Patents

Literature

449results about How to "Precise flow control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

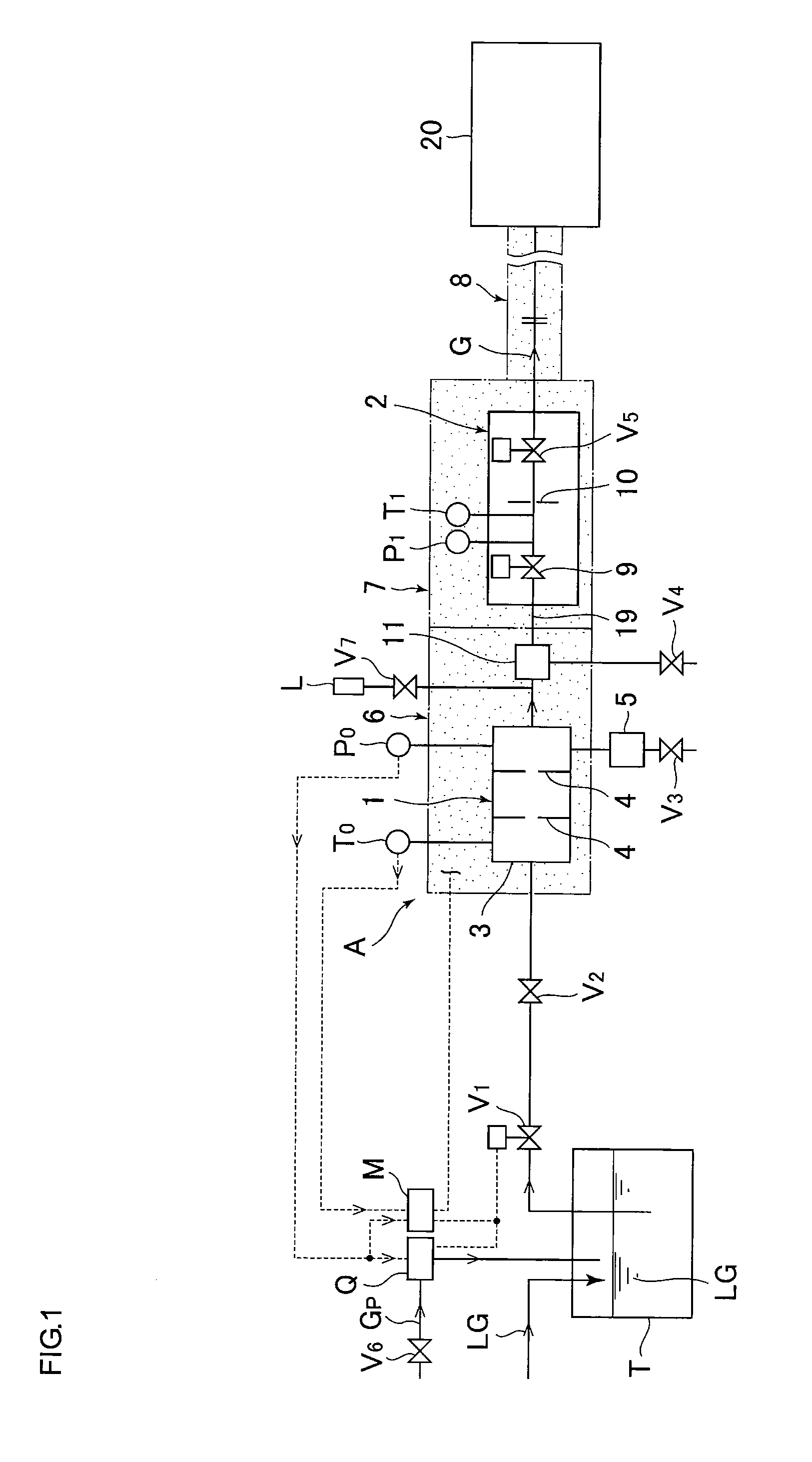

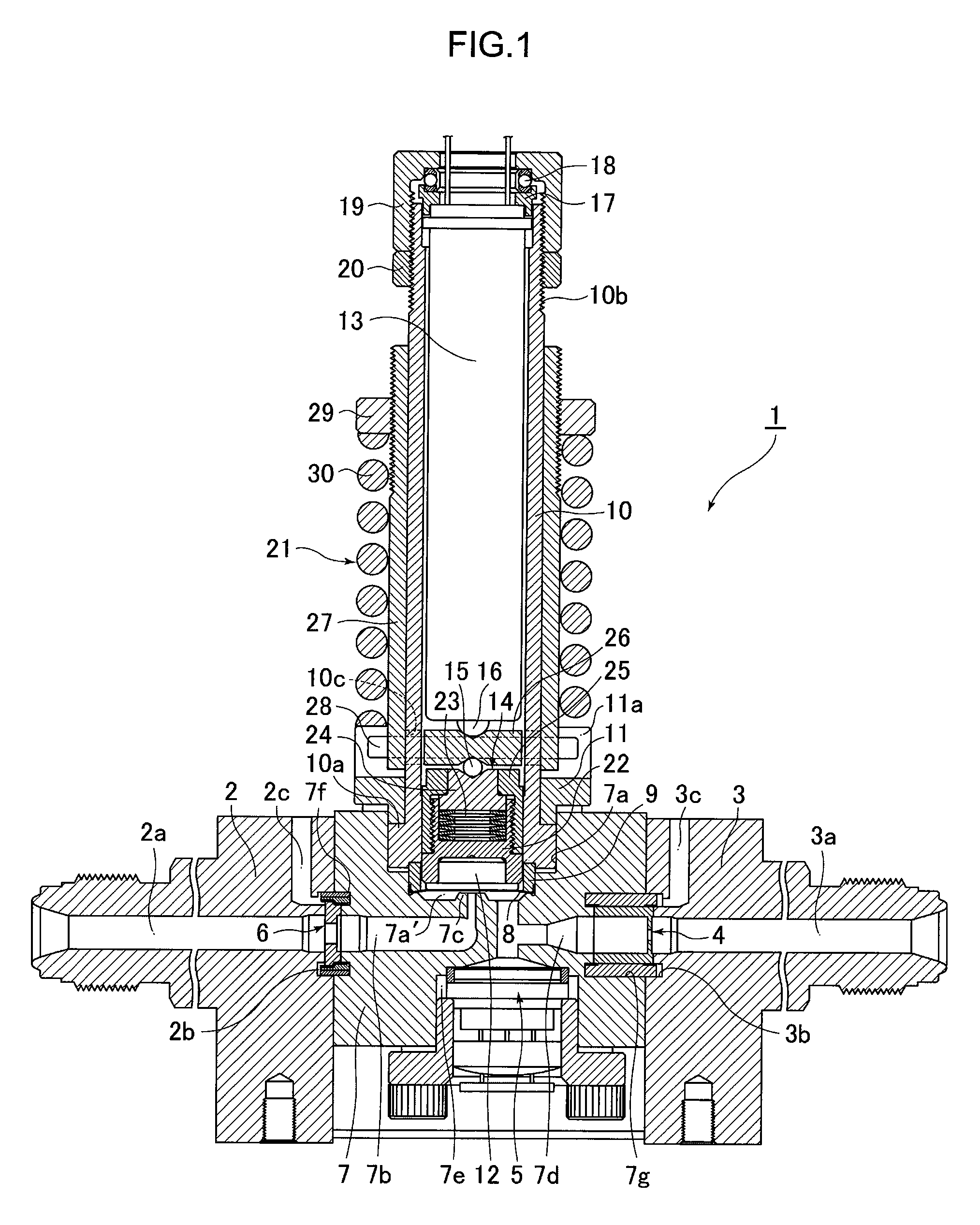

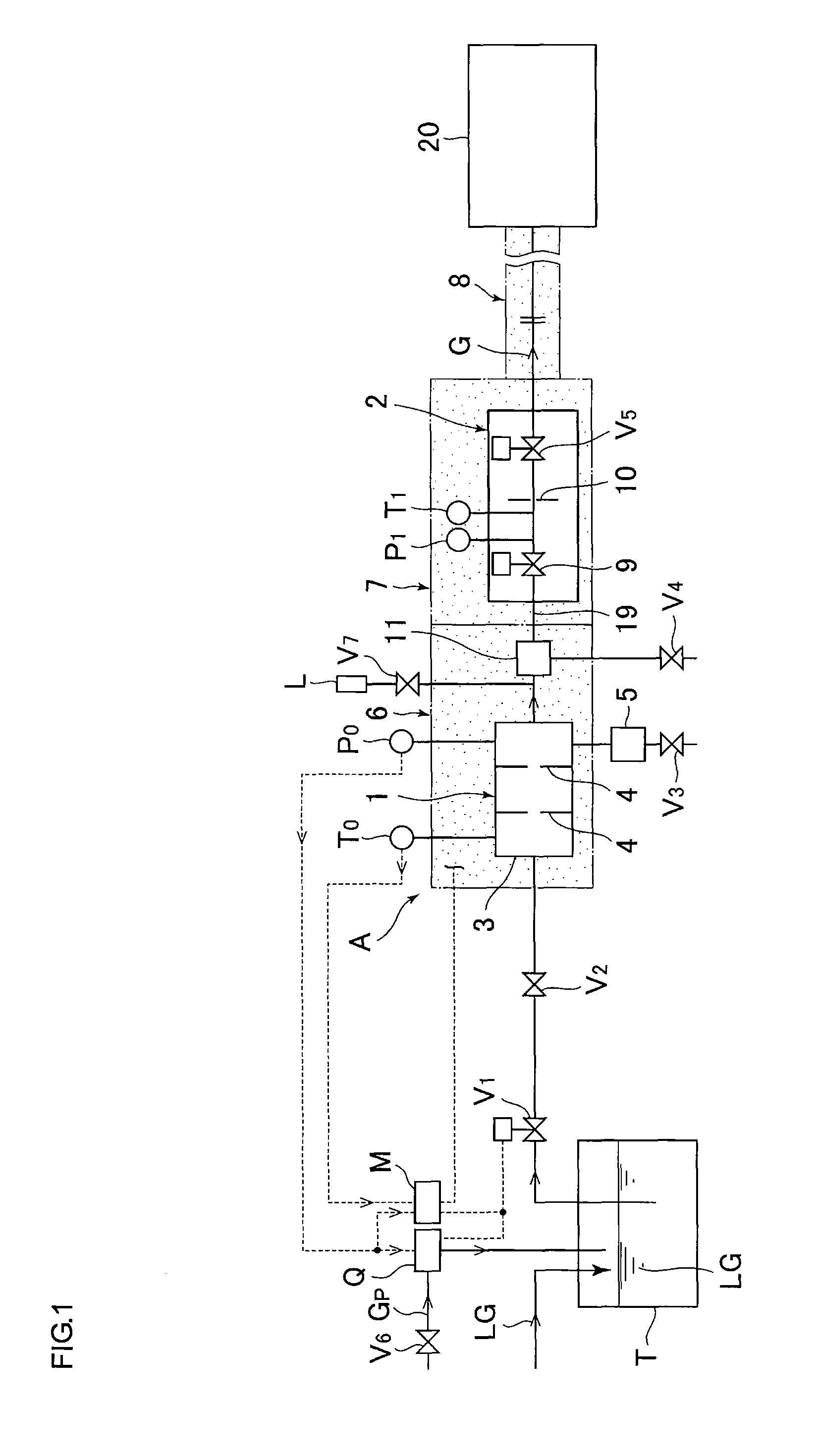

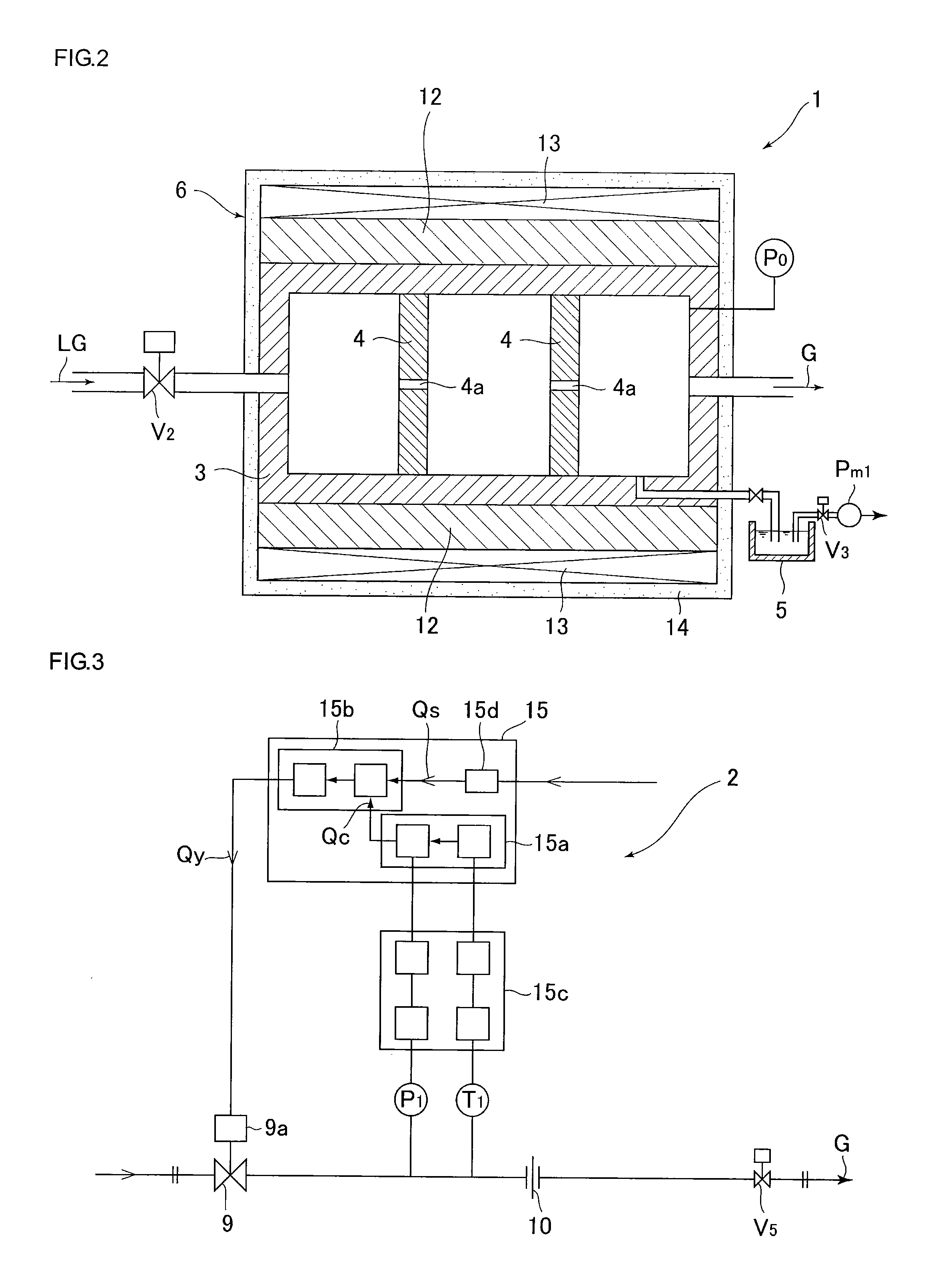

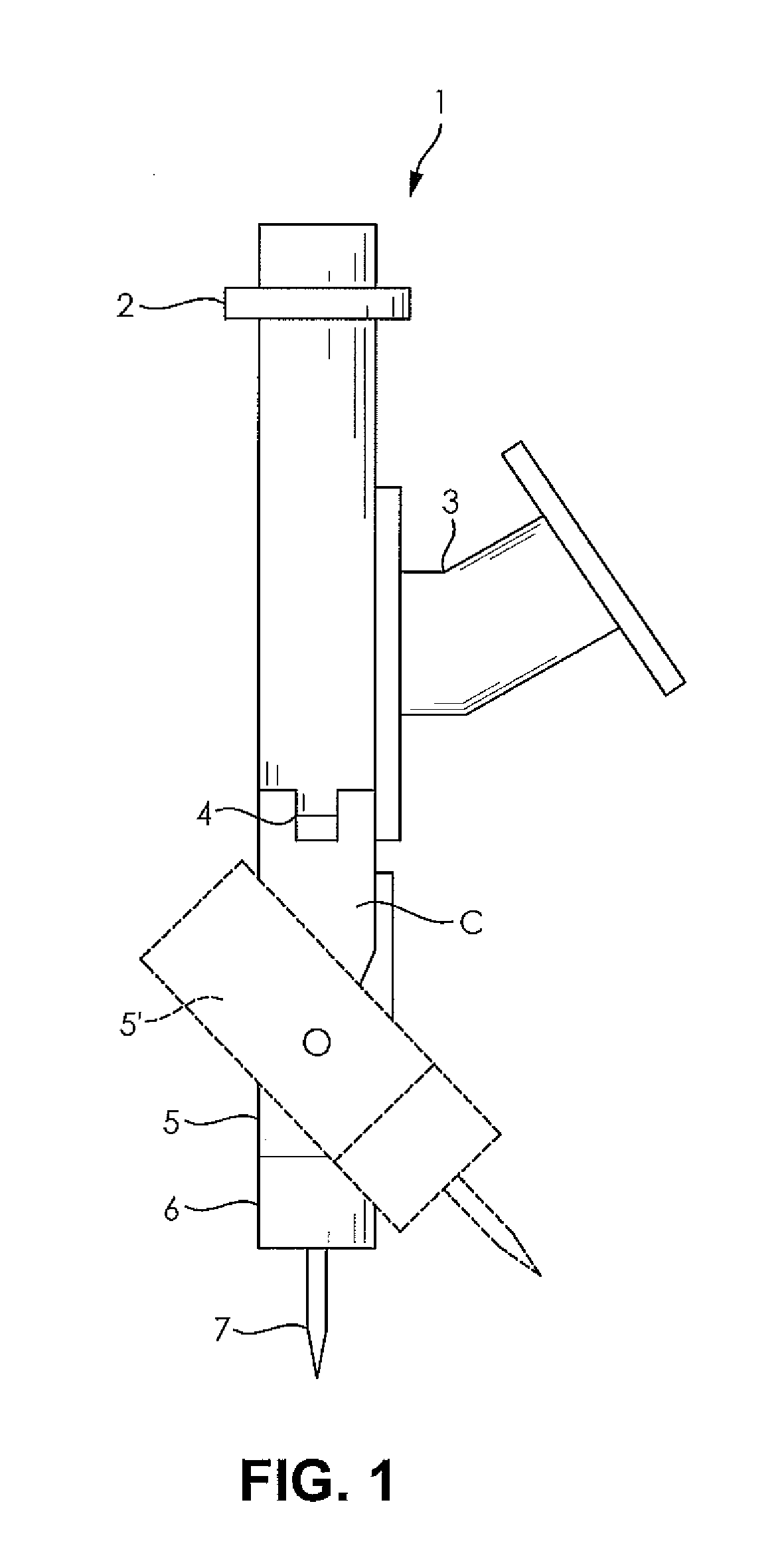

Internal pressure controller of chamber and internal pressure subject -to- control type chamber

InactiveUS20060207595A1Precise flow controlContinuous controlBreathing protectionOperating means/releasing devices for valvesInternal pressureControl signal

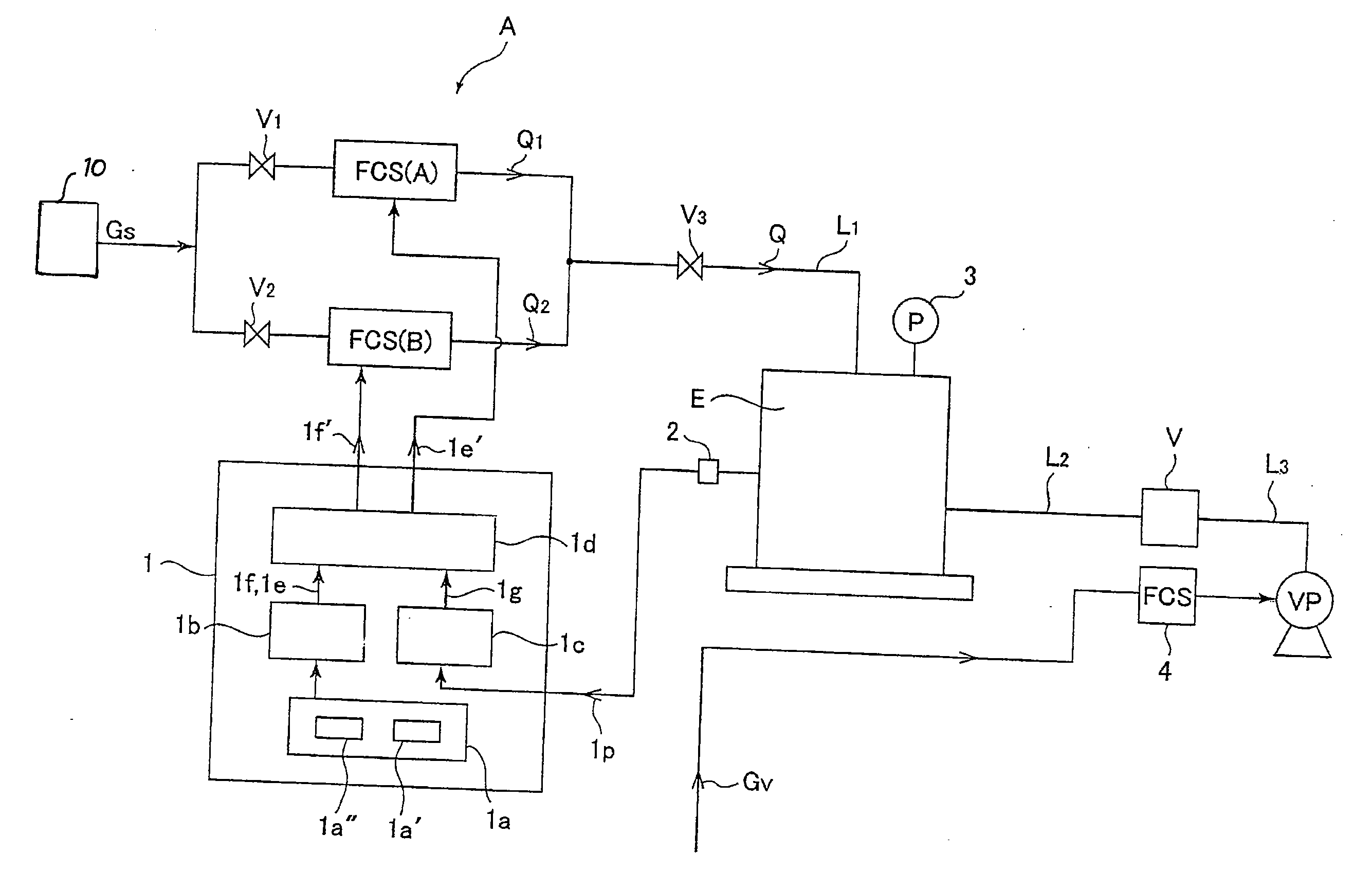

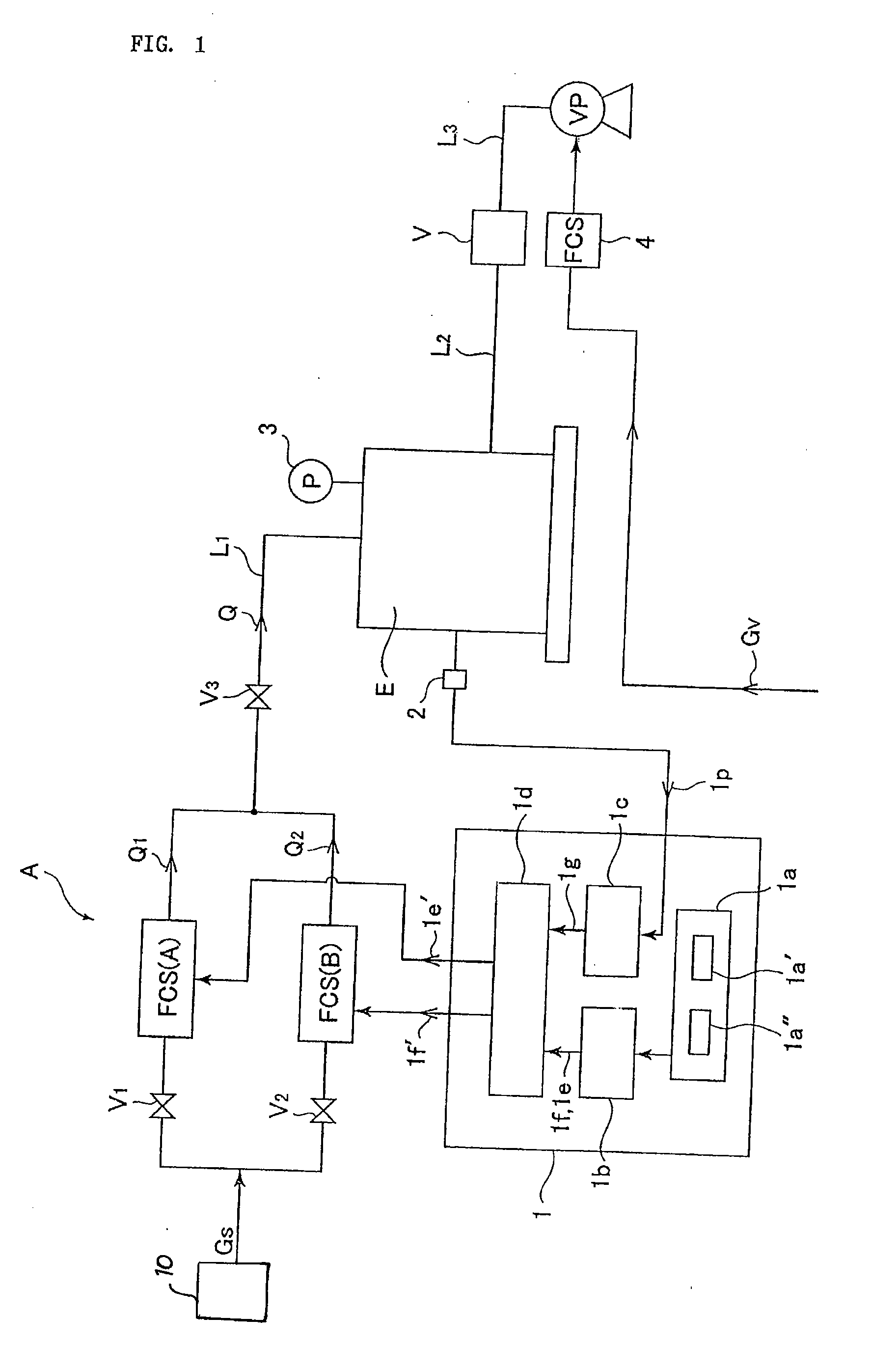

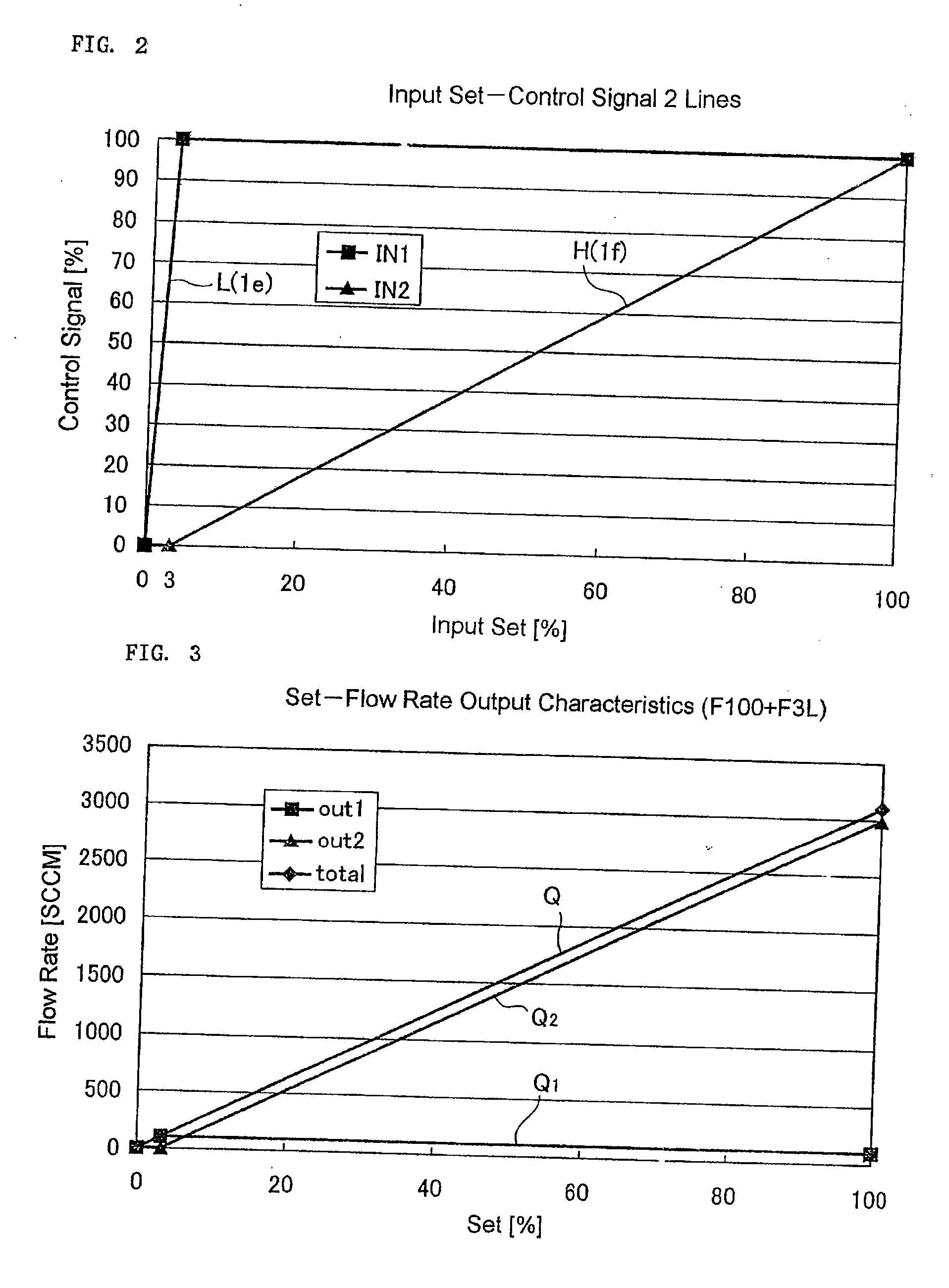

A gas supply facility includes a plurality of pressure type flow controllers connected in parallel, and a first controller to control operation of the plurality of pressure type flow controllers so as to supply a desired gas exhausted by a vacuum pump to a chamber while controlling its flow rate, one of the pressure type flow controllers operates as a second controller to control the gas flow rate range up to 10% of the maximum flow rate supplied to the chamber, while the remaining pressure type flow controllers are made to be ones that control the rest of the gas flow rate range. Furthermore, pressure inside the chamber is controlled by installing a pressure detector in the chamber, inputting the value detected by the detector to the controller, and by adjusting a control signal to the pressure type flow controllers.

