Patents

Literature

37results about How to "Reliable seating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

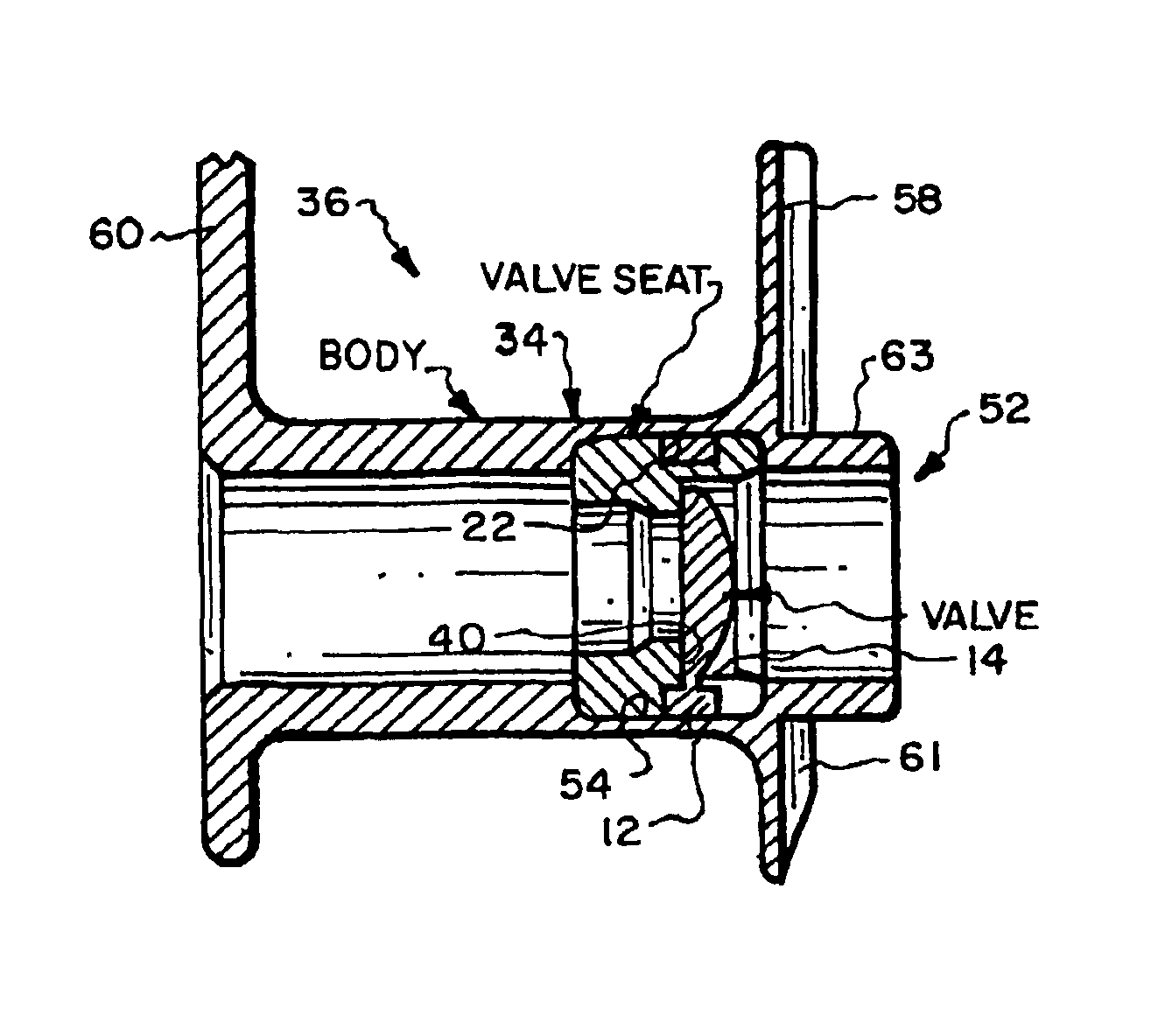

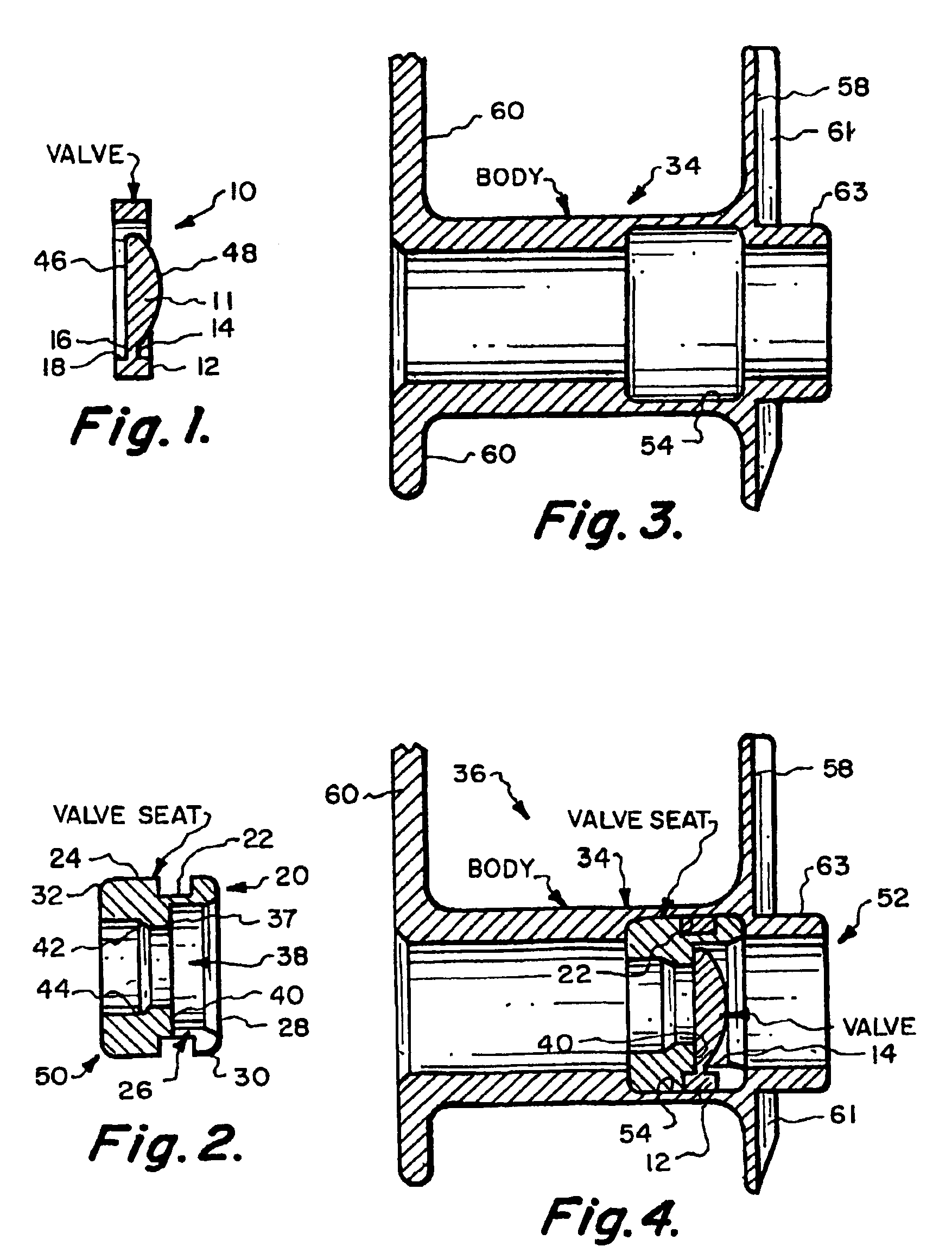

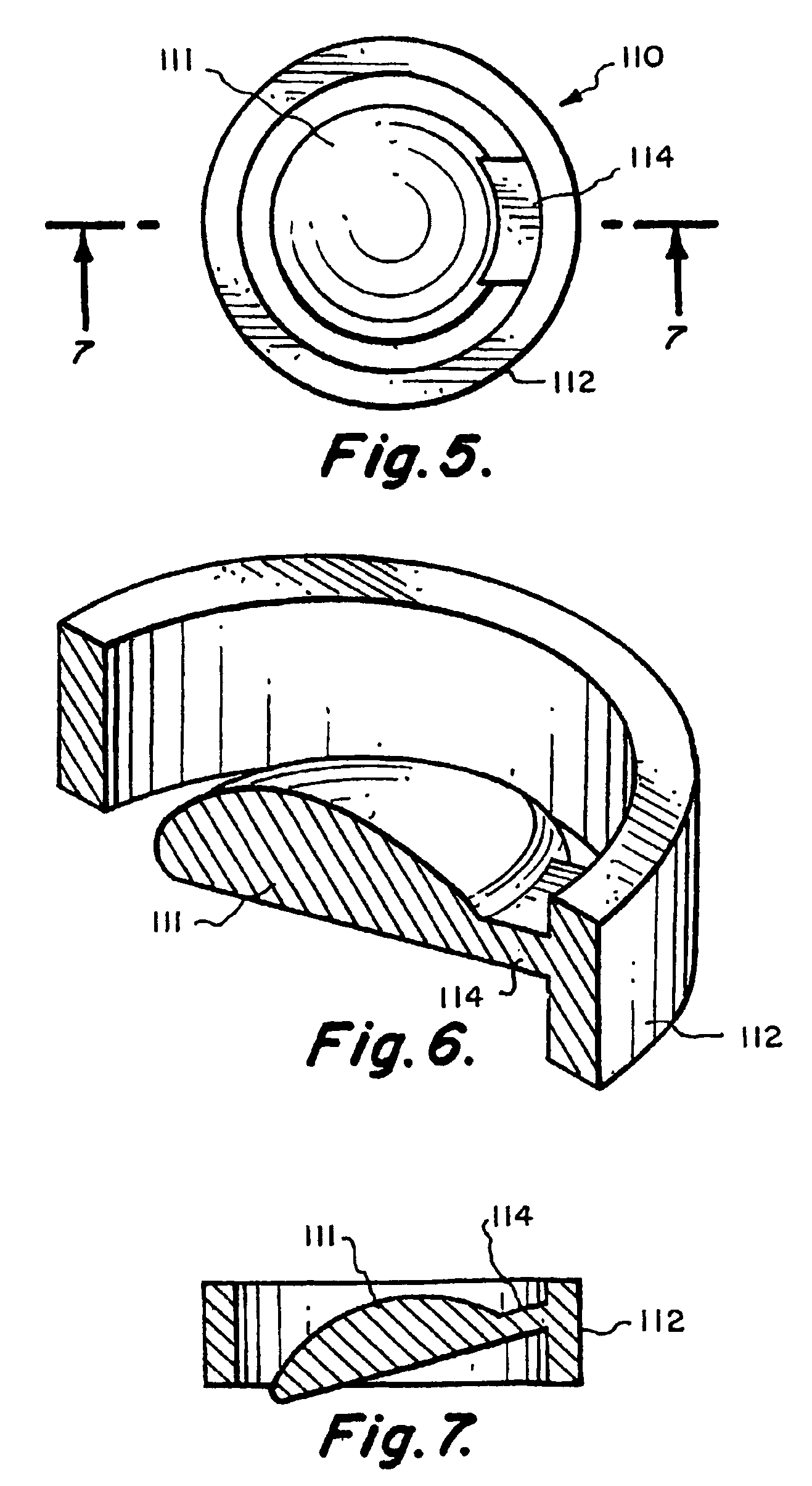

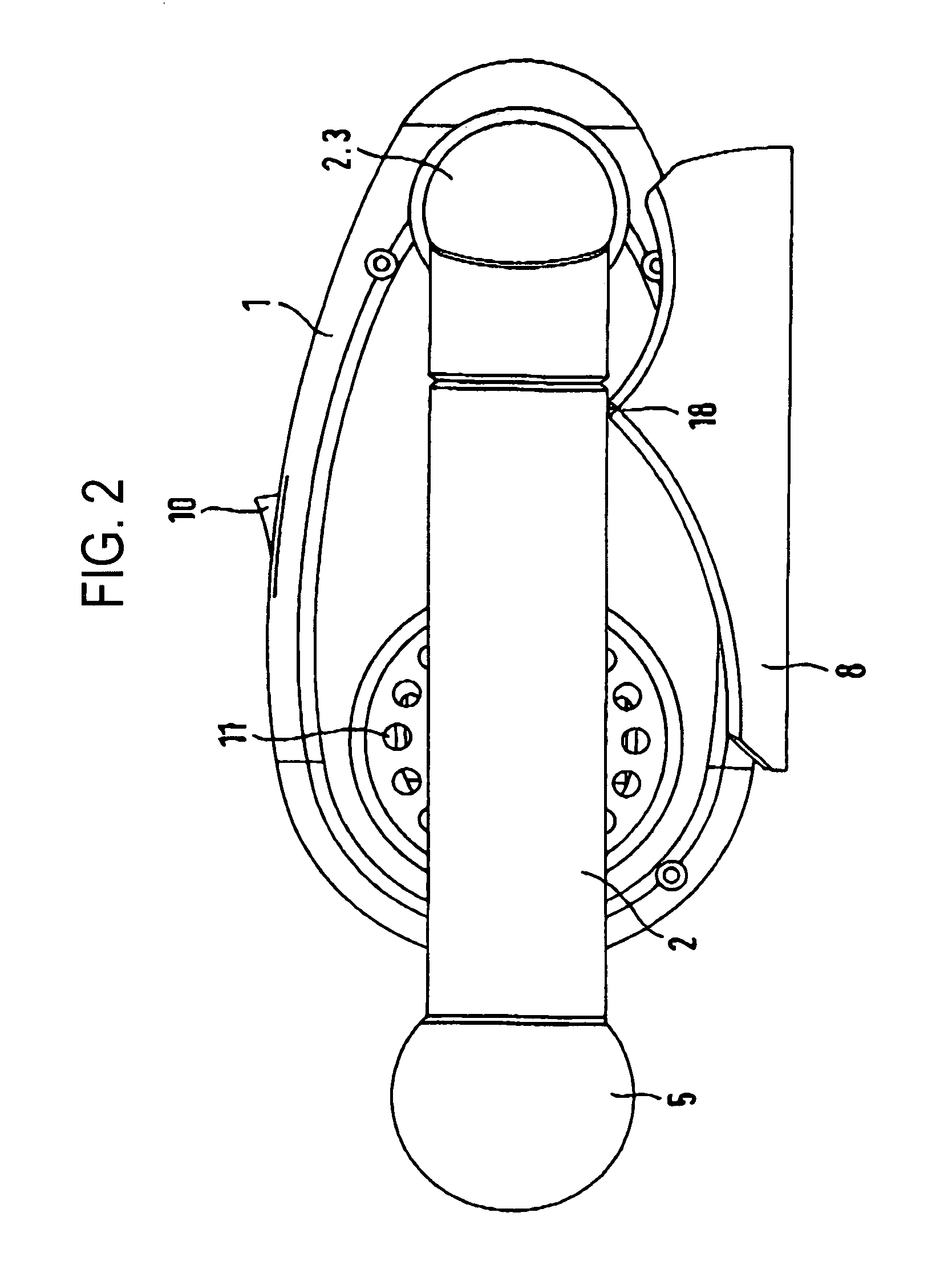

Valve mounting assembly for voice prosthesis-cartridge and ring

The valve mounting system of the invention incorporates a hard cartridge with a grove on its outer, distal surface and a slot communicating distal from the end of the cartridge with the grove and a specially configured elastomeric valve attached to an outer band with a short tab. The band is positioned with the tab aligned with the slot and is stretched and is slid proximally over the cartridge until the tap enters the slot and the band snaps into the seats in the groove. The width of the slot is the same as the width of the tab providing exact alignment of the valve element with the seat provided in the cartridge. The tab can be disposed at an angle to the seat to preload the valve element against the seat.

