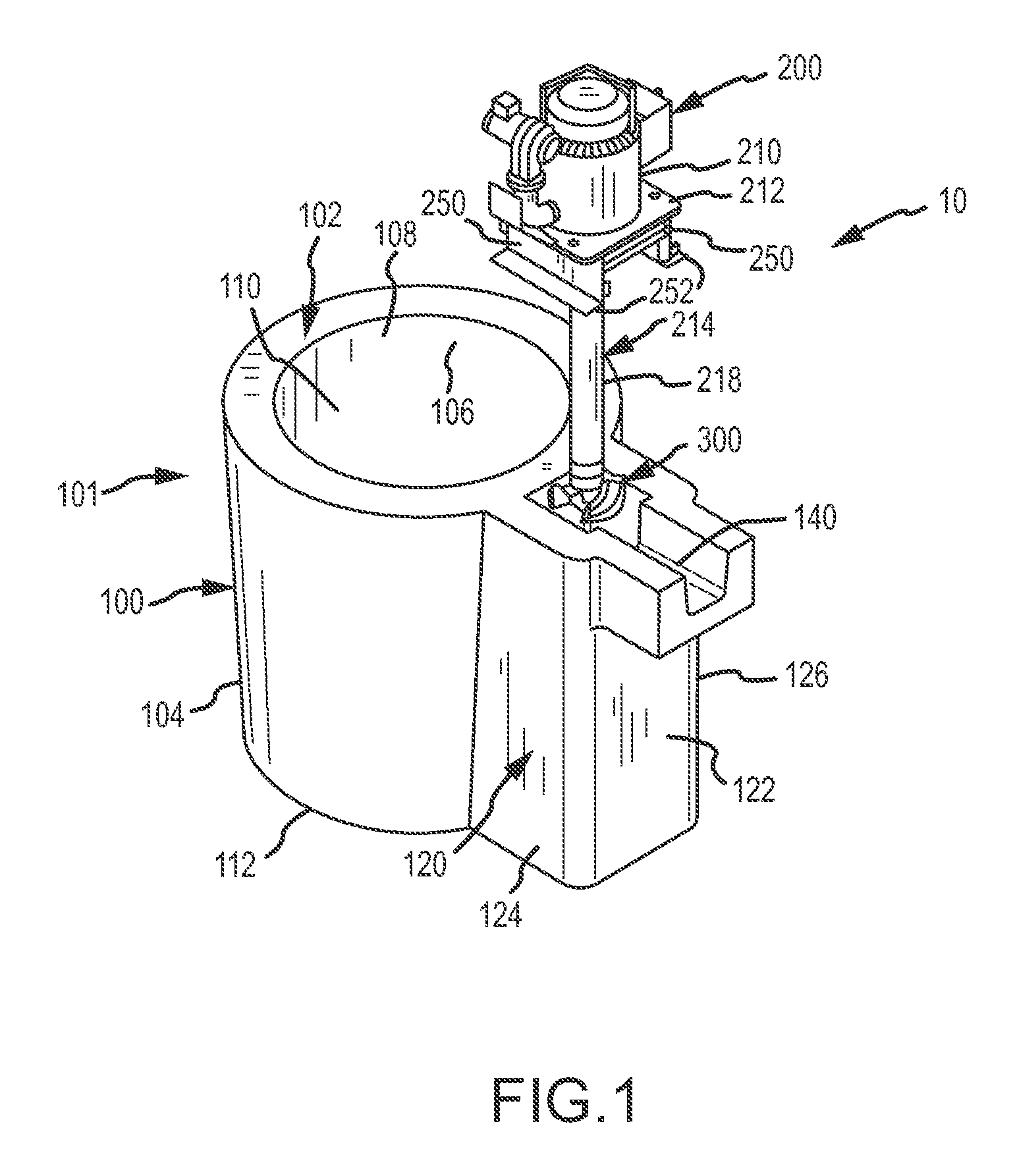

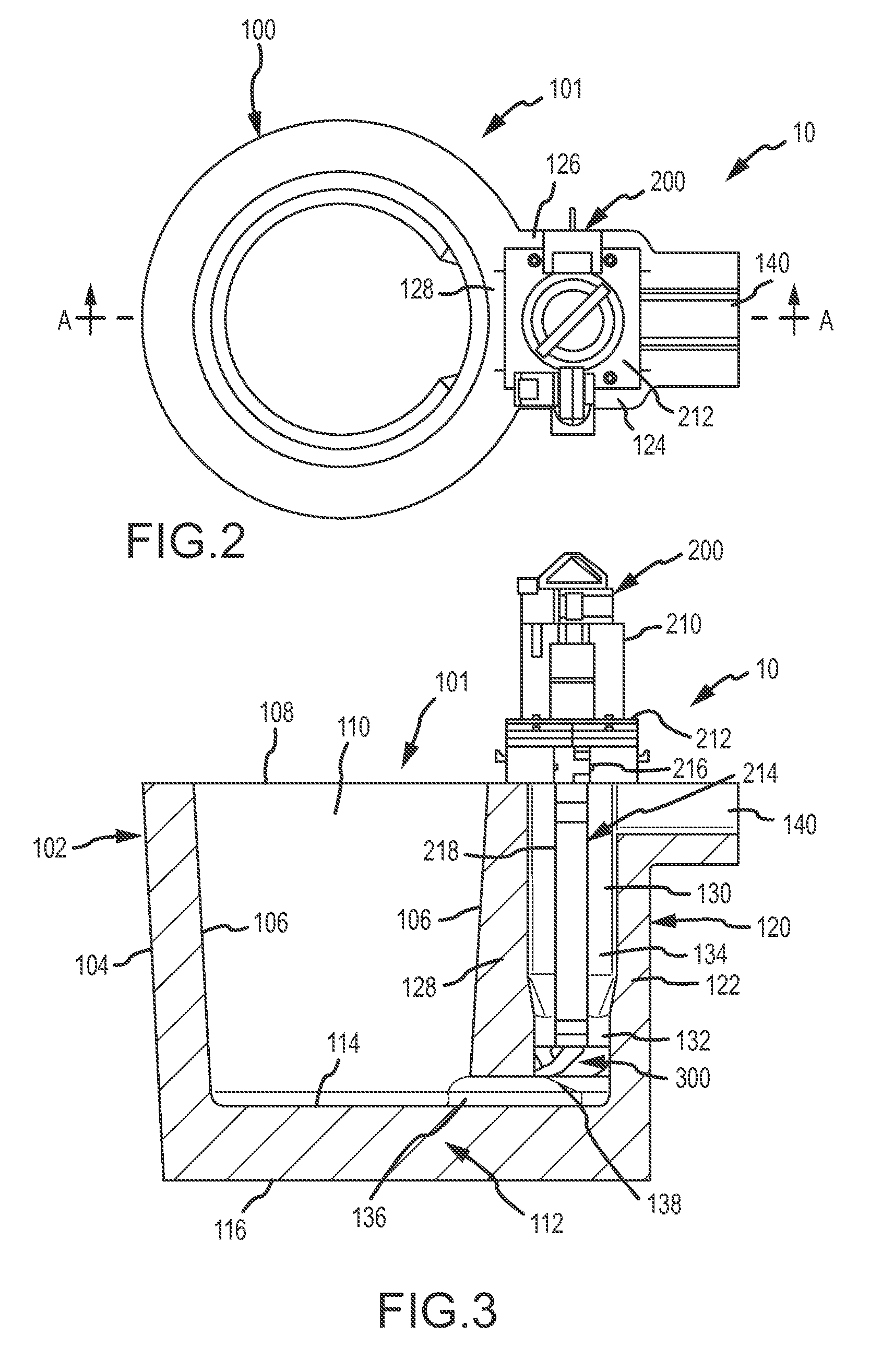

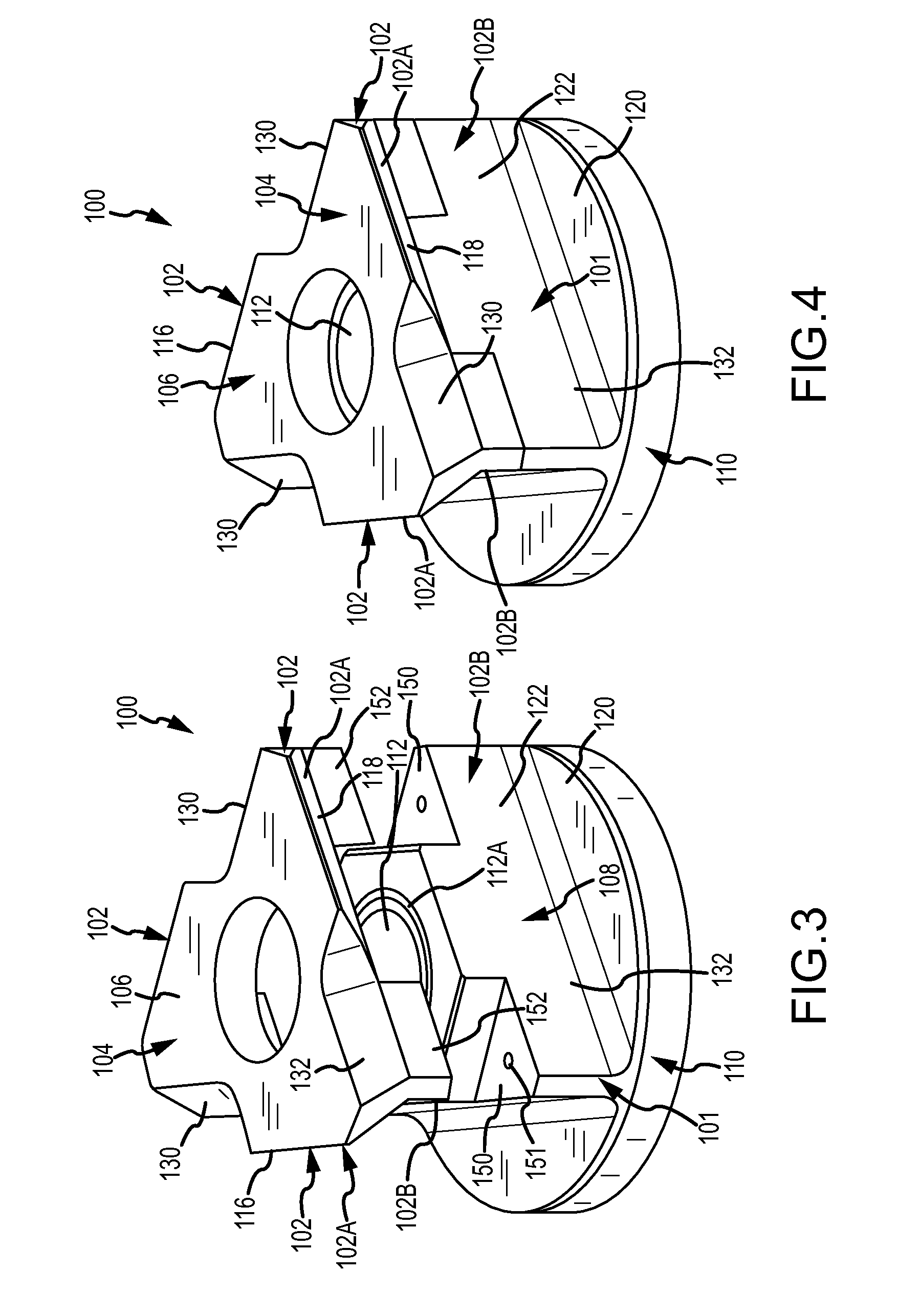

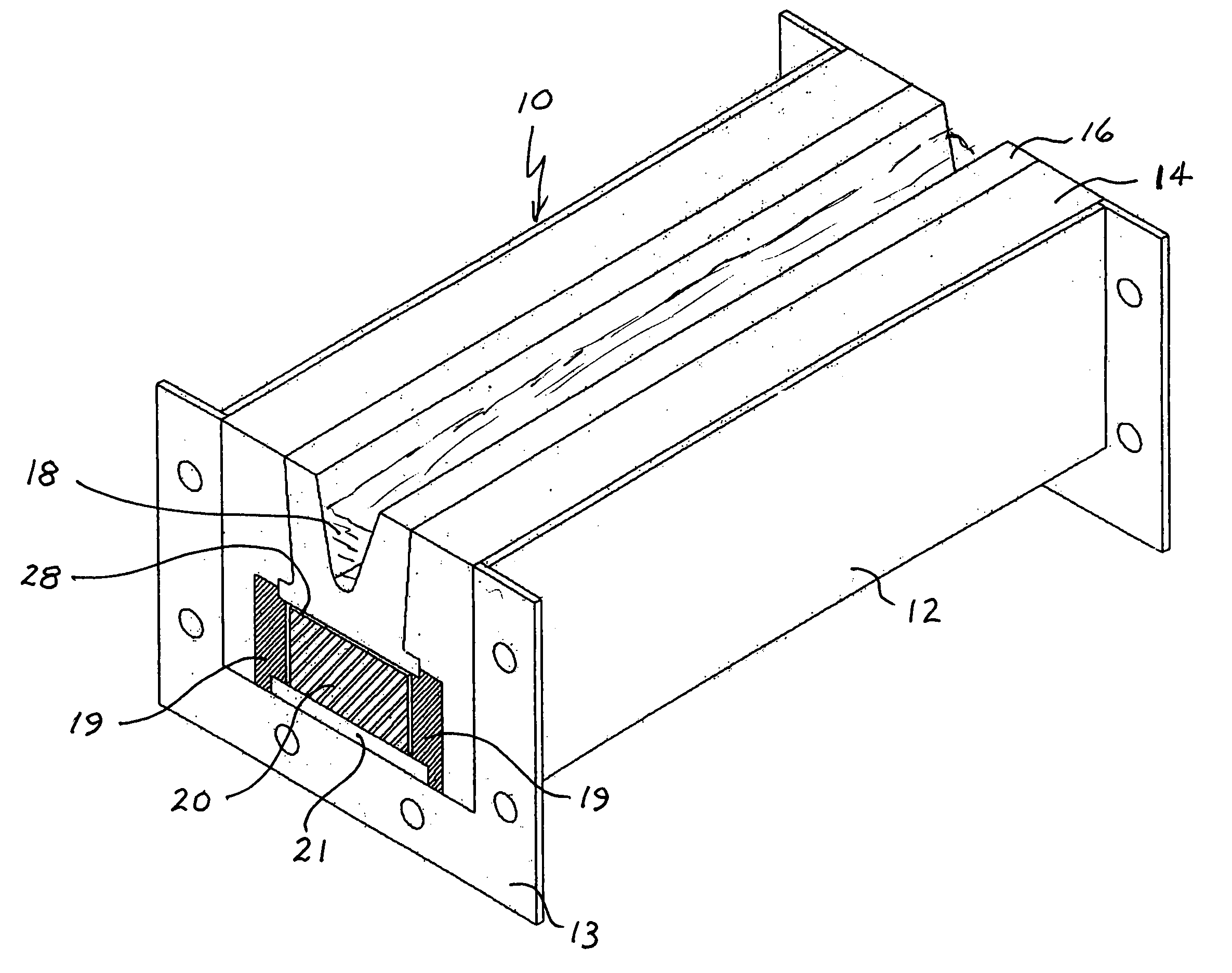

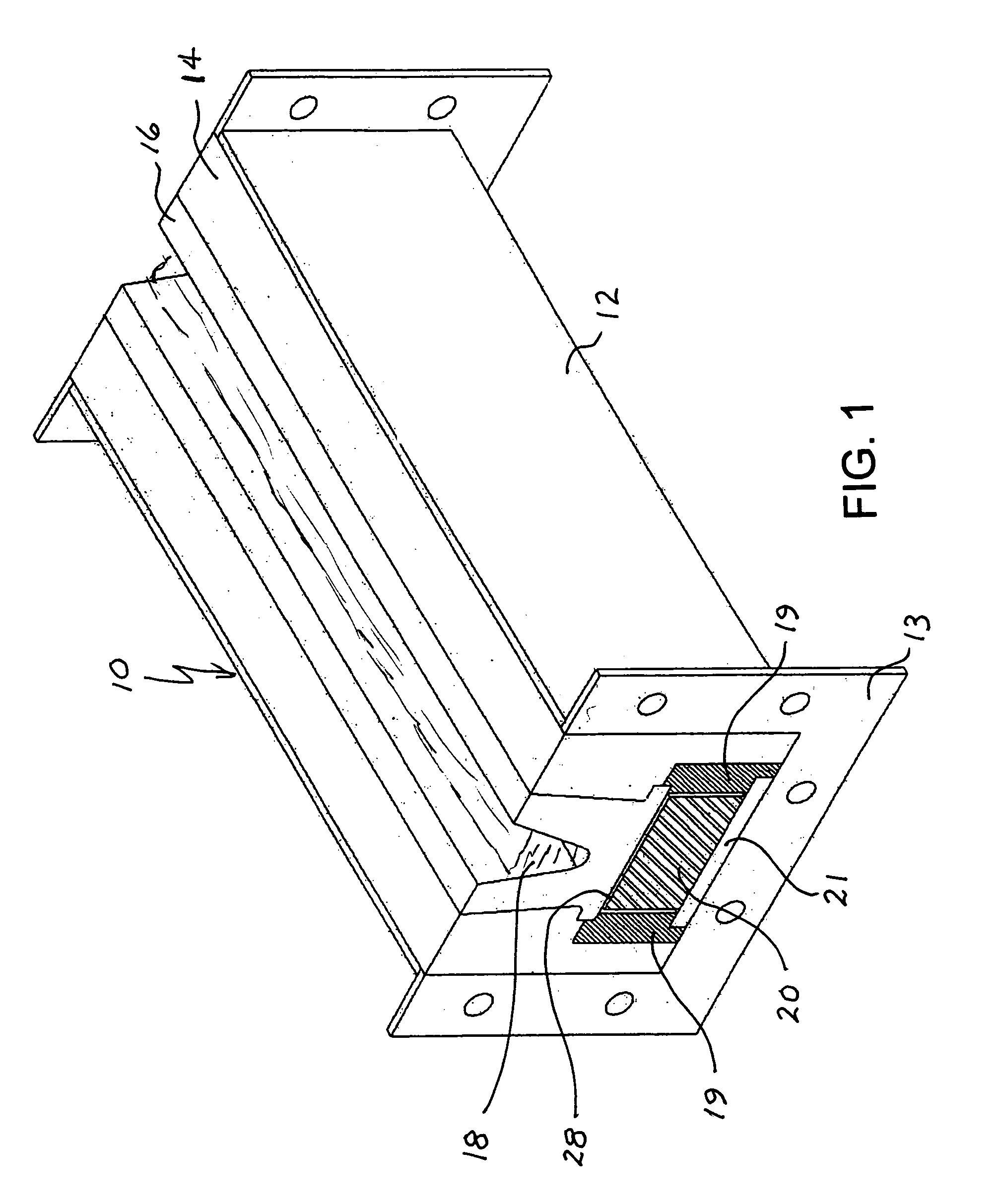

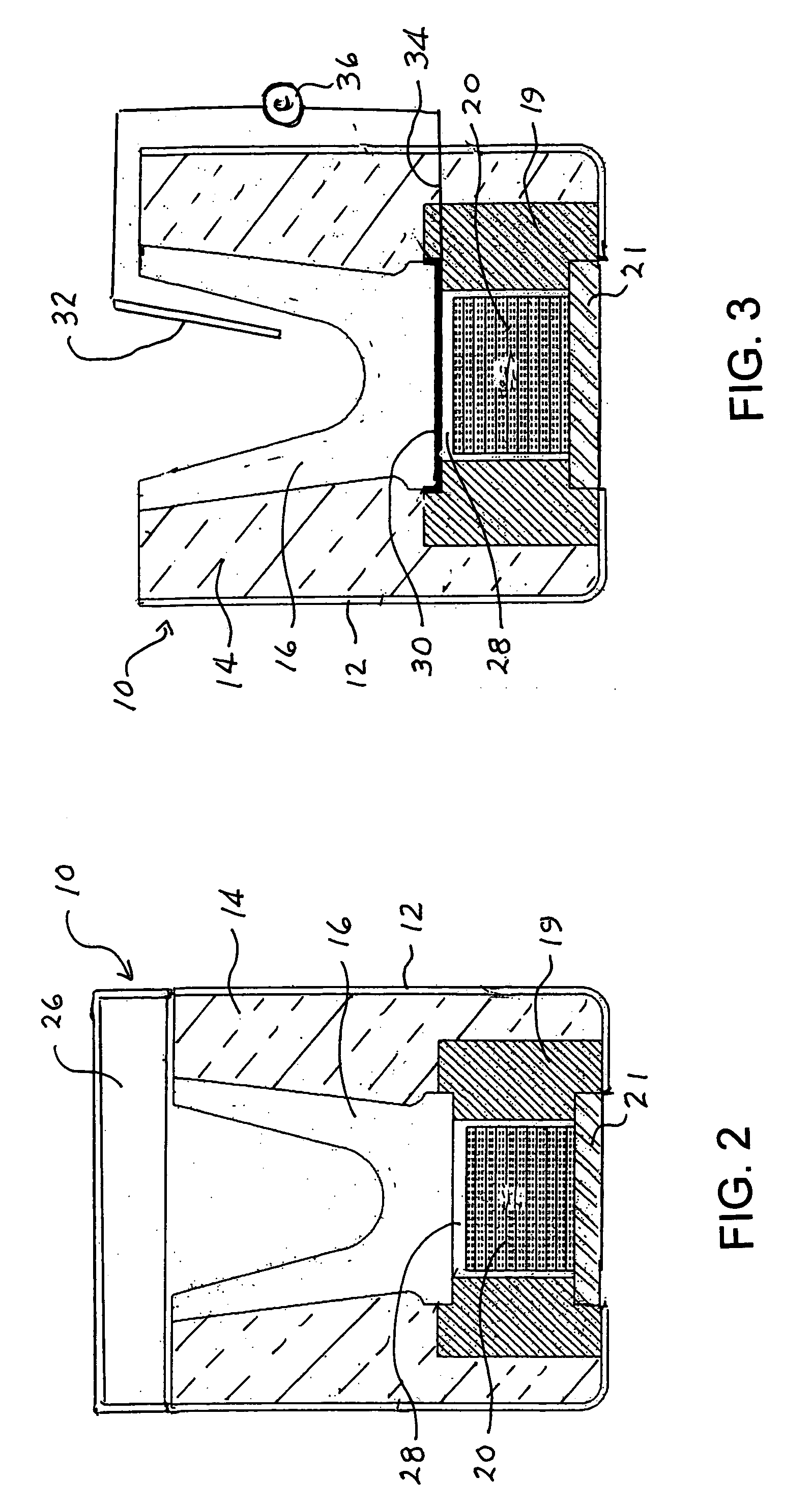

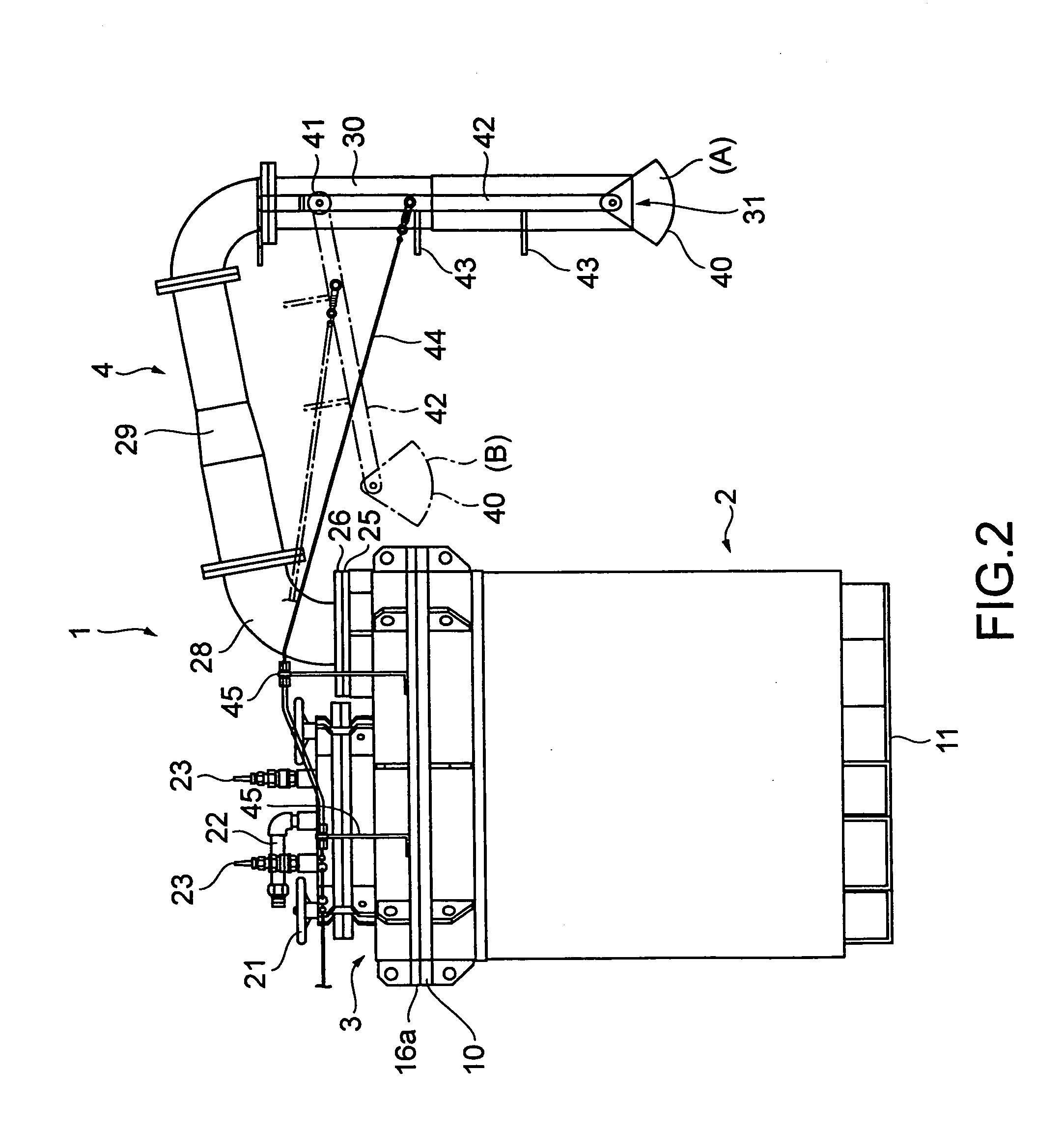

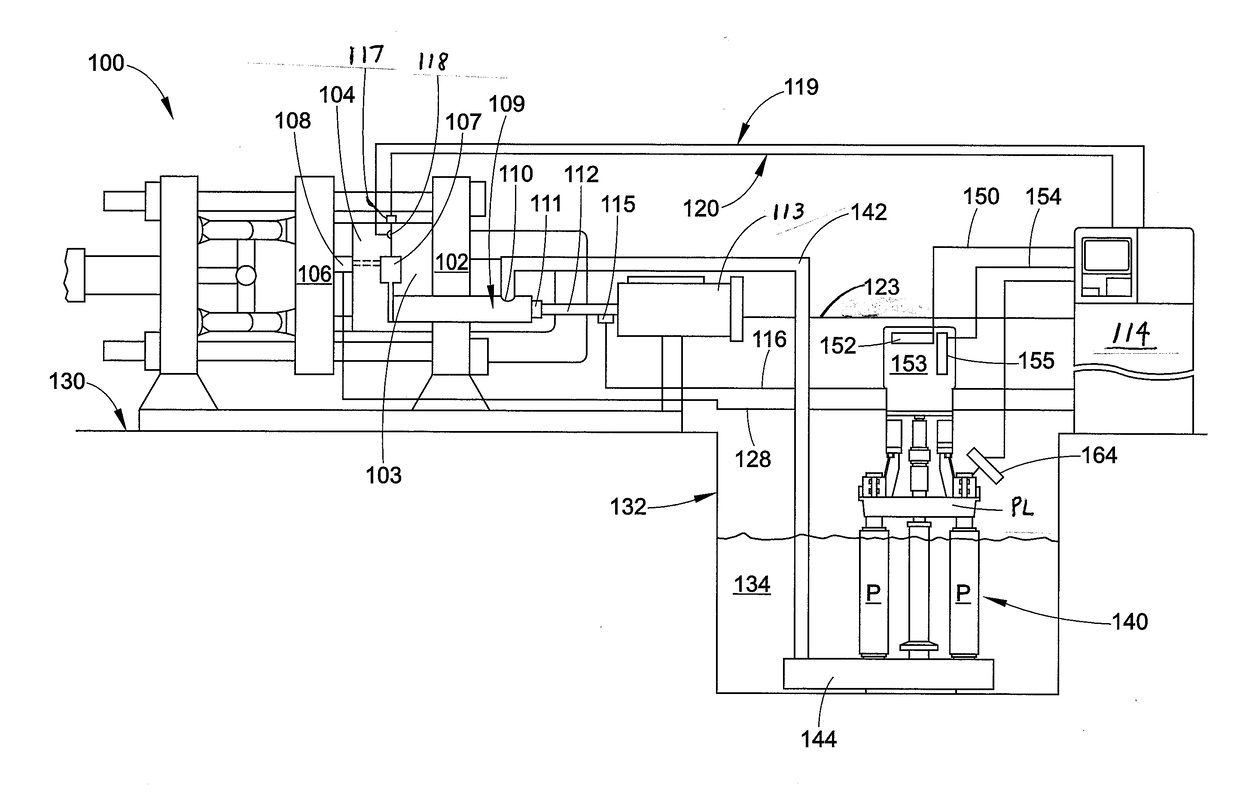

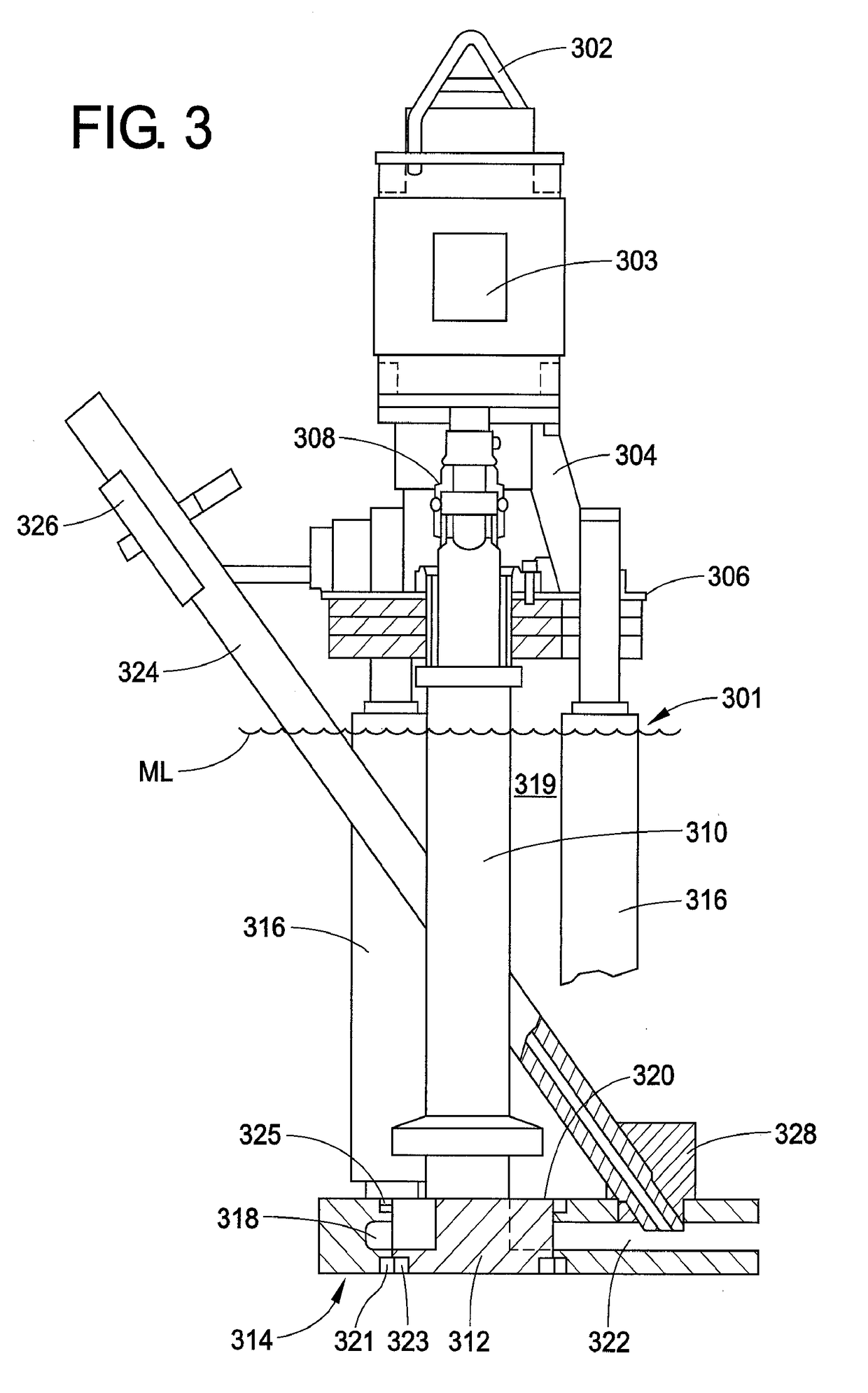

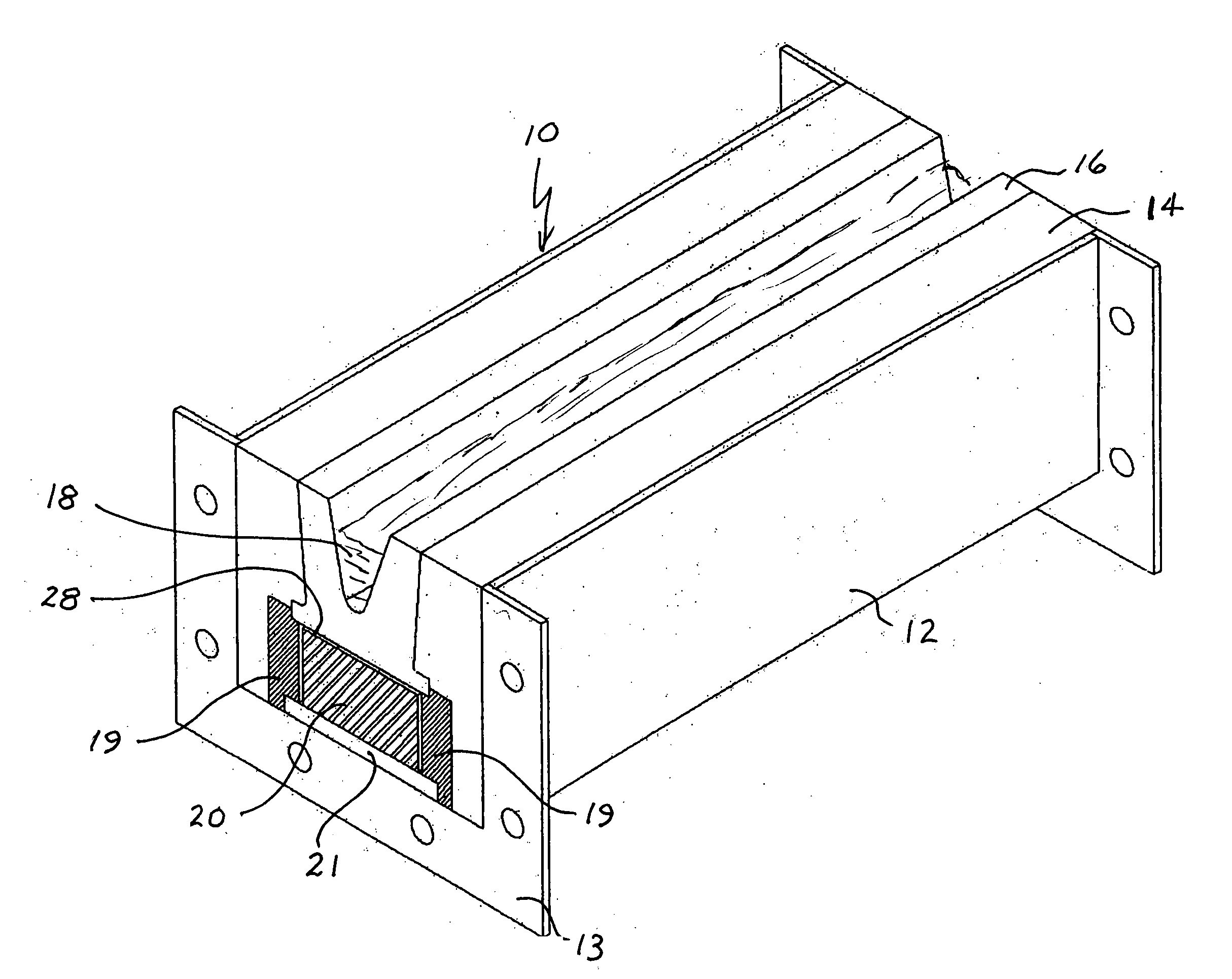

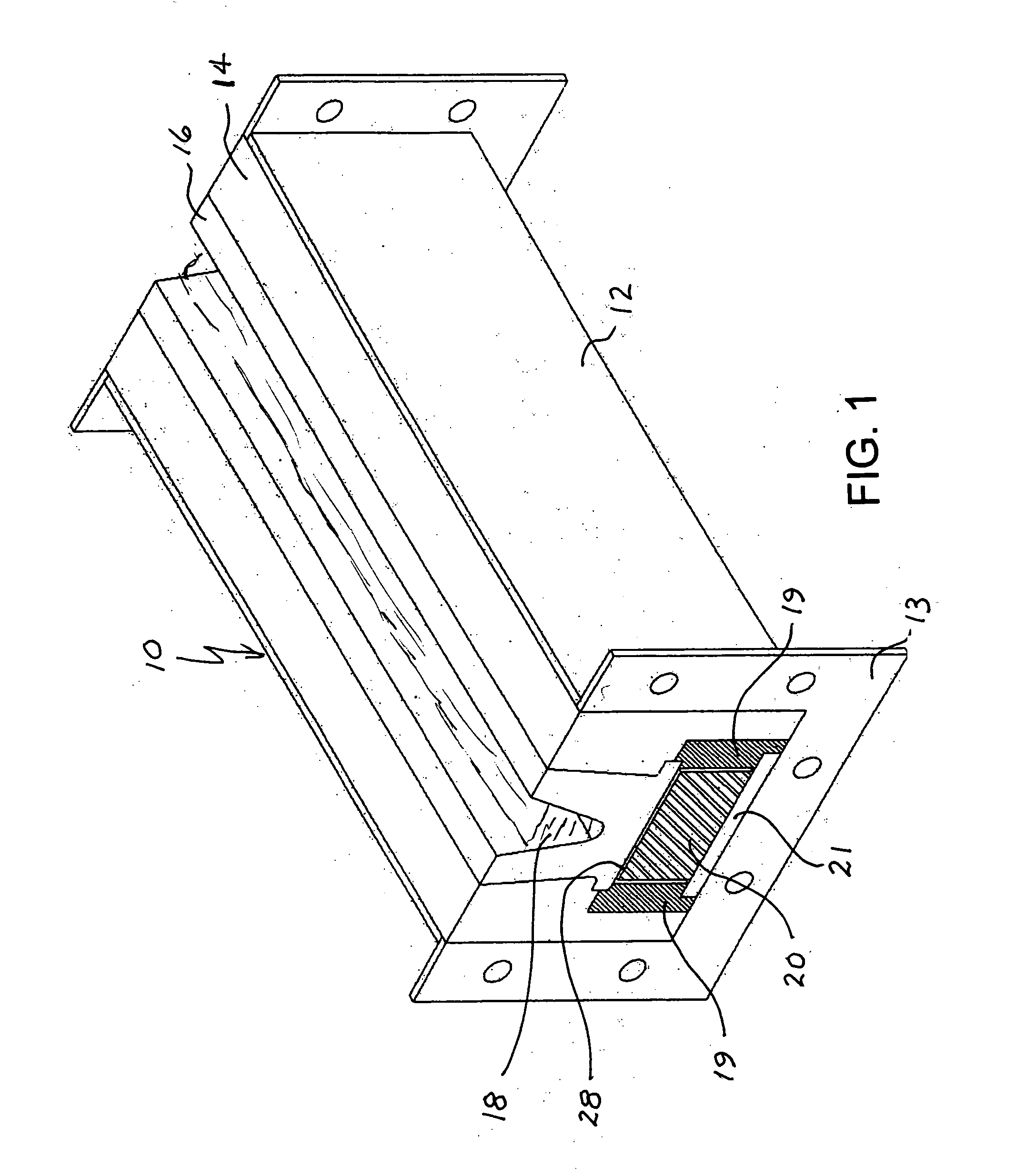

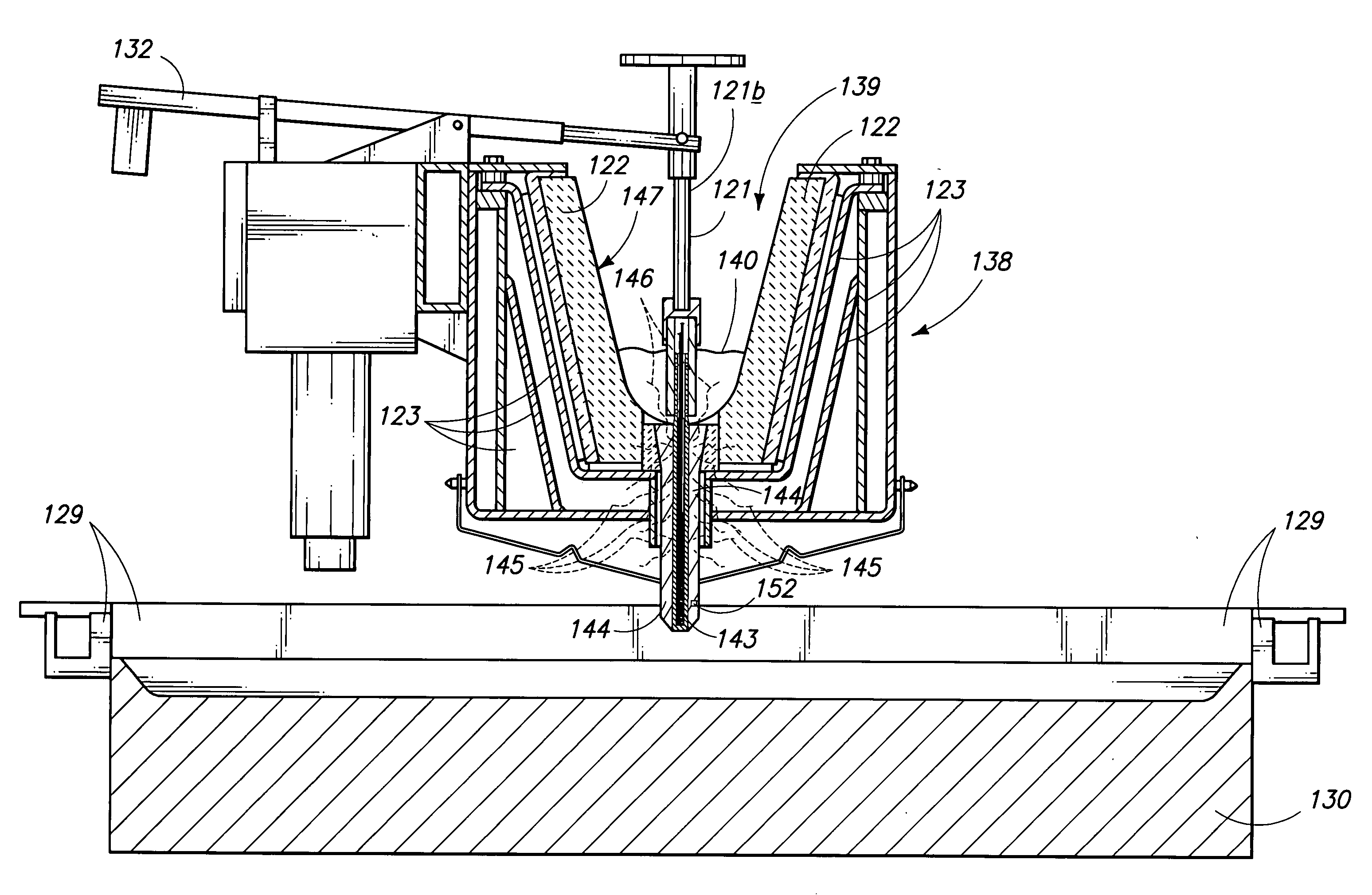

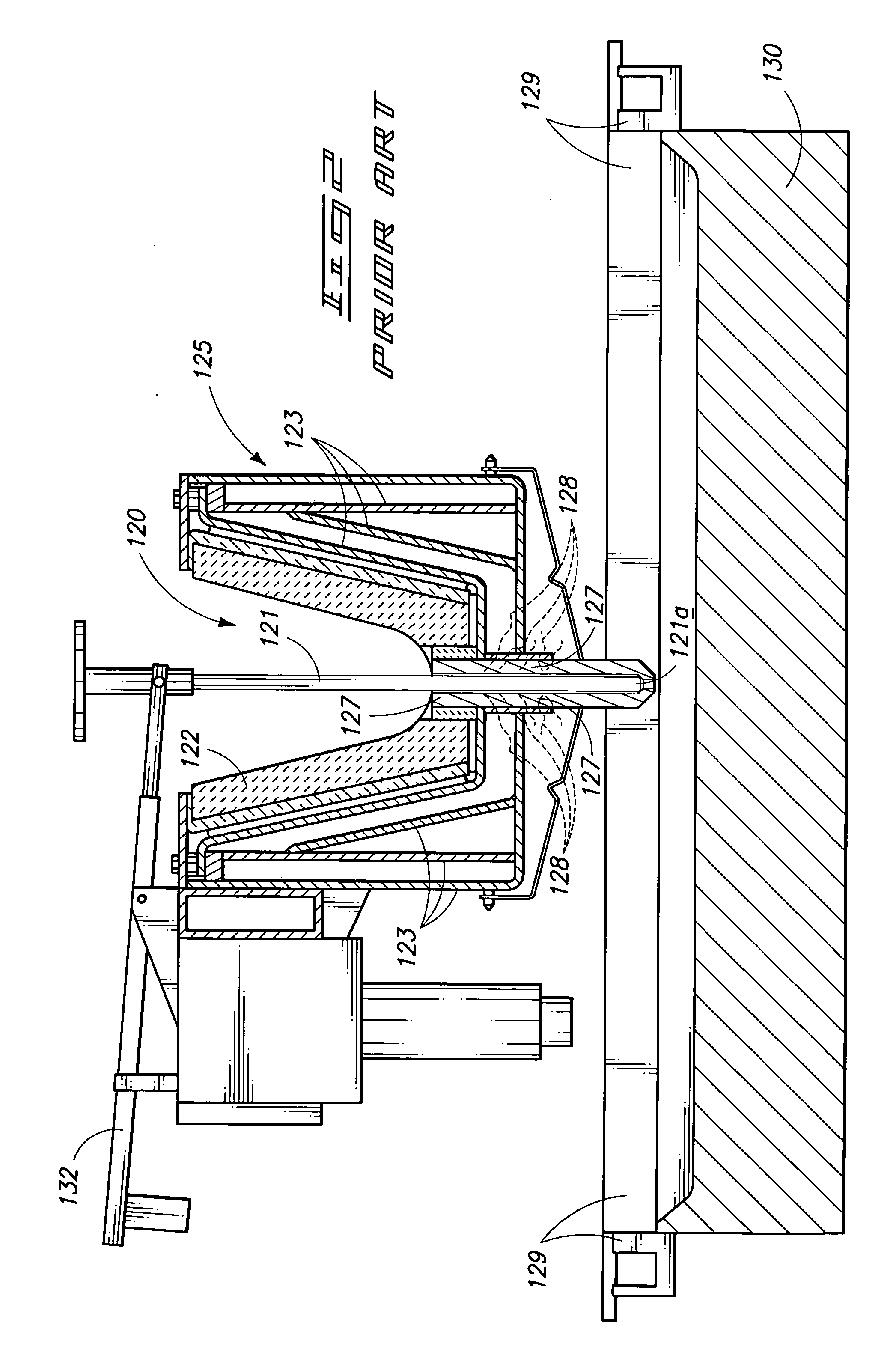

Mold pump assembly

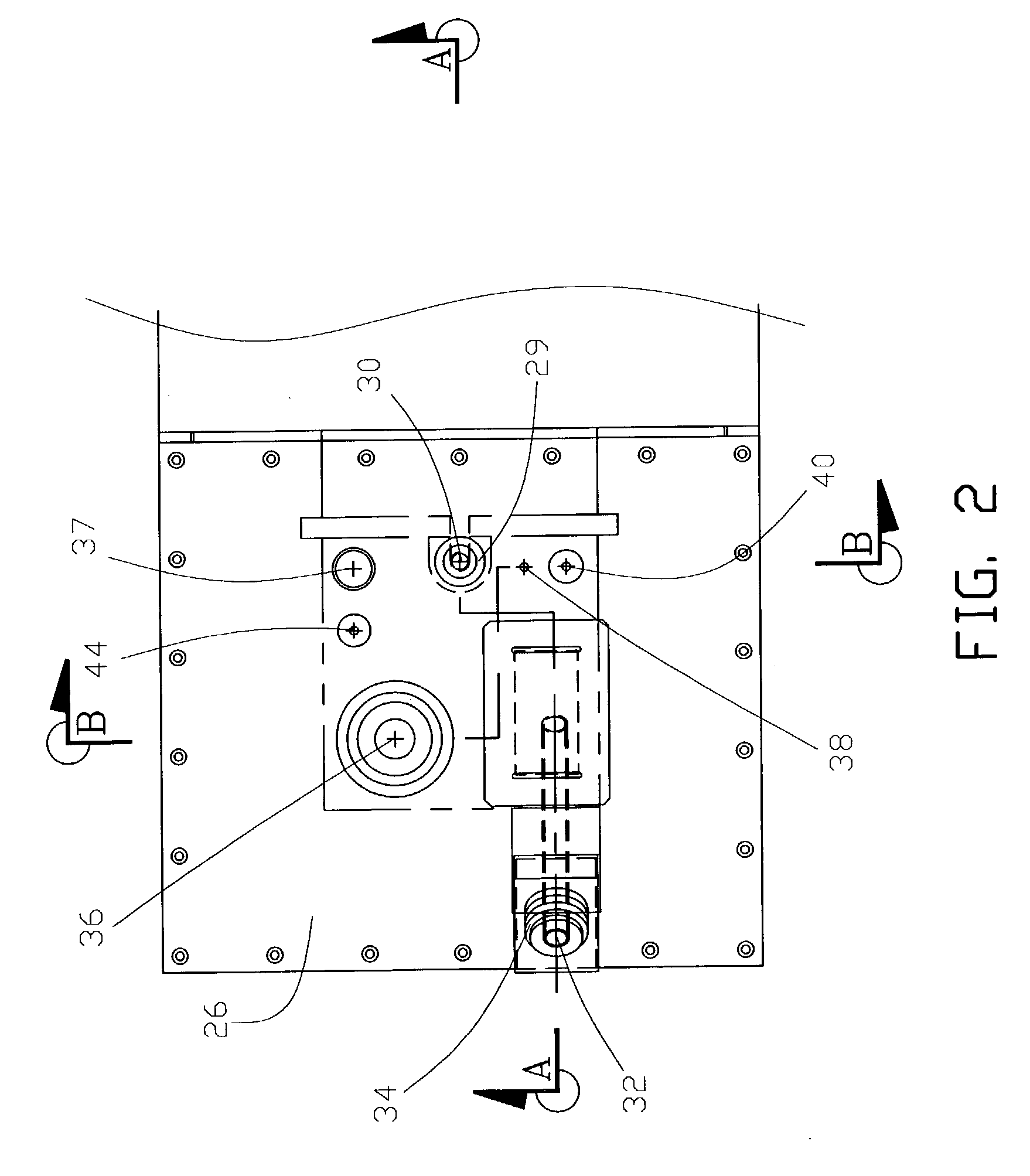

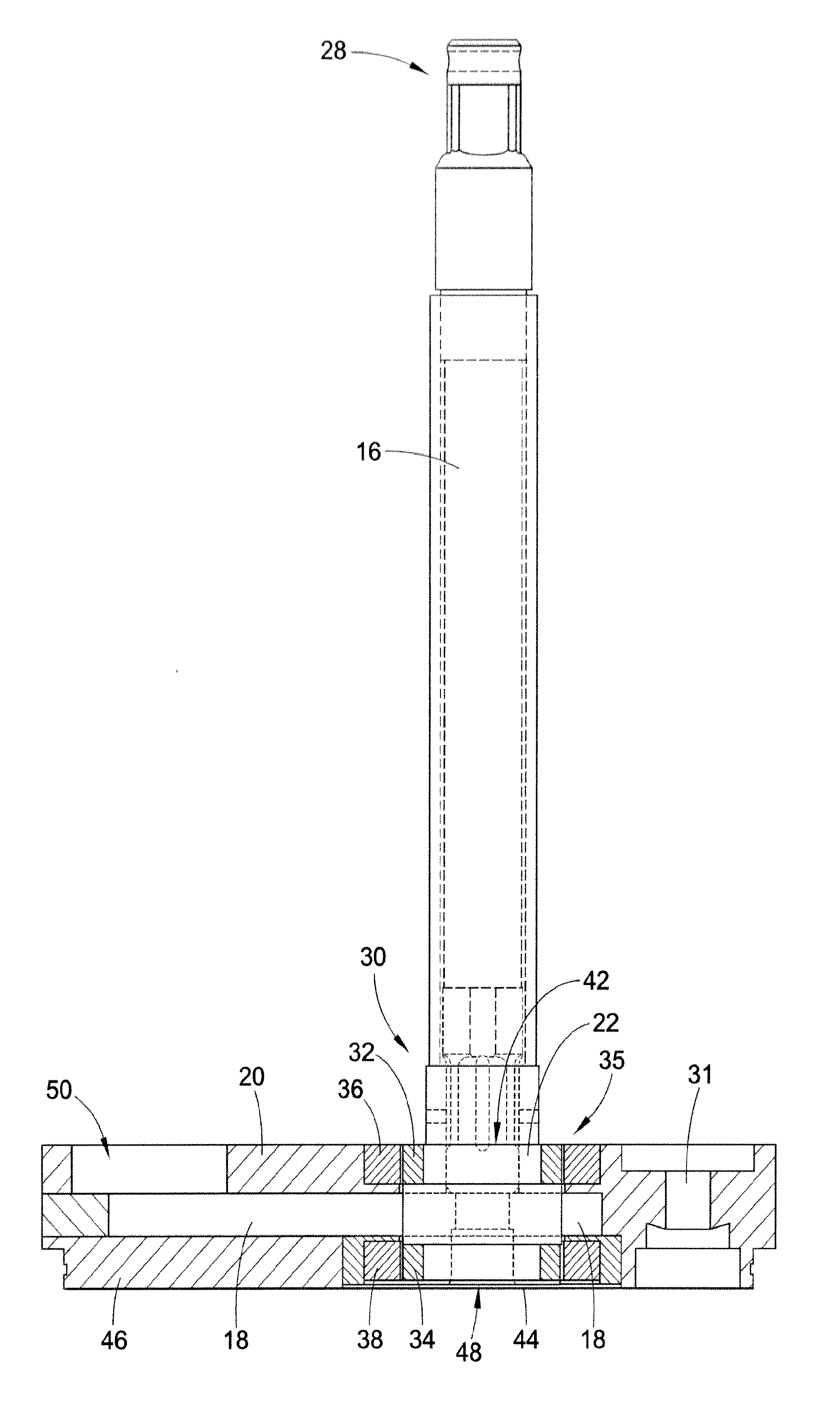

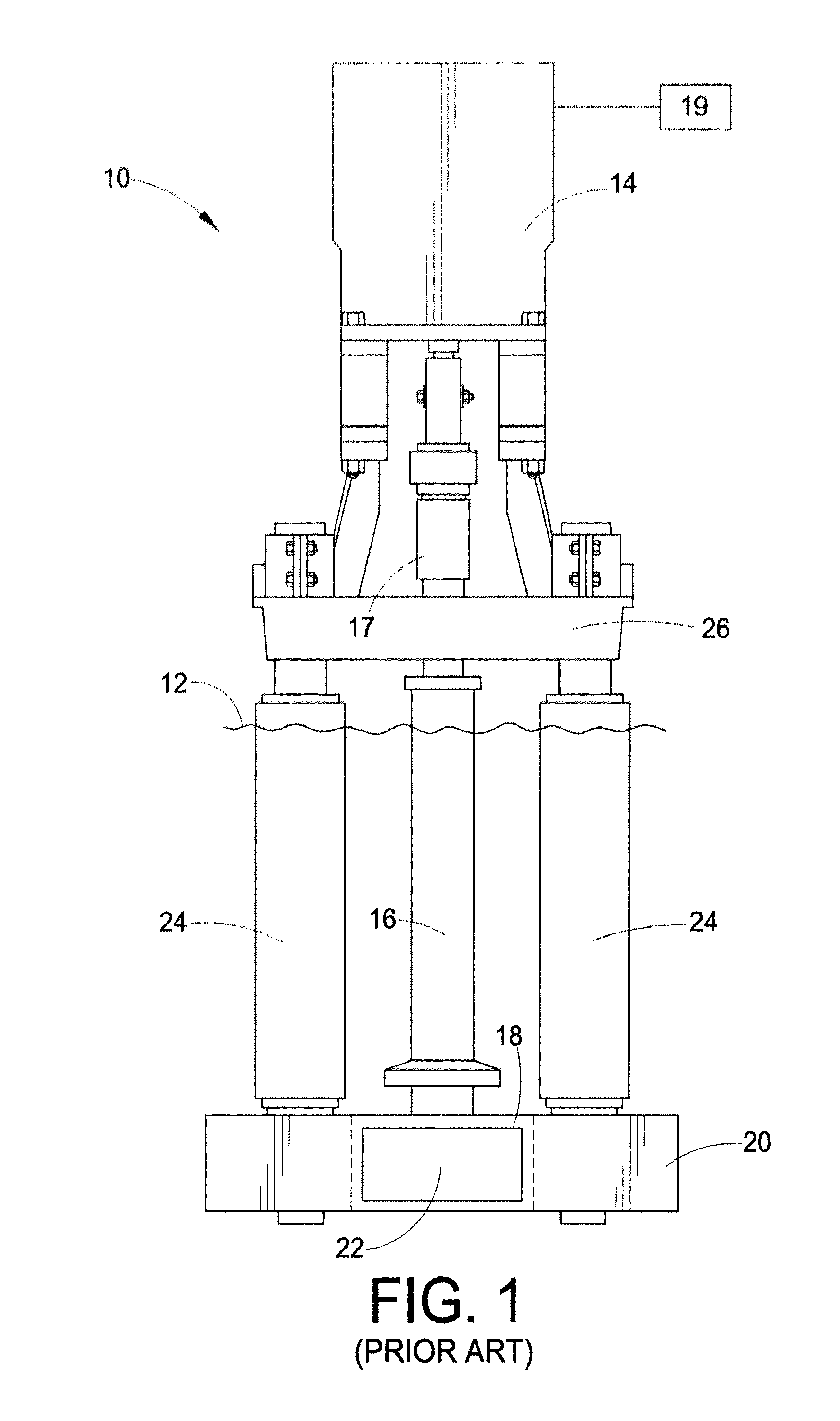

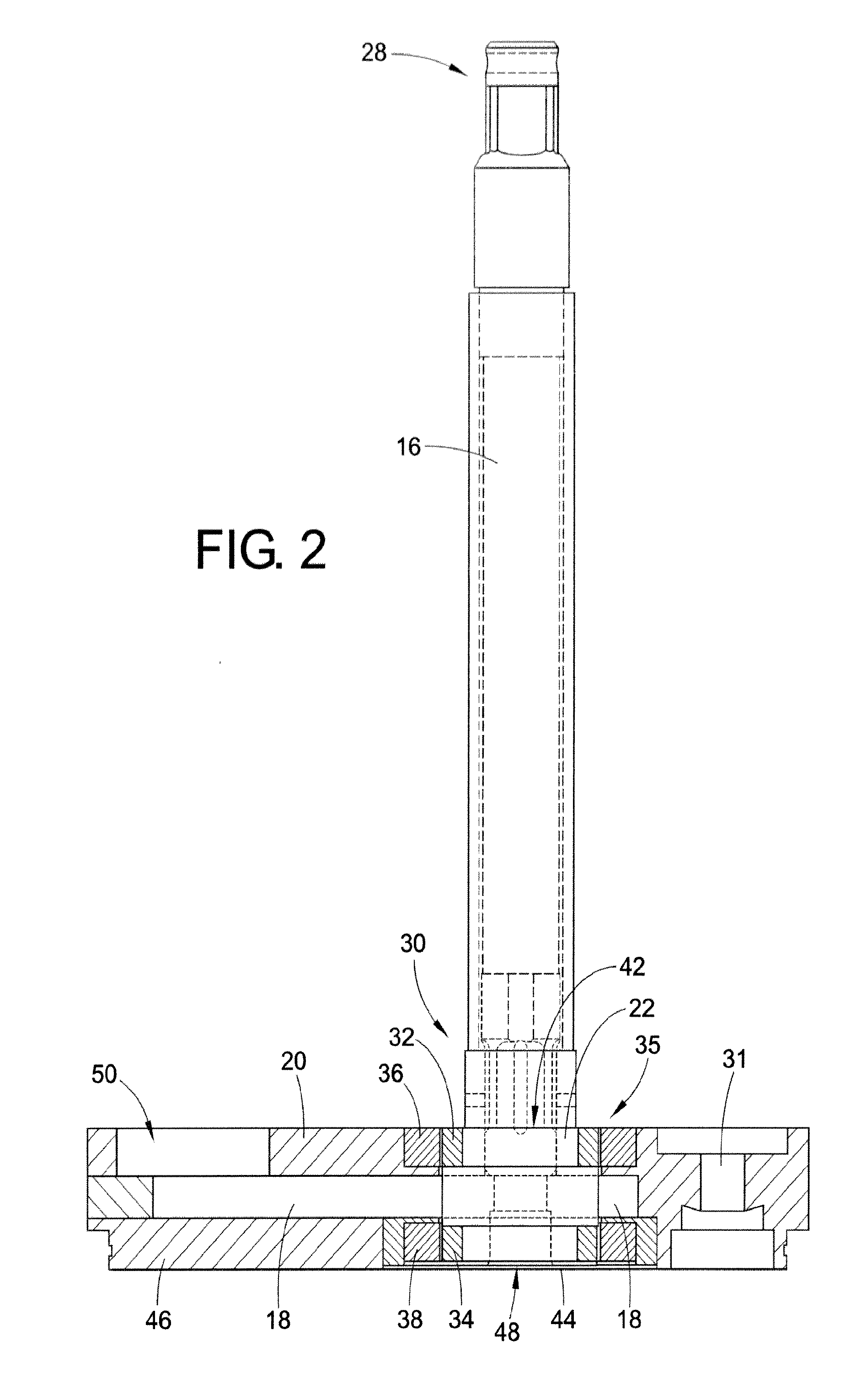

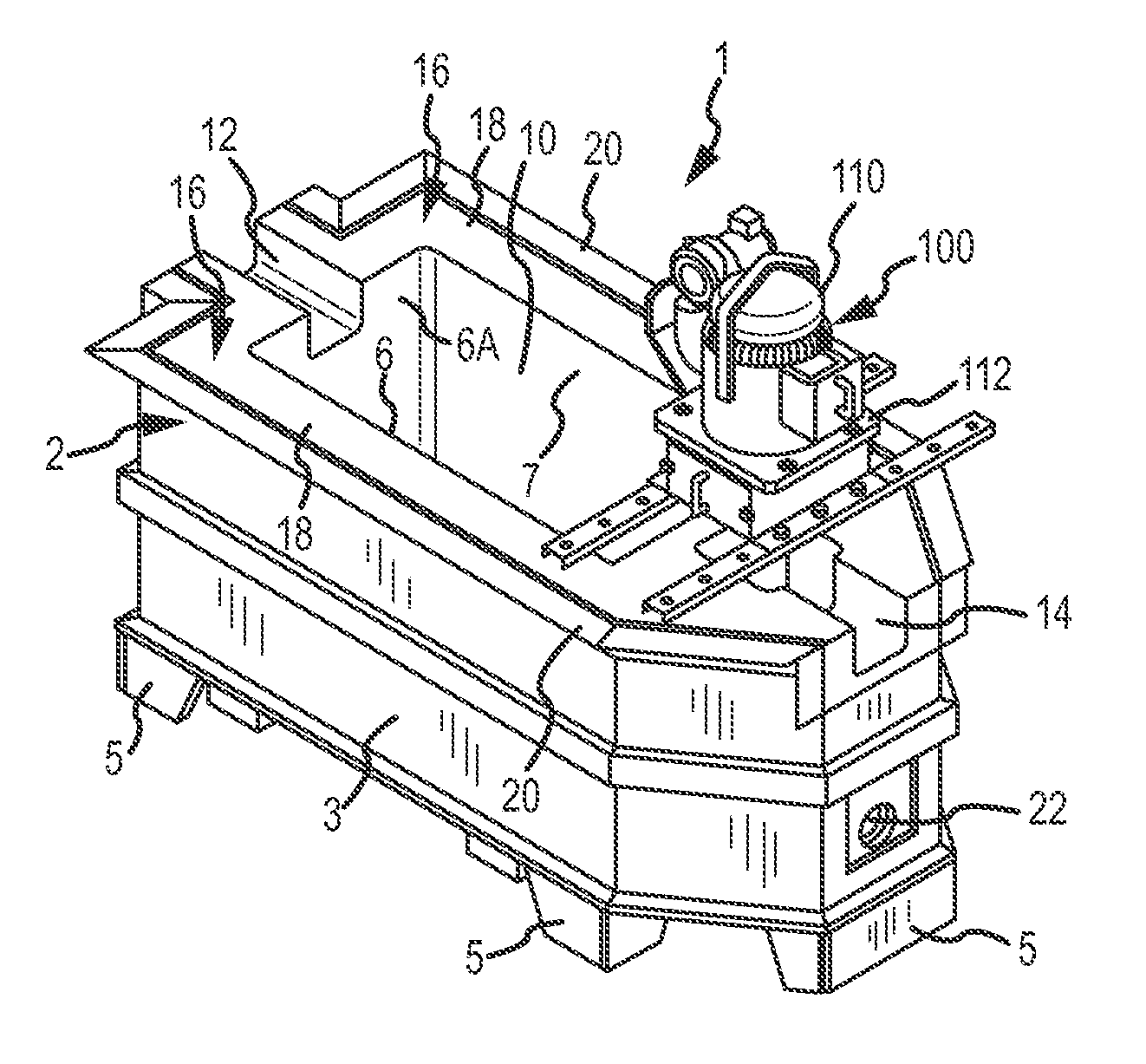

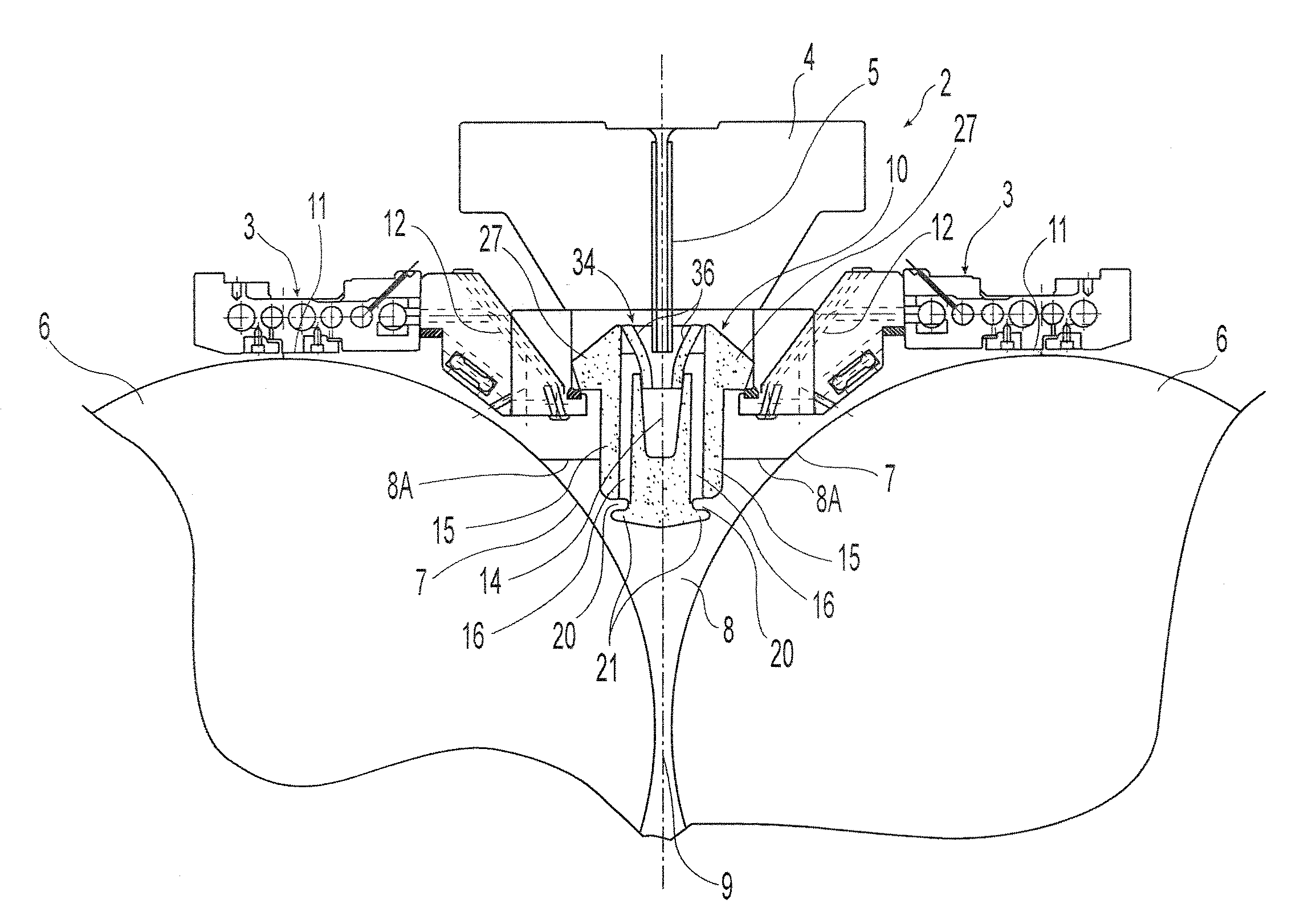

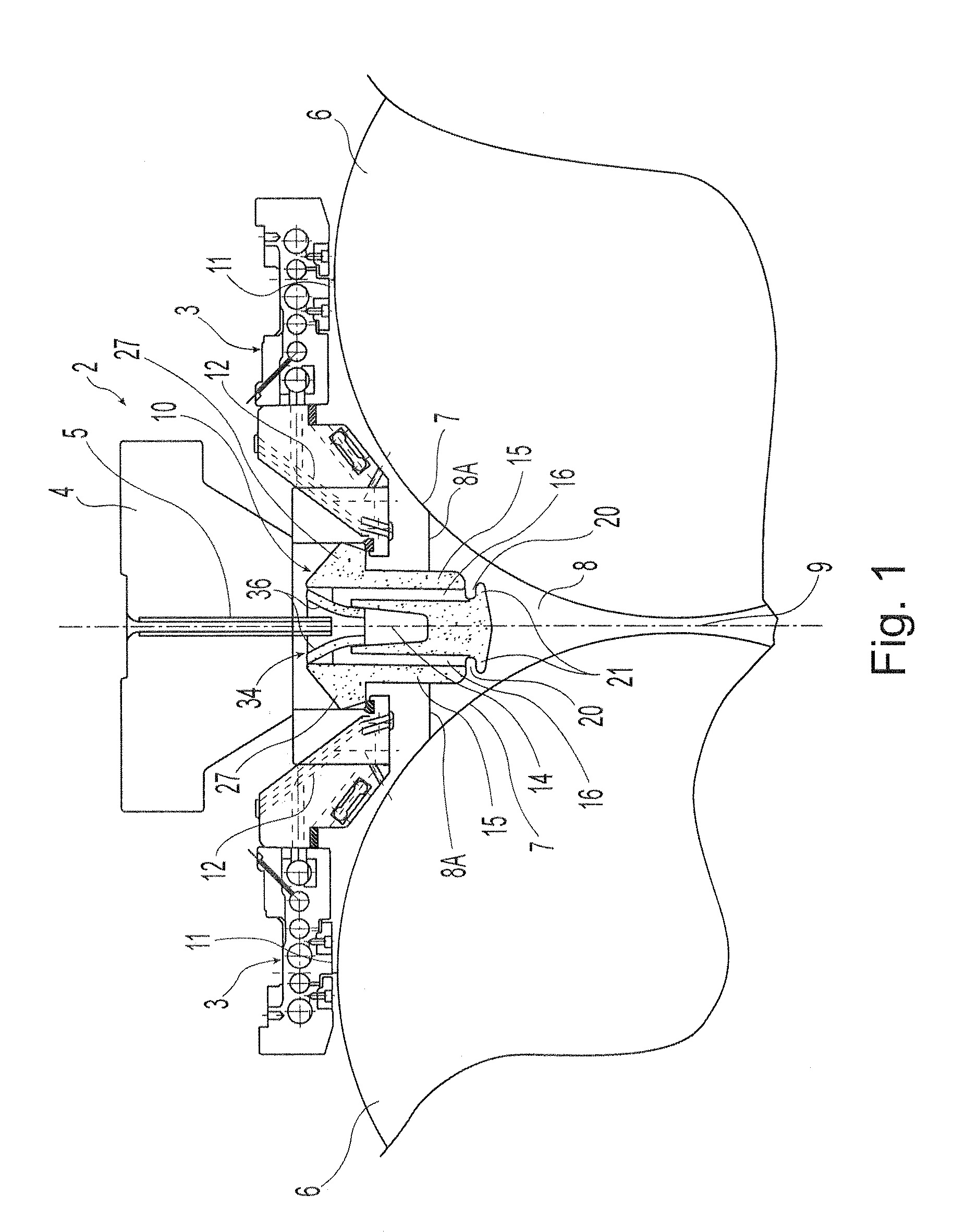

ActiveUS20140044520A1Easy to tunePrecise flow controlSpecific fluid pumpsPump componentsImpellerEngineering

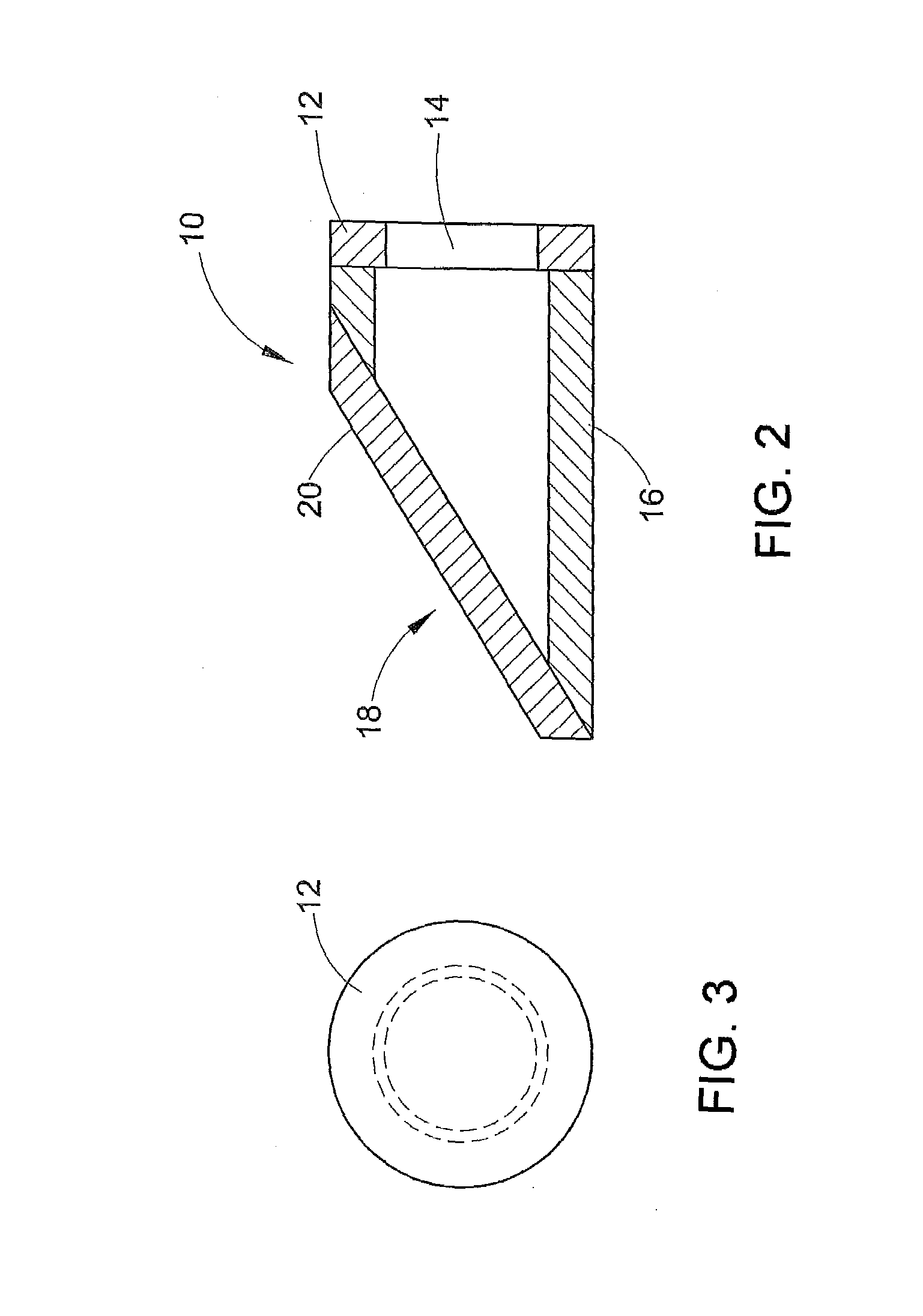

