Patents

Literature

376 results about "Tube socket" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tube sockets are electrical sockets into which vacuum tubes (electronic valves) can be plugged, holding them in place and providing terminals, which can be soldered into the circuit, for each of the pins. Sockets are designed to allow tubes to be inserted in only one orientation. They were used in most tube electronic equipment to allow easy removal and replacement. When tube equipment was common, retailers such as drug stores had vacuum tube testers, and sold replacement tubes. Some Nixie tubes were also designed to use sockets.

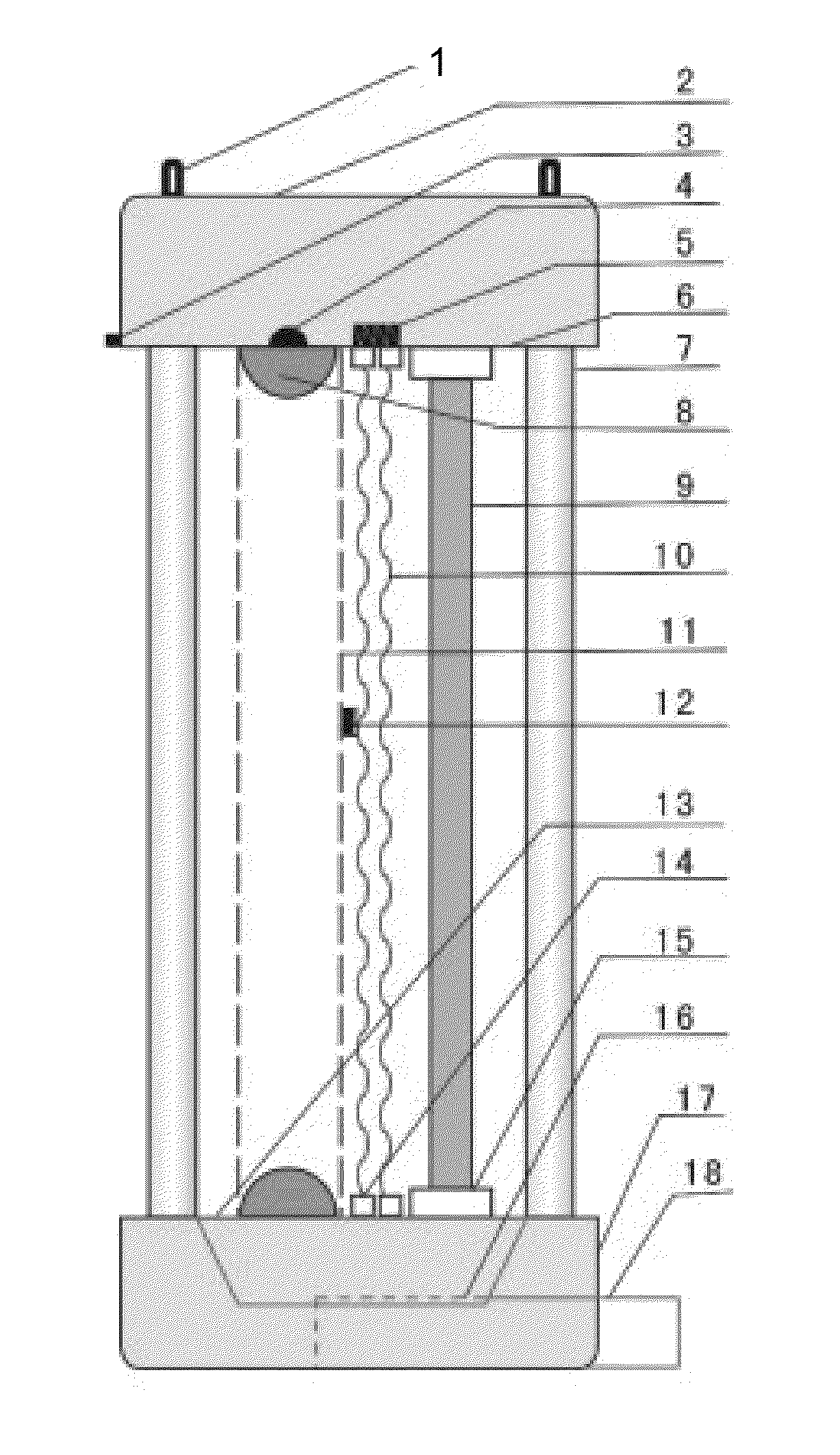

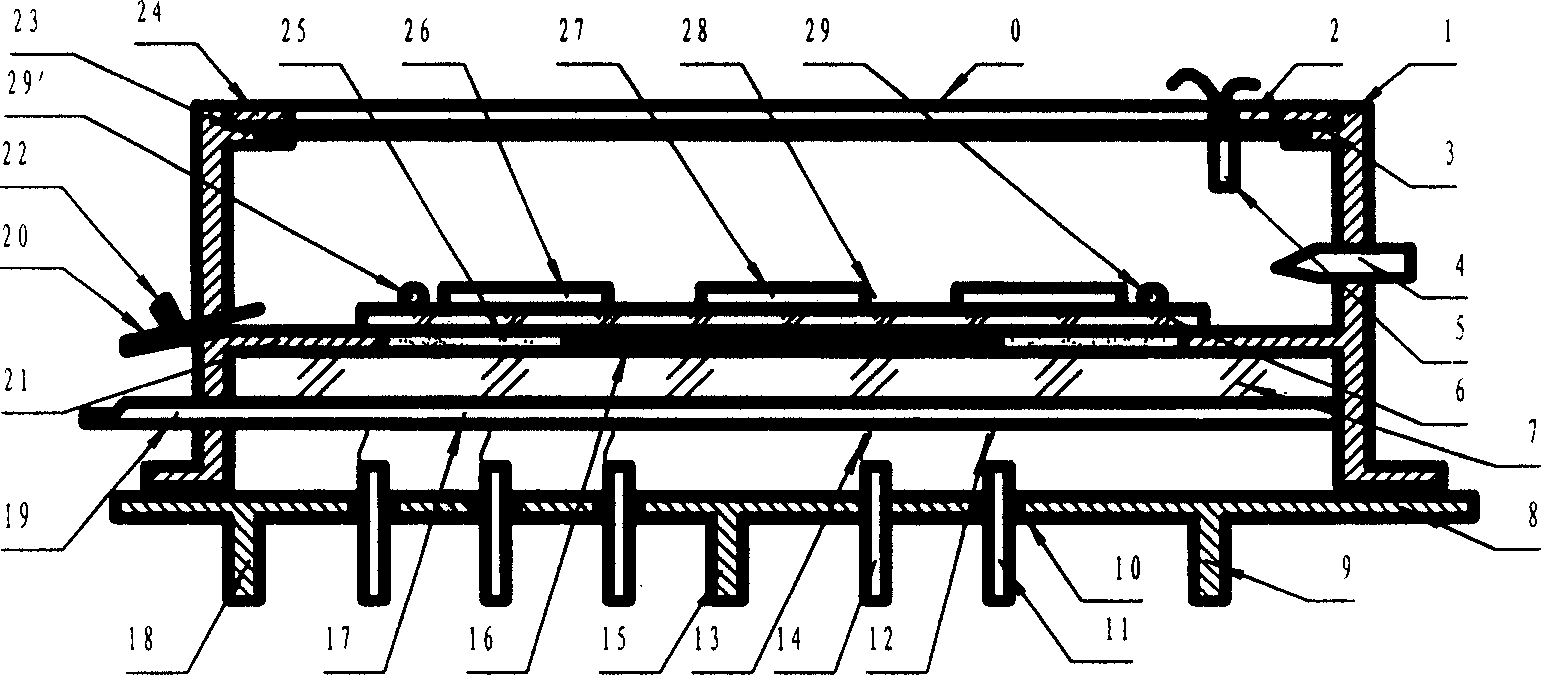

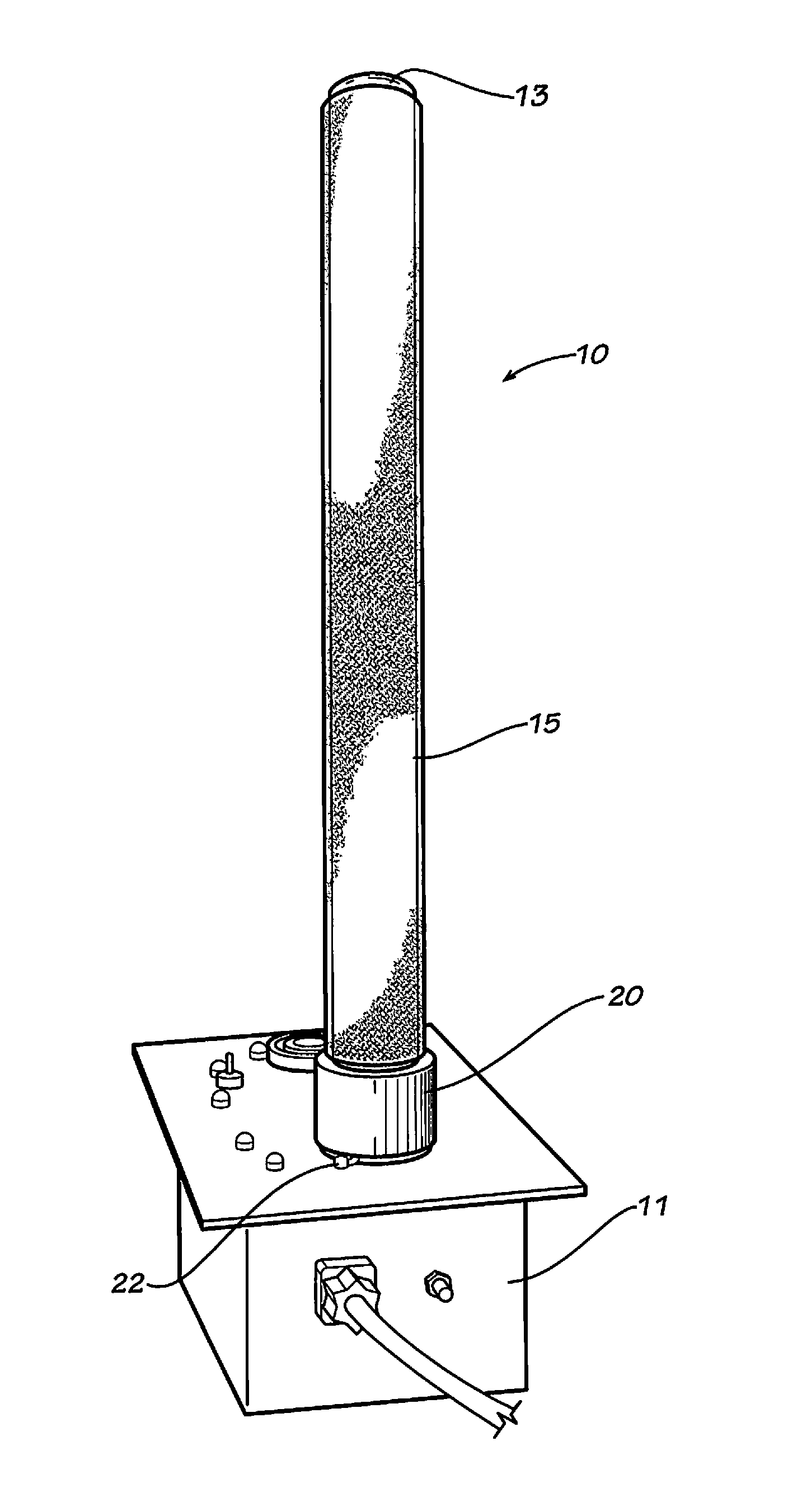

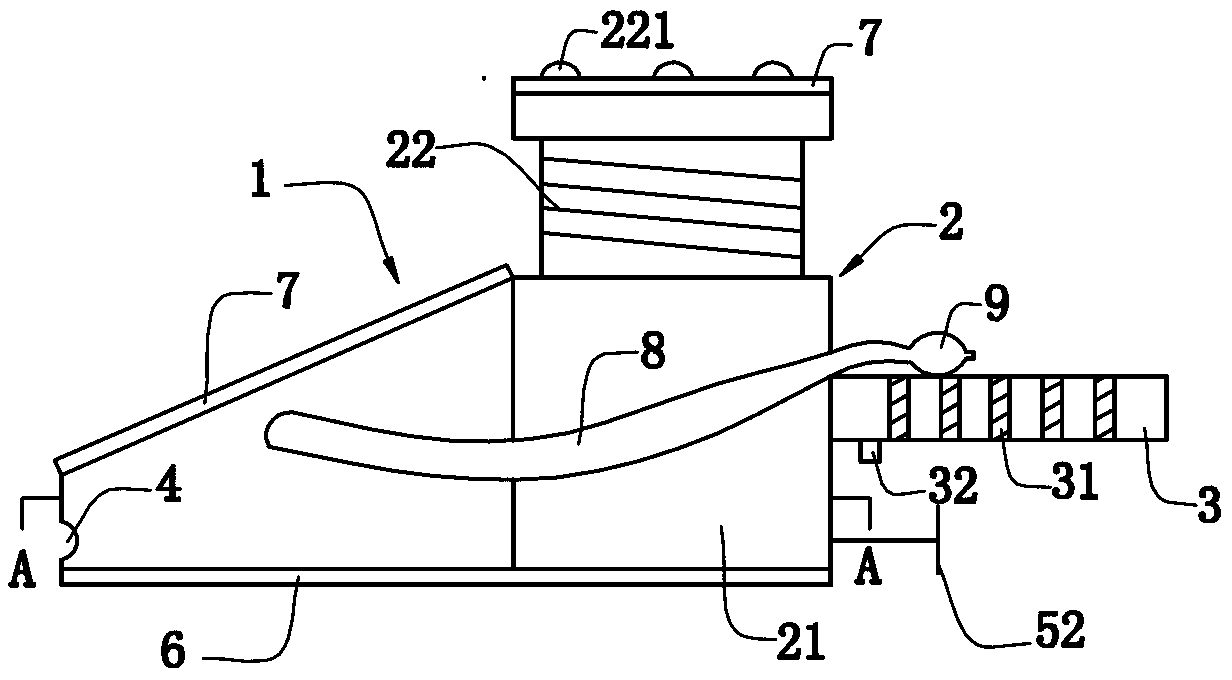

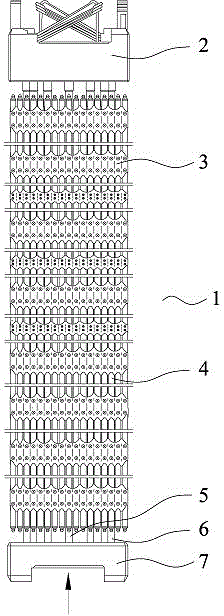

Electric-shock pest killing apparatus with automatic pest body cleanup

InactiveUS8875437B1Suitable for long-term useImprove insecticidal effectElectric shock equipmentsInsect catchers and killersTube socketEngineering

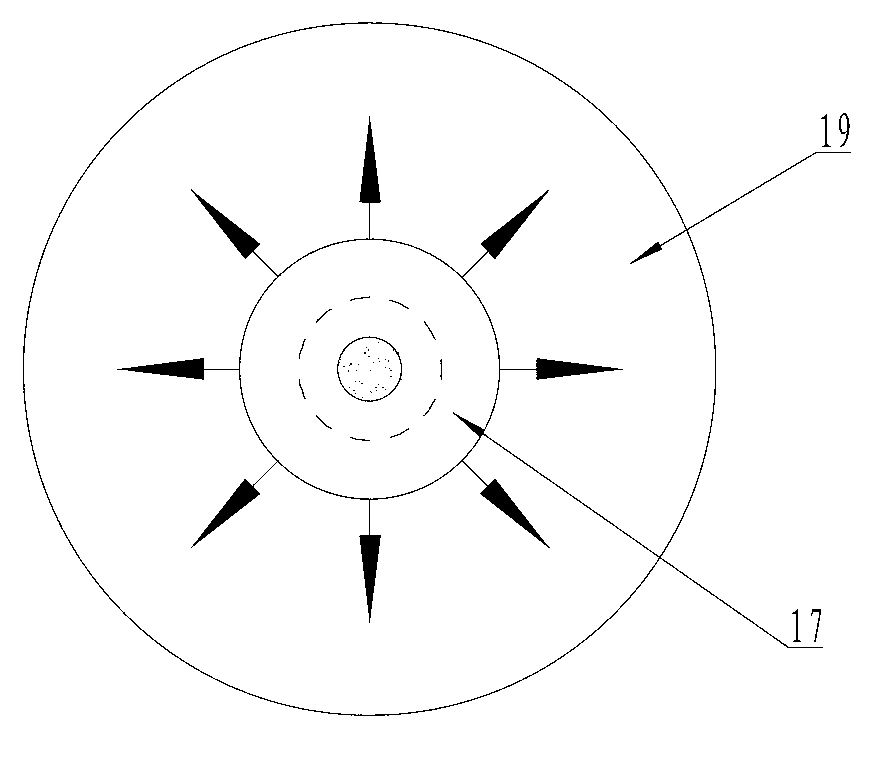

This present invention is a pest killing apparatus having a upper housing separated and supported from a base, cleanup unit, a lamp tube to lure pests, pest collection box, high voltage electric net and control circuit. The pest cleanup unit has an electric drive motor, brush support means and a brush. A vertical pest attraction lamp tube is an inert gas lamp tube or LED light-emitting diodes, reflective material, glass tube and the tube sockets. The lamp tube is located in a central axial or side vertical position between the upper housing and the base to induce insects toward the electric net. The upper housing is provided with attachments so that the apparatus can be suspended. The base is provided with a flat underside so the apparatus may be placed in operation on a horizontal surface.

Owner:XIE ZHILONG

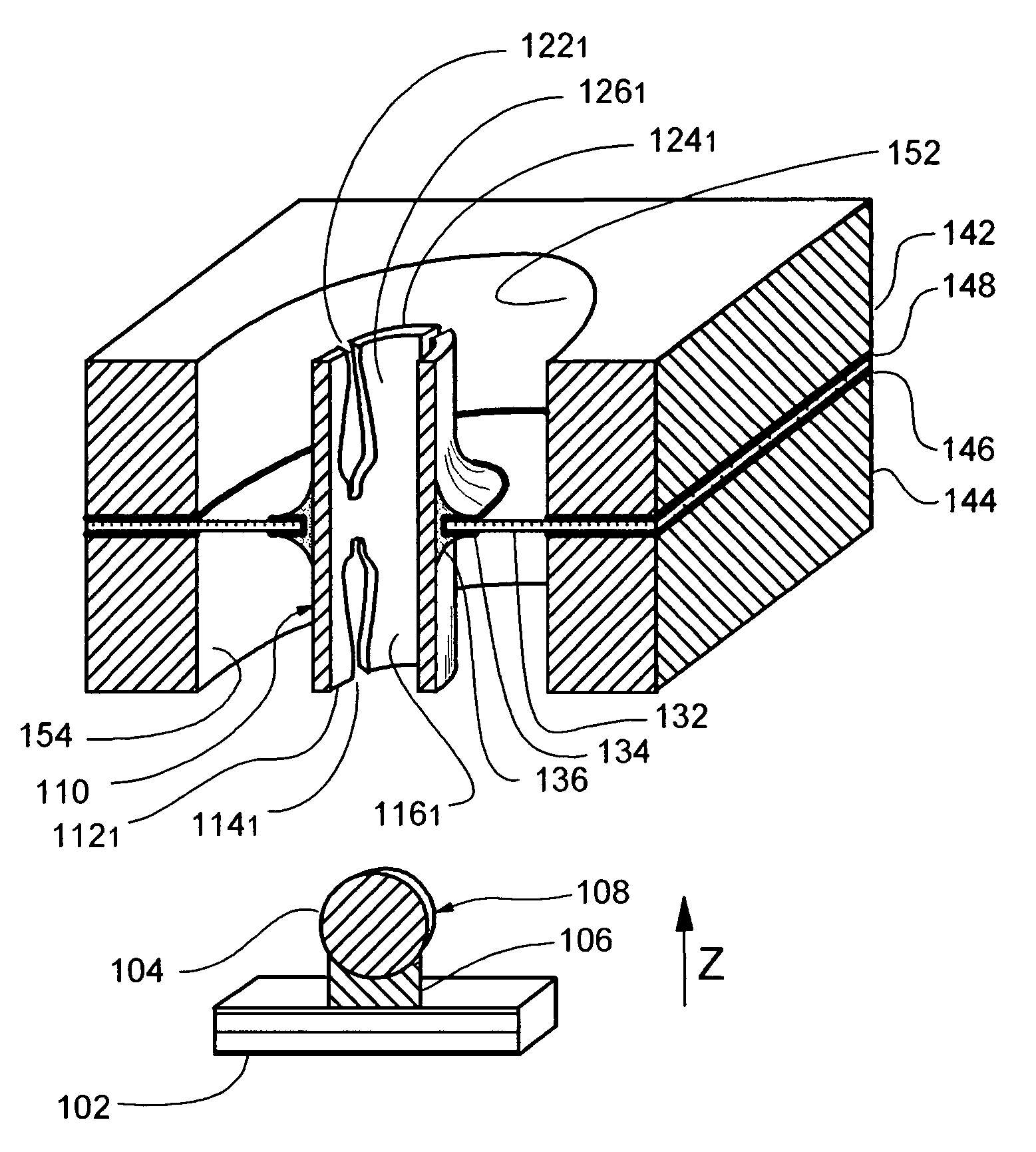

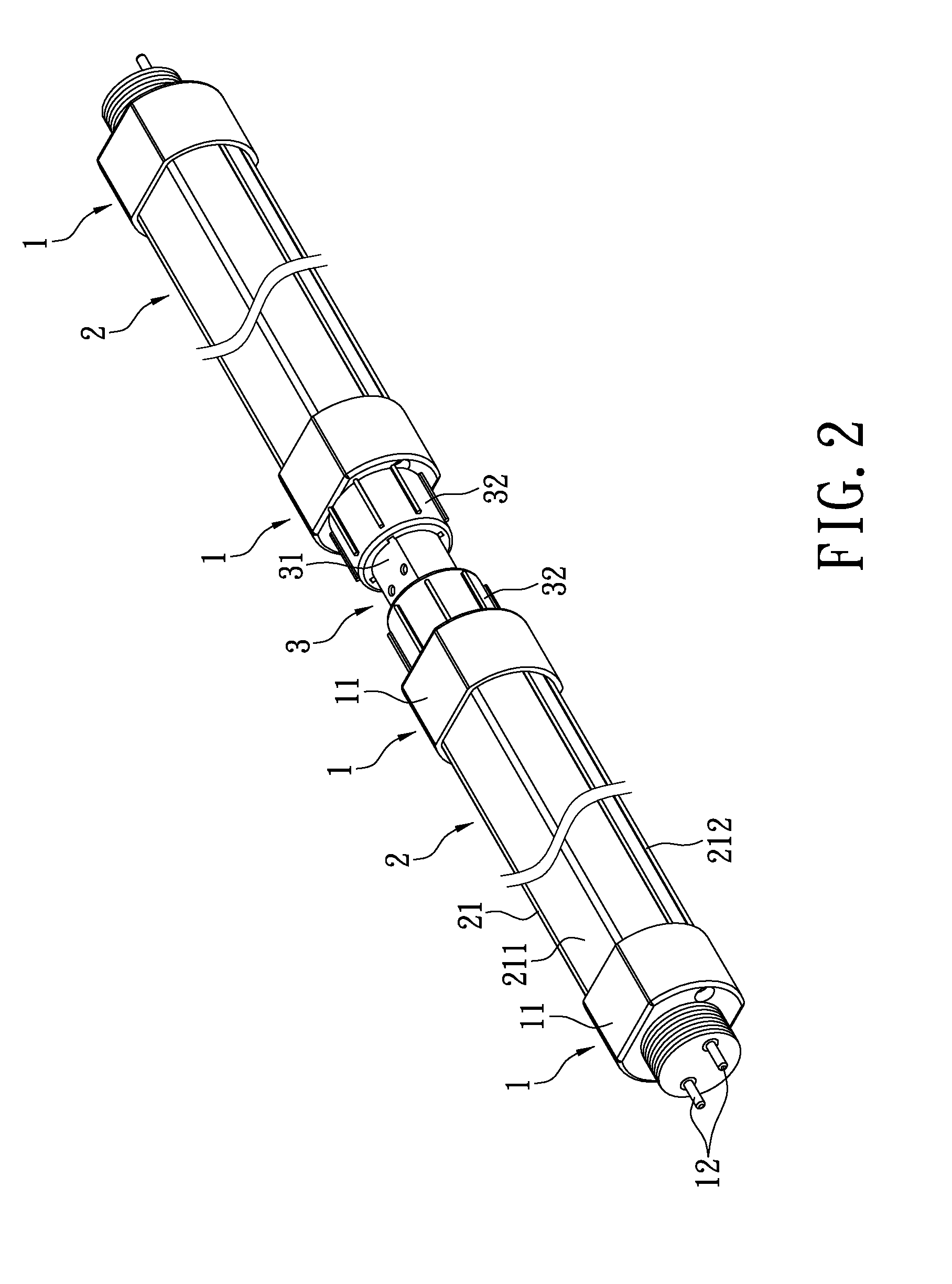

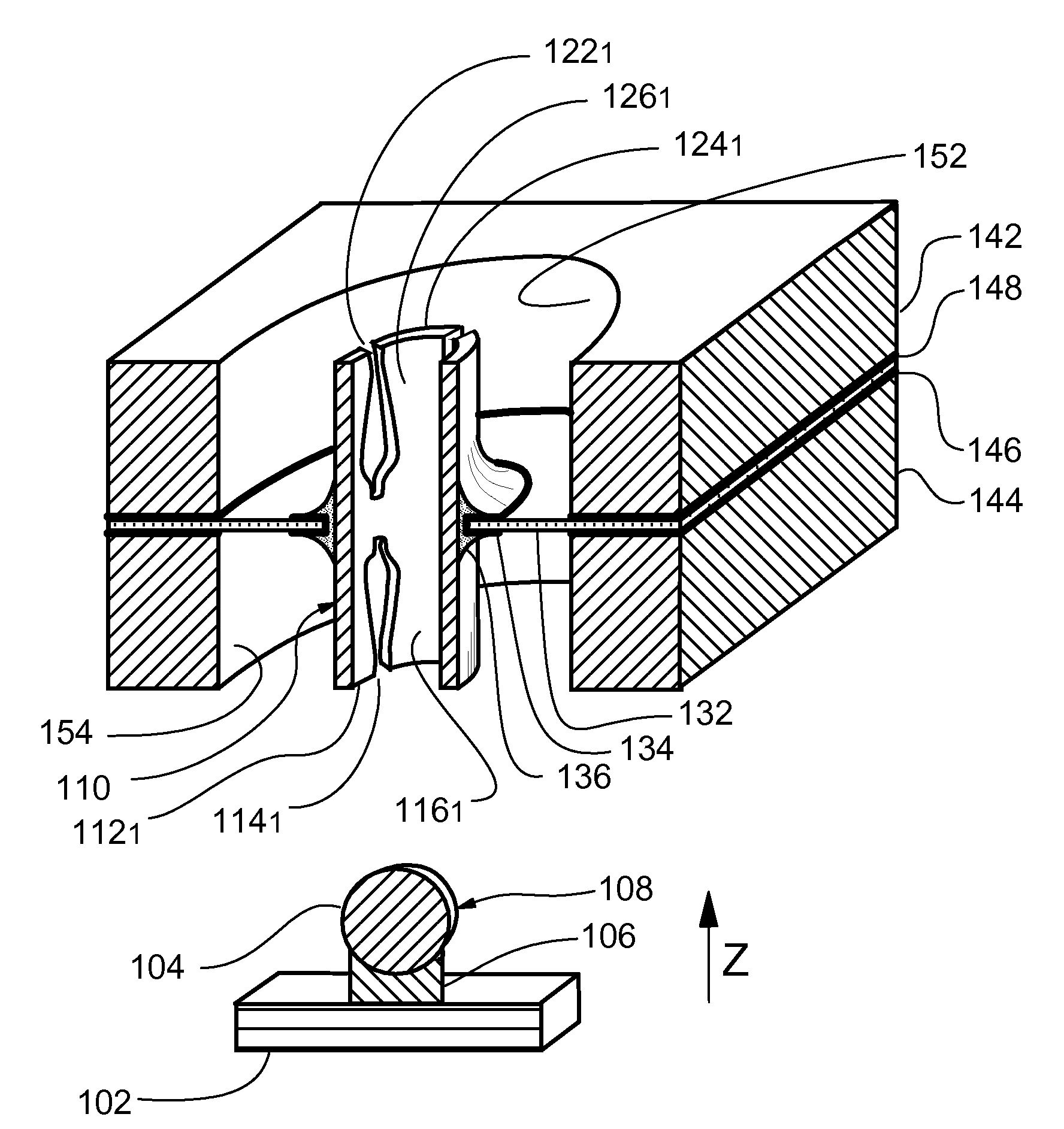

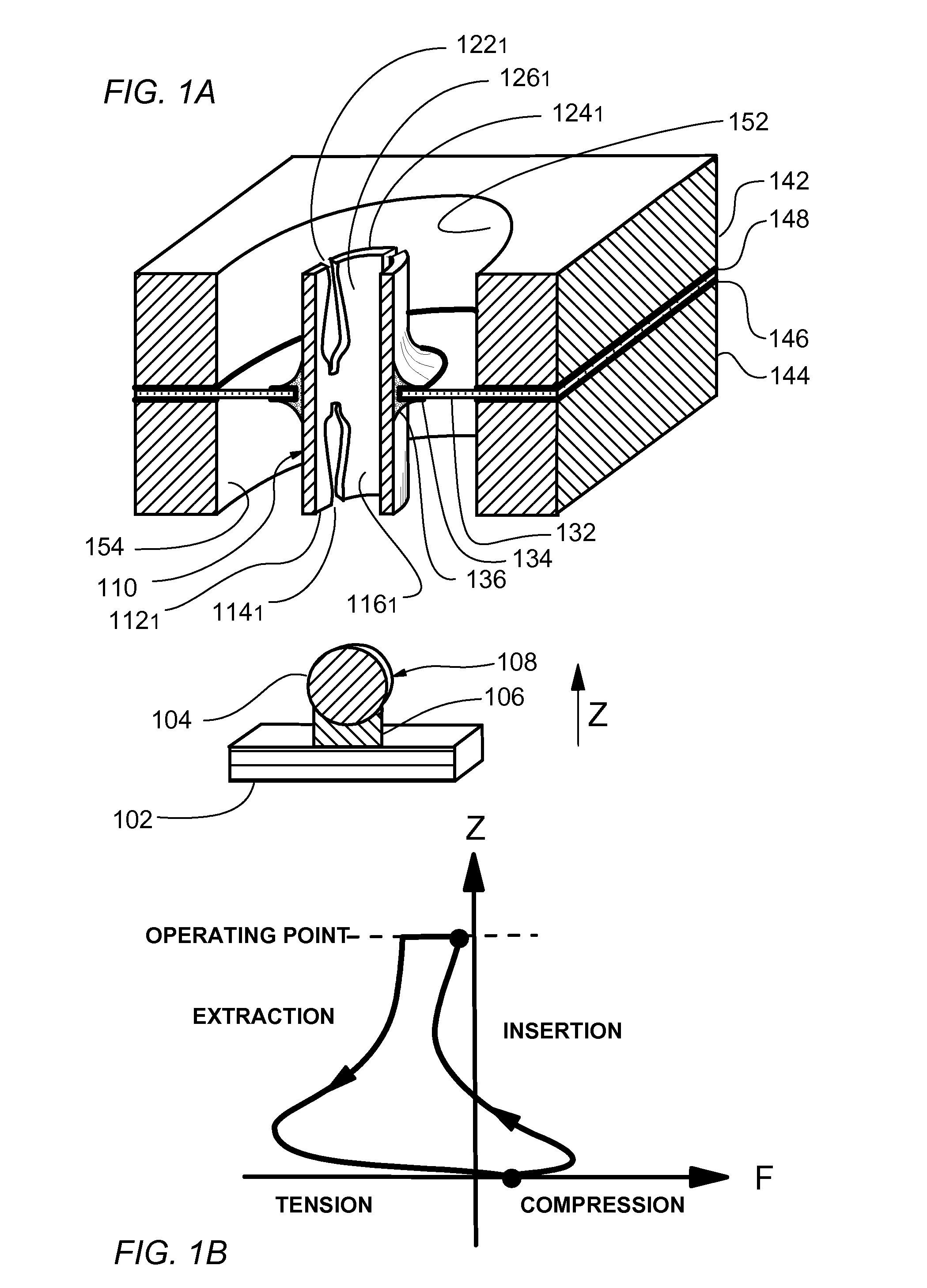

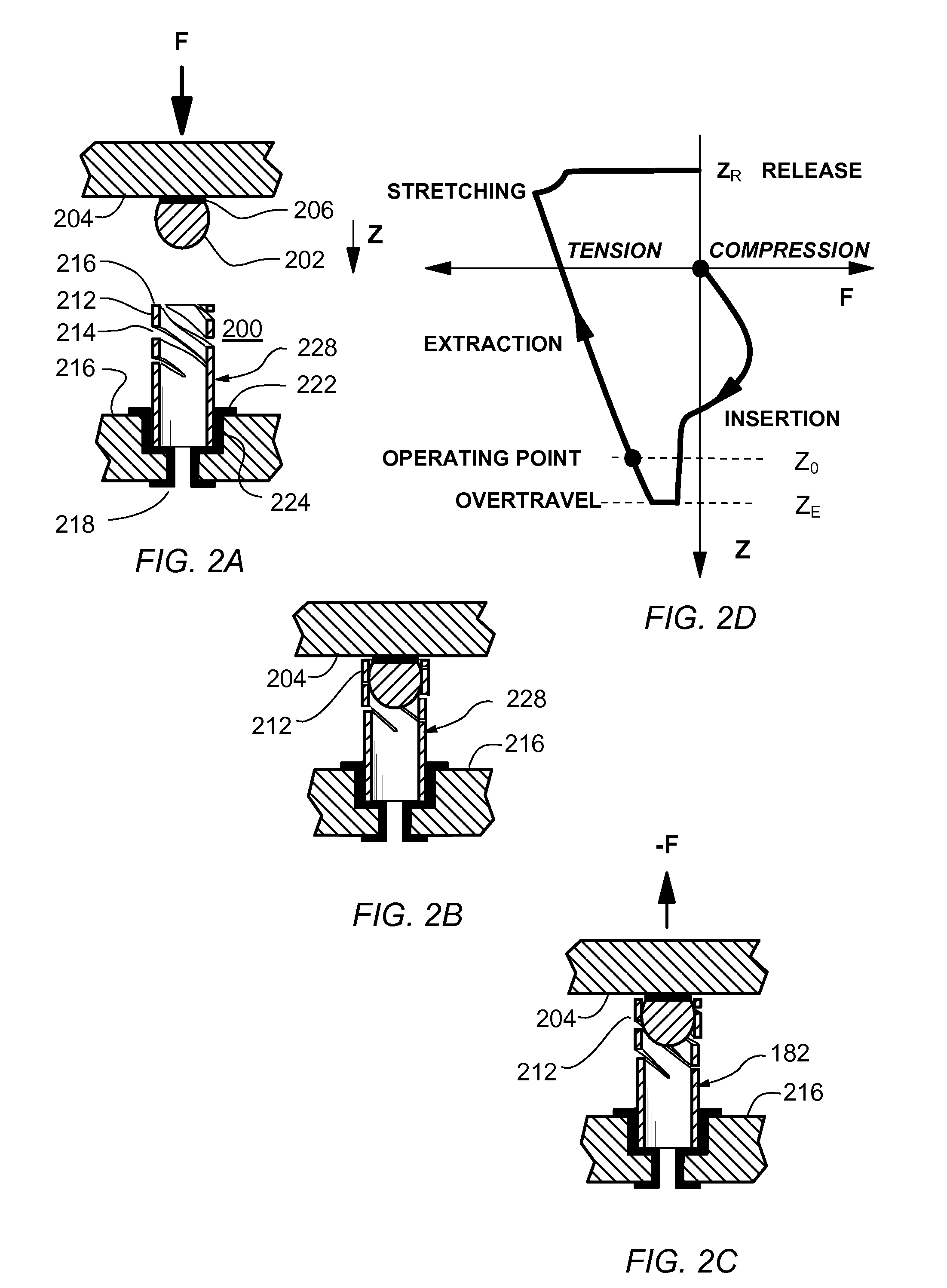

Miniature electrical ball and tube socket with self-capturing multiple-contact-point coupling

