Patents

Literature

109 results about "Packing pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

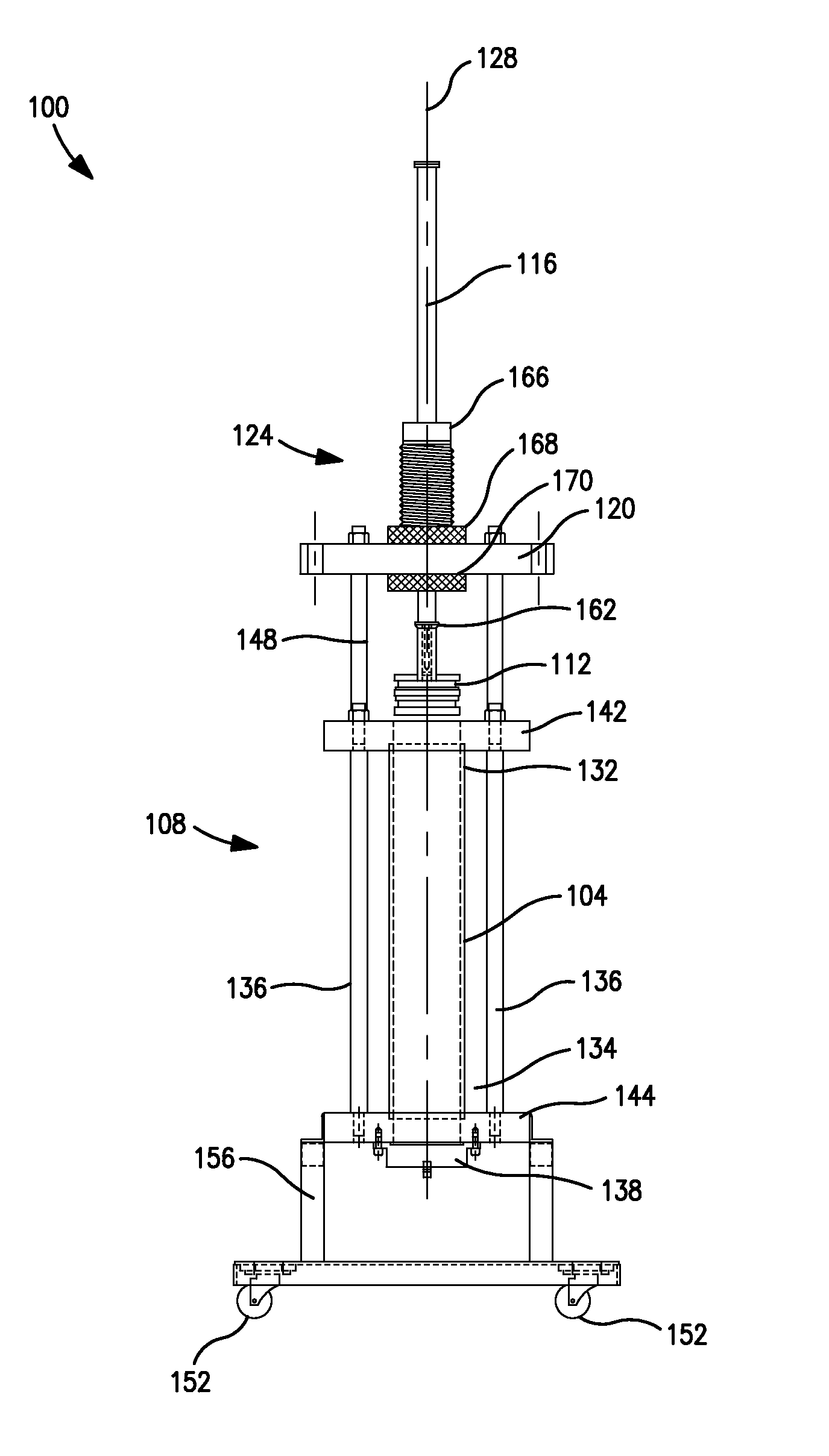

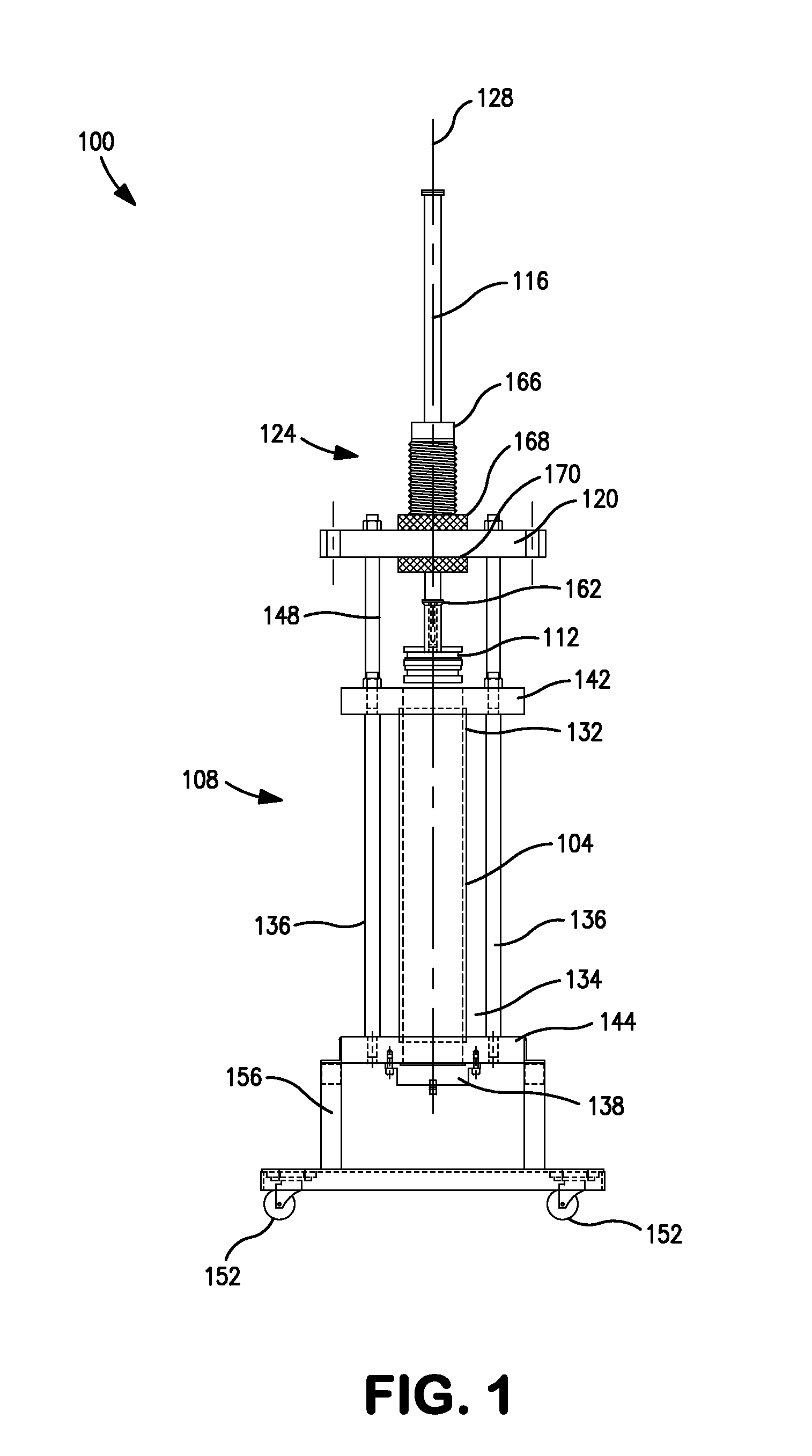

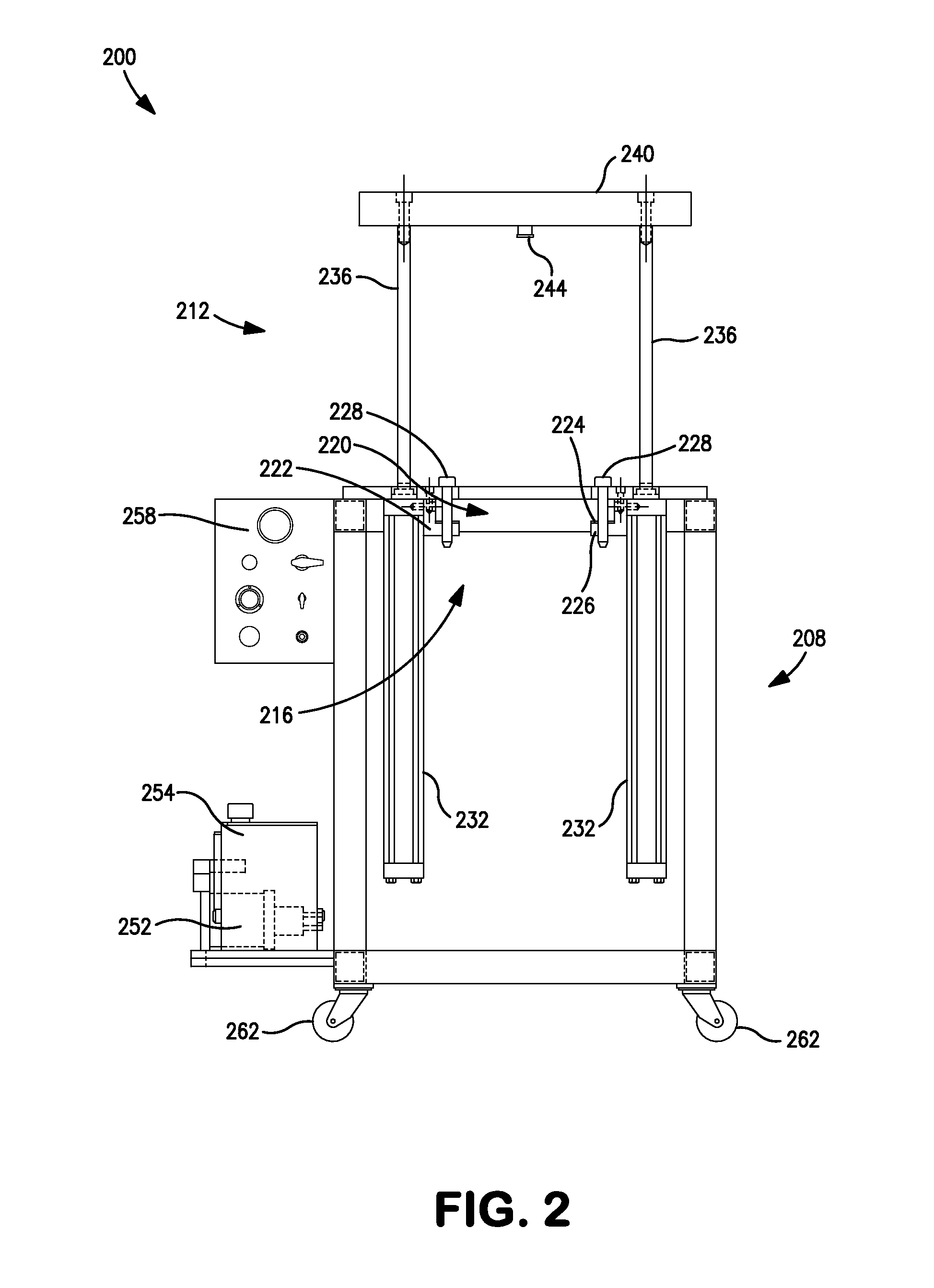

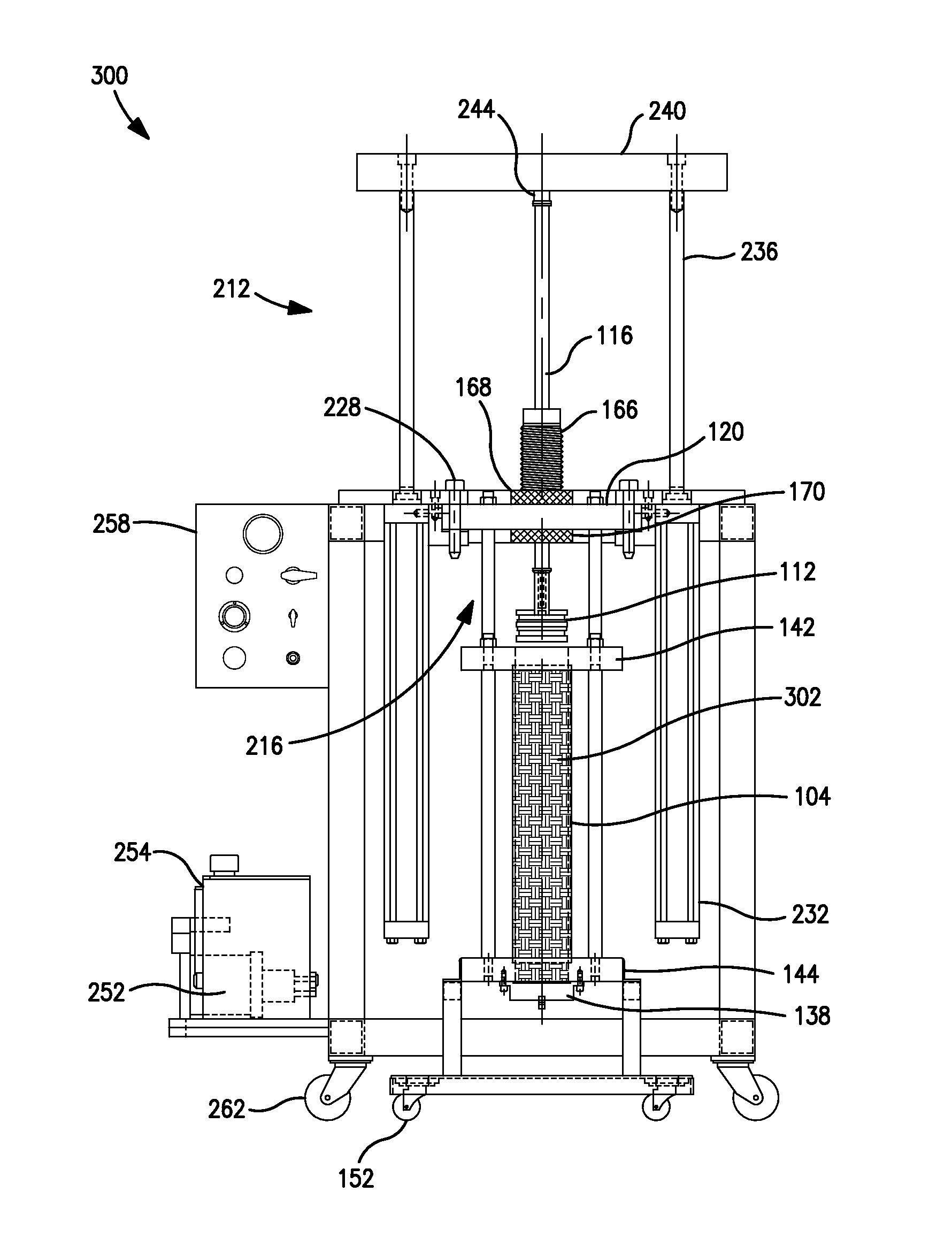

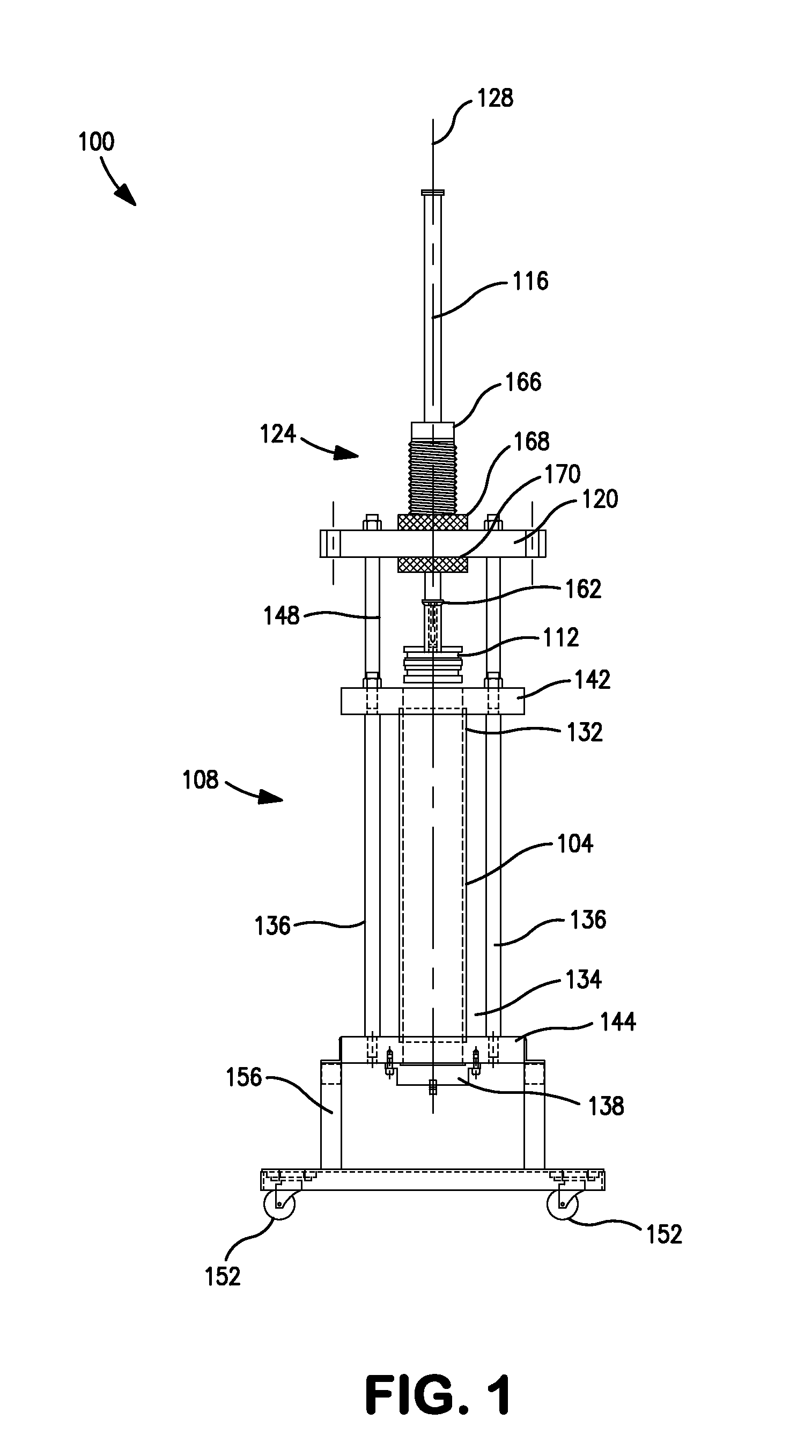

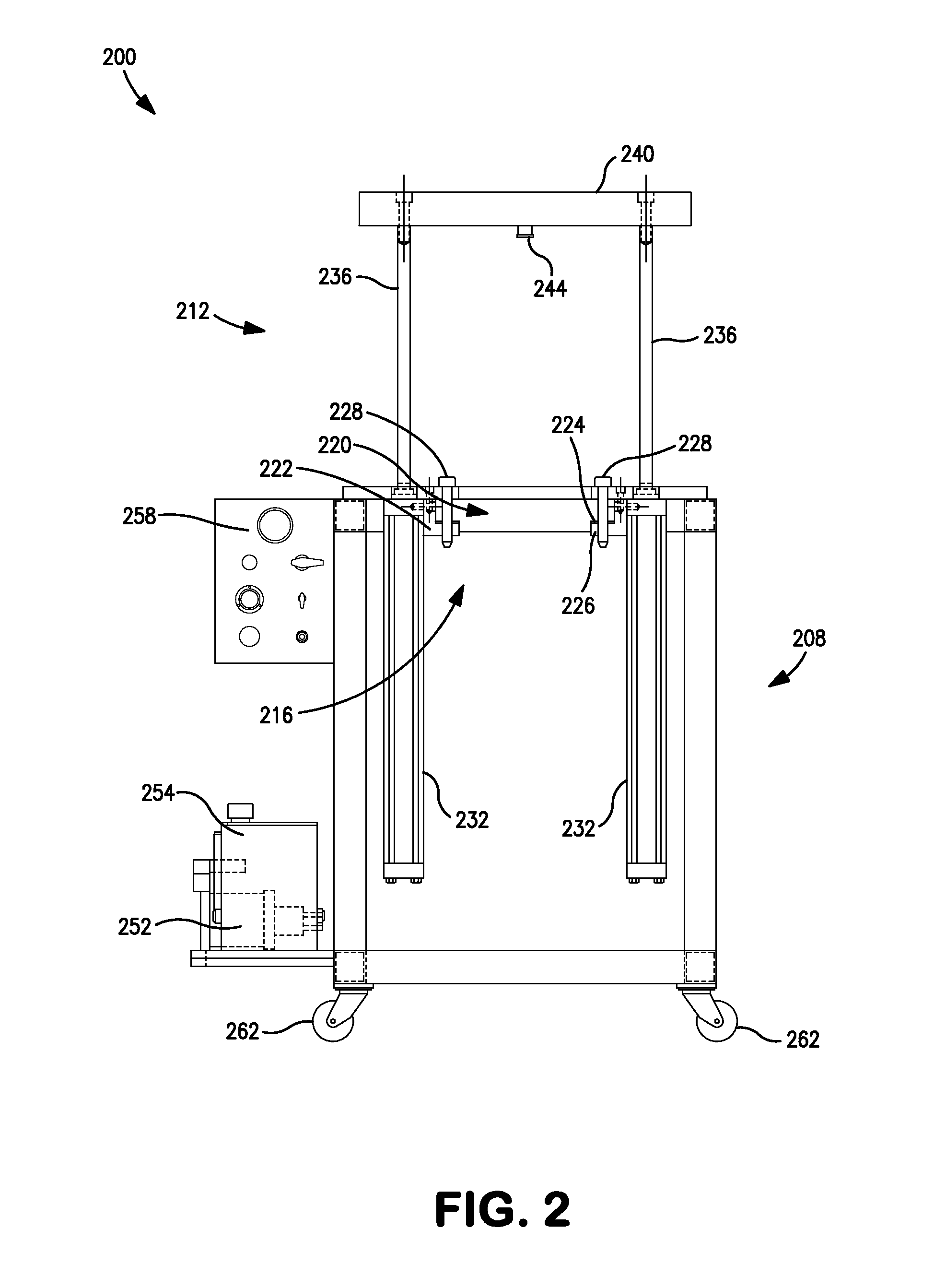

Apparatus and methods for packing chromatography columns

InactiveUS20110120951A1Ion-exchange process apparatusComponent separationEngineeringChromatography column

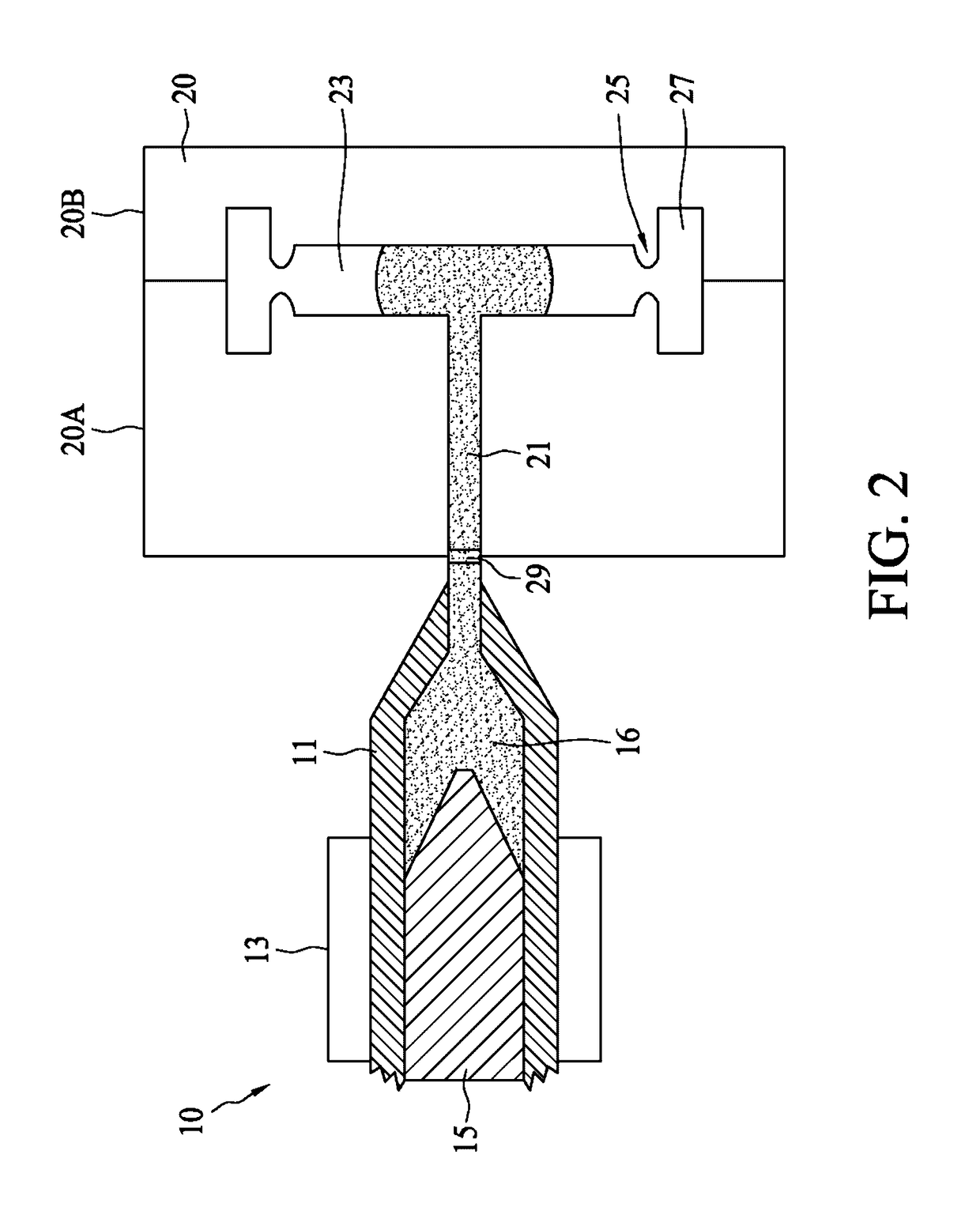

A chromatographic apparatus may include a hydraulic lifting mechanism axially movable from a lowered position to a raised position such that a column and flange of the apparatus are axially movable with the hydraulic lifting mechanism. In a packing system, a mobile column module may be moved into engagement with a packing station by engaging a flange of the column module with a fixture of the packing station. After packing a column of the column module, the column module may be removed from the packing station with a piston head locked in the column to maintain packing pressure. The packing station may be utilized to unpack the column. A hydraulic lifting mechanism may be operated to lower one or more portions of the column module such that the one or more portions may be separately removed from the packing system.