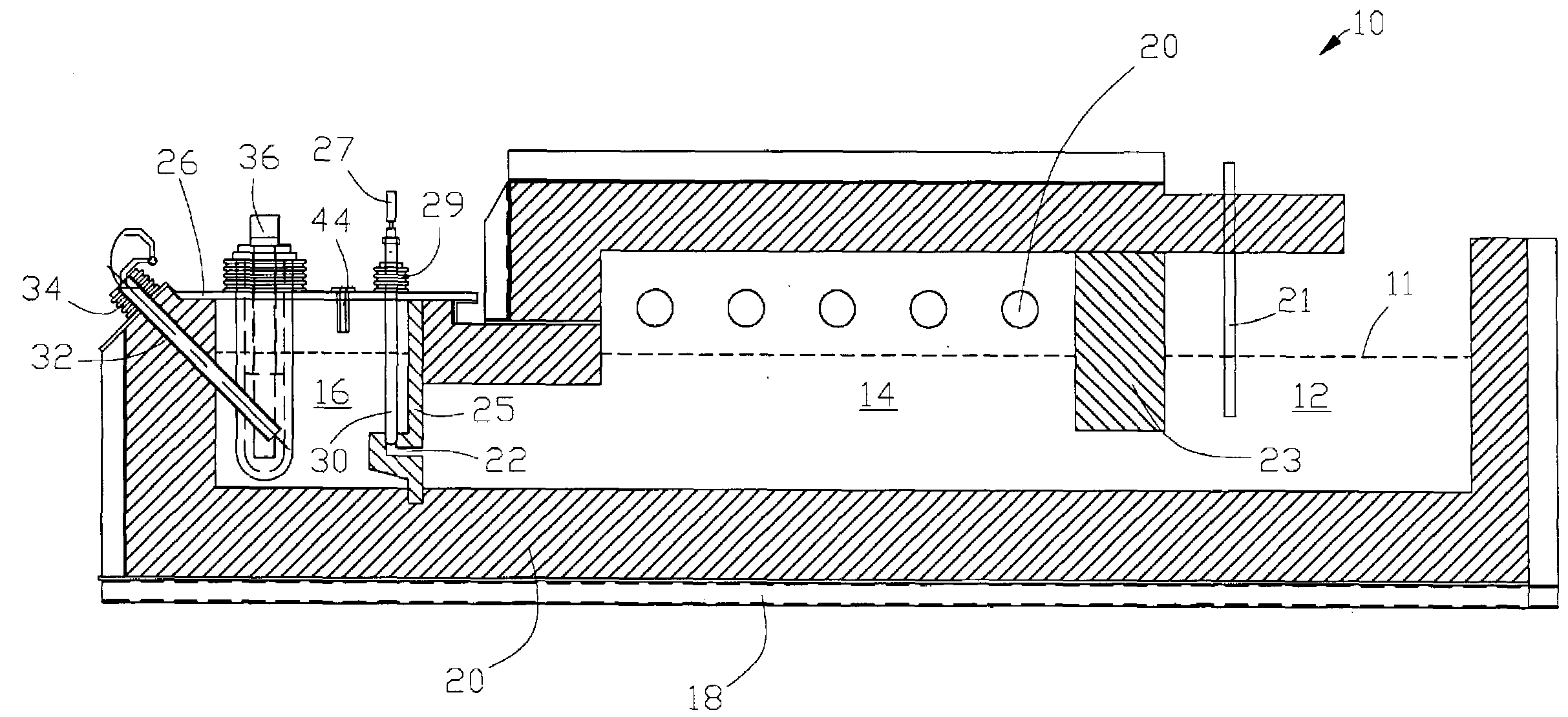

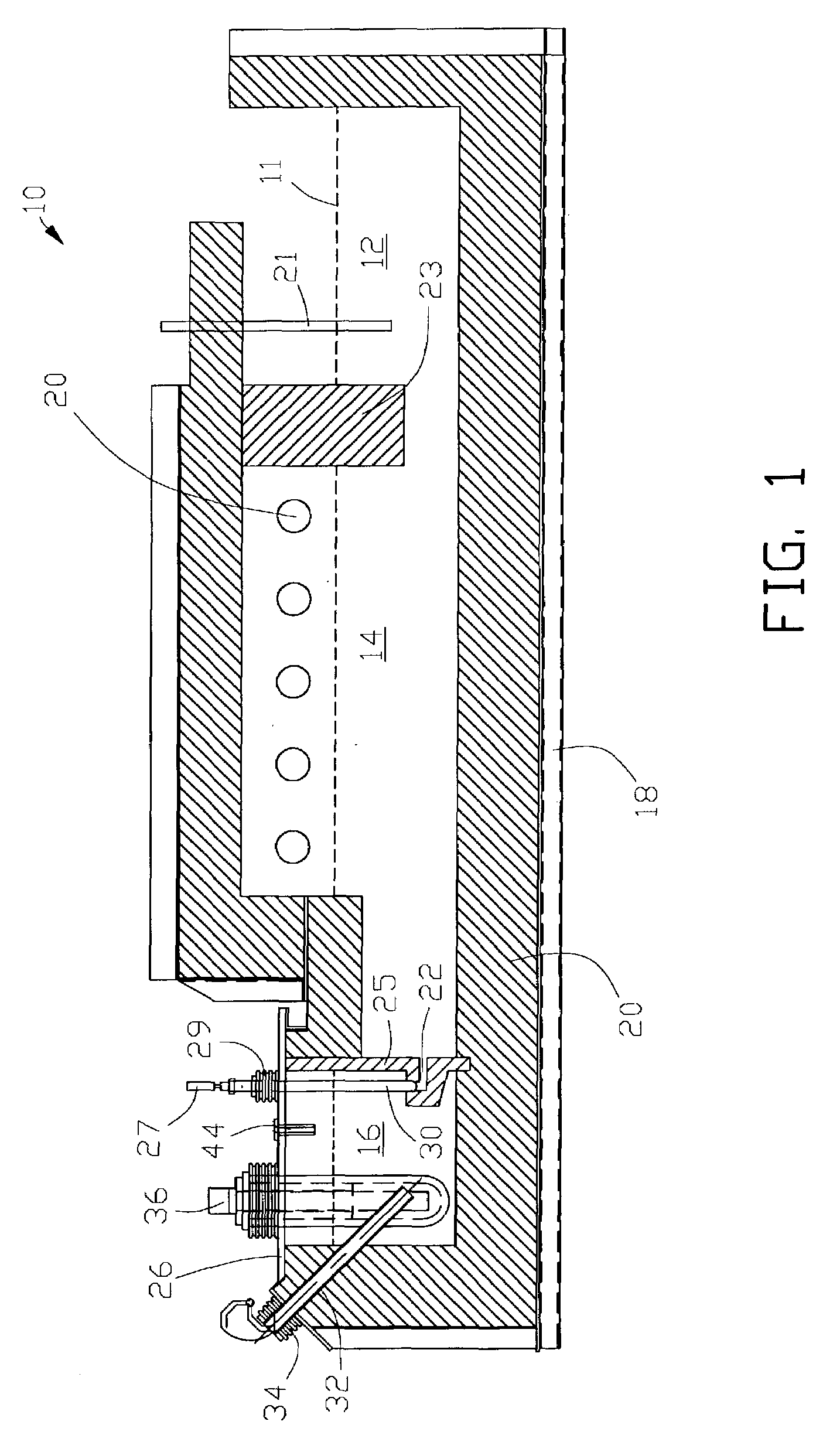

A molten metal pump assembly (10) and method to fill complex molds with molten metal, such as aluminum. The pump assembly includes an elongated shaft (16) connecting a motor (14) to an impeller (22). The impeller is housed within a chamber (18) of a base member such that rotation of the impeller draws molten metal into the chamber at an inlet (48) and forces molten aluminum through an outlet (50). A first bearing (36) is adapted to support the rotation of the impeller at a first radial edge (32) and a second bearing (38) is adapted to support the rotation of the impeller at a second radial edge. A bypass gap (60) is interposed between the second bearing and the second radial edge. Molten metal leaks through the bypass gap at a predetermined rate to manipulate a flow rate and a head pressure of the molten metal such that precise control of the flow rate is achieved.

Owner:PYROTECK INC

Investment casting mold design and method for investment casting using the same

ActiveUS7231955B1Molten metal pouring equipmentsMolten metal supplying equipmentsInvestment castingCasting mold

A method for investment casting includes the steps of positioning a base plate relative to a die; molding a first material between the die and at least a first surface portion of the base plate; securing one or more patterns to the base plate, the one or more patterns comprising a second material; applying one or more coating layers over at least portions of the one or more patterns and at least a portion of the first material; substantially removing the first material through an interior receptacle of a manifold body and the second material through an exterior receptacle of the manifold body to leave one or more shells formed by the coating layers; removing said base plate; introducing molten metal to the one or more shells through the interior receptacle of the manifold body; permitting the molten metal to solidify; and destructively removing one or more investment casting molds.

