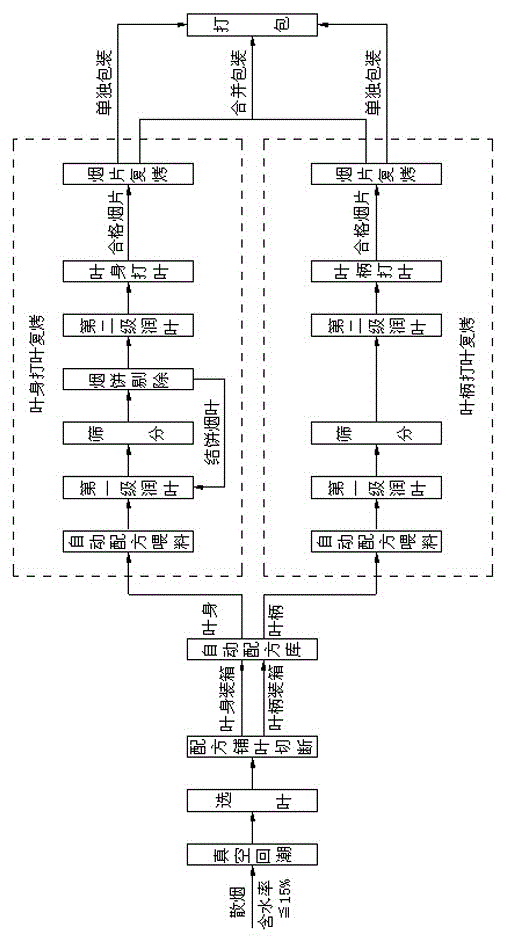

Bulk tobacco formula threshing and redrying processing technology

A technology for threshing and redrying and processing technology, which is applied in the fields of tobacco, tobacco preparation, application, etc., and can solve the processing requirements that are not suitable for threshing and redrying, homogenization of leaves, and consistency of leaf specifications. The tobacco has no problems such as insecticidal, egg killing and removal of green and miscellaneous gas, and it cannot effectively meet the technological requirements of threshing and redrying the raw material formula of loose tobacco, so as to achieve the effect of easy loosening and regaining moisture, improving use value and good appearance quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

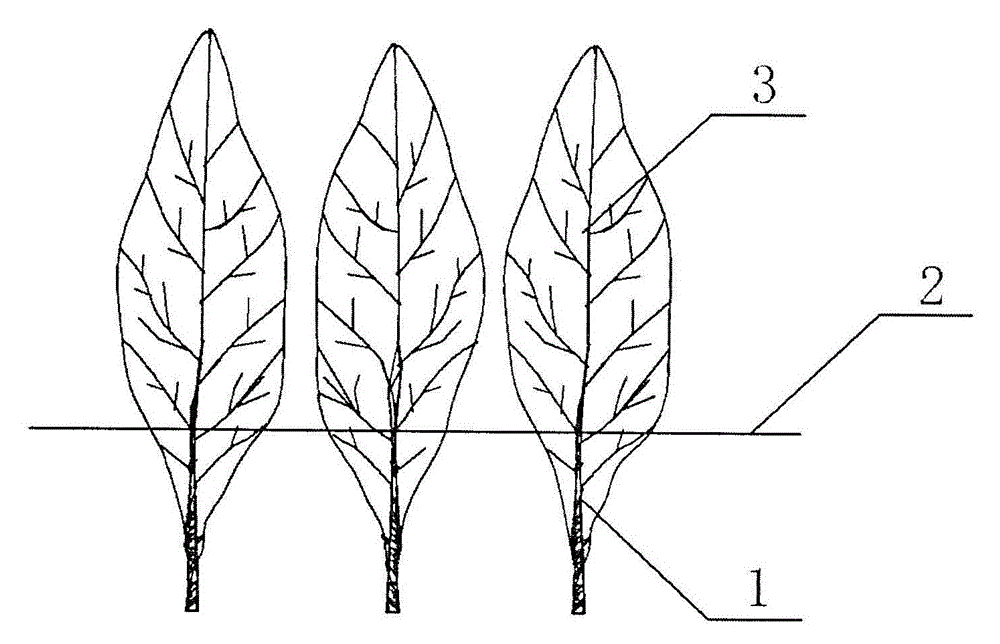

[0080] Taking the 18000kg / h threshing and redrying production line as an example, the loose tobacco raw materials from the original tobacco warehouse, when the moisture content is ≤ 15%, undergo vacuum rehydration. After rehydration, the moisture content is 16% to 18%, and the penetration rate is ≥ 98%. Makes the tobacco leaves soft and loose. Spread the rehydrated tobacco leaves evenly on the selection belt to select leaves, and select according to the main grade, selected top, selected bottom, green smoke, moldy smoke, and mixed parts, and the selected tobacco leaves are classified into smoke boxes. The selected tobacco leaves are sent to the formula leaf laying and cutting process, and the leaf laying is matched according to the recipe requirements, and the leaf laying speed is adjusted according to the prompts of the weighing formula control system of the leaf laying table to complete the initial blending of tobacco leaves. When laying leaves, the petioles are spread outwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com