Patents

Literature

1491 results about "Threshing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Threshing is the process of loosening the edible part of grain (or other crop) from the chaff to which it is attached. It is the step in grain preparation after reaping. Threshing does not remove the bran from the grain.

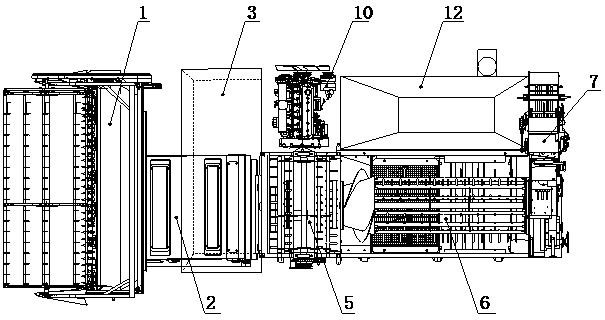

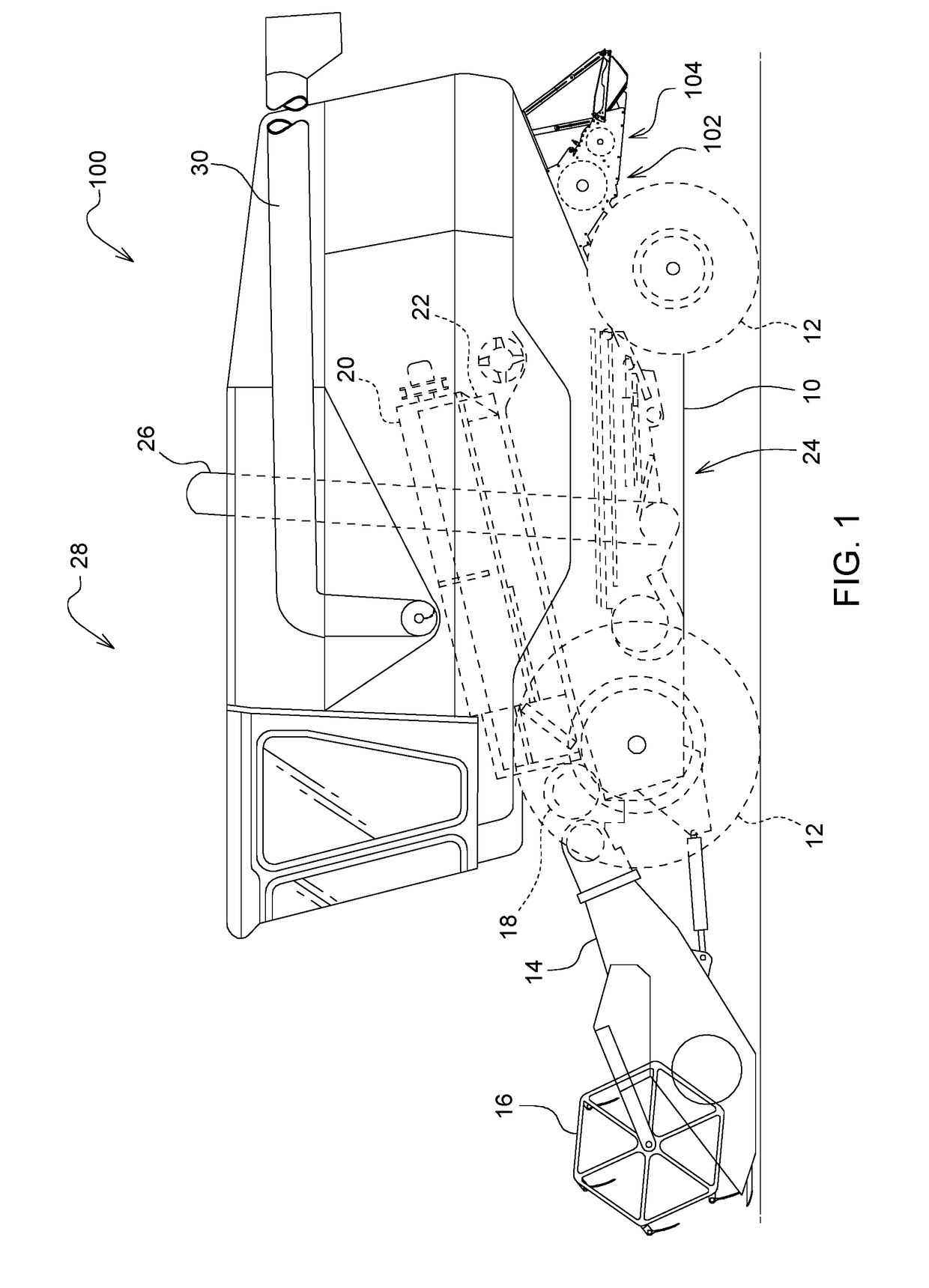

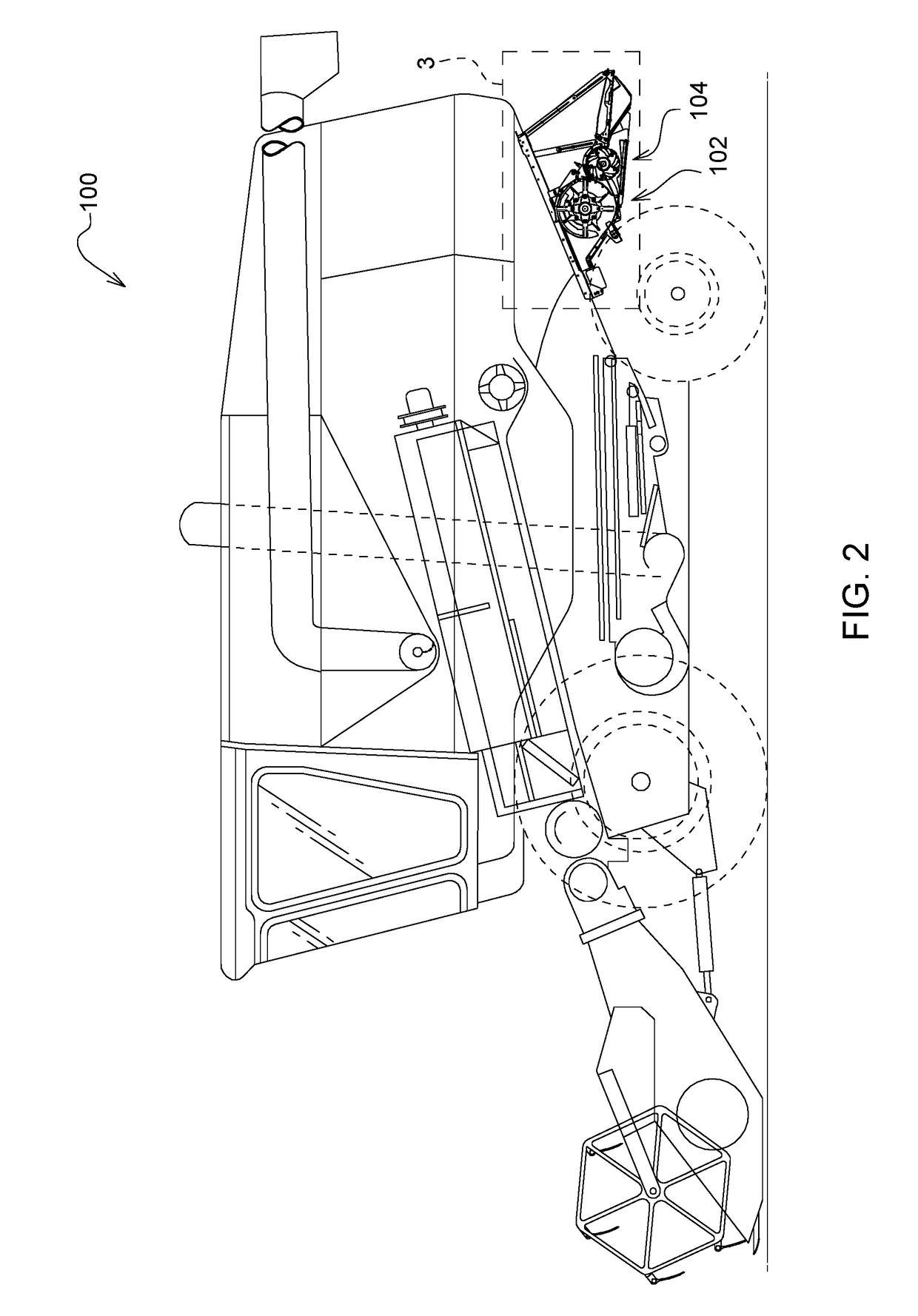

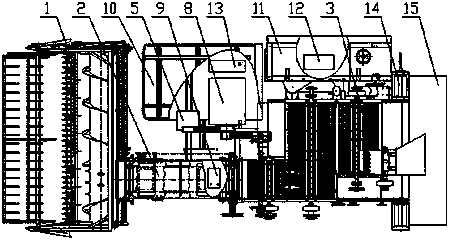

Tangential-longitudinal axial type grain combine harvesting and bundling duplex operation machine

InactiveCN104054449AReduce loss rateImprove work efficiencyMowersBalingAgricultural scienceAgricultural engineering

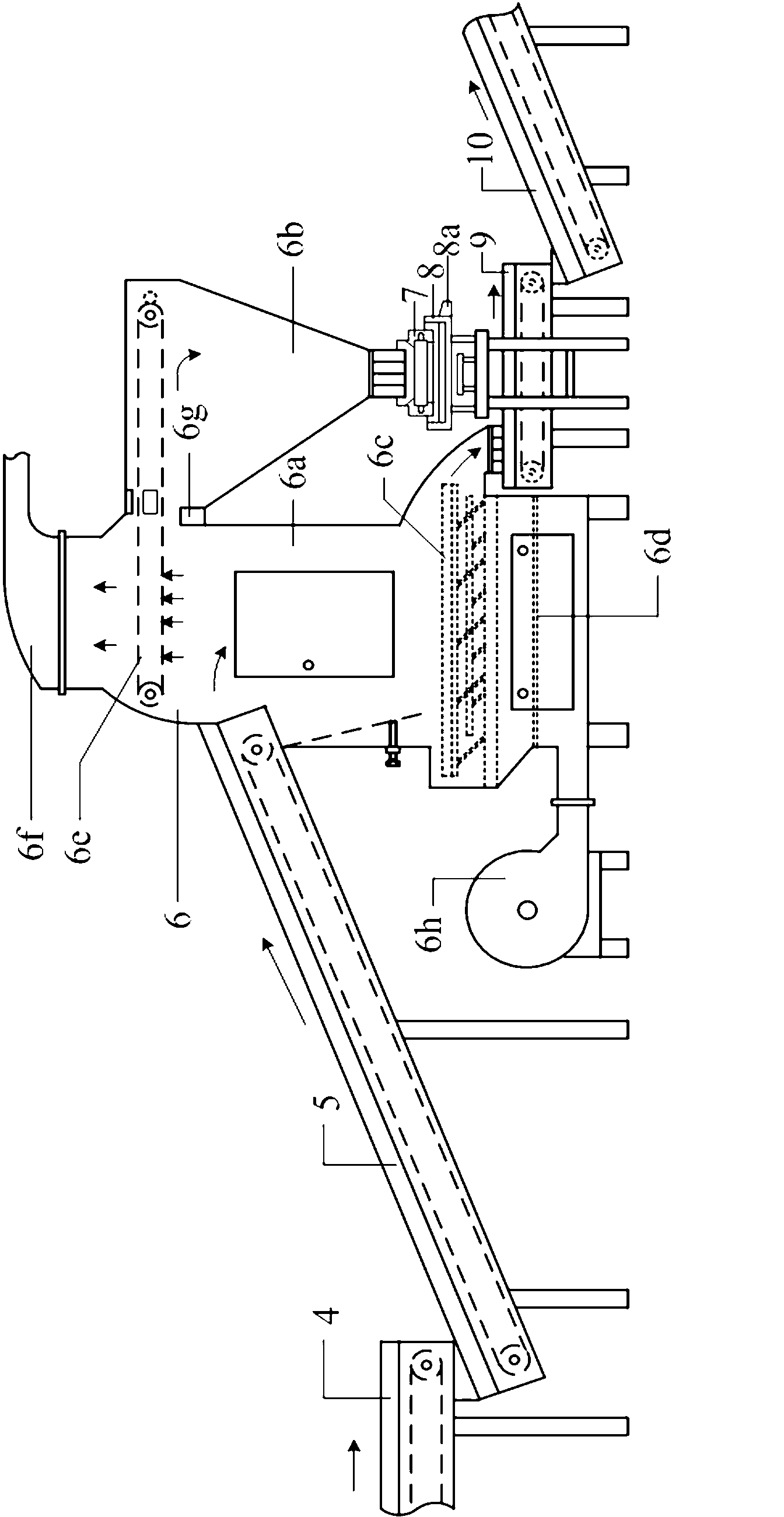

The invention discloses a tangential-longitudinal axial type grain combine harvesting and bundling duplex operation machine which comprises a grain cutting and conveying system, a seed threshing and separating system, a seed cleaning device, a seed collecting and storing system, a straw compressing and bundling device, a chassis walking system and a driving operation system. When the duplex operation machine harvests grain in the field, firstly, the grain cutting and conveying system cuts stalks of grain and conveys the grain to the seed threshing and separating system, straws where seed threshing and separating are conducted are compressed and bundled through the straw compressing and bundling device, seeds obtained through threshing are cleaned through the seed cleaning device, and seeds obtained through cleaning are conveyed to a grain tank through the seed collecting and storing system. The duplex operation machine can meet the requirements for harvesting seeds of rice and wheat and compressing and bundling threshed straws, and has the advantages of being high in work efficiency, stable in work performance, simple in work procedure and capable of saving time and labor.

Owner:JIANGSU UNIV

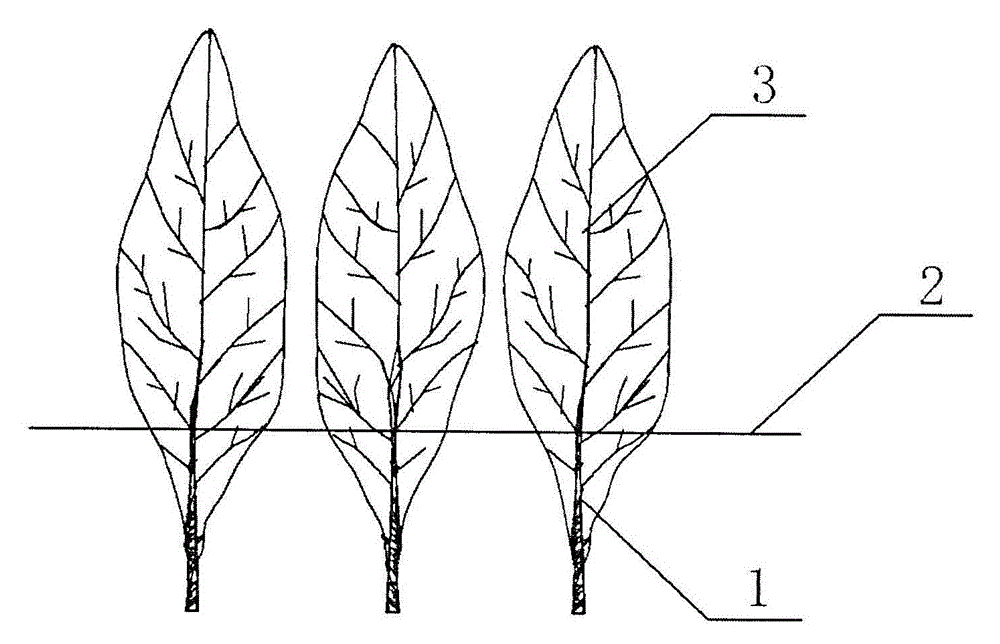

Method for growing nuisance free selenium-rich rice by using biological technique

InactiveCN101292615ANo pollution in the processFormula refiningSoil lifting machinesPlantingContinuous croppingDisease

The invention relates to a method for planting pollution-free rice rich in selenium by adopting biotechnology, belonging to a planting method of plants; the planting method comprises the steps of land selection, soil preparation, application of the soil activator Medina, variety selection and seed treatment, seedling strengthening by means of dry raising and spaced planting cultivation, timely rice transplanting and reasonable compact planting, adequate fertilization, scientific irrigation, adoption of selenium supplementing and transforming technology, comprehensive prevention and control of diseases and pests, harvesting and threshing, drying and storing. The method of the invention has obvious effect; proved by field production trials, the application of the biologics of the Medina can increase the plant yield by 20 percent to 40 percent and decrease the fertilizer dosage by 25 percent to 50 percent and improve the rate of emergence in saline and alkali waste lands by 40 percent to 80 percent; the method can overcome diseases of continuous cropping effectively, eliminate soil crusting and optimizing greenhouses, etc. so as to preserve the soil properties of land capability.