InactiveUS7442045B1Reduce mechanical stressLower self-esteemFinal product manufacturePrinted circuit aspectsLow insertion forceCoupling

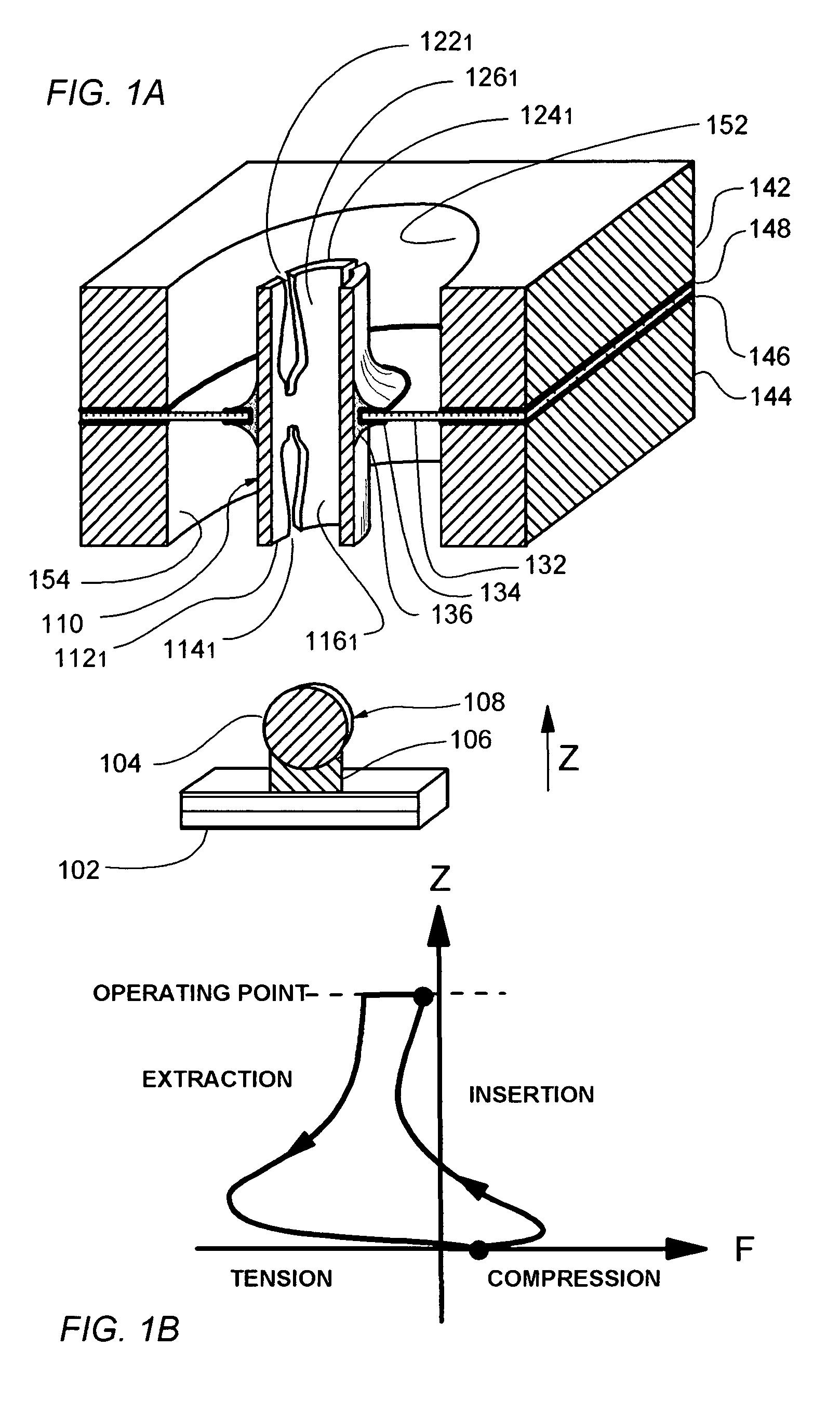

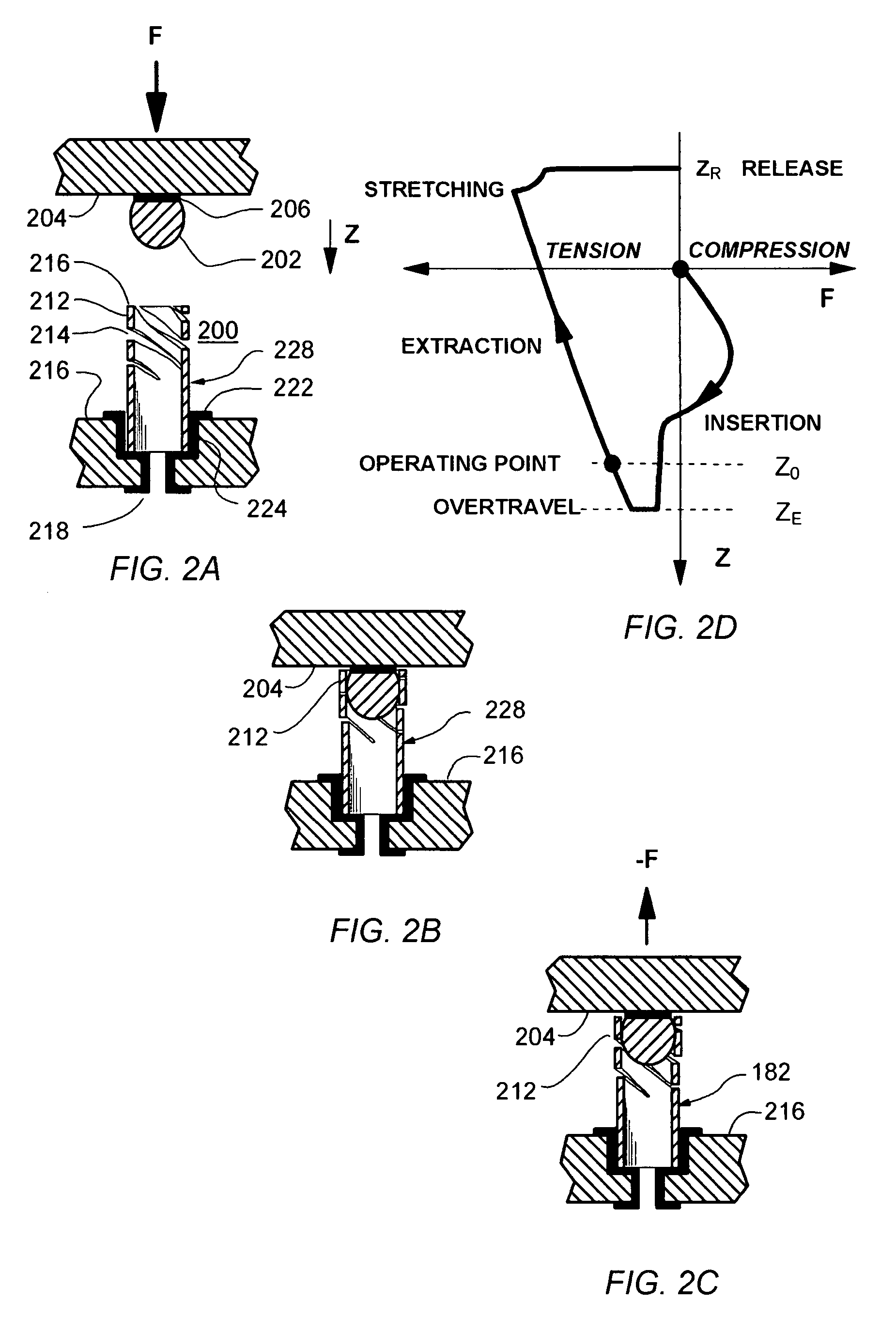

A socket connector for connecting a bulbous terminal or ball wherein the female element grips the terminal with resilient prongs with end tips at low insertion force but positive contact is maintained and wherein attempted withdrawal is normally inhibited by increasing force applied to the post by the female element in response to the withdrawal force. The female element comprises a tube of resilient conductive material that has been sliced or helically partitioned into opposing prongs of a width that decreases with axial distance from the end of the connector so as to allow the prongs of the connector to grip around the ball-like bulbous terminal and mechanically retain the terminal within the connector. The tubular element of the connector may be made by forming prongs in one or both ends of a tube by cuts of a width that increases with distance from the end of the tube.

