Patents

Literature

5254 results about "Plunger pump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A plunger pump is a type of positive displacement pump where the high-pressure seal is stationary and a smooth cylindrical plunger slides through the seal. This makes them different from piston pumps and allows them to be used at higher pressures. This type of pump is often used to transfer municipal and industrial sewage.

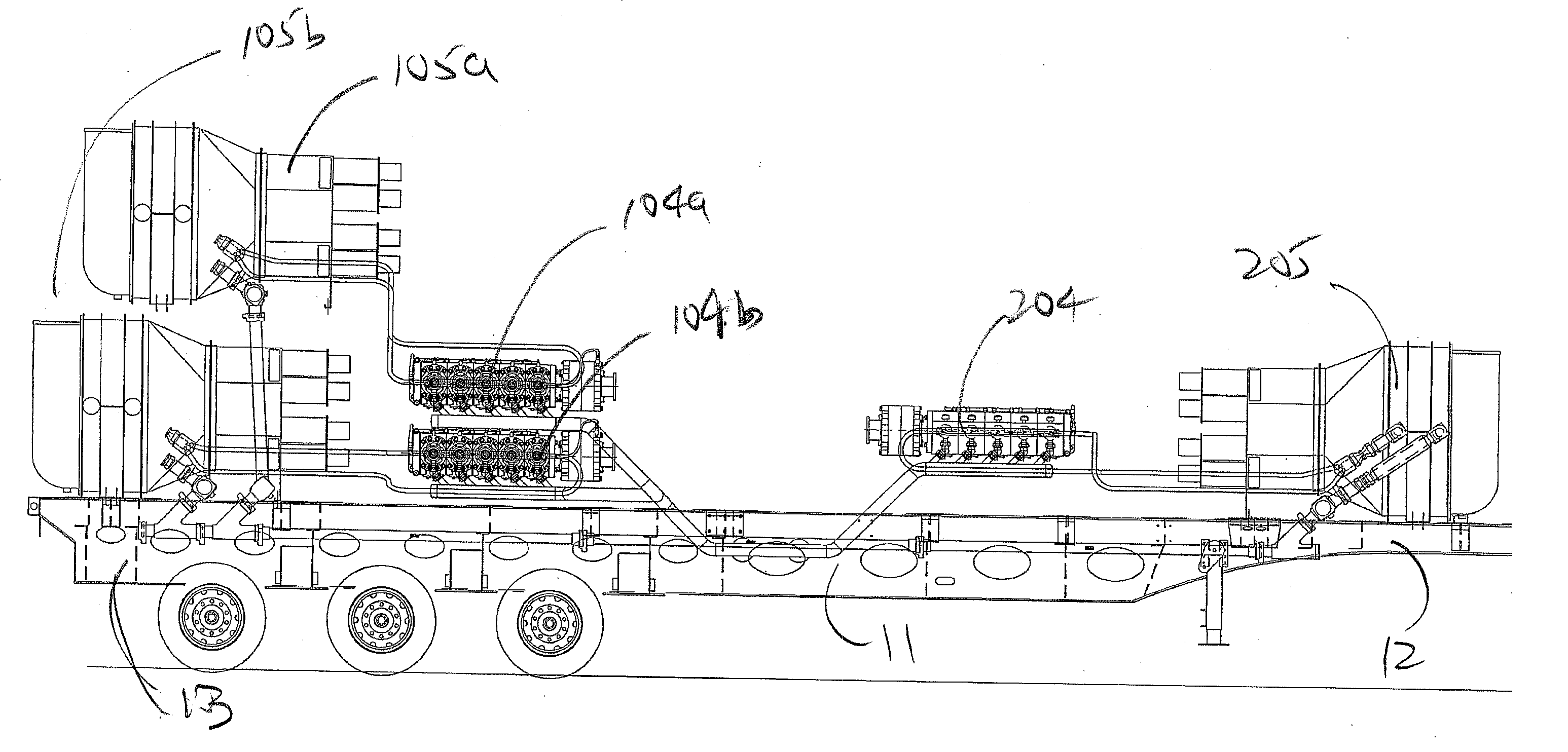

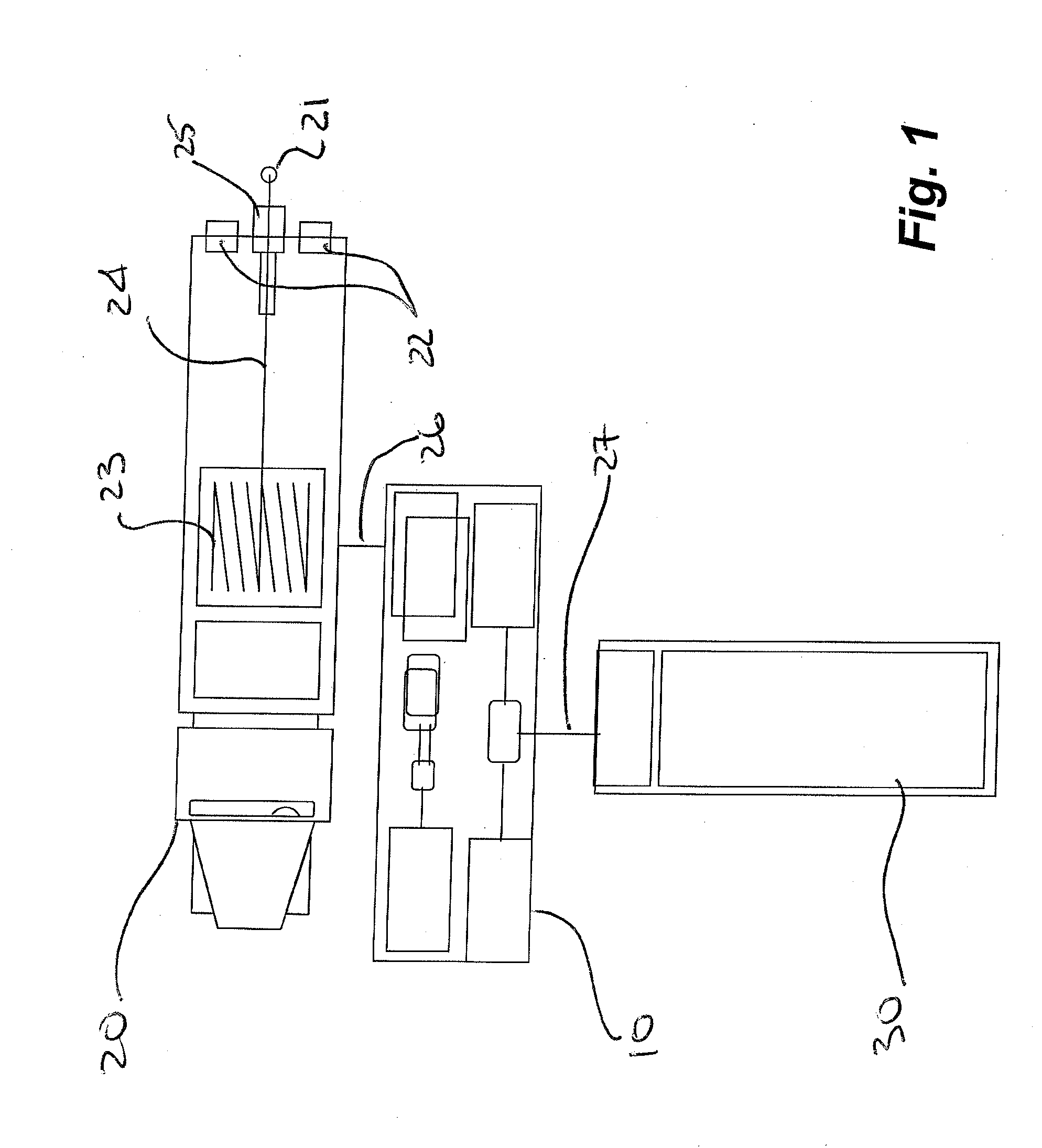

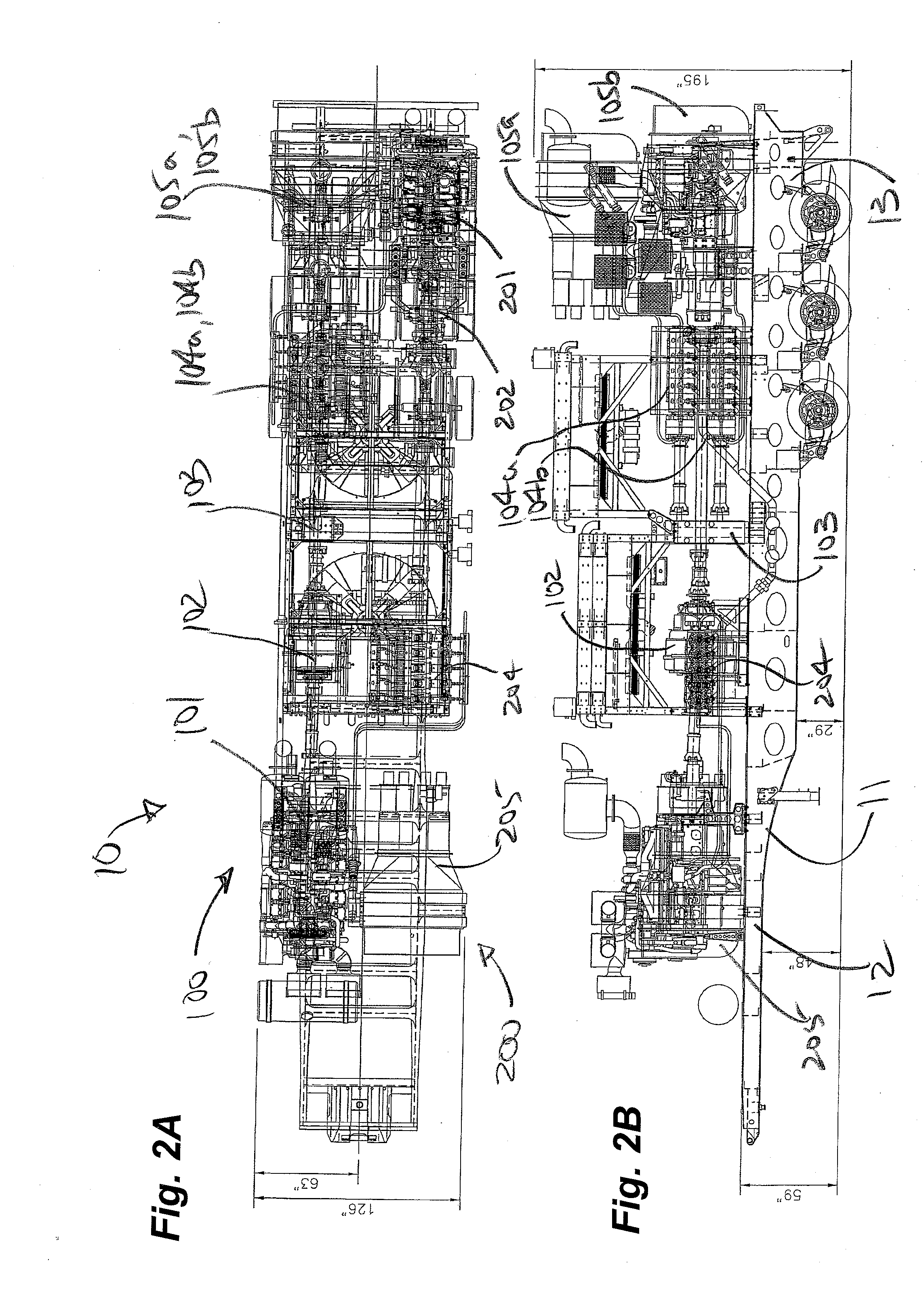

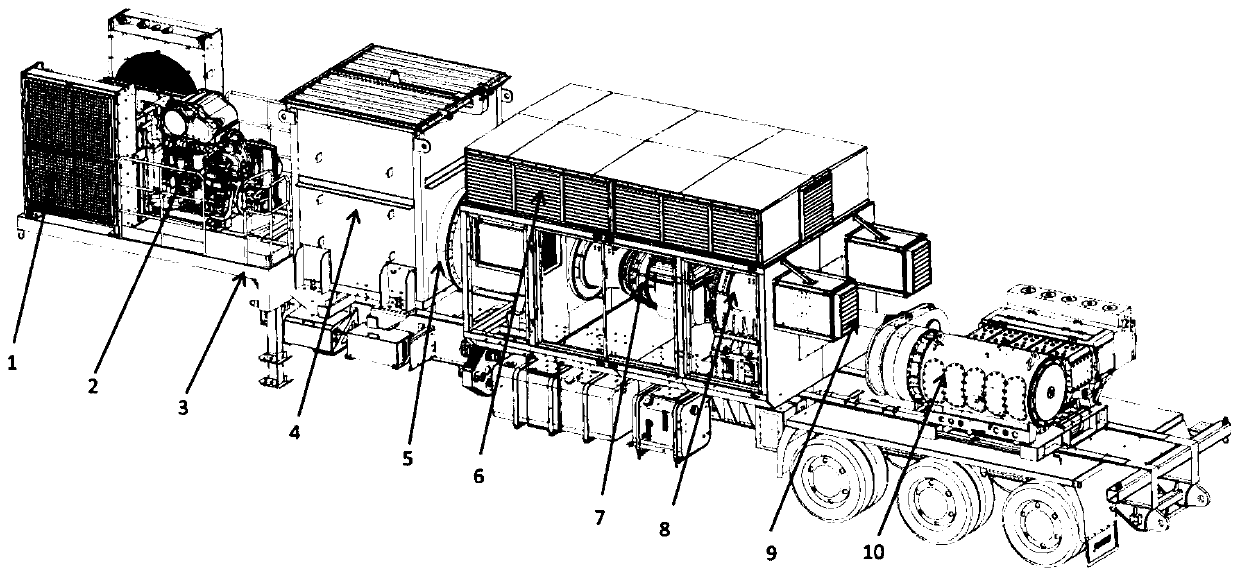

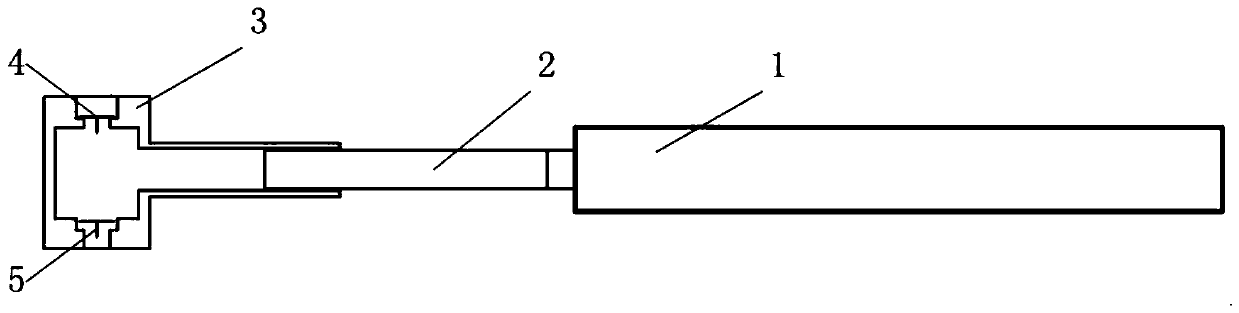

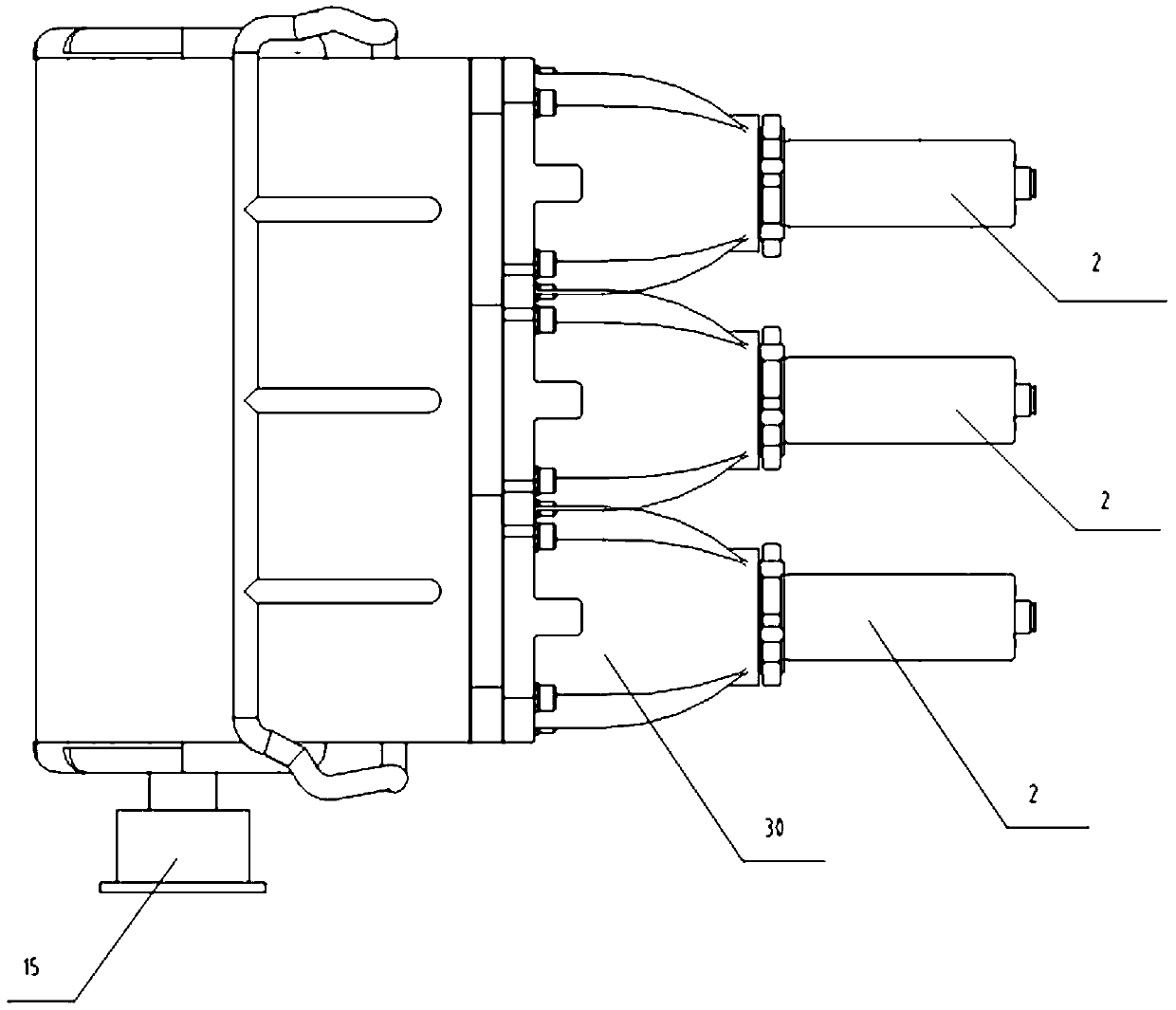

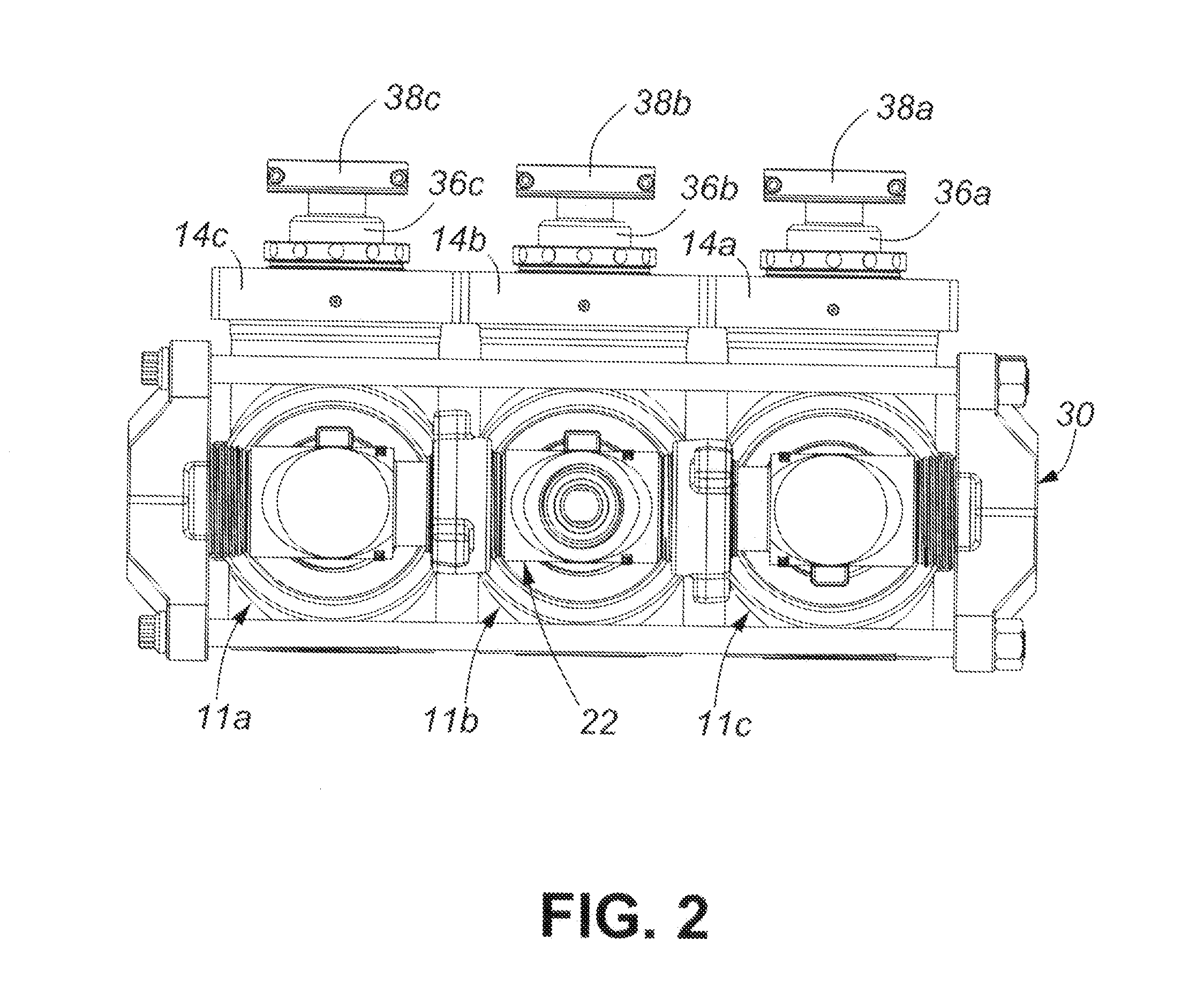

Transportable pumping unit and method of fracturing formations

InactiveUS20060260331A1Increase chanceReduced operating requirementsNon-pressured vesselsPumpsCombustorControl system

A high capacity pumper for liquefied gas incorporates multiple pumping systems distributed in a parallel arrangement and in opposing orientation on a transportable platform such as a trailer. Vaporizers incorporate a burner control system utilizing a primary set of burners operating a baseline and a secondary set of burners providing fine regulating control. A system for fracturing formations is now possible using a minimum number of components including the high capacity pumper, a coiled tubing rig and a source of liquefied gas. An improved manifold for a cryogenic plunger pump includes unions and angled connectors between a supply conduit and each of a plurality of pump heads.