Owner:AGILENT TECH INC

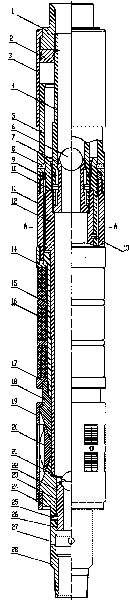

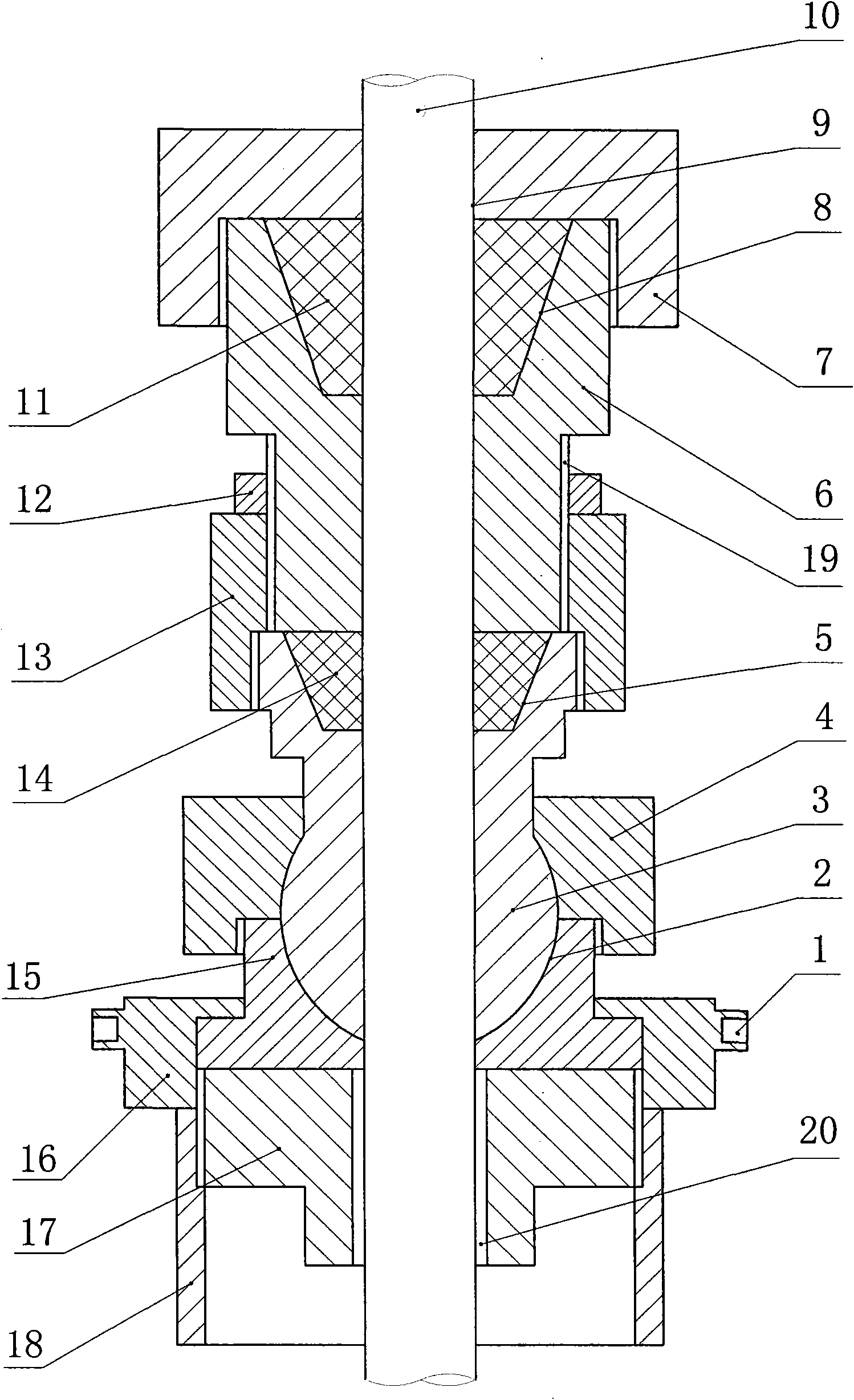

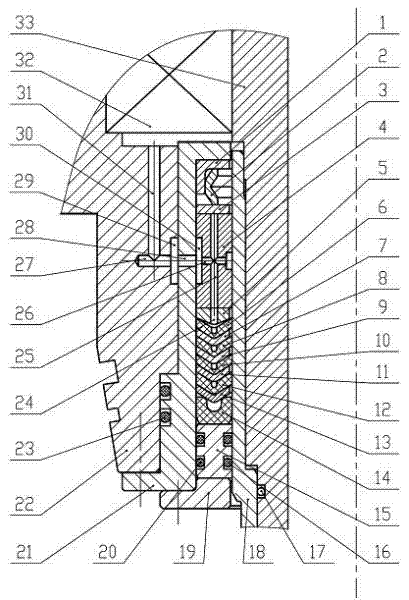

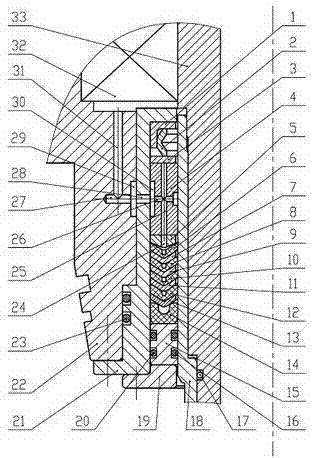

Release packer capable of well-flushing

ActiveCN101737019AReliable seatingRealize layered oil recoveryCleaning apparatusFluid removalHydraulic cylinderUpper joint

The invention discloses a release packer capable of well-flushing, which comprises an upper joint, a piston, a hydraulic cylinder, a separating joint, an ejector sleeve, a packing valve ball, a packing valve seat, a packing shear pin, a lock ring, a junk sub, a connected pipe, an inner pipe, an unset shear pin, an upper rubber cylinder joint, a rubber cylinder shaft, a rubber cylinder, a lower rubber cylinder joint, an upper cone, a slip sleeve, a slip, a lower cone, and a stop joint; wherein the lower cone is provided with a communicated hole and internally provided with a sliding sleeve; the sliding sleeve is positioned above the communicated hole and fixed on the lower cone; the upper part of the sliding sleeve is provided with an upper seal ring, and the lower part of the sliding sleeve is provided with a lower seal ring; a pin is positioned between the upper seal ring and the lower seal ring; a cut-off valve ball is located in the upper port of the sliding sleeve; and the diameter of the cut-off valve ball is smaller than the inner diameter of the packing valve seat. Before packing, the reverse well flushing can be carried out on an oil pipe on the packer so as to wash way sundries in the oil pipe and ensure that a packing pressure is transferred to the piston, the packer can be reliably packed and the well flushing can successfully realize oil production by layer, thereby the invention has obvious economic benefit.

Owner:DONGYING BAIHUA GASOLINEEUM TECH DEV

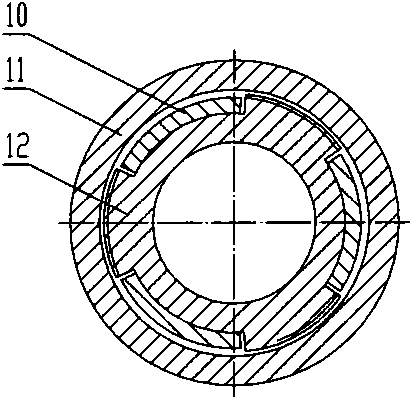

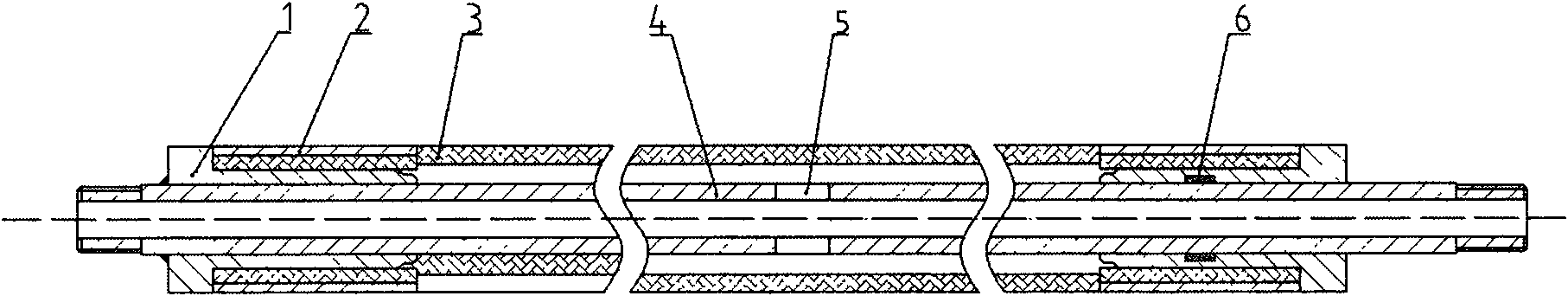

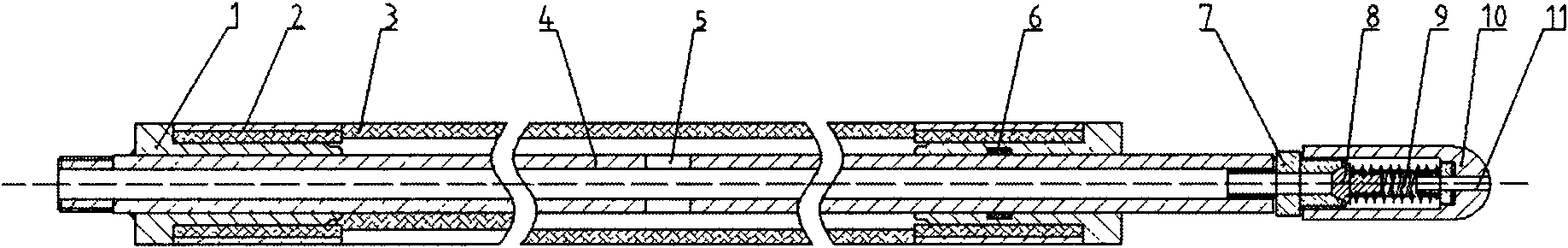

Waterpower hole packer

InactiveCN102155251AWill not be deformed or damagedLarge axial contraction forceDust removalFire preventionEngineeringAxial force

The invention provides a waterpower hole packer. The waterpower hole packer comprises a front hole packer, one or more middle hole packers and a rear hole packer; the rear end of the front hole packer is connected in series with the front end of the middle hole packer; the front end of the rear hole packer is connected in series with the rear end of the middle hole packer; and the front hole packer, the middle hole packer and the rear hole packer have the same structure and comprise expansion capsules and central pipes. By the waterpower hole packer, high-pressure hole packing of rock holes can be realized; the waterpower hole packer has the characteristics of no axial force, high hole-packing pressure, large friction force, high safety and simple structure, and can be widely applied to mining industries such as the coal mine and the like.

Owner:HENAN POLYTECHNIC UNIV

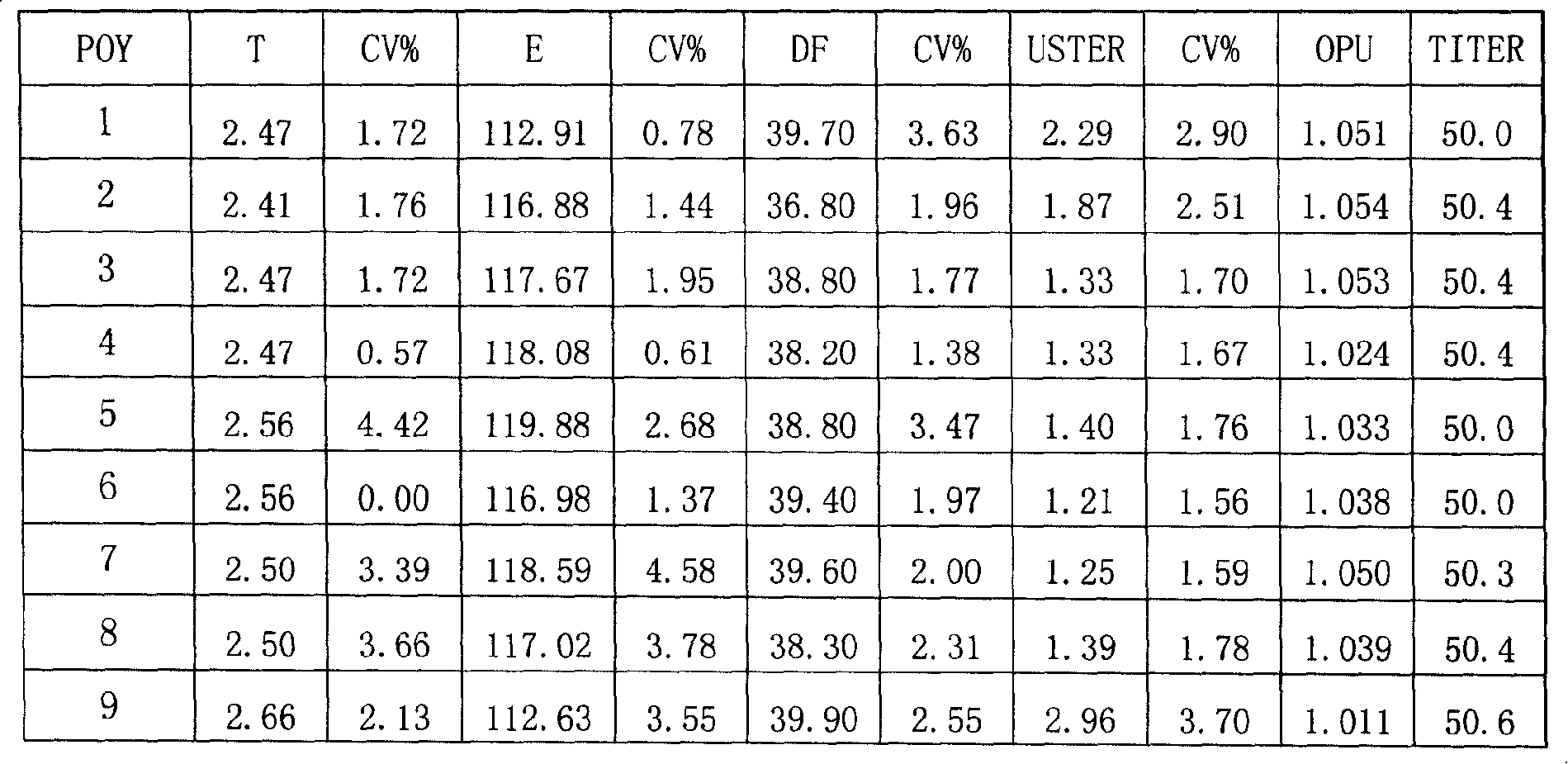

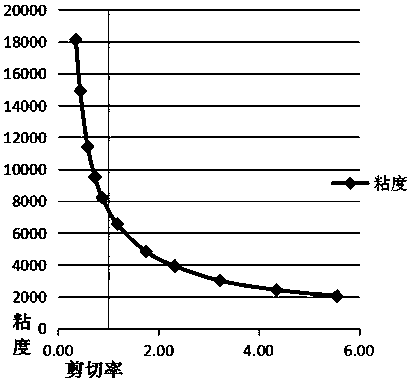

Producing and processing technique for terylene low-elasticity wire

InactiveCN101240458AReduce manufacturing costImprove product qualitySpinning head liquid feederMelt spinning methodsPolyesterGreen environment

The invention relates to a process technology of 48 decitex 144 hole super-fine polyester filament by direct melt direct circular blow technology and POY-DIY line, from the following areas: (1) the overall denier is small, so that 0.6-0.9 metering pump can keep stable reliable speed; (2) the synchronization role of the pressure and the temperature is attained by properly increasing bath temperature, properly reducing viscosity and properly increasing spin pack pressure in the component assembly; (3) the plate is repaired by silicon oil before exflagellation, the injection phenomenon is solved. The tow after leaving the hole is hard to reach the spinning cabinet, through adjusting the pressure of the first floor and second floor, so that second floor is positive pressure and first floor is negative pressure as far as possible. The spinning is sealed independently completely, and no interference by amorphism air current. The pressure and absorbing rate of suction-gun are decreased to absorb mildly the head which have no spinning damage. By 1-3-1 PU disc combination to texturing DTY, this production process can reduce the production cost, stable product quality and green environment protection.

Owner:JIANGSU SHENGHONG CHEM FIBRE CO LTD

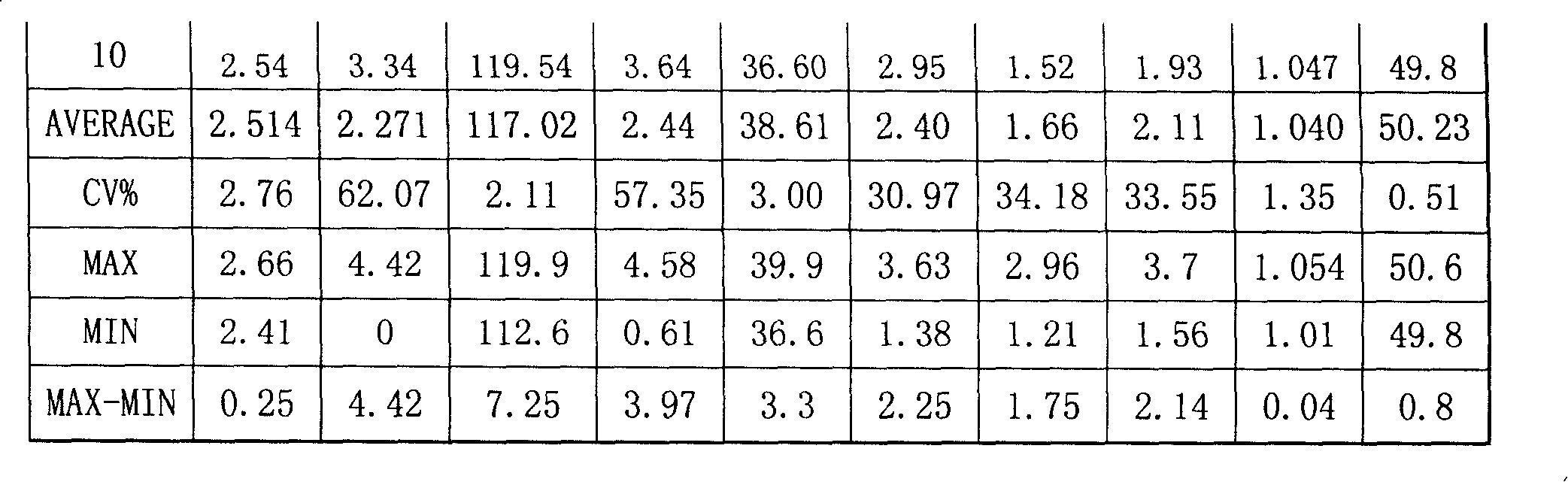

Disposable dental valve device

ActiveUS20140239551A1Low costReduce and eliminate soundSaliva removersBoring toolsMelting temperatureVALVE PORT

A method for forming a disposable dental valve device is disclosed which comprises the steps of injecting a resin into a mold with the melt temperature of the resin being about 201° C. and the mold temperature being about 35° C., filling the resin in the mold for a fill time of about 0.70 seconds, providing a peak first stage fill pressure of about 61.9 Mpa, providing a pack pressure of about 49.5 Mpa, and providing a pack time of about 5 seconds.