Owner:FUJIKIN INC +1

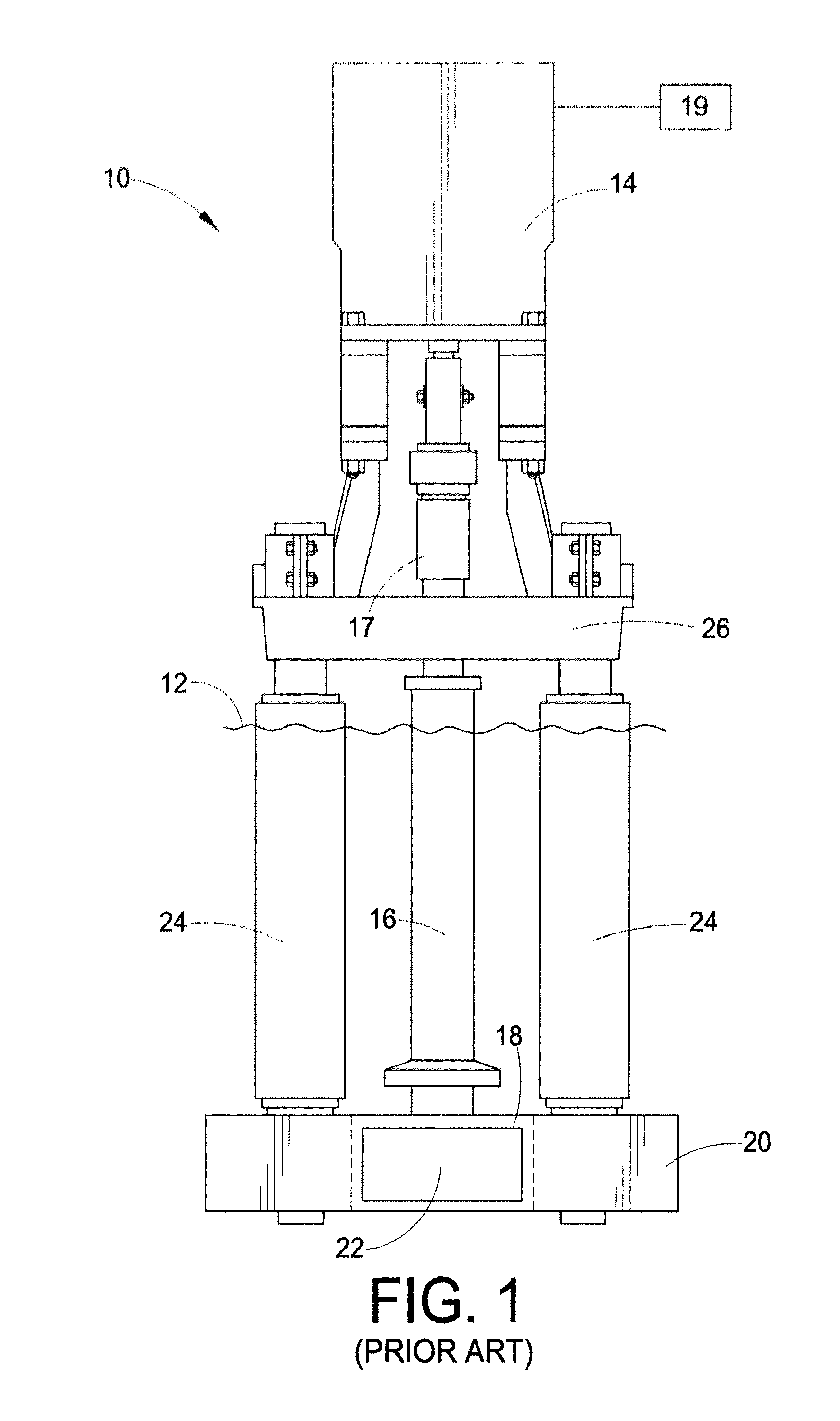

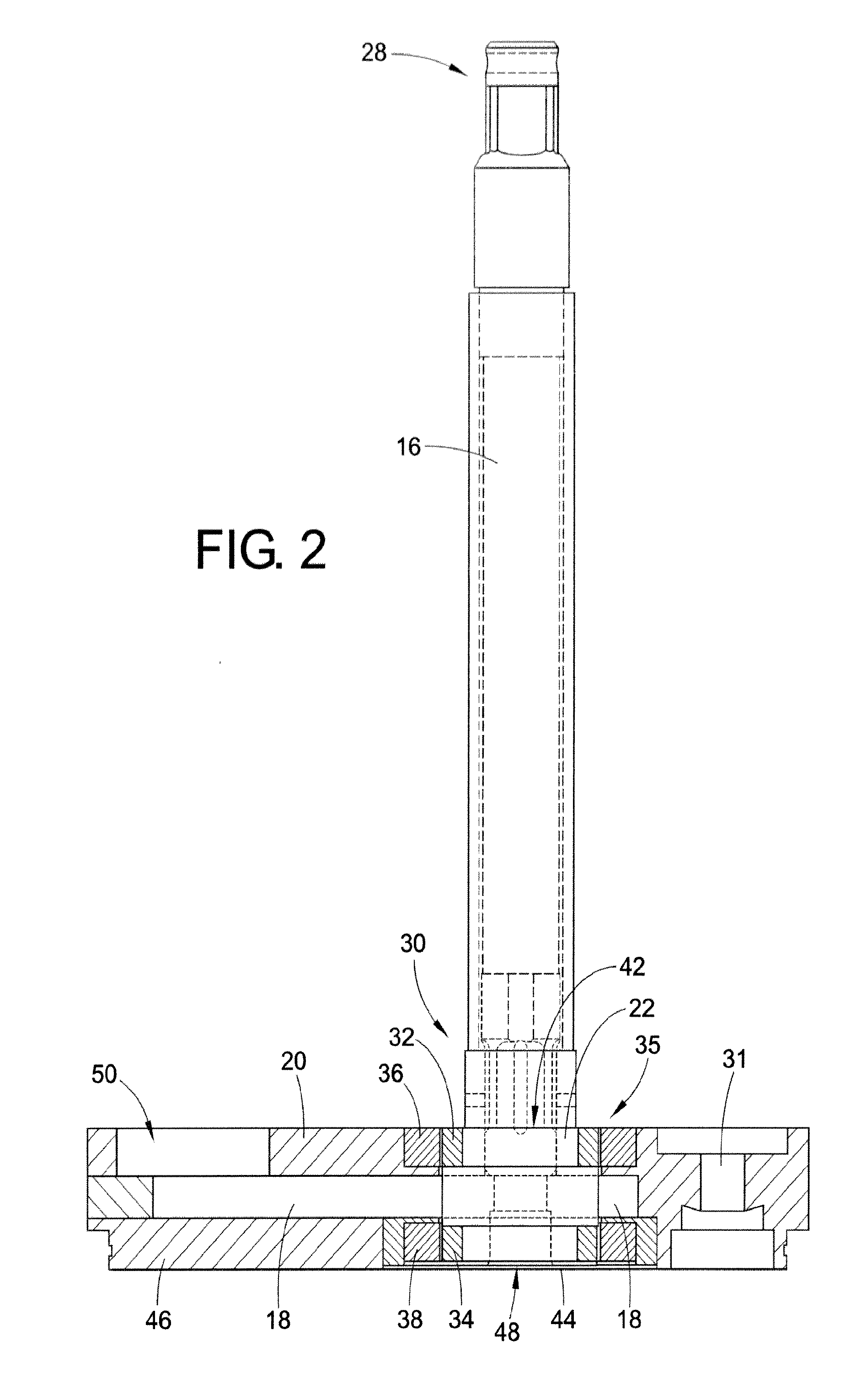

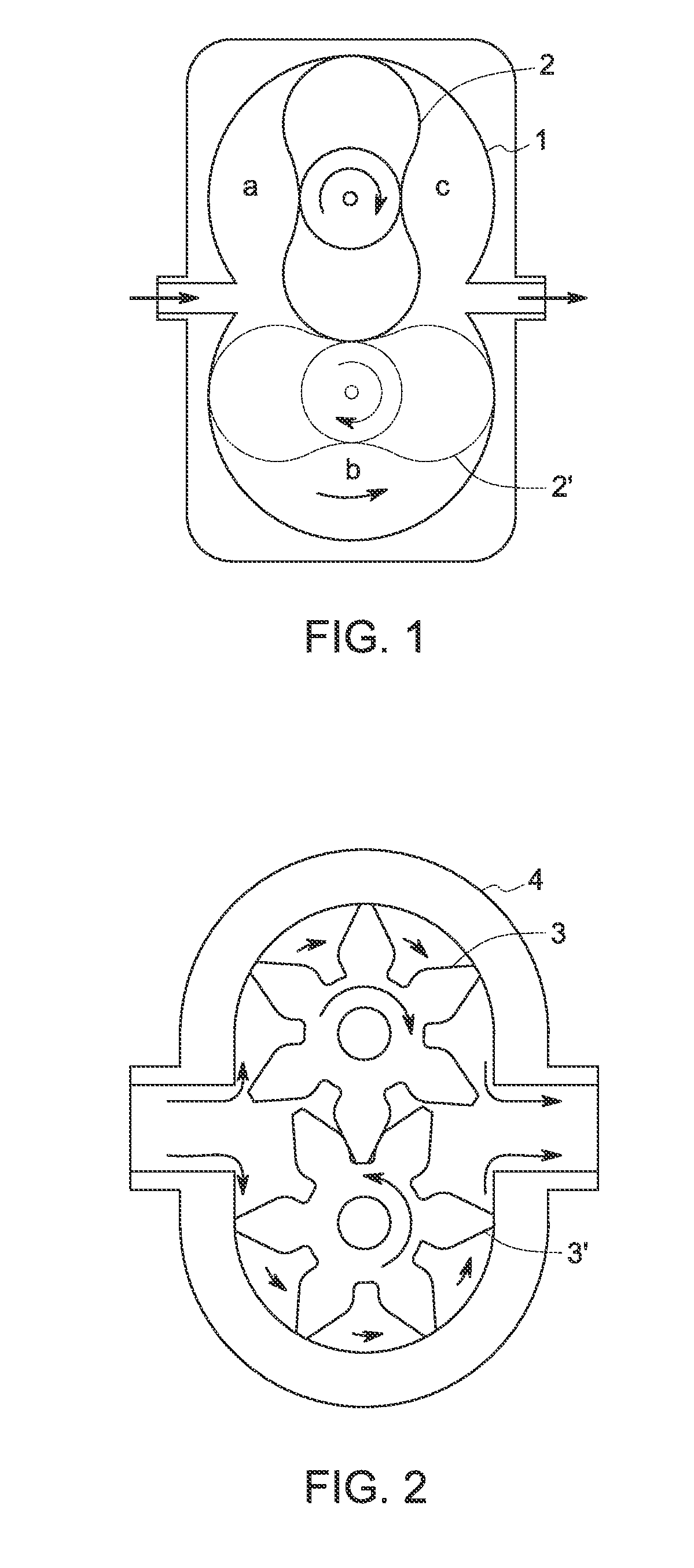

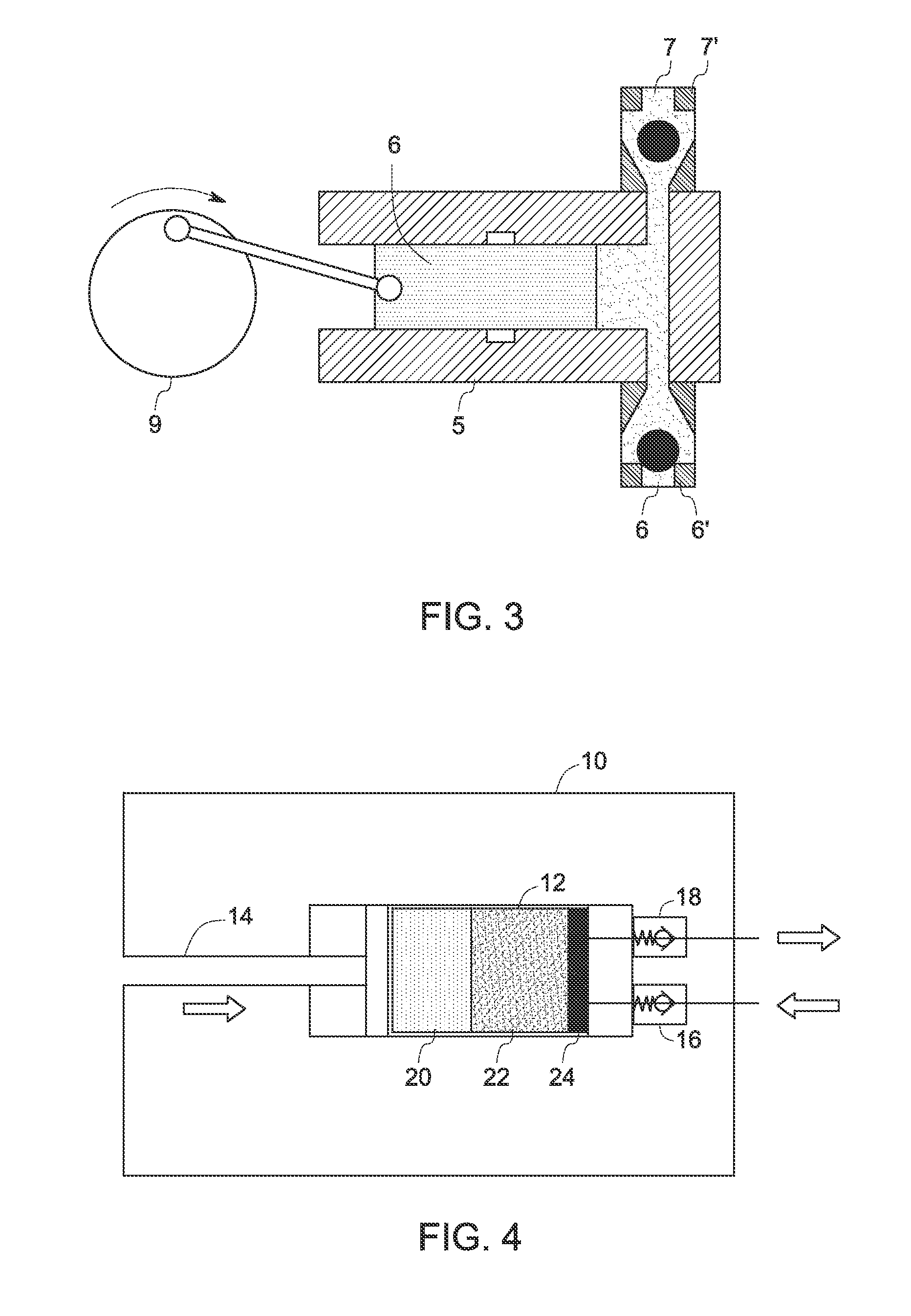

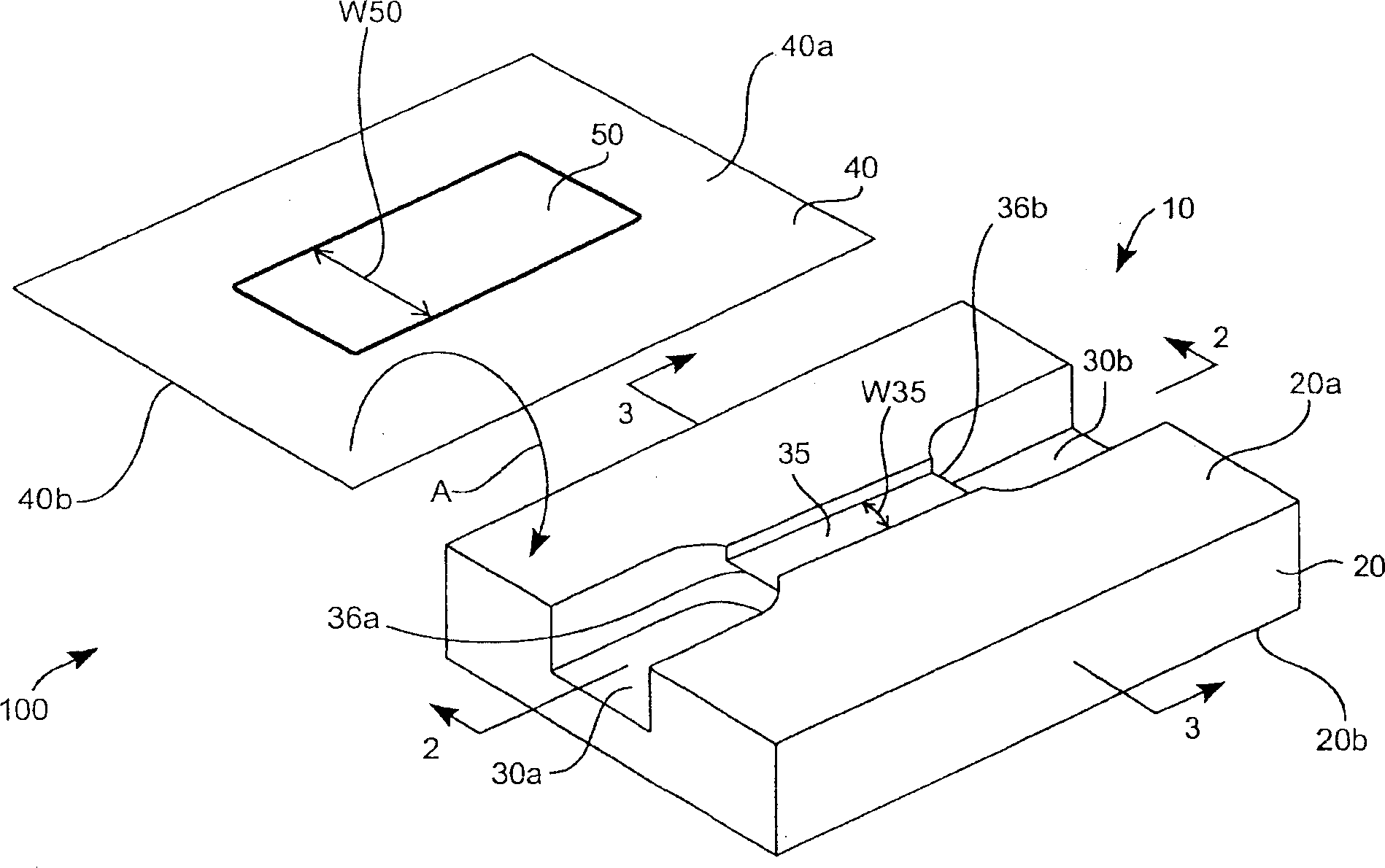

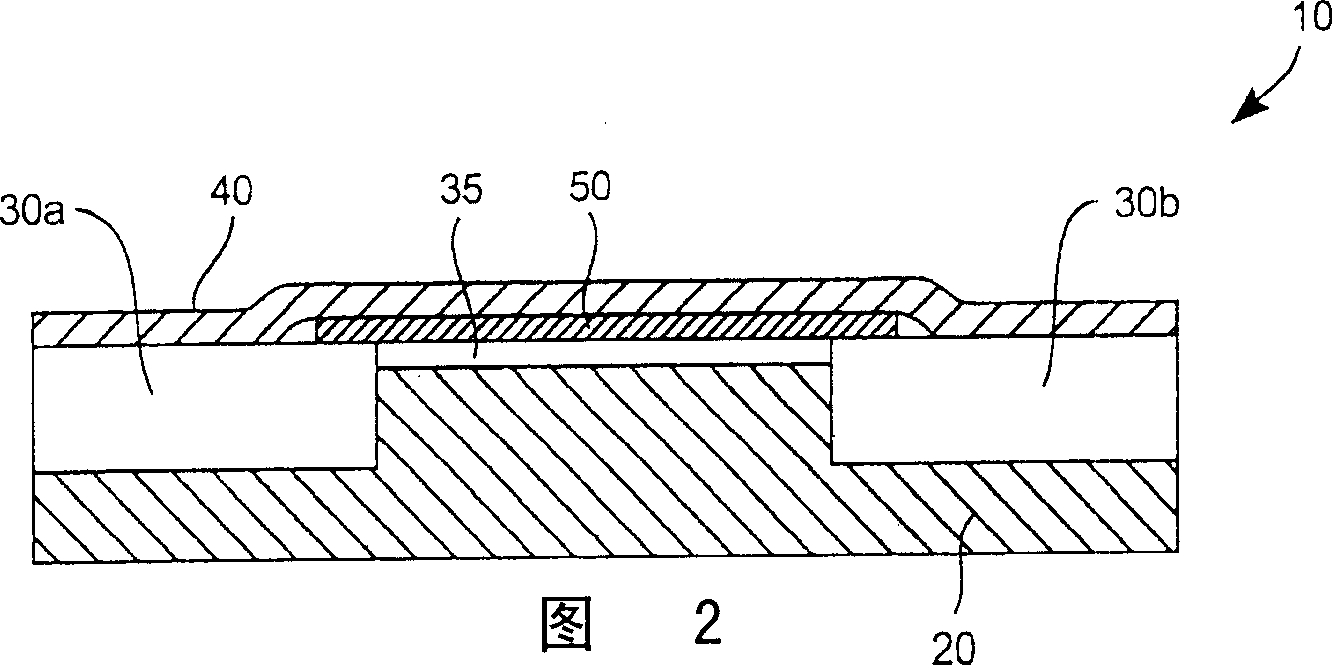

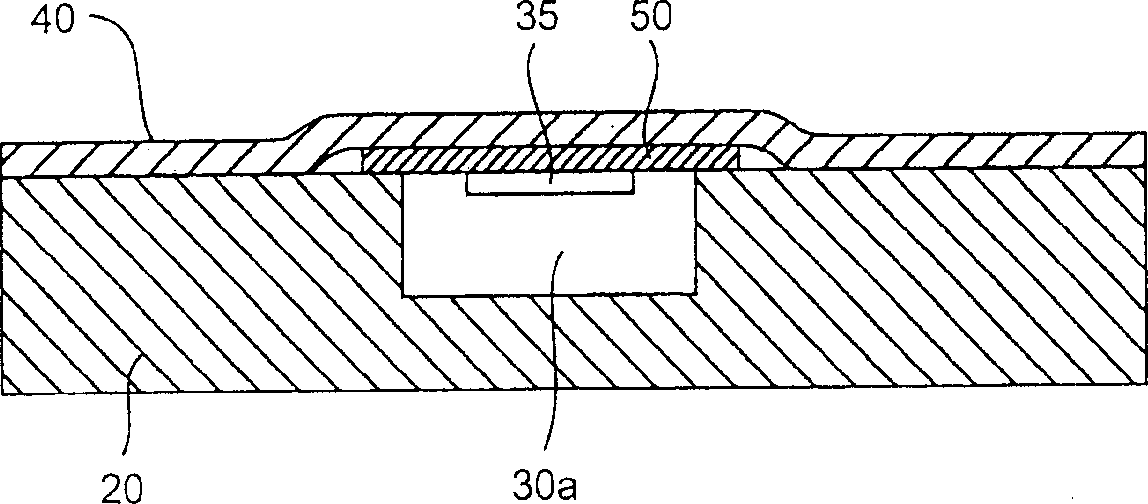

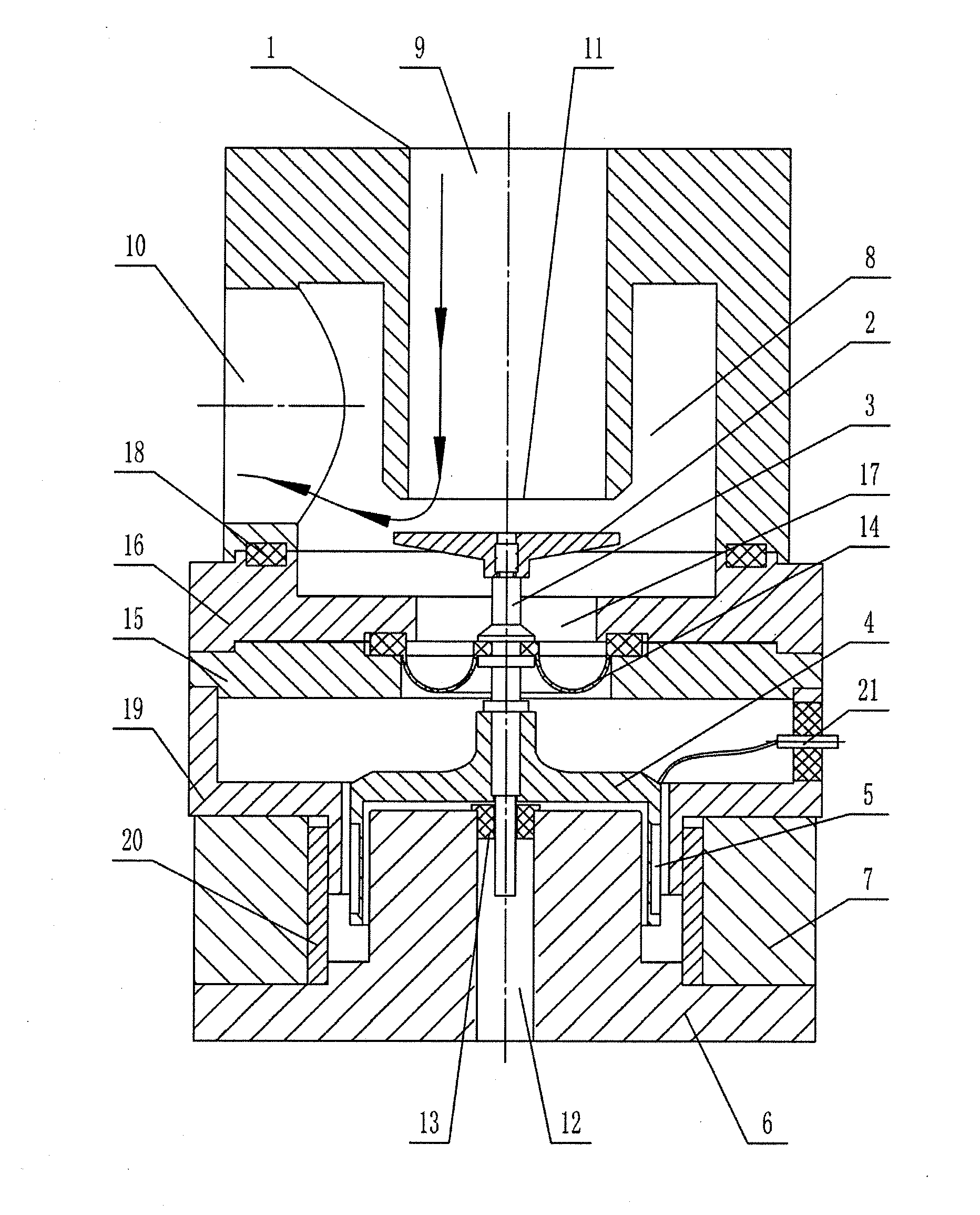

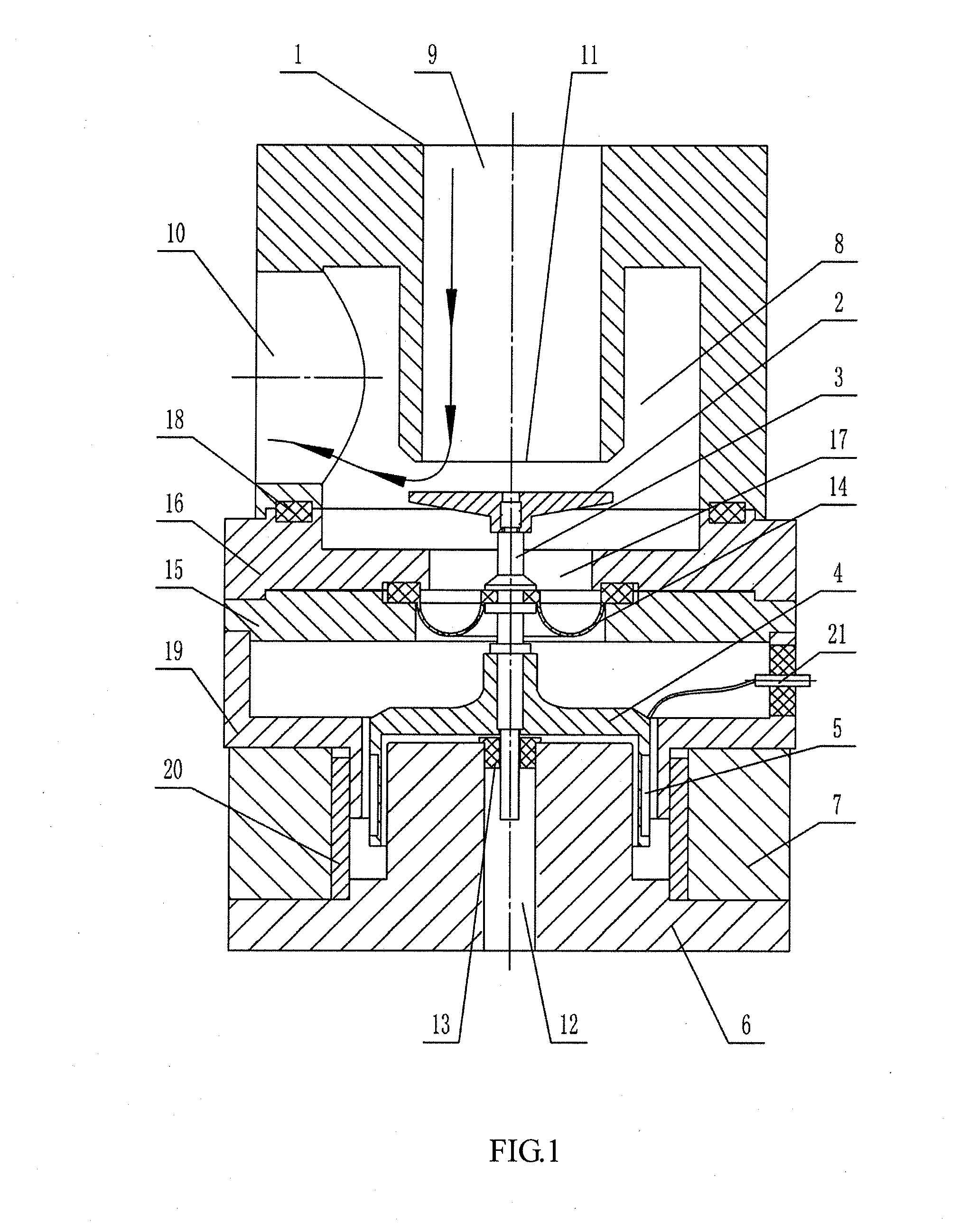

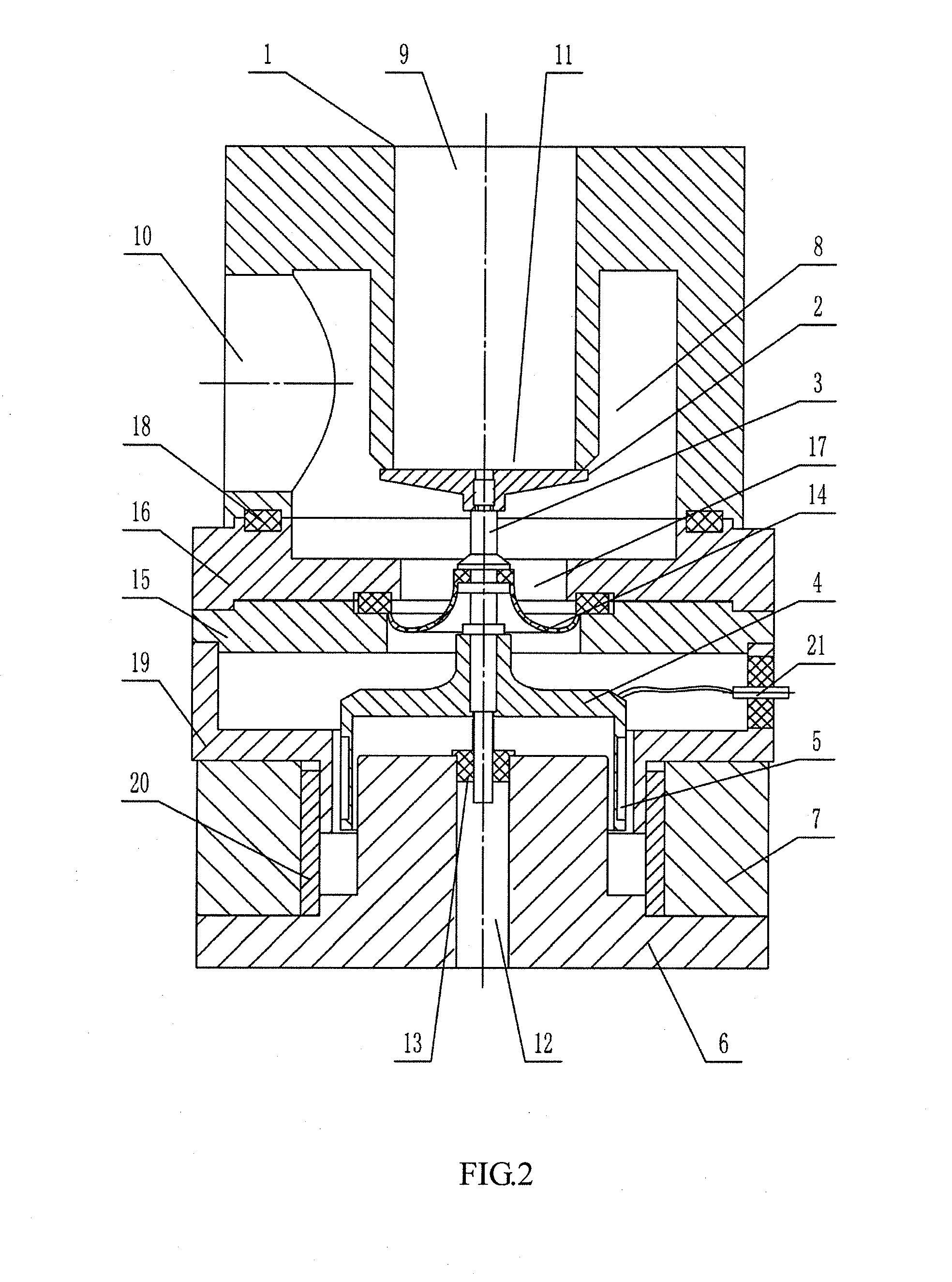

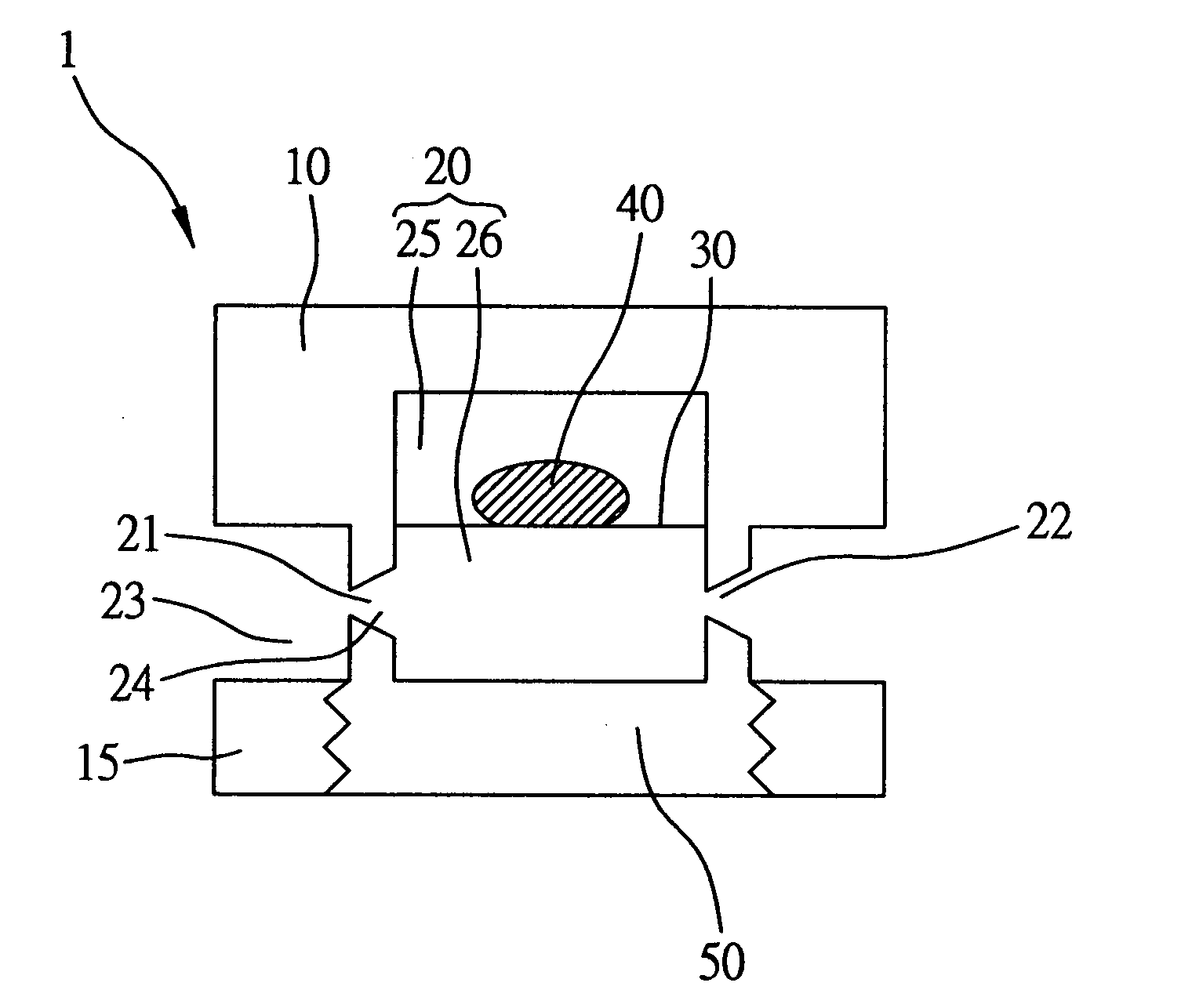

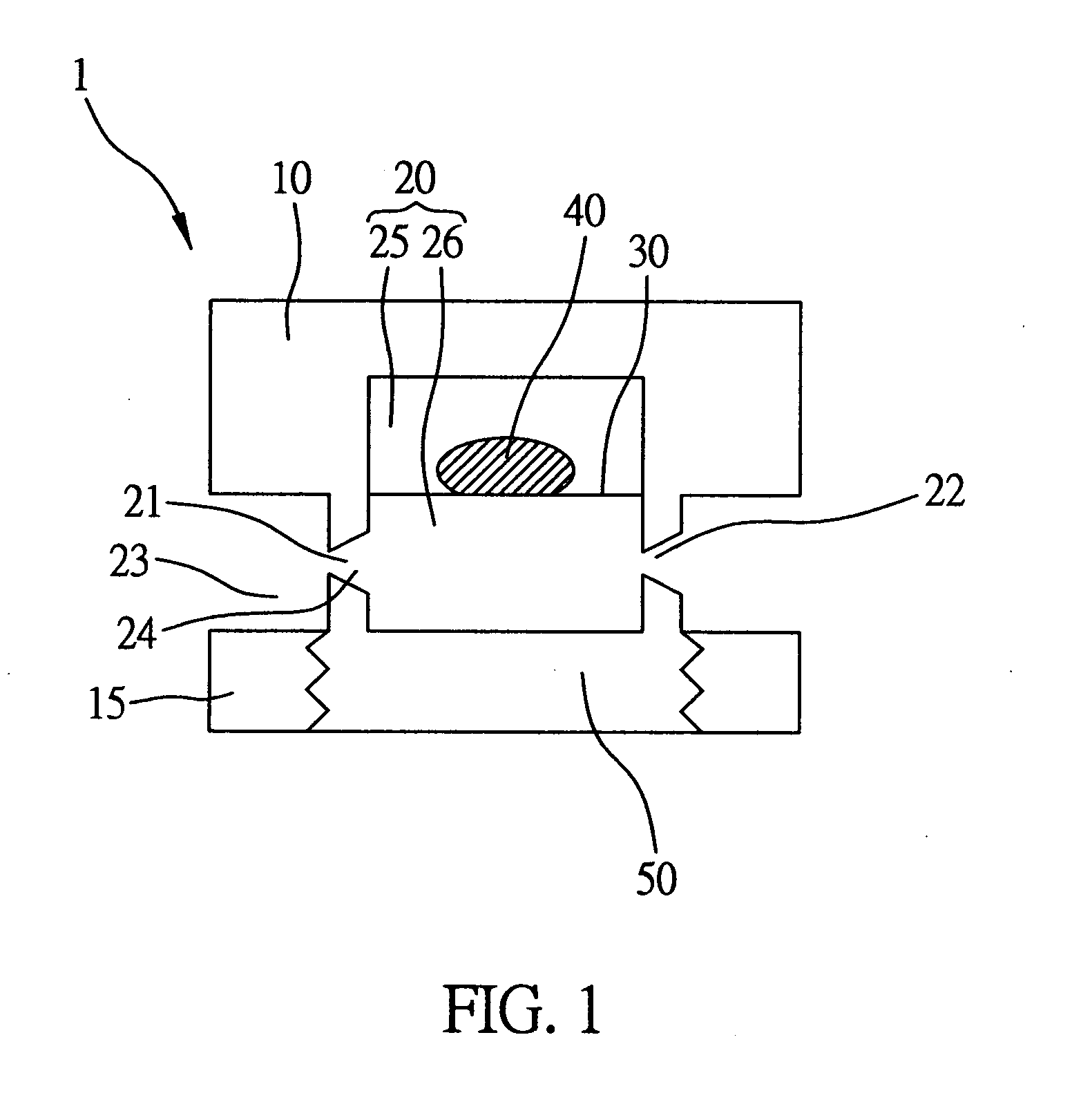

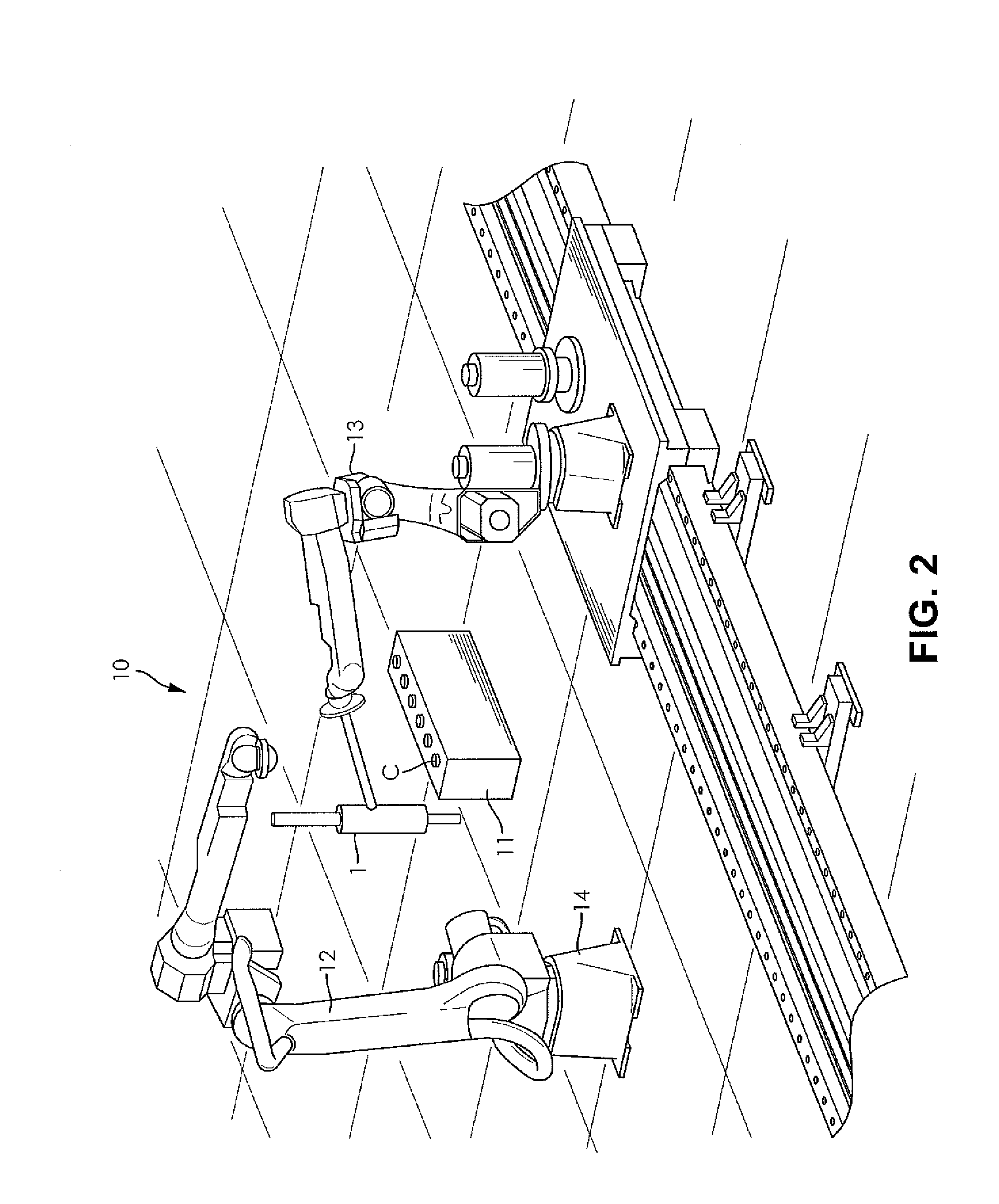

Mold pump assembly

ActiveUS20140044520A1Easy to tunePrecise flow controlSpecific fluid pumpsPump componentsImpellerEngineering

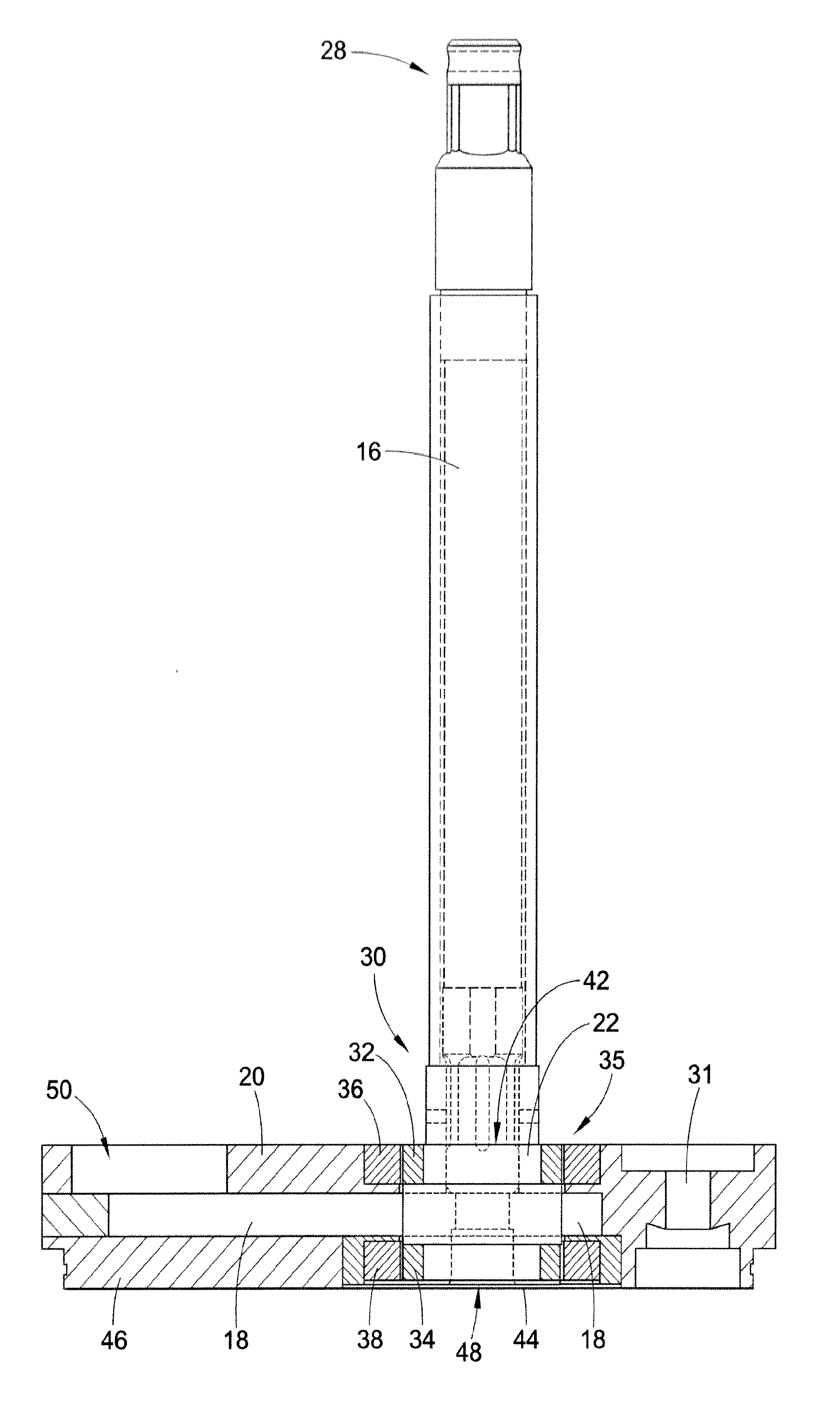

A molten metal pump assembly (10) and method to fill complex molds with molten metal, such as aluminum. The pump assembly includes an elongated shaft (16) connecting a motor (14) to an impeller (22). The impeller is housed within a chamber (18) of a base member such that rotation of the impeller draws molten metal into the chamber at an inlet (48) and forces molten aluminum through an outlet (50). A first bearing (36) is adapted to support the rotation of the impeller at a first radial edge (32) and a second bearing (38) is adapted to support the rotation of the impeller at a second radial edge. A bypass gap (60) is interposed between the second bearing and the second radial edge. Molten metal leaks through the bypass gap at a predetermined rate to manipulate a flow rate and a head pressure of the molten metal such that precise control of the flow rate is achieved.