Owner:CENTURY OILFIELD SERVICES

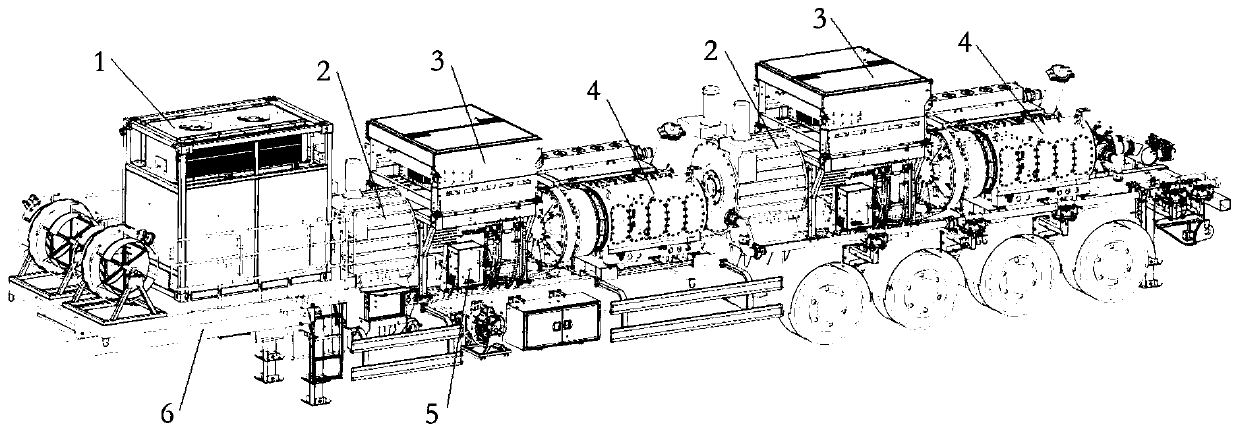

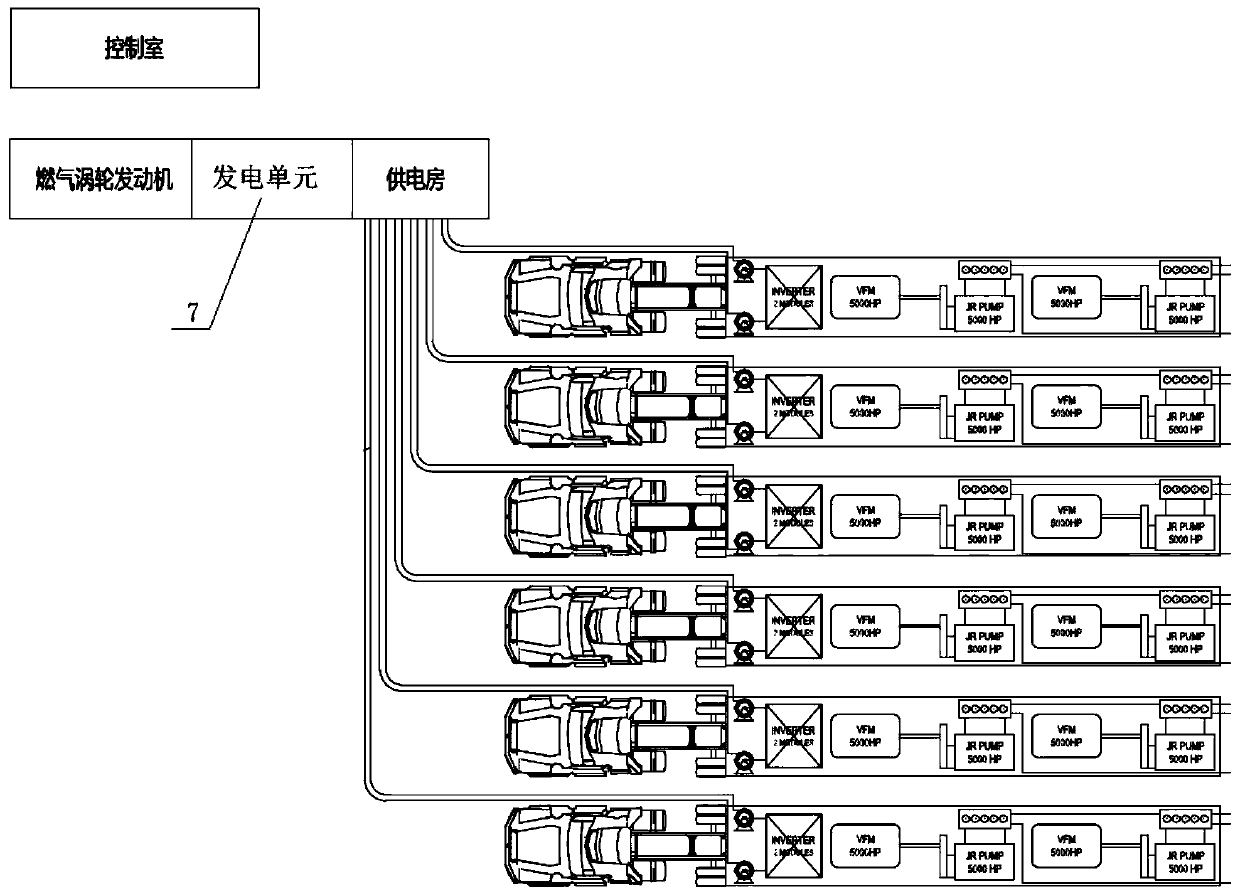

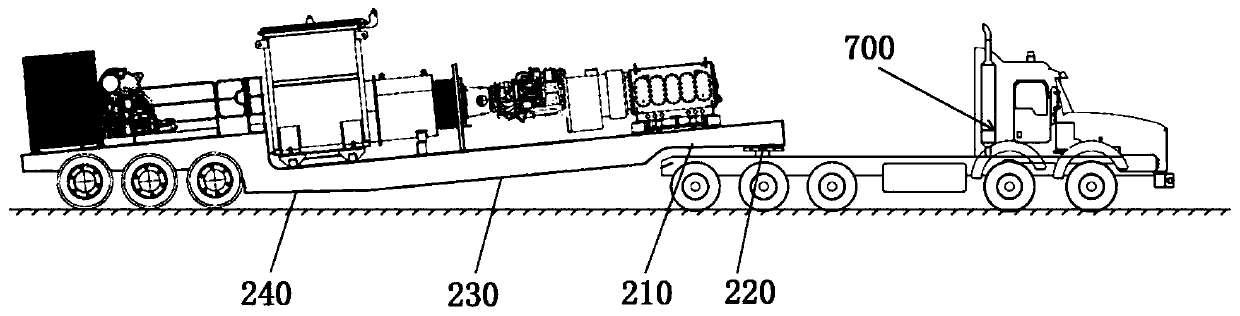

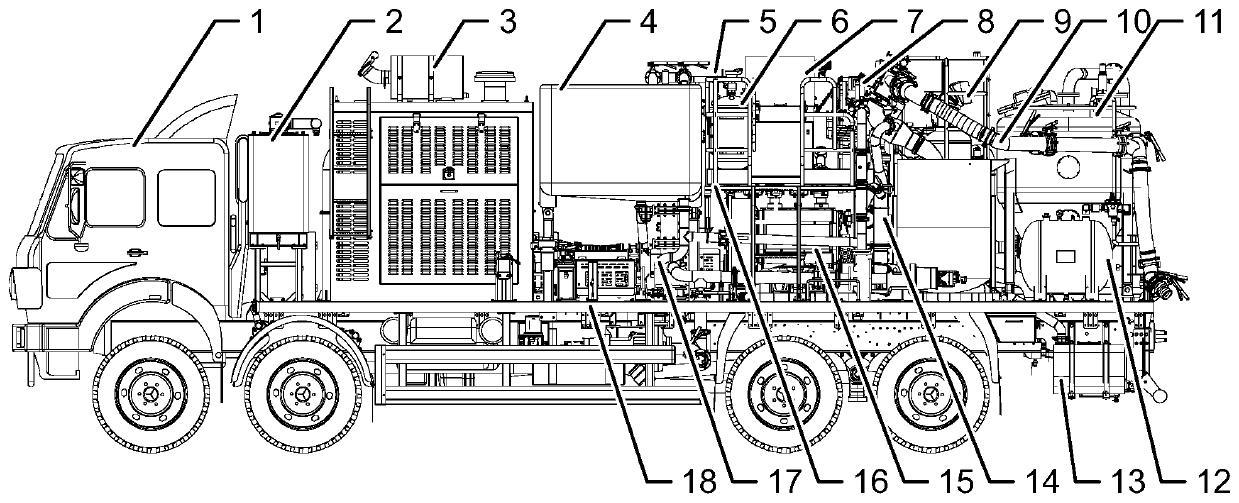

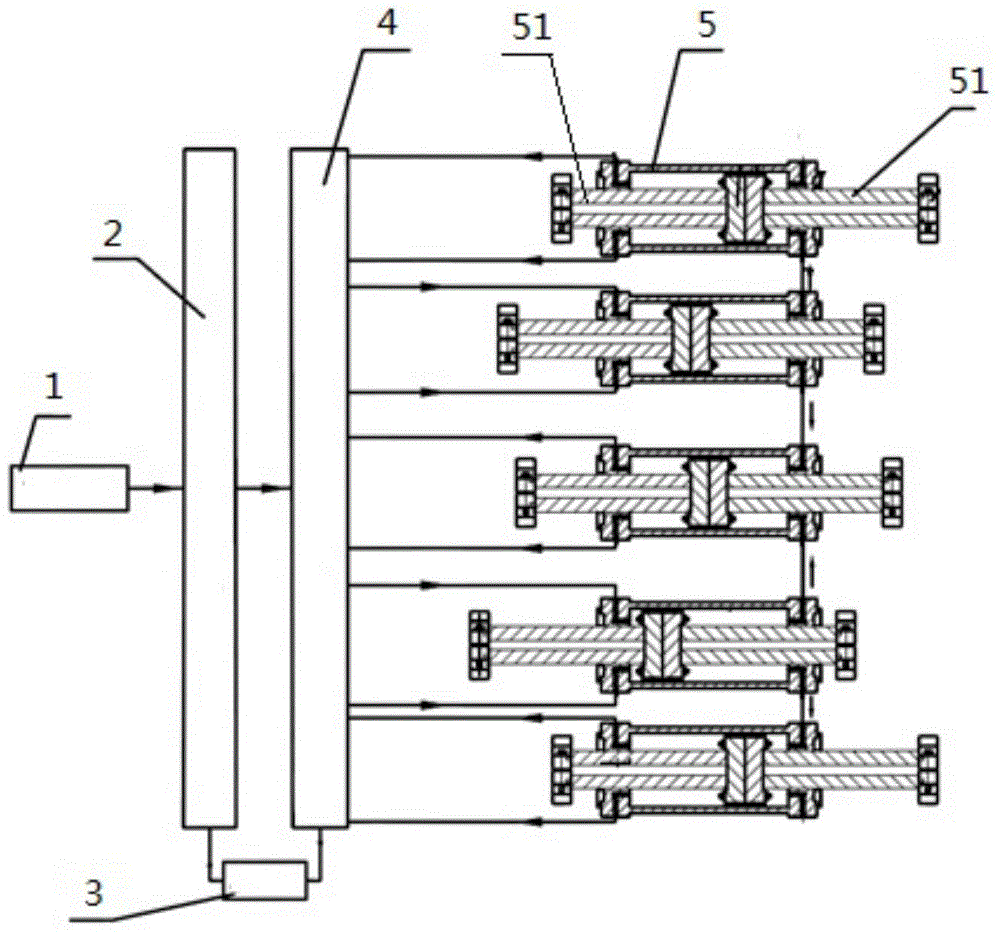

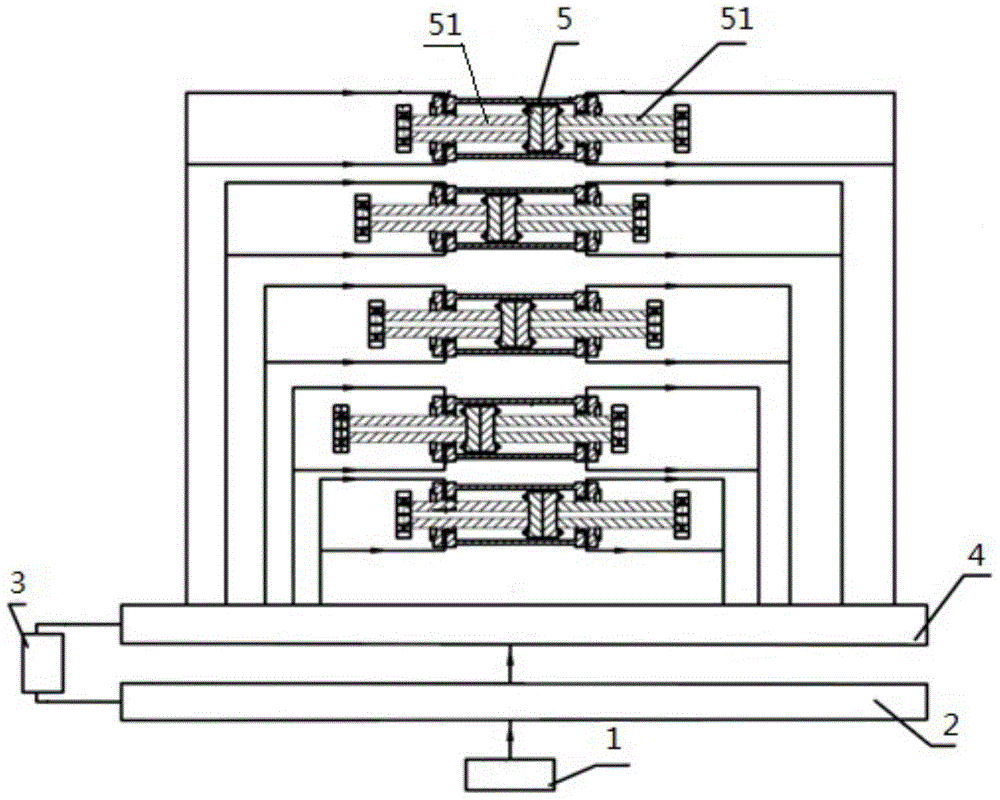

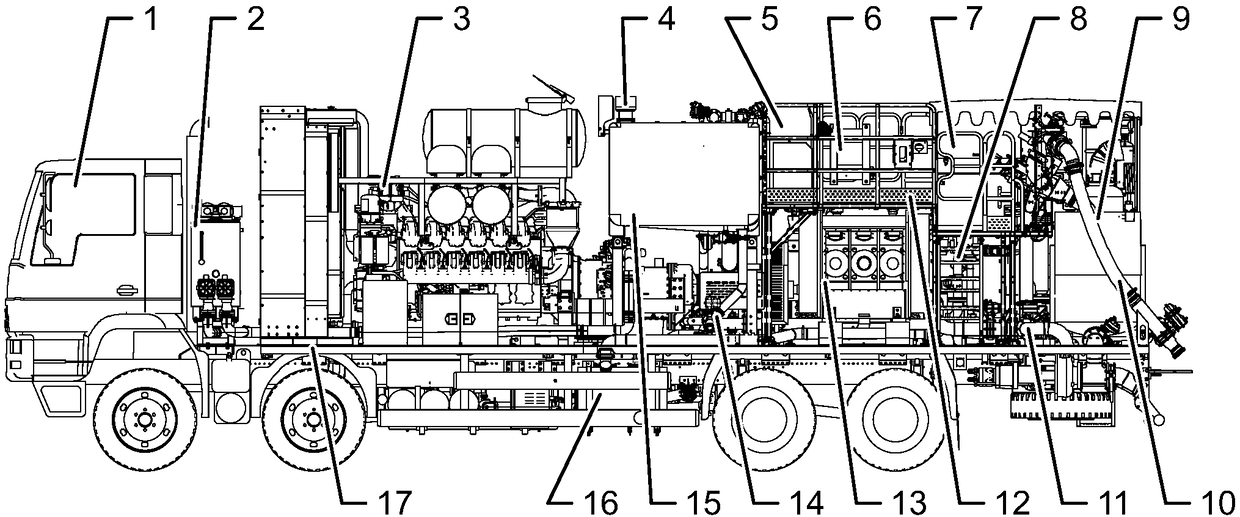

Electric drive fracturing semitrailer with dual engines and dual pumps

PendingCN109882144ARealized pump powerReduce investmentAssociation with control/drive circuitsPositive displacement pump componentsDrive shaftElectrical control

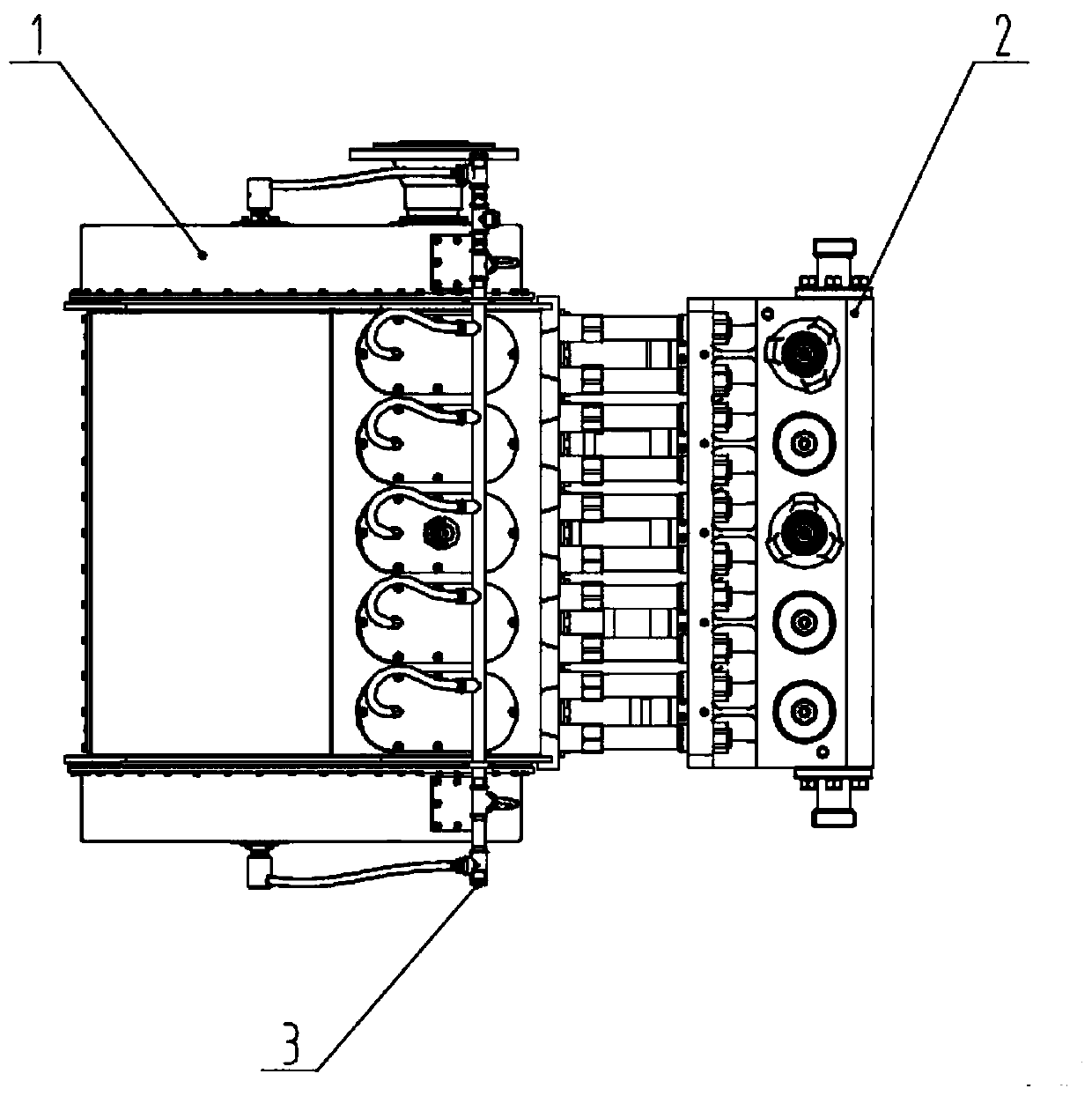

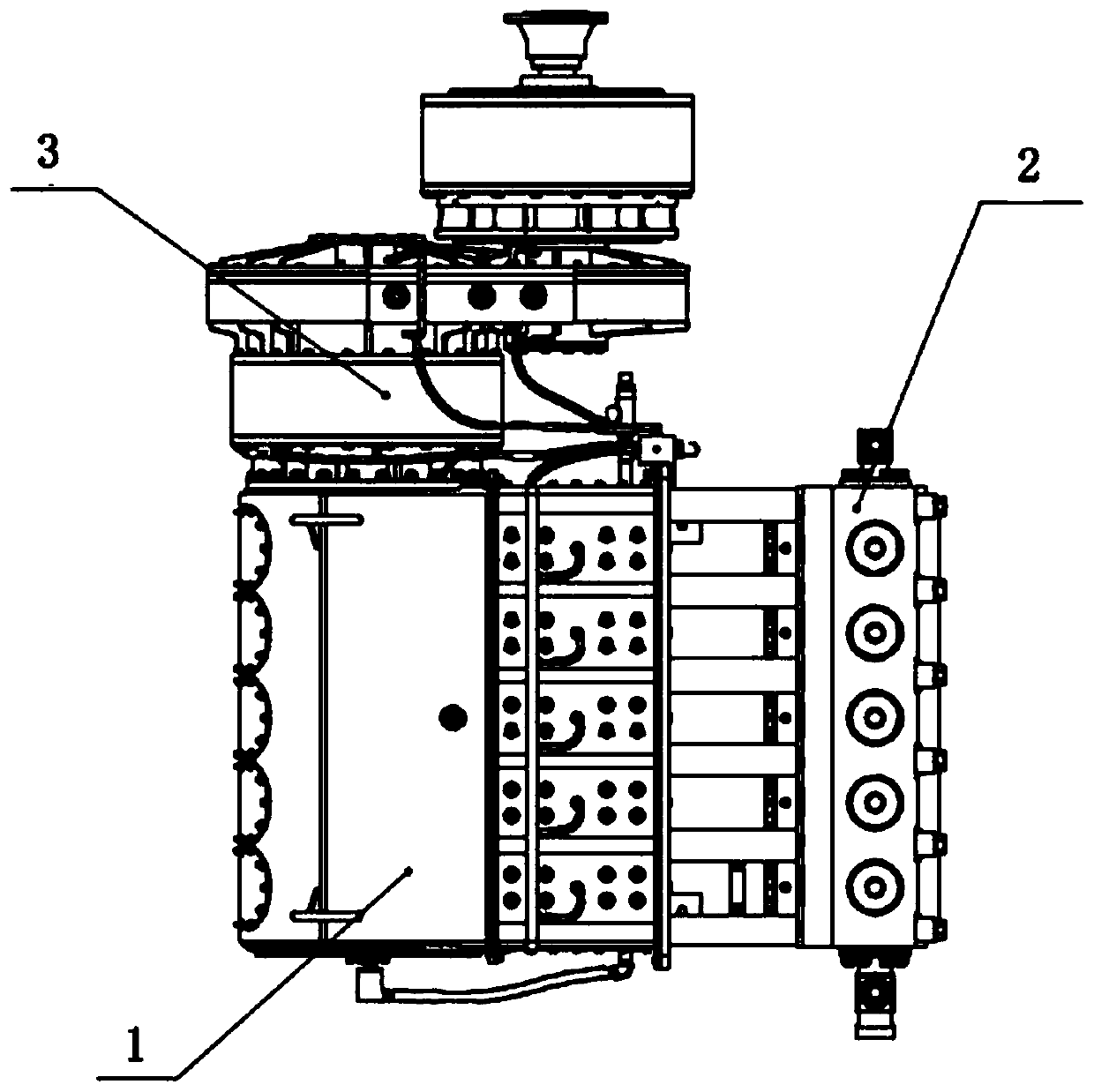

The invention discloses an electric drive fracturing semitrailer with dual engines and dual pumps. The electric drive fracturing semitrailer with the dual engines and the dual pumps comprises a semitrailer body, two plunger pumps, two radiators and an electrical control cabinet. The electric drive fracturing semitrailer with the dual engines and the dual pumps is characterized by further comprising two electromotorsand an inverter unit. The plunger pumps, the radiators, the electrical control cabinet, the electromotors and the inverter unit are integrated in the semitrailer body, the inverterunit is arranged on the gooseneck of the semitrailer body, the output end of the inverter unit individually drives the two electromotors, the other ends of the two electromotors are connected with theplunger pumps correspondingly, lubricating oil of the plunger pumps is cooled through the radiators, and local operation of the electric drive fracturing semitrailer with the dual engines and the dual pumps is realized through the electrical control cabinet. The electric drive fracturing semitrailer with the dual engine and the dual pump has the beneficial effects that the electromotors are adopted to drive the plunger pumps through a transmission shaft, the volume is small, and the economic efficiency, energy conservation and environment protection are achieved. The signal pump power of theplunder pumps is improved, design that the dual pumps are driven by the two electromotors is adopted by the whole fracturing device, the output power of the fracturing device is greatly improved, andthe using requirements are better met.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