Owner:FREUDENBERG MEDICAL

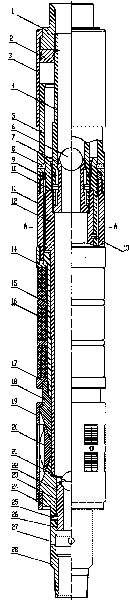

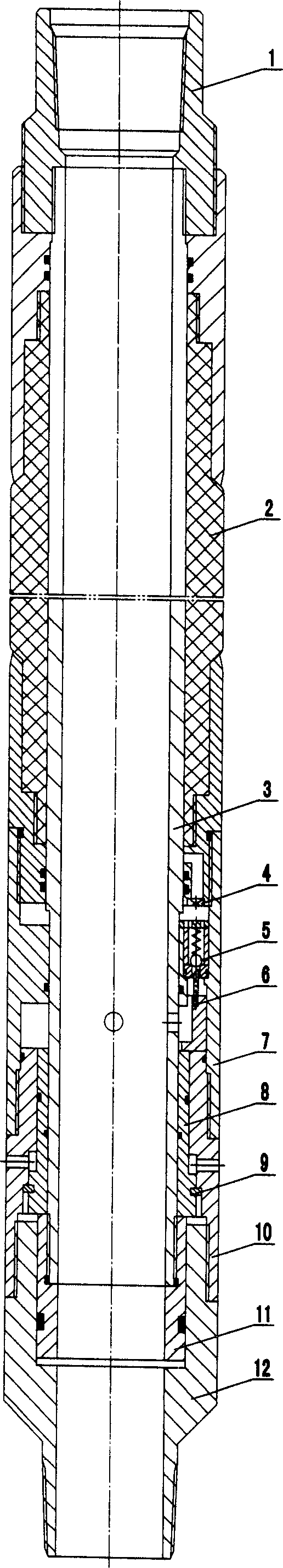

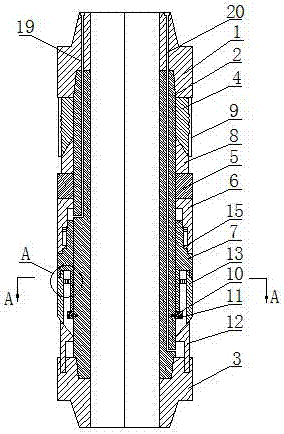

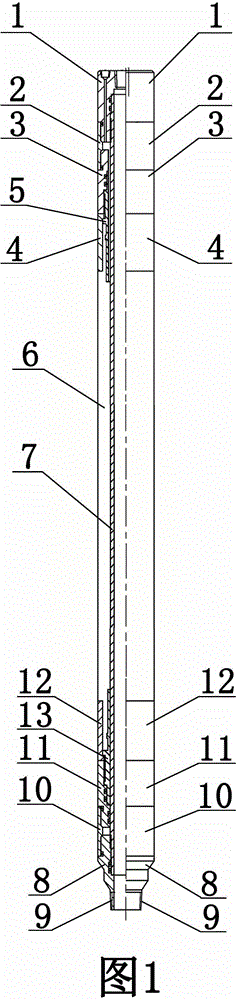

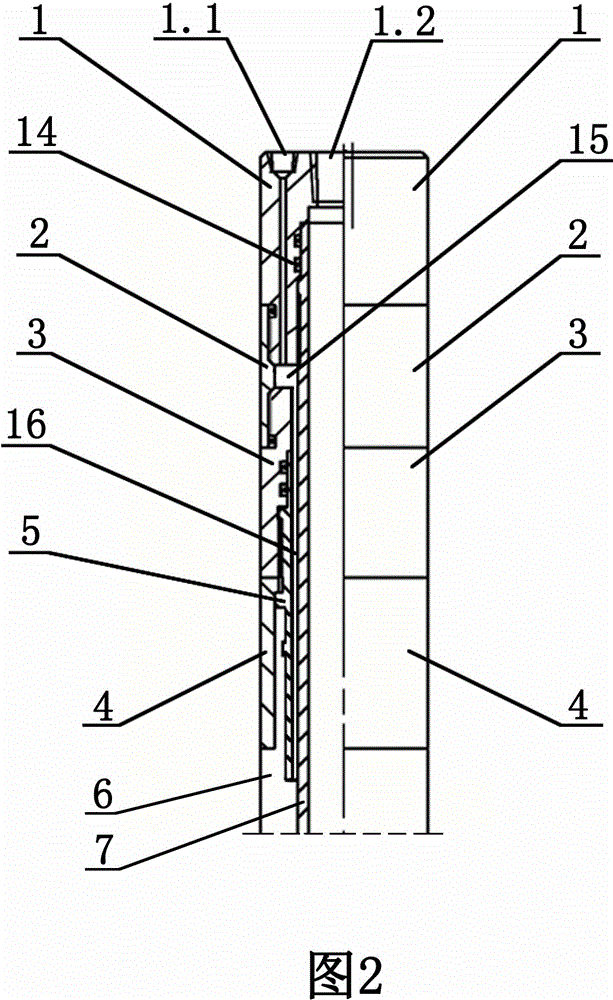

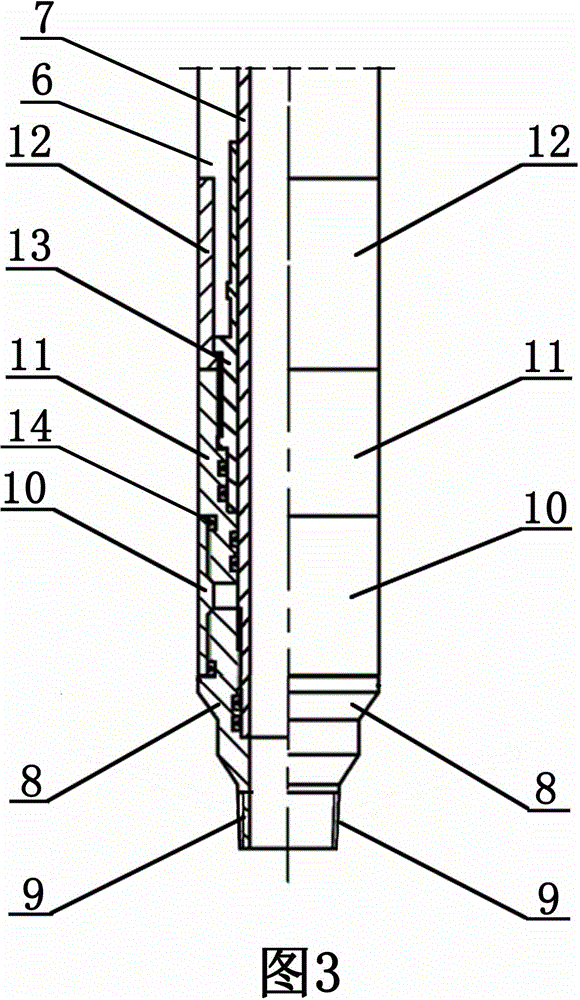

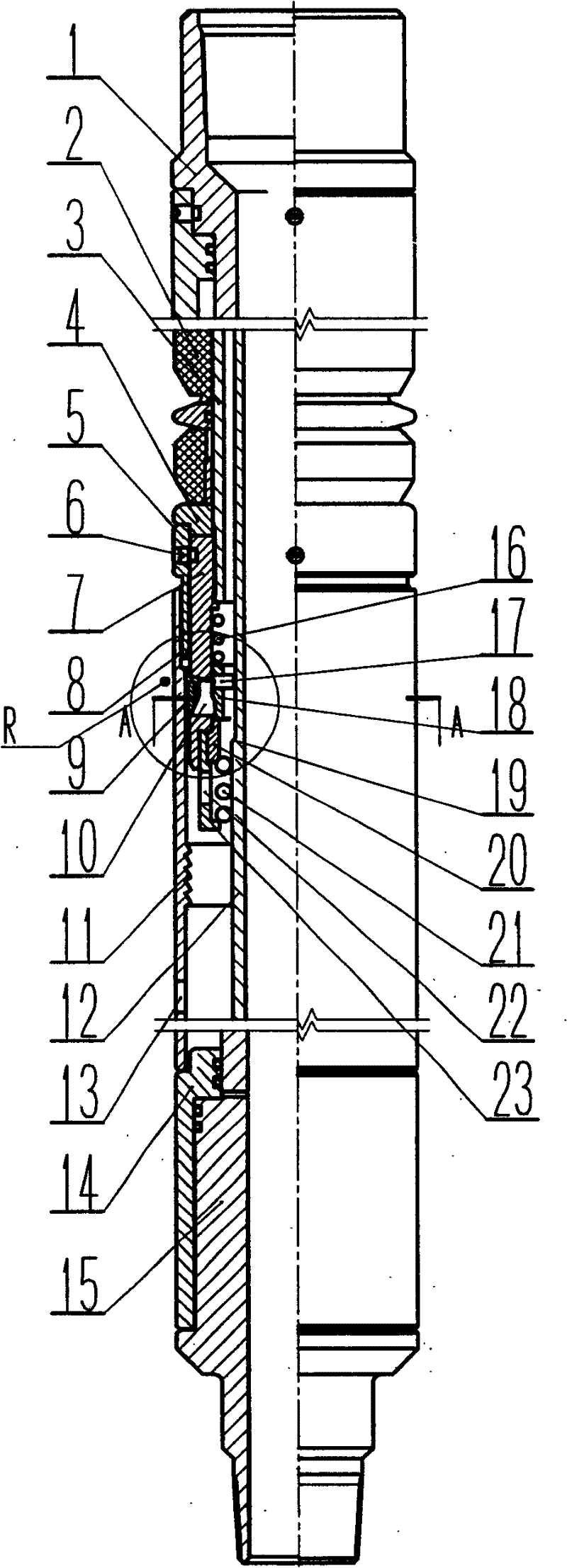

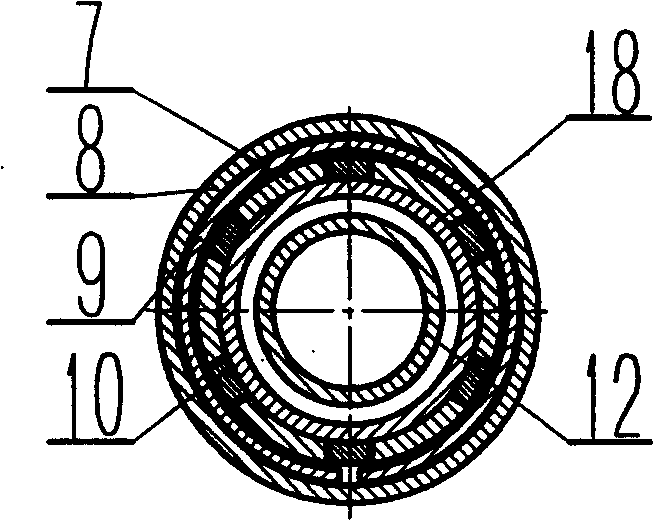

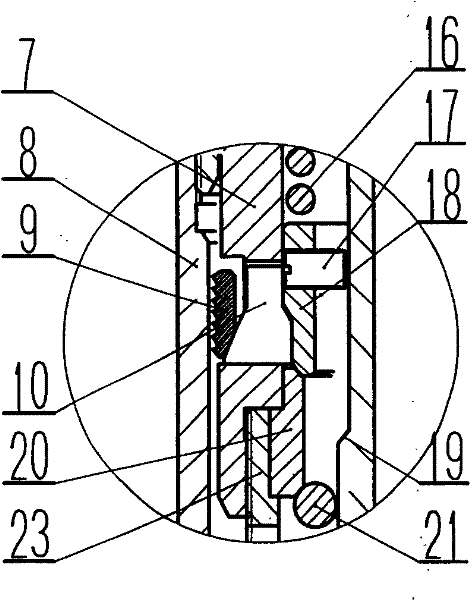

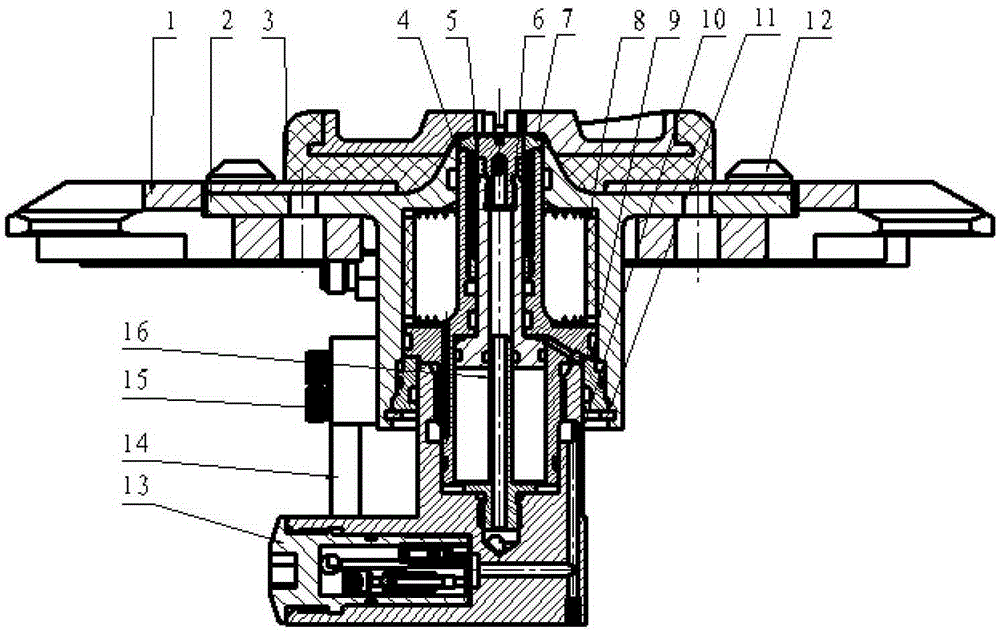

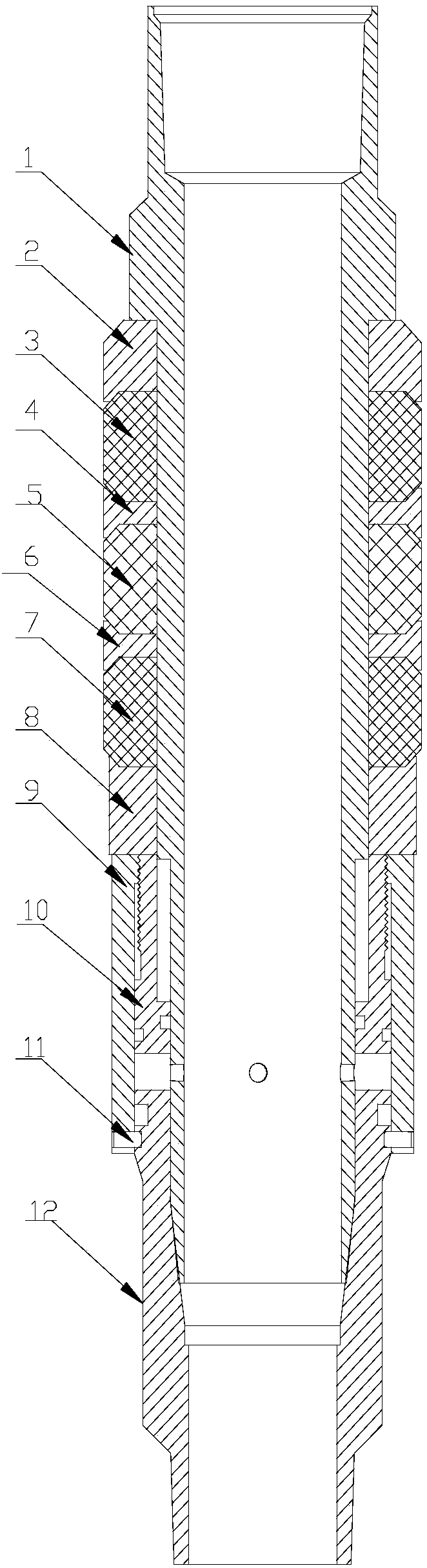

Release packer capable of well-flushing

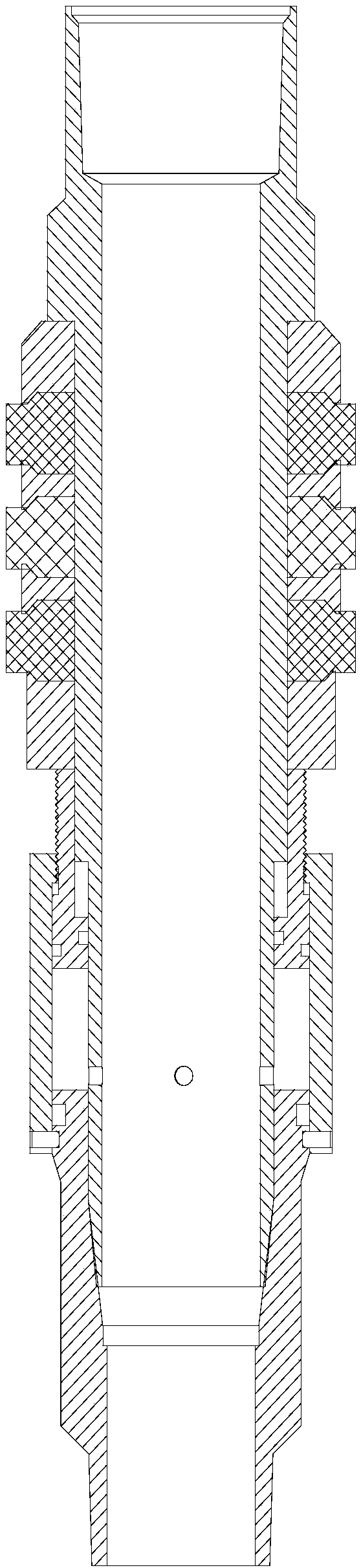

ActiveCN101737019AReliable seatingRealize layered oil recoveryCleaning apparatusFluid removalHydraulic cylinderUpper joint

The invention discloses a release packer capable of well-flushing, which comprises an upper joint, a piston, a hydraulic cylinder, a separating joint, an ejector sleeve, a packing valve ball, a packing valve seat, a packing shear pin, a lock ring, a junk sub, a connected pipe, an inner pipe, an unset shear pin, an upper rubber cylinder joint, a rubber cylinder shaft, a rubber cylinder, a lower rubber cylinder joint, an upper cone, a slip sleeve, a slip, a lower cone, and a stop joint; wherein the lower cone is provided with a communicated hole and internally provided with a sliding sleeve; the sliding sleeve is positioned above the communicated hole and fixed on the lower cone; the upper part of the sliding sleeve is provided with an upper seal ring, and the lower part of the sliding sleeve is provided with a lower seal ring; a pin is positioned between the upper seal ring and the lower seal ring; a cut-off valve ball is located in the upper port of the sliding sleeve; and the diameter of the cut-off valve ball is smaller than the inner diameter of the packing valve seat. Before packing, the reverse well flushing can be carried out on an oil pipe on the packer so as to wash way sundries in the oil pipe and ensure that a packing pressure is transferred to the piston, the packer can be reliably packed and the well flushing can successfully realize oil production by layer, thereby the invention has obvious economic benefit.