Owner:CENTIPEDE SYST

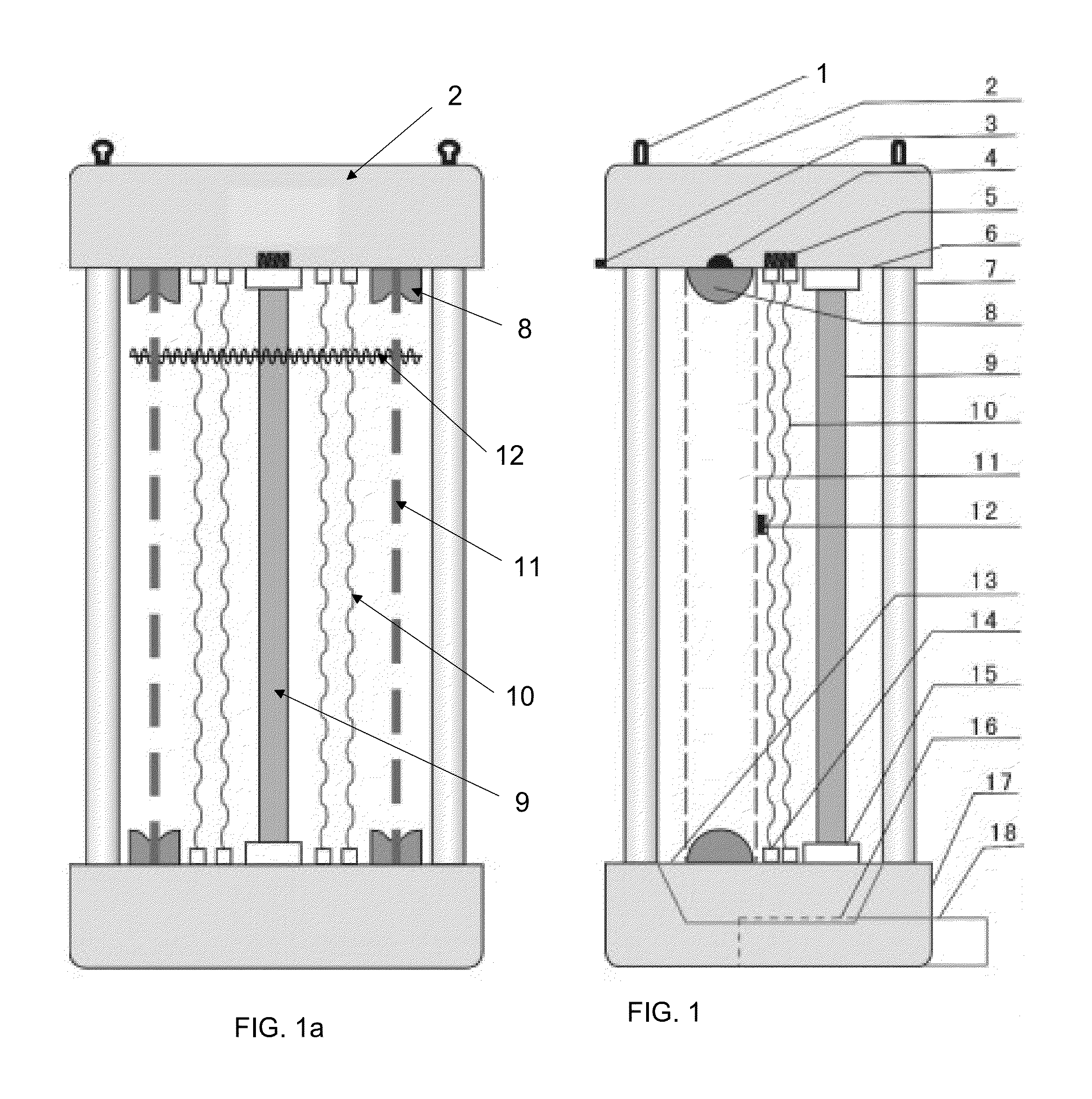

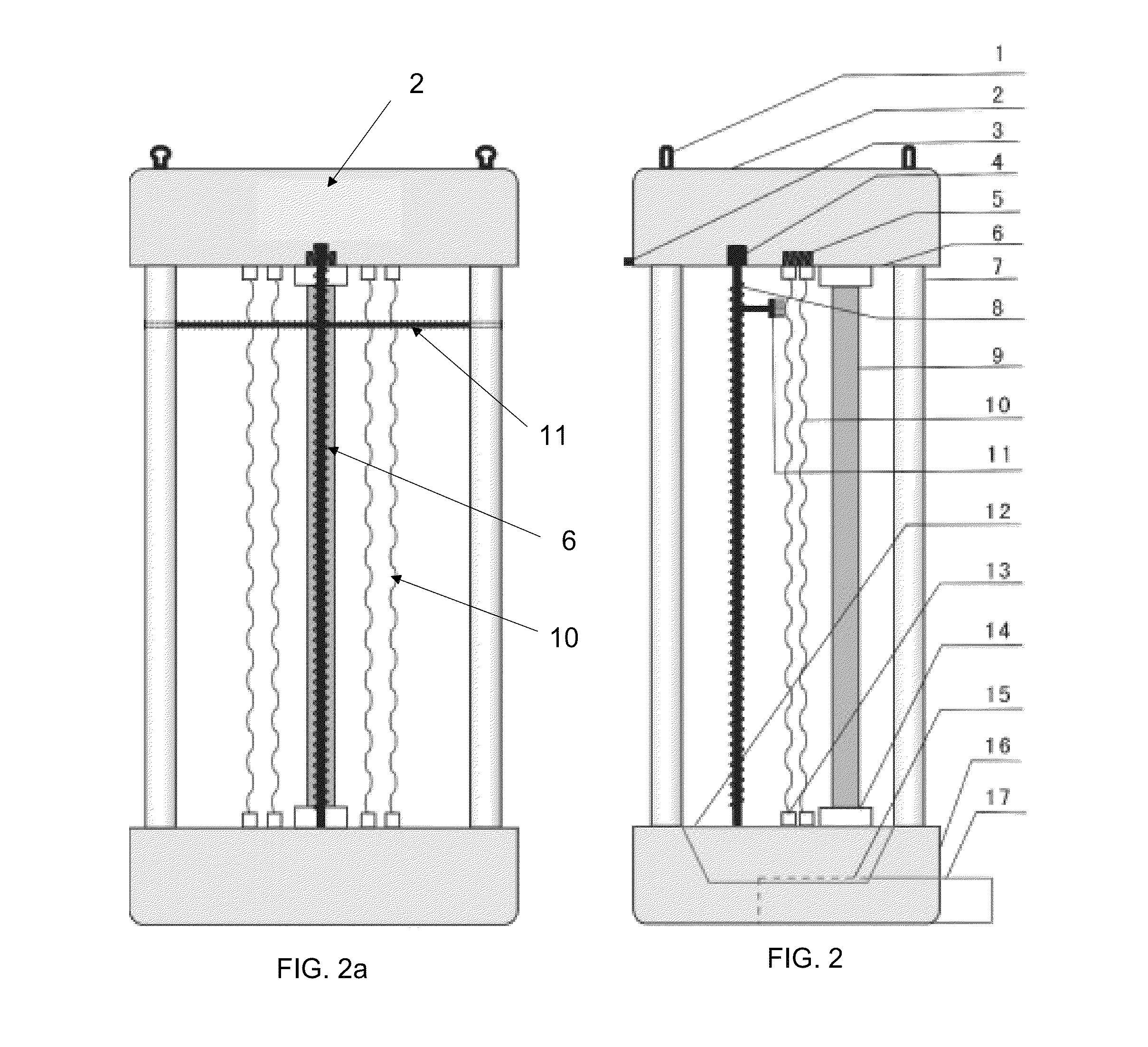

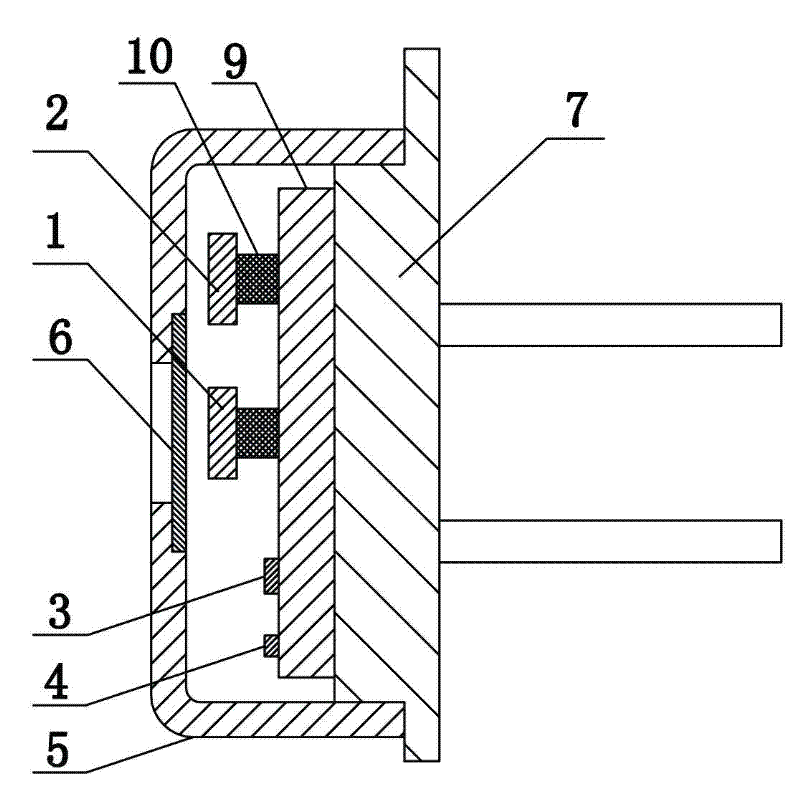

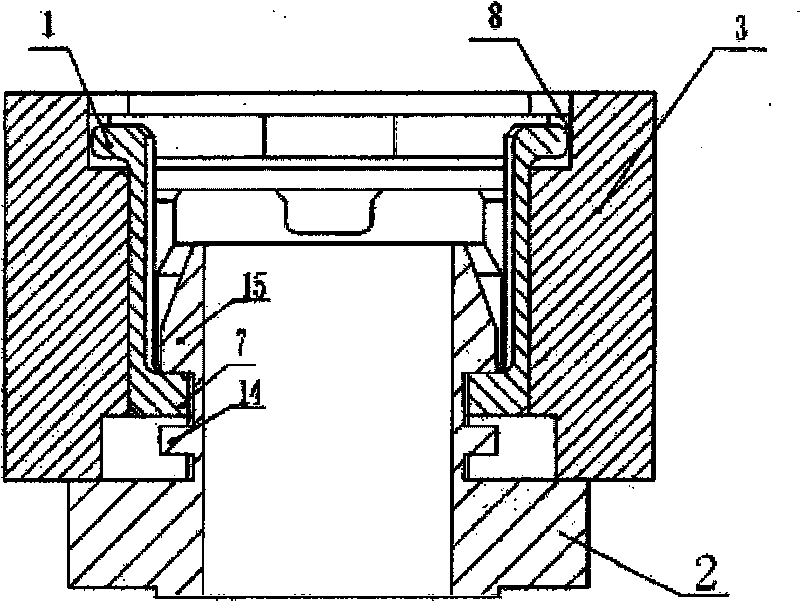

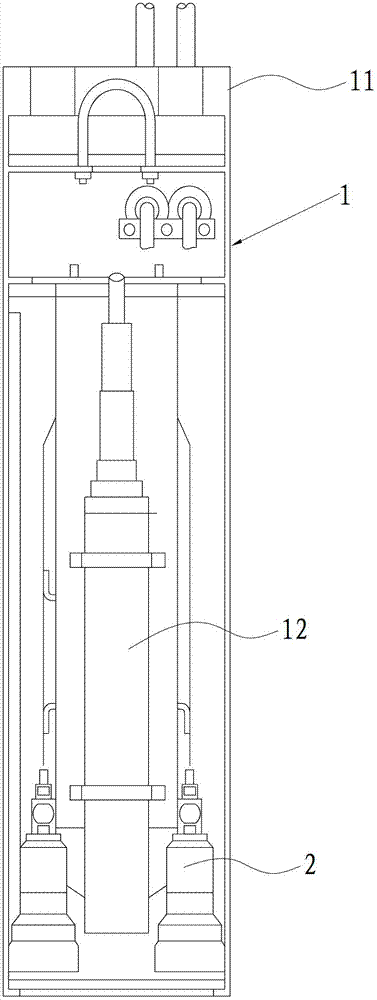

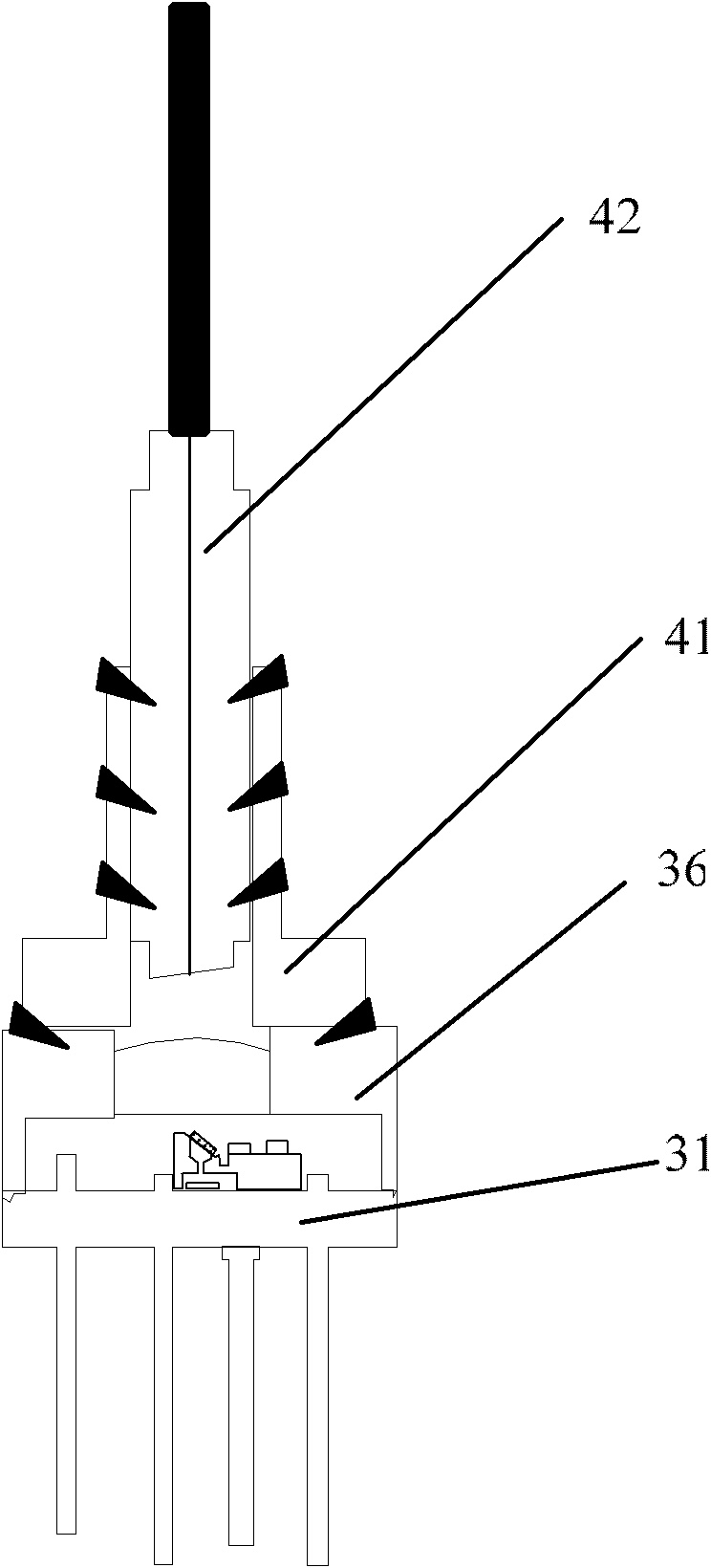

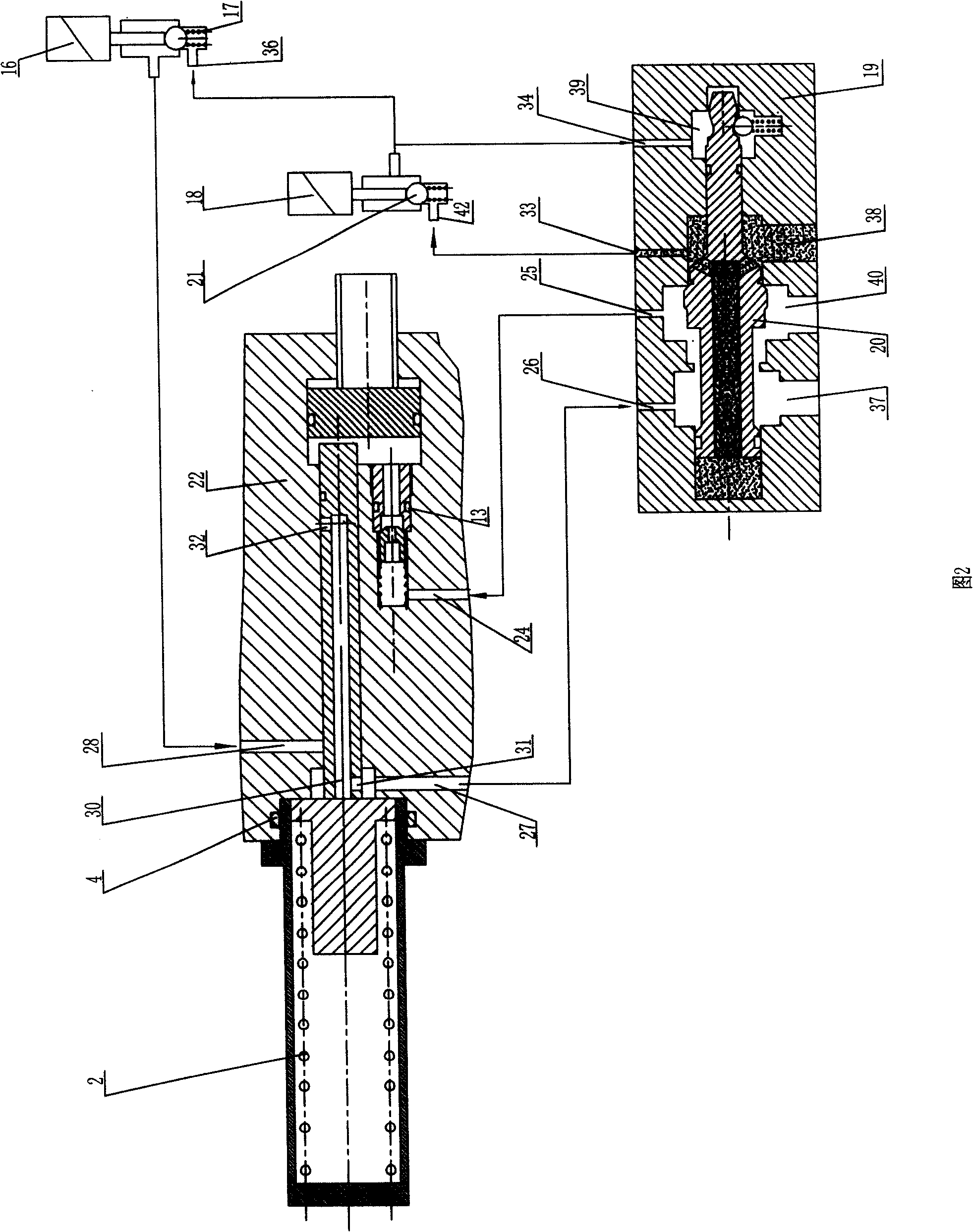

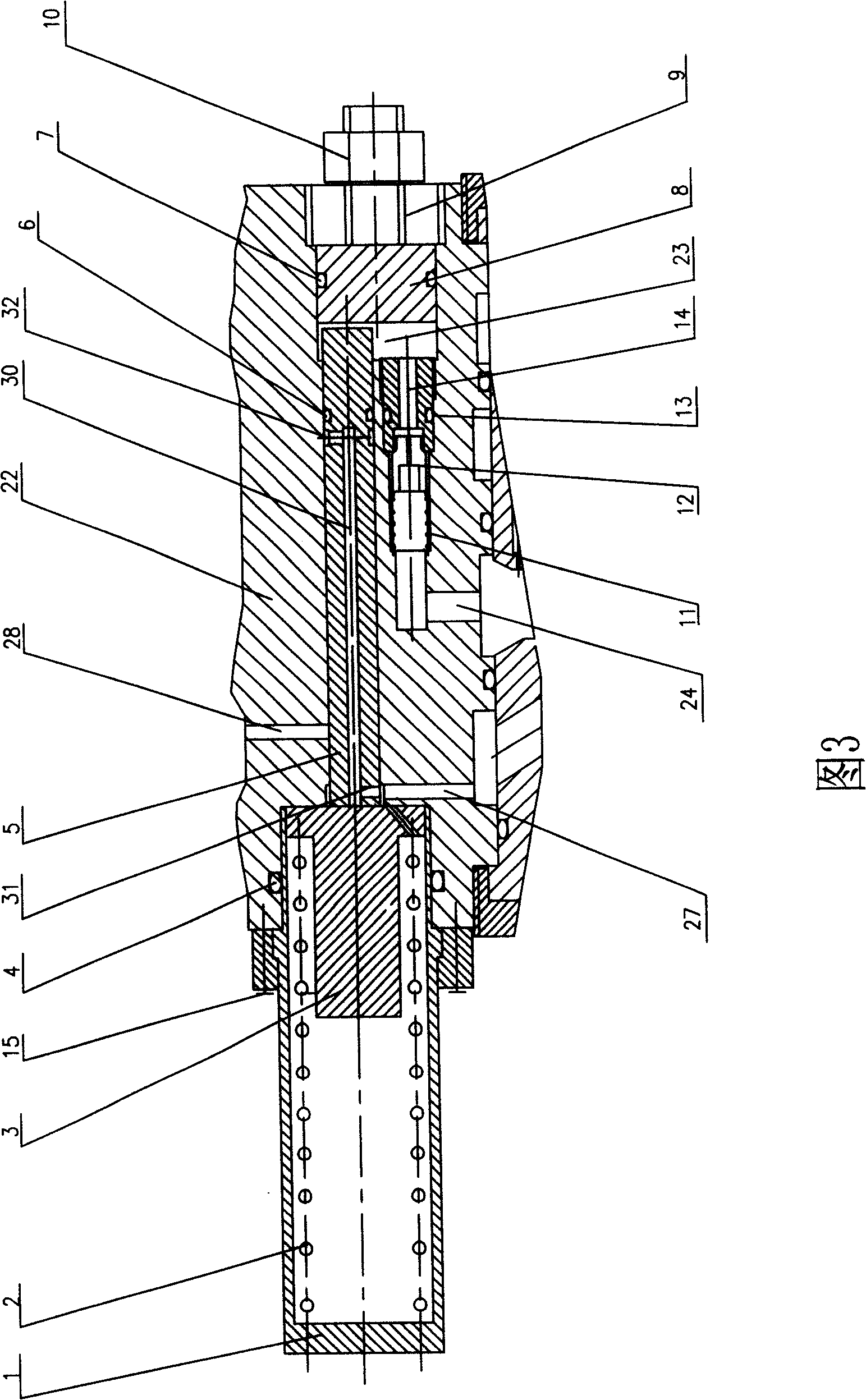

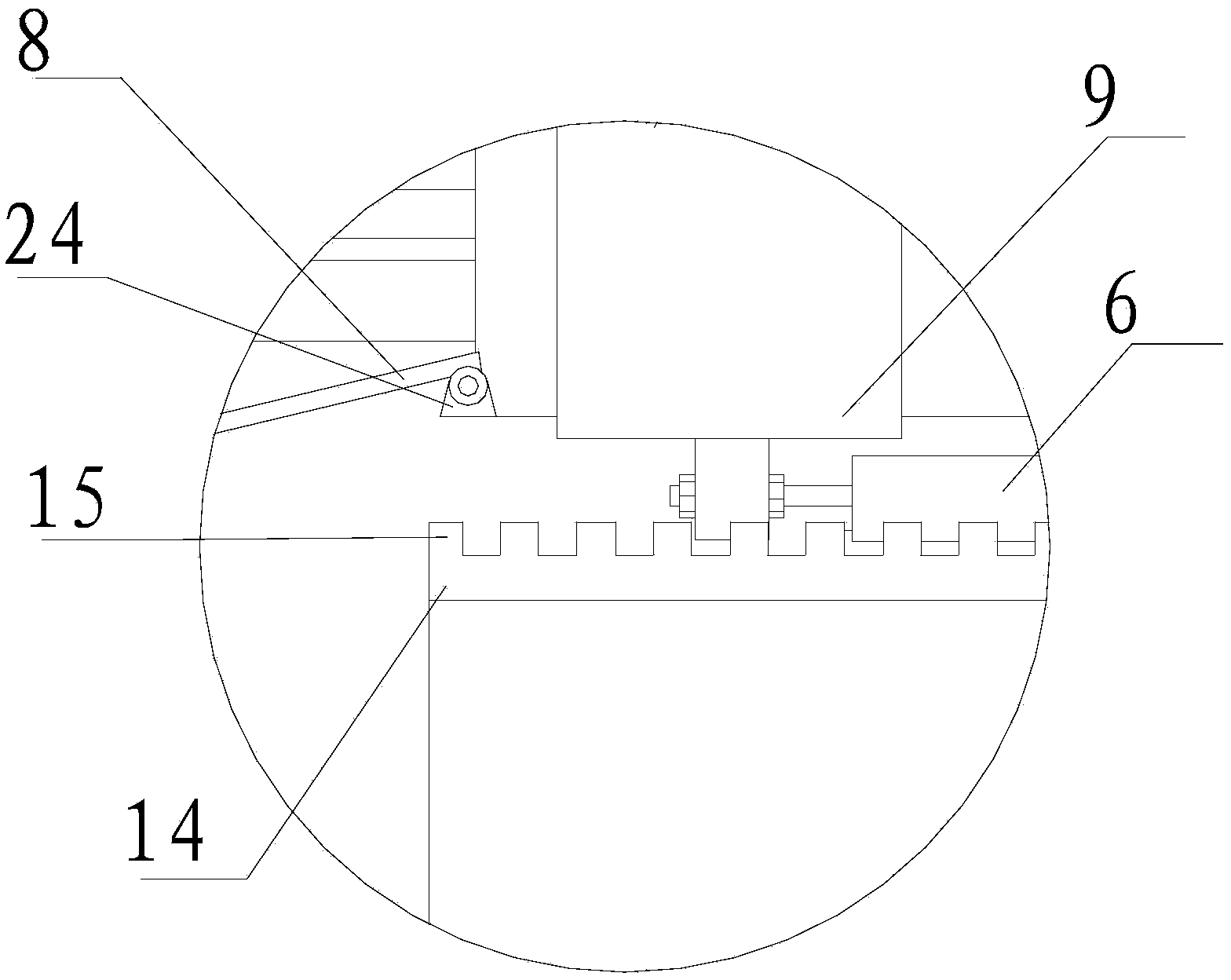

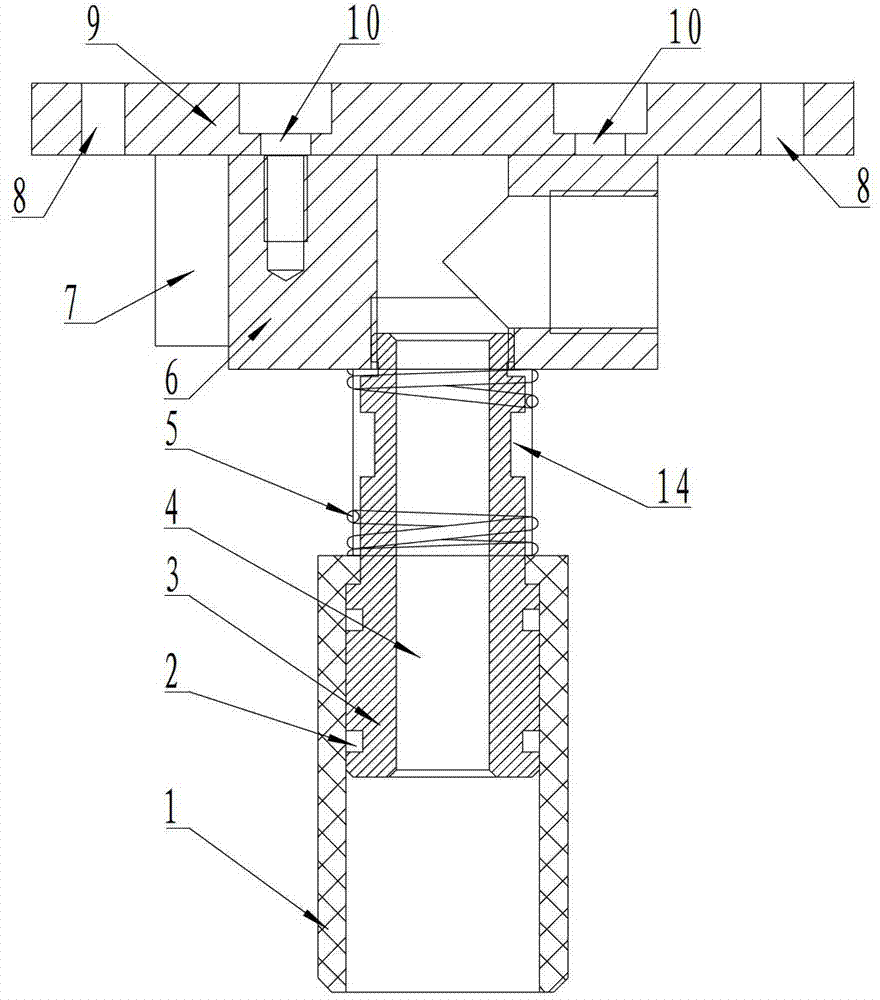

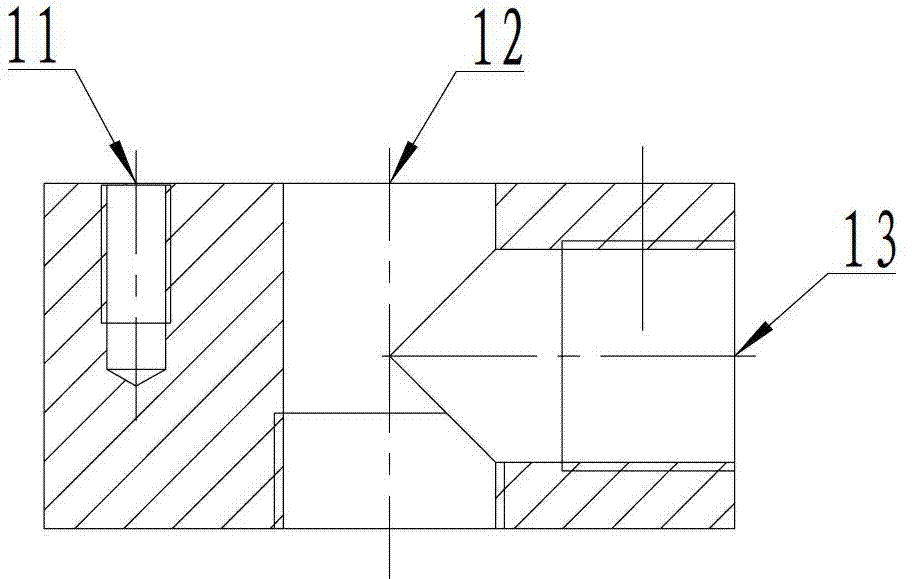

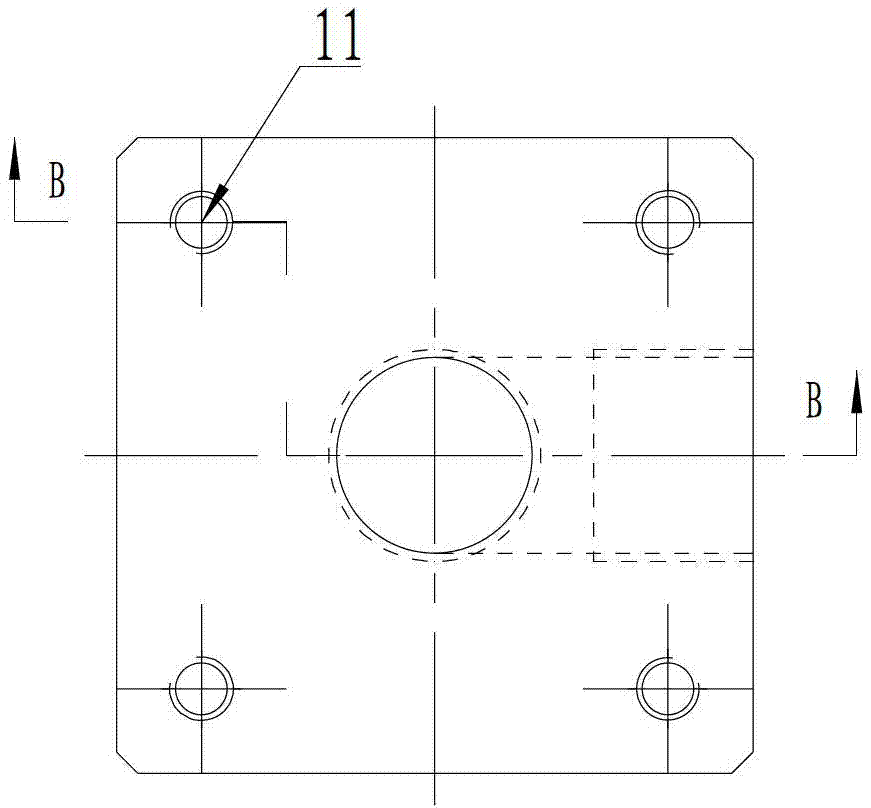

Stepwise magnetic force hoisting type reactor control rod driving mechanism

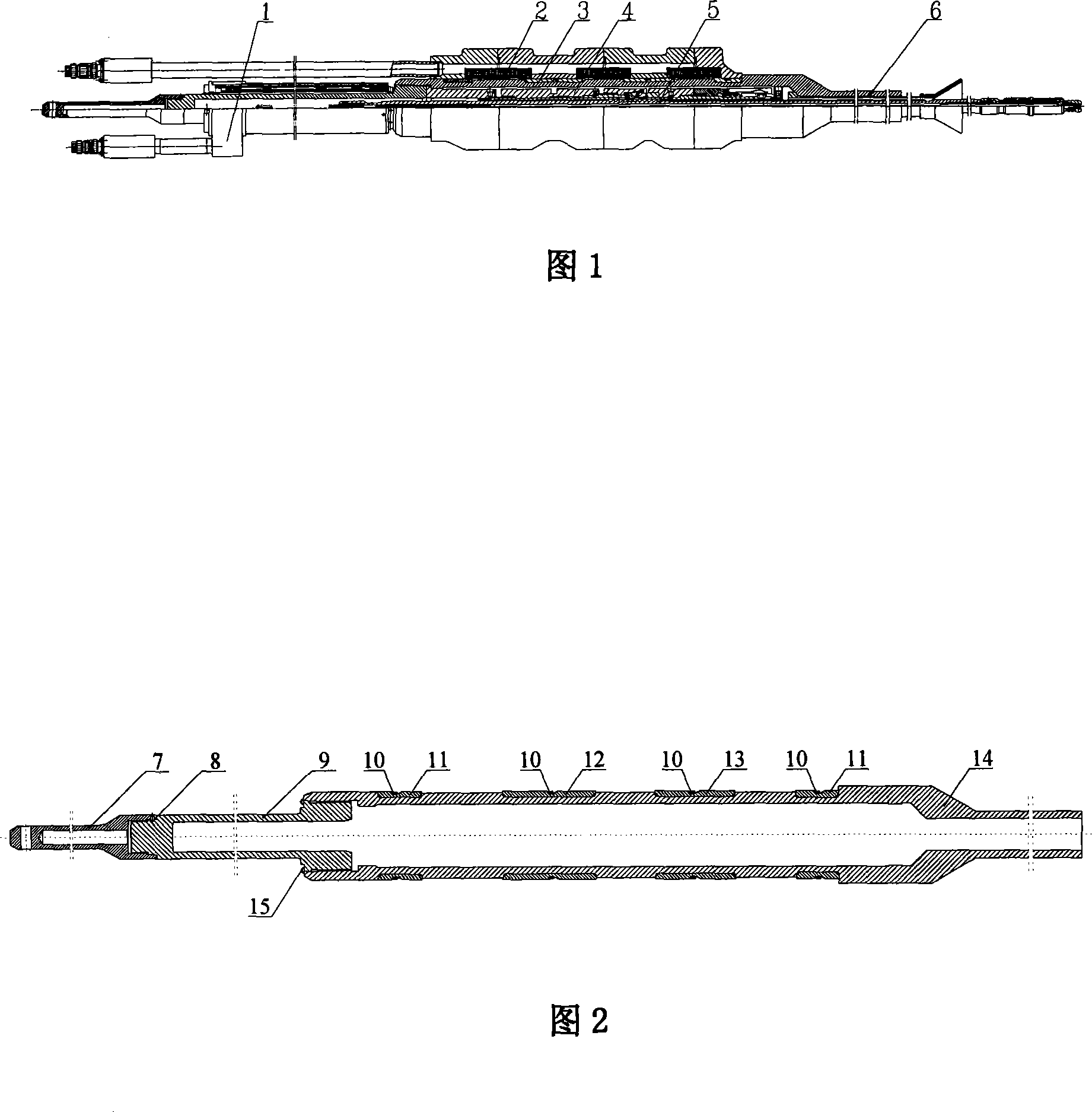

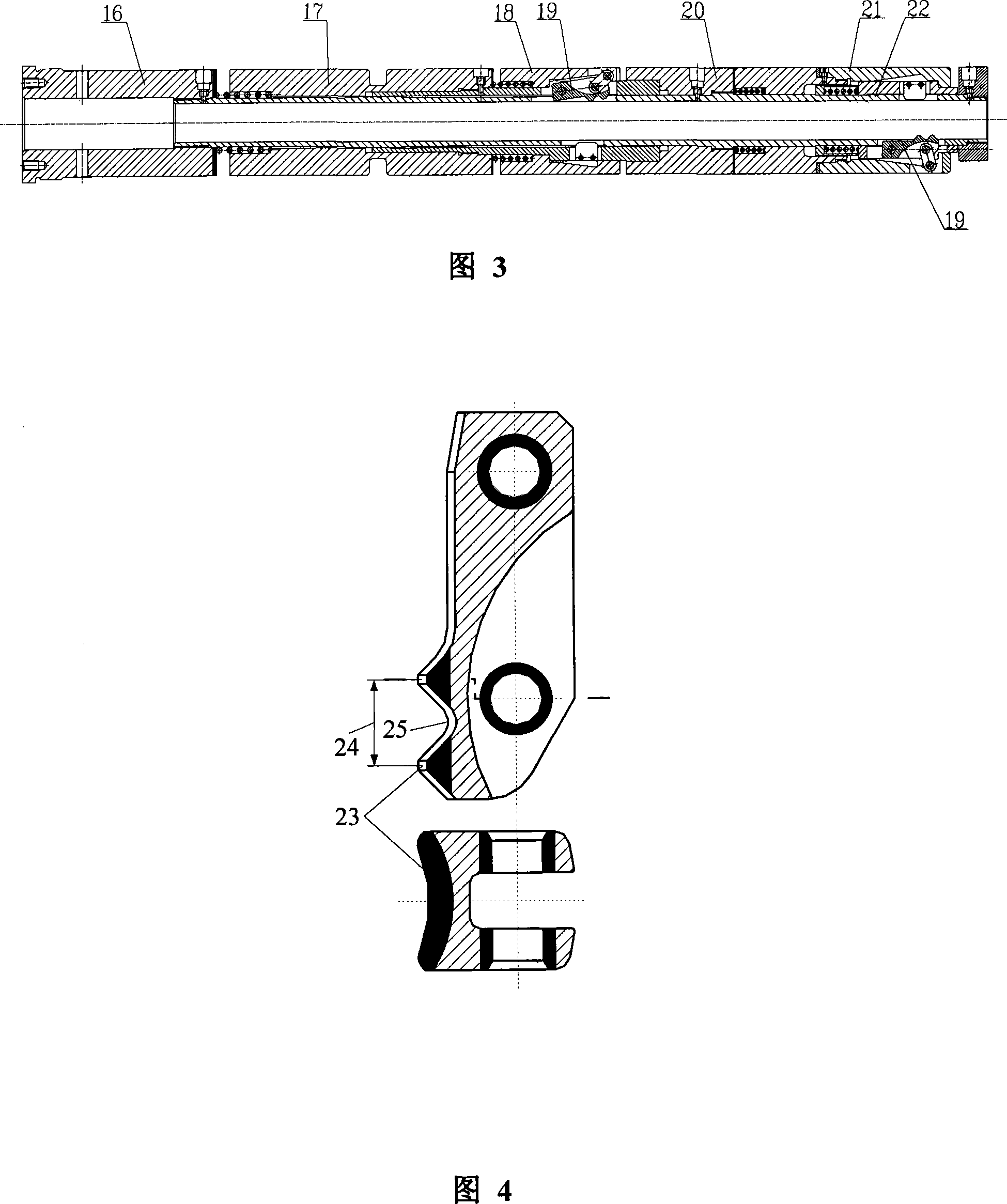

ActiveCN101178946AImprove wear lifeImprove wear resistanceNuclear energy generationNuclear reaction controlTube socketKnuckle

The invention provides a marching type and magnetic jacking reactor control rod drive mechanics, which comprises a rod position detector component, a coil component, a pressure shell component, a knuckle component, a driving rod component, a heatproof lagging component and the like. The whole mechanism is vertically mounted on a top cover of a reactor pressure vessel directly, wherein the pressure shell component consists of a hoisting connector, a travel sleeve and a hermetic case. The travel sleeve of the pressure shell component is an integral blind tube with a blocked upper end and the hermetic case is an integral structure composed of a tube socket of the driving mechanism on the top cover of the reactor pressure vessel, and the hermetic case. The knuckle component is composed of two identical knuckle teeth arranged side by side, the distance between the two knuckle teeth is equal to the teeth space of the driving rod component, and the two sides of the flute between the two knuckle teeth are of transitional circular arc shape. The invention greatly reduces the leakage possibility of the pressure shell of the reactor control rod drive mechanics, and greatly improves the wear resistance, the reliability and the service life of the reactor control rod drive mechanics.

Owner:SICHUAN HUADU NUCLEAR EQUIP MFR

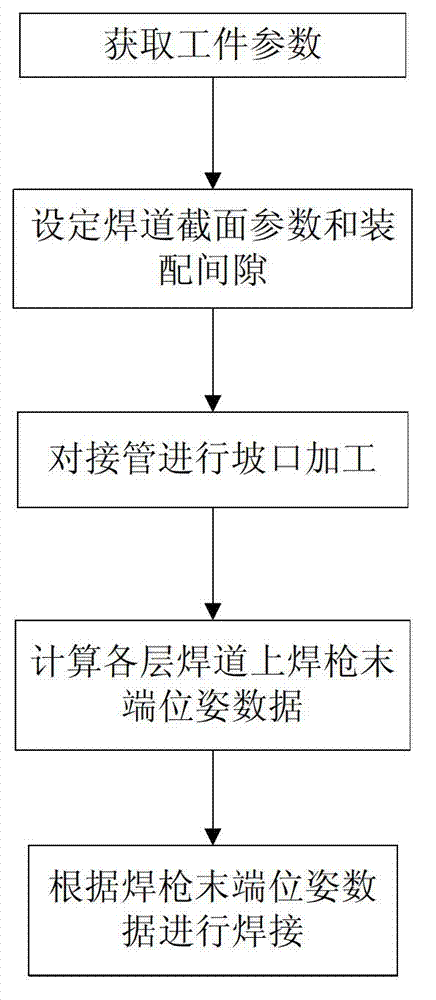

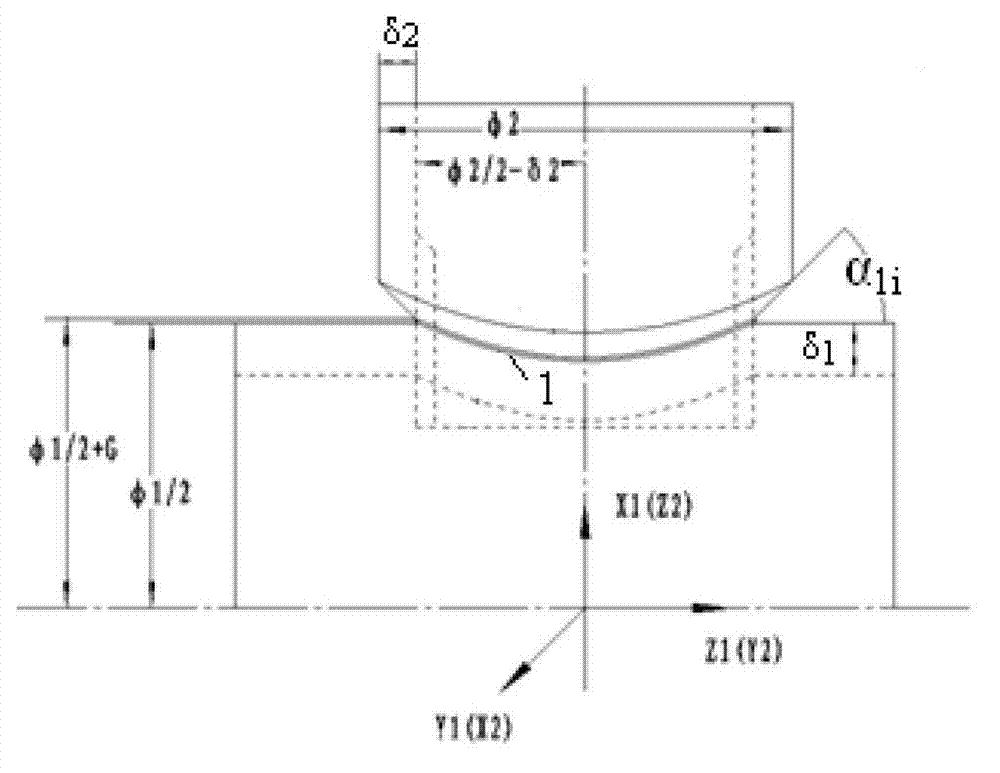

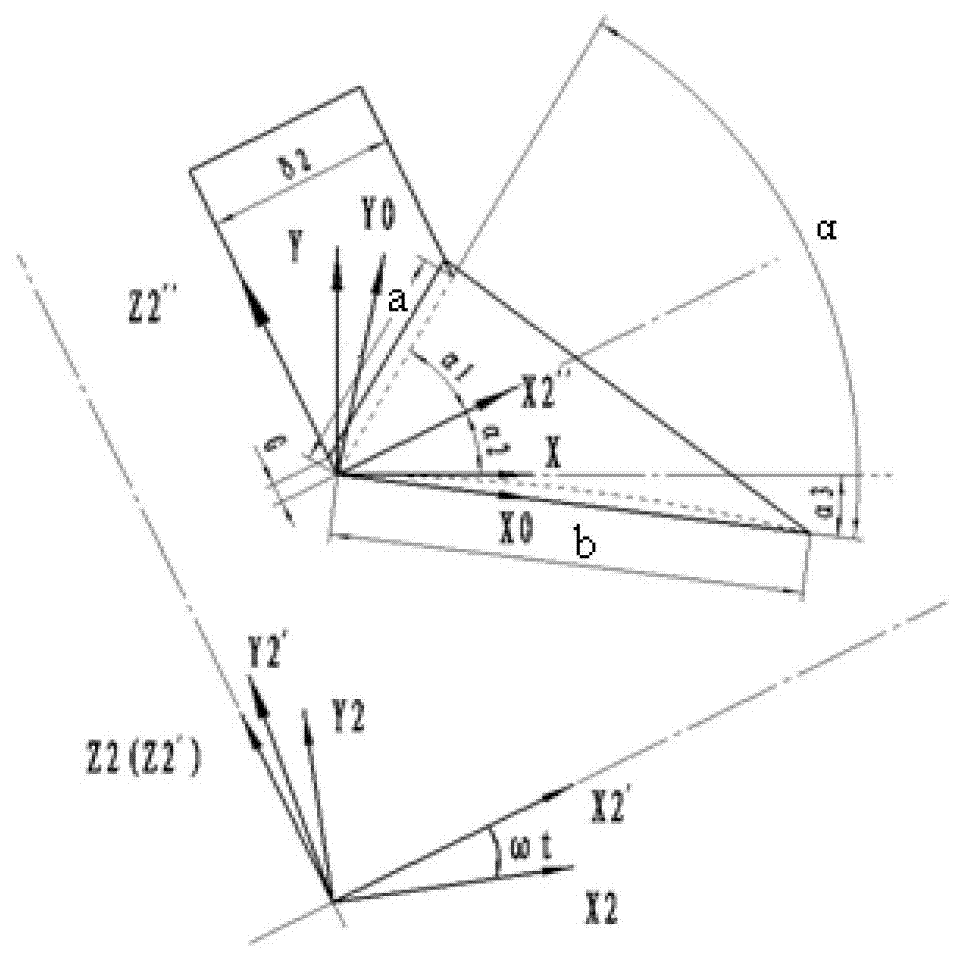

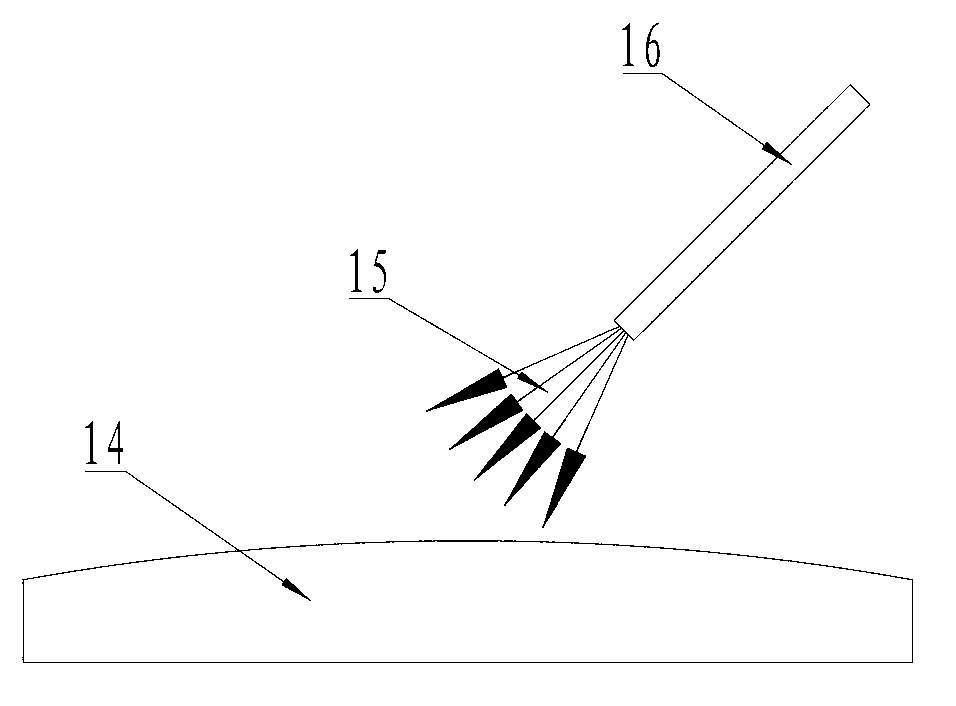

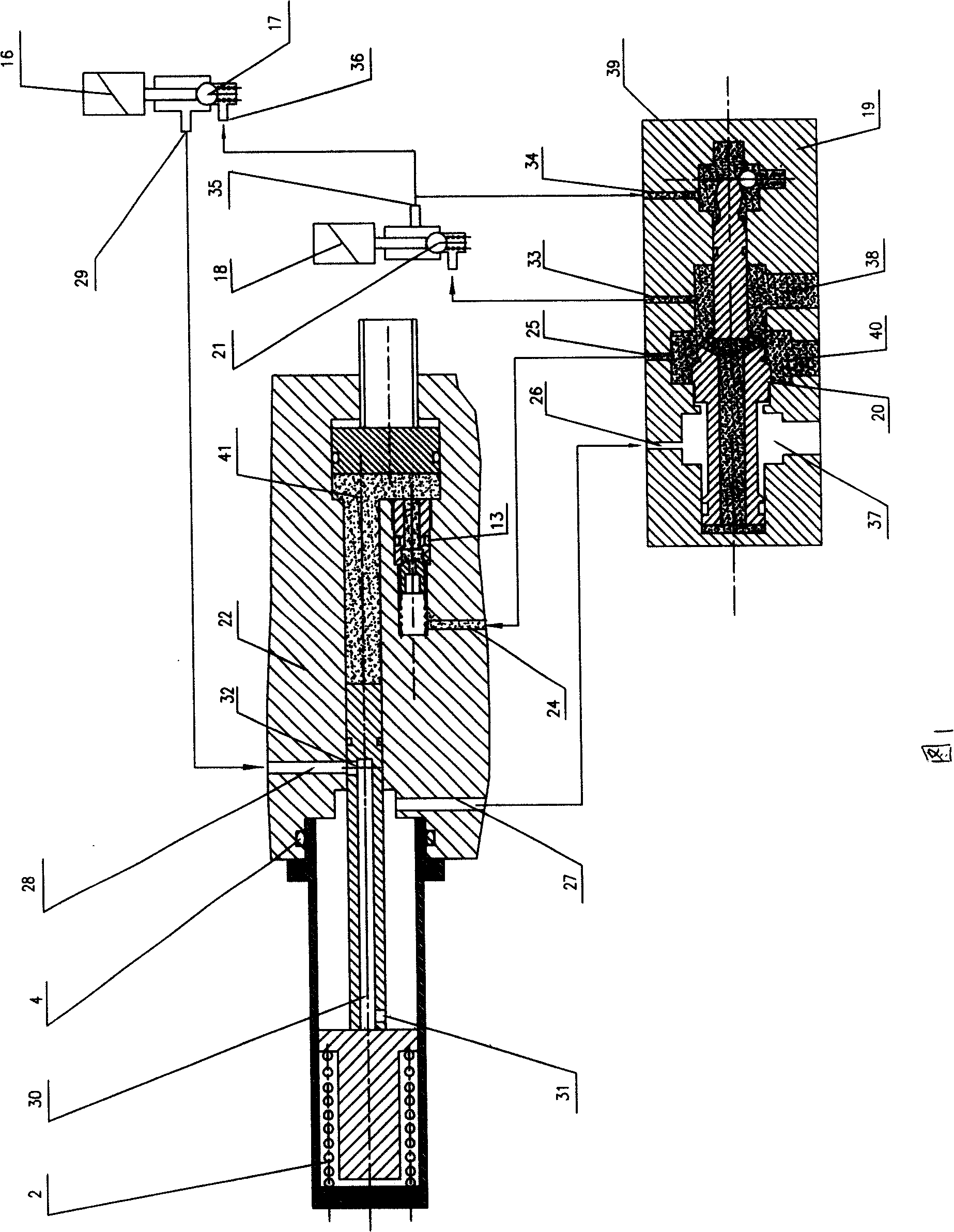

Saddle-shaped track automation welding method of collection box large tube socket