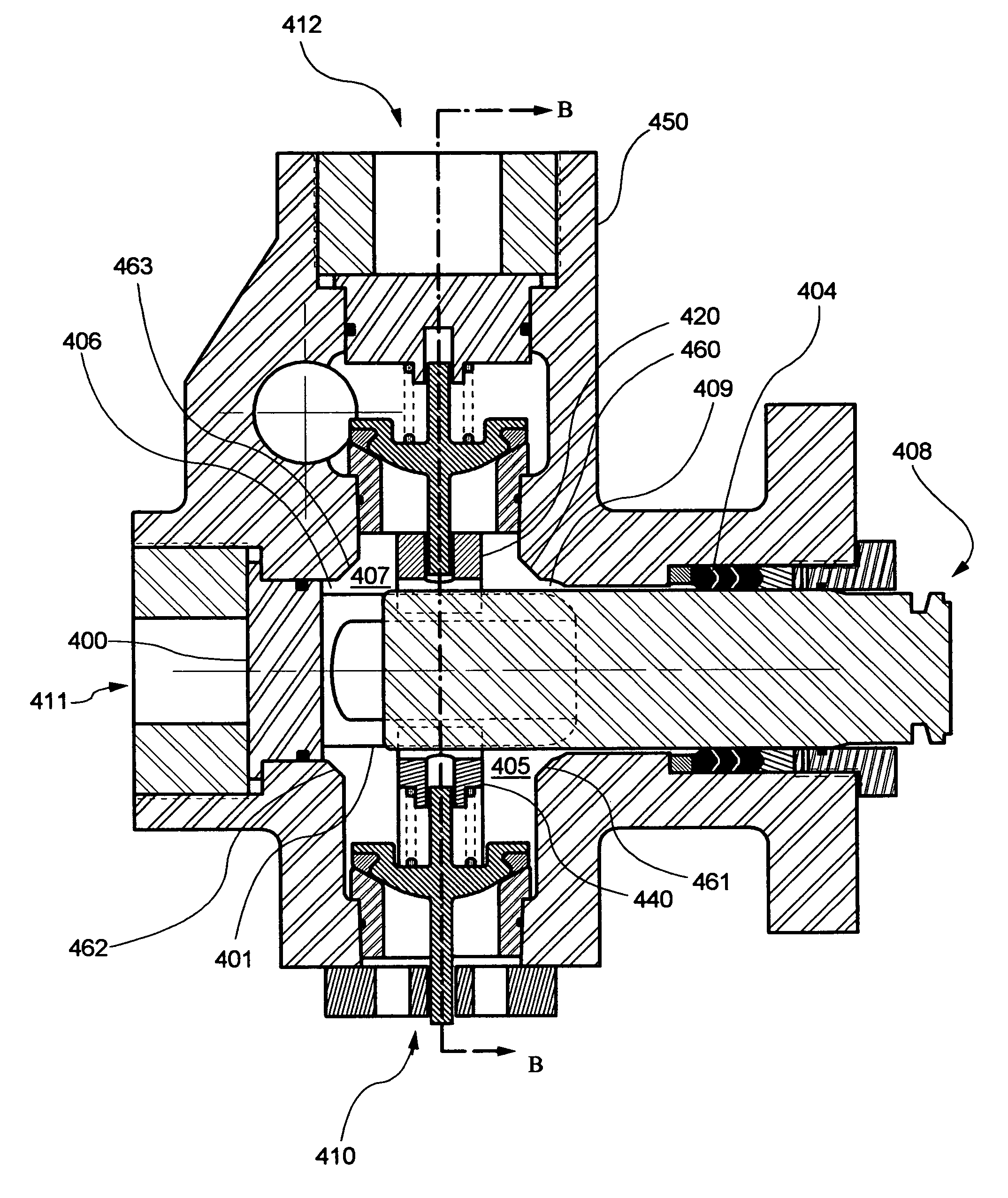

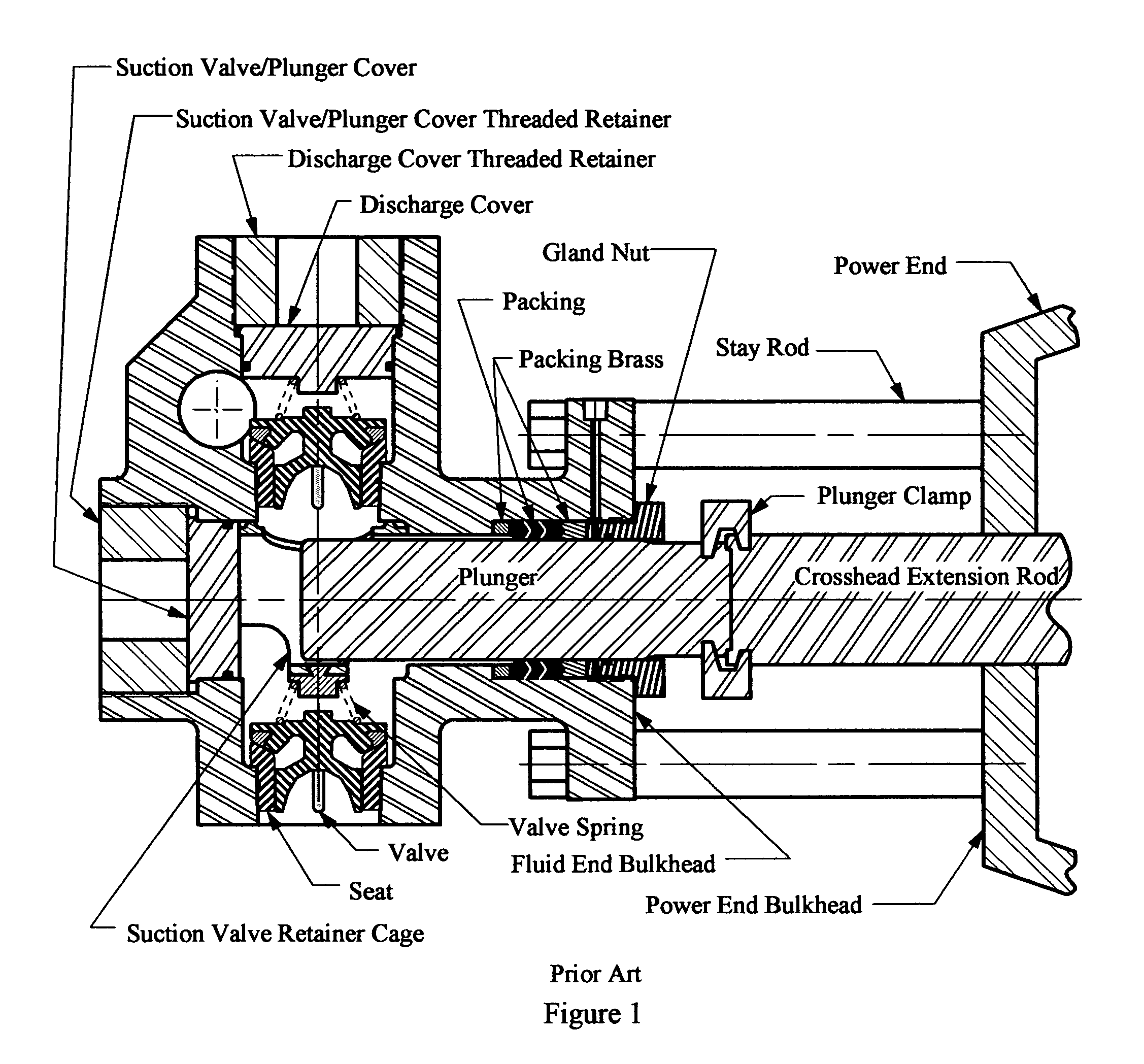

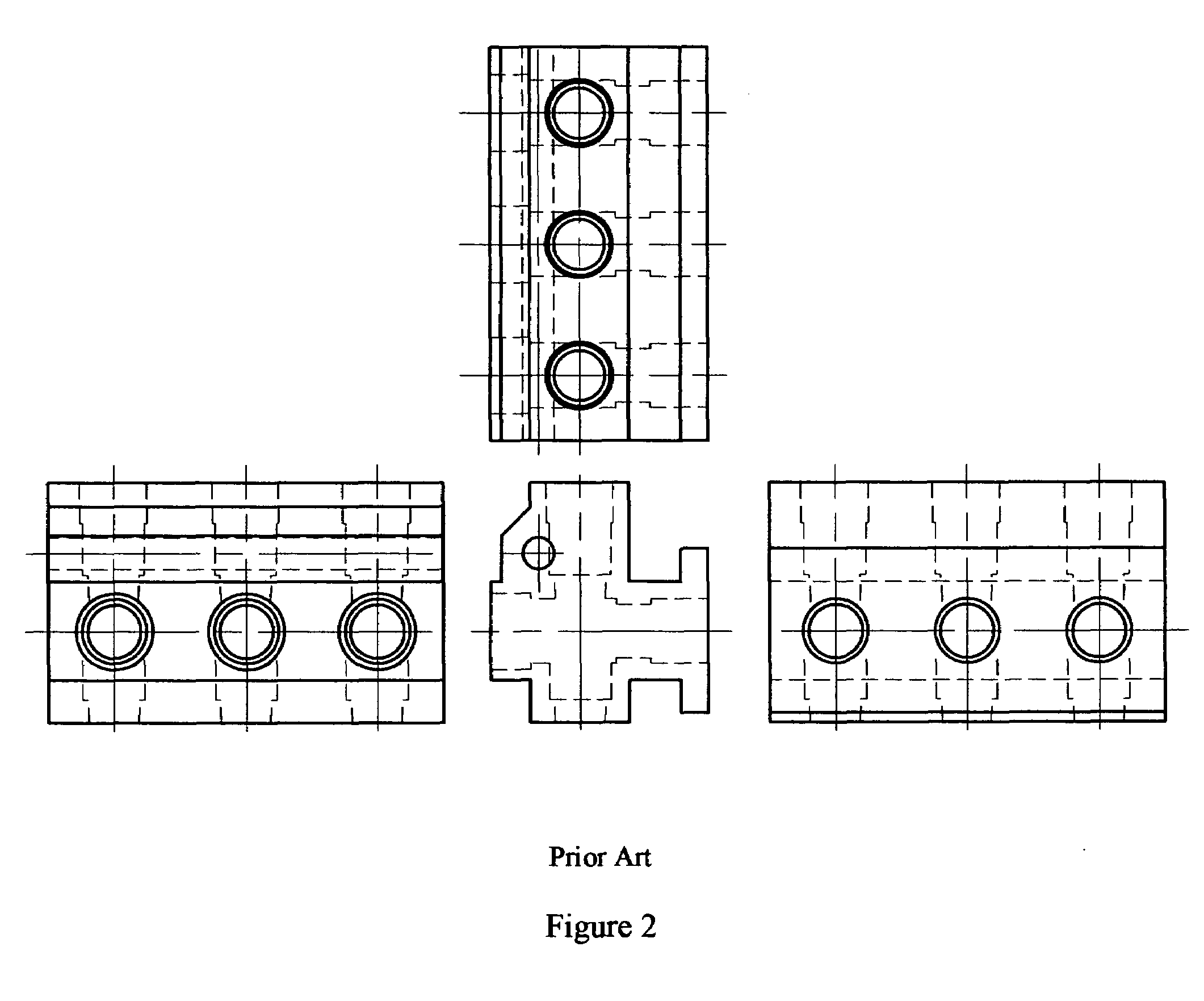

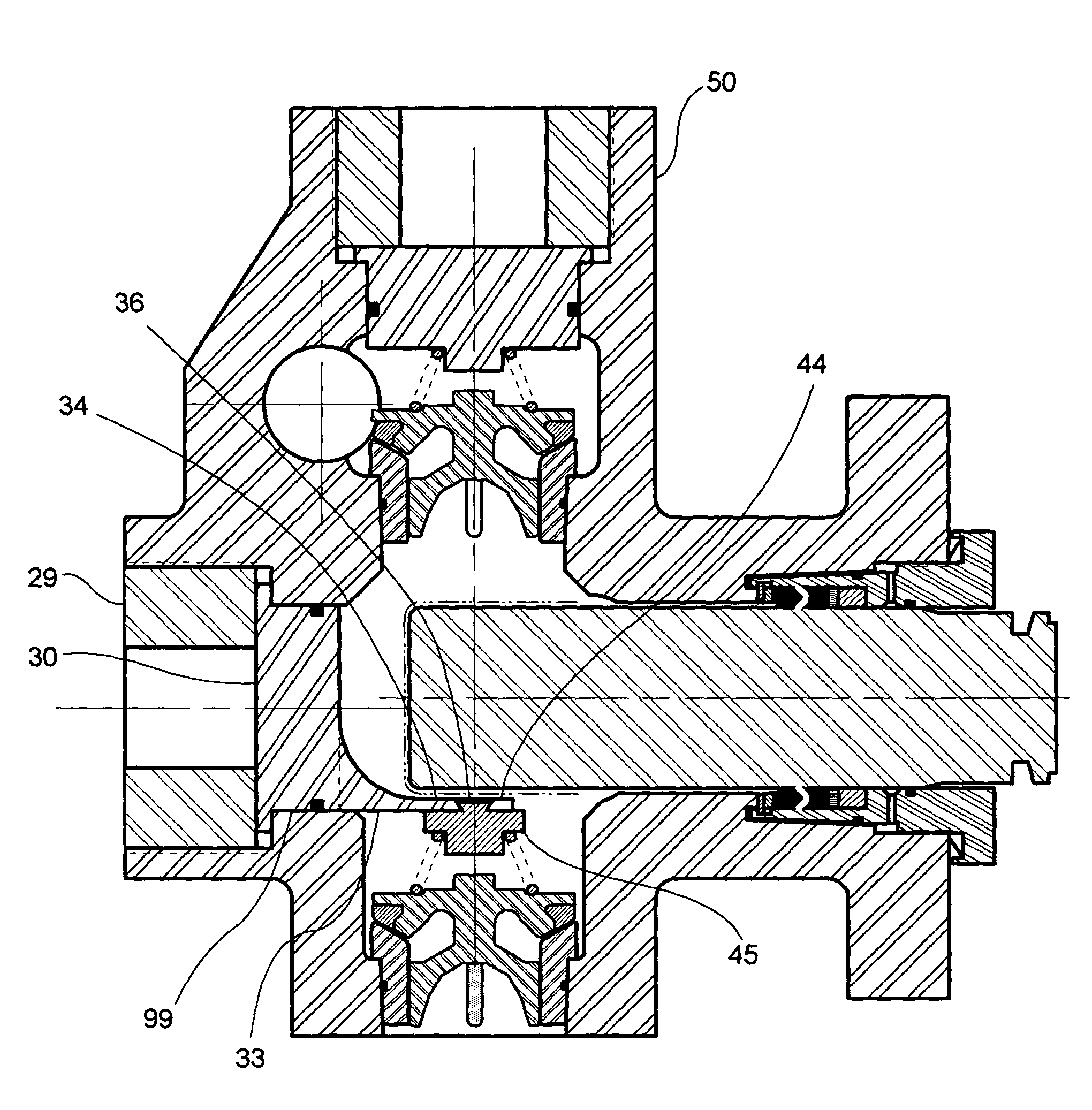

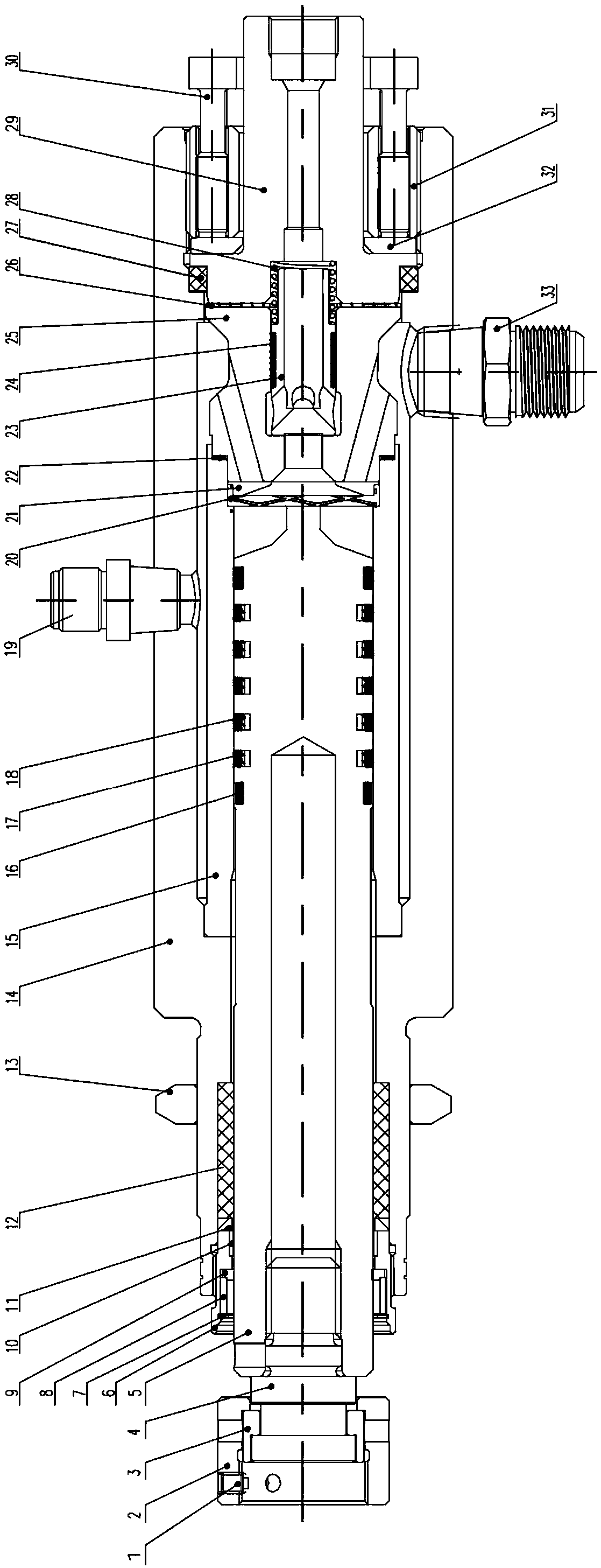

Valve guide and spring retainer assemblies

InactiveUS6910871B1Improve volumetric efficiencyEasy to insertPositive displacement pump componentsCheck valvesStress reliefEngineering

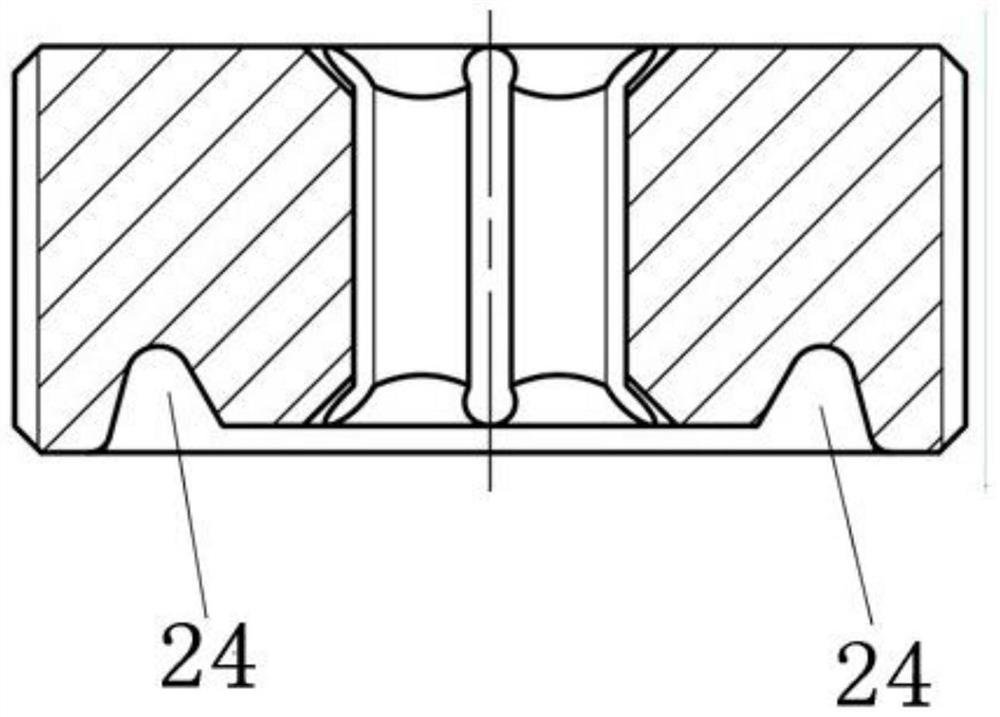

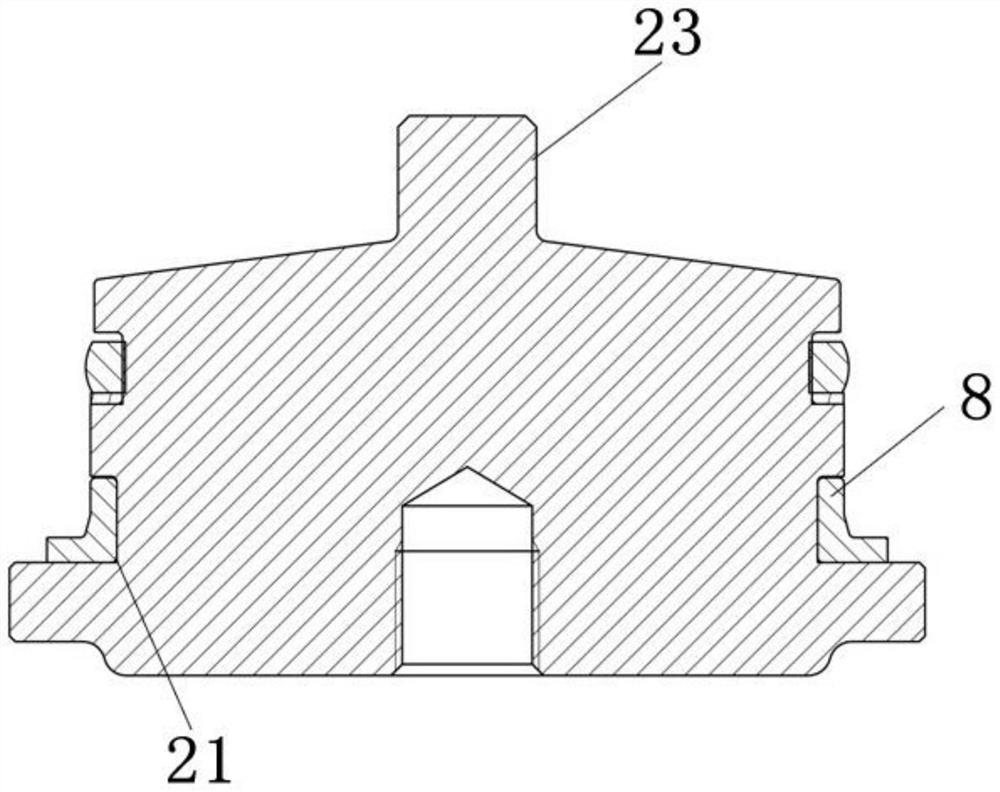

Valve guide and spring retainer assemblies are described for use in plunger pump housings that incorporate structural features for stress-relief. These pump housing structural features accommodate correspondingly-shaped valve guides and / or spring retainers that are internally fixed in place using one or more non-threaded spacers. Plunger pumps so constructed are relatively resistant to fatigue failure because of stress reductions, and they may incorporate a variety of valve styles, including top and lower stem-guided valves and crow-foot-guided valves, in easily-maintained configurations. Besides securing valve guides and / or spring retainers, non-threaded spacers may be shaped and dimensioned to aid in further reducing stress and to improve volumetric efficiency of the pumps in which they are used.

Owner:ALTIS INVESTMENTS LLC

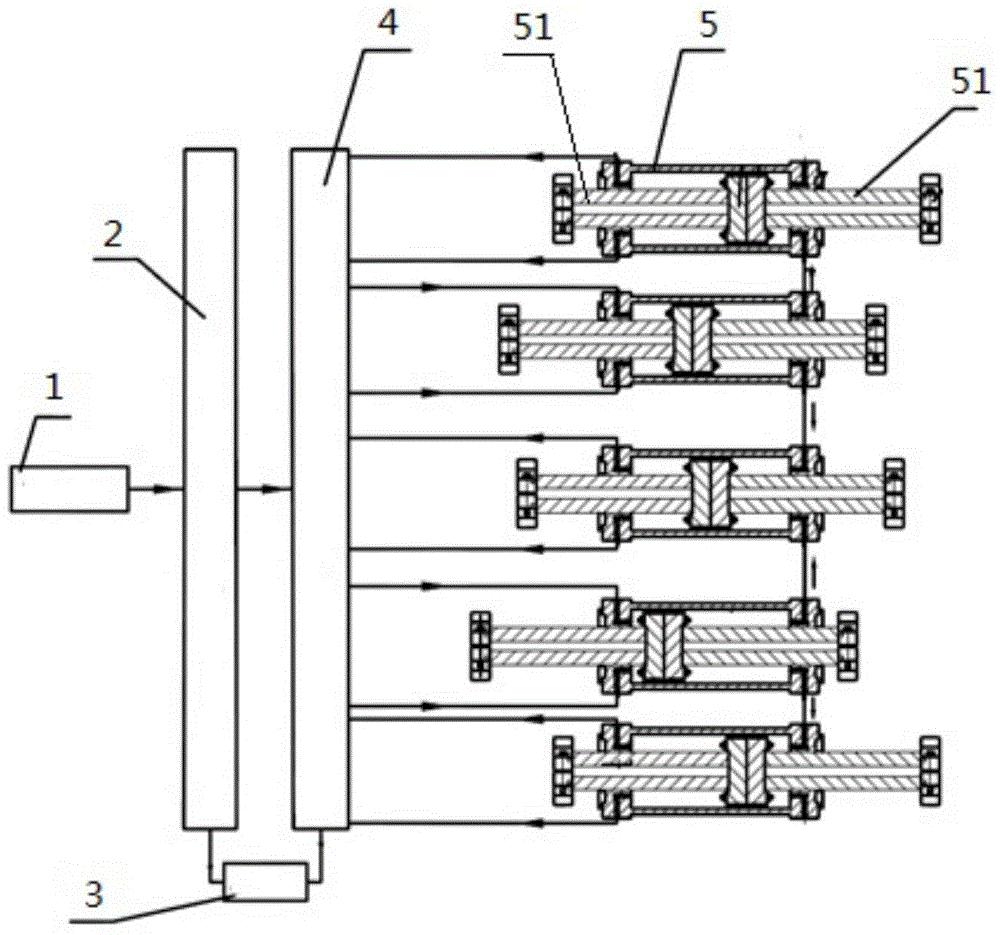

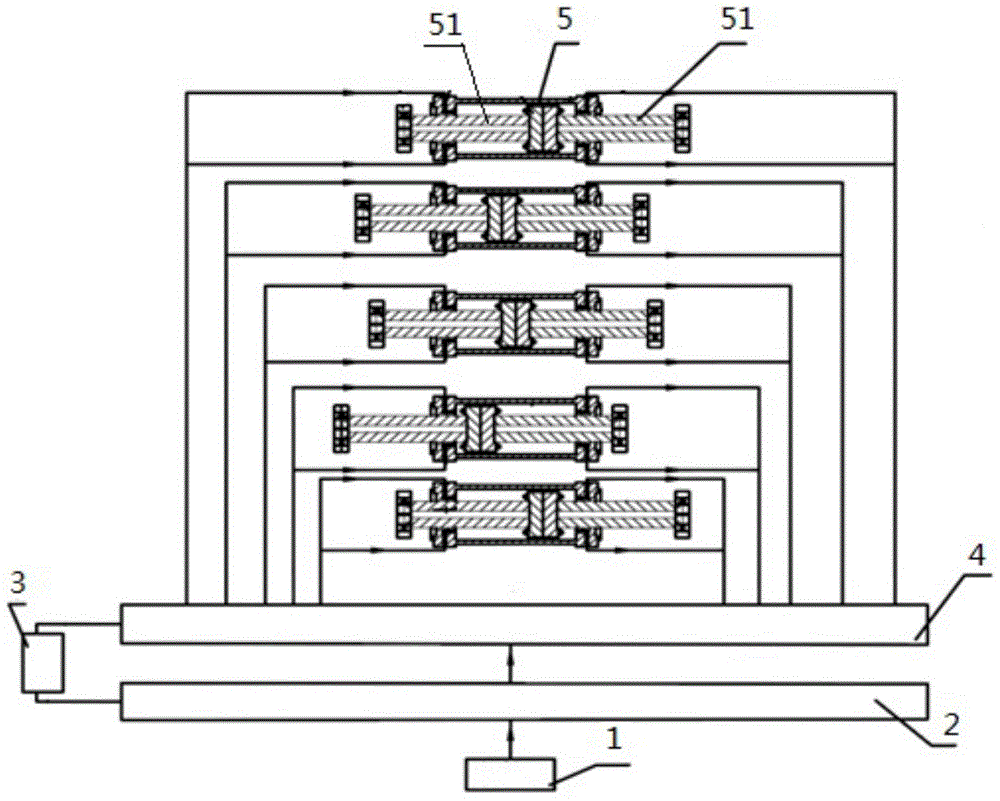

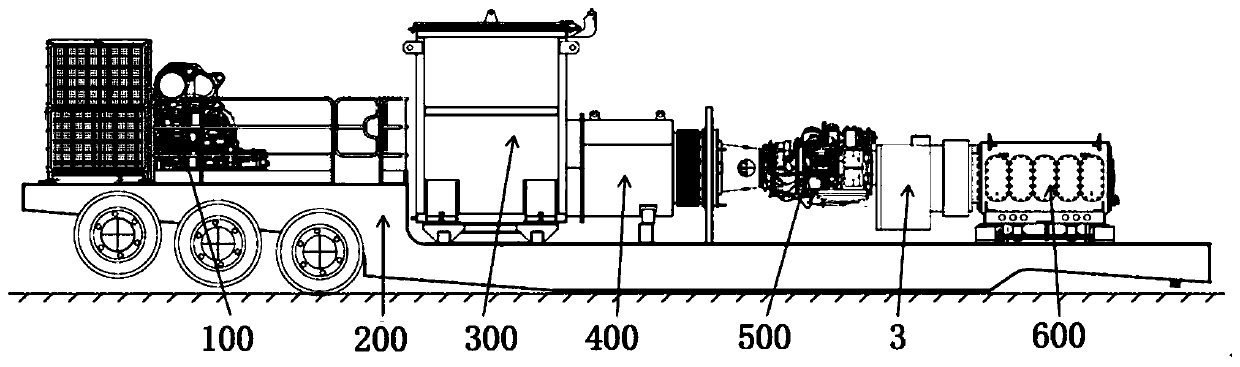

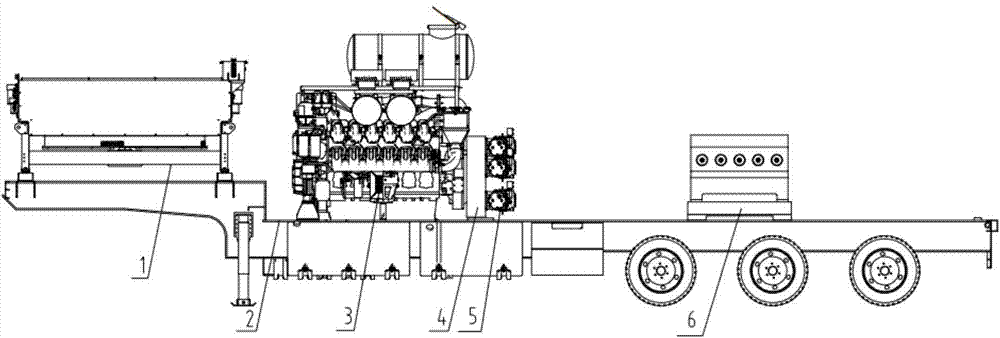

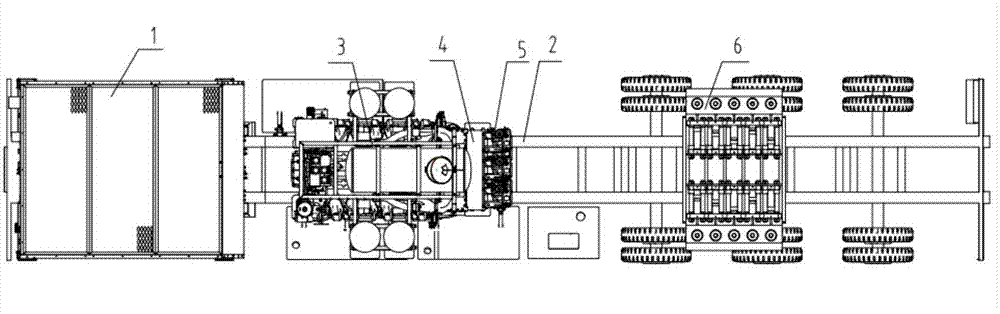

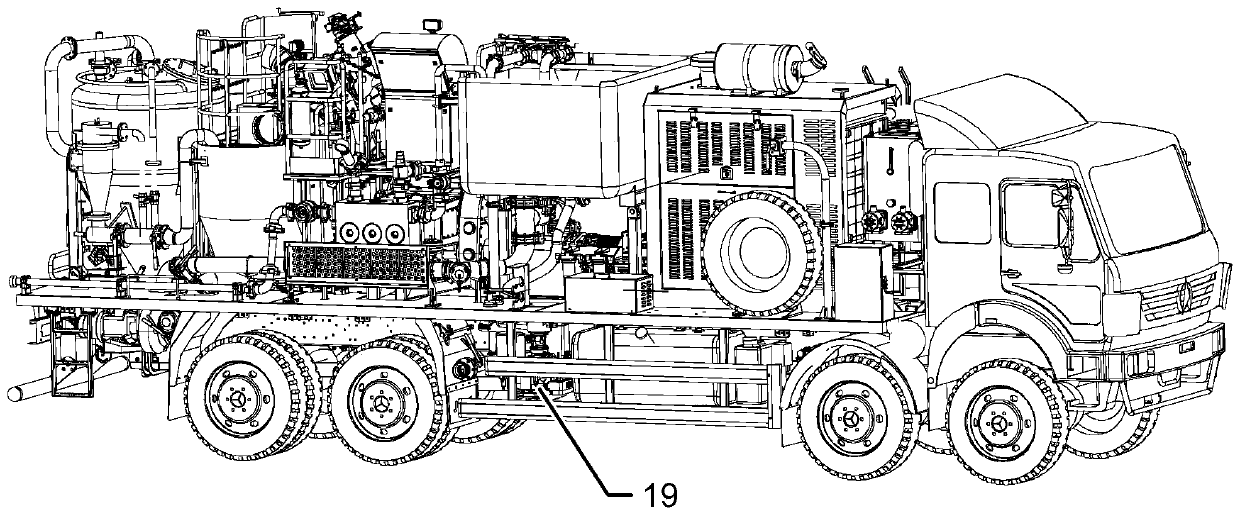

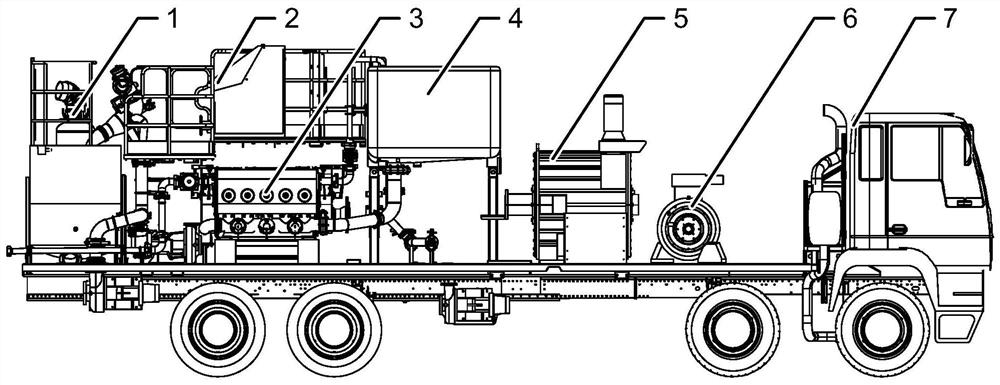

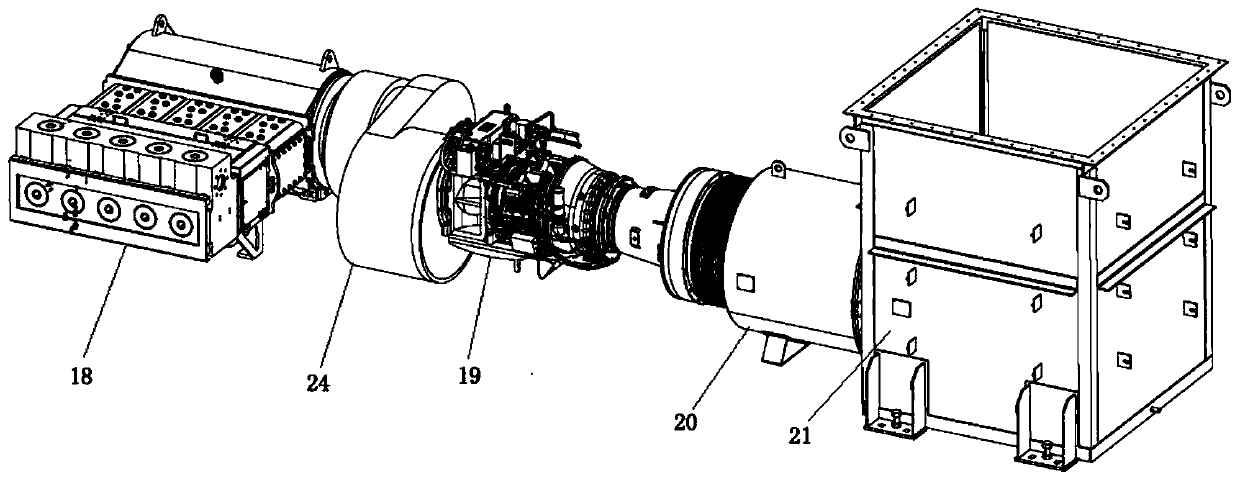

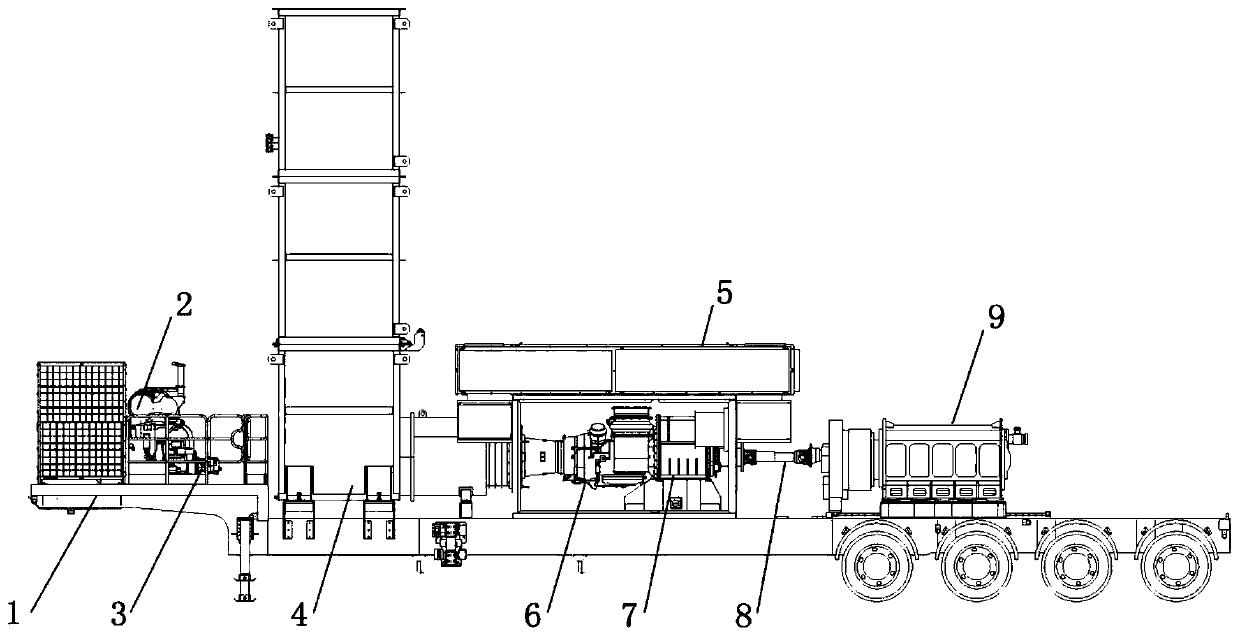

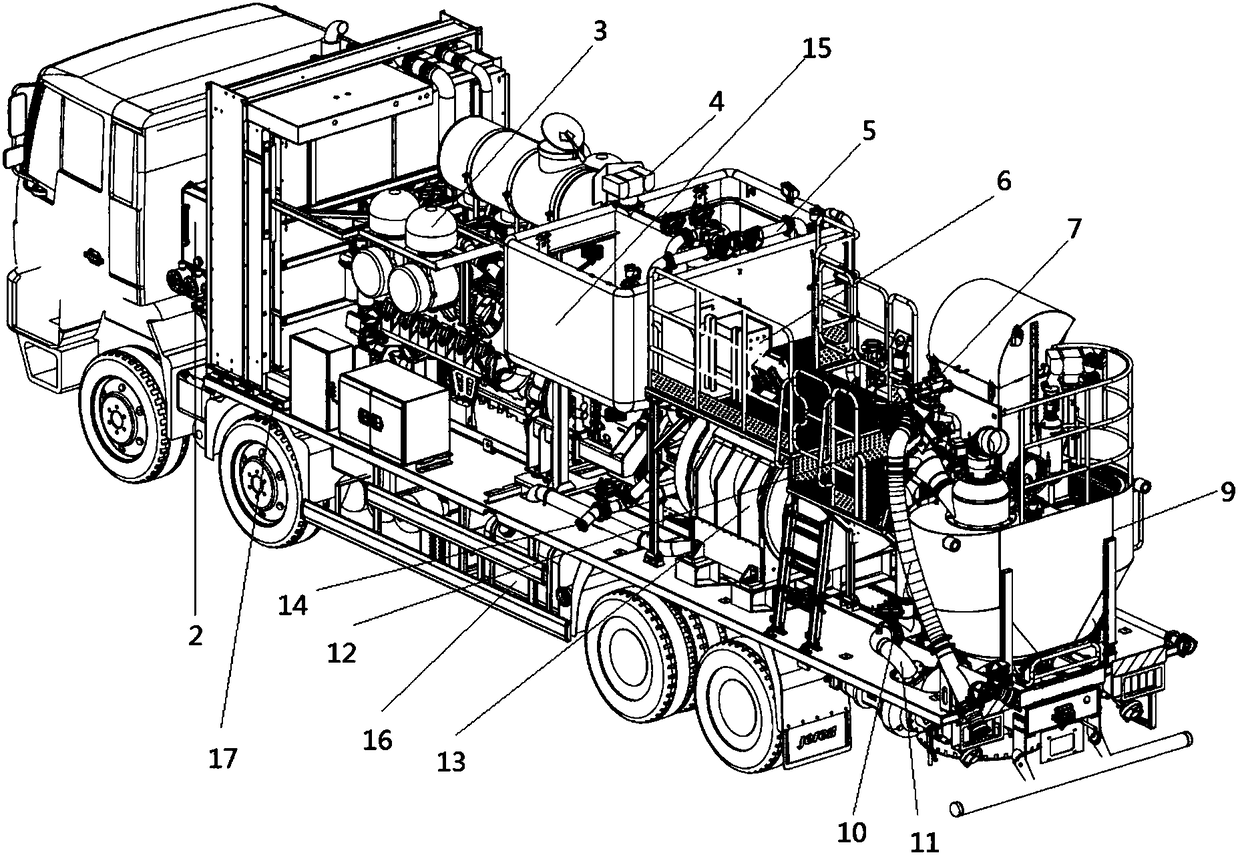

Turbine fracturing semitrailer

PendingCN110485983AReduce volumeReduce weightEngine manufactureEngine fuctionsTransmission lossFailure risk