Owner:濮阳市中原农村实用技术研究所

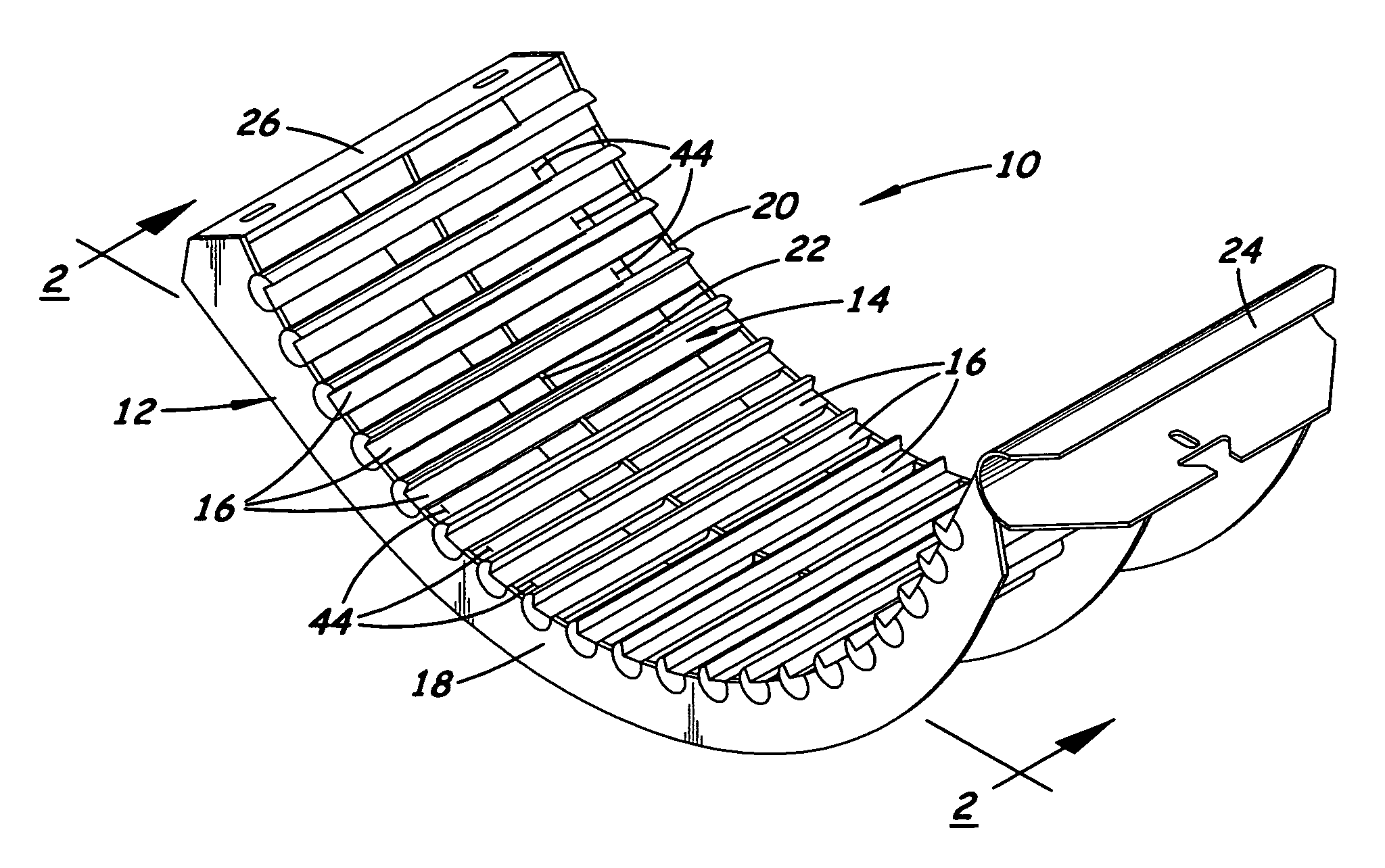

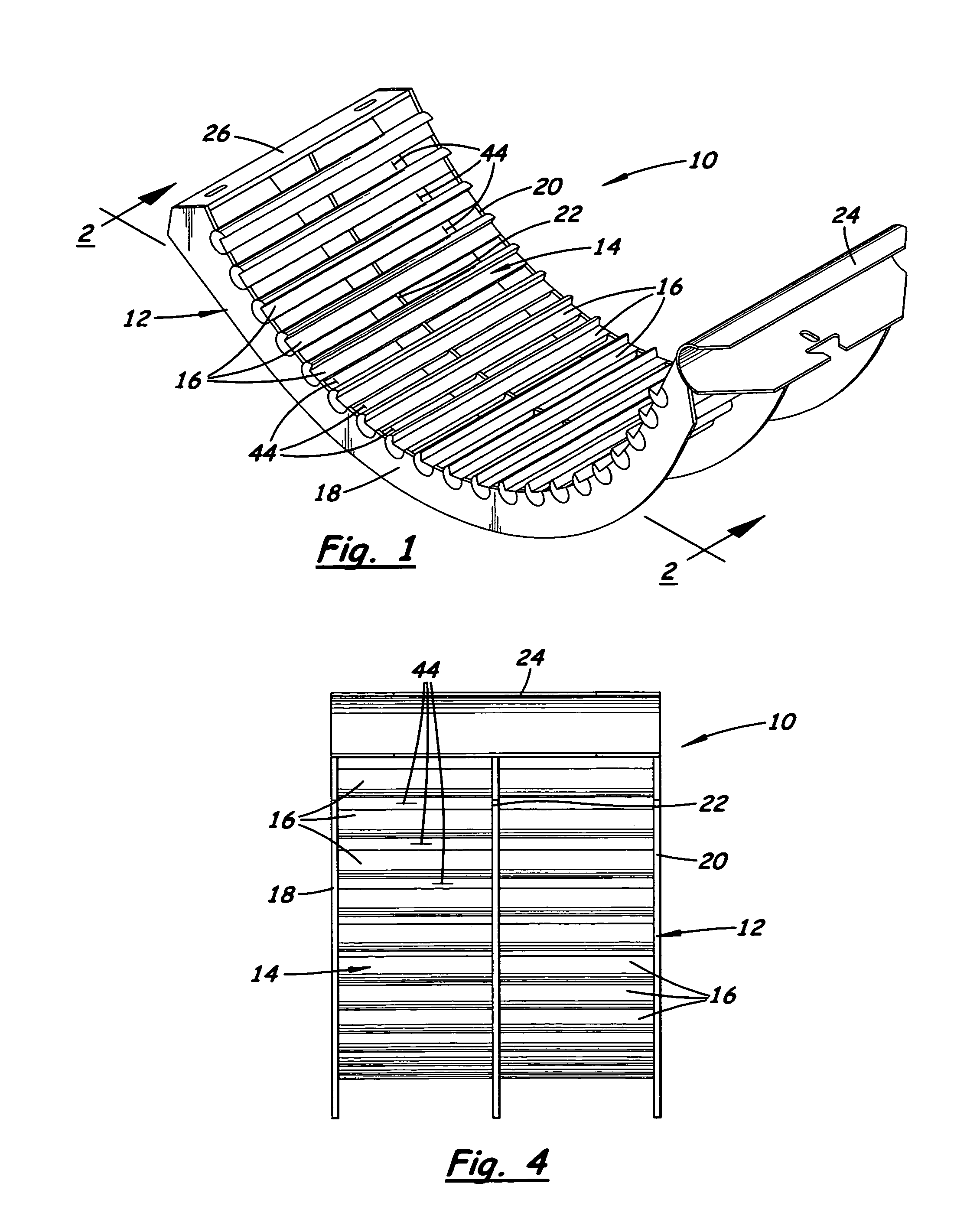

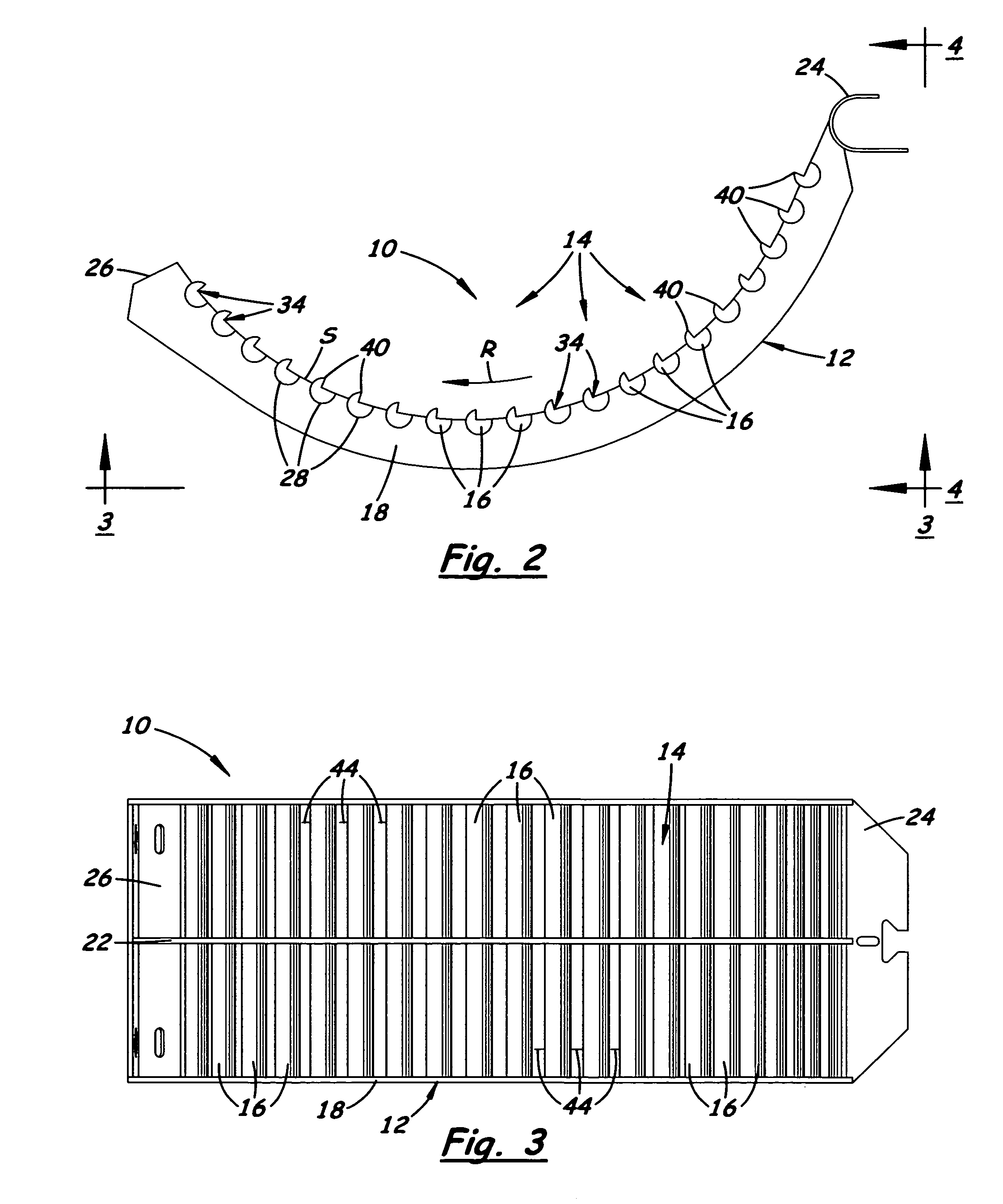

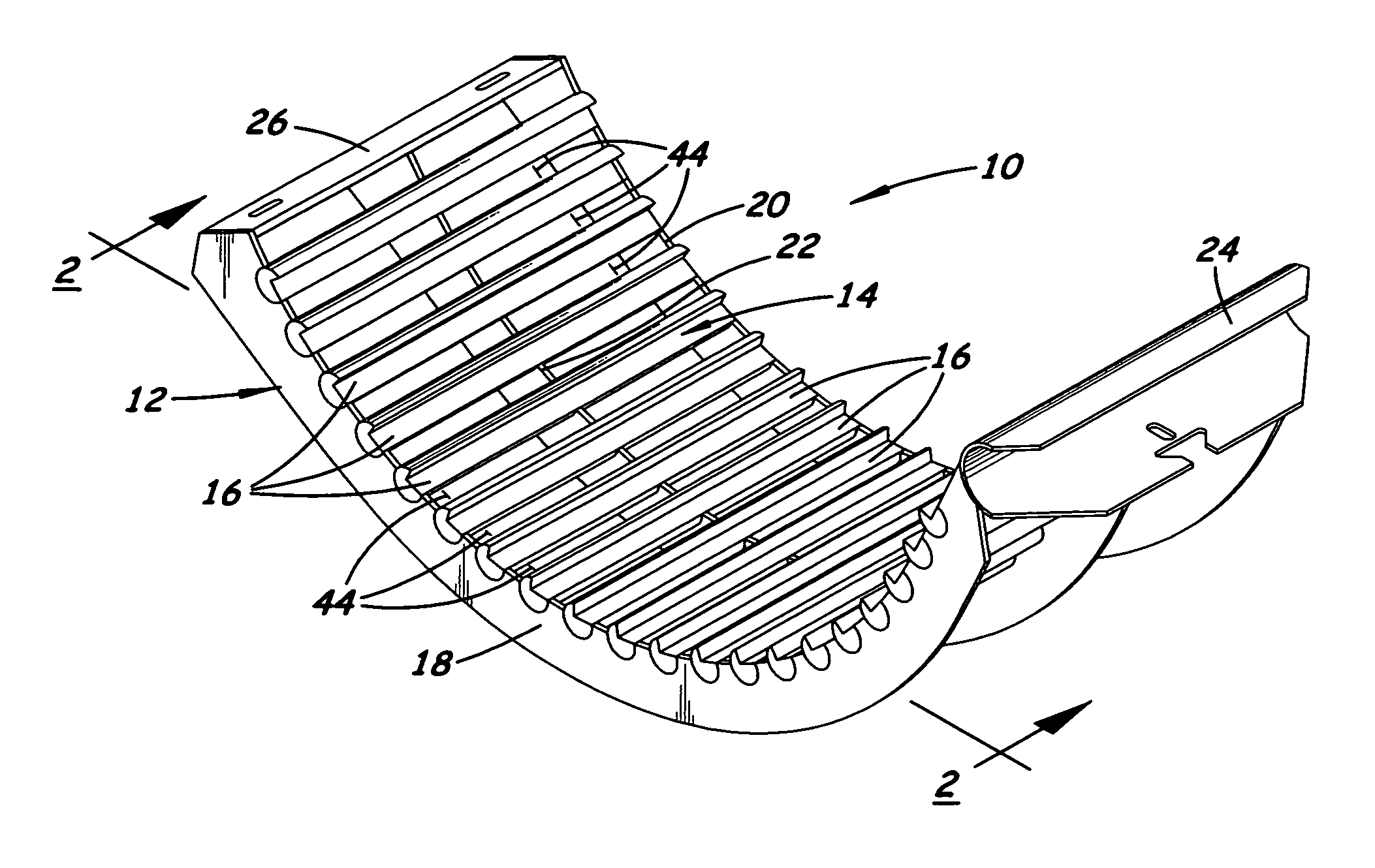

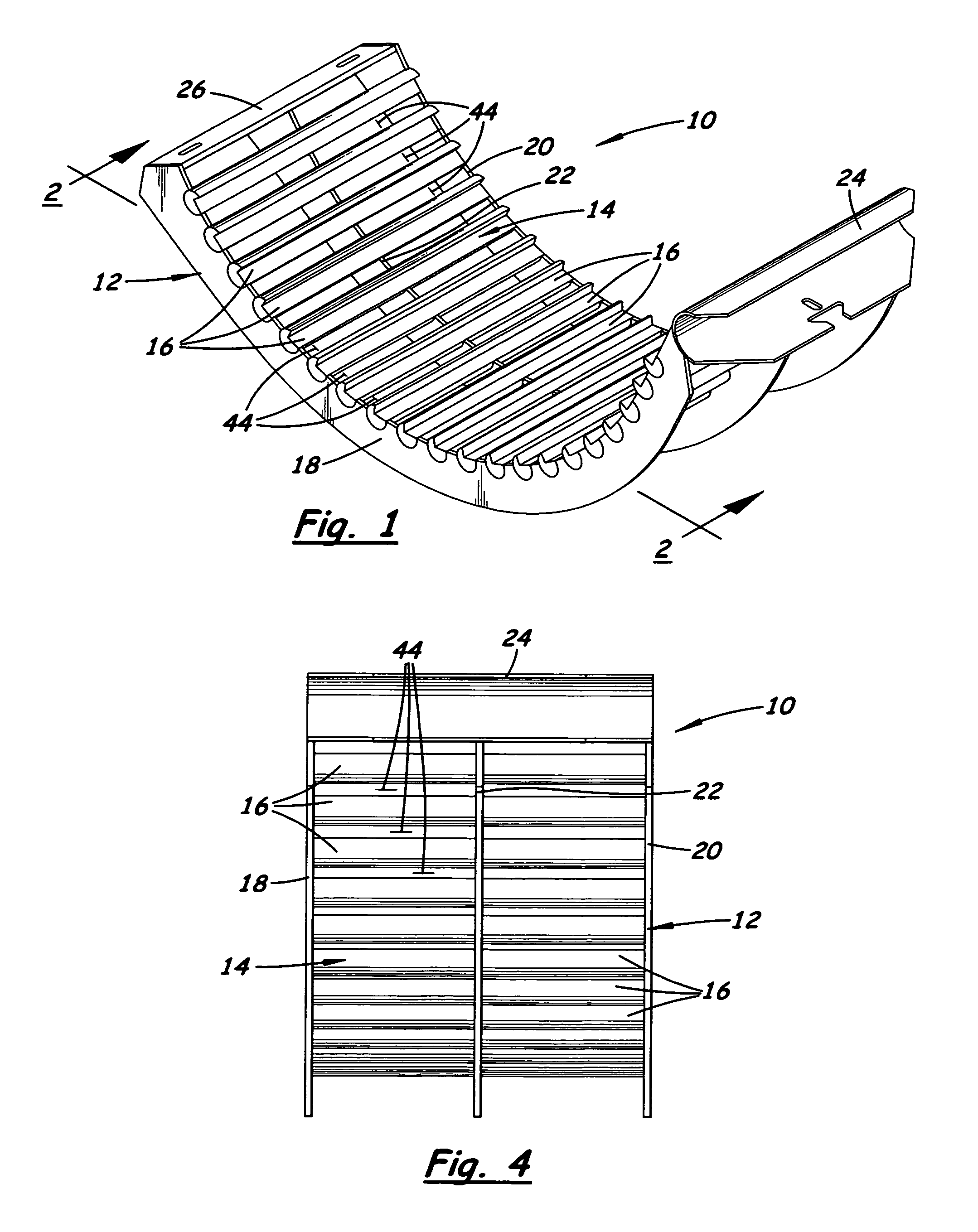

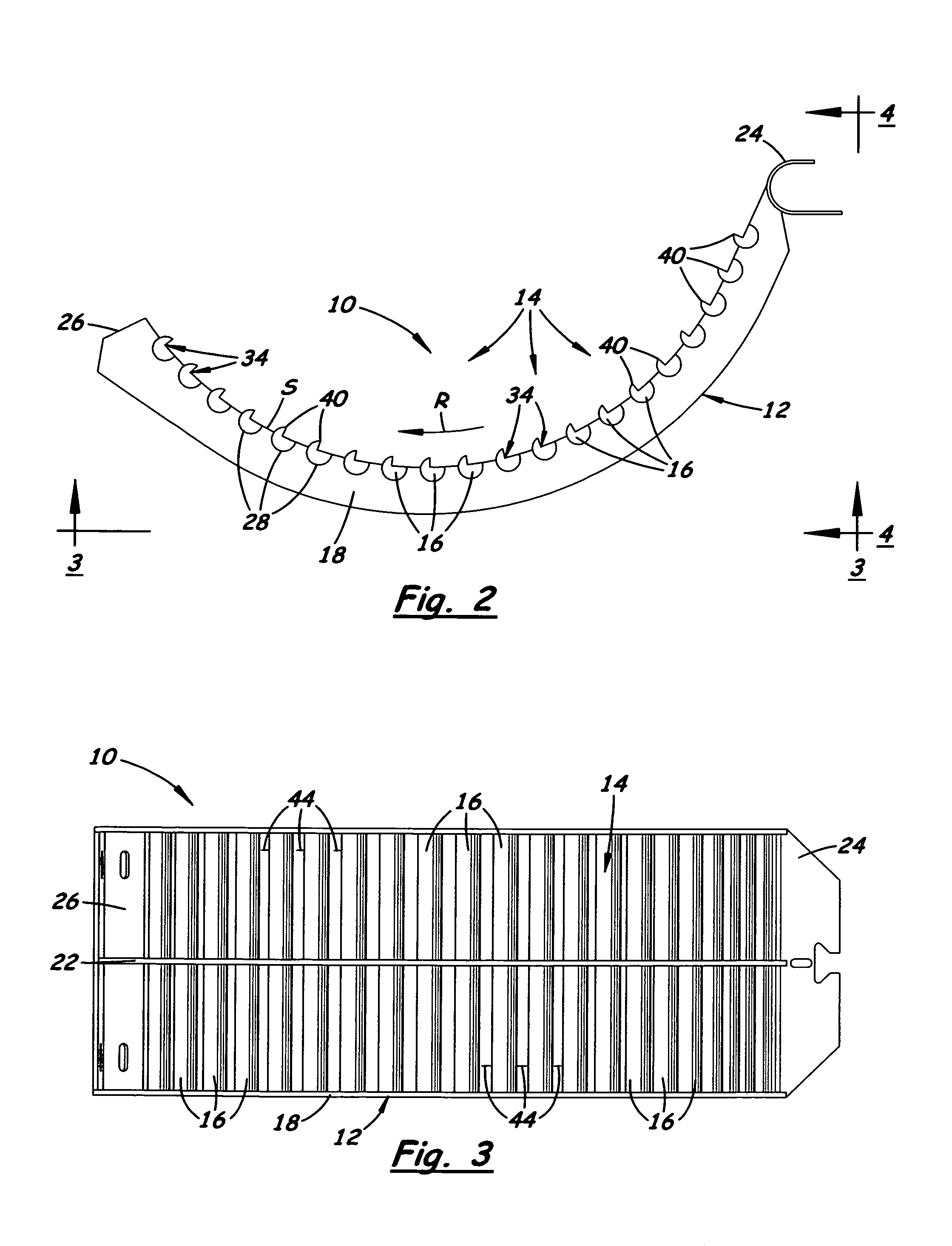

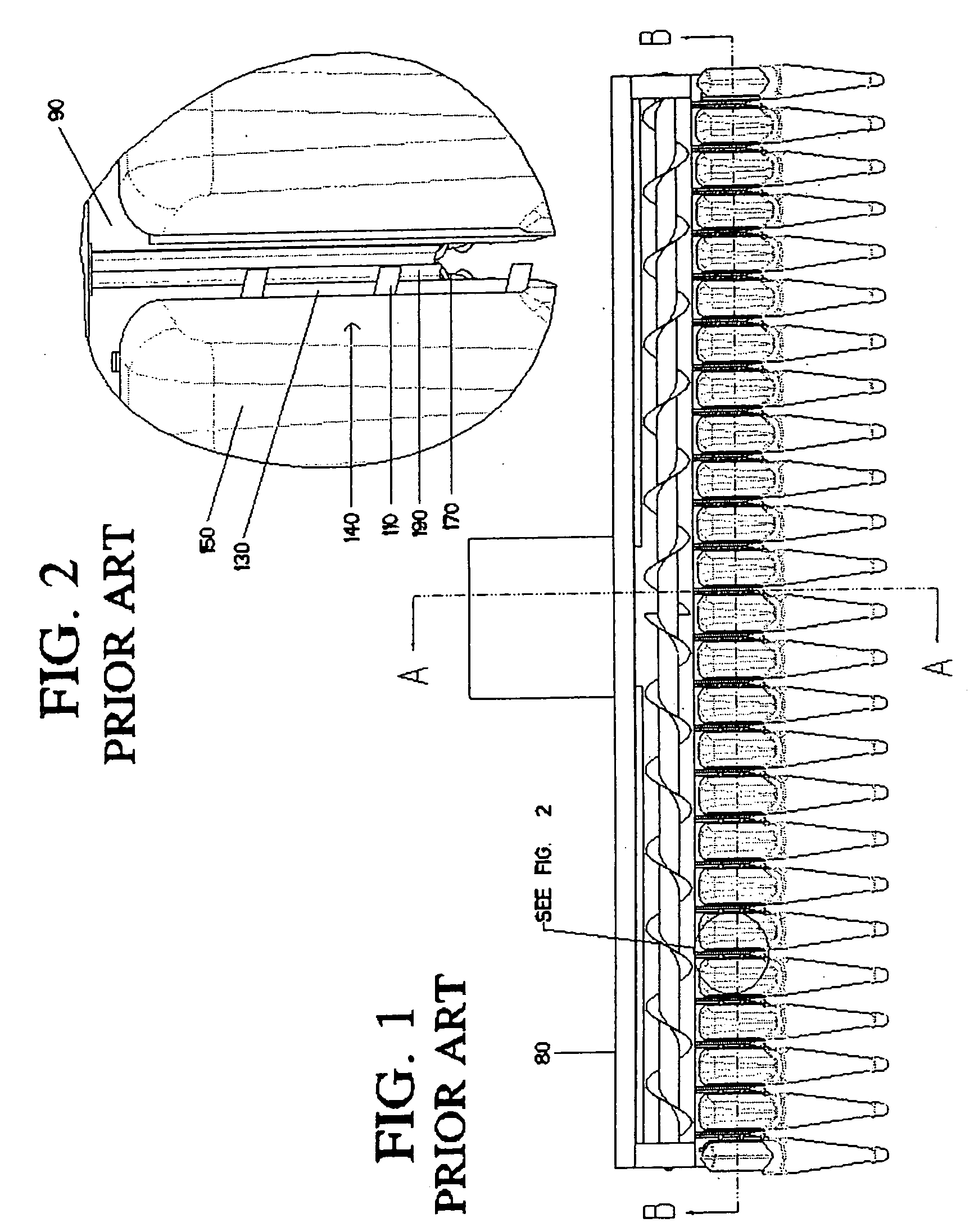

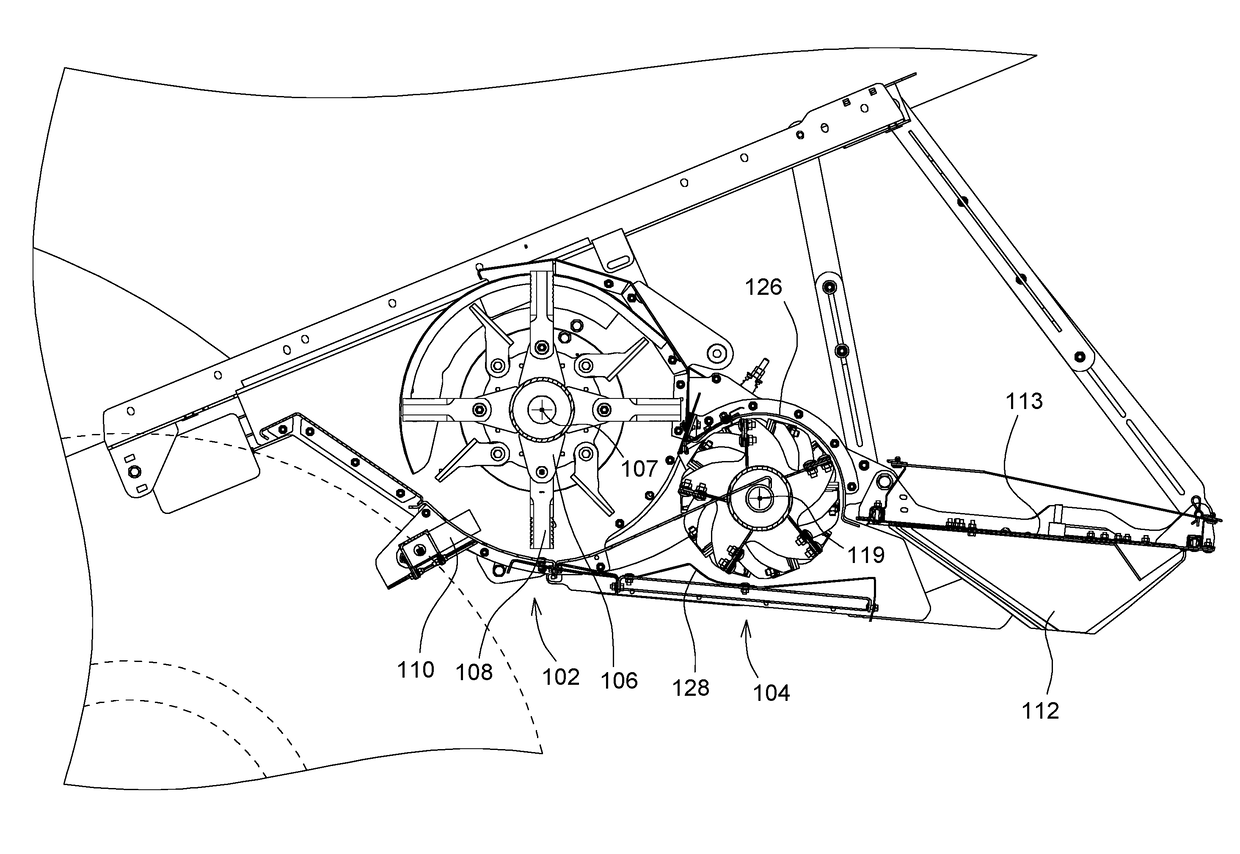

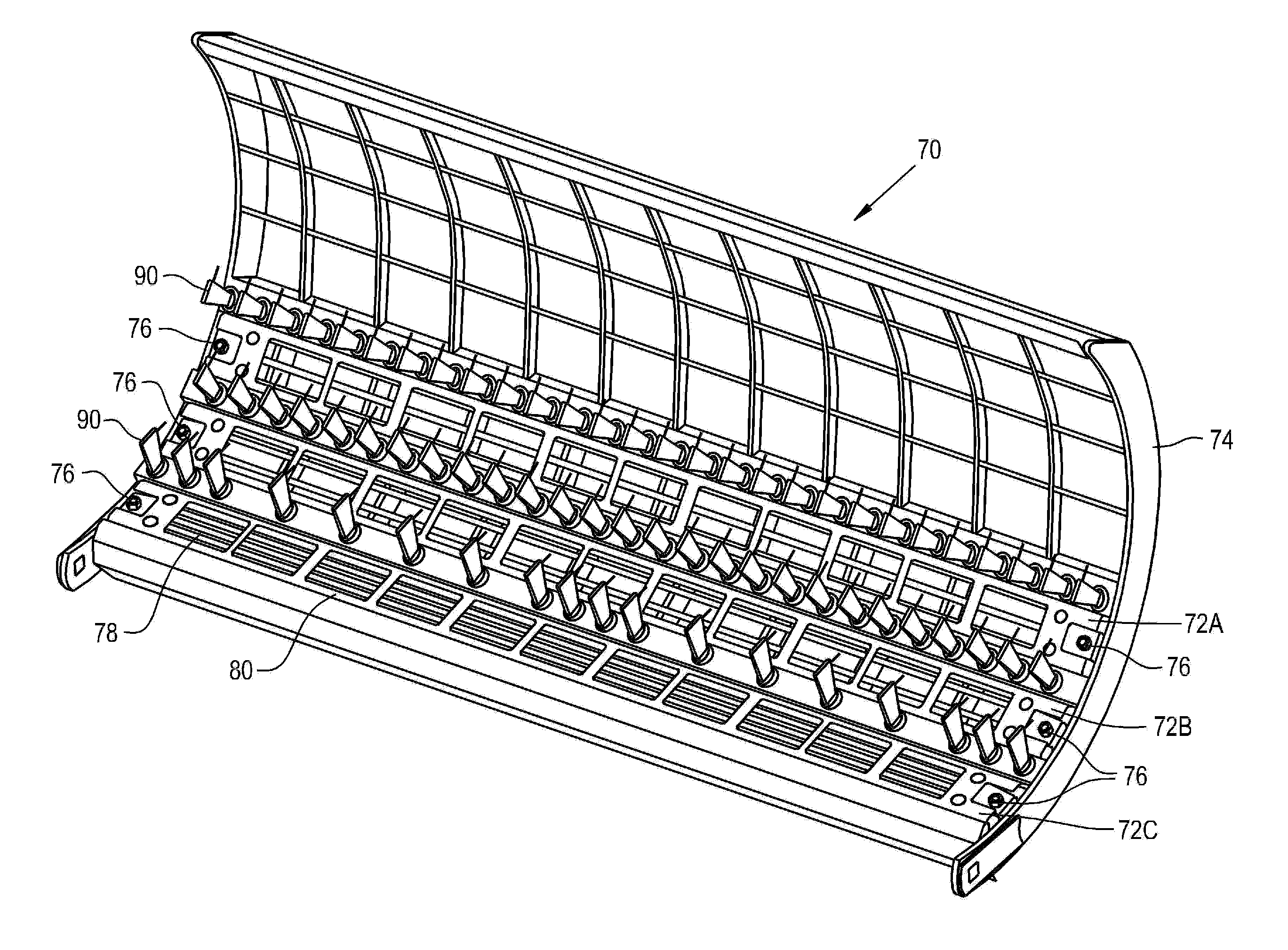

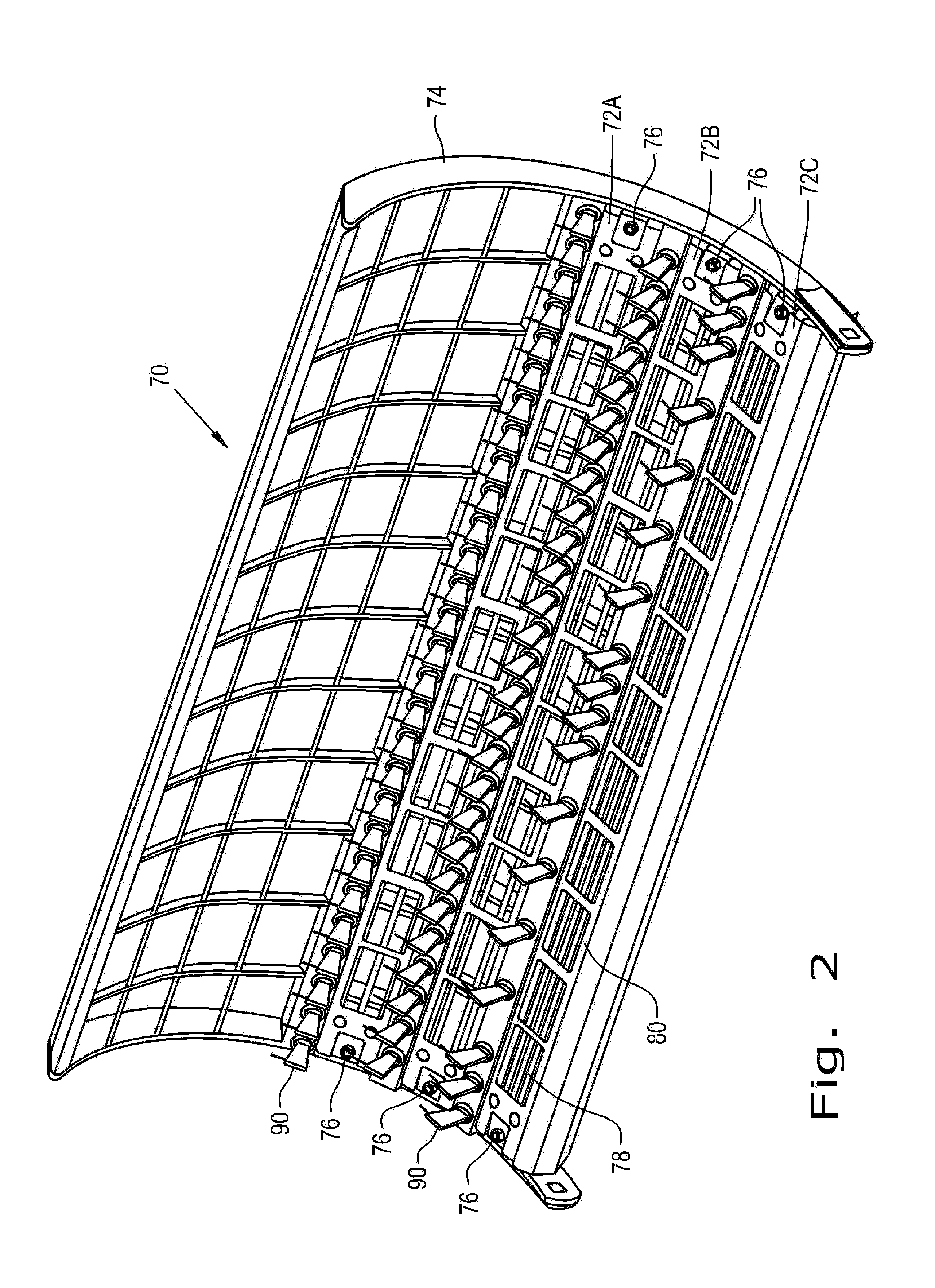

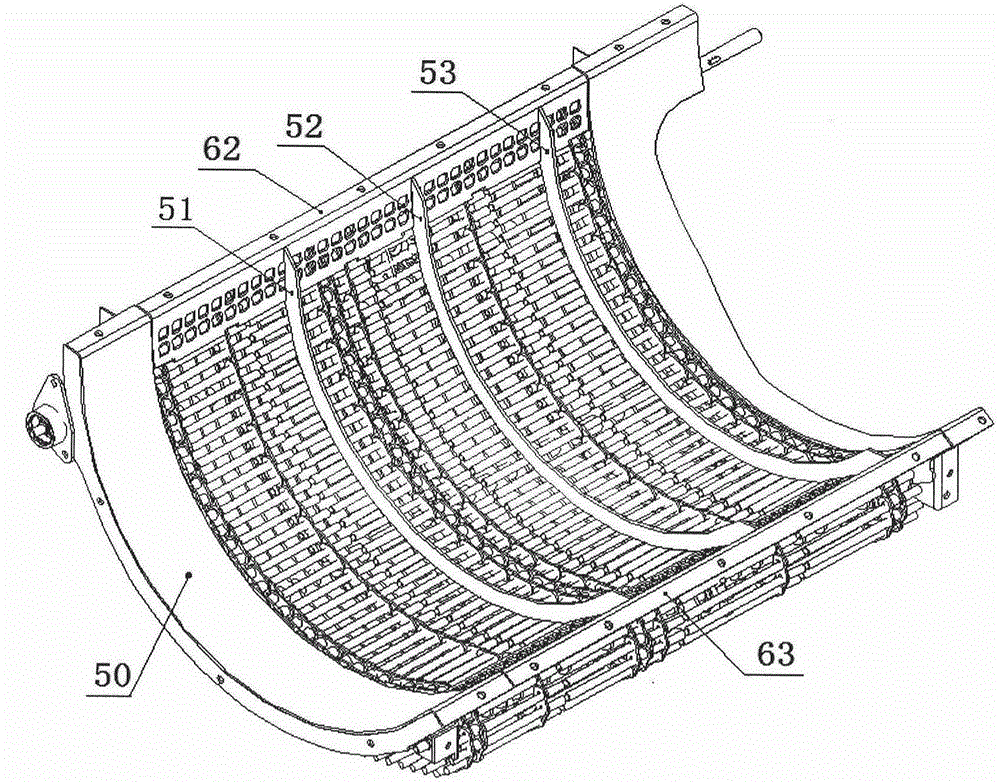

Concave with an array of longitudinally notched spaced apart threshing elements

A concave includes a frame and an array of threshing elements supported by the frame, the threshing elements being spaced apart and extending generally parallel to one another. The threshing elements are configured in the form of round bars each having formed on an upper portion thereof disposed adjacent to an upper portion of the frame a longitudinally-extending notch respectively defining an aggressive threshing edge. The spaced apart relationship and round configuration of the threshing elements reduce plugging of the concave. The threshing edges facing in a direction opposite to the direction of crop material flow restrict crop material flow and thereby enable more effective threshing.

