Plunger pump hydraulic end with long service life

A plunger pump and liquid end technology, applied in the field of plunger pumps, can solve problems affecting the service life of the liquid end, short service life, and prolonged construction time, and achieve the goal of prolonging the service life, improving the service life, and improving the service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

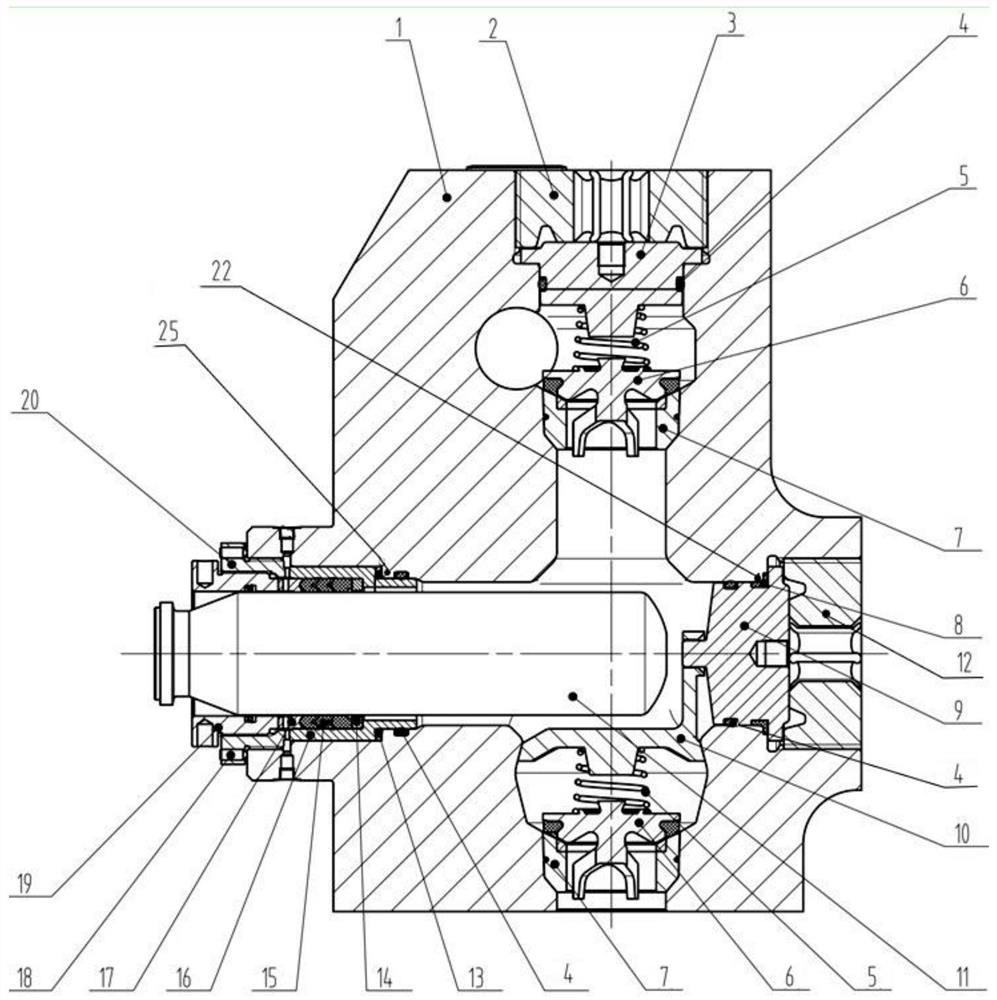

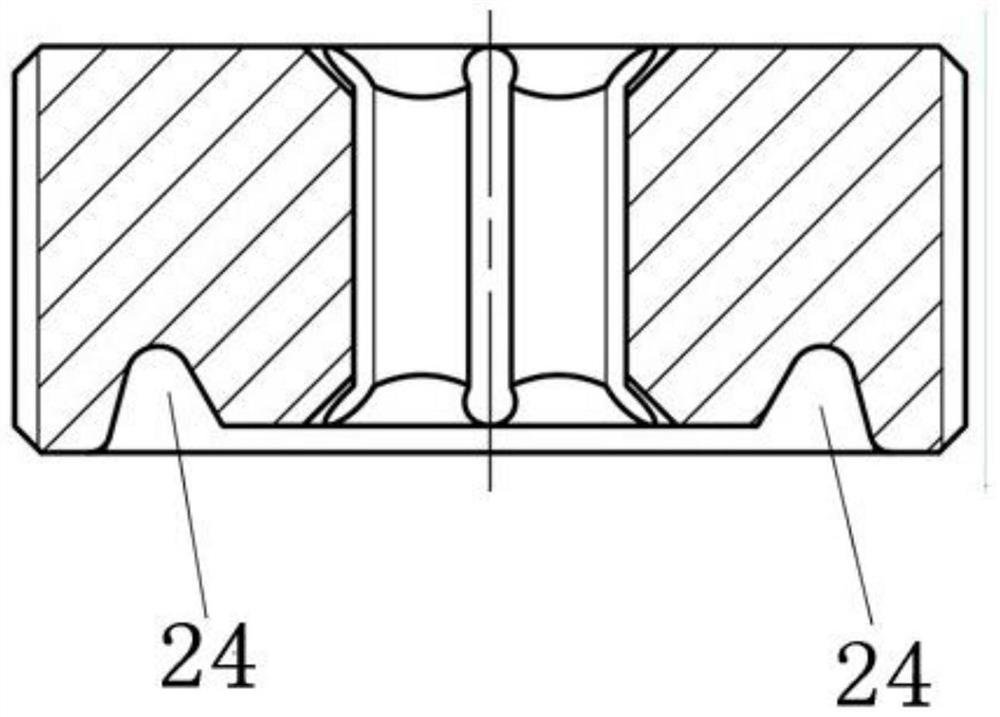

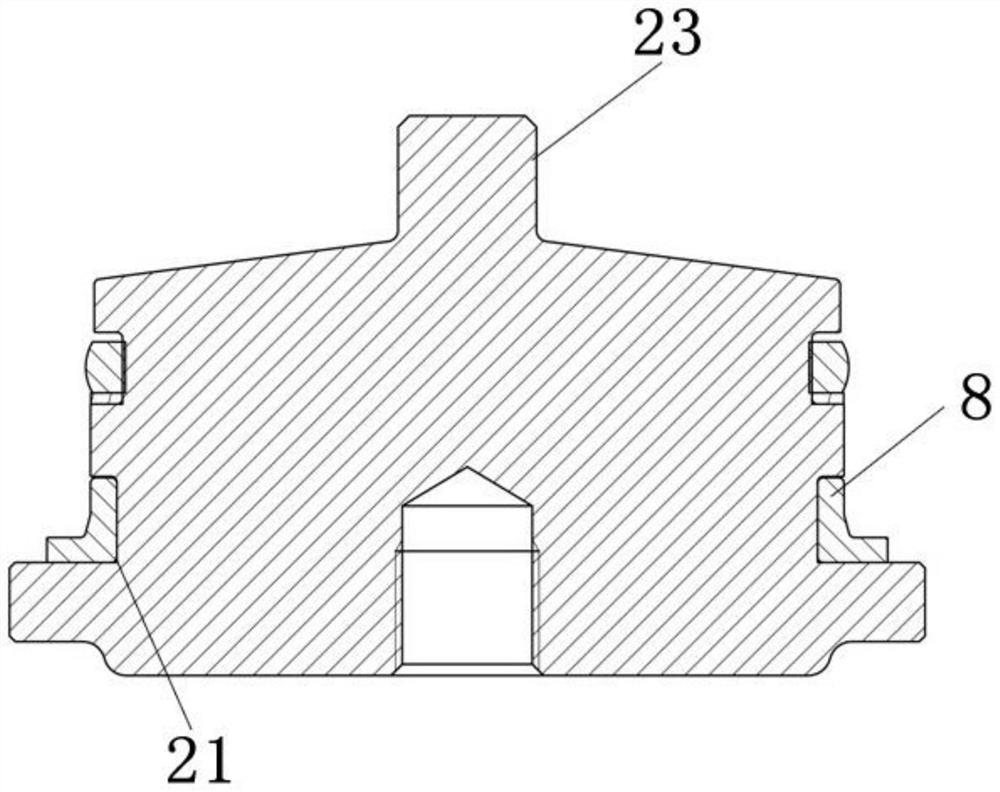

[0025] Such as Figure 1 to 3 As shown, a long-life plunger pump hydraulic end, the plunger pump hydraulic end includes a valve box 1, a plunger 11 and a packing assembly, the valve box 1 serves as a container for liquid delivery, the The plunger 11 is connected to the valve box 1 through a packing assembly. The packing assembly includes a packing assembly, a packing sleeve 16, a packing pressure cap 19, a packing sleeve pressure cap 20, the packing sleeve 16 and The valve box 1 is connected in a sealed manner. Specifically, the packing sleeve 16 and the valve box 1 are sealed by a combination of a D-shaped sealing ring 4 and a sealing gasket 13. Packing sleeve 16 is sealed in two ways. The first seal adopts D-type sealing ring 4. The sealing groove is opened on valve box 1 to prevent fracturing sand from entering between packing sleeve 16 and valve box 1. In the gap, it is convenient to replace the packing 16 later. The second seal is a metal gasket 13 seal, which is used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com