Owner:PYROTECK INC

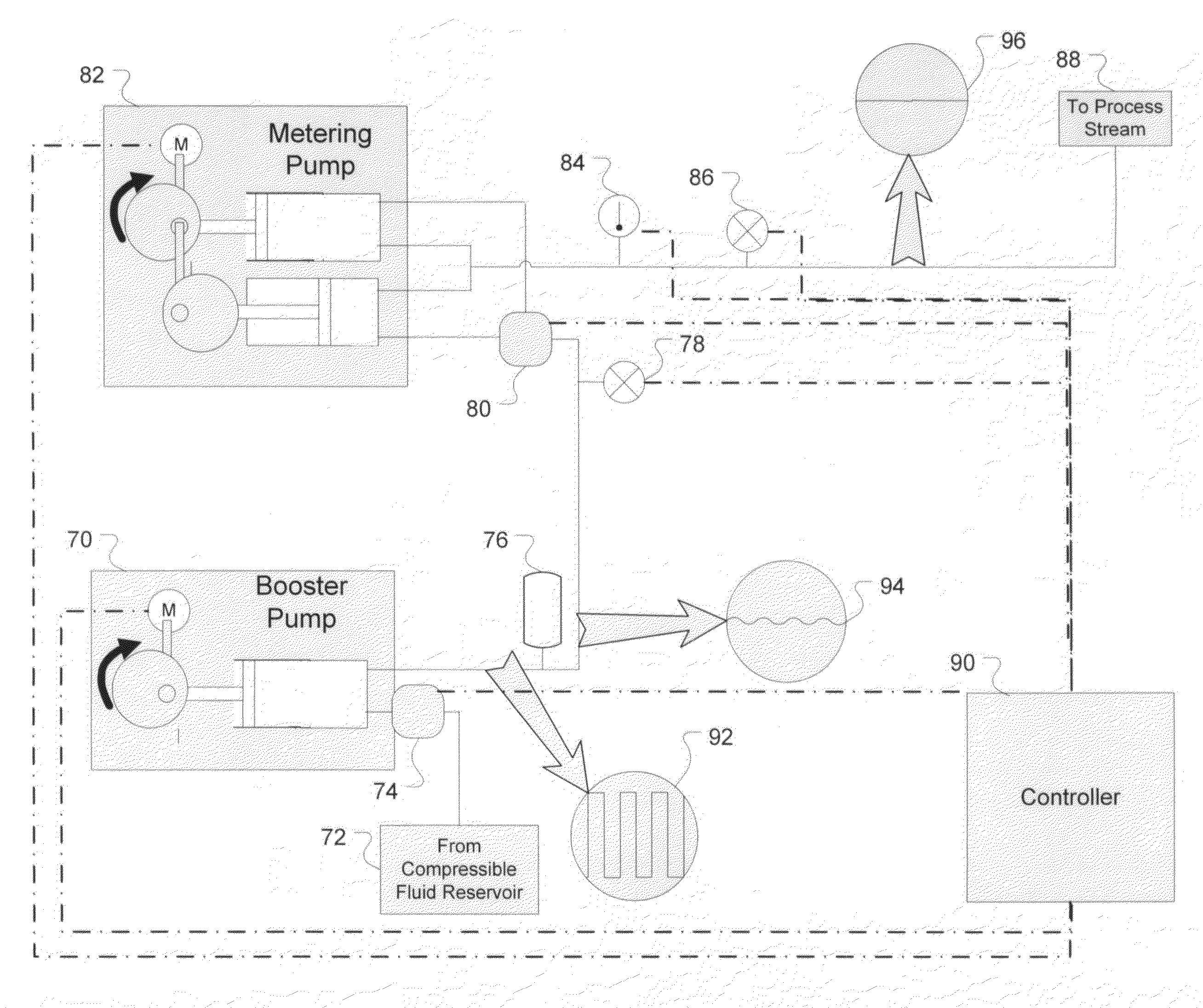

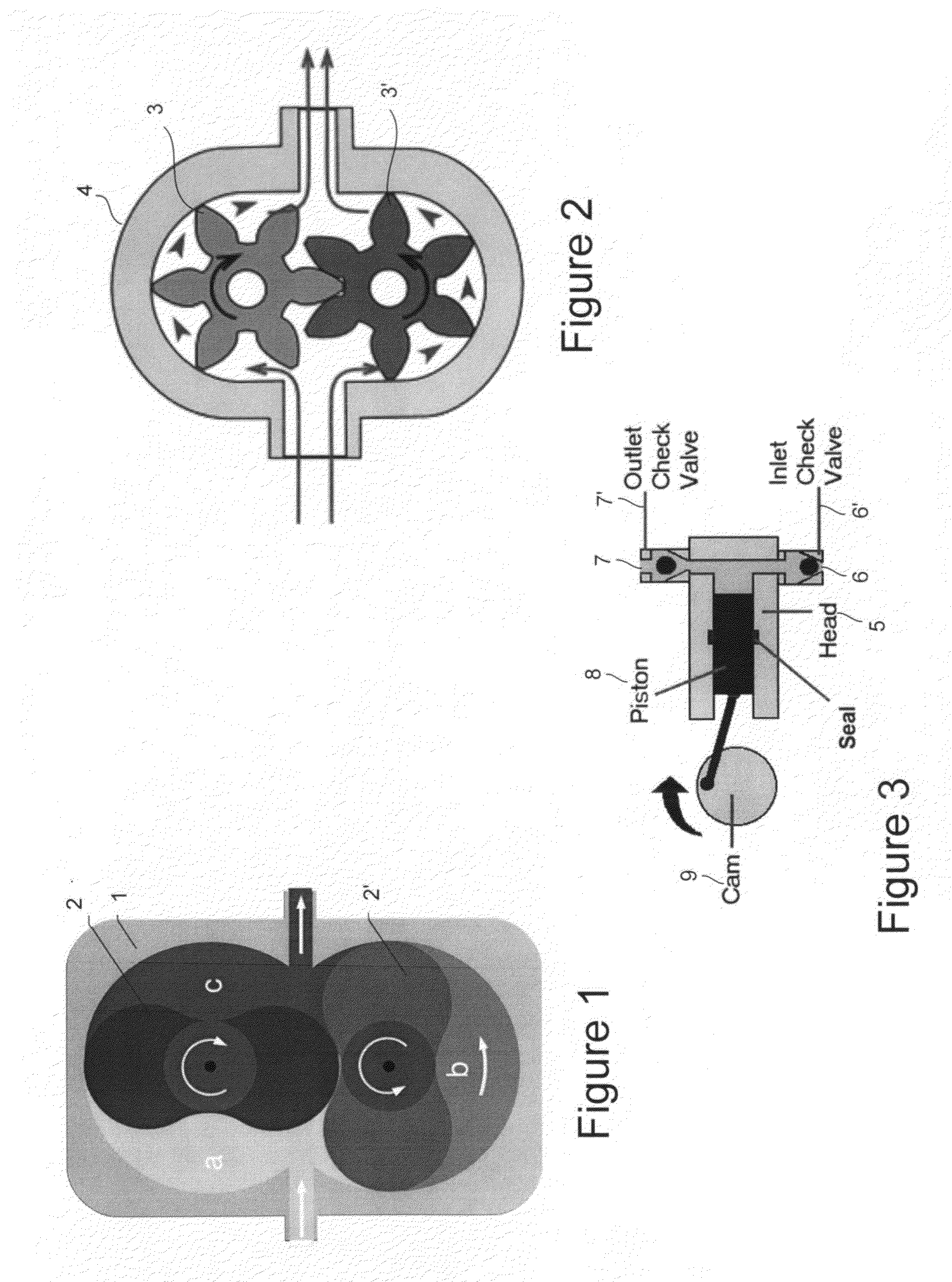

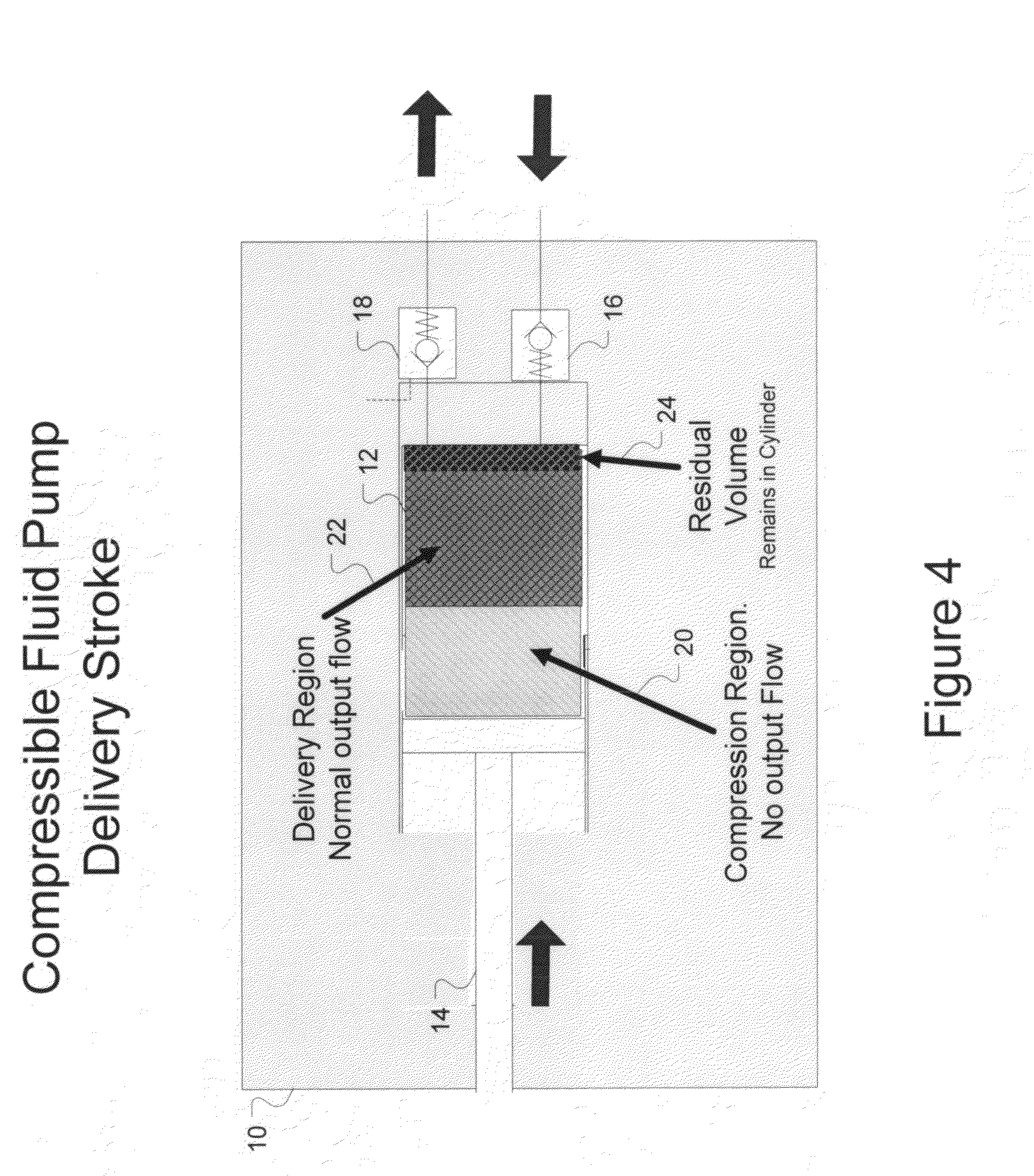

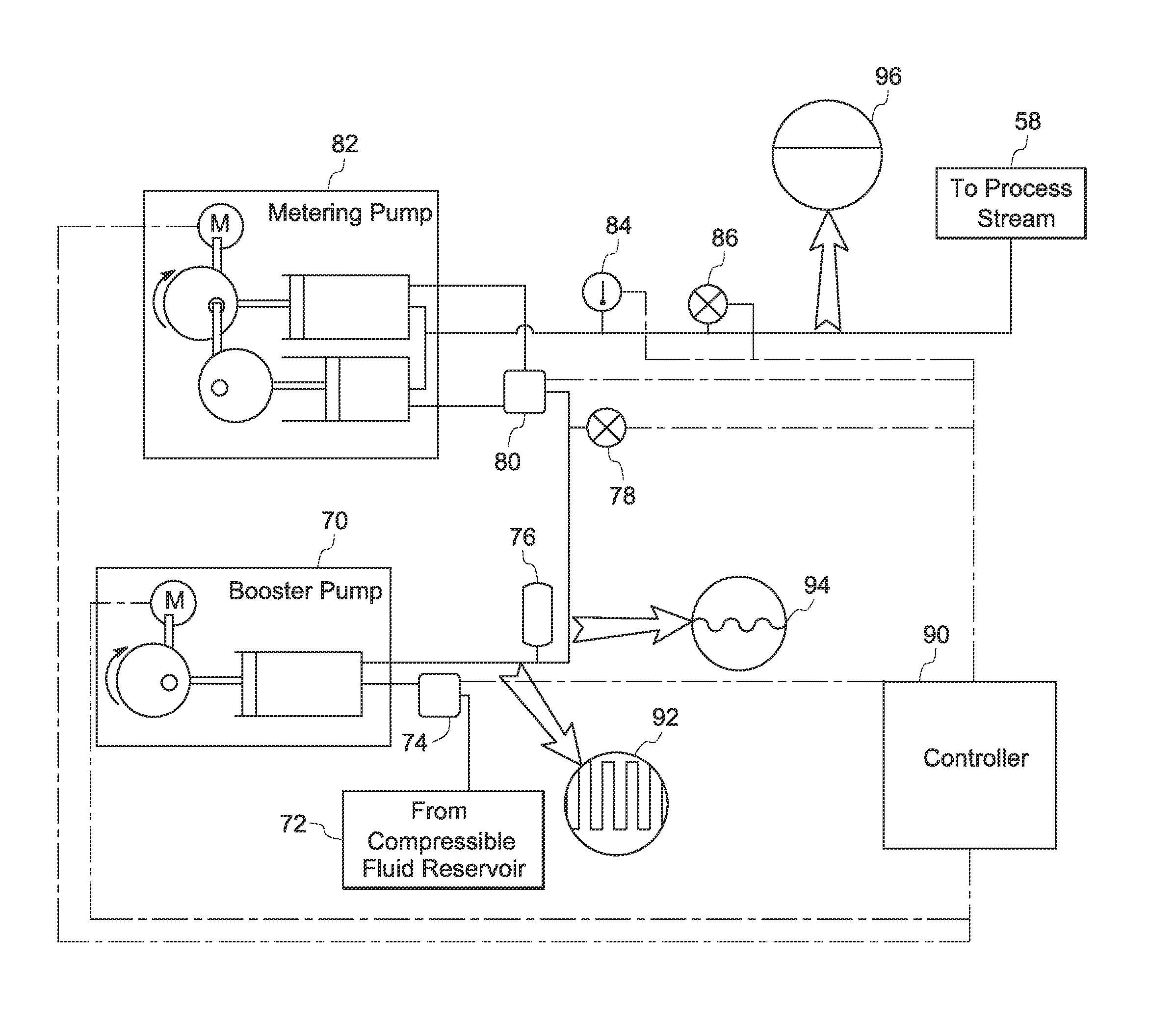

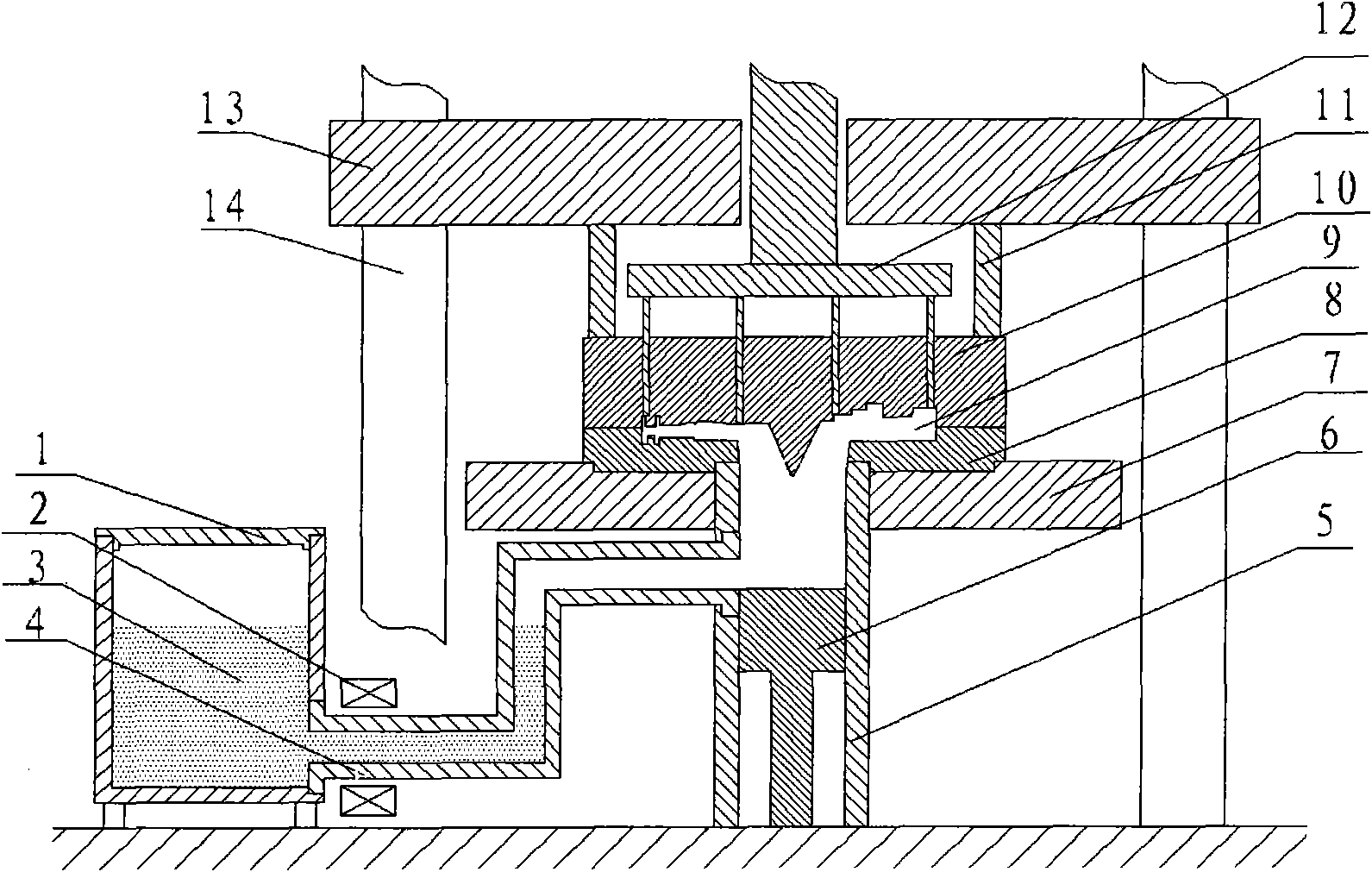

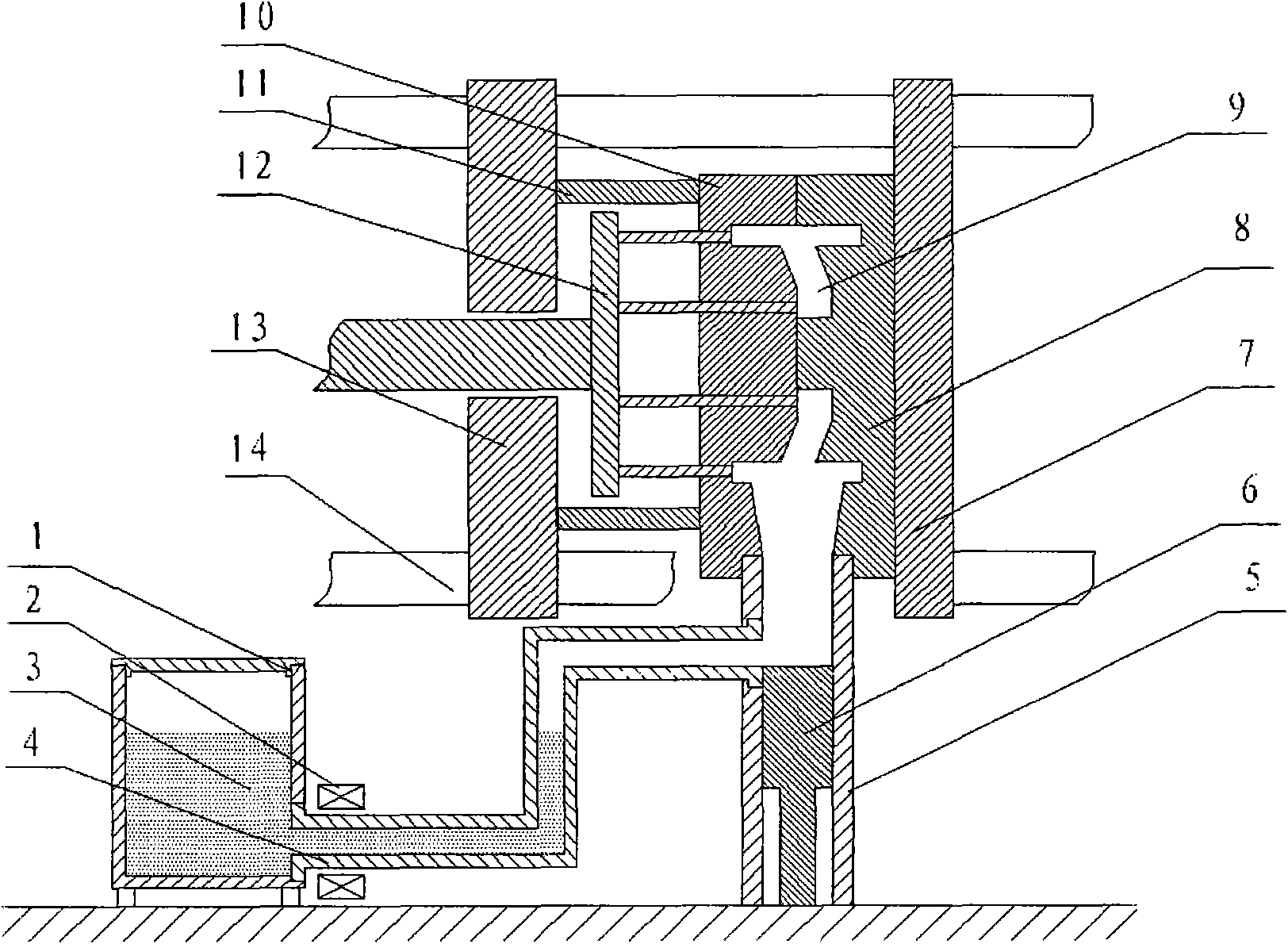

Compressible fluid pumping system

ActiveUS20100040483A1Low compressibilityPrecise functionComponent separationFlexible member pumpsEngineeringHigh pressure

An invention is claimed that enables the pumping of compressible fluids at high pressures when an accurate flow is desired. Two pressure sources, for example pumps plumbed in series, separate thermodynamic work, such as pressurization, at the first pressure source from a volumetric or matter metering function in the second pressure source. One example is a flowstream delivery for a chemical instrumentation system that is manufactured from relatively unsophisticated pumps yet delivers precise flows with low pulsation (<1 %) over pressures greater than 100 bar. An advantage of one embodiment allows the economical conversion of typical HPLC systems to state of-the-art supercritical fluid chromatography (SFC) systems with minimal modification to system components.