Owner:DONGYING BAIHUA GASOLINEEUM TECH DEV

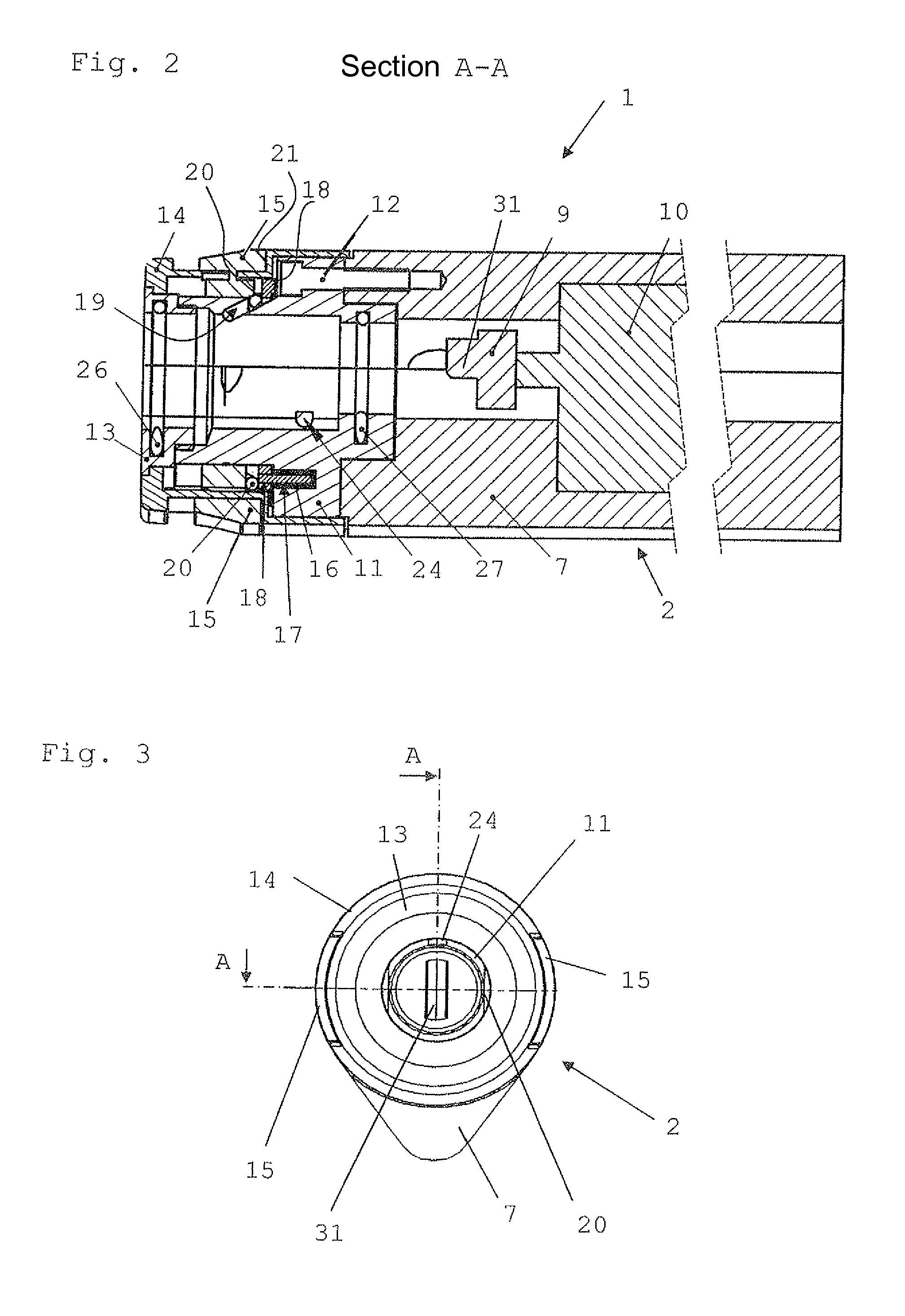

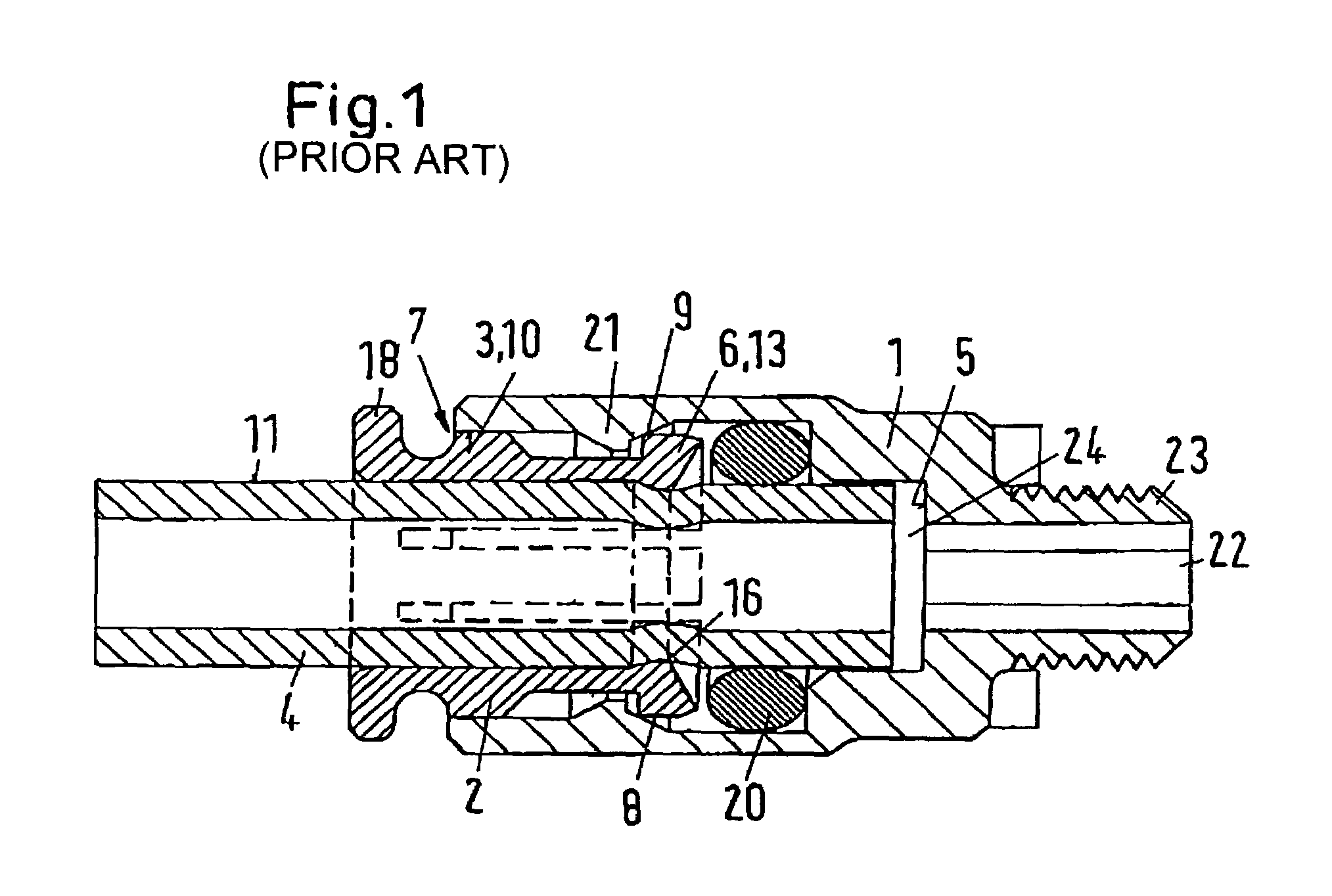

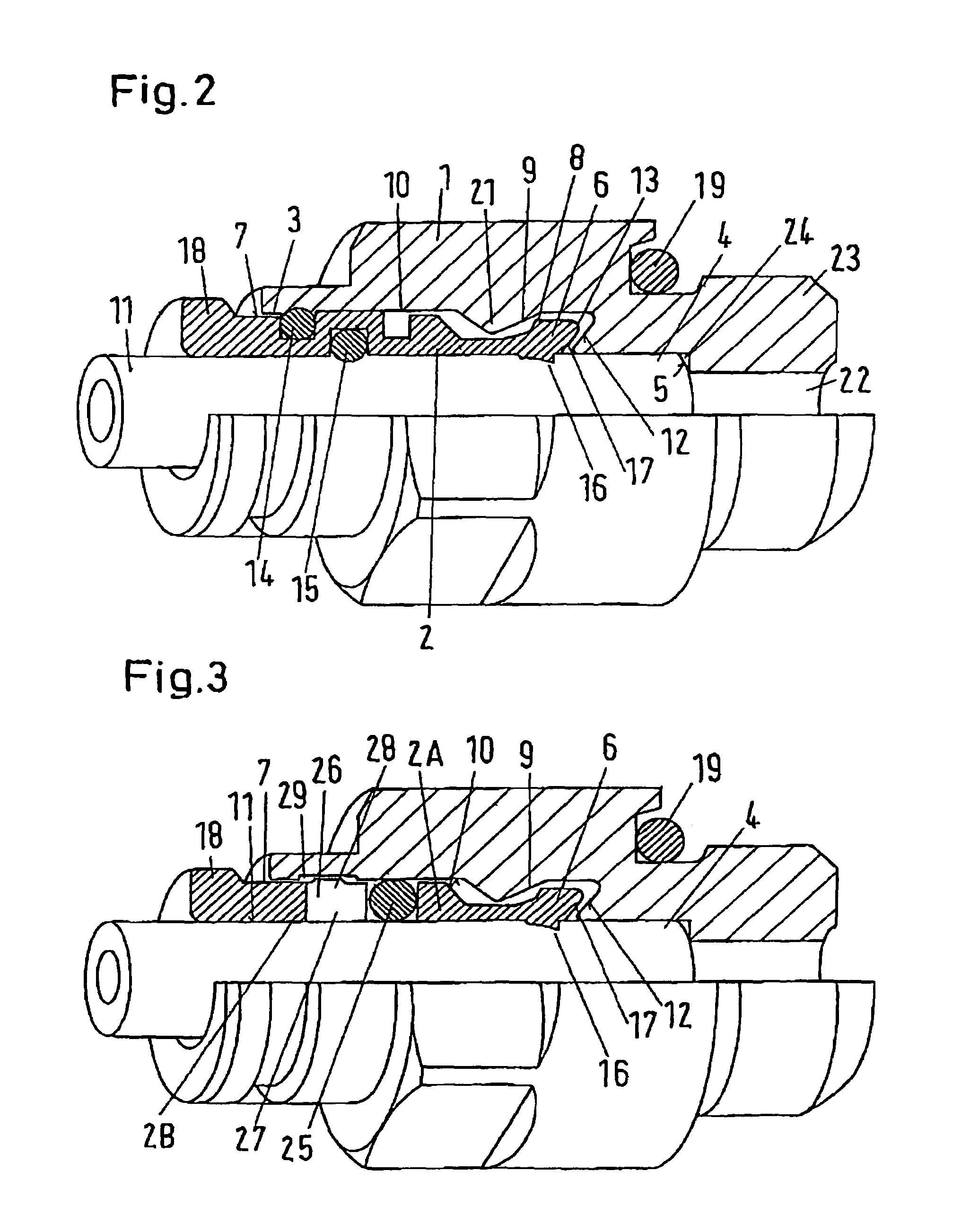

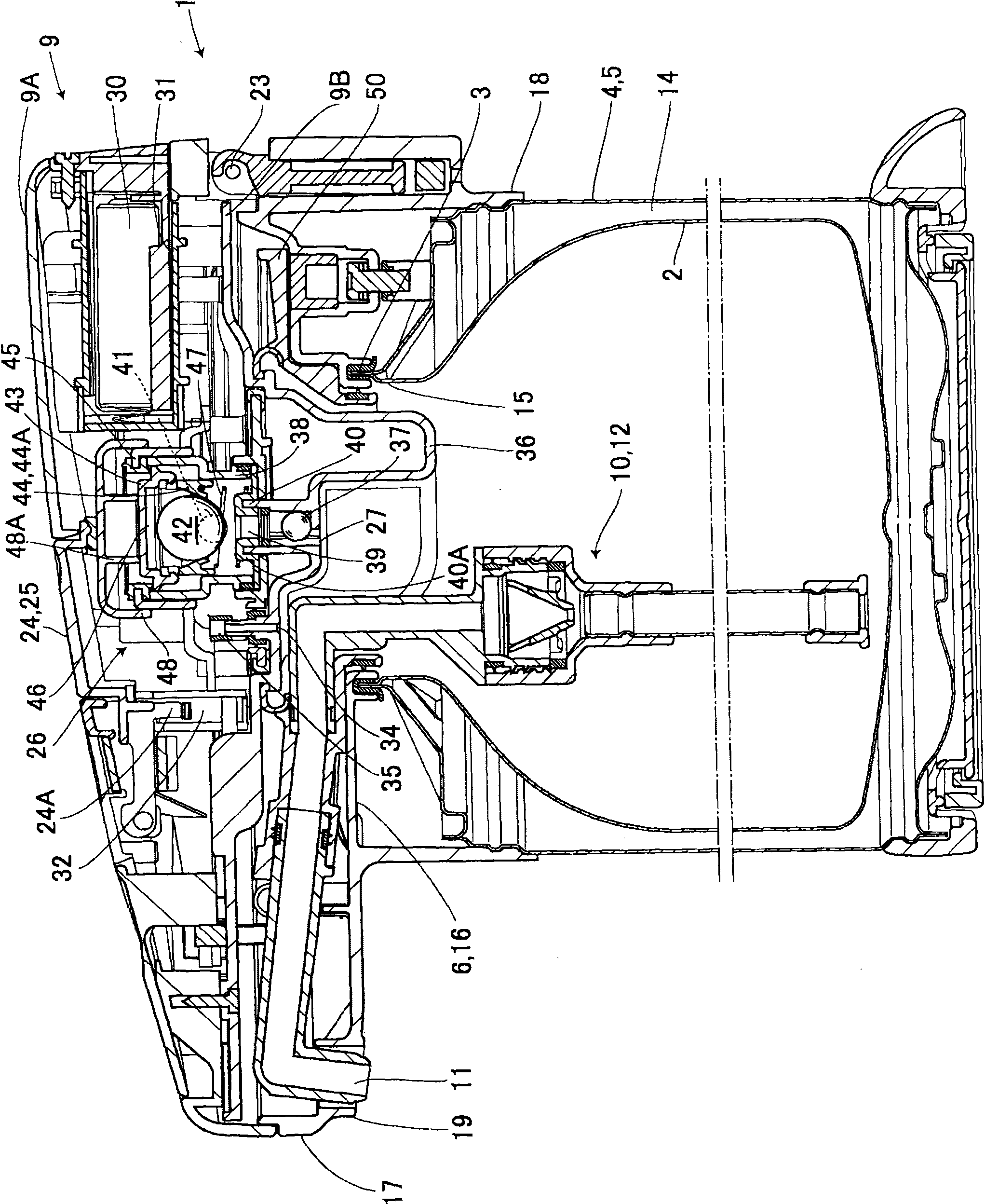

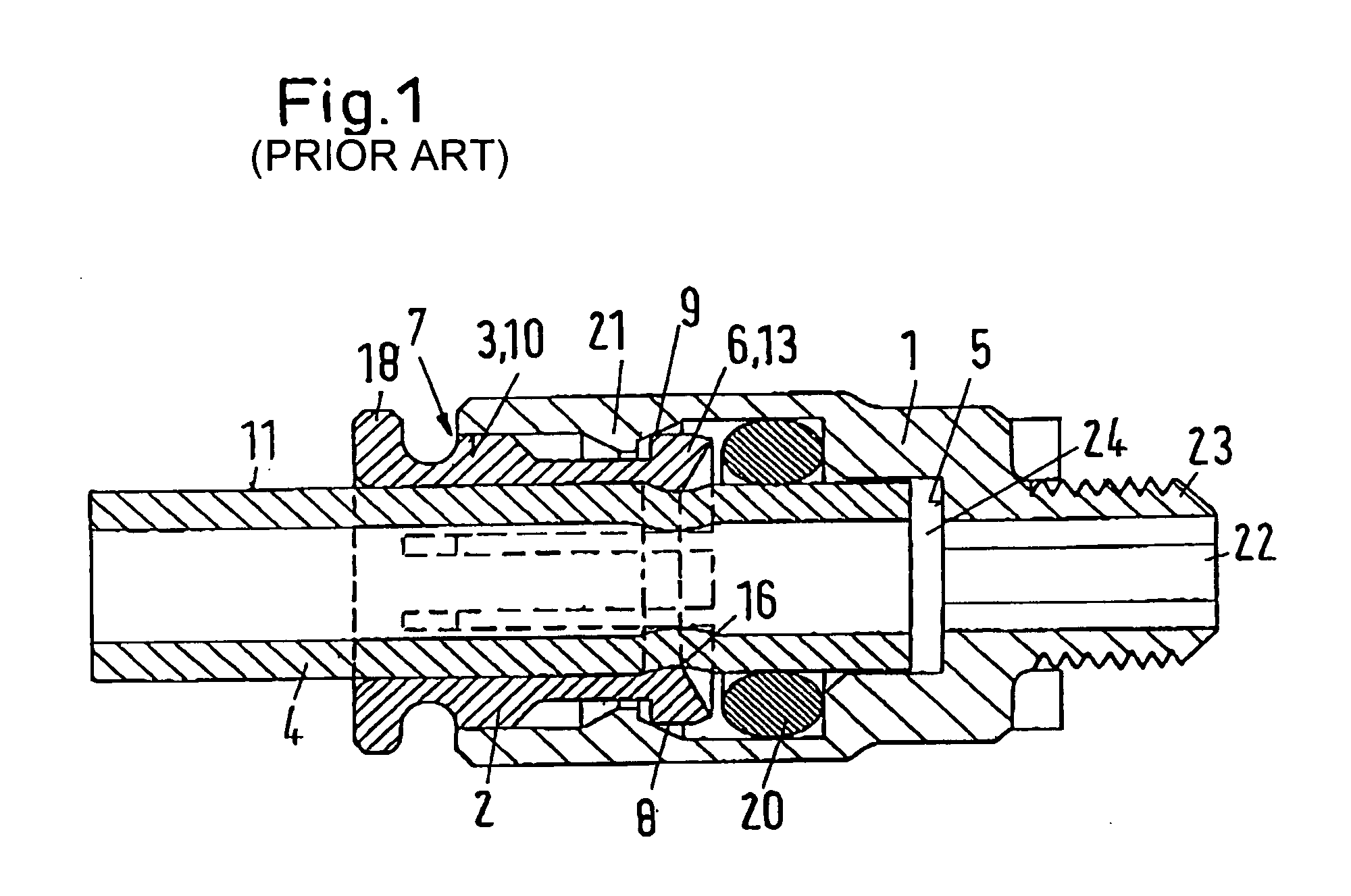

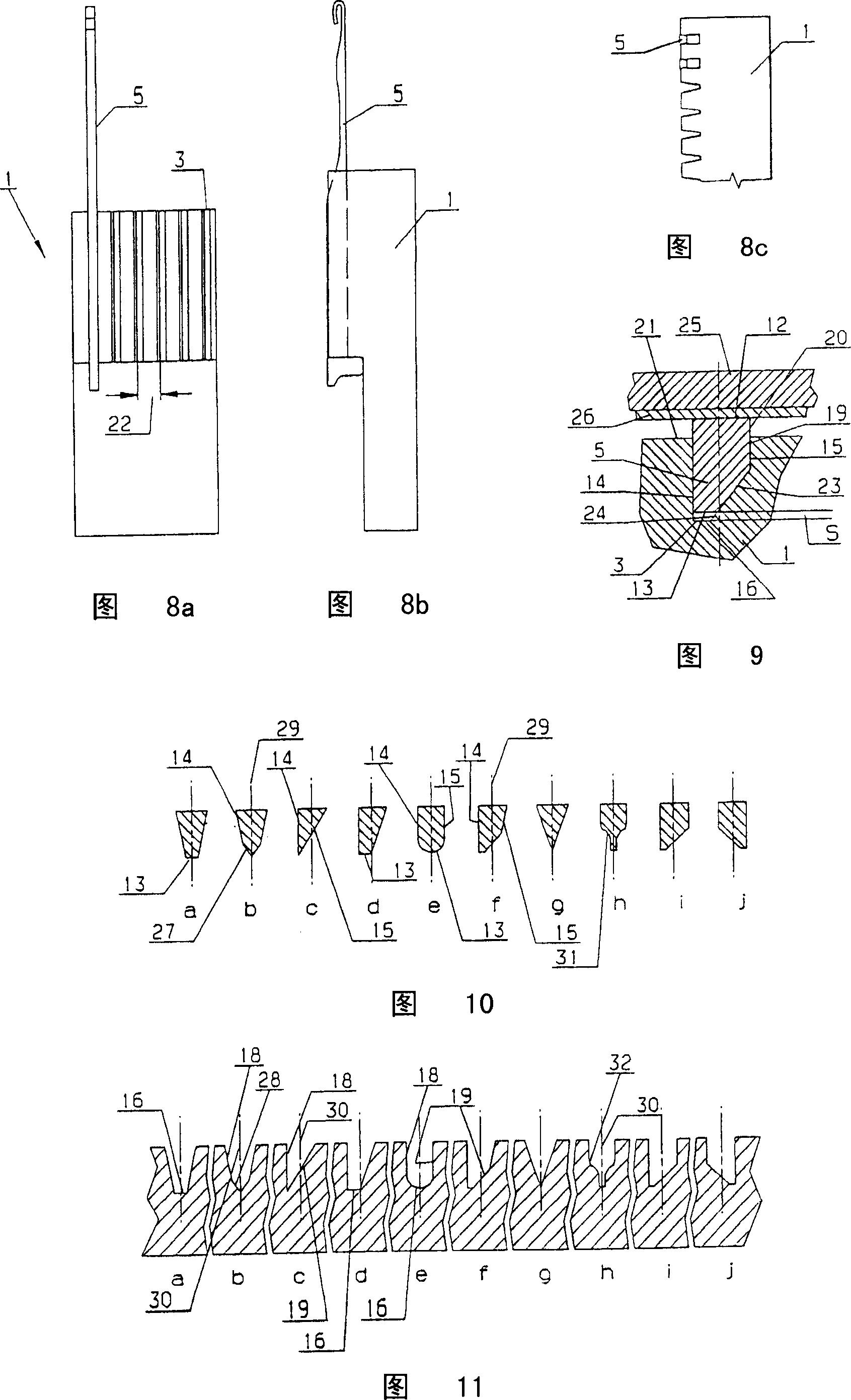

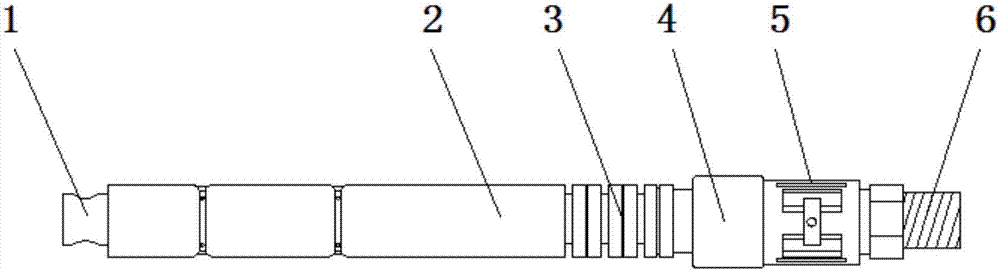

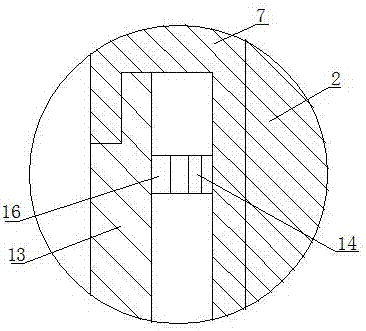

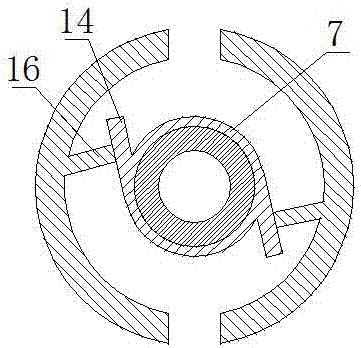

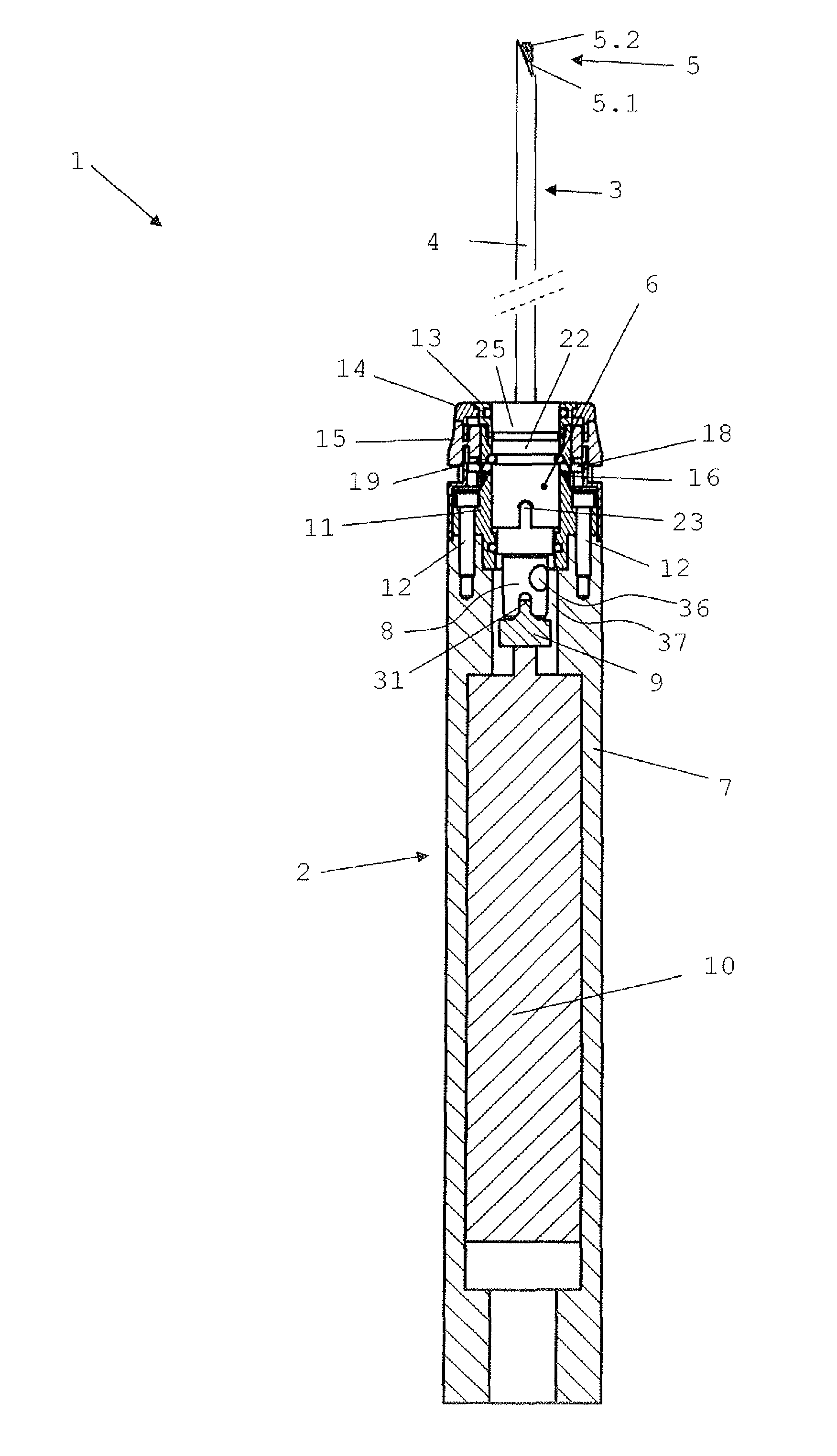

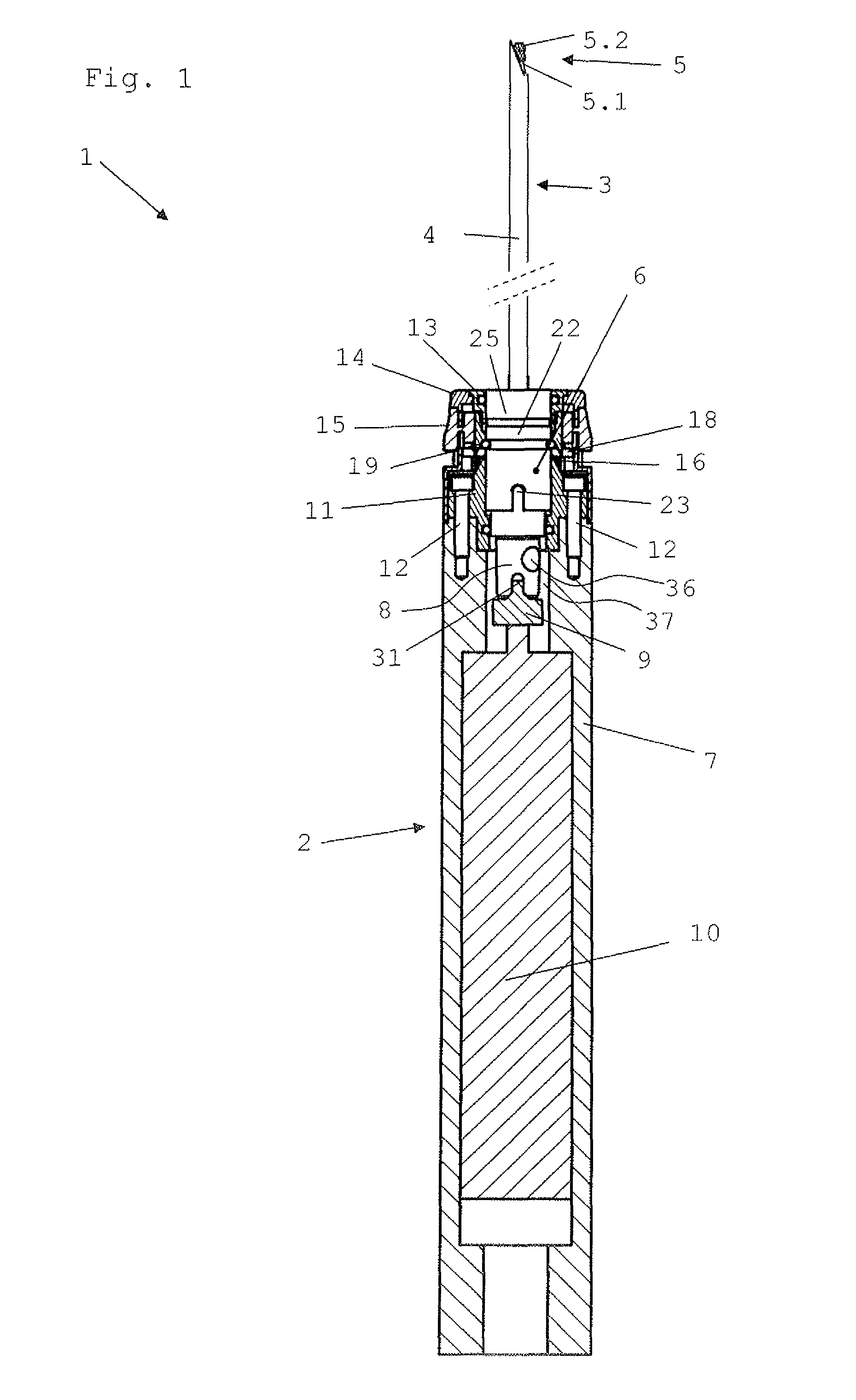

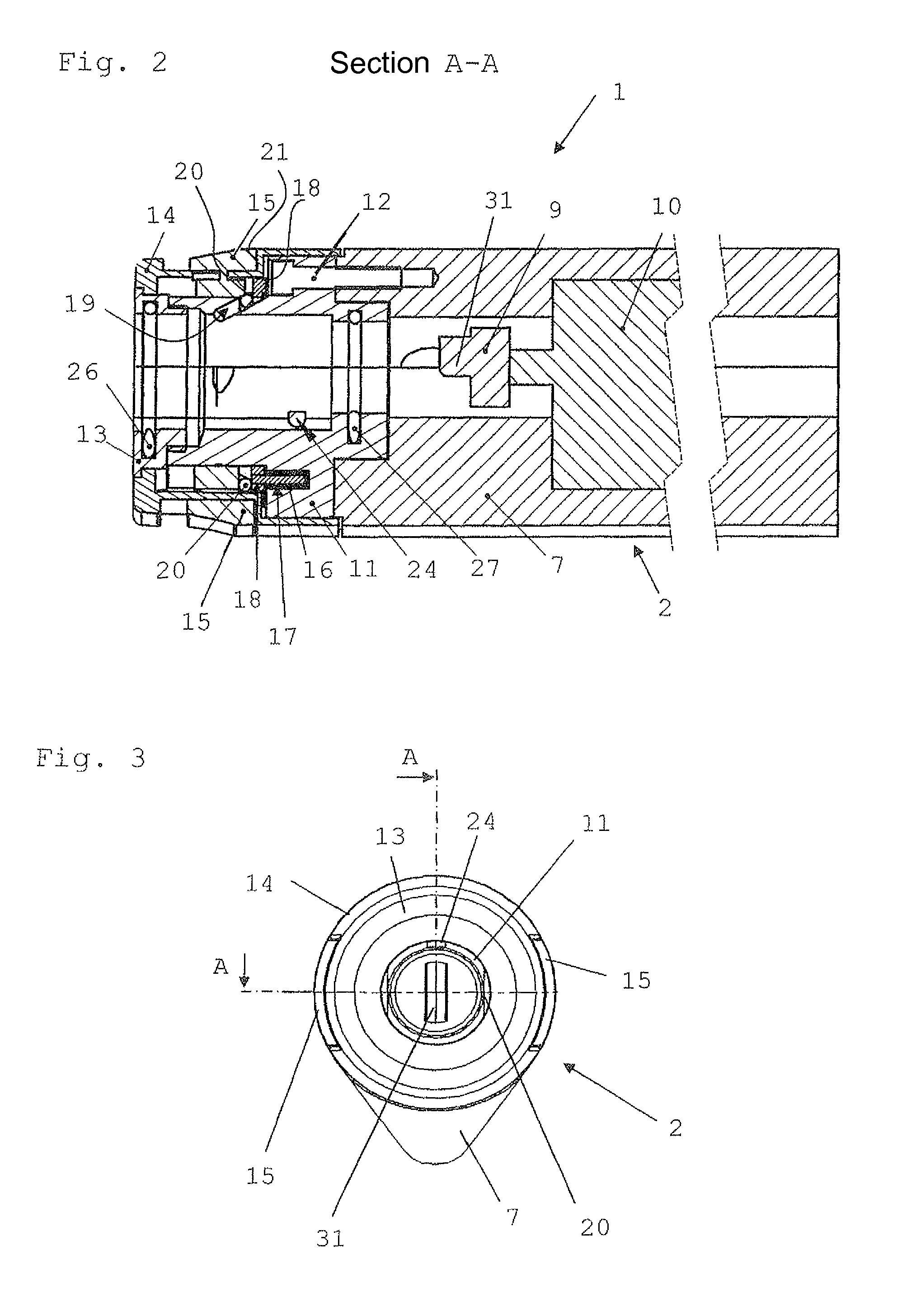

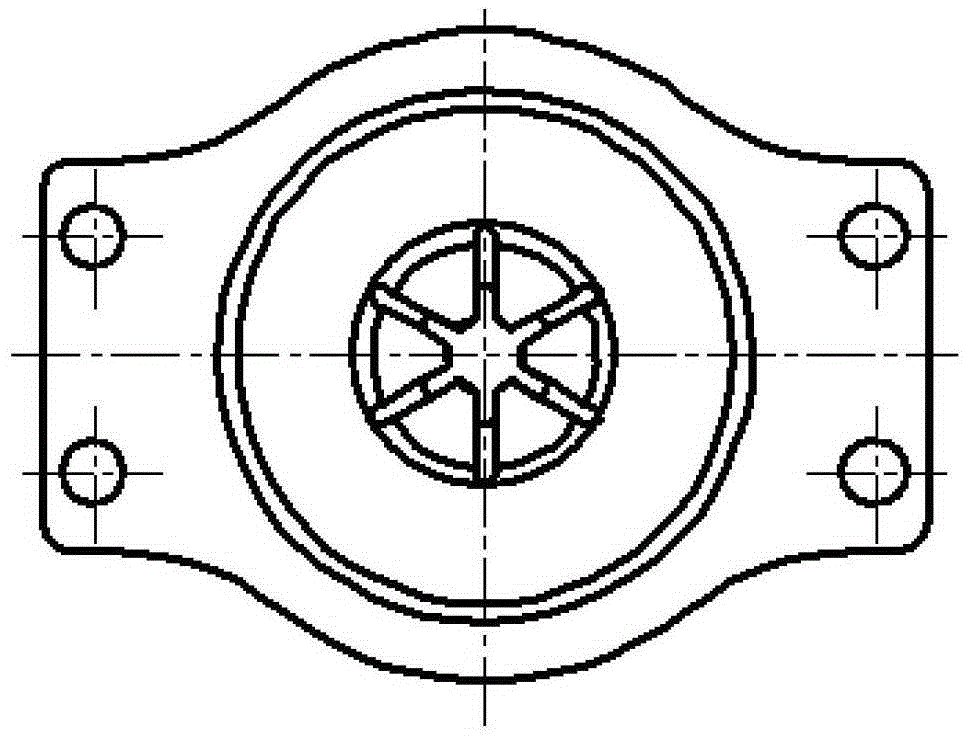

Surgical instrument for detachably connecting a handpiece to a surgical tool

ActiveUS20120253330A1Simple designReliable driveDiagnosticsSurgical manipulatorsDrive shaftEngineering

Surgical instrument with a handpiece having a drive and with a surgical tool, which has a tube and a working part with a shaft and with a tool head, the tube of the surgical tool can be detachably connected to the handpiece by a first coupling part and the shaft of the working part can be detachably connected to a drive shaft in the form of a pin of the drive by a second coupling part simultaneously.

Owner:JOIMAX GMBH

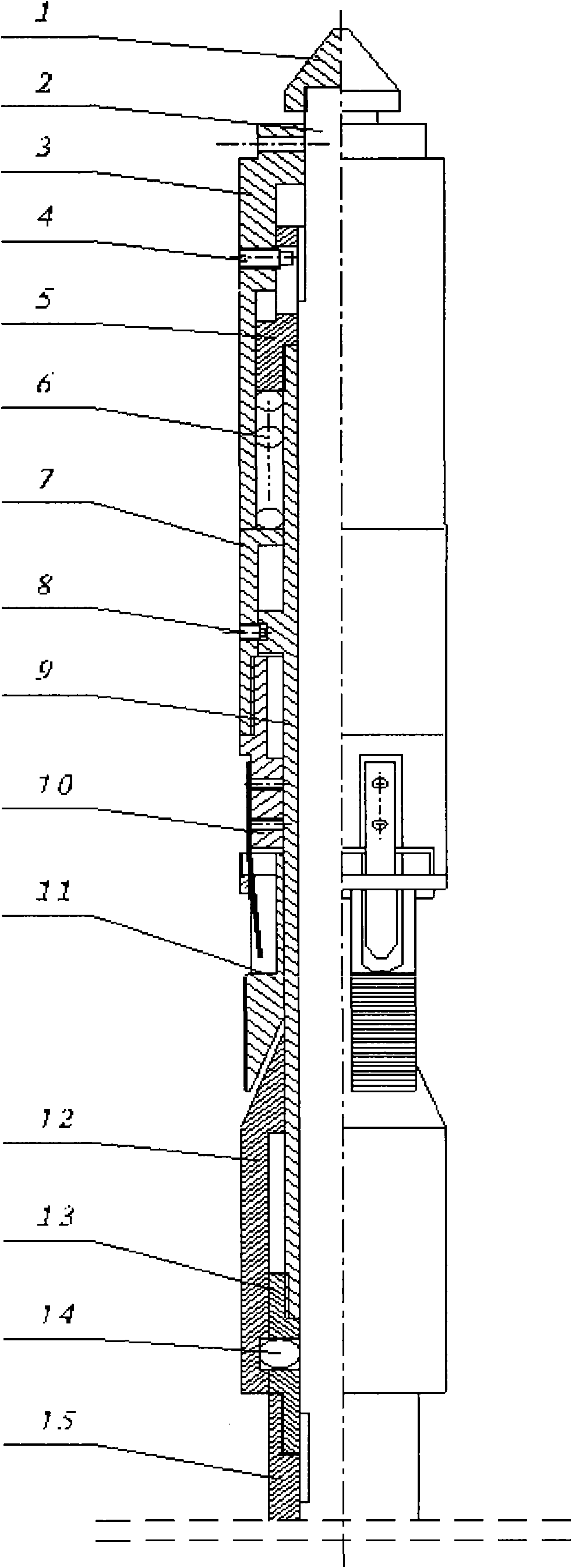

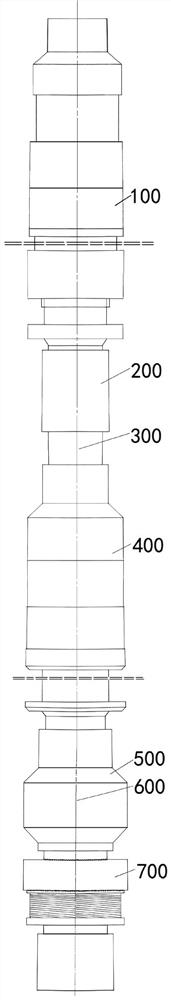

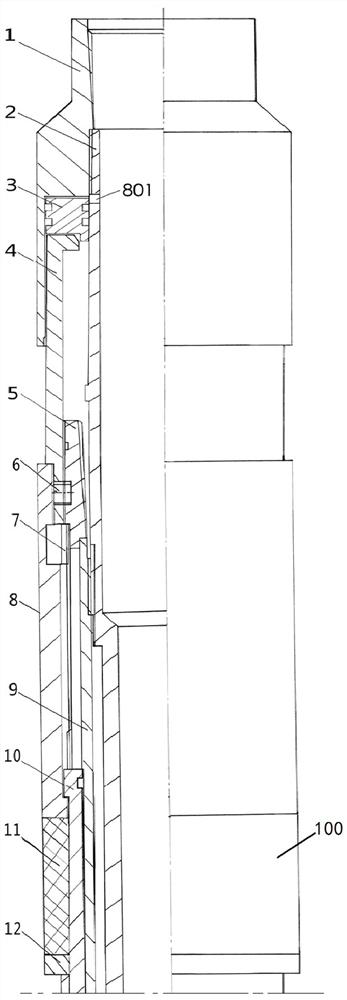

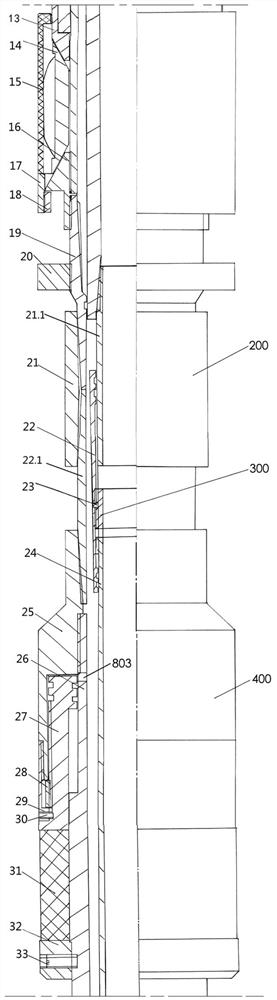

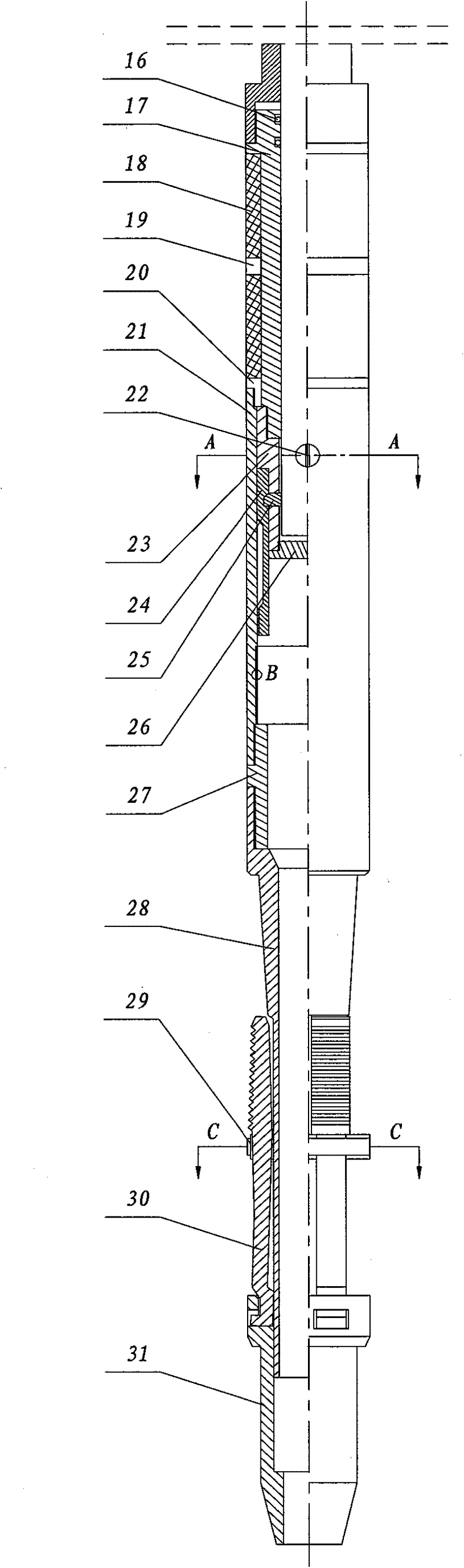

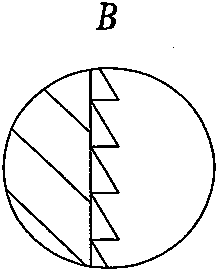

A bridge plug that blocks off oil tube

A bridge plug that blocks off oil tube is used in underground blocking oil tube during a pressure operation in the oil, gas or water well in an oilfield. From top to bottom, the bridge plug consists of salvage part, slip setting part, sealing part and slip release part. Steel wire is used for seat delivery, salvage and unsealing. The slip release part may accurately determine the position of the bridge plug. In both sealing part and slip setting part, self-locking devices are provided to realize reliable sealing. During salvage, a special tool is used to cooperate with the salvage part and unseal and take out the bridge plug. After replacement of packing elements and shear pins and simple maintenance, this bridge plug may be used repeatedly. The bridge plug adopts a double-slip structure and realizes the function of blocking off oil tube by using mechanical vibration and self-locking principle. It has the following advantages: sealing in any position, large sealing pressure difference, salvage, blocking of the oil tubes with a very small aperture, and blocking by section.