The invention discloses a turbine fracturing semitrailer. The turbine fracturing semitrailer comprises a semitrailer body, a turbine engine, a reduction gearbox, a transmission mechanism and a plungerpump; the turbine engine, the reduction gearbox, the transmission mechanism and the plunger pump are arranged on the semitrailer body, the output end of the turbine engine is connected with the reduction gearbox, and the reduction gearbox is connected with the plunger pump through the transmission mechanism in a transmission mode. The turbine fracturing semitrailer has the beneficial effects thatthrough linear connection of the turbine engine, the reduction gearbox, the transmission mechanism and the plunger pump in the power-transmission direction, excessive transmission loss can be avoided, and efficient transmission performance is guaranteed; and the whole semitrailer is small in size, light in weight, low in the use cost, and low in failure risks.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

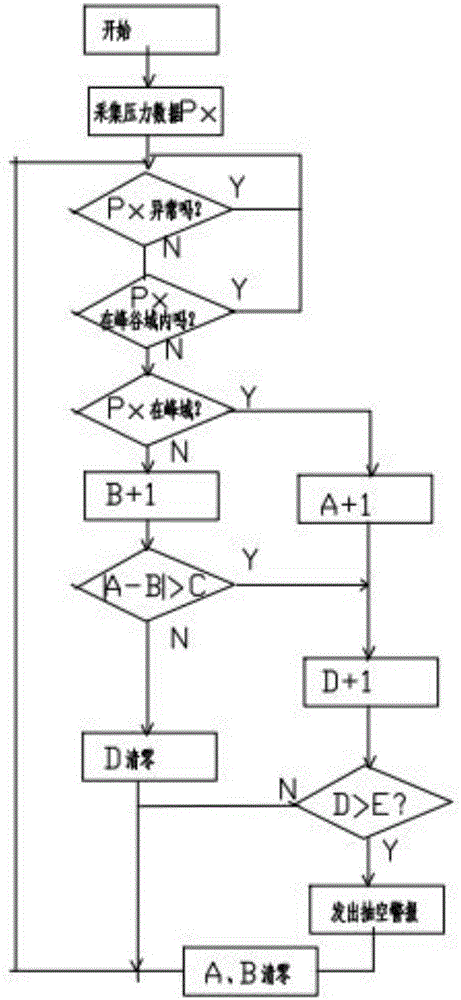

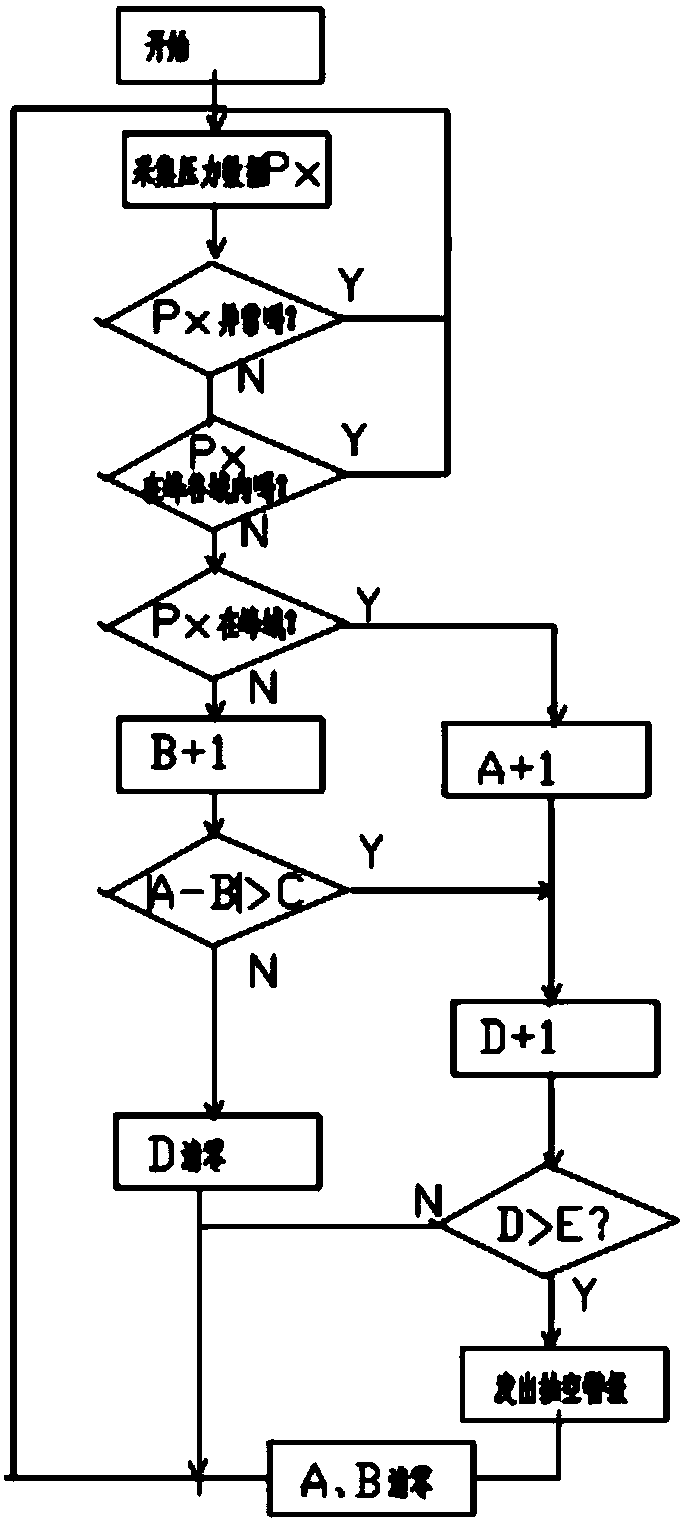

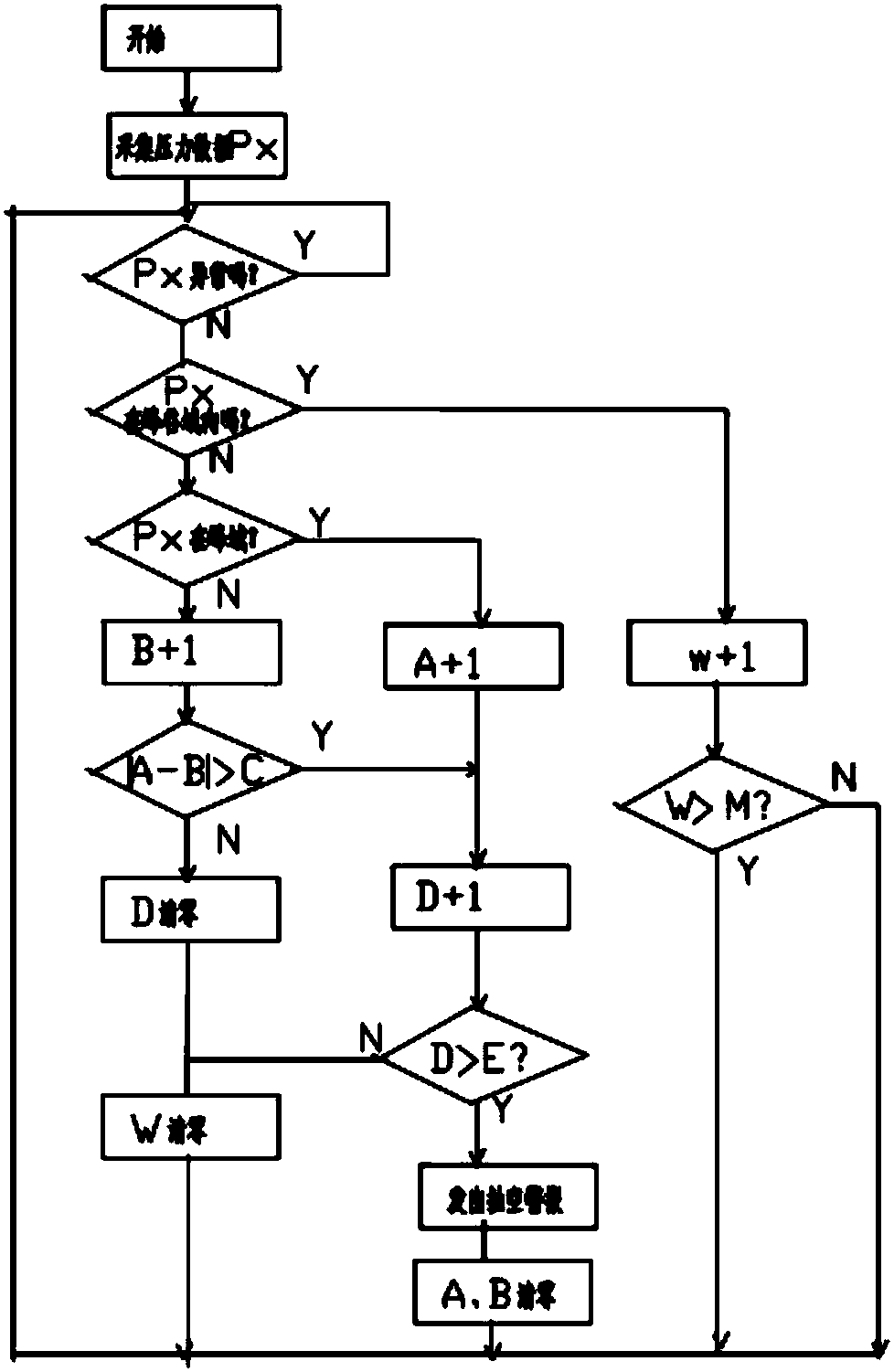

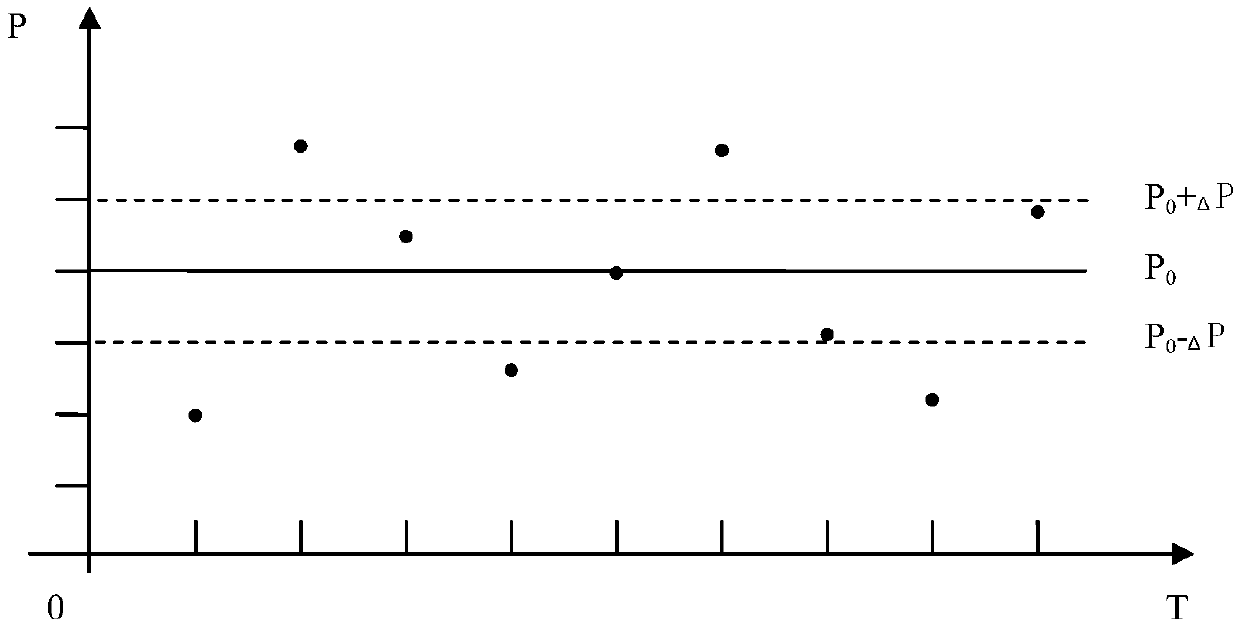

Method for preventing evacuation of plunger pump based on monitoring of output pressure

ActiveCN106438310AImprove protectionThe detection method is accuratePump testingPump controlData acquisitionEngineering

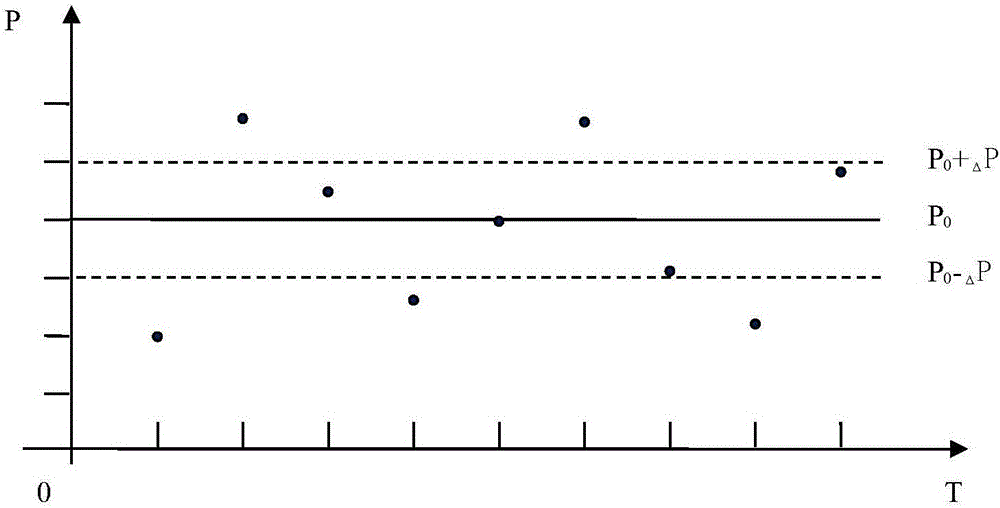

The invention relates to the technical field of monitoring of plunger pumps, in particular to a method for preventing evacuation of a plunger pump based on monitoring of the output pressure. The method relates to the plunger and an output pipeline, and is characterized in that a pressure data acquisition control device is arranged on the outlet pipeline; and a data processing method comprises the following steps that (1) the average value P0 of the output pressure is obtained, specifically, the output pressure setting tolerance delta P is set, the domain above a P0+delta P line is called a peak domain, and the domain below a P0-delta P line is called a valley domain; a peak domain counter A and a valley domain counter B are set correspondingly; the allowable difference value between the peak domain counter A and the valley domain counter B is the numerical value C; and an out-of-tolerance time counter D and an upper limit E are set; (2) pressure data Px is acquired; (3) abnormal data are removed; (4) the number of times of Px falling into the peak domain and the valley domain is calculated; and (5) whether the out-of-tolerance time D of the difference value between the peak domain counter A and the valley domain counter B exceeds a preset value E or not is judged, and if yes, an evacuation alarm is given out. Compared with a detection method in the prior art, the method is accurate and reliable, and false alarms are avoided.

Owner:JEREH OIL & GAS ENG

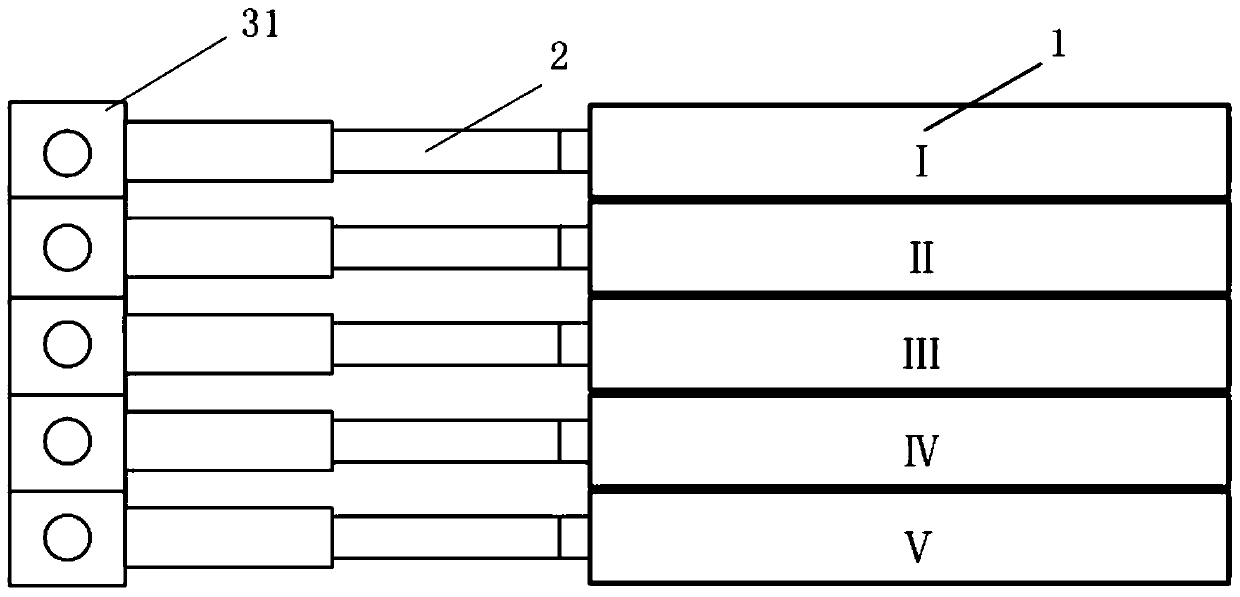

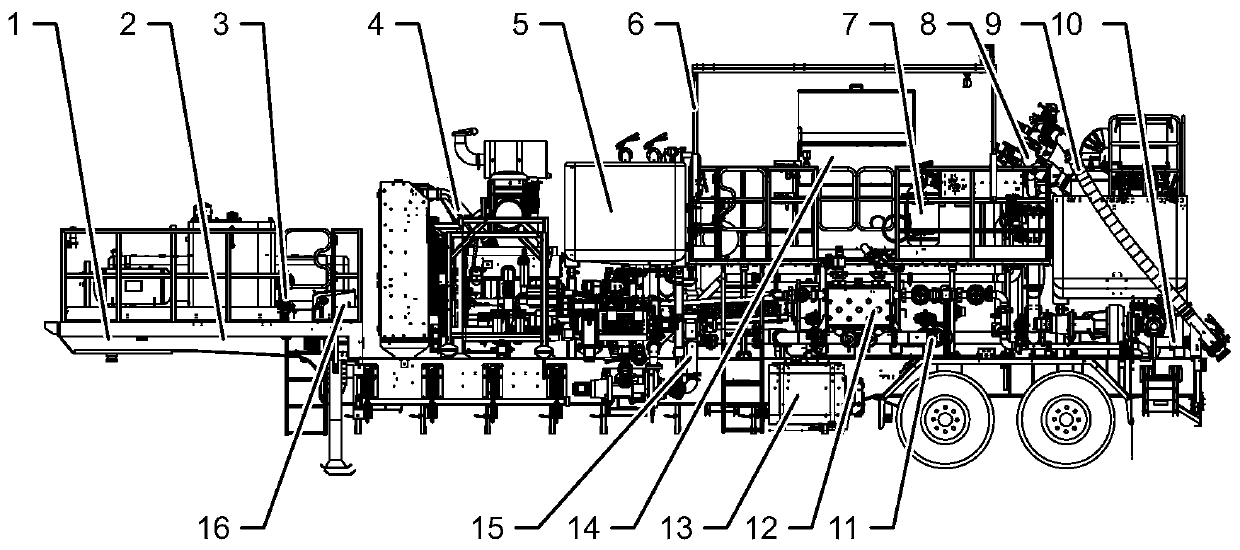

Novel ultra-large-displacement ultrahigh-pressure well cementing equipment

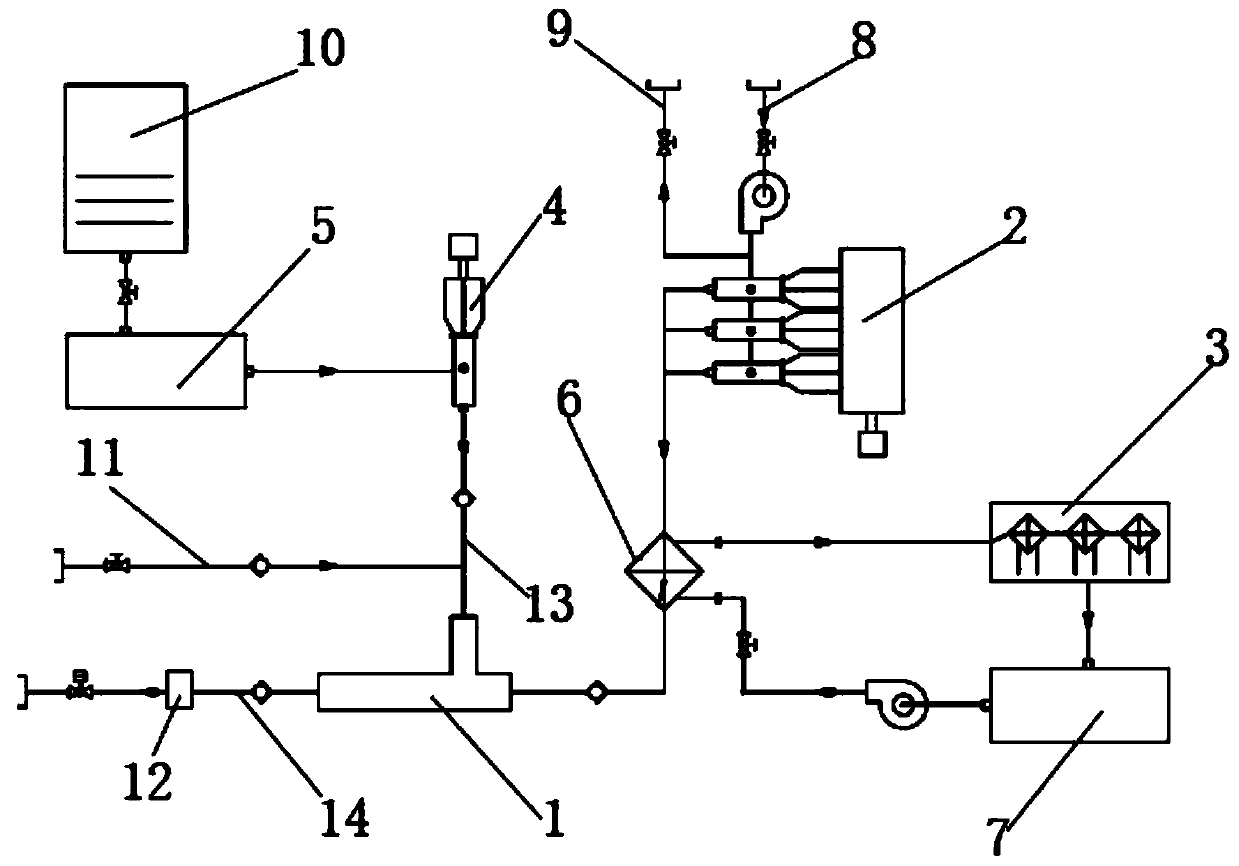

PendingCN111173476AIncrease pressureIncrease displacementItem transportation vehiclesSealing/packingUltra high pressureDrivetrain