Owner:AGILENT TECH INC

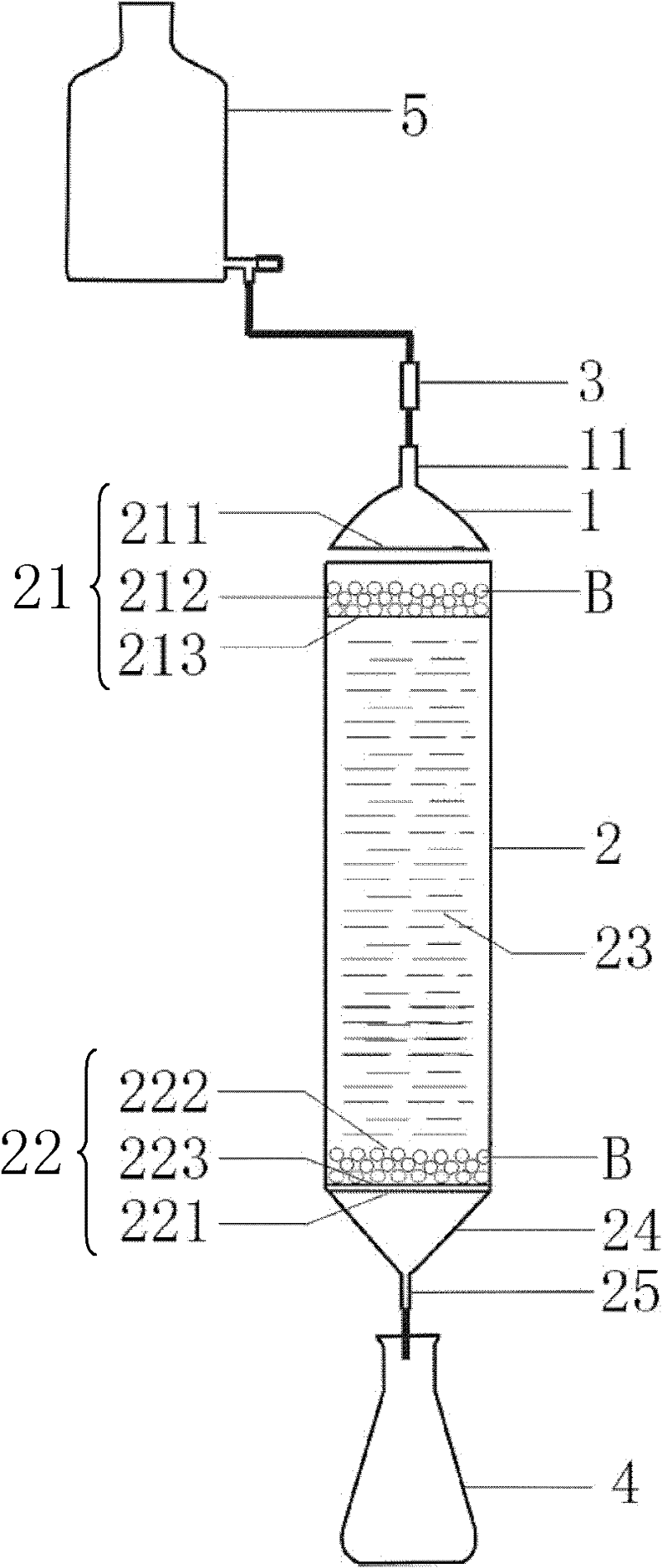

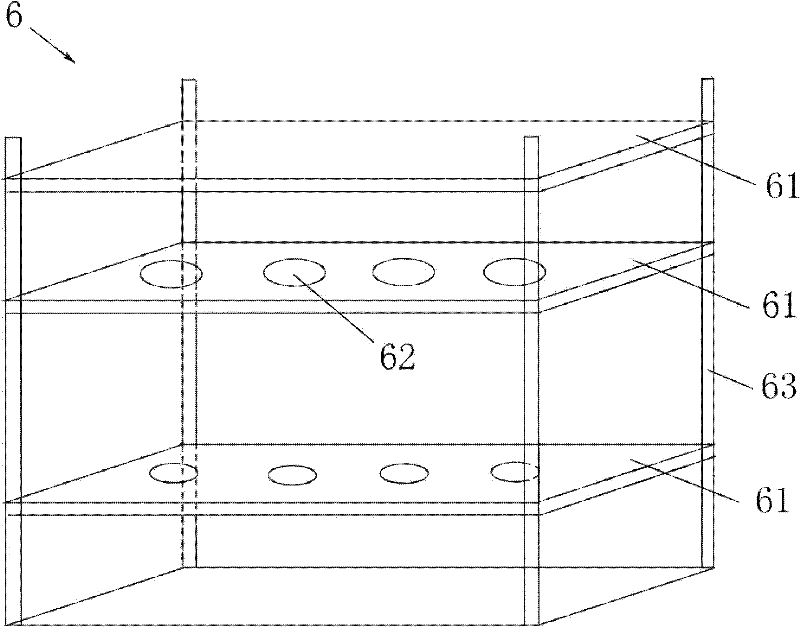

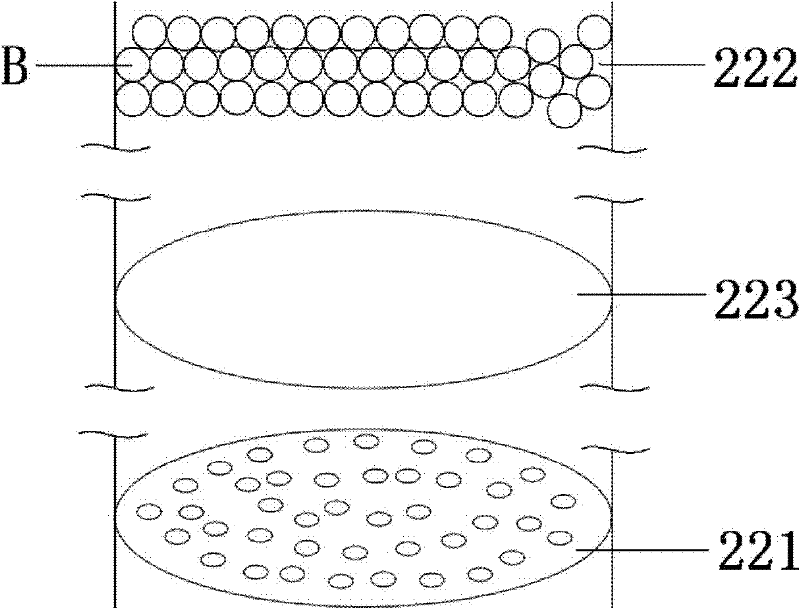

Leaching device used in vertical transfer of pollutants in soil

InactiveCN102411043AReduce the impact of horizontal migrationPrecise control of flow rateEarth material testingSpray nozzleWater flow

The invention relates to a leaching device used in vertical transfer of pollutants in soil. The leaching device comprises a spray nozzle, a water flow meter, a leaching column for holding an experimental earth pillar and a percolate accommodating container, wherein, the leaching column is internally provided with at least two filter layers capable of filtering leaching liquid, a filter layer structure is respectively arranged on the upper and lower ends of the experimental earth pillar, and each filter layer is provided with a filter screen layer, a filter bulb layer and a filter paper layer; and in addition, the height of the leaching column body is 90cm-150cm, and the inner diameter of the cross section of the column body is 5cm-15cm. The leaching device has the advantages that on the basis of the large axial size of the leaching column, vertical transfer of the pollutants in the profile of the deeper soil can be simulated; by setting the water flow meter, the flow velocity and flow rate of injection water can be accurately controlled; by setting the upper filter layer, the injection water can be uniformly sprayed; and by setting the lower filter layer, the filter effect can be ensured and percolate can be timely and effectively discharged.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

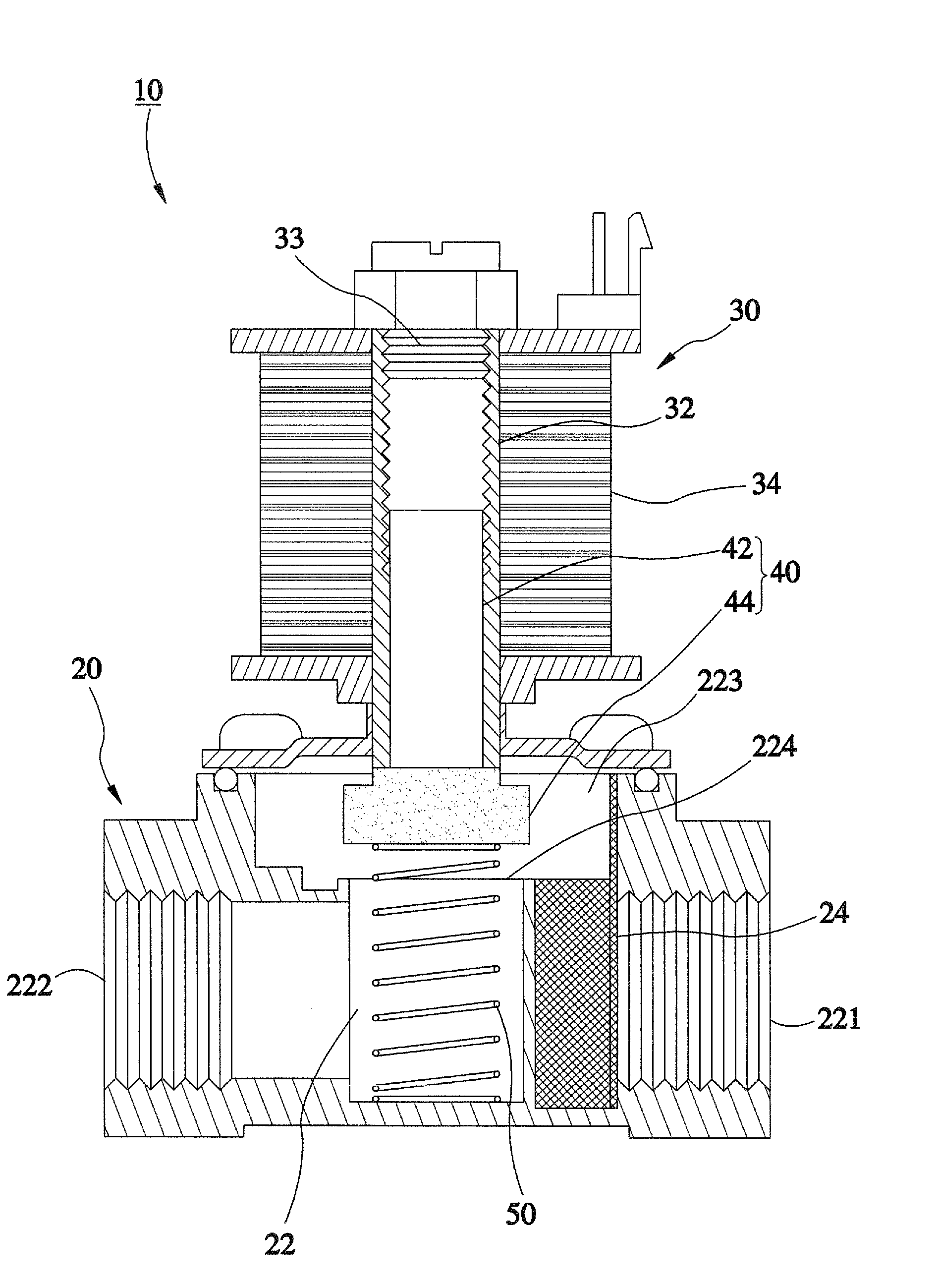

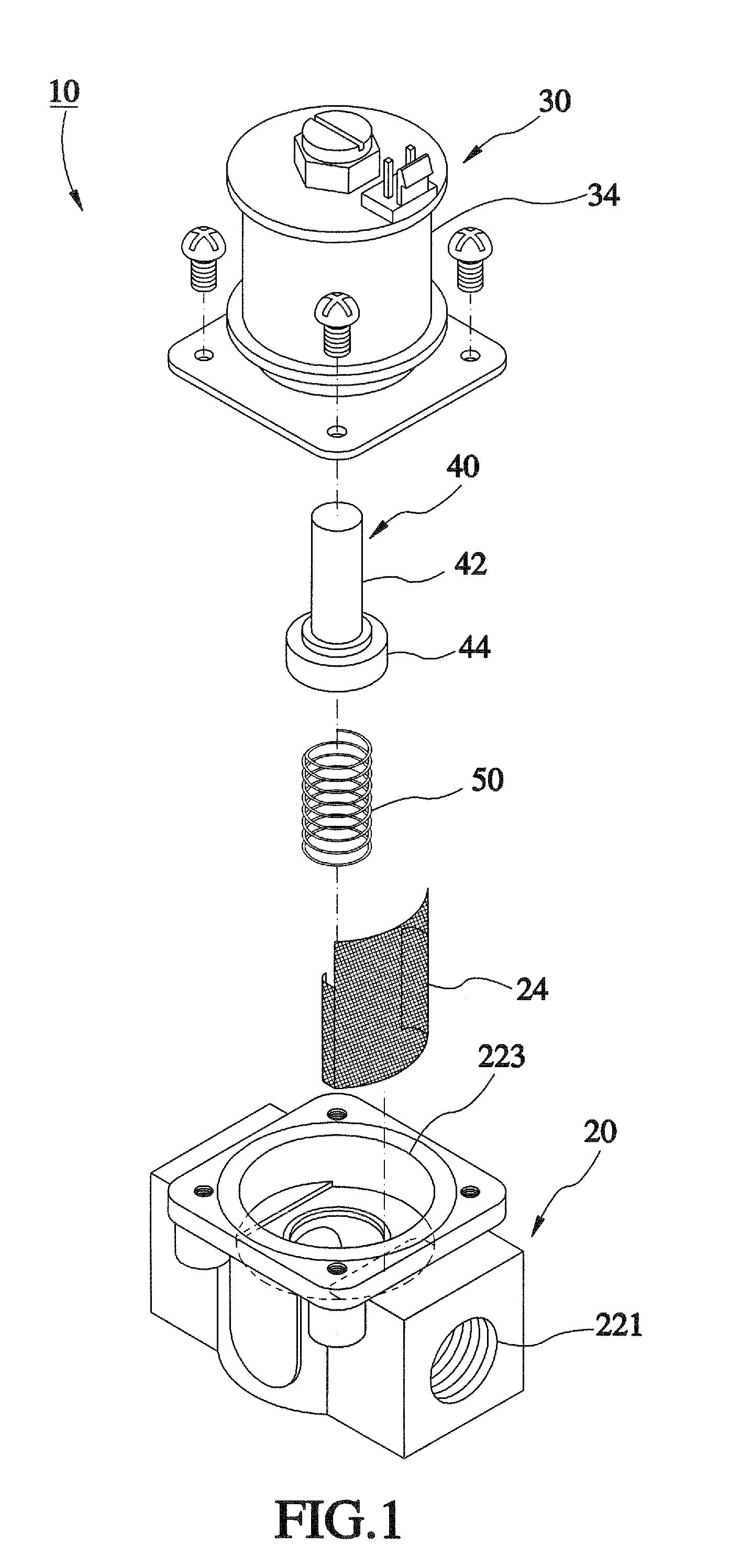

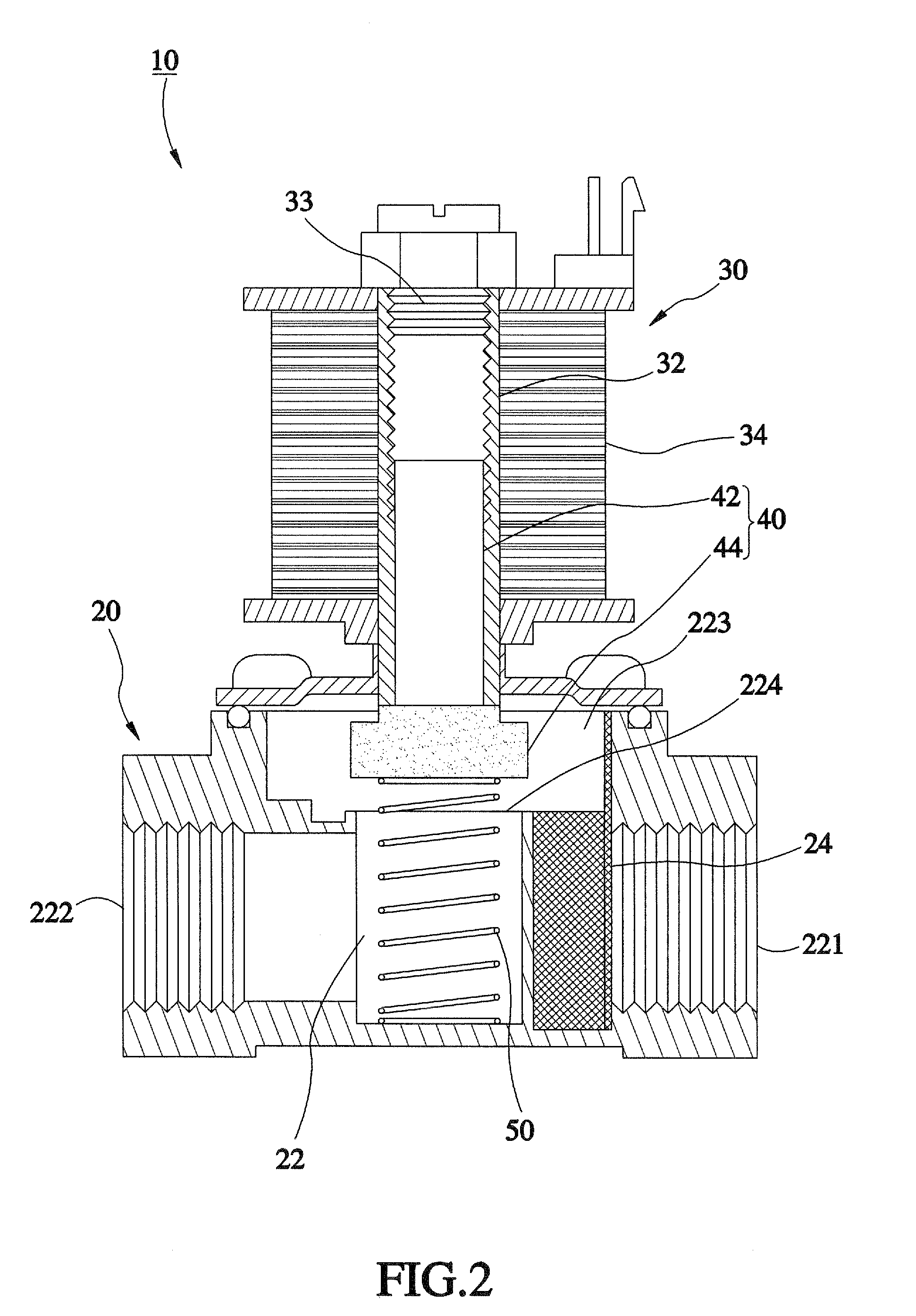

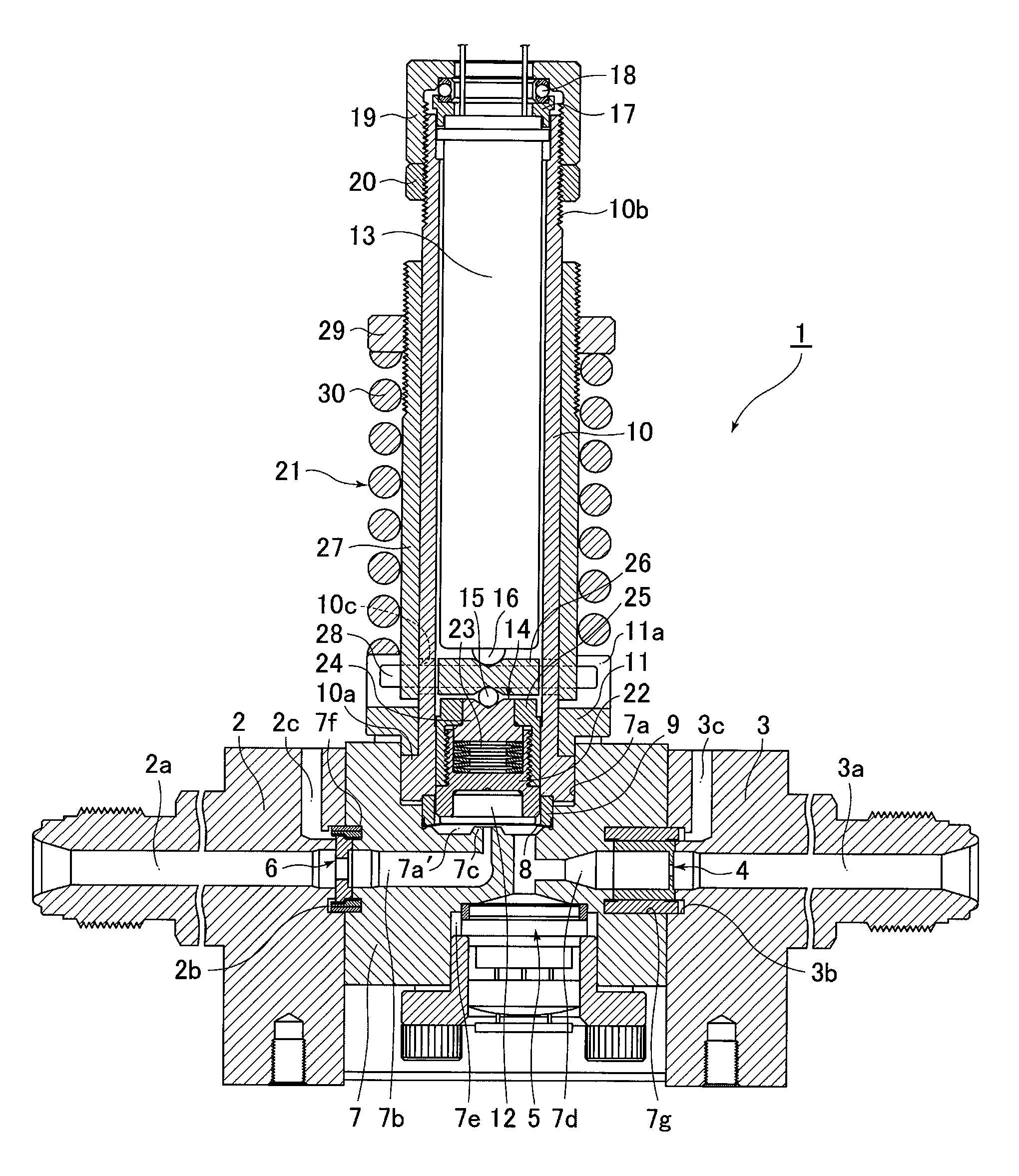

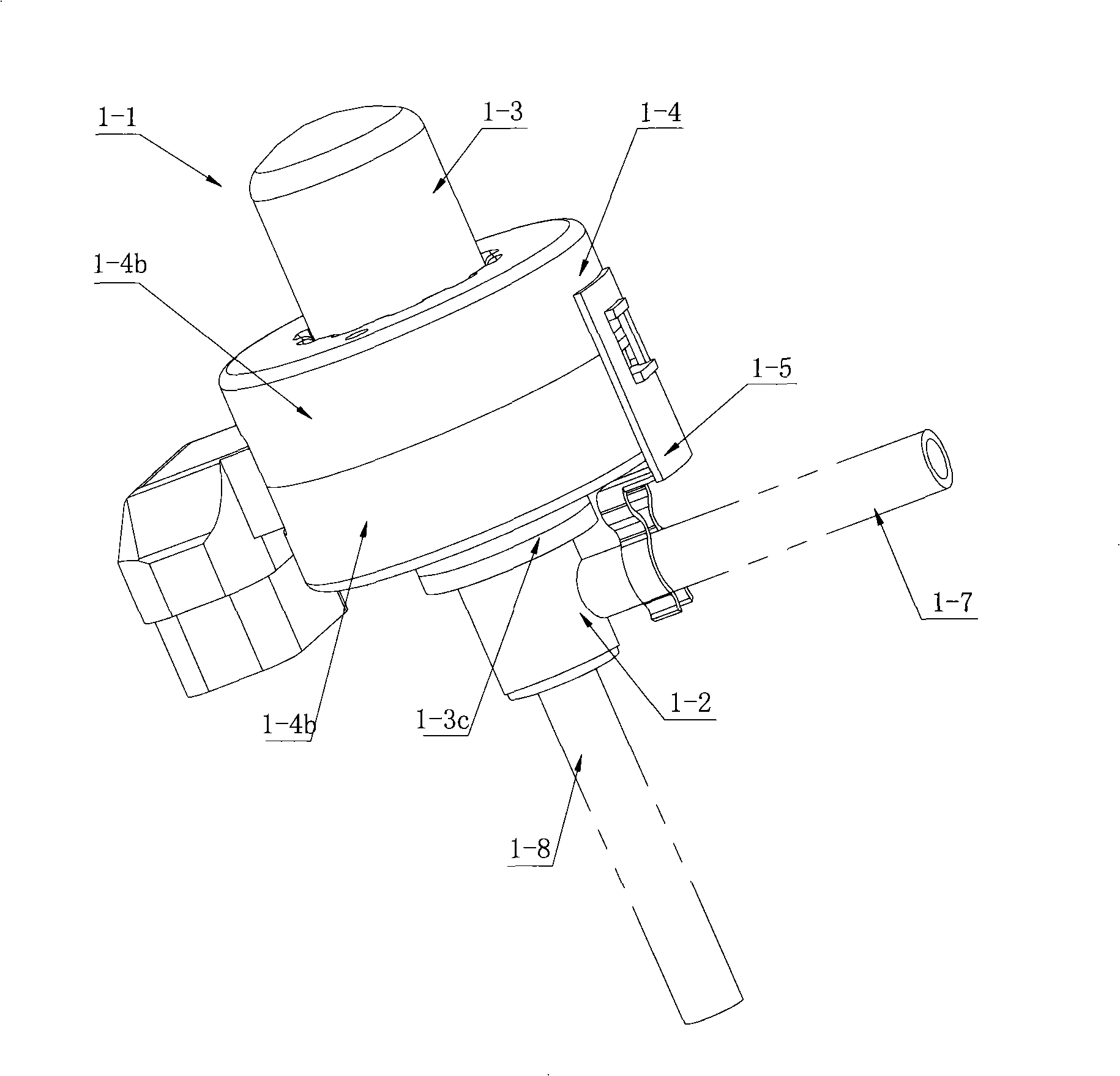

Gas flow rate control valve

InactiveUS20090206291A1Accurate gas flow rate controlPrecise flow controlFuel supply regulationOperating means/releasing devices for valvesProduct gasEngineering

A gas flow rate control valve includes a lower valve block defining a gas flow passage, and an upper valve block having a tube disposed ill communication with the gas flow passage, and a solenoid coil assembly surrounding the tube for generating a magnetic field. A magnetic column has a magnetic portion inserted into the tube and axially movable by the magnetic field generated by the solenoid coil assembly, and a stopper movable with the magnetic portion to change the open cross-sectional area of the gas flow passage so as to control the flow rate of the fuel gas passing through the gas flow passage. A spring member is provided at one of the top and bottom sides of the magnetic column to keep the magnetic column in balance and to provide a return force to the magnetic column after displacement of the magnetic column.

