Patents

Literature

166results about How to "Realize automatic packaging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

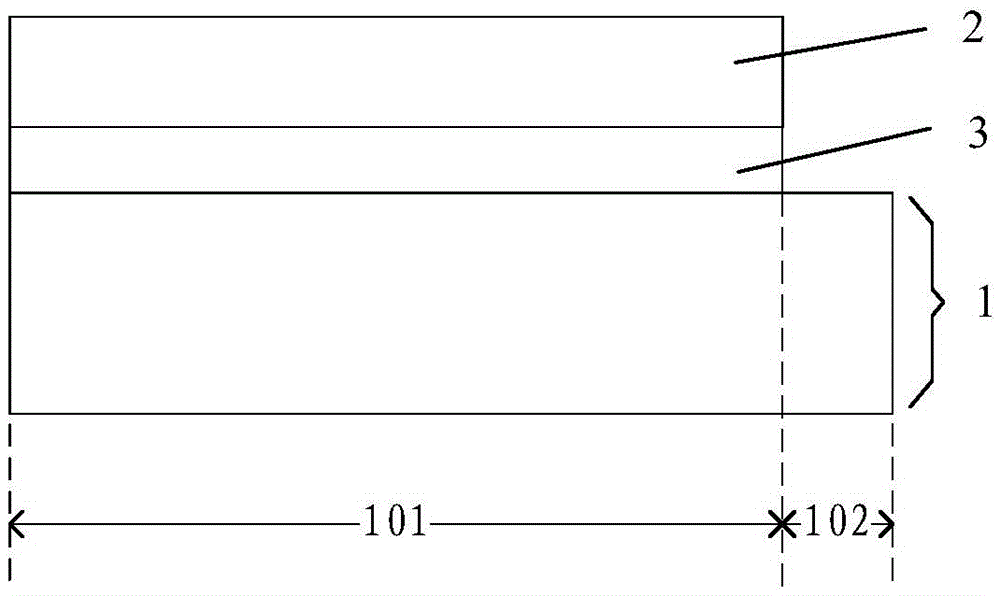

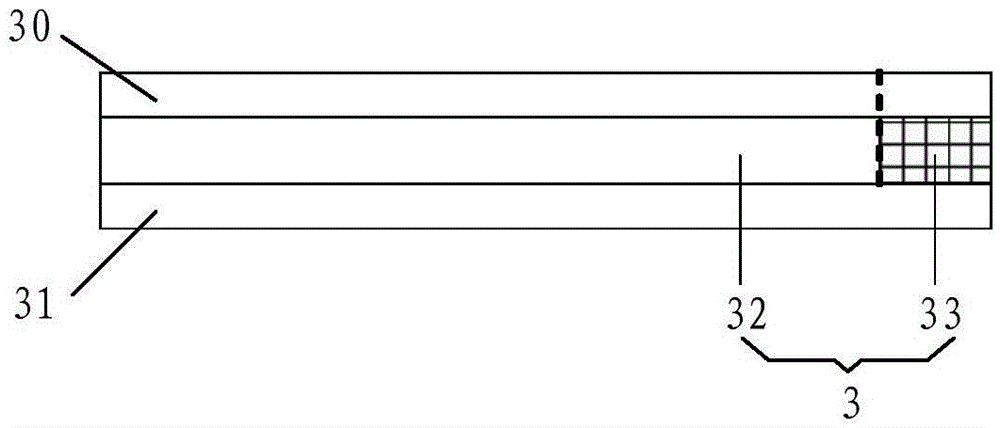

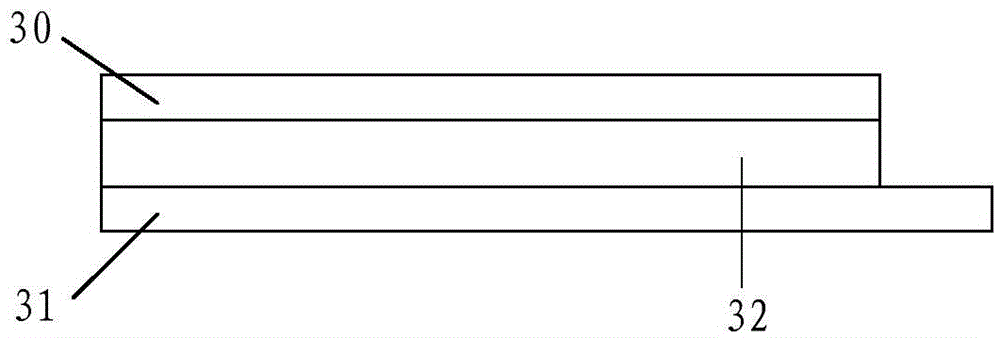

Flexible display panel and packaging method thereof and display device

ActiveCN105633281AReduce difficultyRealize automatic packagingSolid-state devicesSemiconductor/solid-state device manufacturingAdhesiveDisplay device

The invention provides a flexible display panel and a packaging method thereof and a display device, and relates to the technical field of display. Mechanical removal of a non-stick part of an adhesive can be achieved through the packaging method; manual removal is avoided; the packaging efficiency is improved; and achievement of automatic packaging is facilitated. The packaging method of the flexible display panel comprises the steps as follows: a barrier film formed with an adhesive layer is stuck to one side surface, far away from a substrate of the display panel, of the display panel; the non-stick part of the adhesive layer loses the viscidity after being treated through a process, and covers a binding region; a stick part has viscidity and at least covers a display region; the display panel provided with the barrier film is cut, so that the stick part covering the display region in the adhesive layer is separated from the adjacent part and a reserved part in the barrier film is separated from a removed part; and the part except for the stick part covering the display region in the adhesive layer and the removed part of the barrier film are stripped in a mechanical manner. The packaging method is suitable for packaging of the flexible display panel.

Owner:BOE TECH GRP CO LTD

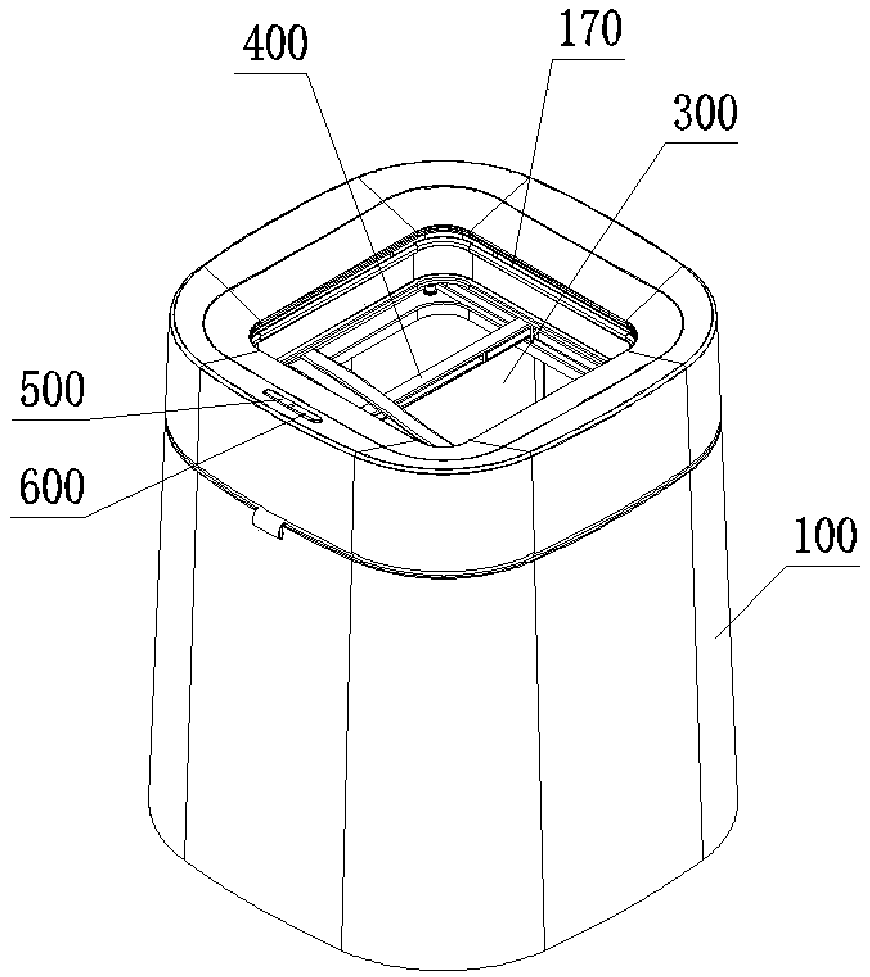

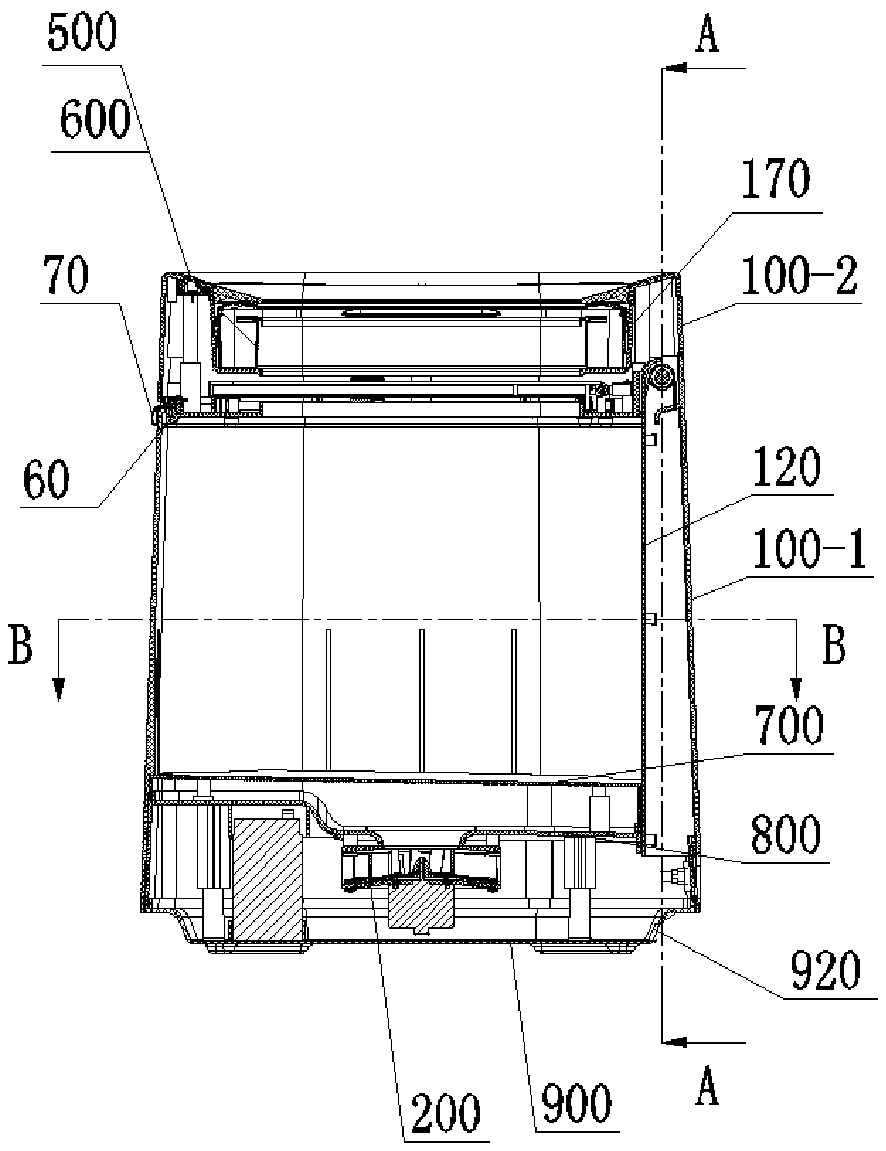

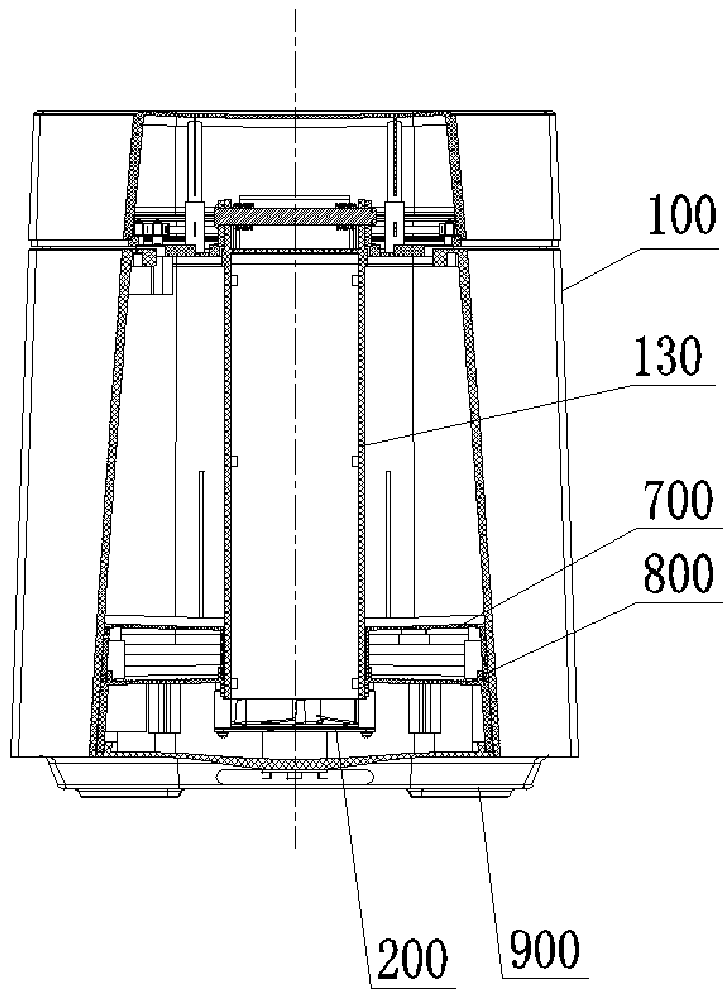

Intelligent garbage can with automatic packing and bag changing functions

PendingCN109625700AMake sure you don't get inhaledReduce security risksRefuse receptaclesControl systemWaste management

The invention provides an intelligent garbage can with automatic packing and bag changing functions. The intelligent garbage can comprises a can body, a garbage bag paving device arranged at the bottom of the can body and a control device, wherein the can body is provided with a garbage throwing opening, an automatic packing mechanism is arranged around the garbage throwing opening, the control device controls the operation of the garbage bag paving device and the automatic packing mechanism, an inner can bottom, an intermediate plate and an outer can bottom are sequentially arranged at the bottom of the can body from top to bottom, at least one first air suction opening is formed in the inner can bottom, at least one second air suction opening is formed in the intermediate plate, the first air suction opening and the second air suction opening are not directly opposite to each other, the garbage bag paving device is installed at the bottom of the intermediate plate, and an air inlet of the garbage bag paving device communicates with the second air suction opening. According to the intelligent garbage can, automatic packing and laying of a garbage bag can be realized, potential safety hazards are remarkably reduced, moreover, the structure is optimized, and the stability of a control system is improved.