Owner:PETROCHINA CO LTD

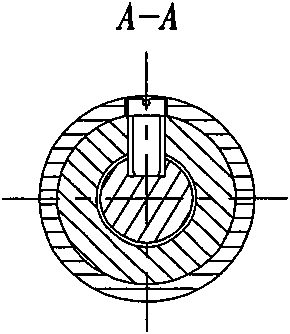

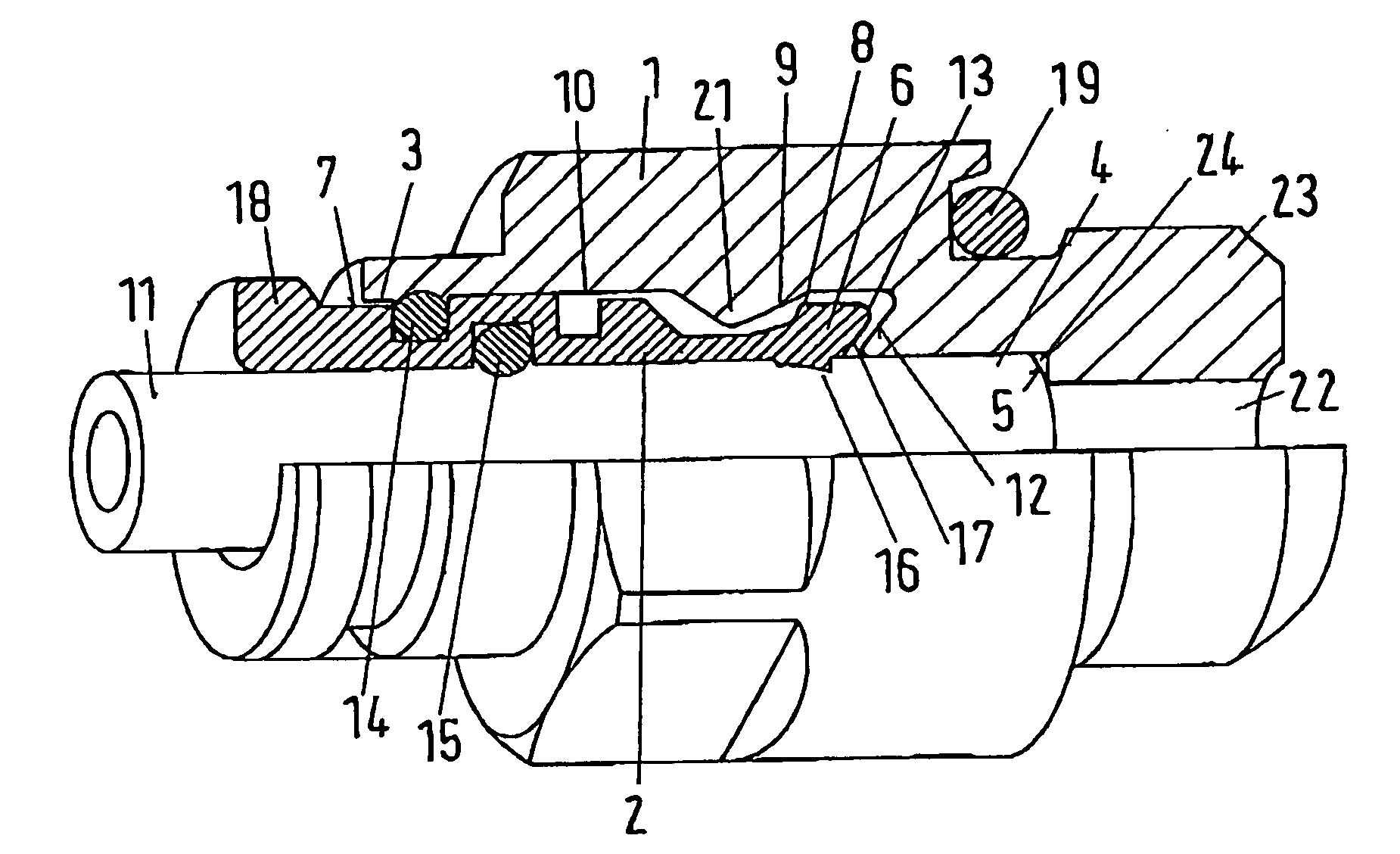

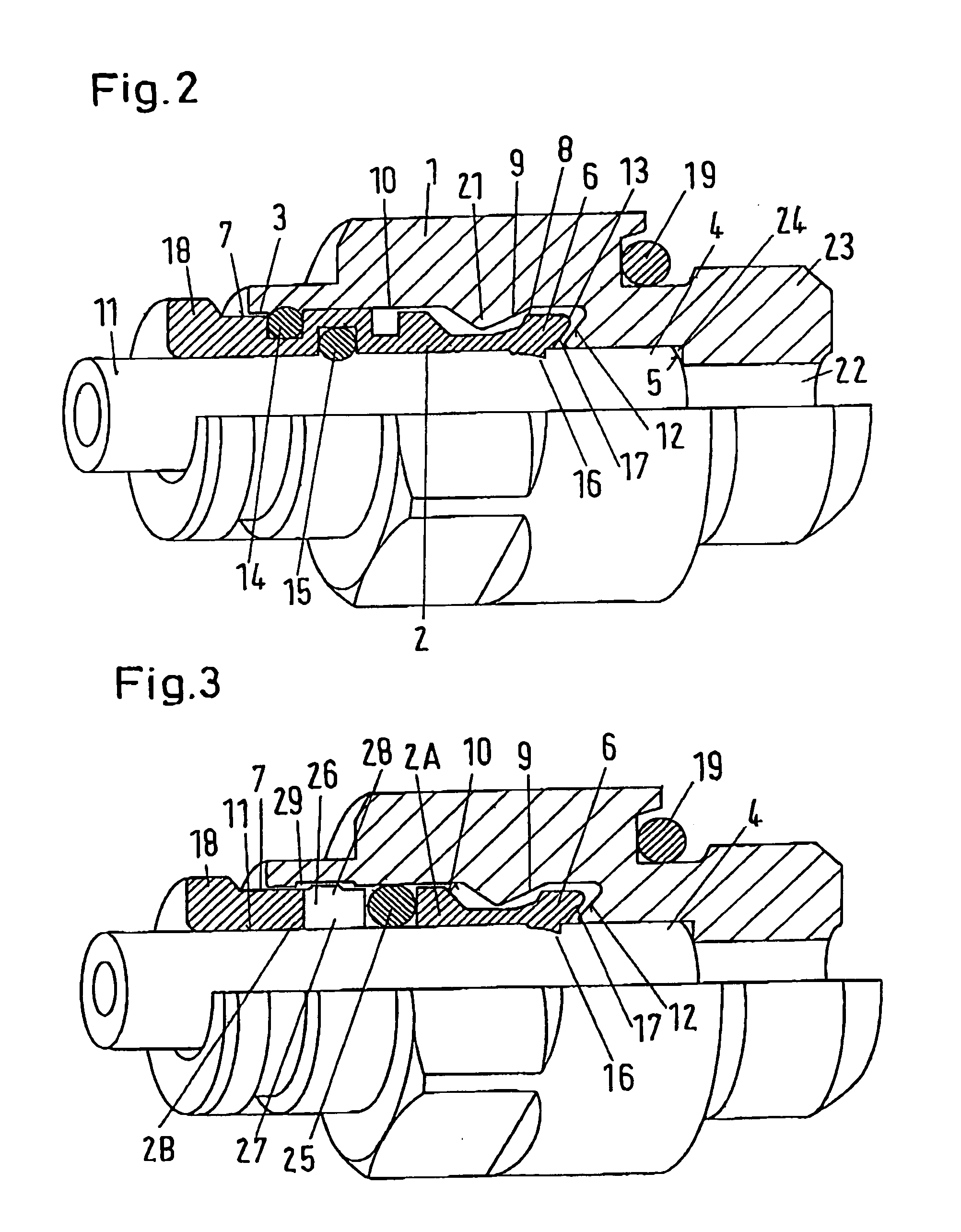

Connecting device for a pipe or similar

InactiveUS7380838B2Simple formatSimple structureSleeve/socket jointsCouplingsEngineeringMechanical engineering

A connecting device for a pipe comprises a coupling body and a clamping collar. The clamping collar is divided into an axially inner function section and an axially outer actuation section, with a seal positioned between facing front sides of the axially inner function section and the axially outer actuation section. The seal is for sealing against an inner wall of the coupling body and against an outer wall surface of a pipe received within the clamping collar, when the clamping collar is within the coupling body.