ActiveCN103111730ASolve automatic continuous weldingSuitable temperatureArc welding apparatusNumerical controlTube socket

The invention relates to a saddle-shaped track automation welding method of a collection box large tube socket. The saddle-shaped track automation welding method comprises a first step of acquiring tool parameters, a second step of setting weld pass section parameters and a fit-up gap G, a third step of edge preparation, wherein bevel angles of connecting tubes and female tube intersecting lines at different positions are determined according to a design principle of a uniform section bevel angle, connector portions of the connecting tubes are machined in a cutting mode, a fourth step of inputting the weld pass section parameters, the fit-up gap G, the tool parameters, the bevel angles and related technological parameters of planned adoptive welding technology into a numerical control welding system to calculate pose data of the tail end of a welding gun, and a fifth step of controlling the welding gun to continuously weld in a layer mode by the numerical control welding system according to the pose data. According to the saddle-shaped track automation welding method of the collection box large tube socket, the purpose of automatic, fast and continuous welding of the intersection line track under different pipe diameters is achieved, weld pass is arranged reasonably, connector quality is good, appearance is attractive, arrangement is ordered, and a technique is wide in application range.

Owner:WISE WELDING TECH & ENG

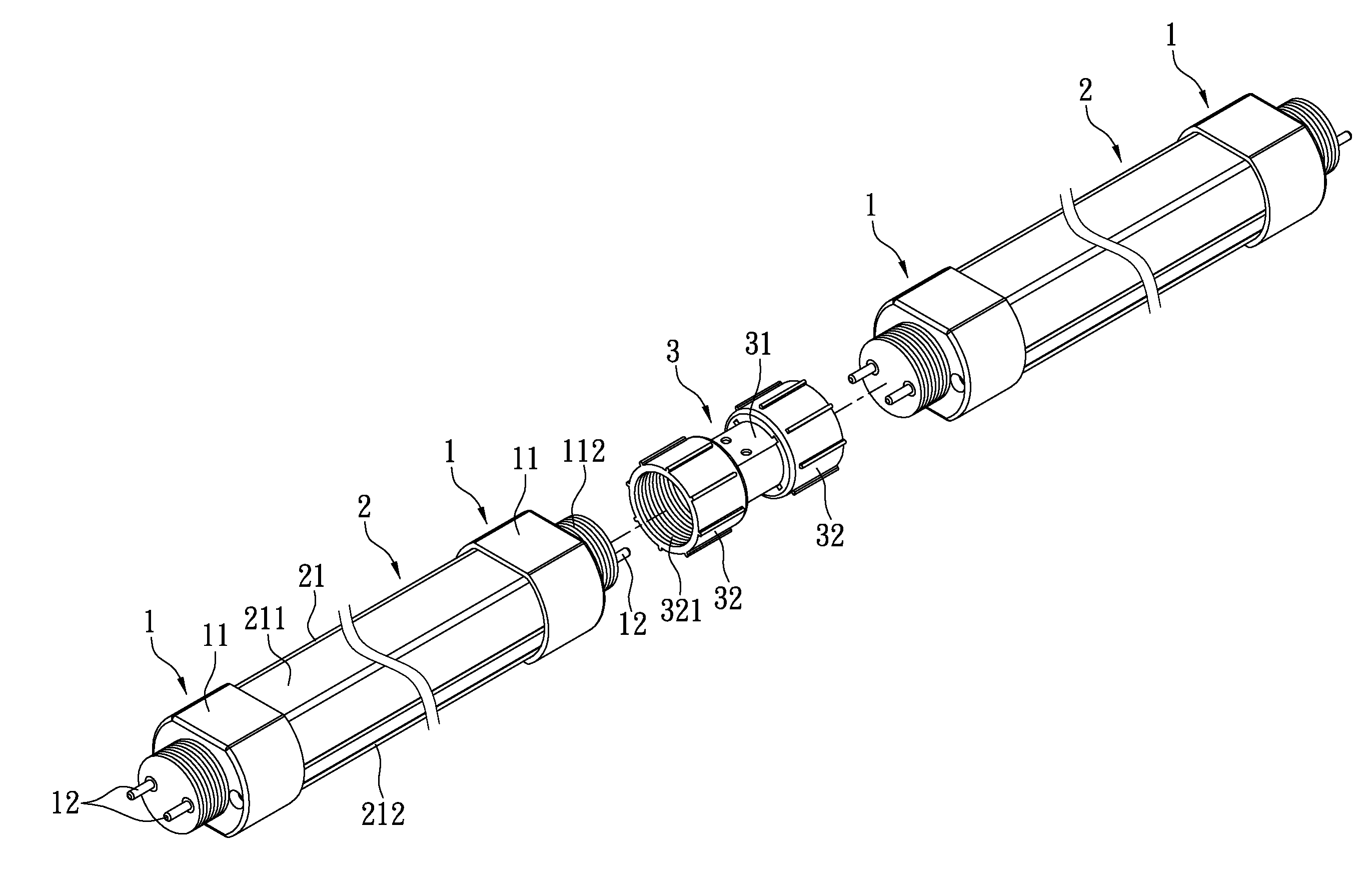

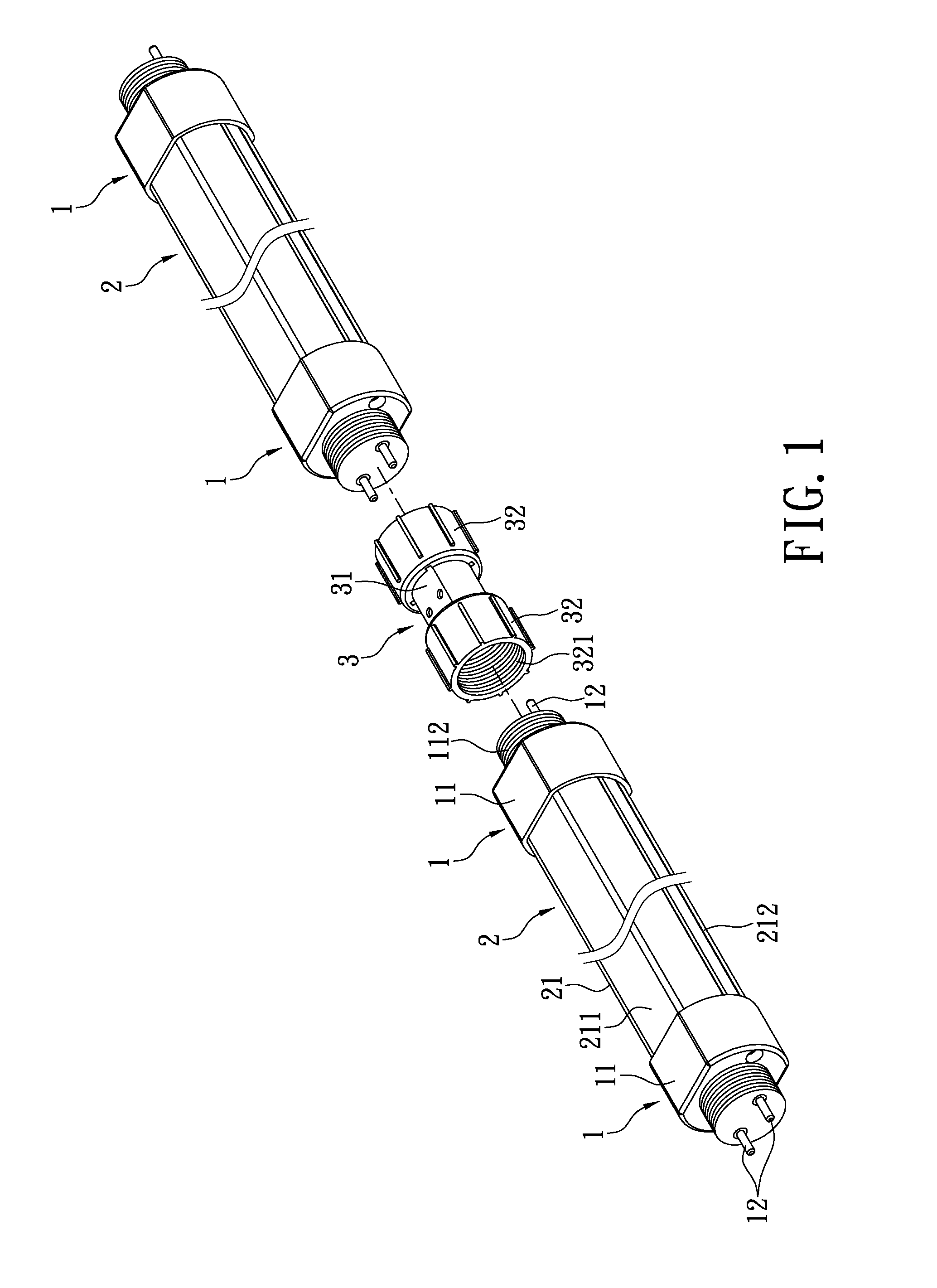

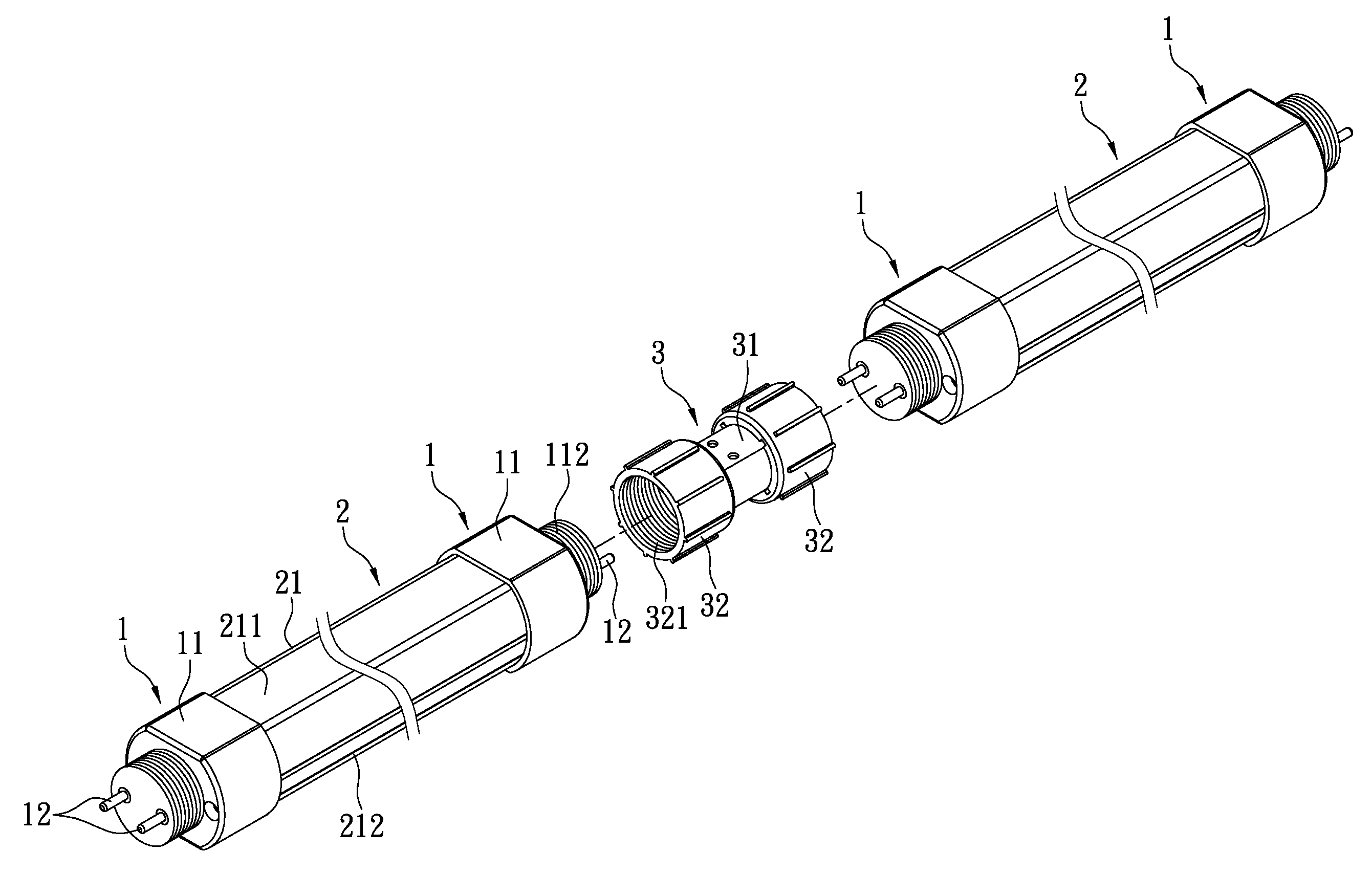

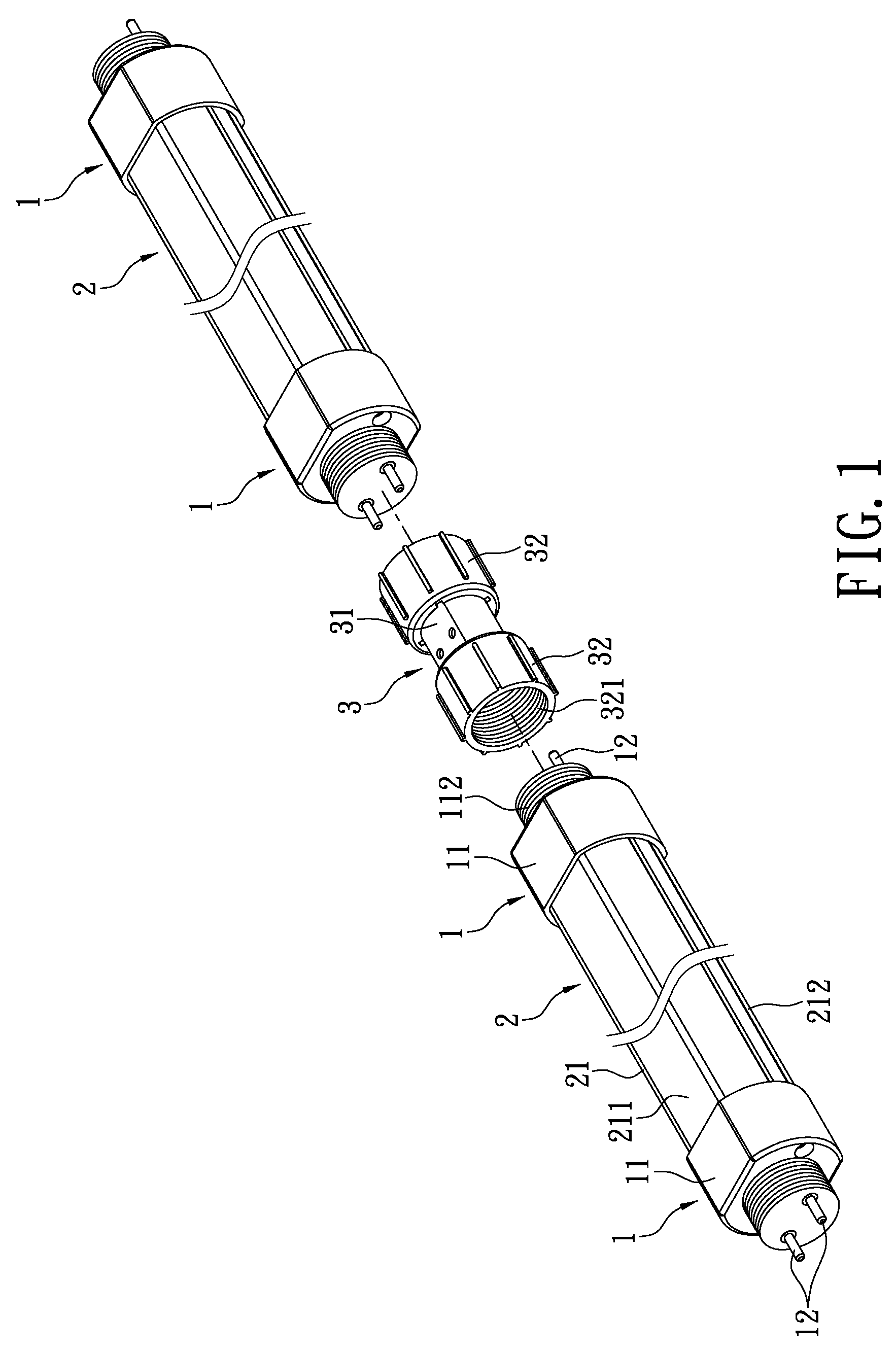

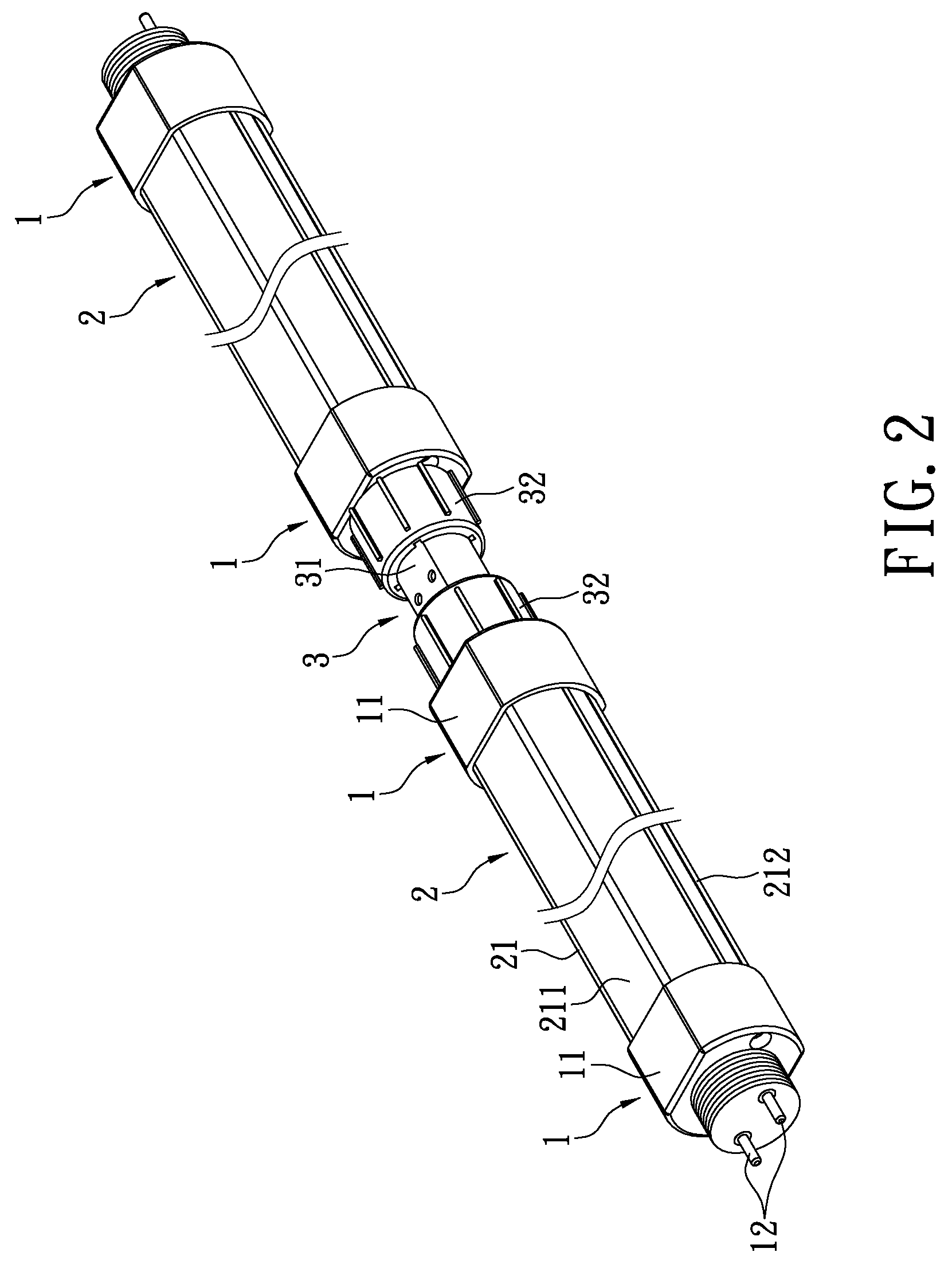

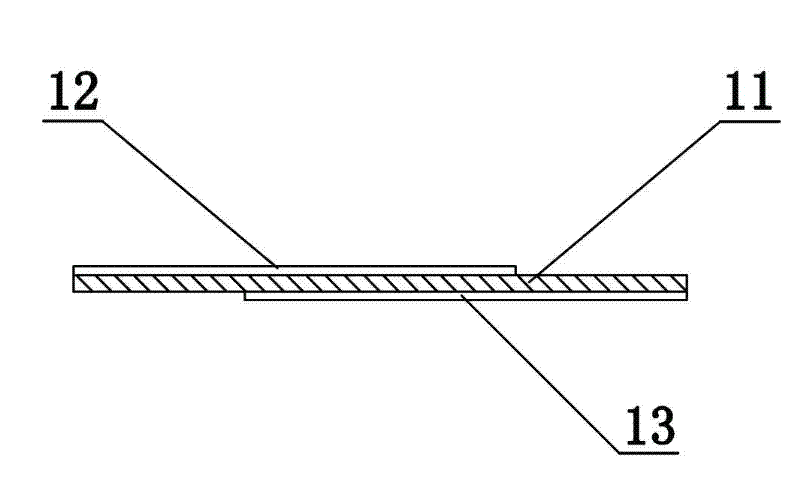

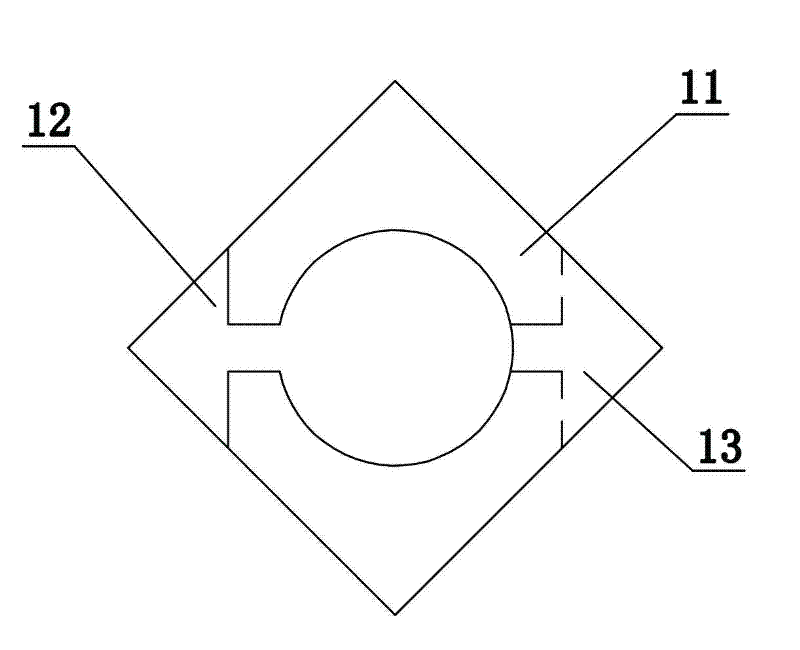

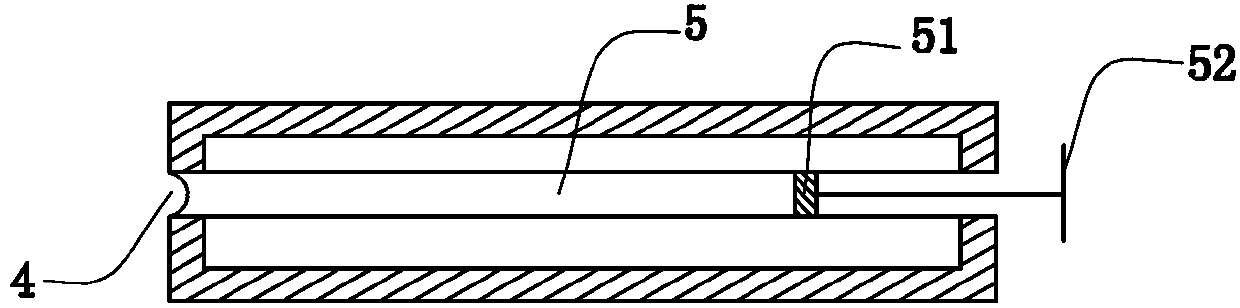

LED tube socket, adaptor and assembly thereof

InactiveUS20140071668A1Many connectionsReliable and fast connectionCoupling device connectionsLighting support devicesTube socketScrew thread

A Light Emitting Diode (LED) tube socket, an adaptor and an assembly thereof, which includes tow sockets capping either end of a LED tube. Each of the sockets has a socket main body, a pair of conductive terminals and a first threaded portion. The pair of the conductive terminals is disposed in the socket main body and electrically connecting a first LED assembly within the socket main body. The socket connects the adaptor via the threaded portions and the seal is watertight. Two or more LED tubes are connected thereby to satisfy a required length.

Owner:HIGH PERFECTION TECH

Miniature electrical ball and tube socket assembly with self-capturing multiple-contact-point coupling

InactiveUS20090068858A1Reduce mechanical stressImprove performanceElectrically conductive connectionsFinal product manufactureCouplingEngineering

A socket assembly for connecting an array of bulbous terminals such as balls wherein the female element is a miniature tube that has resilient prongs that grip the corresponding terminals with varying force during insertion and deletion. The tube is of resilient conductive material that has been sliced or helically partitioned into opposing prongs forming slots of a width that increases with axial distance from the end of the tube so as to allow the prongs of the connector to grip around the ball-like bulbous terminal and mechanically retain the terminal within the connector. The tubular element of the connector may be made by forming prongs in one or both ends of a tube by cuts of a width that increases with distance from the end of the tube.

Owner:CENTIPEDE SYST

Monolithic piezoelectric and ferroelectric crystal multifunctional dew point humidity sensor

This invention discloses a single disk piezoelectricity electrical transistor multi-function dew-point humidity sensor, which comprises the following: sensor outer shell with Kefa tube shell 1 and Kefa tube socket 8; piezoelectricity transistor sensitive element 6 fixed inside the sensor shell; semi-conductive cooling device 7 of the outer single machine control and outer interface legs of the Kefa tube socket 8. It realizes the cooling and heat feedback control, sensitive characteristics compensation and adjusting signals and conversion, which improve the accuracy, resolution rate and dynamic range and pollution status identification of the sensors.

Owner:王世光 +1

LED tube socket, adaptor and assembly thereof

InactiveUS9004716B2Many connectionsReliable and fast connectionCoupling device connectionsPoint-like light sourceTube socketLED lamp

A Light Emitting Diode (LED) tube socket, an adaptor and an assembly thereof, which includes tow sockets capping either end of a LED tube. Each of the sockets has a socket main body, a pair of conductive terminals and a first threaded portion. The pair of the conductive terminals is disposed in the socket main body and electrically connecting a first LED assembly within the socket main body. The socket connects the adaptor via the threaded portions and the seal is watertight. Two or more LED tubes are connected thereby to satisfy a required length.