Owner:SHANGHAI TOWNEW INTELLIGENT TECH CO LTD

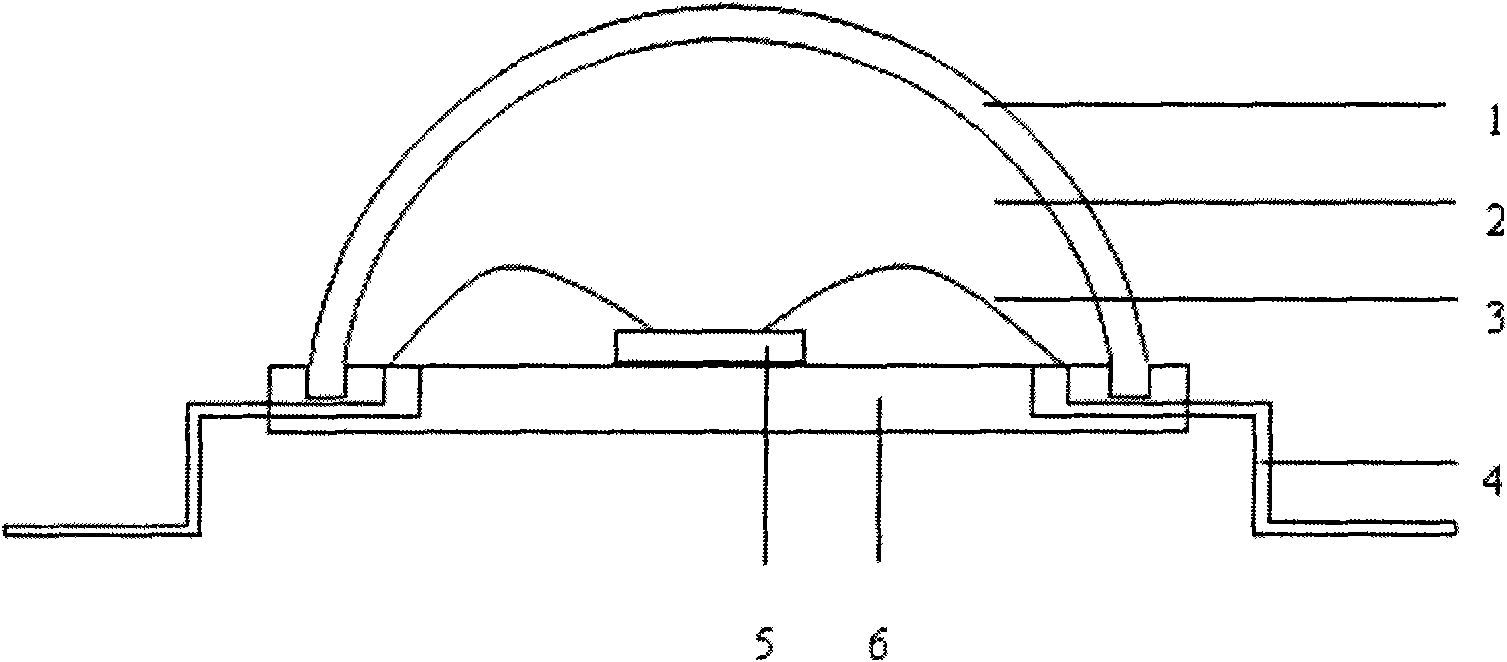

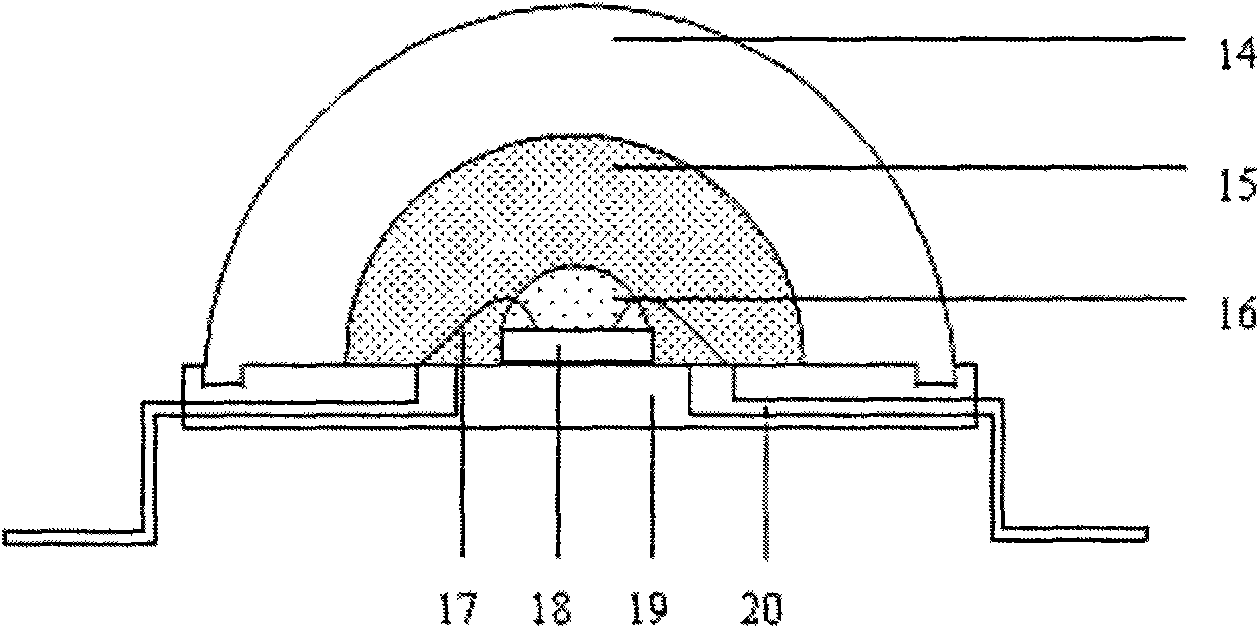

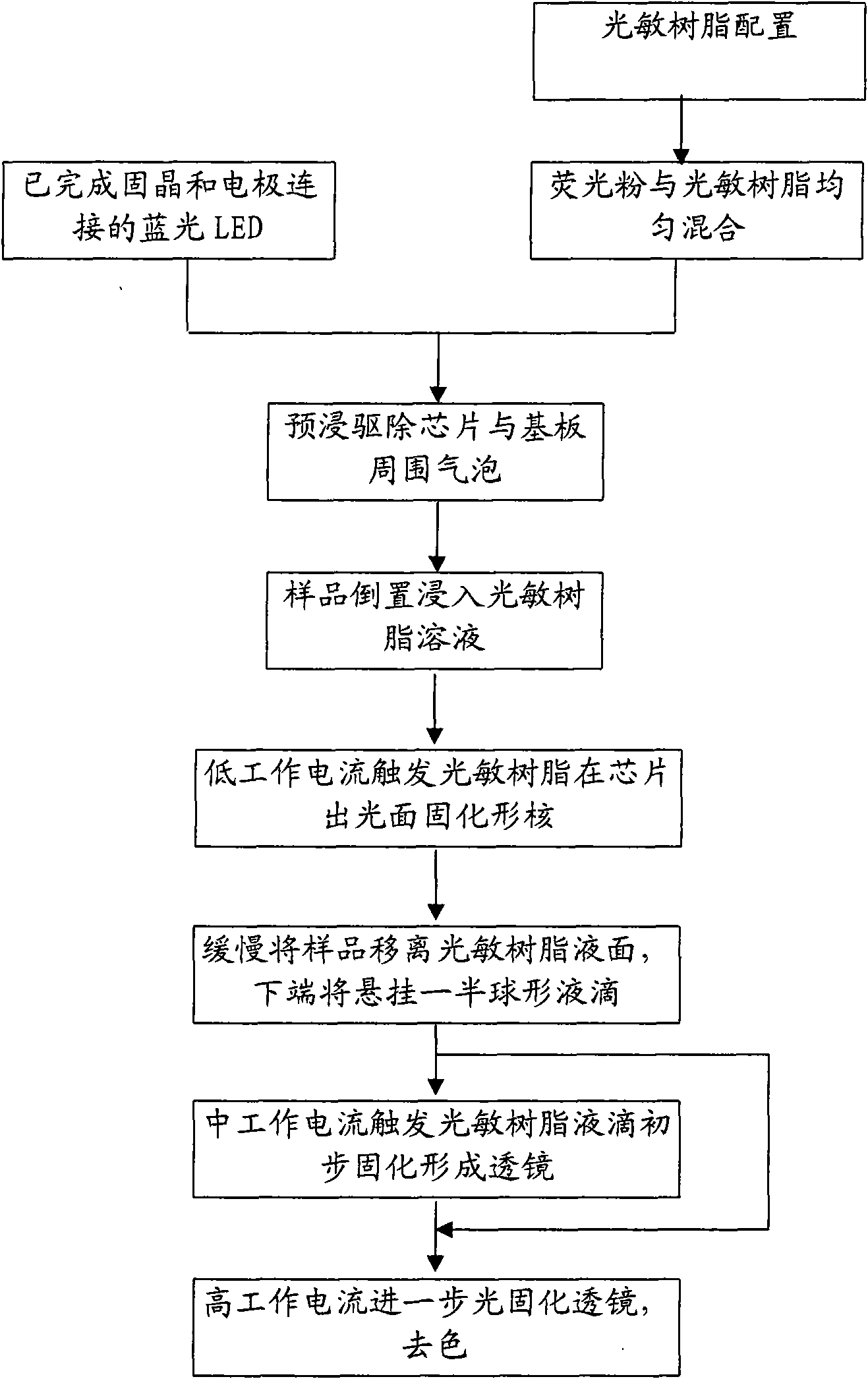

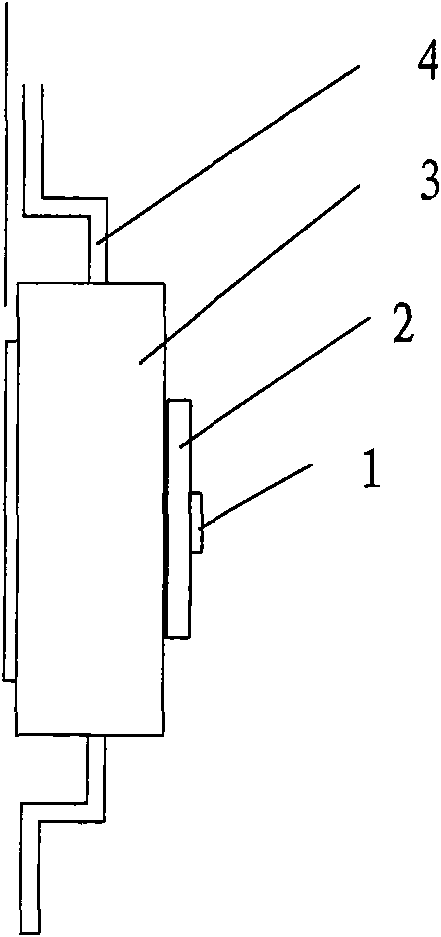

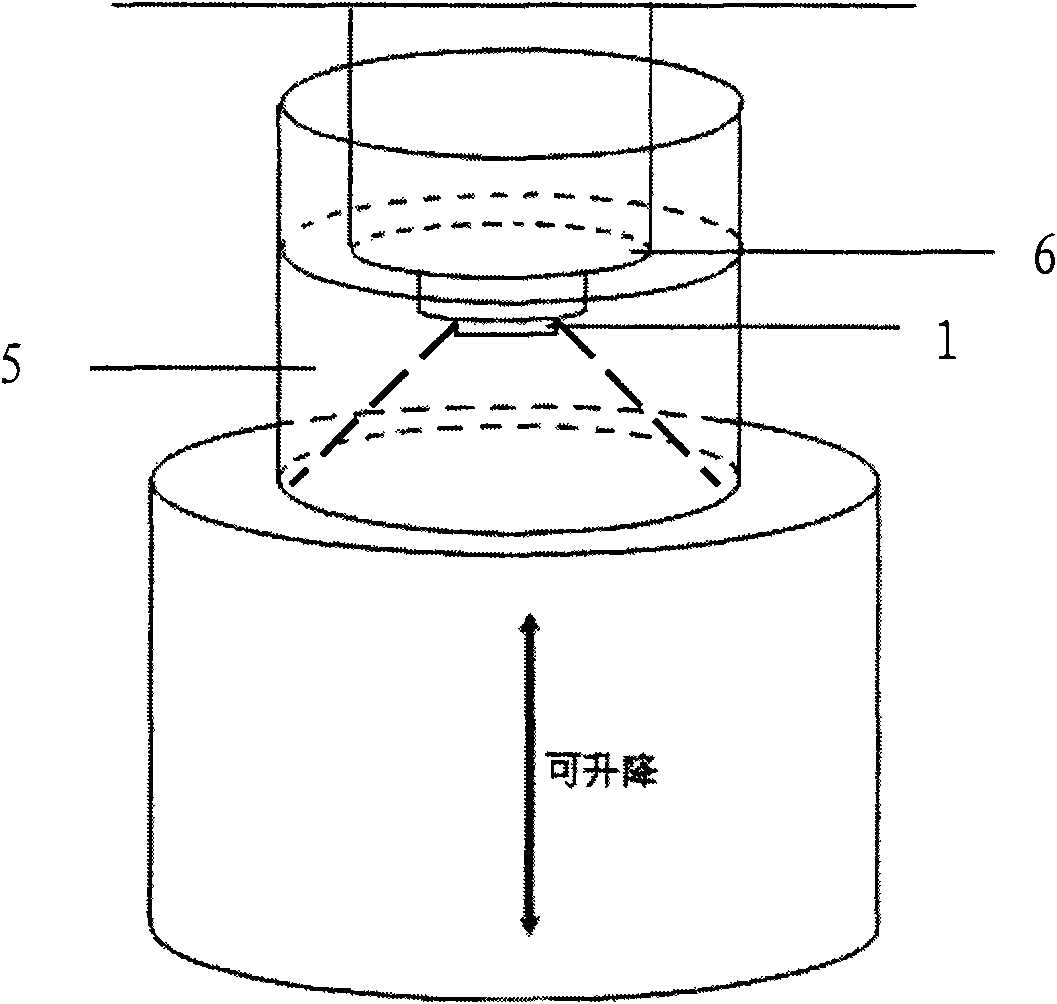

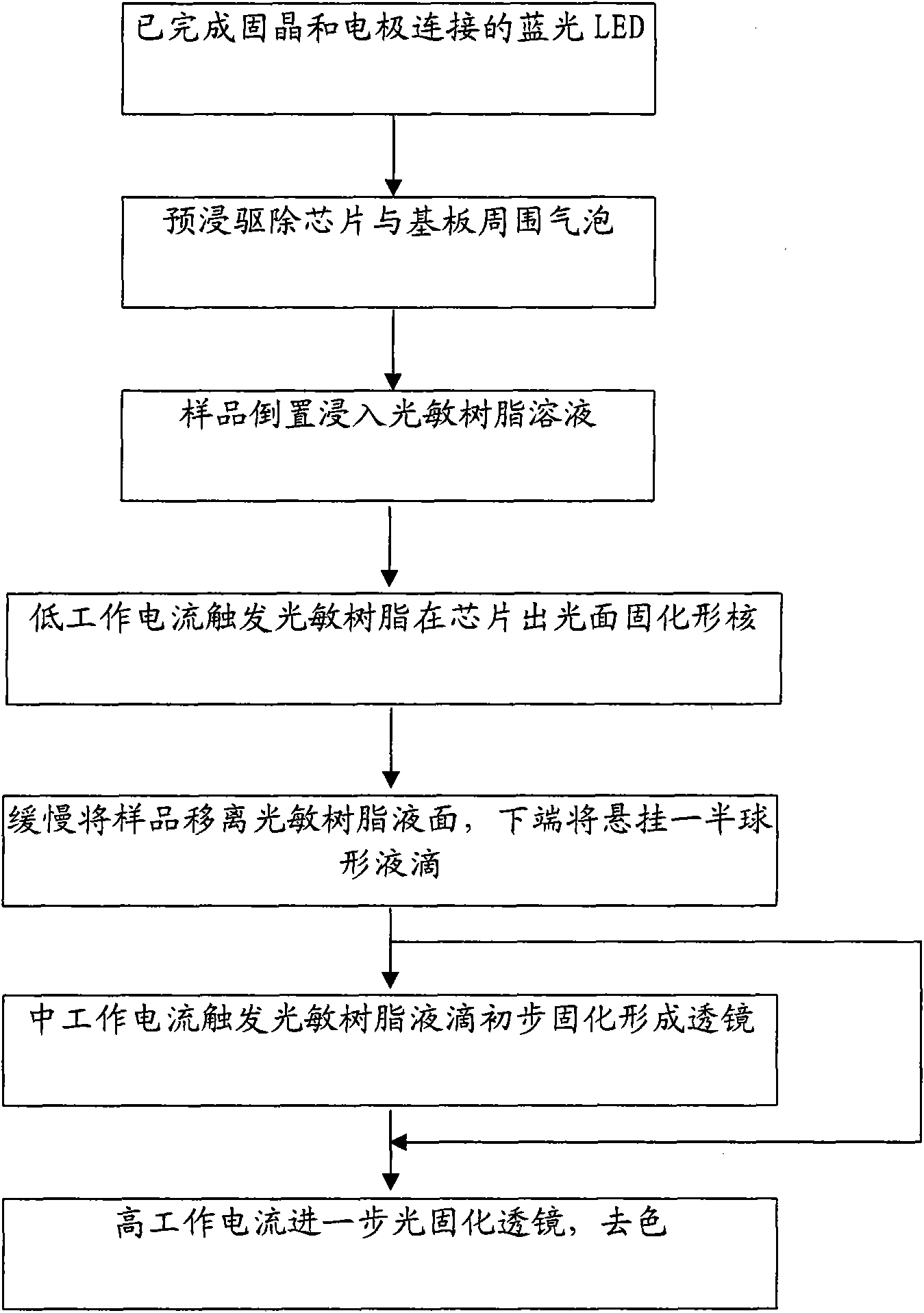

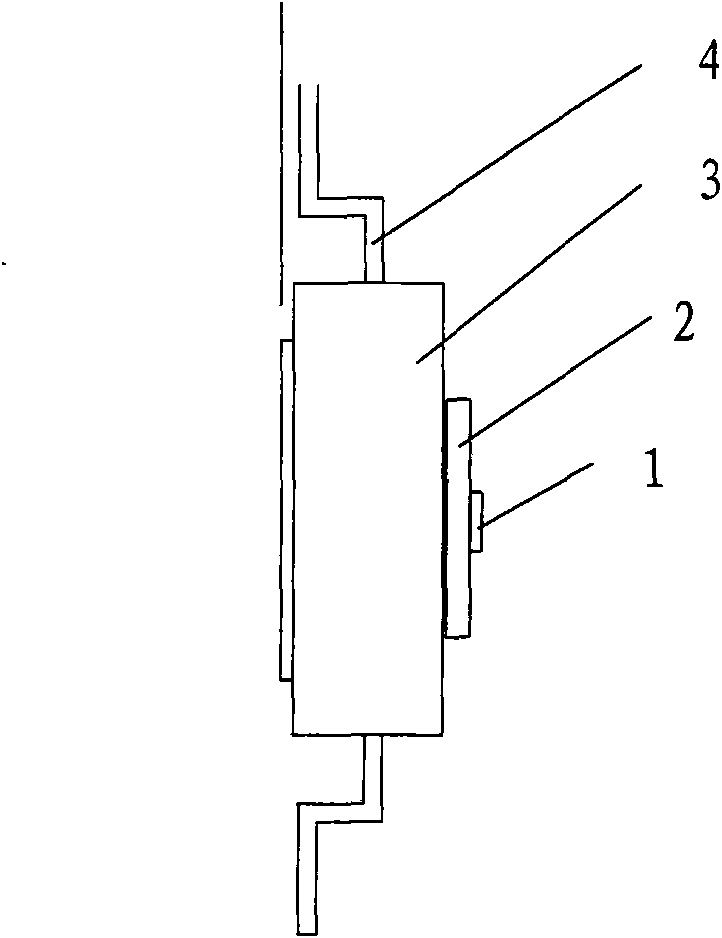

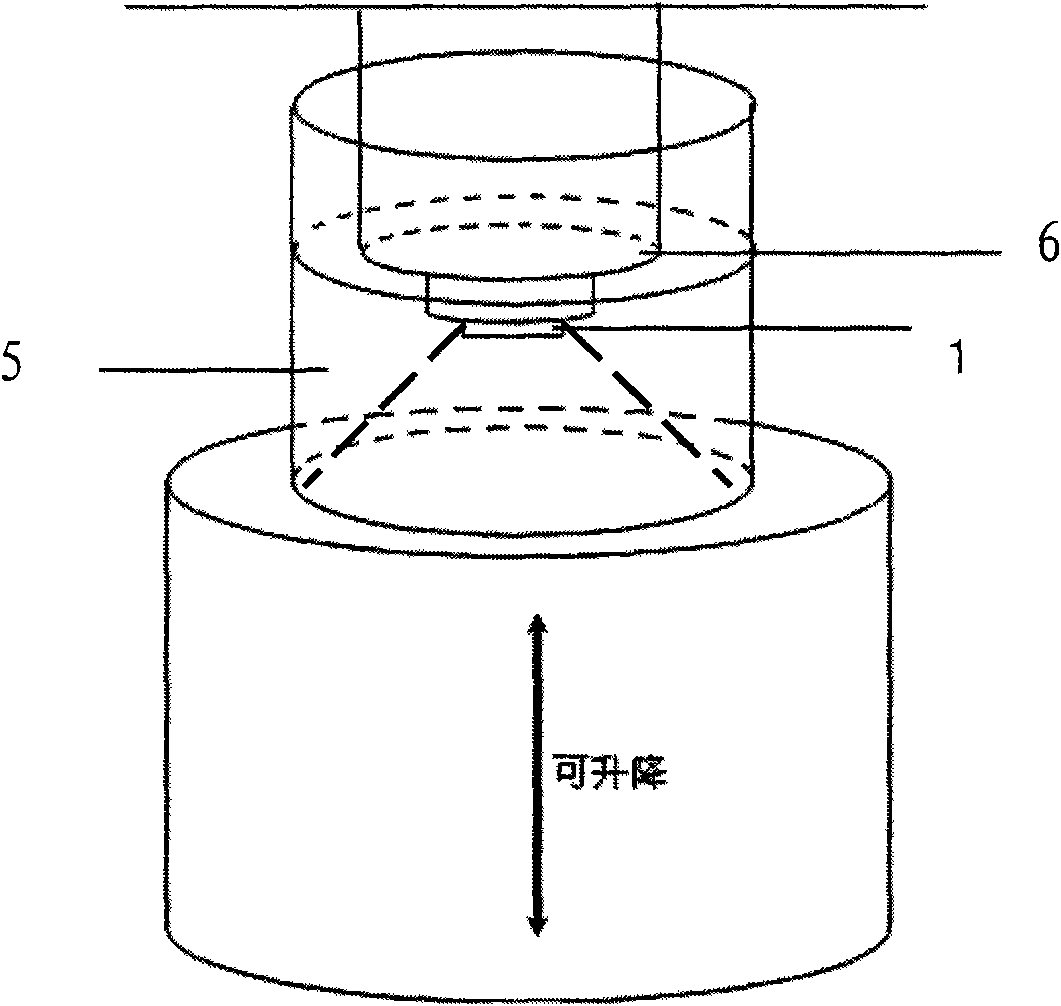

Method for actively encapsulating LED chip and encapsulation structure thereof

InactiveCN101582477AImprove light extraction efficiencyGood process repeatabilitySemiconductor devicesUltraviolet lightsWork in process

The invention discloses an active encapsulation method which utilizes the spontaneous light of a chip to initiate photosensitive resin polymerization for the in-situ preparation of a lens with an LED single layer and multilayer structure. The method includes the following steps: photosensitive resin liquid wave band light which is sensitive to specific wave band light is prepared; an LED semi-finished product which is processed by electrode connection and die bond is presoaked in photosensitive resin for die bond; the LED semi-finished product is inverted to be soaked in the photosensitive resin liquid, low working current is led into and enables the LED chip to be luminous, photosensitive resin is triggered to generate preliminary polymerization, and a photosensitive resin core is formed on the luminous surface of the LED chip; the LED semi-finished product is separated from the surface of the photosensitive resin liquid, and the drops of the photosensitive resin liquid need to be attached to the photosensitive resin core and a chip base; the intermediate working current is led into and enables the LED chip to be luminous, and the drops of the photosensitive resin liquid are stimulated to be solidified; after the solidification of the drops of the photosensitive resin liquid, high working current is led into a sample so as to enable the LED chip to be luminous, and then the steps of solidification and decoloration are carried out, or the sample is irradiated by sunlight, purple light or ultraviolet light to be decolourized; and finally the sample processed by solidification and decoloration is cleaned.

Owner:SUN YAT SEN UNIV

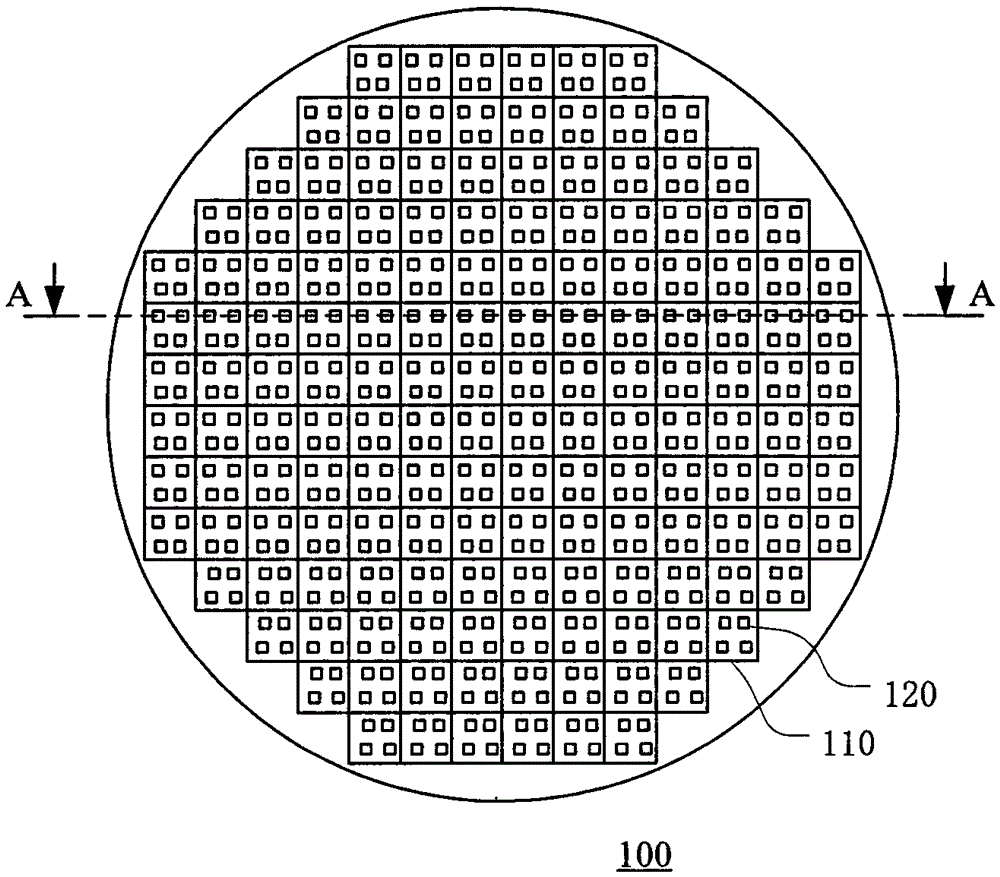

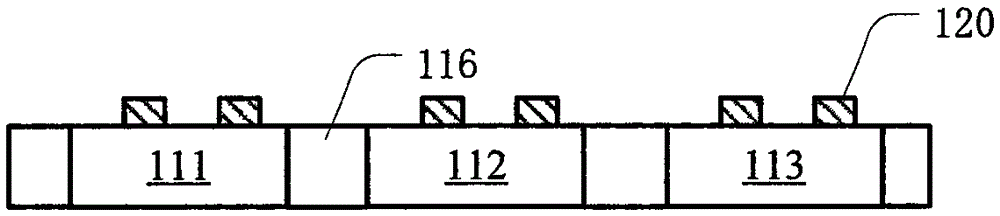

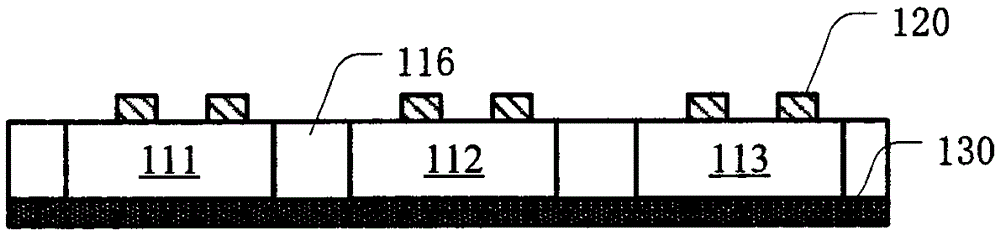

Chip packaging method and packaging assembly

InactiveCN105575825AImplement encapsulationFlexible designSemiconductor/solid-state device detailsSolid-state devicesElectrical performanceLead frame

The invention discloses a chip packaging method and a packaging assembly. The chip packaging method comprises the steps of forming a first packaging layer on multiple chips, wherein the multiple chips comprise opposite first surfaces and second surfaces respectively, and multiple first conductive convex blocks formed on the first surfaces; forming a re-wiring layer on the surface of the first packaging layer; forming multiple second conductive convex blocks on the re-wiring layer so as to form the packaging structure; and separating the packaging structure into multiple packaging assemblies, wherein the re-wiring layer enables the multiple first conductive convex blocks to be connected to the multiple second conductive convex blocks so as to provide a conductive path from the multiple chips to an external circuit. According to the chip packaging method, a lead frame and a bonding wire can be saved, so that flexible pin layout is allowed, and the electrical performance of the packaging assemblies is improved.

Owner:HEFEI SMAT TECH CO LTD

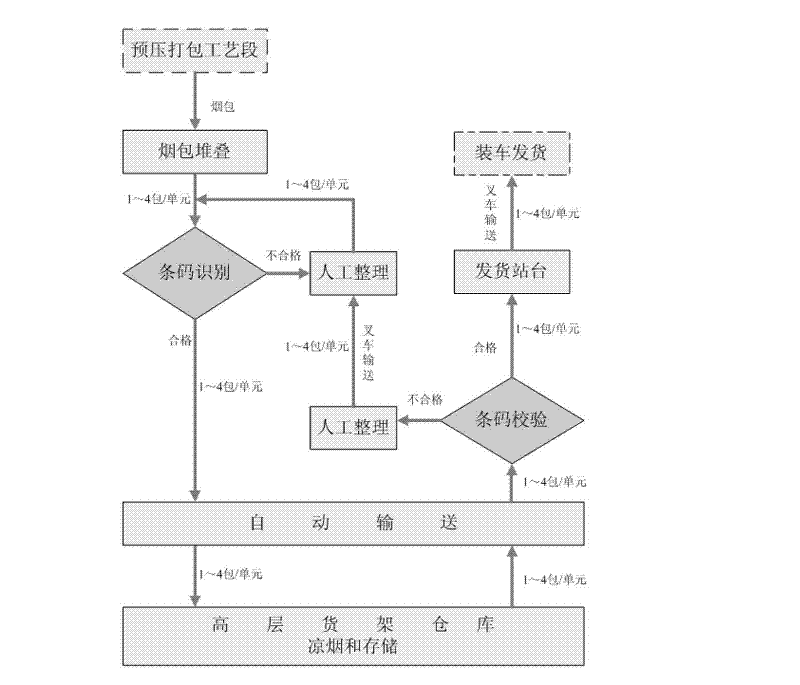

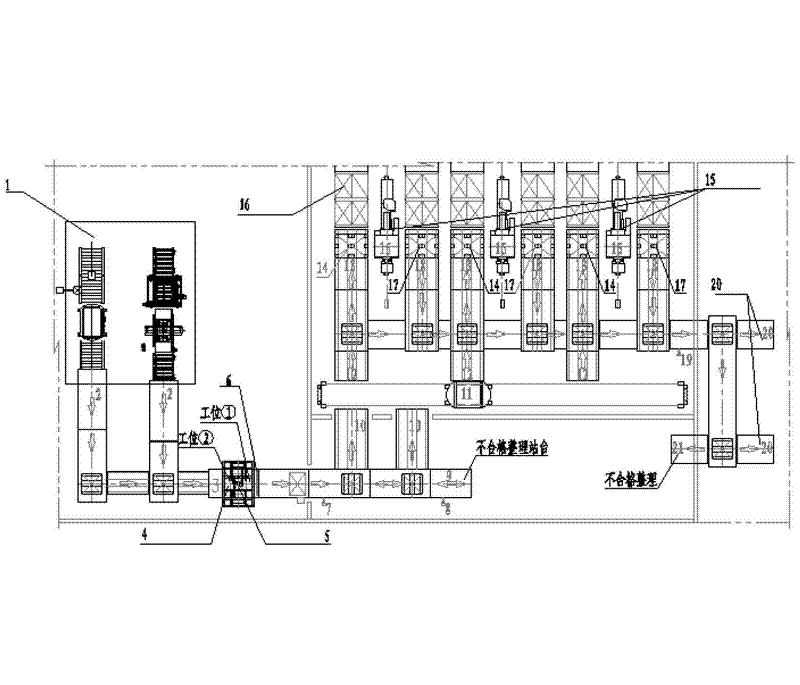

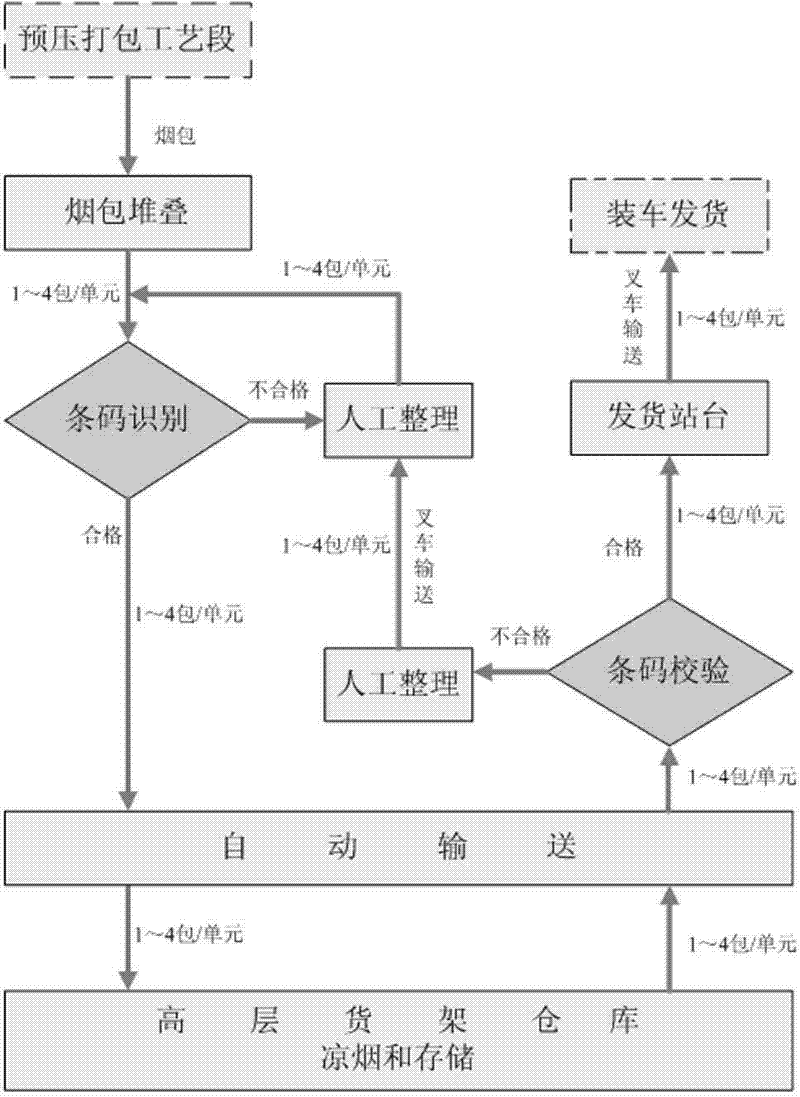

High-efficiency slim cigarette storage method for re-drying finished cigarette packets

InactiveCN102556563ARealize automatic packagingAchieve traceabilityStorage devicesLogistics managementHigh rise

A high-efficiency slim cigarette storage method for re-drying finished cigarette packets relates to a slim cigarette storage method in the tobacco industry, in particular to the high-efficiency slim cigarette storage process for the finished cigarette packets in threshing and re-drying production in the tobacco industry. The method includes the steps: a, pre-pressing and packaging; b, automatically warehousing in; c, storing slim cigarettes; and d, automatically warehousing out. The method has the main advantages that 1, the cigarette packets are stacked in the form of one-four packets / unit to be stored and conveyed, so that conveying flow can be effectively reduced; 2, building of high-rise storage rack warehouses is facilitated, space resources can be used to the maximum extent by means of stacker technology, investment is saved, automation degree level is high, and management is facilitated; 3, the slim cigarette efficiency is improved beneficially, and the quality of tobacco leaves can be better guaranteed; 4, investment cost is effectively reduced by the aid of pallet-free storage; 5, information tracking in the whole course is facilitated, and information traceability is improved; and 6, an advanced logistic system is formed beneficially, and the automated management level of enterprises is improved.

Owner:KUNMING KSEC LOGISTIC INFORMATION IND

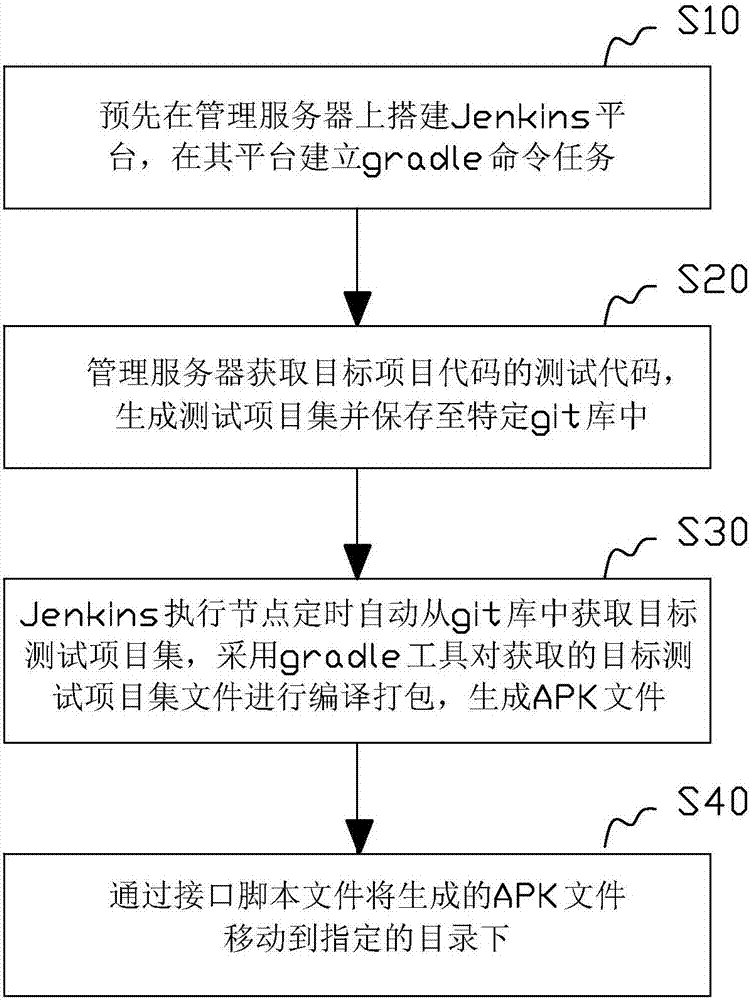

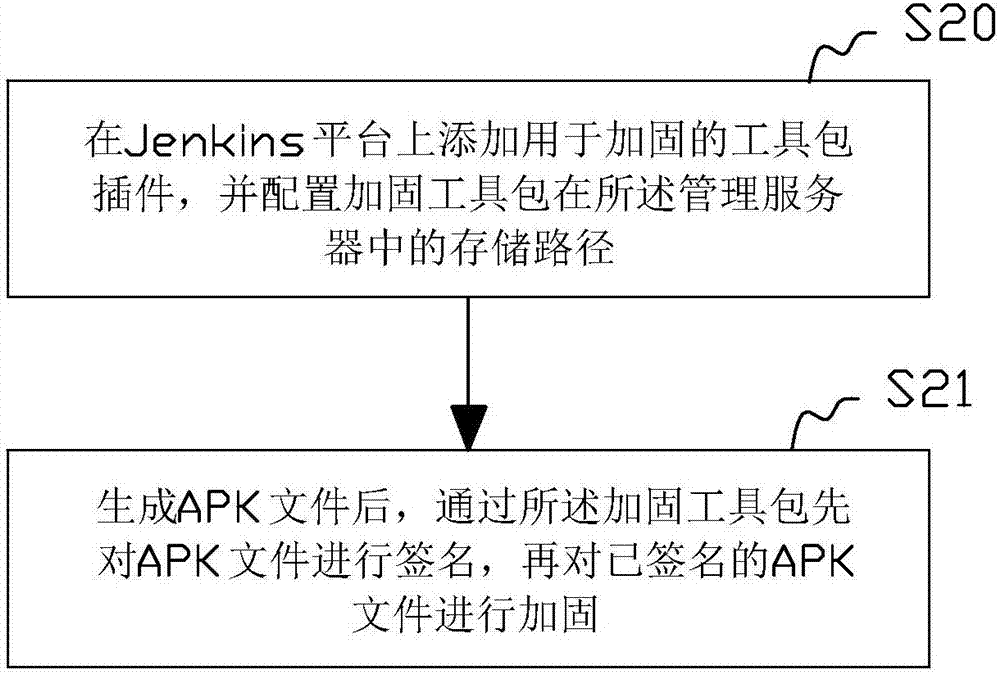

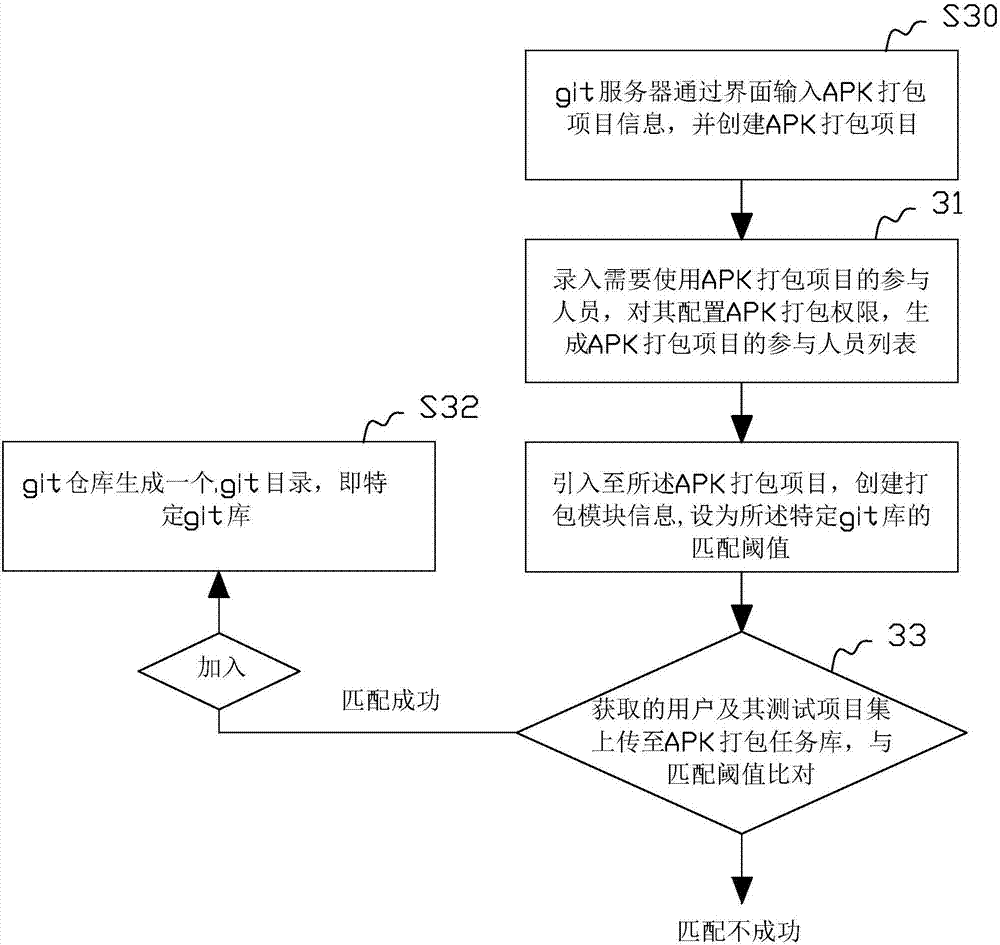

Method and system for automatically packaging APK (Android Package) installation package on server

InactiveCN107301074AImprove securityRealize automatic packagingResource allocationSoftware testing/debuggingOperating systemTest item

The invention relates to a method for automatically packaging an APK (Android Package) installation package on a server. The method at least comprises the following steps that: establishing a Jenkins platform on a management server in advance, and establishing a gradle command task on the platform; obtaining the test code of a target item code by the management server, generating a test item set, and storing the test item set in a git library; automatically obtaining a target test item set from the specific git library by a Jenkins execution node in fixed time, adopting a gradle tool to compile and package an obtained target test item set file by the gradle tool, and generating an APK file; and through an interface script file, moving the generated APK file to an appointed catalogue. The invention aims to establish an automatic operation method and system capable of efficiently, accurately and continuously packaging the APK installation package.