Owner:CSM CORP

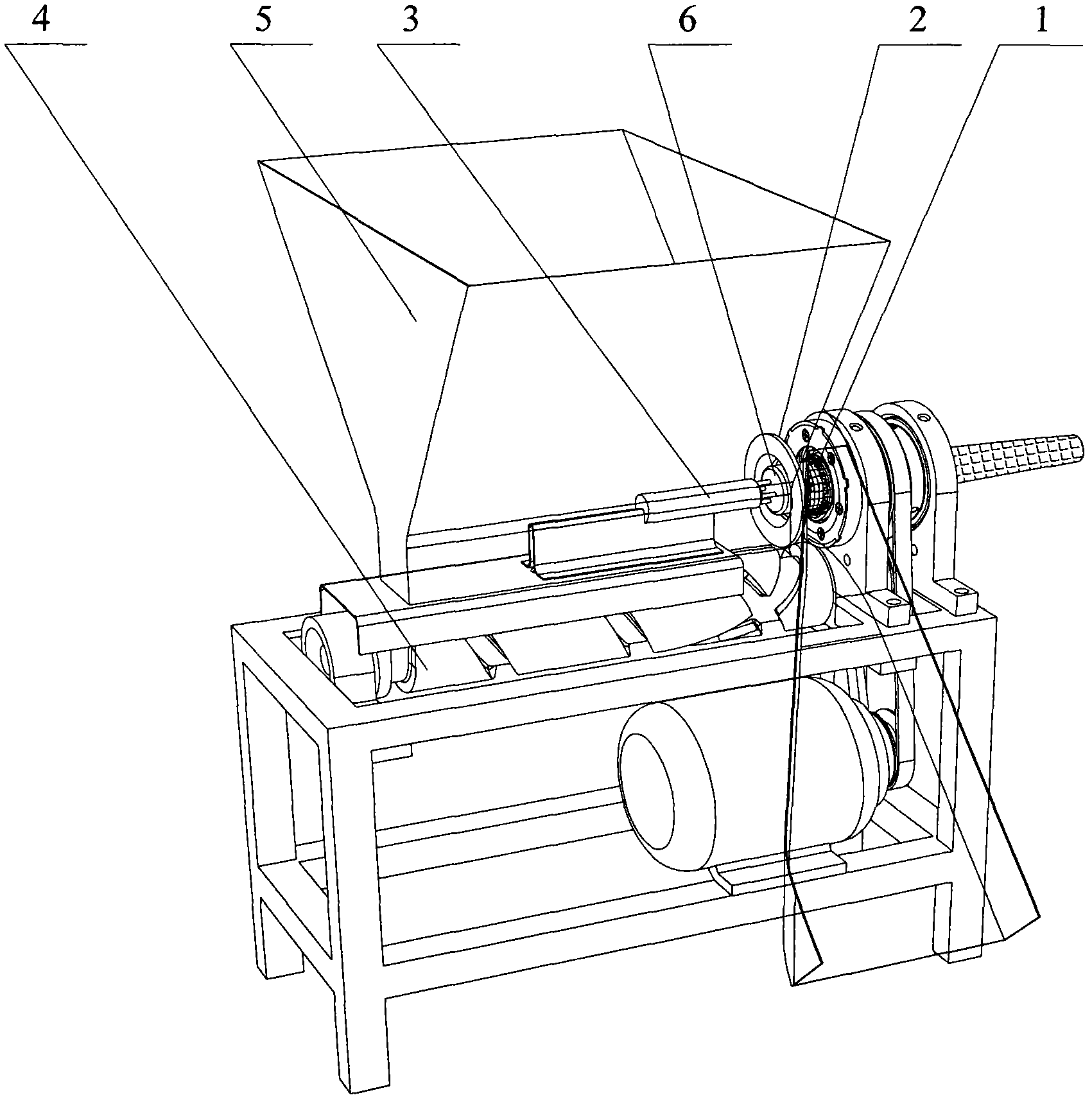

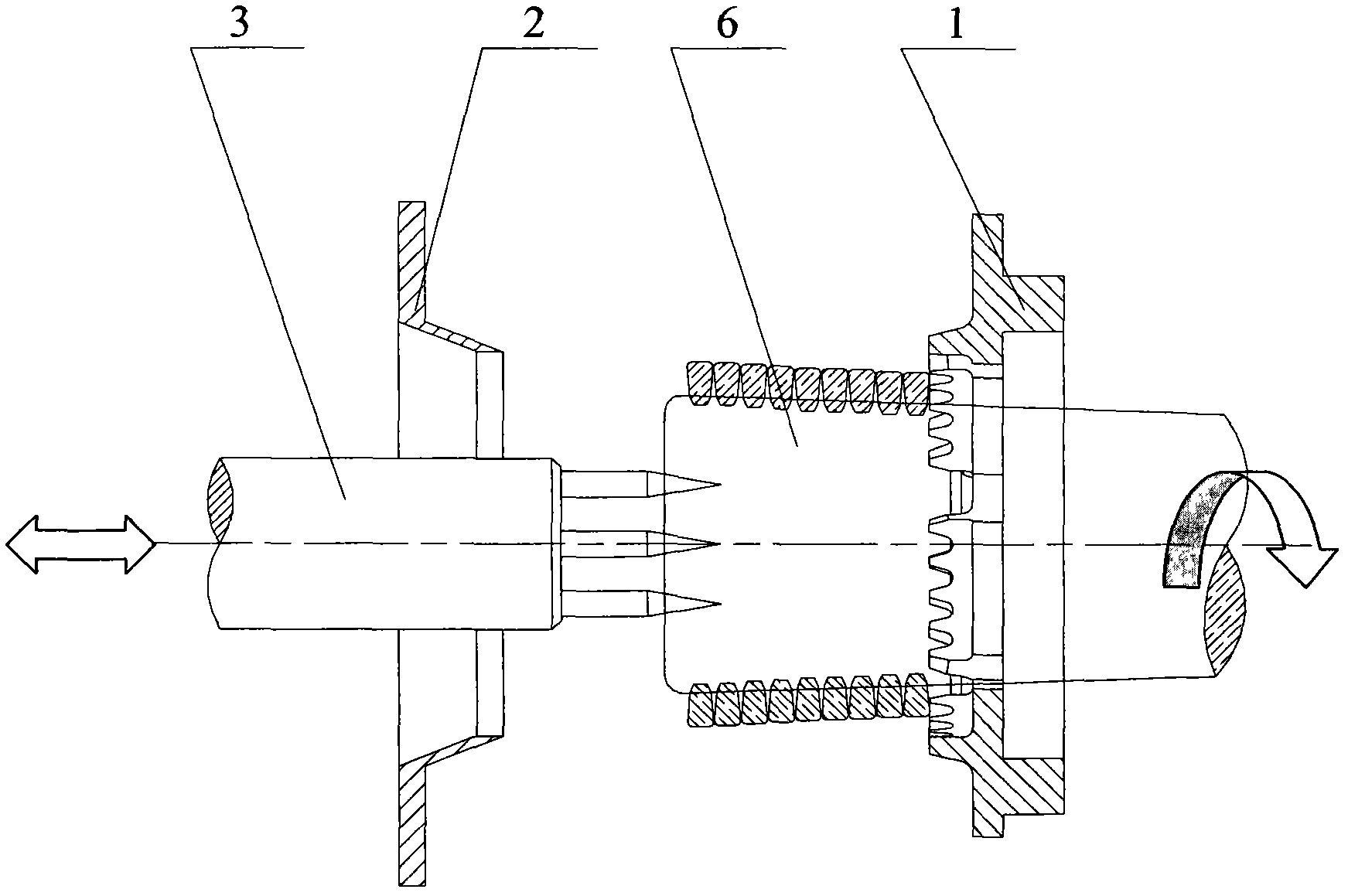

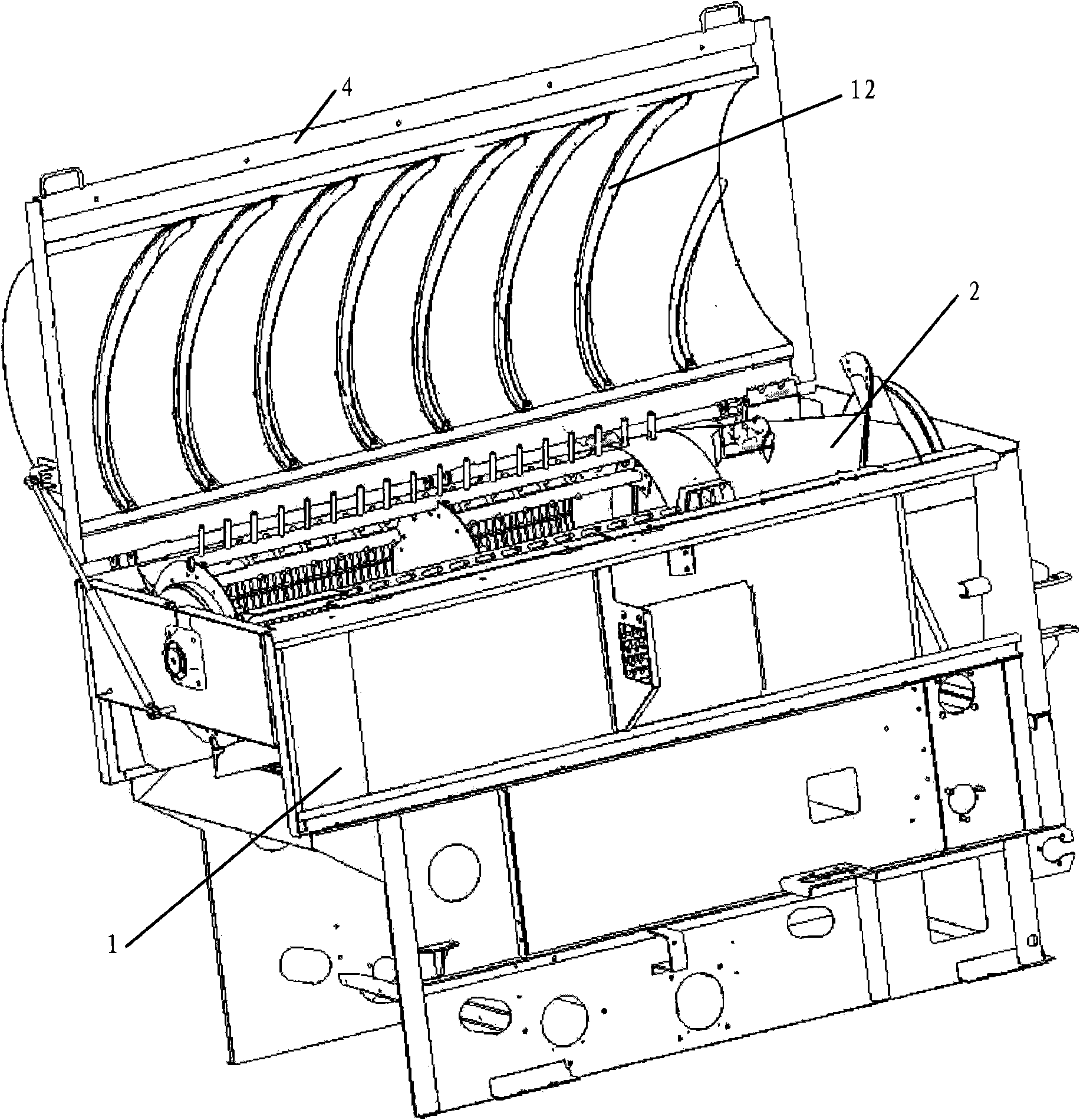

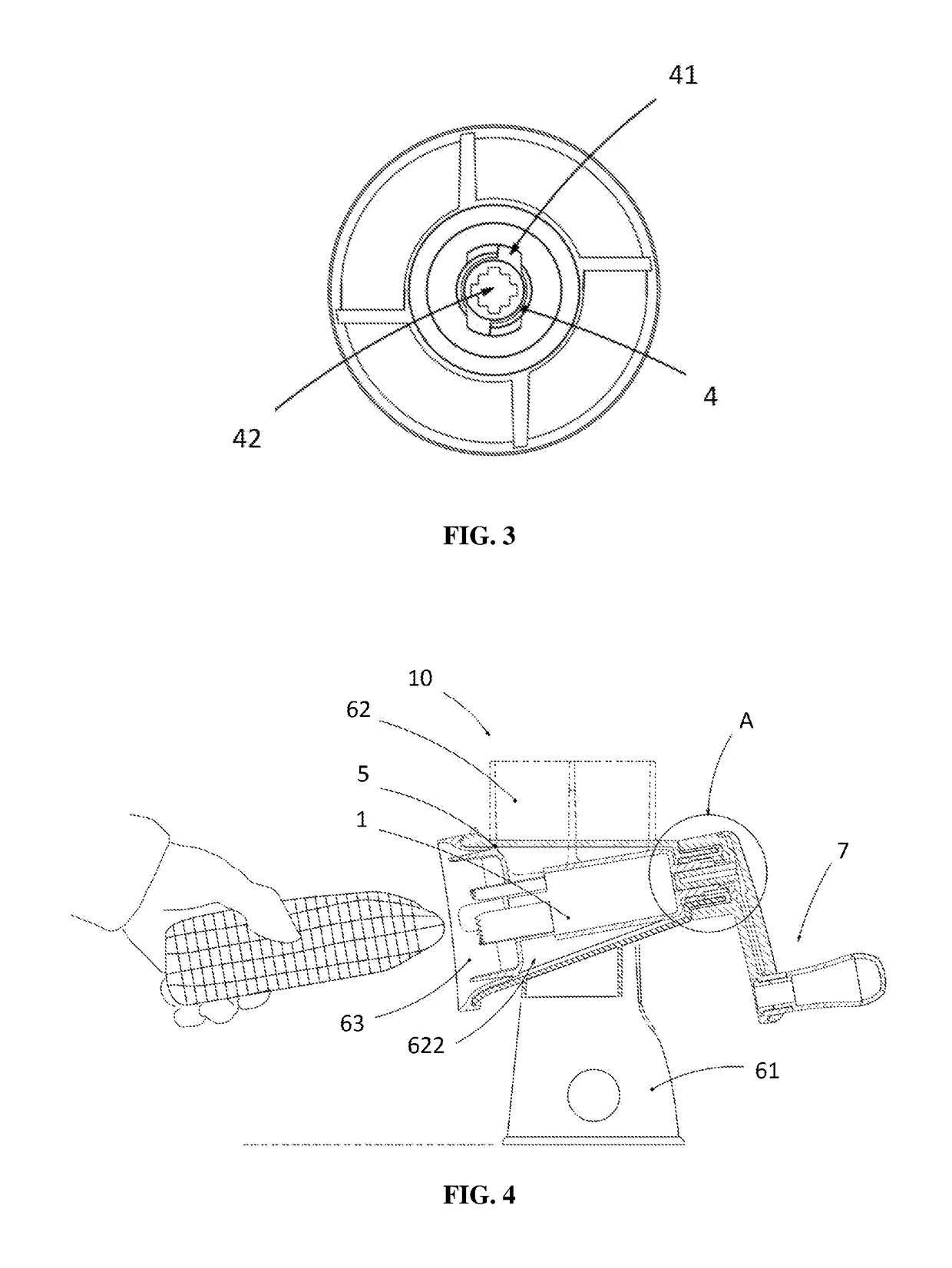

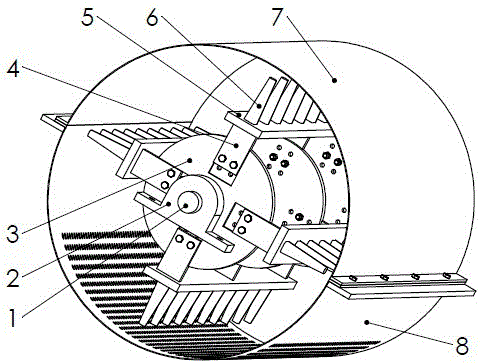

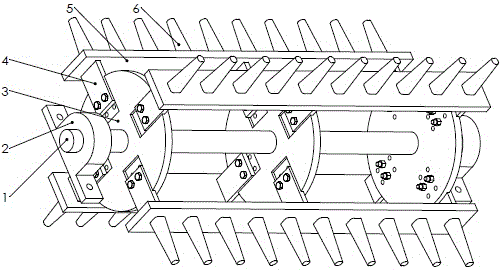

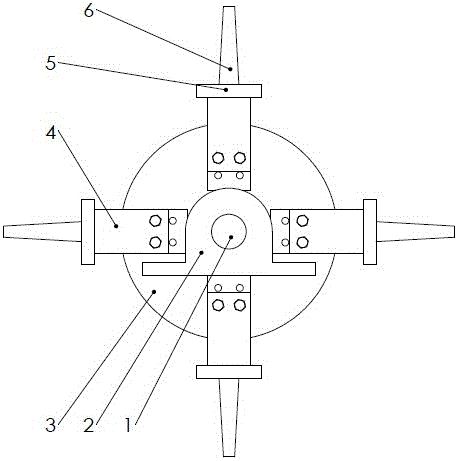

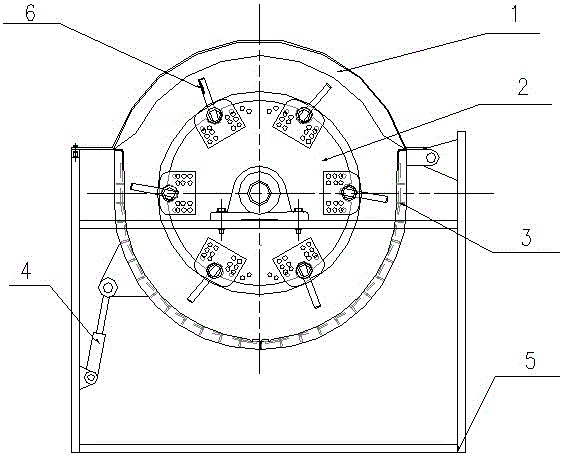

Maize thresher and maize threshing method

InactiveCN102577769AReduce manufacturing costImprove securitySaving energy measuresThreshersAgricultural engineeringThreshing

The invention discloses a maize thresher. The maize thresher comprises a machine frame, a motor, a threshing fluted disc (1), a centering sleeve (2), a push rod (3), a helical wheel (4) and a hopper (5). The centering sleeve is arranged between the threshing fluted disc and the push rod. The push rod is arranged on a sliding table driven by the helical wheel. The motor drives the threshing fluted disc and the helical wheel to rotate respectively. A maize cob clamping mechanism is arranged at the front end of the push rod. The threshing fluted disc, the centering sleeve and the push rod are coaxially aligned. An outlet of the hopper is aligned to a zone between the threshing fluted disc and a locating sleeve. According to a maize threshing method disclosed by the invention, maize cobs are pushed into the rotating threshing fluted discs by passing through the centering sleeve by the push rod, maize seeds are separated from the maize cobs by a tangential force generated between the teeth of the threshing fluted disc and the maize seeds, the maize is threshed completely in a rotary extruding way, and the maize seeds and the threshed cobs are intact. According to the invention, the separated maize seeds are clean and free of residues, the maize cobs are intact and easy to collect, and the maize thresher is simple in structure, small in threshing power, energy-saving and environment friendly, and suitable for families and enterprises.

Owner:长沙齐行机电科技有限公司

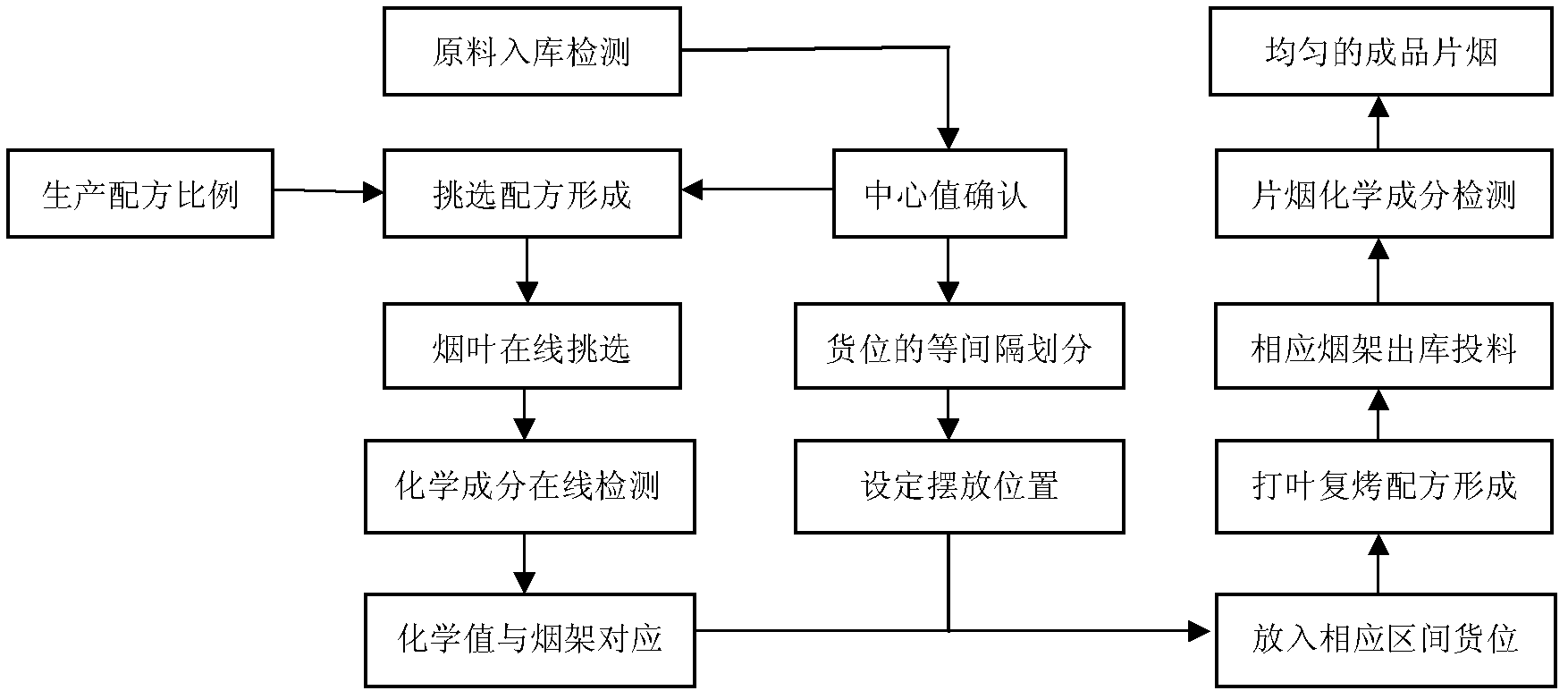

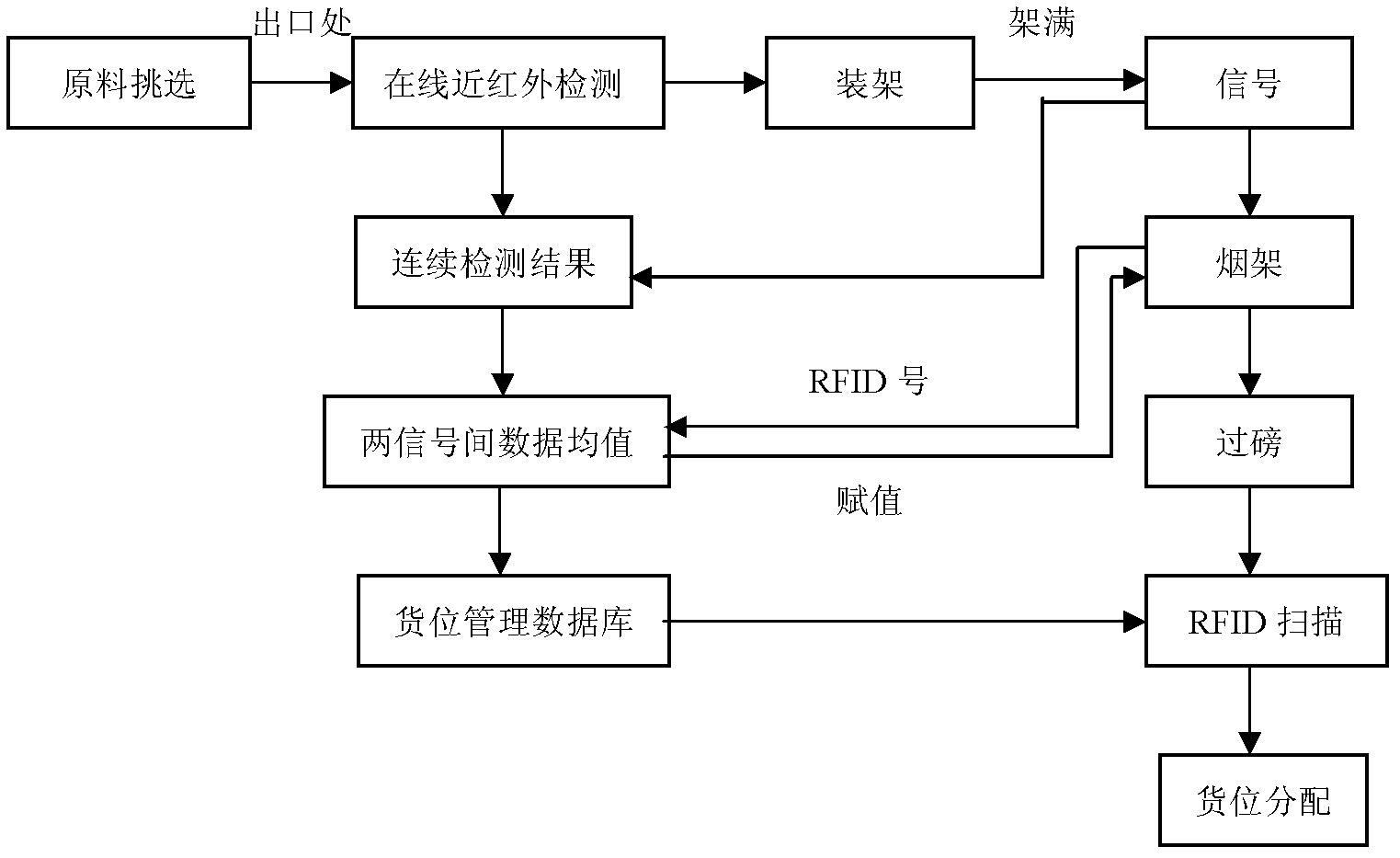

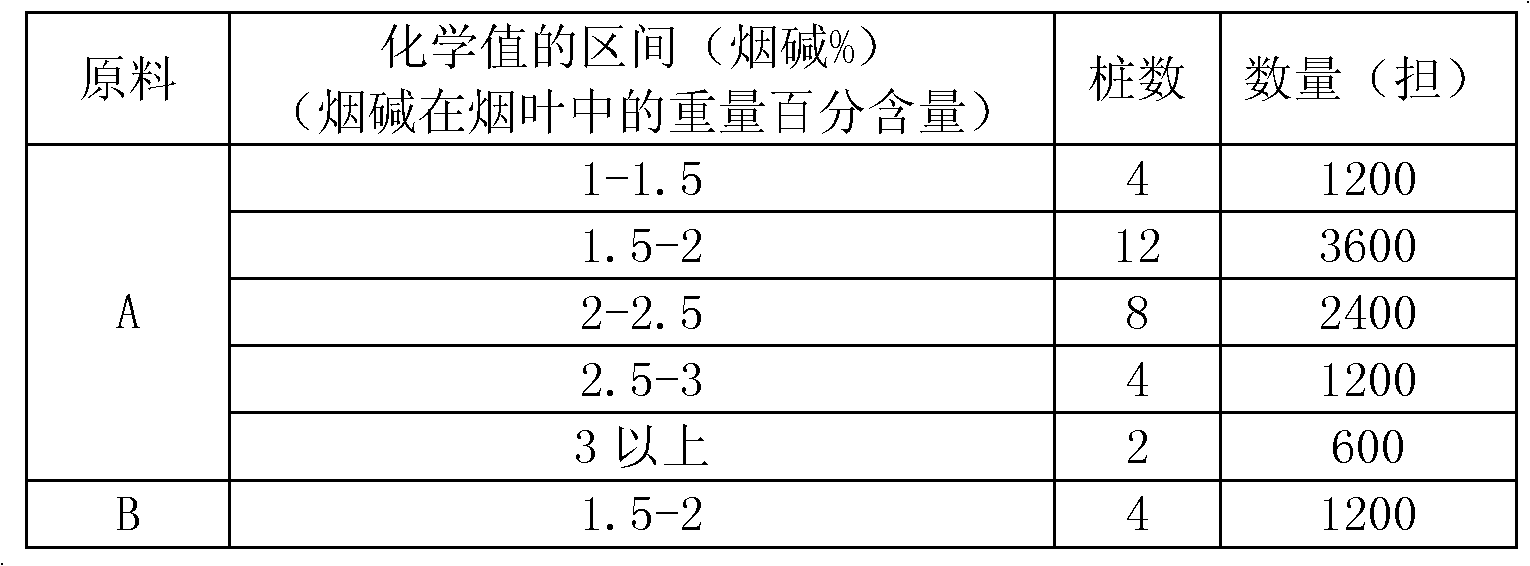

Method for regulating and controlling threshed and re-dried product uniformizing system based on chemical compositions and application thereof

ActiveCN102511922ARegulating Intrinsic Mass UniformityHelpful to guide productionTobacco preparationTobacco treatmentChemical compositionThreshing

The invention discloses a method for regulating and controlling a threshed and re-dried product uniformizing system based on chemical compositions and application thereof, which belong to processing technology of tobacco leaf threshing and re-drying. The method comprises the working procedures of warehousing and detecting raw materials, selecting tobacco leaf formulas to perform primary feed proportioning and performing secondary proportioning of threshed and re-dried feed. The method is mainly characterized in that the tobacco leaf raw materials with different chemical values are distinguished through warehousing and detection of the raw materials, selection of the tobacco leaf formulas, on-line detection and other procedures, then proportioning regulation is performed according to desired values of specific chemical compositions of tobacco leaves, and finally inherent quality uniformity of finished tobacco slices is improved. Inherent chemical compositions are regulated from the leading end of the threshing and re-drying process, and the problem that chemical compositions are in the existing in threshing and re-drying technological process are differently controlled effectively. Compared with the existing technological process, the method has the advantages of being initiative in regulation, simple, convenient, easy to operate and the like.