Owner:HIGH PERFECTION TECH

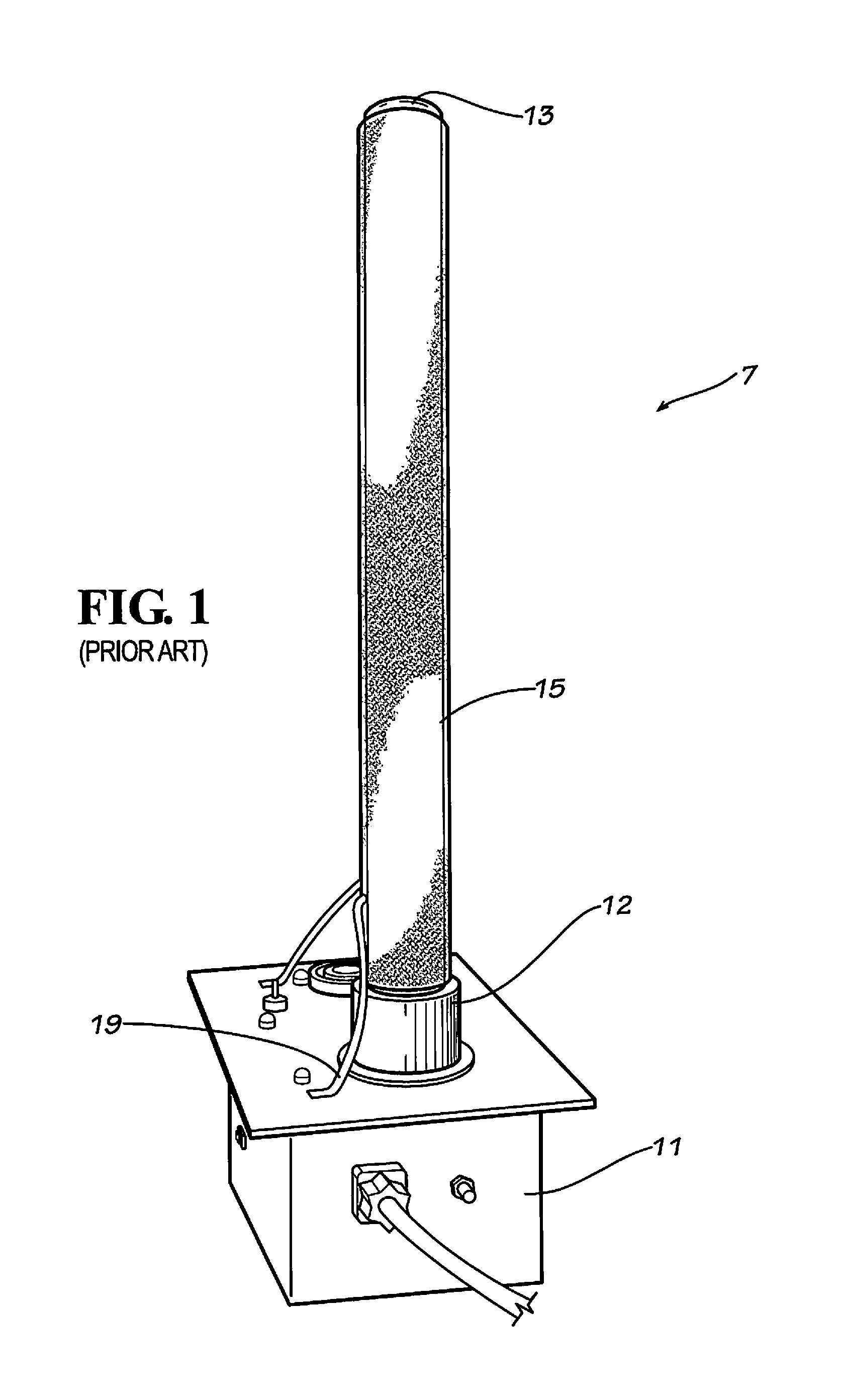

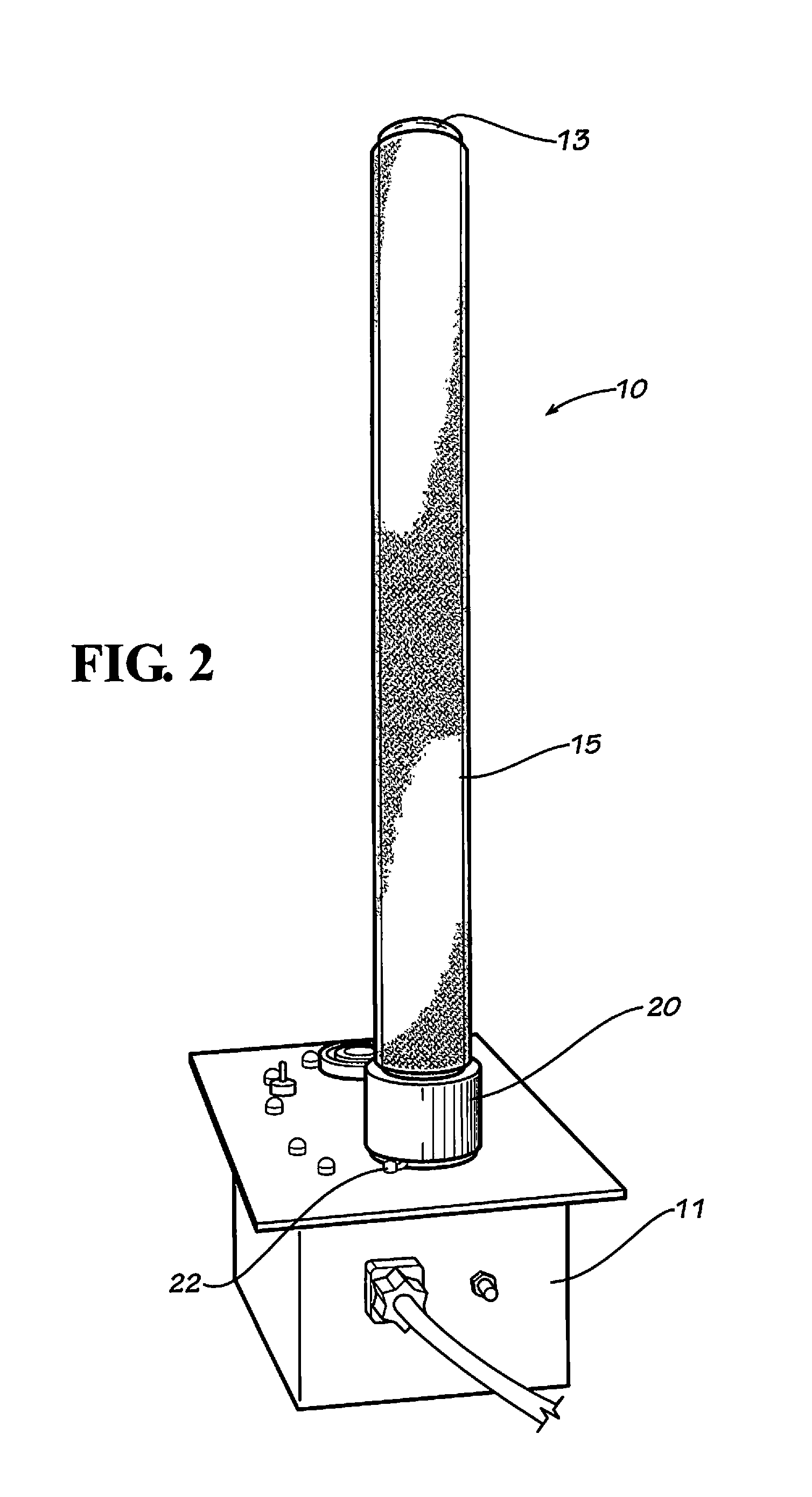

Bi-polar ionization tube base and tube socket

InactiveUS20120154973A1Eliminate contactElectrode carrying meansElectrode constructionsAir treatmentEngineering

The present invention provides an air treatment apparatus. The air treatment apparatus comprises a housing electrically connectable to a voltage source and generating a high voltage and a glass tube. The air treatment apparatus further comprises a tube base electrically connecting internally high voltage to an inner electrode within the glass tube and electrically connected internally an outer electrode surrounding the glass tube and a tube socket electrically connected internally to the outer electrode and electrically connected to a grounding pad, wherein the grounding pad is mechanically connectable to the housing and electrically connectable to the housing.

Owner:BIOCLIMATIC AIR SYST

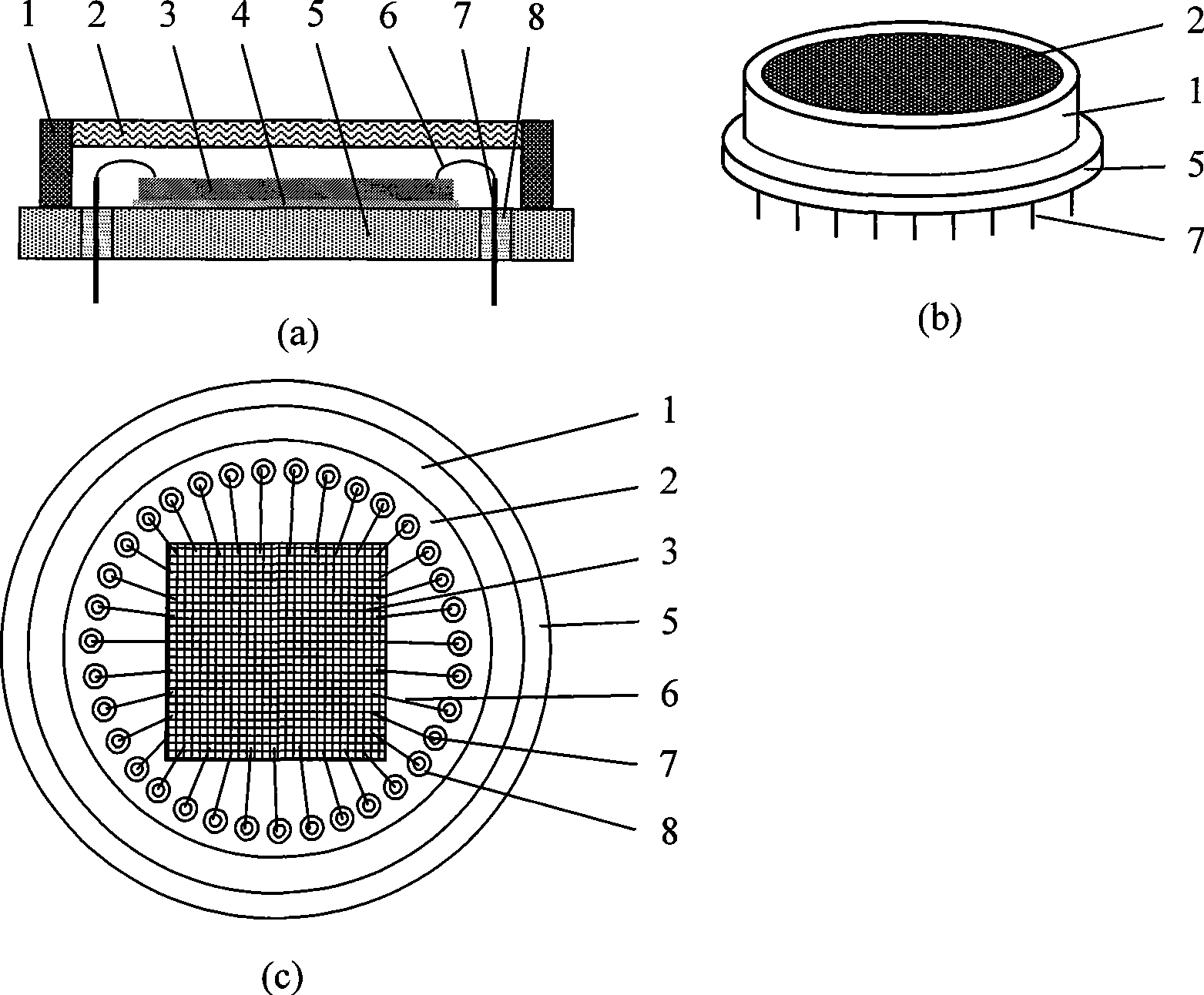

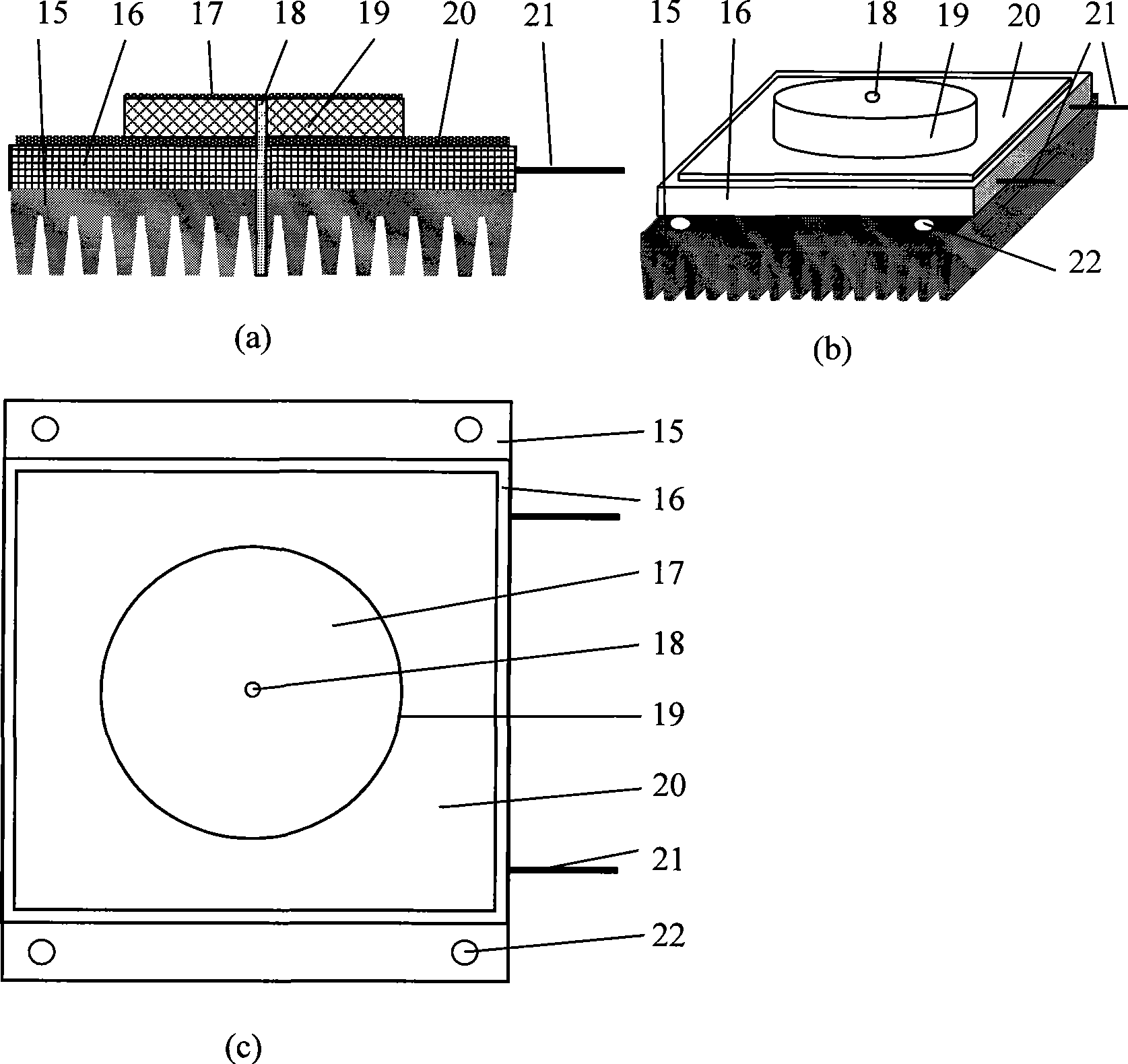

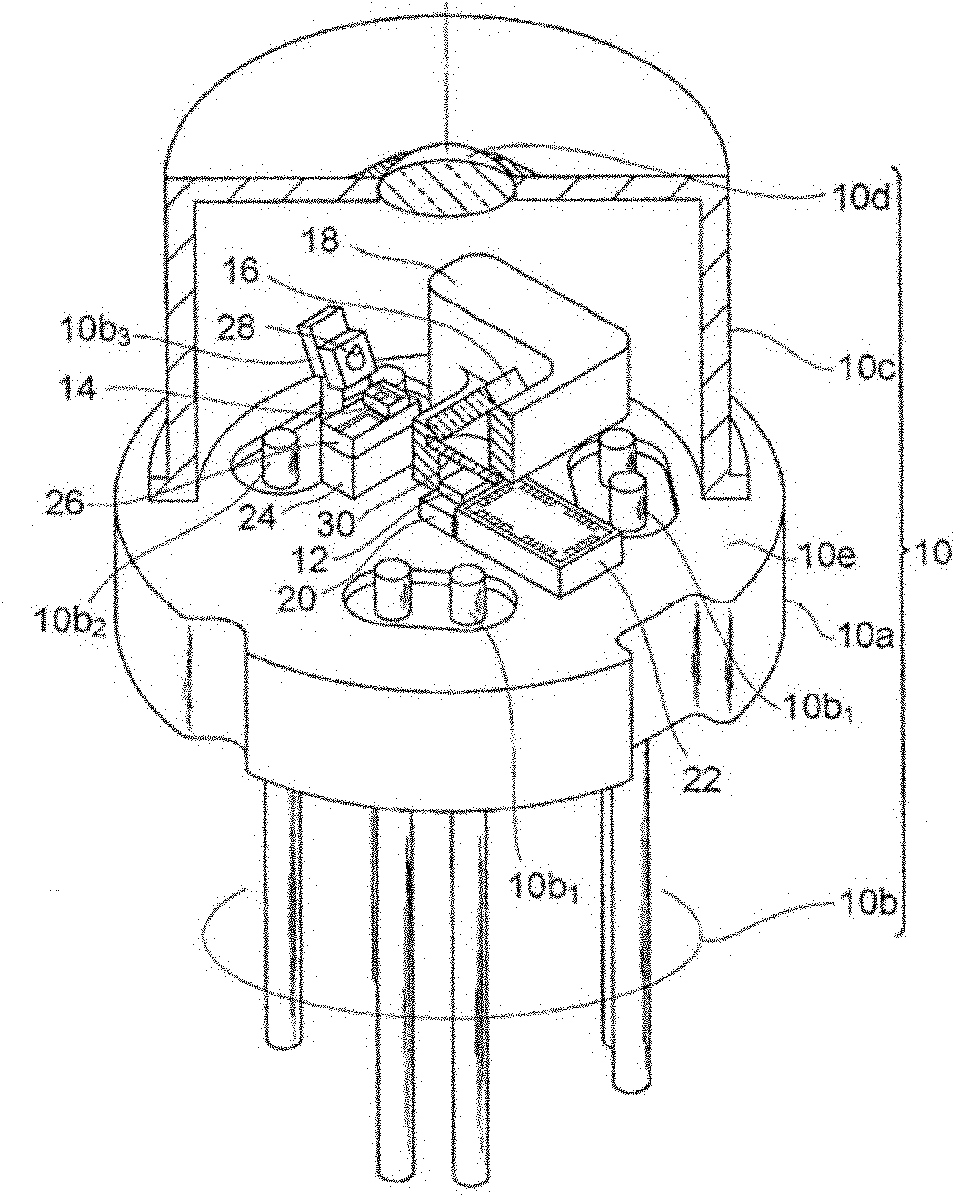

Pyroelectric infrared-sensitive element and pyroelectric infrared detector

InactiveCN102359821AImprove anti-interference abilityResolution timePyrometry using electric radation detectorsLithiumElectrical resistance and conductance

The invention provides a pyroelectric infrared-sensitive element and a pyroelectric infrared detector. The pyroelectric infrared-sensitive element has the following three-layer structure: an upper electrode, a lithium tantalite thin film layer and a lower electrode; meanwhile, the upper electrode can also be utilized as an absorbing layer; therefore, problems that extended response time and reduced sensitivity in the prior art can be solved, wherein the problems are caused by increasing of the thickness of a sensitive element. In addition, the pyroelectric infrared detector comprises: a pyroelectric infrared-sensitive element; a pyroelectric compensating sensitive element; a preamplifier field effect transistor; an impedance matching resistance; a tube cap; an infrared filtering window, which is arranged at the top of the tube cap; a tube socket, which is arranged at the bottom of the tube cap; three tube pins, which are arranged on the tube socket; a circuit board, which is packaged in the tube cap; and two support bodies, which are installed on the circuit board. According to the invention, the pyroelectric infrared-sensitive element has advantages of simple structure, short response time, high sensitivity and strong anti-interference capability and the like.

Owner:郑州炜盛电子科技有限公司

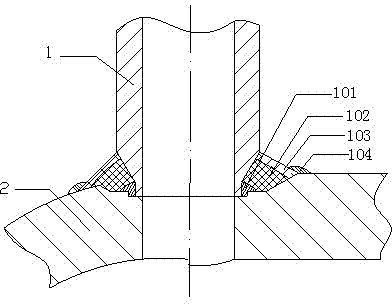

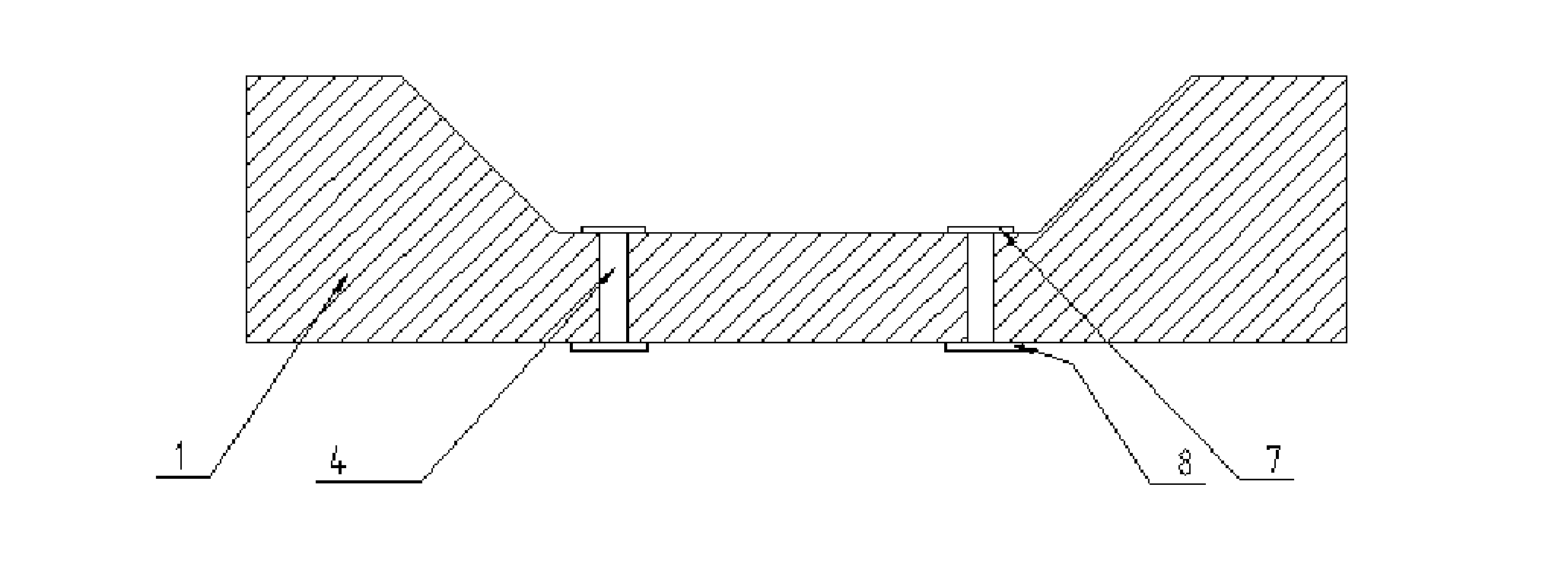

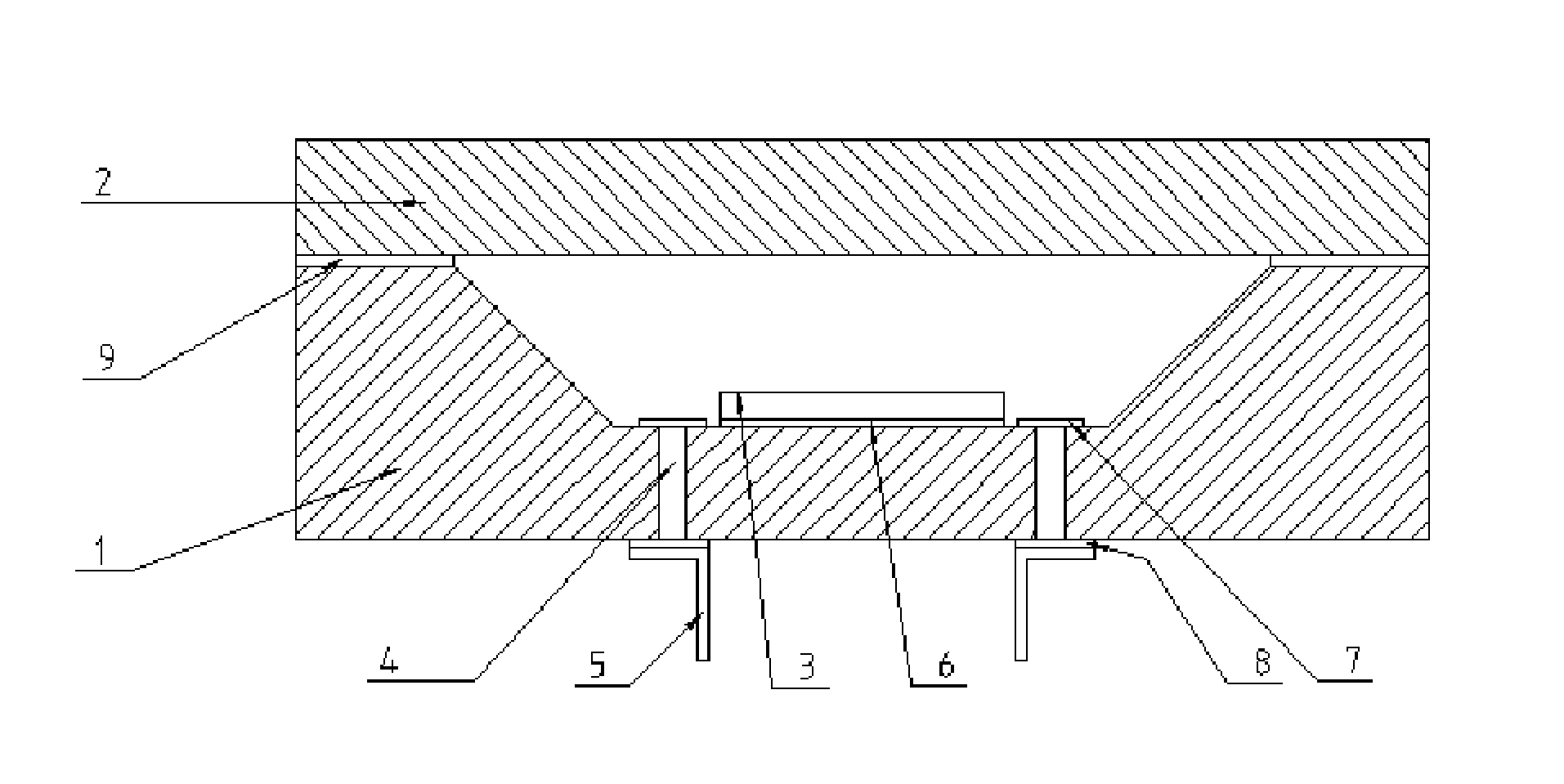

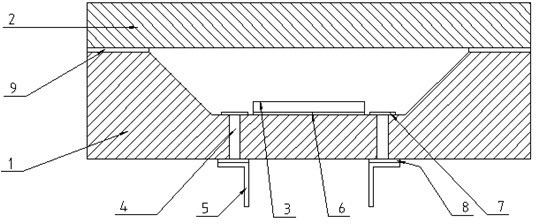

Tube socket fillet weld reheat crack prevention method

ActiveCN103170712ASolve the problem of reheat crackingSimple processArc welding apparatusFillet weldStructural engineering

The invention discloses a tube socket fillet weld reheat crack prevention method which comprises the following steps: first step, installing and welding a tube socket fillet weld; second step, grinding and cleaning the tube socket fillet weld and figuring weld toe; third step, welding a pressure weld pass of the weld toe of the tube socket fillet weld, wherein the welding method of the pressure weld pass is manual tungsten electrode argon-arc welding or welding rod electric-arc welding; fourth step, grinding or machining to eliminate the pressure weld pass of the weld toe, and enabling weld metal and a tube body to smoothly transit; fifth step, grinding and cleaning the test surface of the tube socket fillet weld, and carrying out a 100% nondestructive test; sixth step, after the100% nondestructive test is qualified, carrying out a post-weld heat treatment; seventh step, grinding or polishing the tube socket fillet weld and carrying out a 100% nondestructive review. The tube socket fillet weld reheat crack prevention method is simple in whole technical process, convenient to produce and carry out and good in application effect. The socket fillet weld reheat crack prevention method effectively solves the problem of thick-wall 12 Cr1MoV header tube socket fillet weld reheat crack, ensures production cycles and quality of products and reduces economic losses.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

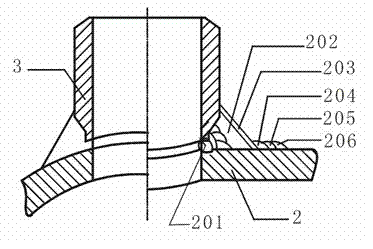

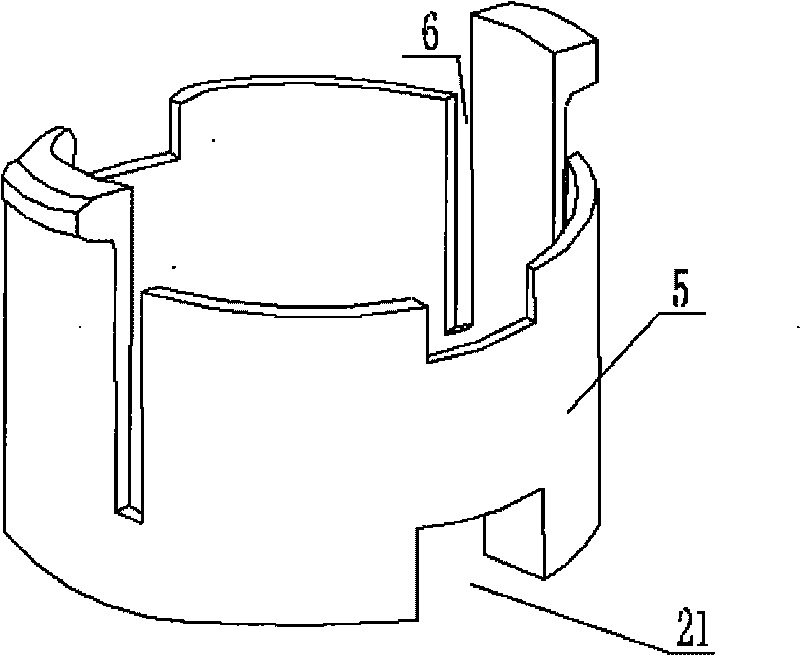

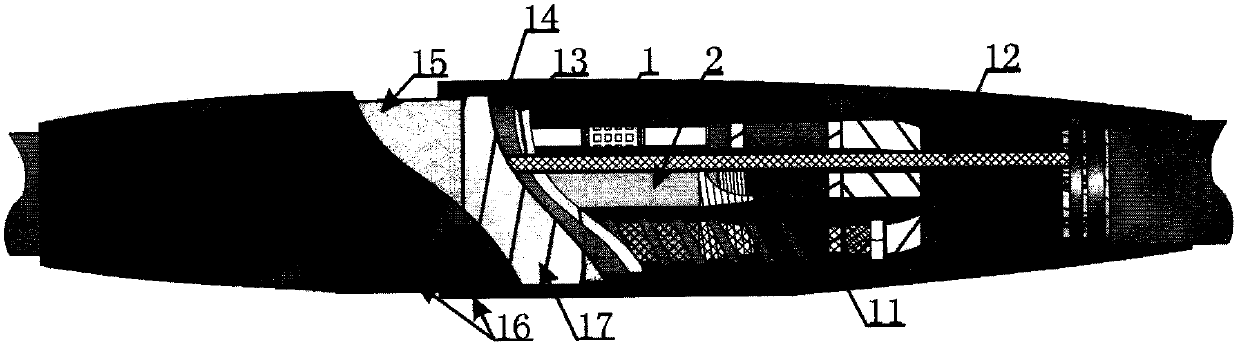

Quick detachable joint of nuclear fuel assembly

ActiveCN101727993ASimple structureAccurate and reliable positioningNuclear energy generationFuel element assembliesMaintainabilityMan-hour