Owner:ZHONGGUANG REDIANYUN TECH CO LTD

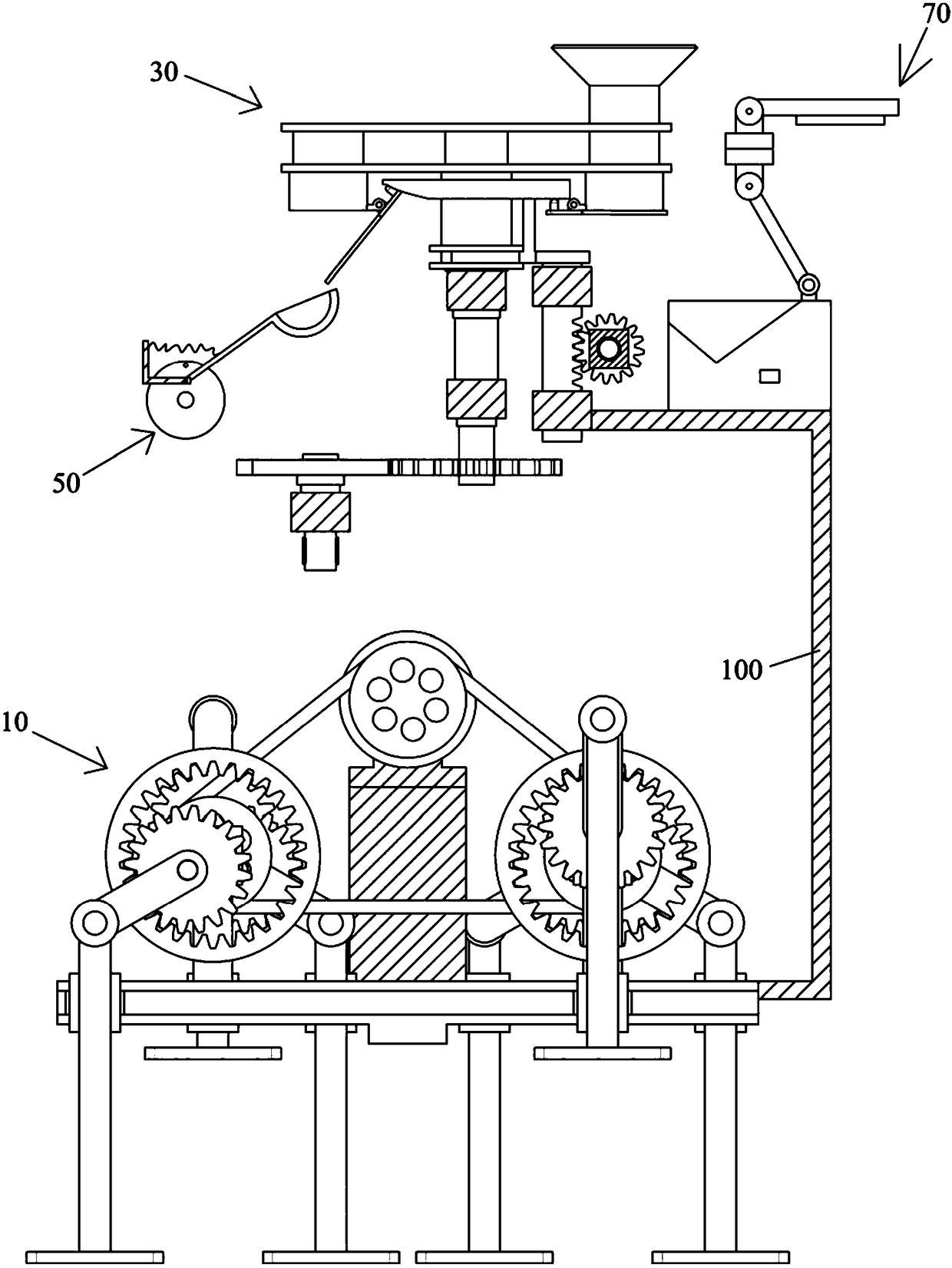

Rice sub-packaging line

PendingCN109051137ARealize automatic packagingSolid materialPackaging machinesChain conveyorManufacturing engineering

The invention discloses a rice sub-packaging line, and belongs to the technical field of central kitchen equipment. The rice sub-packaging line comprises an automatic lunch box blanking machine, a rice sub-packaging machine, a sealing machine, a sucker transferring device, a plate chain conveyor and a rice lifting machine, wherein the automatic blanking machine, the rice sub-packaging machine, thesealing machine and the sucker transferring device are sequentially arranged above the plate chain conveyor; the rice lifting machine is arranged on the side part of the rice sub-packaging machine; and the rice pouring direction of the rice lifting machine directly faces a rice feeding part of the rice sub-packaging machine. According to the rice sub-packaging line provided by the invention, thewhole process of automatically loading rice, automatically discharging lunch boxes, sub-packaging the rice, covering the rice with films, and transferring out of the sub-packaging line is automatic.

Owner:ANHUI ZEJIAYE POWDER ENG

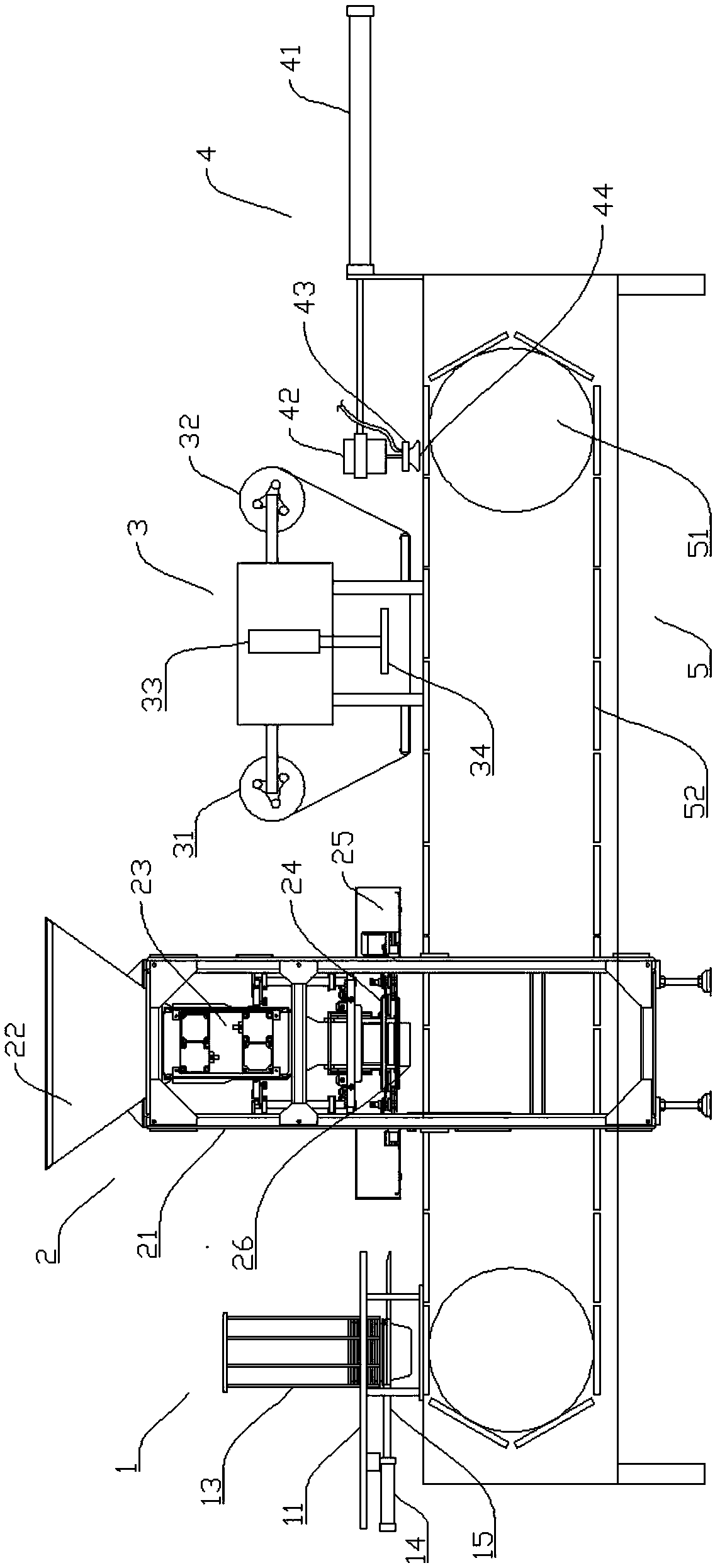

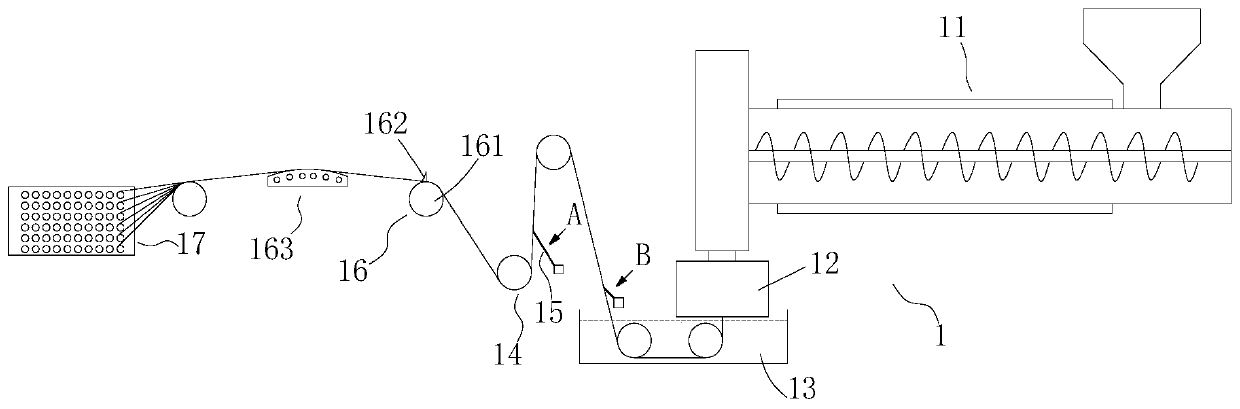

Production assembly line for woven bags

ActiveCN110552076AAvoid stickingAvoid tilting your headPaper article packagingCircular loomsAssembly lineAutomation

The invention relates to the field of production of woven bags, in particular to a production assembly line for woven bags. The production assembly line comprises a ribbonfil production device, a circular weaving device, a roll printing device, a cutting sewing device and a packaging device. Raw materials are heated, melted, extruded and formed into ribbonfil through the ribbonfil production device, the circular weaving device weaves the continuous cylindrical woven bags through the ribbonfil, the woven bags are printed with patterns and characters through the roll printing device, and the printed woven bags are cut off and sewn through the cutting sewing device, then discharged from the cutting sewing device and automatically packaged through the packaging device finally. The production assembly line for the woven bags has the advantages that the production assembly line for the woven bags can achieve production of the woven bags, the overall production efficiency and automation degree are high, the product quality is good, and the production assembly line is suitable for large-scale popularization.

Owner:泗县鸿盛塑业股份有限公司

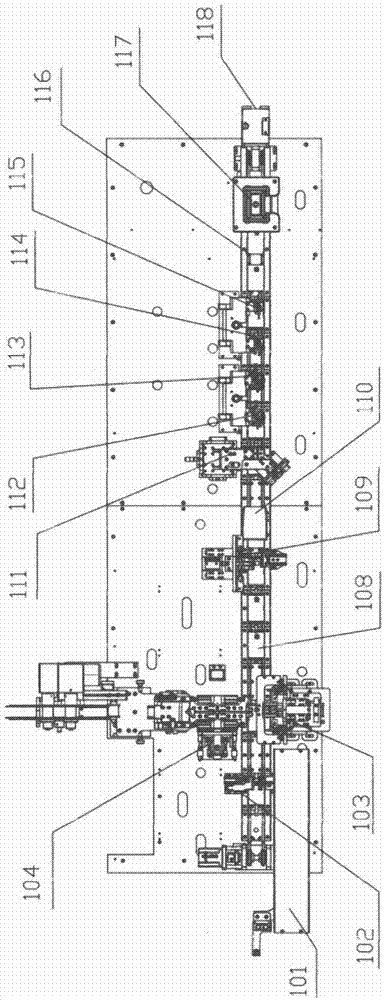

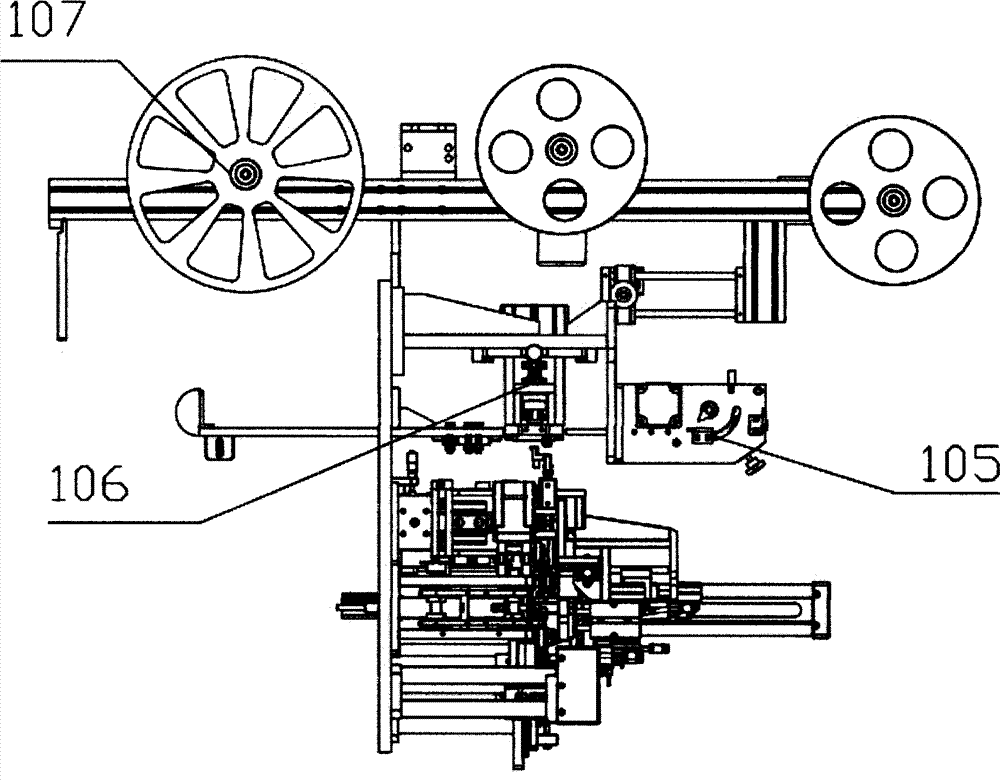

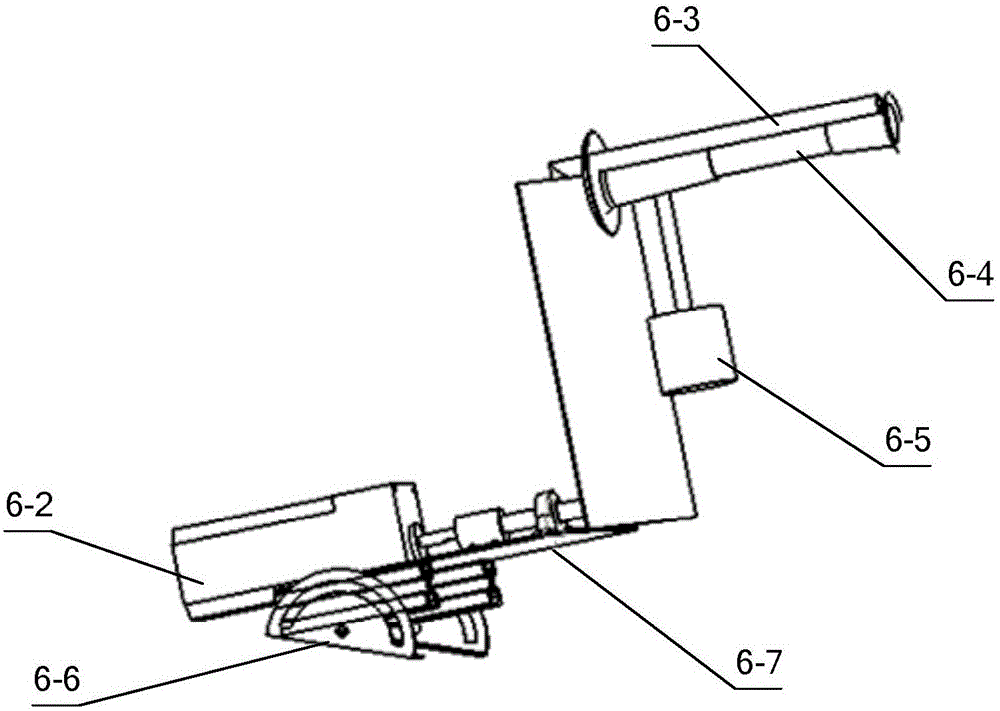

Packaging machine and packaging method for dual-interface card

InactiveCN103192188ARealize automatic packagingRealize automatic card issuance operationWelding/cutting auxillary devicesAuxillary welding devicesButt weldingEngineering

The invention discloses a packaging machine and a packaging method for a dual-interface card. The packaging machine comprises a card-in carrying arm, a Y-direction antenna correction group, a chip turning group, an antenna correction butt-welding group, a charge coupled device (CCD) detection group, a chip push-over group, a first non-contact detection group, a correction spot-welding group, a first hot-welding group, a second hot-welding group, a cold-welding group, a contact detection group, a second non-contact detection group and a cartridge group. By adoption of the scheme, the packaging machine packages a chip of the dual-interface card on the dual-interface card with an antenna selected mechanically or manually, achieves the technical effect of automatic packaging, and can be operated singly or operated by connecting with other equipment. During single operation, automatic card distribution operation and automatic packaging can be realized only by placing the card base with the selected antenna on a material-discharging conveying belt without manual operation, and the operation is flexible and convenient.

Owner:SHENZHEN FINESUN PRECISION MACHINERY & TECH CO LTD

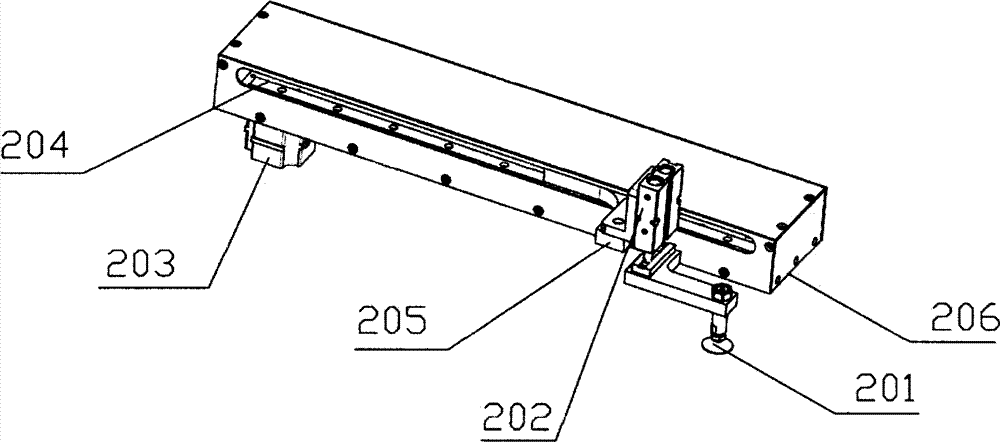

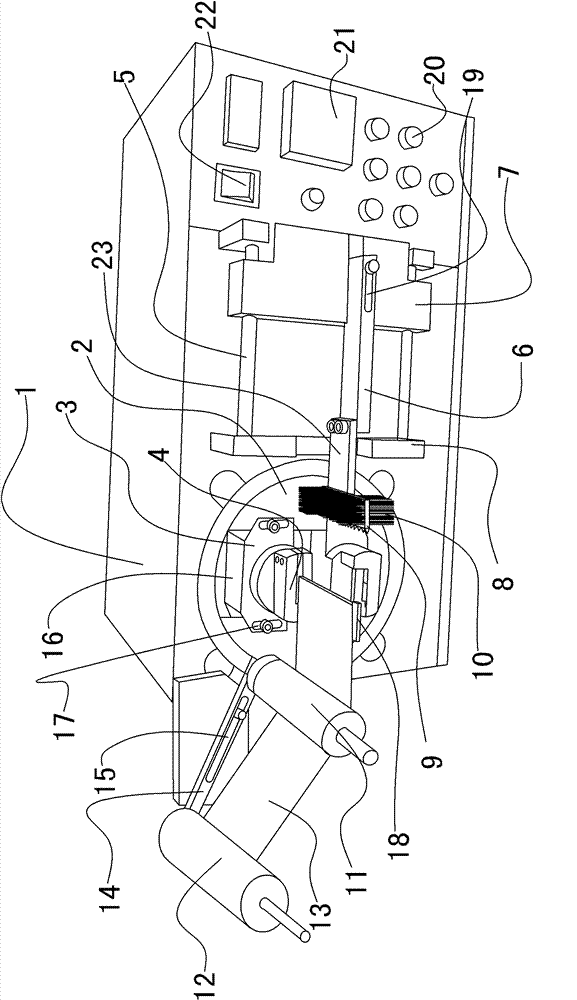

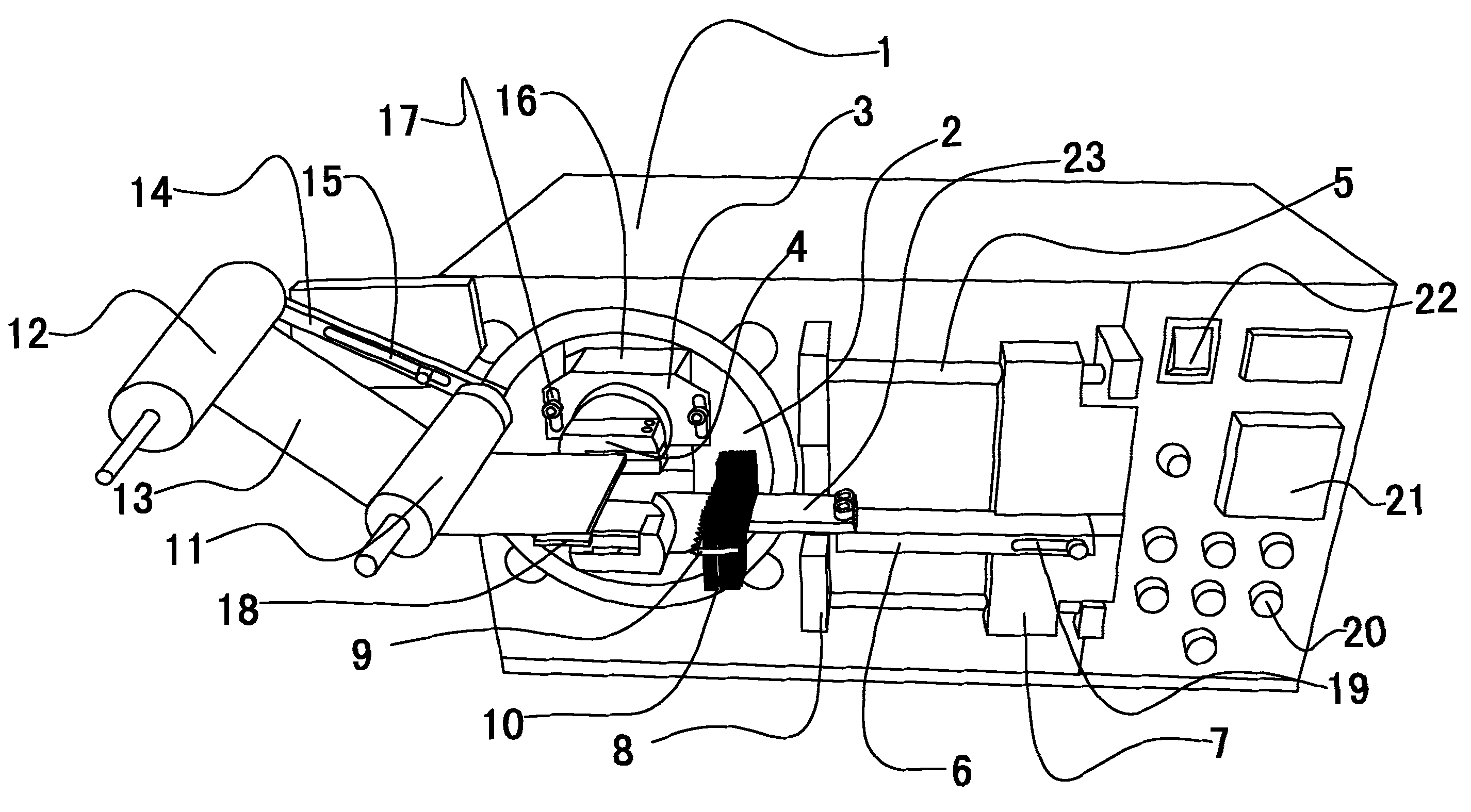

Automatic tape-wrapping machine

InactiveCN102137585BRealize automatic packagingQuality assuranceCooling/ventilation/heating modificationsEngineeringHeat sink

The invention discloses an automatic tape-wrapping machine used for wrapping a heat-radiating fin with an insulating tape. The tape-wrapping machine comprises a machine frame, a main shaft, heat-radiating fin holders, a tape and reel holder, a sliding rail, a sliding block, a knife holder and a cutting knife, wherein the main shaft is installed on the machine frame; a main shaft driving device isarranged in the machine frame; the main shaft driving device drives the main shaft to rotate; more than two heat-radiating fin holders are arranged on the main shaft; a heat-radiating fin holder driving device drives the heat-radiating fin holders to rotate; heat-radiating fin splicing positions for splicing the heat-radiating fins are formed on the heat-radiating fin holders; the tape and reel holder for installing the tape is fixedly installed on the machine frame; the side of the main shaft is provided with the sliding rail; the sliding block capable of sliding along the sliding rail is arranged on the sliding rail; the knife holder is fixedly installed on the sliding block; the cutting knife is installed at the front end of the sliding block; a cutting knife driving device is arrangedon the machine frame; and the cutting knife driving device drives the cutting knife to move back and forth. Through a skilful design, the insulating tape can automatically wrap the heat-radiating fin, so production efficiency is greatly enhanced and quality of the heat-radiating fin can be effectively ensured.

Owner:MOSO POWER SUPPLY TECH

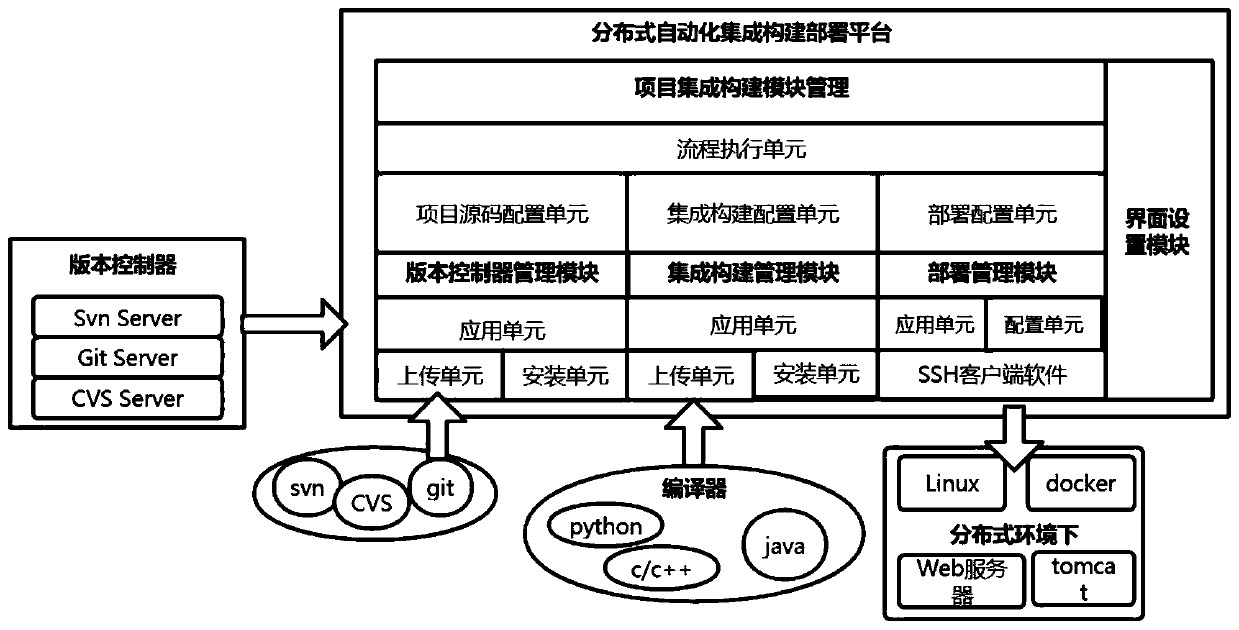

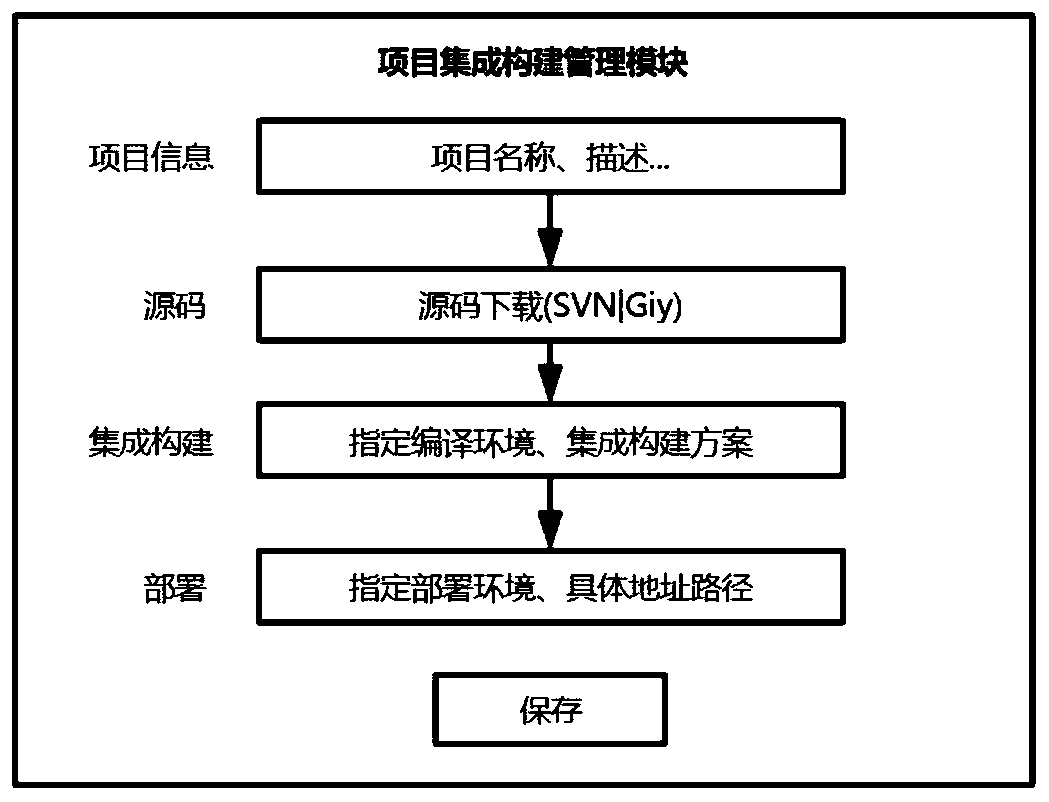

Automatic integrated construction, development and deployment platform and method

ActiveCN111506322ARealize fully automated integrated build deploymentRealize automatic packagingVersion controlSoftware deploymentConstruction managementSoftware development

The invention discloses an automatic integrated construction, development and deployment platform and method. The integrated construction development deployment platform comprises an interface settingmodule, a version controller management module, an integrated construction management module, a deployment management module and a project integrated construction management module. The version controller management module is in butt joint with various version controllers, the integrated construction management module is in butt joint with various compilers, the deployment management module ingeniously uses the universality of ssh instructions, and various deployment servers and containers can be in butt joint. And the project integration construction management module schedules integration construction related instructions at regular time to realize automatic downloading of source codes, automatic compiling, automatic packaging and automatic deployment. Repeated construction of an integrated construction, development and deployment platform for different projects is avoided, automatic integrated construction and deployment of different software projects or products can be achieved through the platform, and therefore the software development efficiency is improved.