Owner:SHANGHAI TOBACCO GRP CO LTD +1

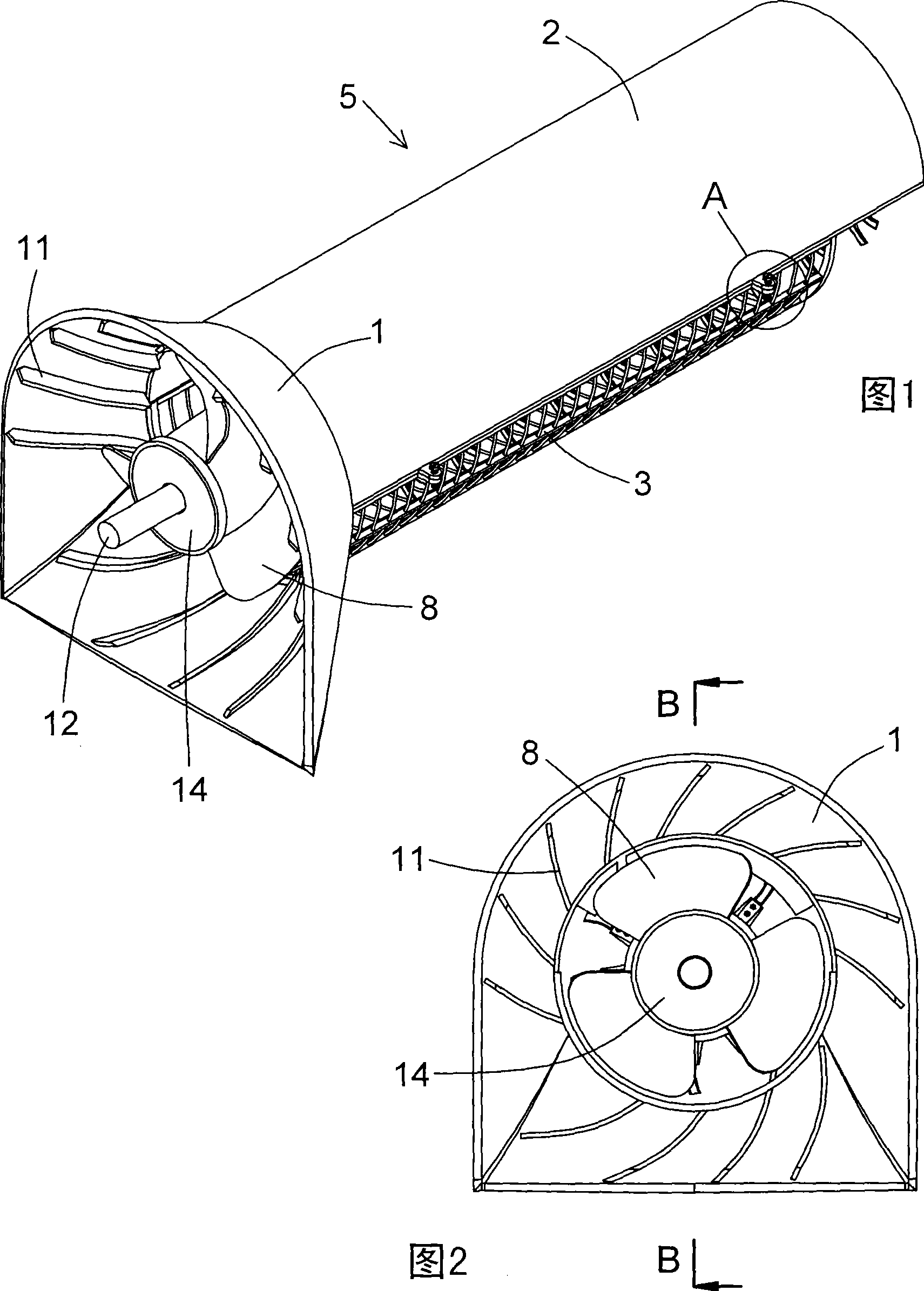

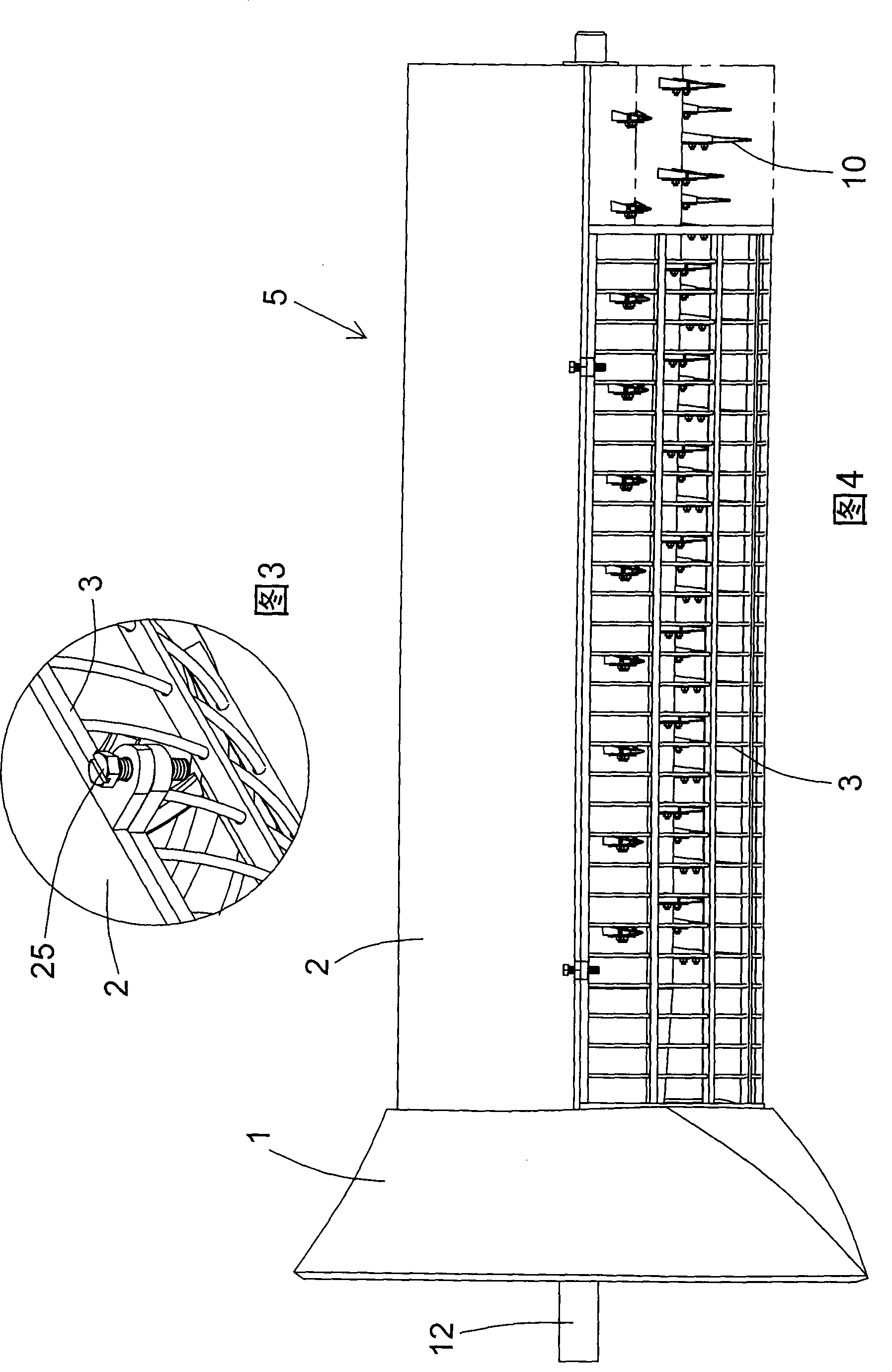

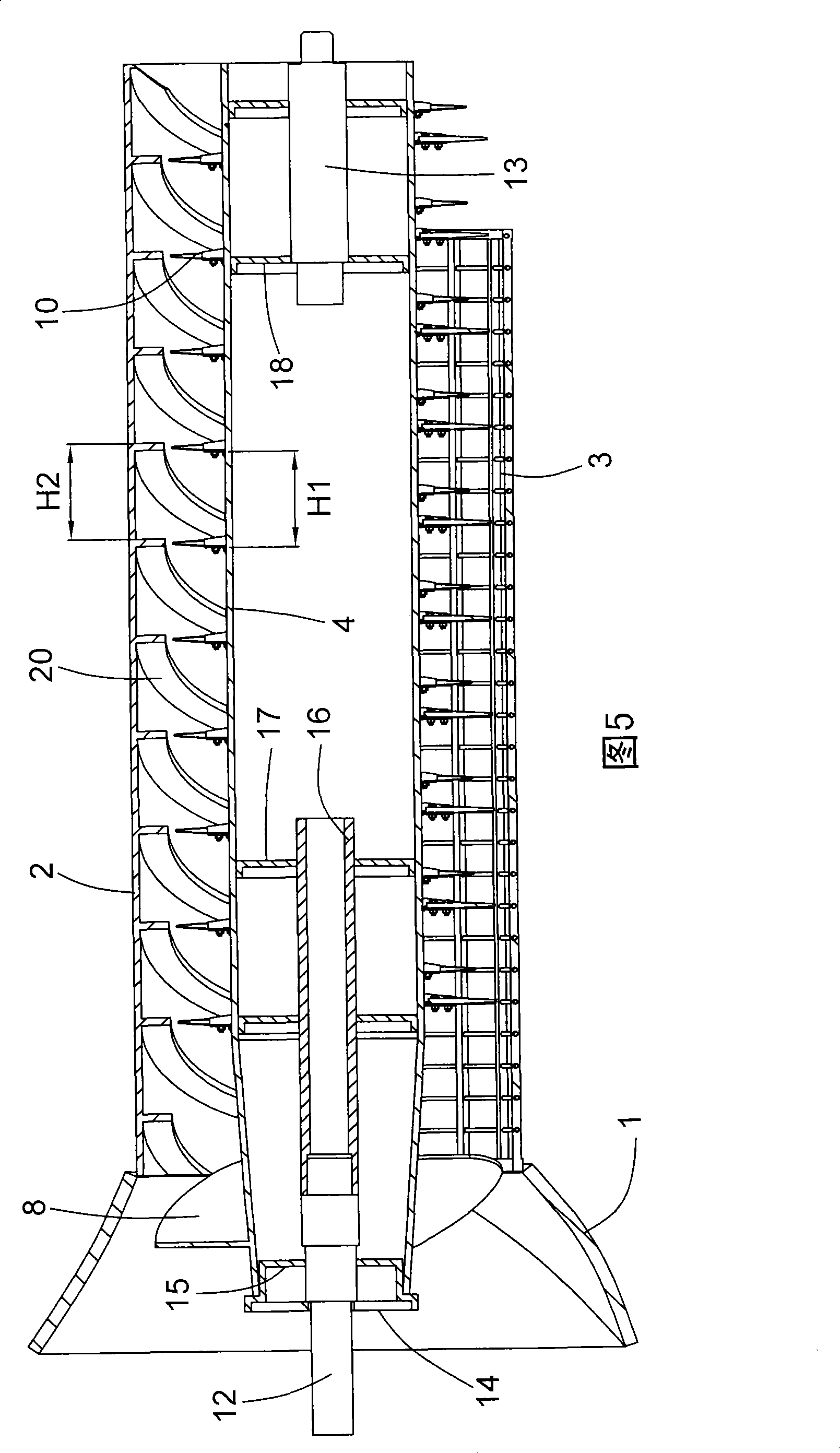

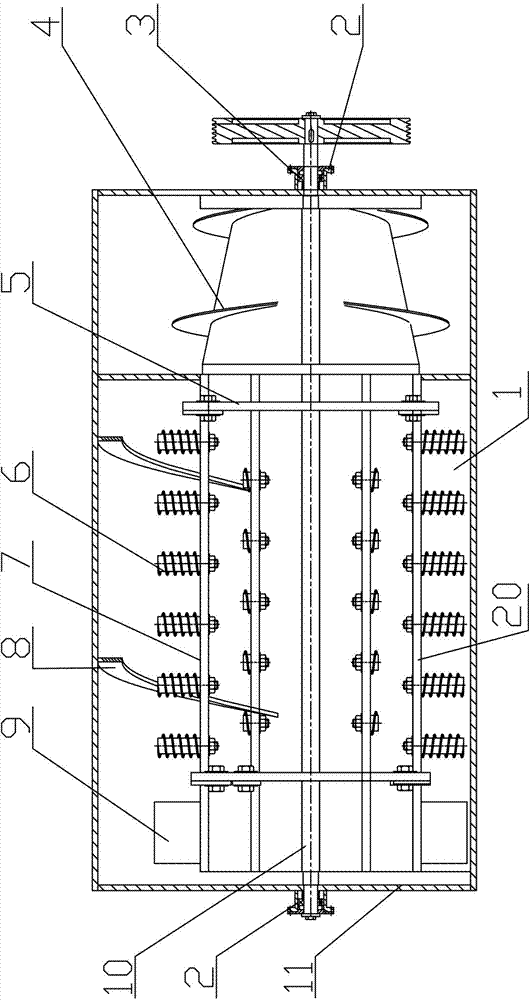

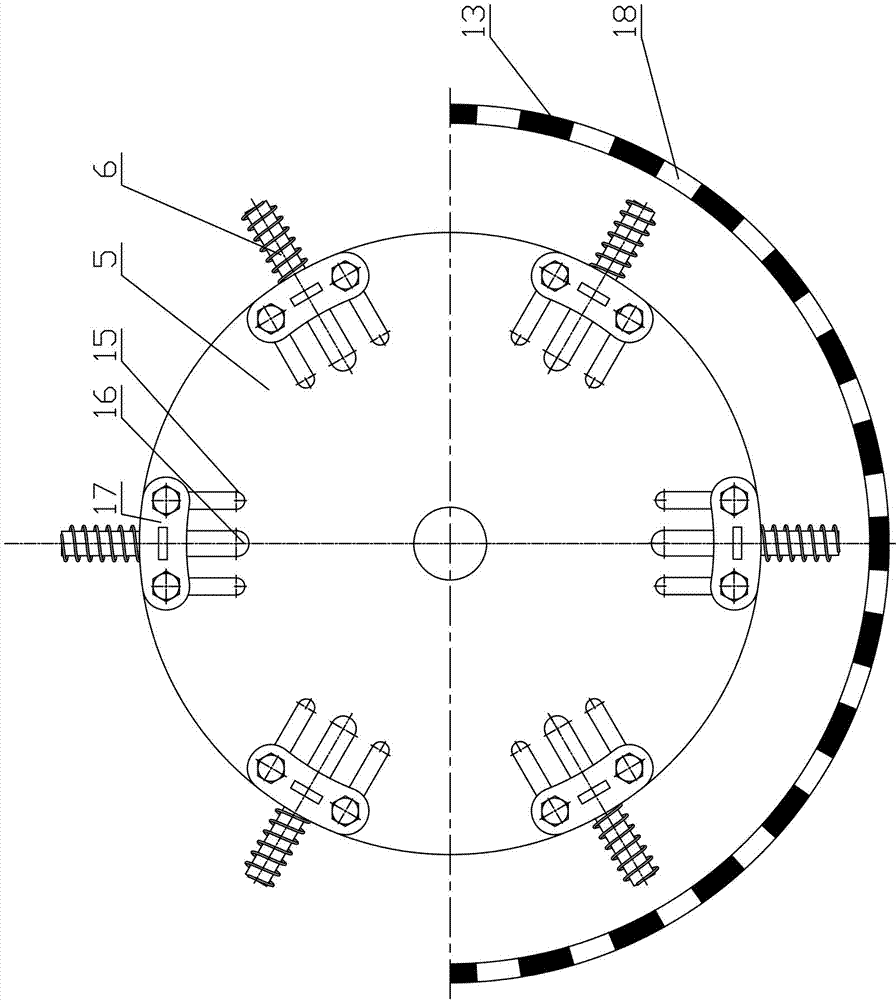

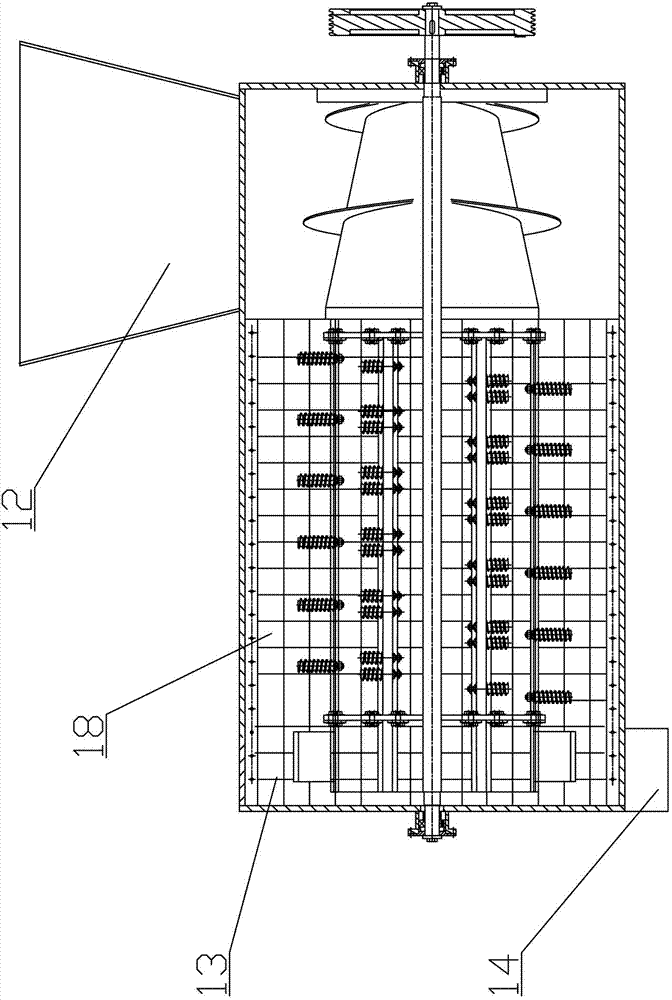

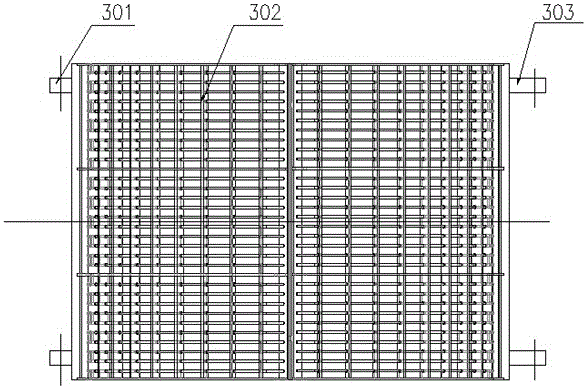

Grain threshing separation device

A grain threshing and separating device consists of a feed inlet, an upper cover, a concave grid and a roller; a plurality of arc stock guide plates are arranged on the inner wall of the shell of the feed inlet, each arc stock guide plate is arranged at a deflection angle in relation to the radial direction of the feed inlet; the roller consists of a front section and a rear section, the front section roller takes a conical shape, the rear section roller takes a cylindrical shape, a blade for feeding is welded on the external surface of the front section roller, a plurality of groups of threshing toothholders are welded on the external surface of the rear section roller, each group of the toothholders is arranged along spiral line direction, each toothholder is fixedly connected with a threshing tooth, the toothholder is connected with the threshing tooth in a dismountable way by a bolt fastener; the two ends of the roller are respectively provided with a front spindle nose and a rear spindle nose, and a plurality of arc flow deflectors are obliquely arranged on the top of the inner wall of the upper cover. The grain threshing and separating device has the advantages of fast feeding, thorough threshing, low entrapment loss, is not likely to be blocked by twisting grass, and can thresh a plurality of grains and harvest various grains in fields.

Owner:黄宝玉

Longitudinally notched threshing element for an agricultural combine threshing concave

Owner:CSM CORP

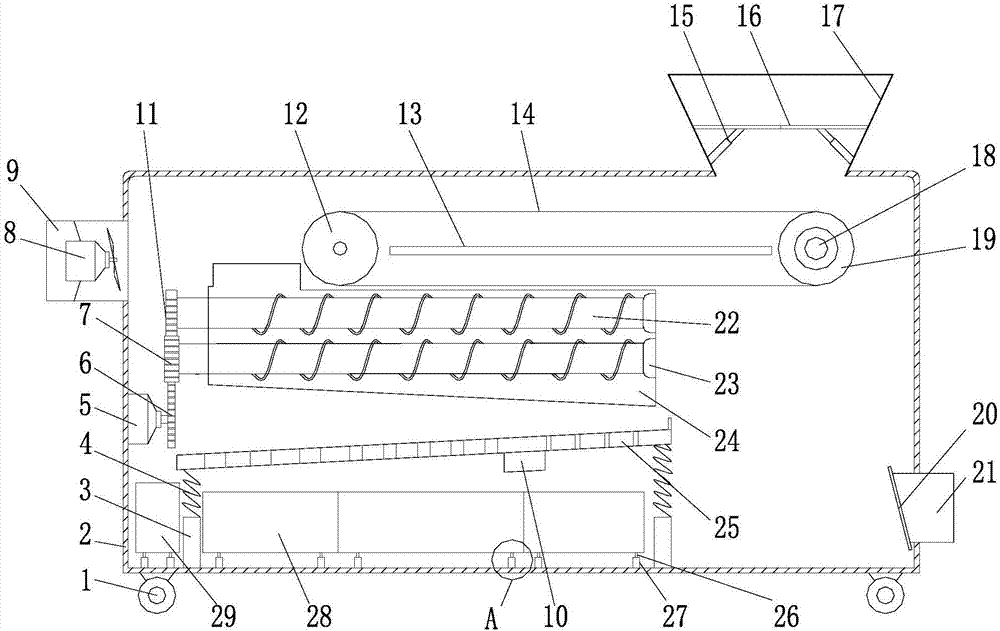

Corn thresher with drying and screening functions

The invention discloses a corn thresher with drying and screening. B. Driven pulley, heating plate, belt, elastic telescopic rod, filling door, filling hopper, motor B, driving pulley, filter screen, air outlet pipe, threshing rod, roller, threshing box, sorting plate, roller , slide rail, corn collection box, cob core collection box, and material retrieving door; the invention adds a heating plate before threshing, which can dry corn cobs, facilitate threshing, and has a sorting board after threshing, which can sort out Corn kernels with different diameters can be used in different categories. There is a shell outside the threshing device, which can effectively reduce dust entering the atmosphere, protect the environment and prevent operators from absorbing a large amount of dust.

Owner:惠安益源信息技术咨询有限公司

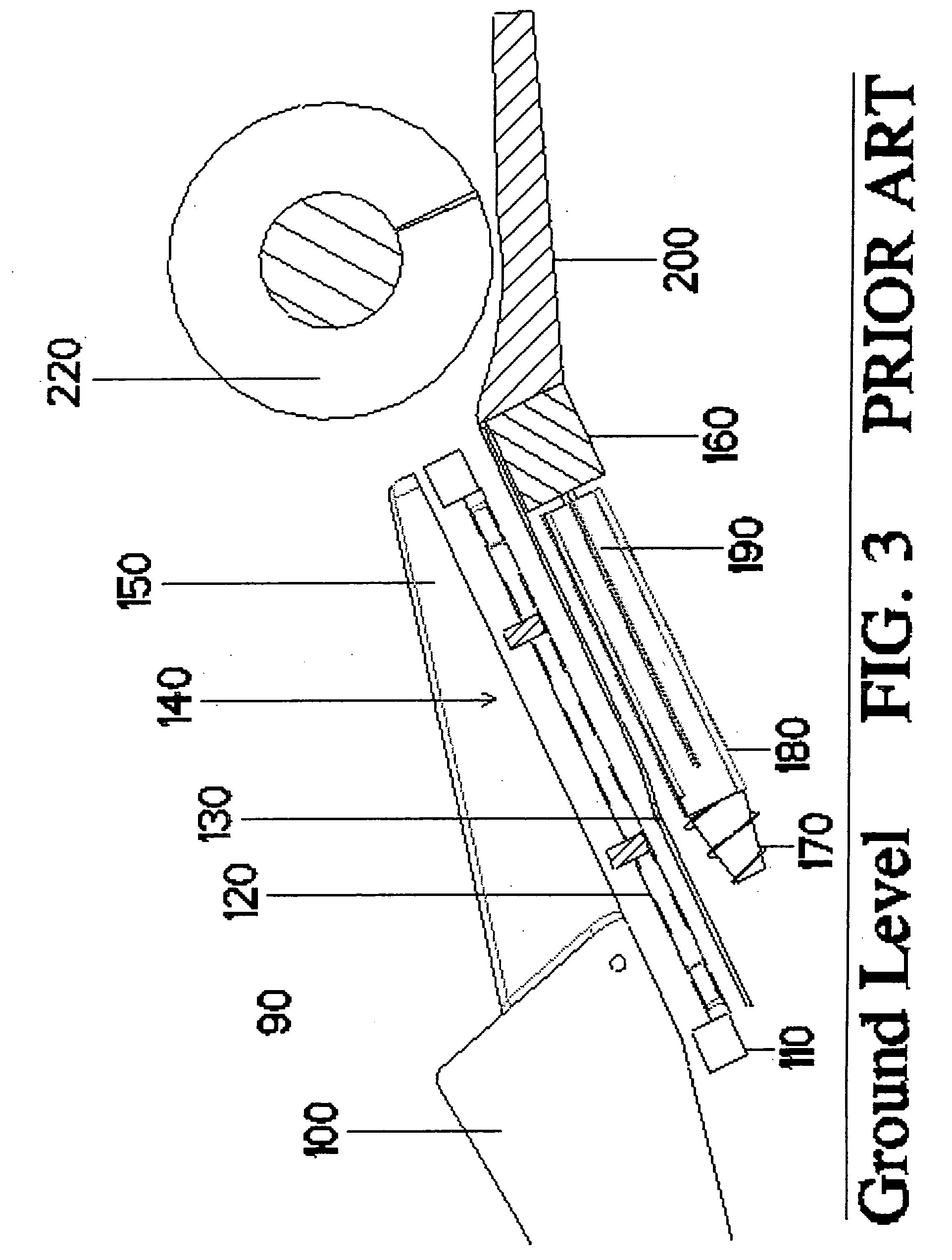

Method and apparatus to reduce stalk shear

The invention provides four (4) methods to reduce stalk shear in a corn head row unit that utilizes a non-variable or dependent drive system. The four methods described include altering the gearbox ratio, increasing the lengths of the fluted portion of the stalk roll, increasing stalk roll diameter or reducing the size of the gathering chain drive sprocket. The invention allows for a more balanced application of multi directional energy to be applied to the corn plant. The resultant effect is to reduce stalk shear which reduces trash intake to the harvester. This novel idea provides the first means and method to which genetically improved taller and healthier corn plants can be harvested with minimal amounts of material other than ears ultimately being transferred to the threshing unit.

Owner:CALMER MARION

System for chopping and spreading residue

A system of chopping and spreading residue for an agricultural combine comprises a chopper disposed in front of a residue accelerator at the rear of an agricultural combine. The chopper is disposed to receive crop residue from a threshing and separating section of the combine and to chop that residue into smaller portions, the residue accelerator is disposed behind the chopper to receive the chopped crop residue from the chopper, and to accelerate it.

Owner:DEERE & CO

Sunflower threshing device with functions of drying and screening

Owner:HEFEI TOTEM LONG MACHINERY DESIGN CO LTD

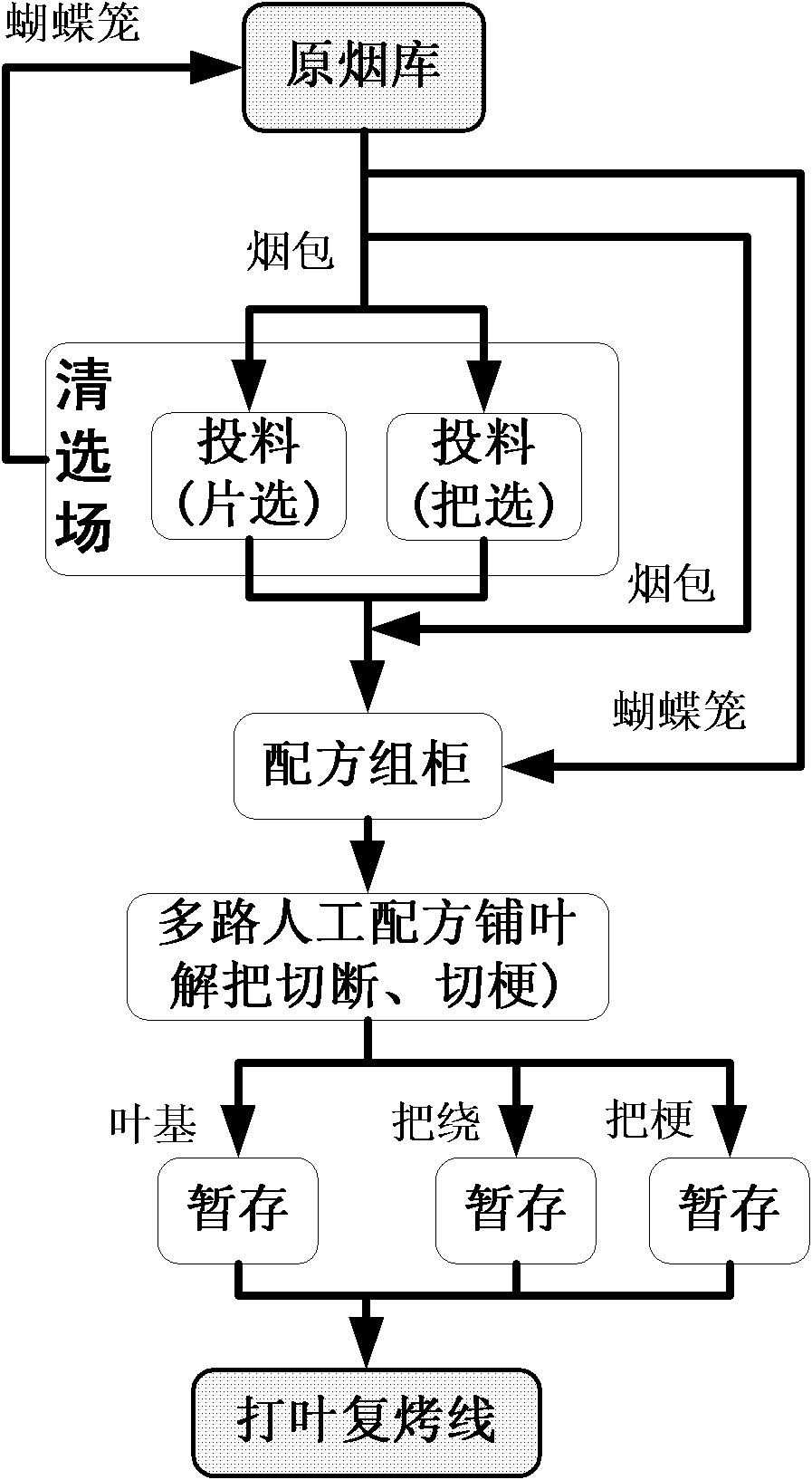

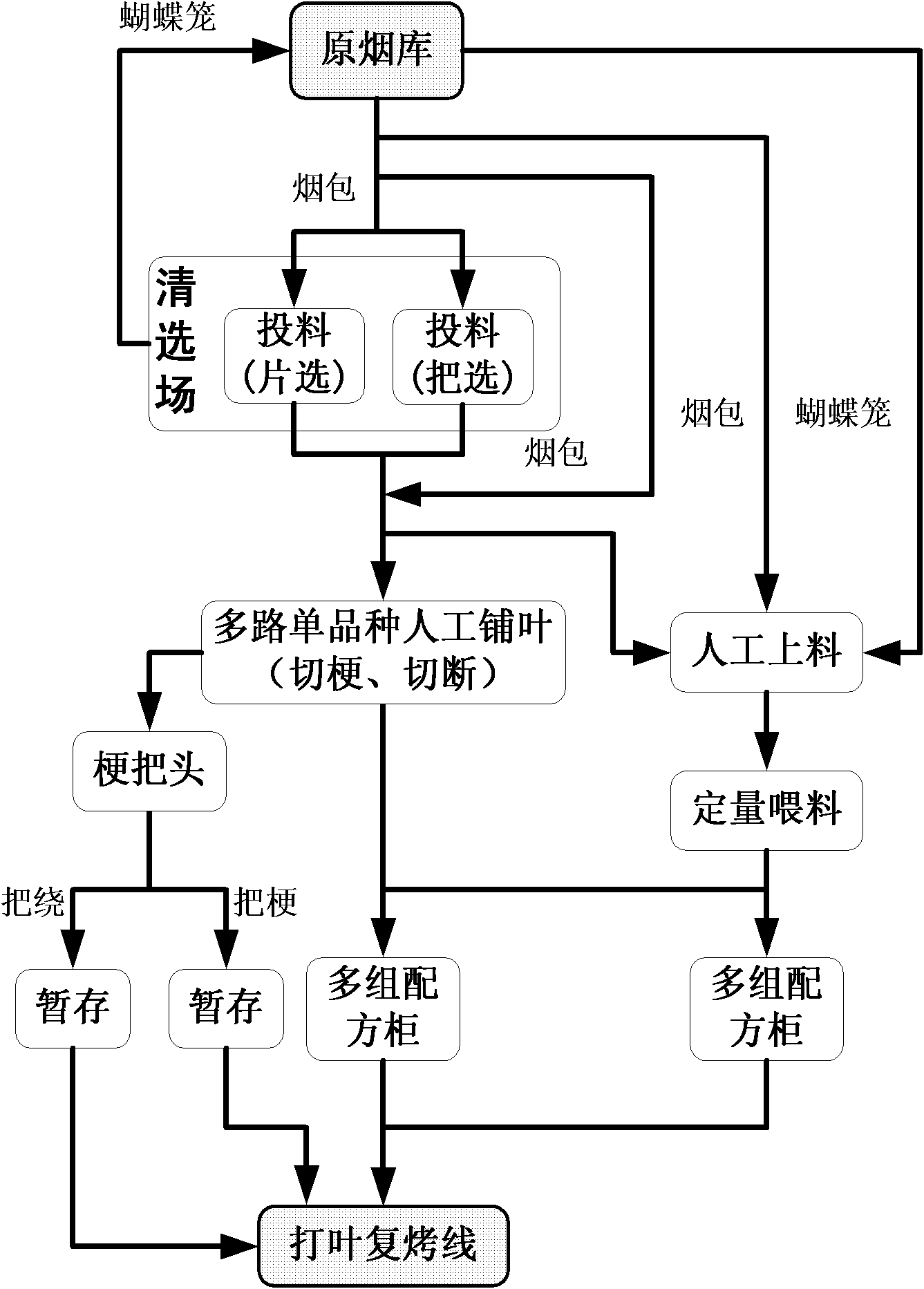

Box-type formula technology of tobacco threshing and redrying production line

ActiveCN102309059AAutomate the processPrecise recipe productionTobacco preparationStorage devicesProduction lineMixed materials

The invention relates to the technical fields of formula threshing and redrying in the tobacco industry, in particular to a box-type formula technology of a tobacco threshing and redrying production line. The box-type formula technology is a machining technology characterized in that the raw tobaccos in different types, different odor types, different producing areas and different grades are automatically proportioned according to the formula through the operations that tobacco leaves are boxed according to each specie according to the modulus theory, then a tobacco box formula module is constructed and temporally stored according to the box-type storage technology, the tobacco boxes leave the storage according to the formula module, the tobacco boxes are turned over, a shuttling materialdistribution car distributes materials according to a uniform amplitude elongated shape, the tobacco leaves are stored according to the module, a cross section discharges materials and the like. According to the technology, the tobacco materials are automatically and precisely proportioned according to the formula, the product quality is effectively reviewed, and the evenness of the raw tobacco mixed material the quality of the flaky tobacco product and the machining flexibility and efficiency of the production line are greatly improved and enhanced.