Owner:GRAND MATE

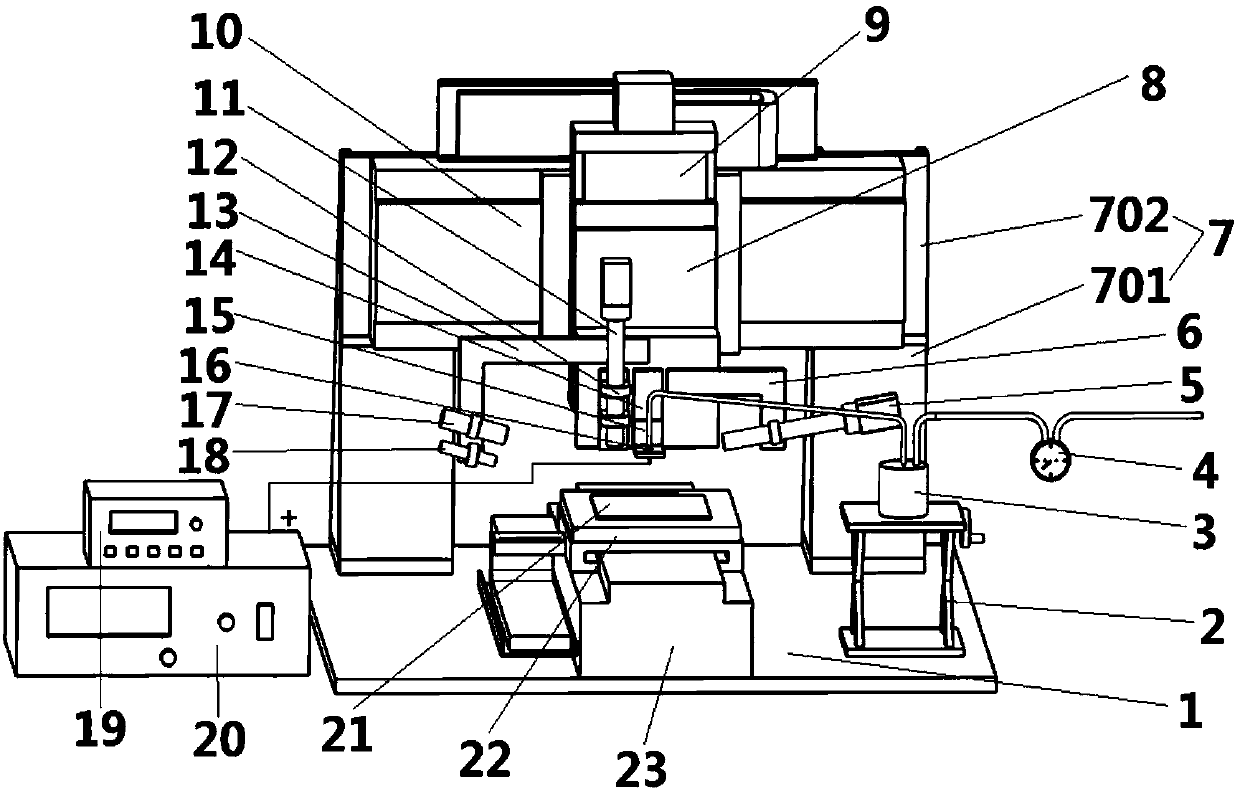

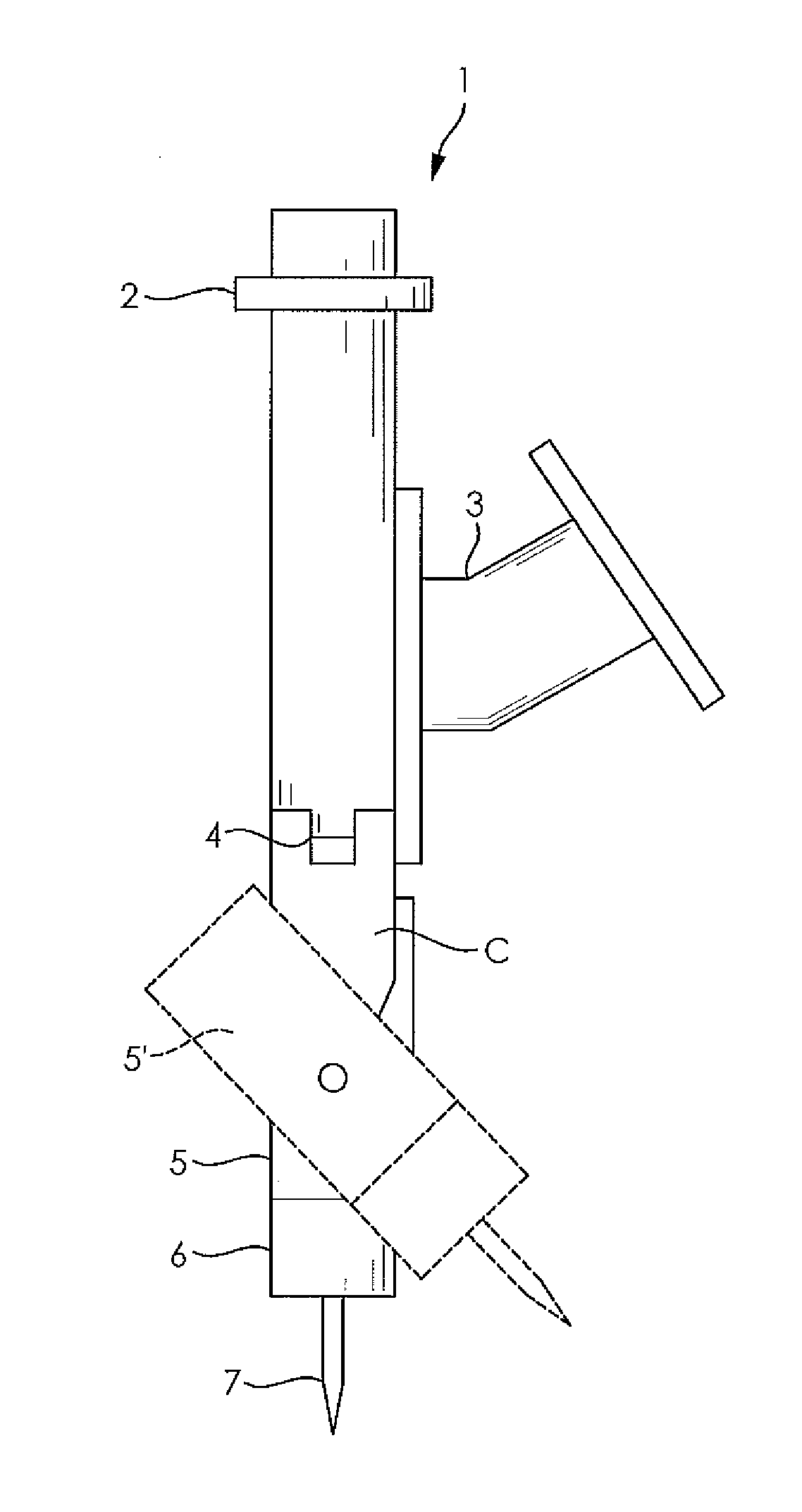

High-precision electric field driven spray deposition 3D printer and working method thereof

PendingCN107932894AHigh frequencyContinuous and stable feedingAdditive manufacturing apparatus3D object support structuresComputer printingImage resolution

The invention discloses a high-precision electric field driven spray deposition 3D printer and a working method thereof, and solves the problems of a traditional 3D printer on multiple aspects of resolution, stability and controllability; high-precision printing of multilayer structures can be realized; the printing process is observed and monitored in real time; and high-precision pattern printing is performed on insulation substrates through electric conducting materials. The high-precision electric field driven spray deposition 3D printer comprises a mounting baseplate; a Y-axle worktable is arranged on the mounting baseplate; a vacuum absorption platform is fixed on the Y-axle worktable; a printing substrate is absorbed on the vacuum absorption platform; a printing nozzle and a vertical observation camera are correspondingly arranged above the printing substrate, and are connected to a Z-axle worktable; the Z-axle worktable is fixed on an X-axle worktable; a squint observation camera is correspondingly arranged on one side of the printing nozzle; an LED light source and a far infrared curing light source are correspondingly arranged on the other side of the printing nozzle; theprinting nozzle communicates with a storage bottle; and the storage bottle is arranged on a lifting table.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

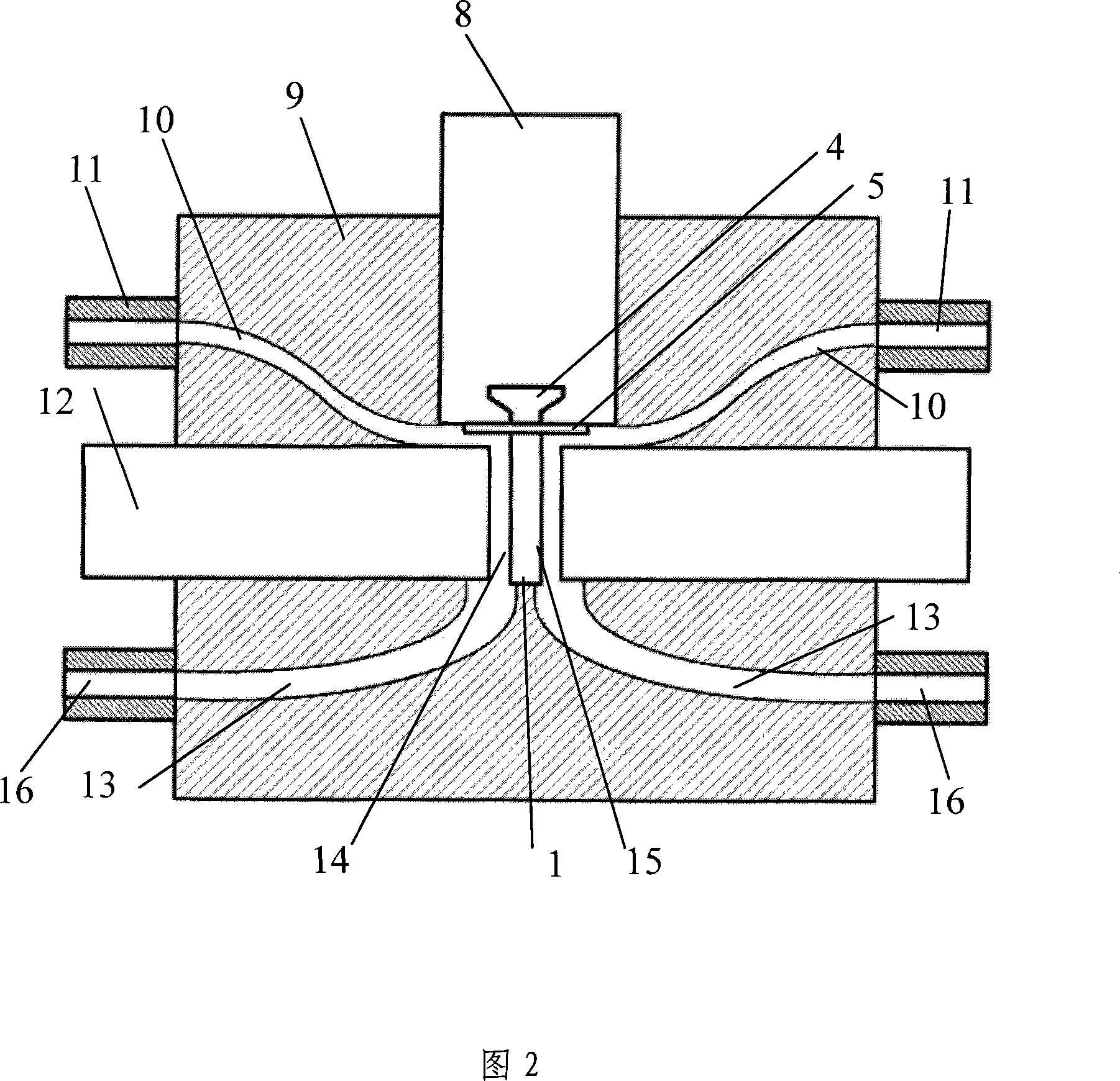

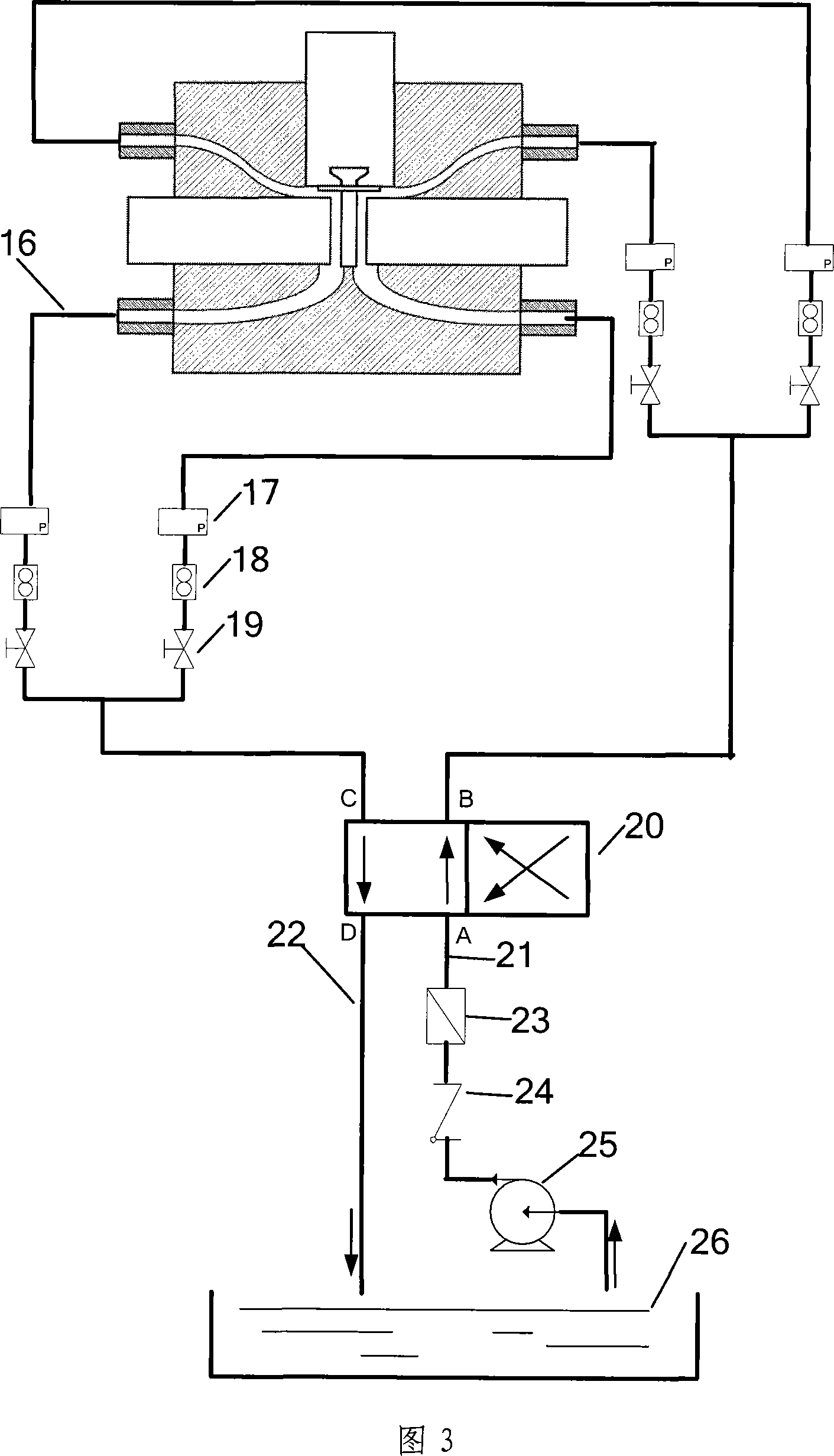

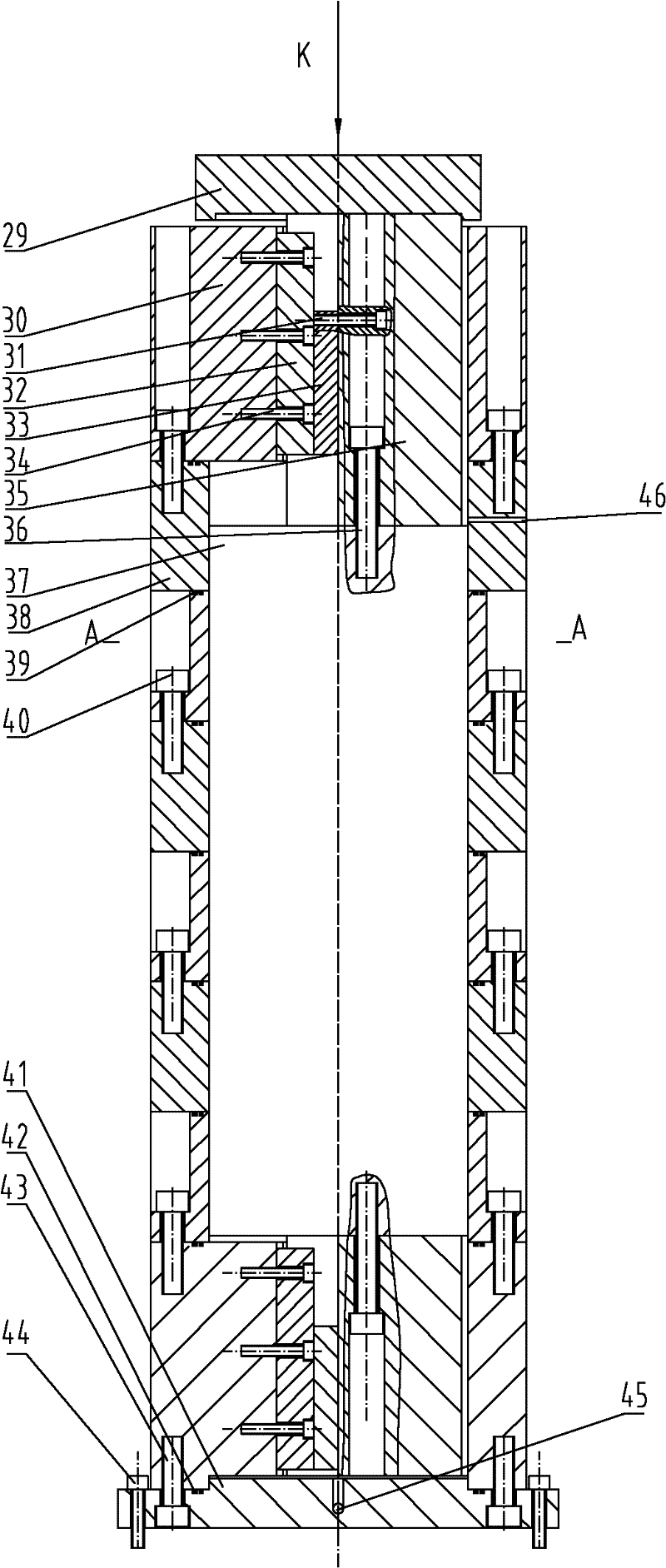

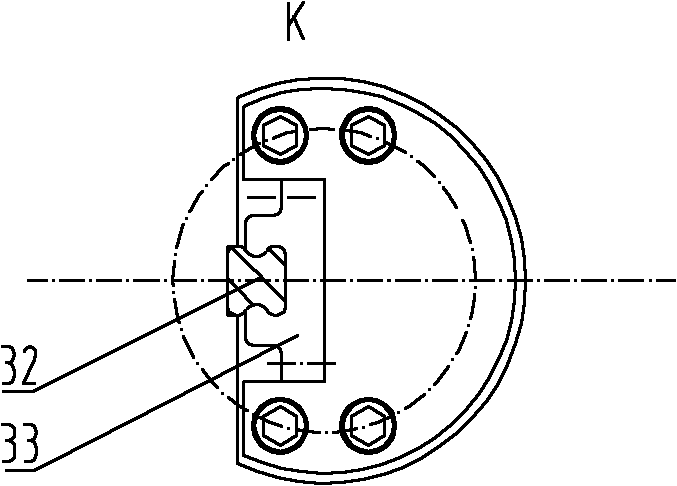

Active control type electrolysing solution flowing method in blade process and electrolysing solution circulating system

InactiveCN101249577AImprove machining accuracyImprove processing qualityMachining working media supply/regenerationTraffic volumeProcessing accuracy

The invention relates to an active-control electrolyte flowing method and an electrolyte circulating system in blade processing, and belongs to the field of electrolytic processing technology. The method is characterized in that (1) an entire blade processing region is divided into a blade concave processing region and a blade convex processing region by a blade; and (2) an active shunting method is adopted to divide the channel into two independent channels including an electrolyte channel for blade concave processing and an electrolyte channel for blade convex processing. The electrolyte circulating system is characterized in that four channels are arranged at the periphery inside a tool fixture (9), extending from the edges to the processing regions, and each channel is respectively connected with a flow rate control pipe. The system is also provided with an electrolyte reversing valve (20) to reverse the flowing direction of the electrolyte. The active-control electrolyte flowing method can achieve more stabile flow field for processing the blade, more uniform flow field state for processing different sections of the blade, and better processing accuracy and surface quality.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

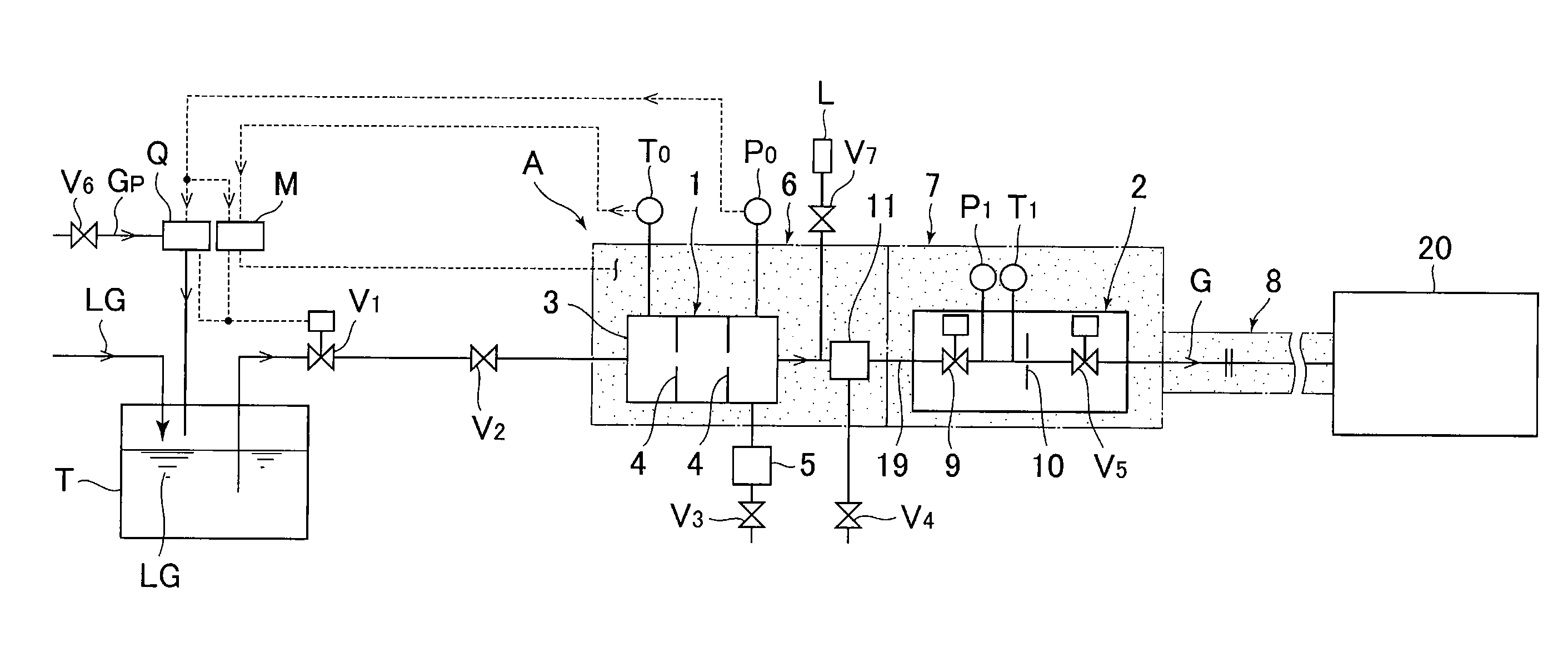

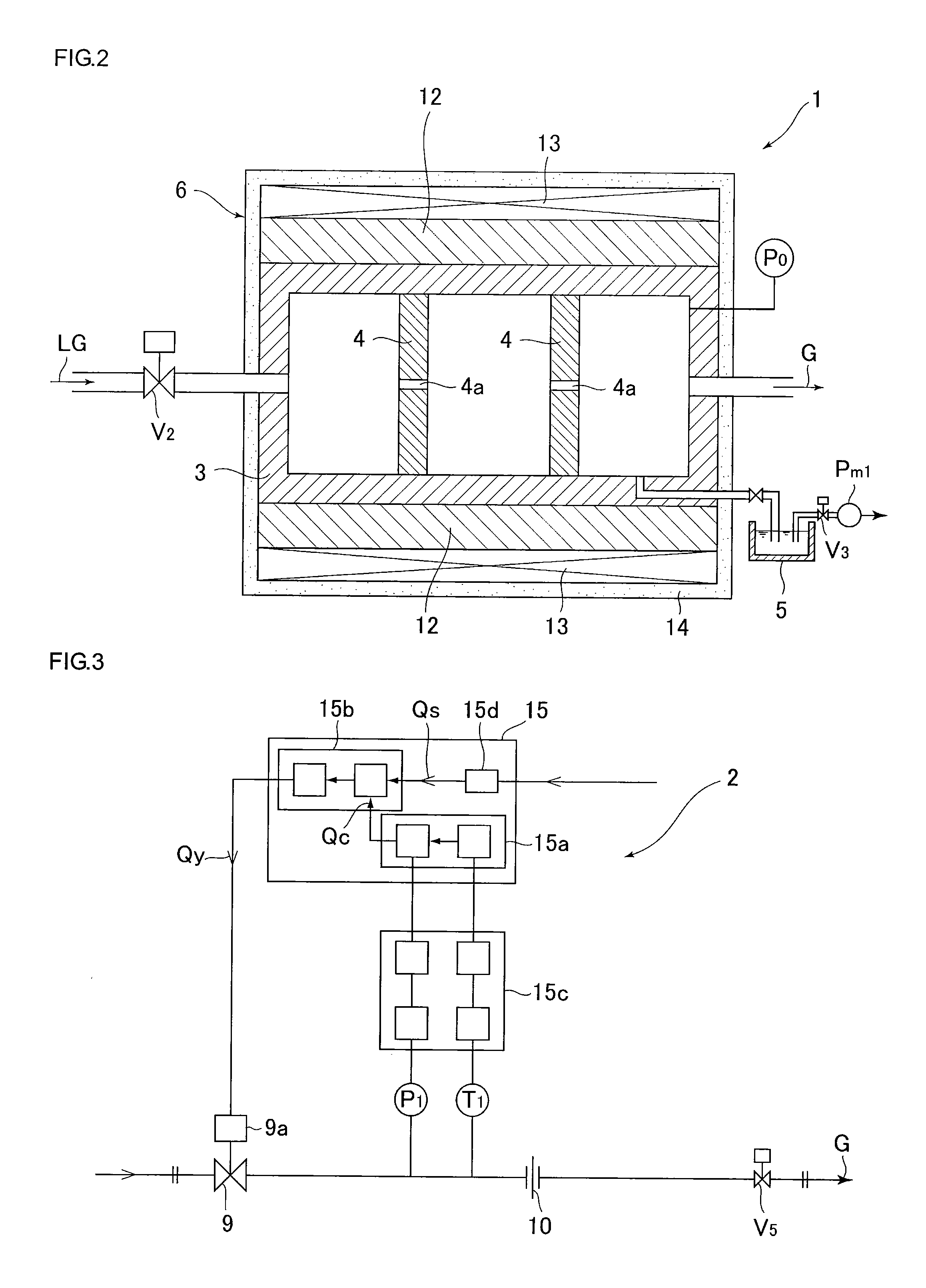

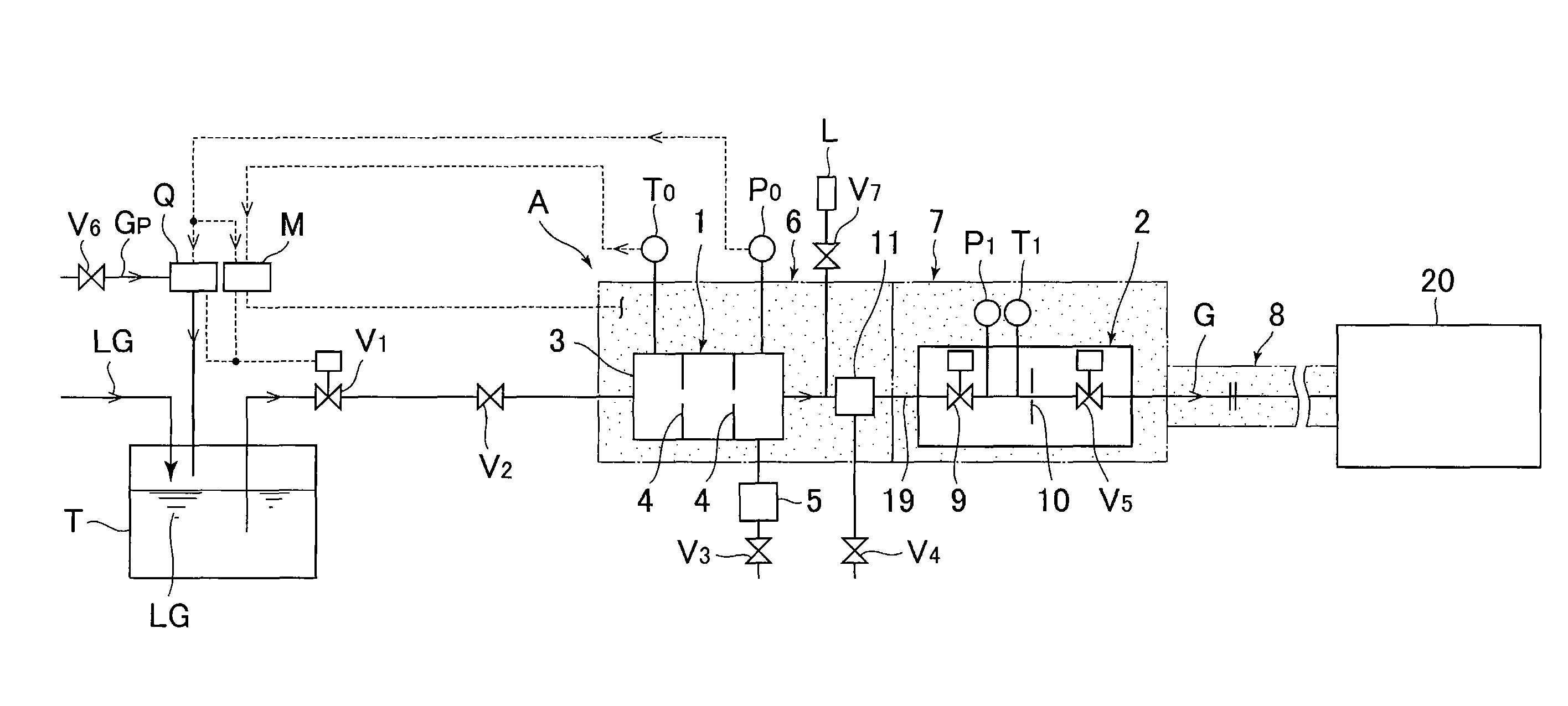

Gas supply apparatus equipped with vaporizer

ActiveUS20110100483A1Stable controlPrecise flow controlInternal combustion piston enginesValve members for heating/coolingTemperature controlEngineering

An energy-saving, downsized gas supply apparatus equipped with a vaporizer is provided, wherein the gas supply apparatus is capable of stably and easily performing highly accurate gas flow rate control without requiring rigorous temperature control on the vaporizer side. The present invention pertains to a gas supply apparatus equipped with a vaporizer that includes (a) a liquid receiving tank; (b) a vaporizer that vaporizes liquid; (c) a high-temperature type pressure type flow rate control device that adjusts a flow rate of a vaporized gas; and (d) heating devices that heat the vaporizer, the high-temperature type pressure type flow rate control device, and desired portions of pipe passages connected to the vaporizer and the high-temperature type pressure type flow rate control device.

Owner:FUJIKIN INC

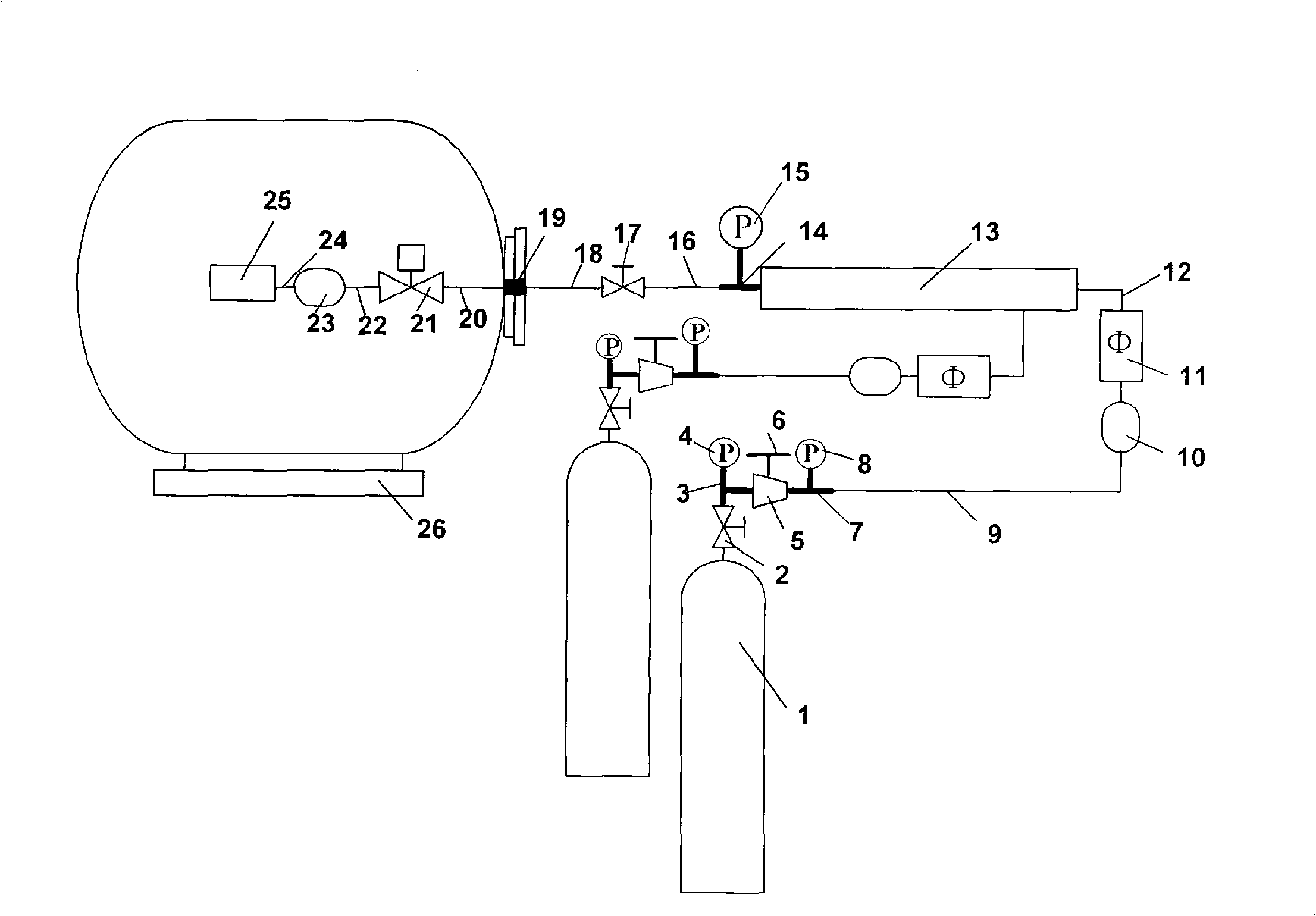

Electric propulsion testing platform gaseous-propellant supply device

InactiveCN101539482AConstant flow and constant pressureConstant pressureEngine testingEngineeringHigh pressure

The invention discloses an electric propulsion testing platform gaseous-propellant supply device which consists of a high pressure gas cylinder, a gas cylinder manual valve, a gas cylinder pressure gauge, a discompressor, a discompressor valve, a discompressor pressure gauge, a metallic hose, a filter in front of a flow controller, the flow controller, a premixing cavity, a pressure sensor, a penetration front manual valve, a penetration flanged joint, an electromagnetic valve, a filter in front of an engine, a tee joint and a stainless steel canaliculus tubule. The gaseous-propellant supply device can propel gas which has single component in certain flow rate and pressure intensity, provides mixed gas propelling agent with certain mixing ratio, and has the advantages of stable work and accurate control of the flow rate.