Owner:RUINA INTELLIGENT EQUIP CO LTD

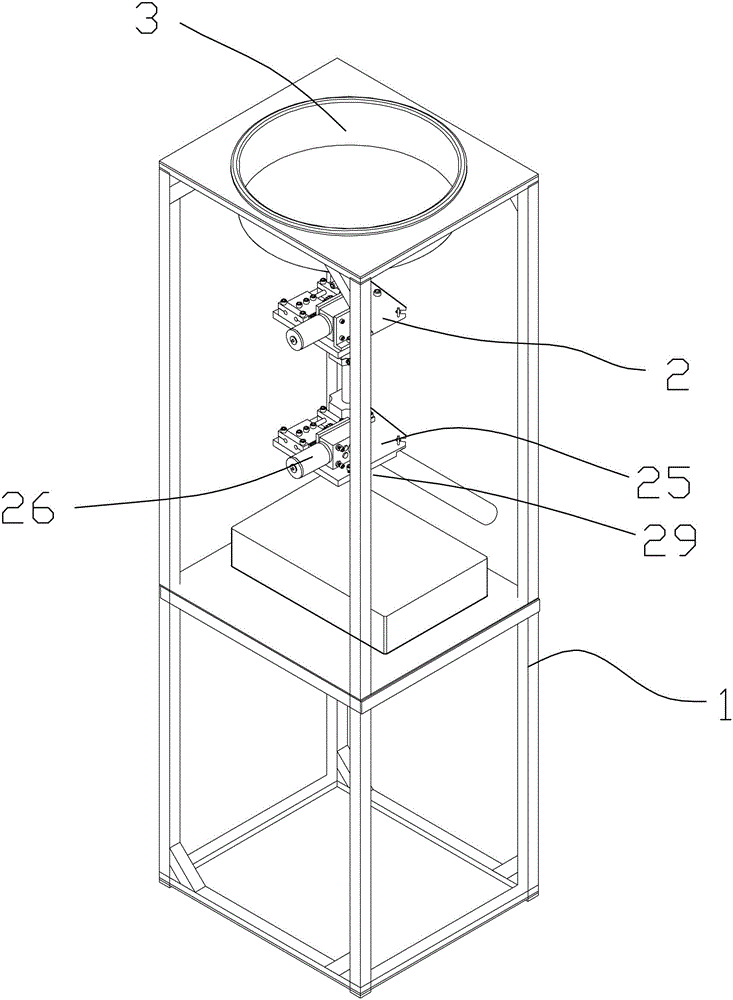

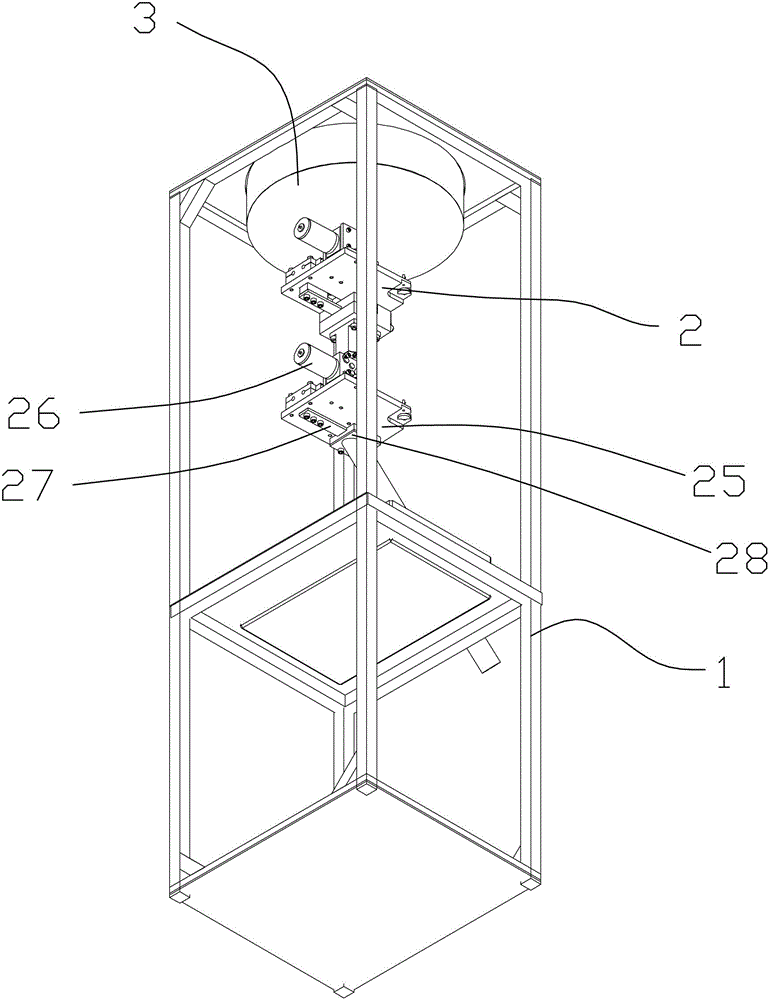

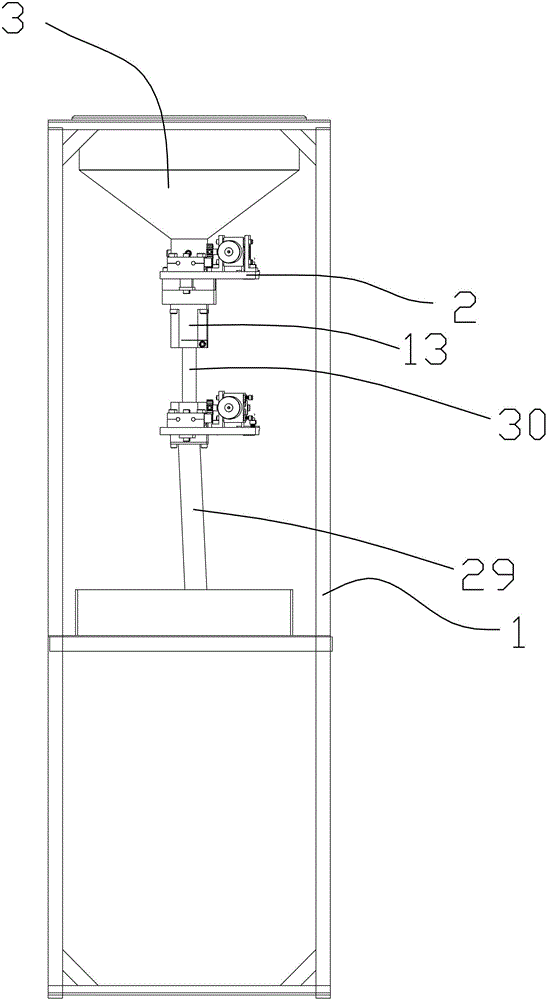

Steel ball racking machine

ActiveCN102910301ARealize automatic packagingReduce labor intensitySolid materialControl systemSteel ball

The invention discloses a steel ball racking machine comprising a rack, a funnel arranged on the rack, an upper valve sealing mechanism, a lower valve sealing mechanism, a racking cylinder, an upper chute, a discharge cylinder, a lower chute, a discharge pipe and a control system, wherein the upper valve sealing mechanism comprises a first supporting plate arranged on the rack, a first driving mechanism is arranged on the first supporting plate, a first transmission mechanism is connected to the first driving mechanism, a first propelling mechanism is connected to the first transmission mechanism, and an upper valve is connected to the first propelling mechanism; the discharge cylinder is arranged on the bottom surface of a second supporting plate, a discharge hole is arranged in the discharge cylinder, a material storage cavity is communicated with the discharge hole, and a lower valve can simultaneously seal the outlet of the material storage cavity and the inlet of the discharge hole; the lower chute is arranged on the discharge cylinder, the lower valve is located in the lower chute, and the inlet of the discharge hole is located in the bottom surface of the lower chute; the discharge pipe is connected with the discharge cylinder; and the control system is electrically connected with the first driving mechanism and a second driving mechanism.

Owner:中山市乾润精密钢球制造有限公司

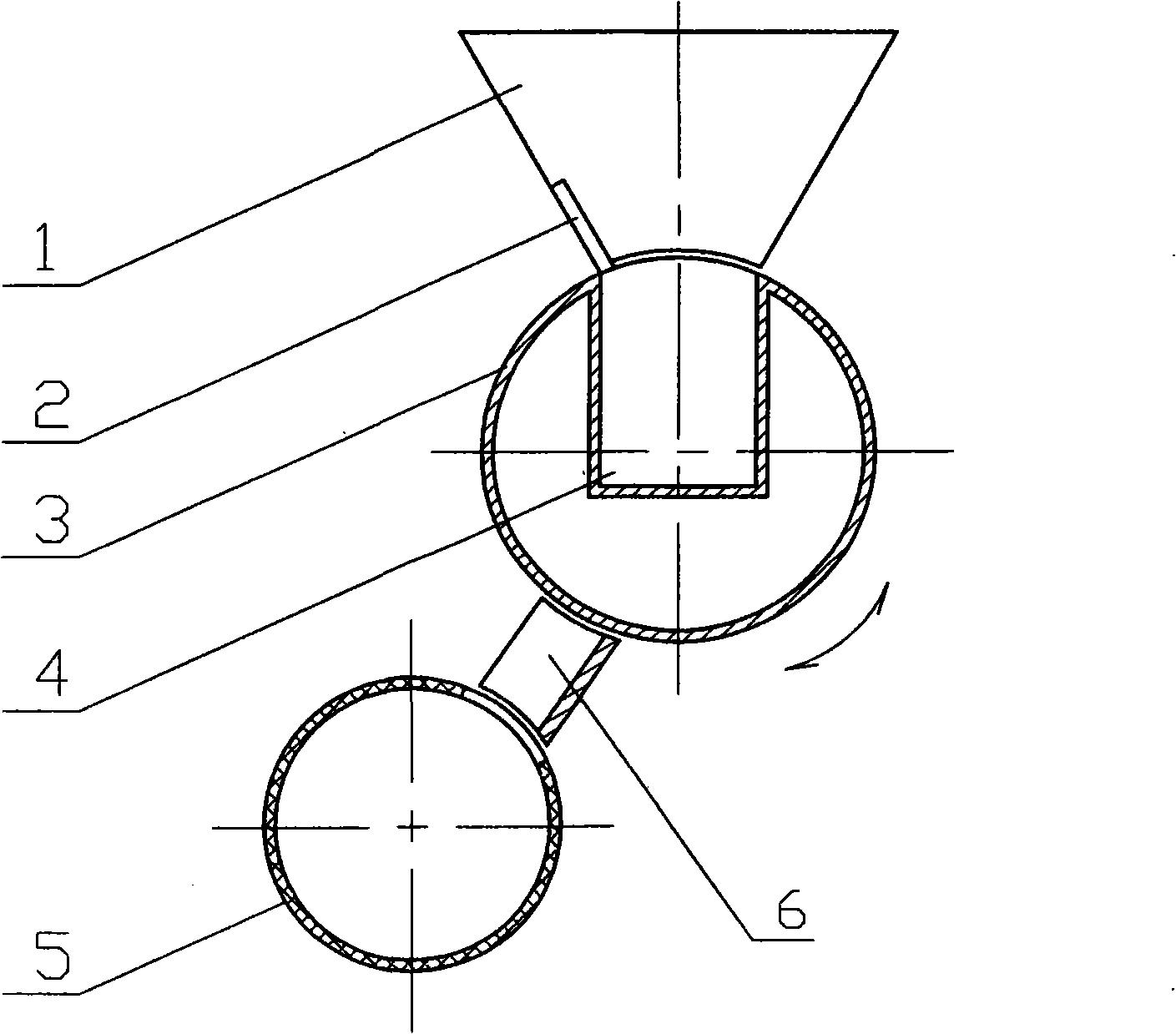

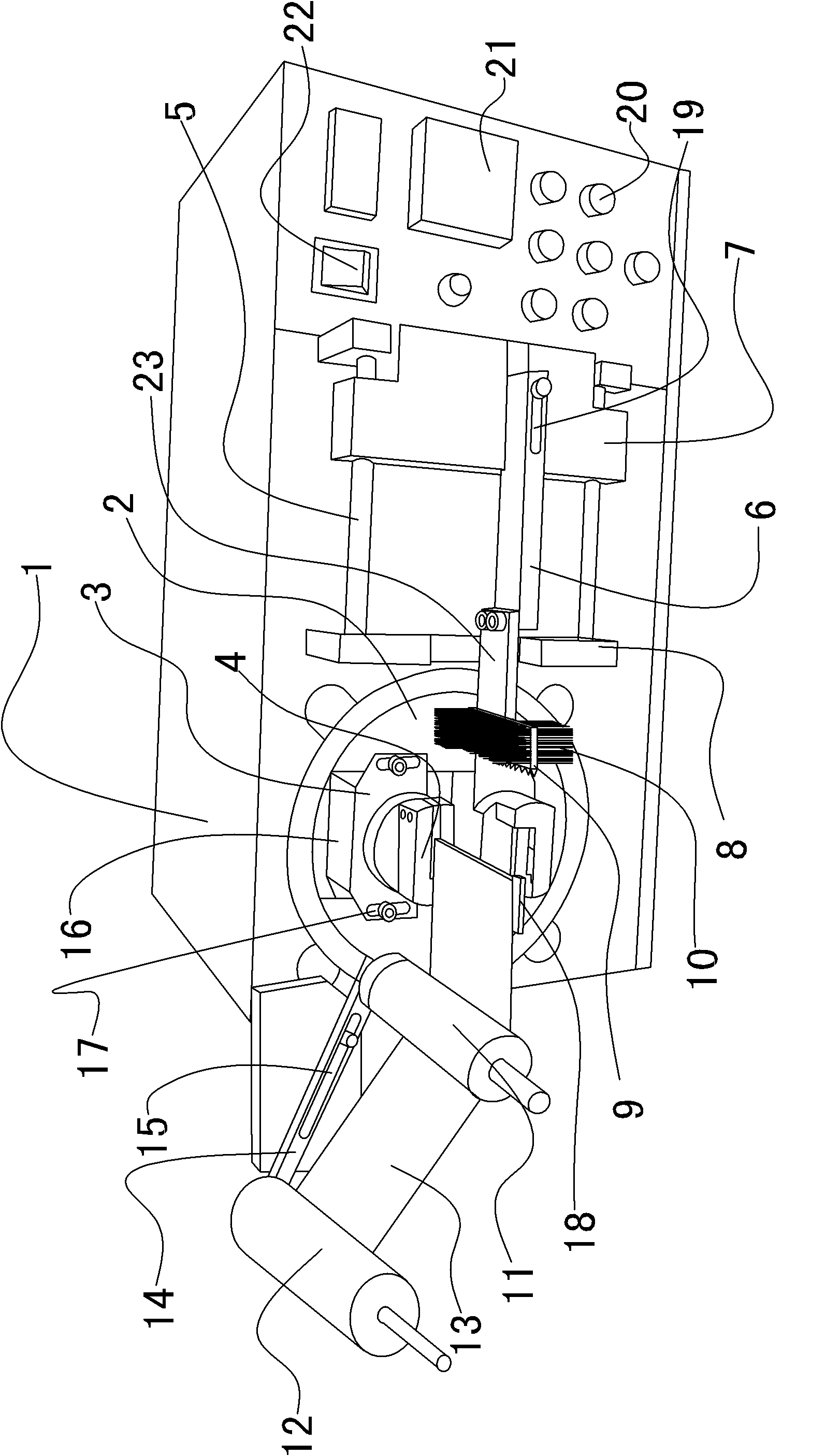

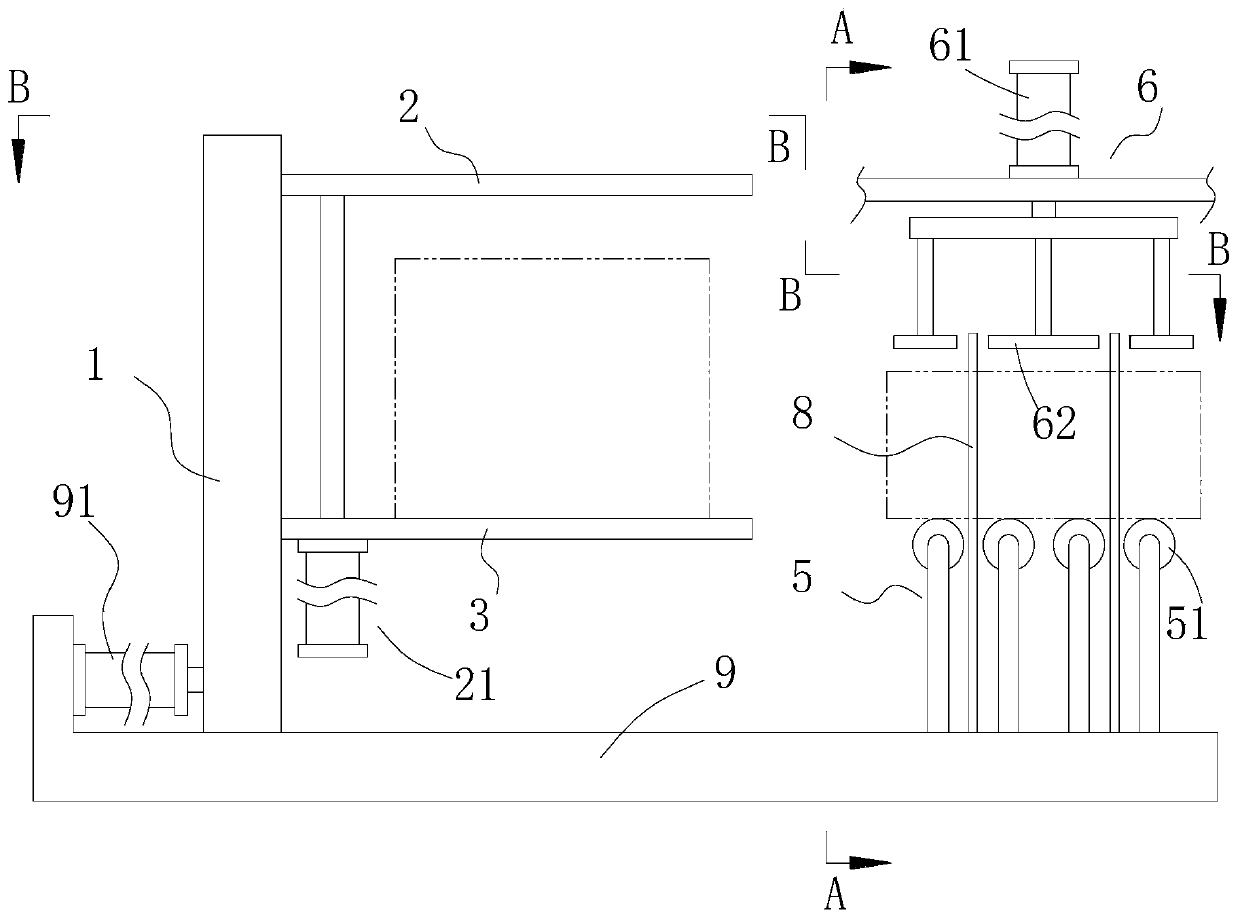

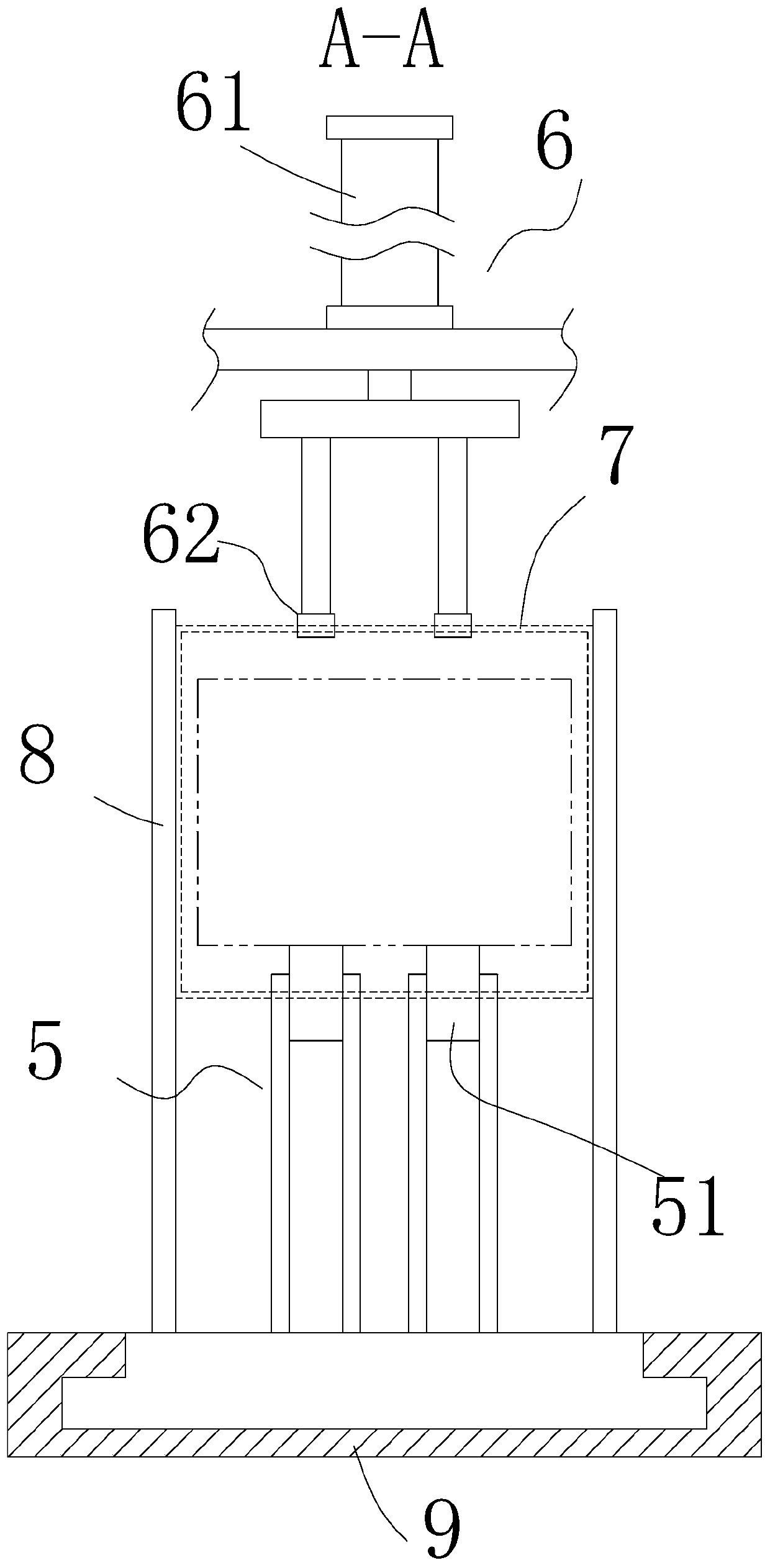

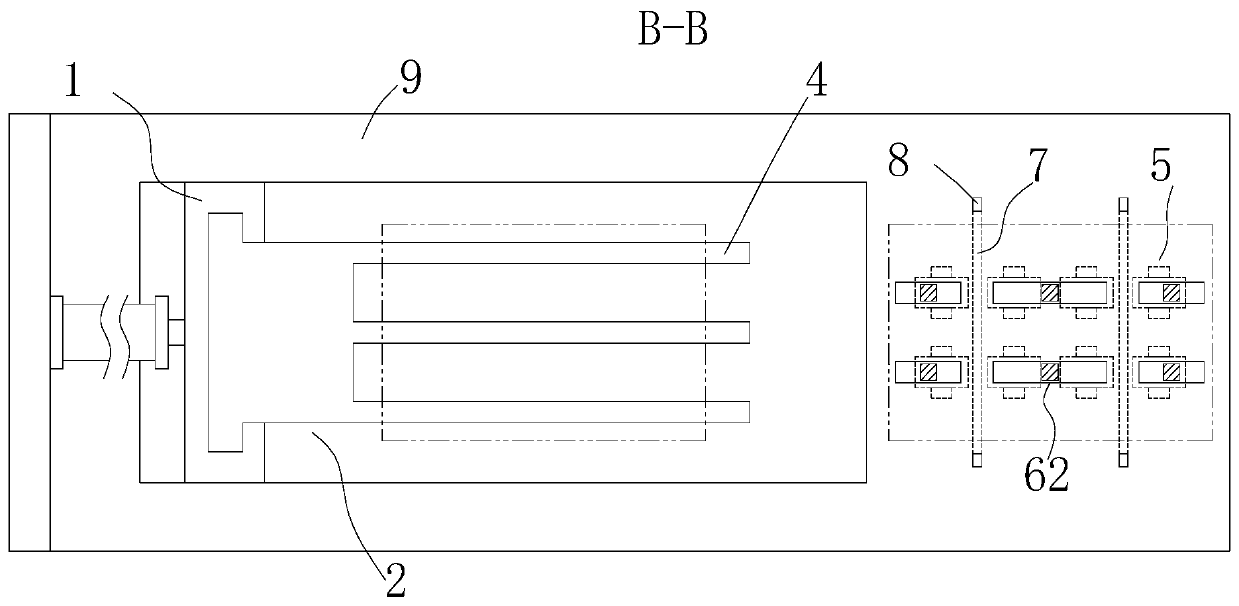

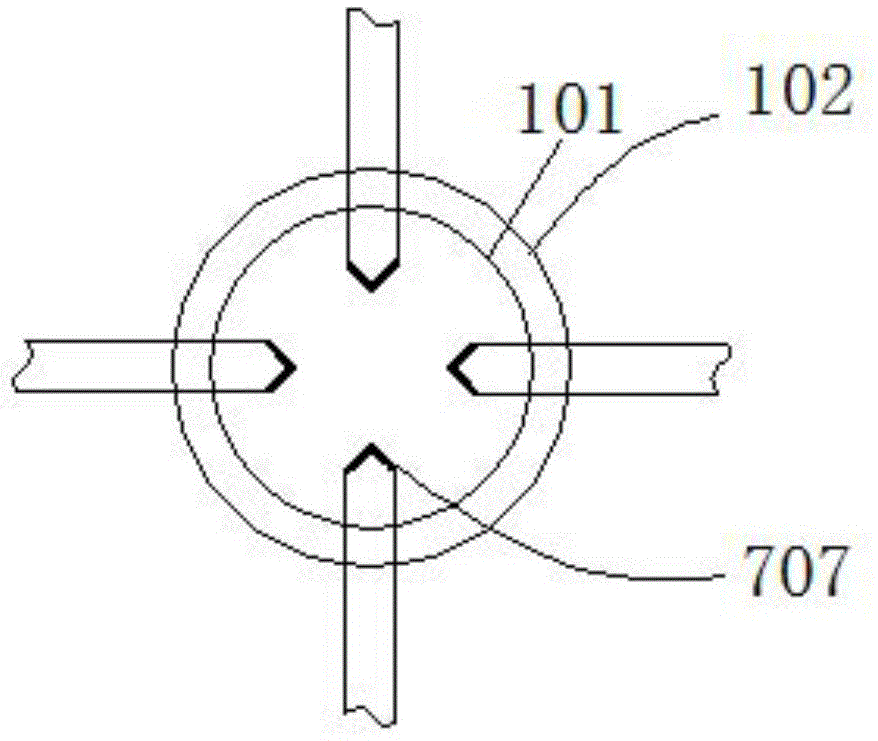

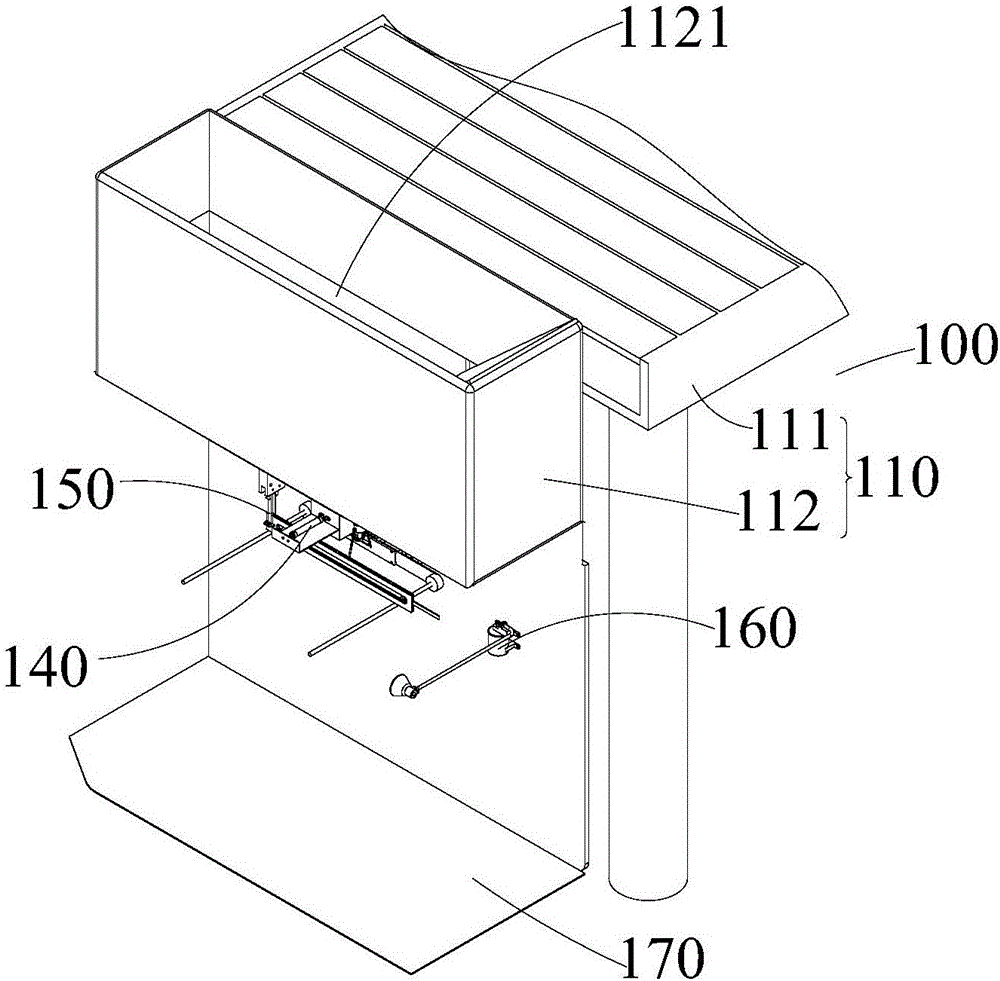

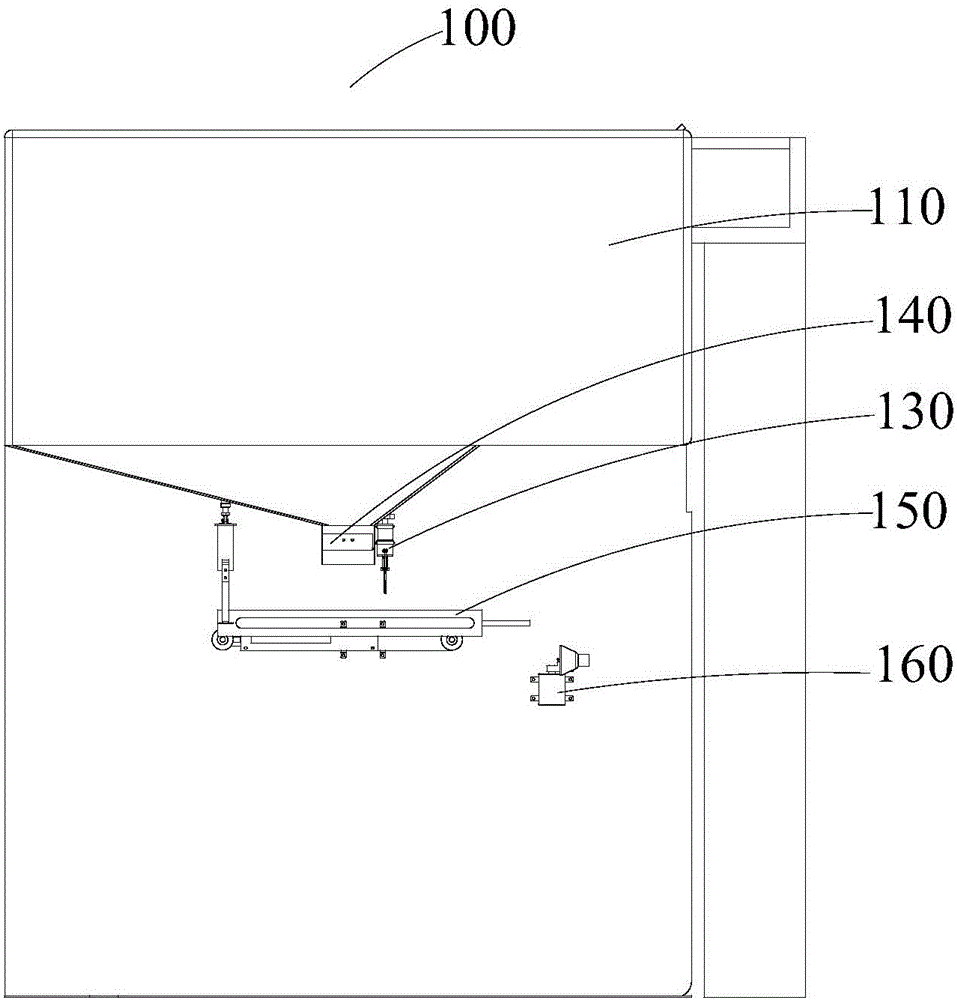

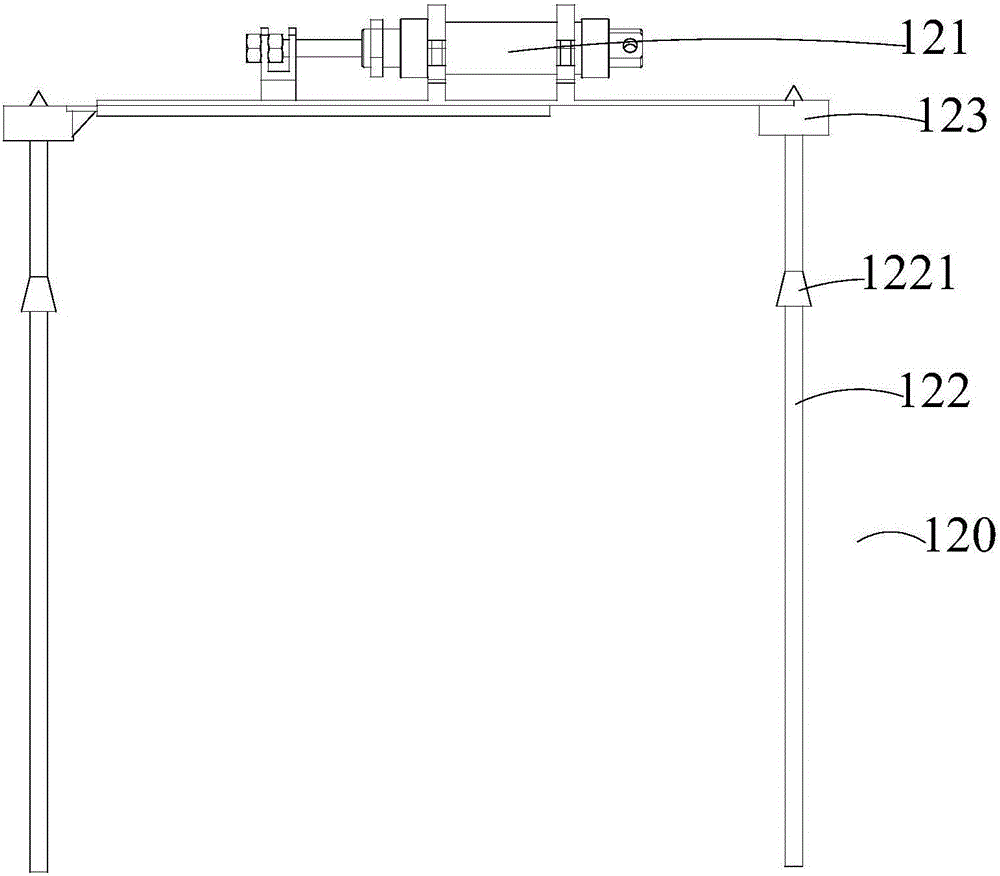

Scallop seed automatic allocation cage loading device

InactiveCN101336617ARealize automatic packagingPrevent crush damageClimate change adaptationPisciculture and aquariaBristleEngineering