Owner:北京航天万源科技有限公司

Flexible-tooth threshing system with adjustable threshing gap

The invention discloses a flexible-tooth threshing system with an adjustable threshing gap. The flexible-tooth threshing system comprises a threshing roller arranged on a rack and a concave grid, wherein the threshing roller is arranged in a threshing chamber, and comprises two gap regulating end plates fixedly arranged on roller shafts; a plurality of threshing tooth fixing rods with flexible threshing spike teeth are arranged between the two gap regulating end plates; a feeding auger which is distributed in a spiral manner is arranged on the roller shaft at the input end of the threshing roller; a feeding hole is formed in a roller housing corresponding to the feeding auger; a plurality of grass discharging plates are distributed on the roller shaft at the output end of the threshing roller; a straw outlet is formed in the roller housing corresponding to the grass discharging plates. The flexible-tooth threshing system with the adjustable threshing gap disclosed by the invention is used, so that acting time of crop silique on the flexible threshing spike teeth is prolonged, instant impact force is lowered, and crushing rate of rapeseeds can be lowered; meanwhile, the gap between the threshing roller and the concave grid is adjustable, and therefore, the flexible-tooth threshing system can meet threshing requirements varies by physical characteristics of a to-be-threshed material, and improves adaptation to the threshing material.

Owner:HUNAN AGRICULTURAL UNIV

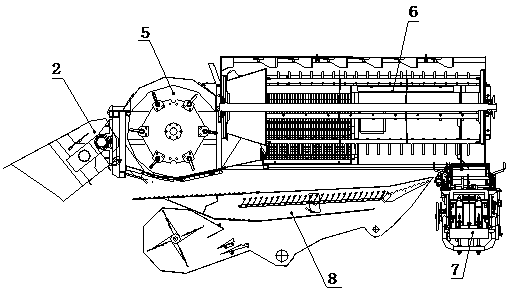

Threshing separation cylinder, threshing separation device and combine harvester

The invention relates to a threshing separation cylinder, a threshing separation device including the threshing separation cylinder and a combine harvester. The threshing separation cylinder is provided with a spin axis and comprises an truncated cone part and a cylindrical part in an axially flowing axis AA' direction in the threshing separation device respectively, wherein the truncated cone part comprises an truncated cone main body, the small diameter end part of the truncated cone main body is at the front end part of the threshing separation cylinder, the truncated cone main body is extended from the small diameter end part along the spin axis direction, the cylindrical part is extended from the big diameter end part of the truncated cone part to the rear end of the threshing separation cylinder along the spin axis of the threshing separation cylinder, wherein helical blades and corn adjusting components are arranged on the truncated cone main body. Separating teeth including spike teeth, bar teeth, plate teeth and arch teeth are arranged on the cylindrical part.

Owner:DEERE & CO

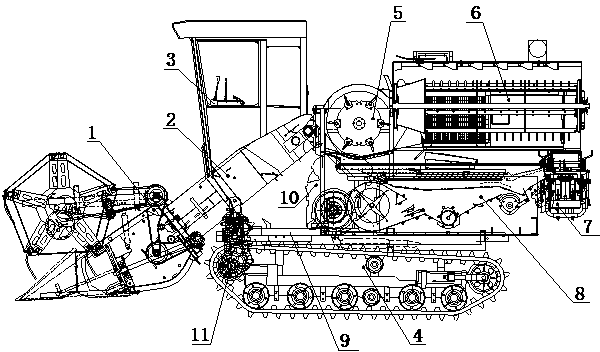

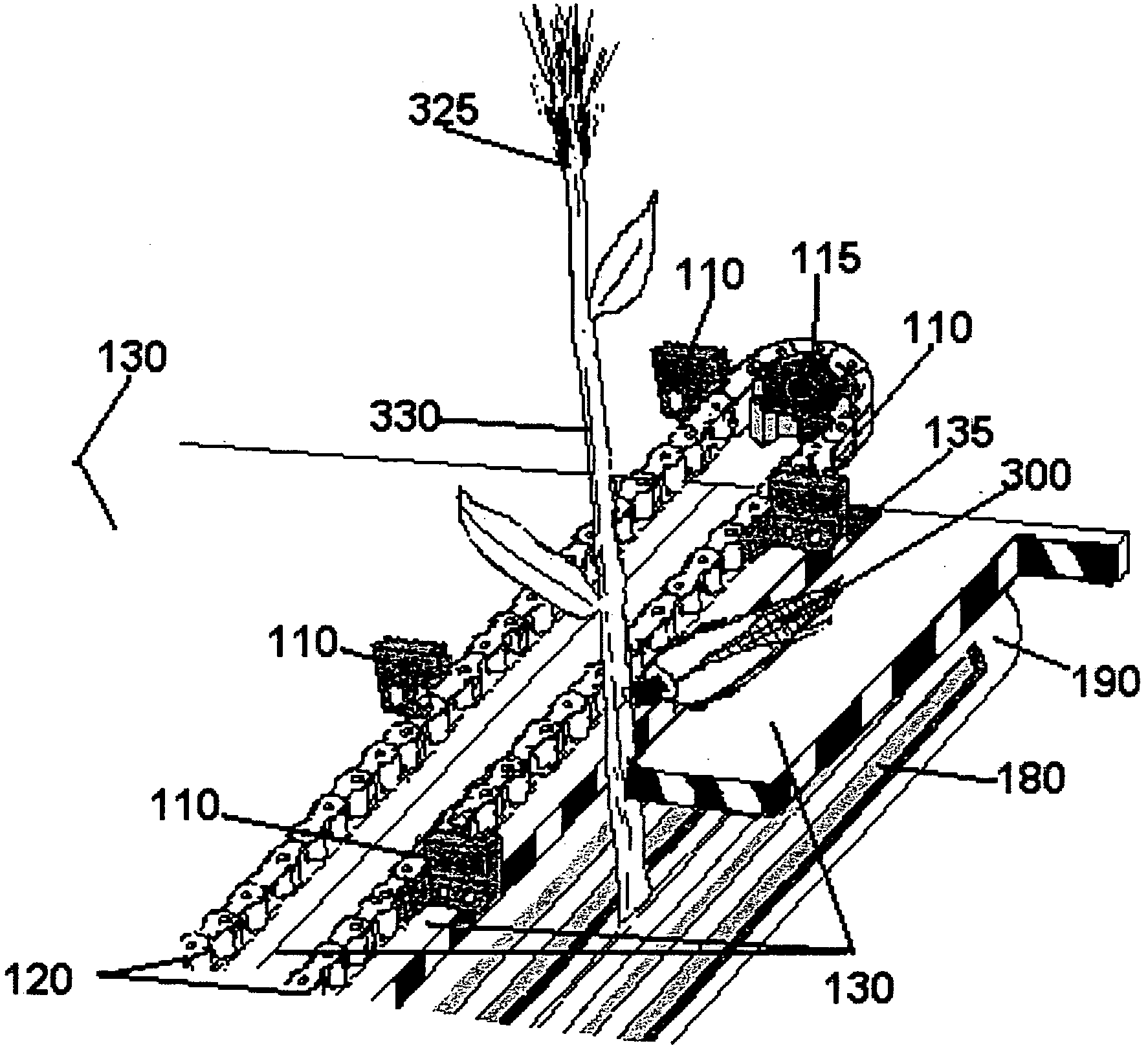

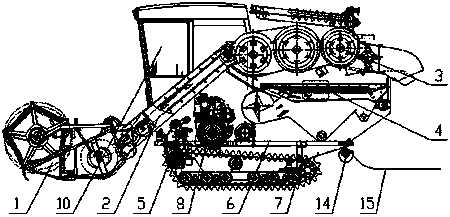

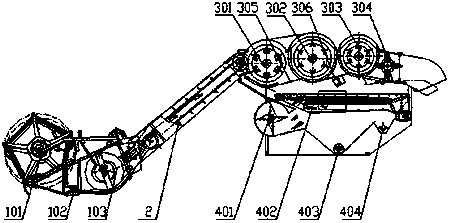

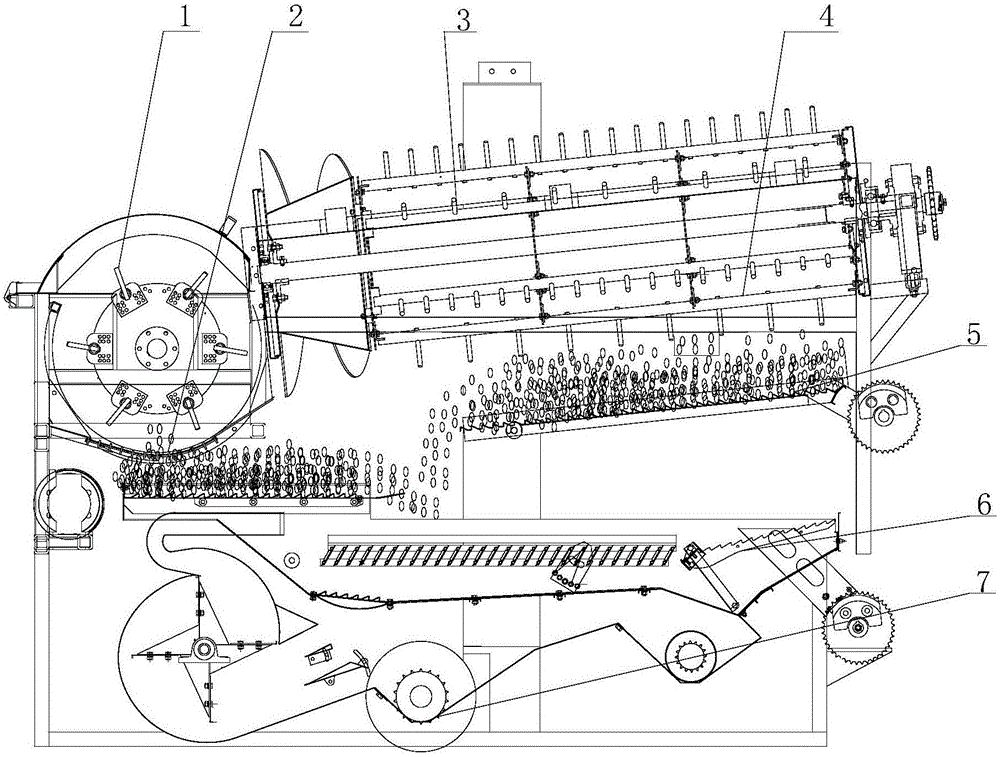

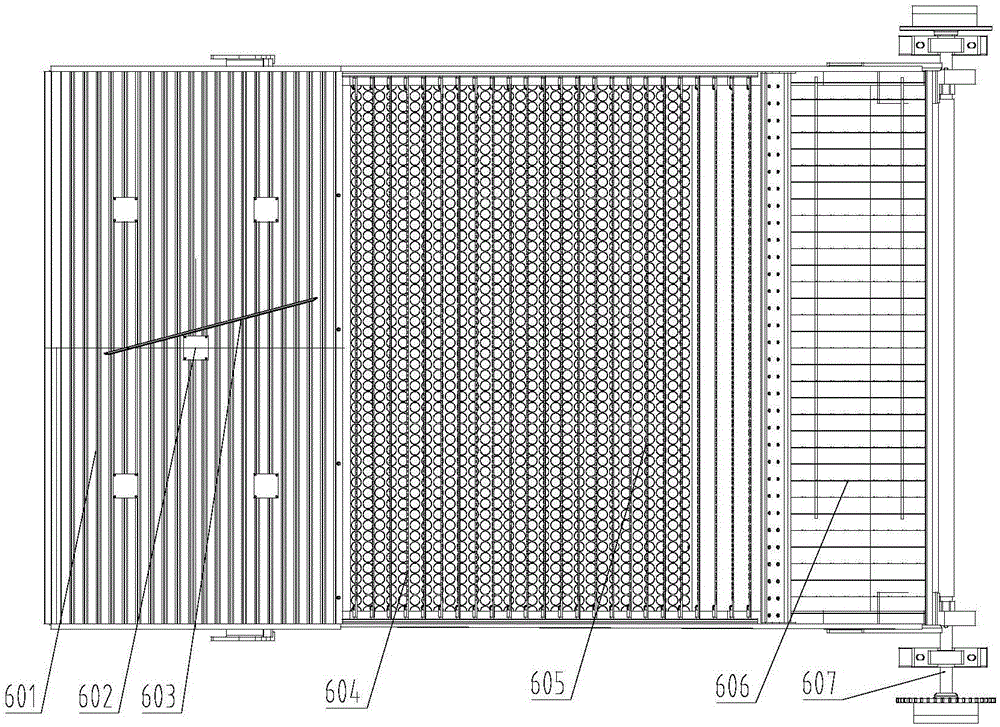

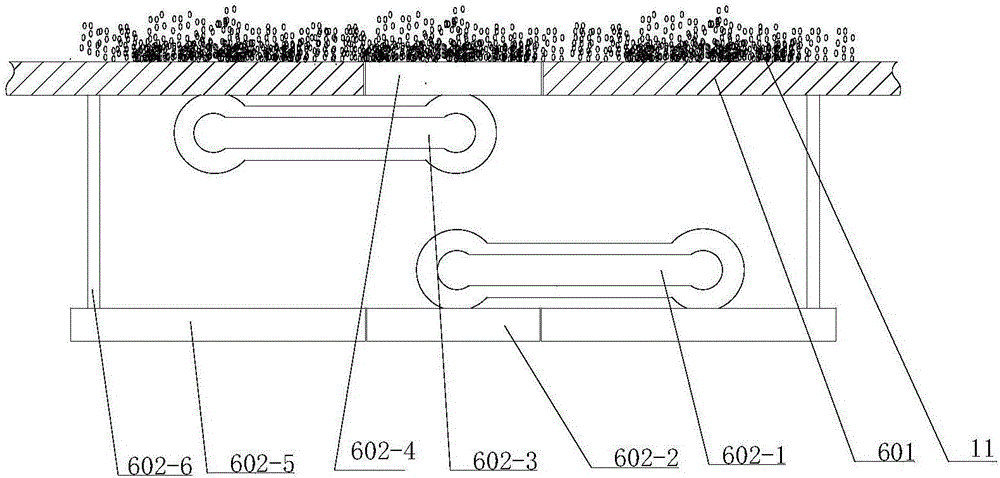

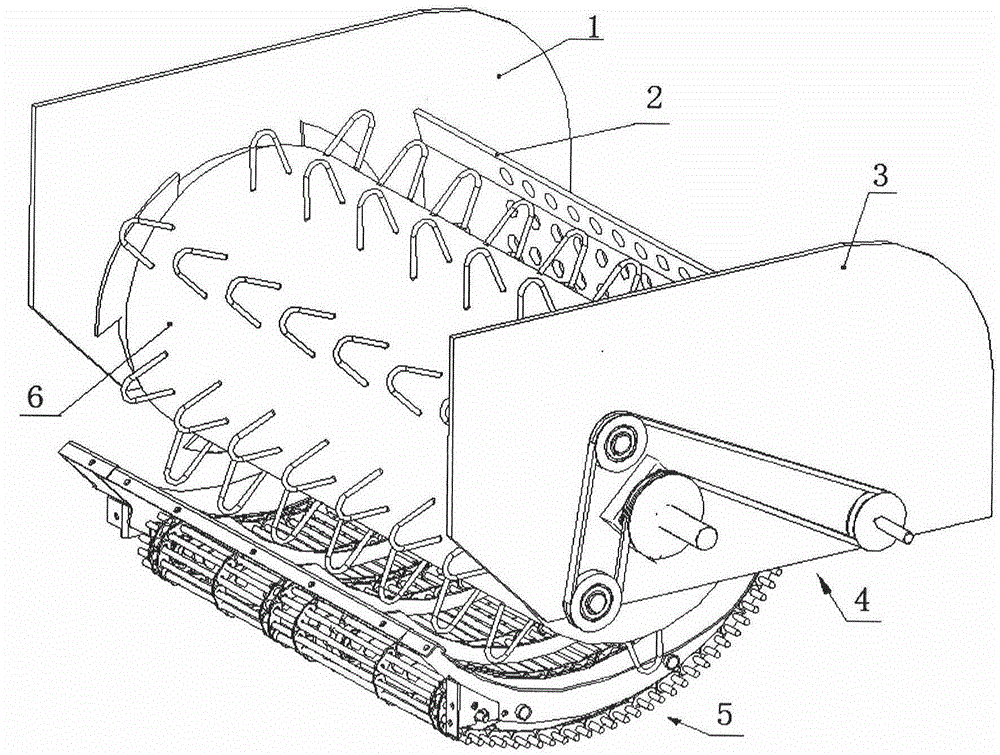

Large-feed-amount crawler-type cutting cross-flow multi-roller combined harvester

The invention relates to a large-feed-amount crawler-type cutting cross-flow multi-roller combined harvester. The large-feed-amount crawler-type cutting cross-flow multi-roller combined harvester comprises a material cutting and conveying system, a threshing, separating and sorting system, a chassis traveling system, a power system and other auxiliary executing devices. A stepped cutting cross-flow multi-roller threshing and separating mode is adopted, so that crops move smoothly, the feed amount is large, and grains can be threshed, separated, sorted and collected and straw can be crushed and thrown after the crops are cut, conveyed and fed. The harvester is provided with a load test system, so that the load of main working parts when the harvester works in a field can be tested, and the acquired data are processed and analyzed by a signal receiving and processing system. A field loss detecting and material receiving device is arranged at the back of the harvester, so that materials can be received conveniently and field loss data can be acquired. According to the harvester, the harvesting requirement of large feed mount of the crops can be met, the efficiency is high, the threshing and separating capacity is high, the grain loss is low, and the field harvesting performance of the main working parts can be tested.

Owner:苏州久富农业机械有限公司

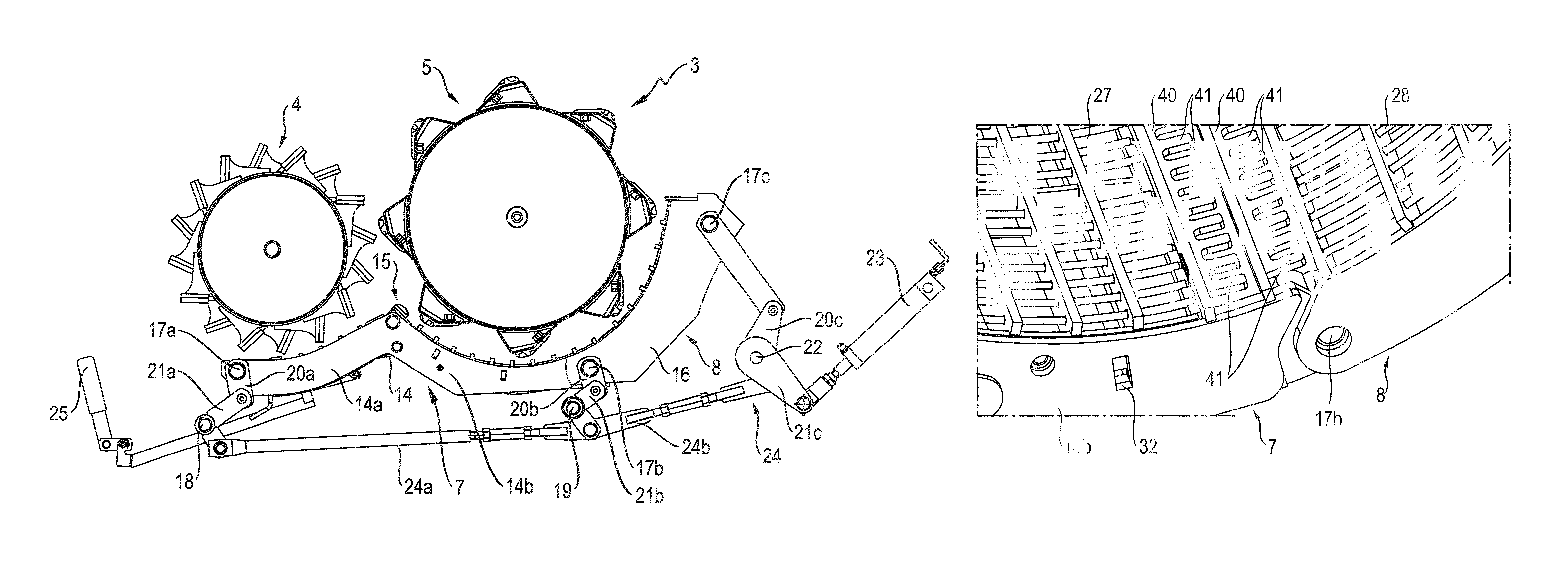

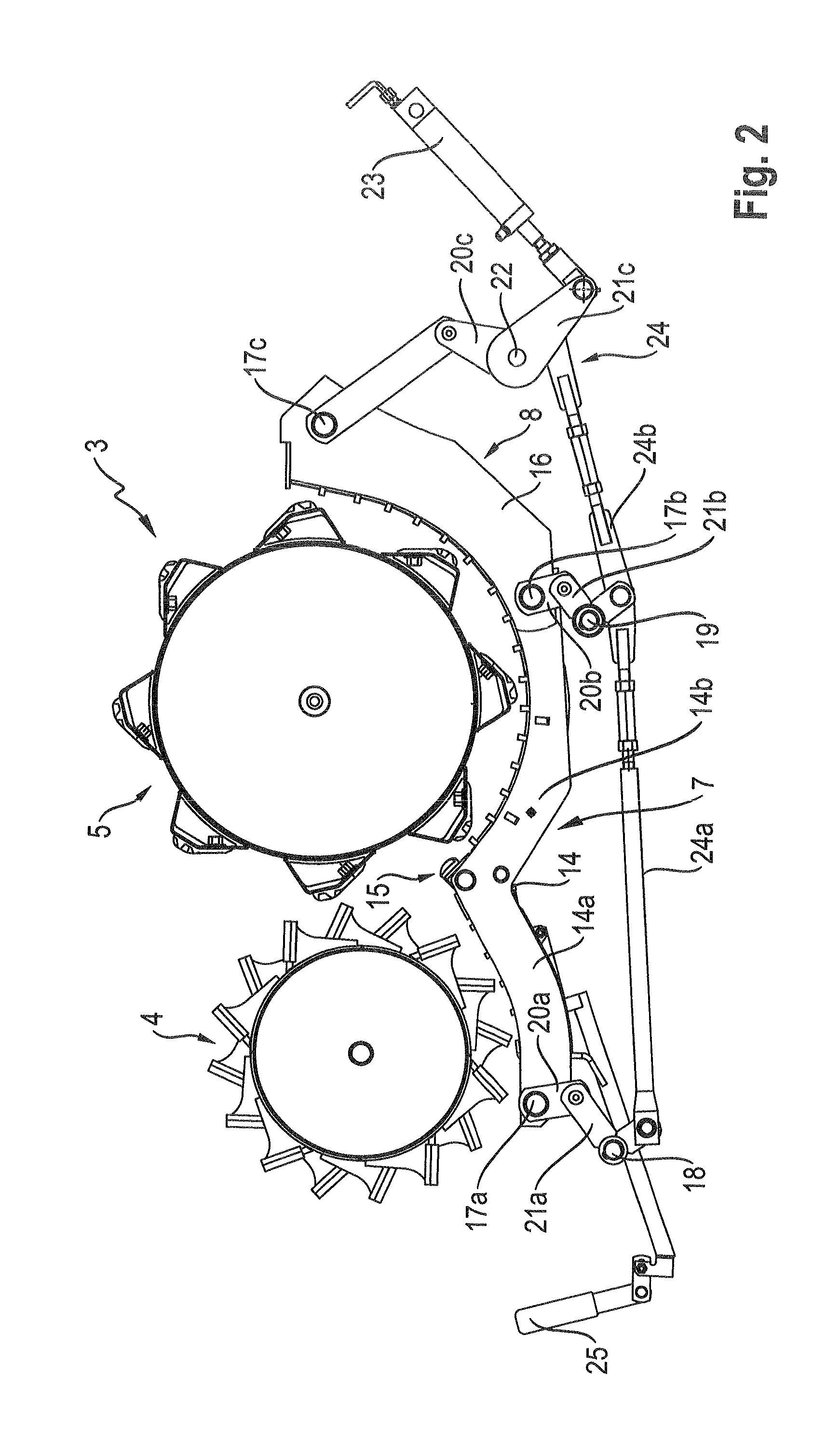

Threshing mechanism with swivellable concaves

A threshing mechanism is formed with a first threshing drum and a second threshing drum disposed one behind the other in a direction of crop flow. A first concave encloses the first threshing drum and the second threshing drum in sections in a circumferential direction. A second concave encloses the second threshing drum in sections in the circumferential direction. The concaves are displaceable in a radial direction of the threshing drums and are formed with at least one crop-processing device disposed at the first concave. The first concave and the second concave are swivellable about a common axis connecting the concaves. The enclosure of the second threshing drum by the first concave and the second concave is approximately identical.

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

Corn thresher

The invention discloses a corn thresher comprising a feeding trough, threshing rollers, a vibrating screen, a cleaning fan, a motor and a rack. The corn thresher is characterized in that a front threshing roller and a rear threshing roller are arranged in parallel; the surface of the front threshing roller is provided with evenly-distributed spiral threshing corrugated tendons; a spiral grid notch board is arranged below the front threshing roller; a machine cover is arranged above the front threshing roller; a buffer cover board is hinged below the feeding windward of the machine cover and is connected with a buffer spring; the surface of the rear threshing roller is provided with spirally-arranged nail teeth; parallel grid notch boards are arranged below the rear threshing roller; and the machine cover is arranged above the rear threshing roller. The corn thresher has the advantages that the corn thresher can directionally feed without impact, flexibly rubs in sequence, threshes differentially by double rollers, has small damage on corn seed particles, has the advantages of high threshing rate, low breakage rate, compact structure, and wide applicability, is convenient to use and adjust, and can simultaneously satisfy requirements on commodity corn threshing and seed corn threshing.

Owner:SHENYANG AGRI UNIV

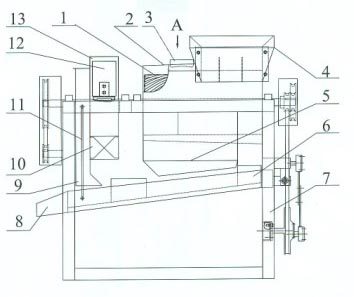

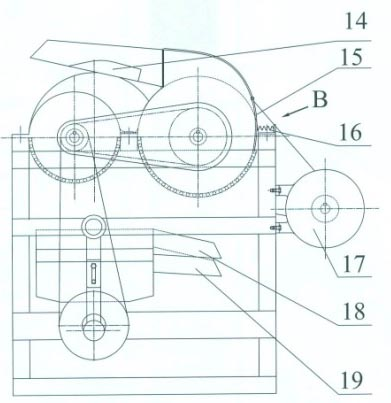

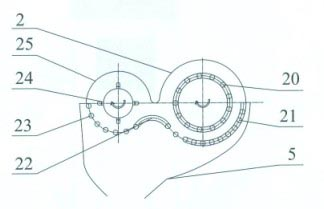

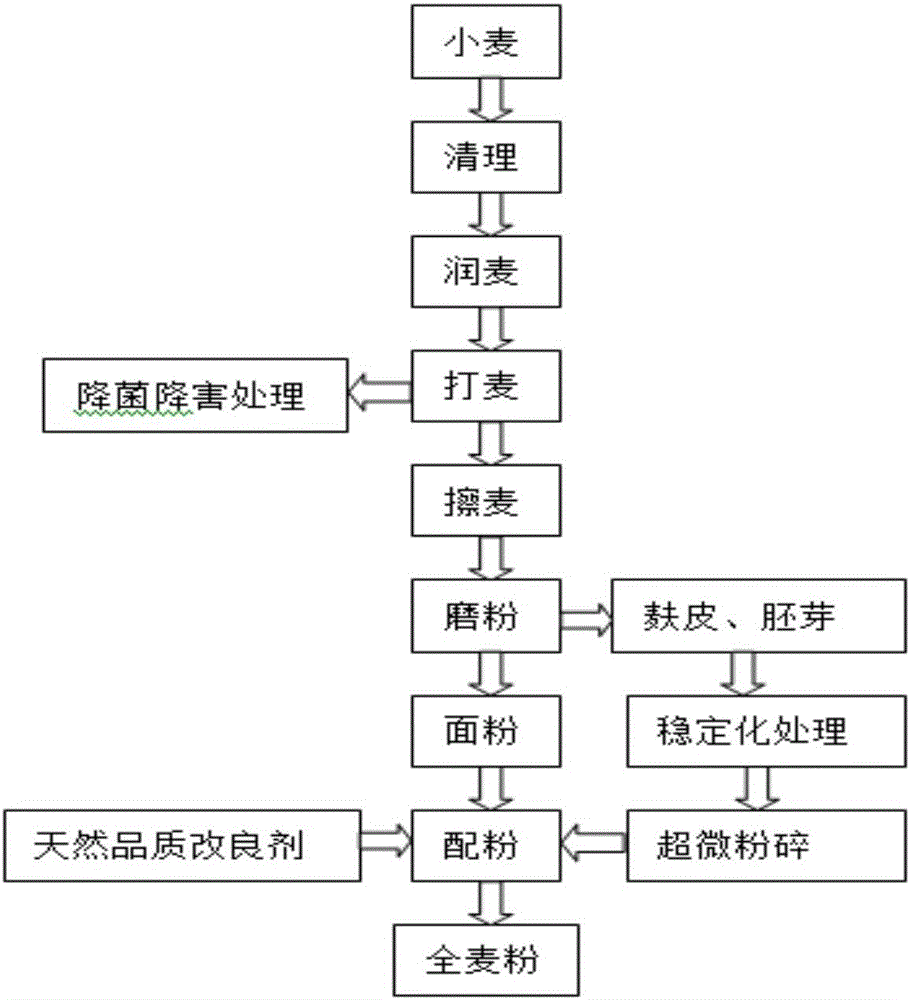

Preparation method of special wholewheat staple food flour with long shelf life

The invention relates to a preparation method of special wholewheat staple food flour with the long shelf life. The method comprises the following steps that a wheat raw material is subjected to impurity removal through the processes such as cleaning, wheat wetting, wheat threshing and wheat rubbing and then threshed, ground and sieved, germs and bran are separated out, and a smashed endosperm material is obtained; the separated germs and bran are treated through microwave humidifying and extrusion expanding and then smashed at the temperature of below 40 DEG C, germ flour and bran flour are obtained and then mixed with endosperms in different proportions, and then the flour special for different kinds of wholewheat staple food is obtained. The preparation method has the following advantages that harmful substances such as eggs and microorganisms can be effectively killed, lipase, protease, amylase and the like can be completely inactivated simultaneously, the product quality is guaranteed, and the shelf life of the product is prolonged; the technological process is shortened, the operation time is short, the nutrient ingredients in wheat grains are protected, and therefore the nutritional value of the product is increased; 3, the wheat aroma of the product is increased, the mouthfeel and the color uniformity are improved, and the specific volume is increased.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