The invention belongs to a component of a locking structure of a nuclear fuel assembly, particularly relates to a joint of an upper tube socket of a nuclear fuel assembly. The invention comprises an upper tube socket and a joint positioned in the upper tube socket, wherein a convex shoulder, a convex lug and a boss are arranged on the joint, a locking ring with a cylindrical hollow structure is also installed in the upper tube socket, the lower end of the locking ring is an inwards convex step, the upper end of the locking ring is provided with an outwards convex component which is matched with a mounting groove at the upper end of the upper tube socket, and the step of the locking ring is clamped in a groove formed between a convex tongue and the convex lug on the joint. Compared with the detachable upper tube socket of the domestic traditional nuclear fuel assembly, the structure is simple, the positioning is accurate and firm, a loose component can not be generated in the processes of disassembly and assembly, and the safety and the reliability are higher. The invention does not have spare parts, is convenient and quick for removing and reassembling the upper tube socket, saves the man-hour and has favorable maintainability.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

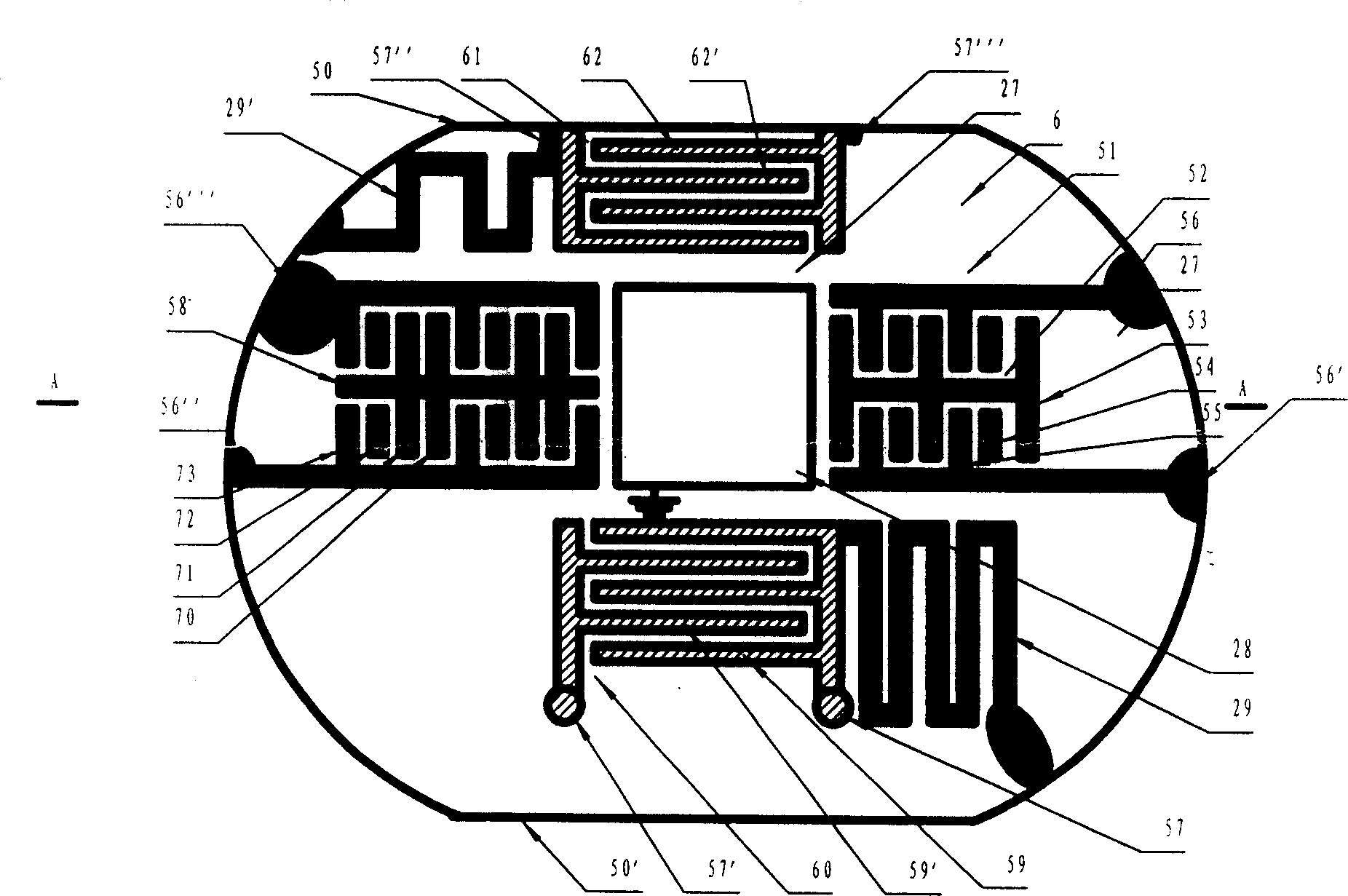

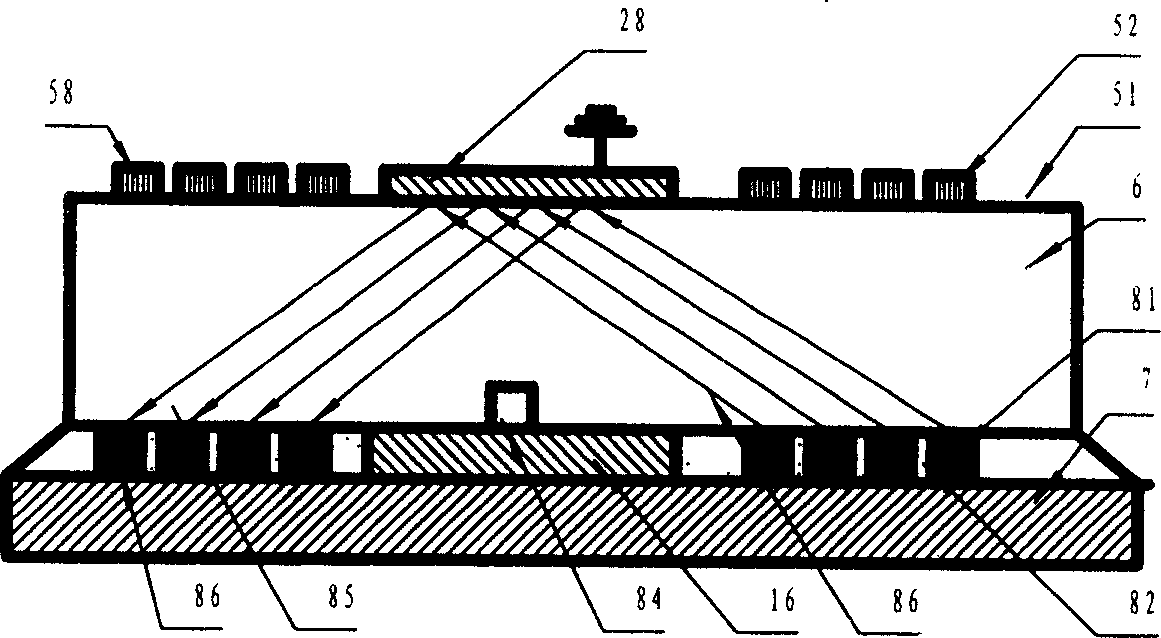

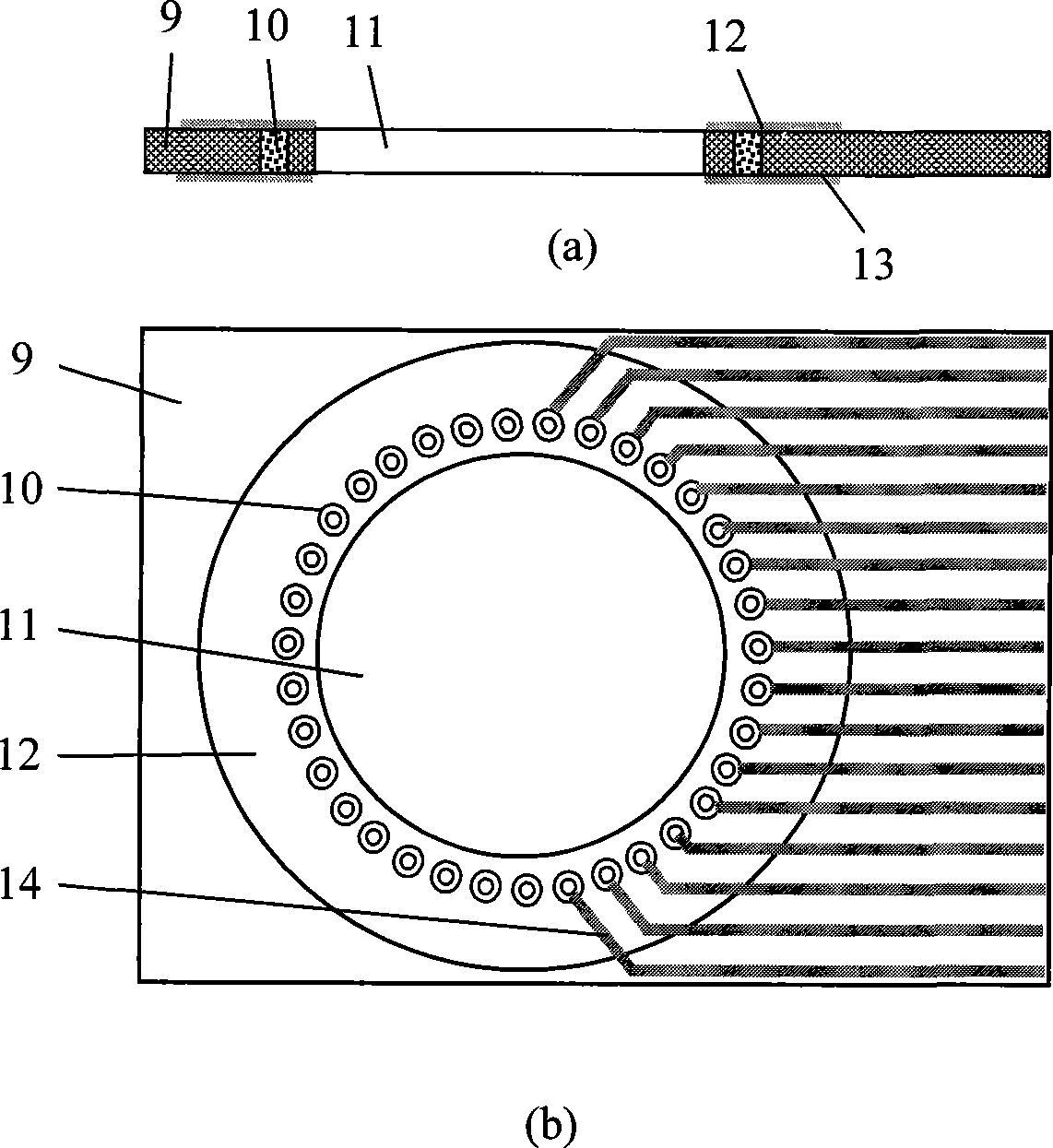

Uncooled array type infrared image sensor

InactiveCN101478634ADissipate quicklyHigh sensitivityTelevision system detailsTelevision system scanning detailsElectrical conductorMetallic materials

The present invention discloses a non-refrigeration array type infrared image sensor and belongs to the technical field of infrared image sensor preparation. The sensor comprises a tubular infrared image sensor structure which is vacuum-encapsulated. The tubular infrared image sensor structure comprises a sensor chip, a tube cap and a tube socket. The sensor chip is adhibited on the tube socket. The tube cap and tube socket are integrated through vacuum-encapsulation. The pressure welding wire of sensor chip is leaded-out through the wire lead of tube socket. The tube socket adopts metal material. A semiconductor chilling plate is fixedly connected below the tube socket. The semiconductor chilling plate is inserted in the electrode leading-out printed circuit board which is permanently connected with the tube socket. An insulation film is provided at the joint. The lead wire on the tube socket is connected with the electrode leading-out printed circuit board. The invention uses the semiconductor chilling plate as a cold source and can guarantee the quick dissipation of infrared energy absorbed by the infrared image sensor. The sensitivity of non-refrigeration array type infrared image sensor is increased.

Owner:COMMUNICATION UNIVERSITY OF CHINA +1

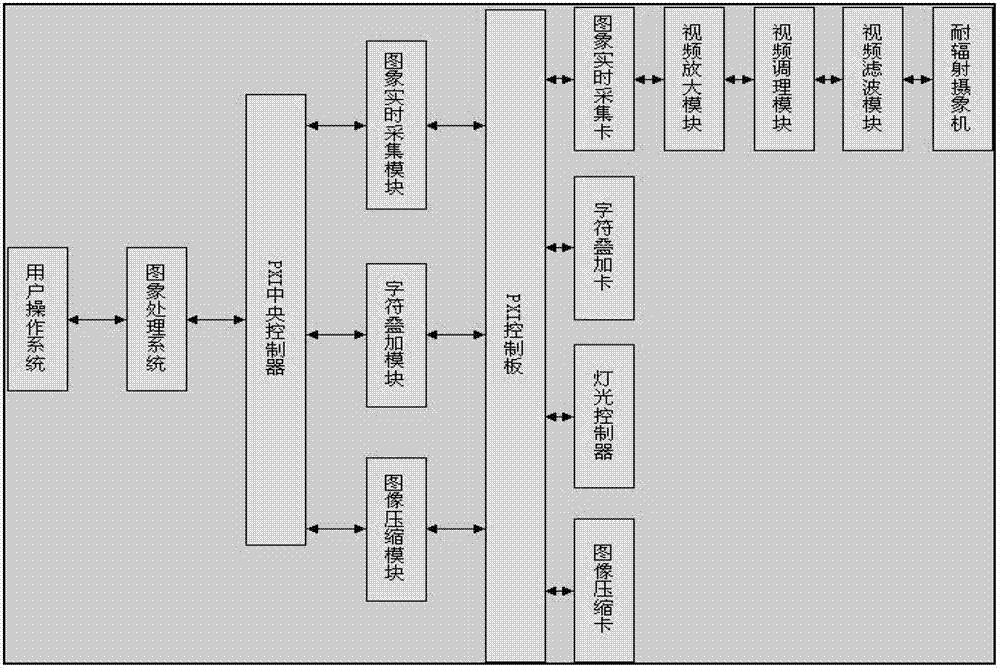

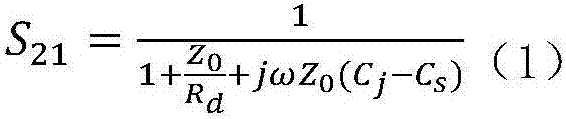

Measuring method and system for actual-position deviation of fuel assembly of nuclear power station reactor core

ActiveCN103594132AAvoid large position deviationImprove safety and reliabilityNuclear energy generationNuclear monitoringNuclear powerNuclear engineering

The invention is suitable for the field of reactor core safety system of a nuclear power station, and discloses a measuring method and a system for actual-position deviation of a fuel assembly of a nuclear power station reactor core. The method comprises following steps of: moving an image acquisition device to a position above a target fuel assembly; acquiring the actual image position of the target fuel assembly by the image acquisition device; comparing the actual position of the target fuel assembly with a standard reference in an industrial machine; and calculating the difference between the actual coordinate and the standard reference by the industrial machine to obtain the deviation dimension. The system comprises the image acquisition device and the industrial machine. The measuring method and the system can measure the deviation between the actual position of a tube socket of the fuel assembly and a standard theoretical position accurately and efficiently, so as to discover abnormal situations and detect and examine timely during the abnormal situations, and therefore risks are effectively avoided and safety and reliability are high.

Owner:GUANGDONG NUCLEAR POWER JOINT VENTURE +3

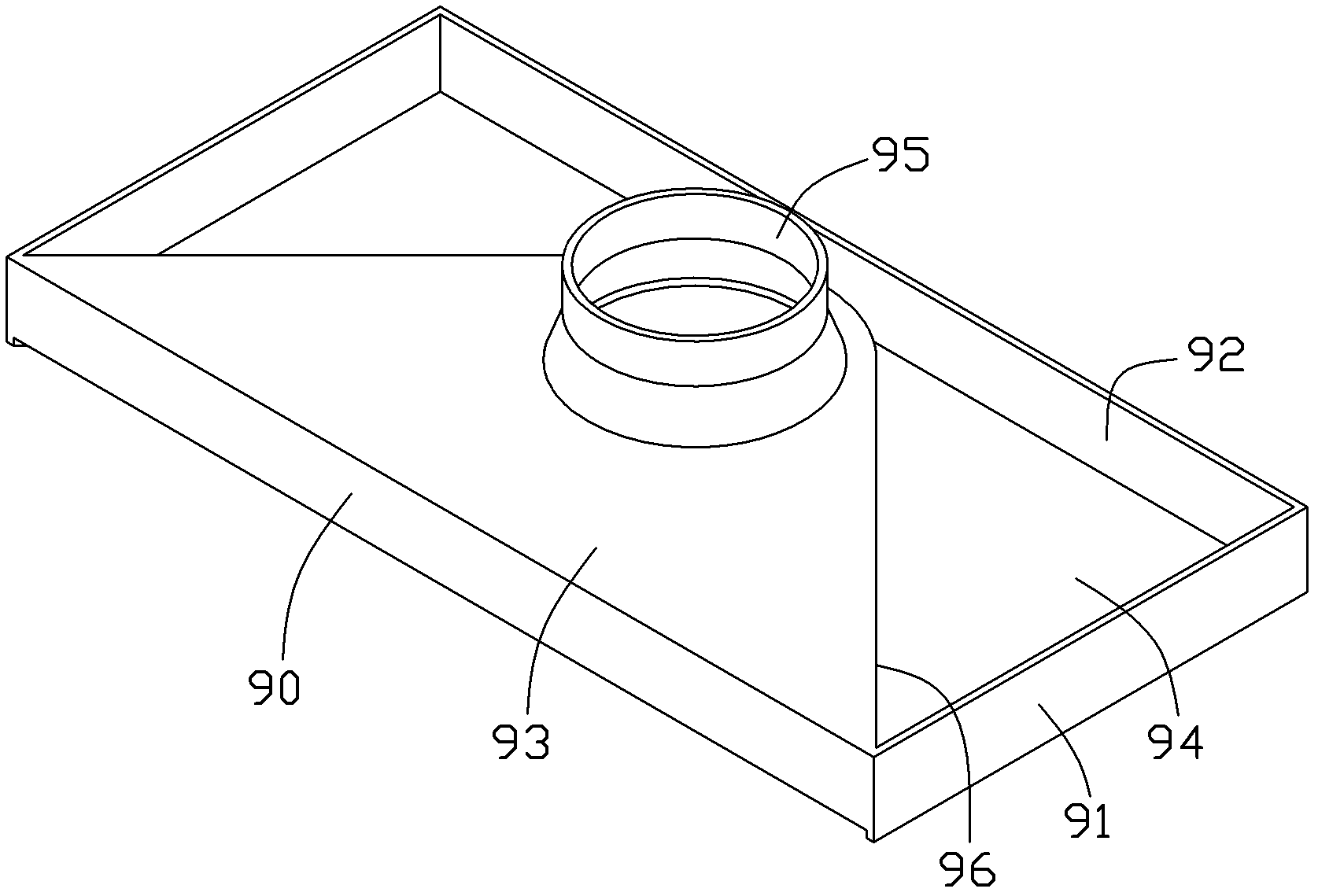

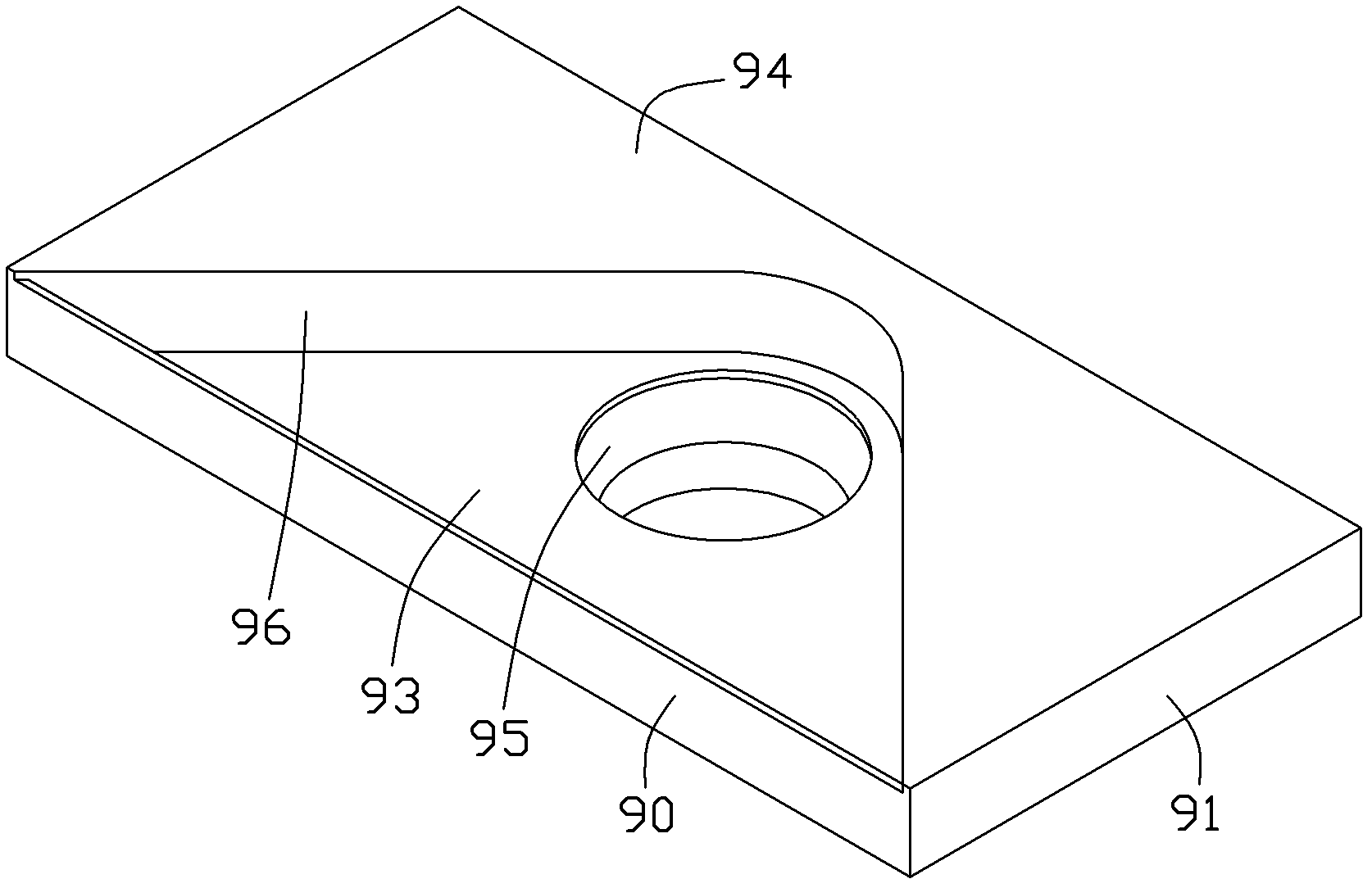

Nozzle structure and road cleaning vehicle with same

The invention provides a nozzle structure, which comprises a top board, a front baffle, two side boards and a partition. The two side boards extend down and out from two sides of the top board respectively, the lower edges of the two side boards form a lower plane of the nozzle structure, the front baffle extends down and out from the front of the top board, two ends of the front baffle are connected with the two side boards, a suction tube socket is reserved on the top board, two ends of the partition are connected with two ends of the front baffle, the middle of the partition is close to the suction tube socket, the lower edge of the front baffle is higher than the lower edge of the partition, the middle of the partition is connected with the rear edge of the suction tube socket or disposed at the rear of the suction tube socket, and the top board is inclined to the front of the suction nozzle structure, namely the height of the top board between the front of the nozzle structure and the lower plane of the nozzle structure is larger than the height of the top board between the rear of the nozzle structure and the lower plane of the nozzle structure. Using the nozzle structure and a road cleaning vehicle with the same can increase entrainment force of air flow, reduce pressure loss and improve absorption efficiency.

Owner:ZOOMLION ENVIRONMENTAL IND CO LTD

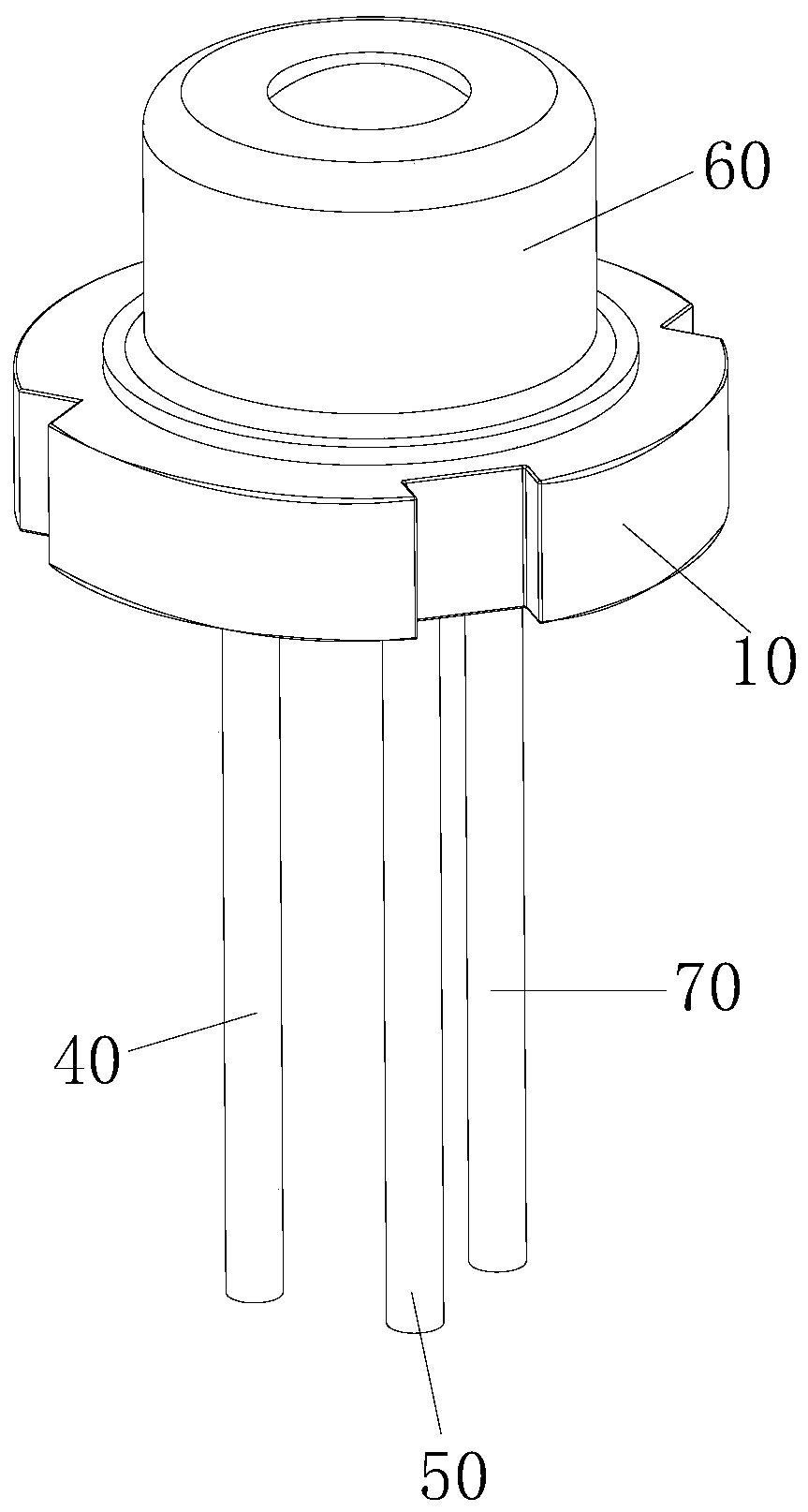

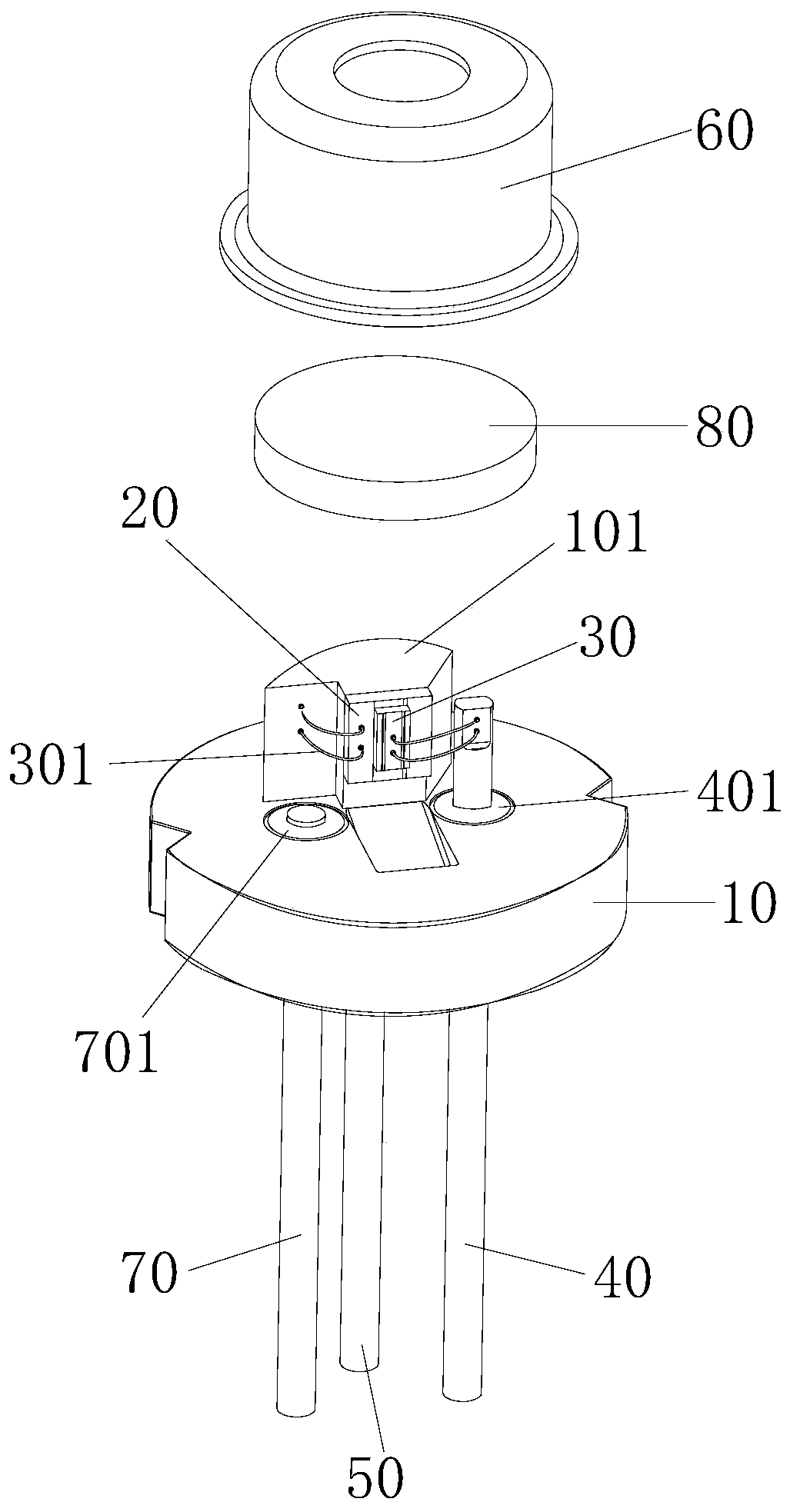

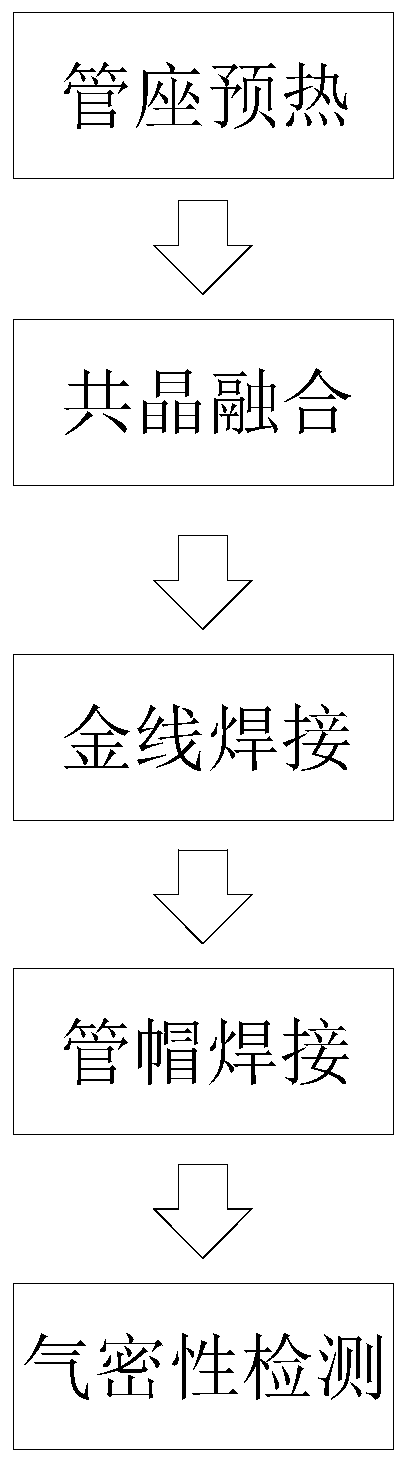

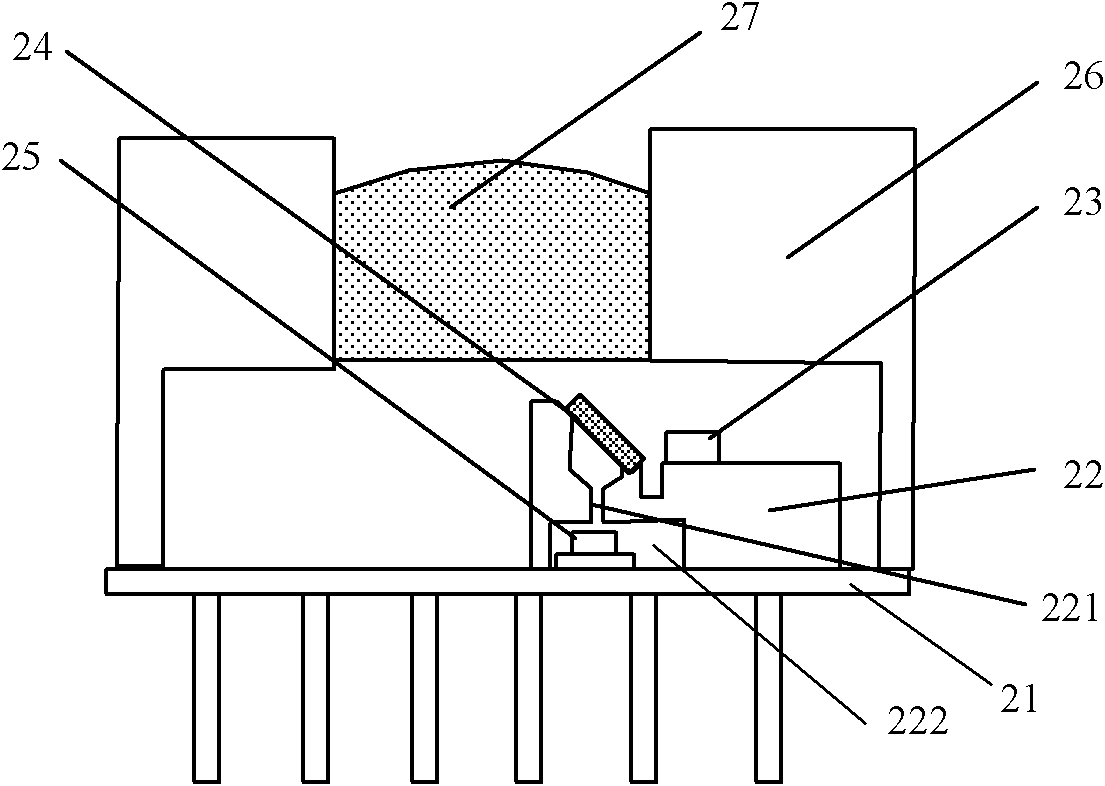

905nm high-power laser with optical lens and packaging process

PendingCN109818254AIncrease productivityReduce process stepsLaser detailsSemiconductor lasersElectricityHigh power lasers