Owner:RTX CORP

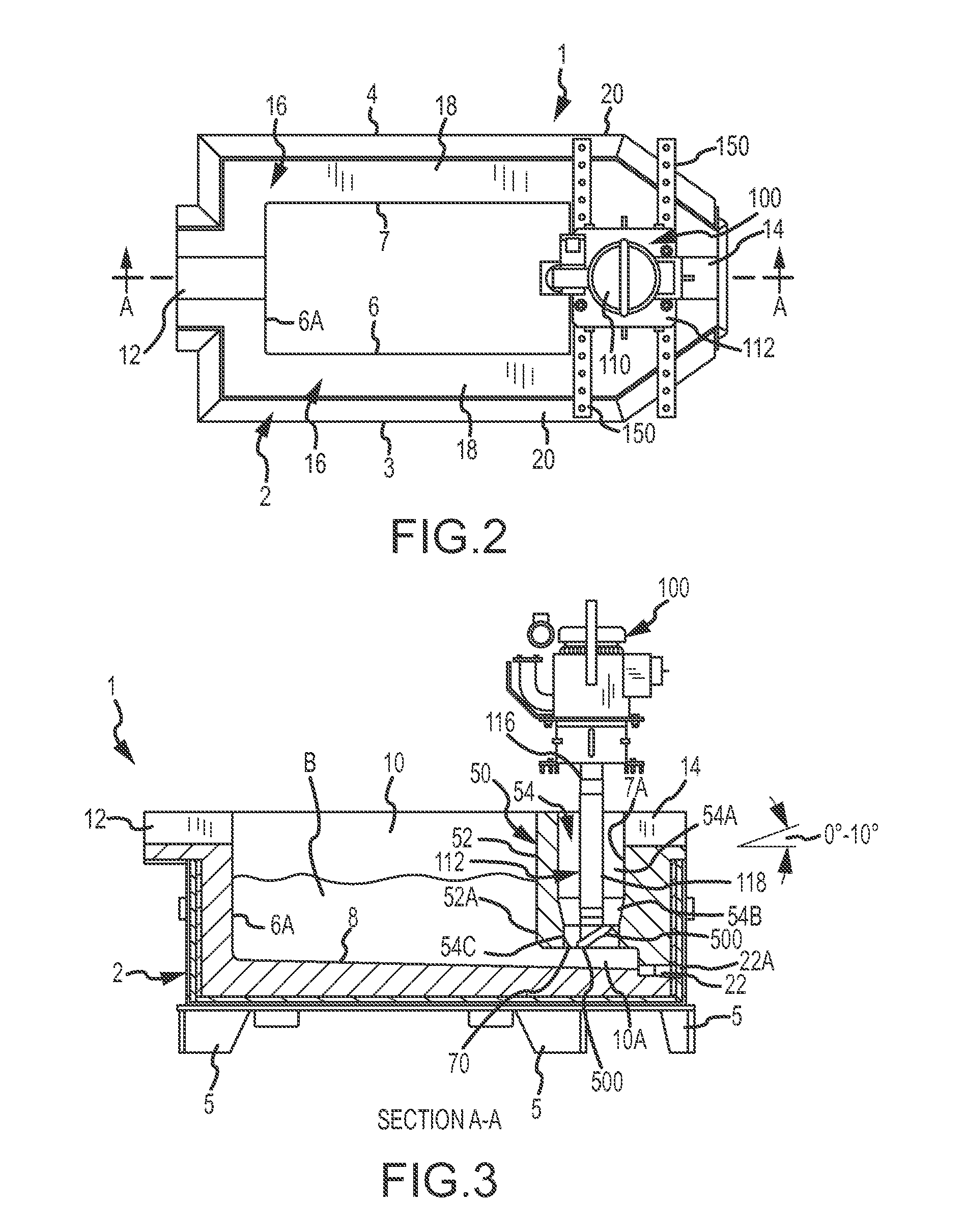

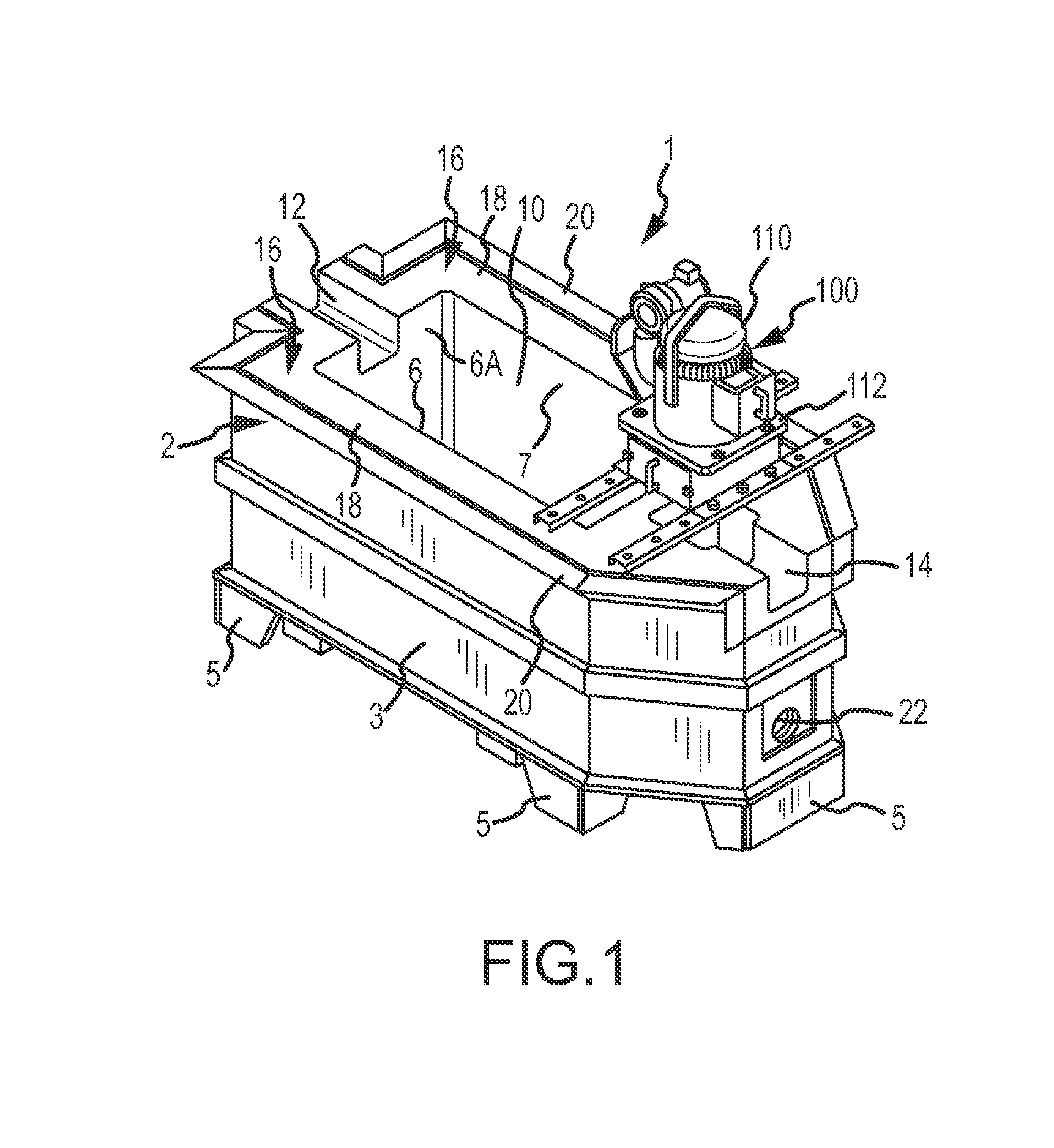

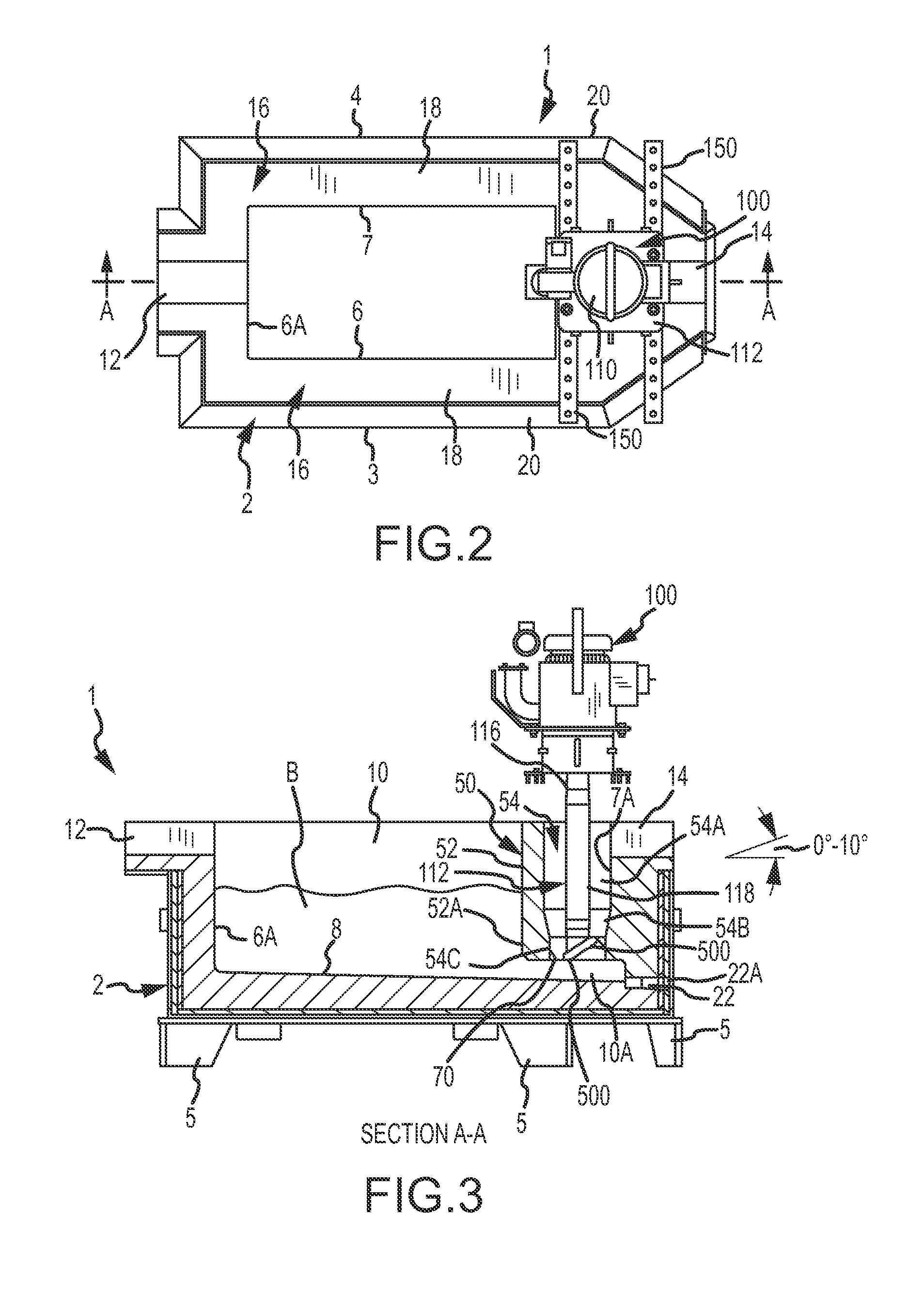

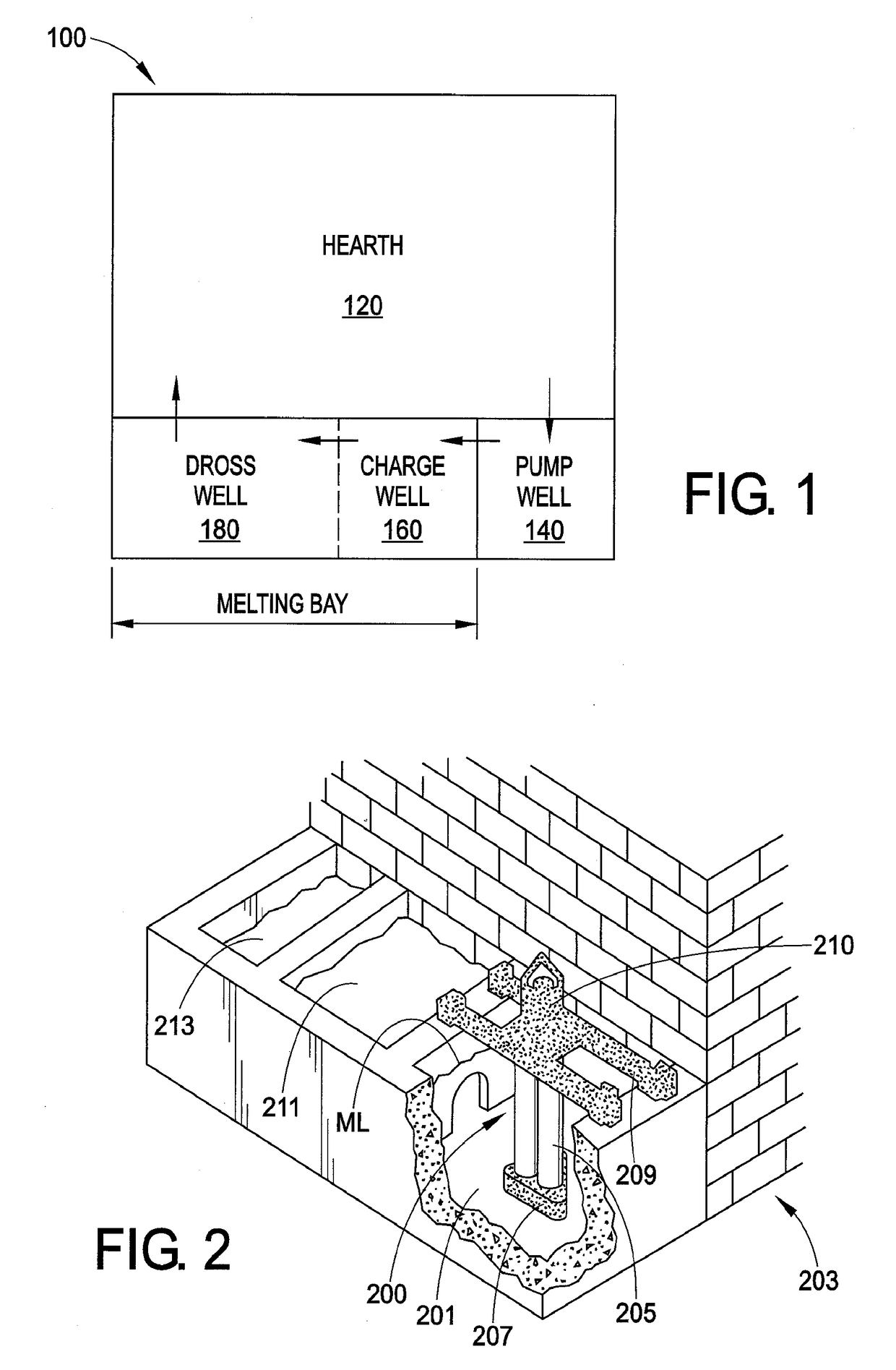

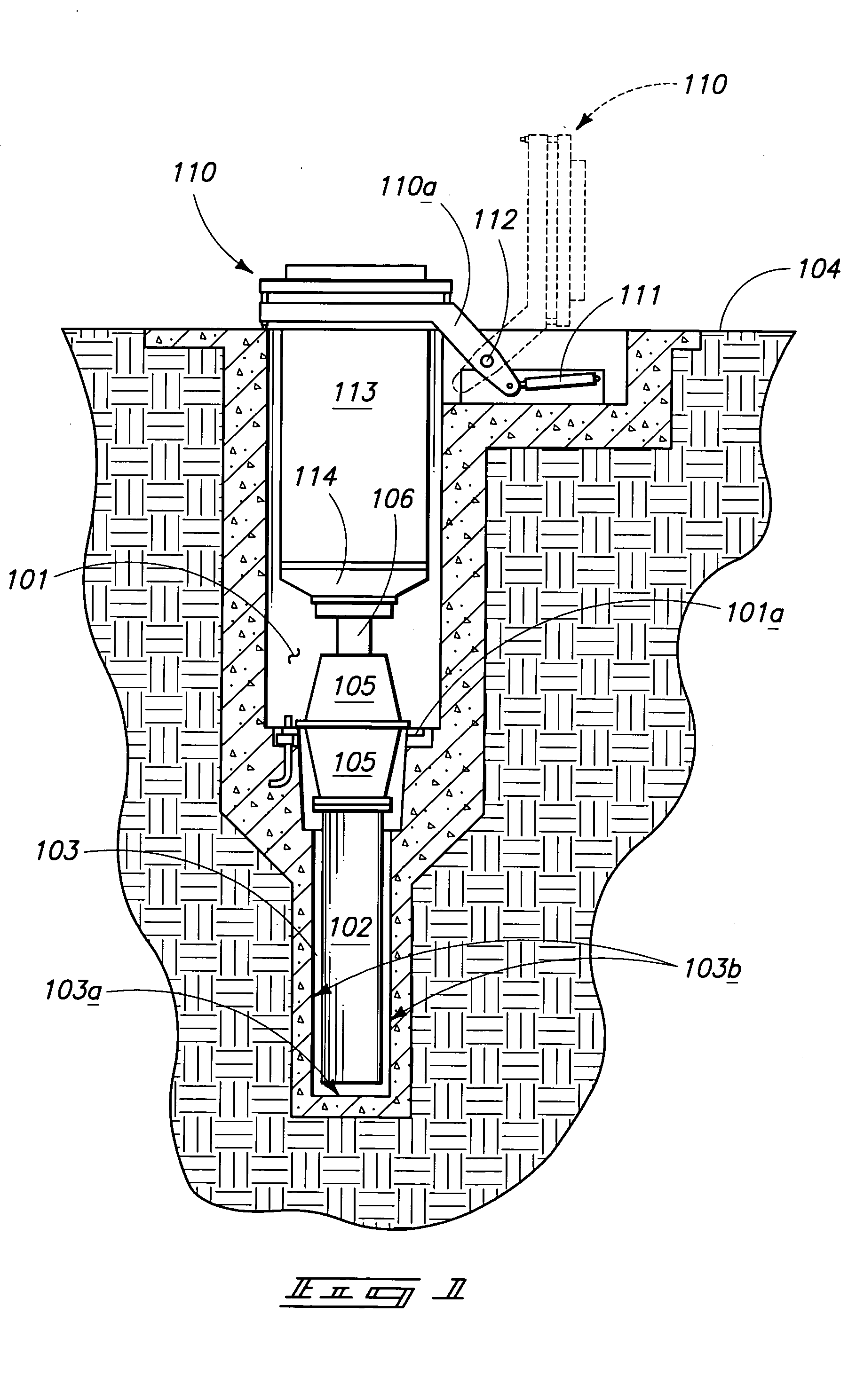

Method of forming transfer well

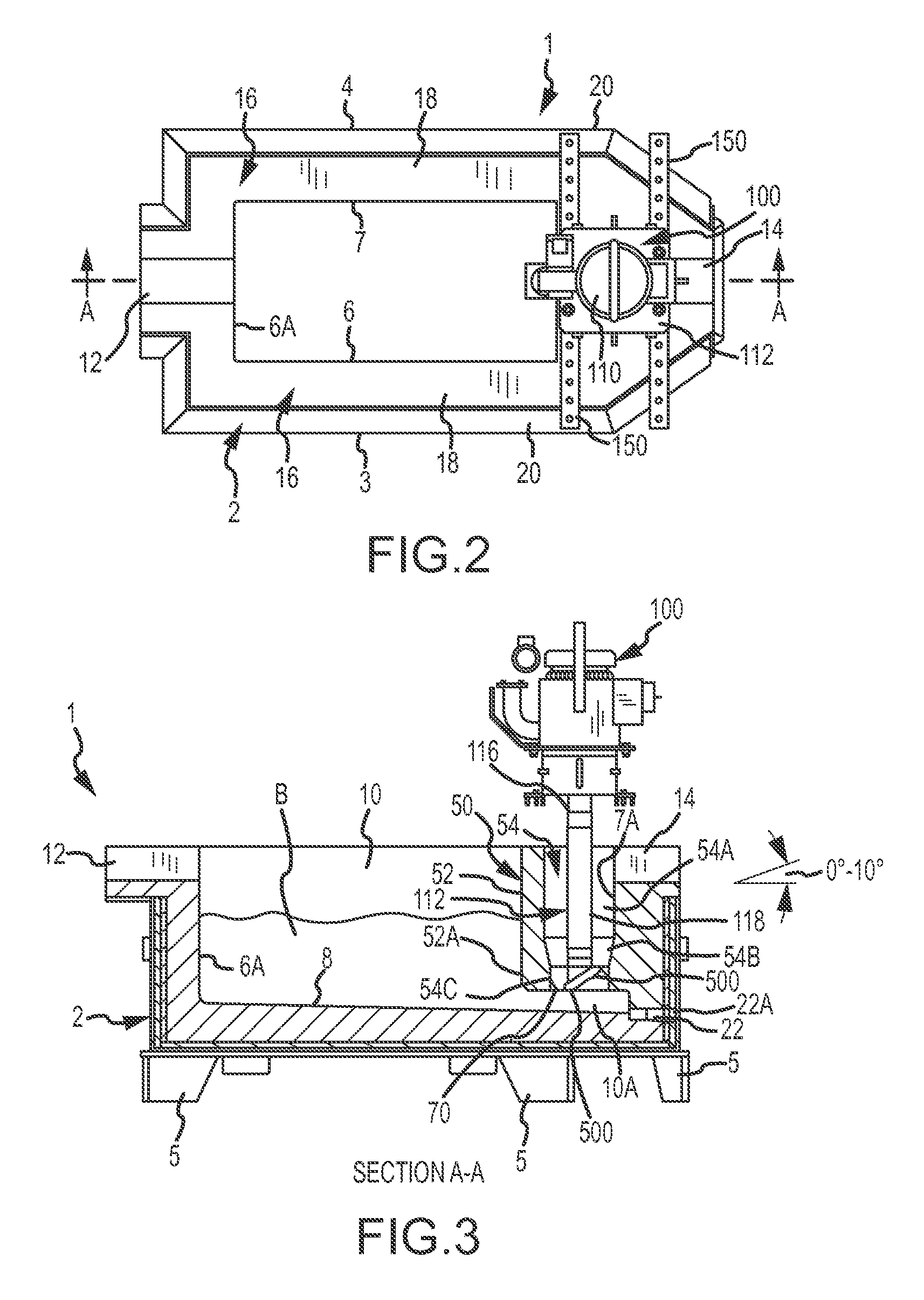

ActiveUS20160082507A1Melt-holding vesselsMolten metal pouring equipmentsMarine engineeringMolten metal

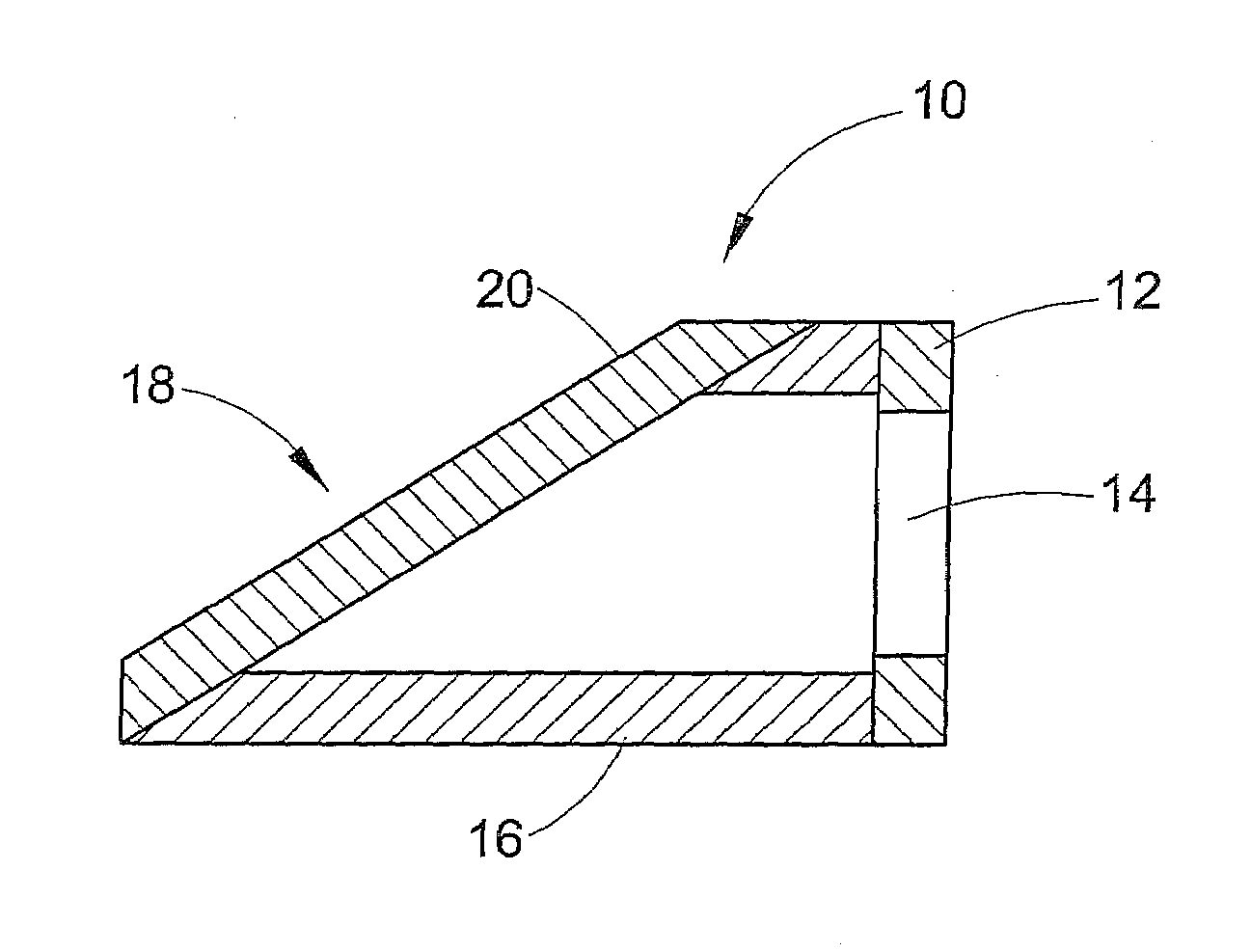

The invention relates to systems for transferring molten metal from one structure to another. Aspects of the invention include a transfer chamber constructed inside of or next to a vessel used to retain molten metal. The transfer chamber is in fluid communication with the vessel so molten metal from the vessel can enter the transfer chamber. A powered device, which may be inside of the transfer chamber, moves molten metal upward and out of the transfer chamber and preferably into a structure outside of the vessel, such as another vessel or a launder.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