Owner:LINCOLN GMBH

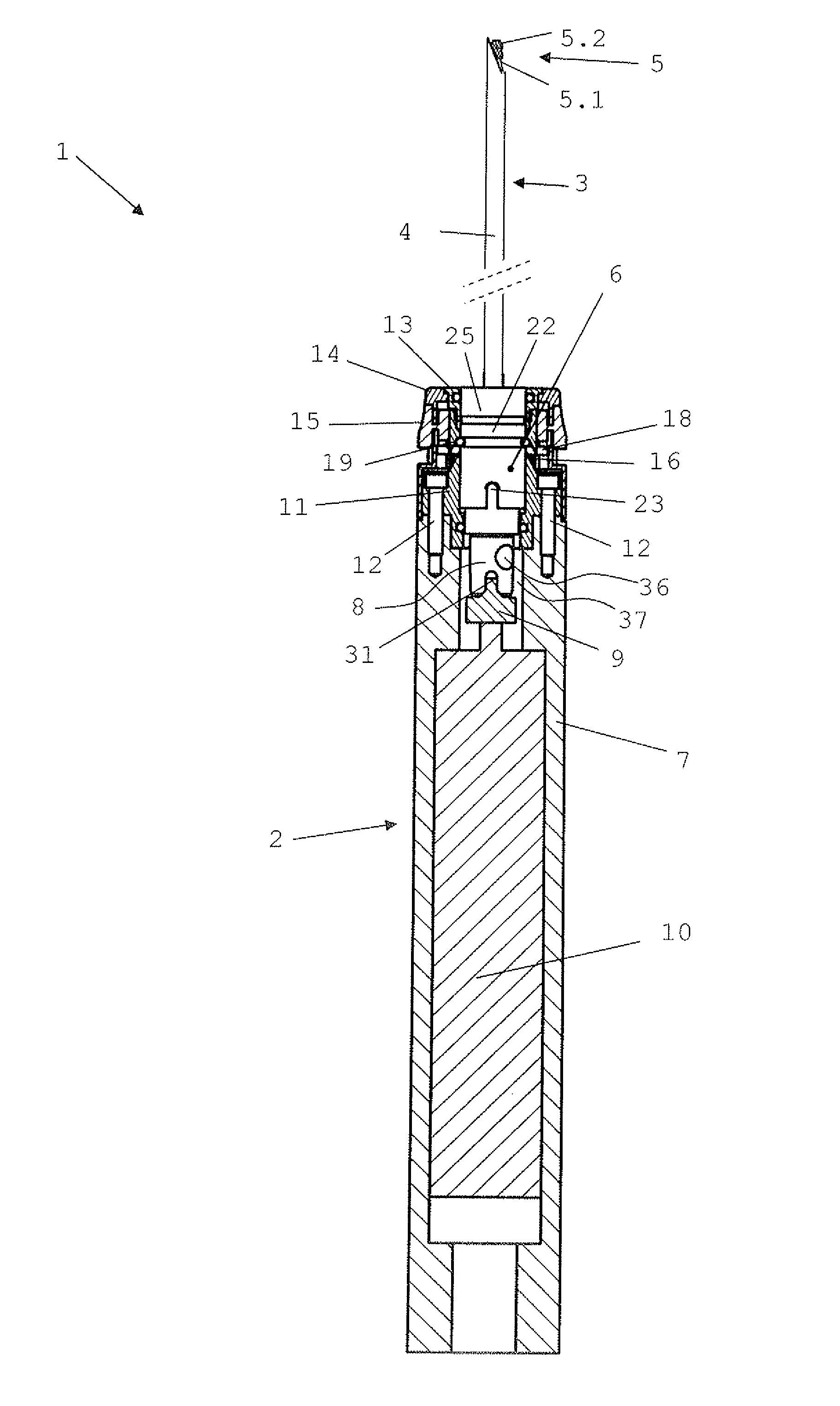

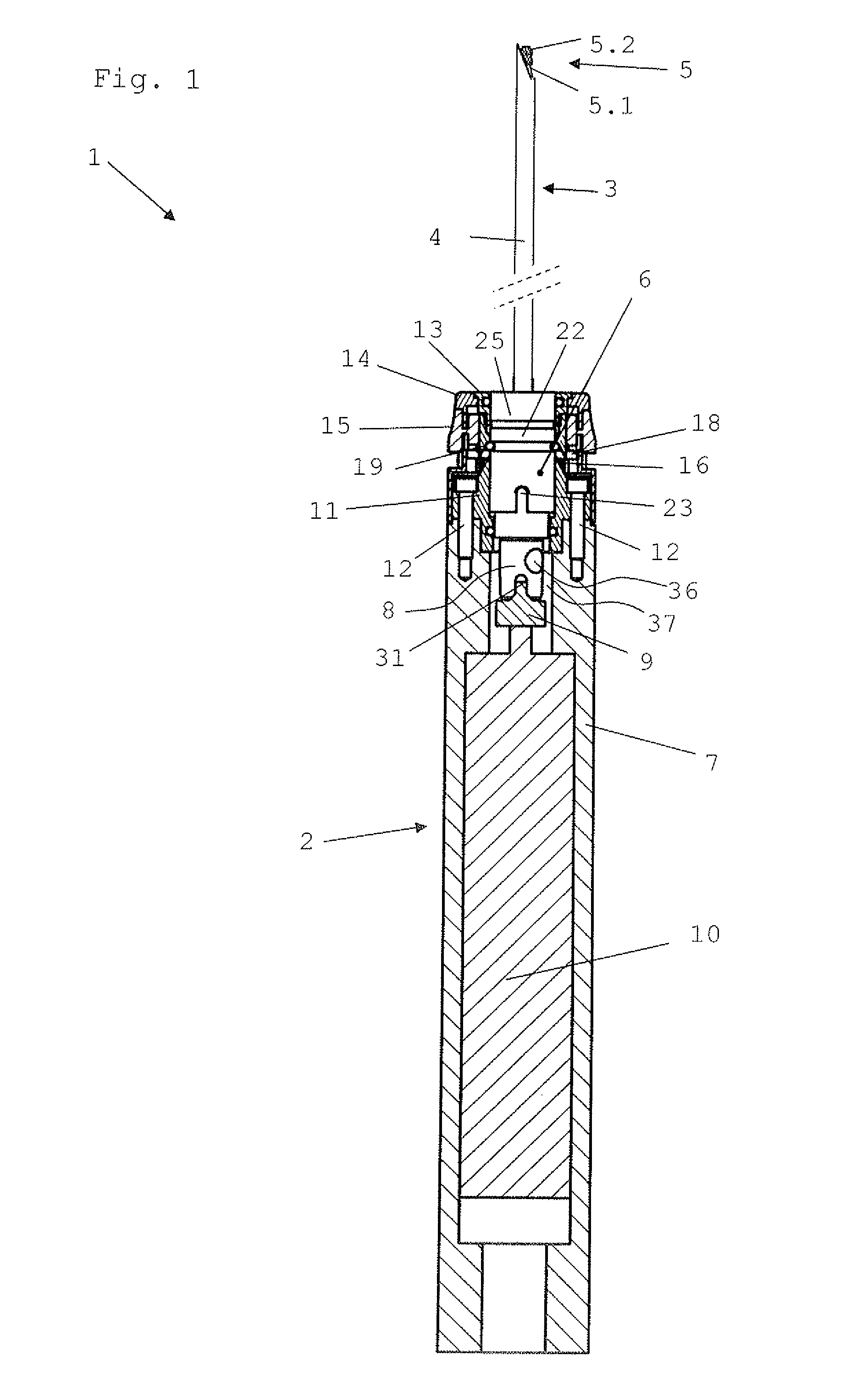

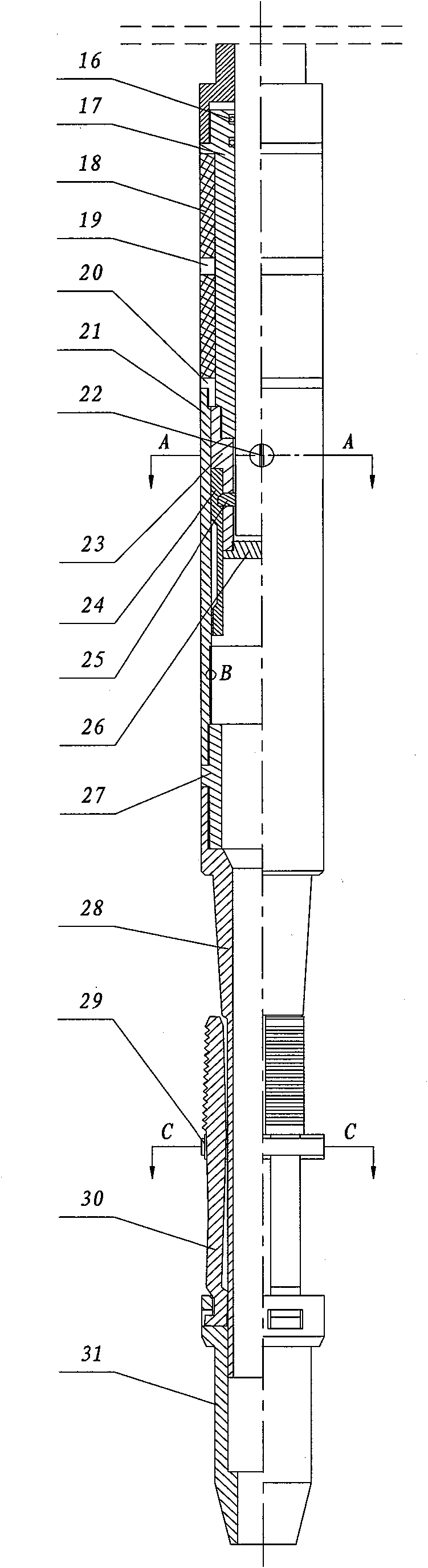

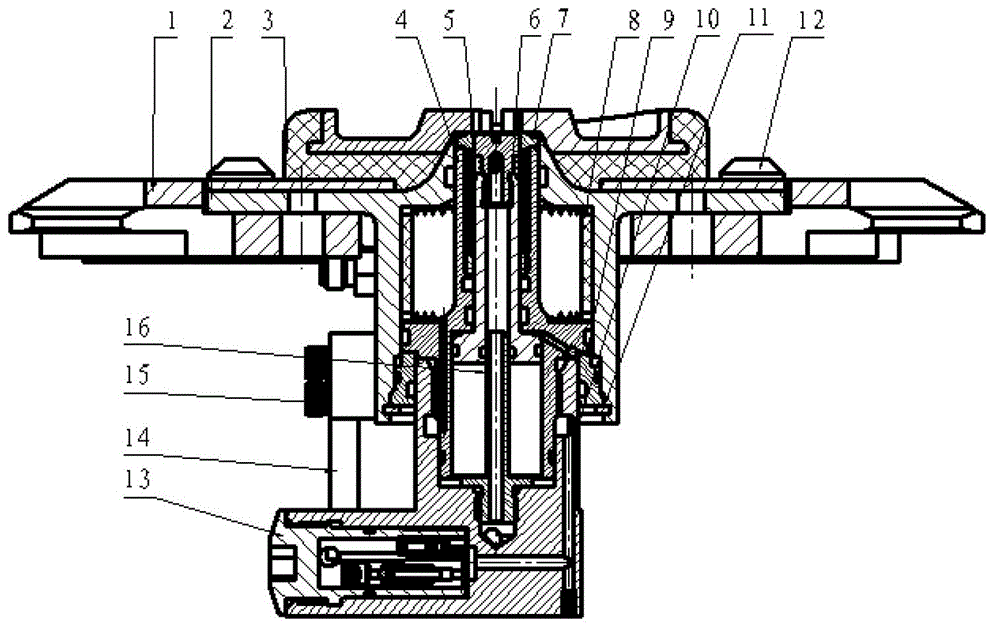

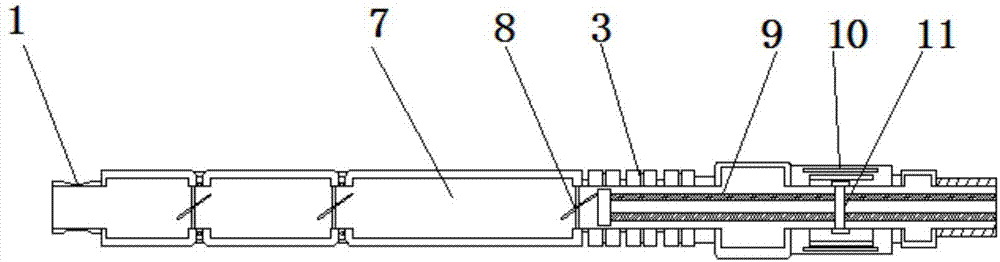

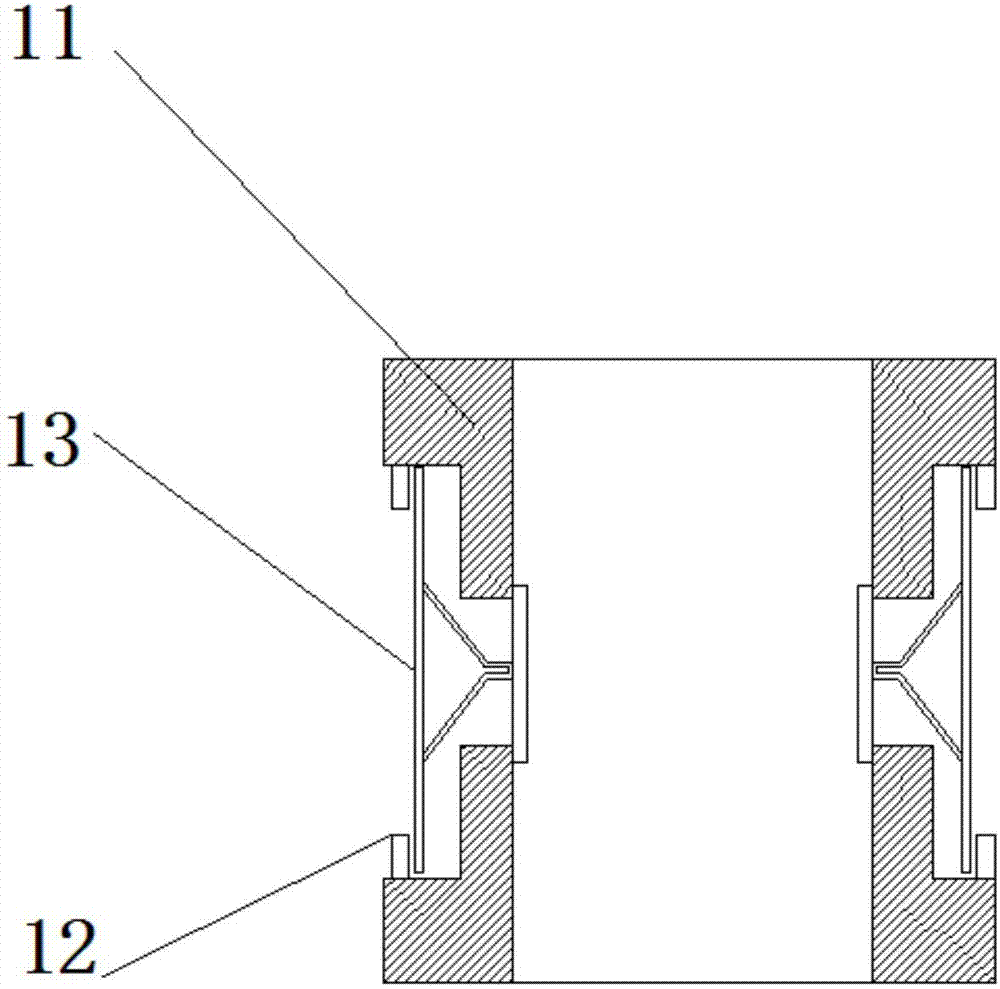

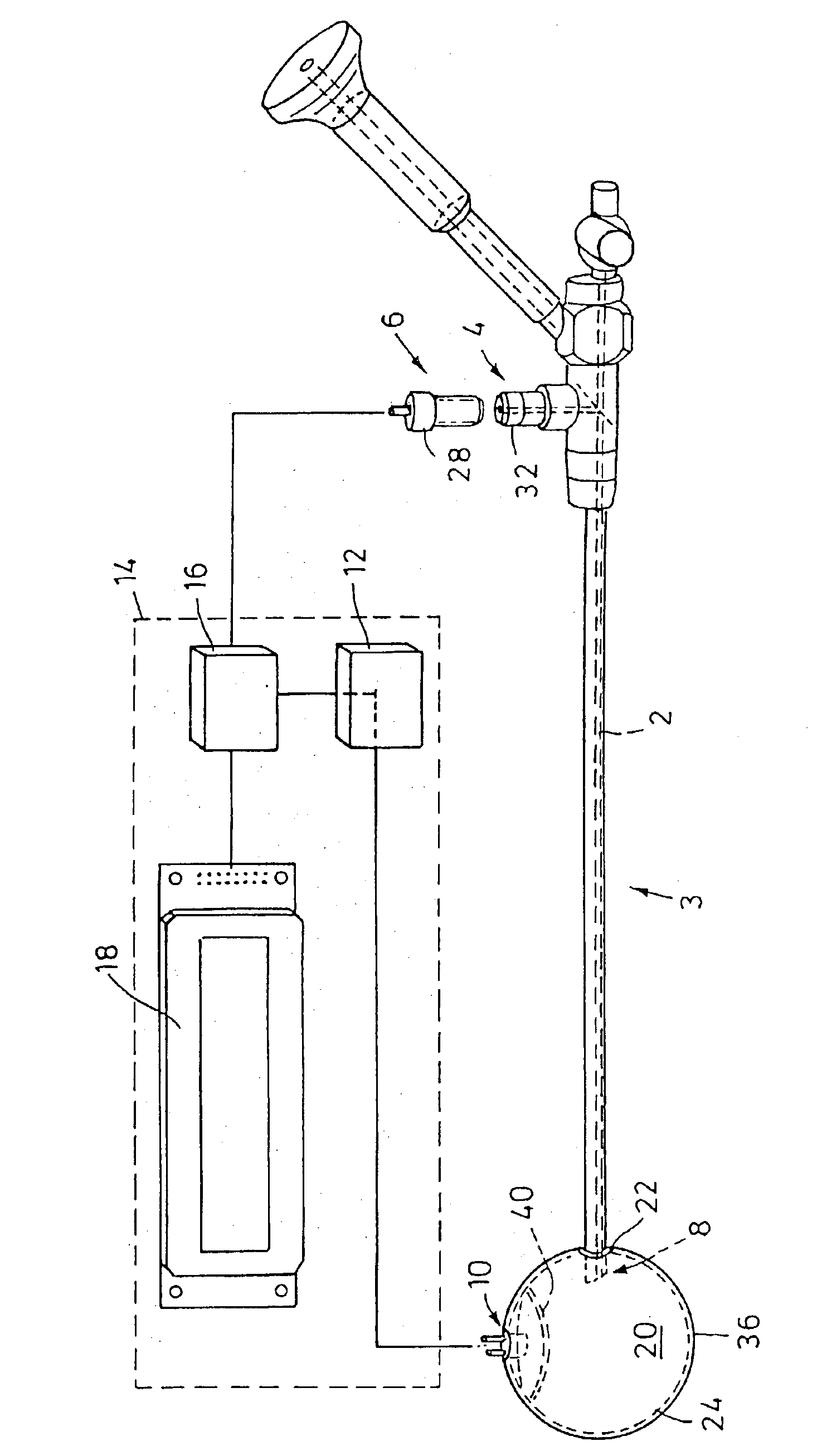

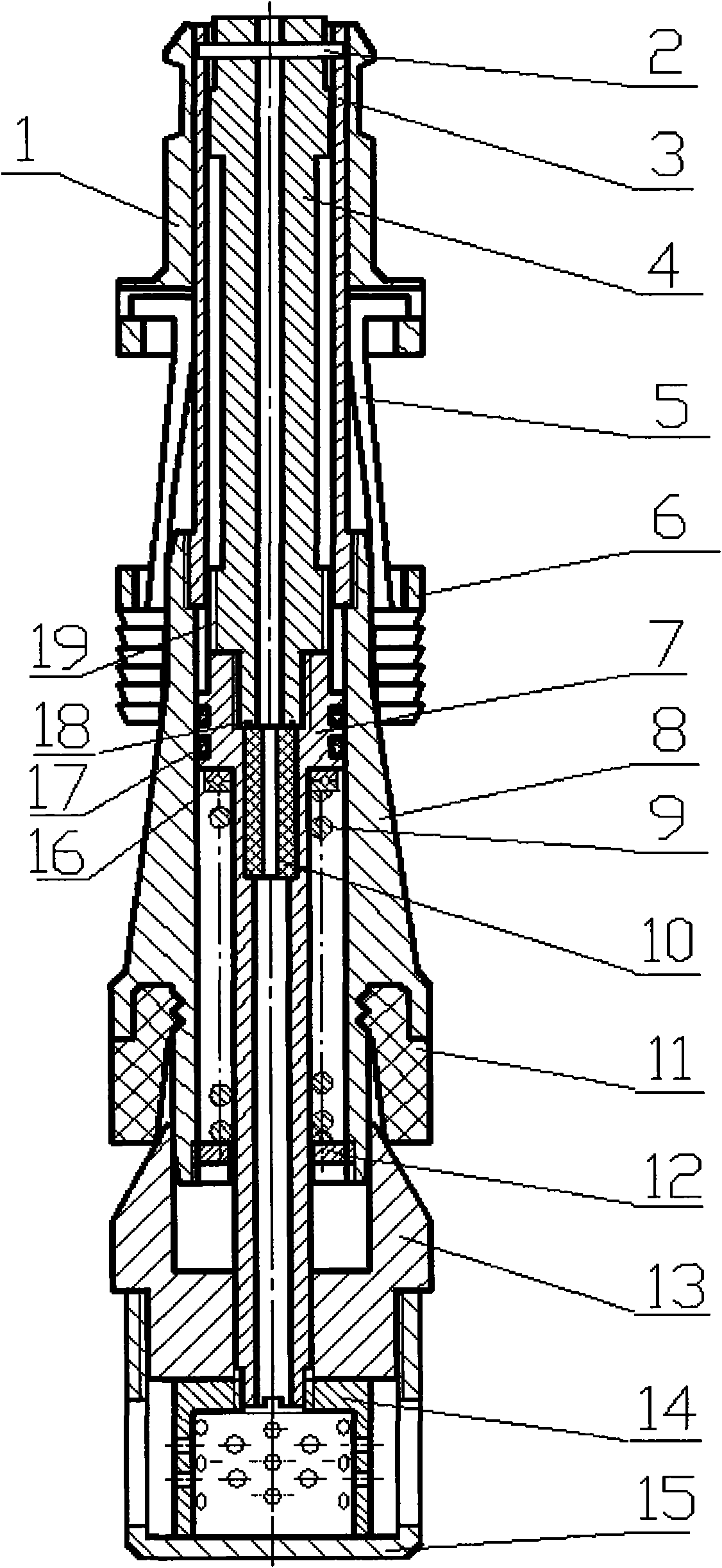

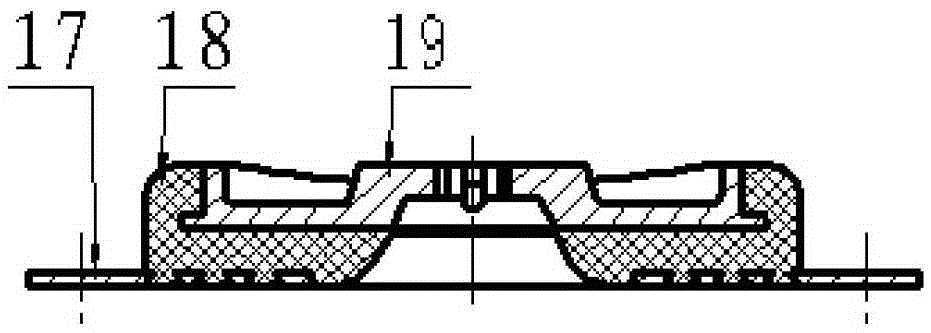

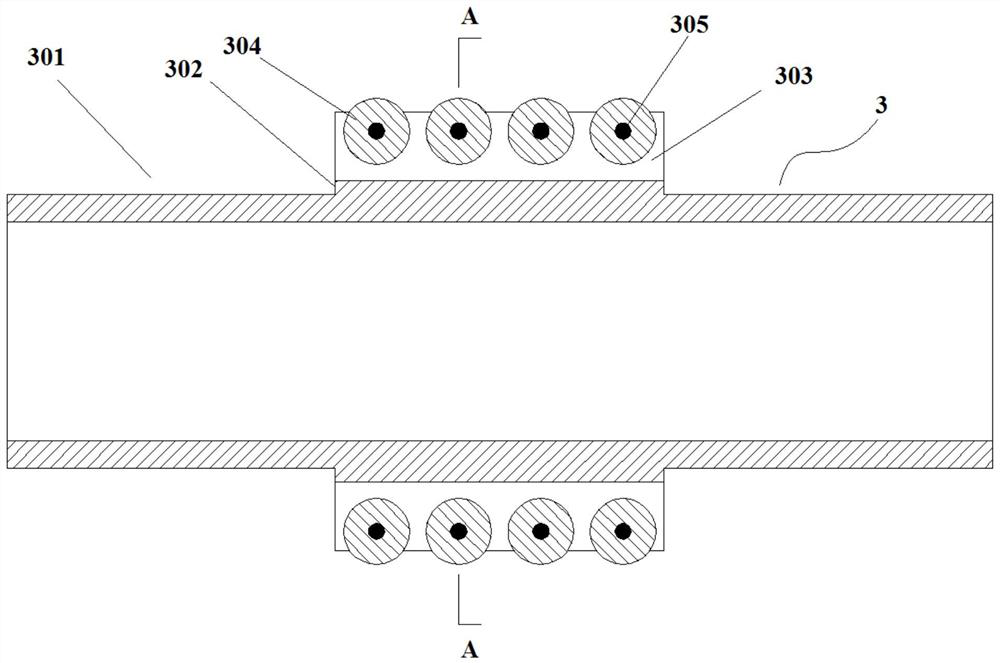

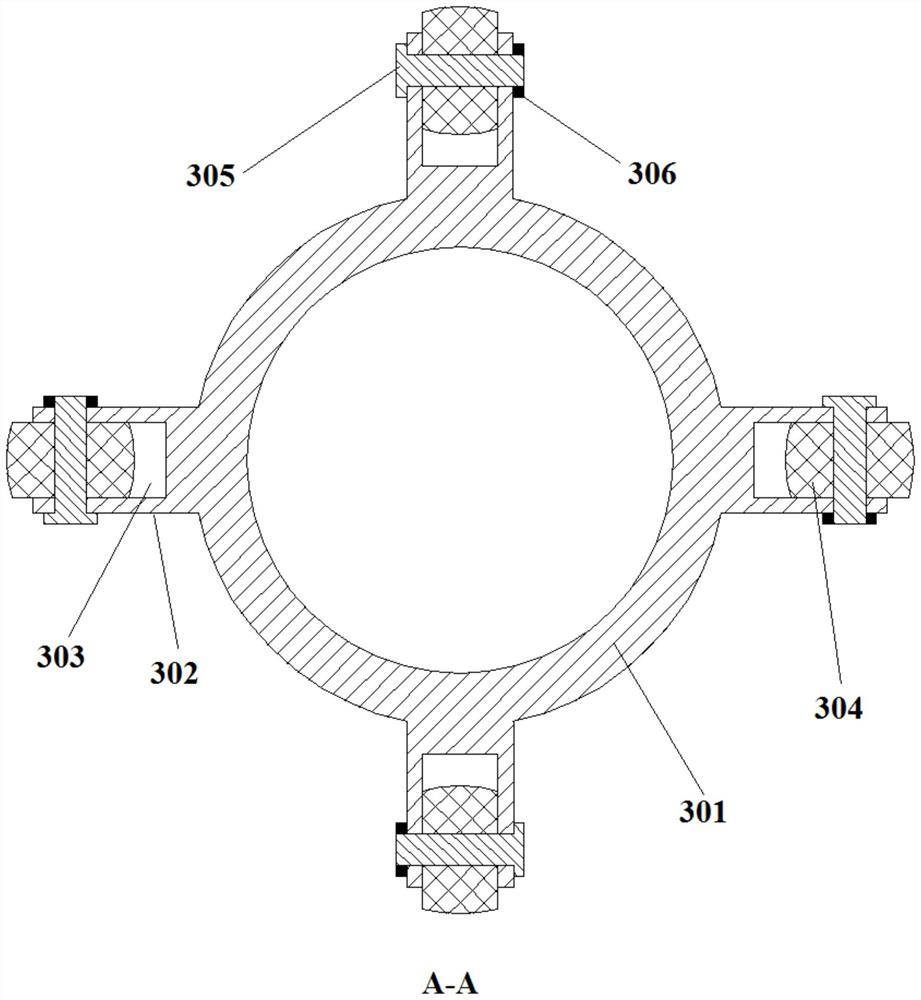

Probe of FDT (Formation Dynamic Test) module type formation tester

ActiveCN103334746ASampling safetyFast samplingBorehole/well accessoriesDynamic monitoringEngineering

The invention discloses a probe of an FDT (Formation Dynamic Test) module type formation tester of a formatting dynamic monitoring system, belonging to the technology of oil-gas exploration. The probe comprises a probe piston, a packer, a probe body, a connecting plate, a connecting screw, a filter sleeve, a filter piston, a probe plug, an elastic block, a positioning sleeve, a baffle ring, a piston body, a pressure-limiting valve, a guide block, a fixing screw and a fluid conveying pipe. According to the probe disclosed by the invention, the area of a formation which is packed by the packer is enlarged, a plurality of diversion trenches are added beside a sampling port of the packer, consequently, liquid sampling is facilitated, and the FDT module type formation tester can be more effectively and safely used in an unconsolidated formation, an oil sheet and a low permeable formation; the FDT module type formation tester is more reliable in sealing, more convenient in positioning and faster in sampling; and the FDT module type formation tester is more convenient and reliable to use, wider in application range and more outstanding in effect.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Device for drying shoes, gloves or garments

InactiveUS7469487B2Flexible usePrevent tippingAgriculture tools and machinesDrying gas arrangementsEngineeringTube socket

The invention relates to a device for drying shoes, gloves or garments comprising a fan which produces an airflow and which is accommodated in a housing. The housing comprises two openings that are connected to two tube sockets which are arranged opposite one another and which are fastened to said housing. The tube sockets are connected to tubes for guiding the airflow. To this end, the tube sockets are angular and one end of each tube socket is rotatably connected to the housing while forming a swivel joint.

Owner:SIDAS CENT

Packer

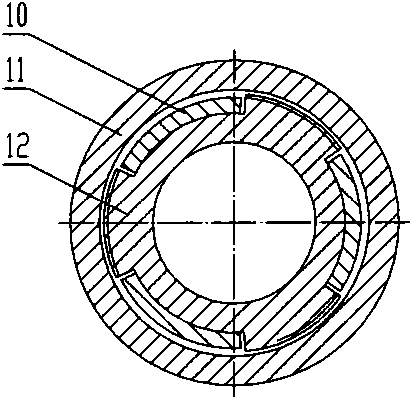

InactiveCN1896454AStrong anchoring forceThere is no problem of bending and eccentric wearSealing/packingCavity pressureCheck valve

This is a kind of packer. The oil pipe is pressed and rubber cylinder is expanded to seal the ring space of oil sleeve. The inner cavity pressure of rubber cylinder assembly keeps constant under the action of check valve. The packer is anchored on the sleeve. After expanding, rubber cylinder assembly firmly attaches on the inner wall of sleeve and seals the ring space of oil sleeve. There is enough anchoring force between rubber cylinder and sleeve to make there is no relative movement between the packer and sleeve. Thus, sealing is firm. Since the rubber cylinder has no slips, the sleeve will not be damaged.

Owner:东营市祥生工贸有限责任公司

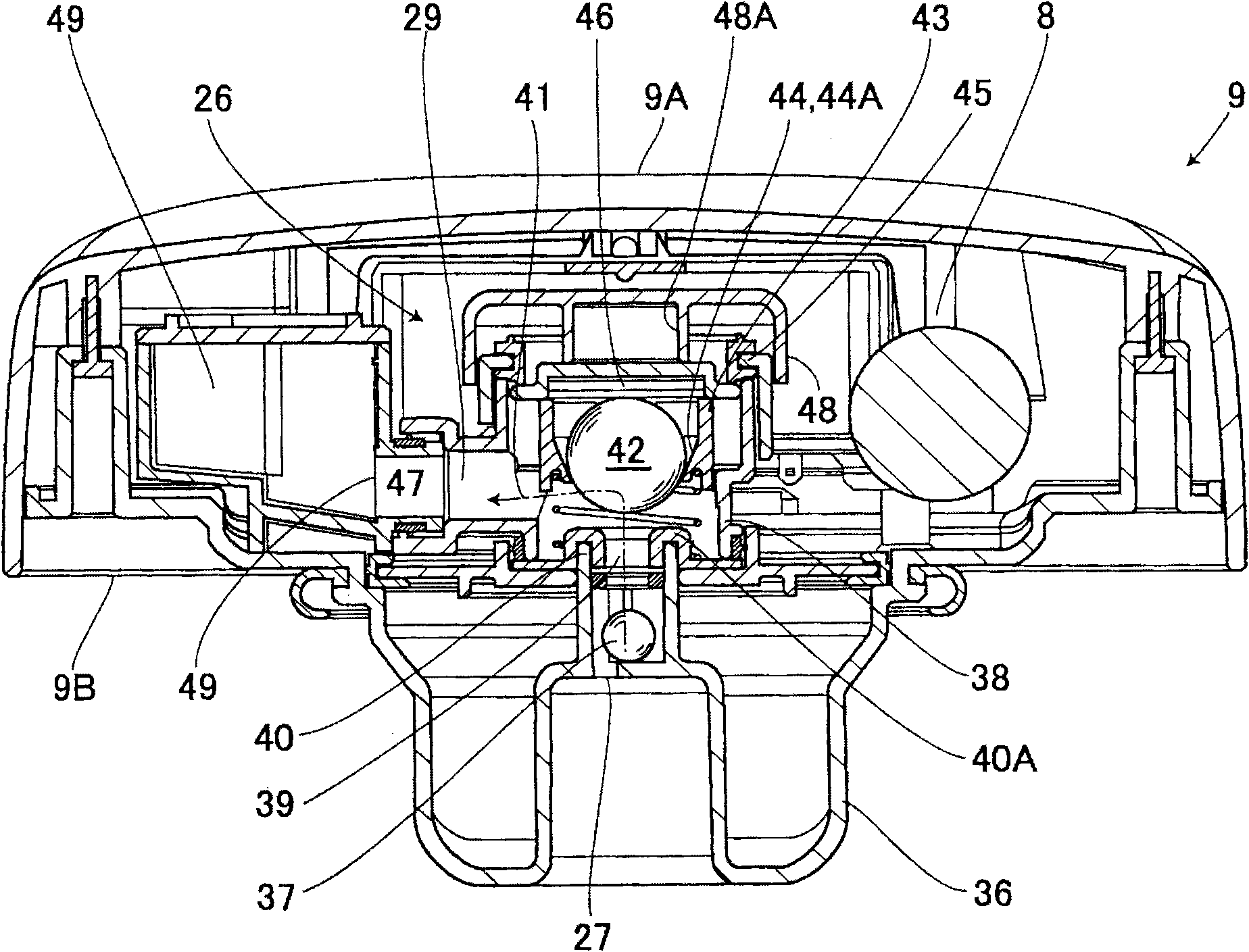

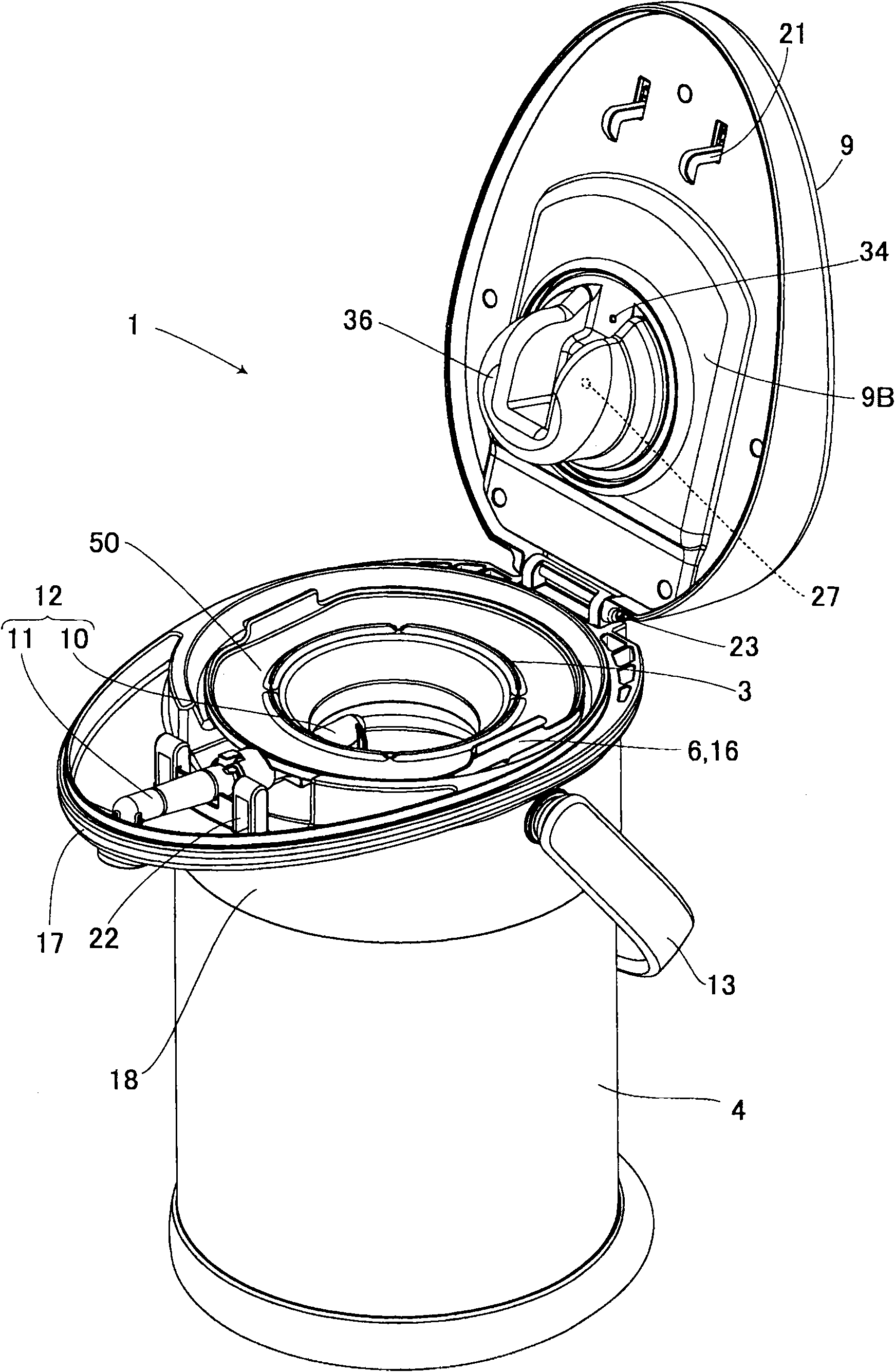

Electric air pressure pot

ActiveCN101843451APlug firmlyDoes not pour out naturallyNon-pressured vesselsEngineeringAtmospheric pressure

The invention relates to an electric air pressure pot, which can guarantee the sanitation when the beverage besides water is filled, appropriate filling amount and light operating force, and can hold the outpouring flow in a certain range to outpour the accommodated liquid. In the electric air pressure pot in which the pressurization to an inner cylinder (2) is performed by a pump (8) to outpour the accommodated liquid, when an outpouring operating member (24) is operated, the pump (8) is acted, a valve body (42) for adjusting the pressure blocks a valve seat (40) at the end of a steam hole (27) to adjust the pressure in the inner cylinder (2) and increasing the pressure, thus the accommodated liquid can be poured out. When the outpouring operating member (24) is pressed, a support (43) descends, a hammer formed by a metallic ball falls on the valve seat (40) to block the valve seat (40), at this time, a gap (46) is provided at the periphery of the hammer, the pressure in the inner cylinder (2) can be reduced due to the micro movement at the occasion of high pressure in the inner cylinder (2).

Owner:THERMOS CHINA HOUSEWARES

Connecting device for a pipe or similar

InactiveUS20080018106A1Simple formatSimple structureSleeve/socket jointsCouplingsEngineeringMechanical engineering

A connecting device for a pipe comprises a coupling body and a clamping collar. The clamping collar is divided into an axially inner function section and an axially outer actuation section, with a seal positioned between facing front sides of the axially inner function section and the axially outer actuation section. The seal is for sealing against an inner wall of the coupling body and against an outer wall surface of a pipe received within the clamping collar, when the clamping collar is within the coupling body.

Owner:LINCOLN GMBH

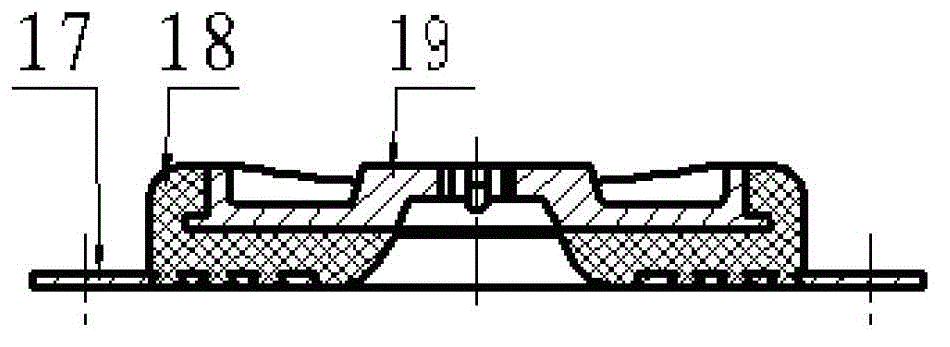

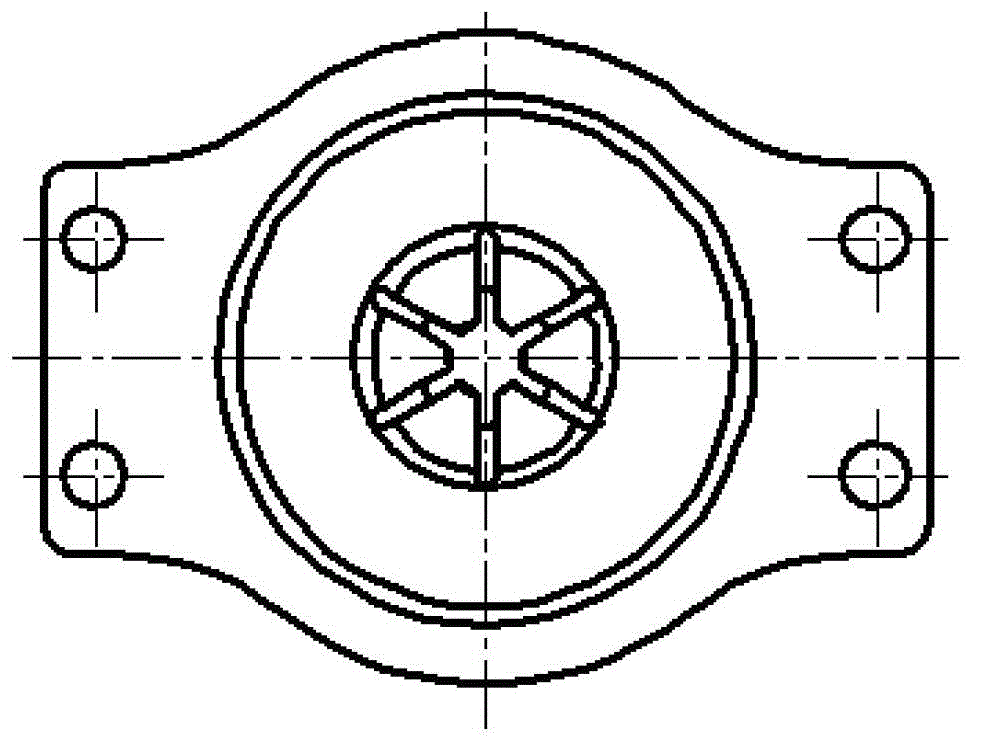

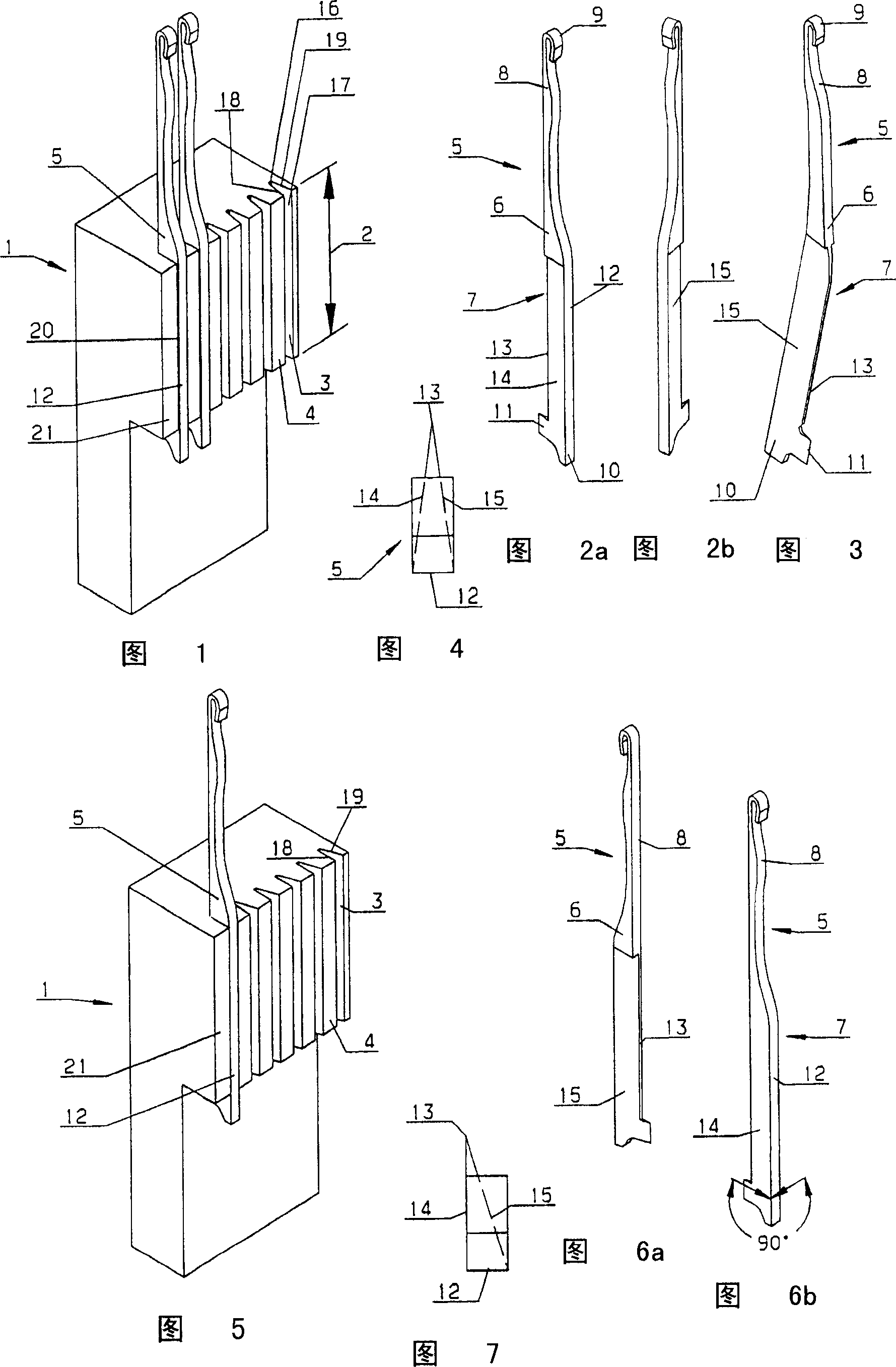

Bar of knitting machine

The invention relates to a bar (1) of a knitting machine, which has a plurality of grooves (3) for accommodating loop-forming elements (5), which are arranged alongside each other along the longitudinal extension of the bar (1), Each groove (3) has a groove base (16), two groove sides (18, 19) and a notch (17). It is also desirable to achieve a satisfactory fit of the loop-forming element in the bar after several replacements of the loop-forming element. For this purpose it is provided that the width of the groove (3) at the notch (17) is greater than the width at the groove bottom (16).