The invention relates to an automatic distribution / cage loading machine for scallop seedlings. The machine comprises a cylindrical distributing roller (3) arranged on a machine frame, a plurality of holes formed in parallel on the cylindrical surface of the distributing roller (3), and distributing boxes (4) respectively arranged inside the holes. A plurality of discharge passages are formed by a plurality of discharge partitions (6) fixed on the machine frame below a feed hopper (1). The upper ends of the discharge passages are corresponding to the positions of the distributing boxes (4) and the lower ends thereof are positioned corresponding to the opening of each cultivation space of a scallop cage (5). The distributing roller drives the distributing boxes to rotate forwards or reversely at the predetermined angles, thereby realizing the automatic separate loading of the scallop seedlings. The automatic distribution / cage loading machine has the advantages of improved labor environment, high production efficiency and accurate distribution amount. Additionally, the automatic distribution / cage loading machine adopts the brush with flexible bristles to prevent the scallop seedlings from being crushed and damaged and thereby ensuring the safe loading of the scallop seedlings.

Owner:侯旭初

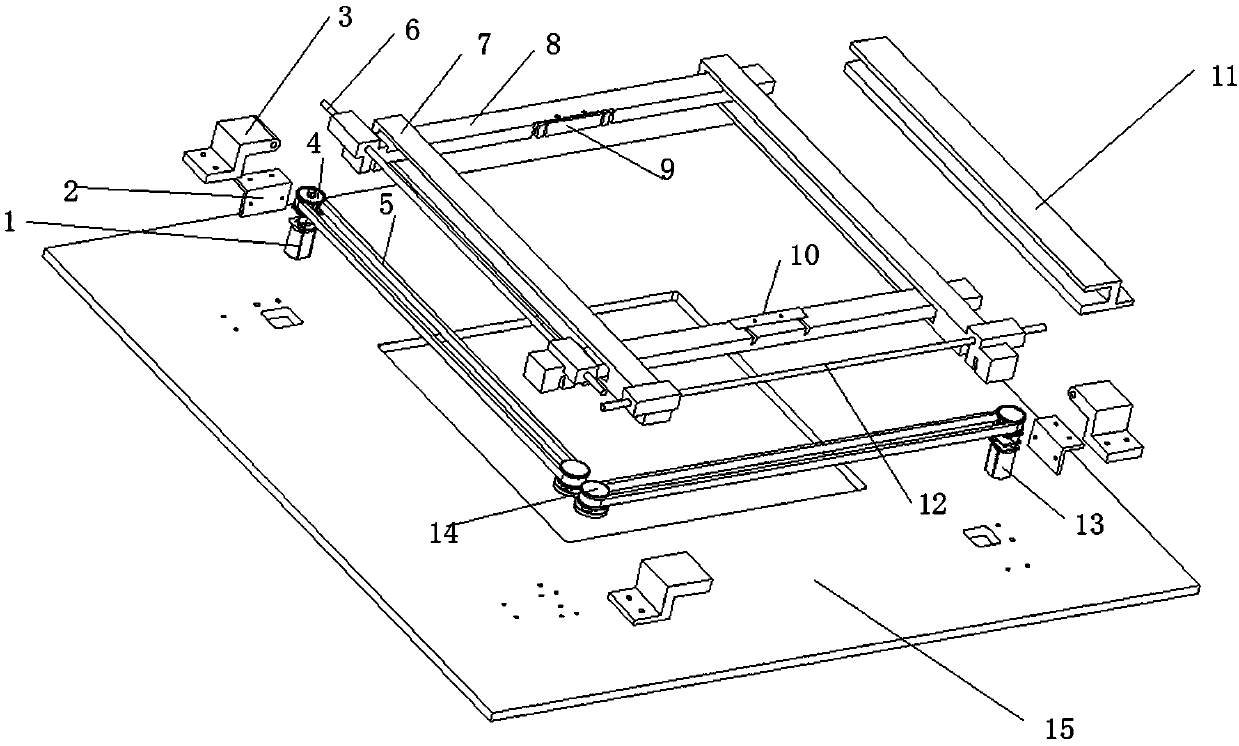

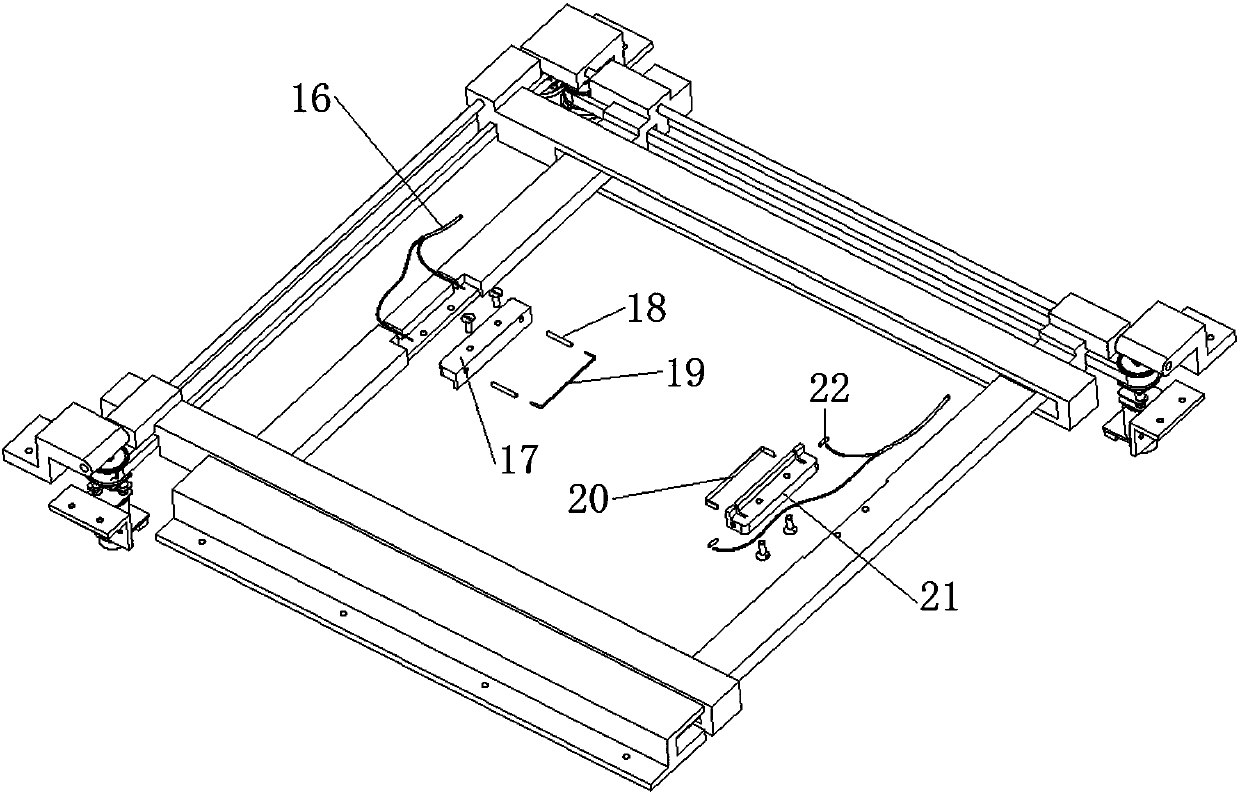

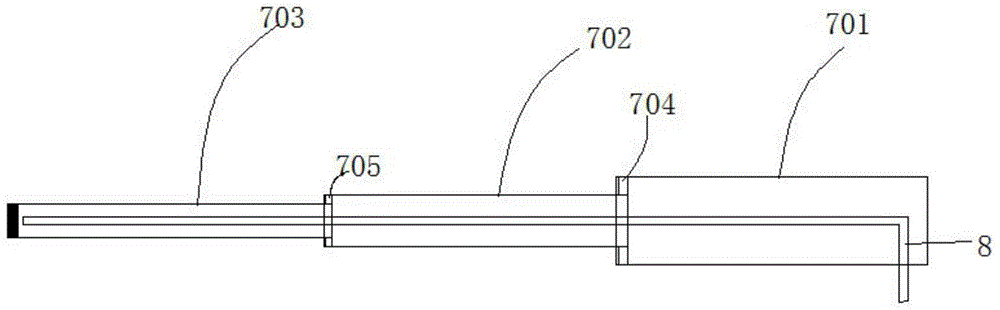

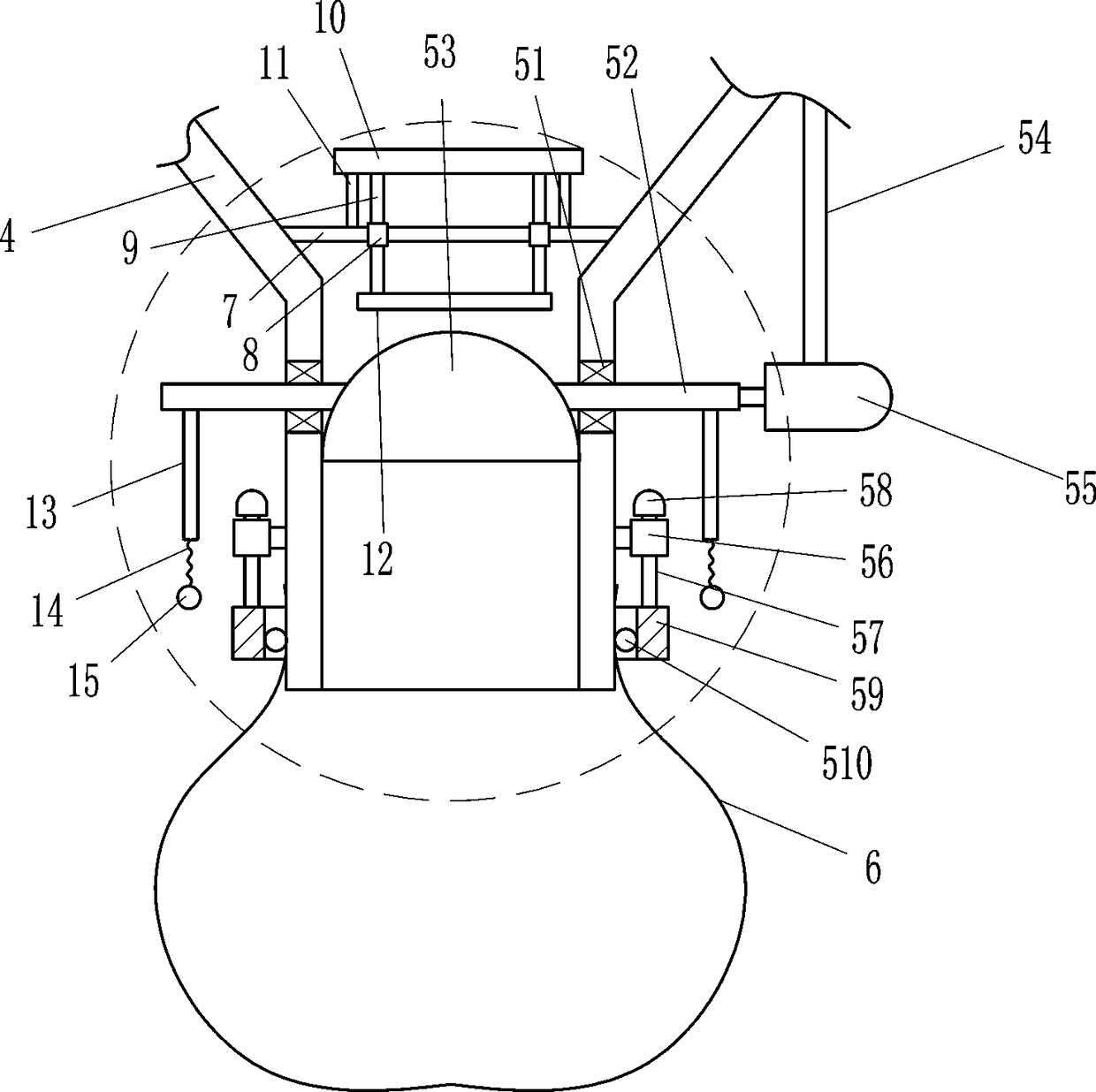

Fusing sealing device for garbage can

InactiveCN109516022ARealize automatic packagingAvoid direct contactRefuse receptaclesWrapper twisting/gatheringEngineeringMechanical engineering

The invention discloses a fusing sealing device for a garbage can. The fusing sealing device comprises a transverse rod mechanism and a rectangle-shaped rod mechanism which are mutually matched, and afusing assembly arranged on the transverse rod mechanism and / or the rectangle-shaped rod mechanism; the transverse rod mechanism is provided with two transverse rods (8) and a transverse rod actuating mechanism matched with the transverse rods (8) in an actuating mode, the rectangle-shaped rod mechanism is provided with two rectangle-shaped rods (7) and a rectangle-shaped rod actuating mechanismmatched with the rectangle-shaped rods (7) in an actuating mode, and the two rectangle-shaped rods (7) sleeve the two transverse rods (8). Fusing and sealing operation of a garbage bag is realized byadopting a mode ofcombination of the rectangle-shaped rod mechanism and the transverse rod mechanism, and thus fusing and sealing of the garbage bag is safer and more convenient.

Owner:SMART VIEW INT LTD

Full-automatic machine part visual flaw detection equipment and method

PendingCN111804601AEfficient automatic detectionReduce false detection rateSortingMachine partsMechanical components

The invention discloses full-automatic machine part visual flaw detection equipment. The equipment comprises a feeding device and a detection device, the feeding device is connected with a feeding rail, the detection device comprises a first view finding mechanism, a first conveyor, a turnover mechanism, a second view finding mechanism, a second conveyor, an arrangement mechanism and a third viewfinding mechanism, an output end of the feeding rail faces the first conveyor, the first conveyor is positioned above the second conveyor, the turnover mechanism faces the second conveyor, and the arrangement mechanism is positioned between the second conveyor and the third view finding mechanism. The invention also discloses a full-automatic machine part visual flaw detection method. According tothe equipment and the method, through the cooperation of a vibration disc, the first view finding mechanism, the first conveyor, the turnover mechanism, the second view finding mechanism, the secondconveyor and the third view finding mechanism, comprehensive, efficient and rapid detection on the front surface, the back surface and the side wall of a part is realized, the false detection rate isreduced, the correct and reliable detection result is ensured, the detection efficiency is accelerated, and the cost is effectively reduced.

Owner:太仓中科信息技术研究院

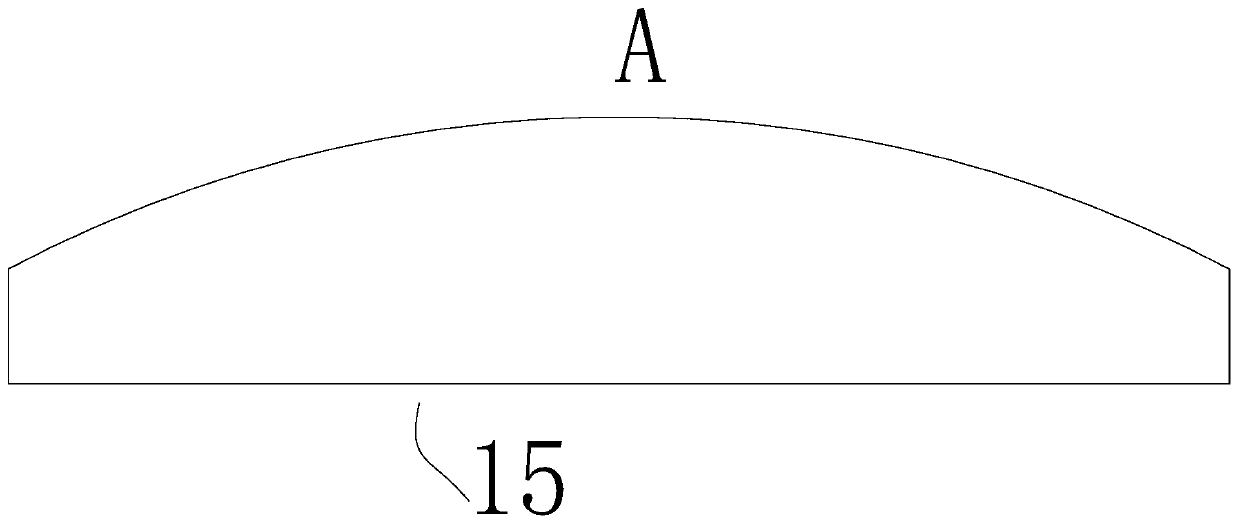

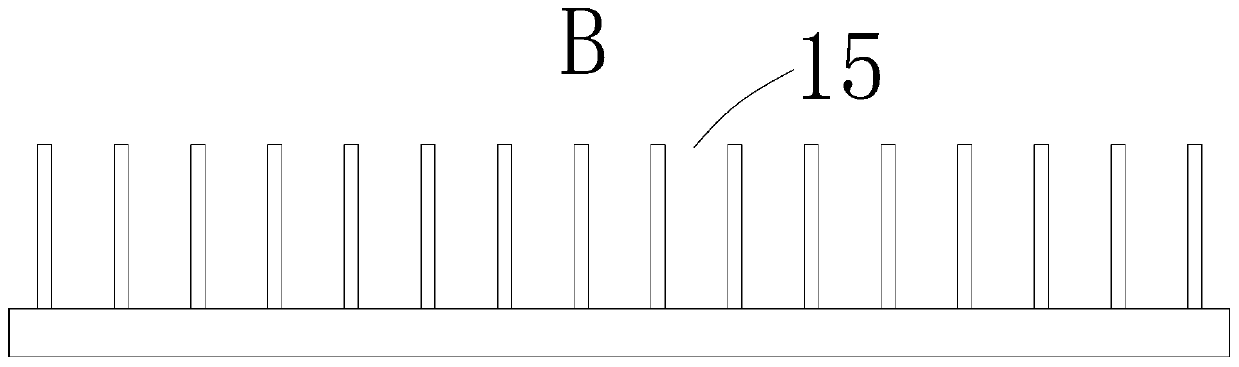

Automatic tape-wrapping machine

InactiveCN102137585ARealize automatic packagingQuality assuranceCooling/ventilation/heating modificationsHeat sinkKnife holder

The invention discloses an automatic tape-wrapping machine used for wrapping a heat-radiating fin with an insulating tape. The tape-wrapping machine comprises a machine frame, a main shaft, heat-radiating fin holders, a tape and reel holder, a sliding rail, a sliding block, a knife holder and a cutting knife, wherein the main shaft is installed on the machine frame; a main shaft driving device isarranged in the machine frame; the main shaft driving device drives the main shaft to rotate; more than two heat-radiating fin holders are arranged on the main shaft; a heat-radiating fin holder driving device drives the heat-radiating fin holders to rotate; heat-radiating fin splicing positions for splicing the heat-radiating fins are formed on the heat-radiating fin holders; the tape and reel holder for installing the tape is fixedly installed on the machine frame; the side of the main shaft is provided with the sliding rail; the sliding block capable of sliding along the sliding rail is arranged on the sliding rail; the knife holder is fixedly installed on the sliding block; the cutting knife is installed at the front end of the sliding block; a cutting knife driving device is arrangedon the machine frame; and the cutting knife driving device drives the cutting knife to move back and forth. Through a skilful design, the insulating tape can automatically wrap the heat-radiating fin, so production efficiency is greatly enhanced and quality of the heat-radiating fin can be effectively ensured.