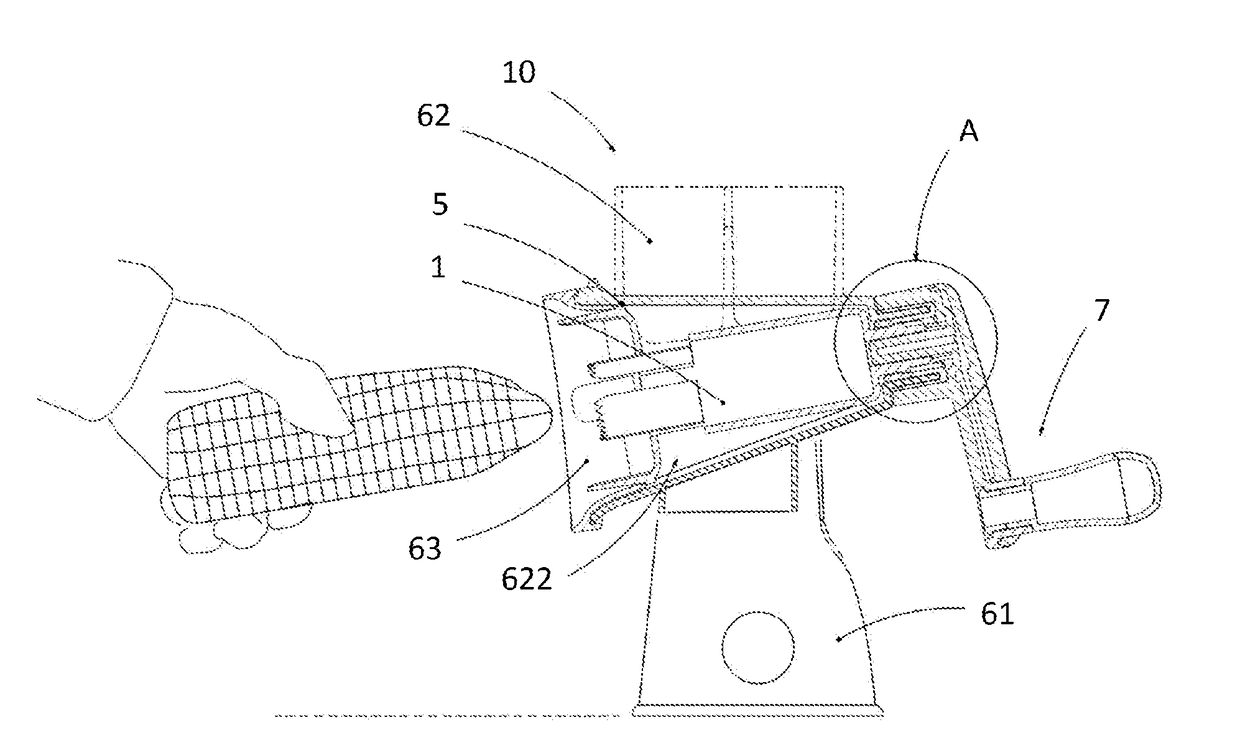

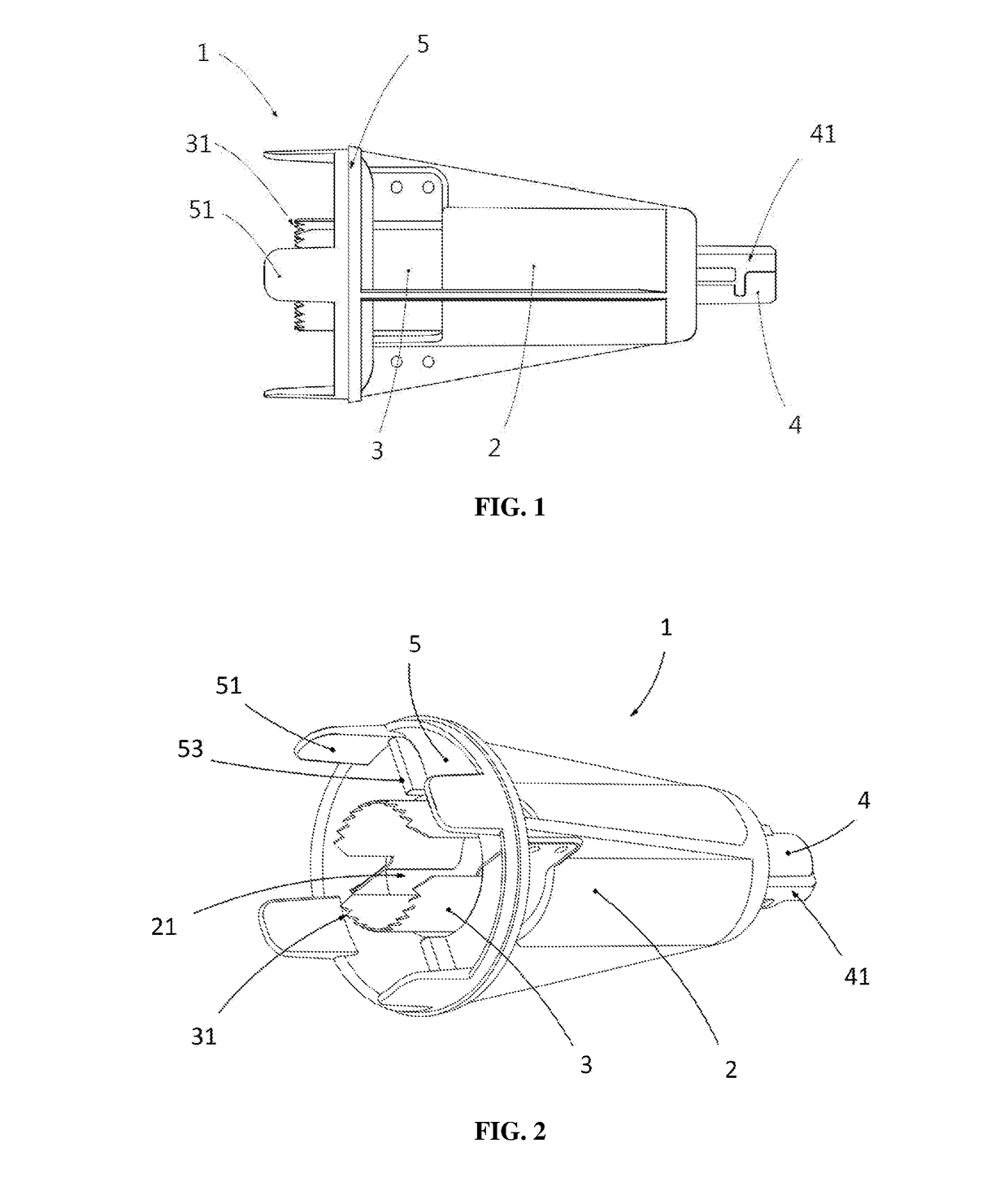

Cutter for Corn Threshing and Rotary Food Processor Therewith

InactiveUS20180184593A1Small volumeEasy to operateThreshersMetal working apparatusThreshingFood processing

The present invention provides a cutter for corn threshing. The cutter is mounted on a rotary food processor with a driving device, which comprises a cylinder with one open end; a cavity disposed in the cylinder to accommodate threshed corn cobs; a cutting member disposed at the middle of the open end of the cavity; and a locking portion disposed at the other end of the cylinder and connected to the driving device of the rotary food processor in a detachable manner. The present invention further discloses a rotary food processor with this cutter. The cutter for corn threshing and the rotary food processor both have the advantages of small volume, simple operation and high practicability.

Owner:WONG YAN KWONG

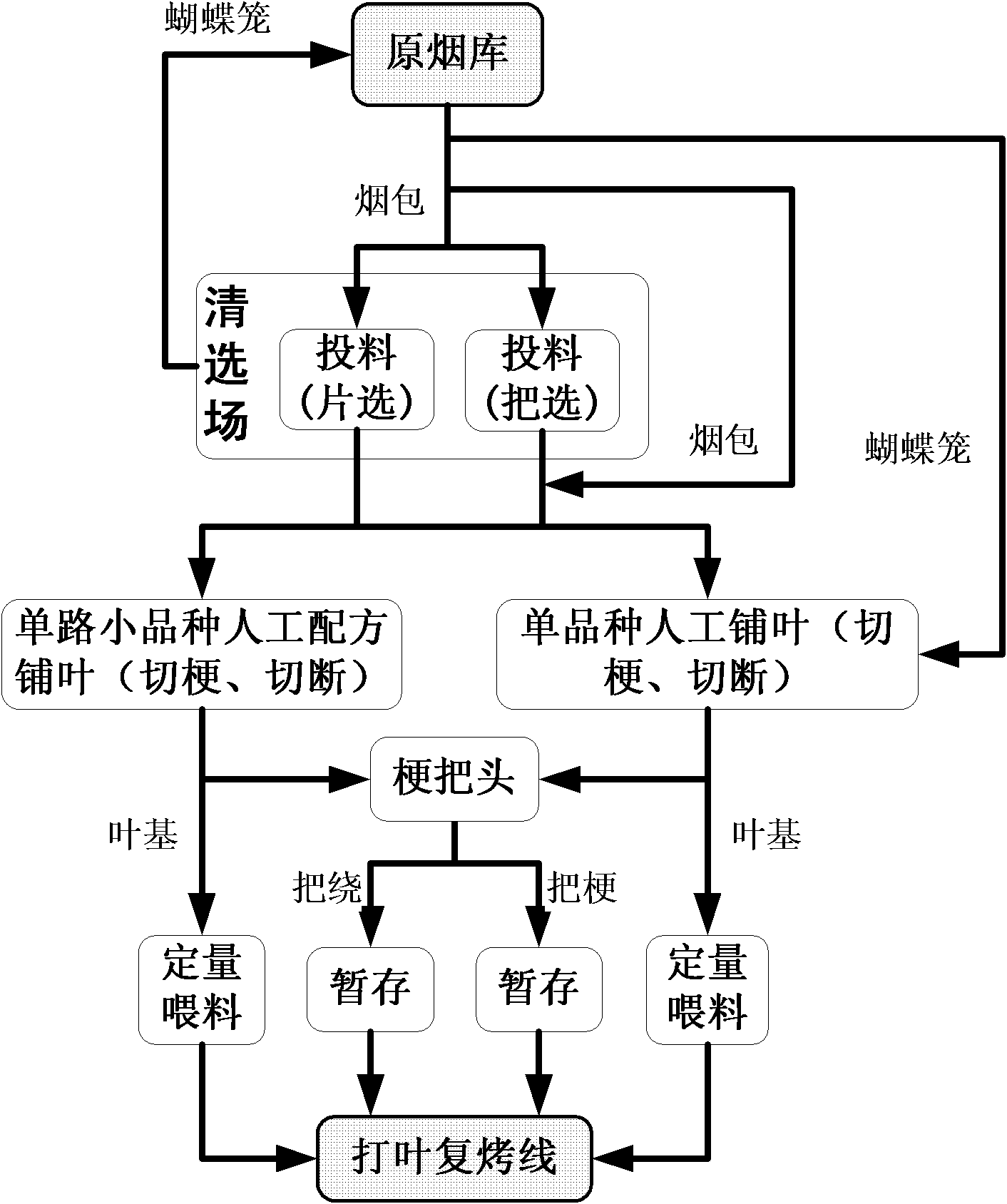

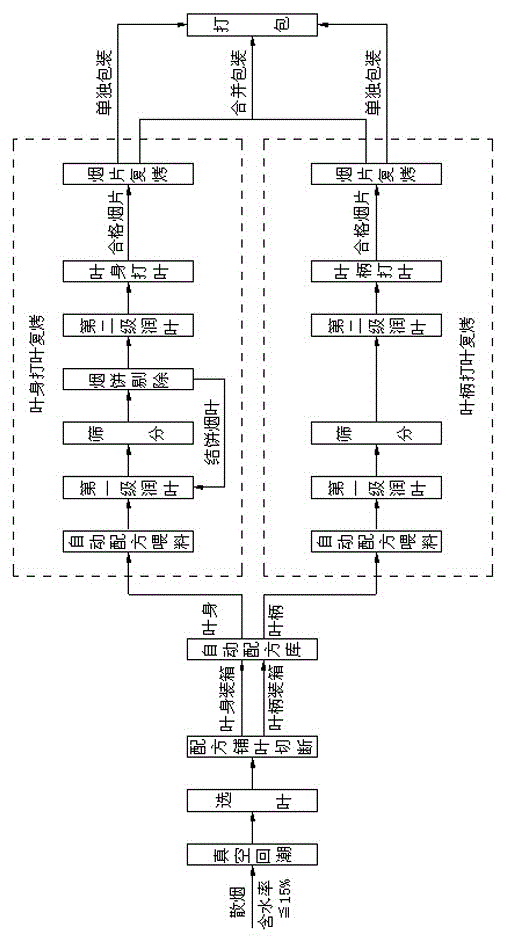

Bulk tobacco formula threshing and redrying processing technology

The invention discloses a bulk tobacco formula threshing and redrying processing technology. The processing technology comprises steps of humidifying leaves through vacuum; selecting the leaves; paving and cutting off the leaves based on the formula; automatically placing the leaves into a formula library; threshing and redrying leaf laminas; threshing and redrying petioles; and packing the leaves. The processing technology is advantageous in that the process for threshing and redrying bulk tobacco is simpler than the process for threshing and redrying bundle tobacco, the processing intensity of leaf conditioning and tobacco strip redrying processes is reduced, the threshing load is reduced, energy is saved, the loss due to tobacco cutting is reduced, the loss of the tobacco aroma during a processing process is reduced, the appearance and quality of finished tobacco strips after threshing and redrying are improved, and the application range of the tobacco strips is expanded. In the process of bulk tobacco formula threshing and redrying, the leaves are cut off, and the leaf laminas and petioles are respectively processed through threshing and redrying. Different processing intensity and customized technology are adopted according to the difference of physicochemical properties of leaf laminas and petioles of the tobacco strips, so that the tobacco group formula is more uniform, internal chemical compositions of the tobacco strips are coordinated, the tobacco strips are high in compatibility, has prominent features and distinct styles, and can more meet demands of cigarette enterprises.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

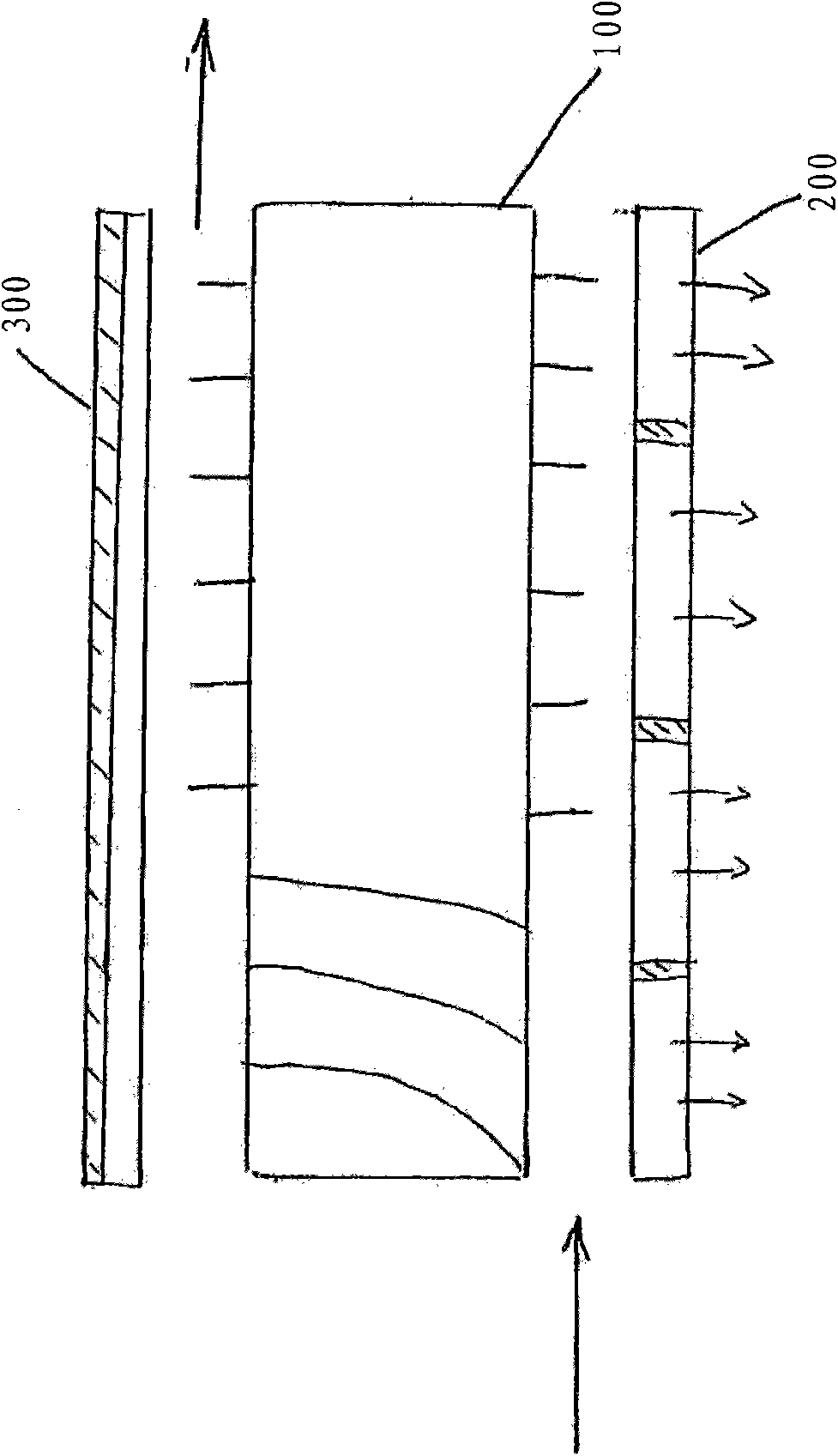

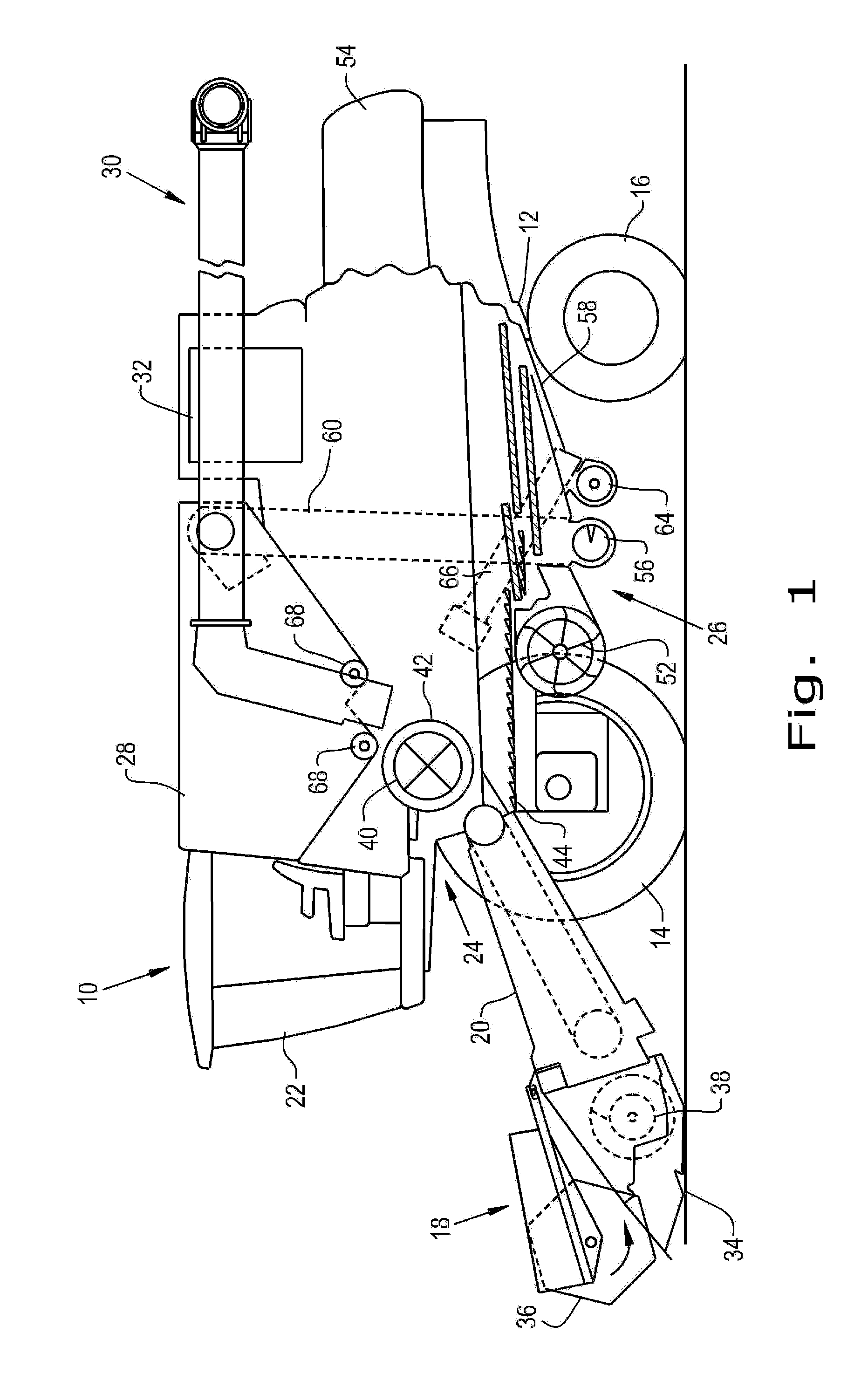

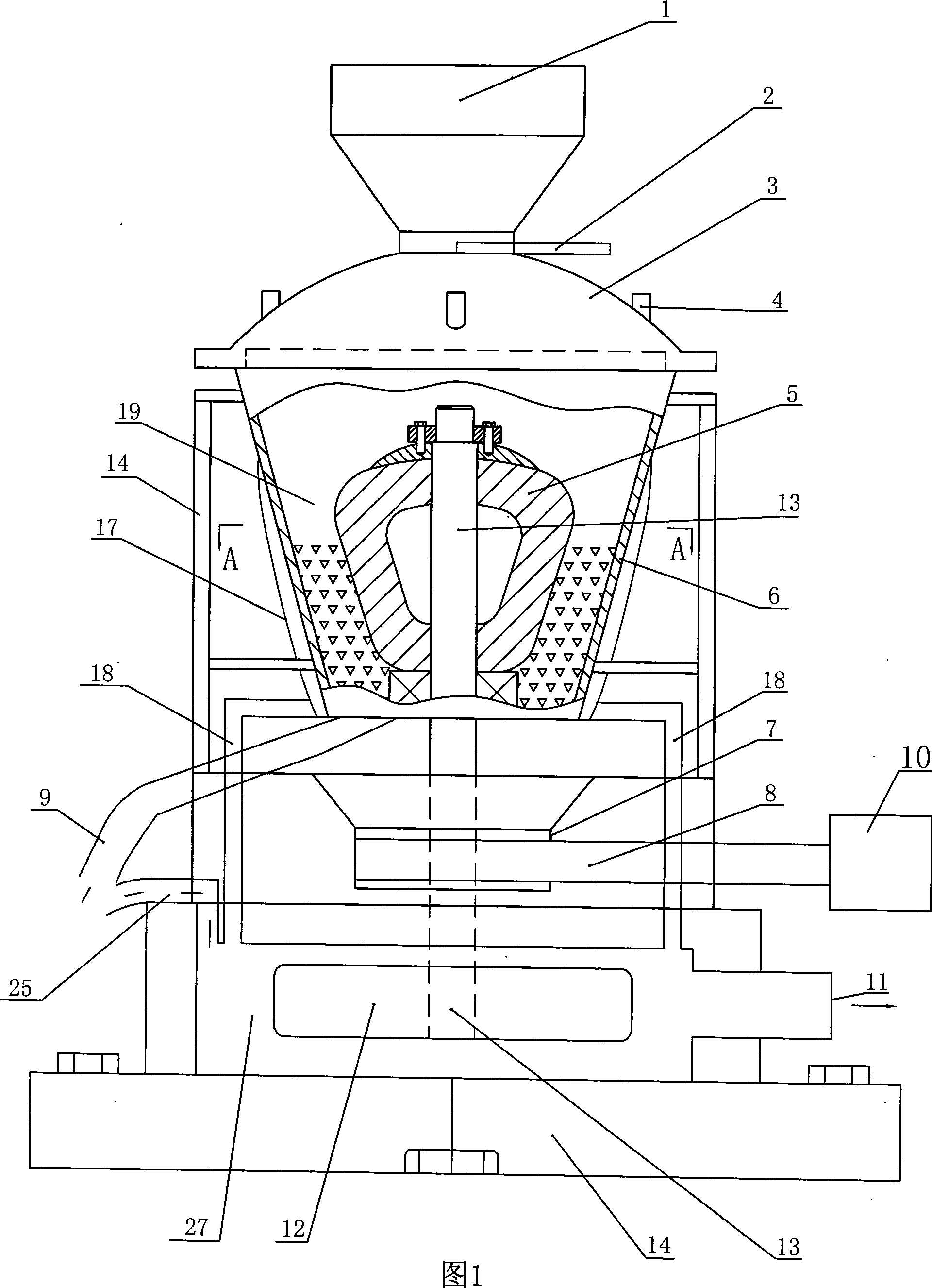

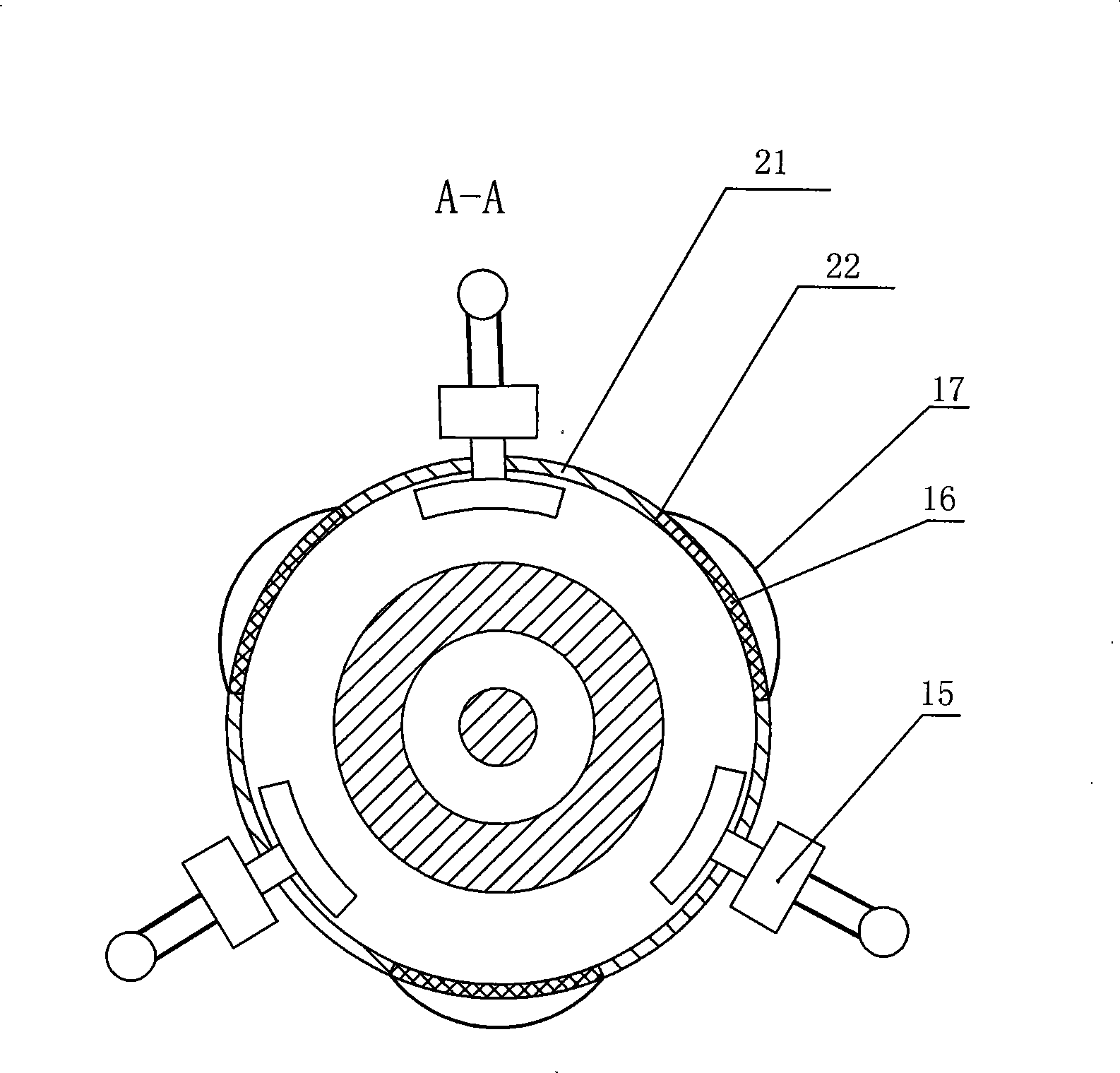

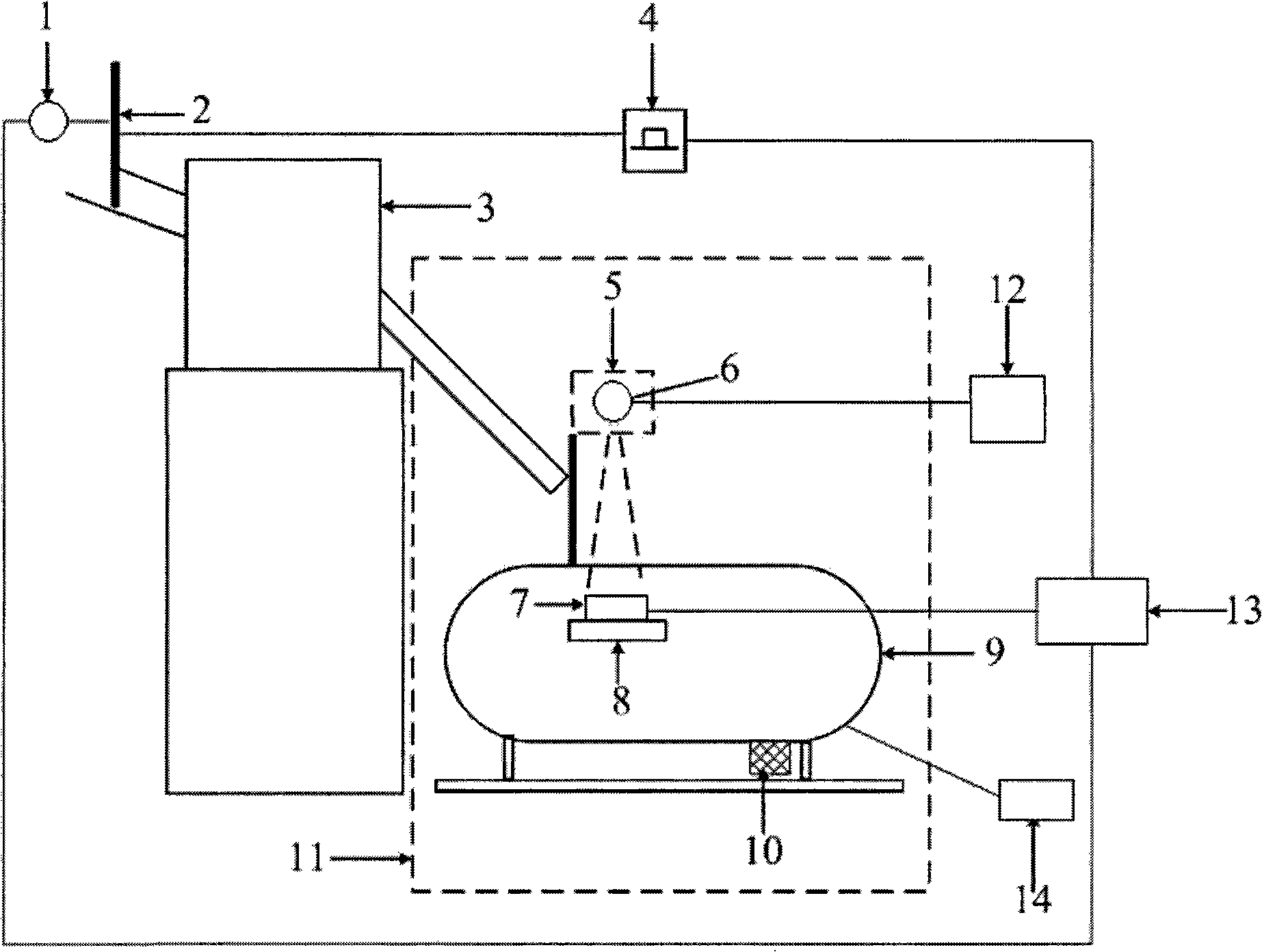

Self-adaption regulation system for threshing segregation loads of tangential flow and longitudinal axial flow devices