Owner:KARL MAYER R&D GMBH

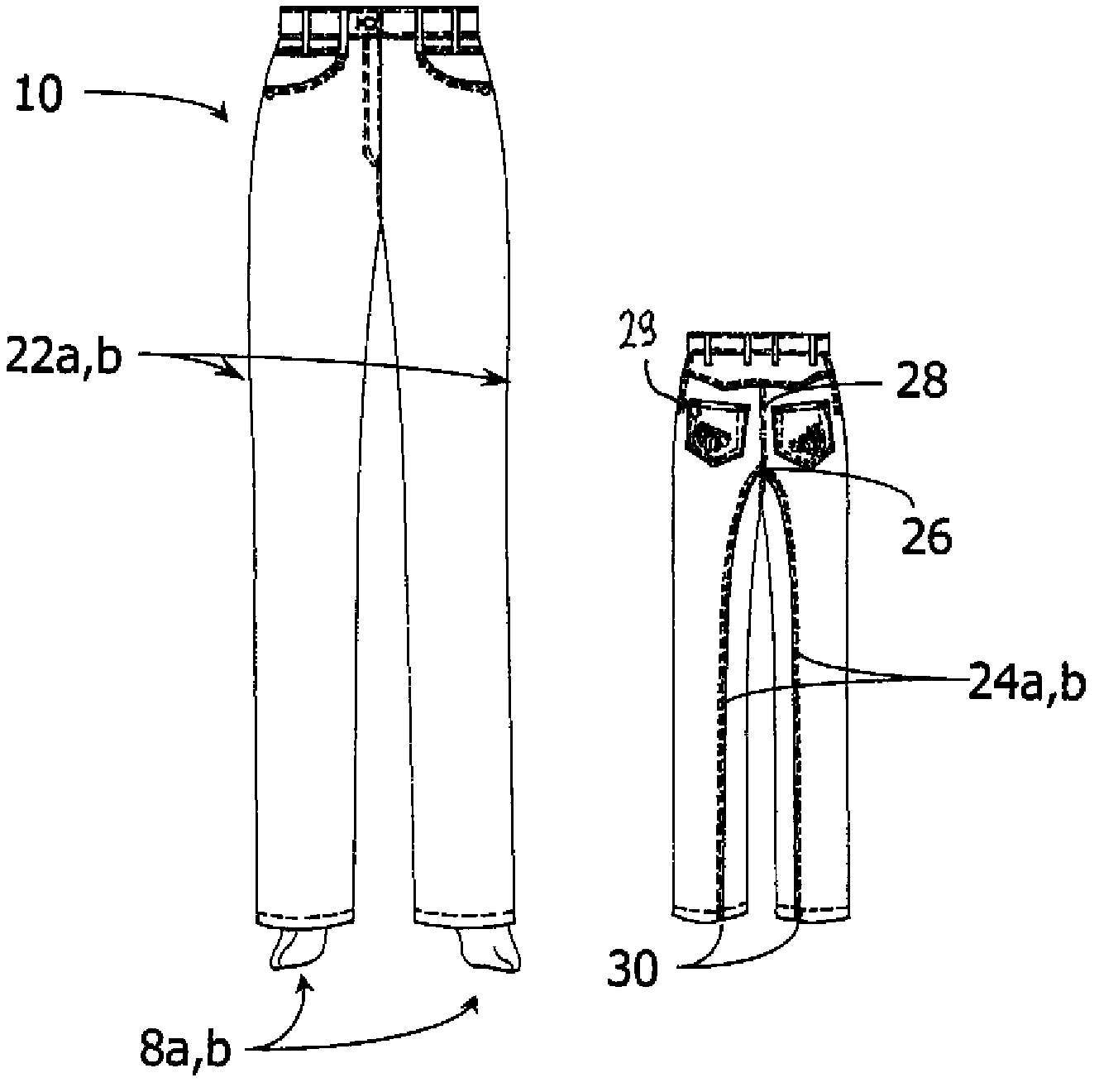

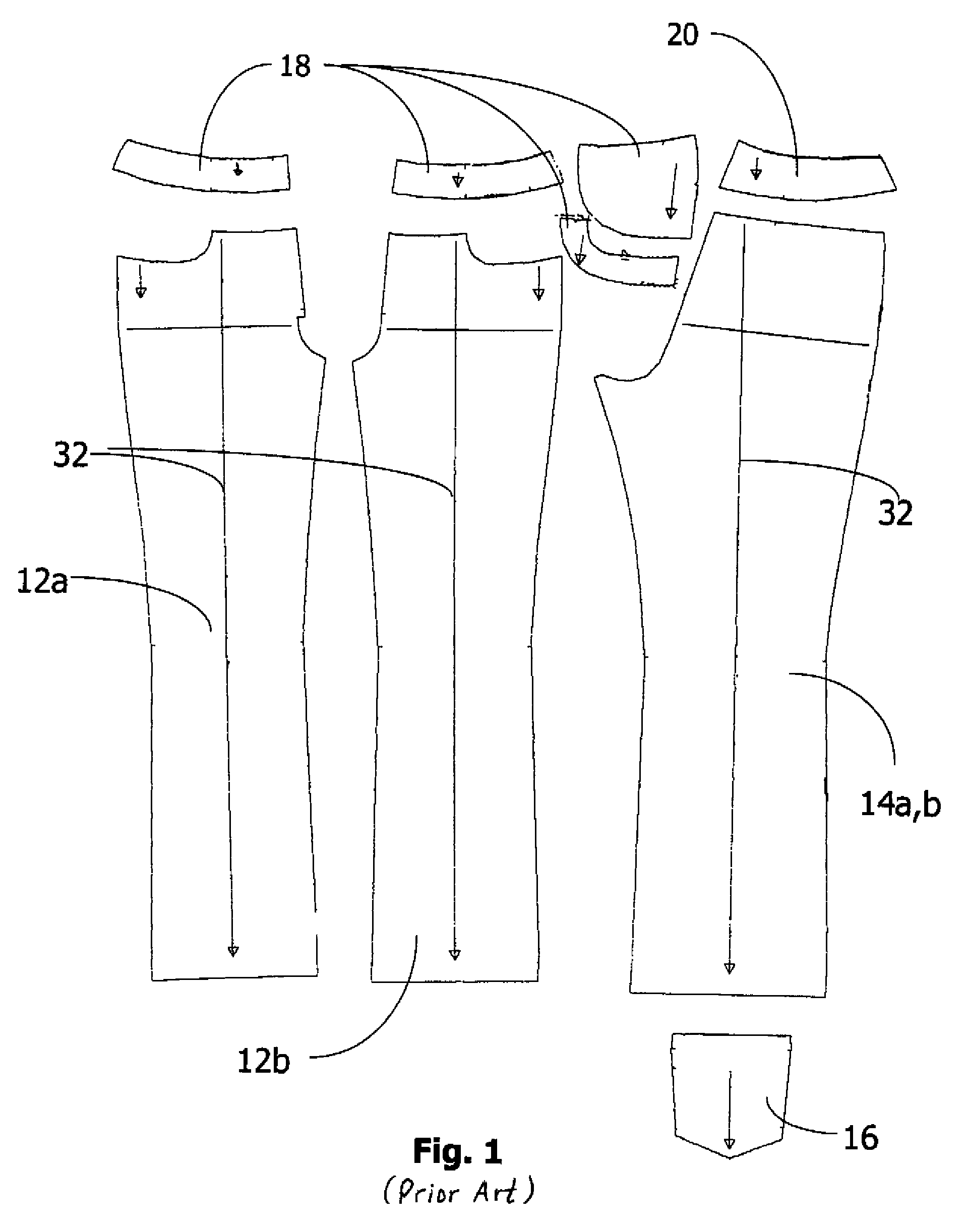

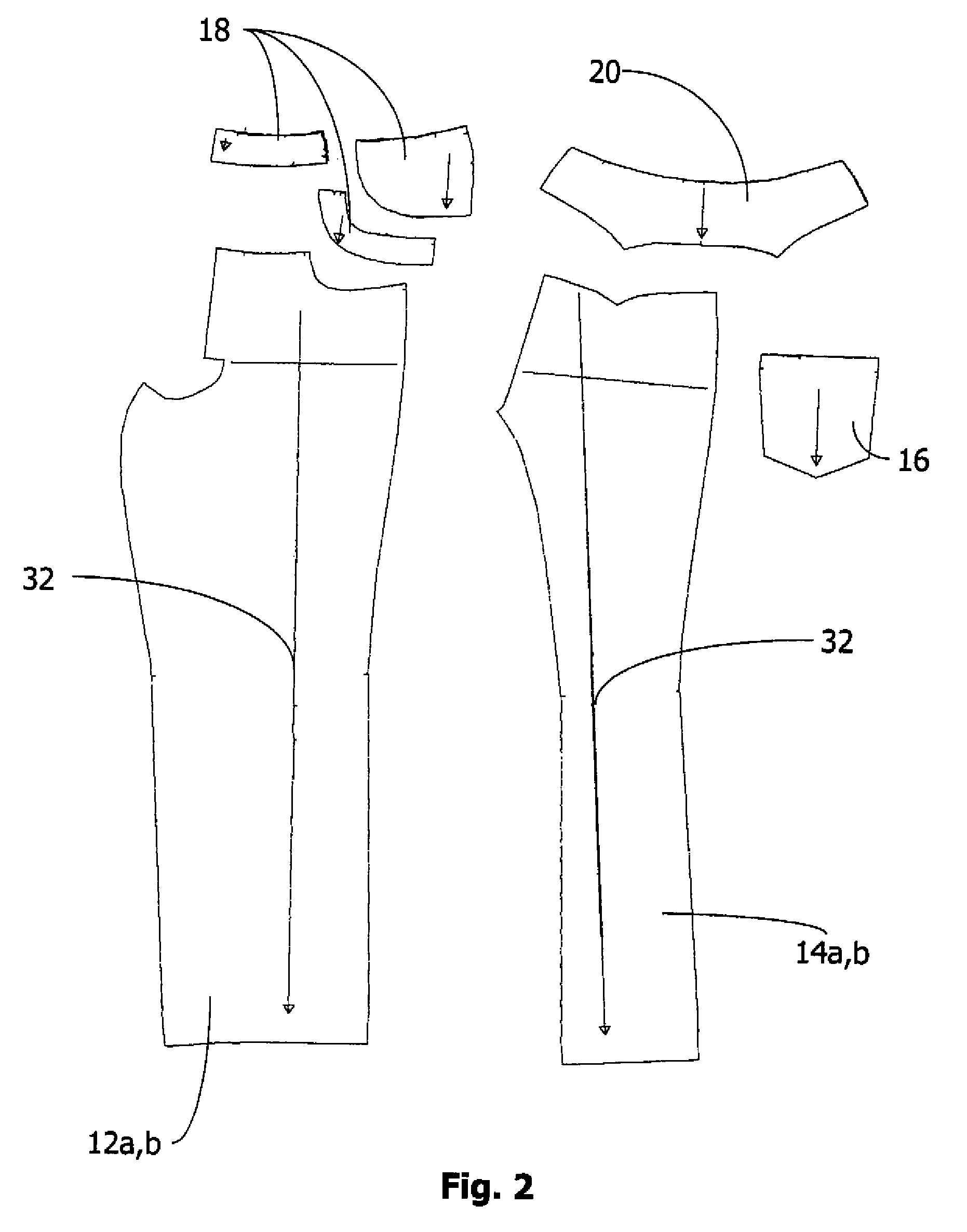

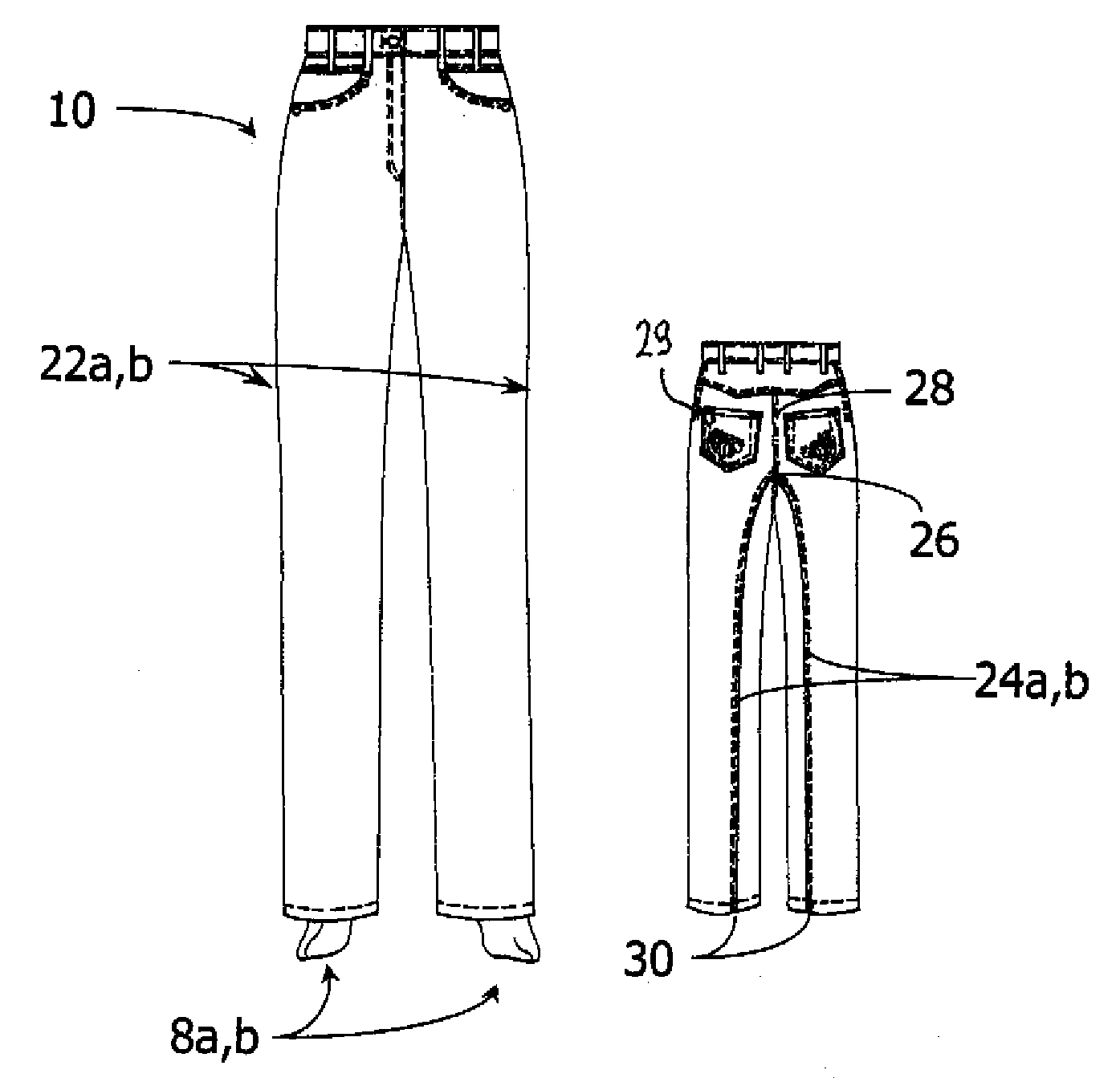

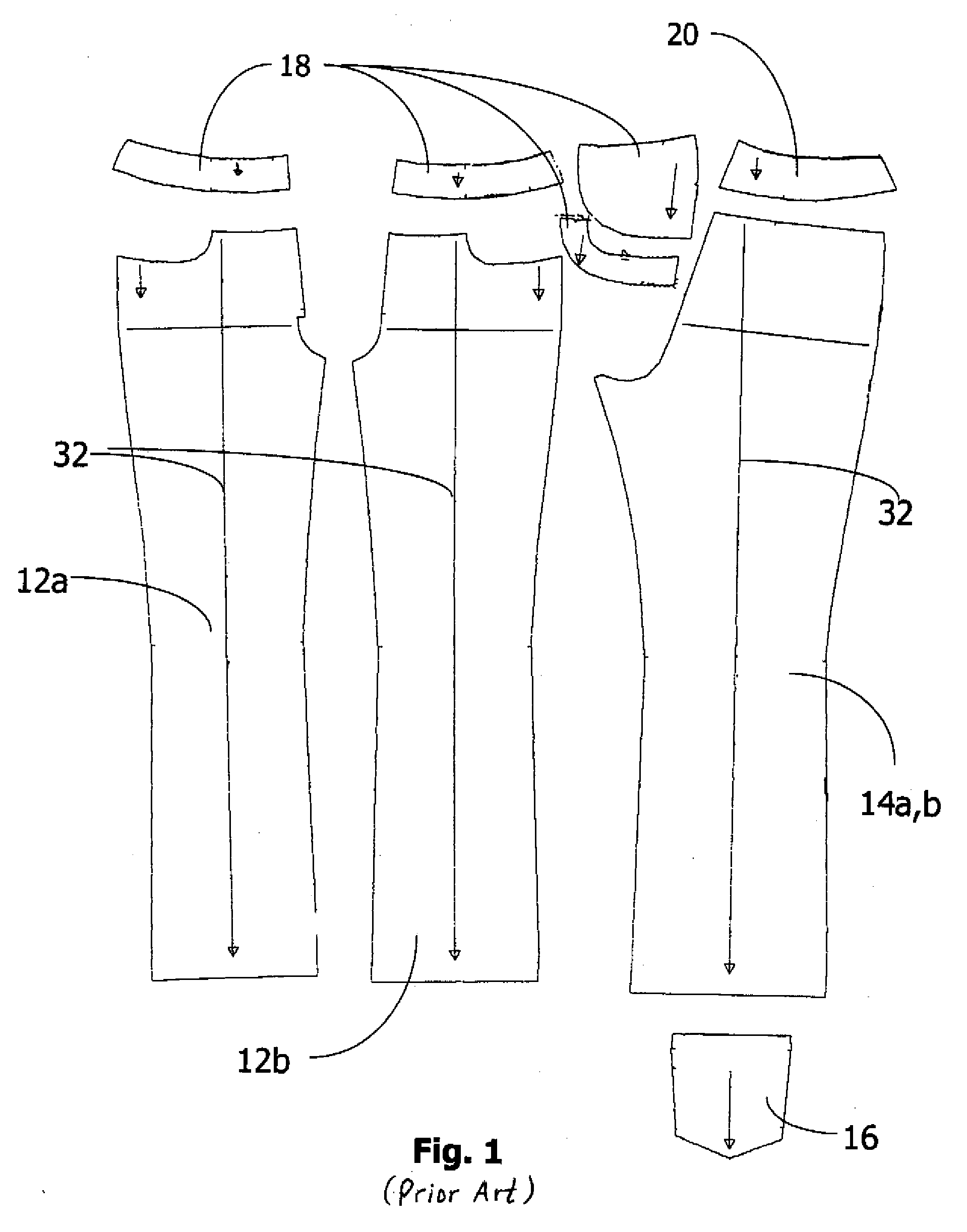

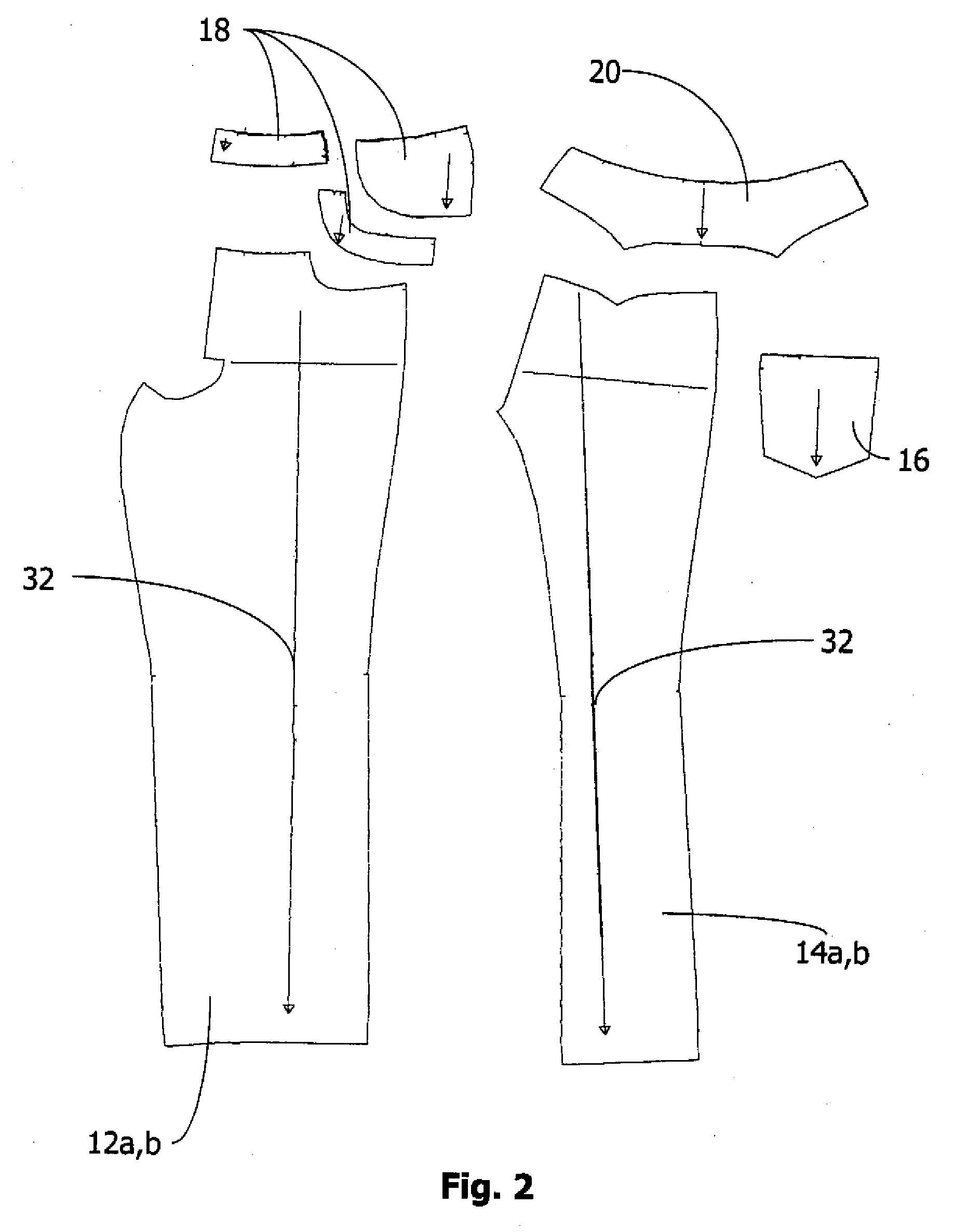

Pants, in particular riding jeans

InactiveUS7805774B2Positively preventing presenceReliable seatingTrousersGarment beltsEngineeringMechanical engineering