Owner:STOMA VENTURES

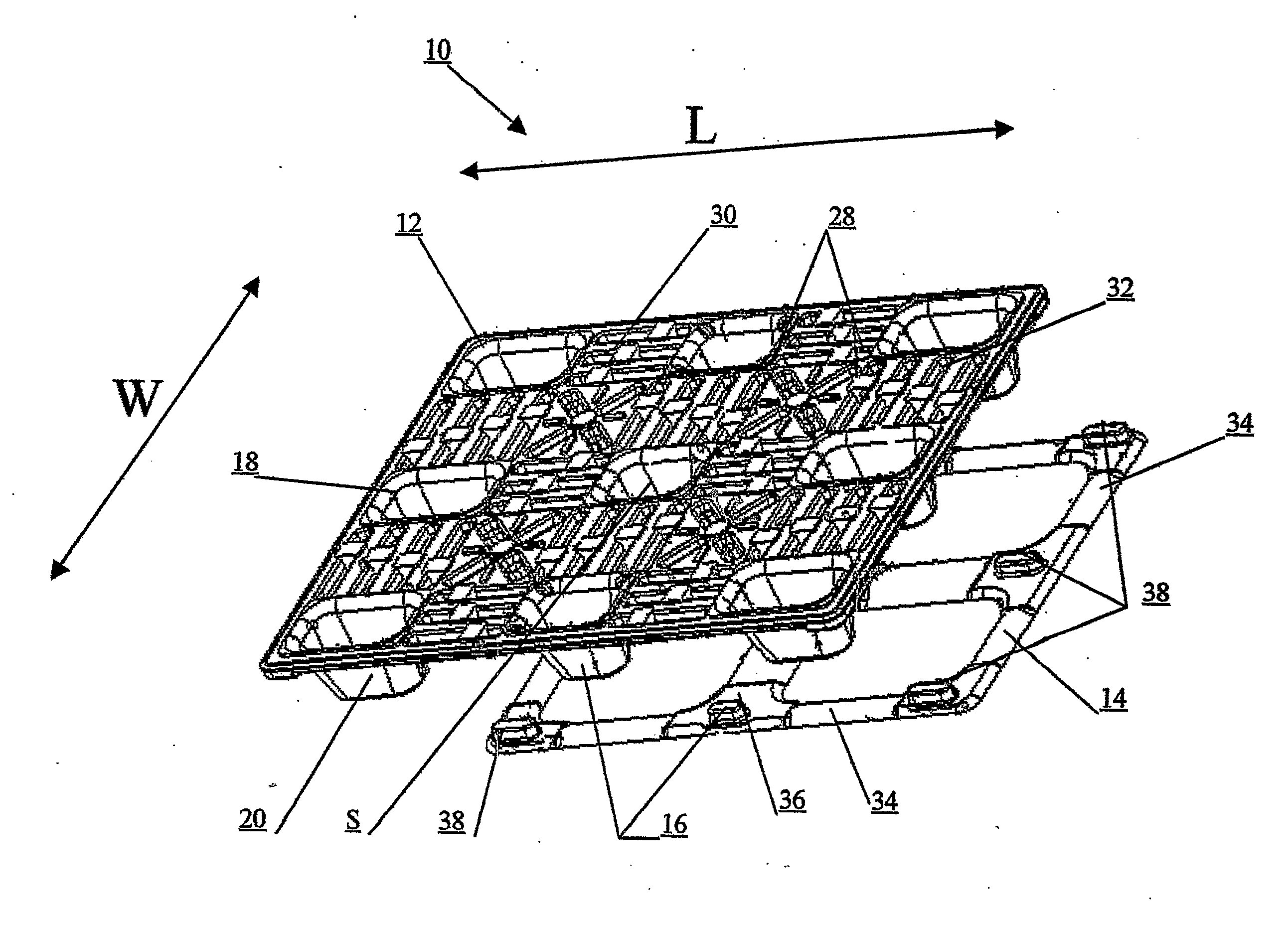

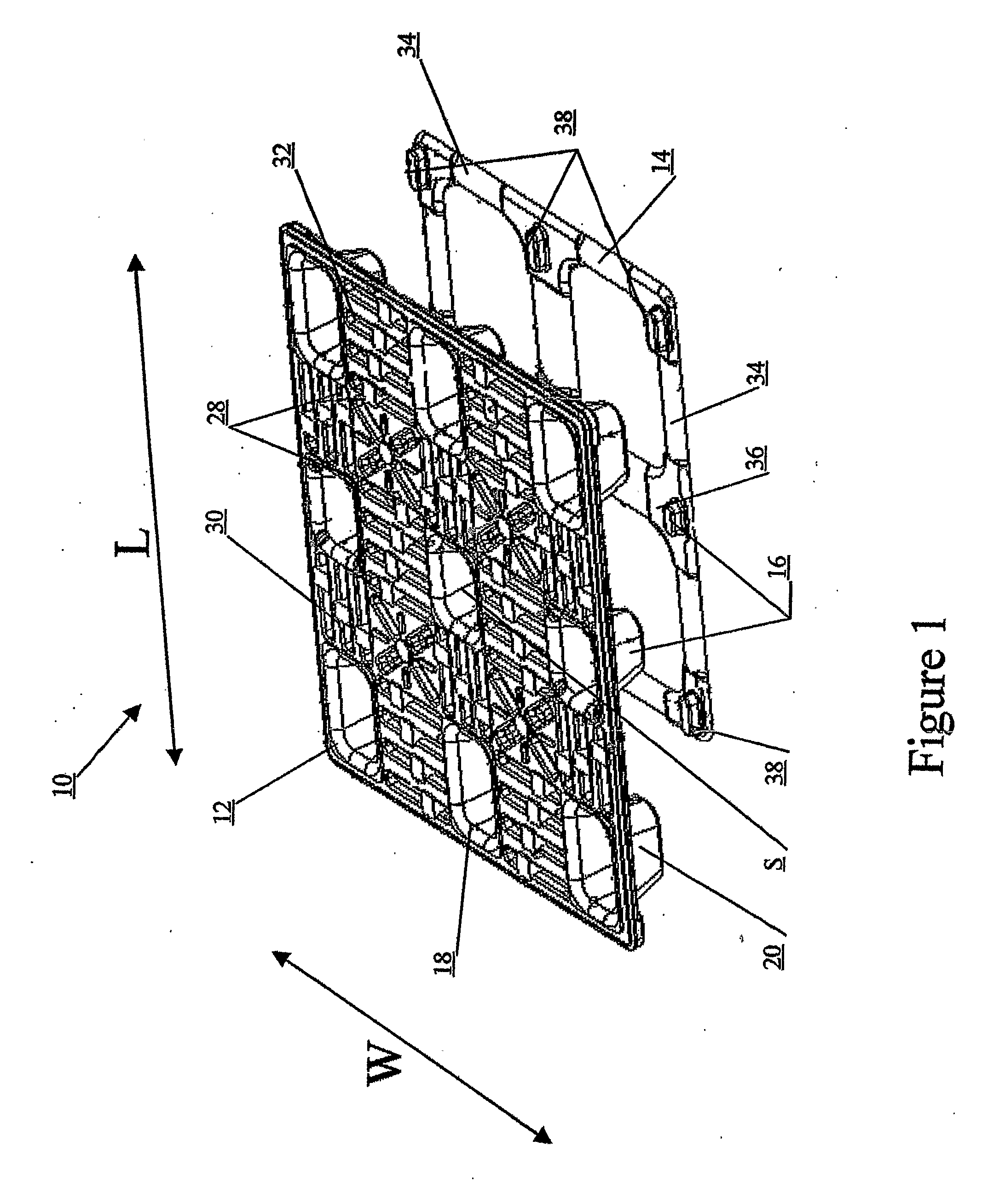

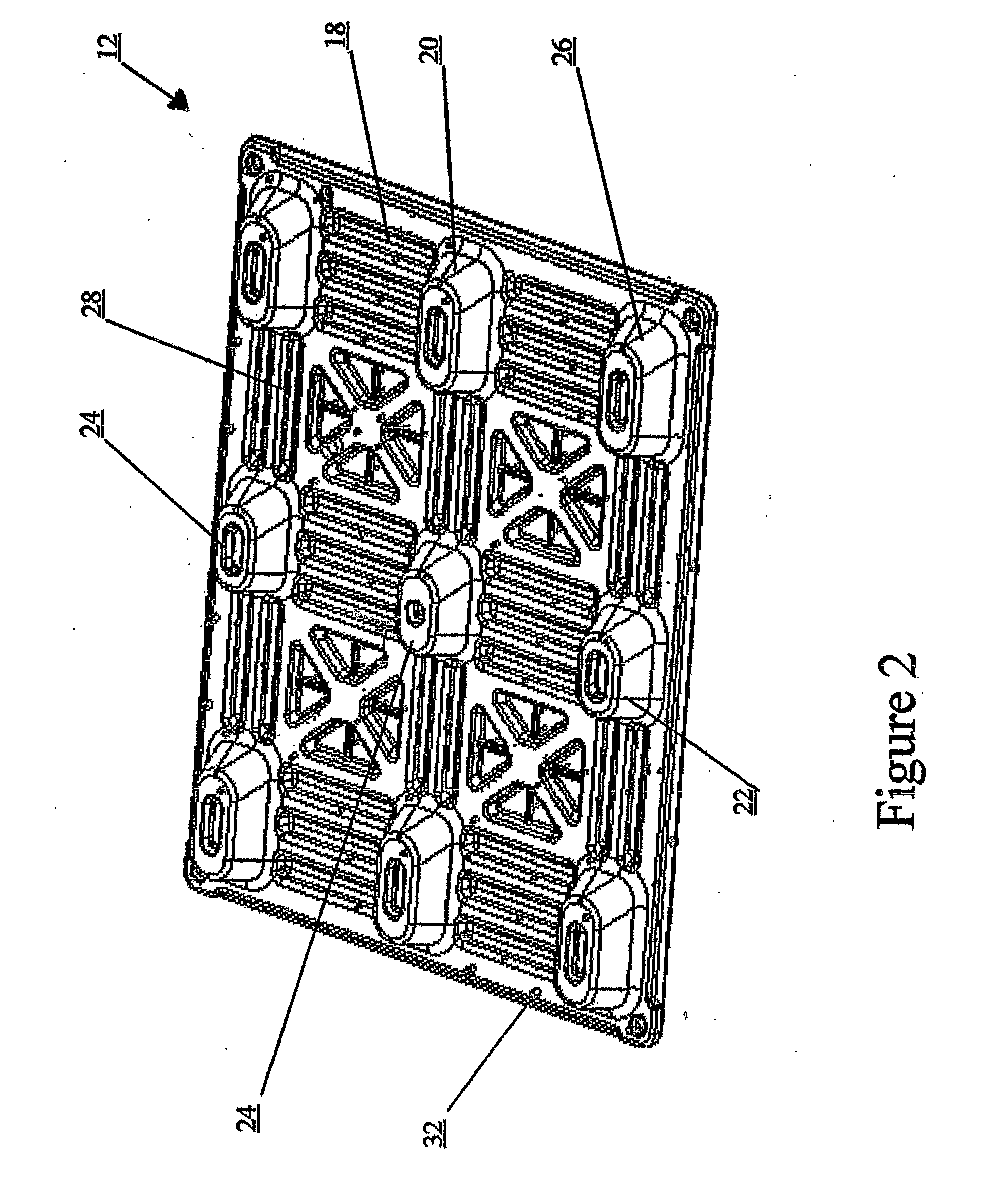

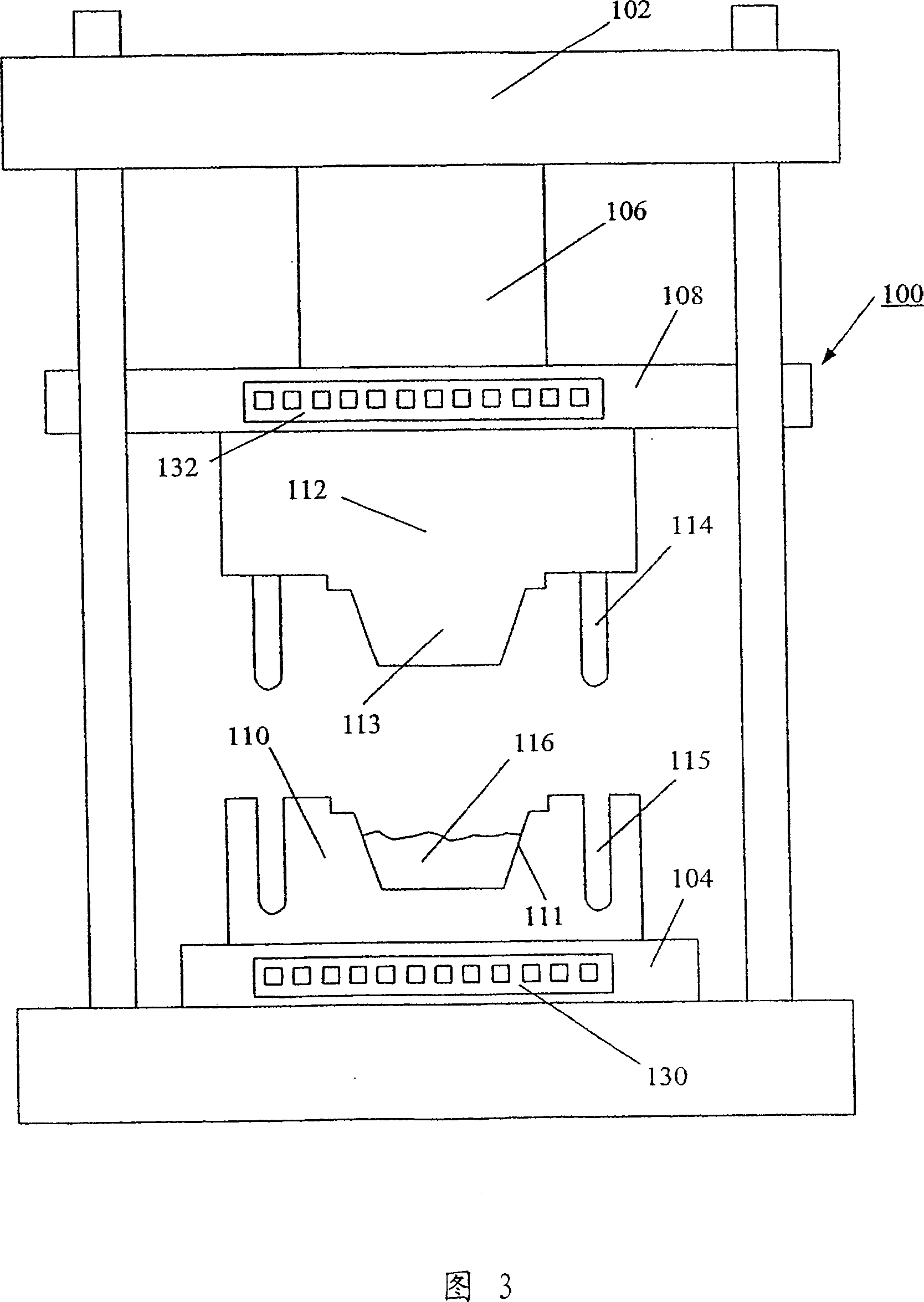

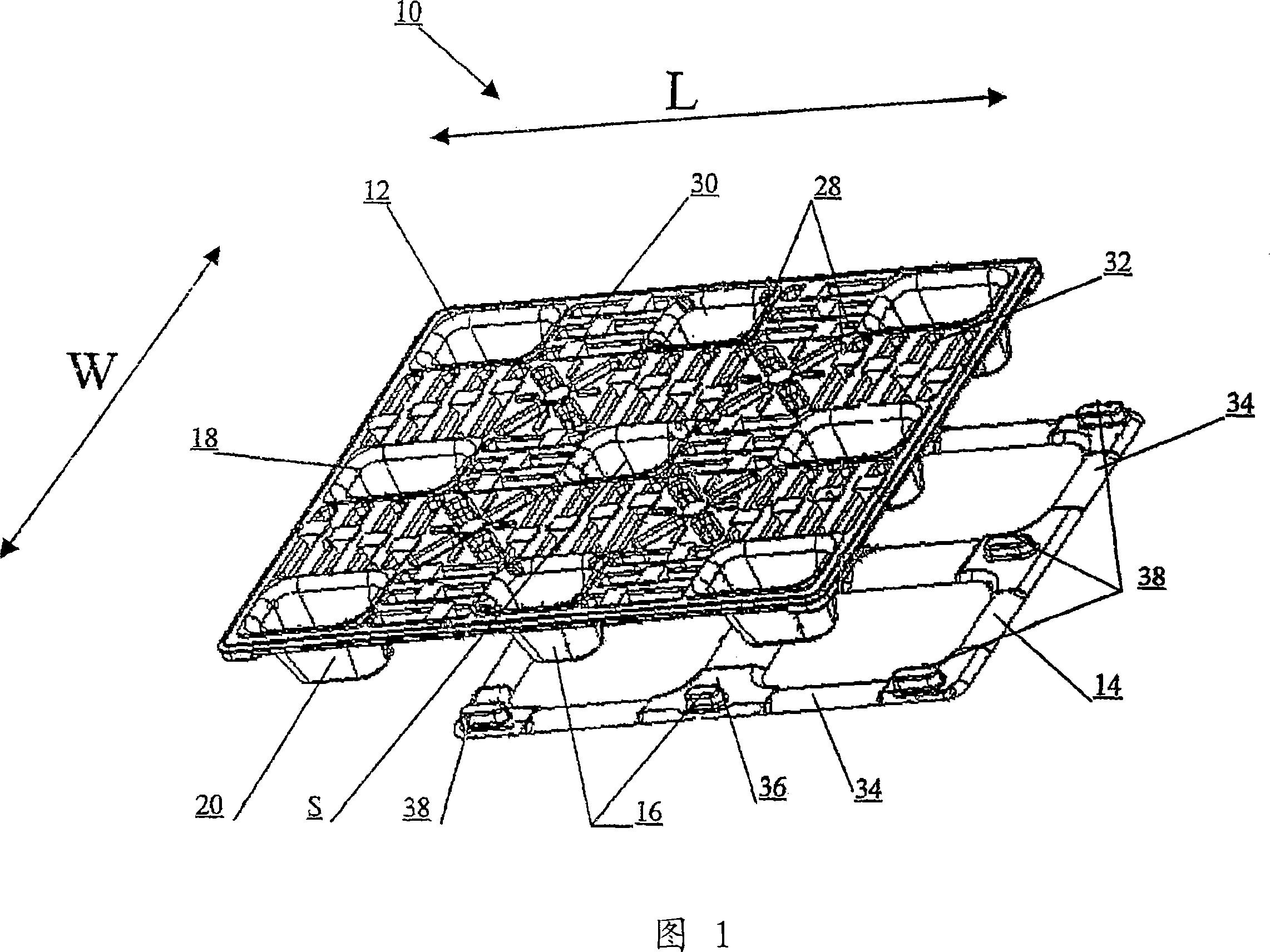

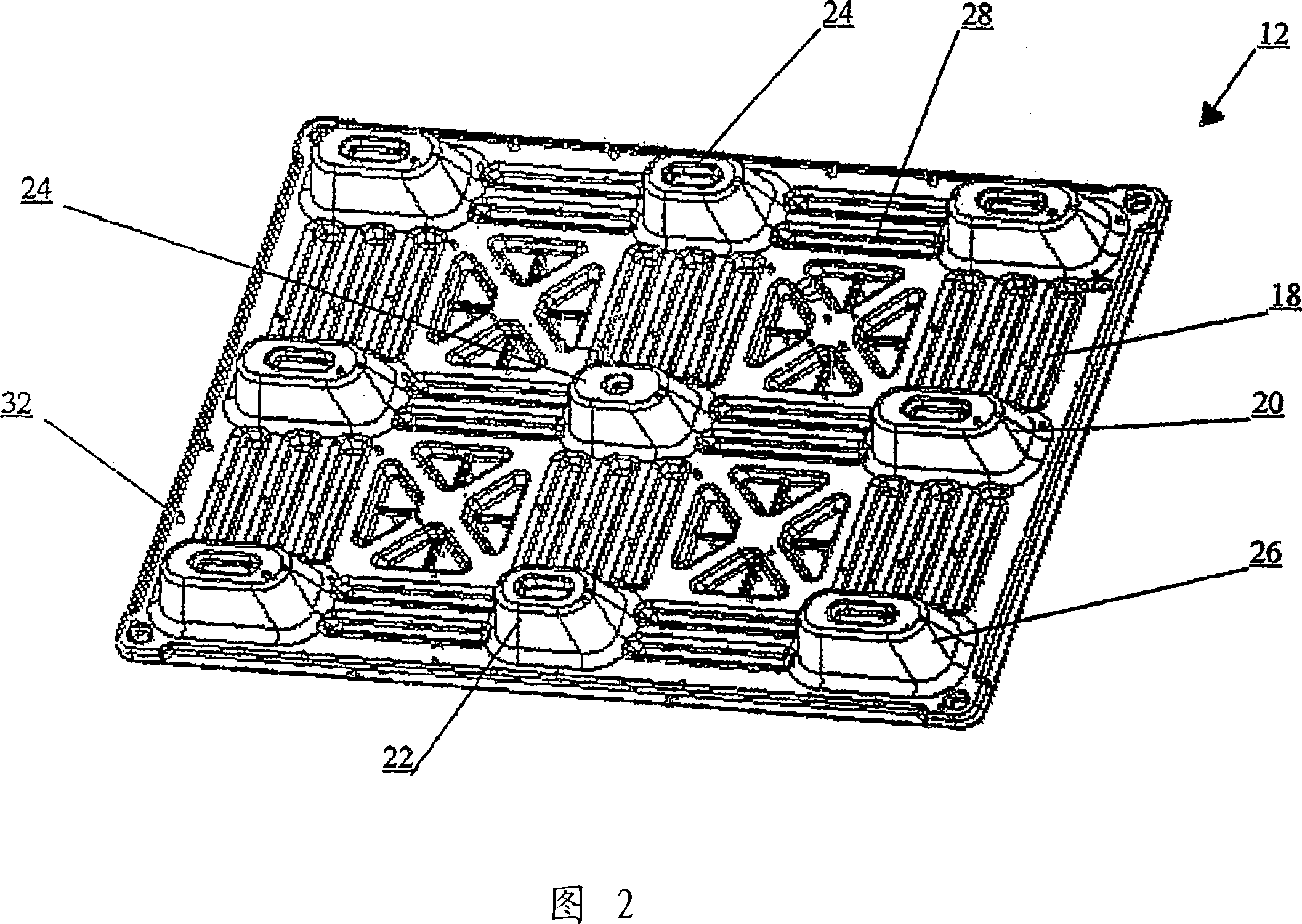

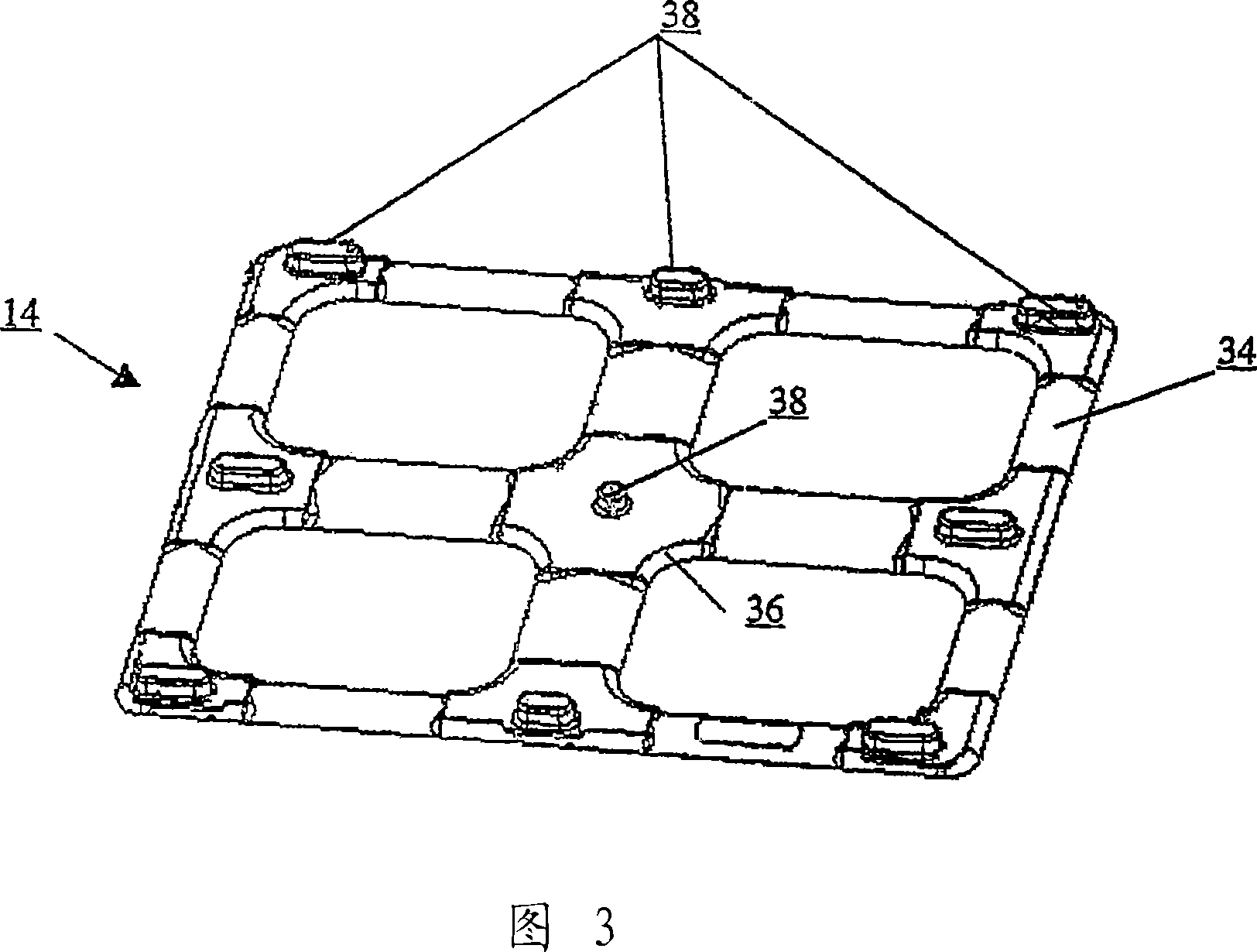

Pallet And Method For Manufacturing The Same

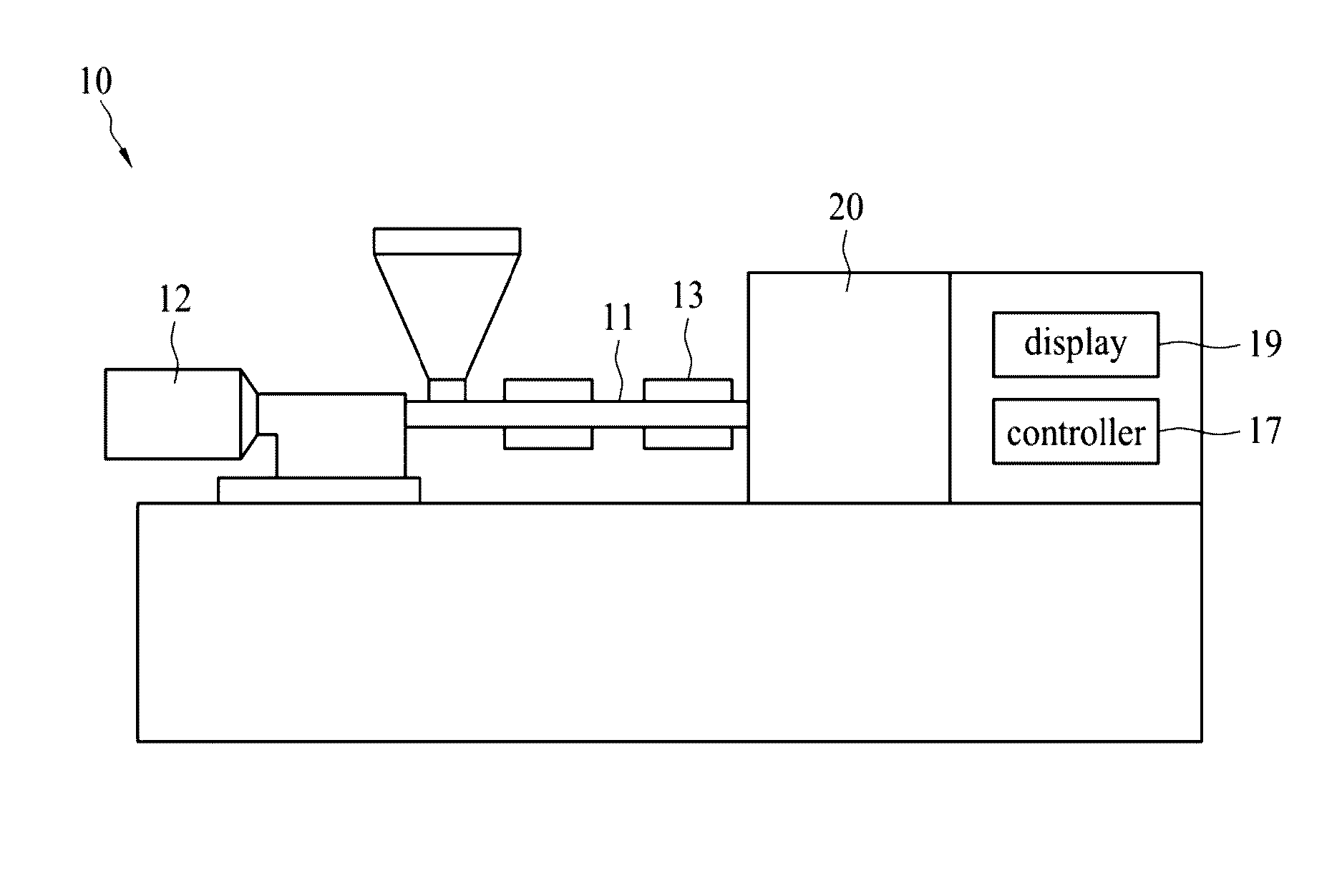

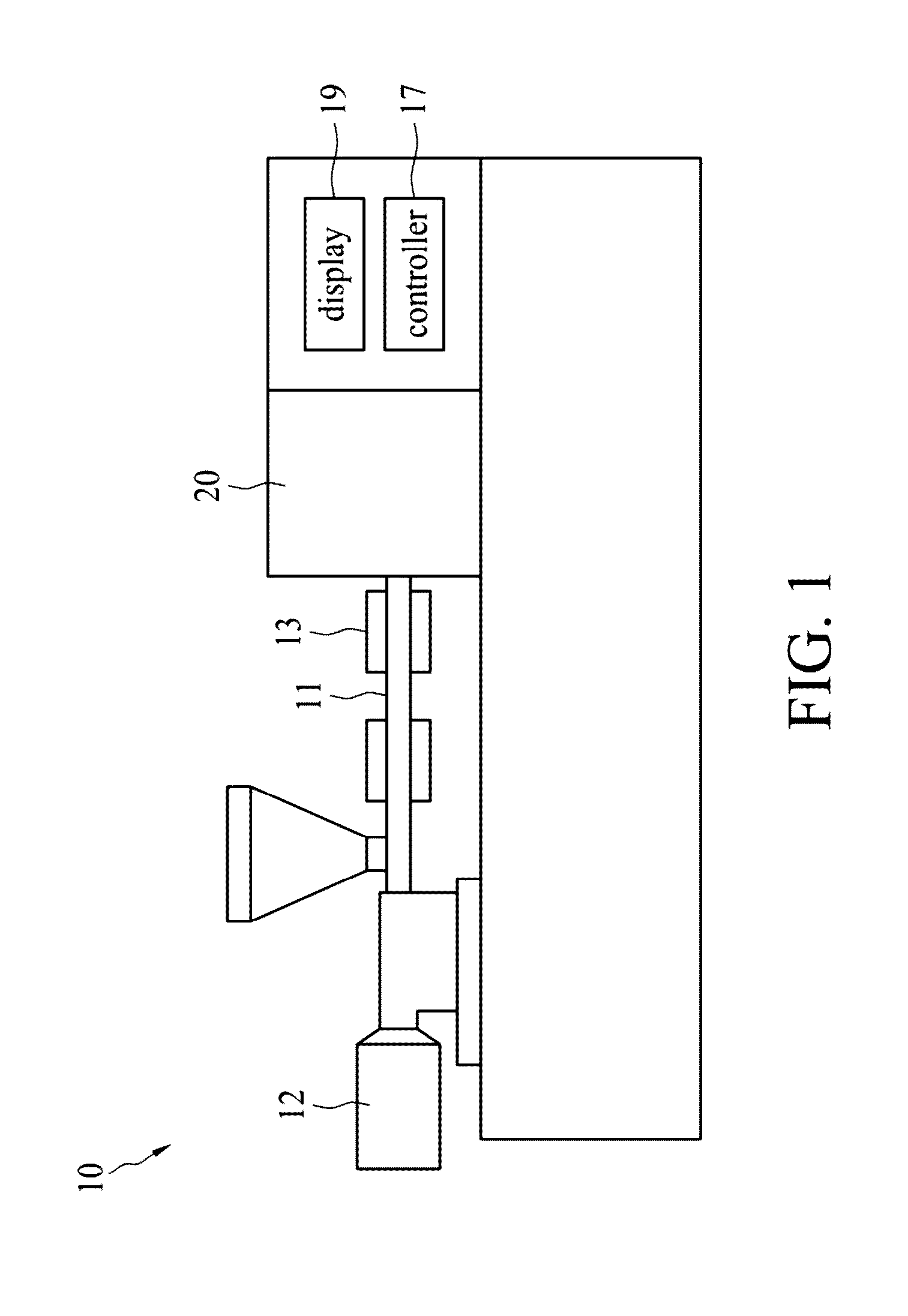

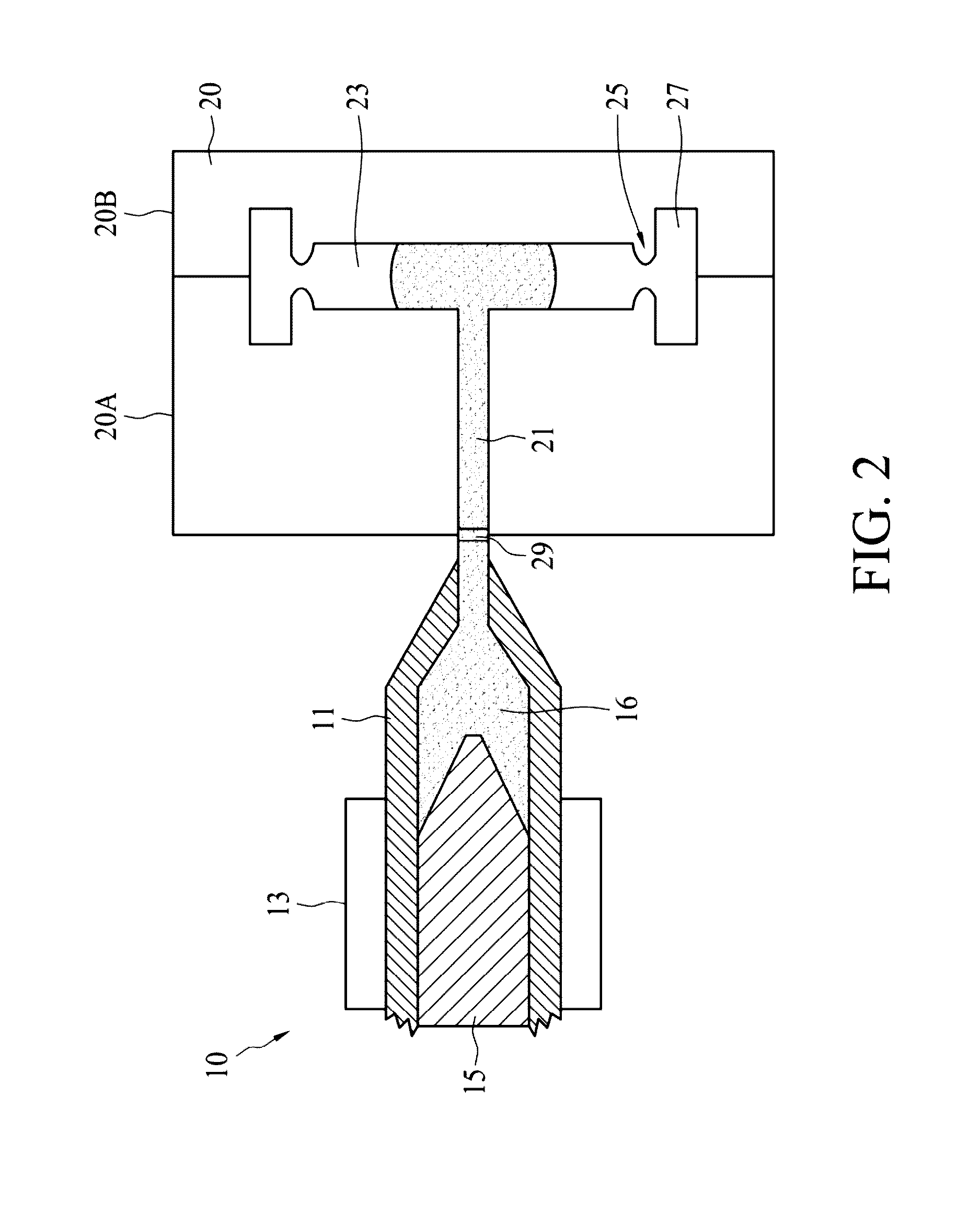

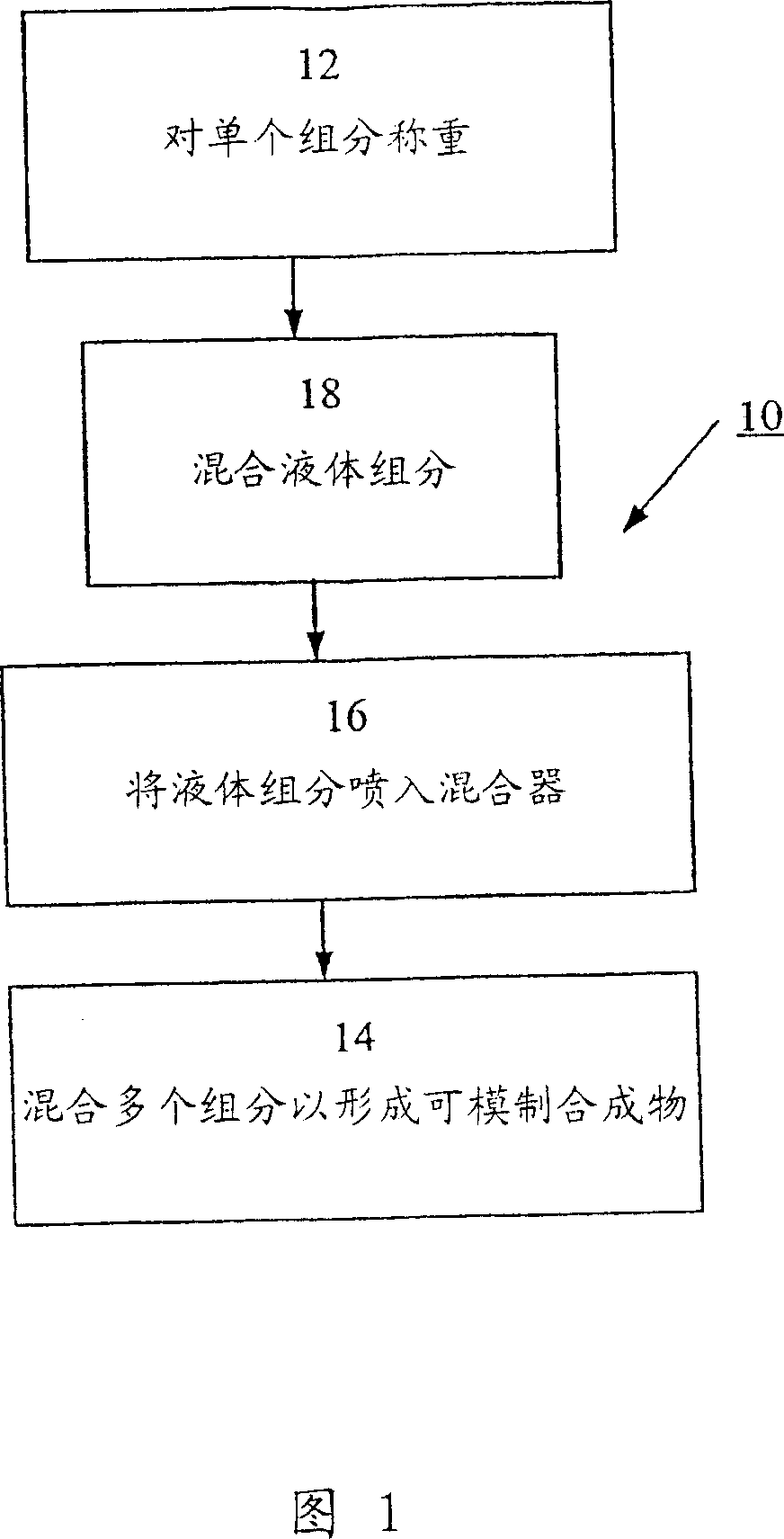

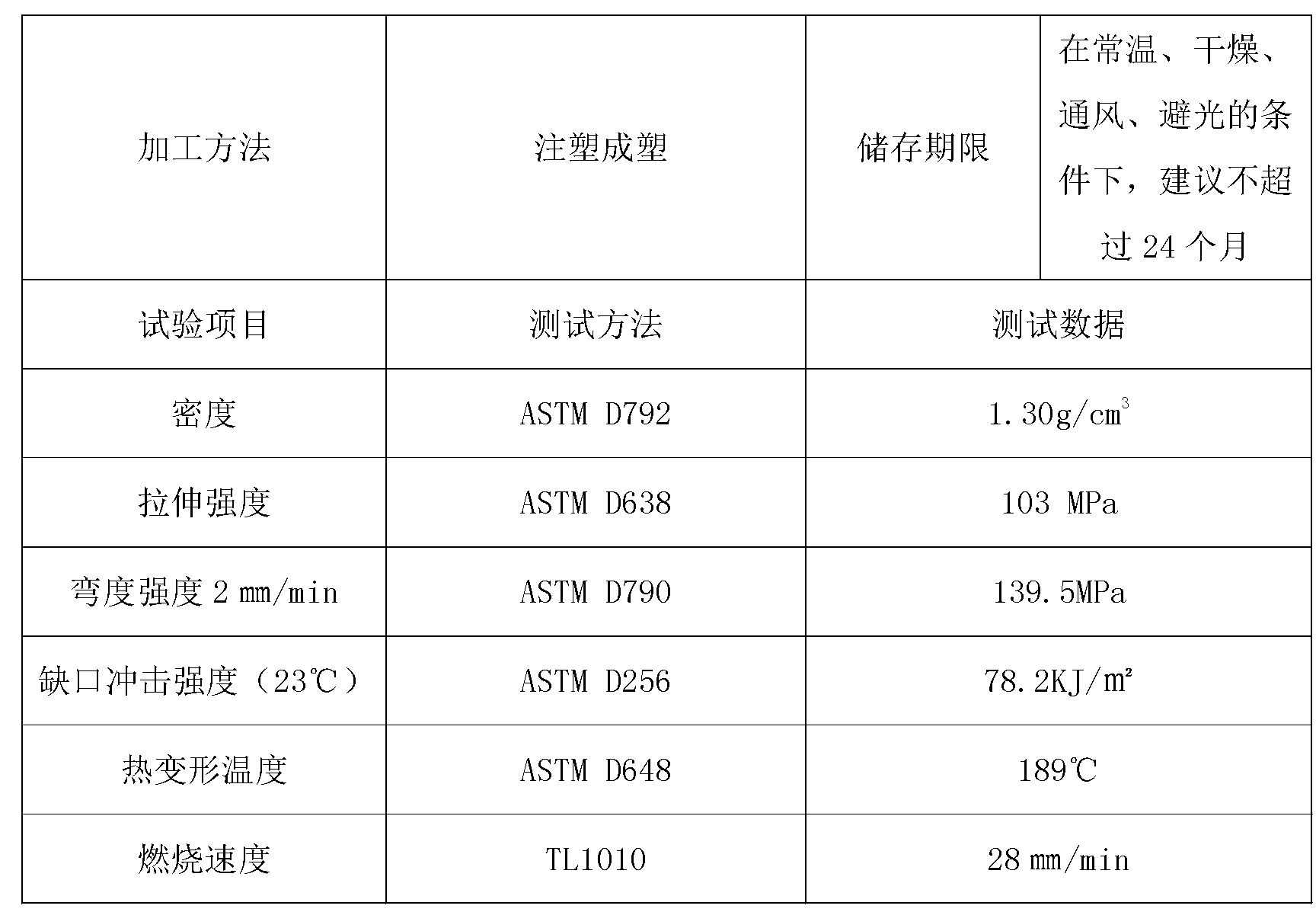

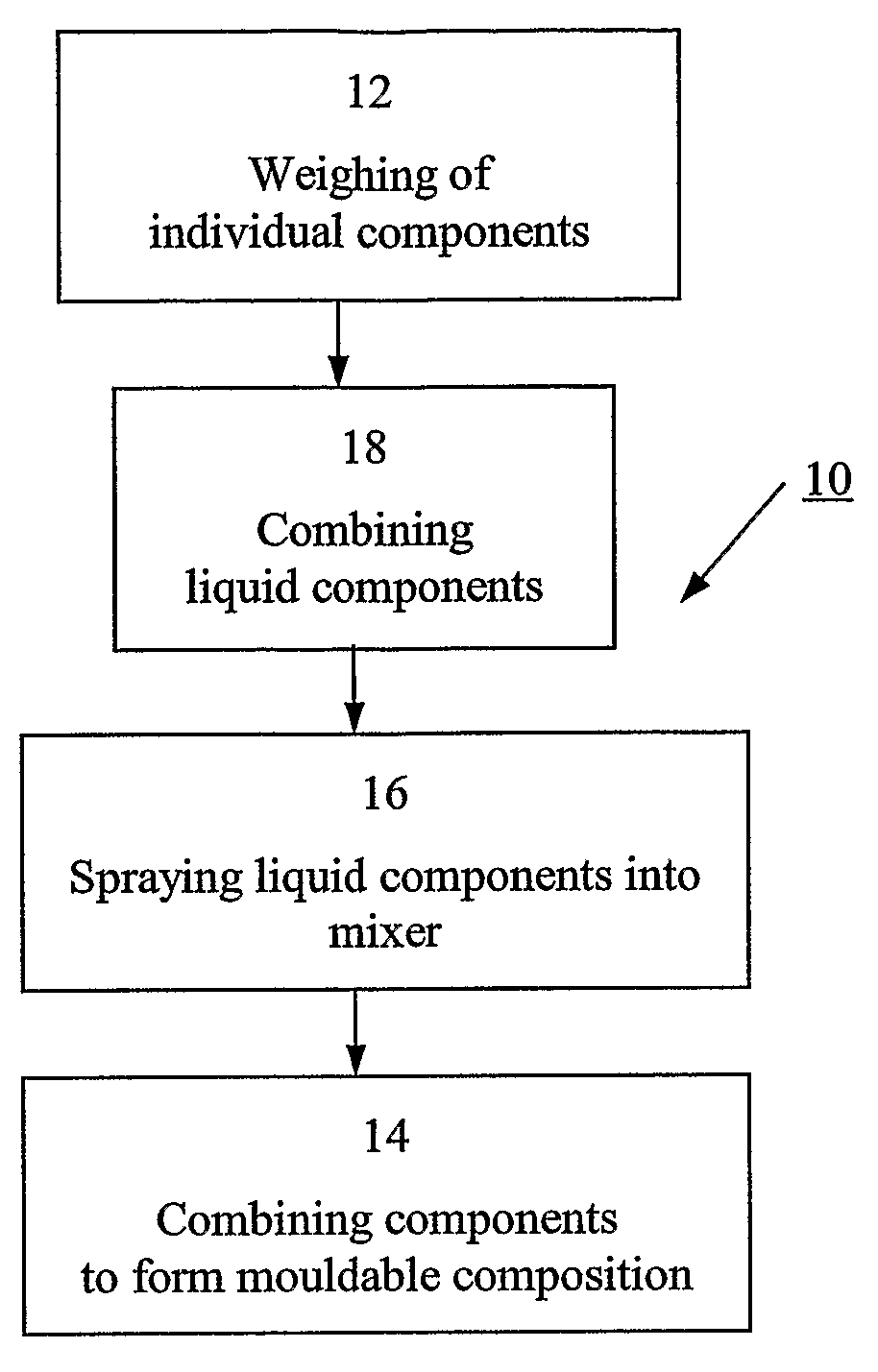

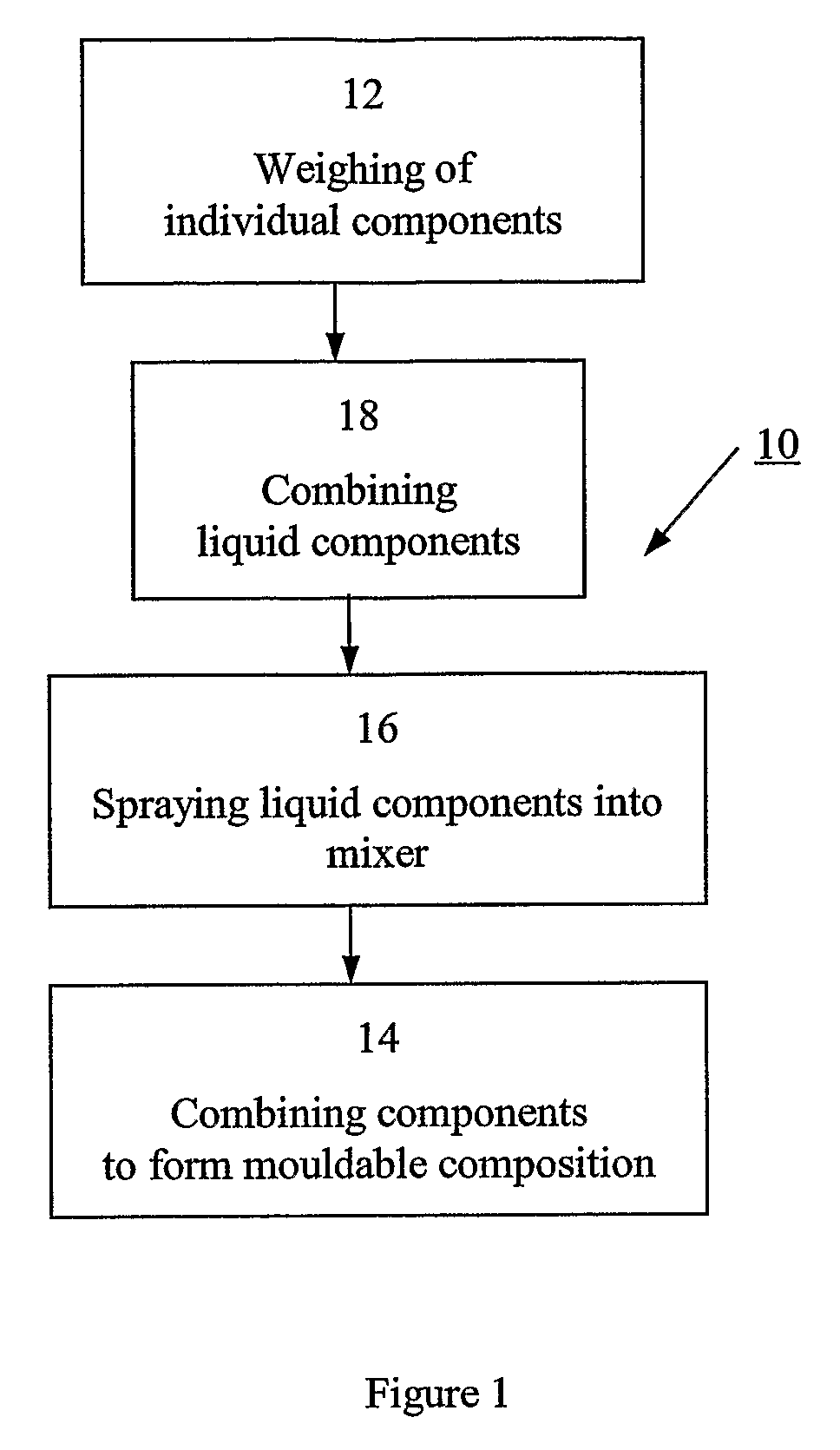

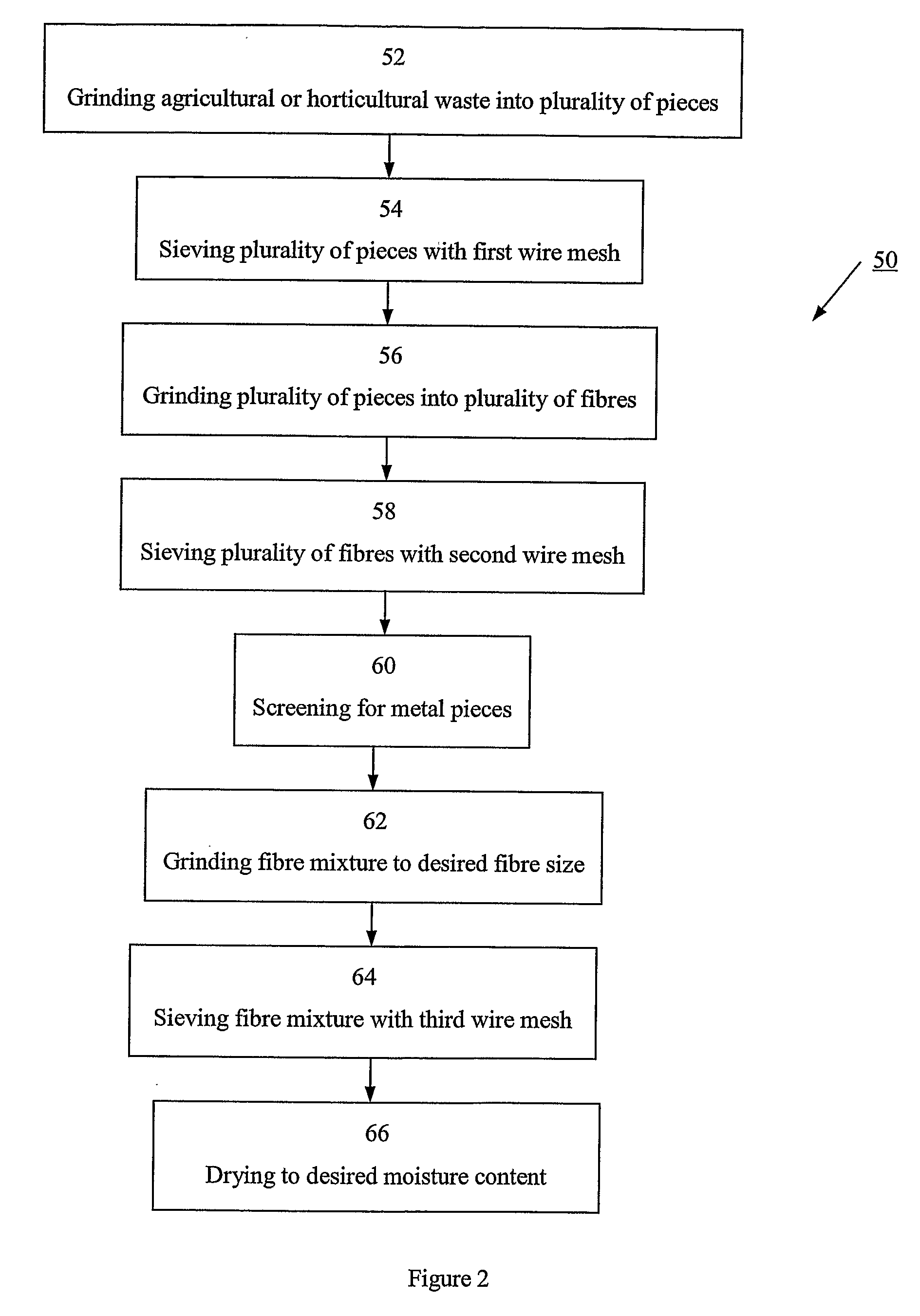

A pallet and a method for manufacturing the same are provided. The pallet comprises a pallet body, a skid to reinforce the pallet body and means to interlock the pallet body and the skid. The pallet body and the skid are moulded from a mouldable composition comprising between about 40 to 60 wt % of a fibre mixture and between about 15 to 45 wt % of an adhesive. The method for manufacturing the pallet begins by preparing the mouldable composition. A mould cavity is loaded with the mouldable composition up to about 90% of the capacity of the mould cavity before applying a packing pressure of between about 435 to 870 psi to the mouldable composition. A predetermined clearance of between about 0.1 to 0.5 mm is maintained between a first mould part defining the mould cavity and a second mould part. A moulded product is removed from the mould cavity when the mouldable composition is substantially cured.

Owner:GPAC TECH (S) PTE LTD

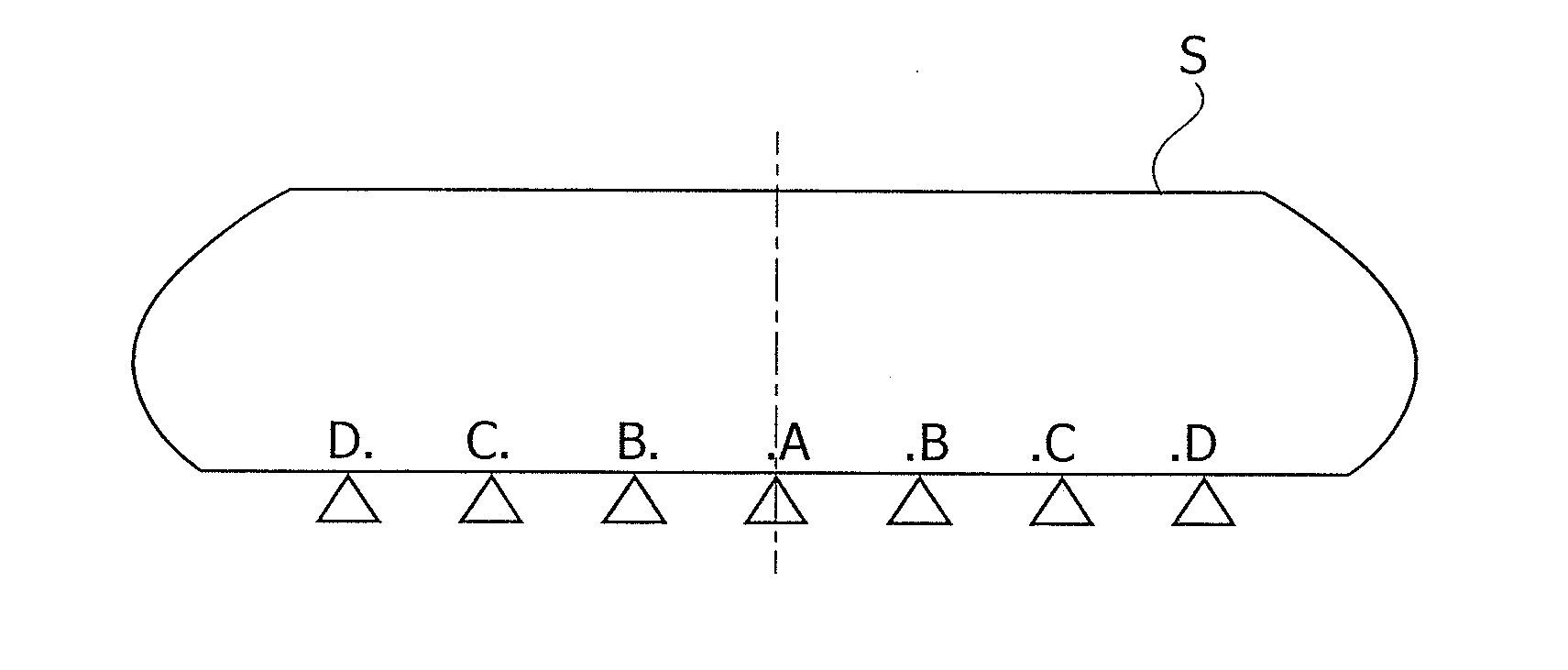

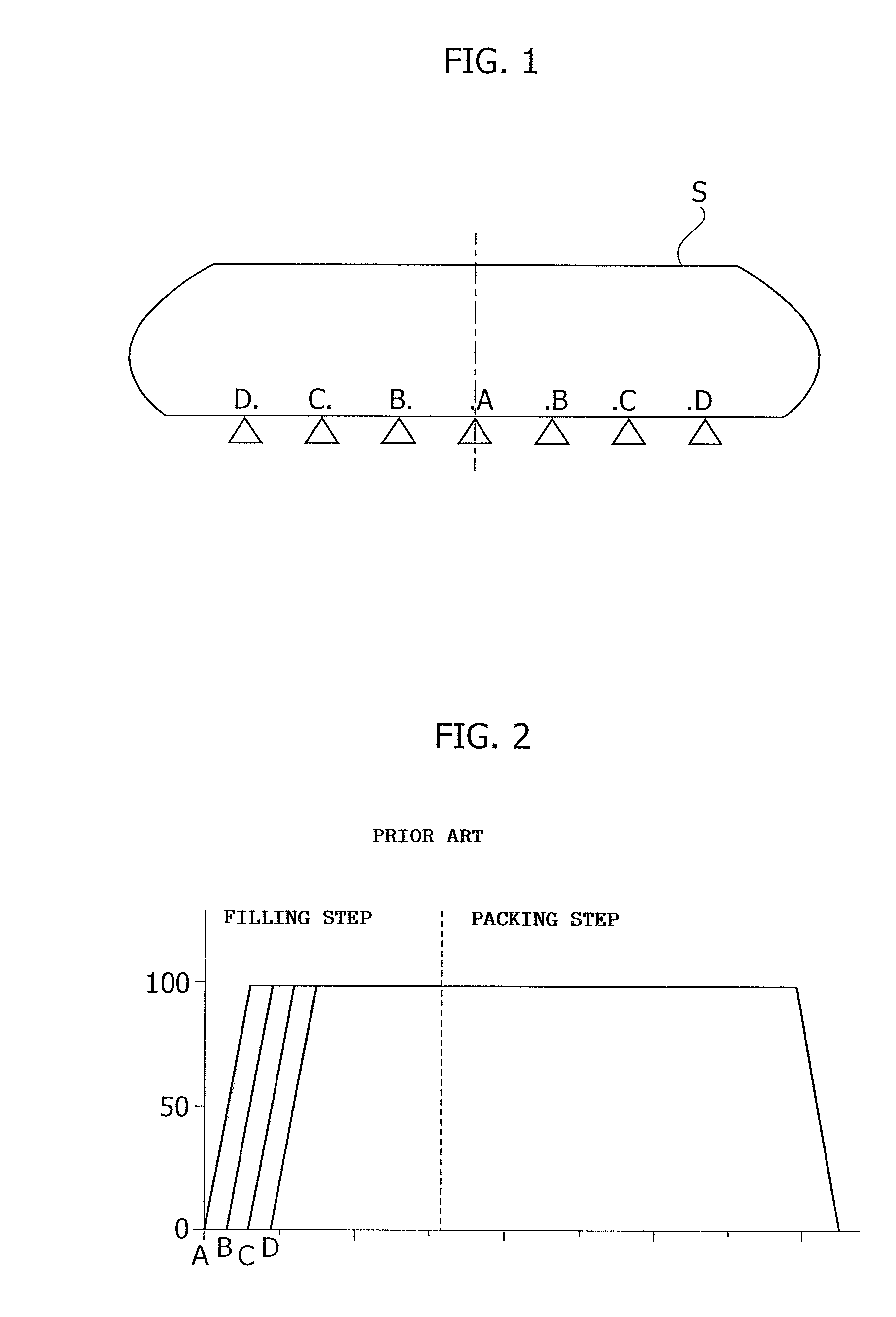

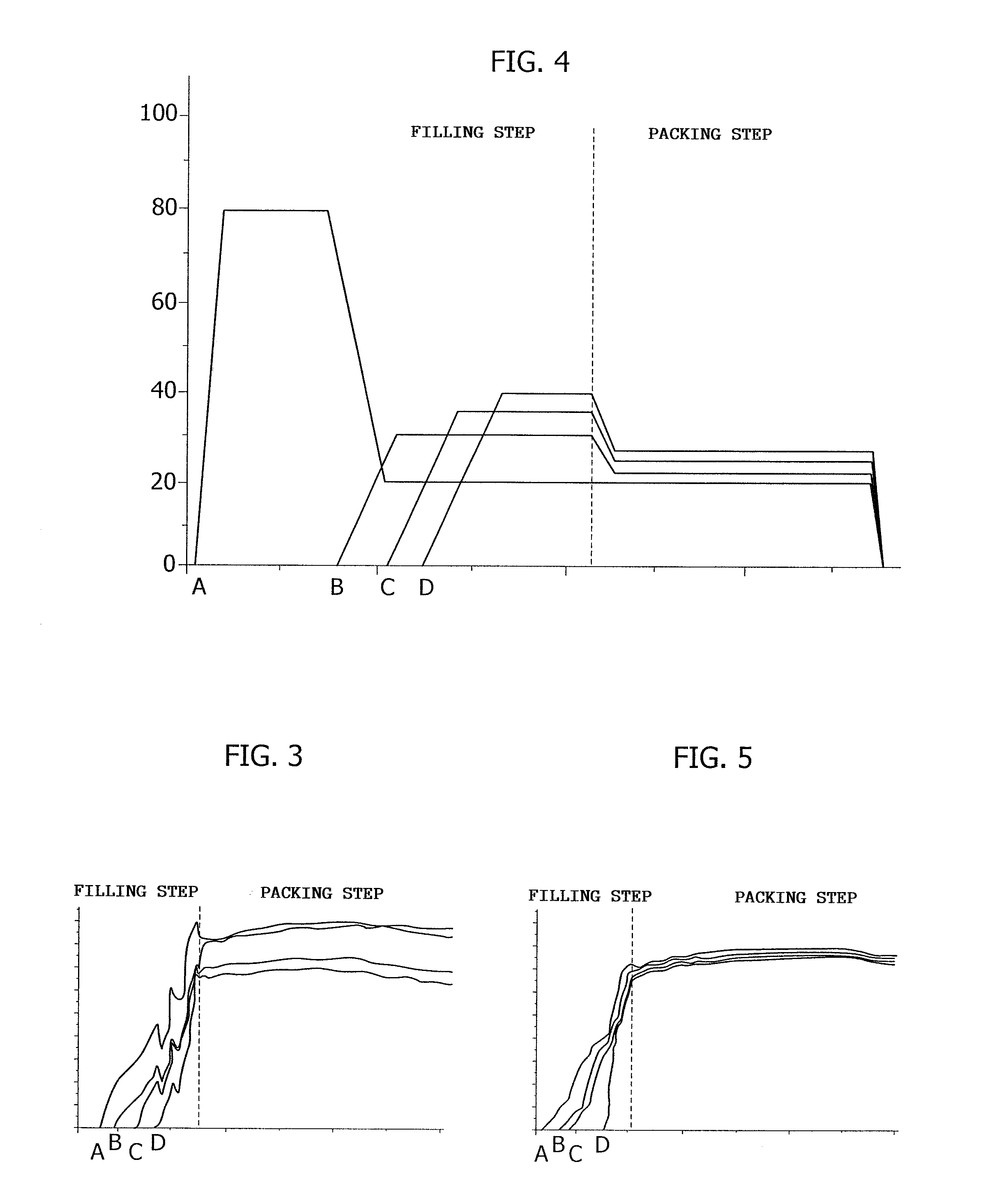

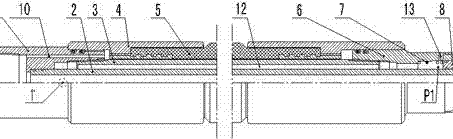

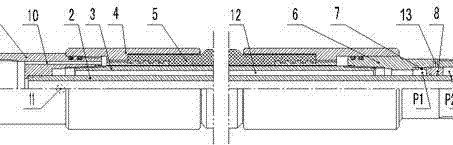

Molding apparatus and method for producing articles molded through sequential injection