Owner:MOSO POWER SUPPLY TECH

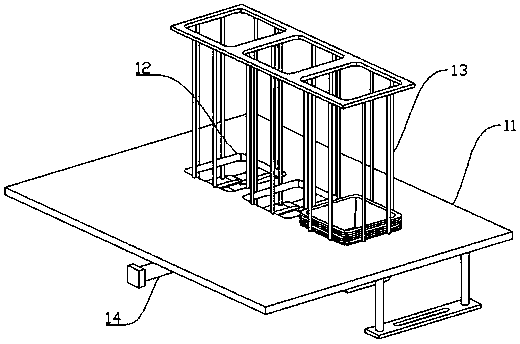

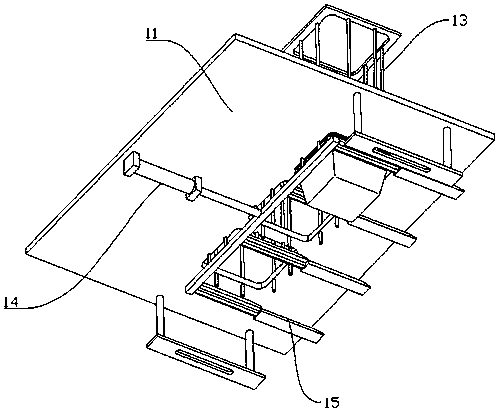

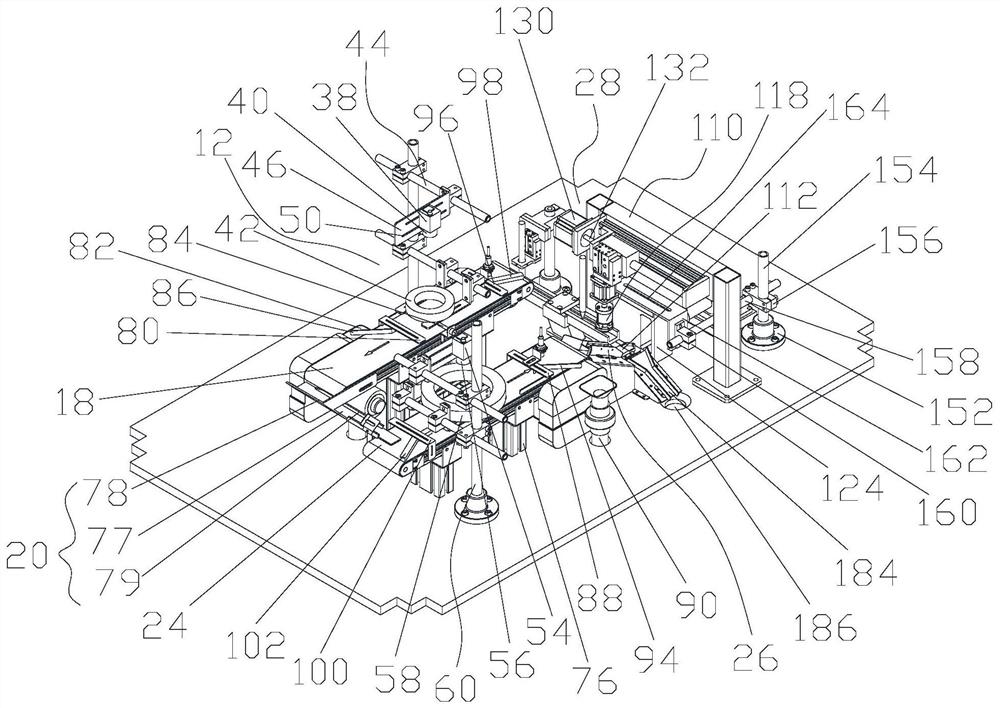

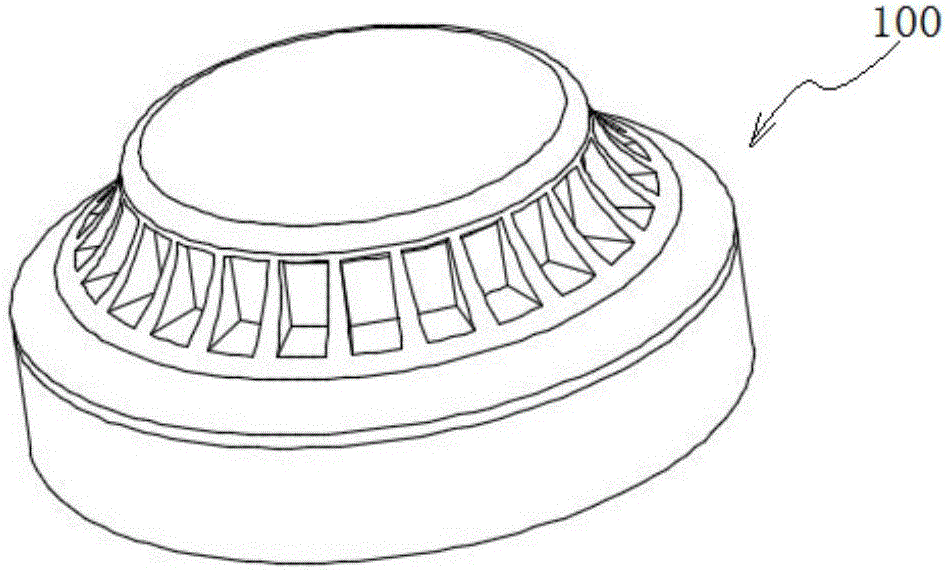

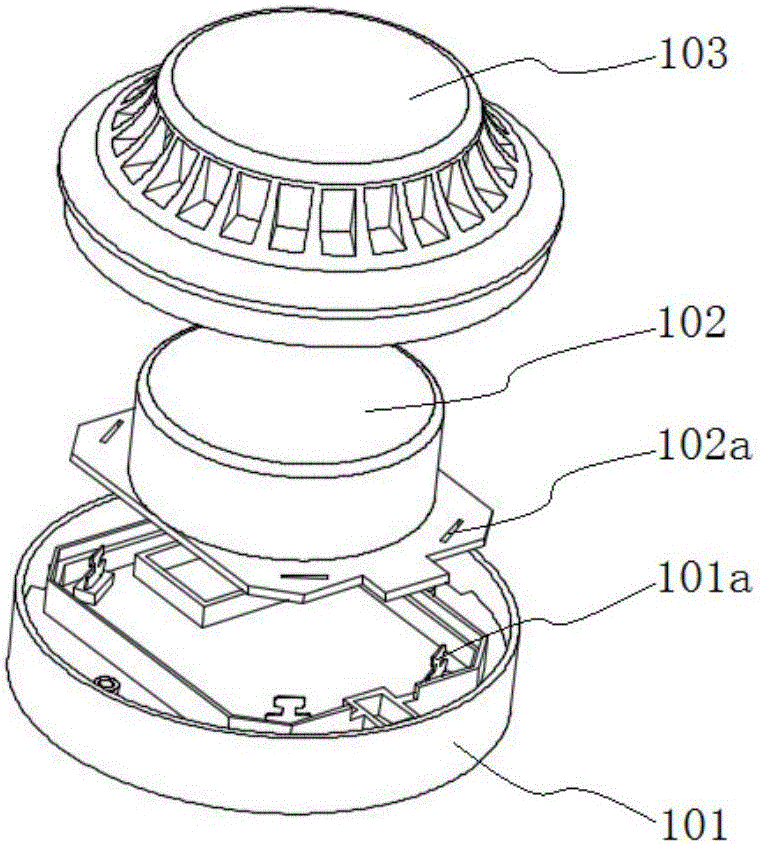

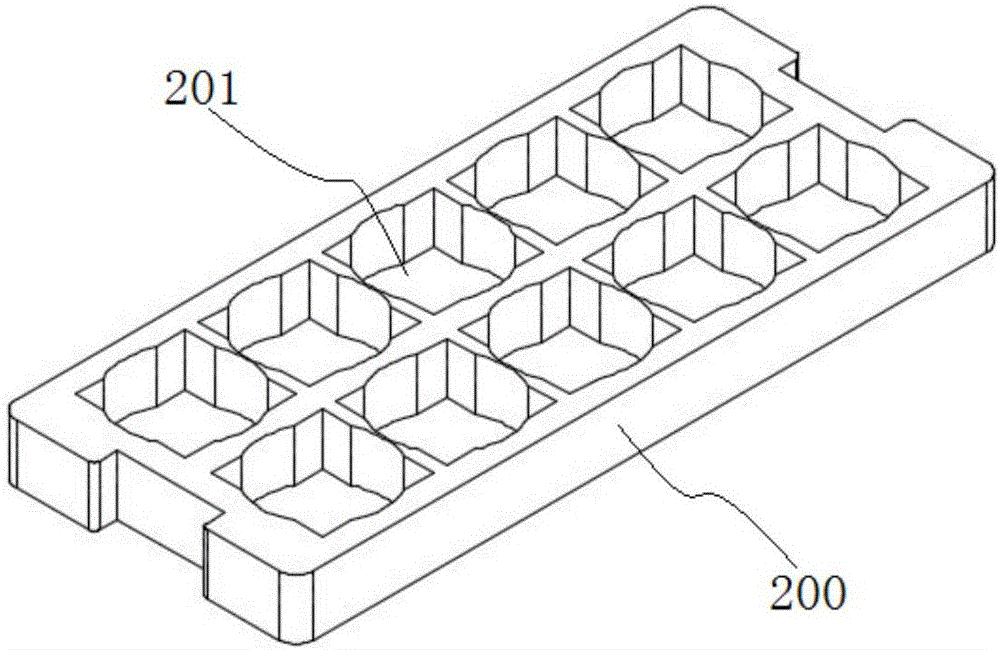

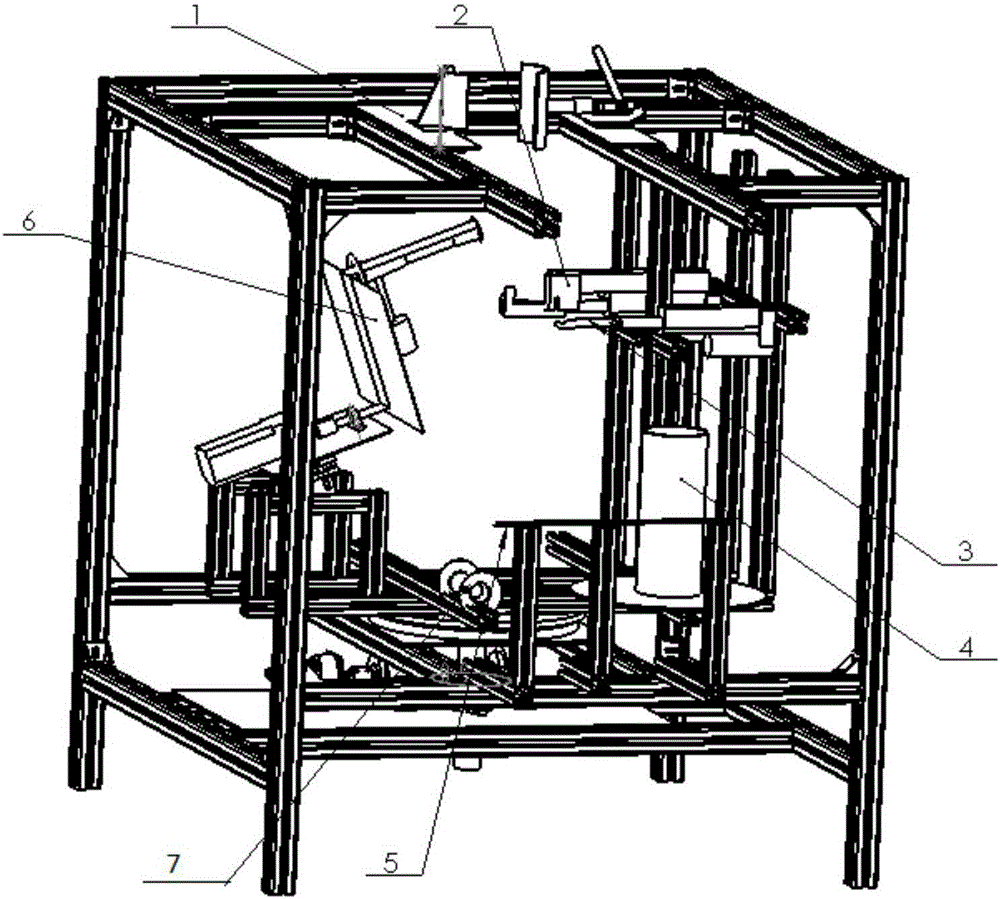

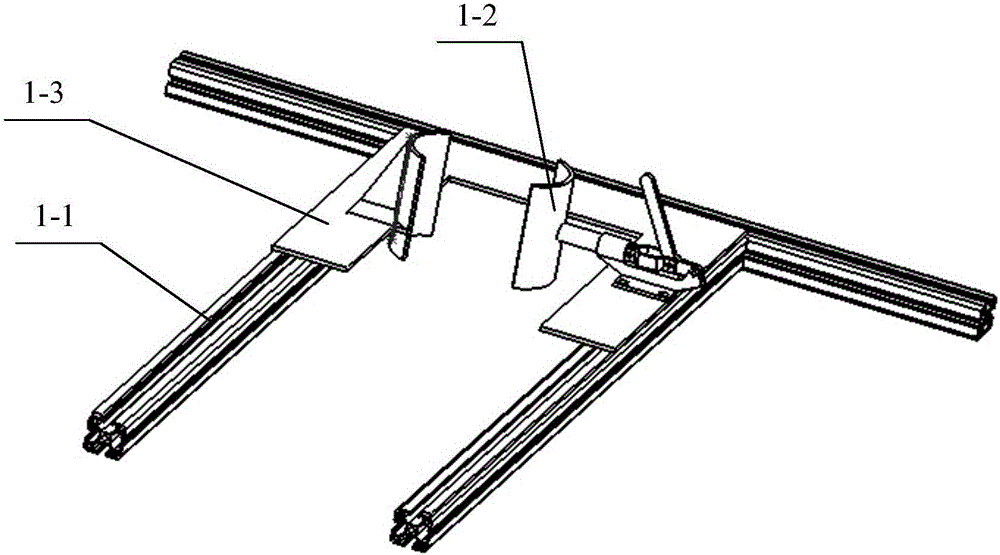

Packing and stacking device for smoke alarm assembly production line

PendingCN106742421AFast packFast palletizingConveyorsStacking articlesMechanical equipmentEngineering

The invention discloses a packing and stacking device for a smoke alarm assembly production line, belonging to the field of product assembly equipment. The packing and stacking device comprises a packing box feeding device, a grabbing and packing device, a conveying device and a stacking device, wherein the conveying device is arranged between the packing box feeding device and the stacking device; the packing box feeding device comprises a package pushing and conveying mechanism and a baffling mechanism; the package pushing and conveying mechanism and the baffling mechanism are arranged on one end of the conveying device; the grabbing and packing device stretches over the conveying device and the product assembly line; the stacking device comprises a stacking pushing and conveying mechanism, a stacking pushing-out mechanism and a lifting stacking mechanism; the stacking pushing and conveying mechanism is arranged on one side of the conveying device; the lifting stacking mechanism is arranged on the other side of the conveying device; and the stacking pushing-out mechanism is arranged on one side of the lifting stacking mechanism. According to the packing and stacking device, manual packing and stacking work is replaced by mechanical equipment, so that packing and stacking efficiency for smoke alarms is greatly improved; and manual labor intensity and labor cost are lowered.

Owner:常州赛凯电器设备有限公司

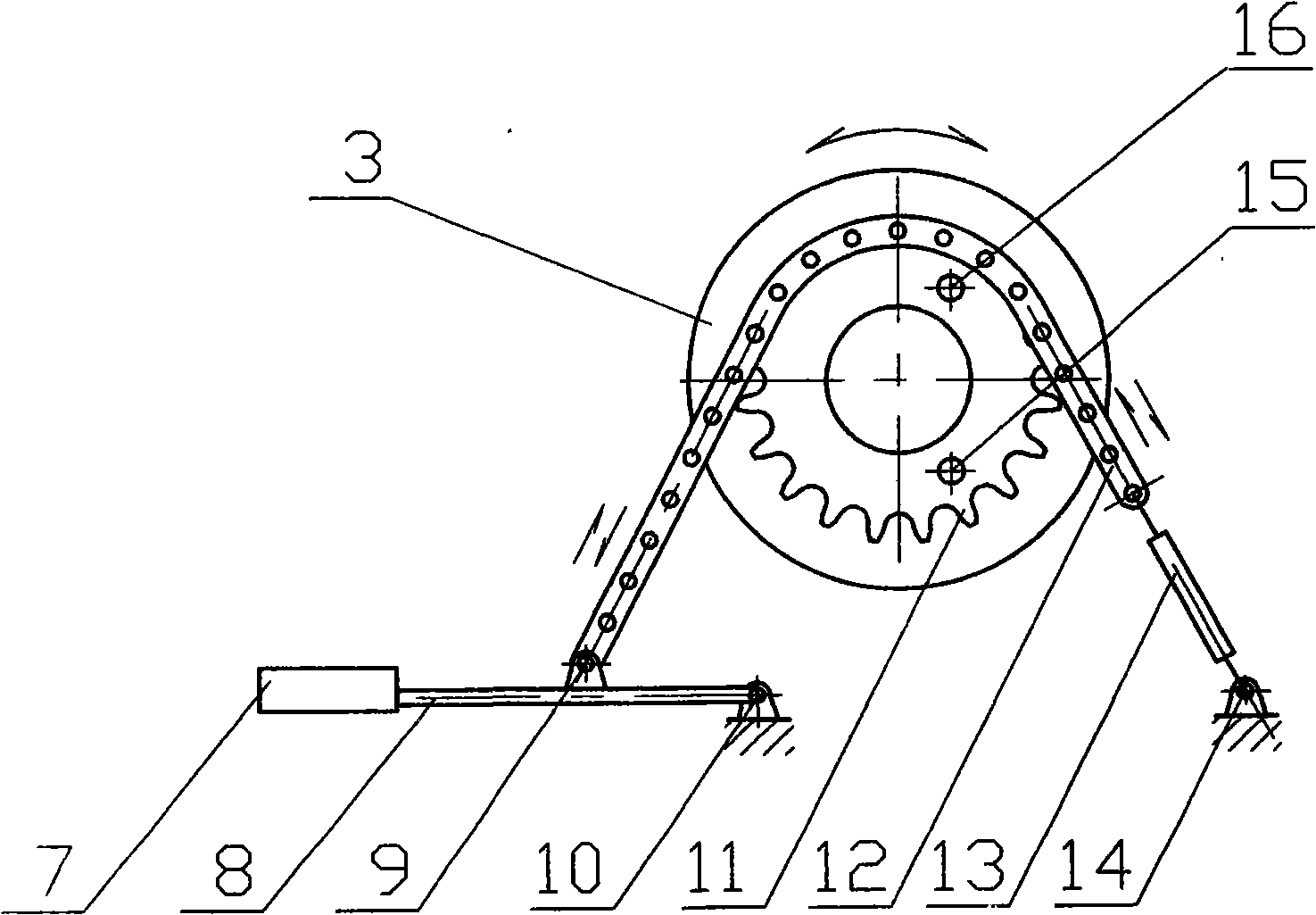

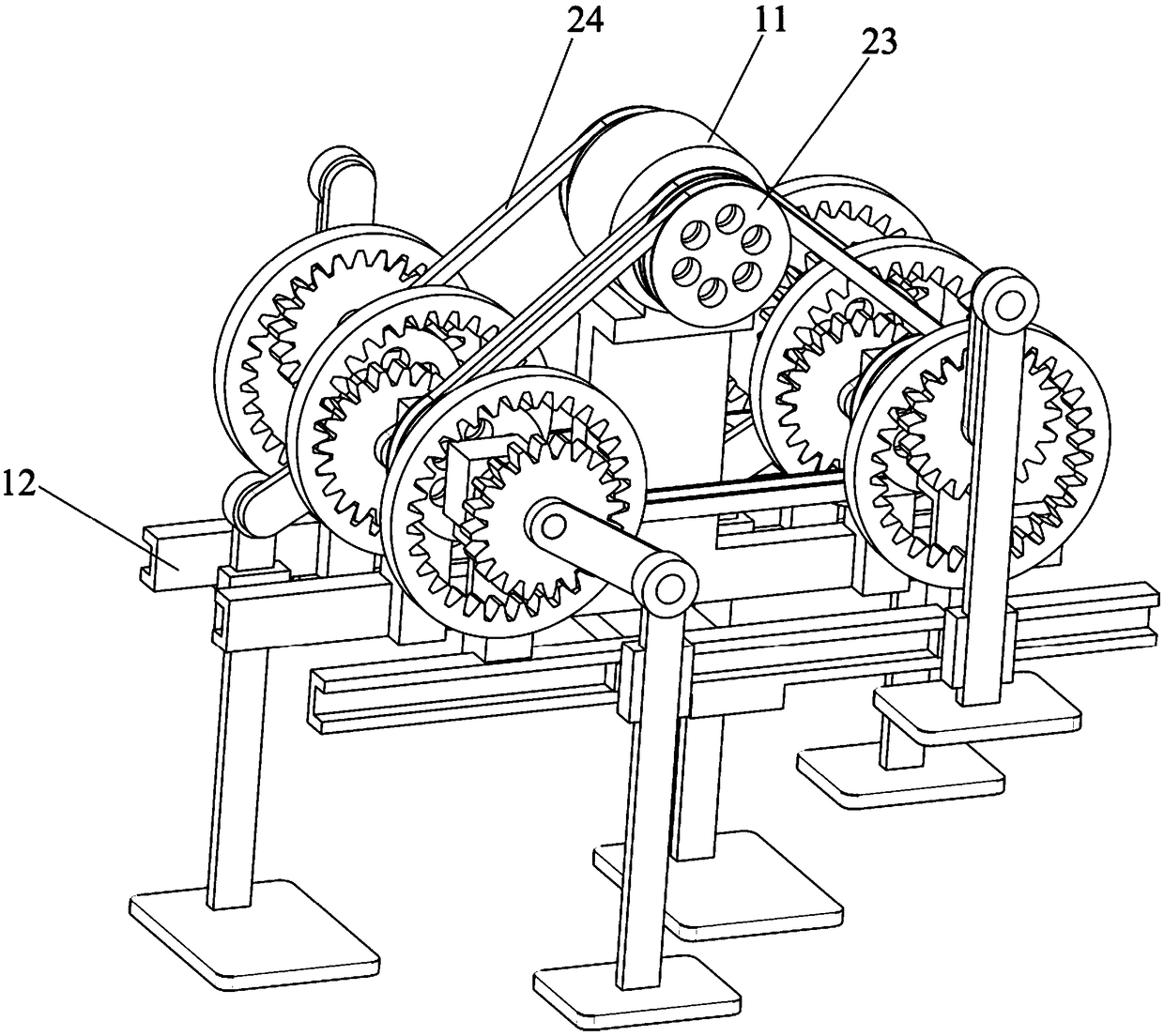

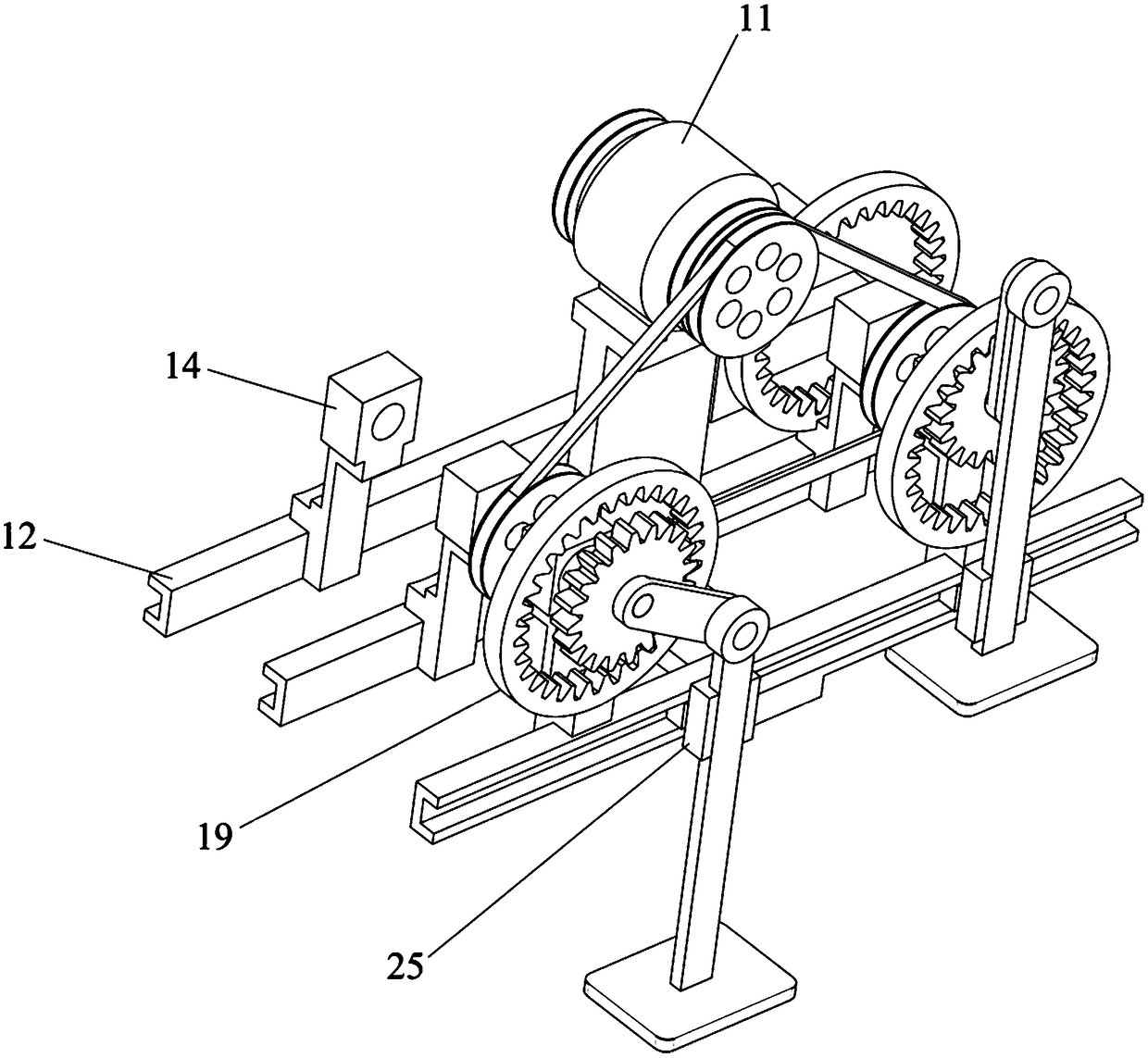

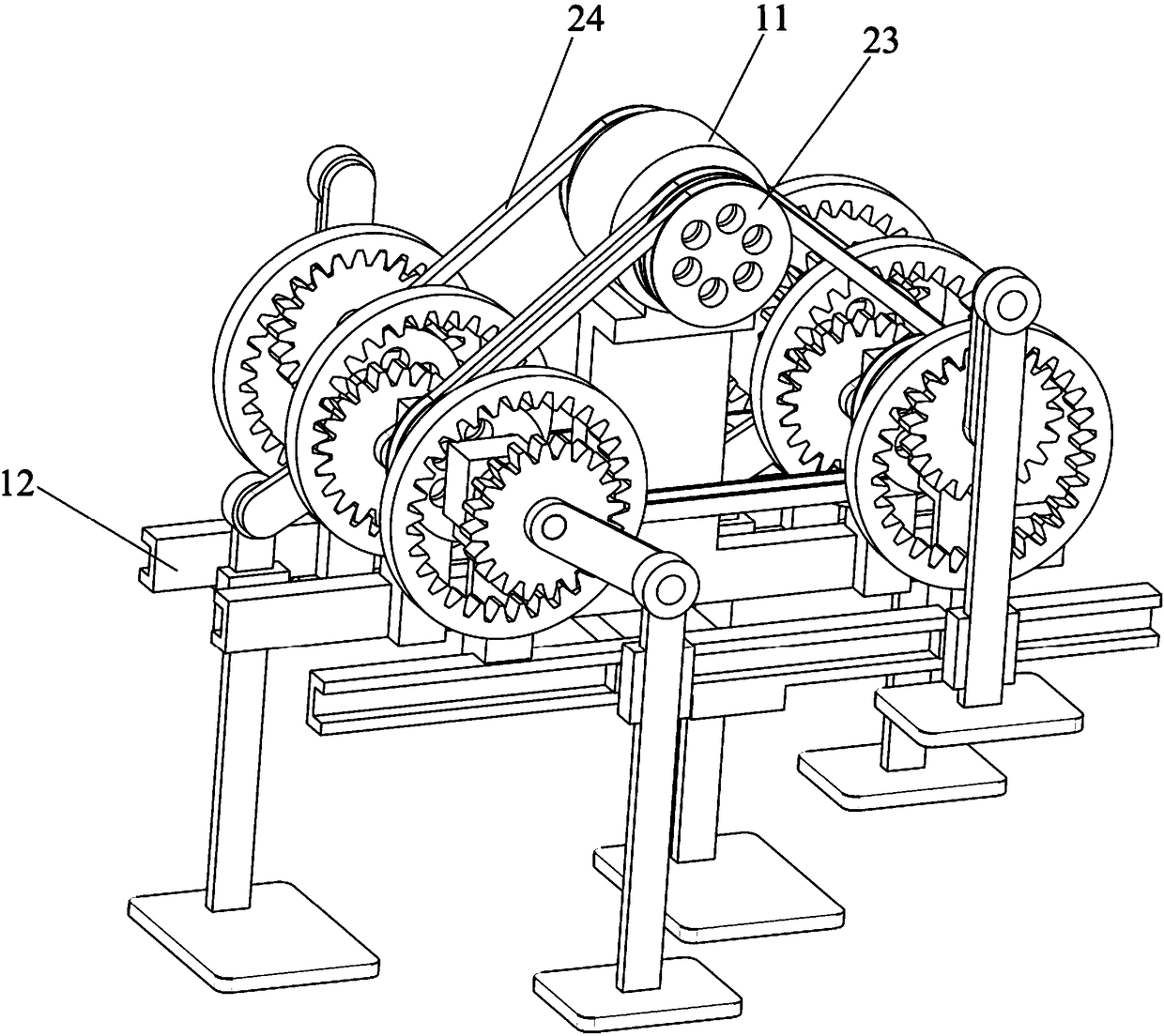

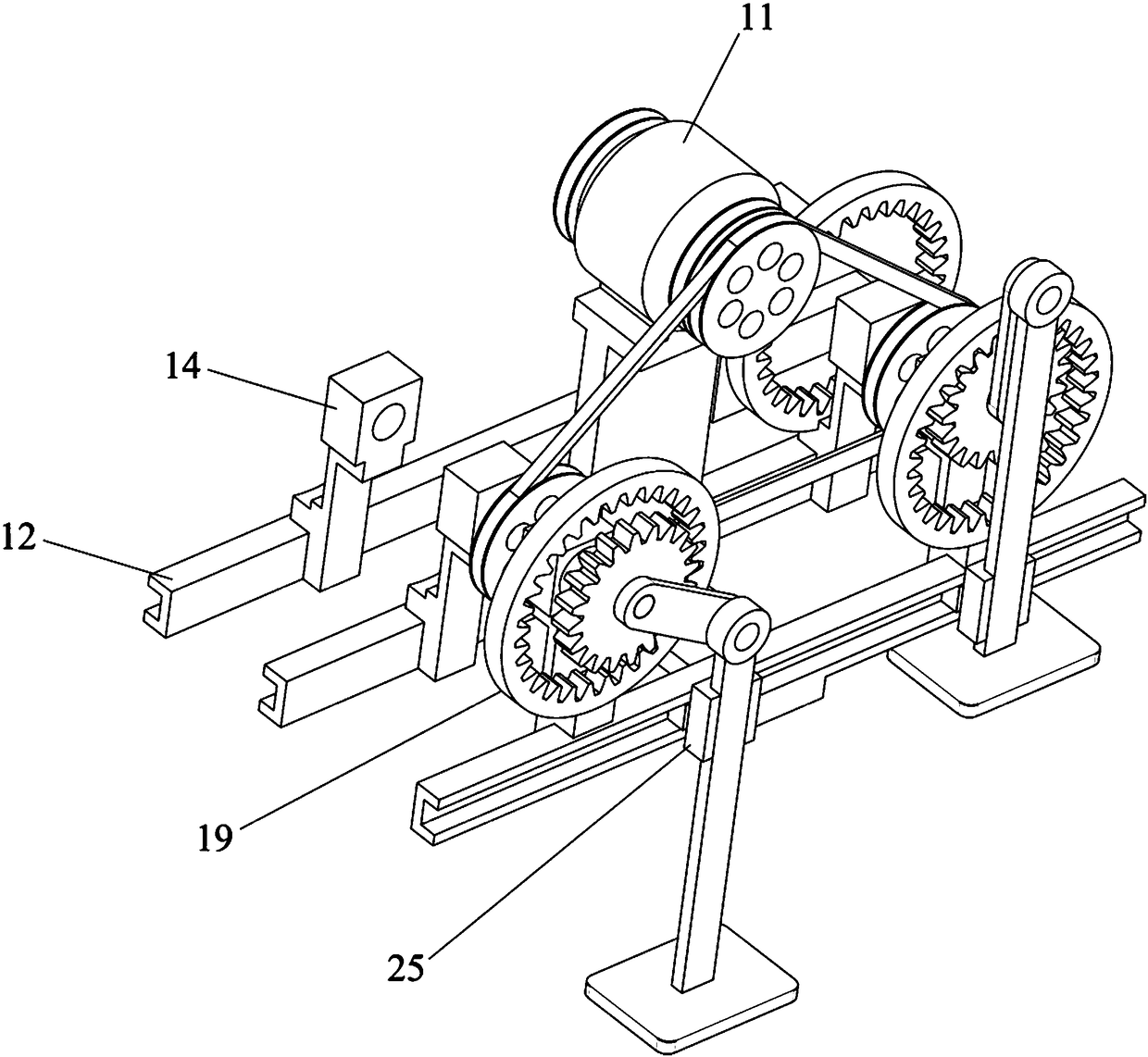

Seedling soil ball baling press with straw ropes

InactiveCN106171821ARealize automatic packagingIn line with the actual situation of the marketForestryVertical planeEngineering

The invention discloses a seedling soil ball baling press with straw ropes. By the aid of the seedling soil ball baling press, problems that existing seedling soil balls are manually baled by straw ropes and the baling quality cannot be guaranteed are solved. The seedling soil ball baling press comprises a clamping mechanism, a shearing mechanism, a hook cutter mechanism, a rotary straw rope mechanism, a seedling tray, a straw rope winding mechanism, a straw rope limiting pipe and a peripheral support. Seedlings can be vertically clamped by the clamping mechanism; the straw rope winding mechanism comprises a spindle, a winding rod assembly, a turntable assembly and a turntable driving mechanism; the spindle can be driven by the turntable driving mechanism so as to drive the turntable assembly and the winding rod assembly to circumferentially move on horizontal planes; a first winding rod can be driven by a stepper motor of the winding rod assembly so as to drive the straw ropes to circumferentially move in vertical planes, and the straw ropes can be wound on seedling soil balls; the straw ropes can be shorn, lifted and collected by the shearing mechanism and the hook cutter mechanism. The seedling soil ball baling press has the advantages that the seedling soil balls with the diameters ranging from 20 centimeters to 35 centimeters can be automatically baled by the seedling soil ball baling press, and accordingly labor force can be liberated from heavy tasks.

Owner:HANGZHOU DIANZI UNIV

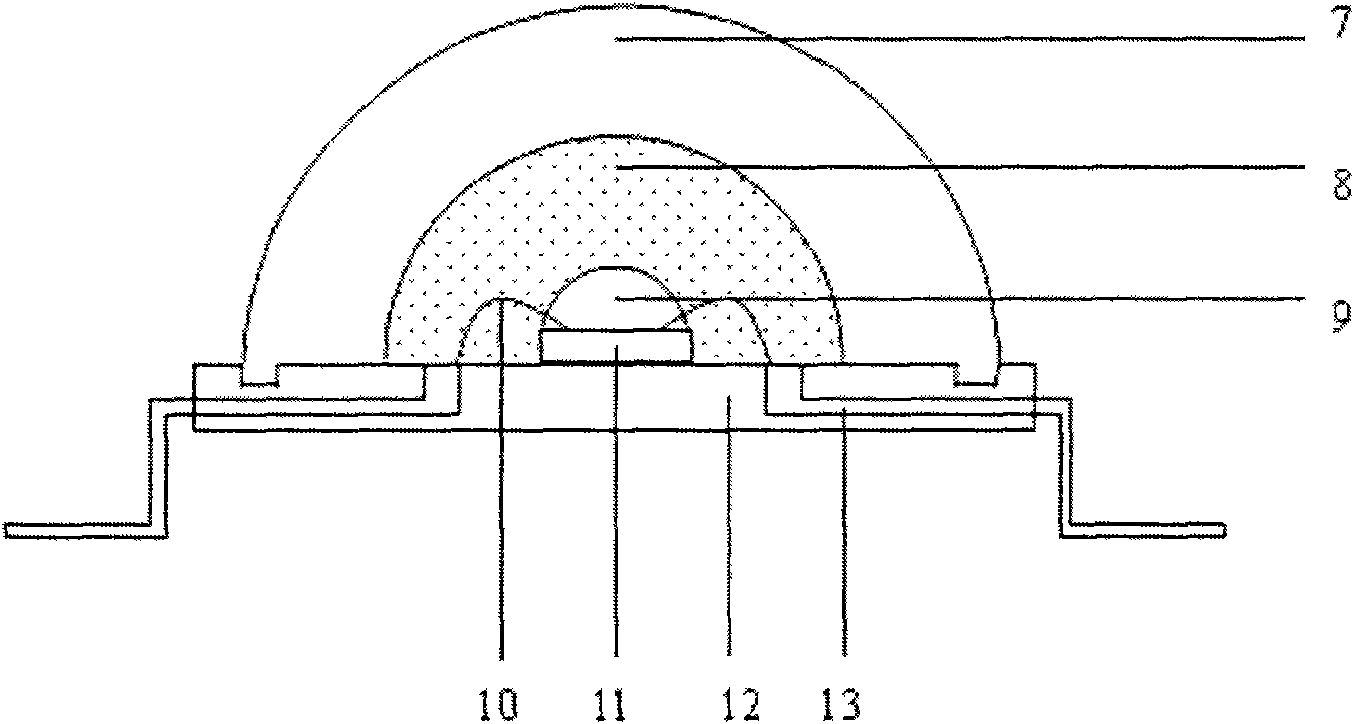

Method for actively packaging blue light LED chip based white light LED

InactiveCN101572287AShorten the timeImprove packaging efficiencySemiconductor devicesEngineeringIrradiation

The invention discloses a method for actively packaging a blue light LED chip based on white light LED, which comprises the following steps: preparing blue light-sensitive photosensitive resin liquid; mixing fluorescent powder into photosensitive resin; presoaking an LED semi-finished product in the photosensitive resin; inversely soaking the LED semi-finished product into the photosensitive resin liquid; soaking the edge of a chip substrate into the photosensitive resin; conducting low operating current to an LED chip to make the chip luminate; triggering the photosensitive resin to polymerize and forming a photosensitive resin core on light emergent surface of the LED chip; slowly lifting the LED semi-finished product to a liquid surface separating from the photosensitive resin liquid, wherein a semi-sphere or a semi-sphere like photosensitive resin liquid drop is attached to the photosensitive resin core and the chip substrate; conducting middle operating current for the LED chip to make the chip luminate, exciting the photosensitive resin liquid drop to solidify; conducting high operating current to a solidified sample of the photosensitive resin liquid drop to make the LED chip laminate; solidifying and decoloring the sample or decoloring the sample through insolation by the sun, or decolcoring by violetray irradiation; and finally cleaning the sample.