Owner:BEIHANG UNIV

Compressible fluid pumping system for dynamically compensating compressible fluids over large pressure ranges

ActiveUS8215922B2Low compressibilityPrecise functionComponent separationFlexible member pumpsState of artEngineering

An invention is claimed that enables the pumping of compressible fluids at high pressures when an accurate flow is desired. Two pressure sources, for example pumps plumbed in series, separate thermodynamic work, such as pressurization, at the first pressure source from a volumetric or matter metering function in the second pressure source. One example is a flowstream delivery for a chemical instrumentation system that is manufactured from relatively unsophisticated pumps yet delivers precise flows with low pulsation (<1%) over pressures greater than 100 bar. An advantage of one embodiment allows the economical conversion of typical HPLC systems to state of-the-art supercritical fluid chromatography (SFC) systems with minimal modification to system components.

Owner:AGILENT TECH INC

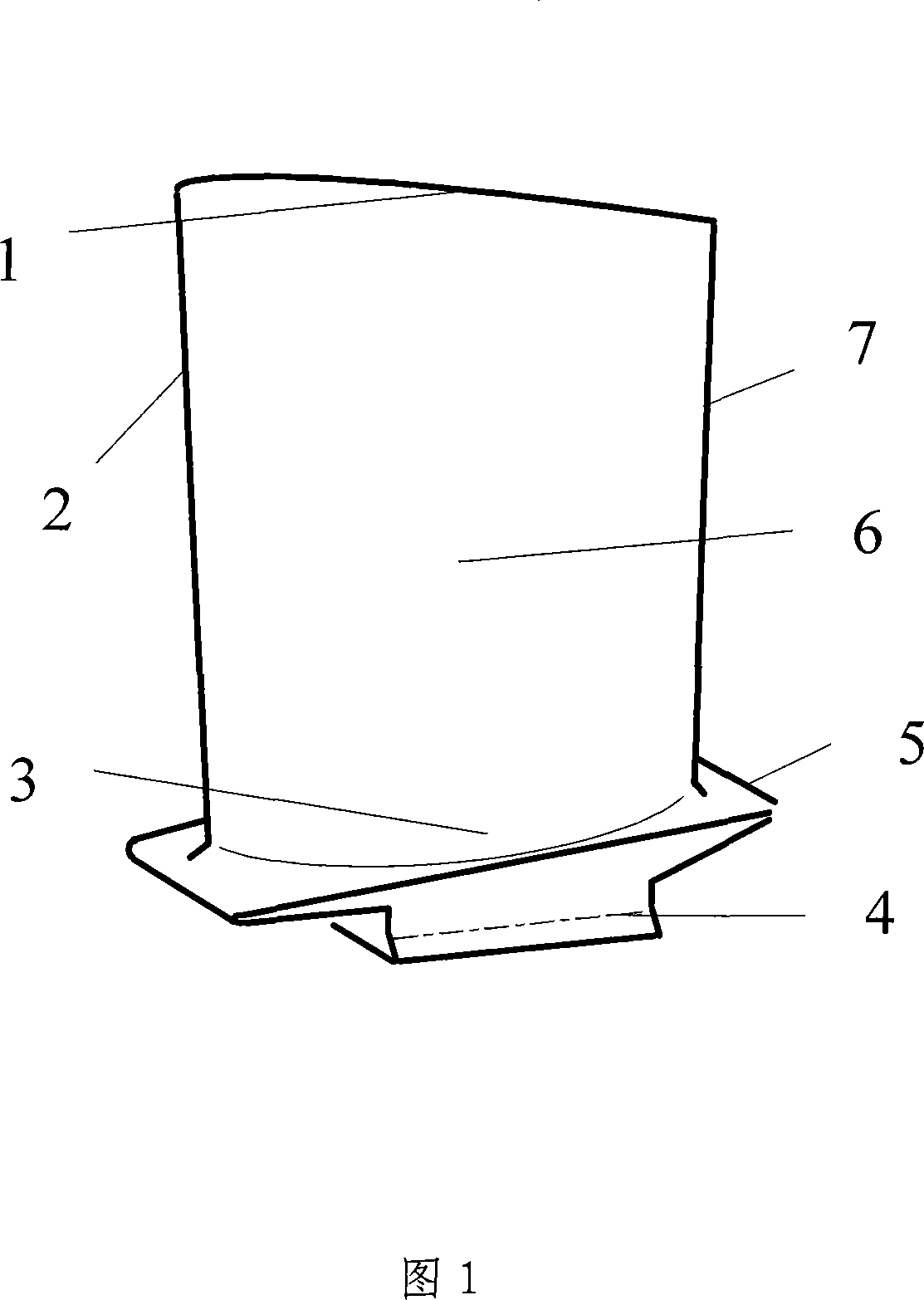

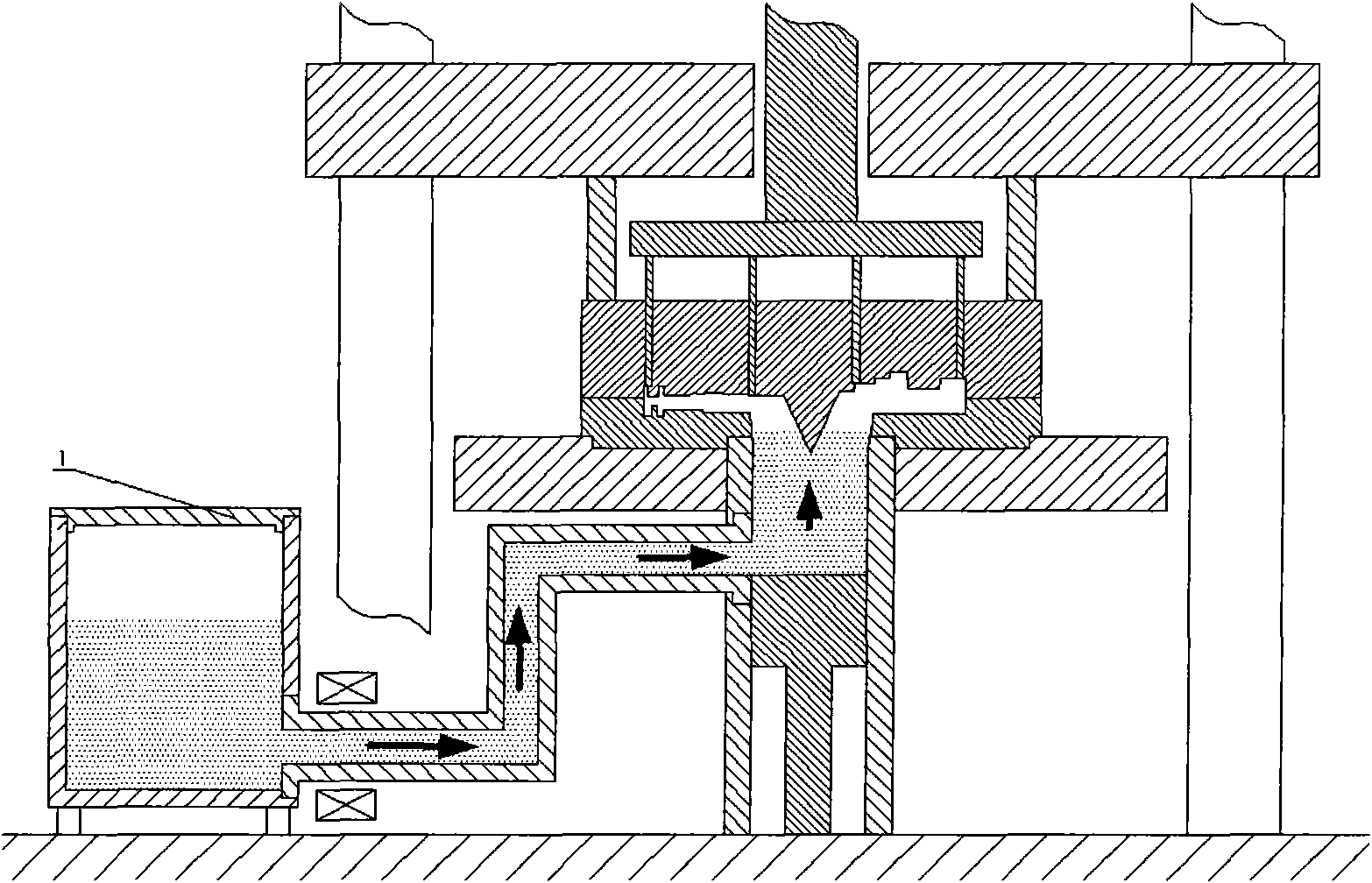

Method for indirect extrusion casting by utilizing filling of electromagnetic force and device thereof

The invention relates to a method for indirect extrusion casting by utilizing the filling of electromagnetic force and a device thereof. In the method, electromagnetic force is utilized to introduce liquid metal into an extrusion chamber to fill part of a mould cavity by a transmission pipeline; when the liquid metal in the mould cavity reaches a preset quantity, the transmission of the liquid metal is stopped; and an extrusion punching head ascends to push the liquid metal to fill the part which is not full in the mould cavity and continuously ascends to extrude and shape the liquid metal, and the liquid metal in the transmission pipeline flows back to a thermal insulation furnace under the function of reverse electromagnetic force. The invention has simple and convenient method, high automatization degree, good stability and skillful structural design of a special device. The liquid metal is transmitted and filled by a sealed transmission pipeline, and oxidation and air suction are reduced; the flow speed and the flow rate are controllable, and the quantification of extrusion casting is realized; at the time of extrusion shaping, the liquid metal in the transmission pipeline flows back, and the production efficiency is enhanced; and the friction and the abrasion of the extrusion punching head and the extrusion chamber are reduced, and the service lives of the extrusion punching head and the extrusion chamber are enhanced.

Owner:SOUTH CHINA UNIV OF TECH

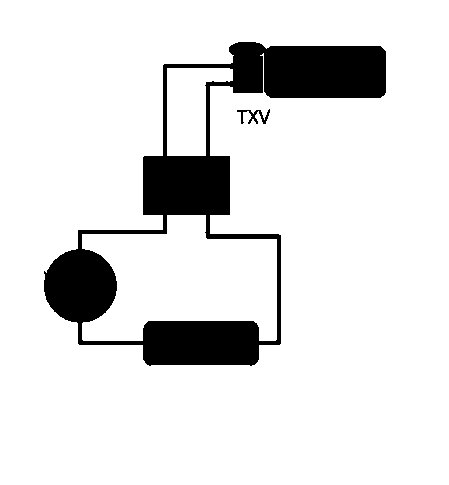

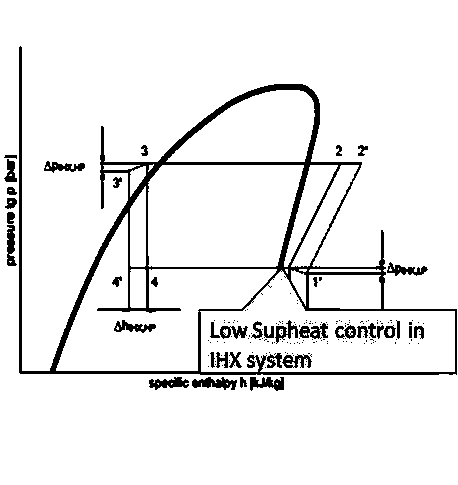

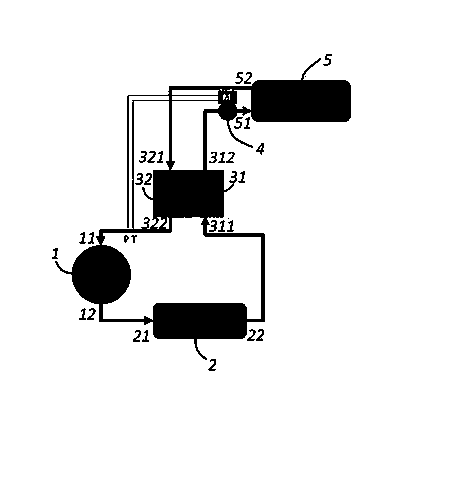

Control method for refrigerant flow quantity in automobile air conditioning system and automobile air conditioning system

InactiveCN103673416AExcellent COPPrecise flow controlEfficient regulation technologiesFluid circulation arrangementEvaporatorEngineering

The invention discloses a control method for the refrigerant flow quantity in an automobile air conditioning system and the automobile air conditioning system. The automobile air conditioning system comprises a compressor, a condenser, an internal heat exchanger and an evaporator and further comprises an electronic expansion valve which is installed between an outlet in a high-pressure side of the internal heat exchanger and an inlet of the evaporator. A controller transmits a control signal to the electronic expansion valve according to the pressure and temperature of an outlet in a low-pressure side of the internal heat exchanger, the electronic expansion valve receives the control signal to adjust the opening degree of the electronic expansion valve, and then the superheat degree of the outlet in the low-pressure side of the internal heat exchanger is controlled. In the other implementation mode, the controller transmits the control signal to the electronic expansion valve according to the pressure and temperature of the outlet in the high-pressure side of the internal heat exchanger, and then the super-cooling degree of the outlet in the high-pressure side of the internal heat exchanger is controlled. According to the superheat degree or the super-cooling degree, the flow quantity of refrigerant entering the evaporator is adjusted.

Owner:HANGZHOU SANHUA RES INST CO LTD

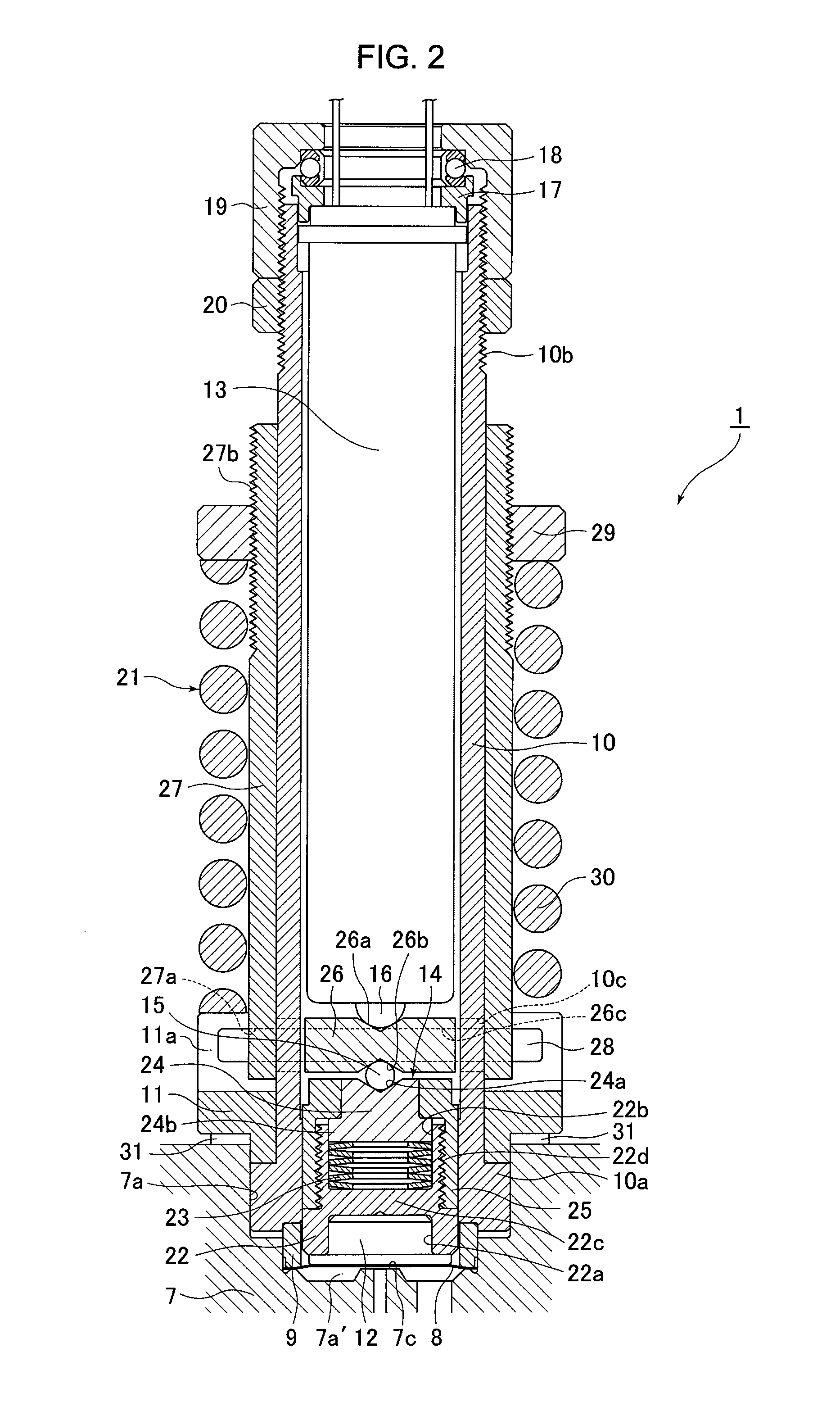

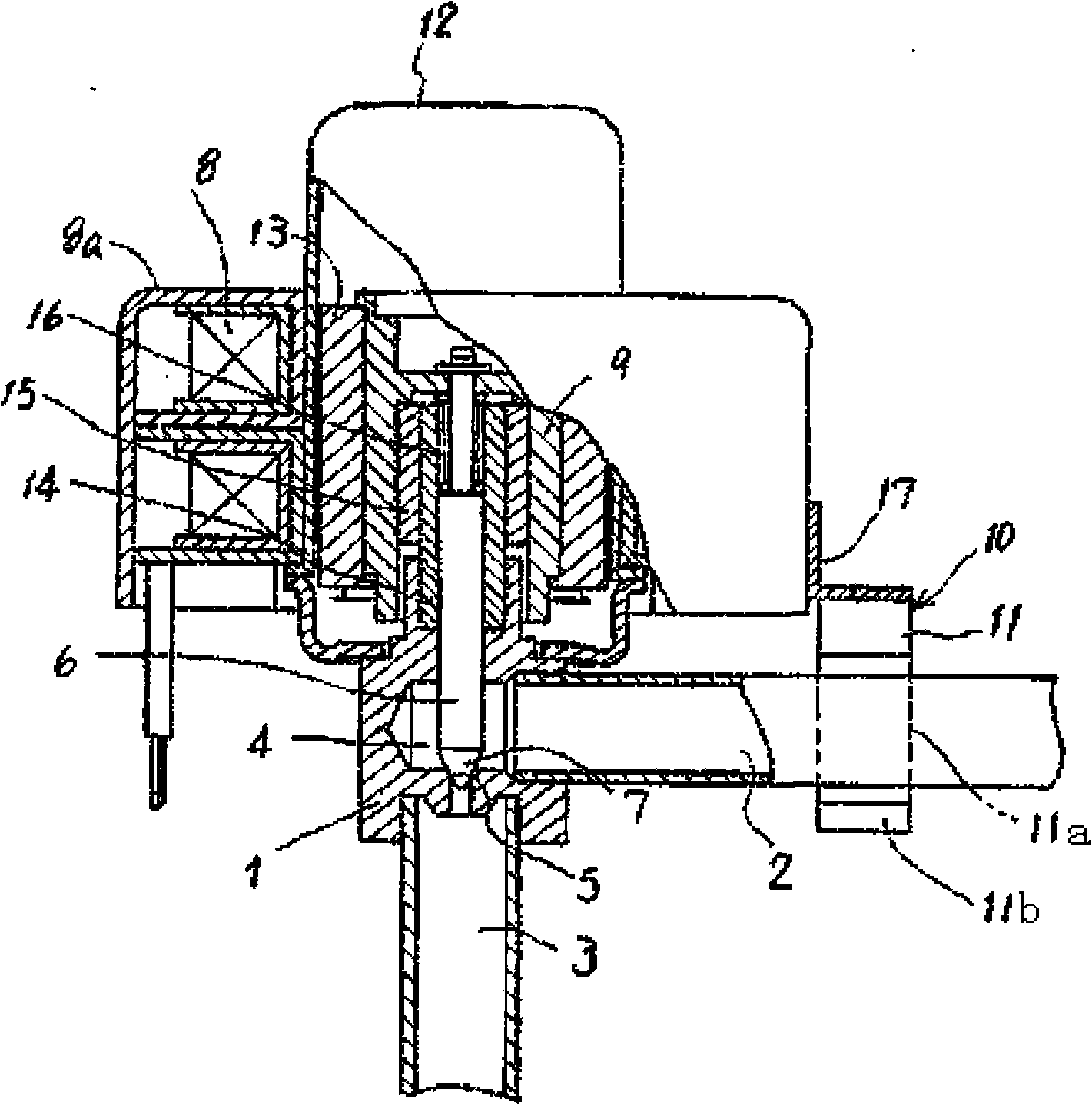

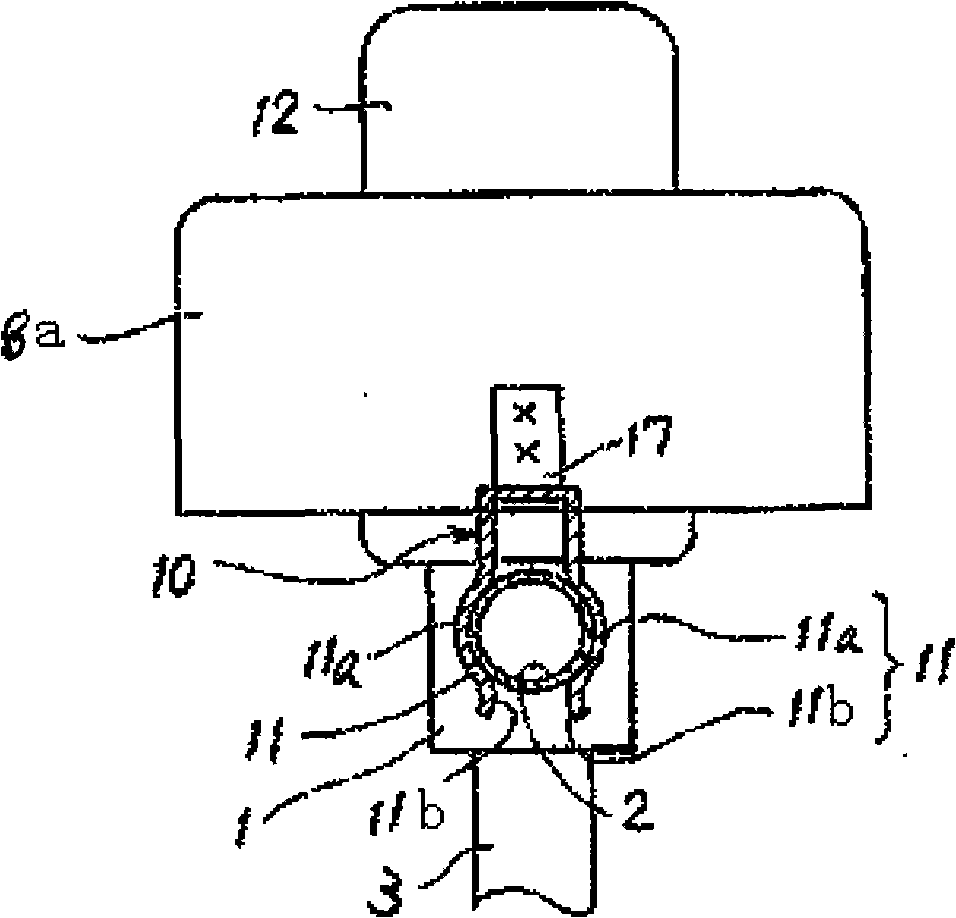

Normally open type piezoelectric element driven metal diaphragm control valve

ActiveUS20100294964A1Precise flow controlReduce loadDiaphragm valvesOperating means/releasing devices for valvesElectricityEngineering

A control valve has a body that forms a valve chamber and a valve seat, a metal diaphragm installed inside the valve chamber and making contact with and departing from the valve seat, an actuator box fixed to the side of the body, a piezoelectric element installed inside the actuator box to thrust the metal diaphragm through mediation of a metal diaphragm presser by elongating downward when voltage is applied, a conical spring mechanism that absorbs elongation of the piezoelectric element at the time when the metal diaphragm makes contact with the valve seat and a prescribed thrust is applied to the valve seat and the like, and a preload mechanism that applies upward compressive force to the piezoelectric element all the time wherein the compressive force applied to the piezoelectric element is externally adjustable.

Owner:FUJIKIN INC

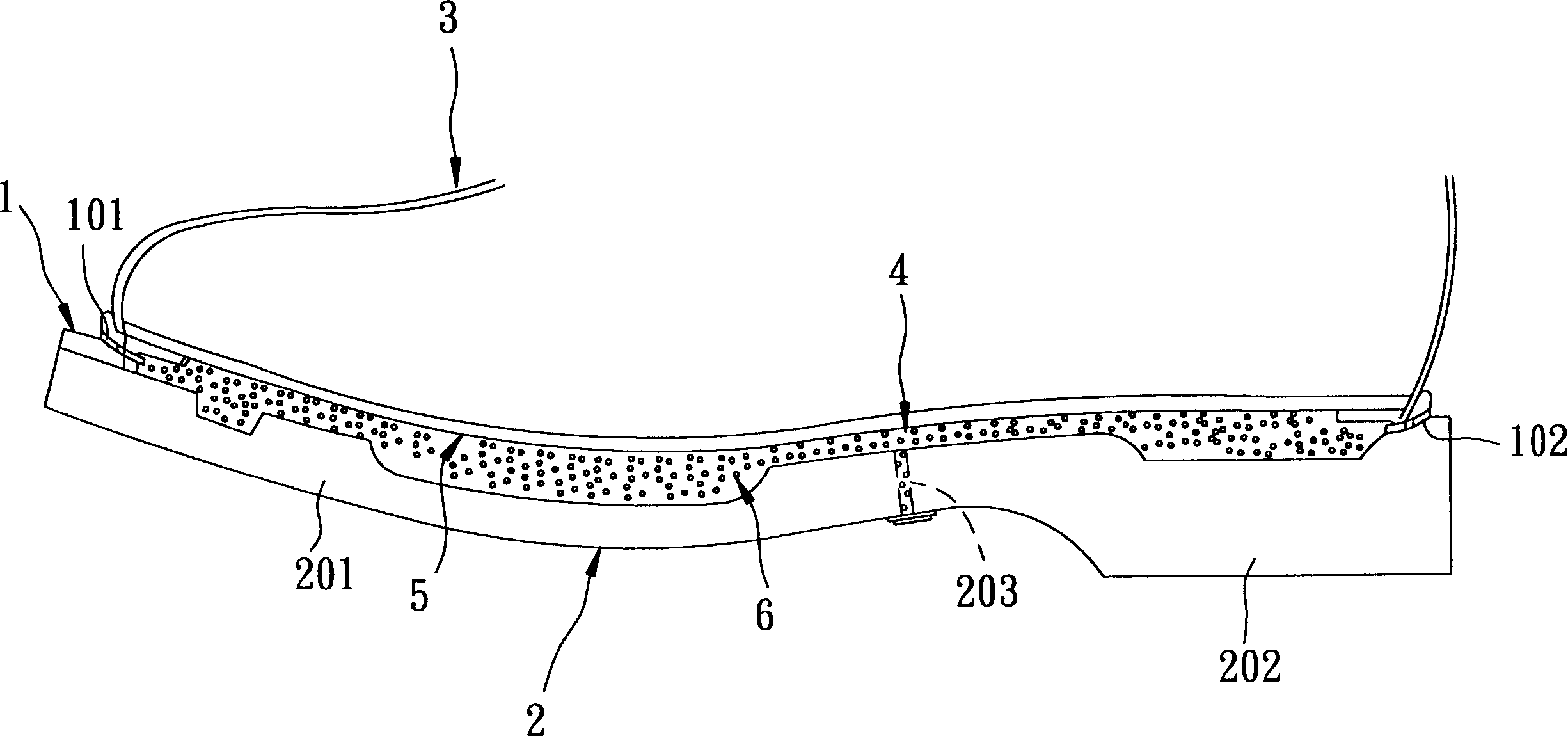

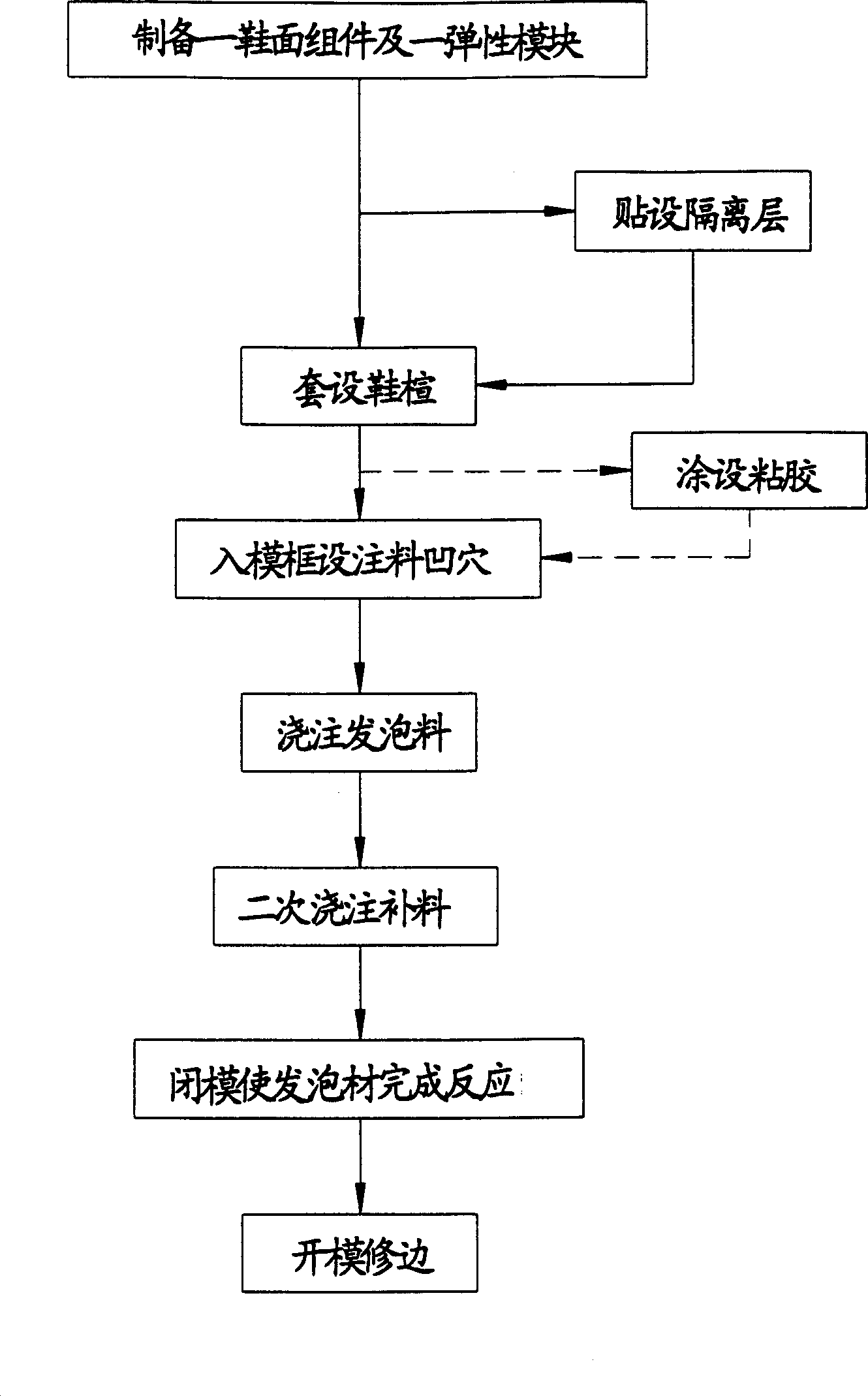

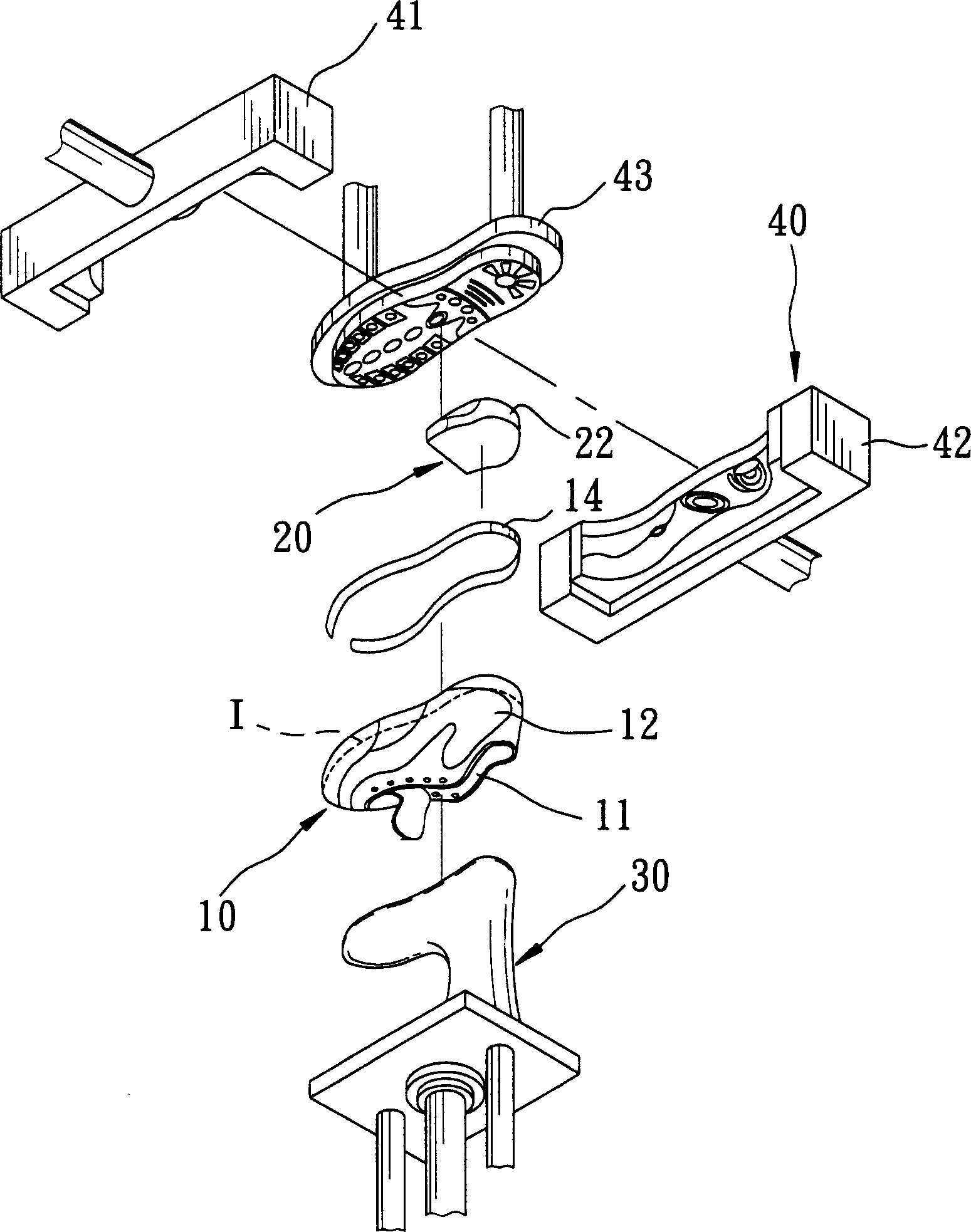

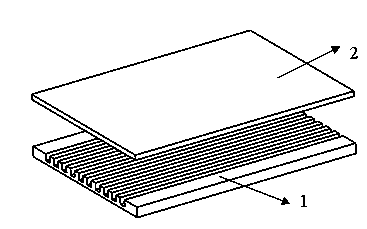

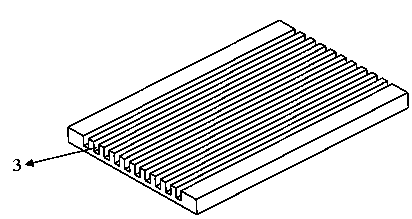

Foamed shoe body formed by integral whole shaping method

InactiveCN1475340AManufacturing Method AdvantagesPrecise flow controlSolesDomestic footwearEngineeringMechanical engineering

A technology for integrally preparing the foamed shoe body includes putting a shoe upper assembly on shoe last and an elastic module in a mould to form an open concave cavity consisting of the bottomsurface of said shoe upper assembly and the inner surface of mould, filling the liquid foaming material in the cavity, closing the mould, and foaming. Its advantages are low cost, and high quality ofproduct.