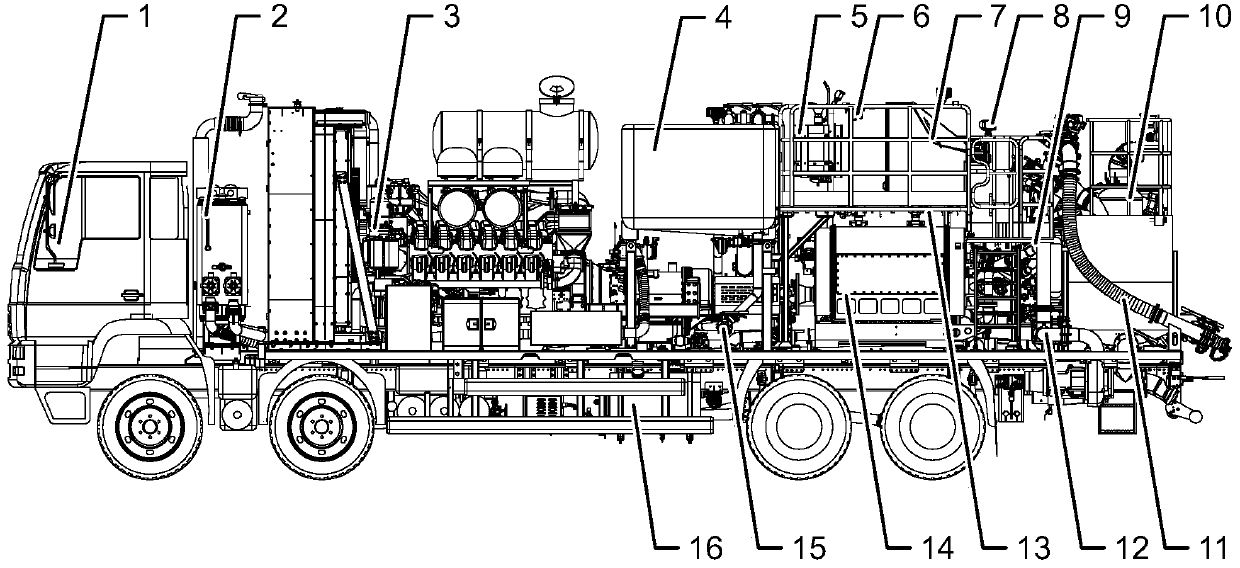

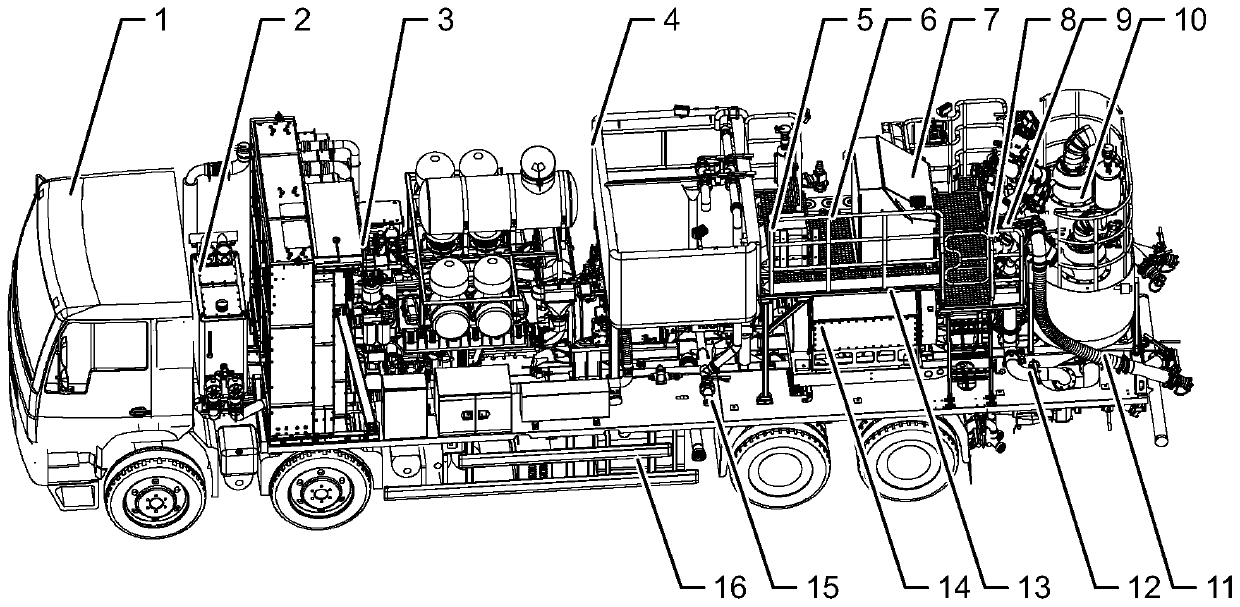

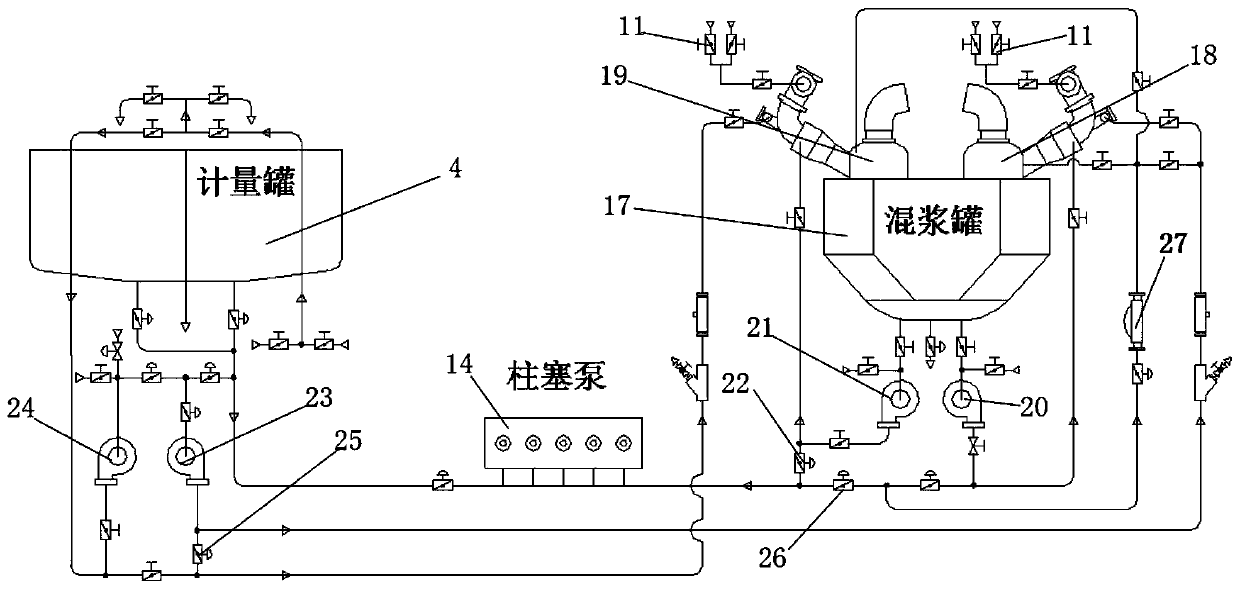

The invention discloses novel ultra-large-displacement ultrahigh-pressure well cementing equipment. The novel ultra-large-displacement ultrahigh-pressure well cementing equipment comprises a loading carrier. A hydraulic system, a power transmission system, a metering tank, an electrical system, an air path system, a control system, an operating platform, a plunger pump, a clean water manifold, a mud manifold, a high-pressure manifold, a mixing system and an ash feeding manifold are mounted on the loading carrier, wherein the plunger pump is a five-cylinder plunger pump. The five-cylinder plunger pump is adopted to increase the pressure and displacement of the well cementing equipment, and the requirements of high pressure and large displacement are met; slurry mixing is carried out by double mixing devices, the mixing efficiency is improved, the stability of the slurry mixing density is improved, and the requirement of long-time uninterrupted operation is guaranteed; a mixing system pipeline is optimized, multiple sets of mixing systems are integrated on one slurry mixing tank, and the stability of the equipment is improved; and the clean water manifold is optimized, so that watersupply requirements of the multiple mixing devices can also be met at the same time by using one injection pump, and the requirement of large displacement is met.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

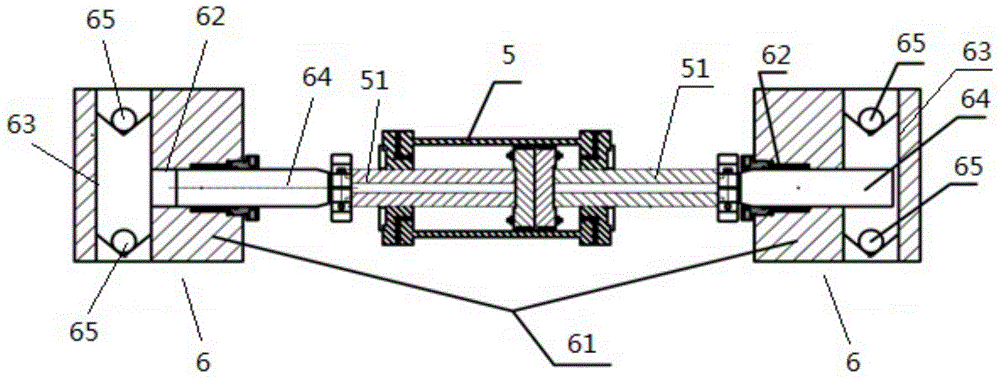

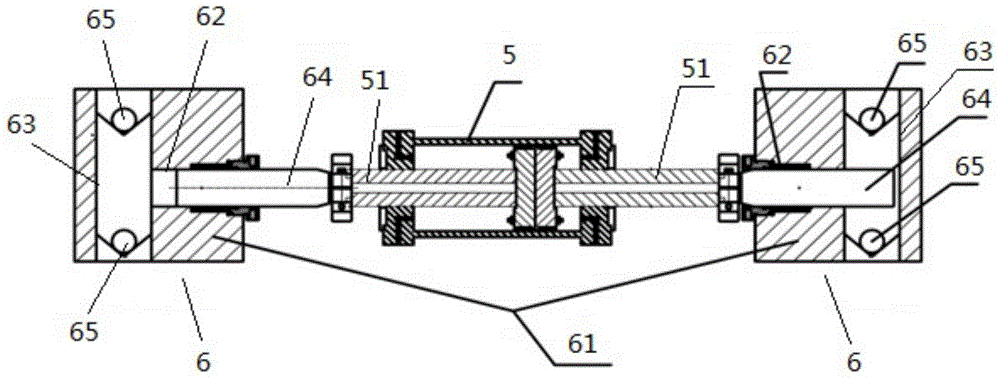

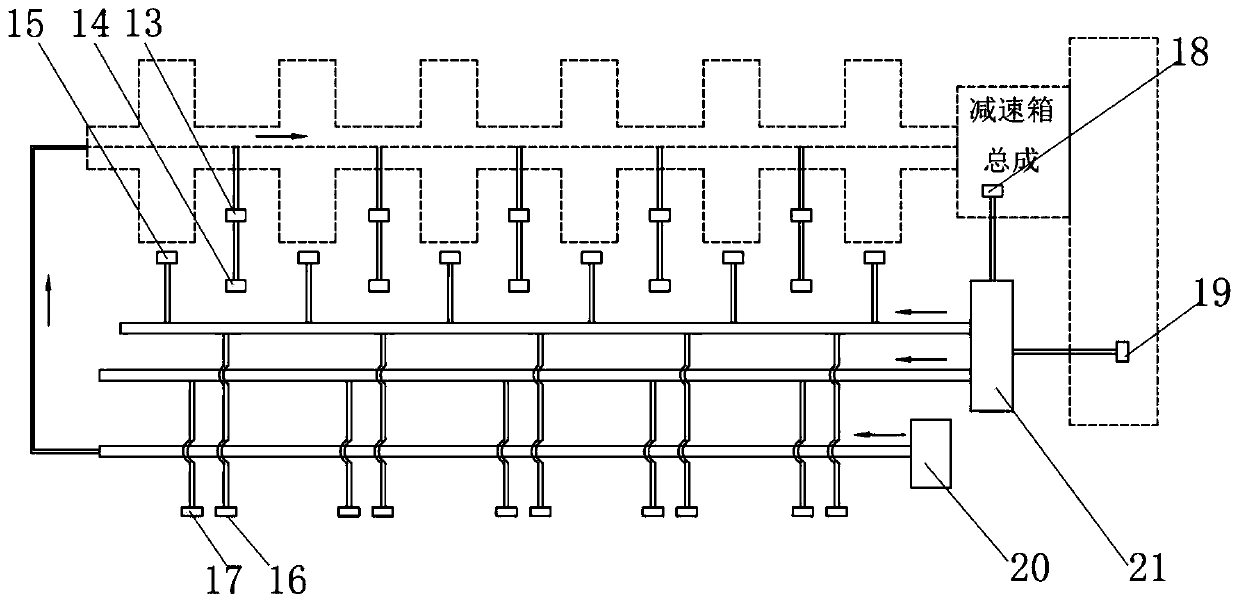

Hydraulic bidirectional pumping device

ActiveCN104612928AExtended service lifeImprove suction efficiencyPiston pumpsPositive-displacement liquid enginesHydraulic cylinderMotor drive

The invention relates to a hydraulic bidirectional pumping device which comprises a prime motor, a hydraulic oil pump, a hydraulic oil tank, a control valve, a double-action hydraulic cylinder and plunger pumps. The prime motor drives the hydraulic oil pump. The hydraulic bidirectional pumping device utilizes the double-action hydraulic cylinder to drive the plunger pumps on both sides; the cylinder number is increased; stroke times are reduced; the service lives of easily damaged parts are prolonged; the coverage range of flow is effectively enlarged; suction efficiency of fracturing fluid is effectively improved; complexity of the integral structure is reduced; cost of manufacturing, maintenance and the like is reduced; the requirements on a lubricating system are lowered; the double-action hydraulic cylinder reciprocates to do work, so that working efficiency is improved.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

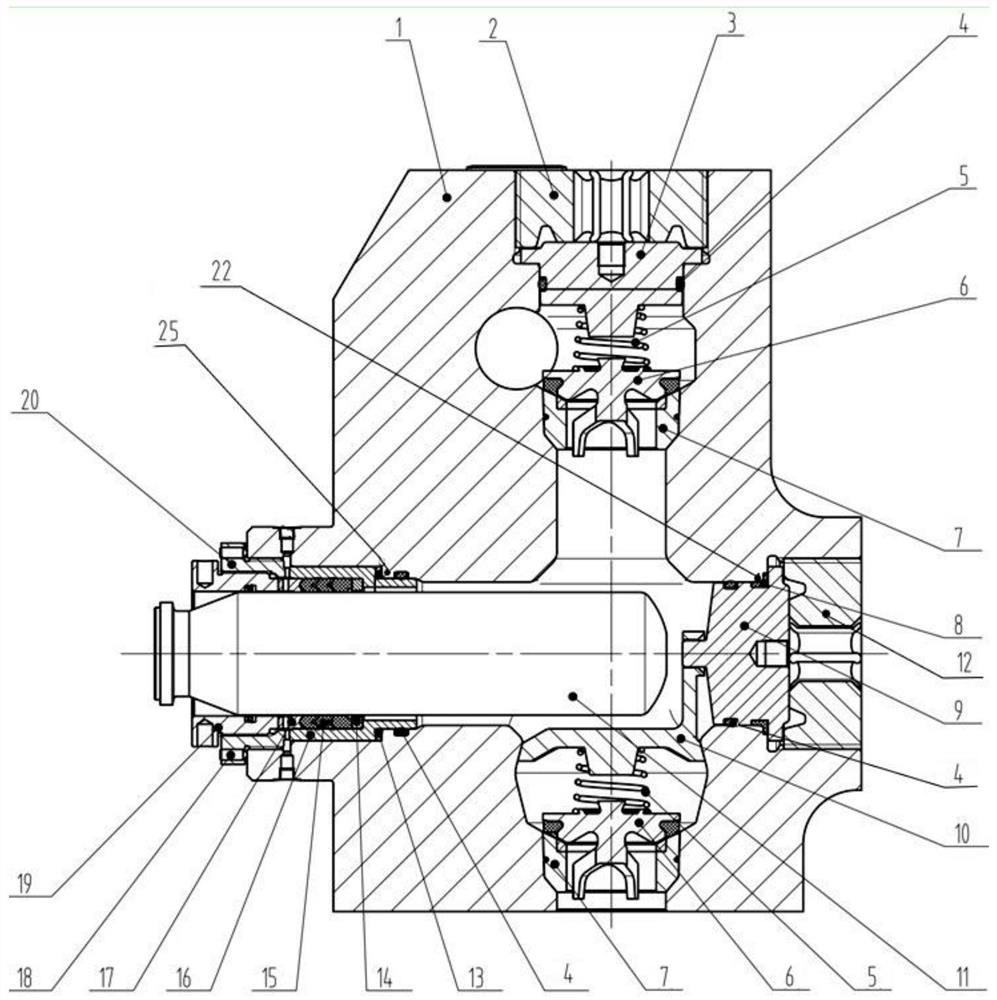

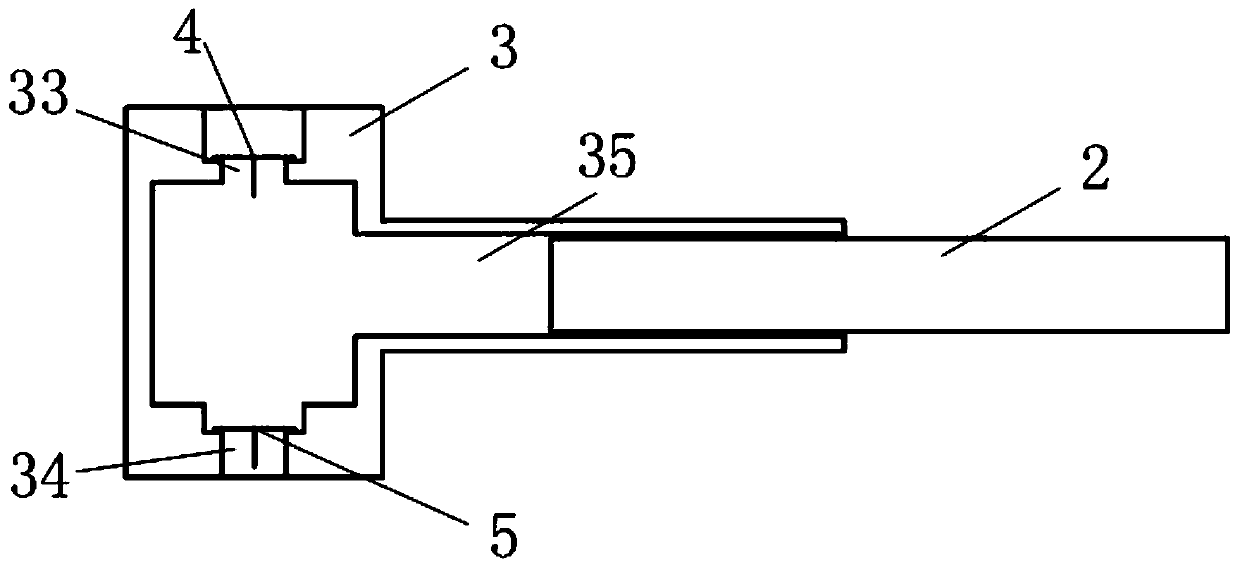

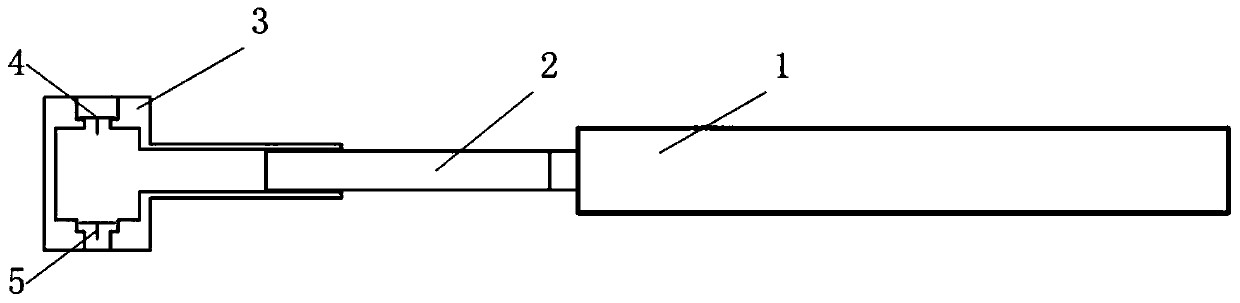

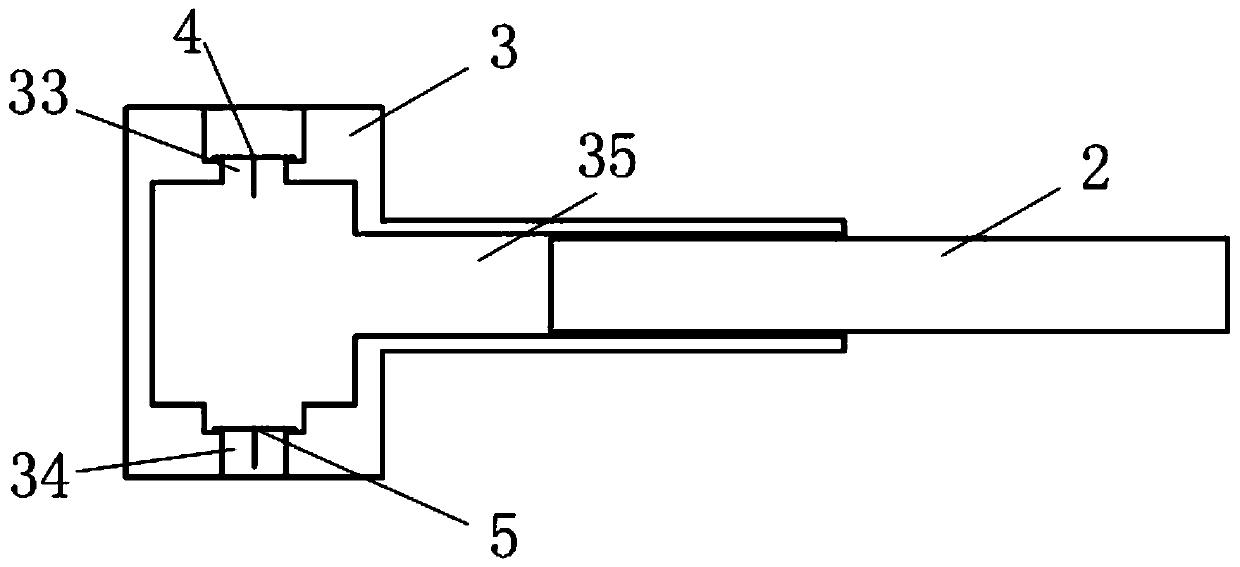

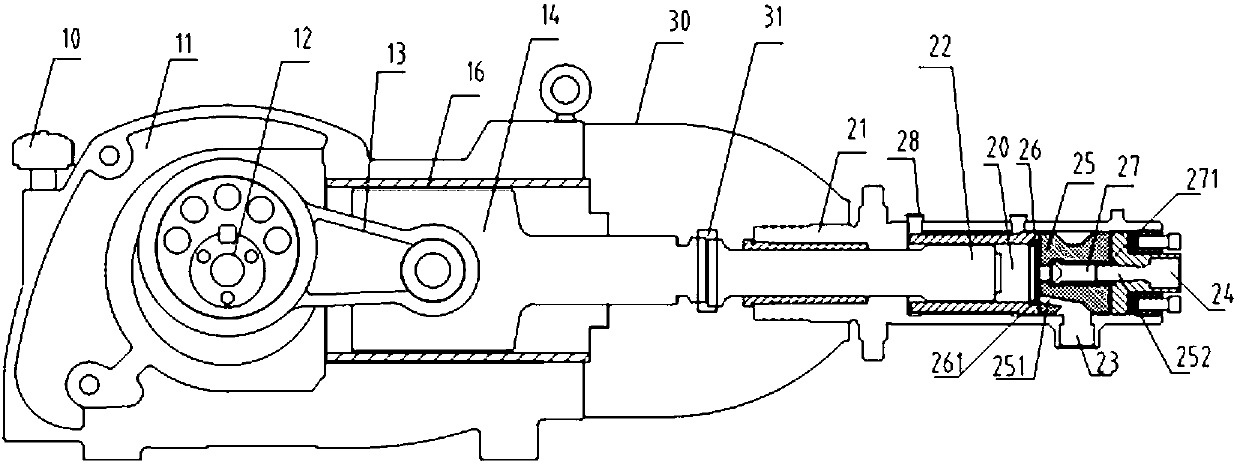

Plunger pump hydraulic end with long service life

PendingCN111692064AExtended service lifeReduced reversibilityPositive displacement pump componentsFluid removalStructural engineeringMechanical engineering

The invention discloses a plunger pump hydraulic end with long service life. The plunger pump hydraulic end comprises a valve box, a plunger, and a packing assembly; the valve box serves as a container for liquid conveying; the plunger is connected to the valve box through the packing assembly; the packing assembly comprises a packing component, a packing sleeve, a packing pressing cap, and a packing sleeve pressing cap; the packing sleeve is connected to the valve box in a sealed manner; the packing component used for sealing fills between the packing sleeve and the plunger; the packing sleeve pressing cap is used for fixing the packing sleeve; and the packing pressing cap is used for fixing the packing component. The plunger pump hydraulic end with the long service life has the beneficial effects that the service lives of the valve box, a suction pressing cover, a suction pressing cap, and a discharging pressing cap are prolonged through optimization design of each of the plunger, the suction pressing cover, and the suction pressing cap, thereby prolonging the service life of the plunger pump hydraulic end.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

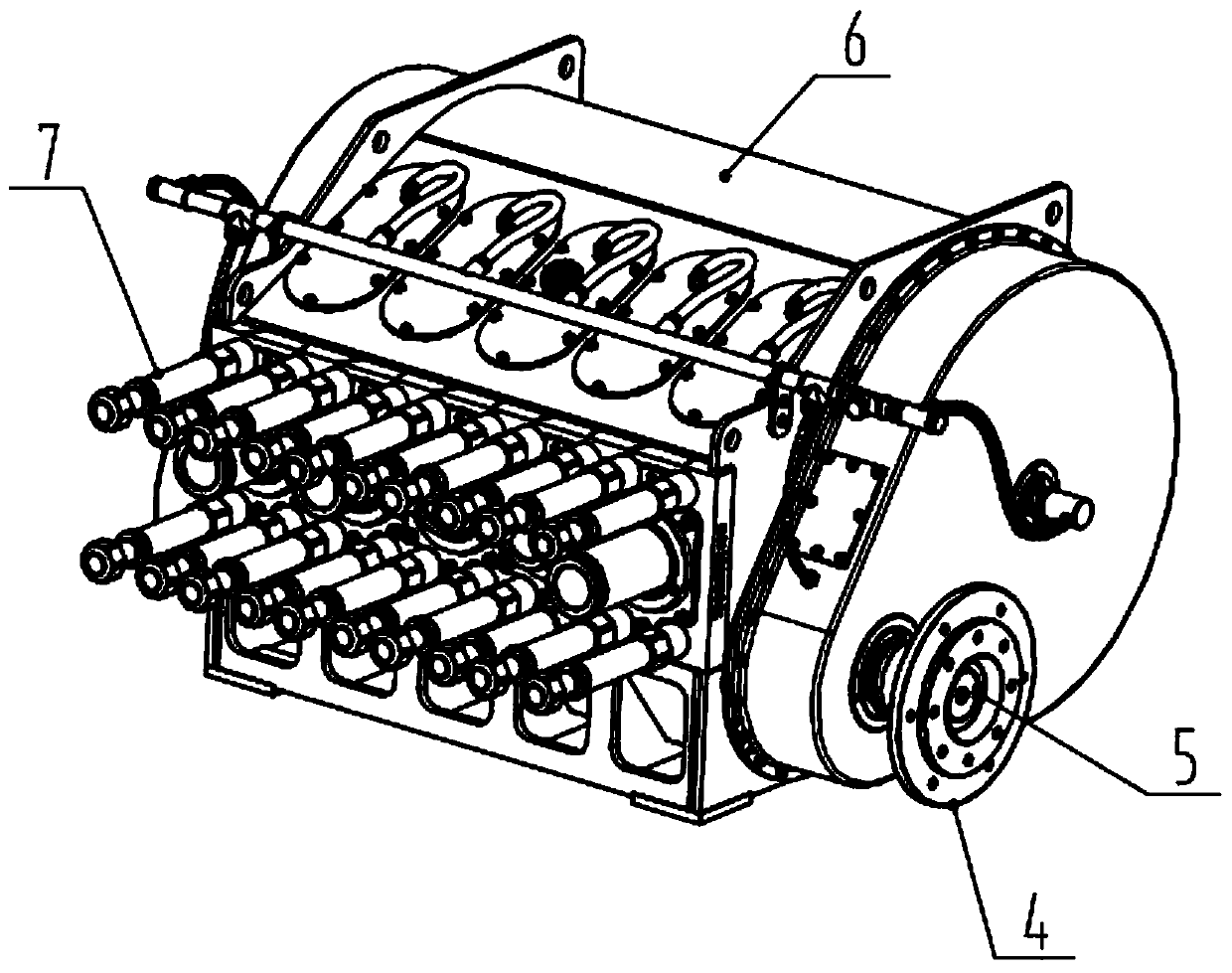

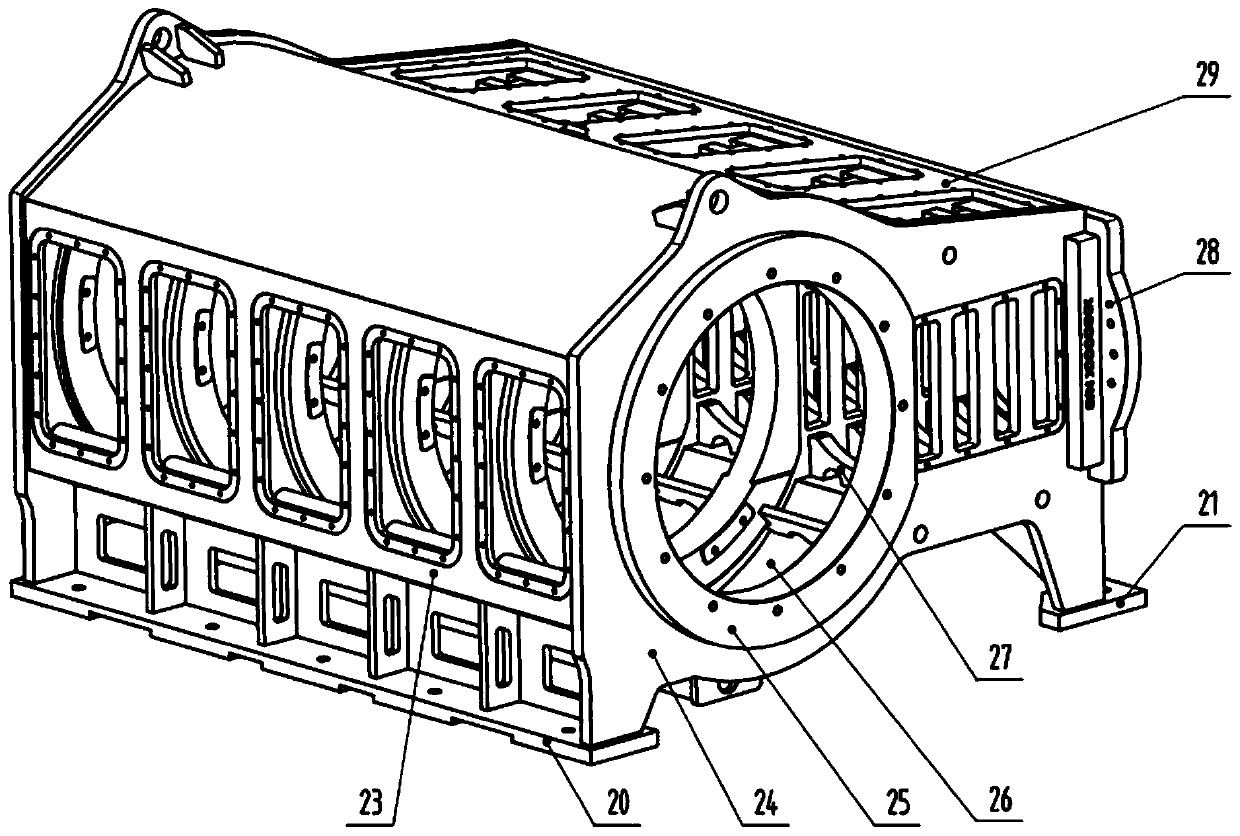

Light five-cylinder plunger pump

PendingCN111441925AIncreased stroke distanceIncrease rated input powerCrankshaftsPositive displacement pump componentsCrankGear wheel