Owner:SUN YAT SEN UNIV

Woven bag packing device

ActiveCN110606231AImprove packaging efficiencyHigh degree of automationPaper article packagingBundling machine detailsEngineeringCantilever

The invention discloses a woven bag packing device. The woven bag packing device comprises a clamping jaw slide block arranged on a frame in a horizontal sliding mode; the clamping jaw slide block isprovided with an upper clamping jaw and a lower clamping jaw; the upper clamping jaw and the lower clamping jaw can mutually approach and leave, and both comprise at least two parallel cantilever jaws; the cantilever jaws are parallel to the sliding direction of the clamping jaw slide block; woven bag support pieces are arranged in the pointing directions of the cantilever jaws; the heights of thewoven bag support pieces meet that the upper clamping jaw and the lower clamping jaw clamp stacked woven bags to transversely shift onto the woven bag support pieces and the woven bag support piecesare not interfered with the cantilever jaws; pressing mechanisms are arranged above the woven bag support pieces, and move down to press the positions between the adjacent cantilever jaws of the upperclamping jaw on the woven bags; and annular packing belts are arranged around moving trajectories above the woven bag support pieces for the woven bags. The woven bag packing device has the advantages of higher packing efficiency, higher automation degree and higher safety.

Owner:泗县鸿盛塑业股份有限公司

Energy-saving and environment-friendly sewage treatment walking robot device

InactiveCN108619765ARealize automatic packagingIngenious structural designStationary filtering element filtersVehiclesEngineeringSewage treatment

The invention discloses an energy-saving and environment-friendly sewage treatment walking robot device which comprises a rack, wherein a walking device is arranged on the rack and comprises a walkingmotor and six walking foot tools; the walking motor is arranged on the rack; three rack guide rails arranged in parallel are arranged on the rack; the rack guide rails are arranged on the same horizontal plane; length directions of the rack guide rails are the same as an advancing direction of the walking device; one walking foot tool is arranged at each of the front part and the rear part of each rack guide rail; and the walking foot tools comprise vertical guide slide rails arranged along the rack guide rails in a sliding manner, and guide rail brackets fixedly arranged on the rack guide rails. The walking device can walk stably; alternating movement of six support legs can be achieved only by one walking motor to achieve a walking function; and the device is ingenious in structural design. A subpackage device can achieve real-time adjustment of subpackage capacity; automatic subpackage is achieved by a simple mechanical mechanism; and the device has practicability.

Owner:杨松礼

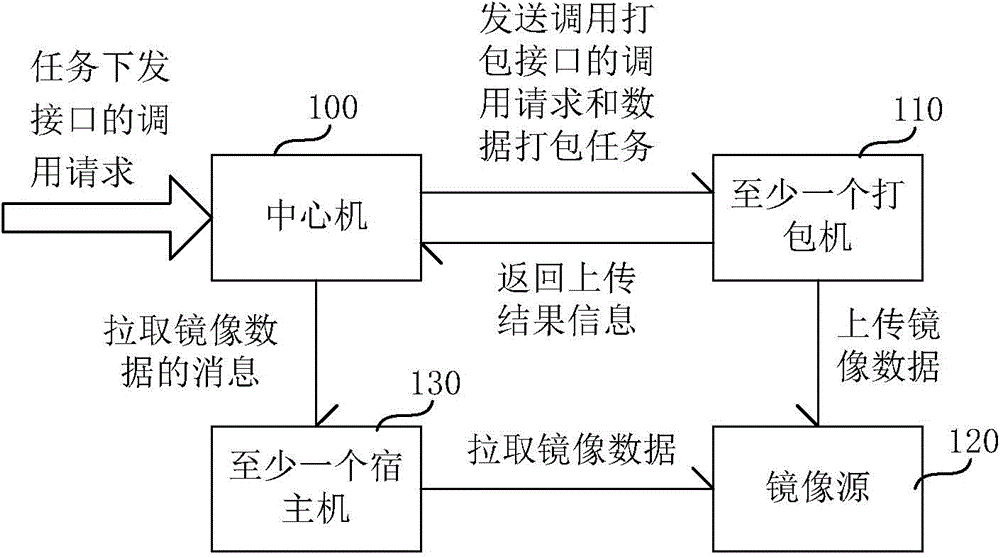

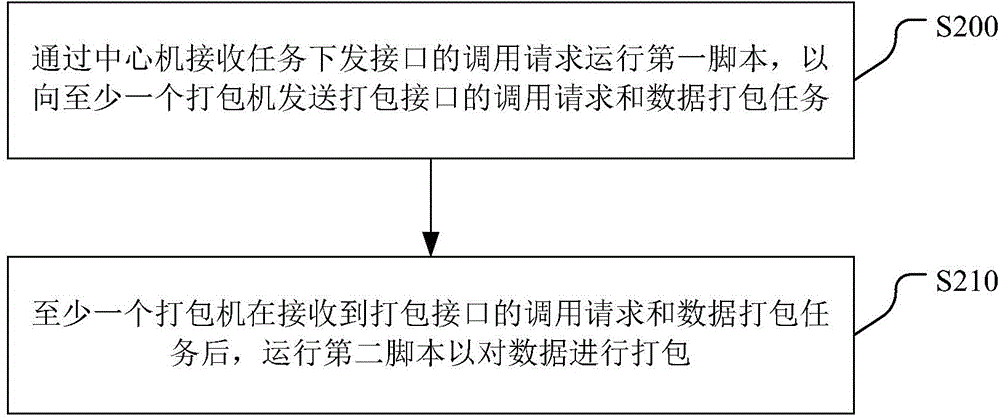

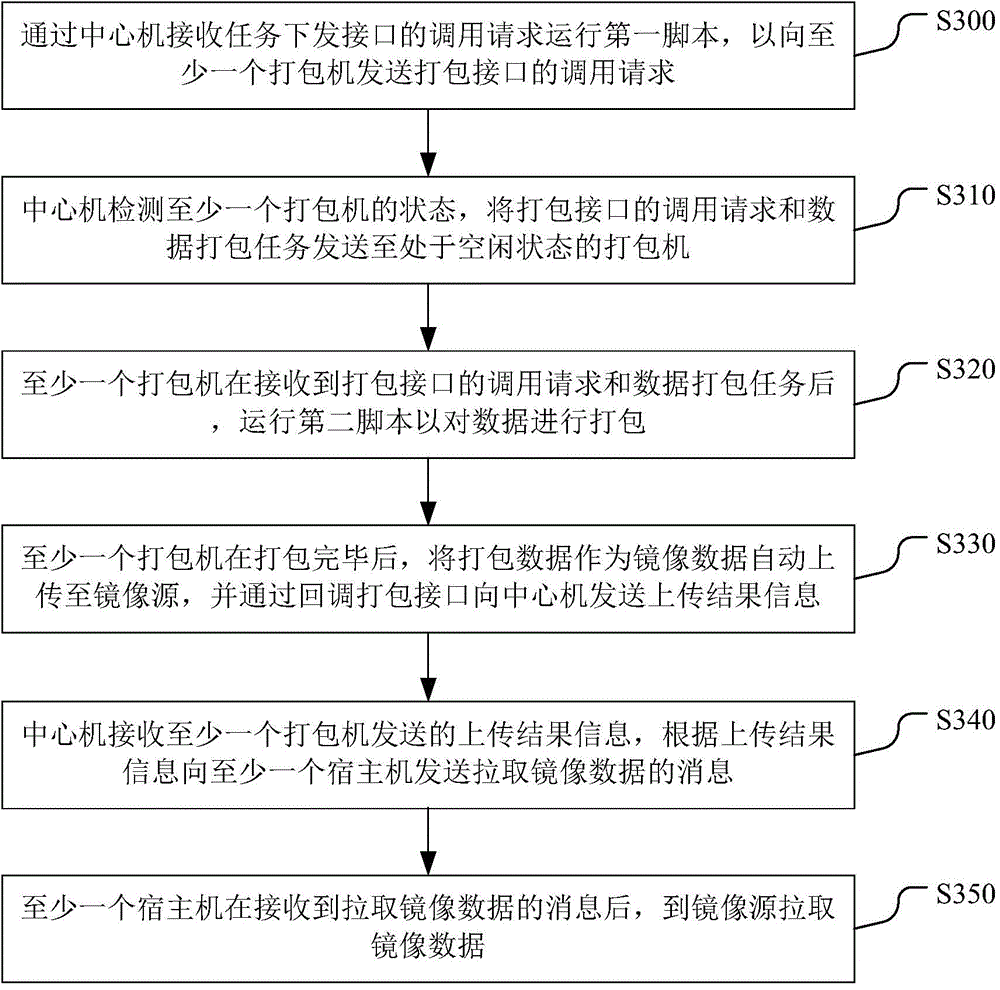

System and method for realizing automatic packing

ActiveCN104881294ASave human resourcesEasy to operateSoftware simulation/interpretation/emulationData packingData pack

The invention discloses a system and a method for realizing automatic packing. The system comprises a center machine and at least one packing machine, wherein a first script for providing a task issuing interface is arranged in the center machine, and a second script for providing a packing interface is arranged in the at least one packing machine; the center machine is used for receiving a call request of the task issuing interface and running the first script so as to send a call request of the packing interface and a data packing task to the at least one packing machine; the at least one packing machine is used for running the second script to pack data after receiving the call request of the packing interface and the data packing task. According to the system and the method, automatic data packing is realized, data packing based on manual command input is not required, labor resources are saved, the defect that packing cannot be performed due to a manual input error is overcome, the system is convenient to operate, and the packing efficiency and accuracy are improved.

Owner:360 TECH GRP CO LTD

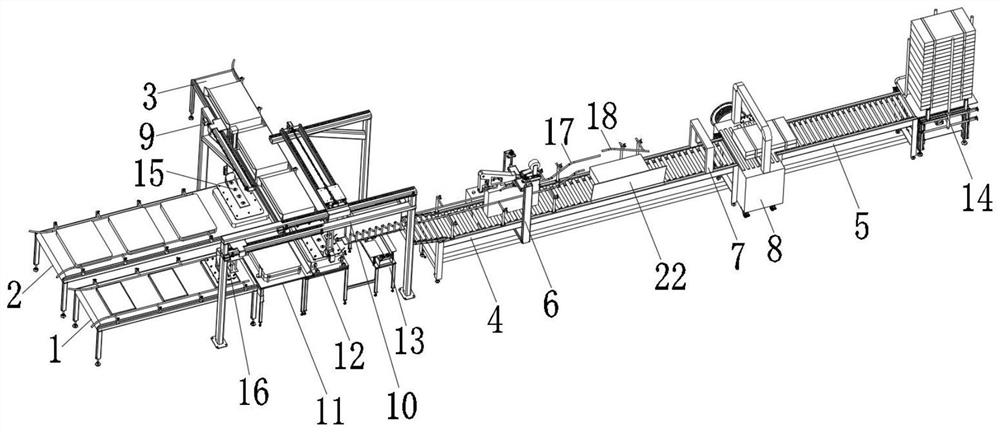

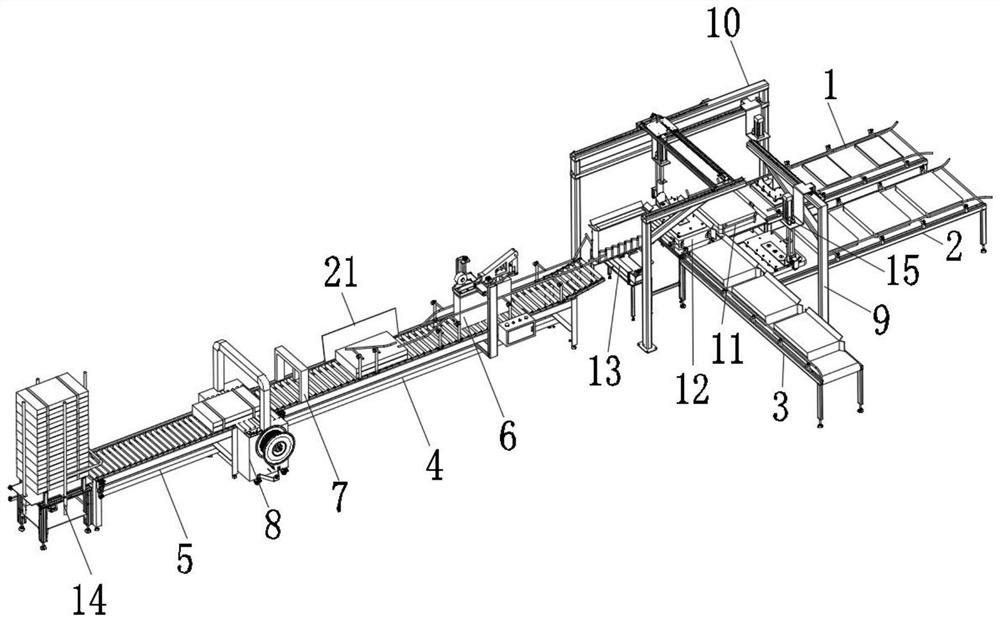

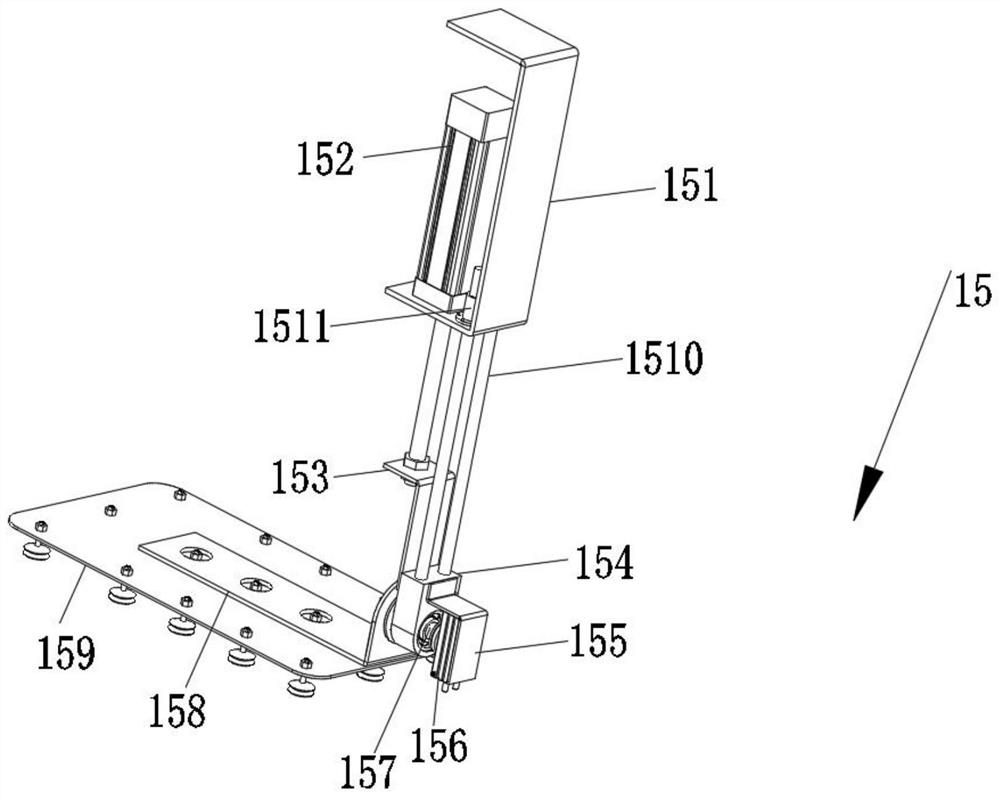

Liquid crystal display screen packaging and code spraying equipment

InactiveCN112389733ASolve cumbersome stepsReduce labor costsPackagingLiquid-crystal displayLiquid crystal

The invention discloses liquid crystal display screen packaging and code spraying equipment. The liquid crystal display screen packaging and code spraying equipment comprises a display screen conveying line, a foam box conveying line, a carton conveying line, a transition roller conveying line, a tail roller conveying line, an adhesive tape sticking machine and a code spraying machine, the displayscreen conveying line, the transition roller conveying line and the tail roller conveying line are co-linearly arranged, and the foam box conveying line is arranged on the back side of the display screen conveying line in parallel. According to the liquid crystal display screen packaging and code spraying equipment, display screens, display screen packaging foam and display screen packaging cartons are transported independently and placed through a turnover adsorption assembly and a display screen adsorption assembly, the tedious step that foam needs to be manually added and then encasement is conducted traditionally is omitted, and automatic packaging of the display screen packaging foam and the packaging cartons in the earlier stage is achieved; a stacking assembly is arranged, and thepurchase cost of an enterprise is reduced compared with robot stacking; and the overall automation degree of the device is high, the working efficiency is high, the use prospect is wide, and more labor cost is reduced.

Owner:安徽速彩电子科技有限公司

Encapsulating method of blue-light LED chip

InactiveCN101567412AShorten the timeImprove packaging efficiencySemiconductor devicesLight irradiationEngineering

The invention discloses an encapsulating method of a blue-light LED chip, which comprises the following steps: photosensitive resin liquid which is sensitive to blue light is prepared; an LED semi-finished product is presoaked in the photosensitive resin, the LED semi-finished product is then reversely soaked in the photosensitive resin liquid, the edge of a chip basal plate is immersed in the photosensitive resin, low working current is introduced to the LED chip to cause the LED chip to irradiate; the photosensitive resin is triggered to occur primary polymerization, and a photosensitive resin core is formed on a light-emitting surface of the LED chip; the LED semi-finished product is caused to slowly ascend to separate the liquid surface of the photosensitive resin, and a semispherical or approximately-semispherical photosensitive resin liquid drop is attached on the photosensitive resin core and a chip base; medium working current is introduced to the LED chip to cause the LED to irradiate so that the photosensitive resin liquid drop is excited to be solidified; high working current is introduced to a sample of the photosensitive resin liquid drop after being solidified so as to cause the LED chip to irradiate, solidification and decolorization are further carried out, or the sample is decolorized through sunshine insolation or through purple light irradiation; and finally the sample after being solidified and decolorized is cleaned.

Owner:SUN YAT SEN UNIV

Lighting single-motor walking robot device

InactiveCN108556955ARealize automatic packagingIngenious structural designMechanical energy handlingVehiclesElectric machineEngineering

The invention discloses a lighting single-motor walking robot device, which comprises a frame, wherein a walking device is arranged on the frame,the walking device comprises a walking motor and six groups of walking feet, and the walking motor is arranged on the frame, a rack guide rail with three parallel settings is arranged on the frame,the rack guide rail is arranged on the same horizontal plane, and the length direction of the rack guide rail is the same as the advancing direction of the walking device, and a group of walking feet are respectively arranged on the front and back positionsof each rack guide rail, the walking foot tool comprises a vertical guide sliding rail which is arranged along the guide rail of the frame and a guide rail bracket fixedly arranged above the rack guide rail. The walking device provided by the invention can smoothly walk, and only one walking motor is required to achievethe alternating movement of six supporting legs, so that the walking function is realized, and the structure design is ingenious. The dispensing device provided by the invention can achieve e real-time adjustment of the packing capacity, and achieve automatic packaging through asimple mechanical mechanism, whichhas practicability.

Owner:王闯

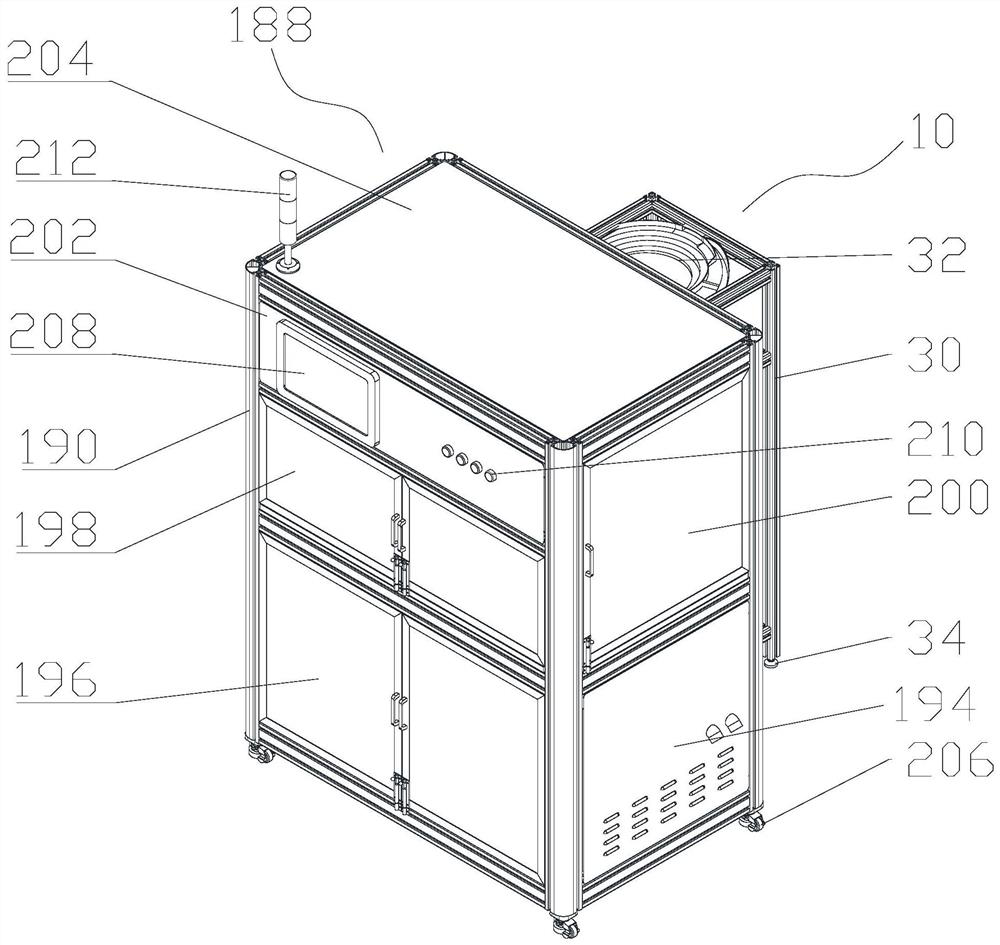

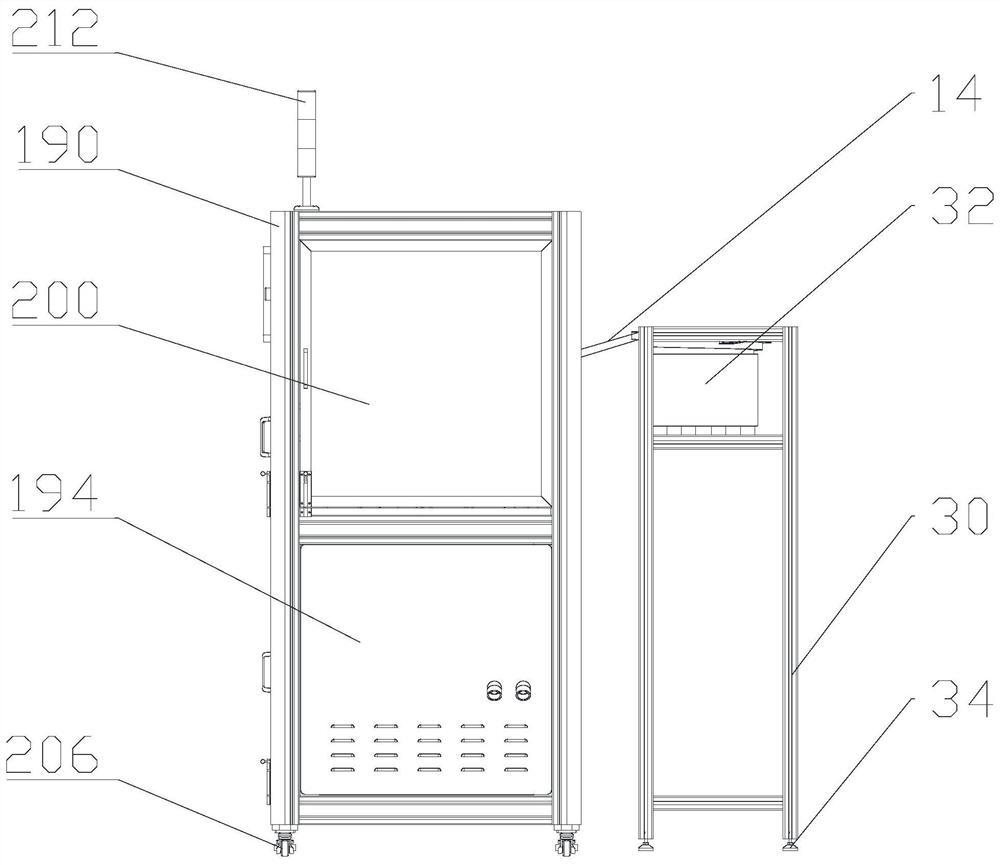

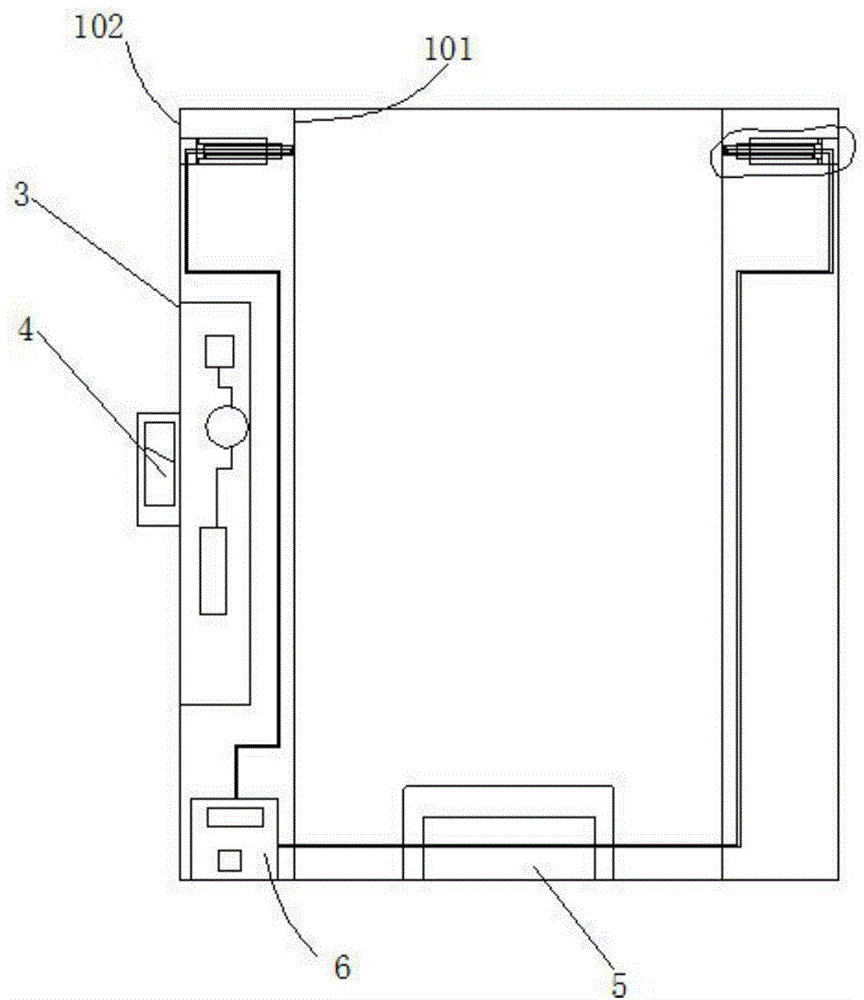

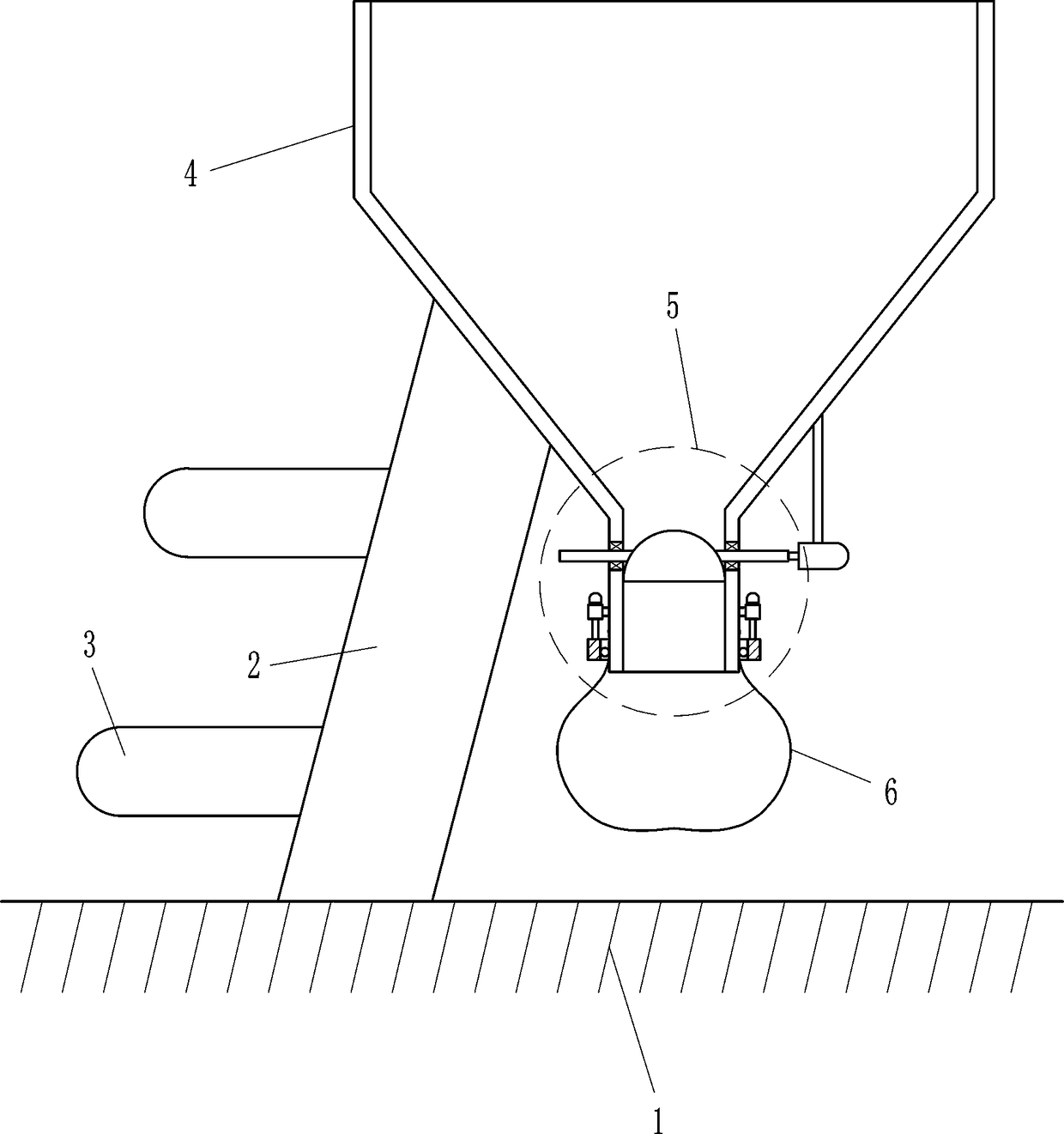

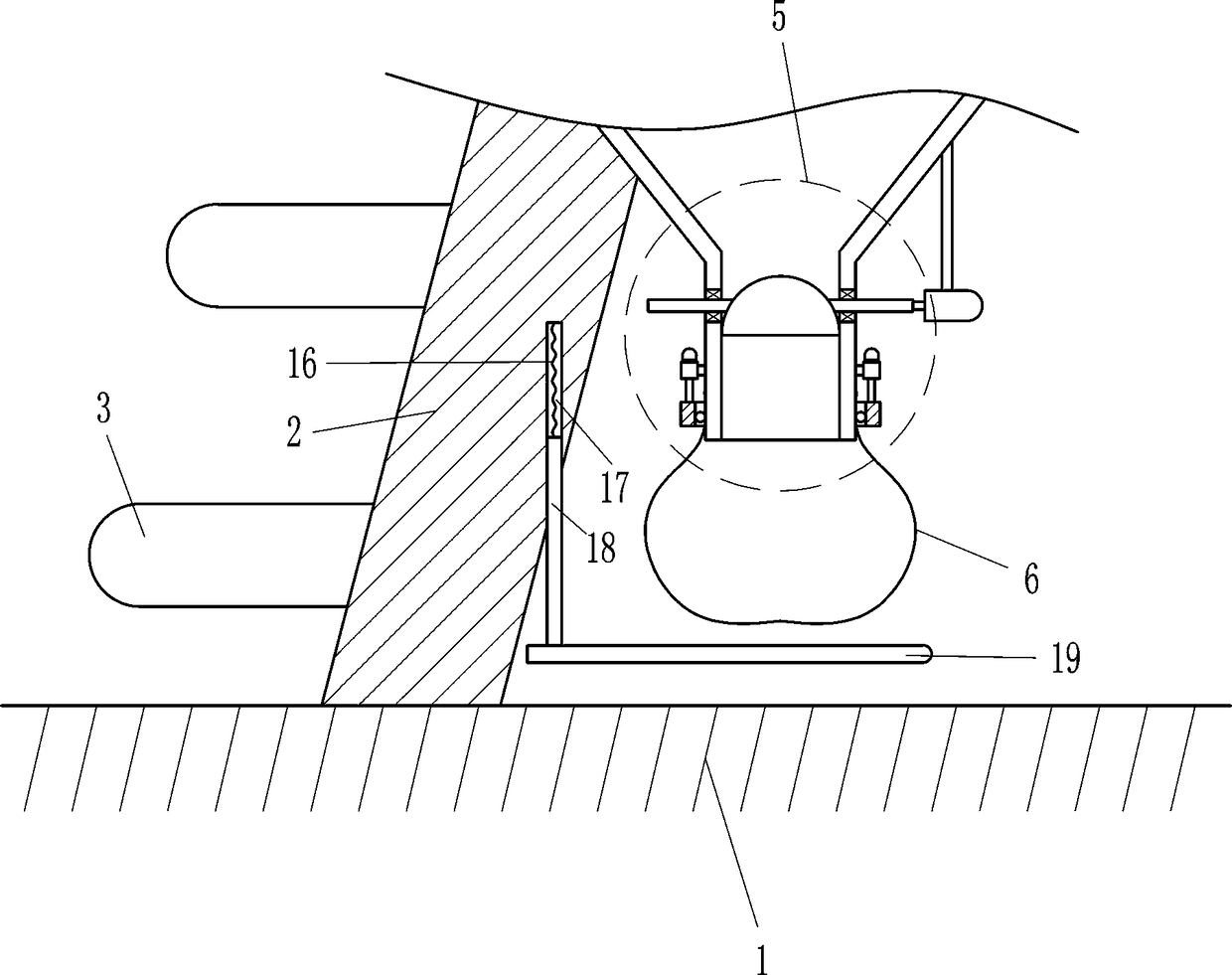

Garbage can with packaging device

InactiveCN104590790ARealize automatic packagingEasy to operateRefuse receptaclesWrapper twisting/gatheringControl switchSanitation

The invention discloses a garbage can with a packaging device. The garbage can comprises a garbage can body and a garbage bag, wherein the garbage can body comprises an inner barrel and an outer barrel; the garbage can is characterized by further comprising a control panel, a control switch, a storage battery, a micro air pump, a plurality of telescopic assemblies and air push pipes; the control panel is positioned on the side wall in the outer barrel, and the control panel and the outer barrel are in threaded connection; the control switch is positioned on the side wall outside the outer barrel, and the control switch and the outer barrel are in gluing connection; the storage battery is positioned at the center of the bottom end in the outer barrel, and the storage battery and the outer barrel are in threaded connection; the micro air pump is positioned at the bottom end in the outer barrel, and the micro air pump and the outer barrel are in threaded connection; the telescopic assemblies surround the upper end of the side wall of the outer barrel of the garbage can; the air push pipes are positioned in the telescopic assemblies, and the air push pipes are in buckling connection with the telescopic assemblies. The garbage can realizes automatic packaging of garbage and is simple in structure and powerful in function; furthermore, the operation of a user is greatly facilitated, and the sanitation condition is improved.