Owner:纪正贤

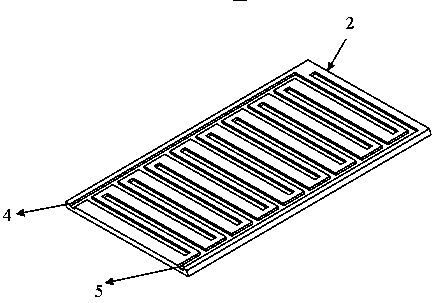

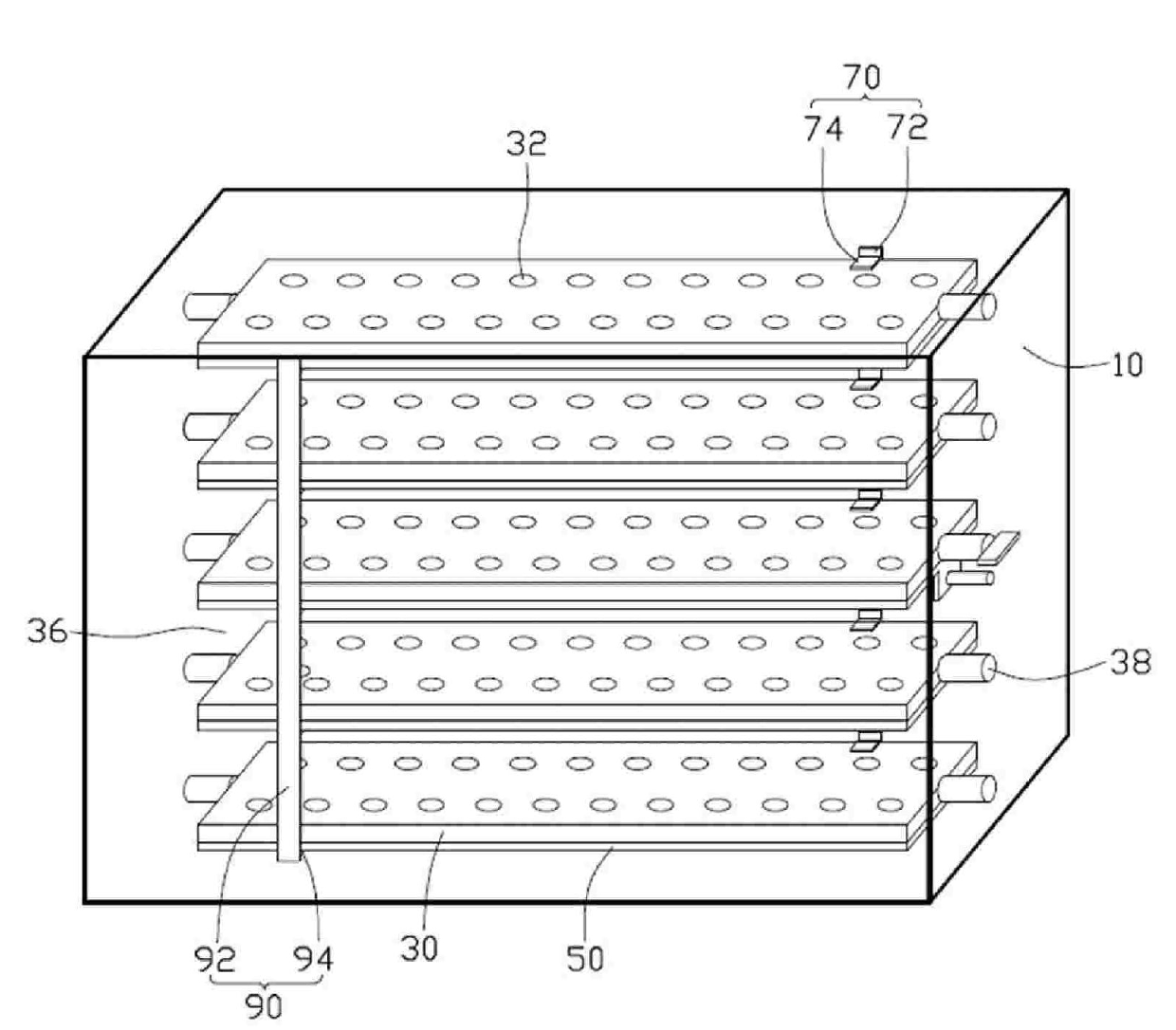

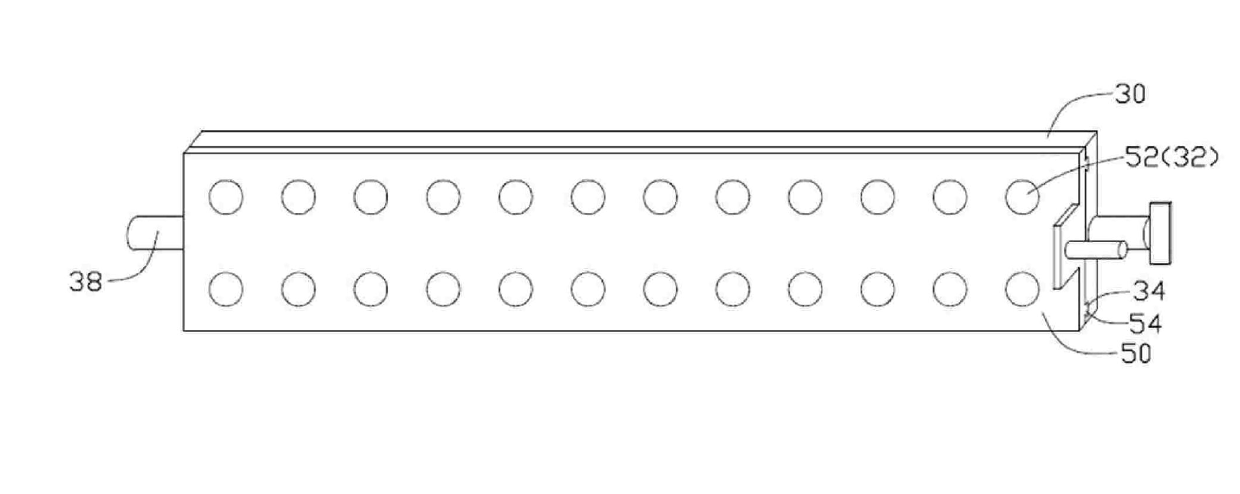

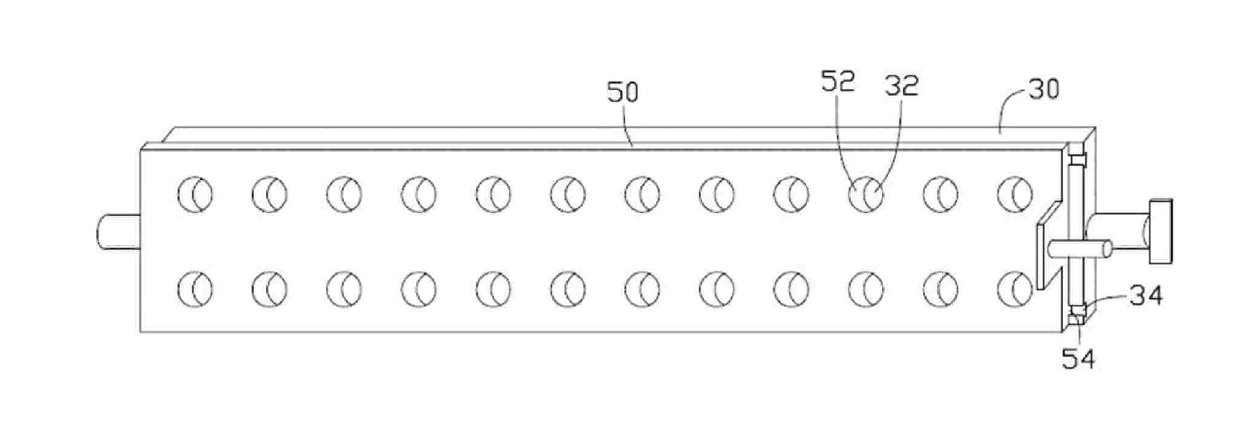

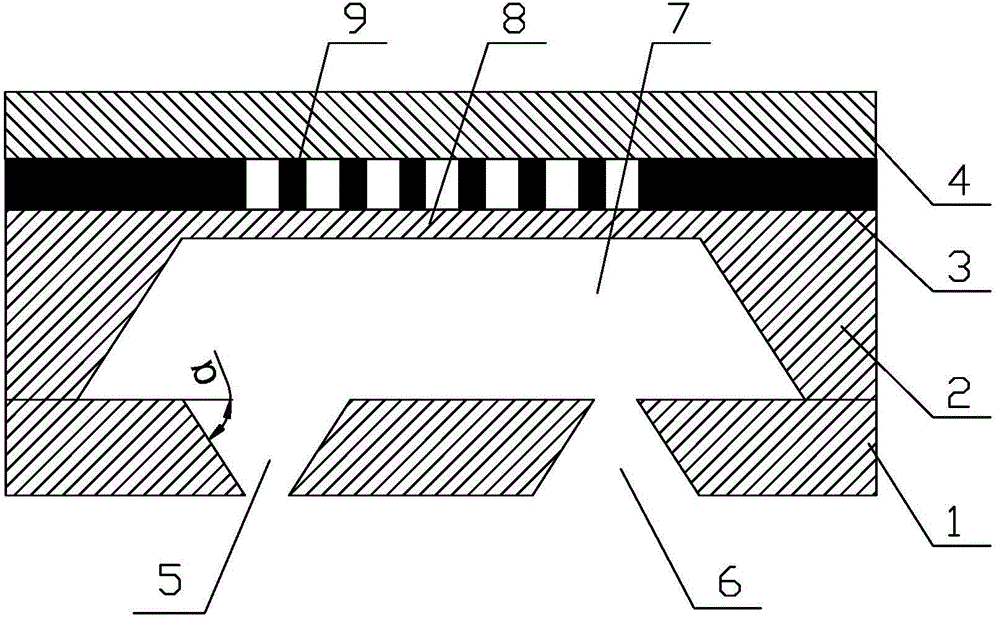

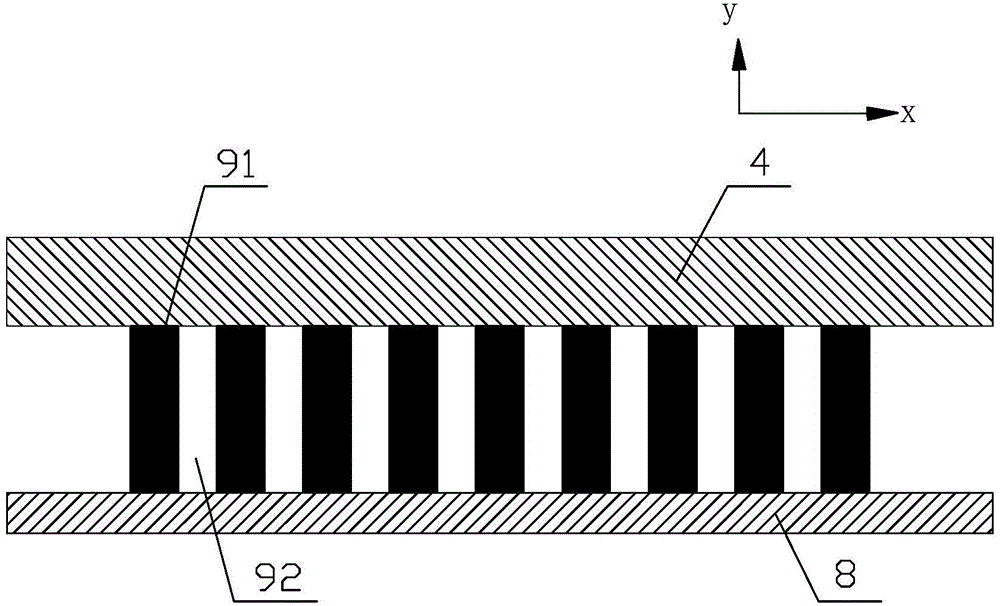

Silicon substrate micro-channel heat exchanger with electric fluid power micro-pump and manufacturing method thereof

ActiveCN103839905ASpeed up the flowGuaranteed uptimeSemiconductor/solid-state device detailsSolid-state devicesPlate heat exchangerLaser engraving

The invention discloses a silicon substrate micro-channel heat exchanger with an electric fluid power micro-pump and a manufacturing method thereof. The silicon substrate micro-channel heat exchanger is formed by sealing a silicon substrate and a top aluminum nitride plate with the electric fluid power micro-pump in a bonding mode. A micro-channel is etched in the surface of the silicon substrate according to the reaction ion etching method so that a flow channel for cooling liquid acetone and a place for heat exchanging can be formed. The electric fluid power micro-pump of the top aluminum nitride plate is manufactured through the laser engraving and gold immersing process or the ion sputtering and evaporating process. The electric fluid power micro-pump has the advantages of being stable in flowing, reliable in operation, accurate in flow control, low in energy consumption and the like, and can be effectively integrated with the silicon substrate micro-channel, and therefore the limited space in a micro-electronics element can be effectively saved, and the silicon substrate micro-channel heat exchanger has the wide application prospect in the micro-electronics heat dissipation field.

Owner:SOUTH CHINA UNIV OF TECH

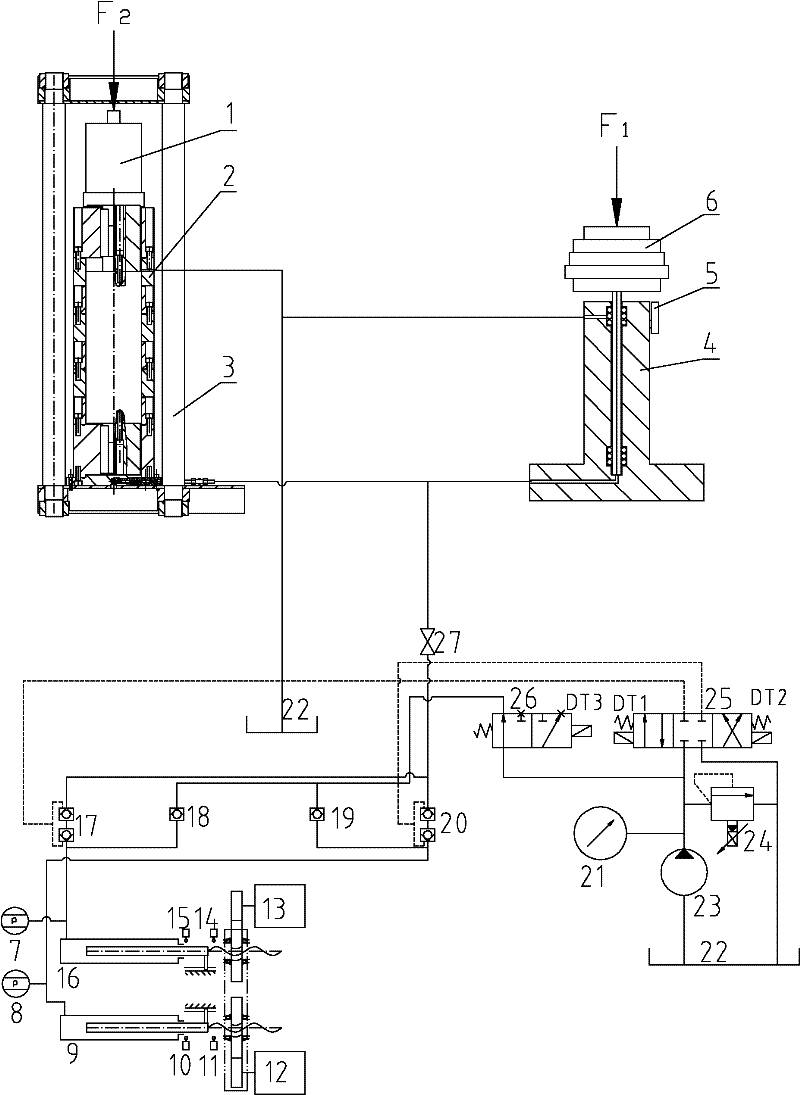

Rolling friction cylinder hydraulic type force standard machine

InactiveCN102175387ASimple structureReduce frictionFluid pressure measurementForce/torque/work measurement apparatus calibration/testingEngineeringCommunicating vessels

The invention provides a rolling friction cylinder hydraulic type force standard machine which belongs to the technical field of mechanical engineering. The main body of the hydraulic type force standard machine consists of a rolling friction plunger type hydraulic cylinder I used as the core and a communicating vessel formed by two rolling friction plunger type hydraulic cylinders according to the Pascal principle. The complete hydraulic type force standard machine also comprises a force measuring instrument, a frame, a rolling friction cylinder II, a displacement sensor, a counterweight, a hydraulic oil feeding system and a hydraulic subsidiary loop. The force standard machine has high working precision; oil cylinder structure and the manufacturing process are simplified; the loading time can be efficiently controlled in the working process; the high pressure hydraulic pump is unnecessary; no pressure and flow pulsation phenomenon exists; the flow control is precise and stable; the minimum stable flow requirement can be met by controlling the precise displacement of plungers; and the stable and accurate system working pressure is maintained.

Owner:JILIN UNIV

Vane type throttle valve

The invention relates to a vane type throttle valve comprising a plurality of vanes, each vane is provided with at least one through hole and slidably connected with a baffle plate; and the baffle plates are provided with penetrating holes which correspond to the through holes positioned on the vanes. The baffle plates can slide relative to the vanes to regulate the opening degree of the through holes positioned on the vanes so as to accurately control the flow rate of fluids passing through the vane type throttle valve, therefore the fluids are saved.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

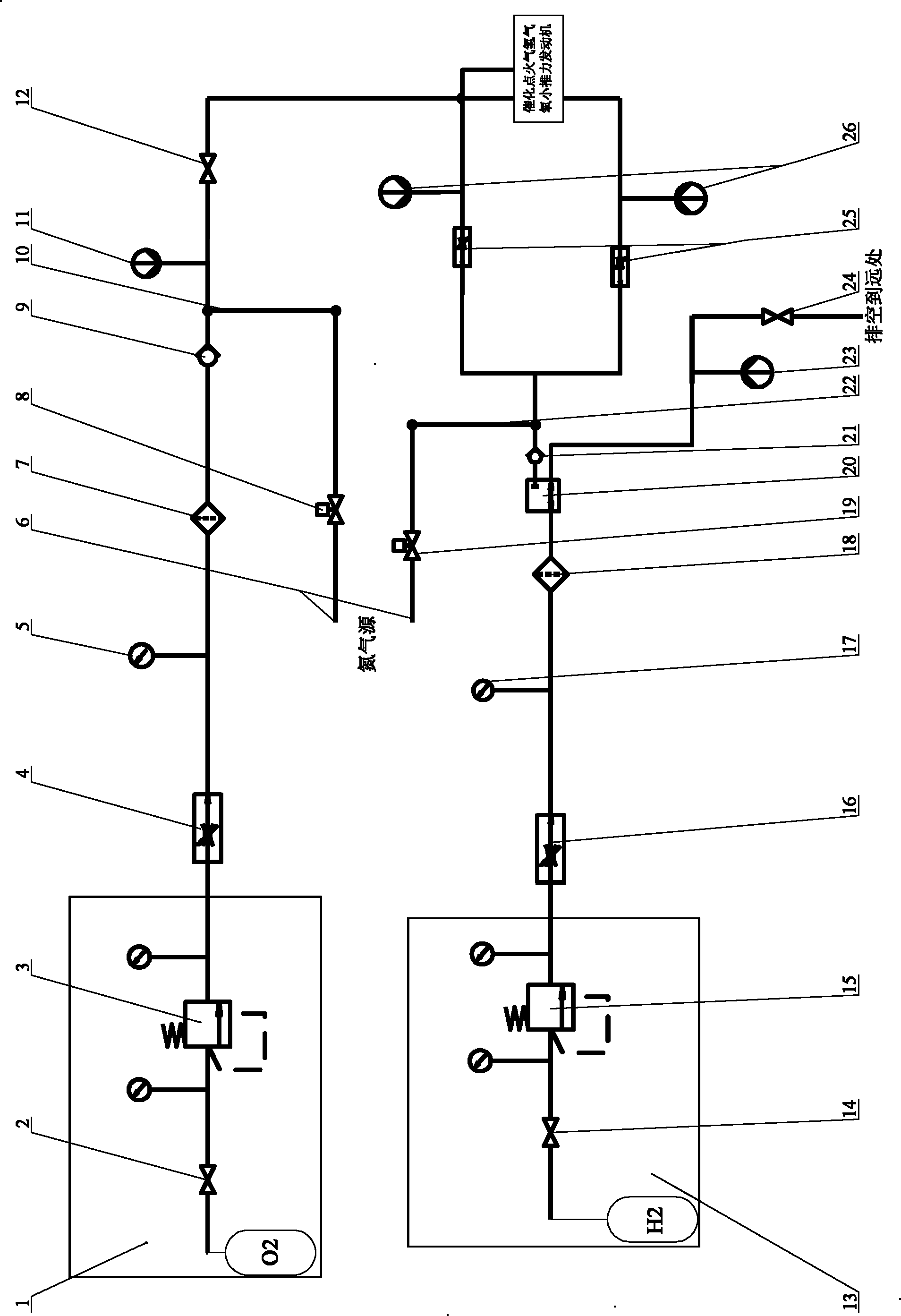

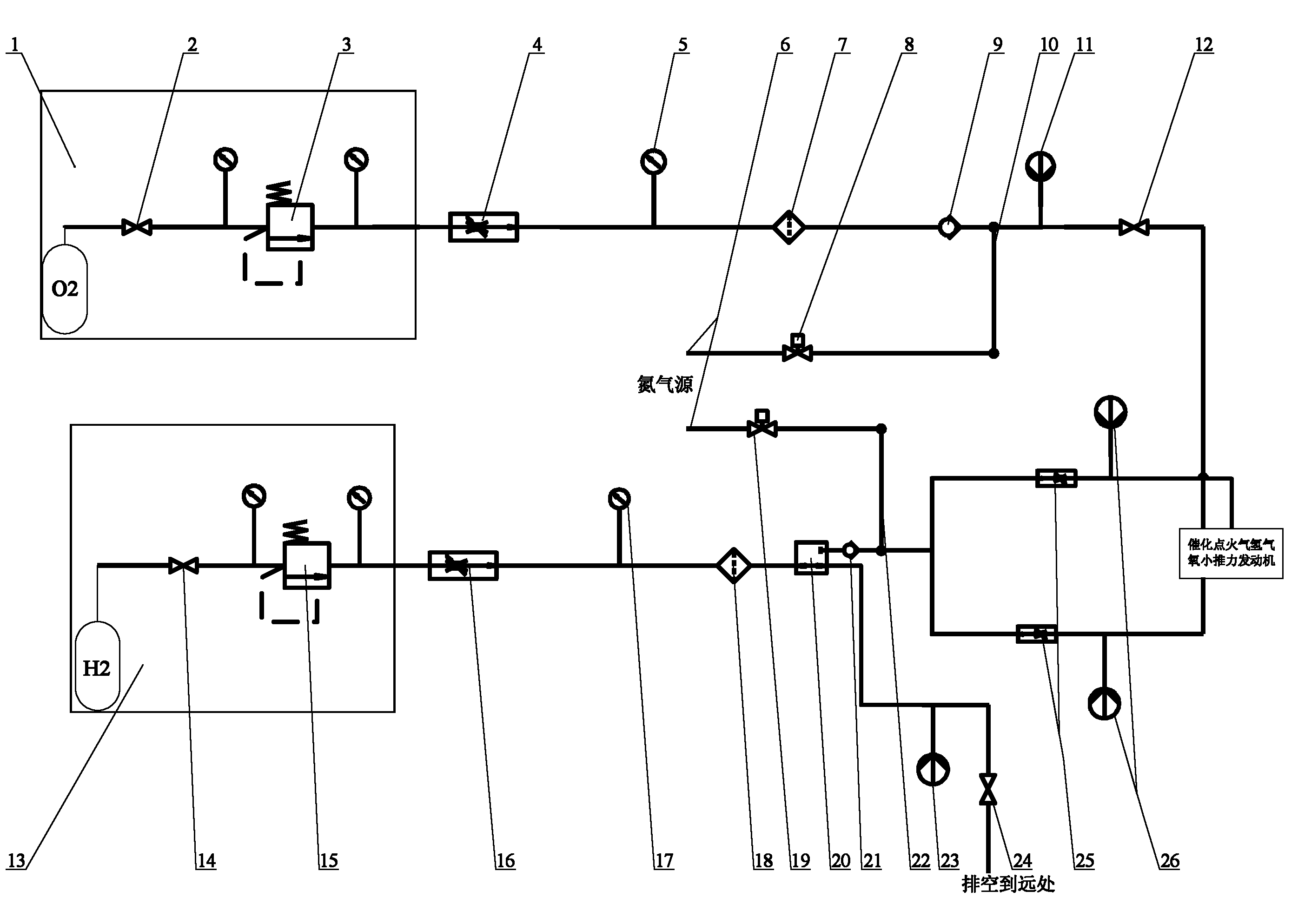

Propelling agent supply system for catalytic ignition hydrogen oxygen small-sized rocket thruster test

The invention discloses a propelling agent supply system for a catalytic ignition hydrogen oxygen small-sized rocket thruster test. The propelling agent supply system comprises an air bottle assembly, a flow controller, a solenoid valve, a check valve, a pressure gauge and a connecting device. A fuel hydrogen (H2) pipeline system consists of a test pipeline and an emptying pipeline, wherein the emptying pipeline is used for coarsely adjusting H2 flow and pressure required by the upstream of a catalytic ignition hydrogen oxygen small thrust engine before the test starts, so that the time of coarsely adjusting H2 flow and pressure intensity and the time of H2 passing through the pipeline in the test process can be shortened by the emptying pipeline to the maximum degree.

Owner:BEIHANG UNIV

Electric Valve

ActiveCN101493156AEnhance card position abilityIncrease elasticityOperating means/releasing devices for valvesEfficient regulation technologiesStator coilEngineering

The invention discloses an electrically operated valve, aiming at the problems that the elasticity of a stopping part for preventing a coil from being loosened corresponding to a valve body is low in the prior art; the technical proposal of the invention comprises a valve seat, a valve needle, the stopping part and a stepping motor which is composed of a rotor and a stator for driving the valve needle and the valve seat to joint or detach; the stopping part is fixedly connected with a stator coil box, and internally concave bending parts which are opposite are additionally arranged above externally convex bending parts on two arm parts extended downwards thereof respectively. As the two arm parts of the stopping part are respectively provided with two bending parts, higher elasticity is obtained under the condition of same deformation, the fixation is reliable and the working noise is low; the valve has the advantages of compact structure and good assembling operability; moreover, the vibration reduction is greatly improved for obtaining accurate flow control; therefore, the valve is particularly suitable for refrigerators, air conditioning refrigerating units, water heaters and dehumidifiers, thus realizing defrosting, the flow control and on-off control and the like of a heating system.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

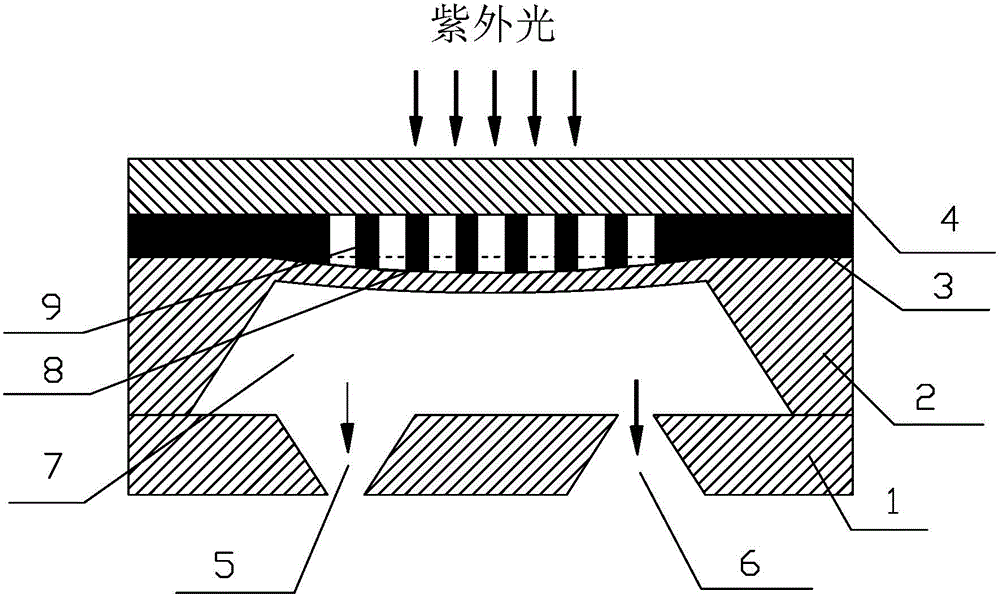

Light driven micro-fluid pump

InactiveCN104481850AQuick responseIncrease working frequencyFlexible member pumpsPositive-displacement liquid enginesLight energyMechanical energy

The invention relates to a light driven micro-fluid pump. The light driven micro-fluid pump converts between light energy and mechanical energy. The light driven micro-fluid pump comprises an outlet / inlet layer, a pump cavity layer, a micro-wire grid array drive unit and a substrate in sequence from the bottom to top; the outlet / inlet layer is provided with an inlet and an outlet; the pump cavity layer comprises a pump cavity and a deformable vibrating diaphragm; the micro-wire grid array drive unit comprises a micro-wire grid array of which the period is hundreds of nanometers, the micro-wire grid array is composed of grid ridges and grid valleys, and the micro-wire grid array is a shape memory material azobenzene liquid crystal elastomer. The light driven micro-fluid pump periodically changes the irradiation light type and light intensity and is capable of precisely controlling the periodic change of the pump cavity volume of the micro-fluid pump so as to generate continuous differential flow. The light driven micro-fluid pump has advantages of fast respond speed, high working frequency, small energy consumption, large drive quantity and the like; the light driven micro-fluid pump is capable of precisely controlling the flow rate and capable of being used for the cell separation, micro-feeding of fluid, micro-injection of medicine, micro-chemical analysis and the like fields; the apparatus manufacturing can use an MEMS processing technique compatible with an IC manufacturing technique, and the apparatus manufacturing is suitable for batch production.