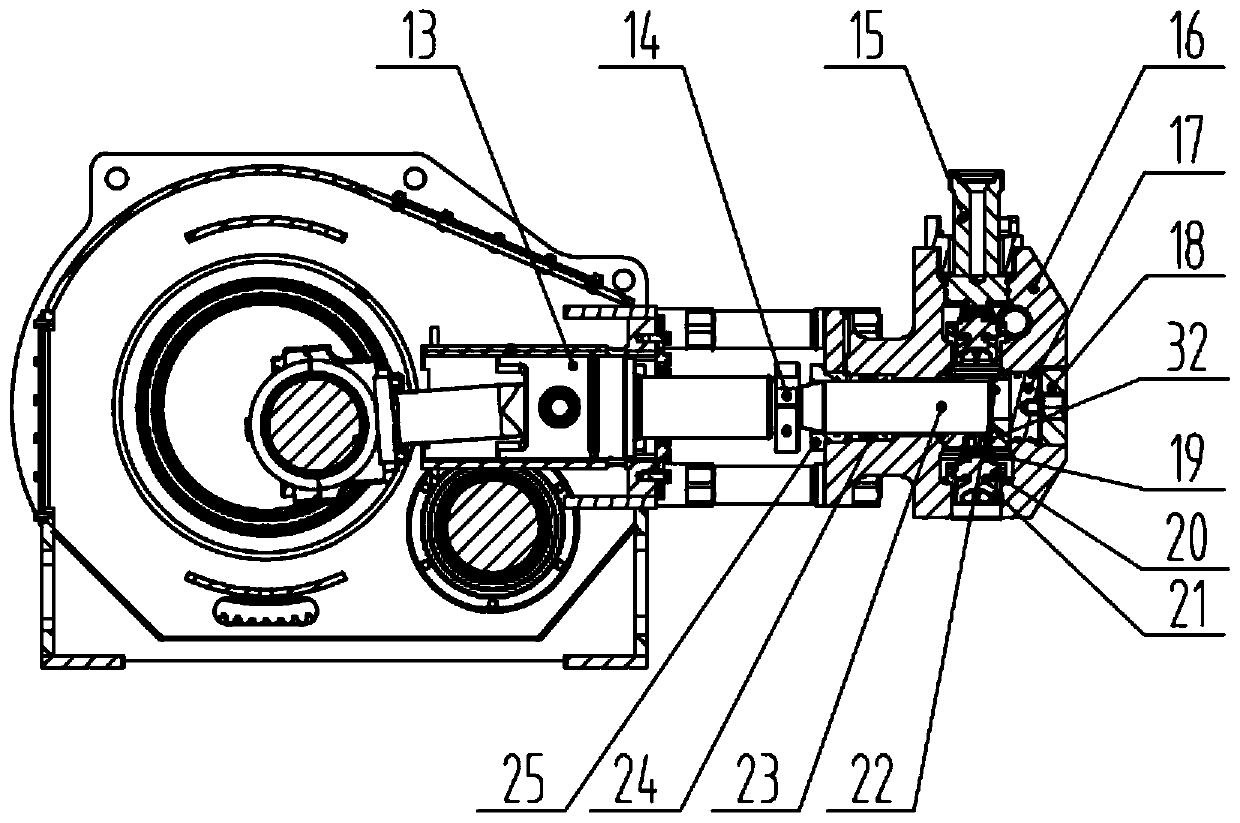

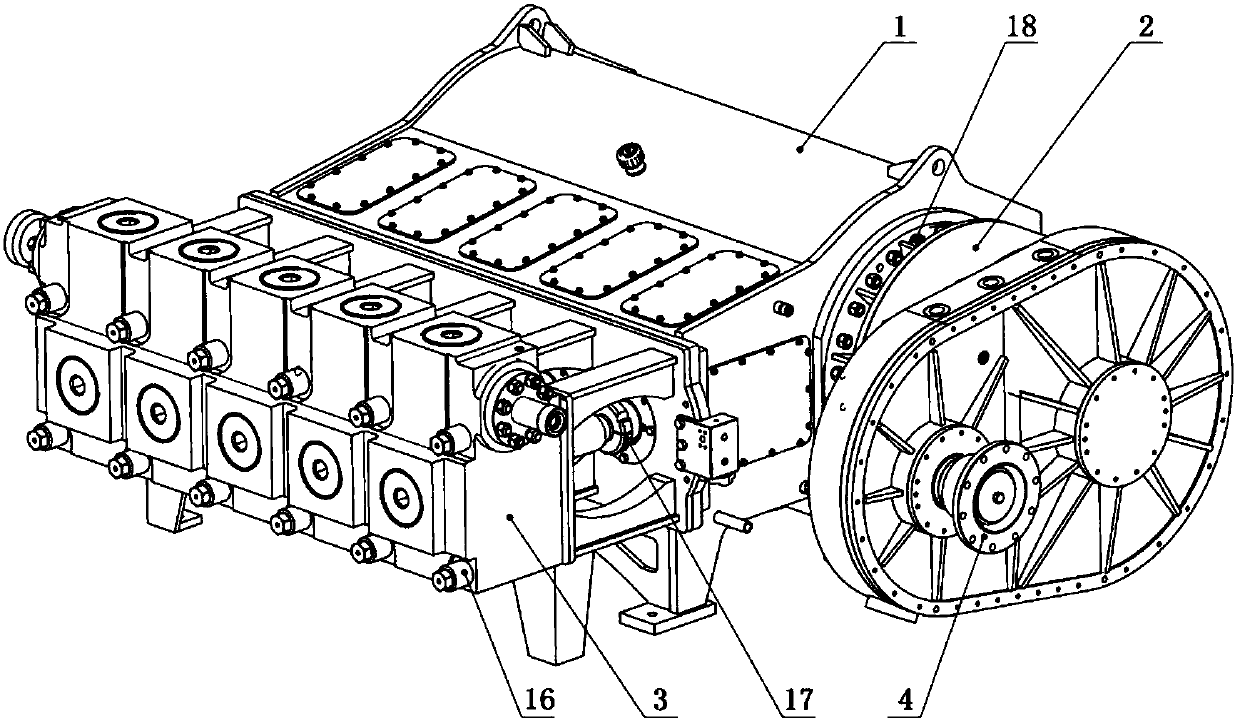

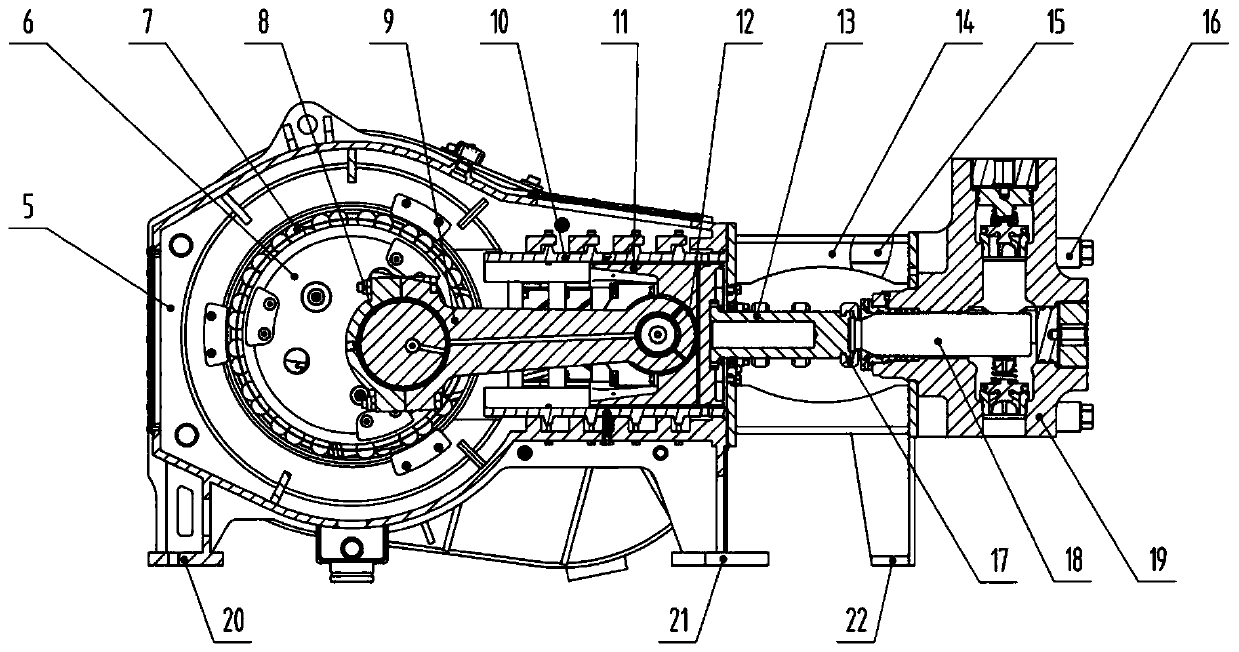

The invention discloses a light five-cylinder plunger pump. The light five-cylinder plunger pump comprises a power end assembly and a hydraulic end assembly, wherein the power end assembly is connected with the hydraulic end assembly; the cylinder spacing of the light five-cylinder plunger pump is 9in; the power end assembly comprises a crank shaft, the crank shaft comprises six crank necks and five crank throws, the crank necks and the crank throws are fixedly connected, the distance between rotating centers of the crank necks and the crank throws is 101.6 mm, and the stroke distance of the light five-cylinder plunger pump is 203.2 mm. According to the light five-cylinder plunger pump, power is increased by increasing stroke, reducing transmission ratio and improving bearing capacity, andmeanwhile, dead weight is reduced by reducing the cylinder spacing, the tooth number of a big gear and the tooth thickness of the big gear and a pinion. The light five-cylinder plunger pump meets conditions of working in the area with severe well cementing operation conditions in aspects of weight and power simultaneously, and working efficiency is increased.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

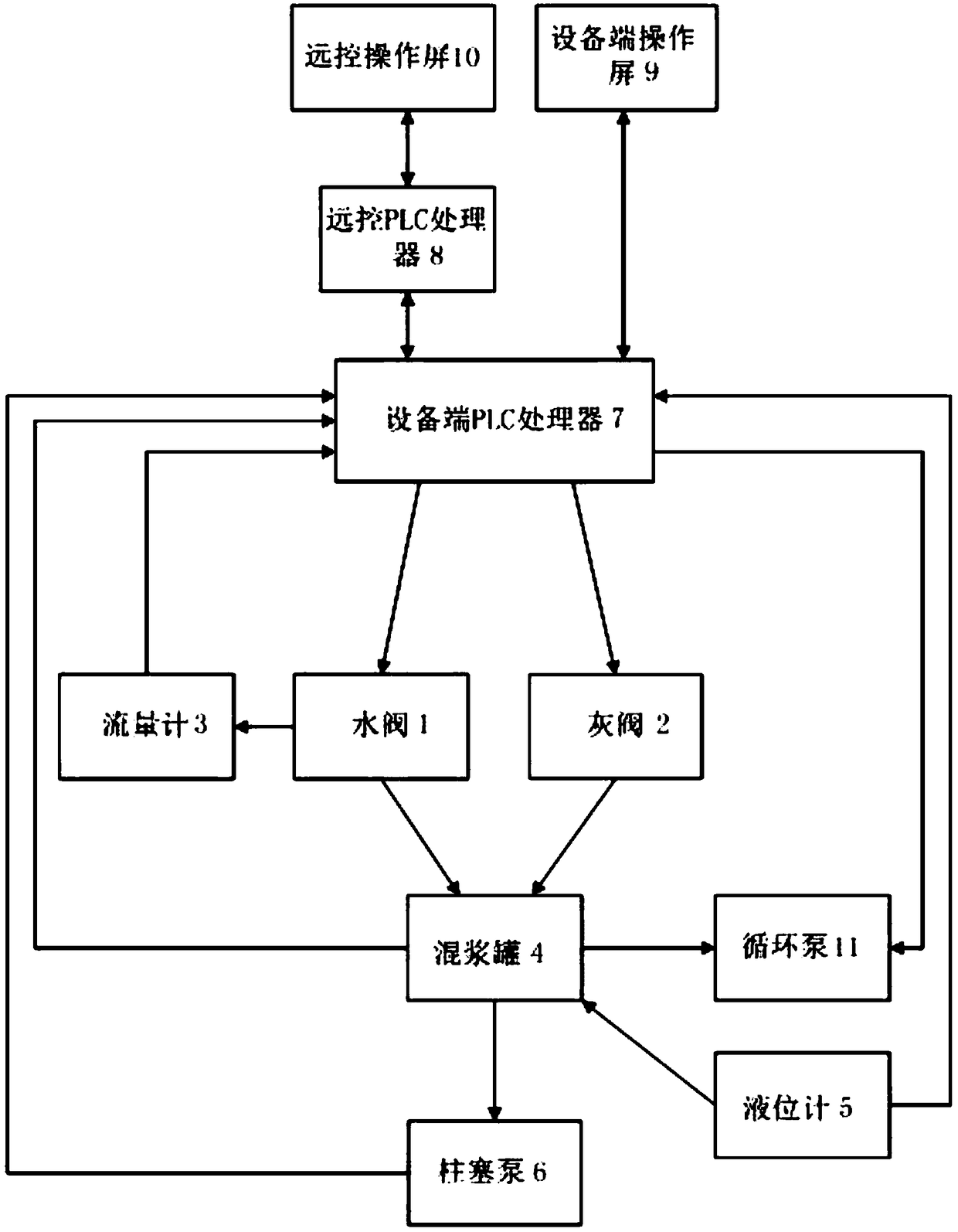

Remote ultra-low-density automatic control system

PendingCN109491318AIncreased level of process automationProgramme control in sequence/logic controllersAutomatic controlSlurry

The invention discloses a remote ultra-low-density automatic control system. The system comprises a control unit, a water valve, a flow meter, a cement valve, a slurry mixing tank, a liquid level meter, a circulation pump and a plunger pump; the cement valve, the water valve, the circulation pump and the plunger pump are connected with the slurry mixing tank separately, the flow meter feeds the water supply amount monitored in real time back to the control unit, the liquid level meter is arranged in the slurry mixing tank, the control unit controls the number of revolutions and preset displacement of the plunger pump to achieve automatic displacement as required, the water demand amount and the cement demand amount are calculated by presetting the water-cement ratio and liquid level valuein the control unit, and therefore the opening degrees of the water valve and the cement valve are controlled; the control unit comprises a remote control unit and an equipment end control unit whichare connected with each other. The remote ultra-low-density automatic control system has the advantage of remote cementing equipment monitoring, remote liquid level automatic control, remote automaticwater supply, remote automatic cement supply, remote automatic premixing, remote automatic density control and remote automatic displacement.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

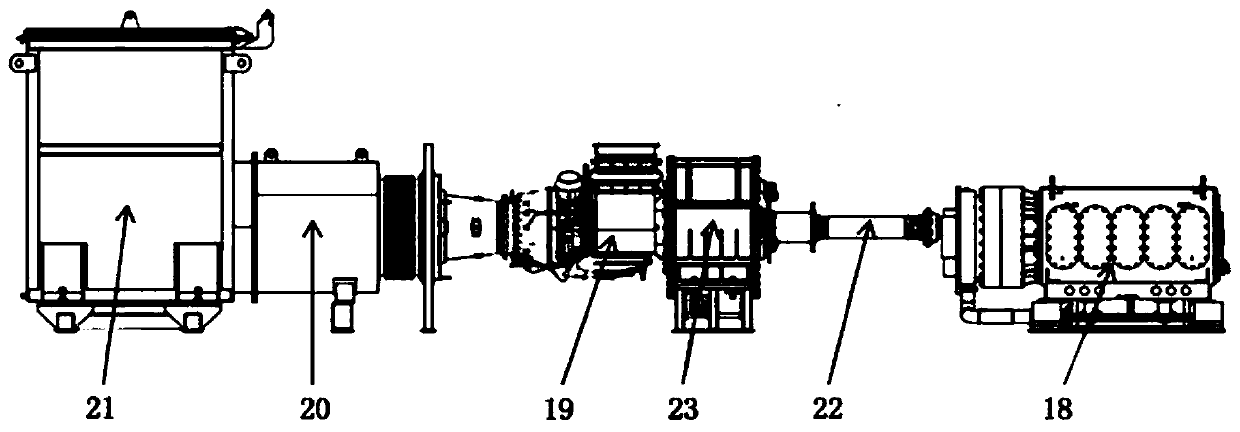

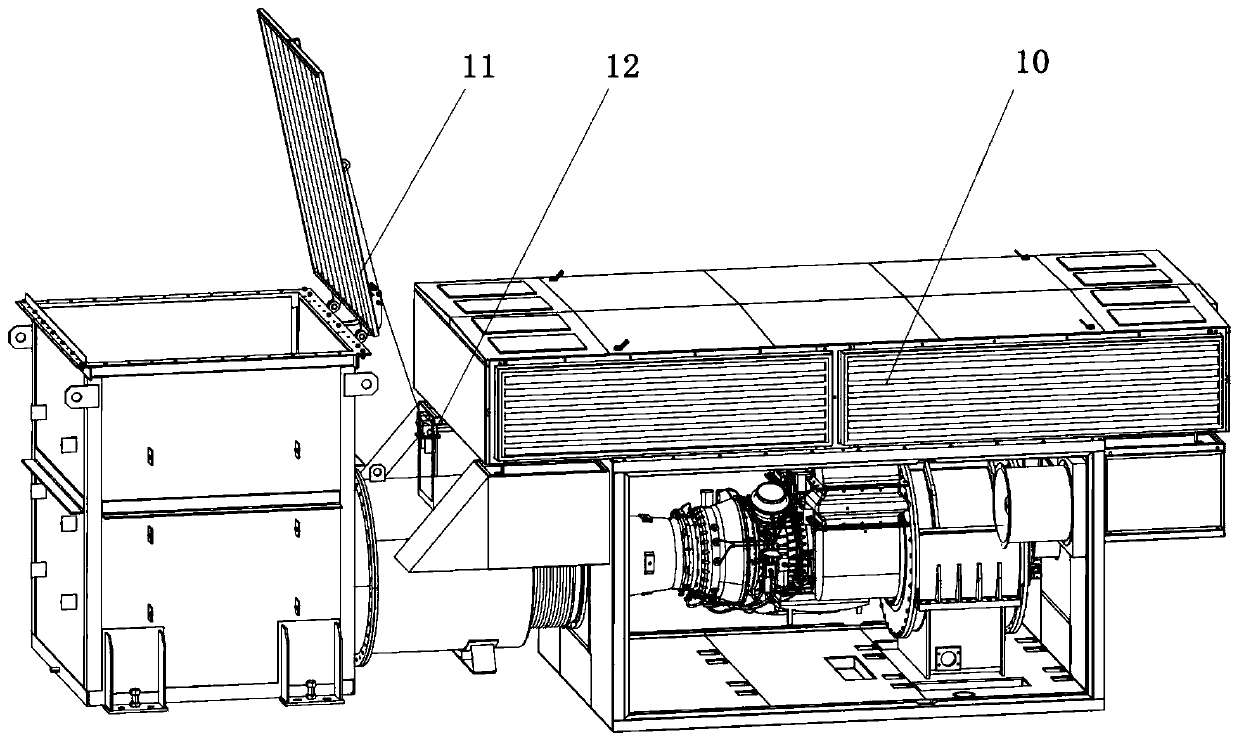

Semitrailer-mounted turbine fracturing equipment

PendingCN110485984AReduce weightLower center of gravityPositive displacement pump componentsFlexible member pumpsOperational costsGravity center

The invention discloses semitrailer-mounted turbine fracturing equipment. Straight-line connection and special chassis design of the whole equipment can double reduce center of gravity of the equipment, stability and safety are better ensured, the structure is simpler, the investment cost and the operation cost are lowered, risks of the whole breakdown of fracturing sites are reduced, transmissionis better, and the semitrailer-mounted turbine fracturing equipment is suitable for continuous operation working conditions with long time and large load. By improving a plunger pump, optimization ofrotating center distances of a crank throw and a crankshaft makes rated power input of the crank throw and the crankshaft increase to 5000-7000 hp, optimization of the transmission ratio of an integrated reduction gearbox on the plunger pump makes the maximum input speed of the integrated reduction gearbox reach 16000 rpm, and ultra-high speed enables reduction gearboxes to be directly connectedwith a turbine engine so as to the solve the problems that turbine fracturing equipment slows down depending on the two reduction gearboxes, and weight of the whole semitrailer is reduced, and boundary dimension of the semitrailer-mounted turbine fracturing equipment is reduced.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

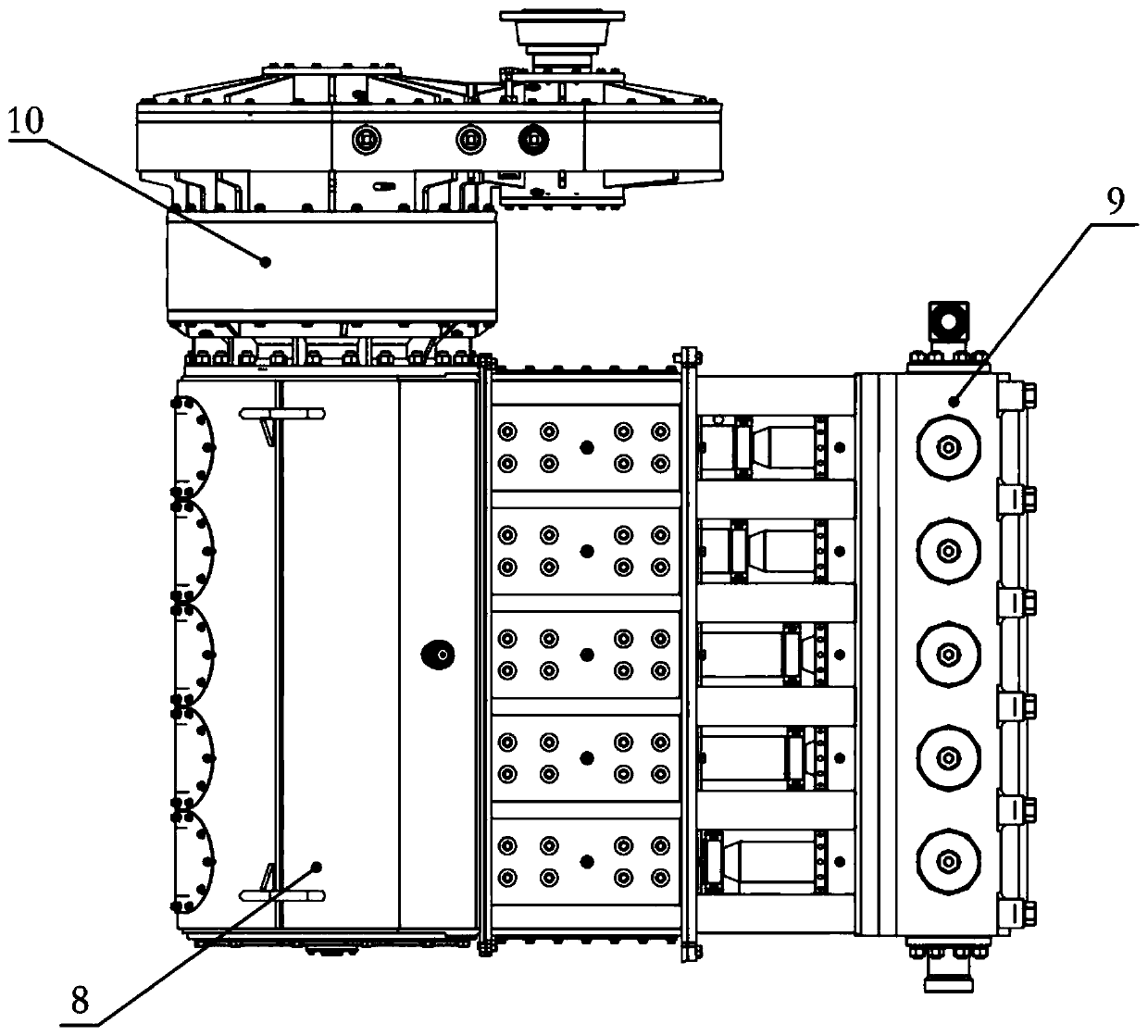

High-power five-cylinder plunger pump

PendingCN110617187AIncrease the carrying areaOptimize layoutPositive displacement pump componentsFluid removalEngineeringMechanical engineering

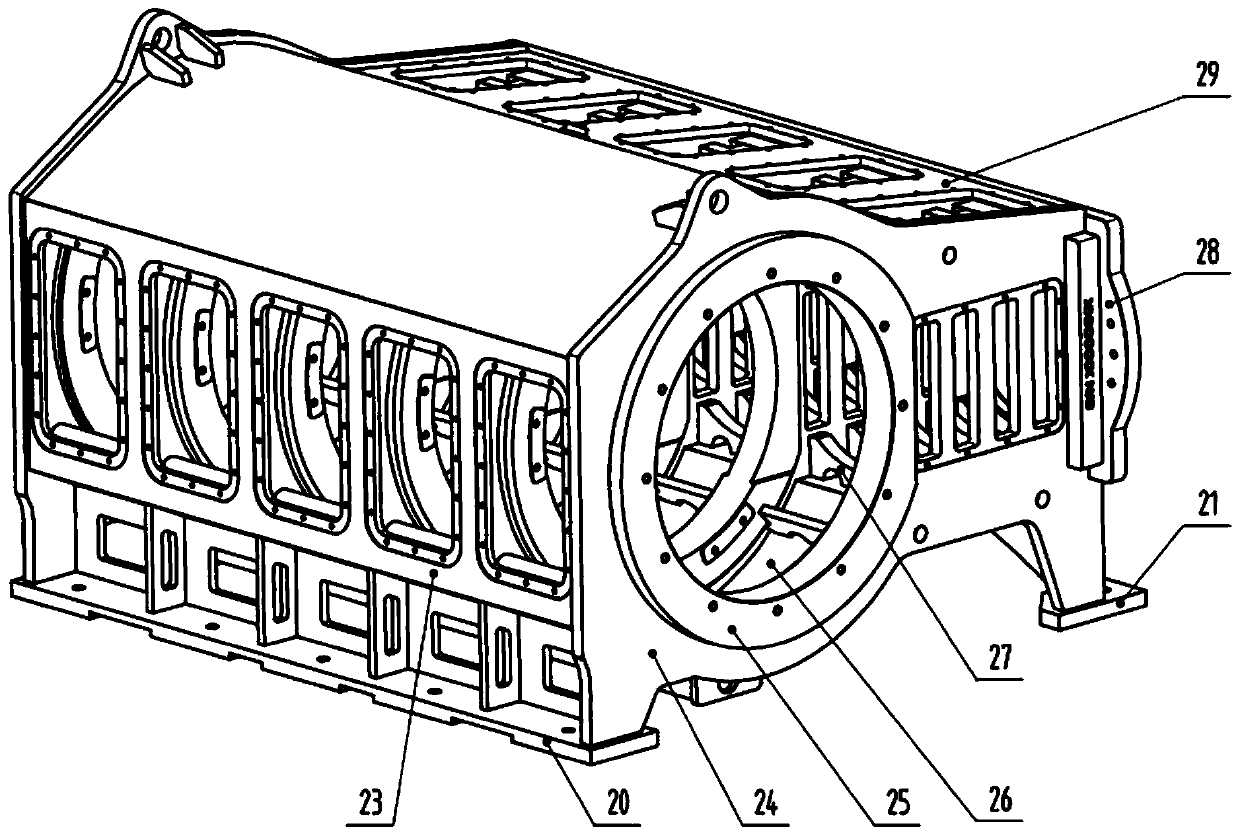

The invention discloses a high-power five-cylinder plunger pump. The plunger pump comprises a power end assembly, a hydraulic end assembly and a reduction gearbox assembly, wherein the power end assembly comprises a crankshaft box body, a crosshead box body and a spacer frame; the crankshaft box body, the crosshead box body and the spacer frame are sequentially connected; the hydraulic end assembly is fixed on the spacer frame; the reduction gearbox assembly is fixed on the crankshaft box body; and the cylinder spacing of the five-cylinder plunger pump is 13-14 inches, so that a guarantee is provided for the output of high power of the five-cylinder plunger pump. According to the high-power five-cylinder plunger pump, the problems that the area of a shale gas fracturing well site is narrowand the number of required fracturing equipment is relatively large are effectively solved, thus reducing the use of equipment, and facilitating the arrangement of the well site.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

Plunger pump driven by linear motor

PendingCN110454352ASolve the real problemReduce intermediate transmission linksPositive displacement pump componentsPumpsLinear motorPlunger pump

The invention discloses a plunger pump driven by a linear motor. The plunger pump is characterized in that the plunger pump is driven by the linear motor, and the movement rule of an assembly is controlled by controlling the movement rule of the linear motor, so that the defects of an existing plunger pump are overcome, and the advantages of the plunger pump are exerted to the maximum extent.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