ActiveUS20160167264A1Cavity-greater regularityCavity-greater homogeneityAuxillary shaping apparatusDomestic articlesElectronic systemsElectronic control system

A molding apparatus for the production of articles molded through sequential injection includes a mold having a cavity, a plurality of electrically actuated injectors arranged at central, intermediate and end positions, respectively, with respect to the mold cavity, and an electronic system for controlling the injectors for the actuation thereof according to a sequential cycle which provides for opening the central injector first, followed by the intermediate injectors and then the end injectors. The electronic control system is configured so that the opening sequential cycle occurs in such a way to obtain more linear and homogeneous pressure in the mold filling step, and lower packing pressure.

Owner:INGLASS SPA

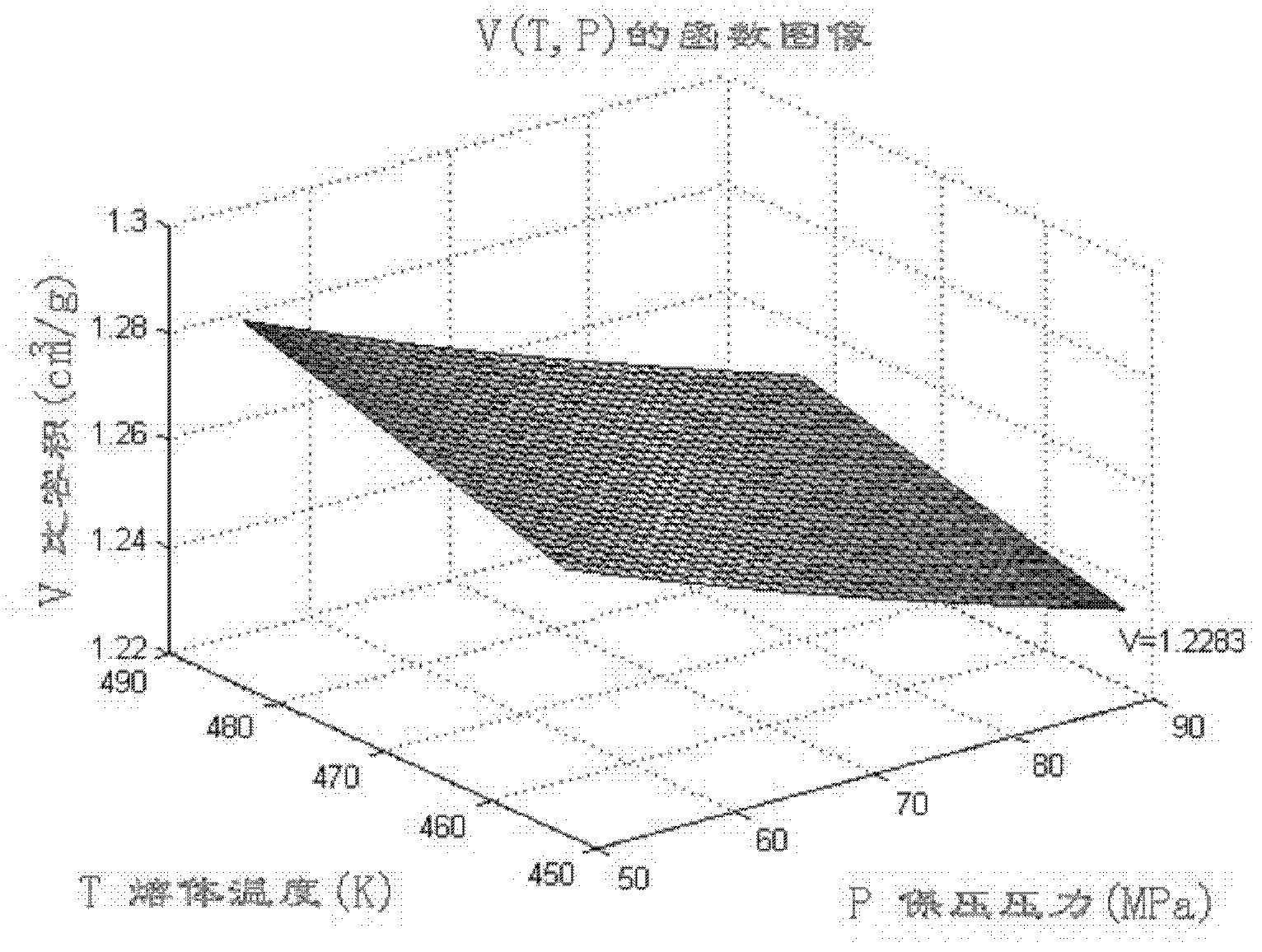

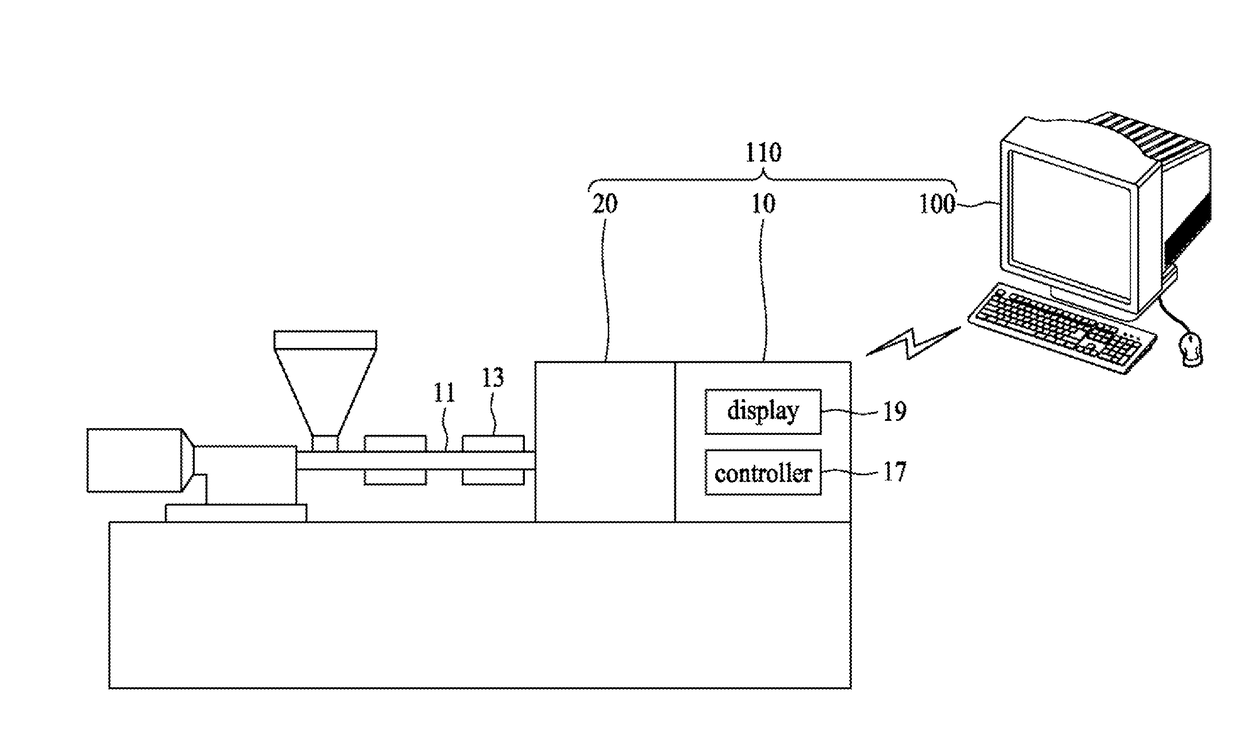

Method for operating a molding machine with a predicted in-mold PVT waveform of a molding resin

A method for operating a molding machine includes steps of specifying a simulating domain corresponding to a genuine domain in a mold disposed on the molding machine; performing a virtual molding by using an initial packing pressure profile to generate an initial state waveform expressing a relationship between an in-mold pressure and an in-mold temperature of the molding resin; obtaining an updated packing pressure profile for applying a molding pressure to at least a portion of the genuine domain while taking into consideration the initial state waveform; repeating the virtual molding while taking into consideration the updated packing pressure profile to generate an updated state waveform of the molding resin; and setting the molding machine taking into consideration the updated packing pressure profile to perform an actual molding by applying an actual molding pressure to the at least a portion of the genuine domain to prepare the molding product.