Owner:CHANGZHOU UNIV

Gas supply apparatus equipped with vaporizer

ActiveUS8931506B2Stable controlPrecise flow controlInternal combustion piston enginesValve members for heating/coolingTemperature controlProduct gas

Owner:FUJIKIN INC

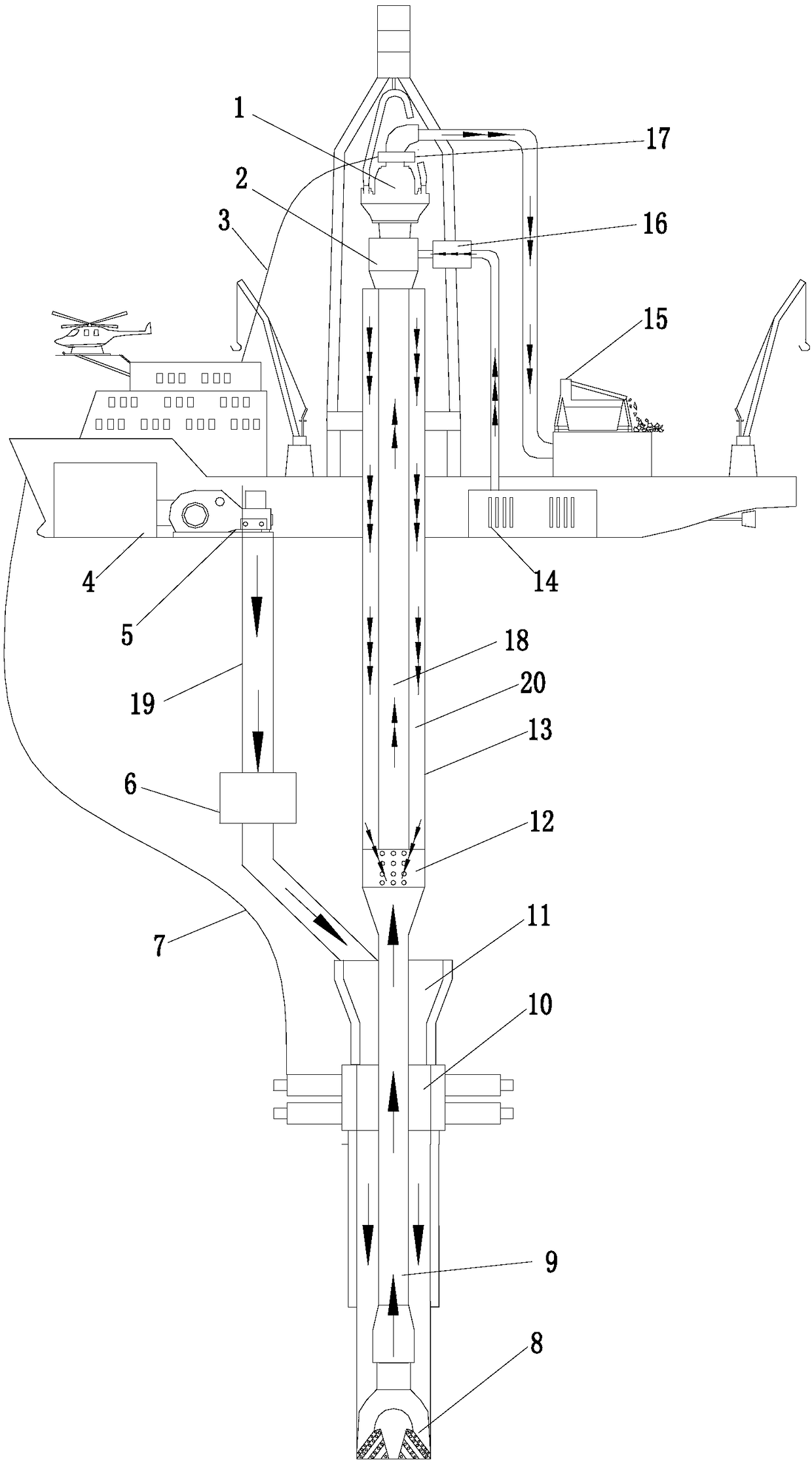

Air-lift reverse circulation drilling system used in deep water without marine riser and method thereof

PendingCN108425651AWill not cause missingConstruction auxiliary time is shortConstructionsDouble wallSlurry

The invention relates to an air-lift reverse circulation drilling system used in deep water without marine riser and method thereof. The system includes a slurry injection system and an air-lift reverse circulation coreing drilling system; the slurry injection system includes a return cone, an injection pipe, a slurry injection pump and a slurry tank which are sequentially connected; the air-liftreverse circulation coring drilling system comprises an air compressor, an air-water faucet, a double-wall drill rod, an air-water mixer and a single-wall drill rod. The air compressor is connected with the air-water faucet. The lower end of the air-water faucet is connected with the double-wall drill rod. The lower end of the double-wall drill rod is respectively connected with the air-water mixer. The lower end of the air-water mixer is connected with the single-wall drill rod. The return cone is arranged on the outer wall of the drill rod connection. The system does not need a water-proof measure, realizes slurry circulation and well wall protection during drilling, and can be applied to any water depth; air-lift reverse circulation principle is used to convey core and debris so as to reduce construction time and cost; the requirements on the slurry injection pump is reduced and the reliability is good.

Owner:GUANGZHOU MARINE GEOLOGICAL SURVEY

Methods for modulation of flow in a flow pathway

Owner:LIFESCAN SCOTLAND

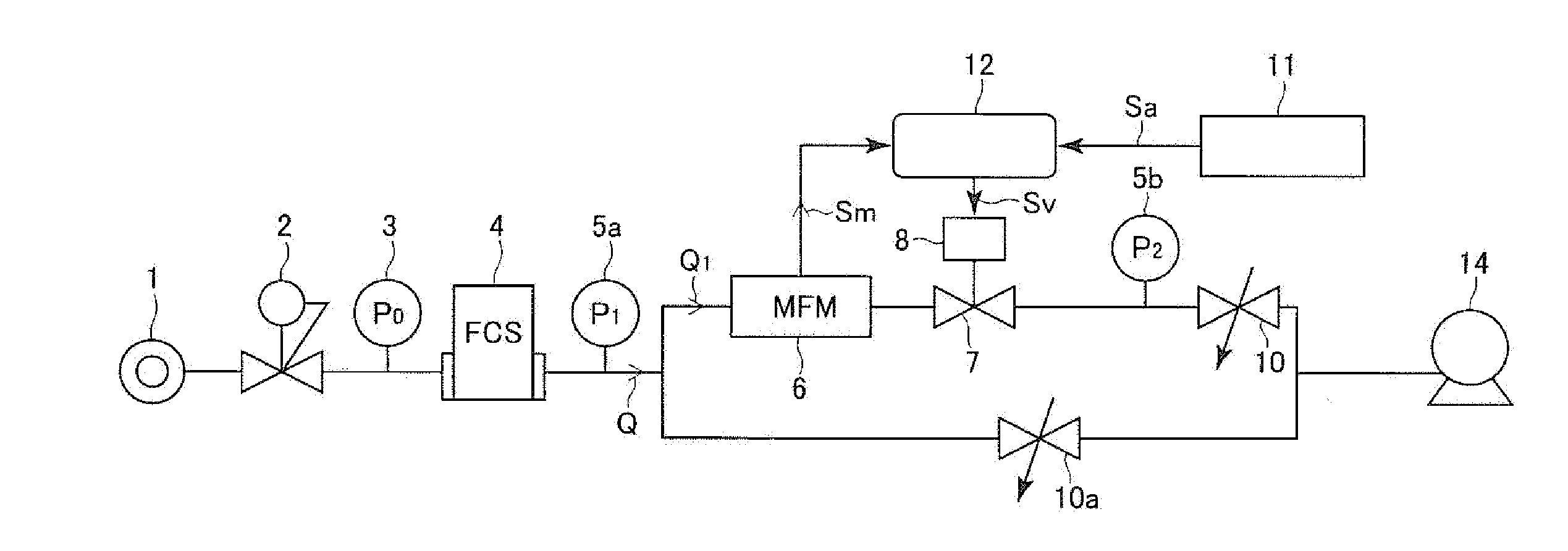

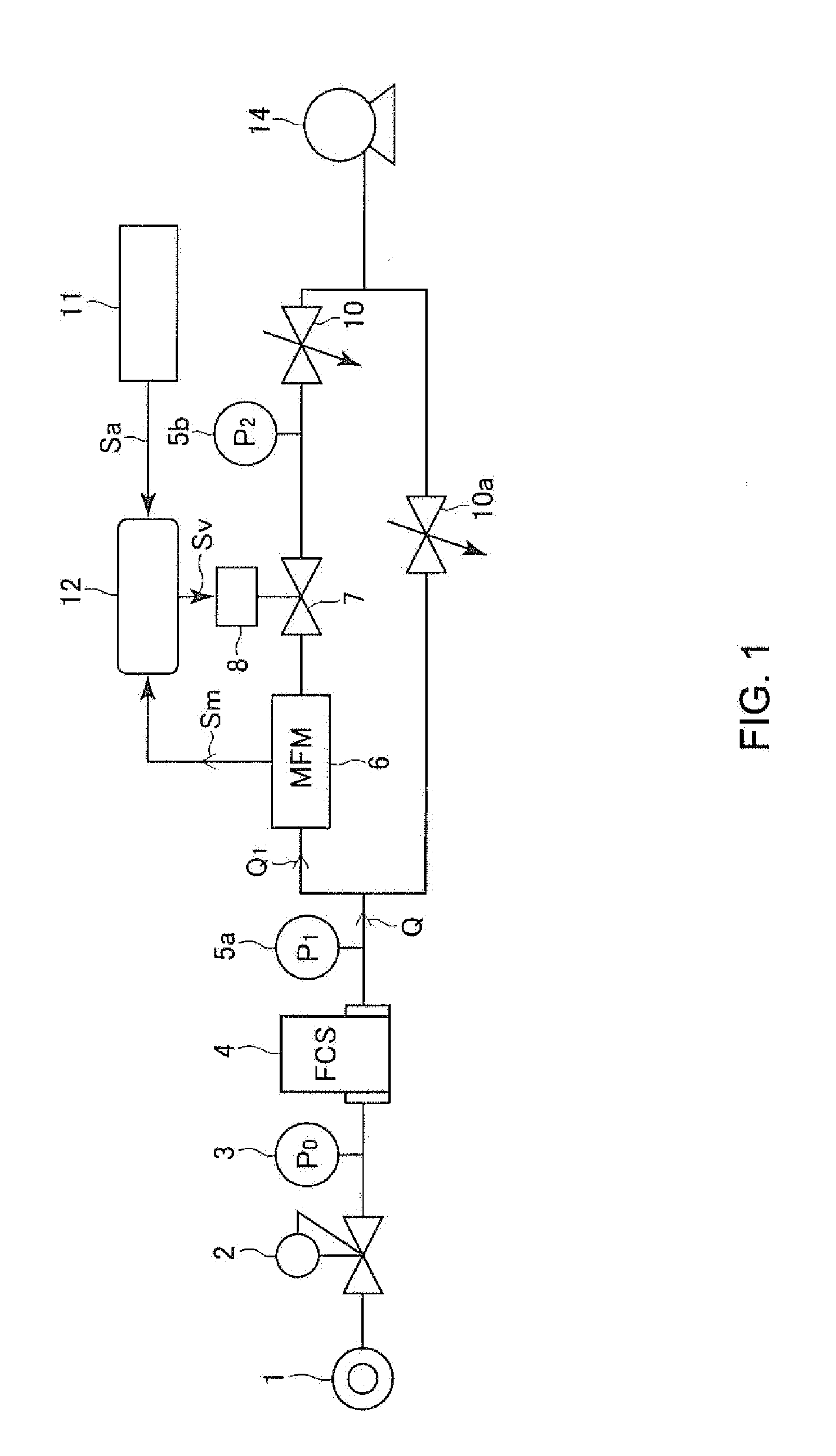

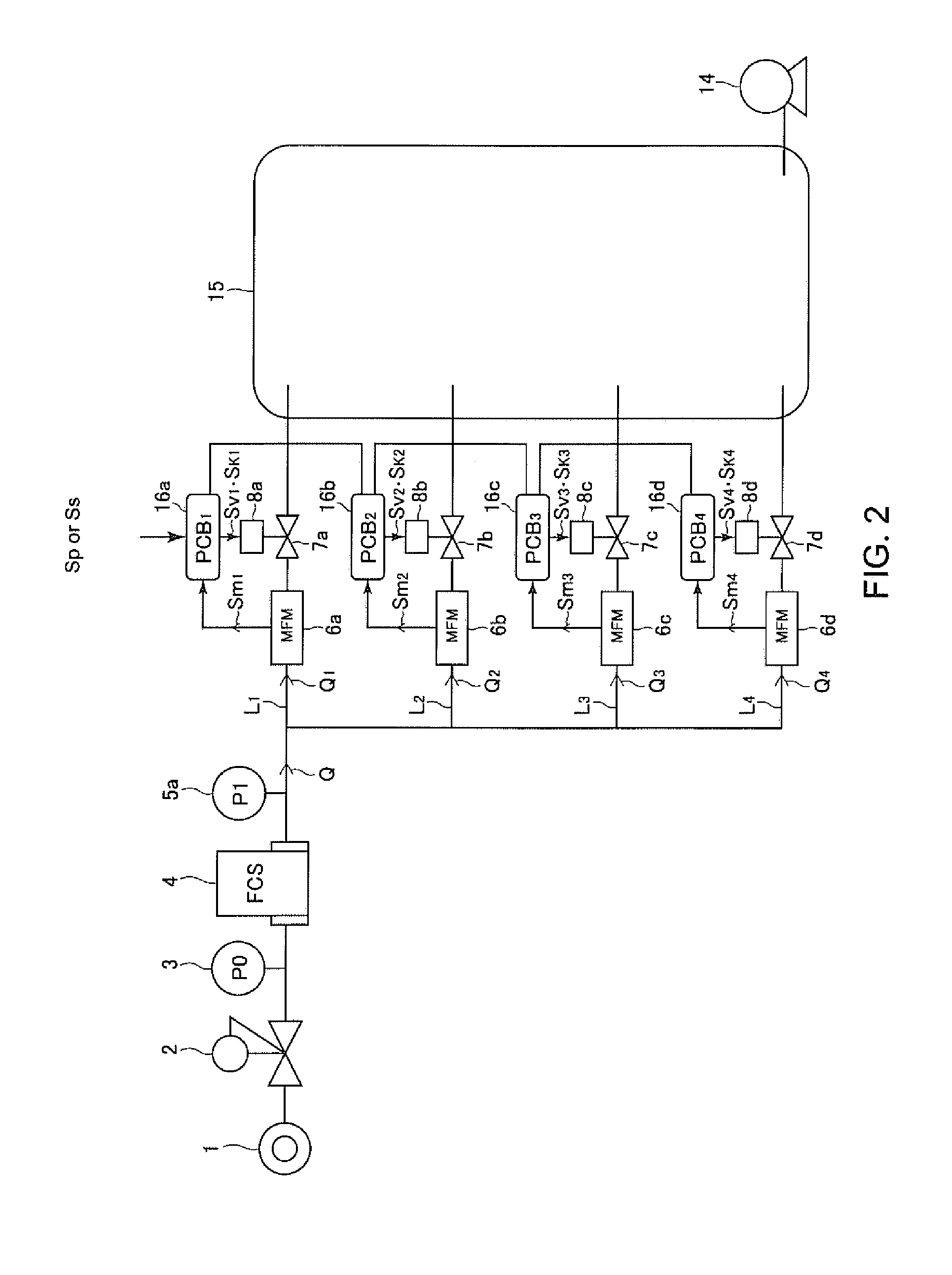

Apparatus for dividing and supplying gas and method for dividing and supplying gas by use of this apparatus

ActiveUS20130220433A1Precise flow controlIncrease production costOperating means/releasing devices for valvesControlling ratio of multiple fluid flowsControl systemEngineering

A gas dividing / supplying apparatus includes a pressure-type flow control system, a plurality of divided flow passages connected in parallel with each other and through which gas flowing from the pressure-type flow control system is divided and supplied to a process chamber, thermal-type mass flow sensors disposed in the divided flow passages, respectively, motor-operated valves disposed on a downstream side of the thermal-type mass flow sensors, respectively, and switching-type controllers that control opening and closing of the motor-operated valves, respectively, and, in the apparatus, the switching-type controllers perform switching between valve opening control for maintaining the motor-operated valves at a predetermined fixed valve opening degree based on a valve opening control command signal and divided flow control for regulating an opening degree of each of the motor-operated valves by feedback control based on a flow detection signal of the thermal-type mass flow sensor by a divided flow control command signal.

Owner:FUJIKIN INC

Flow control proportional valve

ActiveUS20140054479A1Simple structureEasily realizedRespiratorsOperating means/releasing devices for valvesEngineeringMechanical engineering

A flow control proportional valve comprises a valve body and a valve core disposed below the valve body, a valve cover plate is disposed at an upper end of the valve core, the bottom of the valve cover plate is connected to an upper end of a connection rod, a coil rack fixedly mounted at a lower end of the connection rod is wound by an enameled wire which is connected to a power supply unit, a magnetic core and a magnetic ring are disposed under the coil rack, the magnetic ring surrounds the magnetic core, a gap is kept between the magnetic ring and the magnetic core to form a magnetic field, the coil rack is sleeved on the magnetic core and is disposed in the gap.

Owner:BEIJING AEONMED

Micro pump using ferrofluid or magneto-rheological fluid

InactiveUS20050069424A1Improve flow efficiencyImprove pump efficiencyPositive displacement pump componentsFlexible member pumpsWorking fluidMagnetorheological fluid

A micro pump using a ferro-fluid / magneto-rheological fluid to drive a working fluid is proposed. The micro pump has a body with an accommodating space and an opening that communicates with the accommodating space. A ferro-fluid / magneto-rheological fluid and a magnetic field generating unit are disposed on the body. As the ferro-fluid / magneto-rheological fluid is attracted to the magnetic field after being magnetized, the ferro-fluid / magneto-rheological fluid is deformed or shifted to drive the working fluid, so as to control the working fluid to flow in and out of the accommodating space. Accordingly, the pump is improved for its efficiency and precision to control the flow while the back flow of the working fluid is prevented.

Owner:IND TECH RES INST

Robotic cartridge dispenser and method

ActiveUS20150086706A1Precise flow controlEfficient use ofLiquid surface applicatorsSpraying apparatusEngineeringSealant

A system for applying sealant material from a cartridge includes a cartridge fixture storing a plurality of cartridges each cartridge including unique identification information and containing sealant material, a cartridge robot for removing a selected one of the cartridges from the fixture, and a dispense robot for receiving the selected cartridge from the cartridge robot and applying the sealant material contained therein to a workpiece. A controller is connected to the cartridge robot and the dispense robot for operating the robots and a plurality of sensors are connected to the controller for generating the unique identification information for the selected cartridge, sealant usage per workpiece, sealant dispense pressure, sealant dispense temperature; and sealant usage from the selected cartridge.

Owner:FANUC ROBOTICS NORTH AMERICA

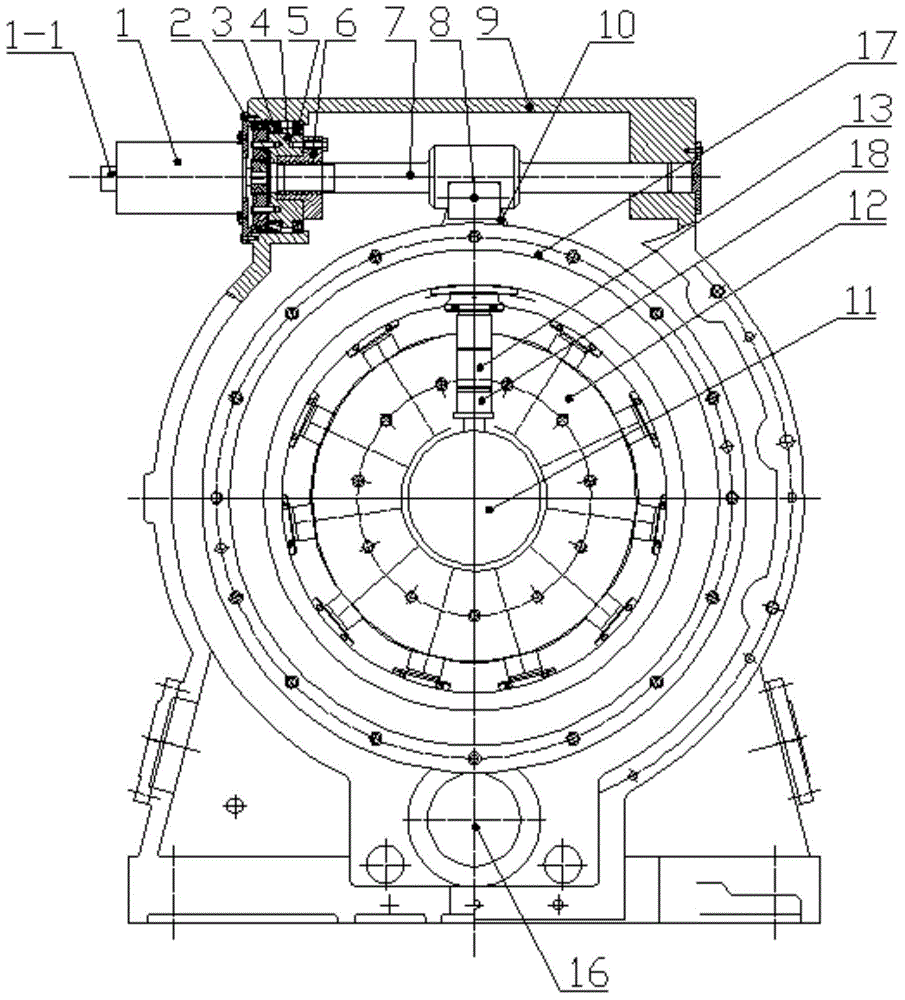

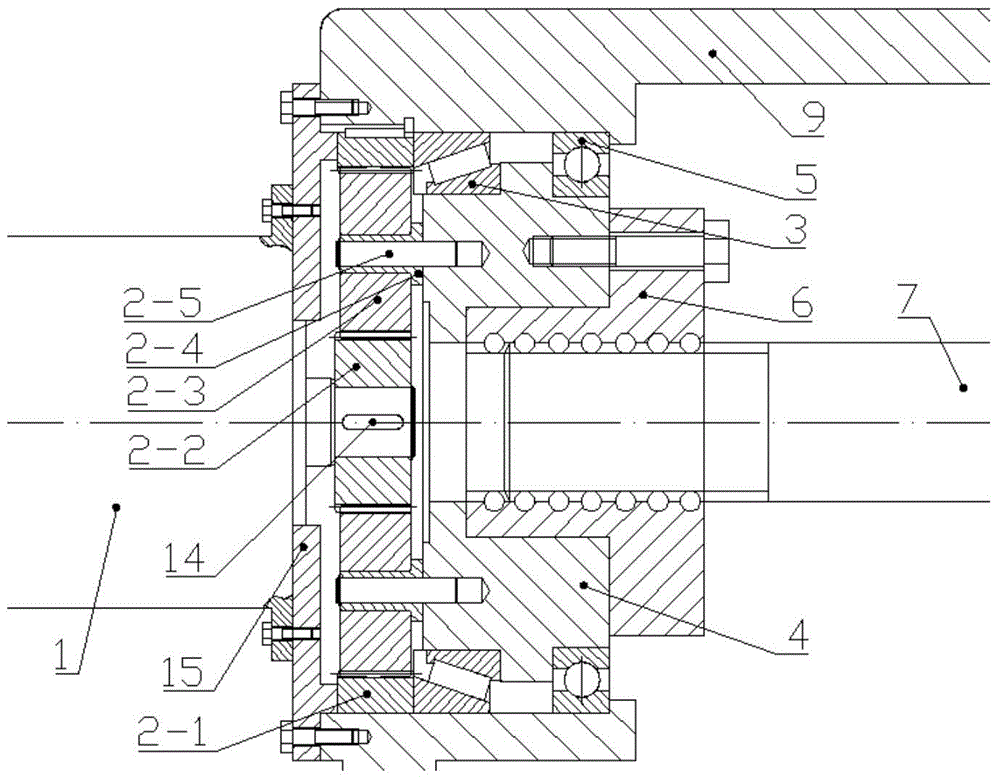

Alternating current servo motor driving device for discharge capacity adjustment of radial plunger pump

InactiveCN104153958AImprove dynamic performancePrecise flow controlPositive-displacement liquid enginesMulti-cylinder pumpsBall bearingMotor drive

An alternating current servo motor driving device for discharge capacity adjustment of a radial plunger pump comprises the shaft flow distribution radial plunger pump. A servo motor is fixed to a shell of the radial plunger pump through an end cover. An output shaft of the servo motor is in clearance fit with a sun wheel of a planetary reducer. A planet wheel of the planetary reducer is connected with a connecting block through a shaft sleeve and a hinge pin. The connecting block is connected with a screw nut. The outer portion of the connecting block is connected with the shell of the radial plunger pump in a matched mode through a conical roller bearing and a deep groove ball bearing. A ball screw is connected with a swing frame beam of the radial plunger pump. The swing frame beam is connected with a swing frame. The servo motor and the planetary reducer are both installed on the shell of the radial plunger pump. The screw nut rotationally drives the ball screw to move horizontally, so that the swing frame is driven to rotate around a swing shaft, and the offset of the radial plunger pump is adjusted. According to the alternating current servo motor driving device, adjustment is accurate and the response speed is high.

Owner:XI AN JIAOTONG UNIV

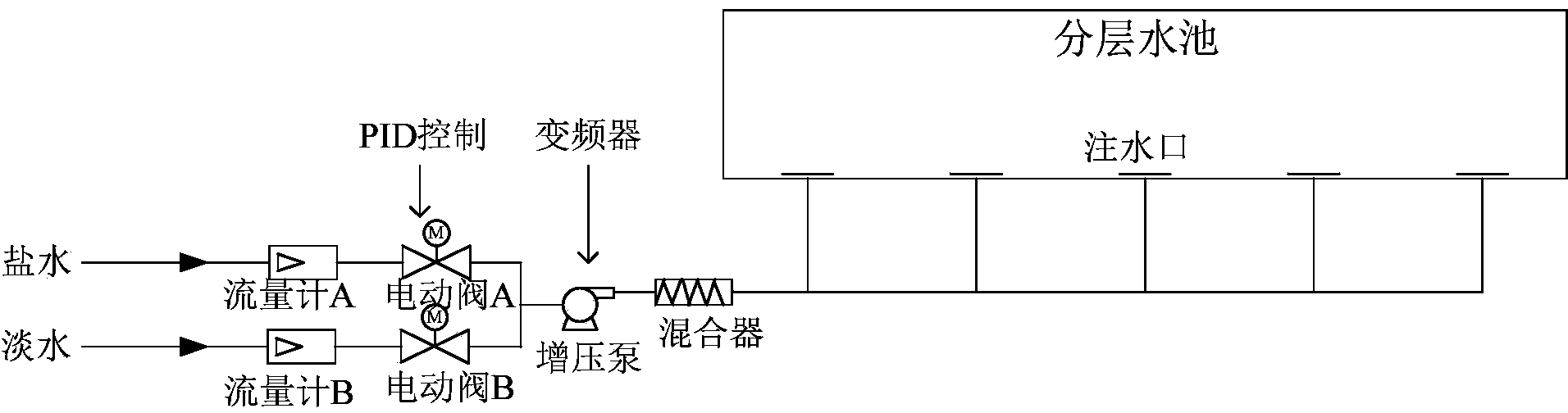

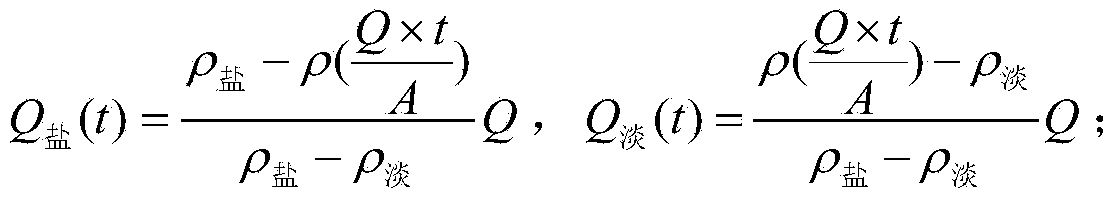

Method for preparing fluid with layered density

ActiveCN103868671ASimple and Effective Layering TechnologyLayering time controllableHydrodynamic testingFrequency changerAutomatic control

The invention discloses a method for preparing fluid with a layered density. The method for preparing the fluid with the layered density can provide a simple and effective layering technology for ocean layered environmental laboratory simulation. According to the method for preparing the fluid with the layered density, the water outlet flow of a fresh water tank and the water outlet flow of a brine tank are controlled with an automatic control method; a mixer is arranged to enable brine and fresh water to be fully mixed; a booster pump is arranged to enable the brine and the fresh water to flow into a layered water pool at a controllable speed, so that layered fluid is formed; the opening degree of an electrically-operated valve is regulated with the PID technology, the rotating speed of the booster pump is regulated through a frequency converter, a dual-regulation method is formed, the flow of the brine and the flow of the fresh water are accurately controlled and are regulated according to a preset flow change rule, and thus a density layered section containing either a jumping layering curve or a linear layering curve is obtained. According to the method for preparing the fluid with the layered density, the layering time is controllable, equipment can be arranged easily, operation is convenient, and the application flexibility is high.

Owner:中国船舶重工集团公司第七〇二研究所

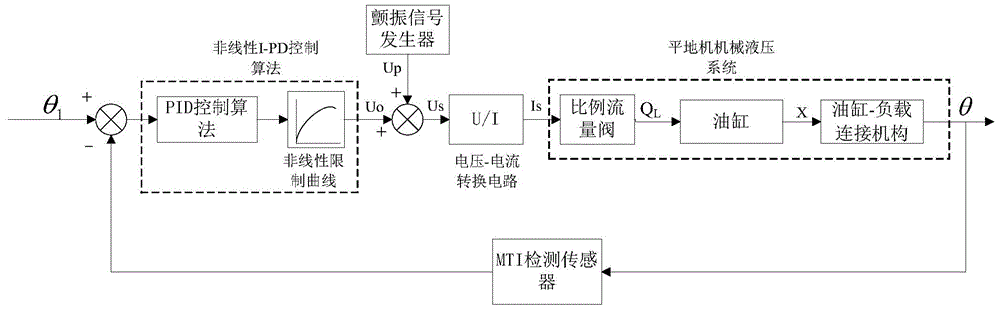

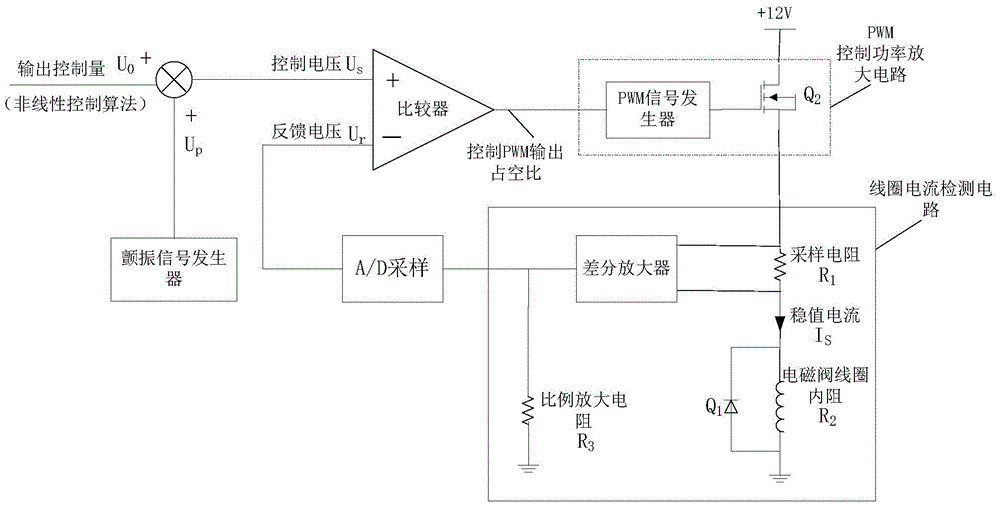

Leveling control system and method of land leveller scraper

InactiveCN103953598AQuick responseEliminate overshootFluid-pressure actuator safetyServomotor componentsMicrocontrollerMechanical wear

The invention discloses a leveling control system of a land leveller scraper. The system comprises a hydraulic system, and also comprises a detection sensor, a microcontroller and a proportional flow valve driving circuit which are connected in sequence, wherein the detection sensor detects the real-time horizontal tilt angel theta of the scraper; the microcontroller computes angular speed omega according to the horizontal tilt angel theta of the scraper through an I-PD control algorithm, which is taken as a reference value and is transmitted into a nonlinear limit curve; if the value omega exceeds the working range of the nonlinear limit curve, the practical output control angular speed omegaref is equal to omegaMAX, wherein omegaMAX is the maximum angular speed provided by the hydraulic system; otherwise omegaref is equal to omega; omegaref is taken as a PWM duty cycle value, obtained control voltage U0 is sent to the proportional flow valve driving circuit comprising a PWM switching voltage controlled constant flow source circuit, and a proportional flow valve is driven, so that the hydraulic system levels the scraper. The system and the method can effectively eliminate the phenomenon of overshoot of the scraper, improve the response speed and the control accuracy of the scraper, reduce system power loss and mechanical wear, and improve the land leveling efficiency.

Owner:SOUTH CHINA AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com