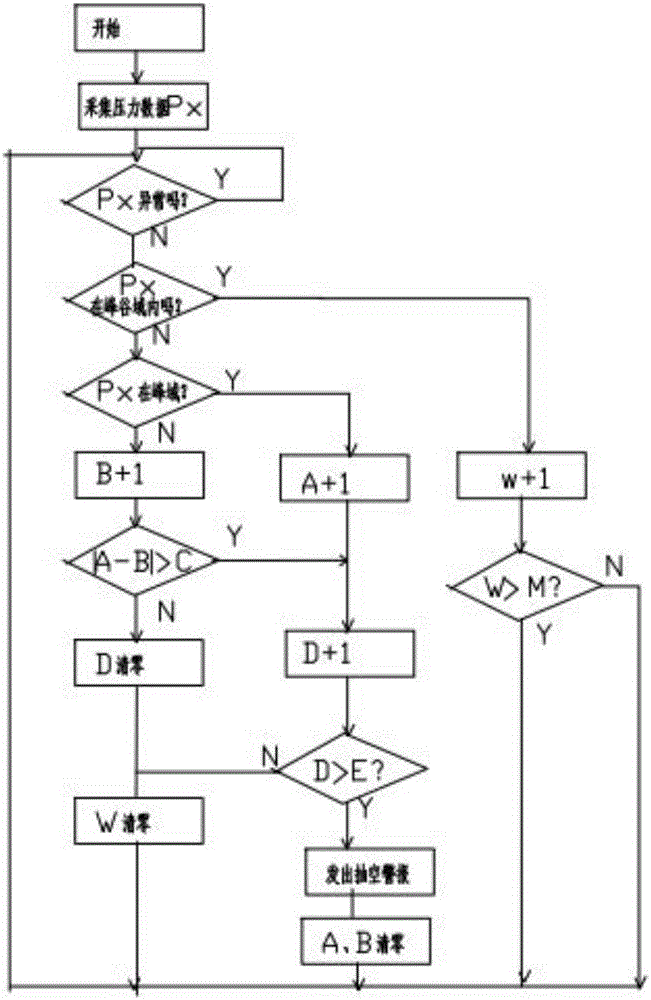

A method for preventing plunger pump from pumping out based on monitoring output pressure

ActiveCN106438310BImprove protectionThe detection method is accuratePump testingPump controlData acquisitionEngineering

Owner:JEREH OIL & GAS ENG

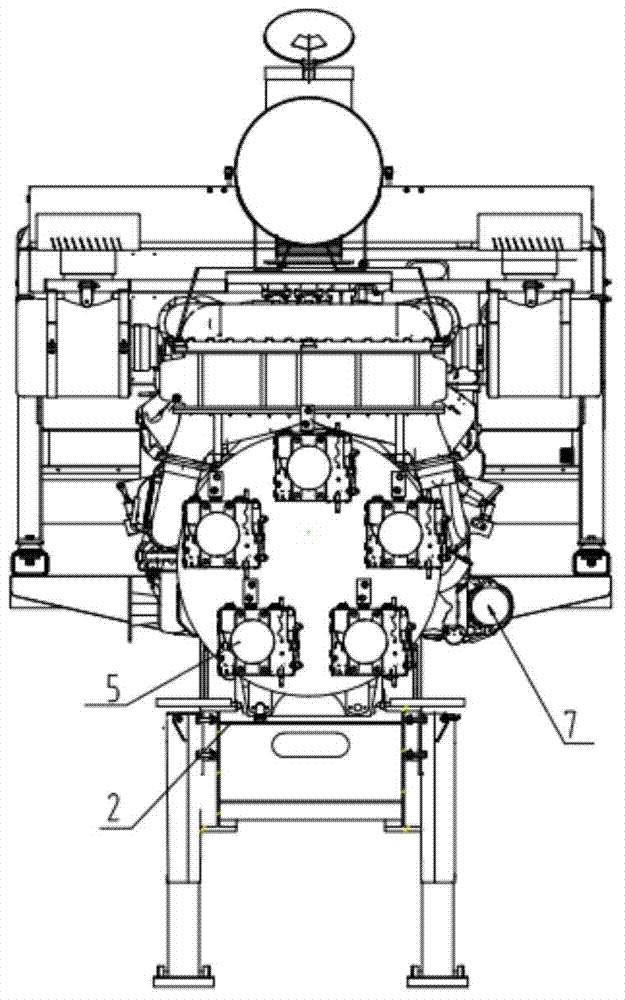

Fracturing transmission and high-pressure discharging system

InactiveCN104727797AExpand the range of selectionSave layout spaceFluid removalTransfer caseEngineering

The invention relates to a fracturing transmission and high-pressure discharging system. The fracturing transmission and high-pressure discharging system comprises a chassis and is characterized in that a high-power engine, a transfer case, a plurality of variable displacement plunger pumps and a double-acting fracturing pump are arranged on the chassis, the output end of the high-power engine is connected with the input end of the transfer case, the output end of the transfer case comprises a plurality of power take-off ports, and each power take-off port is connected with one variable displacement plunger pump; the variable displacement plunger pumps drive the double-acting fracturing pump through a hydraulic system. The fracturing transmission and high-pressure discharging system further comprises a system radiator and a heat dissipation plunger pump used for driving the system radiator, and the heat dissipation plunger pump is connected with one power take-off port of the transfer case. The power take-off ports of the transfer case and the variable displacement plunger pumps are arranged annularly. The fracturing transmission and high-pressure discharging system has the advantages that hydraulic driving replaces mechanical transmission, and working vibration is reduced; the layout space of a whole vehicle is saved, and meanwhile, operating efficiency and the stability of the whole vehicle are improved.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

Novel well cementation truck

PendingCN111075391AEasy to operateFlexible and Efficient MobileItem transportation vehiclesSealing/packingDrivetrainWell cementing

The invention discloses a novel well cementation truck, which comprises a loading body, an electrical system, a plunger pump, a clear water manifold, a mud manifold and a high-pressure manifold, wherein the loading body is provided with a cross beam; the cross beam is provided with a hydraulic system, a power transmission system, a metering tank, an operating platform and a mixing system in sequence; the operating platform is provided with a gas path system and an operating system in sequence; the electrical system supplies power to the well cementation truck; the plunger pump, the clear watermanifold, the mud manifold and the high-pressure manifold are all arranged below the operating platform; the clear water manifold supplies water to the plunger pump and the mixing system; the mud manifold provides mud for the plunger pump; the plunger pump injects the mud into a well through the high-pressure manifold; and the well cementation truck also integrates with a steady pressure ash can,an air compressor and an air bottle. The novel well cementation truck has the beneficial effects that a spatial layout is optimized, and the steady pressure ash can, the air compressor and the air bottle are integrated in one well cementation truck. An ash feeding manifold is optimized, so that the steady pressure ash can supplies ashes, and ash supply equipment can be externally connected for supplying ashes. The large-volume air bottle is adopted, and therefore, air can be supplied to other equipment while the requirements of the well cementation truck are met.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

Linear motor plunger pump

PendingCN110425105ASolve the real problemReduce intermediate transmission linksPositive displacement pump componentsPumpsEngineeringLinear motor

The invention discloses a linear motor plunger pump. The plunger pump is driven through a linear motor, the movement rule of an assembly is controlled by controlling the movement rule of the linear motor, and therefore the defects of an existing plunger pump are overcome, and the advantages of the plunger pump are furthest developed.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

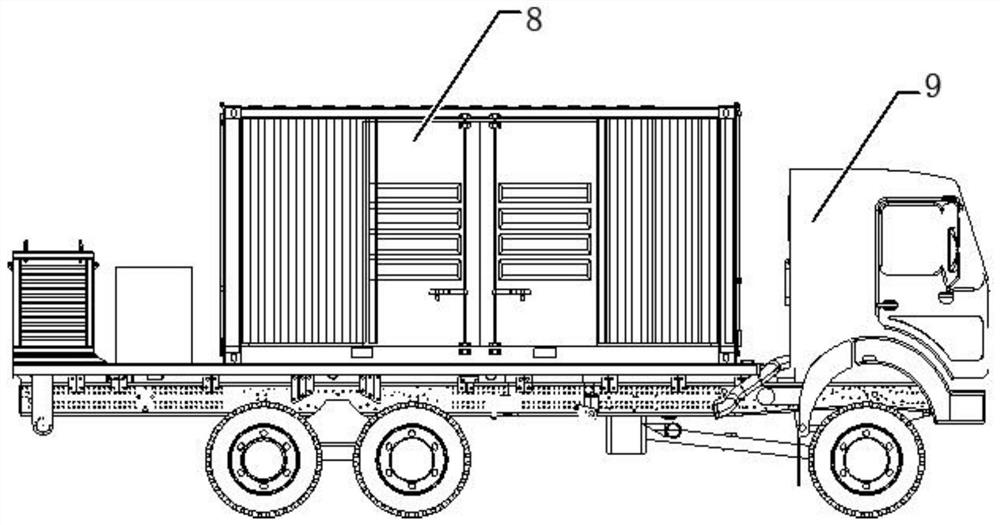

Electrically-driven ultra-large-displacement well cementation equipment

PendingCN111677476AIncrease layout spaceReduce dependenceDischarging apparatusPumpsConvertersFrequency changer

The invention discloses electrically-driven ultra-large-displacement well cementation equipment. The electrically-driven ultra-large-displacement well cementation equipment comprises a first loading body and a second loading body; an auxiliary motor, a main motor, a clear water module, a pumping module, a control module, a hydraulic module and a mixing module are fixedly loaded on the first loading body; and a frequency converter module is fixedly loaded on the second loading body. The electrically-driven ultra-large-displacement well cementation equipment has the beneficial effects that the main motor is adopted to drive a plunger pump, torque converters are reduced, the layout space of the whole vehicle is increased, the auxiliary motor is adopted to drive a whole vehicle hydraulic system, and the number of driving motors is reduced; the frequency converter module and the well cementation equipment are loaded separately, the loading requirement is lowered, the structure is simpler, the occupied space is reduced, one frequency converter module can supply power to all the modules on the multiple first loading bodies at the same time, and use is flexible; and the main motor, the auxiliary motor and the hydraulic heat dissipation device are intensively distributed on the front portion of the first loading body, wiring is simple, connection is convenient, heat dissipation of equipment is intensively achieved, scalding accidents of workers in the operation process are avoided, and operation safety is improved.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

Hydraulic double acting pumping unit

ActiveCN104612928BExtended service lifeImprove suction efficiencyPiston pumpsPositive-displacement liquid enginesHydraulic cylinderMotor drive

The invention relates to a hydraulic bidirectional pumping device which comprises a prime motor, a hydraulic oil pump, a hydraulic oil tank, a control valve, a double-action hydraulic cylinder and plunger pumps. The prime motor drives the hydraulic oil pump. The hydraulic bidirectional pumping device utilizes the double-action hydraulic cylinder to drive the plunger pumps on both sides; the cylinder number is increased; stroke times are reduced; the service lives of easily damaged parts are prolonged; the coverage range of flow is effectively enlarged; suction efficiency of fracturing fluid is effectively improved; complexity of the integral structure is reduced; cost of manufacturing, maintenance and the like is reduced; the requirements on a lubricating system are lowered; the double-action hydraulic cylinder reciprocates to do work, so that working efficiency is improved.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

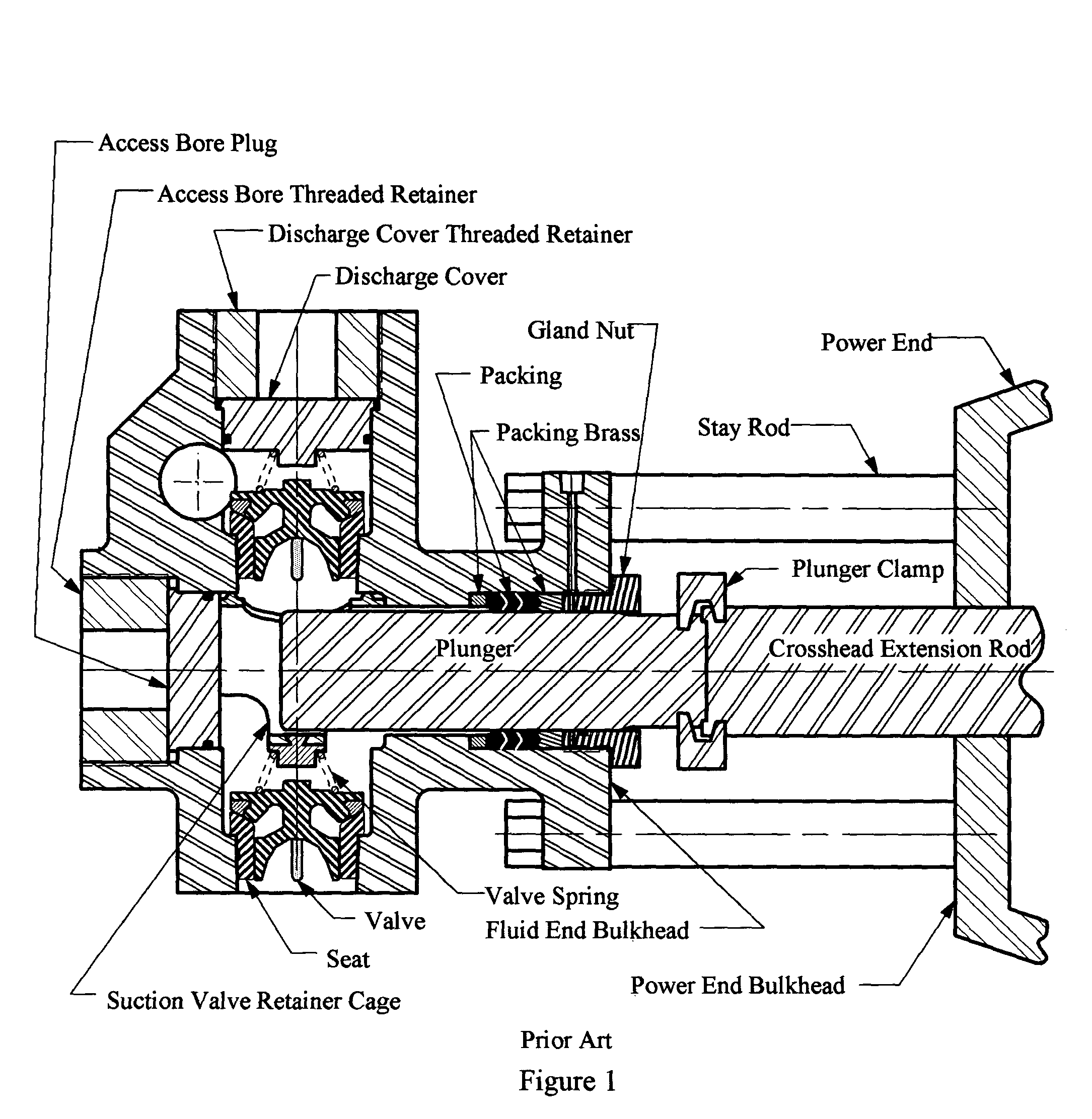

Plunger pump housing and access bore plug

ActiveUS7186097B1Positive displacement pump componentsPositive-displacement liquid enginesStress reliefEngineering

Suction valve spring retainers mounted using an access bore plug are described for use in plunger pump housings having an offset access bore and incorporating structural features for stress-relief. These pump housing structural features accommodate access bore plugs that secure suction valve spring retainers that are internally located substantially centrally over the suction bore transition area of the plunger pump housing. Access bore plugs are secured in place on the pump housing using one or more threaded retainers. Plunger pumps so constructed are relatively resistant to fatigue failure because of stress-reducing structural features, and they may incorporate a variety of valve styles, including top and lower stem-guided valves and crow-foot-guided valves, in easily-maintained configurations. Suction valve spring retainers mounted in plunger pump housings may also incorporate a suction valve top stem guide. Further, certain structural features of access bore plugs may be dimensioned to aid in improving volumetric efficiency of the pumps in which they are used.

Owner:HARRIS CORP

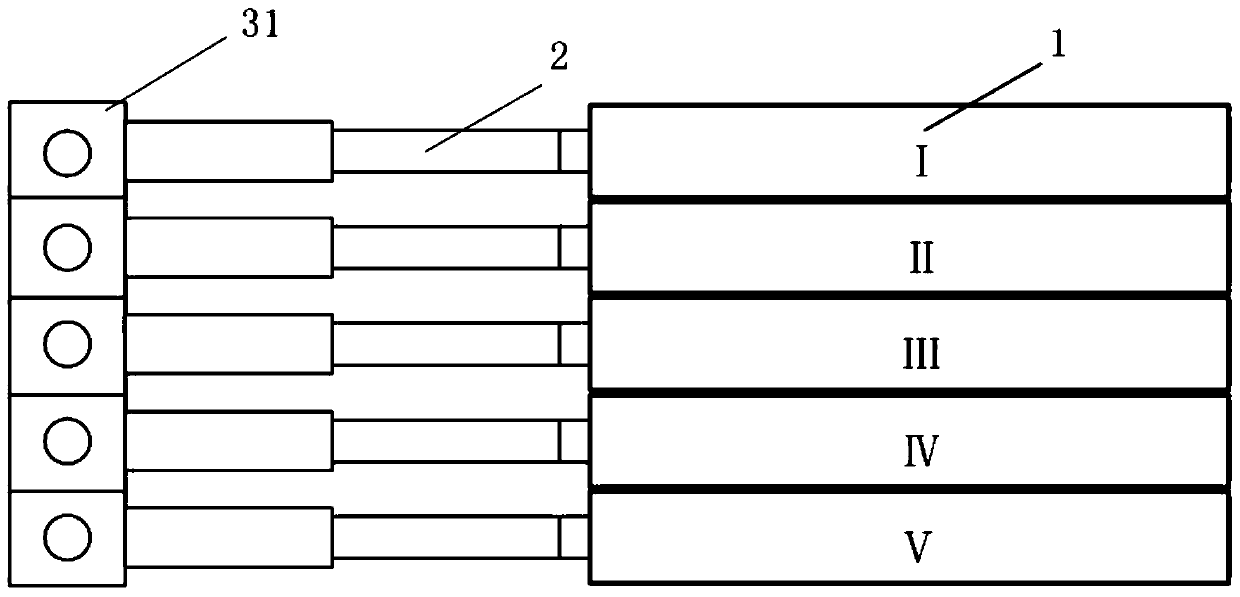

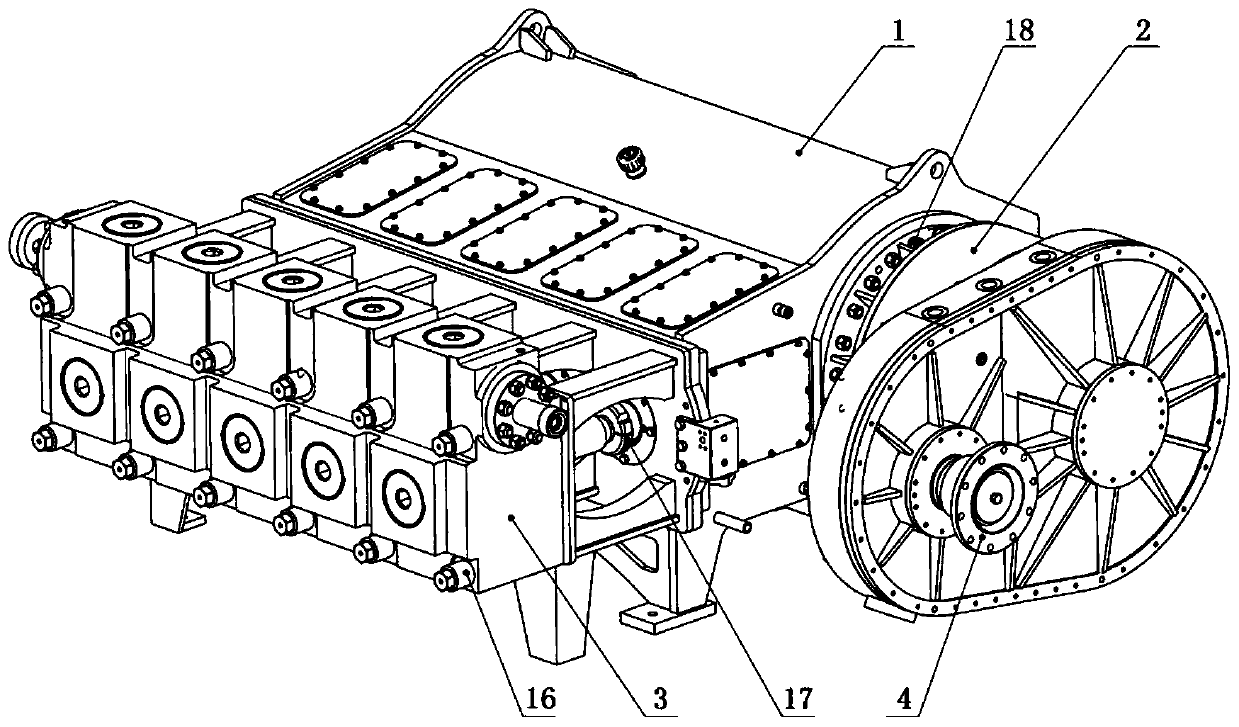

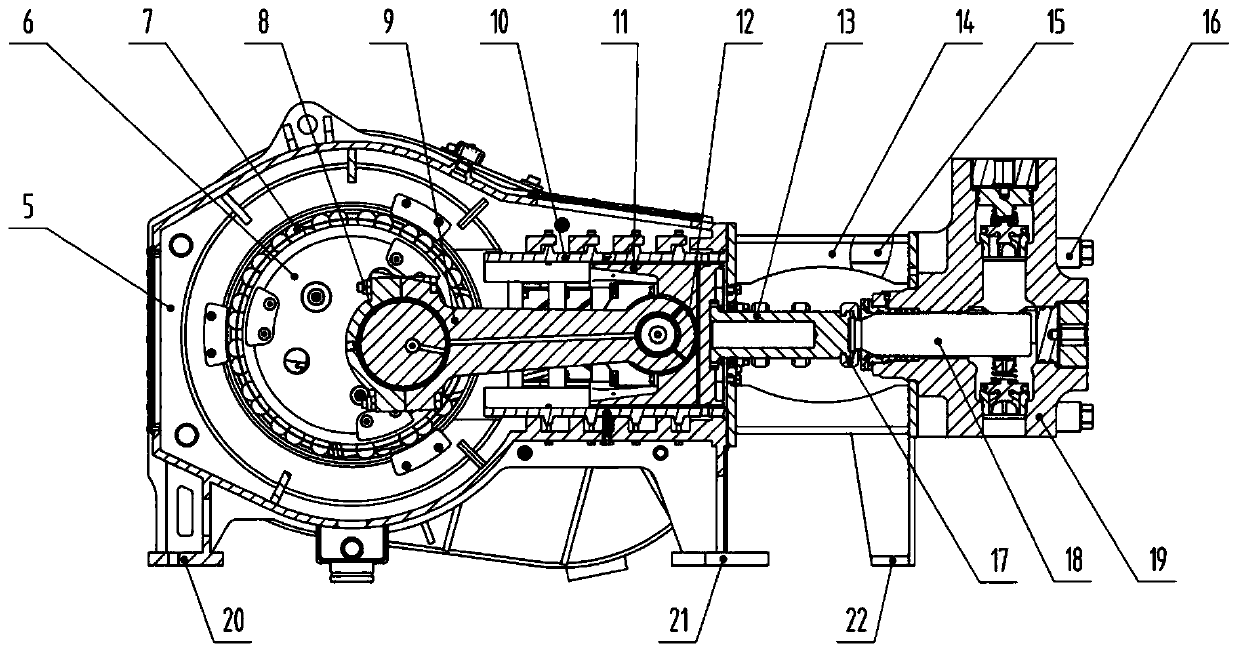

Five-cylinder plunger pump with integral power end structure

PendingCN110617318AExtended service lifeLow strokeCrankshaftsConnecting rod bearingsCrankcaseHigh load

The invention discloses a five-cylinder plunger pump with an integral power end structure. According to the five-cylinder plunger pump, an integral welding structure is adopted for a crankshaft box body and a crosshead box body in a five-cylinder plunger pump power end assembly, so that the structural strength of the power end assembly is higher, the supporting stability is better, and the whole pump vibration can be reduced; the cylinder spacing is 13-14 inches, the bearing area of connecting rods, crossheads and bearing bushes is increased, a guarantee is provided for the output of the high-power of the five-cylinder plunger pump, the high-power five-cylinder plunger pump can effectively solve the problem that the shale gas fracturing well site area is narrow and the required fracturingequipment is relatively large, the use of equipment can be reduced, and the wellsite arrangement is facilitated; the 11-inches long-stroke design can better realize large-displacement operation requirements and improve the operation efficiency; and according to the multi-point supporting design of crankcase bodies, crosshead box bodies and the hydraulic end assembly, the supporting strength of thefive-cylinder plunger pump can be improved, the vibration is reduced, the high-load operation is better guaranteed, and the operation is more stable.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

Plunger pump used for pumping ultralow-temperature liquid nitrogen

InactiveCN102889191ASolve the problem of easy heat absorption and vaporizationReduce deliveryPumpsPositive-displacement liquid enginesReciprocating motionEngineering

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

Cold end of low-temperature high-pressure plunger pump

InactiveCN109404274ASolve the problem of being unable to pump low temperature and high pressure liquid nitrogenHigh conveying medium temperaturePositive displacement pump componentsFluid removalHigh pressureLiquid nitrogen

The invention belongs to the technical field of low-temperature high-pressure plunger pumps, and particularly relates to a cold end of a low-temperature high-pressure plunger pump. The cold end comprises a cold end shell body, a plunger and a cylinder sleeve, wherein the plunger is arranged inside the cylinder sleeve, the cylinder sleeve is located inside the cold end shell body, a connecting locking device is arranged at the front end of the cold end shell body, the cold end shell body comprises a left cavity and a right cavity which communicate with each other, the right cavity internally comprises the cylinder sleeve, a valve set and a discharging flange, and the valve set comprises a valve seat, a high-pressure valve arranged in the valve seat and a low-pressure valve arranged betweenthe cylinder sleeve and the valve seat. According to the cold end of the low-temperature high-pressure plunger pump, the novel valve set structure adopts metal sealing, continuous opening and closingof the high-pressure valve and the low-pressure valve are achieved, and normal-pressure ultralow-temperature liquid nitrogen is converted into high-pressure low-temperature liquid nitrogen and is discharged so that the requirement for high-frequency opening and closing can be met, the characteristics of being low in conveying medium temperature and high in output pressure are achieved, and the problem that a common plunger pump cannot pump the low-temperature and high-pressure liquid nitrogen is solved.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

Device and method for preparing nitrogen foam cement

InactiveCN111206901ALow densityReduce energy consumptionSealing/packingHigh pressure waterNitrogen gas

The invention discloses a device and method for preparing nitrogen foam cement. The preparing device comprises a foam cement producer, a liquid nitrogen evaporator, a liquid nitrogen plunger pump, a foam liquid plunger pump, a foam liquid tank, a heat exchange system, a liquid nitrogen pipeline, a high-pressure cement paste pipeline, a first pipeline, a foam cement discharge pipeline and a densitydetecting device. The heat generated by a power unit, a hydraulic system and other devices in a nitrogen foam well fixing device is recovered through the heat exchange system, the recovered heat is used as a heat source of the liquid nitrogen evaporator, energy conservation and environment protection are realized, the energy utilization rate is high, and equipment input is low. Liquid nitrogen and foam liquid are pressurized through a high-pressure liquid nitrogen plunger pump and a high-pressure foam liquid plunger pump, the mixing uniformity is increased, and the density of foam cement is reduced. The density of the foam cement is detected in real time through the density detecting device, the flow of the liquid nitrogen and / or foam liquid is adjusted according to the density, and the density is simply controlled. By arranging a clear water tank, after operation ends, the equipment and pipelines are flushed, and the service life is polonged.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

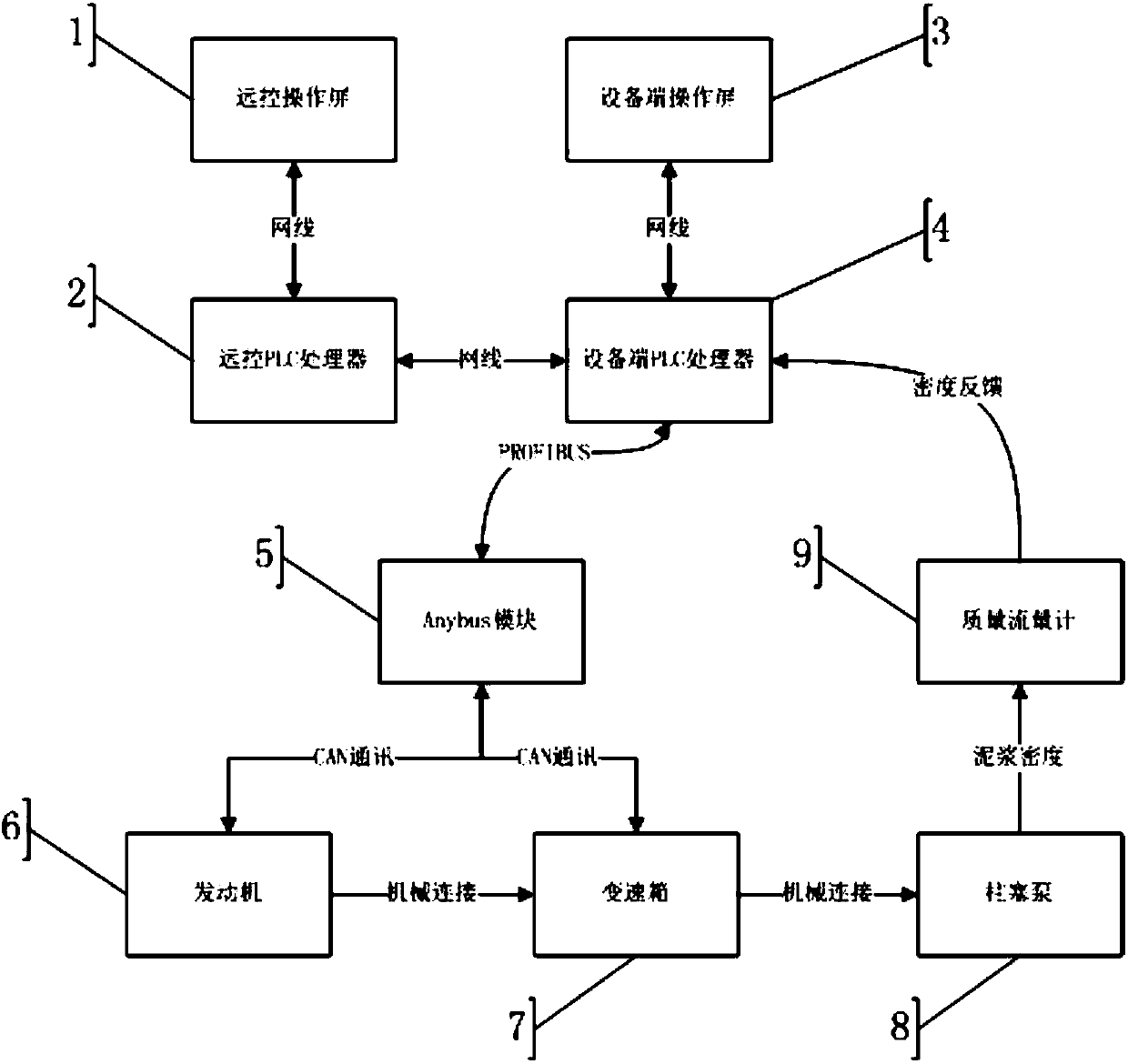

Long-distance automatic displacement and density automatic control system

PendingCN107605427ARealize remote automatic centralized controlRealize the centralized control of the whole processClosed circuit television systemsPump controlAutomatic controlControl system

The invention belongs to the field of oil equipment, and particularly relates to full-automatic intelligent remote-control cementing equipment. A long-distance automatic displacement and density automatic control system being used for the cementing equipment is characterized in that the long-distance automatic displacement and density automatic control system at least comprises a power unit and acontrol unit. The power unit comprises an engine, a gearbox and a plunger pump, and the control unit comprises a device operation screen, a device PLC processor, a remote-control operation screen, a remote-control PLC processor and an Anybus module. Operating personnel write in a set displacement set value or a set density value on the remote-control operation screen or the device operation screen, after the device PLC processor reads the set displacement information, a set gear needed by the current set displacement and the accelerator position are calculated through program internal calculation, so that the rotating speed of the engine and the gears of the gearbox are controlled, finally the long-distance automatic displacement and density automatic control system is used for controllingthe input rotating speed of the plunger pump, and the purpose of controlling the discharging displacement of the plunger pump is achieved.