Owner:东至县文元瓷砖加工厂

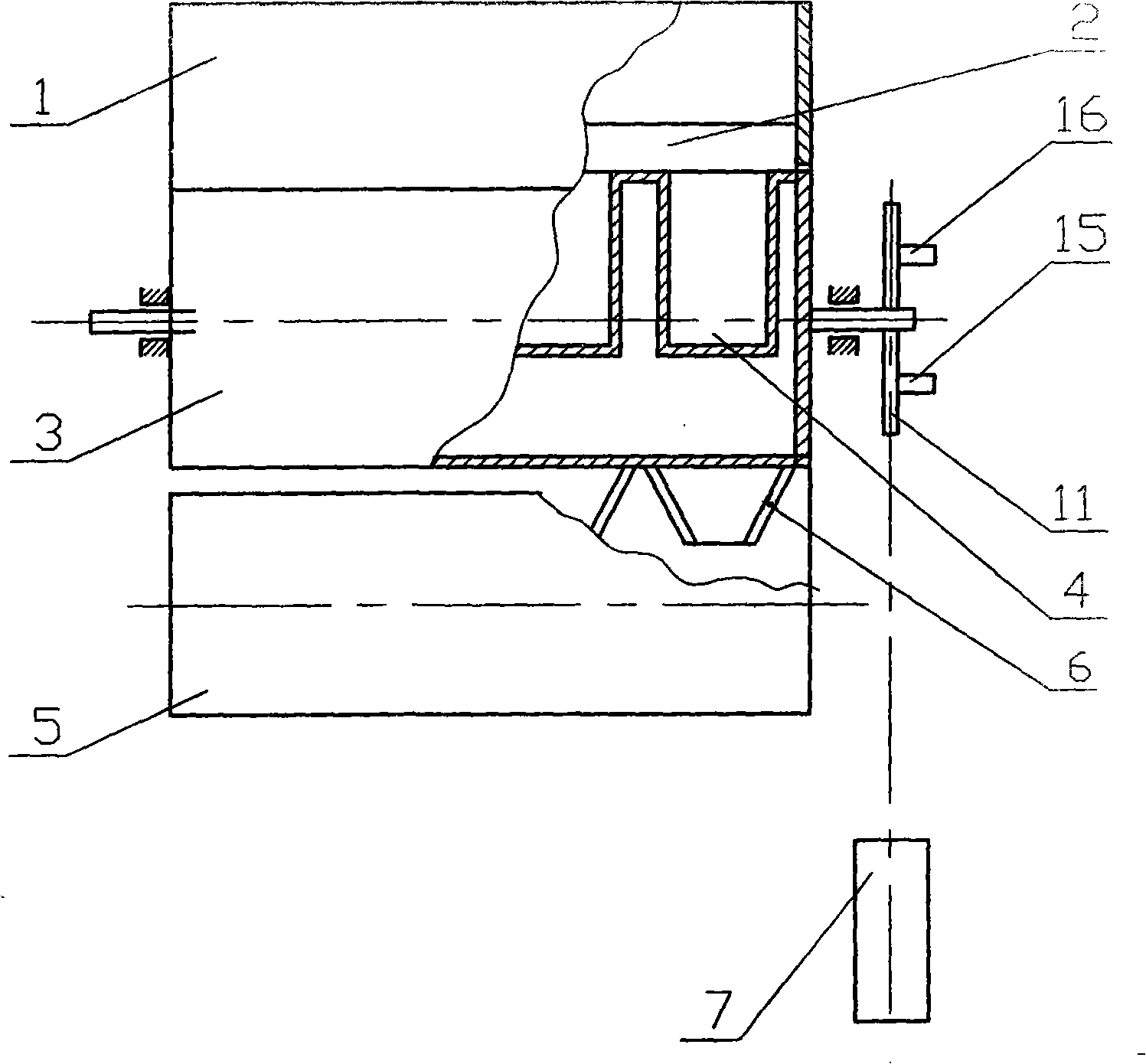

Medicine dreg bagging device

ActiveCN109319176APrevent disengagementRealize automatic packagingSolid materialElectric machineryUser control

The invention relates to a bagging device, in particular to a medicine dreg bagging device. According to the technical purpose to be achieved, the medicine dreg bagging device is provided, medicine dregs can fall into a garbage bag automatically, and labor is saved. According to the technical implementation scheme, the medicine dreg bagging machine comprises a support and the like. The support isarranged on the ground, and two step plates are arranged on the left side of the support. A frame body is arranged on the top of the support. A discharging device is arranged at the lower portion of the frame body. The discharging device comprises bearing seats, a rotating shaft, a semicircular protrusion, a supporting rod, a motor, insertion rings, first guide rods, clamping blocks, circular rings and rubber protrusions. The bearing seats are symmetrically installed at the lower portions of the left wall and the right wall of the frame body in an embedded manner, and the rotating shaft is connected between the bearing seats on the left side and the right side. By means of the medicine dreg bagging device, a user controls the motor to rotate clockwise, the diameter face of the semicircularprotrusion rotates in the clockwise direction, the medicine dregs in the frame body can automatically fall into the collecting bag, when the collecting bag is filled with the medicine dregs, the usercan control the motor to stop rotating, and then the collecting bag is packaged.

Owner:邢台市先进工业技术研究院

Packing device and packing method thereof

ActiveCN105923201ARealize automatic packagingRealize automatic pre-installationWrapper twisting/gatheringWorking environmentPacking method

The invention provides a packing device. The packing device comprises a material collection component, a supporting component, a bag mouth prop-open component and a control component, wherein the material collection component is used for collecting materials; the supporting component allows packing bags to be placed thereon and is located below the material collection component, and the packing bags are fixed on the supporting component; the bag mouth prop-open component is used for propping open the packing bags and located between the material collection component and the supporting component; the control component is electrically connected with the material collection component, the supporting component and the bag mouth prop-open component; and the bag mouth prop-open component props open the packing bags, and the material collection component conveys the materials into the packing bags. According to the packing device, automatic packing of the materials is realized by the material collection component, the supporting component and the bag mouth prop-open component, and further, automatic pre-package of the materials is achieved conveniently and quickly, so that the labor intensity of operators is reduced, the production efficiency is improved, the production cost is lowered, and the working environment is improved. The invention also provides a packing method.

Owner:GREE ELECTRIC APPLIANCES INC

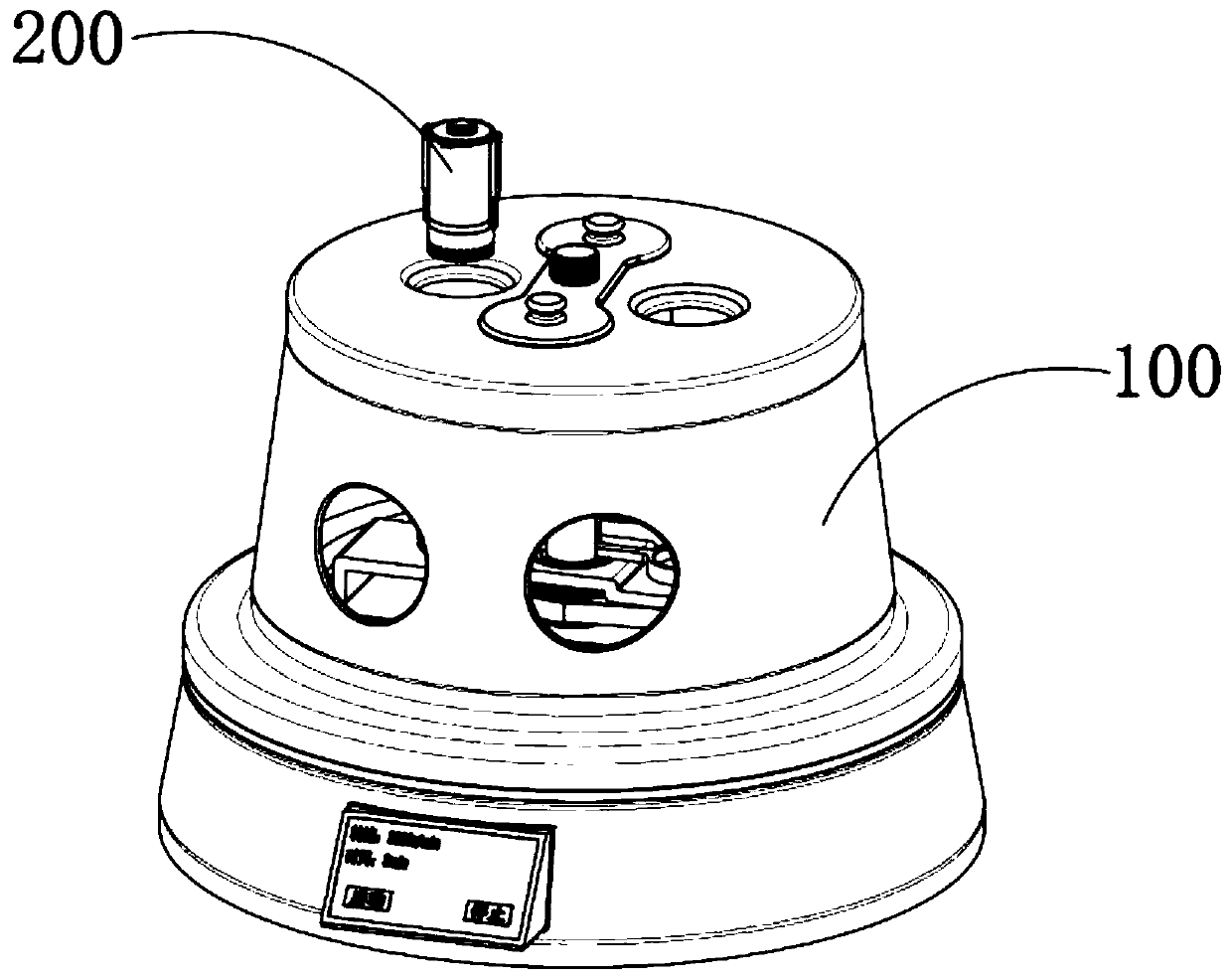

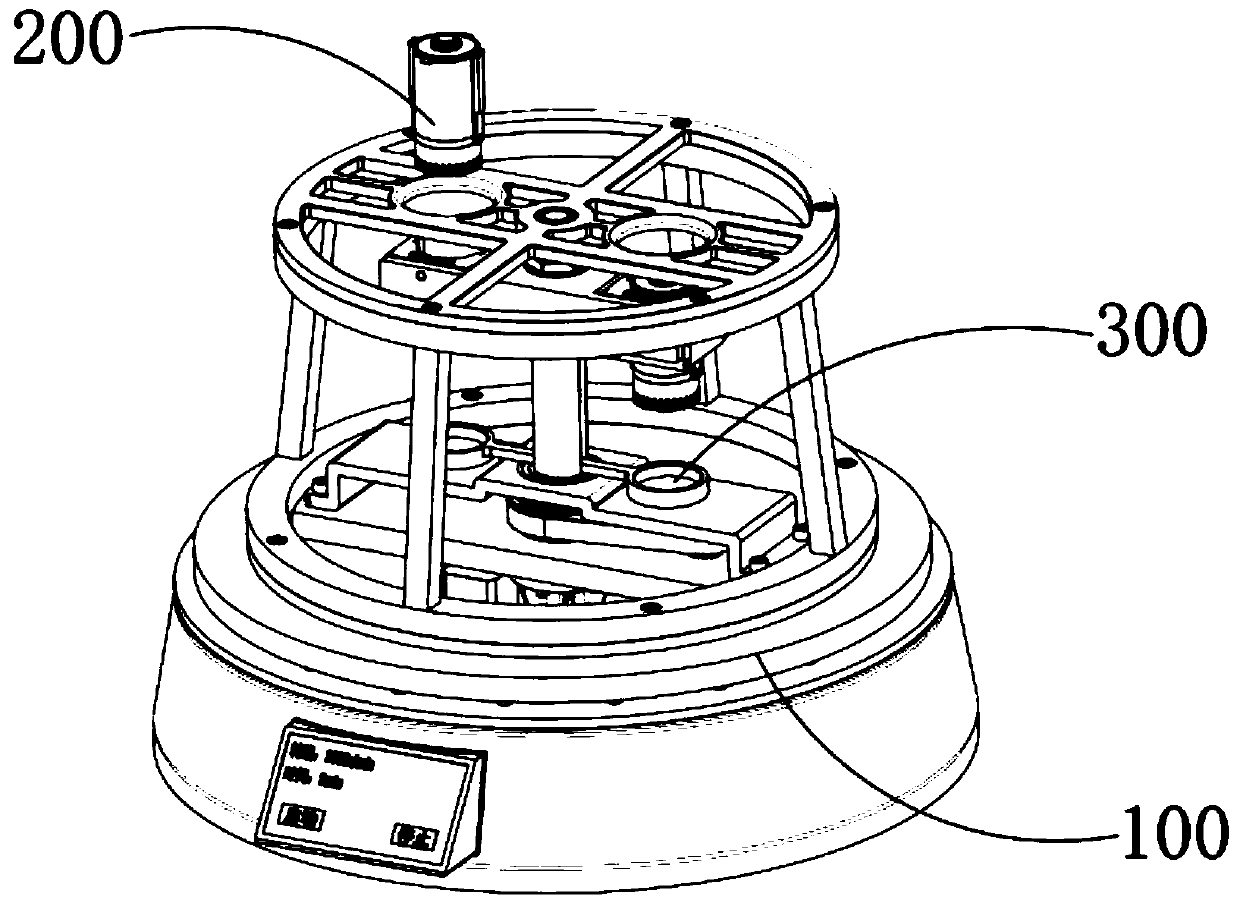

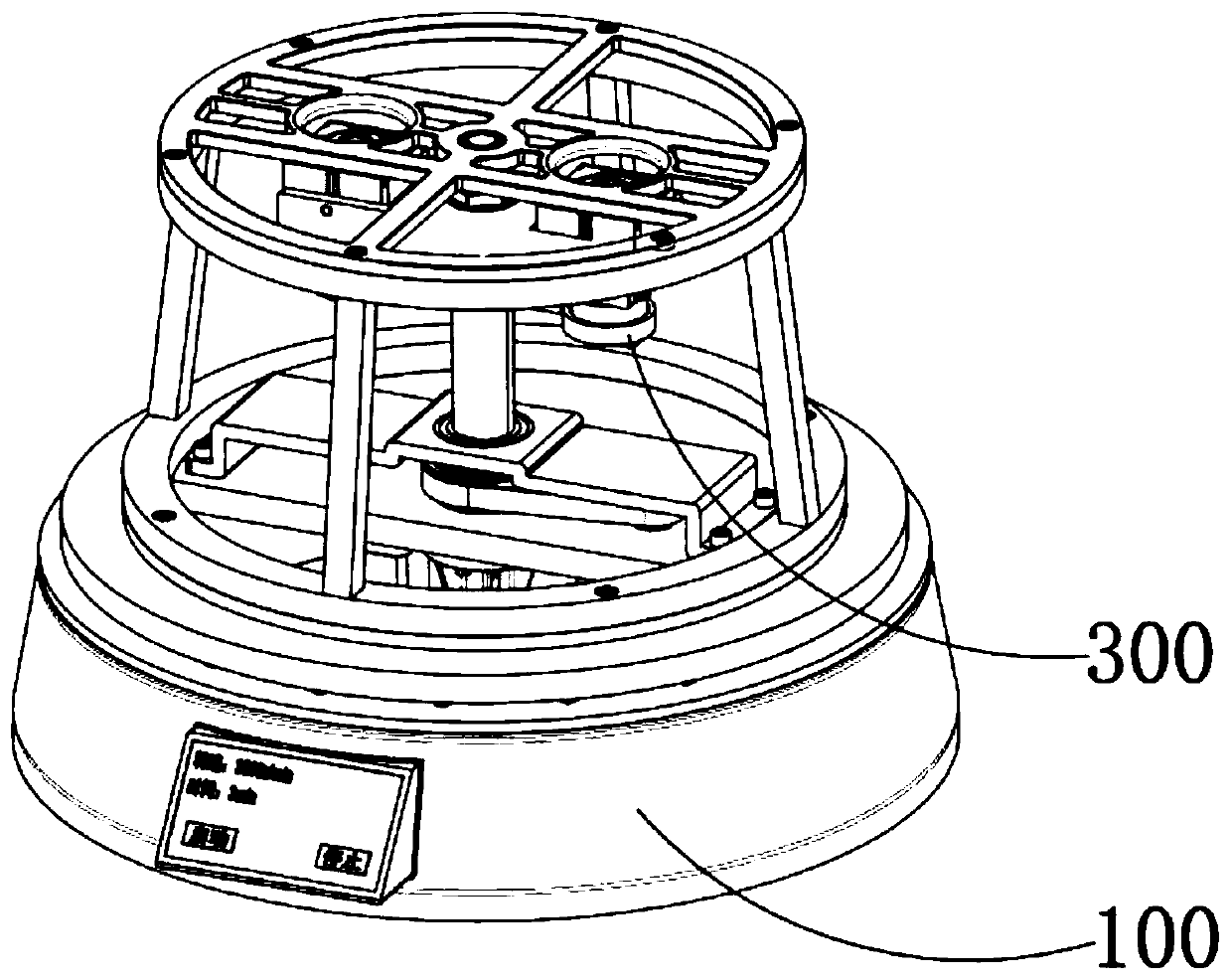

Layering method for blood components of plasma, blood platelets and the like in high-speed centrifugal manner

ActiveCN110038734ARealize automatic packagingEasy to testCentrifugesAutomatic controlBlood component

The invention provides a layering method for plasma, blood platelets, leukocytes and erythrocytes in a high-speed centrifugal manner. The method comprises the following steps that firstly, blood of apatient is quantitatively introduced into a test tube assembly for storage, the test tube assembly containing the blood is installed and inserted into a packaging mechanism, the test tube assembly andthe packaging mechanism are in an isolated state, and a liquid containing part formed by the test tube assembly and the packaging mechanism is integrally installed on a centrifugation device; then, the centrifugation device is started, and the centrifugation device is started to drive an outer-layer tube and the packaging mechanism to rotate to be centrifuged until the blood in the outer-layer tube is centrifuged layered and sequentially comprises a plasma layer, a blood platelet layer, a leukocyte layer and an erythrocyte layer from top to bottom; and finally, an automatic control device isused for switching the state between the test tube assembly and the packaging mechanism from an isolated state to a communicating state, the test tube assembly sequentially discharges all the layers of the layered blood from top to bottom into the packaging mechanism for independent containing, and the plasma layer, the blood platelet layer, the leukocyte layer and the erythrocyte layer which areindependently contained are taken out for later use by a user.

Owner:济南和合医学检验有限公司

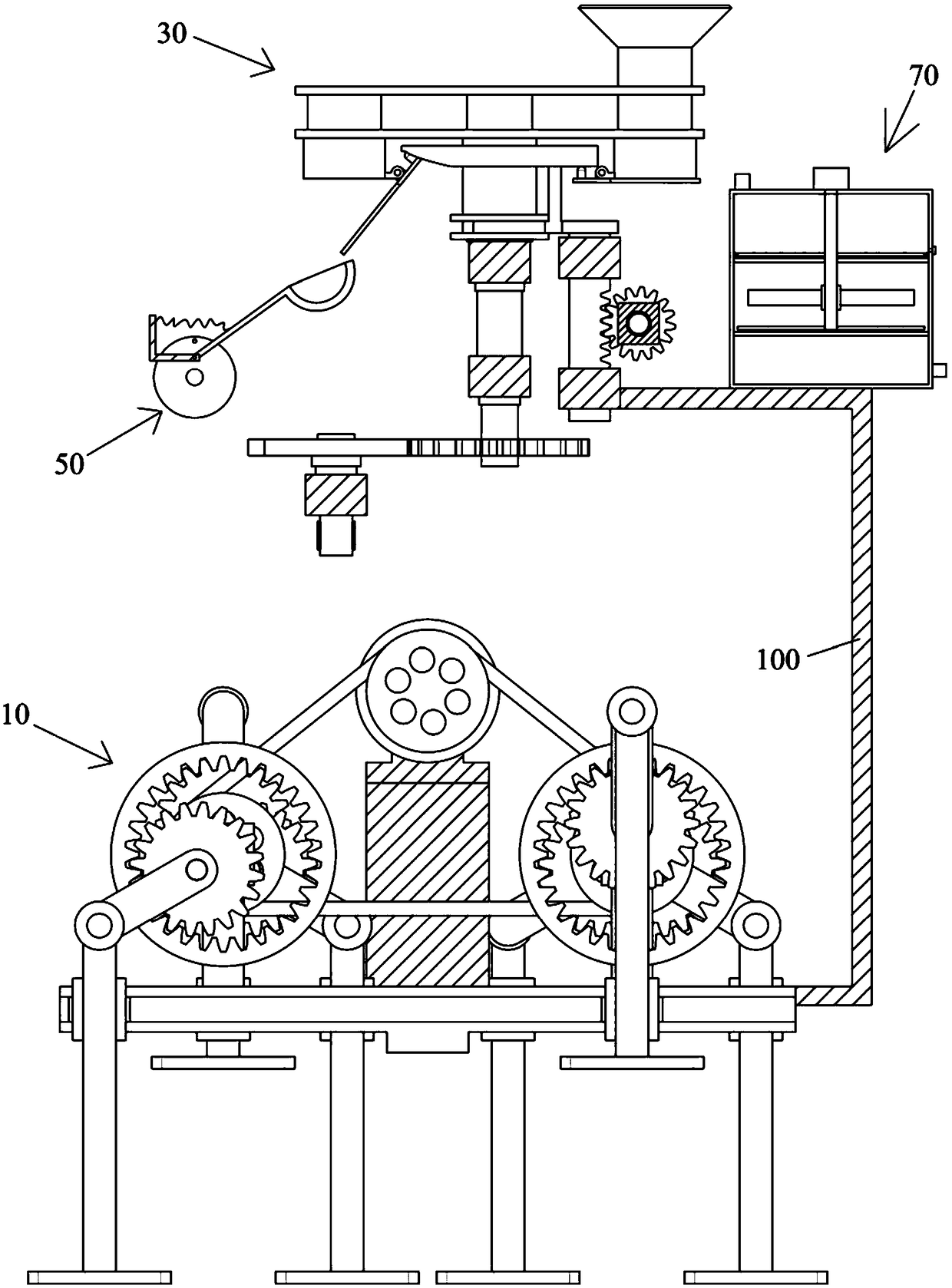

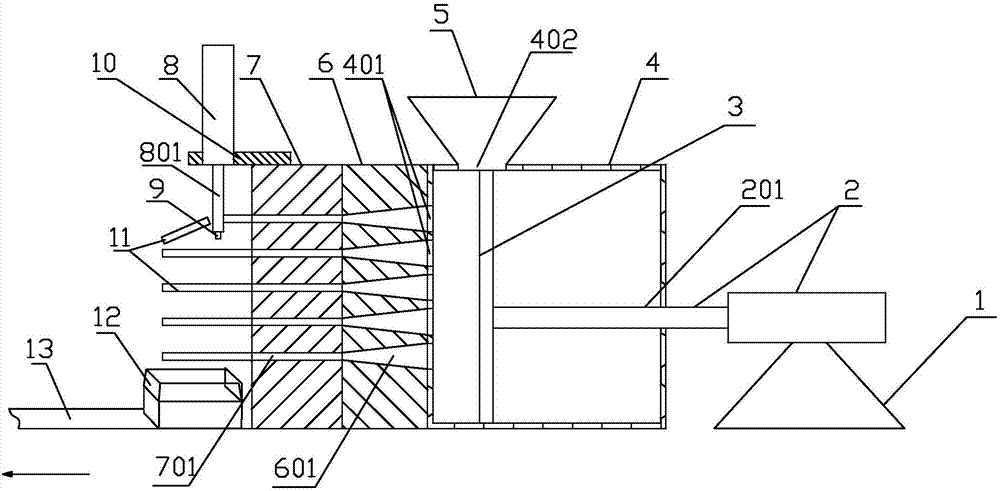

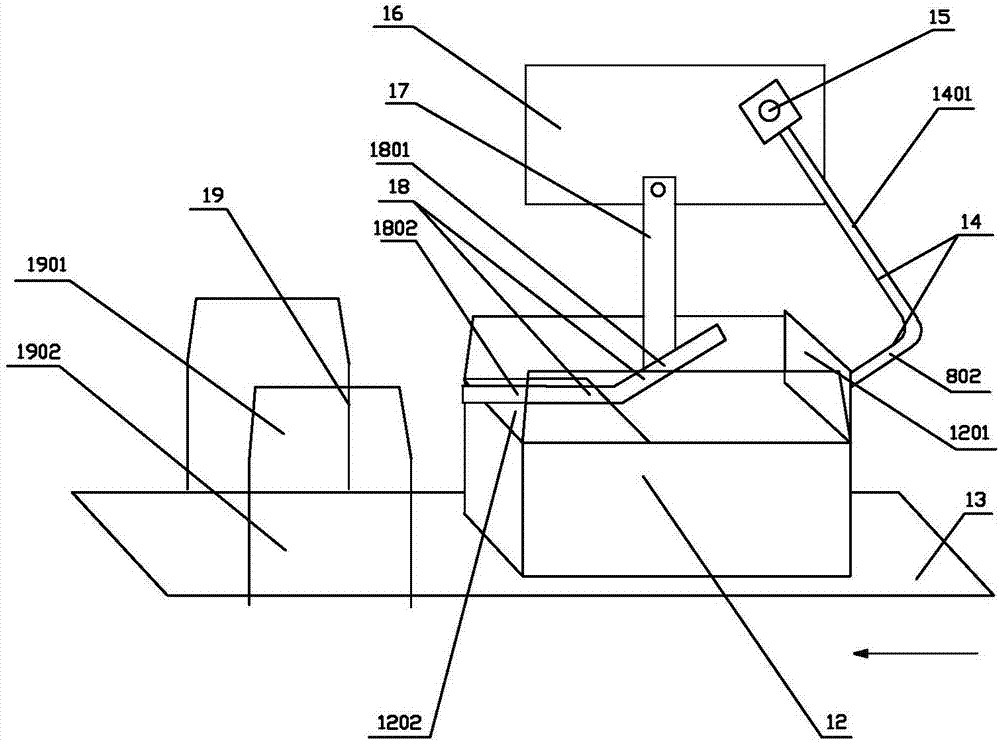

Compression, cutting, forming and automatic packing device for biomass fuel

InactiveCN107499587AImprove tightnessRealize automatic packagingPackagingMetal working apparatusCompression moldingCompression device

The invention relates to a compression, cutting, forming and automatic packing device for biomass fuel. The compression, cutting, forming and automatic packing device comprises a compression device, a cutting-off device and a packing device, wherein the compression device is used for compression forming of viscous material chips, the cutting-off device is used for cutting off the compression-formed biomass fuel into biomass fuel rods with the required sizes, and the packing device is used for encasing the cutting-off-formed biomass fuel rods and automatically packing the biomass fuel rods. Compared with the prior art, the biomass fuel rods can be packed automatically, so that the packing efficiency is high.

Owner:嘉兴正森新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com