Owner:CORETECH SYST

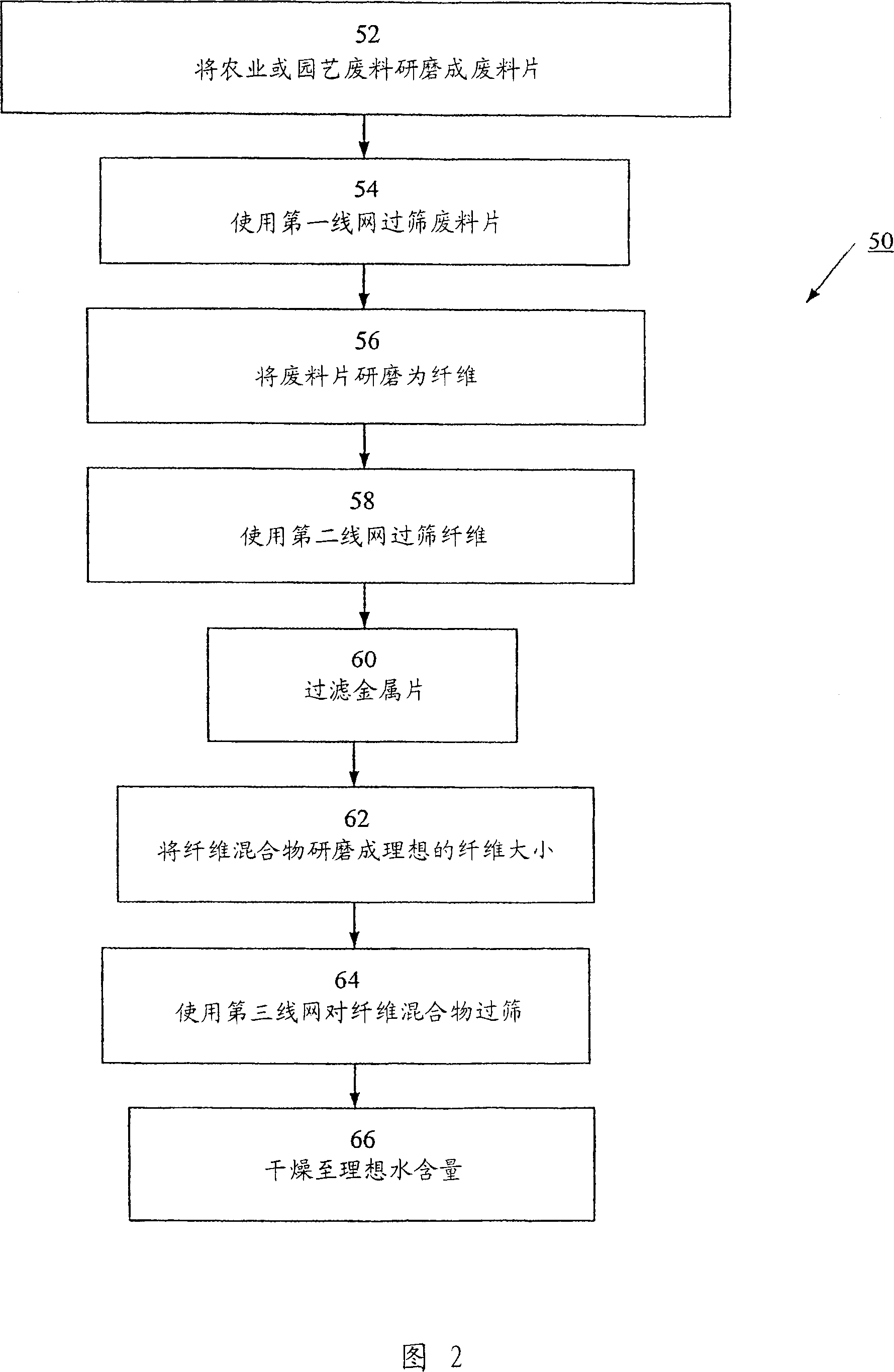

Method for forming high strength mould

A method to form a high strength moulded product is provided. The method begins by preparing a mouldable composition. The mouldable composition comprises between about 40 to 60 wt % of a fibre mixture and between about 15 to 45 wt % of an adhesive. A mould cavity is loaded with the mouldable composition up to about 90 % of the capacity of the mould cavity before applying a packing pressure of between about 435 to 870 psi to the mouldable composition. A predetermined clearance of between about 0.1 to 0.5 mm is maintained between a first mould part defining the mould cavity and a second mould part. The moulded product is removed from the mould cavity when the mouldable composition is substantially cured.

Owner:GPAC TECH (S) PTE LTD

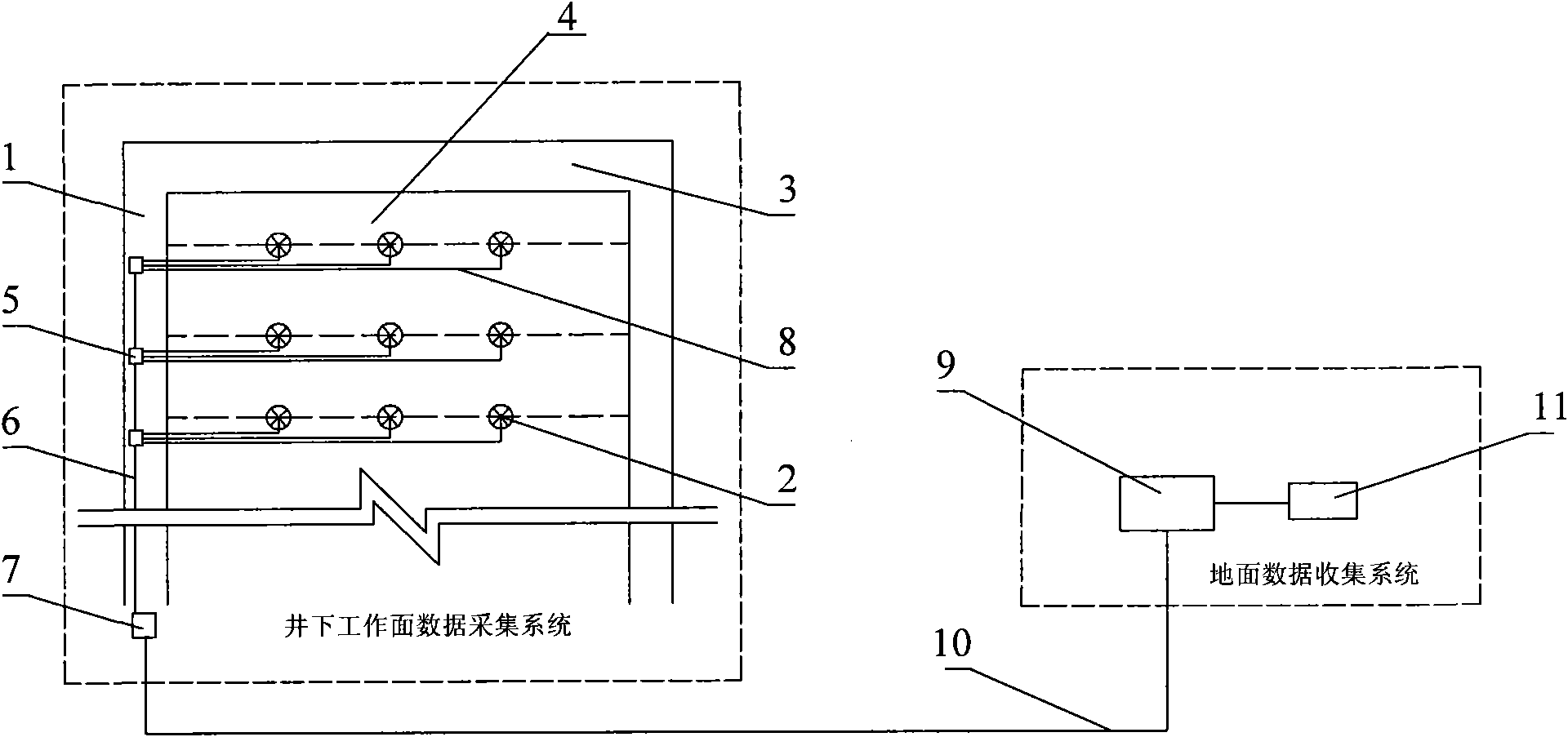

Method of monitoring coal mining solid pack pressure

InactiveCN101586452ASimple methodEasy to operateDrilling rodsMaterial fill-upSolid massPrimary station

Method of monitoring coal mining solid pack pressure, suitable for monitoring pressure situation of goaf pack in mining wells solid packing and coal mining process. Disposing a plurality of packs pressure monitors in packing comprehensive goaf in rows, each row of pack pressure monitors are all disposed uniformly along the working surface; when collecting data, connecting communication line of each row pack pressure monitors with main communicatin line in coal transport lane through junction box, that is the communication line of pack pressure monitor is connected to the main communication through junction box, and then connected with main communication station through the main communication line, at last transmitting data of main communication station to ground data reception system through telephone lines to monitor pressure situation of solid pack on line, and using monitoring host to analyze the pressure data to prevent damage caused by the goaf pack. The invention is provided with simplr method, easy operation, high accuracy, improved packing effect, and the invention can avoid potential safety problems.

Owner:CHINA UNIV OF MINING & TECH

Pallet and method for manufacturing the same

A pallet and a method for manufacturing the same are provided. The pallet comprises a pallet body, a skid to reinforce the pallet body and means to interlock the pallet body and the skid. The pallet body and the skid are moulded from a mouldable composition comprising between about 40 to 60 wt % of a fibre mixture and between about 15 to 45 wt % of an adhesive. The method for manufacturing the pallet begins by preparing the mouldable composition. A mould cavity is loaded with the mouldable composition up to about 90 % of the capacity of the mould cavity before applying a packing pressure of between about 435 to 870 psi to the mouldable composition. A predetermined clearance of between about 0.1 to 0.5 mm is maintained between a first mould part defining the mould cavity and a second mould part. A moulded product is removed from the mould cavity when the mouldable composition is substantially cured.

Owner:GPAC TECH (S) PTE LTD

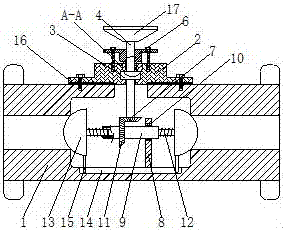

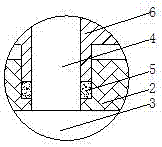

New valve

InactiveCN106949297ASmooth rotationImprove sealingSpindle sealingsOperating means/releasing devices for valvesEngineeringMechanical engineering

The invention discloses a novel valve, comprising a valve body, the top of the valve body is fixedly connected with a valve cover by bolts, the inside of the valve cover is fixedly connected with a first bearing, and the inner cavity of the valve body is provided with a rotating shaft, the top of the rotating shaft passes through the first bearing and the valve cover in turn and extends to the outside of the valve cover, a sealing packing is provided between the rotating shaft and the valve cover, and one end of the rotating shaft outside the valve cover is sheathed There is a pressure ring suitable for the sealing packing, the bottom of the pressure ring extends to the inside of the valve cover, the bottom of the rotating shaft is fixedly connected with the first bevel gear, and the bottom of the valve inner cavity is fixedly connected with a riser , the left end of the riser is provided with a threaded pipe. The threaded rod of the invention drives the valve clack to move laterally, so that the pipeline can be sealed in two directions, which greatly enhances the sealing performance of the valve, so that even if one of the valve clacks is damaged, the liquid will not leak, and the service life of the valve is prolonged.

Owner:吴燕

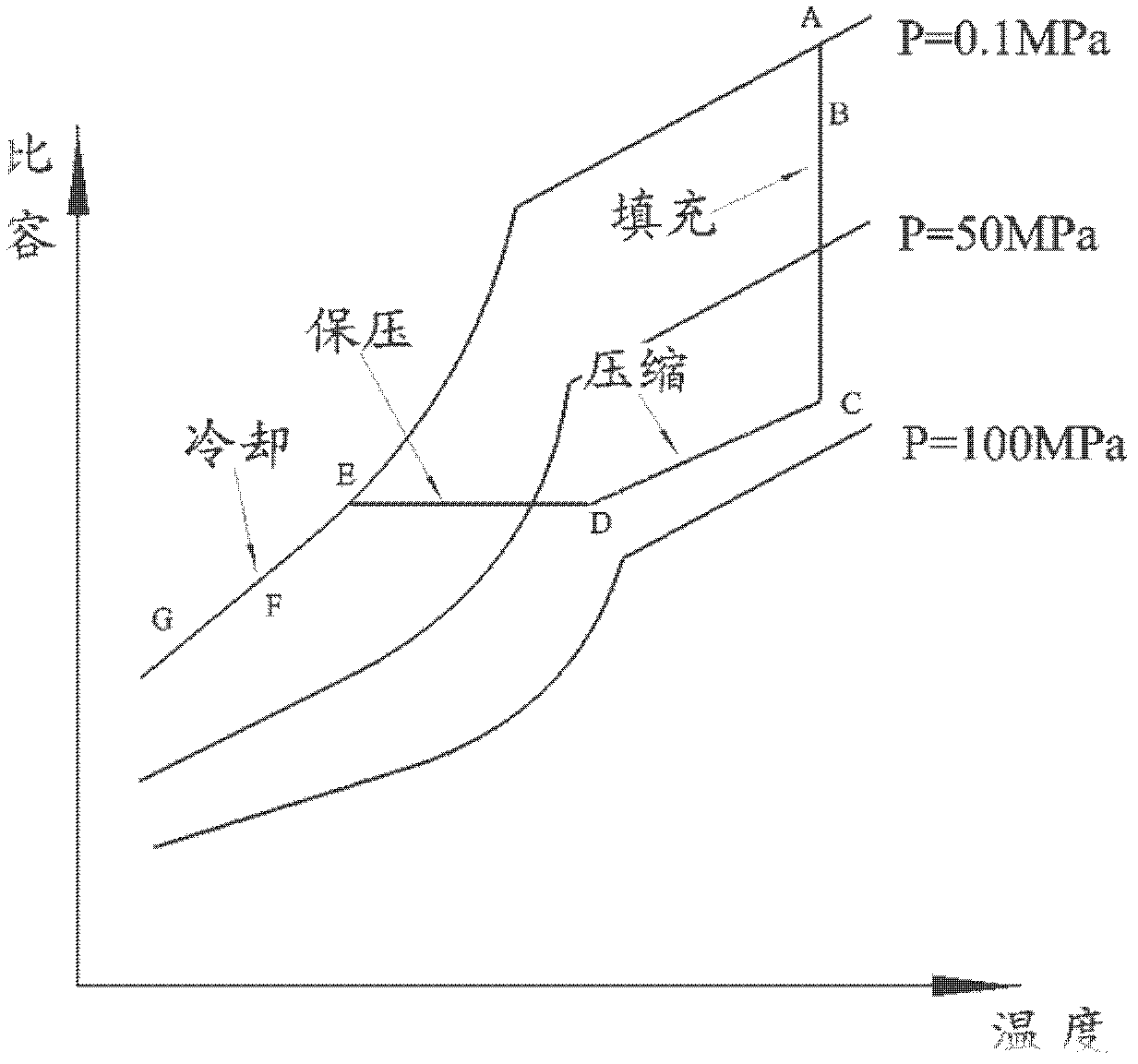

Isometric process control method utilizing PVT (pressure-volume-temperature) relation of polymers

The invention discloses an isometric process control method utilizing PVT (pressure-volume-temperature) relation of polymers. An injection process includes a first step: a PVT curve of an injection molding material is obtained according to the category and the characteristics of the material, an A-B-C-D-E-F process route is obtained from the curve, and an A-B-C section is an injection molding stage; a second step: constant-pressure packing is realized under the maximum packing pressure for a period of time, then isometric packing is carried out, and a C-D section is an isobaric compression stage; a third step: a D-E section is an equal-ratio volume packing stage, a material in a cavity cannot be changed, and cannot backflow or be increased along with reduction of the temperature of the cavity, and packing pressure of melt is obtained by means of calculation by the aid of a Tait equation and physical parameters provided by a PVT database; and a final step: an E-F section is a constant-pressure cooling stage. The constant-pressure packing is realized before the equal-ratio volume packing is realized, the melt is in a flowing state during the constant-pressure packing, accordingly excessively packing alignment is avoided, warpage is low, and quality repeat precision is high.

Owner:BEIJING UNIV OF CHEM TECH

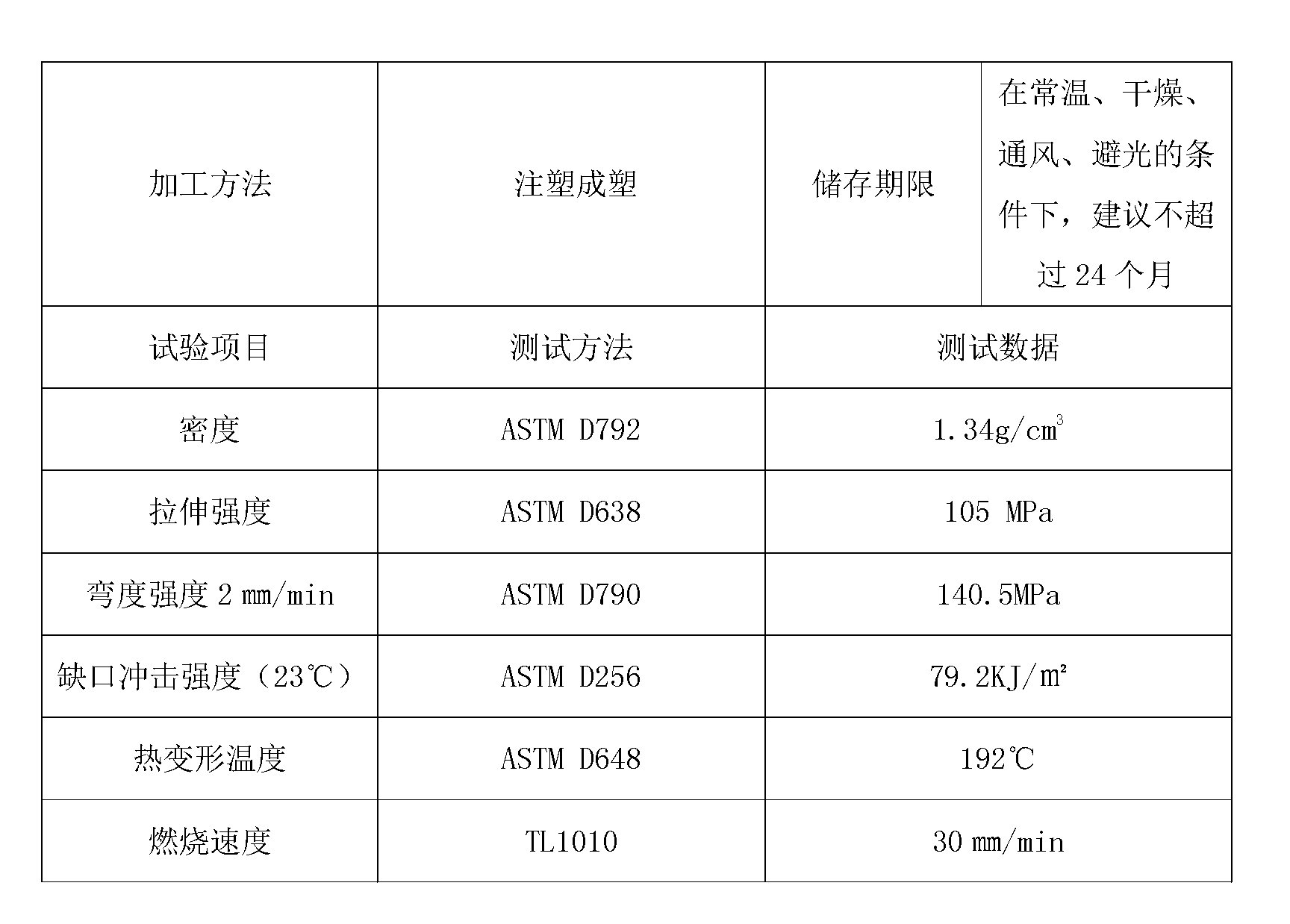

PBT modified nylon PA66 particle material, as well as its preparation method and application in vehicles

The present invention discloses a PBT modified nylon PA66 particle material, which is obtained by mixing a material A of the PBT modified nylon PA66 and a material B of the PBT modified nylon PA66, and then carrying out extrusion granulation. The present invention further discloses applications of the obtained modified nylon PA66 particle material in vehicle parts. The preparation method mainly comprises adding the dried modified material to a heated injection molding machine, setting injection pressures, speeds, injection times and glue injection amounts at different segments of the injection molding machine, and setting a final packing pressure and a packing speed to achieve an optimal injection molding process so as to obtain the final qualified product. After the modified nylon PA66 particle material is used for plastic connection devices of vehicles in the injection molding manner, advantages of high surface finish, good toughness, high strength and the like are provided, demolding is easily performed during injection molding, product quality is stable, a qualification rate is high, production efficiency is improved and production cost is reduced.