Owner:MULLER TANJA

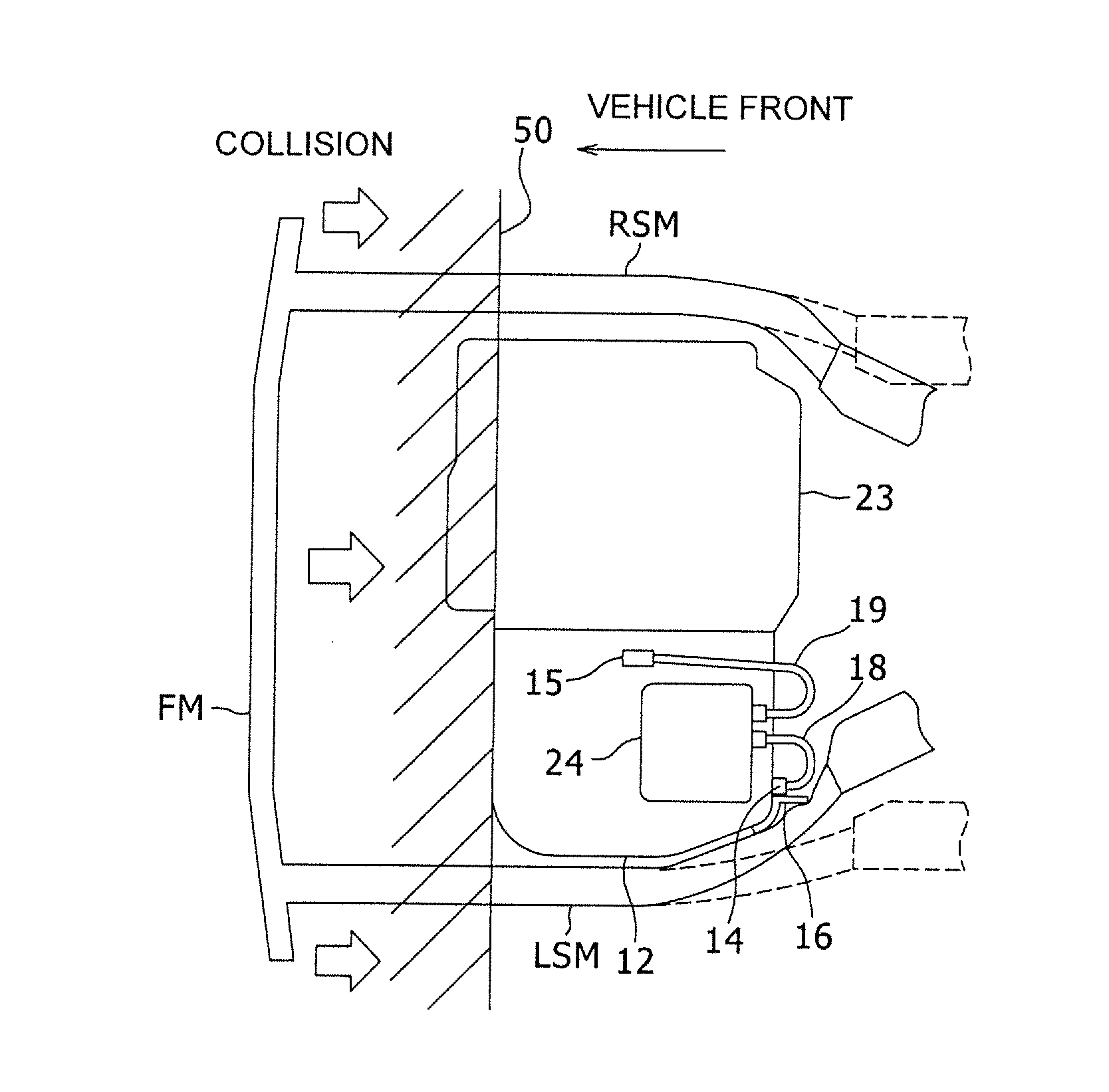

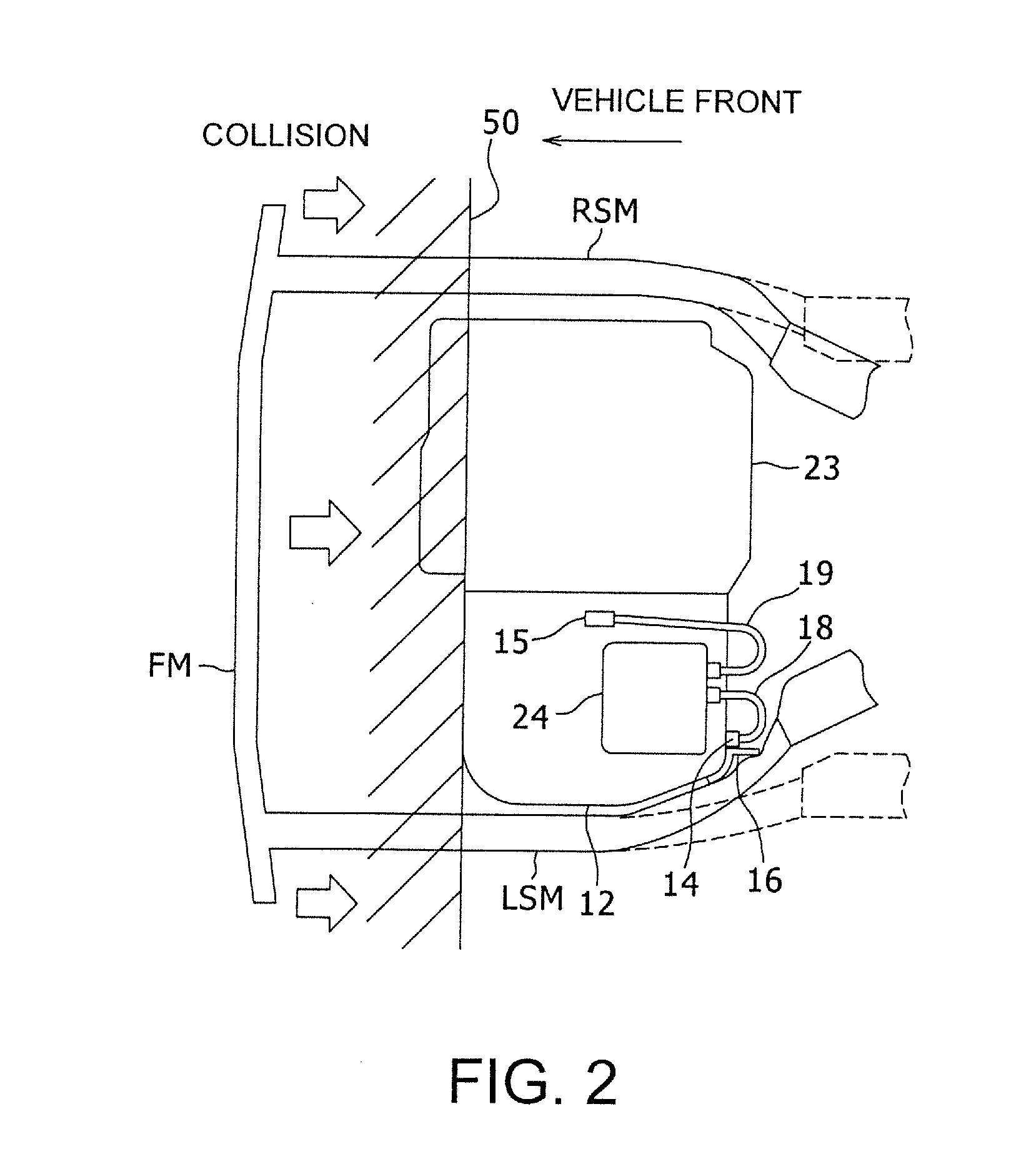

Connector protection structure for motor

InactiveUS20150214812A1Reliably prevent damageSuperior assembly capabilityWindingsSupports/enclosures/casingsEngineeringElectric motor

Owner:TOYOTA JIDOSHA KK

Pressure-resistant packer

PendingCN107882532AAvoid operabilityAvoid time consuming deficienciesSealing/packingGeothermal energy generationHydraulic circuitIndustrial engineering

The invention discloses a pressure-resistant packer. The pressure-resistant packer comprises a shell, a sleeve head is welded to the outer wall of one side of the shell, and a first connecting seat iswelded to the outer wall of the other side of the shell. A clamping groove is formed in the outer side of the side, away from the shell, of the first connecting seat. The inner wall of the clamping groove is connected with a setting sleeve in an inserted mode. An elastic sealing sleeve is connected with the outer wall of the end, close to the shell, of the setting sleeve in a sleeving mode. Connecting pipes are connected with the central axis positions of the outer walls of the two sides of the setting sleeve in a sleeving mode. A second clamping groove is formed in the inner wall of each connecting pipe. The inner wall of each second clamping groove is connected with a sleeve in a clamped mode. According to the pressure-resistant packer, through the elastic sealing sleeve and an anchor,the defects that the existing operation that setting and de-sealing of the packer are controlled by using upward-lifting and downward-placing of a pipe column is cumbersome and long in time consumingare effectively avoided; a multi-stage de-sealing pipe is matched with an upward flipping plate, in-advance de-sealing of an existing packer during failure of a hydraulic circuit can be solved; and through an I-shaped slip sleeve, the supporting property is good, and the upper setting sleeve is matched, the setting state of the packer is not affected, and setting is reliable.

Owner:DAQING TIANDEZHONG PETROLEUM SCI & TECH CO LTD

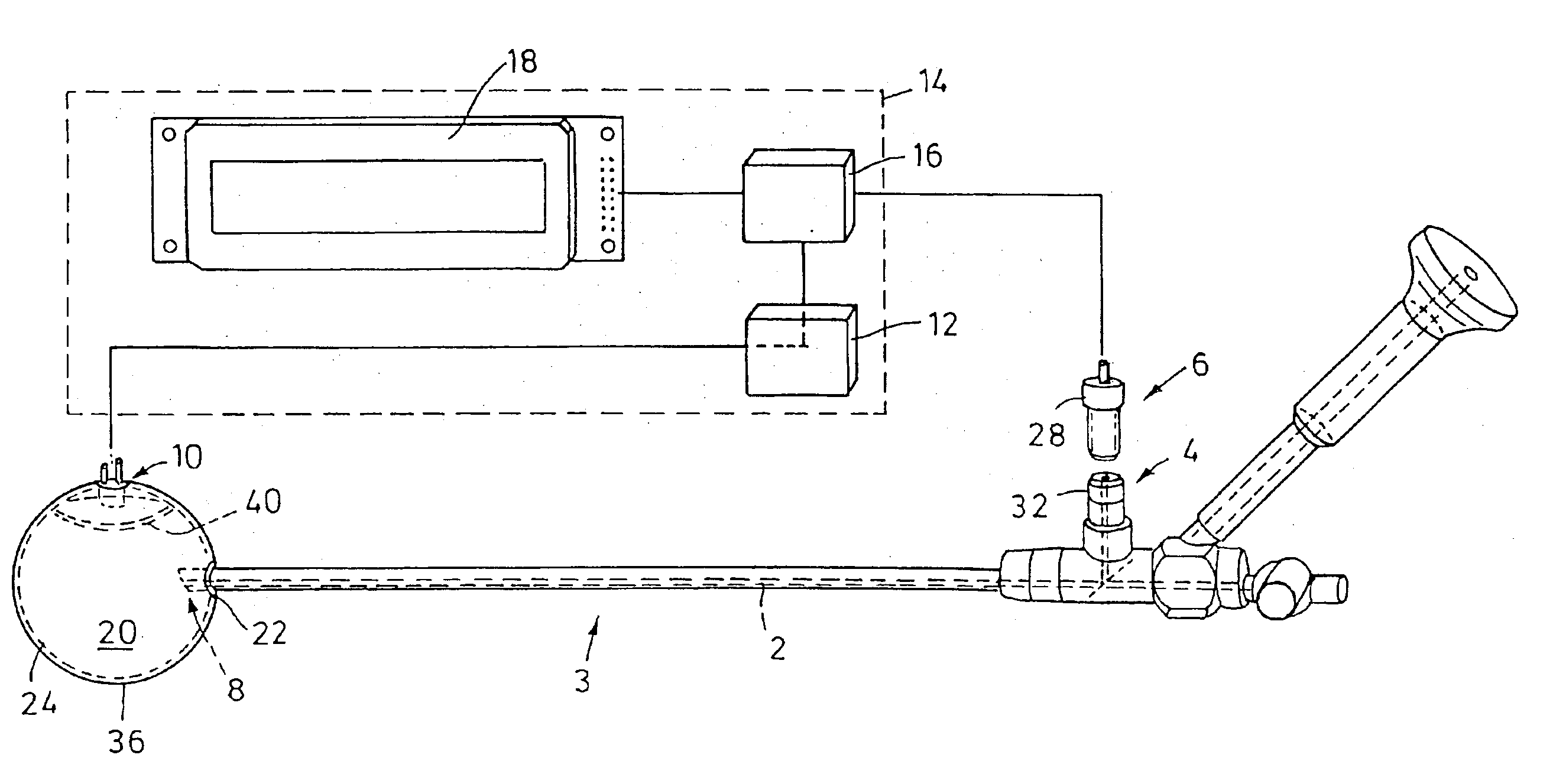

Device for detecting transmission losses by means of measurements

InactiveUS6862085B2Quick checkWithout large expenditureSurgeryMaterial analysis by optical meansLight guideTransmission loss

In a device for detecting transmission losses of optical light guide means (2) of an endoscope (3) by means of measurements, said optical light guide means (2) having an optical inlet portion (4) through which light from a light source (6) is transmitted to an optical outlet portion (8) of the means to be checked, said device comprising at least one light sensor (10) measuring the light intensity emerging from the optical outlet portion (8) of the means (2) to be checked, and an evaluation means (14) for the signal of the at least one light sensor (10), said evaluation means (14) having a display means (18) for displaying the measurement result, it is provided that the at least one light sensor (10) is arranged in a chamber (20), that the optical outlet portion (8) of the light guide means (2) to be checked is adapted to be introduced through an opening (22) of the chamber (20) into the chamber (20), and that the inner surface (24) defining the chamber (20) diffusely reflects the light emerging from the optical outlet portion (8).

Owner:FERTON HLDG

Pants, in particular riding jeans

InactiveUS20080092266A1Positively preventing presenceReliable seatingTrousersProtective garmentMechanical engineeringEngineering

Owner:MULLER TANJA

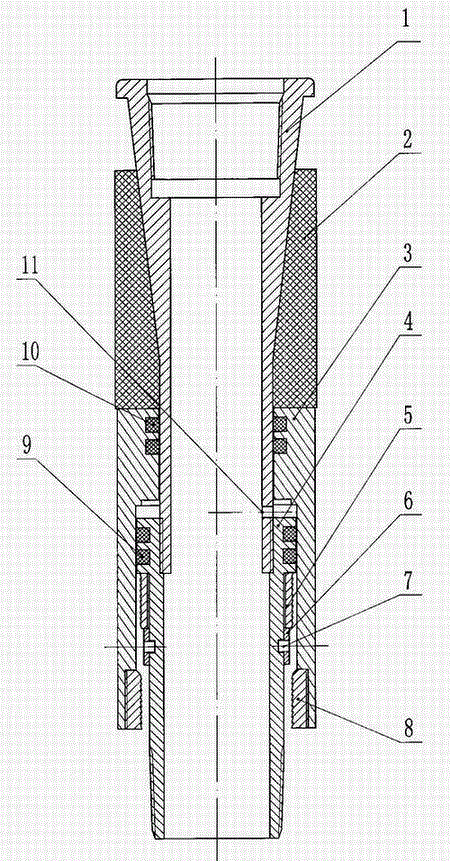

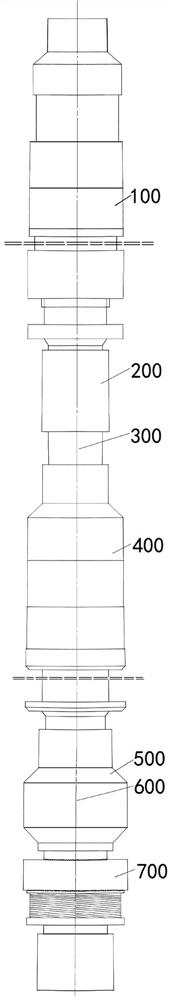

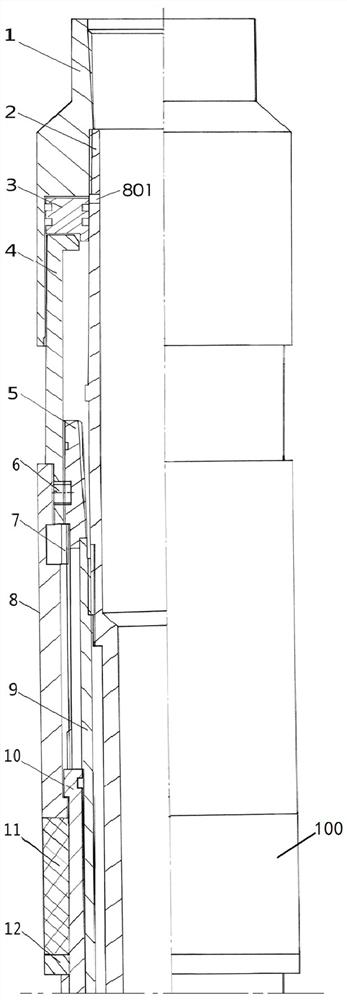

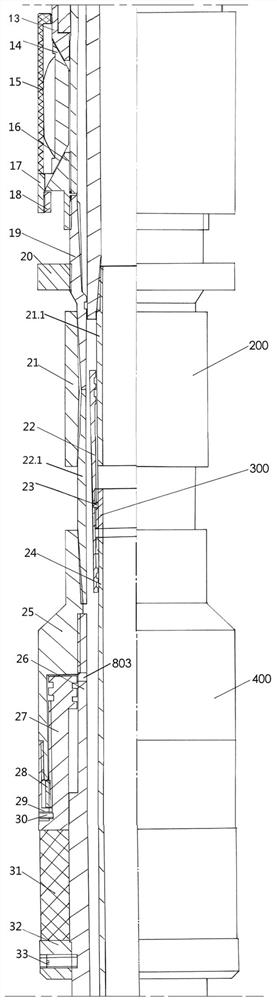

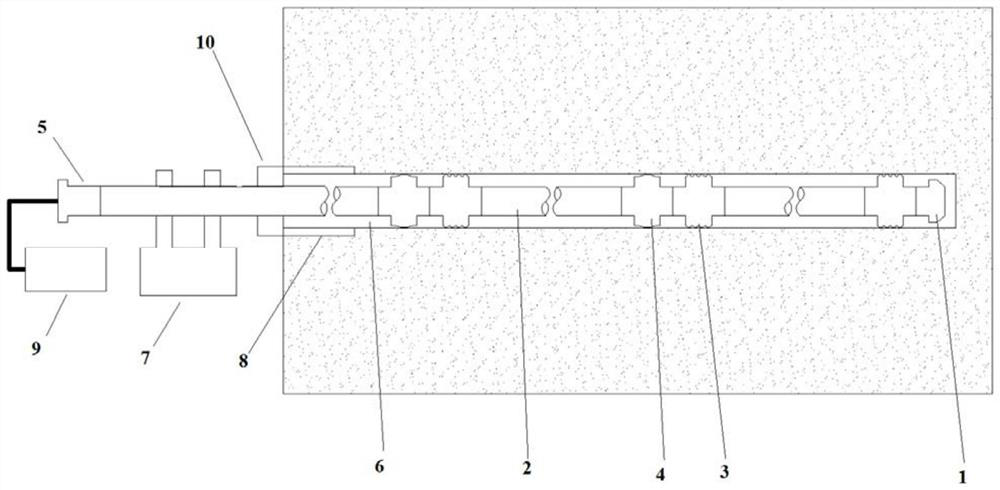

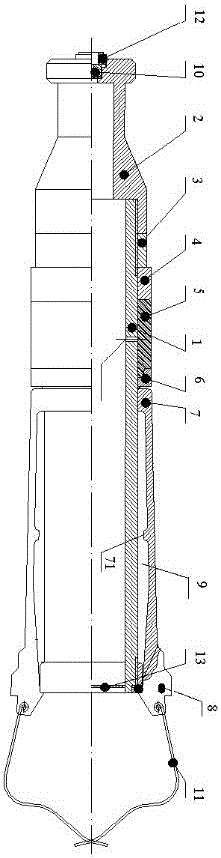

Deep-water packer

ActiveCN107060681ACompact structureEasy to operateSealing/packingMechanical engineeringGeotechnical engineering

The invention relates to a deep-water packer and belongs to the technical field of deep-sea oil-gas testing operation equipment. The packer comprises an upper connector, a central pipe, a lower connector, a clamp, a rubber sleeve, a sliding sleeve and a locking sleeve, and the upper connector is mounted at the top end of the central pipe; the lower connector is mounted at the bottom end of the central pipe, the clamp is mounted on the position, below the upper connector, of the central pipe, and the position, below an upper conical body, of the central pipe is sleeved with the sliding sleeve and the locking sleeve; and a lower conical body is mounted on the position, below the locking sleeve, of the central pipe, and a pressing piece is arranged between the lower conical body and the locking sleeve. The packer is compact in structure and easy and convenient to operate, the defects that the existing operation that pulling up and putting down of a pipe column are utilized to control packer seat sealing and sealing removal is tedious and long in time consumption are overcome, and the problem that an existing packer is subjected to sealing removal in advance when hydraulic oil ways lose efficacy, so that the stratum environment is polluted and destroyed is solved; two hydraulic oil ways of the deep-water packer do not affect the seat sealing state of the packer, and seat sealing is reliable; and the deep-water packer is particularly suitable for ocean deep-water oil-gas well operation.

Owner:YANGTZE UNIVERSITY

Underground throttler

ActiveCN101949281BPrevention and salvage difficultiesAvoid damageFluid removalPetroleum engineeringNozzle

The invention discloses an underground throttler, which is applied in the technical field of gas extracting in an oil and gas field. A fishing head is sheathed on the outer wall of a sliding sleeve; a slips is suspended at the lower end of the fishing head; a slips cone is in threaded connection with the outer wall of the lower end of the sliding sleeve; an upper gas nozzle pipe is fixed in the sliding sleeve through a pin; the slips cone is provided with a central hole which is provided with a lower gas nozzle pipe; the lower end of the lower gas nozzle pipe is provided with a spring; the lower end of the spring is provided with a circular spring seat; a gas nozzle is embedded at the lower part of the stepped central hole of the lower gas nozzle pipe; a seal rubber cylinder is fixed at the lower end of the slips cone; a rubber cylinder cone is arranged at the lower part of the seal rubber cylinder; a protection cover is connected with the lower end of the rubber cylinder cone; and a filter mask is in threaded connection with the lower end of the lower gas nozzle pipe. The underground throttler of the invention has the beneficial effects of adopting the seal rubber cylinder and the rubber cylinder cone to lead the seat sealing to be more reliable, adjusting the position of a seal ring, adopting a spline structure and a knob unloading ring to reduce the damage of the seal ring and prolong the service life of the seal ring, and reducing the damage of the produced sand to the trottler.

Owner:PETROCHINA CO LTD

Expandable air barrier device and method of using same for injection remediation of underground water pollution

ActiveCN102515343BAchieve barrierSmooth connectionSustainable biological treatmentSealing/packingIn situ remediationProtection KIT

Owner:BEIJING MUNICIPAL RES INST OF ENVIRONMENT PROTECTION

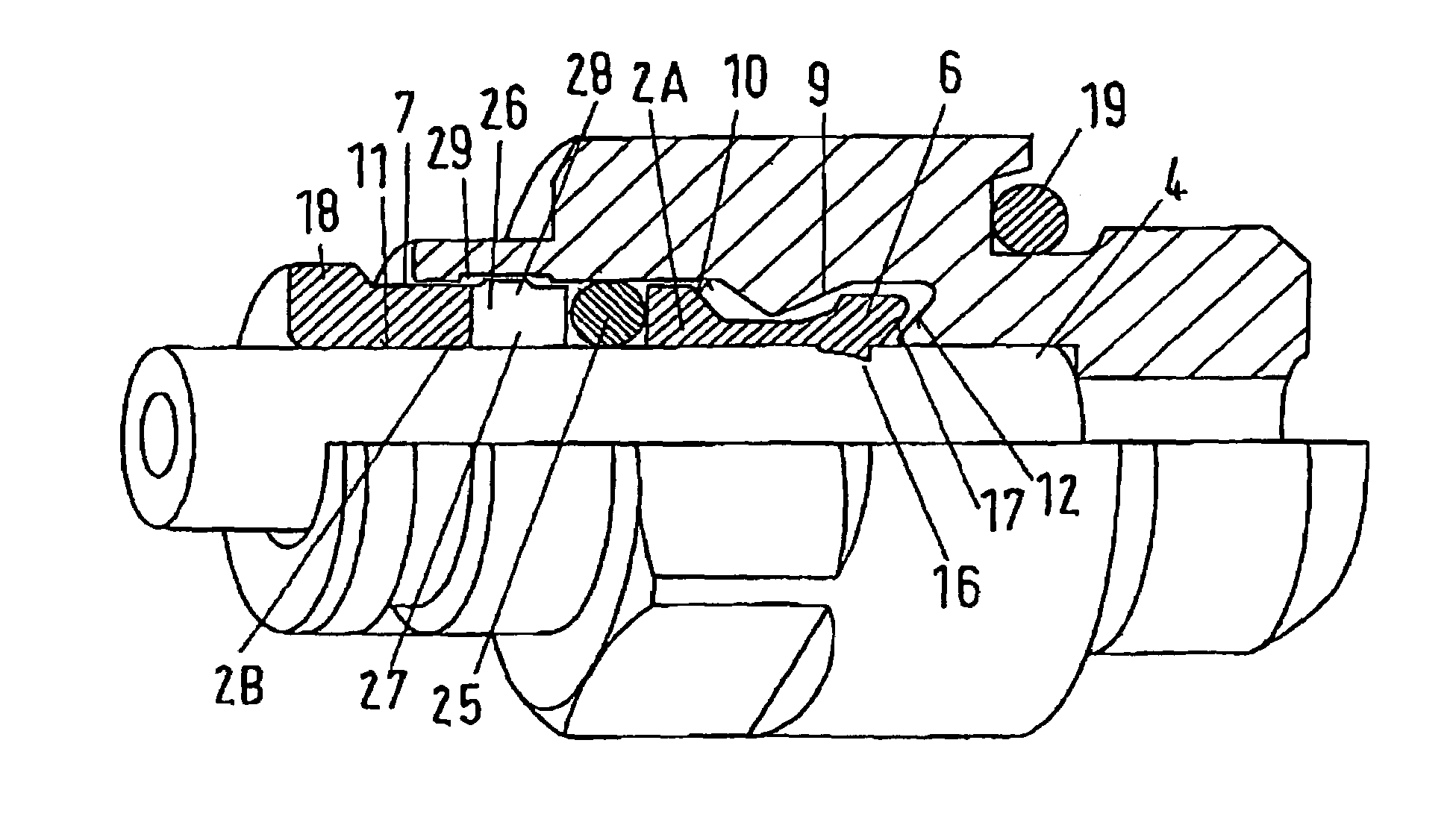

Surgical instrument for detachably connecting a handpiece to a surgical tool

Surgical instrument with a handpiece having a drive and with a surgical tool, which has a tube and a working part with a shaft and with a tool head, the tube of the surgical tool can be detachably connected to the handpiece by a first coupling part and the shaft of the working part can be detachably connected to a drive shaft in the form of a pin of the drive by a second coupling part simultaneously.