The invention discloses a 905nm high-power laser with an optical lens and a packaging process, and relates to the technical field of laser packaging. The laser comprises a tube socket, a heat sink cushion block, a laser chip, a first pin, a second pin and a tube cap shell. A boss is arranged on the upper plane of the tube base, and the heat sink cushion block is fixed on a side wall of the boss. The laser chip is welded to the heat sink cushion block through eutectic fusion, and electric connection points are arranged on the laser chip and the heat sink cushion block. The first pin and the second pin are both arranged below the tube base, and an electric connection point on the laser chip is electrically connected with the first pin through a gold wire. An electric connection point on theheat sink cushion block is electrically connected with an electric connection point on the side wall of the boss through a gold wire, and the second pin is electrically connected with the boss. The beneficial effects of the invention are that the angle of the laser chip is easier to control, and the concentricity of the laser chip and the tube cap can be effectively controlled.

Owner:广东汉瑞通信科技有限公司

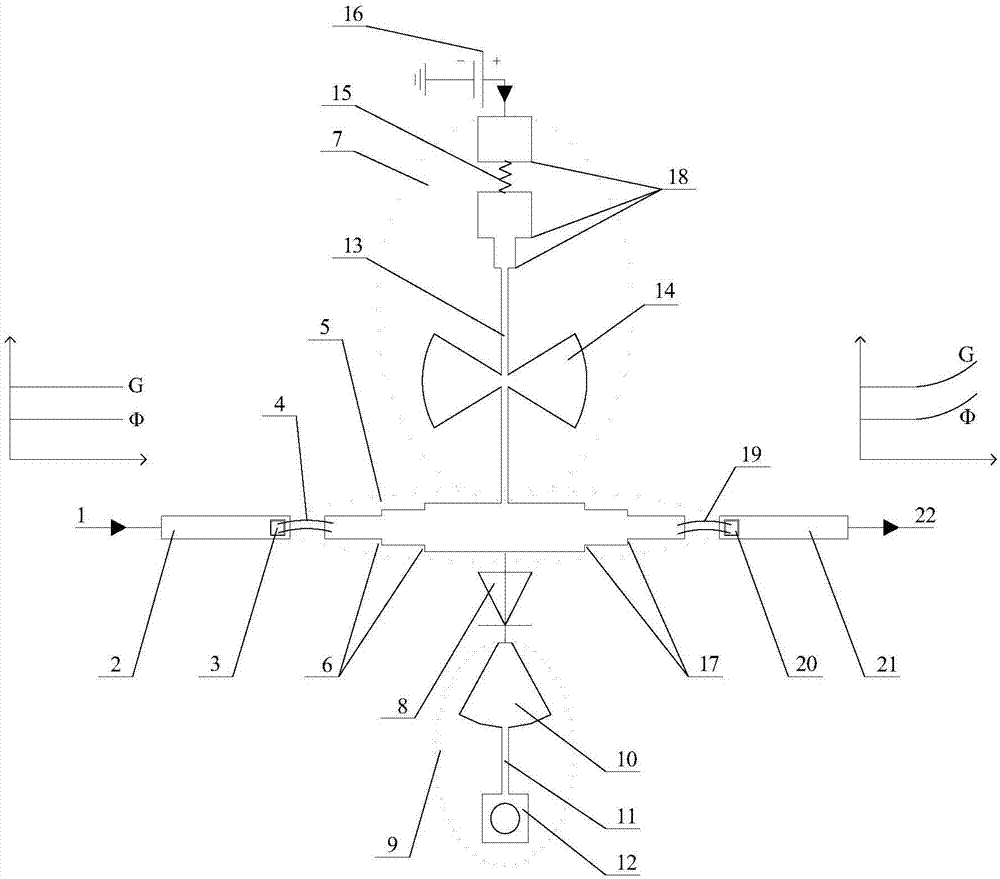

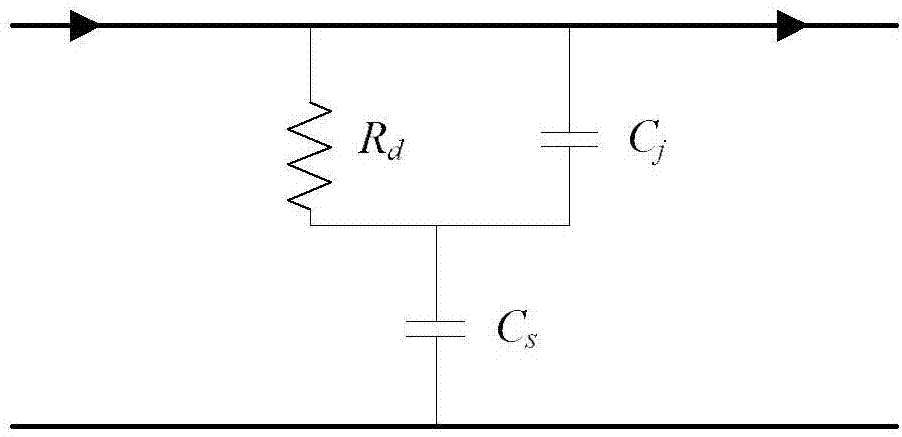

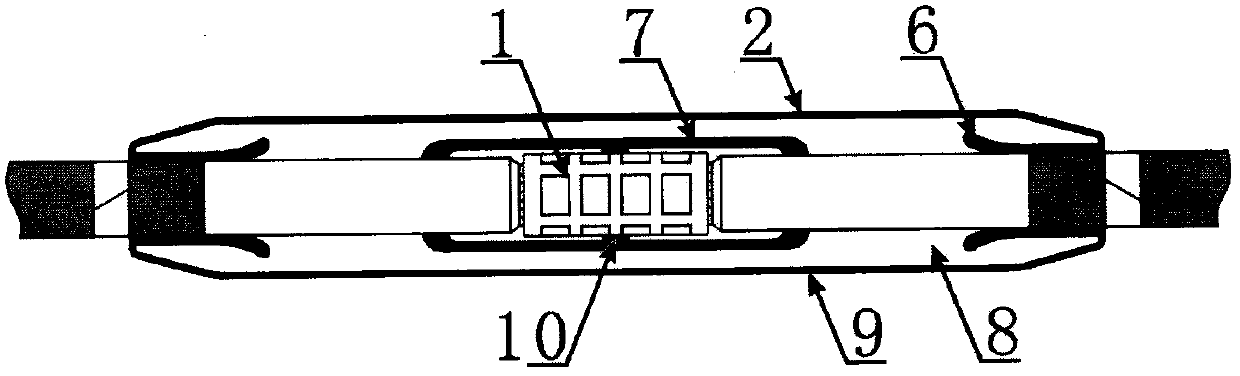

Millimeter wave GaN power amplifier radio frequency predistortion linearizer

ActiveCN107517039ASimple structureLow costAmplifier modifications to reduce non-linear distortionCapacitanceAmplitude compression

The invention provides a millimeter wave GaN power amplifier radio frequency predistortion linearizer and aims at providing the predistortion linearizer which is simple in structure, low in insertion loss, wide in working frequency band and high in stability and is applicable to a millimeter wave GaN power amplifier. The millimeter wave GaN power amplifier radio frequency predistortion linearizer is realized through the following technical scheme that a radio frequency enters a broadband matching network (5) from a radio frequency input port (1) through an input chip capacitor (3) connected with an input microstrip line (2) and a two-level impedance transformation step (6) connected with an input gold wire (4). A GaN Schottky diode (8) and a tube socket circuit (9) generate a distortion radio frequency signal with expanded amplitude and expanded phase. The distortion radio frequency signal matches amplitude compression and phase compression characteristics of a millimeter wave GaN power. The distortion radio frequency signal is output to a radio frequency output port (22) through the two-level impedance transformation step (17) on the output end of the broadband matching network (5), and an output chip capacitor (20) and an output microstrip line (21) connected with an output matching gold wire (19).

Owner:10TH RES INST OF CETC

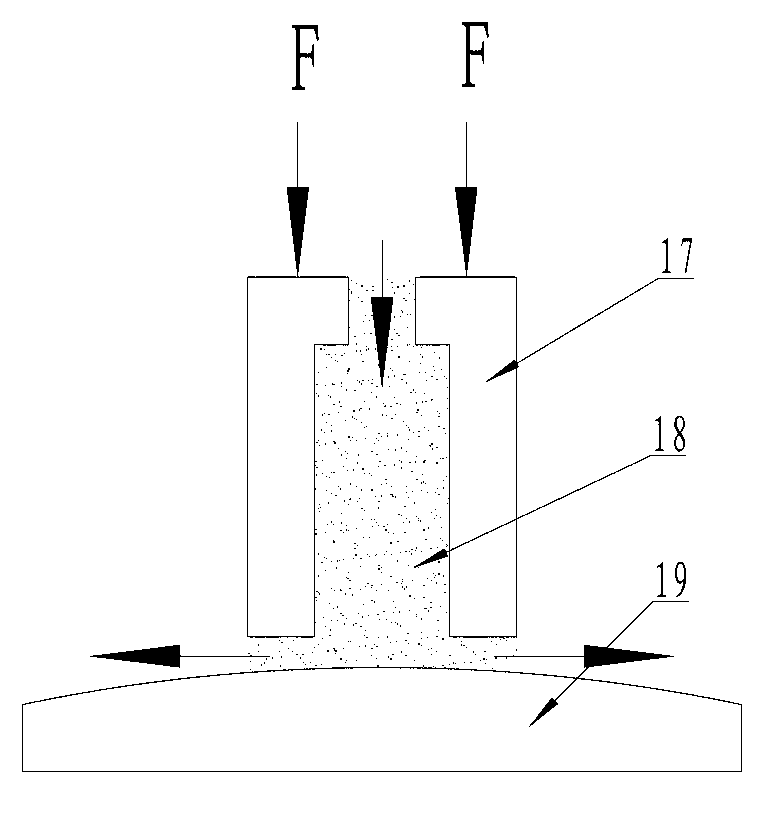

Constraint abrasive flow polishing tool head

A constraint abrasive flow polishing tool head comprises a nozzle, a jacket, an installing plate, a polishing head tube socket and springs, wherein the jacket is sleeved on the nozzle, and the nozzle is fixedly connected with the polishing head tube socket. Sealing grooves are formed in matching surfaces of the nozzle and the jacket. A through hole is formed in the center of the nozzle, a channel which supports an abrasive flow to inflow is arranged in the polishing head tube socket, and the channel is communicated with the through hole. The springs are sleeved on the nozzle and compress the jacket tightly, the polishing head tube socket is fixed on the installing plate through bolts, and the installing plate is connected with a control movement mechanism. The polishing accuracy of a tool surface and a material removal rate are high, the processing damage is little, and the cost is low.

Owner:宣城优度科技服务有限公司

Diode lead wire welding assembly method and device

ActiveCN103903993AImprove assembly qualityImprove assembly work efficiencySolid-state devicesSemiconductor/solid-state device manufacturingTube socketEngineering

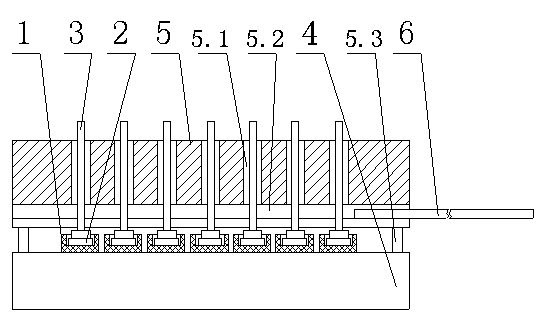

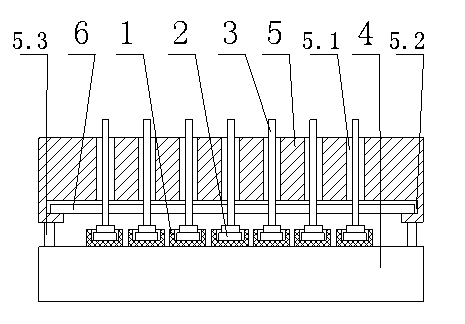

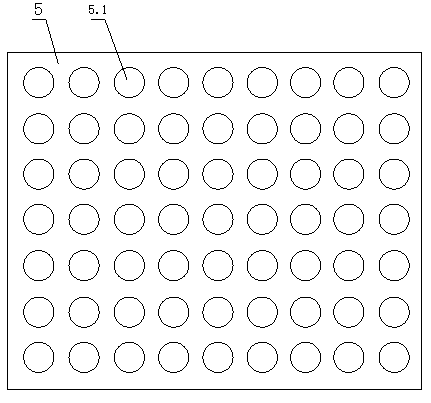

The invention discloses a diode lead wire welding assembly method and device. The method is characterized by placing tube sockets equipped with tube cores of diodes in a welding assembly disc in a matrix arrangement manner in advance, the upper and lower surface of each tube core are respectively placed with a welding flake; then, producing a lead wire assembly disc provided with through-holes, and arranging a movable baffle plate capable of blocking the bottom ends of all through-holes under the lead wire assembly disc; putting one lead wire into each through-hole of the lead wire assembly disc; after placing the lead wire assembly disc placed with the lead wires on the welding assembly disc, withdrawing the movable baffle plate, so that the lead wire in each through-hole drops onto the welding flake of each tube core respectively; and therefore, the welding assembly disc can be sent to a welding device to carry out welding of the lead wires and the tube cores of the diodes. The diode lead wire welding assembly method and device have the advantages of high work efficiency and small labor intensity; the work strain degree can be effectively reduced; and the lead wire assembly quality can be guaranteed to accord with requirements and the like.

Owner:GUIZHOU YAGUANG ELECTRONICS TECH

Formula of modified wear-resistant polytetrafluoroethylene plastic

The invention discloses a formula of a modified wear-resistant polytetrafluoroethylene plastic. The formula comprises a polytetrafluoroethylene matrix and additives, wherein the additives comprise a lubricant, a plasticizer, an anti-wear agent, a buffering agent, a filler and a crosslinking agent, each component in parts by weight is as follows: 65-70 parts of polytetrafluoroethylene plastic, 5-10 parts of the lubricant, 10-15 parts of the plasticizer, 15-20 parts of the anti-wear agent, 1-5 parts of the buffering agent, 5-10 parts of the filler and 3-6 parts of the crosslinking agent. By virtue of the manner, the formula of the modified wear-resistant polytetrafluoroethylene plastic has the advantages of excellent wear resistance and processing performance and can be used in manufacturing bearings, gears, pulleys, electron tube sockets and various plastic housings.

Owner:TAICANG CHENZHOU PLASTIC

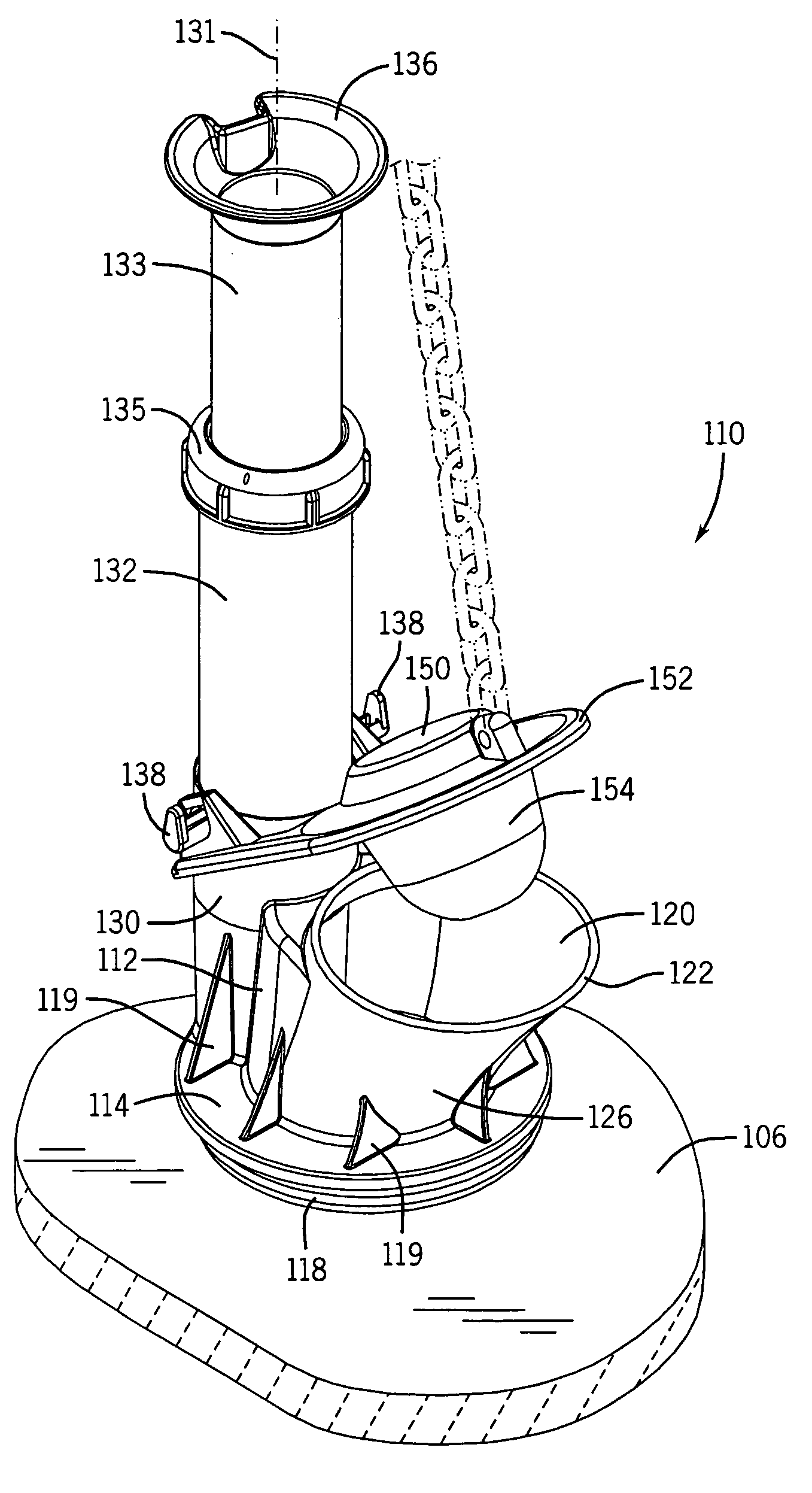

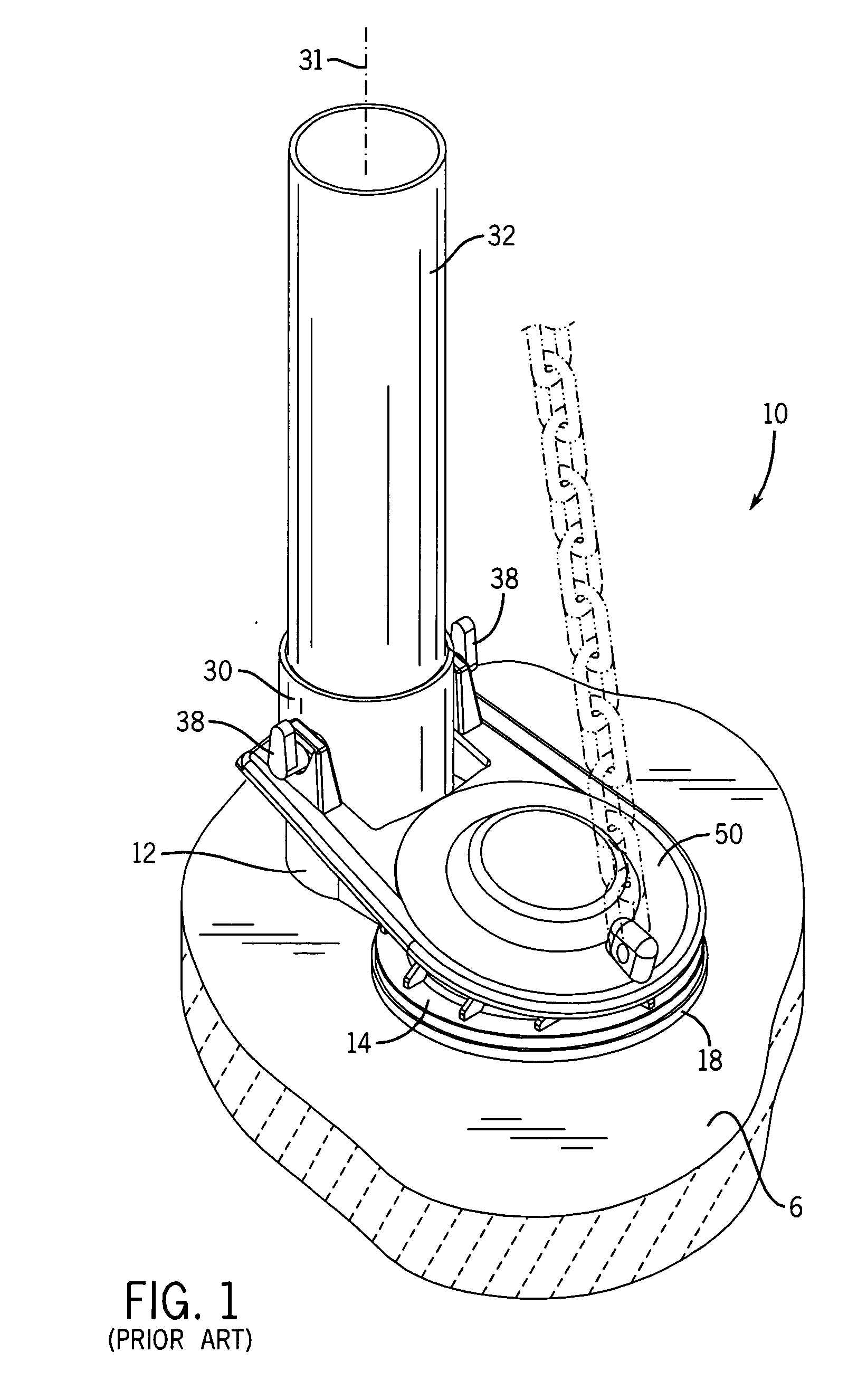

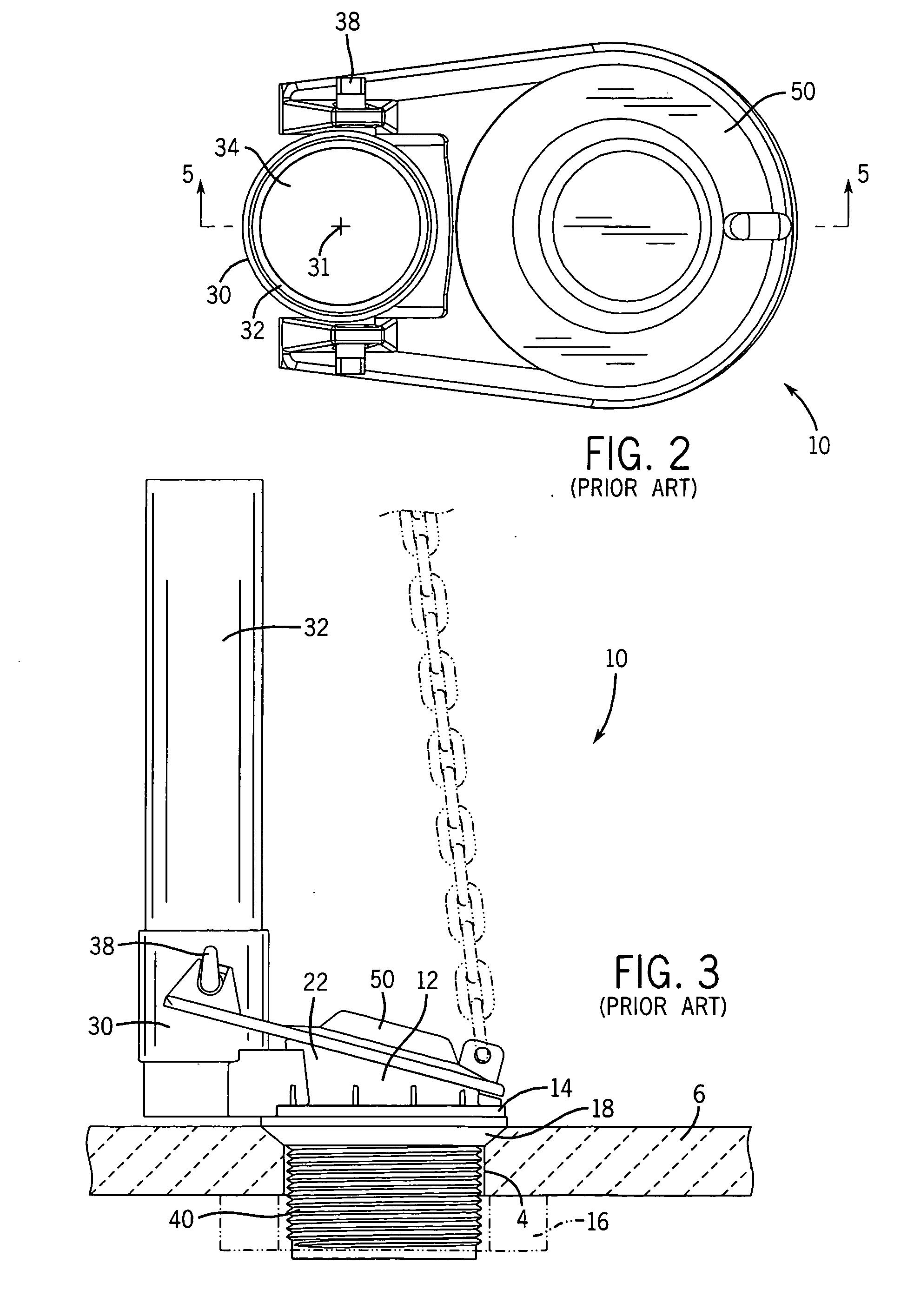

Offset outlet flush valve and method for making same

ActiveUS20070101486A1Readily adapted to tank profileEasy to makeFlushing devicesWater flowEngineering

An offset outlet flush valve has a valve body, the valve body having an inlet comprising an inlet aperture, an overflow tube socket comprising an overflow tube aperture, and an outlet comprising an outlet aperture. The outlet aperture of the valve body, and the wall that defines it, intersects a portion of the inlet aperture and a portion of the overflow tube aperture and the walls that define them. In this way, a water flow continuum is created between the inlet aperture and the outlet aperture and between the overflow tube aperture and the outlet aperture. A number of alternative embodiments of an overflow tube socket and overflow tube are also provided depending upon OEM or after-market application of the offset outlet flush valve.

Owner:LAVELLE IND

Post-radiotherapy oral rehabilitation trainer

InactiveCN103099721ASimple structureIncrease heightGum massageChiropractic devicesOral ulcersPush pull

The invention belongs to the technical field of medical appliances, and in particular relates to a post-radiotherapy oral rehabilitation trainer. The post-radiotherapy oral rehabilitation trainer comprises a square training body and a trapezoidal training body, wherein the square training body comprises a nut tube socket and a thread tube socket which is in threaded connection with the nut tube socket; two side surfaces of the trapezoidal training body are rectangles with different areas, and the height of the side surface with a greater area is consistent with that of the nut tube socket; the side surface with a greater area of the trapezoidal training body is fixedly connected with one side of the nut tube socket, and the side surface with a smaller area of the trapezoidal training body is provided with a gargle spray orifice which is communicated with a gargle guide tube; a passage for the gargle guide tube to pass through is respectively arranged at parts close to the bottoms in the trapezoidal training body and the nut tube socket; and a piston and a push-pull rod which is connected with the piston are arranged in the gargle guide tube. The post-radiotherapy oral rehabilitation trainer is simple in structure, convenient to use, flexible to operate, capable of reducing inflammation of oral ulcers, and good in rehabilitation effect.