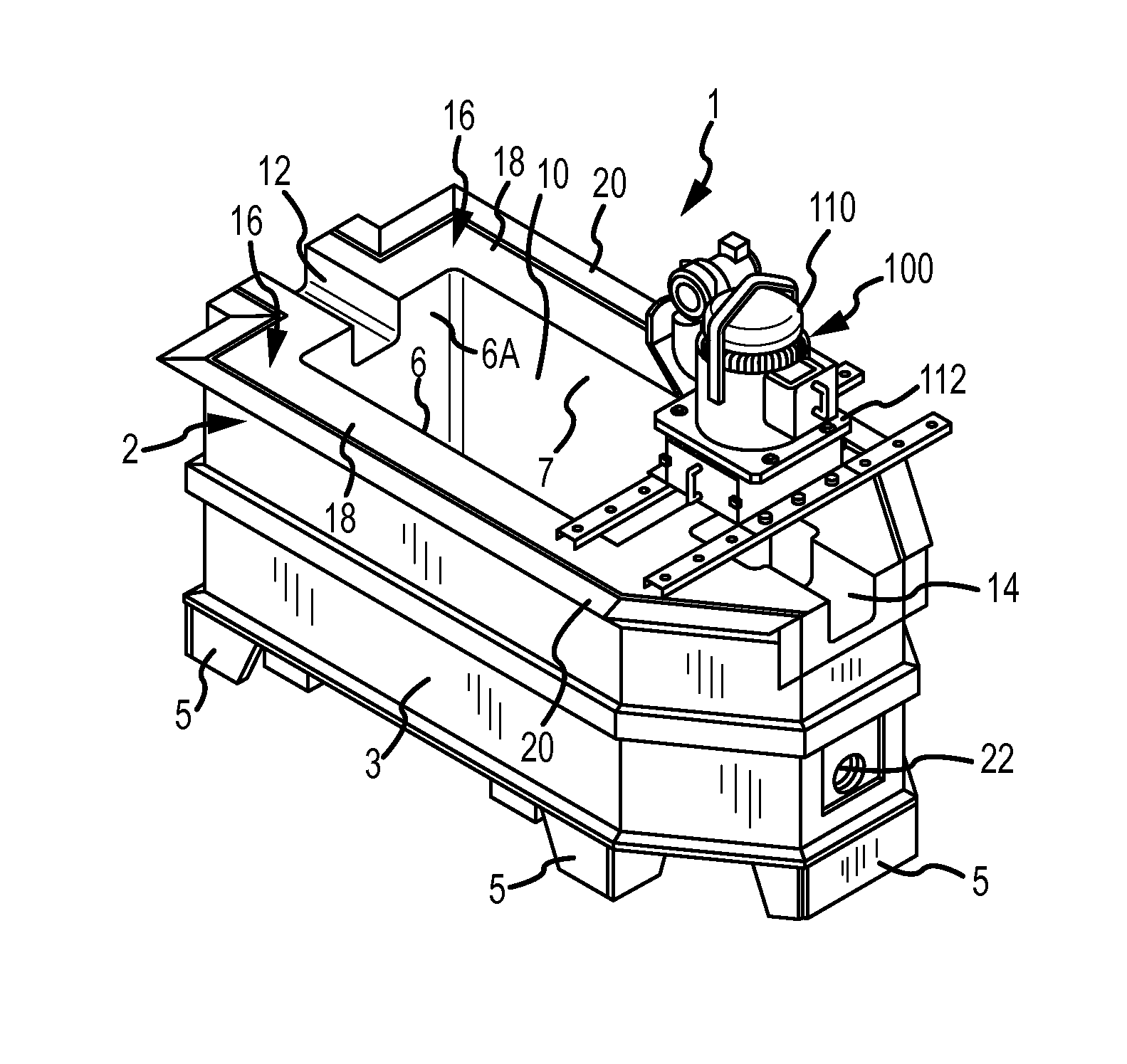

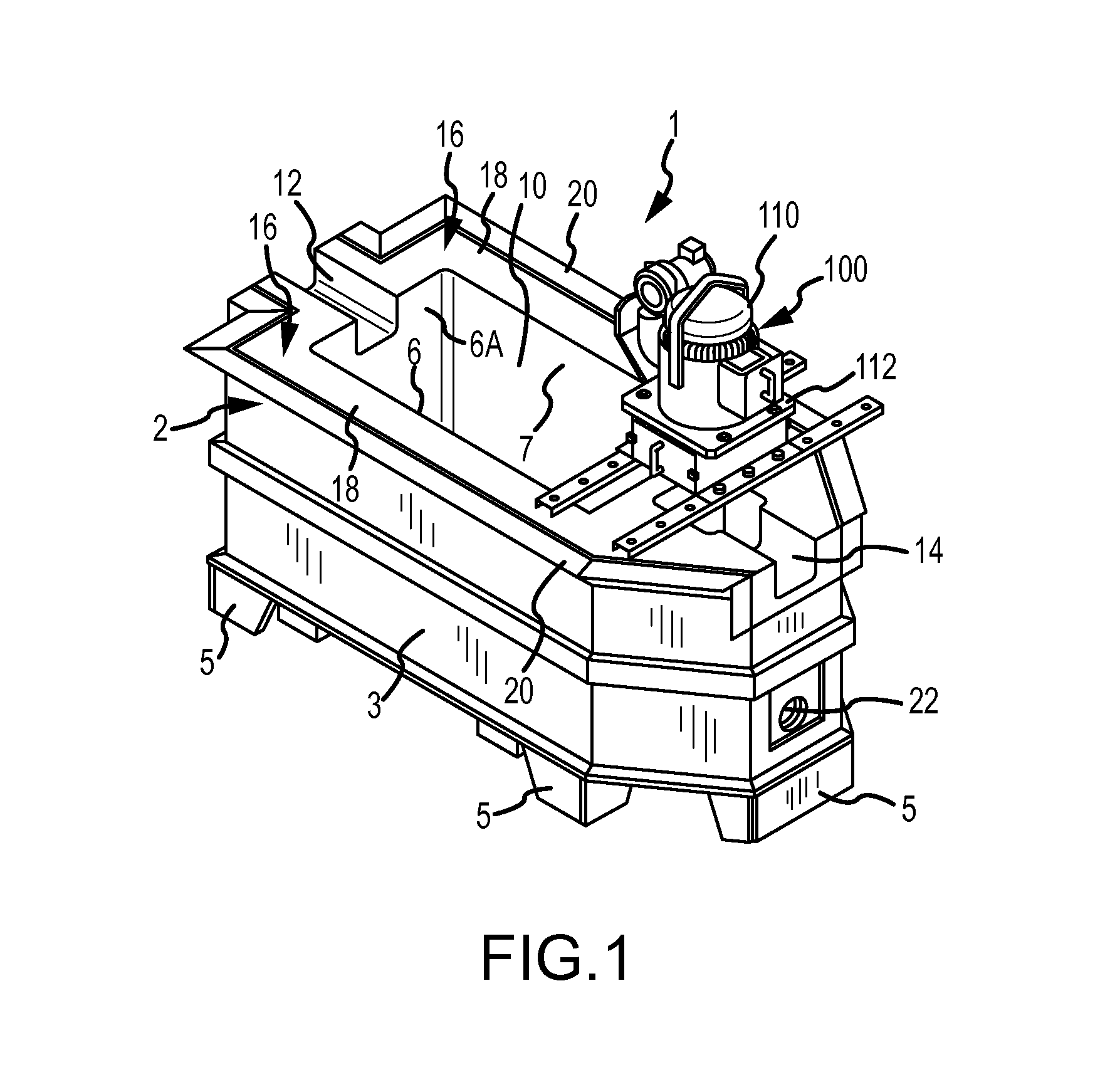

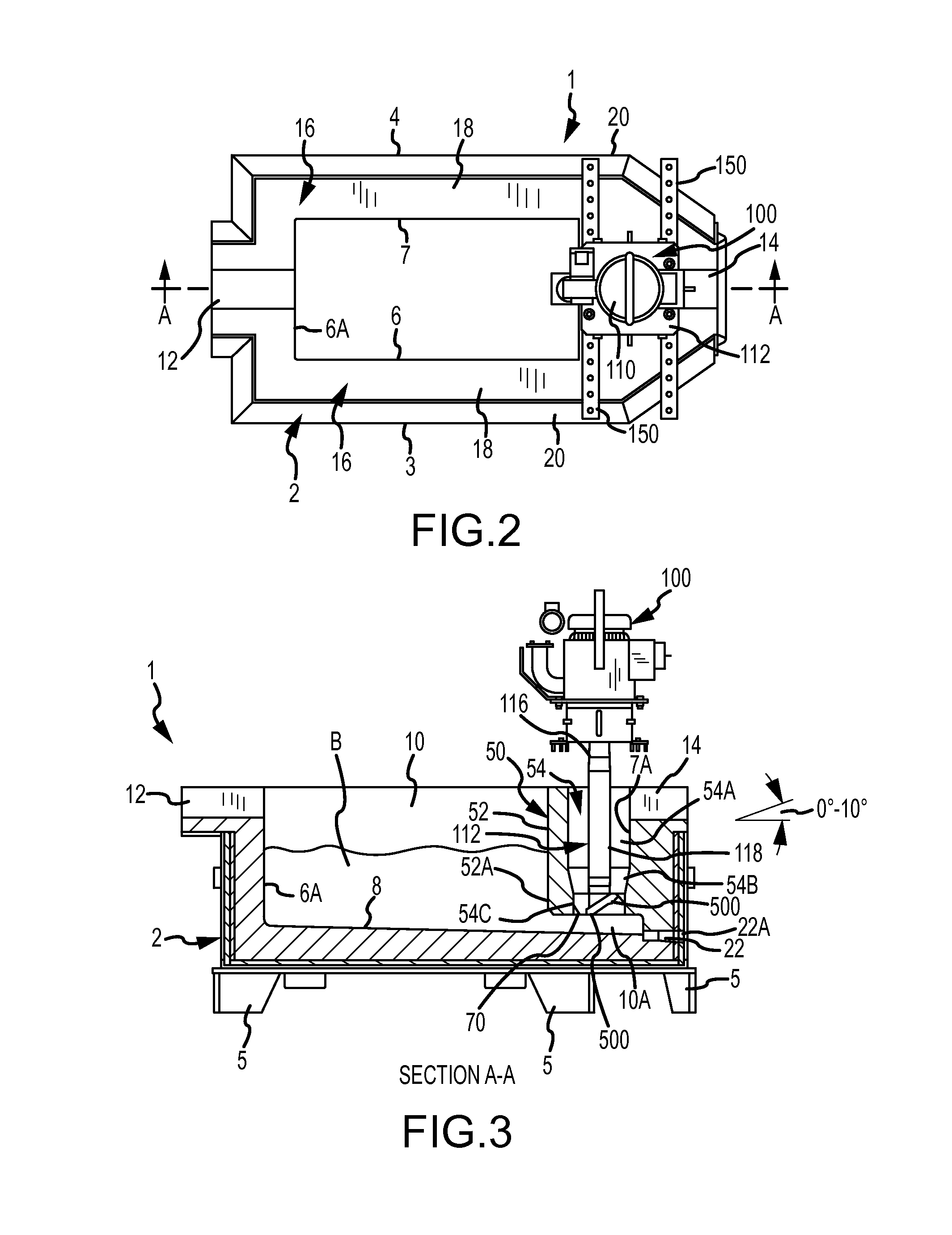

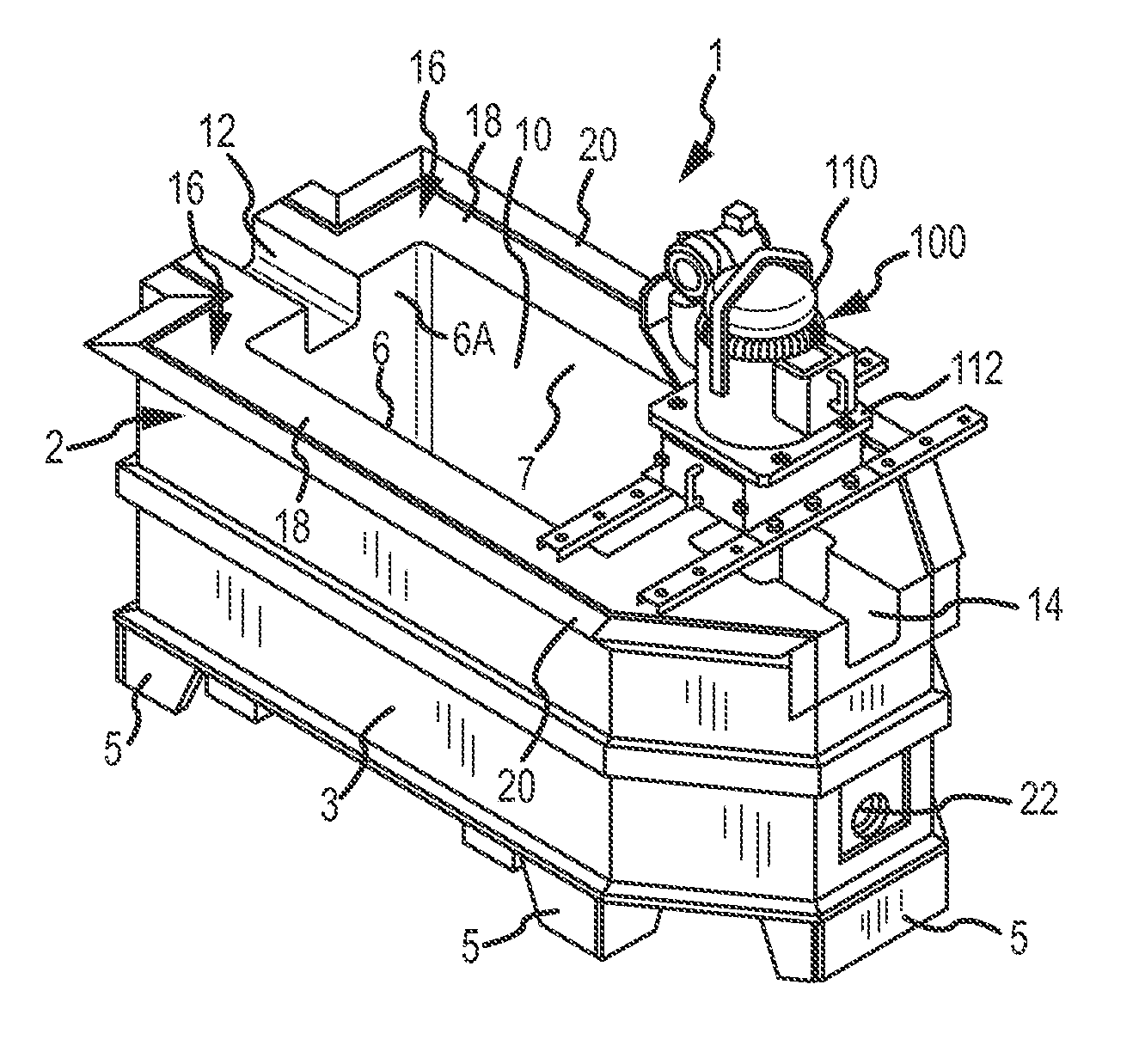

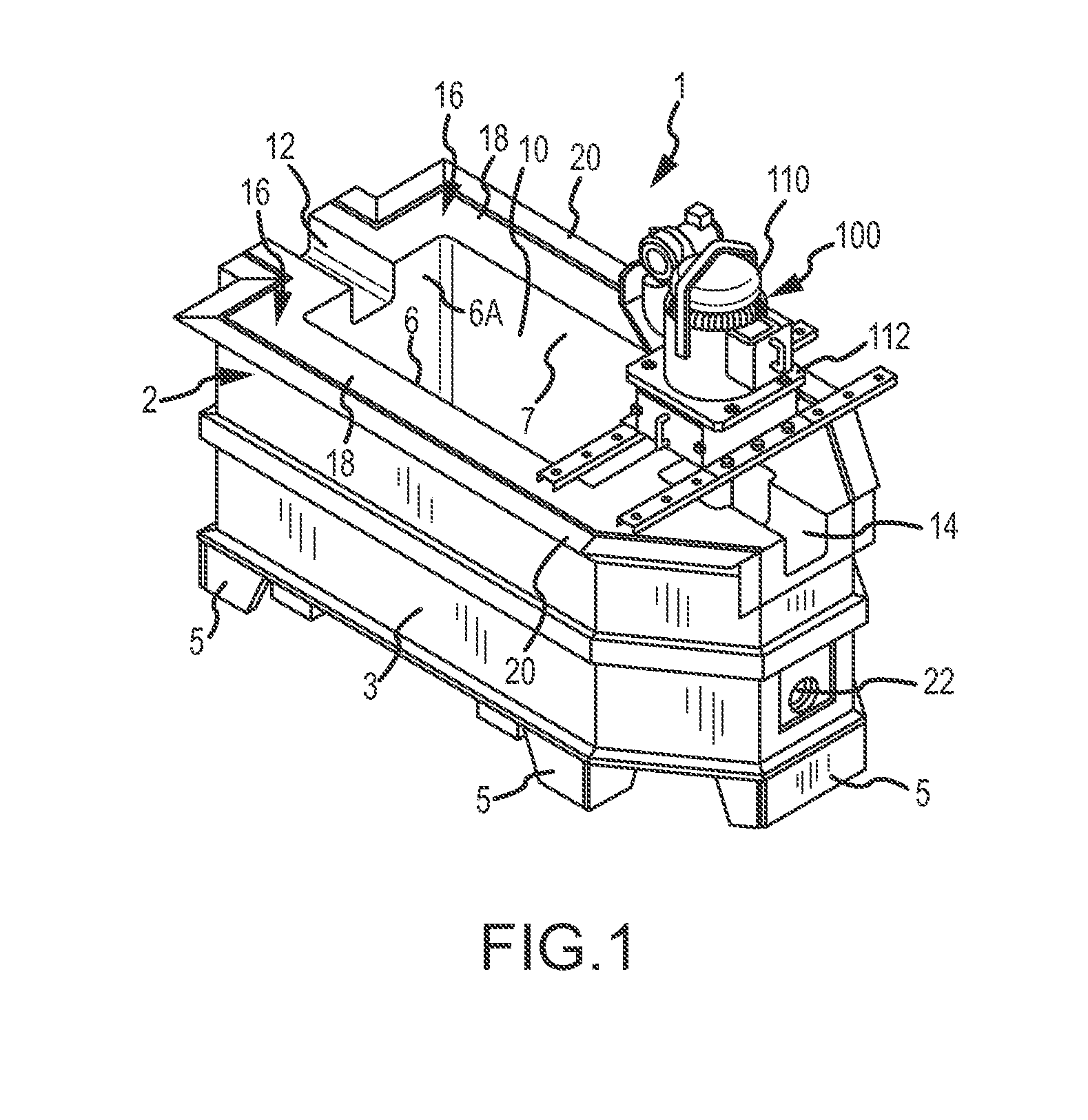

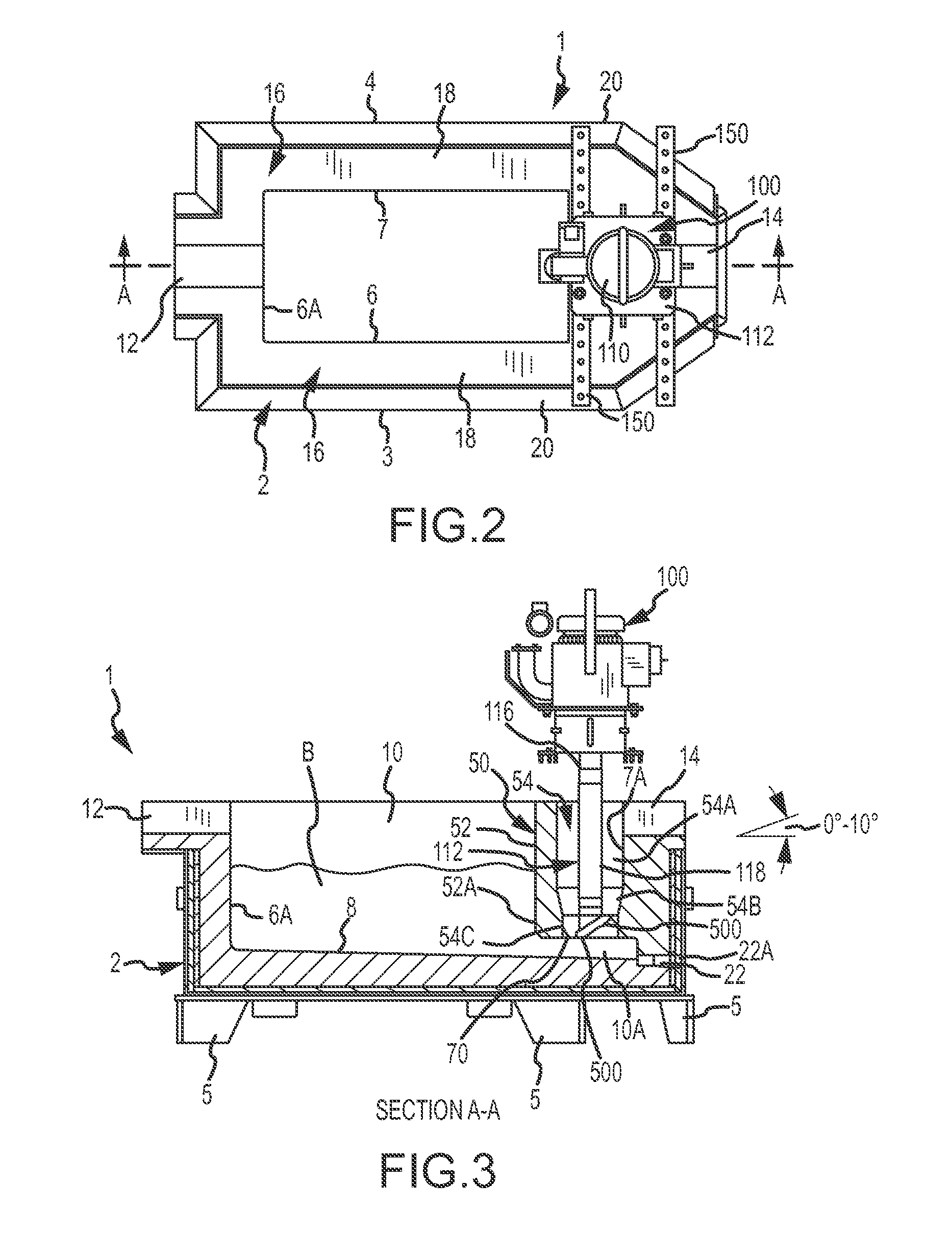

Transfer well system and method for making same

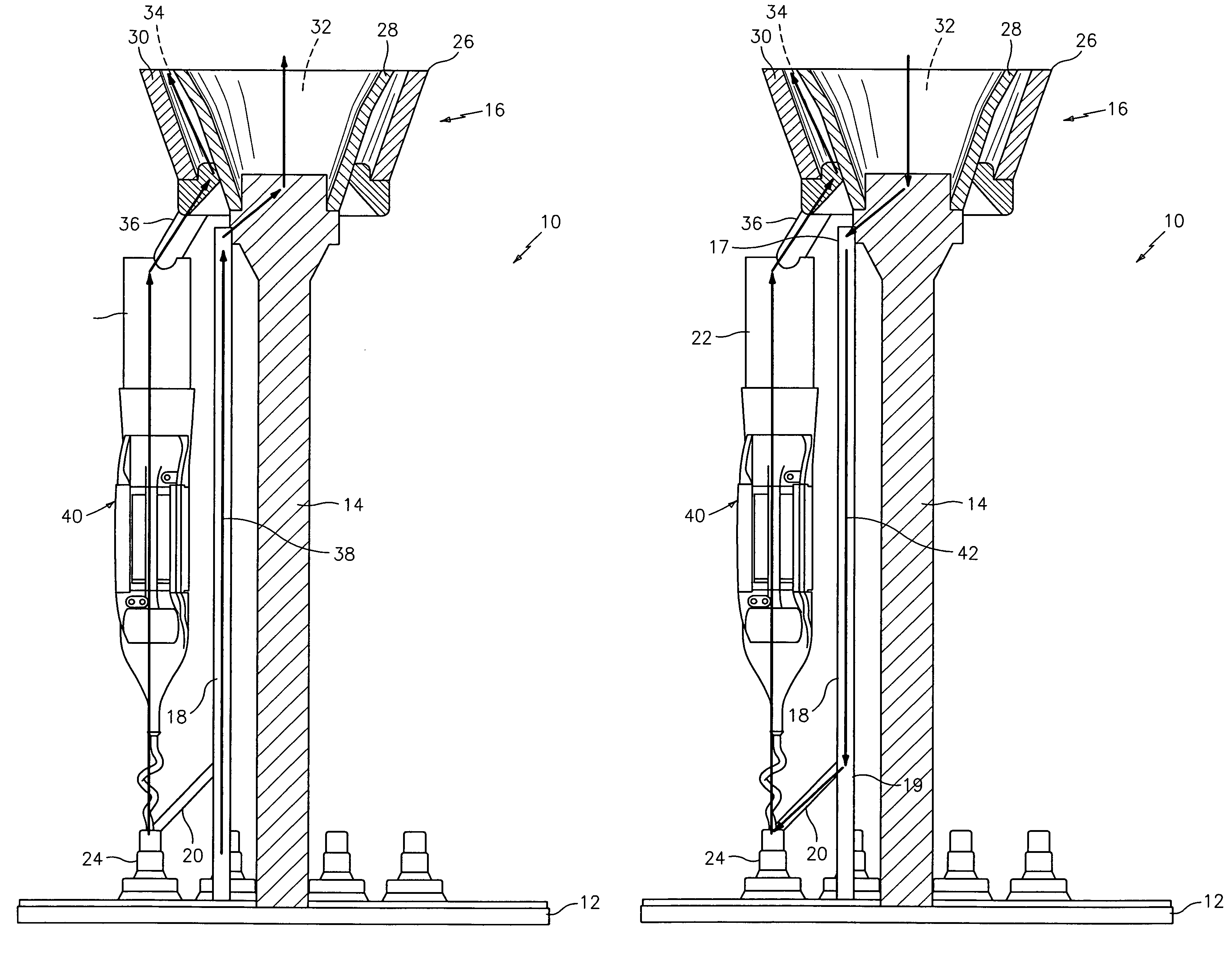

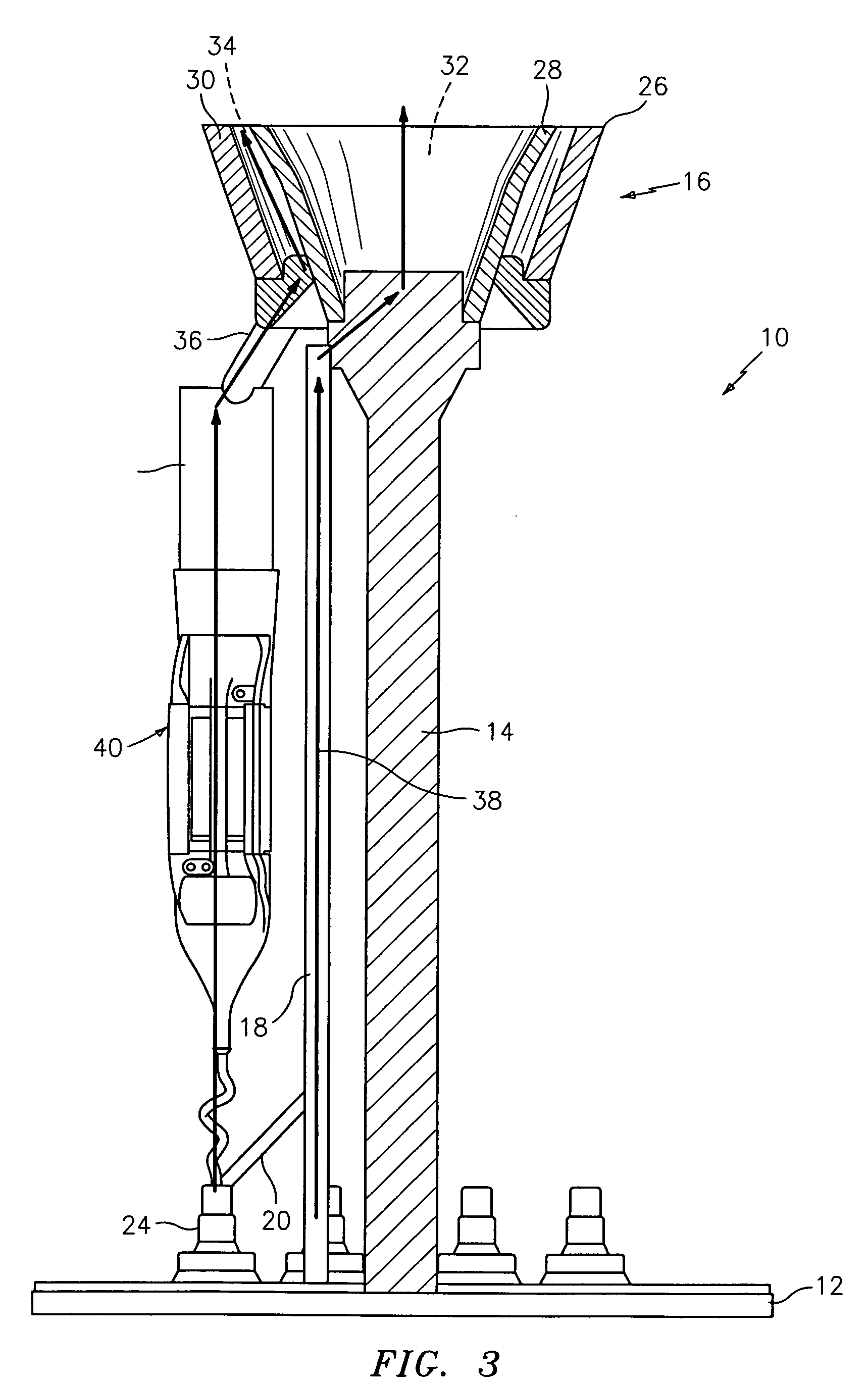

ActiveUS20130292426A1Melt-holding vesselsMolten metal pouring equipmentsMarine engineeringMolten metal

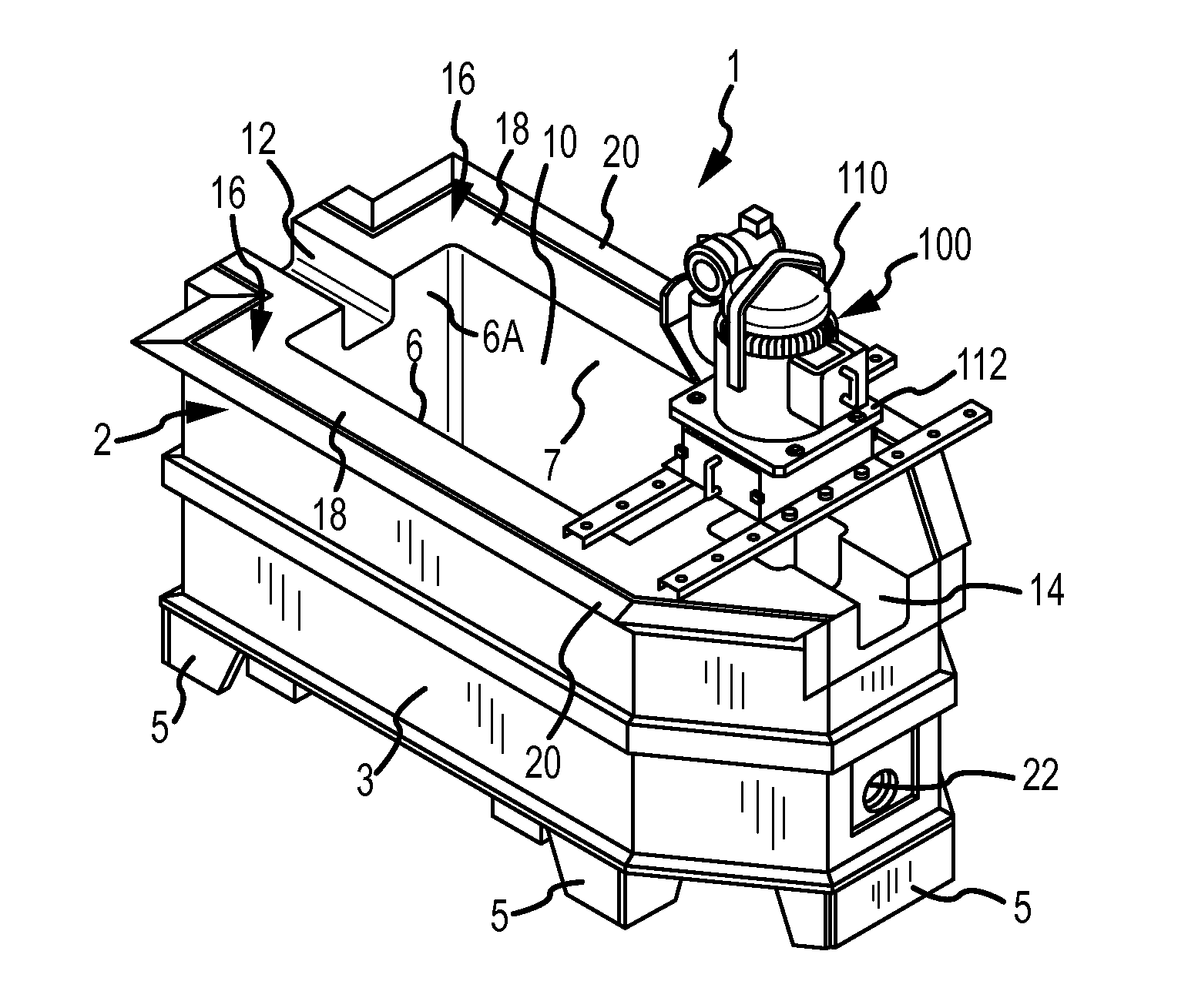

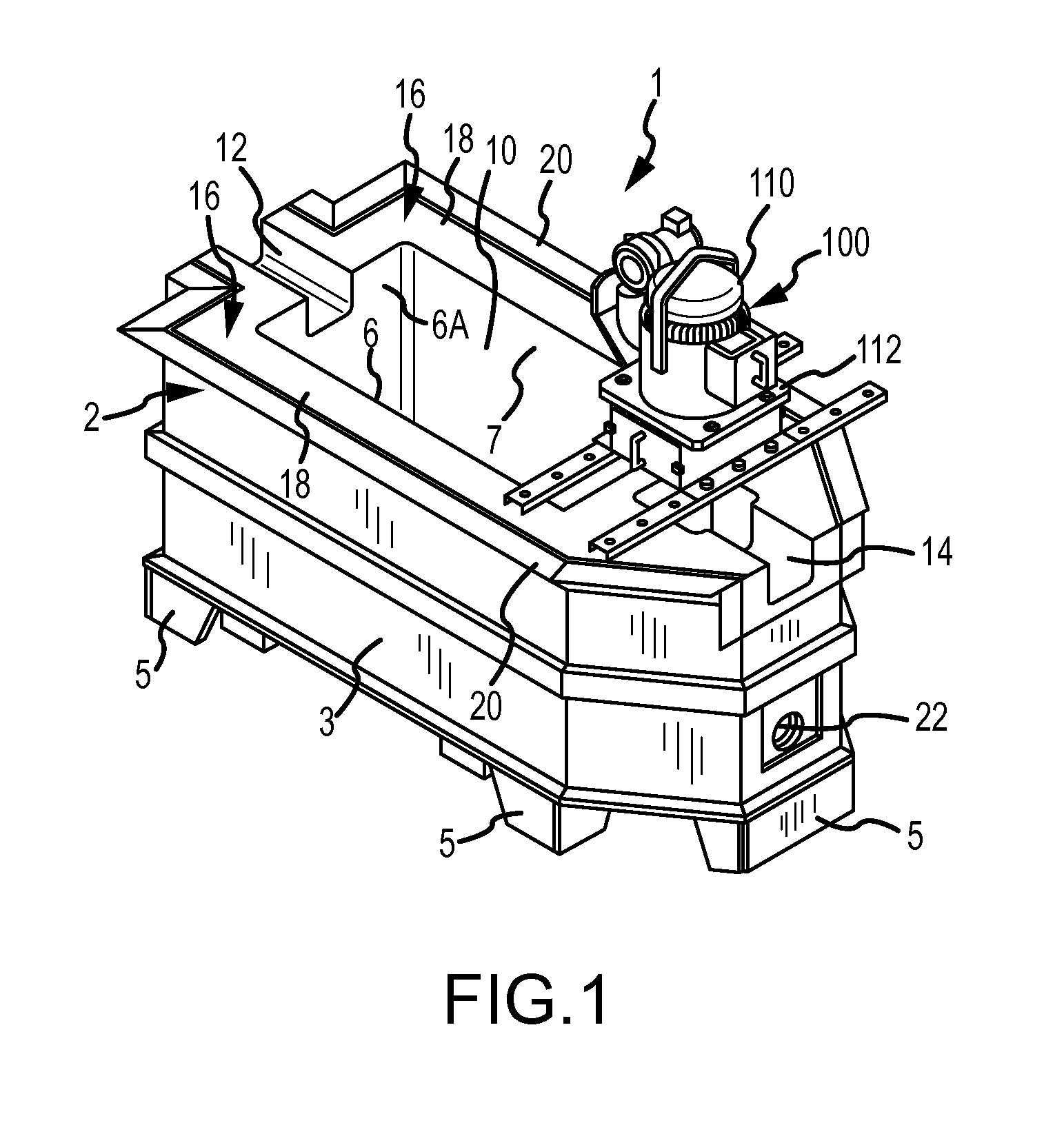

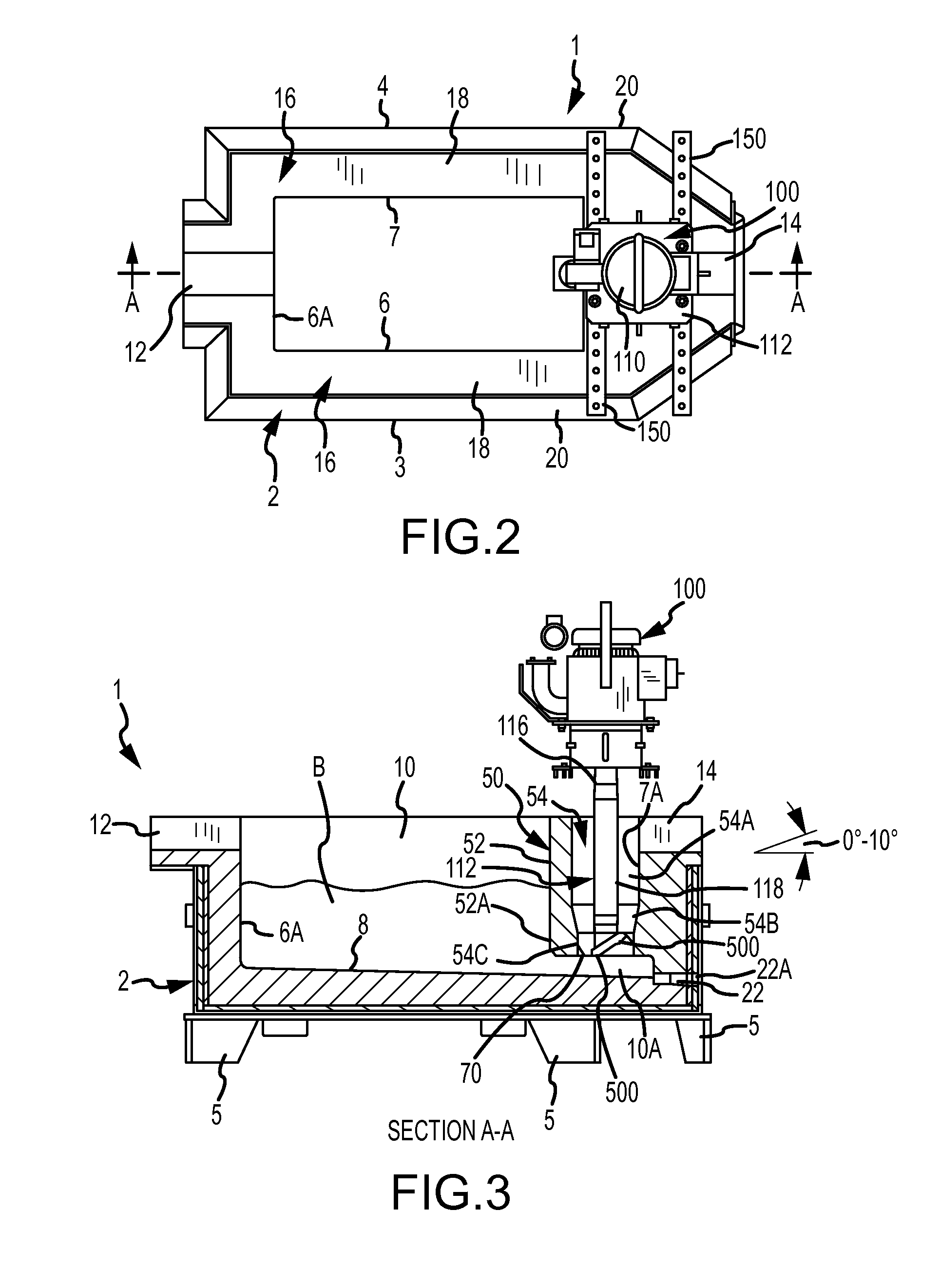

The invention relates to systems for transferring molten metal from one structure to another. Aspects of the invention include a transfer chamber constructed inside of or next to a vessel used to retain molten metal. The transfer chamber is in fluid communication with the vessel so molten metal from the vessel can enter the transfer chamber. A powered device, which may be inside of the transfer chamber, moves molten metal upward and out of the transfer chamber and preferably into a structure outside of the vessel, such as another vessel or a launder.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

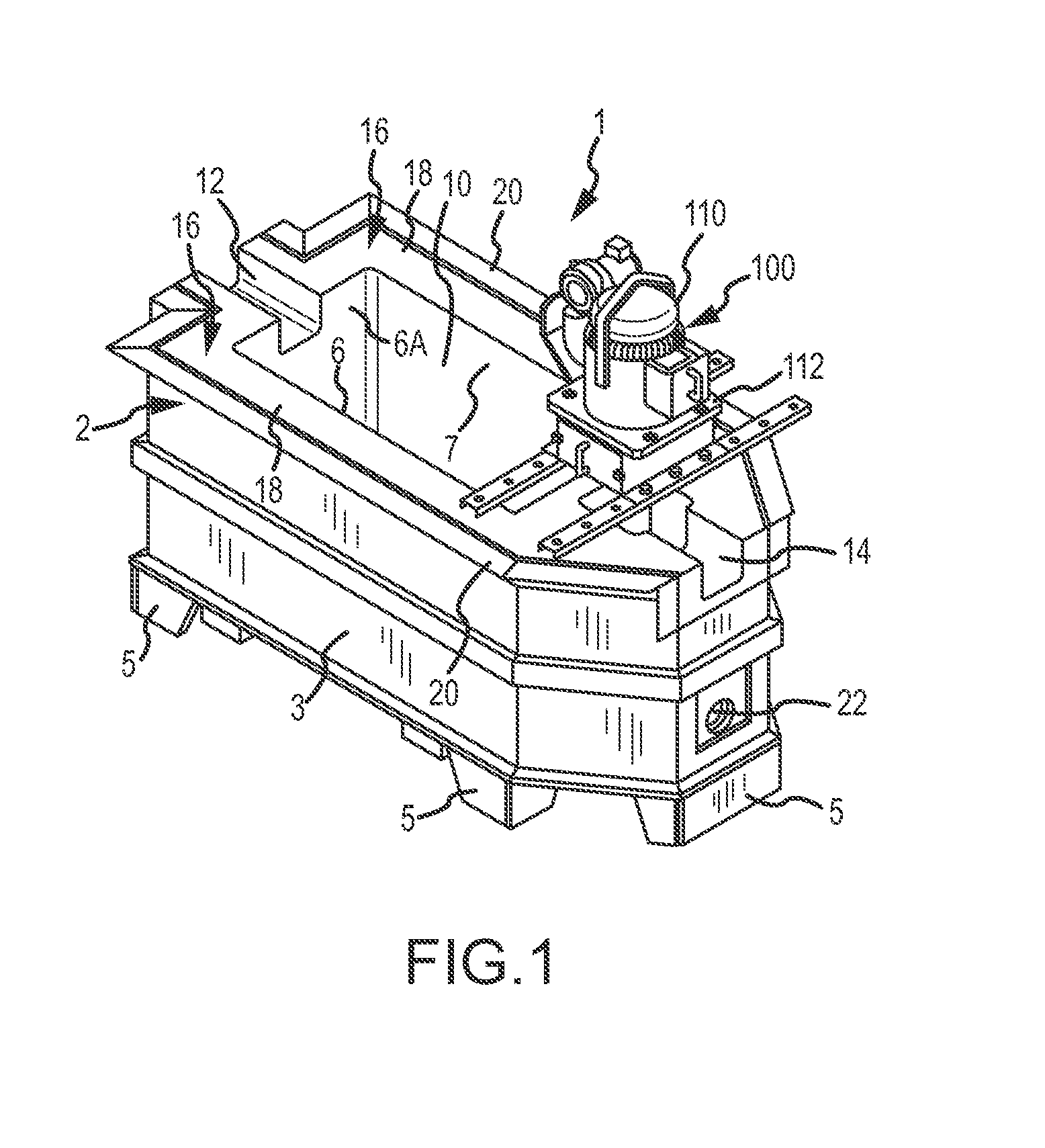

Transferring molten metal from one structure to another

ActiveUS8337746B2Formation of dross in the ladle or launder are greatly reduced or eliminatedEliminate useMolten metal pouring equipmentsStirring devicesDie castingMolten metal