Owner:JOIMAX GMBH

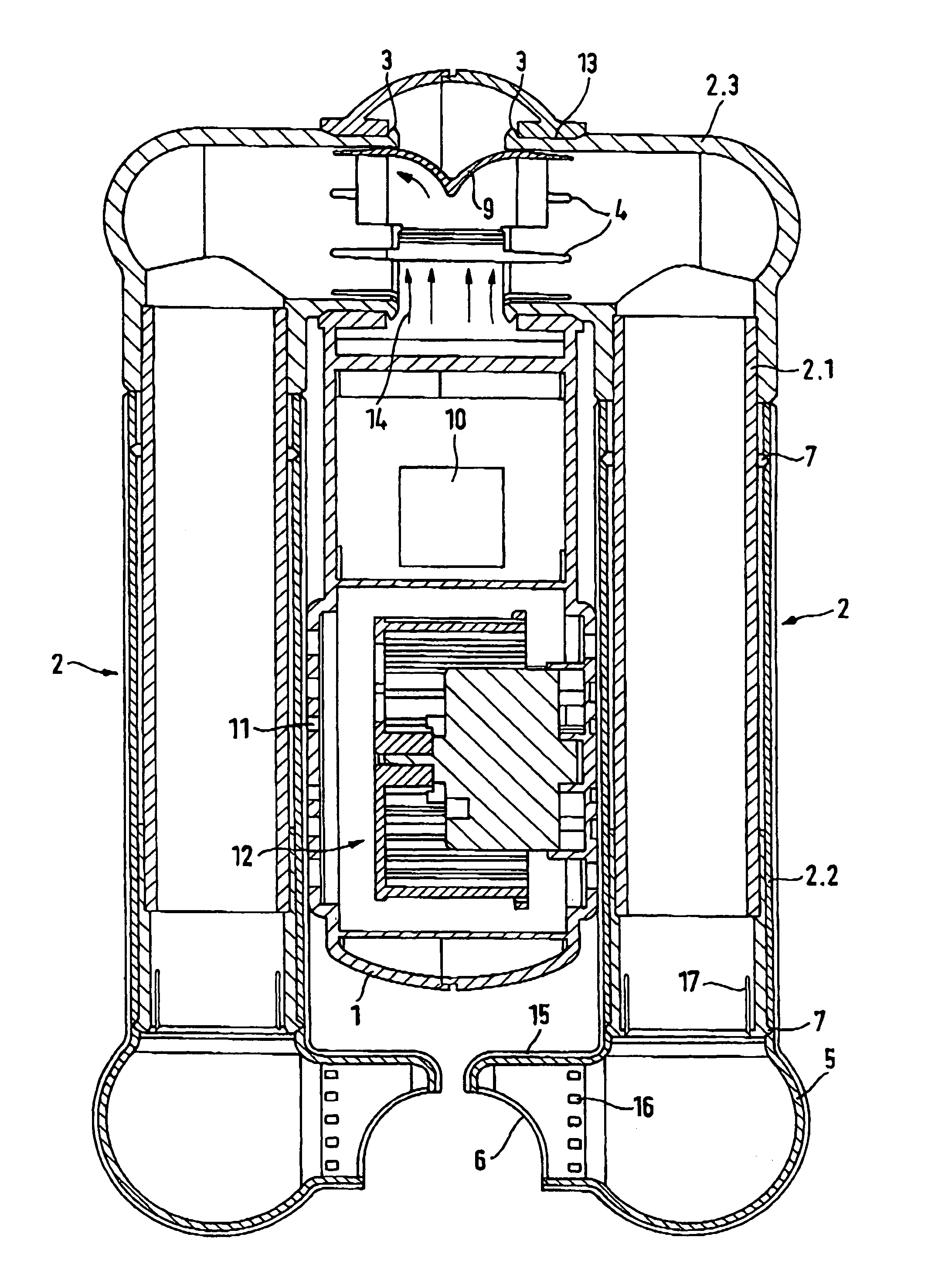

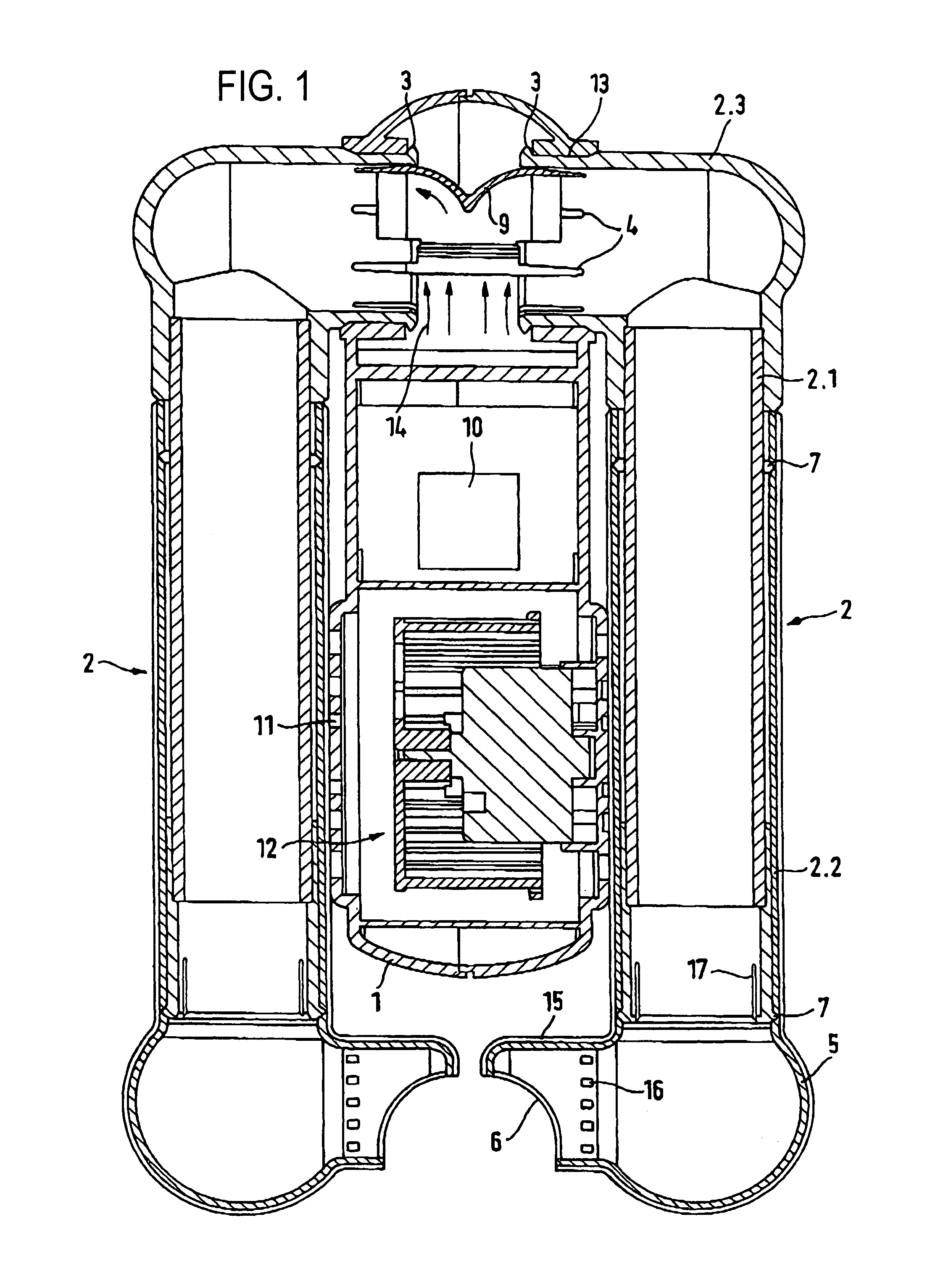

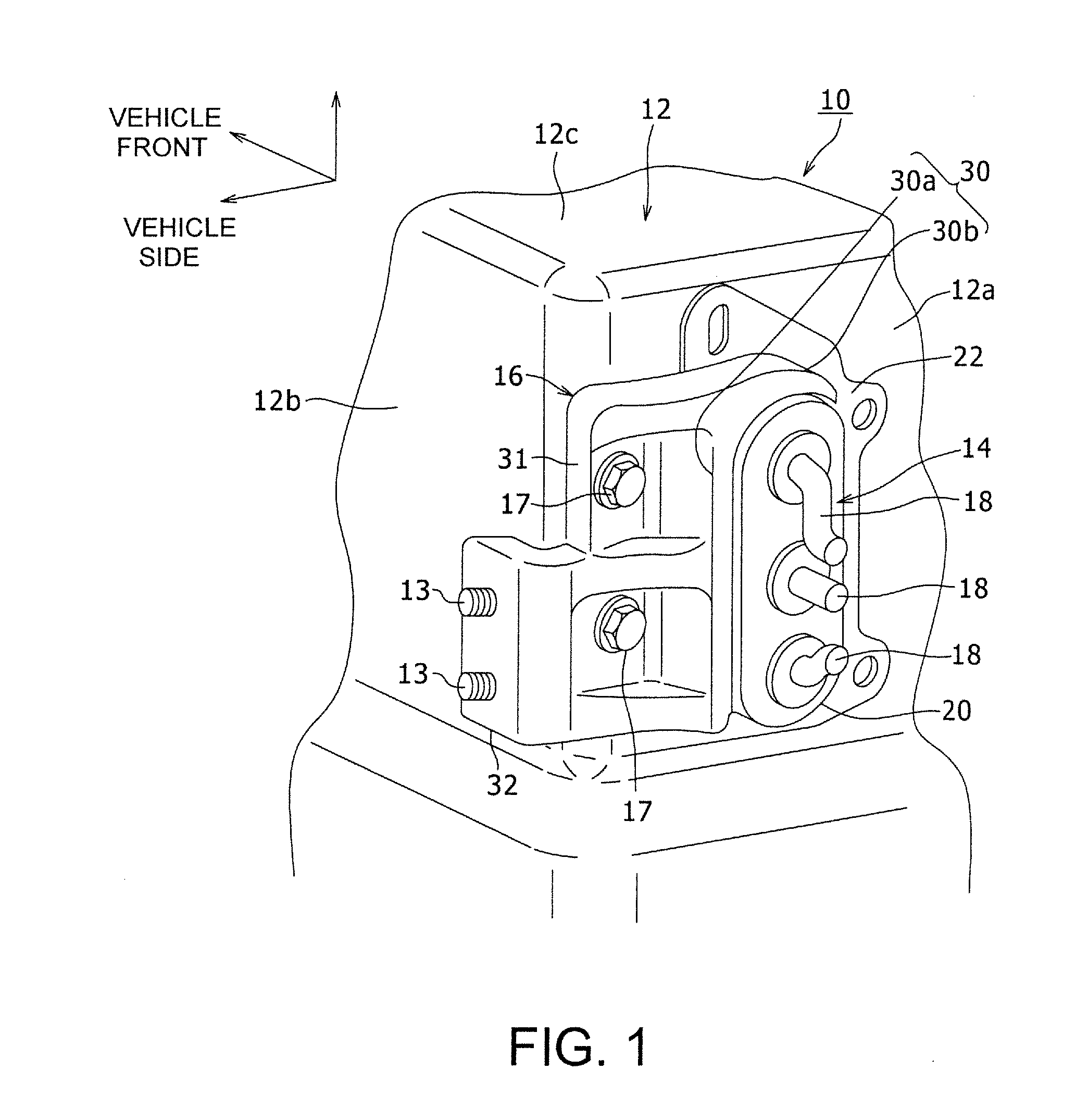

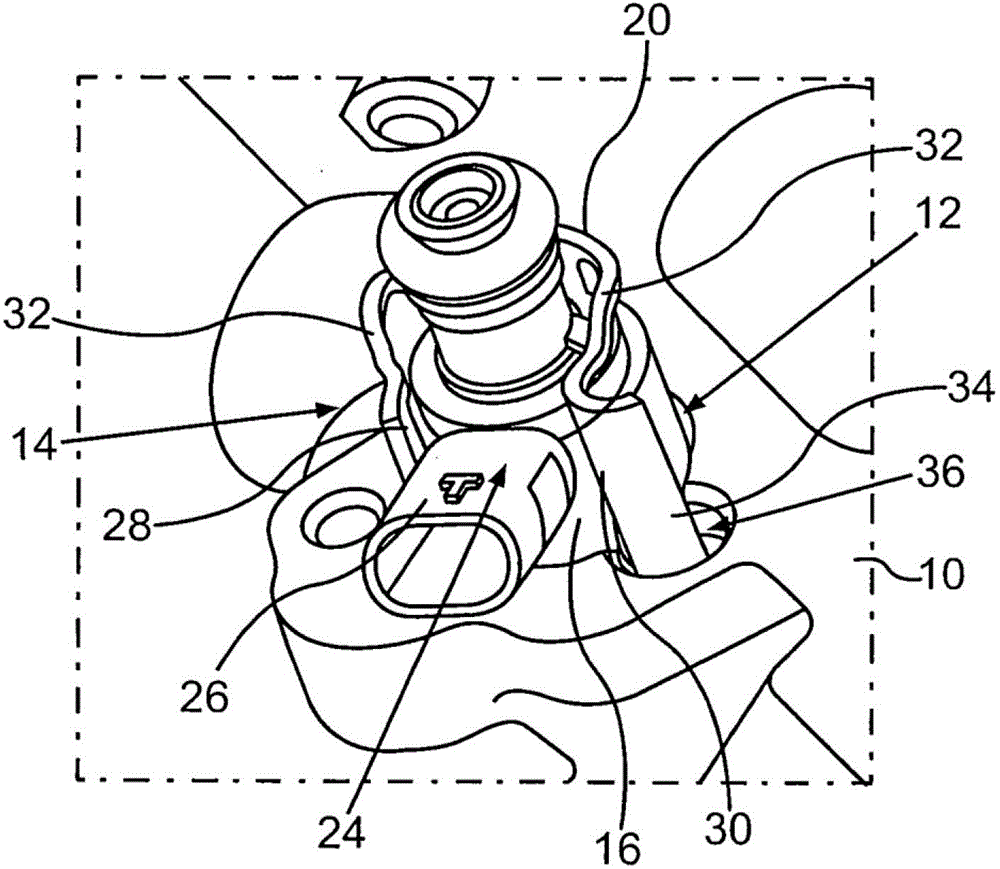

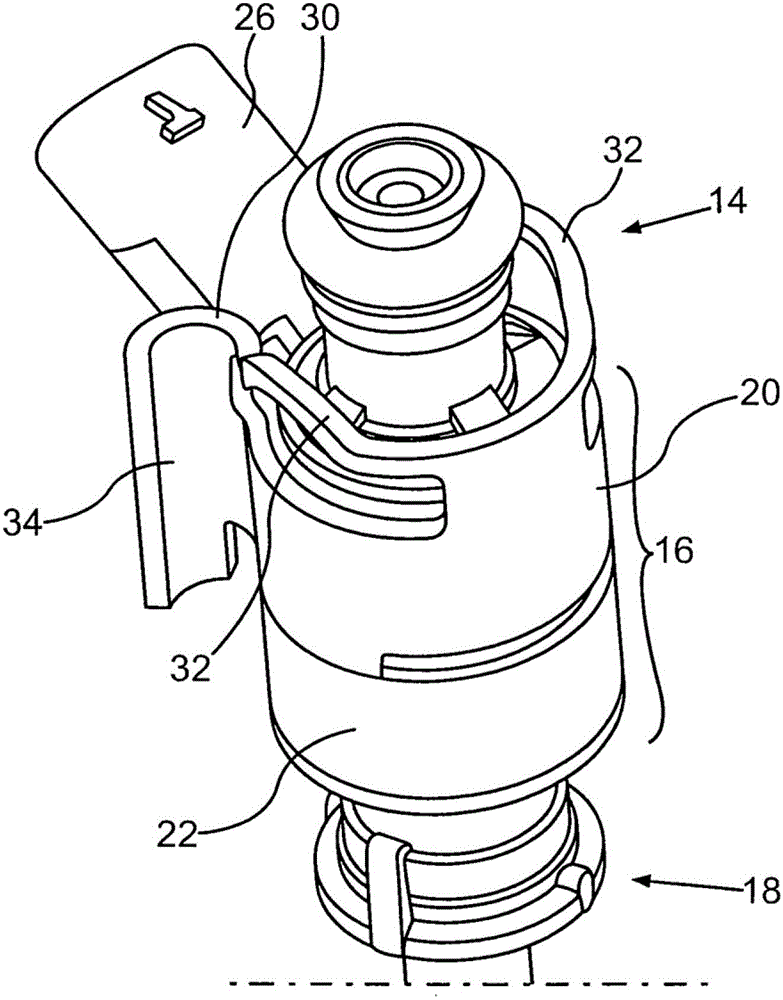

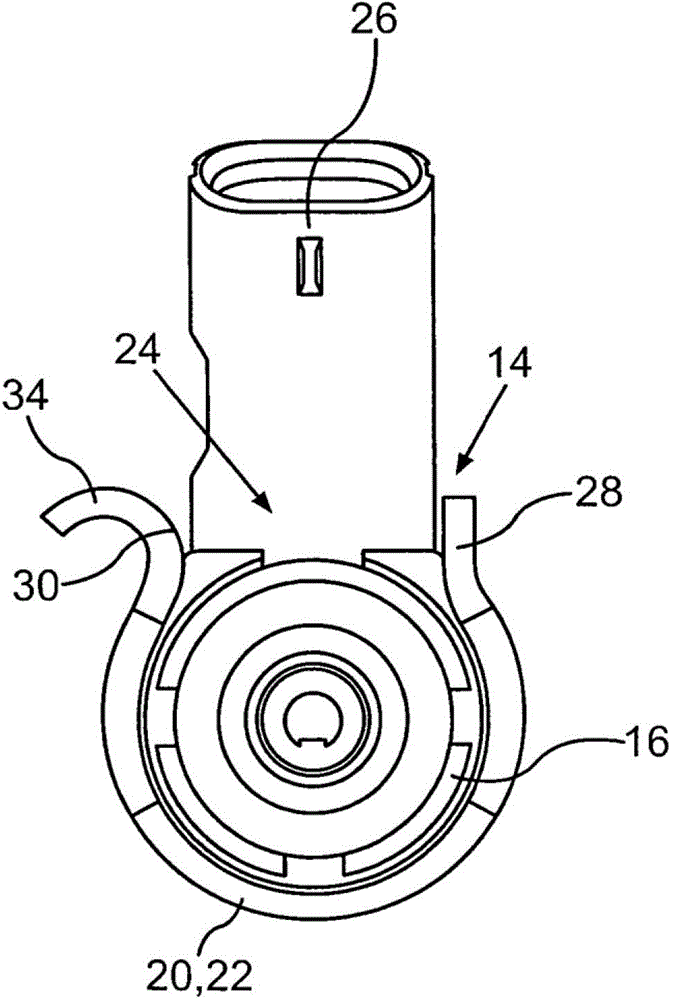

Internal combustion engine with injection valve

InactiveCN103069152AEasy to fixThe rotating position is fixed and reliableLow pressure fuel injectionMachines/enginesCombustion chamberCylinder head

The invention relates to an internal combustion engine for a motor vehicle, having at least one cylinder which is assigned an injection valve (14) for the direct injection of fuel into a combustion chamber of the cylinder, wherein the injection valve (14) is received in a receiving opening (12) of a cylinder head (10) of the internal combustion engine and is held in the receiving opening (12) by a supporting element (20), wherein the supporting element (20) is secured in its rotational position by positively locking engagement of a first positively locking element (24) on the injection valve (14) and by positively locking engagement of a second positively locking element (34) on the cylinder head (10). A supporting element (20) of this type ensures particularly satisfactory securing of the rotational position of the injection valve (14). In the case of structural amendments to the cylinder head (10) or to the injection valve (14), merely the supporting element (20) has to be adapted, with the result that amendments of this type can be realized particularly inexpensively.

Owner:AUDI AG

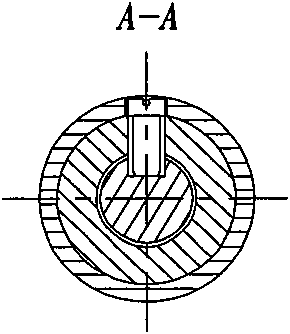

Compression type packer

InactiveCN101165309BEasy to processSmall amount of deformationSealing/packingEngineeringMechanical engineering

The compressed packer has one seat sealing mechanism comprising one locking sleeve, one locking ring, one locking ring seat and one central pipe. Inside the locking ring seat, there are wedged locking blocks with outer surface matching the inner conic surface of the locking ring, locking block support sleeve to hold the locking blocks inside the holes of the locking ring seat, return springs, andlimit stops. The central pipe has steps for pushing the limit stops to shift upwards. The compressed packer has rigid wedged locking block to replace elastic support pawls, and possesses stable and reliable seat sealing, flexible smooth and reliable locking block desterilizing, and flushing path between the central pipe and the locking block support sleeve for flushing job.

Owner:刘宜贵

fdt modular formation tester probe

ActiveCN103334746BSampling safetyFast samplingBorehole/well accessoriesDynamic monitoringEngineering

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Wedge-type compression packer

The invention relates to a wedge-type compression packer. The wedge-type compression packer comprises a steel rib with a conical face; the steel rib is sequentially provided with a sealing barrel, a push barrel and a positioning barrel; the inner bore of the sealing barrel is provided with a conical face; the conical face of the steel rib is matched with the conical face of the sealing barrel; the positioning barrel is provided with a fixed lock ring, a positioning sleeve and a deblocking shear pin; an inner bore at the lower end of the push barrel is provided with a moving lock ring; a sealing ring A is arranged between the push barrel and the positioning barrel; a sealing ring B is arranged between the push barrel and the steel rib; and the steel rib is provided with an overflow pressure guide hole.

Owner:大安市创新机械工程技术有限责任公司

Double packer steam injection integrated device and method for heavy oil development in oilfield

ActiveCN114251077BReliable seatingExtended service lifeFluid removalSealing/packingThermodynamicsOil field

The invention relates to the field of oilfield heavy oil exploitation equipment, in particular to a double packer steam injection integrated device and method for oilfield heavy oil exploitation. The technical solution is: the lower end of the upper packer is connected to the lower packer through the layer spacer tube and the connecting core tube, the lower end of the steam injection valve is equipped with a seat sealer and a one-way oil recovery unit; the inner cavity of the upper packer is installed with a hand The core tube, the lower end of the lost core tube is connected to the layer spacer tube, the connecting core tube, and the compensation core tube. The lower end of the compensation core tube passes through the lower packer and is connected to the seat seal steam injection plug, and the lower side of the ball seat is provided with a seat seal The seat sealer is fixedly connected to the casing inner cavity of the steam injection valve by locking the fixed force pin. The beneficial effect is that the present invention is lowered into the well at one time, so that the seat seal of the two oil layers is reliable, and the material injected during steam injection is avoided. The efficiency of steam injection is improved due to the loss of energy, and at the same time, the corrosion of oil well casing is reduced, and the service life of oil well is prolonged; the construction procedure is reduced, the labor intensity of workers is reduced, and the construction period is shortened.

Owner:SHENGLI COLLEGE CHINA UNIV OF PETROLEUM

Hydraulic setting bridge plug

The invention relates to the technical field of oil field and oil well drilling and production, in particular to a hydraulic setting bridge plug. The hydraulic setting bridge plug comprises an upper connector, an upper conical body, an upper rubber cylinder, an upper spacer ring, a middle rubber cylinder, a lower spacer ring, a lower rubber cylinder, a lower conical body, an outer cylinder, a piston, a pin and a lower connector. The upper connector is connected with the lower connector, and the upper conical body, the upper rubber cylinder, the upper spacer ring, the middle rubber cylinder, the lower spacer ring, the lower rubber cylinder and the lower conical body are sequentially arranged on the upper connector in a sleeving mode from top to bottom. The lower portion of the lower conicalbody is connected with the upper portion of the piston, and the piston is arranged between the outer cylinder and the upper connector. The lower portion of the outer cylinder is connected with the lower connector through the pin, and the upper portion of the piston and the upper portion of the outer cylinder are provided with mutually-matched ratchets correspondingly. A liquid passing hole is formed in the lower portion of the upper connector and located below the piston. According to the hydraulic setting bridge plug, through cooperative use of the three rubber cylinders with different hardnesses, reliable sealing can be achieved, the upper connector and the lower connector are each made of a cast iron material, and thus drilling is facilitated.

Owner:TIANJIN HUIZHU PETROLEUM EQUIP SCI & TECH CO LTD

Underground coal mine nearly horizontal directional drilling large-diameter steel sleeve hole completion system and method

PendingCN114658356AAvoid damageRealize centered installationDirectional drillingWell/borehole valve arrangementsMining engineeringSlurry

The invention provides a coal mine underground nearly horizontal directional drilling large-diameter steel casing pipe hole completion system and method, the system comprises a casing pipe guide head, a plurality of steel casing pipe strings and a slurry conveying device which are sequentially connected in a sealed mode from front to back, and a resistance reduction supporting device is connected between the casing pipe guide head and the steel casing pipe string adjacent to the casing pipe guide head in a sealed mode; a resistance reduction supporting device and a pressure limiting sealer are sequentially connected between every two adjacent steel sleeve strings in a sealed mode from front to back. The outer diameter of the anti-drag supporting device is smaller than that of the directional drilling hole, and the outer diameter of the pressure limiting sealer is smaller than that of the anti-drag supporting device. In the process of lowering the steel sleeve, the steel sleeve is supported at a slightly downward position in the middle of the hole wall by using the resistance-reducing supporter, and the pressure-limiting sealer can be prevented from being damaged; when the steel sleeve is grouted and fixed, the pressure limiting sealer is used for further adjusting the steel sleeve to be located in the middle of the directional drilling hole, segmented exhaust and high-pressure grouting are achieved, the uniformity of the grouting thickness is improved, and the existence of through cracks is avoided.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Double-packer steam injection integrated device and method for oil field thickened oil exploitation

ActiveCN114251077AReliable seatingExtended service lifeFluid removalSealing/packingThermodynamicsOil field

The invention relates to the field of oil field thickened oil recovery equipment, in particular to a double-packer steam injection integrated device and method for oil field thickened oil recovery. According to the technical scheme, the lower end of an upper packer is connected with a lower packer through an interlayer spacing pipe and a connecting core pipe, and a setting device and a one-way oil extraction device are installed at the lower end of a steam injection valve; a releasing core pipe is installed in an inner cavity of the upper packer, the lower end of the releasing core pipe is connected with an interlayer spacing pipe, a connecting core pipe and a compensation core pipe, the lower end of the compensation core pipe penetrates through the lower packer to be connected to a setting steam injection plug, a setting device is arranged on the lower side of a ball seat, and the setting device is fixedly connected to an inner cavity of a shell of the steam injection valve through a locking anchoring force pin. The device has the beneficial effects that the device is tripped into a well at a time, so that the setting of two oil layers is reliable, the loss of injected substances and energy during steam injection is avoided, the steam injection efficiency is improved, meanwhile, the corrosion to an oil well sleeve is reduced, and the service life of an oil well is prolonged; and the construction procedures are reduced, the labor intensity of workers is reduced, and the construction period is shortened.

Owner:SHENGLI COLLEGE CHINA UNIV OF PETROLEUM

A bridge plug that blocks off oil tube

A bridge plug that blocks off oil tube is used in underground blocking oil tube during a pressure operation in the oil, gas or water well in an oilfield. From top to bottom, the bridge plug consists of salvage part, slip setting part, sealing part and slip release part. Steel wire is used for seat delivery, salvage and unsealing. The slip release part may accurately determine the position of the bridge plug. In both sealing part and slip setting part, self-locking devices are provided to realize reliable sealing. During salvage, a special tool is used to cooperate with the salvage part and unseal and take out the bridge plug. After replacement of packing elements and shear pins and simple maintenance, this bridge plug may be used repeatedly. The bridge plug adopts a double-slip structure and realizes the function of blocking off oil tube by using mechanical vibration and self-locking principle. It has the following advantages: sealing in any position, large sealing pressure difference,salvage, blocking of the oil tubes with a very small aperture, and blocking by section.

Owner:PETROCHINA CO LTD

Cava-free automatic liquid drainage throttle device

The invention discloses a cava-free automatic liquid drainage throttle device. The cava-free automatic liquid drainage throttle device comprises a central pipe, one end of the central pipe is sleeved with a fishing neck, and the central pipe is sequentially sleeved with a pressing nut, an upper gland, an elastic sleeve, a lower gland, an expansion force head and a locking piece claw in the direction far away from the fishing neck; the pressing nut is in threaded connection with the central pipe and abuts against the upper gland, the elastic sleeve is clamped between the upper gland and the lower gland, one end of the expansion force head abuts against the other end of the lower gland and is in threaded connection with the central pipe, the locking piece claw is arranged on the expansion force head in a sleeving mode, a cavity is formed between the expansion force head and the central pipe, a limit block is formed on the inner wall of the expansion force head, and an air tap is arranged in the fishing neck. The cava-free automatic liquid drainage throttle device can enable the deblocking process to be easier, avoids the condition that liquid drainage is conducted by enabling a steel wire to trip in a special tool and is convenient to use.

Owner:SHAANXI HUIFENGYUE PETROLEUM TECH DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com