ActiveCN106385999AGuaranteed broken rateGuaranteed Entrainment Loss RateMowersThreshersCrash rateControl system

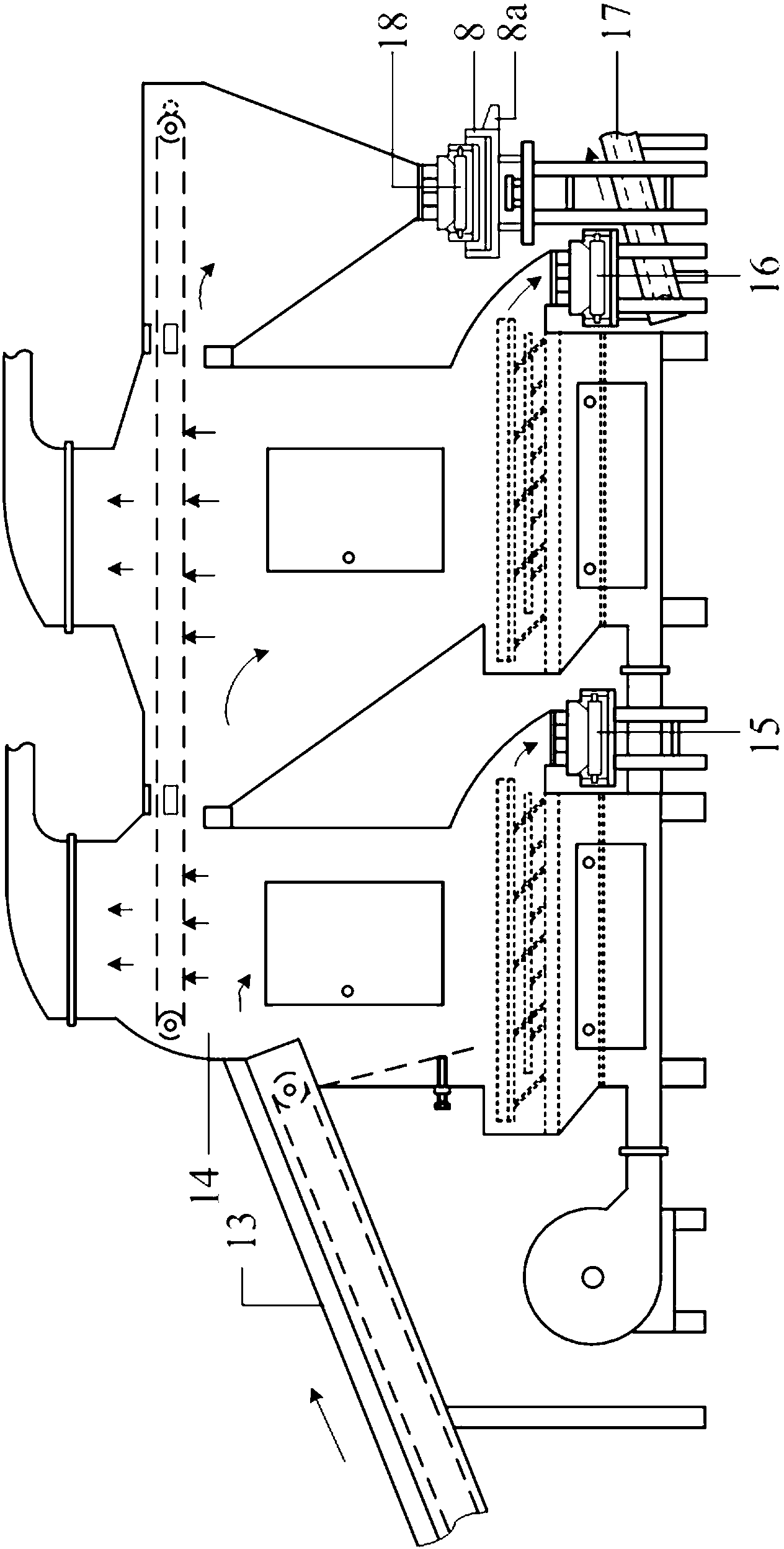

The invention provides a self-adaption regulation system for threshing segregation loads of tangential flow and longitudinal axial flow of a combined harvester and a regulation method. The regulation system mainly comprises a drift loss monitoring device, a grain crashing rate monitoring device, a tangential flow concave exit gap regulation device, a shake plate load monitoring device, a return stroke plate load monitoring device and an online monitoring control system. Through real-time monitoring of a grain crashing rate, a drift loss rate, a tangential flow concave exit gap, a tangential flow drum rotation speed and a longitudinal axial flow drum rotation speed, and according to differential signals of an impact sensor and an inertia force sensor, a load ratio of a tangential flow threshing segregation device and a longitudinal axial flow threshing segregation device can be computed; the tangential flow concave exit gap, the tangential flow drum rotation speed and the longitudinal axial flow drum rotation speed are regulated, so that the threshing segregation load ratio of the tangential flow threshing segregation device to the longitudinal axial flow threshing segregation device could stay in a rational scope; harvesting requirements for different varieties of crops featured by difficult threshing or easy threshing could be satisfied; and optimum threshing ability and high adaptability can be maintained.

Owner:JIANGSU UNIV

Method for peeling fresh kernel corn and machine for peeling quick freezing fresh kernel corn

ActiveCN101433363AGood peeling effectNo loss of nutritionSeed preservation by freezing/coolingVegetable peelingQuick FreezeHardness

The invention relates to a shelling method for fresh corn kernels and a quickly frozen fresh corn kernel sheller. The invention relates to the shelling method and the sheller. The invention solves the problem that the prior common grain sheller can not shell the fresh corn kernels. The shelling method comprises the following main steps: the fresh corn kernels are selected, stored and shelled in an environment of -40 to -30 DEG C and shelled after enzyme deactivation treatment and threshing; and the temperature in a grind cavity of the quickly frozen fresh corn kernel sheller is kept below -5 DEG C and chaff is removed. A grinding wheel (5) is arranged inside a grinding vessel (6); and at least one cooling air inlet (4) is arranged on a sealing cover (3). The fresh corn shelled through the method has good shelling effects and does not lose the nutrition of the fresh corn; the quickly frozen fresh corn kernel sheller is provided with the cooling air inlet, thereby having good heat dissipation effect, ensuring that the quickly frozen fresh corn kernels are not unfrozen by frictional heat during the process of shelling through mechanical friction, and consequently ensuring the hardness of the quickly frozen fresh corn kernels.

Owner:辽宁富安农业发展有限公司

Diameter-adjustable corn threshing and flow cutting roller

The invention provides a diameter-adjustable corn threshing and flow cutting roller. The roller comprises a rotary shaft, a bearing seat, a spoke disk, a connecting seat, a supporting rod, threshing rod teeth, an upper cover plate and a lower concave plate. The roller is characterized in that the rotary shaft is matched with the bearing seat, the spoke disk is connected with the rotary shaft in a key connection mode, the connecting seat is connected with the spoke disk through bolts, the supporting rod is connected with the connecting seat in a welded mode, the threshing rod teeth are connected with the supporting rod in a welded mode, and the upper cover plate and the lower concave plate are connected through bolts after being aligned. The roller has the advantages that the structure is simple, blockage in the threshing process can be effectively prevented by adjusting the threshing gap, so that the grain damage rate and machine fault rate are reduced, efficient corn threshing can be realized, and the roller can be widely applied to agricultural production.

Owner:UNIV OF JINAN

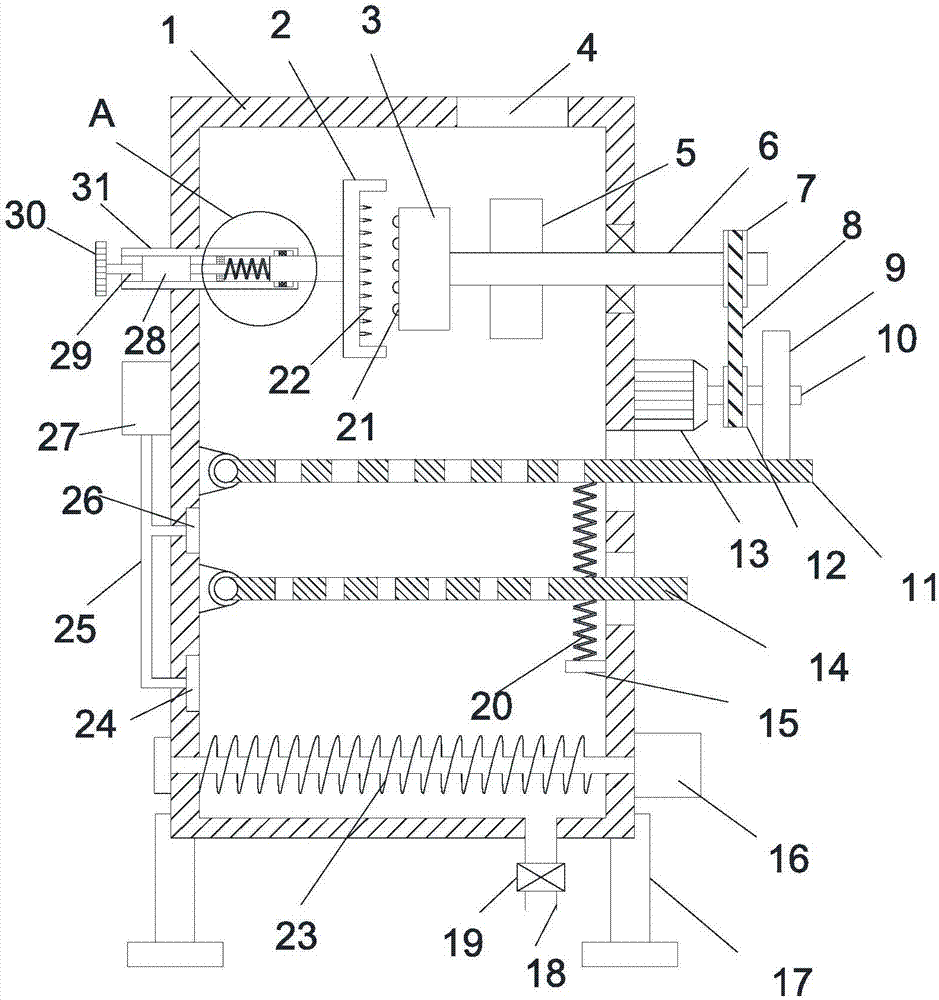

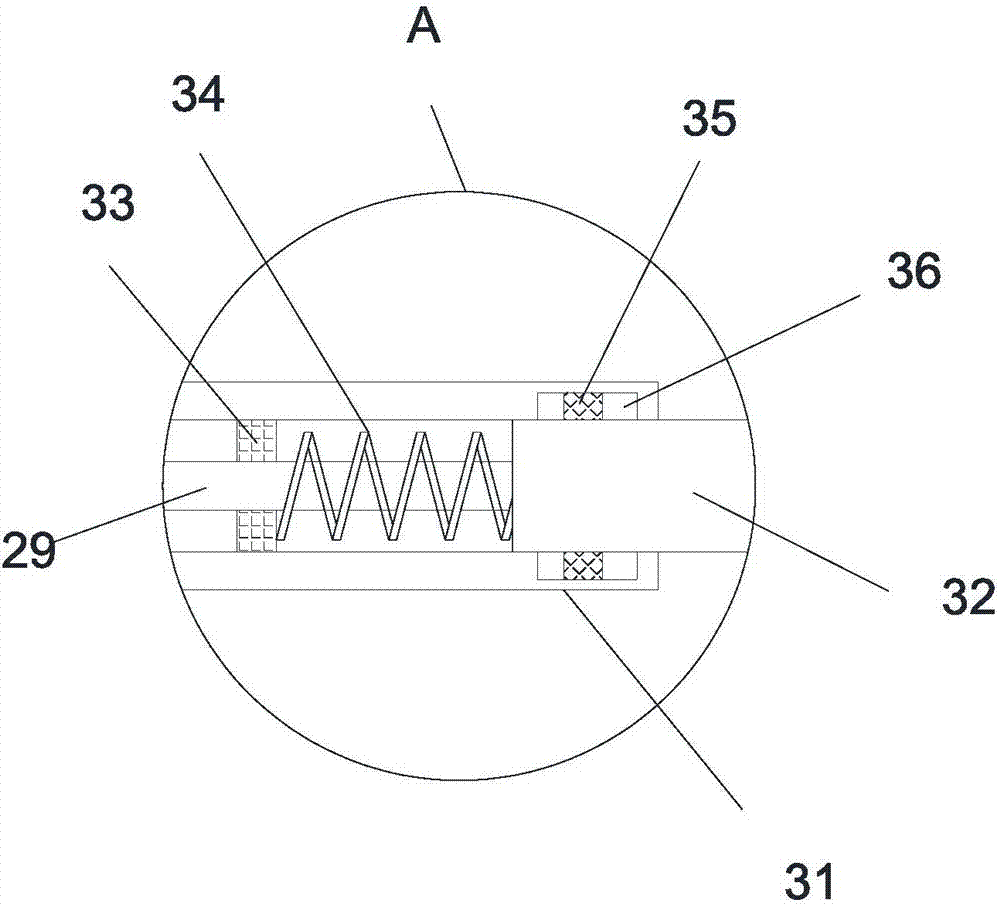

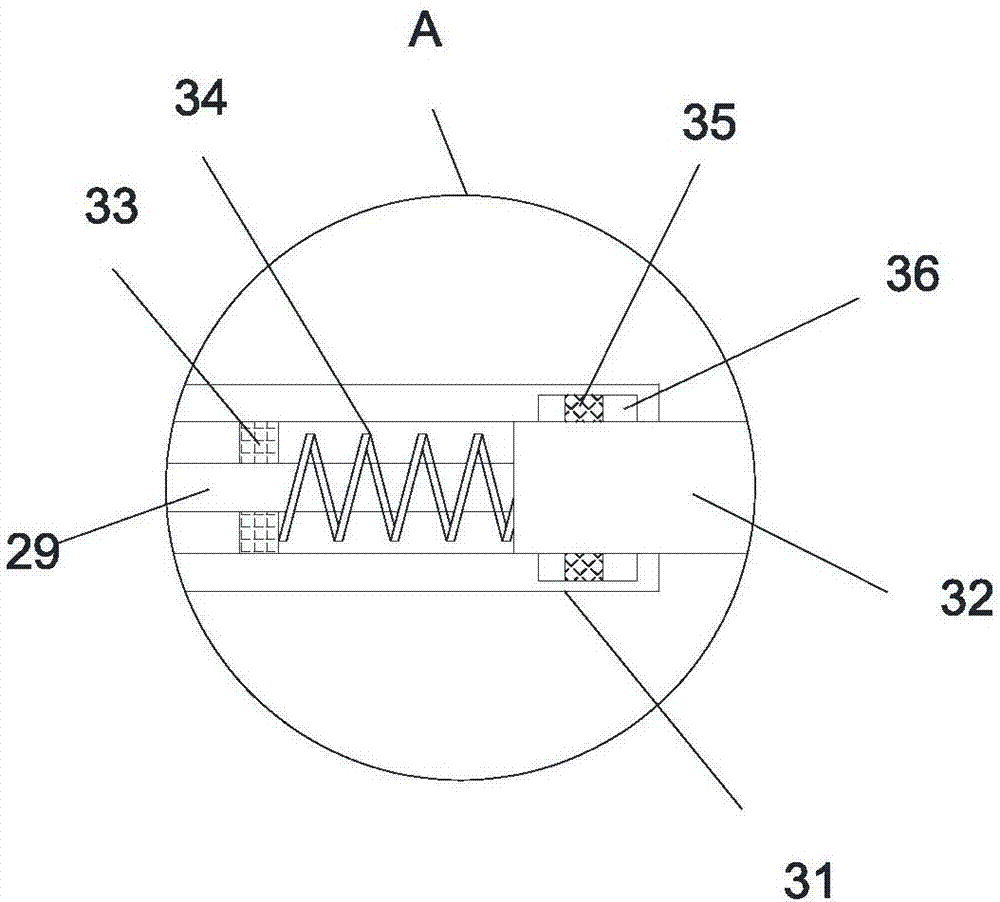

Adjusting device and adjusting method for cereal threshing cylinder concave clearance

PendingCN106664990ALow manufacturing costEasy to install and disassembleThreshersDrive motorSelf adaptive

The invention relates to an automatic adjusting device and method for a cereal threshing cylinder concave clearance. The automatic adjusting device includes a top cover, a threshing cylinder, a concave sieve, a driving motor, a rack, a stress acquisition module, and a signal receiving and processing system. Detection and data analysis is performed on stress applied to a threshing toothed bar, a feedback signal is sent to the driving motor, and then automatic adjustment of the threshing cylinder concave clearance can be achieved. The adjusting device and adjusting method can be used for detection of stress applied to the threshing toothed bar of a threshing separating device and self-adaptive adjustment of the concave clearance while a combined harvester performs field harvesting; a detection device is low in production cost, and is easy to install and demount; the intelligent level of the detection method and result processing is high; and harvesting of various crops can be achieved by adjusting parameters of the signal receiving and processing system.

Owner:JIANGSU UNIV

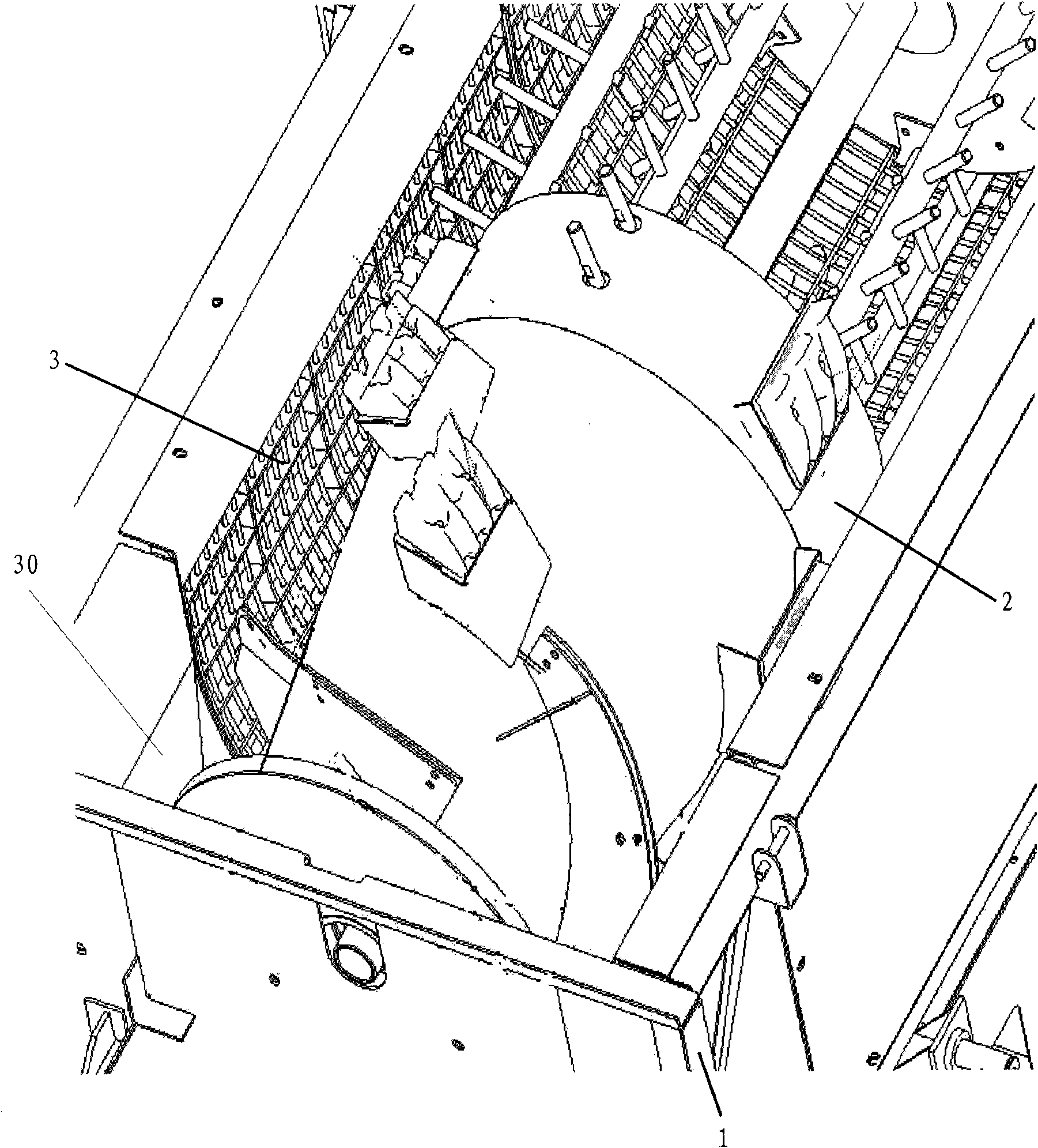

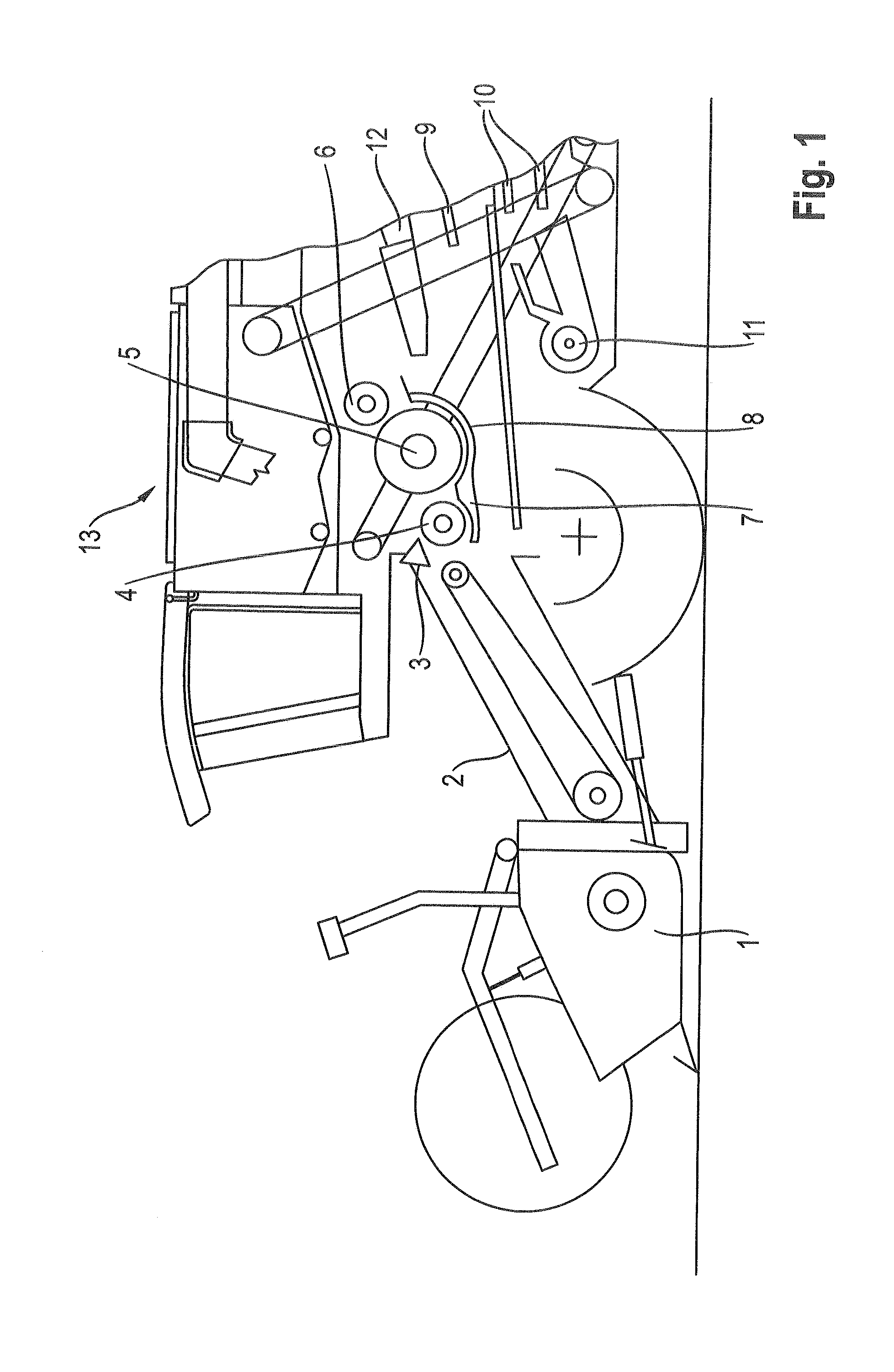

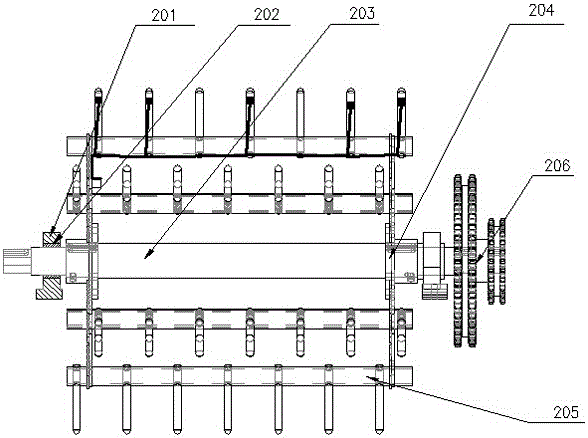

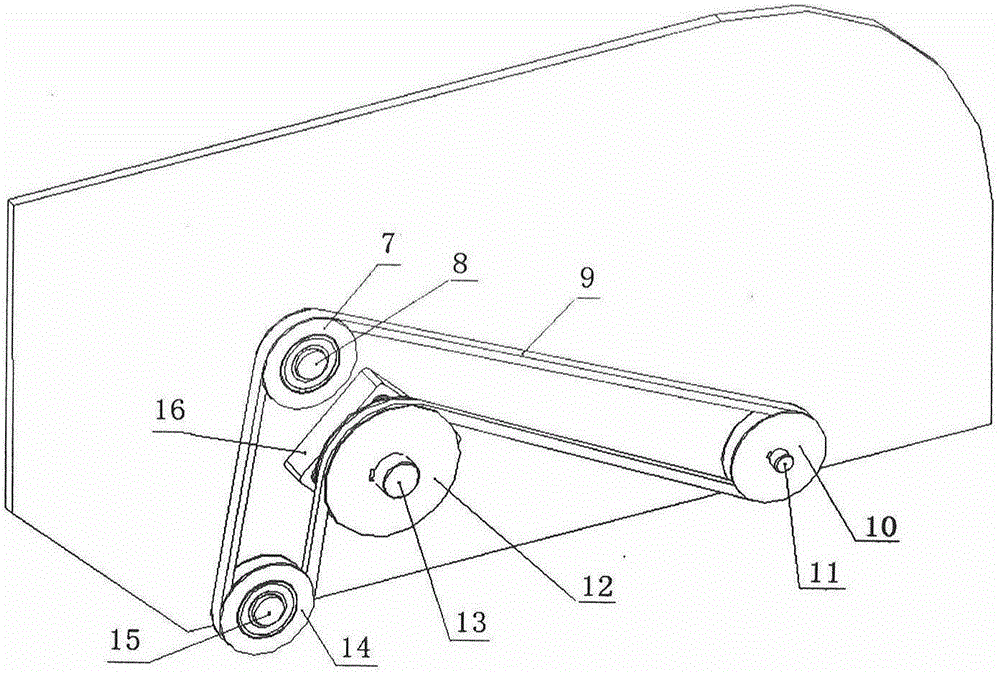

Half-feeding combine harvester threshing and separating device with revolving concave grid

The invention relates to the field of agricultural machinery, in particular to a half-feeding combine harvester threshing and separating device with a revolving concave grid, which is mainly applied to a half-feeding paddy rice combine harvester and is used for enhancing the threshing and separating capabilities, increasing the granule threshing rate, greatly lowering the blockage probability of a threshing device and increasing the production efficiency during operation of the half-feeding paddy rice combine harvester. The half-feeding combine harvester threshing and separating device mainly comprises a left wall plate, a porous plate, a right wall plate, a V-shaped belt transmission assembly, a revolving concave grid assembly and a threshing drum. The half-feeding combine harvester threshing and separating device is reasonable in structure; crops are prevented from being accumulated in the threshing device and causing blockage due to revolving motion of a concave grid surface during operation, the threshing and separating capabilities are enhanced, and adaptation to harvesting of high-yield crops in a wet environment is realized; the upper layer surface of the concave grid moves at a certain linear speed, so that combing and threshing are realized on the upper and lower layers of the crops, overhead and bent grains are combed and threshed, and the loss caused by incomplete threshing is reduced.