A system for transferring molten metal from a vessel and into one or more of a ladle, ingot mold, launder, feed die cast machine or other structure is disclosed. The system includes at least a vessel for containing molten metal, an overflow (or dividing) wall, and a device or structure, such as a molten metal pump, for generating a stream of molten metal. The dividing wall divides the vessel into a first chamber and a second chamber, wherein part of the second chamber has a height H2. The device for generating a stream of molten metal, which is preferably a molten metal pump, is preferably positioned in the first chamber. When the device operates, it generates a stream of molten metal from the first chamber and into the second chamber. When the level of molten metal in the second chamber exceeds H2, molten metal flows out of the vessel and into another structure, such as into one or more ladles and / or one or more launders.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Molten metal transfer system and rotor

The invention relates to systems for transferring molten metal from one structure to another. Aspects of the invention include a transfer chamber constructed inside of or next to a vessel used to retain molten metal. The transfer chamber is in fluid communication with the vessel so molten metal from the vessel can enter the transfer chamber. A powered device, which may be inside of the transfer chamber, moves molten metal upward and out of the transfer chamber and preferably into a structure outside of the vessel, such as another vessel or a launder.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Molten metal transfer vessel and method of construction

ActiveUS20130299525A1Significant comprehensive benefitsFormation of dross in the ladle or launder are greatly reduced or eliminatedMelt-holding vesselsMolten metal pouring equipmentsMolten metalBuilding construction

The invention relates to systems for transferring molten metal from one structure to another. Aspects of the invention include a transfer chamber constructed inside of or next to a vessel used to retain molten metal. The transfer chamber is in fluid communication with the vessel so molten metal from the vessel can enter the transfer chamber. A powered device, which may be inside of the transfer chamber, moves molten metal upward and out of the transfer chamber and preferably into a structure outside of the vessel, such as another vessel or a launder.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

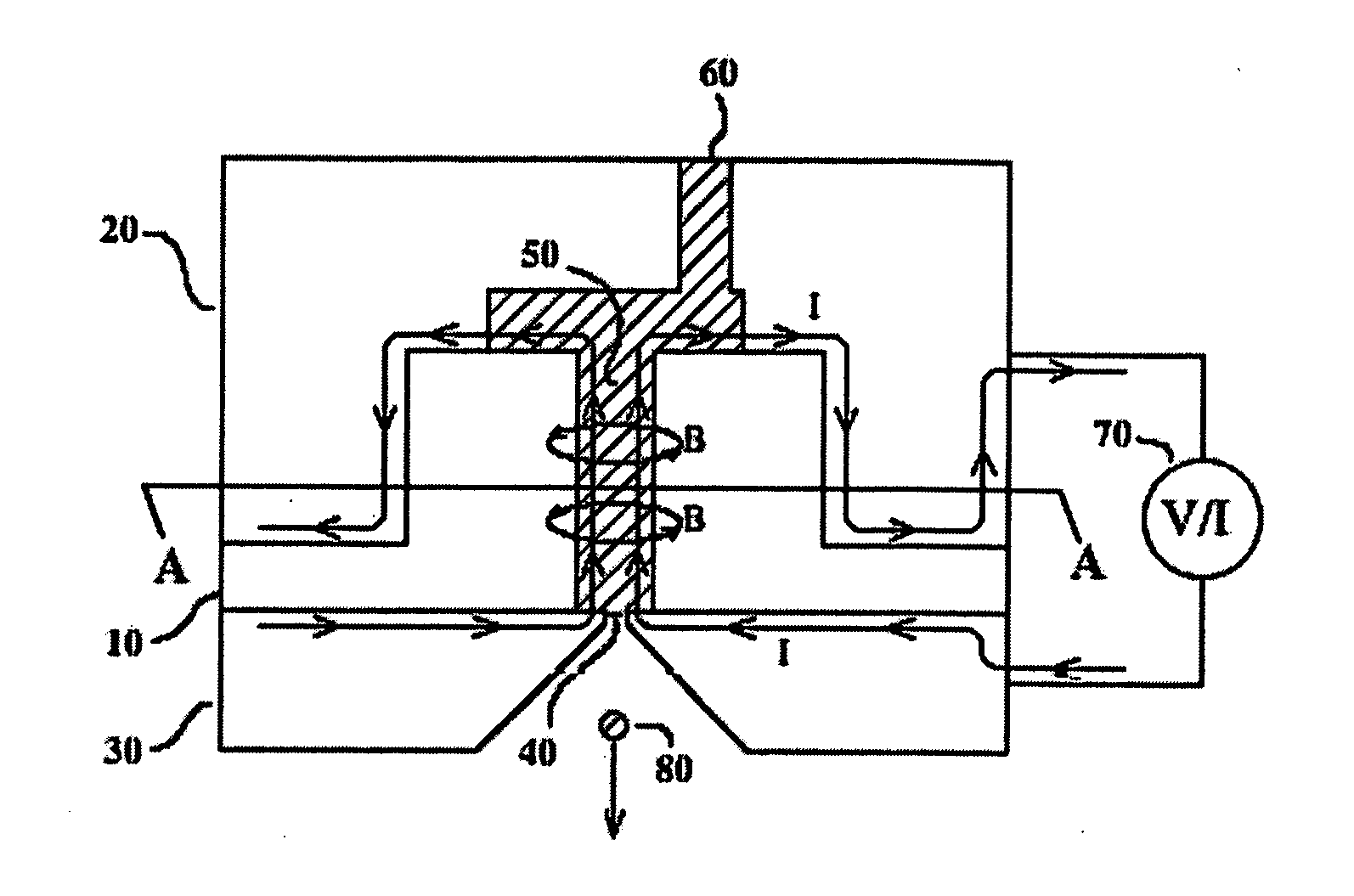

Molten metal transfer and degassing system

ActiveUS20130306687A1Keep the flowReduce the possibilityMelt-holding vesselsMolten metal pouring equipmentsEngineeringMolten metal

Aspects of the invention include a transfer chamber constructed inside of or next to a vessel used to retain and degas molten metal. The transfer chamber is in fluid communication with the vessel so molten metal from the vessel is pulled through the vessel by the pump as it is degassed. This helps maintain a generally constant flow of molten metal through the degassing vessel. Other aspects relate to a system and method for efficiently performing maintenance on components positioned in a vessel.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Ladle with transfer conduit

ActiveUS9011761B2Reduce the amount requiredReduce formationMelt-holding vesselsMolten metal supplying equipmentsMarine engineeringGuide tube

Disclosed is a transportable vessel for use in a factory for processing molten metal. The vessel is not connected to a reverbatory furnace and can be moved to different locations in the factory. The vessel includes a transfer conduit in communication with a cavity of the vessel. A molten metal pump can be positioned in the transfer conduit to move molten metal out of an outlet in communication with the transfer conduit and into another vessel without the need to tip or tilt the transportable vessel.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Molten metal transfer system and rotor

The invention relates to systems for transferring molten metal from one structure to another. Aspects of the invention include a transfer chamber constructed inside of or next to a vessel used to retain molten metal. The transfer chamber is in fluid communication with the vessel so molten metal from the vessel can enter the transfer chamber. A powered device, which may be inside of the transfer chamber, moves molten metal upward and out of the transfer chamber and preferably into a structure outside of the vessel, such as another vessel or a launder.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Transfer well system and method for making same

The invention relates to systems for transferring molten metal from one structure to another. Aspects of the invention include a transfer chamber constructed inside of or next to a vessel used to retain molten metal. The transfer chamber is in fluid communication with the vessel so molten metal from the vessel can enter the transfer chamber. A powered device, which may be inside of the transfer chamber, moves molten metal upward and out of the transfer chamber and preferably into a structure outside of the vessel, such as another vessel or a launder.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

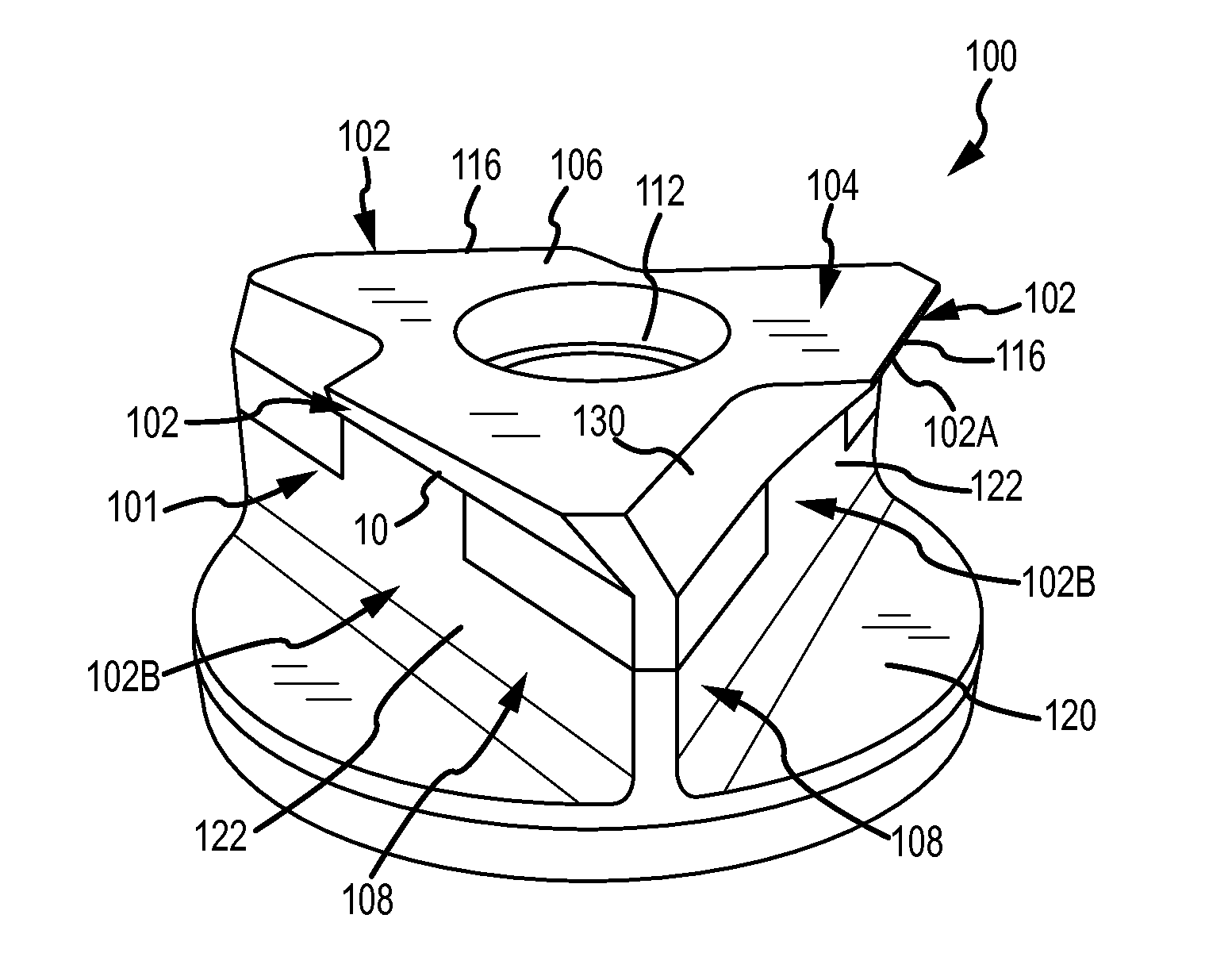

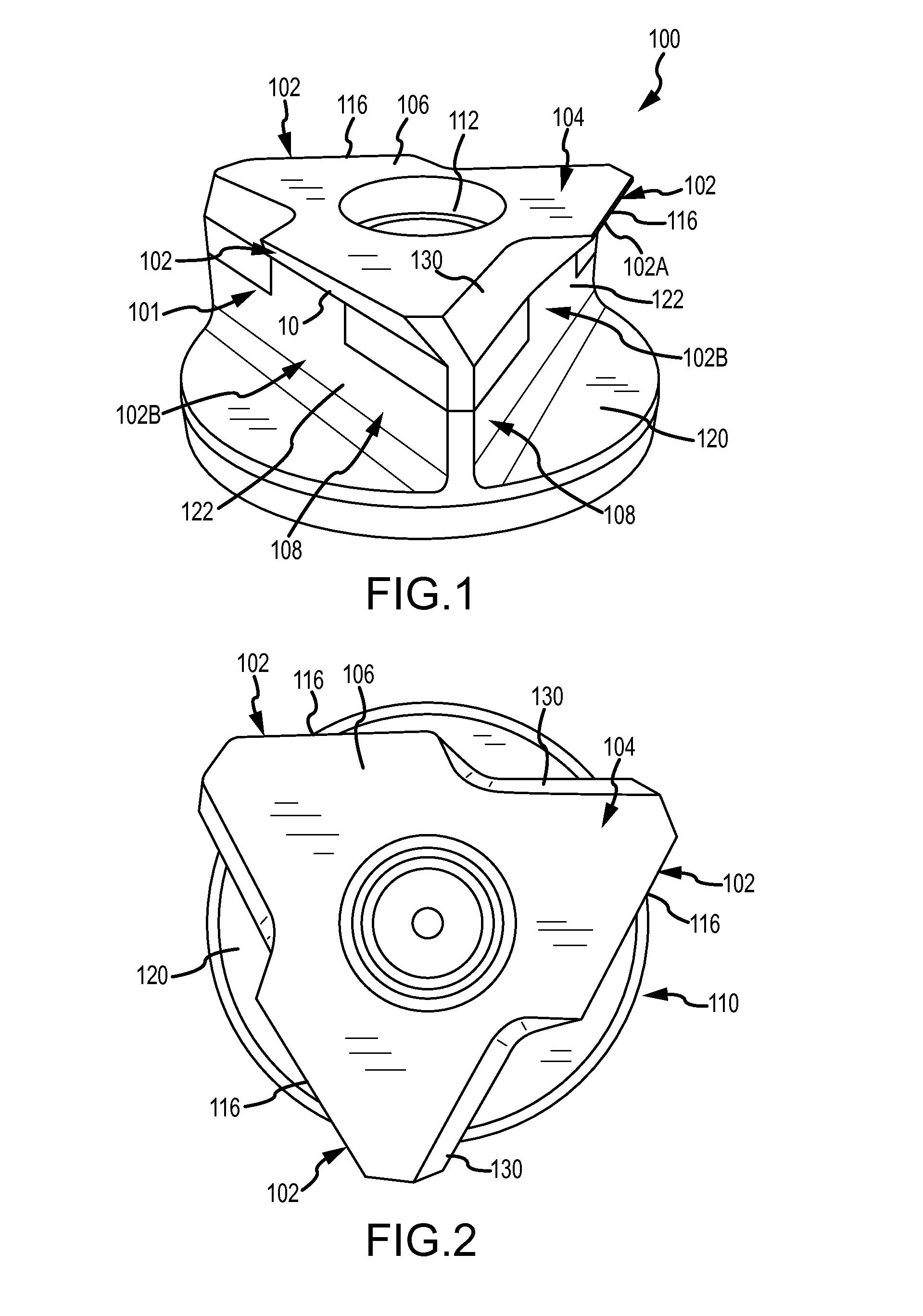

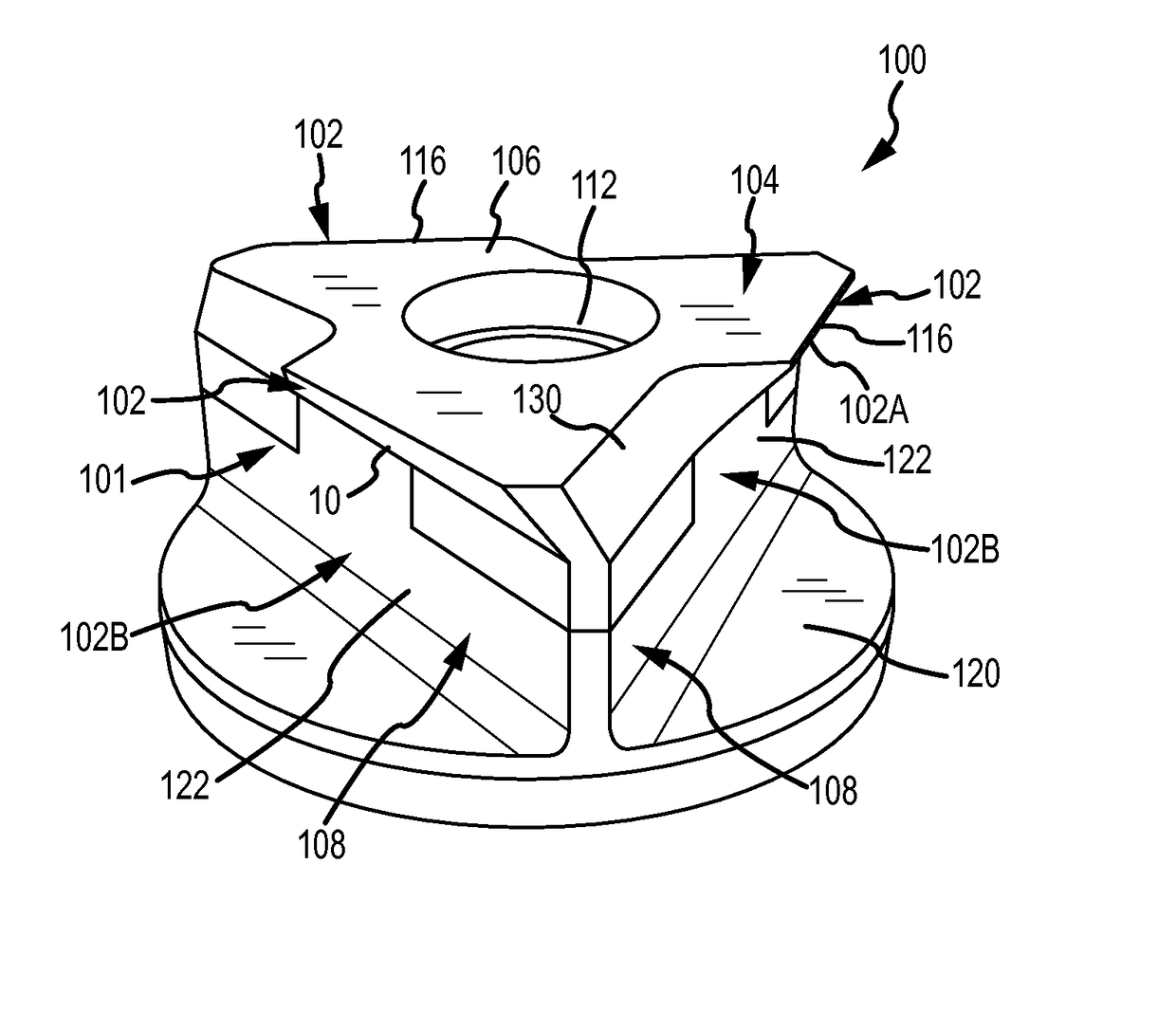

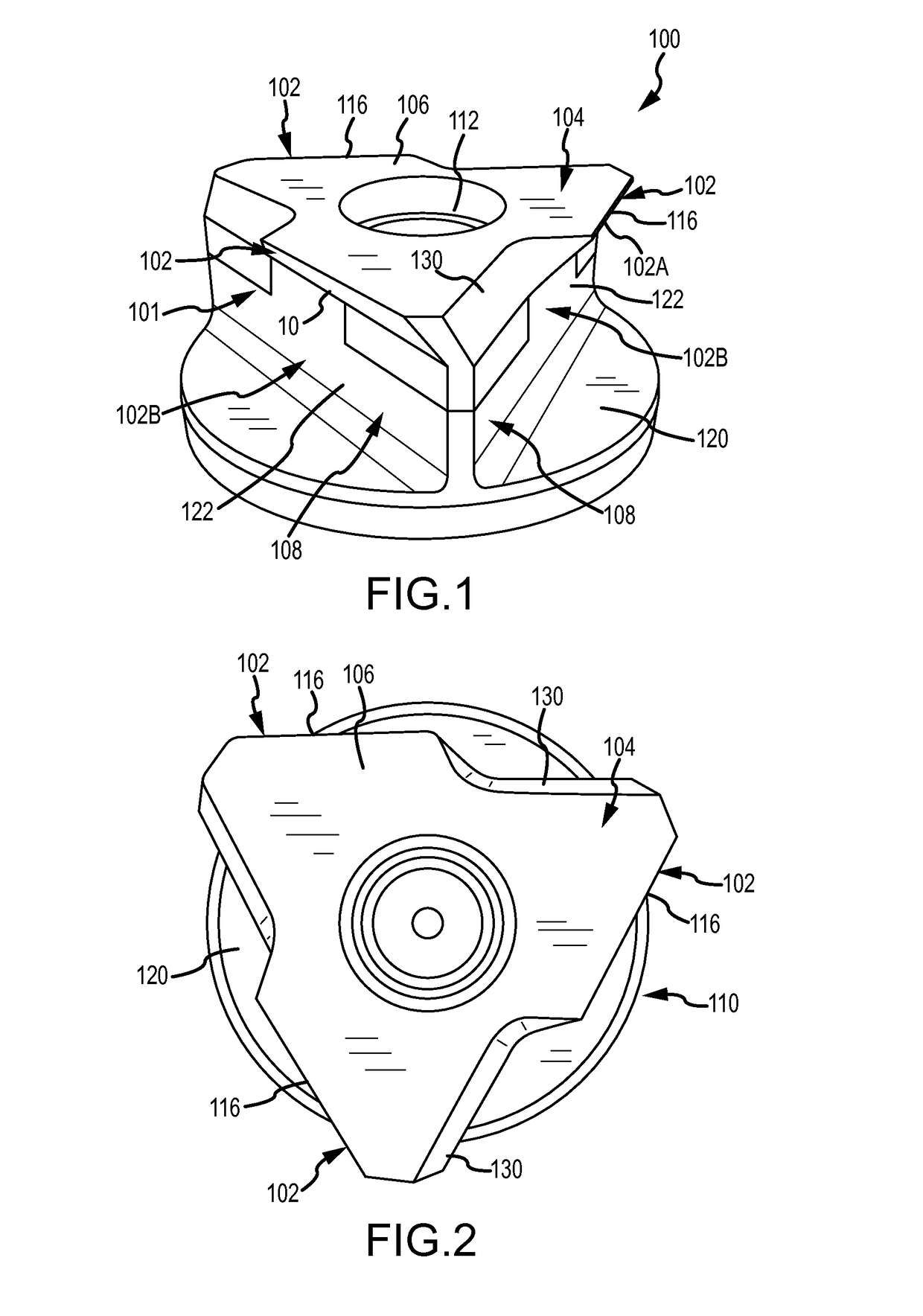

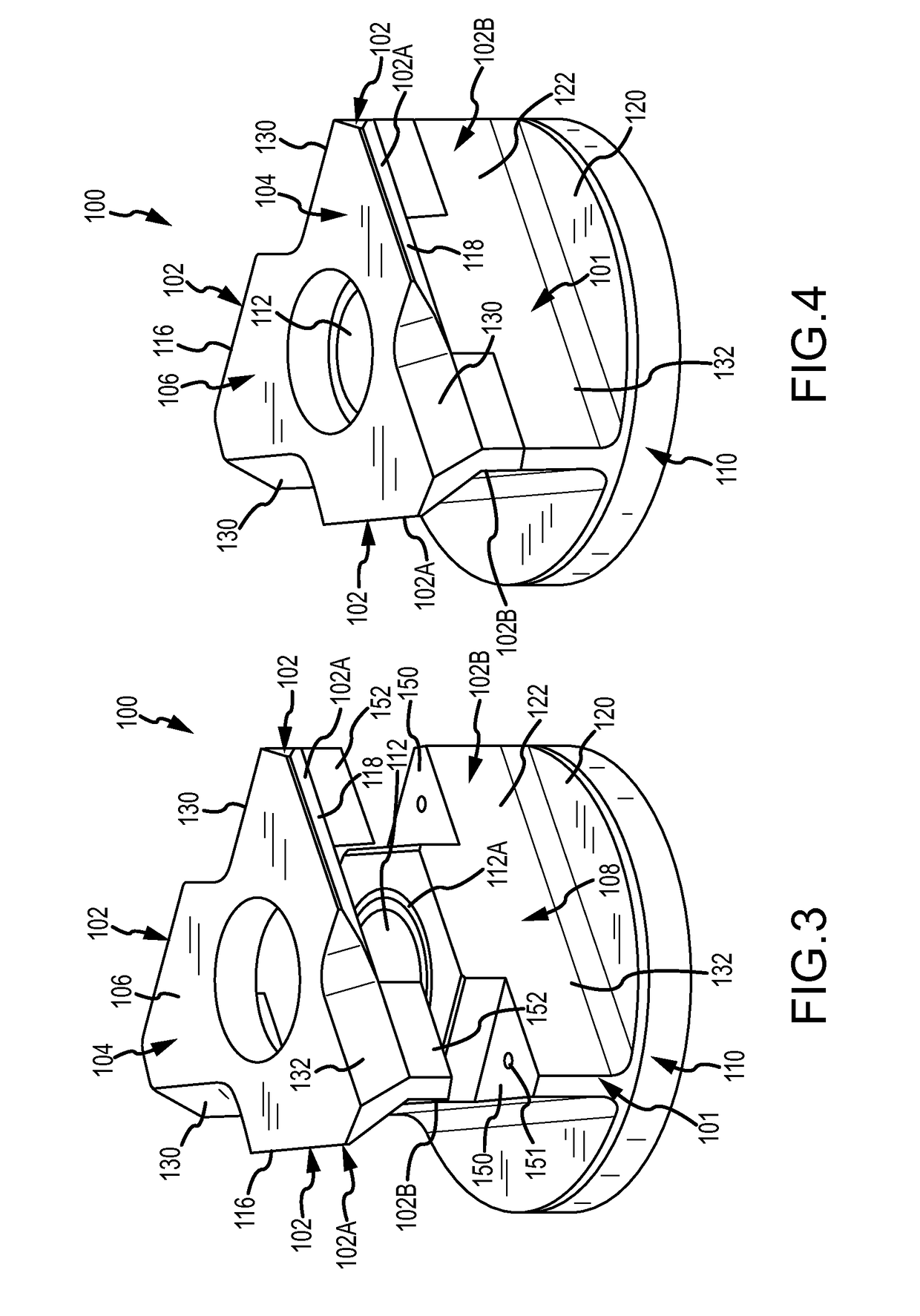

Molten metal rotor with hardened top

Embodiments of the invention are directed to a rotor for a molten metal pump and a molten metal pump including the rotor. The rotor has a main body and a top comprised of a material that is at least twice as hard as the main body. The top, among other things, may form a first portion of each rotor blade wherein the first portion directs molten metal into a pump chamber or other structure in which the rotor is mounted.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Molten metal transfer vessel and method of construction

ActiveUS9409232B2Formation of dross in the ladle or launder are greatly reduced or eliminatedEliminate useMelt-holding vesselsMolten metal pouring equipmentsMolten metalBuilding construction

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

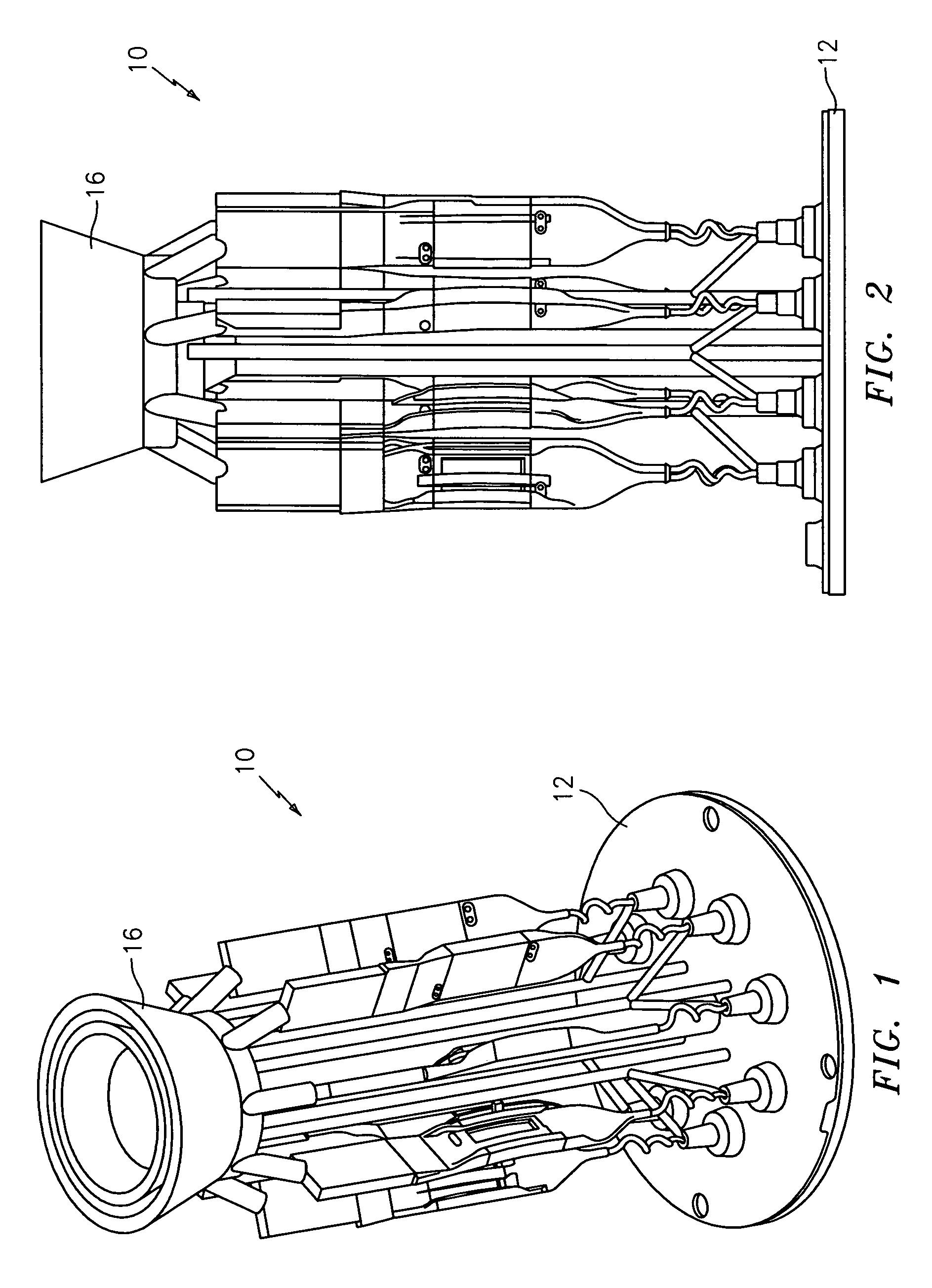

Method and apparatus for production of a cast component

InactiveUS6932145B2Minimize transmission of heatGas turbine plantsFrom frozen solutionsCasting moldMolten metal

A system for producing cast components from molten metal. One form of the present invention includes a system for the precision pouring of molten metal within a casting mold.