Owner:姜阿芳

Single fiber bi-directional optical element and assembly method thereof

InactiveCN102118194ARealize automatic packagingImprove packaging efficiencyFibre transmissionHigh volume manufacturingSingle fiber

The embodiment of the invention discloses a single fiber bi-directional optical element and an assembly method thereof. The single fiber bi-directional optical element comprises a tube socket, wherein a base is fixed on the tube socket; a filter and a laser are fixed on the base; a photoelectric conversion device fixed on the tube socket is arranged below the base and corresponds to the filter; a ray transmitting hole is formed on the base and between the filter and the photoelectric conversion device; and rays emitted by the laser and rays received by the photoelectric conversion device coincide at the incidence point on the filter. The single fiber bi-directional optical element and the assembly method thereof have the advantages that the encapsulation efficiency is high and the large-batch production is facilitated.

Owner:HUAWEI MACHINERY

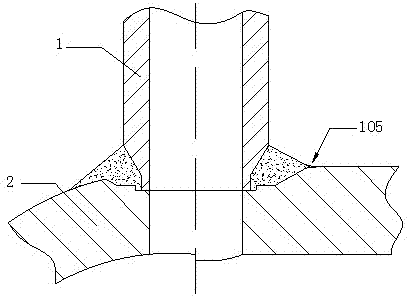

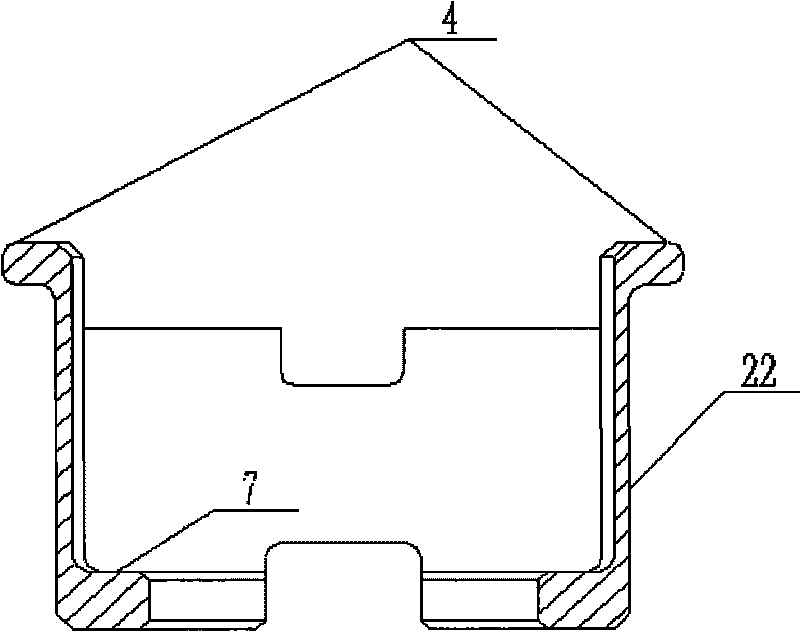

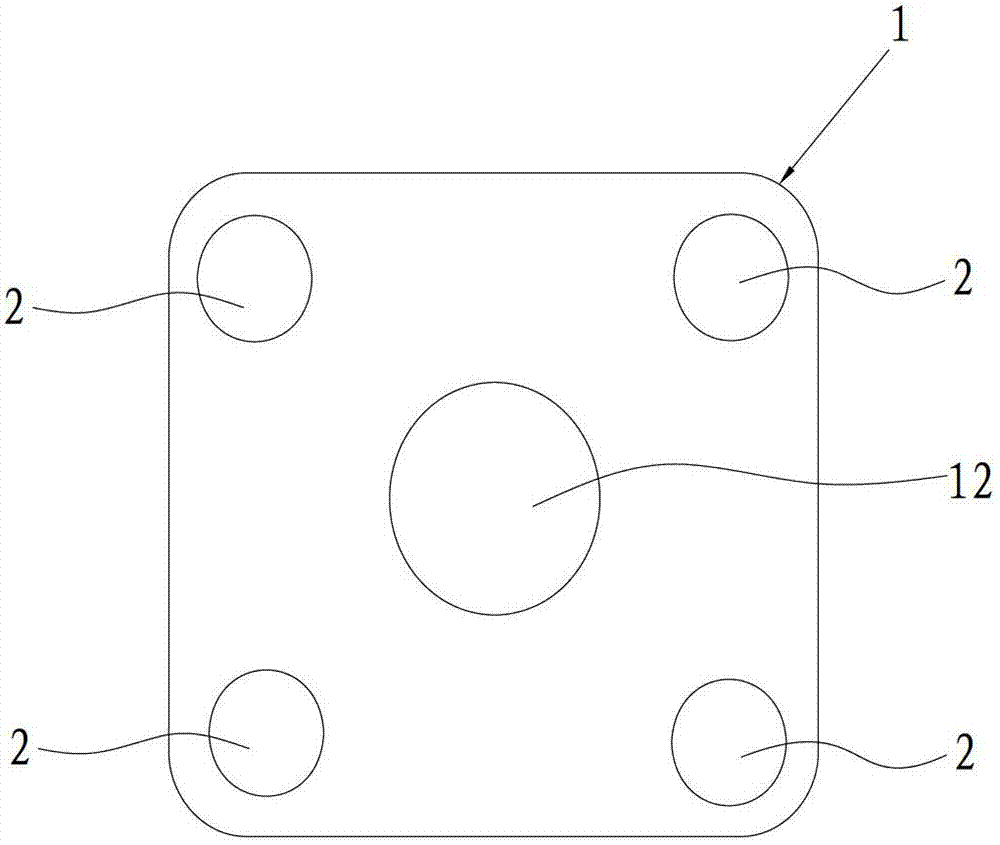

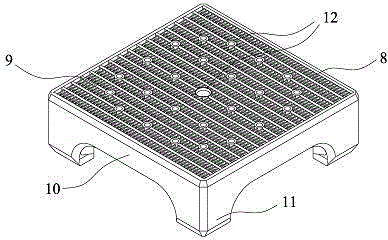

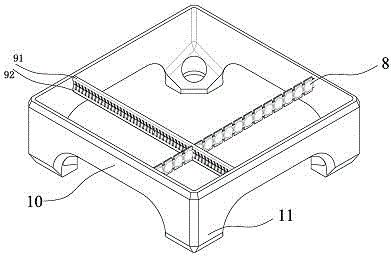

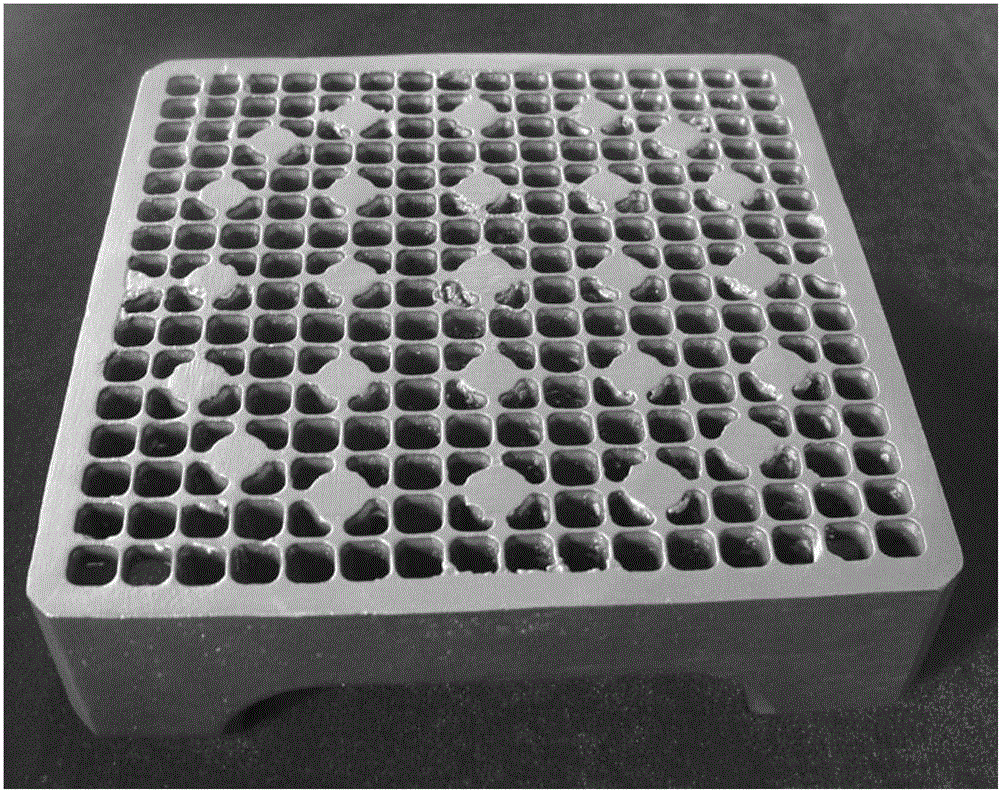

Lower tube socket with function of filtering foreign matters

ActiveCN103337262AIncrease stiffnessHigh strengthNuclear energy generationFuel element assembliesForeign matterEngineering

The invention discloses a lower tube socket with a function of filtering foreign matters. The lower tube socket comprises a plurality of blades having mutually paralleled axles and a plurality of fillet assemblies having mutually paralleled axles, the axles of the fillet assemblies are vertical to the axles of the blades; the fillet assembly is composed of two symmetric fillets, the opposite facesof the two fillets are respectively provided with clamping slots having number corresponding to that of the blades, the blades are clamped in the clamping slots; the blade comprises a plurality of bulges having the same convex directions, two adjacent bulges are connected by a straight section, the upper end surface and the lower end surface of the straight section are provided with grooves, theopening direction of the groove is vertical to the convex direction of the bulge, and the fillet assembly is clamped in the groove. The lower tube socket disclosed by the invention is good in structure strength, filtering ability and coolant pressure drop.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Electromagnetic hydraulic valve possessing self-defence capability

ActiveCN101290070AReduce delay errorStrong self-defenseOperating means/releasing devices for valvesServomotor componentsFailure rateEngineering

The invention discloses an electromagnetic hydraulic valve with the self-defense capability, which comprises a main hydraulic valve, a separating-brake electromagnetic valve and a closing-brake electromagnetic valve. A self-defense delay valve is arranged between the separating-brake electromagnetic valve and the main hydraulic valve; a delay piston cylinder and a throttle valve-group cylinder are arranged side by side in the right cavity of the self-defense delay valve leftward; a delay piston is arranged in the delay piston cylinder; a spring, throttle plugs and a core tube are arranged in turn in the throttle valve-group cylinder from left to right, and the left of the throttle valve-group cylinder is communicated with the main-providing oil interface; an adjusting-position plug is arranged in the right cavity of the self-defense delay valve in order to adjust the motion scope of the delay piston; the blocked wire and nuts are arranged in the right of the adjusting-position plug in turn; and the left cavity of the self-defense delay valve is provided with a spring tube socket, which is provided with a reduction spring, the left of which is connected with a spring anti-thrust plug, which is connected with the delay piston. The invention has the advantages of strong self-defense capability, minor delay error between the separating and the closing, stable technical performance, simple structure, low failure rate and convenient maintenance.

Owner:沈阳广驰工大高压电气有限公司

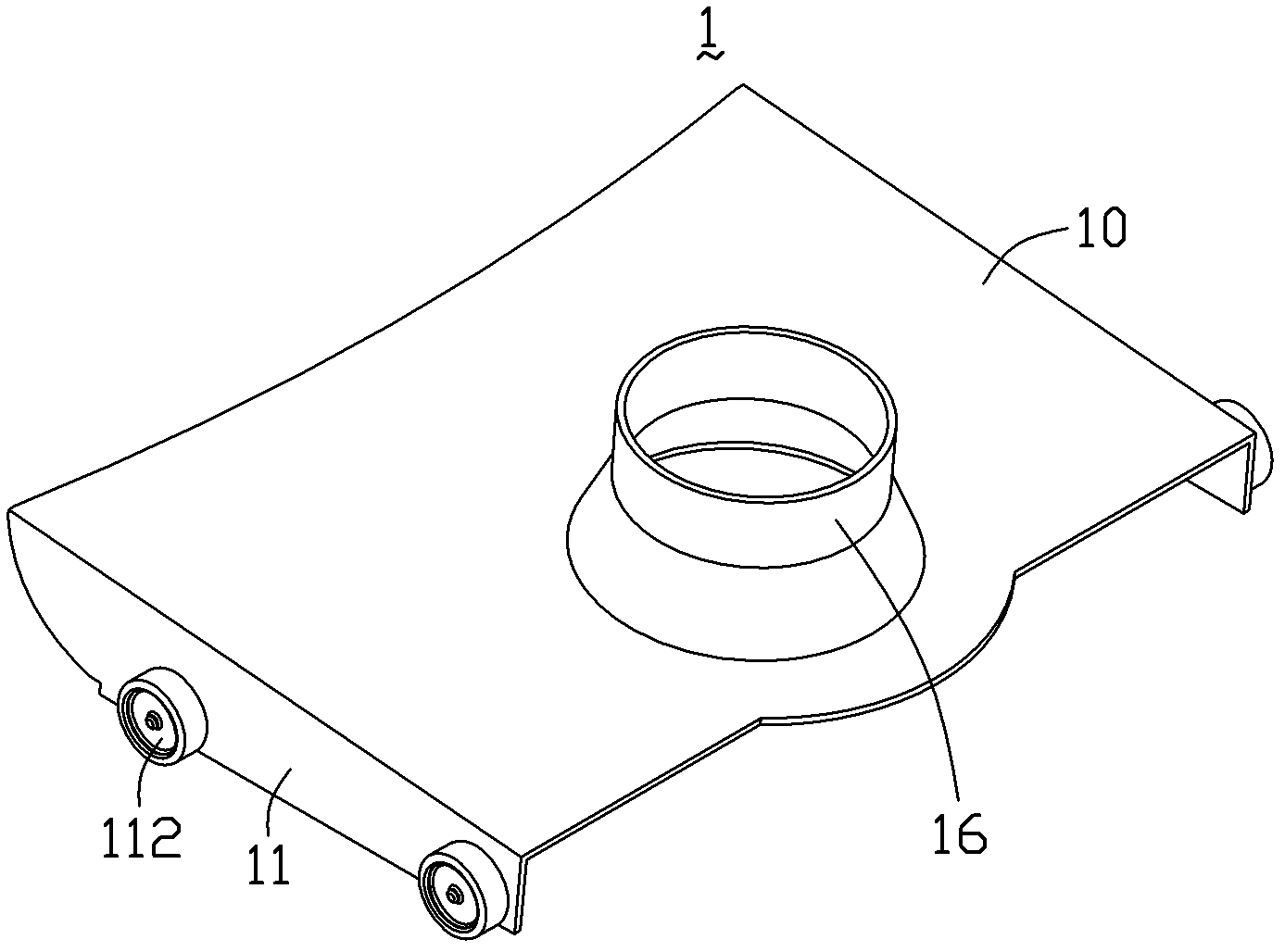

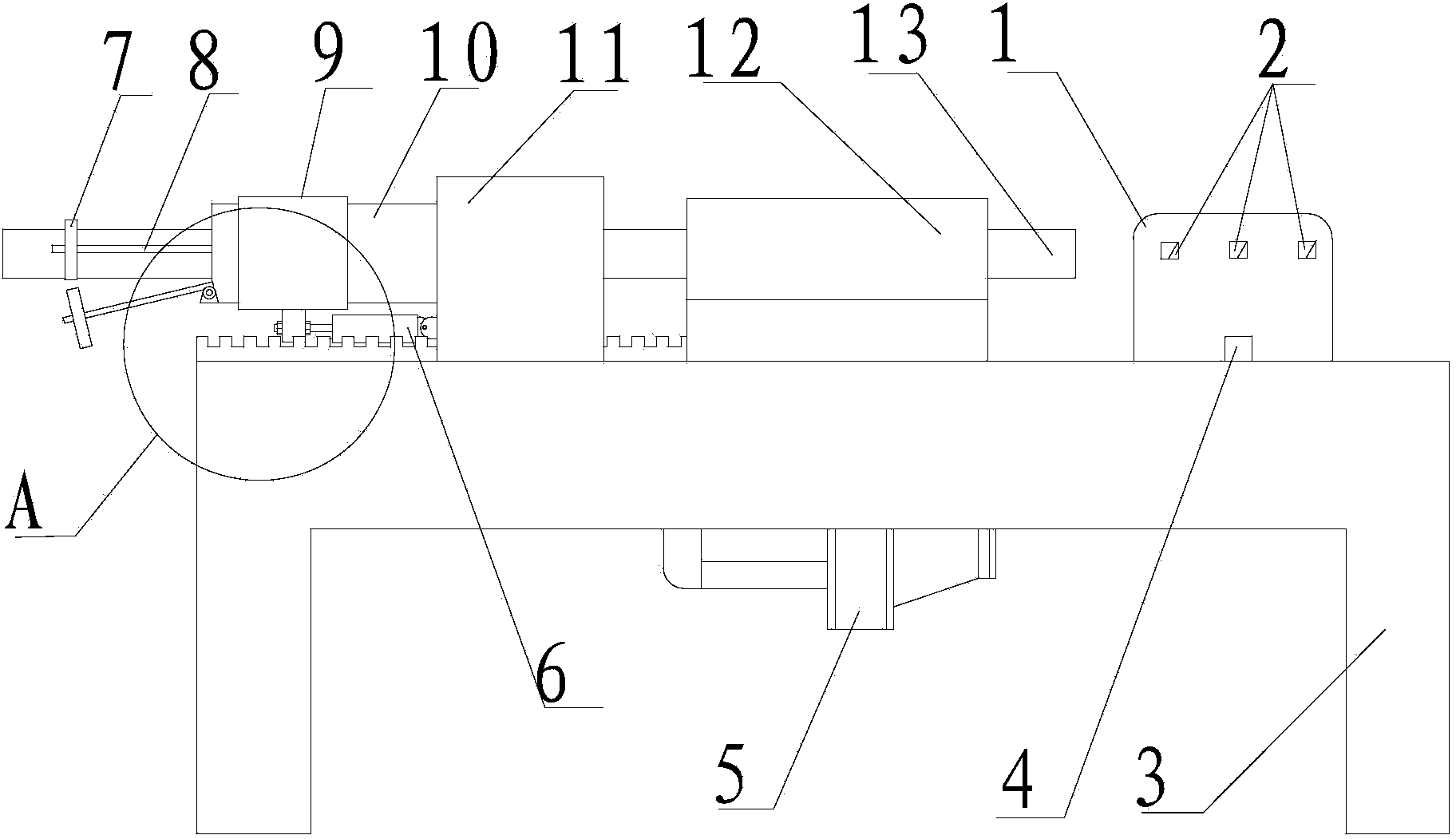

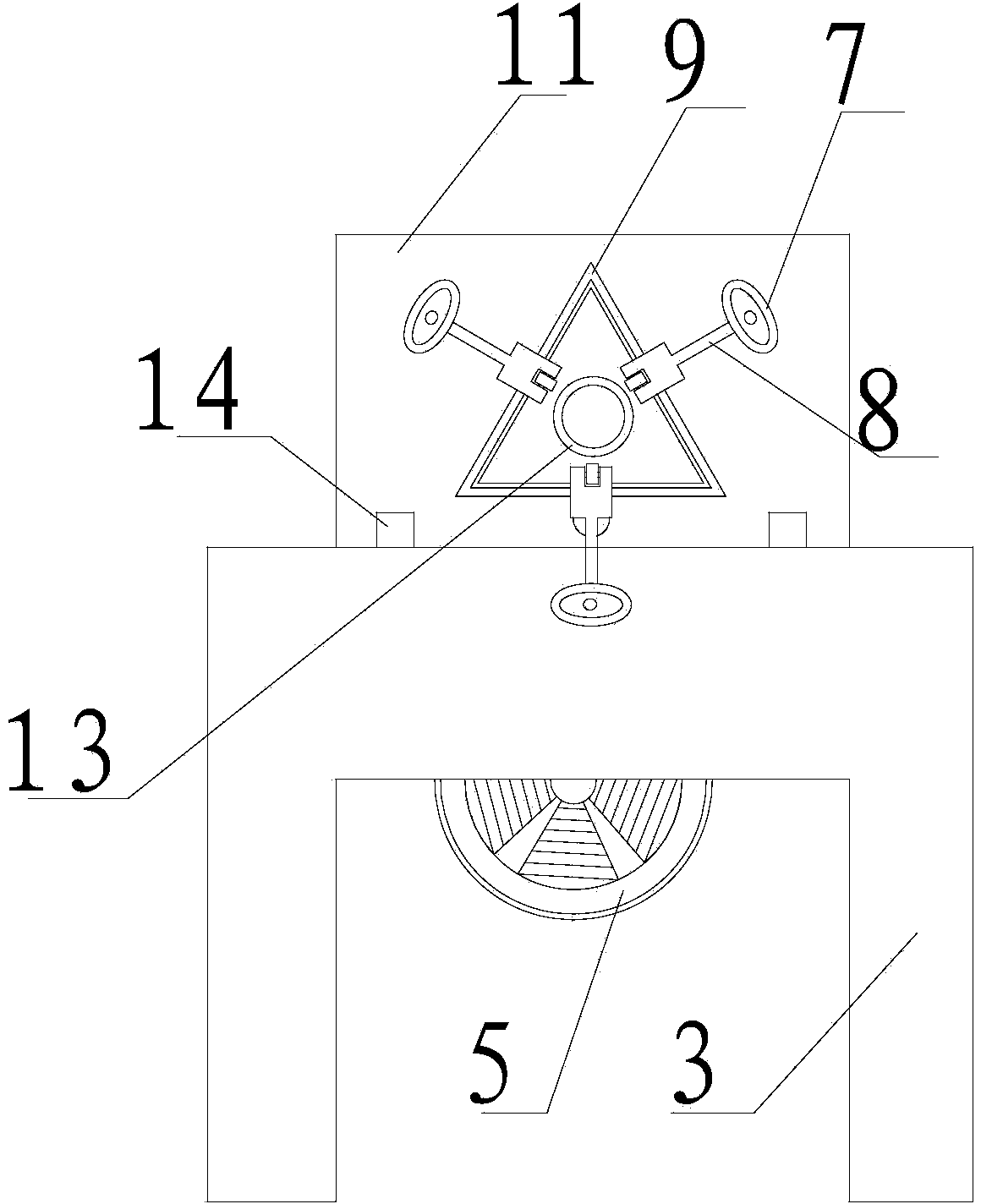

Automatic tube feeding multi-cutter tube cutting device of bearing steel tube

ActiveCN103949717AImprove work efficiencyQuality assuranceTube shearing machinesShearing machine accessoriesEngineeringTube socket

The invention discloses an automatic tube feeding multi-cutter tube cutting device of a bearing steel tube. The automatic tube feeding multi-cutter tube cutting device comprises a workbench, a tool holder, a tool holder track and a tooth track, wherein the tooth track is mounted on the workbench, a tube feeding base is mounted on the tooth track, and the tube feeding base and a triangular base are mounted in a matching manner, the triangular base and a clamping sleeve are mounted in the matching manner, clamping shafts are mounted on the triangular base, clamping wheels are mounted at the tail ends of the clamping shafts, a rotary tube socket is mounted on the workbench, the tool holder track is mounted on the workbench, the tool holder is mounted on the tool holder track, and a plurality of tube cutters are mounted on the tool holder. The automatic tube feeding multi-cutter tube cutting device of the bearing steel tube disclosed by the invention can improve the work efficiency, save energy and lower the investment cost of equipment, and further is simple in structure, convenient in maintenance, low in cost and high in efficiency.

Owner:新昌新天龙纽尚精密轴承有限公司

Constraint abrasive flow ultra-precision machining device

A constraint abrasive flow ultra-precision machining device comprises a polishing tool head, a feeding apparatus, a recovery pedestal and a motion executing mechanism; in the polishing tool head, a sheath is sleeved on the installation step of a nozzle, the nozzle is fixedly connected with a polishing head tube socket, springs are sleeved on the nozzle and tightly compress the sheath, the cooperation surface of the sheath and the nozzle is provided with sealing grooves, the sheath is prepared through using an elastic material insensitive to abrasive wear, the center of the nozzle is punched to form a through hole, a channel for the flow-in of an abrasive flow is arranged in the polishing head tube socket, the polishing head tube socket is fixed on an installation plate, a laser displacement sensor is fixed at one side of the polishing head tube socket, and the installation plate is connected with the motion executing mechanism; and the center of the recovery pedestal is a boss for installing a workpiece, the periphery of the boss is provided with an abrasive flow recovery slot, the periphery of the recovery slot is provided with a ring-shaped abrasive flow baffle plate, the abrasive flow baffle is higher than the upper surface of the workpiece, and an abrasive flow recovery outlet is arranged in the recovery slot. The device has the advantages of high precision, high machining efficiency, small damage and low cost.

Owner:宣城优度科技服务有限公司

Nuclear power fuel assembly tube socket laser additional material forming manufacturing method

InactiveCN106623927ARealize one-piece moldingHigh tensile strengthAdditive manufacturing apparatusIncreasing energy efficiencyNuclear powerPressurized water reactor

The invention provides a nuclear power fuel assembly tube socket laser additional material forming manufacturing method. The method comprises the steps that 1, three-dimensional model design is performed on tube socket drawing paper to obtain a three-dimensional entity model; 2, support adding processing is performed on the suspended position of the obtained model; 3, layering slicing is performed on the model according to the certain thickness; laser powder, laser scanning speed and laser scanning interval parameters of an inner part of each layer of slices are designed; 4, the parameter data obtained in the step 3 is guided into laser selective melting forming equipment, base material leveling and gas washing operation are performed, and parts are started to be manufactured; 5, after the parts are manufactured, thermal treatment is performed on the parts, and internal stress of the parts is removed; 6, linear cutting is adopted for separating the parts from the base material. The pressurized water reactor nuclear power fuel assembly tube socket is rapidly repaired, and integral forming of the tube socket is achieved; the manufacturing period is equal to or shorter than 120 h, the tensile strength is 30% or more higher than that of a tube socket manufactured through a traditional technology, and the material utilization rate is larger than 99.0%.

Owner:CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND

Silicon-based airtight packaging casing

InactiveCN102583218ALow costEasy to getSolid-state devicesFluid speed measurementTube socketAir tightness

The invention discloses a silicon-based airtight packaging casing structure, which is made of monocrystalline silicon for airtight packaging for an MEMS (micro-electromechanical system) chip. The casing comprises a tube socket and a cap, the tube socket is a monocrystalline chip with a socket, through holes are reserved at the bottom of the socket, conductive metal is plated in the trough holes, the through holes serve as signal TSVs (through silicon vias), the MEMS chip to be packaged is placed in the socket, and the cap which is a monocrystalline silicon chip is bonded to the tube socket by means of silicon-silicon direct bonding or eutectic bonding. Silicon serving as airtight seal material can be used for airtight connection. High-temperature sintering process for the silicon-based airtight packaging casing is omitted, so that packaging cost can be lowered.

Owner:HUAZHONG UNIV OF SCI & TECH

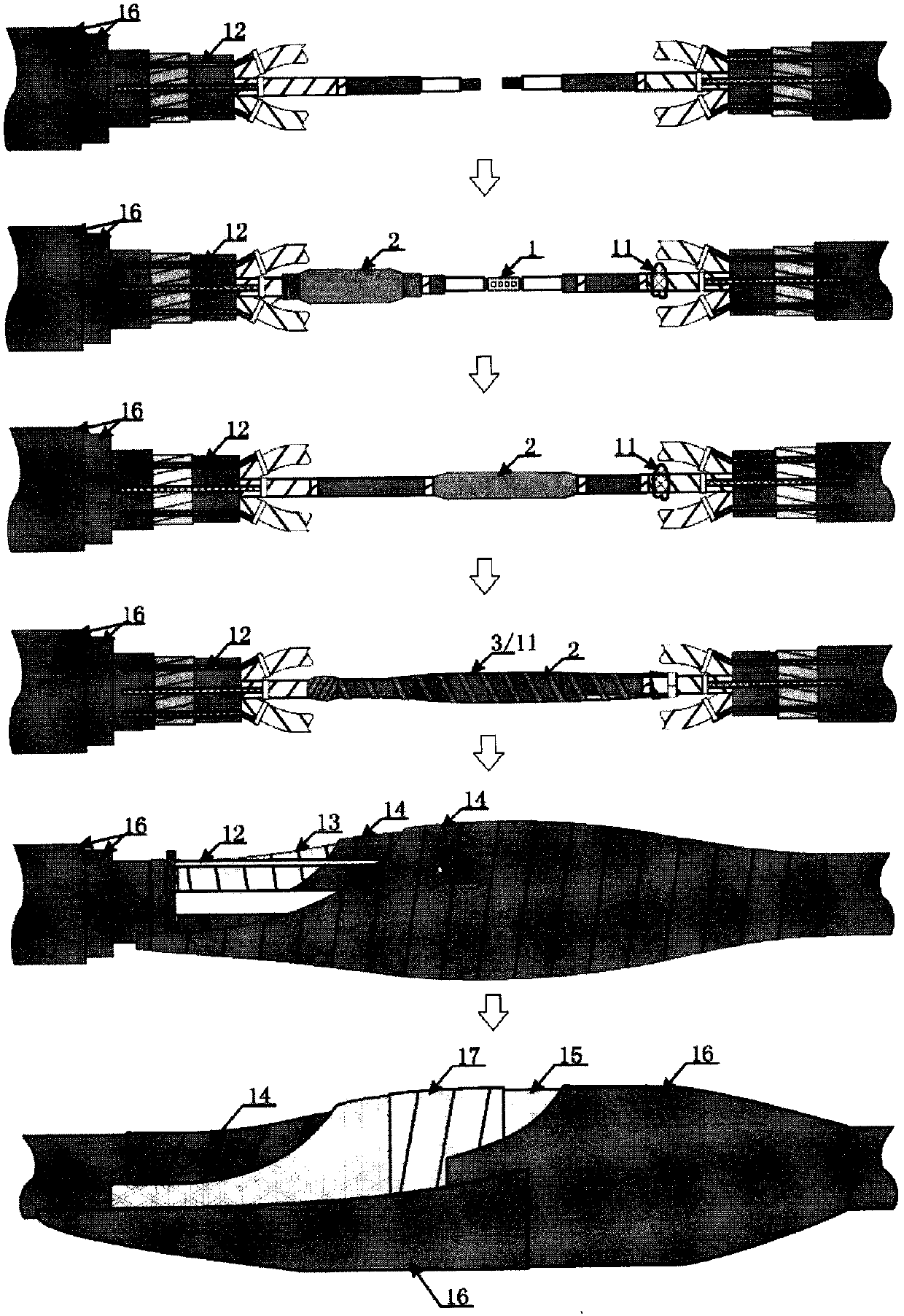

Cable intermediate connector and manufacturing and mounting method therefor

PendingCN107706879AImprove adhesionImprove flame retardant performanceCable junctionsApparatus for joining/termination cablesElectrical conductorPower cable

The invention relates to a cable intermediate connector used for connecting three-phase cable lines of two power cables. The cable intermediate connector comprises a conductor connector, a cold contraction type intermediate connector main body, a cable shielding layer recovery part, a cable inner sheath layer recovery part and a mechanical protection and waterproof sealing part; the intermediate connector adopts a multilayered solid composite dielectric insulation and sealing structure; the intermediate connector main body adopts an integrated type multilayered composite structure, and comprises a stress cone, an internal shielding layer, an insulating layer and an outer shielding layer from inside to outside, wherein the inner shielding layer and the insulating layer adopt non-equal innerdiameter structures, and the inner diameter of the inner shielding layer is larger than that of the insulating layer; multiple semi-conductive stepped contacts are arranged in the middle position ofthe inner shielding layer; the mechanical protection and waterproof sealing part adopts a half-overlapped and wound armoured band; and the outermost layer is sleeved with a thermal shrinkage pipe anda wrapping thermal shrinkage band. The invention provides the cable intermediate connector which is high in conductor connection, insulating and reliable, high in sealing property, high in mechanicalstrength and simple in structure, and the manufacturing and mounting method for the cable intermediate connector, so that a significant meaning to improvement of safety and reliability levels of the cable circuit is achieved.

Owner:GUANGZHOU GO LIK CABLE ACCESSORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com