Owner:JINHUA VOCATIONAL TECH COLLEGE

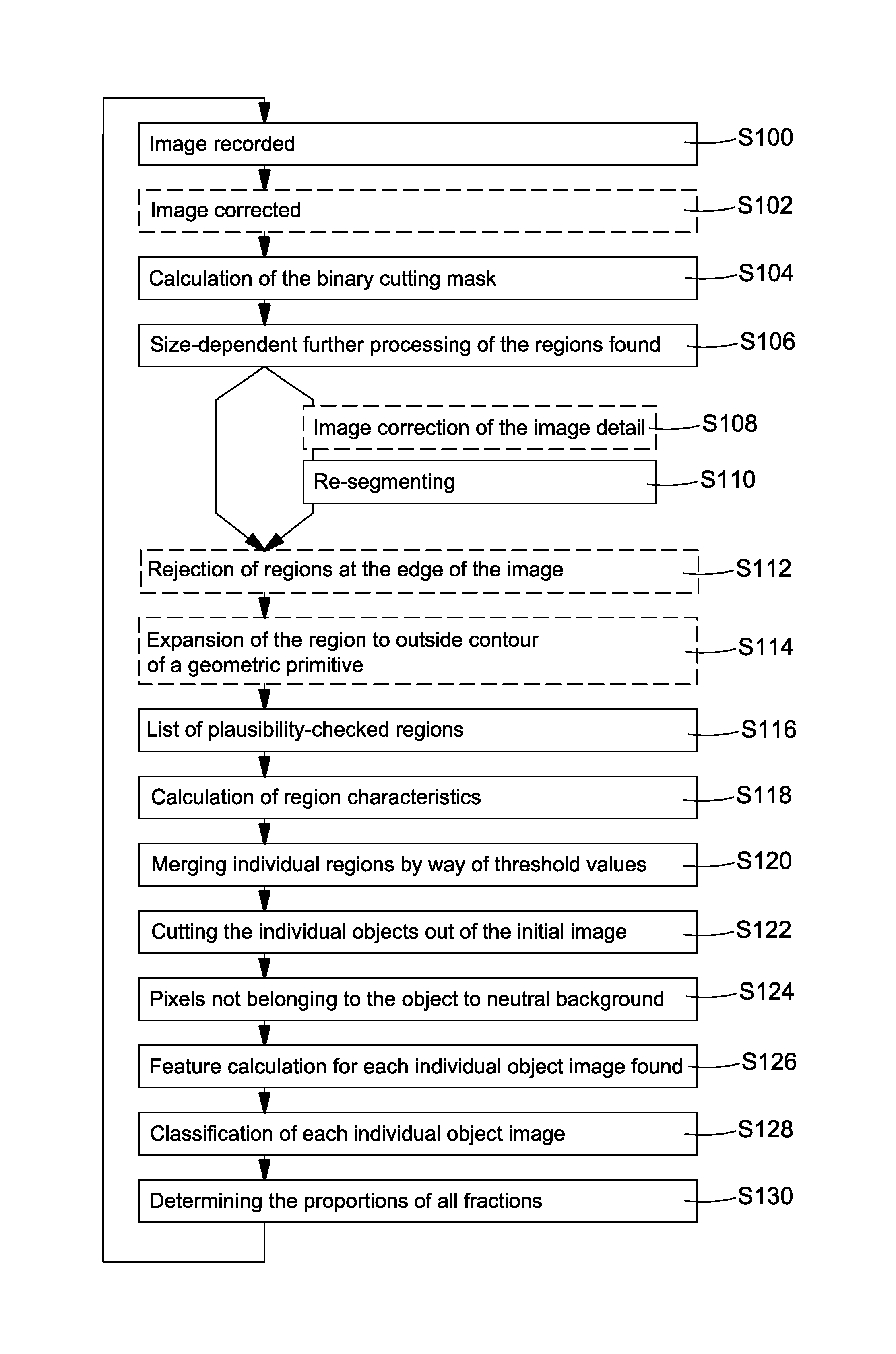

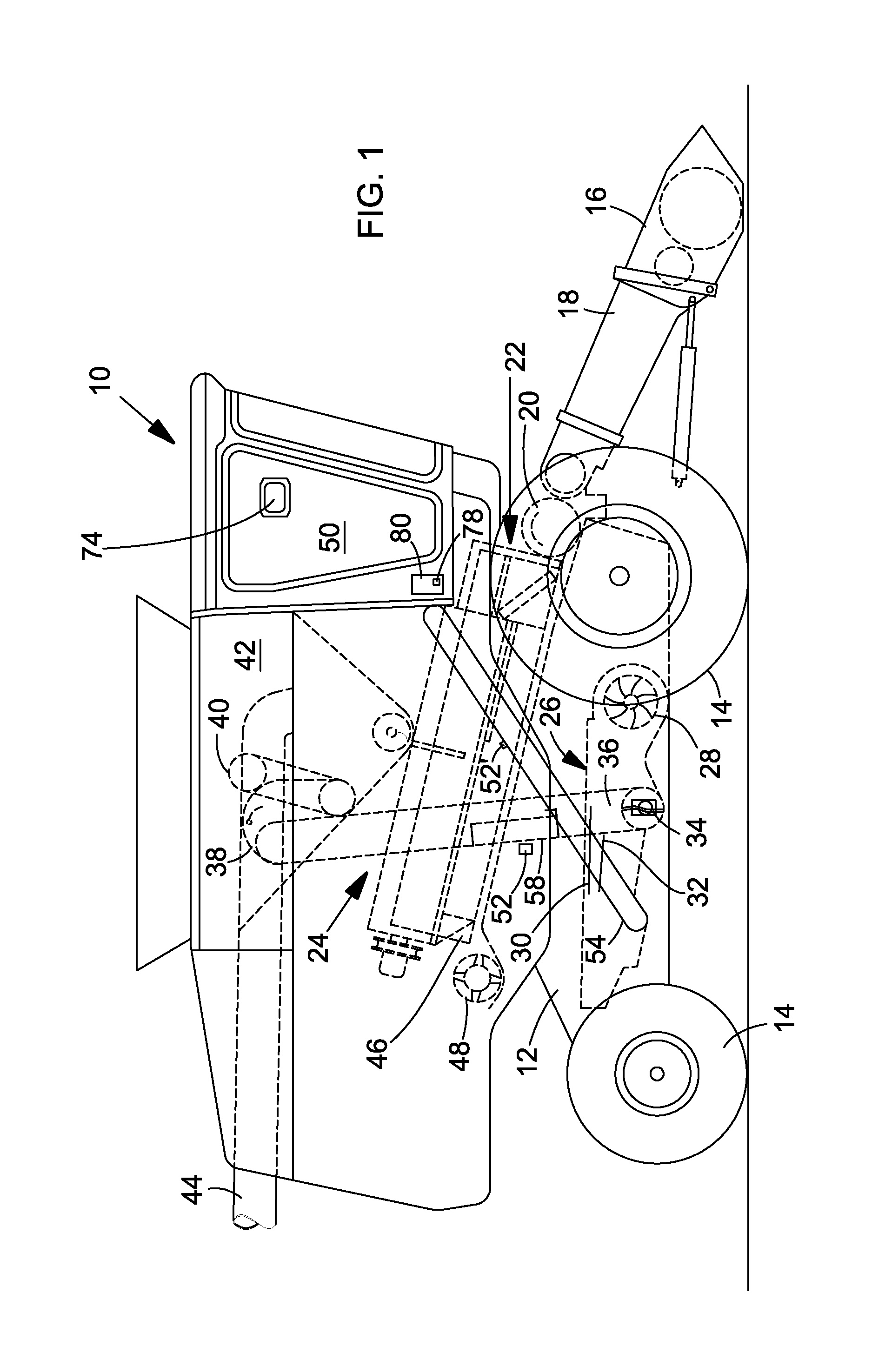

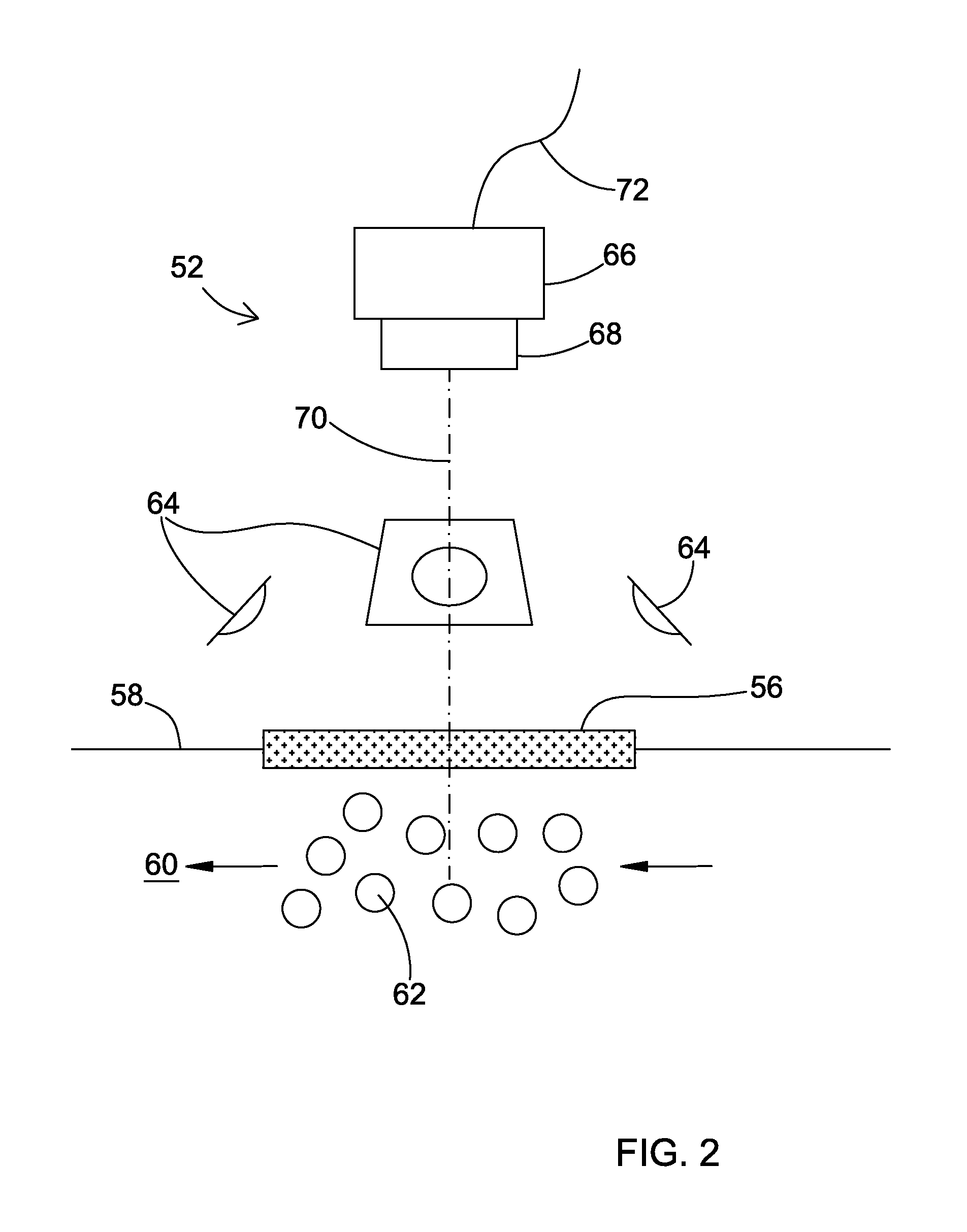

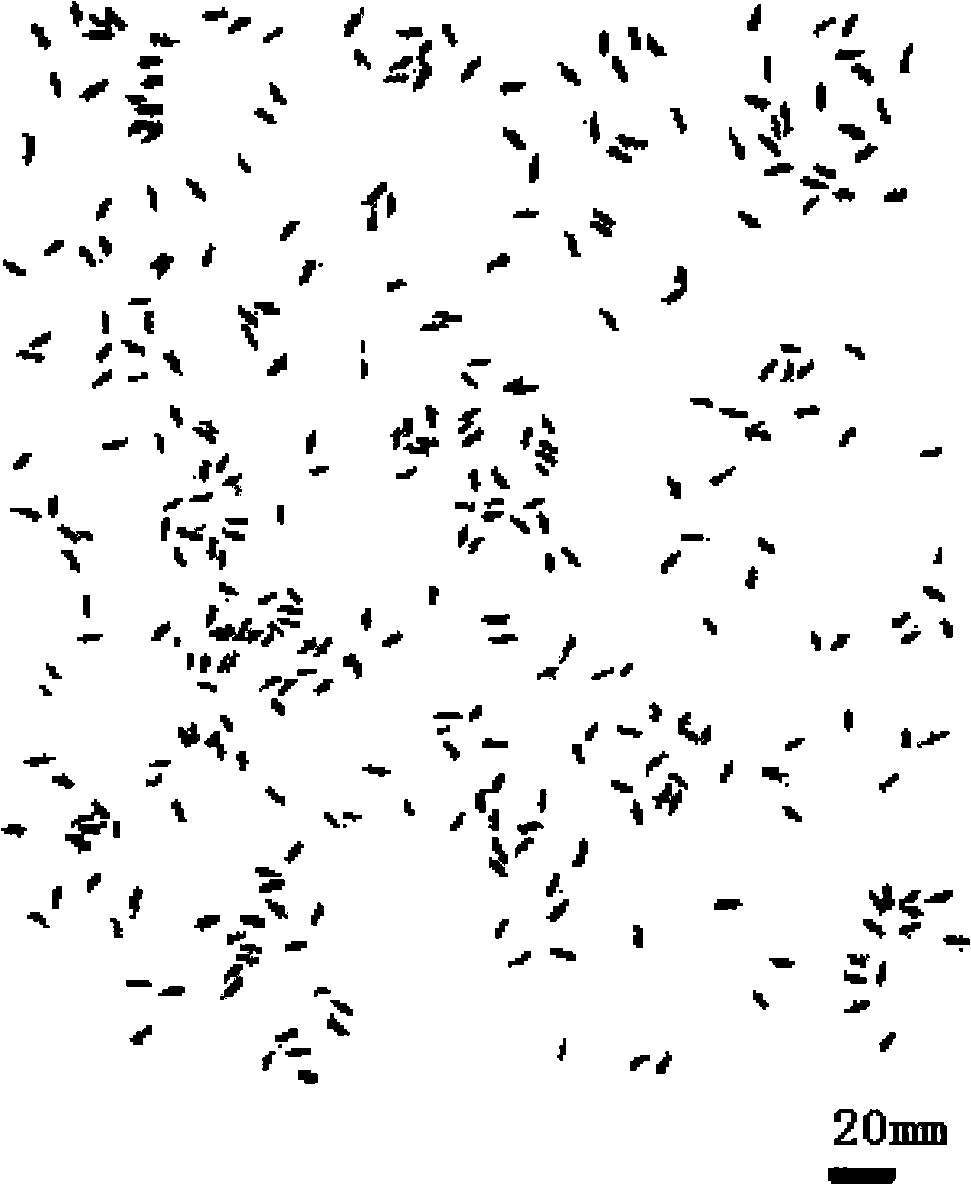

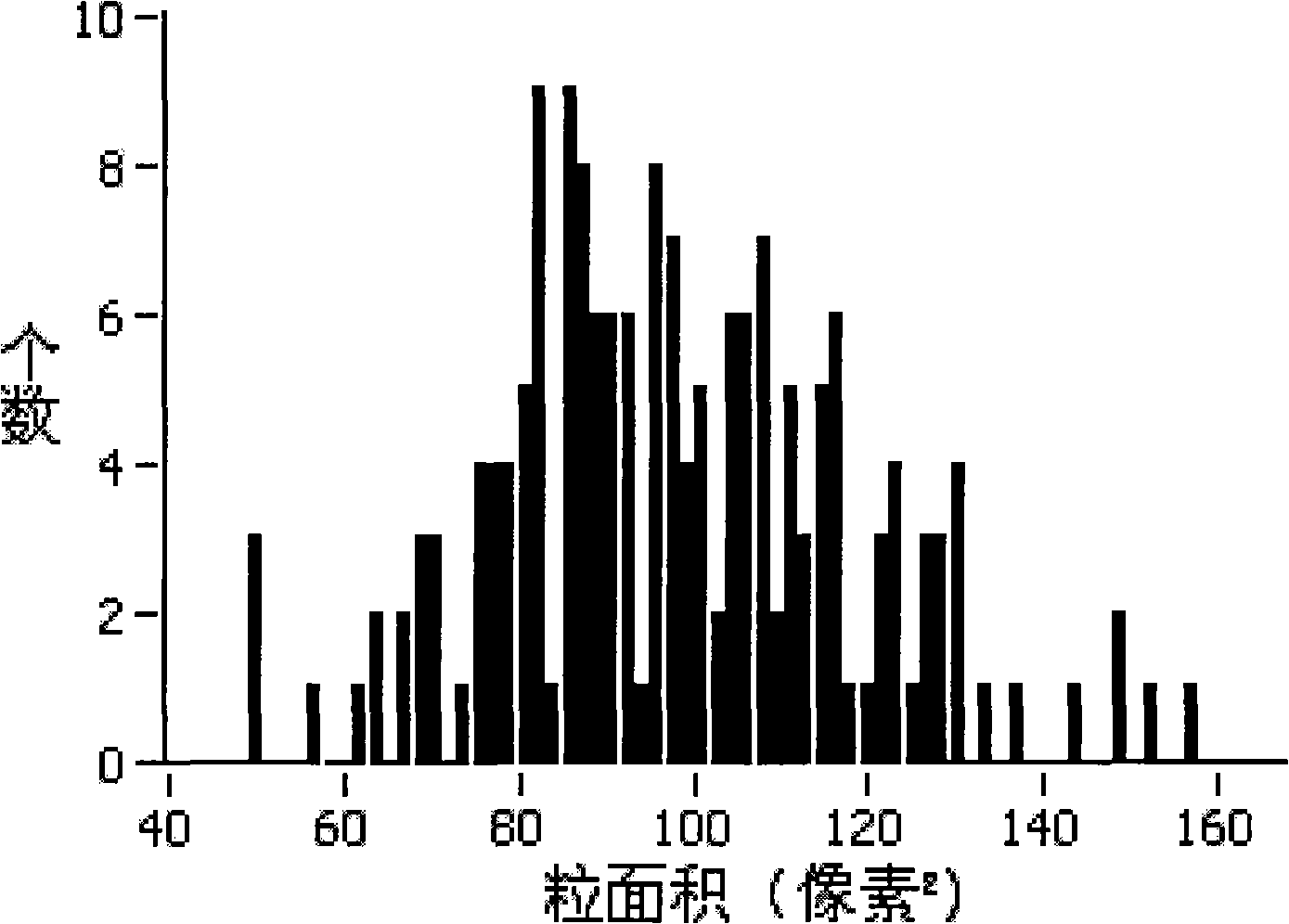

Method and apparatus for the optical evaluation of harvested crop in a harvesting machine

ActiveUS8831292B2Classified better and more accuratelyUniform textureImage enhancementImage analysisObject ClassImaging processing

An arrangement for the optical evaluation of harvested crop in a harvesting machine includes a camera located for taking images of threshed out crop elements (grain and material other than grain) being conveyed within a channel of the machine. An electronic image processing system receives the images and identifies individual objects in the images, these objects being classified into predetermined object classes by way of comparing at least one of color, contour or texture features of the individual objects and corresponding characteristics of reference objects filed in a data bank. The processing system then determines the absolute or relative numbers or areas of the individual objects assigned to the respective object classes.

Owner:DEERE & CO

Rice parameter automatic measuring equipment and method

ActiveCN101339117AAccurate and reliable measurement resultsEasy to operateMaterial analysis using wave/particle radiationIndividual particle analysisNon destructiveMeasurement device

The invention relates to an automatic measurement device of rice parameters, and a method thereof. The device is controlled by a preset computer; a single-plant threshing instrument is used for threshing rice spikes; the grain falls onto a belt through the single-plant threshing instrument and a straight groove type interface; the running belt is used for separating the grain; an X-ray imaging system is used for shooting a X-ray transmission map; a computer is used for processing the images so as to acquire the parameters of the rice. The automatic measurement device adopts the X-ray imaging method; the digital image processing technology is used for processing the shot images so as to acquire the parameters of the rice; the threshed grain needs no decladding treatment; the threshing and the parameter extraction are integrated into one system; and the automatic measurement device has the advantages of non-destructive installation, accurate and reliable measurement results, simple operation, and so on.

Owner:HUAZHONG UNIV OF SCI & TECH

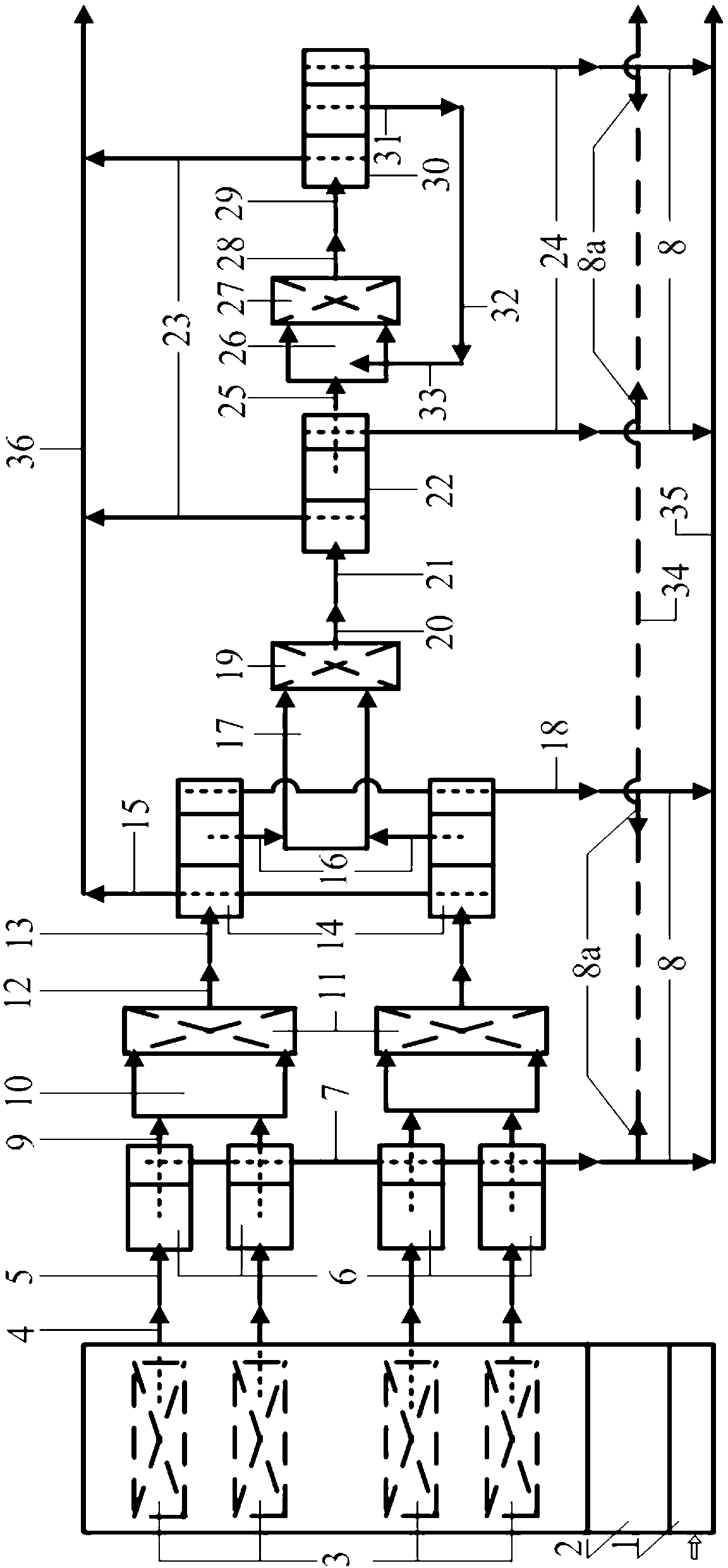

Efficient and energy-saving threshing and air separation process and equipment

ActiveCN103263074ALayout specificationImprove production continuityTobacco treatmentGas current separationProcess engineeringAir separation

The invention relates to an efficient and energy-saving threshing and air separation process and equipment, belonging to the technical field of tobacco material air separation processes and equipment. Four air pressure type double-storehouse air separators are arranged between a first-stage threshing unit and a second-stage threshing unit and connected with one another in parallel, two air pressure type three-storehouse air separators are arranged between the second-stage threshing unit and a third-stage threshing unit and connected with each other in parallel, and air pressure type three-storehouse air separators are arranged between the third-stage threshing unit and a fourth-stage threshing unit as well as behind the third-stage threshing unit and the fourth-stage threshing unit and connected with each other in series. Materials are conveyed by a conveying belt and a vibration groove instead of a conventional air pipeline, so that the materials are not easy to block, the temperature and moisture loss of the materials are reduced, the grinding probability of the materials due to drying is reduced, the transmission power is low, the energy consumption and the noise are greatly reduced, and the large-medium sheet rate of discharged tobacco sheets is increased.

Owner:HONGTA TOBACCO GRP

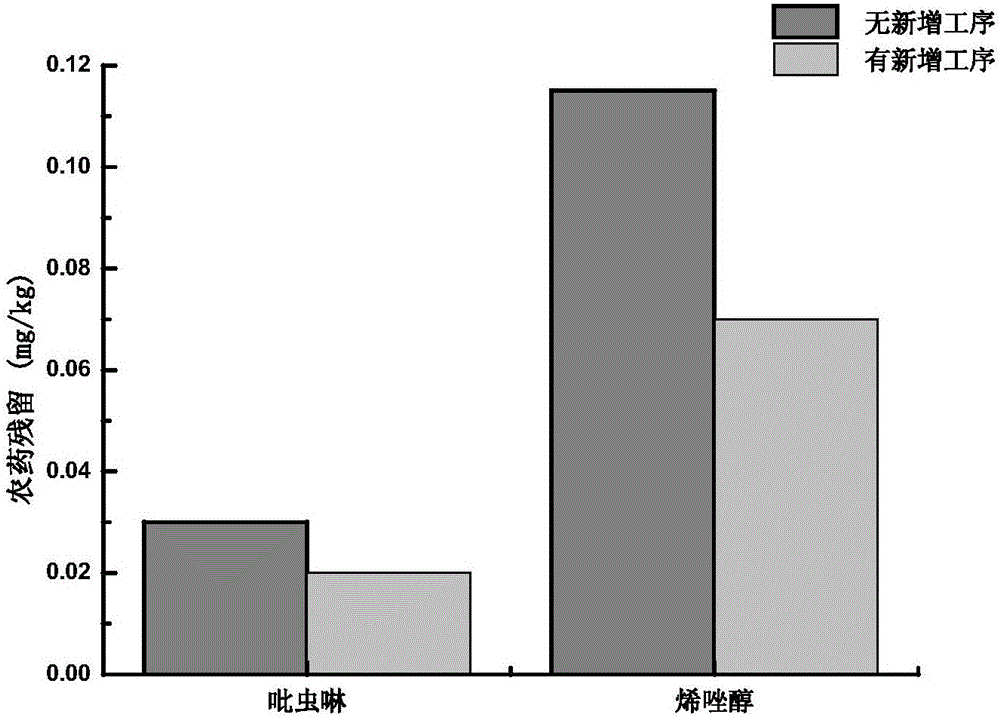

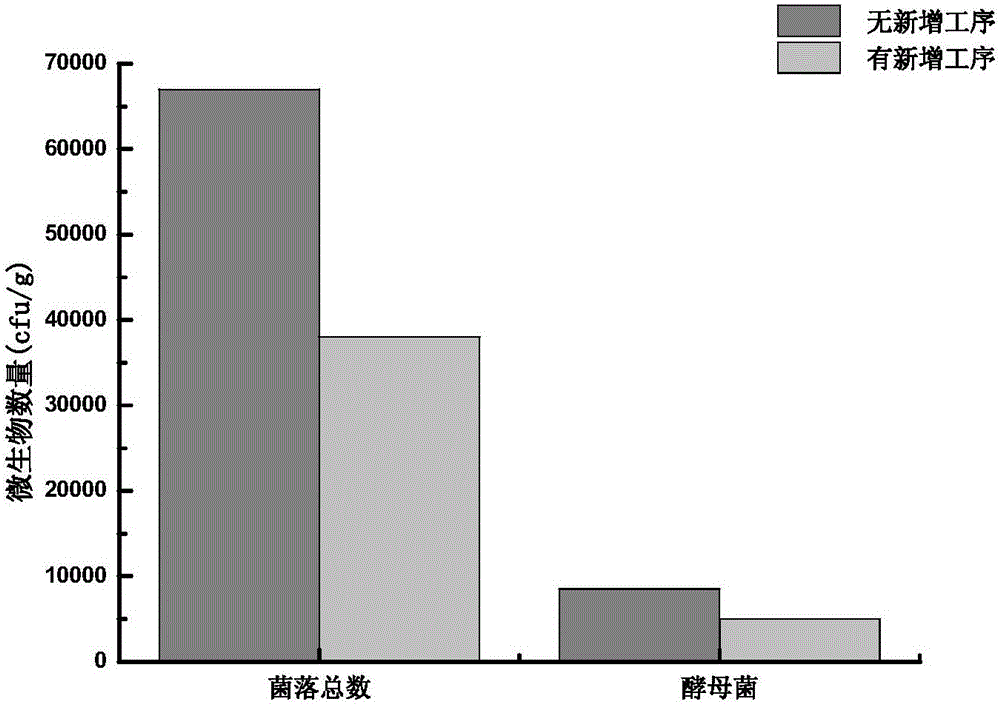

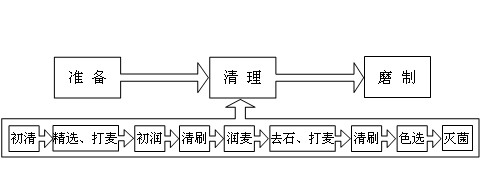

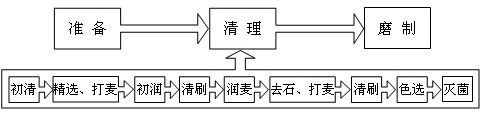

Wheat flour cleaning production process

InactiveCN102527460ADesign scienceGuarantee quality and safetyGrain treatmentsPathogenic microorganismPesticide residue

The invention provides a wheat flour cleaning production process and relates to the technical field of grain processing and production. The wheat flour cleaning production process comprises the following processing steps: preparation, cleaning, grinding and the like, wherein the cleaning processing step comprises primary cleaning, fine cleaning, wheat threshing, primary moistening, brushing, wheat wetting, stone removing, wheat threshing, brushing, color selecting, sterilization and the like. The wheat flour cleaning production process emphasizedly solves the problem that finished wheat flour as wheat contains pesticide residues (toxic residues), chemical residues (toxic residues), mildew, pathogenic microorganisms and various impurities, and also solves the problem of secondary pollution of the products caused in processing and producing through combining the production of common powder and special powder, a wheat path and a powder path are scientific in design, the process is reasonable, and the production cost is low, so that the wheat flour cleaning production can be achieved, and the quality safety of wheat processed products can be guaranteed.

Owner:JIANGSU DAN YU GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com