Owner:ROLLS ROYCE CORP

Heated trough for molten metal

A trough is described for carrying molten metal, comprising an outer shell defined by a bottom wall and two side walls, an insulating layer filling the outer shell and a conductive U-shaped refractory trough body for carrying molten metal, the trough body being embedded in the insulating layer. At least one heating element is positioned in the insulating layer, adjacent to but spaced apart from the trough body, to provide an air gap between the heating element and the trough body.

Owner:NOVELIS INC

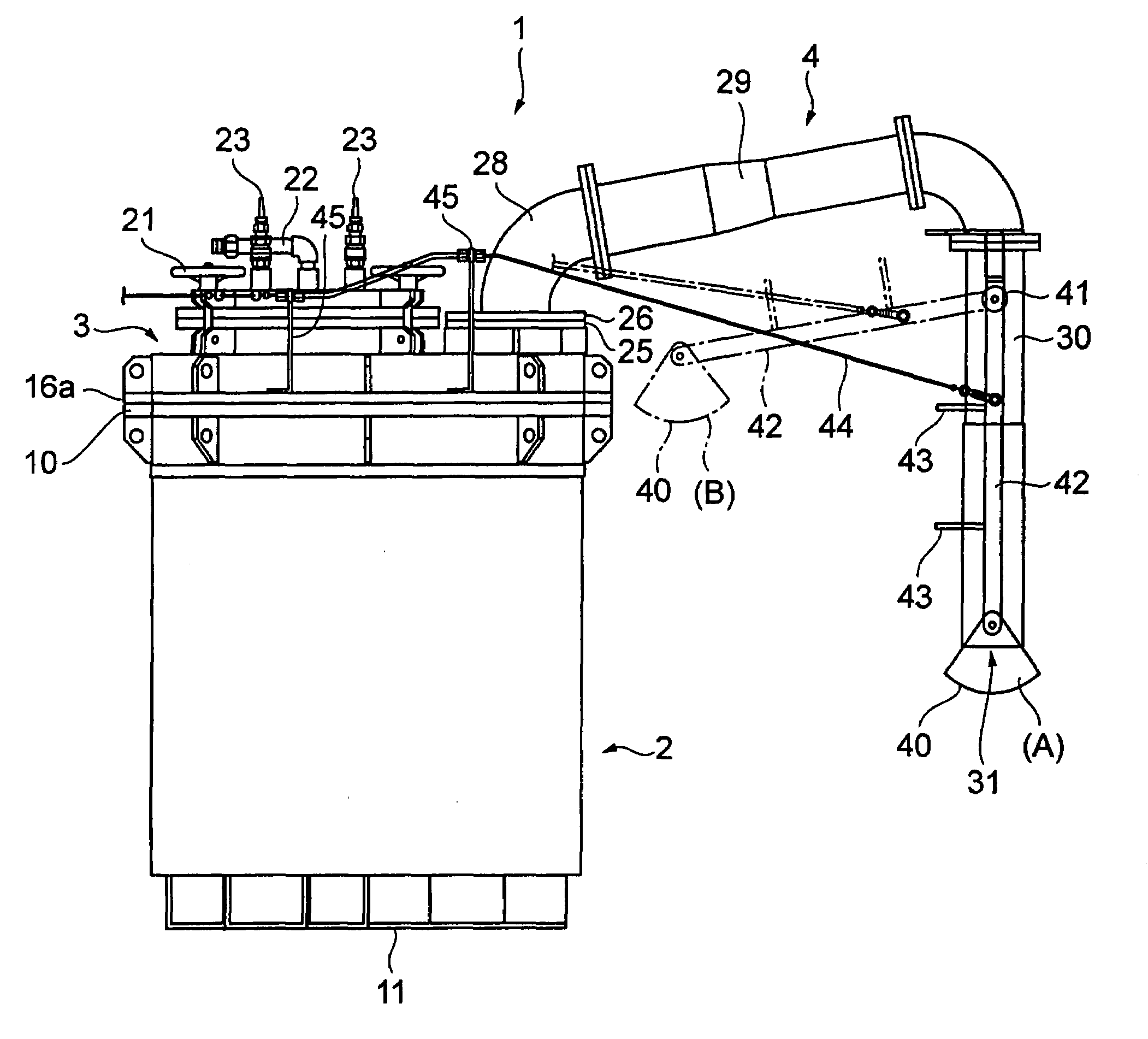

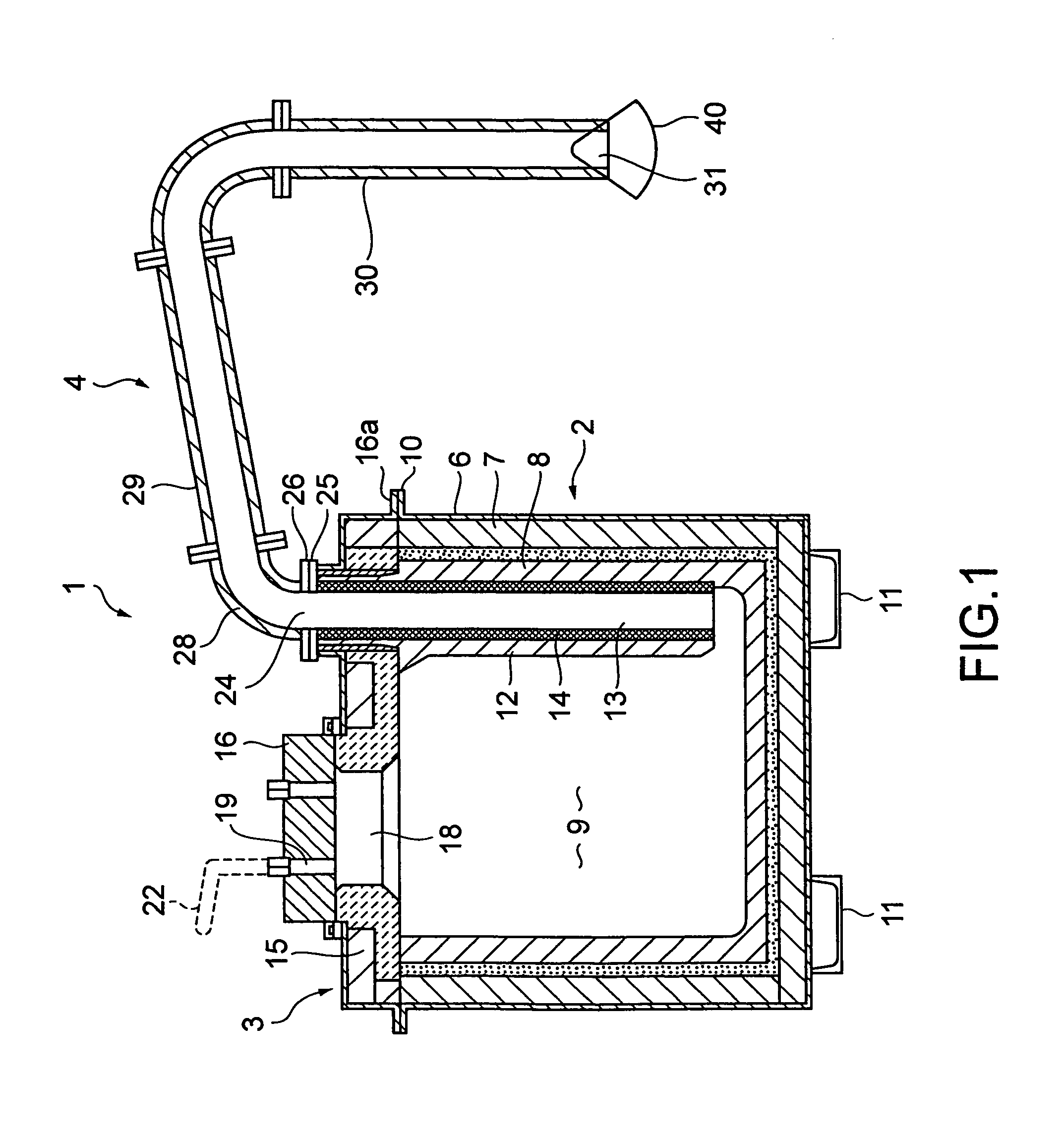

System for supplying molten metal, container and a vehicle

InactiveUS7481966B2Low costMelt-holding vesselsMolten metal supplying equipmentsWire rodHermetic seal

A molten metal supplying system comprising a container having a main body capable of being hermetically sealed and having a passage through which compressed gas is received, a pipe having an outlet supplying molten metal in the container to the outside, the outlet downwardly extending, a reception dish receiving the molten metal capable of being placed below the pipe outlet, a holding member having a fulcrum to the pipe rotatably holding the reception dish, a wire with a first and second end, the first end connected to the reception dish or holding member, a pair of channel members at the outer bottom of the container main body, and a vehicle having a fork that can be inserted and removed from the channel members, a carriage on which the fork is mounted, a lift mechanism for lifting up and down the carriage, and a wire pull and return mechanism mounted on the carriage pulling and returning the wire with it's second end.

Owner:HOEI SHOKAI CO LTD

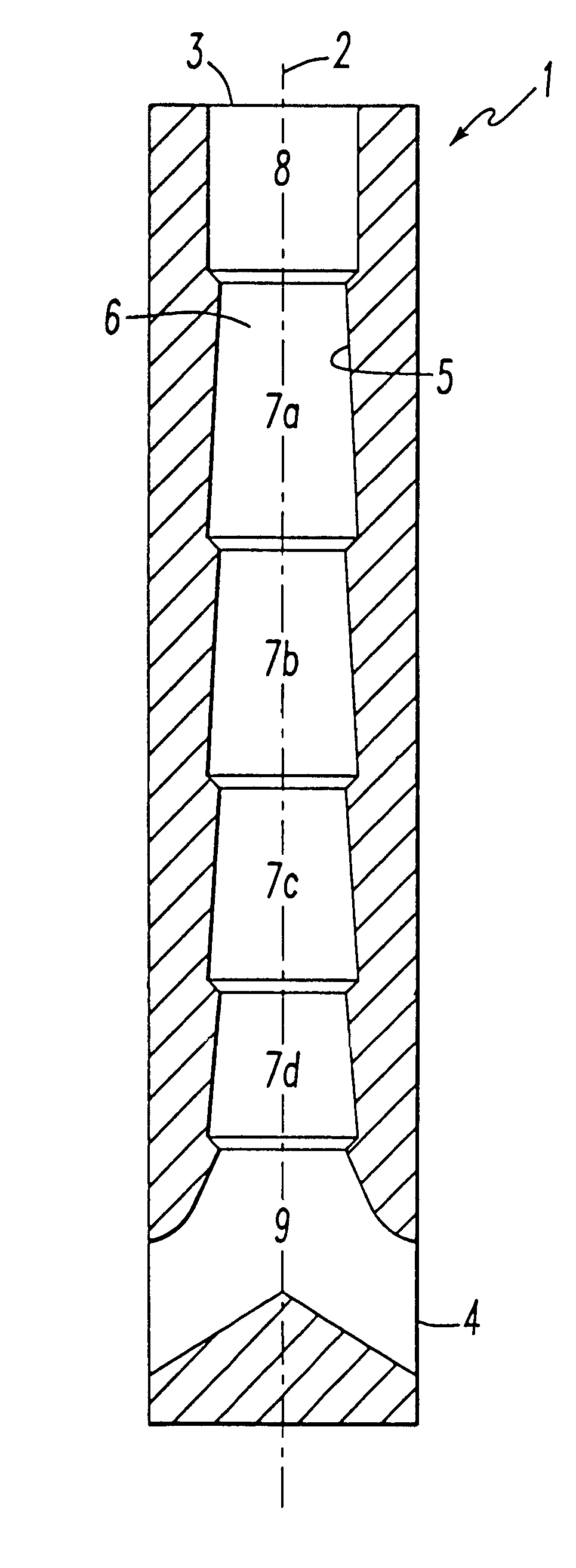

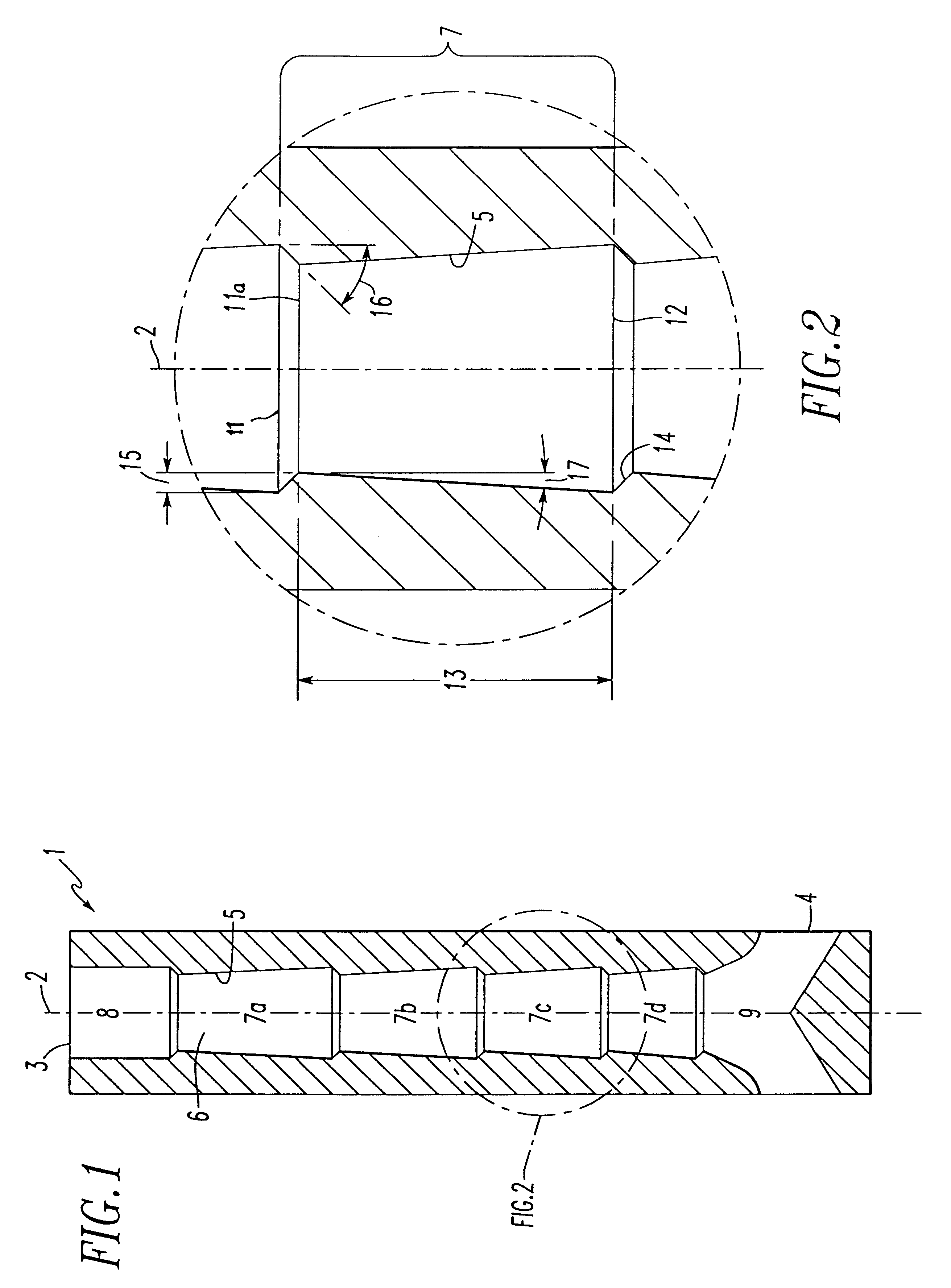

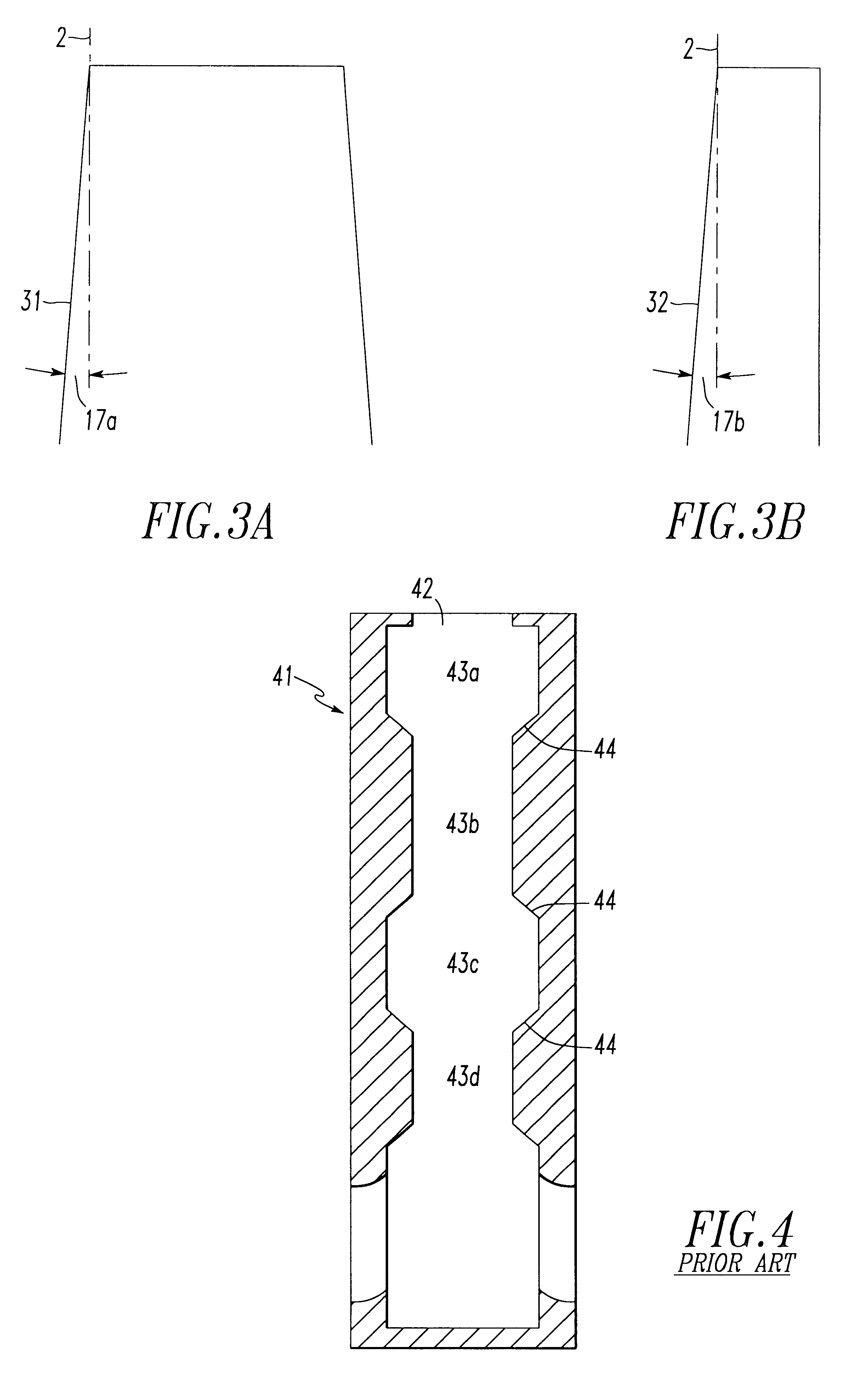

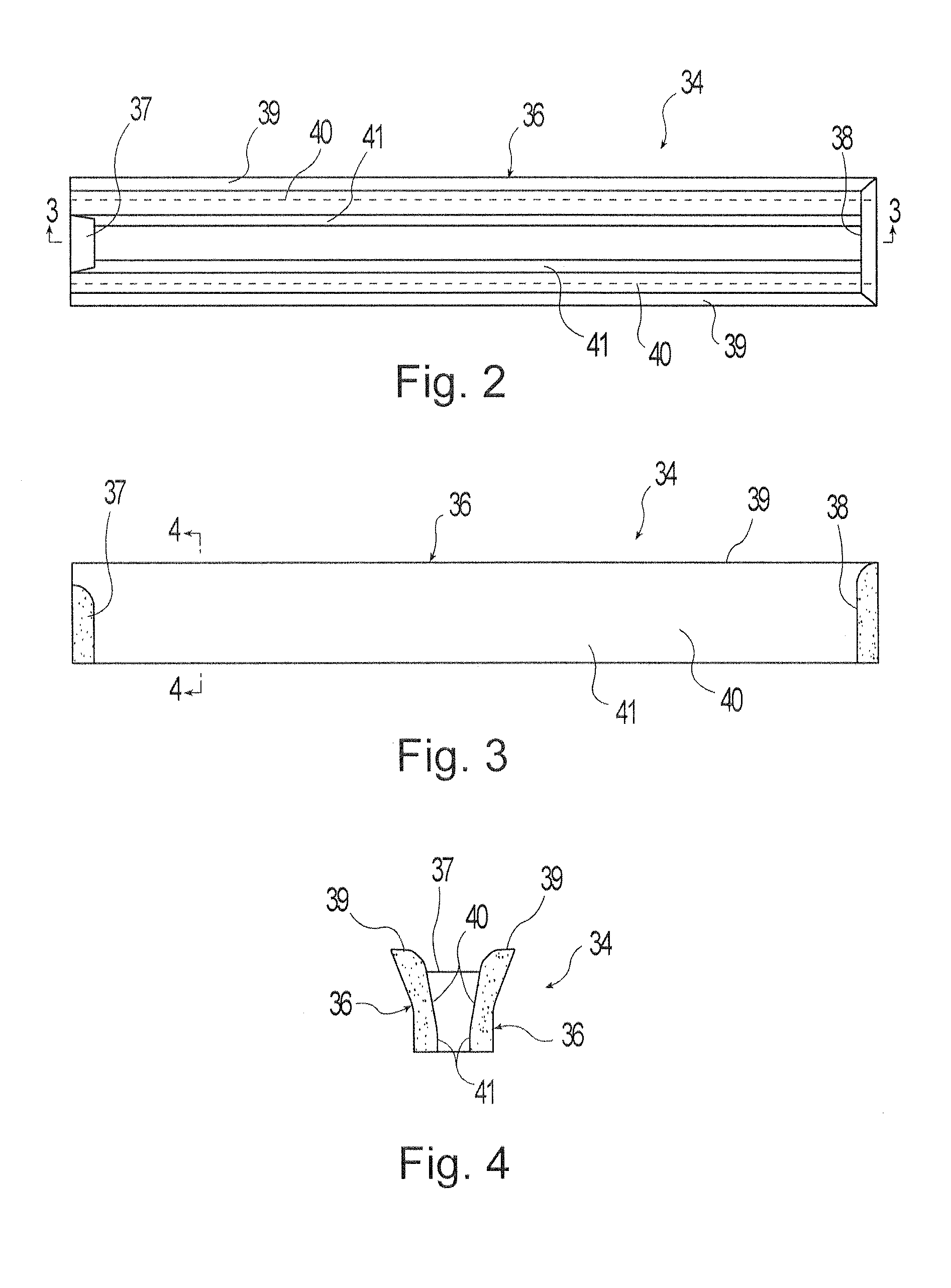

Pour tube with improved flow characteristics

A pour tube for use in the continuous casting of a stream of molten metal has a bore comprising a plurality of fluidly connected sections that improve the flow of molten metal through the bore. The sections reduce asymmetric flow of the molten metal stream and the likelihood of precipitates clogging the bore. Each section comprises a converging portion and a diverging portion. The converging portion deflects the stream toward the center of the bore, while the diverging portion diffuses the stream. The sections may comprise a plurality of frusto-conical sections. The cross-sectional areas of the sections may increase, decrease, or remain the same size from an upstream to a downstream position.

Owner:VESUVIUS USA CORP

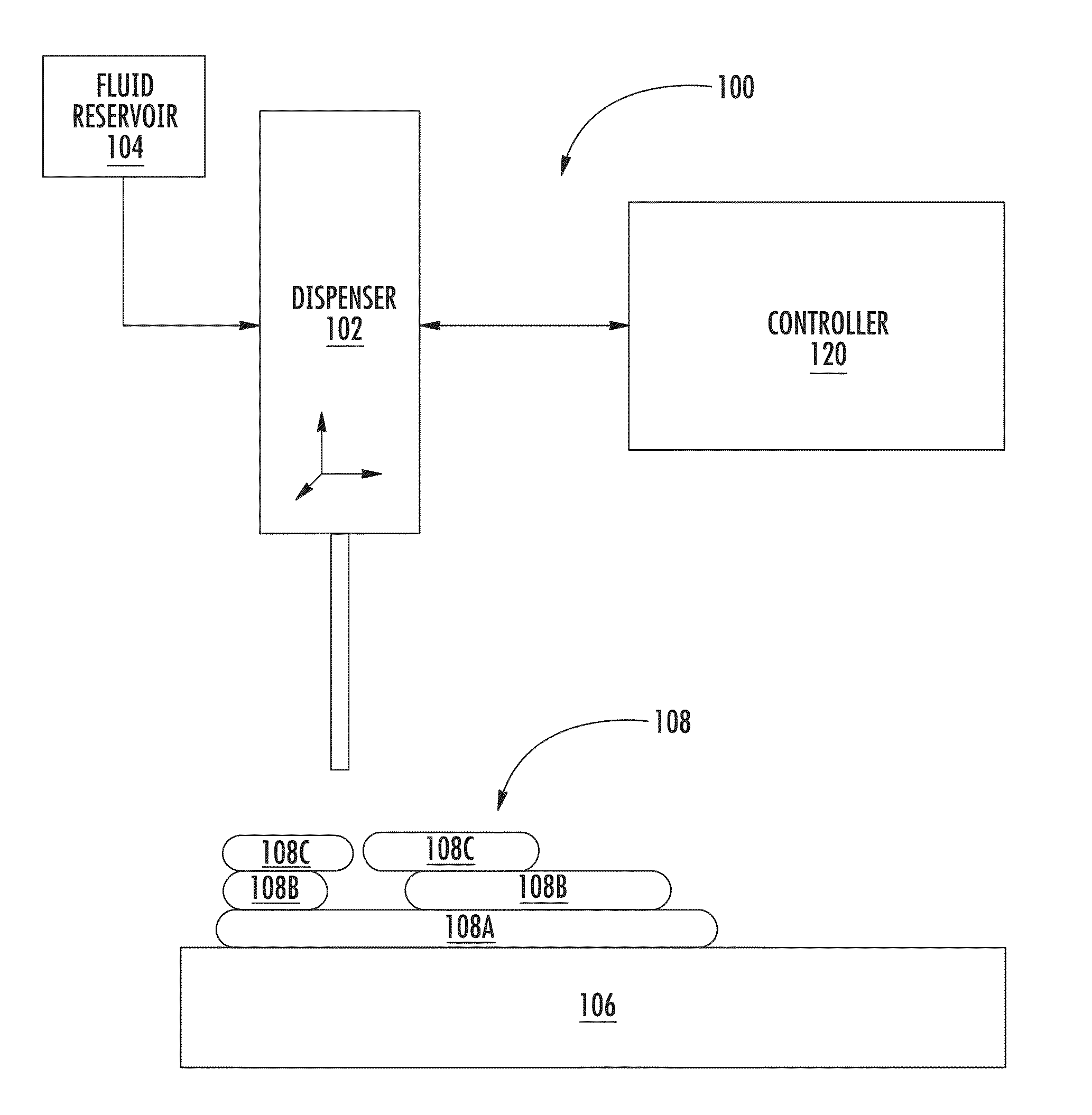

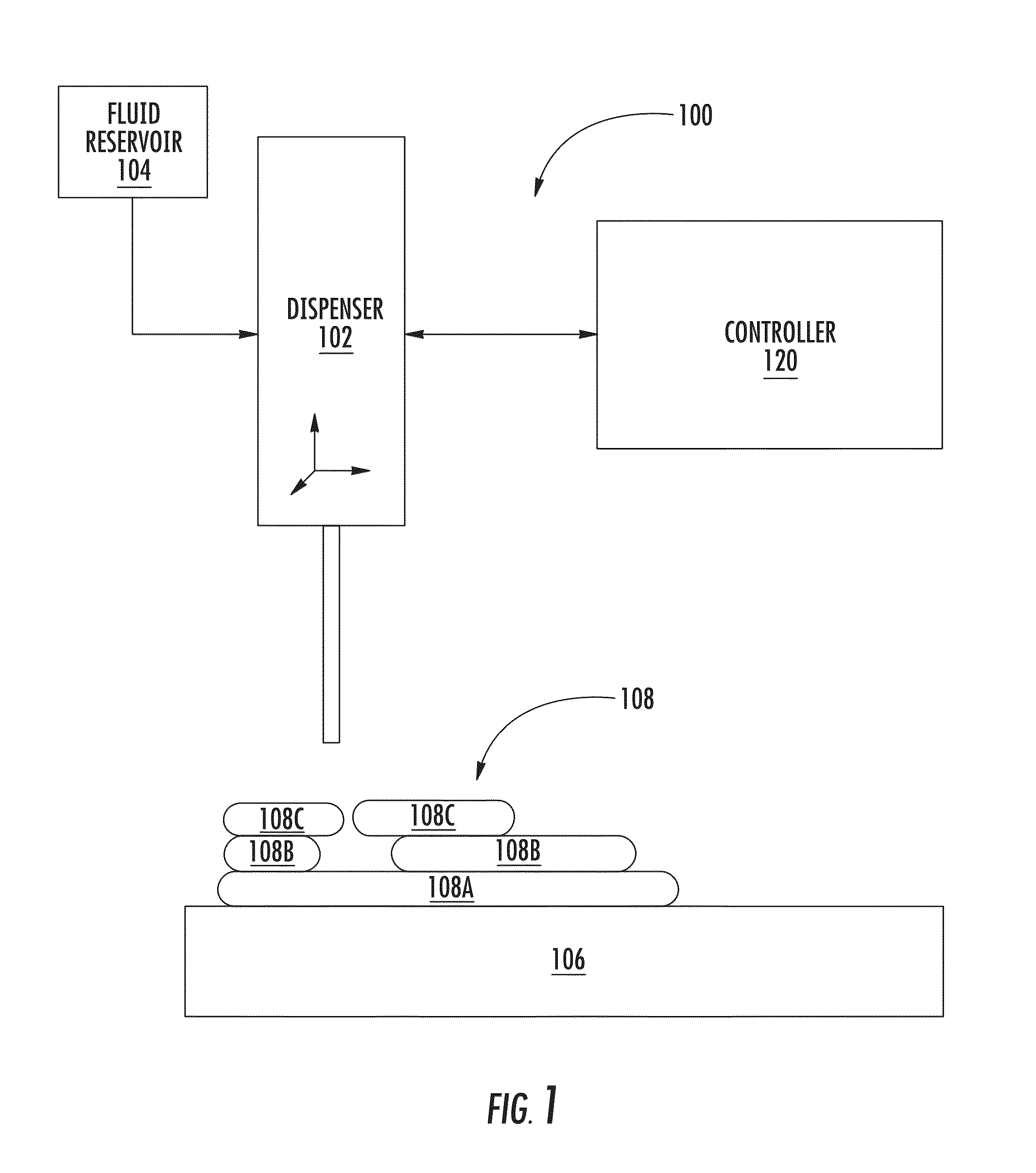

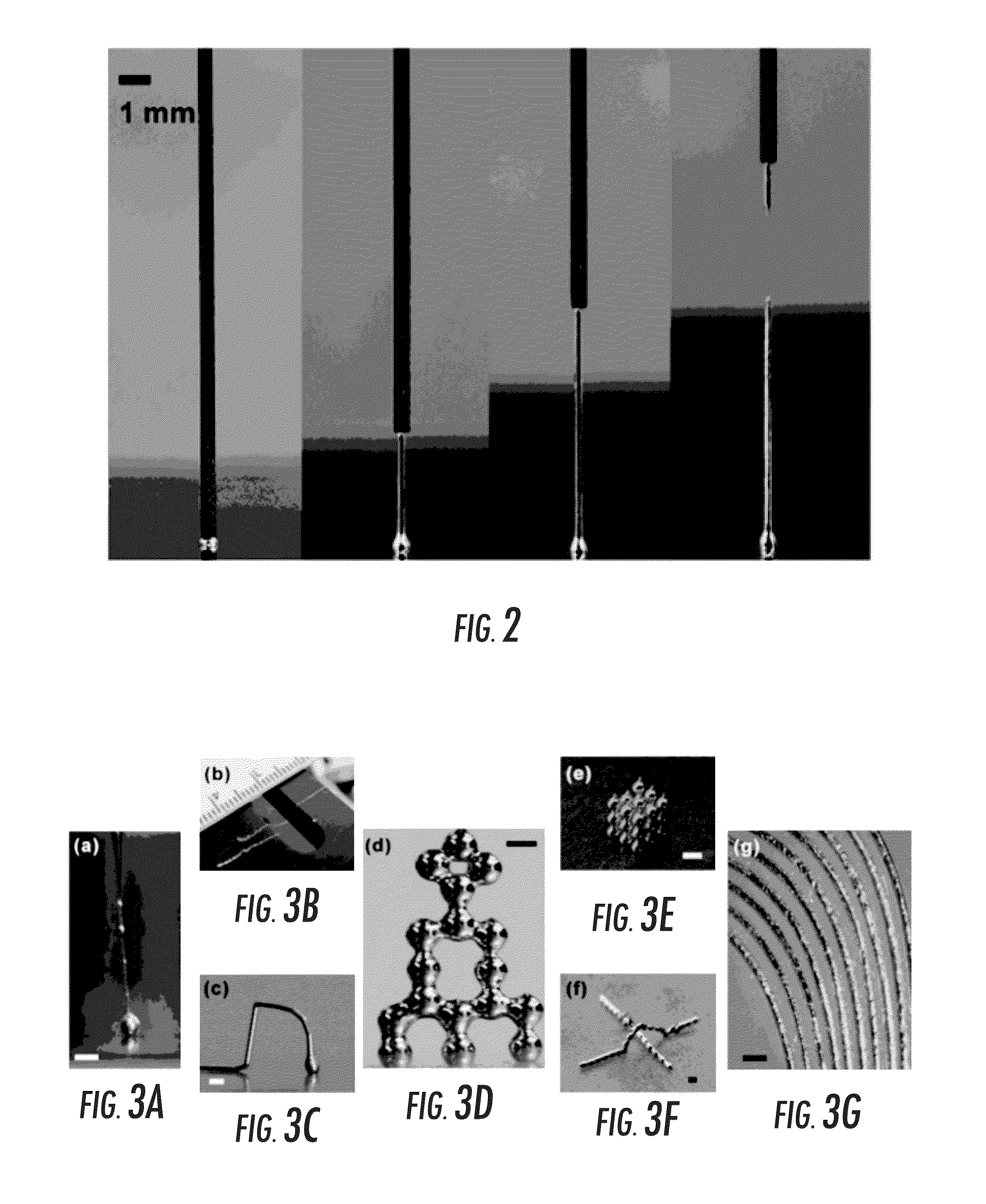

Three-Dimensional Printing of Metallic Materials

InactiveUS20150217367A1Additive manufacturing apparatusMolten metal pouring equipmentsSolid regionMetallic materials

Methods of printing metallic objects include providing parameters of an object for printing, and controlling a deposition of a fluid metallic material to form the object. At least an outer surface region of the fluid metallic material is converted to a solid region after deposition.