Owner:ANHUI KAIDI ELECTRIC

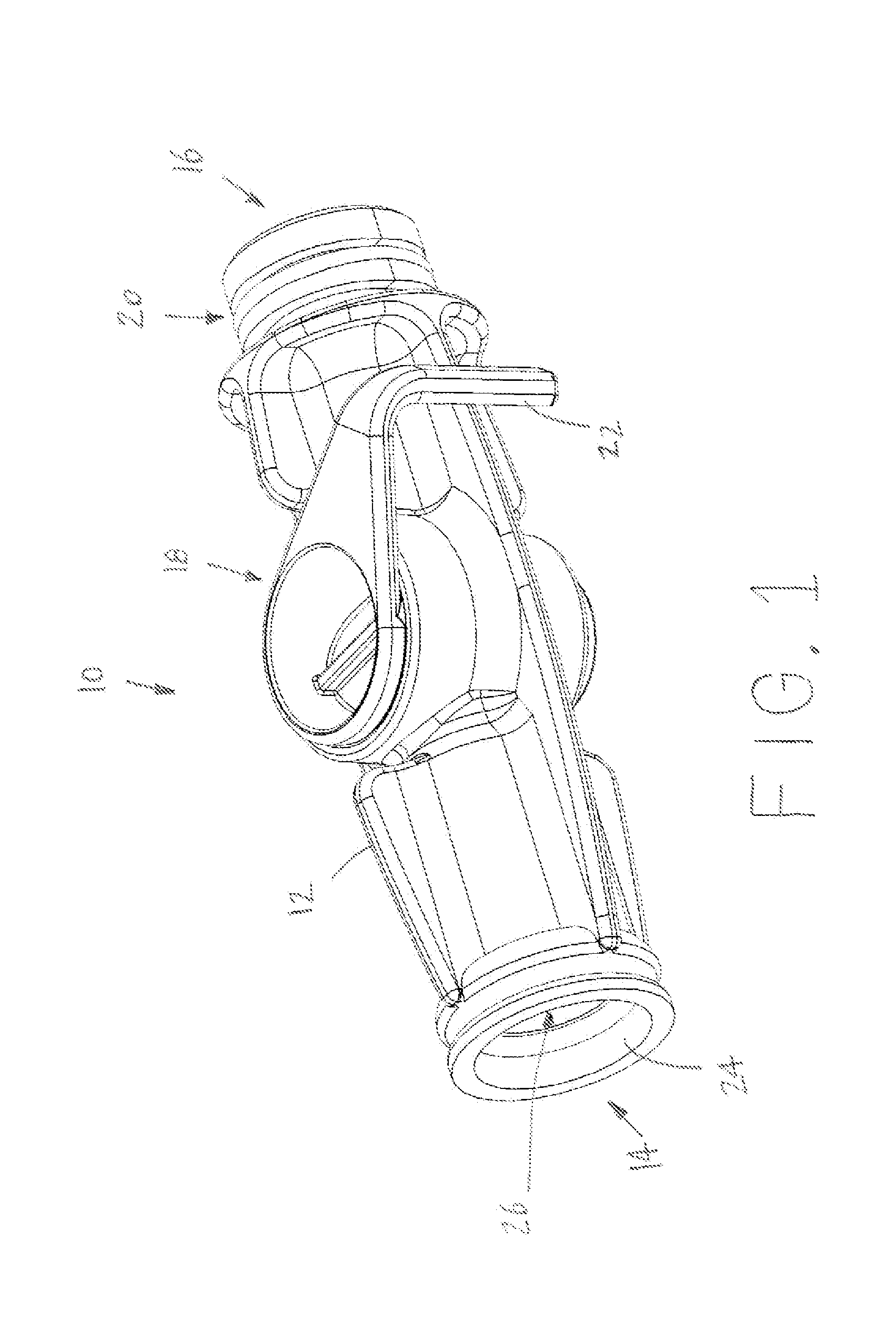

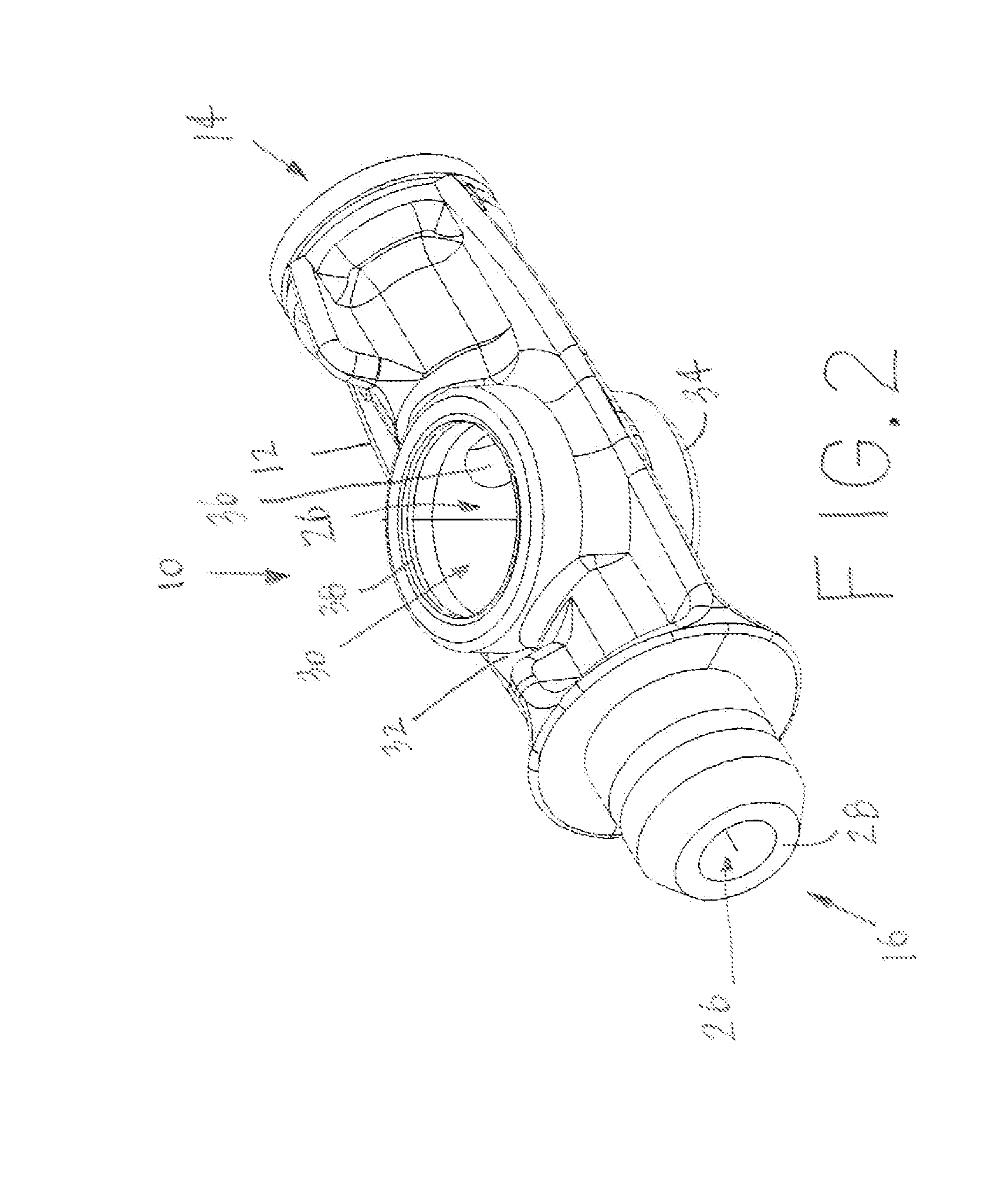

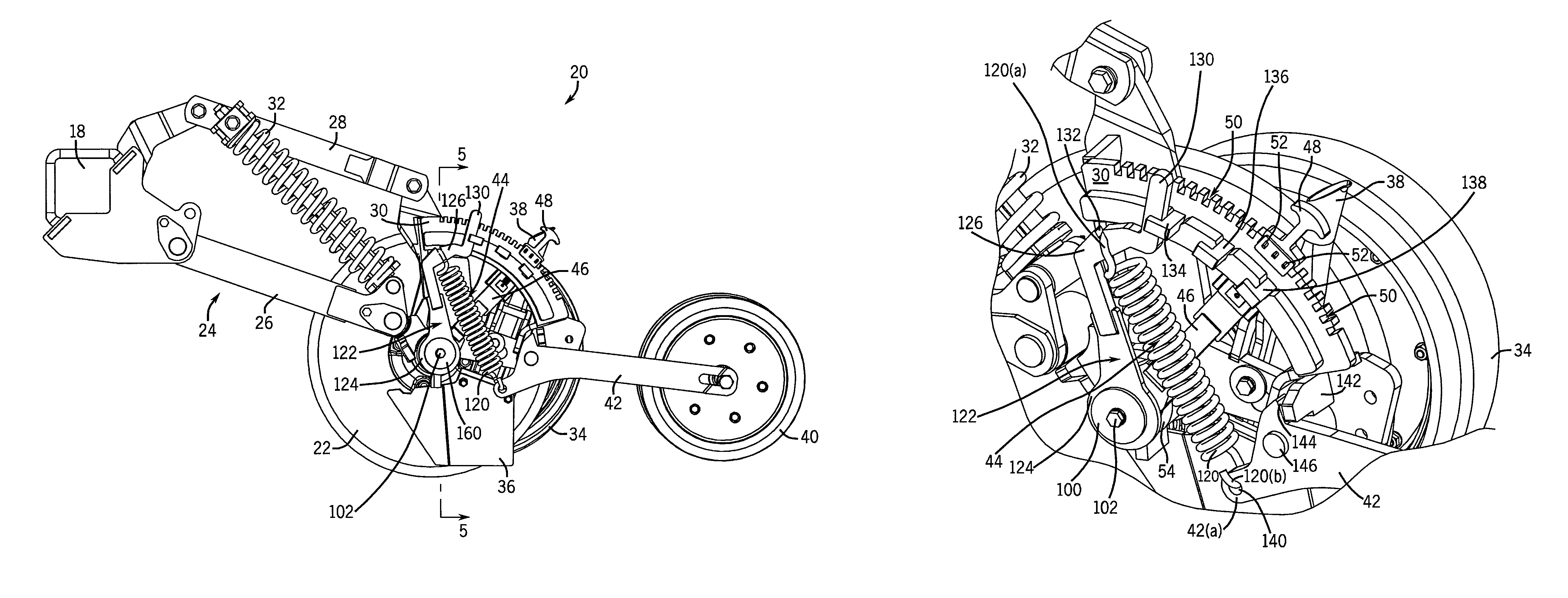

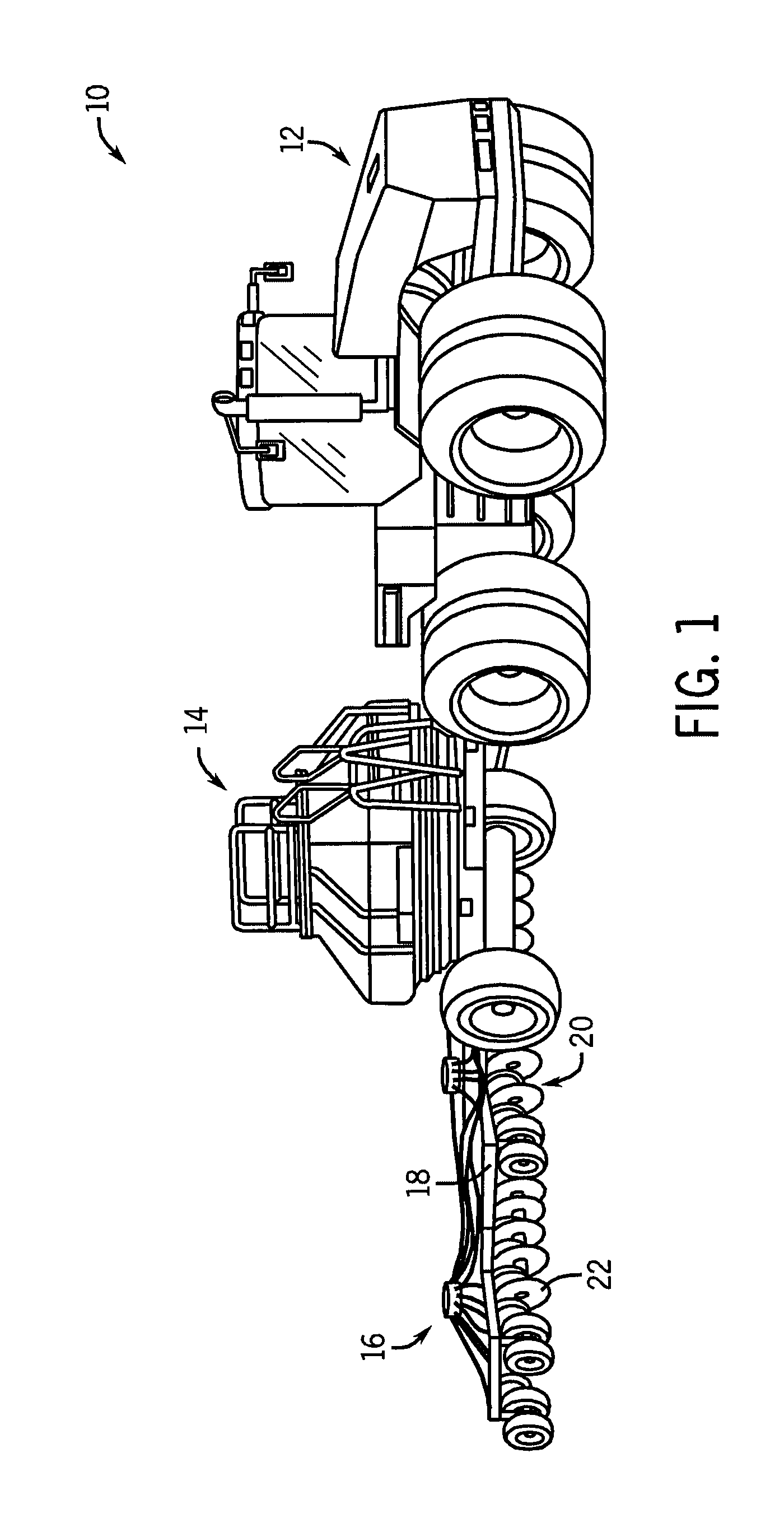

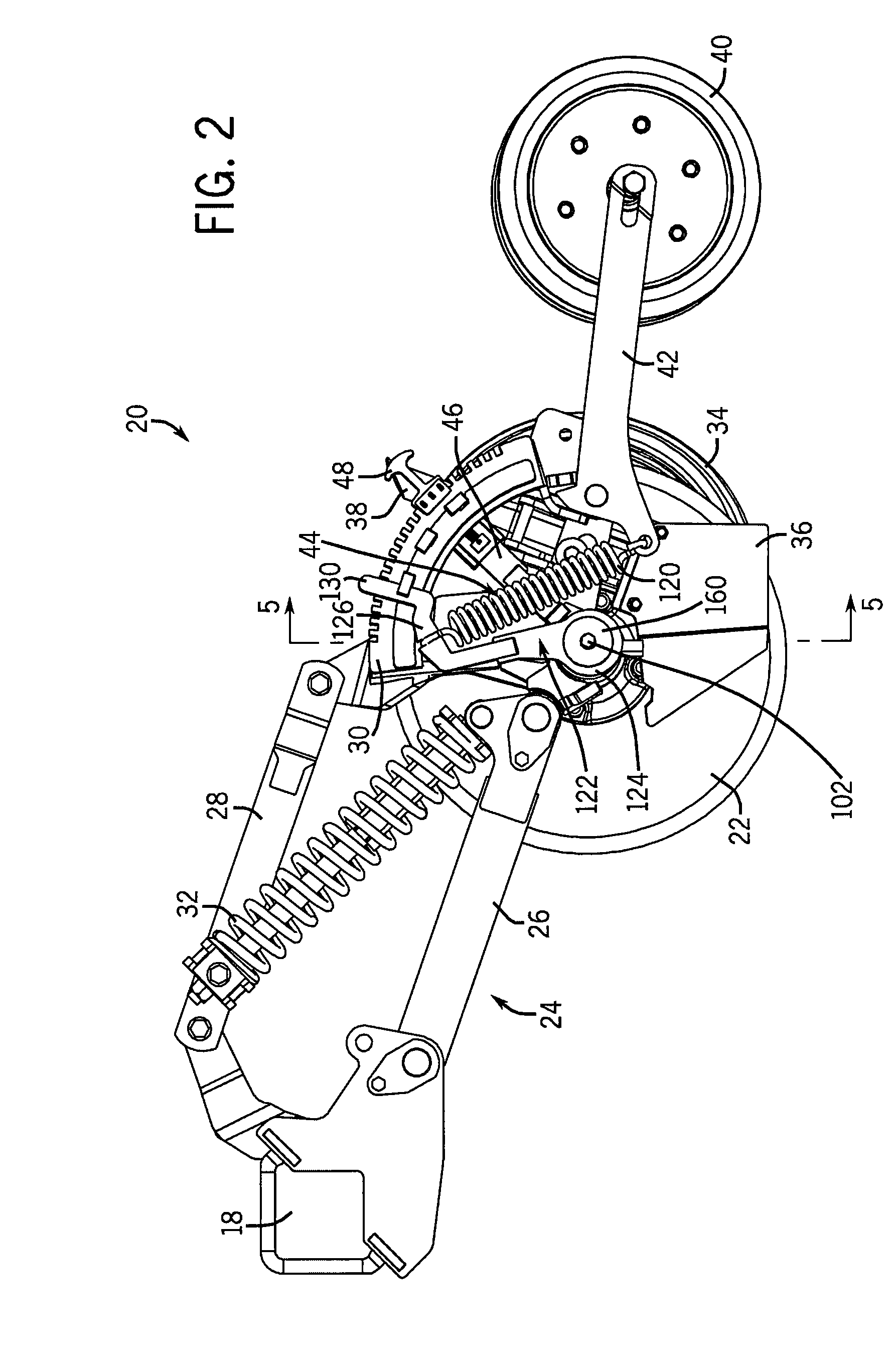

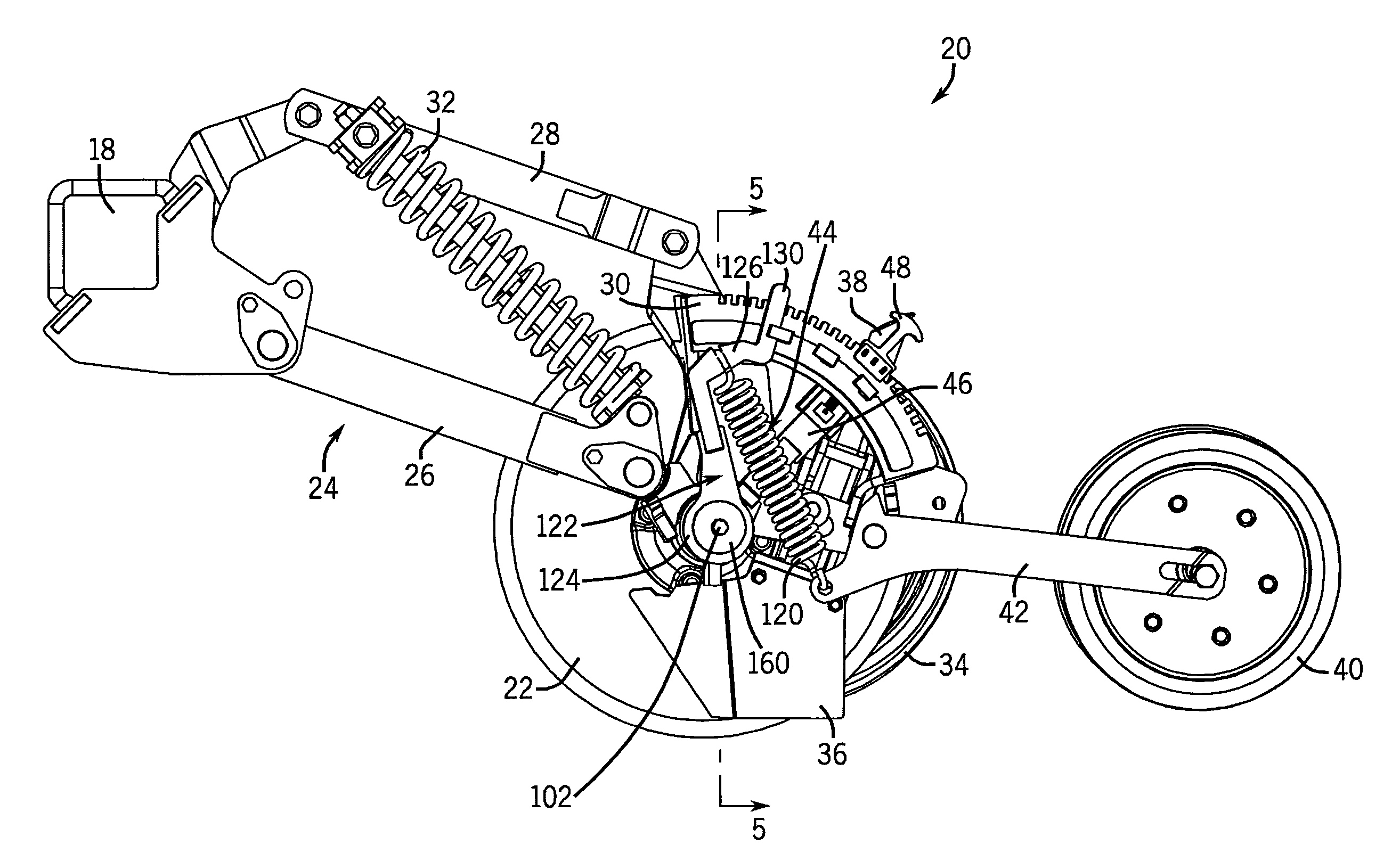

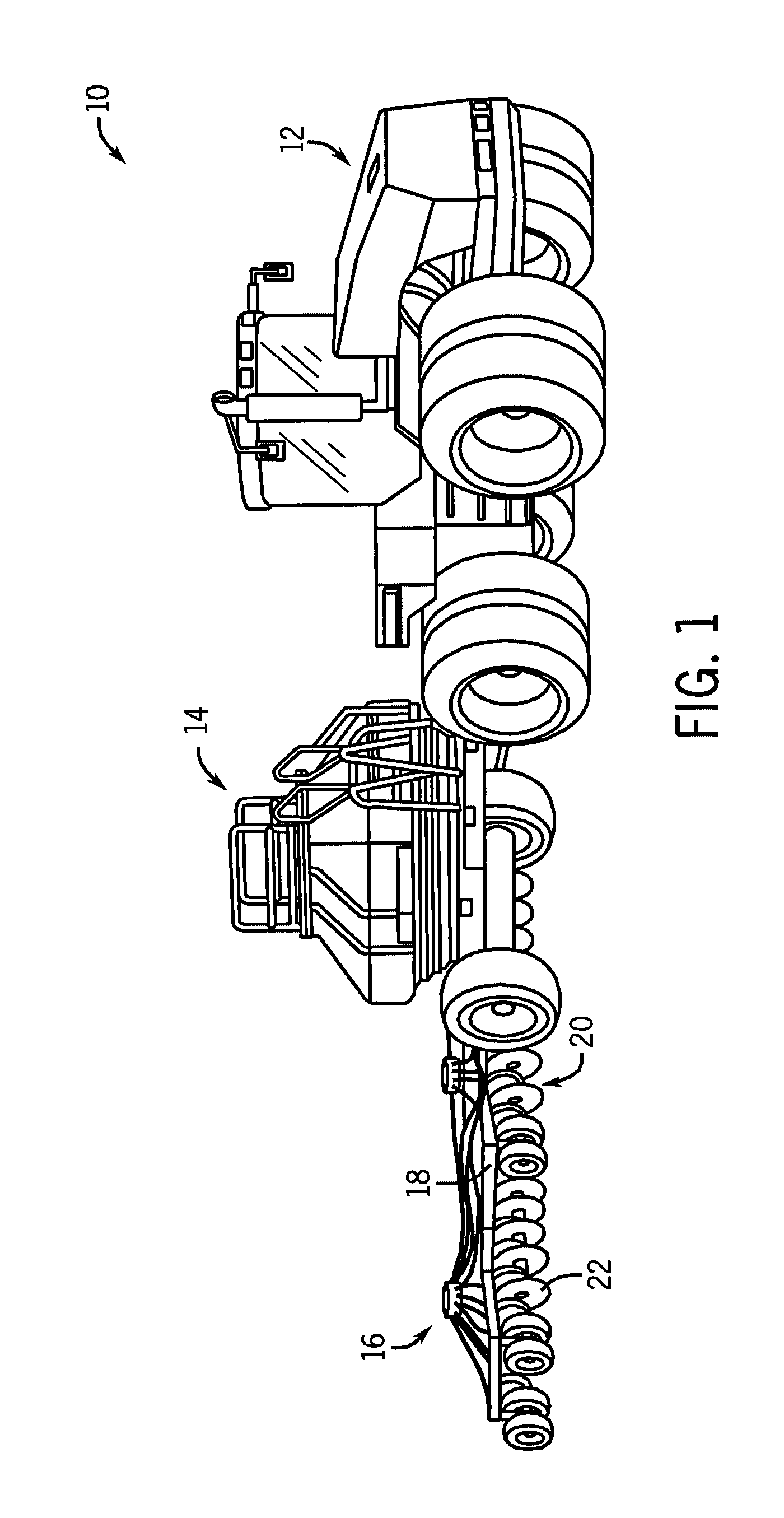

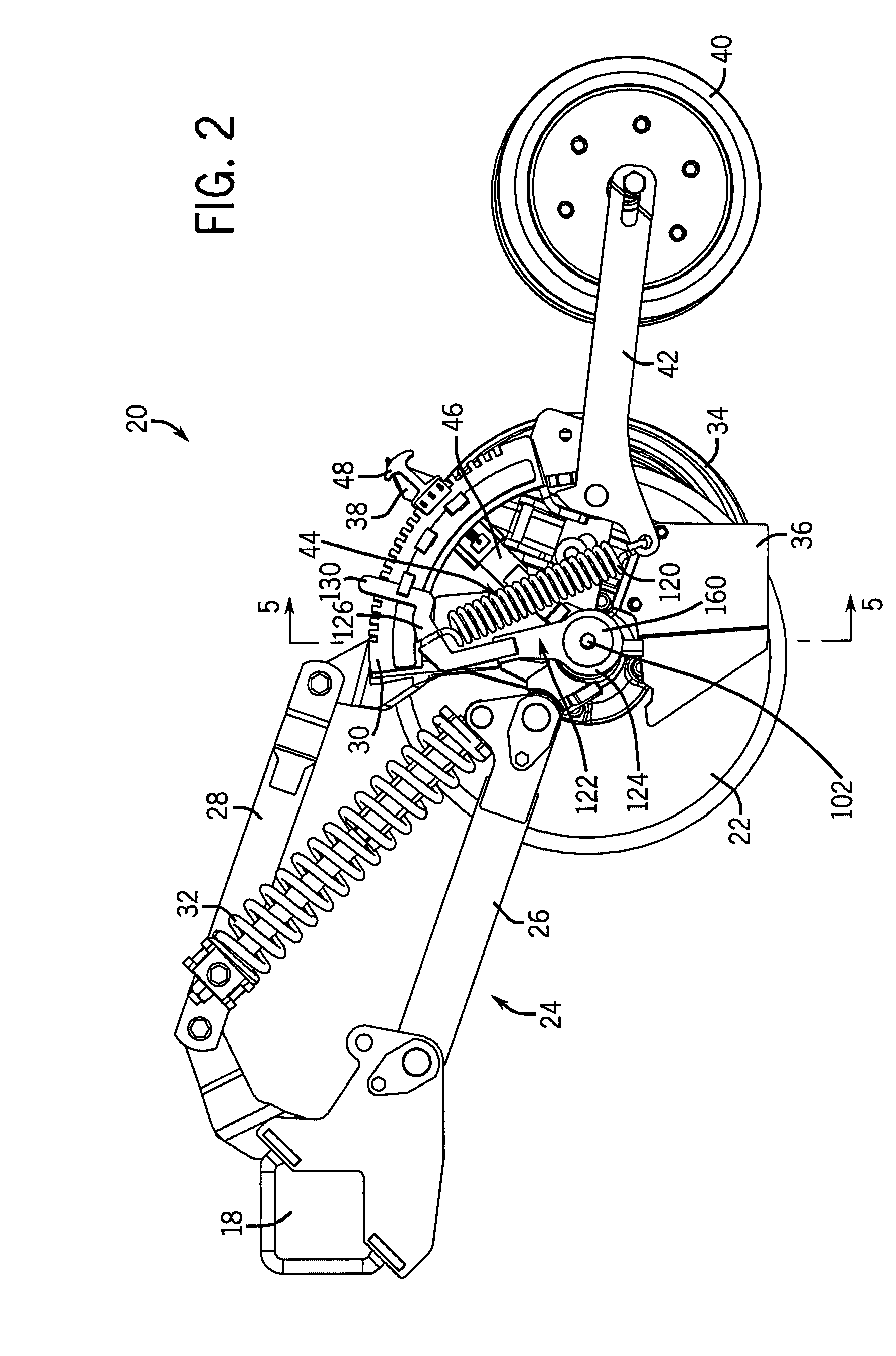

Packing pressure adjustment assembly for a ground opener unit

A packing pressure adjustment assembly for a ground opener unit of an agricultural implement includes a spring interconnected between a rotatable pressure adjustment arm and a trailing arm to which a packer wheel is rotatably mounted. The pressure adjustment arm is centered about an axle of the ground opener unit and is movable between a set of mounting positions that are defined by a set of teeth spaced and arced from one another along a frame portion of the ground opener unit. As the pressure adjustment arm is rotated, the amount of force exerted by the spring on the trailing arm is varied. The packing pressure adjustment assembly is relatively compact and is useful in providing high packing forces, such as a packing force in excess of 100 lbs.

Owner:CNH IND CANADA

Sucker rod deviation-based anti-eccentric wear sealing packing box

The invention discloses a sucker rod deviation-based anti-eccentric wear sealing packing box, which comprises a packing box main body, colloid packing, a steel packing pressure cap and a steel packing pressure cover and is characterized by also comprising a basic rubber cushion, a steel sheet gasket and a steel packing steel jacket. With the unique structure of the packing box main body, eccentric hole structures formed in the middle of the basic rubber cushion and the steel sheet gasket, the matching structure of the steel pacing steel jacket and the steel sheet gasket, the specific structure of the basic rubber cushion and related structures matched with the basic rubber cushion, the whole device enables a deviated sucker rod to drive the circular tube-shaped pacing steel jacket to shift in the derivation direction of an oil-sucking polish rod along the upper surface of the steel sheet gasket so as to drive the round colloid packing placed in the packing steel jacket to shift together, the polish rod is concentric with the packing which penetrates through the polish rod, so that the deviated sucker rod avoids causing eccentric wear of the packing and causing mechanical damage,. Thus, the service life of the packing is prolonged and the packing is intact after being used for one year.

Owner:高洪江

Molding system and method for operating the same

ActiveUS9684295B2Made preciselyEfficiency problemProgramme controlComputer controlMolding machineEngineering

Owner:CORETECH SYST CO LTD

A self-balancing packer and method

The invention relates to a self-balanced packer and belongs to the technical field of oil and gas field reservoir reformation. The self-balanced packer is characterized by comprising an inner central tube and an outer central tube which are positioned in the packer, wherein the outer central tube is sleeved on the inner central tube; a first annular space is formed between the inner central tube and the outer central tube; a packing element is sleeved on the outer central tube, and separates the packer into an upper section structure and a lower section structure; a packing section of the packing element has a large outer diameter; two ends of the packing section of the packing element extend upwards and downwards in an equal diameter manner; the diameter of an equal diameter extension section is smaller than that of an upper and lower packing section; the equal diameter extension section of the packing element fixes the packing element on the outer central tube through upper and lower packing element seats; the upper and lower ends of the inner central tube and the upper and lower packing element seats are connected with an upper joint and a lower joint; a second annular space is formed between the packing element and the outer central tube, and is communicated with a seat packing pressure transfer hole in the upper joint; and the lower joint is provided with a lower annular space pressure introducing hole facing downwards in the radial direction. The self-balanced packer solves the problem that the conventional packer has a poor effect.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD CHANGQING DOWNHOLE TECH CO

Apparatus and methods for packing chromatography columns

InactiveUS8066876B2Ion-exchange process apparatusComponent separationEngineeringChromatography column

Owner:AGILENT TECH INC

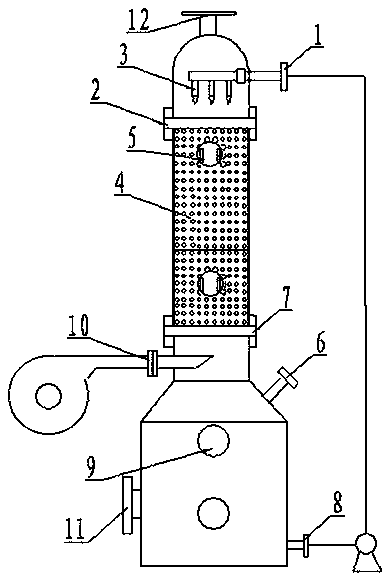

Polypropylene exhaust gas packing spray tower

InactiveCN105363334AFully absorbed and purifiedImprove purification efficiencyDispersed particle separationAgricultural engineeringSpray tower

The invention discloses a polypropylene exhaust gas packing spray tower, which comprises a spray tower body. The spray tower body adopts a cylindrical structure, and is a two-layer structure, the inner layer is a polypropylene layer, and the outer layer is a support steel frame layer, the upper end of the spray tower body is provided with a horizontal spray pipe, the spray pipe is equipped with a spray port on the spray tower body, at the same time, the spray pipe in the spray tower is provided with nozzles, a packing layer is arranged in the spray tower body, and the upper end of the packing layer is equipped with a packing pressure plate. The polypropylene exhaust gas packing spray tower provided by the invention can fully absorb and purify exhaust gas, and at the same time has excellent corrosion resistance, light weight, and high strength.