Owner:CNPC DRILLING RES INST +2

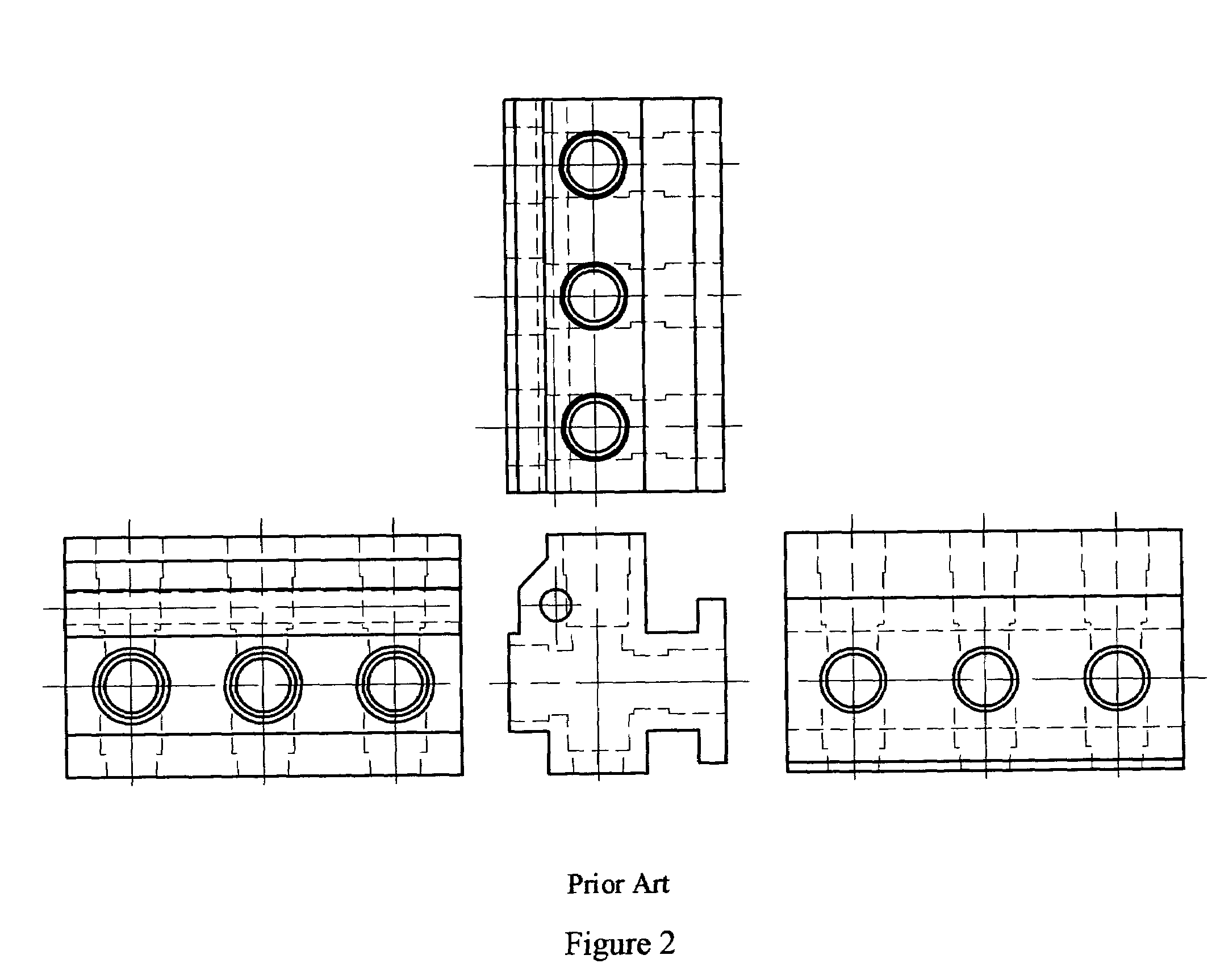

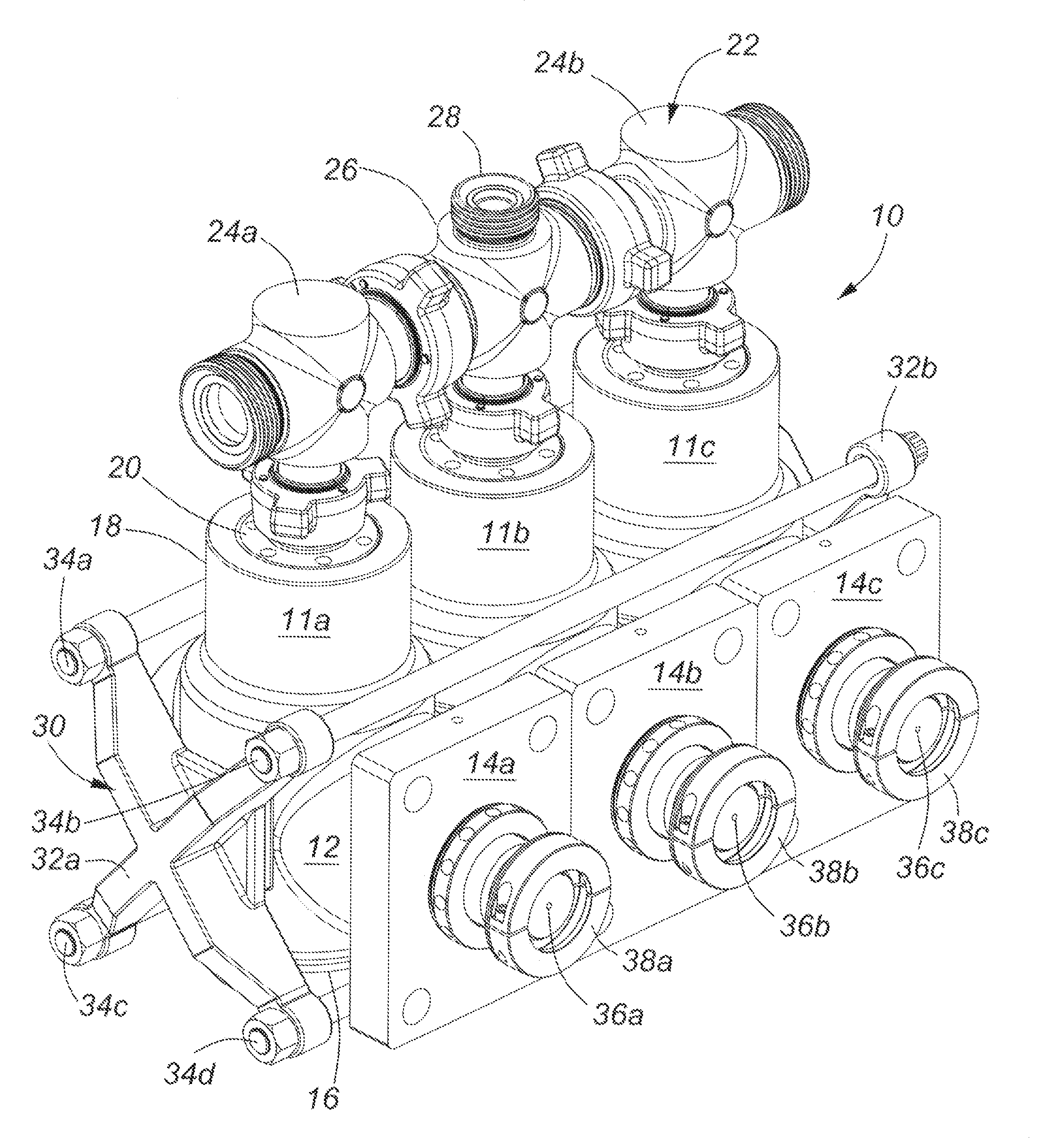

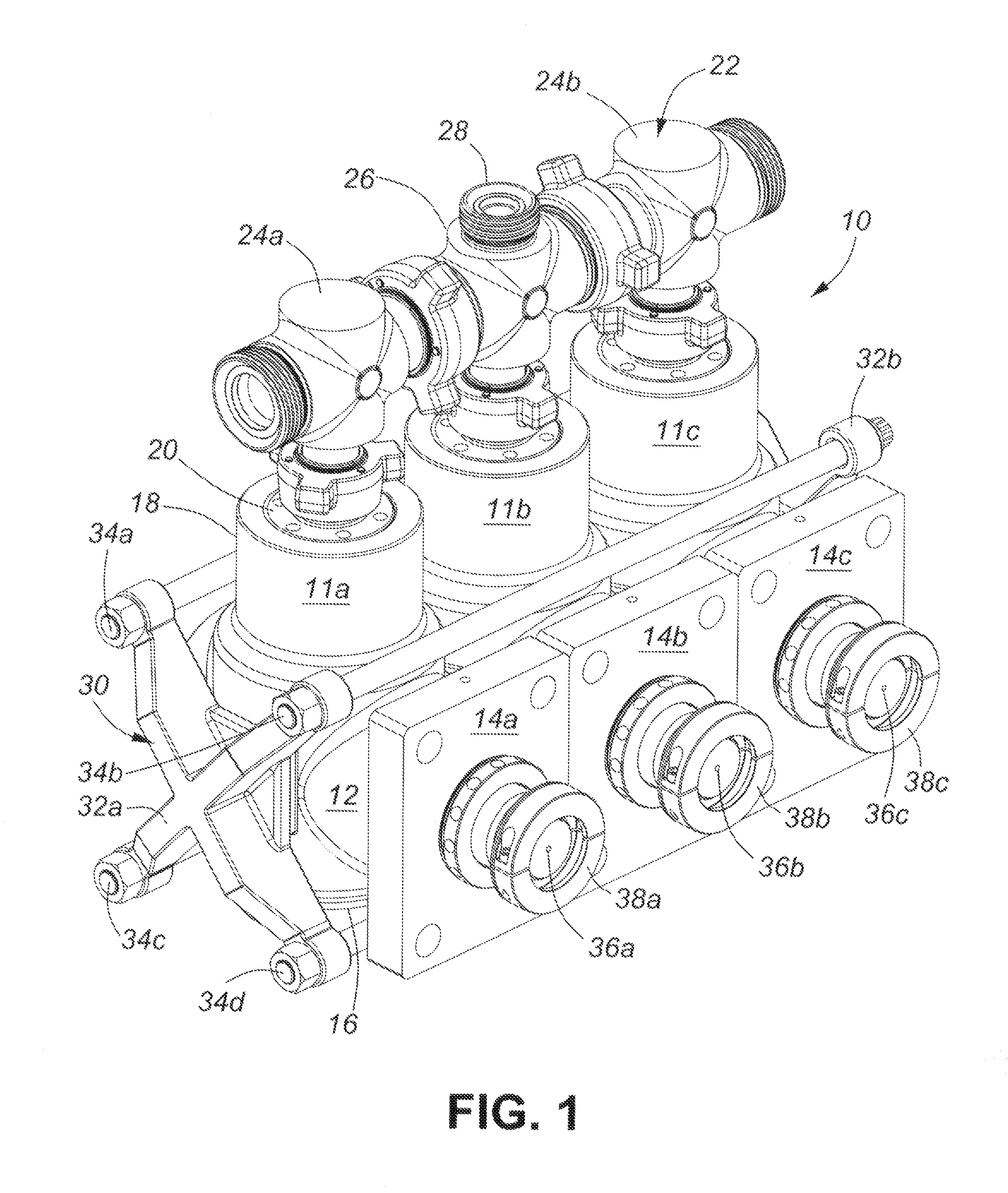

Modular fluid end for a multiplex plunger pump

ActiveUS20120063936A1Simpler and less-costly to manufactureSimpler and less-costly to and maintainPositive displacement pump componentsCylindersEngineeringMechanical engineering

A modular fluid end for a multiplex plunger pump, each module machined from a single-piece steel forging with a plunger bore intersected by a linear suction / discharge bore and pumped fluid is discharged straight out through a top of the module into a discharge manifold made up using 1502 frac iron components. A compression clamp applies a crush load to opposed sides of the modules to extend service life.

Owner:FORUM US

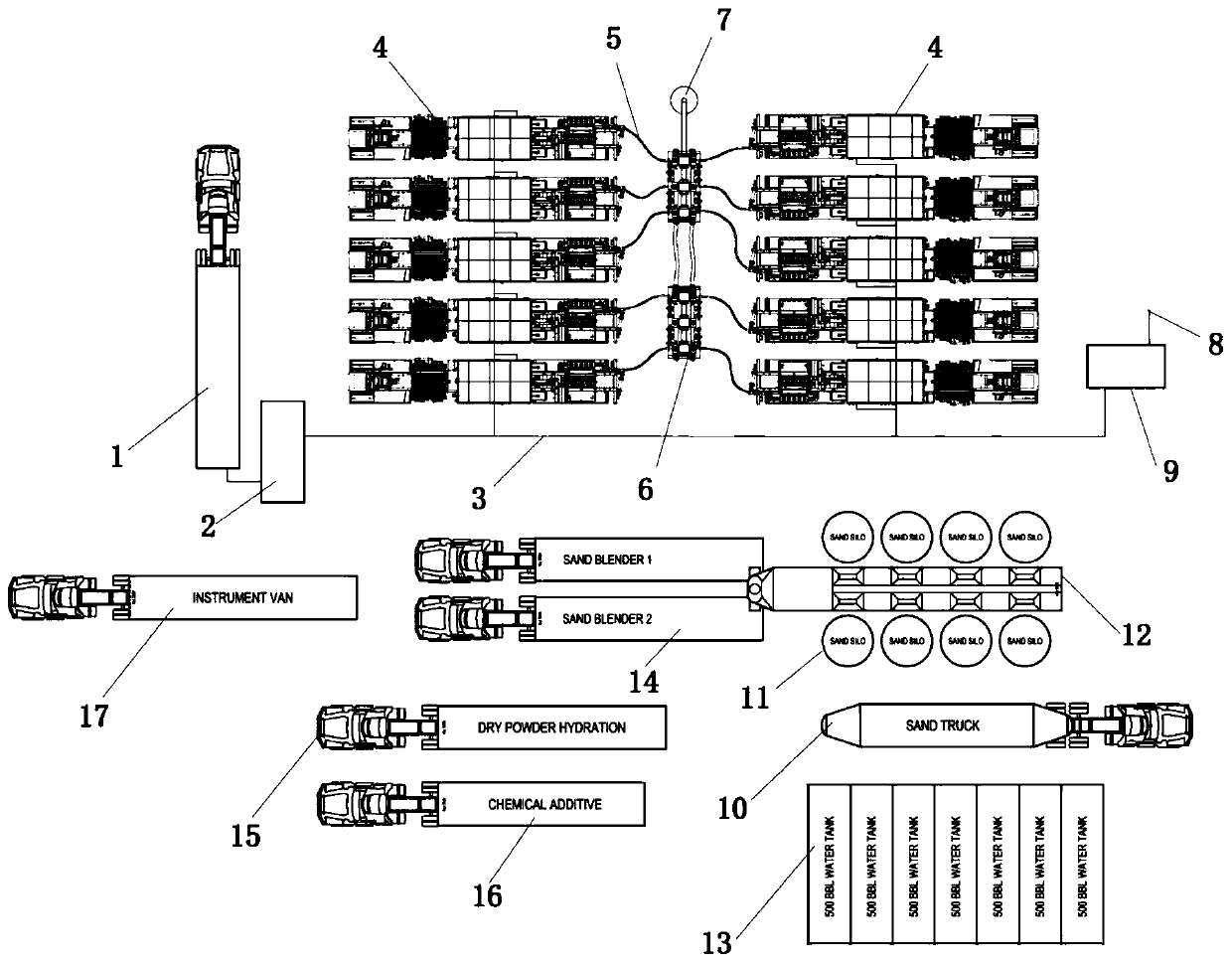

Hydraulic fracturing system for driving plunger pump by using turbine engine

PendingCN110469314ASolve driveTroubleshoot motor drivesTurbine/propulsion fuel supply systemsTransportation and packagingEngineeringHydraulic fracturing

The invention discloses a hydraulic fracturing system for driving a plunger pump by using a turbine engine. The fracturing system comprises a fracturing device, a high-low pressure pipe joint, a mixing device, a sand blender and the like, a power source of the fracturing device is the turbine engine, fuel of the turbine engine is natural gas or diesel, the plunger pump is driven by the turbine engine, the problems of existing diesel driving and electromotor driving are solved, fuel supply of the turbine engine adopting a dual-fuel system is diverse and is not limited, especially, the cost is more saved when the natural gas serves as the fuel. The gas source supply modes of the natural gas are diverse in the whole hydraulic fracturing system, requirements for more clients can be better met,the whole fracturing device is arranged on a straight line in the direction of power transmission, the whole gravity center of the fracturing device is better lowered, and the stability and safety ofthe operation and transferring states of the fracturing device are improved.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

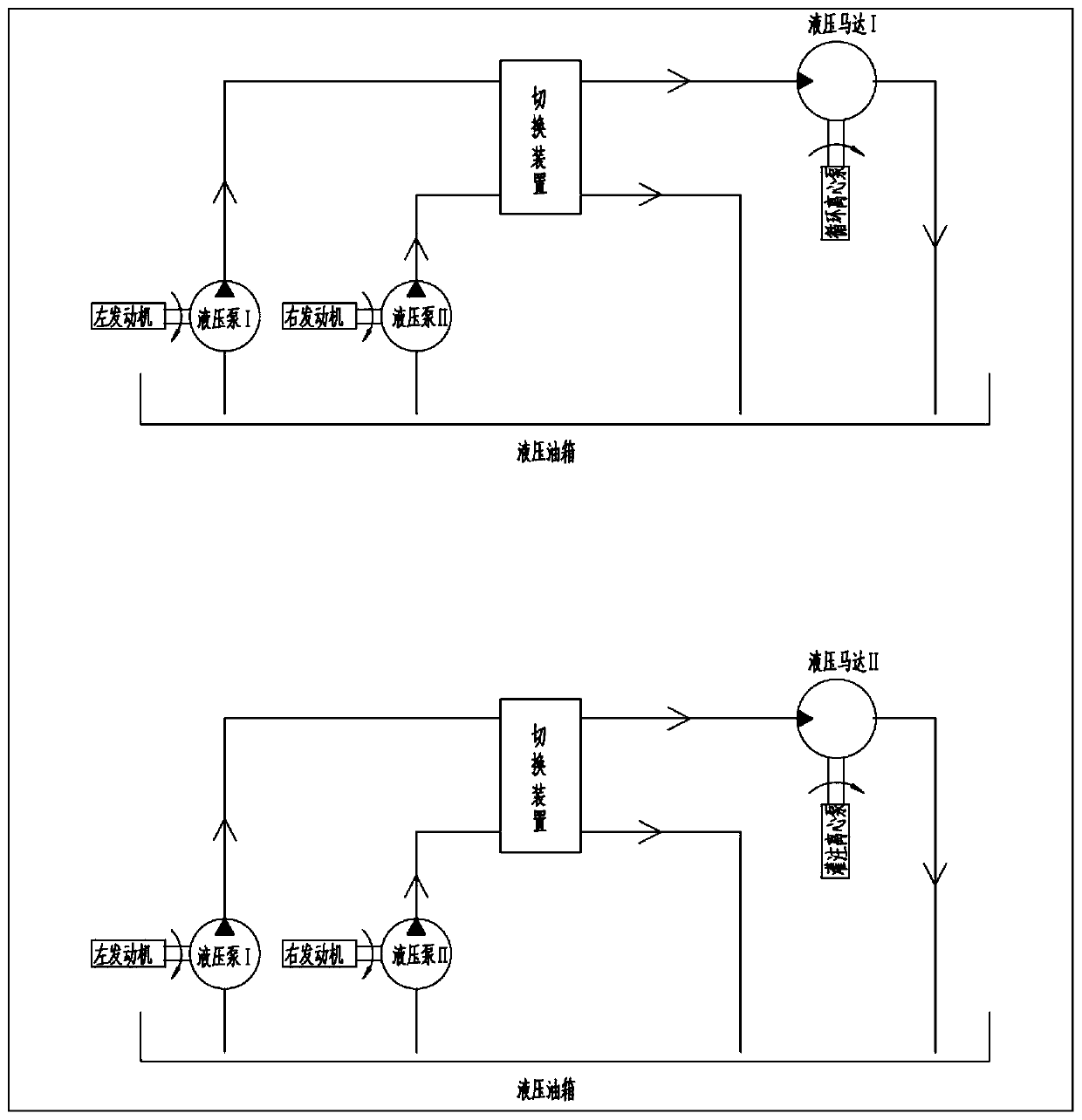

Cementing equipment with mutually standby hydraulic systems

PendingCN110284854AImprove reliabilityImprove securityPump installationsSealing/packingControl systemHydraulic pump

The invention discloses cementing equipment with mutually standby hydraulic systems. The cementing equipment comprises a loading system, a hydraulic system connected with the loading system and a power system for driving the hydraulic system. The hydraulic system at least comprises a hydraulic pump, a switching device and an overflow valve, the hydraulic system is connected with a mixing system, and the hydraulic system is connected with a slurry mixing system provided with an AMS automatic slurry mixing system, a centrifugal pump circulating and filling system; the slurry mixing system is controlled and adjusted through a control system, the control system is arranged on a computer control platform, and the control platform is arranged on the loading system; and the loading system is based on one or more of a vehicle-mounted chassis or a trailer chassis or a skid-mounted chassis, wherein a semi-trailer based on the trailer chassis can be fixedly connected with a plurality of engines, a plurality of gear boxes, a plurality of plunger pumps, at least one metering tank, the slurry mixing system, a high-low pressure manifold, the control system, the hydraulic system and an electrical system.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

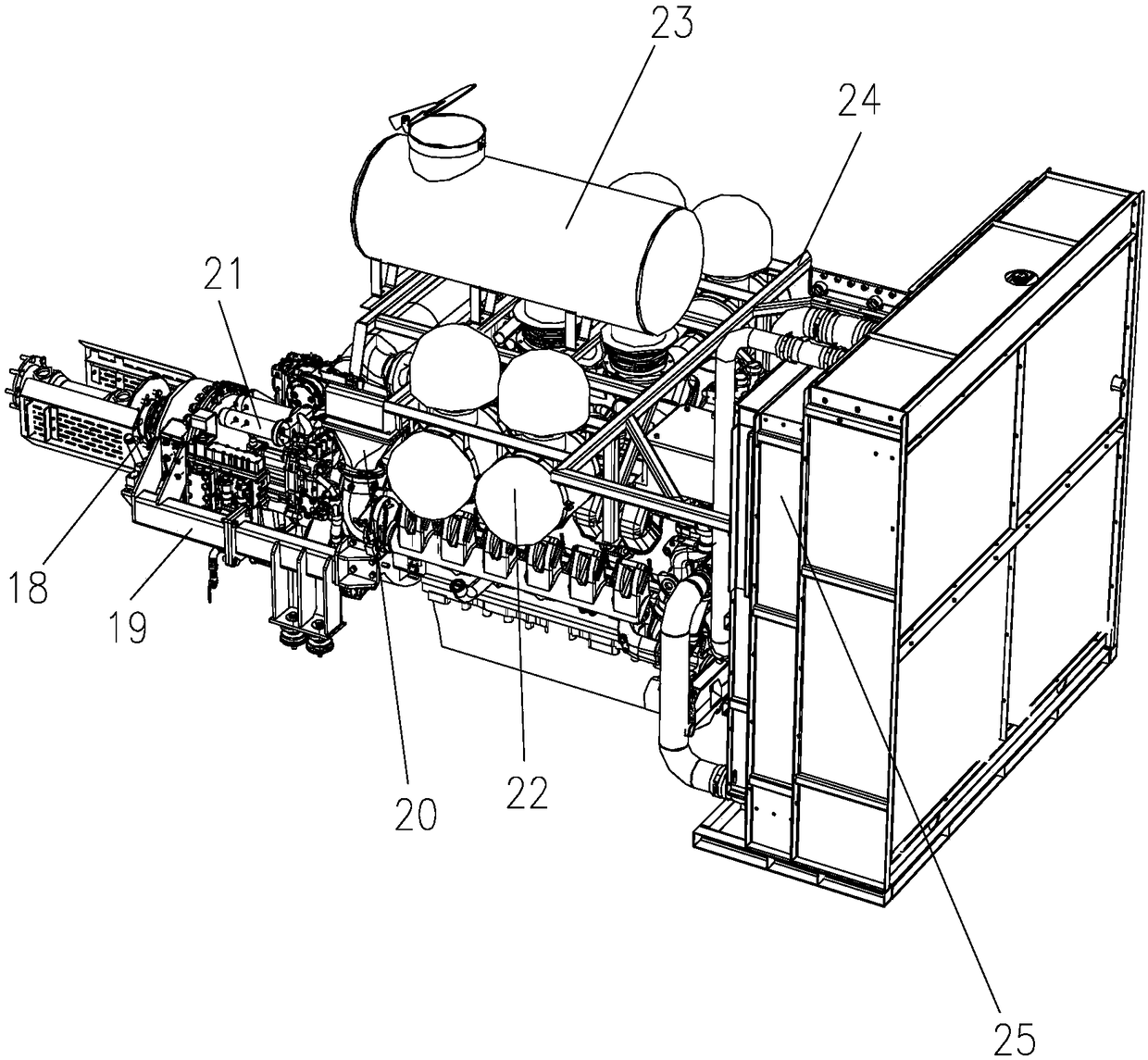

Continuous large-power turbine fracturing equipment

PendingCN111206992AStable and efficient transmissionStable working platformPositive displacement pump componentsGear lubrication/coolingDrive shaftControl engineering

The invention discloses continuous large-power turbine fracturing equipment. The large-power turbine fracturing equipment comprises a turbine engine, a reduction box, a transmission shaft and a plunger pump, wherein the turbine engine and the reduction box are arranged on the same straight line; the reduction box is connected to the plunger pump through a transmission shaft; and an angle of the transmission shaft ranges from 2 degrees to 4 degrees. The continuous large-power turbine fracturing equipment has the beneficial effects that: a chassis T1 material is selected, so that a stable working platform is provided for the equipment; the turbine engine and the reduction box are on the same straight line, the transmission shaft is arranged between the reduction box and the plunger pump, andthe angle of the transmission shaft ranges from 2 degrees to 4 degrees, so that stable and efficient transmission of the turbine engine is guaranteed, and a fault occurrence rate is reduced; a lubricating system driven by an auxiliary power system guarantees that the turbine engine, the reduction box and the plunger pump work under a proper environment; dual lubricating systems guarantee that theplunger pump realizes continuous operation under power of 5000 HP or higher; and the technical means finally can meet continuous large-power operation requirements of the fracturing equipment.

Owner:美国杰瑞国际有限公司

Novel ultra-high-power cementing equipment integrated with remote control

PendingCN108561098AQuick arrangementSave work spacePositive displacement pump componentsPumpsUltra high pressureDrivetrain

The present invention relates to the technical field of petroleum equipment, in particular to novel ultra-high-power cementing equipment integrated with remote control. The novel ultra-high-power cementing equipment integrated with remote control comprises a loading system and a secondary beam, wherein the secondary beam is connected with a hydraulic system, a power transmission system, a meteringtank, an electrical system, a gas circuit system, a control system and a mixing system from front to rear in sequence, the lower portion of the gas circuit system is provided with a plunger pump, theplunger pump is connected with a high-pressure discharge system; a control platform is arranged at the lower part of the electrical system; the control system is positioned above the control platform; and the control system is connected with the remote control system. The novel ultra-high-power cementing equipment integrated with remote control meets the requirements of high pressure, large displacement, long time and continuous uninterrupted operation during the ultra-deep cementing operation and the ultra-high pressure gas well operation; and the occupied area is small, the pipeline connection is simple, and the maintenance frequency is low.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com