Owner:NORTH CAROLINA STATE UNIV

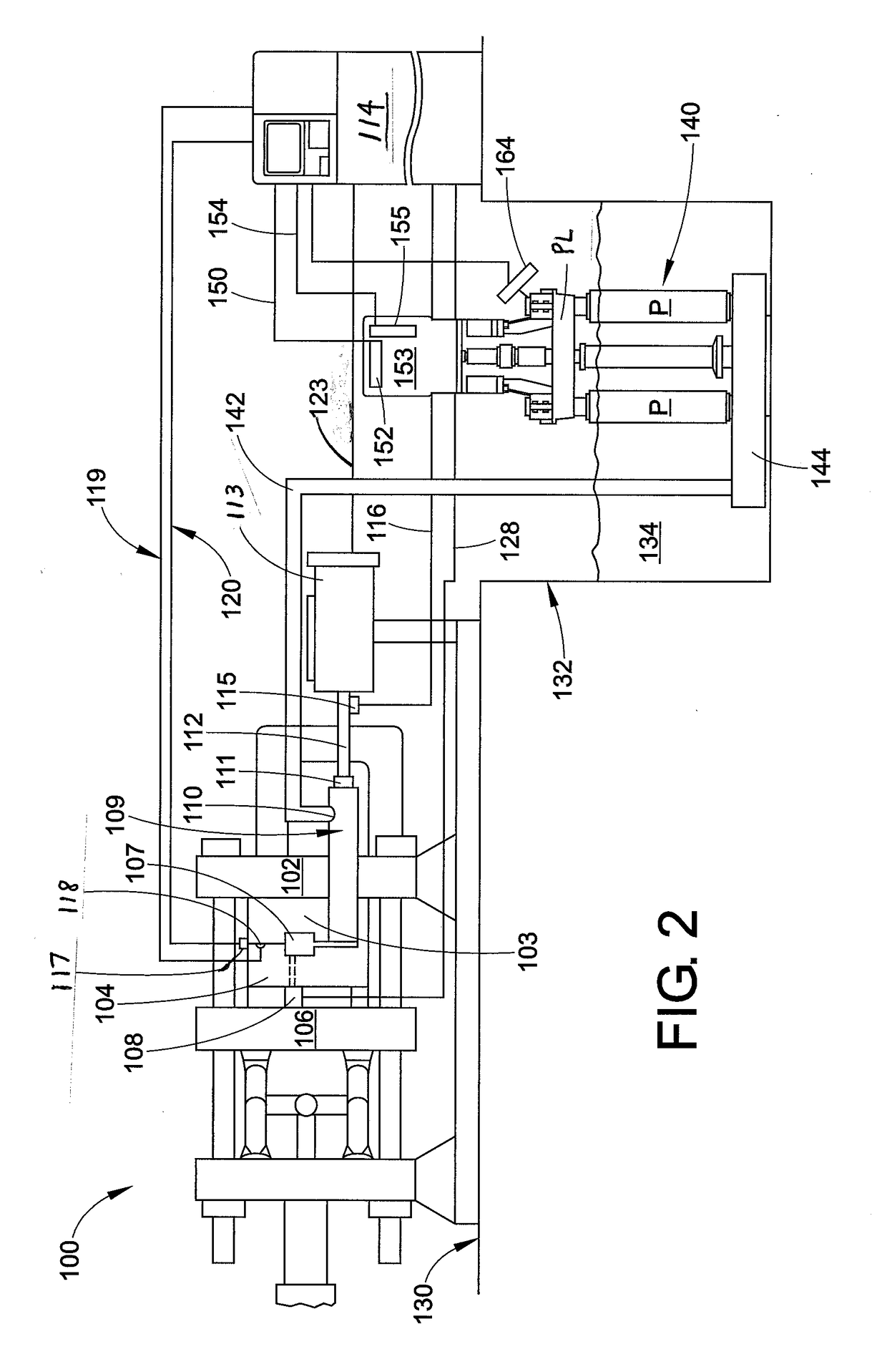

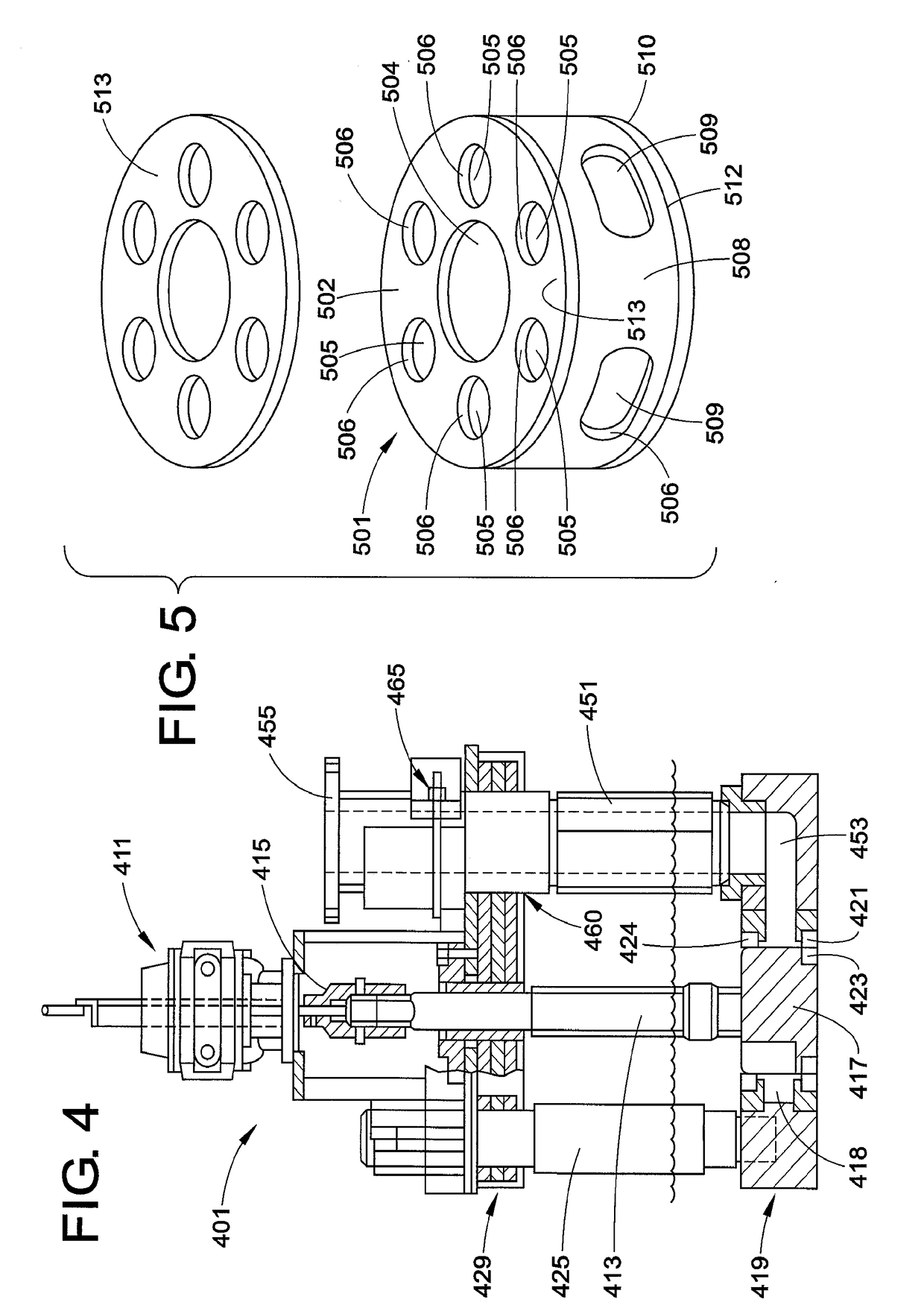

Mold pump

PendingUS20170246681A1Specific fluid pumpsMolten metal supplying equipmentsMolding machineGuide tube

A molding machine for molding material is provided. The machine includes a cavity to be filled with molten metal and a conduit system leading to the cavity, thus forming a system of interconnected hollow spaces. At least one pressure member is moveable in at least part of the conduit system. A centrifugal pump in fluid communication with a reservoir of molten metal is provided, the pump providing molten metal to the hollow space receiving the at least one pressure member.

Owner:PYROTECK INC

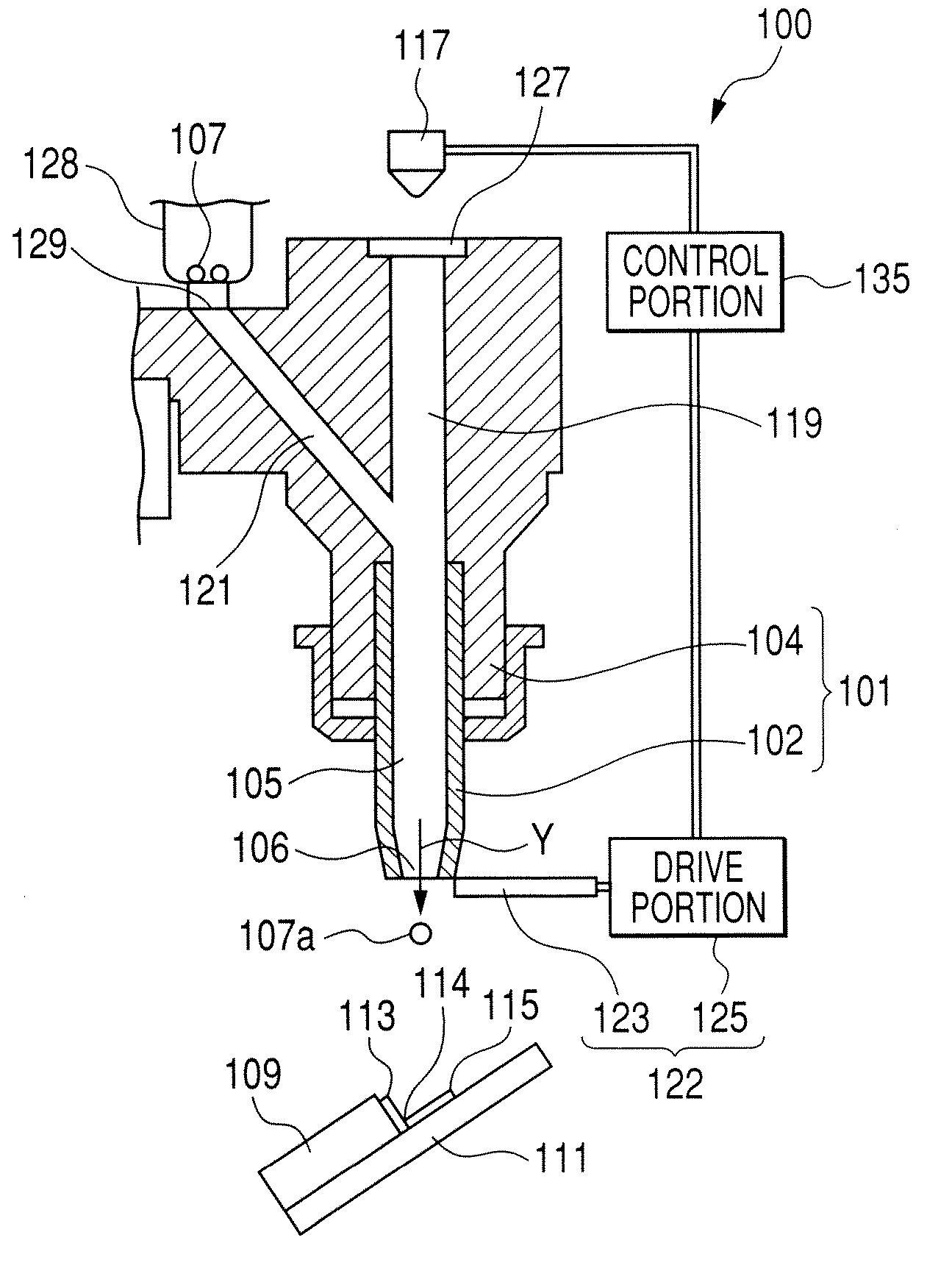

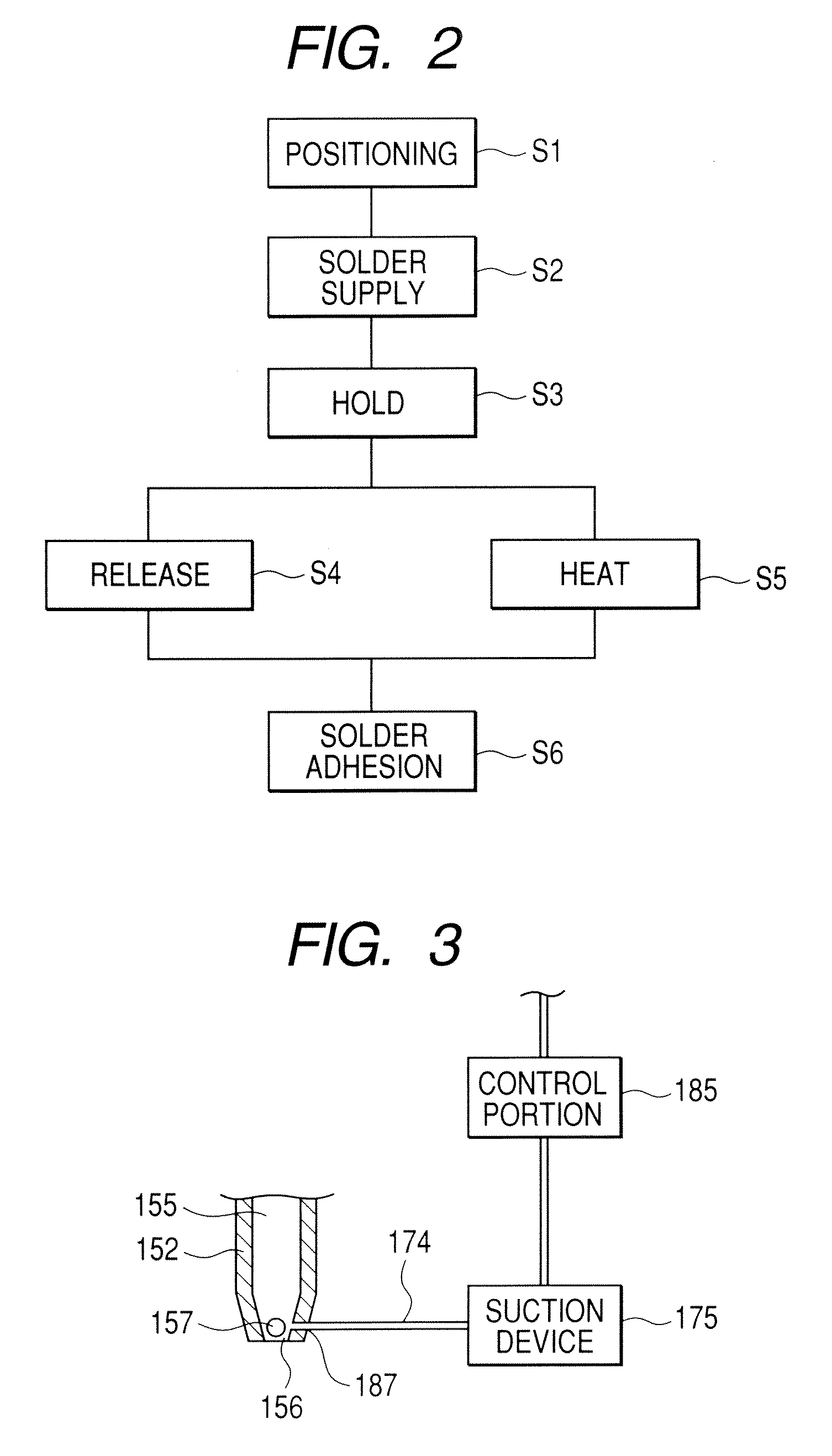

Soldering method, soldering device, bonding method, bonding device, and nozzle unit

Provided is a nozzle unit for use in a bonding device in which bonding between a first member and a second member is effected by providing a bonding member that has been melted by heating at a bonding position where the first member and the second member are to be bonded to each other. The nozzle unit includes: a cylindrical nozzle assembly having an accommodating space accommodating the bonding member, and an opening which allows ejection of the bonding member accommodated in the accommodating space onto the bonding position, which has a diameter larger than the diameter of the bonding member, and which communicates with the accommodating space; and a holding / releasing member for releasably holding the bonding member within the accommodating space.

Owner:TDK CORPARATION

Advanced material for molten metal processing equipment

A molten metal processing apparatus selected from a pump, a degasser, a flux injector, and a scrap submergence device constructed to include at least one element comprised of C / C composite.

Owner:PYROTECK INC

Molten metal rotor with hardened top

Embodiments of the invention are directed to a rotor for a molten metal pump and a molten metal pump including the rotor. The rotor has a main body and a top comprised of a material that is at least twice as hard as the main body. The top, among other things, may form a first portion of each rotor blade wherein the first portion directs molten metal into a pump chamber or other structure in which the rotor is mounted.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Liquid metal droplet generator

Small, high velocity liquid metal droplets are produced for applications that require the accurate and remote placement of small quantities of a metal. The magnetic pressure of current flowing through liquid metal is used to force small quantities of liquid metal through an orifice. Examples of applications are to feed metal fuel into plasma extreme ultraviolet sources, and to place solder bumps on an integrated circuit prior to the attachment of connections.

Owner:PUREX

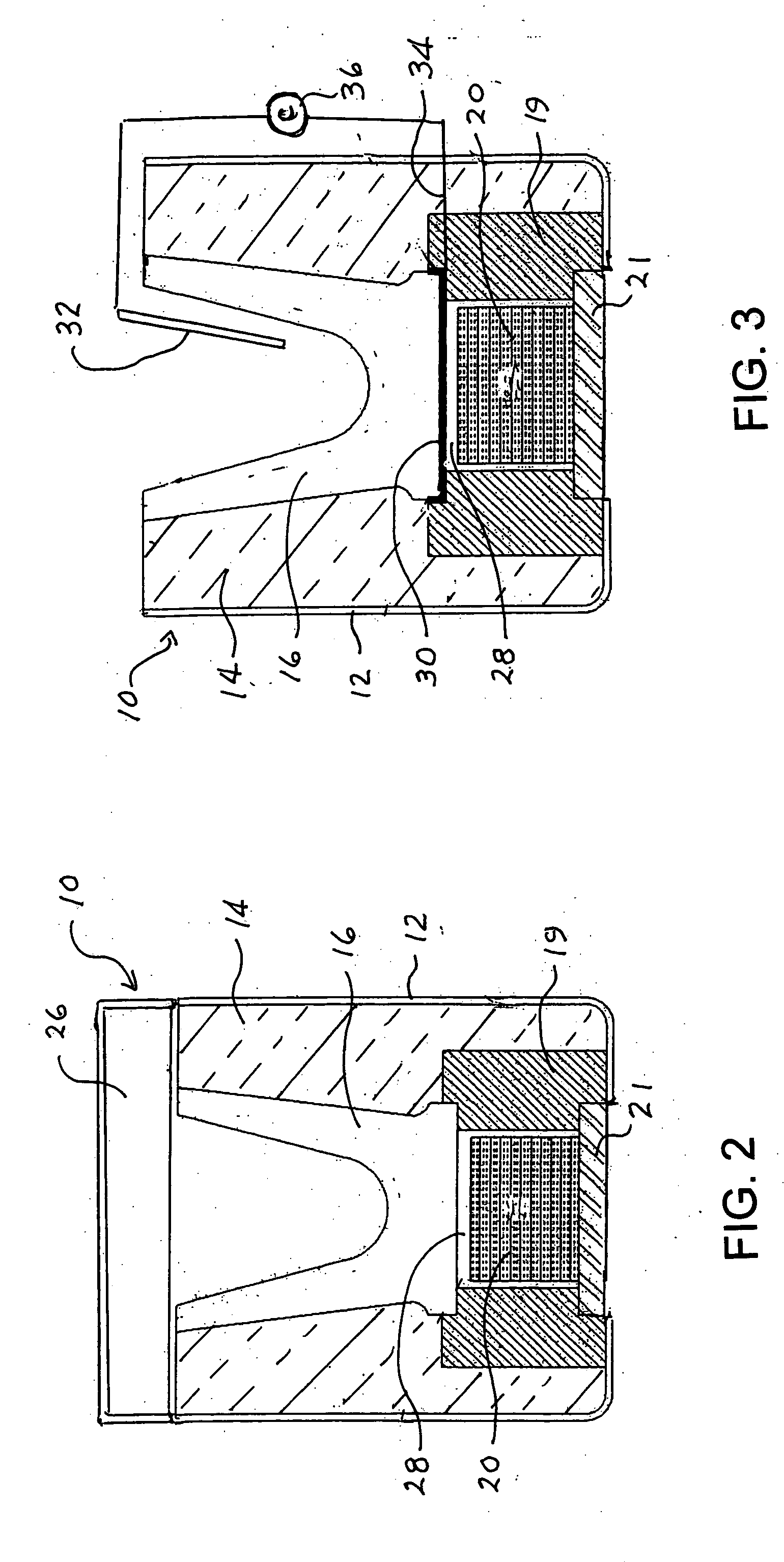

Casting delivery nozzle with insert

InactiveUS20080264599A1Easy to replaceReduces turbulence in flowMolten metal pouring equipmentsMolten metal supplying equipmentsMolten metalNozzle

A metal strip casting apparatus and a method of casting continuous metal strip includes assembling a pair of counter-rotatable casting rolls having casting surfaces positioned laterally forming a nip between for casting, and delivering molten metal through a delivery nozzle disposed above the nip capable to form a casting pool supported on the casting rolls. The delivery nozzle comprises segments each having elongate nozzle body with longitudinally extending side walls, end walls and a bottom part to form an inner trough, a nozzle insert disposed above bottom portions of the inner trough of each segment and supported relative to the nozzle body through which incoming molten metal may be delivered to the inner trough of each segment of the delivery nozzle, and the elongate nozzle body of each segment having passageways in fluid communication with the inner trough and outlet openings capable of discharging molten metal from the nozzle body outwardly into the casting pool.

Owner:NUCOR CORP

Heated trough for molten metal

ActiveUS20050126738A1Melt-holding vesselsMolten metal pouring equipmentsMaterials scienceMolten metal

A trough is described for carrying molten metal, comprising an outer shell defined by a bottom wall and two side walls, an insulating layer filling the outer shell and a conductive U-shaped refractory trough body for carrying molten metal, the trough body being embedded in the insulating layer. At least one heating element is positioned in the insulating layer, adjacent to but spaced apart from the trough body, to provide an air gap between the heating element and the trough body.

Owner:NOVELIS INC

Process for preparing the walls of a mold for molding or shaping to make them ready for the next molding cycle

In a process for preparing the mold walls (12a, 12b) of a mold (12, 12) for the molding or shaping of a molded part after completion of the molding cycle and after removal of the molded part from the mold (12) to make the mold walls ready for the next molding cycle, the tempering of the mold walls (12a, 12b) and the coating of the walls with mold wall treatment agent are carried out independently of each other, i.e., without any time overlap, and in a controlled manner, preferably in a program-controlled manner. To apply the coating, preferably a spray element with centrifugal atomization and air control is used, the mold walls preferably being coated with essentially solvent-free mold wall treatment agent.

Owner:HENKEL IP & HOLDING GMBH

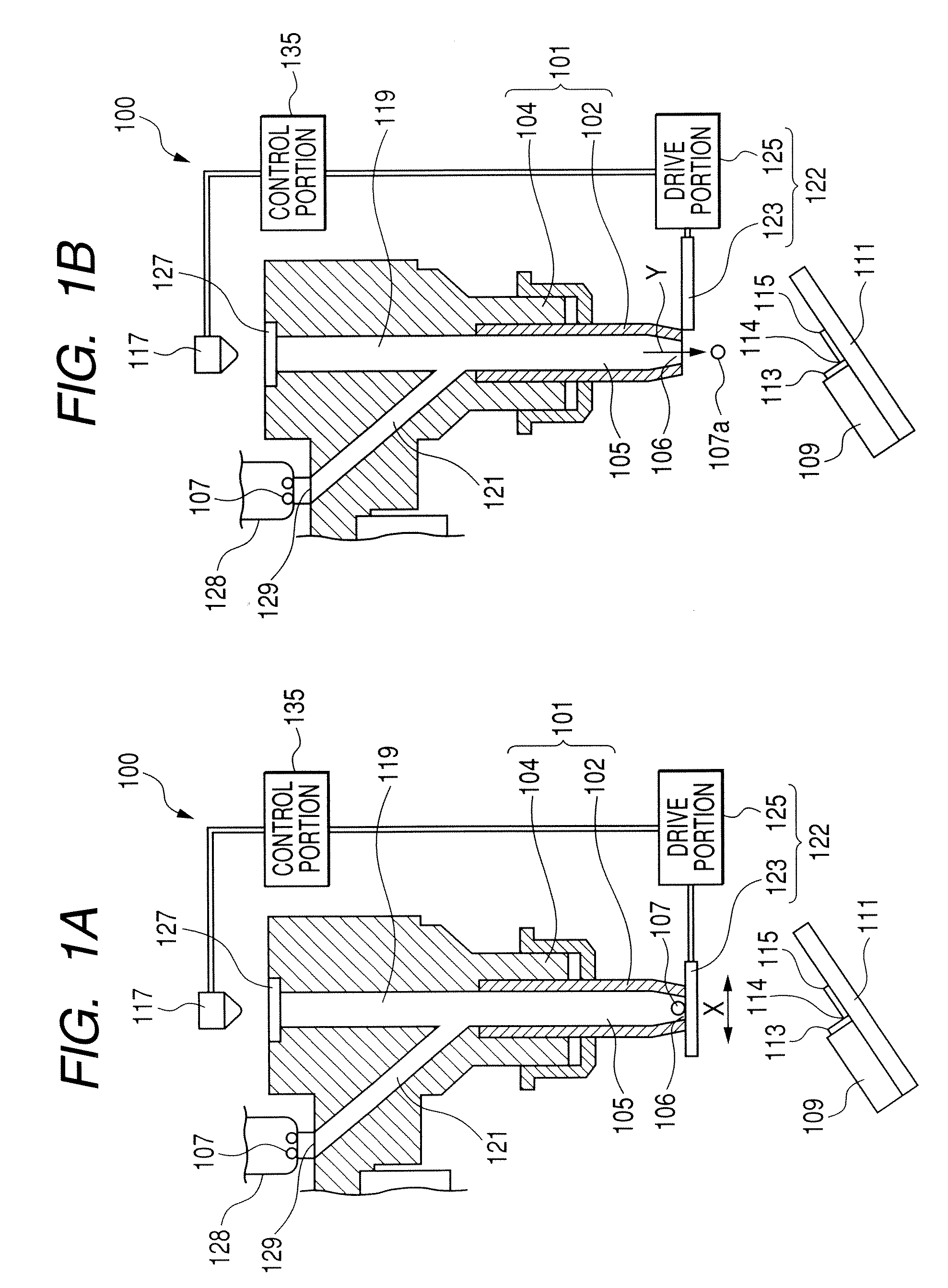

Control pin and spout system for heating metal casting distribution spout configurations

InactiveUS20100032455A1Melt-holding vesselsMolten metal pouring equipmentsDistribution systemEngineering

A control pin system, including an apparatus and method, for use in controlling the flow of molten metal in a molten metal distribution system for casting, with some aspects of the control pin including: a control pin body with an internal cavity and an outer surface, wherein the outer surface is sized and configured to operatively interact with an internal surface of a spout to effectively control the flow of molten metal through a spout aperture; and a heater element within the internal cavity of the control pin body. In other embodiments, the heater may be located within the spout body and transferring heat to the control pin.

Owner:WAGSTAFF INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com