Owner:TAICANG ZHENFENG CHEM EQUIP CO LTD

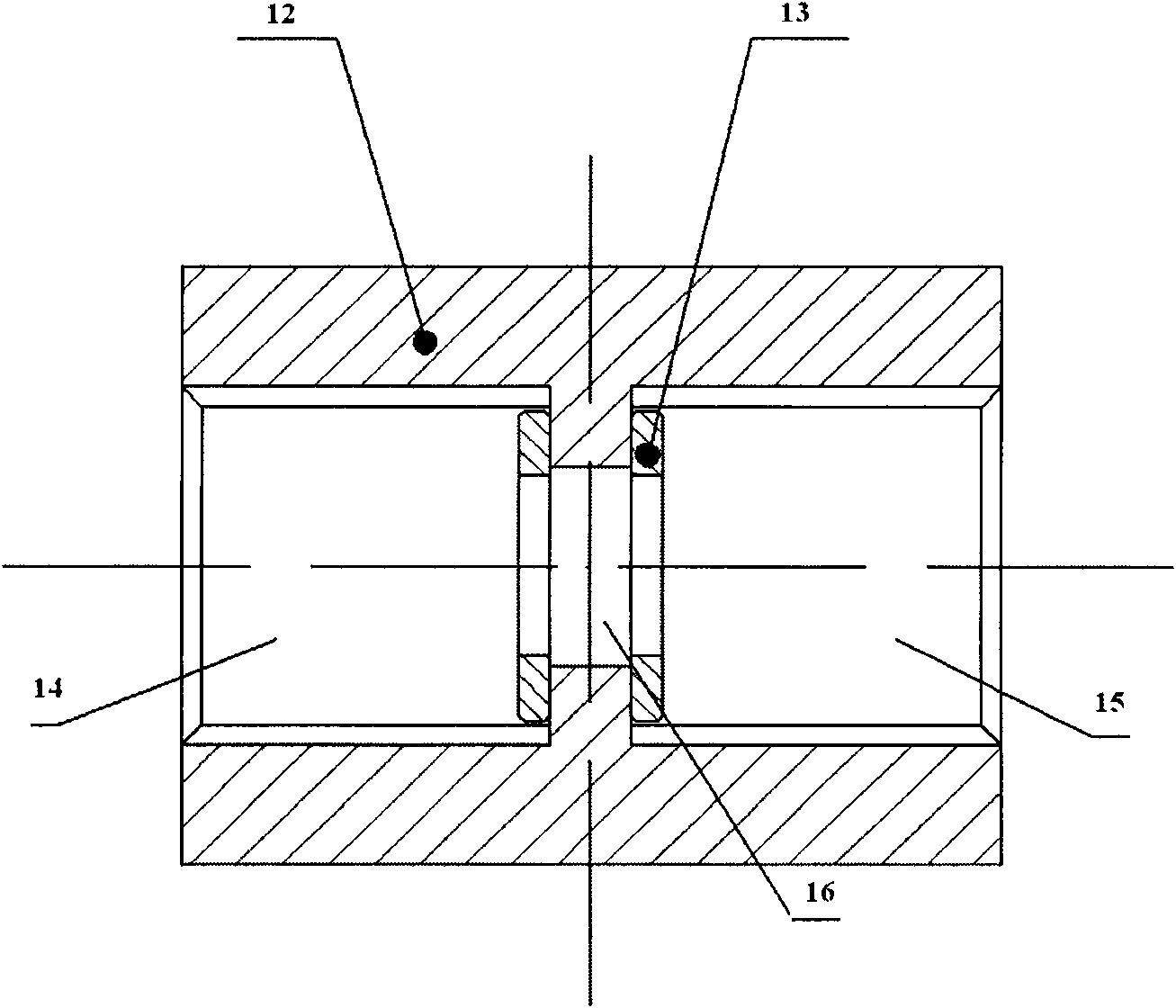

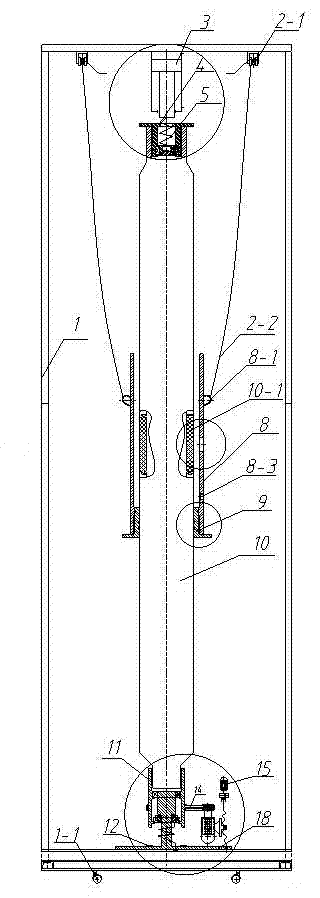

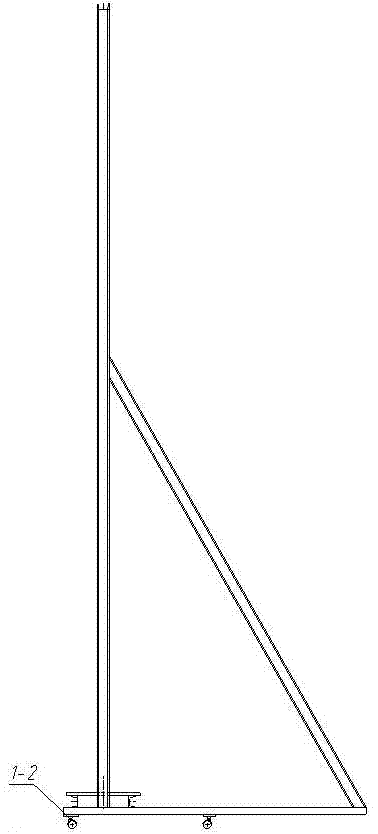

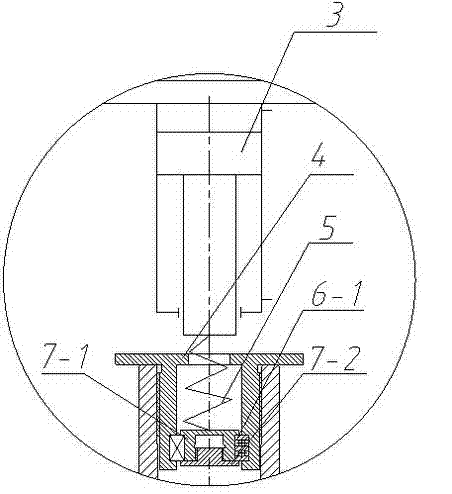

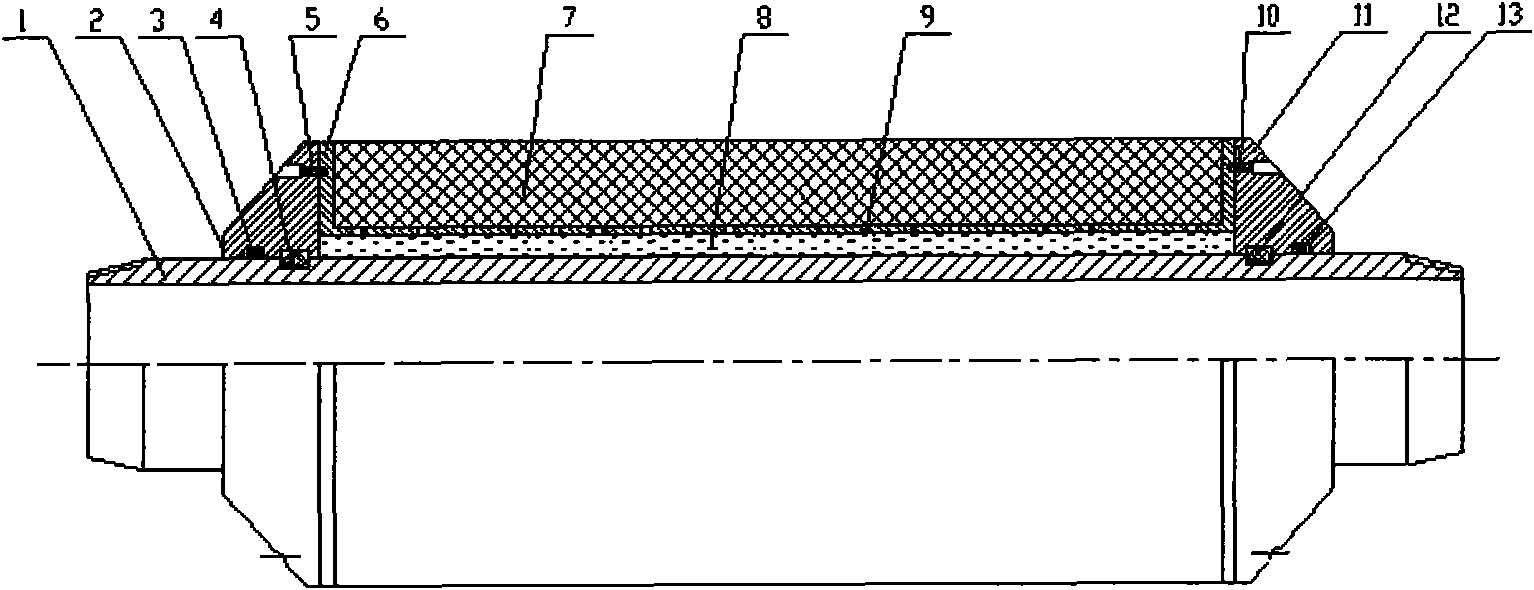

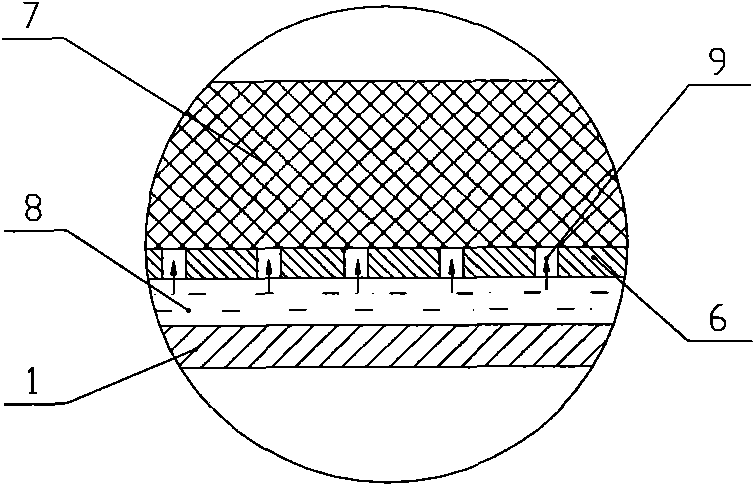

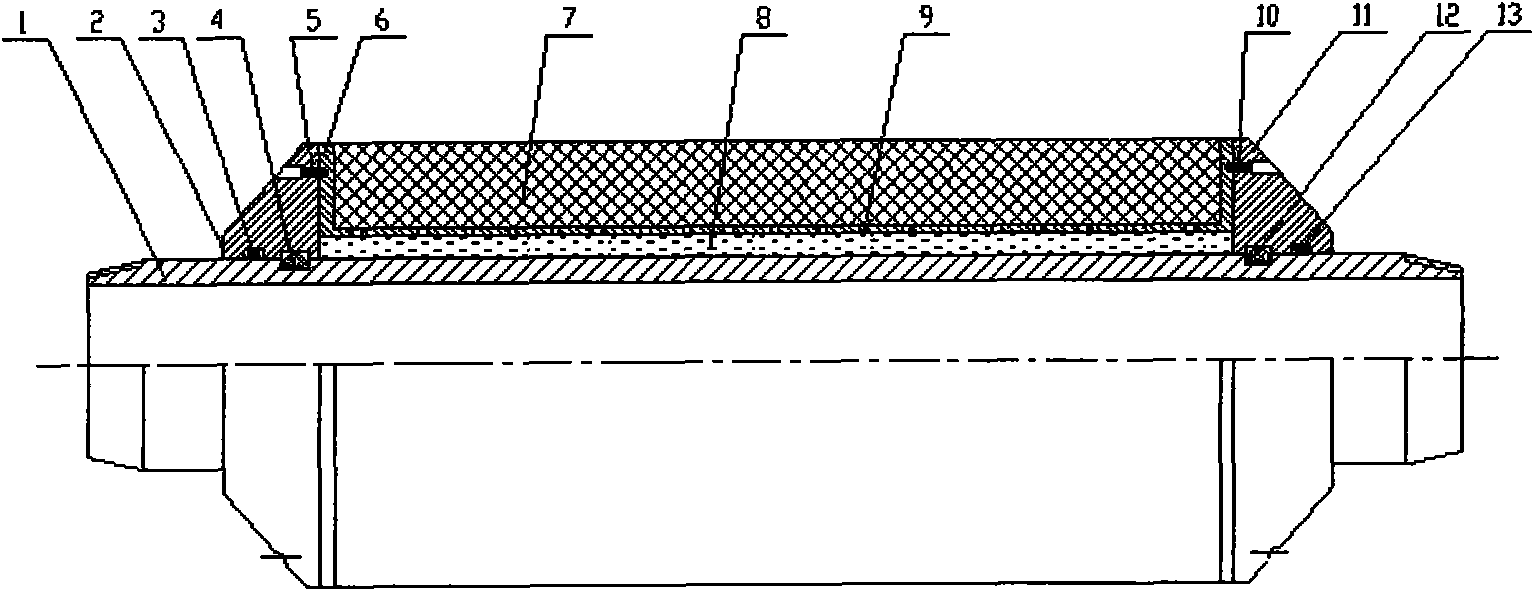

Down-hole annular blowout preventer experiment bench

InactiveCN103196686AUnblock in timeSimple structureStructural/machines measurementHydraulic cylinderBall bearing

The invention discloses a down-hole annular blowout preventer experiment bench, belongs to the technical field of down-hole annular blowout preventing experiments, and is mainly used for experiments of down-hole annular blowout preventers. The experiment bench is composed of a frame part, a testing rubber barrel pressure part, a pressure device part and a drive blowout preventer rotating part. The frame part comprises I-shaped steel, rolling wheels and rolling wheel mounting plates; the testing rubber barrel pressure portion comprises a pulley block, a guy cable, sleeves, sleeve lower connectors, gut cable hooks, observation holes, a high-pressure liquid inlet, sealing pieces and rubber barrels; the pressure device part comprises a hydraulic cylinder, a bearing plate, a tension spring, thrust ball bearings, an upper spring connecting block and a lower spring connecting block; the hydraulic cylinder is fixed in the I-shaped steel, and two spring connecting blocks are matched with the thrust ball bearings; and the drive device is formed through spline transmission or belt transmission or friction wheel transmission. The down-hole annular blowout preventer experiment bench is simple in structure and capable of effectively measuring imposed pressure and packing pressure when the annular blowout preventer works.

Owner:SOUTHWEST PETROLEUM UNIV

Pre-filling self expansion packer for well completion

The invention relates to a pre-filling self expansion packer for well completion. A position limiting ring A and a position limiting ring B are respectively positioned at both ends outside a base pipe and are fixed through clamping a clamp ring A and a clamp ring B fixed in outer wall grooves of the base pipe into grooves arranged on the inner walls of the position limiting ring A and the position limiting ring B, the part between the inner wall of the position limiting ring A and the outer wall of the base pipe as well as the part between the inner wall of the position limiting ring B and the outer wall of the base pipe are respectively sealed by an O-shaped sealing ring A and an O-shaped sealing ring B, a porous separation tube is sheathed on the outer wall of the base pipe, is arranged between the position limiting ring A and the position limiting ring B and is fixed on the position limiting ring A and the position limiting ring B through a screw A and a screw B, expansion media are filled in an annular cavity formed between the inner wall of the porous separation tube and the outer wall of the base pipe, expansion rubber is vulcanized onto the outer wall of the porous separation tube when meeting oil, and the expansion media and the rubber expending when meeting the oil are communicated through seeping holes arranged on the porous separation tube. The pre-filling self expansion packer has the advantages that the structure is simple, the installation and the construction operation are convenient, the packing time is short, the packing pressure difference is great, the well completion time of the permeability reservoir is greatly shortened, the operation cost is reduced, and the operation risk caused by untight packing of the packer is reduced.

Owner:PETROCHINA CO LTD

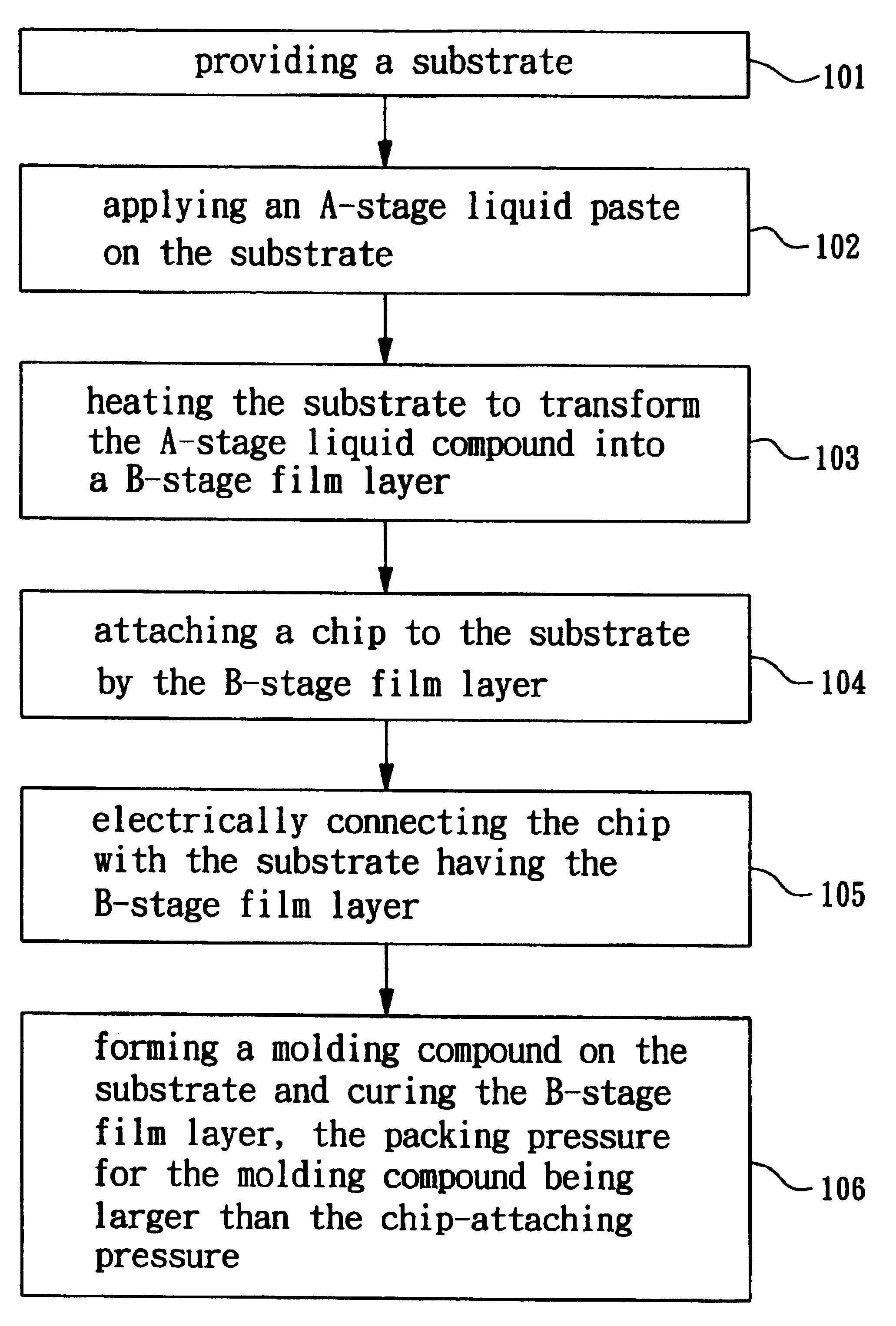

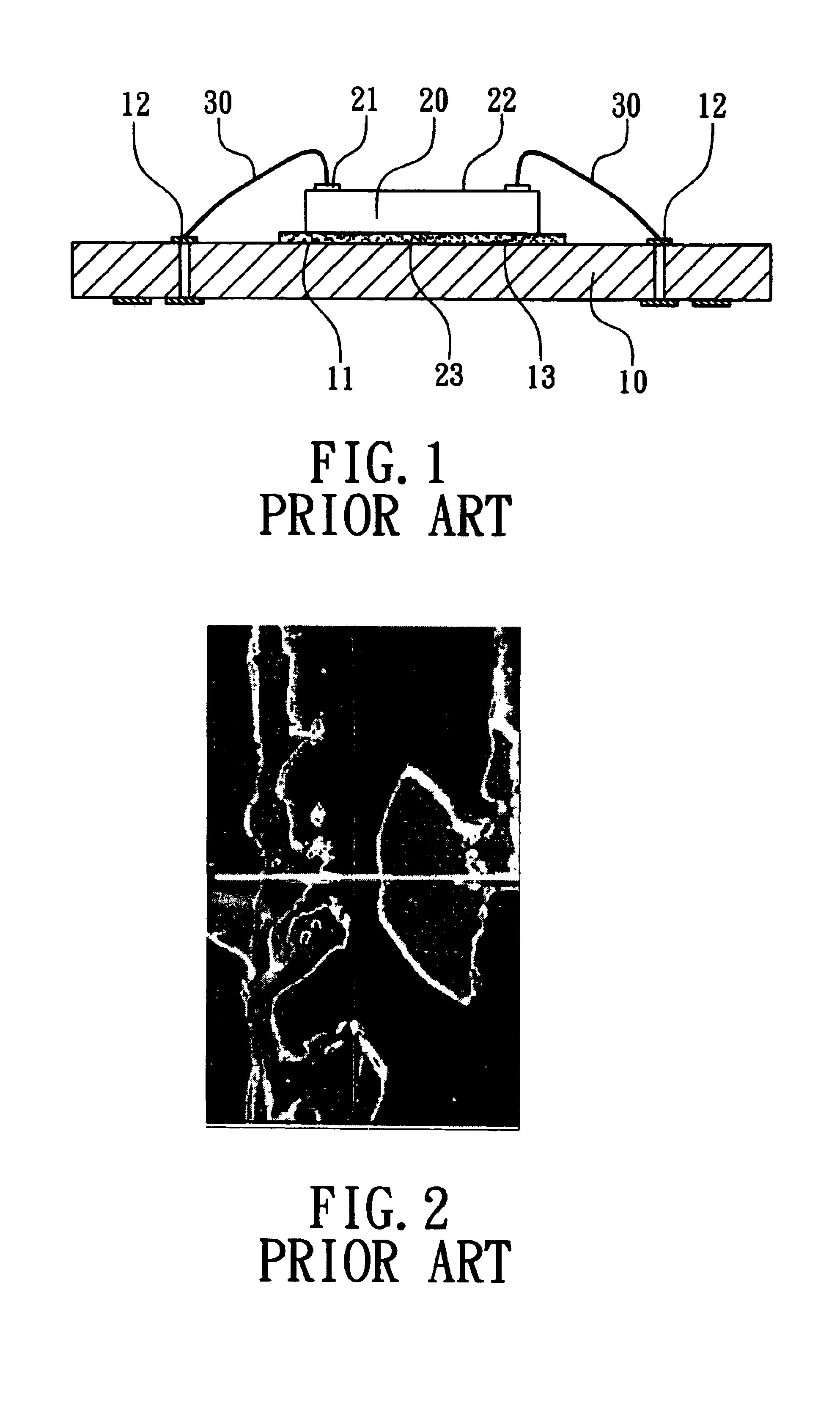

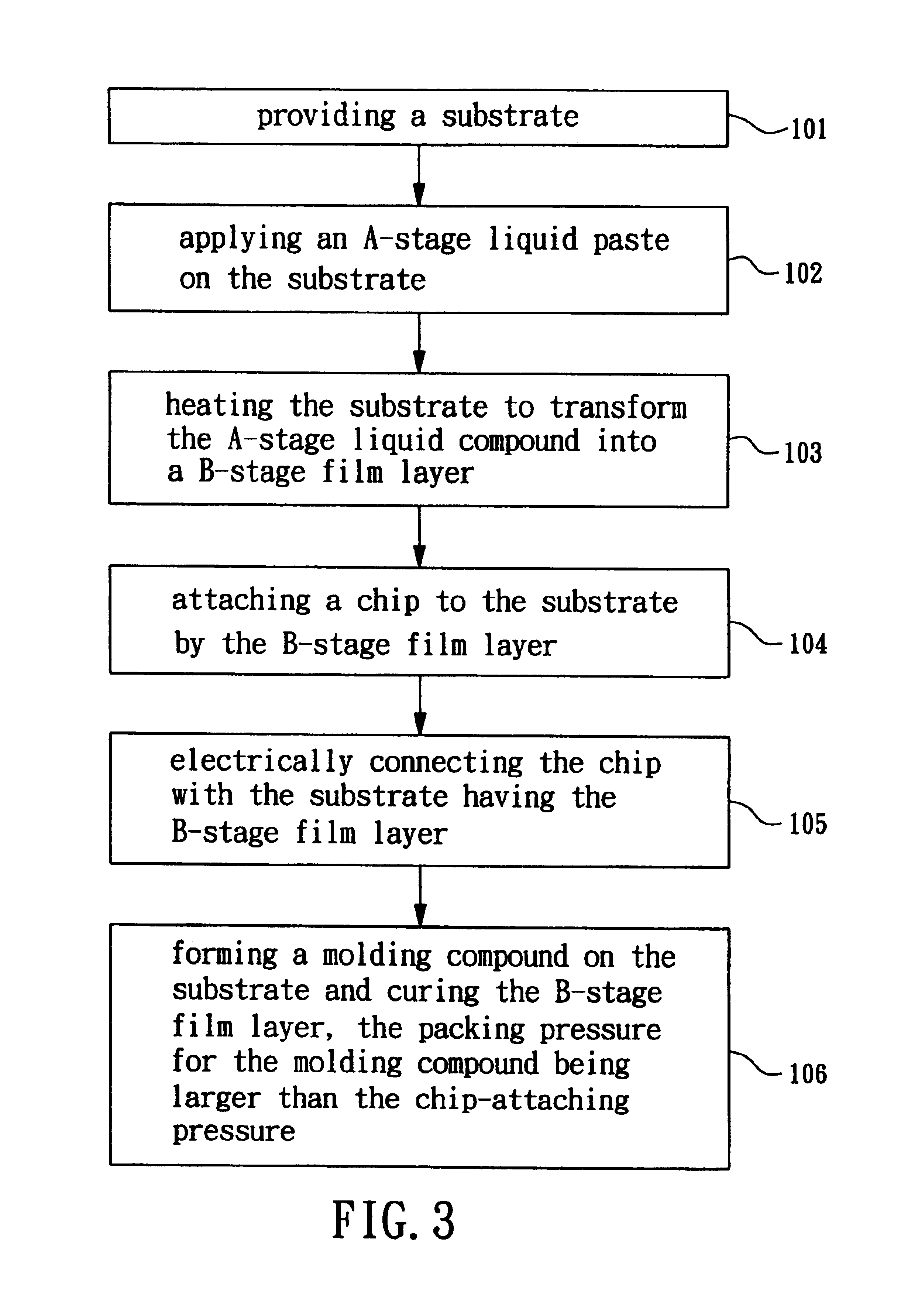

Integrated circuit packaging for improving effective chip-bonding area

ActiveUS6960491B2Improve effective chip-bonding areaImprove reliabilityFilm/foil adhesivesSolid-state devicesShell moldingEngineering

A packaging process for improving effective chip-bonding area is disclosed in the present invention. An A-stage liquid paste is formed on a substrate and partially cured to become a B-stage film layer. The B-stage film layer is maintained without fully cured passing through a chip-attaching step and an electrically connecting step. During the molding step, the packing pressure for the molding compound (1000 psi˜1500 psi) is larger than the chip attaching pressure for enabling the B-stage film layer to be closely compressed in order to improve effective chip-bonding area. The B-stage film layer and the molding compound are cured simultaneous in the molding step.

Owner:CHIPMOS TECH INC

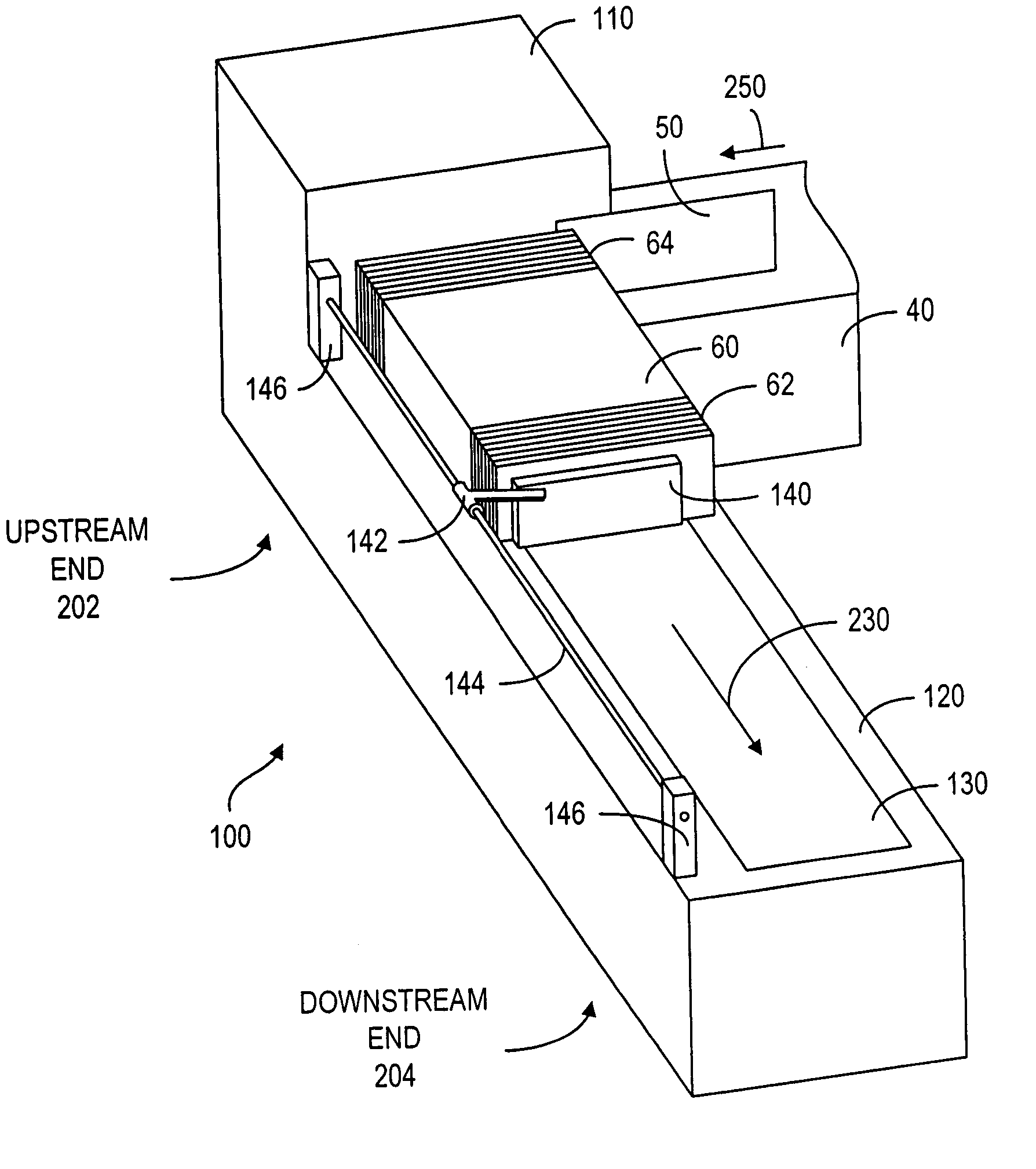

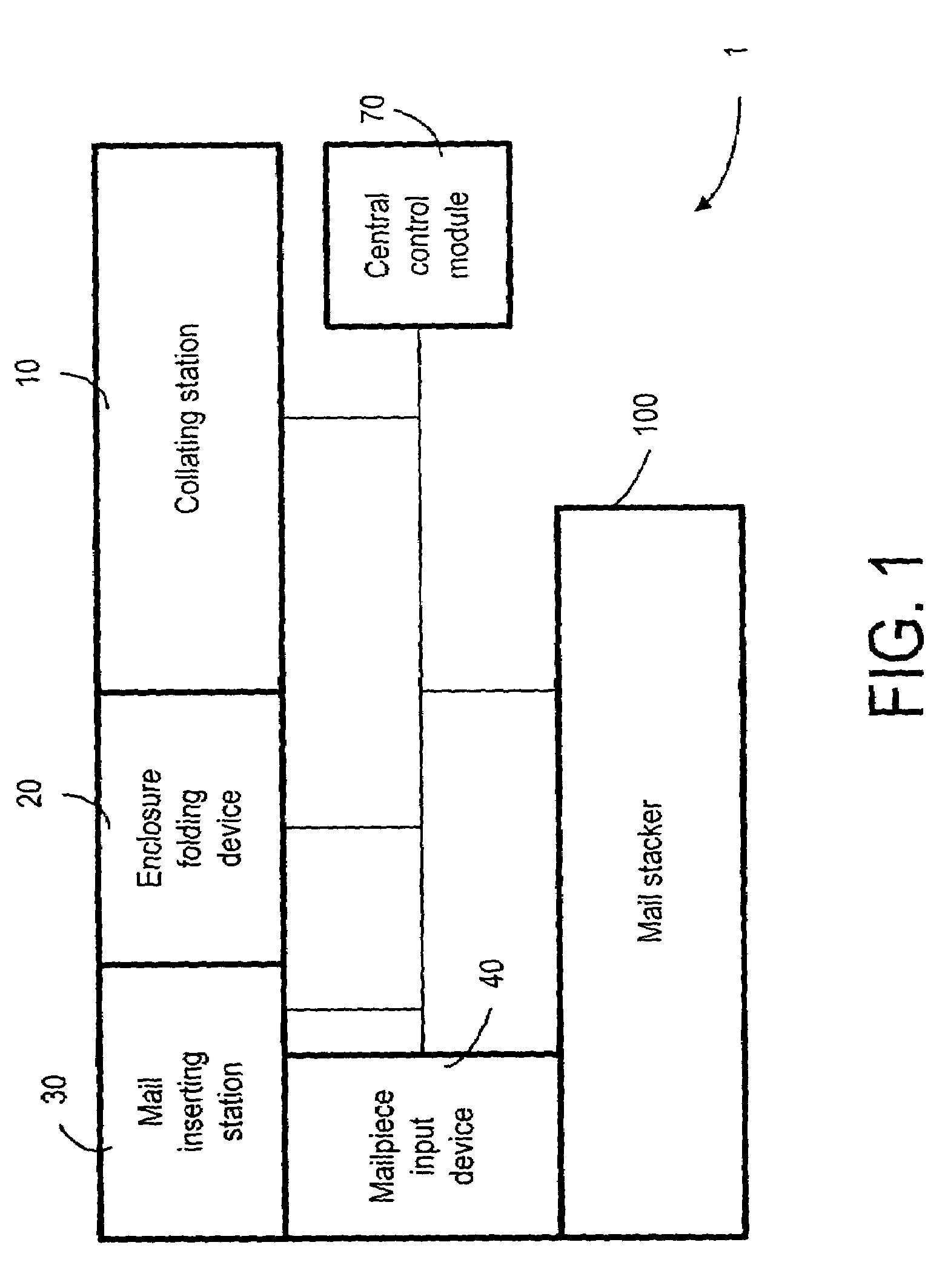

Method and device for improving stacker conveyor speed in a mail stacker

A method and device for stacking a plurality of vertically oriented mailpieces into a stack, wherein mailpieces are sequentially received into the back end of the stack. A paddle is used to support the front end of the stack in order to prevent the top mailpieces from falling forward. A conveyor belt is used to move the mailpieces in the stack and relieve the pack pressure so as to allow new mailpieces to join the stack. Information indicative of the mailpiece thickness is provided to a movement control module so that the conveyor belt is moved according to the thickness of the mailpieces received into the stack. As such, the pressure in the stack can be properly adjusted. The thickness information can be obtained from an upstream collator, for example.

Owner:DMT SOLUTIONS GLOBAL CORP

Packing Pressure Adjustment Assembly For A Ground Opener Unit

A packing pressure adjustment assembly for a ground opener unit of an agricultural implement includes a spring interconnected between a rotatable pressure adjustment arm and a trailing arm to which a packer wheel is rotatably mounted. The pressure adjustment arm is centered about an axle of the ground opener unit and is movable between a set of mounting positions that are defined by a set of teeth spaced and arced from one another along a frame portion of the ground opener unit. As the pressure adjustment arm is rotated, the amount of force exerted by the spring on the trailing arm is varied. The packing pressure adjustment assembly is relatively compact and is useful in providing high packing forces, such as a packing force in excess of 100 lbs.

Owner:CNH IND CANADA

Polytetrafluoroethylene modified nylon PA66 particle material, as well as its preparation method and application in vehicles

The present invention discloses a polytetrafluoroethylene modified nylon PA66 particle material, which is obtained by mixing a material A of the polytetrafluoroethylene modified nylon PA66 and a material B of the polytetrafluoroethylene modified nylon PA66, and then carrying out extrusion granulation. The present invention further discloses applications of the obtained modified nylon PA66 particle material in vehicle parts. The preparation method mainly comprise adding the dried modified material to a heated injection molding machine, setting injection pressures, speeds, injection times and glue injection amounts at different segments of the injection molding machine, and setting a final packing pressure and a packing speed to achieve an optimal injection molding process so as to obtain the final qualified product. After the modified nylon PA66 particle material is used for plastic connection devices of vehicles in the injection molding manner, advantages of high surface finish, good toughness, high strength and the like are provided, demolding is easily performed during injection molding, product quality is stable, a qualification rate is high, production efficiency is improved and production cost is reduced.

Owner:ANHUI KAIDI ELECTRIC

Method to Form a High Strength Moulded Product

InactiveUS20080179790A1Maintaining clearanceReduce gapOther chemical processesMixing methodsFiberShell molding

A method to form a high strength moulded product is provided. The method begins by preparing a mouldable composition. The mouldable composition comprises between about 40 to 60 wt % of a fibre mixture and between about 15 to 45 wt % of an adhesive. A mould cavity is loaded with the mouldable composition up to about 90 % of the capacity of the mould cavity before applying a packing pressure of between about 435 to 870 psi to the mouldable composition. A predetermined clearance of between about 0.1 to 0.5 mm is maintained between a first mould part defining the mould cavity and a second mould part. The moulded product is removed from the mould cavity when the mouldable composition is substantially cured.

Owner:GPAC TECH (S) PTE LTD

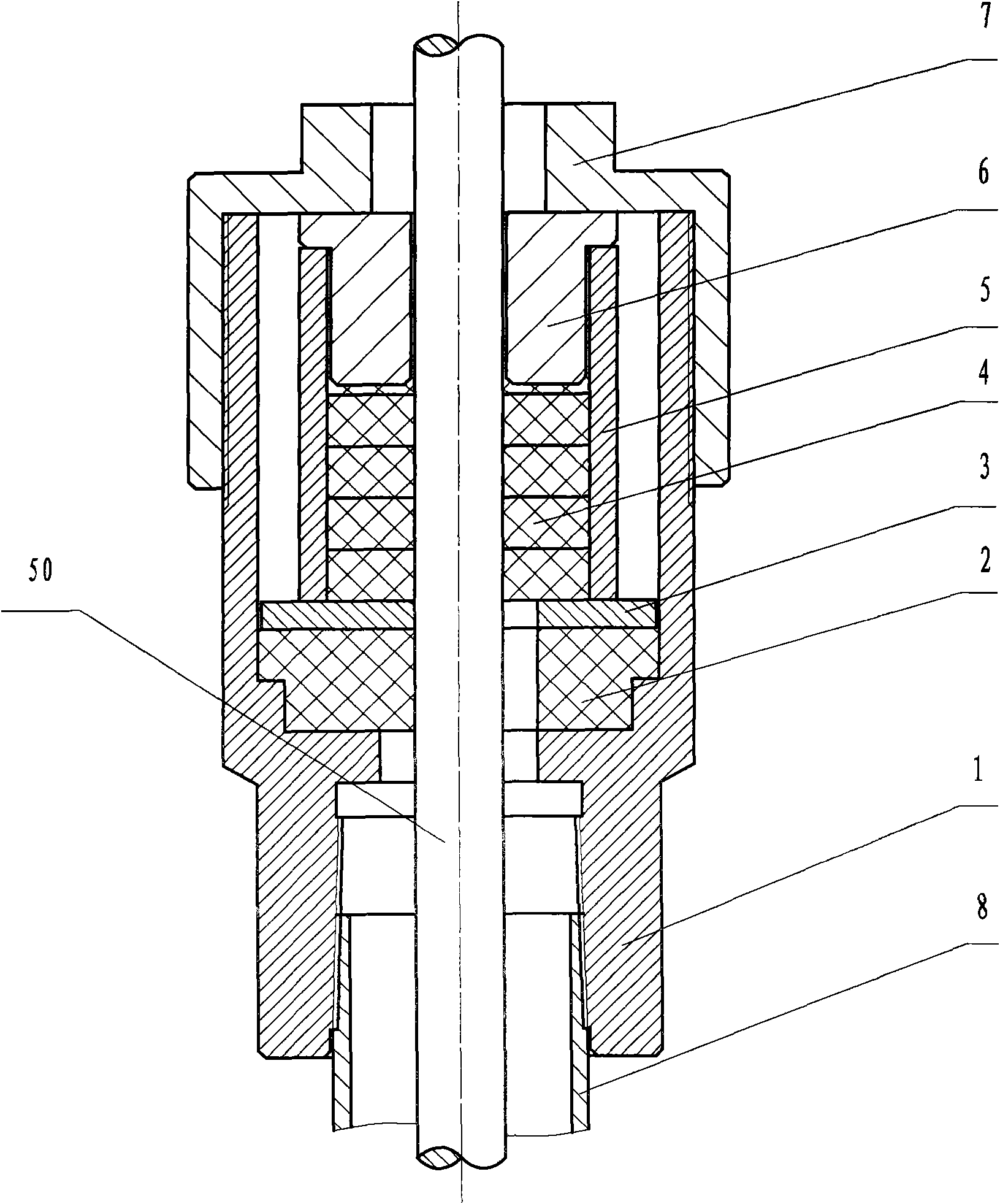

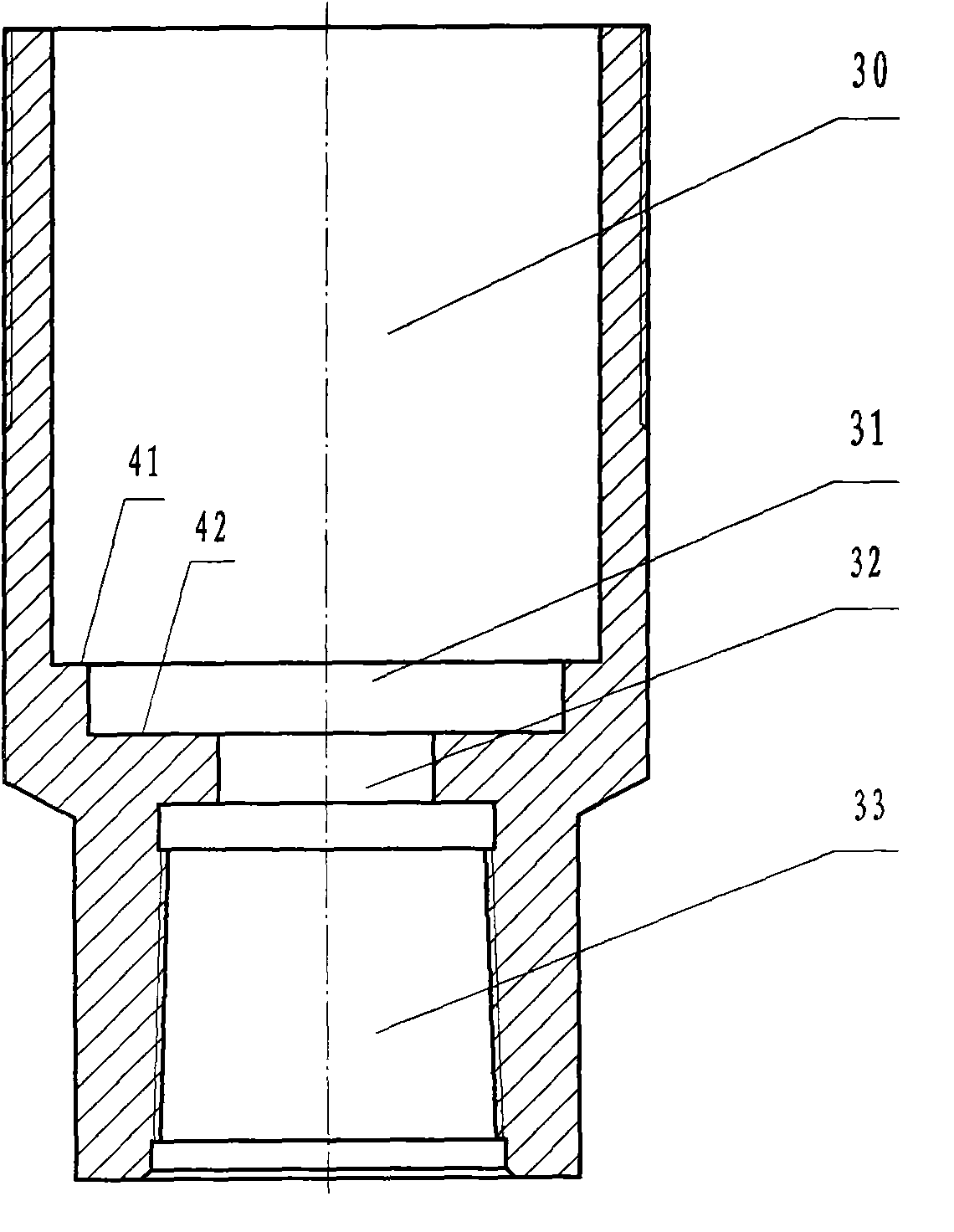

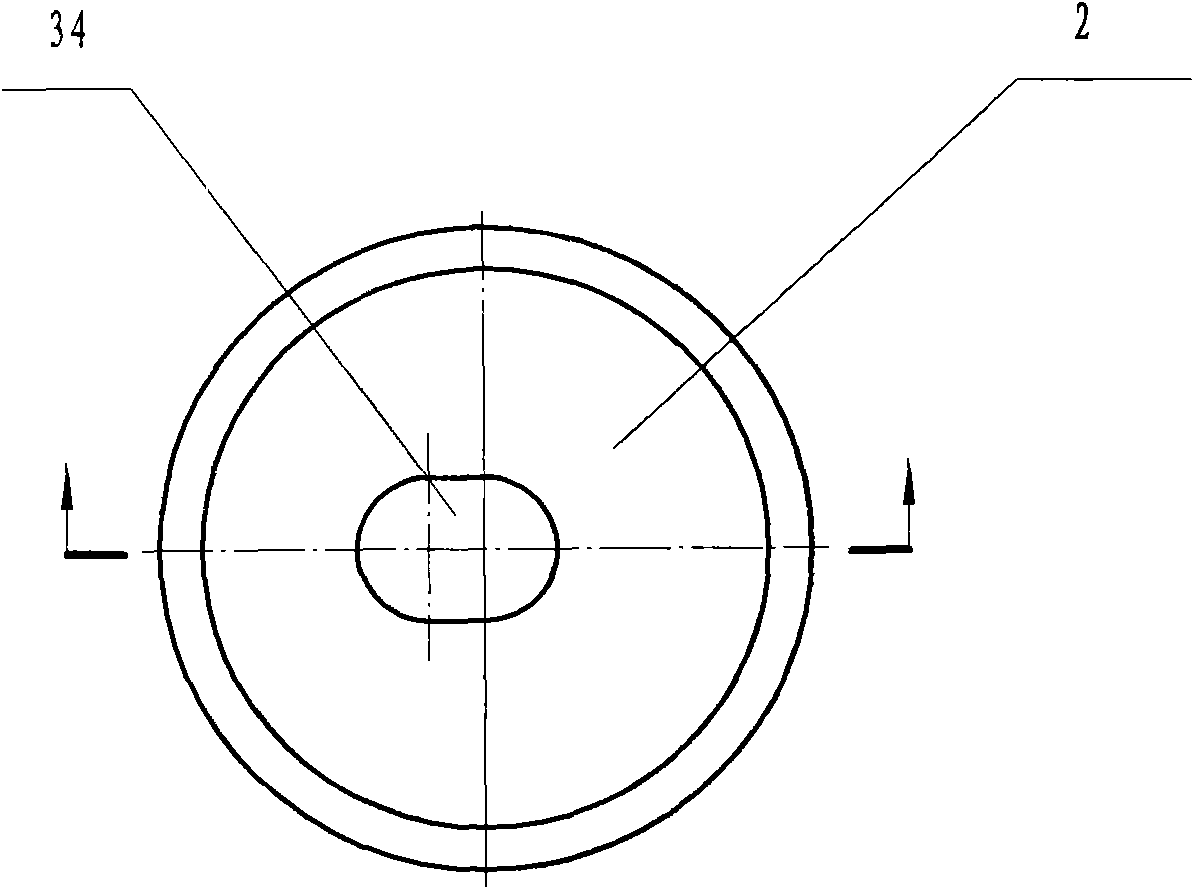

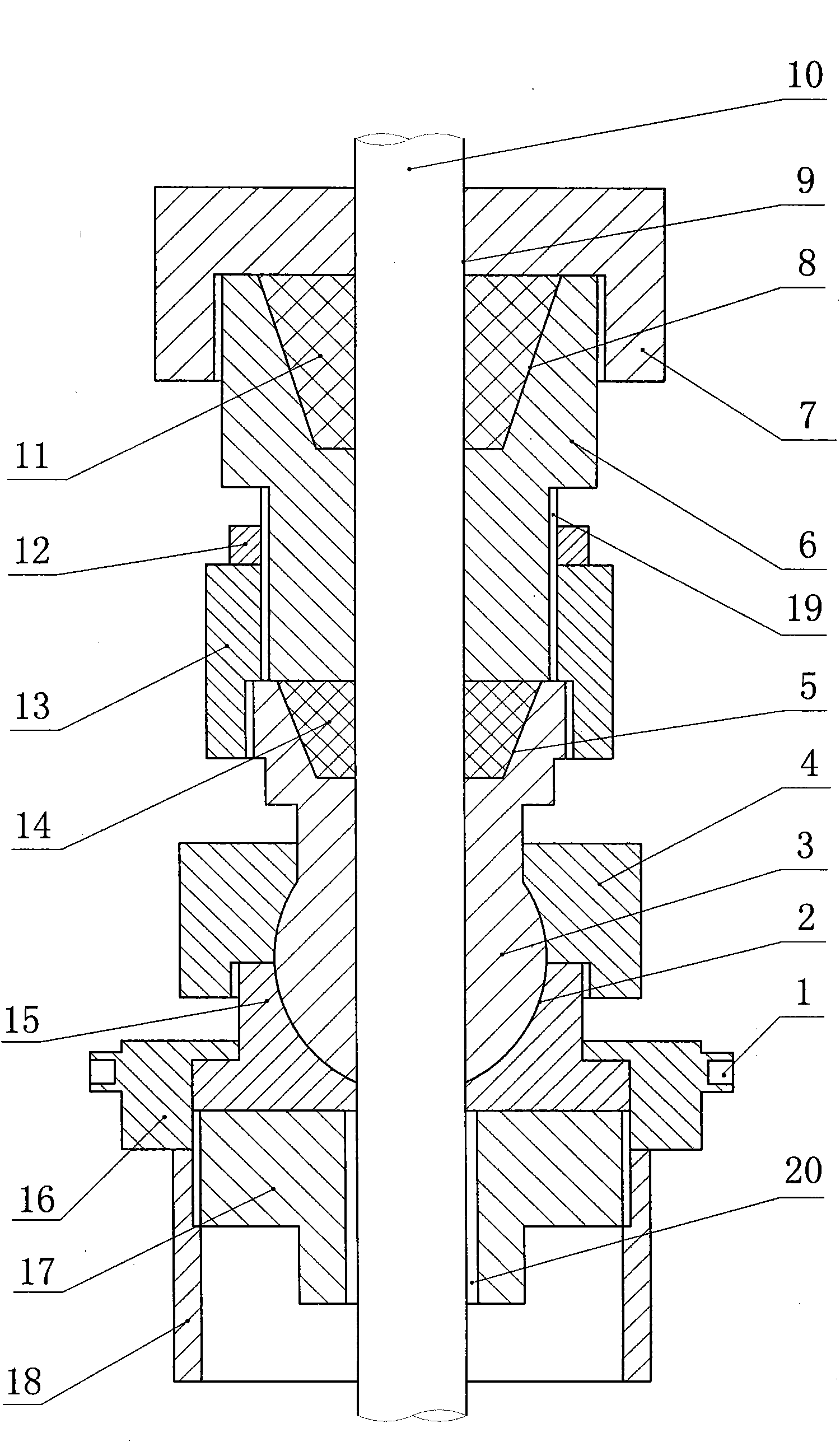

Random and automatic regulating polished rod sealing device of oil pumping machine

The invention provides a random and automatic regulating polished rod sealing device of an oil pumping machine, which can ensure the central position of a polished rod relative to an oil well and comprises a spherical pedestal, wherein a spherical seat the upper end of which is provided with a cambered groove is arranged above the spherical pedestal, and the spherical seat is fixed on the spherical pedestal through a translation pressure cap which is arranged outside the spherical seat; a spherical body the upper end of which is provided with a first groove is arranged above the spherical seat, and the spherical body is fixed on the spherical seat through a spherical pressure cap which is arranged outside the spherical body; a first-level sealed packing is arranged in the first groove at the upper end of the spherical body; a connecting body the upper end of which is provided with a second groove is arranged above the first-level sealed packing, a first-level packing pressure cap is arranged outside the upper end of the spherical body and outside the lower end of the connecting body, and the upper end of the spherical body and the lower end of the connecting body are in threaded connection with the first-level packing pressure cap; a second-level sealed packing is arranged in the second groove at the upper end of the connecting body; and a second-level packing pressure cap is arranged outside the upper end of the connecting body, and the second-level packing pressure cap is in threaded connection with the upper end of the connecting body.

Owner:LIAONING ZHONGRUI S&T

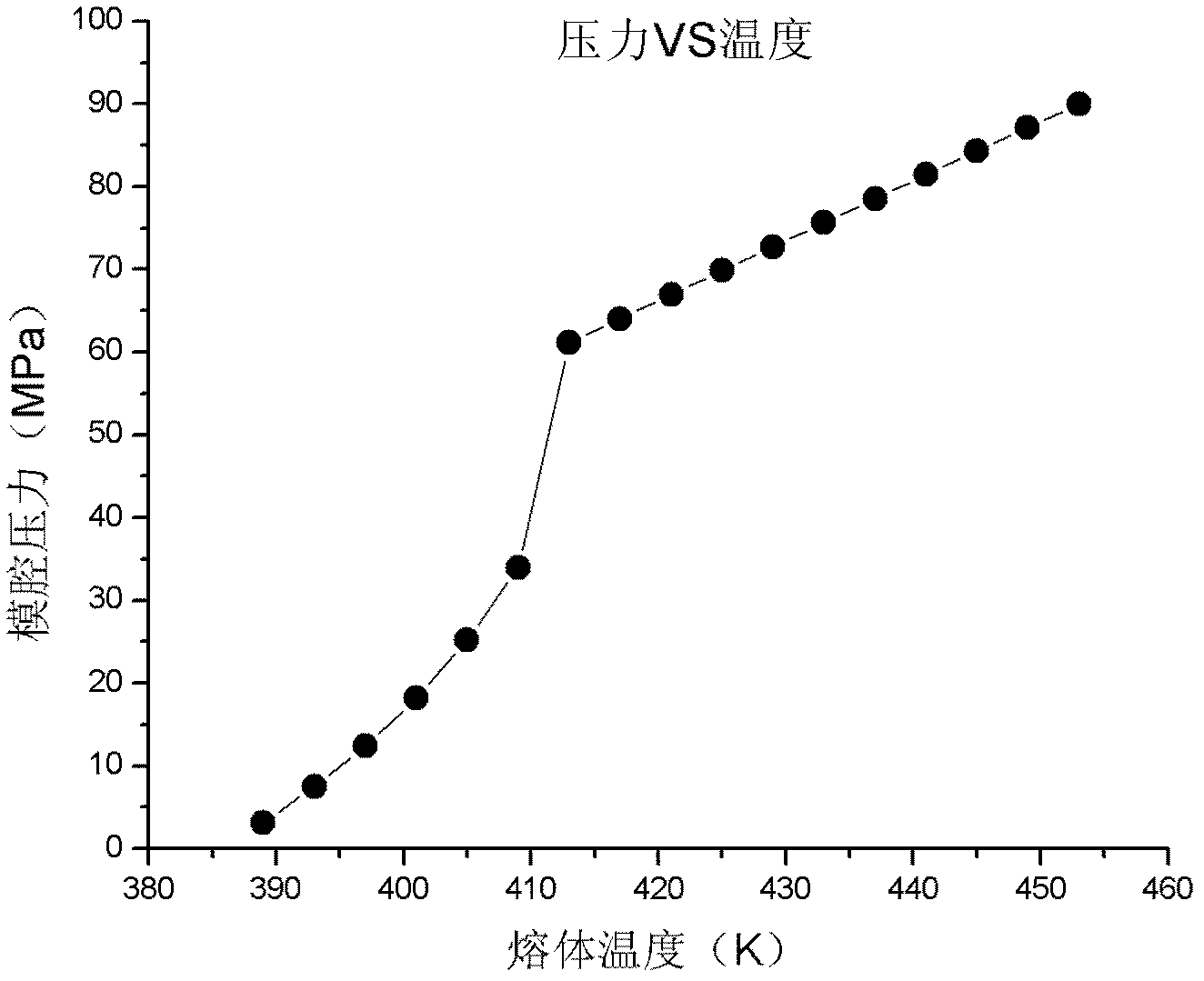

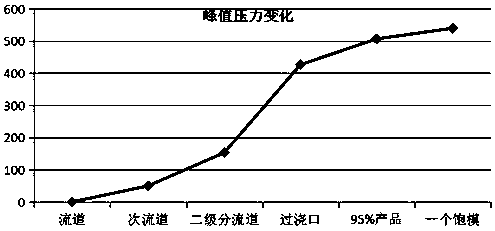

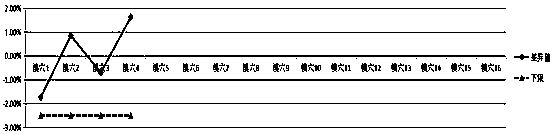

Test method for injection molding process of newly developed die

The invention belongs to the technical field of dies, and particularly relates to a test method for an injection molding process of a newly developed die. According to the method, under the conditionthat a material physical property table and product information provided by a material supplier, production process requirements and die information are known, the injection molding process is pre-designed; continuous injection molding unsaturated die products are sampled and weighed on the premise that the products are not incompletely filled; when injection molding is the stablest, parameters such as a material temperature, a screw rotation speed, back pressure and suck back decompression are found; the freezing time of a pouring gate is found and determined through a weighing method, and the pressure maintaining time is selected; the optimum packing pressure is determined through the combination of weighing and size measurement; the shortest cooling time and die clamping force are determined by observing a plastic part. According to the method, the parameters are determined according to the requirements of the products and the production process, and the method strives for parameterstabilization. The die is adjusted to meet the requirements of the production process. The stablest injection molding parameters are found by the scientific method, so that the stability of later-stage production is ensured, and after the parameters are fixed, the injection molding production is very stable.

Owner:上海普器阁实业有限公司

Dynamic sealing device for rotary blowout preventer

InactiveCN102364039AHigh direct contact cooling efficiencyReduce sinteringSealing/packingInterference fitBlowout preventer

The invention relates to a dynamic sealing device for blocking a rotary blowout preventer between a drill column and a borehole in drilling of oil-gas fields. The dynamic sealing device overcomes the defects that the conventional dynamic sealing device has short service life, is quick in heat emission and is easily sintered. The invention adopts the technical scheme that: a supporting ring is arranged in a packing box, the supporting ring is provided with an oil hole b and an oil hole c, and the outer surface of the supporting ring is provided with an annular groove b; a disc spring is arranged in the supporting ring, a caulking ring is arranged at the lower part of the disc spring, and the supporting ring is arranged between the caulking ring and a pressure ring; the pressure ring is provided with an oil hole a, and a V-shaped sealing ring and a spacing ring are sequentially arranged at the lower part of the pressure ring at intervals; a packing pressure ring is arranged at the lower end of a floating ring, the packing pressure ring is fixed at the end of the packing box, and the packing pressure ring is in clearance fit with a central pipe bush; and the central pipe bush is in interference fit with a central pipe, the packing box is in interference fit with an upper shell of the blowout preventer, and lubricating oil enters an oil hole in the upper shell of the blowout preventer through a bearing. The dynamic sealing device is suitable for relatively high dynamic sealing pressure, reduces sintering of the sealing ring, has low heat emitting abrasion and long service life, and reduces the abrasion rate.

Owner:SOUTHWEST PETROLEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com